Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–1

Page 7C2–1

Section 7C2

Automatic Transmission – 4L60E – Electrical

Diagnosis

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................8

1.1 Introduction............................................................................................................................................................ 8

1.2 General Description............................................................................................................................................... 9

Transmission Adaptive Functions ..................................................................................................................... 11

Limp Home Mode Description ............................................................................................................................ 11

1.3 Transmission Indicators and Messages............................................................................................................ 12

MFD Displays ....................................................................................................................................................... 12

Power Mode..................................................................................................................................................... 12

Normal Mode.................................................................................................................................................... 12

Shift Range Selected........................................................................................................................................ 12

1.4 Electronic Component Description.................................................................................................................... 13

Transmission Control Module (TCM)................................................................................................................. 13

2 Wiring Diagrams and Connector Chart..............................................................................................15

2.1 Wiring Diagrams .................................................................................................................................................. 15

2.2 Connector Chart................................................................................................................................................... 18

2.3 Connector Information ........................................................................................................................................ 19

In-line 20-Way Connector End View................................................................................................................... 19

Transmission Side – X121–X1......................................................................................................................... 19

Harness Side – X121–X1................................................................................................................................. 20

Internal Connector End Views............................................................................................................................ 21

Vehicle Speed Sensor...................................................................................................................................... 21

1-2 Shift Solenoid Valve Connector.................................................................................................................. 21

2-3 Shift Solenoid Valve Connector.................................................................................................................. 21

Pressure Control (PC) Solenoid Valve Connector............................................................................................ 21

Transmission Manual Shift Shaft Switch Assembly.......................................................................................... 22

3-2 Shift Solenoid Valve Assembly Connector................................................................................................. 22

Torque Converter Clutch (TCC) Pulse-Width M odulated (PWM) Solenoid Valve Connector........................... 22

Torque Converter Clutch (T CC) Solenoid Valve Connec tor............................................................................. 22

Transmission Control Module Connector End View – A112–X1...................................................................... 23

3 Tech 2 Information ...............................................................................................................................25

3.1 Tech 2 Diagnostics.............................................................................................................................................. 25

Test Modes........................................................................................................................................................... 25

Diagnostic Trouble Codes................................................................................................................................ 25

Data Display..................................................................................................................................................... 26

Snapshot.......................................................................................................................................................... 26

Additional Functions......................................................................................................................................... 26

Miscellaneous Tests......................................................................................................................................... 27

Programming.................................................................................................................................................... 27

Techline

Techline

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–2

Page 7C2–2

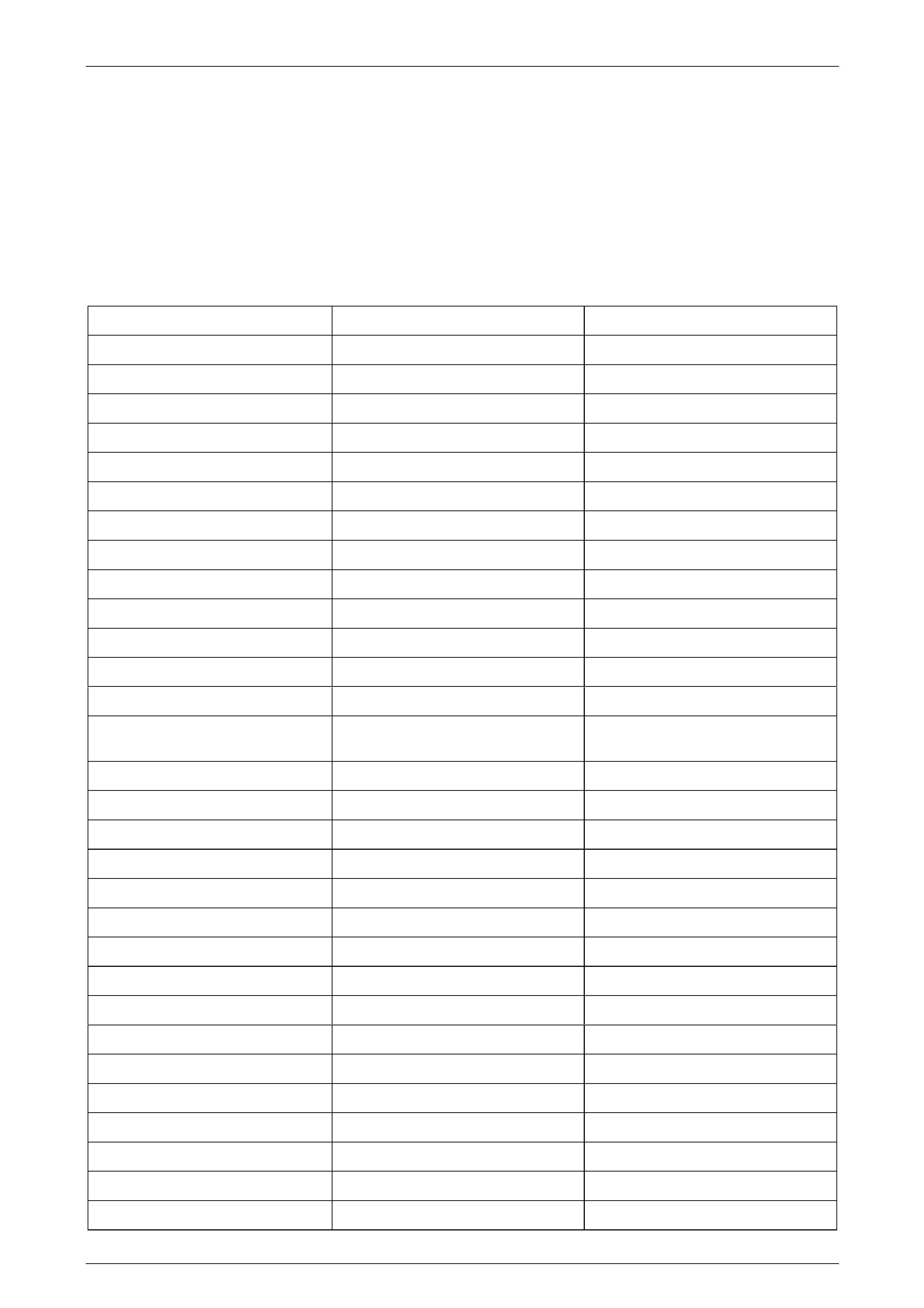

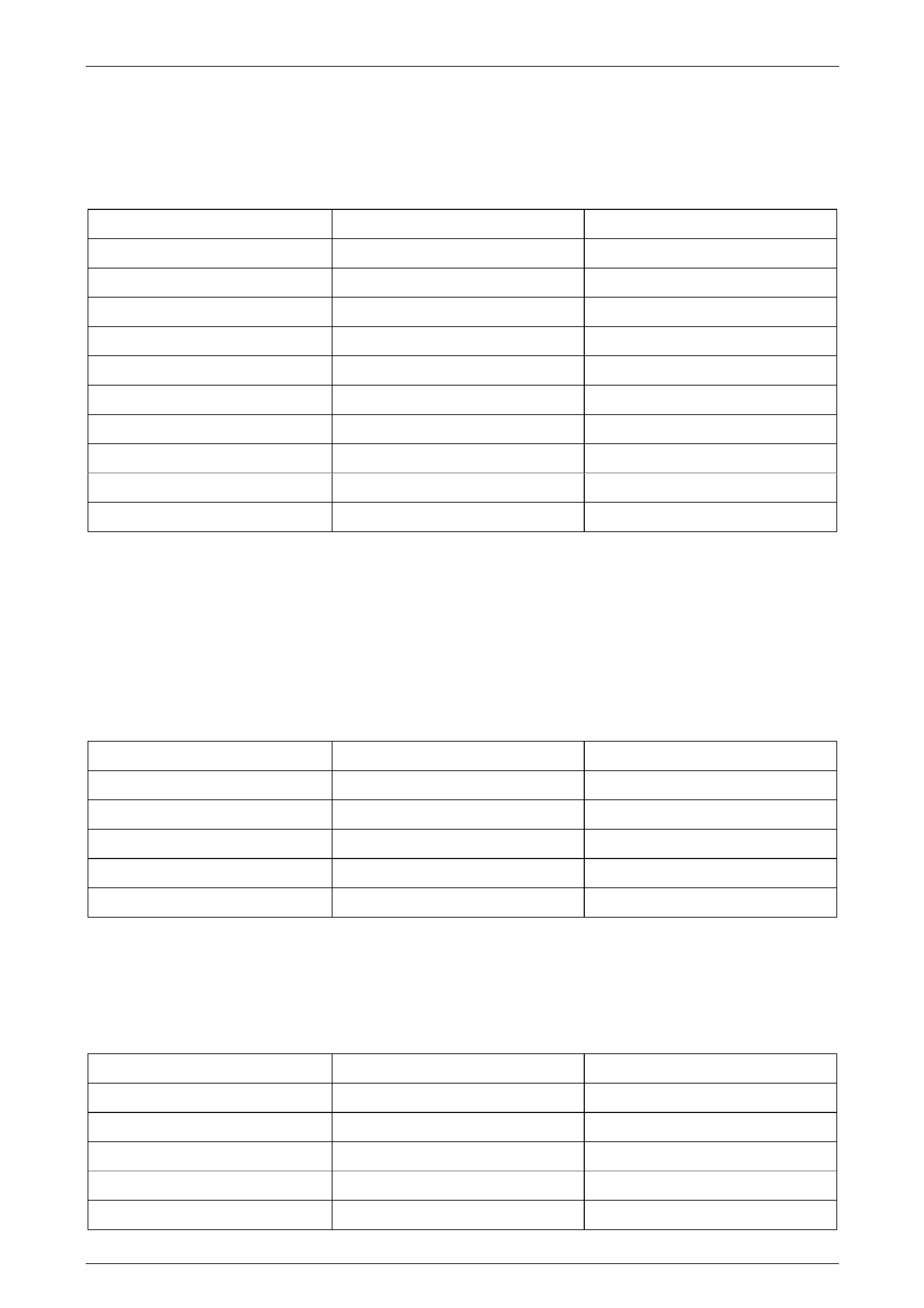

3.2 Data Display ......................................................................................................................................................... 28

Transmission Data............................................................................................................................................... 28

Transmission Data Parameters........................................................................................................................ 28

TCC Data............................................................................................................................................................... 29

TCC Data Parameters...................................................................................................................................... 29

1-2 Shift Data........................................................................................................................................................ 30

1-2 Shift Data Parameters................................................................................................................................ 30

2-3 Shift Data........................................................................................................................................................ 31

2-3 Shift Data Parameters................................................................................................................................ 31

3-4 Shift Data........................................................................................................................................................ 31

3-4 Shift Data Parameters................................................................................................................................ 31

Pressure Control Solenoid Data......................................................................................................................... 32

Pressure Control Solenoid Data Parameters ................................................................................................... 32

Transmission Adapts .......................................................................................................................................... 32

1-2 Adapt Data................................................................................................................................................. 32

2-3 Adapt Data................................................................................................................................................. 32

3-4 Adapt Data................................................................................................................................................. 33

Steady State Adapt Data.................................................................................................................................. 33

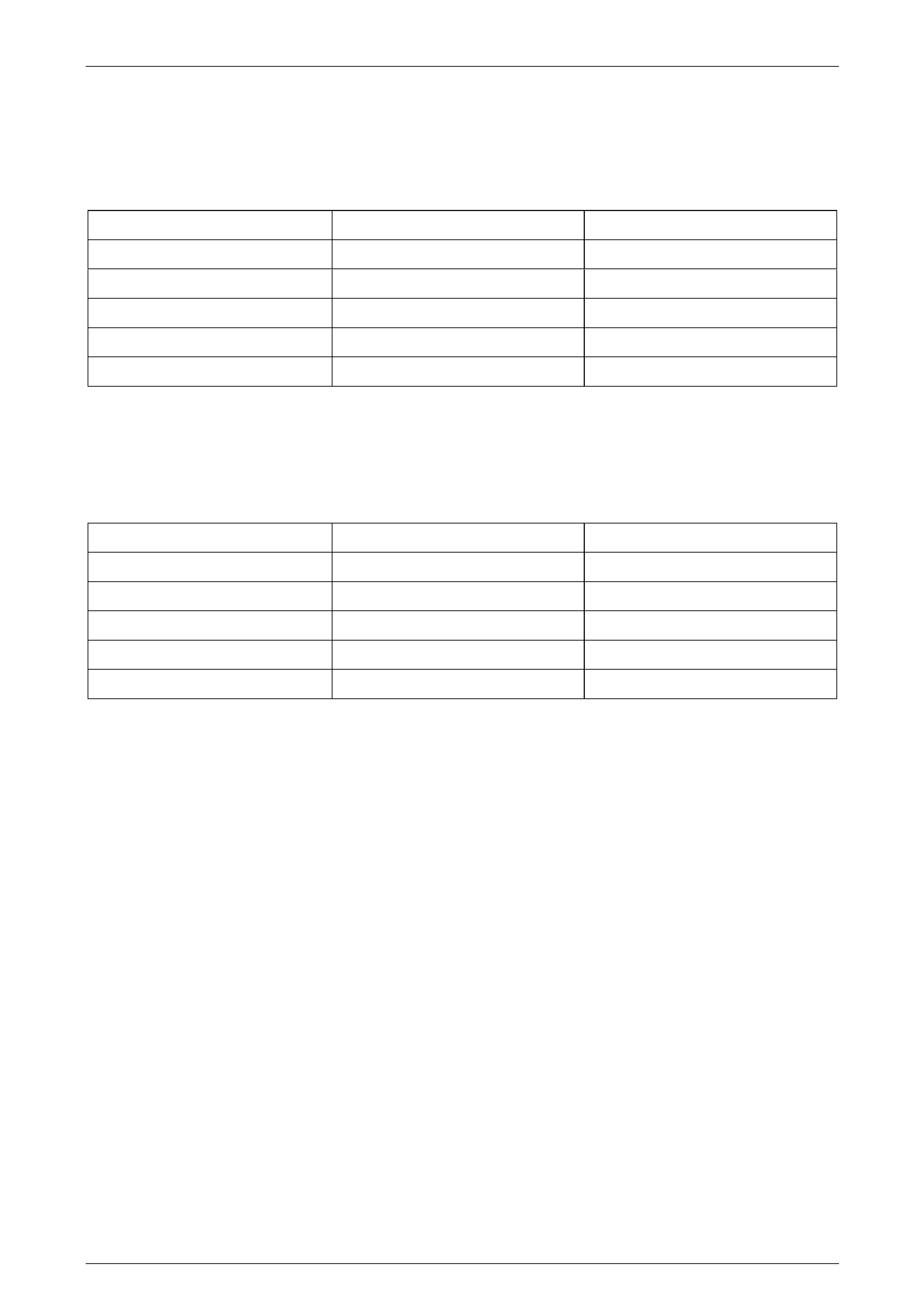

3.3 Tech 2 Data Definitions ....................................................................................................................................... 34

3.4 Miscellaneous Tests............................................................................................................................................ 36

4 Diagnostics...........................................................................................................................................40

4.1 Introduction.......................................................................................................................................................... 40

4.2 Precautions .......................................................................................................................................................... 41

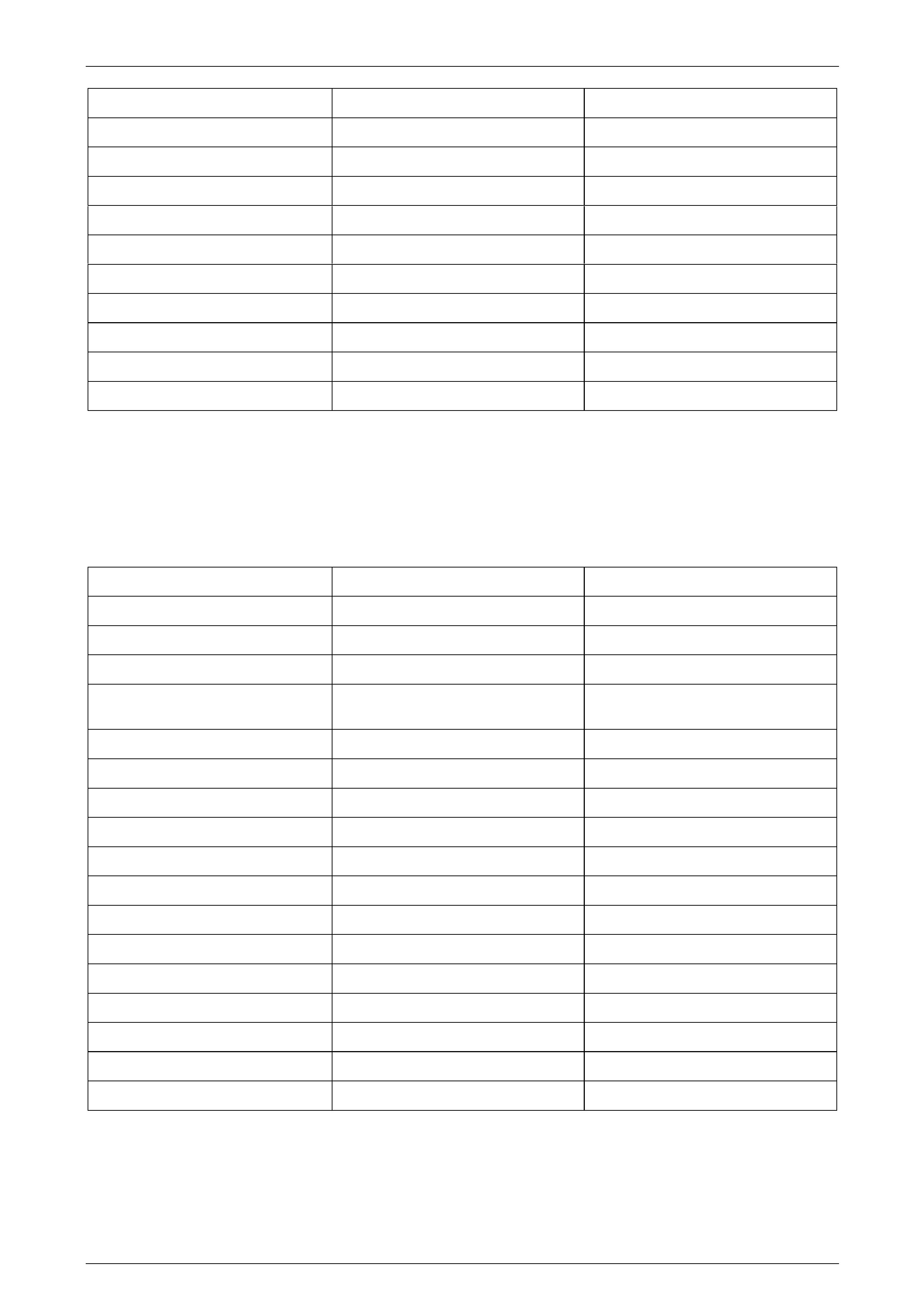

4.3 Diagnostic Trouble Code Tables........................................................................................................................ 42

Multiple DTCs Fault Condition............................................................................................................................ 42

4.4 Diagnostic Trouble Code Definitions................................................................................................................. 43

Type A – Emission Related DTCs....................................................................................................................... 43

Type B – Emission Related DTCs....................................................................................................................... 43

Conditions for Clearing Type A or Type B DTCs.............................................................................................. 43

Type C – Non-emission Related DTCs............................................................................................................... 44

Conditions for Clearing Type C DTCs.............................................................................................................. 44

Current DTCs........................................................................................................................................................ 44

History DTCs........................................................................................................................................................ 44

4.5 Diagnostic System Check................................................................................................................................... 45

Description........................................................................................................................................................... 45

Test Description................................................................................................................................................... 45

4.6 Diagnostic Trouble Code List............................................................................................................................. 46

4.7 DTC P0218 – Transmission Fluid Overtemperature.......................................................................................... 48

DTC Description................................................................................................................................................... 48

Circuit Description............................................................................................................................................... 48

Conditions for Running the DTC........................................................................................................................ 48

Conditions for Setting the DTC........................................................................................................................... 48

Action Taken When the DTC Sets ...................................................................................................................... 48

Conditions for Clearing the DTC ........................................................................................................................ 48

Diagnostic Aids.................................................................................................................................................... 48

Test Description................................................................................................................................................... 49

DTC P0218 Diagnostic Table............................................................................................................................... 49

4.8 DTC P0562 – System Voltage Low ..................................................................................................................... 51

DTC Description................................................................................................................................................... 51

Circuit Description............................................................................................................................................... 51

Conditions for Running the DTC........................................................................................................................ 51

Conditions for Setting the DTC........................................................................................................................... 51

Action Taken When the DTC Sets ...................................................................................................................... 51

Conditions for Clearing the DTC ........................................................................................................................ 51

Diagnostic Aids.................................................................................................................................................... 51

Test Description................................................................................................................................................... 51

DTC P0562 Diagnostic Table............................................................................................................................... 52

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–3

Page 7C2–3

4.9 DTC P0563 – System Voltage High..................................................................................................................... 54

DTC Description................................................................................................................................................... 54

Circuit Description............................................................................................................................................... 54

Conditions for Running the DTC........................................................................................................................ 54

Conditions for Setting the DTC........................................................................................................................... 54

Action Taken When the DTC Sets ...................................................................................................................... 54

Conditions for Clearing the DTC ........................................................................................................................ 54

Diagnostic Aids.................................................................................................................................................... 54

Test Description................................................................................................................................................... 54

DTC P0563 Diagnostic Table............................................................................................................................... 55

4.10 DTC P0601 to P0604 or P1621 – TCM Malfunction............................................................................................ 57

DTC Description................................................................................................................................................... 57

Circuit Description............................................................................................................................................... 57

Conditions for Running the DTC........................................................................................................................ 57

Conditions for Setting the DTC........................................................................................................................... 57

Action Taken When the DTC Sets ...................................................................................................................... 57

Conditions for Clearing the DTC ........................................................................................................................ 57

Test Description................................................................................................................................................... 57

DTC P0601 to P0604 or P1621 Diagnostic Table............................................................................................... 58

4.11 DTC P0711 to P0713 – Transmission Fluid Temperature Sensor.................................................................... 59

DTC Description................................................................................................................................................... 59

Circuit Description............................................................................................................................................... 59

Conditions for Running the DTC........................................................................................................................ 59

DTC P0711 ...................................................................................................................................................... 59

DTC P0712 ...................................................................................................................................................... 59

DTC P0713 ...................................................................................................................................................... 59

Conditions for Setting the DTC........................................................................................................................... 60

DTC P0711 ...................................................................................................................................................... 60

DTC P0712 ...................................................................................................................................................... 60

DTC P0713 ...................................................................................................................................................... 60

Action Taken When the DTC Sets ...................................................................................................................... 60

Conditions for Clearing the DTC ........................................................................................................................ 60

Diagnostic Aids.................................................................................................................................................... 60

Test Description................................................................................................................................................... 61

DTC P0711 to P0713 Diagnostic Table............................................................................................................... 61

4.12 DTC P0719 – Brake Switch Circuit High Input (Stuck On)................................................................................ 63

DTC Description................................................................................................................................................... 63

Circuit Description............................................................................................................................................... 63

Conditions for Running the DTC........................................................................................................................ 63

Conditions for Setting the DTC........................................................................................................................... 63

Action Taken When the DTC Sets ...................................................................................................................... 63

Conditions for Clearing the DTC ........................................................................................................................ 63

Diagnostic Aids.................................................................................................................................................... 63

Test Description................................................................................................................................................... 63

DTC P0719 Diagnostic Table............................................................................................................................... 64

4.13 DTC P0722 – Vehicle Speed Sensor Circuit Low Voltage ................................................................................ 65

DTC Description................................................................................................................................................... 65

Circuit Description............................................................................................................................................... 65

Conditions for Running the DTC........................................................................................................................ 65

Conditions for Setting the DTC........................................................................................................................... 65

Action Taken When the DTC Sets ...................................................................................................................... 65

Conditions for Clearing the DTC ........................................................................................................................ 65

Diagnostic Aids.................................................................................................................................................... 66

Test Description................................................................................................................................................... 66

DTC P0722 Diagnostic Table............................................................................................................................... 66

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–4

Page 7C2–4

4.14 DTC P0723 – Vehicle Speed Sensor Circuit Intermittent.................................................................................. 68

DTC Description................................................................................................................................................... 68

Circuit Description............................................................................................................................................... 68

Conditions for Running the DTC........................................................................................................................ 68

Conditions for Setting the DTC........................................................................................................................... 68

Action Taken When the DTC Sets ...................................................................................................................... 68

Conditions for Clearing the DTC ........................................................................................................................ 68

Diagnostic Aids.................................................................................................................................................... 69

Test Description................................................................................................................................................... 69

DTC P0723 Diagnostic Table............................................................................................................................... 69

4.15 DTC P0724 – Brake Switch Circuit Low Input (Stuck Off) ................................................................................ 71

DTC Description................................................................................................................................................... 71

Circuit Description............................................................................................................................................... 71

Conditions for Running the DTC........................................................................................................................ 71

Conditions for Setting the DTC........................................................................................................................... 71

Action Taken When the DTC Sets ...................................................................................................................... 71

Conditions for Clearing the DTC ........................................................................................................................ 71

Diagnostic Aids.................................................................................................................................................... 71

Test Description................................................................................................................................................... 71

DTC P0724 Diagnostic Table............................................................................................................................... 72

4.16 DTC P0741 – Torque Converter Clutch System – Stuck Off............................................................................. 73

DTC Description................................................................................................................................................... 73

Circuit Description............................................................................................................................................... 73

Conditions for Running the DTC........................................................................................................................ 73

Conditions for Setting the DTC........................................................................................................................... 73

Action Taken When the DTC Sets ...................................................................................................................... 73

Conditions for Clearing the DTC ........................................................................................................................ 74

Diagnostic Aids.................................................................................................................................................... 74

Test Description................................................................................................................................................... 74

DTC P0741 Diagnostic Table............................................................................................................................... 74

4.17 DTC P0742 – Torque Converter Clutch System – Stuck On............................................................................. 76

DTC Description................................................................................................................................................... 76

Circuit Description............................................................................................................................................... 76

Conditions for Running the DTC........................................................................................................................ 76

Conditions for Setting the DTC........................................................................................................................... 76

Action Taken When the DTC Sets ...................................................................................................................... 77

Conditions for Clearing the DTC ........................................................................................................................ 77

Diagnostic Aids.................................................................................................................................................... 77

Test Description................................................................................................................................................... 77

DTC P0742 Diagnostic Table............................................................................................................................... 78

4.18 DTC P0751 – 1-2 Shift Solenoid Valve Performance – No First or Fourth Gear ............................................. 80

DTC Description................................................................................................................................................... 80

Circuit Description............................................................................................................................................... 80

Conditions for Running the DTC........................................................................................................................ 80

Conditions for Setting the DTC........................................................................................................................... 80

Action Taken When the DTC Sets ...................................................................................................................... 80

Conditions for Clearing the DTC ........................................................................................................................ 80

Diagnostic Aids.................................................................................................................................................... 81

Test Description................................................................................................................................................... 81

DTC P0751 Diagnostic Table............................................................................................................................... 81

4.19 DTC P0752 – 1-2 Shift Solenoid Valve Performance – No Second or Third Gear........................................... 83

DTC Description................................................................................................................................................... 83

Circuit Description............................................................................................................................................... 83

Conditions for Running the DTC........................................................................................................................ 83

Conditions for Setting the DTC........................................................................................................................... 83

Action Taken When the DTC Sets ...................................................................................................................... 83

Conditions for Clearing the DTC ........................................................................................................................ 83

Diagnostic Aids.................................................................................................................................................... 84

Test Description................................................................................................................................................... 84

DTC P0752 Diagnostic Table............................................................................................................................... 84

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–5

Page 7C2–5

4.20 DTC P0756 – 2-3 Shift Solenoid Valve Performance – No First or Second Gear............................................ 86

DTC Description................................................................................................................................................... 86

Circuit Description............................................................................................................................................... 86

Conditions for Running the DTC........................................................................................................................ 86

Conditions for Setting the DTC........................................................................................................................... 86

Action Taken When the DTC Sets ...................................................................................................................... 87

Conditions for Clearing the DTC ........................................................................................................................ 87

Diagnostic Aids.................................................................................................................................................... 87

Test Description................................................................................................................................................... 87

DTC P0756 Diagnostic Table............................................................................................................................... 88

4.21 DTC P0757 – 2-3 Shift Solenoid Valve Performance – No Third or Fourth Gear............................................ 90

DTC Description................................................................................................................................................... 90

Circuit Description............................................................................................................................................... 90

Conditions for Running the DTC........................................................................................................................ 90

Conditions for Setting the DTC........................................................................................................................... 90

Action Taken When the DTC Sets ...................................................................................................................... 90

Conditions for Clearing the DTC ........................................................................................................................ 90

Diagnostic Aids.................................................................................................................................................... 91

Test Description................................................................................................................................................... 91

DTC P0757 Diagnostic Table............................................................................................................................... 91

4.22 DTC P0787 – 3-2 Shift Solenoid Control Circuit Low Voltage.......................................................................... 93

DTC Description................................................................................................................................................... 93

Circuit Description............................................................................................................................................... 93

Conditions for Running the DTC........................................................................................................................ 93

Conditions for Setting the DTC........................................................................................................................... 93

Action Taken When the DTC Sets ...................................................................................................................... 93

Conditions for Clearing the DTC ........................................................................................................................ 93

Test Description................................................................................................................................................... 94

DTC P0787 Diagnostic Table............................................................................................................................... 94

4.23 DTC P0788 – 3-2 Shift Solenoid Control Circuit High Voltage......................................................................... 97

DTC Description................................................................................................................................................... 97

Circuit Description............................................................................................................................................... 97

Conditions for Running the DTC........................................................................................................................ 97

Conditions for Setting the DTC........................................................................................................................... 97

Action Taken When the DTC Sets ...................................................................................................................... 97

Conditions for Clearing the DTC ........................................................................................................................ 97

Test Description................................................................................................................................................... 98

DTC P0788 Diagnostic Table............................................................................................................................... 98

4.24 DTC P0894 – Transmission Component Slipping........................................................................................... 100

DTC Description................................................................................................................................................. 100

Circuit Description............................................................................................................................................. 100

Conditions for Running the DTC...................................................................................................................... 100

Conditions for Setting the DTC......................................................................................................................... 101

Action Taken When the DTC Sets .................................................................................................................... 101

Conditions for Clearing the DTC ...................................................................................................................... 102

Diagnostic Aids.................................................................................................................................................. 102

Test Description................................................................................................................................................. 102

DTC P0894 Diagnostic Table............................................................................................................................. 103

4.25 DTC P0961 – Line Pressure Control Solenoid System Performance ............................................................ 109

DTC Description................................................................................................................................................. 109

Circuit Description............................................................................................................................................. 109

Conditions for Running the DTC...................................................................................................................... 109

Conditions for Setting the DTC......................................................................................................................... 109

Action Taken When the DTC Sets .................................................................................................................... 109

Conditions for Clearing the DTC ...................................................................................................................... 109

Diagnostic Aids.................................................................................................................................................. 109

Test Description................................................................................................................................................. 109

DTC P0961 Diagnostic Table............................................................................................................................. 110

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–6

Page 7C2–6

4.26 DTC P0973 – 1-2 Shift Solenoid Control Circuit Low Voltage........................................................................ 112

DTC Description................................................................................................................................................. 112

Circuit Description............................................................................................................................................. 112

Conditions for Running the DTC...................................................................................................................... 112

Conditions for Setting the DTC......................................................................................................................... 112

Action Taken When the DTC Sets .................................................................................................................... 112

Conditions for Clearing the DTC ...................................................................................................................... 112

Test Description................................................................................................................................................. 113

DTC P0973 Diagnostic Table............................................................................................................................. 113

4.27 DTC P0974 – 1-2 Shift Solenoid Control Circuit High Voltage....................................................................... 116

DTC Description................................................................................................................................................. 116

Circuit Description............................................................................................................................................. 116

Conditions for Running the DTC...................................................................................................................... 116

Conditions for Setting the DTC......................................................................................................................... 116

Action Taken When the DTC Sets .................................................................................................................... 116

Conditions for Clearing the DTC ...................................................................................................................... 116

Test Description................................................................................................................................................. 116

DTC P0974 Diagnostic Table............................................................................................................................. 117

4.28 DTC P0976 – 2-3 Shift Solenoid Control Circuit Low Voltage........................................................................ 119

DTC Description................................................................................................................................................. 119

Circuit Description............................................................................................................................................. 119

Conditions for Running the DTC...................................................................................................................... 119

Conditions for Setting the DTC......................................................................................................................... 119

Action Taken When the DTC Sets .................................................................................................................... 119

Conditions for Clearing the DTC ...................................................................................................................... 119

Test Description................................................................................................................................................. 120

DTC P0976 Diagnostic Table............................................................................................................................. 120

4.29 DTC P0977 – 2-3 Shift Solenoid Control Circuit High Voltage....................................................................... 123

DTC Description................................................................................................................................................. 123

Circuit Description............................................................................................................................................. 123

Conditions for Running the DTC...................................................................................................................... 123

Conditions for Setting the DTC......................................................................................................................... 123

Action Taken When the DTC Sets .................................................................................................................... 123

Conditions for Clearing the DTC ...................................................................................................................... 123

Test Description................................................................................................................................................. 123

DTC P0977 Diagnostic Table............................................................................................................................. 124

4.30 DTC P1810, P1815 and P1816 – Transmission Fluid Pressure Position Switch........................................... 126

DTC Description................................................................................................................................................. 126

Circuit Description............................................................................................................................................. 126

Conditions for Running the DTC...................................................................................................................... 126

DTC P1810 .................................................................................................................................................... 126

DTC P1815 .................................................................................................................................................... 126

DTC P1816 .................................................................................................................................................... 126

Conditions for Setting the DTC......................................................................................................................... 127

DTC P1810 .................................................................................................................................................... 127

DTC P1815 .................................................................................................................................................... 127

DTC P1816 .................................................................................................................................................... 127

Action Taken When the DTC Sets .................................................................................................................... 127

Conditions for Clearing the DTC ...................................................................................................................... 127

Diagnostic Aids.................................................................................................................................................. 127

Test Description................................................................................................................................................. 127

DTC P1810, P1815 and P1816 Diagnostic Table.............................................................................................. 128

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–7

Page 7C2–7

4.31 DTC P2763 – Torque Converter Clutch Pressure Control Solenoid Control Circuit High Voltage............. 130

DTC Description................................................................................................................................................. 130

Circuit Description............................................................................................................................................. 130

Conditions for Running the DTC...................................................................................................................... 130

Conditions for Setting the DTC......................................................................................................................... 130

Action Taken When the DTC Sets .................................................................................................................... 130

Conditions for Clearing the DTC ...................................................................................................................... 130

Test Description................................................................................................................................................. 130

DTC P2763 Diagnostic Table............................................................................................................................. 131

4.32 DTC P2764 – Torque Converter Clutch Pressure Control Solenoid Control Circuit Low Voltage.............. 133

DTC Description................................................................................................................................................. 133

Circuit Description............................................................................................................................................. 133

Conditions for Running the DTC...................................................................................................................... 133

Conditions for Setting the DTC......................................................................................................................... 133

Action Taken When the DTC Sets .................................................................................................................... 133

Conditions for Clearing the DTC ...................................................................................................................... 134

Test Description................................................................................................................................................. 134

DTC P2764 Diagnostic Table............................................................................................................................. 134

4.33 DTC P2769 – Torque Converter Clutch Enable Solenoid Control Circuit Low Voltage............................... 137

DTC Description................................................................................................................................................. 137

Circuit Description............................................................................................................................................. 137

Conditions for Running the DTC...................................................................................................................... 137

Conditions for Setting the DTC......................................................................................................................... 137

Action Taken When the DTC Sets .................................................................................................................... 137

Conditions for Clearing the DTC ...................................................................................................................... 138

Diagnostic Aids.................................................................................................................................................. 138

Test Description................................................................................................................................................. 138

DTC P2769 Diagnostic Table............................................................................................................................. 138

4.34 DTC P2770 – Torque Converter Clutch Enable Solenoid Control Circuit High Voltage .............................. 141

DTC Description................................................................................................................................................. 141

Circuit Description............................................................................................................................................. 141

Conditions for Running the DTC...................................................................................................................... 141

Conditions for Setting the DTC......................................................................................................................... 141

Action Taken When the DTC Sets .................................................................................................................... 141

Conditions for Clearing the DTC ...................................................................................................................... 142

Test Description................................................................................................................................................. 142

DTC P2770 Diagnostic Table............................................................................................................................. 142

4.35 DTC U2107– Lost Communication with Body Control Module...................................................................... 143

DTC Description................................................................................................................................................. 143

Circuit Description............................................................................................................................................. 143

Conditions for Running the DTC...................................................................................................................... 143

Conditions for Setting the DTC......................................................................................................................... 143

Action Taken When the DTC Sets .................................................................................................................... 143

Conditions for Clearing the DTC ...................................................................................................................... 143

Diagnostic Aids.................................................................................................................................................. 143

Test Description................................................................................................................................................. 143

DTC U2107 Diagnostic Table ............................................................................................................................ 144

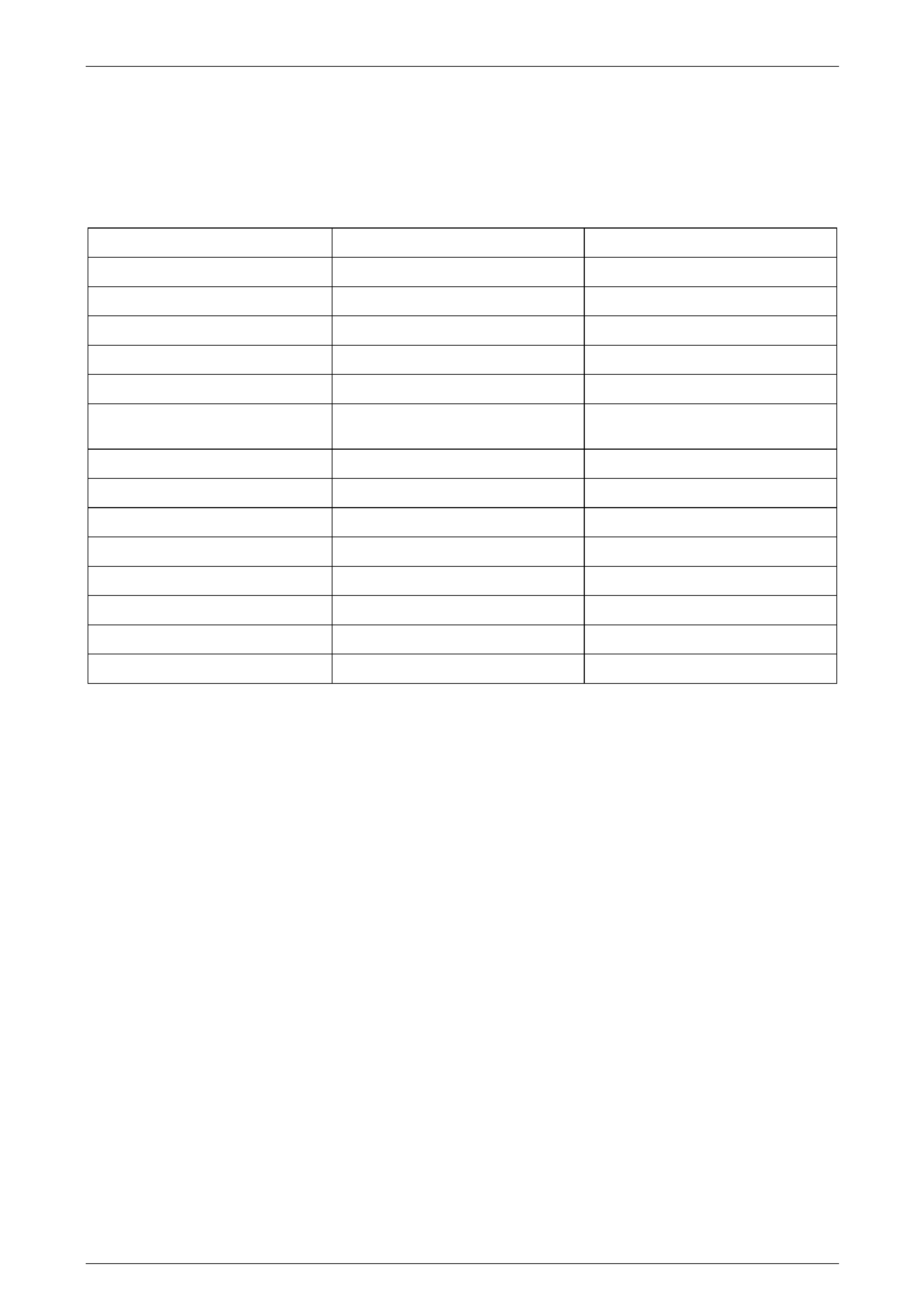

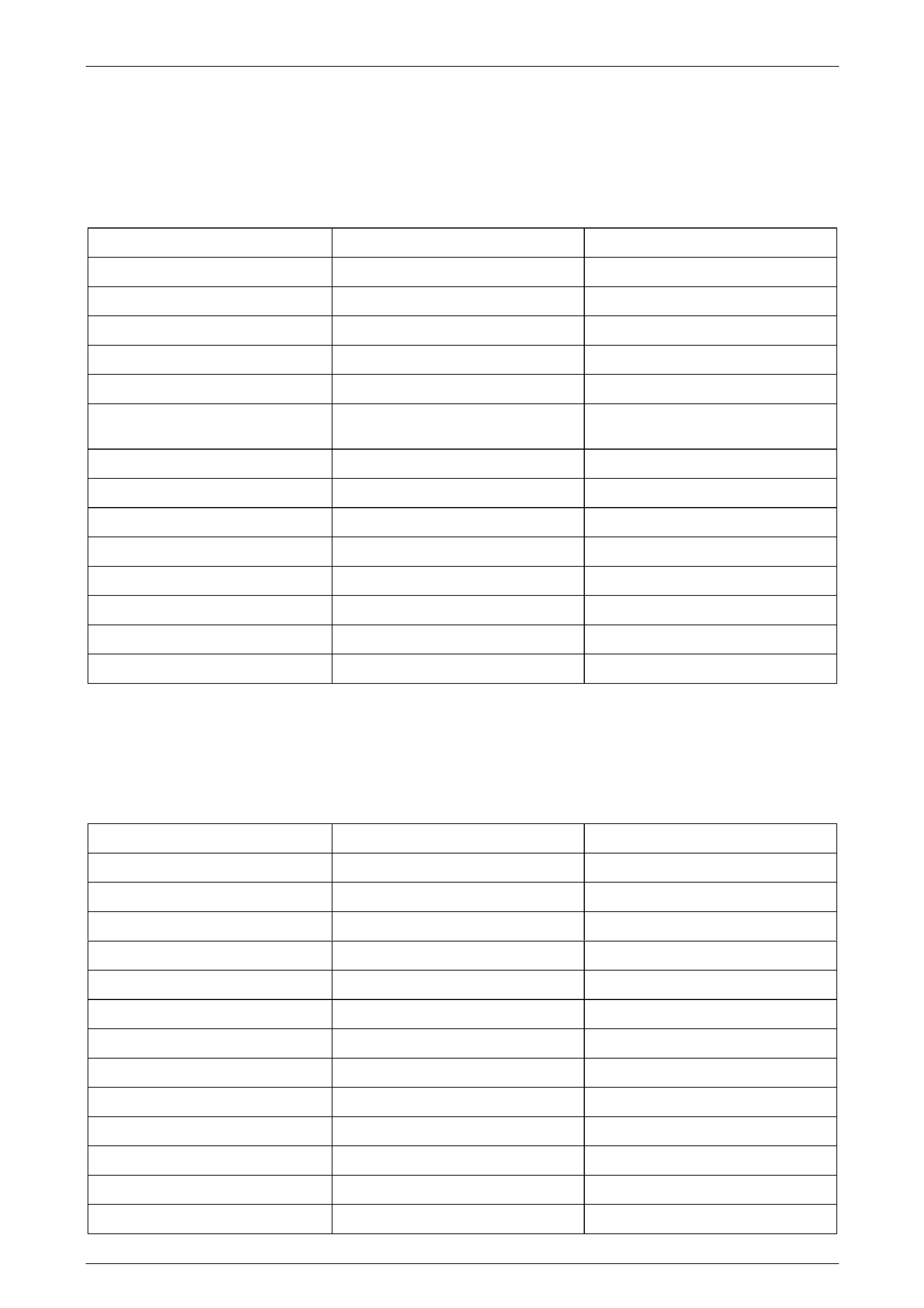

5 Electrical Specifications....................................................................................................................145

5.1 Transmission Fluid Temperature (TFT) Sensor Specifications..................................................................... 145

5.2 Range Reference................................................................................................................................................ 146

5.3 Transmission Fluid Pressure Manual Valve Position Switch Logic.............................................................. 147

5.4 Transmission Range Switch Logic................................................................................................................... 148

5.5 Component Resistance..................................................................................................................................... 149

5.6 Shift Solenoid Valve State and Gear Ratio ...................................................................................................... 150

5.7 Line Pressure..................................................................................................................................................... 151

6 Special Tools ......................................................................................................................................152

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–8

Page 7C2–8

1 General Information

1.1 Introduction

This Section covers the electrical diagnostic for the 4L60E automatic transmission when mated to a V6 engine.

