Service and Park Braking Systems Page 5A-1

Page 5A-86

Section 5A

Service and Park Braking Systems

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

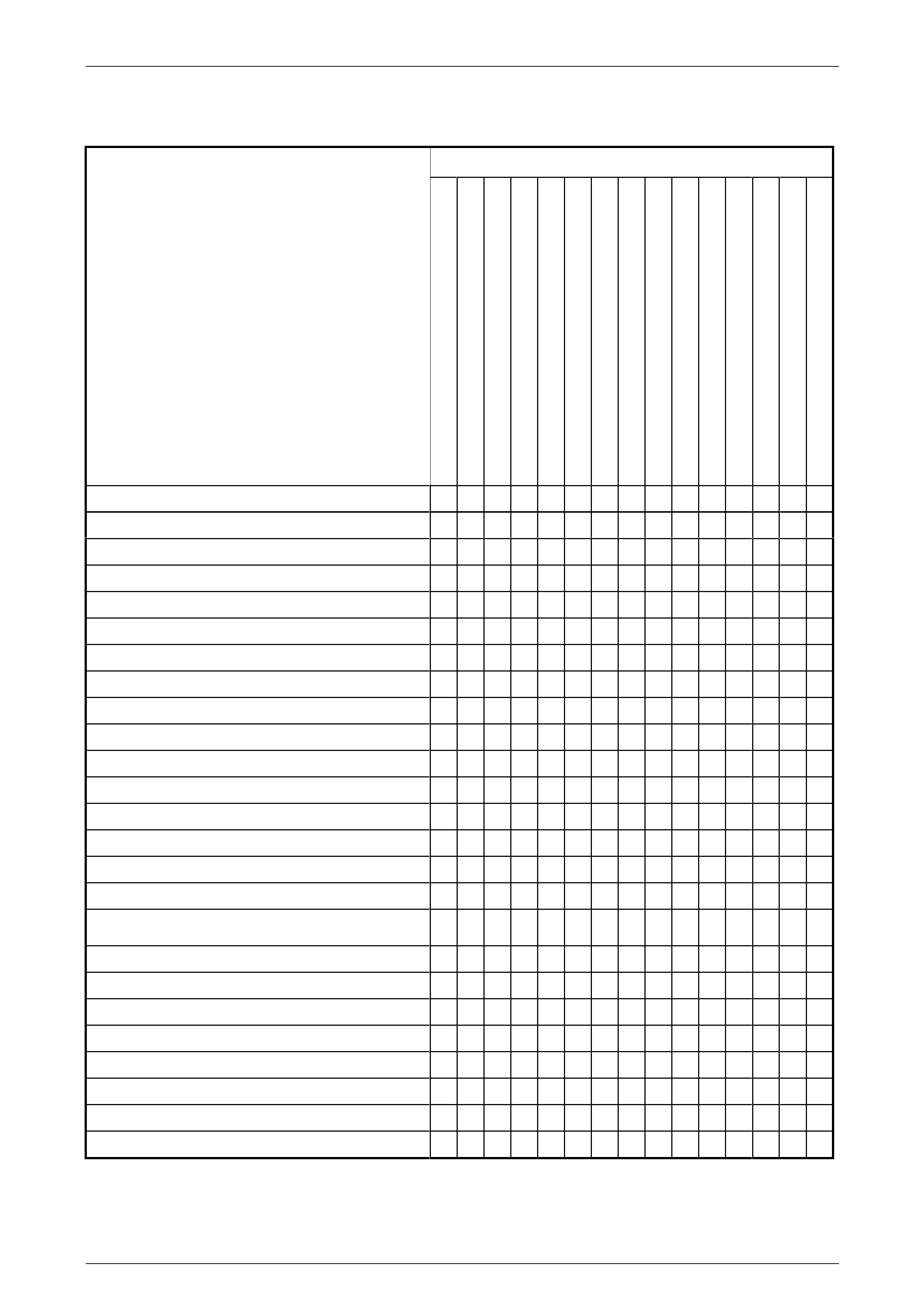

1 General Information ...............................................................................................................................4

1.1 General Description............................................................................................................................................... 4

1.2 Master Cylinder...................................................................................................................................................... 5

Description............................................................................................................................................................. 5

Construction........................................................................................................................................................... 5

Operation................................................................................................................................................................ 6

1.3 Vacuum Brake Booster ......................................................................................................................................... 7

Description............................................................................................................................................................. 7

Construction........................................................................................................................................................... 7

Operation................................................................................................................................................................ 7

Mechanical Brake Assist (MBA)......................................................................................................................... 7

1.4 Front and Rear Brake Calipers ............................................................................................................................. 8

1.5 Brake Pipes and Hoses ......................................................................................................................................... 9

Description............................................................................................................................................................. 9

2. Minor Service Operations..........................................................................................................................10

2.1 Service Warnings, Cautions and Notes............................................................................................................. 10

2.2 Park Brake Cable, Adjust.................................................................................................................................... 12

2.3 Brake Fluid Level Check ..................................................................................................................................... 13

2.4 Brake System Bleed ............................................................................................................................................ 14

2.5 Brake Fluid, Change............................................................................................................................................ 15

Draining Master Cylinder .................................................................................................................................... 15

Draining Brake Calipers ...................................................................................................................................... 16

2.6 Brake Pad Wear, Check....................................................................................................................................... 17

Front or Rear........................................................................................................................................................ 17

2.7 Brake Pads, Replace............................................................................................................................................ 18

Preparation........................................................................................................................................................... 18

Front Brake Pads................................................................................................................................................. 19

Remove............................................................................................................................................................ 19

Installation........................................................................................................................................................ 20

Rear Brake Pads .................................................................................................................................................. 21

Remove............................................................................................................................................................ 21

Reinstall ........................................................................................................................................................... 22

Brake Pad Bedding-In Procedure....................................................................................................................... 22

2.8 Brake Pedal Assembly.............................................................................................................................................. 23

Remove................................................................................................................................................................. 23

Disassemble......................................................................................................................................................... 26

Reassemble.......................................................................................................................................................... 26

Reinstall................................................................................................................................................................ 27

2.9 Park Brake Lever.................................................................................................................................................. 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 29

2.10 Park Brake Warning Lamp Switch...................................................................................................................... 30

Remove................................................................................................................................................................. 30

Inspect .................................................................................................................................................................. 30

Reinstall................................................................................................................................................................ 31

Techline

Service and Park Braking Systems Page 5A-2

Page 5A-86

2.11 Front Park Brake Cable ....................................................................................................................................... 32

Remove................................................................................................................................................................. 32

Reinstall................................................................................................................................................................ 32

2.12 Rear Park Brake Cable/s ..................................................................................................................................... 34

Remove................................................................................................................................................................. 34

Reinstall................................................................................................................................................................ 35

2.13 Front Caliper Brake Hose.................................................................................................................................... 36

Remove................................................................................................................................................................. 36

Reinstall................................................................................................................................................................ 37

2.14 Rear Caliper Brake Hose..................................................................................................................................... 39

Remove................................................................................................................................................................. 39

Reinstall................................................................................................................................................................ 39

2.15 Rear Brake Hoses................................................................................................................................................ 40

Remove................................................................................................................................................................. 40

Reinstall................................................................................................................................................................ 41

2.16 Brake Booster Hose & Valve Assembly – V6 Engine........................................................................................ 42

Replace................................................................................................................................................................. 42

2.17 Brake Booster Hose & Valve Assembly – GEN III V8 Engine........................................................................... 43

Replace................................................................................................................................................................. 43

2.18 Brake Fluid Level Switch..................................................................................................................................... 44

Test ....................................................................................................................................................................... 44

Replace................................................................................................................................................................. 44

3 Major Service Operations....................................................................................................................45

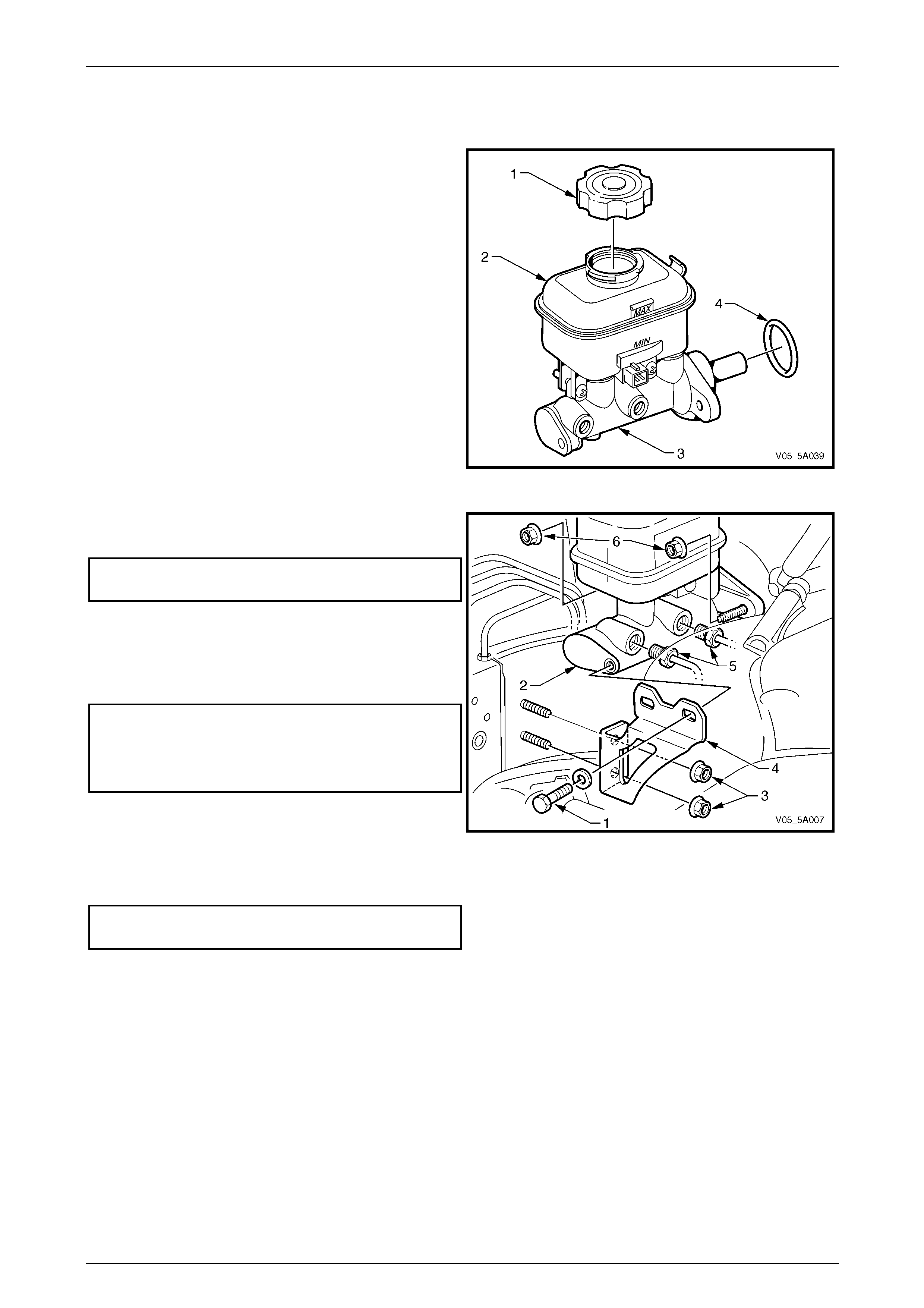

3.1 Master Cylinder.................................................................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 46

3.2 Brake Master Cylinder Reservoir........................................................................................................................ 47

Replace................................................................................................................................................................. 47

3.3 Brake Booster ...................................................................................................................................................... 48

Remove................................................................................................................................................................. 48

Reinstall................................................................................................................................................................ 49

3.4 Front Brake Caliper.............................................................................................................................................. 50

Remove................................................................................................................................................................. 50

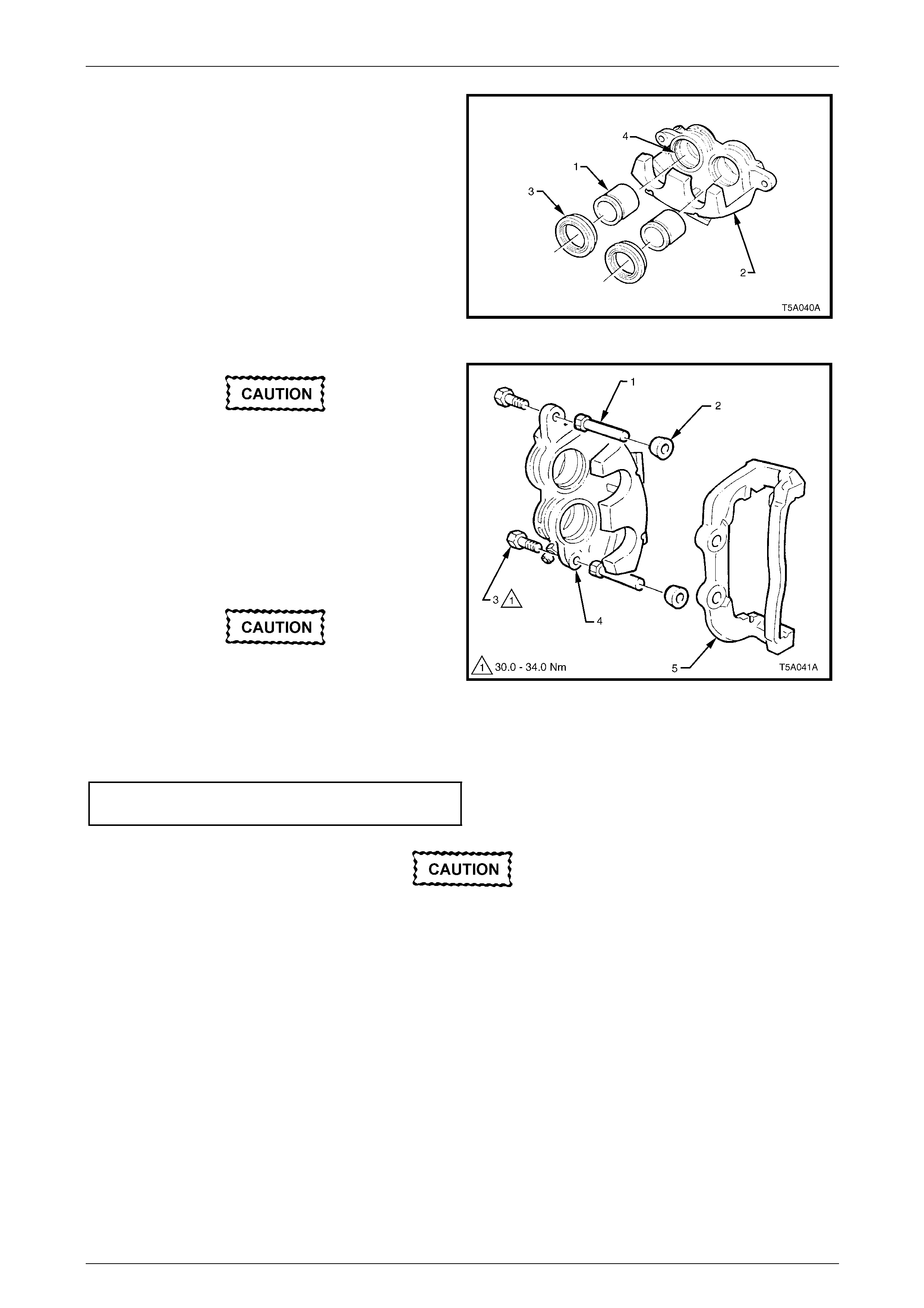

Disassemble......................................................................................................................................................... 51

Clean and Inspect................................................................................................................................................ 52

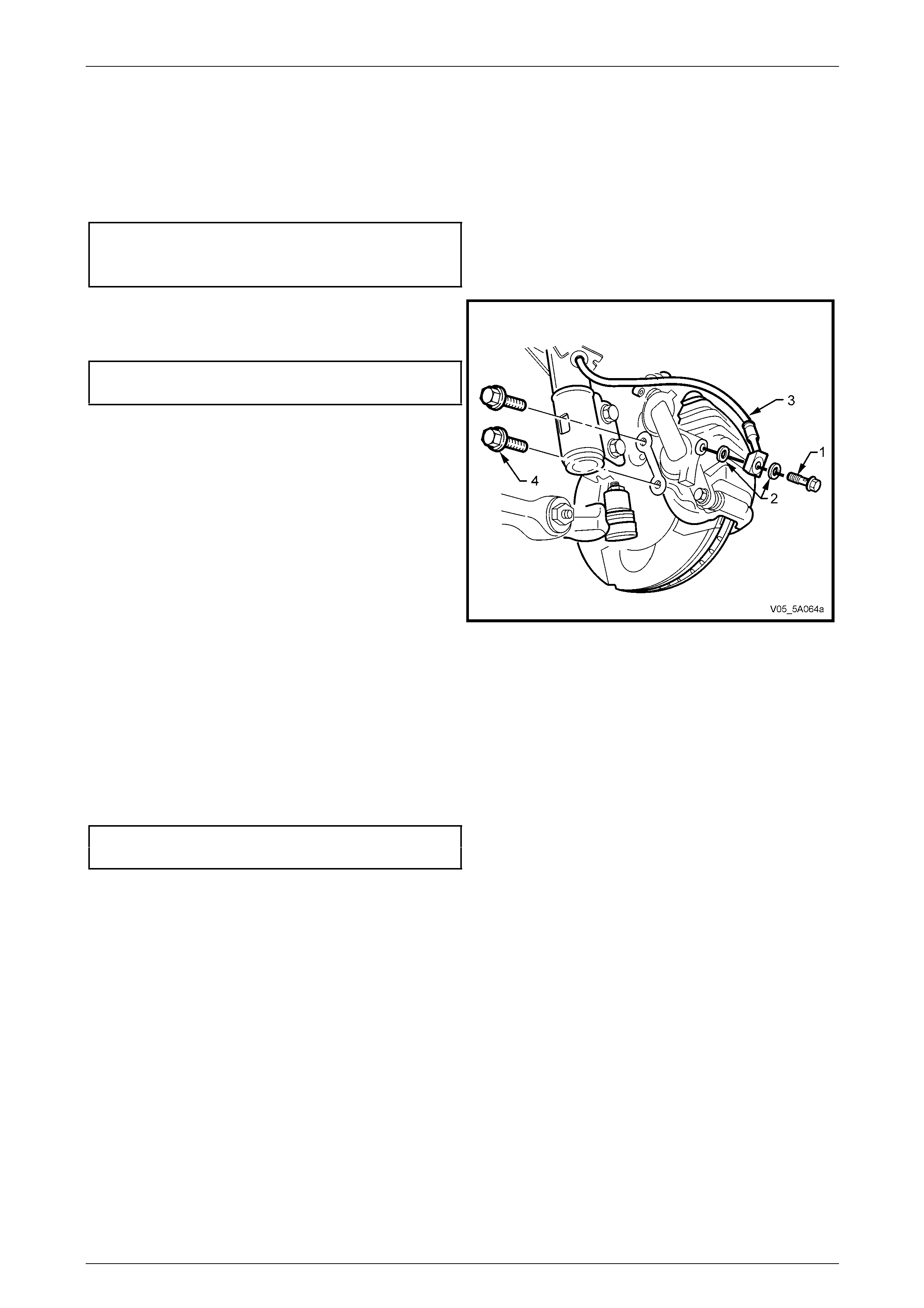

Reassemble.......................................................................................................................................................... 52

Reinstall................................................................................................................................................................ 54

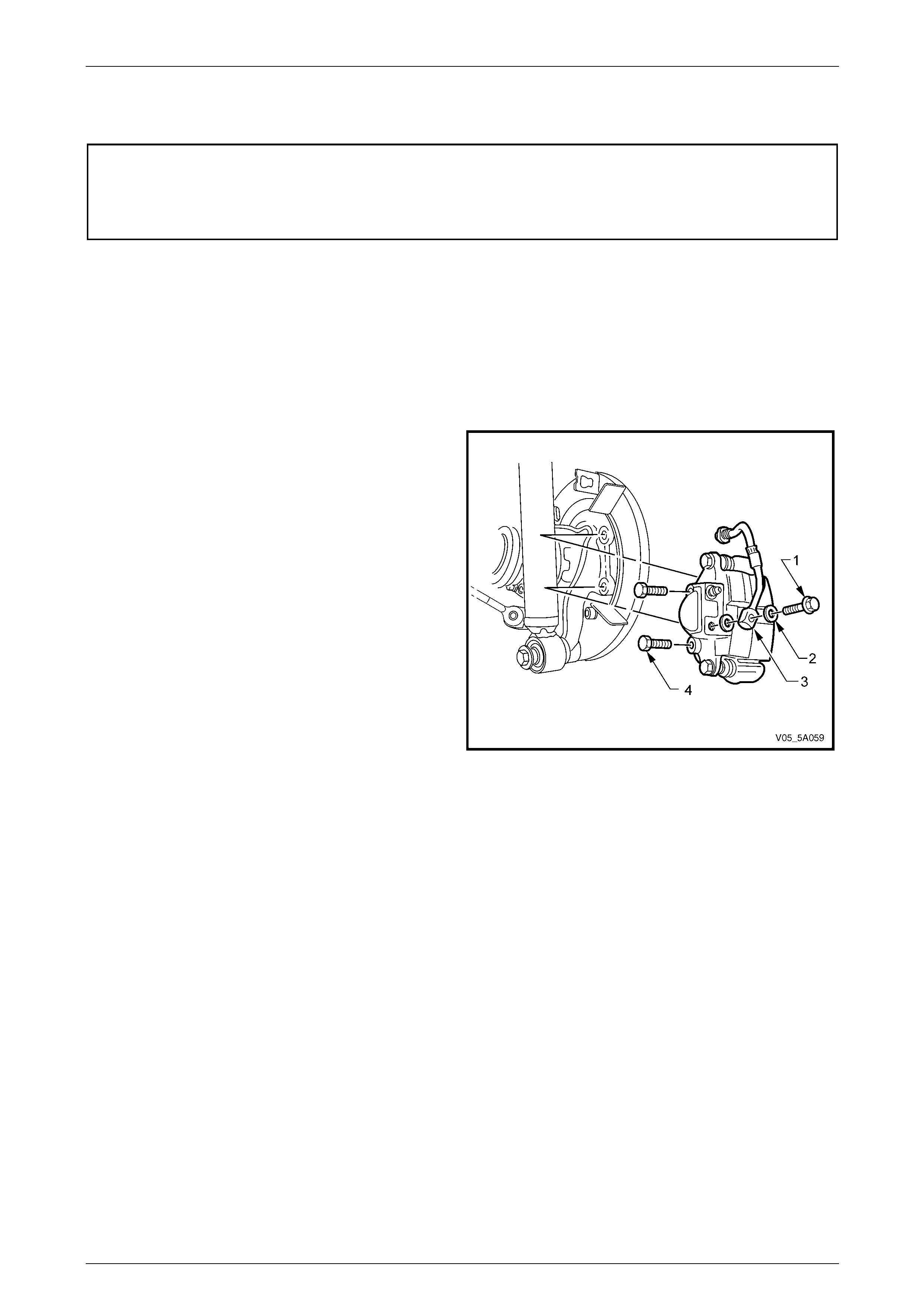

3.5 Rear Brake Caliper............................................................................................................................................... 55

Remove................................................................................................................................................................. 55

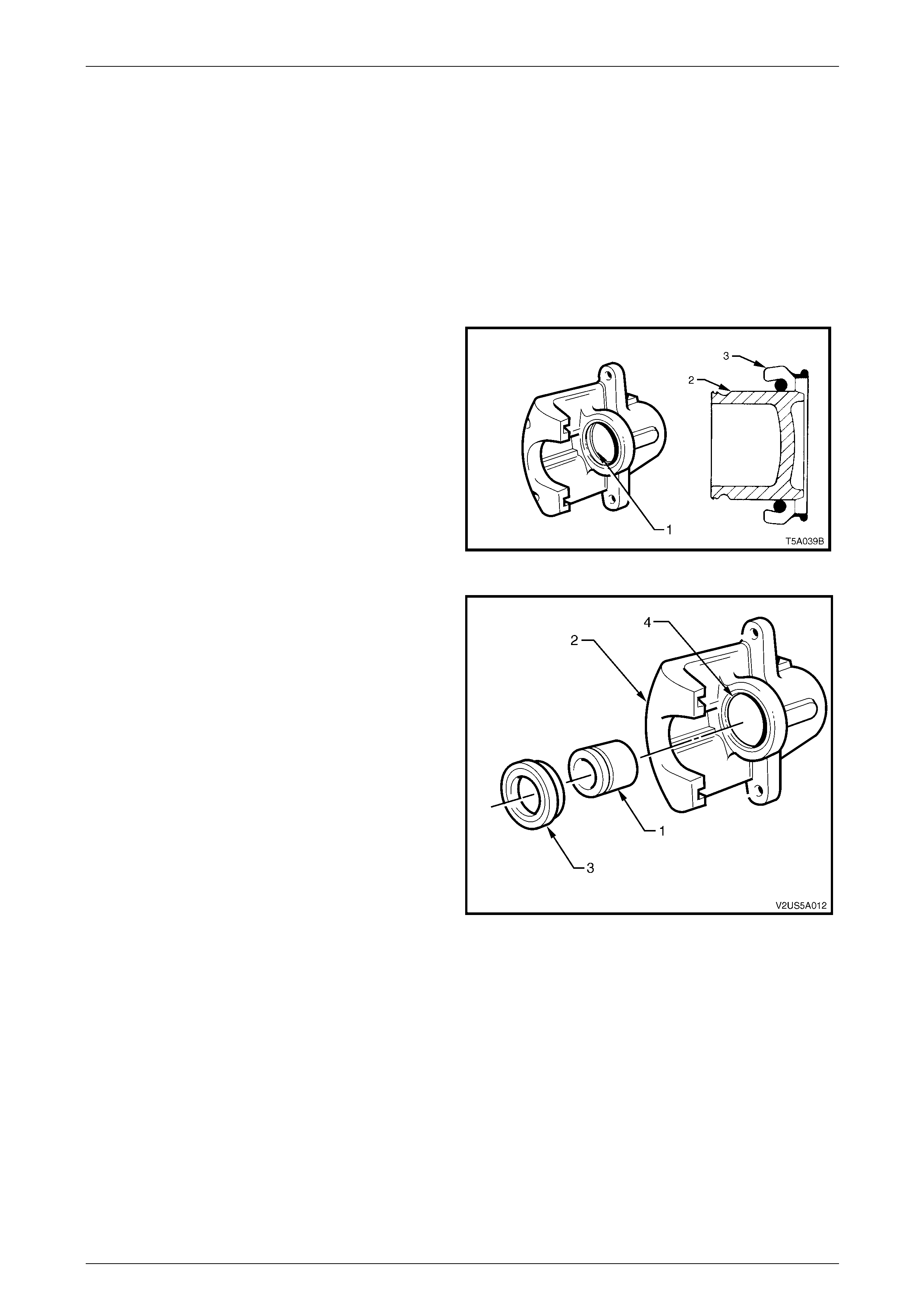

Disassemble......................................................................................................................................................... 55

Clean and Inspect................................................................................................................................................ 57

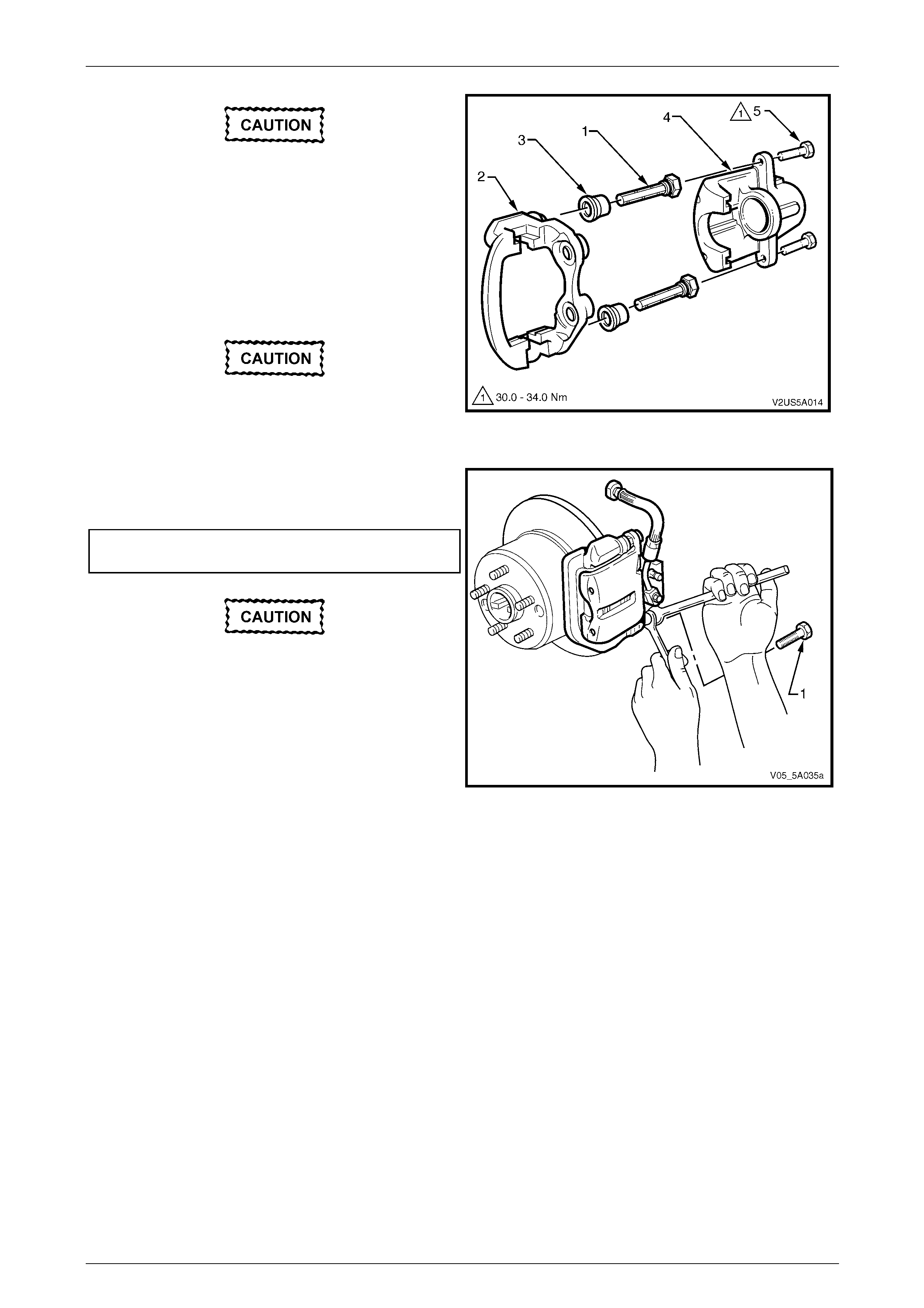

Reassemble.......................................................................................................................................................... 57

Reinstall................................................................................................................................................................ 59

3.6 Front Brake Disc.................................................................................................................................................. 60

Remove................................................................................................................................................................. 60

Inspect .................................................................................................................................................................. 61

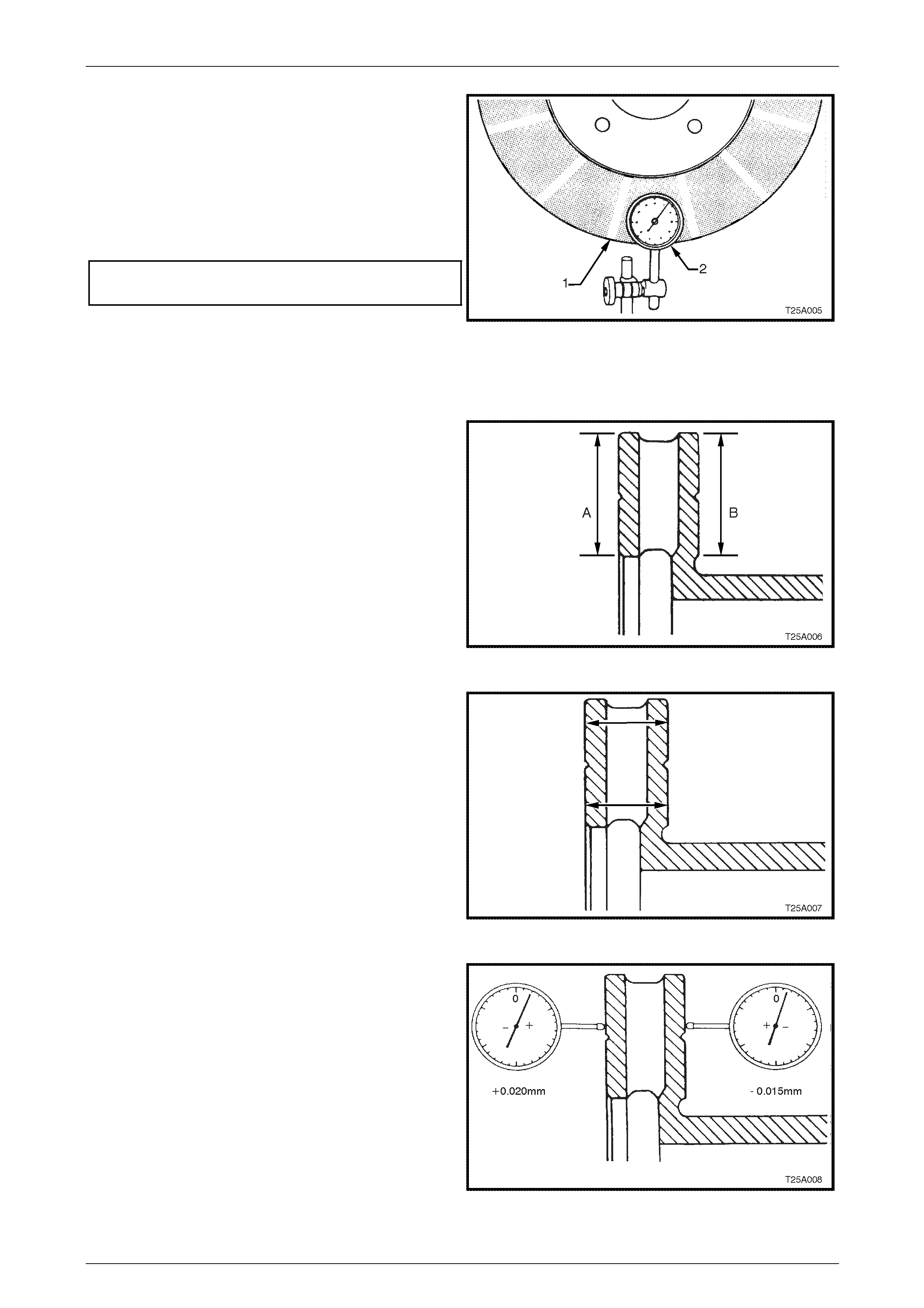

Front Brake Disc and Hub Indexing Procedure................................................................................................. 63

Part 1. Clean Mating Surfaces ......................................................................................................................... 63

Part 2. Indexing Brake Disc to Hub .................................................................................................................. 63

Part 3. Hub Runout Check ............................................................................................................................... 64

Reinstall................................................................................................................................................................ 65

3.7 Rear Brake Disc ................................................................................................................................................... 66

Remove................................................................................................................................................................. 66

Inspect .................................................................................................................................................................. 67

All Models......................................................................................................................................................... 67

Rear Brake Disc and Hub Indexing Procedure.................................................................................................. 68

Part 1 Clean Mating Surfaces .......................................................................................................................... 68

Part 2 Indexing Brake Disc to Hub ................................................................................................................... 69

Service and Park Braking Systems Page 5A-3

Page 5A-86

Part 3 Trunnion Hub Runout Check ................................................................................................................. 70

Reinstall................................................................................................................................................................ 70

3.8 Park Brake Lining Wear, Check.......................................................................................................................... 71

3.9 Park Brake Shoe, Adjust ..................................................................................................................................... 72

3.10 Park Brake Shoe .................................................................................................................................................. 74

Remove................................................................................................................................................................. 74

Reinstall................................................................................................................................................................ 75

3.11 Front Disc Brake Shield ...................................................................................................................................... 77

3.12 Rear Disc Brake Dust Shield............................................................................................................................... 78

Remove................................................................................................................................................................. 78

Reinstall................................................................................................................................................................ 80

4. Diagnosis ..............................................................................................................................................82

5 Specifications.......................................................................................................................................83

6 Torque Wrench Specifications............................................................................................................85

7 Special Tools ........................................................................................................................................86

Service and Park Braking Systems Page 5A-4

Page 5A-86

1 General Information

1.1 General Description

Some illustrations in this Section may show components that are not fitted to all vehicles. Where differences in service

procedures apply, then relevant information relating to those differences are made.

All MY2005 WL Series vehicles are fitted with a Stepped Tandem, Vacuum Suspended type brake booster and a 26 mm

bore master cylinder. Neither the master cylinder nor the brake booster serviceable and m ust be replaced if proven to be

defective.

There are a number of different master cylinders that eac h have unique characteristics to suit the ap plication intended.

Therefore, should a master cylinder ne ed to be replaced, then the correct assembly for that applicati on must be fitted.

Refer to the current Partfinder™ parts catalogue for the correct replacement.

All MY2005 WL Series vehicles are fitted with ventilated discs at the front and solid discs at the rear. The brake ca lipers

are the sliding, reaction type, with twin pistons in the front calipers and a singl e in the rear.

The front disc brake caliper is attached to the steering knuckle support by two bolts, while the front wheel bearing hub

attaches to the steering knuckle, using three bolts. The front dust shield is also attached to the steering knuckl e support

by three pop rivets.

The rear brake backing plate assemb ly is bolted to the trailing arm, as is the disc brake caliper. The machined inner

surface of the disc hub acts as the brake drum for the park brake.

The single shoe, Banksia design park brake is a drum type with a manual adj ustment incorporated into the design. The

park brake is operated by a cable at the rear, connected to an equaliser bracket. Park brake application force is applied

to this equaliser bracket, via a singl e cable, connected to the floor mounted, button release, park brake lever. Adjustment

of the parking brake cables on all W L mod els is provided for, by a threaded end on the front, single cable, at the park

brake lever end.

