Transfer Case and Adaptor Housing 7F – 1

7F-1

Section 7F

Transfer Case and Adaptor Housing

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or

property damage.

1 General Description ...............................................................................................................................3

1.1 General Information............................................................................................................................................... 3

Description............................................................................................................................................................. 3

Arrangement........................................................................................................................................................... 5

Power Flow............................................................................................................................................................. 6

Vehicle Towing....................................................................................................................................................... 6

1.2 Transfer Case Identification.................................................................................................................................. 7

1.3 Transfer Case Maintenance .................................................................................................................................. 8

Inspection............................................................................................................................................................... 8

Lubrication ............................................................................................................................................................. 8

Breather.................................................................................................................................................................. 8

2 Minor Service Operations......................................................................................................................9

2.1 Checking Transfer Case Lubricant Level ............................................................................................................ 9

2.2 Draining and Filling Transfer Case Lubricant ................................................................................................... 10

2.3 Catalytic Converter Bracket................................................................................................................................ 11

Remove................................................................................................................................................................. 11

Reinstall................................................................................................................................................................ 11

2.4 Transmission Support......................................................................................................................................... 12

Remove................................................................................................................................................................. 12

Reinstall................................................................................................................................................................ 12

2.5 Mass Damper........................................................................................................................................................ 13

Remove................................................................................................................................................................. 13

Reinstall................................................................................................................................................................ 14

2.6 Transfer Case Front Output Flange, Slinger and Oil Seal................................................................................ 15

Remove................................................................................................................................................................. 15

Reinstall................................................................................................................................................................ 16

2.7 Transfer Case Rear Output Flange and Oil Seal ............................................................................................... 18

Remove................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 19

2.8 Transfer Case Support Mount............................................................................................................................. 21

Replace................................................................................................................................................................. 21

3 Major Service Operations....................................................................................................................24

3.1 Transfer Case....................................................................................................................................................... 24

Remove................................................................................................................................................................. 24

Reinstall................................................................................................................................................................ 29

3.2 Transfer Case Input Shaft Oil Seal..................................................................................................................... 32

Remove................................................................................................................................................................. 32

Reinstall................................................................................................................................................................ 33

3.3 Adaptor Housing – 4 Speed Transmission........................................................................................................ 34

Remove................................................................................................................................................................. 34

Reinstall................................................................................................................................................................ 35

3.4 Transmission Adaptor Housing Oil Seal ........................................................................................................... 36

Replace................................................................................................................................................................. 36

Techline

Transfer Case and Adaptor Housing 7F – 2

7F-2

4 Transfer Case Symptom Diagnosis....................................................................................................37

4.1 Preliminary Diagnosis......................................................................................................................................... 37

System Operation................................................................................................................................................ 37

Visual/Physical Inspection.................................................................................................................................. 37

Symptom List....................................................................................................................................................... 37

4.2 Popping Noise...................................................................................................................................................... 38

Definition .............................................................................................................................................................. 38

Diagnostic Table.................................................................................................................................................. 38

4.3 Whine or Rumble Noise....................................................................................................................................... 39

Definition .............................................................................................................................................................. 39

Diagnostic Table.................................................................................................................................................. 39

4.4 Growl or Grinding Noise ..................................................................................................................................... 40

Definition .............................................................................................................................................................. 40

Diagnostic Table.................................................................................................................................................. 40

4.5 Clunk During Acceleration and Deceleration.................................................................................................... 41

Definition .............................................................................................................................................................. 41

Diagnostic Table.................................................................................................................................................. 41

4.6 No Front or Rear Drive ........................................................................................................................................ 42

Definition .............................................................................................................................................................. 42

Diagnostic Table.................................................................................................................................................. 42

4.7 Lubricant Leak Diagnosis................................................................................................................................... 43

Definition .............................................................................................................................................................. 43

Diagnostic Table.................................................................................................................................................. 43

5 Specifications.......................................................................................................................................44

6 Torque Wrench Specifications............................................................................................................45

7 Special Tools ........................................................................................................................................46

Transfer Case and Adaptor Housing 7F – 3

7F-3

1 General Description

1.1 General Information

This Section describes the transfer case and adaptor hous ing fitted to AWD vehicles equipped with automatic

transmission.

Description

The transfer case model NV124GM is a single speed, full time, All Wheel Drive (AWD) transfer case assembly.

The transfer case uses a simple planetary gear train acting as a differential to achieve a 38% – 62% torque split between

the front and rear final drives respectivel y.

By utilising this type of gear set, both final dr ives are constantly being driven for maximum traction and the best balance

or vehicle handling characteristics under all operating conditions.

An adaptor housing provides the means by which the transfer case is attached to the rear of the 4 speed automatic

transmission. For Alloytec V6 engine, an adaptor plate is ad ded between the transfer case and adaptor housing.

An extension housing provides the means by which the transfer case is attached to the rear of the 5 speed autom atic

transmission (Alloytec 190 V6 engine). For service operations of the 5 speed transmission extension housing, refer to

Section 7E4 Automatic Tr ansmission – 5L40E – On-vehicle Servicing.

To cater for shaft length, an adaptor shaft is inserted between the transmission output shaft and the input shaft of the

transfer case. Identical adaptor shafts are fitted for 4 speed transmission on V8 engine and 5 speed transmission on

Alloytec 190 V6 engine. A longer adaptor shaft is fitted for 4 speed transmission on Alloytec V6 engine.

A mass damper is fitted to the rear of the transfer case housing to absorb resonance frequencies from the rotating part s.

For vehicles equipped with 5 speed transmission, the speed sensor is internal to the transmission.

For vehicles equipped with 4 speed transmission, the speed sensor is mo unted externally onto the adaptor housi ng and

is secured by a single bolt as in normal practice. The speed sensor pick-up ring is pressed onto, and is an integral part of

the adaptor shaft.

The only serviceable components in the transfer case assembly, are those that do not requir e the ho usings to be split.

That is, the three oil seals, rear output flang e, front output flan ge and slinger, O-ring seals, filler and drain plugs with their

gaskets and the breather hose.

The adaptor shaft is only serviced as a one-piece assembly. In the adaptor housing, the oil seal in is a serviceable

component.

Service operations for the serviceable components are incl uded in this Section.

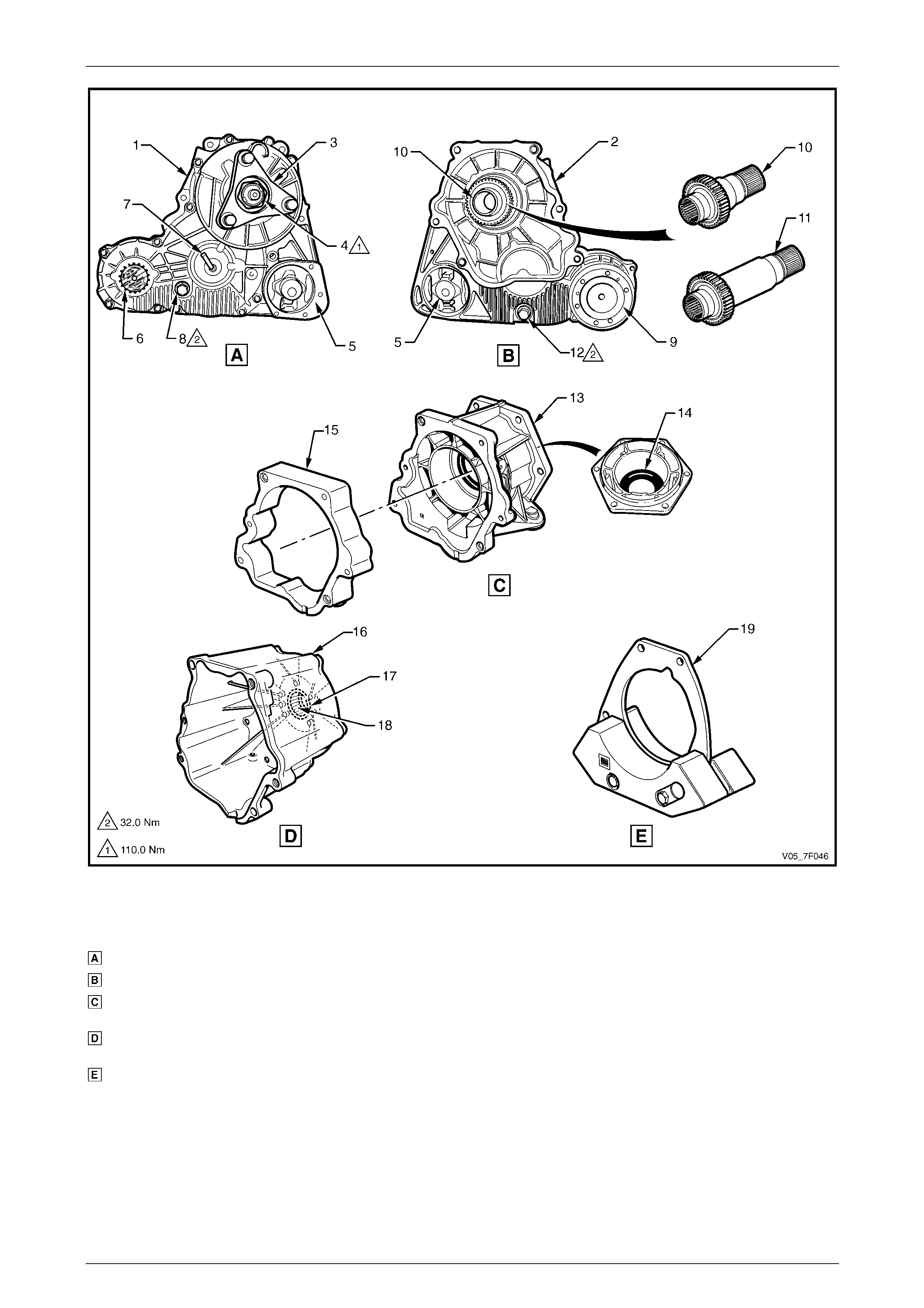

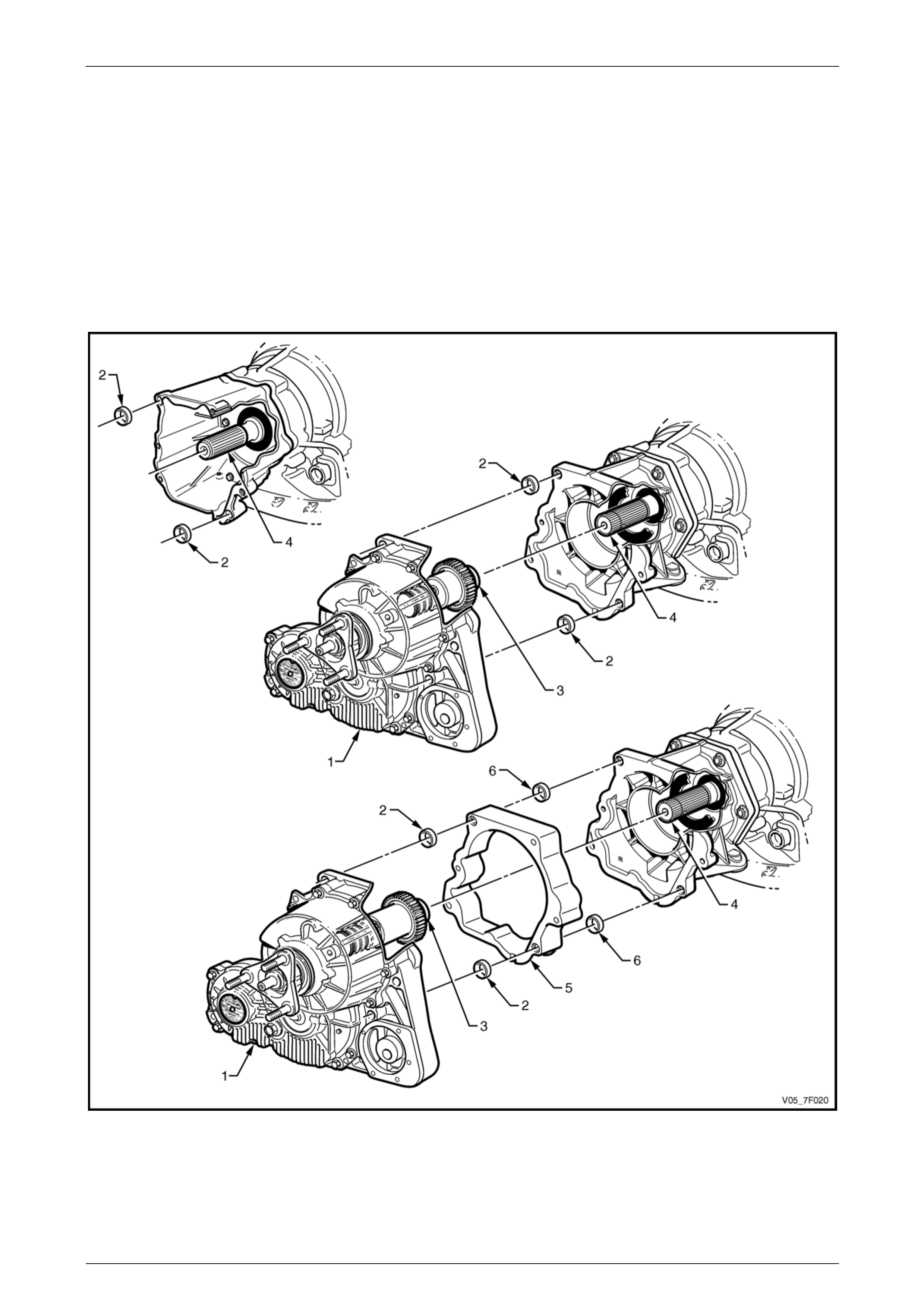

For views of the transfer case, adaptor housing, extension housing and mass damper, refer to Figure 7F – 1.

Transfer Case and Adaptor Housing 7F – 4

7F-4

Figure 7F – 1

Legend

Transfer Case Rear Side

Transfer Case Front Side

Adaptor Housing (4 speed

transmission)

Extension Housing (5 speed

transmission)

Mass Damper

1 Transfer Case Rear Housing

2 Transfer Case Front Housing

3 Rear Output Flange

4 Rear Output Flange Nut

5 Support Mount

6 Identification Tag

7 Breather Pipe

8 Lubricant Filler Plug

9 Front Output Flange

10 Adaptor Shaft

11 Adaptor Shaft (Alloytec V6 engine)

12 Lubricant Drain Plug

13 Adaptor Housing

14 Oil Seal

15 Adaptor plate (Alloytec V6 engine)

16 Extension Housing

17 Oil Seal

18 Needle Bearing

19 Mass Damper (where fitted)

Transfer Case and Adaptor Housing 7F – 5

7F-5

Arrangement

The front and rear housings of the transfer case are made of high density alumini um alloy manufactured by high

pressure injection moulding. The housings contain the input shaft, the front and rear output shafts, a simple planetary

gear set and a connecting gear set. T he internal gears are either supported by ball or roller bearings or caged needle

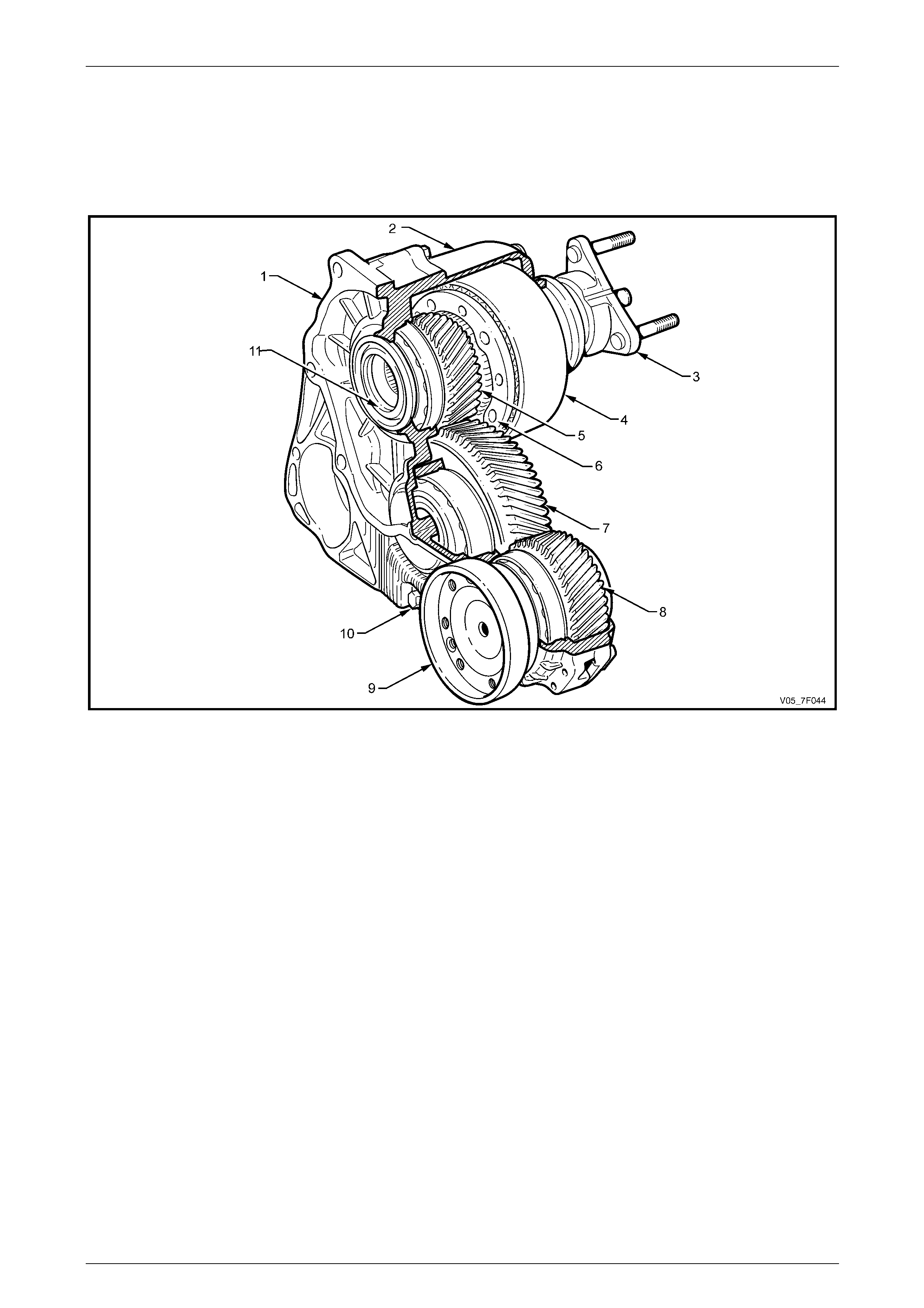

bearings. The organisati on of the gears is displayed in th e following view, refer to Figure 7F – 2.

Figure 7F – 2

Legend

1 Transfer Case Front Housing

2 Transfer Case Rear Housing

3 Rear Output Flange

4 Planetary Gear Set Ring Gear (Annulus)

5 Sun Gear

6 Planetary Gear Set Carrier and Pinions

7 Idler Gear

8 Front Output Gear

9 Front Output Flange

10 Drain Plug

11 Input Shaft

Transfer Case and Adaptor Housing 7F – 6

7F-6

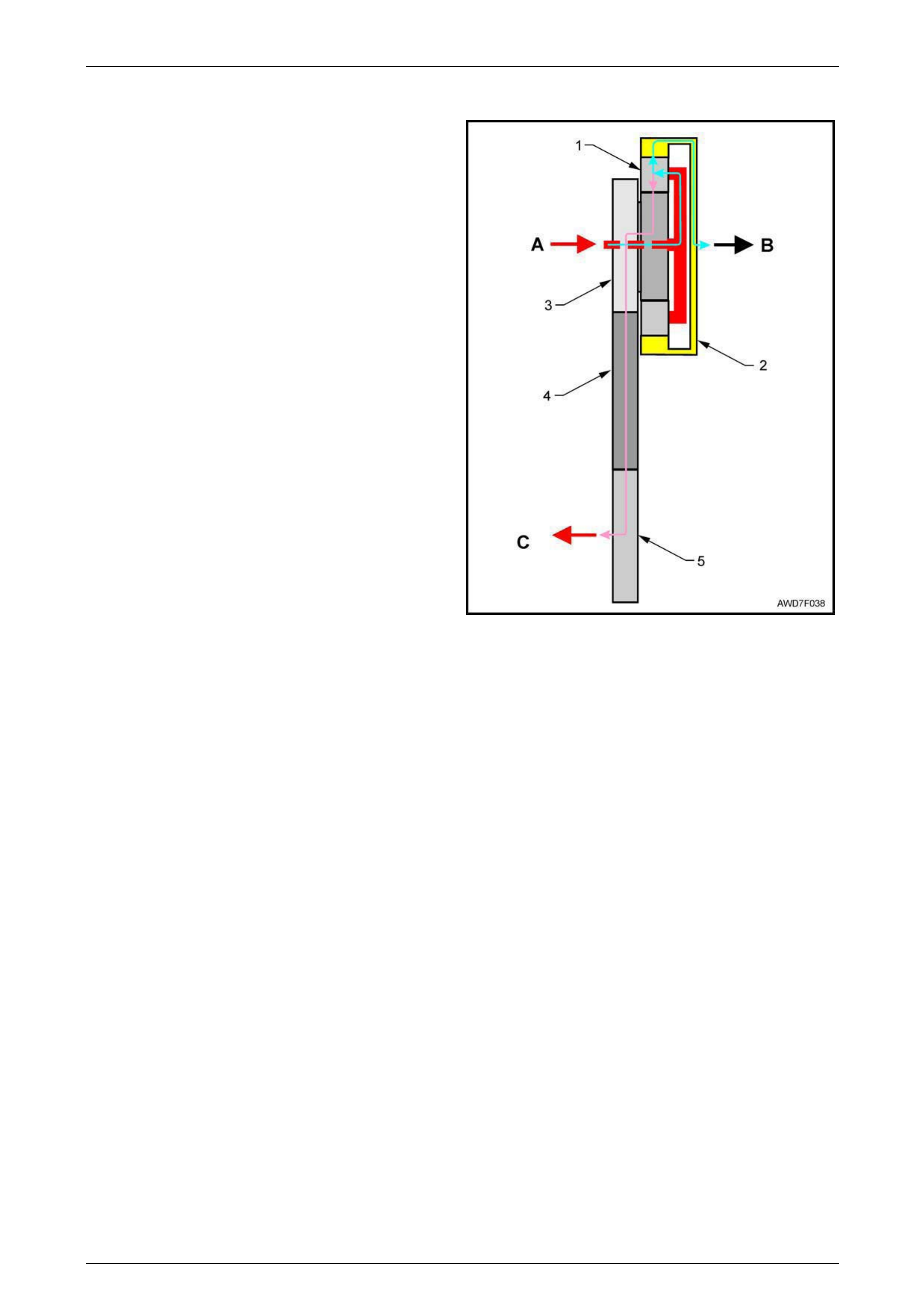

Power Flow

Power from the input shaft (A) is transmitted to the planetary

gears and carrier (1), then out to the rear final drive (B) via

the ring gear (2). Power is also transmitted to the front final

drive (C) via the sun gear (3), idler gear (4) and front output

gear (5).