For diagnosis of the 4L60E automatic transmission when mated to a GEN III V8 engine, refer to

Section 6C3-2 Powertrain Management – GEN III V8 – Diagnostics.

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–9

Page 7C2–9

1.2 General Description

The 4L60E automatic transmission incorporates electronic controls that utilise a transmissi on control module (TCM) to

control shift points through:

• the 1-2 and 2-3 shift solenoid valves,

• the 3-2 downshift solenoid valve,

• a torque converter clutch (TCC) solenoid val v e,

• apply and release through the TCC pulse width modulated (PWM) solenoi d valve, and

• line pressure through the pressure control (PC) solenoid valve.

Electrical signals from various sensors pr ovide information to the TCM about the following:

• vehicle speed,

• throttle position,

• engine coolant temperatur e,

• transmission fluid temperature,

• gear range selector position,

• engine speed,

• converter turbine speed, and

• engine load braking and operating mode.

The TCM uses this information to determine the precise moment to upshift or downshift, apply or release the TCC and

what fluid pressure is needed to apply the clutches. This type of control provides consistent and precise shift points and

shift quality based on the operating conditions of the vehicle.

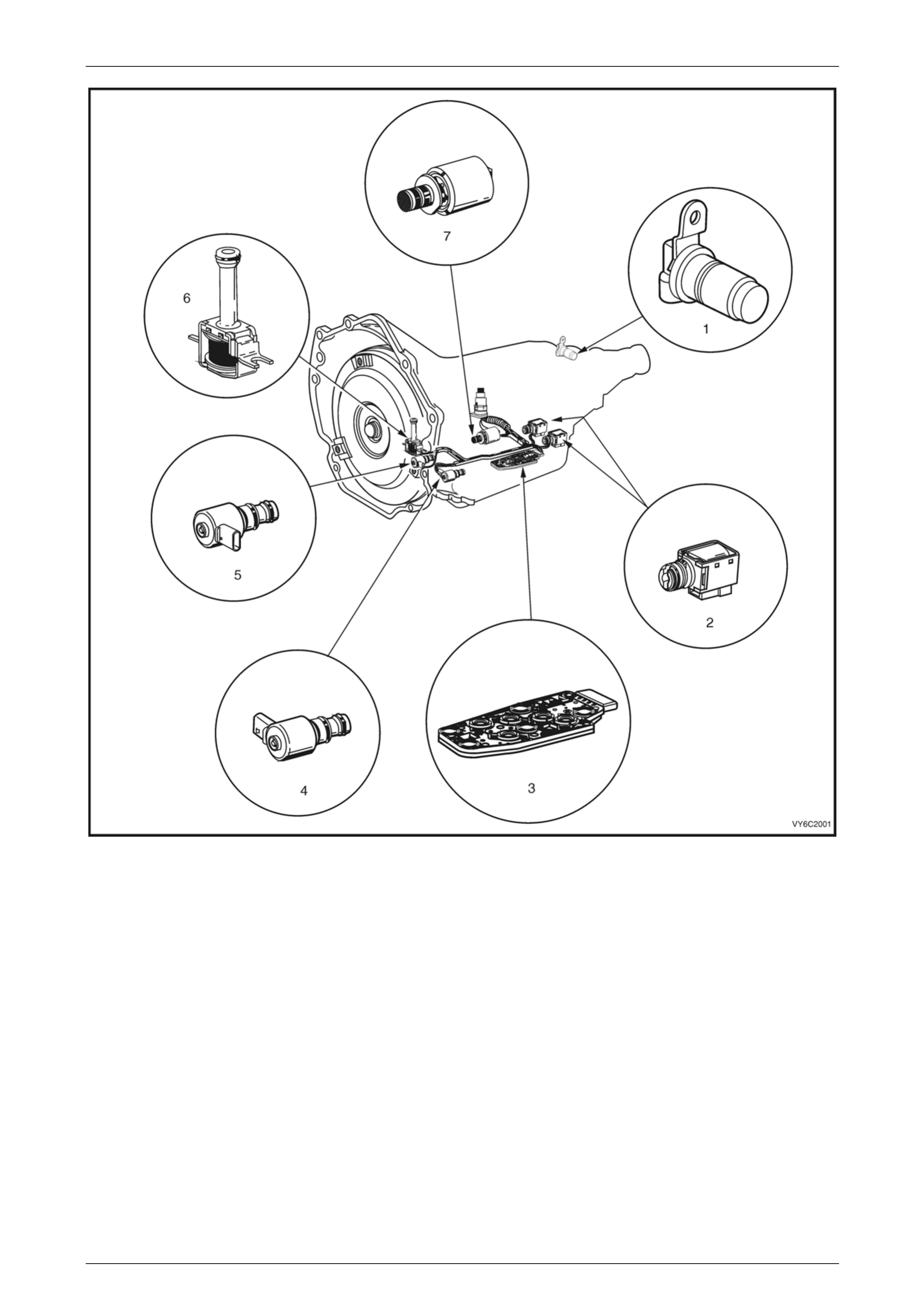

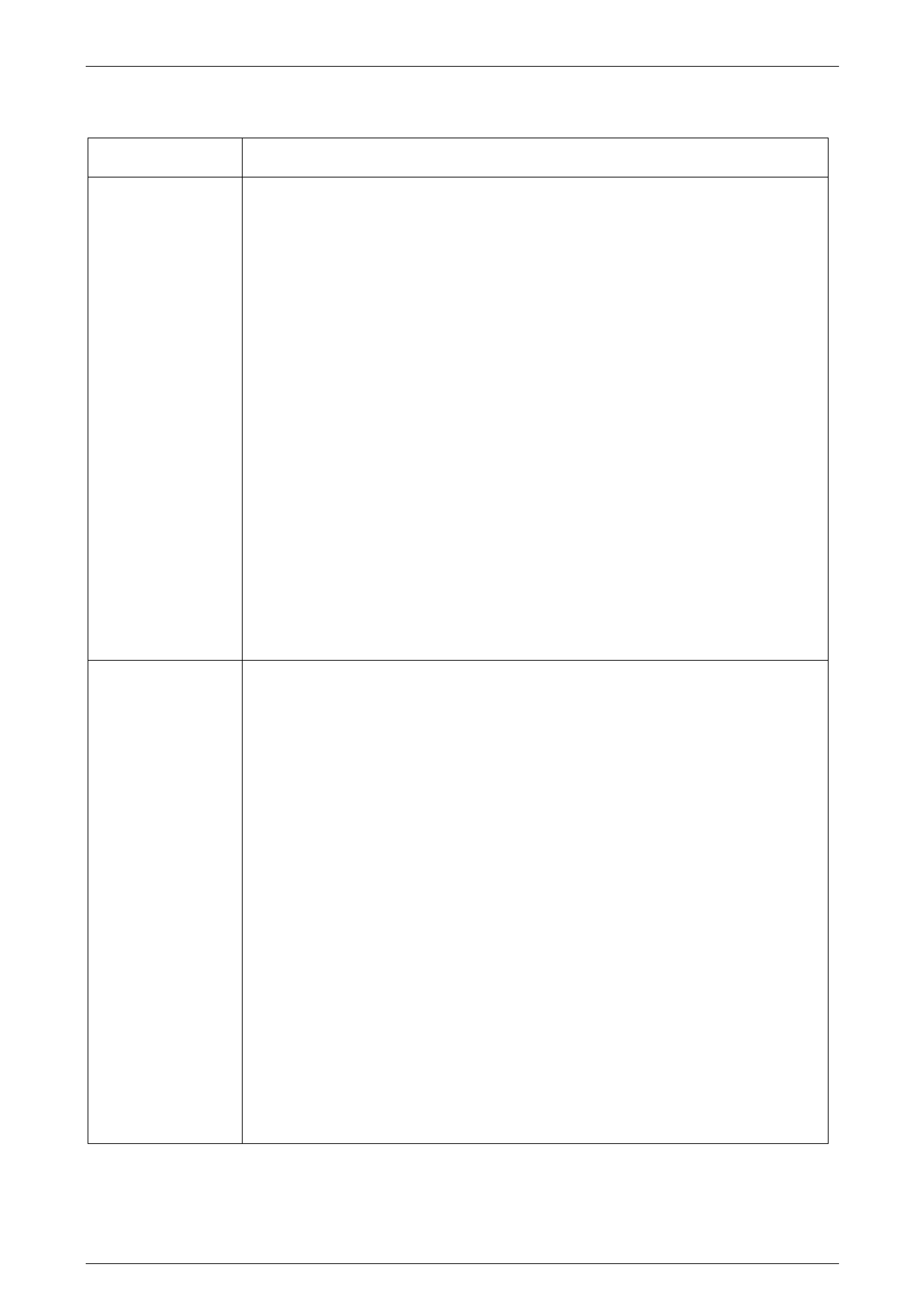

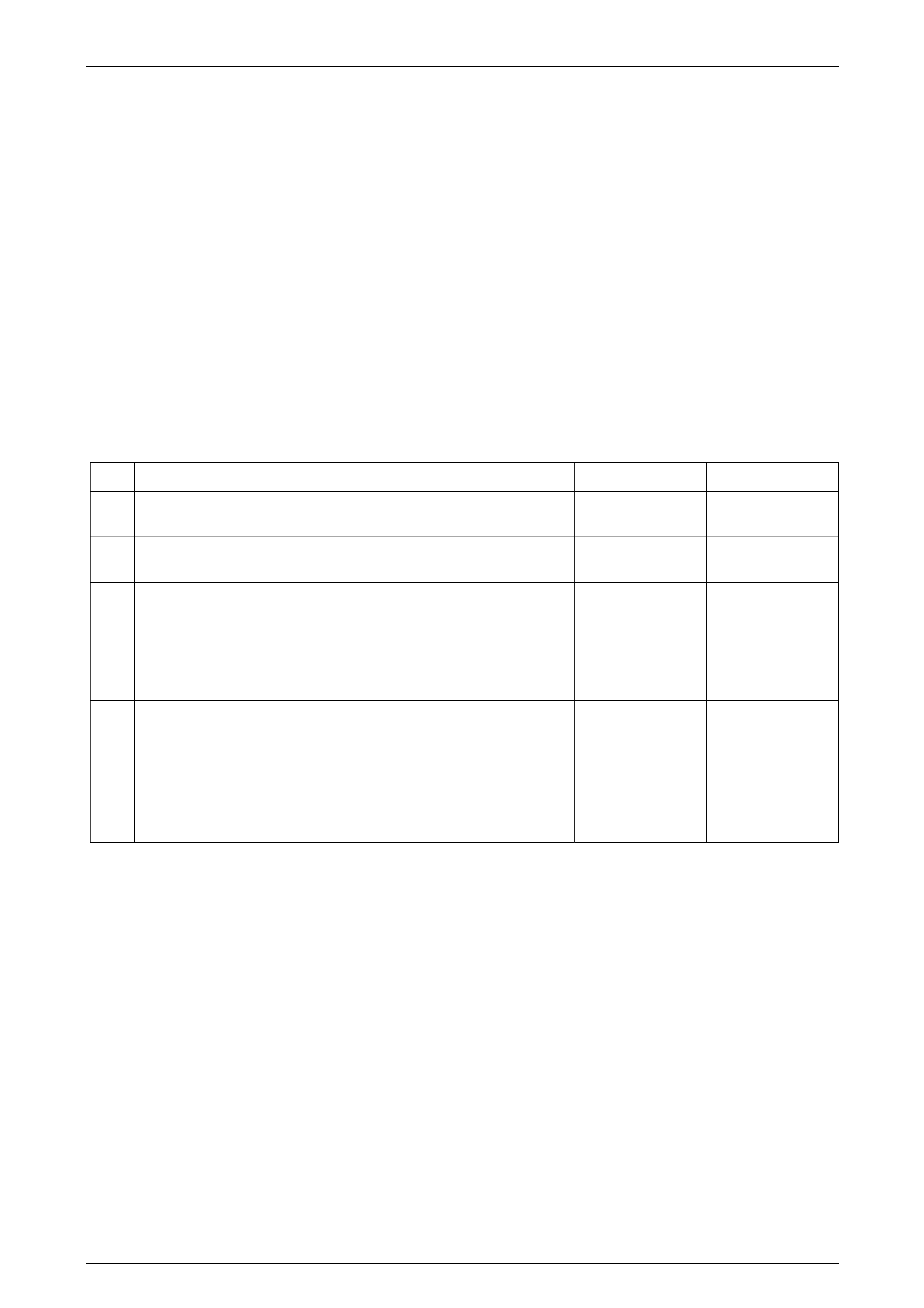

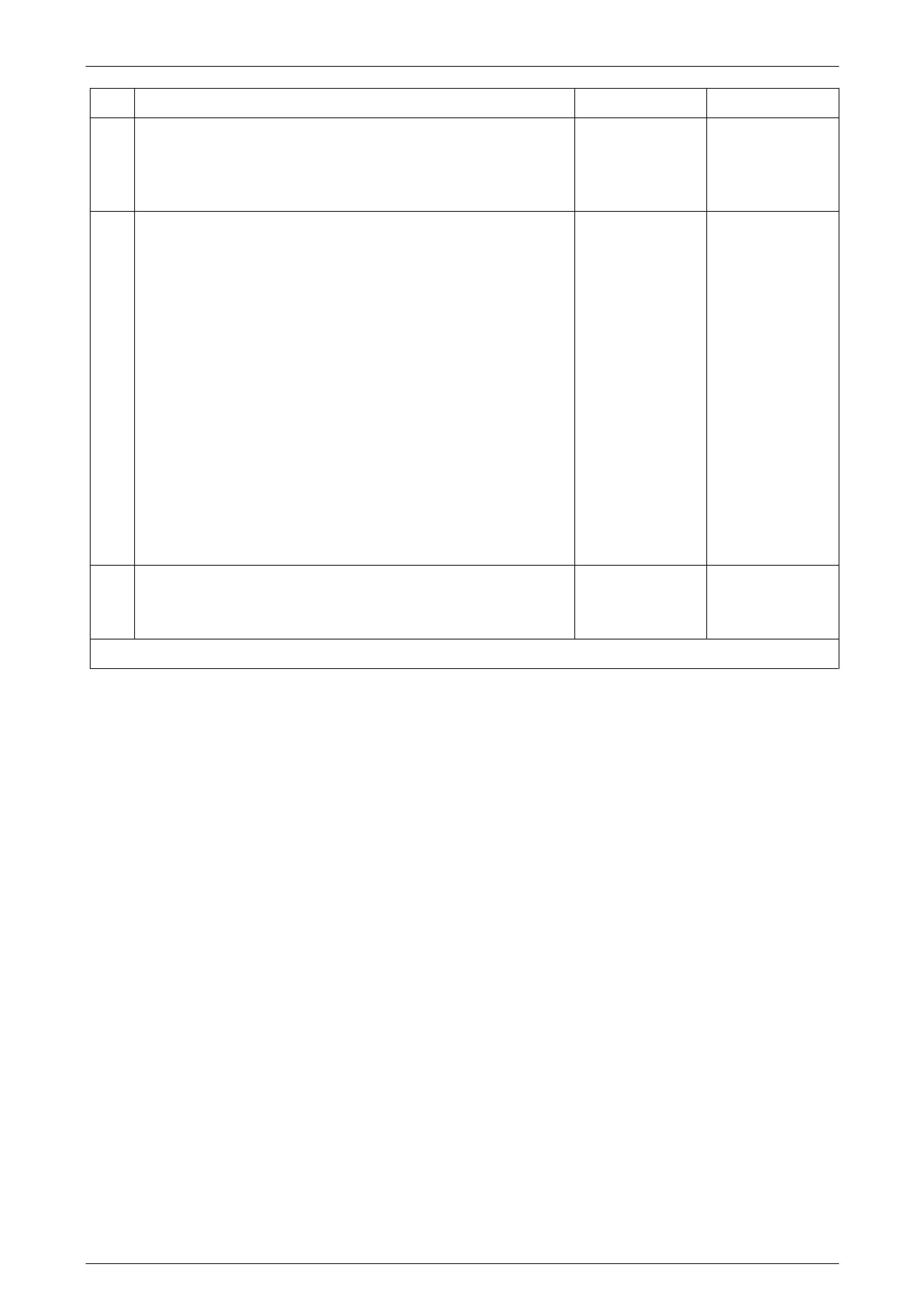

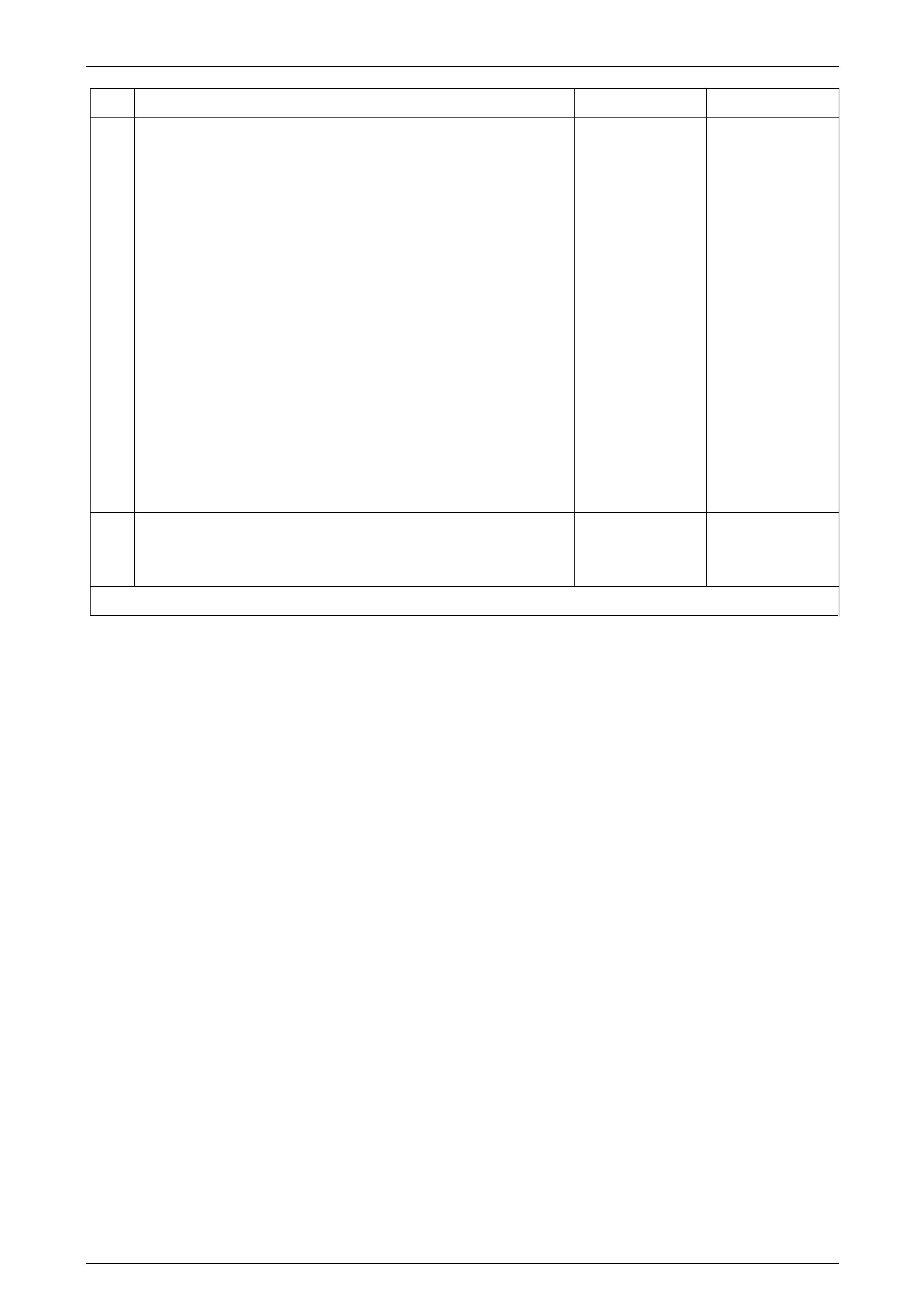

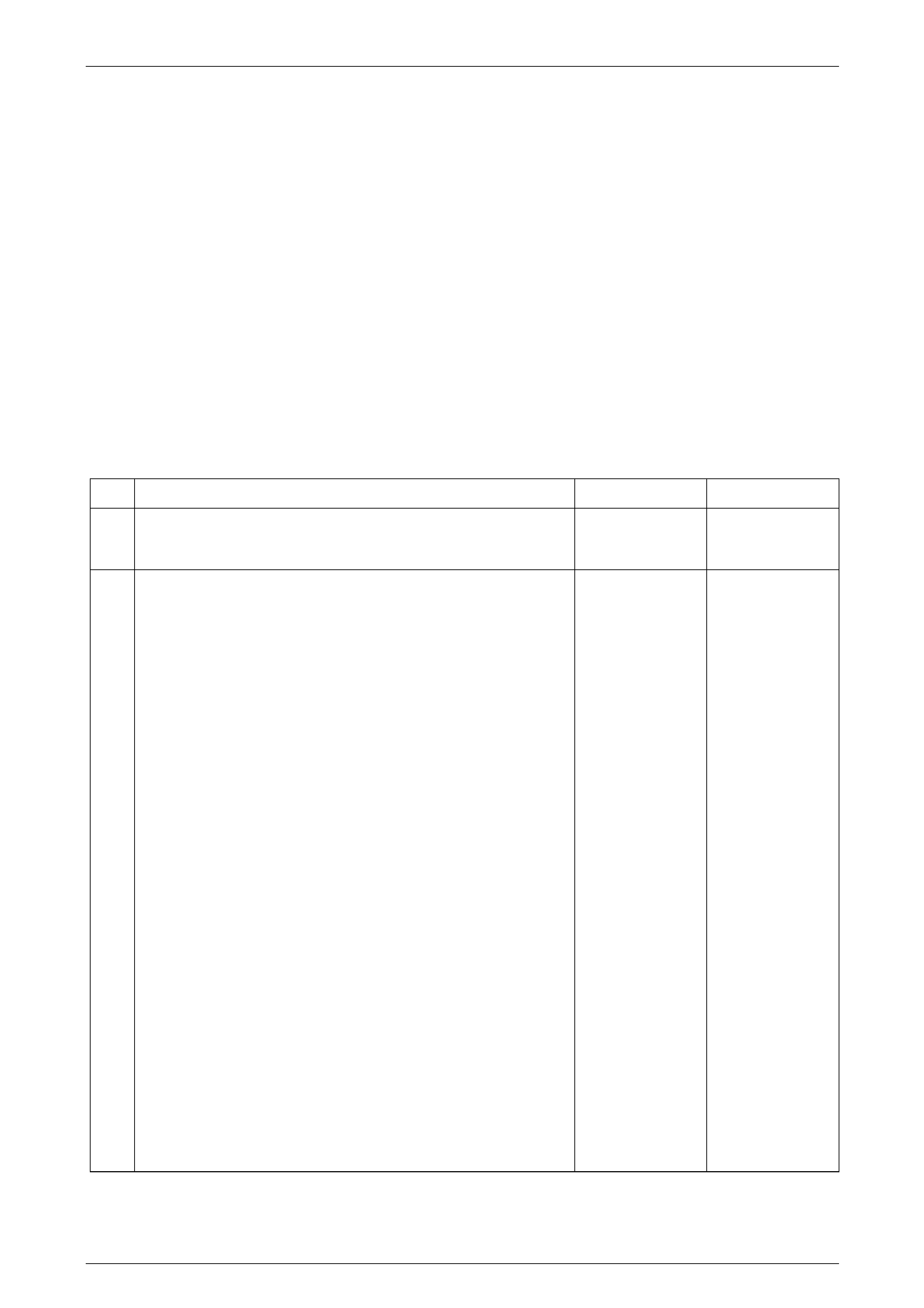

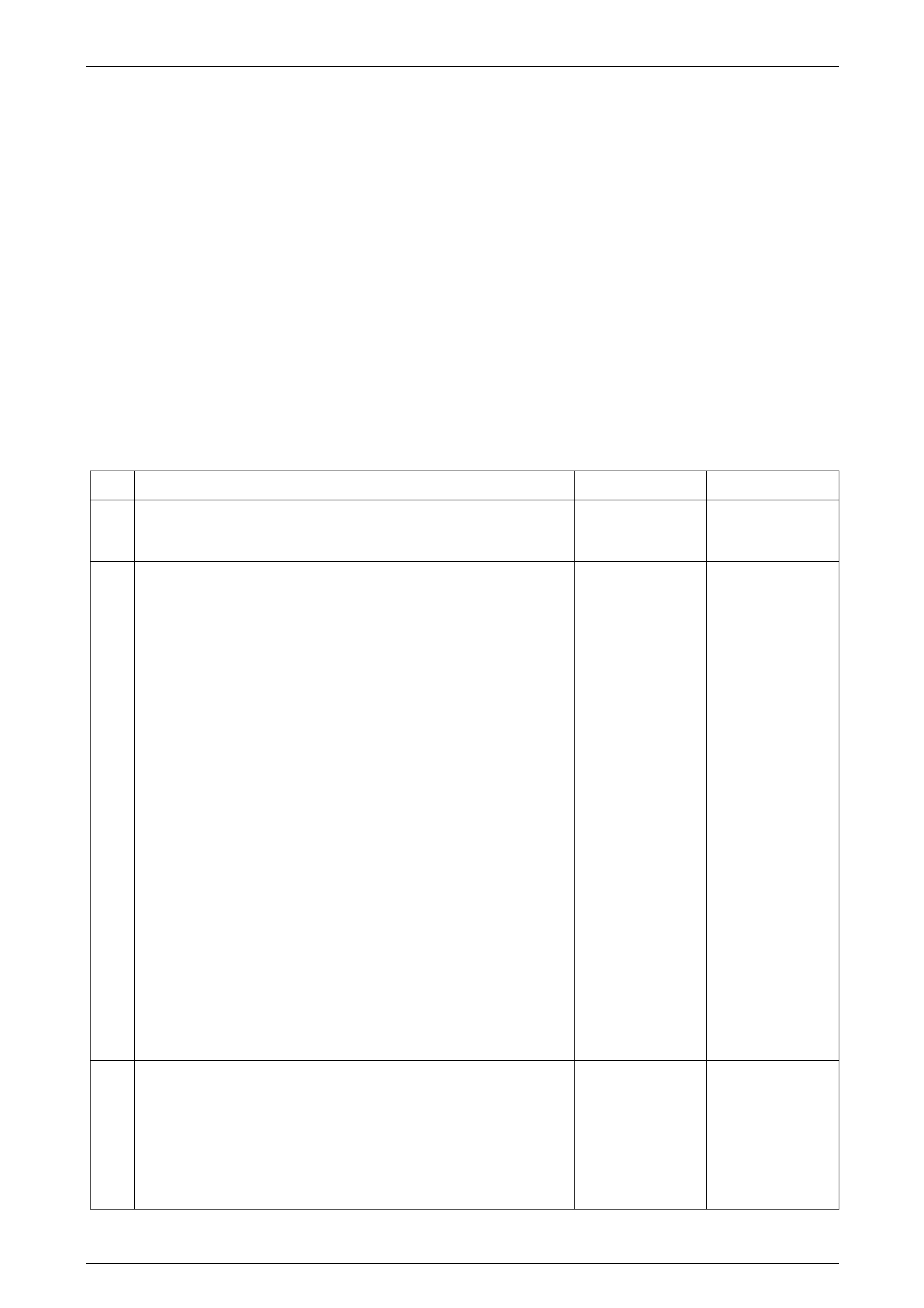

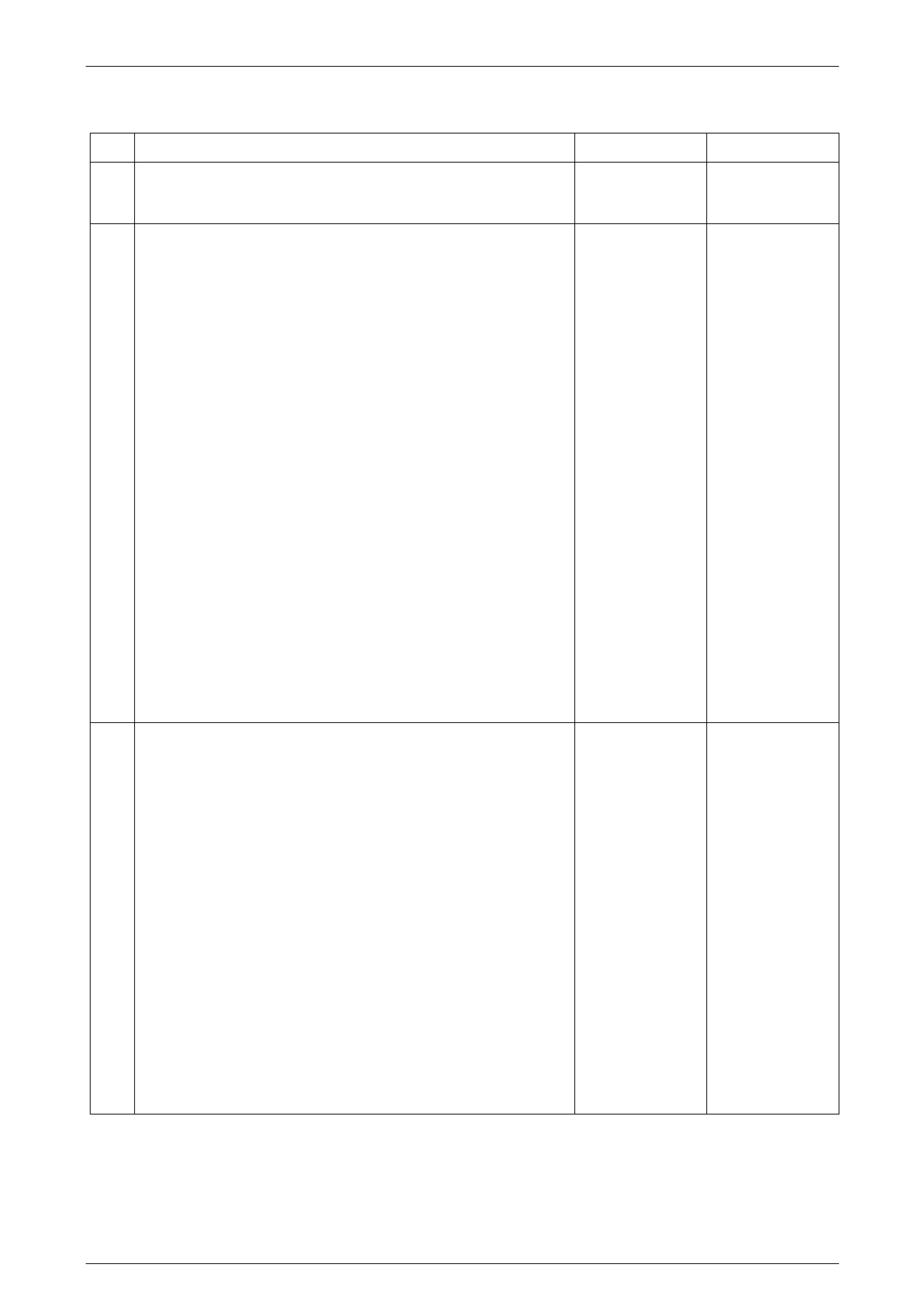

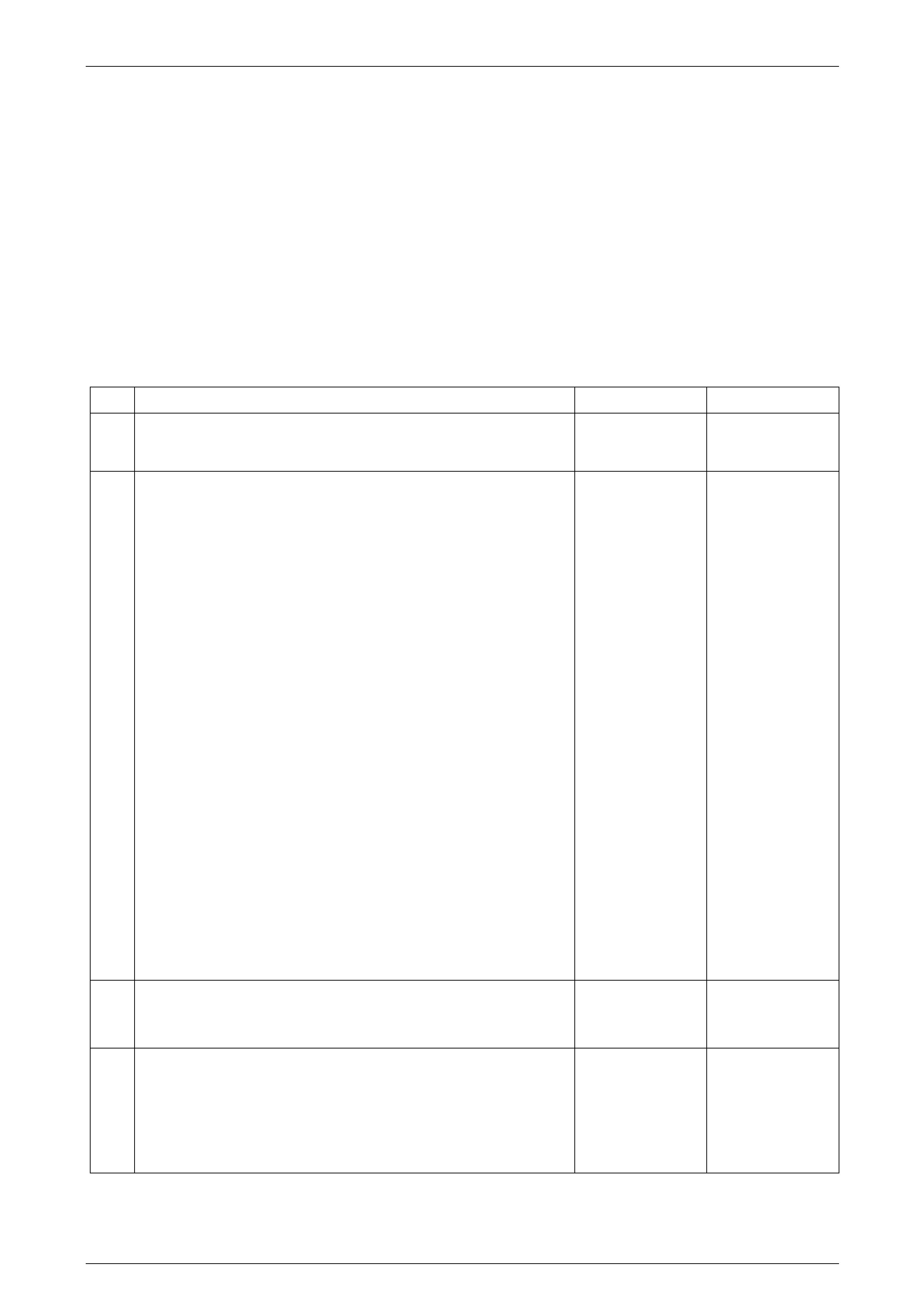

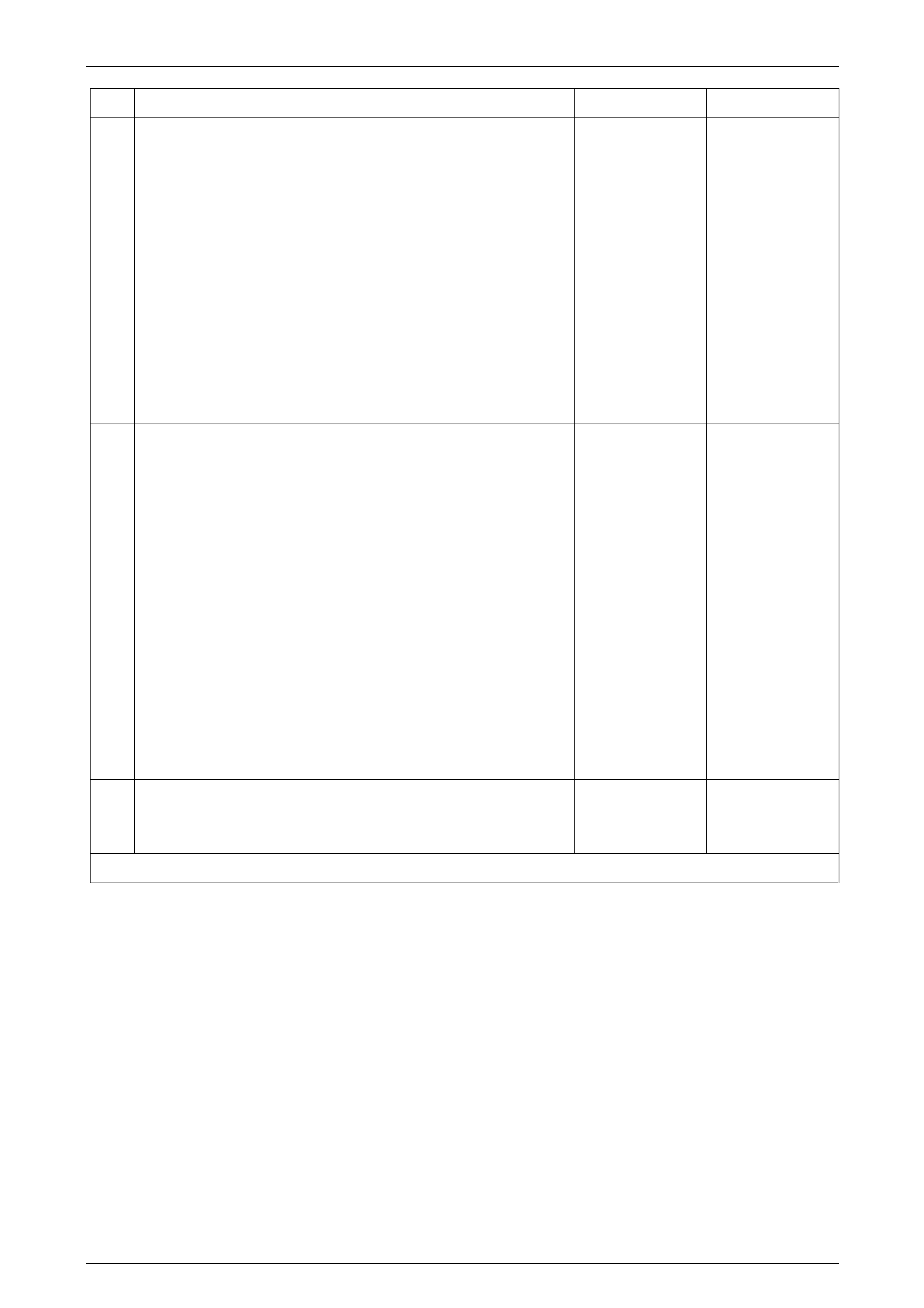

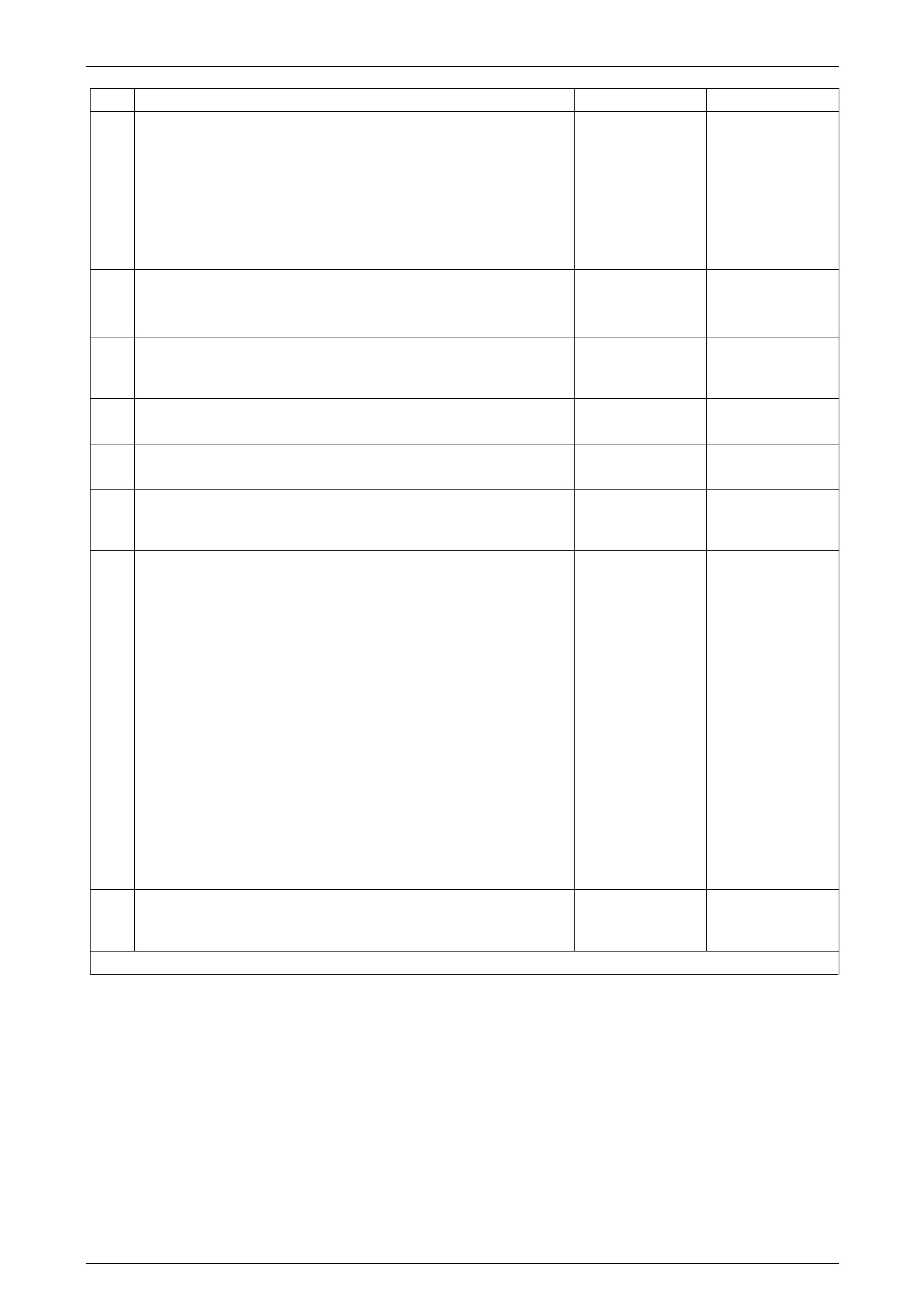

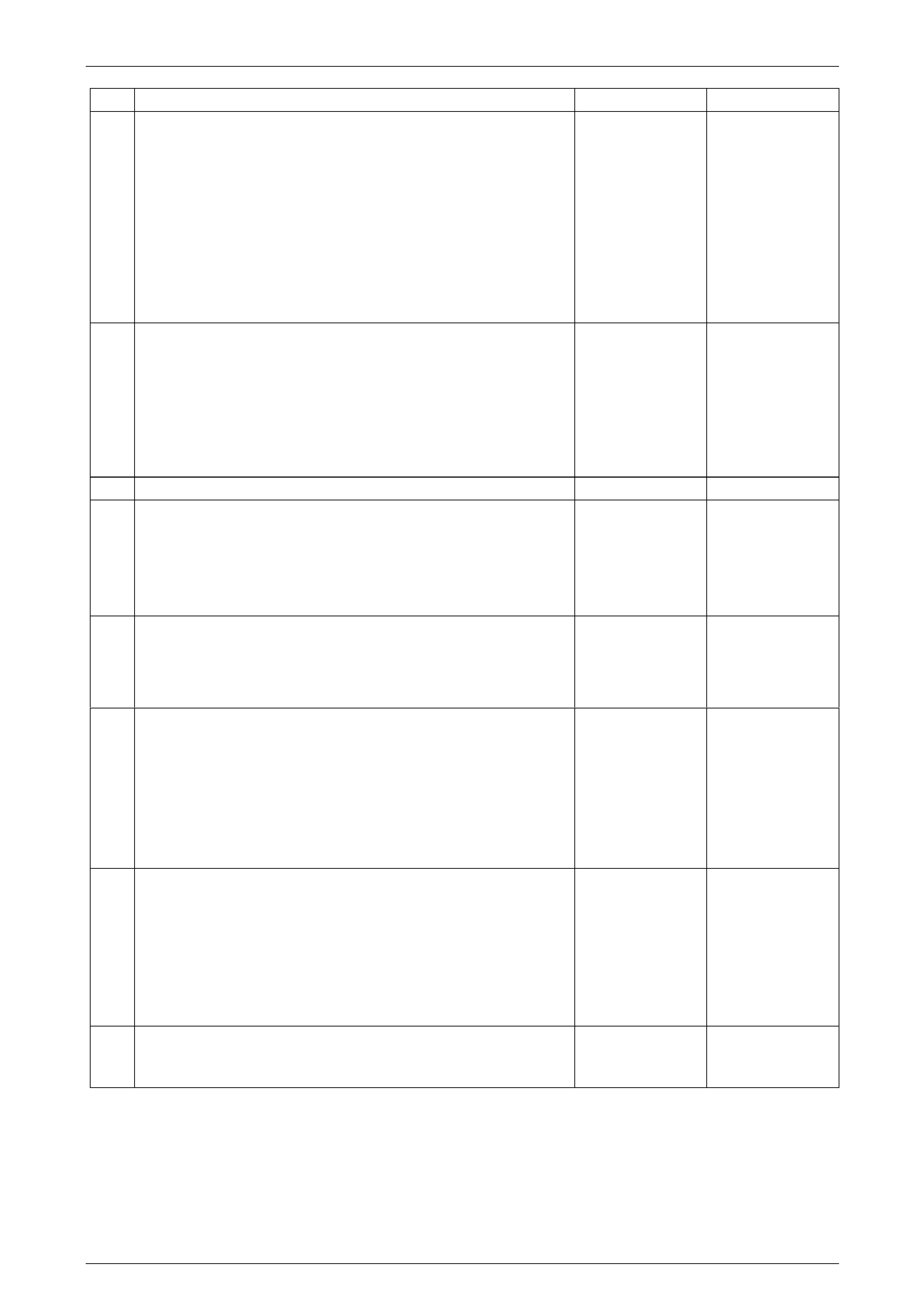

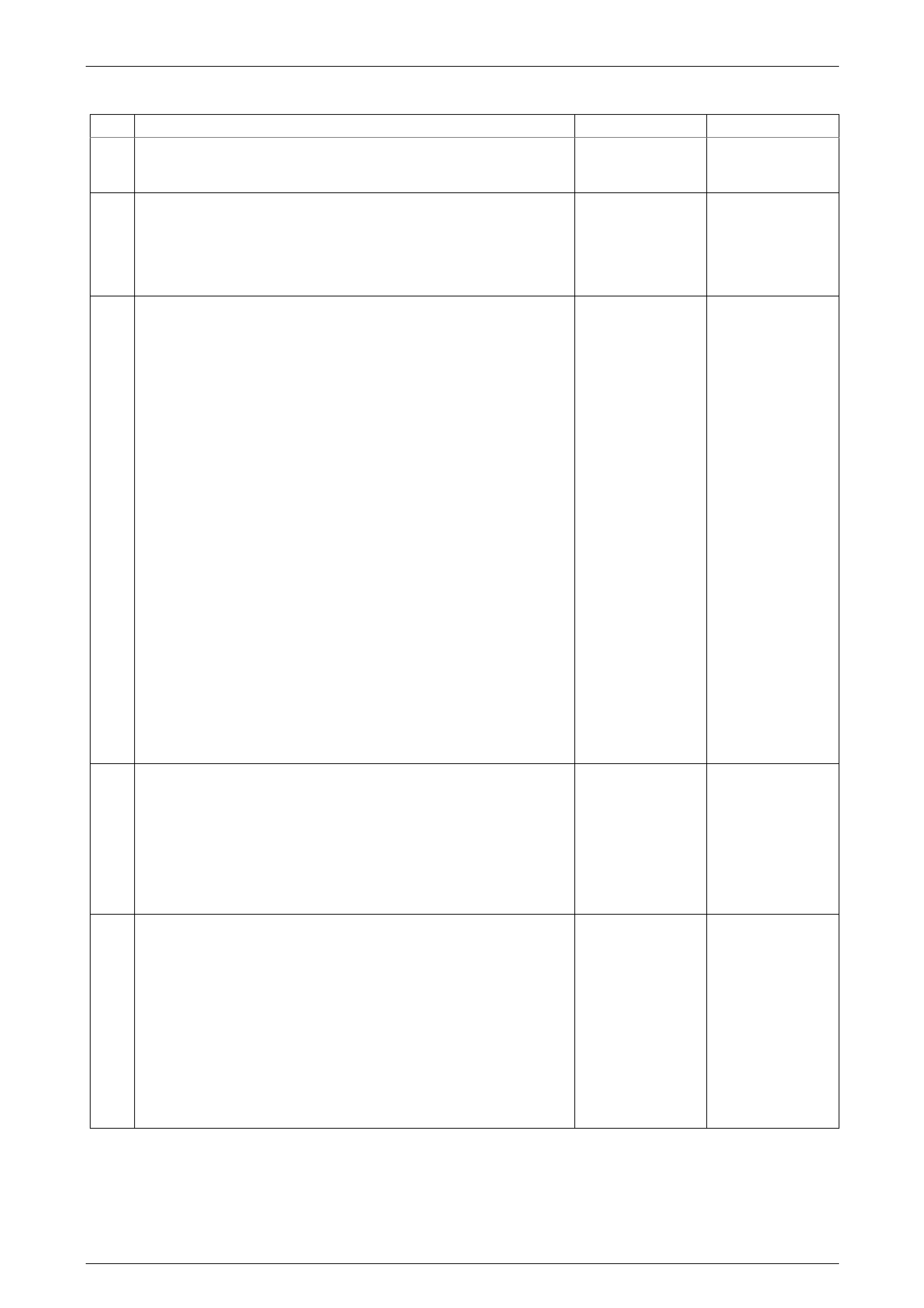

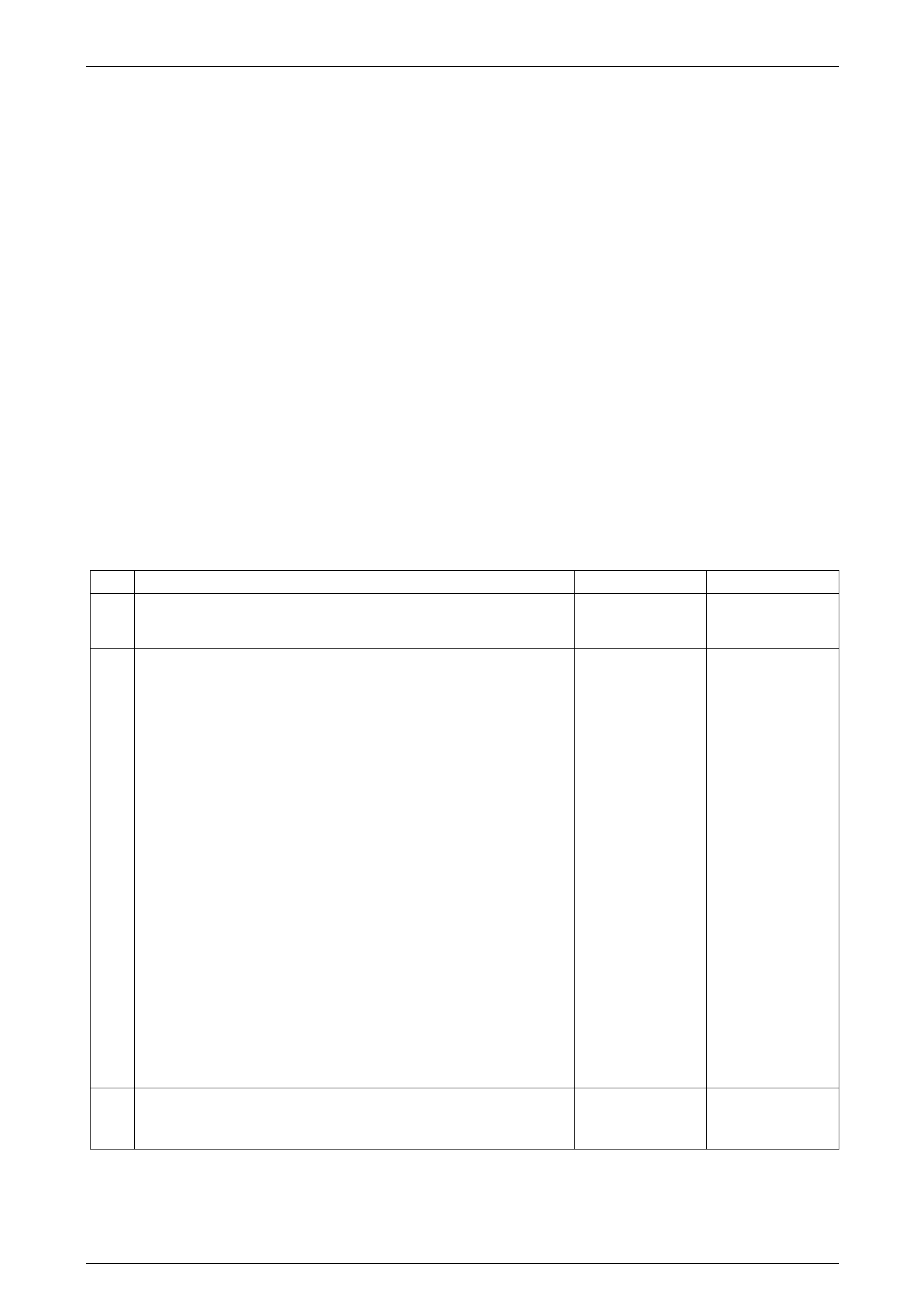

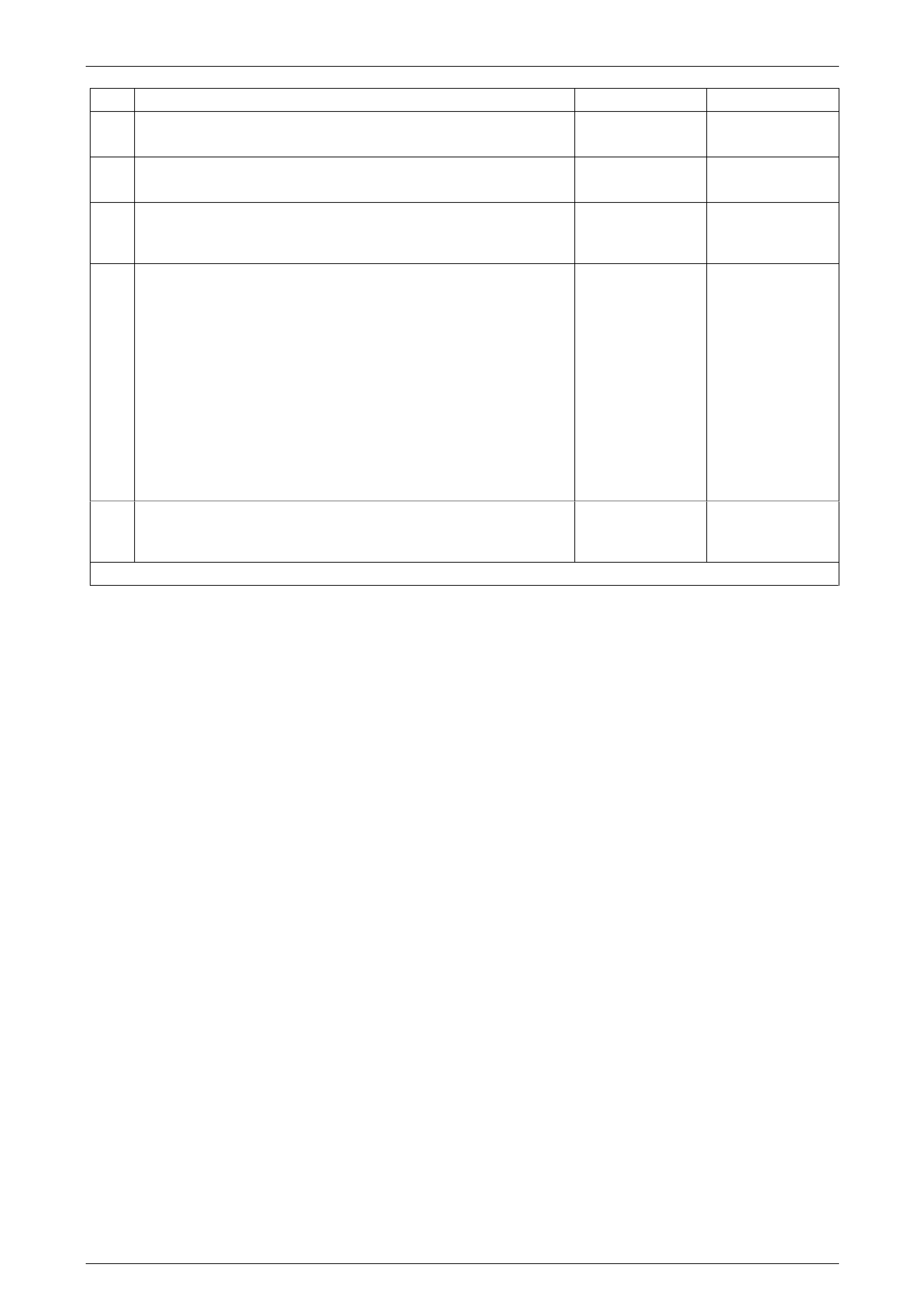

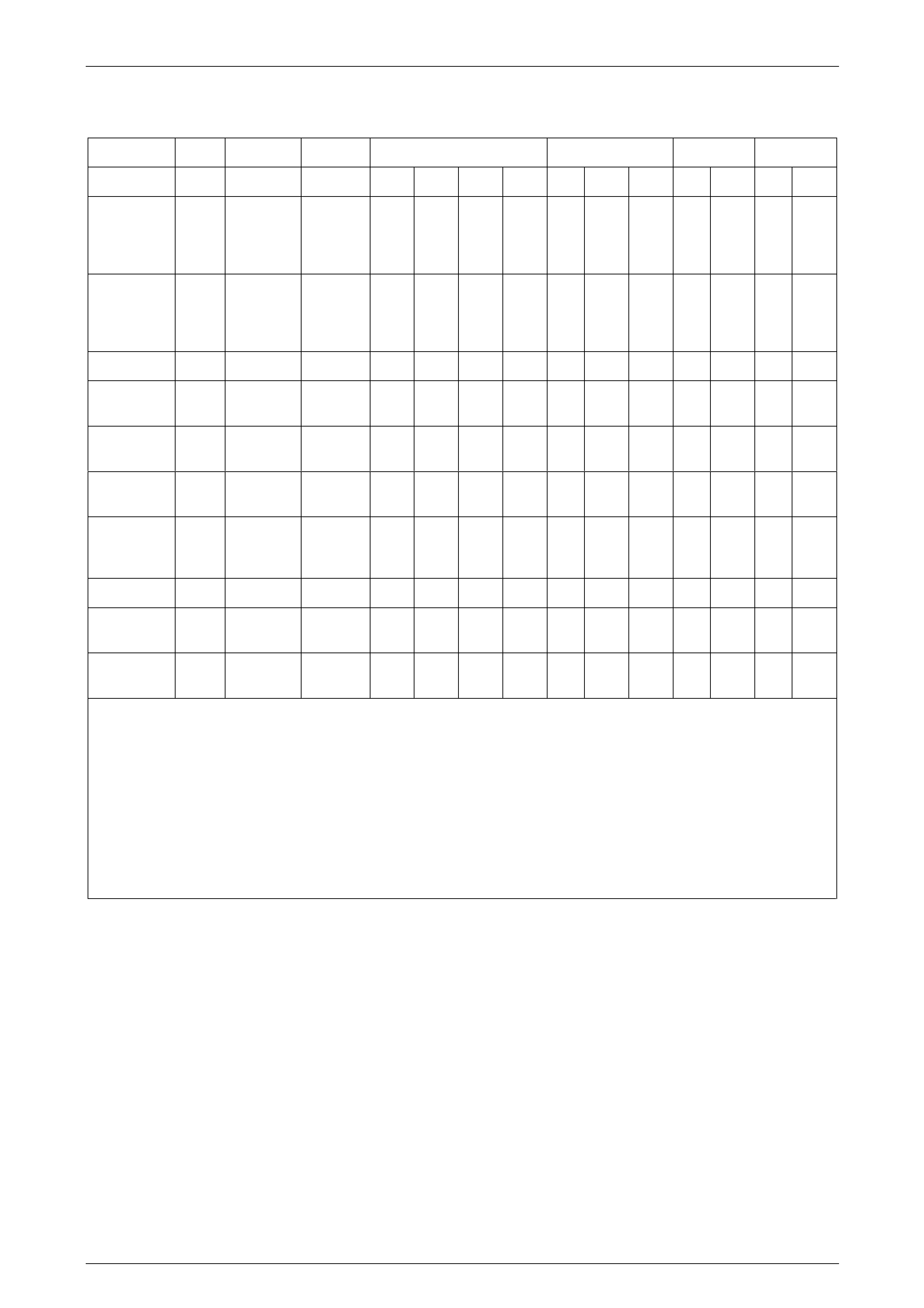

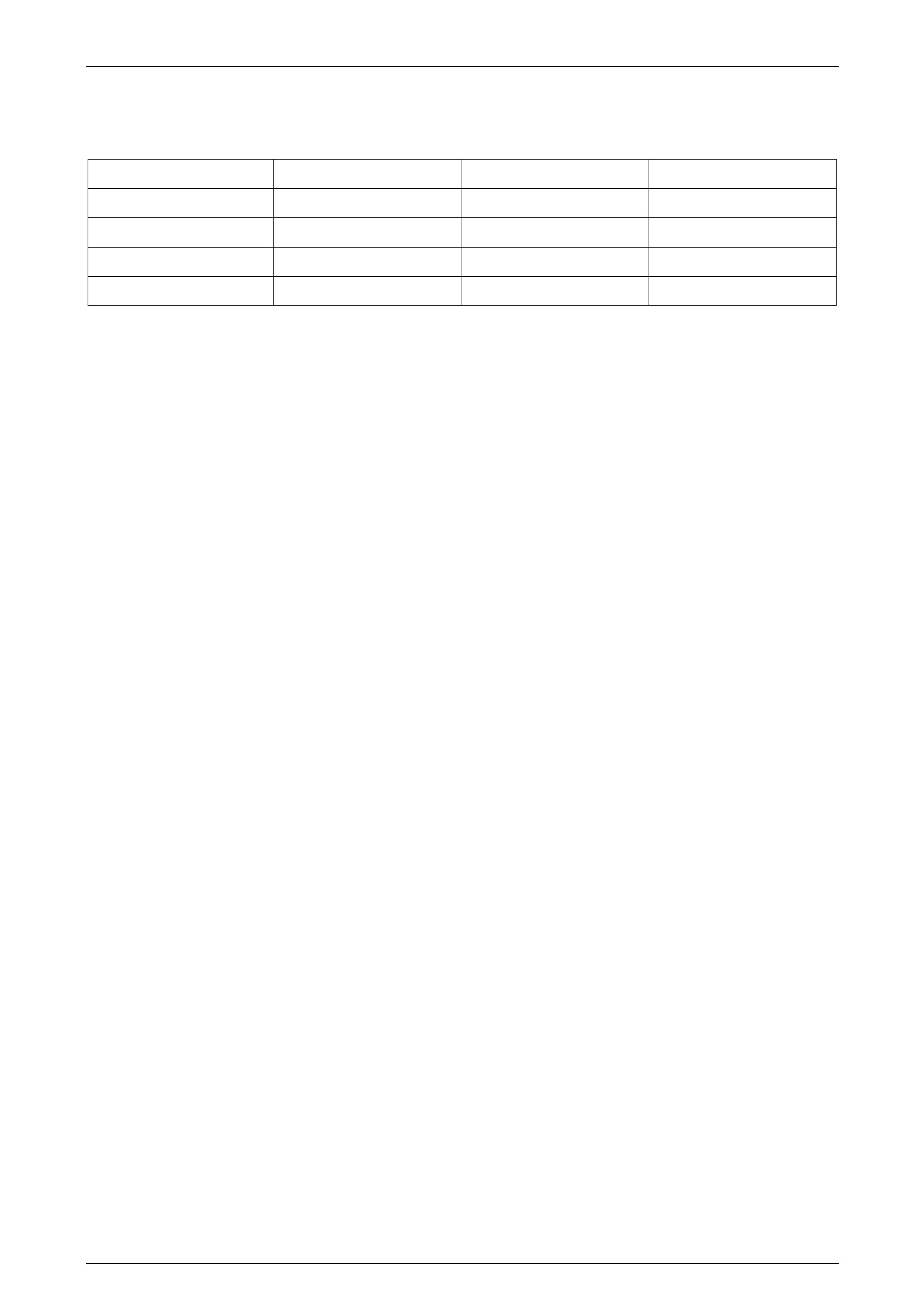

Figure 7C2 – 1 shows the location of the internal electro nic components in the transmission.

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–10

Page 7C2–10

Figure 7C2 – 1

Legend

1 Vehicle Speed Sensor 5 Torque Converter Clutch Pulse Width Modulation (TCC

PWM) Solenoid Valve

2 1-2 Shift Solenoid (Solenoid A) and 2-3 Shift Solenoid

(Solenoid B) 6 Torque Converter Clutch (TCC) Solenoid Valve

3 Automatic Transmission Fluid Pressure (TFP) Manual Valve

Position 7 Pressure Control (PC) Solenoid Valve

4 3-2 Downshift Solenoid

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–11

Page 7C2–11

Transmission Adaptive Functions

The 4L60E automatic transmission uses a line pressure control system, which has the ability to adapt the system line

pressure to compensate for normal wear within the transmission, such as the clutch pack fibre plates, seals, springs, etc.

The adapt feature is similar in function to the long term/short term fuel trim feature of the engi ne management system.

The 4L60E automatic transmission uses the adapt function for garage shifts, upshifts and torque converter clutch (TCC)

application. The TCM monitors the engine torque to determine if the shift is occurring too fast or too slow and adjusts the

pressure control solenoid to maintain the correct shift feel.

Limp Home Mode Description

If a major electrical system failure occurs which could affect vehicle safety or damage the transmission during norma l

operation, the TCM enters a limp home mo de. In the limp home mode, the transmission operates in the following

manner:

• The pressure control solenoid is off and the li ne pressure is at maximum to minimise clutch slippage.

• The TCC solenoid is off, therefore the torque converter clutch is disabled.

• The two shift solenoids are turned off. The transmission will operate in fourth gear if the vehicle has successfully

