HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-1

Page 2B-1

Section 2B

HVAC Climate Control (Manual A/C) –

Servicing and Diagnosis

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct w orkshop practices wi th regard to safety and / or property damage.

1 Refrigerant Handling Precautions........................................................................................................2

2 Service Operations.................................................................................................................................4

2.1 Manifold Gauge Installation.................................................................................................................................. 4

2.2 System Charging and Evacuation........................................................................................................................ 5

Filling a Dial-A-Charge Cylinder ........................................................................................................................... 7

Evacuation and Leak Test..................................................................................................................................... 8

Charging System ................................................................................................................................................... 9

2.3 Checking System Oil Charge.............................................................................................................................. 10

2.4 Flushing the A/C System for Contamination or Lubricating Oil...................................................................... 11

Flushing Procedure.......................................................................................................................................... 11

2.5 Lubricating Oil Compensation............................................................................................................................ 13

Installing the Original Compressor.................................................................................................................... 13

Installing a New Compressor.............................................................................................................................. 13

Evaporator or Condenser.................................................................................................................................... 14

Filter Drier Receiver (FDR).................................................................................................................................. 14

Blown or Ruptured Pipe/Hose ............................................................................................................................ 14

3 System Functional Check....................................................................................................................15

4 Diagnostics...........................................................................................................................................17

4.1 Air-conditioner System Diagnosis...................................................................................................................... 17

Introduction.......................................................................................................................................................... 17

Preliminary Inspection...................................................................................................................................... 17

Air-conditioning System Tests.......................................................................................................................... 17

Preliminary Inspection ........................................................................................................................................ 17

Test 1: Checking Refrigerant Charge................................................................................................................. 18

Test 2: Checking Compressor Clutch Engagement.......................................................................................... 19

Compressor Electrical Connector..................................................................................................................... 20

Test 3: Checking Compressor System Performance........................................................................................ 21

Vehicle Set-up.................................................................................................................................................. 21

Air-conditioning System Performance Chart..................................................................................................... 22

Test 4: Checking Compressor for Less Than Full Stroke (Low Load) Simulation........................................ 23

Vehicle Set Up.................................................................................................................................................. 23

Test Procedure................................................................................................................................................. 23

Test 5: Checking Compressor for Full Stroke Operation (High Load) Simulation......................................... 24

Test 6: TXV Operational Check on Vehicle........................................................................................................ 25

Vehicle Set Up.................................................................................................................................................. 25

Test 7: Noise Diagnosis ...................................................................................................................................... 26

Preliminary Check............................................................................................................................................ 26

Compressor Noise Check................................................................................................................................. 27

5 Specifications.......................................................................................................................................28

6 Special Tools ........................................................................................................................................29

Techline

Techline

Techline

Techline

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-2

Page 2B-2

1 Refrigerant Handling

Precautions

In any vocation or trade, there are established procedures and practices that have been developed after many years of

experience. In addition, occupational hazards may be present that require the observation of certain precautions, or use

of special tools and equipment. Observing the procedures, practices and precautions of servicing refrigeration equipment

will greatly reduce the possibility of damage to the vehicle, as well as virtually eliminating the element of hazard to the

service technician.

Care should be taken when discharging the air-conditioning system to ensure the refrigerant is not released to the

atmosphere but captured for recycling. Environmentally friendly refrigerant R134a is not an ozone depleting substance

but its release would add to the greenhouse warming effect.

Refrigerant R134a is transparent and colourless in both the gaseous and liquid states. At all normal temperatures and

pressures it will be a vapour. The vapour is heavier than air and is non-flammable, non-explosive, non-poisonous and

non-corrosive (except when in contact with moisture).

The following precautions in handling R134a should be observed at all times:

R134a and R12 are not compatible and must

never be mixed.

Always use safety glasses and gloves when

handling or servicing air-conditioning

systems. If R134a does enter the eye, freezing

can occur which could result in blindness.

The procedure outlined below is suggested if

R134a enters the eyes.

• Keep calm.

• Do not rub eyes.

• Splash large quantities of cool water into

the eyes to raise the temperature.

• Tape a sterile eye patch in place to prevent

dirt from entering the eye.

• Go immediately to a doctor or hospital for

professional treatment.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-3

Page 2B-3

If an accident occurs, do not attempt to treat

yourself.

• Always follow correct workshop practices.

• Always work in a well ventilated area.

• Avoid skin contact, as R134a will cause

frostbite on contact with bare skin.

• Do not abuse the refrigerant cylinder, or

any other tools you may need to use.

• Do not w eld or steam clean on or near any

air-conditioning components when

pressurised. This may cause a dangerous

pressure build up in the system.

• Do not discharge refrigerant into an

enclosed area.

• When purging a system, discharge the

refrigerant slowly.

• If it is necessary to transport or carry a

cylinder of refrigerant in a car, keep it in

the luggage compartment.

• Refrigerant cylinders should always be

protected from the radiant heat of the sun.

• When filling a refrigerant cylinder, never

completely fill it. Always leave space for

expansion. If the cylinder is completely

filled and the ambient temperature

increases, hydraulic pressure within the

cylinder will elevate to a dangerous level.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-4

Page 2B-4

2 Service Operations

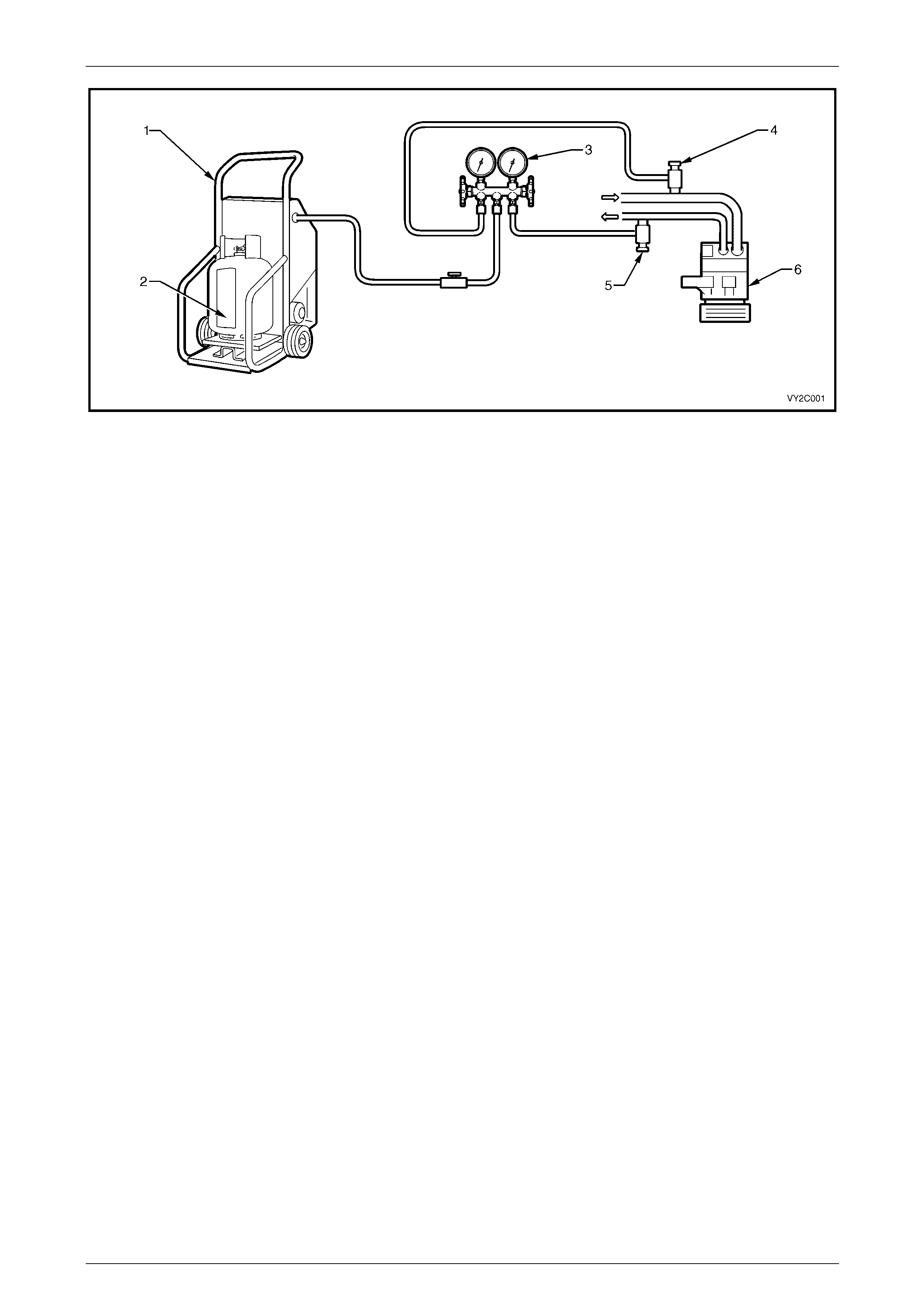

2.1 Manifold Gauge Installation

NOTE

Care should be taken to ensure that vehicle's

refrigerant is not released to the atmosphere

when connecting the manifold gauges.

