HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-1

Page 2C-1

Section 2C

HVAC Climate Control (Manual A/C) –

Removal and Installation

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ...............................................................................................................................5

2 HVAC Controller – Manual A/C .............................................................................................................6

2.1 Manual Controller Assembly................................................................................................................................. 6

Remove................................................................................................................................................................... 6

Reinstall.................................................................................................................................................................. 6

2.2 Water Valve Vacuum Switch................................................................................................................................. 7

Remove................................................................................................................................................................... 7

Reinstall.................................................................................................................................................................. 7

2.3 Air Mix Door Rod Retainer .................................................................................................................................... 8

Remove................................................................................................................................................................... 8

Reinstall.................................................................................................................................................................. 8

2.4 Front Housing/Switch Assembly and Printed Circuit Board.............................................................................. 9

Remove................................................................................................................................................................... 9

Reinstall................................................................................................................................................................ 11

2.5 Mode Switch Vacuum Valve................................................................................................................................ 13

Remove................................................................................................................................................................. 13

Reinstall................................................................................................................................................................ 13

3 Heating, Ventilation and Air-conditioning (HVAC) Unit....................................................................14

3.1 HVAC Unit............................................................................................................................................................. 14

Remove................................................................................................................................................................. 14

Reinstall................................................................................................................................................................ 17

3.2 Evaporator............................................................................................................................................................ 18

Remove................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 19

3.3 Heater Core........................................................................................................................................................... 20

Remove................................................................................................................................................................. 20

Reinstall................................................................................................................................................................ 21

3.4 Blower Motor and Fan Assembly ....................................................................................................................... 22

Remove................................................................................................................................................................. 22

Reinstall................................................................................................................................................................ 22

3.5 Electronic Blower Motor Controller.................................................................................................................... 23

Remove................................................................................................................................................................. 23

Test ....................................................................................................................................................................... 24

Test 1............................................................................................................................................................... 25

Test 2............................................................................................................................................................... 26

Reinstall................................................................................................................................................................ 26

3.6 Intake Blower Duct............................................................................................................................................... 27

Remove................................................................................................................................................................. 27

Reinstall................................................................................................................................................................ 27

3.7 Vent Distribution Housing................................................................................................................................... 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 28

Techline

Techline

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-2

Page 2C-2

4 Vacuum System....................................................................................................................................29

4.1 Vacuum Retention Tests..................................................................................................................................... 29

Check Valve.......................................................................................................................................................... 30

Vacuum Tank........................................................................................................................................................ 32

Vacuum Mode Valve – Manual A/C..................................................................................................................... 33

Water Valve Vacuum Switch – Manual A/C........................................................................................................ 35

Vacuum Solenoid Pack – Auto A/C.................................................................................................................... 36

Vacuum Actuators............................................................................................................................................... 37

Water Valve Actuator........................................................................................................................................... 38

Vacuum Lines – Manual A/C............................................................................................................................... 39

Vacuum Lines – Auto A/C ................................................................................................................................... 41

Vacuum Actuator Lines.................................................................................................................................... 41

Vacuum Manifold Line...................................................................................................................................... 42

4.2 Vacuum Tank........................................................................................................................................................ 43

Remove................................................................................................................................................................. 43

Reinstall................................................................................................................................................................ 43

4.3 Vacuum Actuators............................................................................................................................................... 44

Intake Actuator (fresh / recirculation)................................................................................................................ 44

Remove............................................................................................................................................................ 44

Reinstall ........................................................................................................................................................... 44

Face Actuator....................................................................................................................................................... 45

Remove............................................................................................................................................................ 45

Reinstall ........................................................................................................................................................... 45

Foot Actuator ....................................................................................................................................................... 46

Remove............................................................................................................................................................ 46

Reinstall ........................................................................................................................................................... 46

5 Air-conditioning Lines and Retainers ................................................................................................47

5.1 Replace................................................................................................................................................................. 47

Lines and Retainers Views – V6 RWD................................................................................................................ 48

Lines and Retainers Views – V6 AWD................................................................................................................ 49

Lines and Retainers Views – GEN III V8............................................................................................................. 50

6 Air-conditioning Components.............................................................................................................51

6.1 Thermal Expansion Valve ................................................................................................................................... 51

Remove................................................................................................................................................................. 51

Reinstall................................................................................................................................................................ 51

6.2 A/C Pressure Transducer.................................................................................................................................... 52

Replace – V6......................................................................................................................................................... 52

Replace – GEN III V8............................................................................................................................................ 52

6.3 Condenser Assembly.......................................................................................................................................... 53

V6 Engine ............................................................................................................................................................. 53

Remove............................................................................................................................................................ 53

Reinstall ........................................................................................................................................................... 56

GEN III V8 Engine................................................................................................................................................. 57

Remove............................................................................................................................................................ 57

Reinstall ........................................................................................................................................................... 62

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-3

Page 2C-3

6.4 Filter Drier Receiver............................................................................................................................................. 63

Remove................................................................................................................................................................. 63

Reinstall................................................................................................................................................................ 64

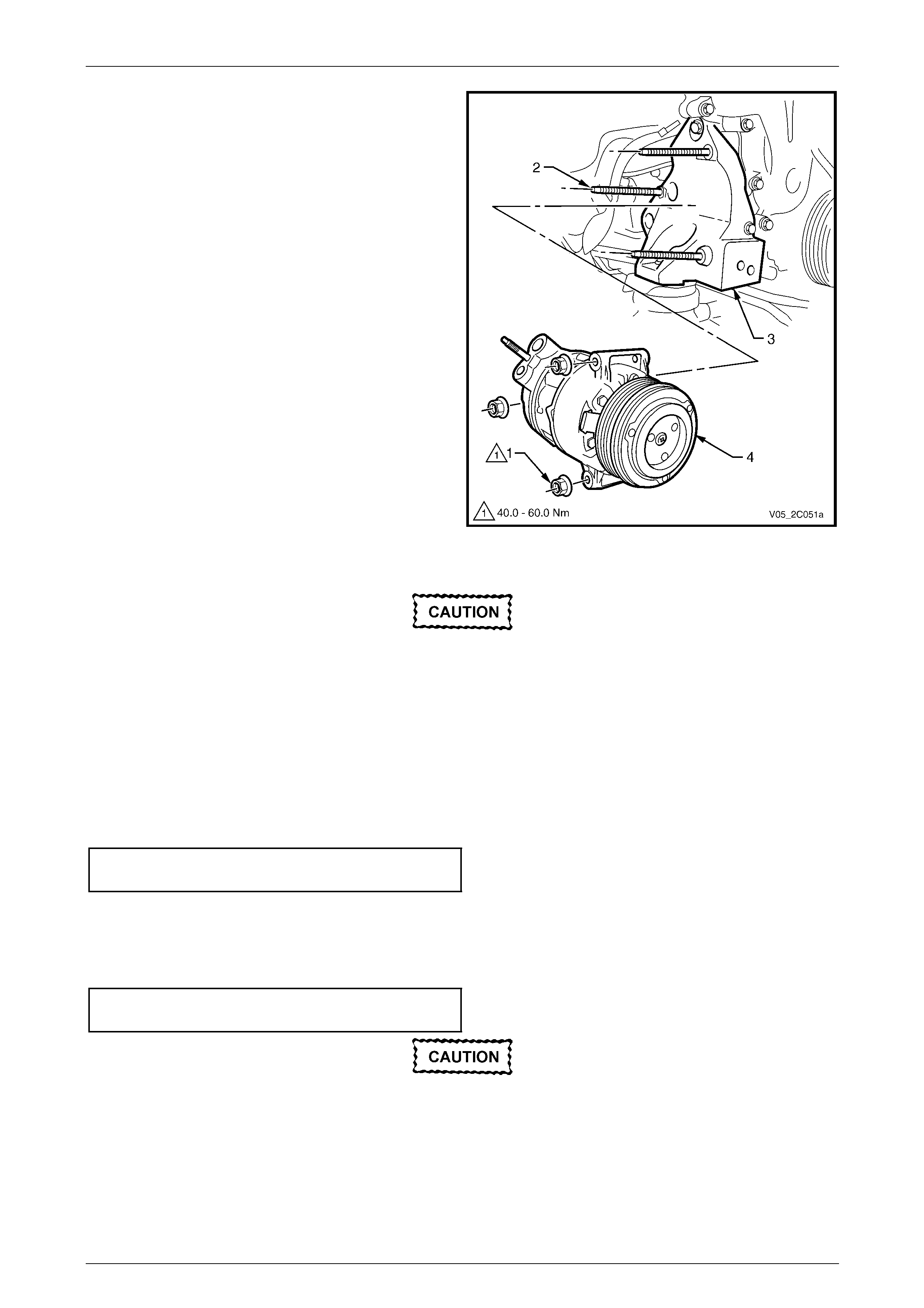

6.5 Air-conditioning Compressor Assembly ........................................................................................................... 65

V6 Engine – RWD................................................................................................................................................. 65

Remove............................................................................................................................................................ 65

Reinstall ........................................................................................................................................................... 66

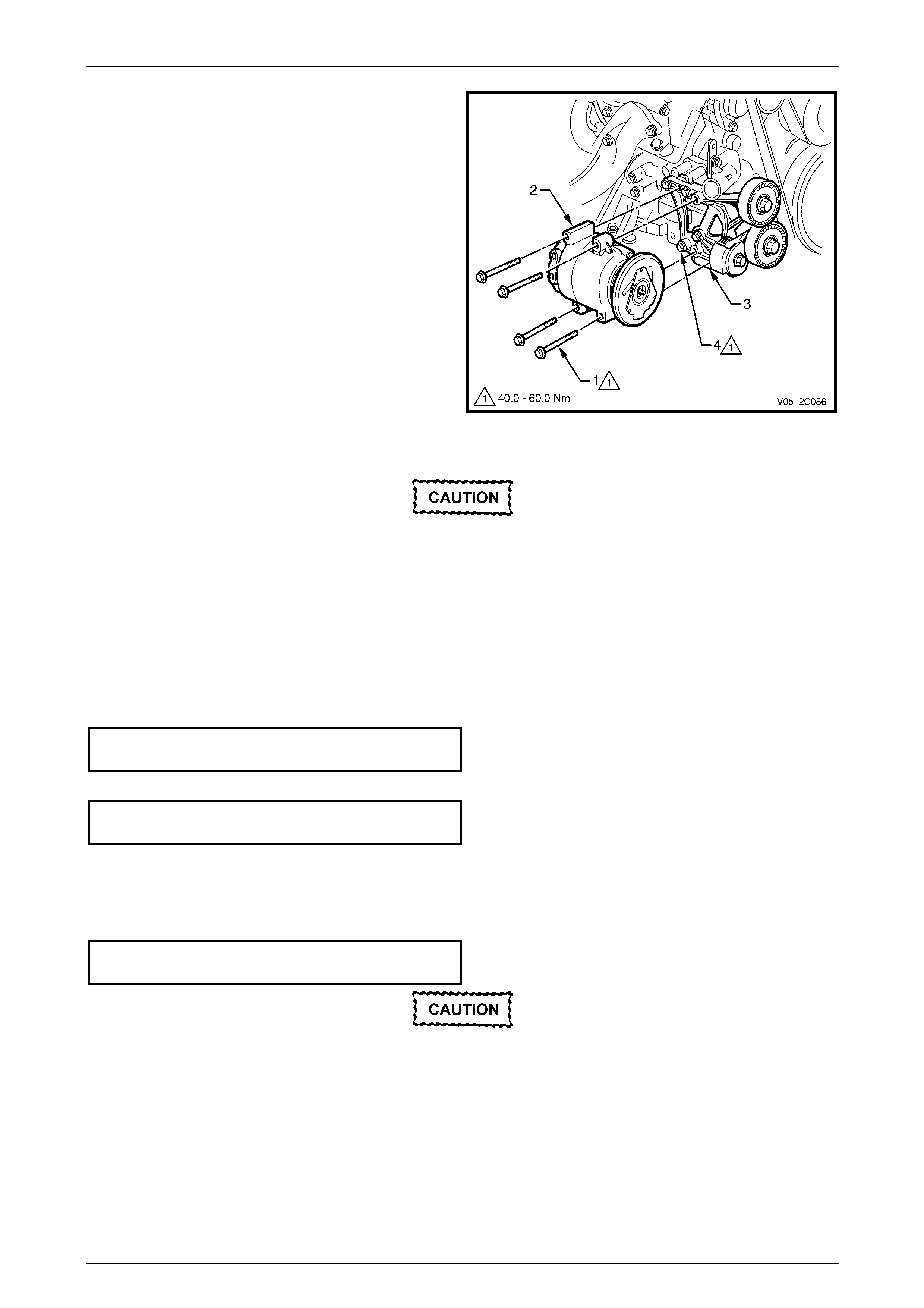

V6 Engine – AWD................................................................................................................................................. 67

Remove............................................................................................................................................................ 67

Reinstall ........................................................................................................................................................... 68

GEN III V8 Engine................................................................................................................................................. 69

Remove............................................................................................................................................................ 69

Reinstall ........................................................................................................................................................... 70

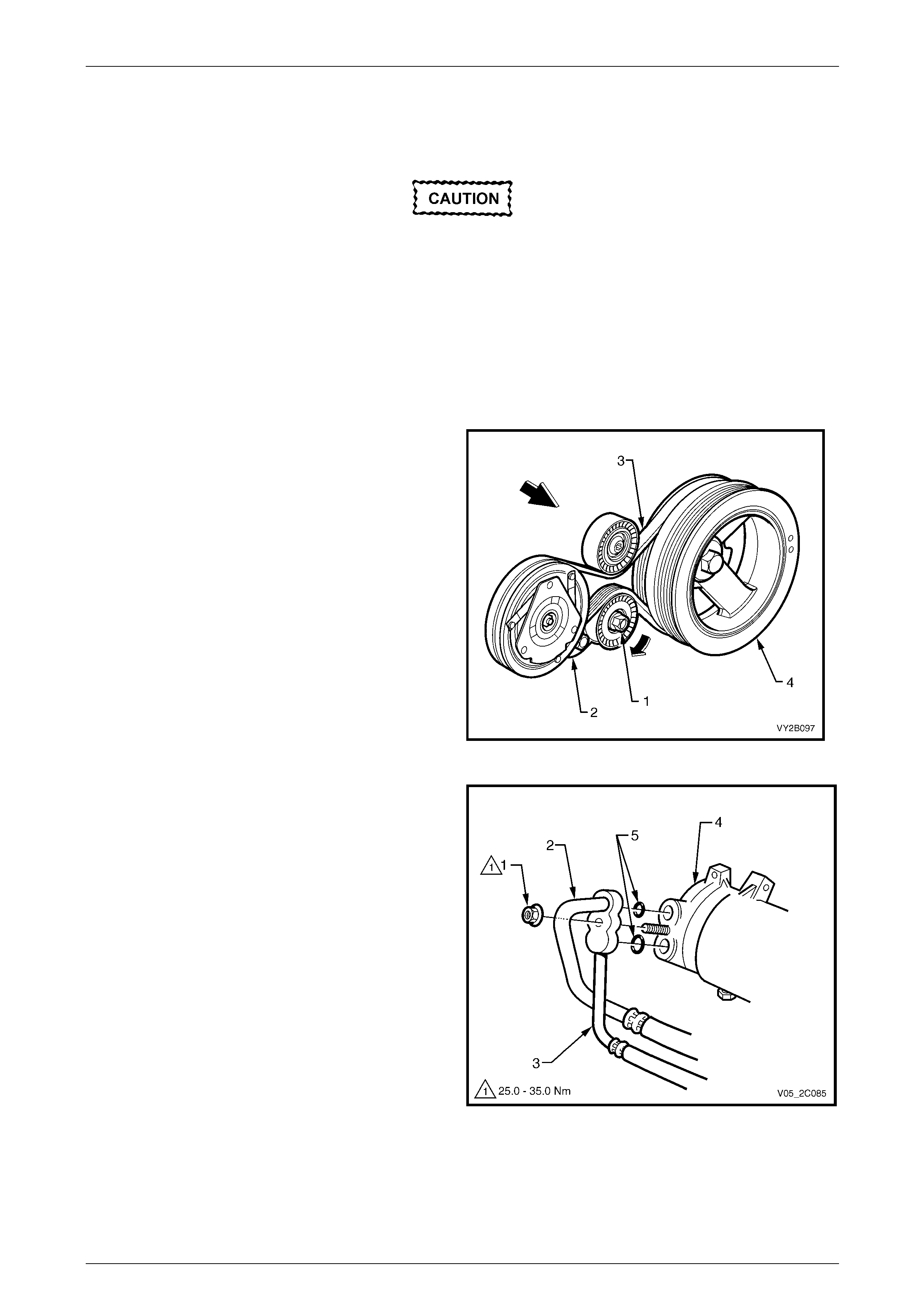

7 Drive Belts and Pulleys........................................................................................................................71

8 Minor Compressor Repairs – GEN III V8............................................................................................72

8.1 Compressor Control Valve.................................................................................................................................. 73

Remove................................................................................................................................................................. 73

Reinstall................................................................................................................................................................ 73

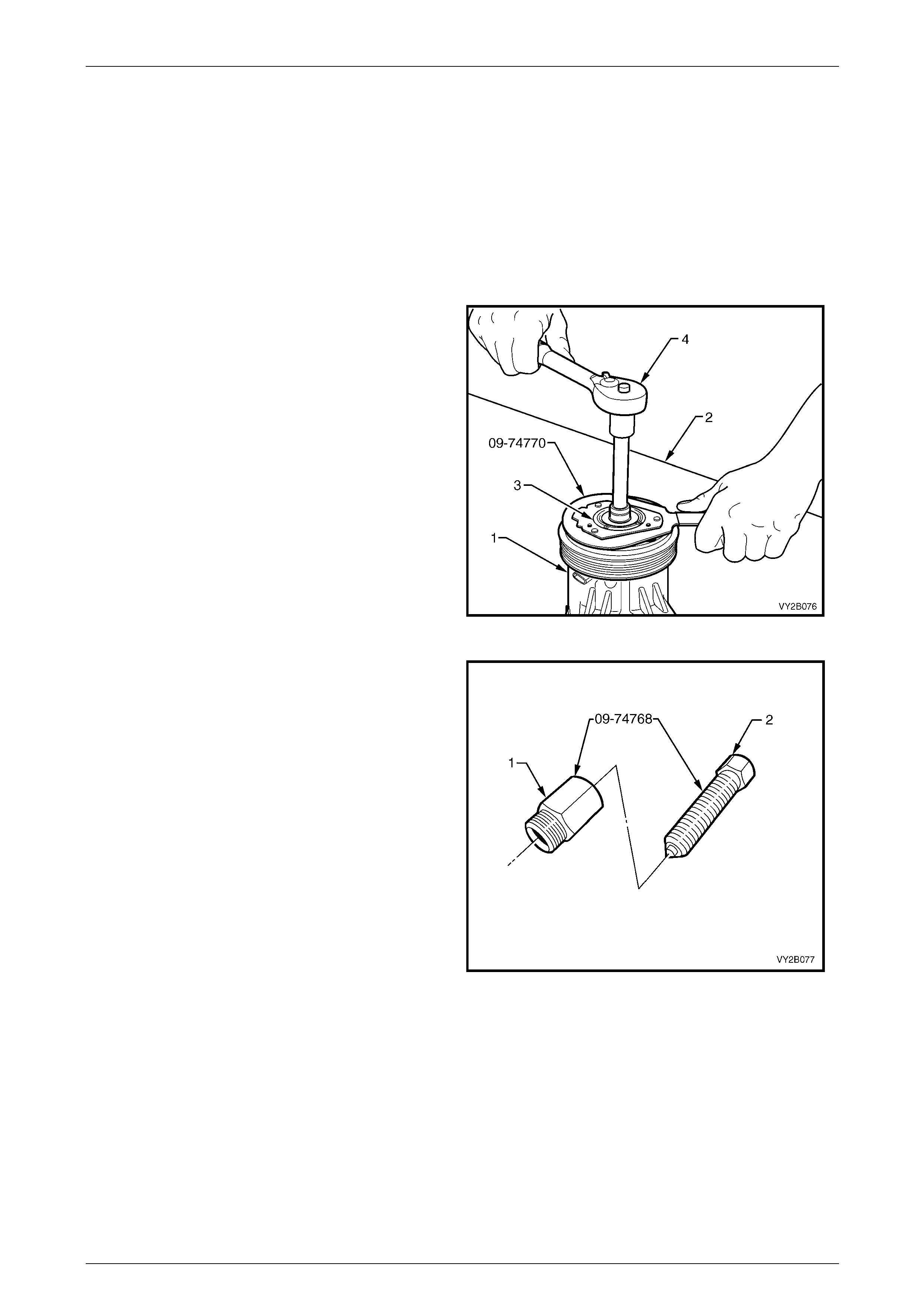

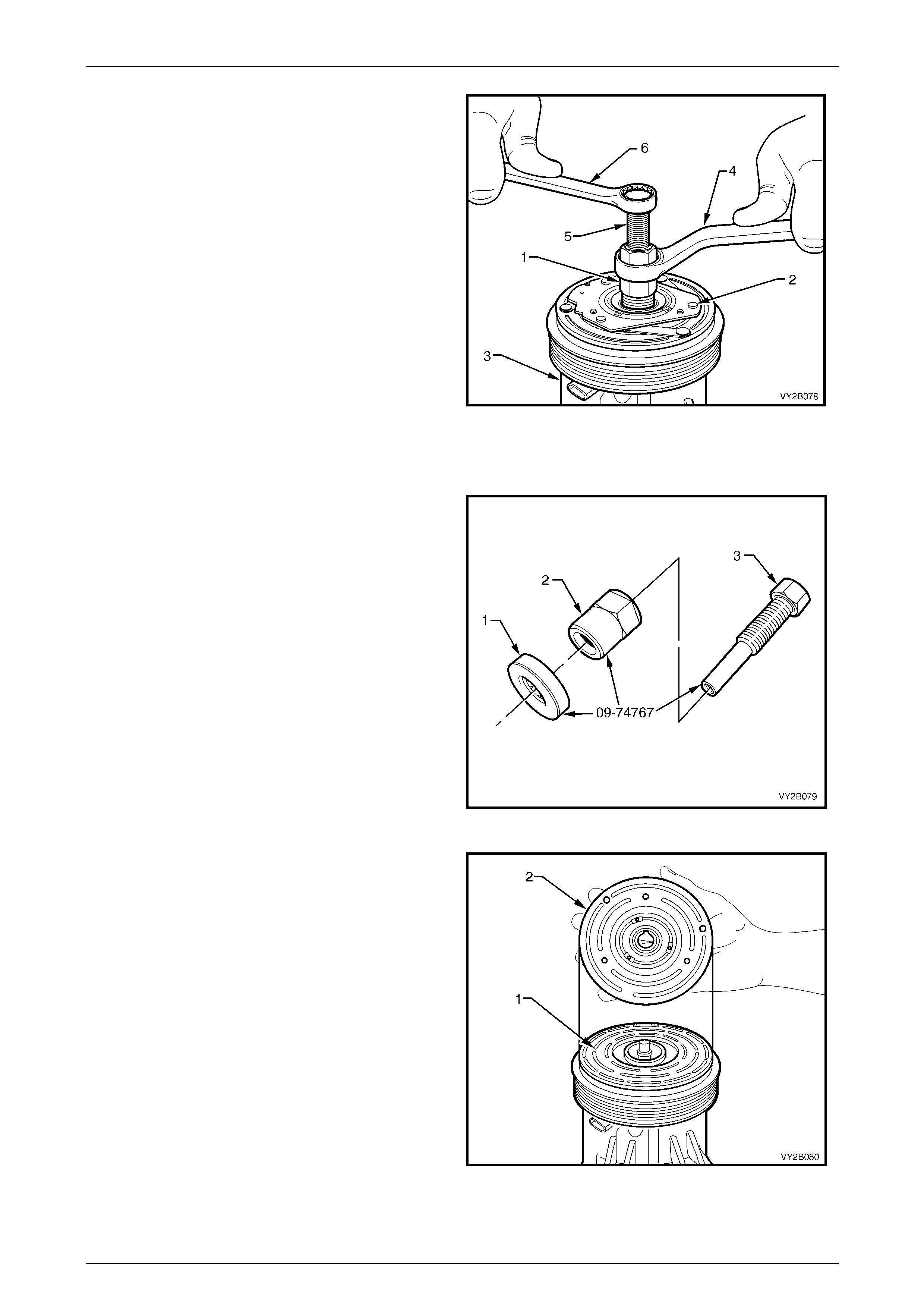

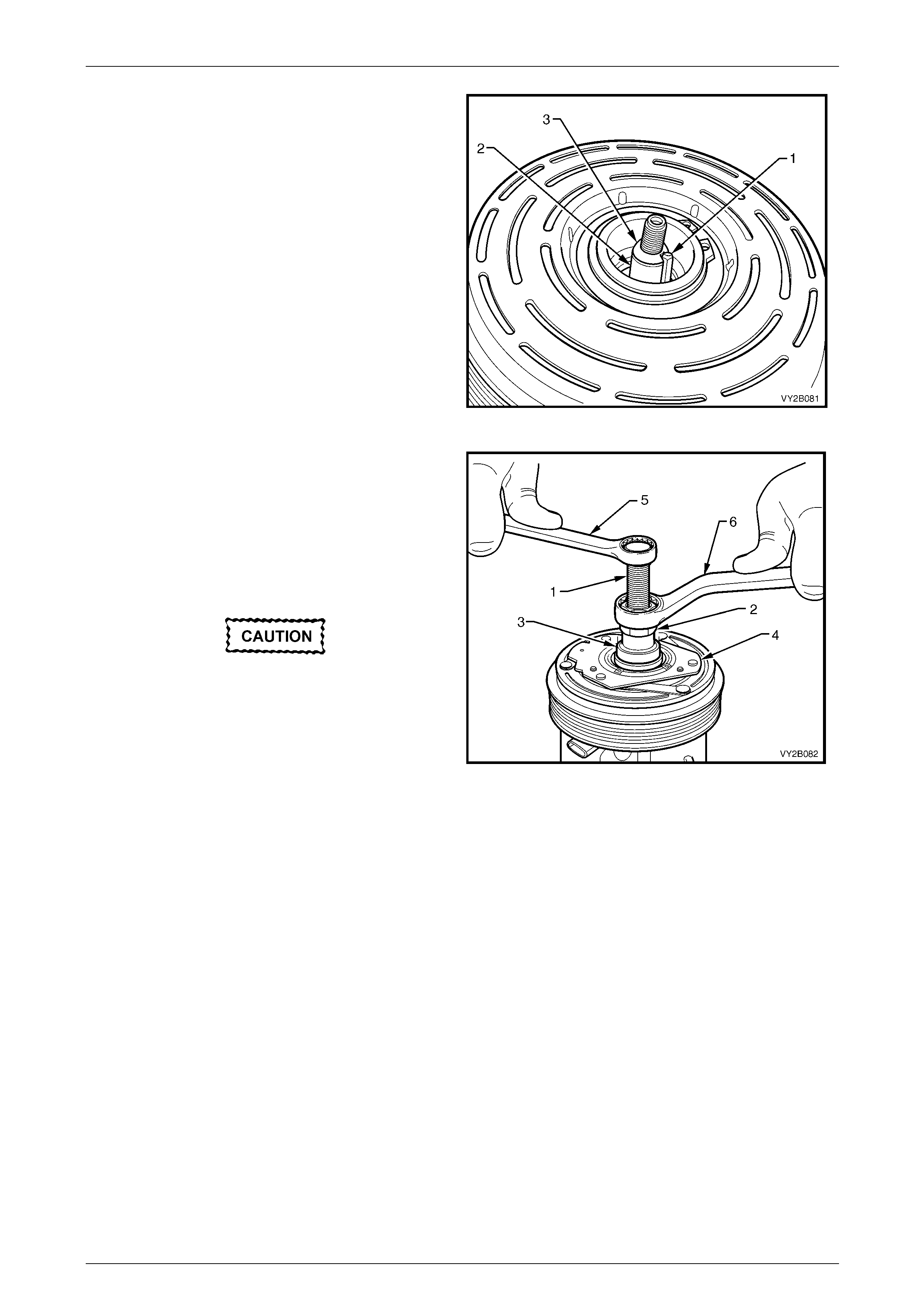

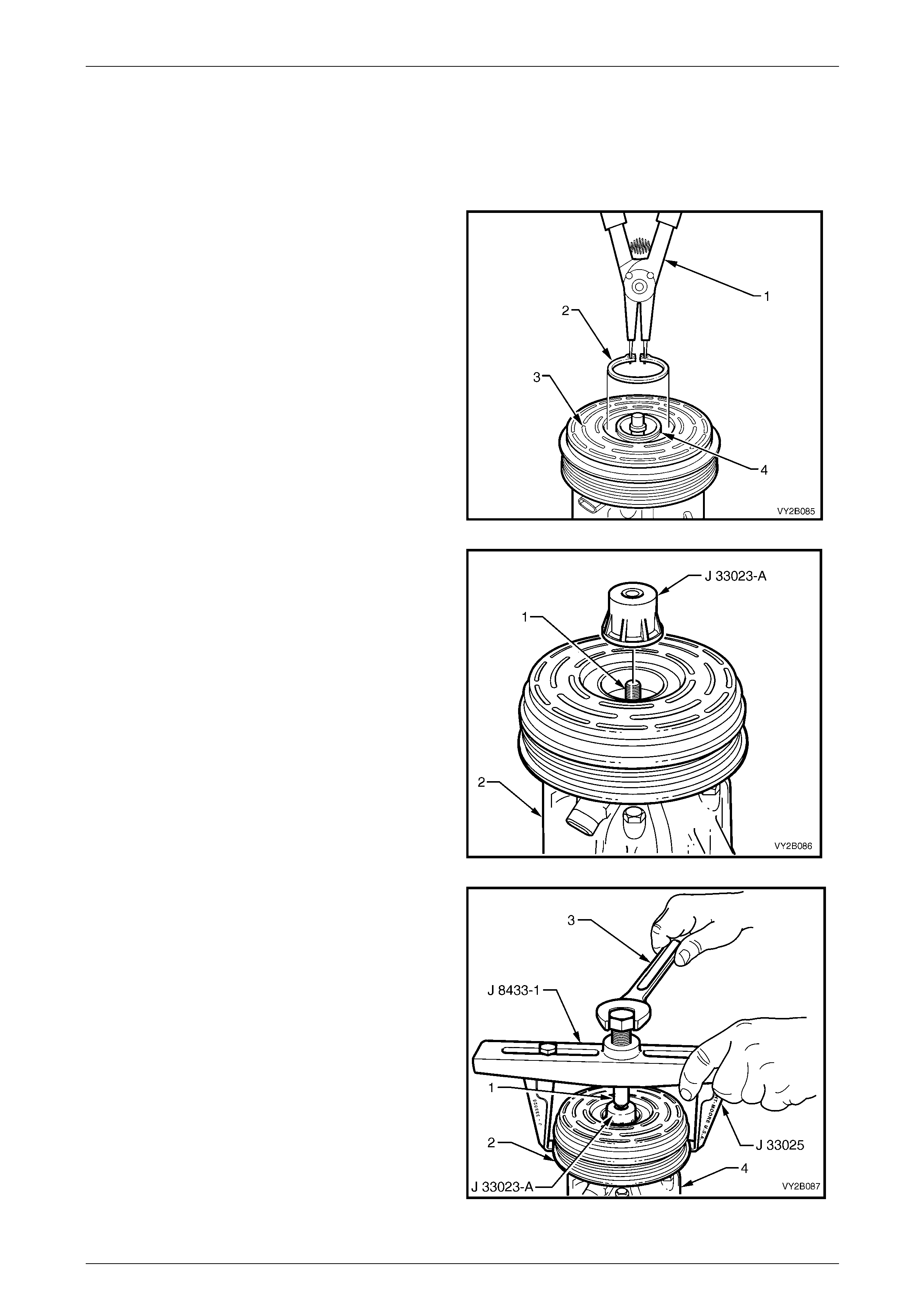

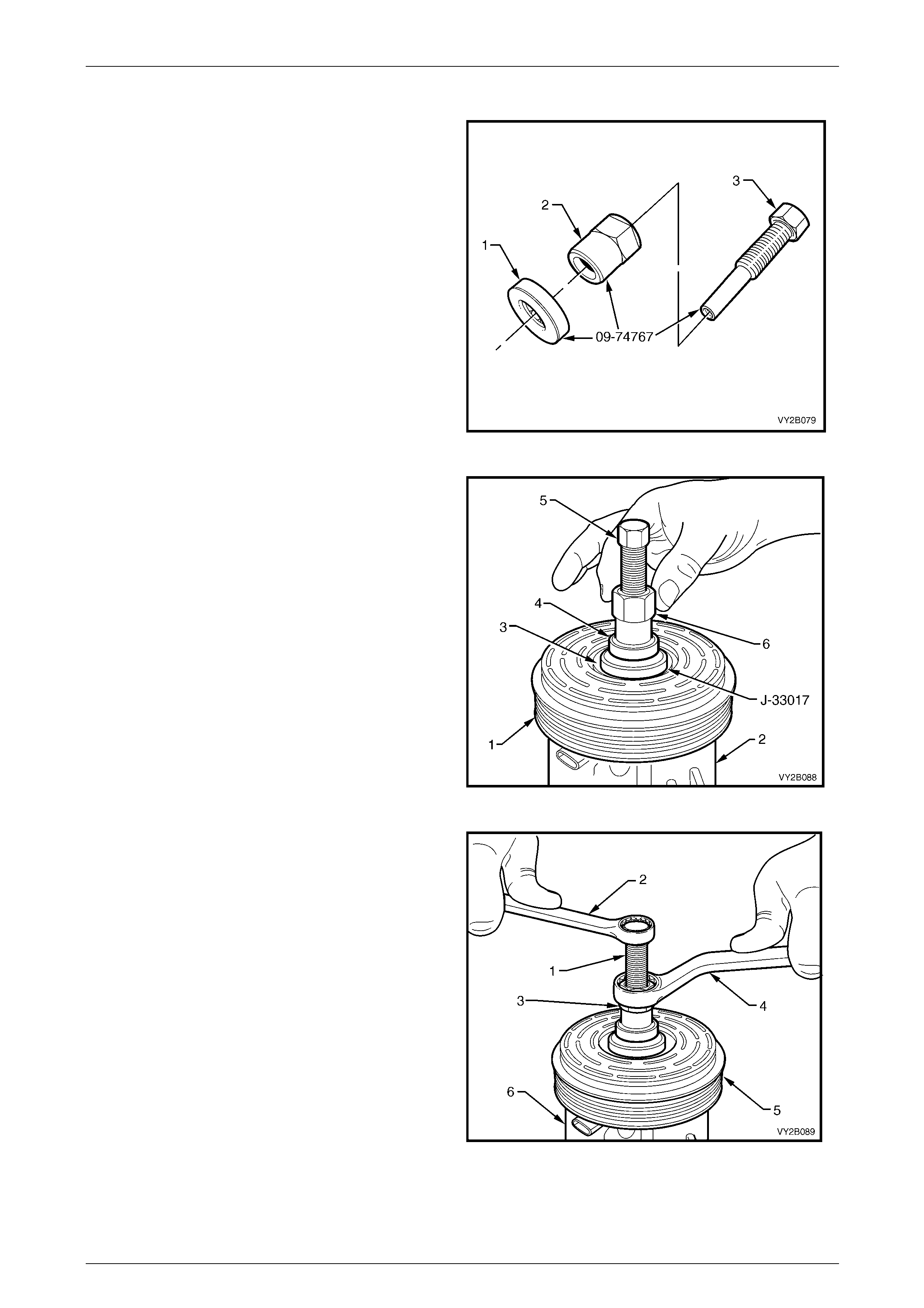

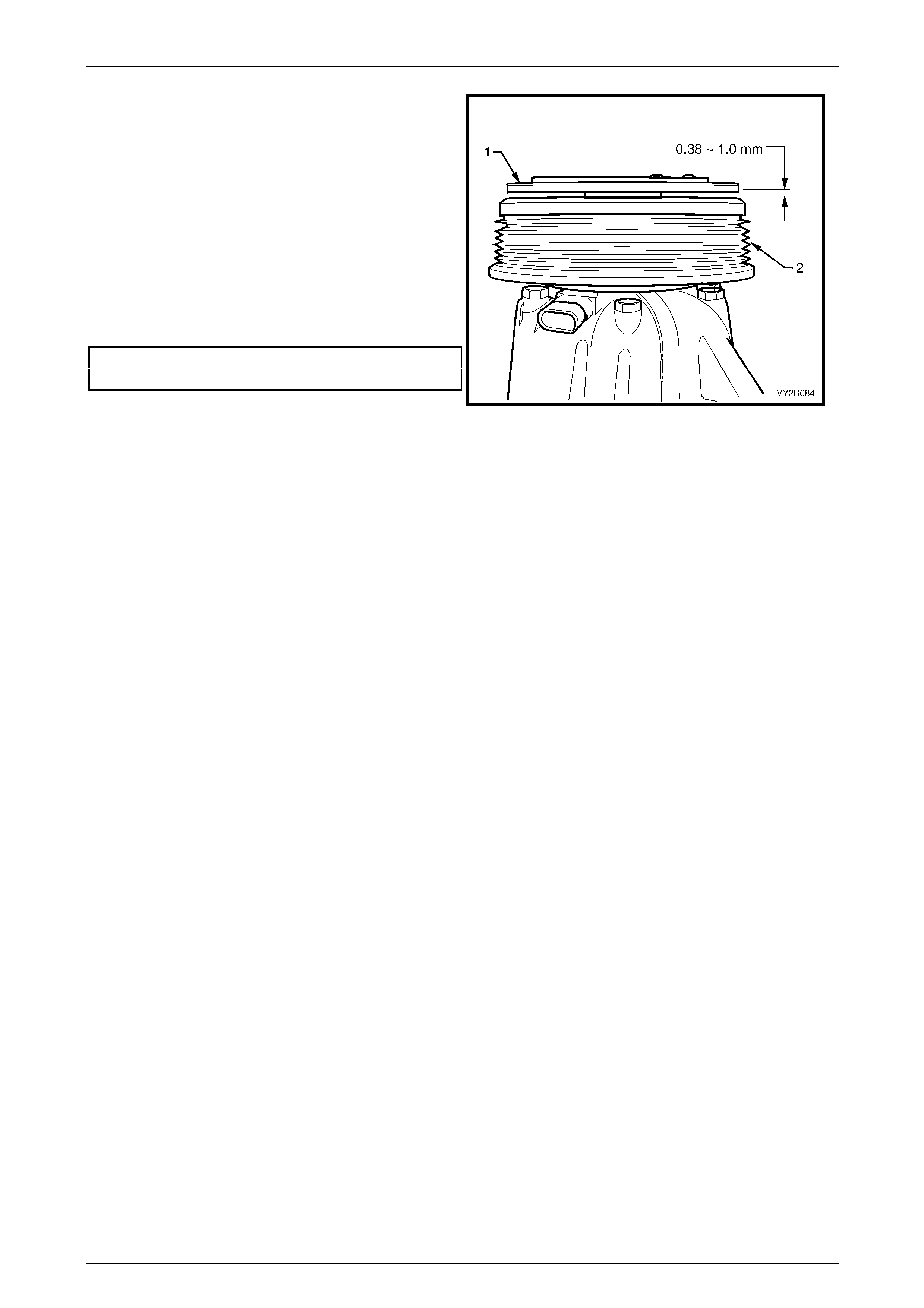

8.2 Clutch Drive Plate and Hub Assembly............................................................................................................... 74

Remove................................................................................................................................................................. 74

Reinstall................................................................................................................................................................ 75

8.3 Clutch Pulley and Bearing Assembly................................................................................................................. 78

Remove................................................................................................................................................................. 78

Reinstall................................................................................................................................................................ 79

9 Under-hood Heater Components........................................................................................................81

9.1 Water Valve Assembly......................................................................................................................................... 81

V6 Engine ............................................................................................................................................................. 81

Remove............................................................................................................................................................ 81

Test.................................................................................................................................................................. 81

Reinstall ........................................................................................................................................................... 81

GEN III V8 Engine................................................................................................................................................. 82

Remove............................................................................................................................................................ 82

Test.................................................................................................................................................................. 82

Reinstall ........................................................................................................................................................... 82

9.2 Heater Hoses and Vacuum Lines ....................................................................................................................... 83

Replace – V6......................................................................................................................................................... 83

Replace – GEN III V8............................................................................................................................................ 85

10 HVAC Inlet, Ducts and Ventilation Outlets ........................................................................................86

10.1 HVAC Inlet Screen Assembly.............................................................................................................................. 86

Remove................................................................................................................................................................. 86

Reinstall................................................................................................................................................................ 87

