Engine Cooling – V6 Engine Page 6B1–1

Page 6B1–1

Section 6B1

Engine Cooling – V6 Engine

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................3

2 General Description ...............................................................................................................................4

2.1 Radiator Assembly ................................................................................................................................................ 4

2.2 Cooling Fans.......................................................................................................................................................... 6

Overview................................................................................................................................................................. 6

Relays................................................................................................................................................................ 7

Cooling Fans and Shroud Assembly.................................................................................................................. 7

Fan Motors......................................................................................................................................................... 8

Operation................................................................................................................................................................ 9

Stage 1 Fan Operation....................................................................................................................................... 9

Conditions for Stage 1 Fan Operation.............................................................................................................. 10

Stage 2 Fan Operation..................................................................................................................................... 11

Conditions for Stage 2 Fan Operation.............................................................................................................. 12

2.3 Coolant Pump....................................................................................................................................................... 14

2.4 Coolant Outlet Housing....................................................................................................................................... 15

2.5 Thermostat ........................................................................................................................................................... 16

2.6 Coolant Filler Cap................................................................................................................................................ 17

2.7 Coolant Recovery Reservoir............................................................................................................................... 18

2.8 Air Baffle, Chutes and Shroud............................................................................................................................ 19

2.9 Engine Coolant Temperature Sensor................................................................................................................. 20

3 Service Operations...............................................................................................................................21

3.1 Service Notes....................................................................................................................................................... 21

Safety.................................................................................................................................................................... 21

Periodic Servicing................................................................................................................................................ 21

Environmental Issues.......................................................................................................................................... 22

3.2 Coolant Maintenance........................................................................................................................................... 23

Topping Up the Cooling System......................................................................................................................... 23

Testing Coolant Concentration........................................................................................................................... 24

Method 1 – Refractometer................................................................................................................................ 24

Method 2 – Hydrometer.................................................................................................................................... 26

3.3 Draining and Filling Cooling System ................................................................................................................. 27

Draining ................................................................................................................................................................ 27

Filling.................................................................................................................................................................... 27

3.4 Cleaning Cooling System.................................................................................................................................... 30

Cooling System Reverse Flush .......................................................................................................................... 30

Radiator............................................................................................................................................................ 30

Engine.............................................................................................................................................................. 31

Heater Hoses and Core.................................................................................................................................... 32

3.5 Drive Belt Tension ............................................................................................................................................... 33

Inspect .................................................................................................................................................................. 33

3.6 Coolant Hoses...................................................................................................................................................... 34

3.7 Pressure Testing.................................................................................................................................................. 36

Coolant Filler Cap Pressure Testing.................................................................................................................. 36

Cooling System Pressure Testing...................................................................................................................... 38

Techline

Techline

Techline

Engine Cooling – V6 Engine Page 6B1–2

Page 6B1–2

3.8 Thermostat ........................................................................................................................................................... 39

Remove................................................................................................................................................................. 39

Test ....................................................................................................................................................................... 42

Dismantle.............................................................................................................................................................. 42

Reassembly.......................................................................................................................................................... 43

Reinstall................................................................................................................................................................ 43

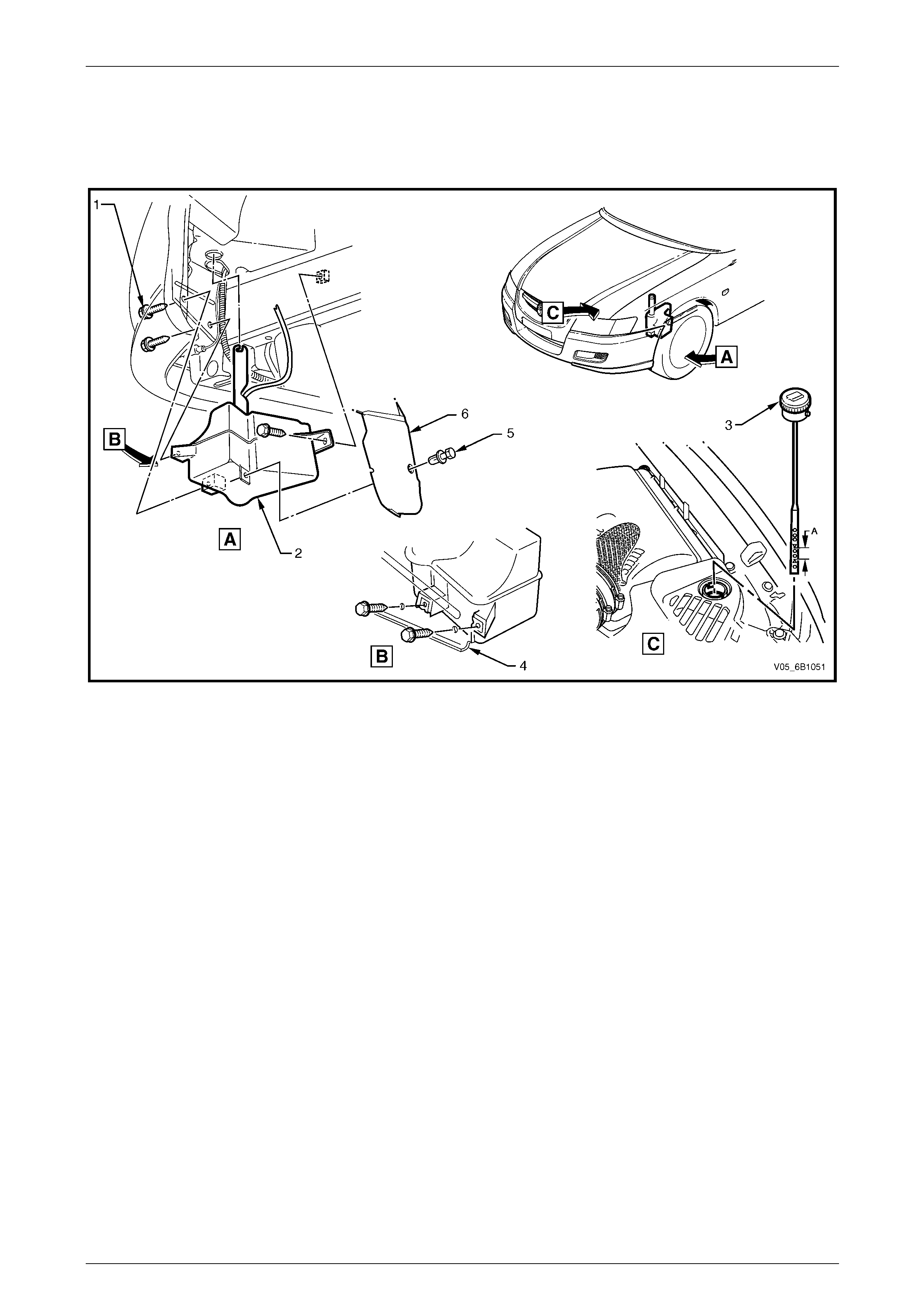

3.9 Coolant Recovery Reservoir............................................................................................................................... 45

Remove................................................................................................................................................................. 45

Inspect .................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 45

3.10 Air Baffle and Chutes .......................................................................................................................................... 46

Remove................................................................................................................................................................. 46

Reinstall................................................................................................................................................................ 46

3.11 Coolant Pump....................................................................................................................................................... 47

Remove................................................................................................................................................................. 47

Inspect .................................................................................................................................................................. 50

Reinstall................................................................................................................................................................ 50

3.12 Coolant Outlet Housing....................................................................................................................................... 51

Remove................................................................................................................................................................. 51

Reinstall................................................................................................................................................................ 53

3.13 Coolant Inlet Pipe................................................................................................................................................. 54

Remove................................................................................................................................................................. 54

Reinstall................................................................................................................................................................ 55

3.14 Cooling Fan and Shroud Assembly ................................................................................................................... 56