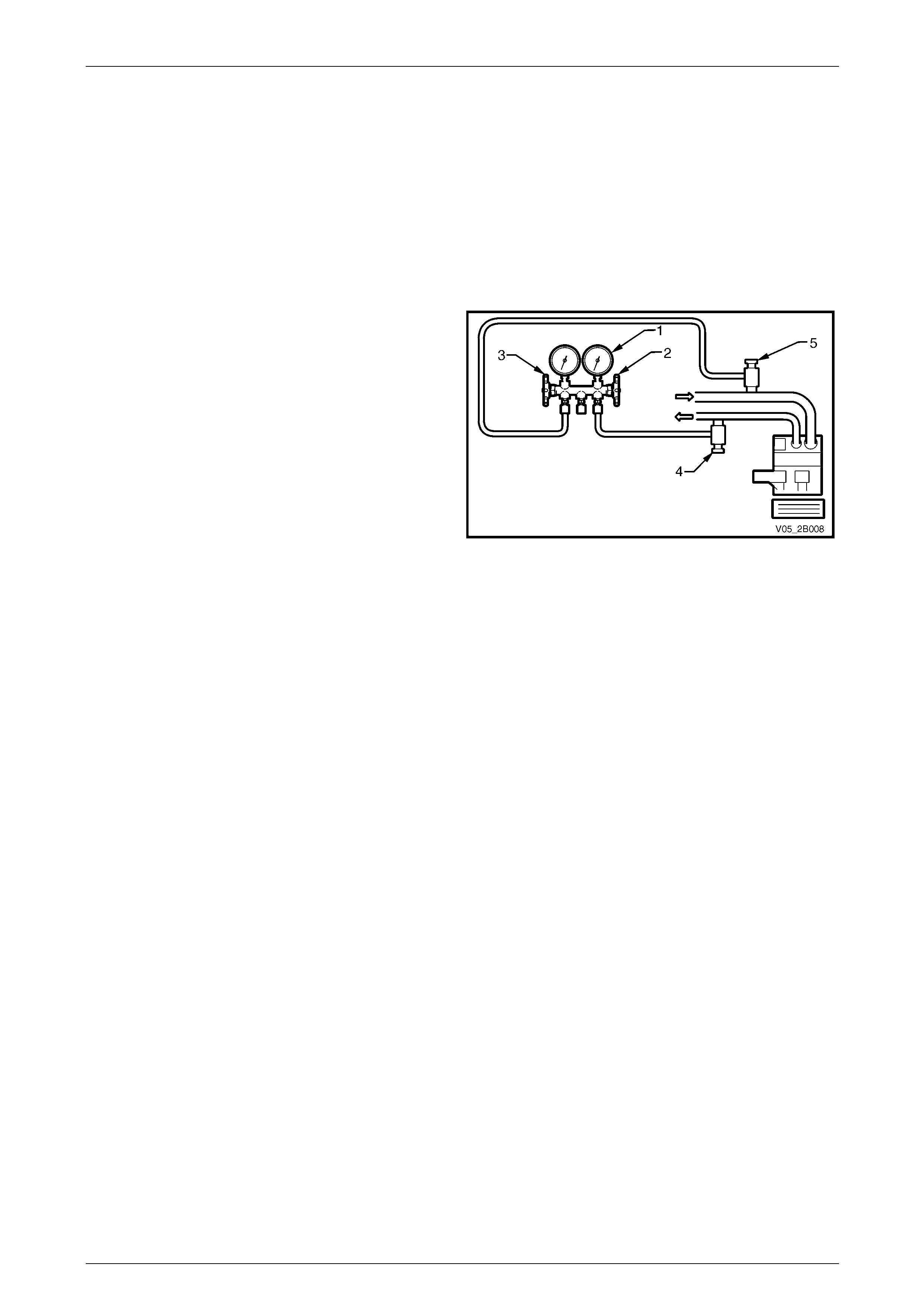

1 Make sure the high pressure valve (2) and low

pressure valve (3) of the manifold gauge set (3) are

firmly closed.

2 Connect the high pressure charging hose to the high

pressure service valve (4) and the low pressure

charging hose to the low pressure service valve (5).

3 Bleed the air from the high and low pressure charging

hoses by slightly opening each pressure valve.

Figure 2B – 1

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-5

Page 2B-5

2.2 System Charging and Evacuation

The wearing of safety goggles and gloves is

mandatory during system charging or

discharging.

Never run the compressor without refrigerant

in the system as the compressor lubricant

relies upon the flow of refrigerant to lubricate

the system components.

NOTE

• All hoses at point of connection to the system

must have isolation valves fitted.

• Care should be taken when discharging the

air-conditioning system to ensure the

refrigerant is not released to the atmosphere

but captured for recycling. R134a is not an

ozone depleting substance but its cost and

the fact that it does contribute to the

greenhouse effect, make it essential that it is

recovered.

A range of Refrigerant Recovery Units (RRU) is now available, which collect refrigerant from air-conditioning systems.

The following procedure describes the use of these units when recovering refrigerant from a vehicle’s air-conditioning

system.

1 Connect the RRU outlet to an R134a recovery cylinder with a refrigerant hose and open the valve on the cylinder.

Ensure the cylinder has sufficient capacity to hold the refrigerant in the system to be serviced. This can be

confirmed by weighing the cylinder or by referring to the volume gauge if fitted.

2 Connect a gauge manifold set to the vehicle air-conditioning system. Connect to both the low pressure and high

pressure sides of the system. Connect the centre hose of the gauge set to the inlet of the recovery unit. Connect

the RRU to an electrical supply.

3 Open the gauge set and quickly connect the stop taps to allow the refrigerant to enter the RRU via the centre hose.

At this point, depending on which unit is being used, the RRU will switch on. If the RRU is not an automated type,

switch the unit on.

4 The automatic recovery unit will operate until the air-conditioning system has been emptied of refrigerant down to

atmospheric pressure. The cylinder can now be closed.

5 Measure the amount of PAG oil removed from the A/C system. This oil is normally separated from the incoming

refrigerant into the RRU. New clean PAG oil must be added into the system before recharging it with refrigerant.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-6