completed a 1-2 upshift in the current ignition cycle. If the vehicle has not completed a 1-2 upshift in the current

ignition cycle, the transmission will operate in third gear. If the transmiss ion is operating in fourth gear, third gear

may be obtained if the engine is stopped briefly and re-star t ed.

In limp home mode, the gear selector lev er is ineffective at selecting forward gear ranges. In third or fourth gear, heat

builds up in the transmission quickly, particularly in stop and go traffic. Excessive heat build-up may cause transmission

failure if the vehicle is driven for extended distances in limp home mode.

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–12

Page 7C2–12

1.3 Transmission Indicators and Messages

The instrument clusters multi-function display (MFD) component of the Instrument ma y display messages relating to this

transmission.

MFD Displays

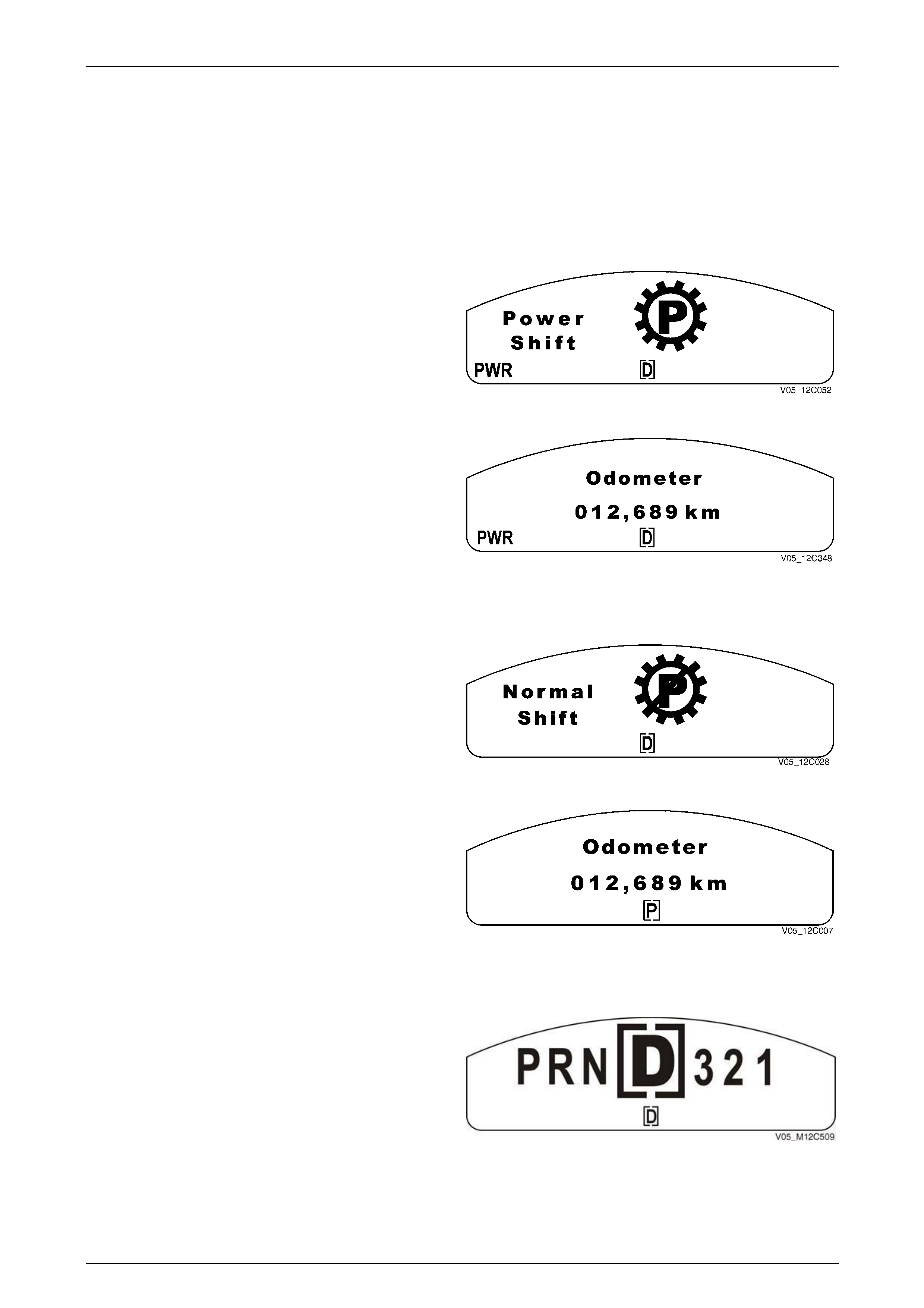

Power Mode

When the transmission is placed in Power Mode, the PWR

icon illuminates and the Power Shift animation is displayed

for 2 seconds.

Figure 7C2 – 2

After 2 seconds, the animated display extinguishes and the

PWR icon remains. The display reverts to the previously

displayed trip computer screen.

Figure 7C2 – 3

Normal Mode

When the transmission is change d from Power Mode to

Normal Mode, the PWR icon extinguishes immediately and

the Normal Shift animation is displa yed for 2 seconds.

Figure 7C2 – 4

After 2 seconds, the animated display extinguishes and the

display reverts to the previous ly displayed trip computer

screen.

Figure 7C2 – 5

Shift Range Selected

The gear icon remains for 2 seconds after it is selected.

While the transmission selector is moving, the constant

icons reflect the selector movement through the gears.

NOTE

If any warning is active, the large dis play symbol

is not shown and only the bracketed constant

icon at the bottom changes when the automatic

transmission selector is moved. Figure 7C2 – 6

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–13

Page 7C2–13

1.4 Electronic Component Description

For all other electrical components not cov ered in this section, refer to General Motors Powertrain Group Electronically

Controlled Automatic Transmission Technician's Guide.

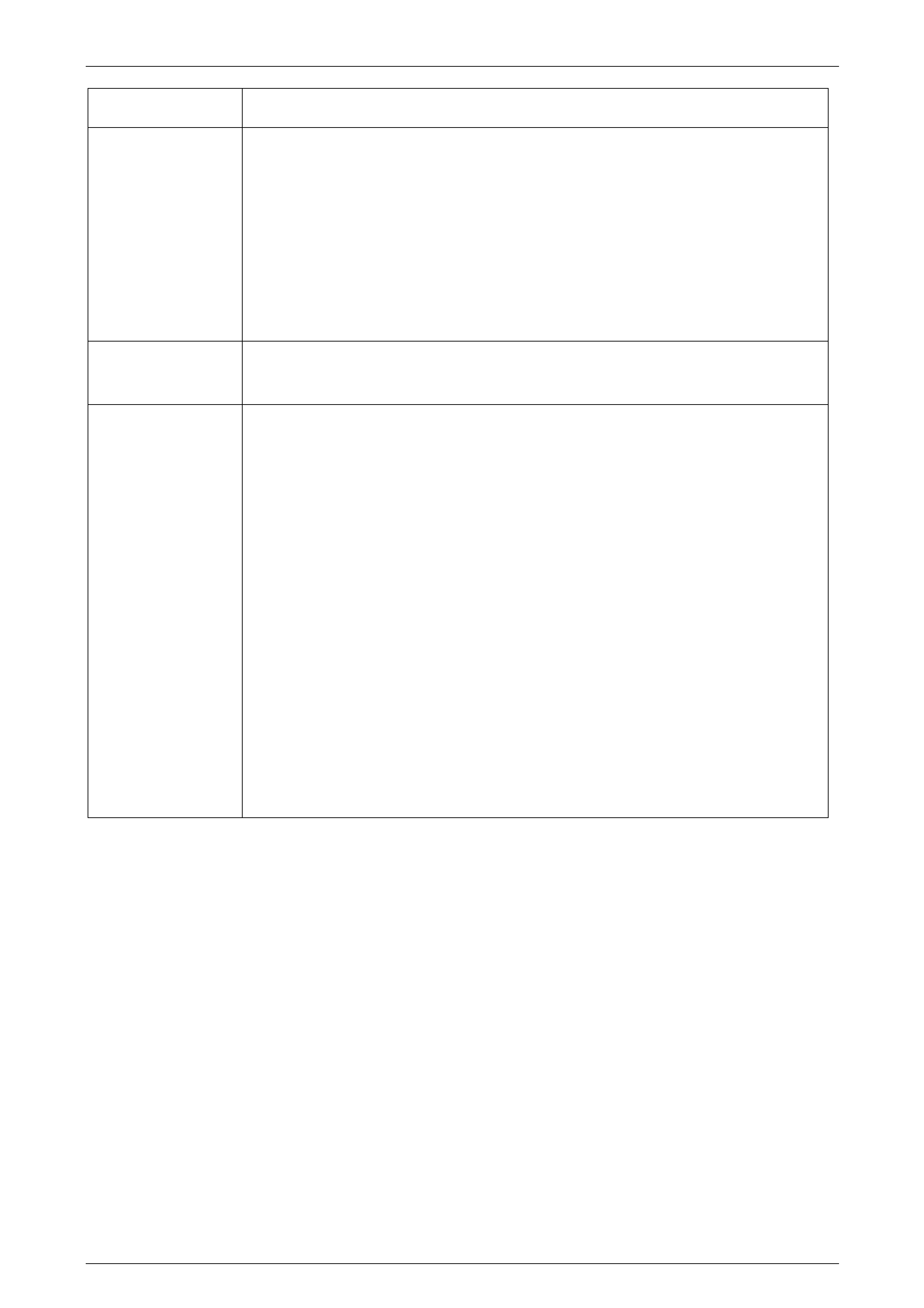

Transmission Control Module (TCM)

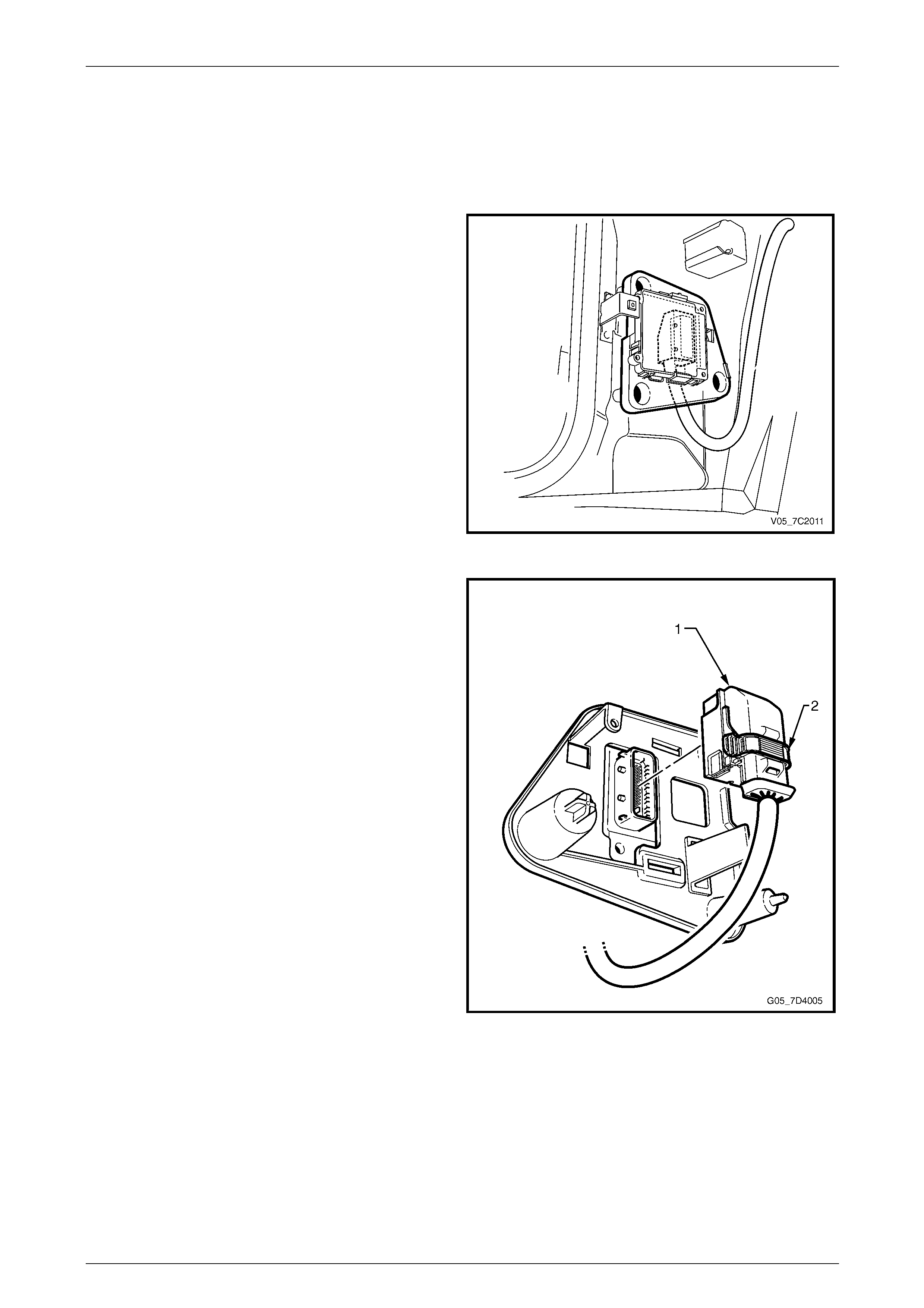

The Transmission Control Mo dule (TCM) is located behind

the left-hand body hinge pillar trim assembly and connects

directly to the transmission wiring harness. A single 49-way

connector is used to make the connection b etween the

vehicle wiring harness and the TCM.

Figure 7C2 – 7

The TCM is an electronic cont rol module receiving input or

providing output to control the operation of the 4L60E

automatic transmission.

The TCM receives the following inputs from the engine

control module (ECM):

• engine speed and torque values,

• engine intake air temperature (IAT), accelerator pedal

position (APP) information,

• engine coolant temperature (ECT),

• driver selected shift mode, and

• air-conditioning (A/C) status.

The ECM provides this data to the TCM through the

databus.

Other TCM inputs are:

• battery and ignition voltage,

• brake switch status,

• transmission fluid temperature (TFT), and

• vehicle speed sensor (VSS). Figure 7C2 – 8

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–14

Page 7C2–14

The TCM provides the following outputs to control the automatic transmission:

• shift solenoids to control transmission shifting,

• torque converter clutch (TCC) pulse width modulated (PWM) solenoid operatio n to control the apply and release of

the torque converter clutch assembly, and

• pressure control (PC) solenoid to regulate the transmission line pressur e.

Other TCM outputs provided to the ECM / PIM are:

• check powertrain icon illumination request,

• vehicle speed,

• transmission fluid temperature,

• commanded gear status,

• TCC status, and

• torque reduction requests.