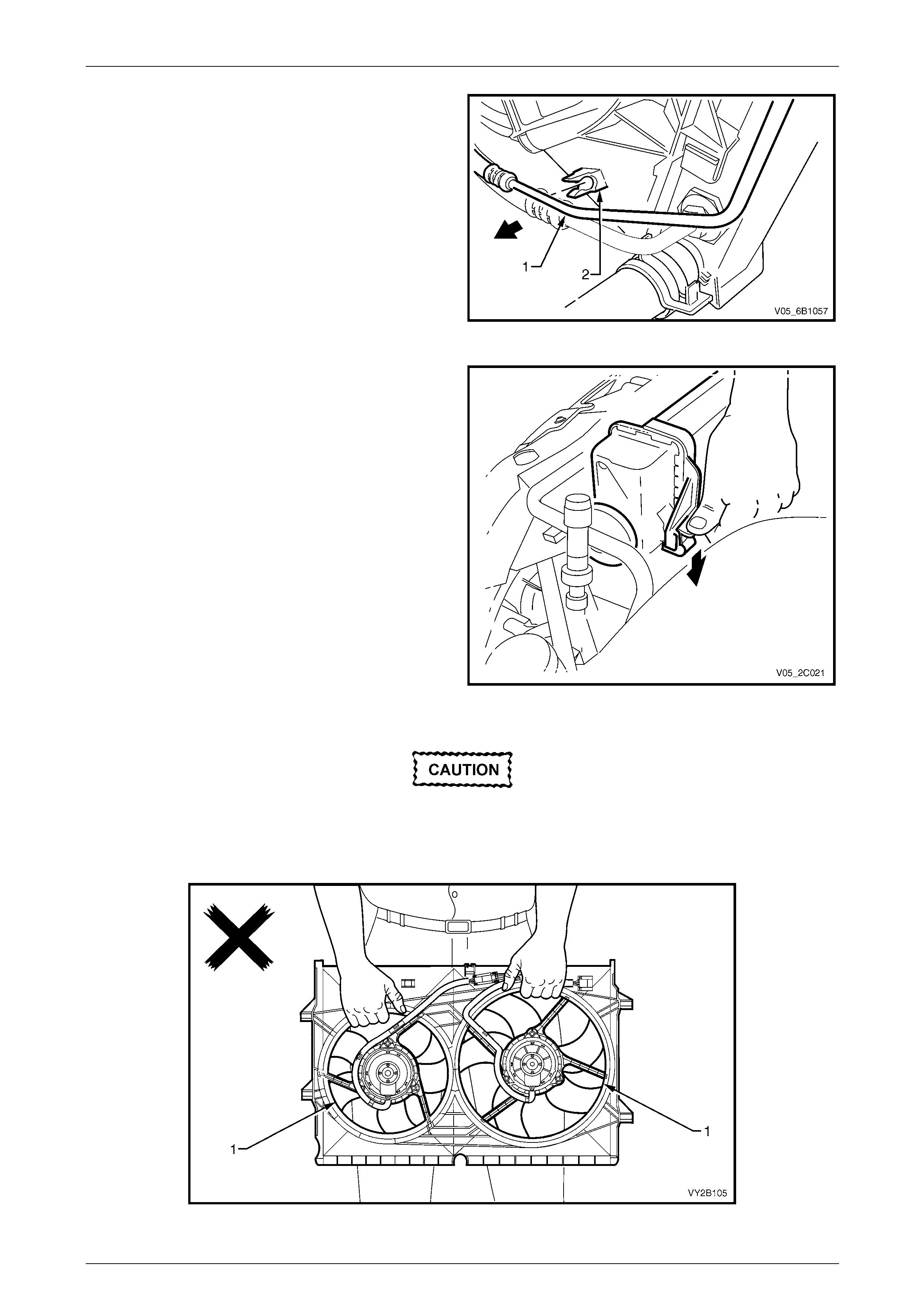

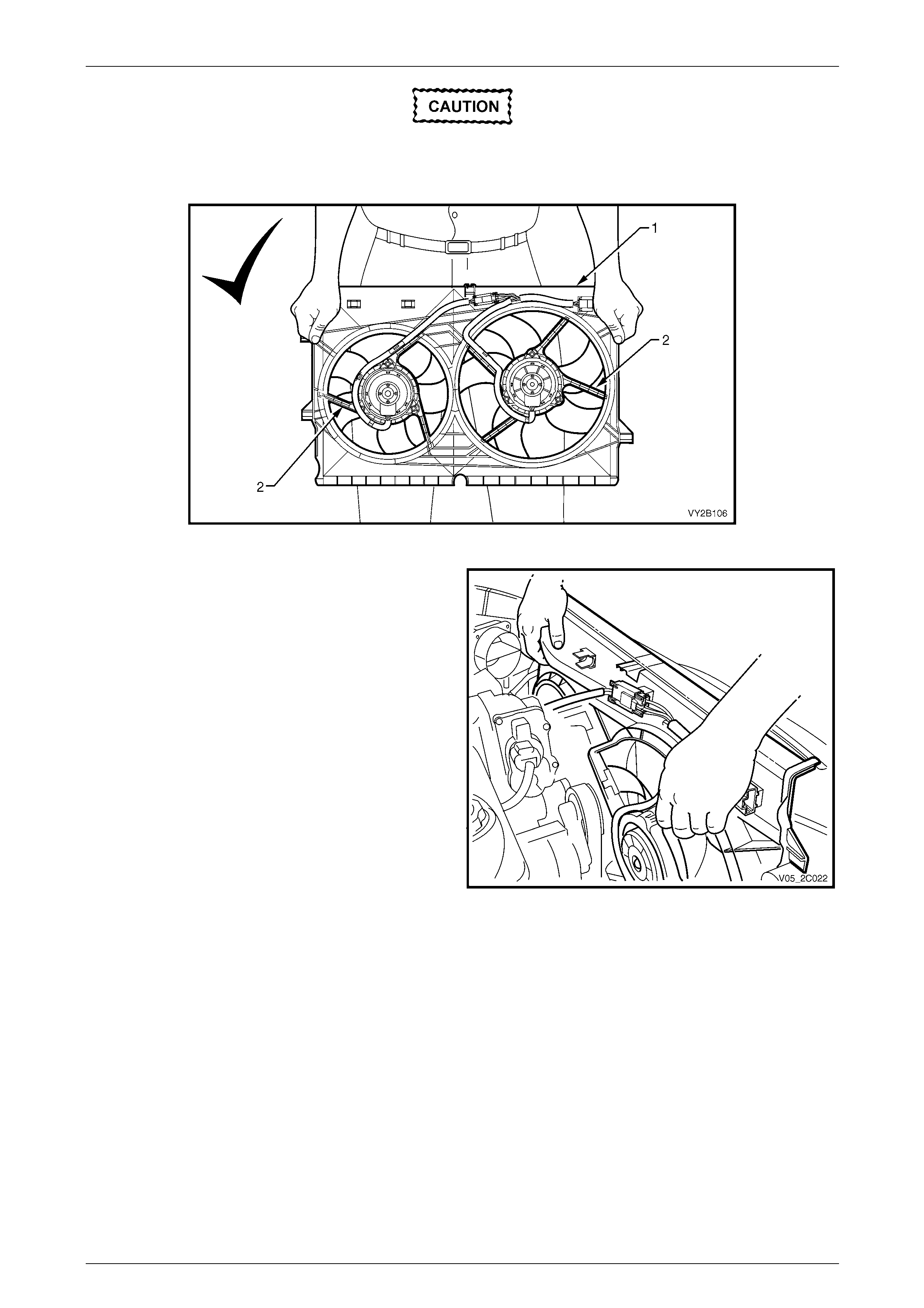

Remove................................................................................................................................................................. 56

Reinstall................................................................................................................................................................ 58

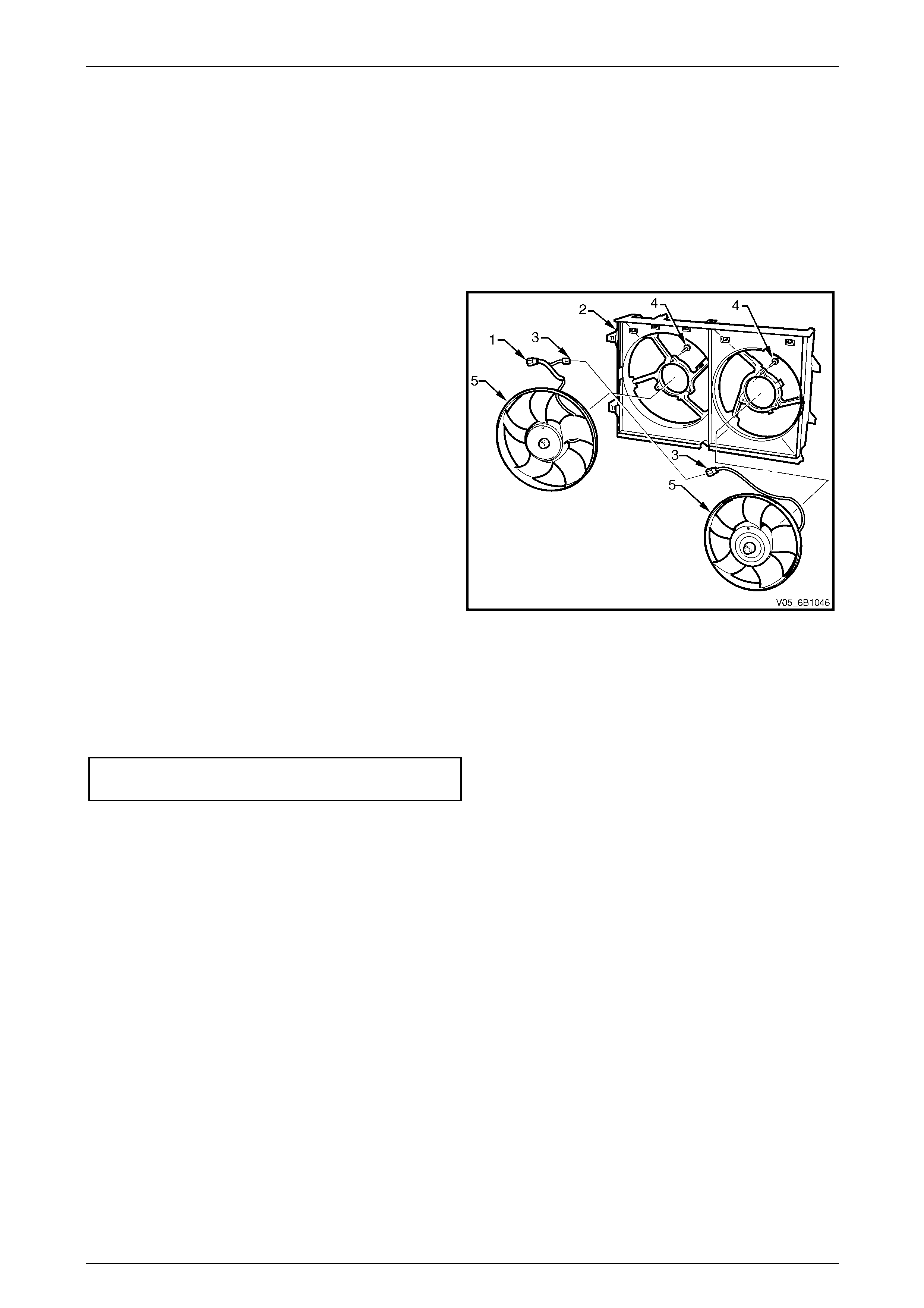

Disassemble......................................................................................................................................................... 59

Reassemble.......................................................................................................................................................... 59

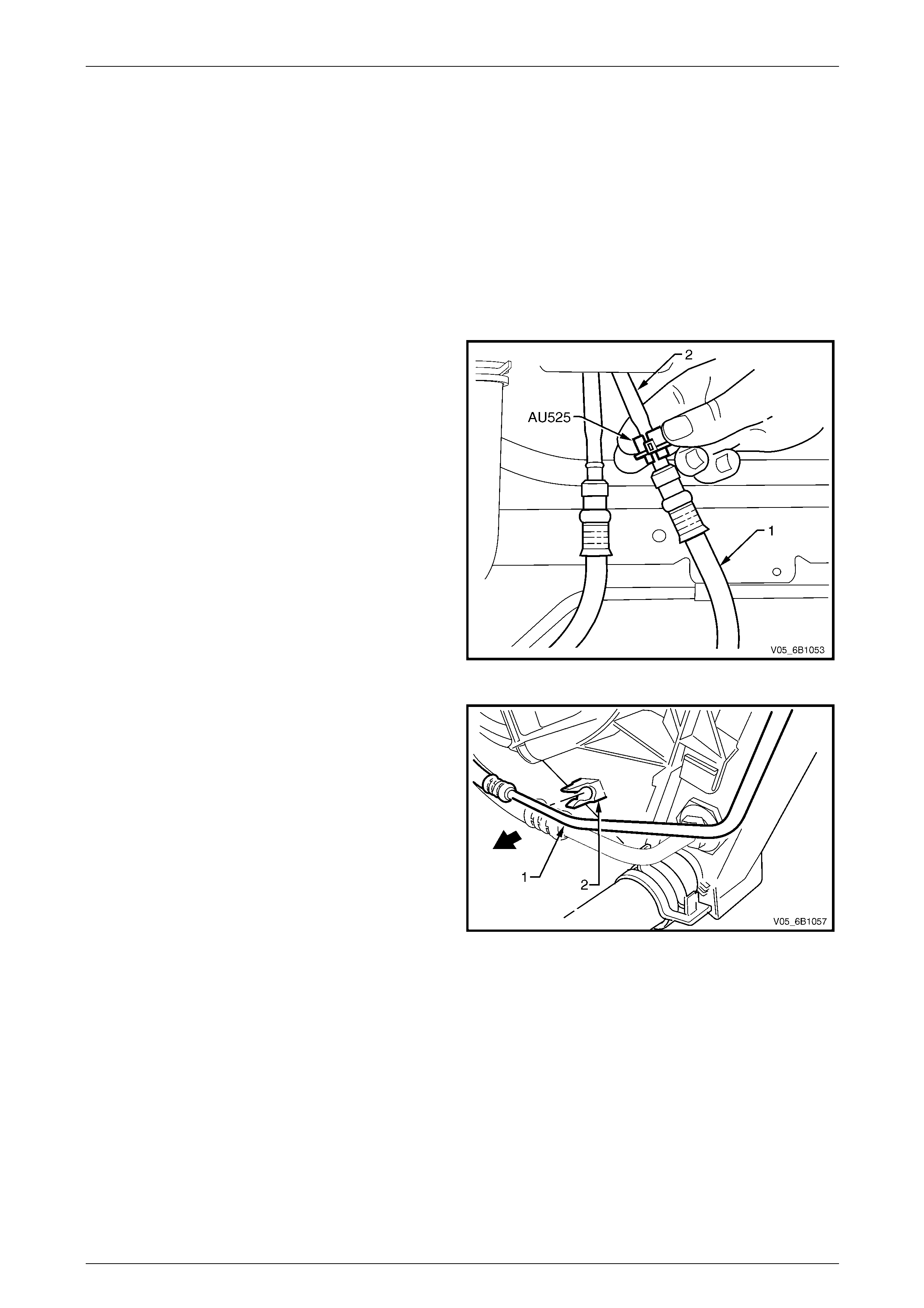

3.15 Flexible Transmission Cooler Hoses ................................................................................................................. 60

Replace................................................................................................................................................................. 60

3.16 Radiator ................................................................................................................................................................ 62

Remove................................................................................................................................................................. 62

Reinstall................................................................................................................................................................ 64

Radiator Repair Procedure ................................................................................................................................. 65

Repairable Leaks ............................................................................................................................................. 65

Repair Method.................................................................................................................................................. 66

Tube Blocking................................................................................................................................................... 66

Header Repair.................................................................................................................................................. 67

General Core Repair........................................................................................................................................ 67

Transmission Oil Cooler Leak Test .................................................................................................................. 68

Transmission Oil Cooler Seal Replacement..................................................................................................... 68

4 Engine Cooling System Diagnosis.....................................................................................................69

4.1 Poor Heater Operation......................................................................................................................................... 69

4.2 Leaking Cylinder Head Gasket ........................................................................................................................... 70

4.3 Question the Customer ....................................................................................................................................... 71

4.4 Diagnostic Chart.................................................................................................................................................. 72

4.5 Problems Not Requiring Disassembly of Cooling System............................................................................... 73

4.6 Problems Requiring Disassembly of Cooling System...................................................................................... 74

4.7 Black Light and Dye Leak Diagnosis Method.................................................................................................... 75

5 Specifications.......................................................................................................................................76

6 Torque Wrench Specifications............................................................................................................78