Page 2B-6

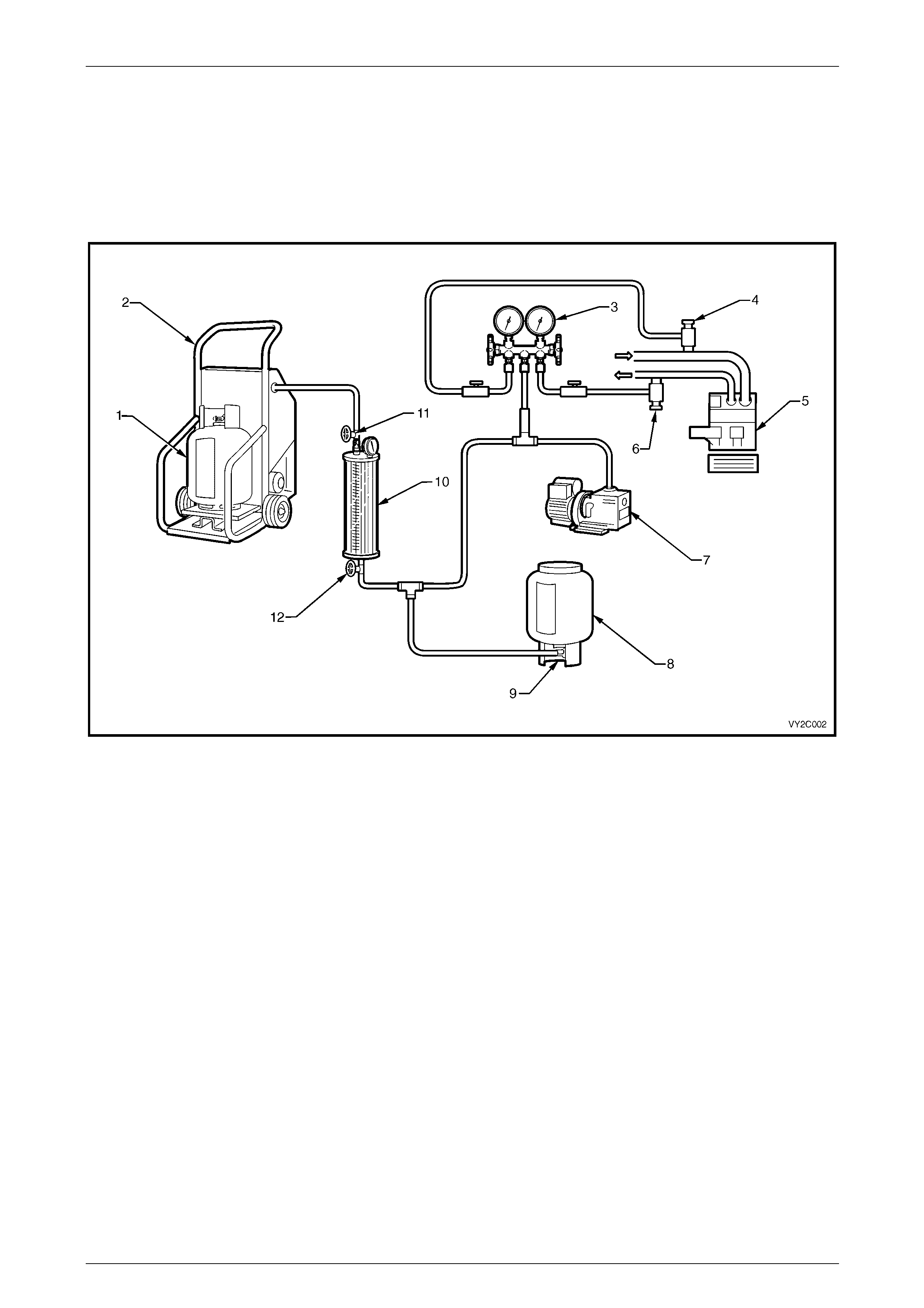

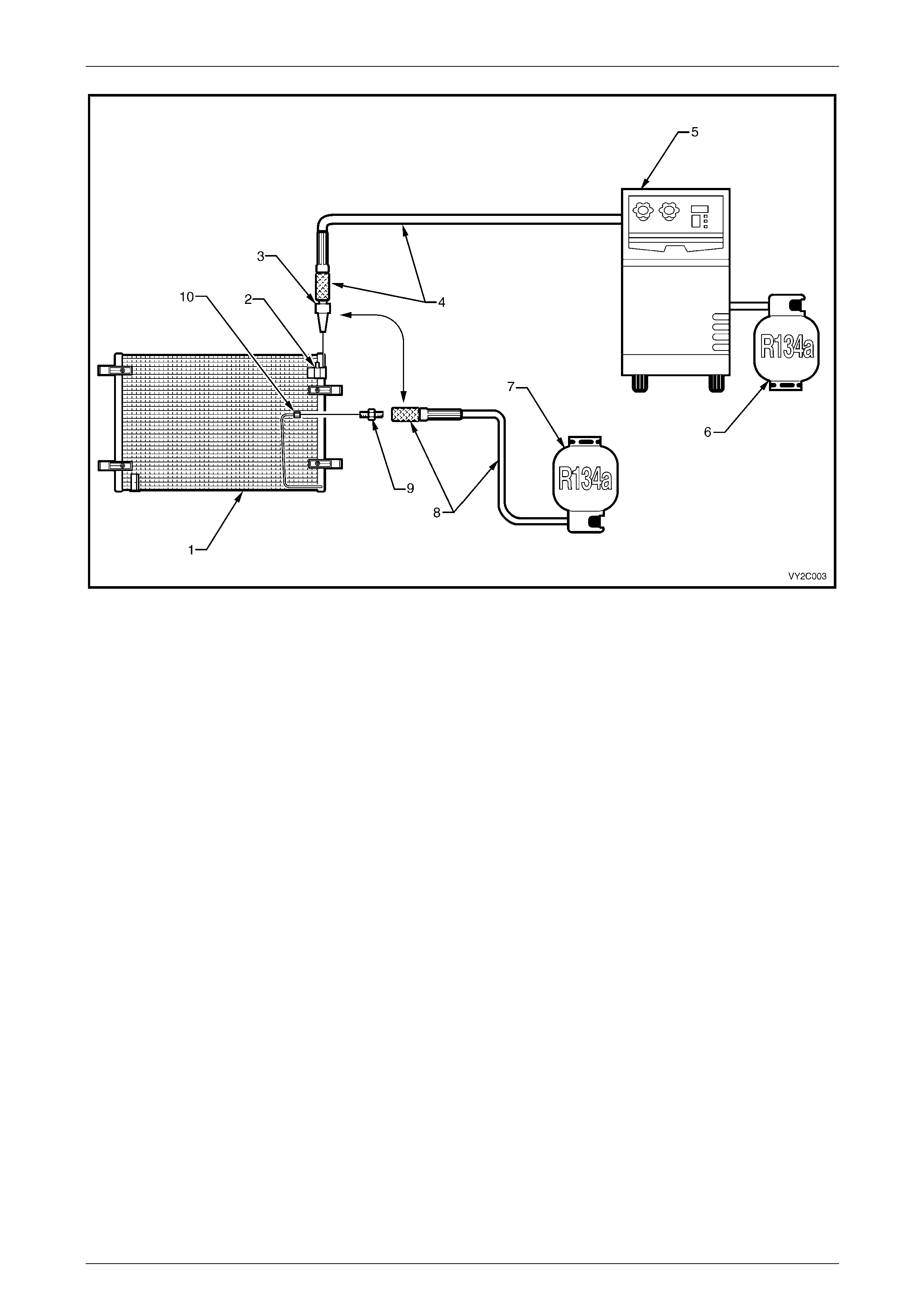

Figure 2B – 2

Legend

1 Refrigerant Recovery Unit (RRU)

2 Refrigerant Recovery Cylinder

3 Manifold/Gauge Set

4 Low Side Charging Adaptor

5 High Side Charging Adaptor

6 Compressor

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-7

Page 2B-7

Filling a Dial-A-Charge Cylinder

1 Open the liquid valve on the R134a supply cylinder, allowing refrigerant to enter the dial-a-charge cylinder.

2 Bleed the dial-a-charge cylinder via the bleed valve on top (behind pressure gauge) as required to allow the

refrigerant to enter. This valve should be connected via a hose to a refrigerant recovery unit (RRU) and recovery

cylinder. When the refrigerant reaches the specified level (800g +/- 25g), close the supply valve at the bottom of the

‘dial-a-charge’ cylinder and be certain the bleed valve is also securely closed. Close the liquid valve on the R134a

supply cylinder.

Figure 2B – 3

Legend

1 Refrigerant Recovery Cylinder

2 Refrigerant Recovery Unit (RRU)

3 Manifold Gauge Set

4 Low Side Charging Adaptor

5 Compressor

6 High Side Charging Adaptor

7 Vacuum Pump

8 R134a Supply Cylinder

9 Liquid Valve

10 Dial-A-Charge Charging Cylinder

11 Bleed Valve

12 Supply Valve

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-8

Page 2B-8

Evacuation and Leak Test

1 Check that both manifold hand valves of the gauge set are closed and turn the RRU off.

2 Connect the charging hoses onto the low and high service valves in the system.

Do Not Use Spanners.

3 Connect the centre manifold charging hose to the vacuum pump inlet.

4 Start the vacuum pump and slowly open the low side manifold valve. The low side gauge reading should decrease

to 98 – 102 kPa vacuum and the high side gauge should read slightly below the zero index of gauge. If high side

gauge reading does not register, check system for a blockage or leak.

NOTE

When the high side gauge is slightly below the

zero index of the gauge, open the high side

manifold valve.

5 After evacuating the system for 15 minutes to a vacuum of –100 kPa, close both the low and high side valves and

stop the vacuum pump. The system must hold a vacuum of –100 kPa for a minimum of 15 minutes. If the specified

vacuum is held then the system has no leaks and may continue to be evacuated for a further 15 minutes.

6 Wear safety goggles.

7 Connect the centre charging hose to the charging cylinder valve on the bottom of the cylinder. Open the bottom

charging cylinder valve. Do not open the low or high side valves on the manifold gauge at this time.

8 Loosen the centre charging hose nut connected to the centre fitting of the manifold gauge set until a hiss can be

heard. Allow the air to escape for a few seconds, then re-tighten the nut.

Under no circumstances should the engine be

started.

9 Partially charge the system with 200 g of R134a by slowly opening the high side manifold valve; the low side gauge

should register a pressure, if not, check for blockage. Close the high side manifold valve as soon as 200 g of

R134a has entered the system.

10 Check the system for leaks with an electronic detector. If a leak is detected, remove refrigerant from system using

the RRU and repair the faulty component or connection. Repeat Steps 4 to 10 after repair of leak.

NOTE

Various types and makes of leak detectors are

currently in use. Whichever leak detector is used,

it is important to follow the manufacturer’s

instructions in regard to adjustment and setting

the instrument prior to conducting the test.

Inspect for leaks by slowly moving the probe of

the detector around all hose connections and

points of possible leakage. Refrigerant R134a is

heavier than air and will be more apparent at the

bottom of a fitting.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-9

Page 2B-9

Charging System

After a leak check has proven the system to be leak free, charge the specified amount of refrigerant into the system as

follows:

1 Open the high side manifold valve slowly. Fill the system with as much of the specified charge as possible, then

close the high side manifold valve.

2 Rotate the compressor by hand for 12 revolutions to ensure no liquid refrigerant is trapped in the suction side of the

compressor.

Failure to comply with this Step may result in

damage to the compressor.

3 Start the engine and engage the compressor clutch and evaporator fan on high speed.

4 Set engine speed to 1500 – 1700 rpm.

5 If the system has been charged with the specified amount (800 ± 25 g), go to Step 7.

6 To complete the charging of the system, slowly open the low side manifold valve until the specified amount has

been charged into the system.

Do not allow more than 275 kPa to be

registered on the low p ressu re gauge.

7 Perform the system functional check, refer to 3 System Functional Check.

If the unit operates satisfactorily, stop the engine, shut the stop valves at the hose connections to the system and

disconnect the hoses taking extreme caution, as the discharge hose can have up to 2070 kPa stored in it. Install service

valve caps as required.

No sight glass is fitted to the system due to PAG oil’s foaming properties, which may be confused with a low gas charge.

Topping up of the system is not recommended.

Accurate system refrigerant charge may only be determined by charging the system with the correct amount of R134a.

Pressure gauge readings together with face air outlet temperatures are the only method of checking and diagnosing the

system cooling capacity (comparing results with the appropriate graph).

If in doubt as to the gas charge as a result of one the following conditions:

• suction pressure low,

• discharge pressure low, or

• air outlet temperature (face) above graph range.

1 Recover the refrigerant from the system using R134a specific equipment.

2 Evacuate the system. Charge with 800 ± 25 g of R134a.

3 Carry out cooling system pressure test and suction (low side) pressure readings comparisons.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-10

Page 2B-10

2.3 Checking System Oil Charge

A replacement compressor is charged at the factory with the total A/C system quantity of lubricating oil. This oil is then

circulated via the refrigerant throughout the entire A/C system. Only the type of oil specified (which is blue in colour) must

be used when adding or changing oil. This oil is not compatible with any other PAG oil.

• V6 – 150 mL of Daphne PS RL897 supplied with the compressor.

• GEN III V8 – 220 mL of Poly alkaline glycol (PAG) supplied with the compressor.

Although it is not necessary to regularly check the oil level within the system, all the A/C system components will hold a

quantity of the oil circulated. Therefore whenever an A/C system component is replaced, a replacement quantity of new

refrigerant (PAG) oil must be added to the system. Where a major loss of system oil has occurred, due to:

• a broken hose or severe leak,

• collision damage to the refrigerant system components, or

• if excess oil is suspected to be in the system.

Then:

1 Recover refrigerant from the system.

2 Remove the compressor, refer to Section 2C HVAC Climate Control (Manual A/C) – Removal and Installation.

3 Carefully drain the refrigerant oil from the compressor while calculating the system oil balancing requirements, refer

to 2.5 Lubricating Oil Compensation.

4 Flush the remaining oil from the rest of the system using R134a refrigerant.

NOTE

A refrigerant recovery unit (RRU) should be used

to flush the system to ensure the R134a is not

vented to the atmosphere. The R134a must be

reclaimed via the RRU into a separate bottle.

5 Add any additional amount of new refrigerant oil to the compressor as determined in (2) above.

6 Install the compressor, replacing the suction and discharge O-rings. Ensure the O-rings are not twisted and the

seals and O-rings are clean.

7 Evacuate then recharge the system.

Do not allow PAG oil to contact either bare

skin or vehicle paintwork. If contact occurs,

w ash PAG oil off immediately.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-11

Page 2B-11

2.4 Flushing the A/C System for

Contamination or Lubricating Oil

Some oil is lost whenever air-conditioning system components are replaced.