With the simple planetary gear set, ratio change is achieved

by one member being the inp ut (driver), another being held

(transmitter) and the third being the output (driven).

If any two members are held, the gear set is locked up. If

one or more members is/are free, then neutral is ach ieve d.

With this particular gear arrangement, the torque split from

the planetary gear set is 38/62, front to rear. Should slip

occur from either a front or rear wheel, then a neutral

situation occurs until traction control restore s grip.

Figure 7F – 3

Vehicle Towing

Before towing the vehicle, comply with all the recommendations stated in the MY 2005 VZ AW D Wagon Owner's

Handbook.

In addition it must be realised that as the automatic transmission does n ot have a rear pump, extensive transmissi on and

transfer case damage will occur if the vehicle is towed at speeds in excess of 55 km/h or distances of more than 55 km.

If it is considered to remove a propeller shaft before towing on all four wheels, then both front and rear prope ller shafts

must be removed. Given the constraints previously mentioned, it is strongly recommended that towing on all four wheels

be avoided where possible and that a flat top truck transport is used, particularly for l ong distances.

Transfer Case and Adaptor Housing 7F – 7

7F-7

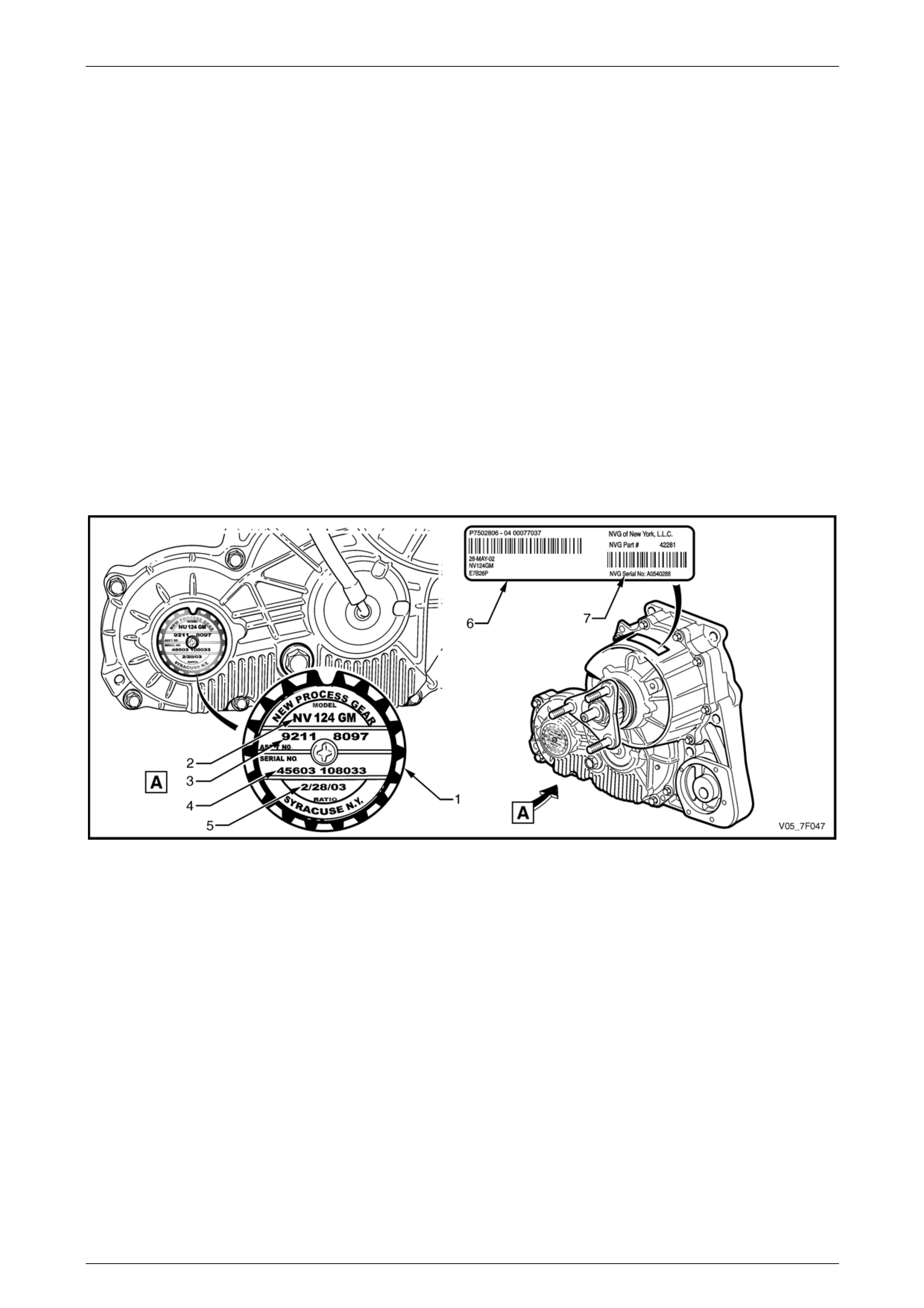

1.2 Transfer Case Identification

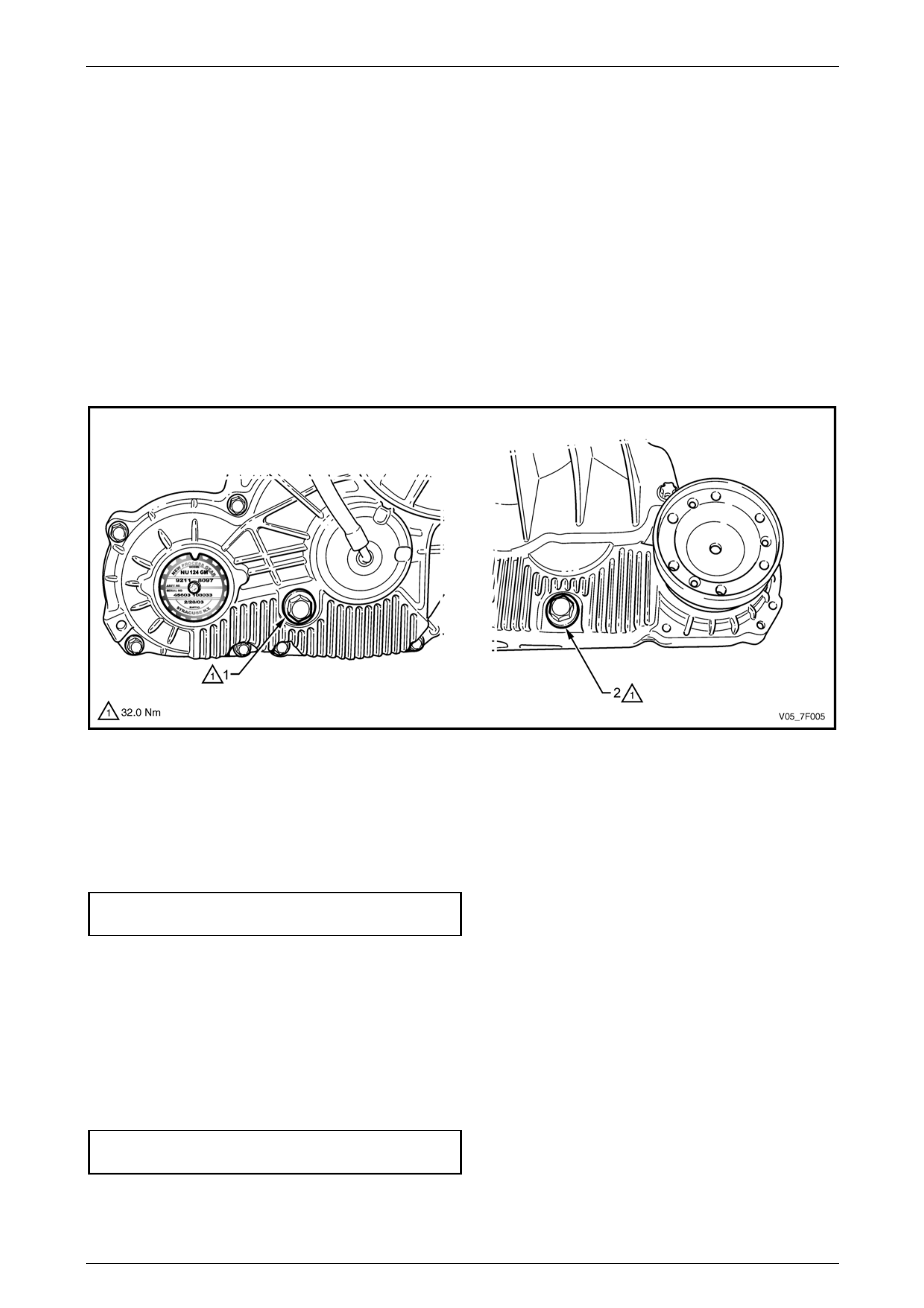

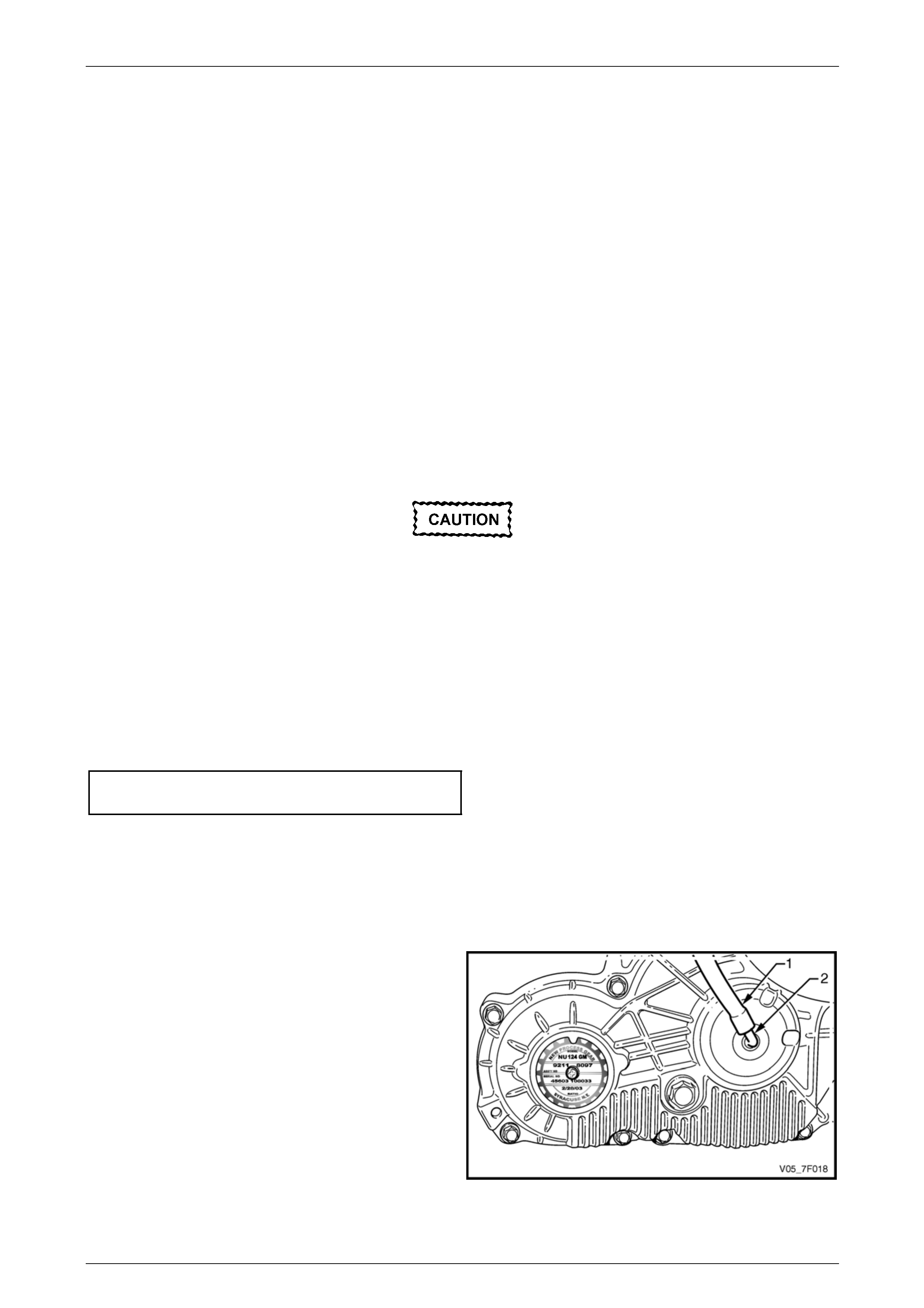

An identification tag (1) is attached to the left side of the transfer case rear housing in the location shown, refer to

Figure 7F – 4.

The identification tag provides the following information that may be required for the procurement of correct service parts:

• model number (2),

• assembly part number (3),

• manufacturer part number (4) and

• build date (5).

NOTE

Although marked as serial nu mber, the number at

location (4) on the identification tag is the

manufacturer part number.

If the identification tag is removed or is dislodged during service op erations, it must be kept with the assembly.

An identification label (6) is located at the top of the transfer case rear housing in the loc ation shown and provides similar

information as the identification tag as well as the transfer case serial num ber (7) as shown.

Figure 7F – 4

Transfer Case and Adaptor Housing 7F – 8

7F-8

1.3 Transfer Case Maintenance

Inspection

A check for lubricant leaks should be ma de at each maintenance service. If there is evidence of leakage, the condition

must be corrected using procedures contained in this Section, then dr ain the remaining lubricant and refill the transfer

case with the approved lubricant, refer to 2.2 Draining and Filling Transfer Case Lubricant.

Lubrication

For the transfer case lubricant draining fre qu ency, refer to Section 0B Lubrication a nd Service.

If it is necessary to drain the lubricant and refill because of loss through a leaking seal, it is vital that onl y the

recommended lubricant be used.

The lubricants approved for use in this transfer case are Esso MTF-LT-1 or Castrol BTO 338.

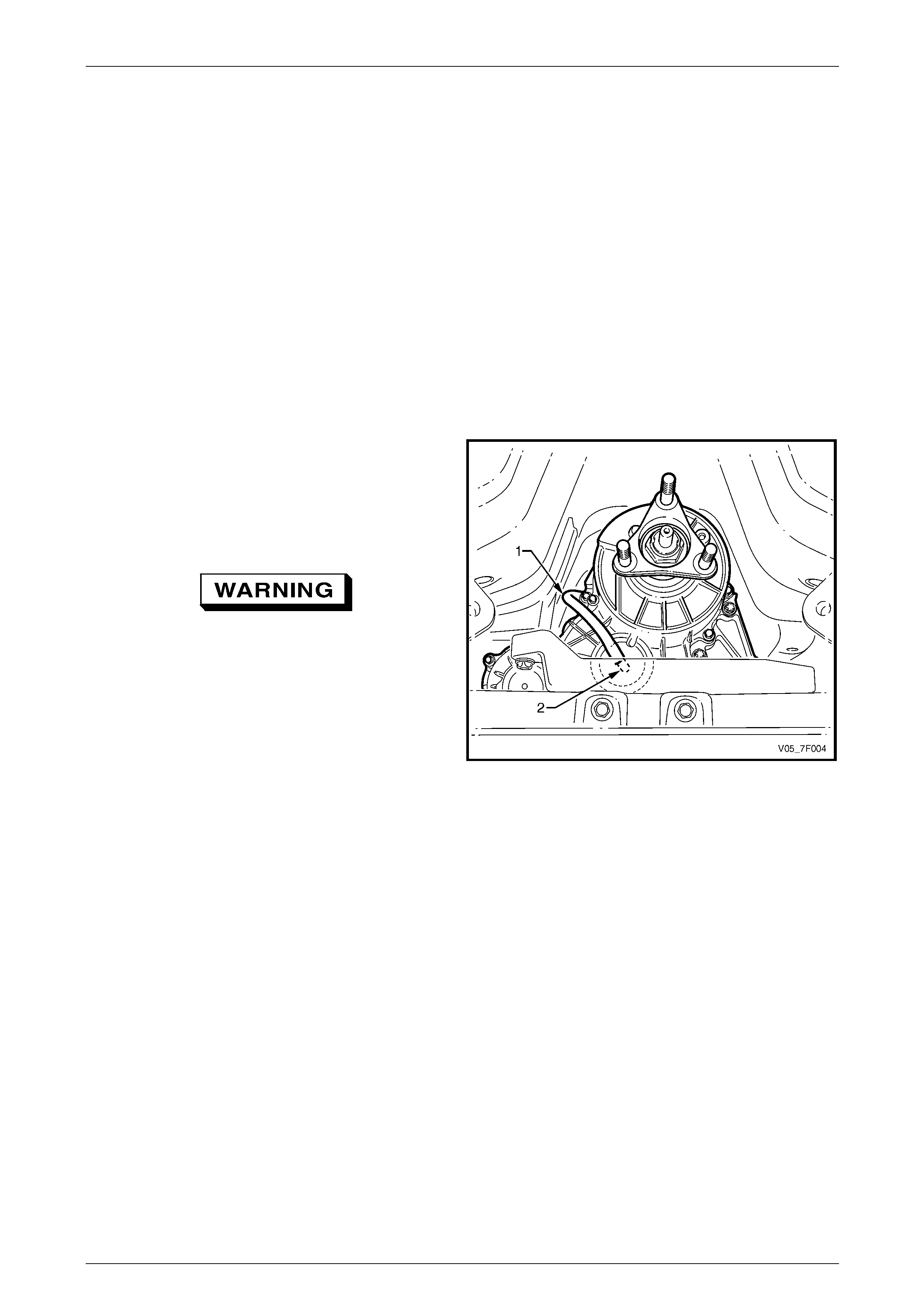

Breather

The breather hose (1) should be inspected at each

maintenance service to ens ure that it is routed correctly and

is in good condition.

Make a check to ensure the open end is not blocked. This

can be achieved by disconn ecting the breather hose from

the breather pipe (2) at the transfer case rear side.

Wear eye protectio n when clearing a b locked

breather hose.

If required, either manually or with compressed air, blow

through the breather hose to unblock it. Then reconnect the

breather hose to the transfer case breather pipe.