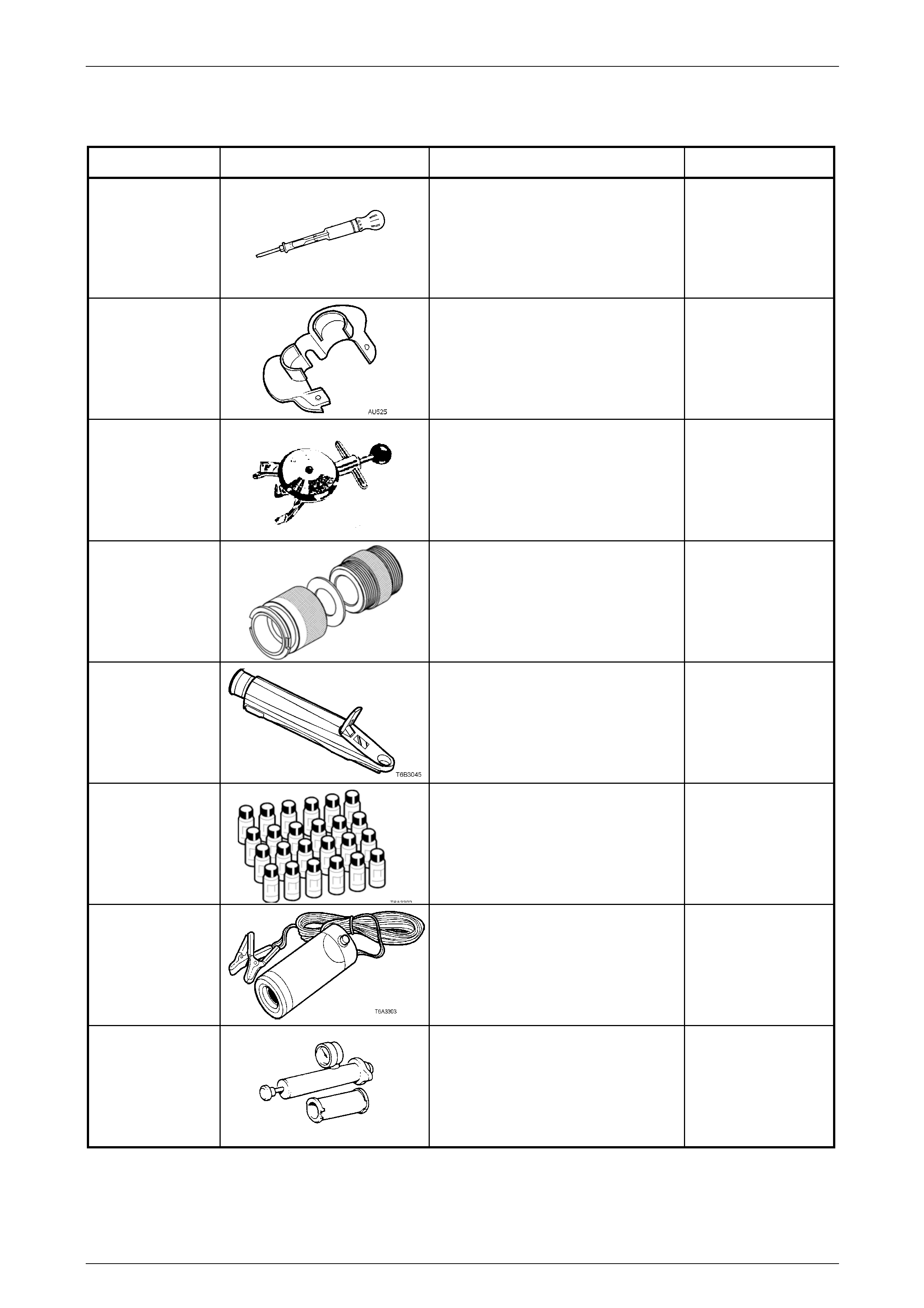

7 Special Tools ........................................................................................................................................79

Engine Cooling – V6 Engine Page 6B1–3

Page 6B1–3

1 General Information

The cooling system for the V6 Alloytec engine has been designed to accommodate this engine’s unique configurati on

and engine cooling performance requirements. The following summary details the majority of these features:

• Revised design radiator asse mbly, including header tanks that incorpor ate a drain tap and a coolant air bleed

facility.

• Coolant plumbing including radiator hoses, inlet pip e, heater pipes, heater hoses and heat er water valve.

• The thermostat assembly and thermostat hous ing are mounted at the rear of the engine.

• The coolant outlet incorporates a ‘screw on’ pressure cap.

• Coolant specification is either DEX-COOL® or equivalent to GM specification.

• Side air chutes and radiator shroud are unique to the MY 2005 vehicle.

• A modified cooling fan operating strateg y res ults in both c oo ling fans being controlled by the Engine Control

Module (ECM).

• With this cooling fan system, two, single-speed electric cooling fans are fitted. When operating on Stage 1, only the

right (larger diameter) fan motor is enabled. When Stage 2 is required, the left (smaller diameter) fan is also

activated. For Stage 1, only one fan motor is operational an d for Stage 2, both fan motors are operational.

• Operation of the cooling fans is depend ent on engine coolant temperature, vehicle speed, A/C request and A/C

system pressure. Refer to Section 6C1-1 Engine Management – V6 – General Information for further information.

The air conditioning system condenser is mounted to the front of the radiator and is located and supported by four clips

moulded into the front of the plastic radiator tanks. The lower clips lock the condenser in place and can be released by

hand to facilitate condens er removal.

The condenser, filter drier receiver, radiator and the fan motors/blades/shroud assembly can be removed and instal led

individually from the vehicle.

Engine Cooling – V6 Engine Page 6B1–4

Page 6B1–4

2 General Description

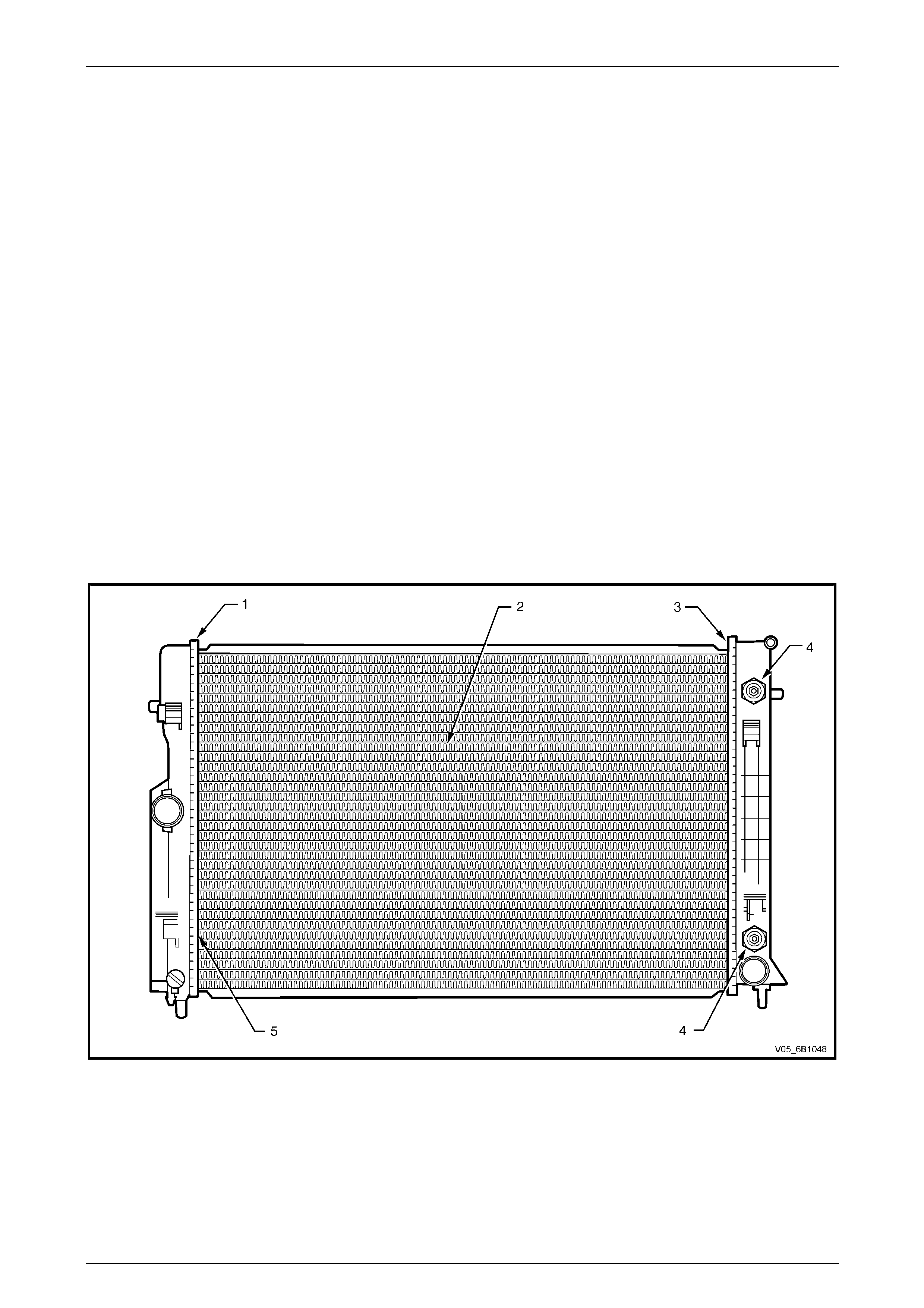

2.1 Radiator Assembly

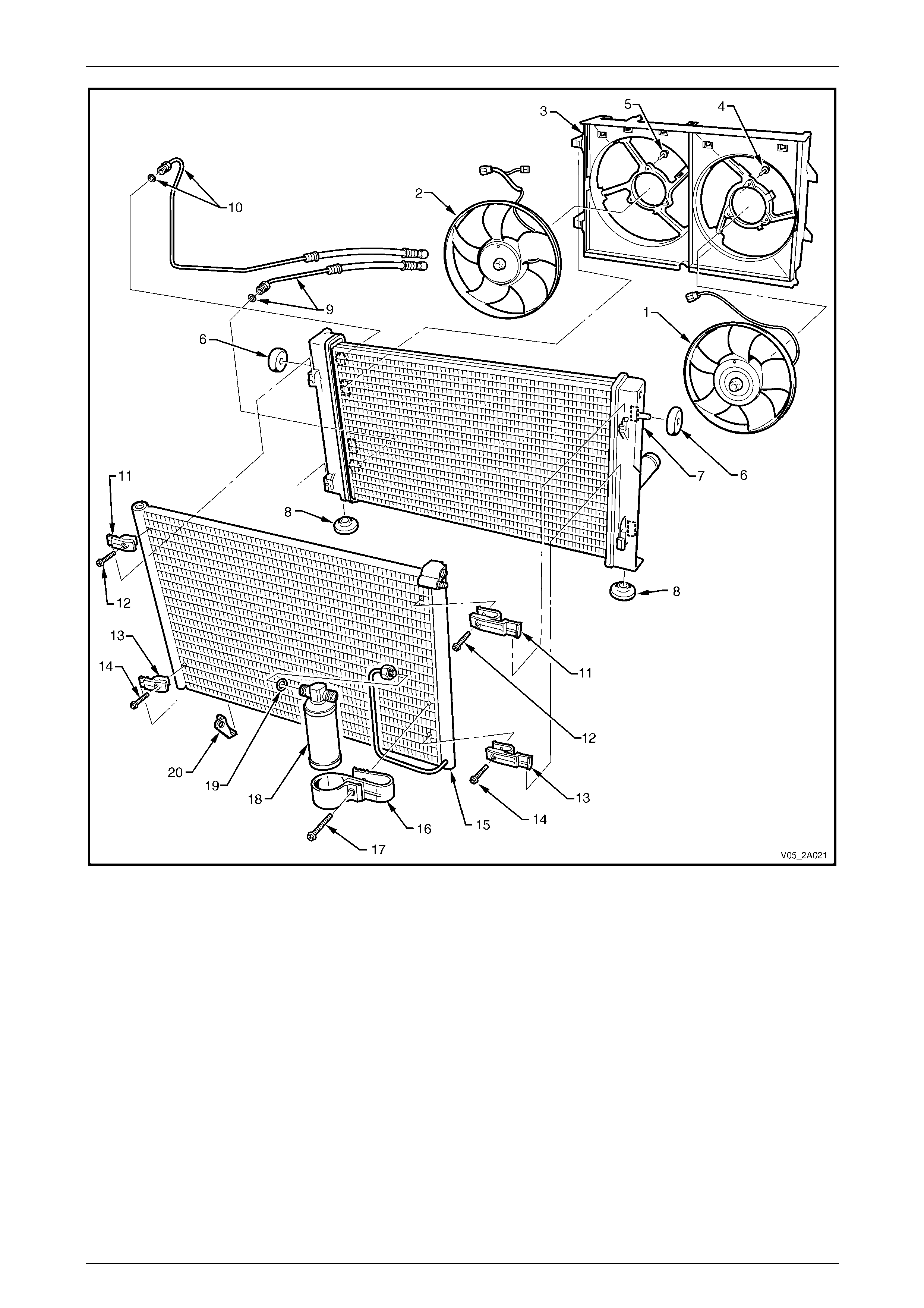

When the vehicle is assembl ed, the condenser, filter drier receiver, cooling fans, fan shroud and radiator are installed

into the engine bay as an assembl ed unit. This unit is described as the radiator assembly or as the Condenser, Radiator

and Fan Module (CRFM).

