Rear Final Drive and Drive Shafts Page 4B1-1

Page 4B1-1

Section 4B1

Rear Final Drive and Drive Shafts

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................4

1.1 General Description............................................................................................................................................... 4

1.2 Final Drive Assembly Identification ..................................................................................................................... 6

Final Drive Application.......................................................................................................................................... 6

1.3 Final Drive Assembly Maintenance...................................................................................................................... 7

Maintenance........................................................................................................................................................... 7

Drive Shaft Bearings and Constant Velocity Joints ............................................................................................ 7

Differential Carrier Assembly.............................................................................................................................. 7

Final Drive Assembly Breather........................................................................................................................... 7

Lubrication ............................................................................................................................................................. 8

2 Minor Service Operations......................................................................................................................9

2.1 General Information............................................................................................................................................... 9

Important Service Requirements.......................................................................................................................... 9

2.2 Checking Differential Carrier Lubricant Level................................................................................................... 10

2.3 Changing/Flushing Rear Axle Lubricant............................................................................................................ 11

2.4 Trailing Arm Outer Rear Wheel Drive Shaft Assembly Hub............................................................................. 12

Check for Run-Out............................................................................................................................................... 12

If Run-out is Within Specification....................................................................................................................... 14

If the Run-out Check, Exceeds Specification.................................................................................................... 14

2.5 Trailing Arm Outer Rear Wheel Drive Shaft Assembly Hub Studs.................................................................. 15

Replace................................................................................................................................................................. 15

2.6 Drive Shaft Assembly.......................................................................................................................................... 18

Remove................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 18

2.7 Drive Shaft and/or Constant Velocity Joints ..................................................................................................... 19

Disassemble......................................................................................................................................................... 19

Inspect .................................................................................................................................................................. 20

Drive Shaft and Boots ...................................................................................................................................... 20

Constant Velocity Joints................................................................................................................................... 21

Reassemble.......................................................................................................................................................... 21

Constant Velocity Joints................................................................................................................................... 21

Drive Shaft and Boots ...................................................................................................................................... 25

2.8 Inner Axle Shaft Seal ........................................................................................................................................... 28

Replace................................................................................................................................................................. 28

2.9 Pinion Oil Seal...................................................................................................................................................... 30

Replace................................................................................................................................................................. 30

2.10 Pinion Flange ....................................................................................................................................................... 33

Replace................................................................................................................................................................. 33

Using Old Oil Seal............................................................................................................................................ 33

Replace (Using New Oil Seal).......................................................................................................................... 35

Techline

Techline

Techline

Rear Final Drive and Drive Shafts Page 4B1-2

Page 4B1-2

3 Major Service Operations....................................................................................................................39

3.1 Outer Rear Wheel Drive Shaft Flange Outer Rear Wheel Drive Shaft Assembly and/or Wheel Bearing...... 39

Remove................................................................................................................................................................. 40

Reinstall................................................................................................................................................................ 45

To Install a New Bearing.................................................................................................................................. 45

To Reinstall Outer Rear Wheel Drive Shaft...................................................................................................... 46

3.2 Final Drive Assembly........................................................................................................................................... 50

Remove................................................................................................................................................................. 50

Reinstall................................................................................................................................................................ 54

3.3 Removed Final Drive Assembly.......................................................................................................................... 59

Disassemble......................................................................................................................................................... 60

Differential Case............................................................................................................................................... 66

Inspect .................................................................................................................................................................. 68

Differential Case............................................................................................................................................... 68

Differential Side Gears and Pinion Gears......................................................................................................... 68

Ring Gear and Pinion....................................................................................................................................... 69

Bearings........................................................................................................................................................... 69

Differential Carrier............................................................................................................................................ 69

Screw Adjusters and Inner Axle Shafts............................................................................................................ 70

Rear Cover....................................................................................................................................................... 70

Reassemble.......................................................................................................................................................... 71

Differential Case............................................................................................................................................... 71

Differential Case Side Bearing Pre-Load Setting ............................................................................................. 74

Hypoid Pinion Positioning Shim Selection ........................................................................................................ 75

Pinion Installation................................................................................................................................................ 78

Differential Backlash Setting .............................................................................................................................. 81

Ring Gear and Pinion Contact Pattern............................................................................................................... 82

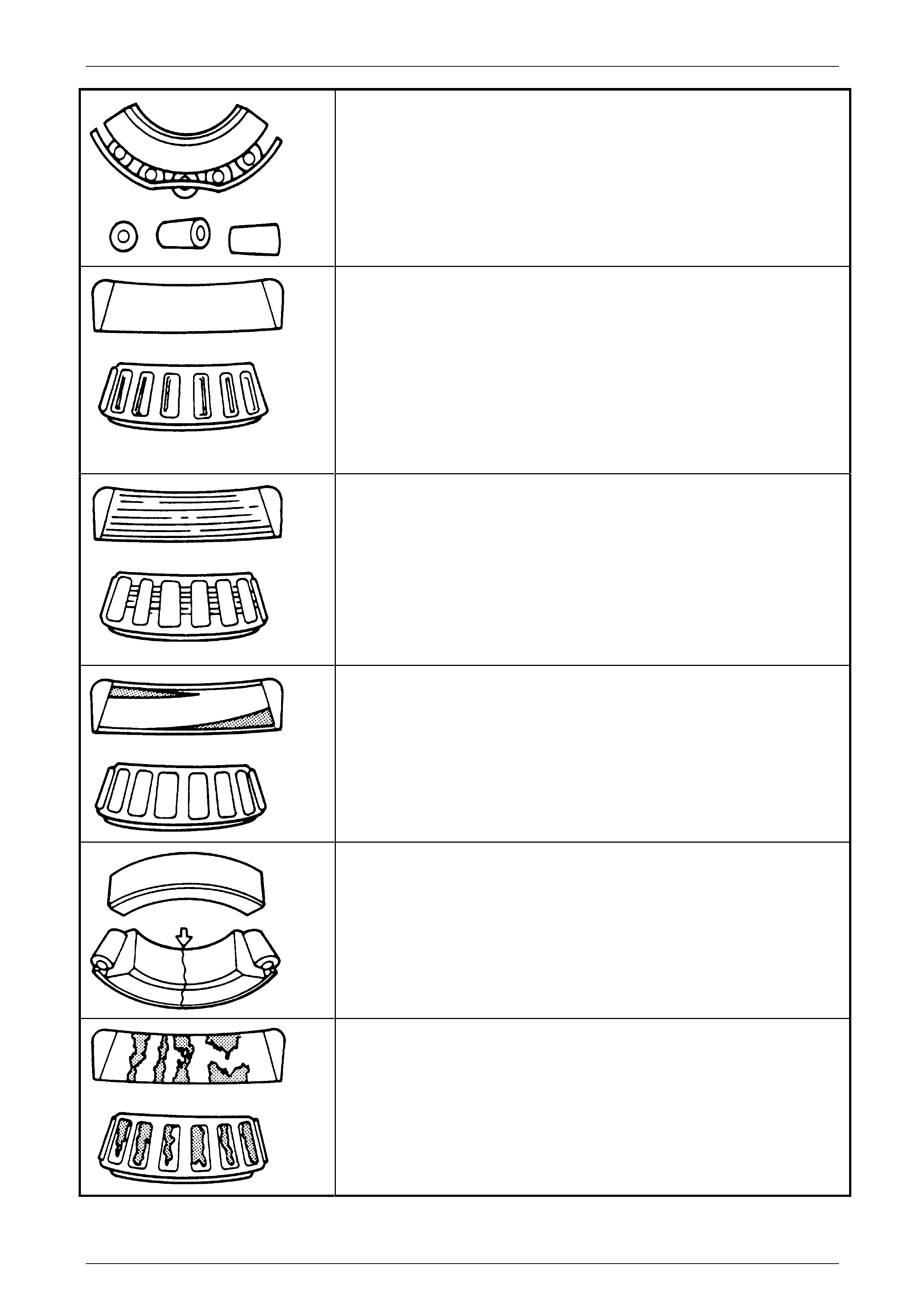

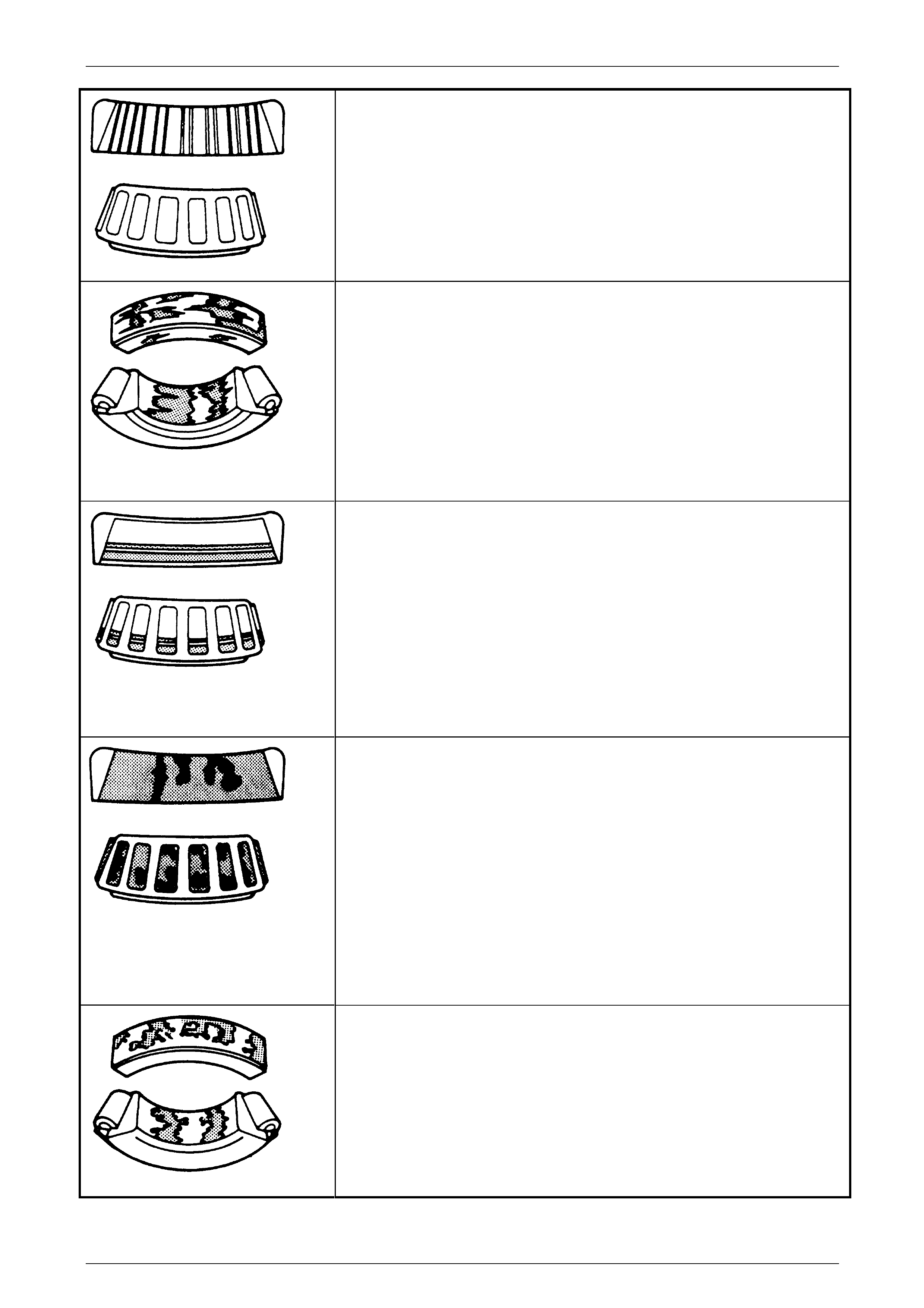

Tooth Marking Nomenclature........................................................................................................................... 82

Ideal Contact.................................................................................................................................................... 84

Acceptable Heel Contacts................................................................................................................................ 84

Acceptable Toe Contacts ................................................................................................................................. 85

3.4 Limited Slip Differential....................................................................................................................................... 86

Disassemble......................................................................................................................................................... 86

Inspect .................................................................................................................................................................. 89

Differential Case............................................................................................................................................... 89

Differential Side Gears and Pinion Gears......................................................................................................... 89

Ring Gear and Pinion....................................................................................................................................... 89

Bearings........................................................................................................................................................... 90

Reassemble.......................................................................................................................................................... 90

3.5 Rear Axle .............................................................................................................................................................. 94

Reassemble.......................................................................................................................................................... 94

4 Diagnosis ..............................................................................................................................................95

4.1 General Information............................................................................................................................................. 95

Road Test ............................................................................................................................................................. 95

Tyre Noise ............................................................................................................................................................ 95

Front Wheel Bearings.......................................................................................................................................... 95

Transmission Rear Bearing (Manual Transmission) ........................................................................................ 96

Backlash Clunk.................................................................................................................................................... 96

Drive-Line Snap.................................................................................................................................................... 96

Engine and Other Contributing Factors............................................................................................................. 96

Rear Final Drive and Drive Shafts Page 4B1-3

Page 4B1-3

4.2 Final Drive Assembly Noise................................................................................................................................ 97

Gear Related Noise.............................................................................................................................................. 97

Ring Gear and Pinion Noise............................................................................................................................. 97

Differential Side Gear and Pinion Noise........................................................................................................... 97

Common Causes of Gear Related Noises ....................................................................................................... 97

Bearing Related Noise......................................................................................................................................... 98

Differential Pinion Gear Bearings..................................................................................................................... 98

Outer Rear Wheel Drive Shaft Wheel Bearings ............................................................................................... 98

Differential Side Bearings................................................................................................................................. 98

Common Causes of Bearing Related Noises................................................................................................... 98

4.3 Final Drive Bearing Diagnosis............................................................................................................................ 99

5 Specifications.....................................................................................................................................102

6 Torque Wrench Specifications..........................................................................................................104

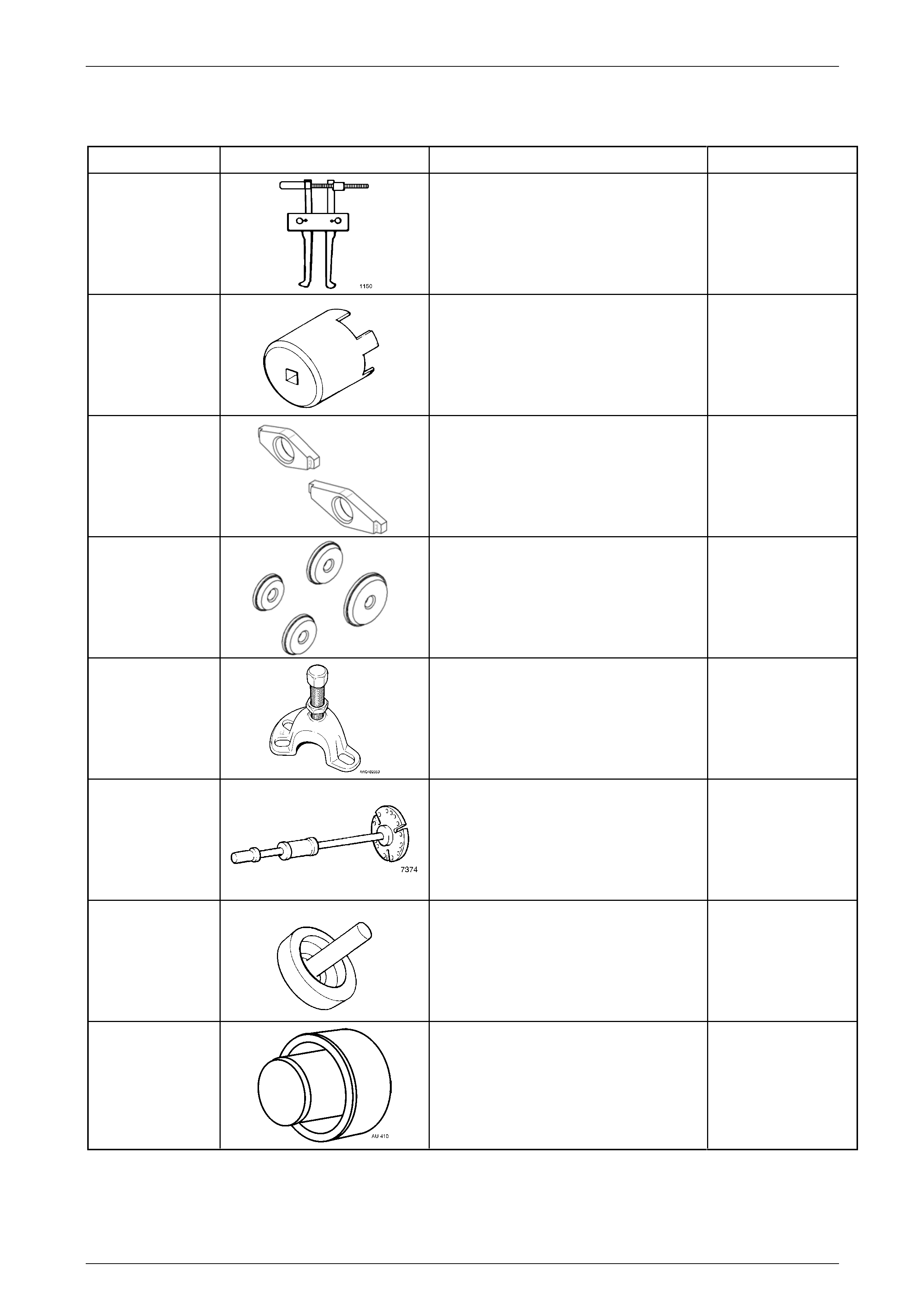

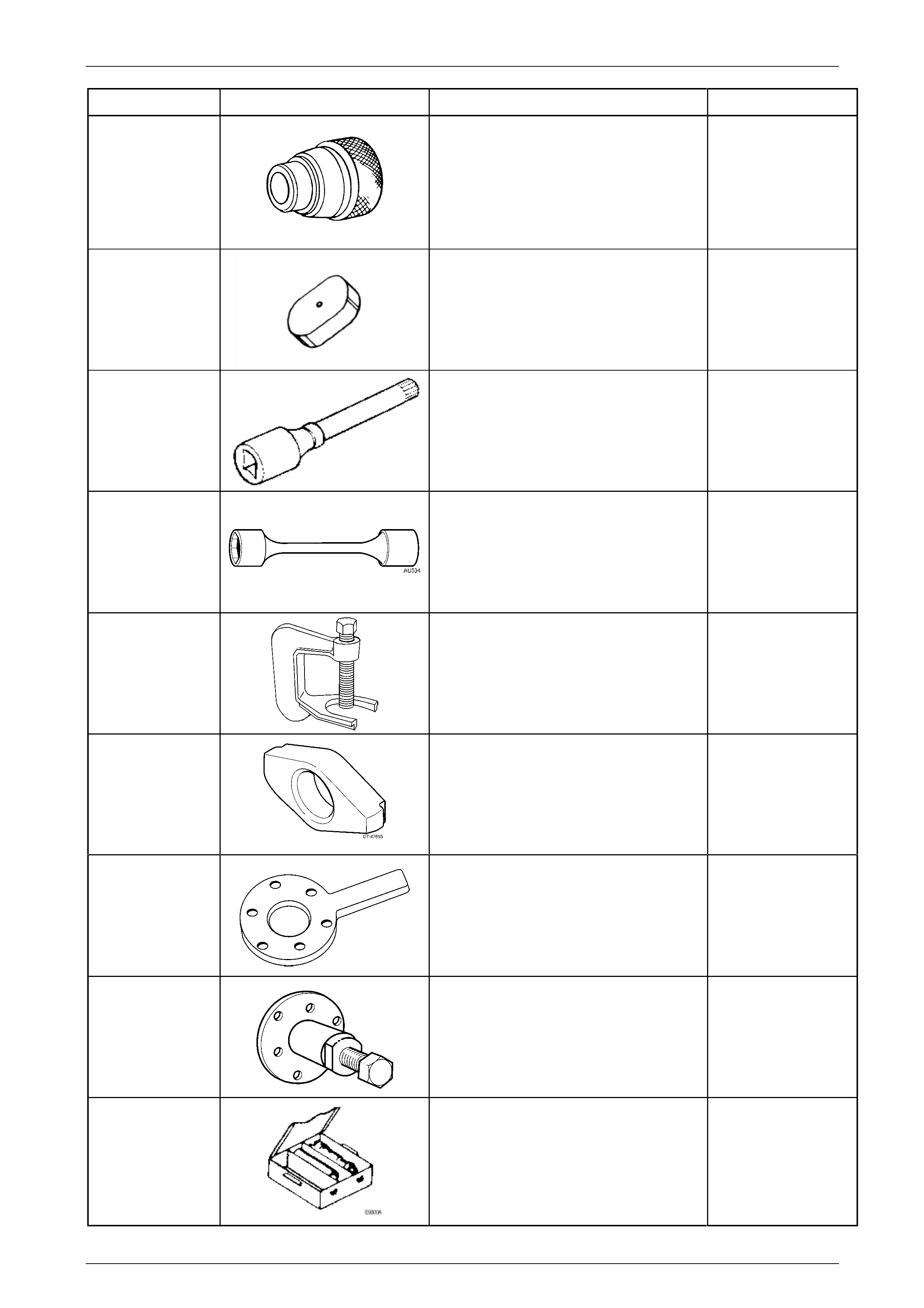

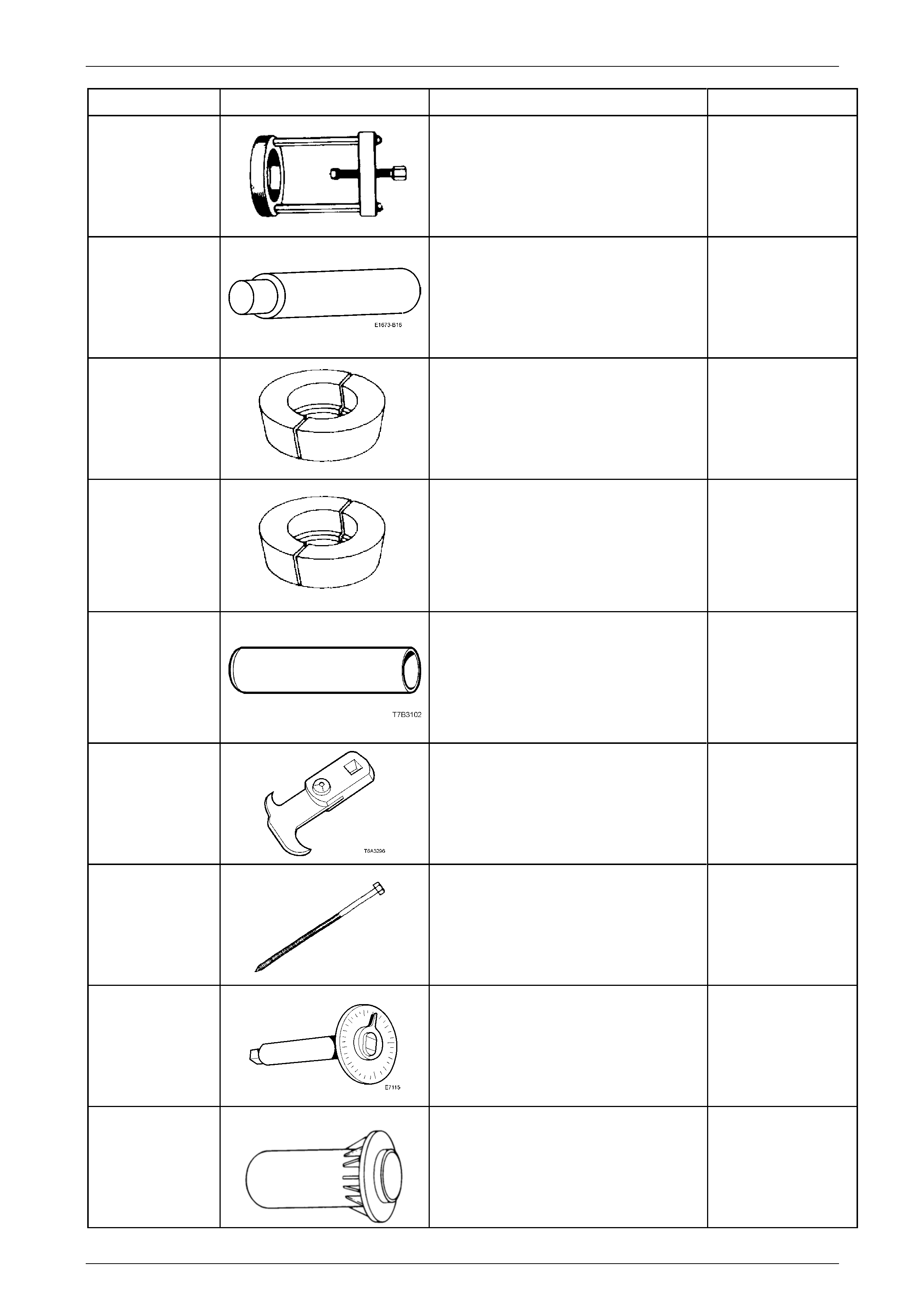

7 Special Tools ......................................................................................................................................105

Rear Final Drive and Drive Shafts Page 4B1-4

Page 4B1-4

1 General Information

1.1 General Description

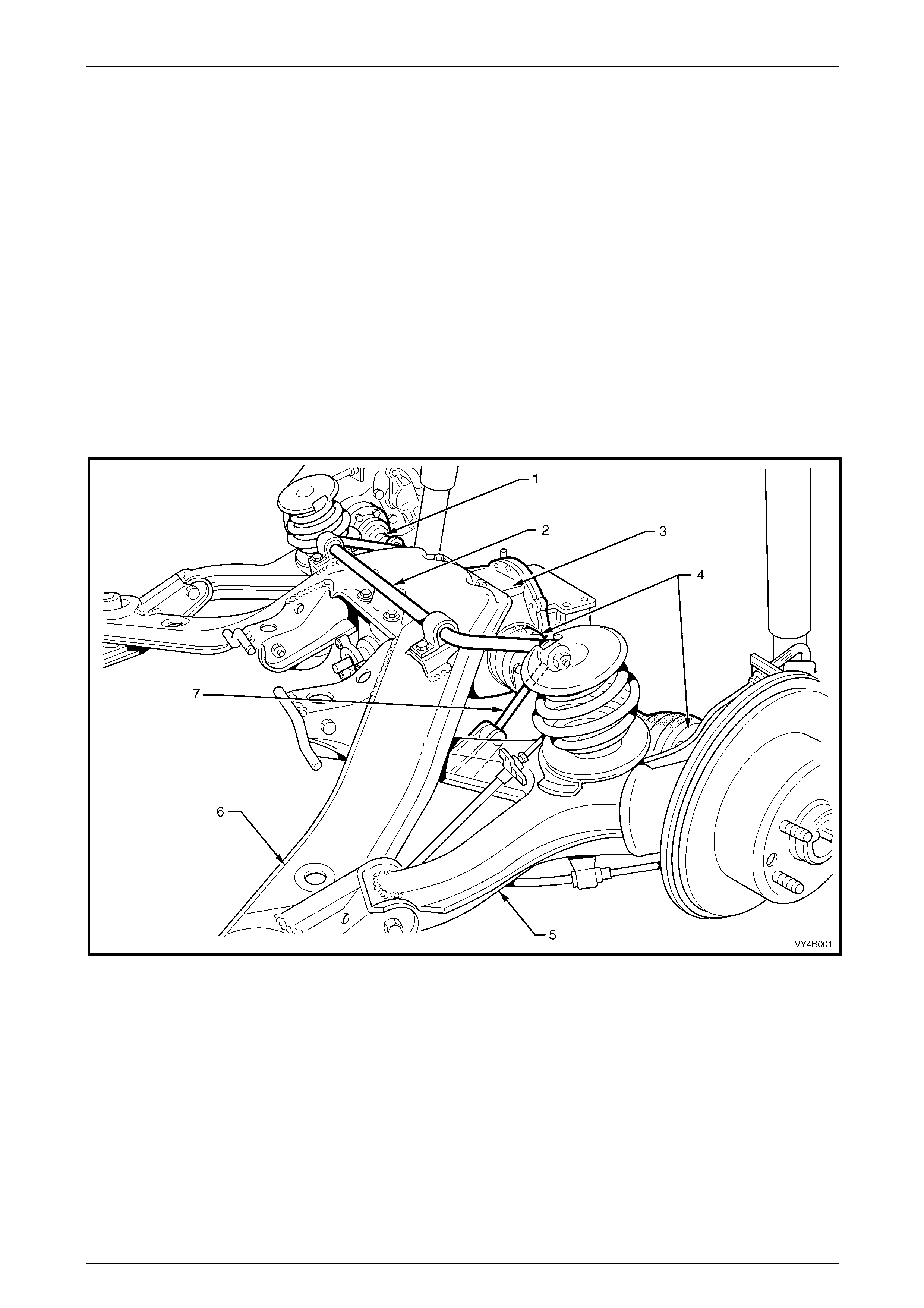

All models are fitted with a rear final drive assembly with a four pinion type differential assembly. The ring gear diameter

and ratio varies with different applications; refer 1.2 Final Drive Assembly Identification, in this Section.

The final drive assembly is mounted directly to a crossmember which is rubber mounted to the vehicle underbody. The

differential case and drive pinion are mounted in opposed taper roller bearings in the carrier. Differential case sid e

bearing pre-load adj ustment is provided by screw adjusters in the sides of the case, while pinion bearing pre-load is

provided by a collapsible spacer. Torque is transferred from the propeller shaft to the final drive assembly via the pinion

flange which is splined to the hypoid pinion. The torque is then transferred from the pinion through the ring gear,

differential case, differential pinion cross shafts, differential pinions, side gears and then via spli nes, to the inner axle

shafts and drive shafts.

The final drive assembl y shou ld be removed from the vehicle for all service operations other than for the removal of the

inner axle shafts, inner axle shaft oil seals, pinion oil seal or the rear cover. Two drive shaft assemblies are used, each

consisting of a shaft which is splined at each end into a ball type constant velocity joint. The inner constant velocity joint

is bolted to the inner axle shaft flange at the differential carrier, with the outer joint bolte d to the outer rear wheel drive

shaft flange at the rear trailing arm.