Figure 7F – 5

Transfer Case and Adaptor Housing 7F – 9

7F-9

2 Minor Service Operations

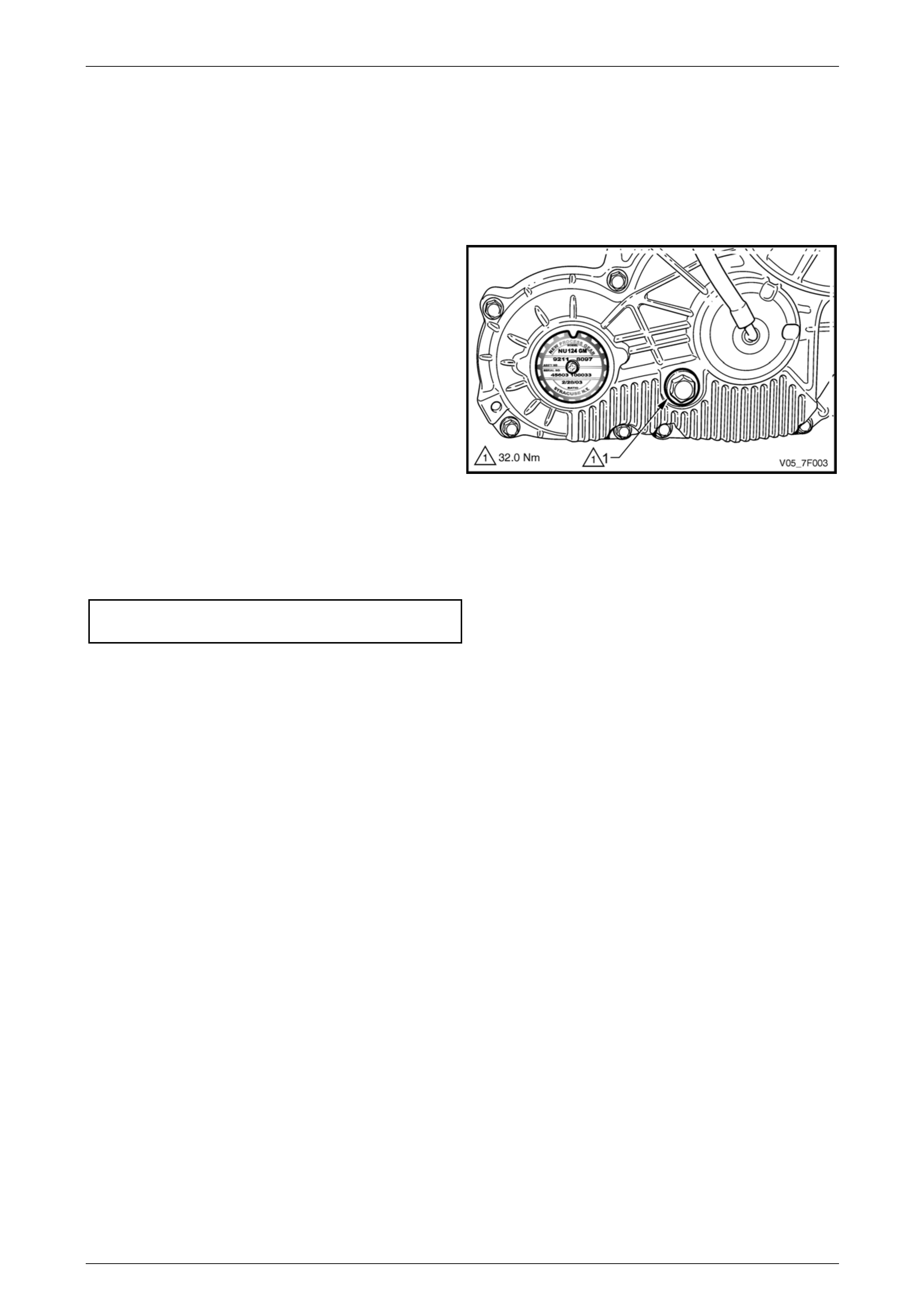

2.1 Checking Transfer Case Lubricant Level

LT Section No. — 04–050

1 Raise the vehicle and suppor t in a safe manner,

ensure the vehicle is level,

refer to Section 0A General Information.

2 Clean the area around the fill er plug (1) on the transfer

case rear housing.

NOTE

For clarity the illustration does not show the

transfer case mounting brac ket and transmission

support.

3 Remove the filler plug and gasket using a suitable size

ring spanner.

4 Check if the lubricant level is correct with the lubric ant

cold and just reaching the filler plug threads in the rear

housing.

5 Replace the filler plug gasket, then reinstall the filler

plug tightening it to the correct torque specification.

Transfer case filler plug

torque specification............................................32.0 Nm

Figure 7F – 6

6 If the lubricant level is low, then the reason must be investigated and corrected. After correction of the l eakage

condition, drain and refill the transfer case, refer to 2.2 Drainin g and Filling Transfer Case Lubricant.

Transfer Case and Adaptor Housing 7F – 10

7F-10

2.2 Draining and Filling Transfer Case

Lubricant

LT Section No. — 04–050

1 Raise the vehicle and suppor t in a safe manner, ensure the vehicle is level,

refer to Section 0A General Information.

2 Clean the area around the fill er plug (1) on the transfer case rear housing and around the drain plug ( 2) on the

transfer case front housing, refer to Figure 7F – 7.

NOTE

For clarity the illustration does not show the

catalytic converter bracket and front propeller

shaft.

Figure 7F – 7

3 Remove the filler plug, using a suitable size ring spanner.

4 Remove the drain plug using a suitable size ring spanner, draining the lubricant into a suitable container of a

minimum 0.5 litre capac ity.

5 Replace the drain plug gasket, then reinstall the drain plug in the front housing, tightening it to the correct torque

specification.

Transfer case drain plug

torque specification............................................32.0 Nm

6 Refill the transfer case with approximately 100 – 160 ml of Esso MTF-LT-1 or Castrol BTO 338 lubricant, until the

lubricant (cold) just reaches the filler plug threads in the rear housing.

NOTE

This is the approximate refill quantity, the dry fill

quantity is 240 ml.

7 Replace the filler plug gask et, then reinstall the fill er plug in the rear housing, tightening it to the correct torque

specification.

Transfer case filler plug

torque specification............................................32.0 Nm

Transfer Case and Adaptor Housing 7F – 11

7F-11

2.3 Catalytic Converter Bracket

LT Section No. — 03–750

Remove

1 Raise the vehicle and suppor t in a safe manner, refer

to Section 0A General Information.

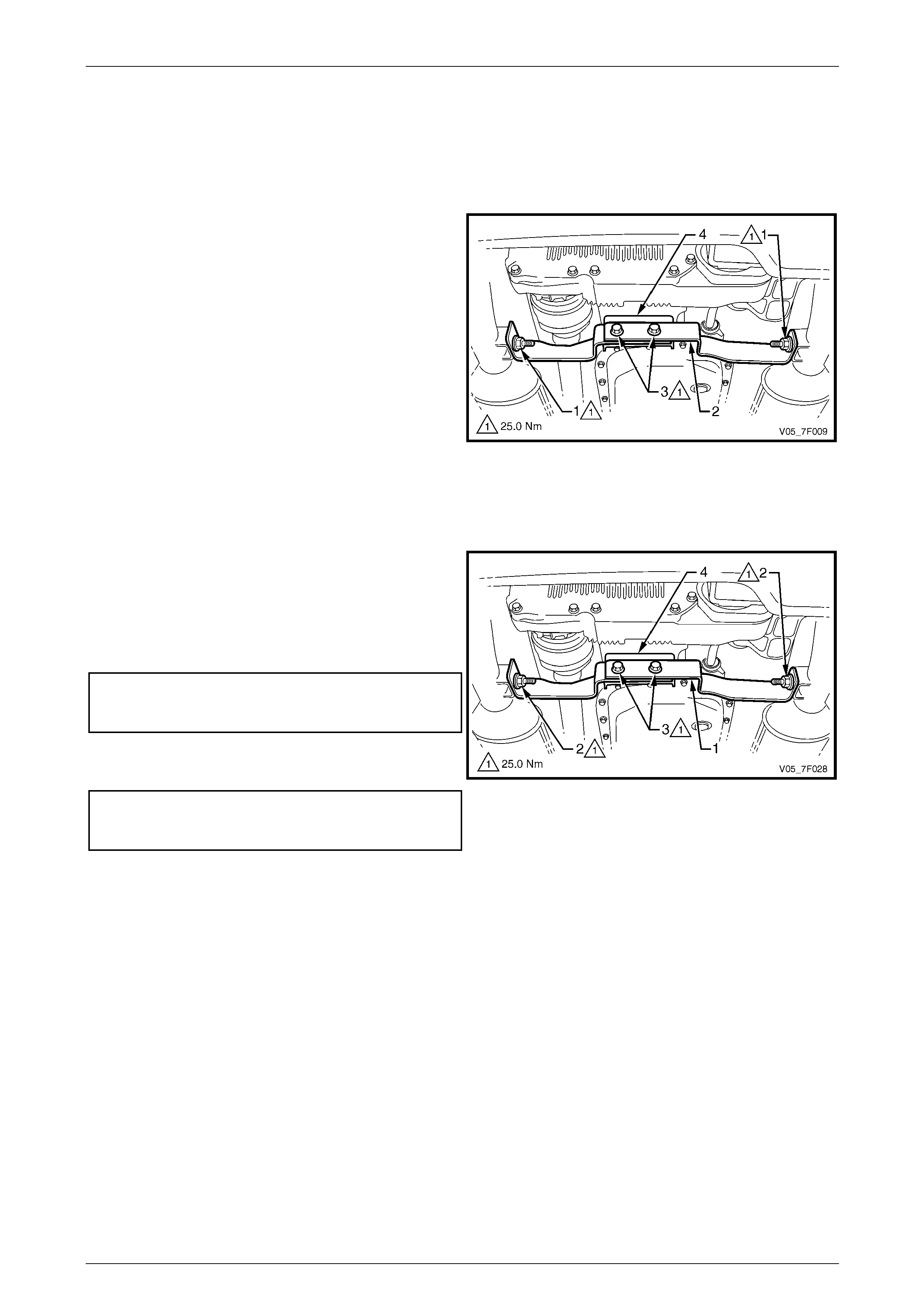

2 Loosen the nuts (1) on each side of the catal ytic

converter bracket (2).

3 Using a felt tipped pen or similar, mark the positio n of

the two bolts (3) attaching the catalytic converter

bracket to the adaptor housing bracket (4) and remov e

the two bolts.

NOTE

This will assist in keeping the alignment of the

exhaust system undisturbed.

4 Remove the loose nuts and the catalytic converter

bracket from the vehicle.

Figure 7F – 8

Reinstall

1 Install the catalytic converter bracket (1) and the two

outer nuts (2) finger tight on each side of the bracket.

2 Align the two bolts (3) with the marks made before

removal and attach the catalytic converter bracket to

the adaptor housing bracket (4). Tighten the two bolts

to the correct torque specification.

Catalytic converter bracket to

adaptor housing bracket attaching bolt

torque specification............................................25.0 Nm

3 Tighten the two nuts attaching the catal ytic converter

bracket to the correct torque specification.

Catalytic converter bracket to

catalytic converter attaching nut

torque specification............................................25.0 Nm

Figure 7F – 9

Transfer Case and Adaptor Housing 7F – 12

7F-12

2.4 Transmission Support

LT Section No. — 04–020

Remove

1 Raise the vehicle and suppor t in a safe manner, refer

to Section 0A General Information.

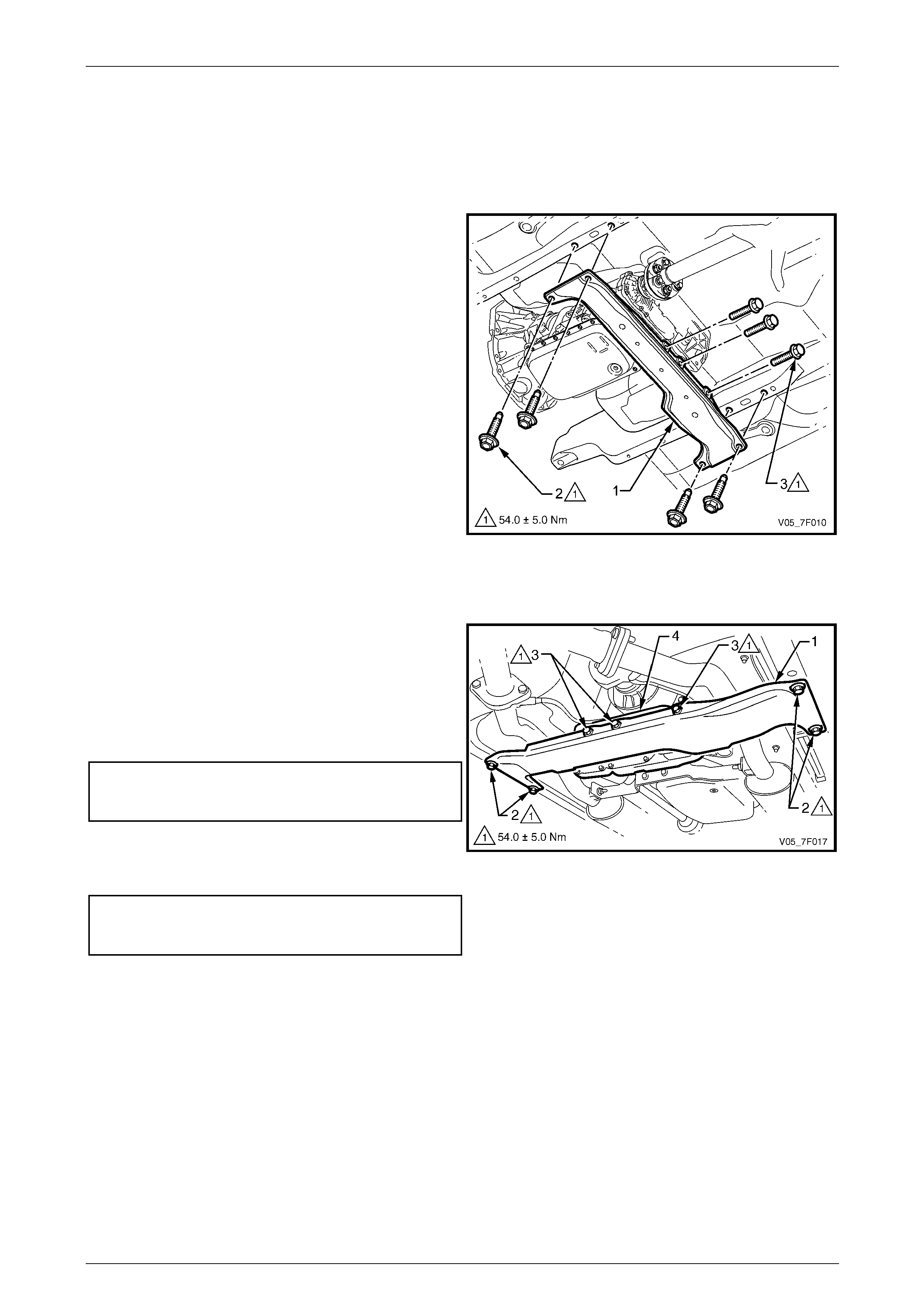

2 Using a felt tipped pen or similar, mark the positio n of

the transmission support (1) to the underbod y side

rails.

NOTE

This will assist in aligning the transmission

support on reinstallation.

3 Remove the four bolts (2) attaching the transmission

support to the underbody side rails.

4 Remove the three bolts (3) attaching the transmission

support to the transfer case rear mounting bracket.

5 Remove the transmission support from the vehicle.

Figure 7F – 10

Reinstall

1 Align the transmission support (1) with the marks

made on the underbody side rail before removal a nd

install the four attaching bolts (2) finger tight.

2 Install the three bolts (3) attaching the transmission

support to the transfer case rear mounting bracket (4).

Tighten the three bolts to the correct torque

specification.

Transmission support to transfer case

rear mounting bracket attaching bolt

torque specification...................................54.0 ± 5.0 Nm

3 Tighten the four bolts attaching the transmiss ion

support to the underbody side rail to the correct torque

specification.

Transmission supp ort to underbody

side rail attaching bolt

torque specification...................................54.0 ± 5.0 Nm

Figure 7F – 11

Transfer Case and Adaptor Housing 7F – 13

7F-13

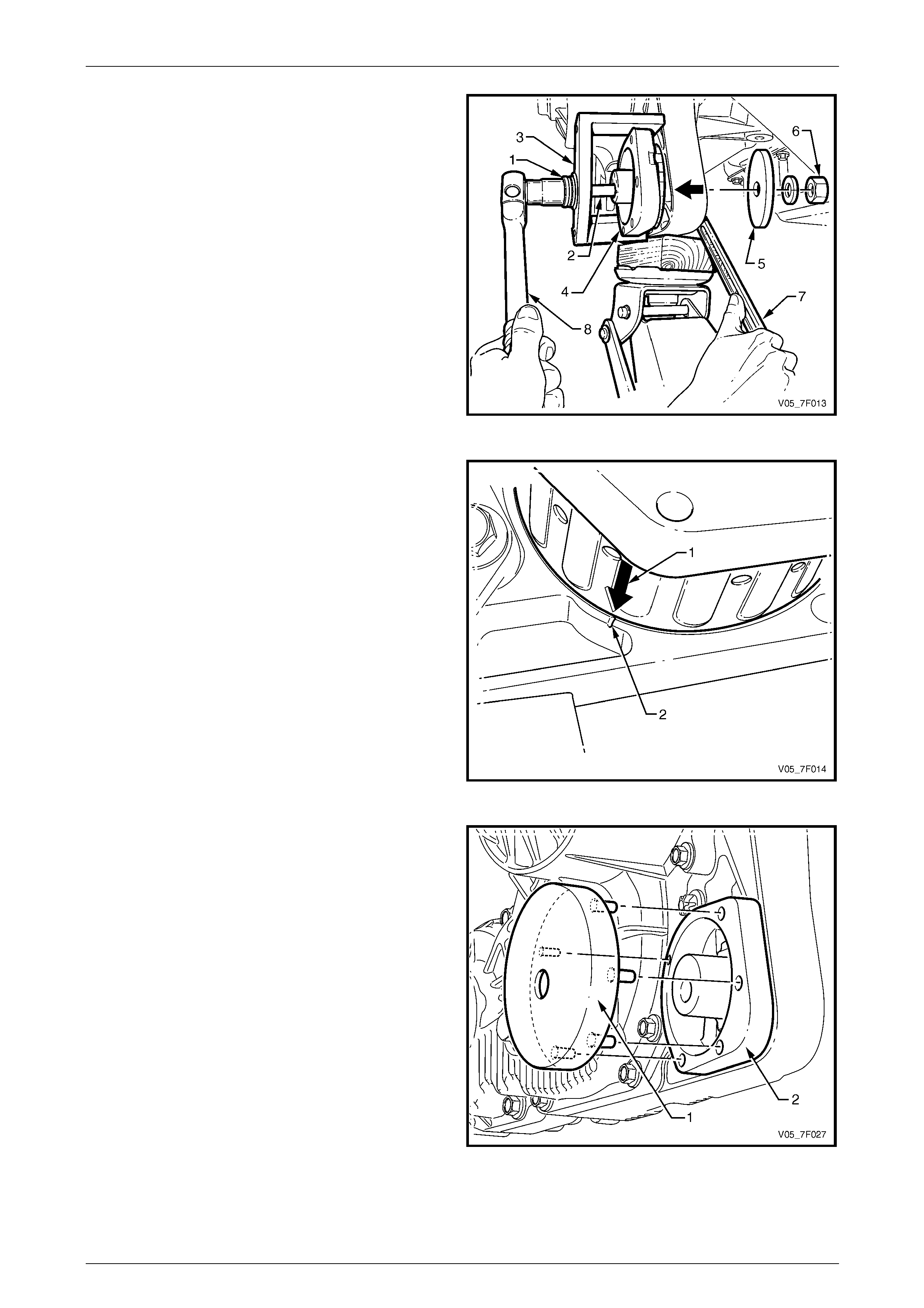

2.5 Mass Damper

LT Section No. — 04–050

Remove

1 Remove the following components:

a Transmission support, refer to 2.4 T r ansmission Support.

b Exhaust system rearward from the two catalytic converters, refer to Section 8B Exhaust System.

c Rear propeller shaft, refer to Section 4C1 Rear Propeller Shaft and Universal Joints.