The radiator has an aluminium core and is of the cross-flow design. Plastic side tanks are attached to the core by clinch

tabs. The clinch tabs are formed as part of the core assem bl y.

Pegs are attached to the lower frame and the upper area of each side tank. These pegs are used to support the radiator

in four rubber mounts. The assembly is hel d in position by two spring clips at the upper mounting loc ations.

A high temperature rubber seal is used to seal the mating surface between the core and each side tank. The seal(s)

must be replaced any time the side tank is removed from the core.

NOTE

The radiator core side tanks or transmission

oil cooler cannot be replaced separately.

If there is a fault with any of these components,

the radiator assembly must be replaced. Small

core repairs may be made using an aluminised

silicon based liquid repair agent. Refer to

3.16 Radiator – Radiator Rep air Procedure in this

Section.

A transmission oil cooler is located in the rig ht-han d side radiator tank. The cooler pipes from and to the transmissio n are

connected to the oil cooler flexible hos es by means of quick connect fittings.

The air conditioning condenser is mounted to the front of the radiator and is located and supported by four clips moulded

into the front of the plastic radiator tanks. The lower clips lock the condenser in place and can be released by hand to

facilitate condenser removal. T he air conditioning receiver drier also forms a part of the complete CRFM assembly.

Each of the cooling fan motors are attached by three screws to the one-piece plastic fan shroud. In turn, the fan shroud is

mounted to the rear of the radiator and is located and supported by four clips moulded into the rear of the plastic ra diator

tanks. The upper clips lock the fan shroud in place and can be released by hand to facilitat e fan shroud removal. The

shroud must be removed to allow fan motor and blade asse mbly removal.

Two harness connectors are mounted to the upper section of the fan shroud allowing the fan motor and blade

assemblies to be removed individually from the shroud. The fan motor and blade is balanced as a n assembly. These two

components are serviced only as a unit and are not to be separated.

For a comprehensive description of the operating strategy and electrical wiring for the Alloytec V6 CRFM,

refer to 2.2 Cooling Fans, in this Section.

The shroud, fan assemblies and transmiss ion cooler hoses can be removed and i nstalled individually from the vehicle.

For removal and installation procedures,

refer to 3.14 Cooling Fan and Shroud Assembly, 3.15 Flexible Tr ansmission Cooler Hose and 3. 16 Radiator in this

Section.

Engine Cooling – V6 Engine Page 6B1–5

Page 6B1–5

Figure 6B1 – 1

Legend

1 LHS (Small) Fan and Motor Assembly

2 RHS (Large) Fan and Motor Assembly

3 Fan Shroud

4 LHS Fan Retaining Screw (3 places)

5 RHS Fan Retaining Screw (3 places)

6 Upper Radiator Insulators (2 places)

7 Radiator

8 Lower Radiator Insulators (2 places)

9 Lower Transmission Cooling Line and Seal

10 Upper Transmission Cooling Line and Seal

11 Upper Condenser Mounting Clips (2 places)

12 Upper Condenser Mounting Clip Screws (2 places)

13 Lower Condenser Mounting Clips (2 places)

14 Lower Condenser Mounting Clip Screws (2 places)

15 Condenser

16 Filter Drier Receiver Mounting Bracket

17 Filter Drier Receiver Mounting Bracket Screw

18 Filter Drier Receiver

19 Filter Drier Receiver O-ring

20 Ambient Air Temperature Sensor Mounting Bracket

Engine Cooling – V6 Engine Page 6B1–6

Page 6B1–6

2.2 Cooling Fans

Overview

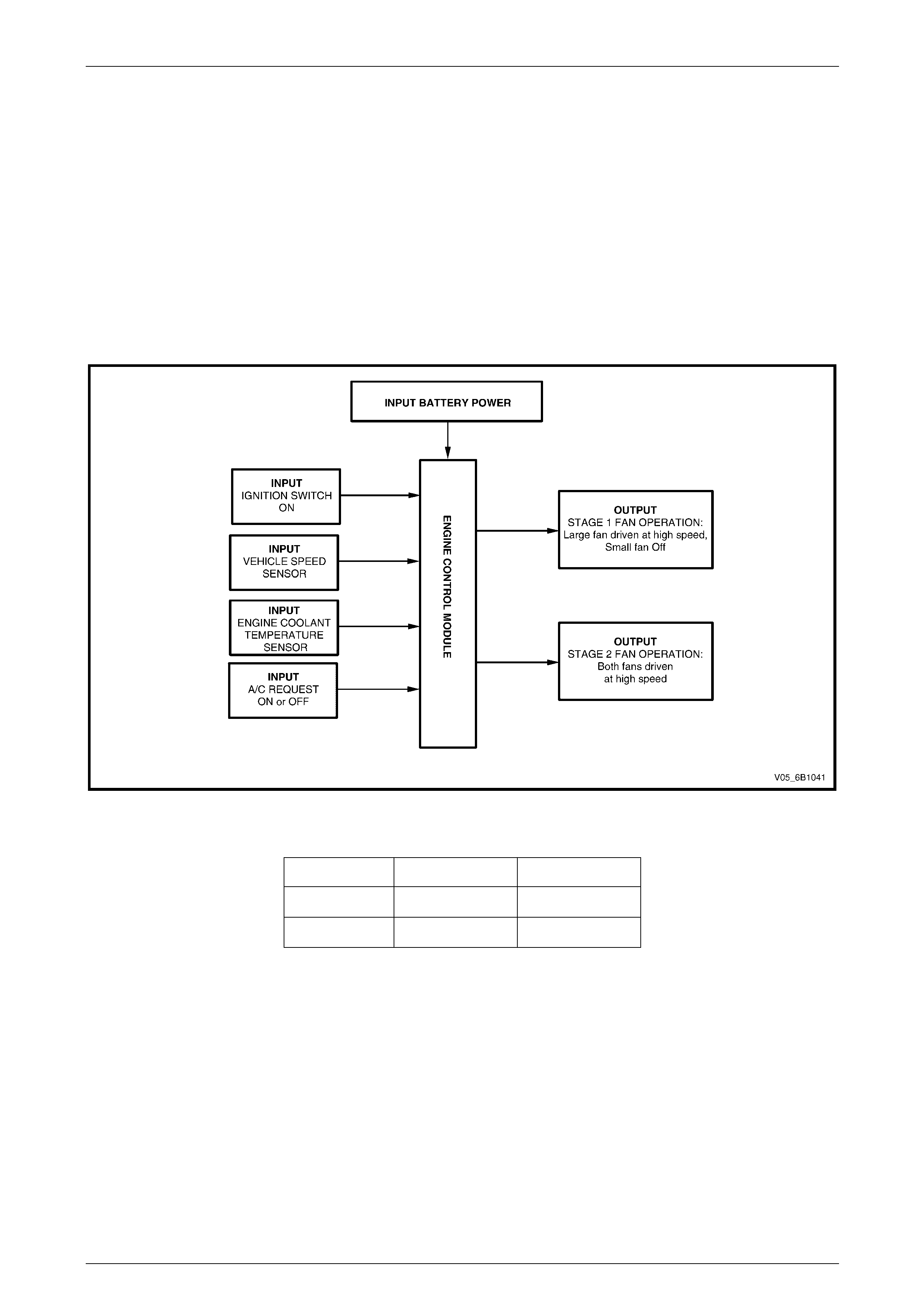

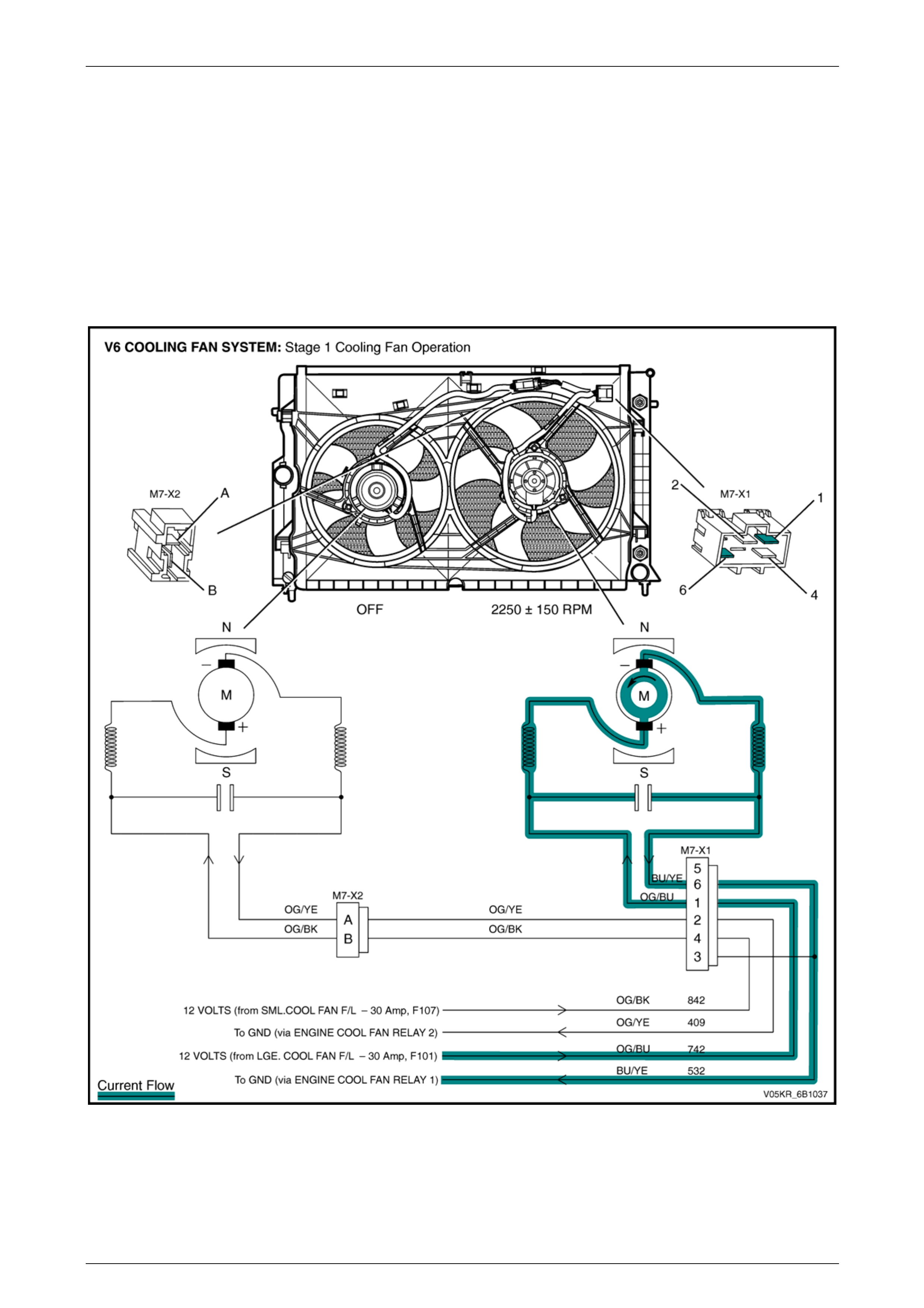

The cooling fan system (280 Watt), consists of two single-speed fans that operate as follows:

• Stage 1 – large diameter fan operates at ma ximum spe ed.

• Stage 2 – small and large dia m eter fans both operate at maximum speed.

The smaller low-speed fan on the left is 293 mm in diameter with a motor rated at 120 Watts, while the larger high-speed

fan on the right is 354 mm in diameter with a motor power rating of 160 Watts.

The following block diagram outlines the op eration of the cooling system, also showing what inputs the Engine Control

Module (ECM) requires.