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-4

Page 2C-4

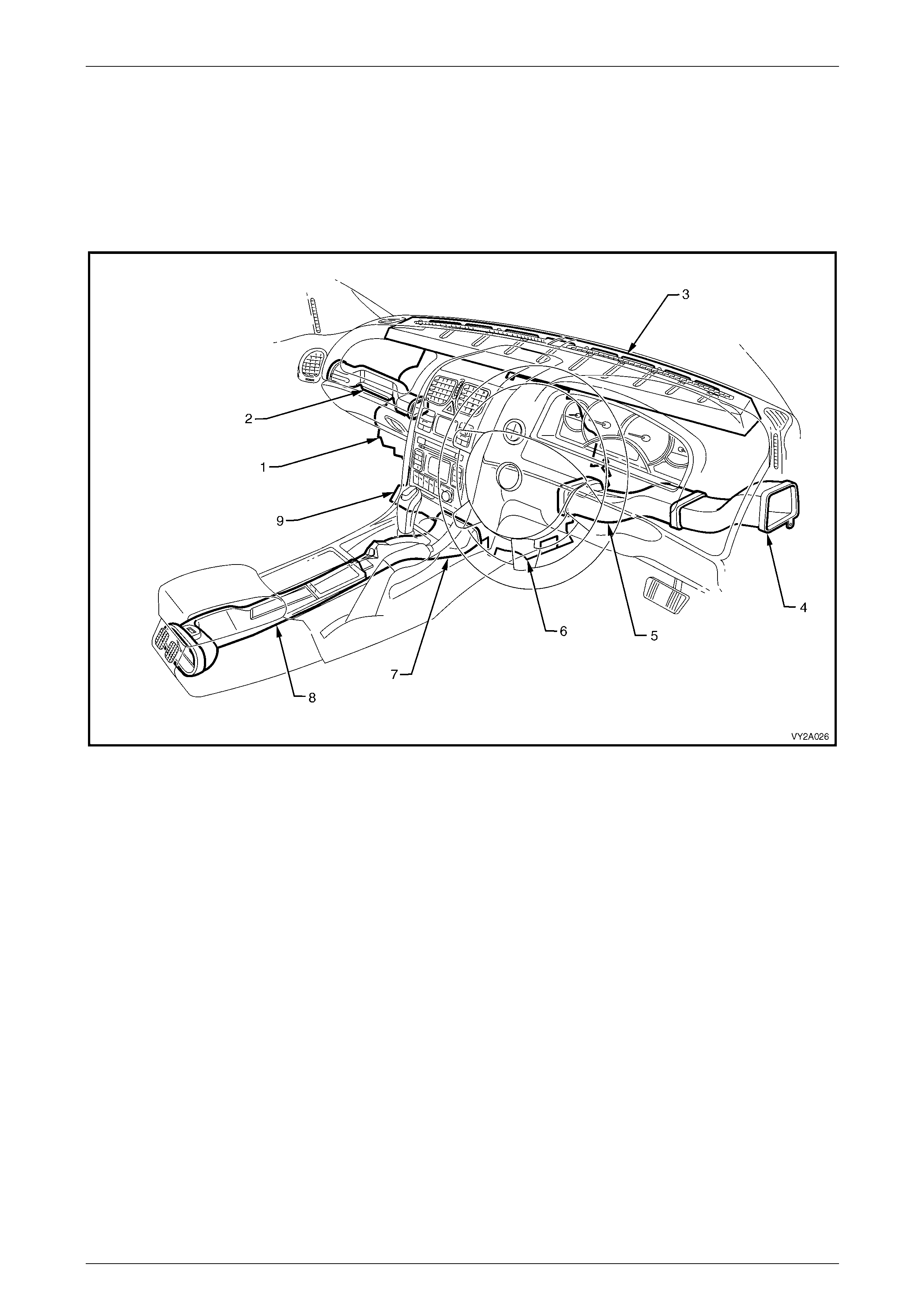

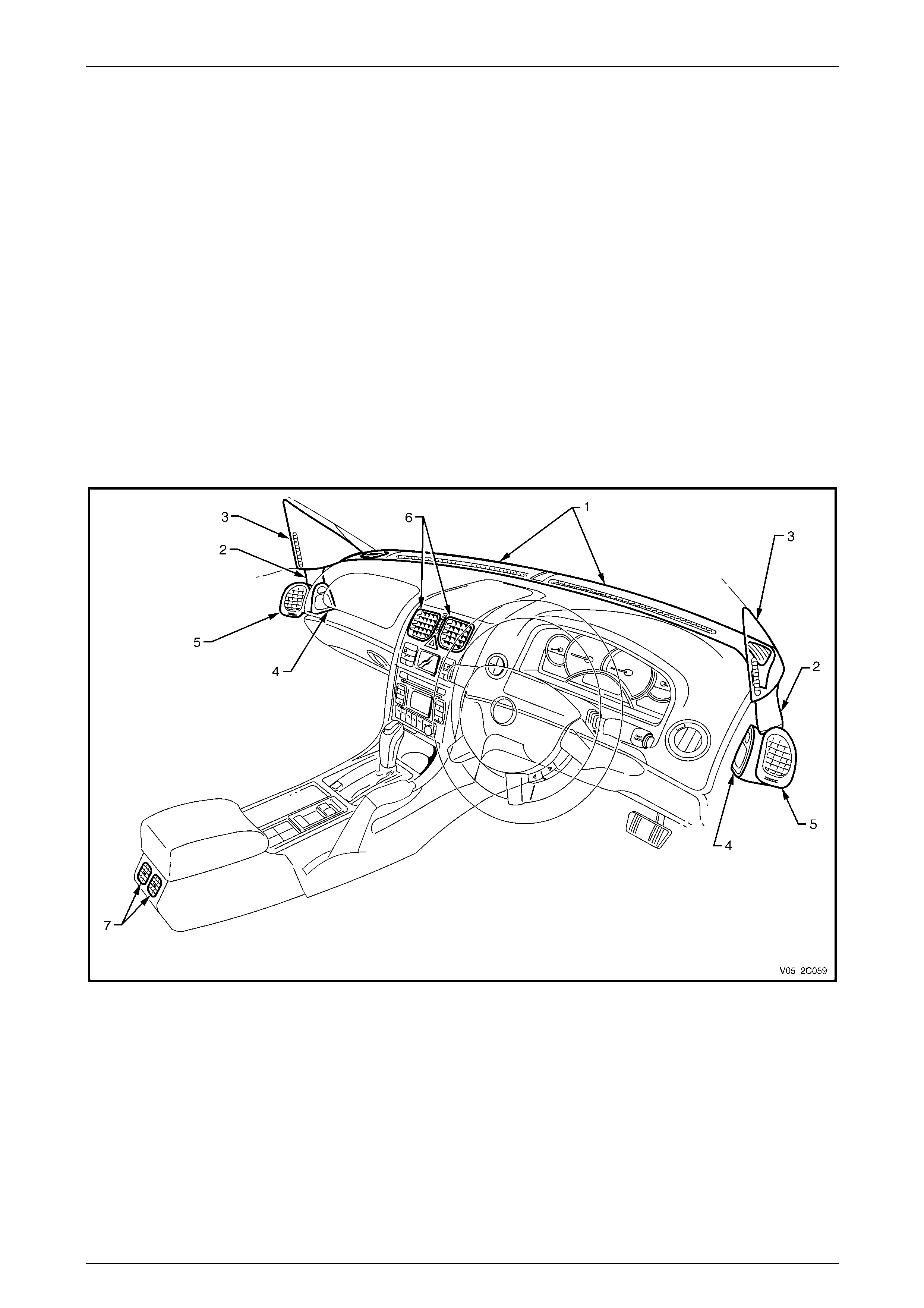

10.2 HVAC System Ducts............................................................................................................................................ 88

HVAC Ducts Views............................................................................................................................................... 88

Sedan, Wagon, Coupe and Crew Cab............................................................................................................. 88

Utility and Regular Cab .................................................................................................................................... 89

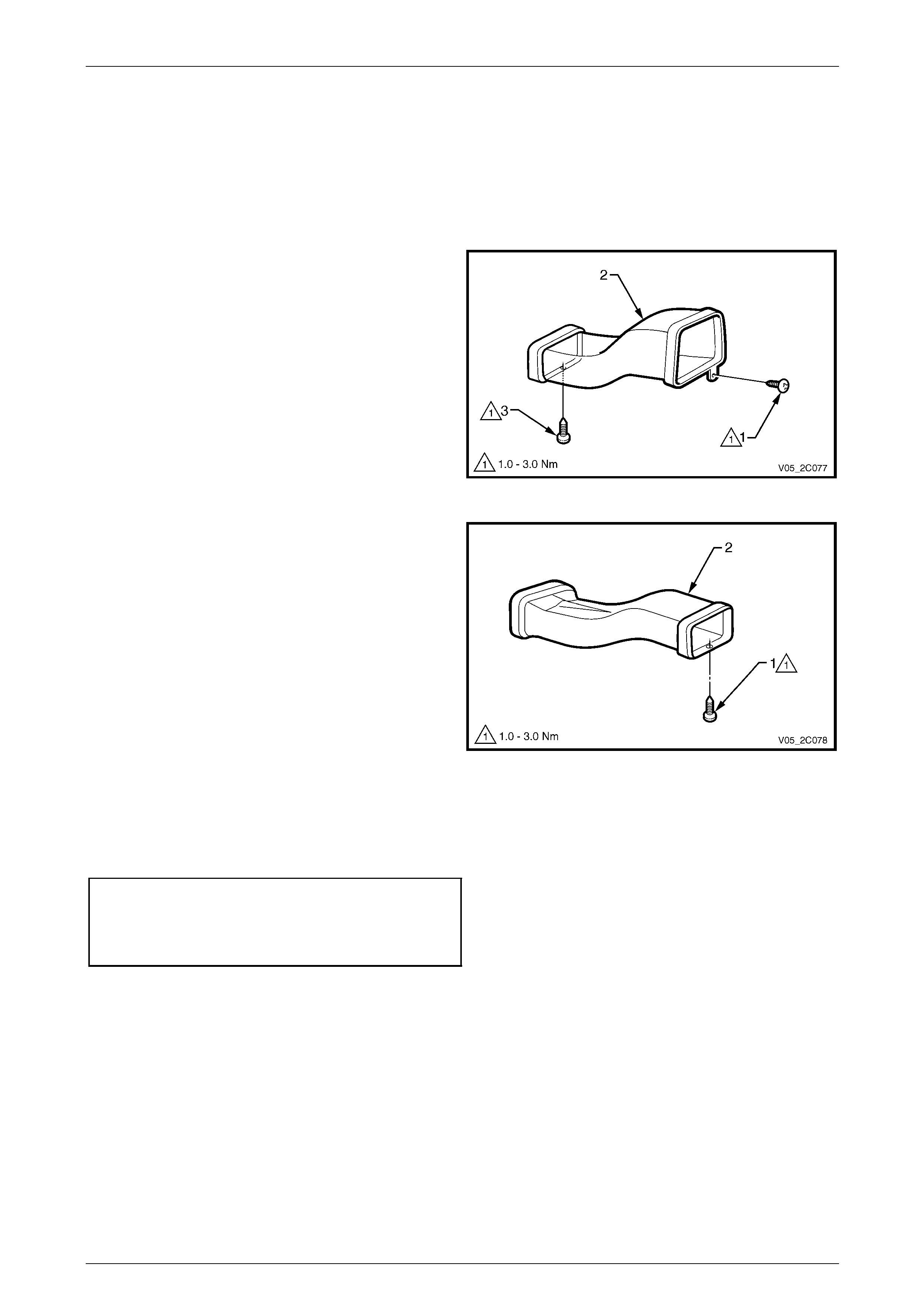

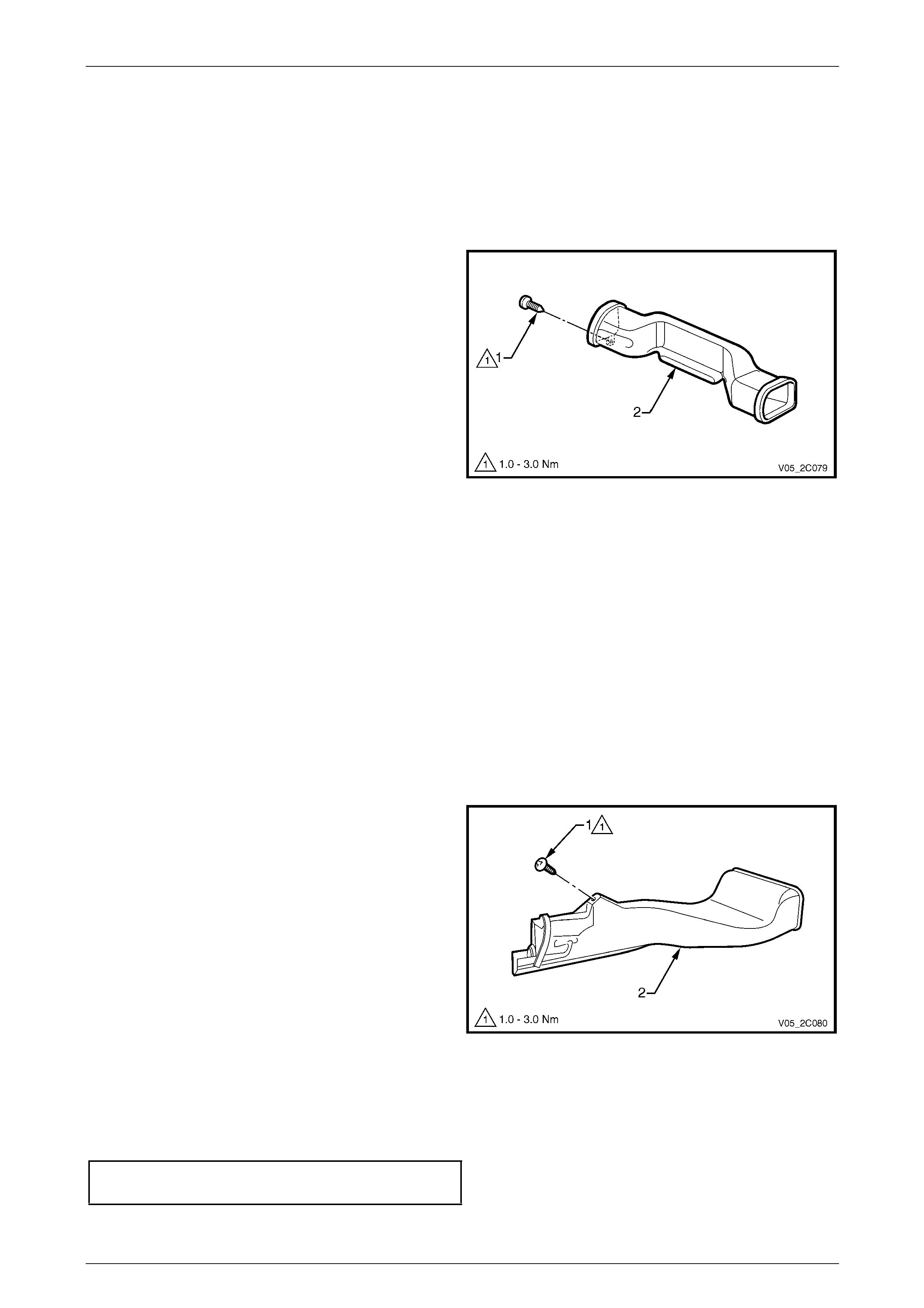

Driver Side Outer and Inner Ducts ..................................................................................................................... 90

Remove............................................................................................................................................................ 90

Reinstall ........................................................................................................................................................... 90

Passenger Side Duct ........................................................................................................................................... 91

Remove............................................................................................................................................................ 91

Reinstall ........................................................................................................................................................... 91

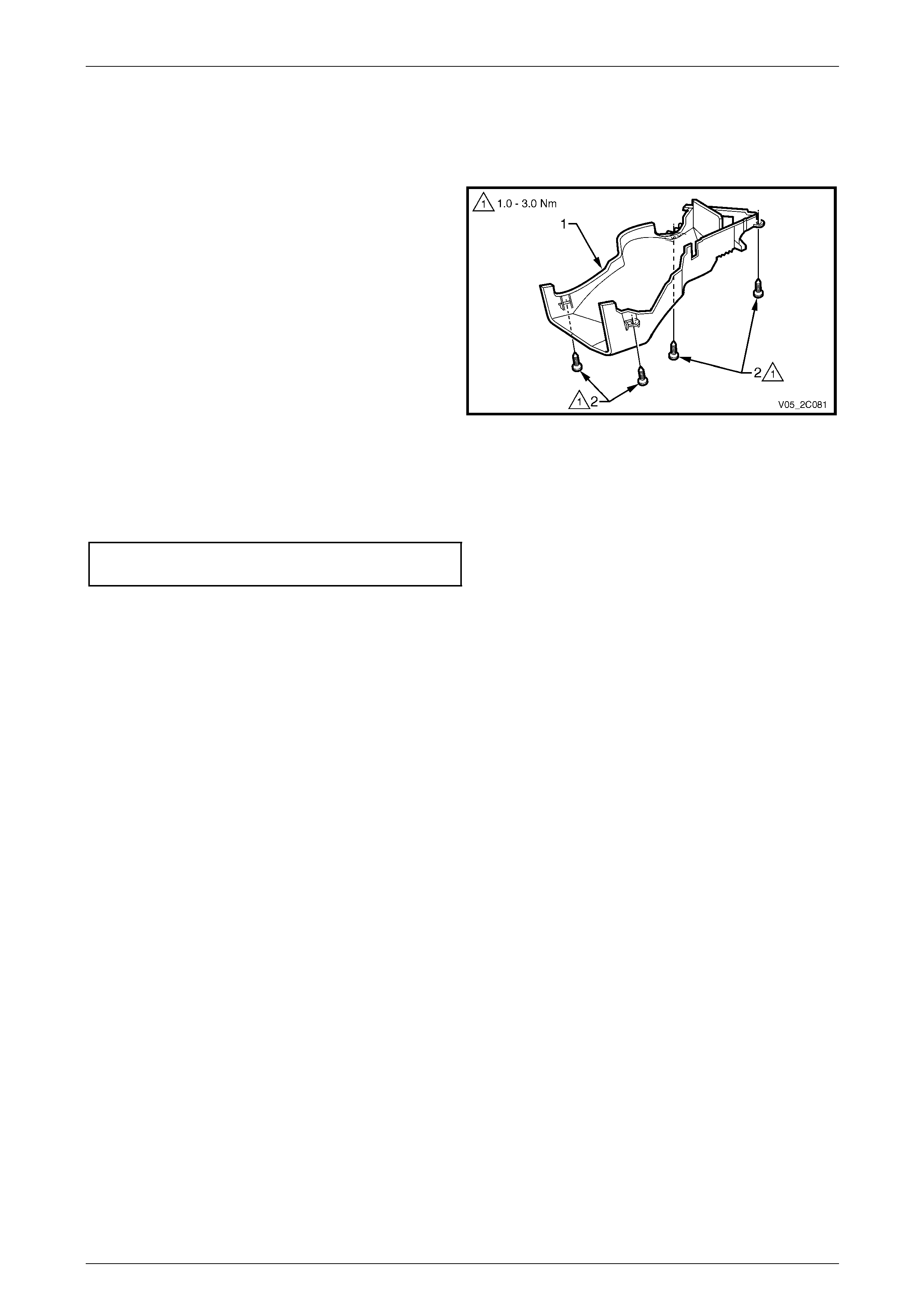

Floor Console Rear Duct (except Utility and Regular Cab).............................................................................. 91

Floor Console Front Duct (except Utility and Regular Cab)............................................................................. 91

Remove............................................................................................................................................................ 91

Reinstall ........................................................................................................................................................... 91

Foot Duct Outlet................................................................................................................................................... 92

Remove............................................................................................................................................................ 92

Reinstall ........................................................................................................................................................... 92

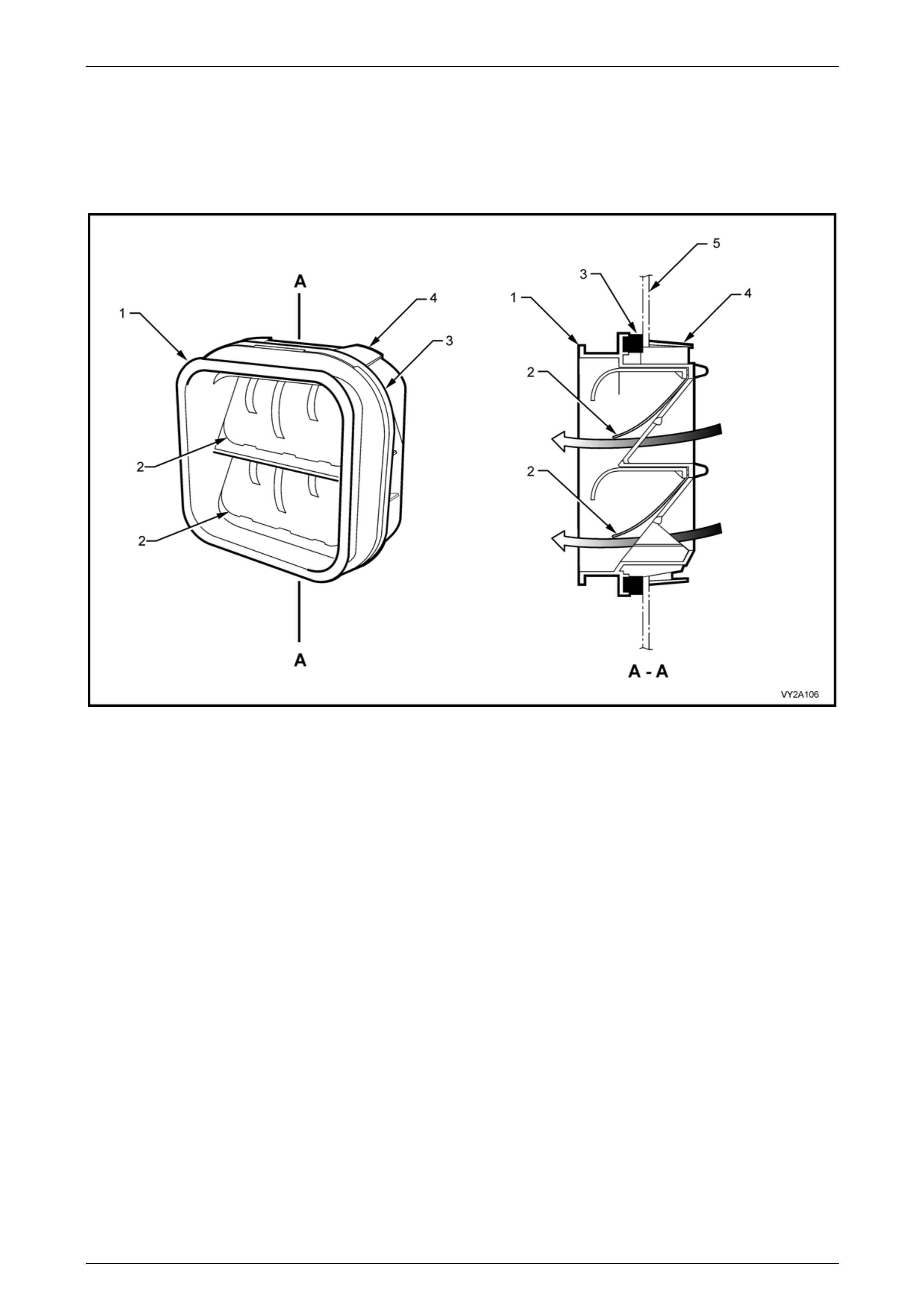

10.3 Cabin Ventilation Outlets .................................................................................................................................... 93

10.4 Body Ventilation Outlets..................................................................................................................................... 94

Remove................................................................................................................................................................. 94

Sedan and Coupe ............................................................................................................................................ 94

Wagon.............................................................................................................................................................. 94

Utility ................................................................................................................................................................ 95

Regular and Crew Cab..................................................................................................................................... 95

Reinstall................................................................................................................................................................ 95

11 Torque Wrench Specifications............................................................................................................96

12 Special Tools ........................................................................................................................................97

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-5

Page 2C-5

1 General Information

This Section describes the removal and installation procedures of the he ater and air-conditioner components, except the

electronic control system components. For removal and installation proced ures of the he ater and air-conditioner