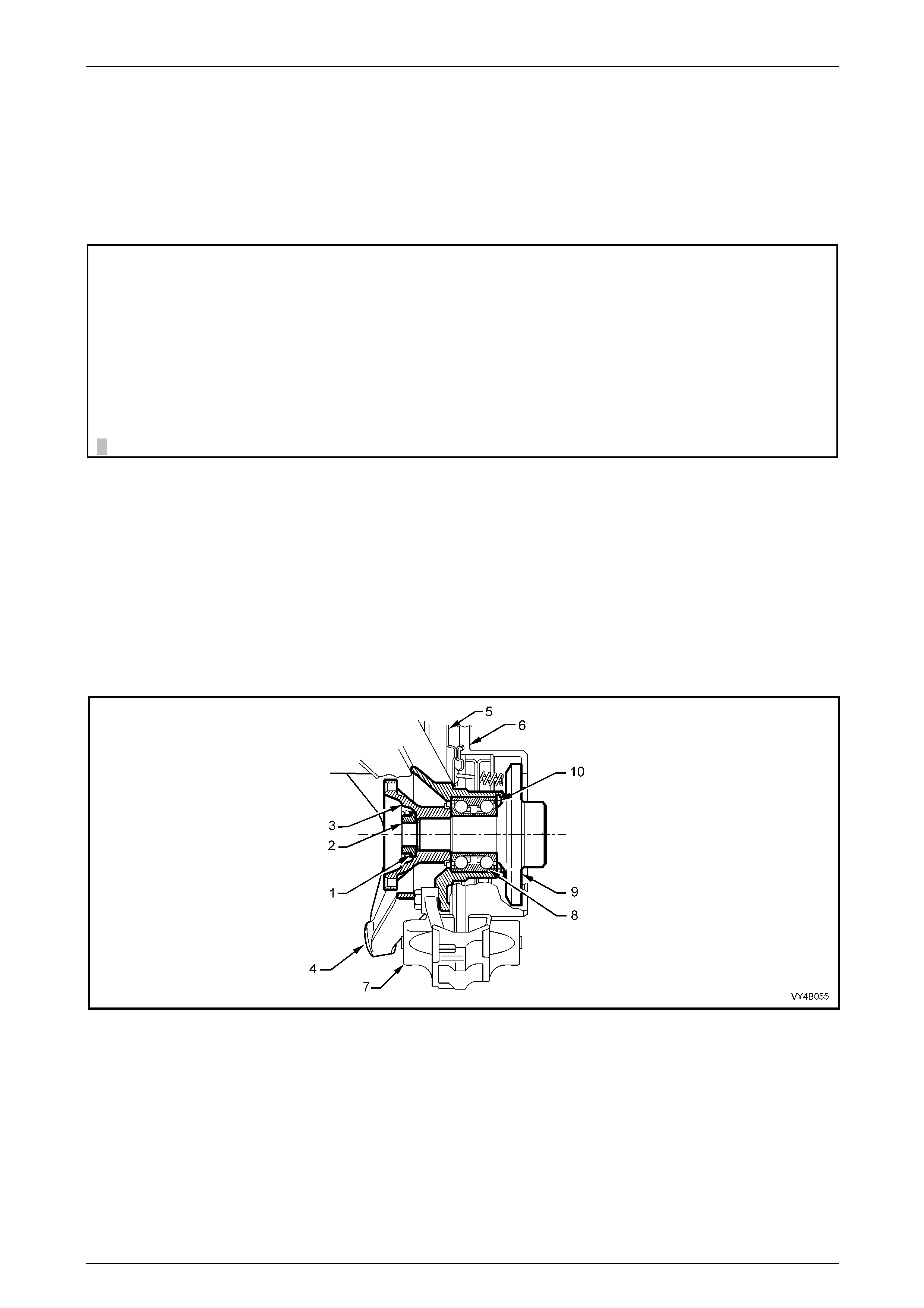

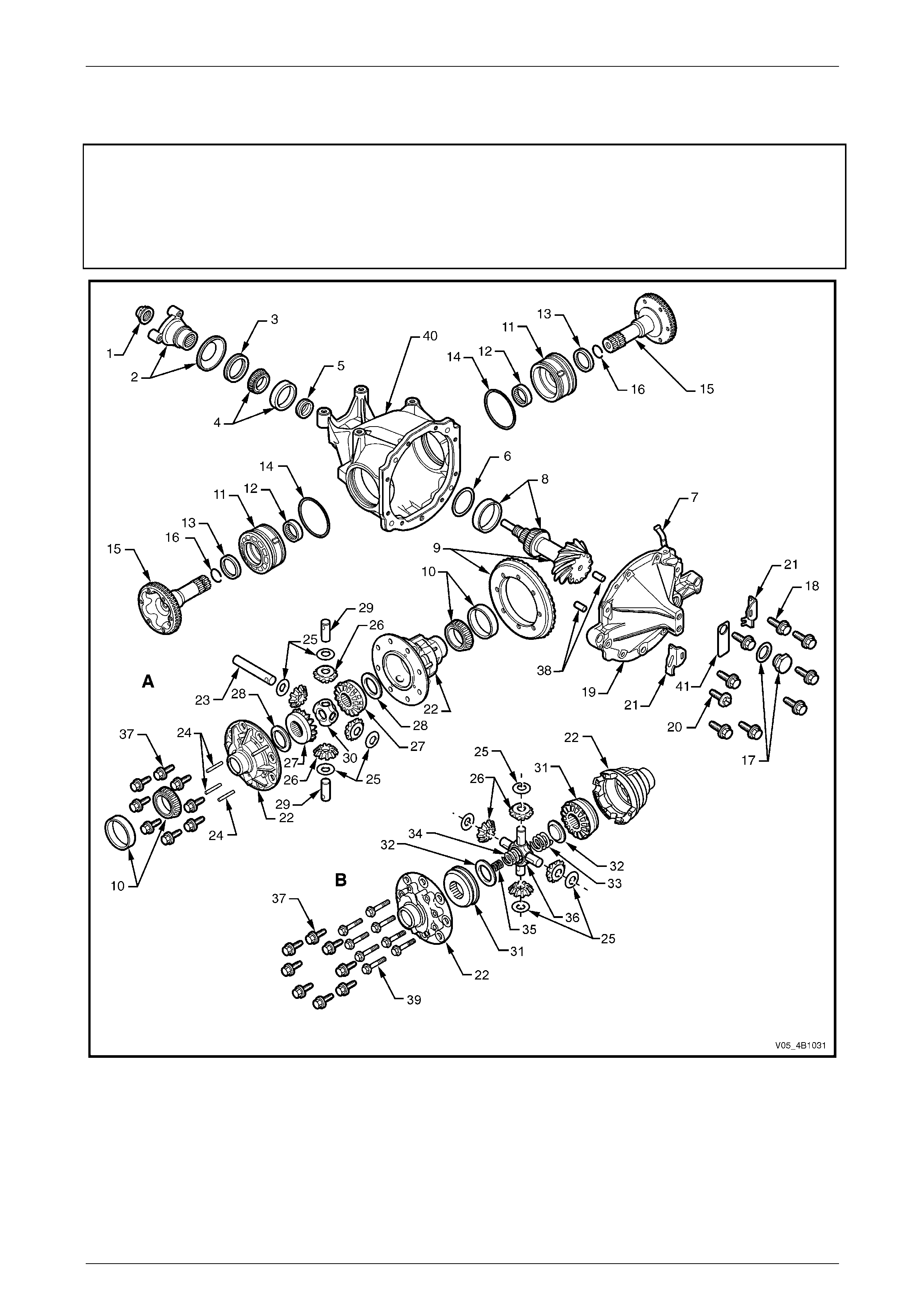

Figure 4B1 – 1

Legend

1 Drive Shaft

2 Rear Suspension Stabiliser Bar

3 Final Drive Assembly

4 Constant Velocity Joints

5 Trailing Arm

6 Rear Suspension Crossmember

7 Rear Stabiliser Bar to Trailing Arm Link

Rear Final Drive and Drive Shafts Page 4B1-5

Page 4B1-5

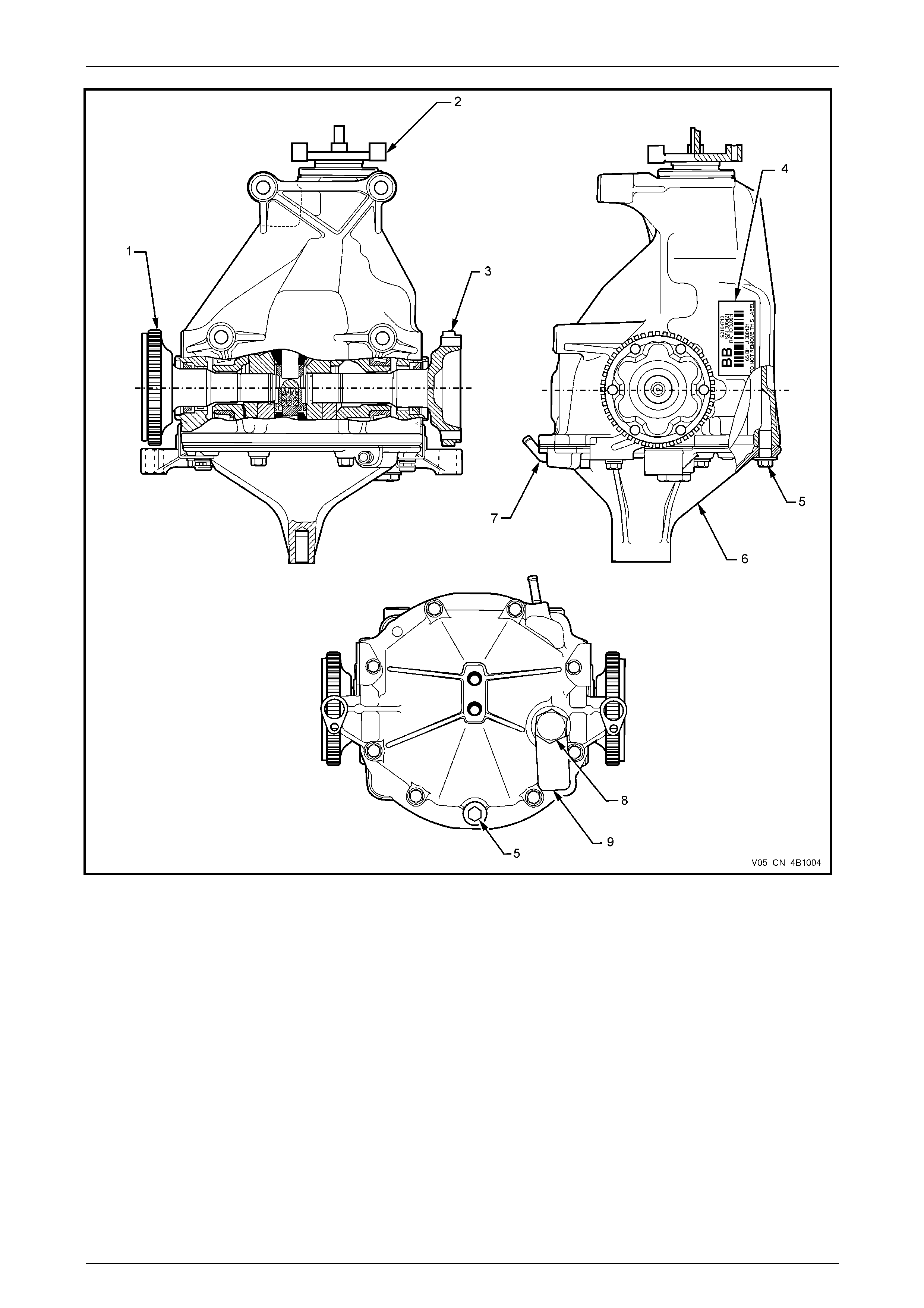

Figure 4B1 – 2

Legend

1 LH Inner Axle Shaft

2 Pinion Flange

3 RH Inner Axle Shaft

4 Identification Label

5 Drain Plug

6 Rear Cover

7 Breather

8 Filler Plug

9 Lubrication Tag

Rear Final Drive and Drive Shafts Page 4B1-6

Page 4B1-6

1.2 Final Drive Assembly Identification

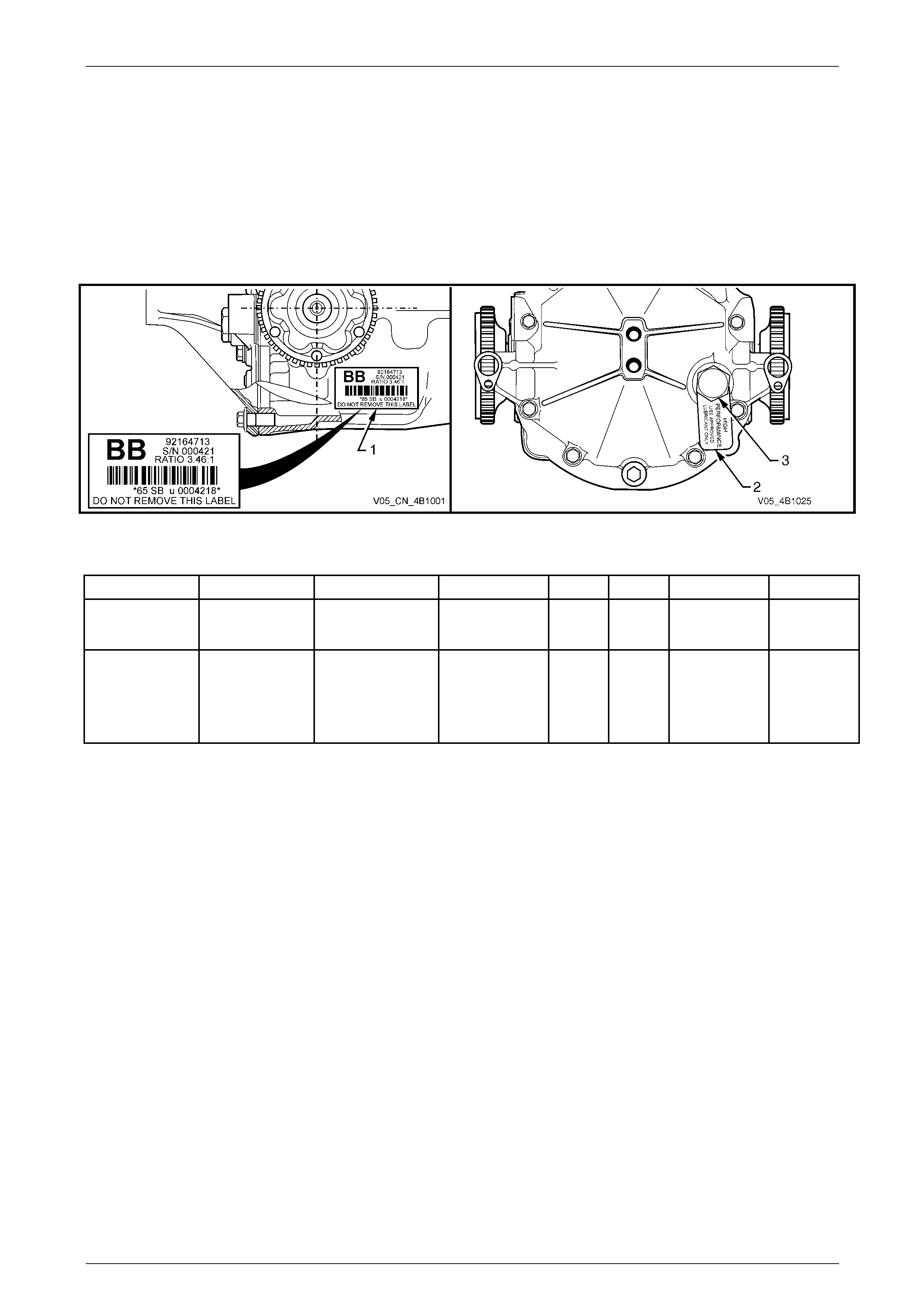

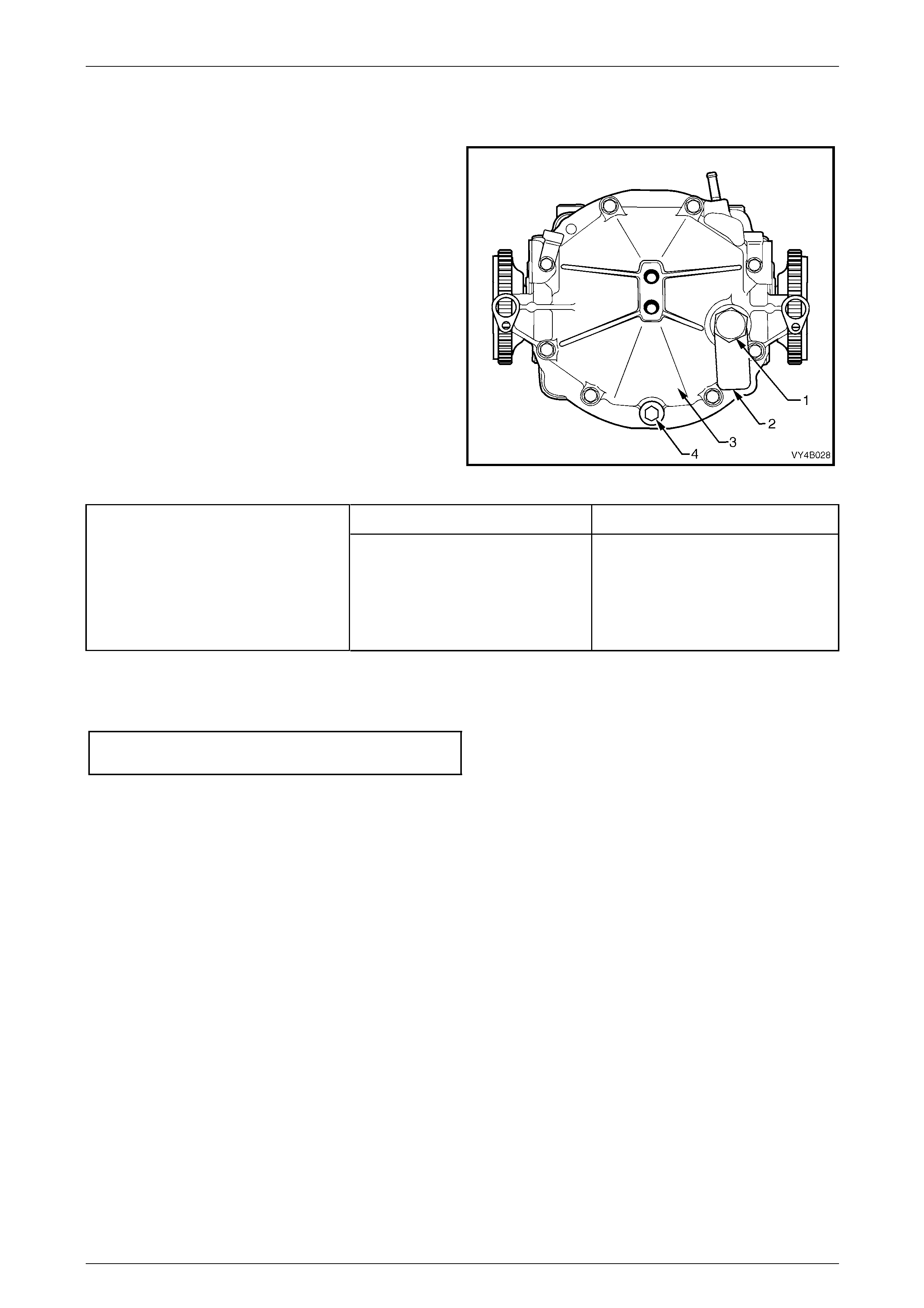

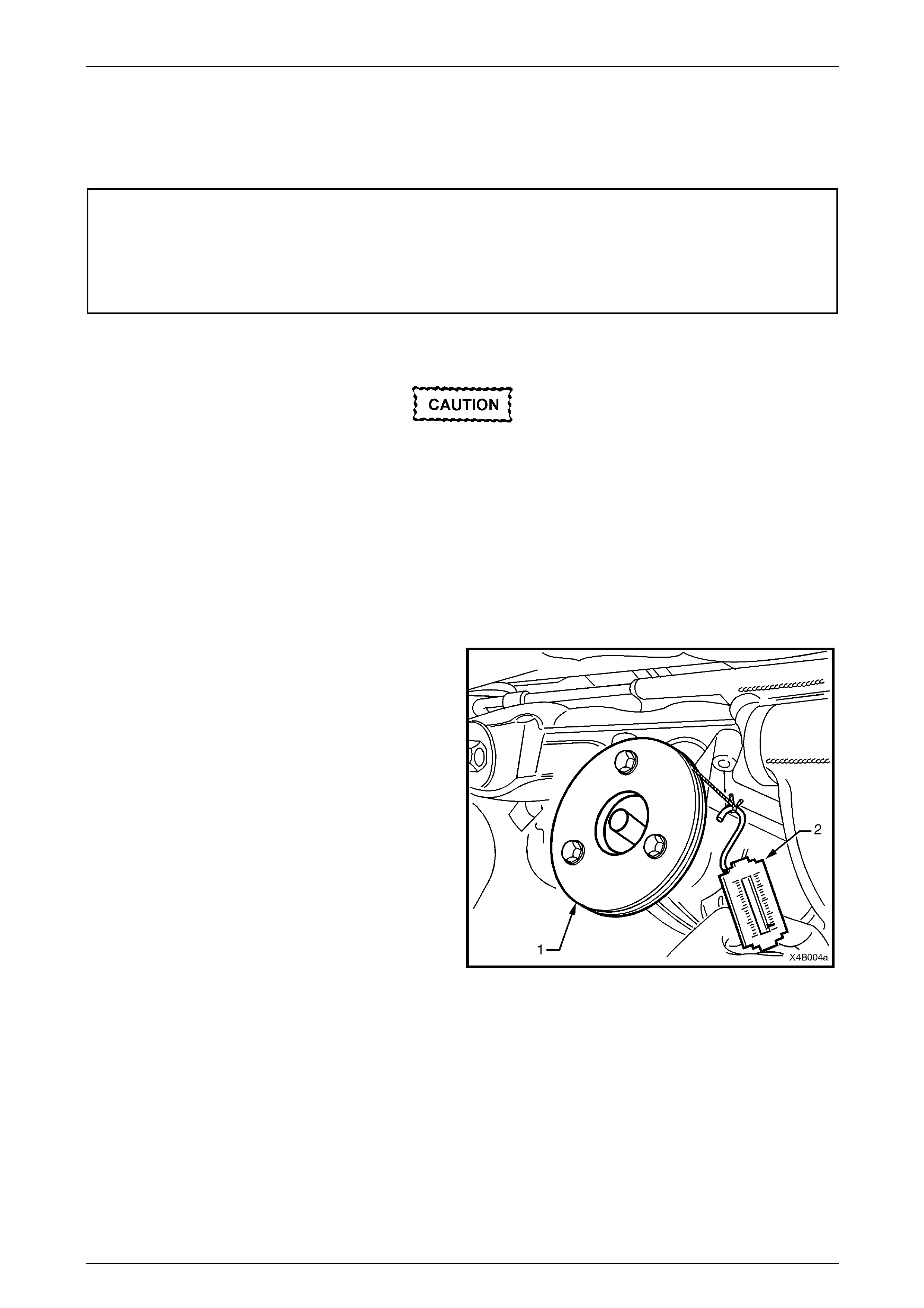

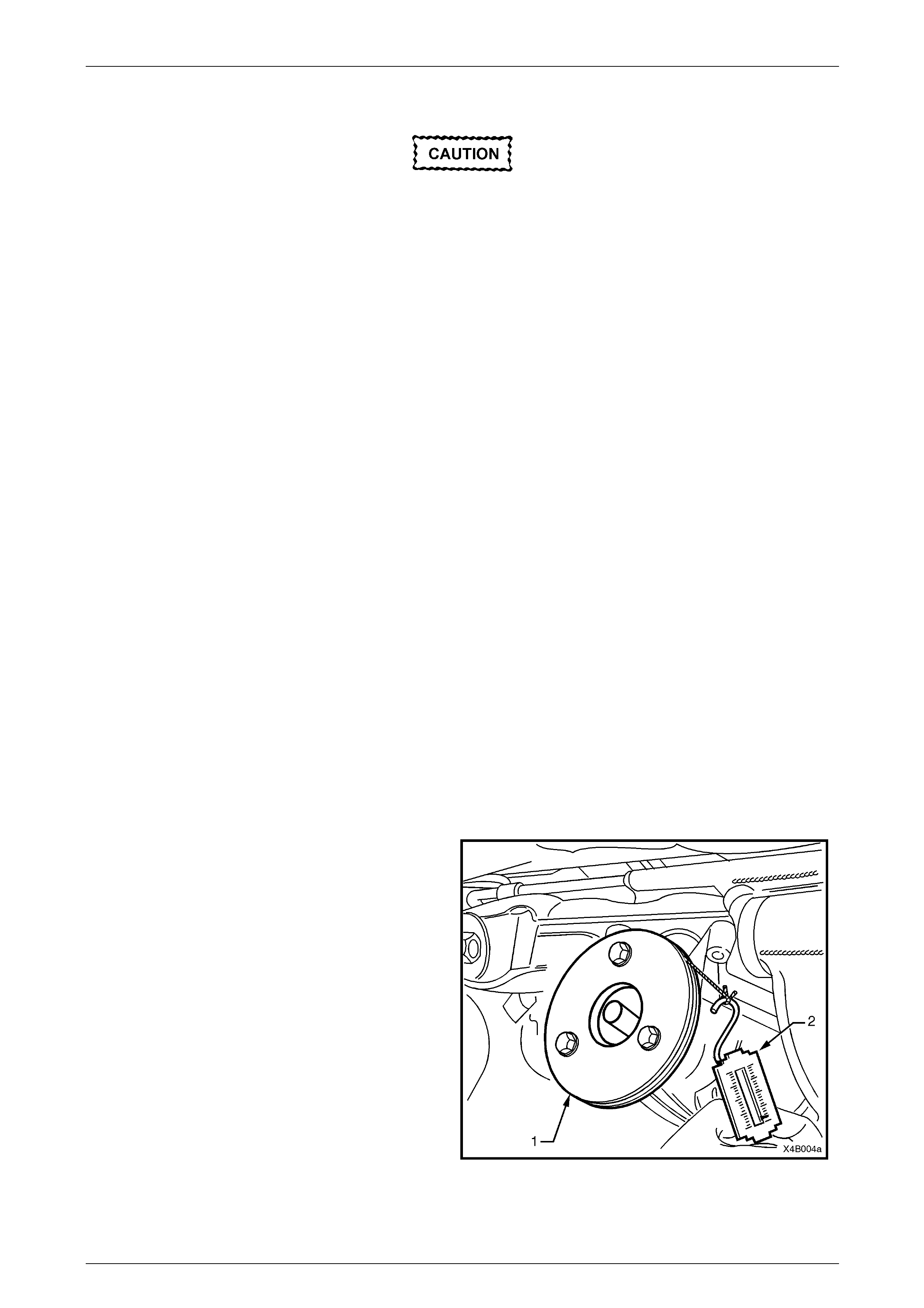

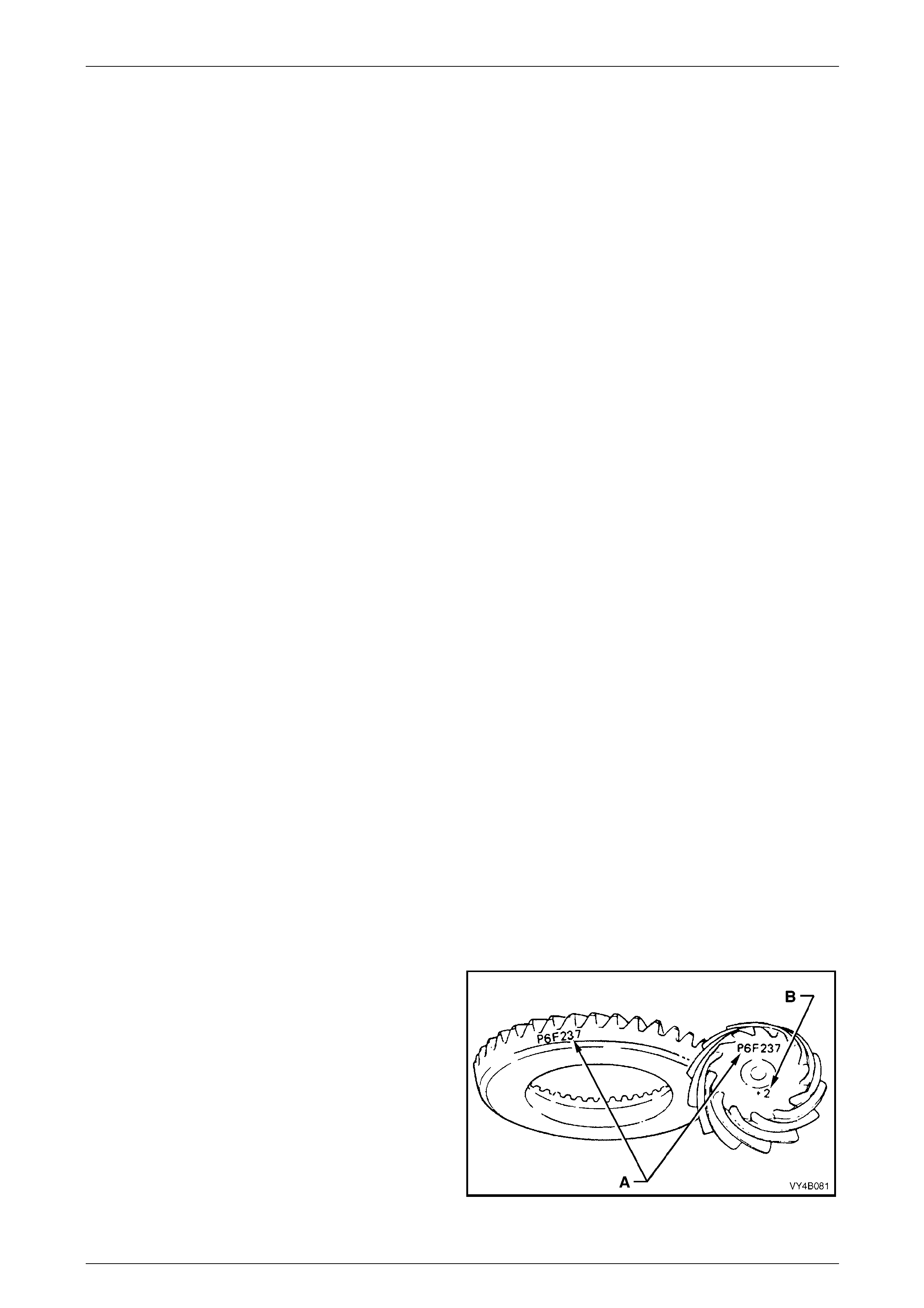

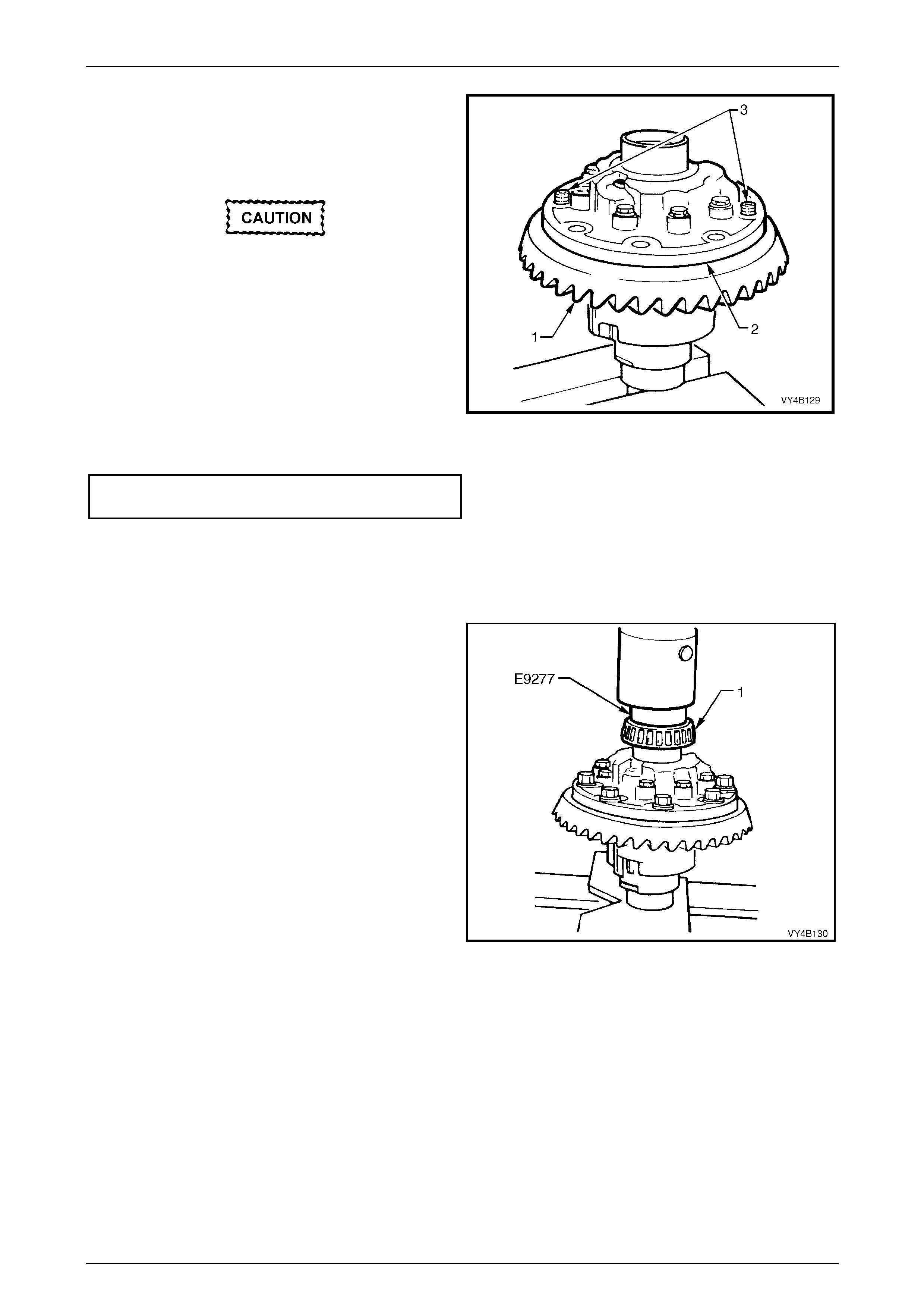

The type of differential fitted to this final drive assembly can be identified by referring to the label (1) attached to the RHS

of the carrier housing and the lubric ation tag (2) under the filler plug (3) on the rear cover.

The locations of the identific ation label and lubrication tag are as shown in Figure 4B 1-3.

The identification label (1) carries the final drive assembly part number for the final drive ratio and the serial n umber of

the assembly.

The code number and bar co de is used for production identification of the final drive assembly.

Figure 4B1 – 3

Final Drive Application

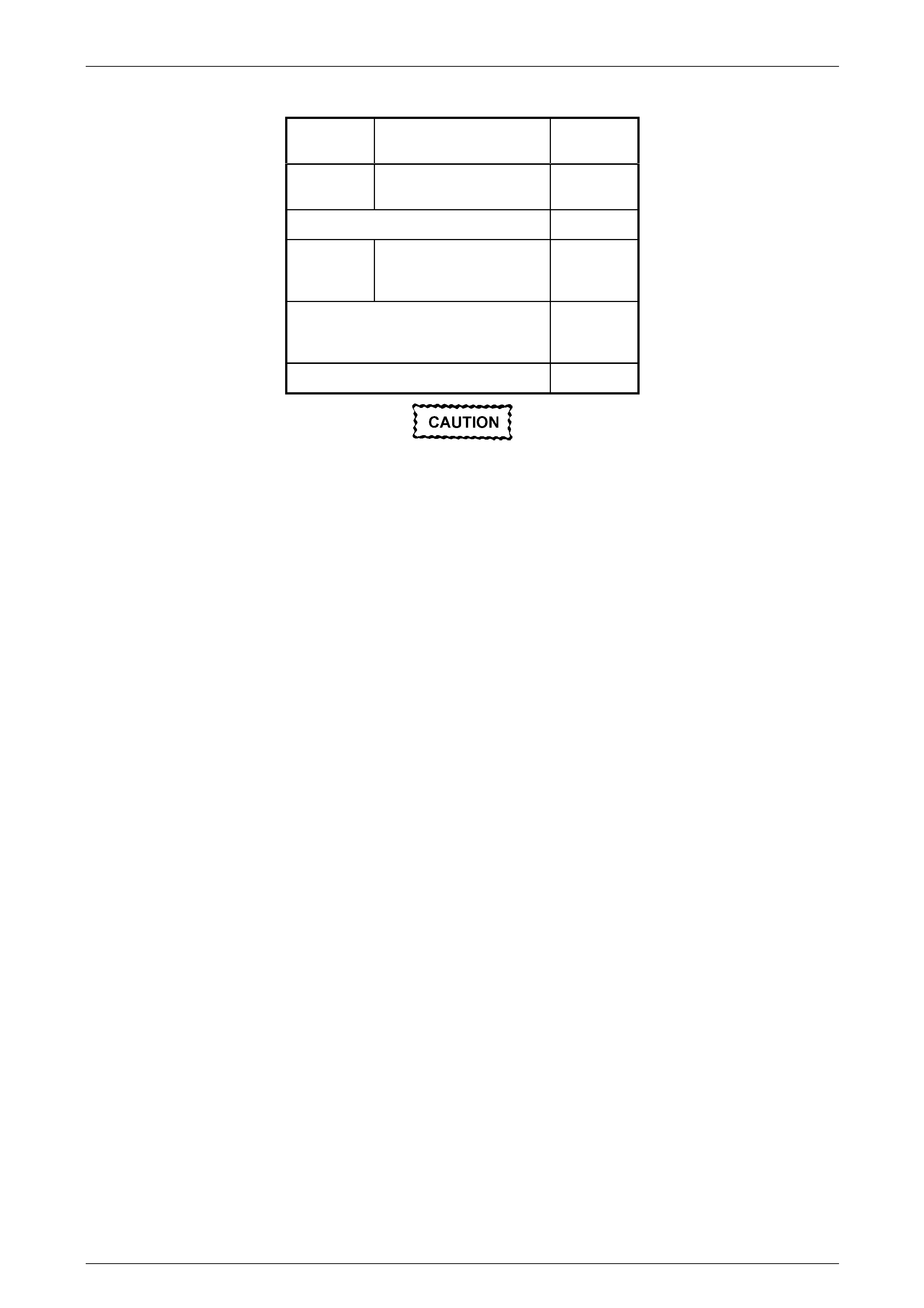

Body Type Engine Transmission Ratio ABS LSD Lubricant I.D. Code

WL – All HFV6

'Alloytec 190'

(P/O LY7)

Automatic

'5L40-E'

(P/O M82) 2.87:1 Y

Y N

Y Synthetic

Synthetic + BB

BC

WL – All

GEN III V8

(P/O LS1)

OR

HFV6 (LPG)

’Alloytec’

(P/O LW2)

Automatic

4L60-E

(P/O M30 3.07:1 Y

Y N

Y Synthetic

Synthetic + ZFF

ZFH

Table 1

Where fitted, the information on the lubrication tag (2) under the filler plug (‘3’ in Figure 4B1-4), will be:

With GEN III V8 or HFV6 'Alloytec 190' vehicles, fitted with the conventiona l differential;

“HIGH PERFORMANCE. USE APPROVED LUBRICANT ONLY”

With GEN III V8 or HFV6 'Alloytec 190' vehicles, fitted with LSD;

“LSD - HIGH PERFORMANCE. USE APPROVED LUBRICANT AND FRICTION MODIFIER”

Rear Final Drive and Drive Shafts Page 4B1-7

Page 4B1-7

1.3 Final Drive Assembly Maintenance

Maintenance

Drive Shaft Bearings and Cons tant Velocity Joints

The drive shaft constant velocity joints are lubricated for life and therefore require no periodic maintenance.

The constant velocity joint boots are to be inspected at every maintenance service. If there is an y evidence of damage to

boots, remove drive shaft and inspect constant velocity joints, refer to 2.6 Drive Shaft Assembly and to

2.7 Drive Shaft and/or Constant Velocity Joints, in this Section.

Differential Carrier Assembly

Check for lubricant leaks at every maintena nce service. If there is evidence of leakage, correct the leak and add lubricant

as necessary. (Refer to 2.2 Checking Differential Carrier Lub r icant Level, in this Section.)

At the time or distance interval specified in the O wner's Handbook, check to ensure that the lubricant level is to the

bottom of the filler plug hole when the differe ntial carrier assembly is COLD.

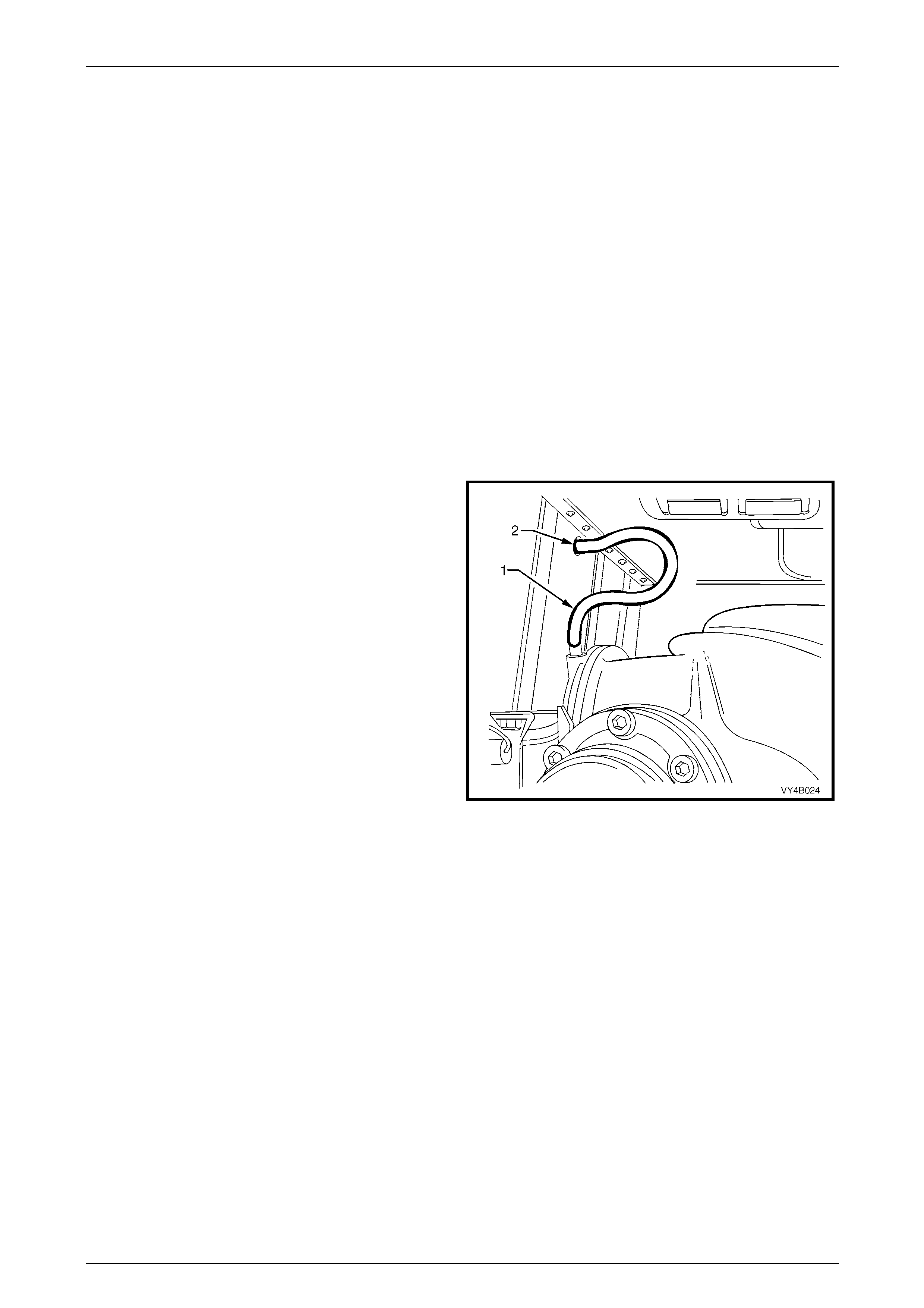

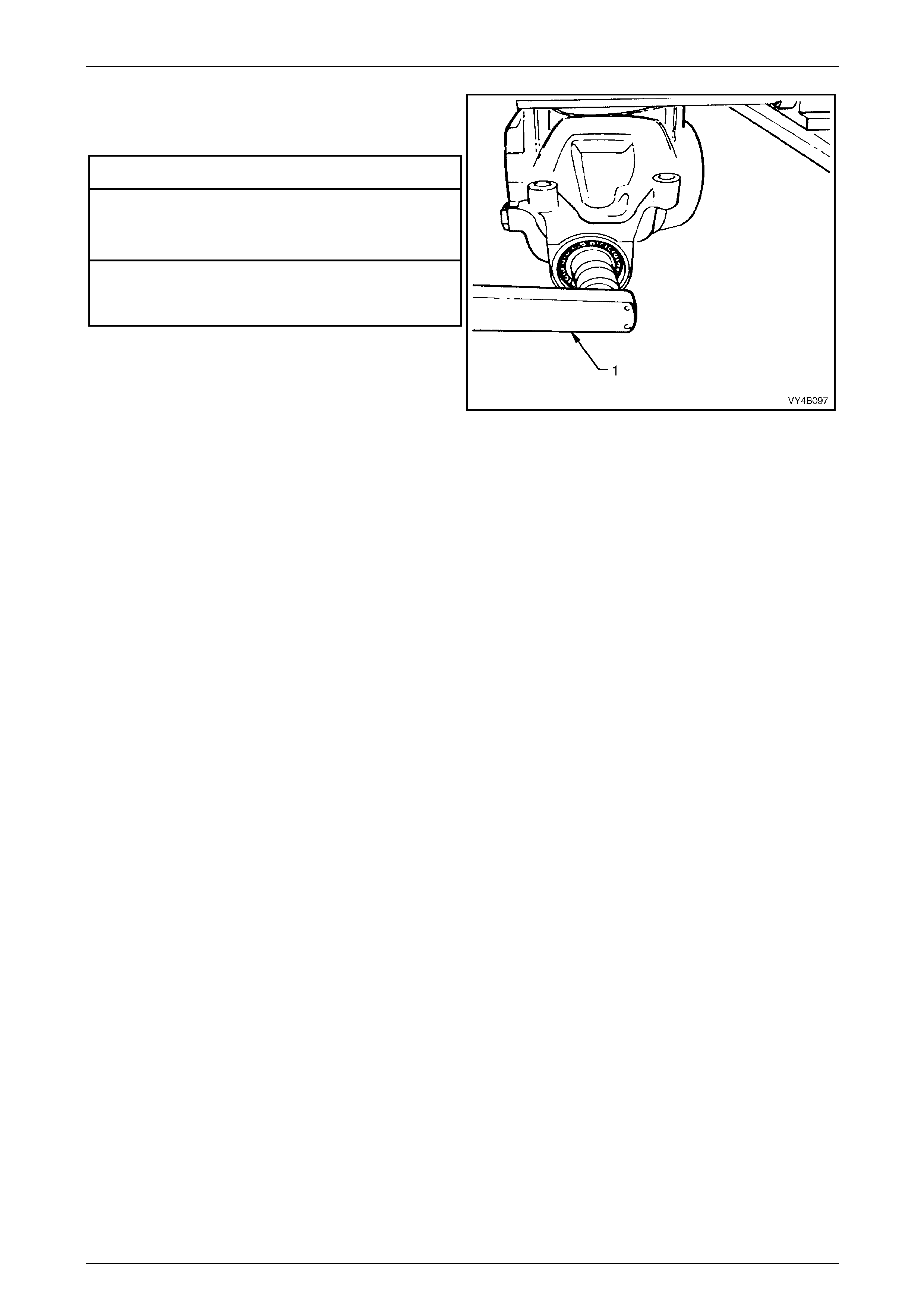

Final Drive Assembly Breathe r

The breather hose (1) should be checked regularly to

ensure that it is not blocked, is correctly routed and not

kinked.

The top end of the breather hose should b e in serted at least

25 mm into the vehicle underbody crossmember hole (2).

Figure 4B1 – 4

Rear Final Drive and Drive Shafts Page 4B1-8

Page 4B1-8

Lubrication

The lubricant level should be checked and topped up (if require d), at the time or distance intervals outlined in the

Owner's Handbook with the differential carrier COLD; refer to 2.2 Checking Differential Carrier Lubricant Level, in this

Section. At this temperature, the lubricant should be level with the bottom of the filler plug hole. This service operation

also details the recommended lubricant for the final drive assembly.

Never use any other than the stated and

recommended lubricant.

NOTES

• The lubricant used in all other ratio rear axle

assemblies, is a synthetic product. The oil

seals in these assemblies have been speciall y

formulated to tolerate this lubricant. It must

also be noted that, using a mineral type

lubricant in any of these final drives, may

cause gear set and/or bearing damage under

high load driving conditio ns.

• When a Limited Slip Different ial (LSD) is fitted

to any rear axle, an approv ed additive such as

Sturaco 7098 MUST also be used, in

conjunction with a synthetic hypoid gear oil.

• If the incorrect lubricant is accide ntall y used i n

the rear axle of any MY 2005 WL Series

vehicle, then the rear axle should be drained,

flushed (with the recomm ended lubricant) and

then refilled with the correct lubricant. The

procedure for this operation is detailed in

2.3 Changing/Flushi ng Rear Axle Lubric ant, in

this Section.

Rear Final Drive and Drive Shafts Page 4B1-9

Page 4B1-9

2 Minor Service Operations

2.1 General Information

Important Service Requirements

1 Whenever a road wheel and/or brake disc is removed from the vehicle, the relationship of the road wheel and the

disc to the hub MUST be marked with a felt tipped pen or similar, in order for those parts to be reinstalled in their

original positions. This is critical to maintain the brake disc and road wheel runout dimension to a minimum.

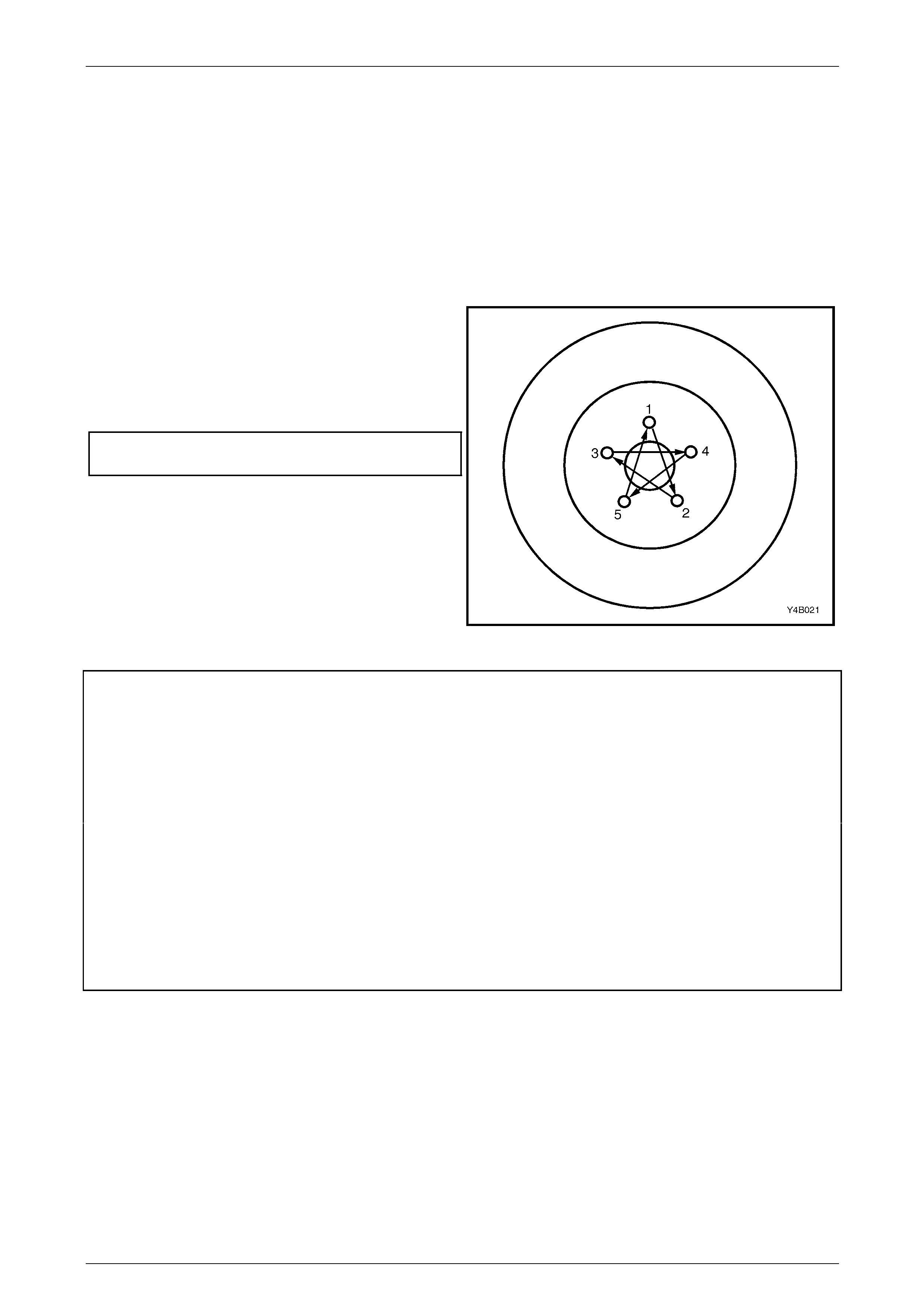

2 When reinstalling road wheels, do not use an impact

gun to tighten wheel nuts unless the impact gun is

fitted with a torque limiter socket (Tool No. AU 534 or

a commercial equivalent). Failure to correctly tighten

wheel nuts to the correct torque specification and in

the correct order, may result in a distorted brake disc,

leading to the development of brake shudder.

Road wheel attaching nut

torque specification................................... 110 – 140 N.m

For a complete description of the method used to

measure both brake disc and outer rear wheel

drive shaft assembly runout and correction, refer to

Section 5A Service and Park Braking Systems.

Figure 4B1 – 5

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W h ere specified in this section, fasteners MUST be repl aced with parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompan ied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied o r in corporate a mechanical thread lo ck and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Rear Final Drive and Drive Shafts Page 4B1-10

Page 4B1-10

2.2 Checking Differential Carrier Lubricant

Level

1 Ensure vehicle is level.

2 Clean area around filler plug (1).

3 Remove filler plug (1) from rear cover (3) (do not lose

the lubrication tag (2) from the plug, if fitted).

4 The lubricant level is to be maintaine d at the bottom

edge of the filler plug hole, when COLD. Use only the

recommended lubricant, detail ed in the following table.

Figure 4B1 – 6

All With Non-LSD Differential All With LSD Differential

All with the V6 engine and

5L40-E automatic transmission

OR

All GEN III V8 engines and automatic

transmission.

1.6 litre Synthetic Hypoid Gear Oil,

SAE 80W-140 such as;

MOBIL Mobilube SHC ID or

CASTROL SAF-XA

1.5 litre Synthetic Hypoid Gear Oil,

SAE 80W-140 such as;

MOBIL Mobilube SHC ID or

CASTROL SAF-XA,

PLUS;

0.1 litre of Sturaco 7098 Oil Additive

5 Inspect filler plug (1) for damage, if OK, reinstall to the rear cover (3) (includi ng the lubrication tag (2). If damaged,

replace plug.

6 Tighten filler plug (1) to the correct torque specification.

Filler plug

torque specification..............................................27 N.m

Rear Final Drive and Drive Shafts Page 4B1-11

Page 4B1-11

2.3 Changing/Flushing Rear Axle Lubricant

1 To drain lubricant from differential carrier assembly, remove filler (1) and drain plugs (4) (refer to Figure 4B1-6) and

allow (preferably warm) lubricant to drain into a suitable container.

2 If flushing is required, use an undiluted quantity of the recommended lubricant for the operation.

3 When the draining and flushing (if required), operation is completed, apply thread sealing tape to rear cover drain

plug (4) thread. Install and tighten drain pl ug (4) to the correct torque specification.

Rear axle drain plug

torque specification..............................................30 N.m

4 Fill the final drive assembly with 1.6 litres of the recommended lubricant. Install the filler plug (1) and lubrication tag

(2) (if fitted) and tighten to the correct torque specification.

Filler plug

torque specification..............................................30 N.m

Rear Final Drive and Drive Shafts Page 4B1-12

Page 4B1-12

2.4 Trailing Arm Outer Rear Wheel Drive

Shaft Assembly Hub

ATTENTION

Vehicle must be at curb weight before final tightening.

Lower shock absorber mounting bolt.

Check for Run-Out

1 Raise the rear of the vehicle and sup port in a safe manner. Refer to Section 0A General Information for the location

of recommended lifting and support poi nts.

2 Remove rear wheel cover (steel wheels) or wheel nut covers (alloy wheels) on that side of the vehicle where the

outer rear wheel drive shaft is to be checked.

3 Mark relationship of wheel to mounti ng flange. Remove road wheel attaching nuts and remove wheel.

Refer to 2.1 General Information in this Section for more information.

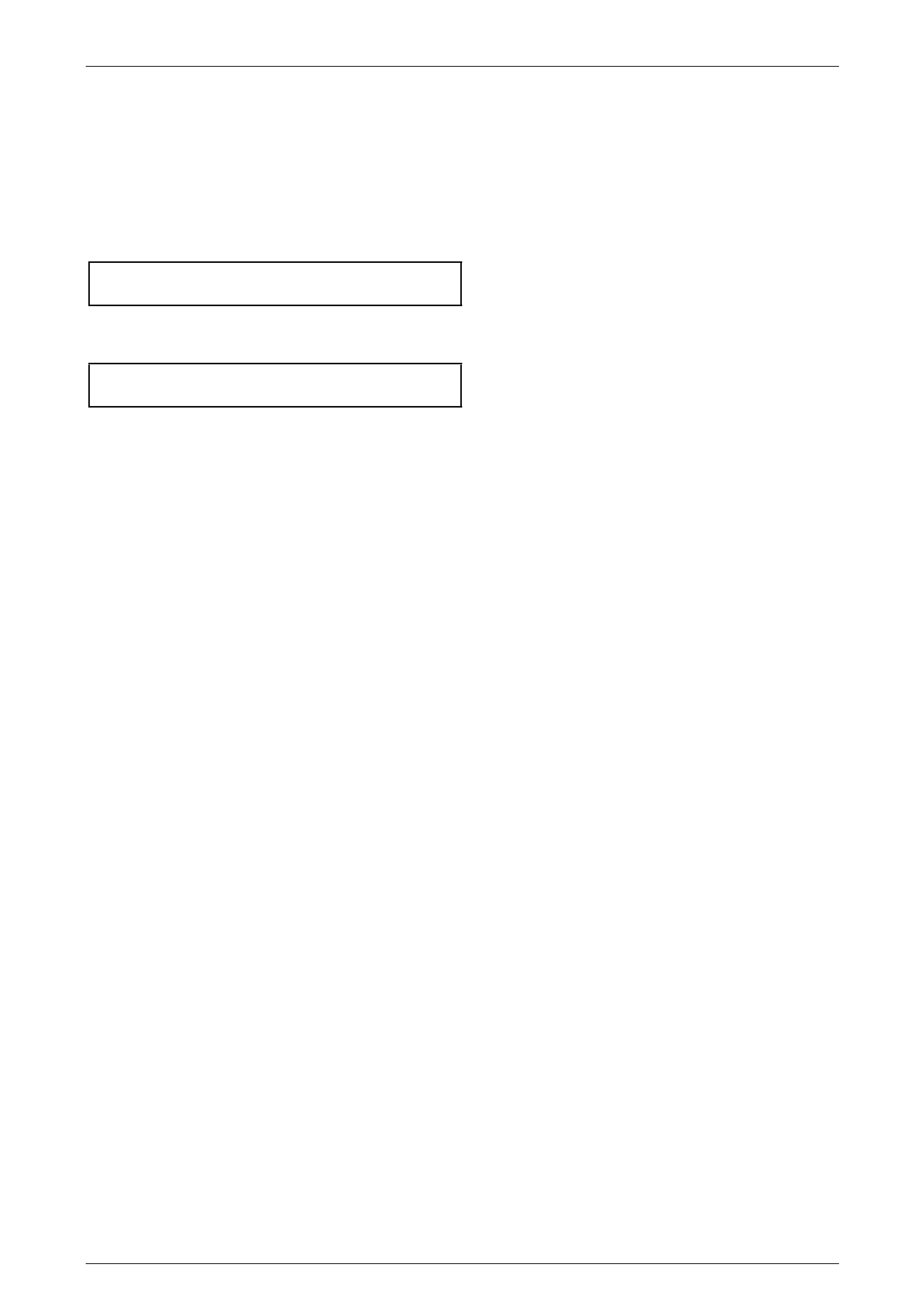

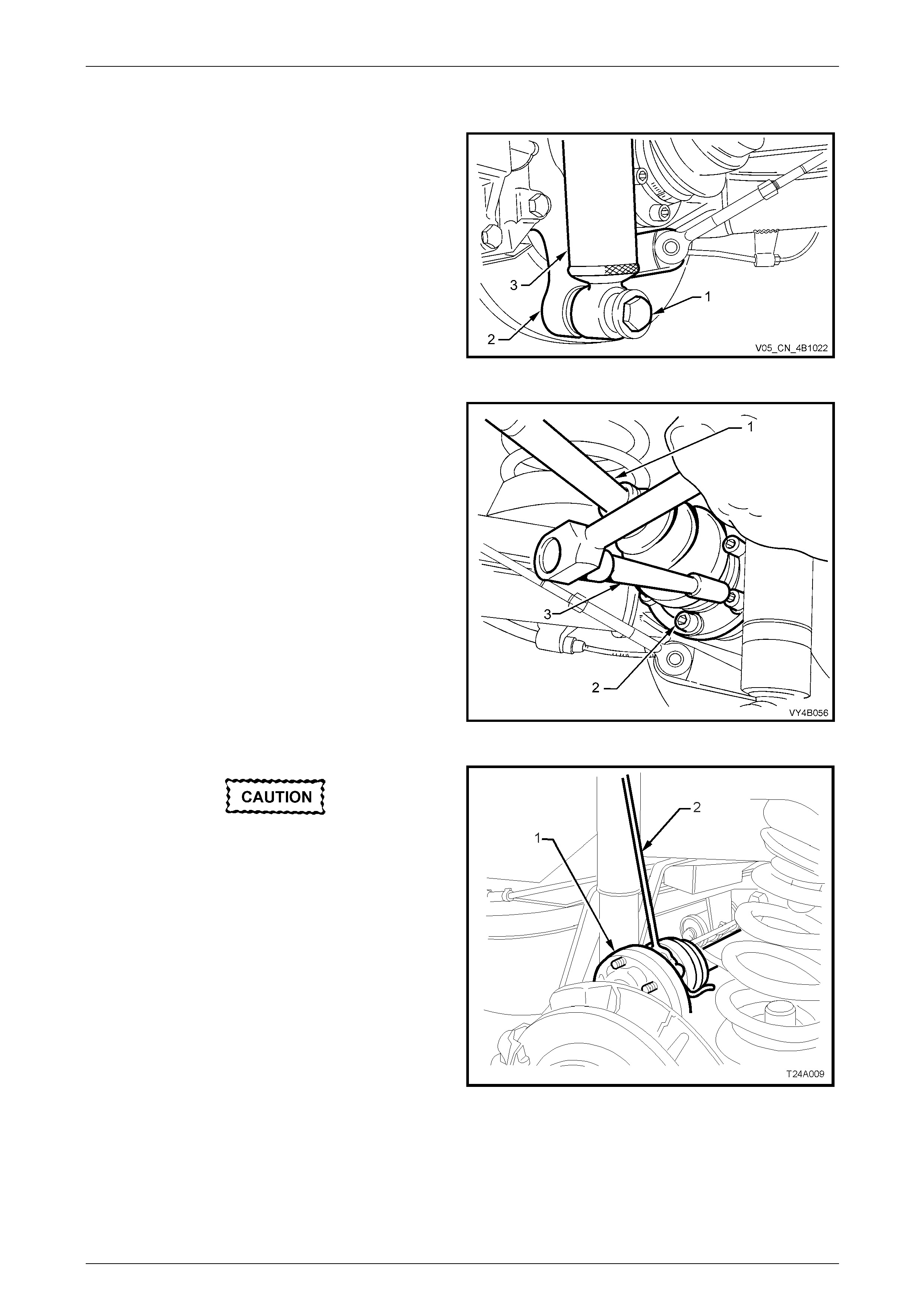

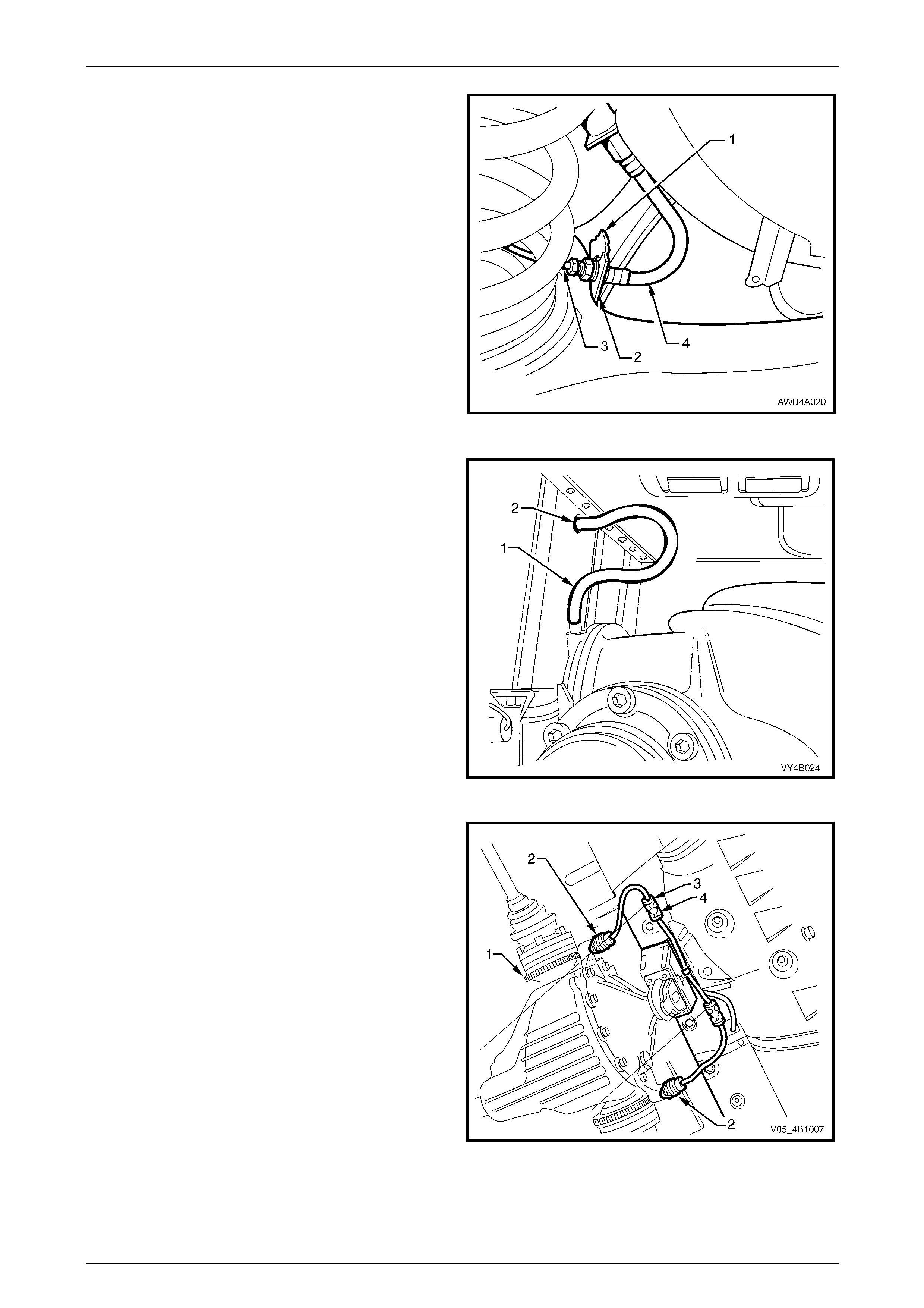

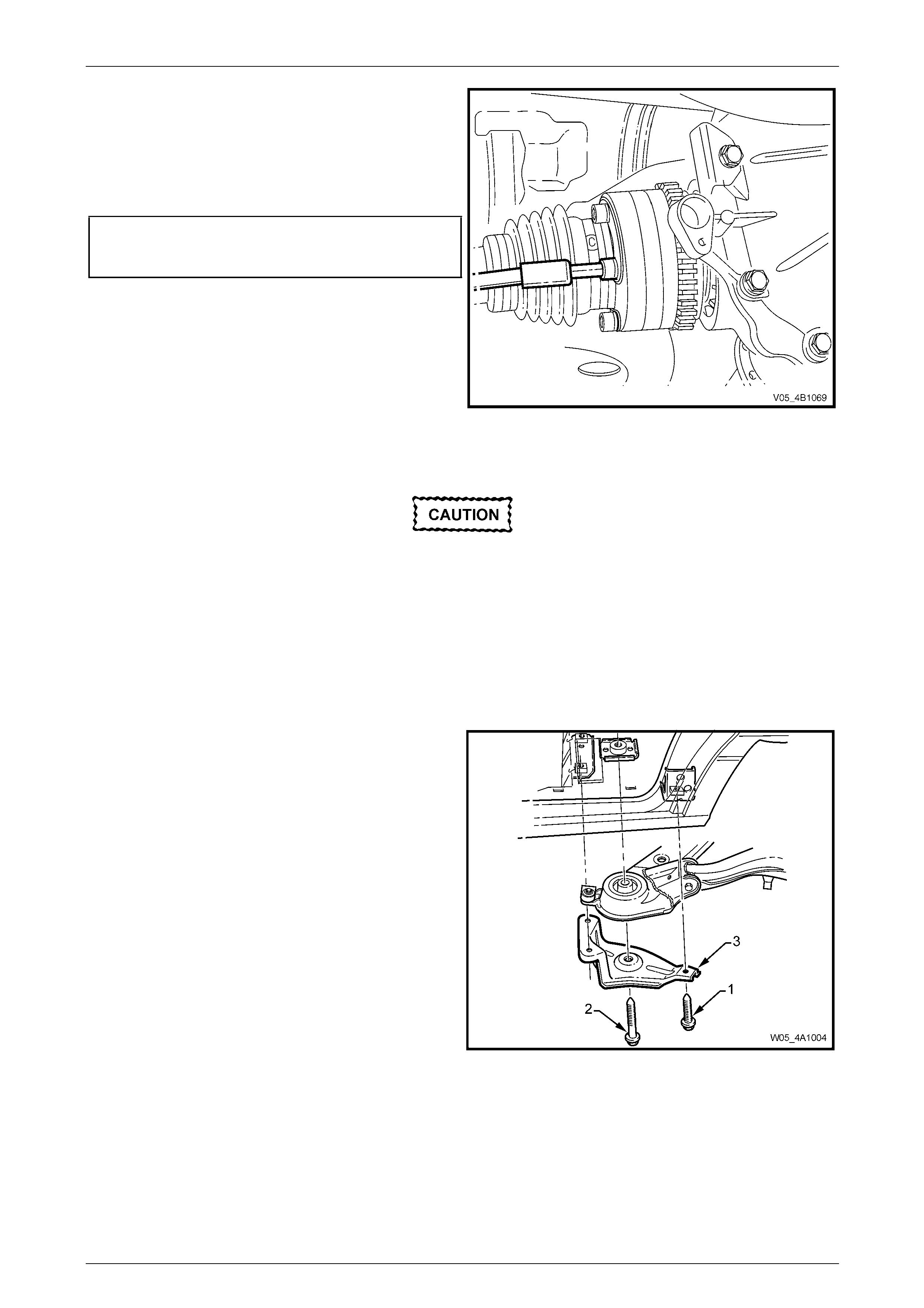

4 Disconnect rear shock absorber lower mounting bolt

(1) from trailing arm (2), and pull lower end of shock

absorber (3) from trailing arm (2).