For a description and servicing information relating to the Anti-lock Brakin g System (ABS), Traction Control (TC),

Electronic Stability Program (ESP), Electroni c Brake Assist (EBA) and/or Electronic Brake Distribution (EBD) s ystems,

refer to Section 5B ABS / TCS /ESP – General Information where direction to specific information on any of these

systems, is detailed.

Service and Park Braking Systems Page 5A-5

Page 5A-86

1.2 Master Cylinder

Description

A tandem master cylinder with a 26 mm diameter bore is used on all MY 2 005 WL Series vehicles, regardless of the

braking system. There are however, unique differences in design, with a br ief summary being:

a An ABS type master cylinder has two pipes connected to the ABS hydraulic modulator; one for the front brakes

(primary) and the other (secondar y) for the rear.

b For those MY 2005 WL Series vehicles fitted with Electronic Brake Assist (EBA) and Electronic Stabi lity Program

(ESP), the master cylinder has unique internal valving to optimise the effect of these features.

c No vehicle in the MY 2005 WL model range has a brake proportioning valve. Front to rear braking balance is

achieved by electronic control from the ABS module (referred to as ‘Electronic Brake Differential – EBD), through

the hydraulic modulator.

It is vital that the correct replacement master cylinder is fitted to any MY 2005 WL Series vehicle. Refer to the current

release of PartFinder™ for the correct part.

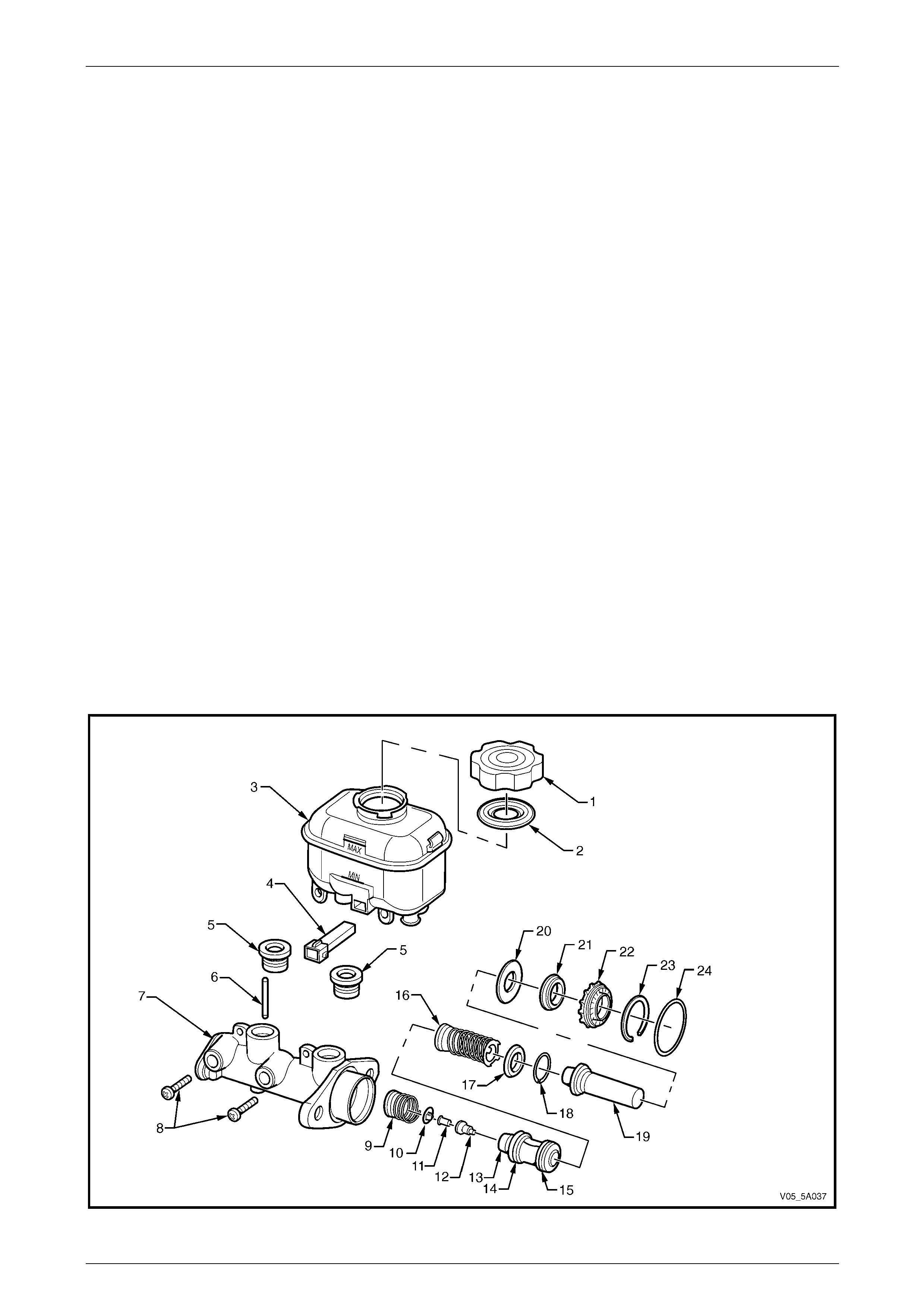

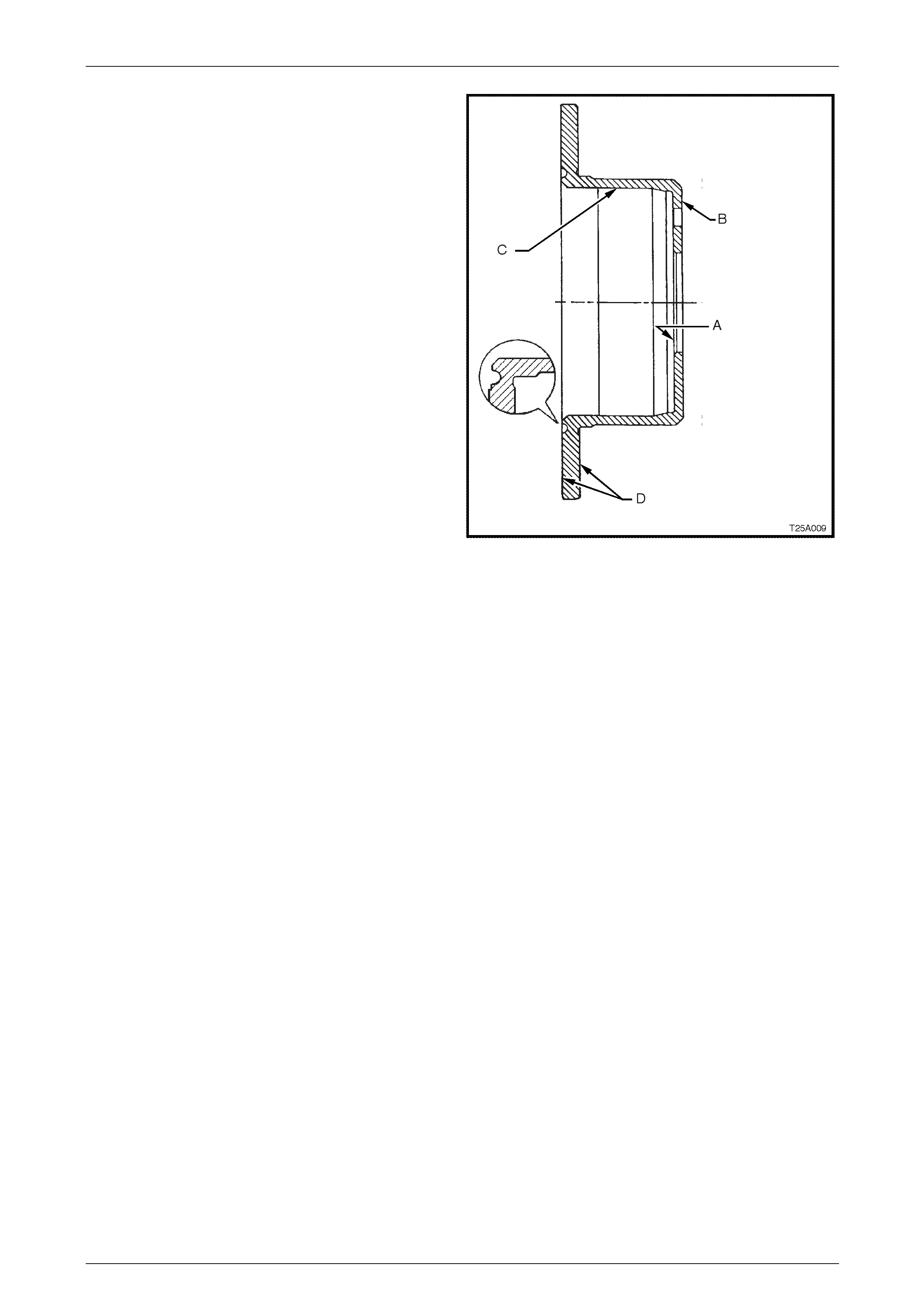

Construction

This tandem, centre valve design master cylinder is attached to the vacuum brake booster, which is mounted to the

engine side of the dash panel. The master cylinder provides separate hydraulic circuits for the application of the brakes,

in a front (primary) to rear (secondary) split arrangement.

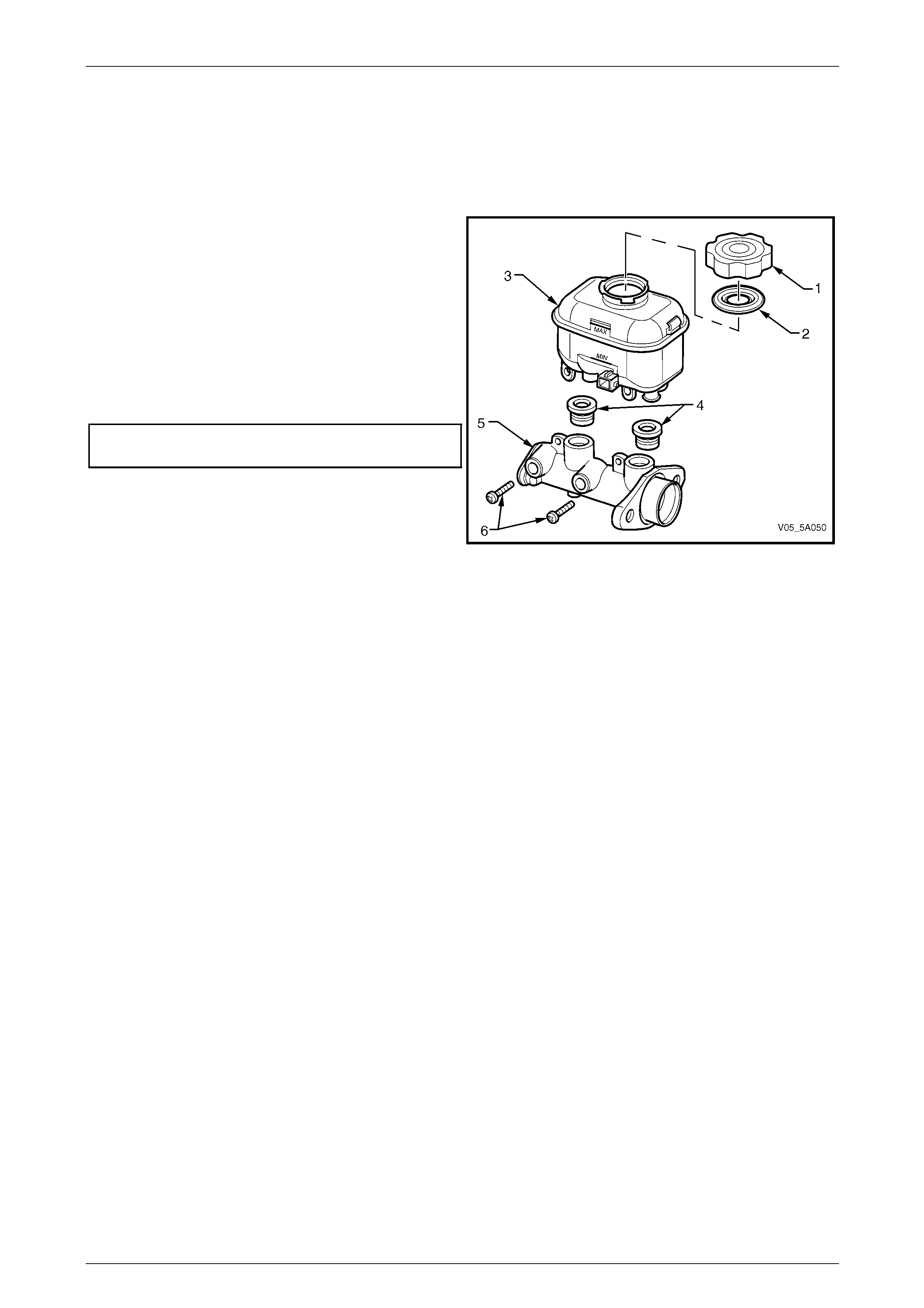

Both of these circuits are fed by separate flui d feed through a common fluid reservoir (3), that has a se al (2) fitted inside

the reservoir cap (1). This seal provides an effective seal against any atmospheric moisture comi ng into contact with the

hygroscopic brake fluid. This provision maintains the brake fluid's boiling point, for a maximum period of time.

The internal parts of the alumi nium a lloy master cylinder comprise a primary piston (19) supported by a gui de bush and

O-ring (22), with a recuperation seal (17) and a secondary piston (15) incorporating a ce ntre valve (12), a caged spring

(11), a recuperation (14) and an L t ype seal (15), a return spring (9) and a piston stop pin (6). The master cylinder bore is

anodised and is not to be hon ed.

An O-ring seal (24) is fitted to the master cylinder mounting flange, to provi de a vacuum seal between the master

cylinder and the vacuum susp ended brake booster.

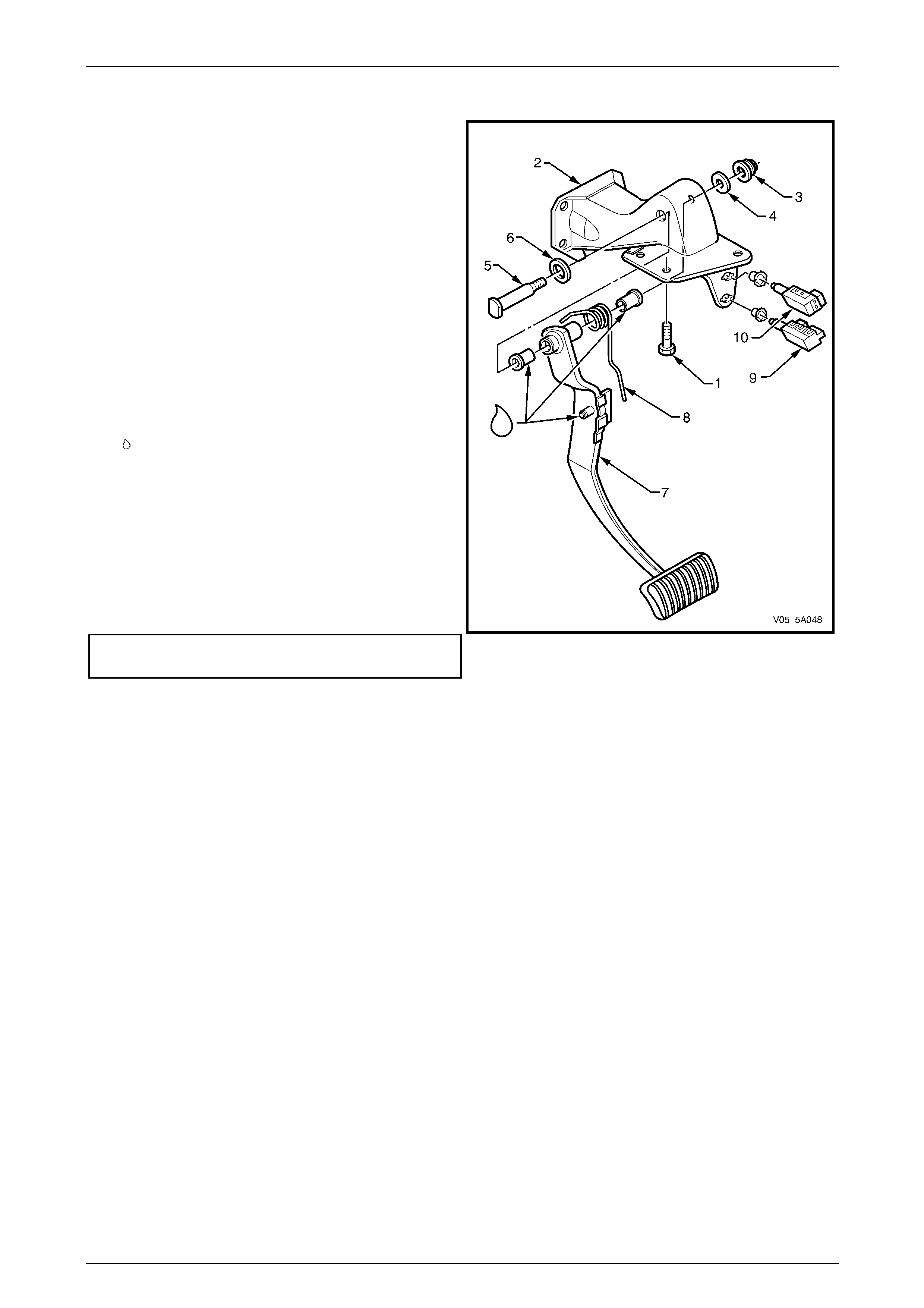

Figure 5A – 1 – Typical Exploded View of Brake Master Cylinder

Service and Park Braking Systems Page 5A-6

Page 5A-86

Legend

1 Reservoir Cap

2 Reservoir Cap Seal

3 Brake Fluid Reservoir

4 Fluid Level Switch

5 Sealing Grommets

6 Cylinder Pin

7 Master Cylinder Body

8 Reservoir Retaining Screw

9 Return Spring

10 Centre Valve Sleeve

11 Centre Valve Spring

12 Centre Valve Plunger and Seal

13 Secondary Piston

14 Secondary Recuperating Seal

15 L Type Primary Seal

16 Return Spring and Retainer

17 Primary Recuperating Seal

18 Washer

19 Primary Piston

20 Primary Piston Support Washer

21 Vacuum Seal

22 Primary Piston Guide Bush and O-ring

23 Circlip

24 O-ring Seal

Operation

When the brake pedal is depressed, force is applied by mechanical linkage to the vacuum suspen ded brake booster.

Vacuum assisted force is then applied to the primar y and secondary master cylinder pistons. As the pis t ons are stroked

in the master cylinder bore, the developed hydraulic pressure is used to apply the front and rear disc brakes.

Once the brake pedal is released, the primary and secondary springs return the pistons to the released position and

brake fluid returns to the reservoir.

Service and Park Braking Systems Page 5A-7

Page 5A-86

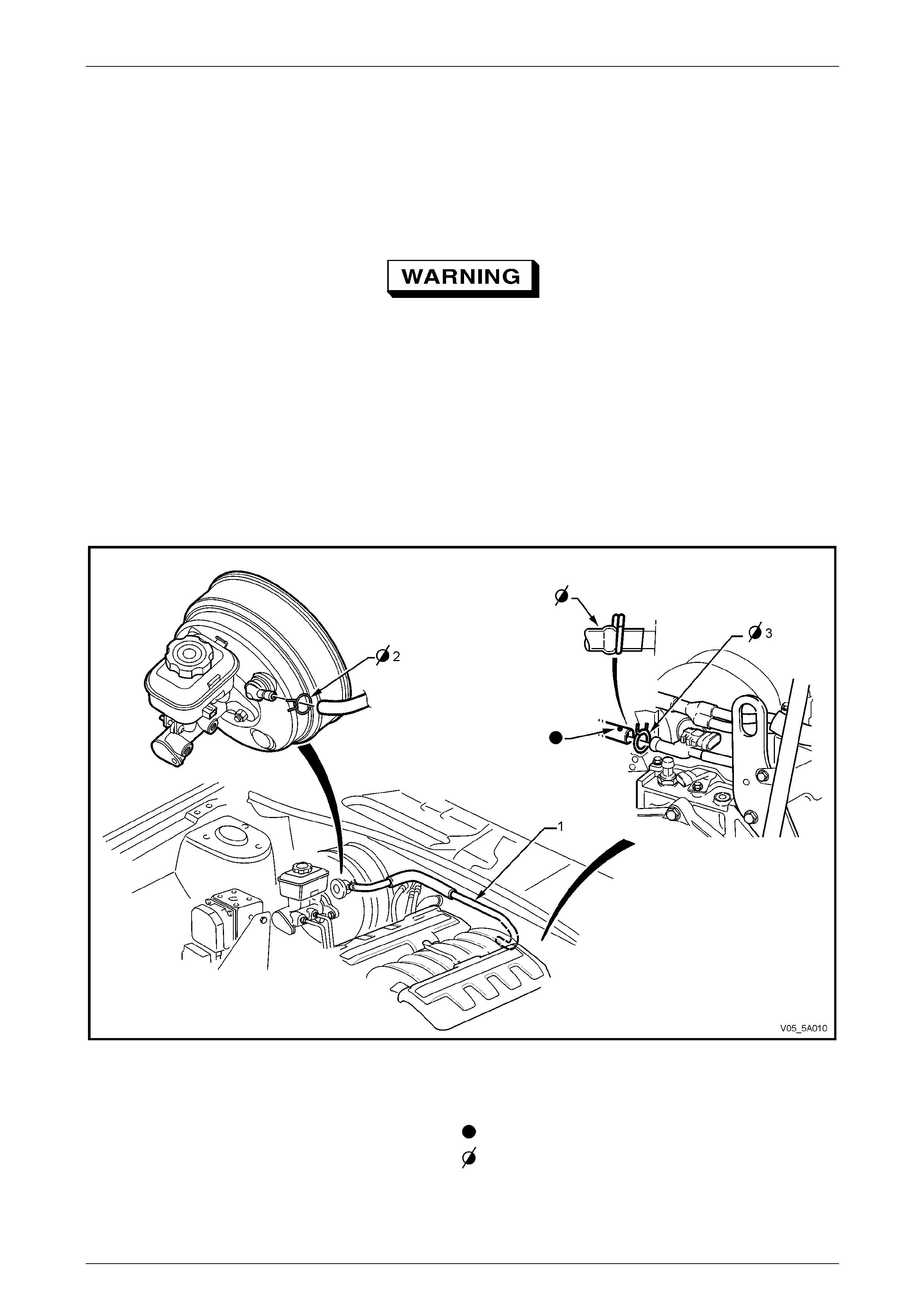

1.3 Vacuum Brake Booster

Description

The brake booster is designed to reduce th e force required to develop the required brake fluid pressure, necessary to

apply the front and rear brakes.

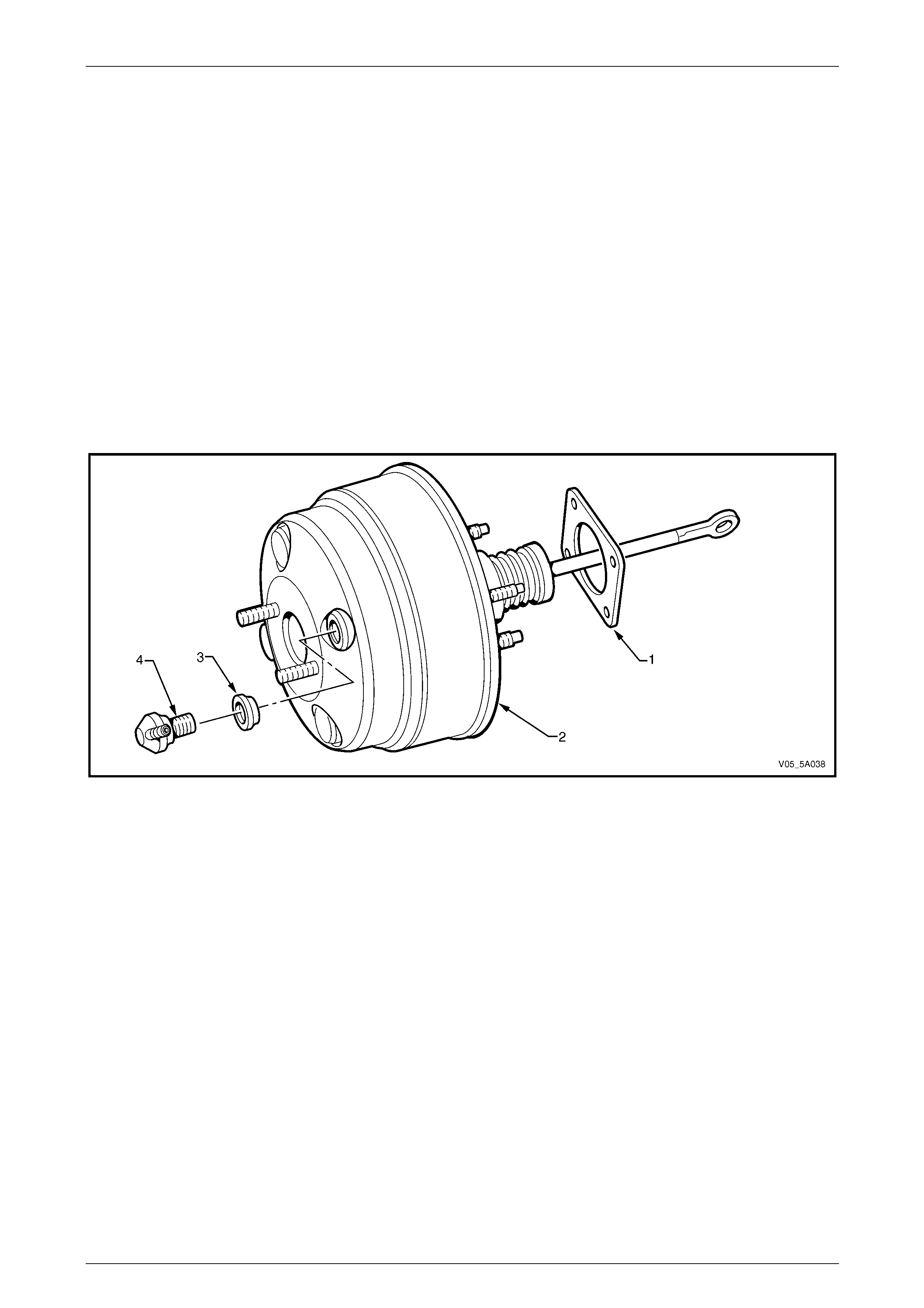

Construction

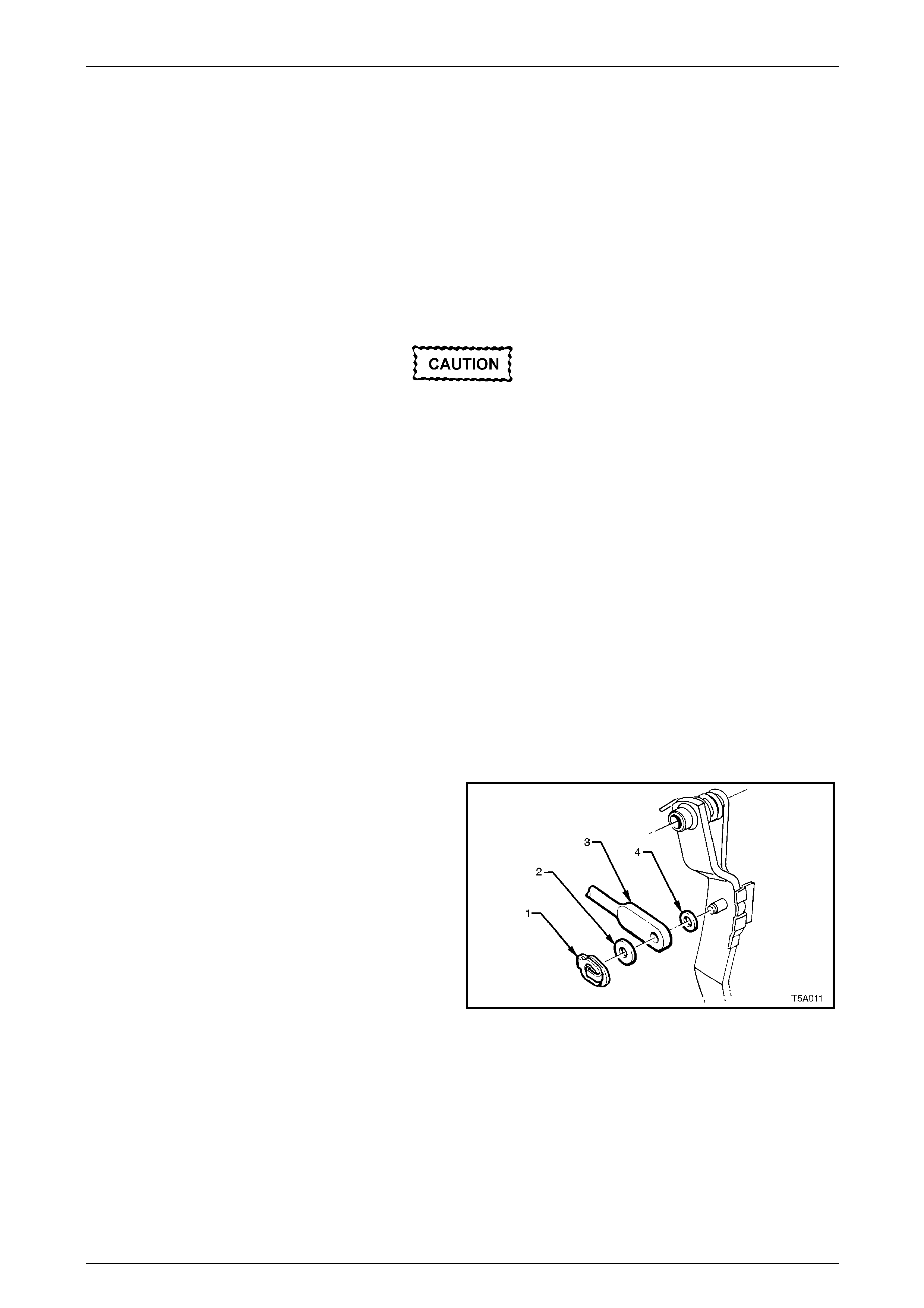

There are no serviced components within the brake booster (2) assembly and, if found to be faulty, the complete unit

must be replaced. A sealing gasket (1) is positioned between the booster and the instrument panel that is used to both

seal the connection and to dampen noise transfer.

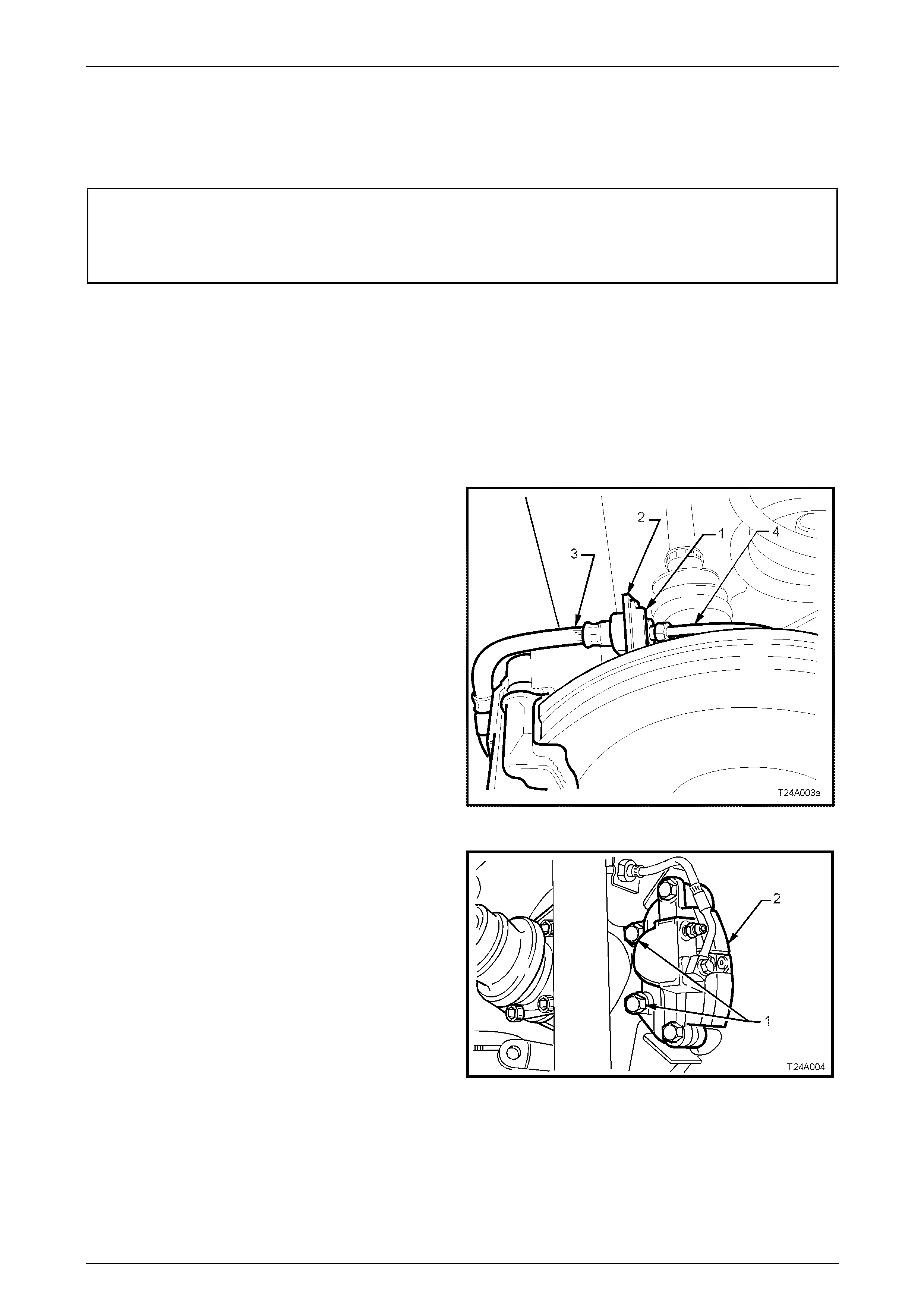

A one-way vacuum valve (4) is fitted to the front casing of the booster assembly, secured by a grommet (3). This non-

return valve is used to maintain the vacuum suppl y in the brake booster for a limited number of brake applications,

should an emergency situ ation occur, such as engine failure.

The barcode label attached to the front of the booster provides the booster part number and build data (e.g. month, day,

year, shift, line number). Check the current release of PartFinder™ for the correct part number for the vehicle requiring

the part.

Figure 5A – 2

Legend

1 Sealing Gasket

2 Vacuum Booster Assembly 3 Sealing Grommet

4 One-way Valve

Operation

When the brake pedal is depressed, movement of the booster input rod controls the opening and closing of internal

valving, allowing atmospheric pressure to enter one side of a diaphragm. With engine vacuum always present on the

other side, the pressure difference provides the required assistance in the movement of the master cylin der pistons and

the application of the brakes.

Mechanical Brake Assist (MBA)

The Mechanical Brake Assist (MBA) feature results from a mecha nical, two stage valving design within the brake

booster, that provides a dual reaction ratio, which has the effect of assisting the driver to reach ABS braking threshold

more easily. To assist in an emergency situation, MBA produces a quick booster response and reduces pedal effort

without affecting the pedal 'feel'.

MBA however, will change the brake peda l feel above a 0.5 to 0.6 g deceleration a nd is a feature of all vacuum boosters ,

fitted to MY 2005 WL Series vehicles with ABS or ABS/TC.