components not covered in this Section,

refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-6

Page 2C-6

2 HVAC Controller – Manual A/C

2.1 Manual Controller Assembly

LT Section No. — 08–155A

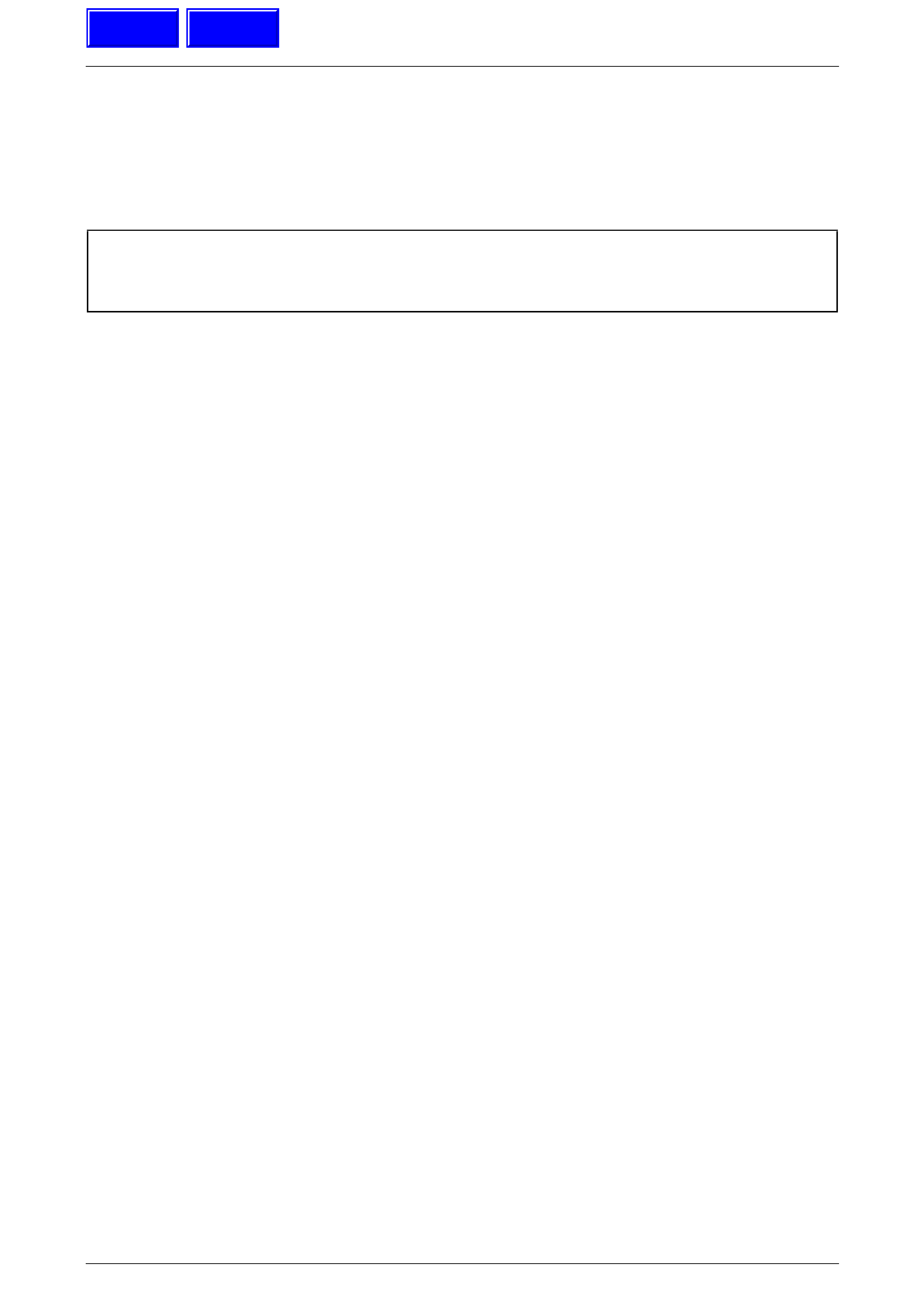

Remove

1 Remove the instrument panel centre fascia, refer to Section 1A3 Instrument Panel and Console.

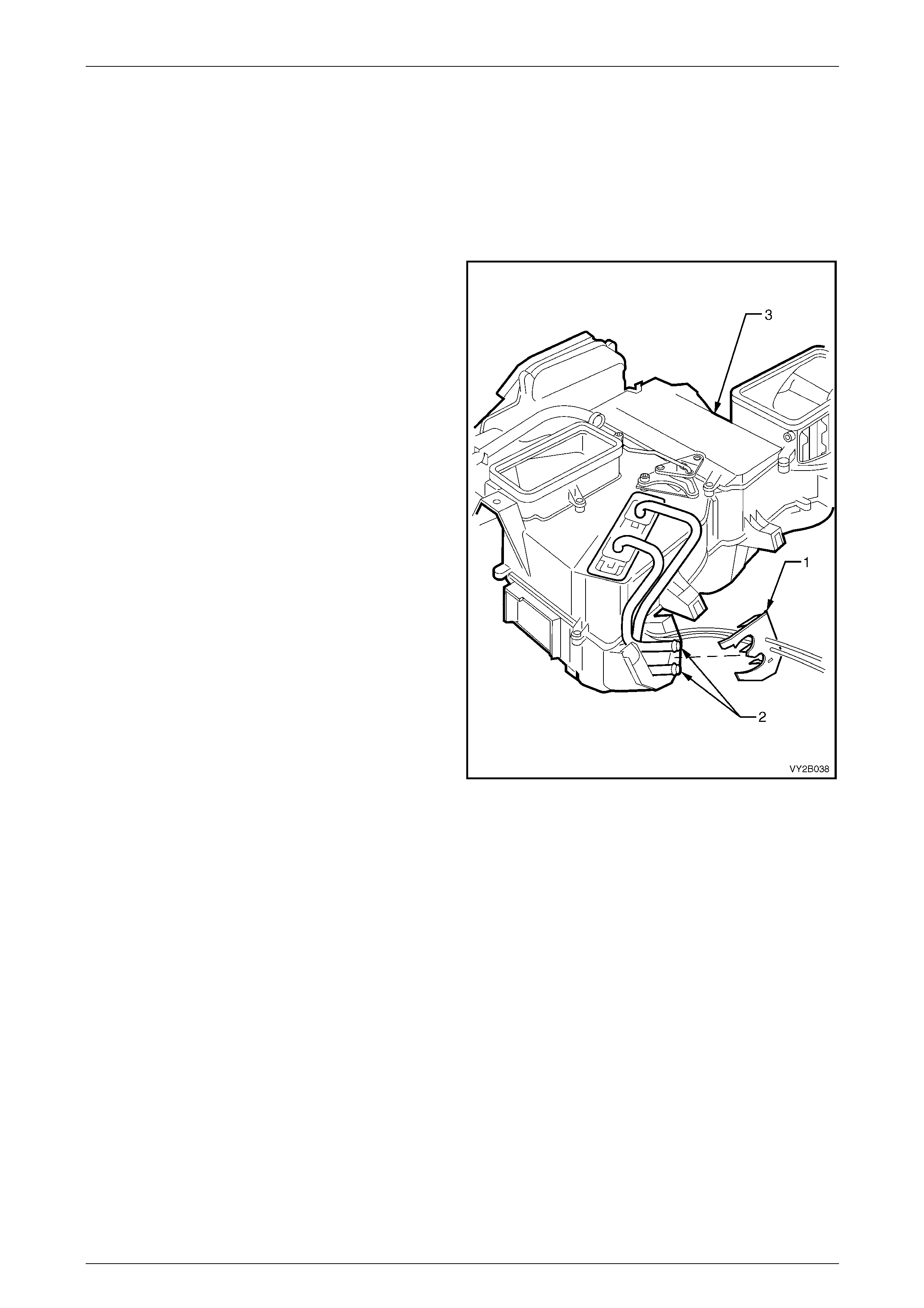

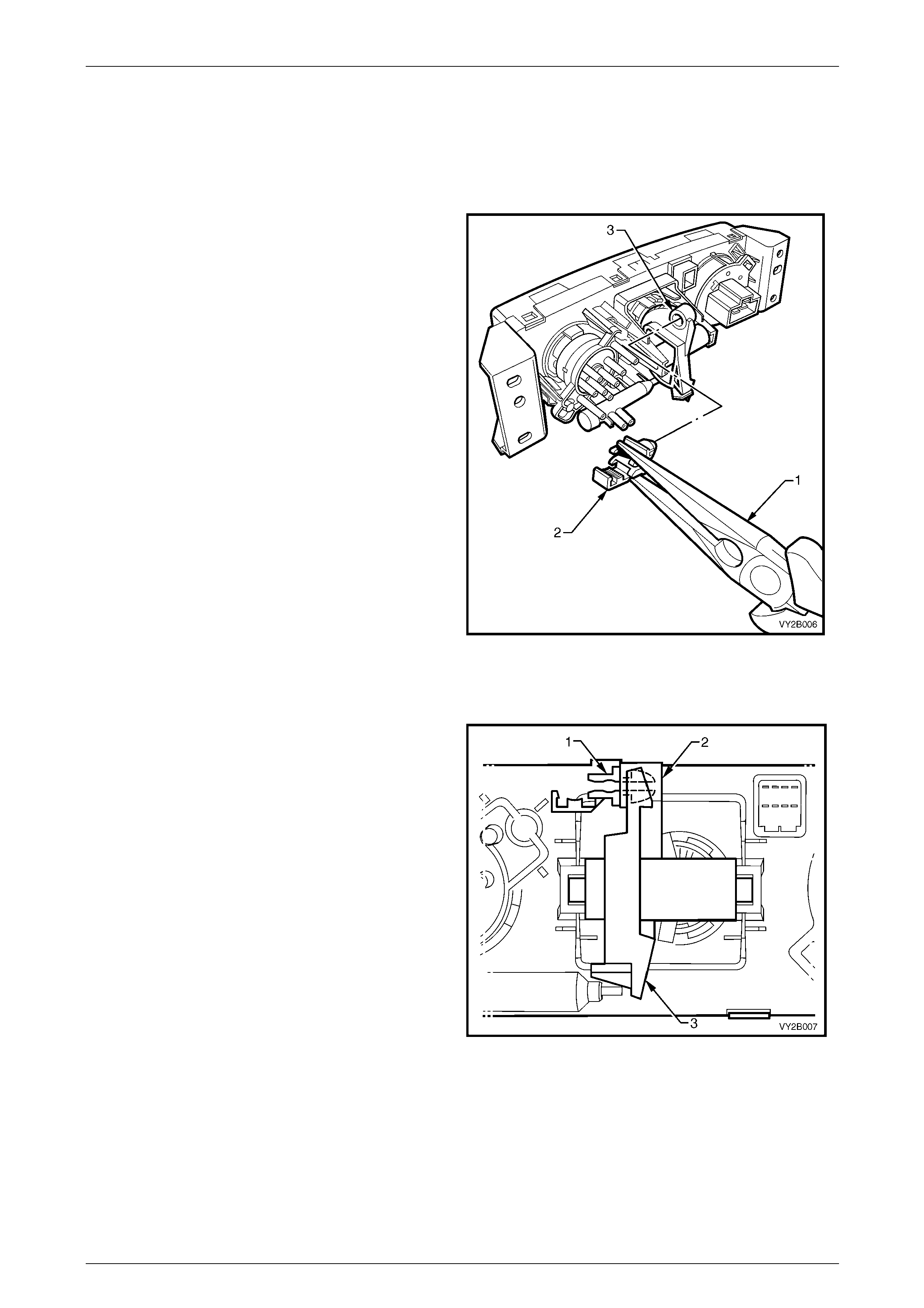

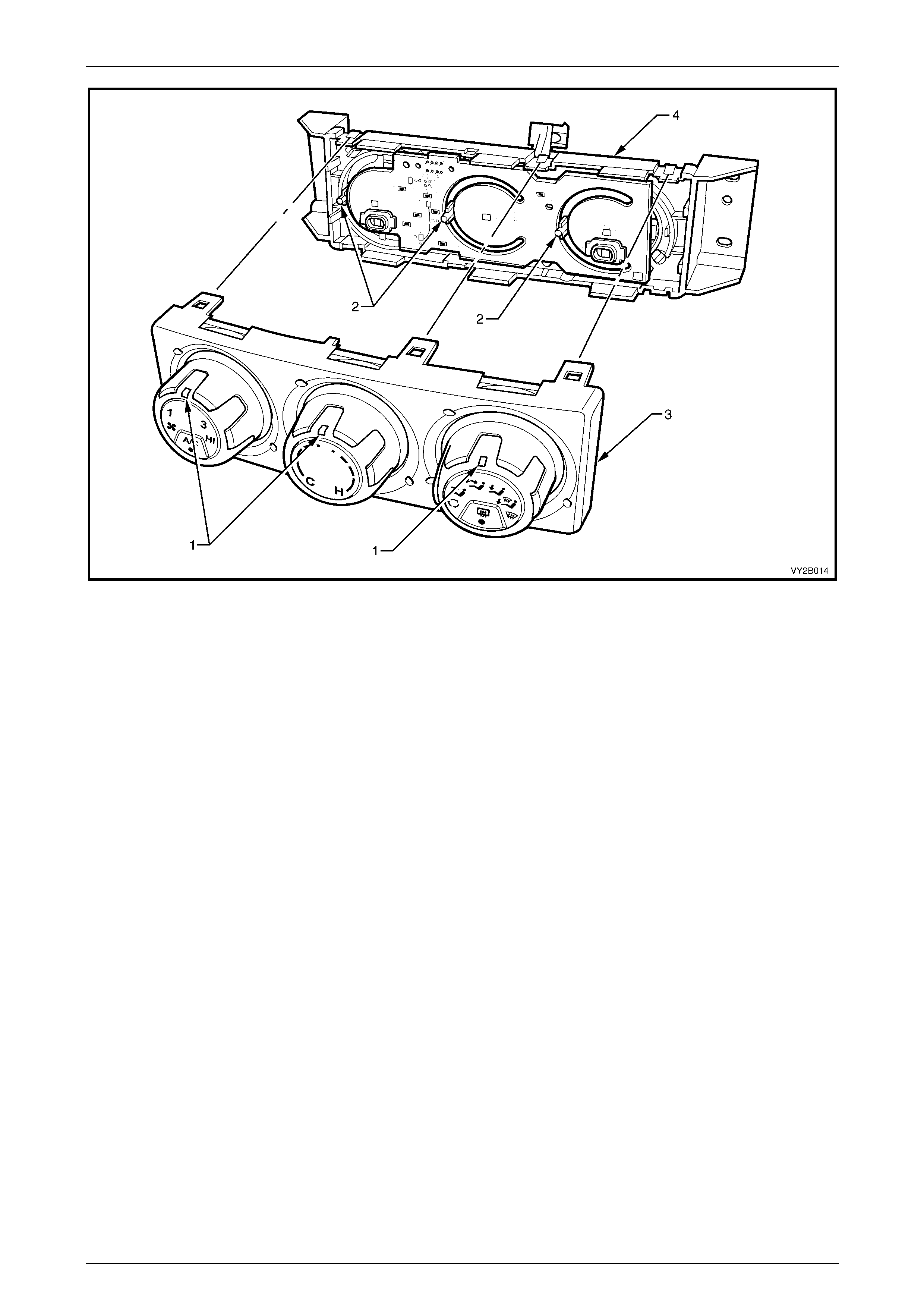

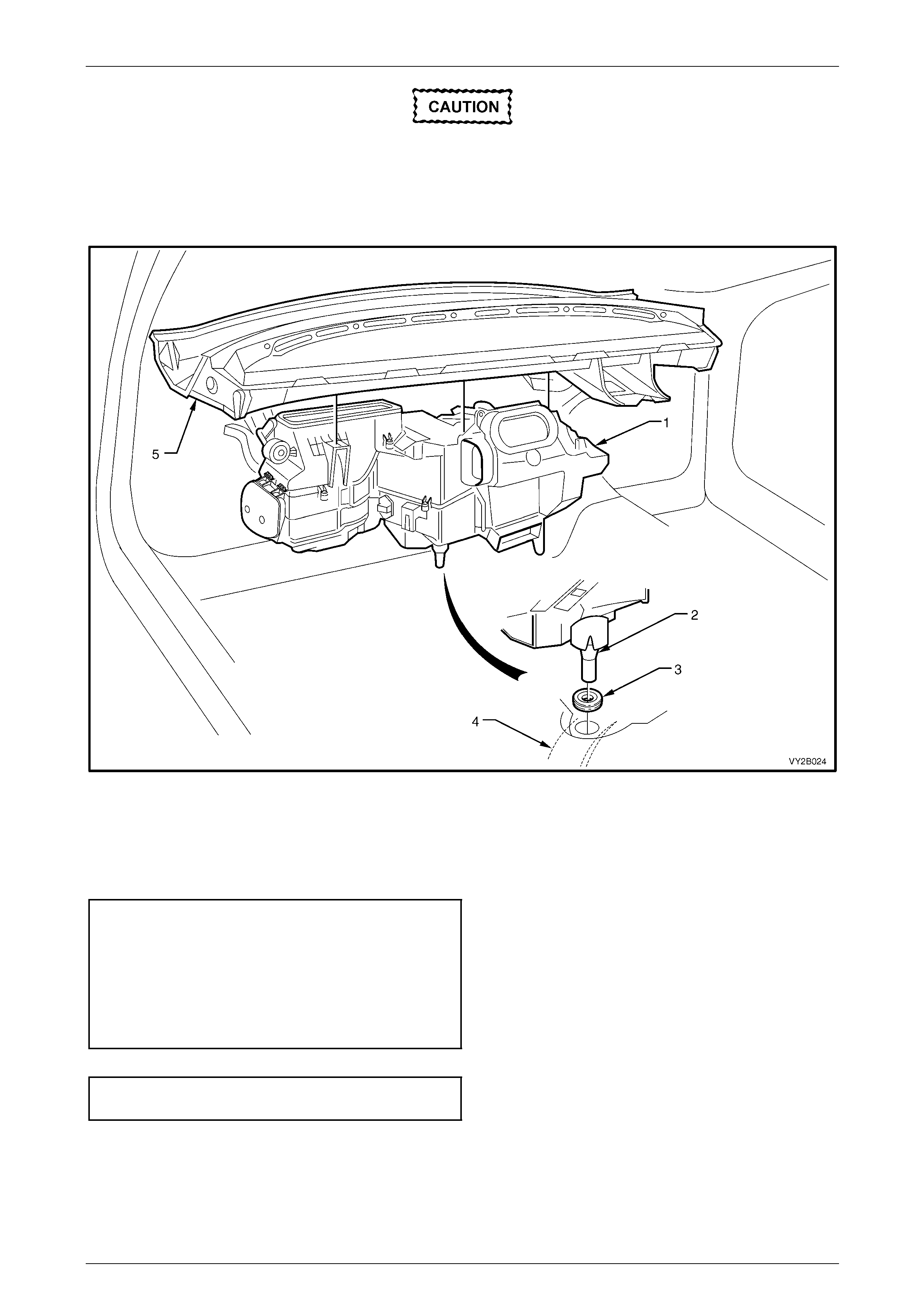

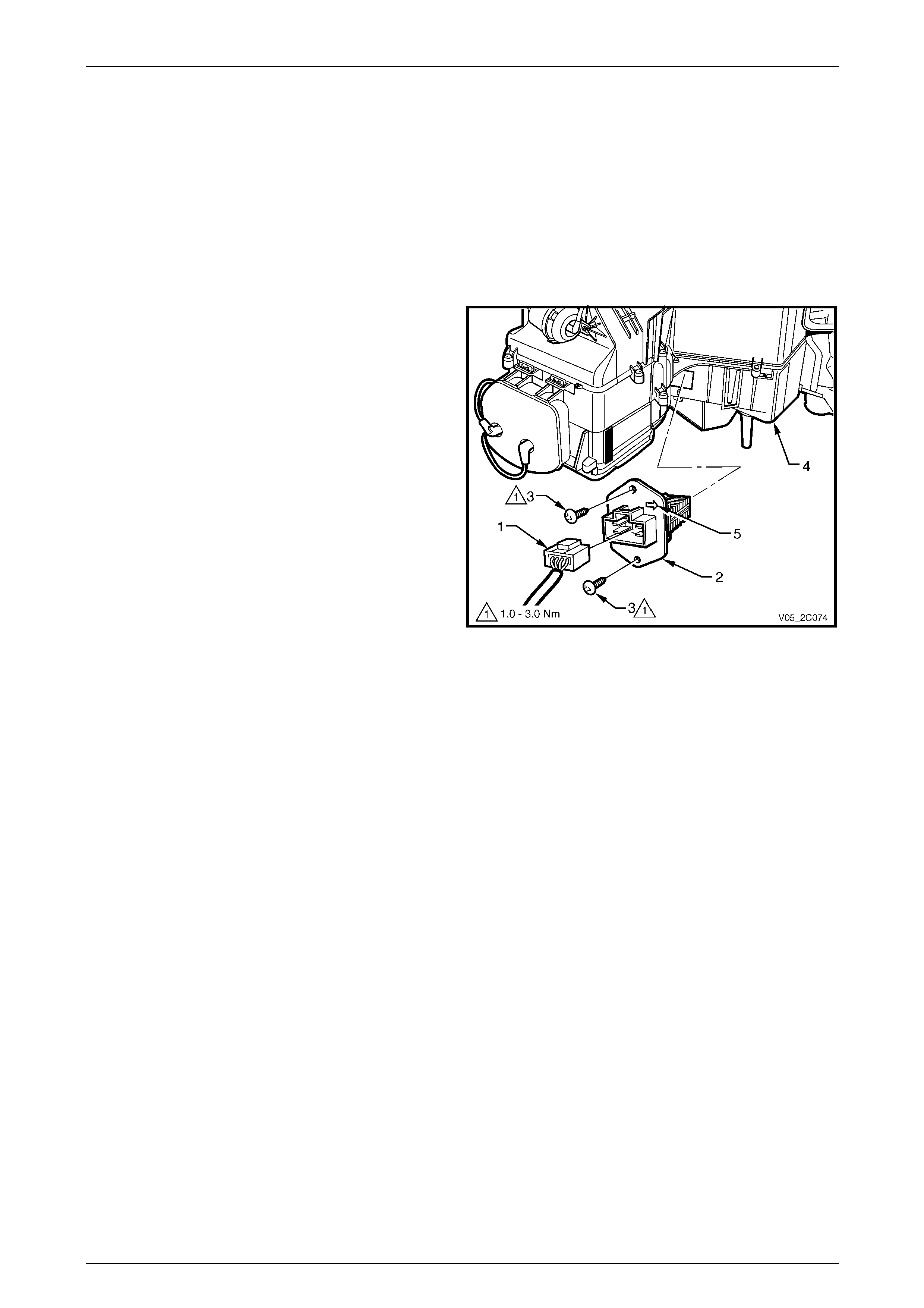

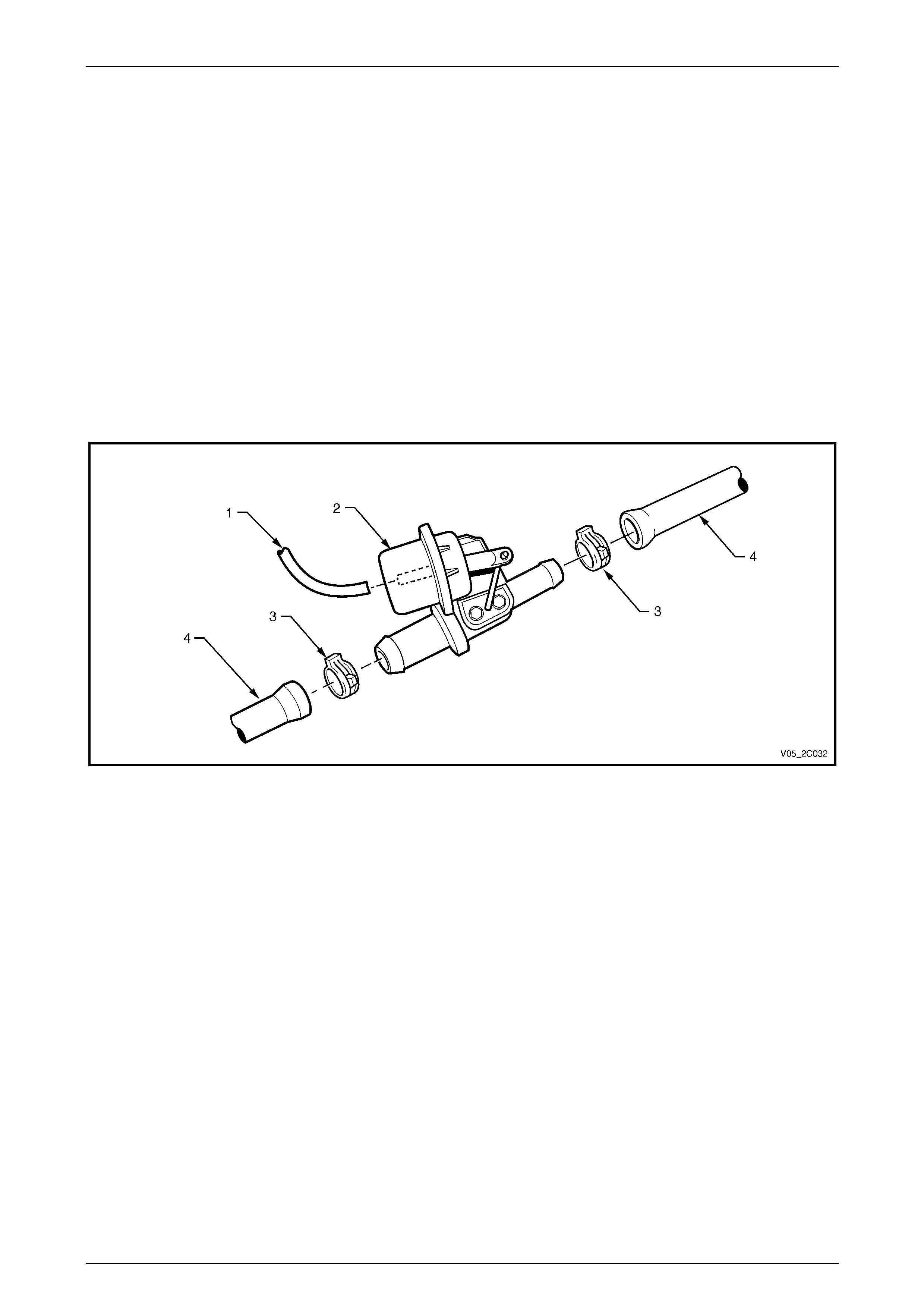

2 From the rear of the HVAC controller, open the air mix door rod retainer (1) and disconnect the rod (2), refer to

Figure 2C – 1.

3 Remove the screw (3), two places each side, attaching the HVAC controller (4) to the instrument panel.

4 Partially remove the HVAC controller assembly outwards from the instrument pan el to access the rear of the

controller.

5 Disconnect the two vacuum hose connections (5 and 6) and two wiring connectors (7).

6 Remove the HVAC controller assembly. NOTE

For service and diagnosis of the manual HVAC

controller, refer to Section 2B HVAC Climate

Control (Manual A/C) – Servicing and Di agnosis.

Figure 2C – 1

Reinstall

1 Install the two wiring connectors (7) and the lower then upper vacuum hose connections (5 and 6), refer to

Figure 2C – 1.

2 Push the control rod (2) toward the HVAC unit (front of vehicle) fully.

3 Seat the HVAC controller assembly (4) in position.

4 Install the attaching screws (3) and tighten to the correct torque specification.

Manual HVAC controller attachin g

screw torque specification...........................1.0 – 3.0 Nm

5 Rotate the temperature switch to the full cold position.

6 Position the air mix door rod retainer (1), so it will close upward.

7 Connect the control rod to the air mix do or rod retainer.

8 Close and lock the retainer over the rod.

9 Check for correct operation of the temperature switch.

10 Reinstall the floor console cover assembly and the instrument pan el centre fascia,

refer to Section 1A3 Instrument Panel and Consol e.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-7

Page 2C-7

2.2 Water Valve Vacuum Switch

LT Section No. — 08–155A

Remove

1 Remove the manual HVAC controller, refer to

2.1 Manual Controller Assembl y.

2 Turn the temperature switch to the full hot position.

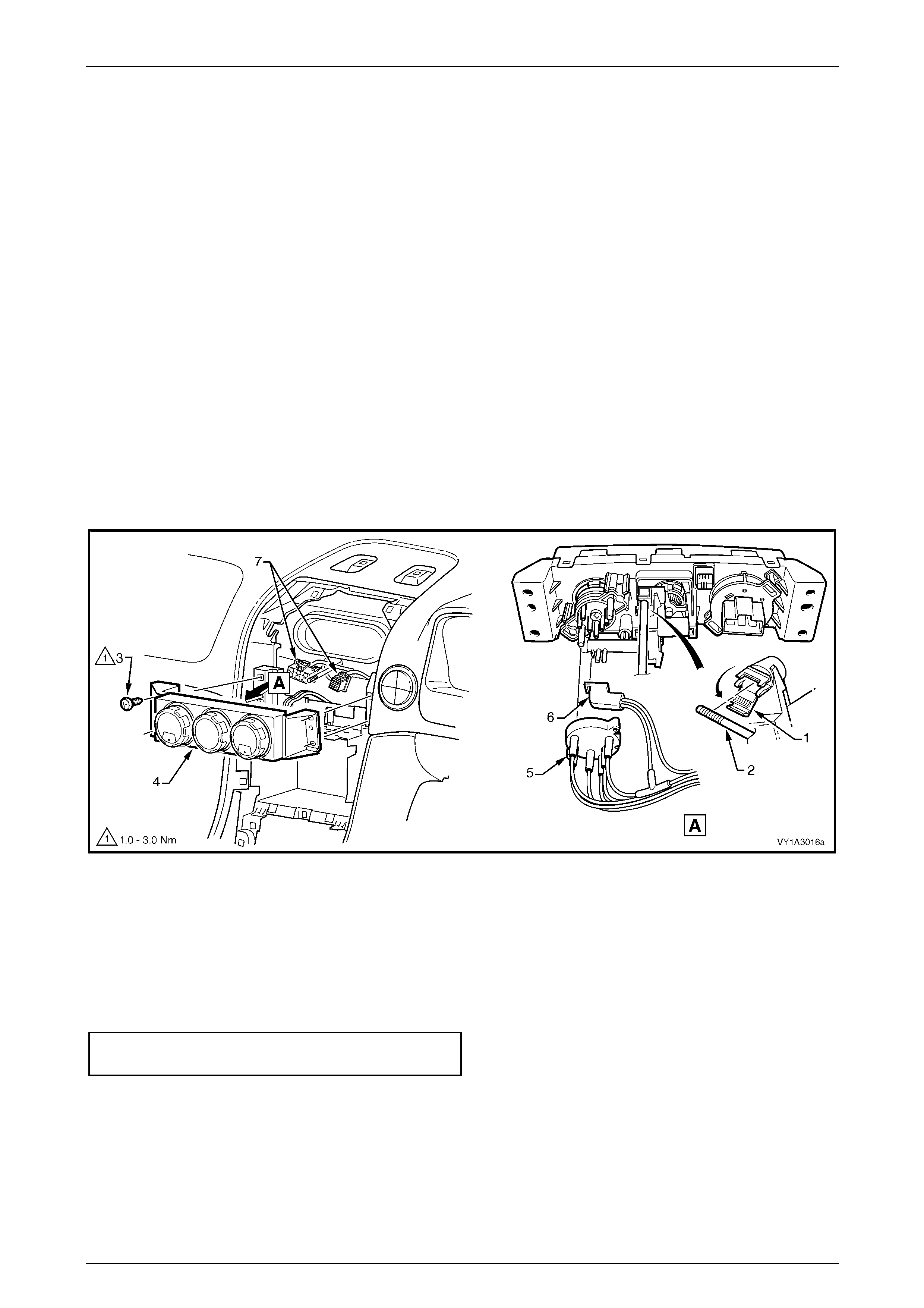

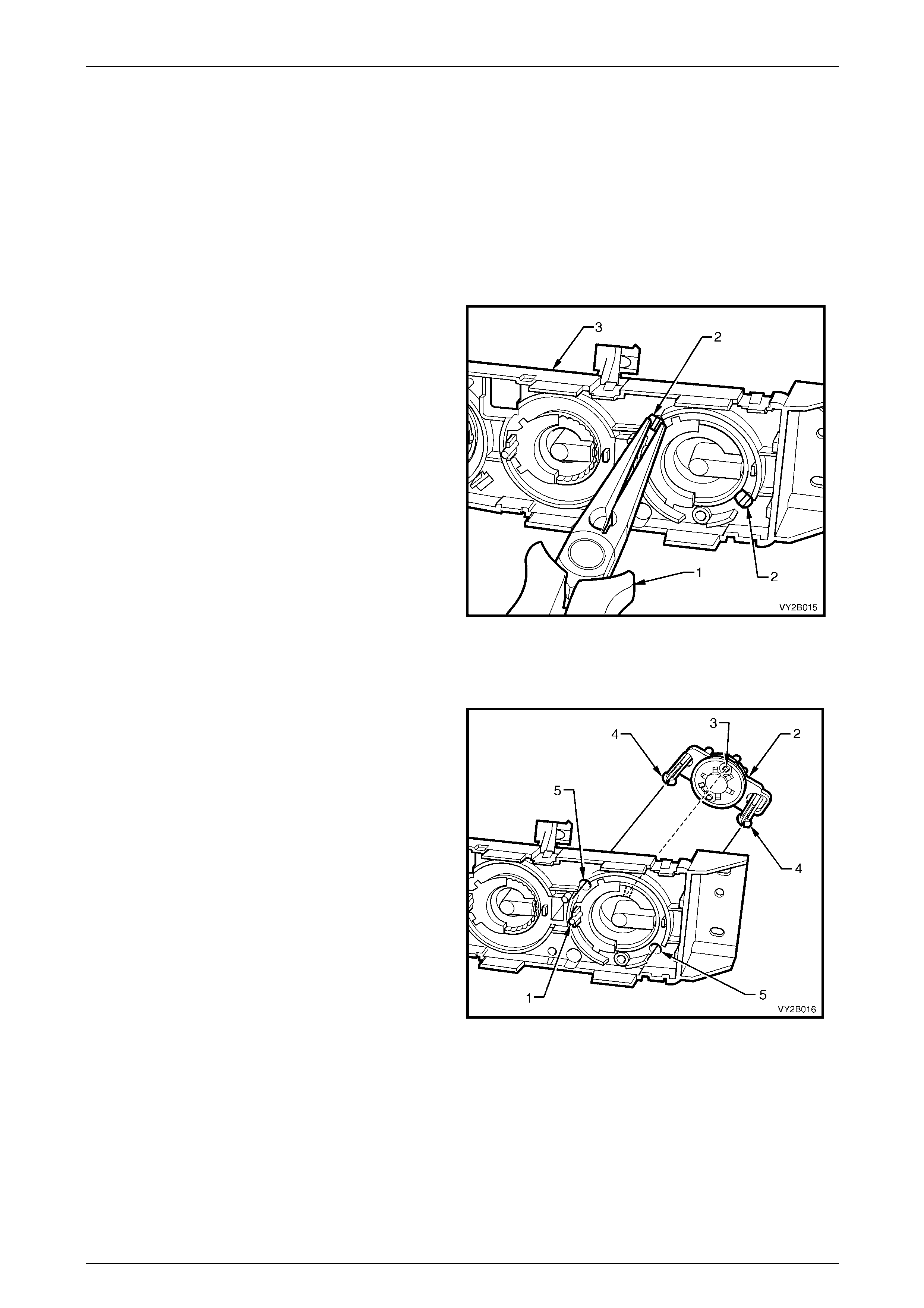

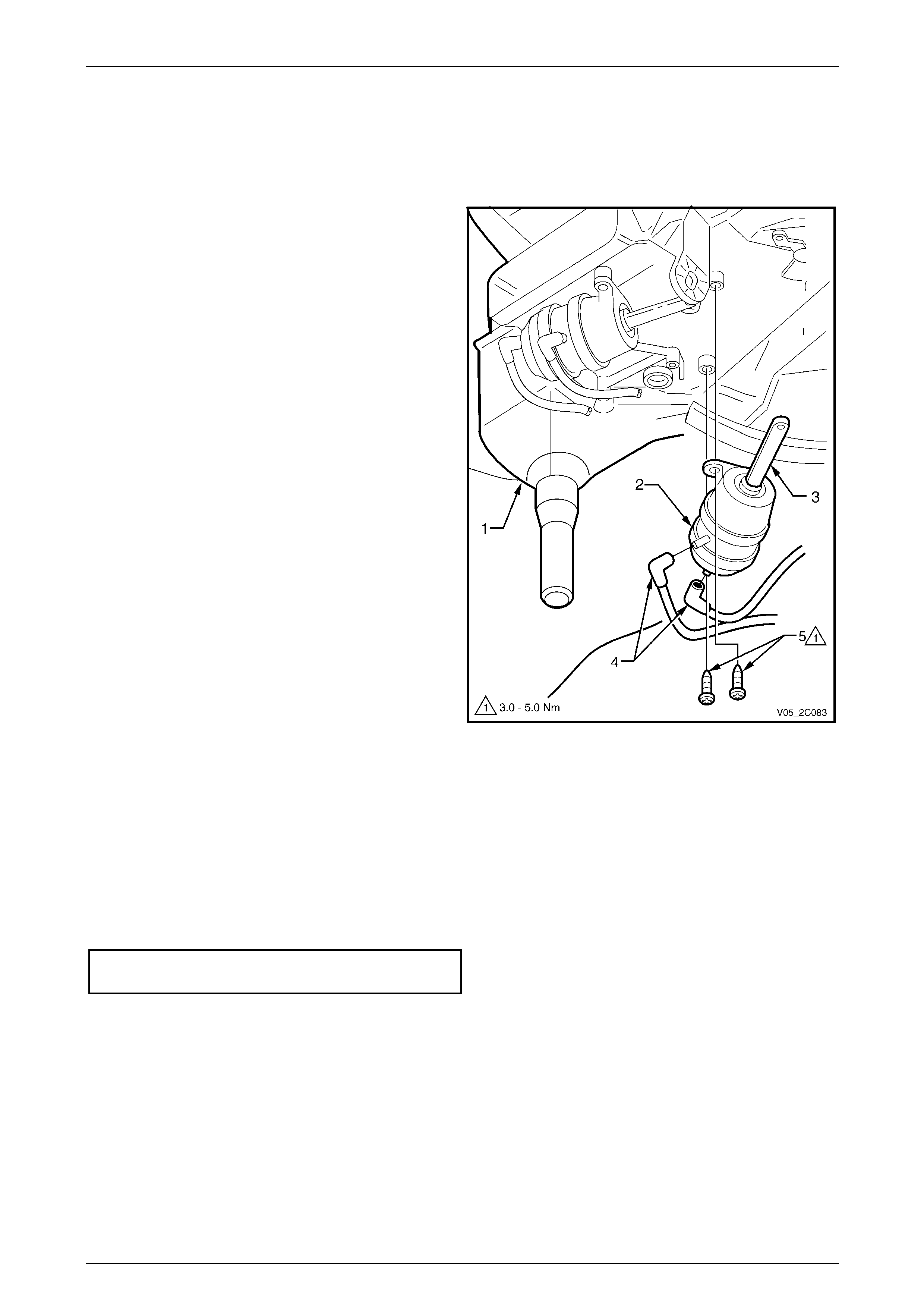

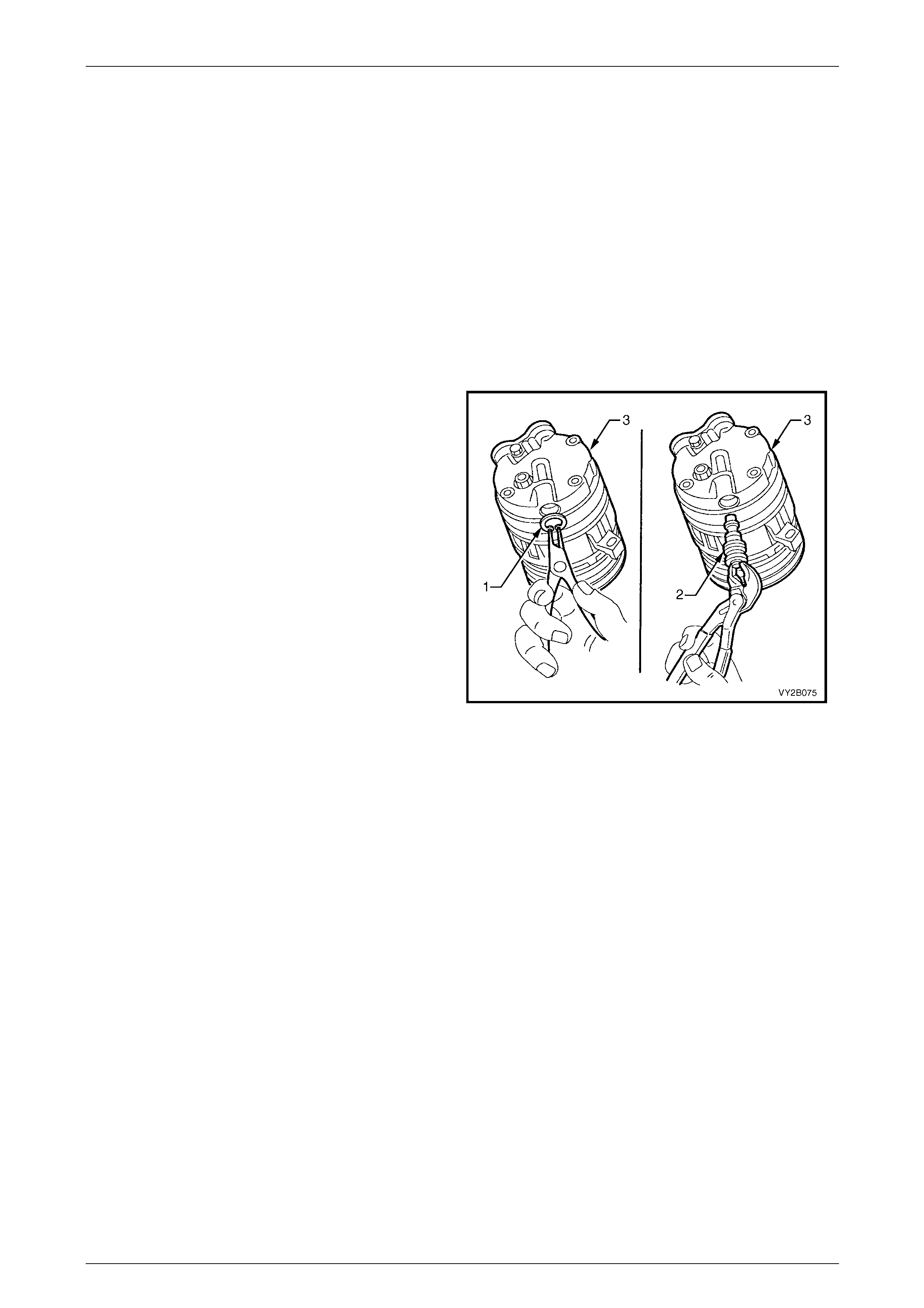

Using needle nose pliers (1), carefully compress the

locking legs (2) of the vacuum switch (3) and withdraw

the switch from the controller rear housing (4) .

Figure 2C – 2

Reinstall

1 Insert the vacuum switch locking legs (1) through the

controller rear housing ensuring the locating

dowels (2) are installed into the two locators (3) of the

rear housing (4).

2 Push the vacuum switch into position ensuring the

locking legs lock into position and retain the switch in

the controller rear housing.

3 Install the controller to the instrument panel, refer to

2.1 Manual Controller Assembl y.

Figure 2C – 3

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-8

Page 2C-8

2.3 Air Mix Door Rod Retainer

LT Section No. — 08–155A

Remove

1 Remove the manual HVAC controller, refer to

2.1 Manual Controller Assembl y.

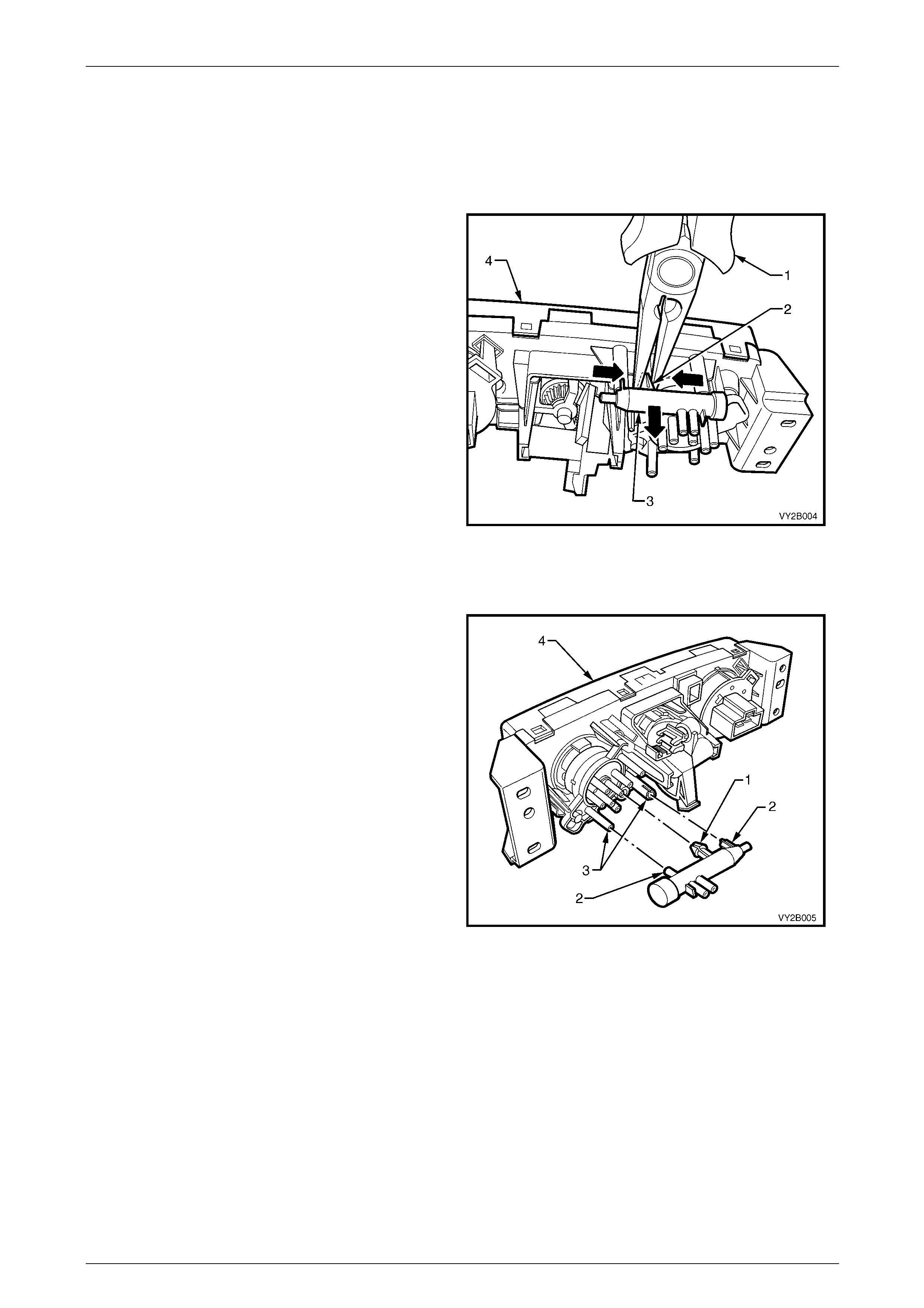

2 Using needle nose pliers (1), carefully compress the

rod retainer (2) together and withdraw the rod retainer

from the crescent gear (3) of the controller.

Figure 2C – 4

Reinstall

1 Insert the rod retainer (1) into the pivot hole (2) of the

crescent gear (3) ensuring it locks into position.

2 Install the controller to the instrument panel, refer to

2.1 Manual Controller Assembl y.

Figure 2C – 5

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-9

Page 2C-9

2.4 Front Housing/Switch Assembly and

Printed Circuit Board

LT Section No. — 08–155A

Remove

1 Remove the manual HVAC controller, refer to 2.1 Manual Contro ller Assembly.

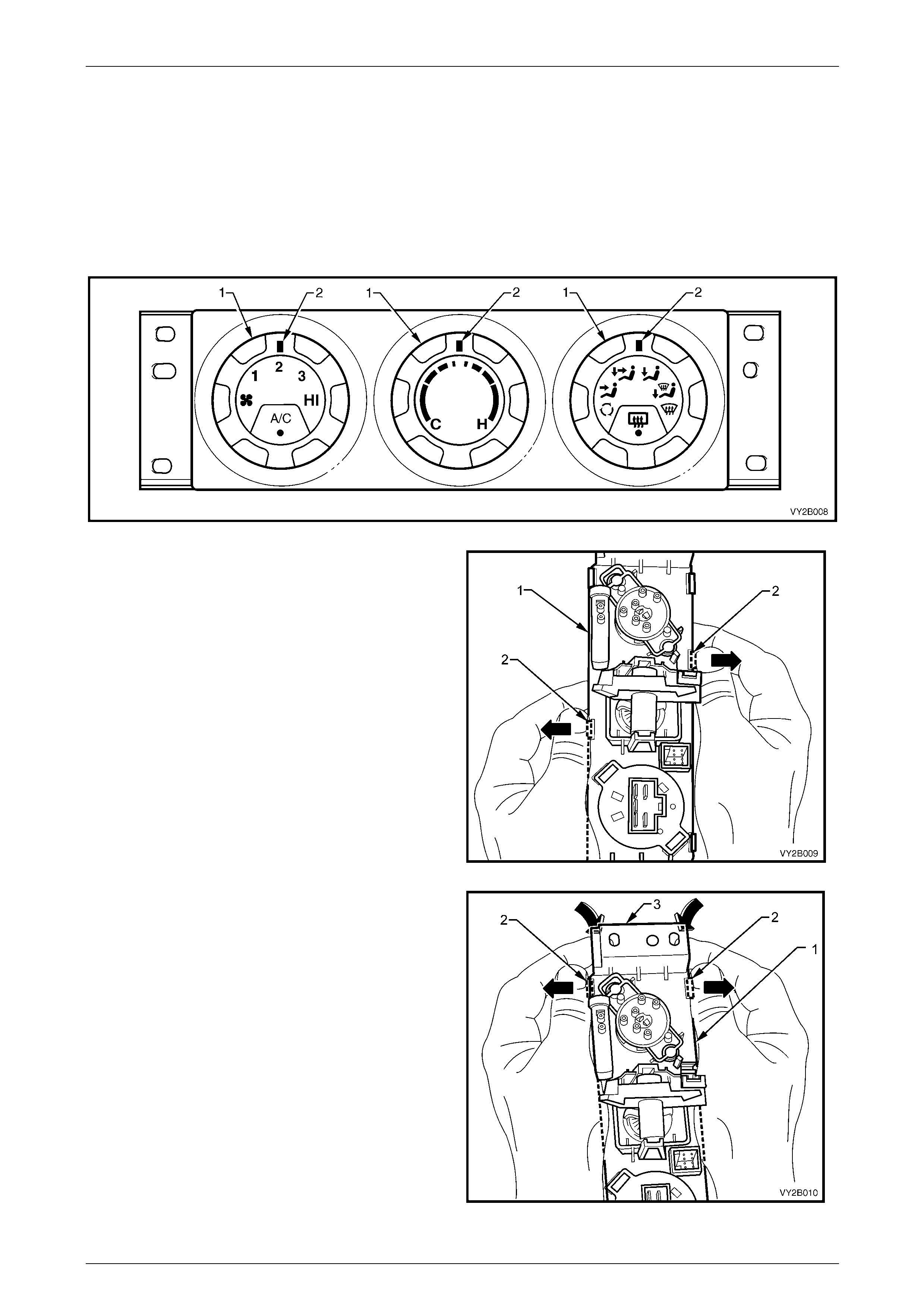

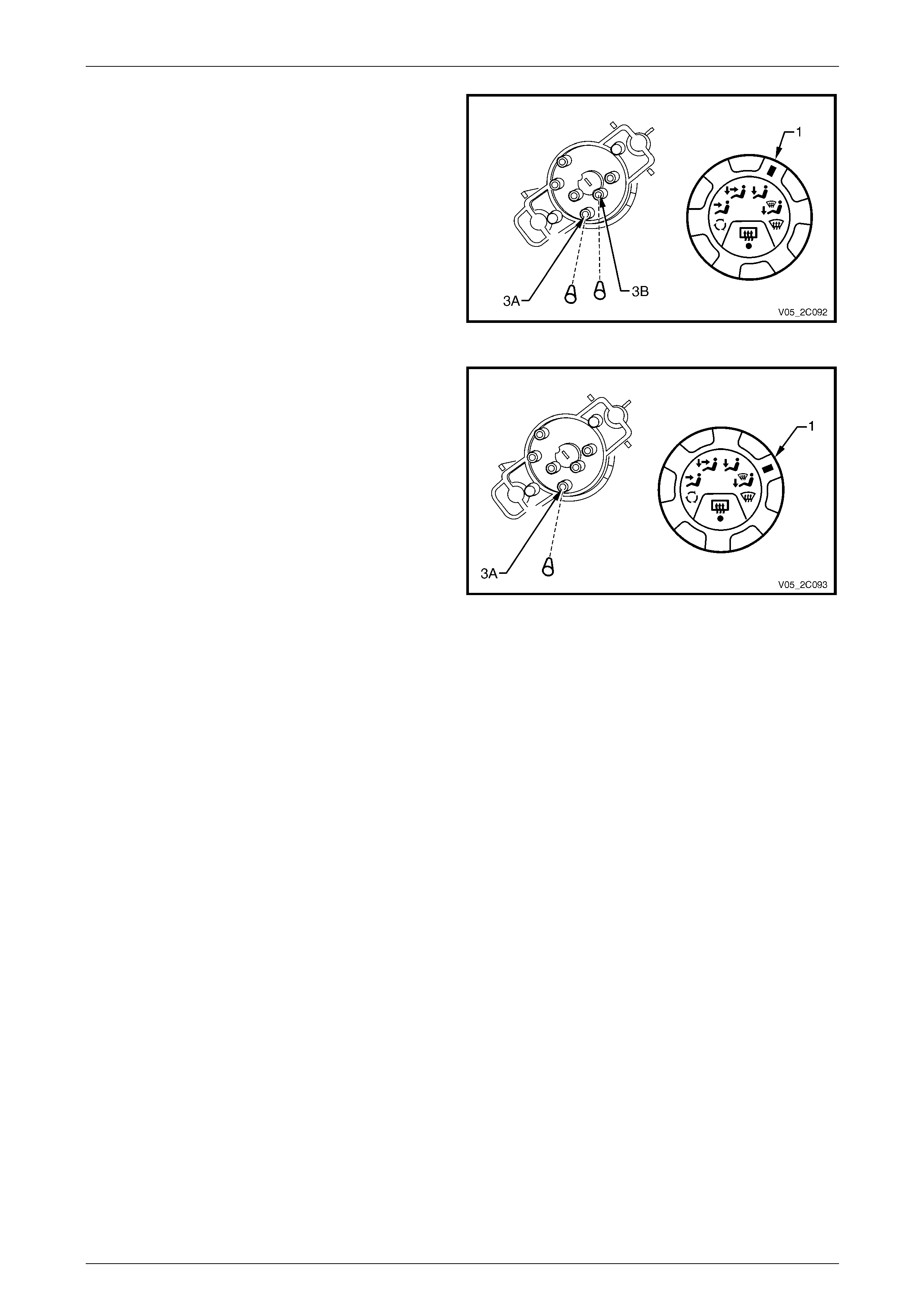

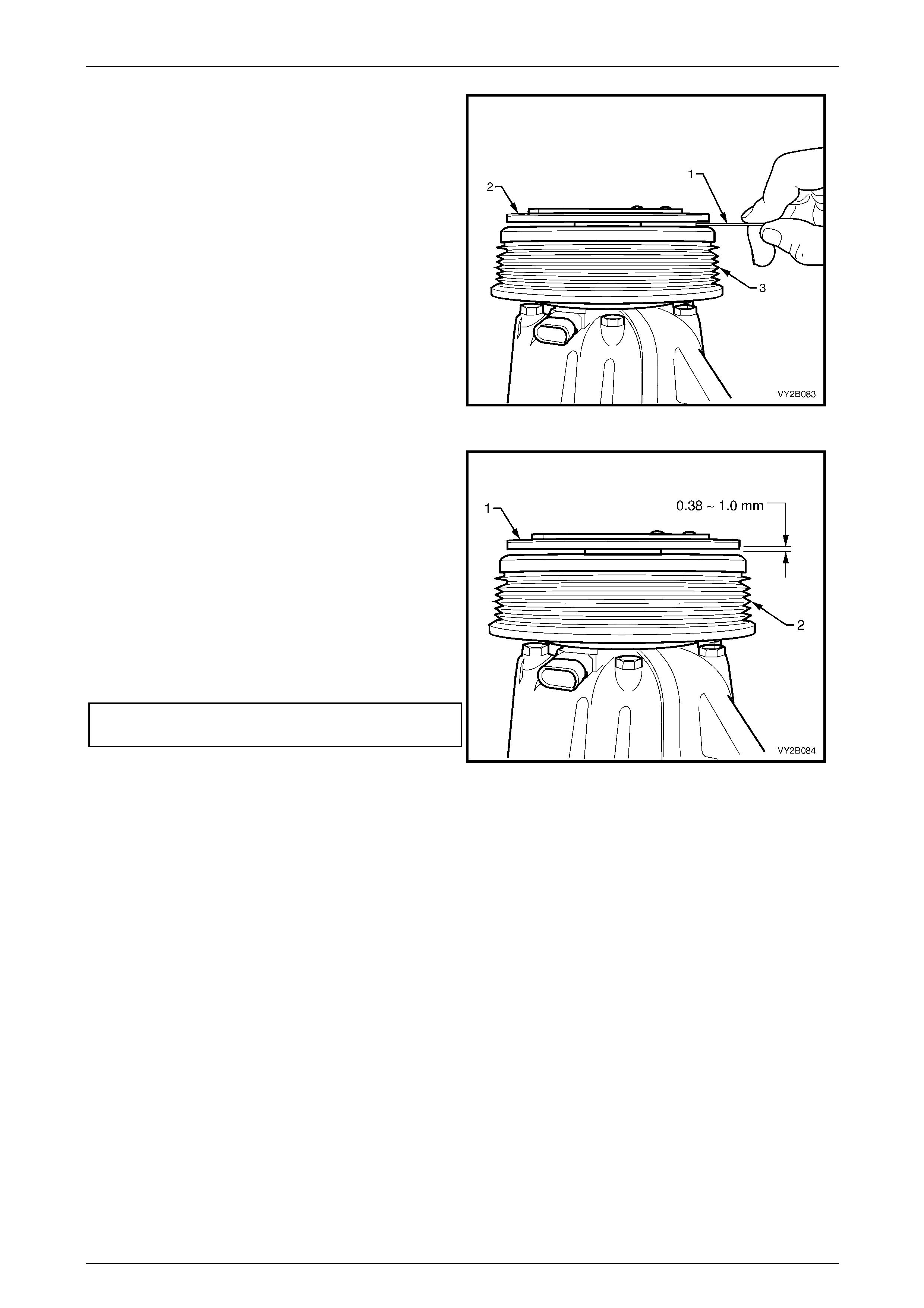

2 Rotate the switches (1) so all switch position indicators (2) are at the 12 o’clock position, refer to Figure 2C – 6.

Figure 2C – 6

3 Holding the controller (1), disengage the middle

retaining tangs of the front housing/switch assembly

from the controller rear housing by carefully moving the

retaining tangs (2) of the front housing o utwards with

thumb pressure.

Figure 2C – 7

4 Continue to disengag e the front housing/switch

assembly from the controller (1) rear housing by

moving the end retaining tangs (2) outwards with

thumb pressure while simulta neously separating the

rear housing from the front housing/switch assembly

using index finger pressure at the mounting flange (3)

of the controller.