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–15

Page 7C2–15

2 Wiring Diagrams and Connector

Chart

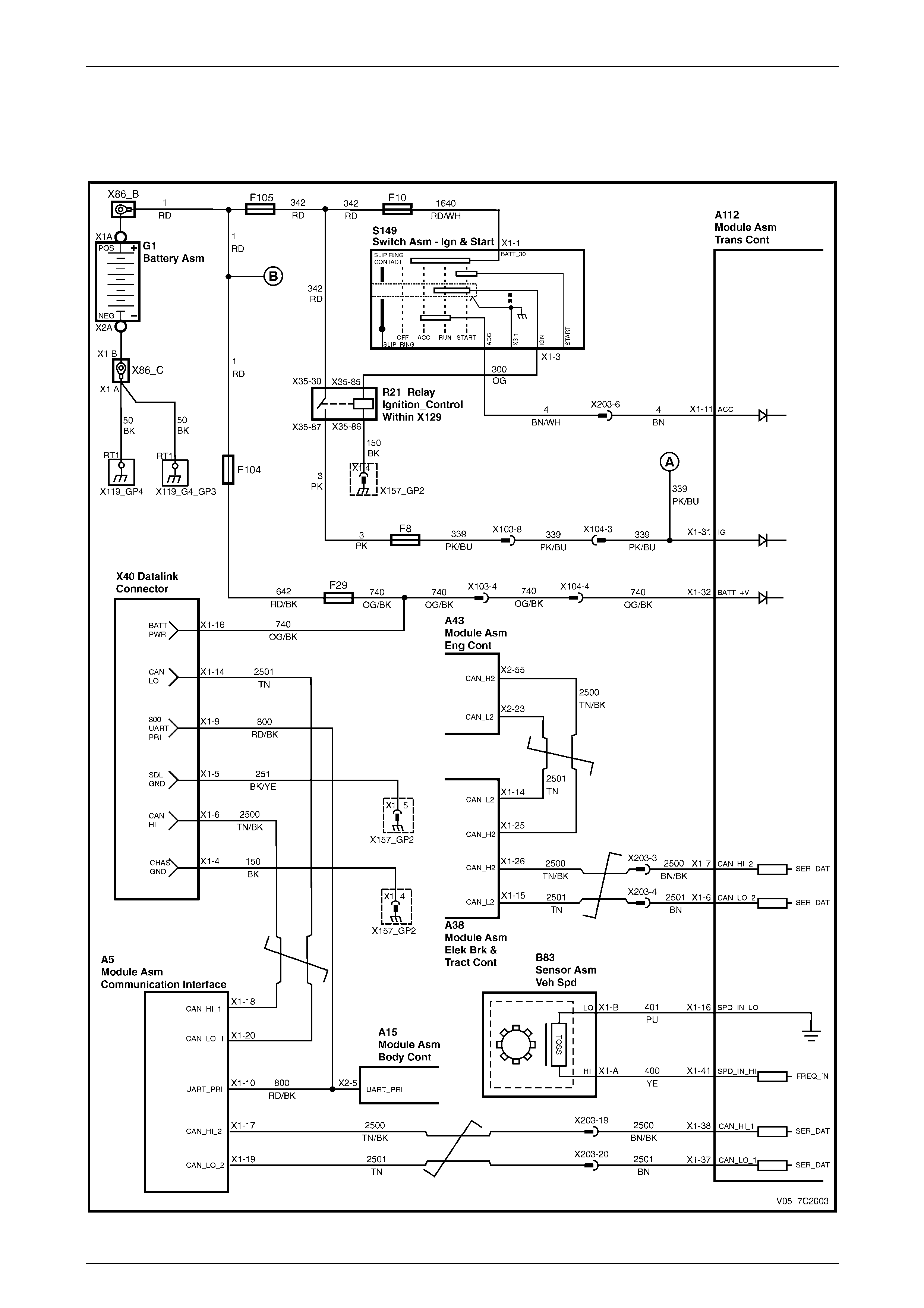

2.1 Wiring Diagrams

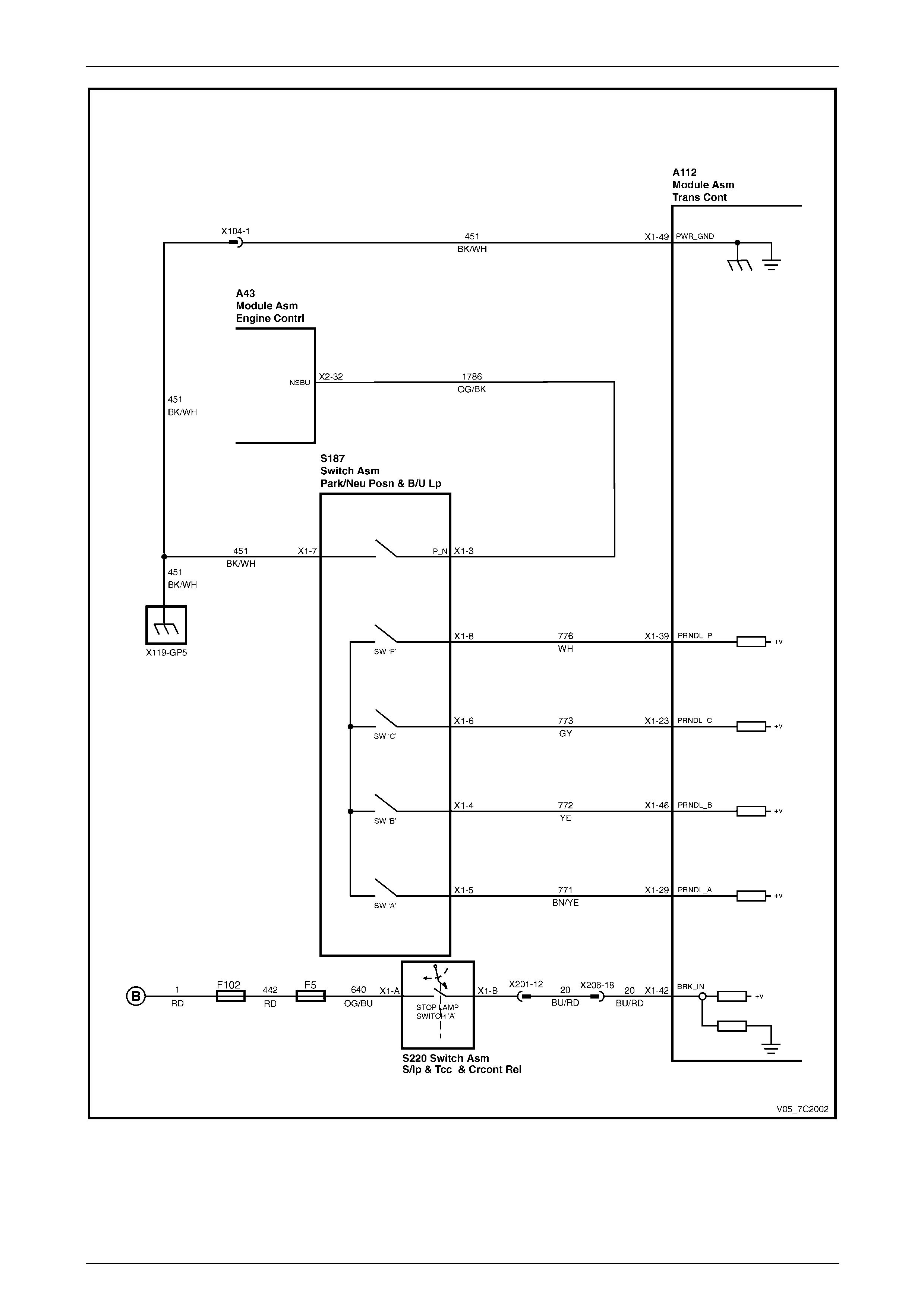

Figure 7C2 – 9

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–16

Page 7C2–16

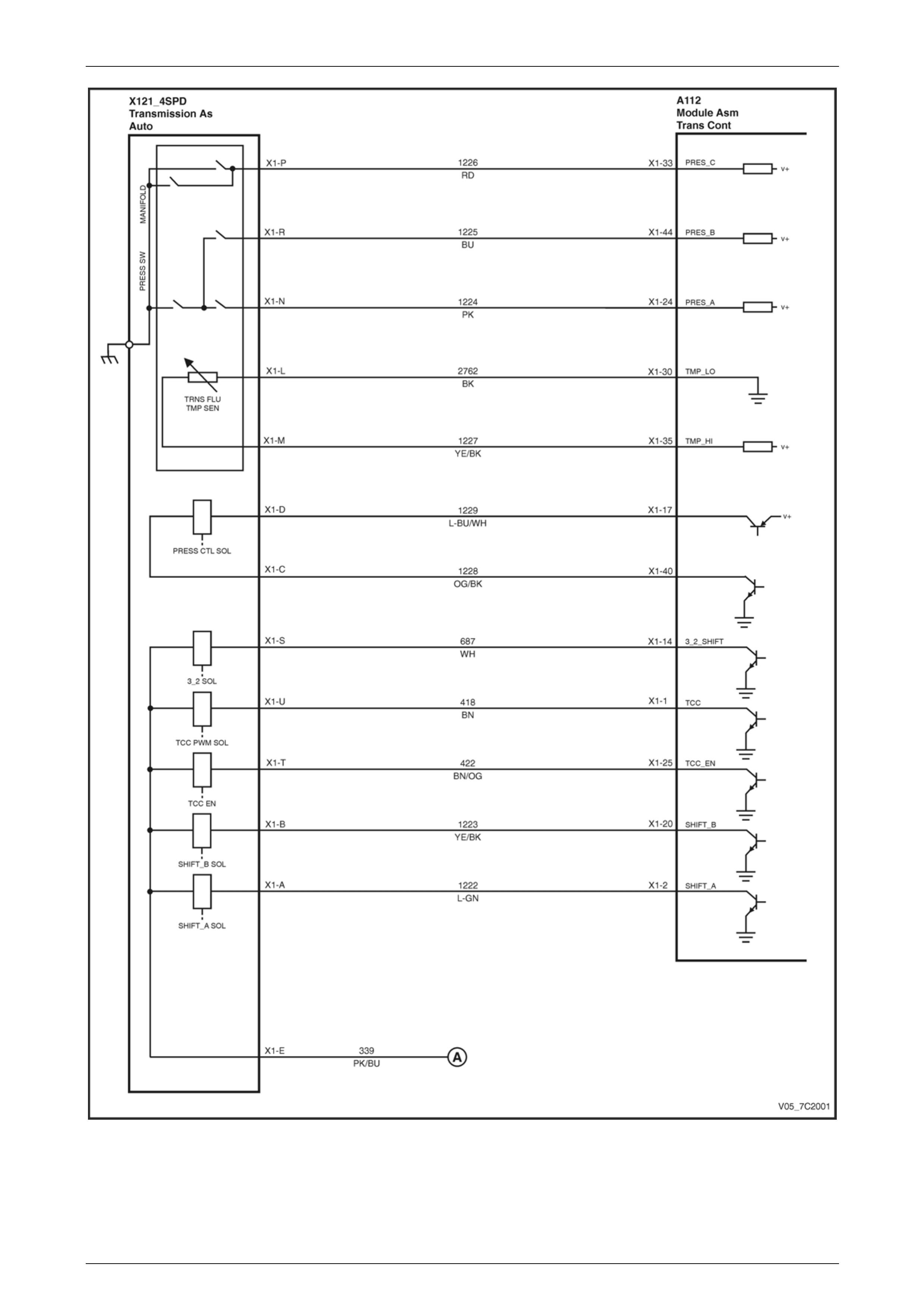

Figure 7C2 – 10

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–17

Page 7C2–17

Figure 7C2 – 11

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–18

Page 7C2–18

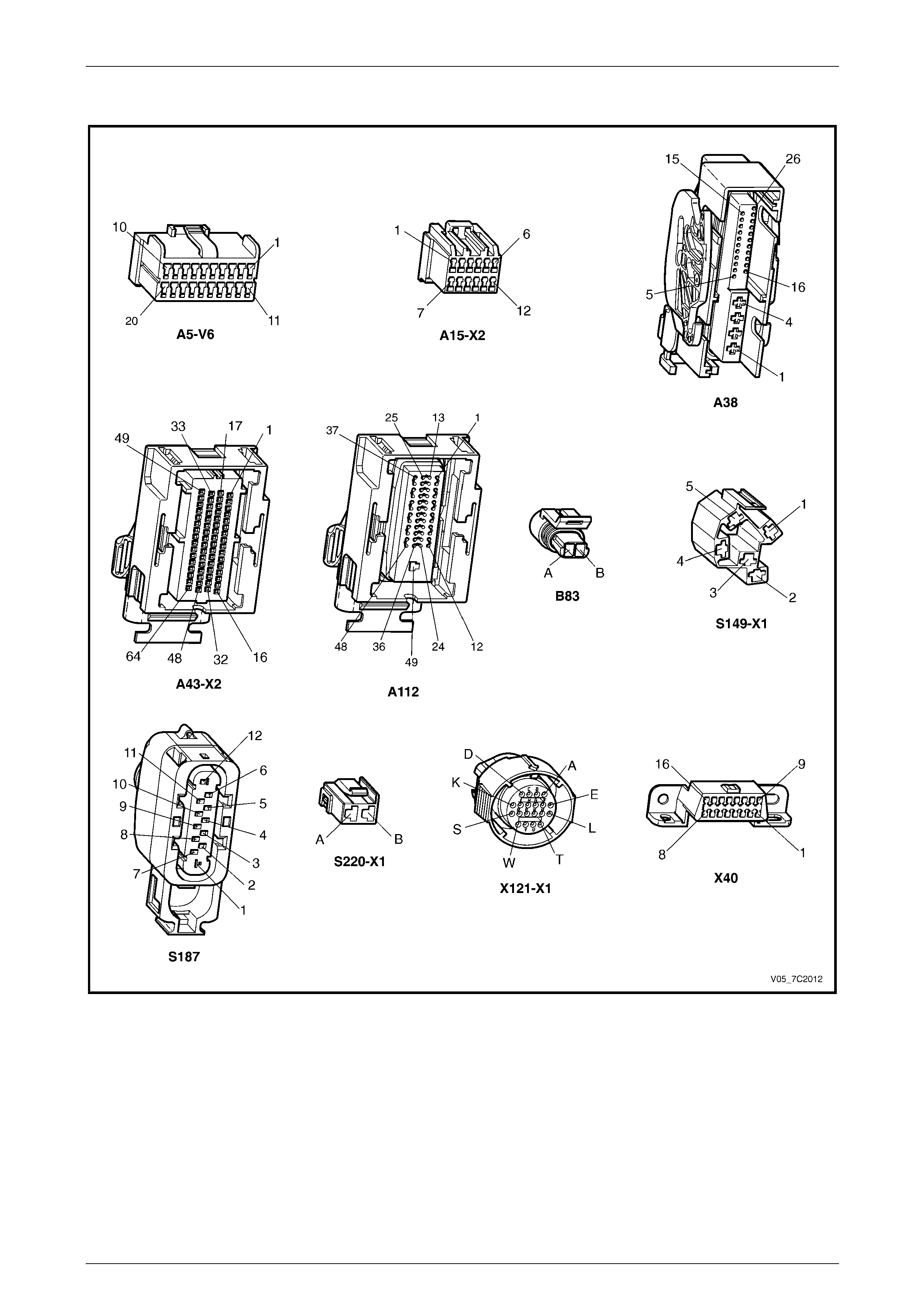

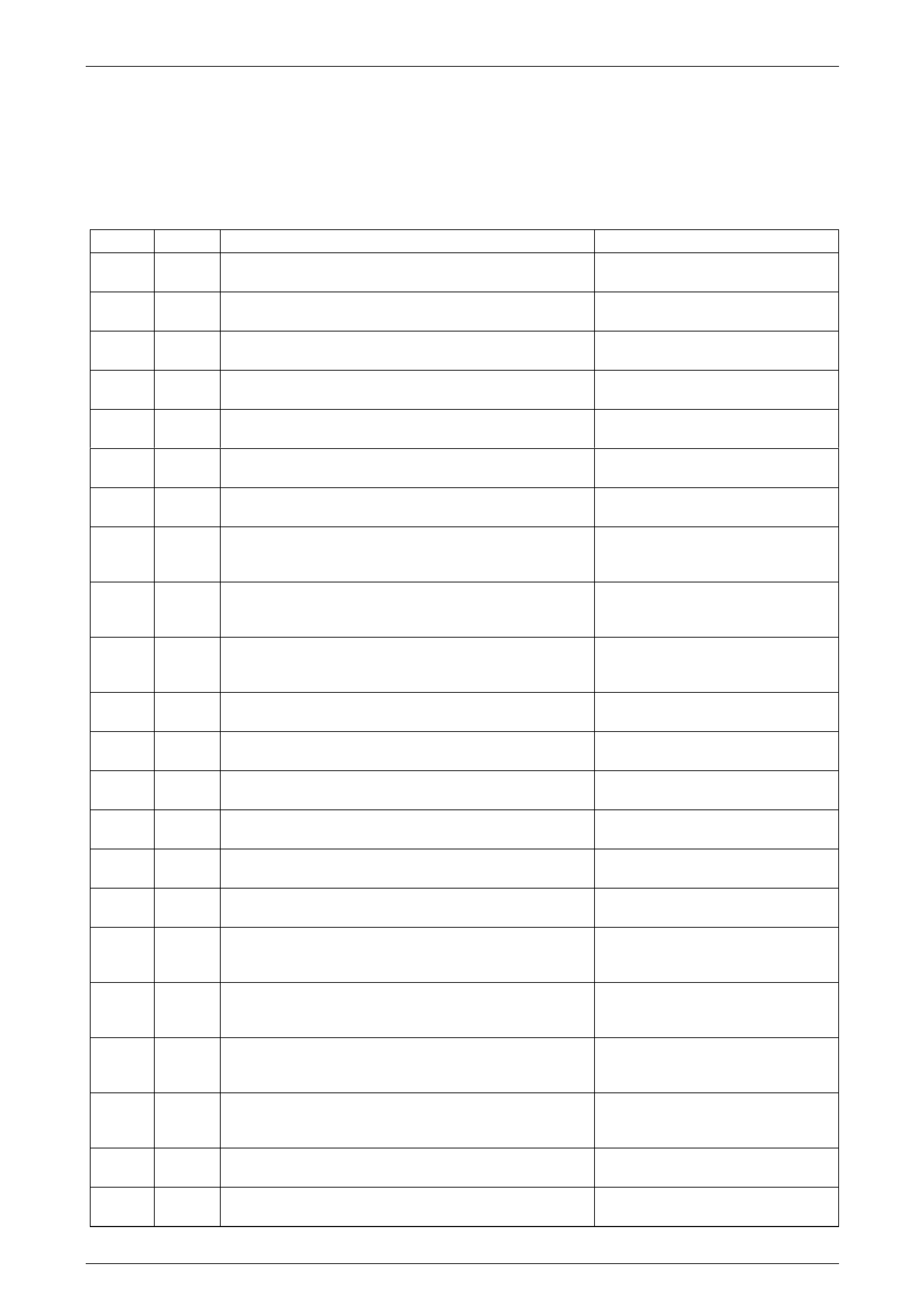

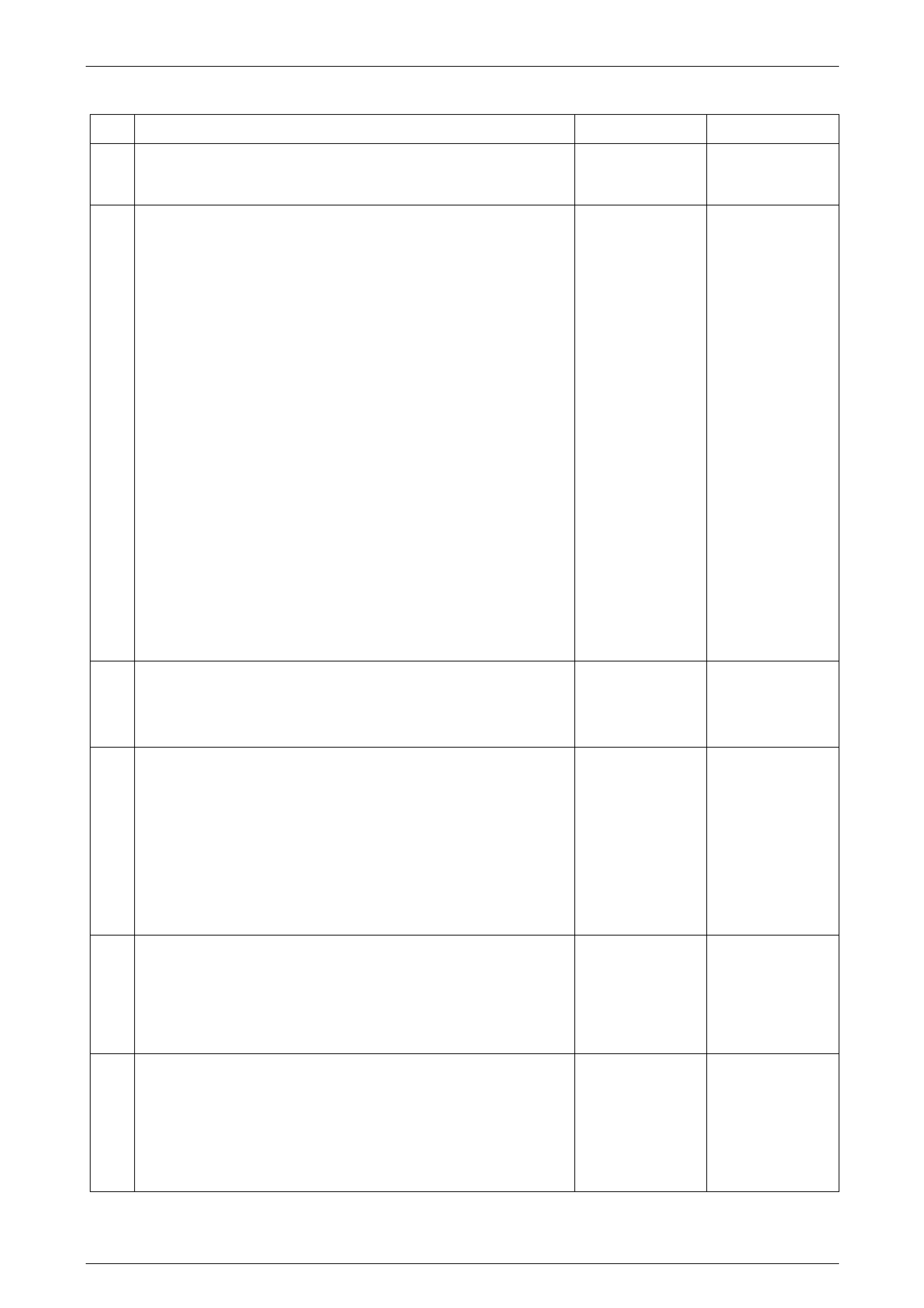

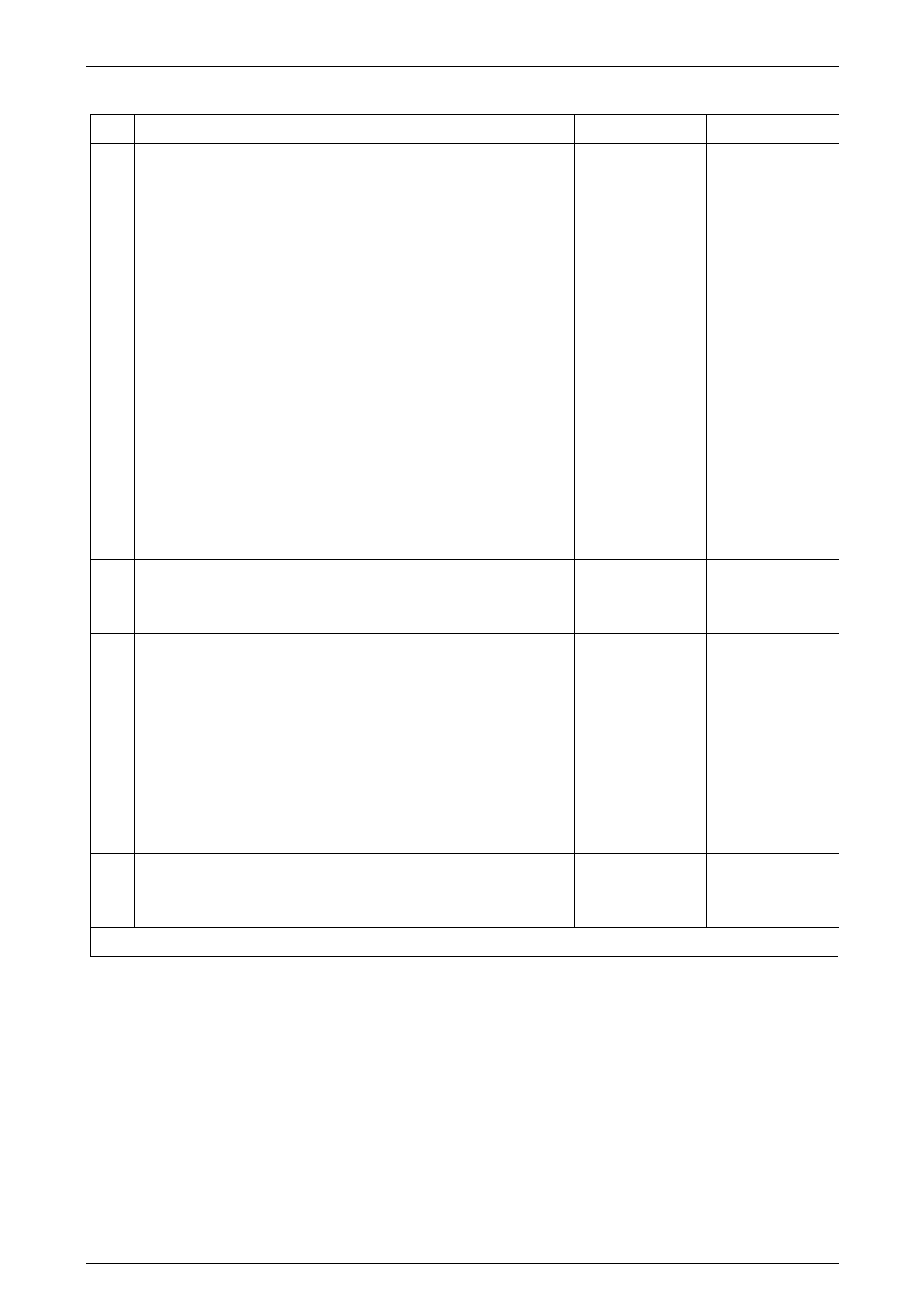

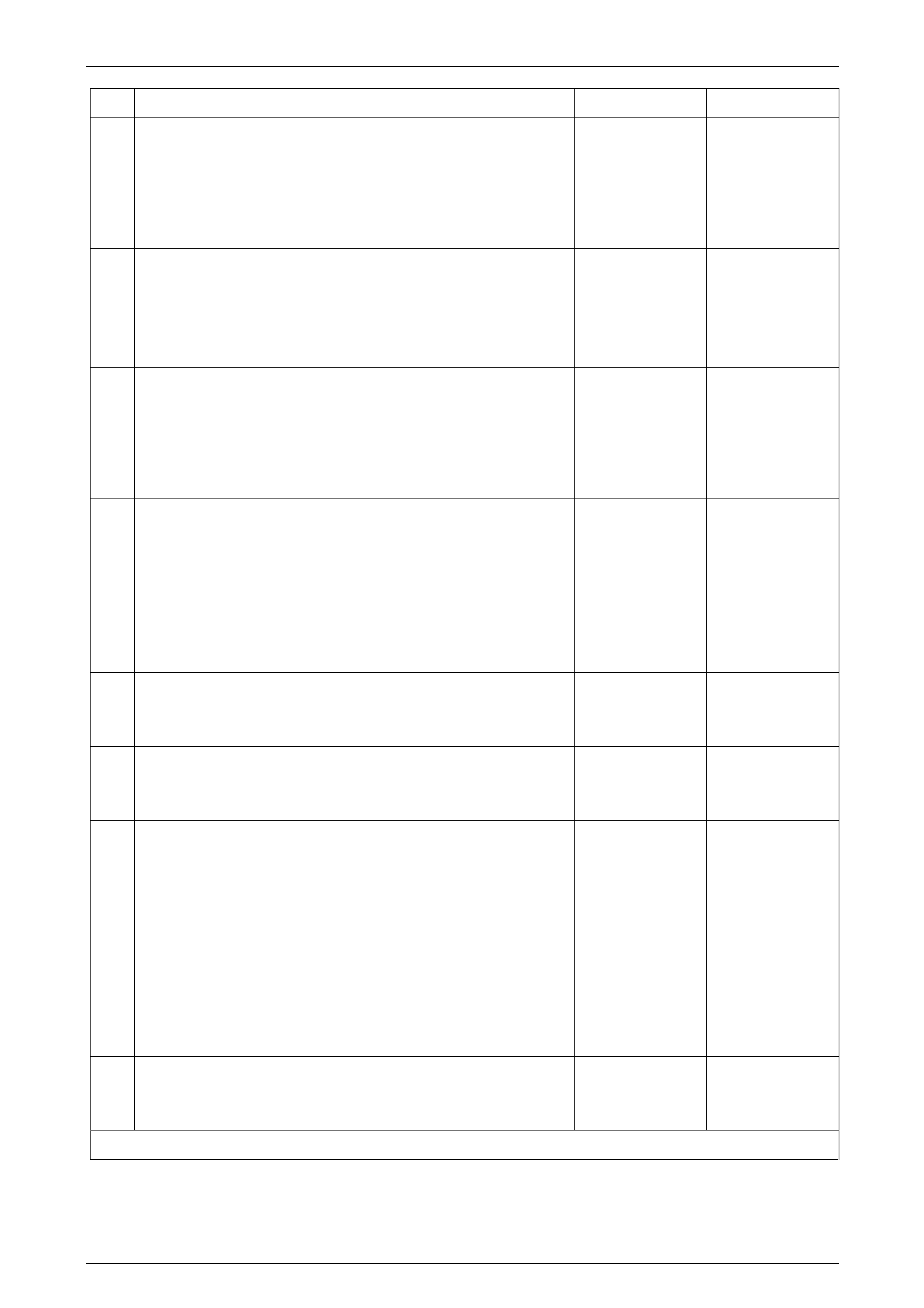

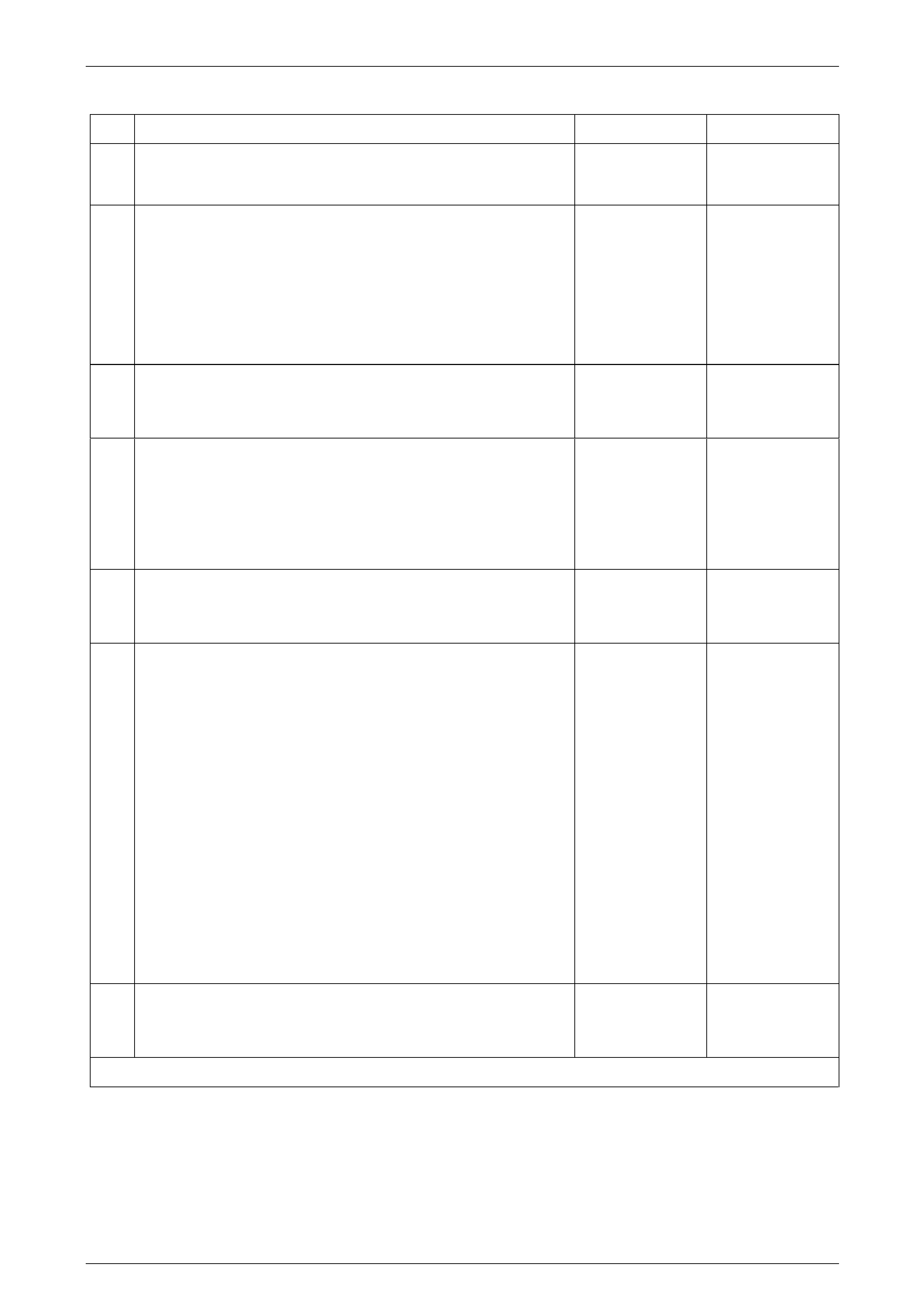

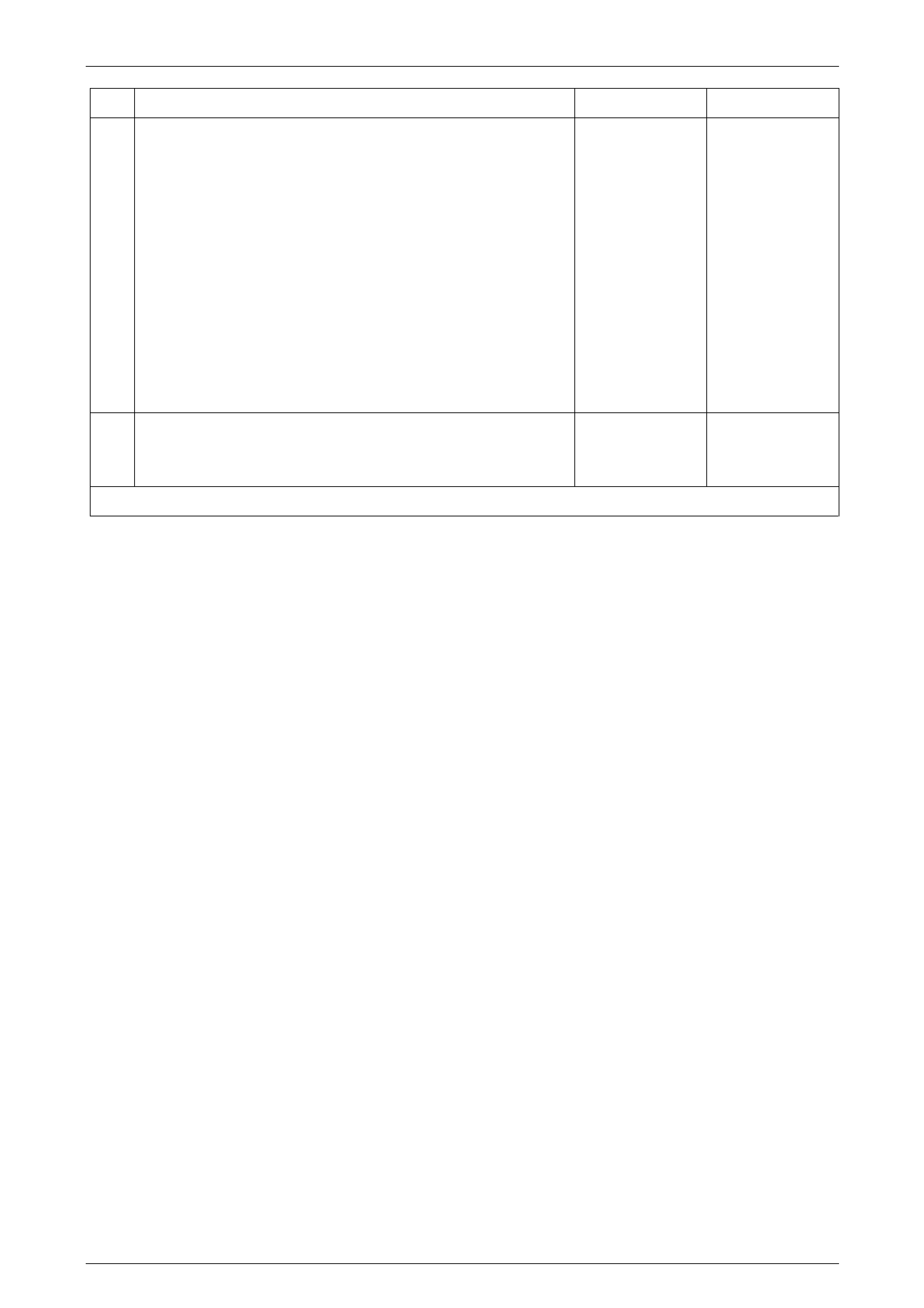

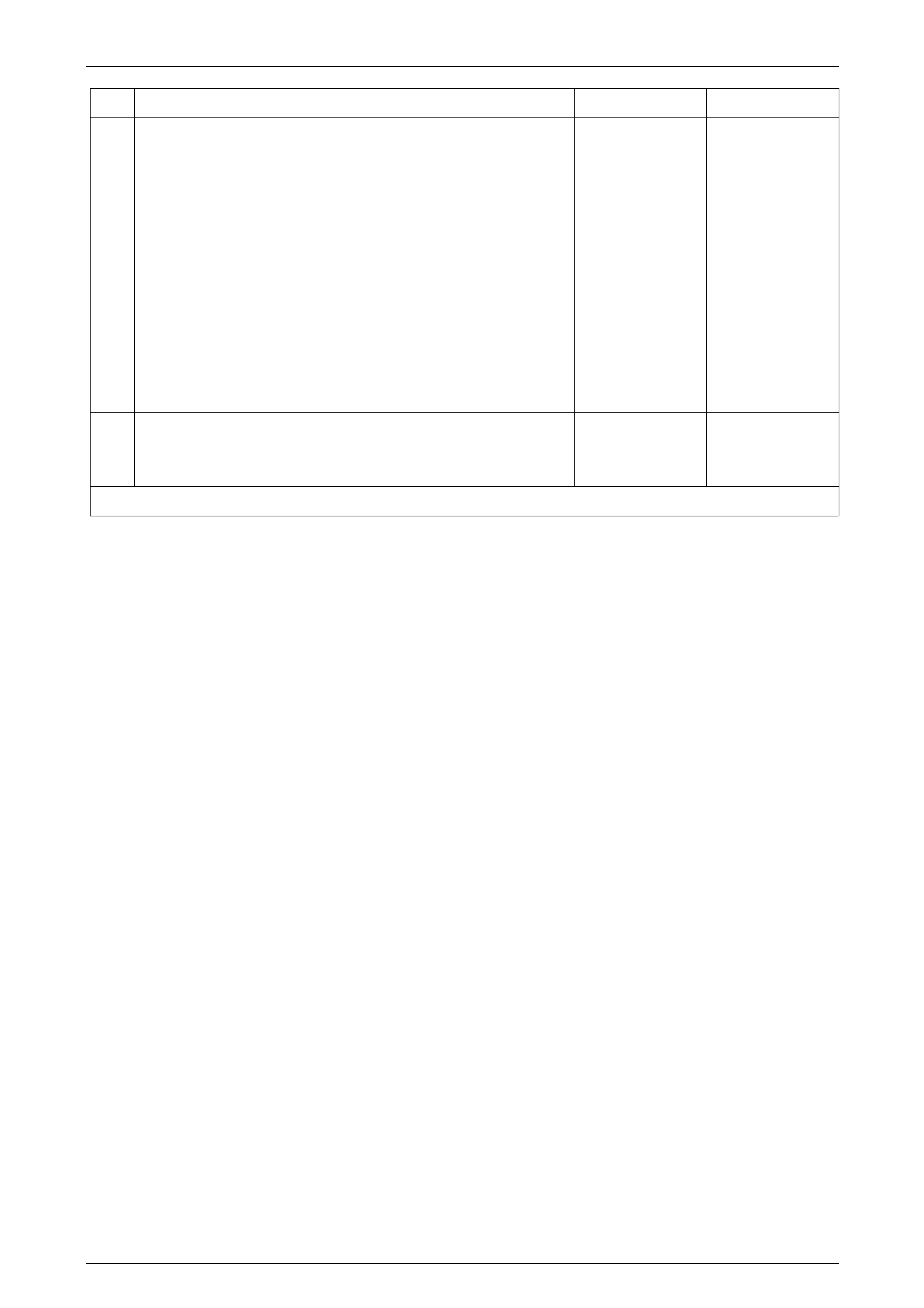

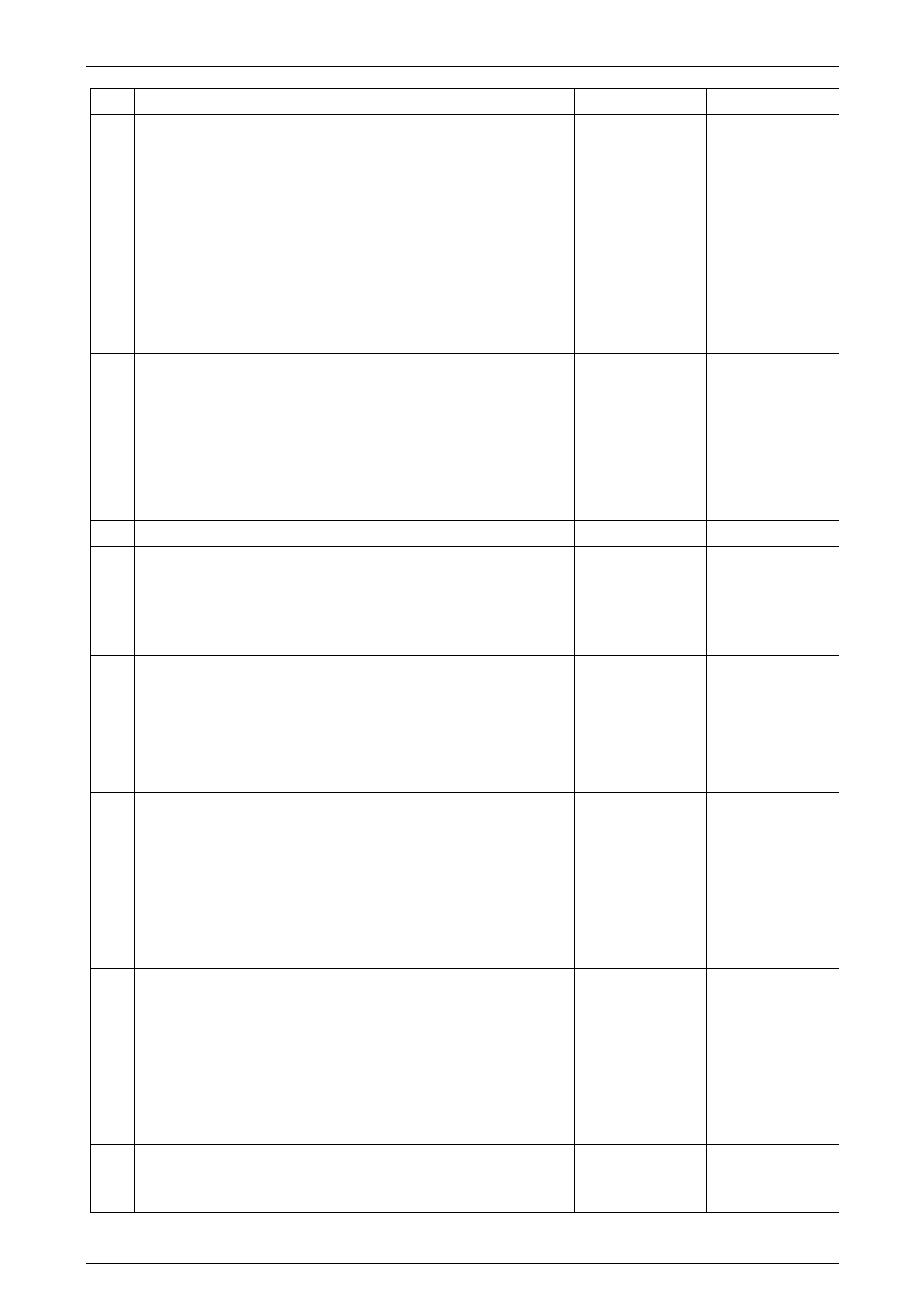

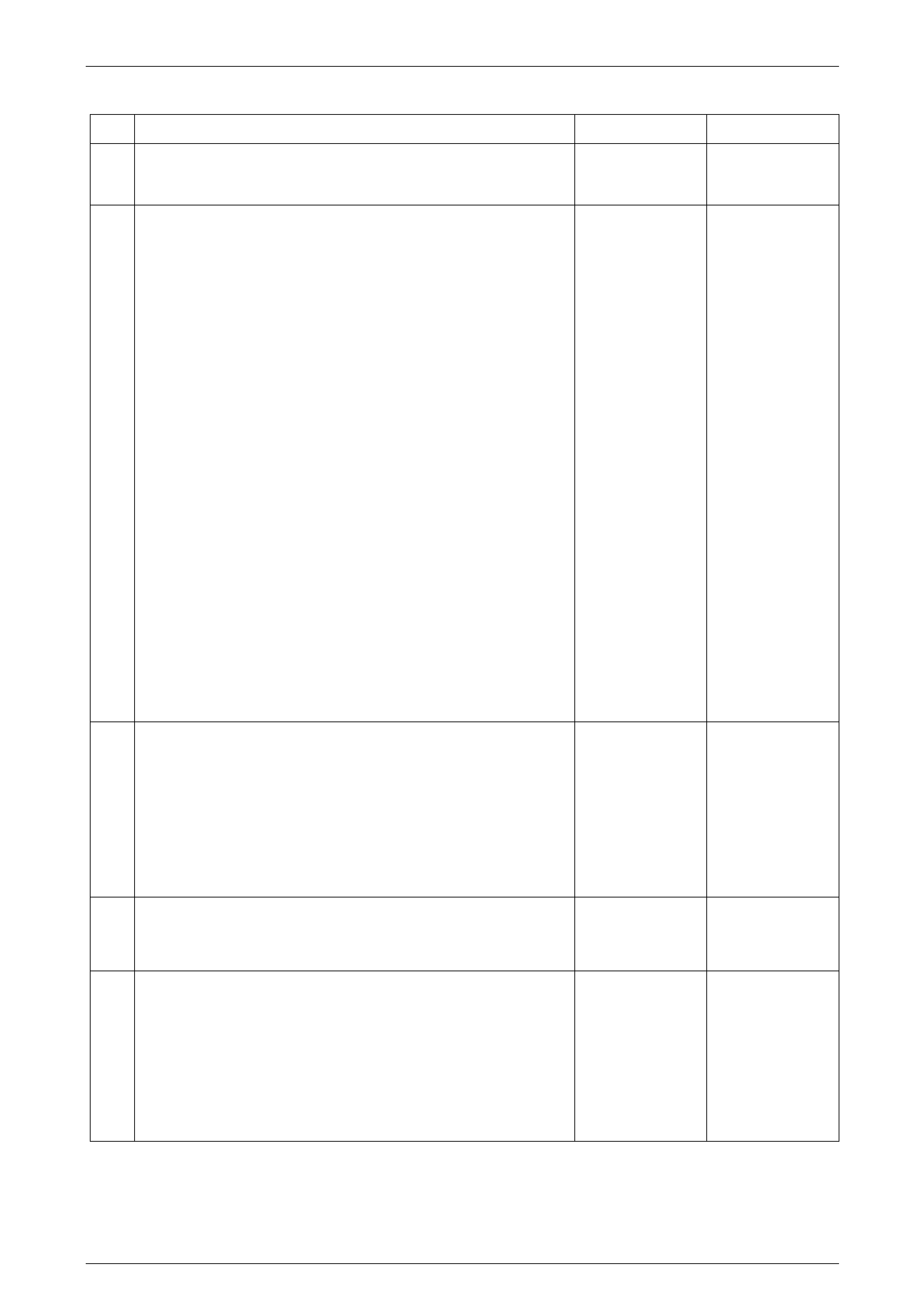

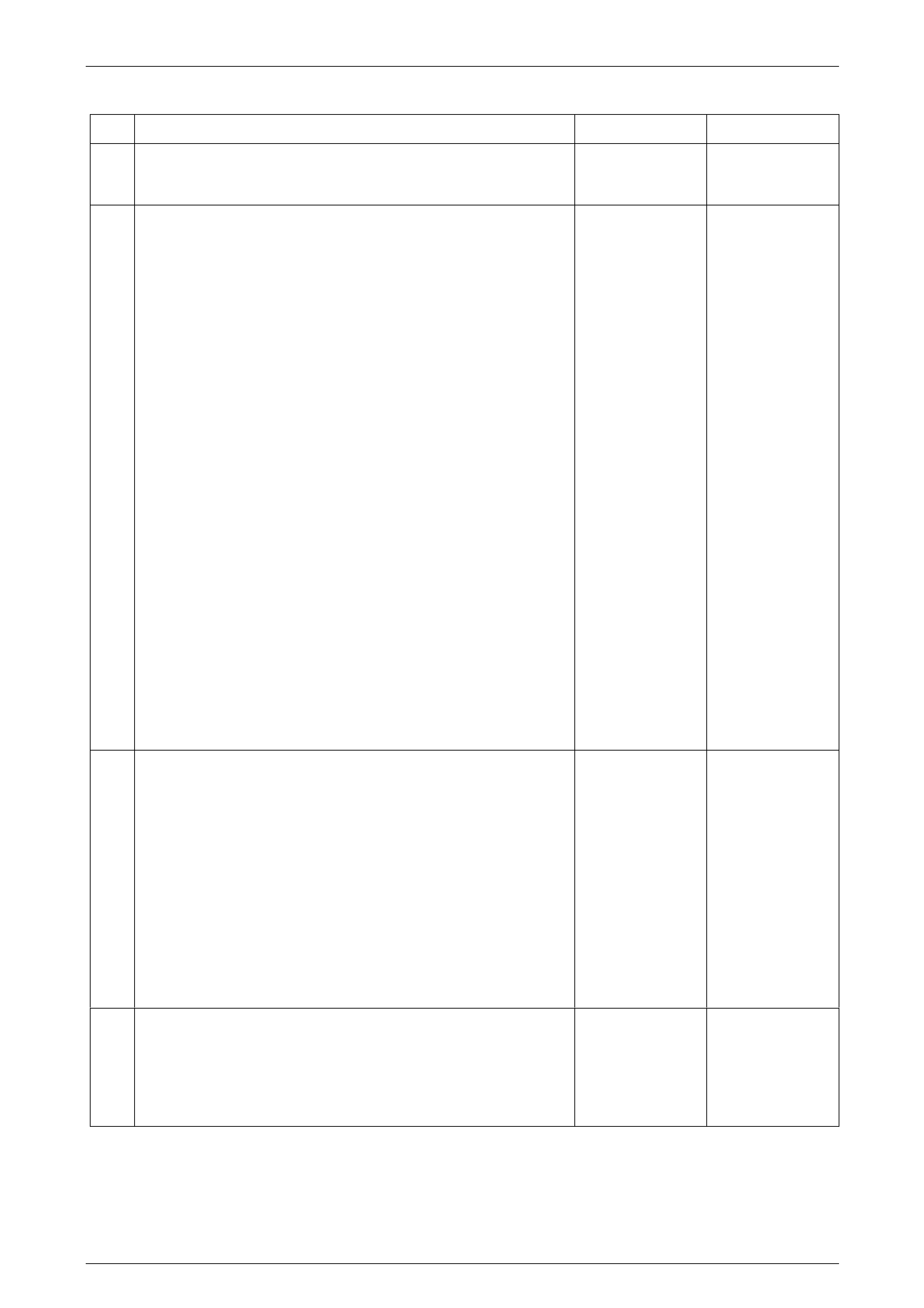

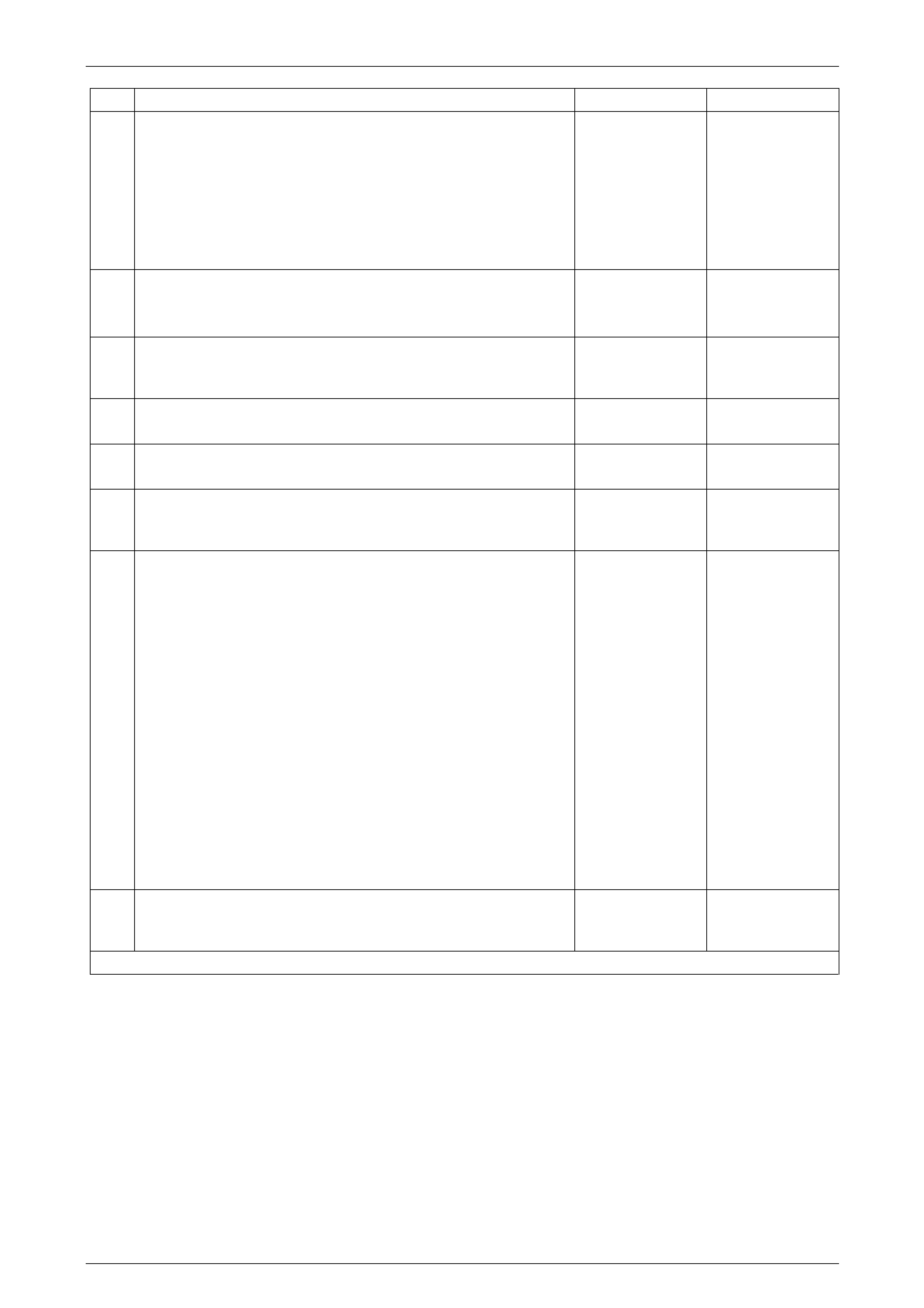

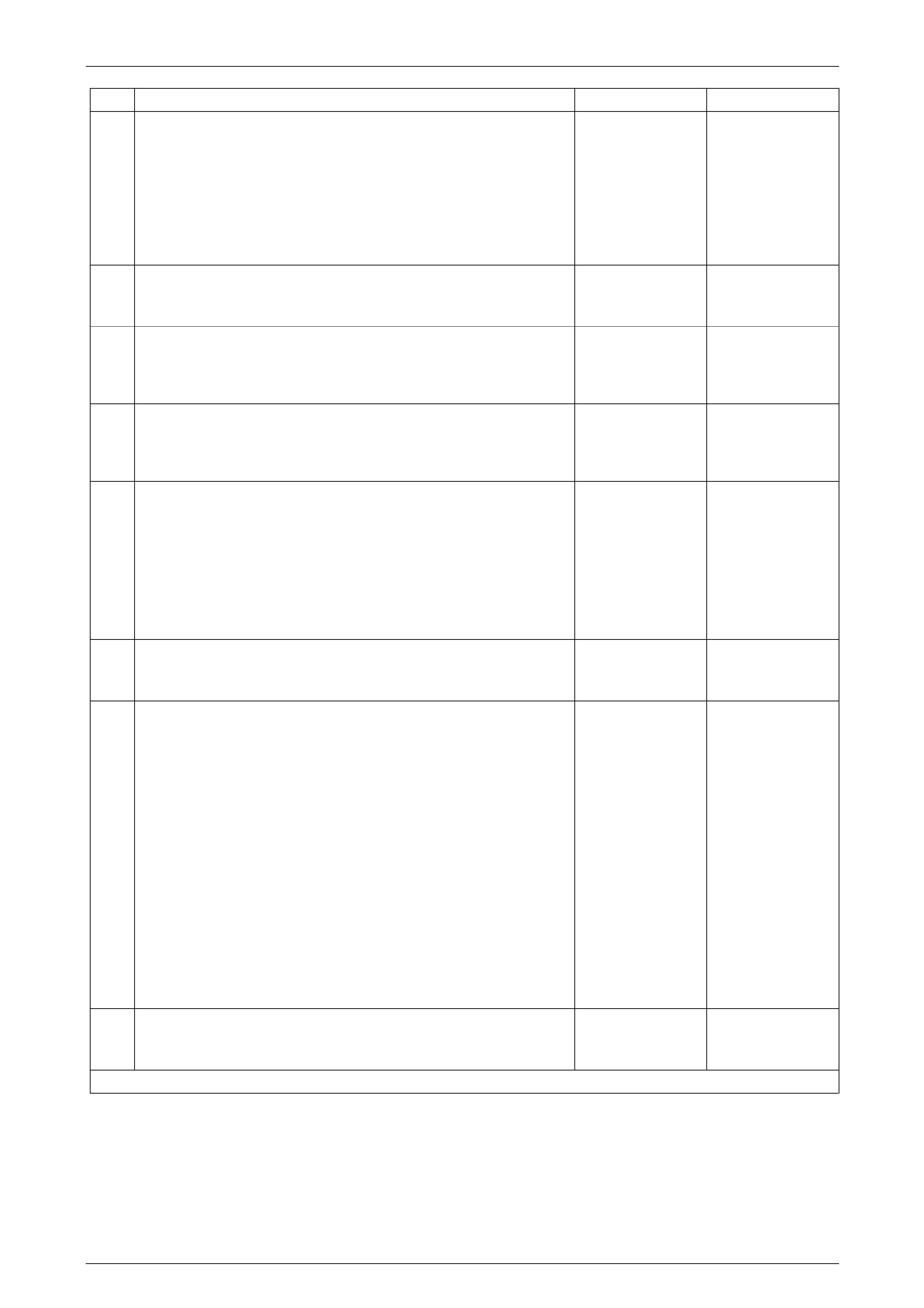

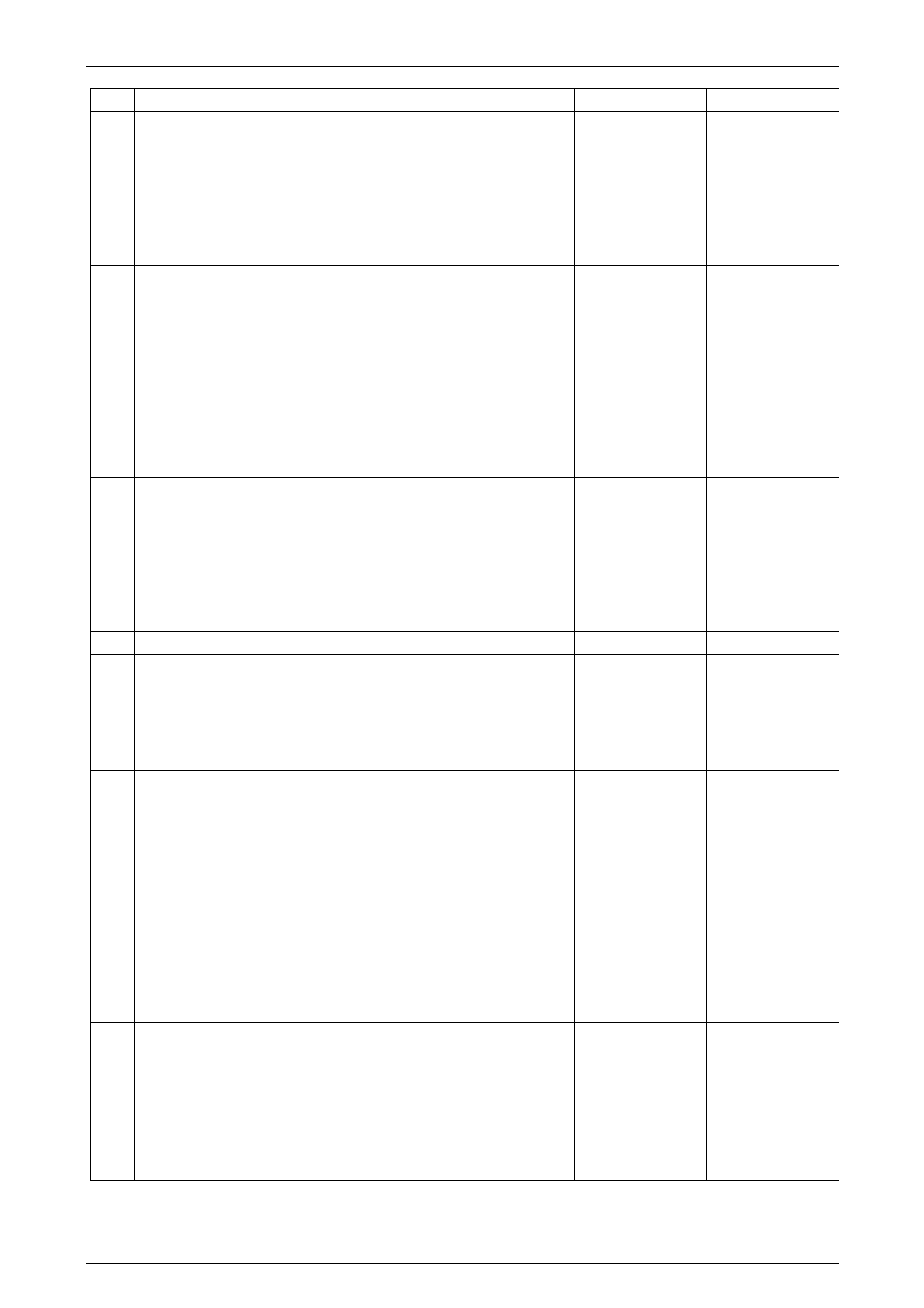

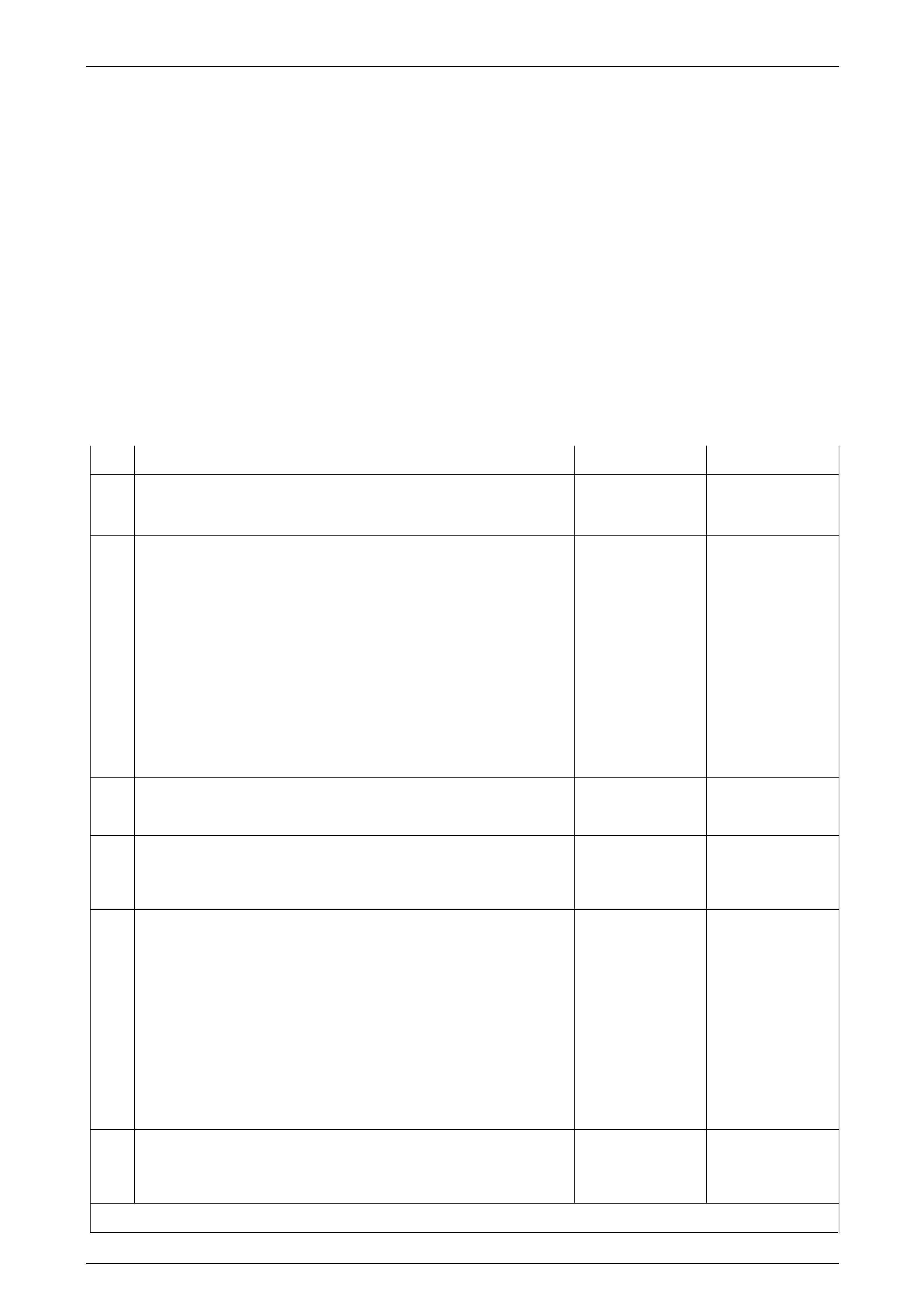

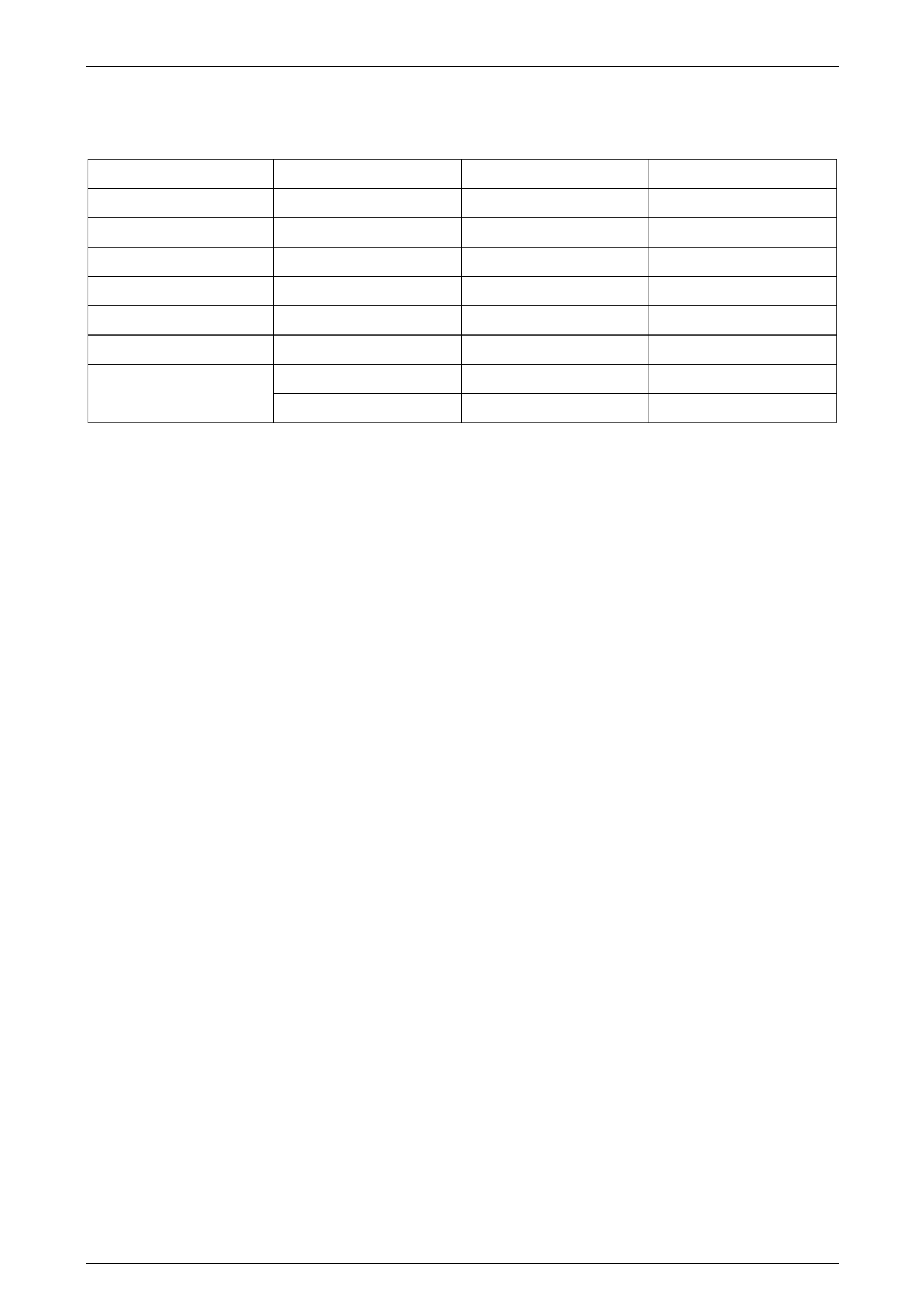

2.2 Connector Chart

Figure 7C2 – 12

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–19

Page 7C2–19

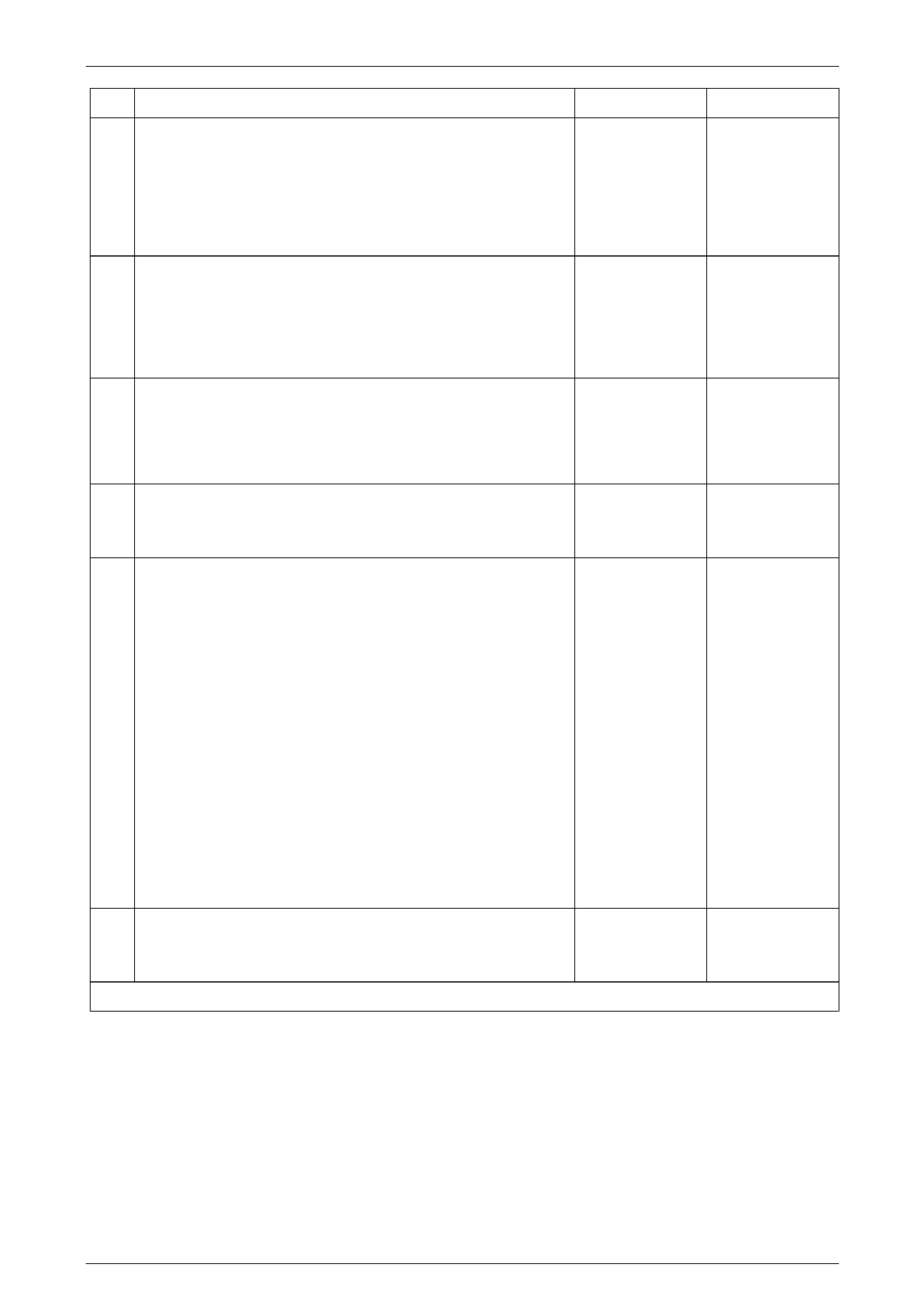

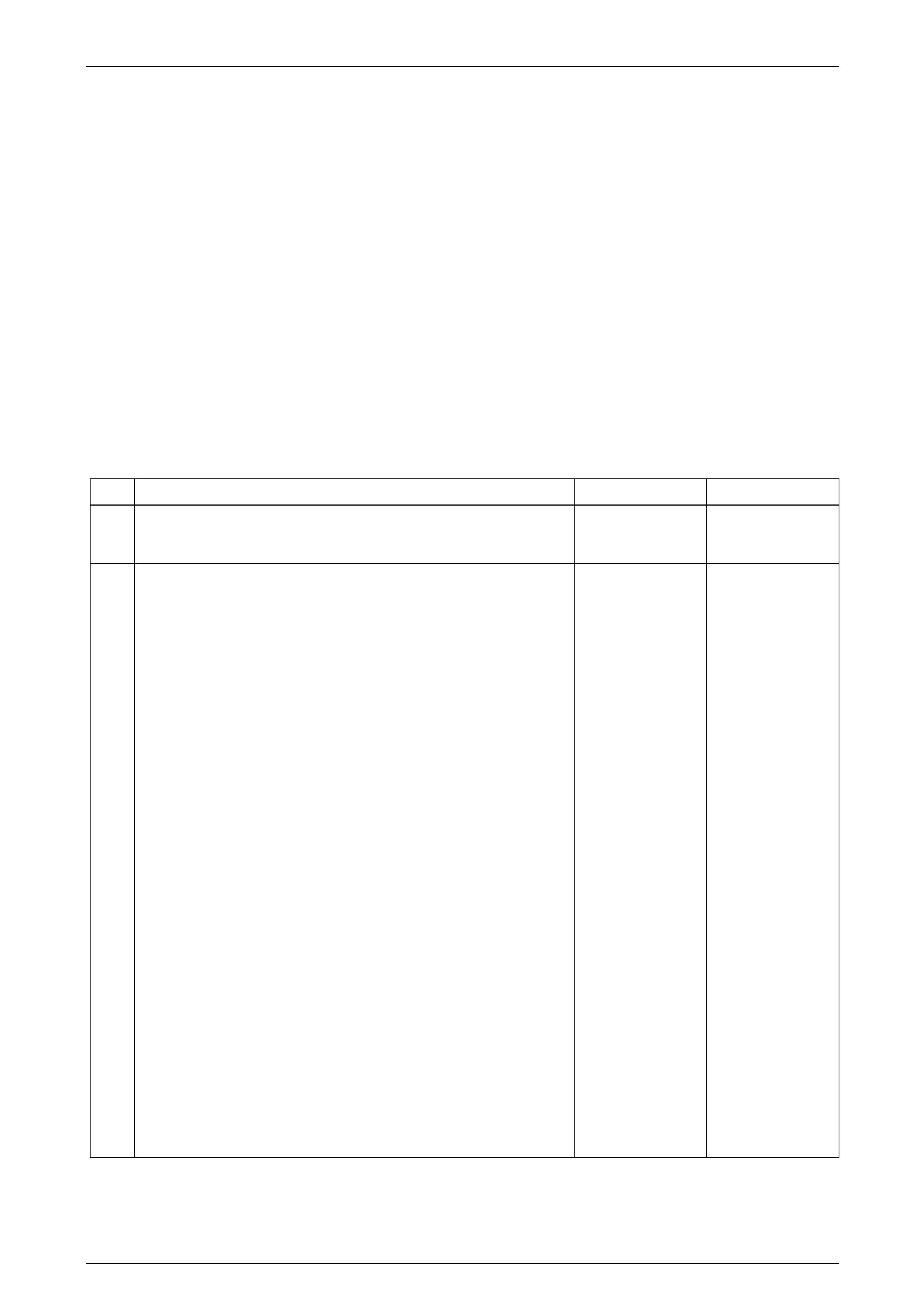

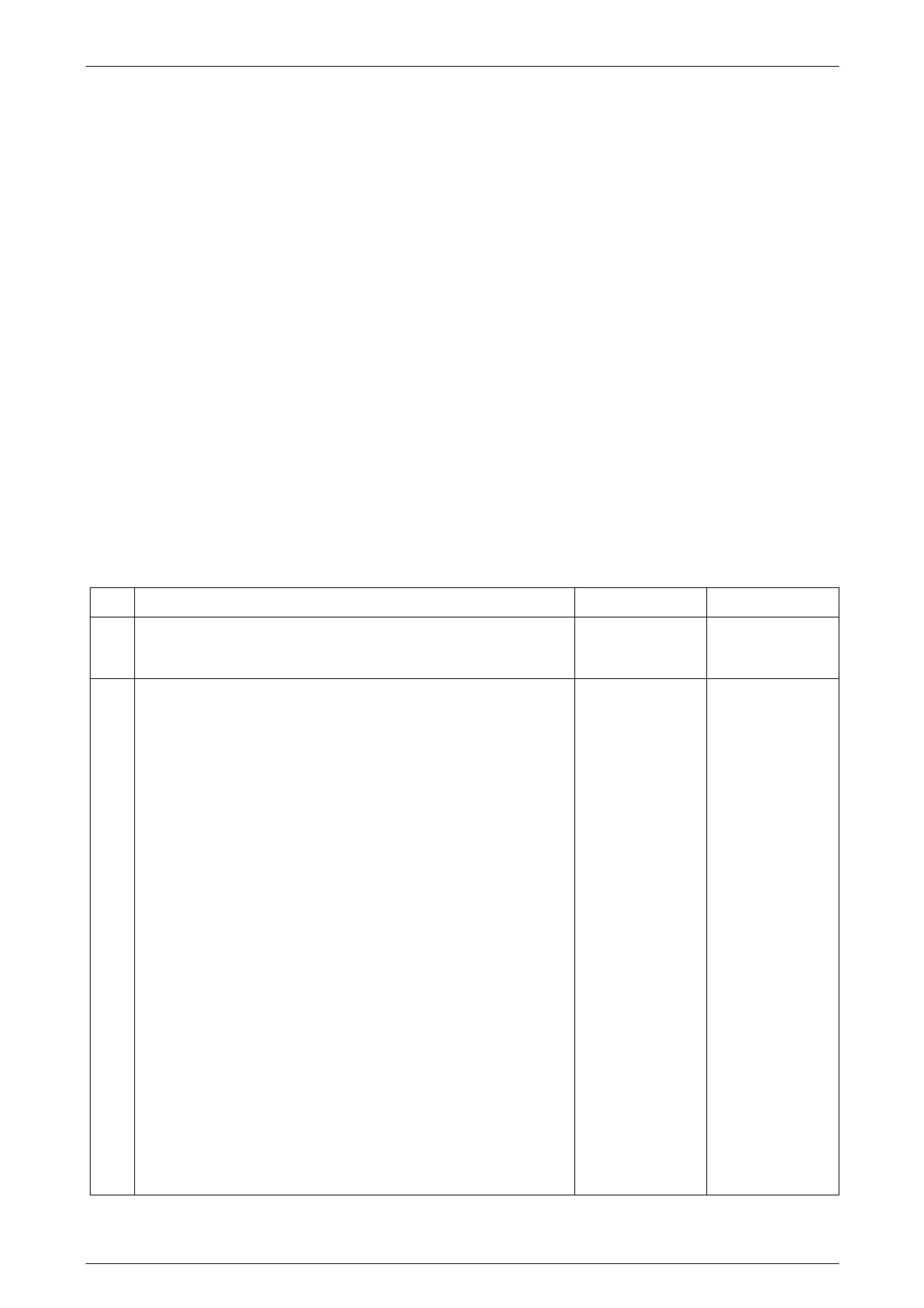

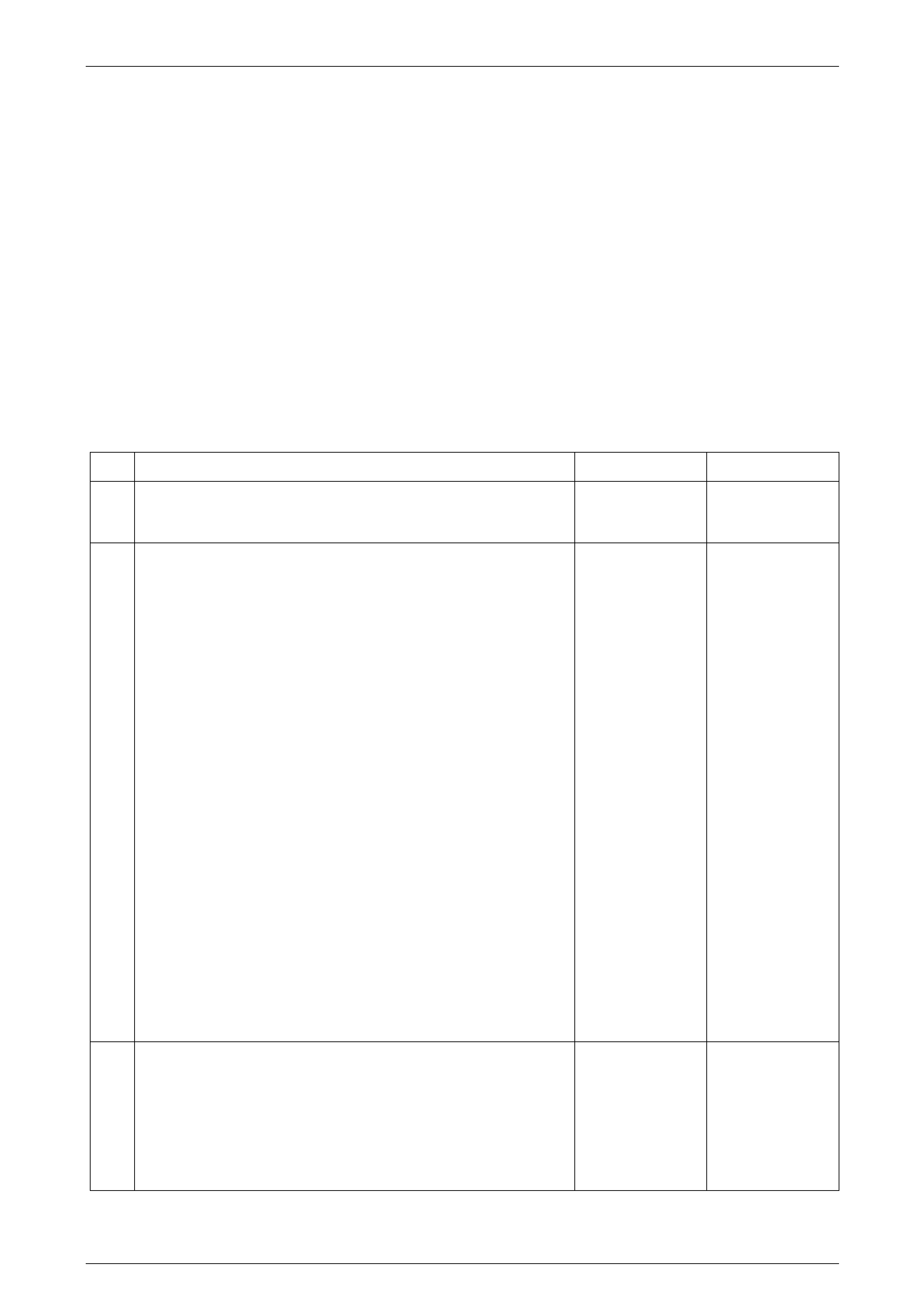

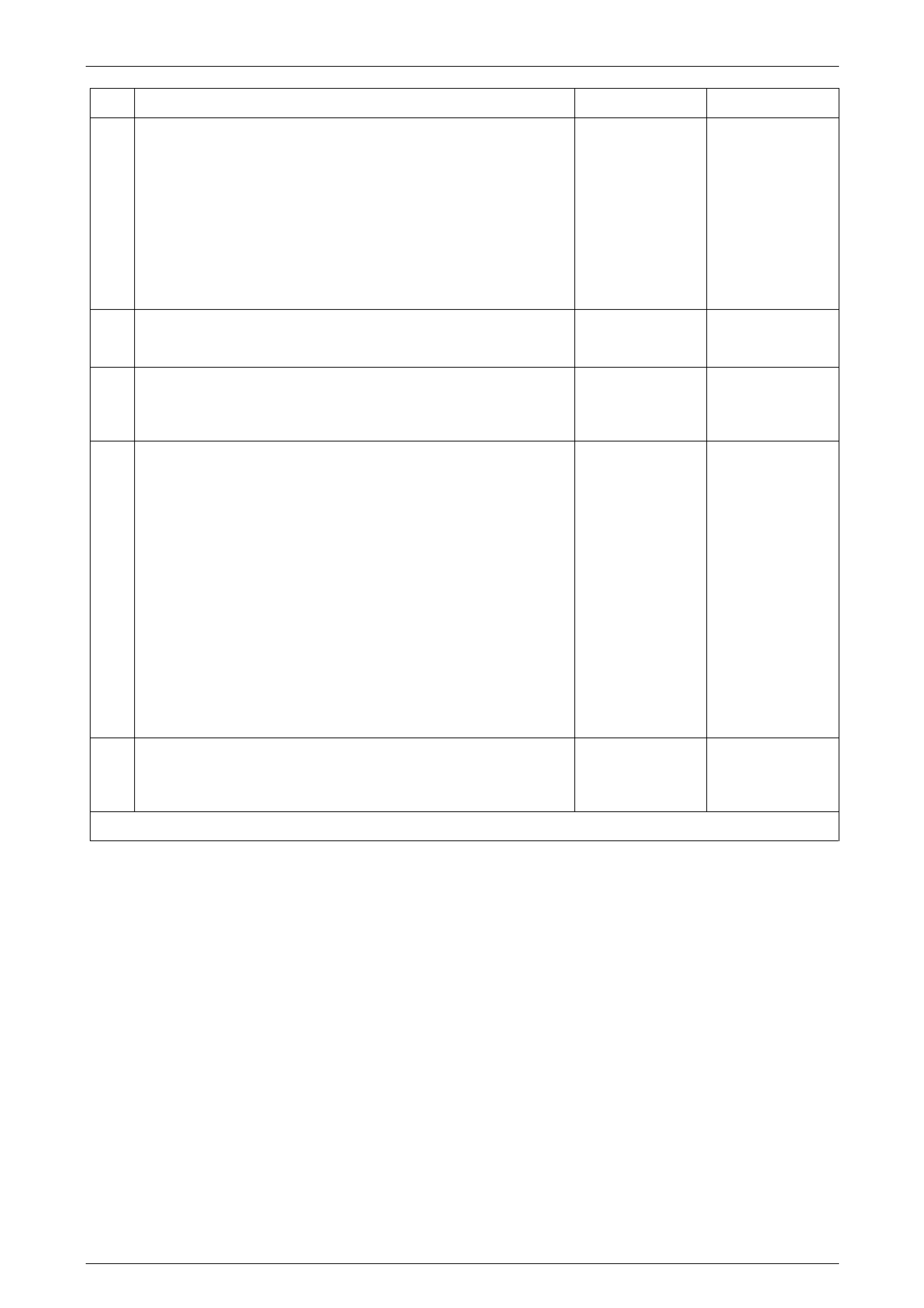

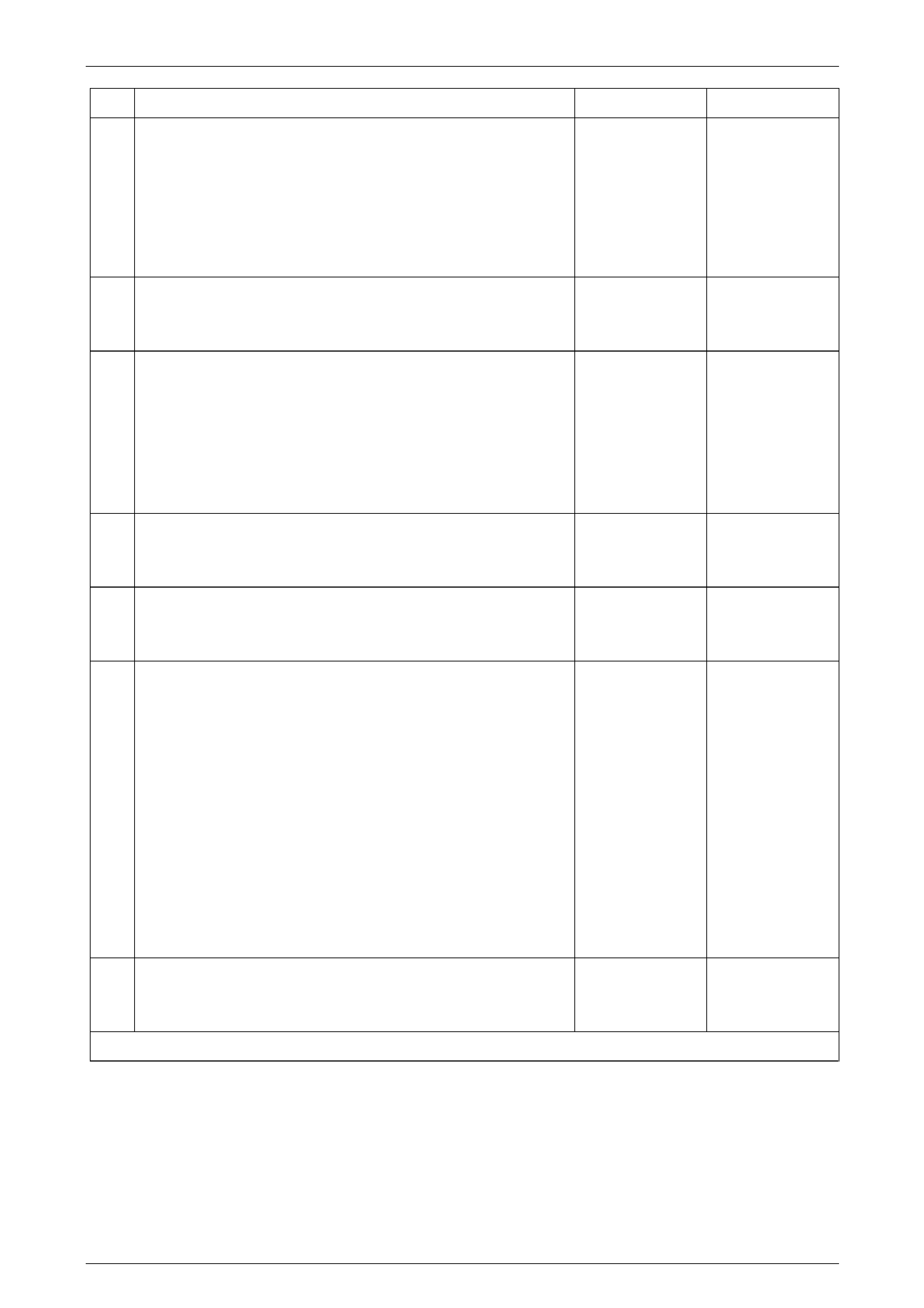

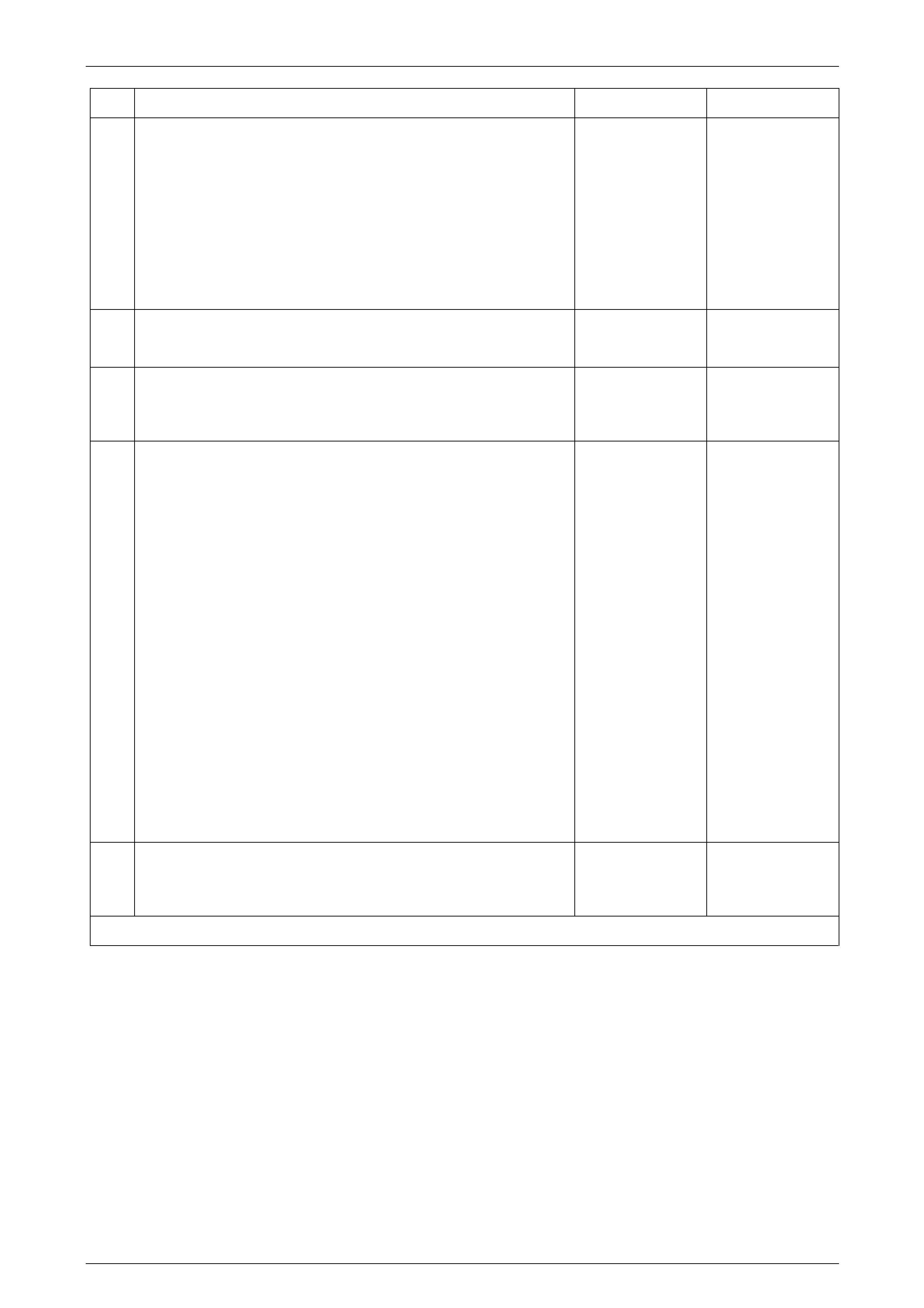

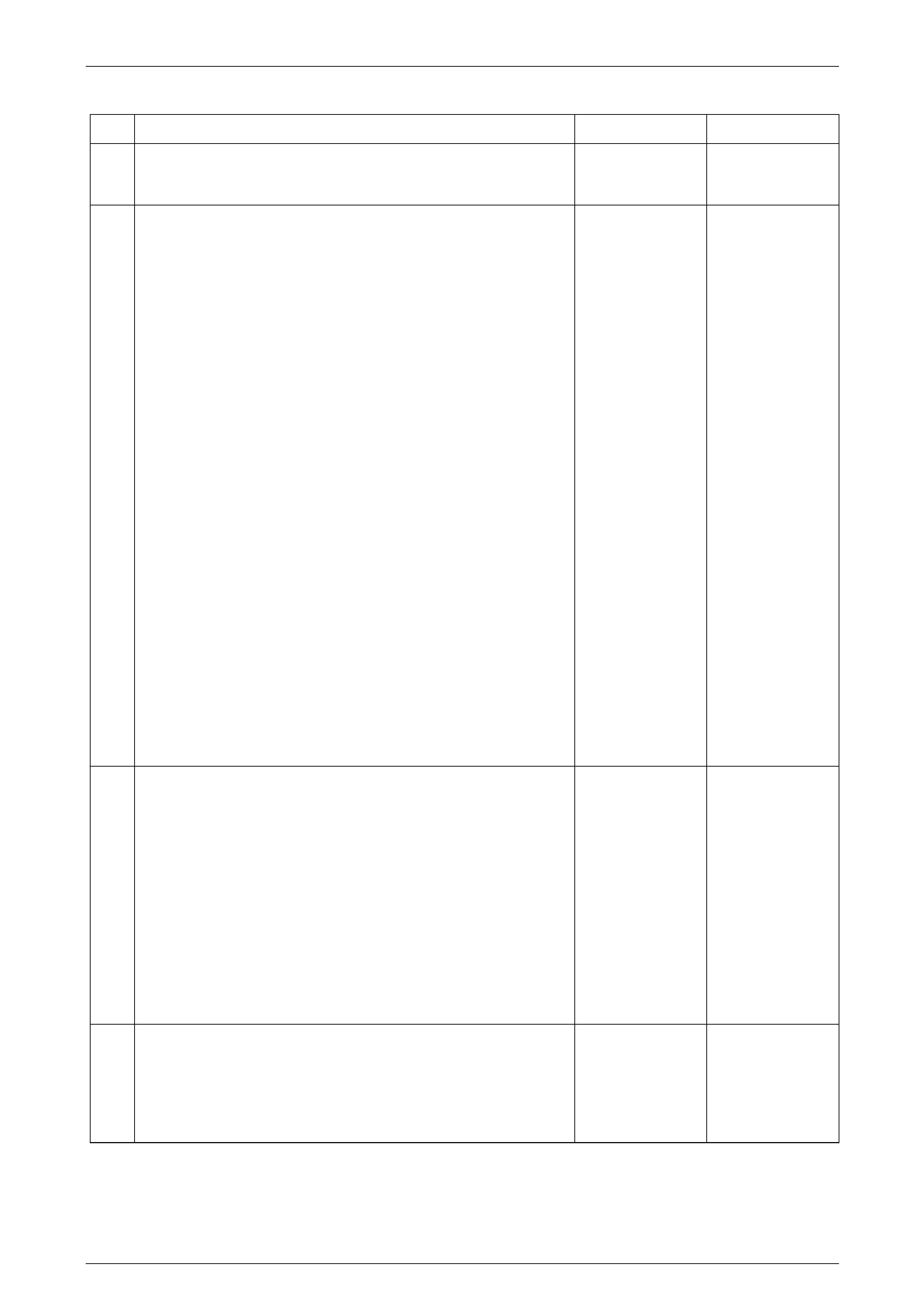

2.3 Connector Information

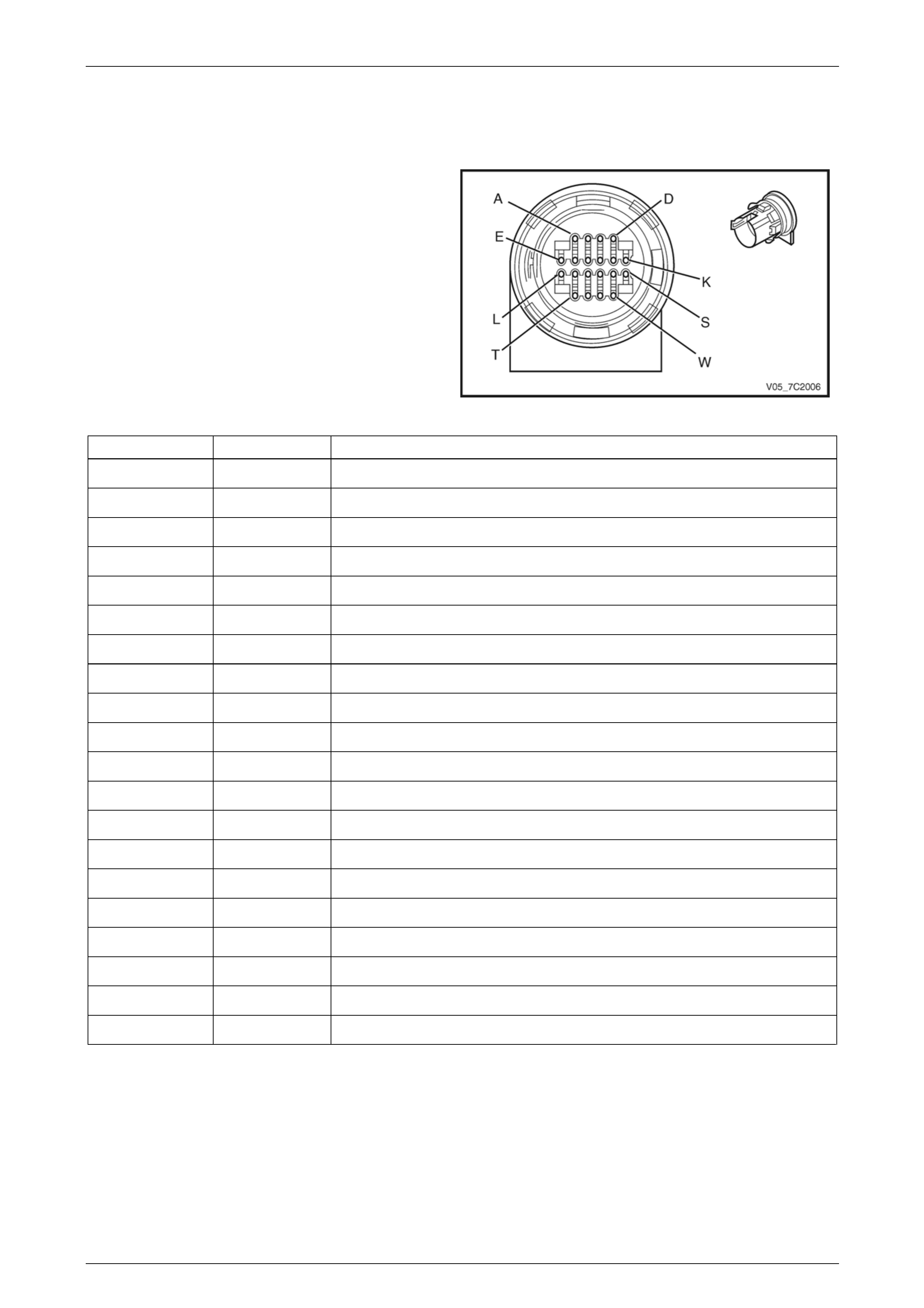

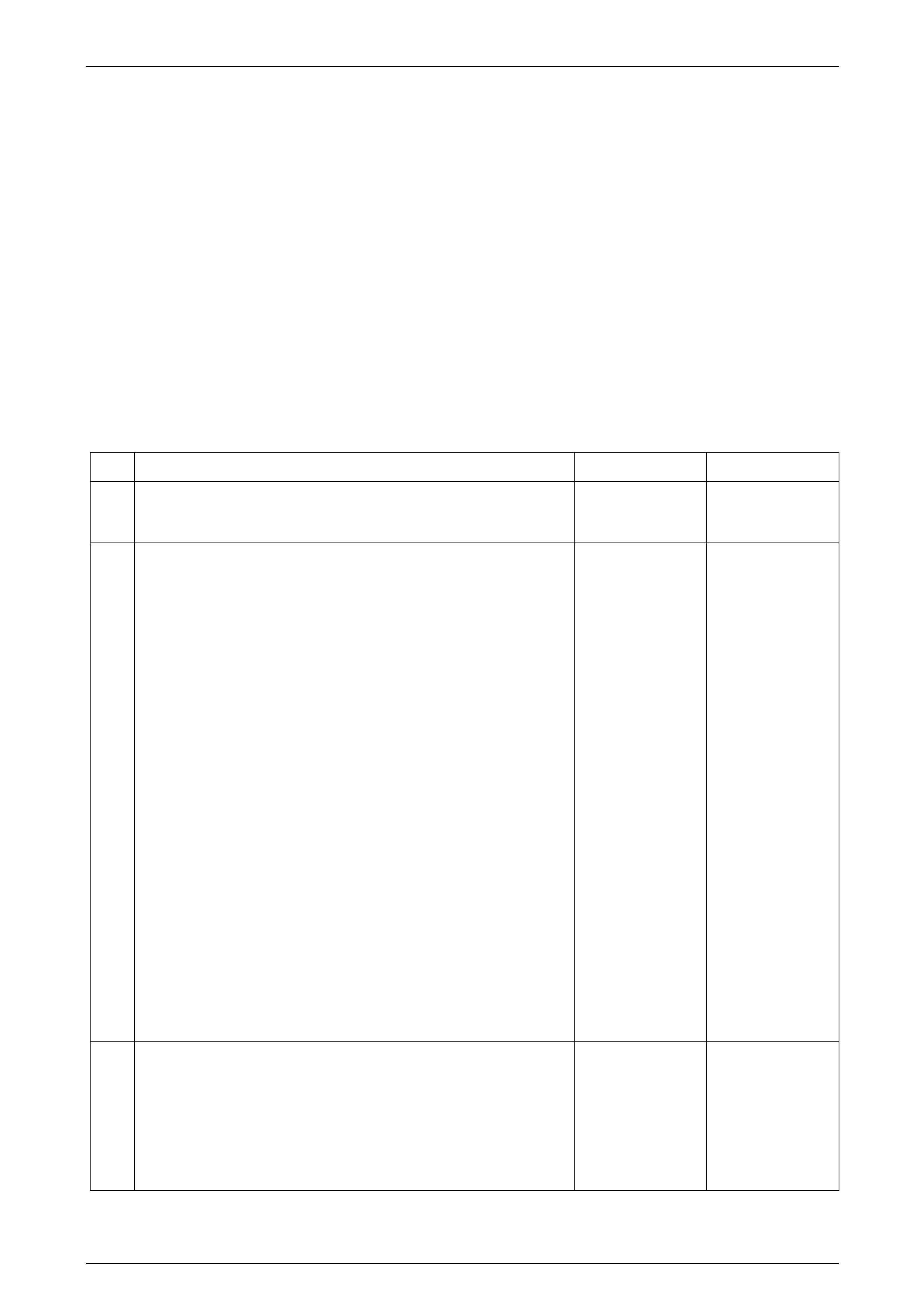

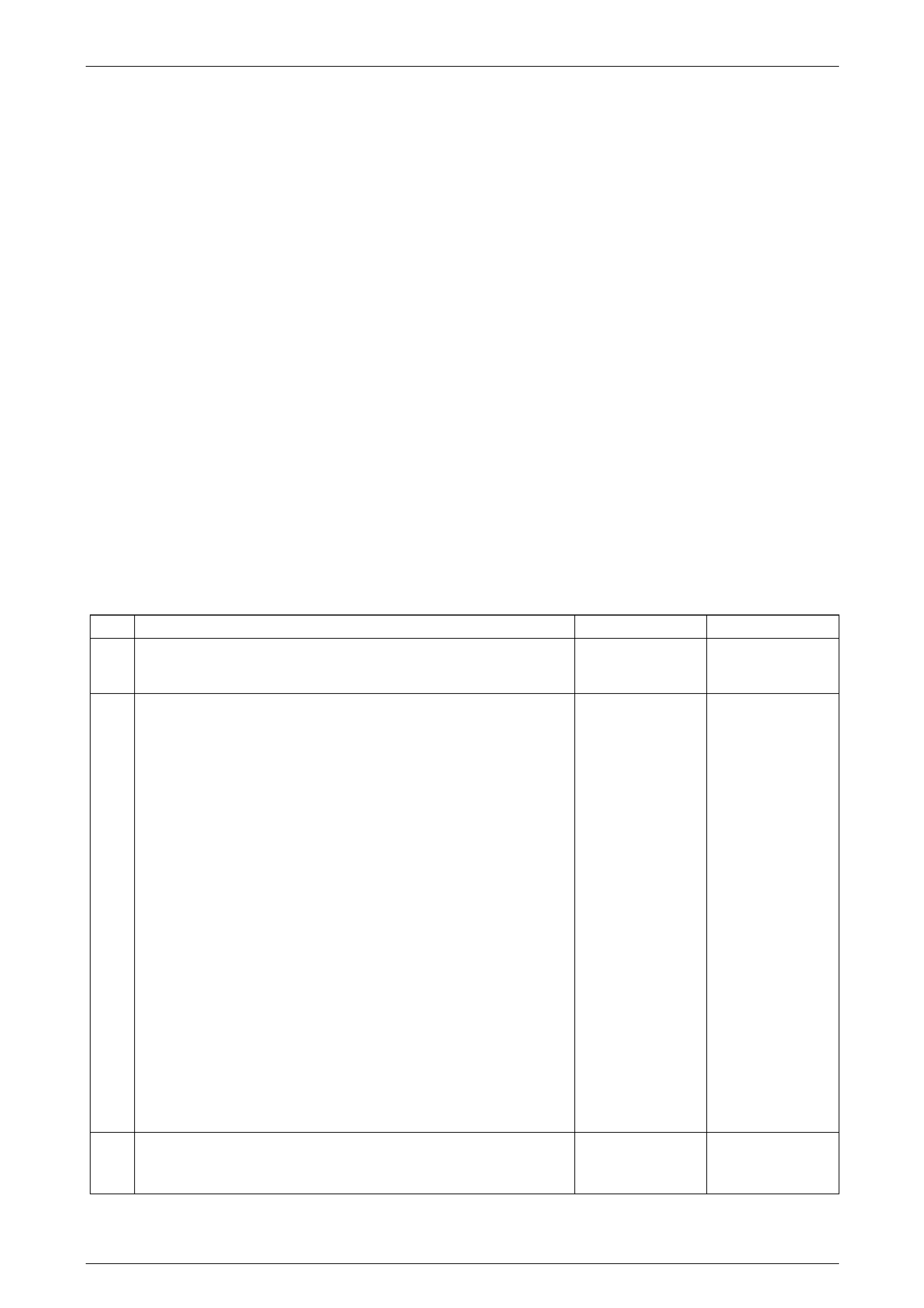

In-line 20-Way Connector End View

Transmission Side – X121–X1

Figure 7C2 – 13

Terminal / Pin Wire Colour Function

X1–A L-GN 1-2 Shift Solenoid Valve Cont rol

X1–B YE 2-3 Shift Solenoid Valve Cont rol

X1–C PU Pressure Control (PC) Solenoid Valve Low Control

X1–D L-BU Pressure Control (PC) Solenoid Valve High Control