Service and Park Braking Systems Page 5A-8

Page 5A-86

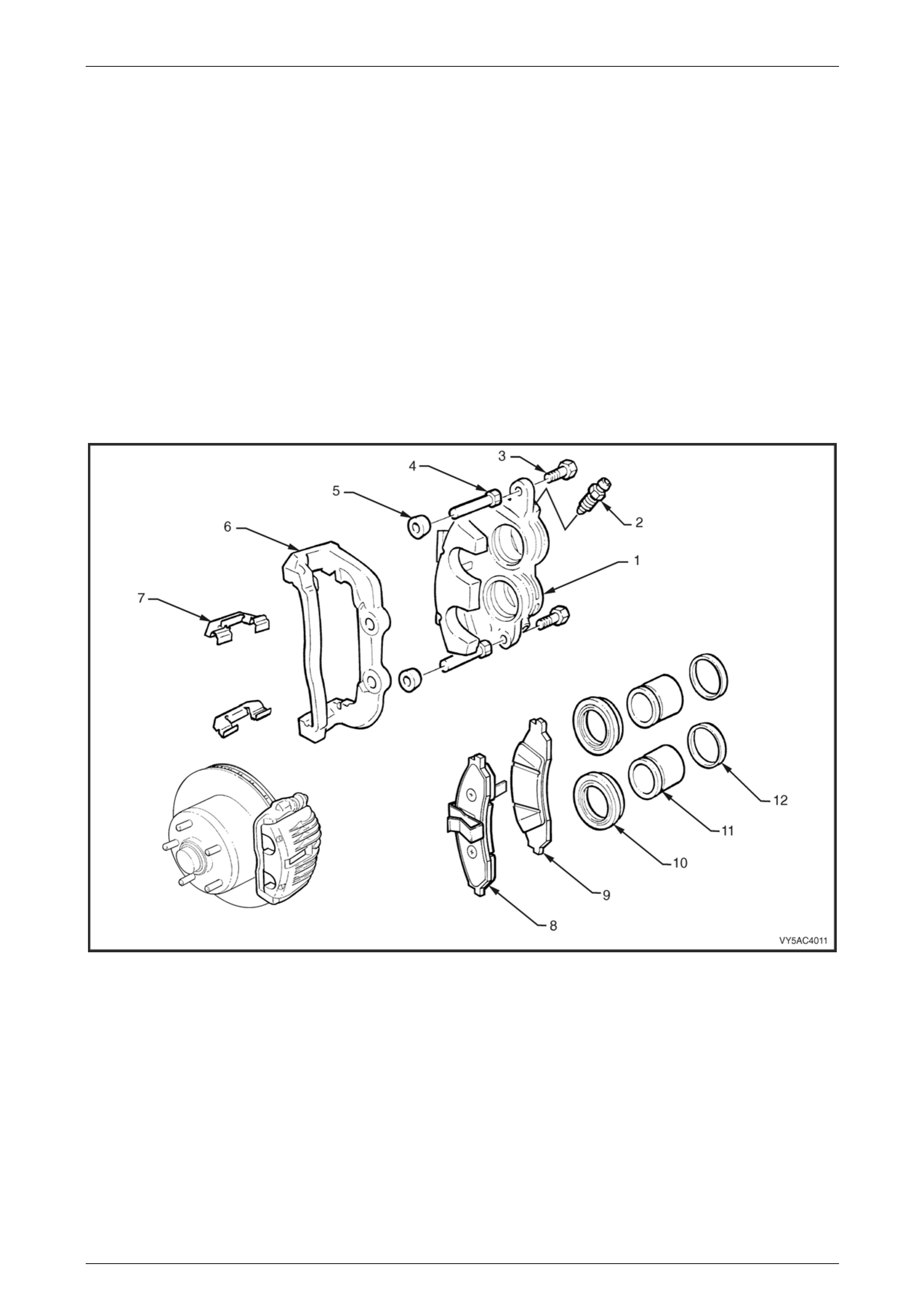

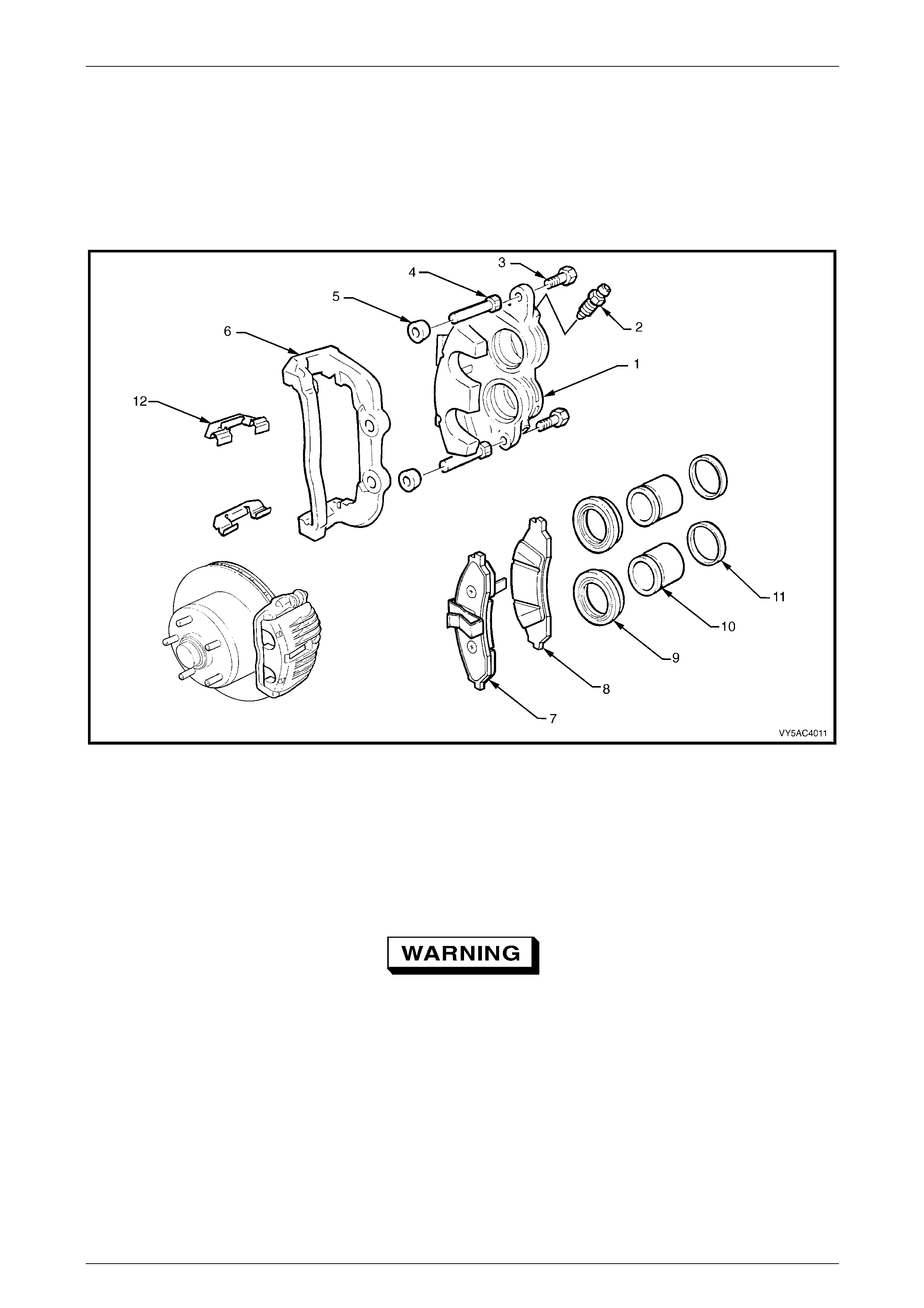

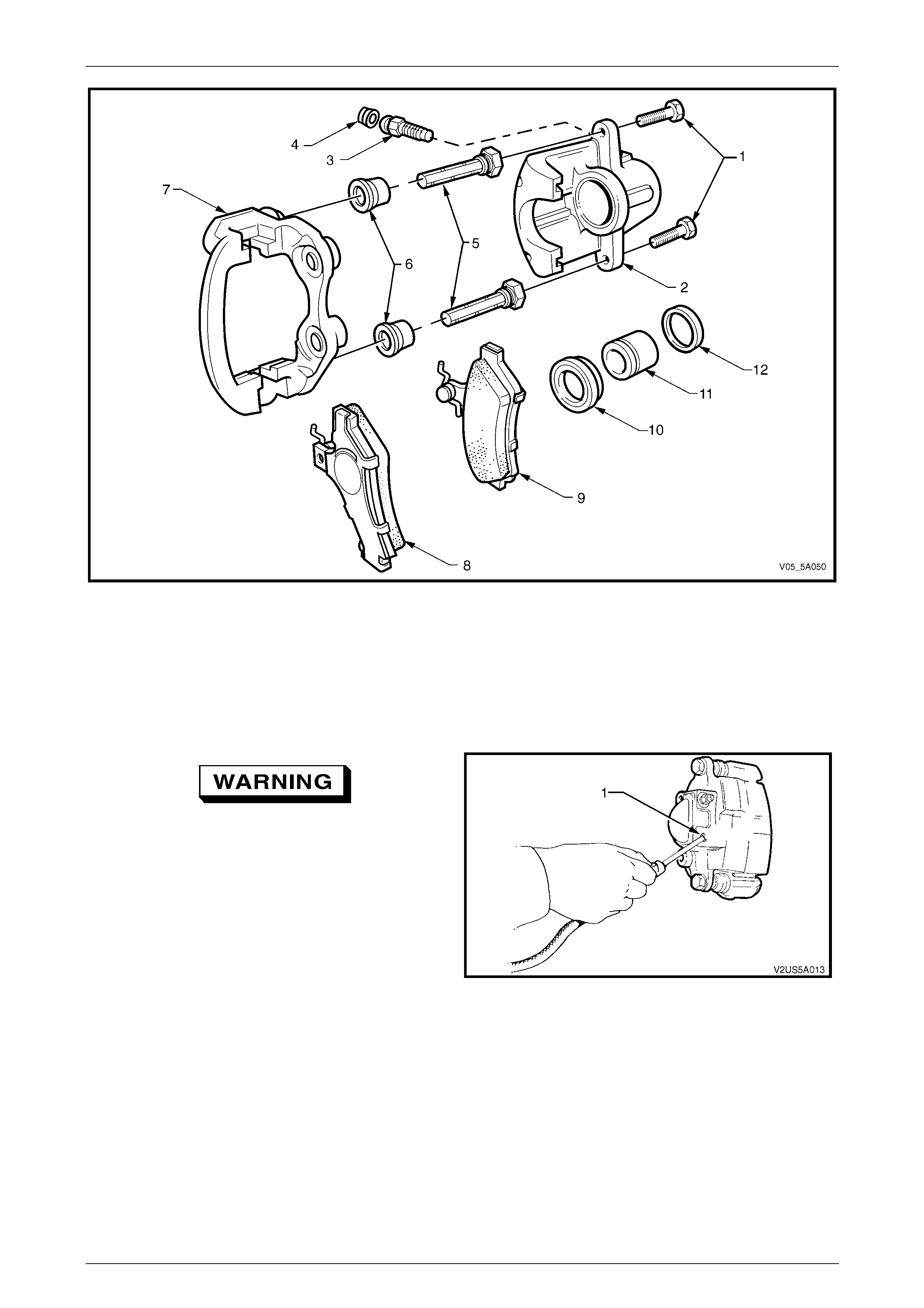

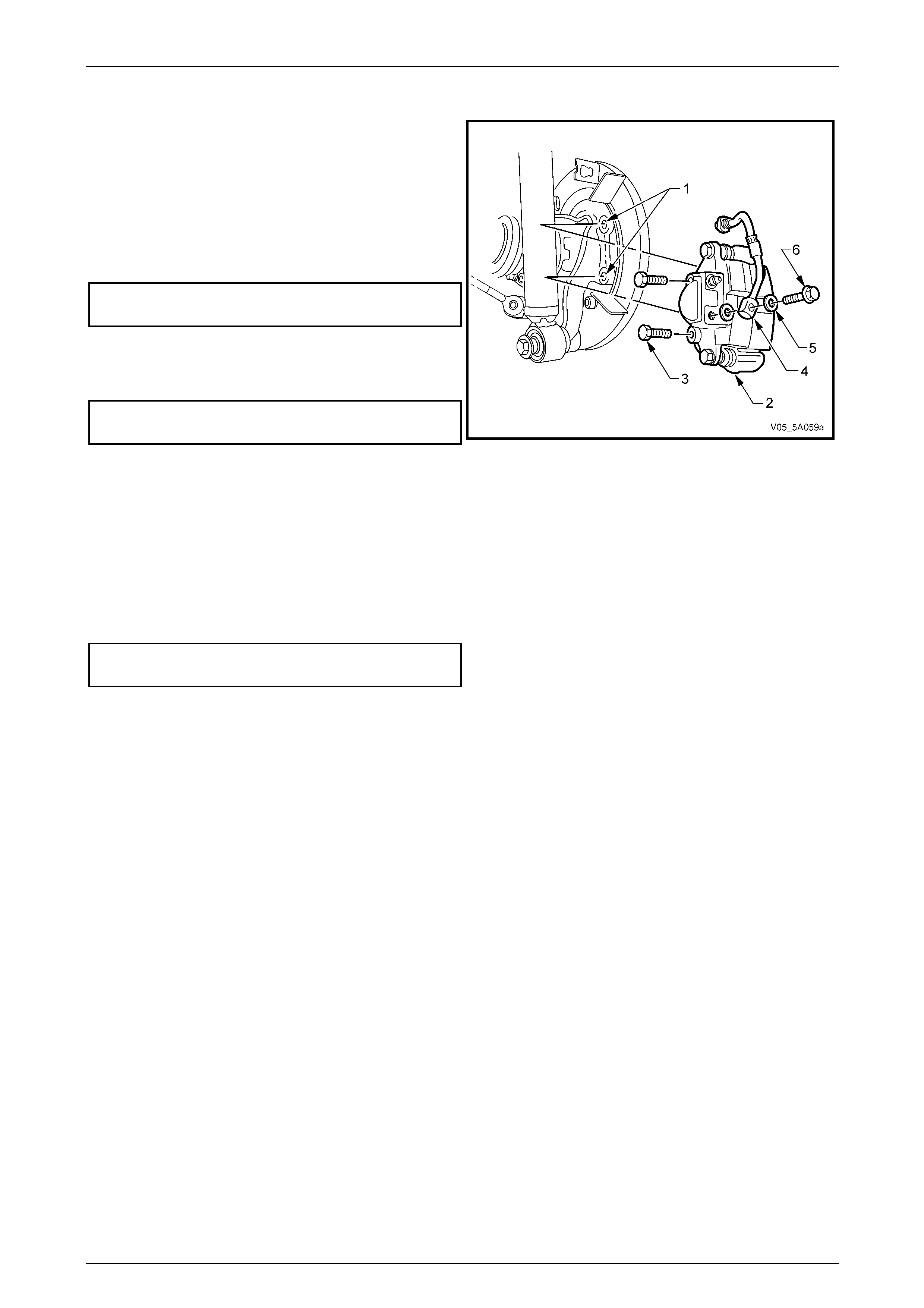

1.4 Front and Rear Brake Calipers

The front and rear brake calip er assemb lies are common for all braking systems available for the MY 2005 WL Series

range of vehicles. An exploded view of the twin piston front caliper is shown in Figure 5A-3.

For the front brakes, the anchor plate is rigidly fi xed to the steering knuckle support arm, while the housing slides within

the anchor plate by means of t wo guide p ins bolted to the housing. Rubber boots are fitted to the guide pins to exclude

moisture, dirt and foreign matter.

The rear brake caliper anchor plates are bolted to the trailing arm and also have a floating housing, sliding over two

guide pins that are fitted with rubber dust boots.

The housing incorpor ates either twin (front) or a single hydraulic piston (rear), each with a seal. When hydrau lic pressure

is applied, the piston forces the inner pad ag ainst the disc and the reaction of the housi ng pulls the outer pad against the

disc. The forces of the pads on each side of the disc are therefore equal.

When the hydraulic pressure is released, the piston seal/s retracts the piston/s a small amount, allowing the moving parts

to relax sufficiently for the pads to remain in close proximity to the disc without dragging. Adjustment for wear is

automatic.

Refer to 2.7 Brake Pads Replace, in this Section, for further informati on regarding brake pad application.

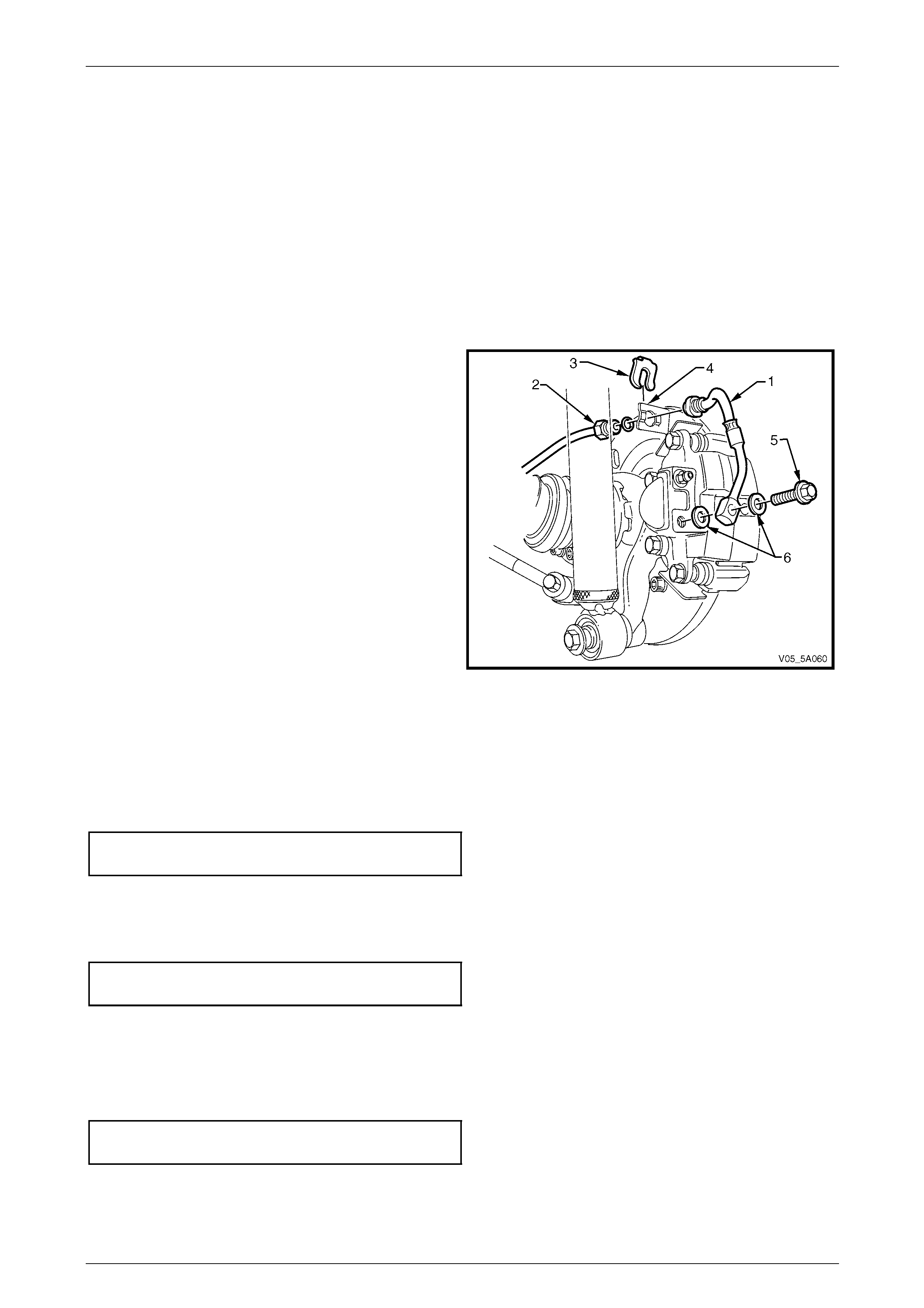

Figure 5A – 3 – Front Brake Caliper – All WL Models

Legend

1 Caliper Housing

2 Bleed Screw

3 Self Locking Bolt (2 places)

4 Guide Pin (2 places)

5 Guide Pin Boot

6 Anchor Plate

7 Clip ( 2 places)

8 Outer Brake Pad

9 Inner Brake Pad

10 Piston Boot (2 places)

11 Piston (2 places)

12 Cylinder Seal (2 places)

Service and Park Braking Systems Page 5A-9

Page 5A-86

1.5 Brake Pipes and Hoses

Description

Except for the one difference detailed here, the brake pipe arran gement carries over from earlier models.

For those WL vehicles fitted with the Electronic Stabilit y Program (ESP), the brake pi pe diameter is increased to 6.35 mm

to increase fluid flow for the ESP System. The pipe fitting for the primary front and the rear brake pipes are both 12 mm

at the master cylinder.

Service and Park Braking Systems Page 5A-10

Page 5A-86

2. Minor Service Operations

2.1 Service Warnings, Cautions and Notes

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W here specified in this section, fasteners MUST be replaced w ith parts of the

same part number or an approved equivalent. Do not use fasteners of an inferior quality or substitute d esig n.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

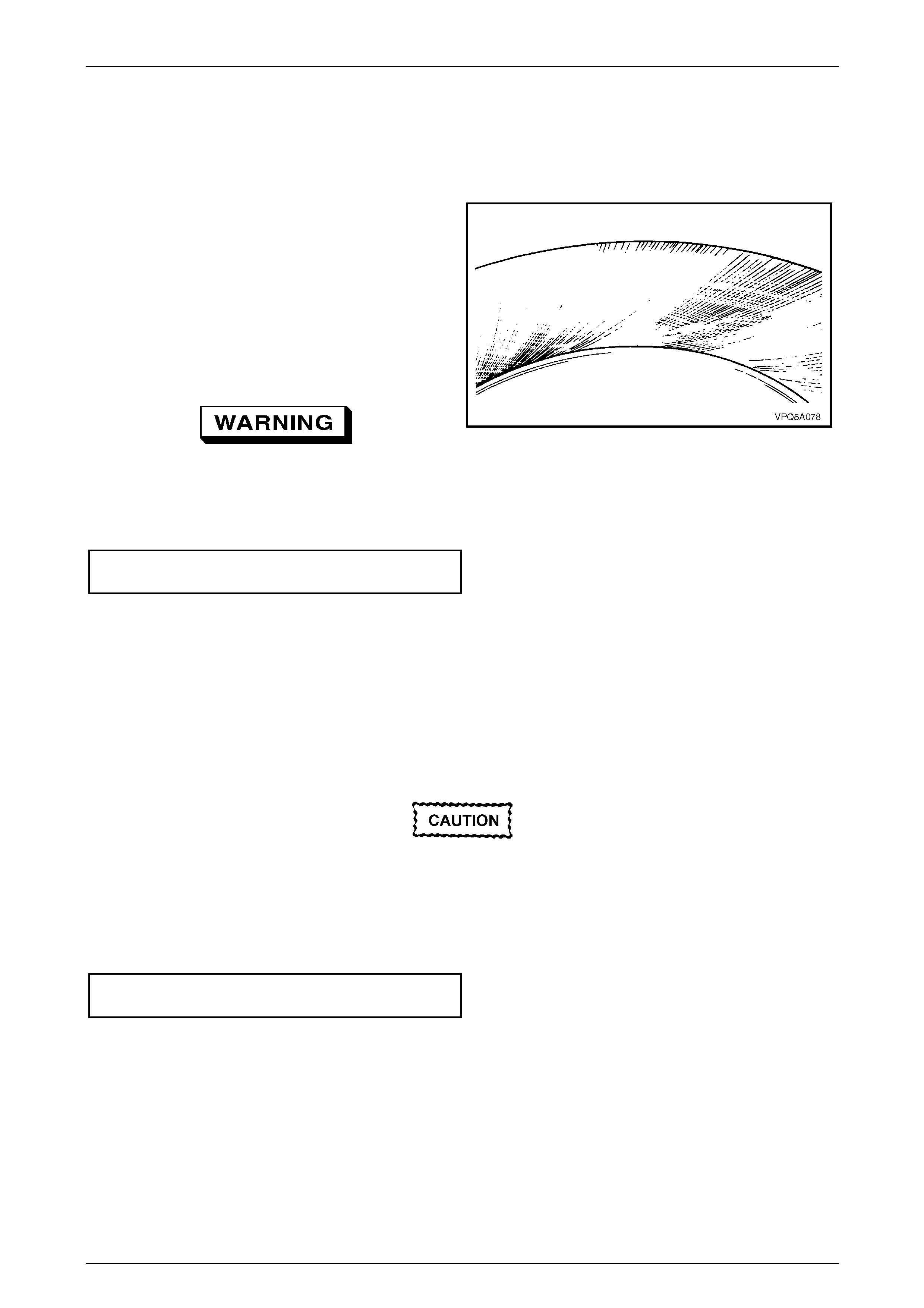

Brake Pads

• While genuine Holden wheel brake parts are not asbestos based in their material composition, a

danger exists that no n-g en uine parts replacement may contain asbestos.

NOT ONLY IS IT IN THE INTERESTS OF PERSONAL SAFETY BUT ALSO THE SAFE AND

RELIABLE OPERATION OF THE BRAKING SYSTEM, THAT ONLY GENUINE PARTS ARE USED

FOR REPLACEMENT PURPOSES.

• When servicing wheel brake parts, do not create dust by grinding or sanding brake linings, by

cleaning wheel brake parts with a dry brush or with compressed air. Breathing in dust that may

contain asbestos fibres can cause serious bodily harm over a lengthy time period.

A water dampened cloth or water based solution should be used to remove any dust on brake

parts. Equipment is commercially available to perform this washing function. These wet methods

prevent brake component fibres from becoming airborne.

Brake Fluid

• The polyglycol brake fluid used in MY 2005 WL Series vehicles is hygroscopic and absorbs

moisture from the air through th e brake hoses etc. The boi ling resistance o f the fluid decreas es as

the moisture content increases and so the possibility of a vapour lock under heavy braking

conditions increases with the age of the fluid. Therefore, for maximum brake effecti veness, a two

yearly change of b rake flu id is mandatory, refer to 2.5 Brake Fluid Change, in this Section.

• To prevent the absorption of moisture from the air or other contamination, it is recommended that

the brake fluid be stored in small (500 ml) containers and that any surplus fluid remaining in a

container after use be di scard ed.

• The only approved brake fluid is Super DOT 4 Plu s and is a vailable in 250 and 500 ml cont ainers. If

pressure bleed ing equipmen t is used, it must be of an appro ved type w ith a diap hragm separating

the brake fluid from the air.

• Brake fluid is extremely damaging to paint. If fluid should accidentally come into contact with a

painted surface, immediate ly wash the fluid fro m th e paint and clean the painted surface.

ABS/TC Components

• Whenever any component that forms part of the ABS is disturbed during any service operation, it

is vital that the complete ABS system be checked, refer to Section 5B, ABS/TCS/ESP – General

Information.

Service and Park Braking Systems Page 5A-11

Page 5A-86

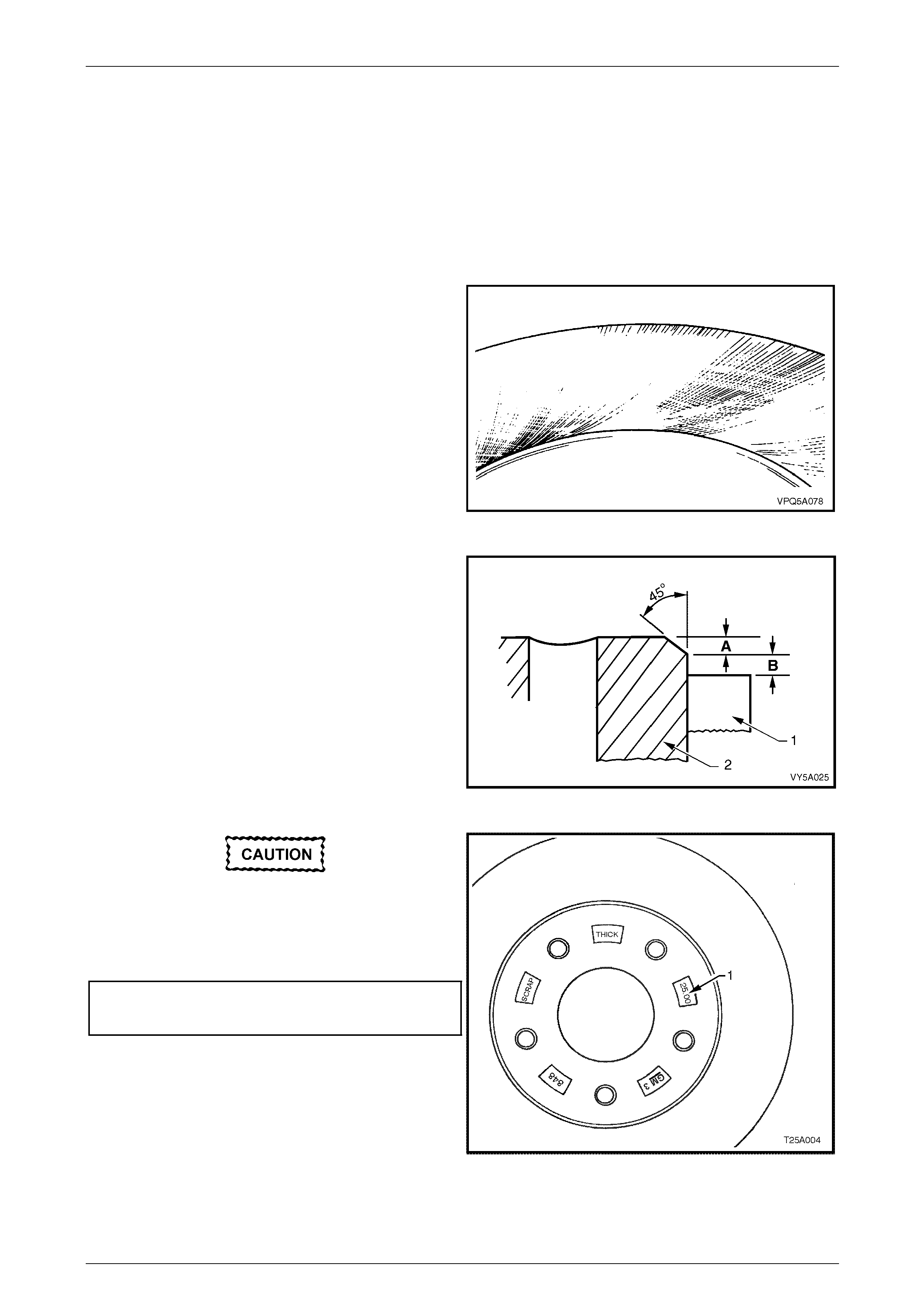

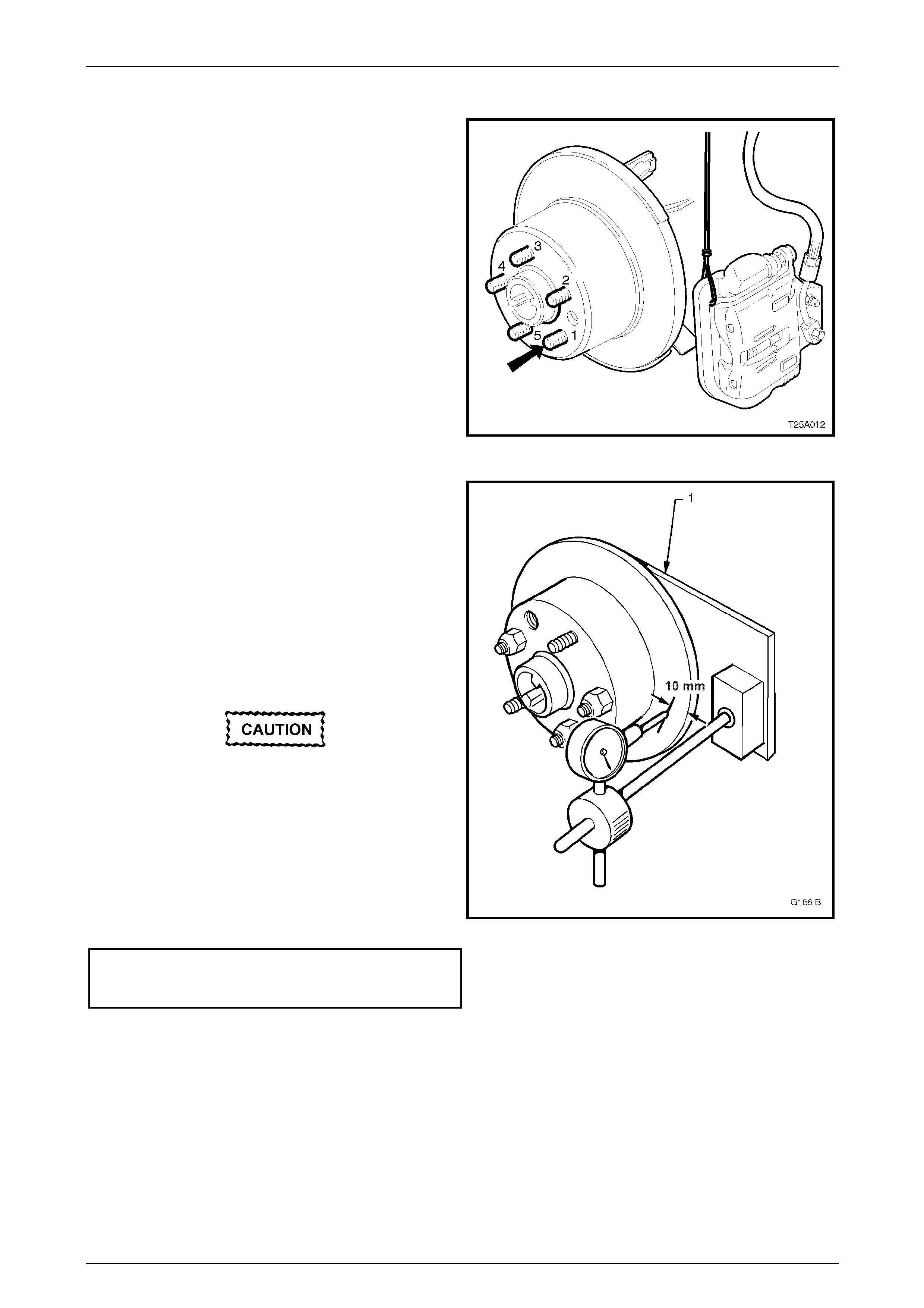

Road Wheels

• Whenever a road wheel and/or brake rotor is removed from or installed to a MY 2005 WL Series

vehicle, it MUST be done in accordance with the recommended procedure, refer to

Section 10 Wheels and Tyres.

• Whenever a road w heel and/or brake di sc is removed from the vehicle, the relationship of the road

wheel and the disc to the hub MUST be marked with a felt tipped pen or similar, to allow those

parts to be reinstalled in their original positions. This is critical to minimise the brake disc and

road wheel runout dimension.

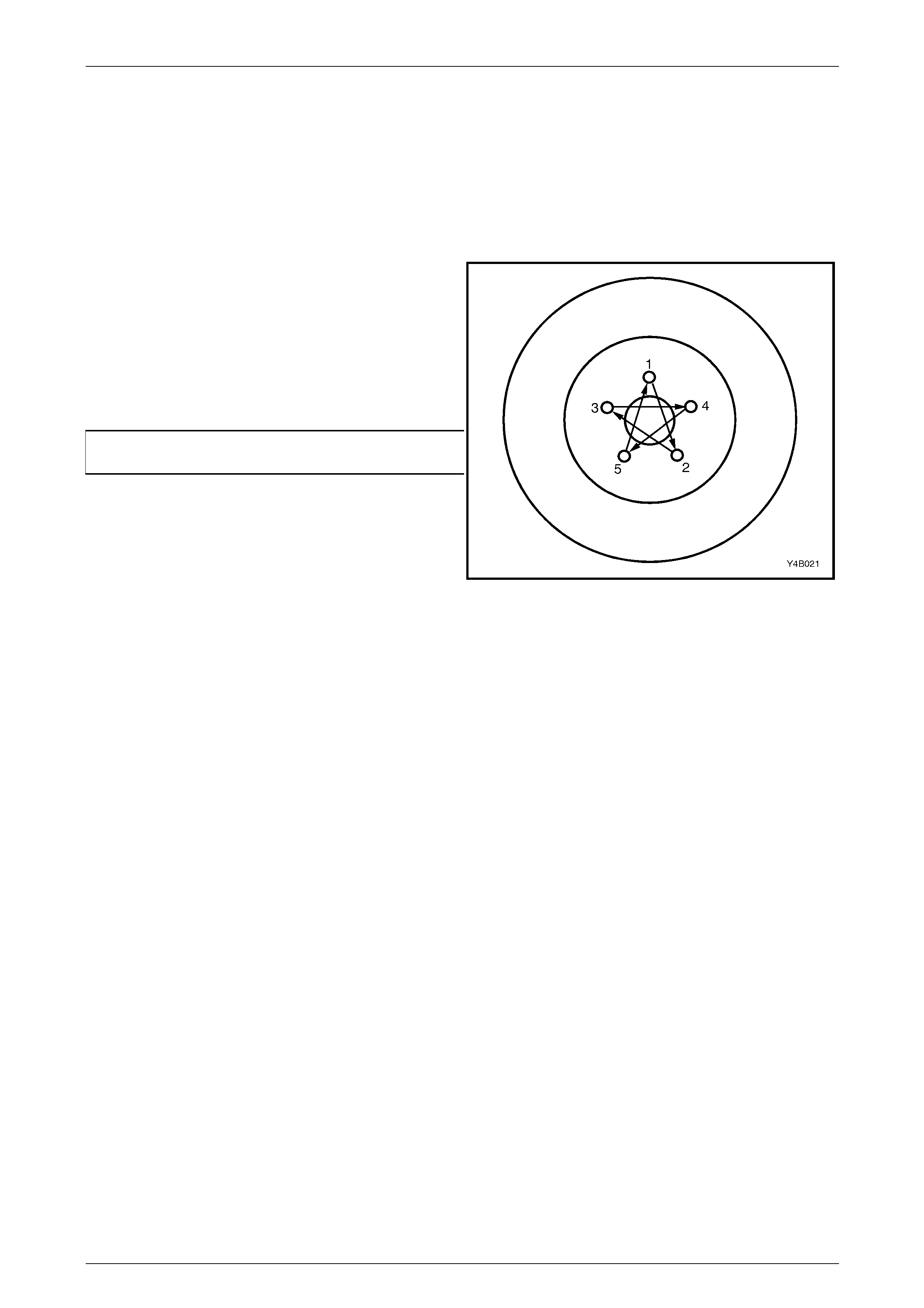

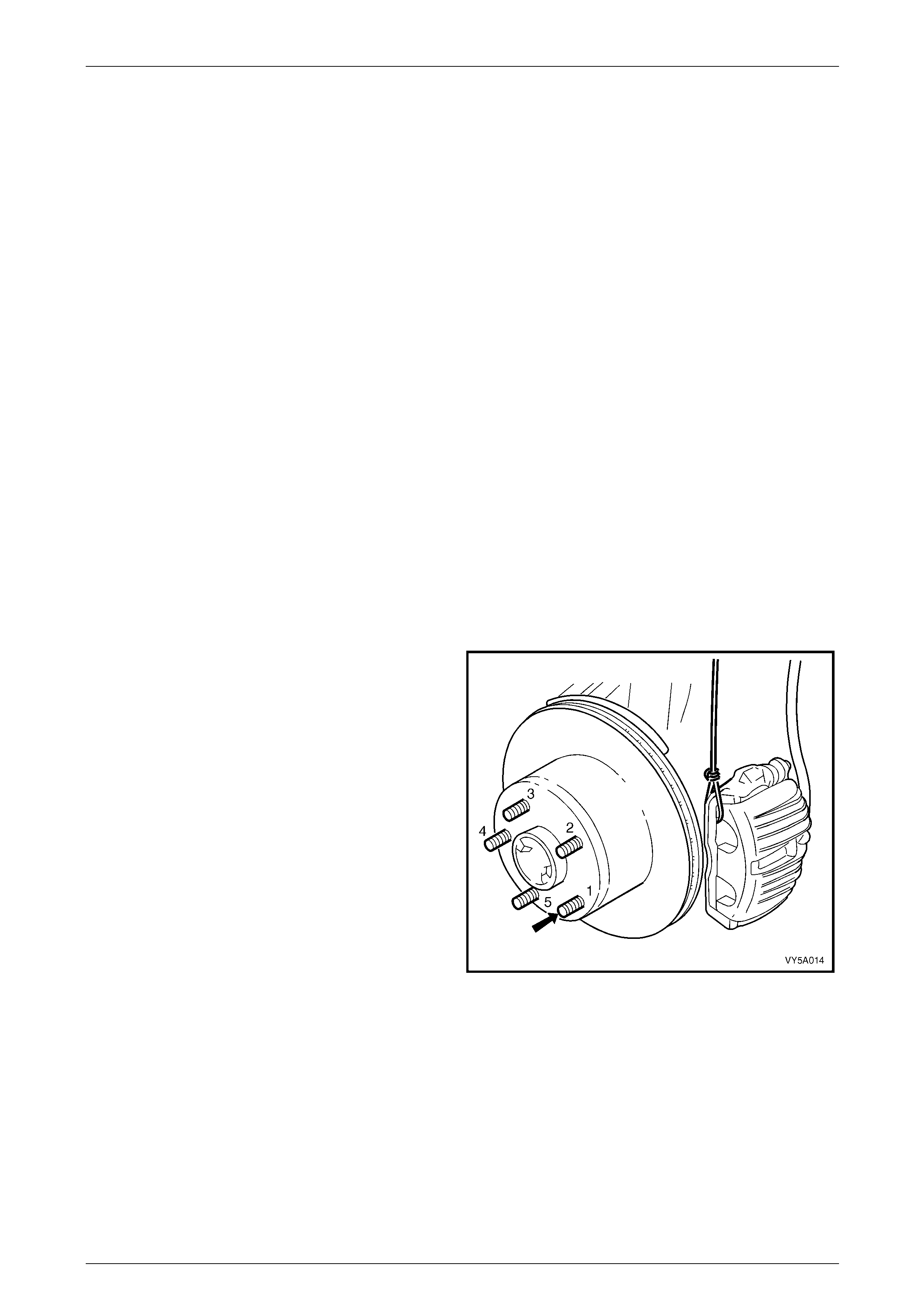

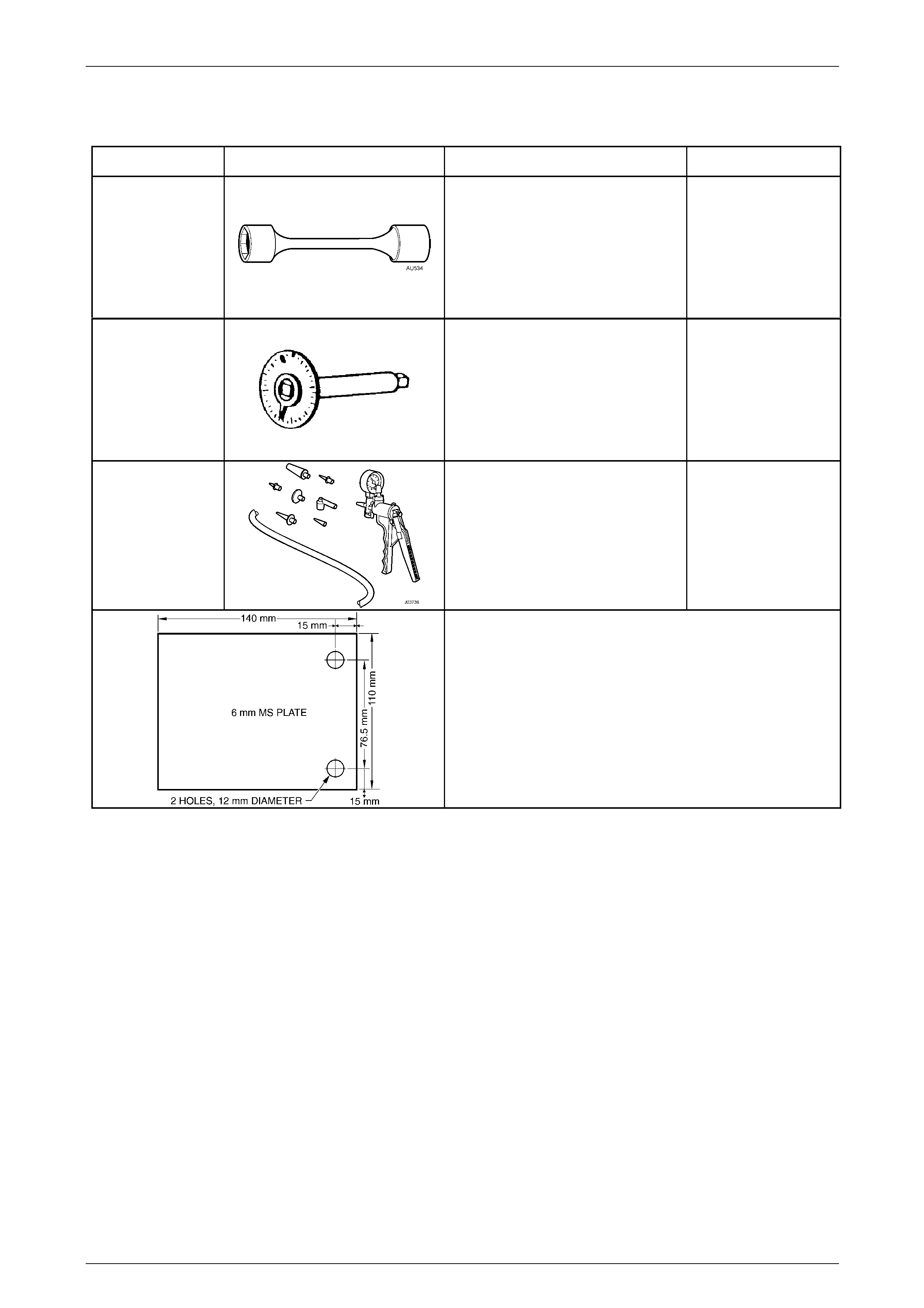

• When reinstalling road wheels, do not use

an impact gun to tighten wheel nuts

unless the impact gun is fitted with a

torque limiter socket (Tool No. AU 534 or

a commercial equivalent). Failure to

correctly tighten w heel nuts to the correct

torque specification and in the correct

order (as shown), may result in a

distorted brake disc, leading to the

development of brake shudder.