Figure 2C – 8

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-10

Page 2C-10

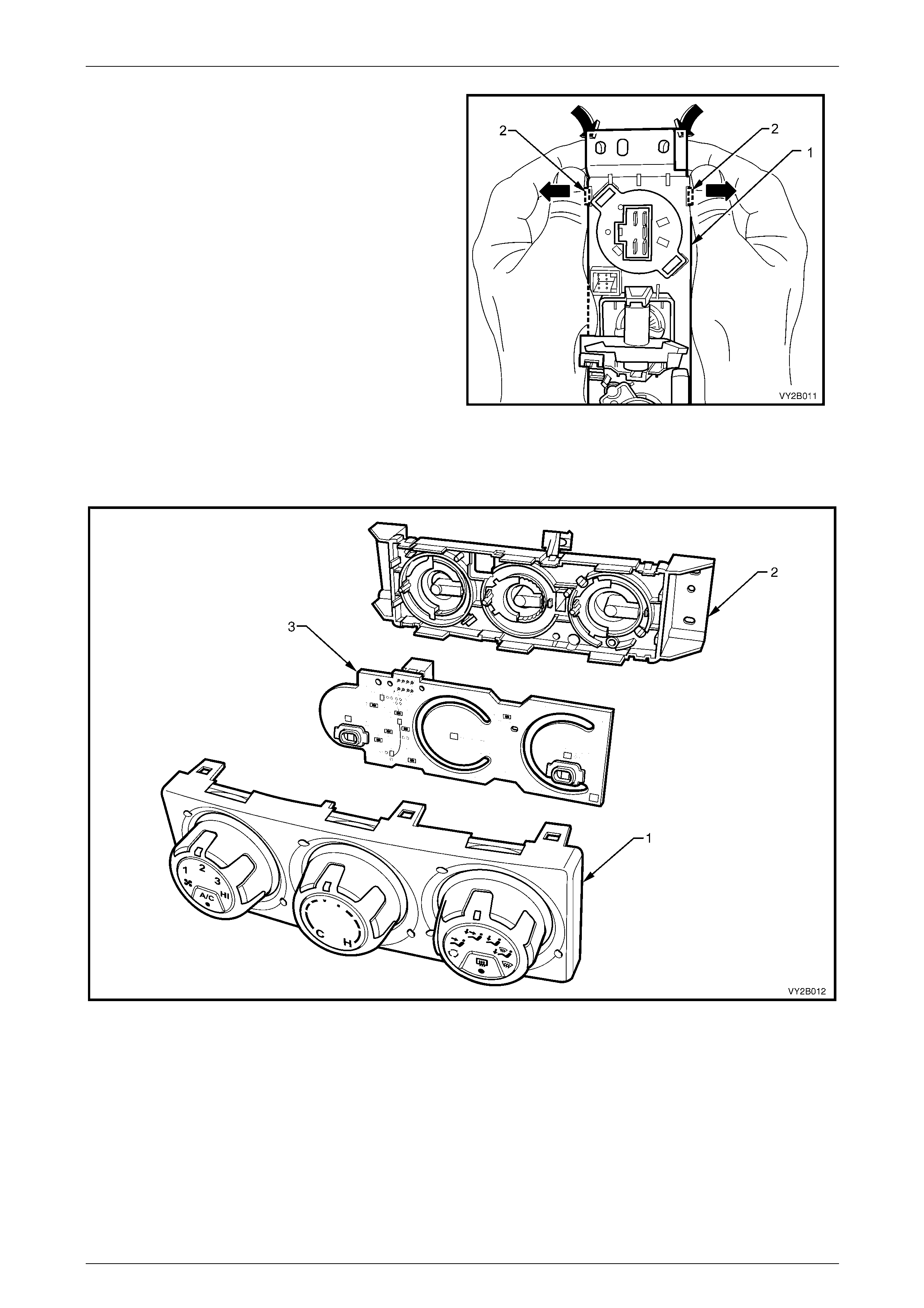

5 Rotate the controller (1) through 180° and disengage

the retaining tangs (2) at the other end of the controller

by using the same technique as described in previous

Step.

Figure 2C – 9

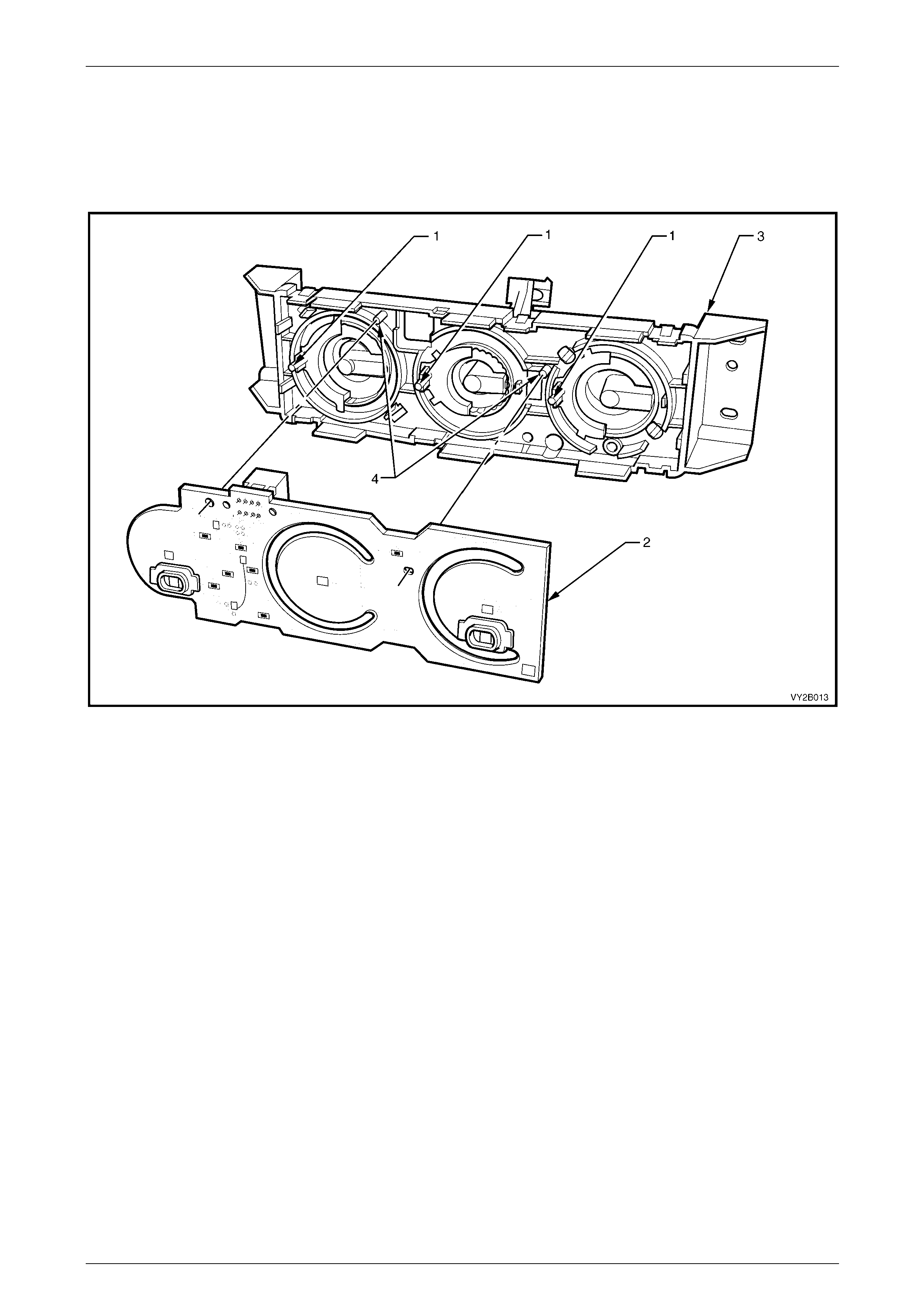

6 Remove the front housing/switch assembly (1) from the rear housing (2), refer to Figure 2C – 10.

7 Remove the printed circuit board (3) from the rear housing.

Figure 2C – 10

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-11

Page 2C-11

Reinstall

1 Ensure the switch shaft pins (1) are located at the 9 o’clock position, refer to Figure 2C – 11.

2 Ensure the locating pins (4) are ali gned with the corresponding holes of the circuit board and install the pr inted

circuit board (2) to the rear housing (3).

Figure 2C – 11

3 Rotate the switches so that all switch position indic ators (1) are at the 12 o’clock pos ition. Ensure all three shaft

pins (2) are still located at exactly the 9 o’clock position, refer to Figure 2C – 12.

4 Install the front housing/s witch assembl y (3) to the rear hou sing (4) ensuring its six retaining tan gs are fully

engaged over the rear housing tang protrusions.

5 Ensure all the switches rotate freely and the switch position indicators align correctly with all switch positions.

Ensure all switches do not rotate past intended rotation limits.

6 Install the controller to the instrument panel, refer to 2.1 Manual Controller Assembly.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-12

Page 2C-12

Figure 2C – 12

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-13

Page 2C-13

2.5 Mode Switch Vacuum Valve

LT Section No. — 08–155A

Remove

1 Remove the manual HVAC controller, refer to 2.1 Manual Contro ller Assembly.

2 Remove the front housing/switch assembly and printed circuit board from the rear housing,

refer to 2.4 Front Housing/Switch Assembly and Printed Circuit Board.

3 Using needle nose pliers (1), compress both pairs of

locking tangs (2) of the mounting dowels on the mode

switch vacuum valve and withdraw the switch

assembly from the controller rear housing (3).

Figure 2C – 13

Reinstall

1 Ensure the mode shaft pin (1) is located at the

9 o’clock position. On the mode switch valve

assembly (2) ensure the larger drive pin (3) is

positioned at the 12 o’clock po sition.

2 Align the mounting dowels (4) to the corresponding

holes (5) in the rear housing a nd install the switch

assembly ensuring the locking tangs of the mounting

dowels engage fully into the rear housing

3 Install the front housing/switch assembly and printed

circuit board to the rear housing, refer to

2.4 Front Housing/Switch Assembly and Printed

Circuit Board.

4 Ensure all switches rotate freely and all th e switch

position indicators align corre ctly with all switch

positions. Ensure all switches do not rotate p ast

intended rotation limits.

5 Install the controller to the instrument panel, refer to

2.1 Manual Controller Assembl y.

Figure 2C – 14

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-14

Page 2C-14

3 Heating, Ve ntilation and Air-

conditioning (HVAC) Unit

3.1 HVAC Unit

LT Section No. — 08–150

Remove

NOTE

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes prior to

disconnecting the batter y.

1 Disconnect the battery ground lead.

2 Disable the occupant protection system, refer to Section 12M Occupant Protection System.

3 Discharge the air-conditioning system,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

4 Drain engine coolant into a su itable, clean container, refer to:

• Section 6B1 Engine Co oling – V6, or

• Section 6B3 Engine Cooling – GEN III V8.

5 Remove instrument panel pad assemb ly and brackets & braces,

refer to Section 1A3 Instrument Panel and Consol e.

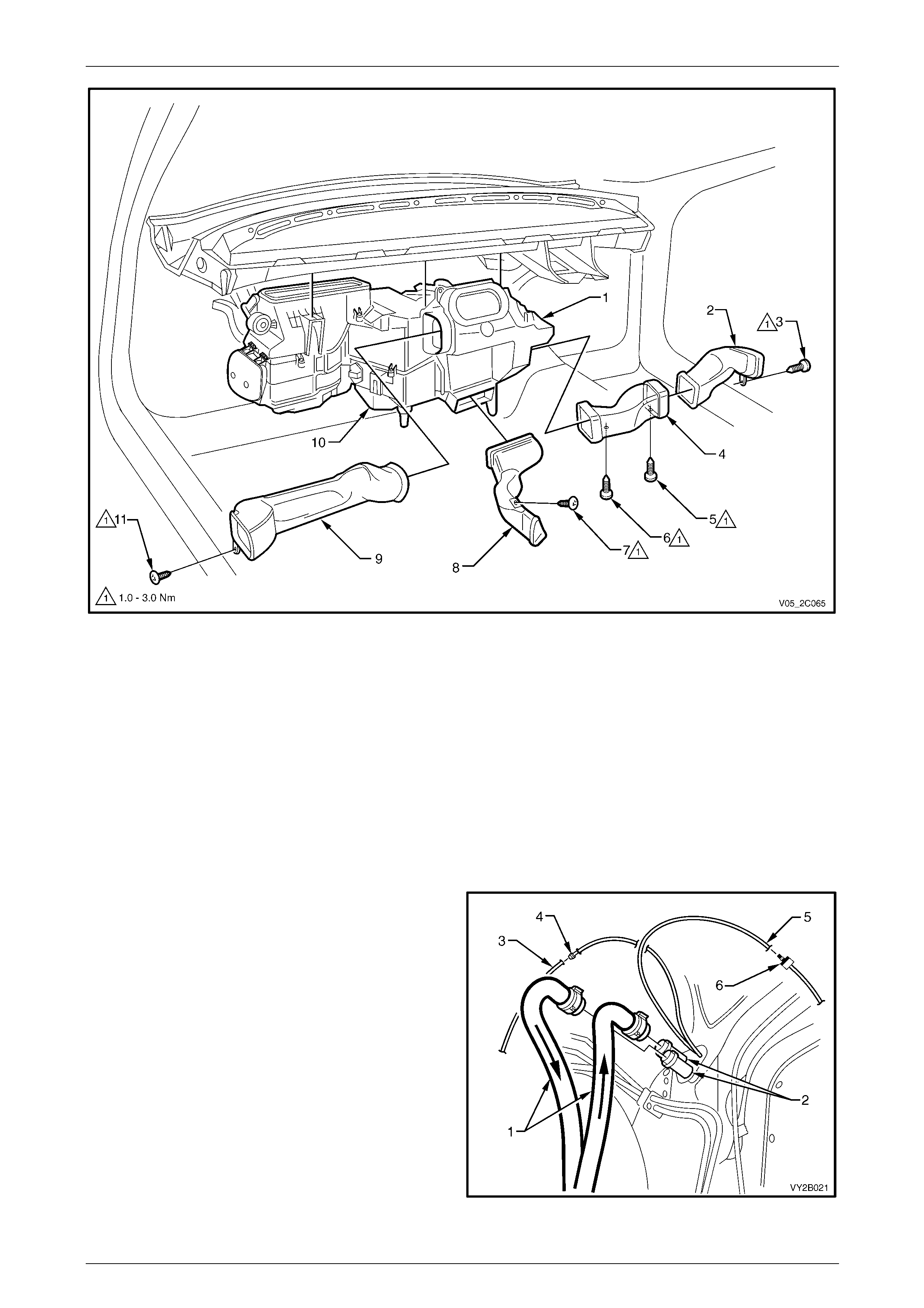

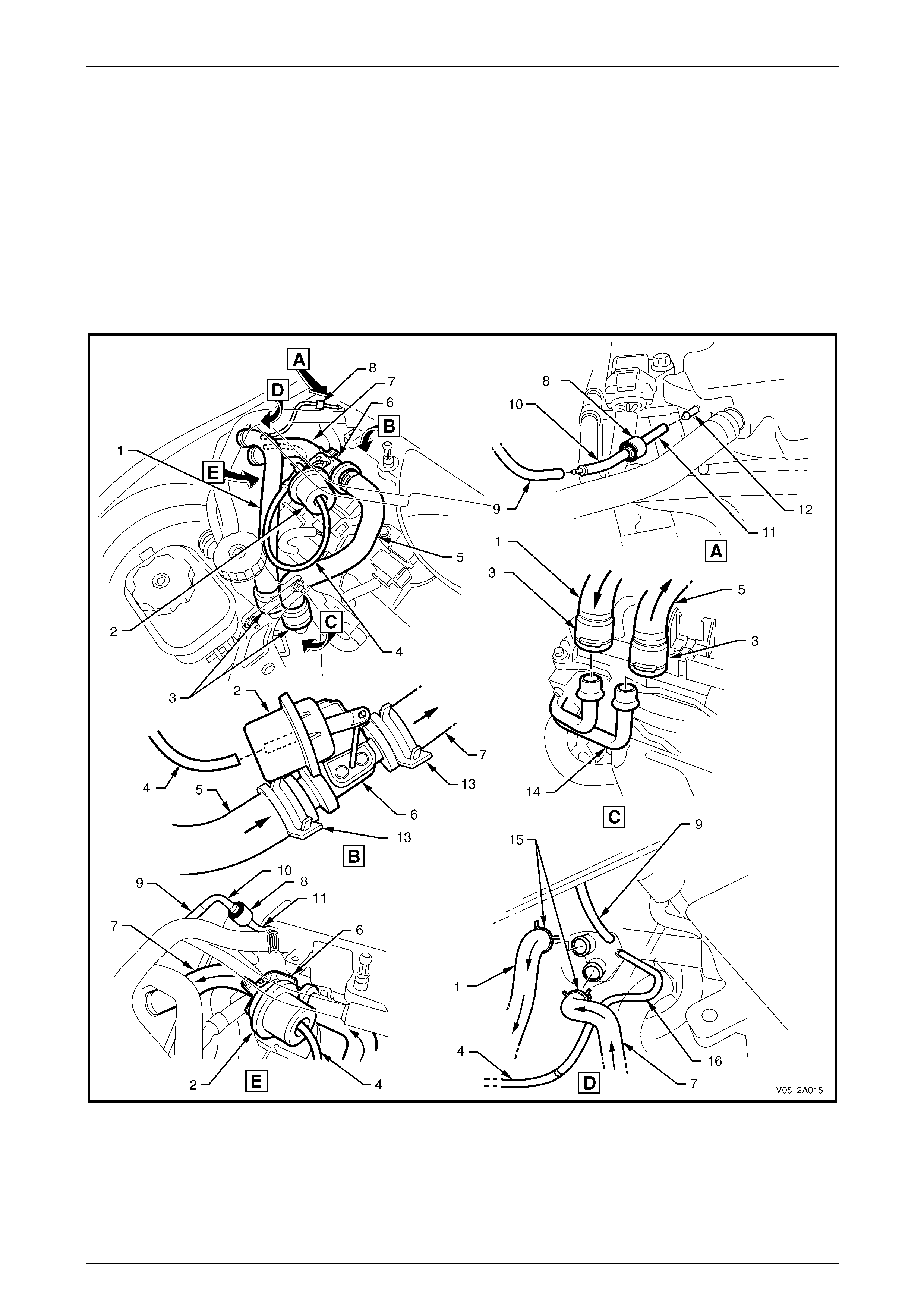

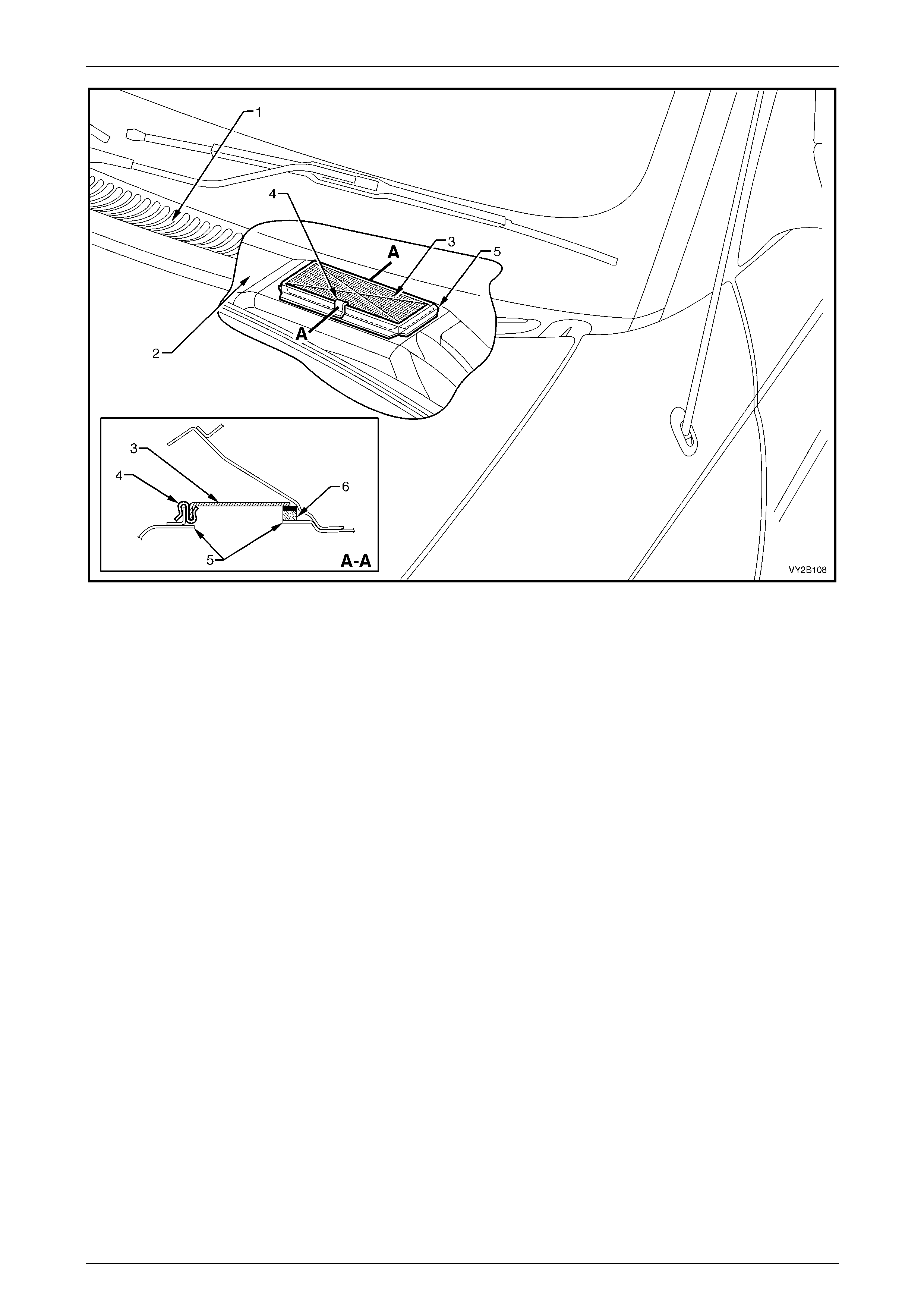

6 Remove the side and console air ducts from the HVAC unit as required, refer to Figure 2C – 15.

NOTE

• Some of the screws shown have been

removed with the instrument panel.

• The foot air duct remains attached when the

HVAC unit is removed

• The steering column (not shown) does not

require removal for HVAC unit removal.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-15

Page 2C-15

Figure 2C – 15

Legend

1 HVAC Unit

2 Driver Side Outer Duct

3 Screw

4 Driver Side Inner Duct

5 Screw

6 Screw

7 Screw

8 Floor Console Front Duct

9 Passenger Side Duct

10 Foot Duct

11 Screw

7 Remove the body control module (BCM), refer to Section 12J Body Control Modul e.

8 Remove the antenna lead from the retaining clips located at the HVAC unit case join.

9 Remove the instrument panel inflatable restraint module assembly,

refer to Section 12M Occupant Protection System.

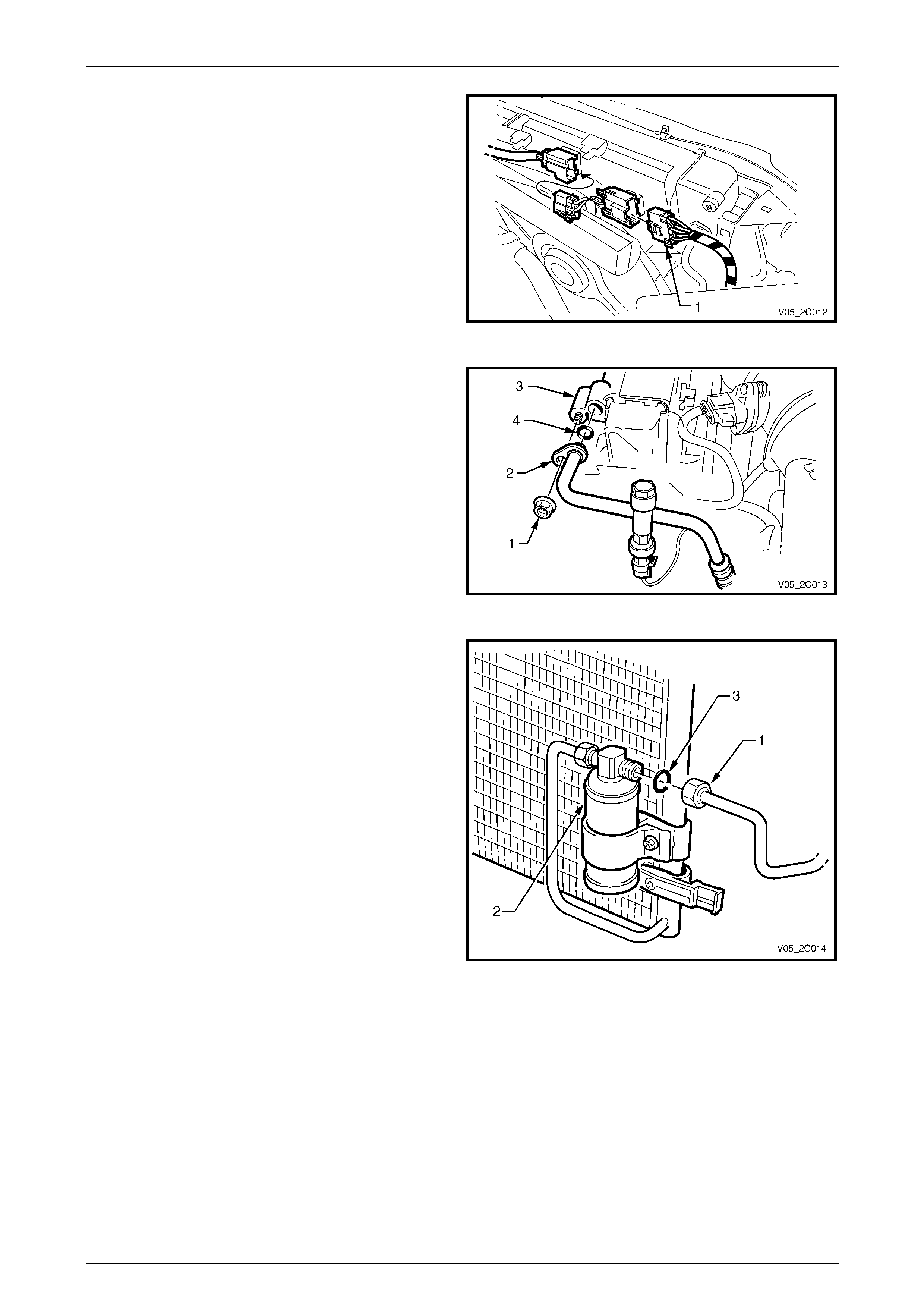

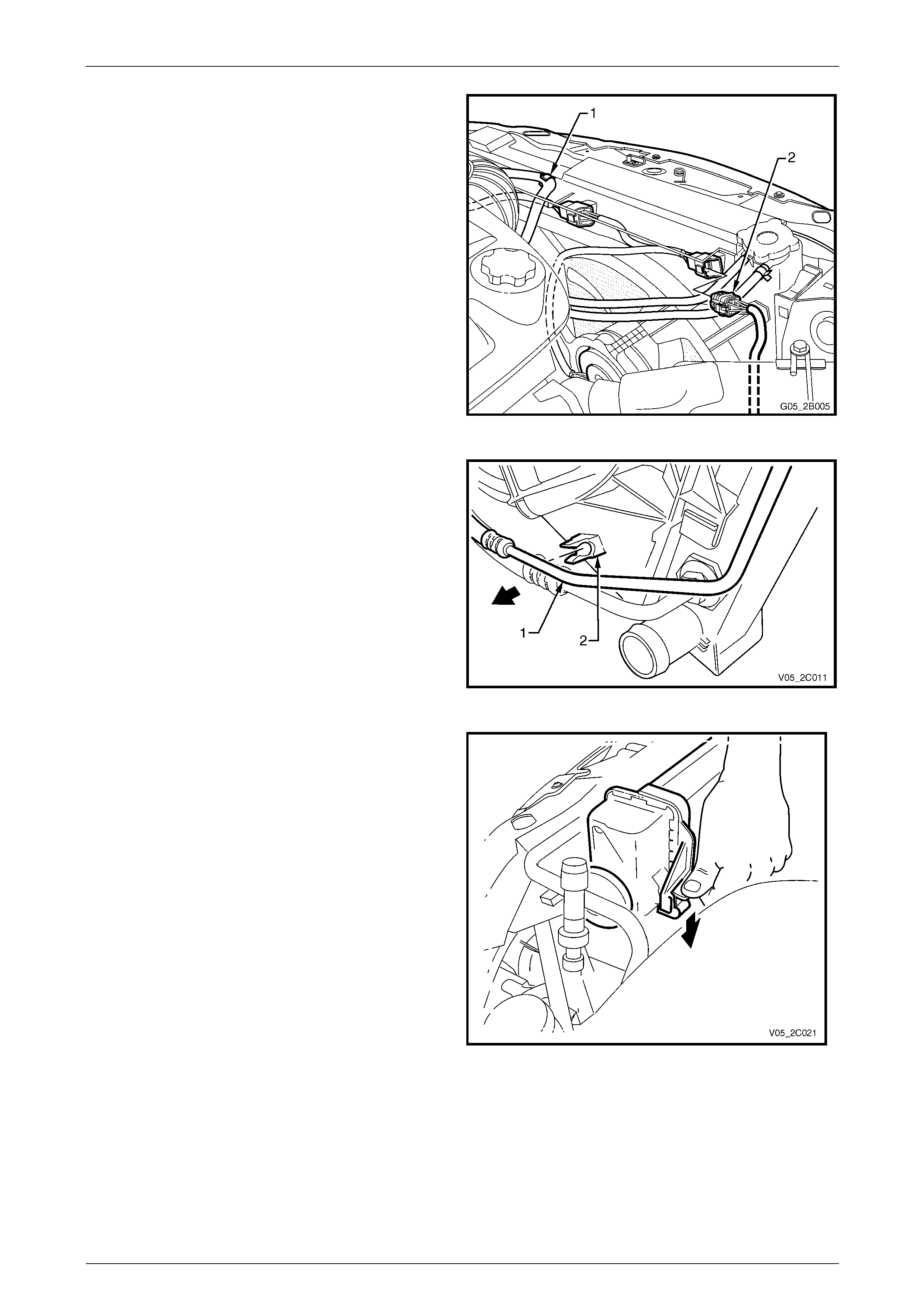

10 Mark the heater hoses (1) in relation to the heater core

pipes (2) to maintain correct coolant flow and

disconnect the heater hoses.

11 Disconnect the water valve vacuum hose (3) at the

joiner (4).

12 Disconnect the vacuum supply hose (5) at the check

valve (6).

13 Remove the thermal expansion valve, refer to

6.1 Thermal Expansion Valve.

14 Remove the screws retaining the HVAC unit to the

dash panel, refer to Figure 2C – 17.

NOTE

The steering column (not shown) does not have

to be removed for HVAC unit removal

Figure 2C – 16

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-16

Page 2C-16

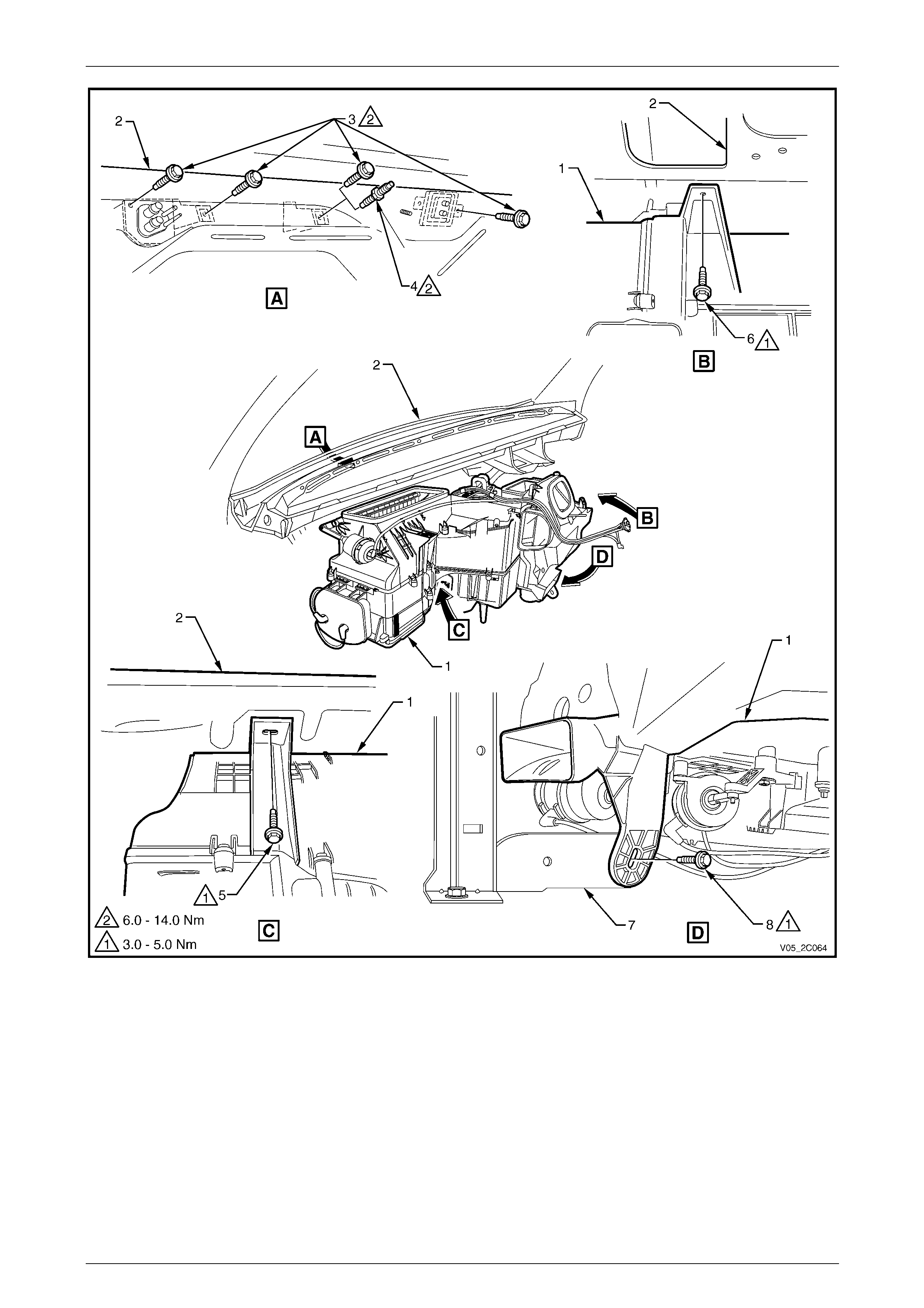

Figure 2C – 17

Legend

1 HVAC Unit

2 Dash Panel

3 Screw – Dash Panel, Engine Compartment

(V6 – 4 places / GEN III V8 – 3 places)

4 Stud – Dash Panel, GEN III V8 Engine Compartment

5 Screw – Dash Panel, Passenger Compartment Left-hand

6 Screw – Dash Panel, Cabin Right-hand

7 Lower Radio Bracket Assembly

8 Screw – Lower Radio Bracket Assembly

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-17

Page 2C-17

When removing the HVAC unit from the

vehicle take care not to strain the heater core

tubes and evaporator core tubes.

15 Remove the HVAC unit (1) from the vehicle by disengaging the drain tube (2) from the body grommet (3) installed

in the transmission tunnel (4), refer to Figure 2C – 18.

16 Carefully lift the HVAC unit away from the dash panel (5).

Figure 2C – 18

Reinstall

Reinstallation of the HVAC unit is the reverse of the removal procedure, noting the following:

1 Tighten the screws / stud attaching the HVAC unit to the correct torque specificati on, refer to Figure 2C – 17.

HVAC unit to lower radio bracket assembly

attaching screw torque specification...........3.0 – 8.0 Nm

HVAC unit to dash panel attaching

screw torque specification

(passenger compartment side) ...................3.0 – 8.0 Nm

HVAC unit to dash panel attaching

screw / stud torque specification

(engine compartment side) .......................6.0 – 14.0 Nm

2 Tighten the screws attaching the air d ucts to the correct torq ue specification, refer to Figure 2C – 15.

Side and console air duct attachi ng

screw torque specification...........................1.0 – 3.0 Nm

3 Fill the cooling system with the correct specification and quantity of coolant and pressure-test the system, refer to:

• Section 6B1 Engine Co oling – V6 Engine, or

• Section 6B3 Engine Cooling – GEN III V8.

4 Evacuate and charge the air-conditioning system with refrigerant,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-18

Page 2C-18

3.2 Evaporator

LT Section No. — 08–150

Remove

1 Remove the HVAC unit, refer to 3.1 HVAC Unit.

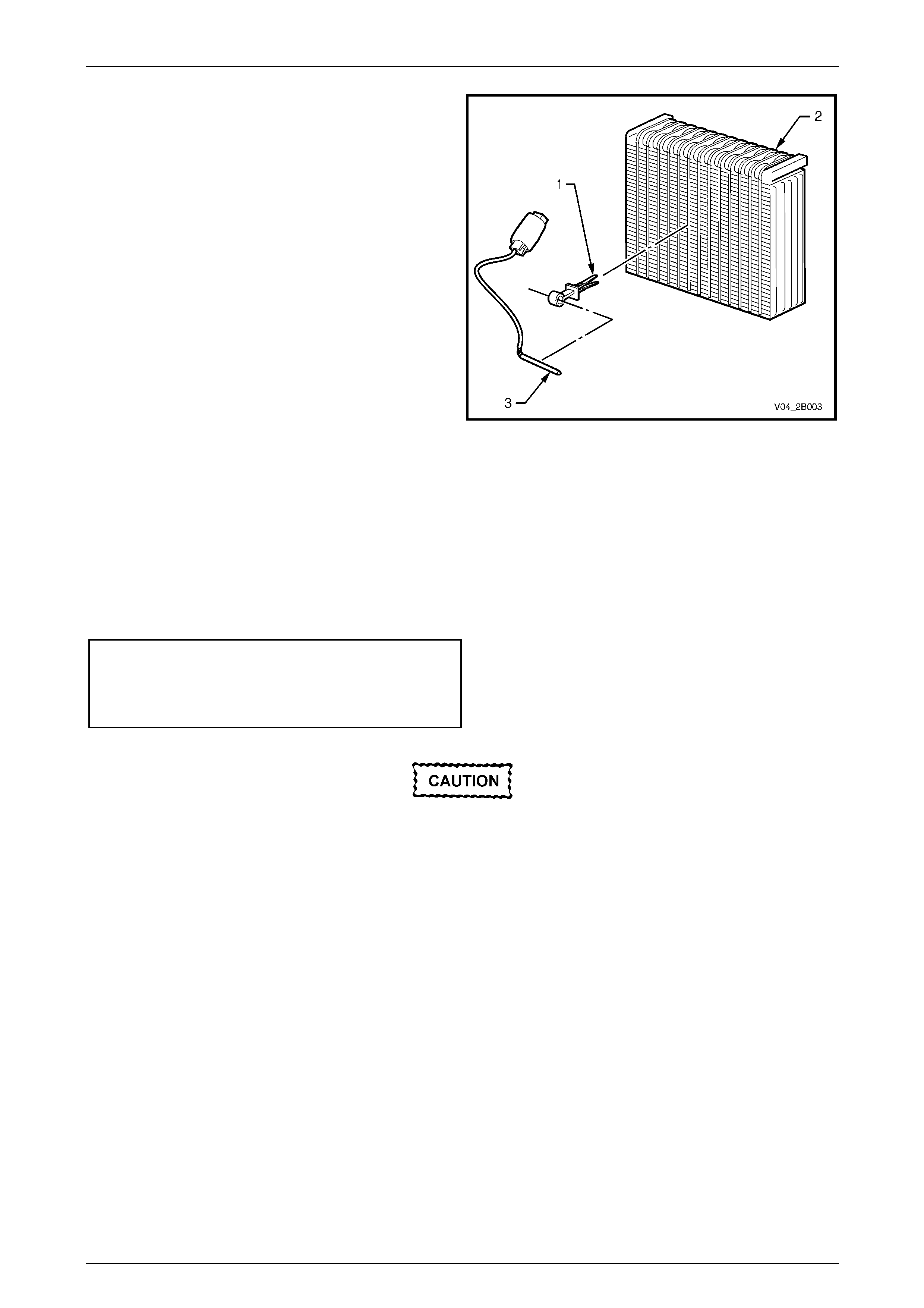

2 On OCC (Auto A/C) units, disconnect the wiring

harness connector (1) from the evaporative

temperature sensor connector (2).

3 Remove the venturi pipe (3) from the evaporator

cover (4).

Figure 2C – 19

4 Remove the screw (1) and washer securing the air mix

door quadrant lever (2) to the evaporator cover (3) and

move the quadrant lever aside.

5 Remove the two screws (4) from the evaporator

cover (3), swing the cover open and remove it.

6 Carefully remove the evaporat or from its cavity in the

HVAC case.

NOTE

A foam insulator may also be removed with the

evaporator.

Figure 2C – 20

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-19

Page 2C-19

7 If required, on OCC (Auto A/C) units, remove the

evaporator temperature sens or (3) by removing its

mounting clip (1) from the evaporator (2).

Figure 2C – 21

Reinstall

Reinstallation of the evaporator is the reverse of removal the procedur e, noting the following:

1 Ensure the foam insulator is correctly seated in the HVAC case.

2 If required, on OCC (Auto A/C) units, install the evaporator temperature sensor in the correct position on the

evaporator, refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

3 Tighten the attaching screws to the correct torque specification.

HVAC unit case attaching screw

torque specification.....................................1.0 – 3.0 Nm

Air mix door quadrant lever att achi ng

screw torque specification...........................1.0 – 3.0 Nm

The total quantity of lubricating oil in the air-

conditioning system must be maintained. If a

compressor, evaporator, condenser, filter

drier receiver, or air-conditioning line is

replaced, a specified quantity of lubricating

oil must be added to the system to

compensate for oil removed with the original

component. Refer to Section 2B HVAC

Climate Control (Manual A/C) – Servicing and

Diagnosis.