Figure 4B1 – 7

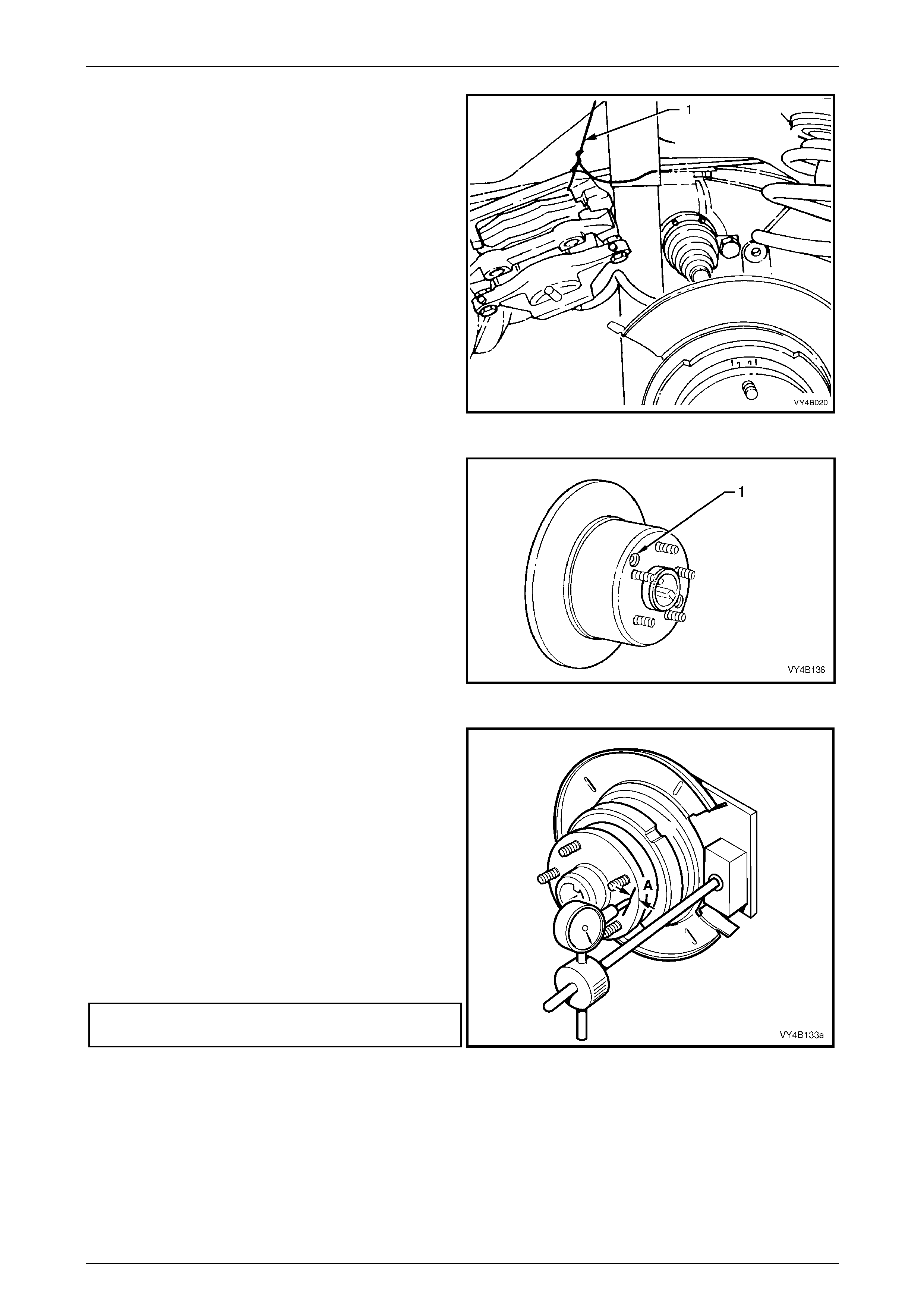

5 Remove brake caliper anchor plate to trailing arm

attaching bolts (1), remove caliper (2) from disc.

Figure 4B1 – 8

Rear Final Drive and Drive Shafts Page 4B1-13

Page 4B1-13

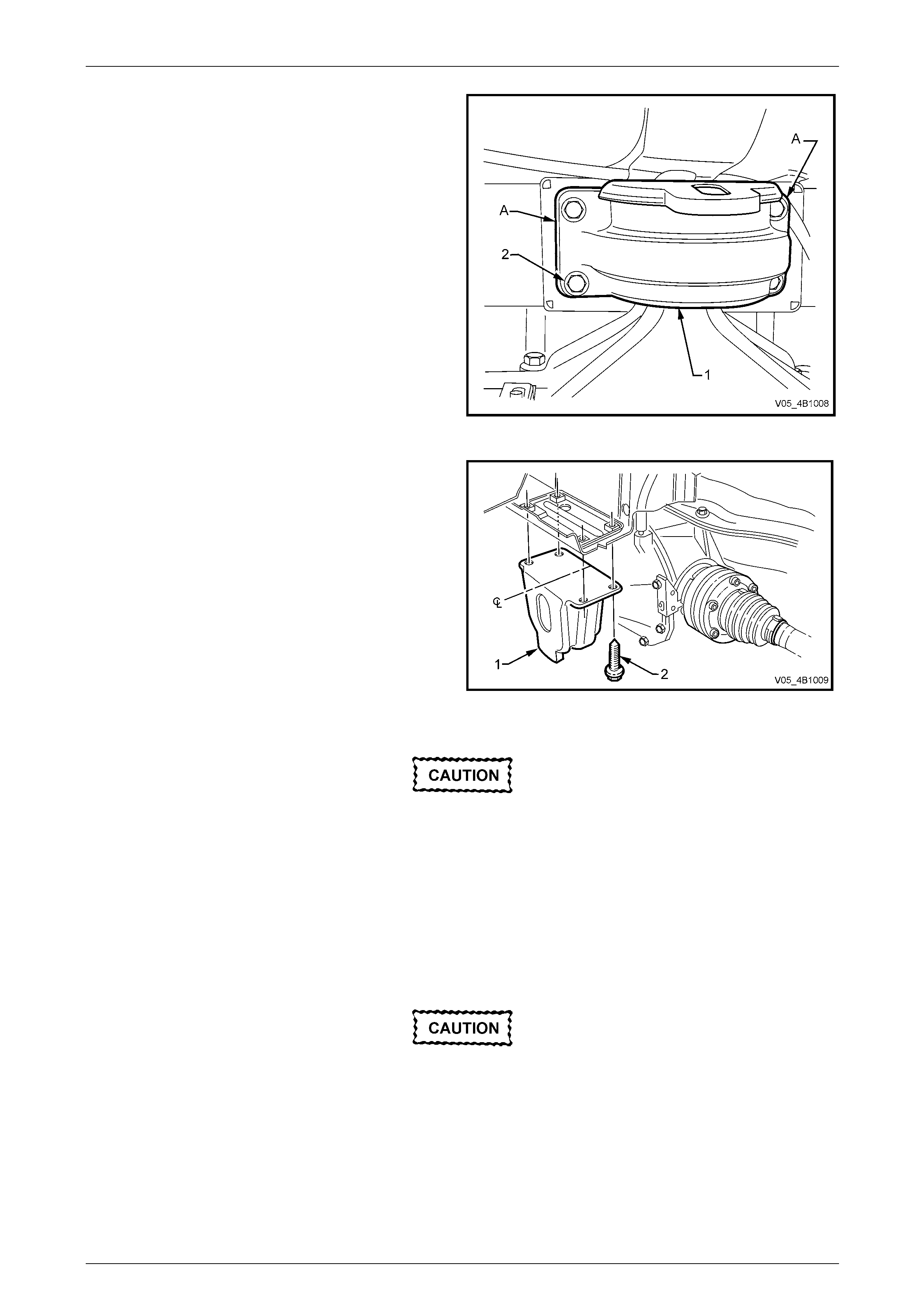

6 Using tie wire (1), secure caliper to lower end of shock

absorber upper mounting. DO NOT ALLOW CALIPER

TO HANG BY BRAKE HOSE.

7. Mark the brake disc position to outer rear wheel drive

shaft assembly, using a felt tipped pen or similar, then

remove the brake disc from the outer rear wheel drive

shaft assembly (Shown already removed in Figur e

4B1-9).

Figure 4B1 – 9

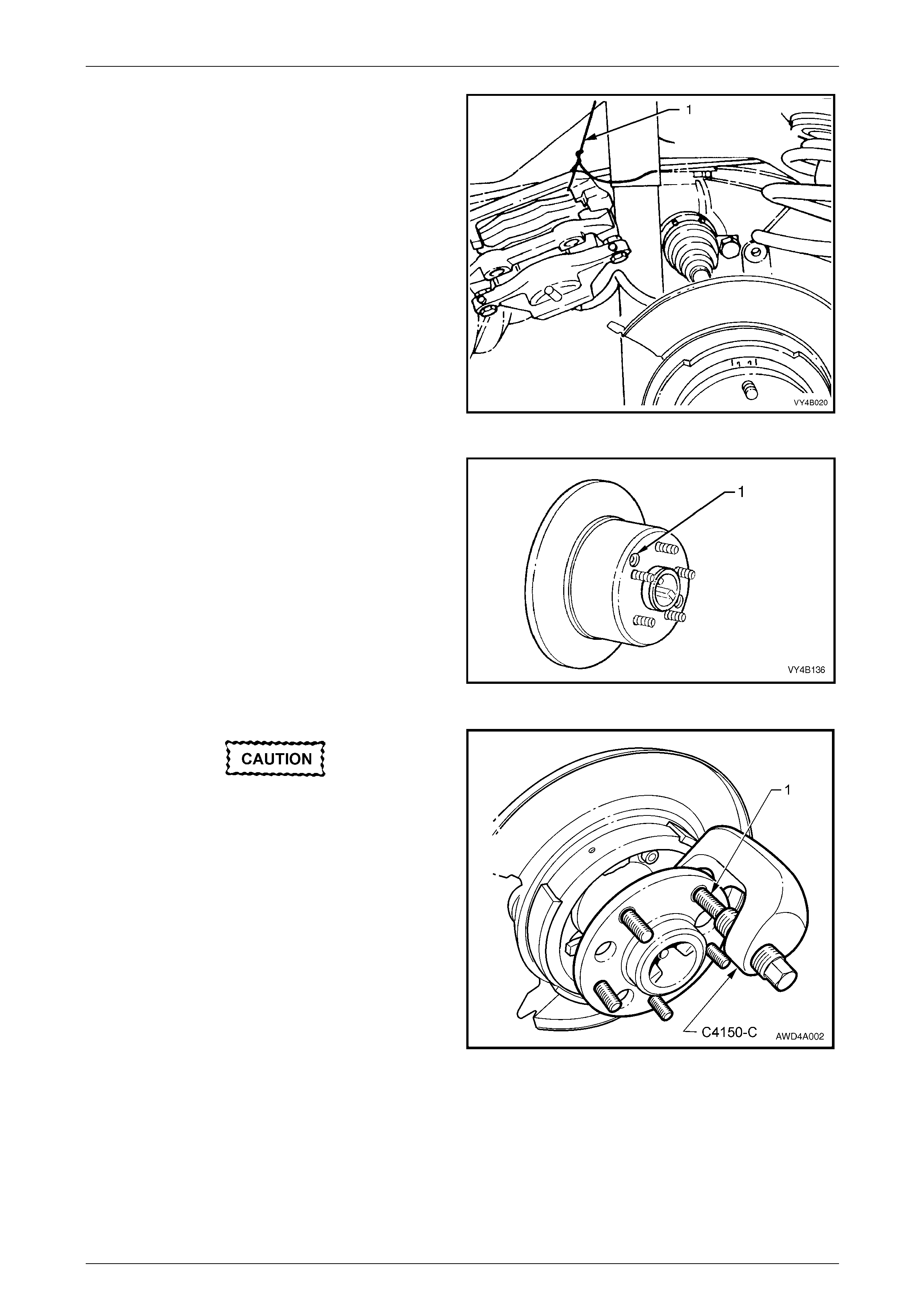

8 If the park brake shoe needs to be adjusted to allow

disc removal, the following method sh ould be adopted:

a Remove the access hole plug (1) from the hole

provided in the disc.

b Using a suitable lever such as a screwdriver,

loosen the park brake shoe screw adjuster, until

the disc is freed.

c After disc removal, reinstall the access hole plug

to prevent loss.

Figure 4B1 – 10

9 Clean the rear outer rear wheel drive shaft face by

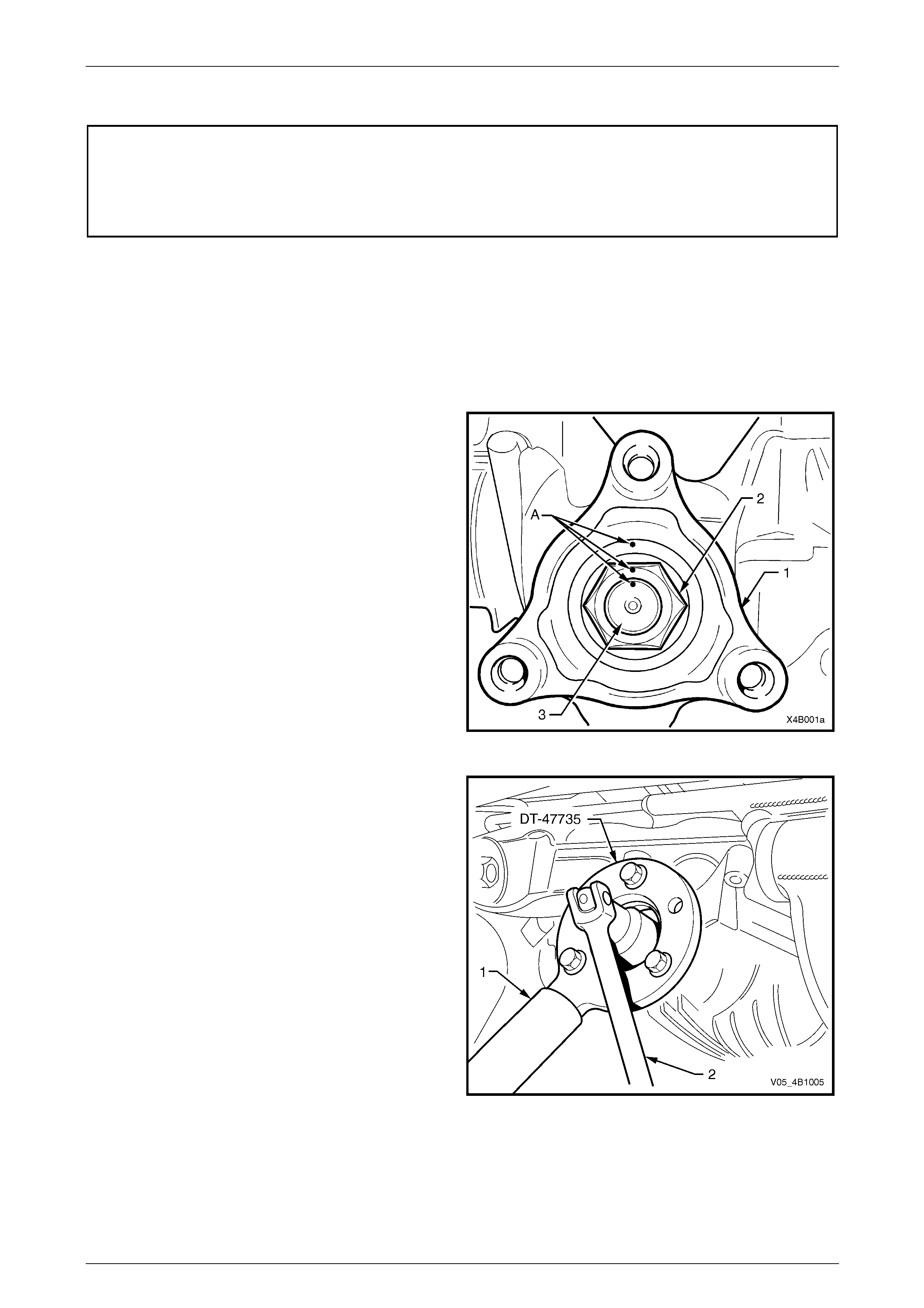

rubbing lightly with fine emer y paper.

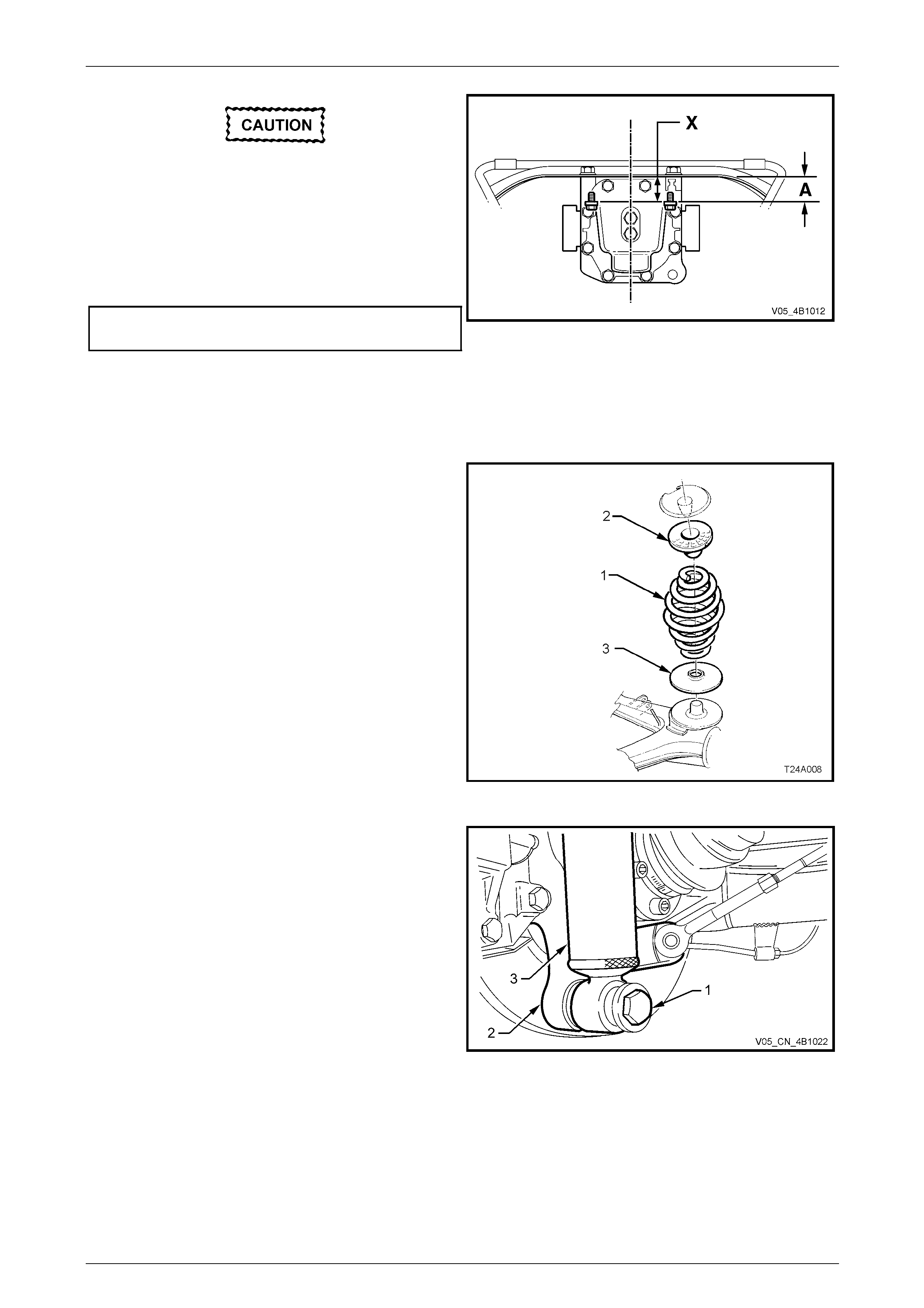

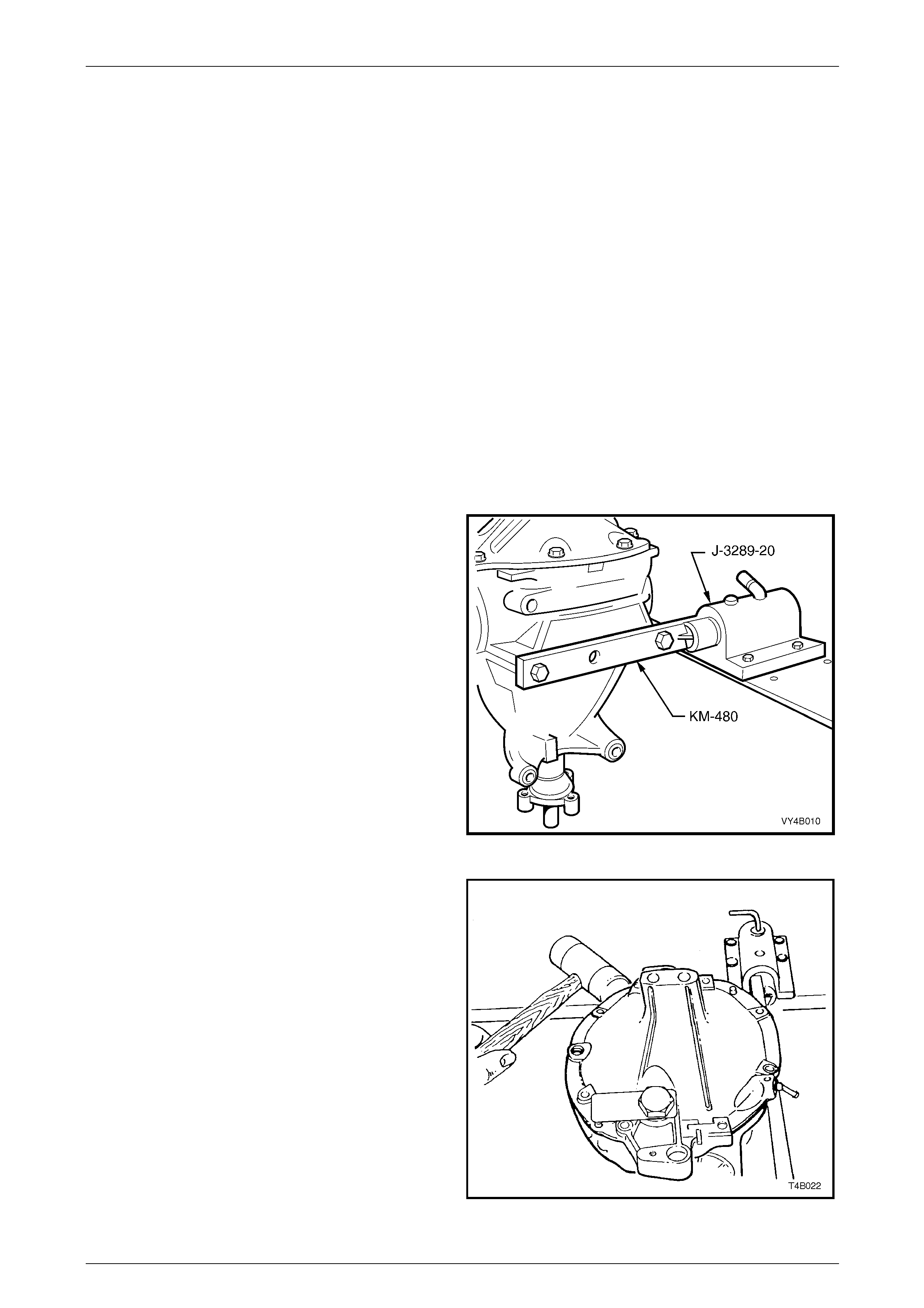

10 Mount the pre-fabricated mounting plate (refer

7 Special Tools in this Section for details) to the brake

caliper mounting points on the rear traili ng arm, using

the caliper mounting bolts.

11 Mount a magnetic based dial indicator stand, install a

dial indicator, positioning the pointer at a distance of 5

mm in from the outer edge (‘A’).

12 Using the wheel studs, carefully rotate outer rear

wheel drive shaft assembly hub, noting the points of

maximum and minimum lateral run-out. The difference

between these two dimensio ns is the Total Indicated

Runout (TIR).

Maximum outer rear wheel drive shaft

assembly hub, total indicated runout............... 0.060 mm

Figure 4B1 – 11

Rear Final Drive and Drive Shafts Page 4B1-14

Page 4B1-14

If Run-out is Within Specification

1 Reinstall brake disc over the o uter rear wheel drive shaft wheel studs, ensuring that the alignment marks made

prior to disassembly, are aligned.

2 Clean the threads of the brake caliper attaching bolts

(1) and apply a thread sealant such as Loctite 243 (or

equivalent).

3 Reinstall the brake caliper a nchor plate (2) and secure

with the attaching bolts (1), tightened to the correct

torque specification.

Brake caliper anchor plate to trailing

arm bolt torque specification................................85 N.m

Figure 4B1 – 12

Vehicle must be at curb weight and on all

four wheels before the shock absorber

mounting bolt torque is applied.

4 Reinstall shock absorb er to trailin g arm, fit washer to

the lower mounting bolt, install bolt and tighten to the

correct torque specification.

z Shock absorber lower mounting

bolt torque specification.....................................115 N.m

Figure 4B1 – 13

5 Reinstall road wheel, aligning marks made prior to removal, install and tighten attaching nuts.

6 Remove safety stand and lo wer vehicle.

7 Tighten road wheel attaching nuts to the correct torque specification an d in the correct sequence

(refer to Important Service Requirements in 2.1 General Information, in this Section).

Road wheel attaching nut

torque specification..................................110 – 140 N.m

8 Refit wheel cover/wheel nut caps.

If the Run-out Check, Exceeds Specification

1 The outer rear wheel drive shaft assembly m ust be repl aced, refer to

3.1 Outer Rear Wheel Drive Shaft Flange Ou ter Rear W heel Drive Shaft Assembly and/or Wheel Bearing, in this

Section.

Rear Final Drive and Drive Shafts Page 4B1-15

Page 4B1-15

2.5 Trailing Arm Outer Rear Wheel Drive

Shaft Assembly Hub Studs

ATTENTION

Vehicle must be at curb weight before final tightening.

Lower shock absorber mounting bolt.

Replace

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove rear wheel cover or wheel nut caps o n that side of the vehicle where the stud/s are to be replaced.

3 Mark relationship of wheel to mounti ng flange. Loosen then remove road wheel attaching nuts. Remove the road

wheel. Refer to 2.1 General Information in this Section for more information.

4 Loosen and disconn ect rear shock absorber lower

mounting bolt (1) from trailing arm (2) and pull lower

end of shock absorber (3) from trailing arm (2).

Figure 4B1 – 14

5 Loosen and remove brak e caliper anchor plate to

trailing arm attaching bolts (1) and remove calip er (2)

from disc.

Figure 4B1 – 15

Rear Final Drive and Drive Shafts Page 4B1-16

Page 4B1-16

6 Using tie wire (1), secure the brake caliper to lower

end of shock absorber upper mounting. DO NOT

ALLOW CALIPER TO HANG BY BRAKE HOSE.

7 Mark the brake disc position to outer rear wheel drive

shaft assembly, using a felt tipped pen or similar, then

remove the brake disc from the outer rear wheel drive

shaft assembly (Shown already removed in Figur e

4B1-16).

Figure 4B1 – 16

8 If the park brake shoe needs to be adjusted to allow

disc removal, the following method sh ould be adopted:

a Remove the access hole plug (1) from the hole

provided in the disc.

b Using a suitable lever such as a screwdriver,

loosen the park brake shoe screw adjuster, until

the disc is freed.

c After disc removal, reinstall the access hole plug

to prevent loss.

Figure 4B1 – 17

The use of a hammer and punch to remove a

wheel stud is not permitted, as distortion of

the outer rear w heel dri ve shaft assembly w ill

most likely occur. This would subsequently

result in brake shudder.

9 Use Tool No. C4150-C, remove the wheel stud (1) to

be replaced.

Figure 4B1 – 18

Rear Final Drive and Drive Shafts Page 4B1-17

Page 4B1-17

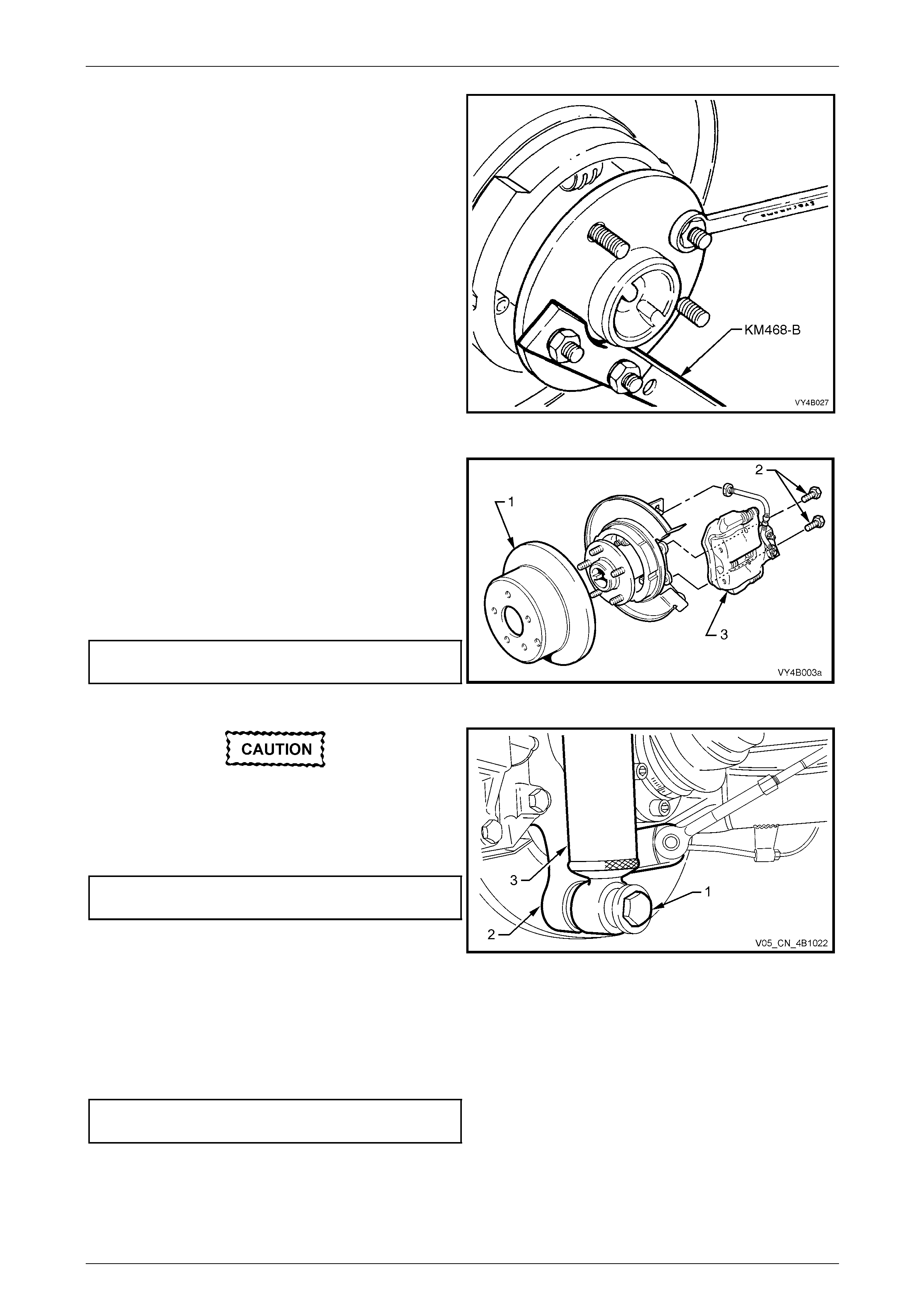

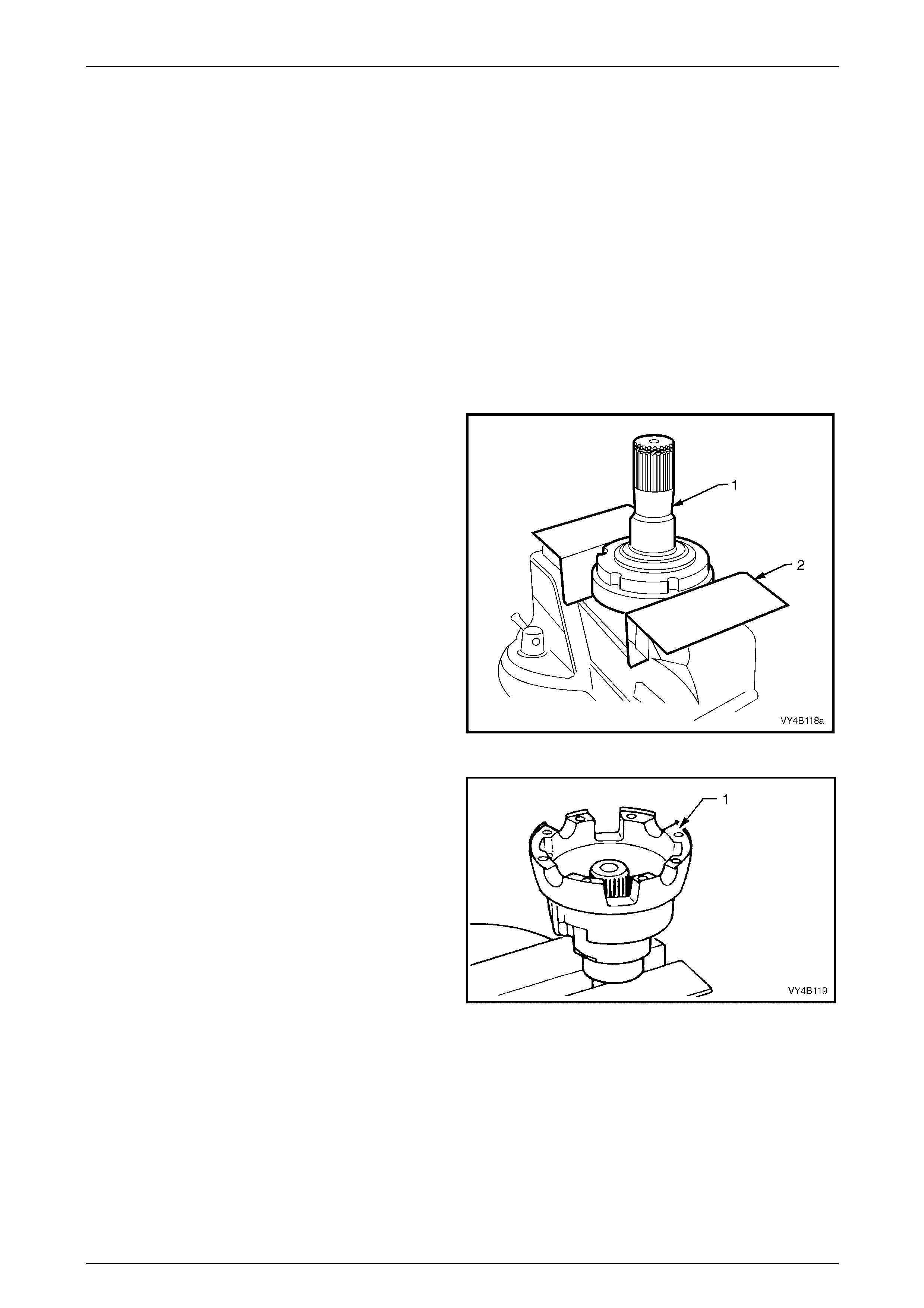

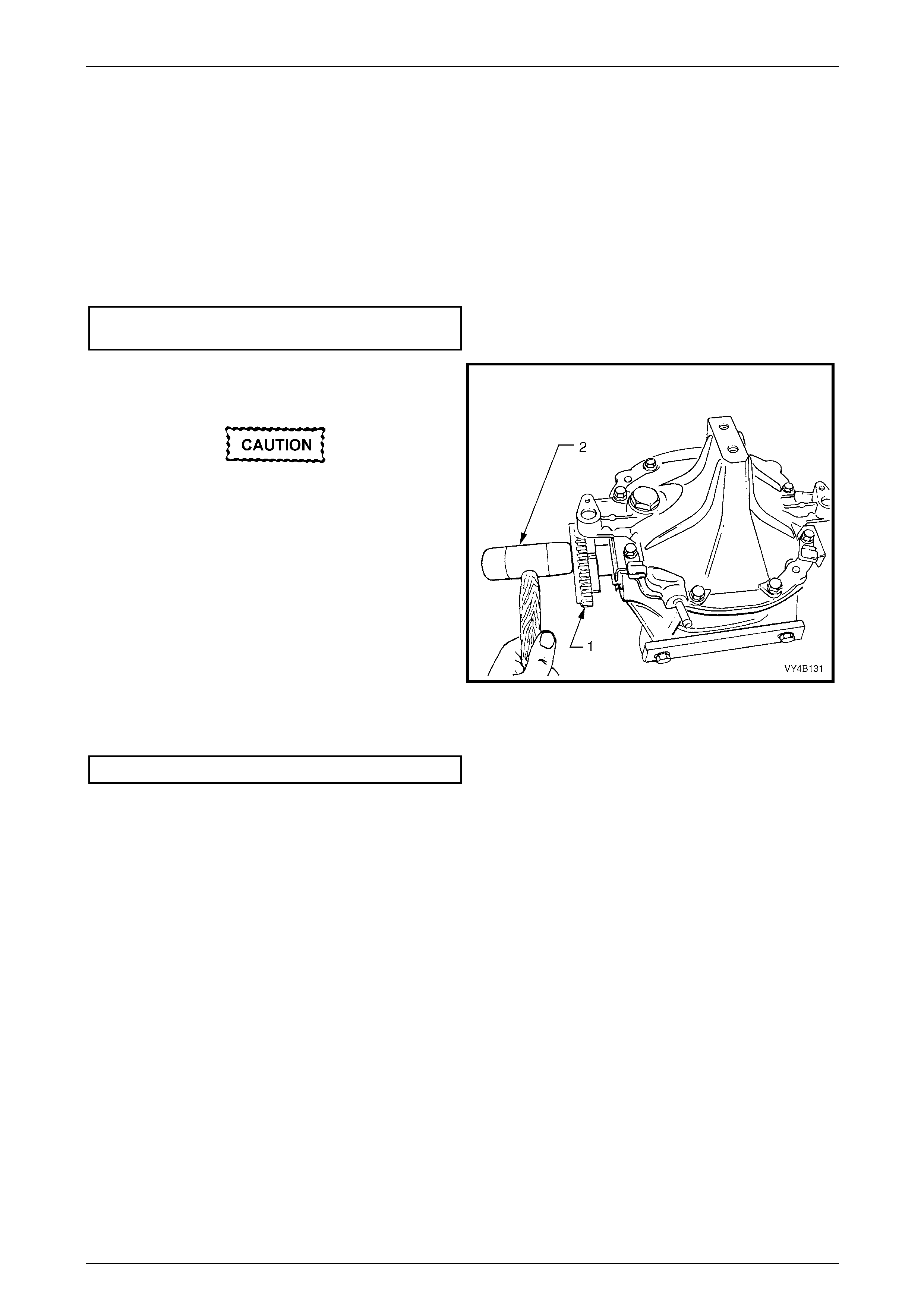

10 Install Tool No. KM468-B holding bar, with two wheel

nuts to the outer rear wheel drive shaft assembly hub

studs. Install a new stud into hub. Assemble some

suitable size washers and a reversed wheel nut, onto

stud. Tighten wheel nut to draw in stud. When stud is

fully installed, remove wheel nut and washers.

11 Install any remaining studs in the same manner.

12 Remove holding bar, T ool No. KM-468-B.

Figure 4B1 – 19

13 Reinstall brake disc (1) over the outer re ar wheel drive

shaft wheel studs, ensuring that the marks made prior

to disassembly, are aligned.

14 Clean the threads of the brake caliper attaching bolts

(1) and apply a thread sealant such as Loctite 243 (or

equivalent).

15 Reinstall brake calip er (3) anchor plate to trailing arm

attaching bolts (2) and tighten to the correct torque

specification.

Brake caliper anchor plate

torque specification..............................................85 N.m

Figure 4B1 – 20

Vehicle must be at curb weight and on all

four wheels before this torque is applied.

16 Reinstall shock absorb er (3) to traili ng arm (2), fit

washer to the lower mounting bolt, install bolt (1) and

tighten to the correct torque specification.

z Shock absorber lower mounting

bolt torque specification.....................................115 N.m

Figure 4B1 – 21

17 Reinstall road wheel, aligning marks made prior to removal, install and tighten attaching nuts.

18 Remove safety stand and lo wer vehicle.

19 Tighten road wheel attaching nuts to the correct torque specification and in the correct sequence

(refer to Important Service Requirements in 2.1 General Information, in this Section).

Road wheel attaching nut

torque specification..................................110 – 140 N.m

20 Refit wheel cover/wheel nut caps.

Rear Final Drive and Drive Shafts Page 4B1-18

Page 4B1-18

2.6 Drive Shaft Assembly

ATTENTION

The following fasteners MUST be replaced w hen performing these operations:

All removed drive shaft constant velocity joint attaching bolts.

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Use a felt tipped pen or similar, to identify the drive

shaft as being either right or left and also, which

constant velocity joint is the outer.

NOTE

It is important that the drive shaft orientation is

marked, to maintain the shaft ‘wind-up’ direction

when reinstalled.