Figure 6B1 – 2

With 12 volts applied and the fans mount ed to the radiator with a condenser fitted, the operatin g speeds are:

Stage 1 Stage 2

Large Fan 2,250 ± 150 rpm 2,250 ± 150 rpm

Small Fan Inoperative 2,050 ± 150 rpm

Engine Cooling – V6 Engine Page 6B1–7

Page 6B1–7

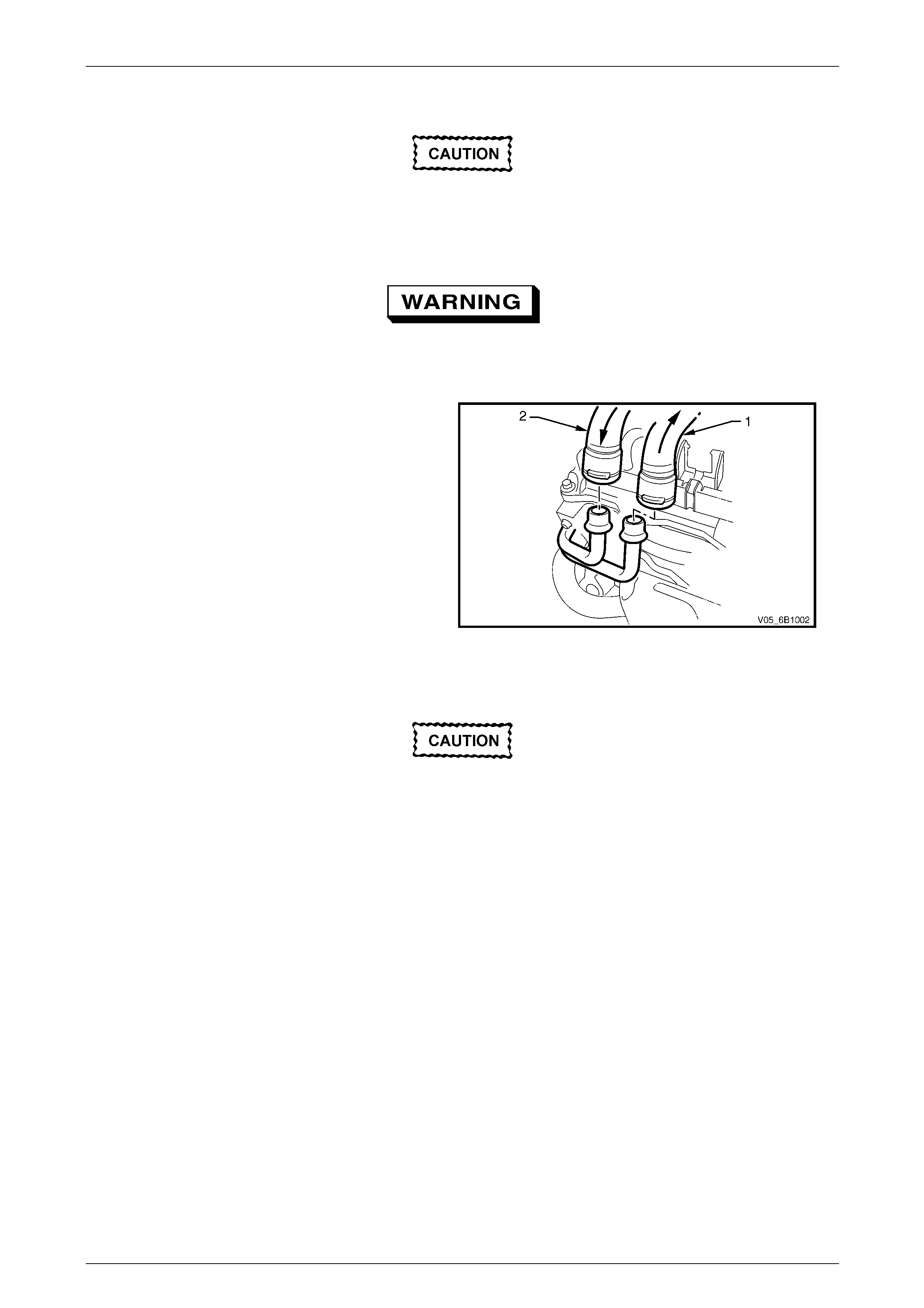

Relays

The engine coolin g fan relays are located in the fuse and

relay compartment under the hood.

Legend

1 Cooling Fan Relay 1 for large fan operation.

2 Cooling Fan Relay 2 for small fan operation.

Figure 6B1 – 3

Cooling Fans and Shroud Assembly

Figure 6B1 – 4

Legend

1 Fan Shroud

2 Radiator Drain Tap

3 Radiator

4 Fan Shroud Lower Support

5 Fan Shroud Upper Support / Locking Retainer

6 Small, Left Fan – 5 Blade, 293 mm Diameter

7 Small, Left Fan Motor – 120 Watt, Single-speed

8 Left Fan Motor Harness Connector (2 terminal)

9 Left and Right Fan Motor Harness Connector (4 terminal)

10 Oil Cooler, Upper Line Connection

11 Oil Cooler, Lower Line Connection

12 Large, Right Fan – 5 Blade, 354 mm Diameter

13 Large, Right Fan Motor – 160 Watt, Single-speed

Engine Cooling – V6 Engine Page 6B1–8

Page 6B1–8

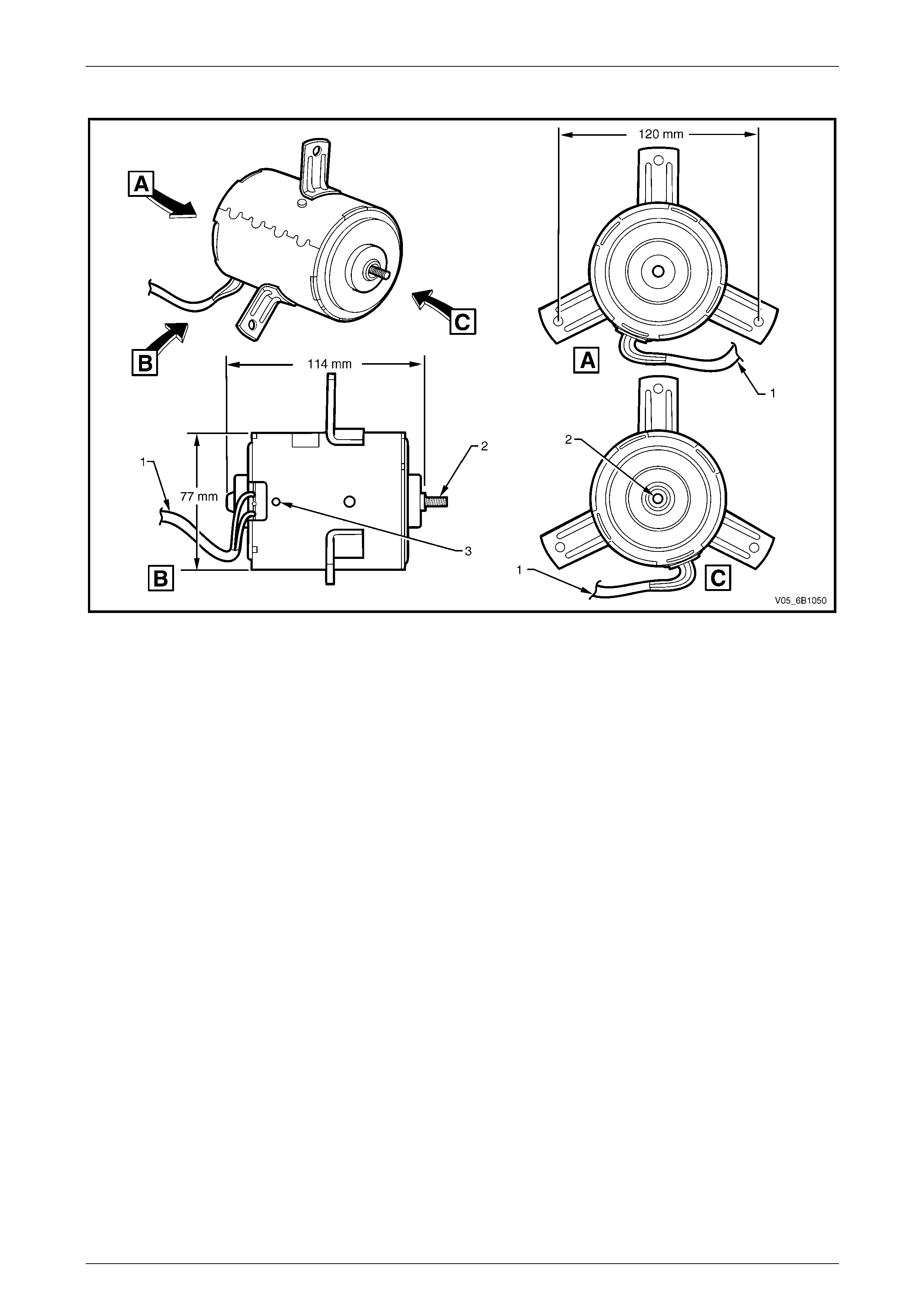

Fan Motors

Figure 6B1 – 5

Legend

1 Two-wire Harness 2 Armature Shaft 3 Drain Hole

The fan motors are 12 Volt and single-sp ee d, with an internal construction of the fan motor consisting of two brushes and

two permanent magnets. A two-wire pigtail harness is permanently connected to both motors and is attached to the

polypropylene fan shroud at two locations by integral clips moulded as part of the fan shroud.

The RHS motor harness is directly connected to the engine harness through a 6-pin connector. It also carries a n

additional 2-pin connector, which attaches to the LHS motor harness and enables individual removal of the LHS and

RHS fan and motor assemblies when necessary, refer to Figure 6B1 – 4. The two associated electrical connectors are

attached to the shroud by way of slide lock clips. The motor is attached to the fan shro ud by three bolts at threaded

mounting flanges spot-welded symmetrically around the fan housing, refer to Figure 6B1 – 5.

The enclosed fan motor housing is constructed of yellow zinc coated steel. A drain hole is located in the bottom of the

housing to allow for breathing and dra ining of any moisture ingress.

Both fan motors rotate in an anticlockwise direction when vie wed from the fan motor side.

The RHS motor is rated at 160 Watts and drives the larger diameter (354 mm) fan blade at approximately

2,250 ± 150 rpm.

The LHS motor is rated at 120 Watts and drives the smaller diameter (293 mm) fan blade at approximately

2,050 ± 150 rpm.

Both LHS and RHS fan and motor are balanced as a unit and fan blades must not be separated from their respective

motors. Fan motors and blades are serviced only as an assembled unit. However, it should be noted that the central nut

attaching the fan blade to the motor shaft has a left-hand thread.

There are also suppression capacitors incorporated into the fan motor, located on the brush holders. These suppression

capacitors help eliminate fan motor noise through the radio speakers. As these capacitors are not serviced separately,

should a problem occur with either capacitor, the motor assembly must be replaced.

Engine Cooling – V6 Engine Page 6B1–9

Page 6B1–9

Operation

Each of the engine cooling fan motors has two terminals; one pos itive and one negative. The positive terminals are

permanently connected to battery voltage, via fusible links F101 (large fan) and F107 (small fan).

Stage 1 Fan Operation

The large cooling fan o peration is enabled when the ECM via circuit 335 energises the Engine Cooling F an Relay 1 (R7).

When the negative terminal is connected to g r ound through Engine Co oling Fan Relay 1 ( R7), the large cooling fan

(right) operates.

The ECM determines when to ena ble the Engine Cooling Fan Relay 1 (R7), based on inputs from the A/C request signal,

Engine Coolant Temperature (ECT) sensor and the Vehicl e Speed Sensor (VSS).

Figure 6B1 – 6

Engine Cooling – V6 Engine Page 6B1–10

Page 6B1–10

Conditions for Stage 1 Fan Operation

1 The ECM turns Engine Cooling Fan Relay 1 (R7) ON when:

• Air conditioning request indicated (YES) and the vehicle speed is less than 30 km/h;

• Air conditioning pressure is greater than 1,500 kPa;

• Coolant temperature is greater than 104° C; or

• An ECT sensor failure is detected by the ECM.

Refer to Section 6C1-2 Engine Management – V6 – Diagnostics for additional information; or

• When the ignition s witch is turned from ON to OFF and the engine coolant temperature is above 117° C, the

ECM will continue to energise the Engine Cooling Fan Rel ay 1 (R7) for approximately four minutes.

2 The ECM turns Engine Cooling Fan Relay 1 (R7) OFF when the following conditions have been met:

• Air conditioning request not indicated (NO) and the coolant temperature is less than 99° C; or

• Air conditioning request indic ated (YES) with pressure less than 1,170 kPa, vehicle speed greater than

50 km/h and coolant tempera t ure less than 99° C.