Road wheel attaching nut

torque specification....................................110 – 140 Nm

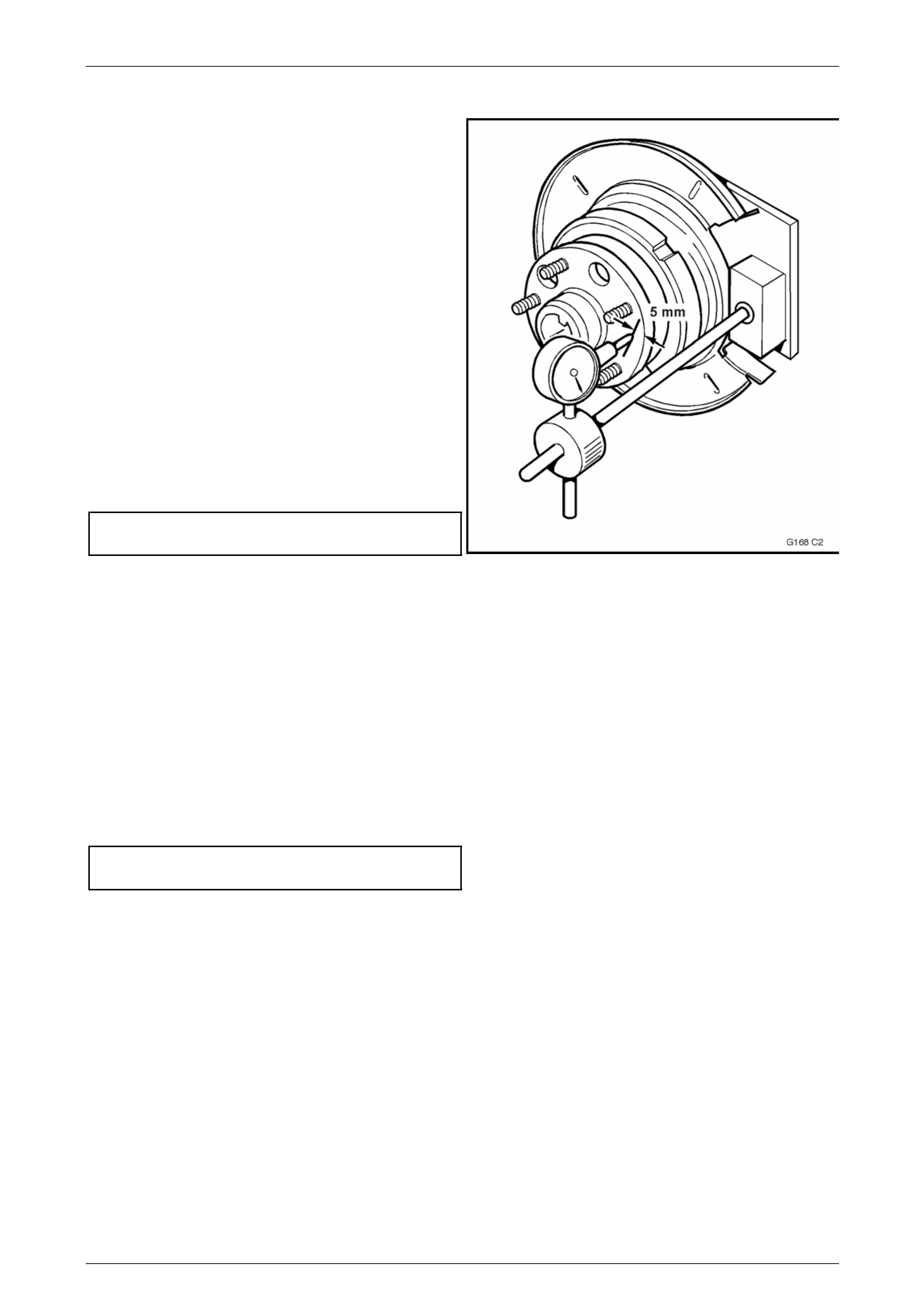

For a complete description of the method used to

measure both brake disc and trunnion assembly runout

and correction, refer to 3.6 Front Brake Disc or

3.7 Rear Brake Disc, in this Section.

Figure 5A – 4

Service and Park Braking Systems Page 5A-12

Page 5A-86

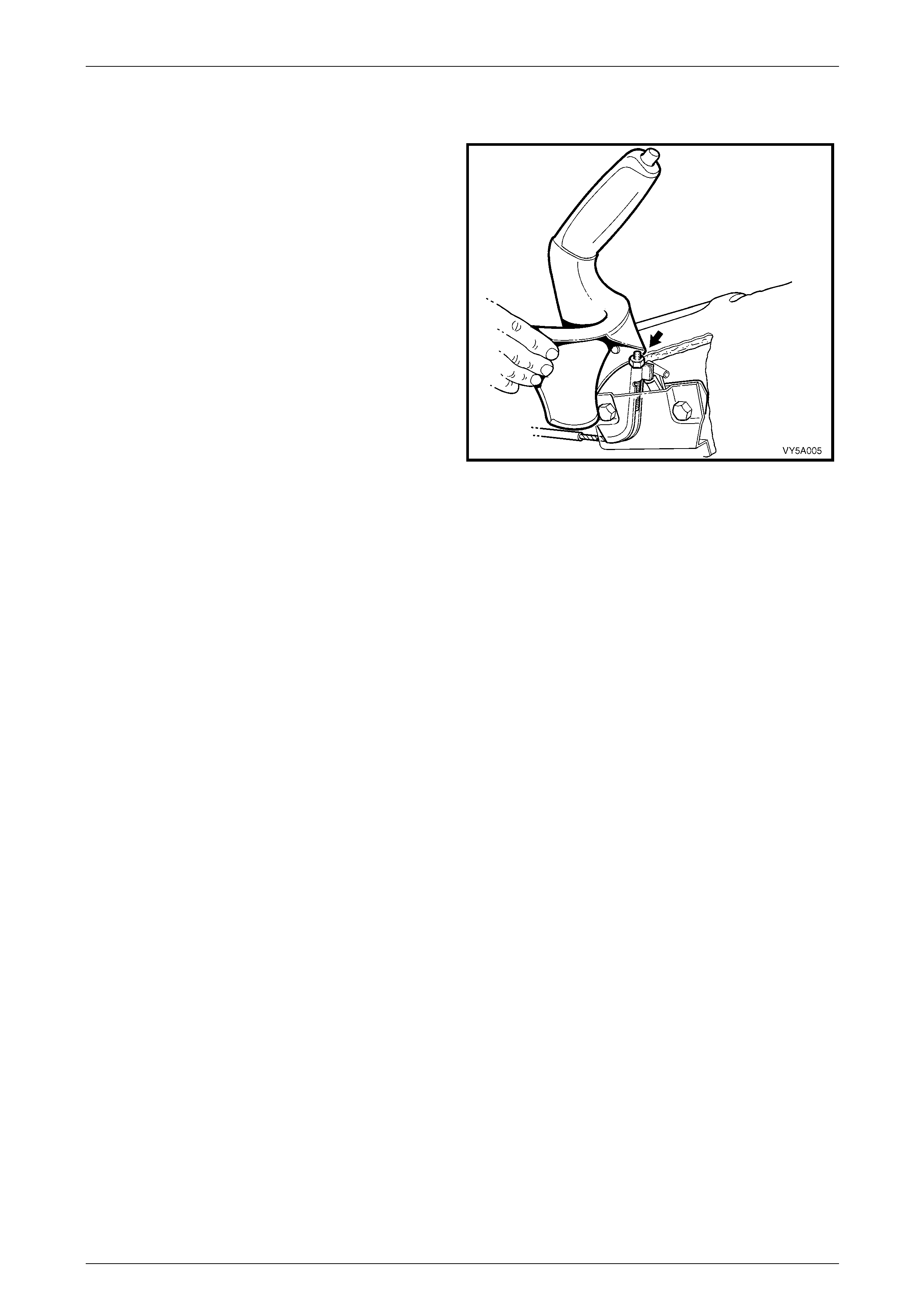

2.2 Park Brake Cable, Adjust

1 Raise rear of vehicle and support on jack sta nds under

each lower control arm, to maintain the correct

suspension attitude.

2 Loosen the park brake cable a djustme nt nut several

turns.

3 Apply the park brake until the lever is extended 4 – 6

clicks.

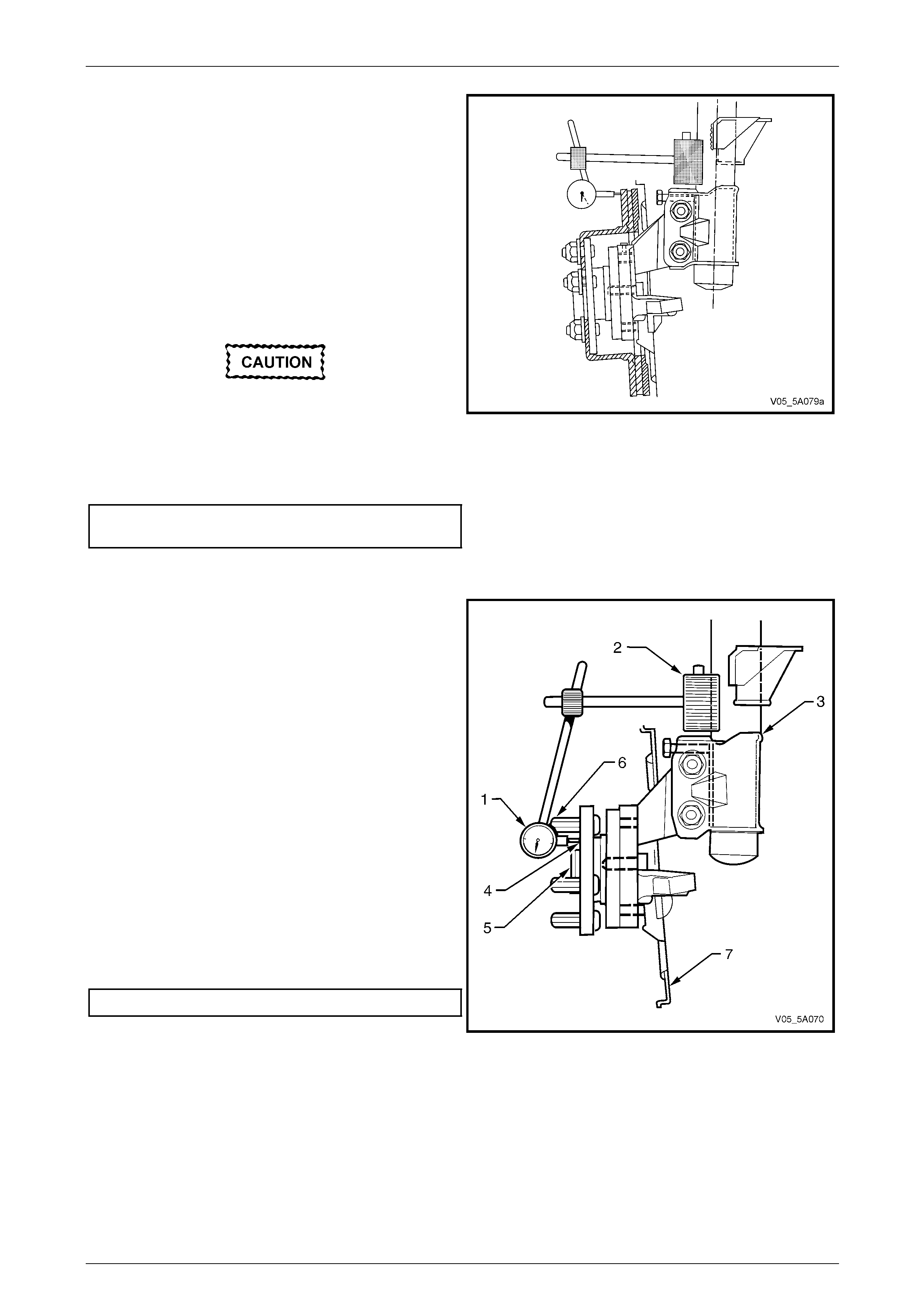

4 Using a dial type torque wrench and a deep socket,

tighten the cable adjustment nut (arro w) until a torque

of 2 Nm is applied.

5 Check that this adjustment applies the park brake

shoes to a firm drag torque, by turning each rear

wheel.

NOTE

• With a new par k brake i nstallation or one that

has the correct park brake shoe adjustment,

the thread on the front cable should protrude

through the adjustment nut by 15 – 20 mm.

• If the park brake cannot be satisfactorily

adjusted by the above method, it will be

necessary to refer to 3.9 Park Brake Shoe,

Adjust, in this Section.

Figure 5A – 5

Service and Park Braking Systems Page 5A-13

Page 5A-86

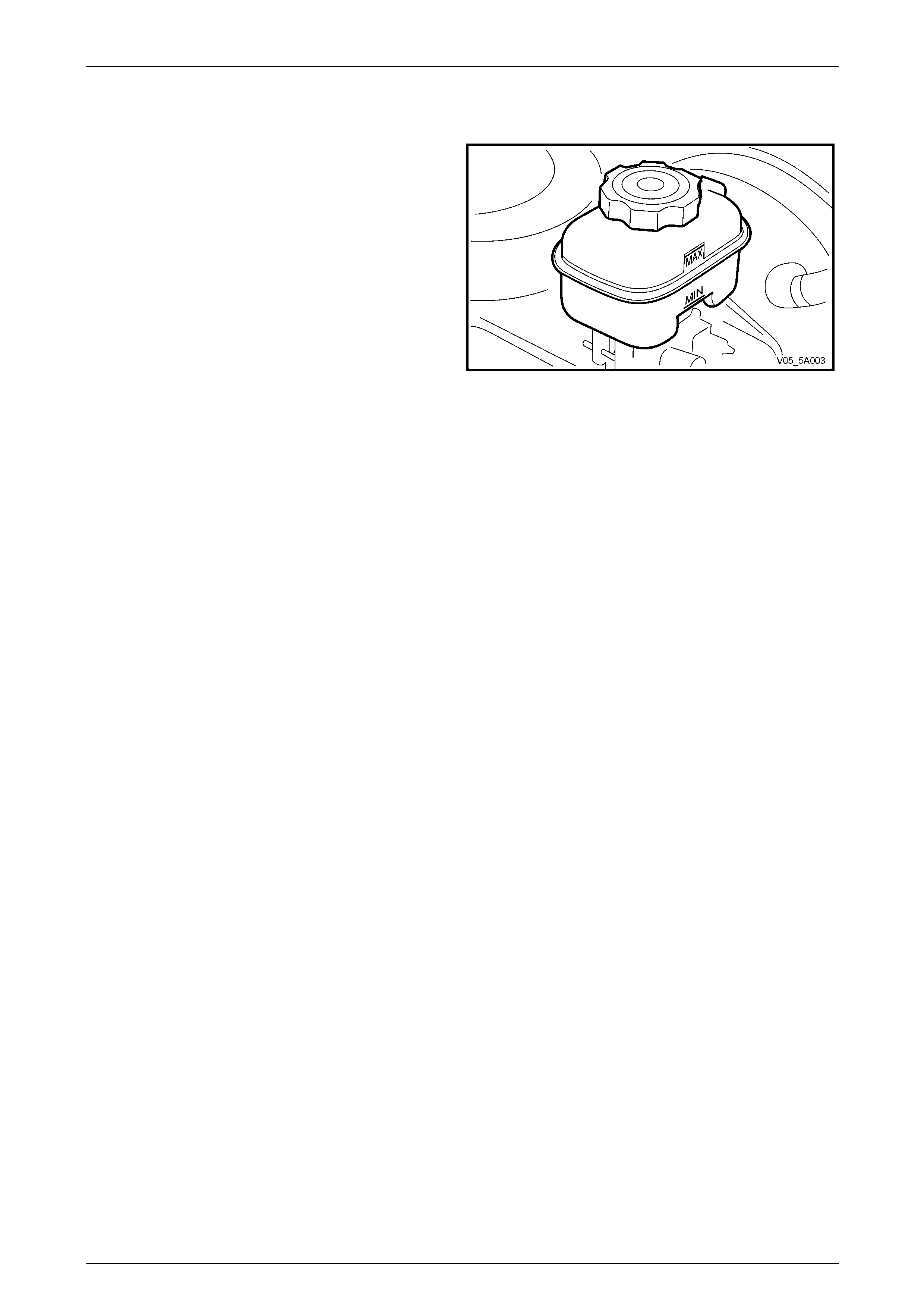

2.3 Brake Fluid Level Check

Check that the fluid level is between the MIN and MAX level

markings on the translucent reservoir housing.

NOTE

If the fluid is between the markings, do not

remove reservoir cap, as brake fluid exposed to

the atmosphere will quickly absorb moisture.

Should the addition of fluid be required, wipe the sides of

the reservoir cover clean, then unclip and remove the

reservoir cap. Top up fluid using heavy duty brake fluid that

complies with Super DOT 4 Plus.

Figure 5A – 6

Service and Park Braking Systems Page 5A-14

Page 5A-86

2.4 Brake System Bleed

LT Section No. – 04-725

Do not re-use any brake fluid discharged

during the bleeding process.

Remove air from other components of the brake s ystem as follows:

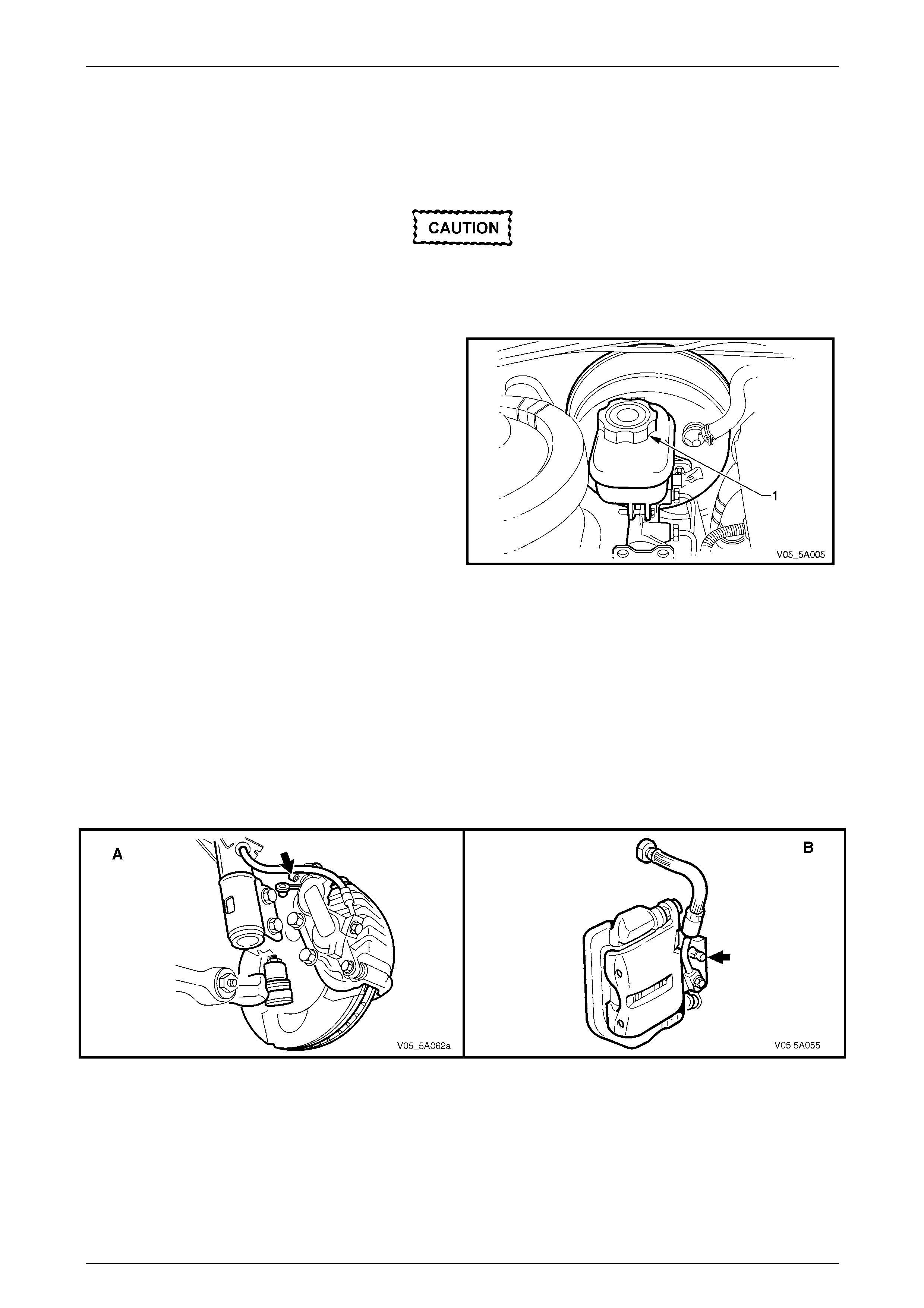

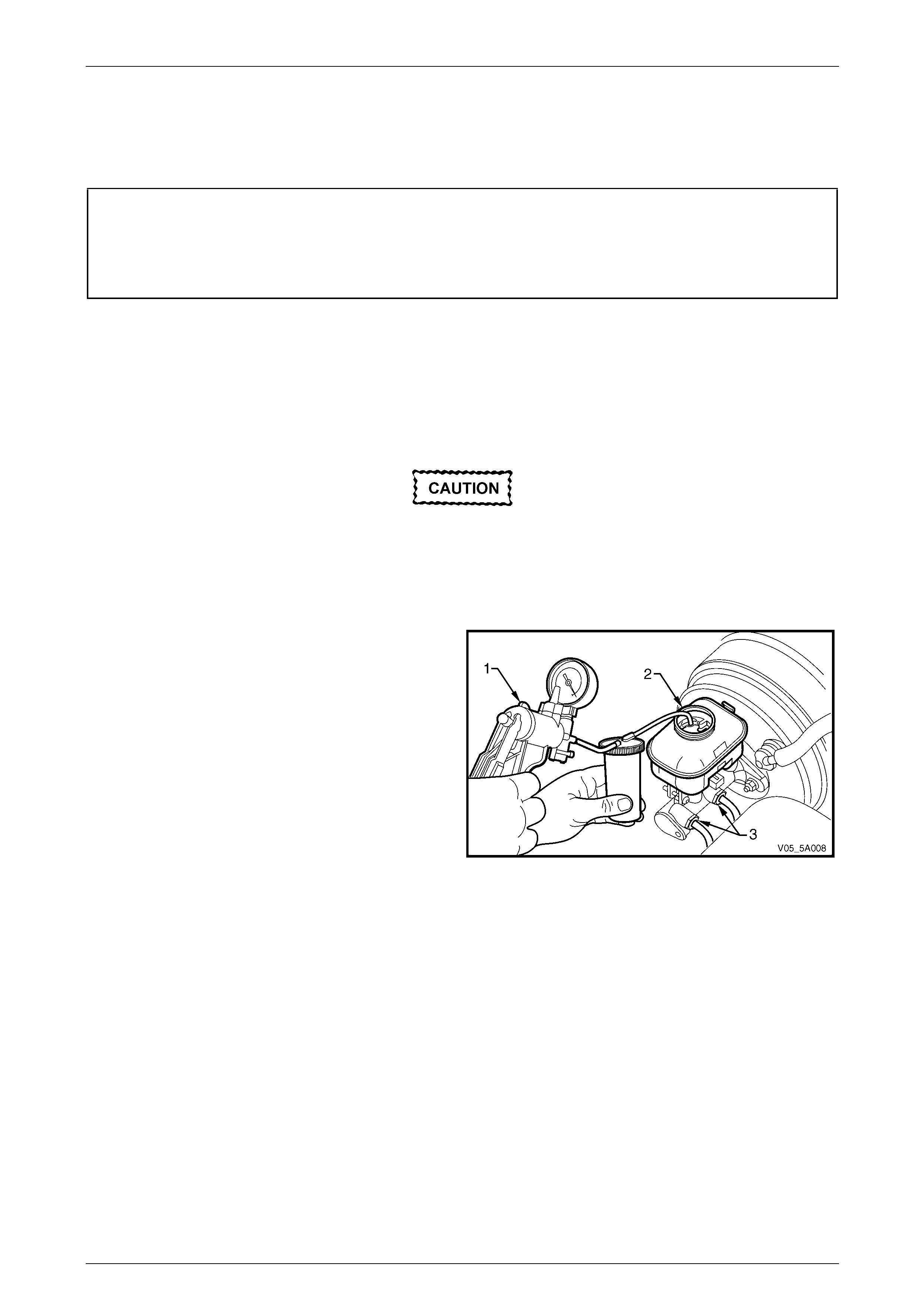

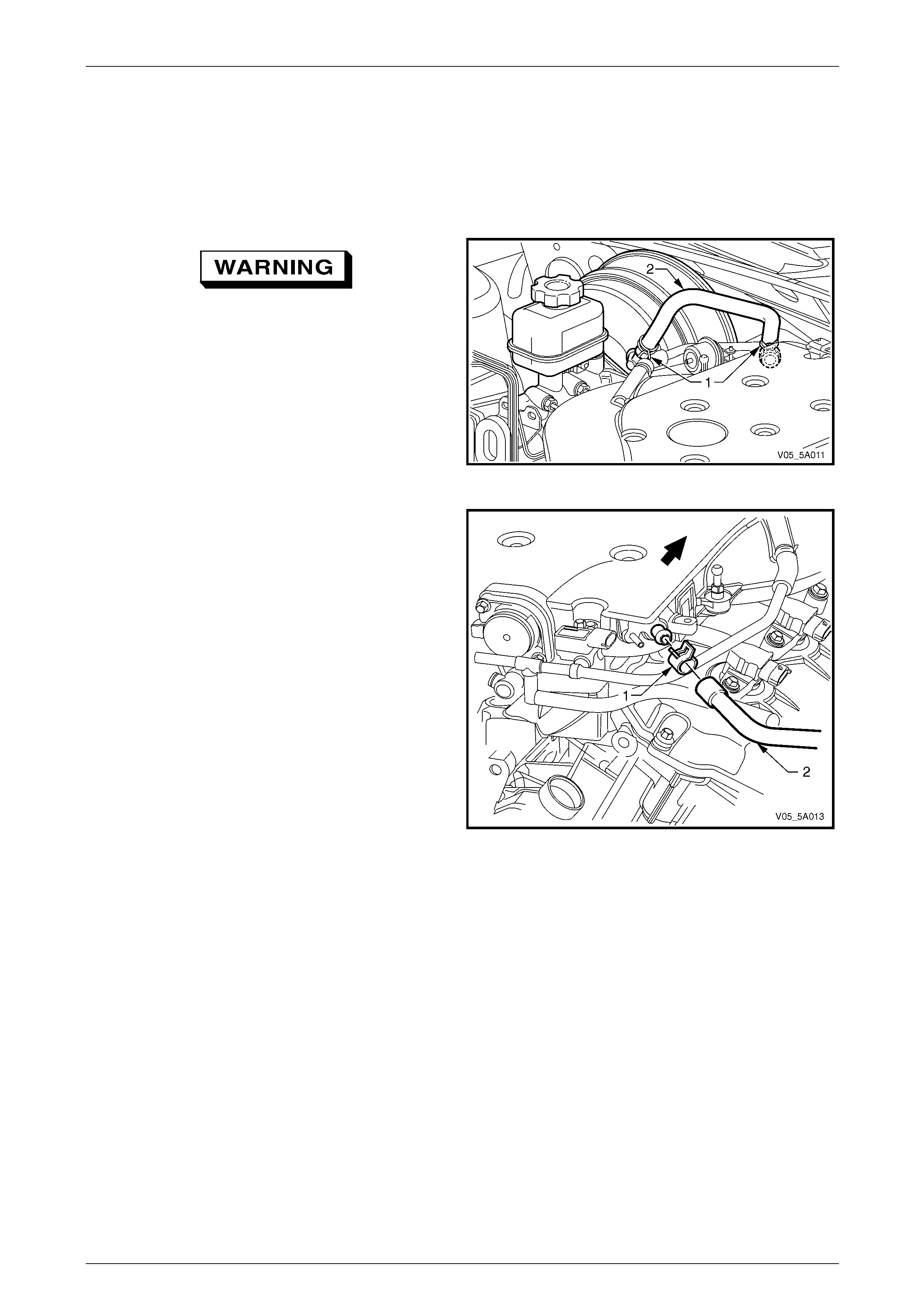

1 Remove master cylinder reservoir cap (1) and fit a

commercially availabl e pressure bleed cap.

Figure 5A – 7

2 Connect cap to pressure bleed pump and pressurise system to no more than 345 kPa.

3 Open brake bleeder of line to be ble d and pump brake pedal one stroke/secon d for approximately 10 strokes, then

close bleeder. During this operation the pressure bleeder to the master cylinder should not be turned off. It is

essential that this volume and rate of flow is maintained to ensure air trap ped in pipes is carried out of the system

with the flow of the fluid and not allowed to retreat between strokes of the brake pedal.

4 At the conclusion of the brake bleedin g process, check that all dust caps are installed to the brake bleeder valves.

NOTE

View A shows the brake bleeder location for the

front brake caliper, while view B is for the rear.

Figure 5A – 8

Service and Park Braking Systems Page 5A-15

Page 5A-86

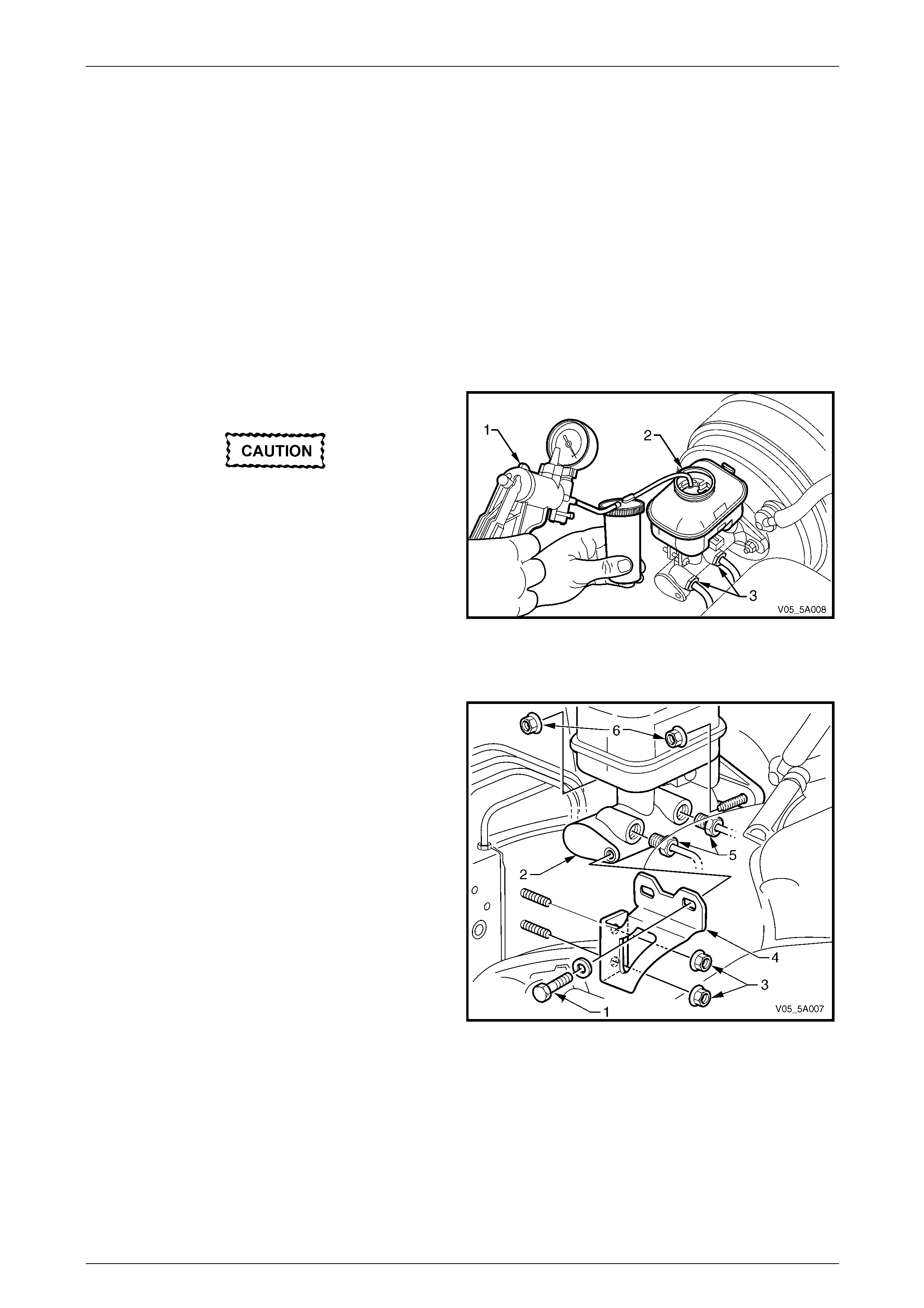

2.5 Brake Fluid, Change

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Brake caliper to trailing arm attaching bolts.