4 Evacuate and charge the system with refrige rant,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-21

Page 2C-21

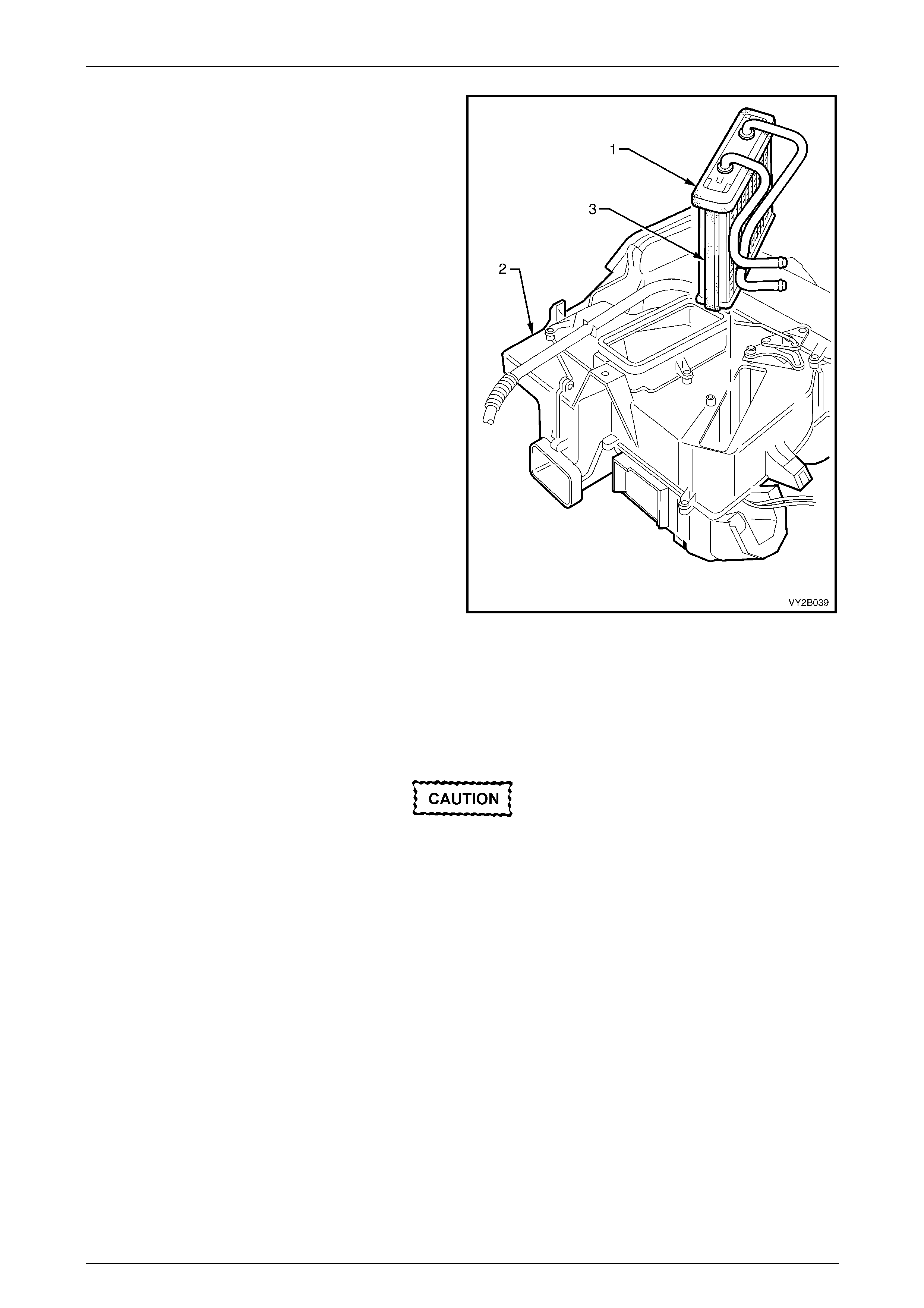

3 Remove the heater core (1) from the HVAC case (2)

without damaging the foam seal (3) located on top and

sides of the heater core.

Figure 2C – 23

Reinstall

Reinstallation of the heater c ore is the reverse of removal the procedure, noting the following:

1 Ensure the foam seals are not damaged when installing heater core to the HVAC unit case.

The total quantity of lubricating oil in the air-

conditioning system must be maintained. If a

compressor, evaporator, condenser, filter

drier receiver or air-conditioning line is to be

replaced, a specified quantity of lubricating

oil must be added to the system to

compensate for oil removed with the original

component. Refer to Section 2B HVAC

Climate Control (Manual A/C) – Servicing and

Diagnosis.

2 Evacuate and charge the system with refrige rant,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-22

Page 2C-22

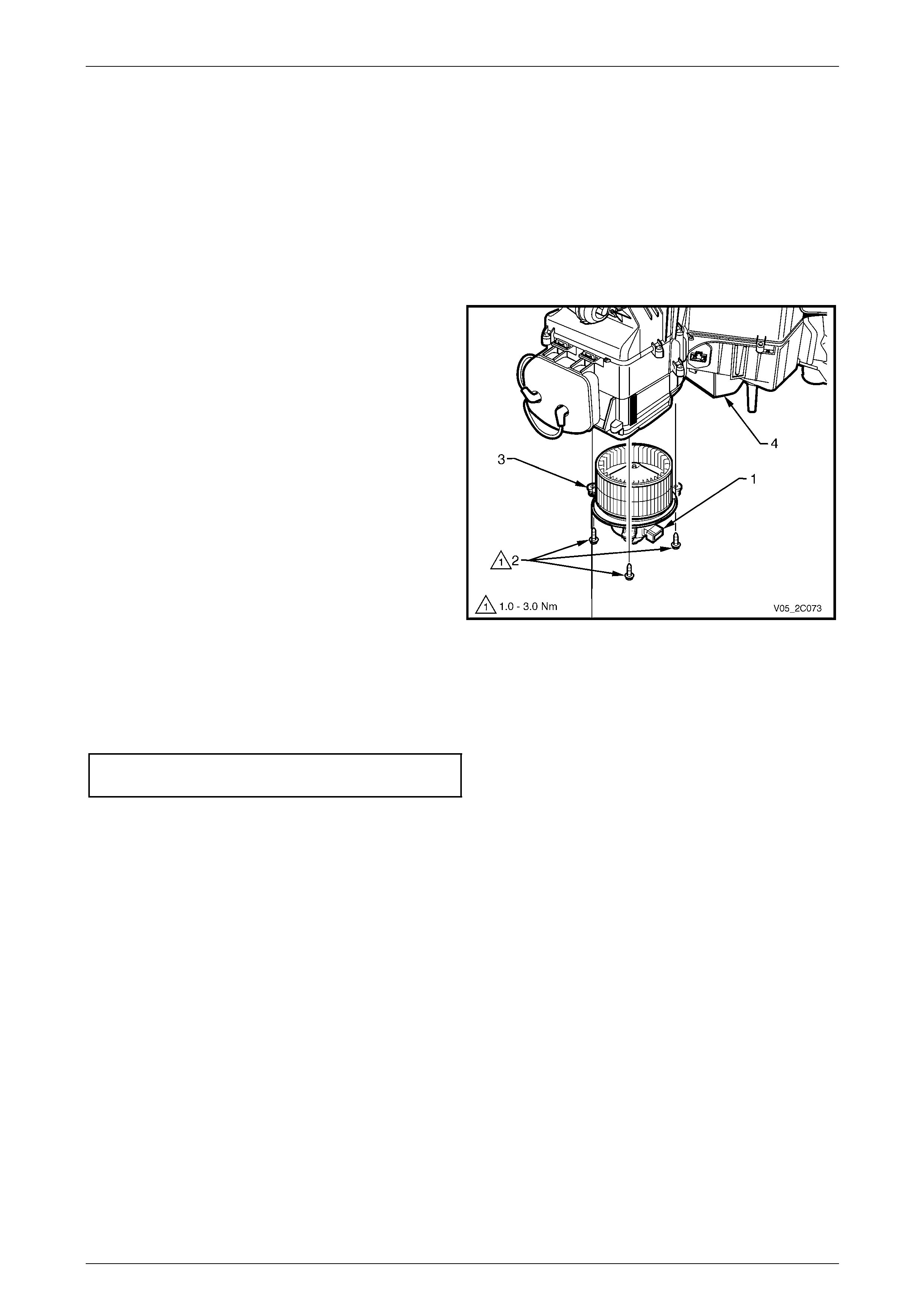

3.4 Blower Motor and Fan Assembly

LT Section No. — 08–150

Remove

1 Remove the left-hand instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Consol e.

2 If required, on OCC (Auto A/C) units, disconnect the wiring harness connector from the vacuum solenoid pack.

3 Disconnect the wiring harness connector from the

blower motor sub-harness connector (1)

4 Remove the three screws (2) attaching the blower

motor and fan assembly (3) to the HVAC unit (4) and

remove the assembly.

NOTE

The screw closer to the rear of the vehicle also

secures the fuse mounting bracket to the blower

motor and fan assembly mounting flange.

Figure 2C – 24

Reinstall

Reinstallation of the blower motor and fan assembly is the reverse of the removal procedure. Tighten the attaching

screws to the correct torque specification.

Blower motor and fan assembly

attaching screw torque specification...........1.0 – 3.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-23

Page 2C-23

3.5 Electronic Blower Motor Controller

LT Section No. — 08–150

Remove

1 Remove the left-hand instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Consol e.

2 Remove the instrument panel compartment assembly, refer to Section 1A3 Instrument Panel and Console.

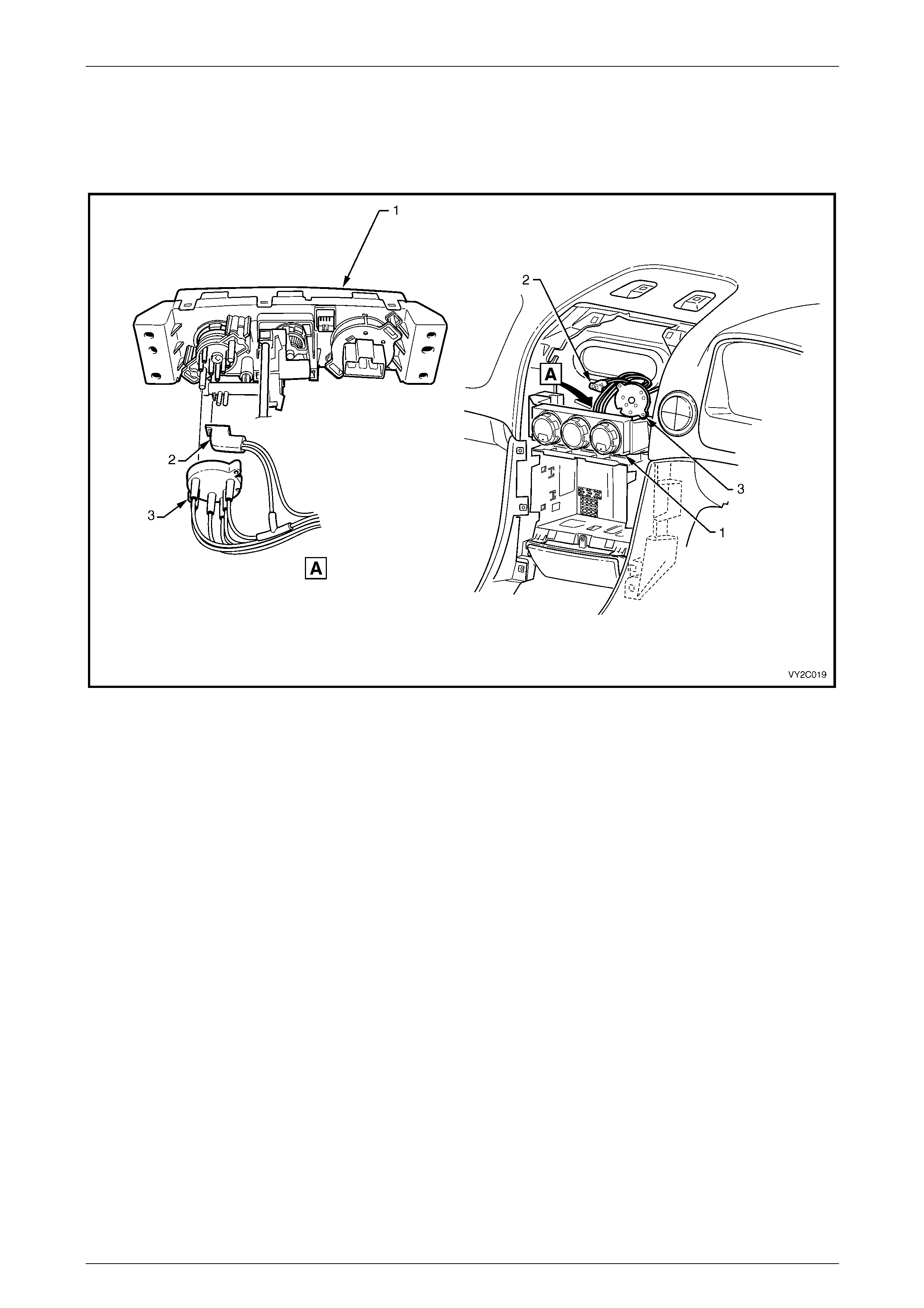

3 Remove the wiring harness connector (1) from the

electronic blower motor controller (2).

4 Remove the two screws (3) attaching the cont roller to

the side of the HVAC unit (4).

5 Remove the controller from the HVAC unit.

Figure 2C – 25

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-24

Page 2C-24

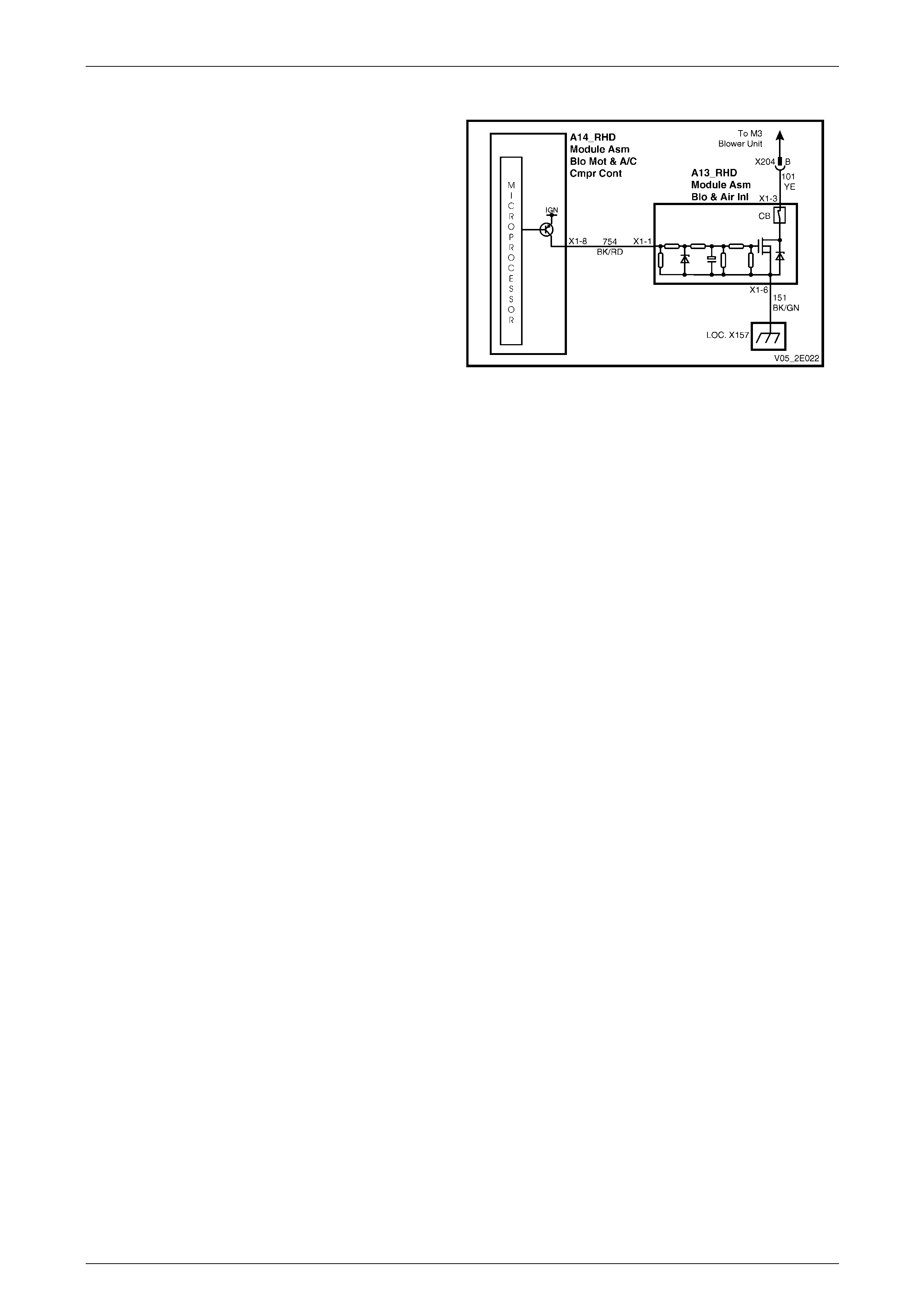

Test

The electronic blo wer motor controller (A13) provides a

ground circuit for the HVAC blower unit through its internal

power transistor circuitry.

Circuit 754 provides the control voltage to the module, which

determines the speed of the blower fan.

The blower speed controller incorporates an internal

resetable circuit breaker (CB). This circuit breaker is used to

prevent damage to the blower motor electrical circuit i n the

case of electrical current surges, blower motor lock up on

slower speeds or extreme temperature.

If any of the above situations occur in the blower motor

circuit, the controller’s internal resetable circuit breaker will

trip and render the blower motor ino perative. The internal

circuit breaker can then be reset by either of the two

following methods:

• After the ignition has been turned from the Off to the

On position.

• Manually moving the fan speed to position 4. All

blower functions will then return.

NOTE

If the blower motor switches off while driving and

resumes after the ignition has been turned back

on, do not replace the blower speed contro ller as

it has performed the function it was designed to

do. Check the blower motor and circuit for

voltage issues also ins pect the blower motor fan

for foreign material caught in the plastic impeller.

If the blower speed controller switches the

blower motor off at a frequ ency of (say) once per

month, inspect the blower motor fan’s plastic

impeller for foreign material (e.g. leaves, paper,

etc). If no foreign material is present, replace the

blower motor.

Figure 2C – 26

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-25

Page 2C-25

The use of an ohmmeter can be very limit ed when testing

the blower motor module, except for a transistor short circui t

occurrence between terminals X1-3 and X1-6.

Connector Details

Pin Number Function

X1-1 Fan Speed Cont

X1-2 No Connection

X1-3 Blower Motor

X1-4 No Connection

X1-5 No Connection

X1-6 Ground

Two possible fault conditions associated with this controller

are provided in the following tables to assist the technician

in identifying faults.

Figure 2C – 27

Test 1

The blower fan runs continuously at maximum speed when the ignition switch is turned on.

Step Action Yes No

1 1 Turn ignition switch off.

2 Remove wiring connector from the OCC control module.

3 Turn ignition switch on.

Does the fan continue to run?

Replace the

electronic blower

motor controller

Repair circuit 754 or

test the OCC control

module

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-26

Page 2C-26

Test 2

The blower fails to operate.

Step Action Yes No

1 Inspect the applicable OCC system fuses, refer to Section 12O Fuses,

Relays and Wiring Harnesses.

Are the fuses serviceable? Go to Step 2 Replace as required

2 1 Turn the ignition switch off.

2 Place a temporary test lead (capa ble of handling 30 amps)

between the electronic blower motor controller connector

A13 – X1 pin 3 and a known ground.

3 Turn on the ignition.

Does the fan speed operate at maximum sp eed? Go to Step 3 Repair circuit 101

3 Using a multimeter set to measure resistance, test for continuity

between the electronic blower motor controller connector A13 – X1

pin 6 and a known ground.

Does the multimeter indicate continuity? Go to Step 4 Repair circuit 151

4 1 Using a multimeter set to measure voltage, test for voltage at

electronic blower motor controller connector A13 – X1 pin 1.

2 Vary the blower fan speed using either the soft keys on Tech 2

or the fan speed button on the OCC control modu le.

Does the voltage increase as the fan speed indication increases? System OK

Repair circuit 754 or

test the OCC control

module

Reinstall

Reinstallation of the electronic blower motor controller is the reverse of the removal procedure, noting the following:

1 Install the controller with the arro w (5) pointing towards the rear of the vehicle, refer to Figure 2C – 25.

2 Tighten the attaching screws to the correct torque specification.

Electronic blower motor controller

attaching screw torque specification...........1.0 – 3.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-27

Page 2C-27

3.6 Intake Blower Duct

LT Section No. — 08–150

Remove

1 Remove the HVAC unit, refer to 3.1 HVAC Unit.

2 Either disconnect the vacuum line (1) from the vacuum

actuator (2), or remove the vacuum actuator, refer to

4.3 Vacuum Actuators.

3 Remove the five screws (3) attaching the intake

blower duct (4) to the HVAC case and remove the

duct.

Figure 2C – 28

Reinstall

Reinstallation of the intake blower duct is the reverse of the removal procedure, noting the foll owing:

1 Ensure the duct is correctly seated on the HVAC case.

2 Tighten the screws to the correct torque specification.

Intake blower duct attaching

screw torque specification...........................1.0 – 3.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-28

Page 2C-28

3.7 Vent Distribution Housing

LT Section No. — 08–150

Remove

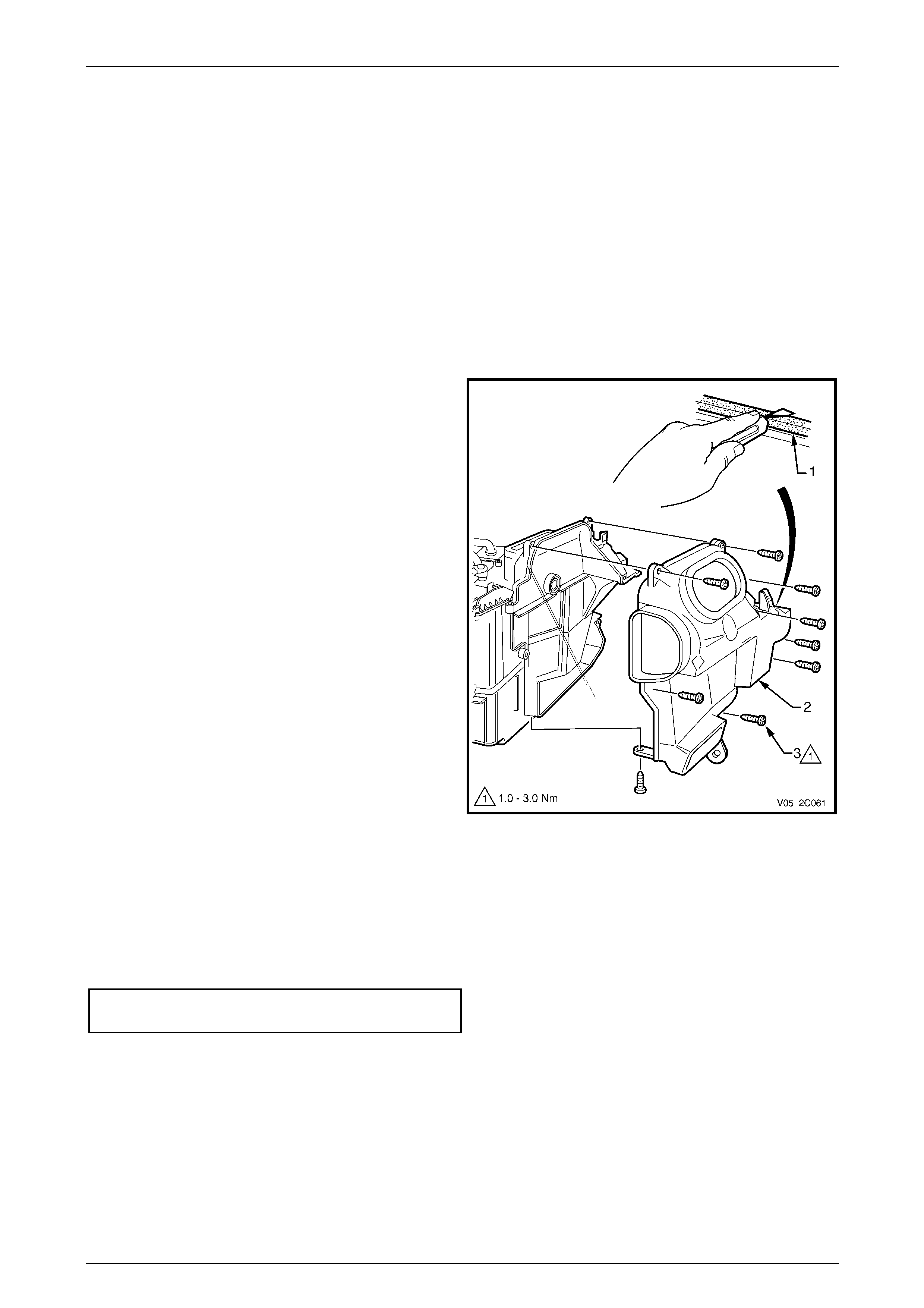

1 Remove the HVAC unit, refer to 3.1 HVAC Unit.

2 On OCC (Auto A/C) units, remove the aspirator tube,

refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

3 As required, remove the wiring harness from the HVAC case.

4 Either disconnect the face actuator pushrod and vacuum lines, or remove the actuator,

refer to 4.3 Vacuum Actuators.

5 Carefully cut the driver side inner duct outl et foam

seal (1) on a 45° angle at the join of the vent

distribution housing (2) to the HVAC case, two places.

6 Remove the nine screws (1) attaching the v ent

distribution housing to the HVAC case and remove the

housing.

Figure 2C – 29

Reinstall

Reinstallation of the vent distribution housing is the revers e of the remov al procedure, noting the following:

1 Ensure the housing is correctly seated on the HVAC case.

2 Tighten the screws to the correct torque specification.

Vent distribution housing attaching

screw torque specification...........................1.0 – 3.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-29

Page 2C-29

4 Vacuum System

4.1 Vacuum Retention Tests

LT Section No. — 08–150

To operate efficiently, the HVAC system requires a constant vacuum source and all vacuum components must have no

vacuum leaks. Vacuum is supplied by the en gin e induction system and is retained within t he HVAC system by the action

of the one-way check valve located in the engine compartment.

A vacuum reserve is stored within the vacuum tank located on the left-hand side of the HVAC unit. Any of the following

components may cause or contribute to a vacuum leak within the HVAC system:

• check valve,

• vacuum tank,

• vacuum mode valve – manual A/C,

• water valve vacuum switch – manual A/C,

• vacuum solenoid pack – auto A/C,

• vacuum actuators,

• water valve actuator, and

• vacuum lines.

Symptoms of a vacuum leak may be as follows:

• constant coolant flow through the heater core,

• air always directed to the windscreen,

• air directed to ventilation outlets that are not selected,

• dust and/or smog ingress into the cabin despite the selection of the recirculation mode, or

• constant hissing noise emanating from a leaking or disconnected vacuum hose or com ponent.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-30

Page 2C-30

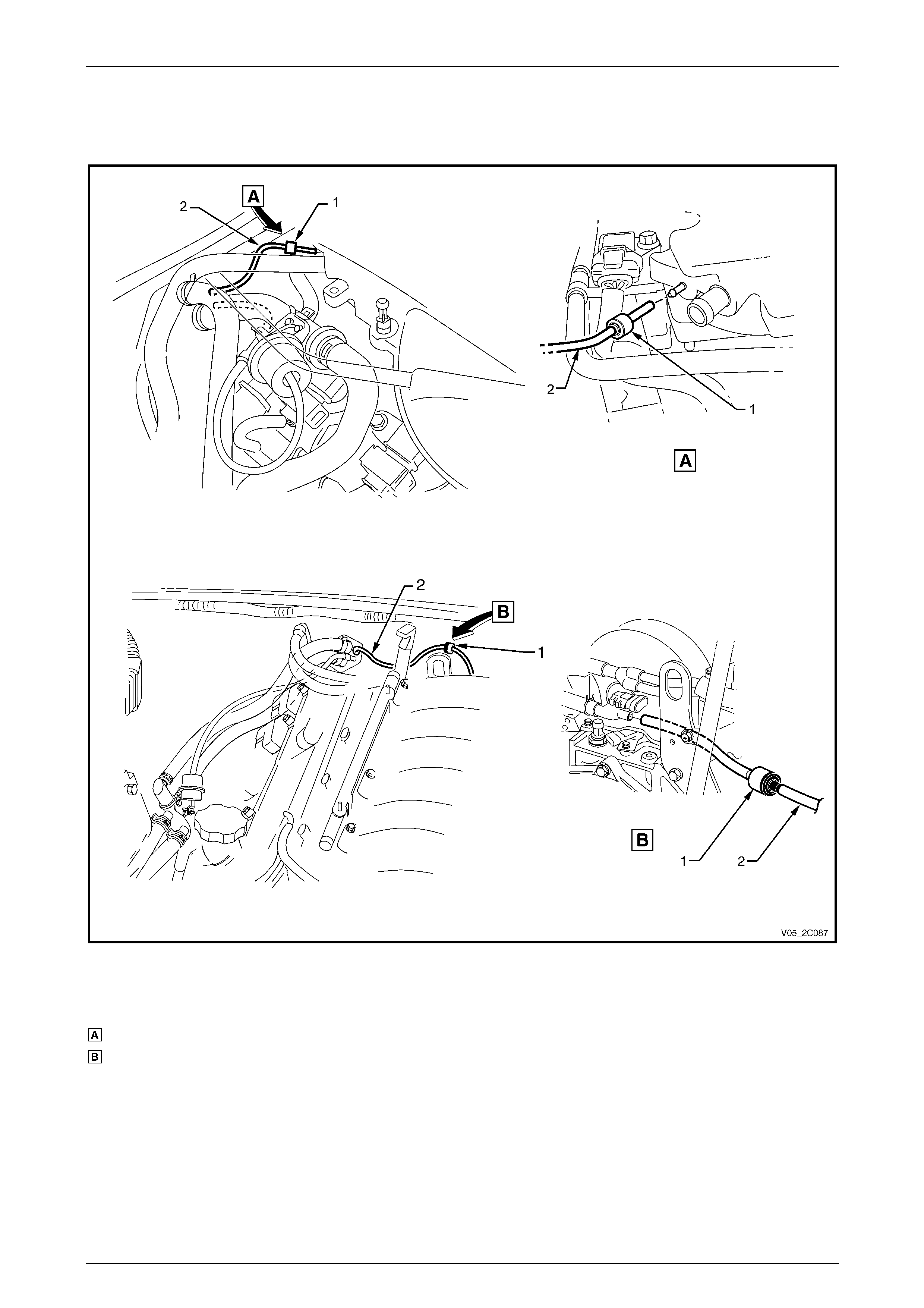

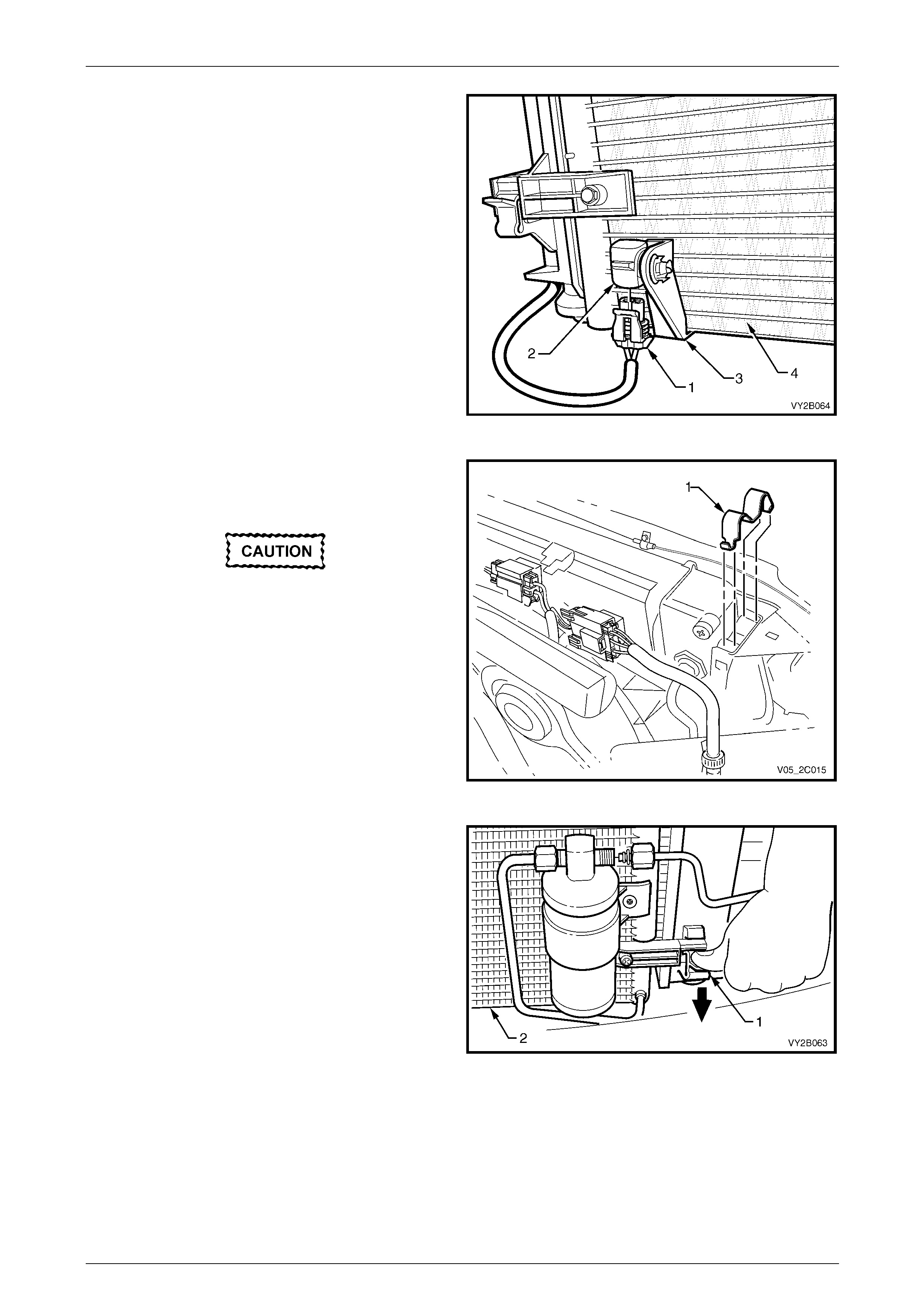

Check Valve

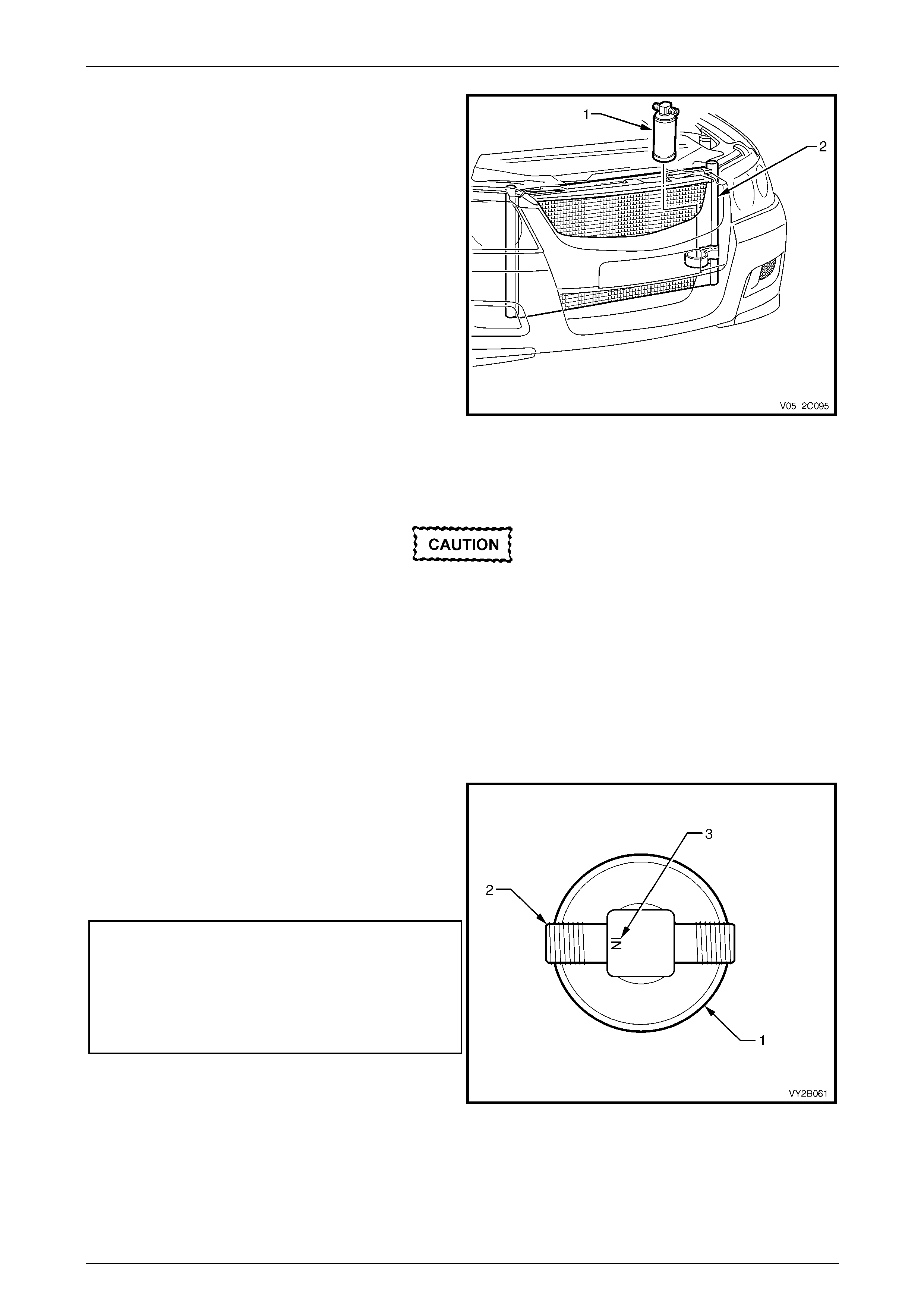

1 Locate the check valve (1) at the rear of the engine a nd disconnect the vacuum line sup pl y line (2) from the check

valve, refer to Figure 2C – 30.