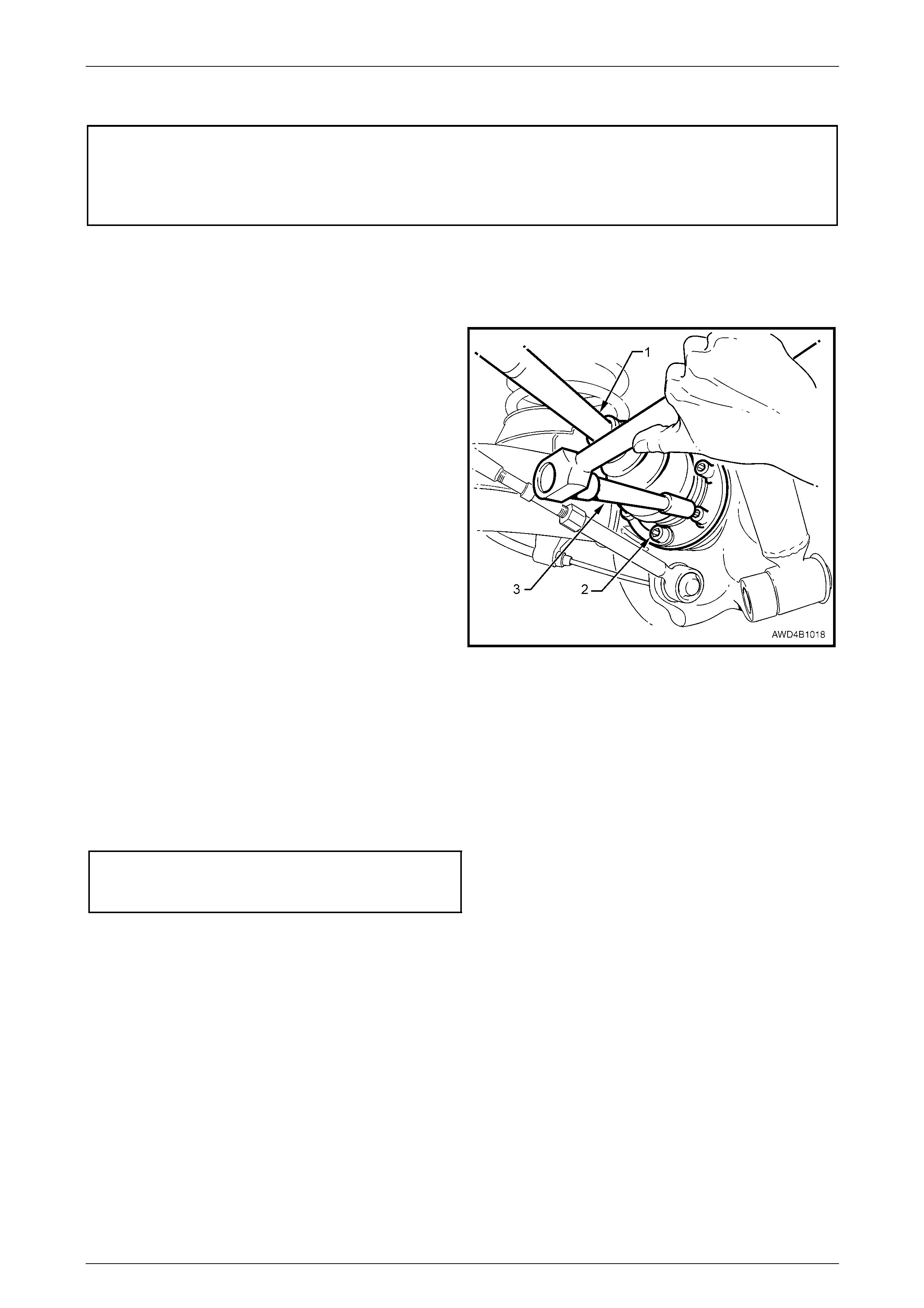

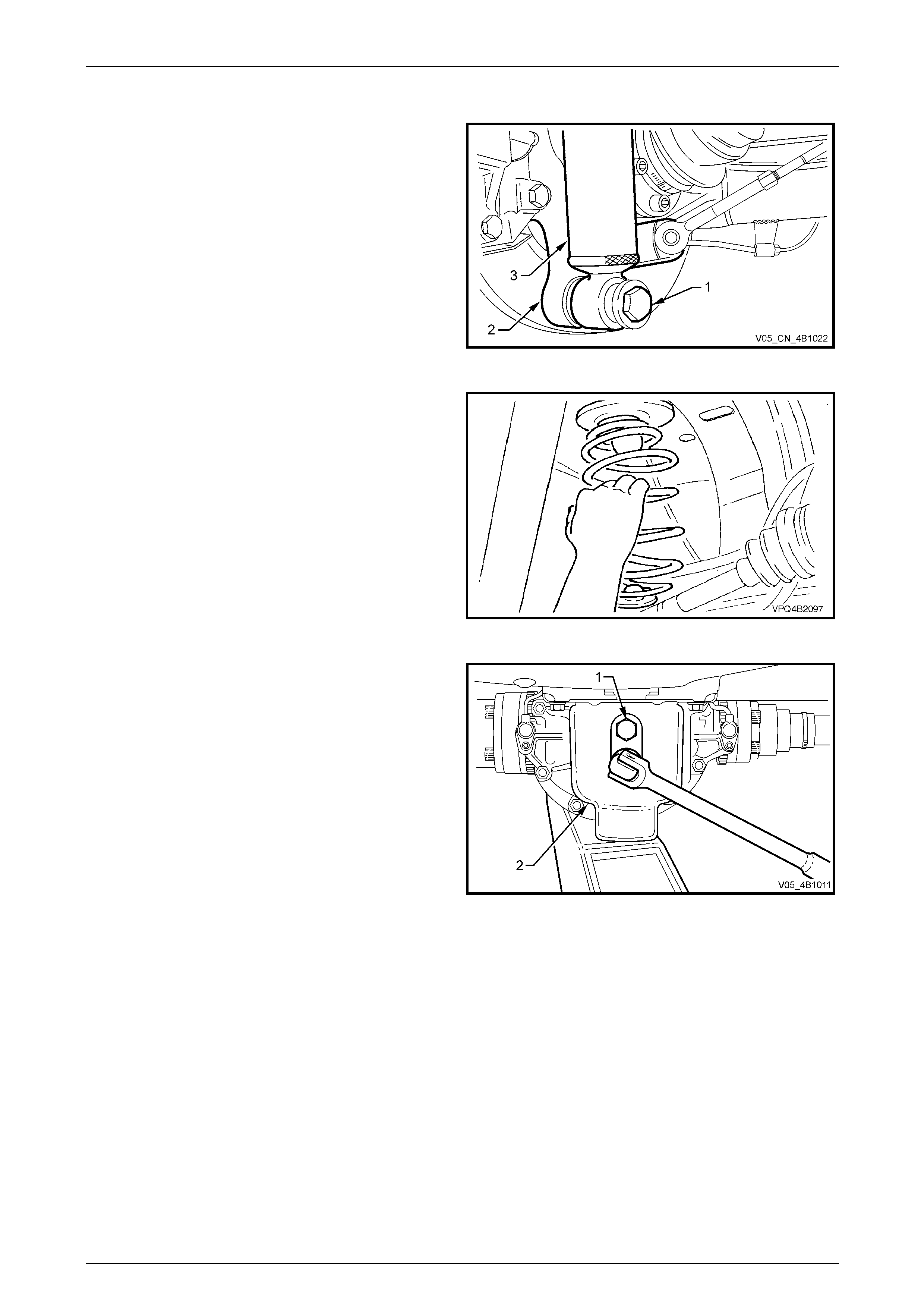

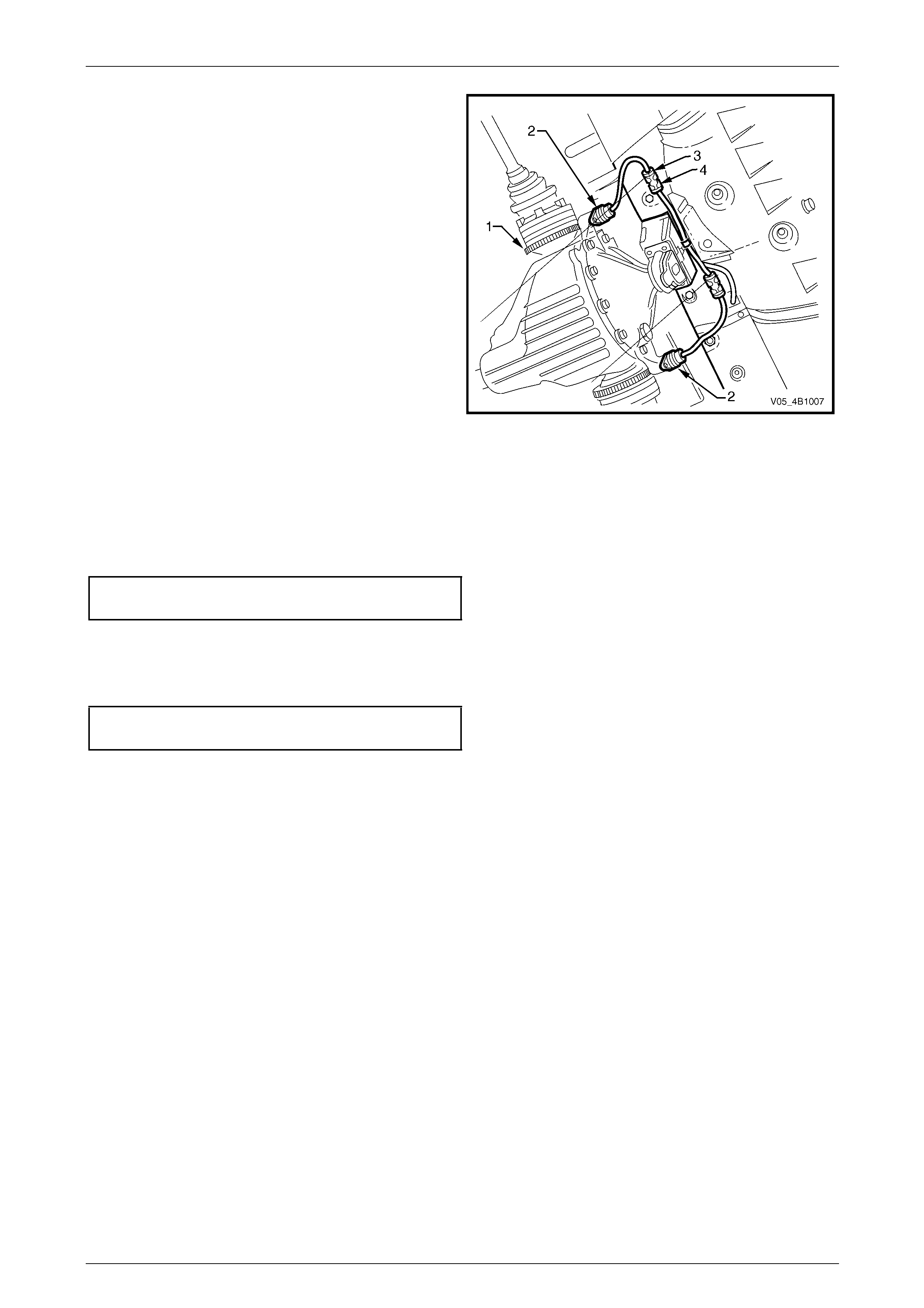

3 With the park brake firmly applied, use an 8 mm Allen

key socket and suitable socket equipm ent (3) remove

drive shaft inner constant velocity joint to inner axle

shaft and outer constant velocity joint to outer rear

wheel drive shaft flange attaching bolts (2) (six places)

and plates, remove drive shaft (1).

NOTE

During drive shaft removal and reinstallati on, the

drive shaft must be supported to keep constant

velocity joint deflection to a minimum. Figure 4B1 – 22

Reinstall

Reinstallation of the drive shaft is reversal of the removal procedure, noting the following points.

1 When reinstalling the drive shaft, ensure that either constant velocity joint is not deflected excessively and that the

orientation is the same as before remov al, u sing the identification marks previously applied.

2 Reinstall the drive shaft, then six NEW bolts and three plates at each end, tightening to the correct torque

specification.

Drive shaft constant velocity joint

bolt torque specification.......................................50 N.m

plus 90° turn angle

Rear Final Drive and Drive Shafts Page 4B1-19

Page 4B1-19

2.7 Drive Shaft and/or Constant Velocity

Joints

There are three repair kits available for drive shaft constant velocity joint repairs:

a A ‘Boot Kit’, which consists of a boot, boot clamps and retaining circlip, common for both the plunge and fixed

designs.

b A ‘Constant Velocity Joint Kit’, which contains the same items as the Boot Kit plus a 'fixe d' design constant velocity

joint and lubricant of the correct type and quantity.

c A ‘Constant Velocity Joint Kit’, which contains the same items as the Boot Kit plus a 'plunge' design constant

velocity joint and lubricant of the correct type and quantity.

NOTE

• Sealant for the constant velocity joint covers

is not supplied in any kit. The correct sealant

however, is available in 75 gram tubes.

• Both the dust cap and the dust shield are

available as separate items and not included

in any of the available kits.

Disassemble

NOTE

Except where noted differences apply, the

following procedures apply to either the fixed or

plunge type of constant velocity joint.

1 Remove drive shaft assembly, refer to

2.6 Drive Shaft Assembly in this Section.

2 Clean outside of assembly with a suitable solvent

before disassembling.

3 Clamp assembly, by drive shaft (1), in a vice fitted with

soft metal jaws.

4 Using tin snips or other suitable cutting tool, cut boot

clamps (2) in raised crimped area and remo ve clamps.

Figure 4B1 – 23

5 Using a suitable drift (1) and hammer, tap end dust

shield cap (3) from the outer end of the constant

velocity joint. being disassembled.

6 After changing the clamping, use a simil ar procedure

to dislodge the inner dust shield (2) from the constant

velocity joint.

Figure 4B1 – 24

Rear Final Drive and Drive Shafts Page 4B1-20

Page 4B1-20

7 Using suitable circlip pliers, remove the circlip (1) from

the end of drive shaft where the constant velocity joint

is to be removed. Discard the removed circlip.

NOTE

Do not re-use circlips once they have been

removed. Always use new snap rings on

reassembly.

8 Wipe the excess lubricant from the outer joint surfaces

then apply correction fluid across the inner race, ball

carrier and outer race as indic ated b y 'A'.

NOTE

This step is necessary to maintain the original

relationship of these three components.

9 Remove assembly from vice. Slide inner dust shield

and boot towards the centre of the drive shaft. Figure 4B1 – 25

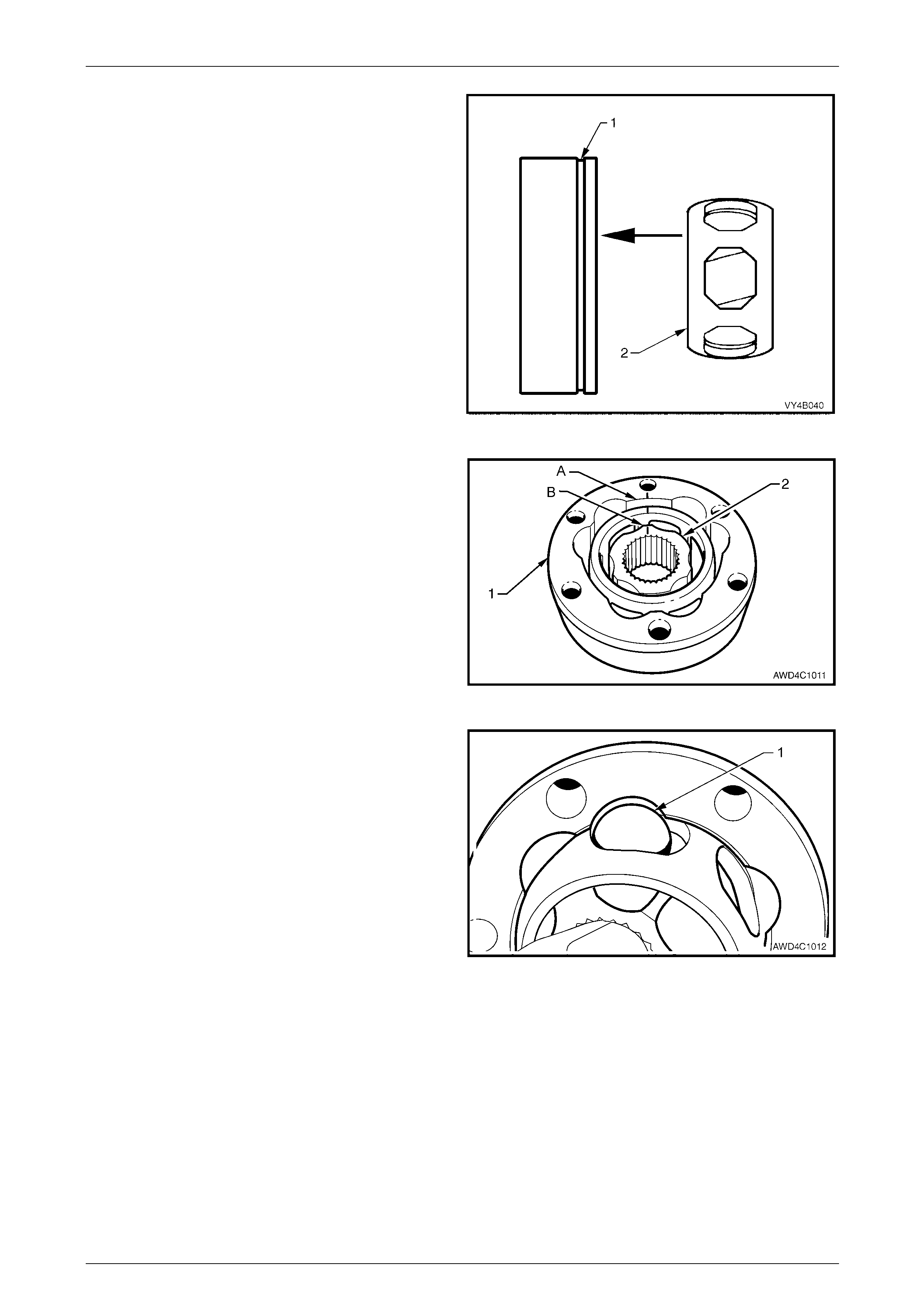

10 Using suitable press plates (such as Tool No. J22912-

01), supporting inner race (1), press drive sha ft from

constant velocity joint, using a suitable drift (2).

NOTE

While the press plates must support the inner

race, if clamped too tight to the drive shaft, then

the shaft splines will foul against the press

plates.

11 Repeat process to remove remaining constant velocity

joint, as required.

12 Remove boots and dust shields from drive shaft,

ensuring boots are not dam aged on edges of shaft

splines. Figure 4B1 – 26

Inspect

Drive Shaft and Boots

1 Clean shaft and boot/s in a suitable cleaning solvent.

2 Inspect drive shaft for twisting, cracking or excessive spline wear.

NOTE

As the drive shaft is not serviced separately, if

found to be defective, then the complete drive

shaft must be replaced.

3 Inspect boots and replace if split, fatigued, cracked or worn.

Rear Final Drive and Drive Shafts Page 4B1-21

Page 4B1-21

Constant Velocity Joints

Complete disassembly of the constant

velocity joints is not recommended. The

internal components are a precision fit and

develop their own characteristic wear

patterns. Intermixing components could

result in looseness, binding and/or premature

failure of the joint.

1 Inspect grease in joint and, if obviously contaminated

and/or has been subjected to dirt/water ingress, the

joint has probably suffered damage and should be

replaced.

2 If inspection reveals that the joint has not been

contaminated, clean joint by soaking in a suitable

cleaning solvent.

3 Once grease has been removed, insp ect internal

components by tilting inner race to one si de to expose

each ball.

NOTE

Take care not to pivot the inner race too sharply,

as the balls can become dislodged. If this does

occur and the origi nal location of the balls is lost,

then the constant velocity joint should be

replaced.

Figure 4B1 – 27

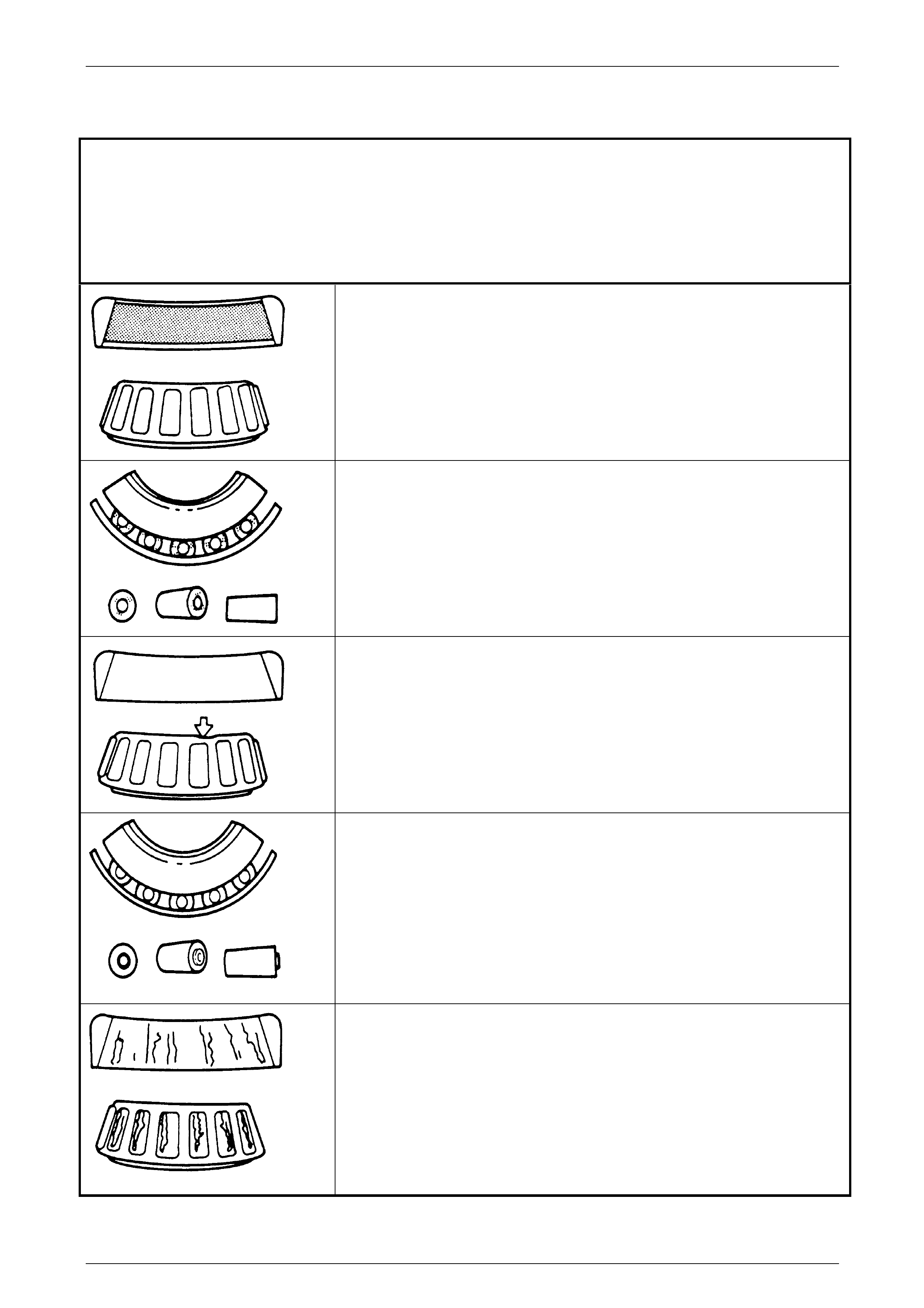

4 Replace the constant velocity joint assembly if there is severe pitting, galling, pla y between balls and the cage

windows, any cracking or damage to ca ge, outer race, pitting or galling or chips in raceways.

Reassemble

Constant Velocity Joints

NOTES

• During the removal, cleaning and inspection

of a constant velocity joint, it is possible for

the joint to become disassembled. Should the

disassembly of a constant velocity (CV) joint

be required and, notwithstanding the earlier

recommendation, it is possible to reassemble

the CV joint, provided the foll owing procedure

is followed EXACTLY.

• All components, including the individual balls,

MUST be maintained in their original

relationship to each other, to minimise the

creation of a noisy or binding joint.

• Under no circumstances are components

from one constant velocity joint to be mixed

with components from another CV joint.

Rear Final Drive and Drive Shafts Page 4B1-22

Page 4B1-22

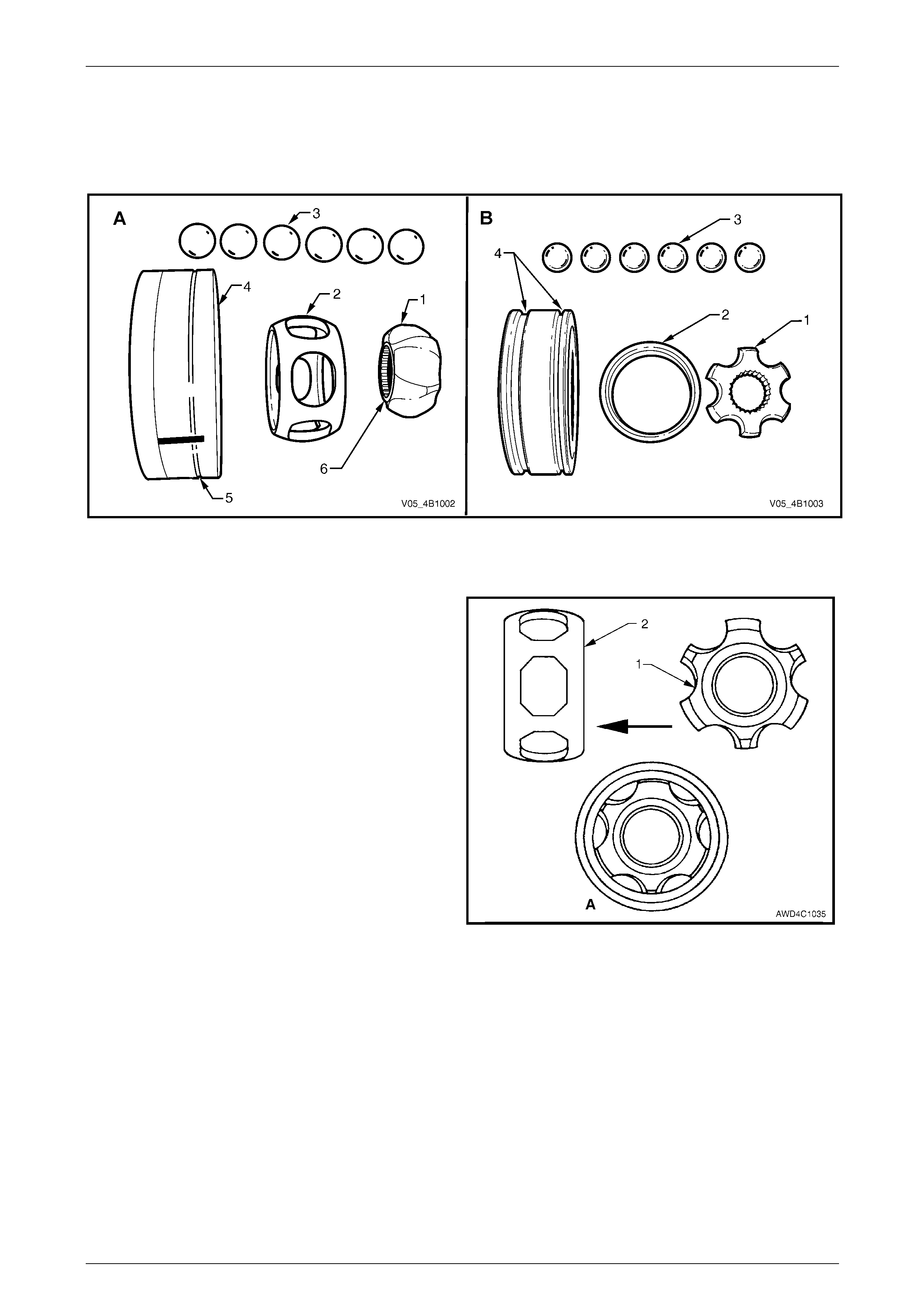

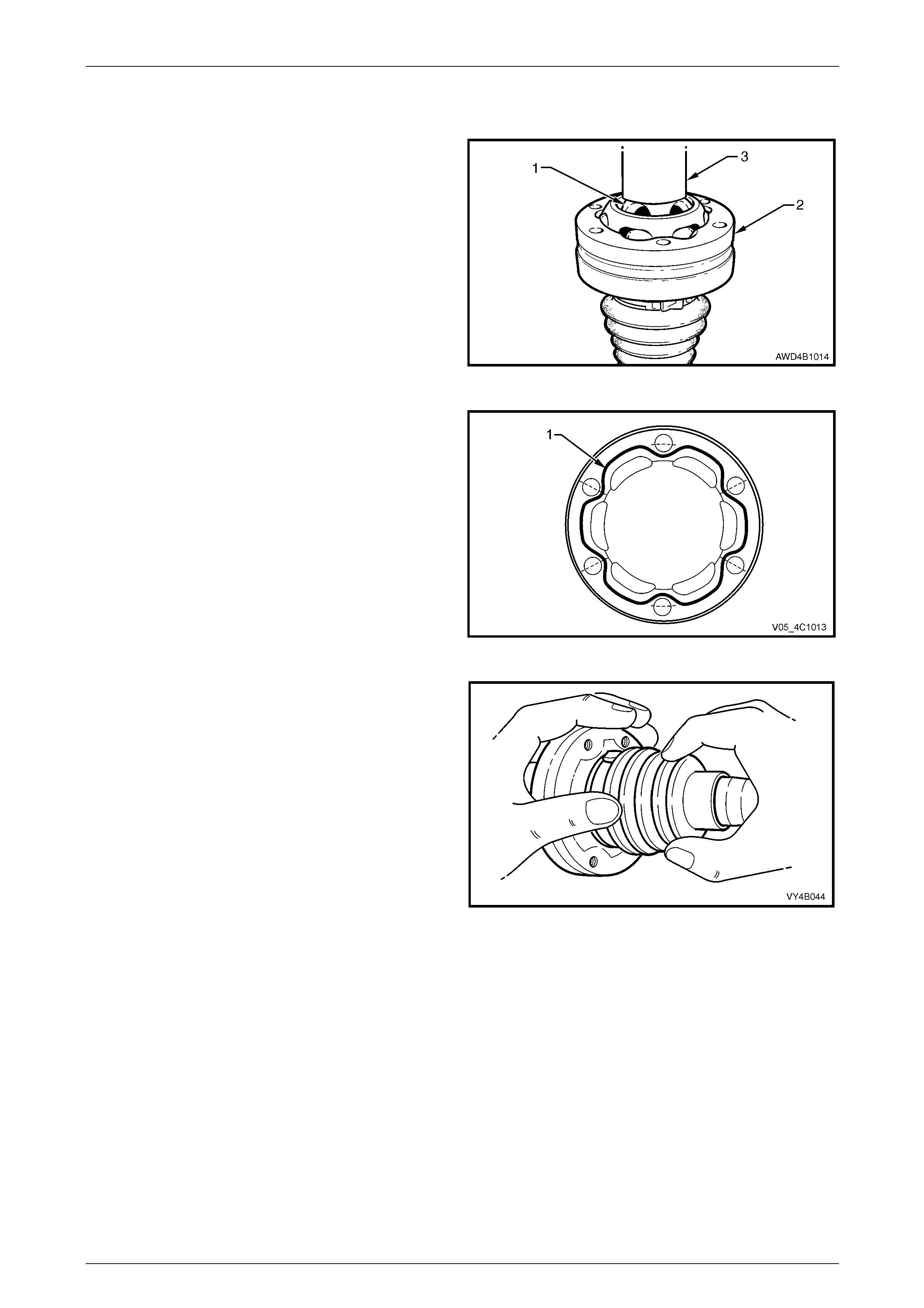

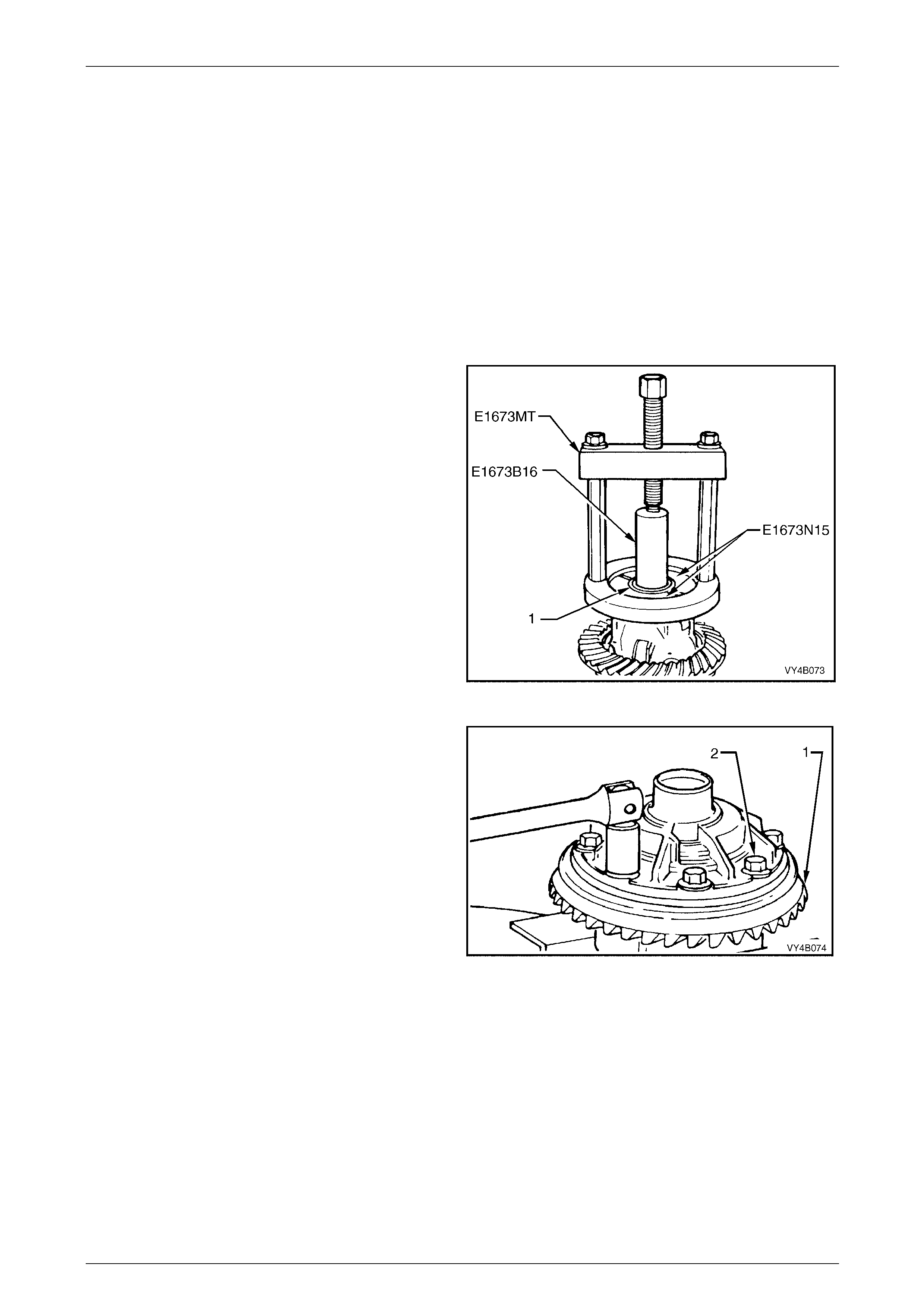

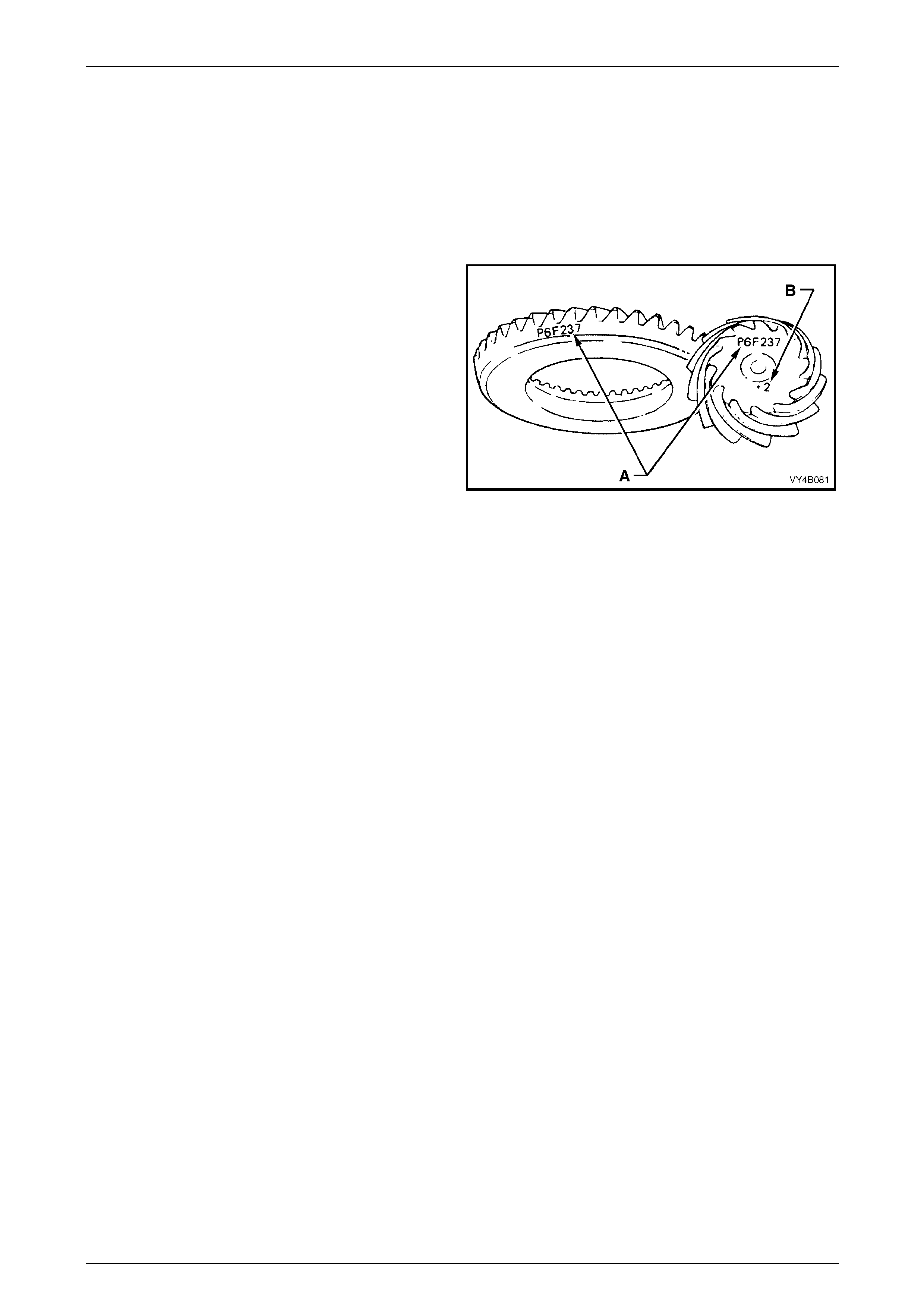

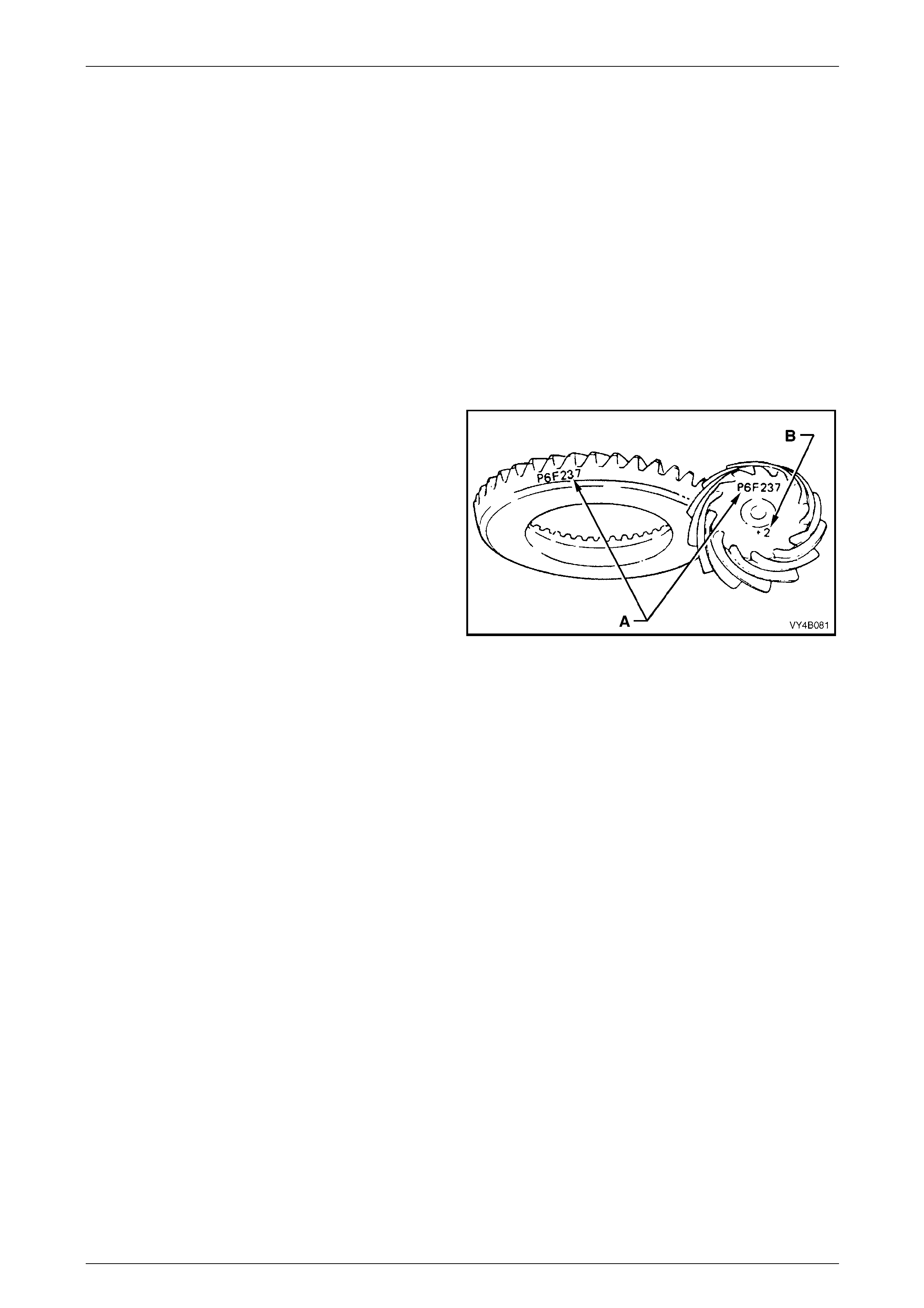

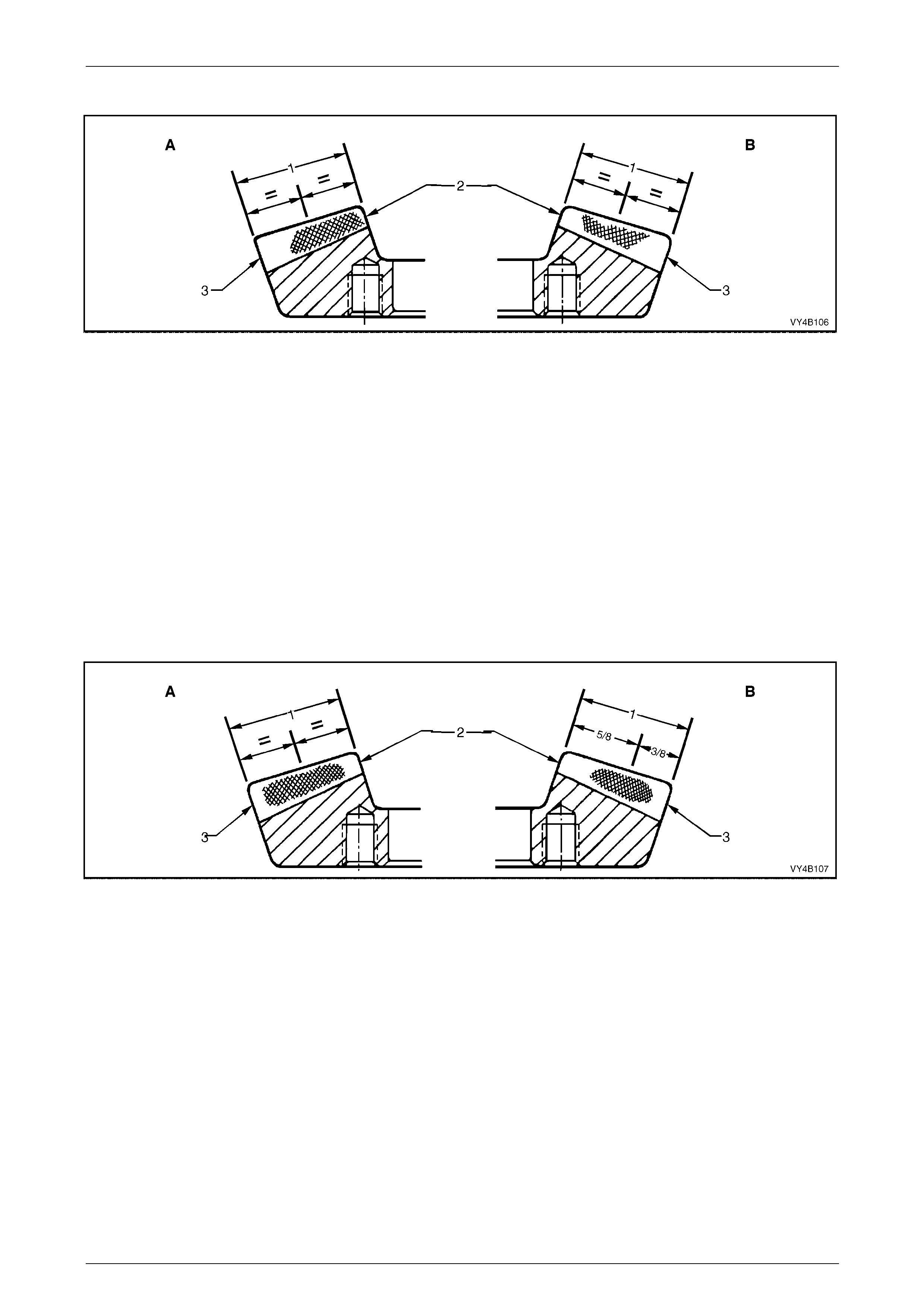

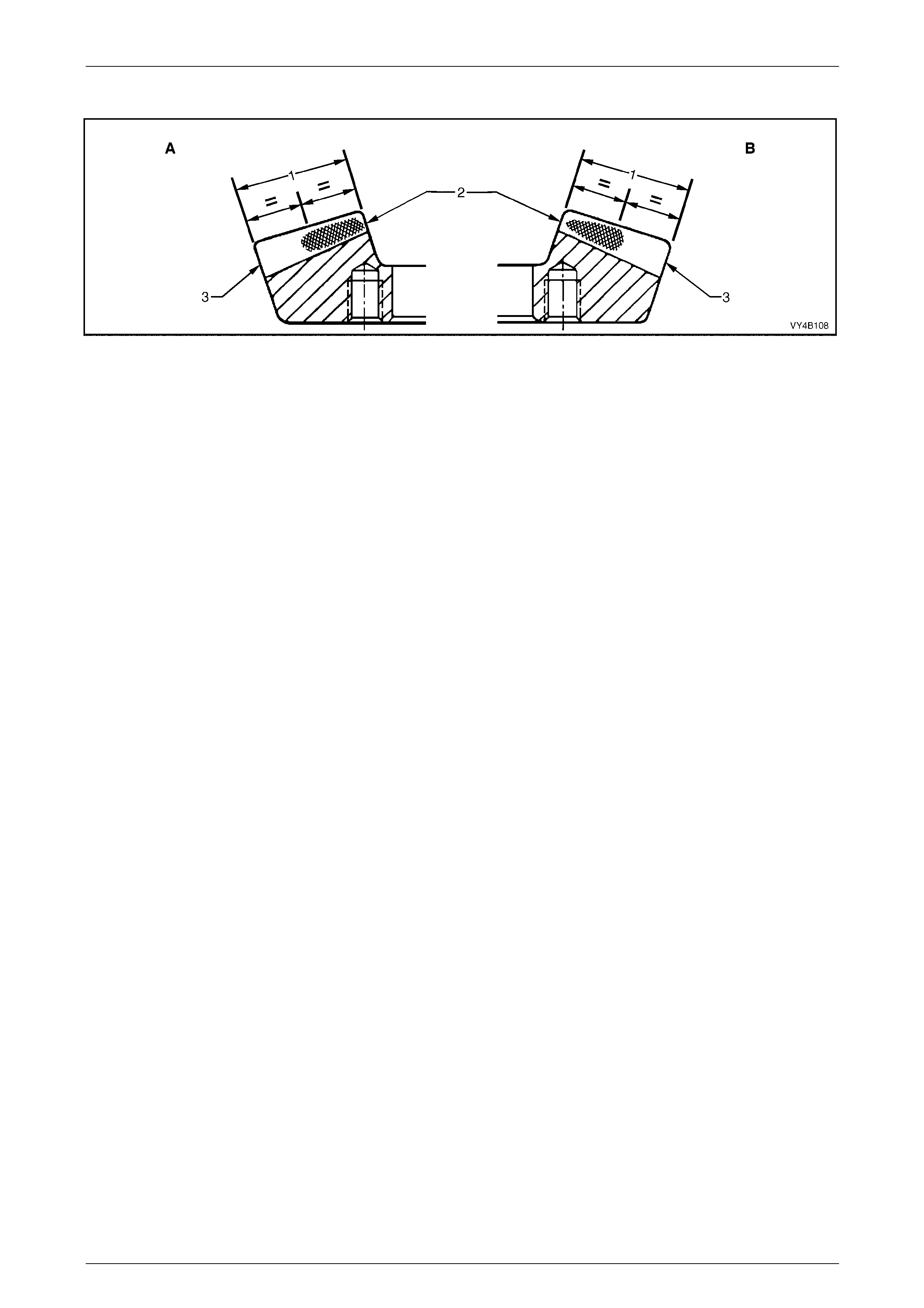

Shown in Figure 4B1 – 28, are exploded views of each constant velocity joint type; view 'A' is the plunge design, while

view 'B' shows the fixed design.

With the plunge joint ('A'), note the ide ntification groove (5) on the outer race and the identificatio n step (6) on the inner

race (1). Conversely, the fixed joint ('B') has two grooves (4) on the outer race, a chamfer on the cage (2) and straight

ball raceways on the inner race (1).