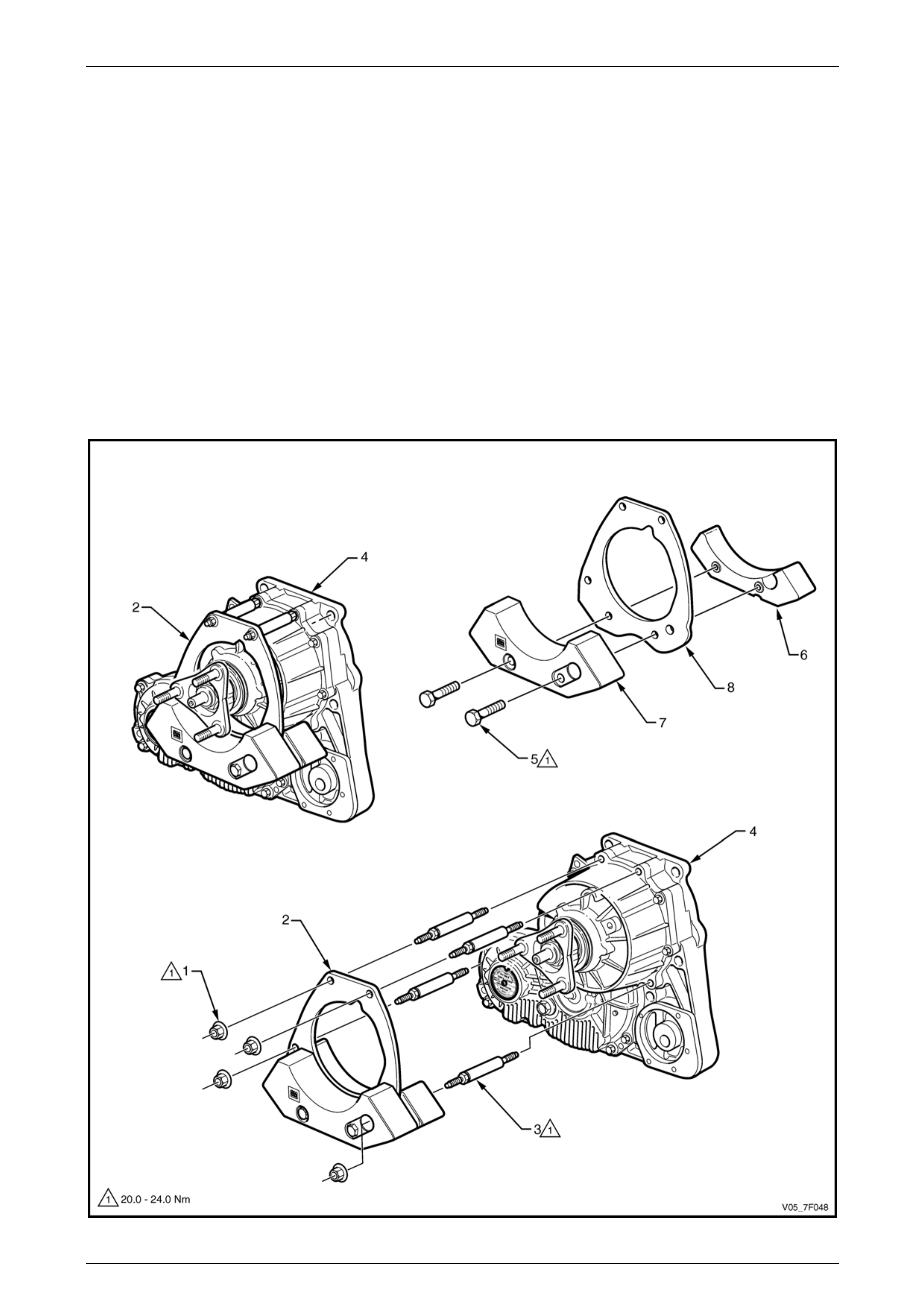

2 Remove the four nuts (1) attaching the mass damper (2) to the four studs (3) and remove the mass damper from

the studs.

3 If required, remove the four studs from the transfer case housing (4).

4 If required, disassemble the mass Damper b y removing the two bolts (5) and separating the forward block (6) and

rearward block (7) from the plate (8).

Figure 7F – 12

Transfer Case and Adaptor Housing 7F – 14

7F-14

Reinstall

Reinstallation of the mass damper is the reverse of the removal procedure, noting the following:

1 Tighten the bolts attaching the two blocks to the correct torque specification.

Mass damper blocks attaching bolt

torque specification.................................20.0 – 24.0 Nm

2 Tighten the studs attaching the mass dampe r to the transfer case housing to the correct torque specification.

Mass damper attaching stud

torque specification.................................20.0 – 24.0 Nm

3 Tighten the nuts attaching the mass damp er to the studs to the correct torque specification.

Mass damper attaching nut

torque specification.................................20.0 – 24.0 Nm

Transfer Case and Adaptor Housing 7F – 15

7F-15

2.6 Transfer Case Front Output Flange,

Slinger and Oil Seal

LT Section No. — 04–050

Remove

1 Remove the following components:

a Catalytic converter bracket, refer to 2.3 Catalytic Converter Bracket.

b Front propeller shaft, refer to Section 4C2 Front Propeller Shaft and Universal Joints.

2 Place a drip tray under the transfer case.

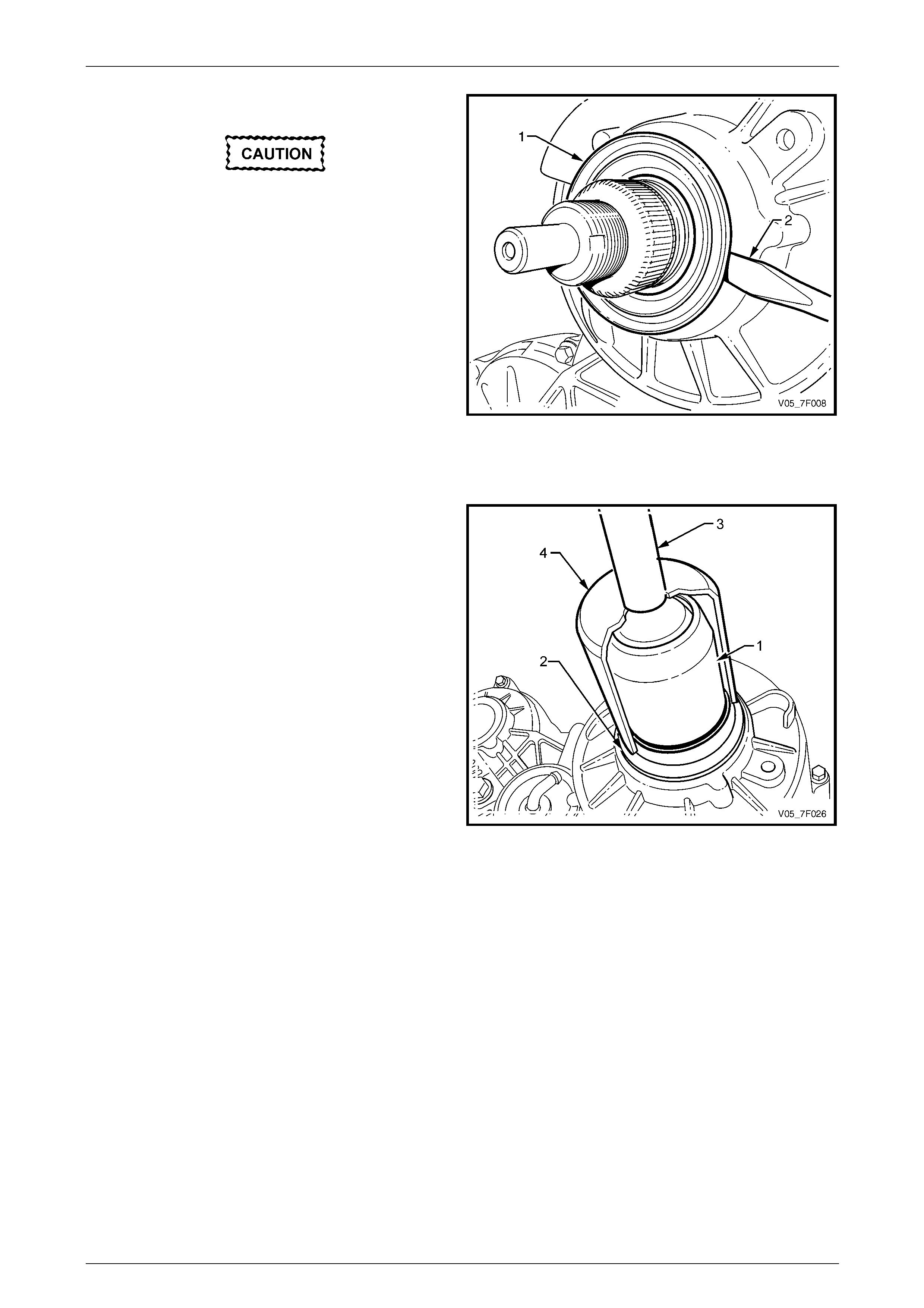

3 Using three suitable scre ws (1) 8 mm long, attach the

slide hammer, Tool No. 7374 (2), to the transfer case

front output flange.

4 Use the slide hammer to dislodge the s nap ring from

the front output shaft, then remove the front output

flange and discard the snap ri ng.

5 Remove the slide hammer from the front output flange.

Figure 7F – 13

6 Use a screwdriver (1) or similar lever to prise the

slinger (2) from the front output shaft. Discard the

removed slinger.

NOTE

The front output shaft slinger will be distorted

during the removal operation and can not be

reused.

Figure 7F – 14

Transfer Case and Adaptor Housing 7F – 16

7F-16

Take care during the seal removal operation

not to damage the transfer case machined

surfaces.

7 Remove the front output oil seal (1) using a large

screwdriver or similar, working around the oil seal

outer perimeter. Discard the removed oil seal.

8 Use a small screwdriver or wire hook to remove the

O-ring seal (2) from the front output shaft inner

diameter. Discard the removed O-ring seal.

Figure 7F – 15

Reinstall

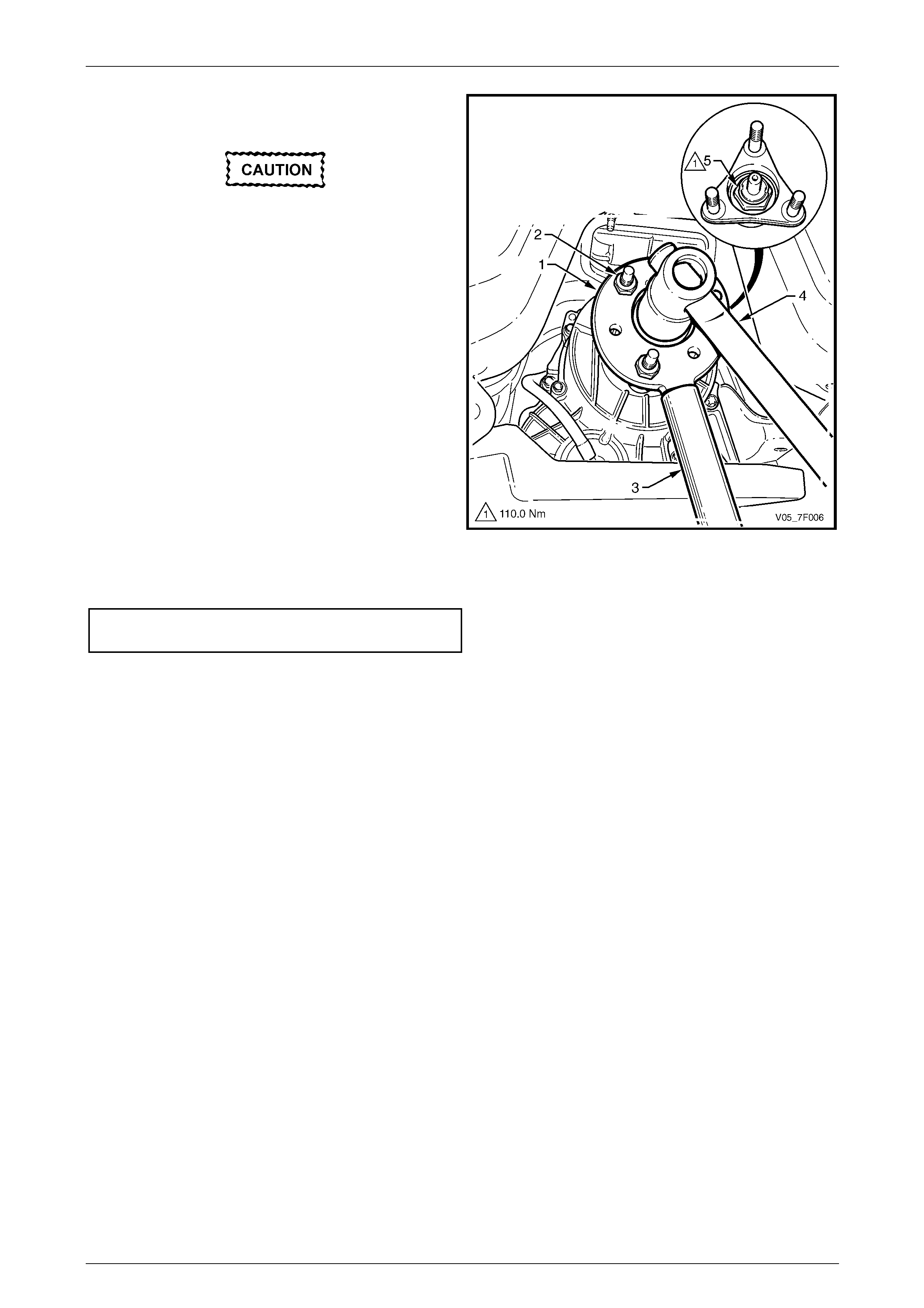

1 Install the seal protector Tool No. DT-47602-1 (1) over

the front output shaft and push to fully install.

2 Lubricate a new front output oil seal (2) with

Mobilgrease XHP 222 or equivalent, ensuring the

recesses between the oil seal lips are filled to

approximately 50%, then slide the oil seal over the

seal protector.

3 Install the driver Tool No. AU-355-A (3) into the seal

installer Tool No. DT-47602-2 (4), then fully install the

oil seal in the transfer case front housing.

4 Remove the seal installation and protector tools.

Figure 7F – 16

5 Install a new slinger (1) onto the front output shaft,

tapping into place using a pl astic hammer (2) until the

slinger contacts the machined step on the fro nt output

shaft.

6 With the transmission in Neutral, rotate the rear

propeller shaft to ensure the slinger has been instal led

square to the front output shaft. Correct as required.

7 Lubricate a new O-ring seal (3) with a smear of

Mobilgrease XHP 222 or equivalent and install in the

groove of the front output shaft inner diameter.

8 Lubricate the internal splines of the front output shaft

with 1 gram of Weicon™ standard grade, anti-seize

grease #37771.

NOTE

This grease is the onl y product approved for use

in this application and is available in a 10 gram

syringe. Figure 7F – 17

Transfer Case and Adaptor Housing 7F – 17

7F-17

9 Install a new snap ring to the end of the front output flange splines.

10 Align the splines of the front output flange with the mating splines in the front output shaft.

If the front propeller shaft is bolted to the

front output flange prior to installation, do not

use the impact of the p l u nge CV joint to install

the front output flange, as brinelling of the

bearing balls will prob a bly result.

11 Using a plastic hammer, drive the flanged front output shaft into the transfer case until the snap ring o n the front

output flange engages behind the front output shaft splines. Tug on the flange to ensure that engagement has

occurred.

12 Check the transfer case lubricant level, refer to 2.1 Checking Transfer Case Lubricant Level.

13 Reinstall the following components:

a Front propeller shaft, refer to Section 4C2 Front Propeller Shaft and Universal Joints.

b Catalytic converter bracket, refer to 2.3 Catalytic Converter Bracket.

Transfer Case and Adaptor Housing 7F – 18

7F-18

2.7 Transfer Case Rear Output Flange and

Oil Seal

LT Section No. — 04–050

Remove

1 Remove the following components:

a Transmission support, refer to 2.4 T r ansmission Support.

b Exhaust system rearward from the two catalytic converters, refer to Section 8B Exhaust System.

c Rear propeller shaft, refer to Section 4C1 Rear Propeller Shaft and Universal Joints.

d Mass damper, if fitted, refer to 2.5 Mass Damper.

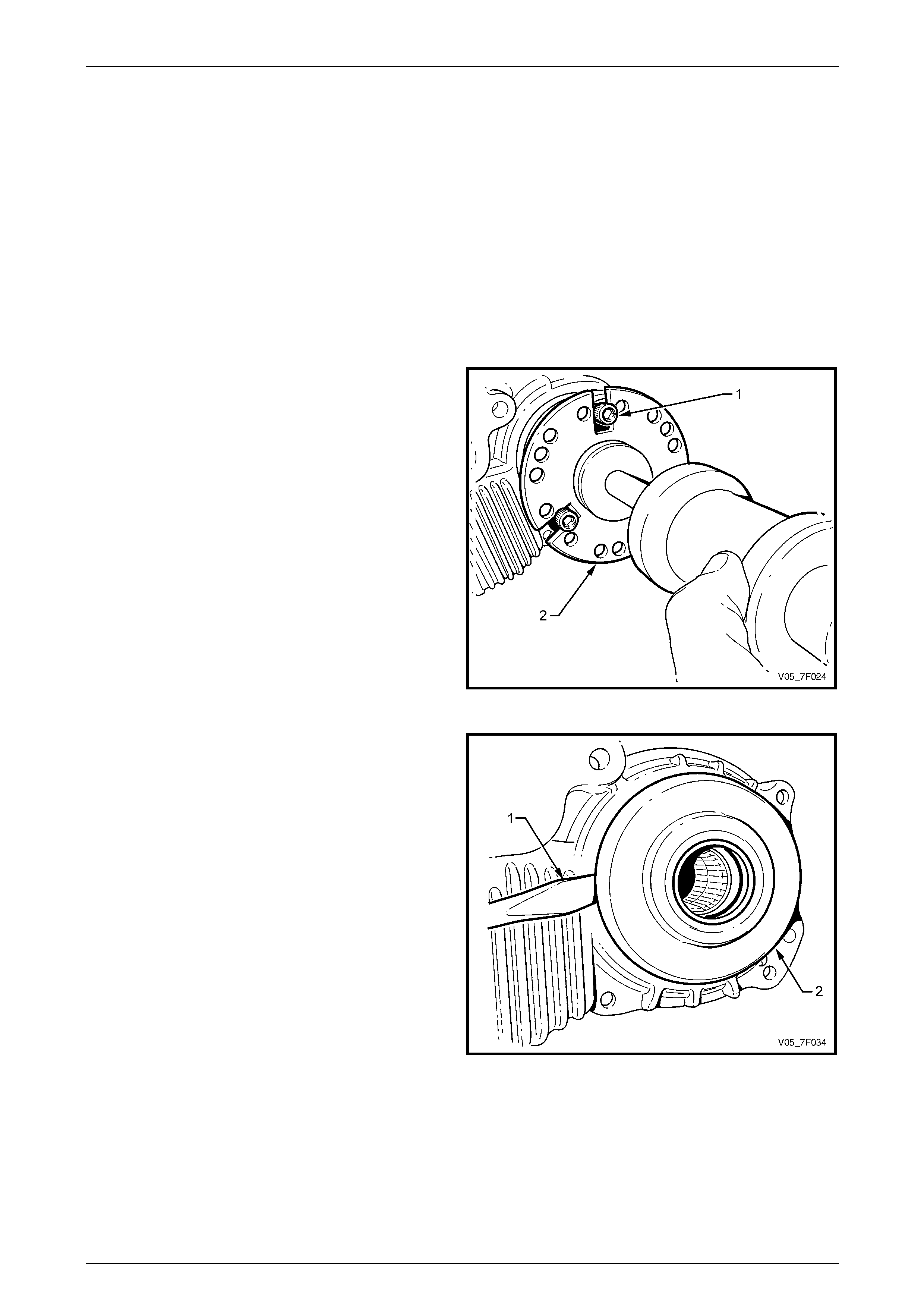

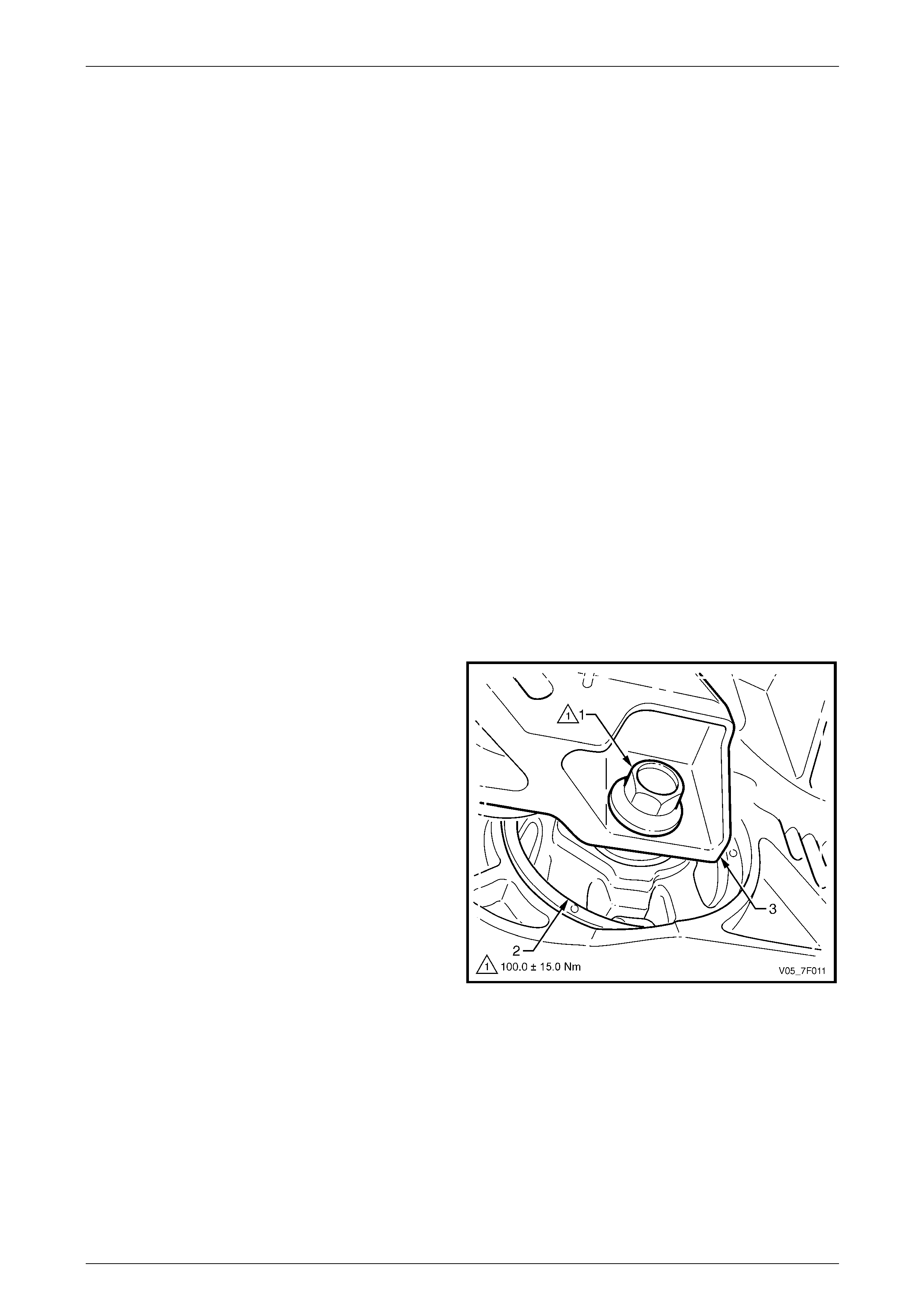

2 Locate the holding tool, Tool No. DT-47735 (1), onto

the transfer case rear output flange.