Figure 2C – 30

Legend

V6 Engine

GEN III V8 Engine

1 Check Valve

2 Vacuum Line Supply Line

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-31

Page 2C-31

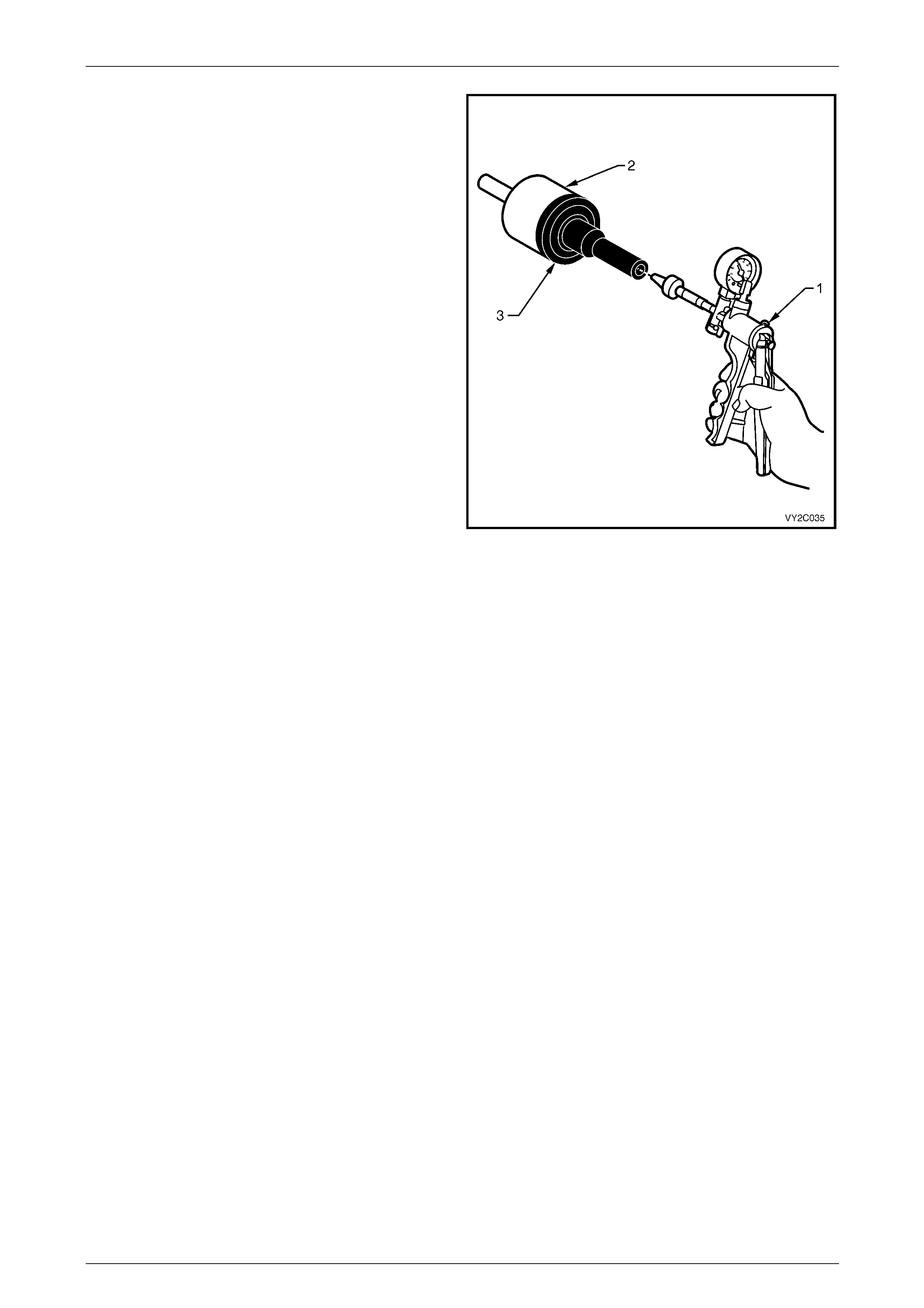

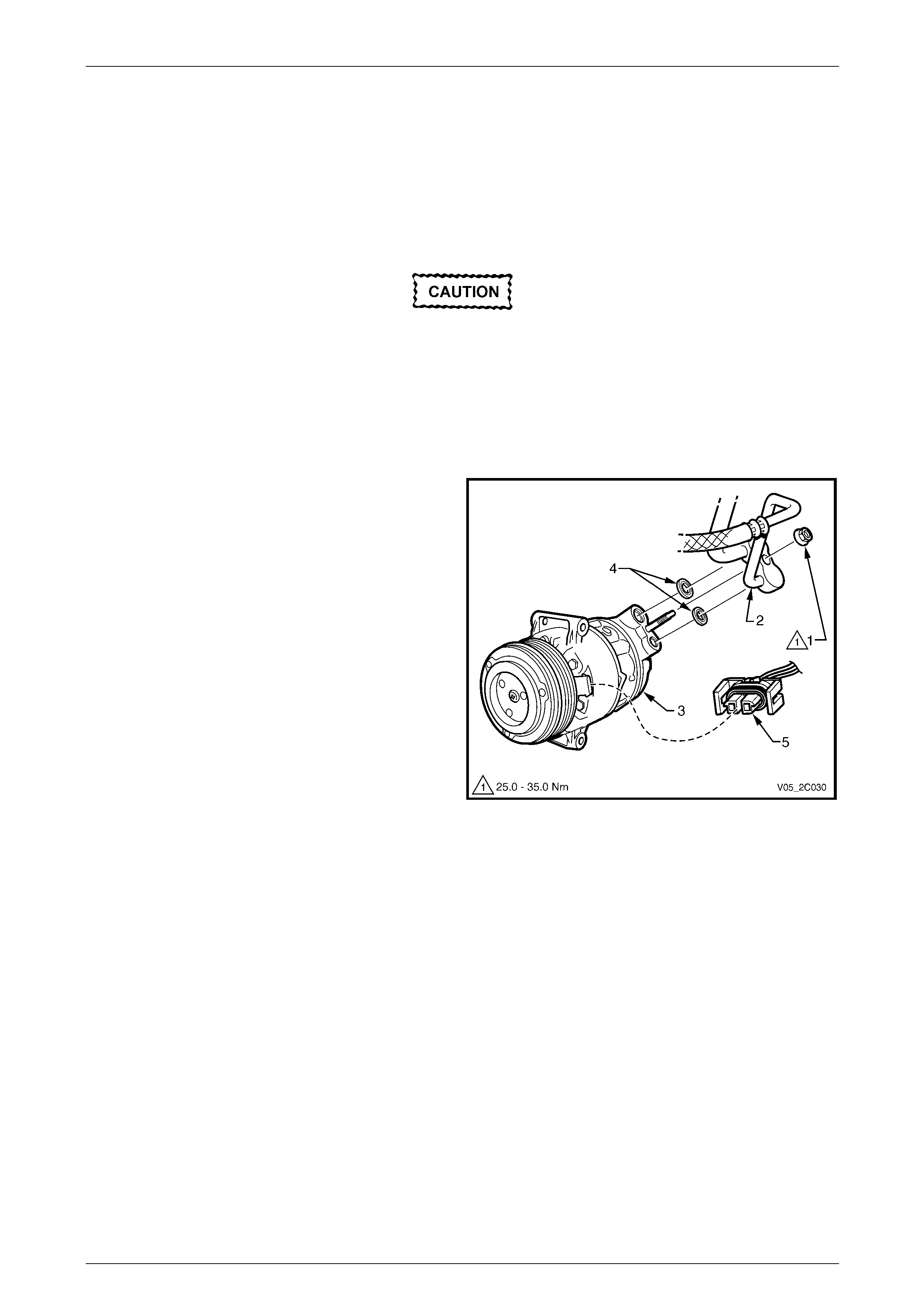

2 Connect a vacuum pump (1) to the check valve (2) at

the port of the valve black section (3).

3 Using the vacuum pump, create a vacuum and

observe the vacuum pump gauge needle:

• If the needle remains steady it indicates the

check valve is retaining vacuum.

• If the vacuum reading decreases, it indicate s a

leak in the check valve.

4 If a vacuum leak is indicated, replace the che ck valve.

5 Check the vacuum supply lines connected to the

check valve, replace if require d.

Figure 2C – 31

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-32

Page 2C-32

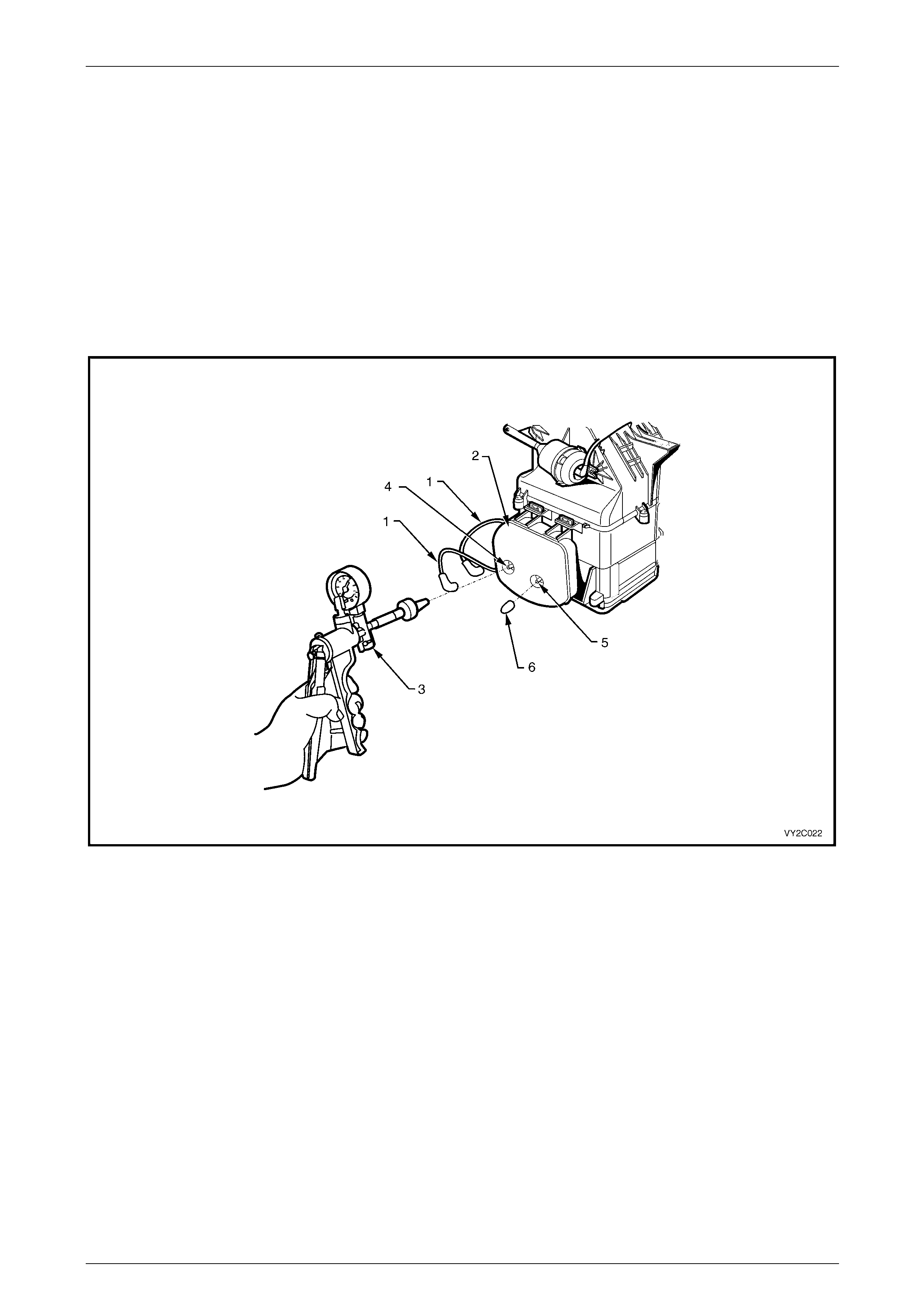

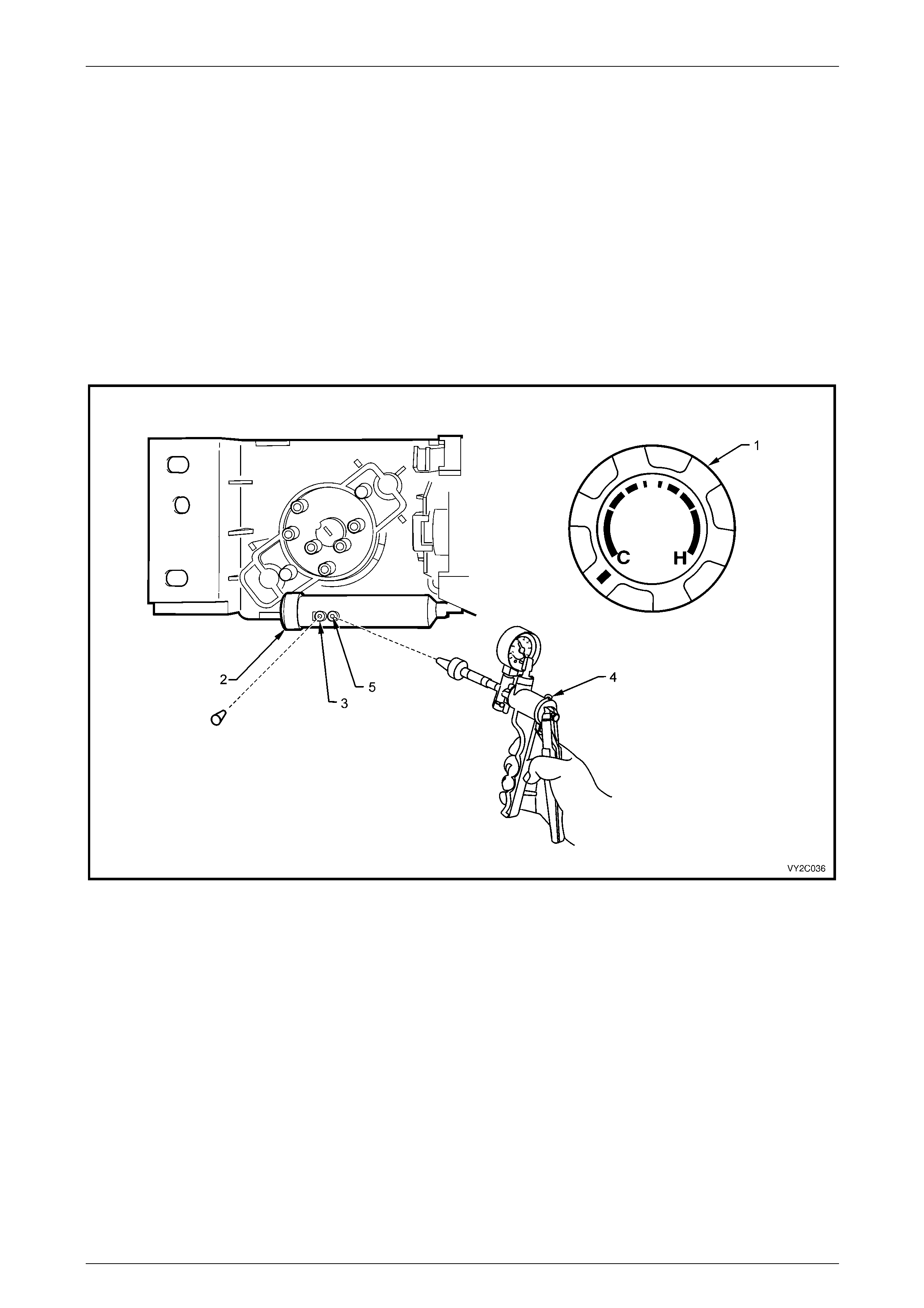

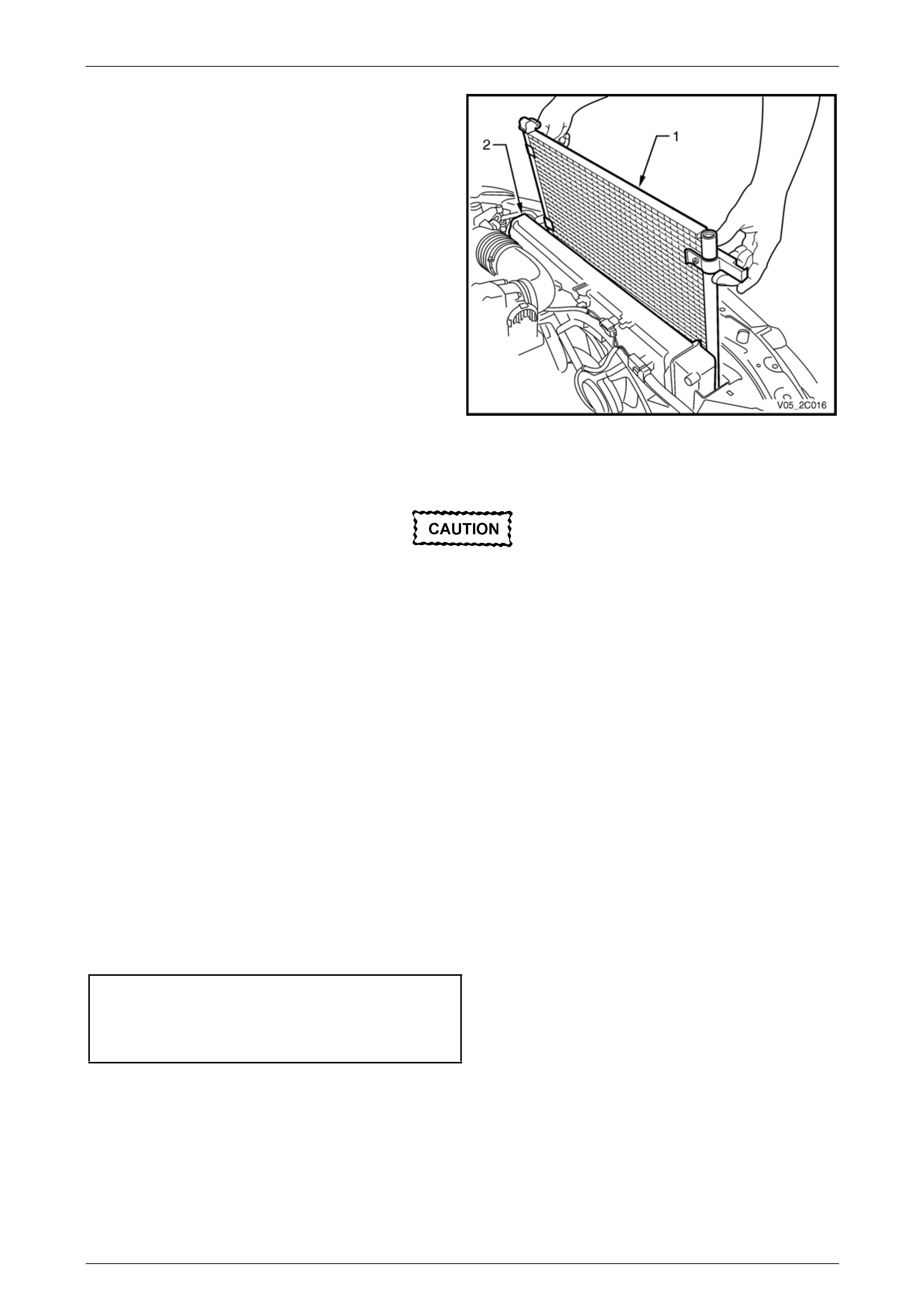

Vacuum Tank

1 Gain access to vacuum tank, refer to 4.2 Vacuum Tank.

2 Disconnect both vacuum lines (1) from the vacuum tank (2), refer to Figure 2C – 32.

3 Connect a vacuum pump (3) to the tank vacuum supply port (4) and cover the vacuum feed port (5) with a plug (6)

or finger.

4 Using the vacuum pump, create a vacuum and obs erve the vacuum pump gauge needle:

• If the needle remains steady it indicates the tank is retaining vacuum.

• If the vacuum reading decreases, it indicate s a leak in the tank.

5 If a vacuum leak is indicated, replace the vacuum tank, refer to 4.2 Vacuum Tank.

Figure 2C – 32

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-33

Page 2C-33

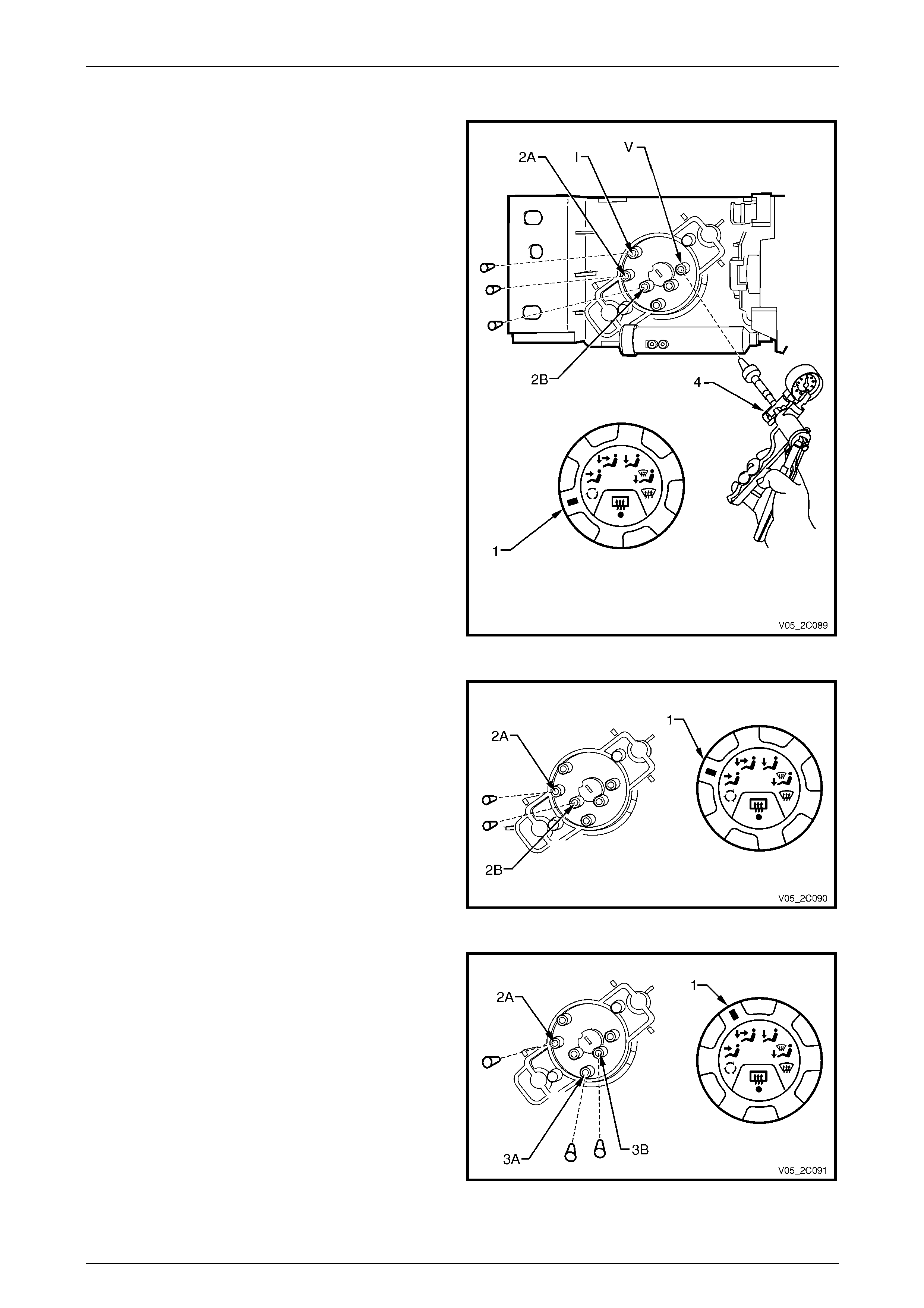

Vacuum Mode Valve – Manual A/C

1 Remove the HVAC manual controller, refer to

2.1 Manual Controller Assembl y.

2 Set the vacuum control switch (1) to recirculation

mode.

3 Plug the following ports on the vacuum mod e valve:

• intake (I)

• face 1 (2B)

• face 2 (2A)

4 Connect a vacuum pump (4) to the vacuum supply

port (V) of the vacuum mode valve. Create a vacuum

and observe the pump needle:

• If the needle remains steady, it indicates the

vacuum mode valve retains vacuum i n this

position.

• If the vacuum reading decreases quickly, it

indicates a leak in the vacuum mode valve.

5 Remove the plugs from the ports as required. If a

vacuum leak is indicated, replace the vacuum mode

valve, refer to 2.5 Mode Switch Vacuum Valve.

Figure 2C – 33

6 Set the vacuum control switch (1) to face mode.

7 Plug the following ports on the vacuum mode valve:

• face 1 (2B)

• face 2 (2A).

8 Perform the face mode vacuum test as described in

steps 4 and 5.

Figure 2C – 34

9 Set the vacuum control switch (1) to bi-level mode.

10 Plug the following ports on the vacuum mode valve:

• face 2 (2A)

• foot 1 (3B)

• foot 2 (3A).

11 Perform the bi-level mode vacuum test as de scribed in

steps 4 and 5.

Figure 2C – 35

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-34

Page 2C-34

12 Set the vacuum control switch (1) to floor mode.

13 Plug the following ports on the vacuum mode valve:

• foot 1 (3B)

• foot 2 (3A).

14 Perform the floor mode vacuum test as described in

steps 4 and 5.

Figure 2C – 36

15 Set the vacuum control switch (1) to blend mode.

16 Plug the foot 2 (3A) port on the vacuum mode valve.

17 Perform the blend mode vacuum test as describe d in

steps 4 and 5.

18 Reinstall the HVAC manual c ontroller, refer to

2.1 Manual Controller Assembl y.

Figure 2C – 37

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-35

Page 2C-35

Water Valve Vacuum Switch – Manual A/C

1 Remove the HVAC manual control ler, refer to 2.1 Manual Controller Assembly.

2 Set the temperature control switch (1) to the full cold position, refer to Figure 2C – 38.

3 On the water valve vacuum switch (2), block the water valve port (3) with a suitable p lug.

4 Connect a vacuum pump (4) to the vacuum supply port (5) of the water valve vacuum switch. Create a vacuum and

observe the pump needle:

• If the needle remains steady, it indicates the water valve vacuum switch retains vacuum.

• If the vacuum reading decreases quickly, it indicates a leak in the water valve vacuum switch.

5 If a vacuum leak is indicated, replace the water valve vacuum switch, refer to 2.2 Water Valve Vacuum Switch.

6 Reinstall the HVAC manual c ontroller, refer to 2.1 Manual Controller Assembly.

Figure 2C – 38

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-36

Page 2C-36

Vacuum Solenoid Pack – Auto A/C

1 Remove the vacuum solenoid pack,

refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

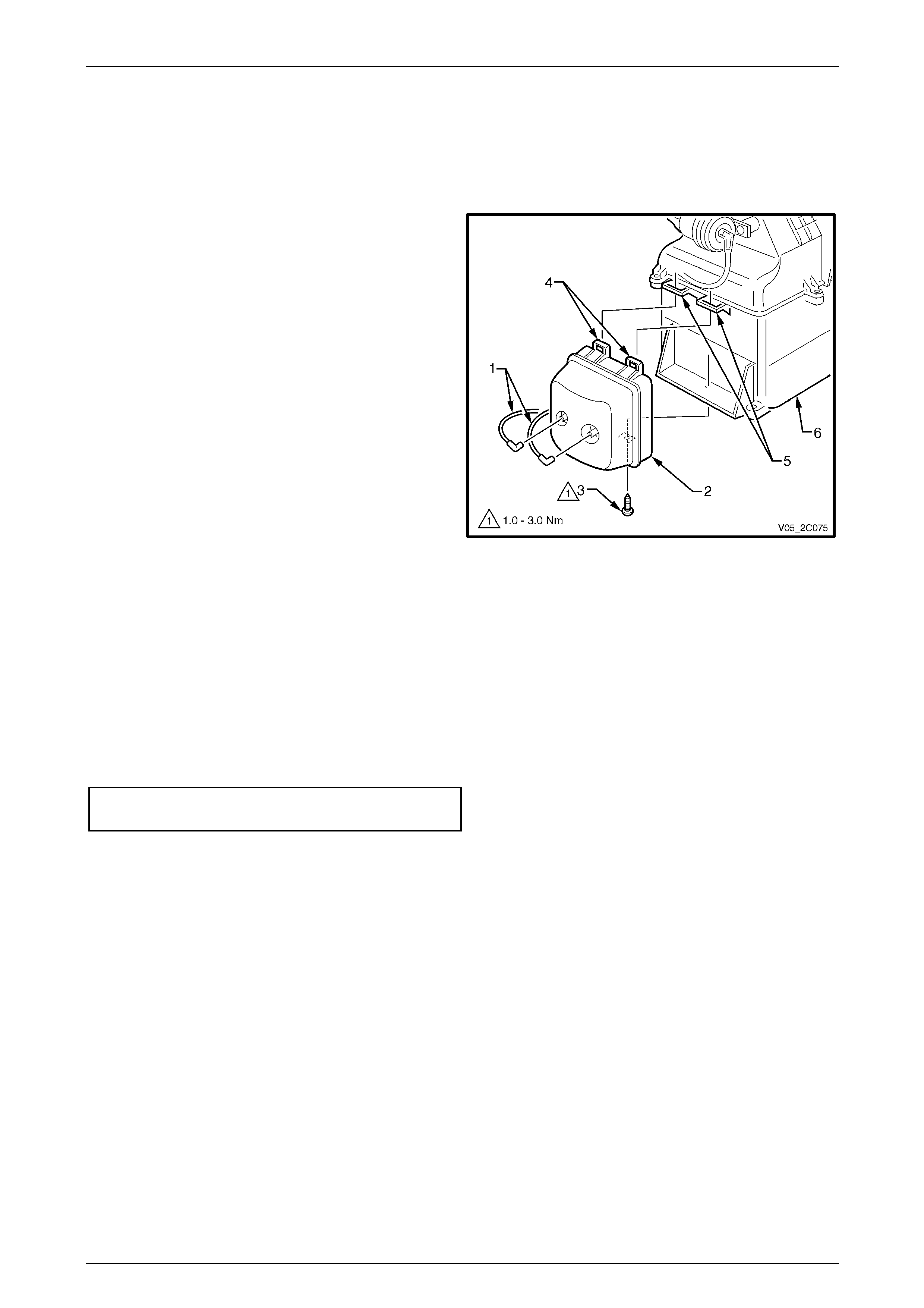

2 Connect a vacuum pump (1) to the vacuum supply

port (2) of solenoid (3) and plug the actuator port (4)

below it.

3 Using the vacuum pump, create a vacuum and

observe the vacuum pump gauge needle:

• If the needle remains steady it indicates the

solenoid is retaining vacuum.

• If the vacuum reading decreases, it indicate s a

leak in that solenoid.

4 Repeat steps 2 and 3 for each remaini ng solenoid.

5 If a vacuum leak is indicated, replace the vacuum

solenoid pack, refer to

Section 2F HVAC Occupant Climate Control (Auto

A/C) – Removal and Installation.

Figure 2C – 39

If the problem is isolated to one mode and the solenoid

does not show any signs of leakage, check the relevant

vacuum circuit in Vacuum Lines in this Section.

The function of the solenoid connections and the colour of

the attached vacuum lines are listed below:

Legend

1 Fresh/Recirculation (Blue)

2 Face 1 (White)

3 Face 2 (Green)

4 Foot 1 (Pink)

5 Foot 2 (Orange)

6 Water valve (Yellow)

7 Vacuum supply (Black)

Figure 2C – 40

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-37

Page 2C-37

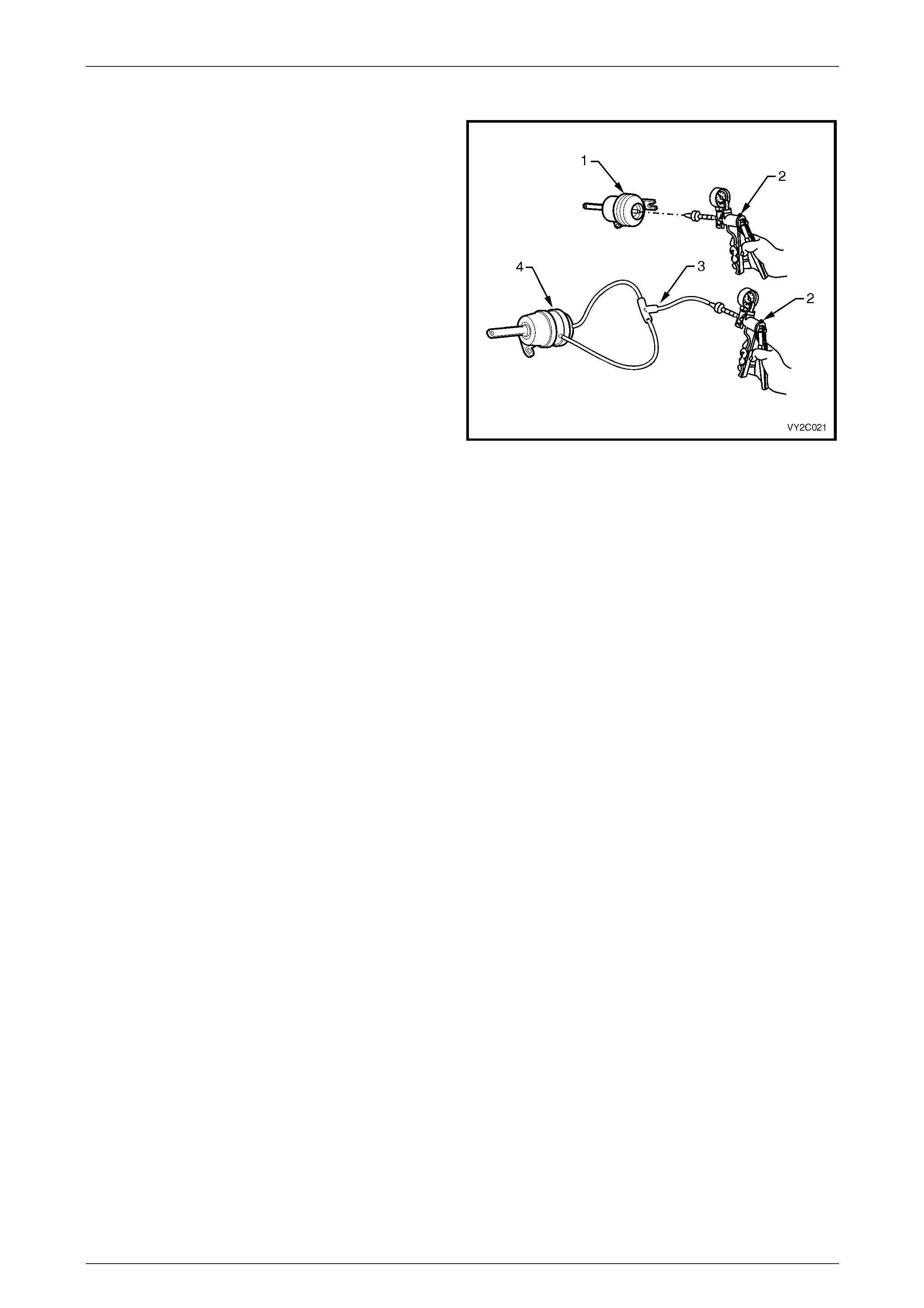

Vacuum Actuators

1 Remove the vacuum actuator, refer to

4.3 Vacuum Actuators.

2 For a single stage intake vacuum actuator (1), connect

the vacuum pump (2) to the rear port of the actuator.

For a two stage face or foot vacuum actuator (4),

connect the vacuum pump to the rear and si de ports

with a vacuum tee piece (3).

3 Using the vacuum pump, create a vacuum and

observe the vacuum pump gauge needle:

• If the needle remains steady it indicates the

actuator is retaining vacuum.

• If the vacuum reading decreases, it indicate s a

leak in the actuator.

4 If a vacuum leak is indicated, replace the vacuum

actuator, refer to 4.3 Vacuum Actuators.

Figure 2C – 41

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-38

Page 2C-38

Water Valve Actuator

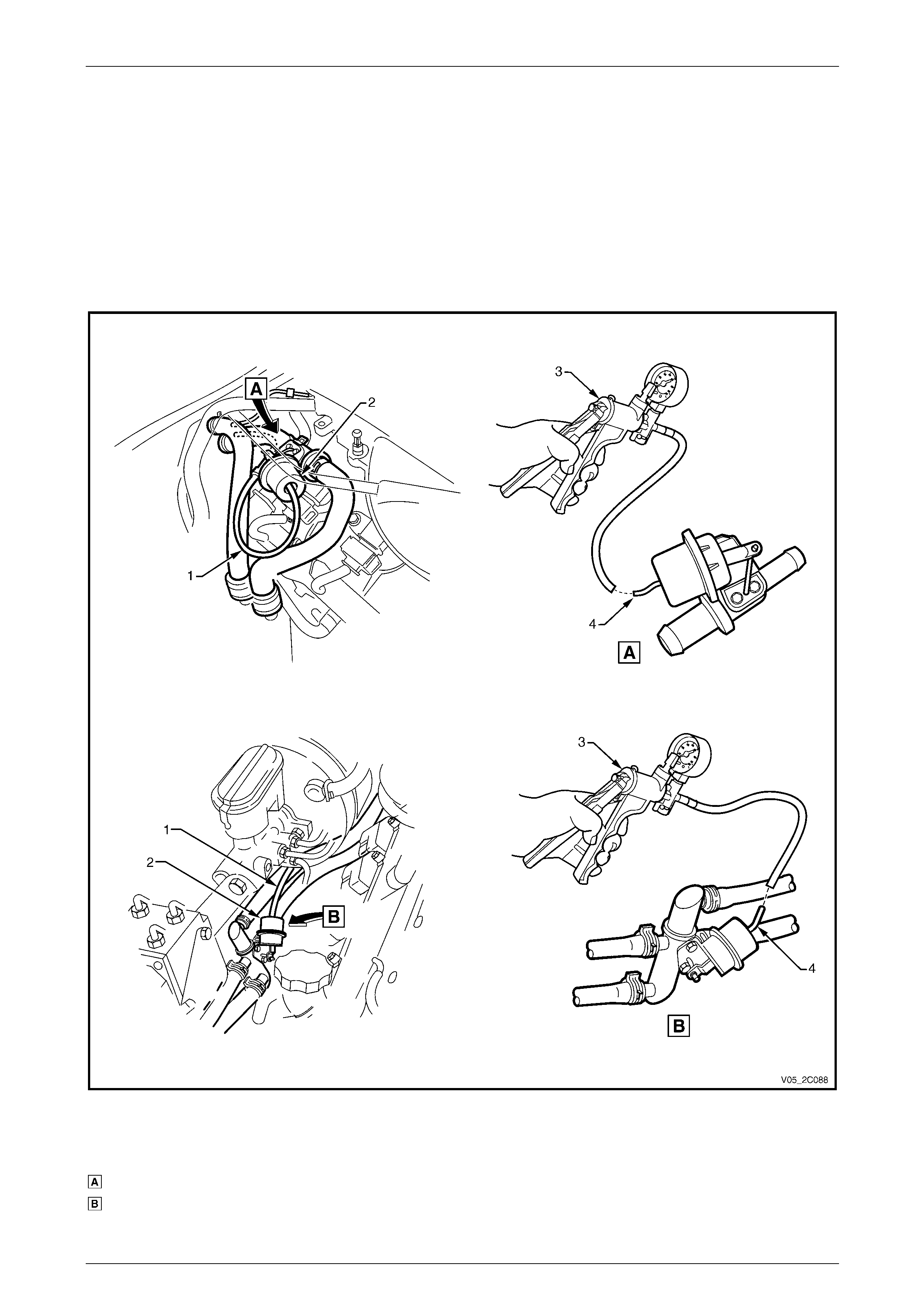

1 Disconnect the vacuum supply line (1) from the water valve actuator (2), refer to Figure 2C – 42.

2 Connect a vacuum pump (3) to the actuator vacuum port (4).

3 Using the vacuum pump, create a vacuum and obs erve the vacuum pump gauge needle:

• If the needle remains steady it indicates the actuator is retaining vacu um.

• If the vacuum reading decreases, it indicates a leak in the actuator.

4 If a vacuum leak is indicated, replace the water valve assembly, refer to 9.1 Water Valve Assembly.

Figure 2C – 42

Legend

V6 Engine

GEN III V8 Engine

1 Vacuum Supply Line

2 Water Valve Actuator 3 Vacuum Pump

4 Actuator Vacuum Port

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-39

Page 2C-39

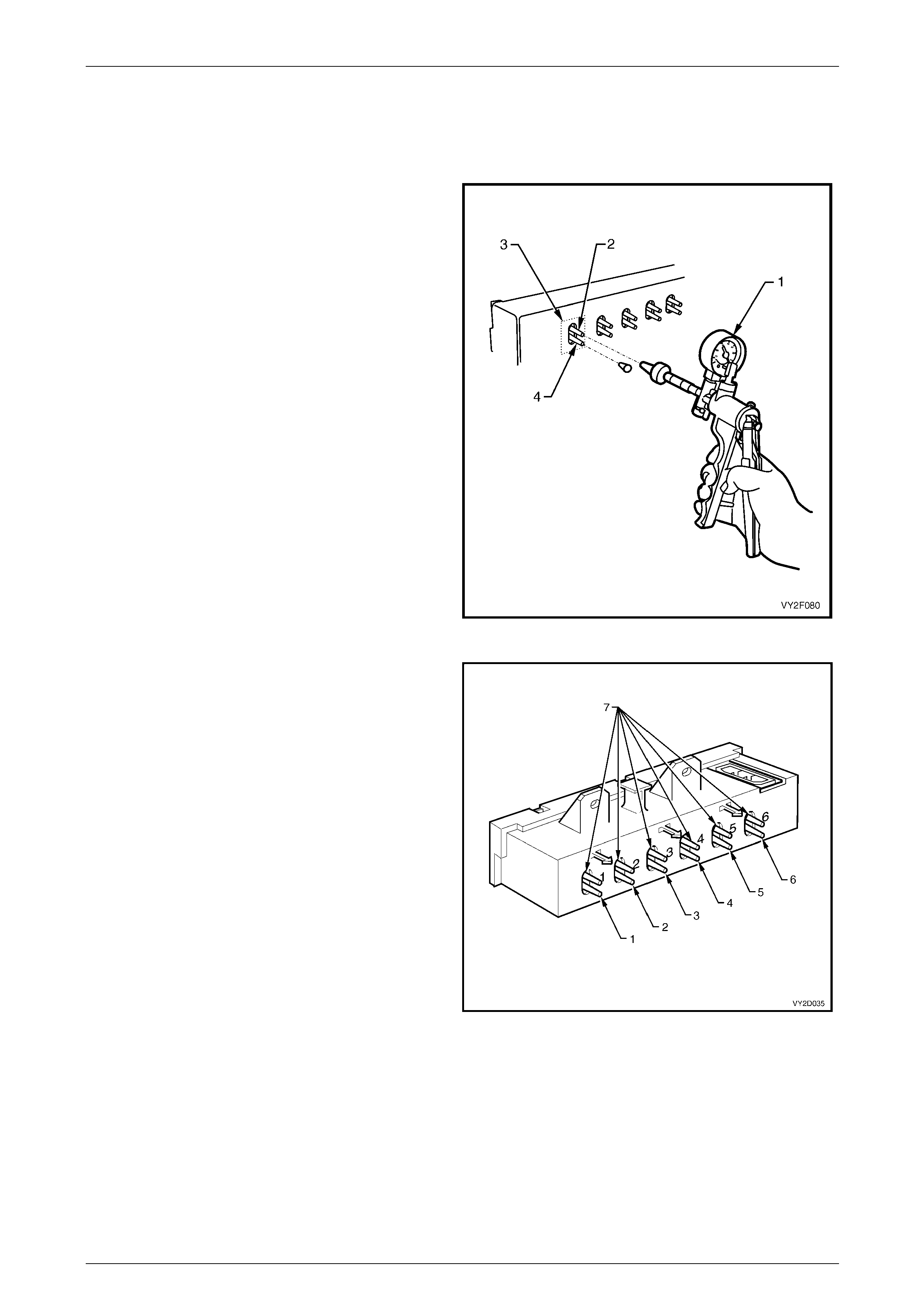

Vacuum Lines – Manual A/C

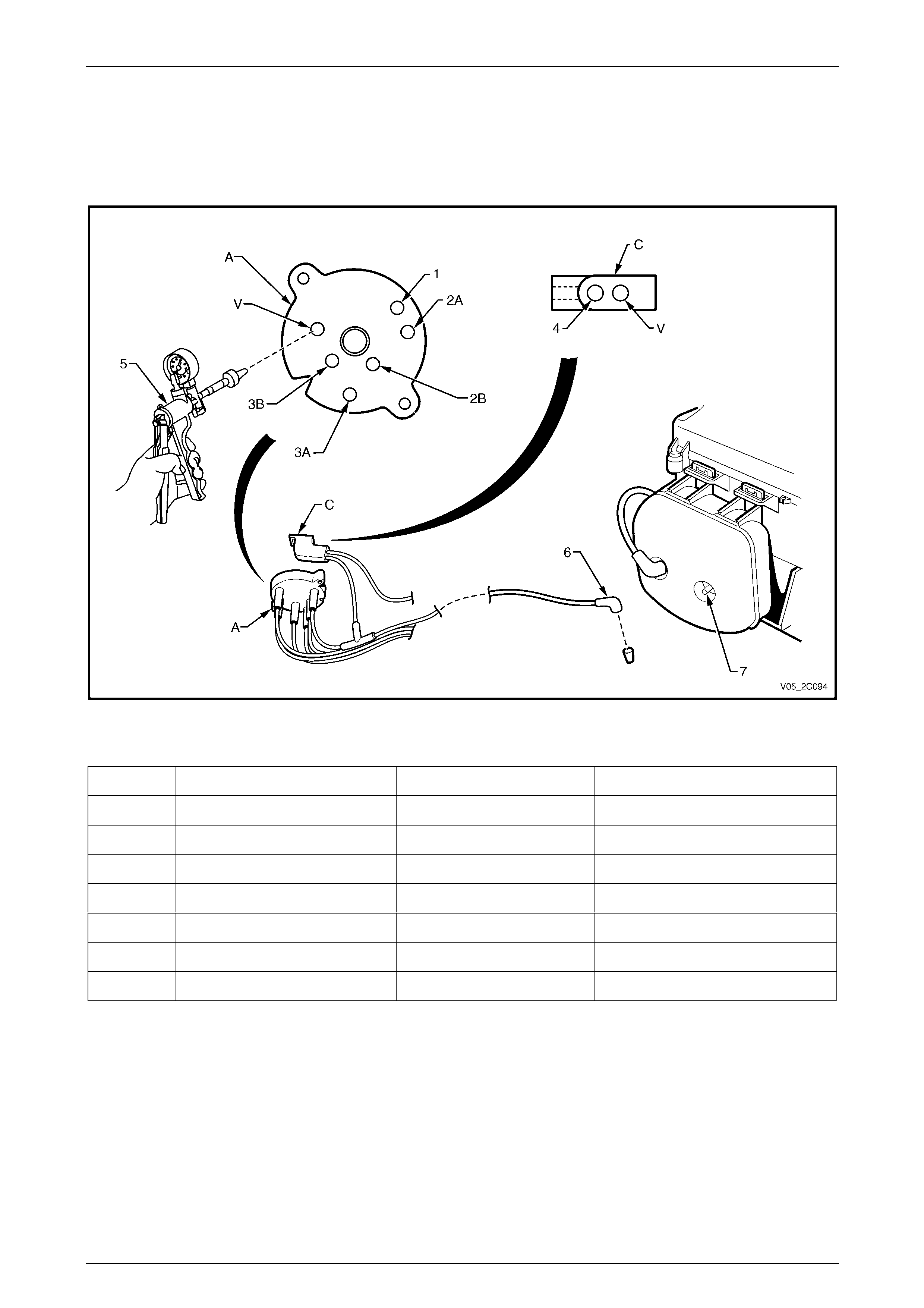

1 Remove the instrument panel centre fascia, refer to Section 1A3 Instrument Panel and Console.

2 From the back of the HVAC controller (1), remove the water valve vacuum switch valve connector (2) and the mode

valve plastic manifold (3), refer to Figure 2C – 43.