Figure 4B1 – 28

Plunge Type

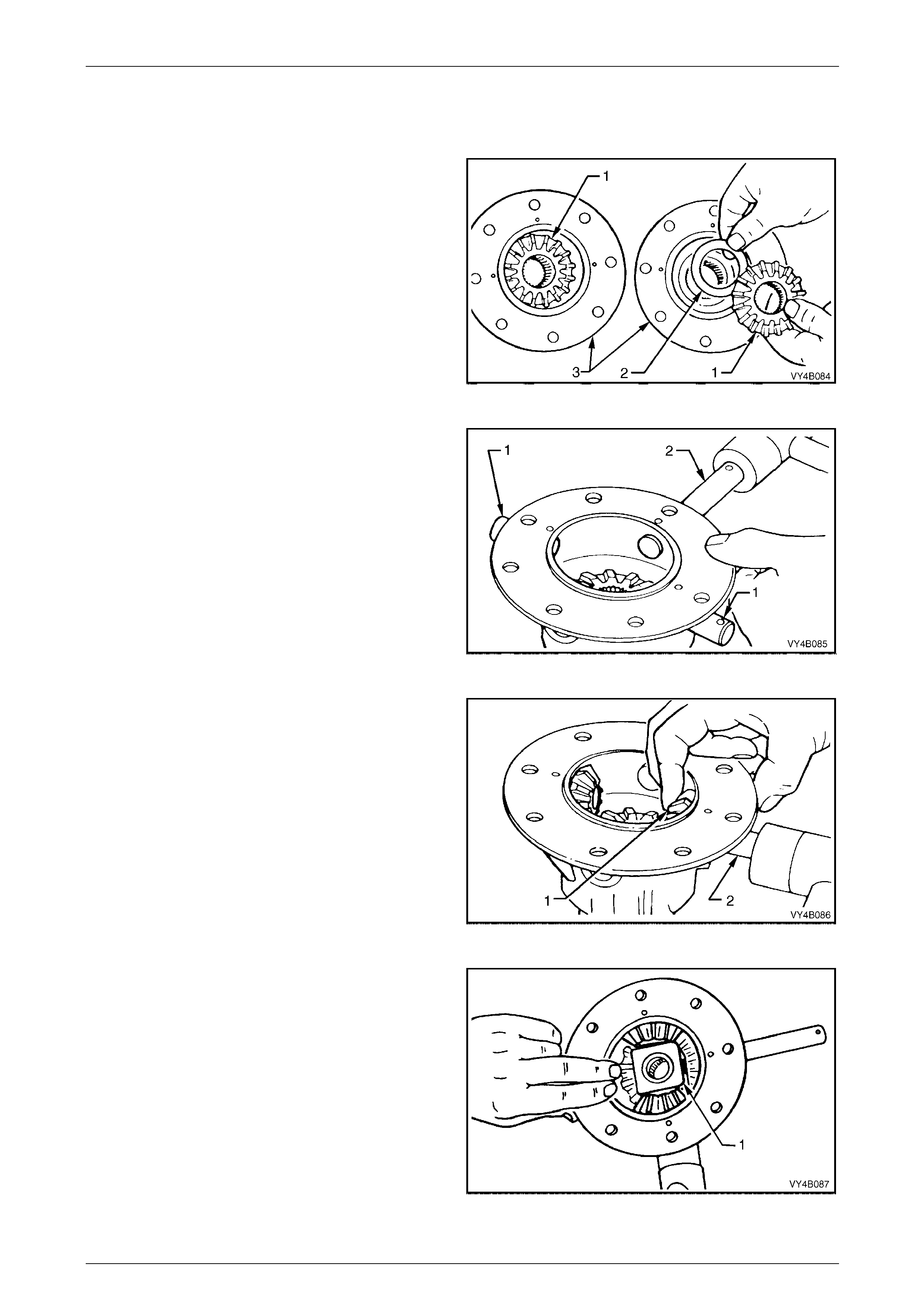

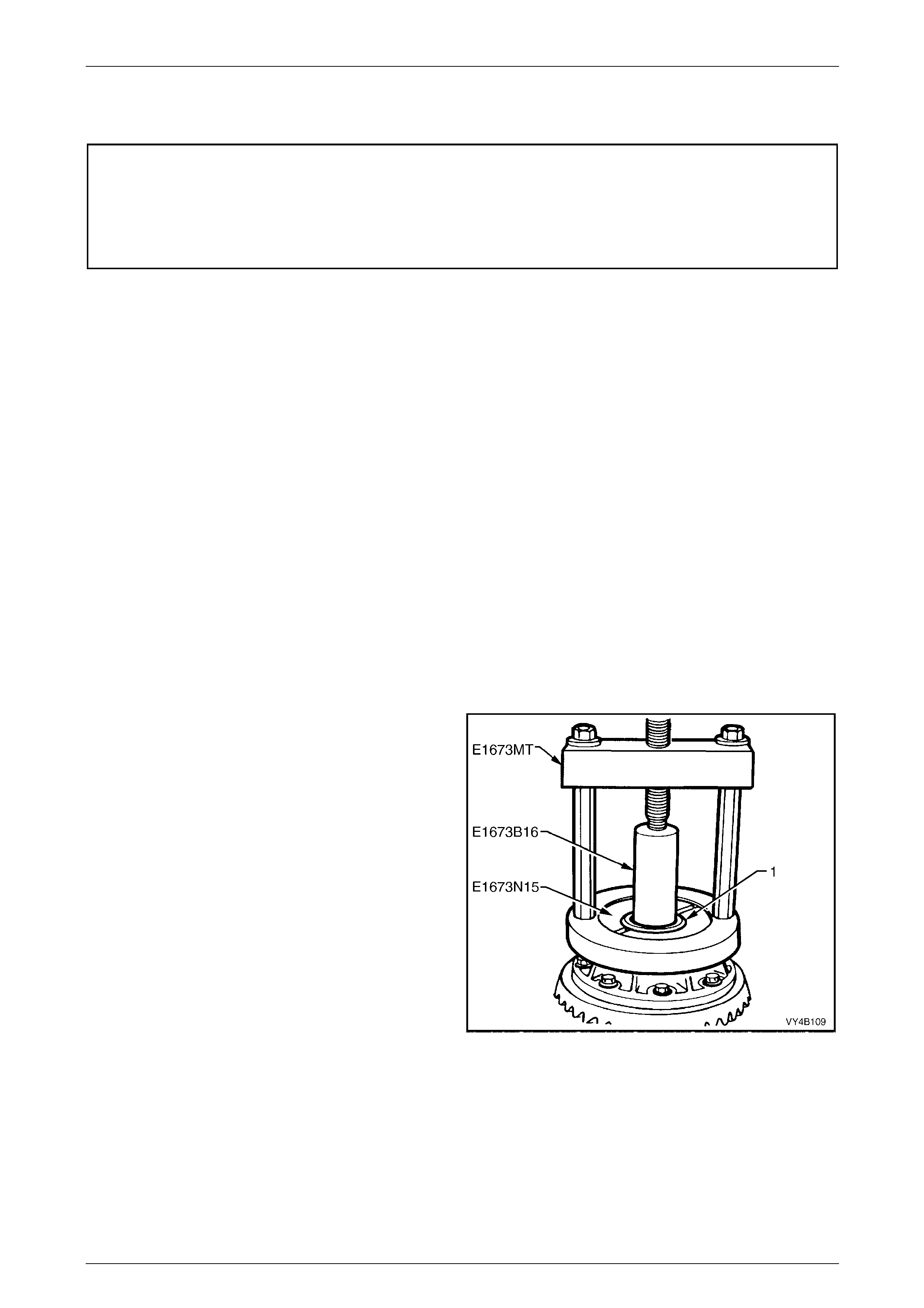

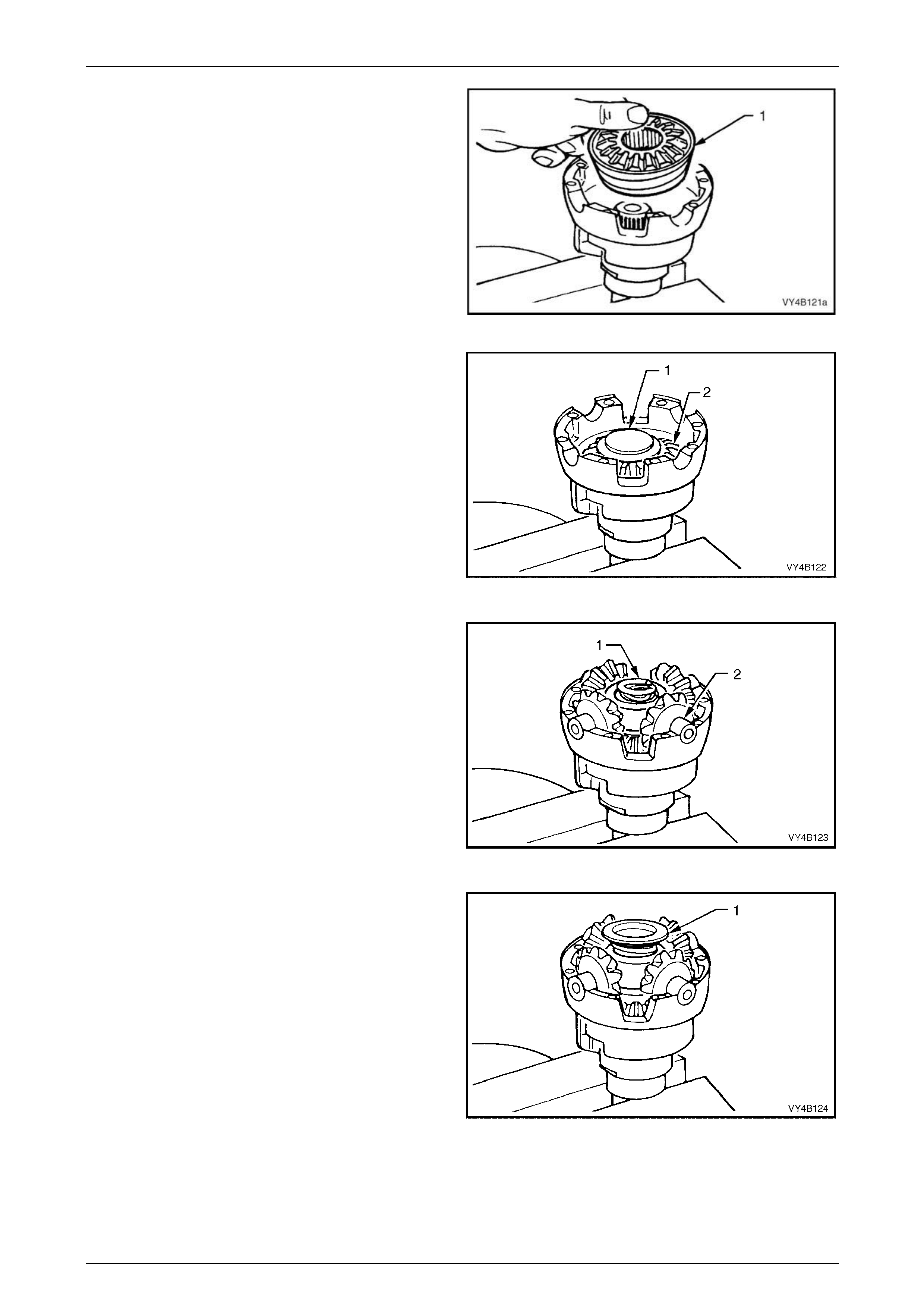

1 Place the inner race (1) into the cage (2) and position

centrally.

Figure 4B1 – 29

Rear Final Drive and Drive Shafts Page 4B1-23

Page 4B1-23

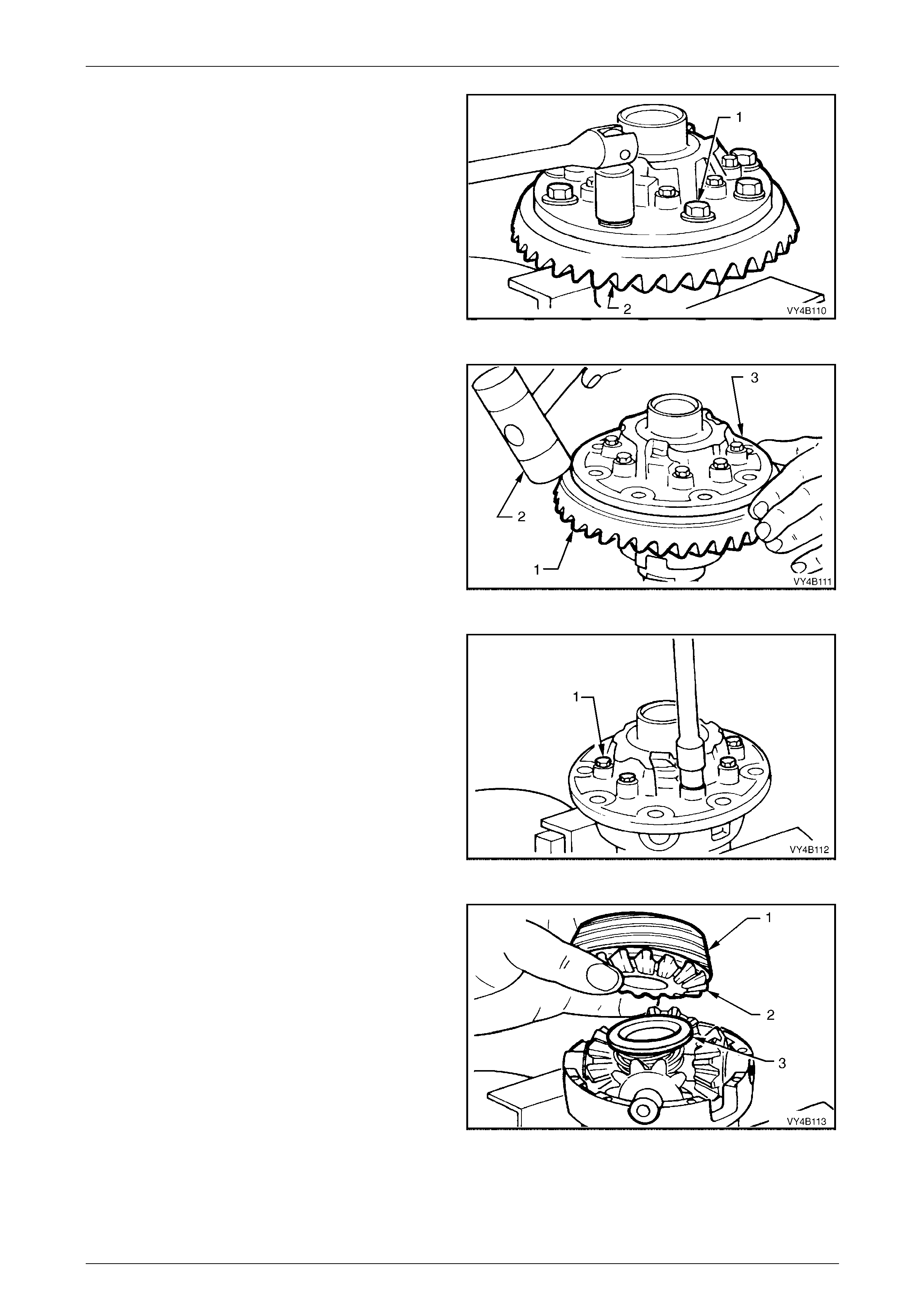

2 Place the inner race and cage assembly (2) into the

outer race (1). Make sure that the identification groove

(1) and step (2) are on opposite sides of the assembly,

as shown.

Figure 4B1 – 30

3 Align the thick sections (A) on the outer race (1) , with

the narrow ones (B) on the inner race (2), aligning the

three marks made before disassembly.

Figure 4B1 – 31

4 Tilt the cage and inner race, as shown and fit one ball

(1).

Repeat this process for the remaining five balls.

Figure 4B1 – 32

Rear Final Drive and Drive Shafts Page 4B1-24

Page 4B1-24

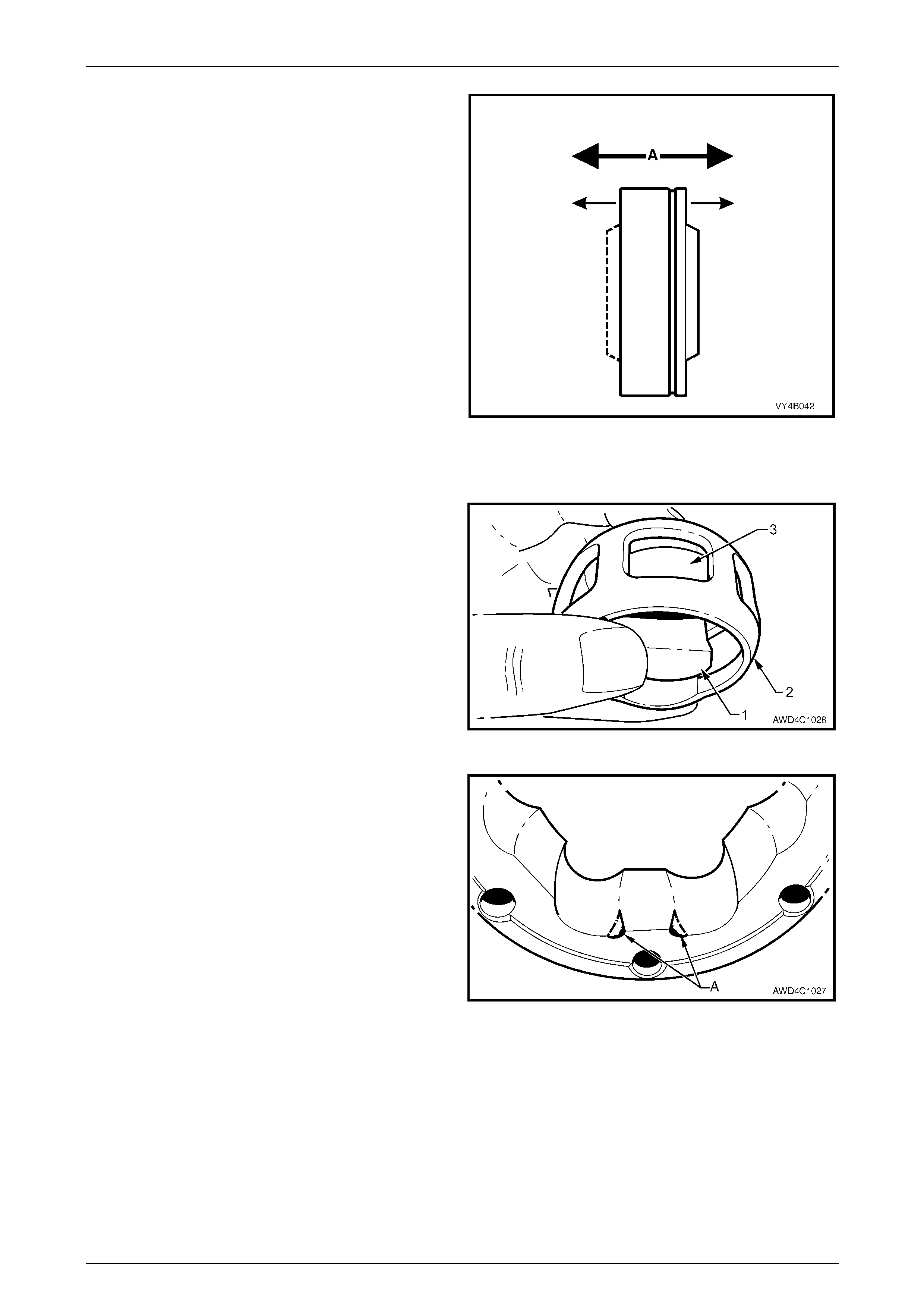

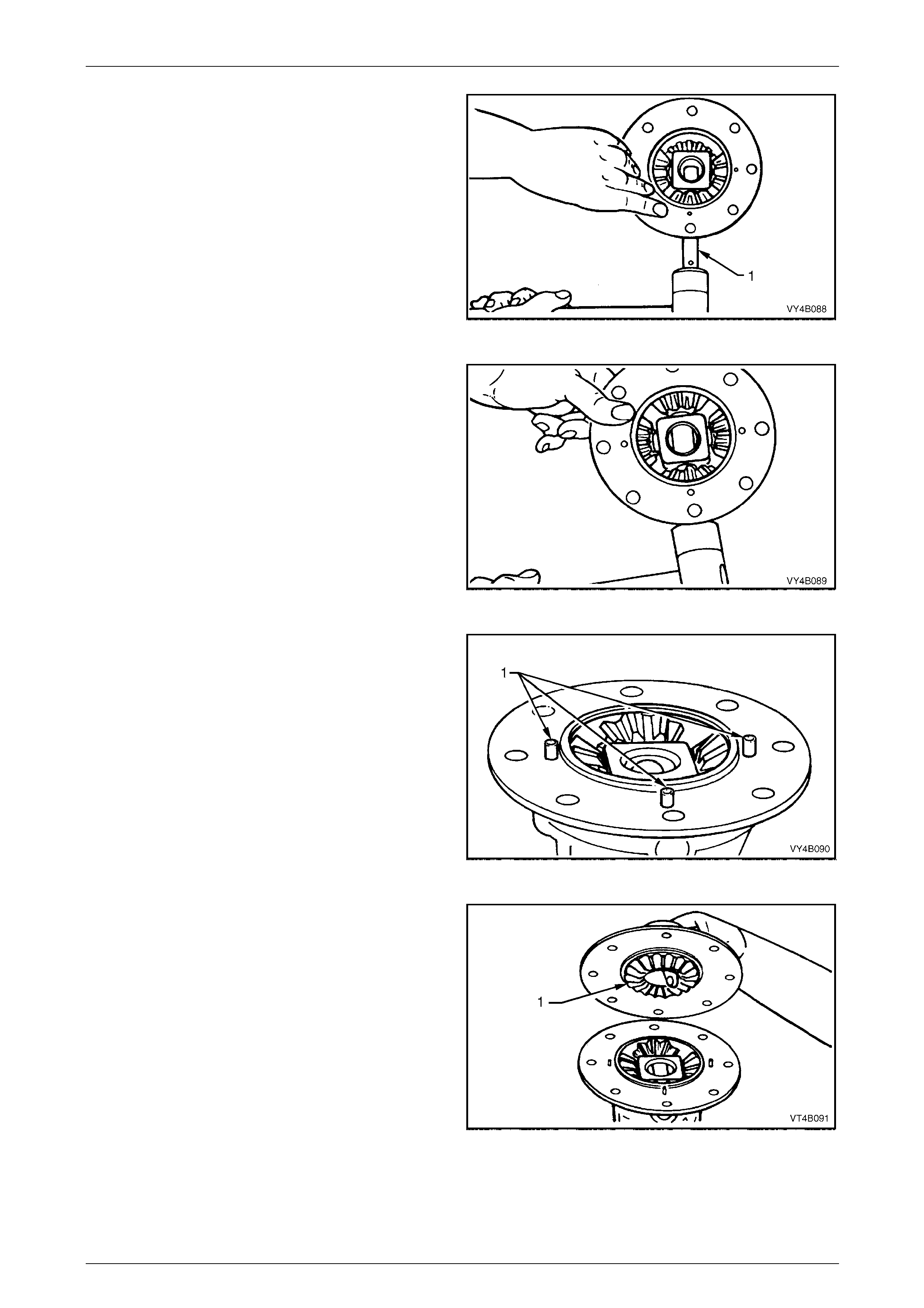

5 When assembly of the constant velocity joint is

complete, check for plunge movement of the inner

members, as indicated by ‘A’. If NO plunge movement

can be achieved, then the constant velocity joint has

NOT been correctly assembled.

If such a situation occurs, the constant velocity joint

must be disassembled and the assemb ly process

repeated until such time that the required plunge

movement is achieved.

Figure 4B1 – 33

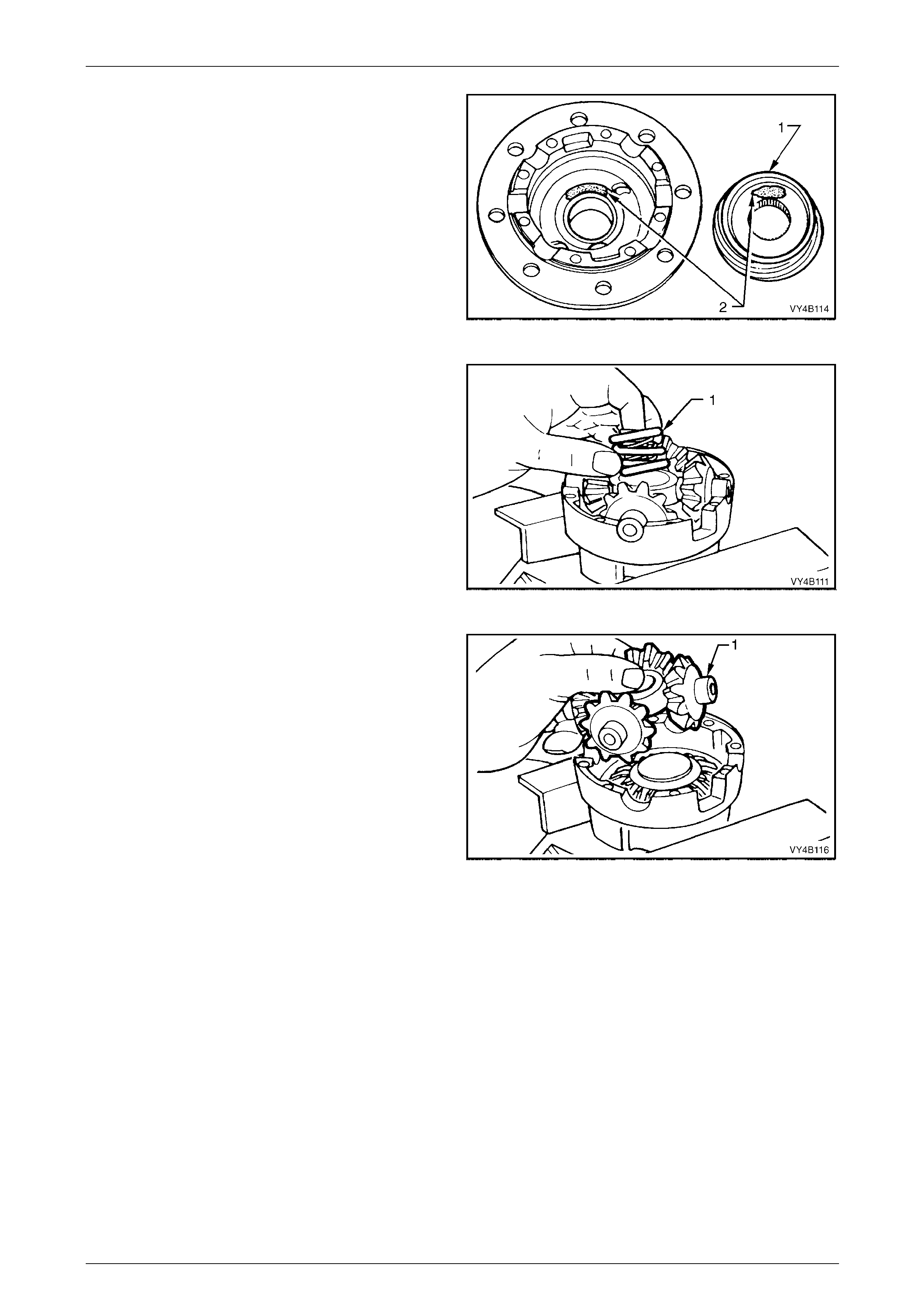

Fixed Type

1 With the inner race (1) at 90° to the ball cage (2),

insert one 'leg' (3) of the inner race into one of the ball

holes, then manipulate the inner race unti l installed

inside the ball cage. Check that the relatio nship marks

are both on the same side.

NOTE

The fine groove on the inner edge of the ball

cage and the chamfered spline edge, should

both be opposite the relationship marks.

Figure 4B1 – 34

2 Reinstall the ball cage and in ner race into the outer

race, following this next procedure:

a Locate the two reliefs in the ball grooves in the

outer race, indicated by 'A'. There will be similar

reliefs on the opposite side.

Figure 4B1 – 35

Rear Final Drive and Drive Shafts Page 4B1-25

Page 4B1-25

b With the ball cage and inner race at 90° to the

outer race, install at the relief points (as shown),

then manipulate the ball cage to fit inside the

outer race. Ensure that the relationship marks

are all on the same side and aligned.

Figure 4B1 – 36

3 Tilt the ball cage and inner race as shown, and fit the

balls, in their correct order, one at a time.

4 Check that the three relationship marks (1) are in

alignment.

5 Check that axial movement is minimal.

Figure 4B1 – 37

Drive Shaft and Boots

1 Remove old sealing bead of silicon from dust shields, dust caps and constant velocity joints.

2 Slide a NEW small boot clamp over the drive shaft, then install both dust shield and boot assemblies onto drive

shafts, ensuring that boots are not damaged by sharp edges on each end by the shaft splines.

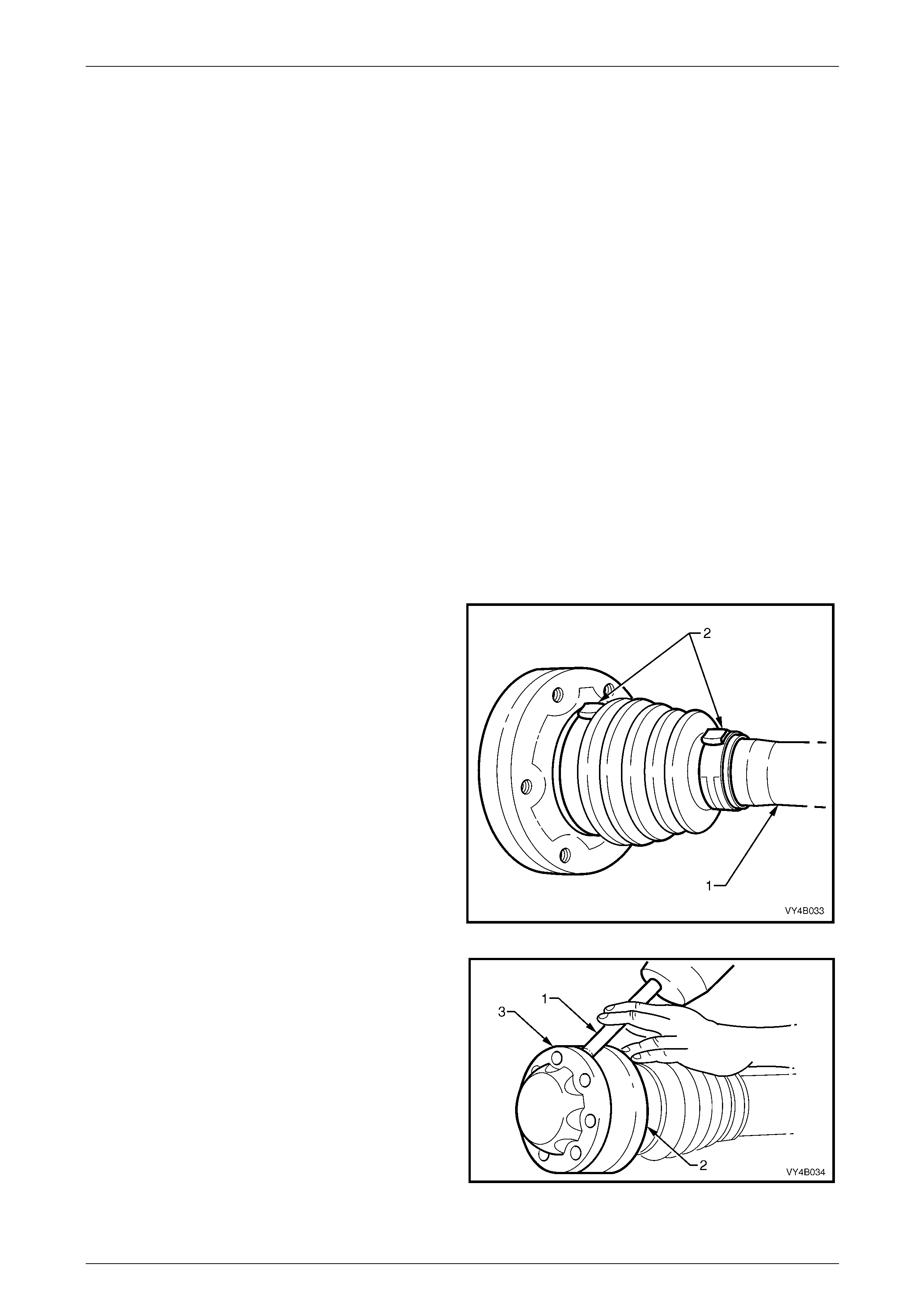

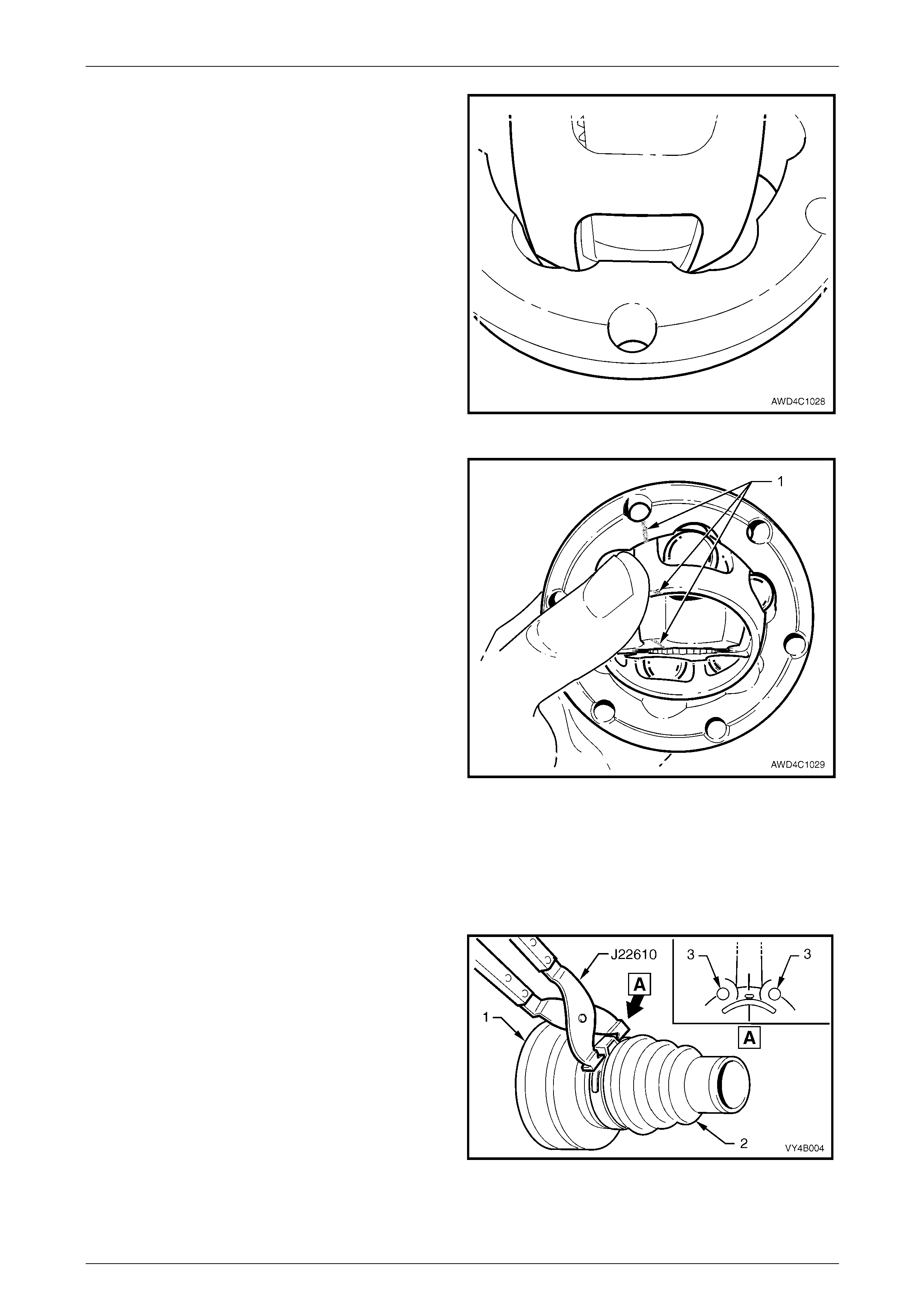

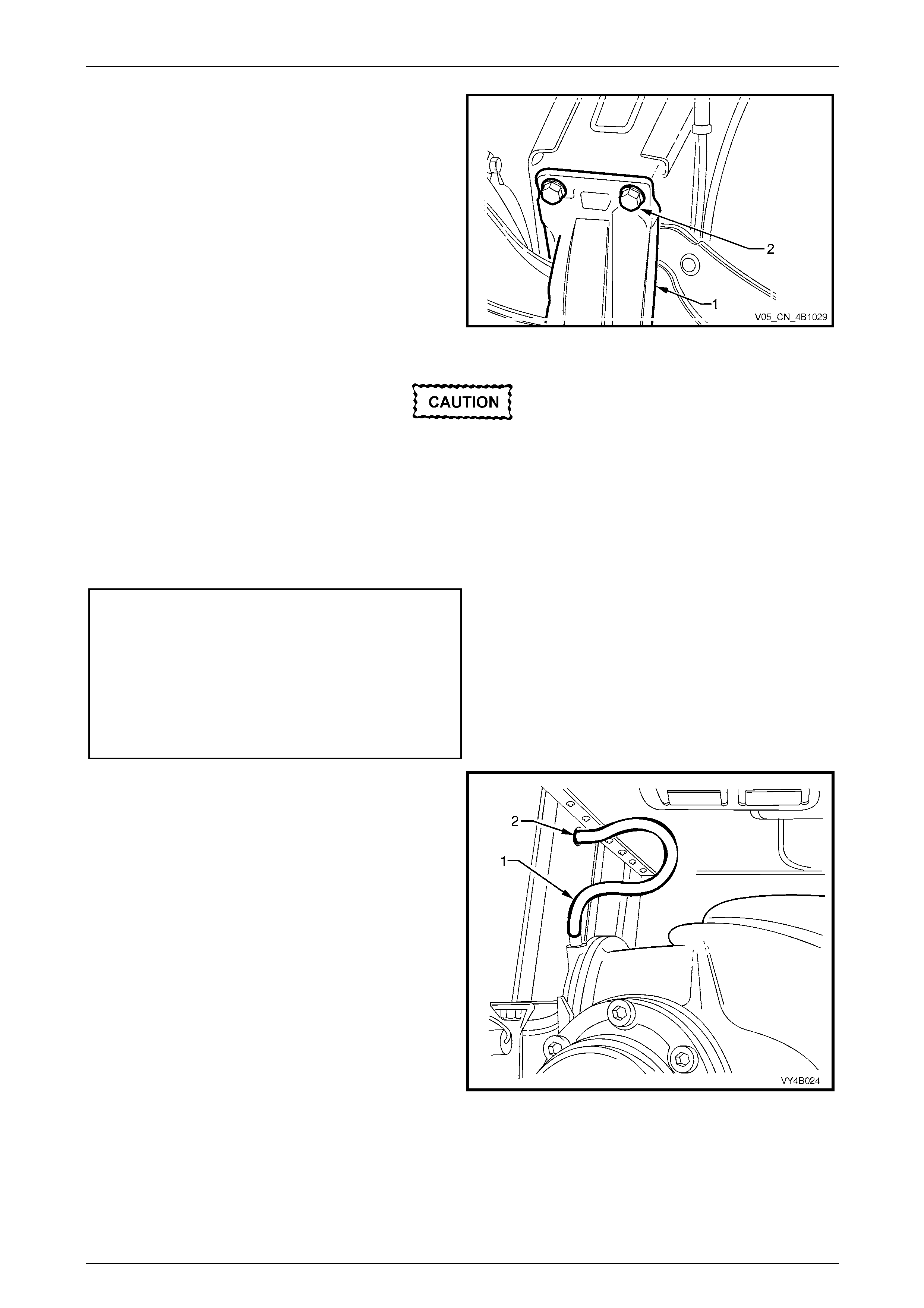

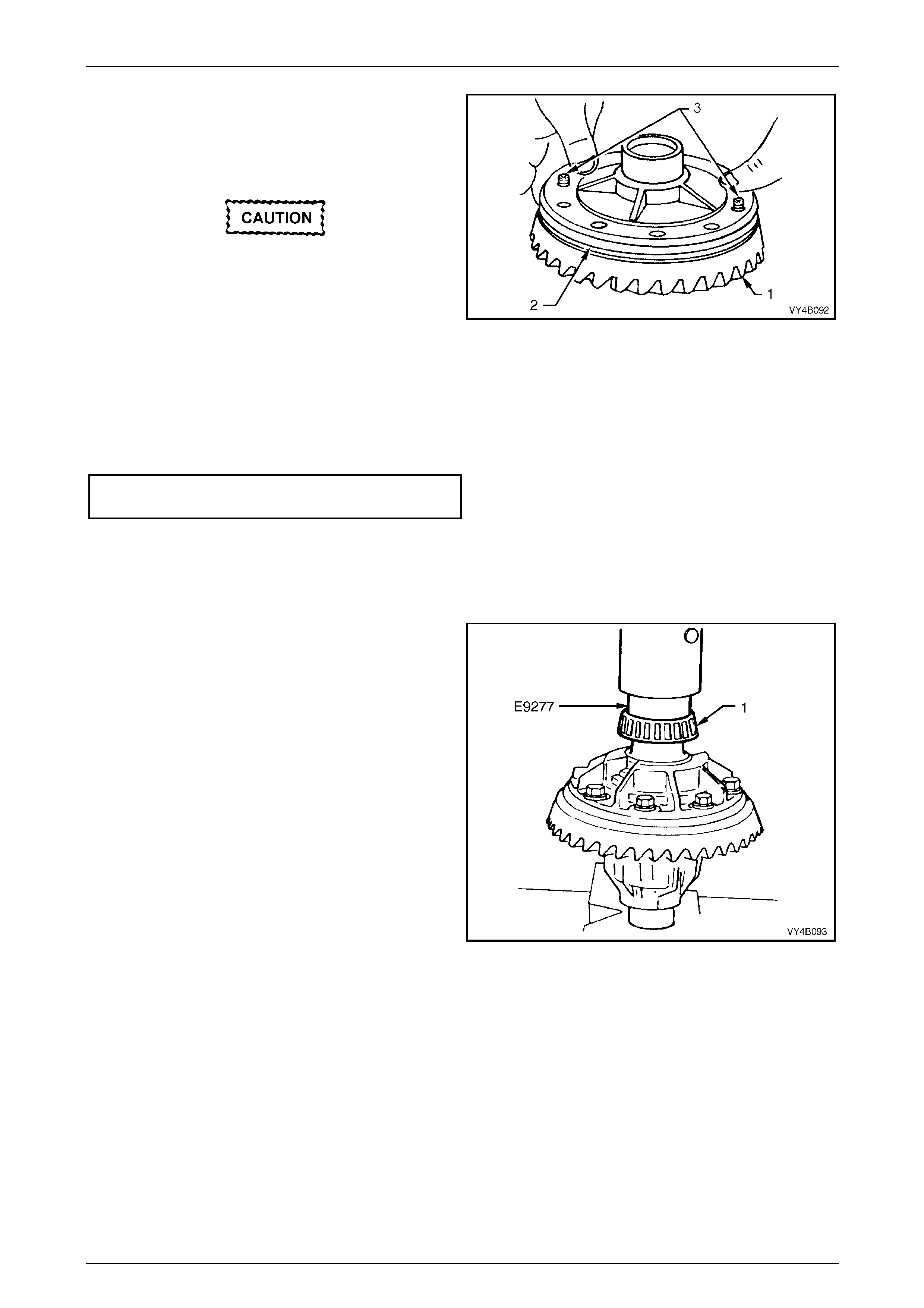

3 Position a NEW large boot clamp over boot (2) and

place boot over dust shield (1). Using Tool No.

J22610, securely crimp boot clamp, ensuring the crimp

is positioned mid-way between two bolt holes (3, in

view ‘A’).

Figure 4B1 – 38

Rear Final Drive and Drive Shafts Page 4B1-26

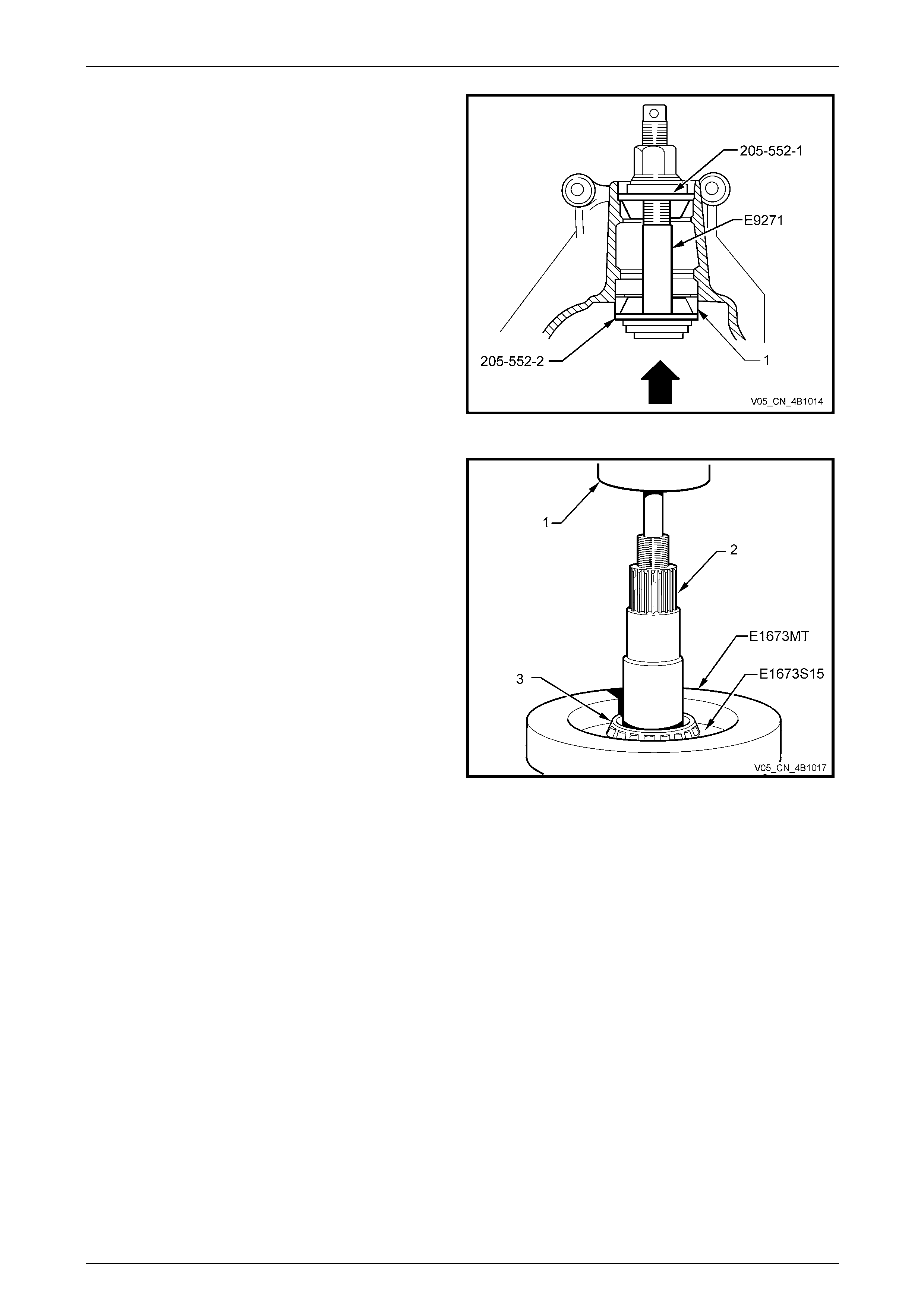

Page 4B1-26

4 Pack inside section of joint and boot with one tube of grease (40 grams) and pack half tube (20 grams) to outside

section of joint. Work the joint by hand to distribute grease onto all surfaces, inside the joint.