The holding tool must be firmly clamped to

the transfer case rear output flange to avoid

damaging the studs.

3 Install a suitable flat washer over each stud, then

secure the holding tool with the three ret ain ing nuts (2)

of the rear propeller shaft front rubber coupling.

4 With a suitable size length of pipe (3) fitted over the

tang of the holding tool, use a 36 mm deep s ocket and

suitable socket equipment (4) to remove the rear

output flange retaining nut (5).

NOTE

Do not discard the output flange retaining nut at

this stage as it will be used for the reinstallation

process.

5 Remove the holding tool from the rear output flange.

Figure 7F – 18

6 Locate the extracting tool, Tool No. DT-47736 (1), onto

the rear output flange.

7 Install a 25 mm spacer (2) (e.g. flat washers) over

each stud, then secure the extracting tool with the

three retaining nuts (3) of the rear propeller shaft front

rubber coupling.

NOTE

Unless the extracting tool is clamped up tight to

the rear output flange, there will not be sufficient

thread on the forcing screw (4) to remove the

rear output flange from the rear output shaft

splines.

8 Using suitable size spann ers, whil e holding the

extracting tool rotate the forcing screw (4) to remove

the rear output flange.

9 Remove the extracting tool from the rear output flange. Figure 7F – 19

Transfer Case and Adaptor Housing 7F – 19

7F-19

10 Clean the exposed part of the rear output shaft.

Take care during the seal removal operation

not to damage the transfer case machined

surfaces.

11 Remove the rear output oil seal (1) using a large

screwdriver (2) or similar, working ar ound the oil seal

outer perimeter. Discard the removed oil seal.

Figure 7F – 20

Reinstall

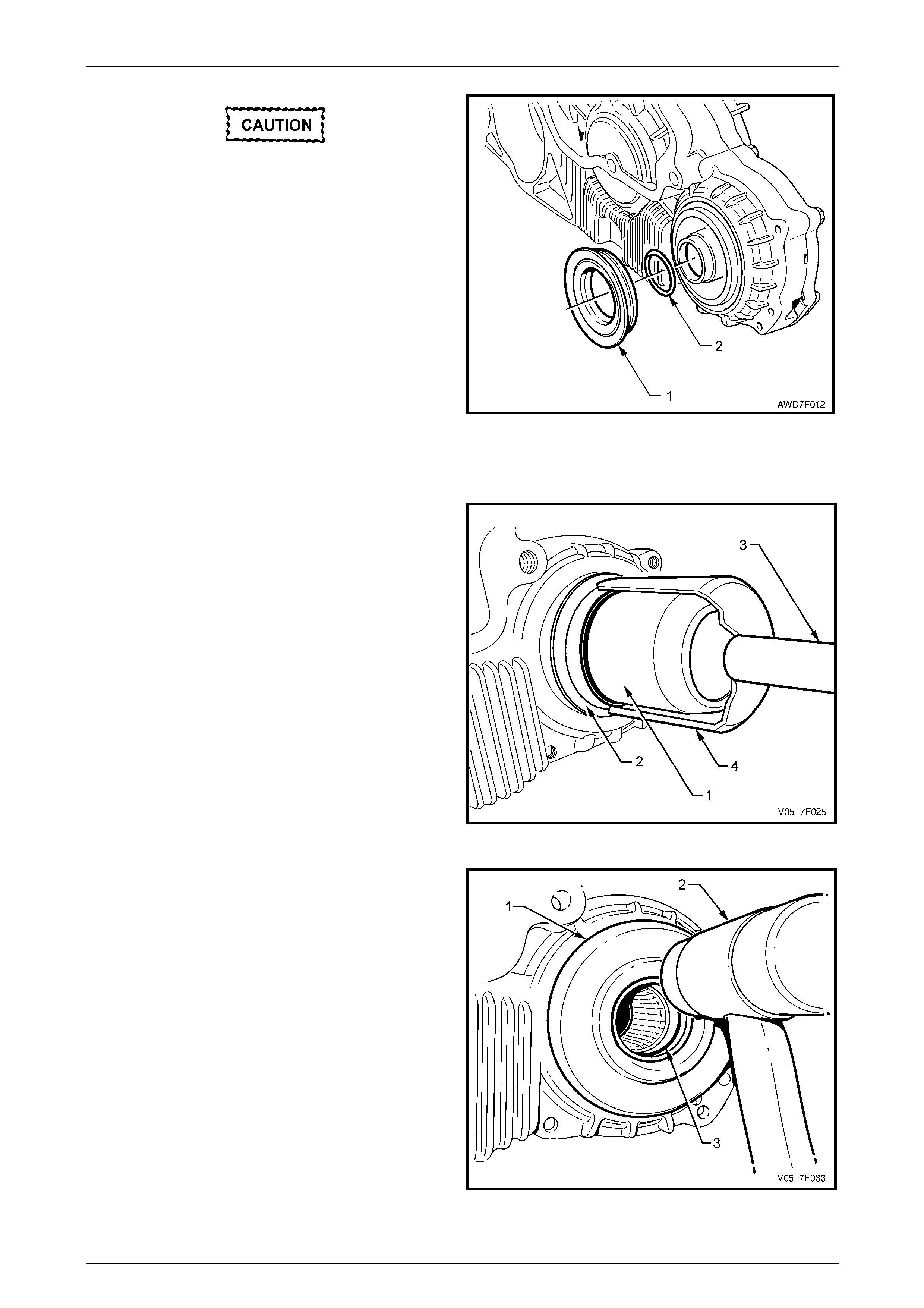

1 Install the seal protector, Tool No. DT-47601-2 (1),

over the transfer case rear output shaft and push to

fully install.

2 Lubricate a new rear output oil seal (2) with

Mobilgrease XHP 222 or equi valent, ensuring the

recesses between the oil seal lips are filled to

approximately 50%, then slide the oil seal over the

seal protector.

3 Install the driver, Tool No. AU-355-A (3), into the seal

installer, Tool No. DT-47601-1 (4), then fully install the

oil seal in the transfer case rear housing.

4 Remove the seal installation and protector tools.

Figure 7F – 21

5 Lubricate the splines of the transfer case rear output sh aft with 1 gram of Weicon™ standard grade, anti-seize

grease #37771.

NOTE

This grease is the only product approved for use

in this application and is available in a 10 gram

syringe.

6 Smear the rear output oil seal surface with petroleum jelly (e.g. Vaseli ne™ ), then install the rear output flange

engaging the splines with those on the transfer case rear output shaft.

7 Using a plastic hammer, tap the rear output flange onto the rear output shaft enough to enable the original retaining

nut to be installed.

Transfer Case and Adaptor Housing 7F – 20

7F-20

8 Locate the holding tool, Tool No. DT-47735 (1) onto

the transfer case rear output flange.

The holding tool must be firmly clamped to

the transfer case rear output flange to avoid

damaging the studs.

9 Install a suitable flat washer over each stud, then

secure the holding tool with the three ret ain ing nuts (2)

of the rear propeller shaft front rubber coupling.

10 With a suitable size length of pipe (3) fitted o v er the

tang of the holding tool, use a 36 mm deep s ocket and

suitable socket equipment (4) to fully install the rear

output flange by tightening the original reta ining nut.

11 Using the same socket equipment, remove and

discard the original retaining nut, then install a new

retaining nut to the rear output flange.

NOTE

The new nut fitted to the rear output flange has

loctite applied to its thread which will cure when

the nut is installed.

12 Tighten the new retaining nut (5) securing the rear

output flange to the correct torque specification.

Transfer case rear output flange

retaining nut torque specification .....................110.0 Nm

Figure 7F – 22

13 Check the transfer case lubricant level, refer to 2.1 Checking Transfer Case Lubricant Level.

14 Reinstall the following components:

a Mass damper, if fitted, refer to 2.5 Mass Damper.

b Rear propeller shaft, refer to Section 4C1 Rear Propeller Shaft and Universal Joints.

c Exhaust system rearward from the two catalytic converters, refer to Section 8B Exhaust System.

d Transmission support, refer to 2.4 T r ansmission Support.

Transfer Case and Adaptor Housing 7F – 21

7F-21

2.8 Transfer Case Support Mount

LT Section No. — 04–050

Replace

1 Remove the following components:

a Catalytic converter bracket, refer to 2.3 Catalytic Converter Bracket.

b Transmission support, refer to 2.4 T r ansmission Support.

2 With a wooden block and suitable hydraulic lifting equipment, support the transmission / transfer case on the

transfer case housing.

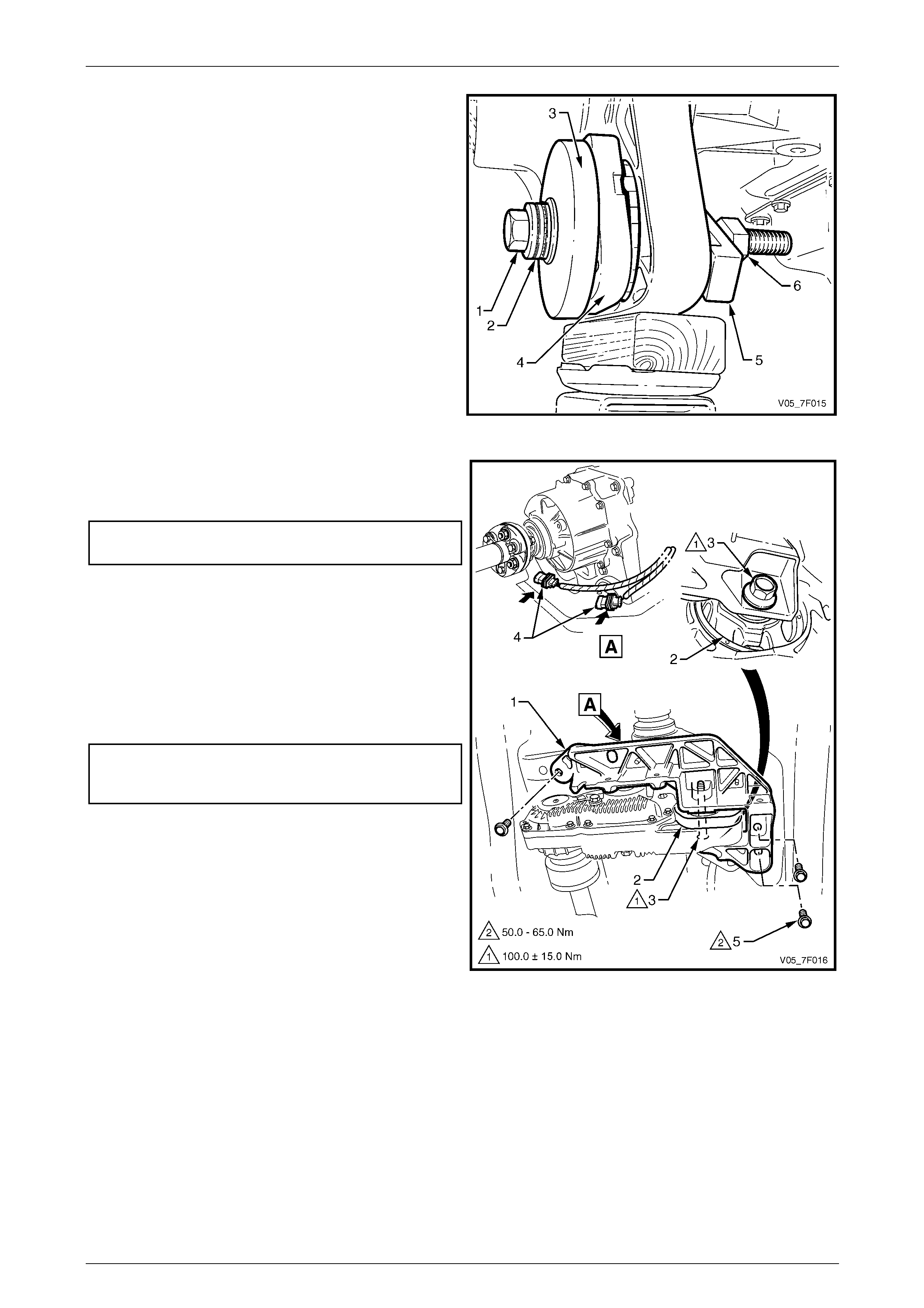

3 Remove the bolt (1) securing the rubber supp ort

mount (2) to the transfer case rear mounting

bracket (3).

Figure 7F – 23

4 Using a felt tipped pen or similar, mark the positio n of

the transfer case rear mounting bracket (1) to the

vehicle underbod y. NOTE

This will assist in aligning the rear mounting

bracket on reinstallation.

5 Disconnect the wiring harness connectors (2) and

separate from the rear mounting bracket by sliding

them off their support.

6 While supporting the rear mounting bracket, remove

the three bolts (3) attaching it to the vehicle

underbody.

7 Remove the rear mounting bracket from the vehicl e.

Figure 7F – 24

Transfer Case and Adaptor Housing 7F – 22

7F-22

8 Lower the rear of the transfer case enough to allow

access to the support mount.

9 Feed the thrust bearing (1) onto the forcing bolt (2) of

the support mount remover/installer tool assembl y,

Tool No. DT-47597.

10 Feed the remover bracket, Tool No. DT-47597-4 (3),

onto the forcing bolt and thrust bearing, then fit these

parts to the support mount (4) on the rear side.

11 Install the remover disc, Tool No. DT-47597-3 (5) over

the forcing bolt on the support mount forward side,

rotate to align as required. Install the flat washer and

nut (6) to complete the remover tool assembly.

12 While holding the nut with a ring spanner (7), tighten

the forcing bolt with a suitable socket equi pment (8) to

remove the support mount towards the rear of the

transfer case housing.

13 Disassemble the remover tool, then remove the

support mount and discard. Figure 7F – 25

14 Wipe clean the mountin g surfaces, both in the transfer

case housing and the replac ement support mount

itself, then coat both surfaces with a soap solution.

15 Place the new support mount in the opening on the

transfer case housing rear side, alignin g the arrow (1)

moulded into the support mount with the notch (2) in

the housing.

Figure 7F – 26

16 Fit the installer plate, Tool No. DT -47597-2 (1), to the

rear surface of the support mount (2), aligning the five

pins on the installer plate with the corresponding holes

in the support mount rear surface.

NOTE

The location of the smaller diameter pin is

closest to the transfer case.

Figure 7F – 27

Transfer Case and Adaptor Housing 7F – 23

7F-23

17 Feed the forcing bolt (1) and thrust bearing (2) in the

installer plate (3), on the support mount (4) rear side.

NOTE

The illustration shows the new support mount

partially installed.

18 Install the stepped installer bracket, T ool

No. DT-47597-1 (5), over the forcing bolt, ali gning it

with the transfer case housing forward side, as shown.

Install the flat washer and nut (6) to complete the

installer tool assembly.

19 While holding the nut with a ring spanner, tighten the

forcing bolt using a suitable socket equipment to fully

install the support mount into the transfer case

housing.

20 Disassemble and remov e the installer tool.

Figure 7F – 28

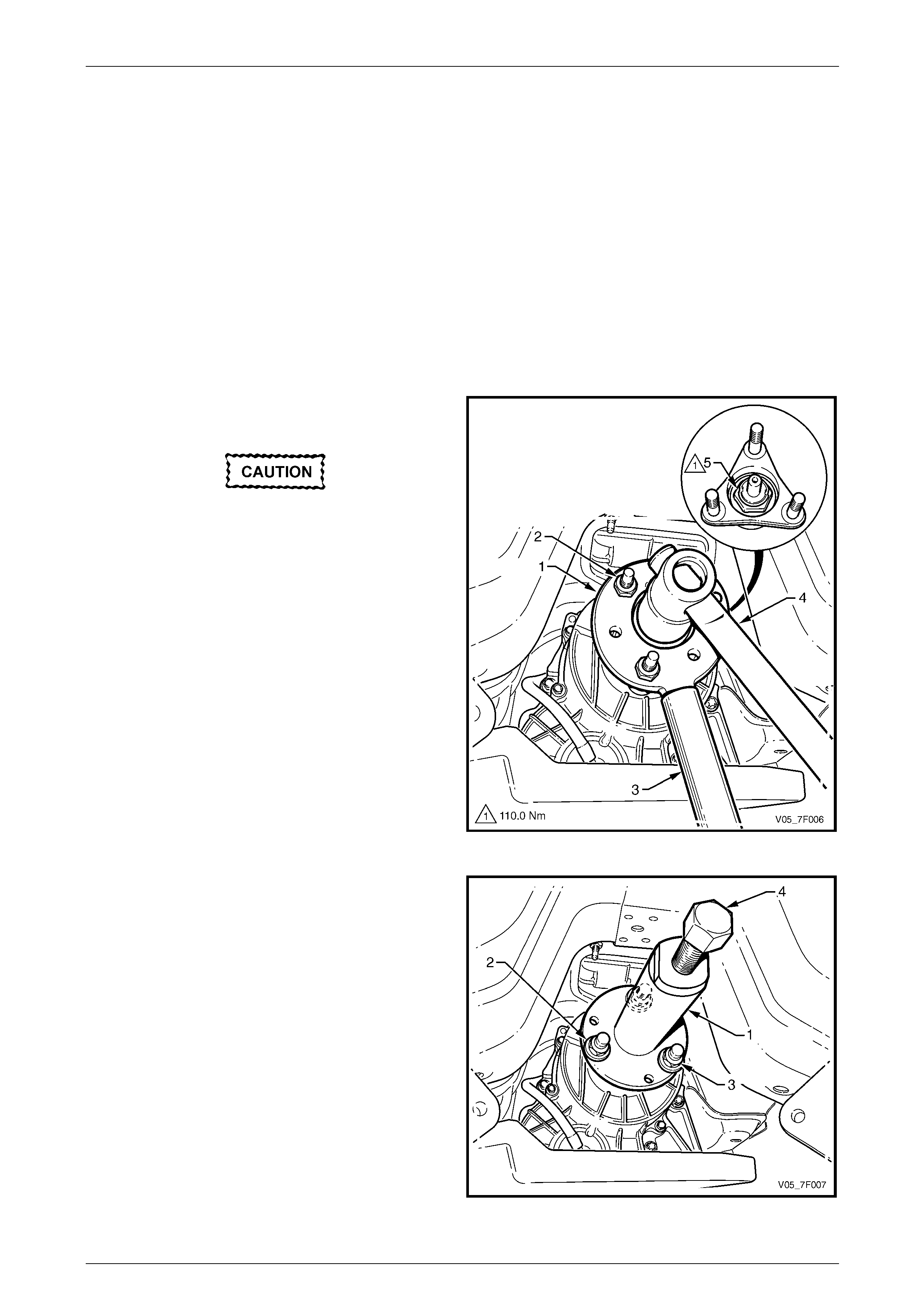

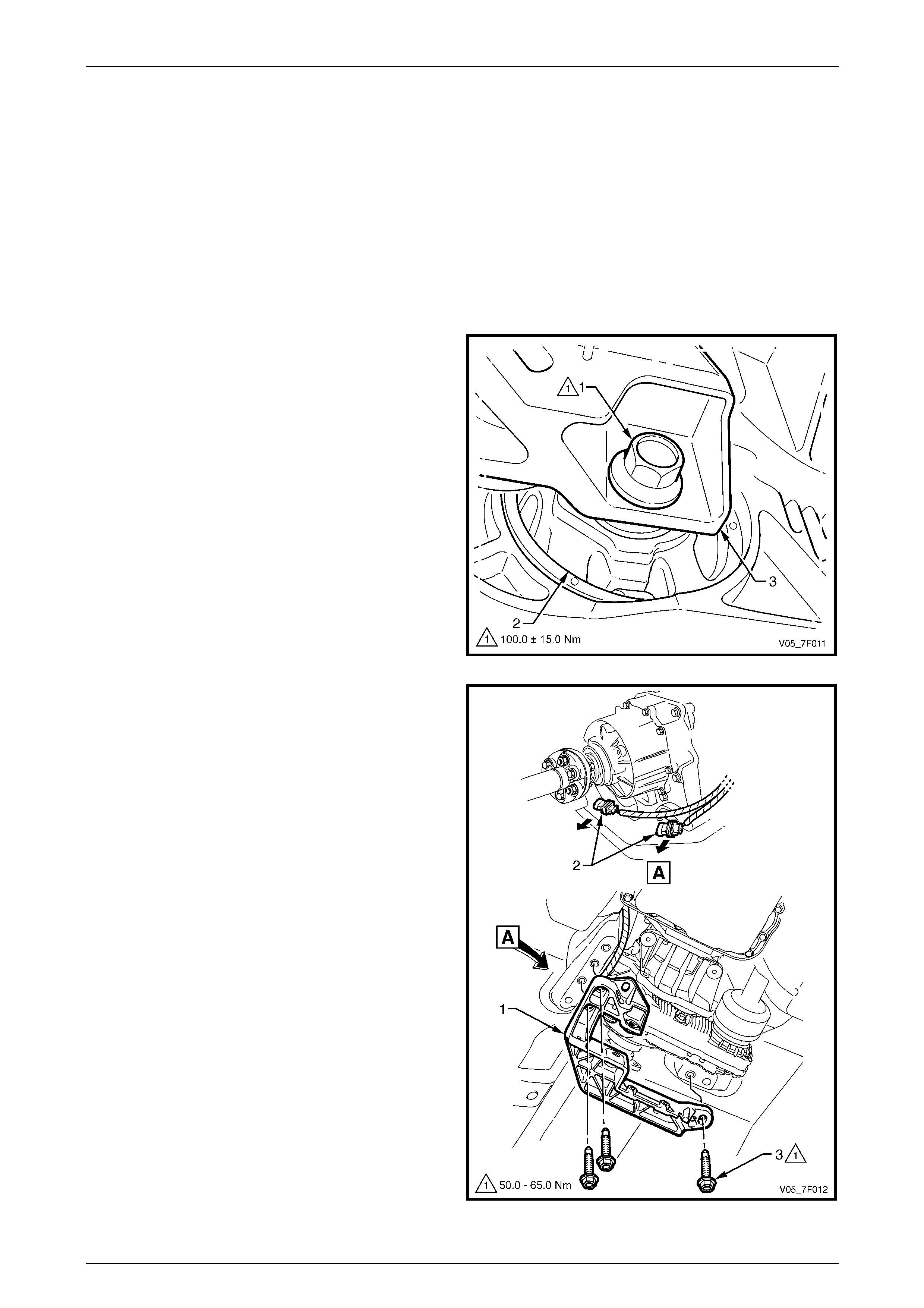

21 Secure the transfer case rear mounting brac ket (1) to

the support mount (2) with the attaching bolt (3).