Draining Master Cylinder

Brake fluid will cause damage to the paint

work. If contact does occur, immediately

wash the brake flui d o ff with water.

1 Thoroughly cle an master cylinder, especially around wheel brake line connections.

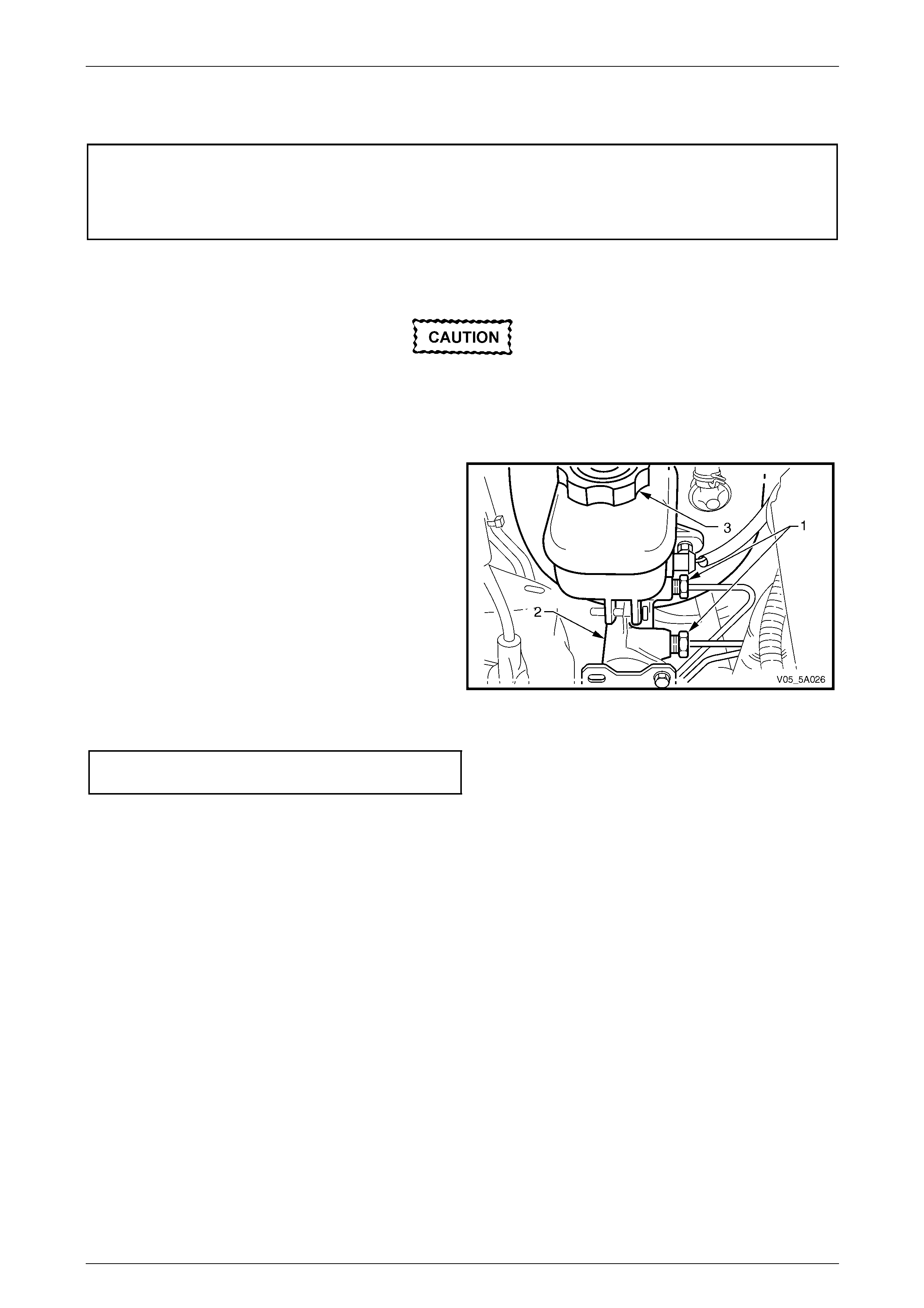

2 Disconnect wheel brake lines (1) from master cylinder

(2), then remove reservoir cap (3).

3 Allow master cylinder to drain into a container until

empty.

4 Fill master cylinder reservoir with fresh, specified

brake fluid from a sealed 500 ml container and ensure

reservoir is maintained at least half full for remain der

of procedure.

5 Allow fluid to flow from open connection ports until

fluid is free of air. Collect discharged fluid in a suitable

container and then discard. Do not allow fluid to

contact paintwork.

6 Reinstall the brake lines (1) to master cylinder (2) and

tighten to specified torque.

Brake pipe to master cylinder

flare nut torque specification.................................14 Nm

Figure 5A – 9

Service and Park Braking Systems Page 5A-16

Page 5A-86

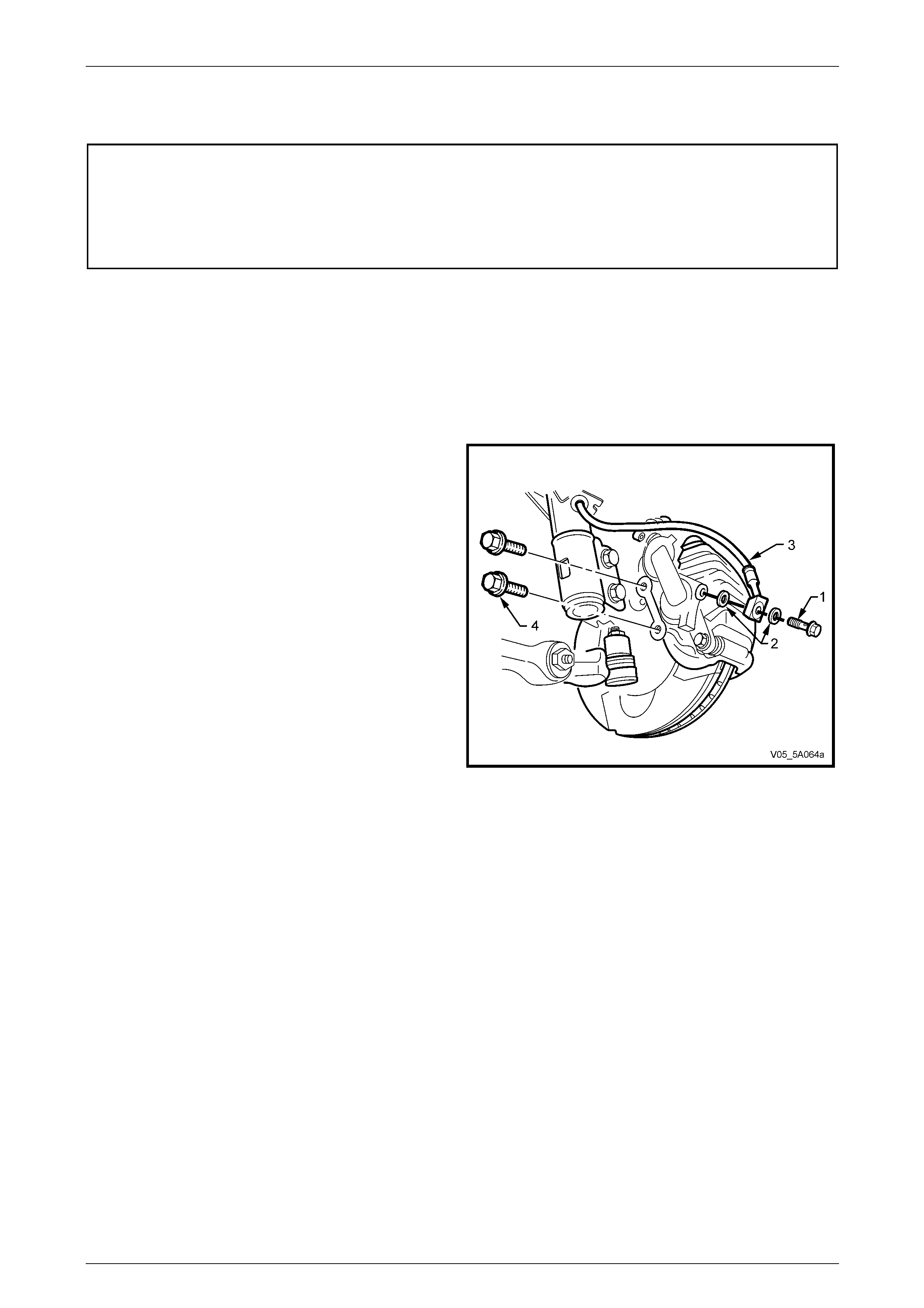

Draining Brake Calipers

1 Raise the vehicle and suppor t in a safe manner. Refer

to Section 0A General Information for the location of

recommended lifting and support points.

2 Mark position of wheels relative to hub a nd remove

wheels.

3 Loosen the left hand front caliper bleed screw (bold

arrow, in 'A', Figure 5A – 8).

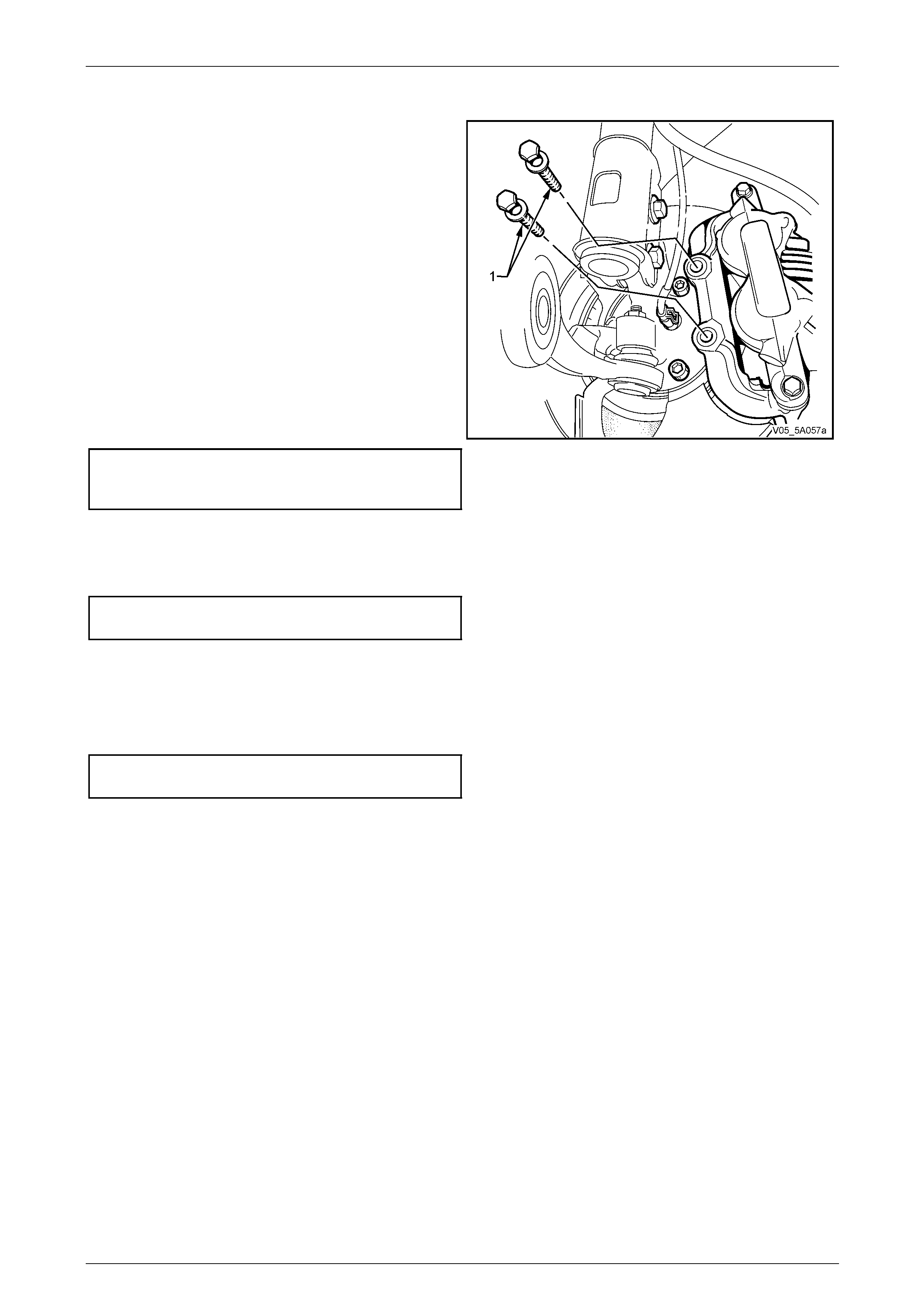

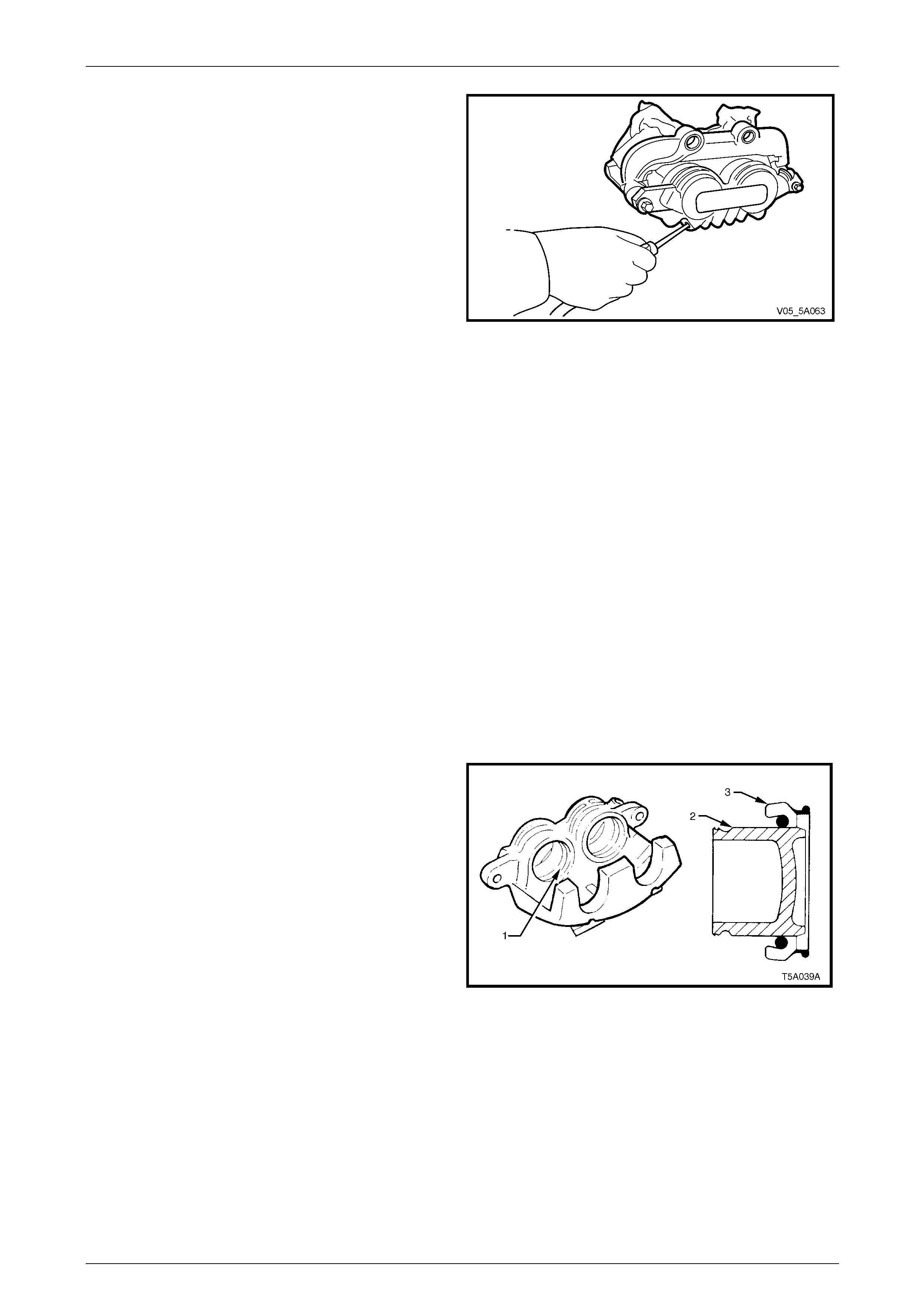

4 Remove front left hand caliper anchor plate retaining

bolts.

5 Hold caliper upside d own and remove bleed scre w to

drain contents of caliper into suitable rece ptacle.

6 Hand tighten bleed screw and reinsta ll caliper

assembly, using NEW bolts.

7 Tighten caliper anchor p late retaining bolts to specified

torque.

() Front brake caliper anchor plate

bolt torque specification........................................85 Nm

plus 45° turn angle

Figure 5A – 10

8 Repeat steps 2 to 7 for the other front caliper and the rear caliper assemblies. Note that a different toque

specification applies to the rear caliper attaching bolts.

9 Tighten the rear brake caliper anchor plate bolts to the correct torque specificatio n.

Rear brake caliper anc hor

bolt torque specification........................................85 Nm

10 Bleed brake system, refer to 2.4 Brake System Bleed, in this Section.

11 Reinstall road wheel in original pos ition and lower vehicle.

12 Tighten road wheel nuts in a ' s tar' pattern, to the specified torque. Refer to 2.1 Service Warnings, Cautions and N otes,

in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

13 Road test the vehicle to ensure correct brake operation.

Service and Park Braking Systems Page 5A-17

Page 5A-86

2.6 Brake Pad Wear, Check

Front or Rear

NOTE

The procedure and minimum thickness

specification is common to both front and rear

brake pads, despite the fact that only the front

brake caliper procedure is provided.

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information in this Service Information

for the location of recommended lifting and supp ort points.

2 Remove rear decorative wheel nut caps.

3 Mark the relationship of the road wheel to hub or brake rotor. Loosen, then remove the road wheel attaching nuts,

working in a 'star' pattern. Refer to 2.1 Service Warnings, Cautions and Notes, in this Section.

4 Remove the pads to be checked, from the caliper

ensuring that the original pad positions are noted.

Refer to 2.7 Brake Pads, Replace, in this Section.

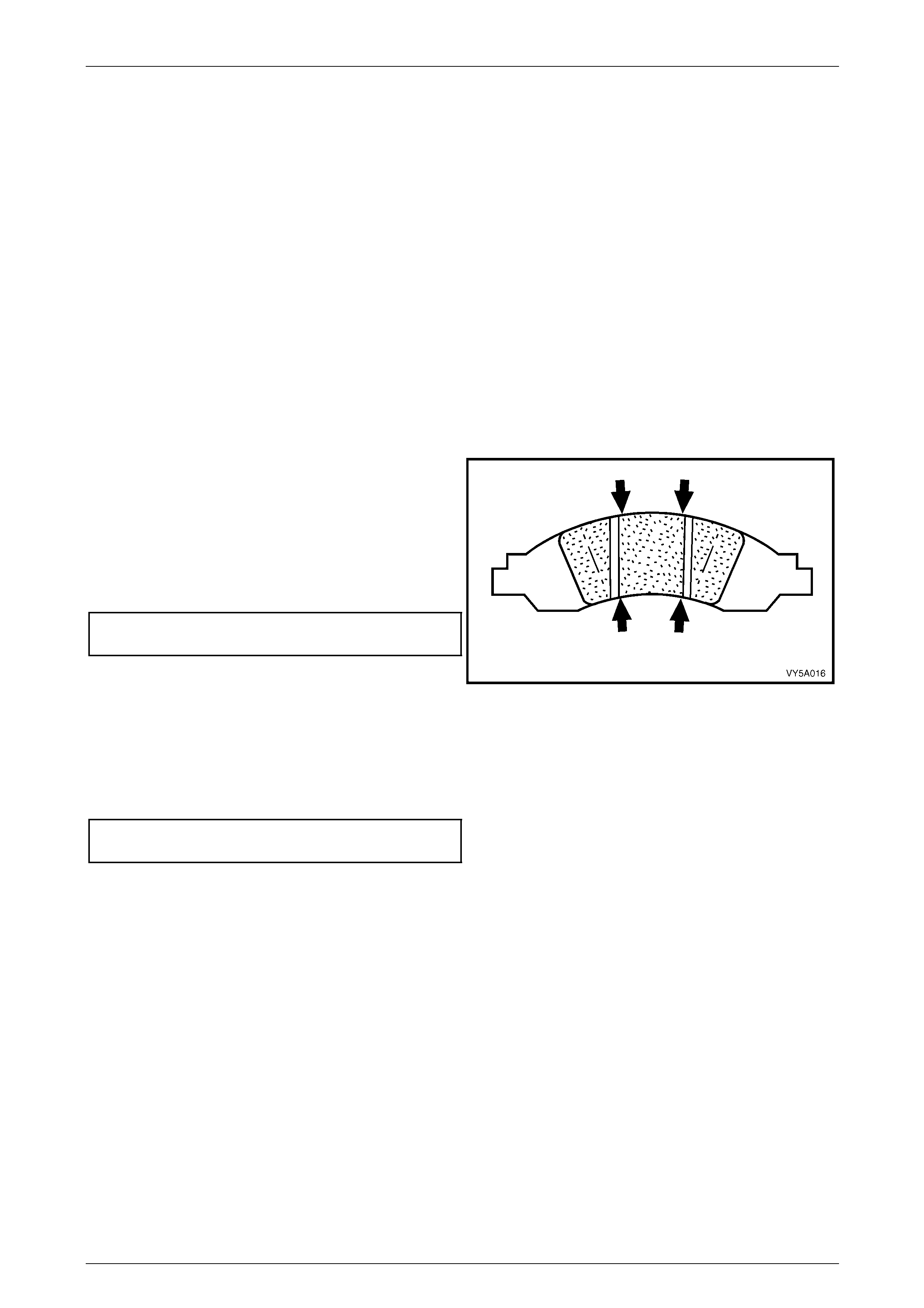

5 Using vernier calipers, check the brake pa d thickness

in the four locations shown. The min imum lining

thickness should be no less that the thickness

specified. Also, pad wear should be even – if not, then

the cause must be established and corrected.

Brake pad minimum lining

thickness before replacement............................ 2 mm

6 If not being replaced, reinstall the brake pads in

the same locations, prior to removal. Refer to

2.7 Brake Pads, Replace, in this Section, for the

required procedures for this operati on. Figure 5A – 11

7 Reinstall road wheel and secure with the wheel nuts but do not fully tighten.

8 Lower the vehicle to the ground an d tighten the wheel nuts to the specified torque, working in a star pattern, refer to

2.1 Service Warnings, Cautions and Notes, in this Section.

Road wheel attaching nut

torque specification...................................110 – 140 Nm

9 Reinstall decorative wheel nut caps.

10 Road test vehicle to ensure correct brake operatio n.

Service and Park Braking Systems Page 5A-18

Page 5A-86

2.7 Brake Pads, Replace

LT Section No. – 04-750 and 04-825

ATTENTION

The following fastener has micro-encapsulated sealant applied to the threads and should be replaced () on

reassembly:

Brake caliper gui de pin bolts.

Preparation

NOTE

This 'Preparation' stage is common for the front

or rear brake pad replacemen t.

• Do not completely remove the brake line,

nor empty the reser voir. If this does occur,

complete bleeding of the braking system,

will be necessary.

• Do not attempt to re-use the removed fluid.

• Brake fluid will damage paint-work.

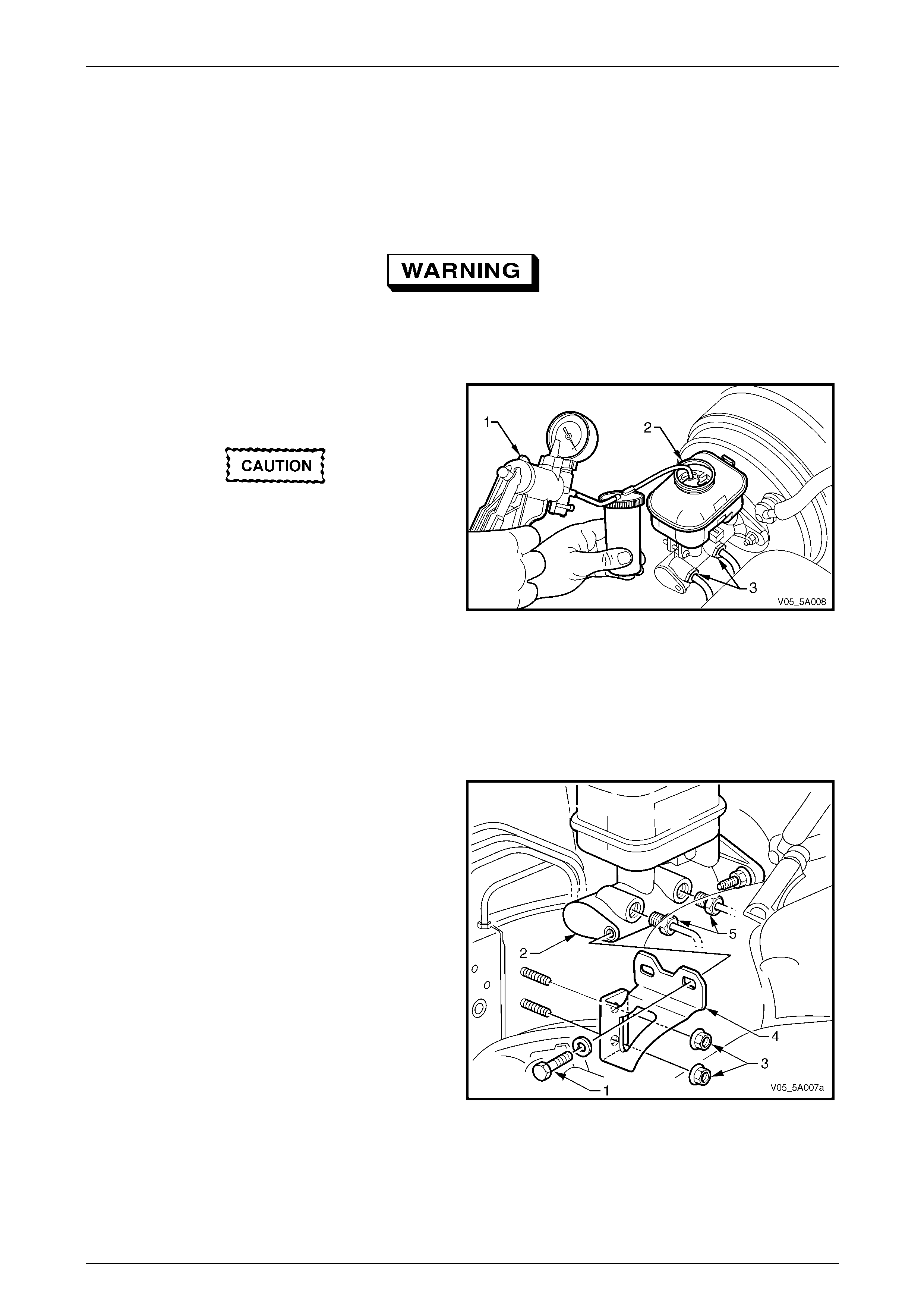

1 Unscrew the master cylinder reservoir cap.

2 Using a hand vacuum pump (1), Tool No. J23738-A or

a commercially available eq uivalent or syringe,

remove fluid from the reservoir (2) until it is

approximately half full.

NOTE

Hold the brake fluid level float down with the

suction tube, during this operation.

3 Reinstall the reservoir cap.

NOTE

Removal of fluid from the reservoir is needed to

stop reservoir overflow when caliper piston is

pushed back in its bore during pad rep lacement.

Figure 5A – 12

Service and Park Braking Systems Page 5A-19

Page 5A-86

Front Brake Pads

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information in this Service Information

for the location of recommended lifting and supp ort points.

2 Remove the wheel cover or the decorative wheel nut caps, then mark the relationship of the road wheel to one of

the wheel studs.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to

2.1 Service Warnings, Cautions and Notes, in this Section.

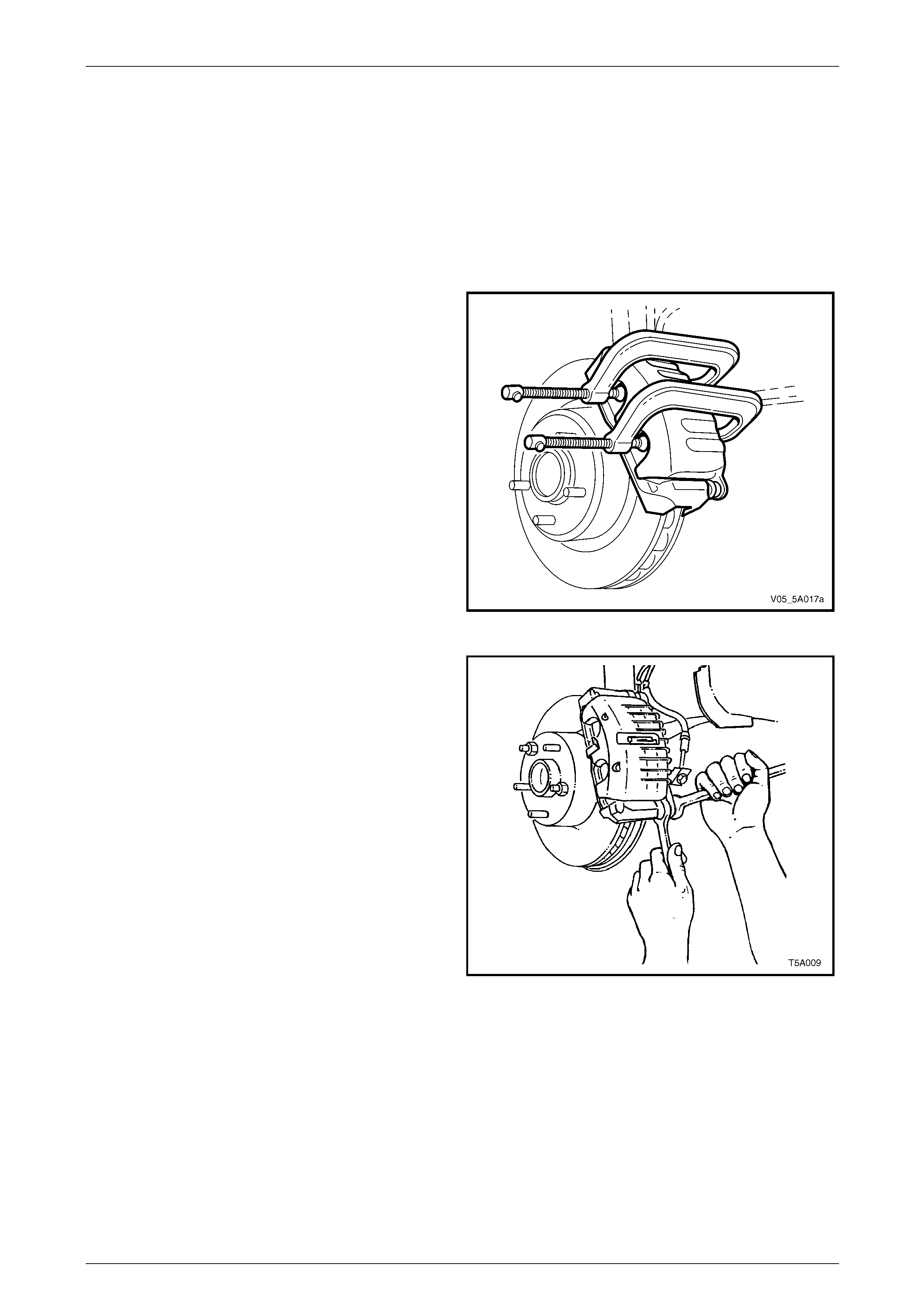

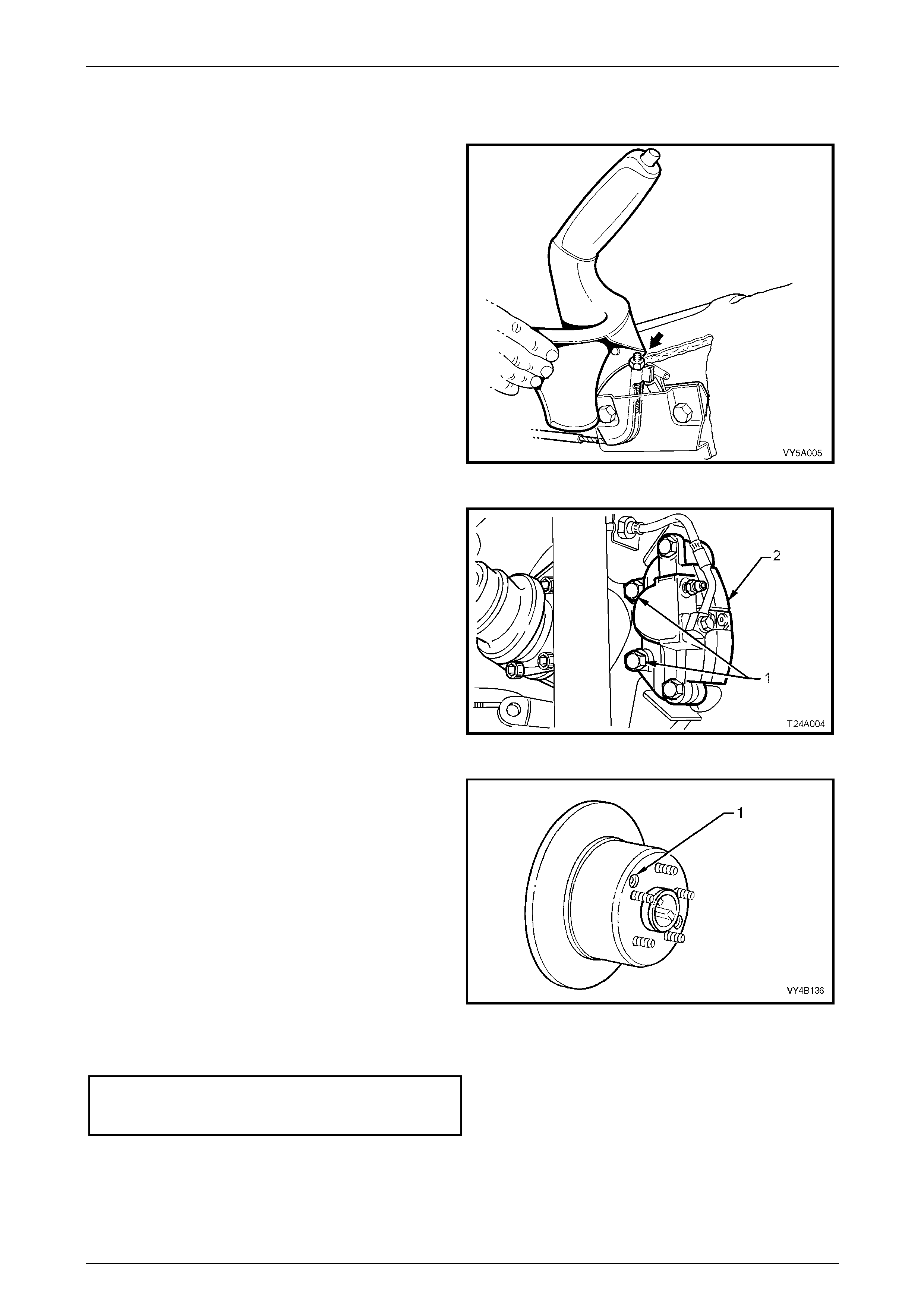

4 Using G-clamps as shown, tighten until the caliper

pistons bottom in each bore.

Figure 5A – 13

5 Using a suitable size open end spanner to hold the

lower guide pin, remove and discard the guide pin bolt.

NOTE

Old bolts must not be re-used, as they are vital

safety components which have a micro-

encapsulated adhesive on the bolt threa d.

6 Swing caliper assembly up from the anchor plate and

disc. Support caliper with a wire hook.

7 Remove worn pads from anchor plate.

8 Inspect condition of brake disc.

9 Check guide pins for free movement in the anchor

plate. If there is restriction of movement, replace

guide pins and/or guide pi n boots. Refer to

3.4 Front Brake Caliper, in this Section.

10 Clean any dirt from both the piston face, which

contacts the inner pad, and the caliper head area

which contacts the outer pad. Figure 5A – 14

11 Install new brake pads as follows:

Service and Park Braking Systems Page 5A-20

Page 5A-86

Installation

1 Thoroughly cle an both piston contact faces, using a suitable solve nt such as Prepsol™, if required.

2 Install the outer pad to the caliper, noting that a leg of the steel spring should sit on top of the inner pad.

3 Reinstall the brake caliper h ousing, ensuring that the outer spring clip e ng ages with the middle finger of the caliper

housing.

4 Install and tighten a NEW guide pin self locking bolt to the correct torque specification.

Brake caliper guide pin

bolt torque specification........................................32 Nm

NOTE

• Use a suitable open end spanner to prevent

the guide pin from rotating when tightening

the guide pin bolt.

• Do not wedge anything bet ween the guide pi n

hex and the caliper as it could cause incorrect

alignment of the pin which would then restrict

the free sliding of the caliper relative to the

anchor plate.

5 Fill master cylinder to correct level with fresh, brake fluid of the correct specification.

6 Depress and hold the brake pedal down in the app lied position for at least 5 seconds, to ensure that the inner pads

stick to the pistons.