Where the system has been ruptured, contaminated, or a compressor has to be removed and reinstalled or replaced, the

system should be checked for contamination and, if so, the entire system must be flushed.

Currently the only method recommended when flushing is using the refrigerant R134a.

NOTE

A Refrigerant Recovery Unit (RRU) should be

used to capture the R134a used for flushing. The

R134a must be reclaimed via the RRU into a

separate bottle. Use only a dedicated R134a

RRU.

The complete air-conditioning system must

contain the correct quantity of PAG

refrigerant oil.

Flushing Procedure

1 Flush the individual components.

2 Self made flushing fittings will be required as A/C system component fittings all differ in size, shape and thread size.

3 Invert the decanting cylinder to use refrigerant in liquid form.

4 Reverse flush the components.

5 Do not flush through a compressor otherwise possible internal damage could occur.

6 Recover / recycle the flushing refrigerant, the recovery device will remove contaminants through its filtration system.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-12

Page 2B-12

Figure 2B – 4

Legend

1 Condenser

2 Condenser Inlet

3 Flush Gun

4 Recovery Hose and End Fitting

5 Refrigerant Recovery Unit (RRU)

6 Refrigerant Recovery Cylinder

7 R134a Supply Cylinder

8 Flushing Hose And End Fitting

9 Adaptor

10 Condenser Outlet

NOTE

To carry out the reverse flush procedure the

positions of items 3 and 4 will be swapped with

items 8 and 9.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-13

Page 2B-13

2.5 Lubricating Oil Compensation

The total amount of lubricating oil in the air-conditioning system must be maintained. If a compressor, evaporator,

condenser, filter drier receiver, hose or pipe is to be replaced, a specified amount of lubricating oil must be added to the

system to compensate for oil removed with the original component.

Installing the Original Compressor

1 Drain and measure the refrigerant oil contained in the compressor.

2 Charge the oil through the discharge port of the compressor with the same amount of new refrigerant oil.

NOTE

If the amount of oil in the original compressor was

not checked, then approximately 150 mL (V6) or

220 mL (V8) of new oil should be added to the

compressor being installed. (This is assuming the

compressor being installed has first been

drained).

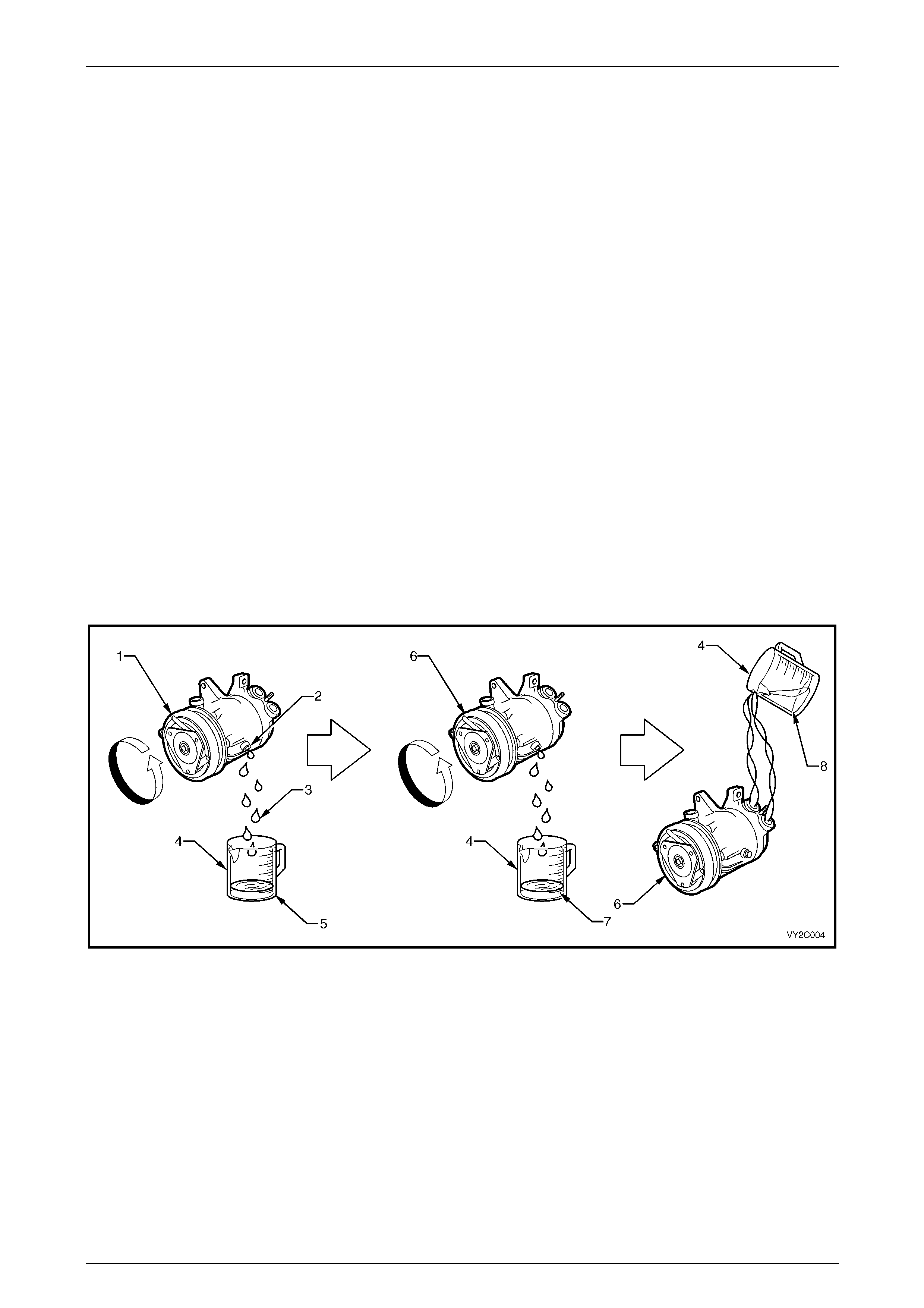

Installing a New Compressor

1 Drain and measure refrigerant oil from the original compressor drain plug.

2 Drain factory installed refrigerant oil from new compressor drain plug. The lubricant quantity will be approximately

150 mL (V6) or 220 mL (V8).

3 Measure the same amount of new refrigerant oil that was drained from the original compressor into a graduated

container. Install this amount of new oil into the new compressor through the suction / discharge port whilst turning

the compressor clutch pulley front face.

Figure 2B – 5

Legend

1 Original Compressor

2 Drain Plug Location

3 Drained Refrigerant Oil from Original Compressor

4 Graduated Container

5 Refrigerant Oil – Total Amount Removed: e.g. 100 mL

6 New Compressor

7 Drained Refrigerant Oil from New Compressor

8 Refrigerant Oil – Total Amount to be Installed: 100 mL

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-14

Page 2B-14

Evaporator or Condenser

Drain as much of the original oil as possible from the evaporator or condenser. Add the same amount of new refrigerant

oil, either to the original or new evaporator or condenser.

• If replacing the condenser – add approximately 40 mL.

• If replacing the evaporator – add approximately 50 mL.

Filter Drier Receiver (FDR)

If replacing the FDR – add approximately 15 mL.

The FDR must be replaced whenever the system has been opened to the atmosphere for repair.

Blown or Ruptured Pipe/Hose

When replacement is required, add approximately 40 mL

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-15

Page 2B-15

3 System Functional Check

Step Action Yes No

1 Is the fault specifically isolated to this system? Go to Step 2 Refer to Section 0D

Vehicle Diagnostics.

2 Does the OCC control module power-up?

Go to Step 3

Refer to Section 2E

HVAC Occupant

Climate Control

(Auto A/C) –

Diagnostics

3 Set the OCC control module to:

• fresh air position (recirculate off),

• Mode to Face,

• temperature set to T MIN, and

• blower speed set to High.

Were you able to adjust heating and ventilation controls as instructed? Go to Step 4

Refer to Section 2E

HVAC Occupant

Climate Control

(Auto A/C) –

Diagnostics

4 Perform the following:

• park the vehicle in a shaded area,

• open the hood and windows,

• open all ventilation outlets and adjust to the straight-ahead

position, and

• using a thermometer, note the ambient temperature. Go to Step 5 —

5 Connect the manifold gauges, refer to 2.1 Manifold Gauge

Installation. Go to Step 6 —

6 Start the engine and bring engine speed to 1700 rpm. Allow the

pressure gauge needles to stabilise. Go to Step 7 —

7 Does the A/C compressor clutch engage?

Go to Step 8

Refer to Test 2:

Checking

Compressor Clutch

Engagement

8 Are there any abnormal air-conditioning system noises?

NOTE

Rectify any abnormal noise conditions before continuing

with the System Functional Check. Refer to Test 7:

Noise Diagnosis Go to Step 9

9 Check the manifold gauge pressures.

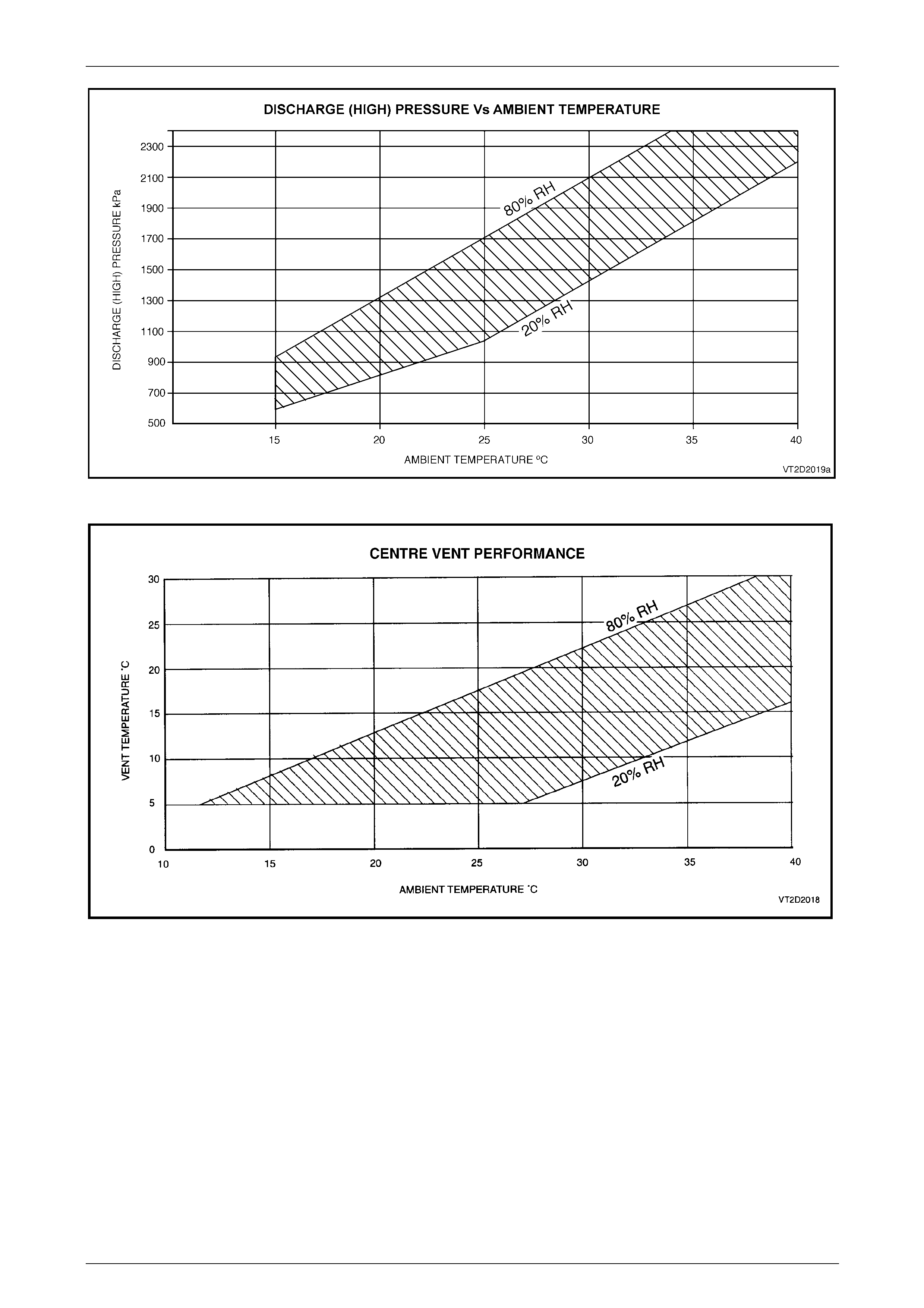

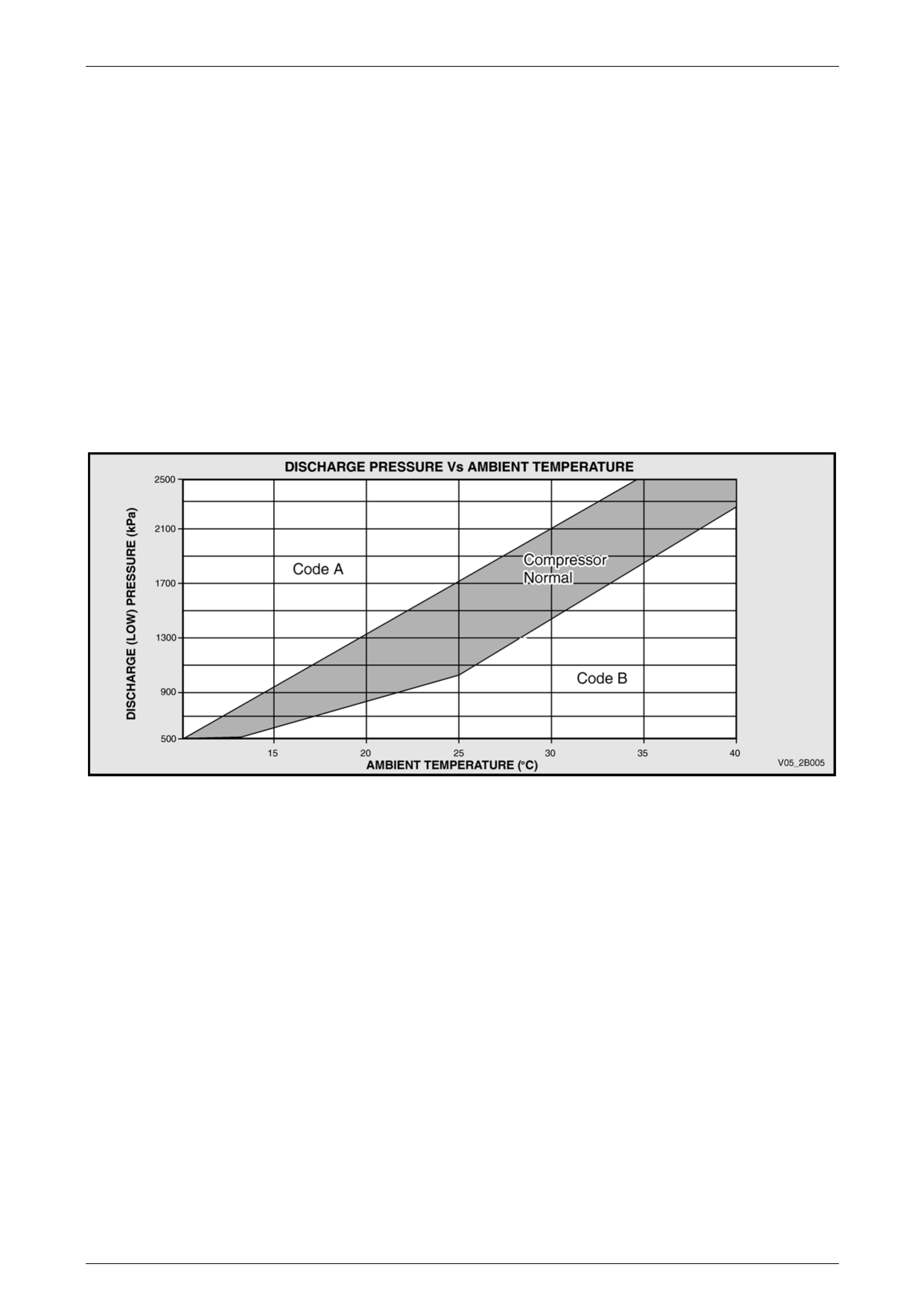

Are the pressures within the shaded area in Figure 2B – 6? Go to Step 10 Refer to 4

Diagnostics

10 Insert a thermometer probe approximately 50 mm into the centre vent

louvre.

Is the temperature within the shaded area in Figure 2B – 7? System OK Refer to 4

Diagnostics

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-16

Page 2B-16

Figure 2B – 6

Figure 2B – 7

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-17

Page 2B-17

4 Diagnostics

4.1 Air-conditioner System Diagnosis

Introduction

This diagnostic is the starting point for verifying and diagnosing all air-conditioning system related complaints. It

represents the correct path to follow from a customer complaint or condition through delivery of the vehicle back to the

customer.

Preliminary Inspection

The preliminary inspection covers all physical and visual inspections of interior and under-hood components. Many

problems can be detected by a thorough inspection of the air-conditioning system. Failure to perform this step could

result in wasted time proceeding through the remaining tests.

Air-conditioning System Tests

These tests were developed by producing known system problems and recording the air-conditioning system pressures

at various ambient temperatures.

To find the problem, compare the vehicle’s performance test readings to the readings on the charts for your ambient

temperature and humidity. When all pressure and temperature readings fall outside the limits of a given chart, use that

chart to repair the vehicle.

NOTE

There is some variance in readings between

systems of different vehicles, however the target

areas of the charts have been developed to

accommodate these changes.

Index to System Tests

Test 1: Checking Refrigerant Charge

Test 2: Checking Compressor Clutch Engagement

Test 3: Checking Compressor System Performance

Test 4: Checking Compressor for Less Than Full Stroke (Low Load) Simulation

Test 5: Checking Compressor for Full Stroke Operation (High Load) Simulation

Test 6: TXV Operational Check on Vehicle

Test 7: Noise Diagnosis

Preliminary Inspection

1 Perform the system functional check, refer to 3 System Functional Check.

2 Check the A/C fuse.

3 A/C blower fan operation.

4 Air mix door. Move the door rapidly from cold to hot.

5 Ensure the air mix door fully opens and closes. Re-calibrate the air mix motor / door movement,

refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

6 Air-conditioner clutch coil connection.

7 Air-conditioner pressure sensor connection.

8 Accessory drive belt. Replace if damaged or missing, refer to Section 6A1 Engine Mechanical – V6 or,

Section 6A3 Engine Mechanical – GEN III V8.

9 Engine cooling fan operation – at idle, the cooling fan must be on at any A/C mode and must be rotating in the

correct direction (drawing ambient air through the condenser towards the engine).

10 Condenser – Check for restricted air flow.

11 Dealer technical bulletins for updates on A/C system.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-18

Page 2B-18

Test 1: Checking Refrigerant Charge

This procedure is designed for use with gauges that have been calibrated correctly.

The ambient air temperature should be at least 15 °C, and the ignition key in the OFF position.

Step Action Yes No

1 Connect the high and low side pressure gauges to the system, refer to

2.1 Manifold Gauge Installation.

Is the high side pressure reading greater than 400 kPa?

Check compressor

clutch engagement.

Refer to Test 2:

Checking

Compressor Clutch

Engagement Go to Step 2

2 If the high pressure side is below 400 kPa, perform Evacuation and

Leak Test, refer to 2.2 System Charging and Evacuation.

Was the gas leak found?

Go to Step 3

Add refrigerant dye

to the A/C system.

Perform a pin point

inspection with a

black light after the

vehicle has driven

for a week with the

A/C operating

3 1 Recover the refrigerant.