X1–E RD Ignition Voltage

X1–F — Not Used

X1–G — Not Used

X1–H — Not Used

X1–J — Not Used

X1–K — Not Used

X1–L BN Transmission Fluid Temperature (TFT) Sensor Low Reference

X1–M GY Transmission Fluid Temperature (TFT) Sensor Signal

X1–N PK Transmission Fluid Pressure Switch A Sensor Signal

X1–P OG Transmission Fluid Pressure Switch C Sensor Signal

X1–R BU Transmission Fluid Pressure Switch B Sensor Signal

X1–S WH 3-2 Shift Solenoid Valve Cont rol

X1–T BK Torque Converter Clutch (TCC) Solenoid Valve Control

X1–U BN Torque Converter Clutch (T CC) PWM Solen oid Valve Control

X1–V — Not Used

X1–W — Not Used

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–20

Page 7C2–20

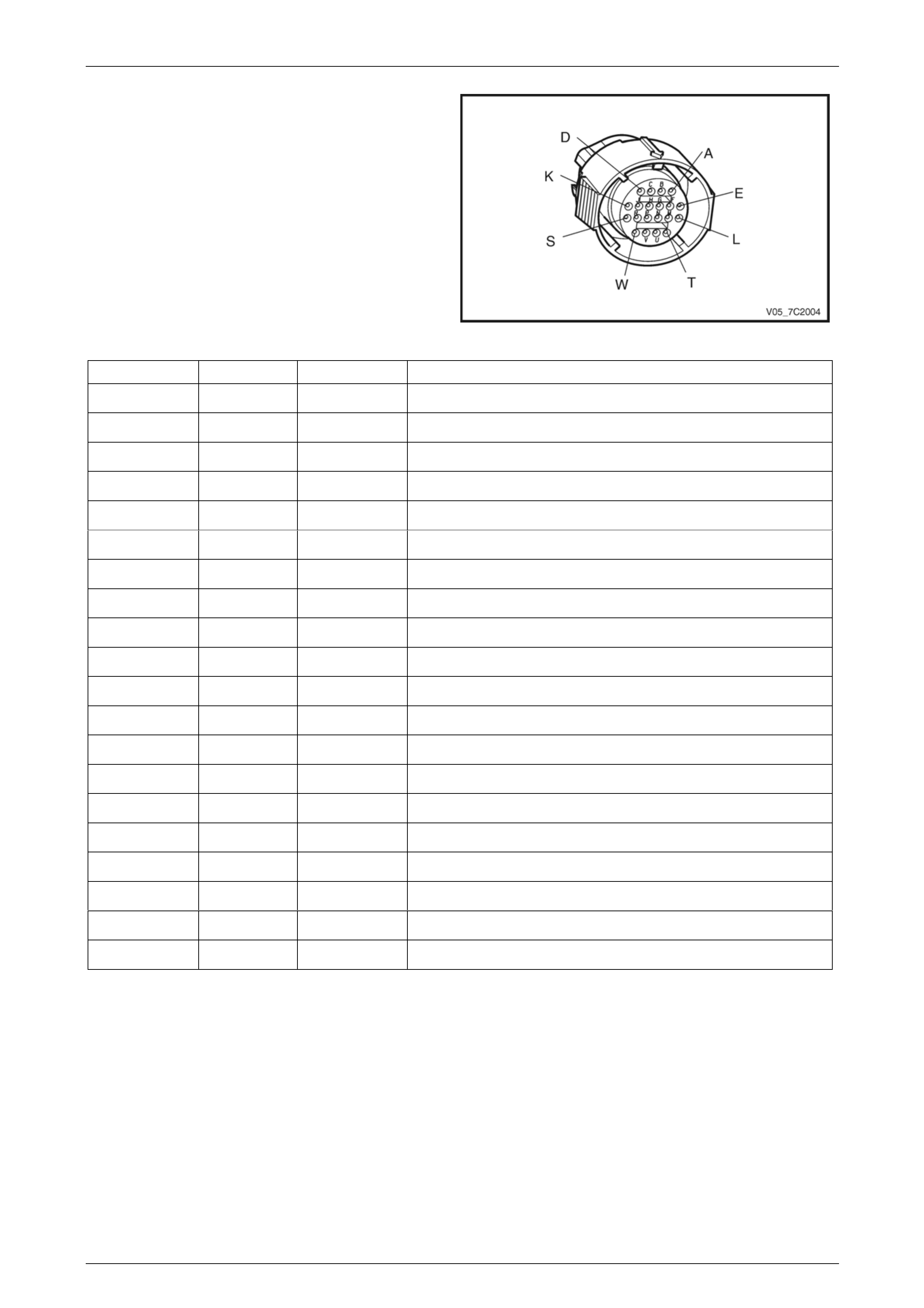

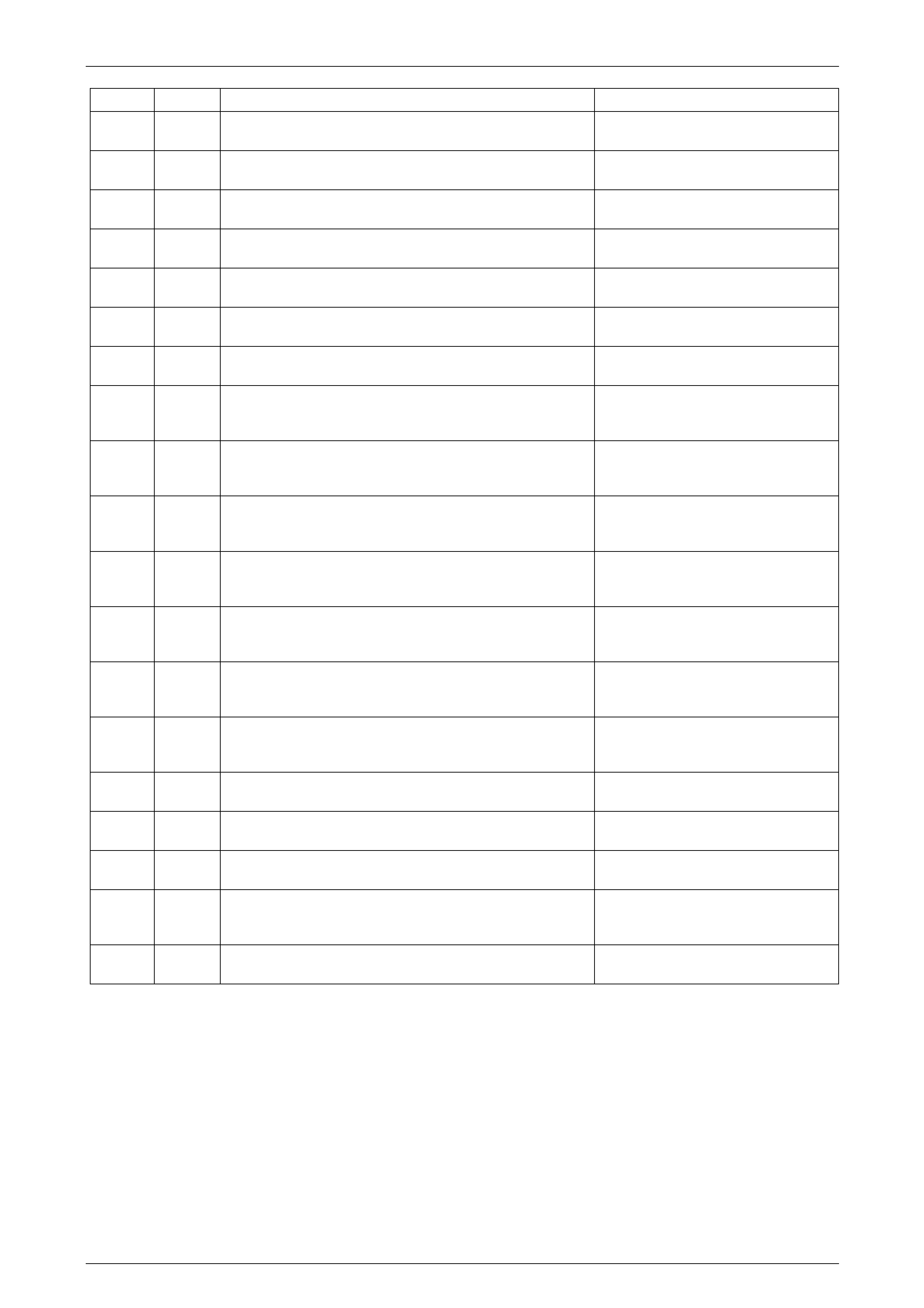

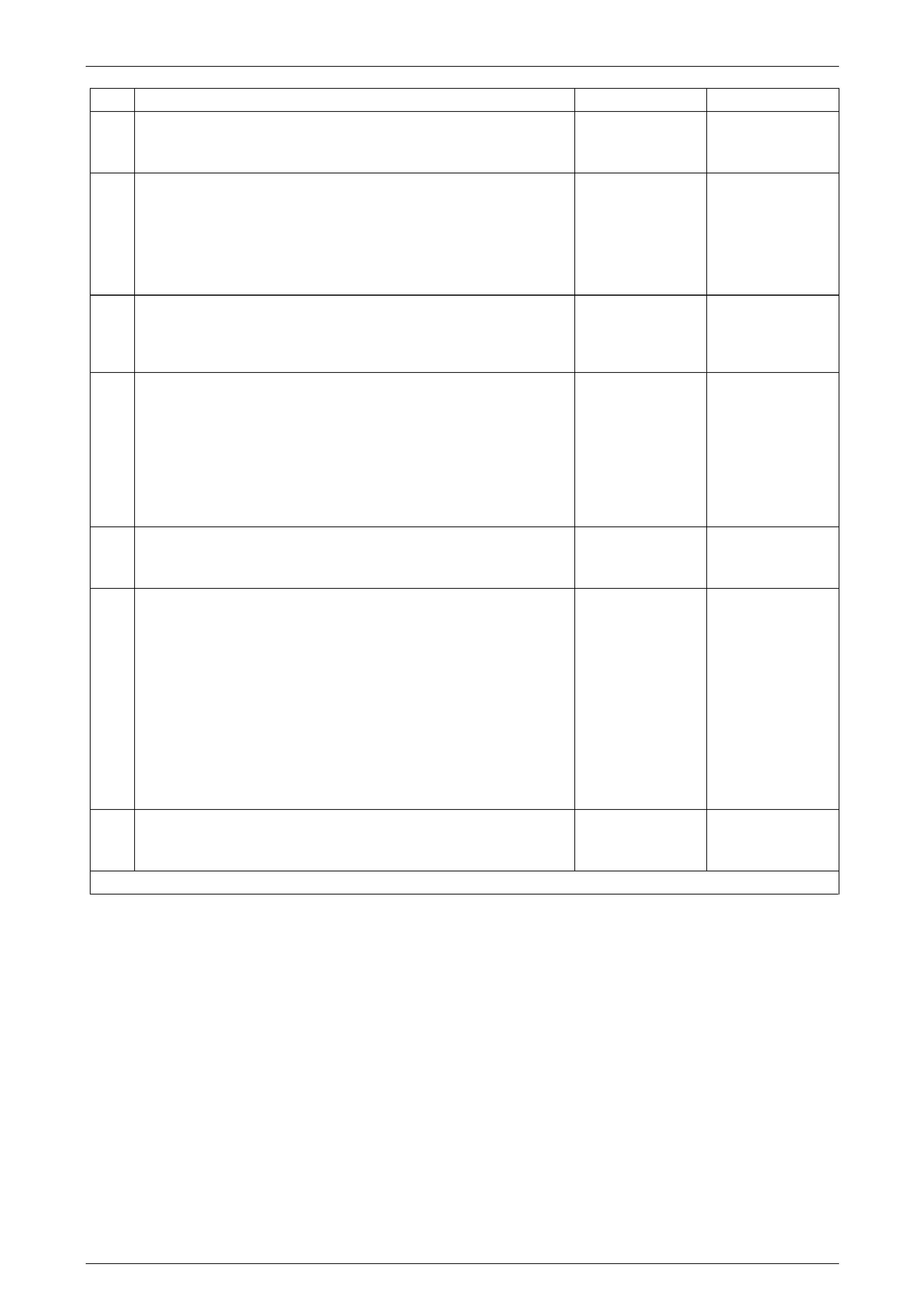

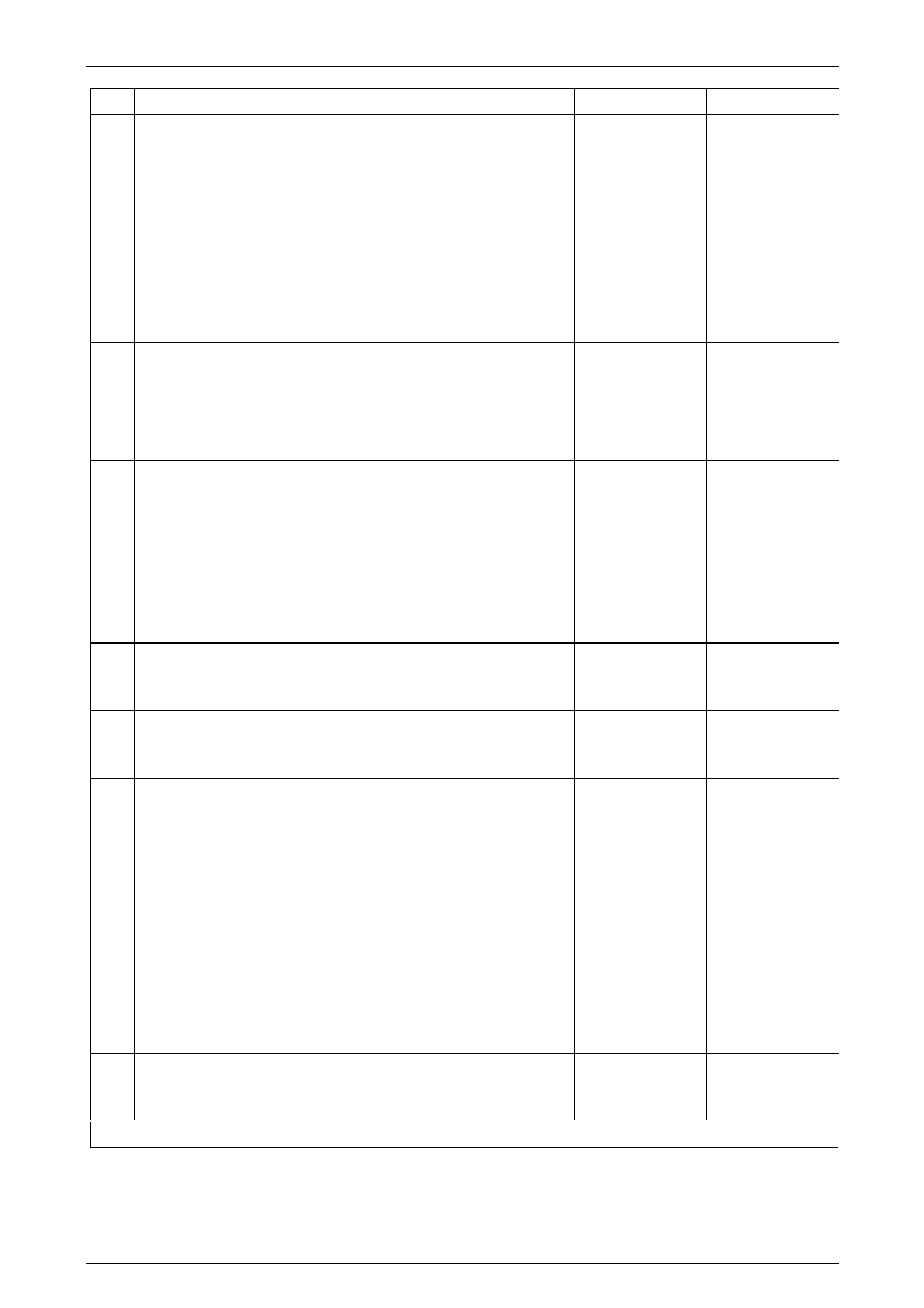

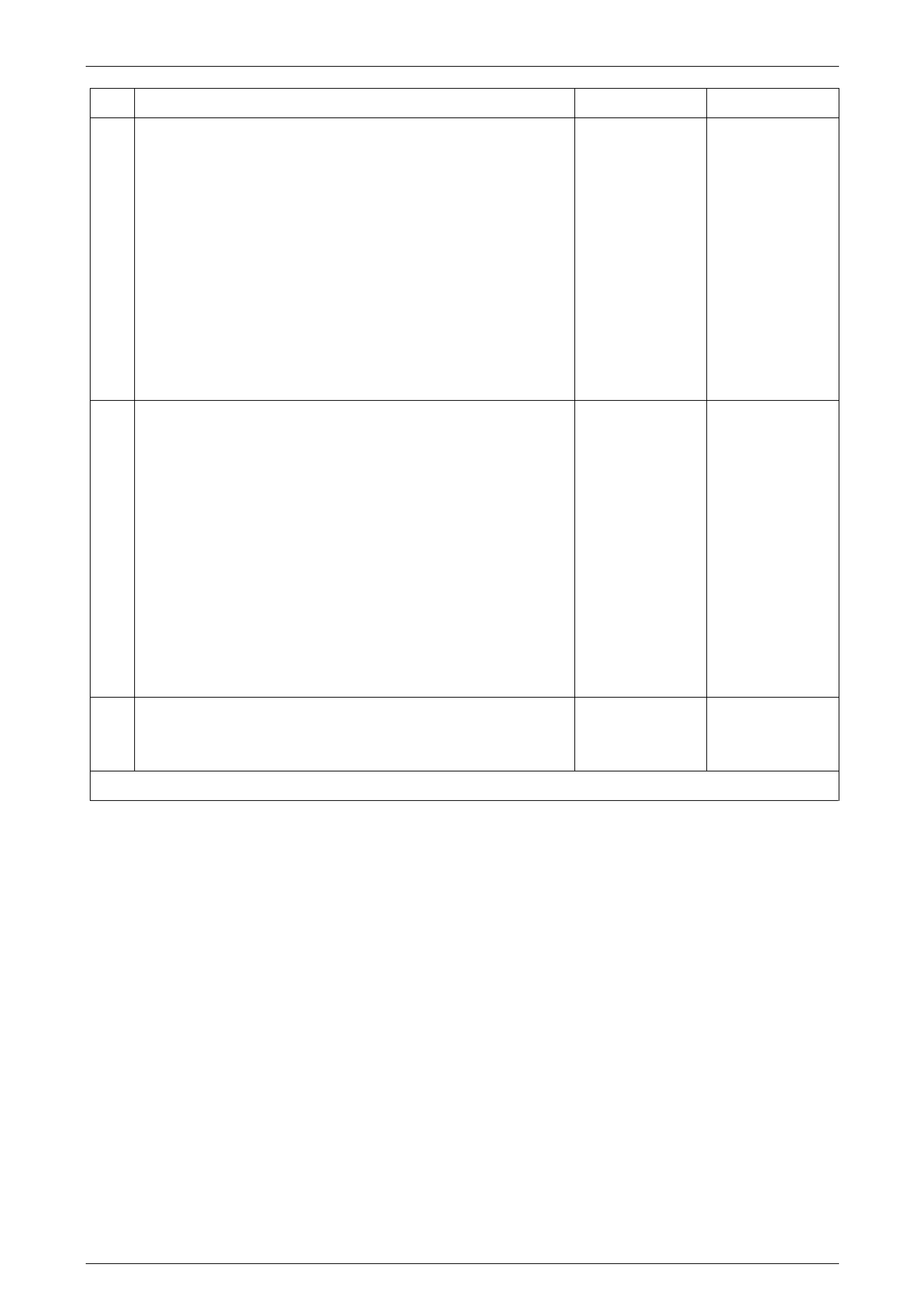

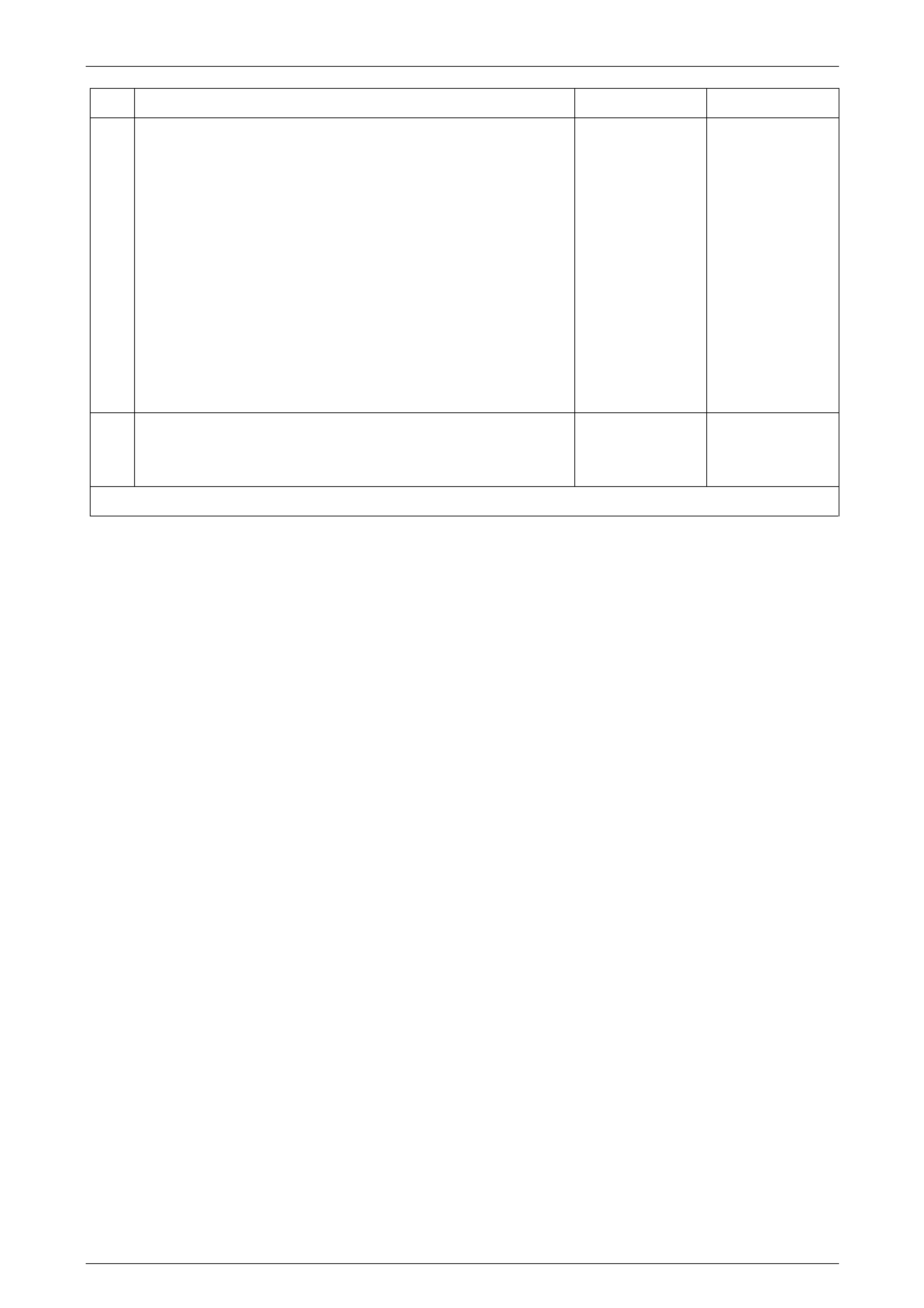

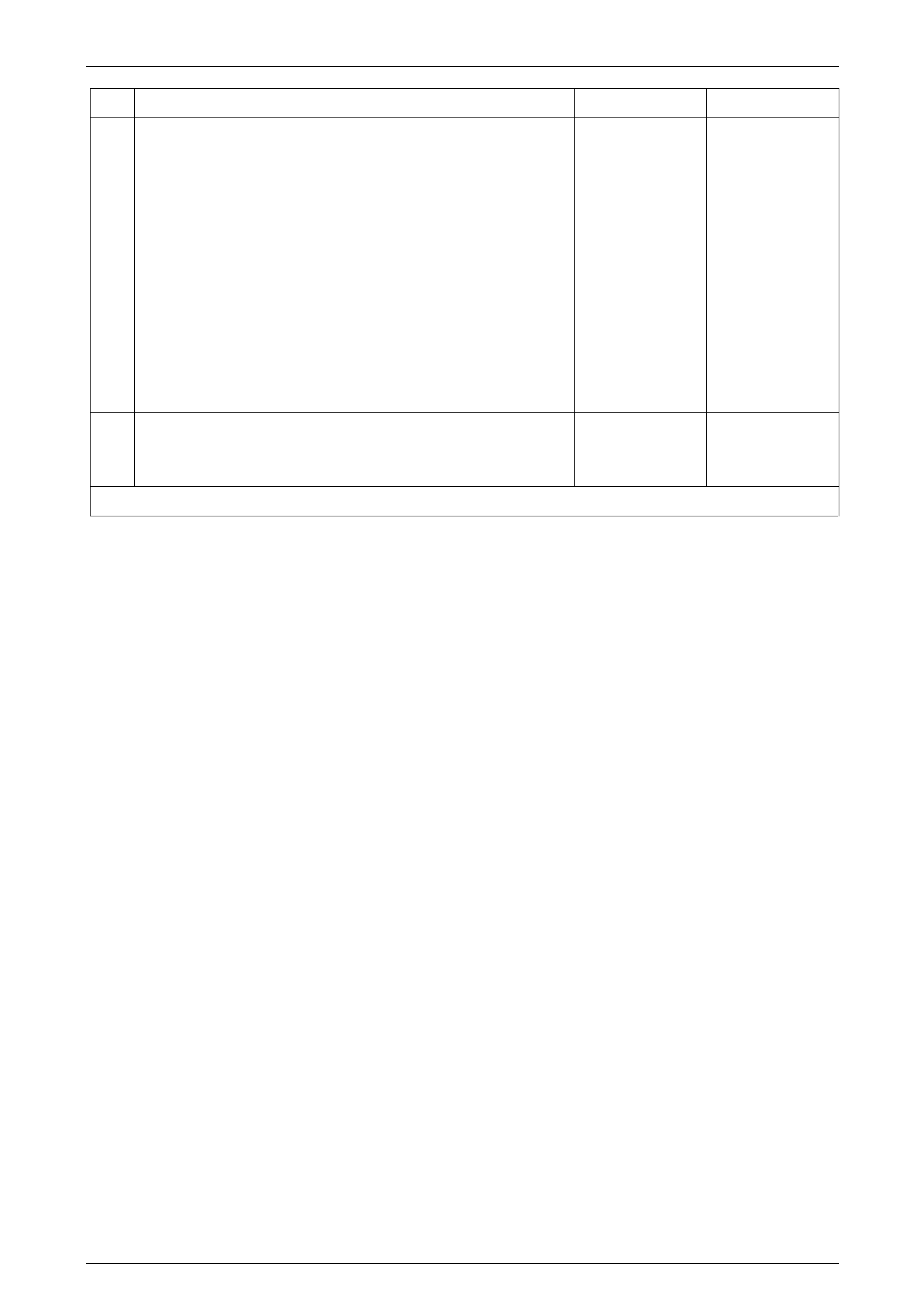

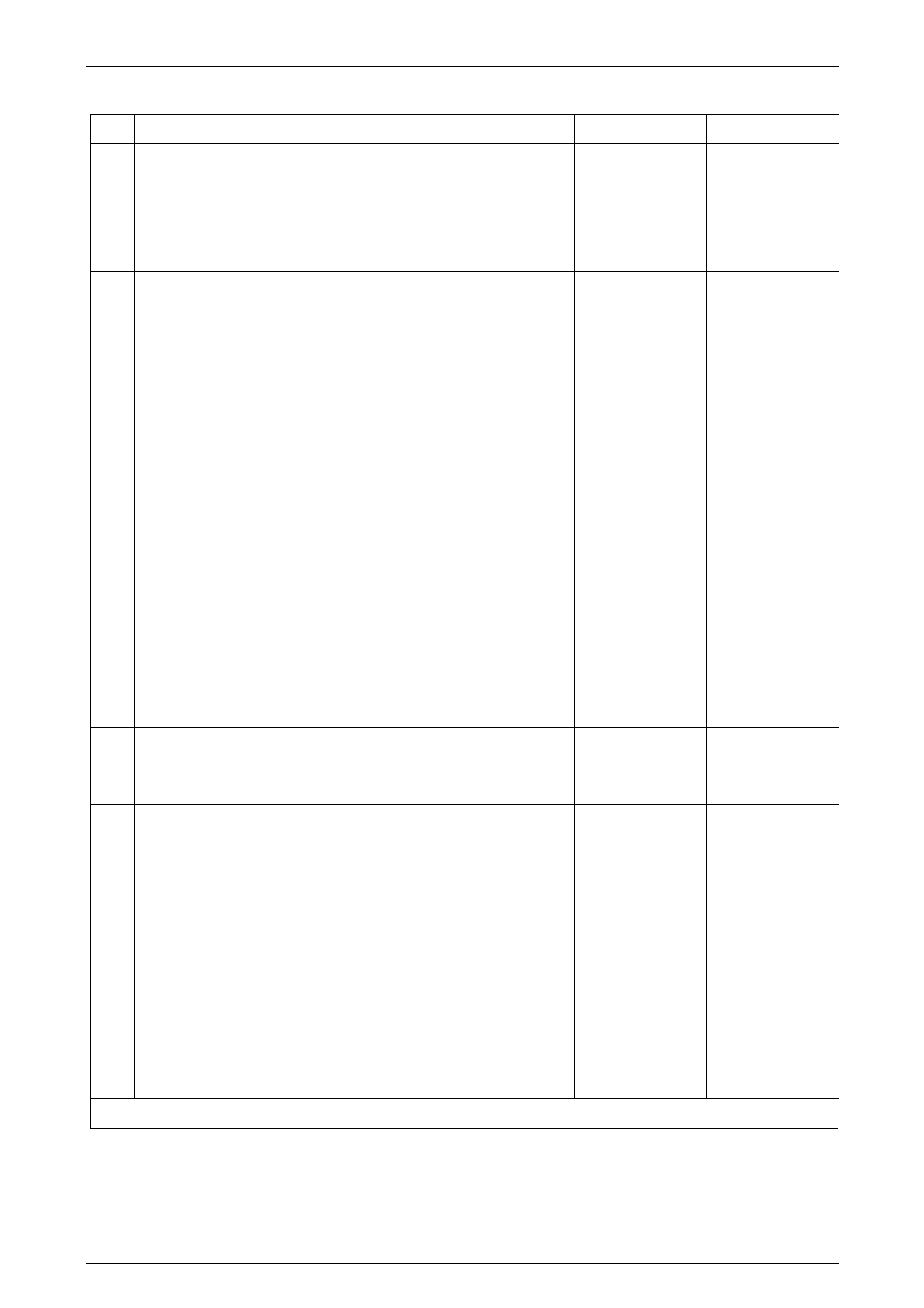

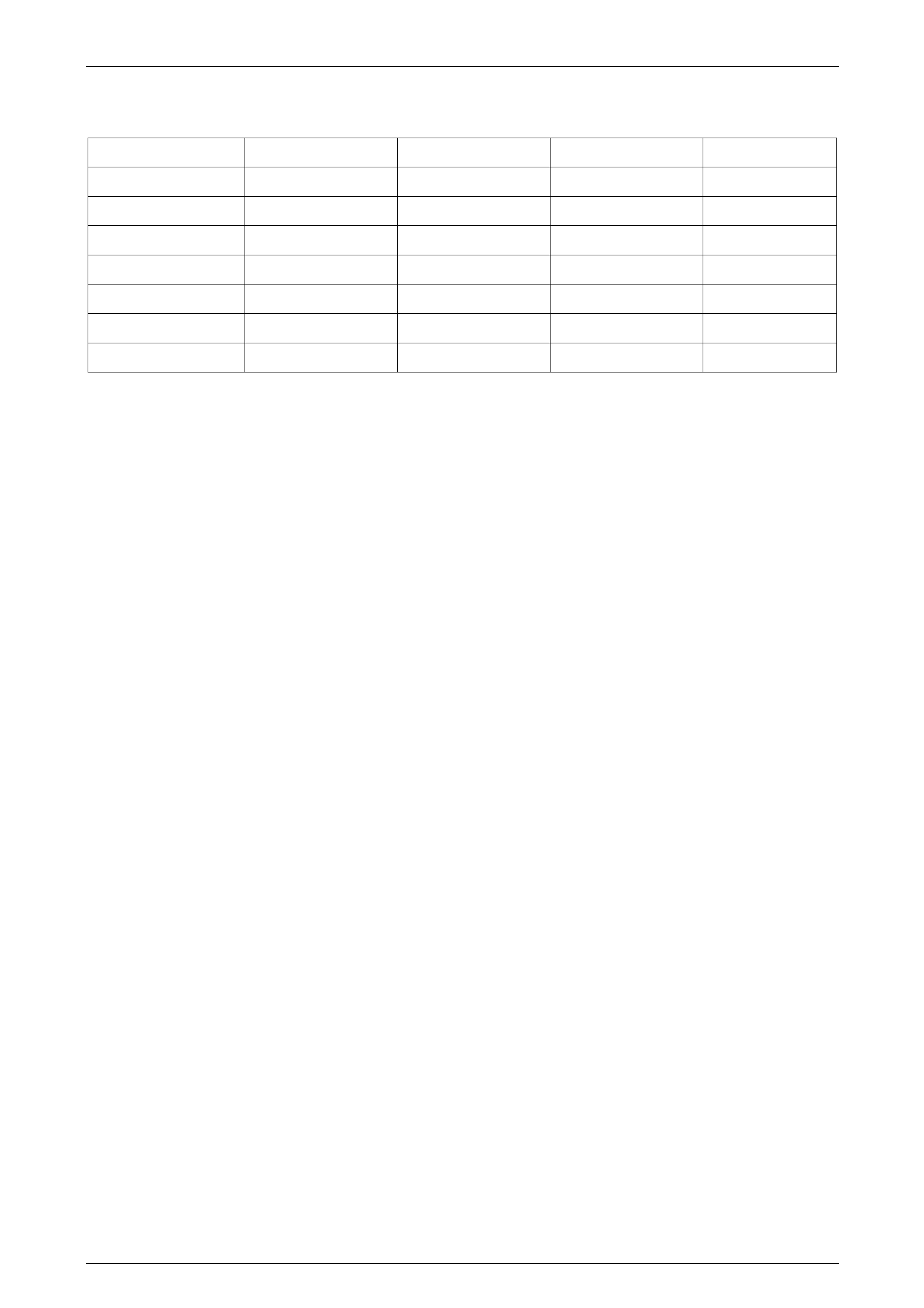

Harness Side – X121–X1

Figure 7C2 – 14

Terminal / Pin Wire Colour Circuit No. Function

X1–A L-GN 1222 1-2 Shift Solenoid Valve Cont rol

X1–B YE / BK 1223 2-3 Shift Solenoid Valve Cont rol

X1–C OG / BK 1228 Pressure Control (PC) Solenoid Valve Low Control

X1–D L-BU / WH 1229 Pressure Control (PC) Solenoid Valve High Control

X1–E PK / BU 339 Ignition Voltage

X1–F — — Not Used

X1–G — — Not Used

X1–H — — Not Used

X1–J — — Not Used

X1–K — — Not Used

X1–L BK 2762 Transmission Fluid Temperature (TFT) Sensor Low Reference

X1–M YE / BK 1227 Transmission Fluid Temperature (TFT) Sensor Signal

X1–N PK 1224 Transmission Fluid Pressure Switch A Sensor Signal

X1–P RD 1226 Transmission Fluid Pressure Switch C Sensor Signal

X1–R BU 1225 Transmission Fluid Pressure Switch B Sensor Signal

X1–S WH 687 3-2 Shift Solenoid Valve Control

X1–T BN / OG 422 Torque Converter Clutch (T CC) Solenoi d Valve Control

X1–U BN 418 Torque Converter Clutch (T CC) PWM Solen oid Va lve Control

X1–V — — Not Used

X1–W — — Not Used

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–21