7 Refill master cylinder if neces sary.

8 Reinstall wheels, aligning marks made prior to removal and lower vehicle to the ground.

9 Tighten road wheel attaching nuts to the specified torque, working in a star pattern, as detailed in

2.1 Service Notes and Cautions, in this Section.

Road wheel attaching

nuts torque specification ...........................110 – 140 Nm

10 Reinstall decorative wheel nut caps.

11 Carry out the Brake Pad Bedding-In Procedure, detailed in this Section.

Service and Park Braking Systems Page 5A-21

Page 5A-86

Rear Brake Pads

Remove

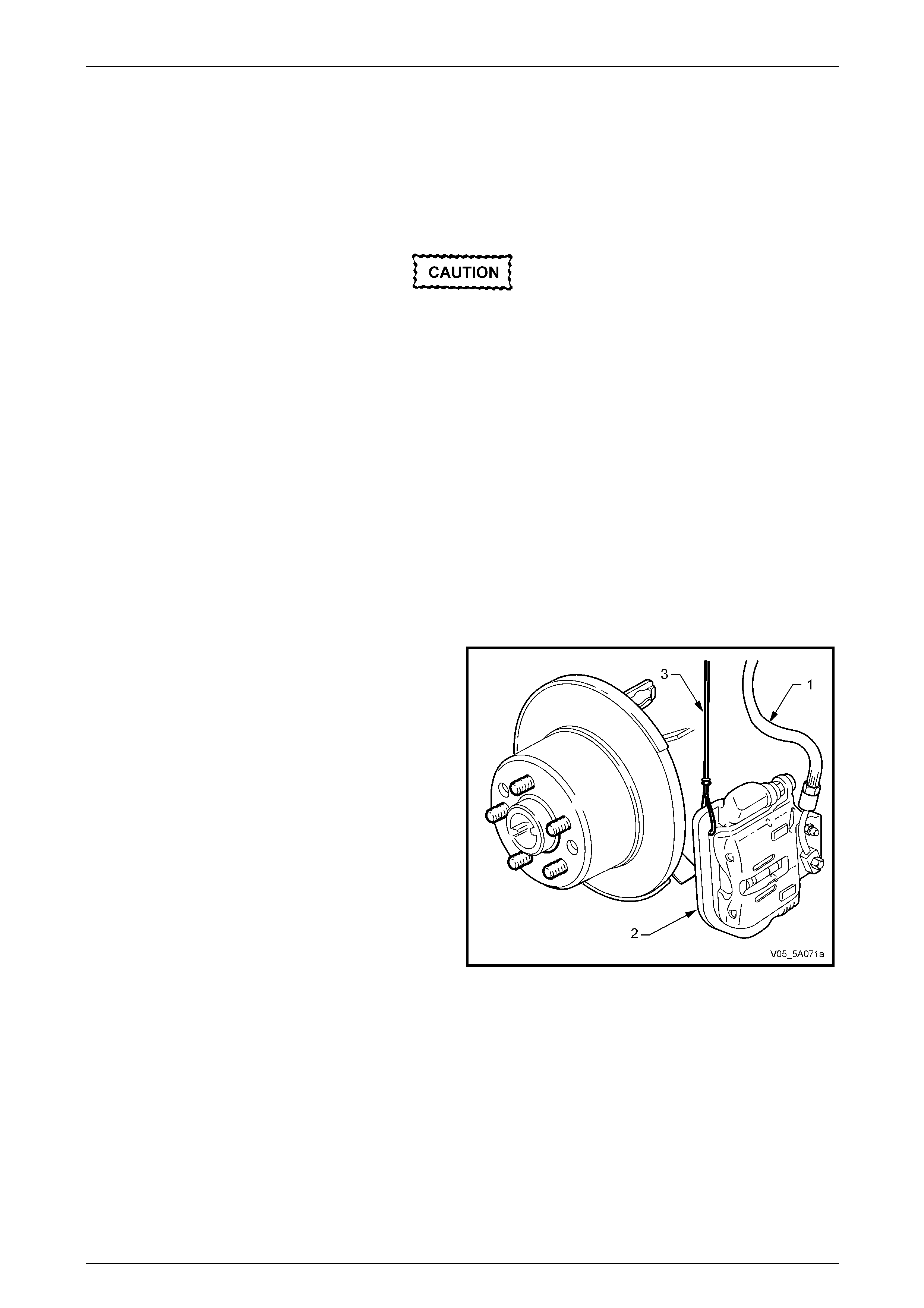

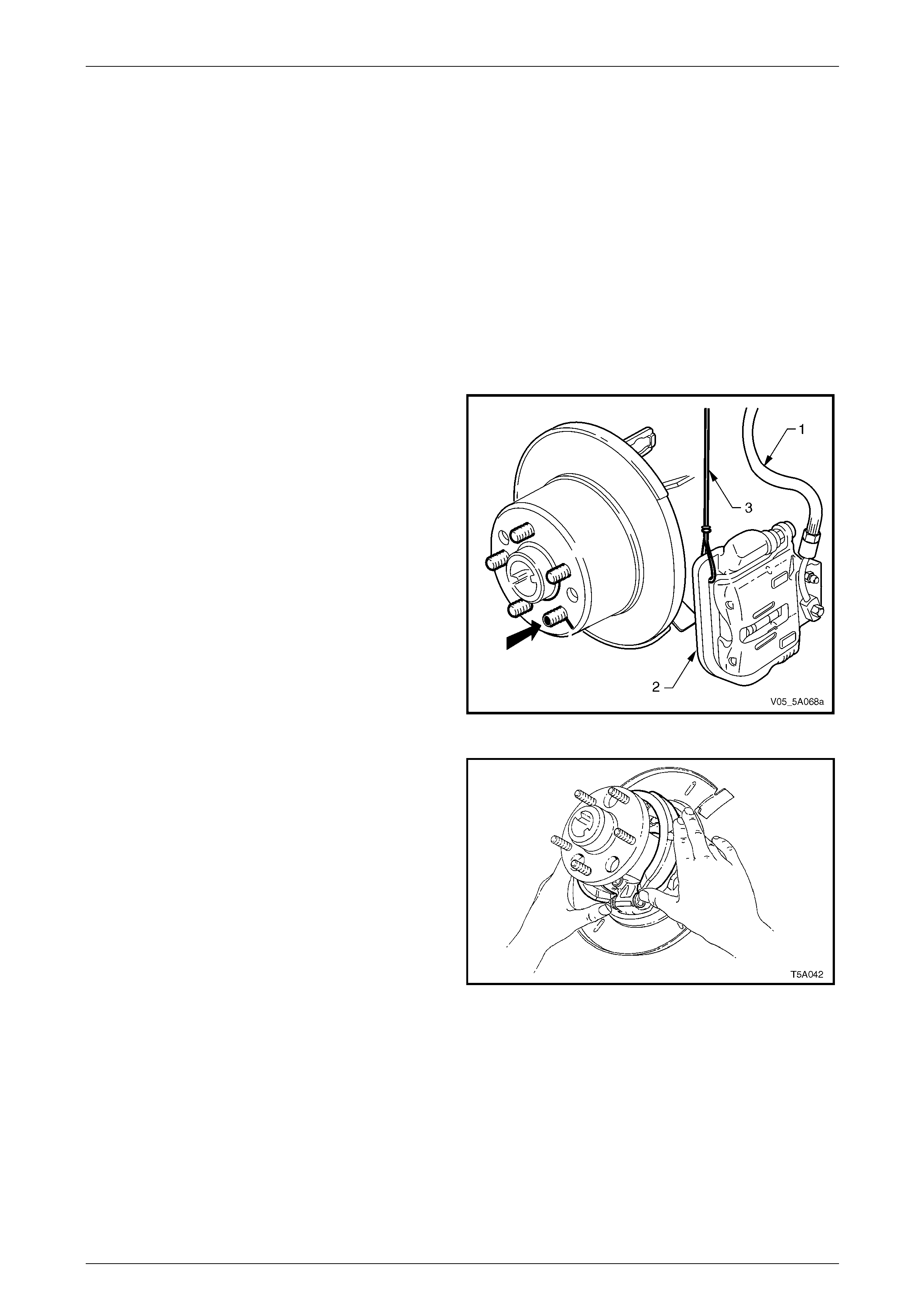

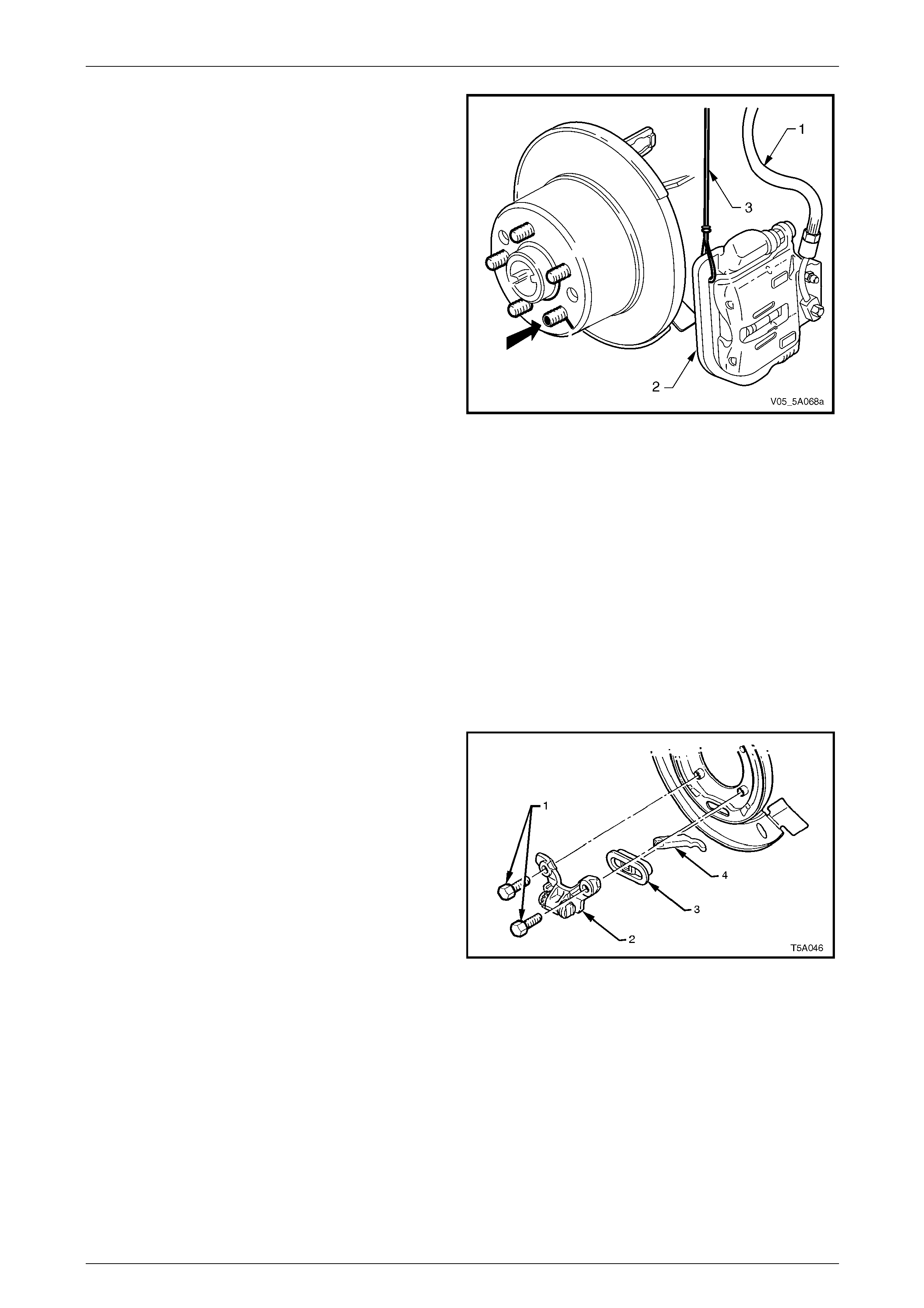

1 Using a G-clamp as shown, tighten unti l the caliper

piston bottom in its bore.

Figure 5A – 15

2 Using a suitable set spanner to hol d the lower guide

pin, use a suitable ring spanner remove the guide pin

bolt (1). Discard the removed bolt.

NOTE

• Old bolts must not be re-used as they are

vital safety components which have a micro-

encapsulated adhesive on the bolt threa d.

• While the disc rotor shown is solid, the

Coupe arrangement is t he same, except with

a vented rotor.

3 Swing the caliper assembly up from the anch or plate

and disc. Using a wire hook, support the caliper.

4 Remove the worn pads from the anchor plate.

5 Inspect the brake disc condition. Refer to

3.7 Rear Brake Disc.

6 Check the guide pins for free movement in the anchor

plate. If there is restriction of movement, replace the

guide pins and/or guide pi n boots. Refer to

3.5 Rear Brake Caliper.

7 Clean any dirt from both the piston face, which

contacts the inner pad, and the caliper head area

which contacts the outer pad.

Figure 5A – 16

Service and Park Braking Systems Page 5A-22

Page 5A-86

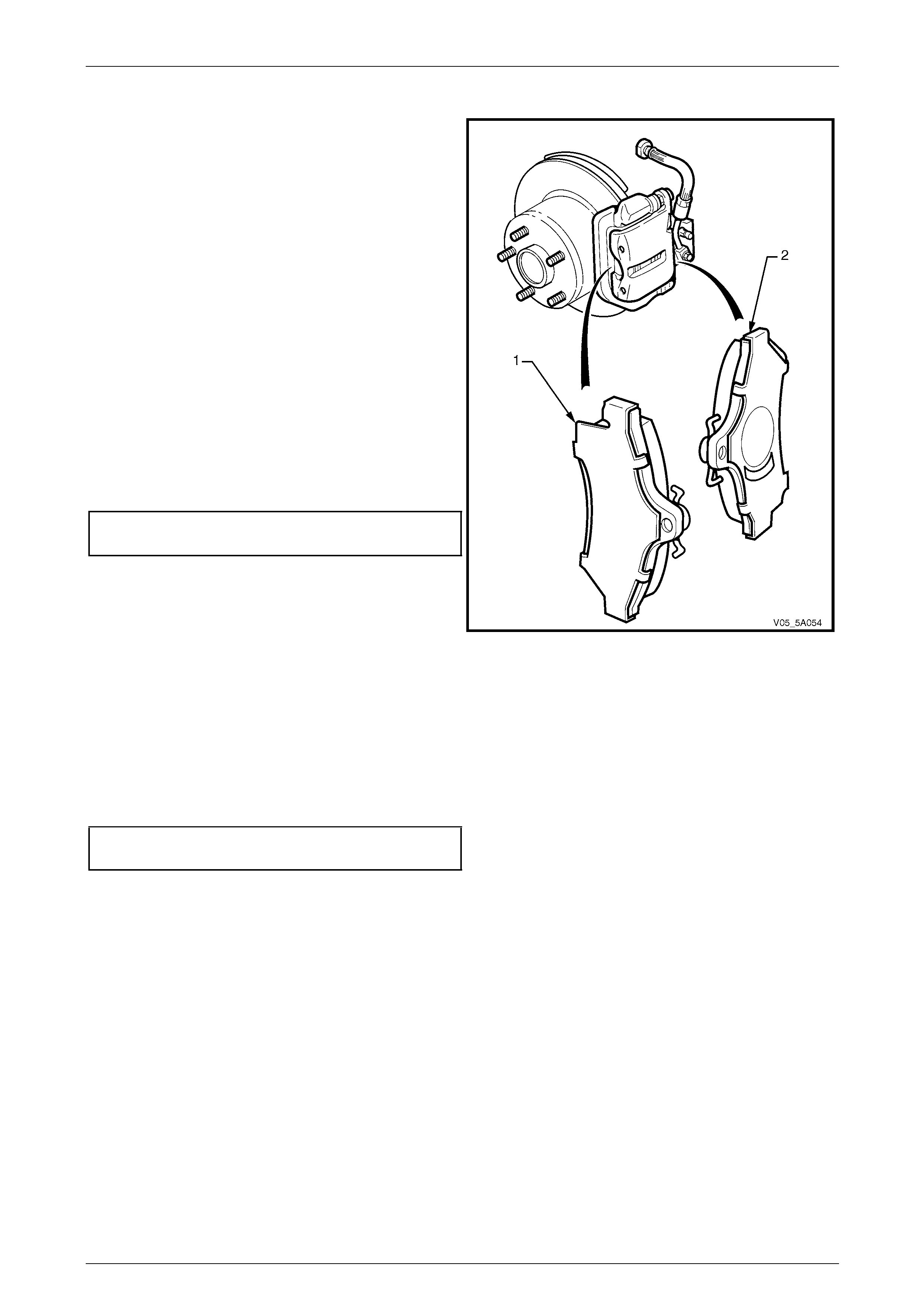

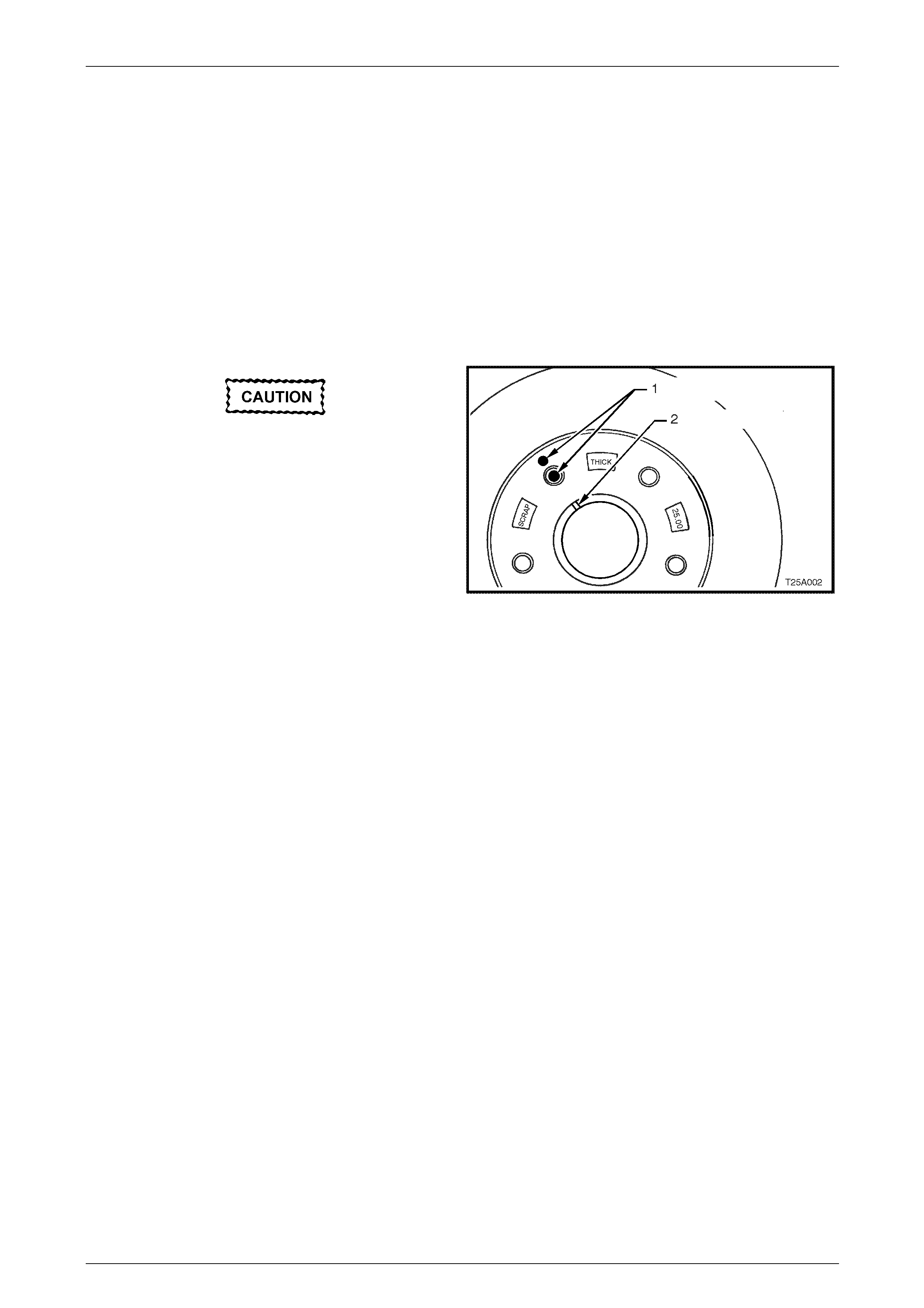

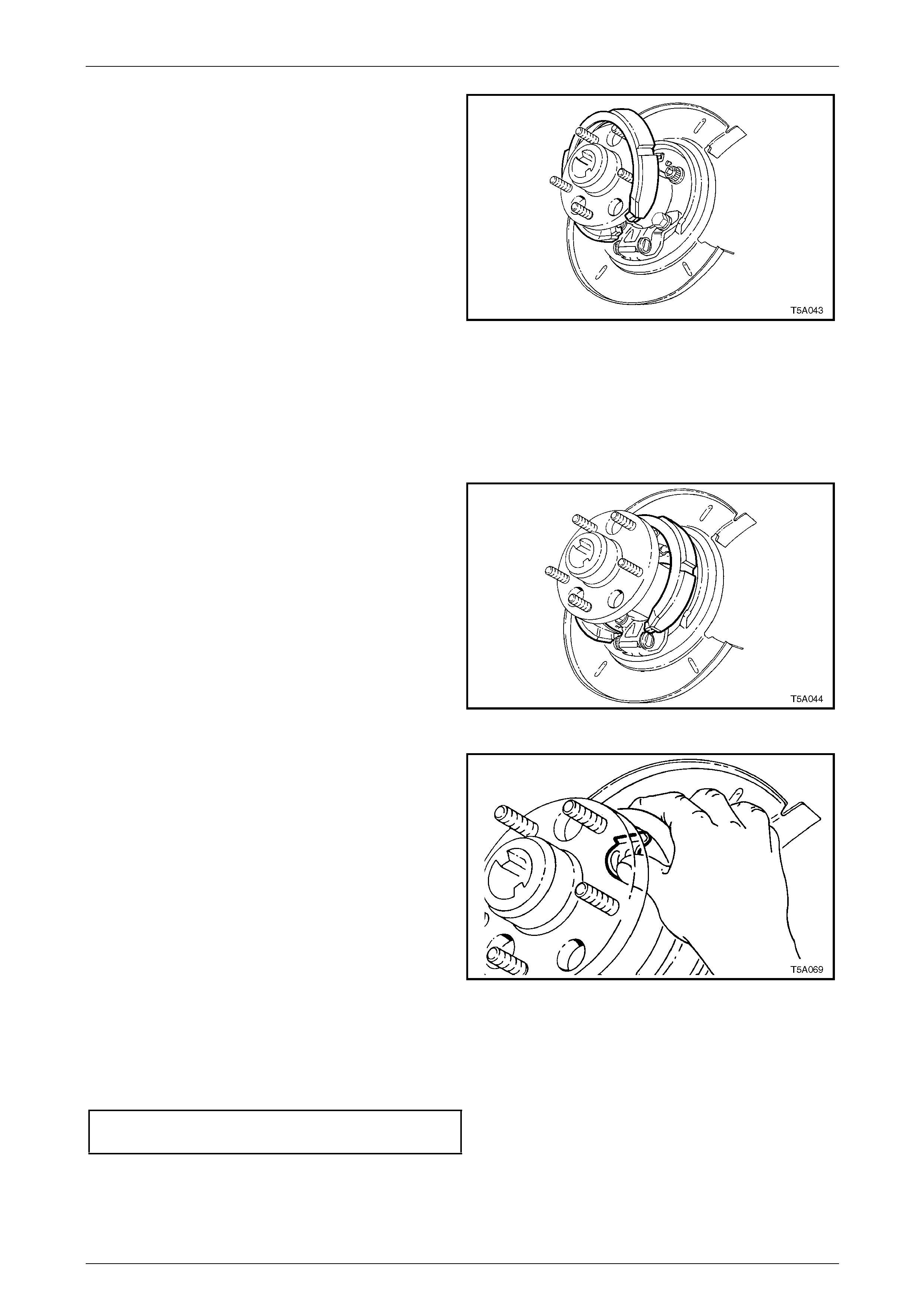

Reinstall

For noise damping effectiveness, it is critical that the brake

pad and shim assemblies are installed in the correct

locations. For example:

a The outer pad (1) (which is retained by the fingers of

the brake caliper housing), has a full shim.

b The inner pad (2) has a shim that has an asymmetrical

cut-out above the caliper piston and must be correctly

installed to the caliper by having the cut-out on the

lower half of the pad when installed in the caliper (in-

car position).

As illustrated, the brake pads shown, should onl y be fitted to

the left hand side, rear brake caliper.

1 Reinstall caliper housing over brake pads. Ensure

spring clip is located correctly in the top of the cali per

body.

2 Install a NEW guide pin, self locking bolt.

3 Use a suitable set spanner to prevent the guide pin

from rotating, then tighten the guide pin bolt to the

correct torque specification.

Brake caliper guide pin

bolt torque specification........................................32 Nm

NOTE

Do not wedge anything between the guide pin

hex and the caliper as this could cause incorrect

alignment of the pin, restricting the free sliding o f

the caliper relative to the anchor plate. Figure 5A – 17

4 Fill master cylinder to correct level with fresh brake fluid of the correct spec ificatio n.

5 Depress brake pedal sev eral times to bring pad assemblies into position against disc.

6 Refill master cylinder if neces sary.

7 Reinstall wheels, aligning marks made prior to removal and lower vehicle to the ground.

8 Tighten road wheel attaching nuts to the specified torque, working in a star pattern (refer to

2.1 Service Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nuts specification ......................................110 – 140 Nm

9 Reinstall decorative centre wheel cover.

10 Carry out the Brake Pad Bedding-In Proc edure, detailed in this Section.

Brake Pad Bedding-In Procedure

Whenever brake pads ar e replaced, they should be burnished, by the follo wing bedding-in procedure:

1 Perform a minimum of 10 moderate (0.3 to 0.4 g deceleration) brake applications from 70 km/h down to 40 km/h

every 500 metres.

NOTE

• A panic stop would be classified as being a

0.9 g deceleration braking effort, so a

moderate deceleration rate of 0.4 g would be

one that requir ed ap pro ximatel y half t he brak e

pedal effort needed for a panic stop.

• Do not perform this procedure at less than

500 metre intervals, as the excessive heat

build-up, may adversely affect the frictional

characteristics of the new brake pad material.

Service and Park Braking Systems Page 5A-23

Page 5A-86

2.8 Brake Pedal Assembly

LT Section No. – 04-600

Remove

Disable the SRS (Air Bag). Refer to

Section 12M Occupant Protection System.

1 If fitted, remove front suspension strut tower brace, refer to Section 1A1 Body.

2 Thoroughly cle an around the master cylinder, paying

particular attention to the reservoir cap and b r ake line

connections.

Brake fluid will damage the paint work if it

comes into contact with it. Should spillage

occur onto paint work, immediately wash the

brake fluid off with water.

3 Remove the master cylinder reservoir cap and set to

one side.

4 Using a hand vacuum pump (1), special tool J23738-A

or a commercially available hand vacuum pump or

syringe, siphon as much brake fluid from the master

cylinder reservoir (2) as possible.

NOTE

Hold the brake fluid level float down with the

suction tube, during this operation.

5 Reinstall the reservoir cap.

Figure 5A – 18

6 Disconnect the brake lines (5) from the master cylinder

(2) and allow any residual br ake fluid to drain from the

master cylinder into a container.

7 Plug the openings in both the master c ylinde r and the

pipes to prevent fluid loss and dirt ingress.

8 Remove the bolt (1) securing the master cylinder

bracket (4) to the end of the master cylinder (2).

NOTE

If the vehicle is fitted with the manual

transmission, support the clutch fluid reservoir

bracket, during bolt (1) removal. Use tie wire to

secure the reservoir and bracket in an upright

position, to one side.

9 Remove the nuts (3) securing the master cylinder

bracket (4) to the adjacent strut tower.

10 Remove the bracket (4) securing the master cylinder

to the adjacent strut tower. Figure 5A – 19

Service and Park Braking Systems Page 5A-24

Page 5A-86

11 As required, remove the following c ompo ne nts:

a Instrument panel lower trim panel assembly, refer to Section 1A3 Instrument Panel and Console.

b Driver side instrument panel lower trim plate assembly, refer to Section 1A3 Instrument Panel and Console.

c Instrument panel lower trim panel retainer, refer to Section 1A3 Instrument Panel and Console.

d Remove the Body Control Module (BCM) from its mounting bracket but le ave all electrical connectors

installed, refer to Section 12J Body Control Module.

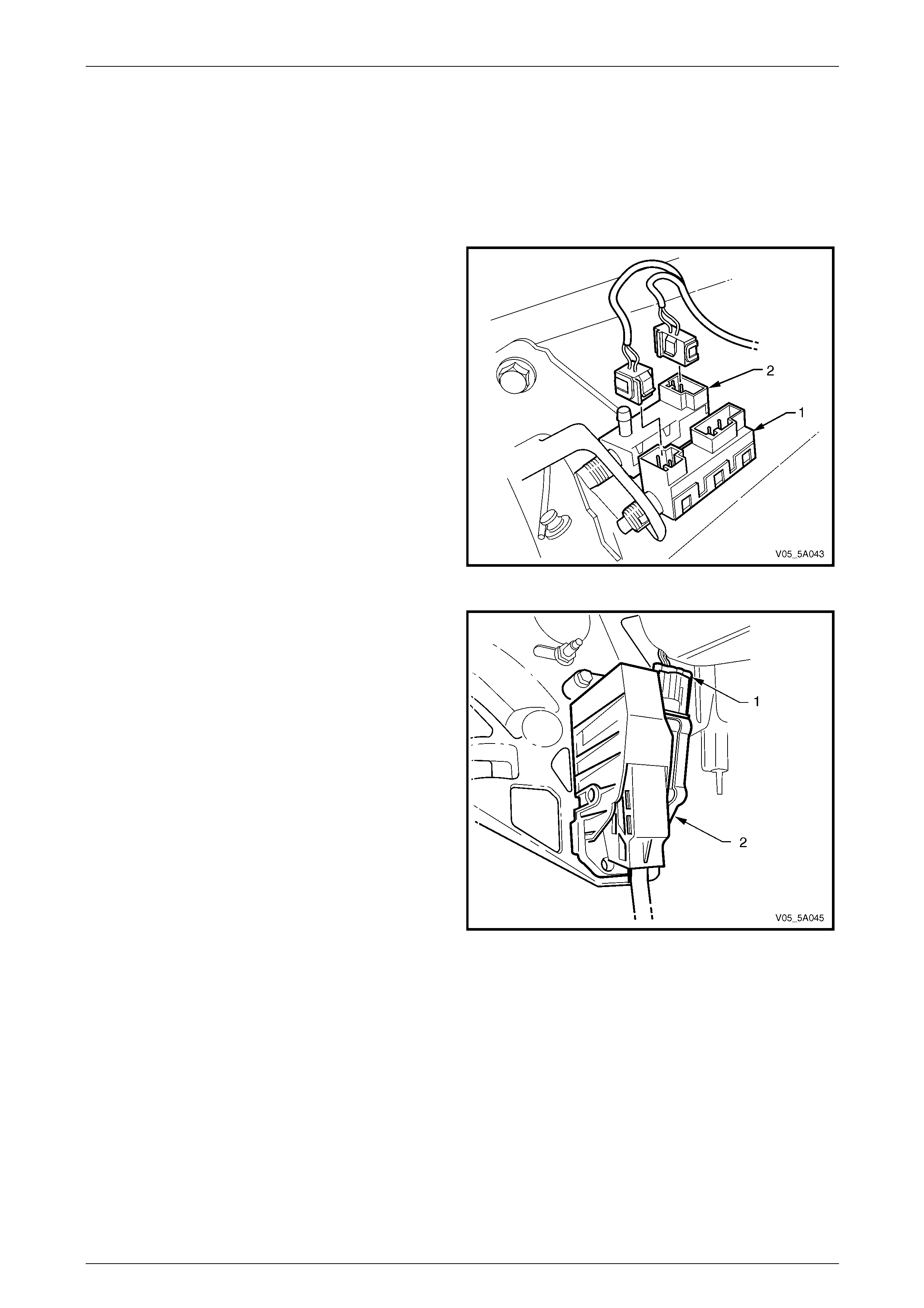

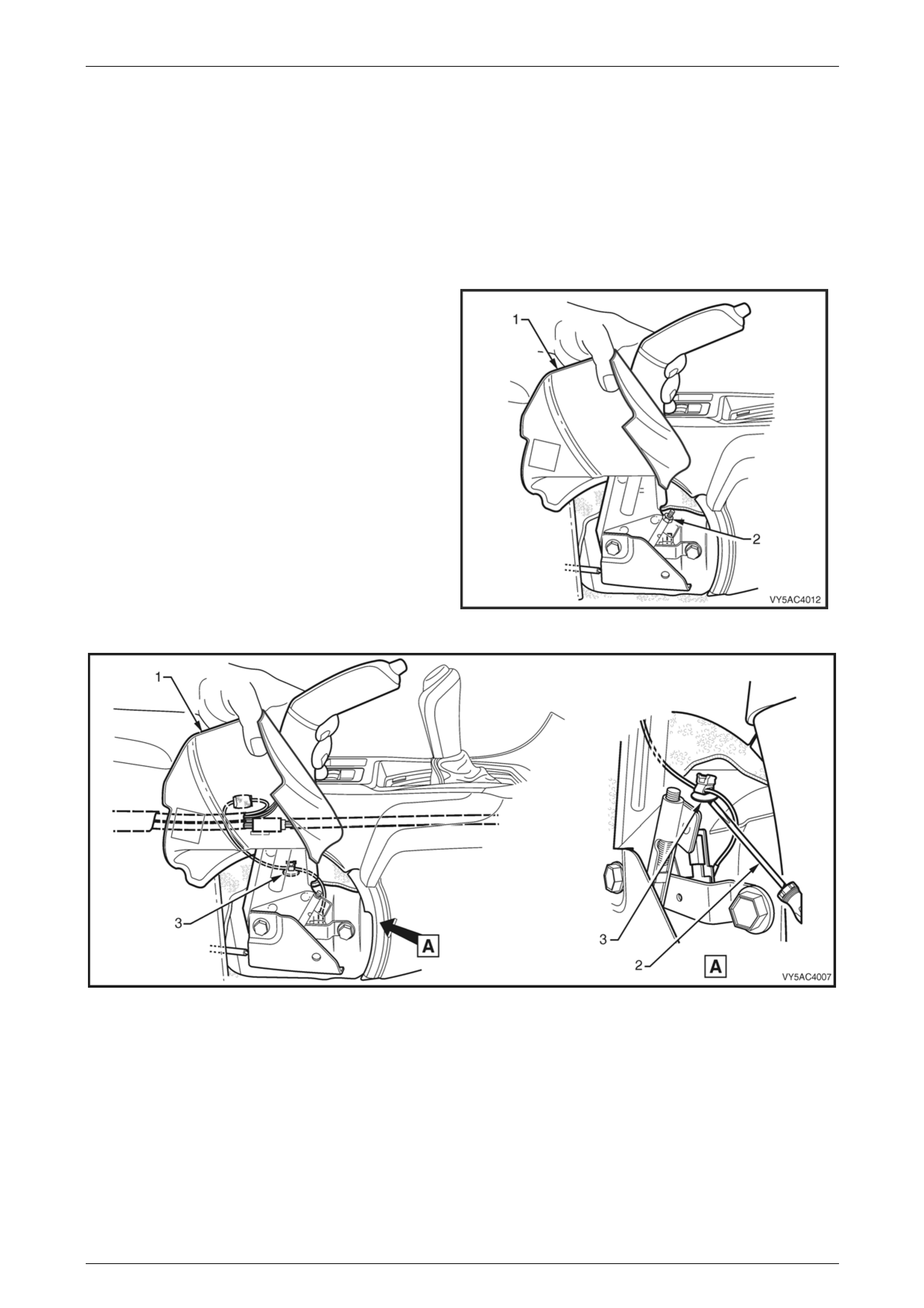

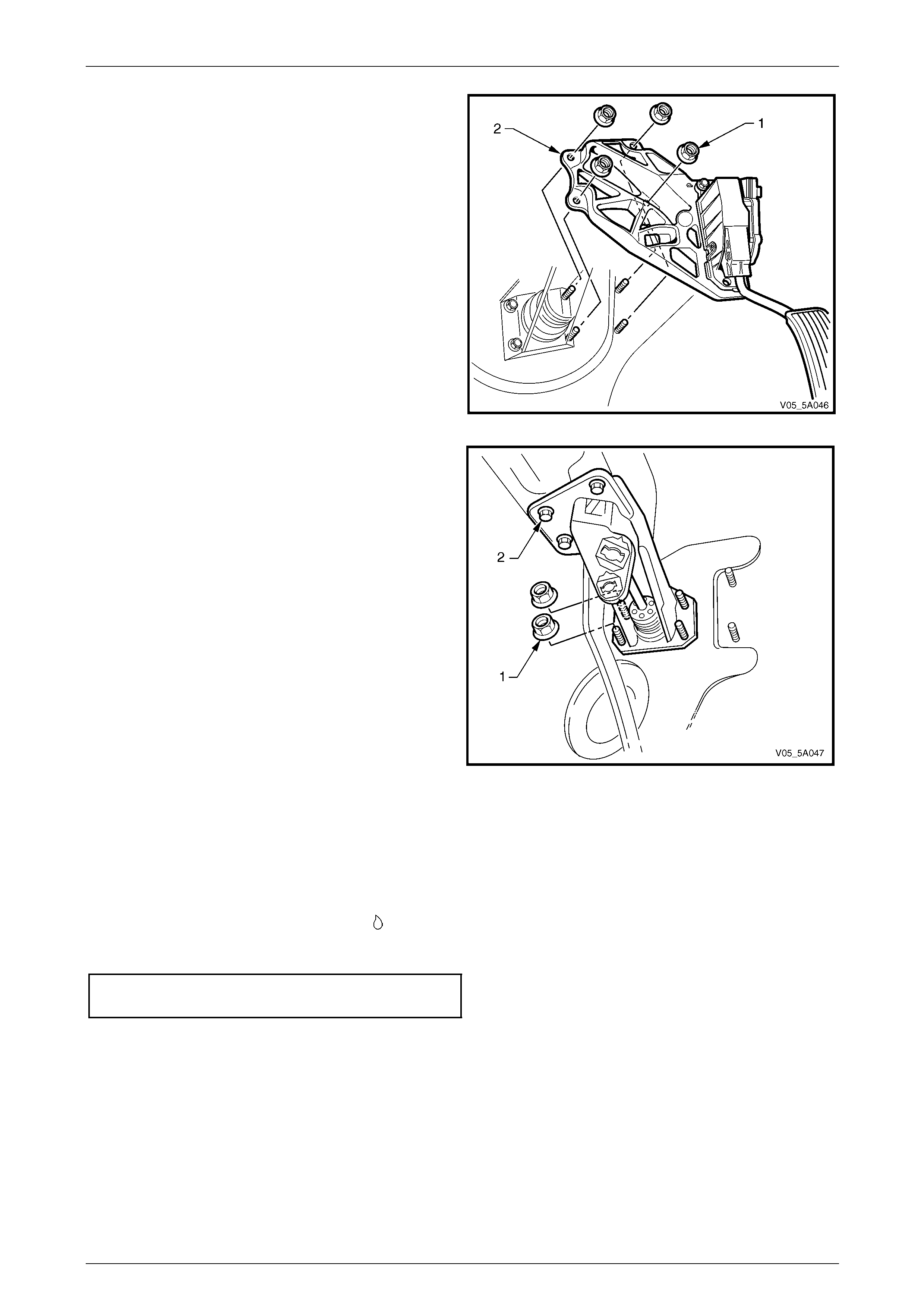

12 Disconnect the wiring harness connectors from the

stop lamp switch (1) and the cruise cancel switch (2).