2 Repair the system leak.

3 Evacuate and re-charge the system.

Is the high side pressure reading greater than 400 kPa? Check for correct

system operation Go to Step 2

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-19

Page 2B-19

Test 2: Checking Compressor Clutch Engagement

Step Action Yes No

1 Run the engine at idle. Set the OCC control module to:

• normal A/C mode,

• high blower speed, and

• temperature to full cold.

Does the compressor clutch engage?

Check the

compressor system

performance. Refer

to Test 3: Checking

Compressor System

Performance Go to Step 2

2 Are there any engine management DTC's which may effect the

operation of the air-conditioning compressor clutch operation? Refer to Section

6C1-2 Engine

Management – V6 –

Diagnostics, or

Section 6C3-2

Powertrain

Management – GEN

III V8 – Diagnostics Go to Step 3

3 1 Turn off the ignition.

2 Using a multimeter check the compressor clutch coil windings

resistance.

Does the multimeter display 3.42 ± 0.2 Ohms? Go to Step 4

Replace the

compressor. Refer

to Section 2C HVAC

Climate Control

(Manual A/C –

Removal and

Installation

4 Check the compressor clutch air gap using a feeler gauge.

Is the air gap 0.3 to 0.76 mm?

Go to Step 5

Replace the

compressor. Refer

to Section 2C HVAC

Climate Control

(Manual A/C –

Removal and

Installation

5 1 Turn off the ignition switch.

2 Disconnect the compressor clutch wiring connector at the

compressor.

3 Connect a jumper lead from a good vehicle ground to the

compressor clutch terminal X1-A using a suitable electrical kit

adapter plug.

The coil windings have a diode connected across

them. Serious damage to the clutch could occur if the

battery polarity if not properly connected. Refer to

Compressor Electrical Connector for correct terminal

identification.

4 Temporarily connect a fused jumper wire from the positive

battery terminal to the compressor clutch terminal X1-B.

Does compressor clutch engage when contact with the lead is made? Go to step 6

Replace the

compressor. Refer

to Section 2C HVAC

Climate Control

(Manual A/C –

Removal and

Installation

6 Check the vehicle wiring harness and electrical connector to the

compressor clutch. Refer to the Section 12P Wiring Diagrams.

Is the wiring harness / connector circuit OK?

Go to Step 7

Repair the electrical

fault in the vehicle

harness. Refer to

Section 12P Wiring

Diagrams for

information on

electrical diagnosis

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-20

Page 2B-20

Step Action Yes No

7 1 Using Tech 2, view the air-conditioning pressure sensor

pressure / voltage status parameter in the engine control module

data list. Refer to Section 6C1-2 Engine Management – V6 –

Diagnostics or, Section 6C3-2 Powertrain Management – GEN

III V8 – Diagnostics.

2 Compare the air-conditioning pressure sensor pressure / voltage

values correspond to the pressure gauge readings.

Are the actual gauge and pressure sensor values within 5 % of each

other? Go to step 8

Replace the air-

conditioning

pressure sensor.

Refer to Section 2C

HVAC Climate

Control (Manual A/C

– Removal and

Installation

8 Check the high pressure side pressure reading at idle.

NOTE

If the refrigerant pressure is above 2900 kPa the air-

conditioning pressure sensor will disengage the

compressor.

Is the high pressure side pressure above 2900 kPa?

Check the

compressor system

performance. Refer

to Test 3: Checking

Compressor System

Performance —

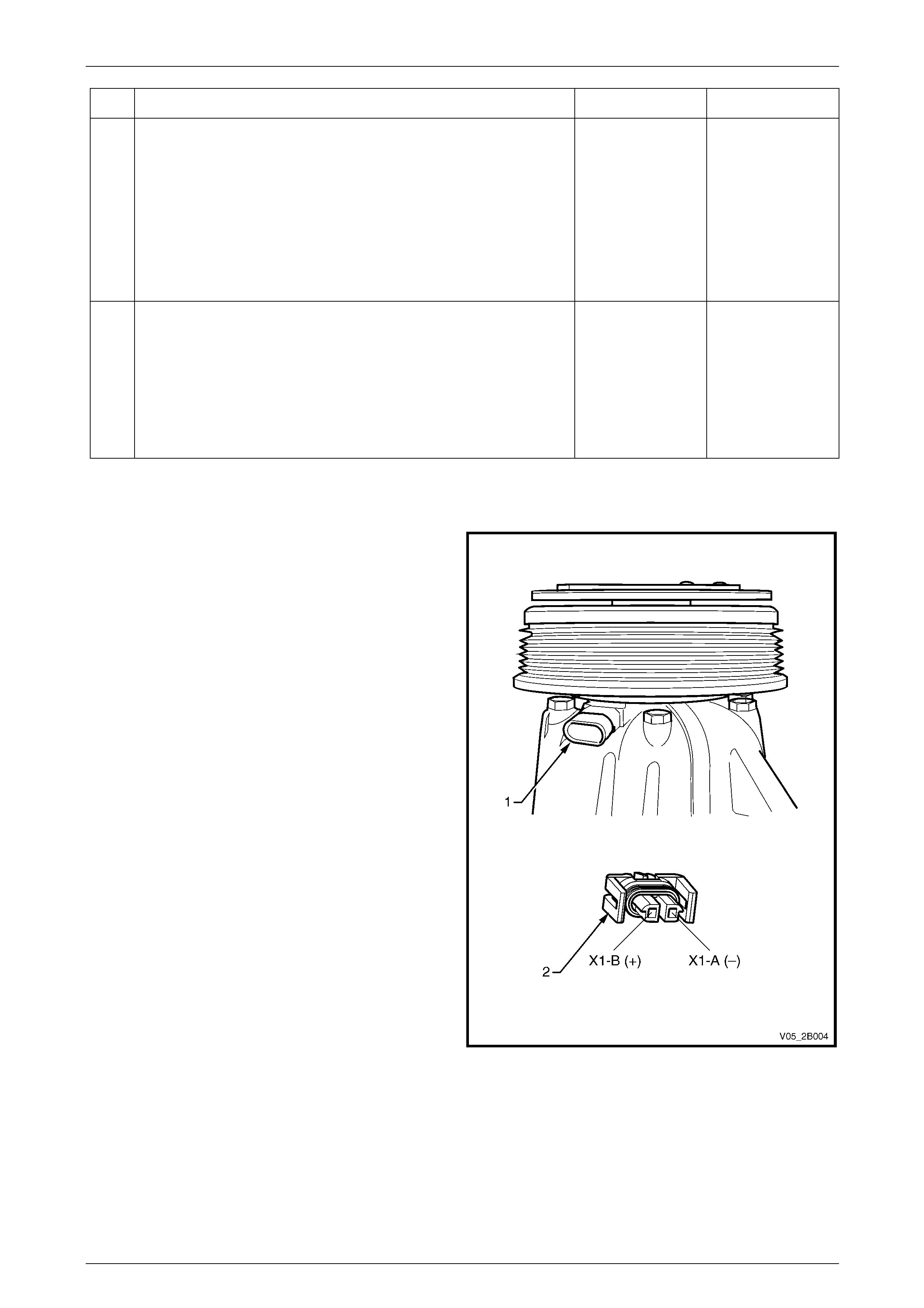

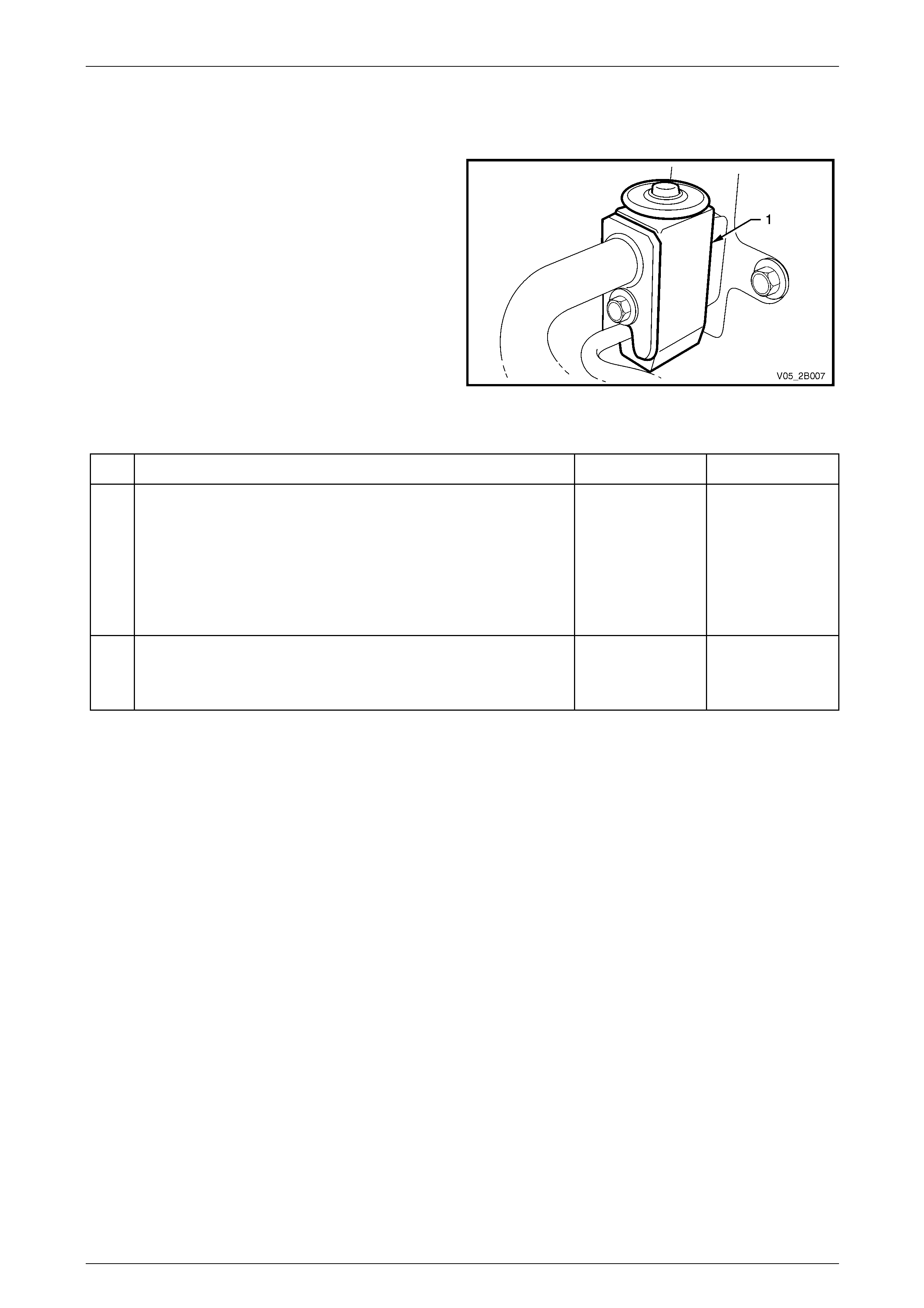

Compressor Electrical Connector

NOTE

The compressor clutch electrical connector (1) is

located near the accessory drive belt pulley.