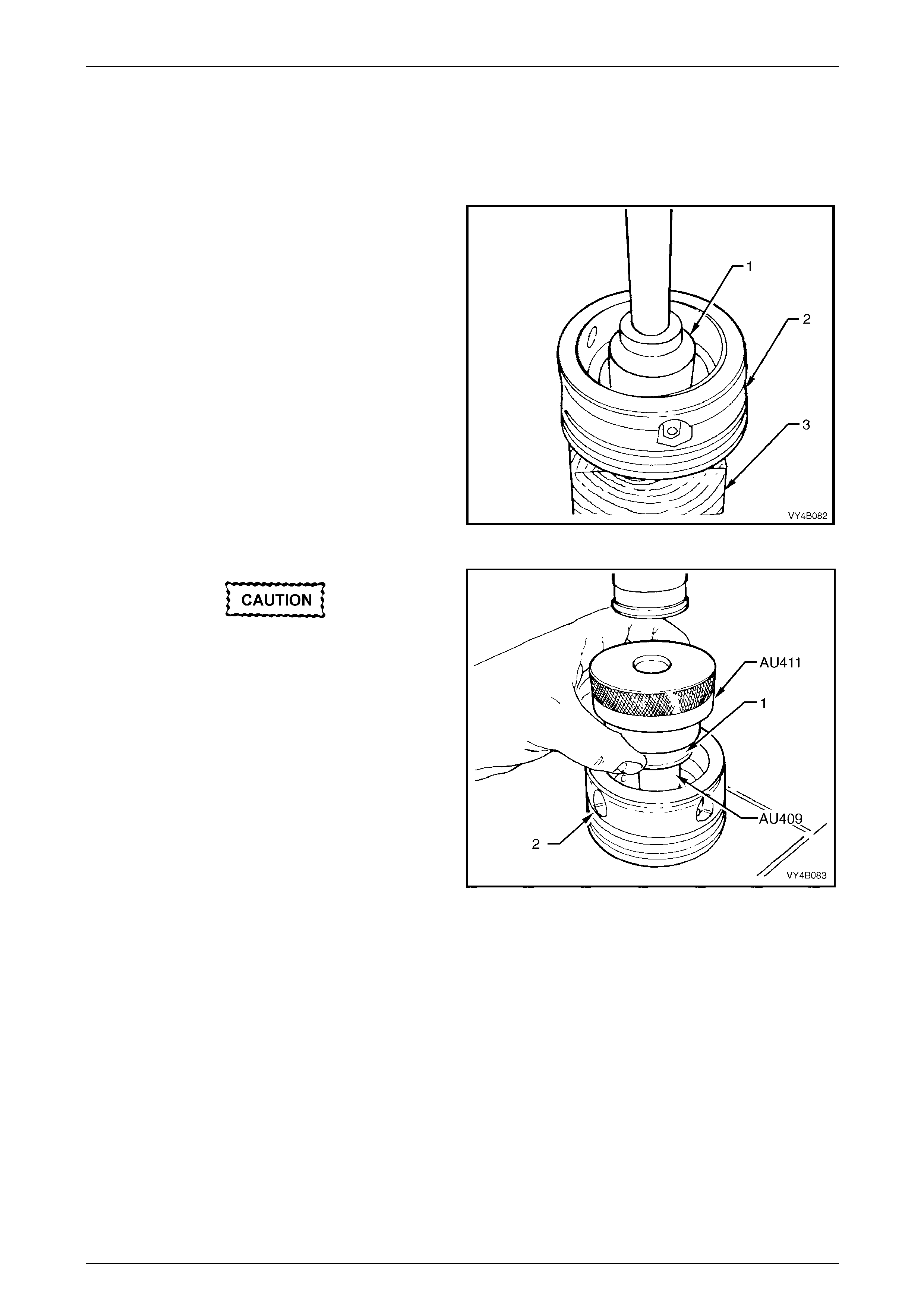

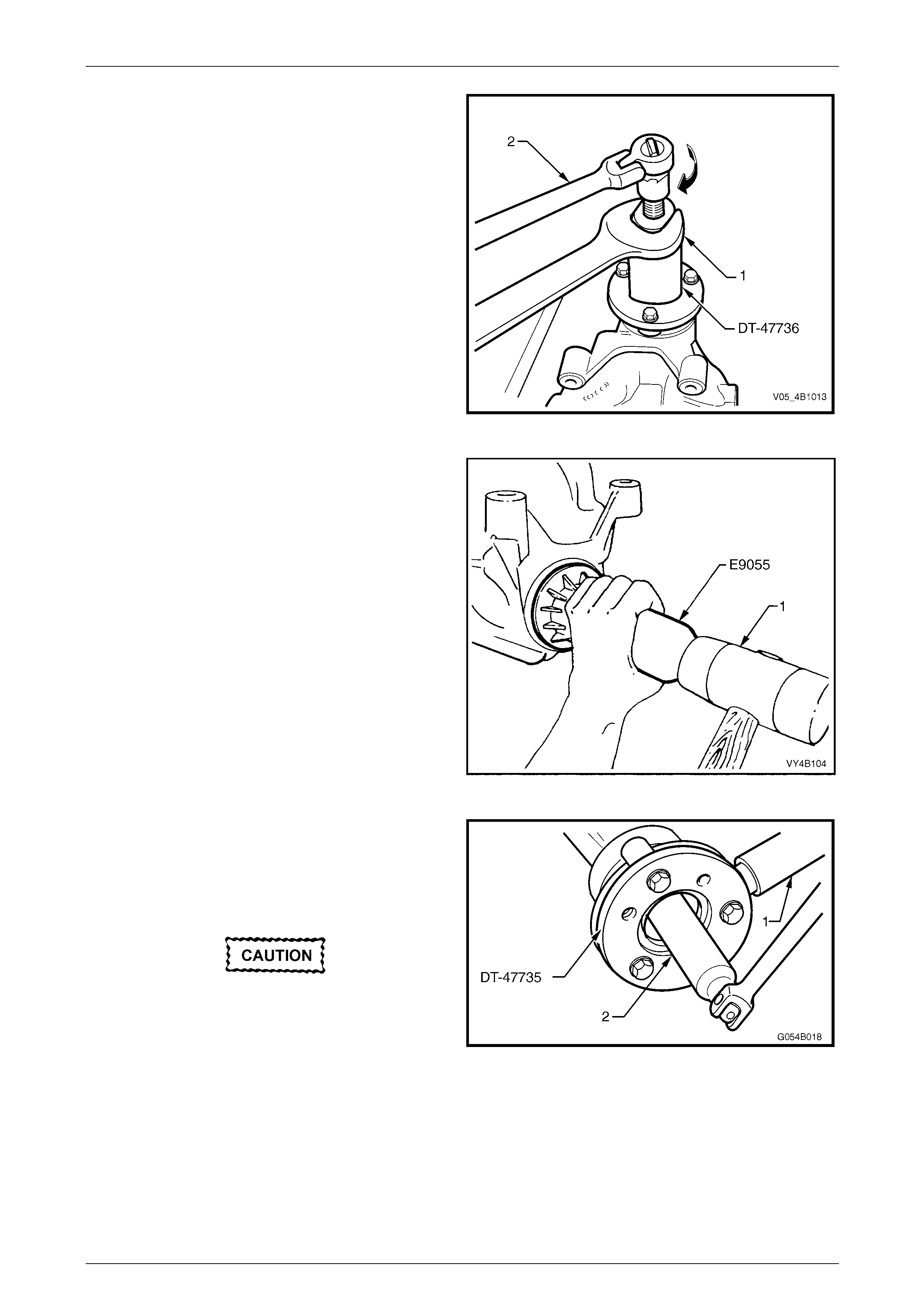

5 Using a suitable size tube (3) (or socket), press the

constant velocity joint (2) onto the drive shaft, ensuring

that the press load is taken by the inner race (1).

NOTE

While the plunge type constant velocity joint Is

shown, the procedure for either t ype is similar.

6 Install a NEW circlip to secure the constant velocity

joint, at each end.

Figure 4B1 – 39

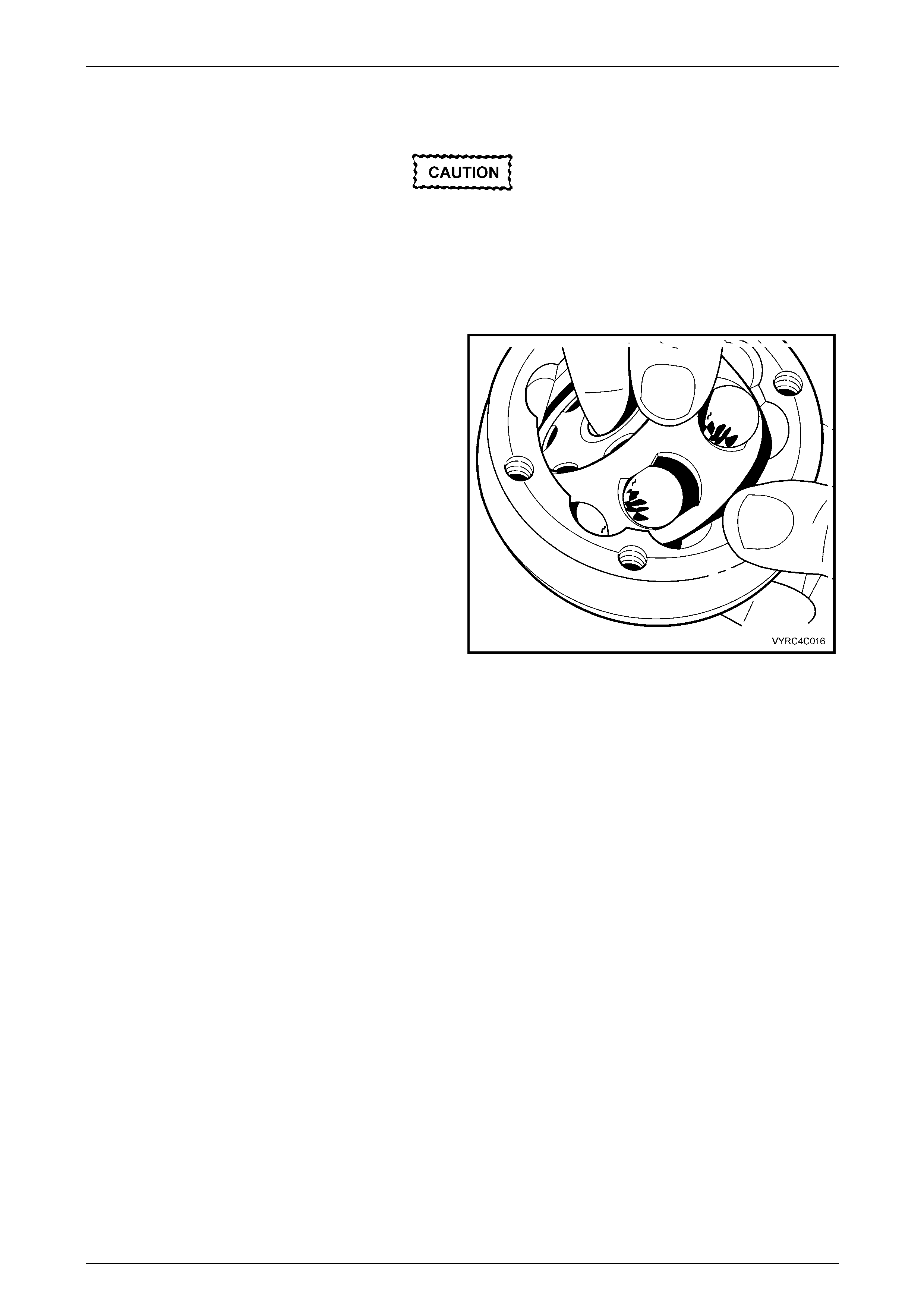

7 Apply a 2 mm bead (1) of Loc tite 510 High

Temperature Gasket Eliminator sealant or equivalent,

to dust caps/shields. Take care not to contaminate the

constant velocity joint grease with sealant.

Figure 4B1 – 40

8 Position dust caps and dust shields ont o constant

velocity joints, ensuring that all bolt holes align.

NOTE

Temporarily install three of the retaining bolts to

assist with the alignment.

9 Using a suitable punch and hammer, tap caps and

shields into place.

Figure 4B1 – 41

Rear Final Drive and Drive Shafts Page 4B1-27

Page 4B1-27

10 Locate small ends of boots into boot grooves on drive

shafts, ensuring that boots are not twisted.

With each joint, pr y up the small e nds of boots from

the shaft (1) to equalise air pressure inside and

outside of boots and work out any dim ples before

crimping the small clamp/s.

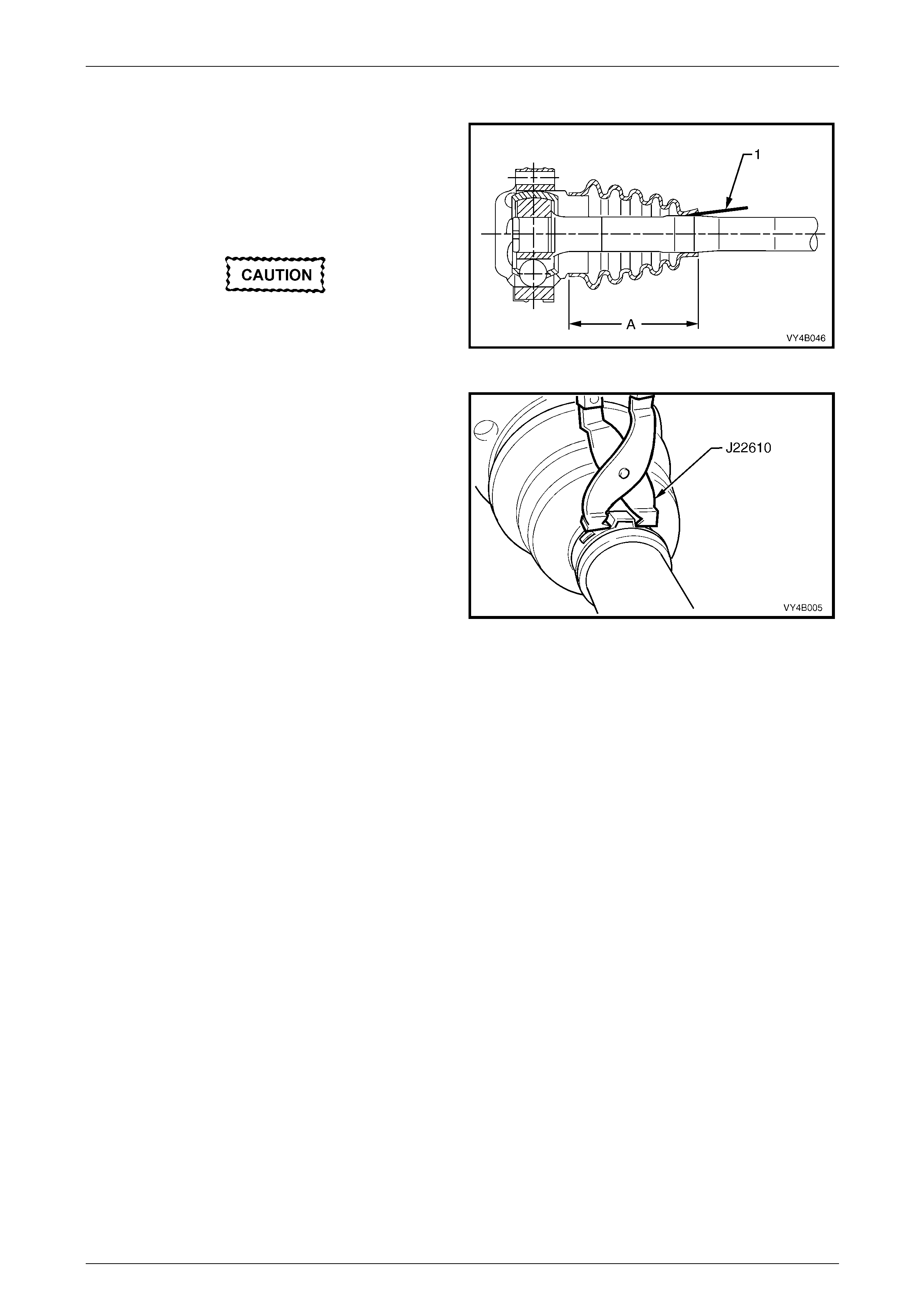

The location distance ’A’, only applies to the

plunge type constant velocity joint and

should be set at 81 mm before tightening the

small clamp. Figure 4B1 – 42

11 Position small clamps over ends of boots an d using

Tool No. J22610, crimp ends of clamps unti l a gap

between the clamp 'ears' of 1 to 2 mm is achieved.

12 Reinstall drive shaft, refer to

2.6 Drive Shaft Assembly – Reinstall in this Section.

Figure 4B1 – 43

Rear Final Drive and Drive Shafts Page 4B1-28

Page 4B1-28

2.8 Inner Axle Shaft Seal

Replace

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove drive shaft from side of vehicle which seal is to be replaced, refer to 2.6 Drive Shaft Assembly – Remove

in this Section.

• During drive shaft removal, keep drive

shaft supported so that it does not hang

on one end.

• Drive shaft joint deflection should be kept

to a minimum.

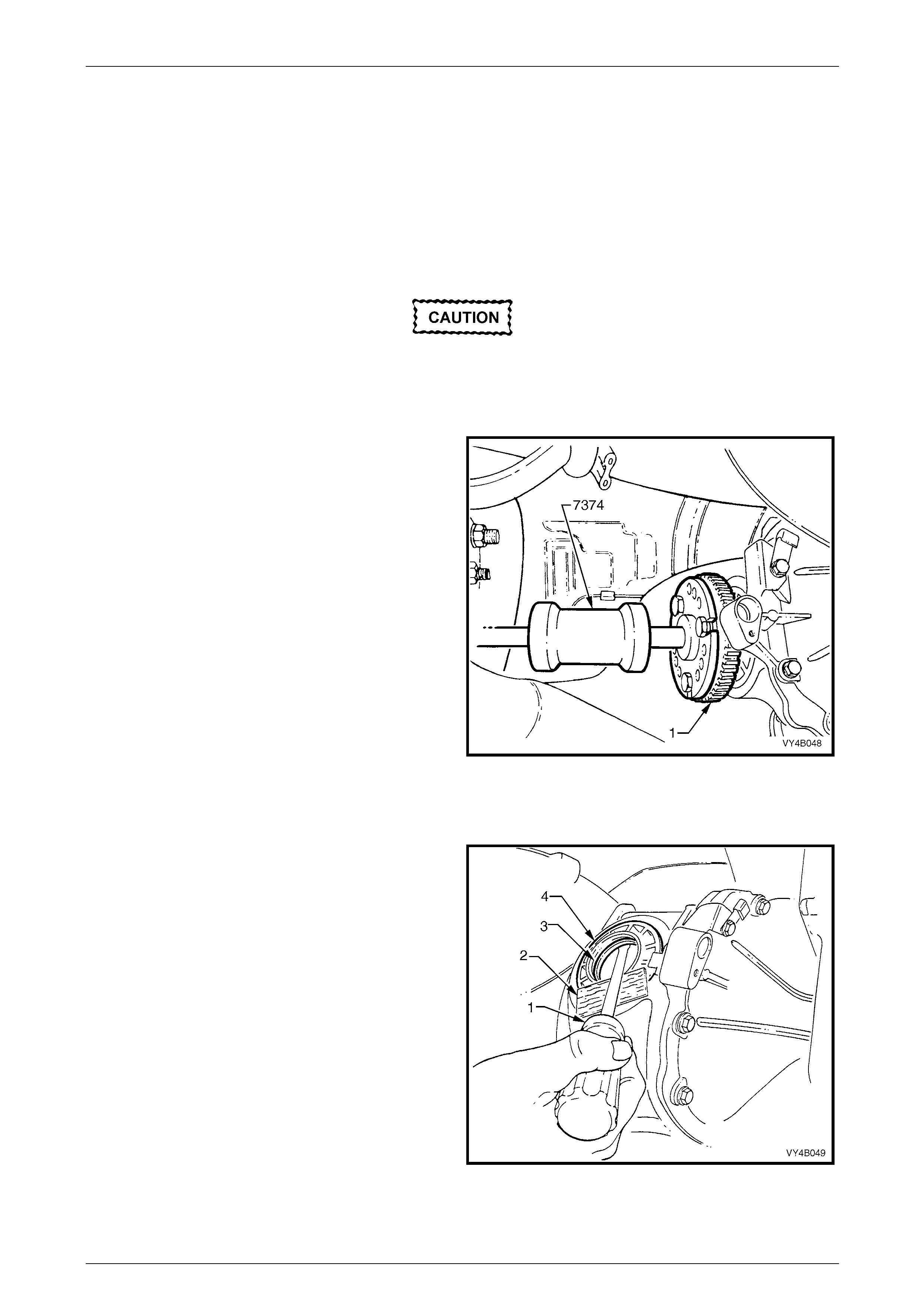

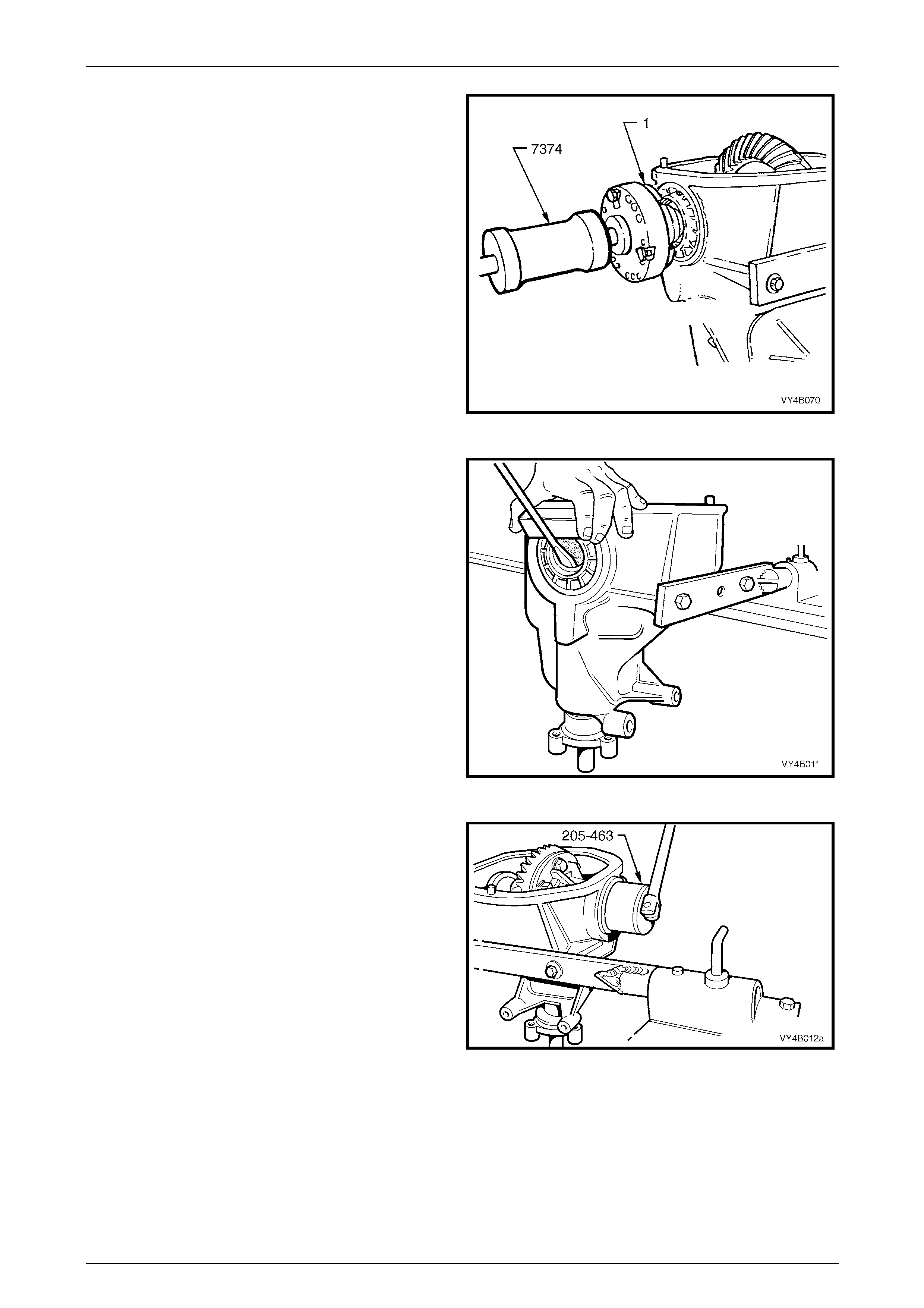

3 Remove inner axle shaft (1) by installing slide

hammer, Tool No. 7374 with three suitabl e size bolts

to axle flange. Use slide hammer to release axle shaft

spring clip.

NOTE

When the axle shaft is removed, a smal l amount

of lubricant may leak from differential carrier.

Figure 4B1 – 44

4 Clean around seal bore and housi ng area to make sure that no foreign matter enters axle shaft needle bearing in

the screw adjuster.

5 Using a suitable scre wdriver (1) and a block of wood

(2), lever seal (3) from screw adjuster bore (4).

NOTE

Take care not to damage the screw adjuster's

aluminium housing (4) with the scre wdriver blad e

(1), as this could cause oil leaks to occur, after a

new oil seal was fitted.

Figure 4B1 – 45

Rear Final Drive and Drive Shafts Page 4B1-29

Page 4B1-29

6 Before installation of a new seal, examine seal surface of inner axle shaft and remove any nicks or burrs. Should

this inspection show that the surface is marked, a new inner axle shaft should b e fitted.

NOTE

• The left hand inner axle shaft is shorter in

length than the right hand shaft.

• Check that the spring clip in end of axle shaft

is not damaged and moves freely in groove.

Replace spring clip if necessary, by

expanding ends of clip and removing from

shaft. Only expand the ends of a new clip

enough to allow installation into shaft groove.

7 Examine seal bore in screw adjuster and remove any nicks or burrs.

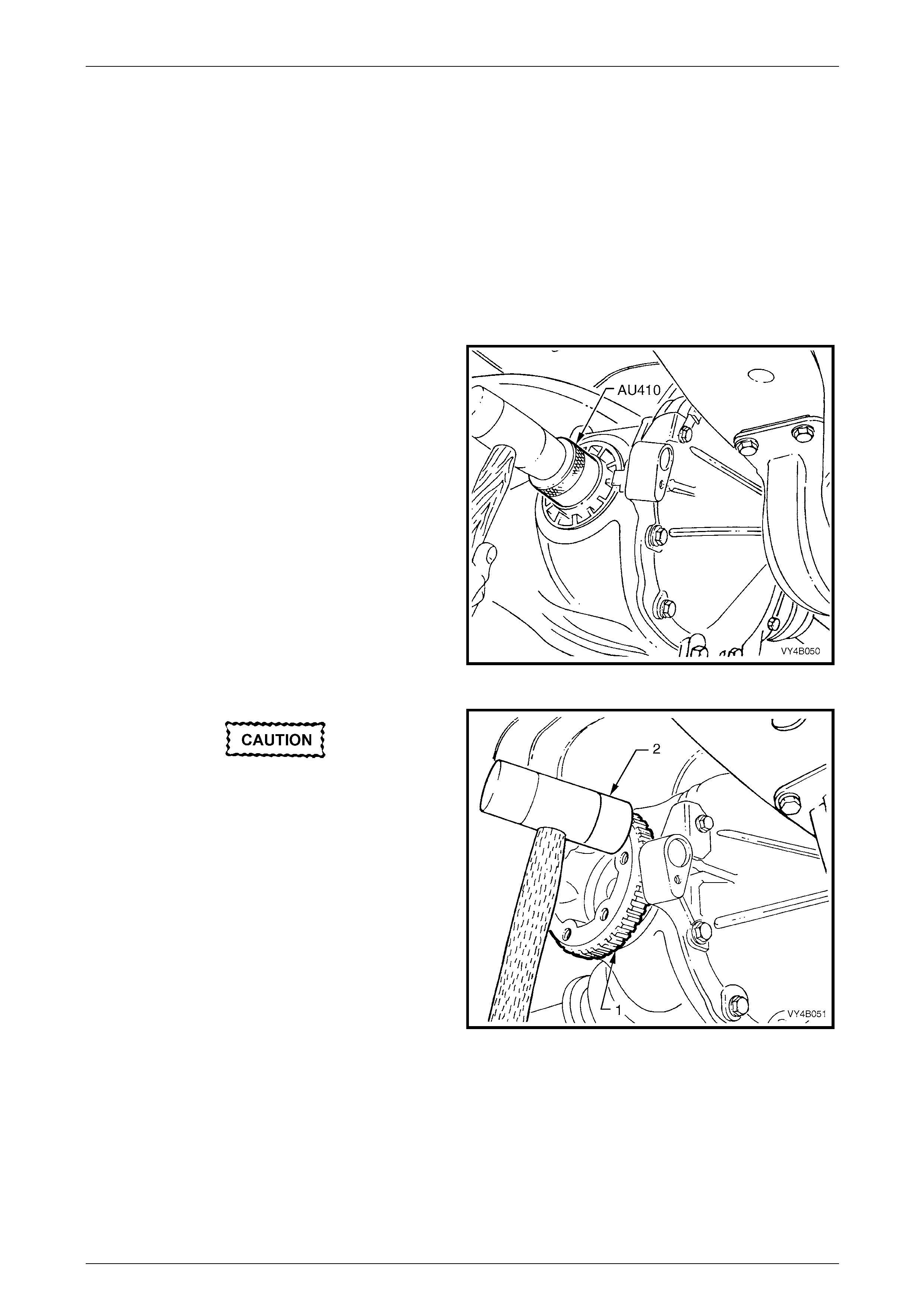

8 Lubricate seal lips and outsi de diameter with

Mobilgrease XHP 222 grease (or equivalent). Install

seal using Tool No. AU410, u ntil seal bottoms in bore.

Figure 4B1 – 46

Take care when installing the inner axle shaft

that the securing spring clip or the shaft

splines do not damage the seal lips.

9 Reinstall inner axle sh aft (1), aligni ng splines with

clutch cone (if fitted with a Limited Slip Differential)

and side gear.

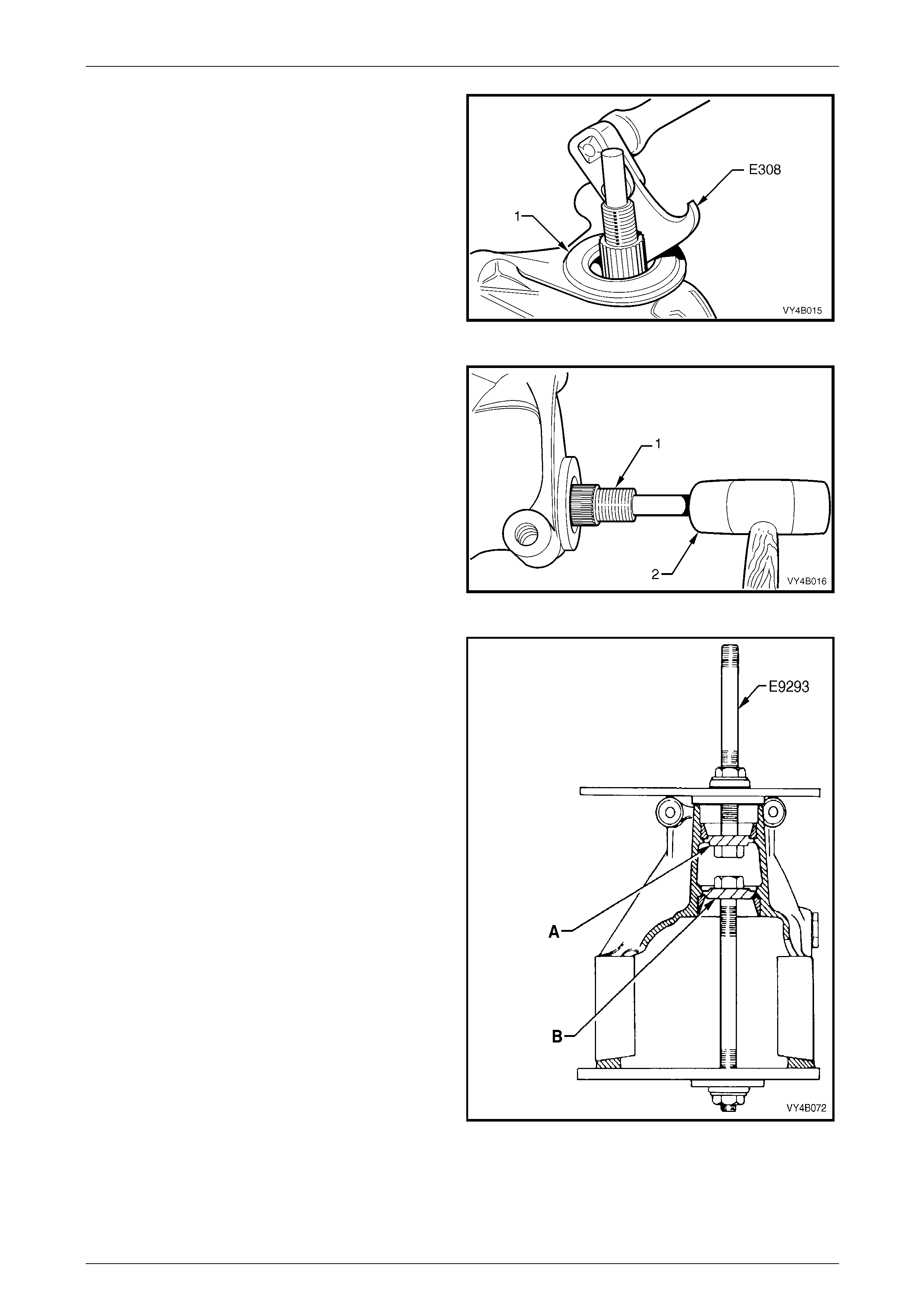

10 Lightly hit on end of axle shaft flange (1) with a soft

faced hammer (2) to compress spring clip on shaft into

clutch cone and side gear splines. F ully engage shaft

(1) until clip snaps into side gear groove.

11 Reinstall drive shaft, refer to 2.6 Drive Shaft Assembly,

in this Section.

Figure 4B1 – 47

12 Remove safety stands and lower vehicle.

13 Check and fill differential carrier to correct le vel with specified lubricant.

Refer to 2.2 Checking Differential Carrier Lubricant Level, in this Section.

Rear Final Drive and Drive Shafts Page 4B1-30

Page 4B1-30

2.9 Pinion Oil Seal

ATTENTION

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

Pinion flange retaining nut threads.

Replace

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Mark the position of the propeller shaft rear coupling to pinion flange, using a felt tipped pen or similar.

3 Remove propeller shaft, refer to Section 4C1 Propeller Shaft and Universal Joints. This operation may also require

partial exhaust system removal.

4 Lightly centre-punch ali gnment marks (A) on the pinion

flange (1), flange nut (2) and pini on end (3) as an aid

for reassembly.

NOTE

By reassembling to the original position, the

flange run-out will be minimised and the pinion

bearing preload will be maintained.

Figure 4B1 – 48

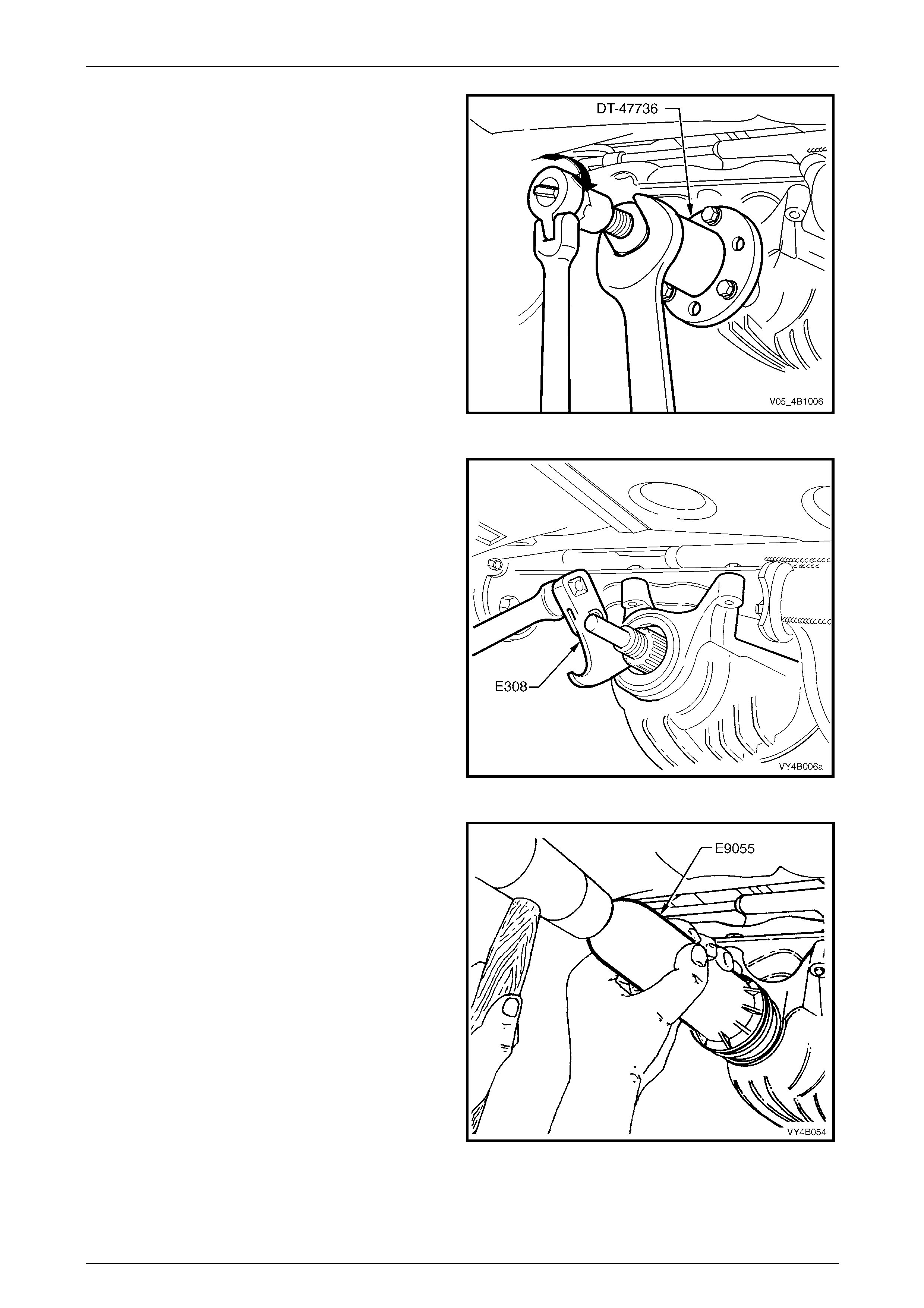

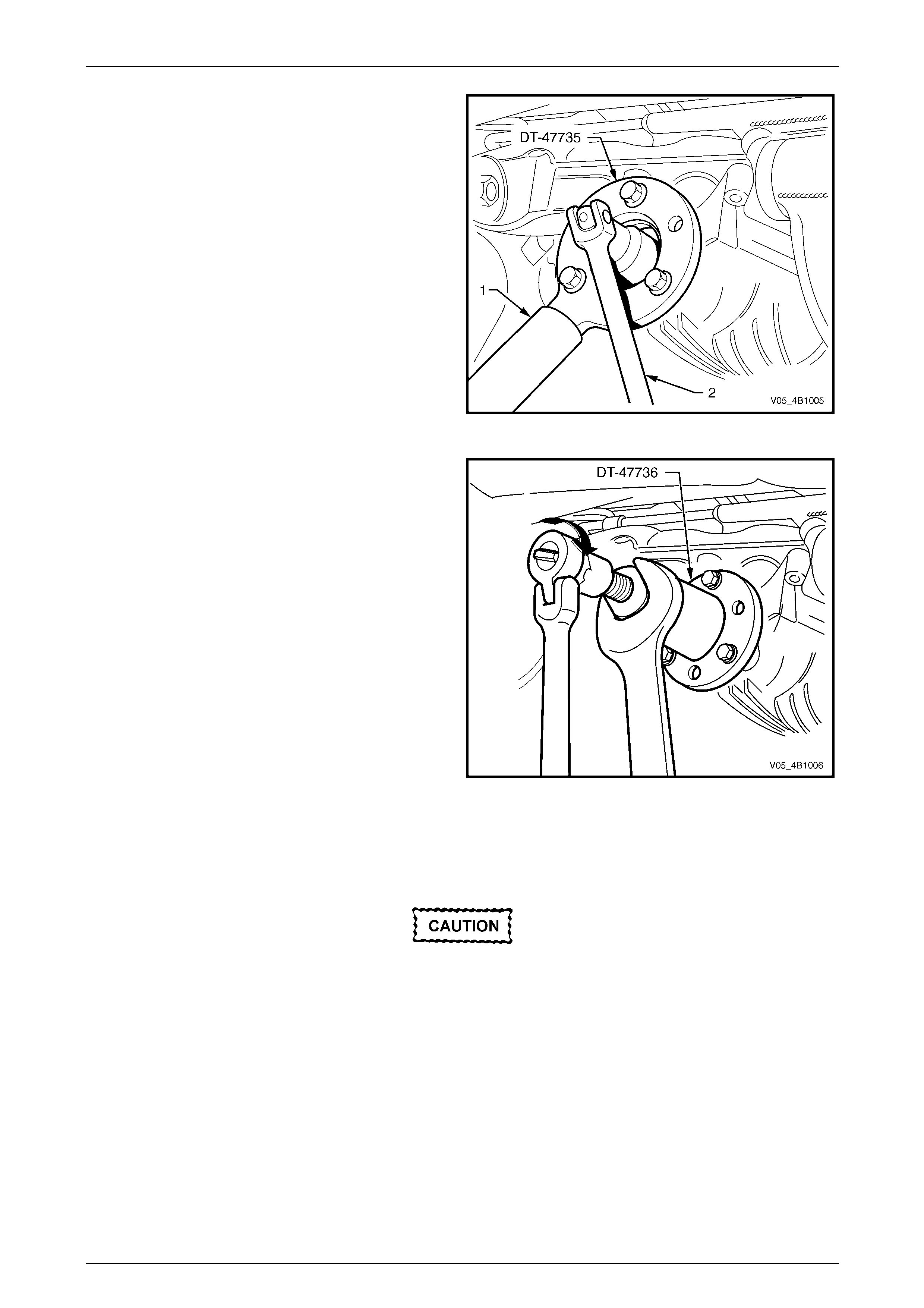

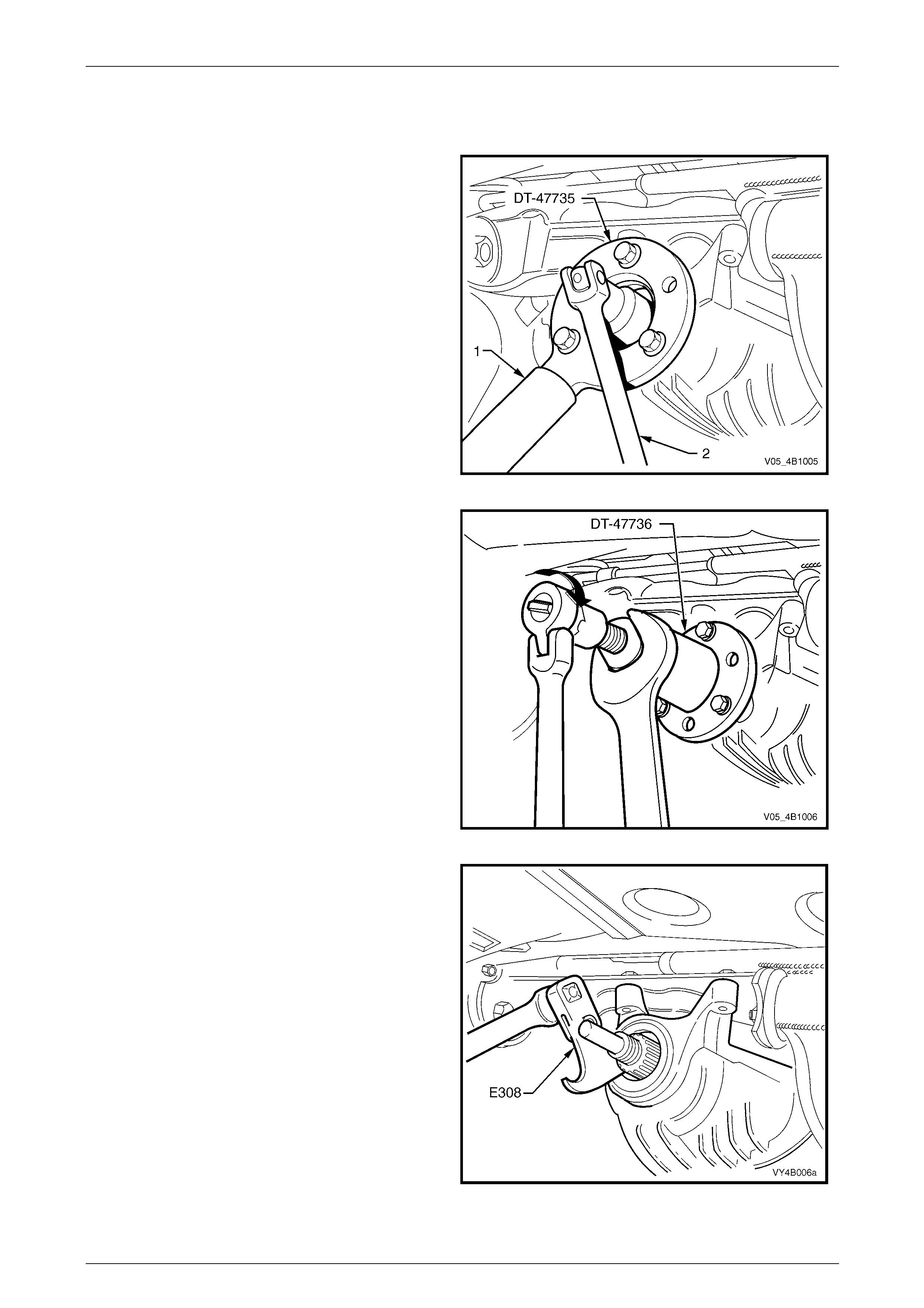

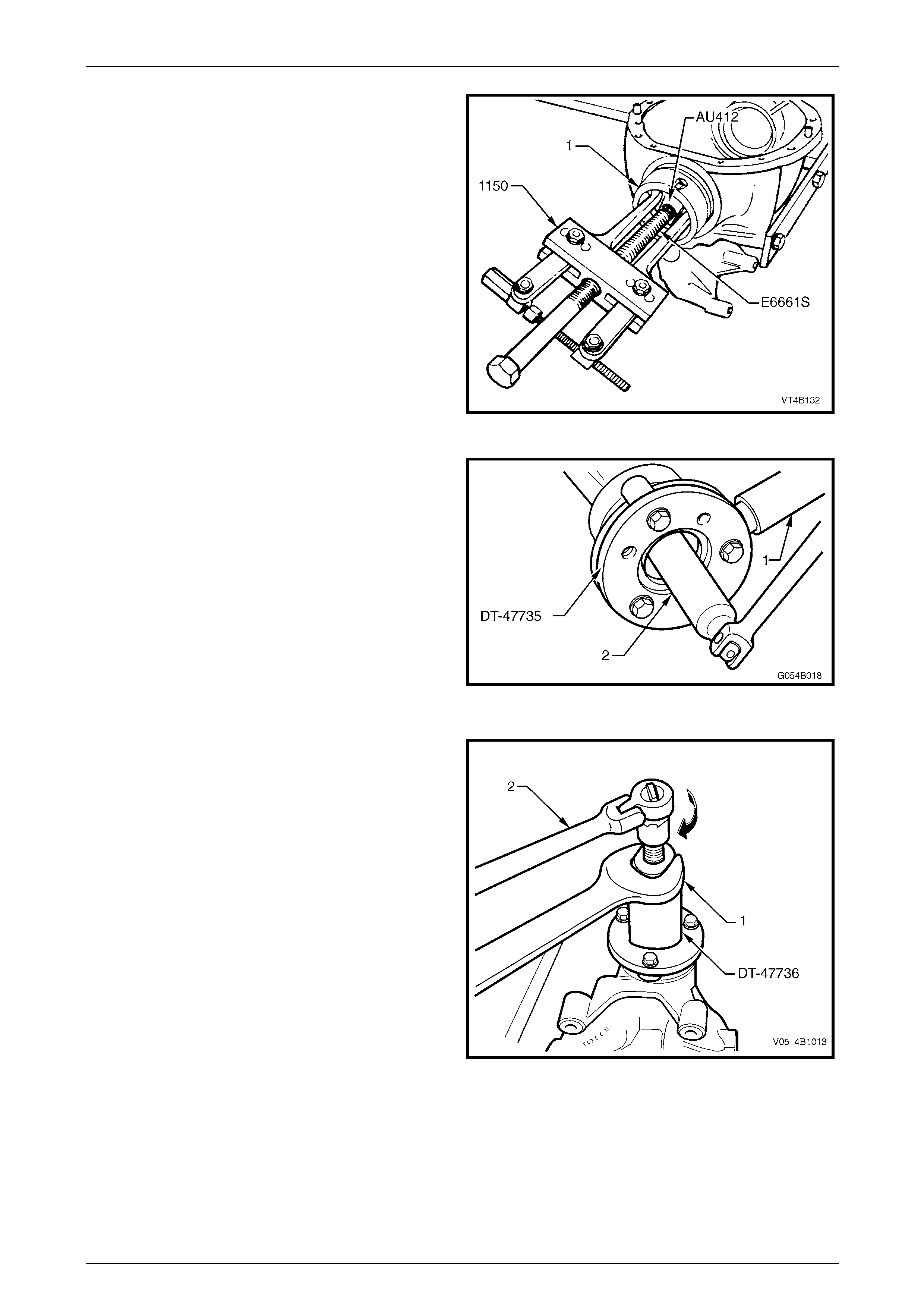

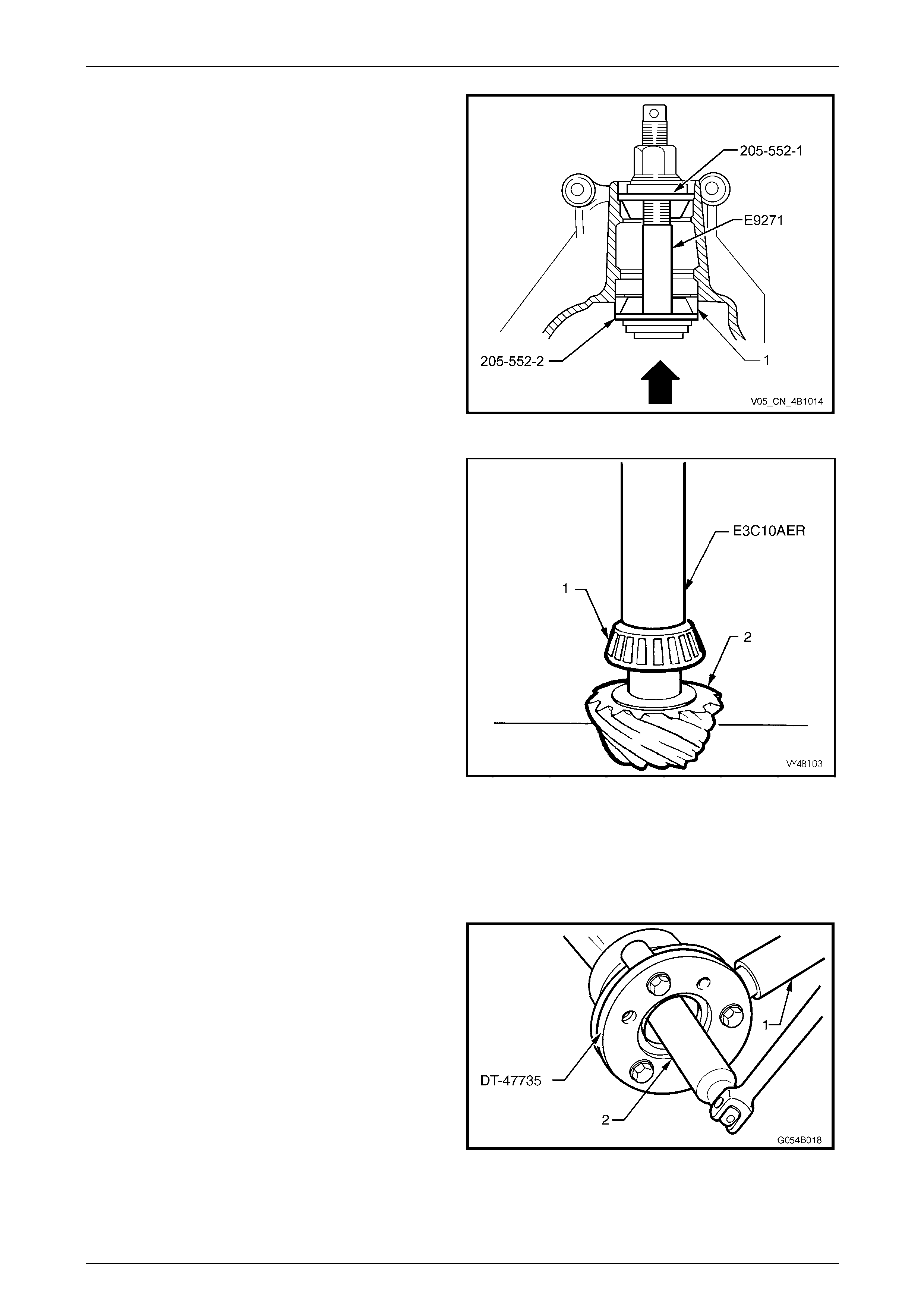

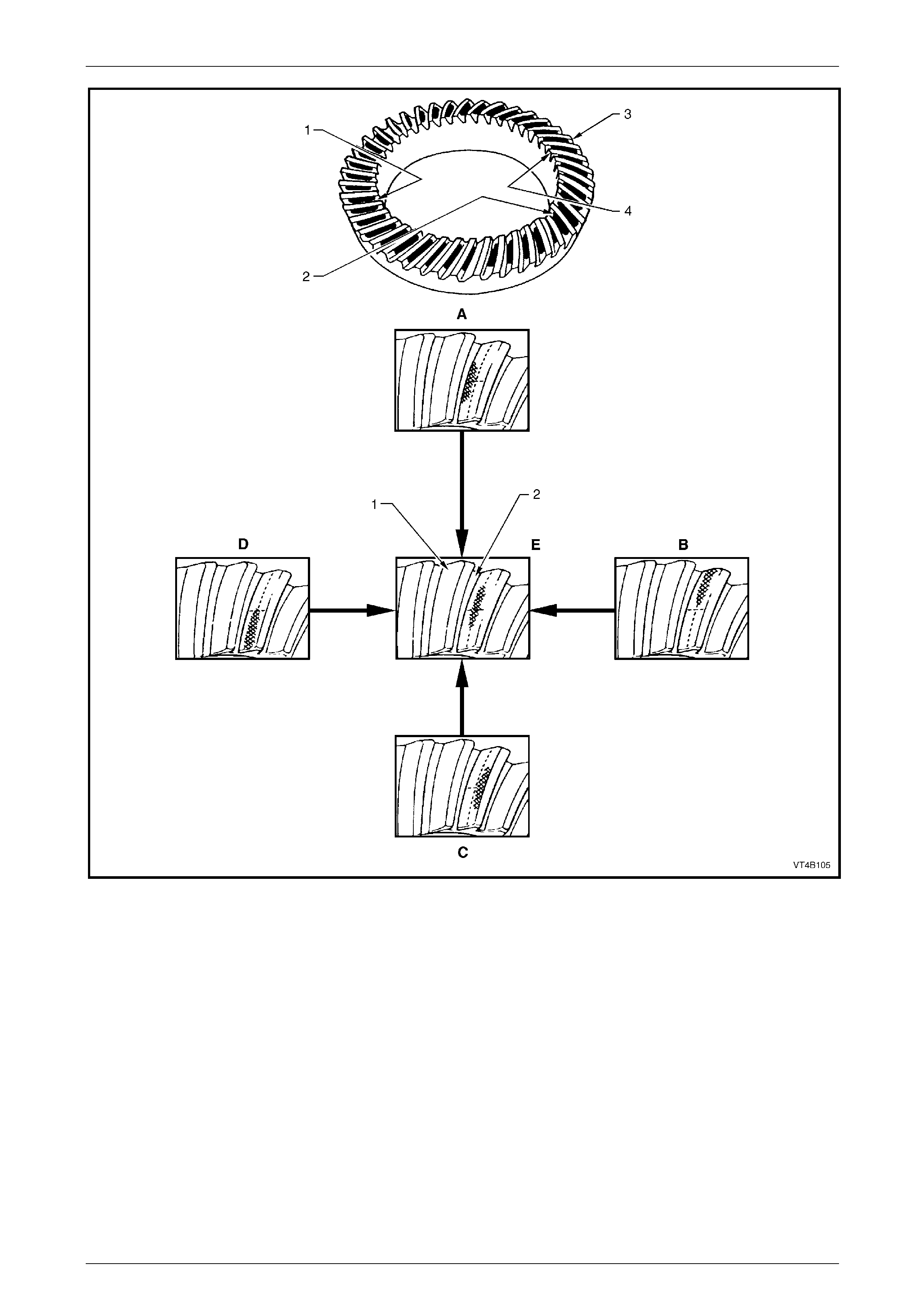

5 Attach Tool No. DT-47735 to the pinion flange, using

three suitable bolts to hold pinion flange.