Tighten the bolt to the correct torque specification.

Transfer case support mount

attaching bolt torque specification.........100.0 ± 15.0 Nm

22 Secure the wiring harness co nnectors (4) to the rear

mounting bracket by sliding them on their support.

23 With the hydraulic lifting equipment, lift the rear of the

transfer case and align the rear mounting bracket with

the marks made on the underbody before removal.

24 Secure the rear mounting bracket to the underbody

with the three attaching bolts (5). Tighten the three

bolts to the correct torque specification.

Transfer case rear mounting bracket

to underbody attaching bolt

torque specification.................................50.0 – 65.0 Nm

25 Lower the transfer case and remove the hydraulic

lifting equipment.

26 Reinstall the following components:

a Transmission support, refer to

2.4 Transmission Support.

b Catalytic converter bracket, refer to

2.3 Catalytic Converter Bracket.

Figure 7F – 29

Transfer Case and Adaptor Housing 7F – 24

7F-24

3 Major Service Operations

3.1 Transfer Case

LT Section No. — 04–050

Remove

1 Remove the following components:

a Catalytic converter bracket, refer to 2.3 Catalytic Converter Bracket.

b Transmission support, refer to 2.4 T r ansmission Support.

c Exhaust system rearward from the two catalytic converters, refer to Section 8B Exhaust System.

NOTE

Prior to their removal, it is good practice to mark

the flanges of the rear and front propeller shafts,

indicating their relative position to each other.

Use a felt tipped pen or similar. These marks will

assist to match the shafts position on

reassembly.

d Rear propeller shaft, refer to Section 4C1 Rear Propeller Shaft and Universal Joints.

e Front propeller shaft, refer to Section 4C2 Front Propeller Shaft and Universal Joints.

2 With a wooden block and suitable hydraulic lifting equipment, support the adaptor housing or the rear of the

transmission oil pan.

3 Remove the bolt (1) securing the rubber supp ort

mount (2) to the transfer case rear mounting

bracket (3).

Figure 7F – 30

Transfer Case and Adaptor Housing 7F – 25

7F-25

4 Using a felt tipped pen or similar, mark the positio n of

the transfer case rear mounting bracket (1) to the

vehicle underbod y.

NOTE

This will assist in aligning the rear mounting

bracket on reinstallation.

5 Disconnect the wiring harness connectors (2) and

separate from the rear mounting bracket by sliding

them off their support.

6 While supporting the rear mounting bracket, remove

the three bolts (3) attaching it to the vehicle

underbody.

7 Remove the rear mounting bracket from the vehicl e.

8 If fitted, remove the mass damper, refer to

2.5 Mass Damper.

Figure 7F – 31

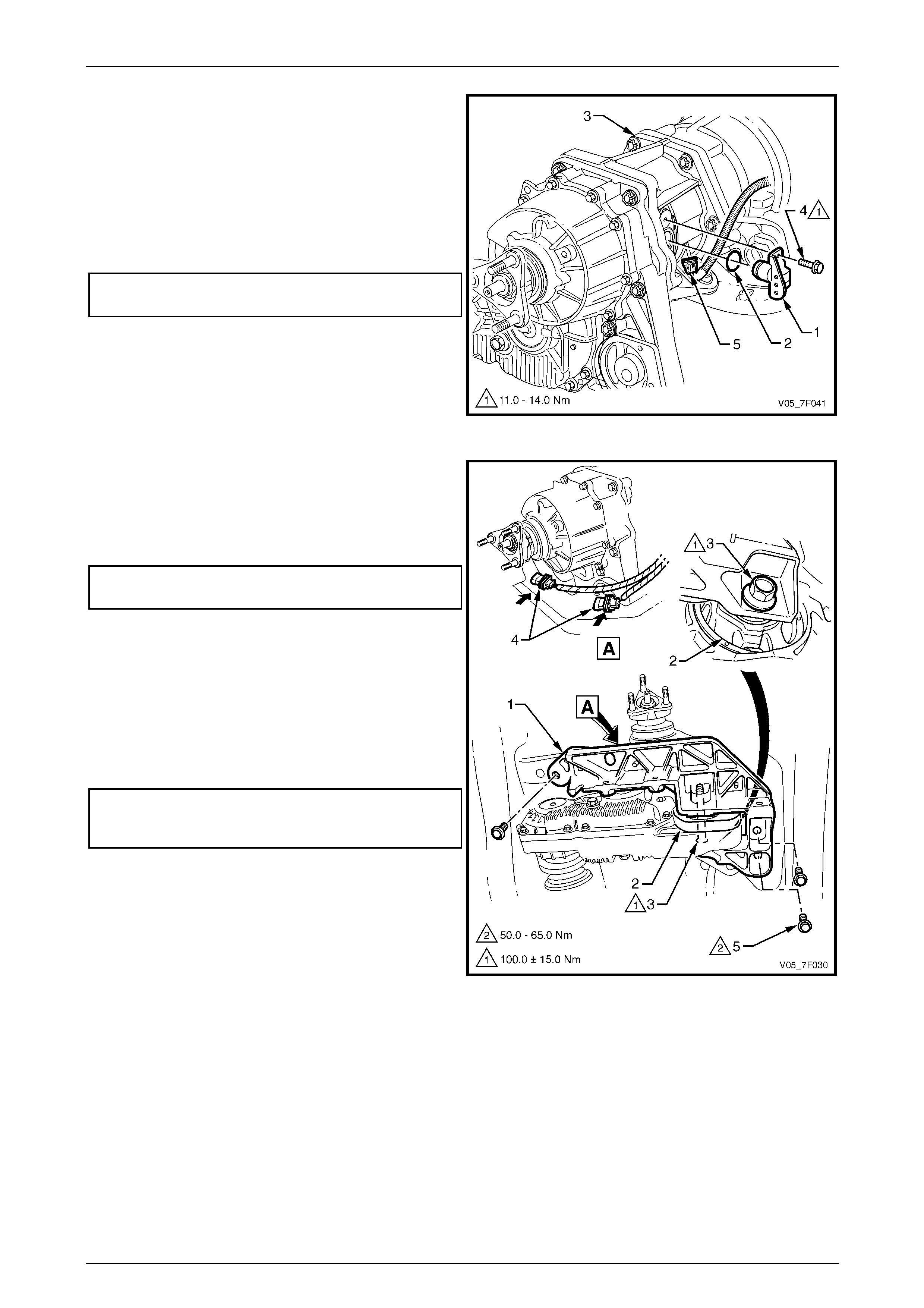

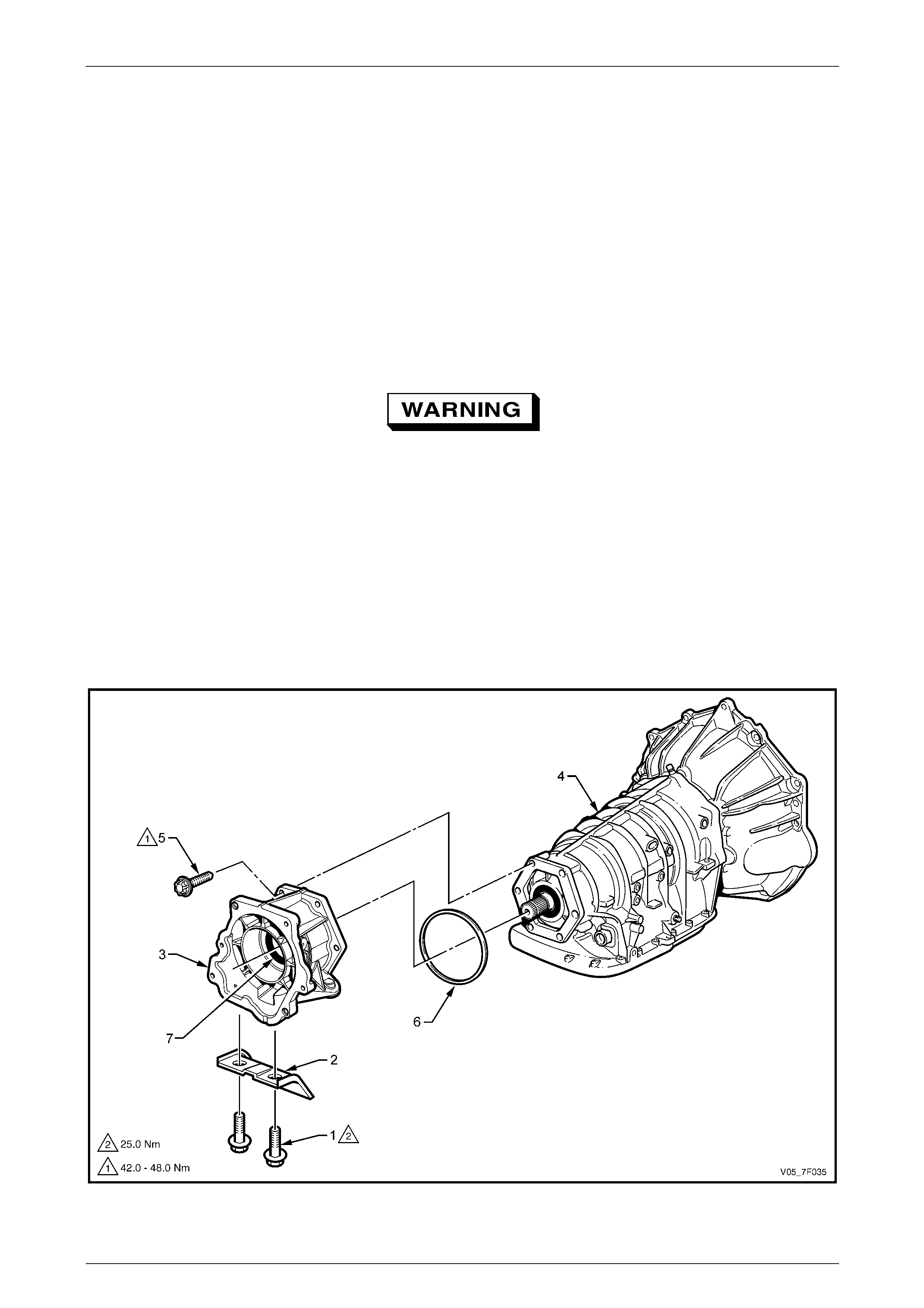

9 If the transfer case is fitted to a 4 speed transmission,

remove the vehicle speed sensor as foll ows:

a Slowly lower the hydraulic support to gain

access to the speed sensor.

b Disconnect the wiring harness connector (1).

c Remove the bolt (2) attaching the speed sensor.

d With a pulling and turning motion, remove the

speed sensor and O-ring seal from the adaptor

housing.

NOTE

The speed sensor removal is a precautionary

measure to avoid possible damage from the

adaptor shaft pick-up ring teeth.

Figure 7F – 32

Transfer Case and Adaptor Housing 7F – 26

7F-26

10 Disconnect the transfer case breather hose (1) from

the vent fitting (2) and secure to one side.

Figure 7F – 33

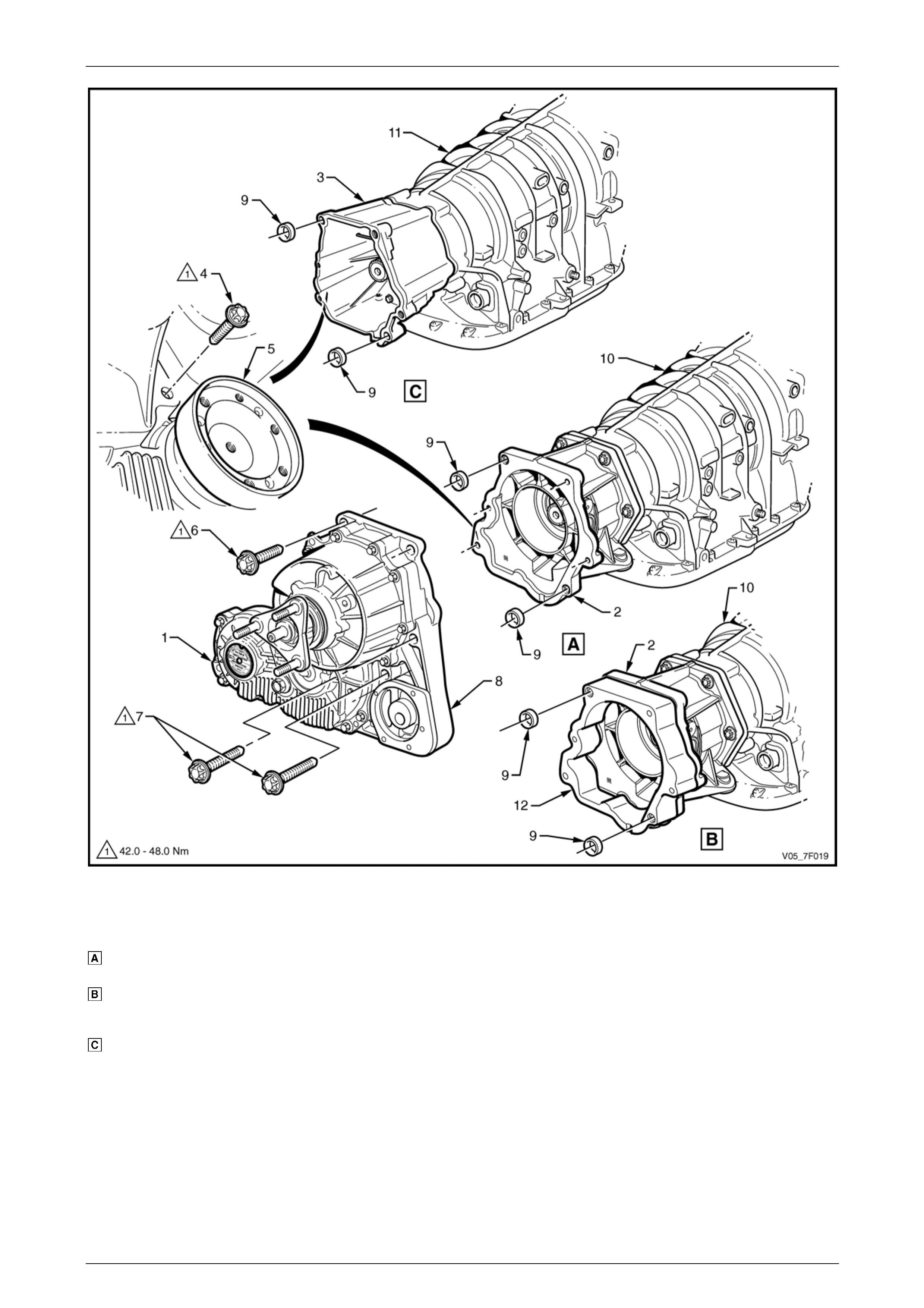

11 Using an E14 Torx socket and suitable socket equipment, remove the bolts attaching the transfer case housing (1)

to the adaptor housing (2) or extension housing (3) located as follows, refer to Figure 7F – 34:

• one bolt (4) on the forward side of the transfer case, adjacen t to the front output flange (5),

• bolt (6), three places, on the rear side of the transfer case and

• two bolts (7) on the rear side of the transfer case, adjacent to the support mount (8).

NOTE

Take note of the location of the two longer

bolts (7).

Transfer Case and Adaptor Housing 7F – 27

7F-27

Figure 7F – 34

Legend

Adaptor Housing with V8 Engine

and 4 Speed Transmission

Adaptor Housing and Plate with

Alloytech V6 Engine and

4 Speed Transmission

Extension Housing with 5 Speed

Transmission

1 Transfer Case Housing

2 Adaptor Housing

3 Extension Housing

4 Transfer Case Bolt (forward flange)

5 Front Output Flange

6 Transfer Case Bolt (rear flange)

7 Transfer Case Bolt (rear flange)

8 Support Mount

9 Locating dowel ring

10 4 Speed Transmission

11 5 Speed Transmission

12 Adaptor Plate (Alloytech V6 engine)

Transfer Case and Adaptor Housing 7F – 28

7F-28

12 While supporting the transfer case (1), pul l rearward to dislodge it from the two locating dowel rings (2) and until the

adaptor shaft (3) internal splines are clear of the transmission main shaft (4), refer to Figure 7F – 35.

13 Carefully lo wer the transfer case and remove it from the vehicle.

NOTE

While the transfer case is removed, do not rotate

the transmission output shaft.

14 If required, remove the two locating dowel rings (2).

15 If required, for a transfer case fitted to a 4 speed transmission on Alloytech V6 engine, remove the adaptor plate (5)

and the two locating dowel rings (6) from the adaptor housing.

Figure 7F – 35

Transfer Case and Adaptor Housing 7F – 29

7F-29

Reinstall

1 For a transfer case fitted to a 4 speed transmission:

a Inspect the front of the adaptor shaft for excess wear in the seal area. If deep grooving is evide nt, then it is

strongly recommended to replace the adaptor shaft, refer to 3.2 Transfer Case Input Shaft Oil Seal and the

oil seal located in the adaptor housing, refer to 3.4 Transmission Adaptor Housing Oil Seal.

b On the adaptor shaft, lubricate the internal splines and the front outer diameter contacting the seal, with

molybdenum disulphide gre ase.

c If previously removed on Alloytech V6 engine, reinstall the two locating dowel rings (6) and the a daptor

plate (5) to the transmission adaptor hous ing, refer to Figure 7F – 35.

2 For a transfer case fitted to a 5 speed transmission, lubricate the internal splines of the adaptor shaft with

molybdenum disulphide gre ase.

3 Check if the adaptor shaft is fully installed with the snap ring engaged in the input shaft groove, tug on the adaptor

shaft to ensure that engagement has occurred.

4 Ensure the two locating dowel rings (2) are correctly positioned on the adaptor housing or adaptor plate or

extension hous ing as applicable, refer to Figure 7F – 35.

5 With a suitable hydraulic lifting equipment, raise the transfer case and line it up with the adaptor/extension housing.

When installing a transfer case onto an

adaptor housing fitted to a 4 speed

transmission, take care not to damage the

housing oil seal while engaging the adaptor

shaft.

6 Align the transfer case front face parallel to the ada pt or/extension housing machined re ar face, then move the

transfer case forward to engage the splines of the adaptor shaft (3) with those of the transmission output shaft (4).

If required, rock the transfer case output flange back and forth to assist with spline engag ement.

7 Push the transfer case forward to engage b oth locating dowel rings (9), ins t all the bolt (4) on the forward flange, the

three bolts (6) and two bolts (7) on the rear flange attachi ng the transfer case to the ada ptor/extension housing,

then tighten to the correct torque specif ication, refer to Figure 7F – 34.

Transfer case to adaptor housing

attaching bolt torque specification...........42.0 – 48.0 Nm

NOTE

Only the presence of an oil leak will determine if

the adaptor housing seal has been damaged

during installation of a transfer case to a 4 speed

transmission.