Figure 2C – 43

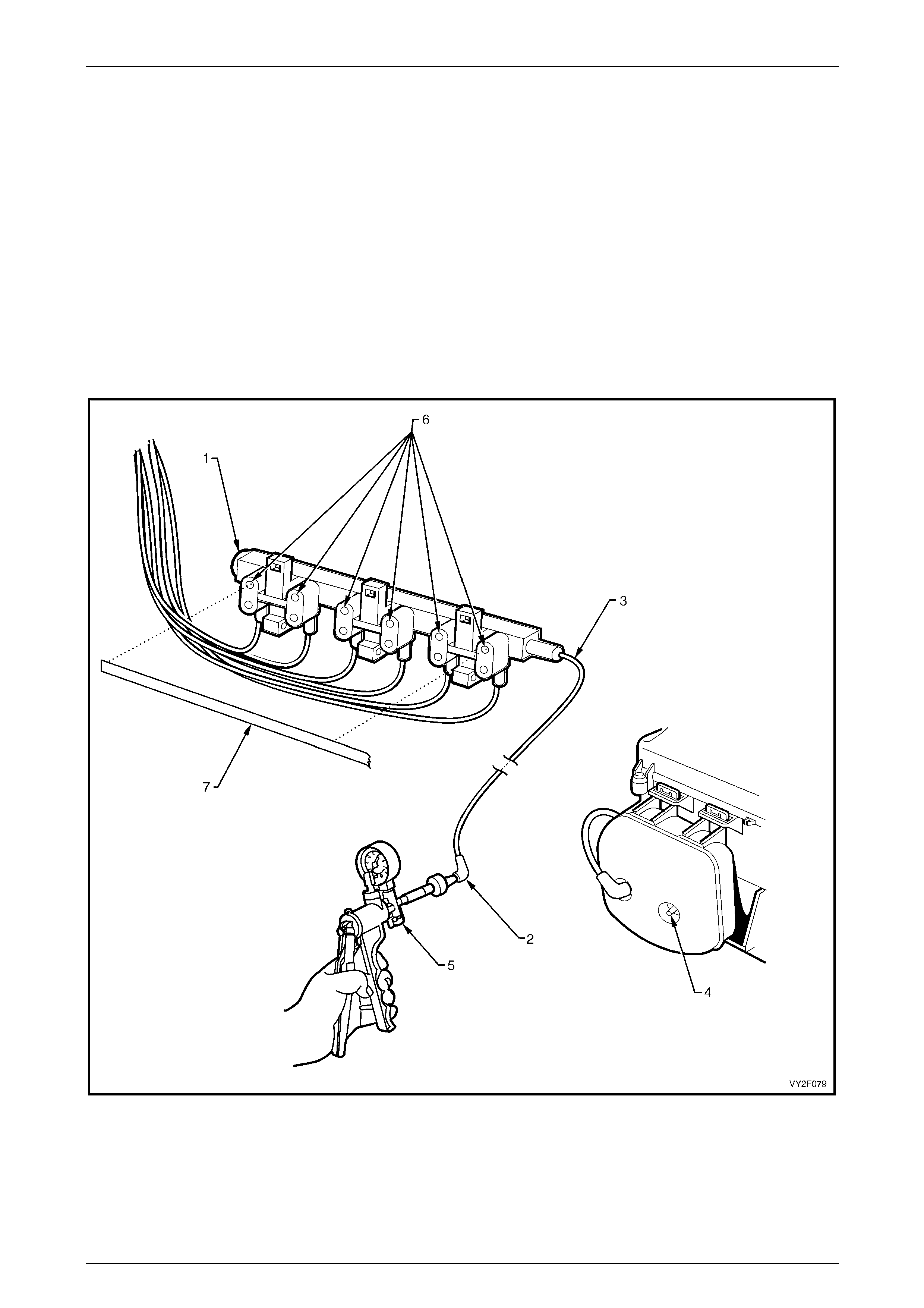

3 Connect a vacuum pump (5) to the appropriate port of the plastic vacuum manifold (A), refer to Figure 2C – 44 and

the associated table, for the follo wing:

• intake line – port (1),

• face 2 line – port (2A),

• face 1 line – port (2B),

• foot 2 line – port (3A), and

• foot 1 line – port (3B).

4 Using the vacuum pump, create a vacuum and obs erve the vacuum pump gauge needle:

• If the needle remains steady it indicates the vacuum circuit is retaining vacuum.

• If the vacuum reading decreases, it indicates a vacuum leak in that vacuum circuit.

5 If a vacuum leak is indicated check the vac uu m tubing for da mage or loose connection to the plastic vacuum

manifold and/or the associated vacuum actuator. If there is no damage or loose conn ection, perform a vacuum test

on the connecting vacuum actuator, refer to Vacuum Actuators in this Section.

6 Test the vacuum supply lines of the plastic vacuum manifold (A) as follo ws:

a Remove the connector (6) of the vacuum mode valv e supply line from the vacuum tank port (7) and plug the

connector.

b Plug the port (V) of the water valve vacuum switch connector (C).

c Connect the vacuum pump to the port (V) of the plastic vacuum manifold and repeat Step 4.

d If a vacuum leak is indicated check the vac uu m tubing for da mage or loose connection to the plastic vacuum

manifold.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-40

Page 2C-40

7 Test the water valve line and actuator as follows:

a Connect the vacuum pump to the port (4) of the vacuum s witch connector (C) and repeat Step 4.

b If a vacuum leak is indicated check the vac uu m tubing for damage or loose connection to the water valve

actuator. If there is no damage or loose connection, perform a vacuum test on the water valve actuator, refer

to Water Valve Actuator in this Section.

Figure 2C – 44

Port Actuator Vacuum line colour Function when vacuum applied

V — Black Vacuum Supply

1 Intake Blue Recirculation

2A Face 2 Green Bi-level

2B Face 1 White Face / Recirculation

3A Foot 2 Orange Blend

3B Foot 1 Pink Foot / Bi-level

4 Water valve Yellow Full cold

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-41

Page 2C-41

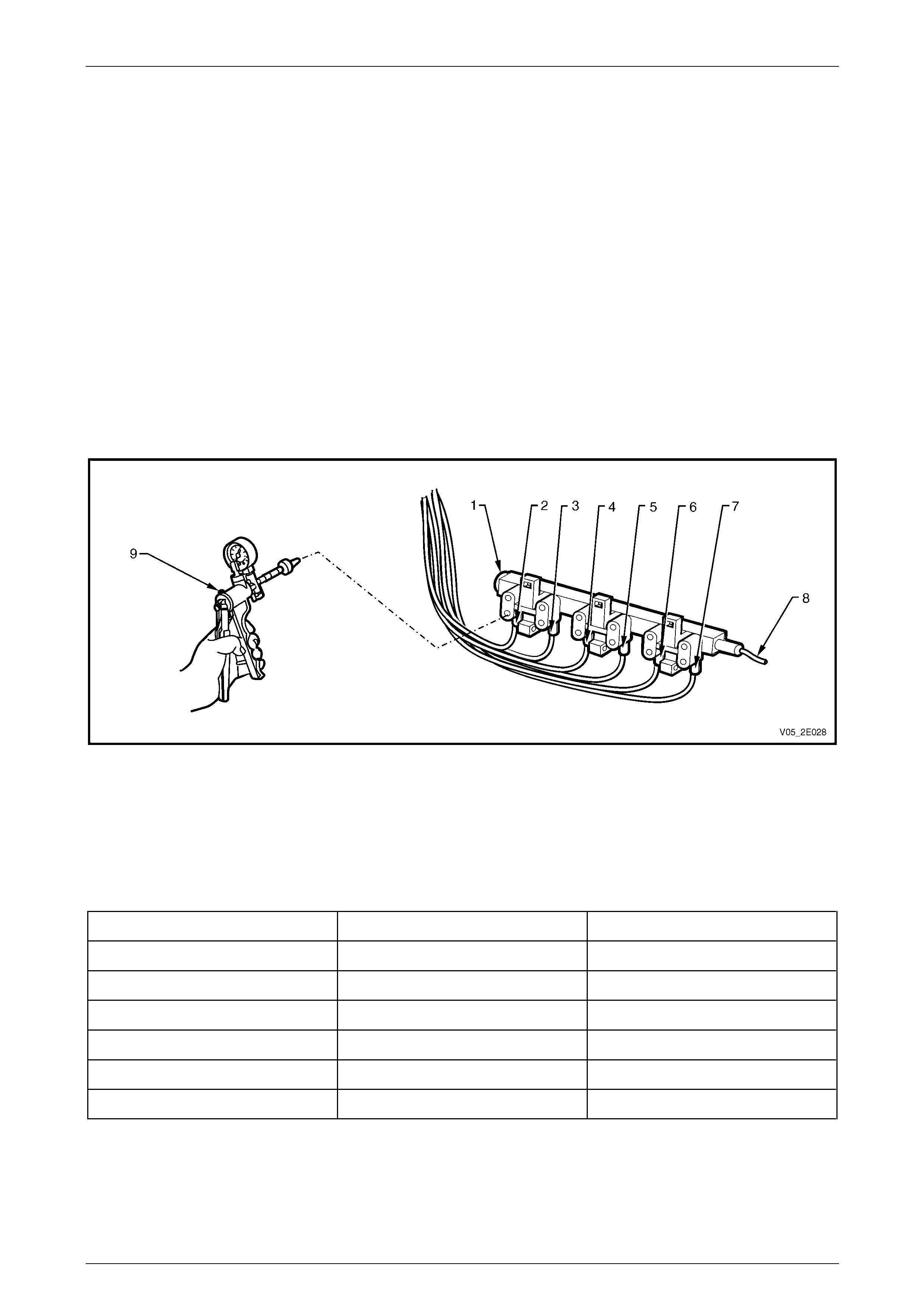

Vacuum Lines – Auto A/C

Vacuum Actuator Lines

1 Remove the left-hand instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Consol e.

2 Remove the plastic manifold from the vacuum solenoid pac k. If required,

refer to Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation.

3 Connect a vacuum pump (9) to the appropriate port of the vacuum manifold (1), refer to Figure 2C – 45 and the

associated table.

4 Using the vacuum pump, create a vacuum and obs erve the vacuum pump gauge needle:

• If the needle remains steady it indicates that vacuum circuit is retain ing vacuum.

• If the vacuum reading decreases, it indicate s a vacuum leak in that vacuum circuit.

5 If a vacuum leak is indicated check the vac uu m tubing for damage or loose connection to the man ifold and/or

vacuum actuator. If there is no damage or loose connection, perform a vacuum test on the connectin g vacuum

actuator.

Figure 2C – 45

Legend

1 Plastic Vacuum Manifold

2 Water Valve (Yellow)

3 Foot 2 (Orange)

4 Foot 1 (Pink)

5 Face 2 (Green)

6 Face 1 (White)

7 Fresh / Recirculation (Blue)

8 Vacuum Supply (Black)

9 Vacuum Pump

Actuator Vacuum line colour Function When Vacuum Applied

Intake Blue Recirculation

Face 1 White Bi-level

Face 2 Green Face

Foot 1 Pink Blend

Foot 2 Orange Foot / Bi-level

Water valve Yellow Full cold

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-42

Page 2C-42

Vacuum Manifold Line

1 Remove the left-hand side instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Consol e.

2 Remove the plastic vacuum manifold (1) fro m the solen oi d pack, refer to Figure 2C – 46.

3 Remove the connector (2) of vacuum manifold line (3) from the vacuum tank manifold line port (4).

4 Connect a vacuum pump (5) to the vacuum manifold line connector. Seal the vacuum supply ports (6) on the

plastic vacuum manifold using a suitable strip of electrical tape (7).

5 Using the vacuum pump, create a vacuum and obs erve the vacuum pump gauge needle:

• If a vacuum leak is indicated, check the condition of the vacuum line for da mage or loose connection to the

plastic manifold and vacuum tank. Replace components as necessar y.

• If there is no fault or loose connection detected, perform a vacuum test on the vacuum tank and the ch eck

valve (if not already tested).

Figure 2C – 46

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-43

Page 2C-43

4.2 Vacuum Tank

LT Section No. — 08–025

Remove

1 Remove the left-hand instrument panel lower trim

plate assembly, refer to

Section 1A3 Instrument Panel and Co nsole.

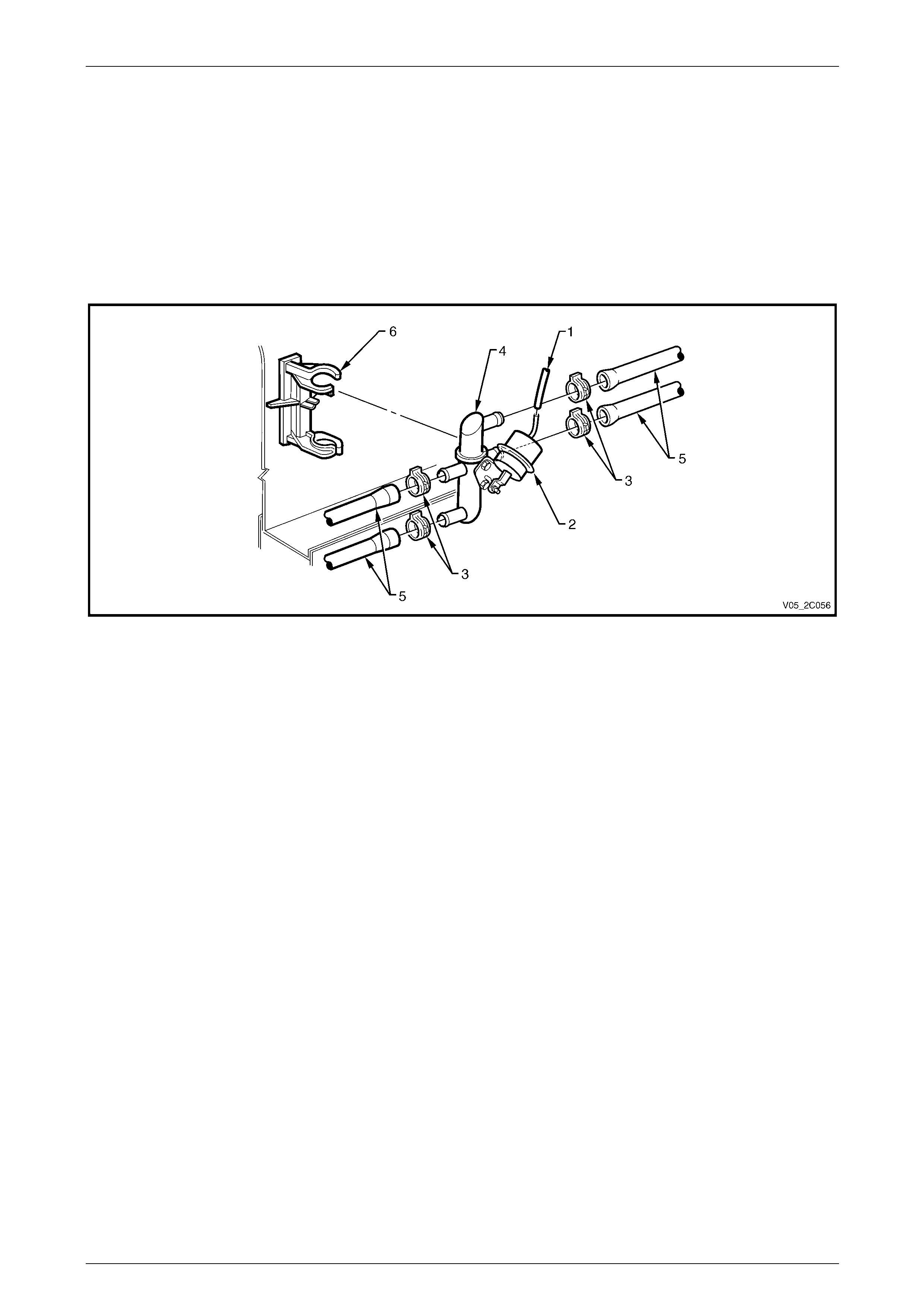

2 Remove the two vacuum lines (1) from the vacuum

tank (2).

3 Remove the screw (3) located under the vac uum tank.

4 Move the lower section of the vacuum tank out wards

and lower the tank to disengage the retai ni ng tangs (4)

from the locating slots (5) on the side of the HVAC unit

case (6).

Figure 2C – 47

Reinstall

Reinstallation of the vacuum tank is the reverse of the removal procedure, noting the following:

1 Ensure the vacuum lines are installed correctly:

• the line with the larger connecting el bow (vacuum source) is connected to the tank port closer to the engine

compartment, and

• the line with the smaller connecting elbow is connected to the tank port closer to the cabin.

2 Tighten the screw attaching the tank to the correct torque s pecification.

Vacuum tank attaching screw

torque specification.....................................1.0 – 3.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-44

Page 2C-44

4.3 Vacuum Actuators

LT Section No. — 08–150

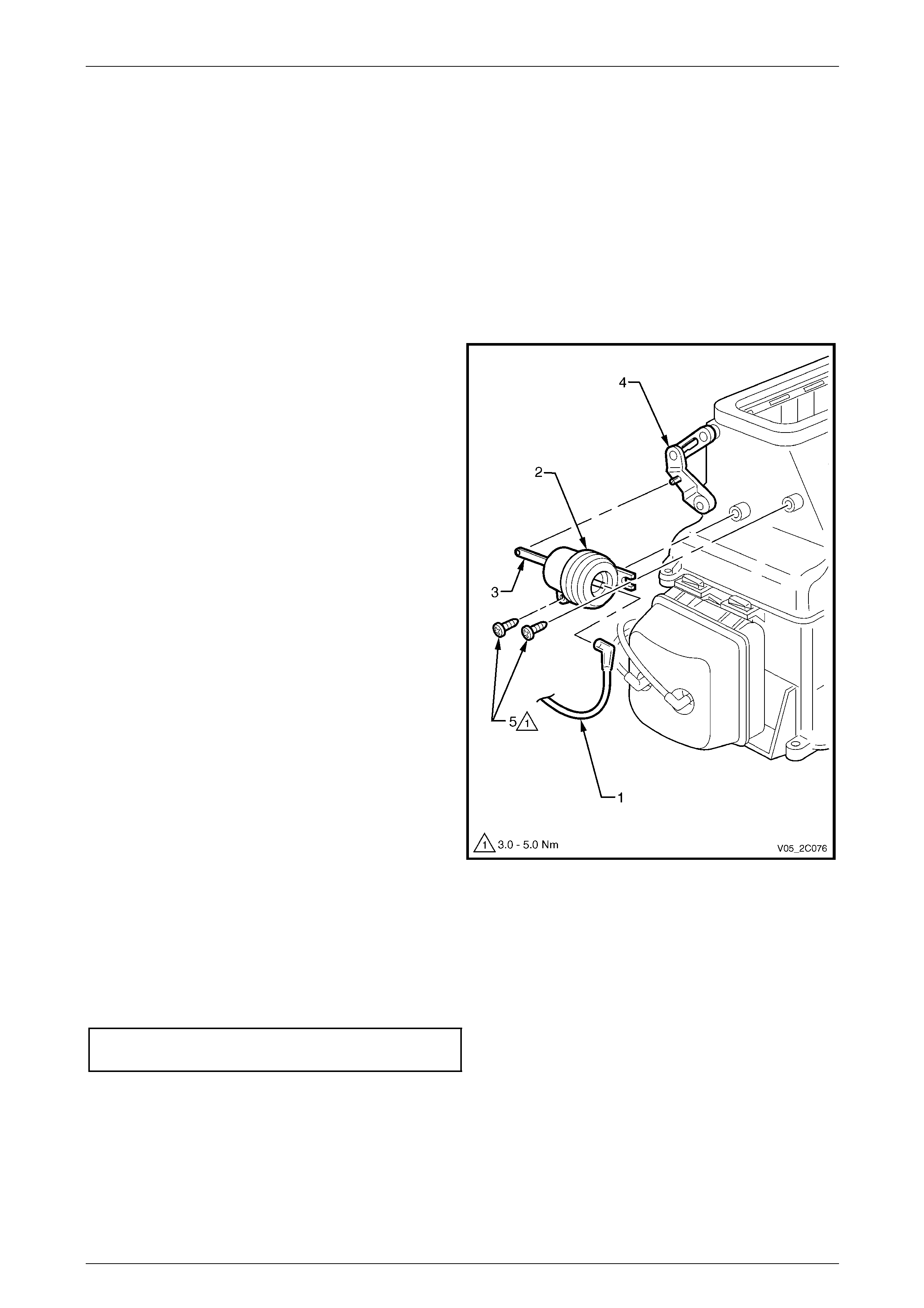

Intake Actuator (fresh / recirculation)

Remove

1 Remove the left-hand instrument panel lower trim plate assembly and left-hand instrument panel outer cover,

refer to Section 1A3 Instrument Panel and Consol e.

2 Remove the vacuum tank, refer to 4.2 Vacuum Tank

3 Remove the vacuum line (1) from the intake

actuator (2).

4 Remove the pushrod (3) from the actuator lever (4).

5 Remove the two screws (5) attaching the actuator to

the HVAC case and remove the actuator.

Figure 2C – 48

Reinstall

Reinstallation of the intake (fresh / recirculation) actuator is the reverse of the remov al procedure, noting the following:

1 Ensure the blue vacuum line is connected to the actuator.

2 Tighten the screws attaching the actuator to the correct torque specification.

Intake actuator attaching

screw torque specification...........................3.0 – 5.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-45

Page 2C-45

Face Actuator

Remove

1 Remove the HVAC unit, refer to 3.1 HVAC Unit.

2 From the underside of the HVAC unit (1), locate the

face actuator (2).

3 Remove the pushrod (3) from the door lever.

4 Remove the vacuum lines (4) from the actuator.

5 Remove the two crews (5) attaching the actuator to

the HVAC case and remove the actuator.

Figure 2C – 49

Reinstall

Reinstallation of the face actuator is the rev erse of the removal pr ocedure, noting the following:

1 Ensure the vacuum lines are installed correctly:

• the green vacuum line is connected to the side of the actuator and

• the white vacuum line is connected to the rear of the actuator.

2 Tighten the screws attaching the actuator to the correct torque specification.

Face actuator attaching screw

torque specification.....................................3.0 – 5.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-46

Page 2C-46

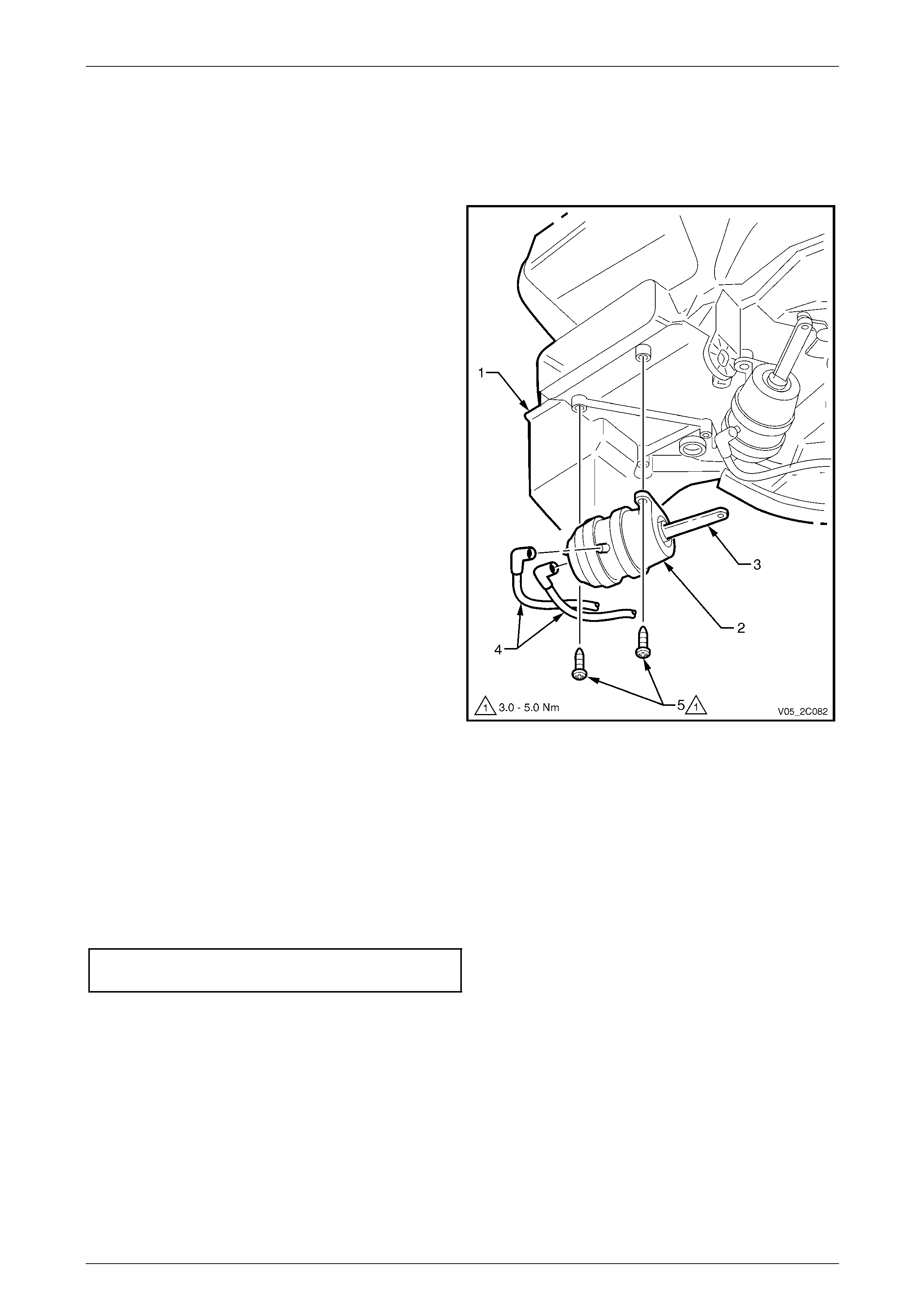

Foot Actuator

Remove

1 Remove the HVAC unit, refer to 3.1 HVAC Unit.

2 From the underside of the HVAC unit (1), locate the

foot actuator (2).

3 Remove the pushrod (3) from the door lever.

4 Remove the vacuum lines (4) from the vacuu m

actuator.

5 Remove the two screws (5) attaching the vacuum

actuator to the HVAC case and remove the actuator.

Figure 2C – 50

Reinstall

Reinstallation of the foot actuator is the reverse of the removal procedure, noting the follo wing:

1 Ensure the vacuum lines are installed correctly:

• the orange vacuum line is connected to the si de of the actuator and

• the pink vacuum line is connected to the rear of the actuator.

2 Tighten the two screws attaching the actuator to the correct torque specifi cation.

Foot actuator attaching screw

torque specification.....................................3.0 – 5.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-47

Page 2C-47

5 Air-conditioning Lines and

Retainers

5.1 Replace

LT Section No. — 08–200

The total quantity of lubricating oil in the air-

conditioning system must be maintained. If a

compressor, evaporator, condenser, filter

drier receiver or air-conditioning line is

replaced, a specified quantity of lubricating

oil must be added to the system to

compensate for oil removed with the original

component. Refer to Section 2B HVAC

Climate Control (Manual A/C) – Servicing and

Diagnosis.

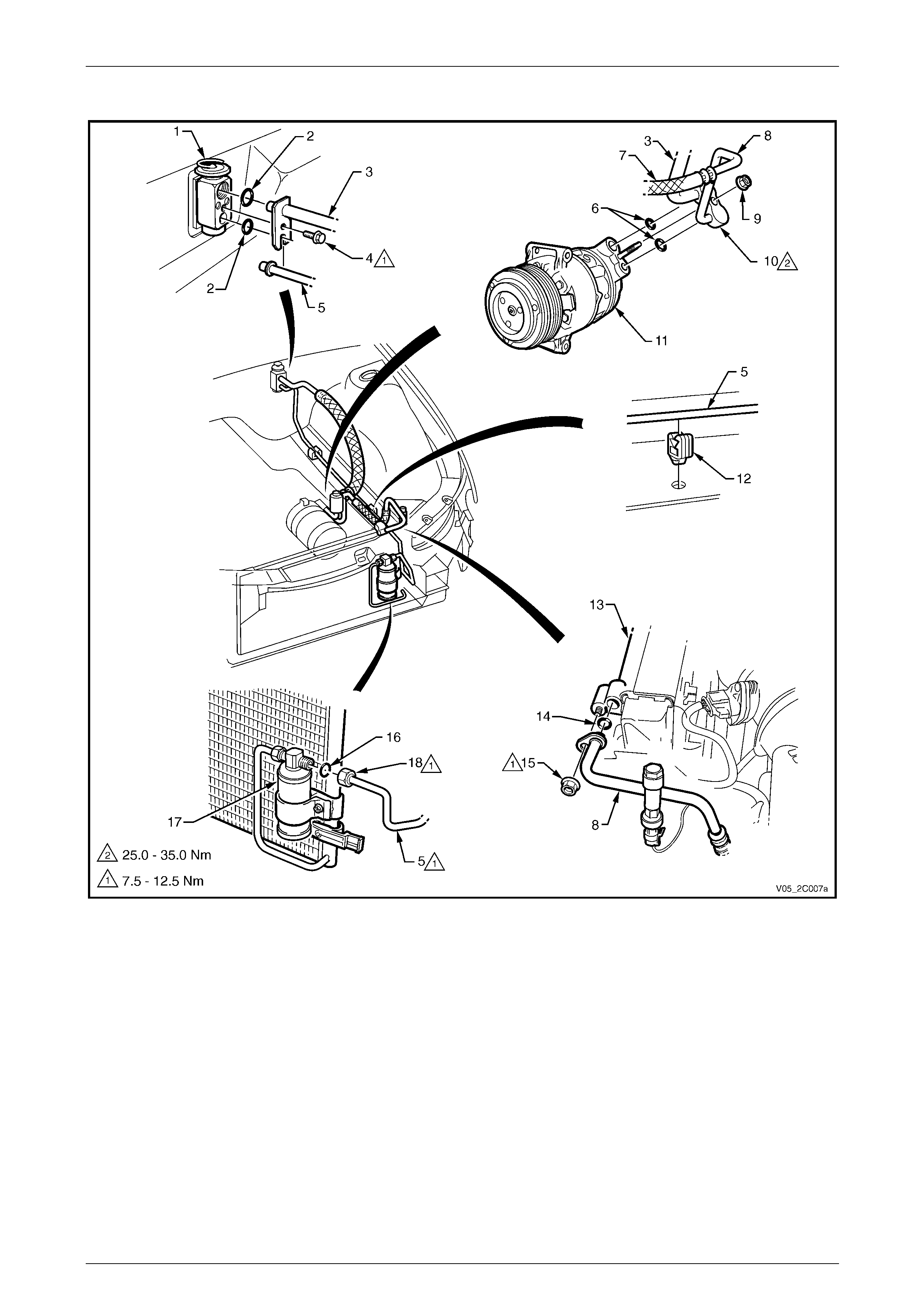

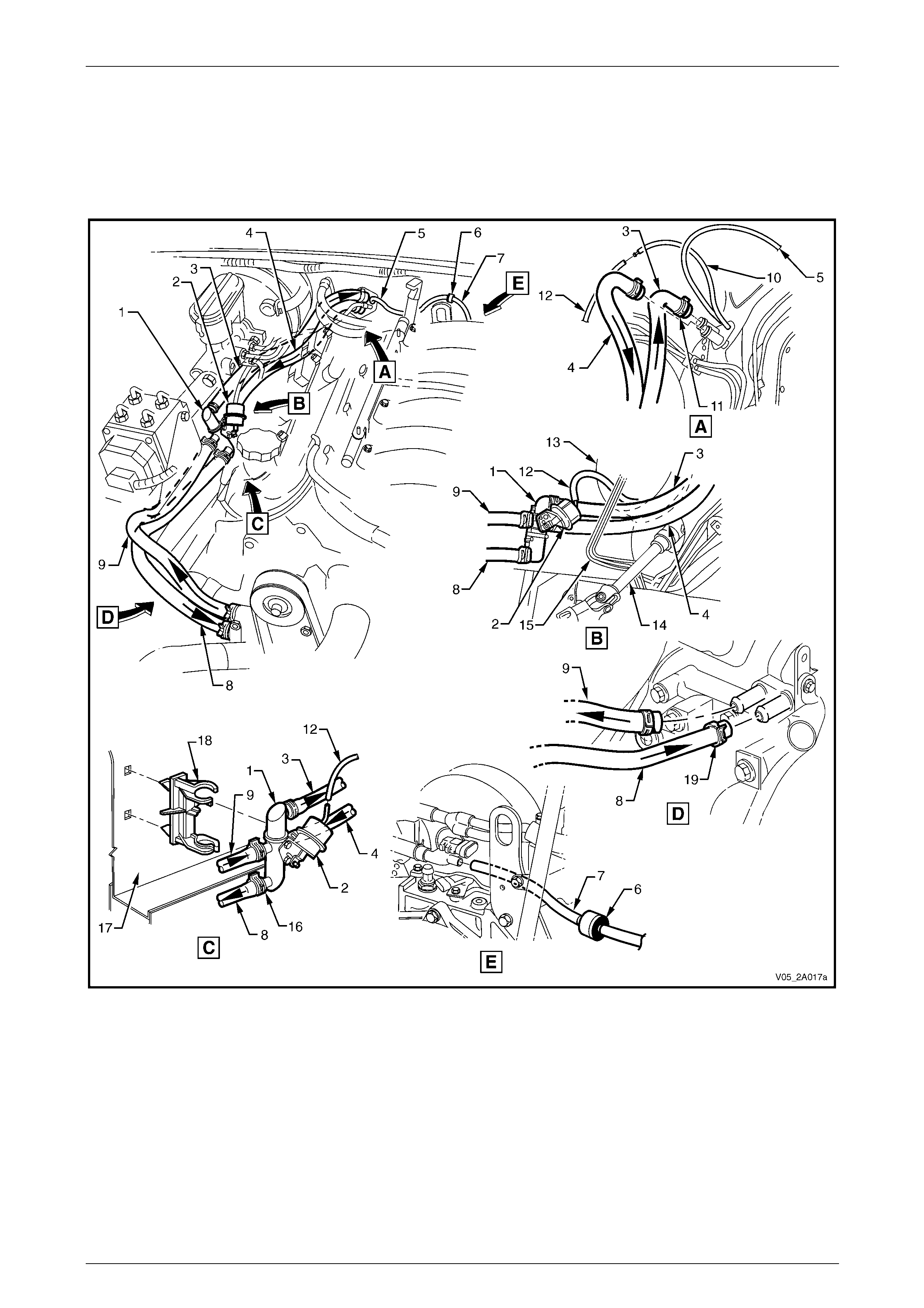

The following illustrations provide under hood views of the air-conditioning line connections and retainers:

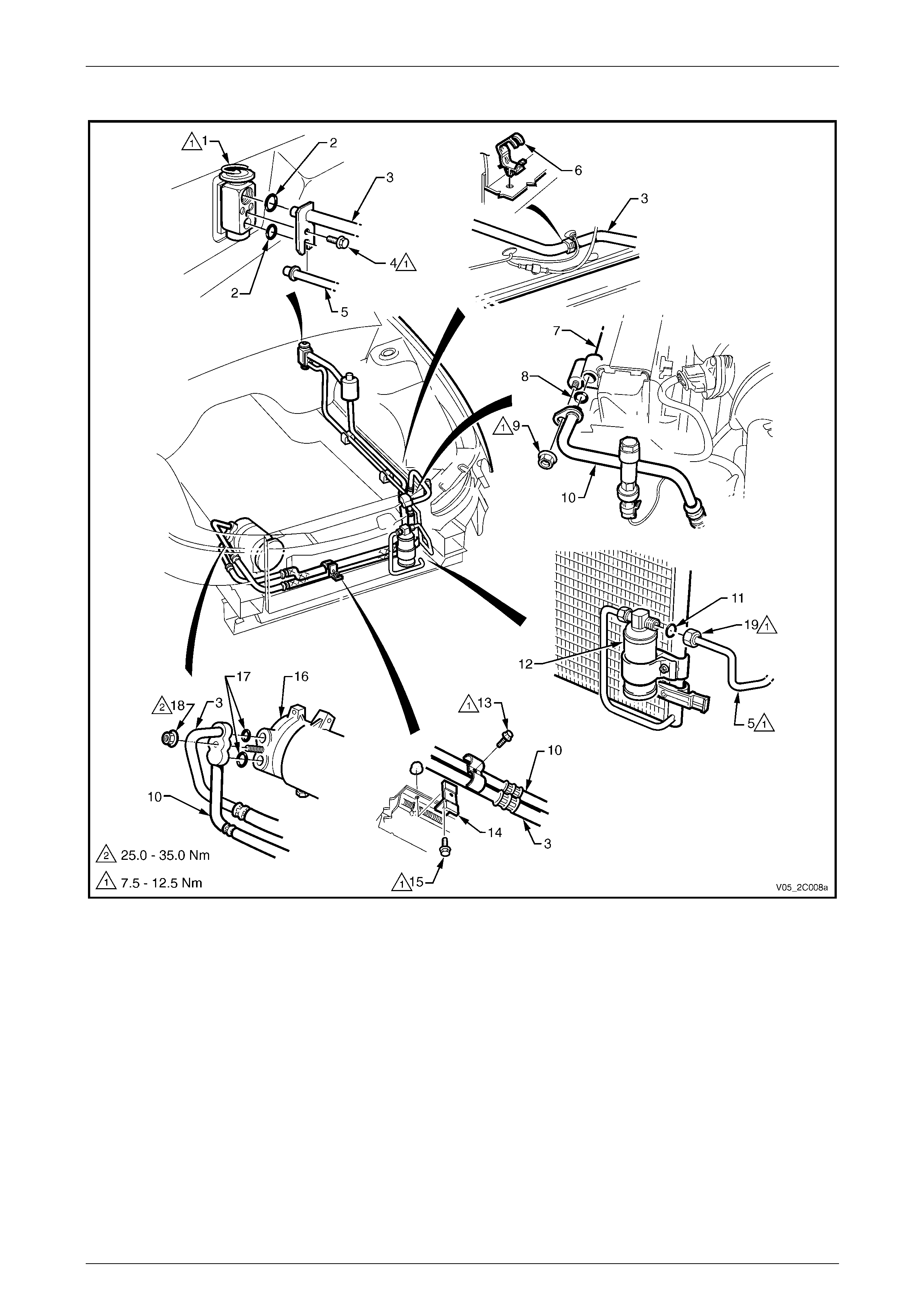

• for RWD vehicle with V6 engine, refer to Figure 2C – 5 1

• for AWD vehicle with V6 engine, refer to Figure 2C – 5 2

• for RWD or AWD vehicle with GEN III V8 engine, refer to Figure 2C – 53 .

Replace the components as required ensuring the fasteners are tightened to the correct torque specification.