NOTE

Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x

1.5 x 40, with the thread extending to within 12

mm of the head.

6 Insert a suitable length of pipe (1) over the tang of the

installed tool for leverage, then remove the pinion

flange retaining nut, using a commercia lly available,

30 mm deep socket and socket bar (2).

7 Remove Tool No. DT -47735 from the pinion flange.

Figure 4B1 – 49

Rear Final Drive and Drive Shafts Page 4B1-31

Page 4B1-31

8 Place drain tray beneath differential carrier.

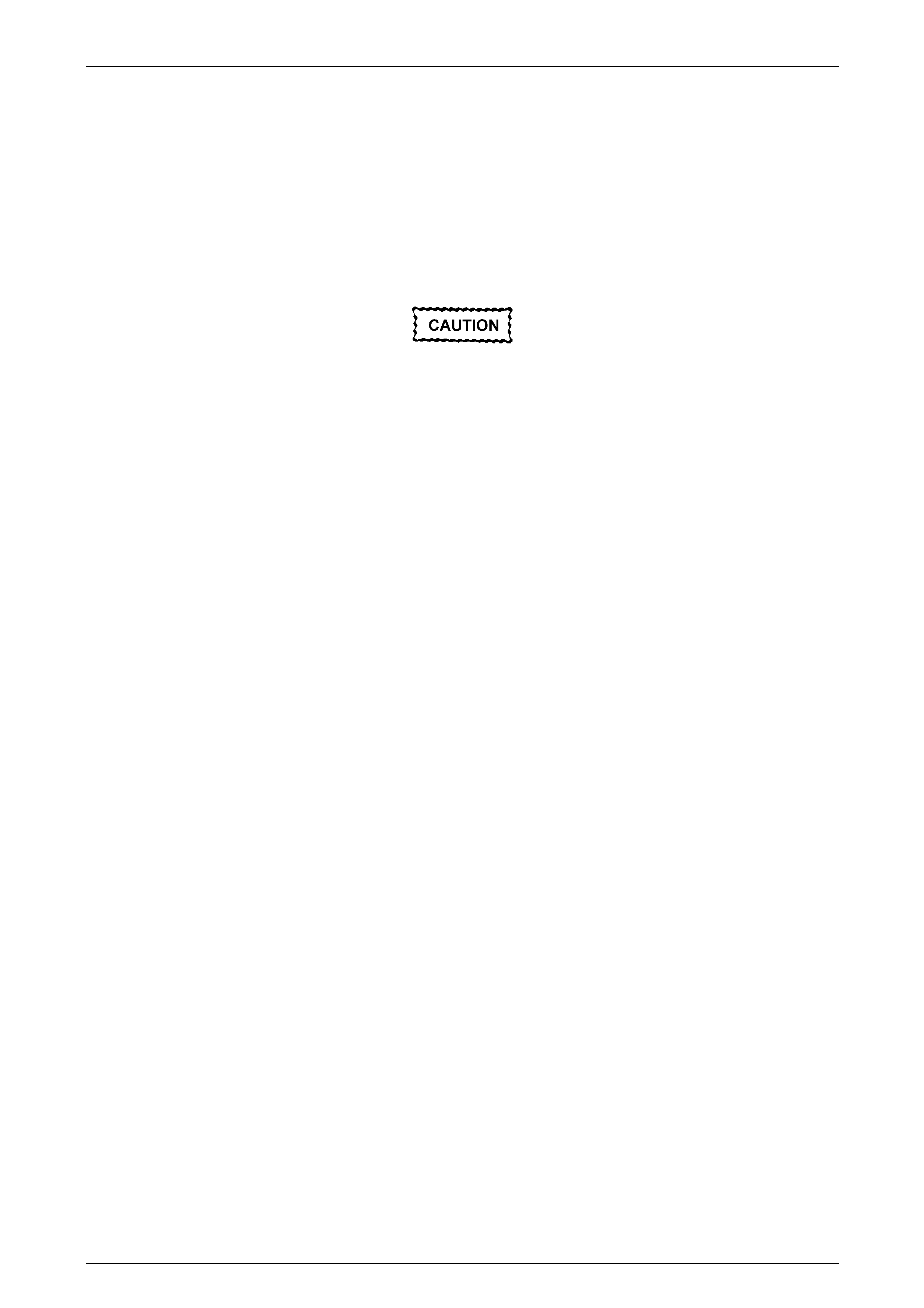

9 Install extractor, Tool No. DT-47736 to the pinion

flange using the same three b olts used to se cure the

flange holding tool, DT-47735 (refer to Figure 4B1-49).

10 While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening the

forcing screw in the direction indic ated.

Figure 4B1 – 50

11 Prise pinion oil seal from carrier bore using Tool No.

E308 or a universal seal removin g tool.

Figure 4B1 – 51

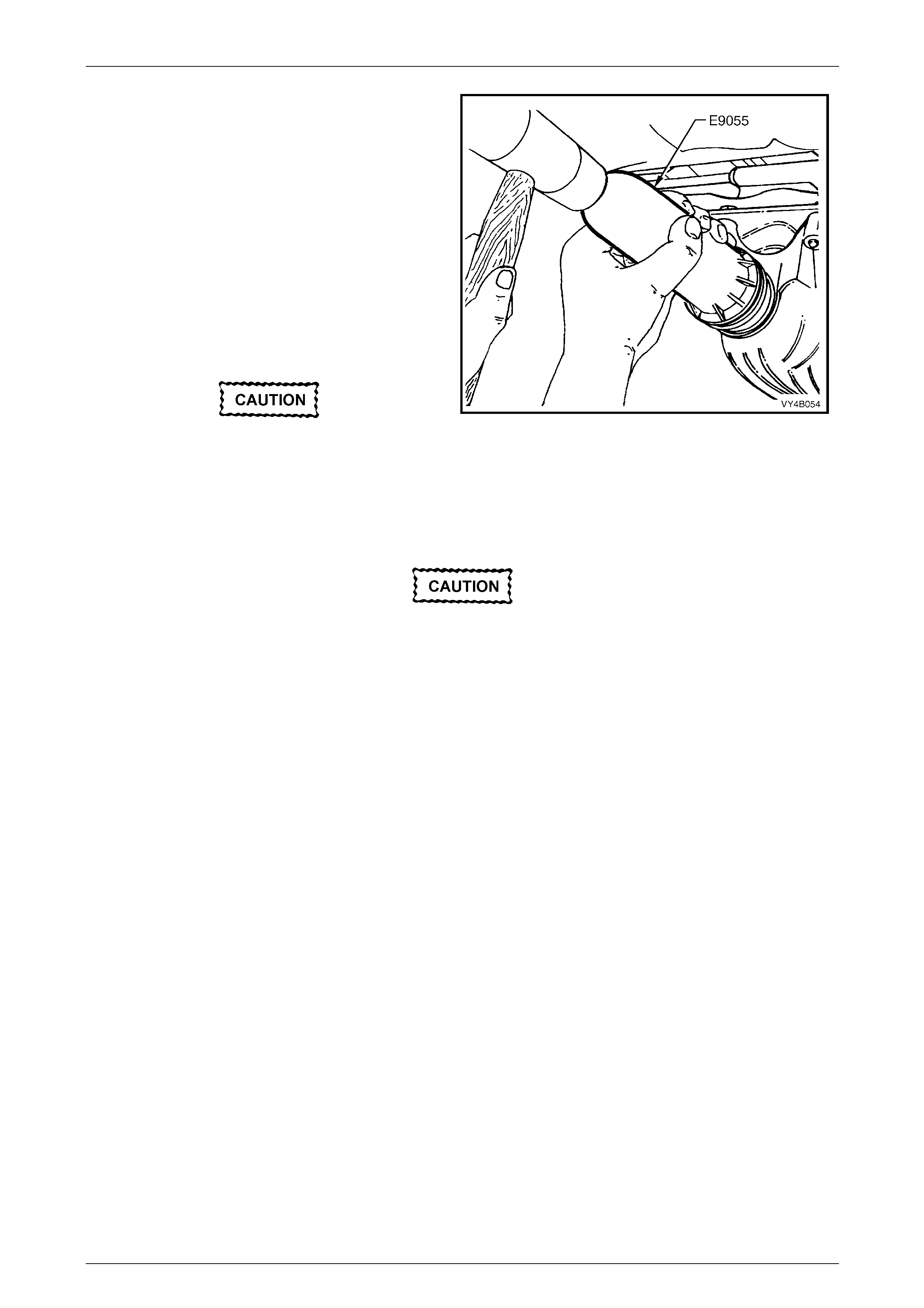

12 Lubricate the lips of a new pinion oil seal and the outer

diameter with Mobilgrease XHP 222 or equivalent

grease.

13 Start oil seal into differential carrier housing and drive

seal squarely into position us ing Tool No. E9055. Seal

fits flush to 0.25 mm below carrier housing surface.

14 Ensure that pinion shaft is free from burrs and that

flange oil seal surface is free from damage.

Figure 4B1 – 52

Rear Final Drive and Drive Shafts Page 4B1-32

Page 4B1-32

15 Clean the threads of the pinion shaft and the flange retaining nut, removing any oil, dirt or grease.

16 Coat splines and seal surface of pinion flange with differential gear lubricant, and install flange onto pini on shaft

splines. Ensure that centre-punch marks are aligned.

17 Reinstall holdin g tool DT-47735 to the pinion flang e.

18 Apply a thread locking compound such as Loctite 243 or equivalent, to the threads of the pinion flange retaining

nut, then reinstall the nut.

19 Tighten the flange retaining nut until all centre-punch marks alig n. Then carefully tighten the nut to a position n ot

more than 5° past the aligned setting.

• The pinion flange is an interference fit on

pinion shaft splines and should only be

pulled into place by tightening the

retaining nut. Do not used force or a

hammer the flange during the installation

process.

• Should the retaining nut be over-tightened

and pre-load exceeded, it will be

necessary to remove the pinion from the

carrier and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load reading.

20 Reinstall prope ller shaft rear coupling to the pinion flange,

refer to Section 4C1 Propeller Shaft and Universal Joints.

21 If removed previously, reconnect exhaust system, in the reverse to the removal procedure.

Refer to Section 8B Exhaust System, for details.

22 Remove safety stands and lower vehicle.

23 Check lubricant level and top up as necessary. Refer to 2.2 Checking Differentia l Carrier Lubricant Level, in this

Section.

24 Start vehicle and check for exhaust leaks.

Rear Final Drive and Drive Shafts Page 4B1-33

Page 4B1-33

2.10 Pinion Flange

Replace

ATTENTION

The following fasteners MU ST be replaced when performing th ese operations:

Drive shaft attaching bolts.

Pinion flange retaining nut.

Using Old Oil Seal

Resulting from production tolerances in the

length of the pinion flange, it is essential that

the following method be used when installing

a new pinion flange.

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove propeller shaft, refer to Section 4C1 Propeller Shaft and Universal Joints.

3 Remove both drive shafts, refer to 2.6 Drive Shafts, in this Section.

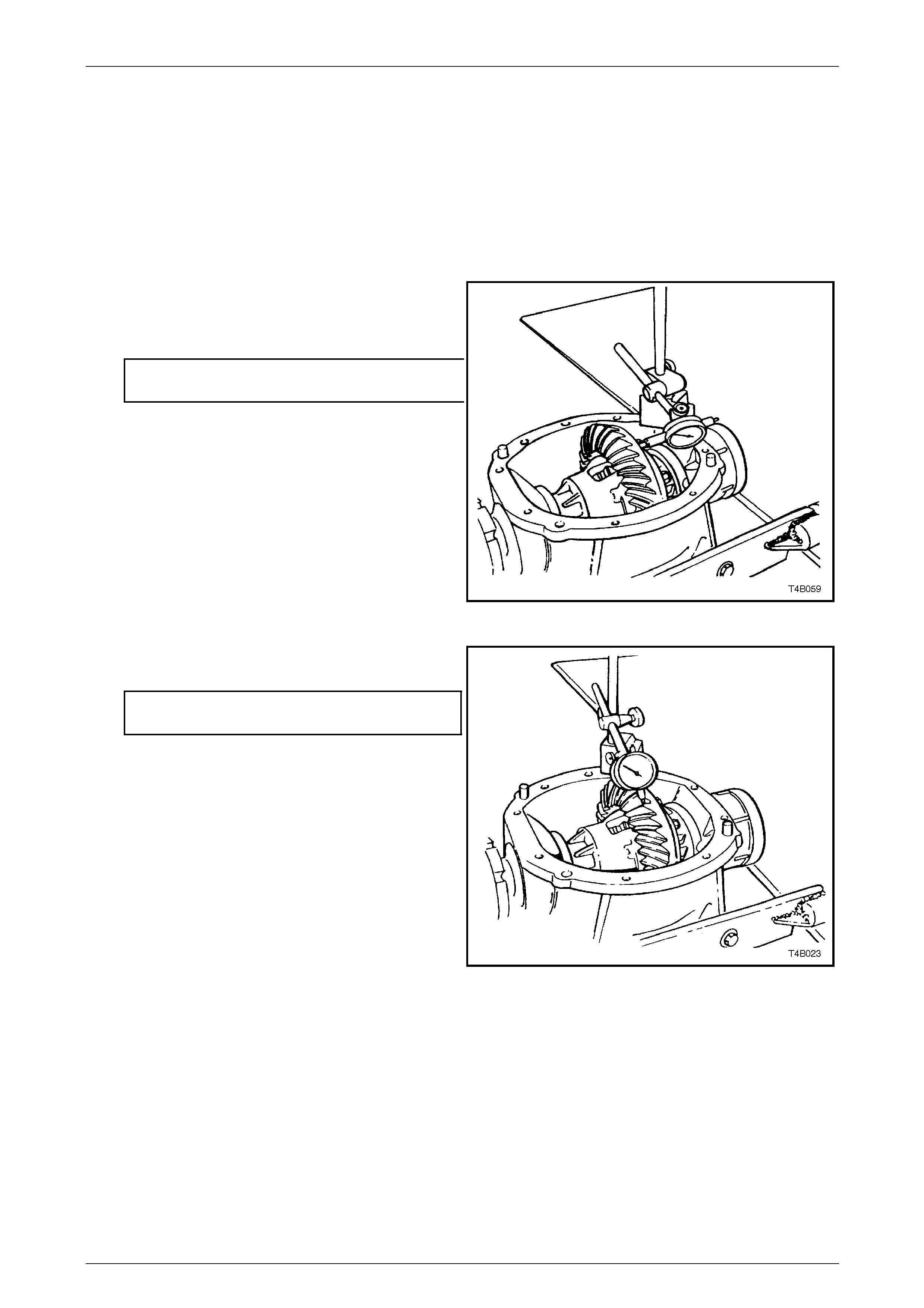

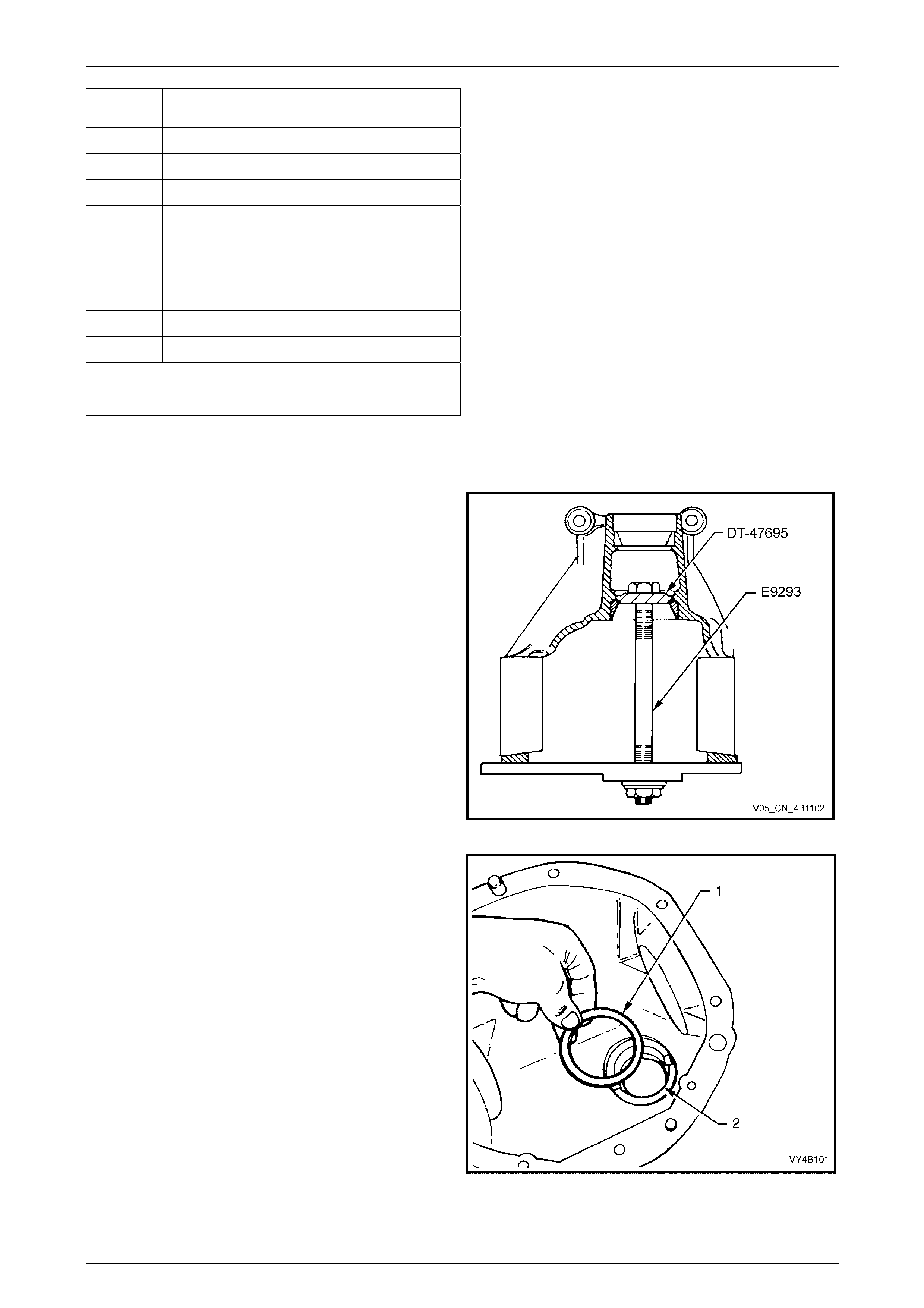

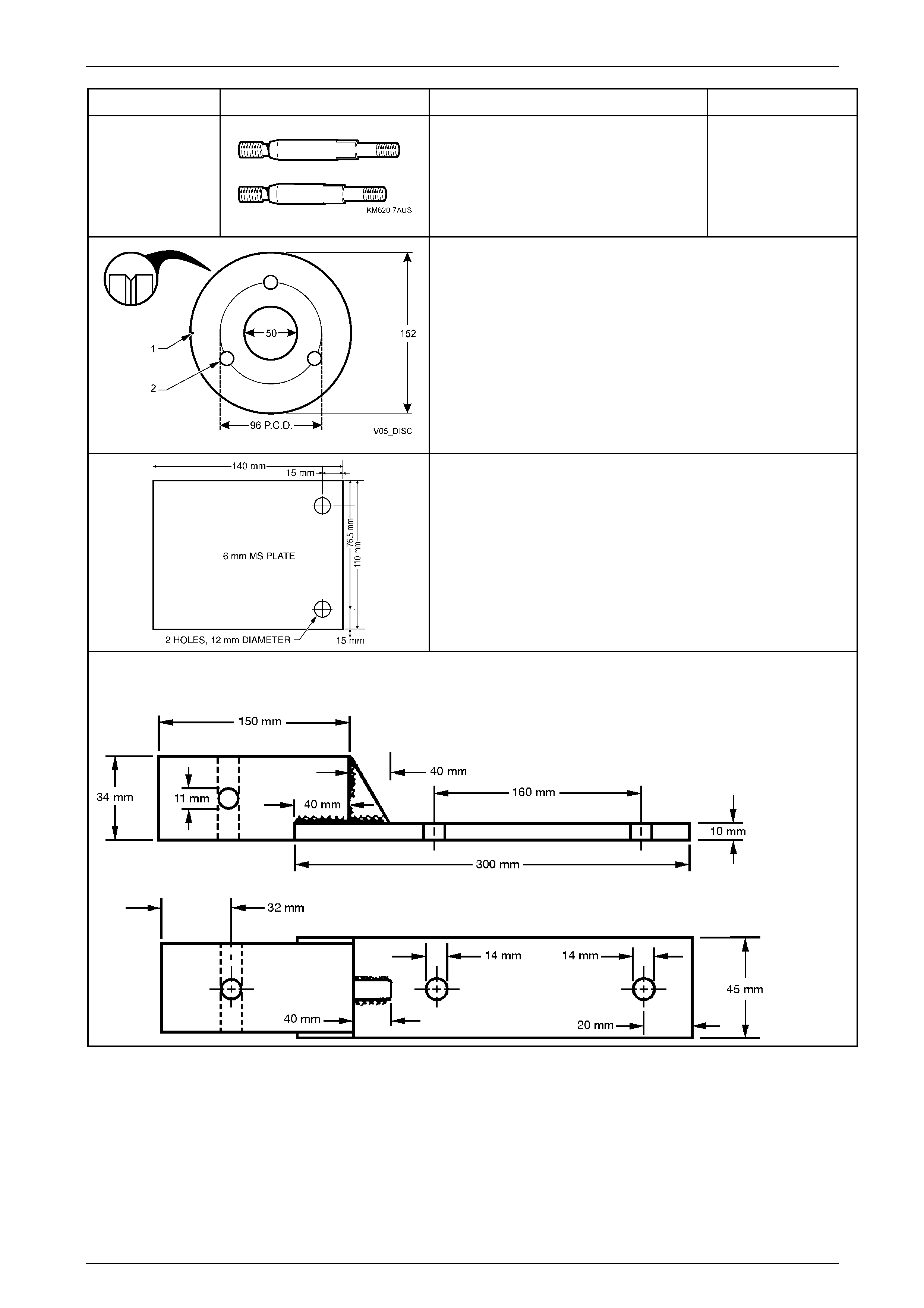

4 Check and record pre-load at pini on flange as follows:

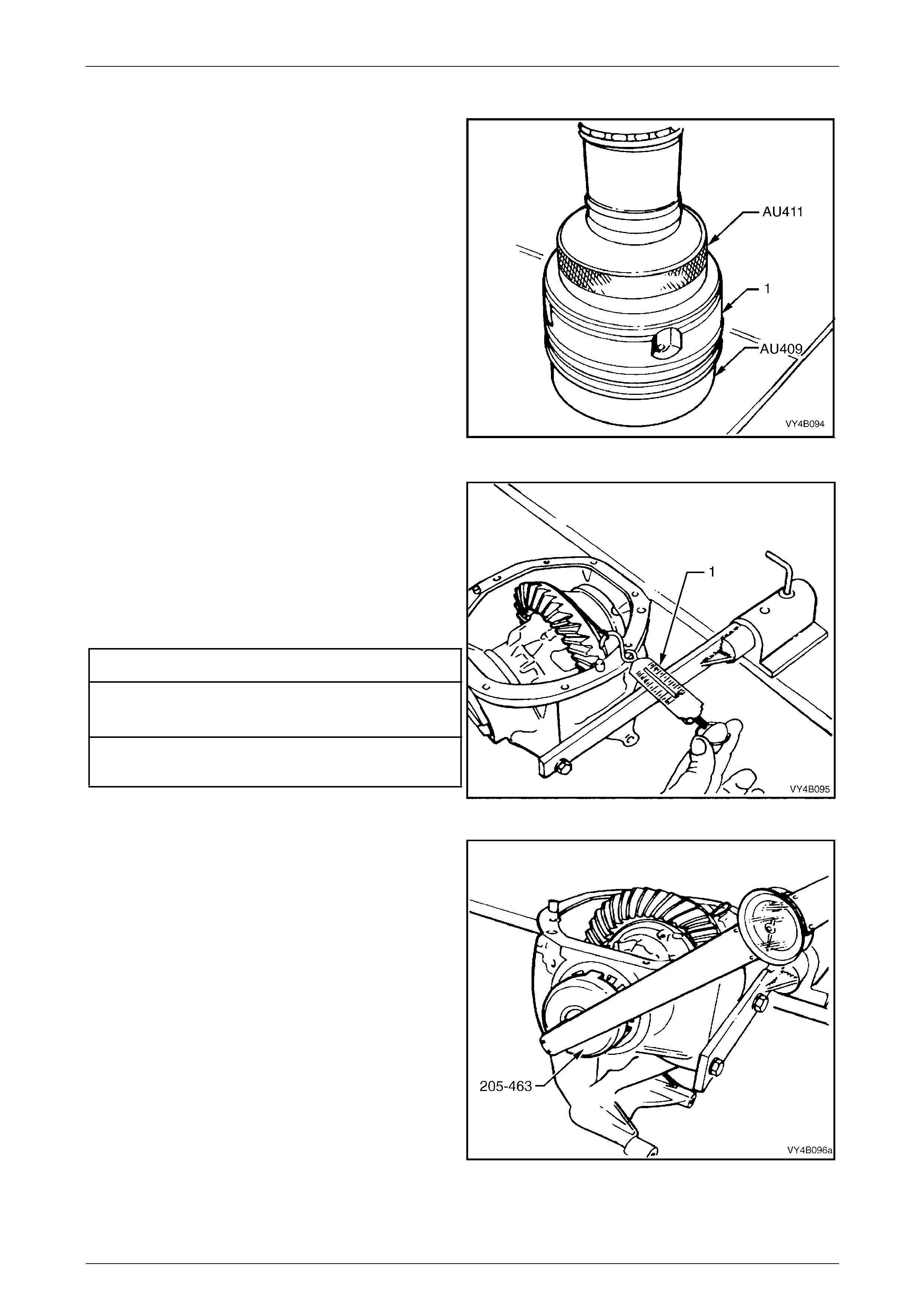

a Fit a pulley (1) to pinion flange, using three

suitable bolts and attach a cord around p ulley

and to a spring scale (2).

NOTE

• Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12

x 1.5 x 40, with the thread ext ending to within

12 mm of the head.

• For details of the fabricated pulley, refer to

7 Special Tools at end of this Section.

b Start rotation of pulley and whilst in motion

(approximately 50 – 60 rpm) note and record

reading of spring balance.

This pre-load reading includes pinion bearin gs,

side bearings, meshing effect of gear set and

pinion oil seal.

To determine pre-load, multipl y readi ng on

spring balance by radius of pulley.

Figure 4B1 – 53

Example: With a pulley diameter of 152 mm, the radius is 76 mm, which equals 0.076 m. With a spring balance reading

of 25 N, the pre-load equals 0.076 m x 25 N = 1.9 N.m.

5 Remove pulley from pinion flange.

Rear Final Drive and Drive Shafts Page 4B1-34

Page 4B1-34

6 Attach Tool No. DT-47735 to the pinion flange, using

three suitable bolts to hold pinion flange.

NOTE

Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x

1.5 x 40, with the thread extending to within 12

mm of the head.

7 Insert a suitable length of pipe (1) over the tang of the

installed tool for leverage, then remove the pinion

flange retaining nut, using a commercia lly available,

30 mm deep socket and socket bar (2).

8 Remove Tool No. DT -47735 from the pinion flange.

Figure 4B1 – 54

9 Place drain tray beneath differential carrier.

10 Install extractor, Tool No. DT-47736 to the pinion

flange using the same three bolts used in step 6.

NOTE

Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x

1.5 x 40, with the thread extending to within 12

mm of the head.

11 While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening the

forcing screw in the direction shown.

Figure 4B1 – 55

12 Ensure that pinion shaft thread is free from burrs, oil, dirt or grease, then coat splines and seal surface of a new

pinion flange with the recommend ed rear axle lubricant.

13 Install the new pinion flange a nd a new retaining nut.

The pinion flange is an interference fit on

pinion shaft splines and should only be pulled

into place by tightening the retaining nut. Do

not used force or a hammer the flange during

the installation process.

Rear Final Drive and Drive Shafts Page 4B1-35

Page 4B1-35

14 Tighten flange retaining nut gradually until pinion shaft end play is reduced to approximately 0.50 mm.

Should the retaining nut be over-tightened

and the pre-load exceeded, it will be

necessary to remove the differential carrier

assembly and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

15 Attach pulley to the new pinion flange and using a spring balance, check pre-load. Continue tightening nut while

alternatively turning pin io n to seat bearings, until the pre-load figure rec orded previously (Step 4b) is reached.

Further increase this original pre-load reading by 0.5 N.m.

NOTE

Rotate pinion an extra 30 – 4 0 turns a nd r e-c heck

the preload to ensure that no change has

occurred.

16 Reinstall drive shafts, refer to 2.6 Drive Shafts, in this Section.

17 Reinstall propeller shaft, refer to Section 4C1 Propeller Shaft and Univ ersal Joints.

18 If removed previously, reconnect exhaust system, in reverse to the removal procedure.

Refer to Section 8B Exhaust System, for details.

19 Lower vehicle to the ground.

20 Check lubricant level and top up as necessary with the recommended lubricant,

refer to 2.2 Checking Differential Carrier Lubricant Level, in this Section.

21 Start vehicle and check for exhaust leaks.

Replace (Using New Oil Seal)

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove propeller shaft, refer to Section 4C1 Propeller Shaft and Universal Joints.

3 Remove both drive shafts, refer to 2.6 Drive Shafts, in this Section.

4 Check and record pre-load at pini on flange as follows:

a Fit a pulley (1) to pinion flange, using three

suitable bolts and attach a cord around p ulley

and to a spring scale (2).

NOTE

• Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12

x 1.5 x 40, with the thread ext ending to within

12 mm of the head.

• For details of the fabricated pulley, refer to

7 Special Tools at end of this Section.

b Start rotation of pulley and while in motion

(approximately 50 – 60 rpm), note and record

reading of spring balance.

This pre-load reading includes pinion bearin gs,

side bearings, meshing effect of gear set and

pinion oil seal.

To determine pre-load, multipl y readi ng on

spring balance by radius of pulley.

Figure 4B1 – 56

Rear Final Drive and Drive Shafts Page 4B1-36

Page 4B1-36

Example: With a pulley diameter of 152 mm, the radius is 76 mm, which equals 0.076 m. With a spring balance reading

of 25 N, the pre-load equals 0.076 m x 25 N = 1.9 N.m.

5 Remove pulley from pinion flange.

6 Attach Tool No. DT-47735 to the pinion flange, using

three suitable bolts to hold pinion flange.

NOTE

Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x

1.5 x 40, with the thread extending to within 12

mm of the head.

7 Insert a suitable length of pipe (1) over the tang of the

installed tool for leverage, then loosen the pinion

flange retaining nut, using a commercia lly available,

30 mm deep socket and socket bar (2) until end play

can be felt in the pinion shaft.

8 Check the oil seal and differential side bearing pre-

load using the spring scale and pulley, as detailed in

steps 4a and 4b. Record oil seal and side bearing pre-

load for later use.

9 Remove Tool No. DT -47735 from the pinion flange. Figure 4B1 – 57

10 Place drain tray beneath differential carrier.

11 Install extractor, Tool No. DT-47736 to the pinion

flange using the same three b olts used previously.

NOTE

Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x

1.5 x 40, with the thread extending to within 12

mm of the head.

12 While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening the

forcing screw in the direction shown.

Figure 4B1 – 58

13 Prise pinion oil seal from carrier bore using Tool No.

E308 or a universal seal removin g tool.

Figure 4B1 – 59

Rear Final Drive and Drive Shafts Page 4B1-37

Page 4B1-37

14 Lubricate a new pinion oil seal lips and the outer

diameter with Mobilgrease XHP 222 grease or

equivalent.

15 Start oil seal into differential carrier housing and drive

seal squarely into position us ing Tool No. E9055. Seal

fits flush to 0.25 mm below carrier housing surface.

16 Ensure that pinion shaft is free from burrs, then clean

the threads of the pinion shaft, removing any oil, dirt or

grease.

17 Coat splines and seal surface of pinion flange with

differential gear lubricant, then reinstall flange to the

pinion shaft splines.

18 Install a new flange retaining nut, then tighten to draw

the pinion flange onto the pinion shaft spli nes.

The new pinion flange will be an interference

fit on pinion shaft splines and should only be

pulled into place by tightening the retaining

nut. Do not used force or a hammer the

flange during the installation process.

Figure 4B1 – 60

19 Continue to tighten the flange retaining nut gradually until pinion shaft end play is reduced to approximately 0.5

mm.

Should the retaining nut be over-tightened

and the pre-load exceeded, it will be

necessary to remove the differential carrier

assembly and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

20 Check new oil seal and differential assemb ly pre-load using spring balance as previously outlined in steps 4a and

4b. Record pre-load for reassembly refer ence.

21. The pre-load reading for differential assembly obtained in step 8, is subtracted from pre-load reading obtained in

step 20. The difference bet ween these fi gures represents extra lip tension of new seal expressed as a N.m pre-

load figure. The difference be tween the pre-load readings o btained in steps 8 and 20 must be added to pre-load

reading obtained in step 4b to obtain a total pre-load reading.

Rear Final Drive and Drive Shafts Page 4B1-38

Page 4B1-38

Theoretical Example

Step 20 New oil seal and side

bearing preload setting. 1.47 N.m

Step 8 Old oil seal and side

bearing preload reading. 1.02 N.m

Subtract Step 8 from Step 20 0.45 N.m

Step 4b Complete differential

assembly preload

reading. 1.47 N.m

The preload readi ng combination will be

the sum of:-

1.47 N.m

plus

0.45 N.m

Which gives a total preload reading of:- 1.92 N.m

Should the retaining nut be over-tightened

and the pre-load exceeded, it will be

necessary to remove the differential carrier

assembly and install a new collapsible

spacer. Under no circumstances must the

retaining nut be backed off to decrease the

pre-load setting.

22 Continue tightening retaining nut while alternatel y turning pinion to seat bearings until total pre-load figure obtained

in step 21 is achieved, then i ncrease this pre-load readin g by 0.11 to 0.34 N.m. Further rotate pinion an extra 30 –

40 turns and recheck pre-load to ensure that no change has occurred.

NOTE

It must be realised that the pre-load readings in

the example are only theoretical. In practice, the

figures could differ greatly, so the readings

obtained when performing the actual operations,

are the ones to use.

23 Reinstall drive shafts, refer to 2.6 Drive Shafts, in this Section.

24 Reinstall propeller shaft, refer to Section 4C1 Propeller Shaft and Univ ersal Joints.

25 If removed previously, reconnect exhaust system, in the reverse to the removal procedure.

Refer to Section 8B Exhaust System, for details.

26 Lower vehicle to the ground.

27 Check lubricant level and top up as necessary, refer to 2.2 Checking Differential Carri er Lubricant Level.

28 Start vehicle and check for exhaust leaks.

Rear Final Drive and Drive Shafts Page 4B1-39

Page 4B1-39

3 Major Service Operations

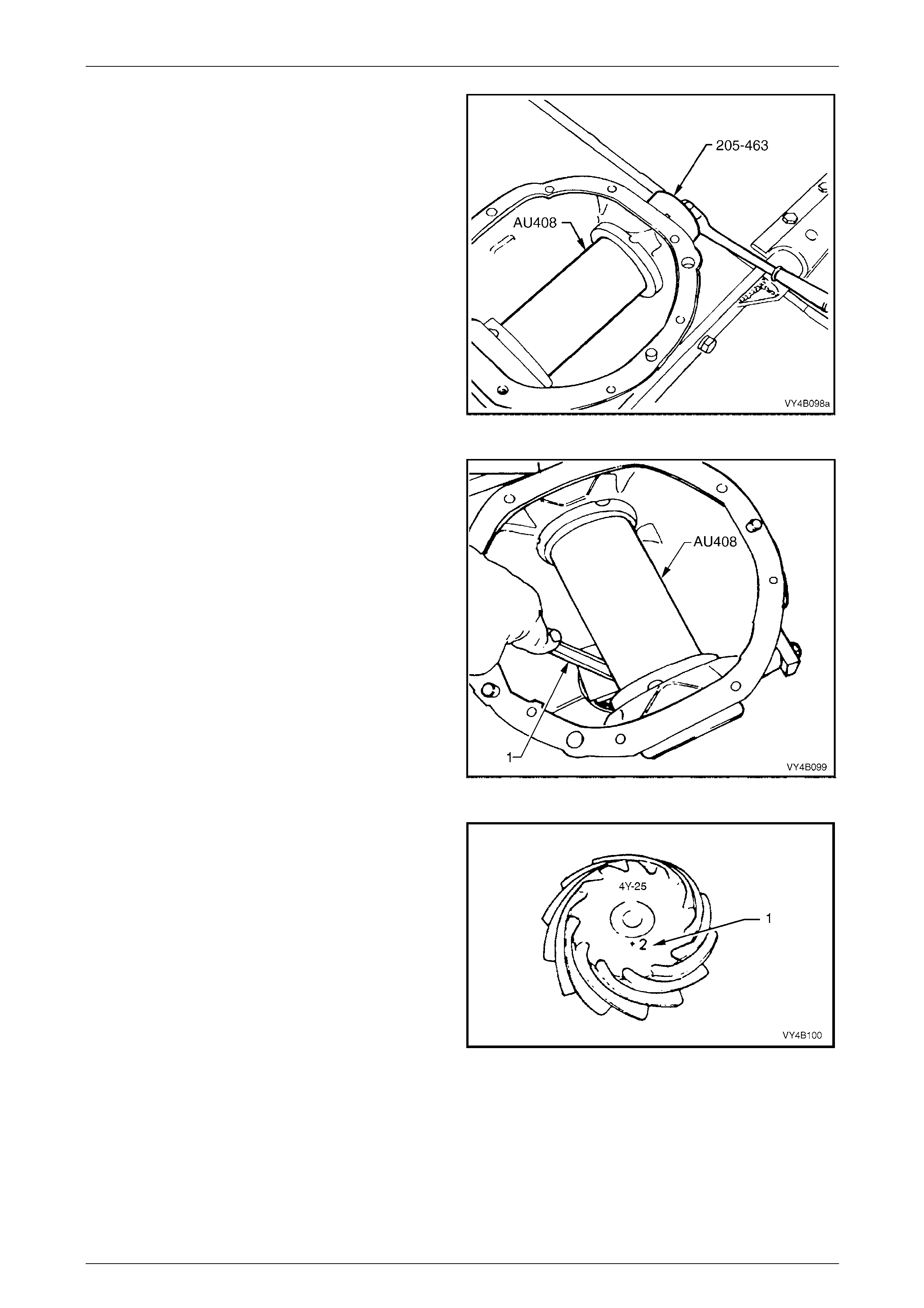

3.1 Outer Rear Wheel Drive Shaft Flange

Outer Rear Wheel Drive Shaft Assembly

and/or Wheel Bearing

ATTENTION

The following fasteners MU ST be replaced when performing th ese operations:

Collar nut to outer rear wheel drive shaft assembly

Drive shaft constant velocity joint attaching bolts.

Lower rear disc brake shield to trailing arm bolts

Vehicle must be at curb weight before final tightening.

zLower shock absorber mounting bolt.

NOTE

• The following procedure involves the removal

of the outer rear wheel drive shaft flange,

outer rear wheel drive shaft and/or wheel

bearing with the trailing arm installed in the

vehicle. A similar procedure is included in

Section 4A1 Independent Coil Spring Rear

Suspension, when the trailing arm is removed

from the vehicle.

• The rear wheel bearing should only be

removed if it is faulty, or if the outer rear

wheel drive shaft assembly is to be removed.

Figure 4B1 – 61

Legend

1 Collar Nut Lock Plate

2 Collar Nut

3 Outer Rear Wheel Drive Shaft Flange

4 Trailing Arm

5 Brake Backing Plate

6 Brake Disc

7 Brake Caliper

8 Rear Wheel Bearing

9 Outer Rear Wheel Drive Shaft Assembly

10 Rear Wheel Bearing Retaining Ring

Rear Final Drive and Drive Shafts Page 4B1-40

Page 4B1-40

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 On the side of the vehicle where the trailing arm is to be removed, remov e the wheel trim or wheel nut covers, mark

relationship of road wheel to hub (e.g. end of wheel stud), with a felt tipped pen or similar. Loosen then remove

road wheel attaching nuts. Remove the roa d wheel.

3 Remove brake hose retaining clip (1) from brake

backing plate bracket (2). Disconnect rear caliper

brake hose (3) from brake pipe (4) and disconnect

pipe from backing plate bracket (2).

4 Plug open ends of brake pipe (4) and hose (3) to

prevent fluid loss and foreign matter entry.

Figure 4B1 – 62

If the brake pipe to hose is not disconnected,

the brake caliper must be secured to the

vehicle underbody. The caliper is not to hang

by the brake hose.

5 Remove brake caliper anchor plate to trailing arm

attaching bolts (1) and remove caliper (2) from disc.

6 Remove brake disc from the wheel bearing hub.

NOTE

While the brake disc to hub location is m arked in

production, ensure that the disc to hub position

is carefully marked (e.g. disc to end of wheel

stud), with a felt tipped pen or similar. This is

necessary to overcome the possibility of

inducing a brake shudder condition after

reassembly.

Figure 4B1 – 63

7 If the park brake shoe needs to be adjusted to allow

disc removal, the following method sh ould be adopted:

a Remove one of the access hole plugs (1) from

one of the access holes provided in the disc.

b Using a suitable lever such as a screwdriver,

loosen the park brake shoe screw adjuster, until

the disc is freed.

c After disc removal, reinstall the access hole plug

to prevent loss.