8 Connect the breather hose (1) to the vent fitting (2) on

the transfer case.

Figure 7F – 36

Transfer Case and Adaptor Housing 7F – 30

7F-30

9 For a transfer case fitted to a 4 speed transmission,

install the vehicle speed sens or (1) as follows:

a Lubricate a new O-ring seal (2) with petrole um

jelly and install it to the speed sensor.

b Position the speed sensor in the adaptor

housing (3).

c Secure the speed sensor with the bolt (4),

tightening it to the correct torque specification.

Vehicle speed sensor attachin g bolt

torque specification.................................11.0 – 14.0 Nm

d Connect the wiring harness connector (5) to the

speed sensor.

Figure 7F – 37

10 If fitted, reinstall the mass damper, refer to

2.5 Mass Damper.

11 Secure the transfer case rear mounting brac ket (1) to

the support mount (2) with the attaching bolt (3).

Tighten the bolt to the correct torque specification.

Transfer case support mount

attaching bolt torque specification.........100.0 ± 15.0 Nm

12 Secure the wiring harness co nnectors (4) to the rear

mounting bracket by sliding them on their support.

13 With the hydraulic lifting equipment lift the rear of the

transfer case and align the rear mounting bracket with

the marks made on the underbody before removal.

14 Secure the rear mounting bracket to the underbody

with the three attaching bolts (5). Tighten the three

bolts to the correct torque specification.

Transfer case rear mounting bracket

to underbody attaching bolt

torque specification.................................50.0 – 65.0 Nm

15 Lower the transfer case, then remove the hydraulic

lifting equipment.

16 Ensure the transfer case lubricant level is correct, refer

to 2.1 Checking Transfer Case Lubricant Level.

Figure 7F – 38

Transfer Case and Adaptor Housing 7F – 31

7F-31

17 Reinstall the following components:

NOTE

Prior to installation, align the position of the two

propeller shafts with each other by matching the

marks done prior to removal. It may take up to six

turns for the marks to match.

a Front propeller shaft, refer to Section 4C2 Front Propeller Shaft and Universal Joints.

b Rear propeller shaft, refer to Section 4C1 Rear Propeller Shaft and Universal Joints.

c Exhaust system rearward from the two catalytic converters, refer to Section 8B Exhaust System.

d Transmission support, refer to 2.4 T r ansmission Support.

e Catalytic converter bracket, refer to 2.3 Catalytic Converter Bracket.

18 Check the automatic transmission fluid level, refer to:

• Section 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing, for 4 speed automatic transmission, or

• Section 7E4 Automatic Tr ansmission – 5L40E – On-vehicle Servicing, for 5 speed automatic transmission.

Transfer Case and Adaptor Housing 7F – 32

7F-32

3.2 Transfer Case Input Shaft Oil Seal

LT Section No. — 04–050

Remove

1 Remove the transfer case from the adaptor/extension housing, refer to 3.1 T ransfer Case.

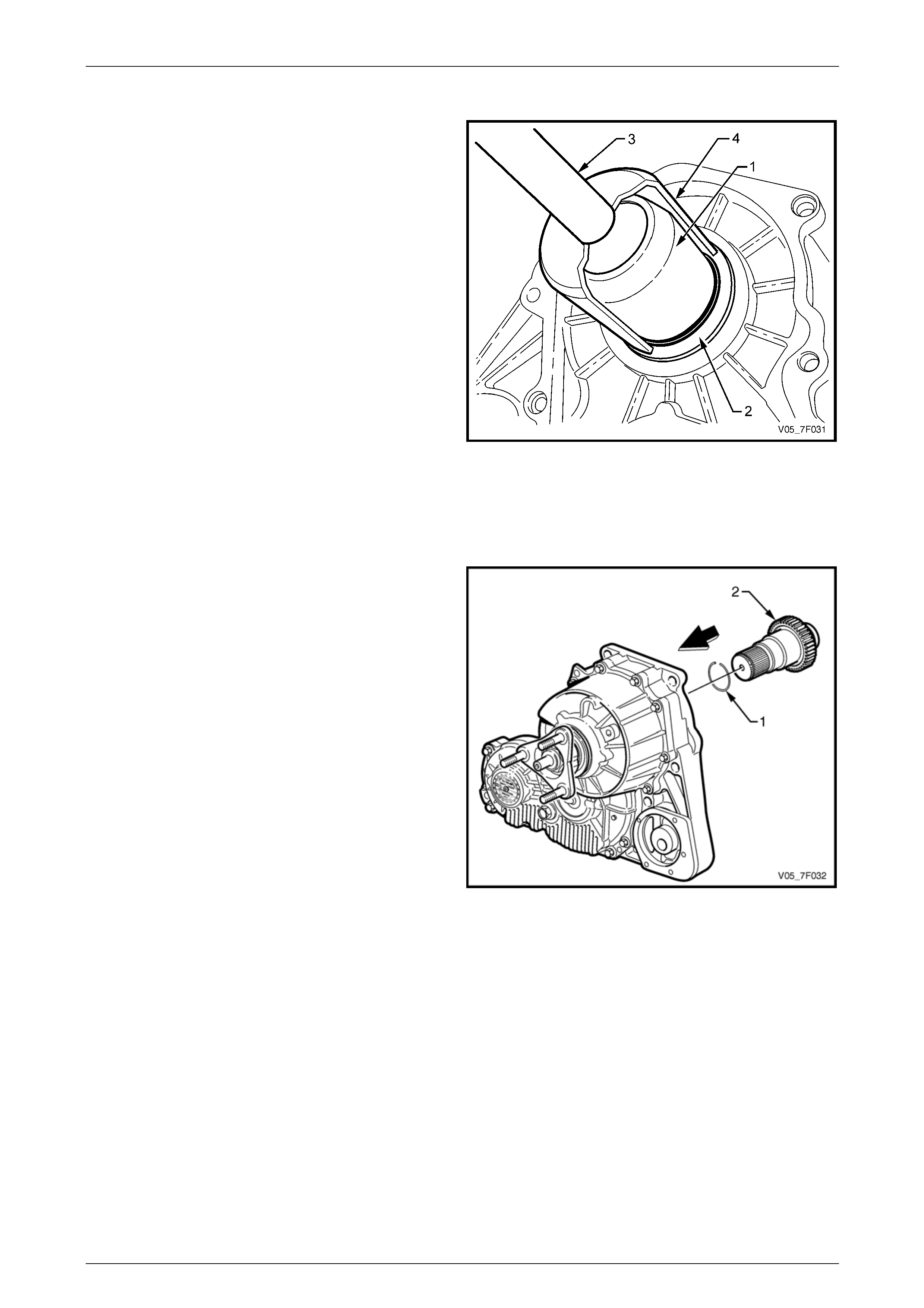

2 Lever the adaptor shaft (1) from the front of the

transfer case (2) by using a large screwdriver (3) or

similar tool between the adaptor shaft step and the oil

seal (4), then remove the adaptor shaft.

NOTE

Some resistance will be felt until the snap

ring (5) at the end of the adaptor shaft is

dislodged from the groove behind the splines in

the inner diameter of the input shaft.

3 Remove the snap ring from the adaptor shaft and

discard the snap ring.

NOTE

Short adaptor shaft shown, longer shaft fitted for

Alloytech V6 engine, refer to F igure 7F – 1.

Figure 7F – 39

4 Use a small screwdriver or wire hook to remove the

O-ring seal (1) from the inside of the front input shaft.

Discard the O-ring seal.

Take care during the seal removal operation

not to damage the transfer case machined

surfaces.

5 Remove the front input oil seal (2) using a large

screwdriver or similar, working around the oil seal

outer perimeter. Discard the removed oil seal.

Figure 7F – 40

Transfer Case and Adaptor Housing 7F – 33

7F-33

Reinstall

1 Install the seal protector, Tool No. DT-47600-1 (1),

over the front input shaft and push to fully install.

2 Lubricate a new front input oil seal (2) with

Mobilgrease XHP 222 or equi valent, ensuring the

recesses between the oil seal lips are filled to

approximately 50%, then slide the oil seal over the

seal protector.

3 Install the driver, Tool No. AU 355-A (3), into the seal

installer, Tool No. DT-47600-2 (4), then fully install the

oil seal in the transfer case front housing.

4 Remove the seal installation and protector tools.

5 Lubricate a new O-ring seal with a smear of

Mobilgrease XHP 222 or equivalent and install into the

groove of the front input shaft inner diameter.

6 Lubricate the internal splines of the front input shaft

with 1 gram of Weicon™ standard grade, anti-seize

grease #37771.

NOTE

This grease is the onl y product approved for use

in this application and is available in a 10 gram

syringe.

Figure 7F – 41

7 Fit a new snap ring (1) onto the end of the adaptor

shaft (2).

NOTE

Short adaptor shaft shown, longer shaft fitted for

Alloytech V6 engine, refer to F igure 7F – 1.

8 Engage the splines of the adaptor shaft with those in

the front input shaft and drive the adaptor shaft until

the snap ring engages the groove behind the front

output shaft splines.

NOTE

It is only necessary to use light force to fully

install the adaptor shaft.

9 Reinstall the transfer case on t o the adaptor housing,

refer to 3.1 Transfer Case.

Figure 7F – 42

Transfer Case and Adaptor Housing 7F – 34

7F-34

3.3 Adaptor Housing – 4 Speed

Transmission

LT Section No. — 04–100

Remove

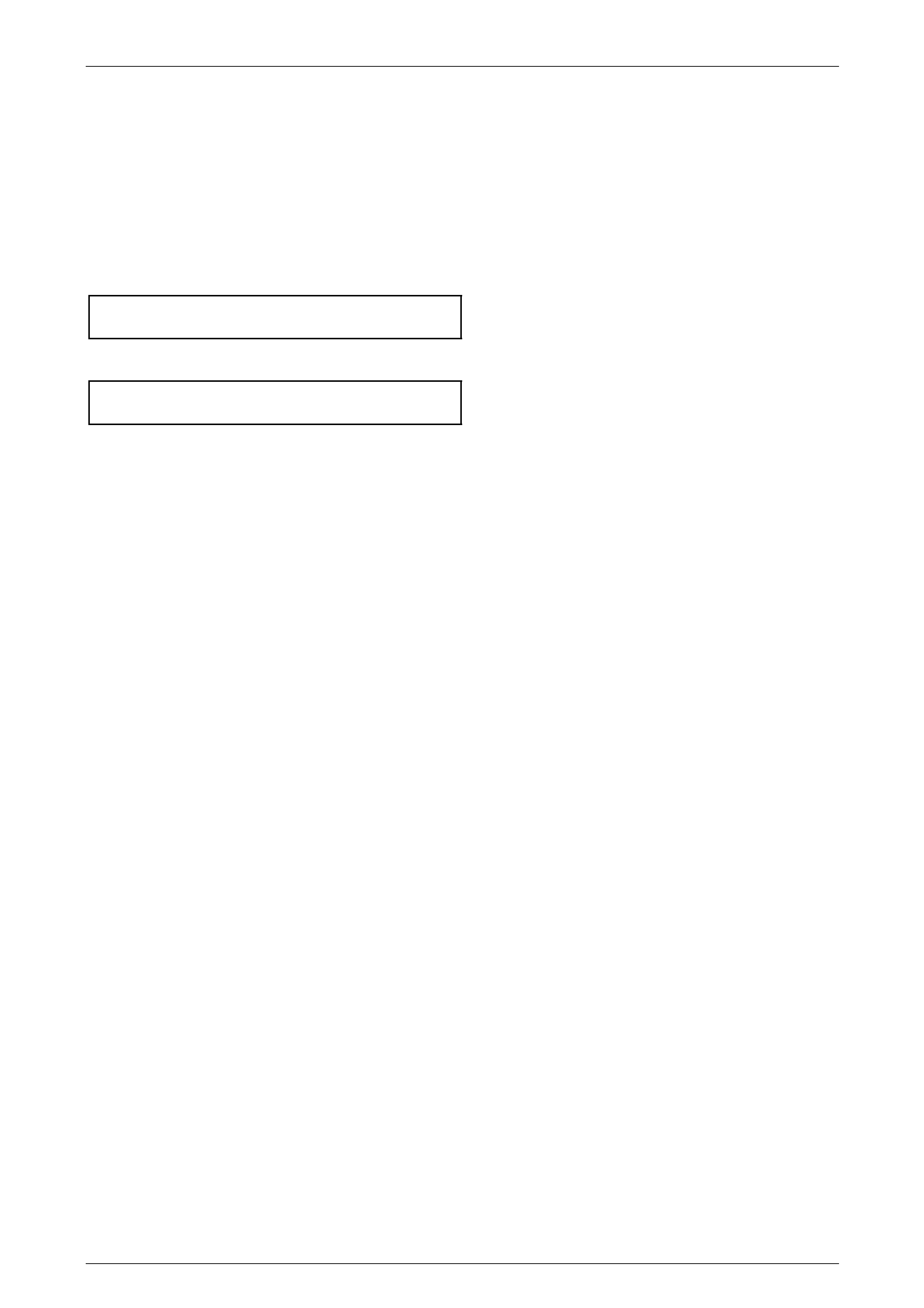

1 Remove the transfer case and the vehicle s peed sensor from the adaptor housing, refer to 3.1 Transfer Case.

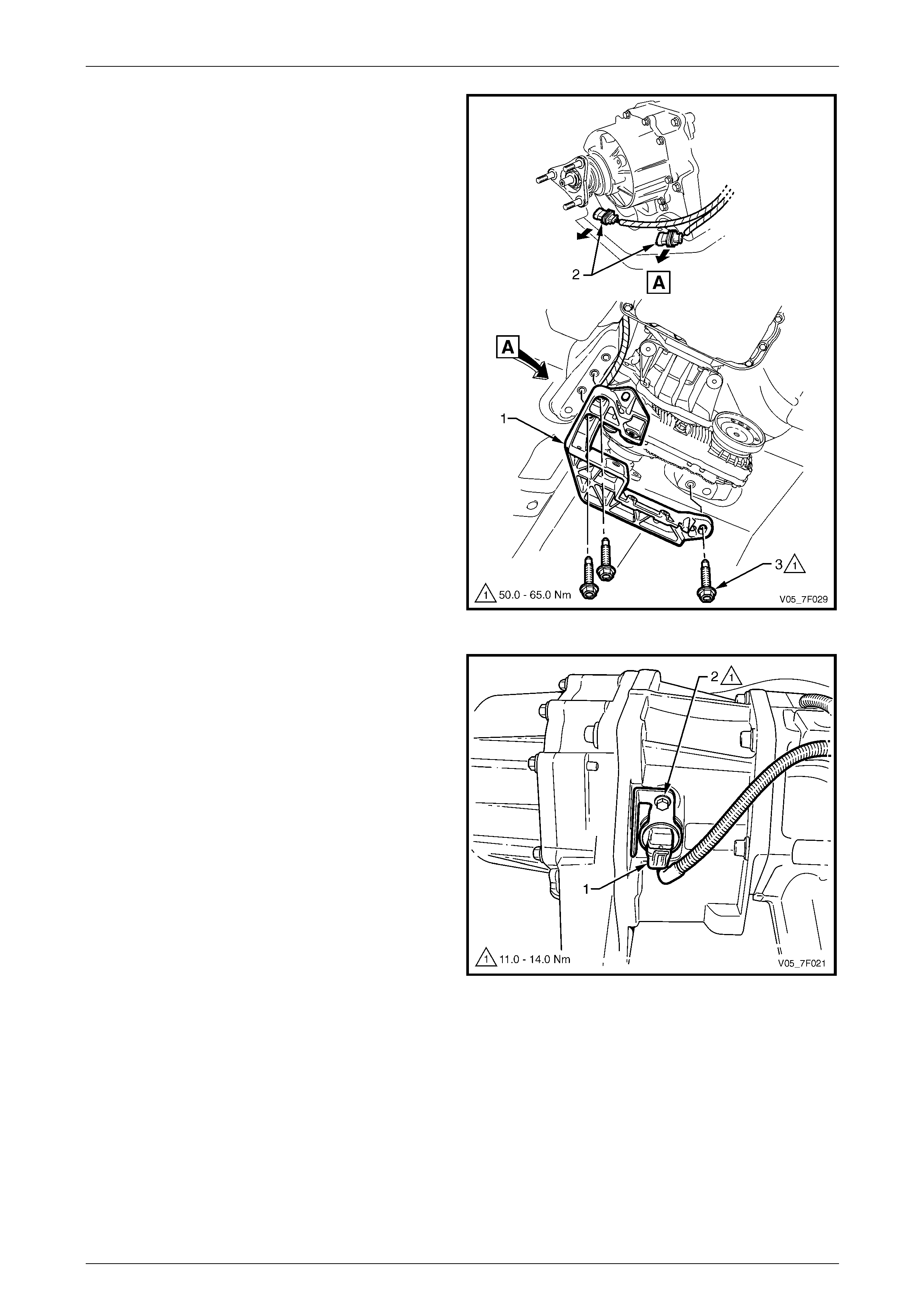

2 Remove the two bolts (1) attaching the bracket (2) to the adaptor ho using (3) and remove the bracket,

refer to Figure 7F – 43.

3 Place a drain tray under the rear of the automatic transmission (4) to catch residual transmission fl uid once the seal

between the transmission and adaptor housing is broken.

If the transmission oil p an feels hot, take care

to avoid scalding from the hot automatic

transmission fluid that will flow from the rear

of the transmission.

4 Using an E14 Torx socket and suitable equipment, remove the bolt (5), six places, attaching the adaptor housing to

the rear of the automatic transmission.

5 If required, support and tap the adaptor housing with a rubber hammer, to break the seal with the transmission

housing.

6 Remove the adaptor housing and O-ring seal (6) from the rear of the automatic transmission, discard the O-ring

seal.

7 If required, remove the oil seal (7) from the adaptor housing, refer to 3.4 Transmission Adaptor Housing Oil Seal .

Figure 7F – 43

Transfer Case and Adaptor Housing 7F – 35

7F-35

Reinstall

1 If required, install a new oil seal in the a da ptor housing, refer to 3.4 Transmission Adaptor Housing Oil Seal.

2 Clean the mating surfaces of the transmission and the adaptor housing.

3 Install a new square section O-ring seal (6) that has be en lubricated with a smear of petr oleum jelly on the adaptor

housing (3) forward side, refer to F igure 7F – 43.

4 Lubricate the oil seal lips (7) wit h petro leum jelly and then reinsta ll the adaptor housing to the rear of the

transmission.

5 Install the Torx bolt (5), six places, attaching the ad aptor housing and tighten to the correct torque specification.

Adaptor housing to transmission case

Torx bolt torque specification..................42.0 – 48.0 Nm

6 Reinstall the adaptor hous ing bracket (2) and tighten the two attaching bolts (1) to the correct torque sp ecification.

Adaptor housing bracket attachin g

bolt torque specification.....................................25.0 Nm

7 Reinstall the transfer case an d the vehicle speed sensor onto the adaptor housing, refer to 3.1 Transfer Case.

8 Check the automatic transmission fluid lev el,

refer to Section 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

Transfer Case and Adaptor Housing 7F – 36

7F-36

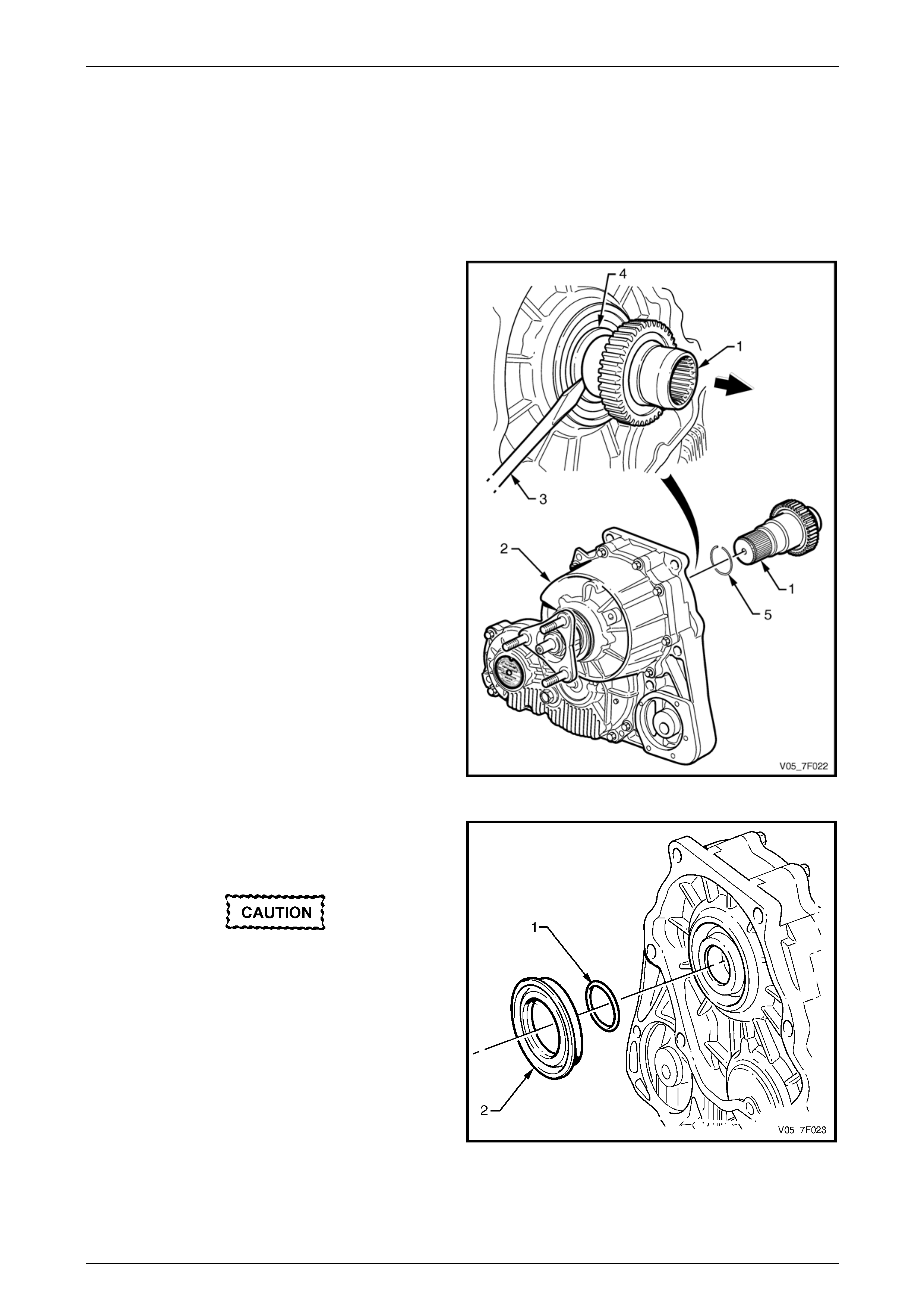

3.4 Transmission Adaptor Housing Oil Seal

LT Section No. — 04–100

Replace

1 Remove the following compo nents from the vehicle, as required:

a Transfer case, refer to 3.1 Transfer Case.

b Adaptor housing, refer to 3.3 Adaptor Housing.