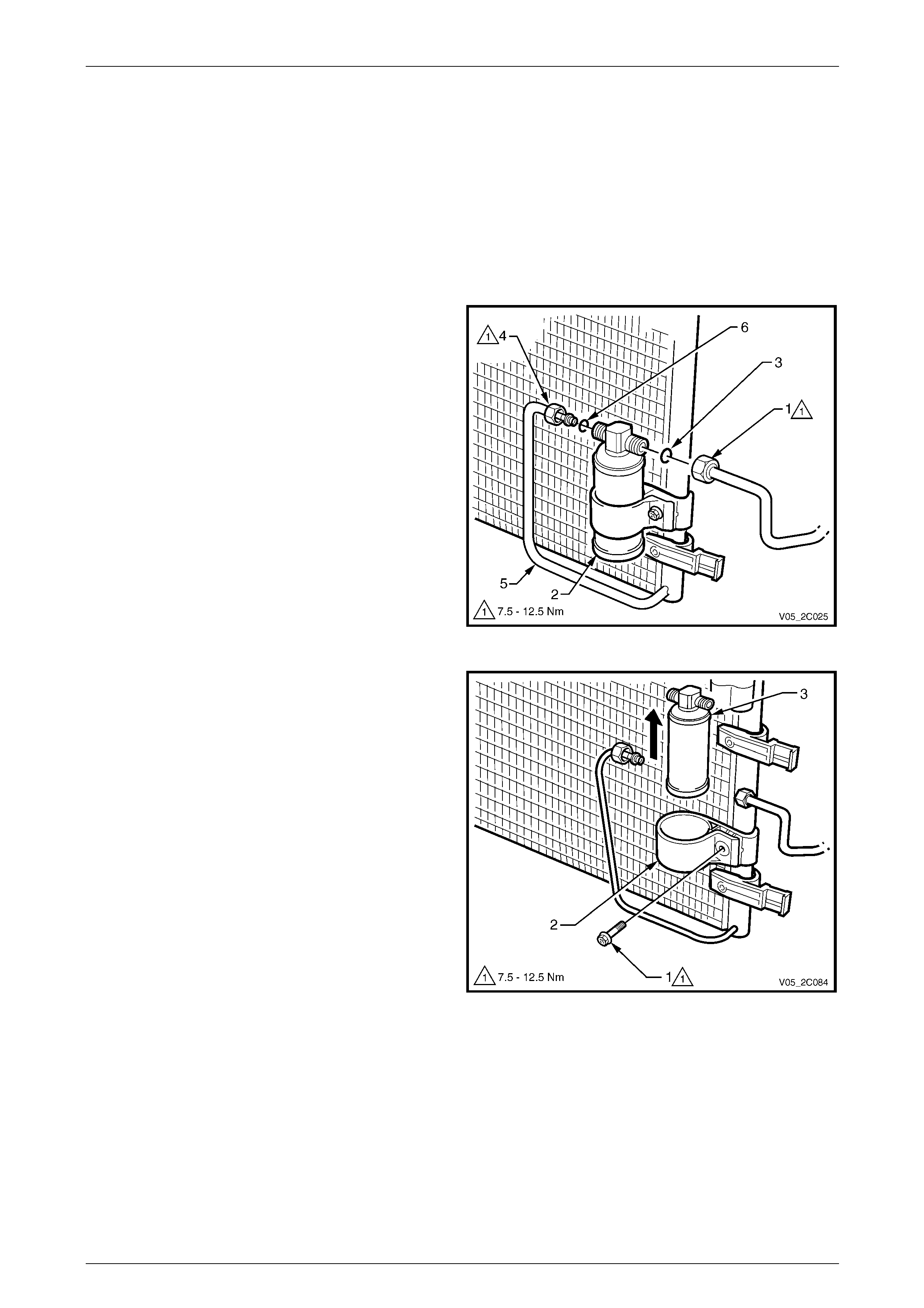

Liquid and suction li ne retaining plate

to TXV screw torque specification.............7.5 – 12.5 Nm

Liquid line to filter dryer receiver union

torque specification...................................7.5 – 12.5 Nm

Discharge line to condenser nut

torque specification...................................7.5 – 12.5 Nm

Suction line bracket attaching screw

torque specification...................................7.5 – 12.5 Nm

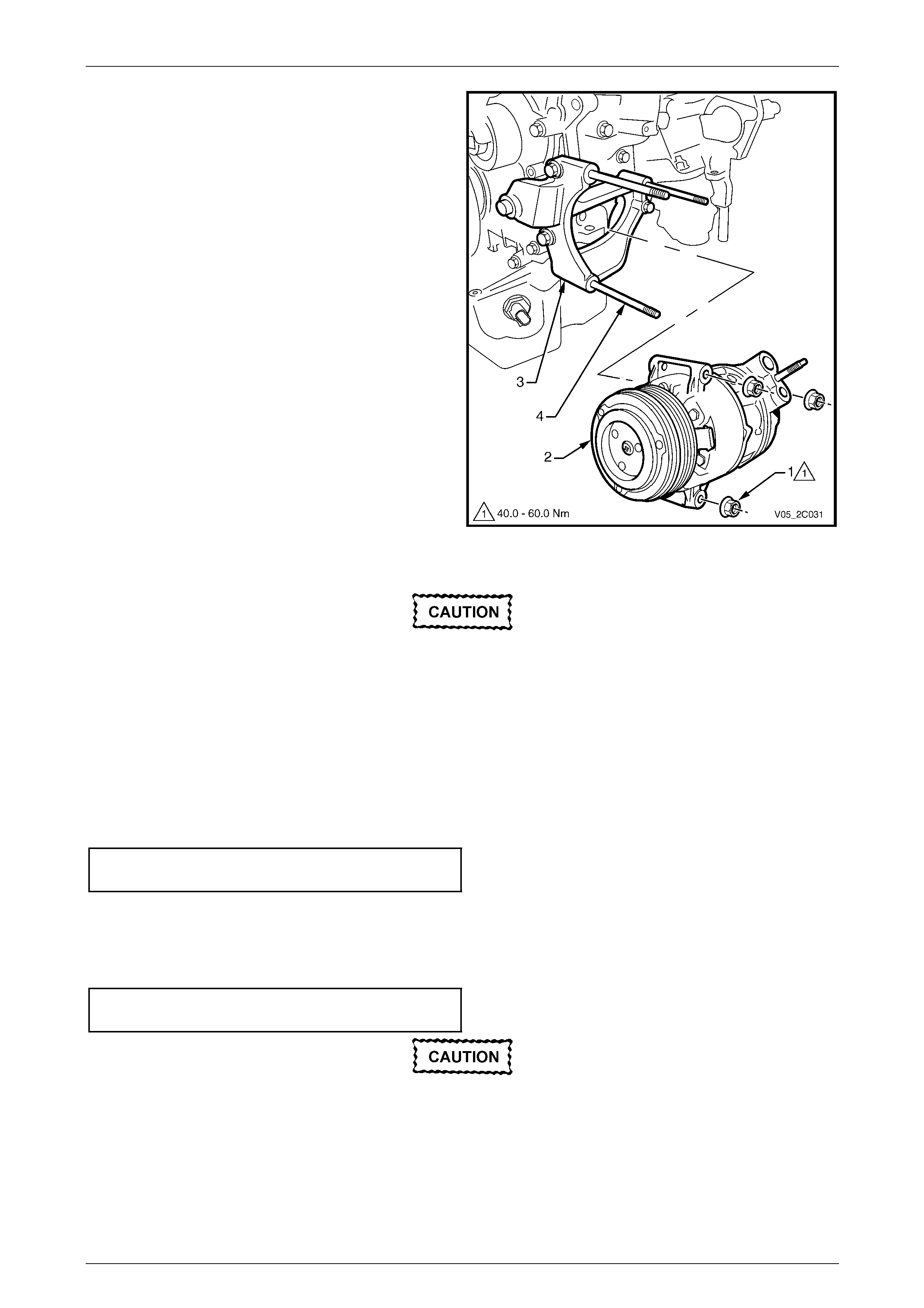

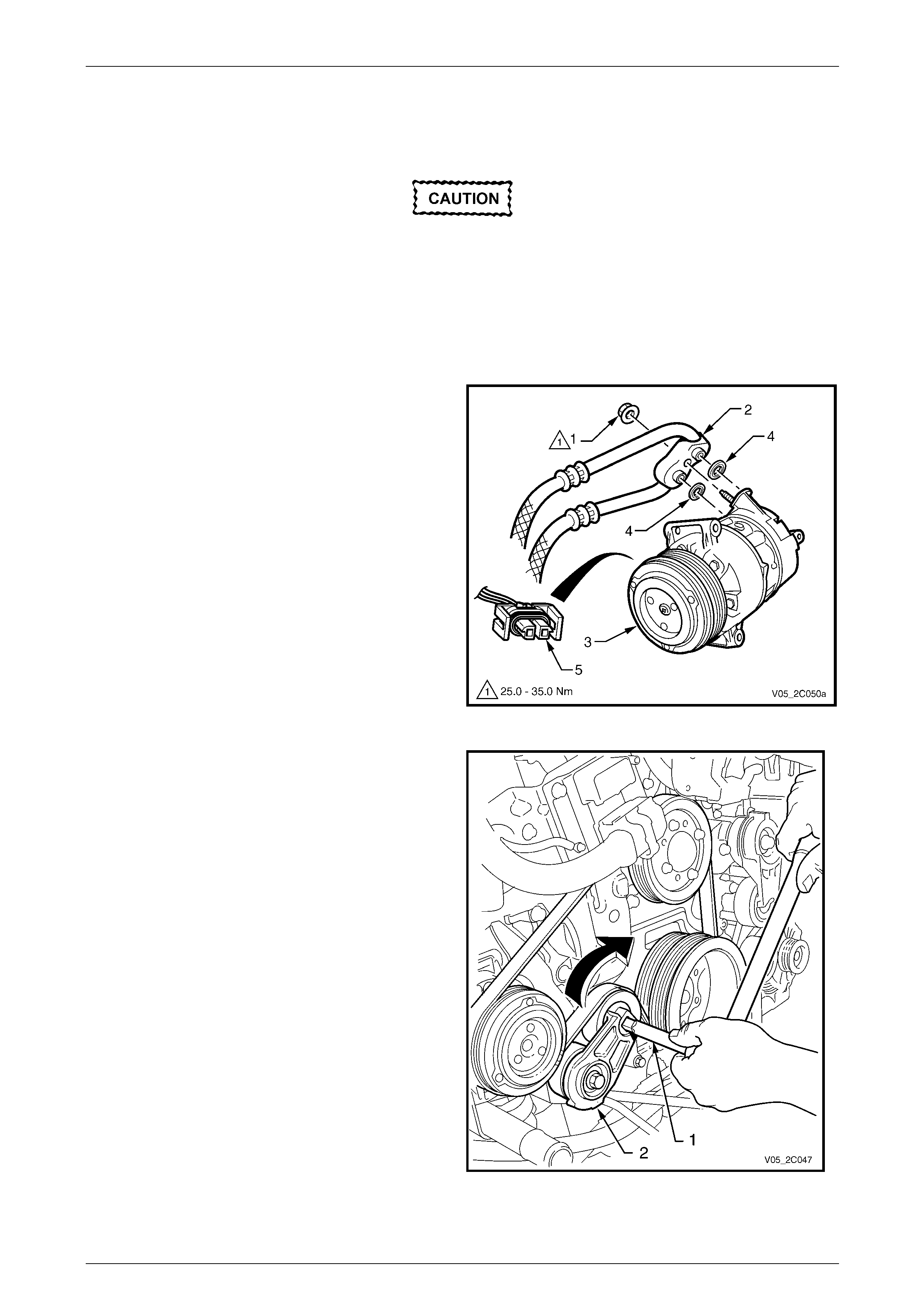

Compressor suction / discharge lin e

pad retaining nut torque specification .....25.0 – 35.0 Nm

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-48

Page 2C-48

Lines and Retainers Views – V6 RWD

Figure 2C – 51

Legend

1 Thermal Expansion Valve (TXV)

2 O-ring – TXV

3 Suction Line

4 Screw

5 Liquid Line

6 Seals – Compressor

7 Discharge Line

8 Discharge Line

9 Nut

10 Compressor Pad

11 Compressor

12 Liquid Line Clip

13 Condenser

14 O-ring – Condenser

15 Nut

16 O-ring – FDR

17 Filter Drier Receiver (FDR)

18 Union

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-49

Page 2C-49

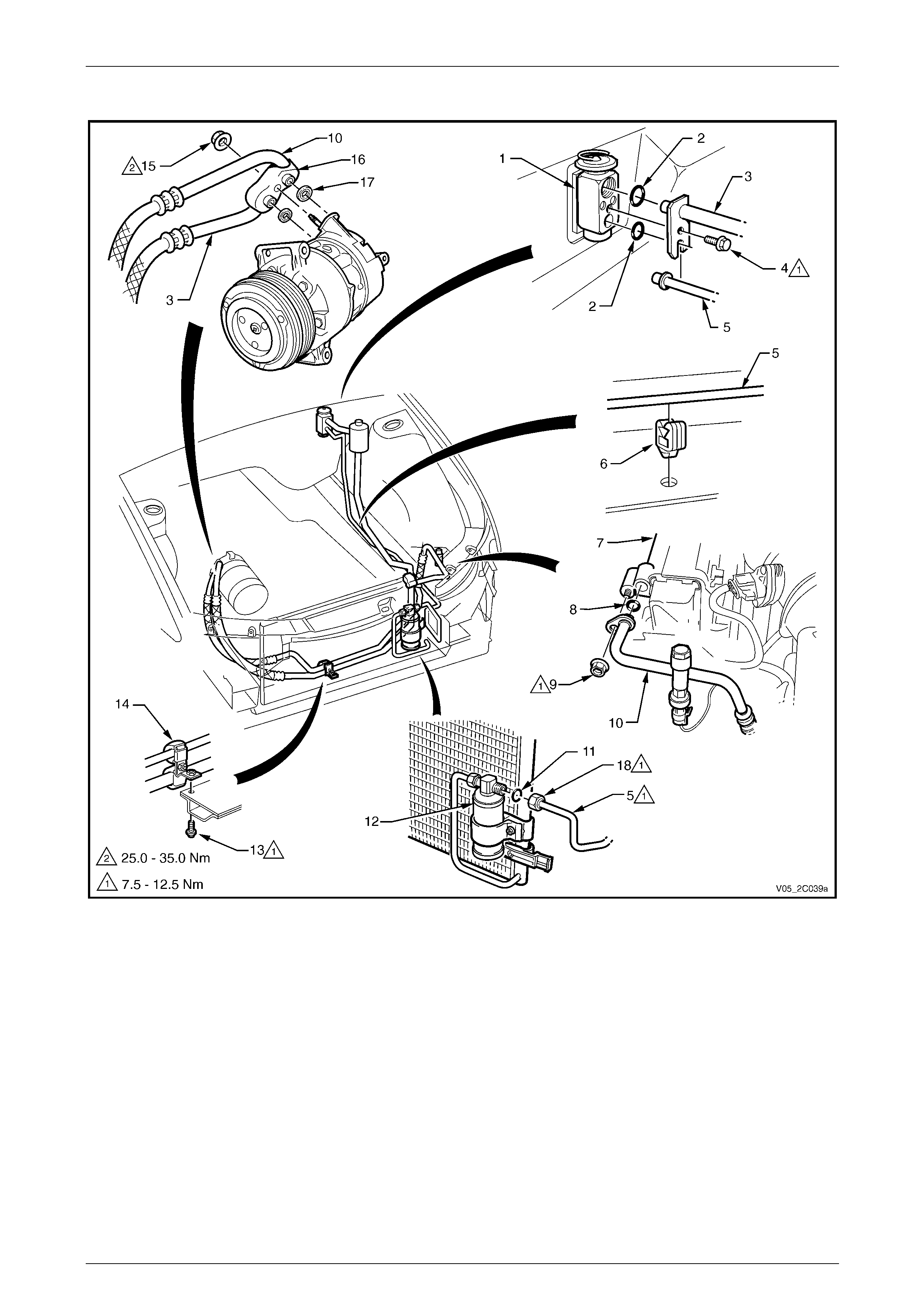

Lines and Retainers Views – V6 AWD

Figure 2C – 52

Legend

1 Thermal Expansion Valve (TXV)

2 O-ring – TXV

3 Suction Line

4 Screw

5 Liquid Line

6 Clip – Liquid Line

7 Condenser

8 O-ring – Condenser

9 Nut

10 Discharge Tube

11 O-ring – FDR

12 Filter Drier Receiver

13 Support Bracket screw

14 A/C Lines Support Bracket

15 Compressor Pad Nut

16 Compressor Pad

17 Compressor Seals

18 Union

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-50

Page 2C-50

Lines and Retainers Views – GEN III V8

Figure 2C – 53

Legend

1 Thermal Expansion Valve (TXV)

2 O-ring – TXV

3 Suction Line

4 Screw

5 Liquid Line

6 Liquid Line Clip

7 Condenser

8 O-Ring – Condenser

9 Nut

10 Discharge Line

11 O-Ring – FDR

12 Filter Drier Receiver (FDR)

13 Bracket Screw

14 A/C Lines Bracket

15 Screw

16 Compressor

17 Seals – Compressor

18 Compressor Pad Nut

19 Union

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-51

Page 2C-51

6 Air-conditioning Components

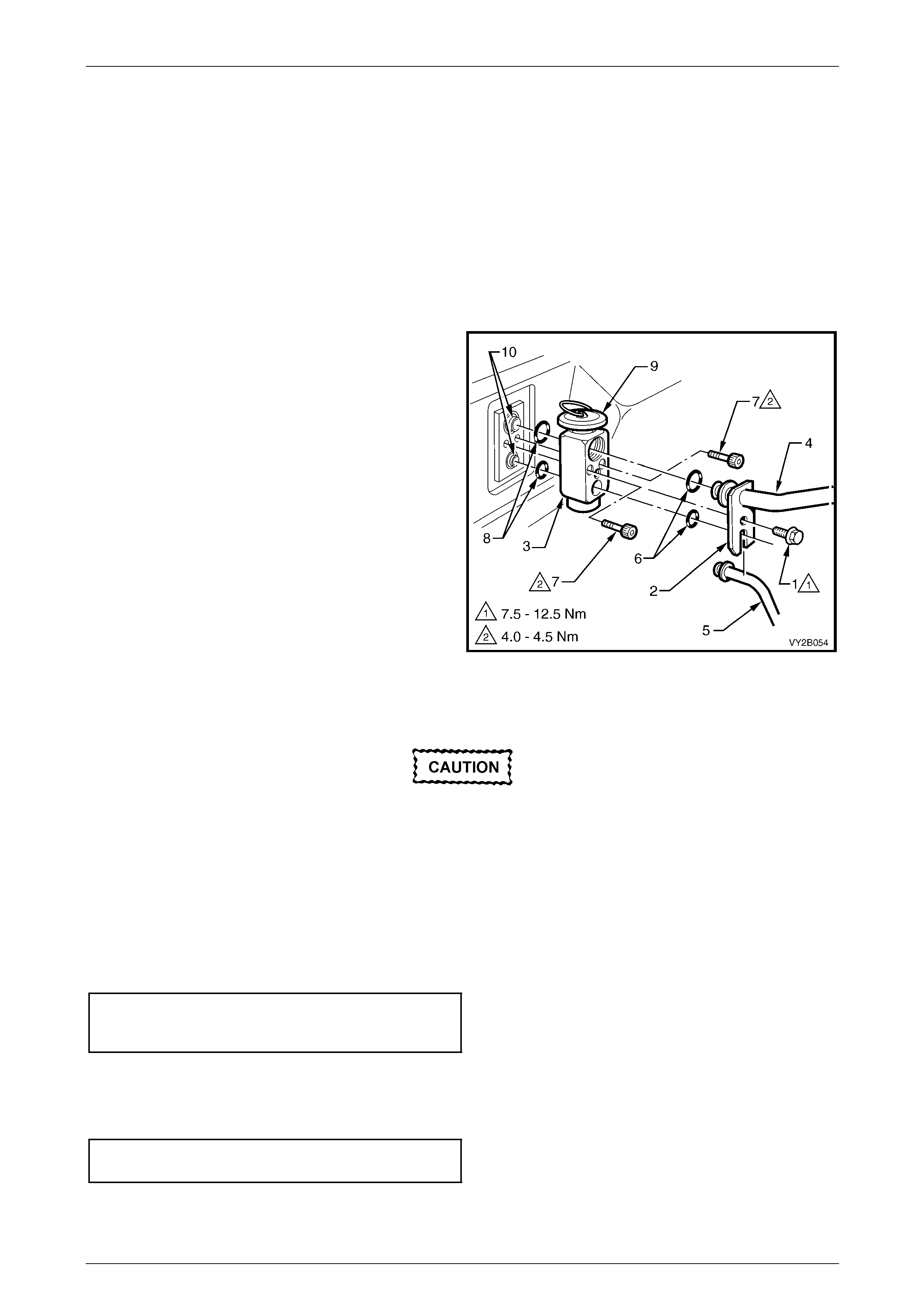

6.1 Thermal Expansion Valve

LT Section No. — 08–200

Remove

1 Recover the refrigerant from the air-conditioning system,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

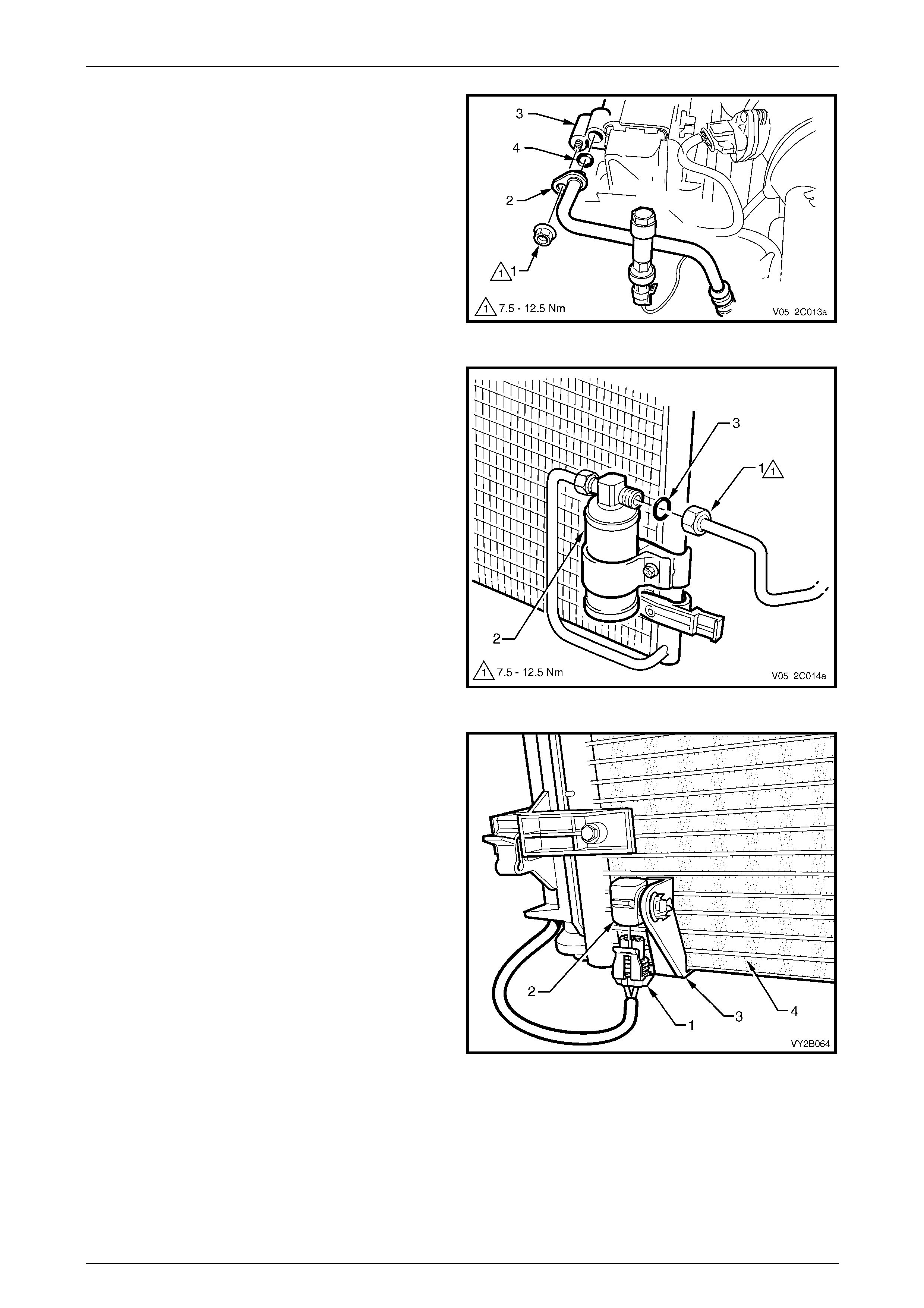

2 Remove the washer faced screw (1) retaining the

liquid and suction line plate (2) to the thermal

expansion valve (T XV) (3).

3 Remove the suction line (4) and the li quid line (5).

4 Remove and discard the liquid and suction line

O-rings (6).

5 Unscrew the two cap screws (7) and remove the TXV.

6 Remove and discard the evap orator tube O-ri ngs (8).

Figure 2C – 54

Reinstall

The total quantity of lubricating oil in the air-

conditioning system must be maintained. If

lubricating oil loss has occurred during TXV

replacement, oil must b e added to the system

to compensate.

1 Lubricate and fit two new O-rings to the evaporator tubes.

2 Install the thermal expansion valve (TXV) with the diaphrag m (9) facing upwards, onto the evaporator tubes (10),

refer to Figure 2C – 54.

3 Install the TXV to the evaporator tube plate and the two cap screws. Tighten the screws to the correct torque

specification.

Thermal expansion valve to

evaporator tubes securing

screw torque specification...........................4.0 – 4.5 Nm

4 Fit a new lubricated O-ring on to the suction line and the liquid line.

5 Install the liquid line and then the suction line plate onto the TXV.

6 Install the washer faced screw and tighten to the correct torque specification.

Liquid and suction li ne retaining plate

to TXV screw torque specification.............7.5 – 12.5 Nm

7 Evacuate and charge the A/C system with refrigerant,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-52

Page 2C-52

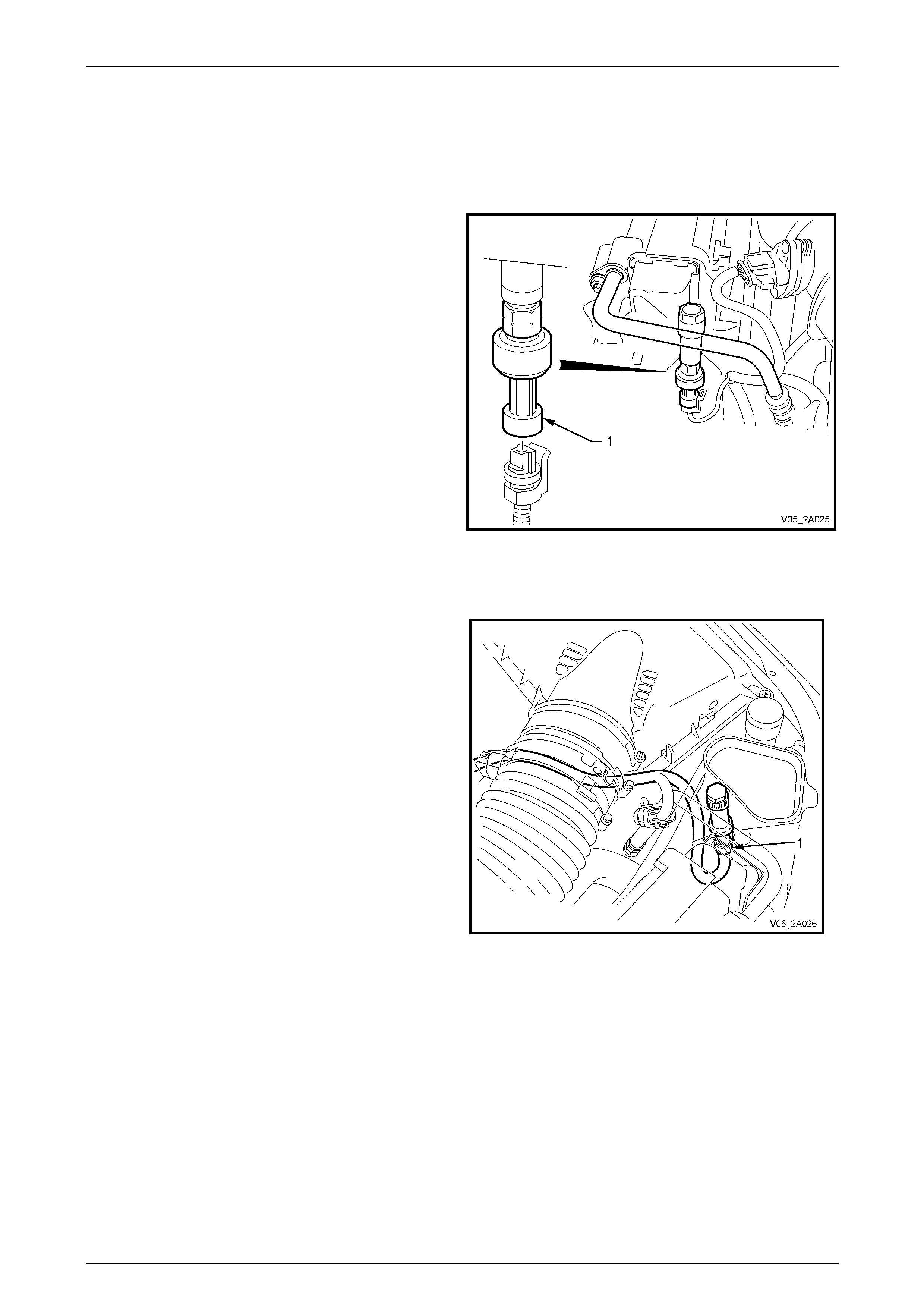

6.2 A/C Pressure Transducer

LT Section No. — 08–200

Replace – V6

To replace the A/C pressure transducer (1), refer to

Section 6C1-3 Engine Management – V6 – Service

Operations.

Figure 2C – 55

Replace – GEN III V8

To replace the A/C pressure transducer (1), refer to

Section 6C3-3 Powertrain Management – GEN III V8 –

Service Operations.

Figure 2C – 56

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-53

Page 2C-53

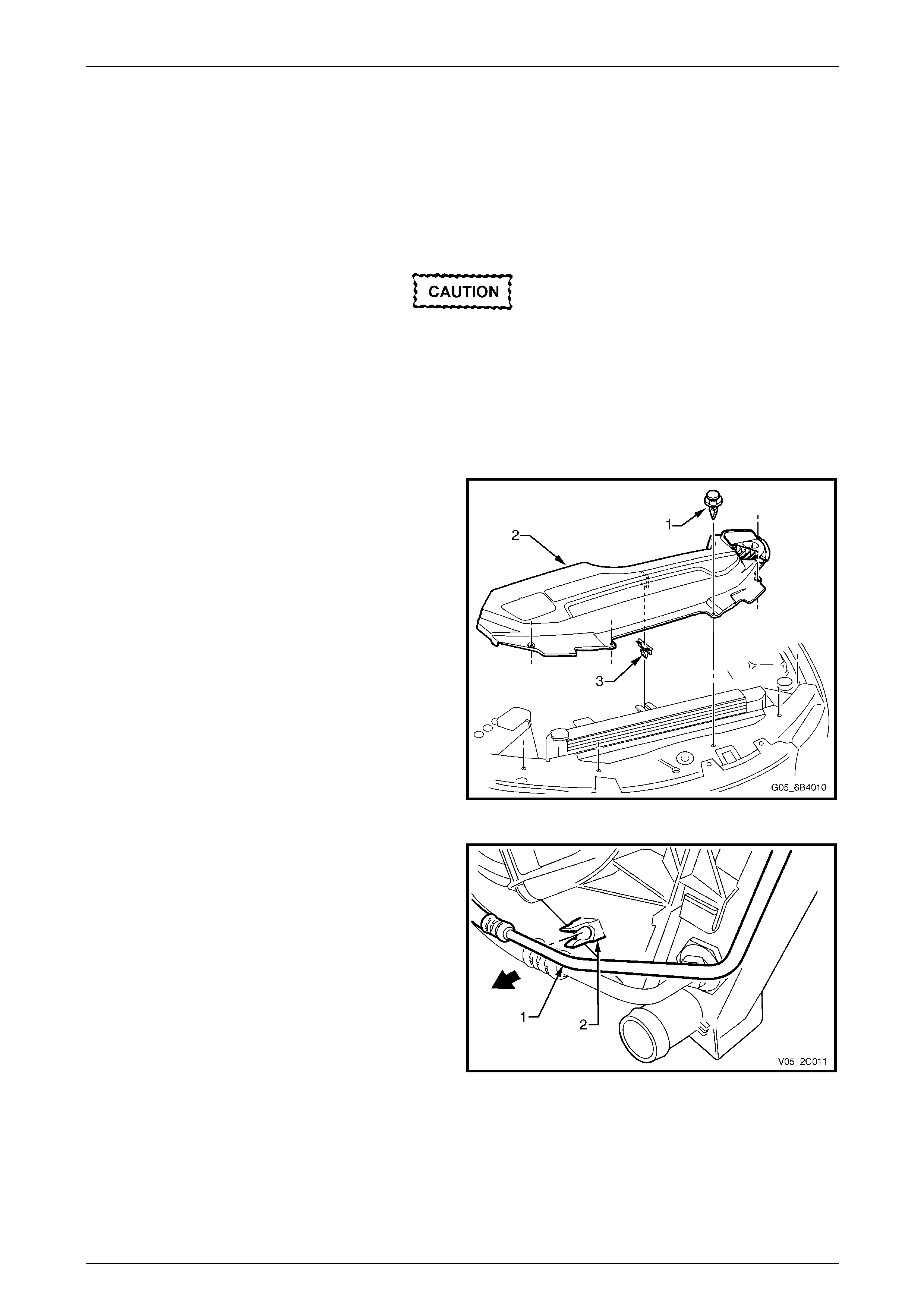

6.3 Condenser Assembly

LT Section No. — 08–200

V6 Engine

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes

before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Recover the refrigerant from the A/C system,

refer to Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

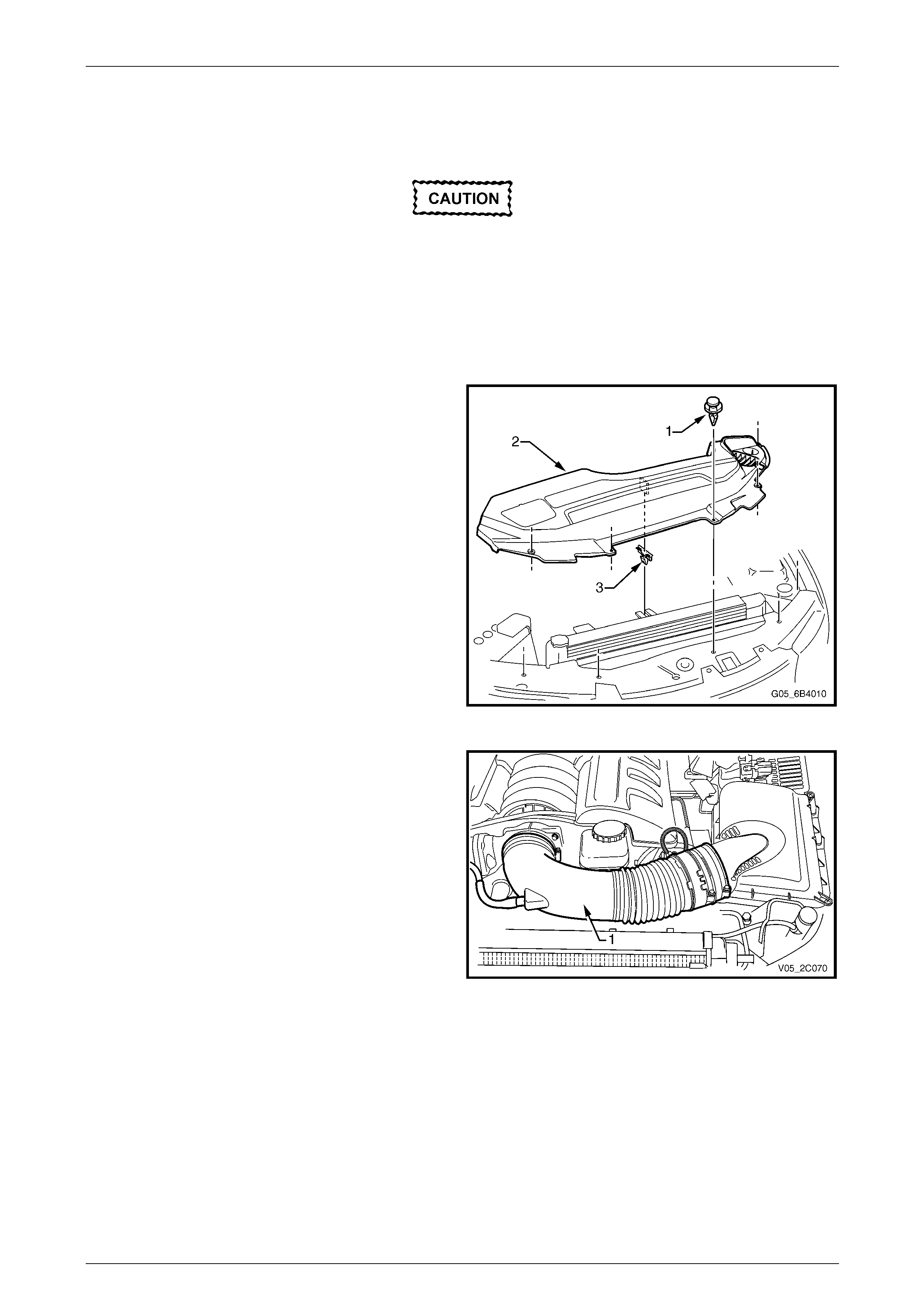

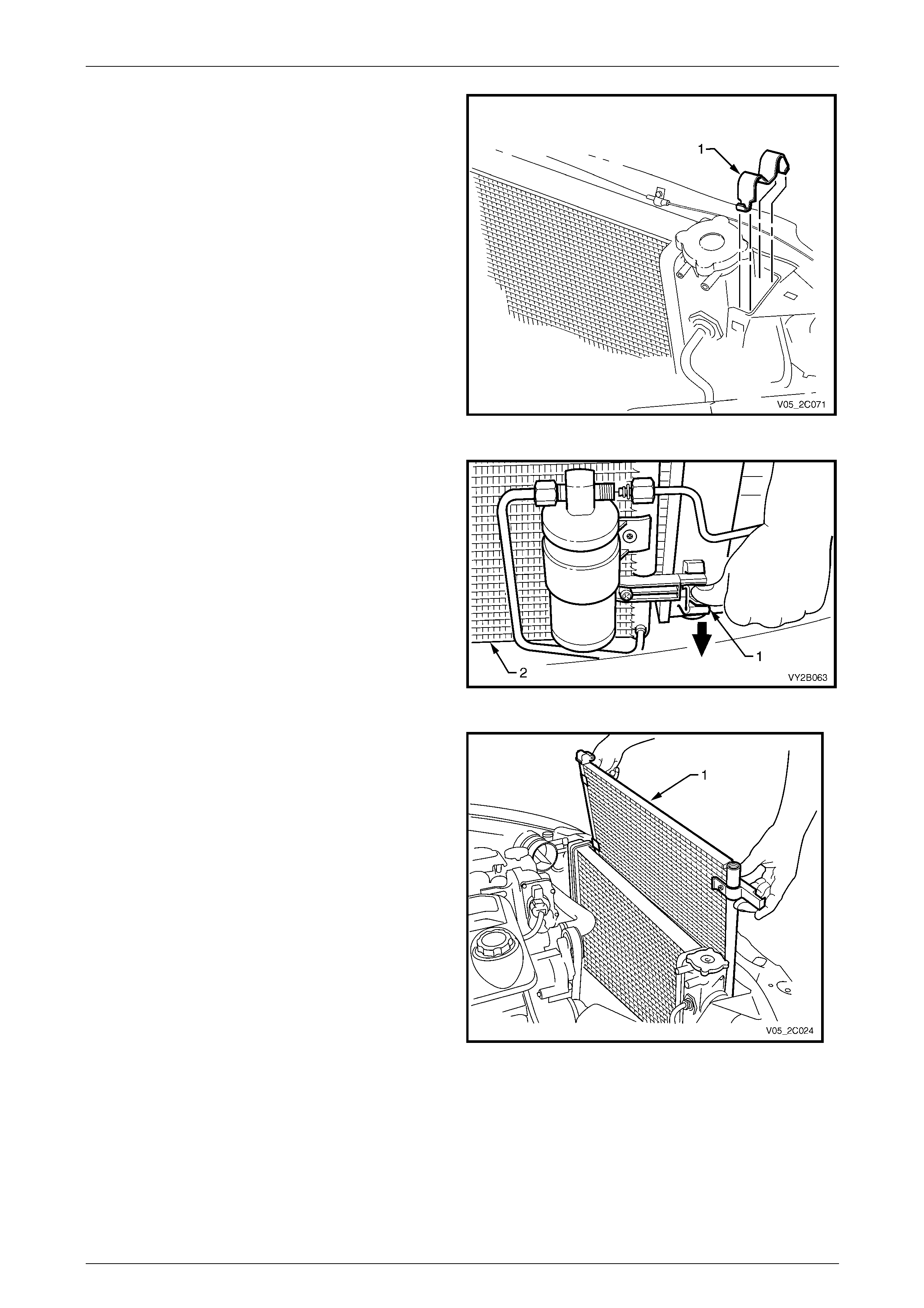

3 Remove the upper radiator shroud (2) as fol lows:

• Using a fine, flat-blade scre wdriver to prise the

centre pin of the retainer (1) up ward and remove

the retainer, five places.

• Lift up the radiator shroud to disenga ge the

retaining clip (3) and remove the shroud.

Figure 2C – 57

4 Release the automatic transmission upp er co oling

pipe (1) from the integral clip (2) on the fan shroud.

Figure 2C – 58

HVAC Climate Control (Manual A/C) – Removal and Installation Page 2C-54

Page 2C-54

5 Depress tang on main wiring harness to cooling fan

motor wiring harness connector (1) and separate the

connector.

Figure 2C – 59