The wiring harness connector (2) connections

must be observed when undertaking Step 5 of

the diagnostic table.

Figure 2B – 8

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-21

Page 2B-21

Test 3: Checking Compressor System Performance

The following test is designed to increase the load on the air-conditioning system to ensure that during the test the

compressor is operating at maximum displacement.

Vehicle Set-up

1 Select the highest blower speed for the HVAC fan.

2 Open the hood and doors.

3 Select the vehicle’s temperature control setting to full cold and engage A/C.

4 Stabilise the vehicle’s interior temperature to match ambient temperature.

5 Insert a thermometer in vehicle’s centre vent position.

6 Set the engine at fast idle (1500 rpm).

Using the information obtained from the test, plot the point where the ambient temperature intersects with the discharge

pressure. If the intersection point does not fall within the shaded area (compressor normal) in Figure 2B – 9, it will fall in

either Code A area or Code B area. Use the Air-conditioning System Performance Chart to assist in determining the true

system fault.

Figure 2B – 9

The chart on the following page lists what the possible causes are that fall into the Code A and Code B categories.

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-22

Page 2B-22

Air-conditioning System Performance Chart

CODE A: (Possible causes) CODE B: (Possible causes)

1 Over charge of lubricating oil or refrigeran t –

symptoms:

• Low side pressure is to specification or higher.

• High side pressure is to high.

Action

a Refrigerant overcharge

Evacuate and recharge A/C system, refer to

2.2 System Charging and Evacuation.

b Oil overcharge

Recover refrigerant. Remove and drain compressor

of oil. If the measured amount of oil is greater than

100 cc, flush complete A/C system, refer to

2.2 System Charging and Evacuation.

1 Compressor not pumping – symp t oms:

• Low side pressure high.

• High side pressure lower than specification.

Action

a Check A/C system for leaks. (Note below)

b Repair leak. Evacuate and recharge the A/C

system, refer to 2.2 System Charging and

Evacuation.

c Carry out TXV testing, go to Test 6: TXV

Operational Check on Vehicle.

2 Refrigerant undercharge – symptoms:

• Low side pressure to specification.

• High side pressure to low.

Action

a Check A/C system for leaks. (Note below)

b Repair leak. Evacuate and recharge the A/C

system, refer to 2.2 System Charging and

Evacuation.

c Carry out TXV testing, go to Test 6: TXV

Operational Check on Vehicle.

2 Compressor control valve problem –

symptoms

• Low side pressure to high.

• High side pressure to specification.

Action

Go to Test 4: Checking Compressor for Less Than Full

Stroke (Low Load) Simulation.

3 TX Valve jammed open – symptoms:

• Low side pressure to specification or higher.

• High side pressure to high.

Action

Carry out TXV testing, go to Test 6: TXV Operational

Check on Vehicle.

3 TX Valve or Filter Drier restricted – symptoms:

• Low side pressure to specification.

• High side pressure to low.

Action

a Feel the inlet and outlet tubes of the Filter Drier,

both tube temperatures should be the same. If

temperatures are different, check the Filter Drier

orientation (flow direction).

b If orientation correct – replace the Filter Drier.

c Carry out TXV testing, go to Test 6: TXV

Operational Check on Vehicle.

4 Engine cooling fan problem – symptoms:

• Low side pressure to specification or higher.

• High side pressure to high.

Action

Check engine cooling fan operation. Refer to

Section 6B1 Engine Cooling – V6, or Section 6B3 Engine

Cooling – GEN III V8

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-23

Page 2B-23

Test 4: Checking Compressor for Less Than Full Stroke (Low Load) Simulation

Vehicle Set Up

1 Select the lowest blower speed for the HVAC fan.

2 Close the doors and windows.

3 Select the vehicle’s temperature control setting to full cold and engage A/C.

4 Set the air to Recirculation mode.

5 Set the engine to a fast idle of 1500 rpm.

Test Procedure

Step Action Yes No

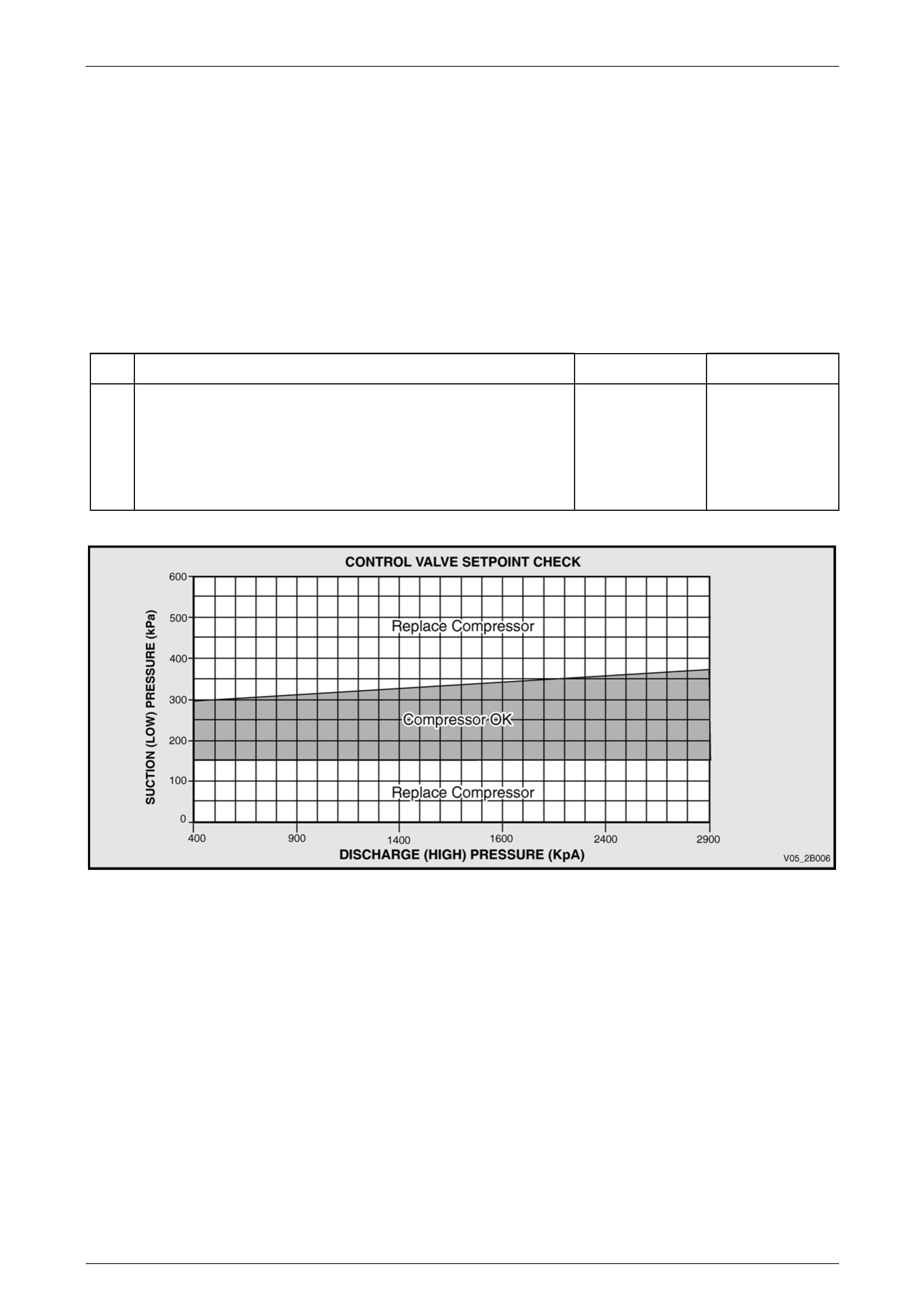

1 Check the system’s high and low gas pressures.

Do the high and low side pressure readings intersect in the shaded

area of the graph (below)?

Go to Test 5:

Checking

Compressor for Full

Stroke Operation

(High Load)

Simulation

Replace the

compressor. Refer

to Section 2C

HVAC Climate

Control (Manual A/C

– Removal and

Installation

Figure 2B – 10

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-24

Page 2B-24

Test 5: Checking Compressor for Full Stroke Operation (High Load) Simulation

Vehicle Set Up:

1 Select the highest blower speed for the HVAC fan.

2 Open the hood and doors.

3 Select the vehicle’s temperature control setting to full cold and engage A/C.

4 Set the air to fresh air inlet mode.

5 Insert thermometer in vehicle’s centre vent position.

6 Set the engine at fast idle (3000 rpm).

Step Action Yes No

1 1 Using gauges, measure the system’s high and low pressures.

2 Subtract the low side reading from the high side reading and

compare the difference to the value shown in Figure 2B – 10.

Is the difference less than 210 kPa? Go to Step 2

Go to Test 3:

Checking

Compressor System

Performance

2 1 Turn the ignition off.

2 Rotate the compressor clutch front plate (not the pulley).

Does front plate turn freely by hand? Go to Test 3:

Checking

Compressor System

Performance

Replace the

compressor. Refer

to Section 2C

HVAC Climate

Control (Manual A/C

– Removal and

Installation

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-25

Page 2B-25

Test 6: TXV Operational Check on Vehicle

Vehicle Set Up

1 Start the engine. Leave the front doors open

2 Set the HVAC controls to:

• Maximum A/C,

• Highest blower speed,

• Face position, and

• Fresh air mode.