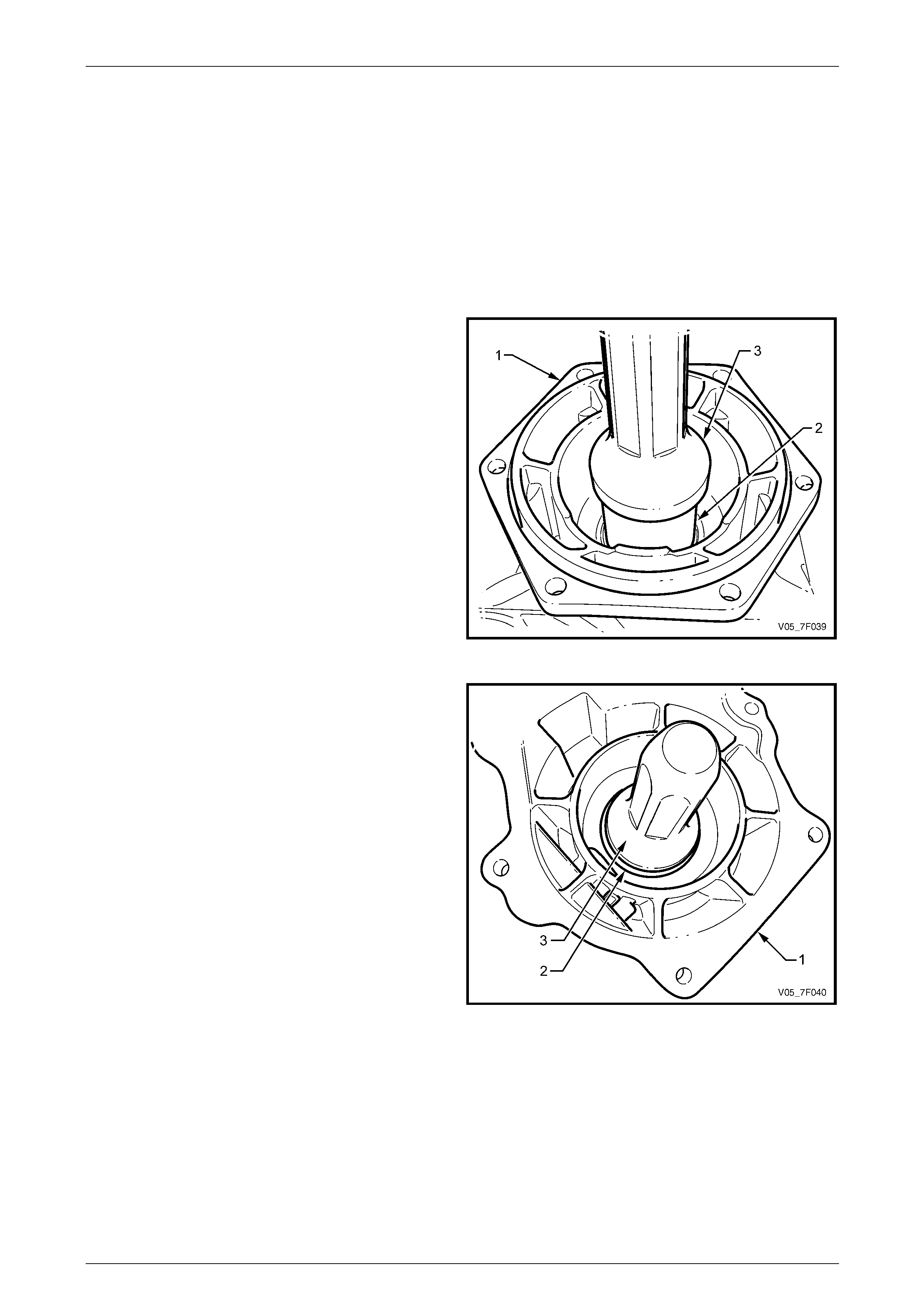

2 Support the adaptor housing (1) on a flat surface,

forward side facing upward.

3 Use the sleeve, Tool No. E1896-6 (or 3A8-6) (2), and

the seal installer, Tool No. J 21426 (3), to drive the oi l

seal out of its location, towards the rear section of the

adaptor housing. Discard the removed oil seal.

NOTE

Alternatively to the sleeve (2) a suitable piece of

pipe (OD 57 mm) can be used to remove the oil

seal.

Figure 7F – 44

4 Support the adaptor housing ( 1) on a flat surface, rear

side facing upward.

5 To facilitate the installation, lu bricate a new oil seal (2)

with petroleum jelly and p osition it into the adaptor

housing.

6 Use the seal installer, Tool No. J 21426 (3), to drive

the new oil seal in place, working from the rear

towards the front of the adaptor housing.

7 Lubricate the seal lips with petroleum jelly, before

reinstalling the adaptor ho using to the rear of the

transmission.

8 Reinstall the following components:

a Adaptor housing, refer to 3.3 Adaptor Housing.

b Transfer case, refer to 3.1 Transfer Case.

Figure 7F – 45

Transfer Case and Adaptor Housing 7F – 37

7F-37

4 Transfer Case Symptom

Diagnosis

4.1 Preliminary Diagnosis

System Operation

Review the system operation to familiarise yo urself with the system functions, refer to 1 General Description.

As the internal components are not serviced separately, should an internal component failure be determined, then the

transfer case must be replaced as an assembly.

Visual/Physical Inspection

1 Inspect the easily accessible or visually inspect the system components for obvious damag e, or for conditions that

could cause the symptom.

2 Inspect for the correct lubrication type and level, refer to 2.1 Checking Transfer Case Lubricant Level.

As this assembly has a very specific lubricati on requirement, if in doubt drain the lubricant and refill with the known

correct fluid, refer to 2.2 Draining and Filling Transfer Case Lubric ant .

Symptom List

To diagnose the symptom, refer to the appro priate symptom diagnostic procedure:

• 4.2 Popping Noise

• 4.3 Whine or Rumble Noise

• 4.4 Growl or Grinding Noise

• 4.5 Clunk During Acceleration and Deceleration

• 4.6 No Front or Rear Drive

• 4.7 Lubricant Leak Diagnosis.

Techline

Transfer Case and Adaptor Housing 7F – 38

7F-38

4.2 Popping Noise

Definition

A faulty internal component that causes a po pping noise in the transfer case.

Diagnostic Table

Cause Defect and Correction

Internal damage Probable gear teeth damage that has caused subsequent bearing failure due to metallic

debris.

Replace the transfer case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 39

7F-39

4.3 Whine or Rumble Noise

Definition

A faulty internal component that causes a whine or rumbling noise in the transfer case.

Diagnostic Table

Cause Defect and Correction

Faulty bearings Failure of one or more interna l bearing(s).

Replace the transfer case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 40

7F-40

4.4 Growl or Grinding Noise

Definition

A faulty internal component that causes a growl or grinding noise in the transfer case.

Diagnostic Table

Cause Defect and Correction

Internal damage Possible damage to the plane tary carrier pinion teeth, the carrier, the ring gear and/or

sun gear teeth. Loss of lubrica nt contributes to the damage noted.

Replace the transfer case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 41

7F-41

4.5 Clunk During Acceleration and

Deceleration

Definition

During acceleration or deceleration, a clunk is heard or felt from the transfer case.

Diagnostic Table

Cause Defect and Correction

Incorrect lubricant level Inspect the transfer case for correct lubricant level, refer to 2.1 Checking Tr ansfer Case

Lubricant Level.

If the lubricant level is low, then the reason must be determined and corrected before

placing the vehicle back into service.

Internal damage Excessive backlash in the geartrain caused b y teeth wear.

Replace the transfer case, refer to 3.1 Transfer Case.

Loose rear output flange nut Rear output flange retaining nut loose, causing flange splines to wear.

Replace the rear output flange, refer to 2.7 Transfer Case Rear Output Fl ange and Oil

Seal.

If a new rear output flange does not correct the condition, then replace the transfer

case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 42

7F-42

4.6 No Front or Rear Drive

Definition

The transfer case is not delivering engine torque to the rear and front prope ller shafts.

Diagnostic Table

Cause Defect and Correction

Internal damage Probable planetary gear set damage creating a permanent neutral condition.

Replace the transfer case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 43

7F-43

4.7 Lubricant Leak Diagnosis

Definition

A visible indication of lubrica nt external leakage from the transfer case is evident.

Diagnostic Table

Cause Defect and Correction

Drain or fill plug Replace the leaking plug and gasket, refer to 2.2 Draining and Filling T r ansfer Case

Lubricant.

Rear output shaft seal leaking Overfilled or incorrect transfer case lubricant level, refer to 2.1 Checking Transfer Case

Lubricant Level.

Blocked vent, check for correct routing and no kink of vent hose. Cle ar blocked vent

line, refer to 1.3 Transfer Case Maintena nce.

The seal is improperly installe d, worn or damaged. Inspect the rear output flange seal

surface for excessive wear or damage.

Replace the rear output shaft flange and oil seal, refer to 2.7 Transfer Case Rear

Output Flange and Oil Seal.

The seal bore is damaged or the housing is cracked.

Replace the transfer case, refer to 3.1 Transfer Case.

The rear output shaft bearing is worn.

Replace the transfer case, refer to 3.1 Transfer Case.

Front output shaft seal leaking Overfilled or incorrect transfer case lubricant level, refer to 2.1 Checking Transfer Case

Lubricant Level.

The vent hose is blocked, check for correct routing and no kink of vent hose. Clear

blocked vent line, refer to 1.3 Transfer Case Maintenance.

The seal is improperly installe d, worn or damaged. Inspect the front output flange seal

surface for excessive wear or damage.

Replace the front output shaft flange and oil seal, refer to 2.6 Transfer Case Front

Output Flange, Slinger and Oil Seal.

The seal bore is damaged or the housing is cracked.

Replace the transfer case, refer to 3.1 Transfer Case.

The front output shaft bearing is worn.

Replace the transfer case, refer to 3.1 Transfer Case.

Leaking from the vent The transfer case is overfilled.

Restore to correct level, refer to 2.1 Checking Transfer Case Lubricant Level.

The vent hose is blocked, check for correct routing and no kink of vent hose. Clear

blocked vent line, refer to 1.3 Transfer Case Maintenance.

Adaptor housing fluid leak Check if the leaking fluid is automatic transmission fluid.

If it is not, refer to input shaft oil seal leaking, in this Table, otherwise continue.

Remove the transfer case and inspect the front of the adaptor shaft for wear or damage

at the seal contact area, refer to 3.1 Transfer Case.

Replace adaptor housing oil seal, refer to 3.4 Transmission Adaptor H ousing Oil Seal.

Input shaft seal leaking Overfilled or incorrect transfer case lubricant level, refer to 2.1 Checking Transfer Case

Lubricant Level.

The vent hose is blocked, check for correct routing and no kink of vent hose. Clear

blocked vent line, refer to 1.3 Transfer Case Maintenance.

The seal is improperly installe d, worn or damaged. Inspect the input seal surface for

excessive wear or damage.

Replace the input shaft oil seal, refer to 3.2 Transfer Case Input Shaft Oil Seal.

The seal bore is damaged or the housing is cracked.

Replace the transfer case, refer to 3.1 Transfer Case.

The input shaft bearing is worn.

Replace the transfer case, refer to 3.1 Transfer Case.

Lubricant leak from the transfer

case housing join Replace the transfer case, refer to 3.1 Transfer Case.

Lubricant leak from either of

the transfer case housings Replace the transfer case, refer to 3.1 Transfer Case.

Transfer Case and Adaptor Housing 7F – 44

7F-44

5 Specifications

General

Make...........................................................................................................New Process Gear

Model.....................................................................................................................NV 124 GM

Type.....................................................................................................Full Time Single Speed

Torque Split ......................................................................................38% – 62% Front to Rear

Gearing

Input from Transmission Output Shaft............................................. 3 pinion Planetary Carrier

Output to Rear Final Drive....................................................................... Planetary Ring Gear

Output to Front Final Drive .......................................................Sun Gear and Helical Gearing

Lubricants

Lubricant Type.................................................................................................Esso MTF-LT-1

.................................................................................................................. or Castrol BTO 338

Quantity – Dry Fill........................................................................................................240 ml

– Service Refill (after Draining)....................................approximately 100 – 160 ml

Oil Seal Lip and O-Ring Lubricant .........................................................Mobilgrease XHP 222

............................................................................................................................. or equivalent

Front Input, Front Output and Rear Output Shaft Splines...............Weicon™ Standard Grade

Anti-seize Grease #73331

Transfer Case and Adaptor Housing 7F – 45

7F-45

6 Torque Wrench Specifications

Transfer Case Filler Plug......................................................................32.0 Nm

Transfer Case Drain Plug.....................................................................32.0 Nm

Catalytic Converter Bracket to Adaptor Housing

Bracket Attaching Bolt..........................................................................25.0 Nm

Catalytic Converter Bracket to Catalytic Converter

Attaching Nut........................................................................................25.0 Nm

Mass damper blocks attaching bolt ...........................................20.0 – 24.0 Nm

Mass damper attaching stud .....................................................20.0 – 24.0 Nm

Mass damper attaching nut.......................................................20.0 – 24.0 Nm

Transmission Support to Transfer Case Rear

Mounting Bracket Attaching Bolt .................................................54.0 ± 5.0 Nm

Transmission Support to Und erbo dy Side Rail

Attaching Bolt..............................................................................54.0 ± 5.0 Nm

Transfer Case Rear Output Flange Retaining Nut..............................110.0 Nm

Transfer Case Support Mount Attaching Bolt..........................100.0 ± 15.0 Nm

Transfer Case Rear Mounting Bracket to

Underbody Attaching Bolt..........................................................50.0 – 65.0 Nm

Transfer Case to Adaptor Housing Attaching Bolt.....................42.0 – 48.0 Nm

Vehicle Speed Sensor Attaching Bolt........................................11.0 – 14.0 Nm

Adaptor Housing to Transmission Case Torx Bolt.....................42.0 – 48.0 Nm

Adaptor Housing Bracket Attaching Bolt...............................................25.0 Nm

Transfer Case and Adaptor Housing 7F – 46

7F-46

7 Special Tools

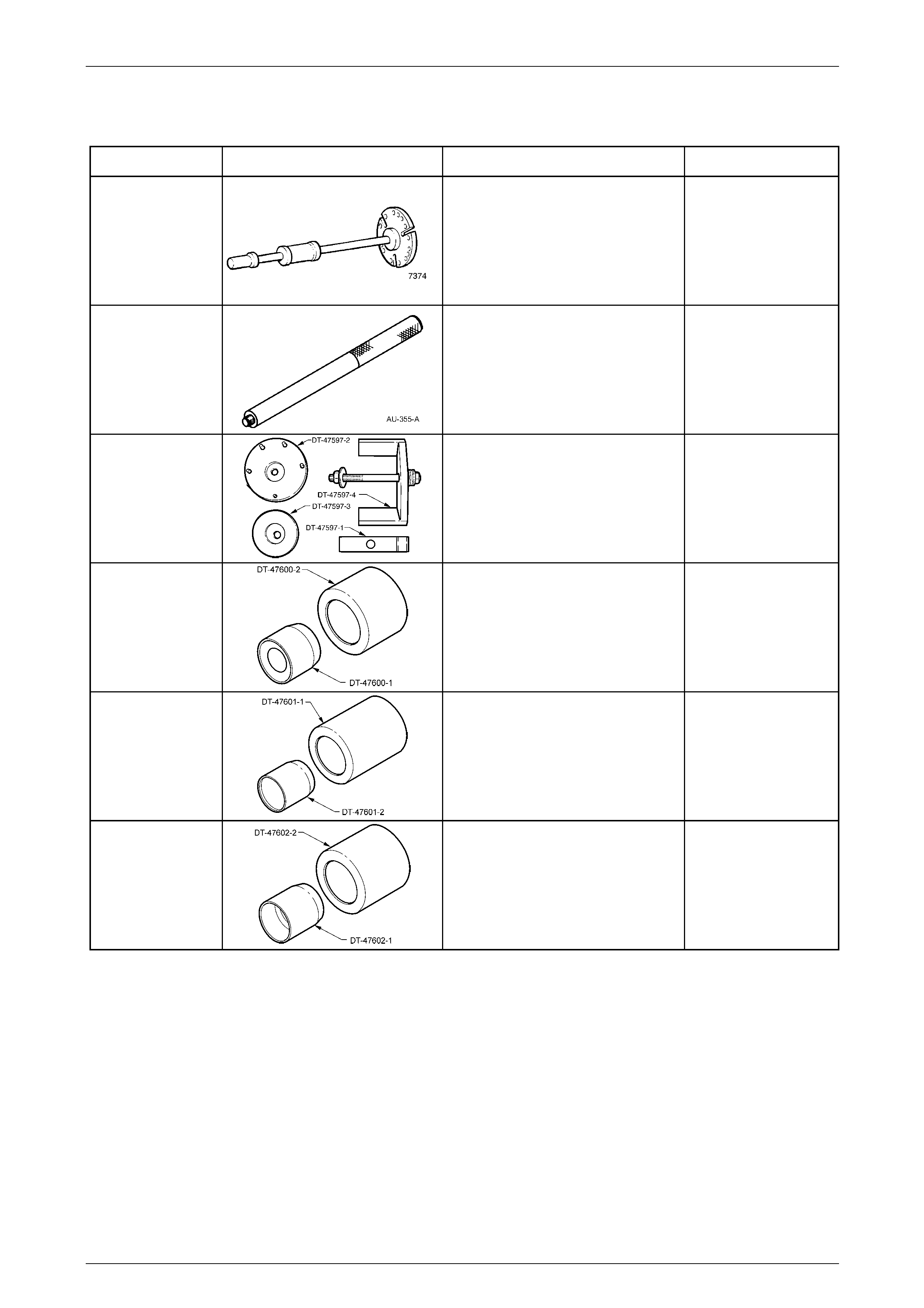

Tool Number Illustration Description Tool Classification

7374

Slide Hammer

Used with three screws to remove the

front output flange from the transfer

case.

Previously released.

Desirable

AU-355-A

Driver

Used in conjunction with various

installers.

Previously released.

Available

DT-47597

Support Mount Remover/Installer

Used to remove and install the

support mount from/to the transfer

case rear mounting bracket.

Previously released.

Available

DT-47600

Seal Protector and Installer

Used to protect and install the front

input shaft oil seal to the transfer

case.

Previously released.

Available

DT-47601

Seal Protector and Installer

Used to protect and install the rear

output shaft oil seal to the transfer

case.

Previously released.

Available

DT-47602

Seal Protector and Installer

Used to protect and install the front

output shaft oil seal to the transfer

case.

Previously released.

Available

Transfer Case and Adaptor Housing 7F – 47

7F-47

Tool Number Illustration Description Tool Classification

E1896-6

Sleeve

Used in conjunction with seal installer

J 21426 to remove the oil seal from

the adaptor housing.

Previously released.

Unique

J 21426

Seal Installer

Used in conjunction with sleeve

E1896-6 to remove the oil seal from

the adaptor housing and to install the

new seal.

Previously released.

Unique

DT-47735

Holding Tool

Used to hold the rear output flange

when loosening/tightening the flange

nut.

New release.

Unique

DT-47736

Extractor

Used to remove the rear output flange

from the rear of the transfer case.

New release.

Unique