Figure 6B1 – 7

Engine Cooling – V6 Engine Page 6B1–11

Page 6B1–11

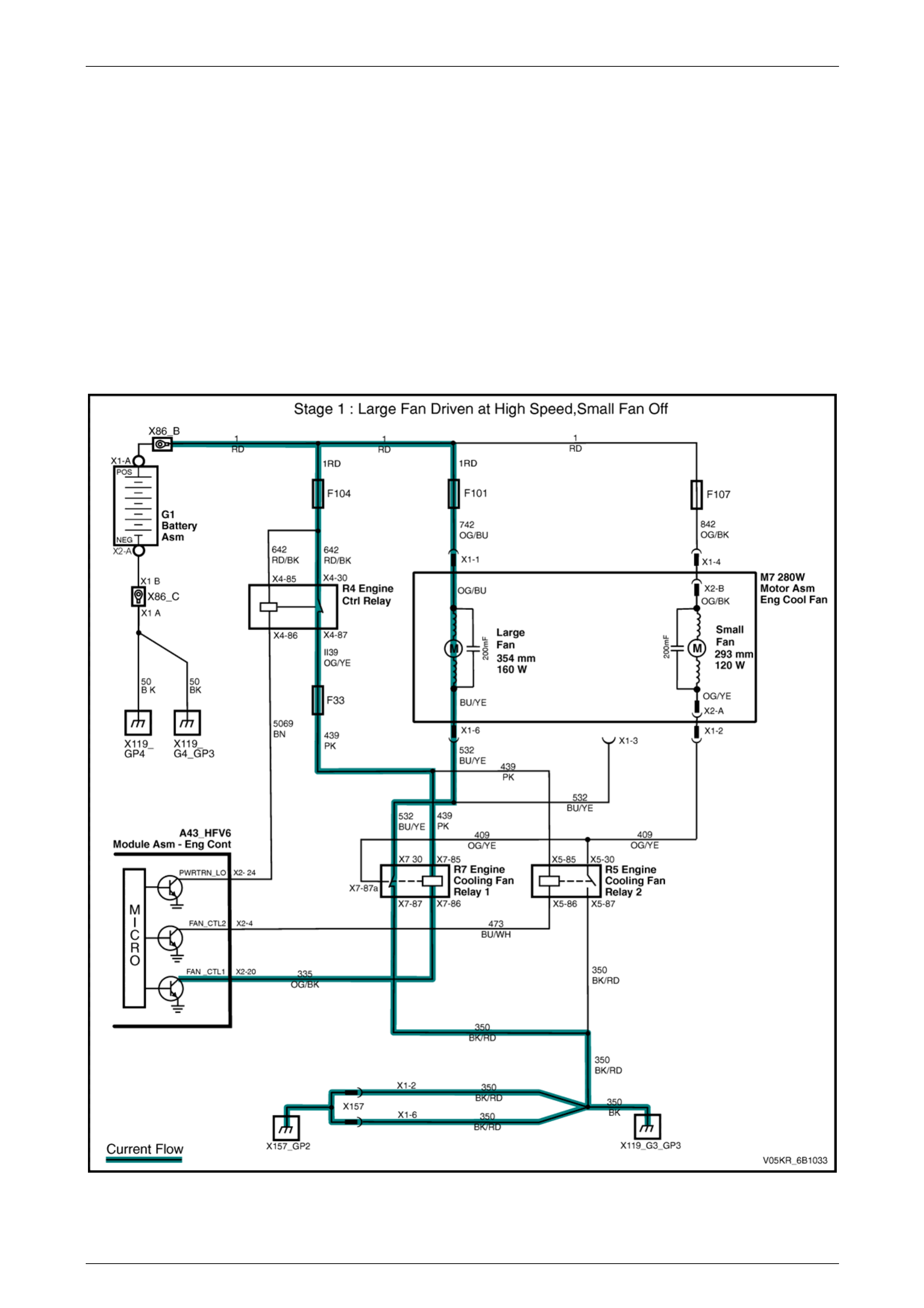

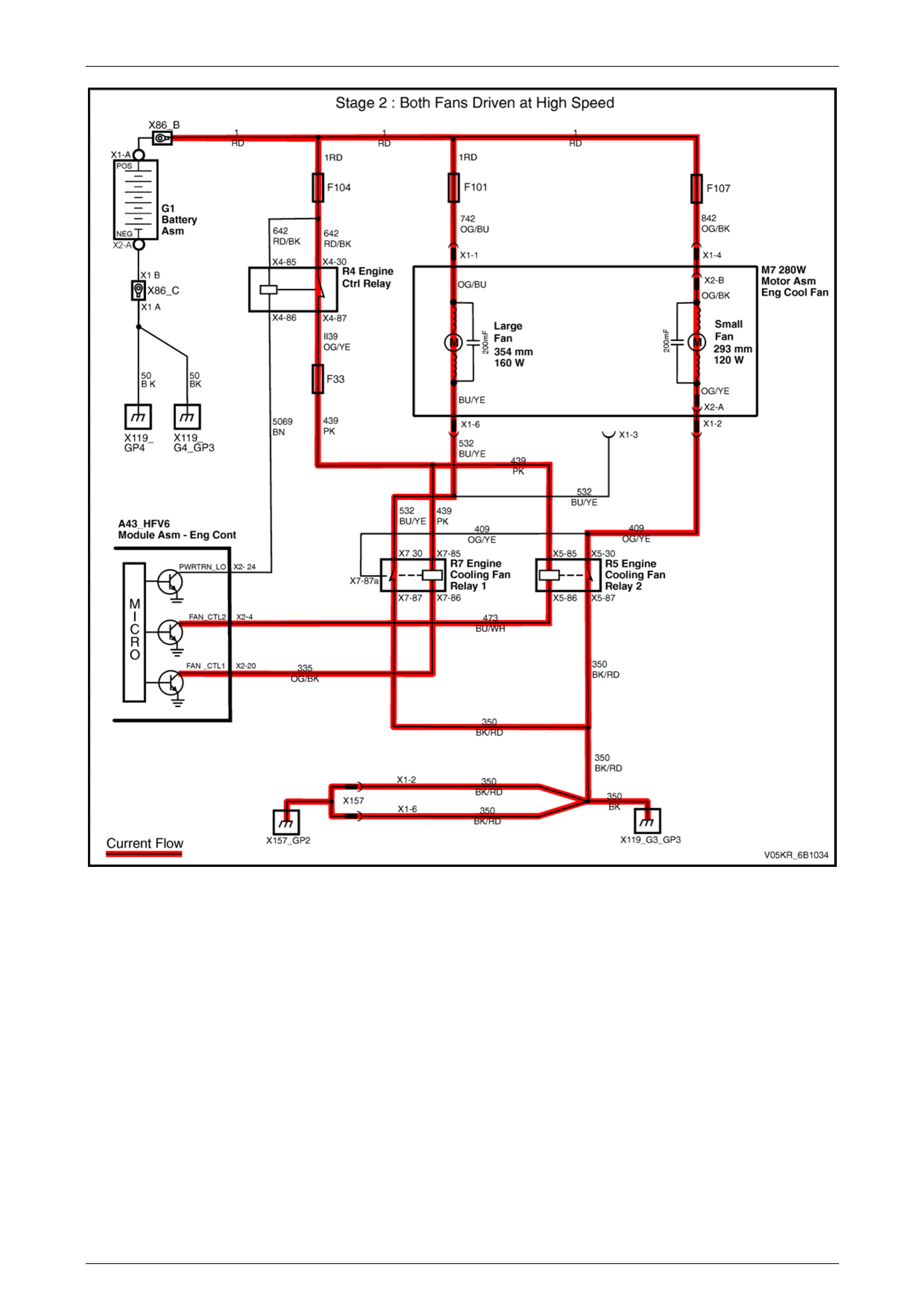

Stage 2 Fan Operation

The small (left) cooling fan operation is enabled when the ECM via circuit 473 energises the Engine Cooling Fan Re lay 2

(R5). When the negative terminal is connected to earth via the Engine Cooling Fan Relay 2 (R5), the small cooling fan

operates. Both cooling fans are now operational, the large fan via Engine Coolin g Fan Relay 1 (R7) and the small cooling

fan via Engine Cooling Fan Relay 2 (R5).

Figure 6B1 – 8

Engine Cooling – V6 Engine Page 6B1–12

Page 6B1–12

Conditions for Stage 2 Fan Operation

The ECM determines when to ena ble the Engine Cooling Fan Relay 2 (R5), based on in puts from the ECT sensor.

1 The ECM turns Engine Cooling Fan Relay 2 (R5) ON if the Engine Cooling Fan Relay 1 (R7) has bee n energised

for one second and the following conditions have been met:

• If there is a ECM message response fault, setting a DTC P125 8;

• The ECM detects an ECT sensor failure. Refer to Section 6C1-2 Engine Management – V6 – Diagnostics in

this Service Information for additional information;

• Engine coolant temperature is above 1 08° C; or

• Air conditioning pressure is greater than 2,000 kPa.

NOTE

If the large engine-cooling fan is off when the

criteria for turning the small engine-co oling fan o n

are first met, the small engin e-cooli ng fan will turn

on 5 seconds after the large engine-coolin g fan is

switched on.

2 If both the large and small cooling fans ar e enabled, the ECM turns the small engine-cooling fan OFF (via Engine

Cooling Fan Relay 2) when:

• The engine coolant temperature is less than 103° C; and

• Air conditioning request is not indicated (NO); or

• Air conditioning request is indicated (YES) and the press ure is less than 1,500 kPa.