3 Take a note of the high and low side pressure gauge

readings once the gauge needles have stabilised.

4 Locate the TXV (1) at the rear of the engine

compartment.

5 Set the engine at fast idle.

Figure 2B – 11

Step Action Yes No

1 1 Apply freeze spray (or equivalent) over the TXV sensing disc

until it is frosted over.

2 View the high and low side pressure readings. The high side

reading should be reduced from what it was before the spray

was applied.

Did the high side pressure reading reduce once the temperature at the

TXV was reduced? Go to Step 2 Replace the TXV

2 Note the high and low pressures change as the TXV warms up.

Did the TXV react to the temperature change by noting the change in

pressures? TXV operation OK Replace the TXV

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-26

Page 2B-26

Test 7: Noise Diagnosis

Preliminary Check

The purpose of this test is to observe for any loud knocking noises from the compressor, or any other noises that may

come from the accessory drive belt slipping.

Step Action Yes No

1 Inspect, and if necessary, rectify any faults with the accessory drive

belt and drive belt tensioner. Refer to Section 6A1 Engine Mechanical

– V6 or, Section 6A3 Engine Mechanical – GEN III V8. Go to Step 2 —

2 Run the engine and check for possible compressor noise.

Does the noise last longer than 30 seconds? Go to Step 4 Go to Step 3

3 1 Allow engine to run for a few minutes.

2 Stop engine and let it rest for a minute.

3 Restart engine.

Is any noise detected using this procedure?

Go to Step 5

It is normal to

observe a liquid

slugging condition.

This may occur after

extended system

shutdown at warmer

ambient

temperatures,

followed by an

overnight ambient

temperature drop

4 Check if the system has a low refrigerant charge. Refer to Test 1:

Checking Refrigerant Charge.

Is there enough system gas, etc.? Go to Step 6 Go to Step 7

5 Check if the TXV is stuck closed or open.

Is the TXV stuck open?

Carry out TXV

diagnosis. Refer to

Test 6: TXV

Operational Check

on Vehicle Go to Step 6

6 Check for any loose compressor bolts and / or A/C plumbing

contacting body work.

Are any mounting bolts loose? Tighten bolts and/or

relocate plumbing Go to Step 7

7 1 Recover refrigerant and replace compressor.

2 Recharge the system.

Are the gas pressures within specification, refer to Test 4: Checking

Compressor for Less Than Full Stroke (Low Load) Simulation? System checks

complete Go to Step 1

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-27

Page 2B-27

Compressor Noise Check

Vehicle Set Up:

1 Prepare to build up high side pressure to 2000 kPa by preventing the engine cooling fans from operating by

temporarily disconnecting the cooling fan electrical connectors.

2 Select the lowest blower speed for the HVAC fan.

3 Open the hood.

4 Select the vehicle’s temperature control setting to full cold and engage A/C.

5 Set the air to fresh air inlet mode.

6 Set the engine idle speed to idle.

Step Action Yes No

1

After engine is started, d o not allow the h igh pressure

to exceed 2000 kPa as compressor overload noises

will become apparent, which is normal but not

desirable for any length of time.

1 Run engine for 5 minutes with the A/C on at 1700 rpm.

2 Allow the pressure gauge needles to stabilise.

3 Listen for abnormal compressor A/C system noises.

Is the low side pressure within normal range? Refer to

Figure 2B – 10.

Carry out Test 3:

Checking

Compressor System

Performance Go to Step 2

2 Check to see if the High side pressure is at or above 2000 kPa.

Was a clunk heard that lasted for 2 to 4 seconds duration? This noise is normal

for a load increase System OK

3 1 Turn off the engine and allow the gas pressures to stabilise.

2 Start engine and switch on A/C.

Was slugging or quick knocking observed at all?

Excess oil or liquid

is causing slugging,

refer to Test 3:

Checking

Compressor System

Performance or

jammed open TX

Valve, refer Test 6:

TXV Operational

Check on Vehicle

No excess oil or

liquid is apparent in

the system

4 1 Turn off the engine and allow the gas pressures to stabilise.

2 Start engine and switch on A/C.

3 Observe the gas pressures with cooling fans running / not

running.

Was ticking, a squeal or growling observed, especially at idle speed?

Inspect the

accessory drive belt

and tensioner for

damage and rectify

as necessary

Accessory drive belt

and tensioner are

operating OK

5 1 Observe the high side gas pressure.

2 Increase the engine revs above 2000 rpm.

Is the refrigerant pressure higher than normal and associated with a

rumble, growl, groan or A/C system pulsation through the hoses?

Refrigerant could be

overcharged, refer

to Test 1: Checking

Refrigerant Charge

The condenser may

have an air flow

restriction issue,

refer to Section 2C

HVAC Climate

Control (Manual

A/C) – Removal and

Installation

The refrigerant level

and the condenser

airflow are OK

6 1 Observe the high and low side gas pressures with the cooling

fans running / not running.

2 Reduce the engine revs to idle speed slightly above.

Is a continuous metallic knock or groan observed from the

compressor?

Check the

compressor

mounting bolts for

tightness, refer to

Section 2C HVAC

Climate Control

(Manual A/C) –

Removal and

Installation. The compressor is

mounted securely

HVAC Climate Control (Manual A/C) – Servicing and Diagnosis Page 2B-29

Page 2B-29

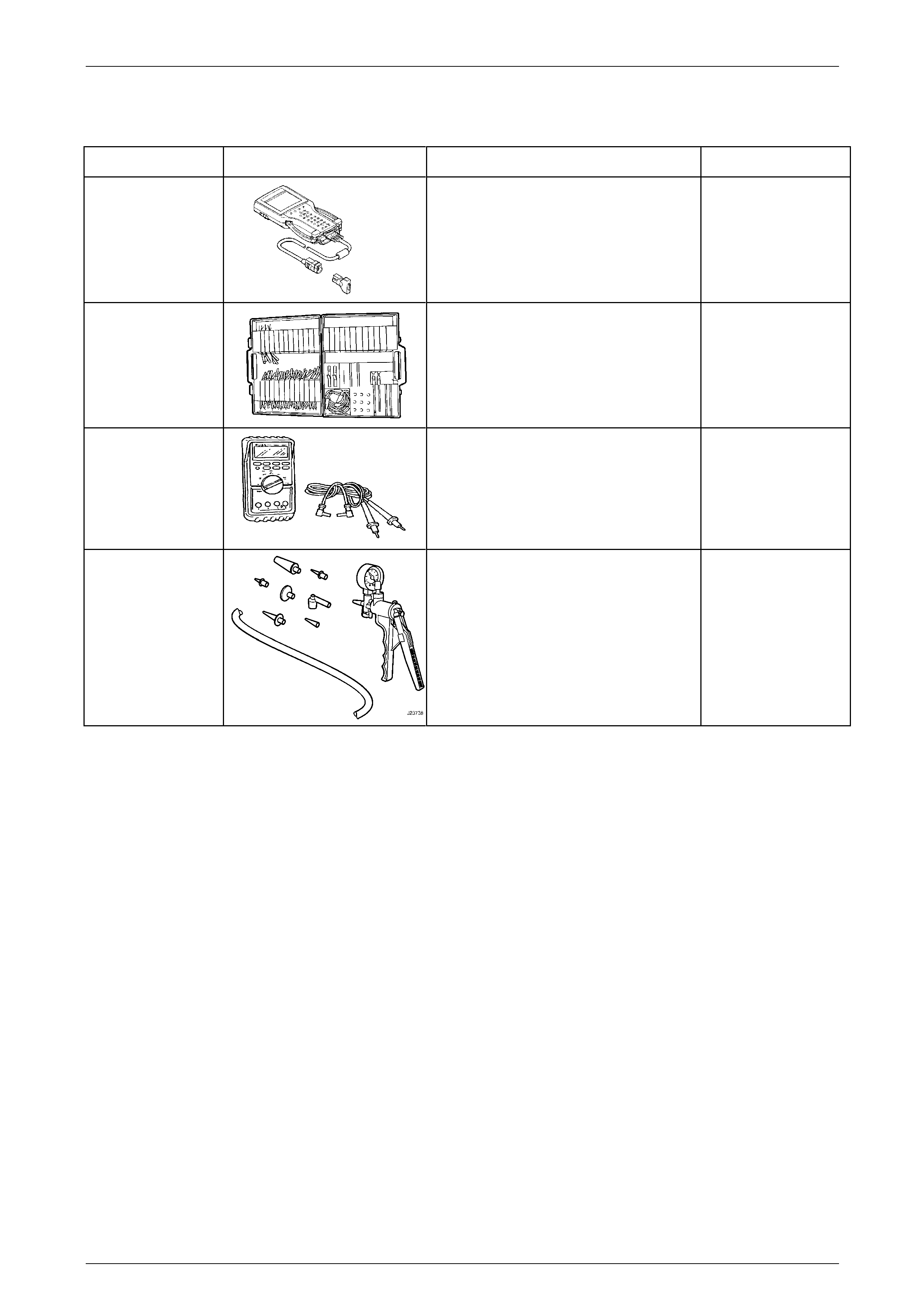

6 Special Tools

Tool Number Illustration Description Tool Classification

7000086I

TECH 2 DIAGNOSTIC SCAN TOOL

• Used for diagnosis of vehicle

electrical system.

• Previously released.

Mandatory

J35616-A

(KM609)

CONNECTOR TEST ADAPTOR KIT

• Used when carrying out electrical

diagnostic circuit checks.

• Previously released.

Desirable

3588

(J39200)

DIGITAL MULTIMETER

• Must have at least 10 MΩ input

impedance and be capable of

reading frequencies.

• Previously released.

Available

J23738 VACUUM PUMP

• Used for testing HVAC system

components, i.e. check valve,

HVAC controller, HVAC unit

vacuum tank, lines and actuators.

• Previously released.

Desirable