Page 7C2–21

Internal Connector End Views

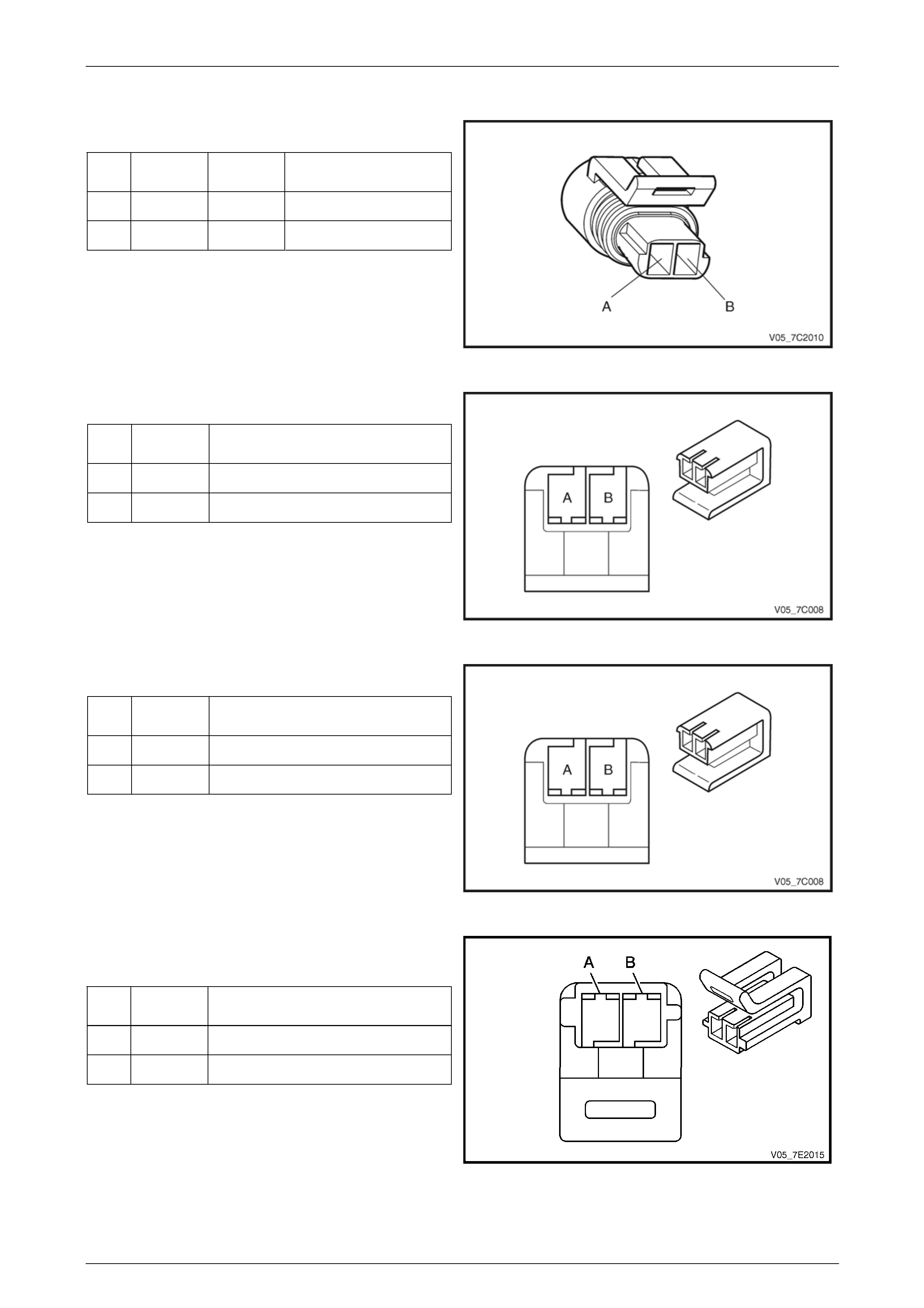

Vehicle Speed Sensor

Pin

Wire

Colour Circuit

No. Function

A YE 400 VSS High Signal

B PU 401 VSS Low Signal

Figure 7C2 – 15

1-2 Shift Solenoid Valve Connector

Pin

Wire

Colour Function

A L-GN 1-2 Shift Solenoid Valve Cont rol

B RD Ignition Voltage

Figure 7C2 – 16

2-3 Shift Solenoid Valve Connector

Pin

Wire

Colour Function

A YE 2-3 Shift Solenoid Valve Control

B RD Ignition Voltage

Figure 7C2 – 17

Pressure Control (PC) Solenoid Valve

Connector

Pin

Wire

Colour Function

A PU PC Solenoid Valve High Control

B L-BU PC Solenoid Valve Control

Figure 7C2 – 18

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–22

Page 7C2–22

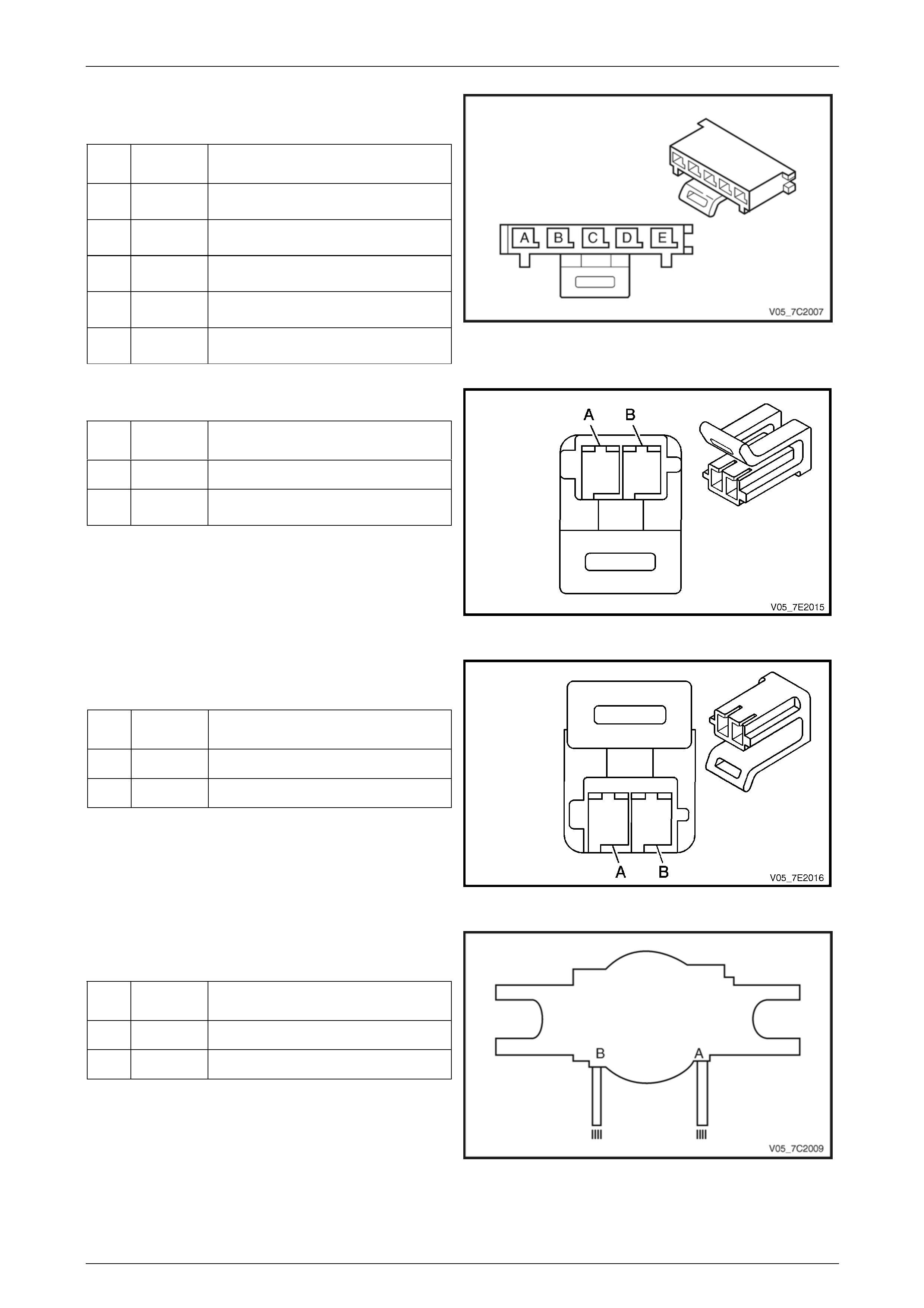

Transmission Manual Shift Shaft S witch

Assembly

Pin Wire

Colour Function

A BN Transmission Fluid Temperat ure

(TFT) Sensor Low Reference

B GY Transmission Fluid Temperat ure

(TFT) Sensor Signal

C PK Transmission Fluid Pressure Switch

Signal A

D OG Transmission Fluid Pressure S witch

Signal C

E BU Transmission Fluid Pressure Switch

Signal B

Figure 7C2 – 19

3-2 Shift Solenoid Valve Assembly Connector

Pin

Wire

Colour Function

A RD Ignition Voltage

B WH 3-2 Downshift Solenoid Valve

Control

Figure 7C2 – 20

Torque Converter Clutch (TCC) Pulse-Width

Modulated (PWM) Solenoid Valve Connector

Pin

Wire

Colour Function

A RD Ignition Voltage

B TN TCC PWN Solenoid Valve Control

Figure 7C2 – 21

Torque Converter Clutch (TCC) Solenoid Valve

Connector

Pin

Wire

Colour Function

A RD / BK Ignition Voltage

B BK TCC Solenoid Valve Control

Figure 7C2 – 22

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–23

Page 7C2–23

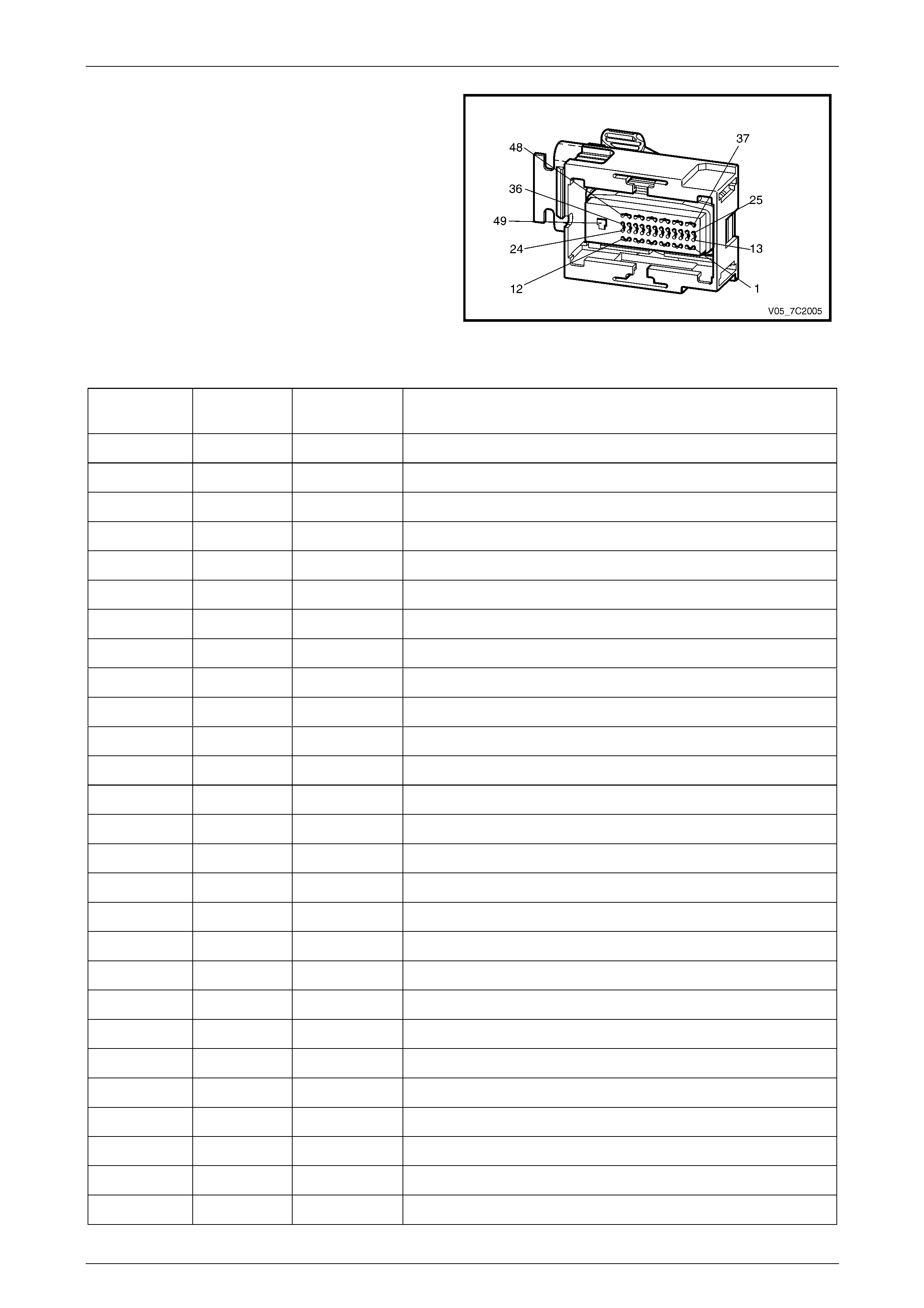

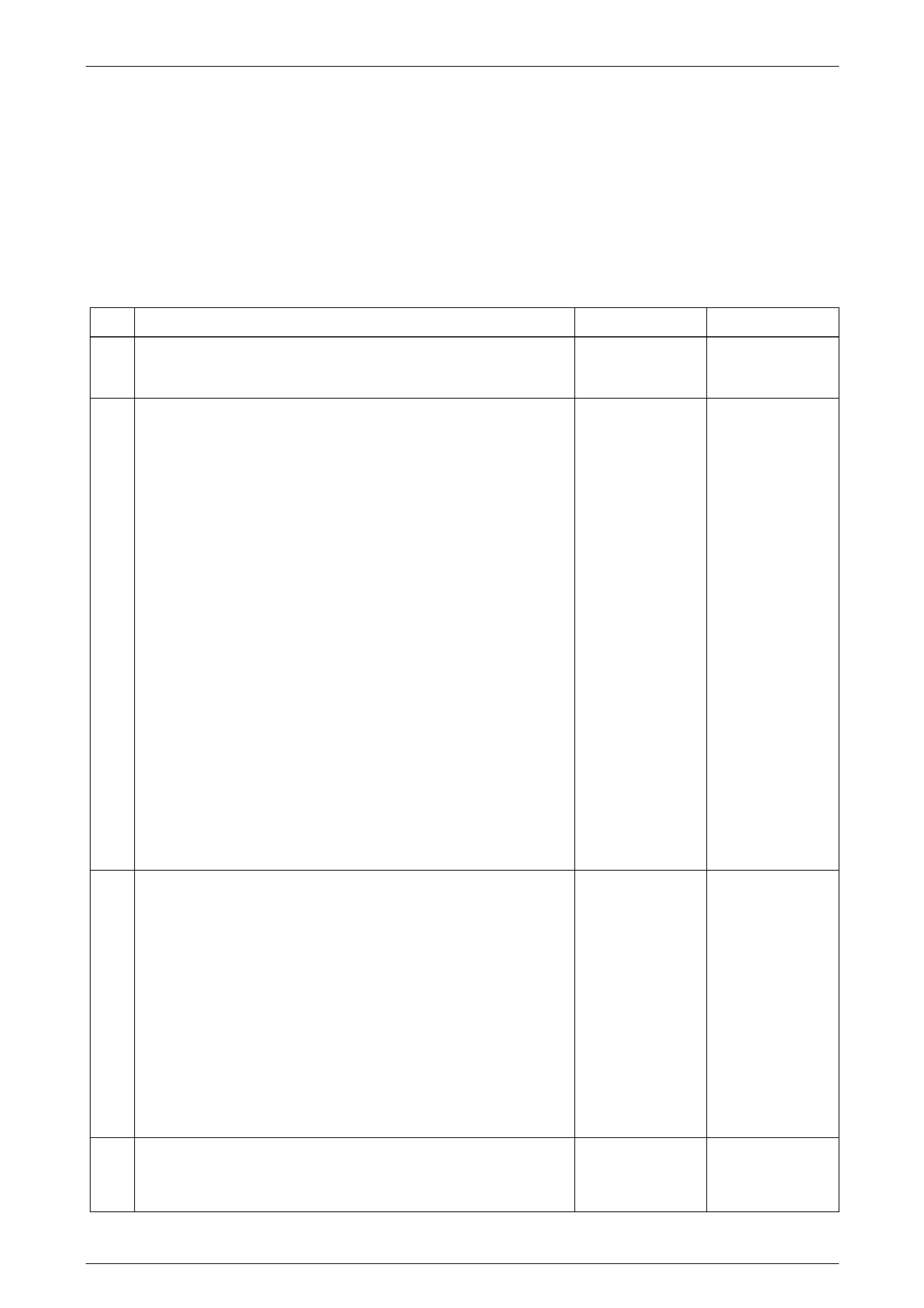

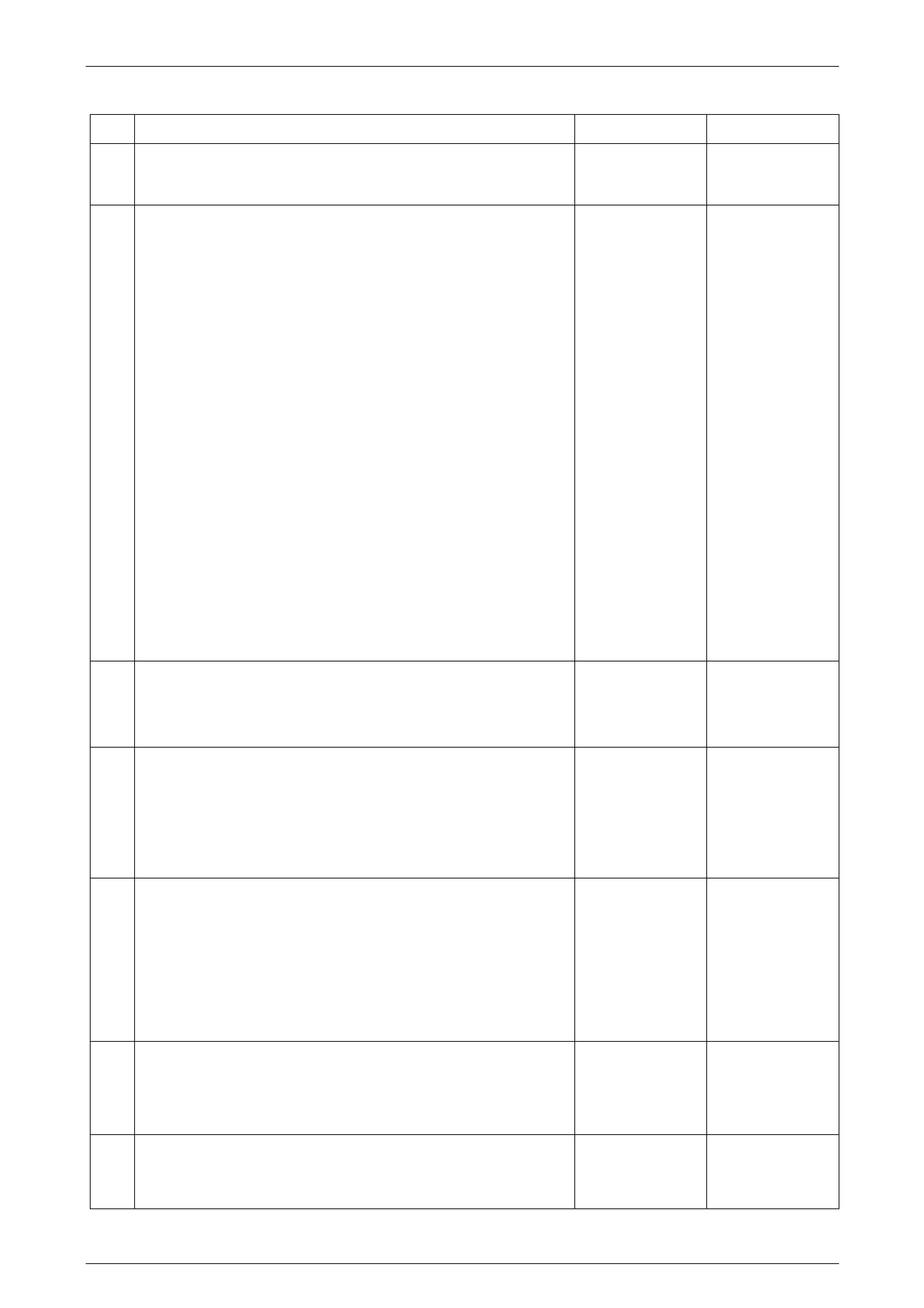

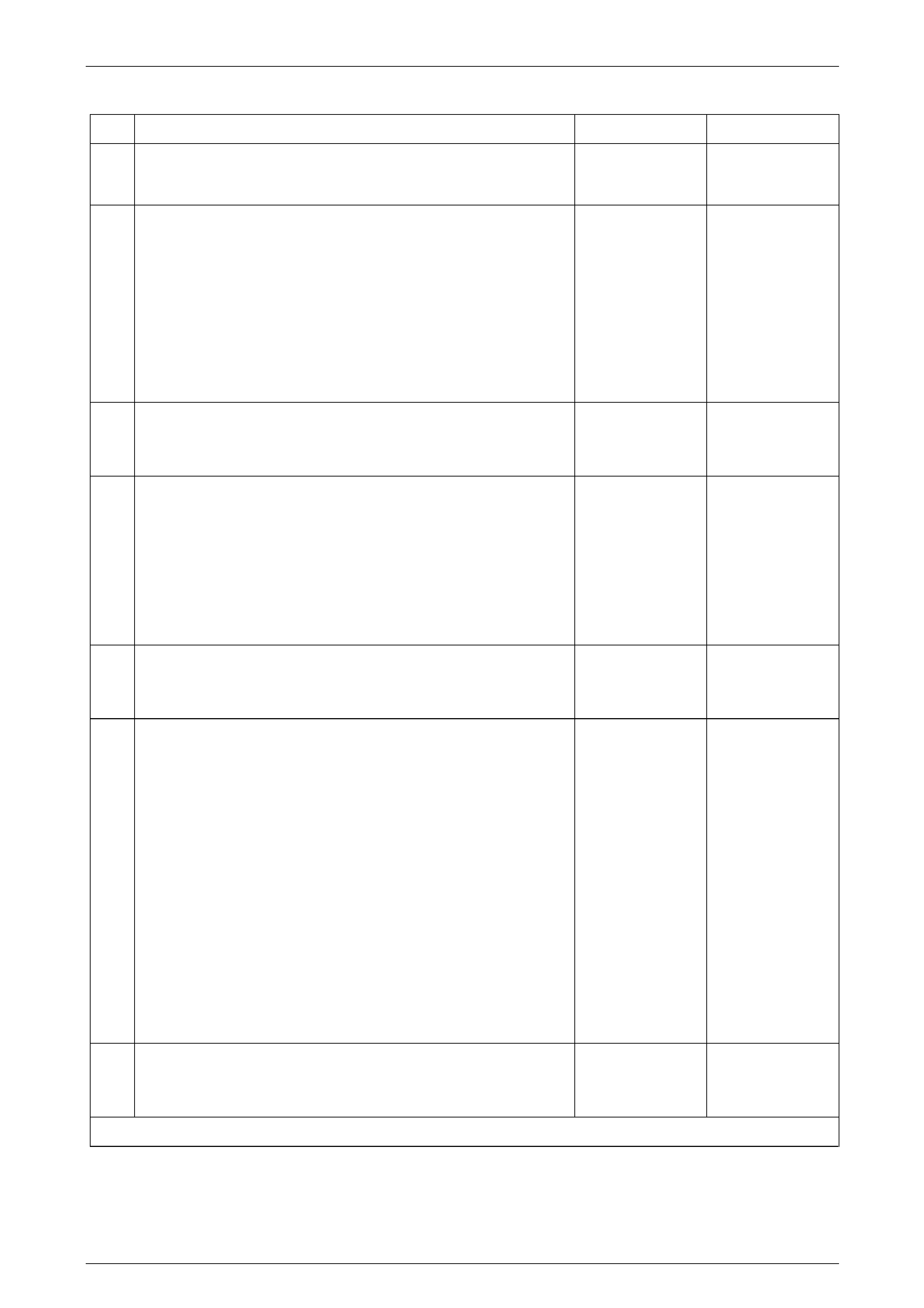

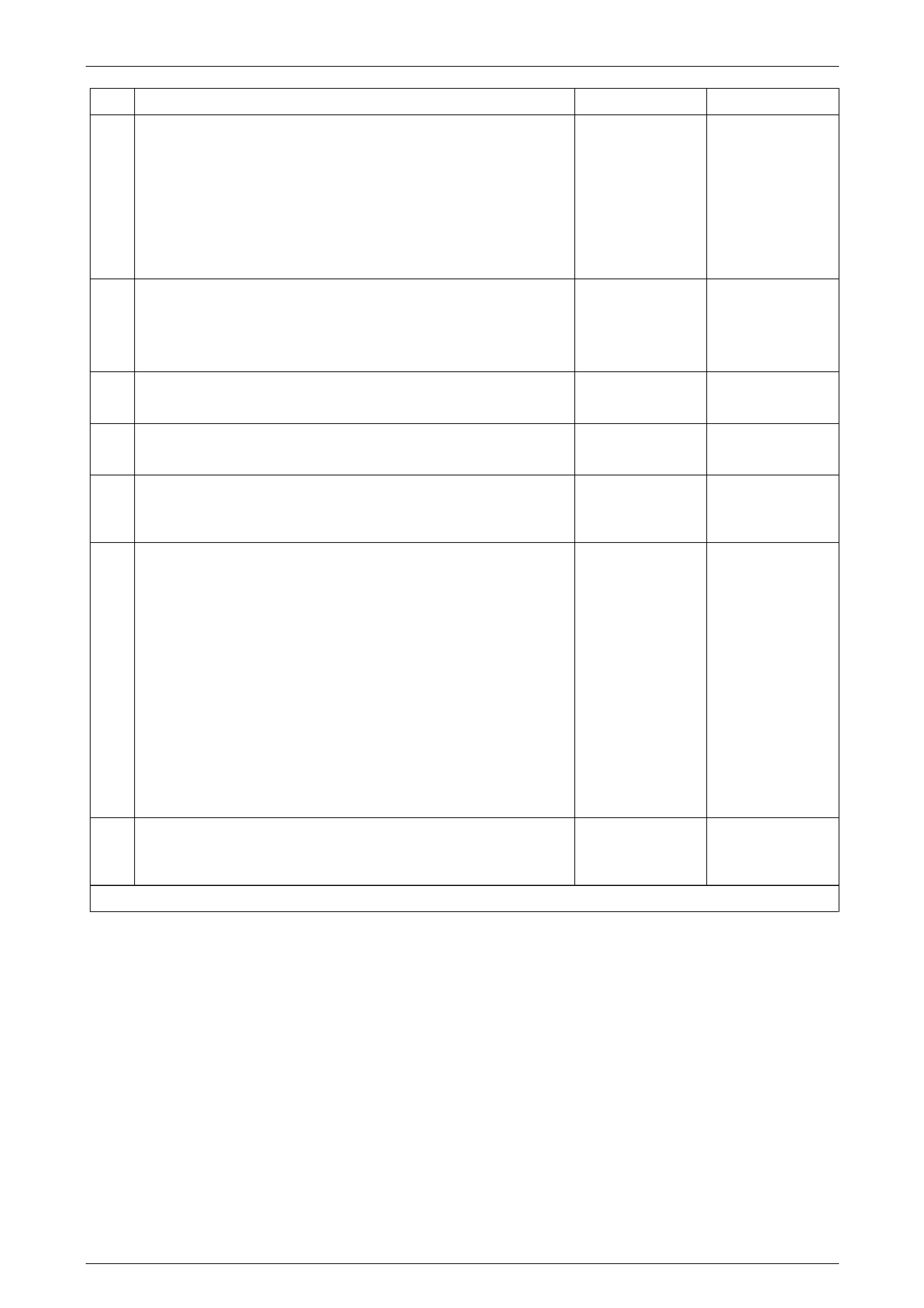

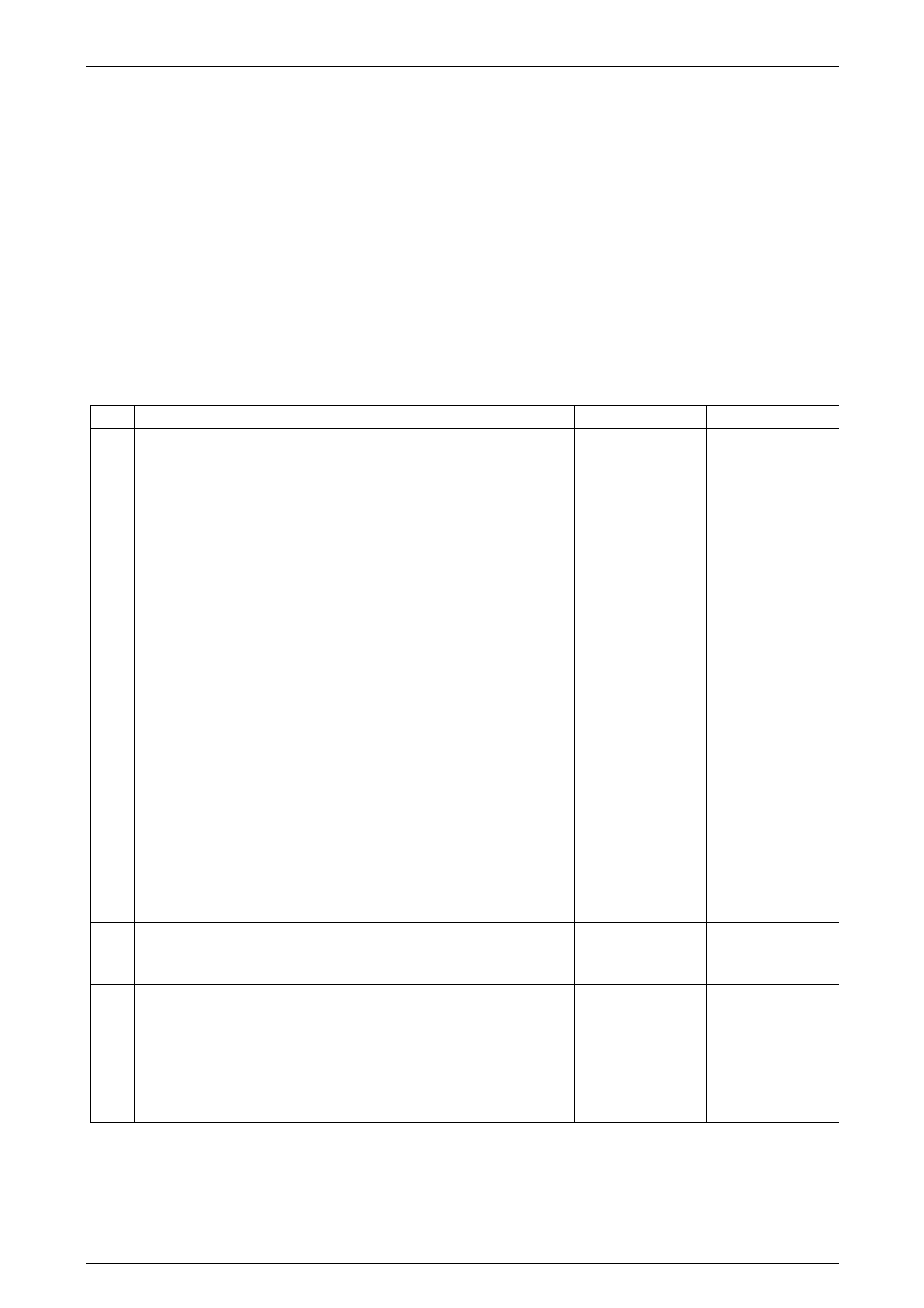

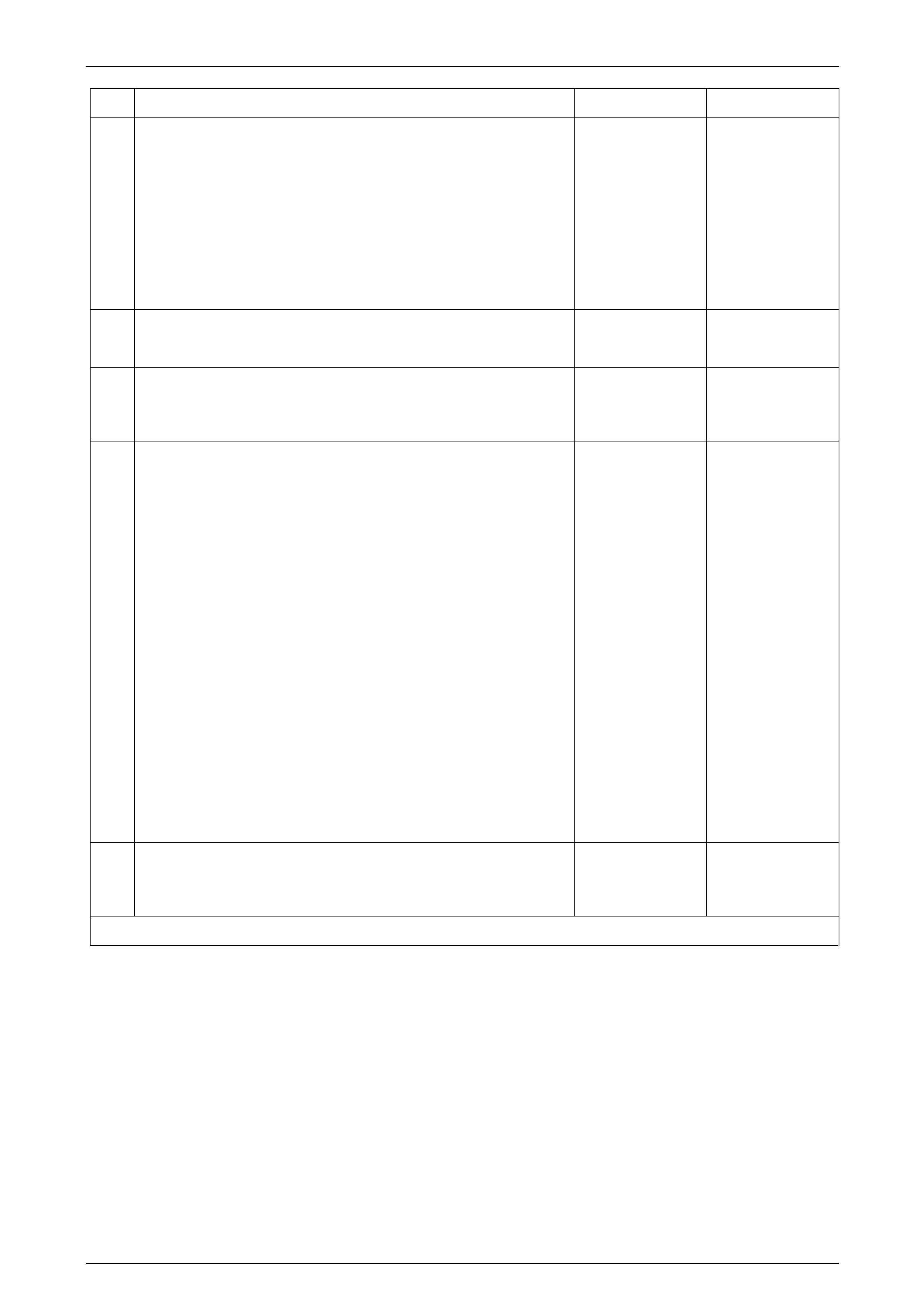

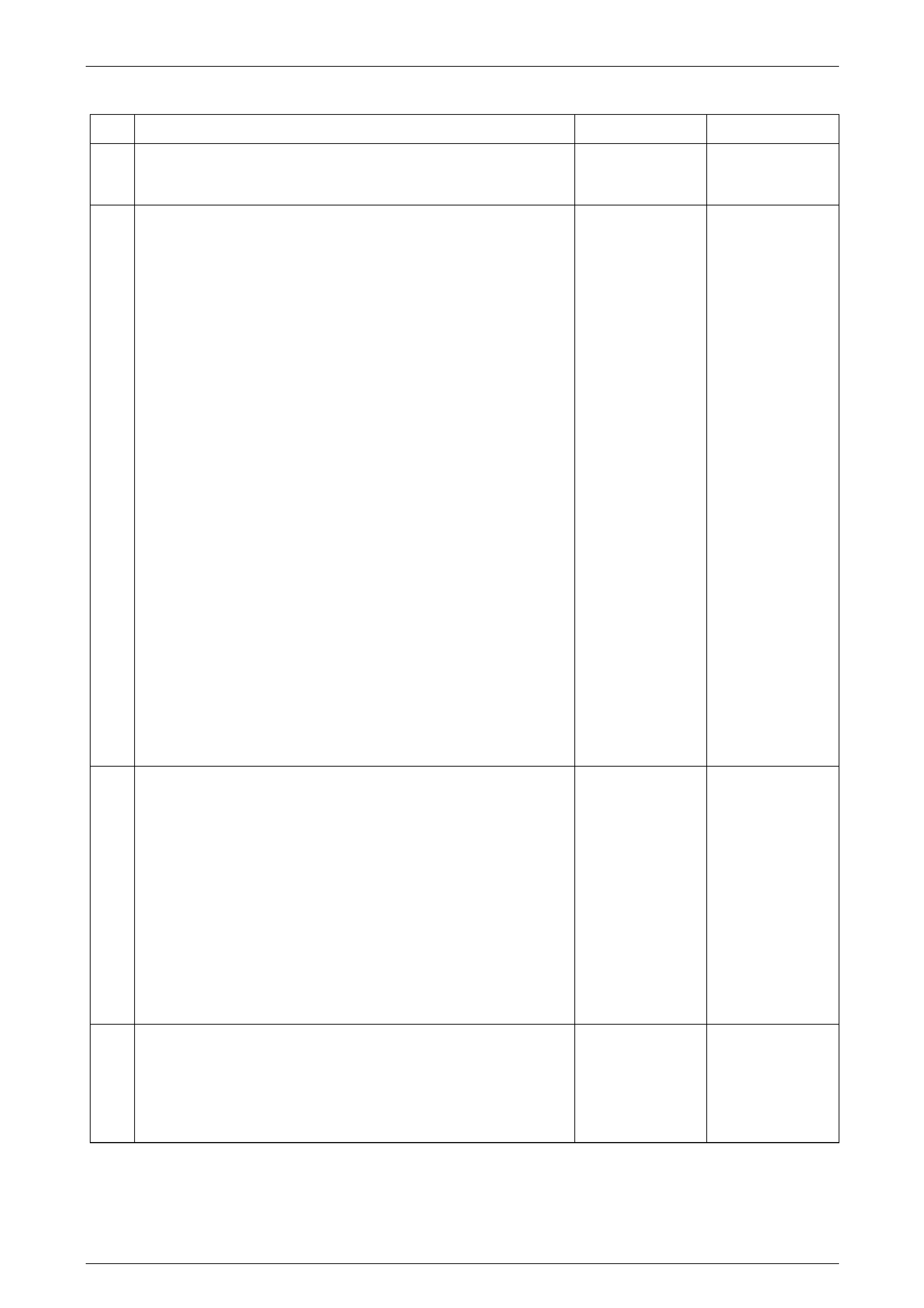

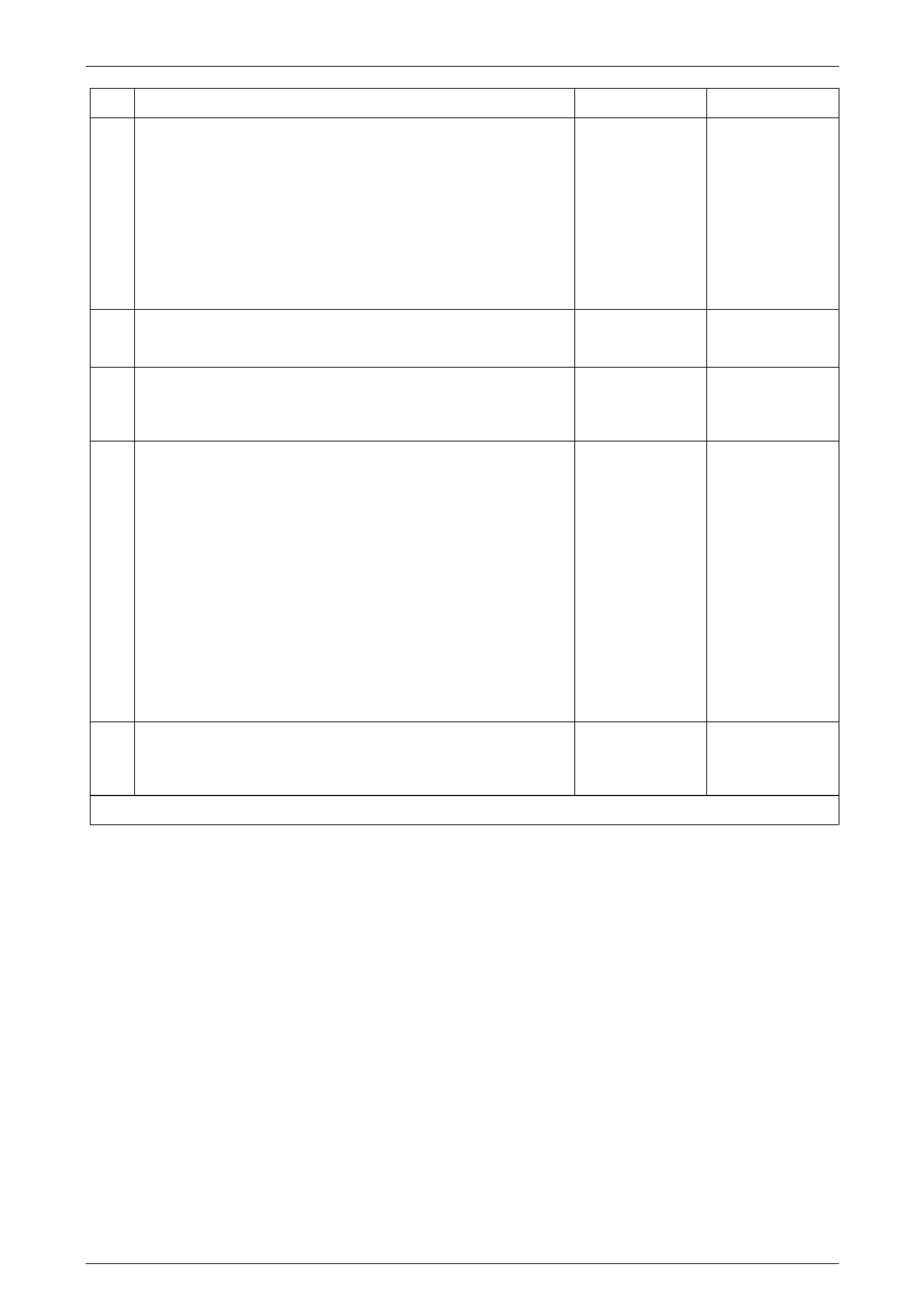