Engine Cooling – V6 Engine Page 6B1–13

Page 6B1–13

Figure 6B1 – 9

Engine Cooling – V6 Engine Page 6B1–14

Page 6B1–14

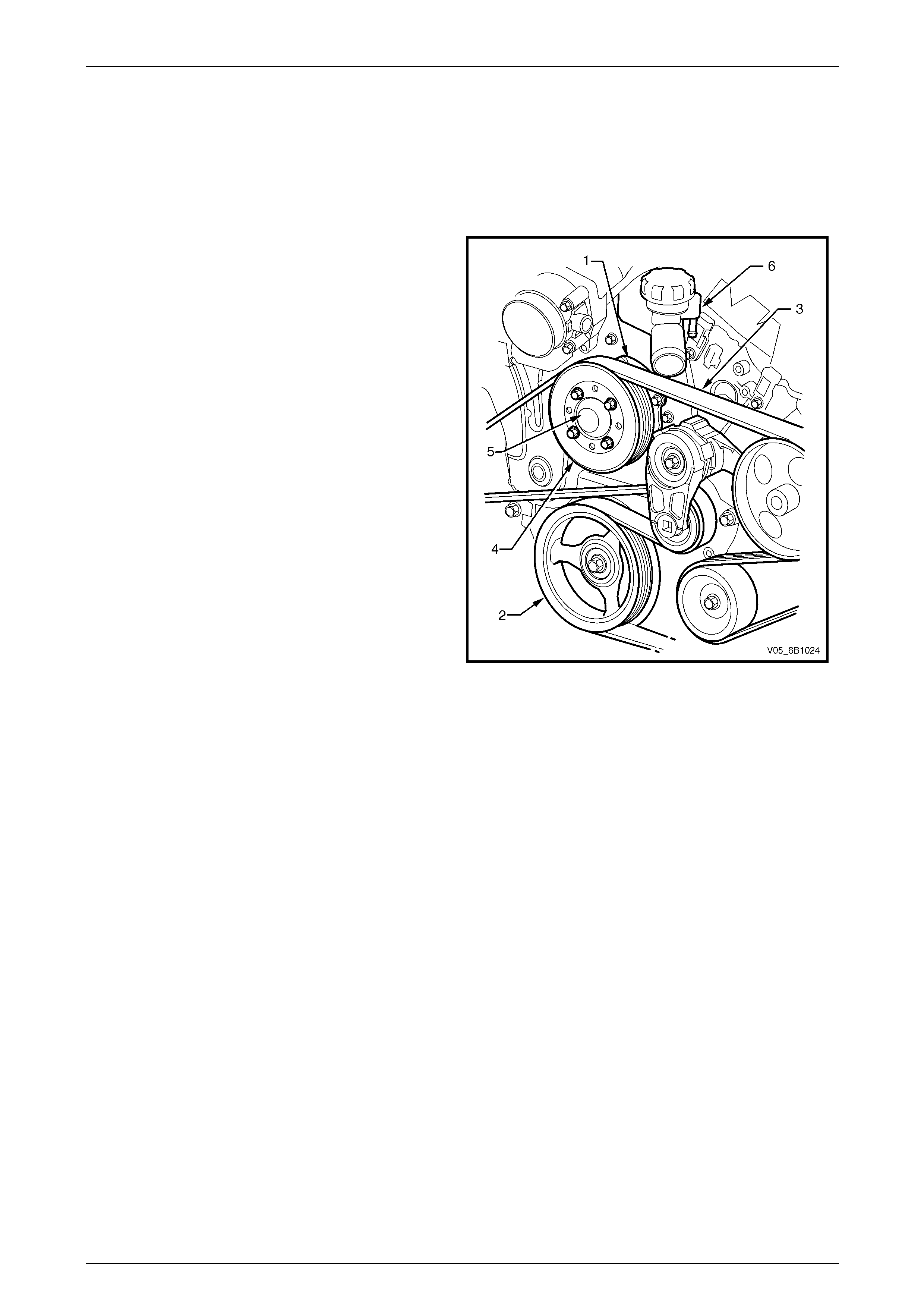

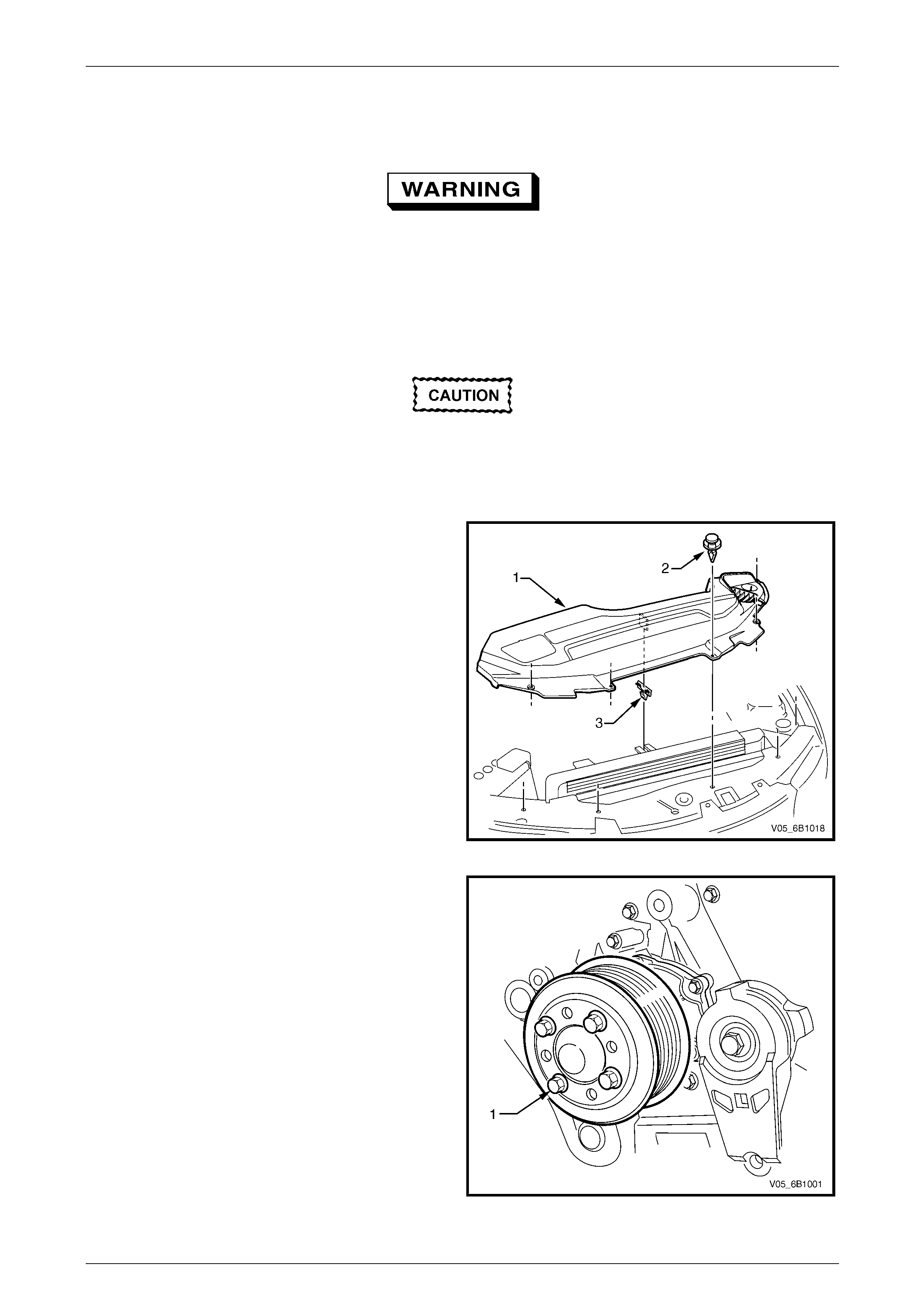

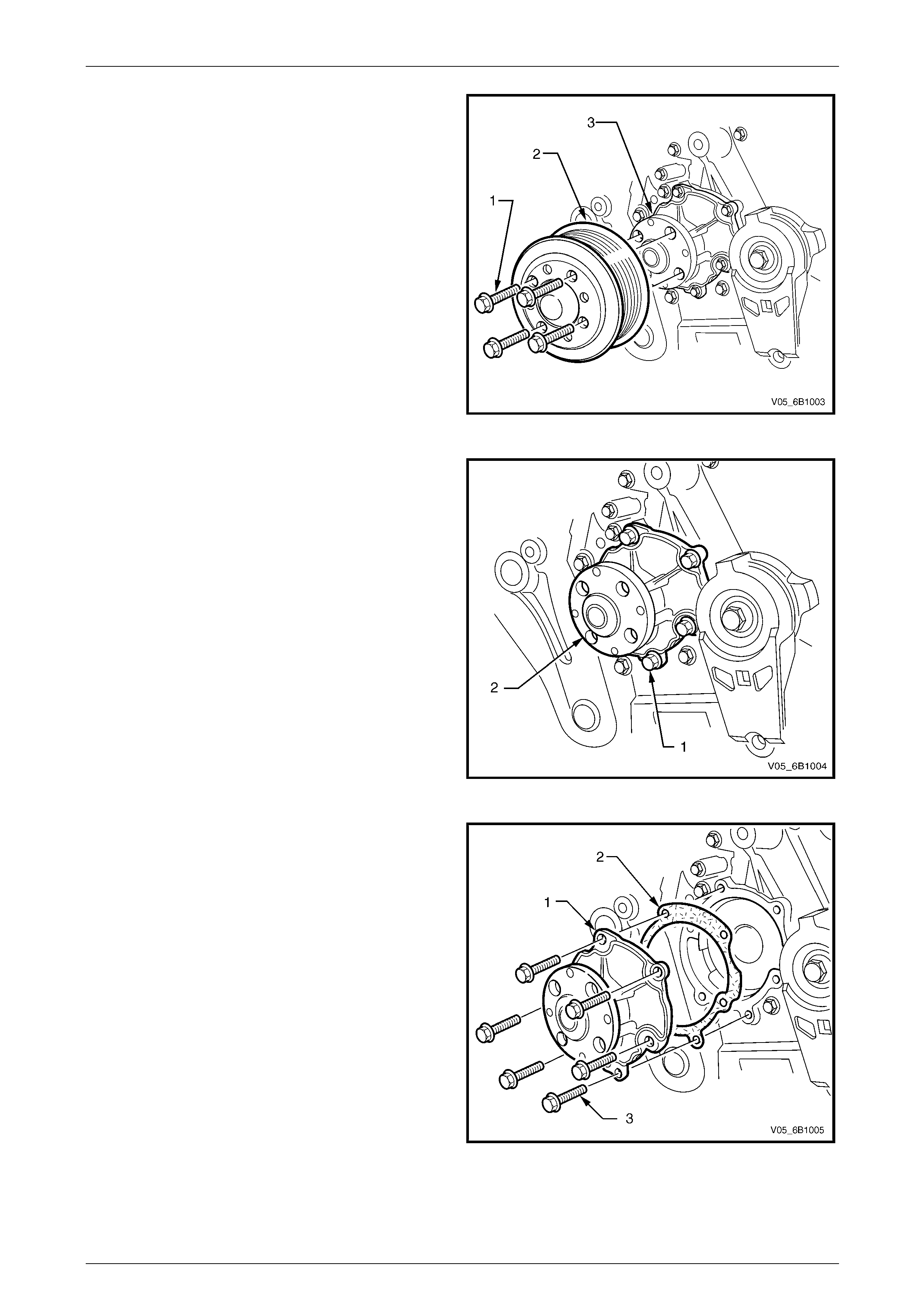

2.3 Coolant Pump

The coolant pump is a centrifugal vane impeller type pump. The pump consists of a housi ng and an impeller. The

impeller is a flat plate mounte d on the p ump shaft with a series of flat or curved blades (vanes). When the impe ller

rotates, the coolant between the vanes is thrown outward by centrifugal force. The impeller shaft is supported by sealed

bearings. The sealed bearings do not need to be lubricated. Grease cannot leak out, dirt and water cannot get in as long

as the seal is not damaged or worn.