NOTE

Refer to Section 12E Cruise Control for further

information on the cruise control switch.

Figure 5A – 20

13 Disconnect the accelerator pedal wiring harness

connector (1) from the accelerator pedal sen s or (2).

Figure 5A – 21

Service and Park Braking Systems Page 5A-25

Page 5A-86

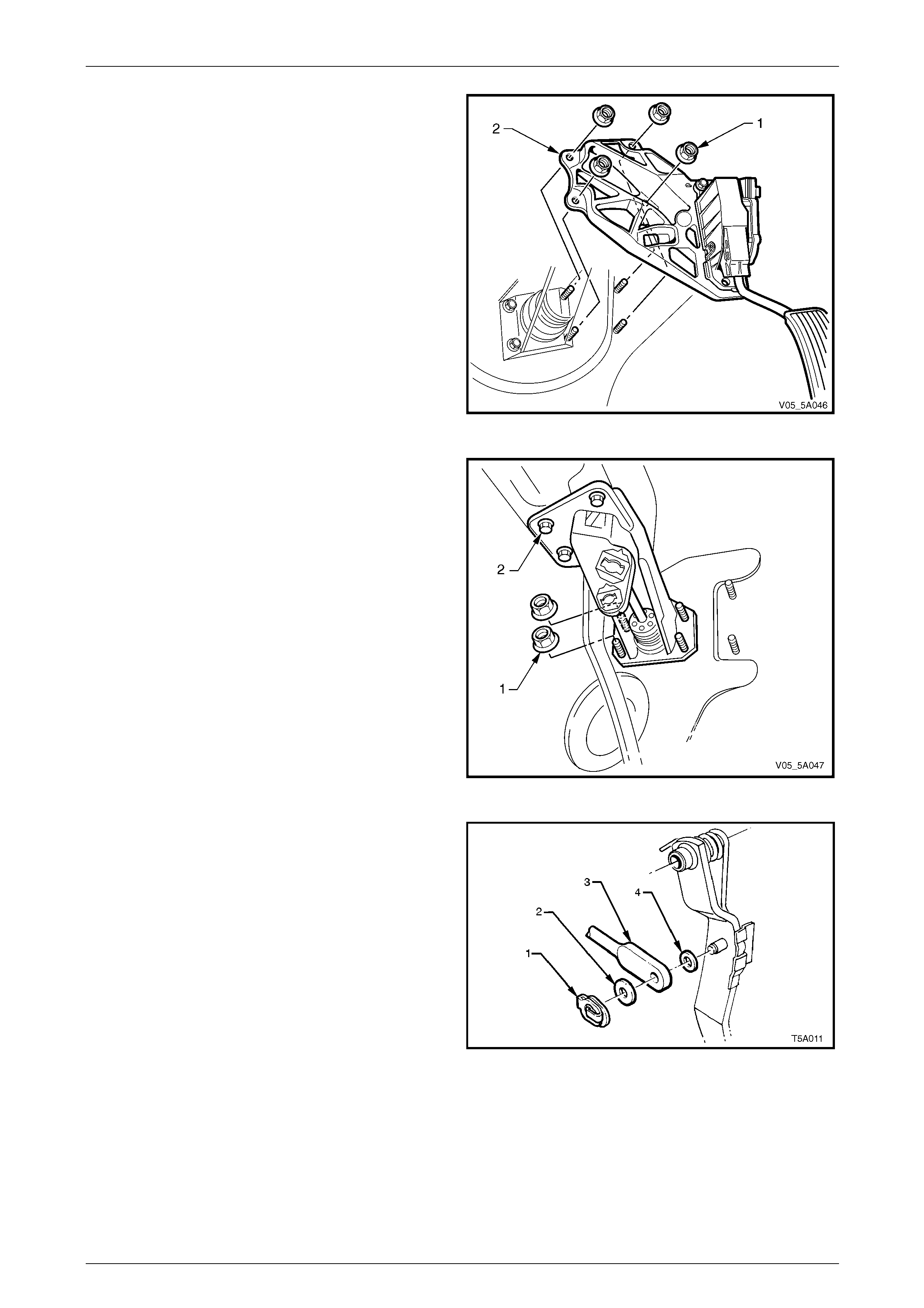

14 Remove the four nuts (1) securing the accelerator

pedal sensor bracket (2) to the brake pedal support

bracket and the dash panel.

Figure 5A – 22

15 Remove the remaining two nuts (1) securing the brake

booster to the brake pedal support bracket.

16 Remove the three bolts (2) securing the brake ped al

support bracket to the dash reinforcement.

17 From the engine compartment, pull the brake booster

forward, to disengage the four studs from the brake

pedal support bracket.

18 Lower the brake pedal assembly, rear end first and

removed from under the instrument panel.

Figure 5A – 23

19 Remove the push rod retaining clip (1), pus h rod (3)

and washers (2 and 4) from the brake pedal .

Figure 5A – 24

Service and Park Braking Systems Page 5A-26

Page 5A-86

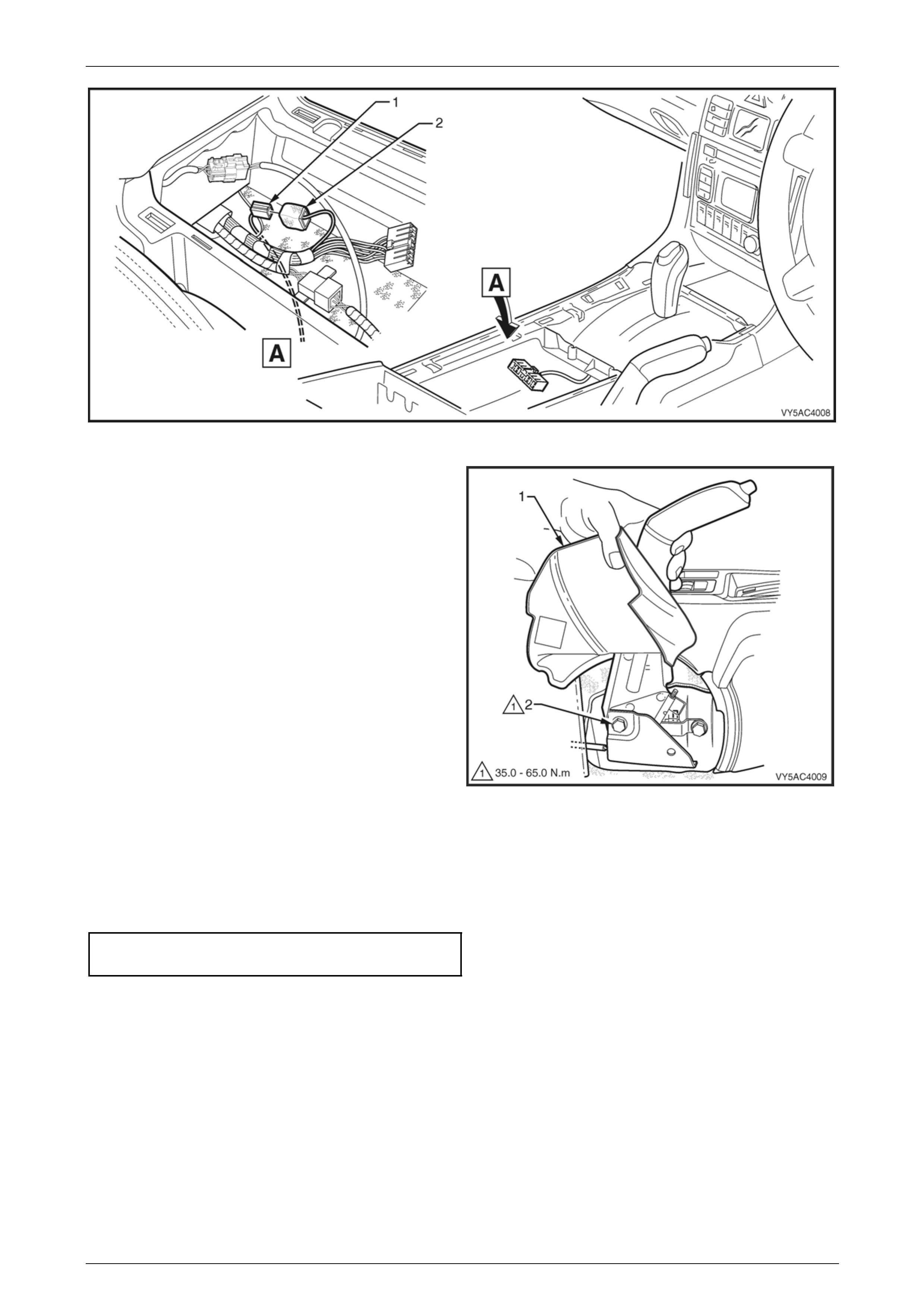

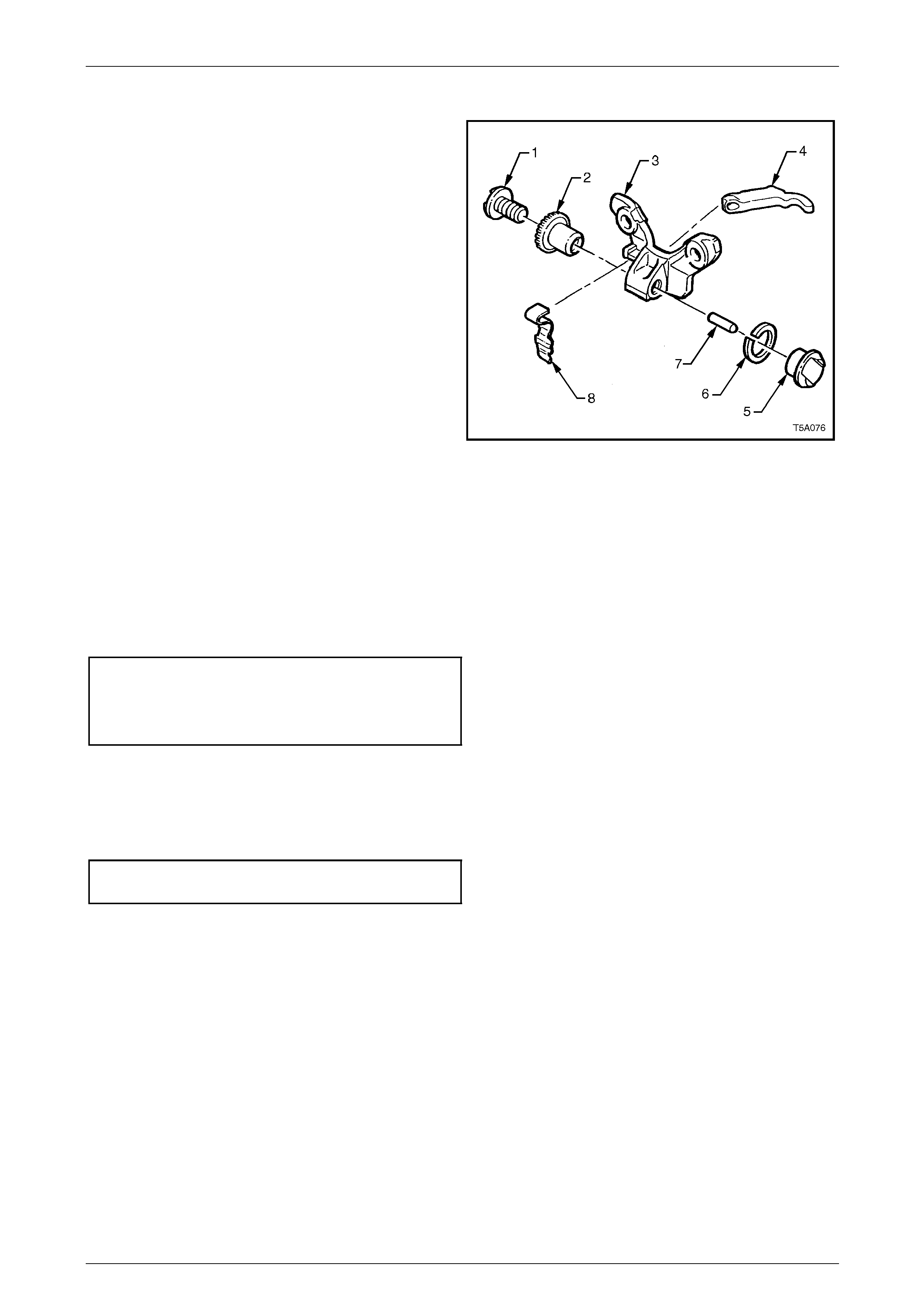

Disassemble

1 Remove the nut (3) and washer (4) securing the brake

pedal shaft (5) to the brake pedal support (5).

2 Carefully remove the shaft and washer (6) from the

brake pedal support (2).

3 Withdraw the brake pedal (7) and return spring (8)

assembly.

4 Turn the cruise cancel switch (10), to the left (counter-

clockwise), then pull to remove from the brake pedal

support (2).

5 Turn the stop lamp switch (9), to the left (counter-

clockwise), then pull to remove from the brake pedal

support (2).

Reassemble

1 Lubricate all bearing surfaces (indicated by the symbol

) with an NLGI No. 2 lithium soap based EP grease

with molybdenum disulphide, such as Shell Retinax

HDX2 grease or BP Energrease LMS-EP 2 3 (or

equivalent).

2 Hold the brake pedal (7) and return spring (8) in

position and insert the brake ped al support shaft (5)

and washer (6) through the brake pedal support (2).

3 Reinstall the brake peda l shaft retaining washer (4)

and nut (3), then tighten to the correct torque

specification.

Brake pedal support shaft nut

torque specification...............................................55 Nm Figure 5A – 25

4 If removed, reinstall the cruise cancel switch (10):

a Insert the switch into the pedal bracket switch retainer, with the wiring harness connector at the 1 o'clock

position.

b Push the switch into the retainer and turn clockwise until the wiring harness connector is at the 3 o'clock

position. At this point a click should be felt, indicating that the switch is locked into place. No further

adjustment is required.

5 If removed, reinstall the stop lamp (9), following the same procedure as for the cruise cancel switch.

Service and Park Braking Systems Page 5A-27

Page 5A-86

Reinstall

1 Reinstall the brake pedal assembly into the vehicle and install the three bolts (2) securin g the brake pedal support

assembly to the steering column, refer to Figure 5A – 23. Do not tighten the bolts at this time

2 Push the brake booster rear ward to engage the four studs with the brake pedal support assembly.

3 Reinstall the push rod (3), washers (2 and 4) and retaining clip (1). Refer to Figure 5A – 24.

4 Reinstall the accelerator pedal assembly, refer to Figure 5A – 22.

5 Reinstall and tighten the four brake pedal assembly to brake booster nuts to the correct torque specific ation.

Brake pedal support to brake

booster nut torque specification............................25 Nm

6 Reinstall and tighten the two remaining accelerator pedal assembly to dash panel nuts to the specified torque.

Refer to Figure 5A – 22.

Accelerator pedal sensor bracket

attaching nut torque specification..........................25 Nm

7 Reinstall the wiring harness connectors to the stop lamp and the cruise cancel switches.

8 Reinstall the accelerator pedal sensor wiring harness connector, refer to Figure 5A – 21.

9 Tighten the three brake pedal support bracket to the dash reinforcement bolts to the correct torque specificatio n,

refer to '2' in Figure 5A – 23.

Brake pedal support bracket

bolt torque specification........................................25 Nm

10 Reinstall the master cylinder support bracket and tighten the nuts and bolt to the correct torque specification.

Master cylinder to bracket

bolt torque specification........................................10 Nm

Master cylinder bracket to strut tower

attaching nuts torque specification..........................8 Nm

11 Place a clean container under the brake master cylinder, unplu g the brake lines and master cylinder outlet ports

and reinstall the pipes to the master cylinder, refer to Figure 5A – 19.

12 Tighten the brake pipe flare nuts to the correct torque specification.

Brake pipe to master cylinder

flare nut torque specification.................................14 Nm

13 Bleed the brake system. Refer to 2.4 Brake System Bleed, in this Section.

14 Reinstall the instrument panel lower trim panel retainer, lower trim panel and driver side lower trim plate, refer to

Section 1A3 Instrument Panel and Co nsole.

Enable the SRS (Air Bag). Refer to

Section 12M Occupant Protection System.

15 Road test the vehicle to check for correct brake, stop lamp and cruise control operation.

Service and Park Braking Systems Page 5A-28

Page 5A-86

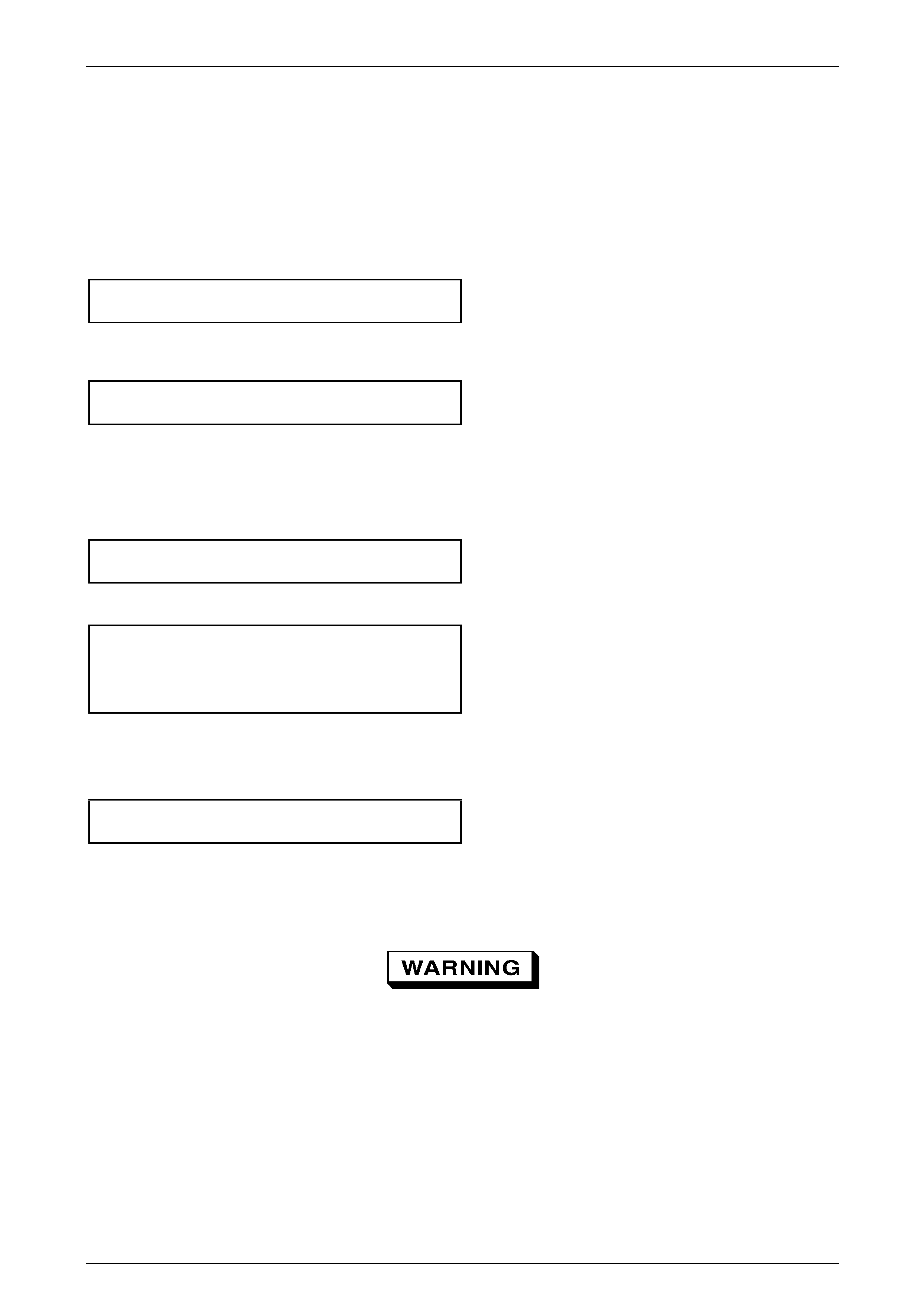

2.9 Park Brake Lever

LT Section No. – 04-675

Remove

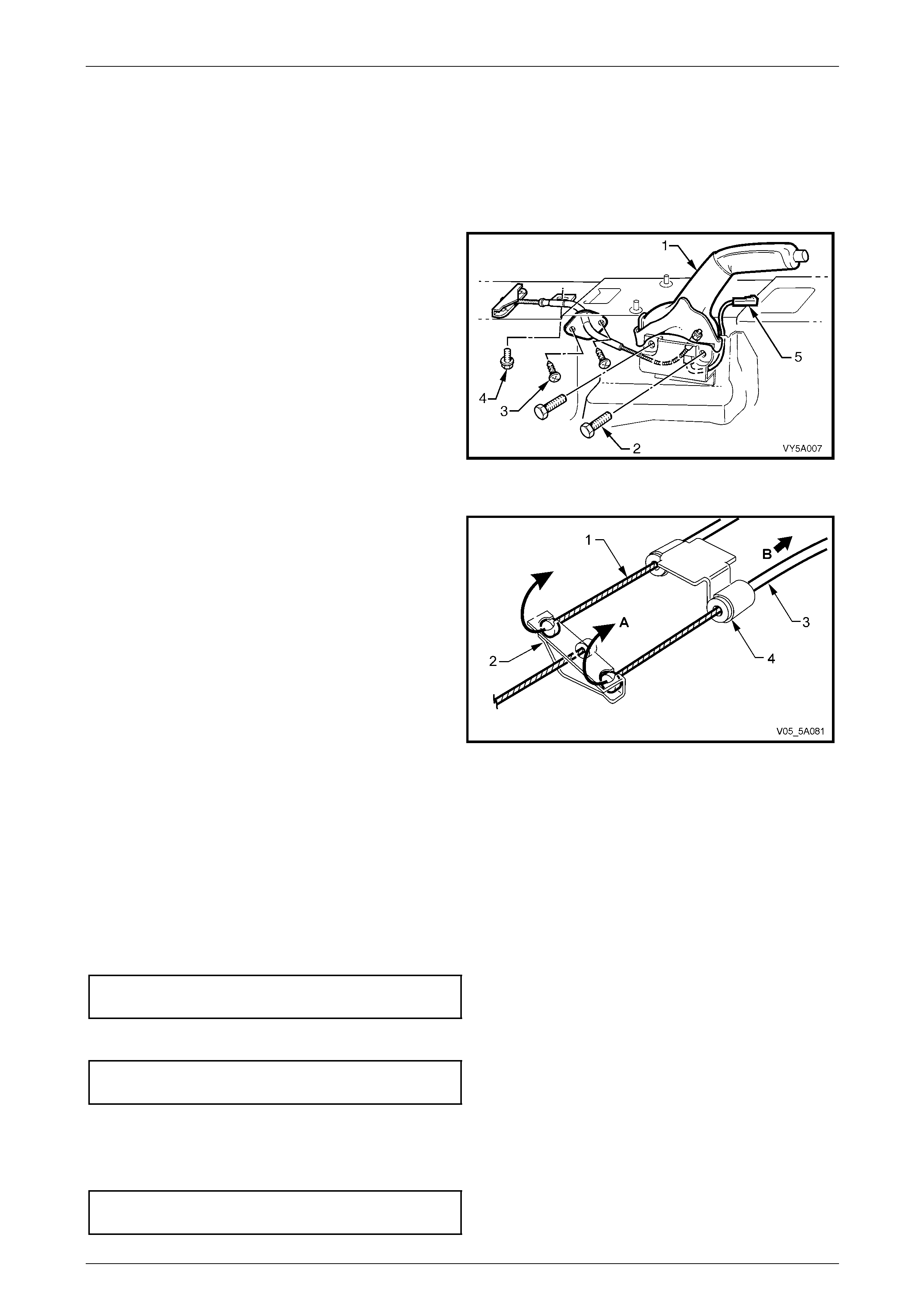

1 Remove the right hand front seat. Refer to Section 1A7 Seat Assemblies .

2 Set the park brake in the fully released position.

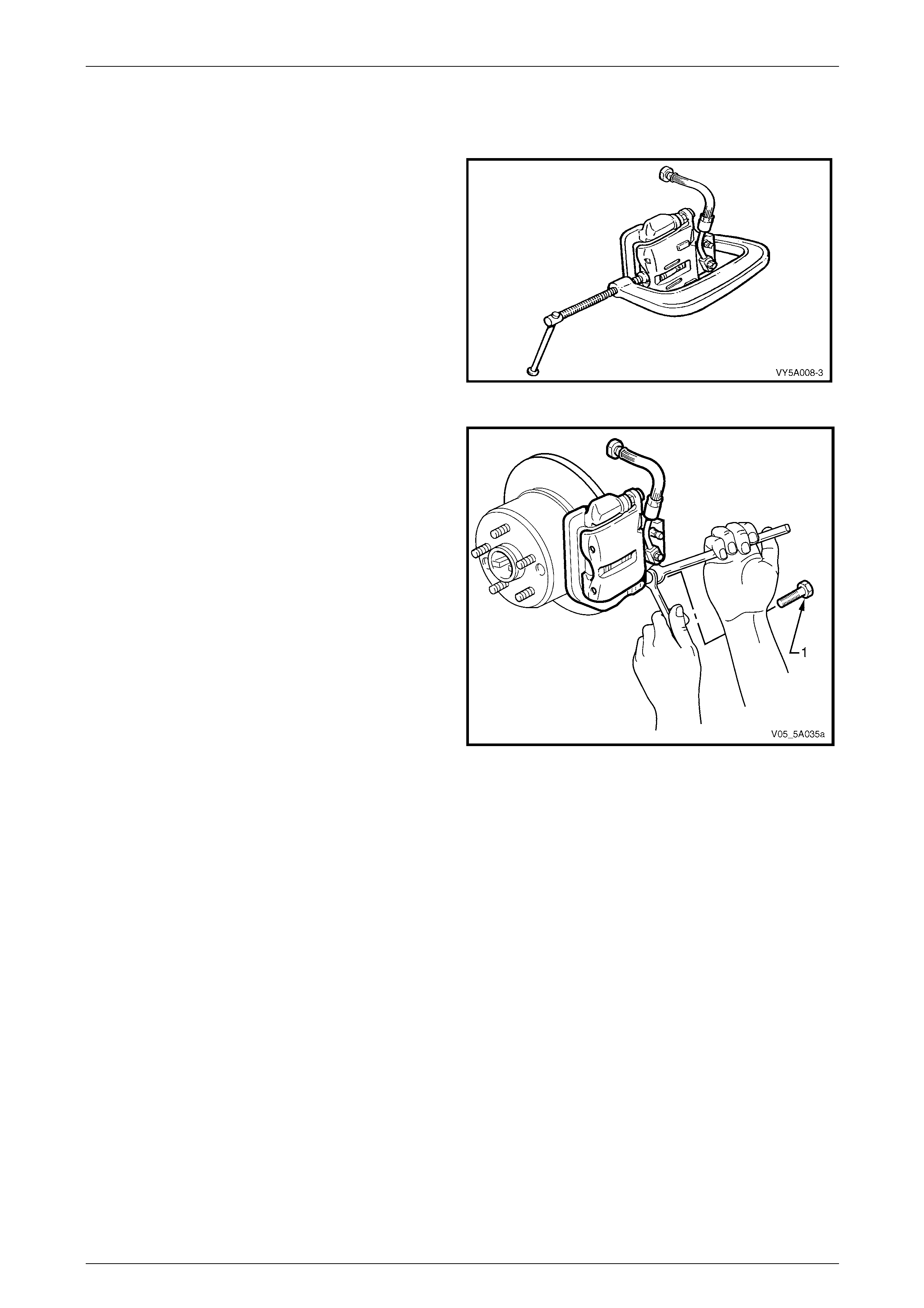

3 Slip the park brake lever boot (1) to one side, then

remove the park brake front cable adjusting nut (2),

using a deep socket.

4 Whilst holding the park brake lever bo ot (1) to one

side, use a screwdriver (2) to prise the park brake

warning lamp switch harness r etain ing clip (3) from the

transmission tunnel.

Figure 5A – 26

Figure 5A – 27

5 Remove the floor console cover assembly. Refer to Section 1A3, Instrument Panel and Console.

6 Disconnect the park brake warning lamp switch harness connector (1) from the main vehicle wiring harness

connector (2).

Service and Park Braking Systems Page 5A-29

Page 5A-86

Figure 5A – 1

7 While holding the park brake lever boot (1) to one

side, remove the park brake lever retaining bolt (2),

two places.

8 Carefully lift the park brake lever assemb ly upwards to

free the cable (2).

9 Remove the lever assembly from the vehicle.

Figure 5A – 28

Reinstall

Reinstallation is the reverse of the removal procedure, noting the following:

1 Tighten the park brake lev er bolts to specified torque.

Park brake lever bolt

torque specification...............................................50 Nm

2 Reinstall the threaded end of the front park brake cable and then install the adjusting lock nut. Adjust the park

brake cable. Refer to 2.2 Park Brake Cable, Adjust, in this Section.

Service and Park Braking Systems Page 5A-30

Page 5A-86

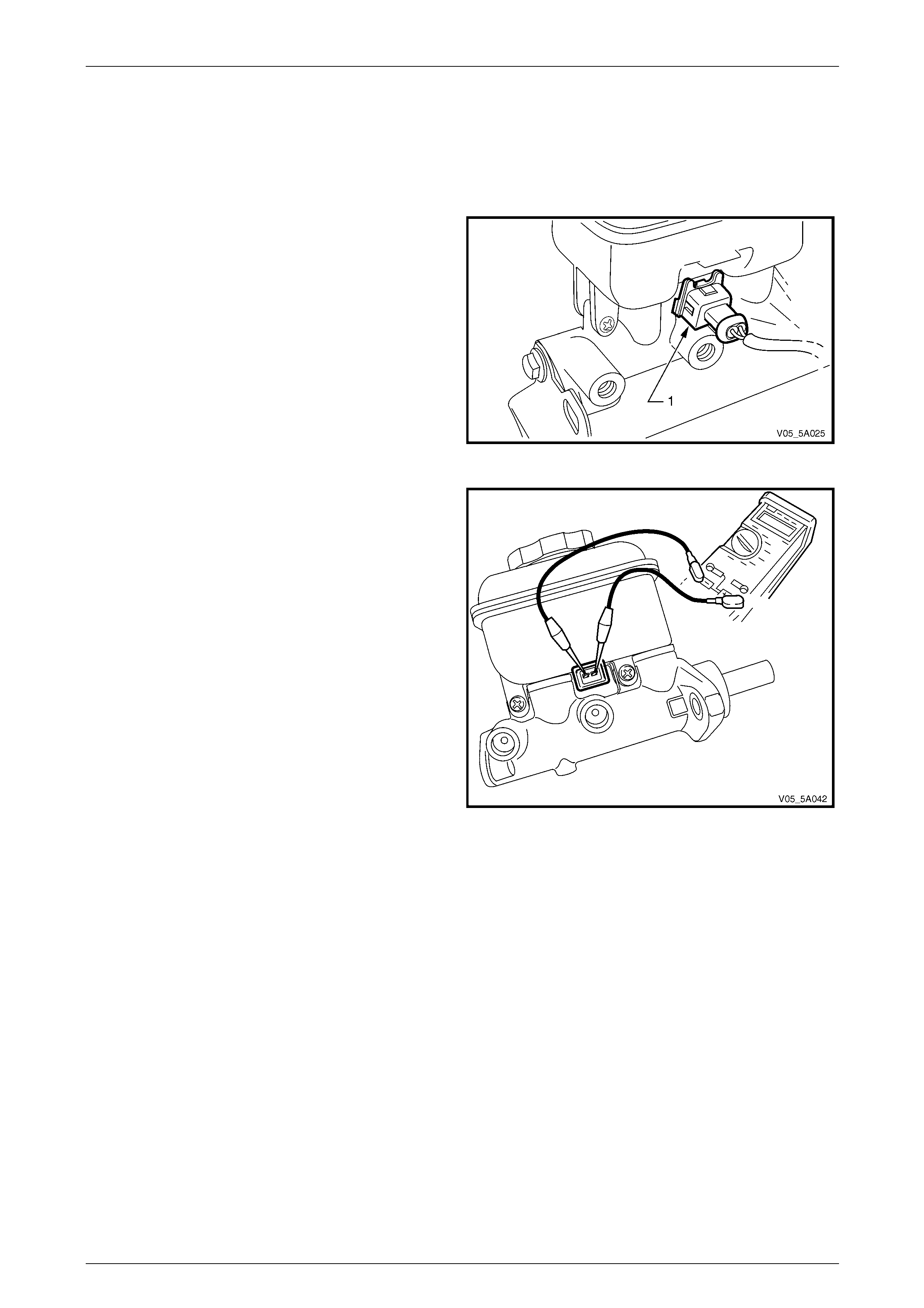

2.10 Park Brake Warning Lamp Switch

LT Section No. – 04-675

Remove

1 Remove the park brake lever. Refer to 2.9 Park Brake Lever, Remove, in this Section.

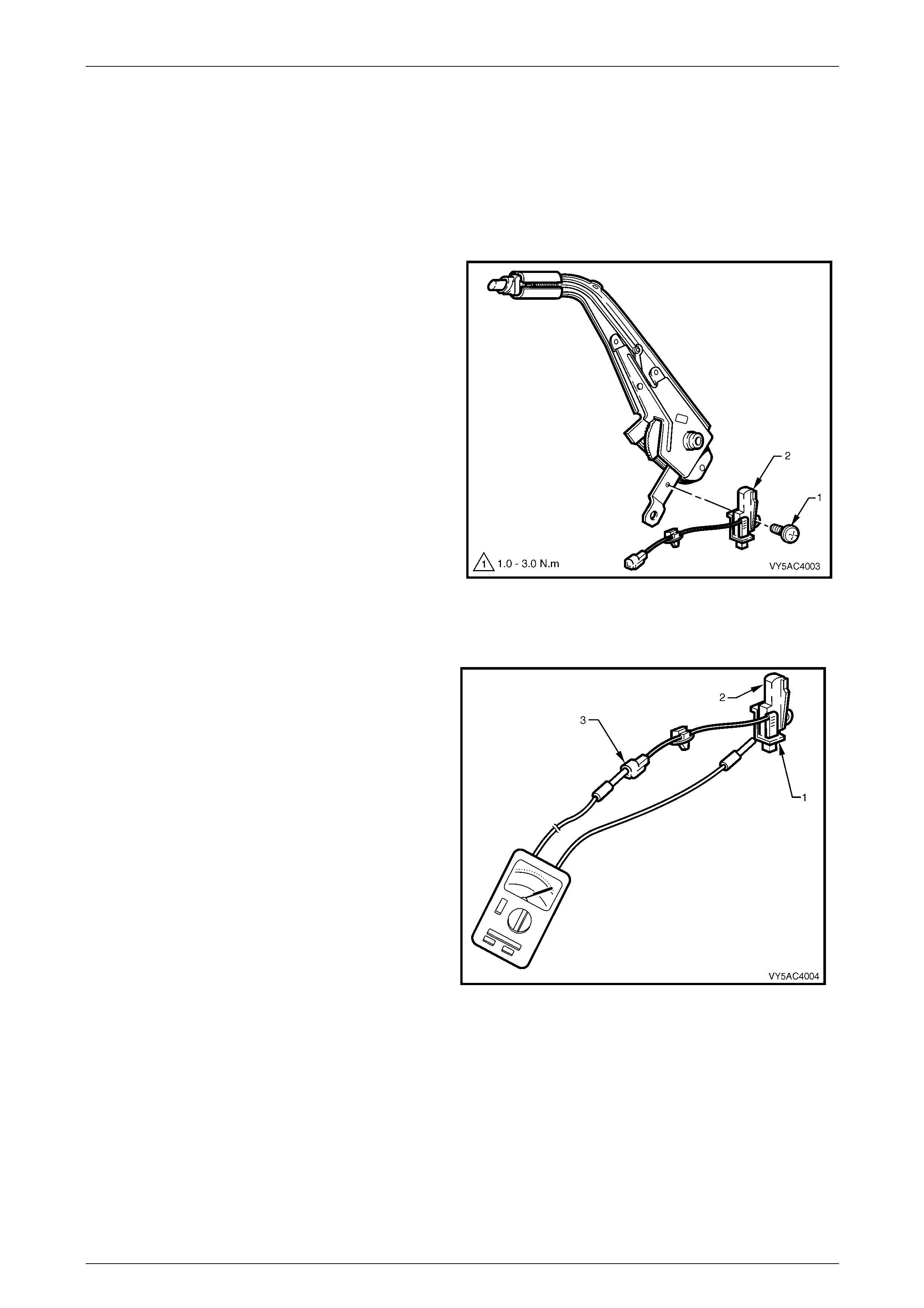

2 Remove the park brake warning lam p switch retaining

screw (1), and remove the switch (2).