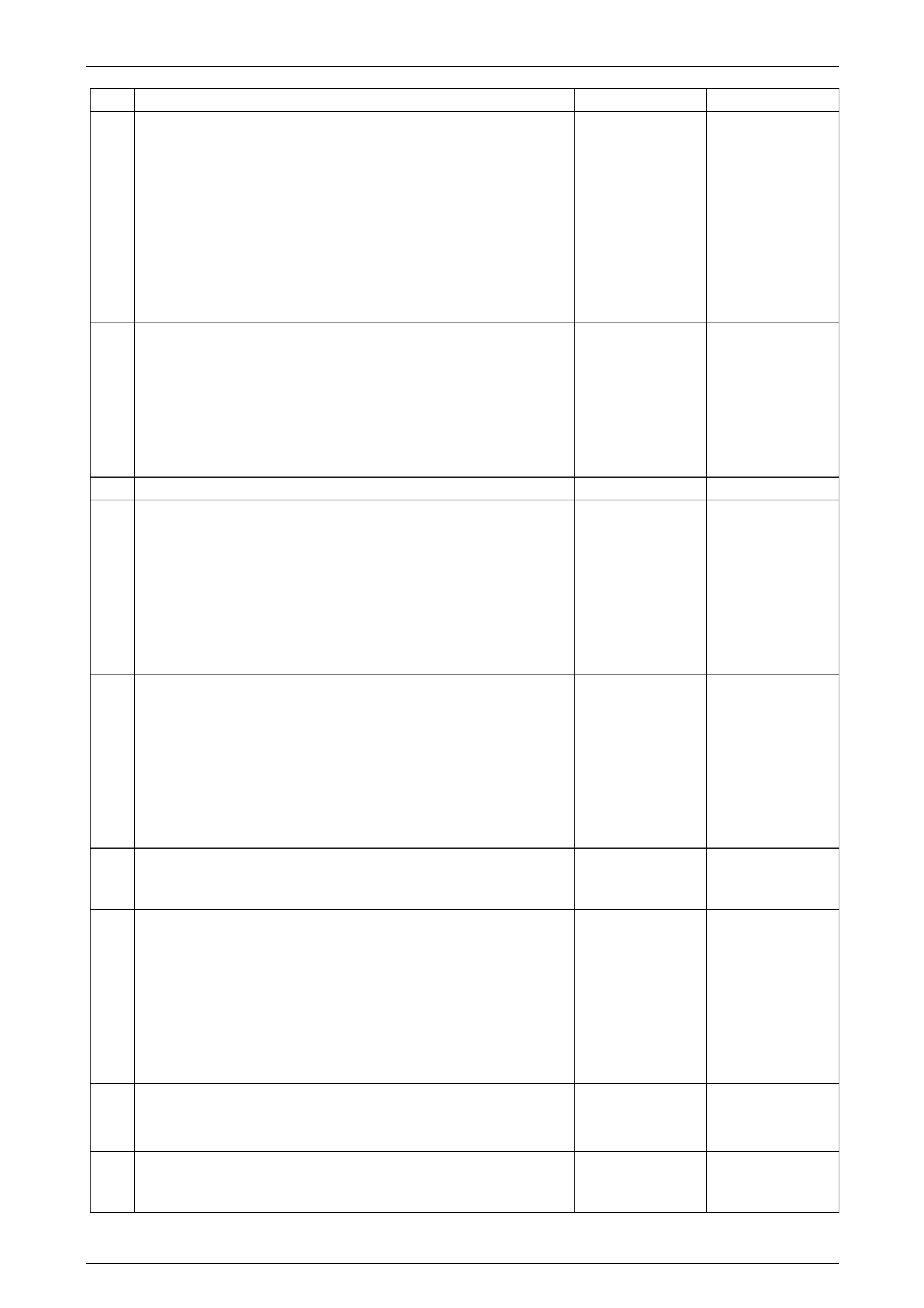

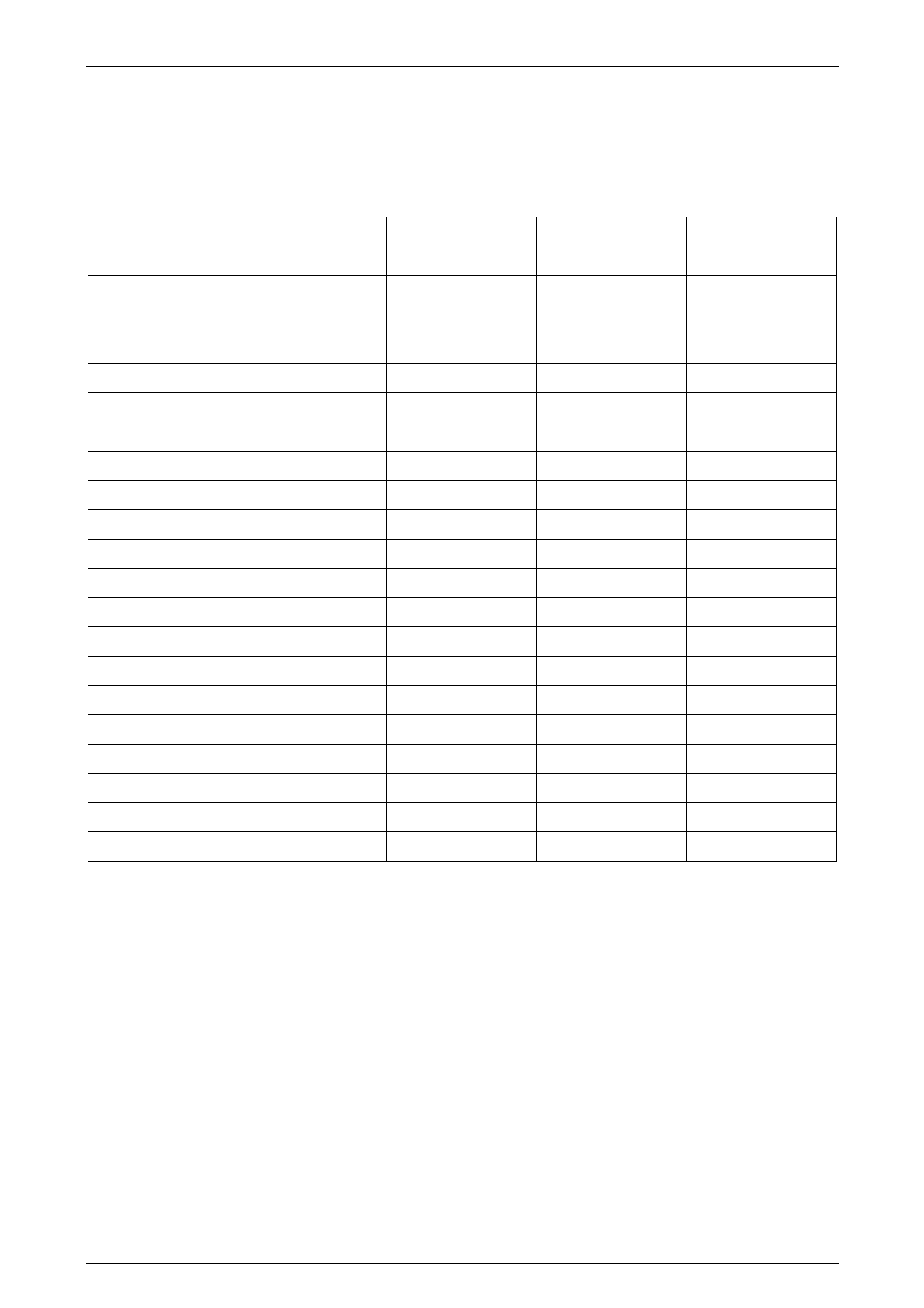

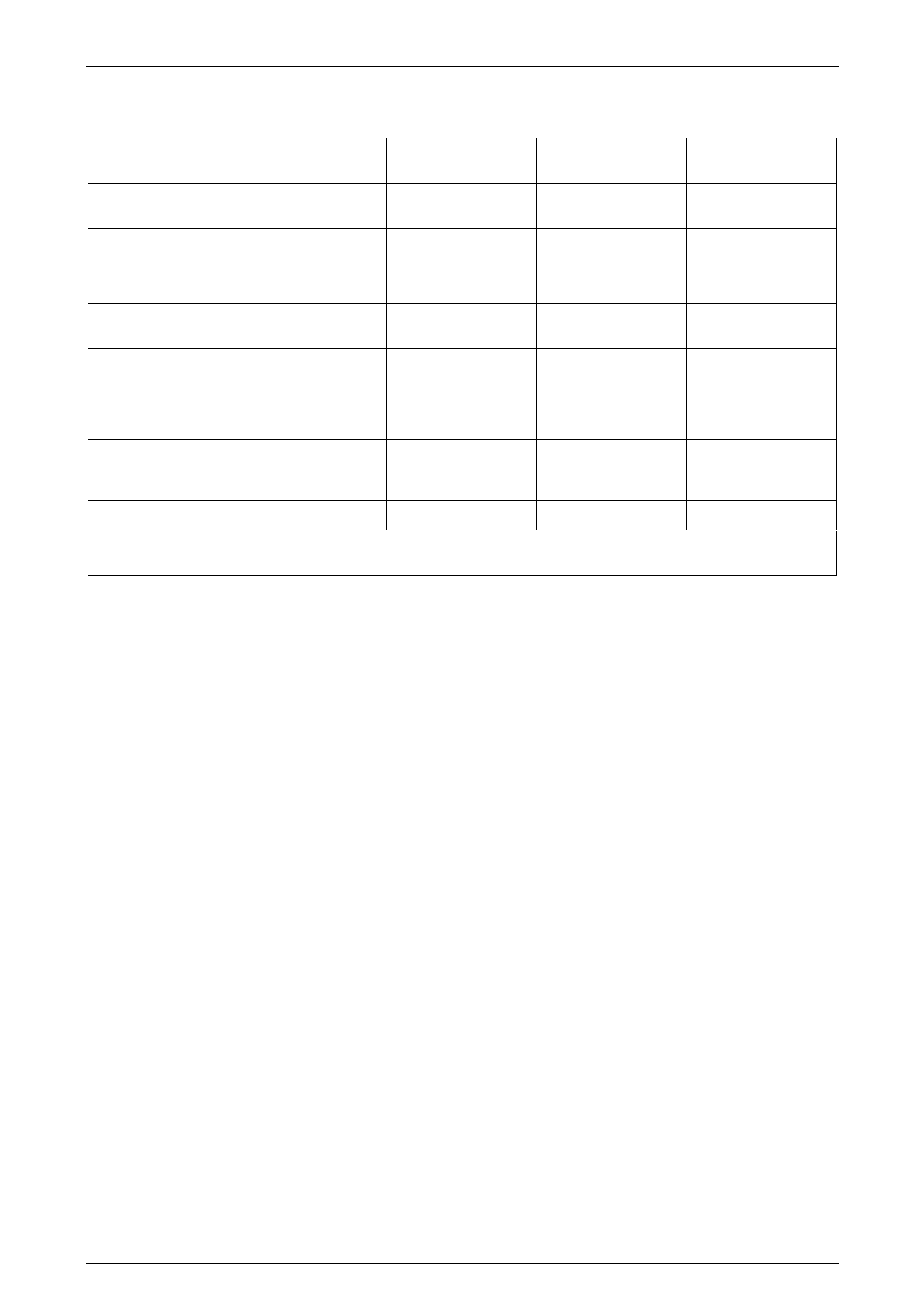

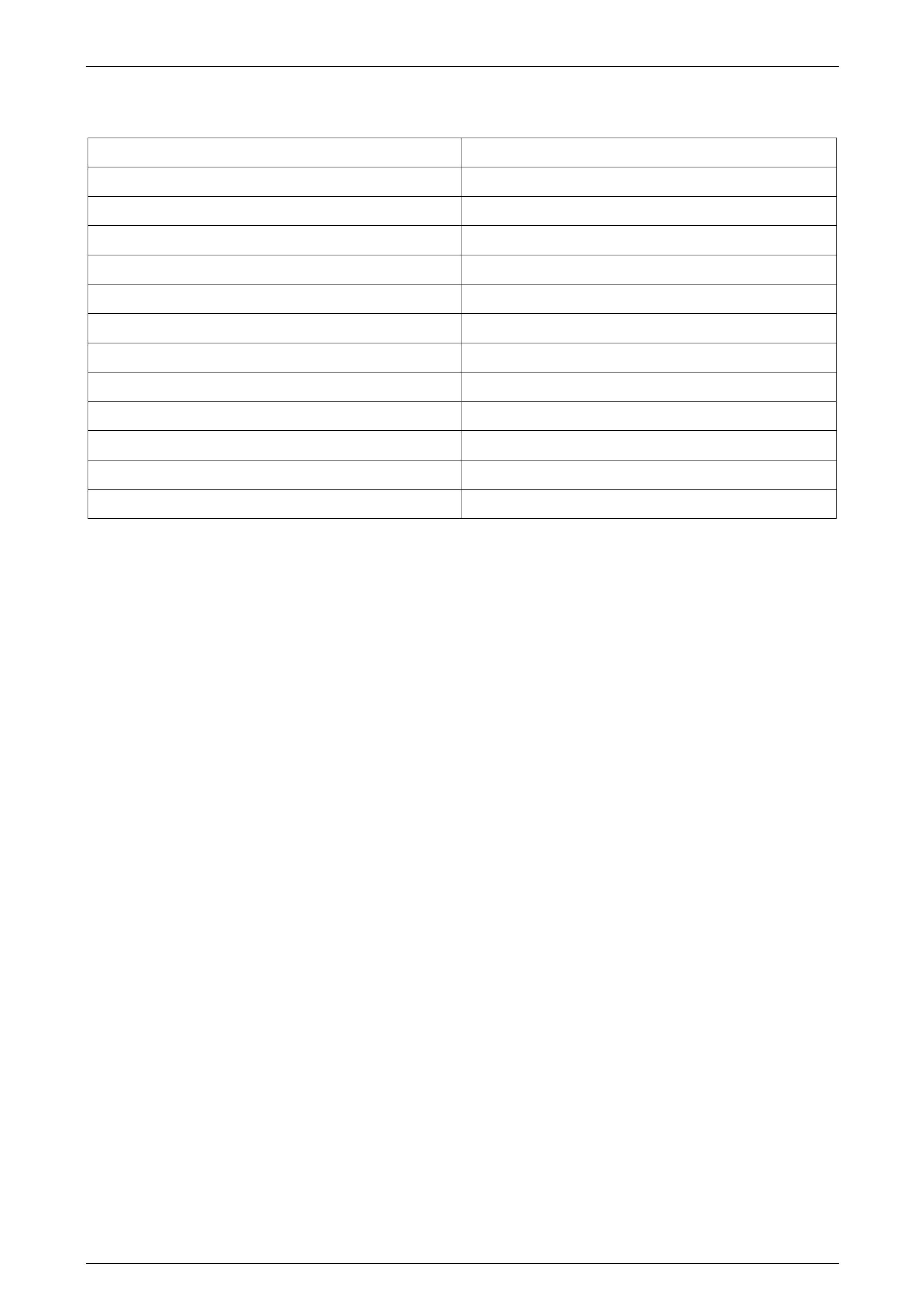

Transmission Control Module Connector End

View – A112–X1

Figure 7C2 – 23

Terminal/

Pin Wire Colour Circuit No. Function

X1–1 BN 418 Torque Converter Clutch (TCC) PWM Solenoid Va lve Control

X1–2 L-GN 1222 1-2 Shift Solenoid Va lve Control (Solenoid A)

X1–3 — — Not Used

X1–4 — — Not Used

X1–5 — — Not Used

X1–6 BN 2501 High Speed GMLAN Serial Data Bus – (CAN 2 Low)

X1–7 BN / BK 2500 High Speed GMLAN Serial Data Bus – (CAN 2 High)

X1–8 — — Not Used

X1–9 — — Not Used

X1–10 — — Not Used

X1–11 BN 4 Accessory Voltage

X1–12 — — Not Used

X1–13 — — Not Used

X1–14 WH 687 3-2 Downshift Solenoid Valve Control

X1–15 — — Not Used

X1–16 PU 401 Output Speed (OSS) Sensor – Lo w Signal

X1–17 L-BU / WH 1229 Pressure Control (PC) Solenoid Valve High Control

X1–18 — — Not Used

X1–19 — — Not Used

X1–20 YE / BK 1223 2-3 Shift Solenoid Valve Control (Solenoid B)

X1–21 — — Not Used

X1–22 — — Not Used

X1–23 GY 773 Park/Neutral Position and Back-up Lam p Switch C Signal

X1–24 PK 1224 Transmission F luid Pressure Switch A Signal

X1–25 BN / OG 422 Torque Converter Clutch (TCC) Solenoid Va lve Control

X1–26 — — Not Used

X1–27 — — Not Used

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–24

Page 7C2–24

X1–28 — — Not Used

X1–29 BN / YE 771 Park/Neutral Position and Back-up Lamp Switch A Signal

X1–30 BK 2762 Transmission F luid Temperature (TFT ) Sensor Low Reference

X1–31 PK / BU 339 Ignition Voltage

X1–32 OG / BK 740 Battery Voltage

X1–33 RD 1226 Transmission F luid Pressure Switch C Signal

X1–34 — — Not Used

X1–35 YE / BK 1227 Transmission Fluid Temperature (TFT) Sensor High Signal

X1–36 — — Not Used

X1–37 BN 2501 High Spee d GMLAN Serial Data Bus (CAN 1 Low)

X1–38 BN / BK 2500 High Speed GMLAN Serial D ata Bus (CAN 1 High)

X1–39 WH 776 Park/Neutral Position and Back-up Lamp Switch P Sign al

X1–40 OG / BK 1228 Pressure Control (PC) Solenoid Valve Low Control

X1–41 YE 400 Output Speed (OSS) Sensor – High Signal