Figure 4B1 – 64

Rear Final Drive and Drive Shafts Page 4B1-41

Page 4B1-41

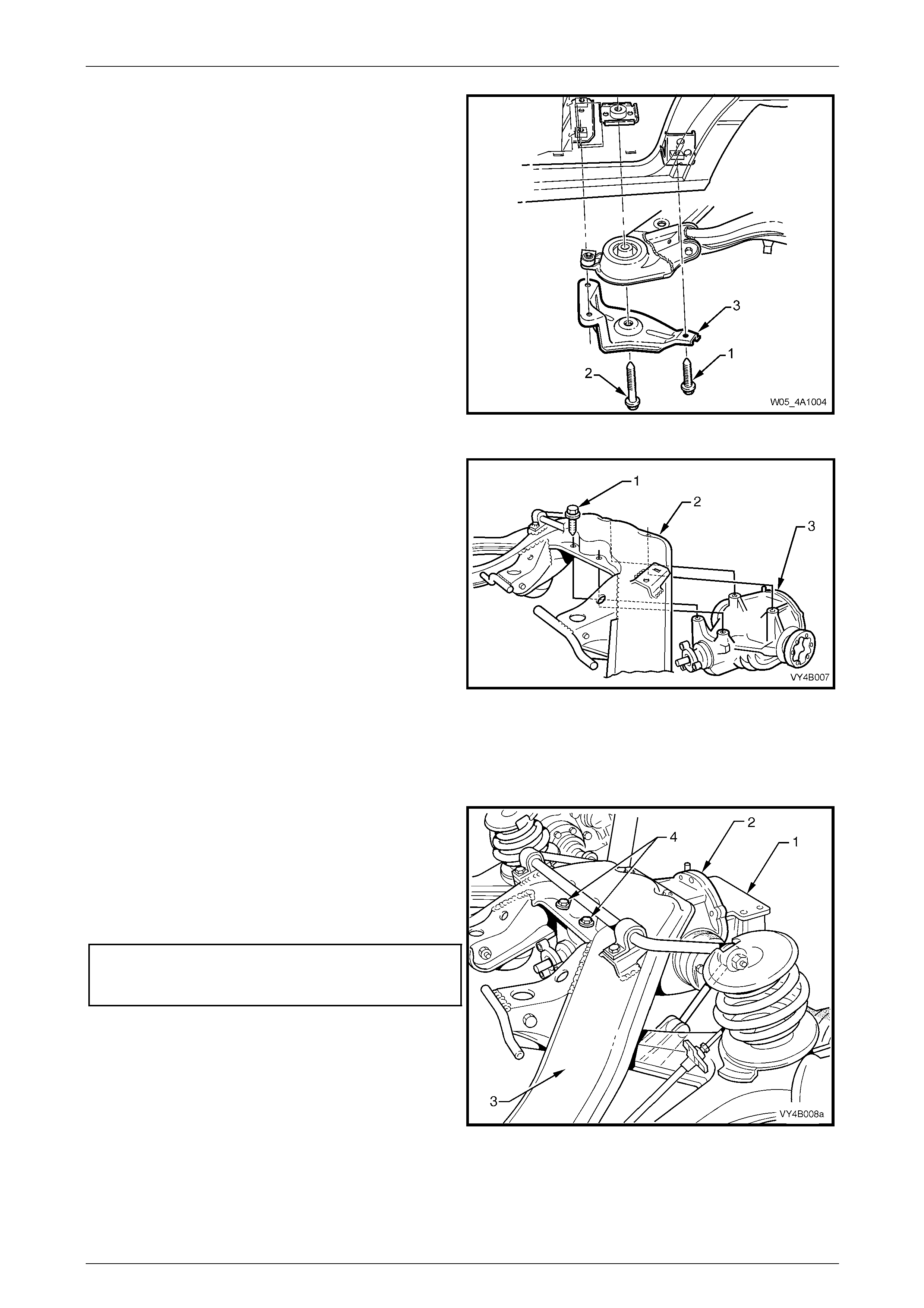

8 Position floor jack with a block of wood under the trailing arm (2). Raise jack slightly to take spring load off trailing

arm.

9 Disconnect rear shock absorber lower mounting bolt

(1) from trailing arm (2), and pull lower end of shock

absorber (3) from trailing arm. Leave the su pporting

jack and wooden block in position.

Figure 4B1 – 65

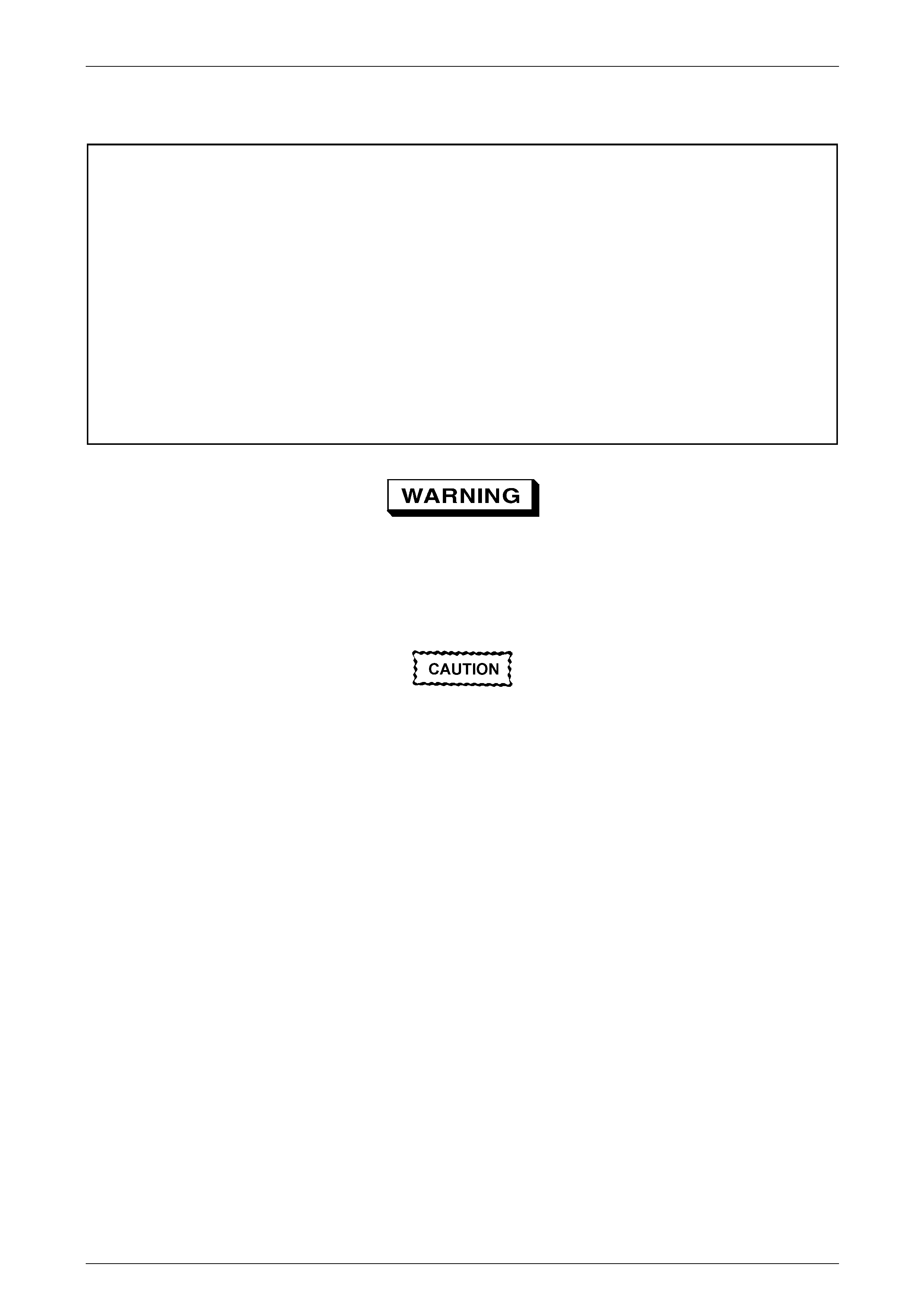

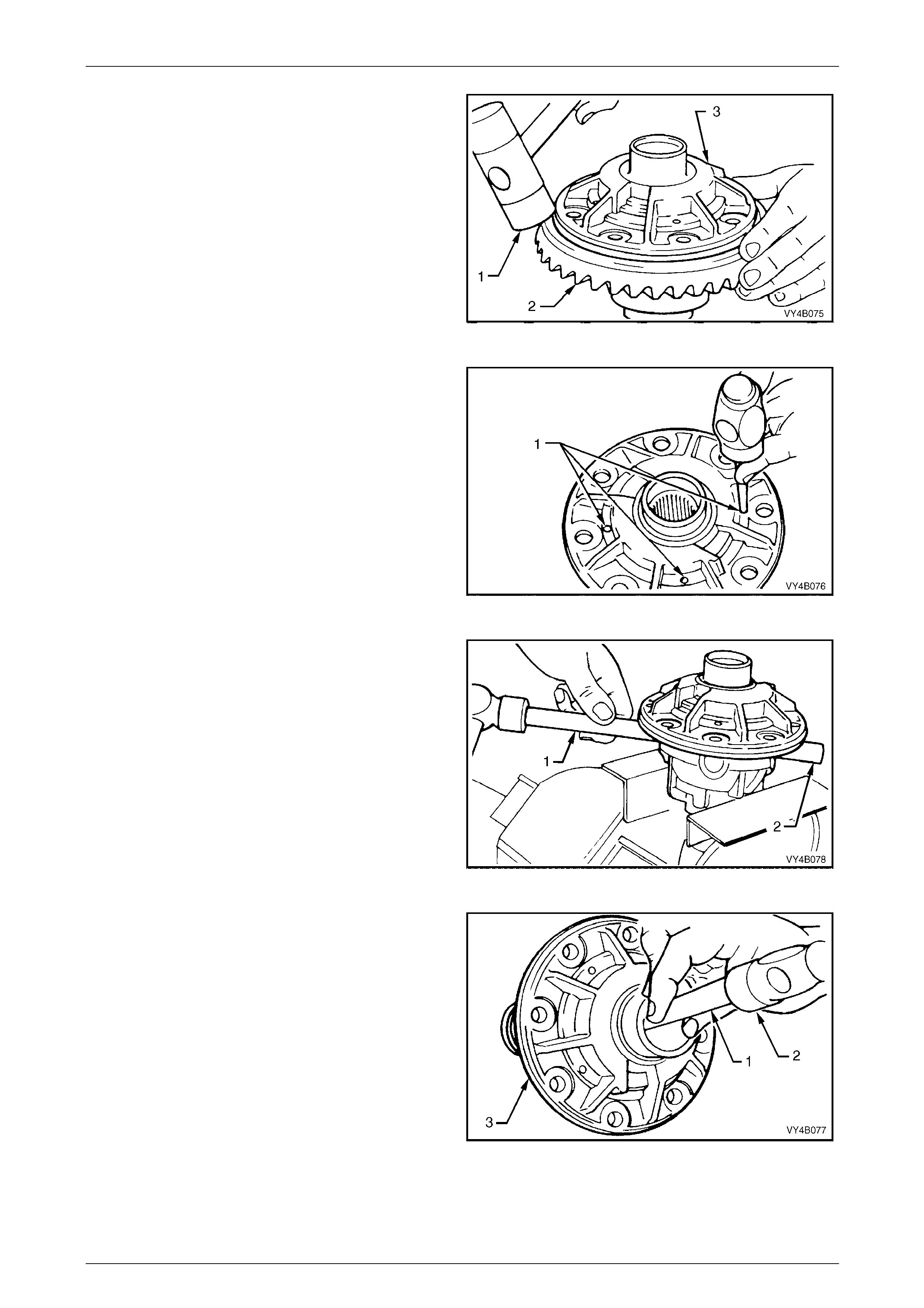

10 Install holding bar, T ool No. KM 468 over the wheel

studs to hold outer rear wheel drive shaft assembly

from rotating.

11 Loosen then remove the six drive shaft (1) constant

velocity joint to outer rear wheel drive shaft flange

attaching bolts (2) and plates, using an 8 mm Allen

key socket and suitable socket equipment (3).

12 Discard the removed bolts as they must be repl aced

on reassembly.

Figure 4B1 – 66

Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the

trailing arm is lowered. This will lead to

premature failure of the boot and eventual

failure of the joint if left unchecked.

13 Separate drive shaft from flange and lift upward. While

keeping the outer constant velocit y joint (1) in the

same plane as the drive shaft, use a piece of wire (2)

and tie up the drive shaft assembly to lower end of

shock absorber upper mounti ng.

14. The supporting jack may no w be lowered and the

wooden block removed.

Figure 4B1 – 67

Rear Final Drive and Drive Shafts Page 4B1-42

Page 4B1-42

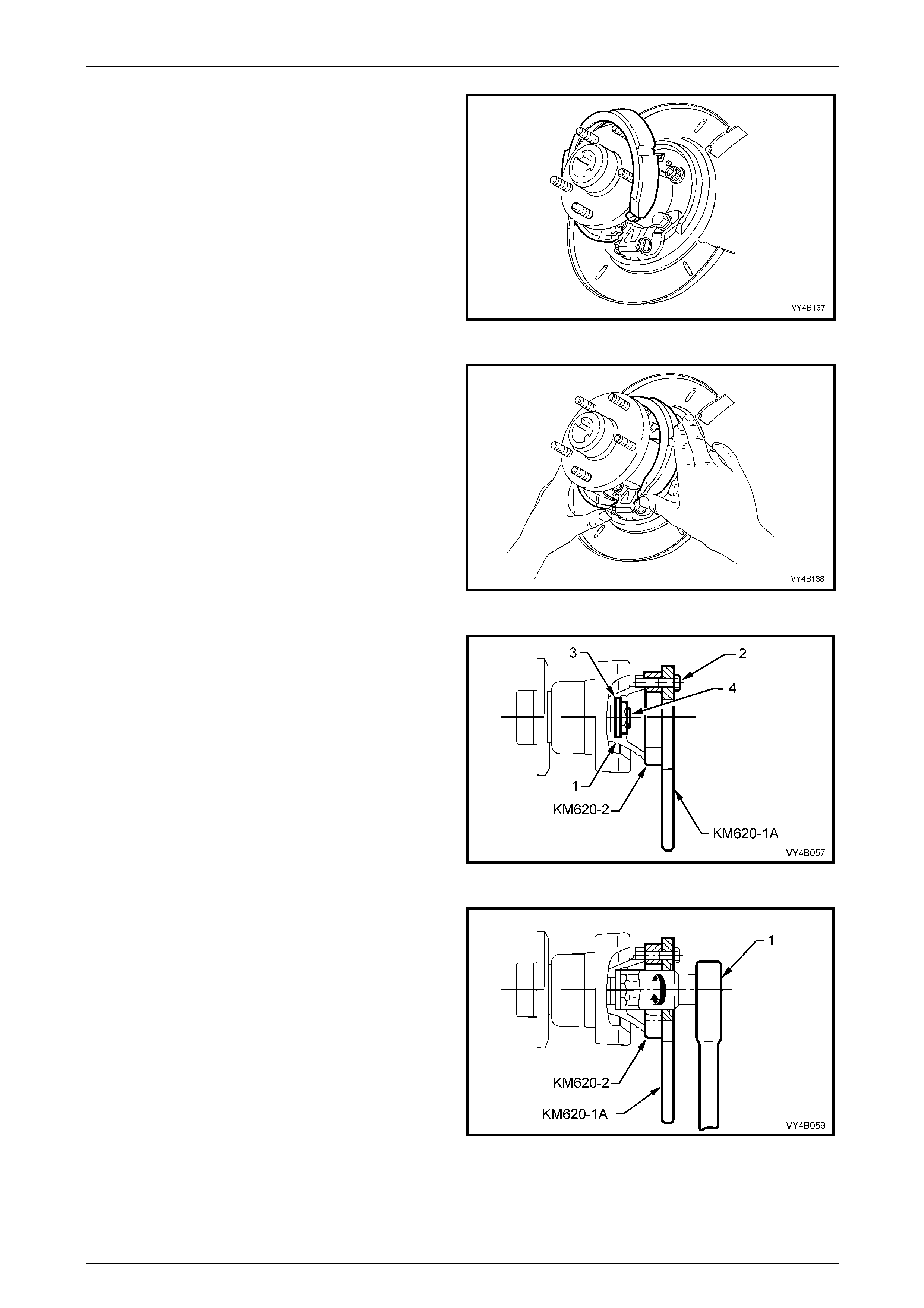

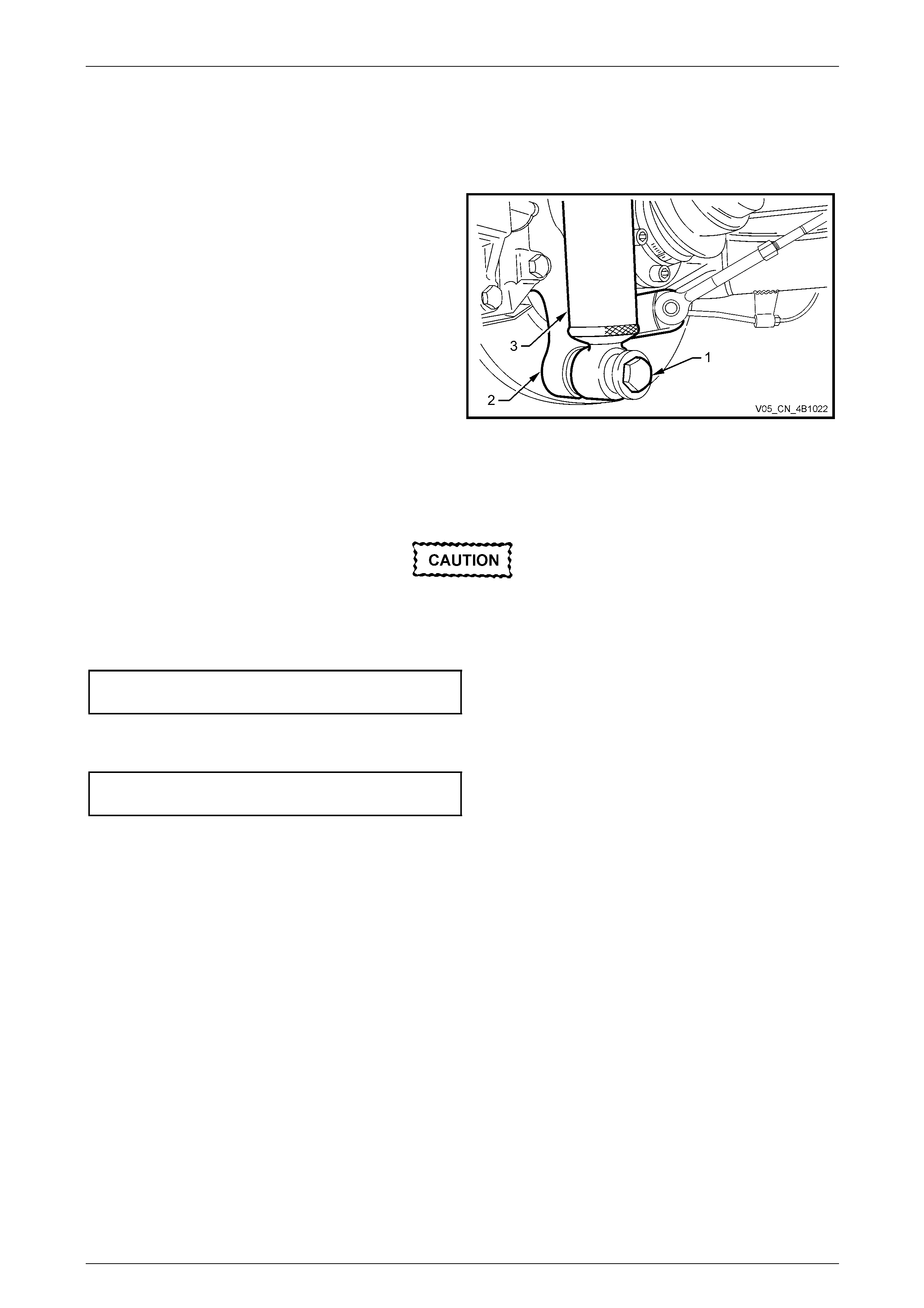

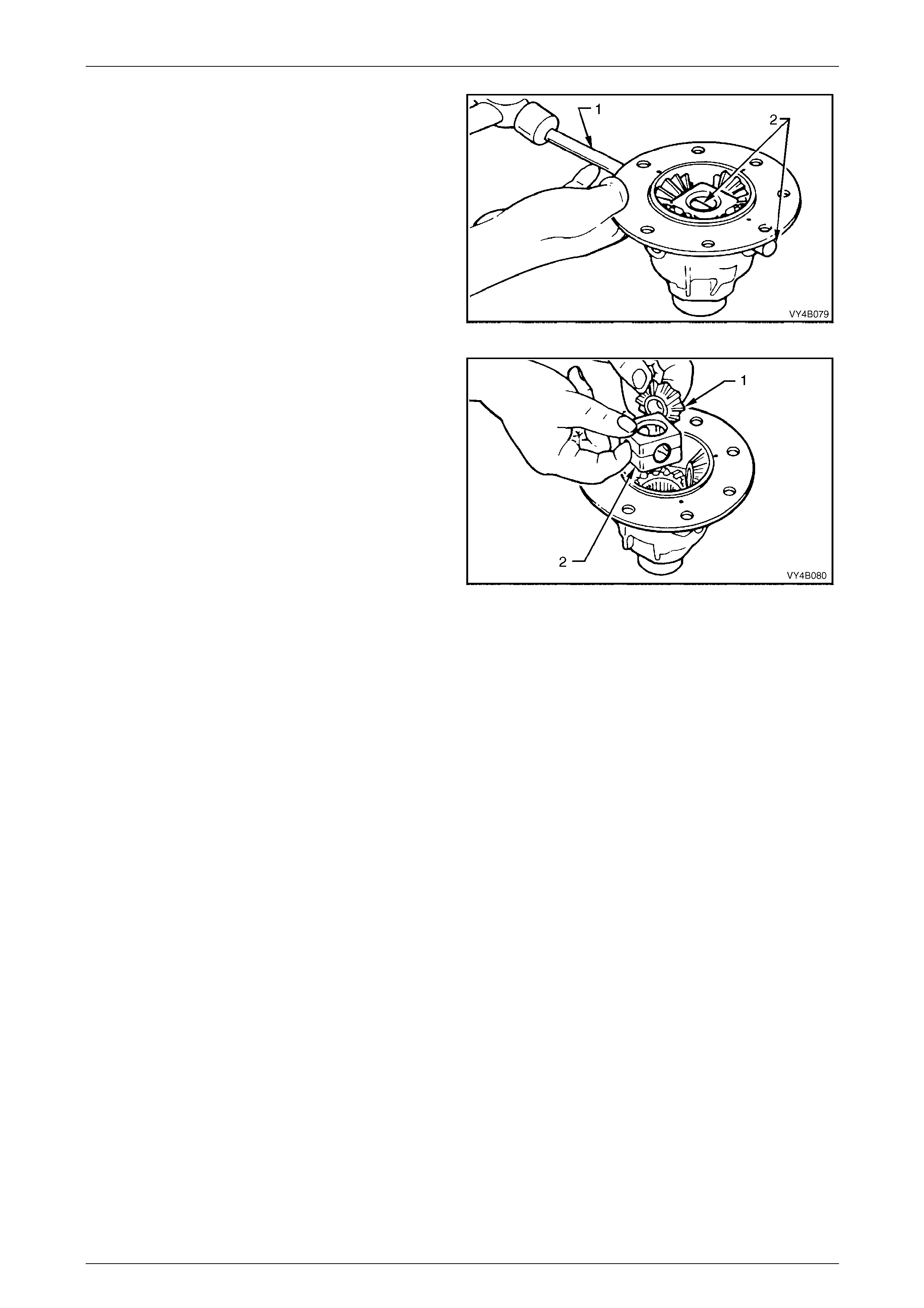

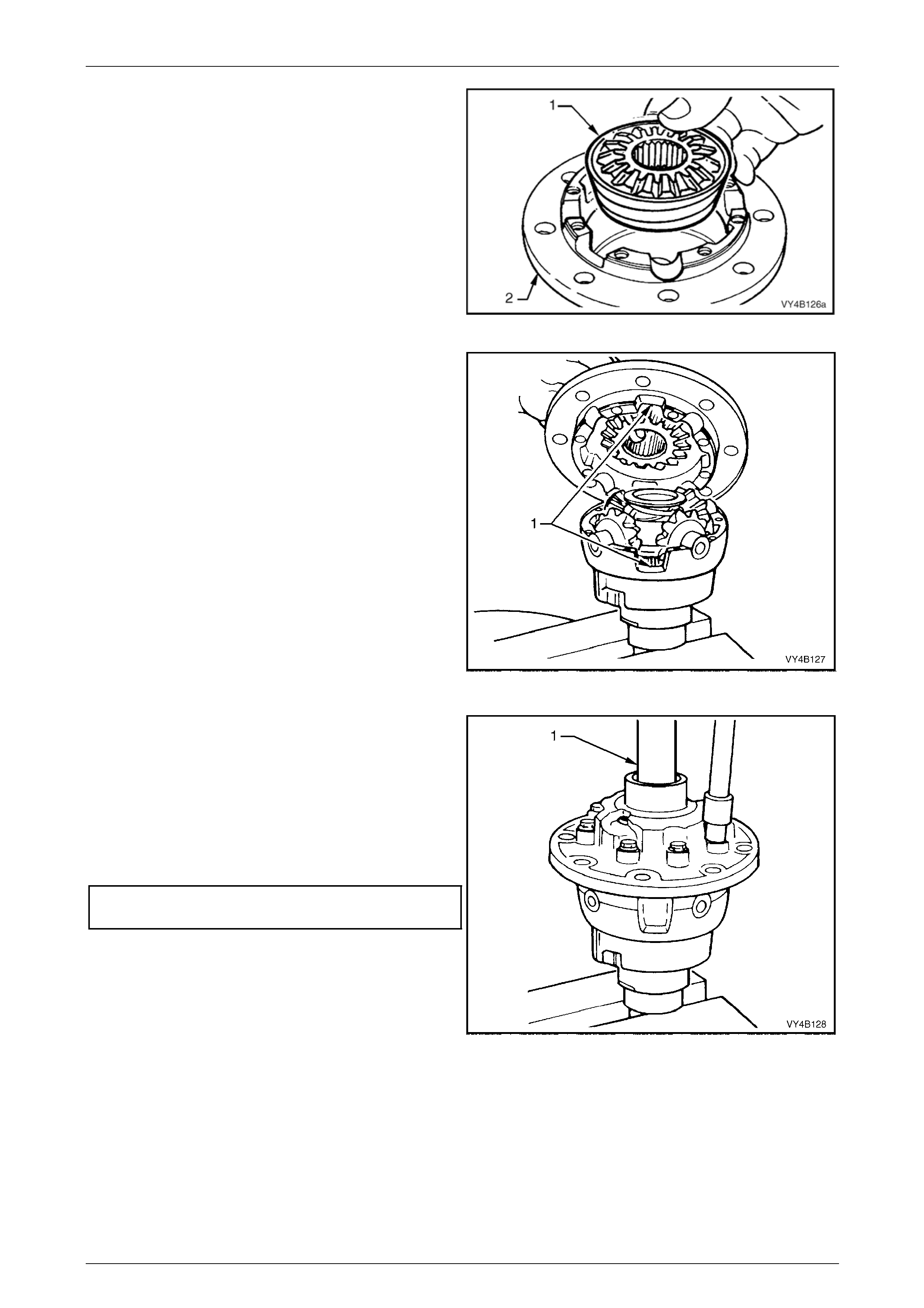

15 Remove park brake shoe b y g rasping each end as

shown. Push up on one end of the shoe, dislodging

the end from the actuator pin and the shoe from the

retaining clip.

Figure 4B1 – 68

16 Using a screwing motion, rotate the park brake shoe

around the outer rear wheel drive shaft flange to

remove it from the vehicle.

17 Remove the park brake shoe spring retainer by prisi ng

from the rear disc shield, with a screwdriver or similar

lever.

18 Using suitable socket equipment, loosen then remove

the two lower bolts securing the park brak e adjuster

and brake backing plate to th e trailing arm. Discard the

removed bolts.

19 Using Tool No. AU416 and suitable socket equipment,

loosen then remove the two upper brake backing plate

to the trailing arm, Torx bit headed bolts. Figure 4B1 – 69

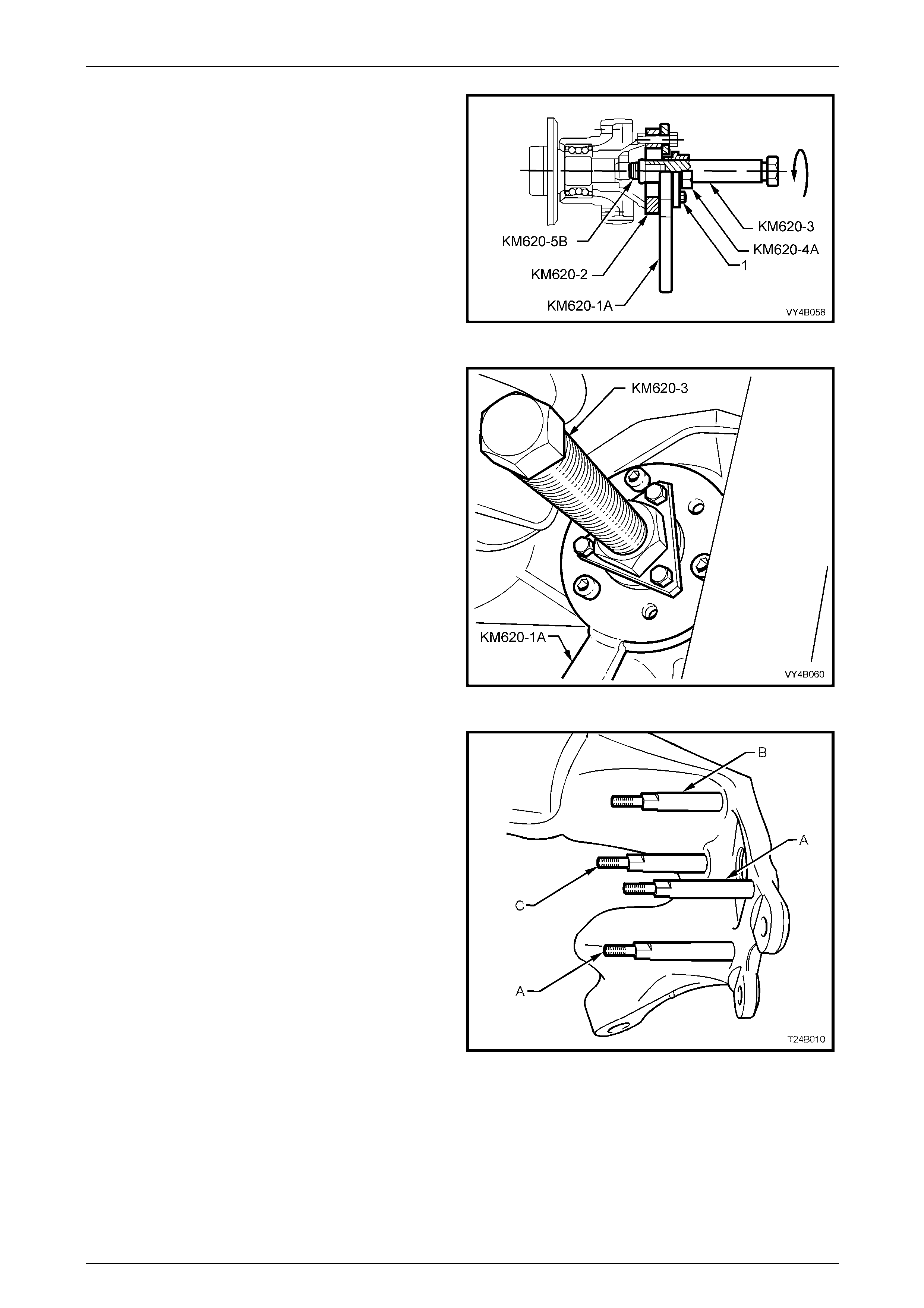

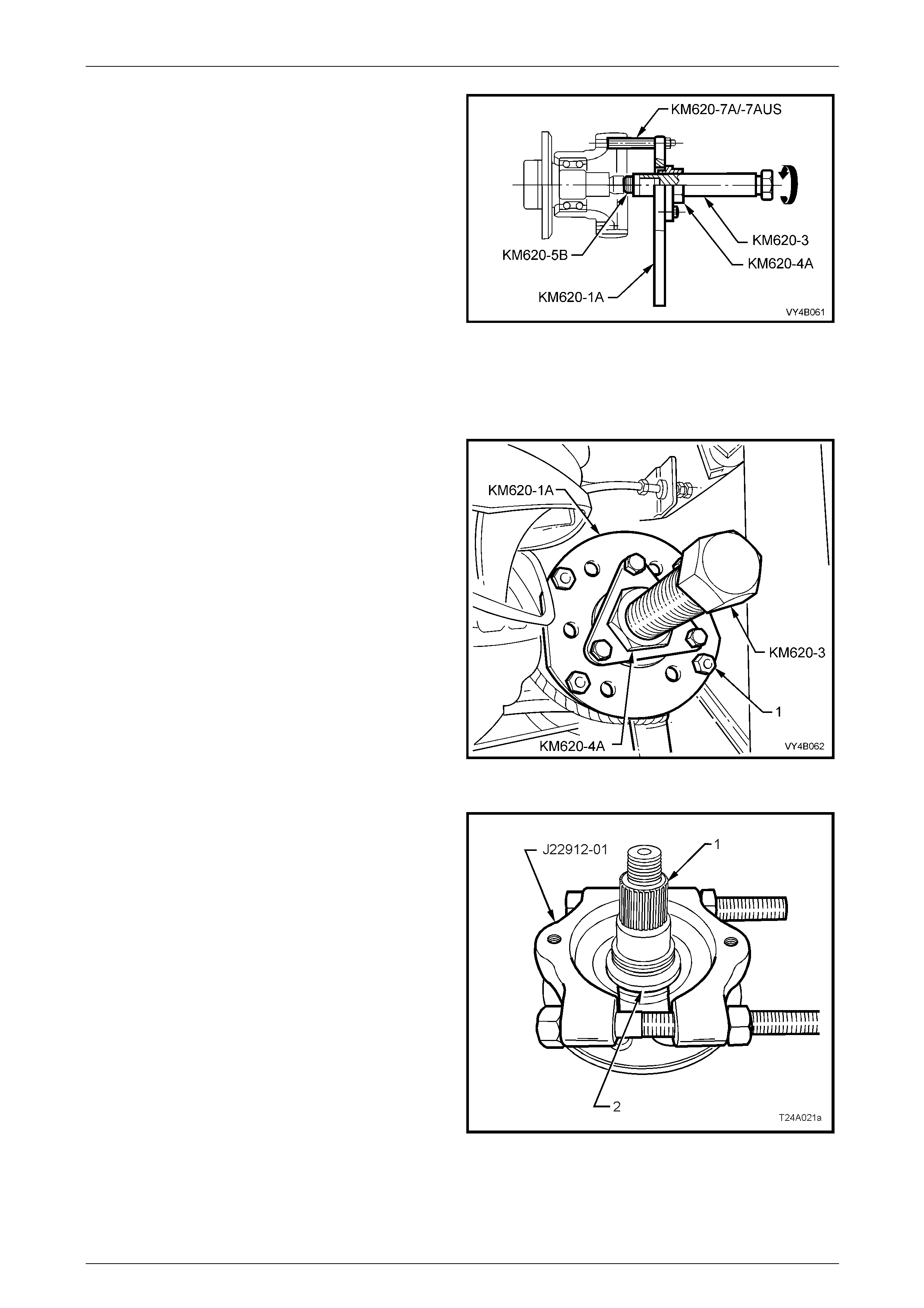

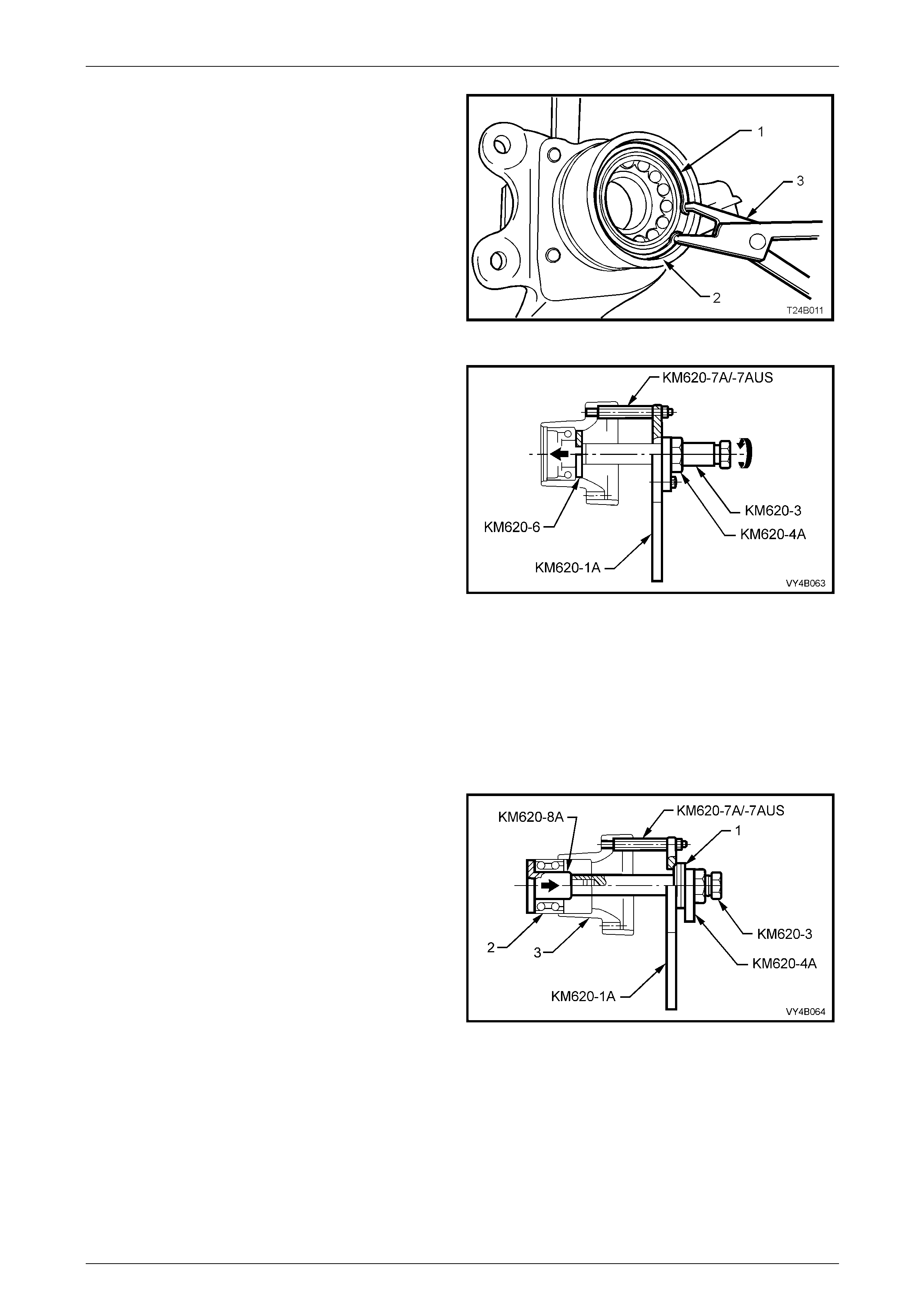

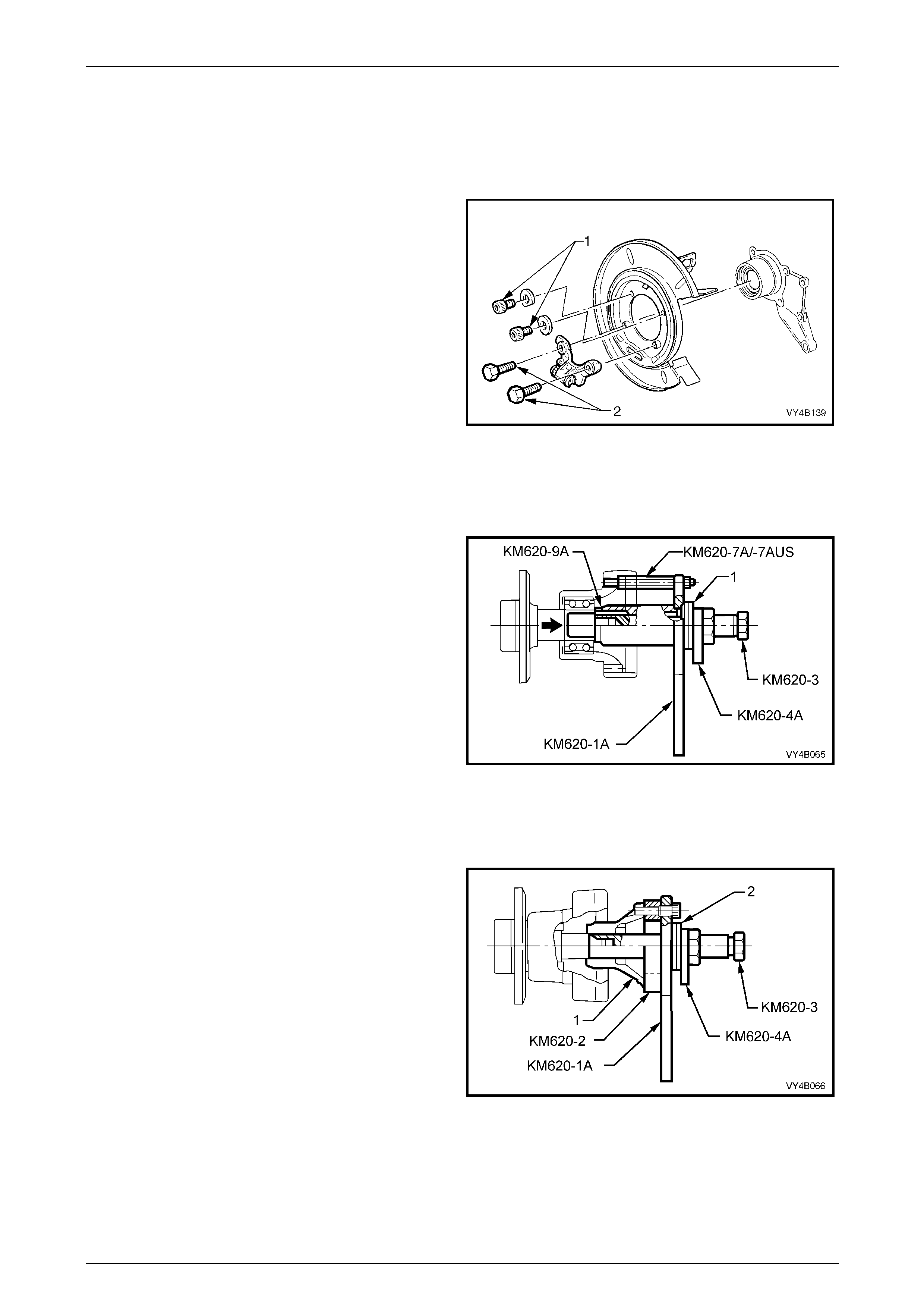

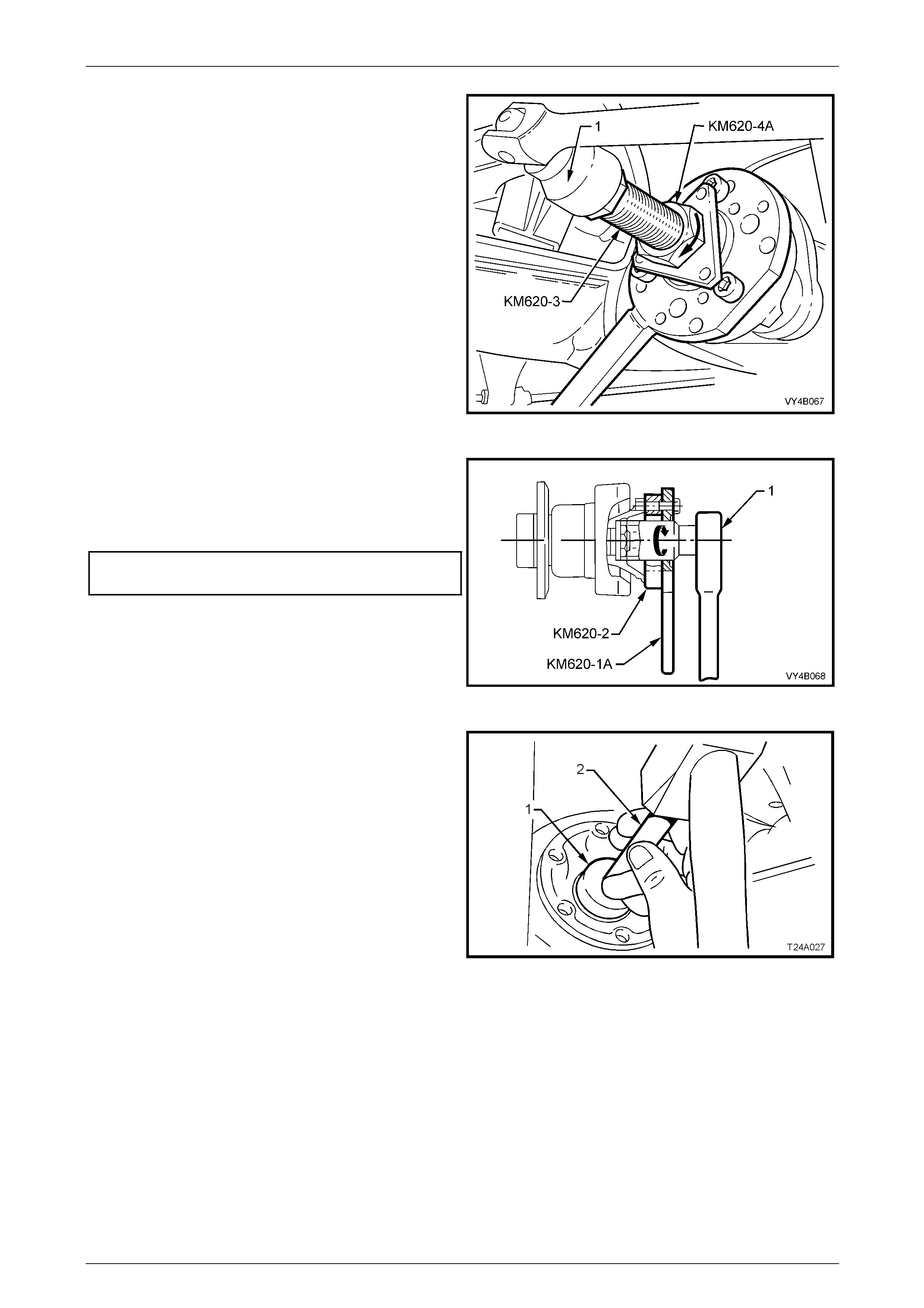

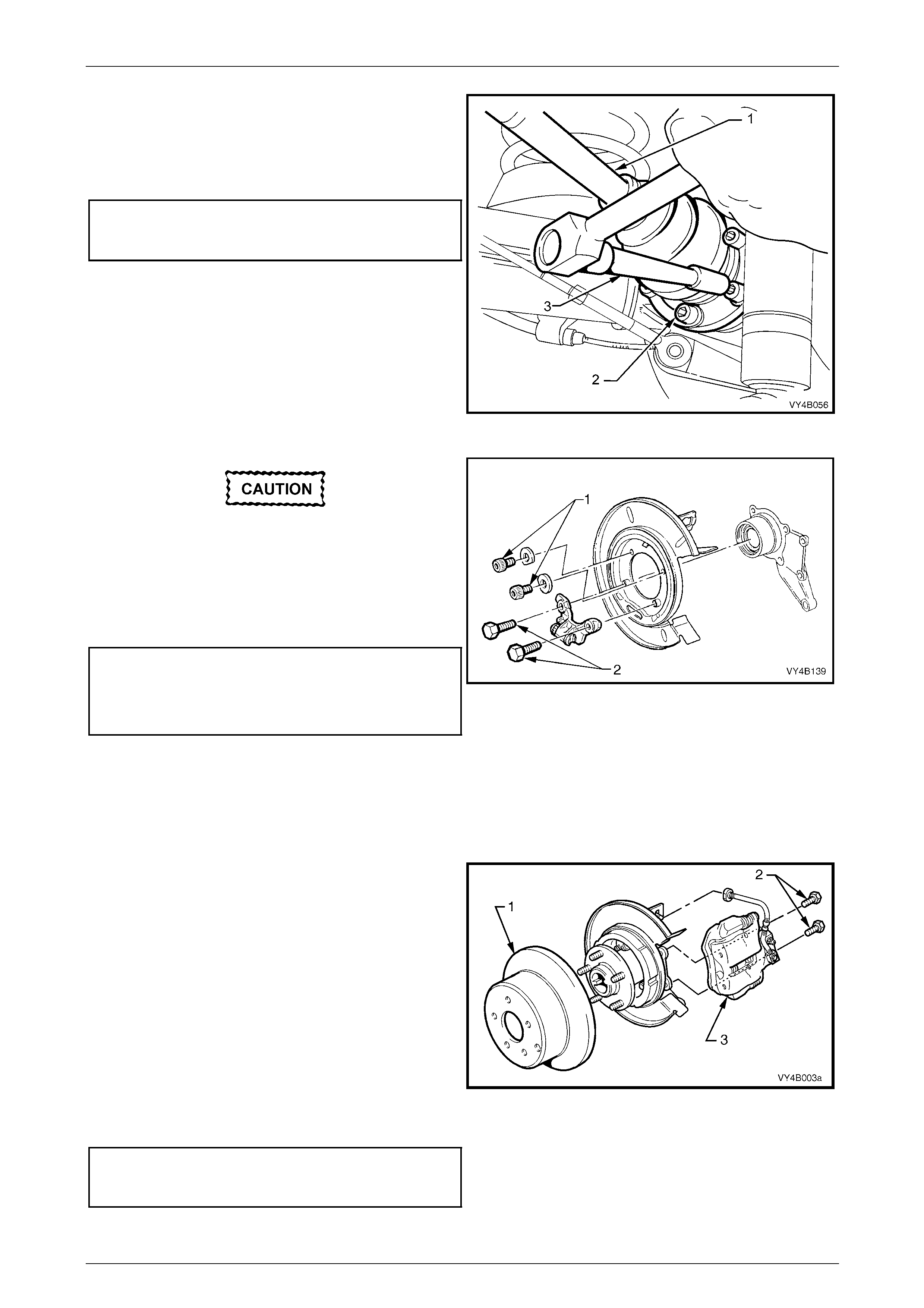

20 Secure flange holding tool, KM620-1A and outer rear

wheel drive shaft flange ring tool KM620-2 to outer

rear wheel drive shaft flange (1) with three of the

removed drive shaft constant velocity joint to outer