Figure 5A – 29

Inspect

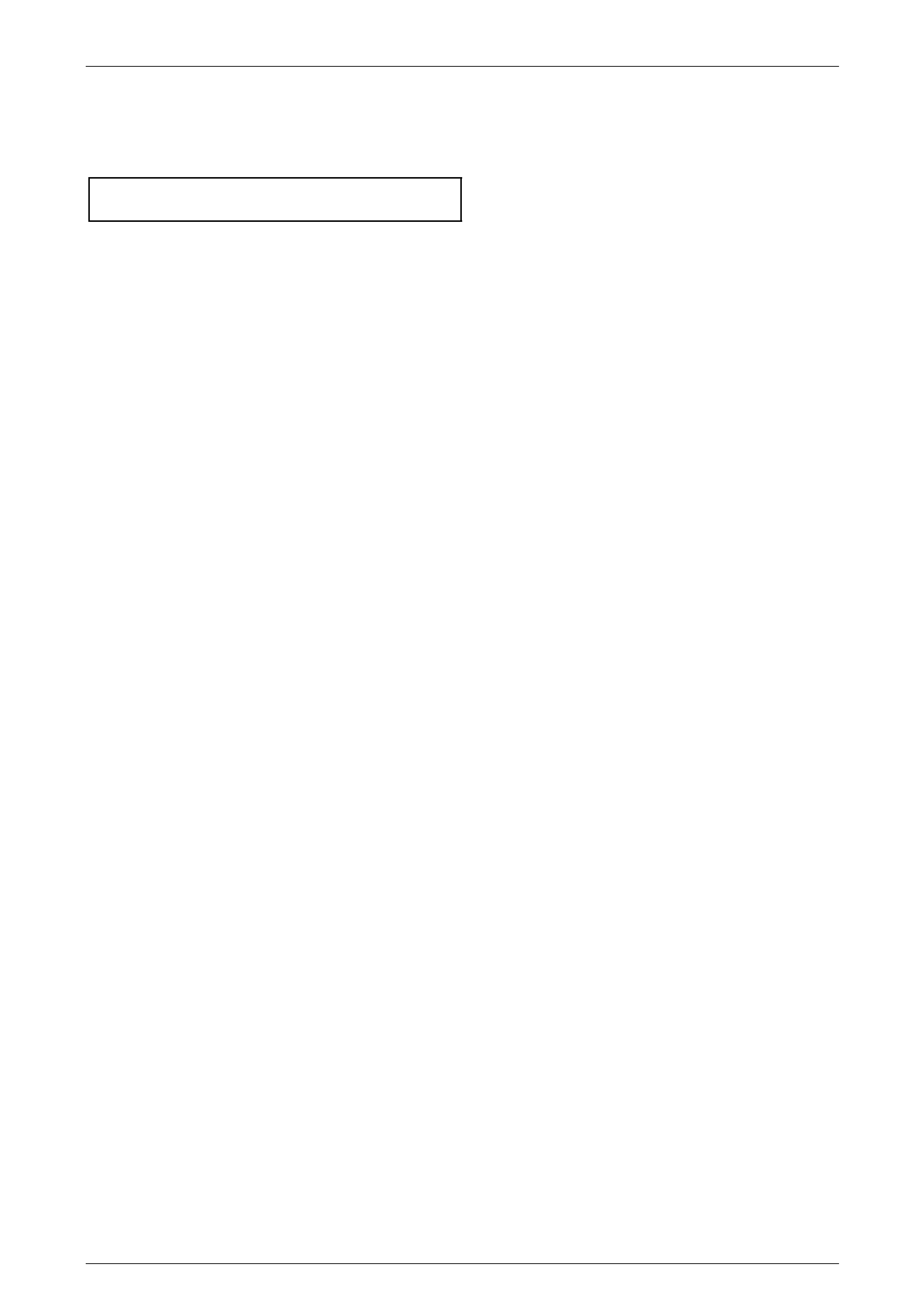

1 While holding the park brake warning lamp switch (1),

depress and release the plunger (2), checking that the

plunger moves freely.

2 Using a multimeter, check that there is continuity

between the terminal (3) and t he switch body.

3 With the multimeter still connected, check that there is

no continuity when the s witch plunger is depressed.

4 If any of the above tests fail, replace the park brake

warning lamp switch.

Figure 5A – 30

Service and Park Braking Systems Page 5A-31

Page 5A-86

Reinstall

Reinstallation is the reverse to the removal proce dure, noting the following:

1. Tighten the park brake warning lamp switch retaining screw to the specified torque.

Park brake warning lamp switch

screw torque specification.......................................2 Nm

NOTE

For further information on the park brake

warning lamp operation, refer to Section 12C

Instrumentation.

Service and Park Braking Systems Page 5A-32

Page 5A-86

2.11 Front Park Brake Cable

LT Section No. – 04-675

Remove

1 Set park brake in the fully released p osition.

2 Remove driver’s seat. Refer to Section 1A7 Seat

Assemblies for the procedure.

3 Remove the park brake lever (1). Refer to

2.9 Park Brake Lever, in this Section.

4 Remove the centre console and lift the carpet to gain

access to the two front cable escutcheon screws (3).

Refer to Section 1A3 Instrument Panel and Console,

for details.

5 Remove the two screws (3).

6 Raise the vehicle and suppor t in a safe manner. Refer

to Section 0A General Information for the location of

the recommended lifting and support points. Figure 5A – 31

7 Pull each park brake inner rear cable (1) forward and

up (A), out of the equaliser bracket (2) to release.

8 Pull the outer cables (3) to the rear (B) to remove the

cable from the underbody retaining bracket (4).

9 Remove the front cable outer cable retaining bracket

bolt from the vehicle underbod y, refer to ‘4’ in

Figure 5A – 31.

NOTE

Depending on the engine/transmission fitted to

the vehicle, it may be necessary to first remove

the propeller shaft to enable access to this bolt.

Refer to Section 4C1 Rear Propeller Shaft and

Universal Joints for the proce dure. Figure 5A – 32

10 Manoeuvre the front cable assembly and equaliser bracket, through the aperture in the floo r pan, removing the

cable assembly from inside the vehicle.

Reinstall

Reinstallation is the reverse to the removal procedure, a pa r t from the following:

1 Manoeuvre the front cable and equ aliser bracket assembly, through the hole in the floor p an, ensuring that the

rubber seal is correctly positioned. Install the two self tapping screws ('3' in Figure 5A – 31) securing the plate to

the floor pan and tighten to the correct torque specification.

Front park brake cable plate retaining

screw torque specification....................................2.0 Nm

2 Reinstall the park brake lever and tighten bolts ('2' in Figure 5A – 31) to the specified torque.

Park brake lever bolt

torque specification...............................................50 Nm

3 Reinstall the park brake front cable adjusting nut a few threads to secure the cable.

4 Reinstall the outer front cable retaining bracket bolt to the vehicle underbody ('4' in Figure 5A – 31) , tightening to

the correct torque specification.

Outer front cable bracket

bolt torque specification........................................25 Nm

Service and Park Braking Systems Page 5A-33

Page 5A-86

5 As required, reinstall the propeller shaft. Refer to Section 4C1 Re ar Propeller Shaft and Universal Joints for the

procedure and the specified torque specifications.

6 Reinstall the driver’s seat and centre console. Refer to Section 1A7 Seat Assemblies and

Section 1A3 Instrument Panel and Co nsole, for the necessary procedures.

7 Reinstall the two rear cables to the eq ualiser bracket.

8 Adjust the park brake. Refer to 2.2 Park Brake Cable, Adjust in this Section.

9 Lower the vehicle to the ground

10 Check for correct park brake operation.

Service and Park Braking Systems Page 5A-34

Page 5A-86

2.12 Rear Park Brake Cable/s

LT Section No. – 04-675

Remove

1 Release park brake.

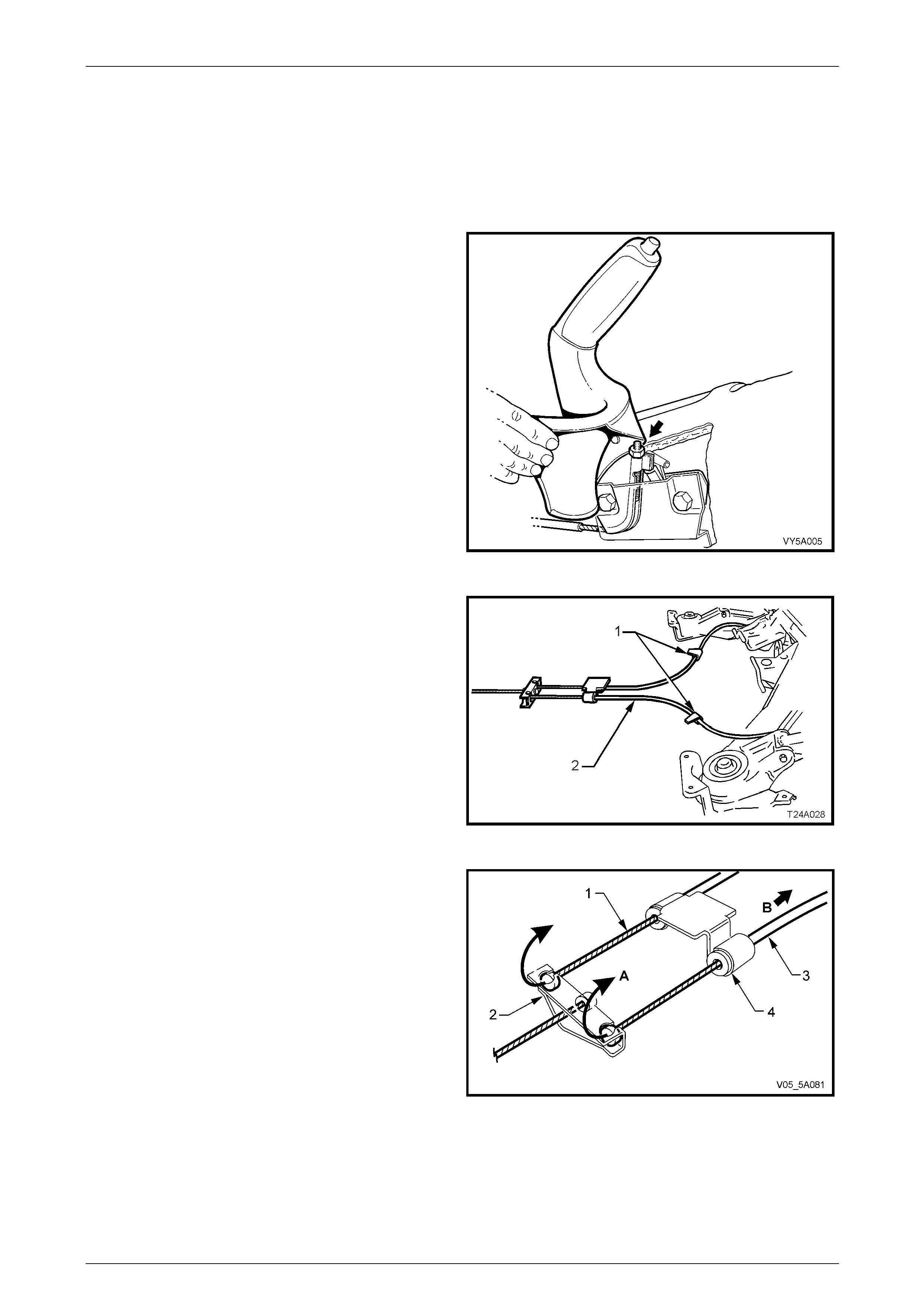

2 Using a deep socket, loosen the front cabl e adjusting

nut (arrow) until the nut is almost removed.

3 Using a floor jack under centre of differential carrier,

jack up and support rear of vehicle on safety stands

under rear trailing arms.

Figure 5A – 33

4 To provide sufficient access, it may be necessary to

remove the propeller shaft from the vehicle. Refer to

Section 4C1 Rear Propeller Shaft and Univer sal Joints

for the necessary procedures.

5. As required, unclip the cable/s (2) from the underbody

clip/s (1).

Figure 5A – 34

1 Remove the front of the rear inner cable/s (1), by first

wrapping rag around the inner cable to protect it from

damage, then use pliers to pull the ba ll nipple forward

and up (A), to free from the equaliser bracket (2).

2 Pull the outer cable/s (3) rearward (B) to release from

the vehicle underbody bracket (4).

Figure 5A – 35

Service and Park Braking Systems Page 5A-35

Page 5A-86

3 Disconnect the rear clevis from the rear park brake

actuating lever by gripping with pliers and pivoting the

cable rearwards.

Figure 5A – 36

Reinstall

Reinstallation of the rear park brake cable/s is the reverse of removal procedure, except for the following points:

1 Reinstall the cable throu gh the trailing arm retainer, then fit the cable cl evis to the park brake actuating lever.

2 Pull the outer cable/s forward to reinstall into the vehicle underbo dy bracket.

3 Wrap rag around the inner cable to protect it from damage, then use pli ers to pull the ball end on the inner cable

forward to engage into the equaliser bracket.

4 If removed, reinstall the propeller shaft. Refer to Section 4C1 Rear Propeller Shaft and Universal Joints for all

details.

5 Adjust park brake cable, refer to 2.2 Park Brake Cable, Adjust, in this Section.

Service and Park Braking Systems Page 5A-36

Page 5A-86

2.13 Front Caliper Brake Hose

LT Section No. – 04-750

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove the wheel covers or decorative wheel nut caps, then mark the relationship of the road wheel to one of the

wheel studs.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to 2.1 Service Warnin gs,

Cautions and Notes in this Section, for detailed information. Remove the road wheel.

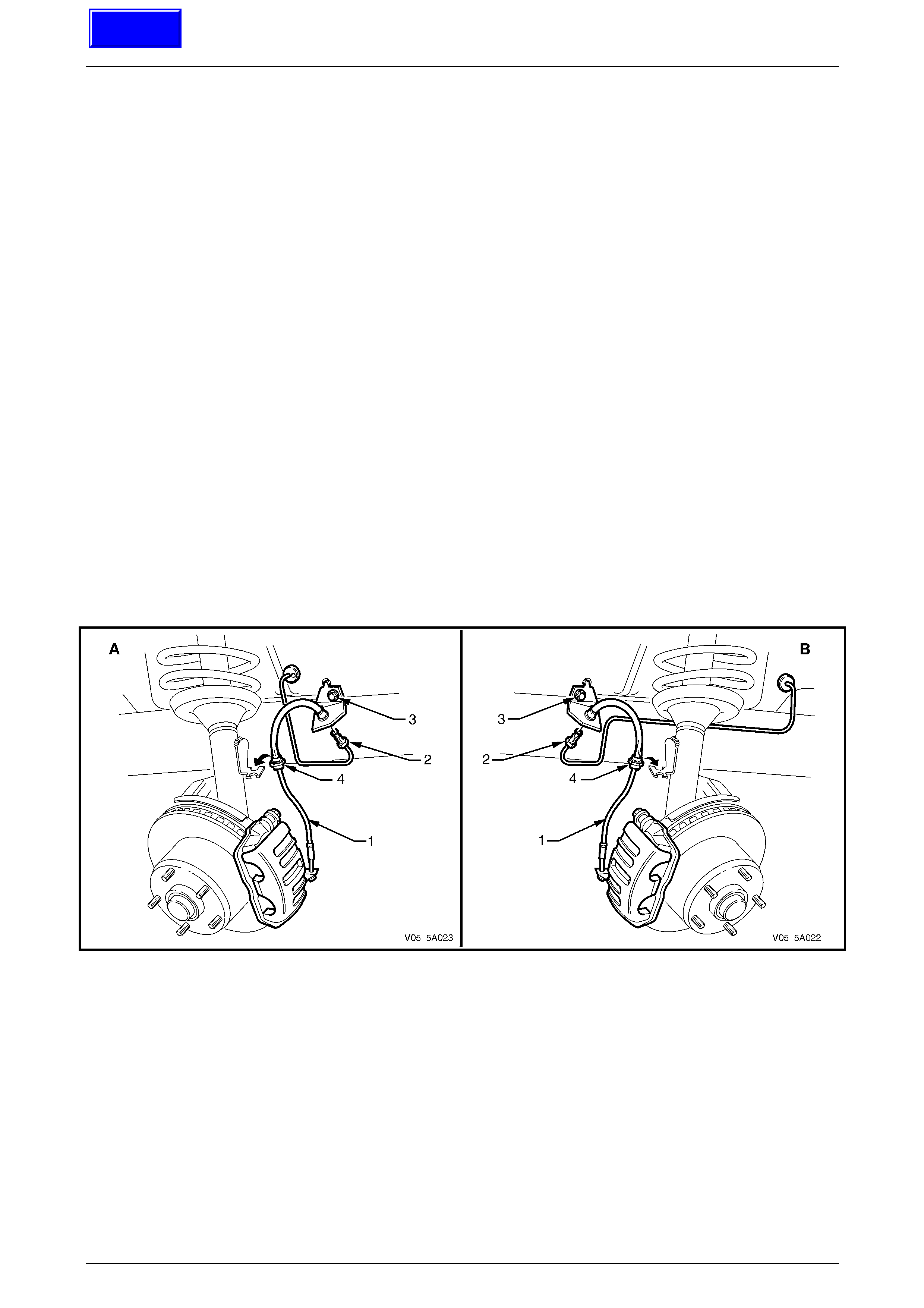

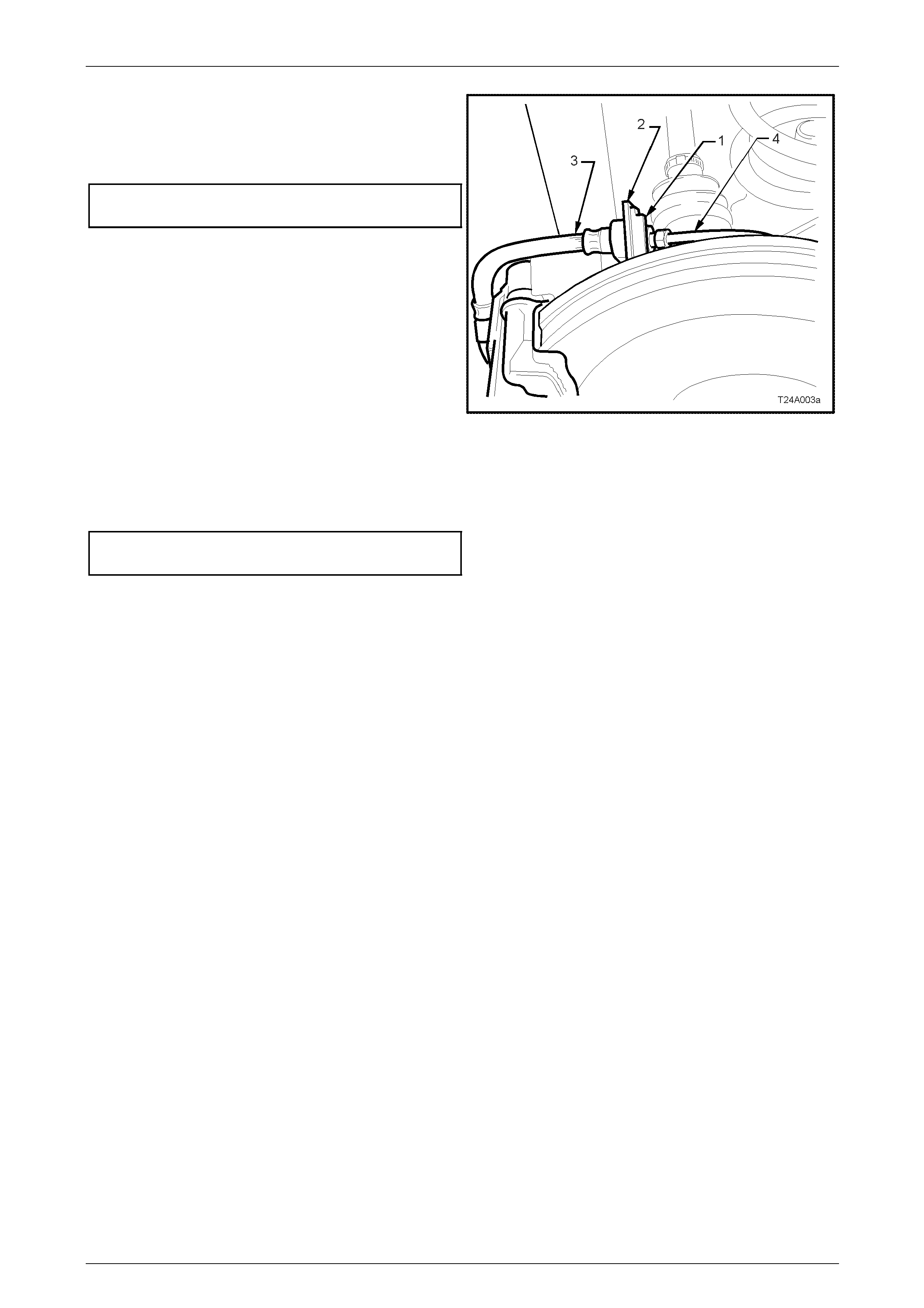

4 Thoroughly cle an connections at each end of brake hose (1), refer to Figure 5A – 37.

5 Disconnect brake pipe (2) from hose (1), then plug pipe to reduce fluid loss.

6 Remove the screw (3) securing the hose bracket to the inne r skirt panel.

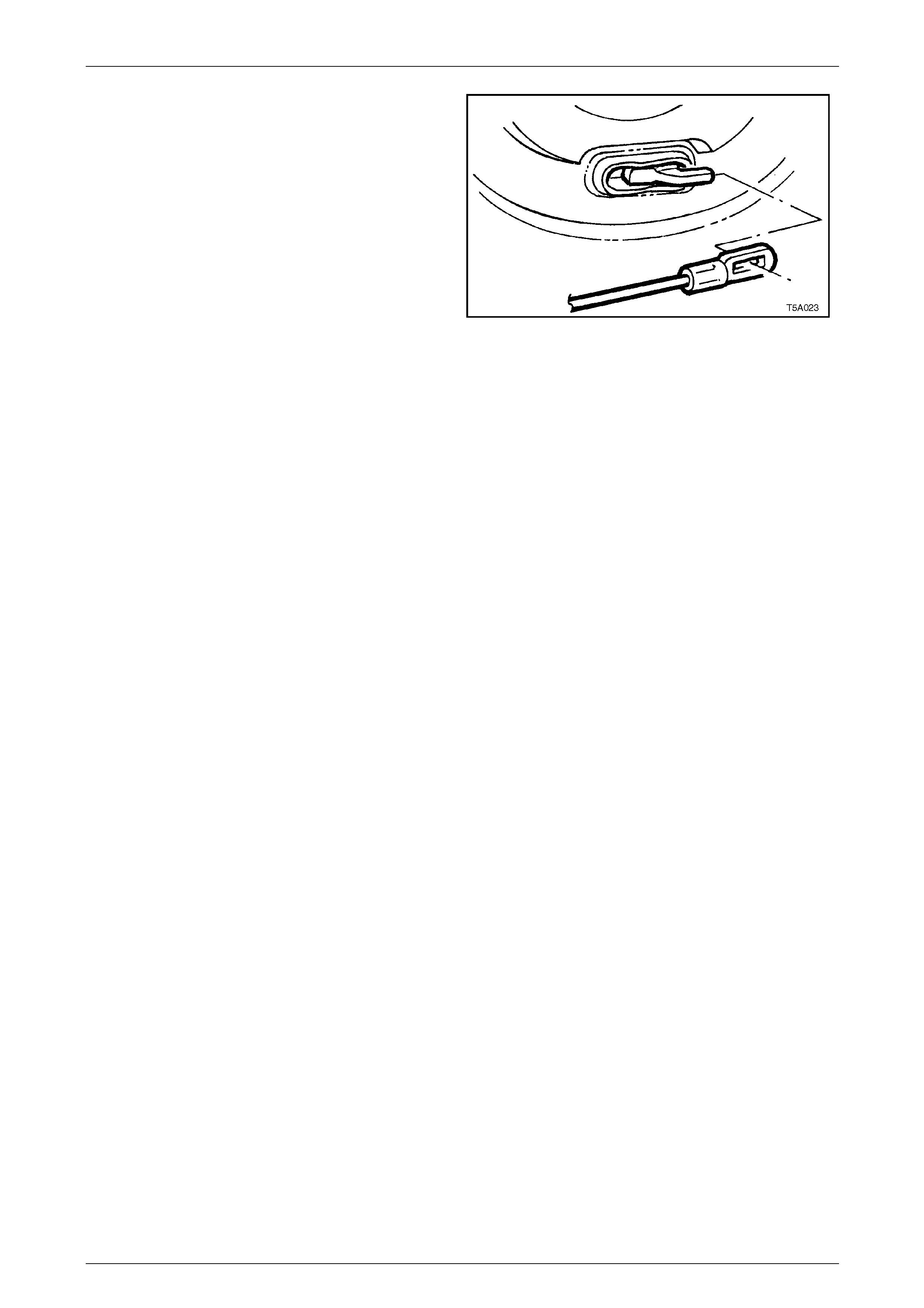

7 Remove the brake hose retaining clip at the suspension tower bracket by first, prising the end at the brake hose

end free, using a screwdriver or similar. Remove the clip from the strut bracket, then discard.

8 Rotate the brake hose until the flats on the b r ake hose grommet are aligned with the slot in the strut bracket, then

remove the hose and grommet.

NOTE

View 'A' shows the right front brake hose, while

view 'B' shows the left front brake hose.

Figure 5A – 37

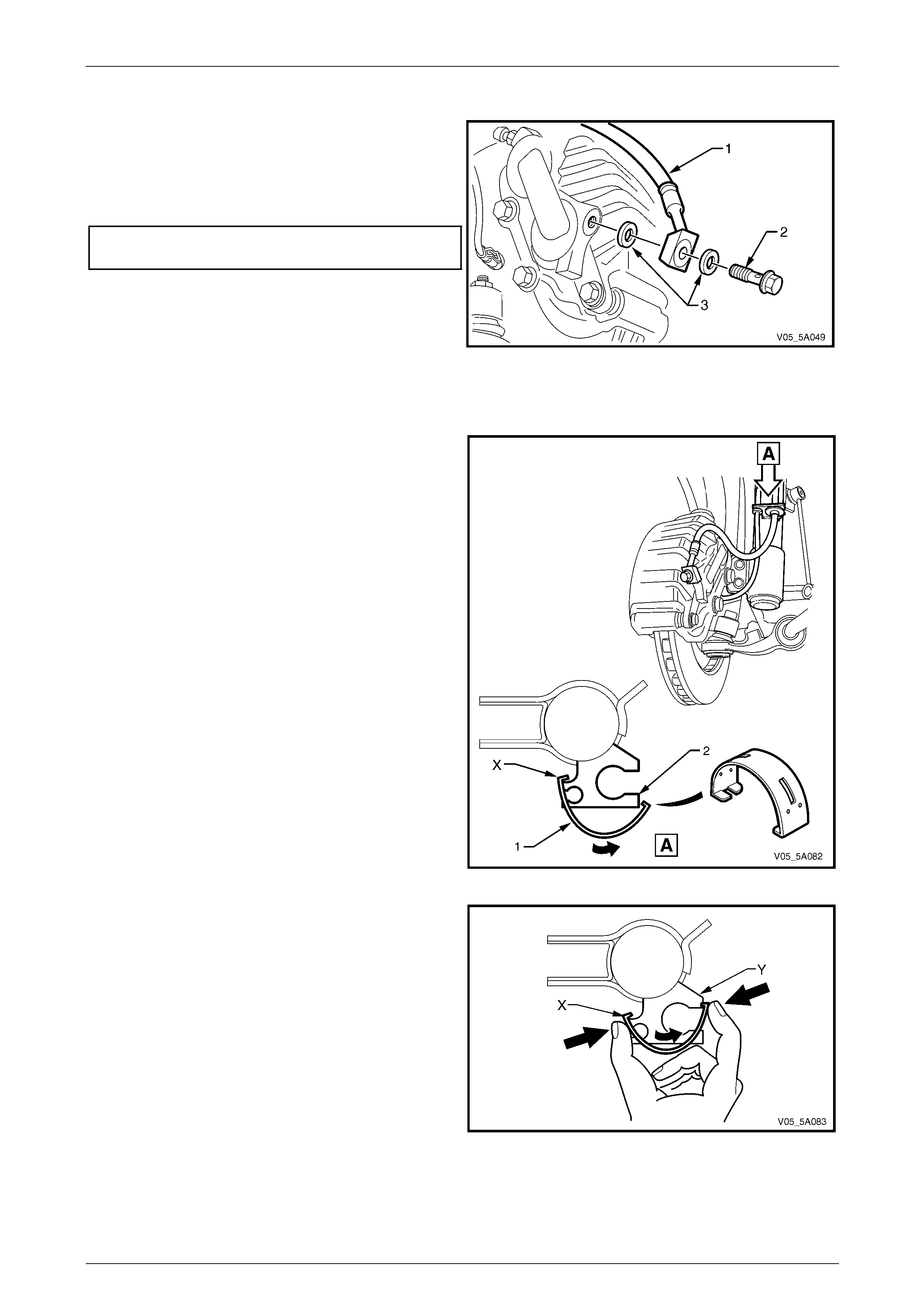

9 Referring to Figure 5A – 38, remove the banjo bolt (2), sealing washers (3), then remove the brake hose (1) from

the caliper. Discard the removed copper washers, as they must be replaced on reassembly.

Techline

Service and Park Braking Systems Page 5A-37

Page 5A-86

Reinstall

1 Ensure brake hose and caliper mating surfaces are

clean and free from burrs.

2 Reinstall brake hose (1) to caliper, using NEW copper

sealing washers (3), then tighten the b anjo bolt (2) to

specified torque.

Brake hose to caliper banjo

bolt torque specification........................................35 Nm

Figure 5A – 38

3 Reinstall hose and gr ommet into suspension strut bracket, refer to ‘4’ in Figure 5A – 37. Secure by turning the

grommet through 90°.

4 Install a NEW brake hose retaining clip, as follows:

a Slide one end of the retaining clip (1) over the

brake hose retaining bracket (2) at point ‘X’,

checking that the strut bracket is aligned with the

slot in the clip.

Figure 5A – 39

b While holding the installed end ‘X’ in place,

rotate the clip around the brak e hose retaining

bracket until the clip ‘clicks’ into position, at point

‘Y’.

c Squeeze the clip firmly with the thumb and

forefinger of one hand as indic ated, to ensure

that the clip ends are fully engage d.

Figure 5A – 40

5 Reinstall the scre w (3) to retain the hose bra cket to the inner skirt panel.

6 Remove plug from brake pipe (2) and rec on nect to hose (1).

Service and Park Braking Systems Page 5A-38

Page 5A-86

7 Tighten the flare nut to the correct torque specification.

Brake pipe to brake hose

flare nut torque specification.................................15 Nm

8 Check that the brake hose is not twisted.

9 Bleed brake/s, refer 2.4 Brake System Bleed, in this Section.

10 Reinstall road wheel, aligning marks made on removal and lower vehicle.

11 Tighten road wheel attaching nuts to the correct torque specification, working in a star pattern, refer to

2.1 Service Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

Service and Park Braking Systems Page 5A-39

Page 5A-86

2.14 Rear Caliper Brake Hose

LT Section No. – 04-750

Remove

1 Raise rear of the vehicle and support in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Remove the decorative wheel nut caps, then mark the relationship of the road wheel to one of the wheel studs.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer 2.1 Service Warnings,

Cautions and Notes in this Section, for detailed information. Remove the road wheel.

4 Thoroughly cle an connections at each end of brake

hose (1).

5 While holding the hose (1) with a back-up spanner,

loosen then disconnect brake pipe (2) from brake hose

(1). Plug the pipe open end.

6 Remove retainer clip (3) from hose and withdraw hose

from bracket (4).

7 Remove the banjo bolt (5) and two copper washers

(6). Unbolt and remove brake hose from caliper.

Figure 5A – 41

Reinstall

1 Ensure brake hose and caliper mating surfaces are clean and free of burrs.

2 Reconnect brake hose to caliper, ensuring that the locating peg al igns with the dimple in the caliper. Use NEW

copper sealing washers, then tighten the banjo bolt to specified torque.

Brake hose to caliper banjo

bolt torque specification........................................35 Nm

3 Fit hose correctly into mountin g plate bracket and reinstall retainer. Check that hose is not twisted.

4 Remove plug from brake pipe and rec on nect to hose. While using a back-up spanner on the brake hose to prevent

twisting, tighten pipe to specified torque.

Brake pipe to brake hose flare

nut torque specification.........................................15 Nm

5 Bleed brake/s, refer to 2.4 Brake System Bleed, in this Section.

6 Reinstall road wheel, aligning marks made on removal and lower vehicle.

7 Tighten road wheel attaching nuts to the specified torque, tightening in a star pattern, refer to

2.1 Service Warnings, Cautions and Notes, in this Section.

Road wheel attaching bolt

torque specification...................................110 – 140 Nm

8 Road test the vehicle to ensure correct brake operation.

Service and Park Braking Systems Page 5A-40

Page 5A-86

2.15 Rear Brake Hoses

LT Section No. – 04-750

Remove

1 Raise rear of the vehicle and support in a safe manner. Refer to Section 0A General Information for the location of

recommended lifting and support points.

2 Thoroughly cle an connections at each end of the rear brake hose to be removed.

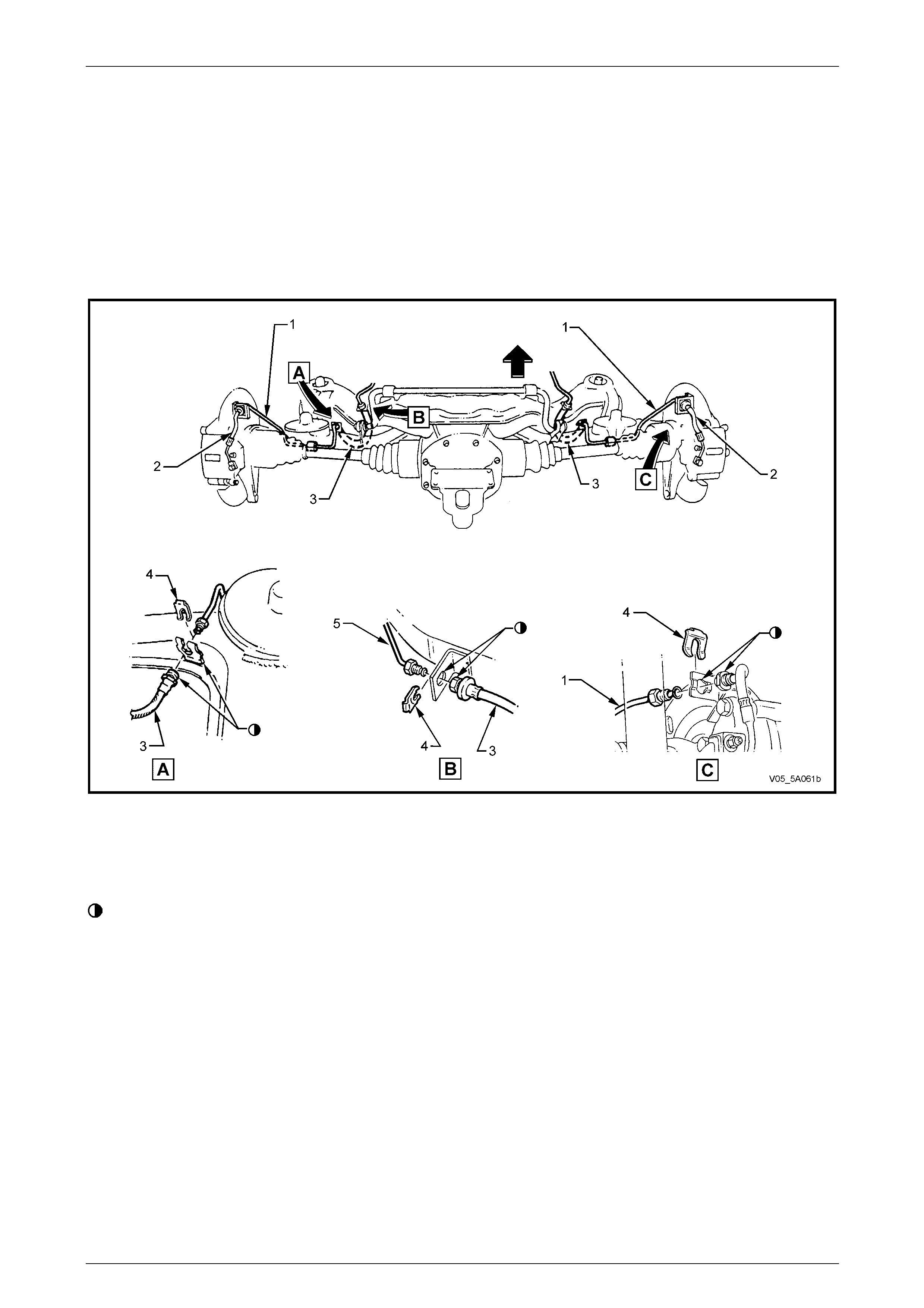

Figure 5A – 42

Legend

View A LH Shown – RH opposite

View B With ABS/TC – LH shown, RH opposite

View C RH shown, LH opposite

Align Flats on Bracket and Hose

1 Rear Brake Pipe

2 Rear Brake Hose, Caliper to Rear Brake Pipe

3 Rear Brake Hose

4 Retaining Clip

5 Brake Hose Connection Pipe

3 Disconnect brake pipe (5) from brake hose (3) at trailing arm brackets (View B). Plug open end of brake pipe/s to

reduce fluid loss and to prev ent foreign matter entry.

4 Disconnect rear brake pipe (1) connection from brake hose (3) (Vie w A), while holding the hose with a back-up

spanner. Plug all pipe ends to prevent fluid loss and foreign material entry.

5 Remove retaining clips (4) from the end of each hose end and withdraw hose/s from brackets.

NOTE

Refer to Operation 2.14 Rear Caliper Br ake Hose

for procedure to remove the rear caliper hose (2).

Service and Park Braking Systems Page 5A-41

Page 5A-86

Reinstall

1 Ensure brake hose ends and pipe mating surfaces are clean and free of burrs.

2 Fit hose (3) into mounting plat e brackets and reinstall retaining clips (4). Check that the hose (3) is n ot twisted.

3 Remove plugs from brake pipes (1 and 5), then reconnect to hose ends. Tighten all pipe nuts to specified torque.

Brake pipe flare nut to brake

hose torque specification ......................................15 Nm

4 Bleed brake/s, see 2.4 Brake System Bleed, in this Section.

5 Lower vehicle to the ground and road test to check for corre ct brake operation.

Service and Park Braking Systems Page 5A-42

Page 5A-86

2.16 Brake Booster Hose & Valve Assembly –

V6 Engine

Replace