X1–42 BU / RD 20 Stop Lamp Switch Signal

X1–43 — — Not Used

X1–44 BU 1225 Transmission Fluid Pressure S witch B Signal

X1–45 — — Not Used

X1–46 YE 772 Park/Neutral Position and Back-up Lamp Switch B Signal

X1–47 — — Not Used

X1–48 — — Not Used

X1–49 BK / WH 451 Power Ground

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–25

Page 7C2–25

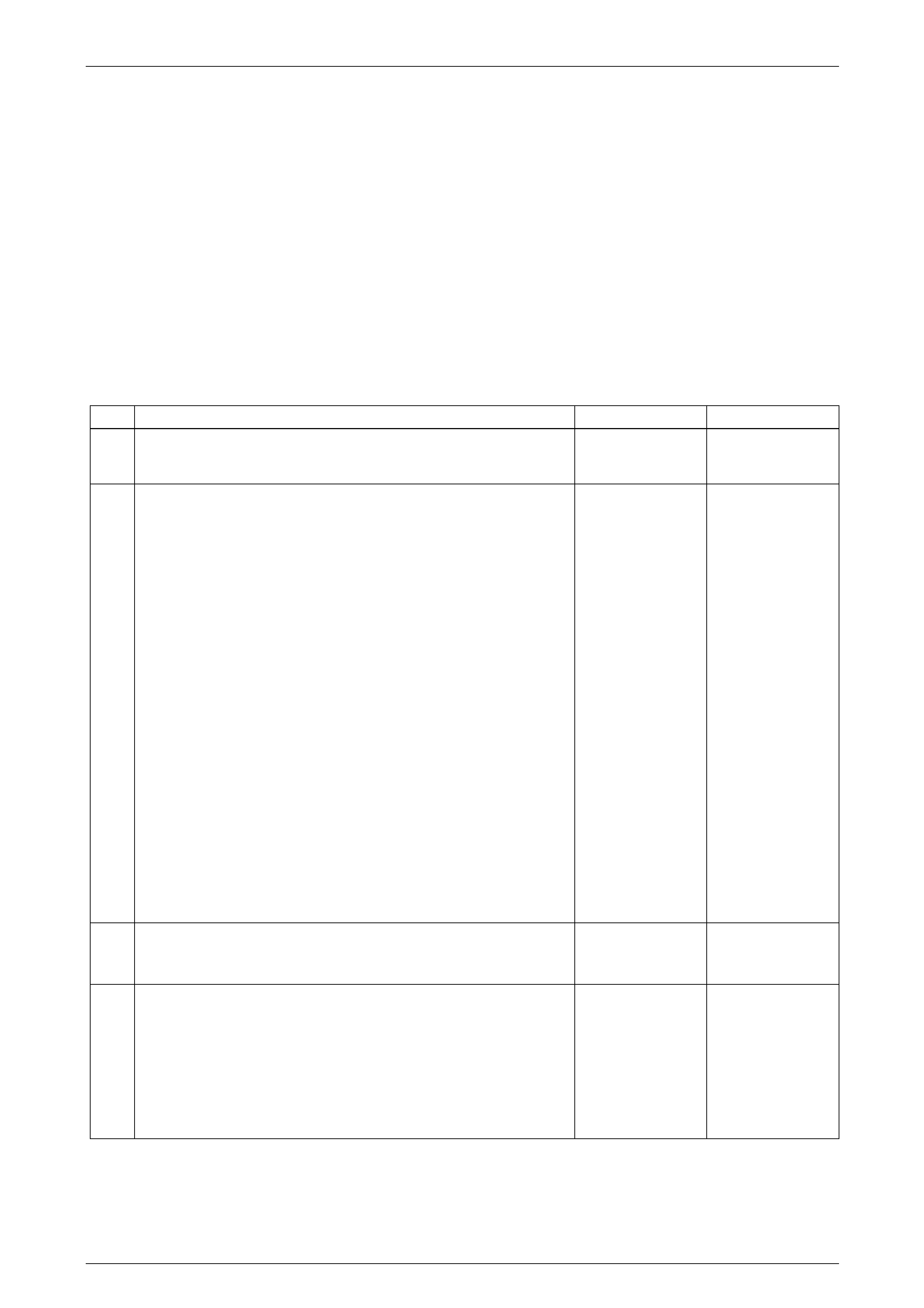

3 Tech 2 Information

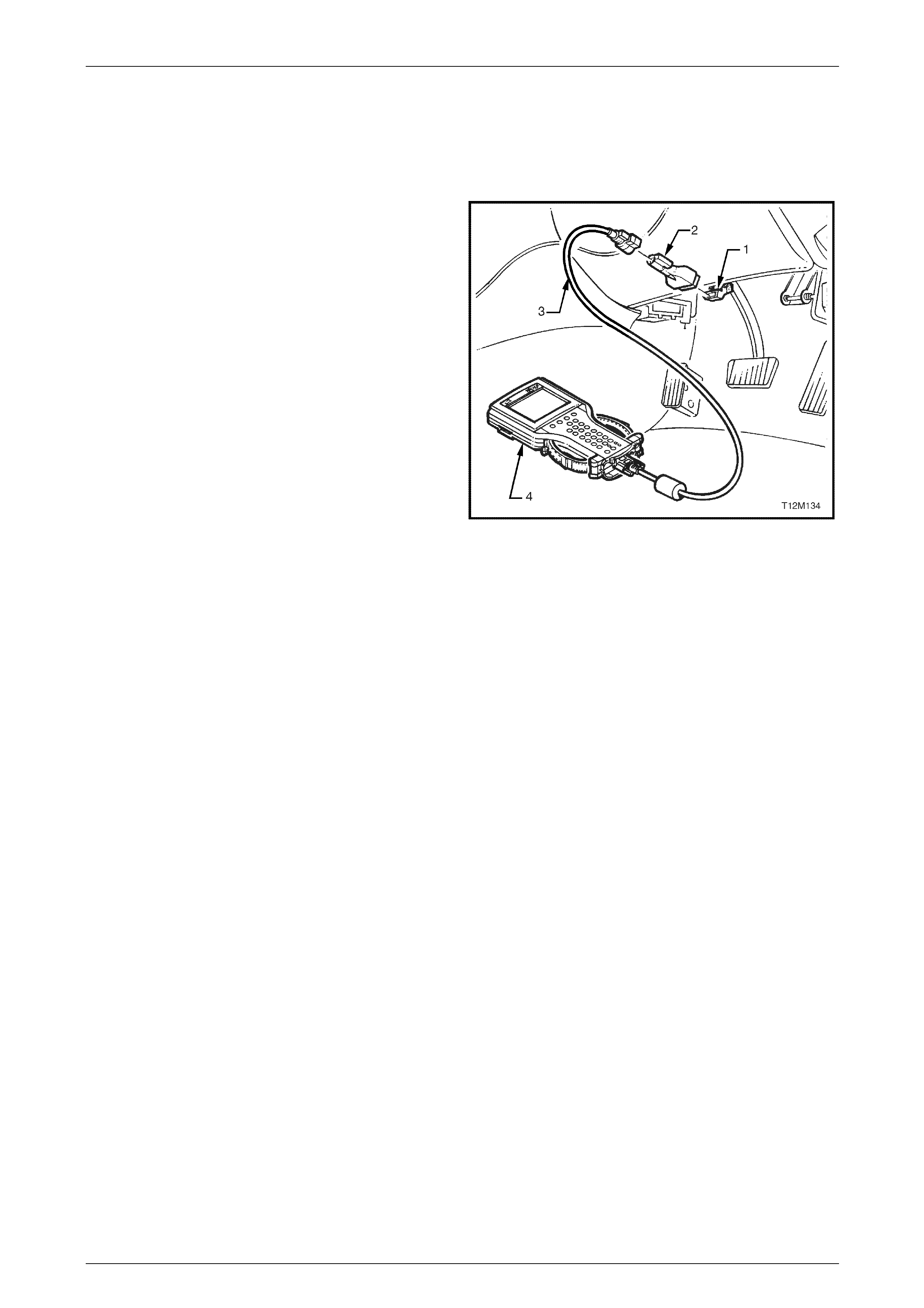

3.1 Tech 2 Diagnostics

Tech 2, with the appropriate software, cables and adapters,

when connected to the serial data link con ne ctor (DLC) can

read seat and exterior rear-view mirror serial data. The DLC

is attached to the instrument panel trim retai ner beneath the

steering wheel.

1 DLC

2 DLC Adapter

3 DLC Cable

4 Tech 2

For additional general information on connecting and

operating Tech 2, refer to Section 0C Tech 2.

Figure 1A7 – 24

Test Modes

Tech 2 has six test modes for diagnos ing the transmission. To get to these various test modes, on Tech 2 select:

Diagnostics / Model Year / Model / Transmission / Automatic Transmission

and follow Tech 2’s prompts. This will then display the following menu operations.

Diagnostic Trouble Codes

If Diagnostic Trouble Codes is selected, a selection list is displayed which contains:

• Read DTC Information – Once selected, both current and history diagnostic trouble co des (DTCs) stored in the

transmission control module will be displayed.

• Clear Engine & Transmission DTC(s) – Once selected, DTCs stored in the transmission control module (TCM)

and engine control module (ECM) memory may be cleared.

• Freeze Frame / Failure Records – Shows Freeze Frame / Failure Records information. Freeze Frame / Failure

Records are types of snapshots stored in the memory of the TCM and contain data parameters from the TCM at

the time the DTC set.

NOTE

For a complete list of TCM DTCs, refer to

4.6 Diagnostic Trouble Code List. For further

information on Tech 2 and it functions, refer to

Section 0C Tech 2.

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–26

Page 7C2–26