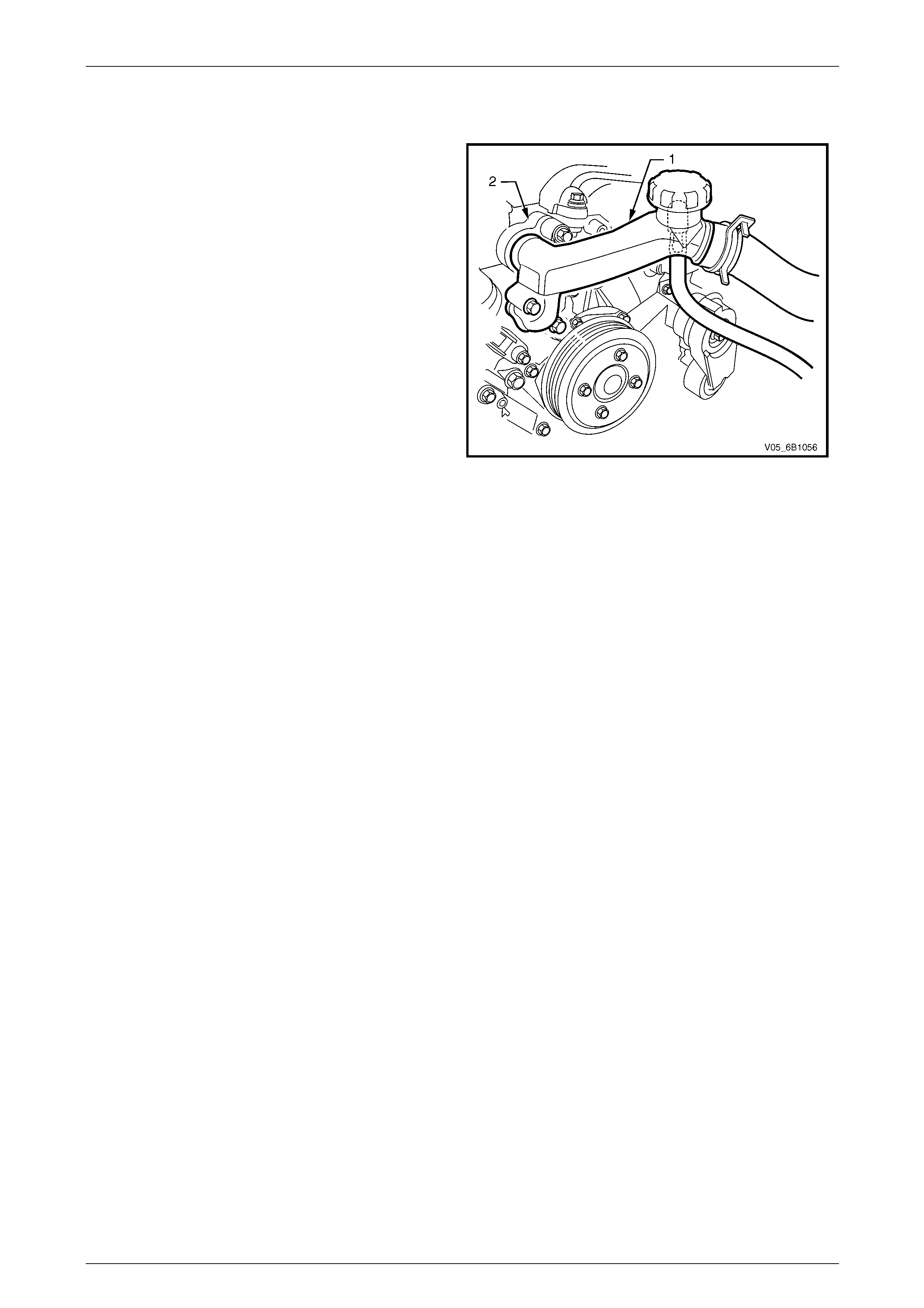

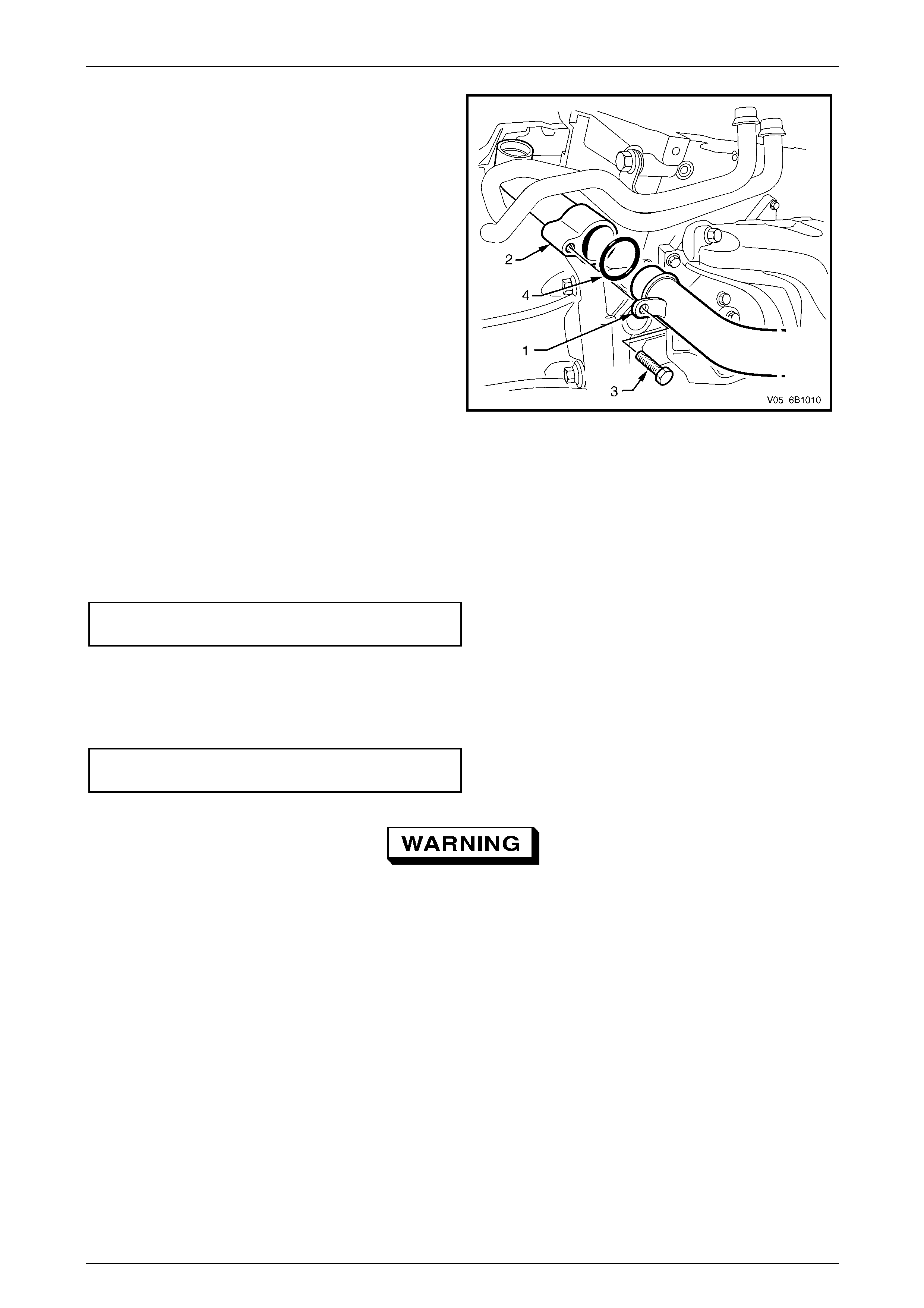

The coolant pump (1) is mounted to the engine front cover

and is driven by the crankshaf t pulley (2) via a multi-ribbed

drive belt (3), turning the pump pulle y (4), bolted to the

coolant pump flange (5). Coolant enters the engine

through the coolant inlet pipe and thermostat at the rear of

engine and passes through the engine to the coolant

pump on the front engine cover and exits via the coolant

outlet housing (6) located at the front of the intake

manifold.

Figure 6B1 – 10

Engine Cooling – V6 Engine Page 6B1–15

Page 6B1–15

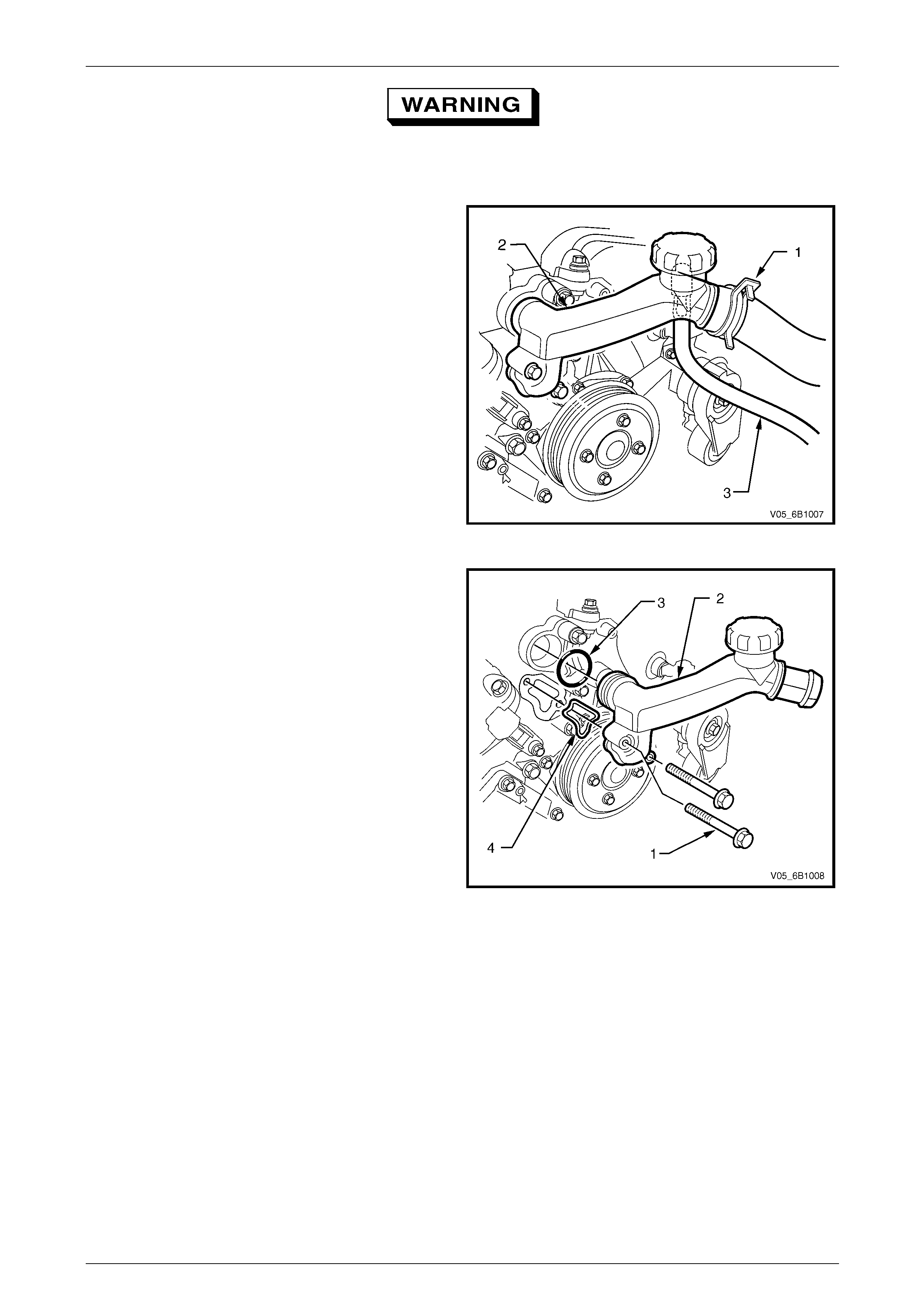

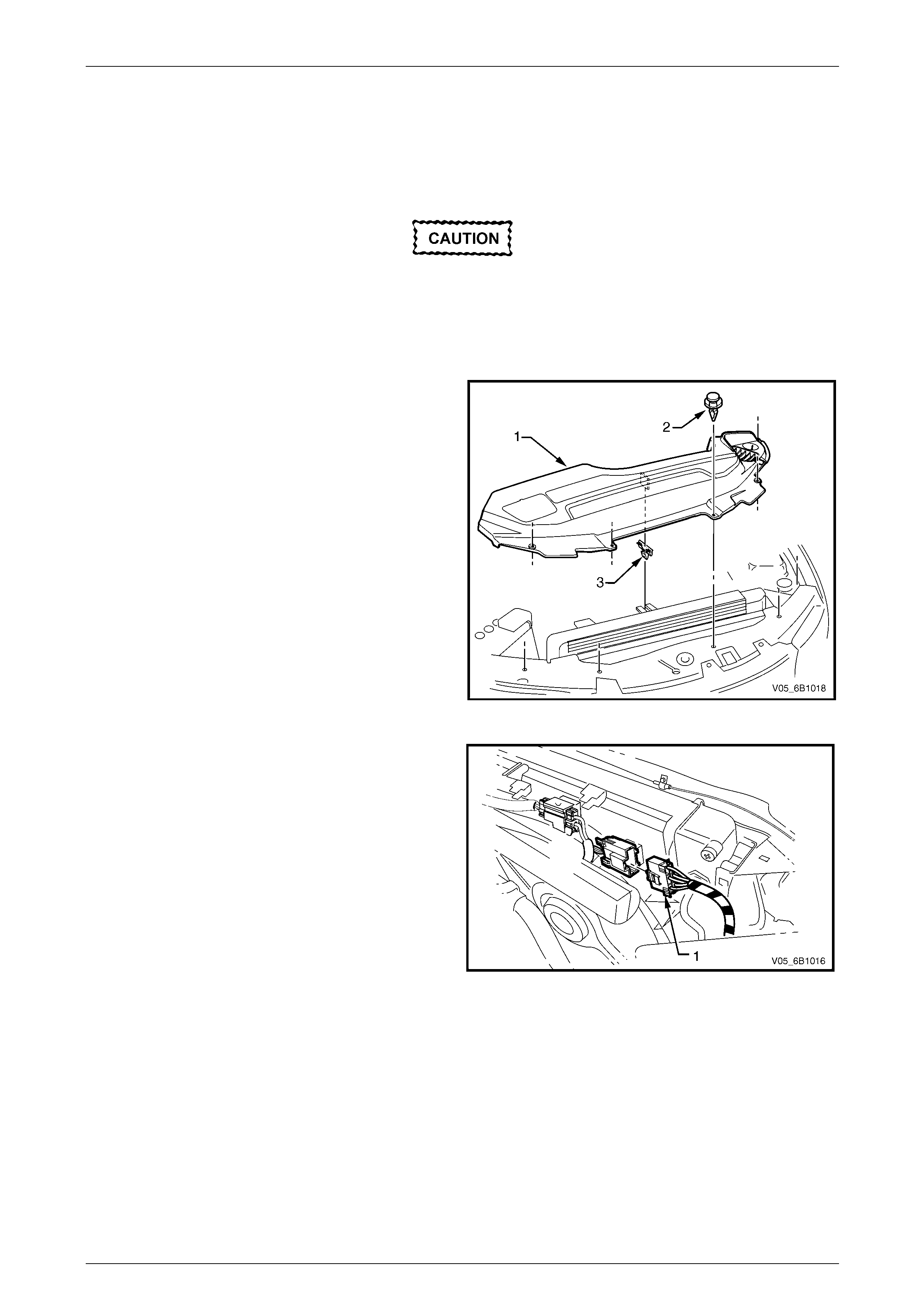

2.4 Coolant Outlet Housing

The coolant outlet housing (1) is located at the front of the

intake manifold (2).

The coolant outlet housing i ncorporates the coolant filler

pressure cap and coolant recovery reserv oir hose

connection.

Figure 6B1 – 11

Engine Cooling – V6 Engine Page 6B1–16

Page 6B1–16

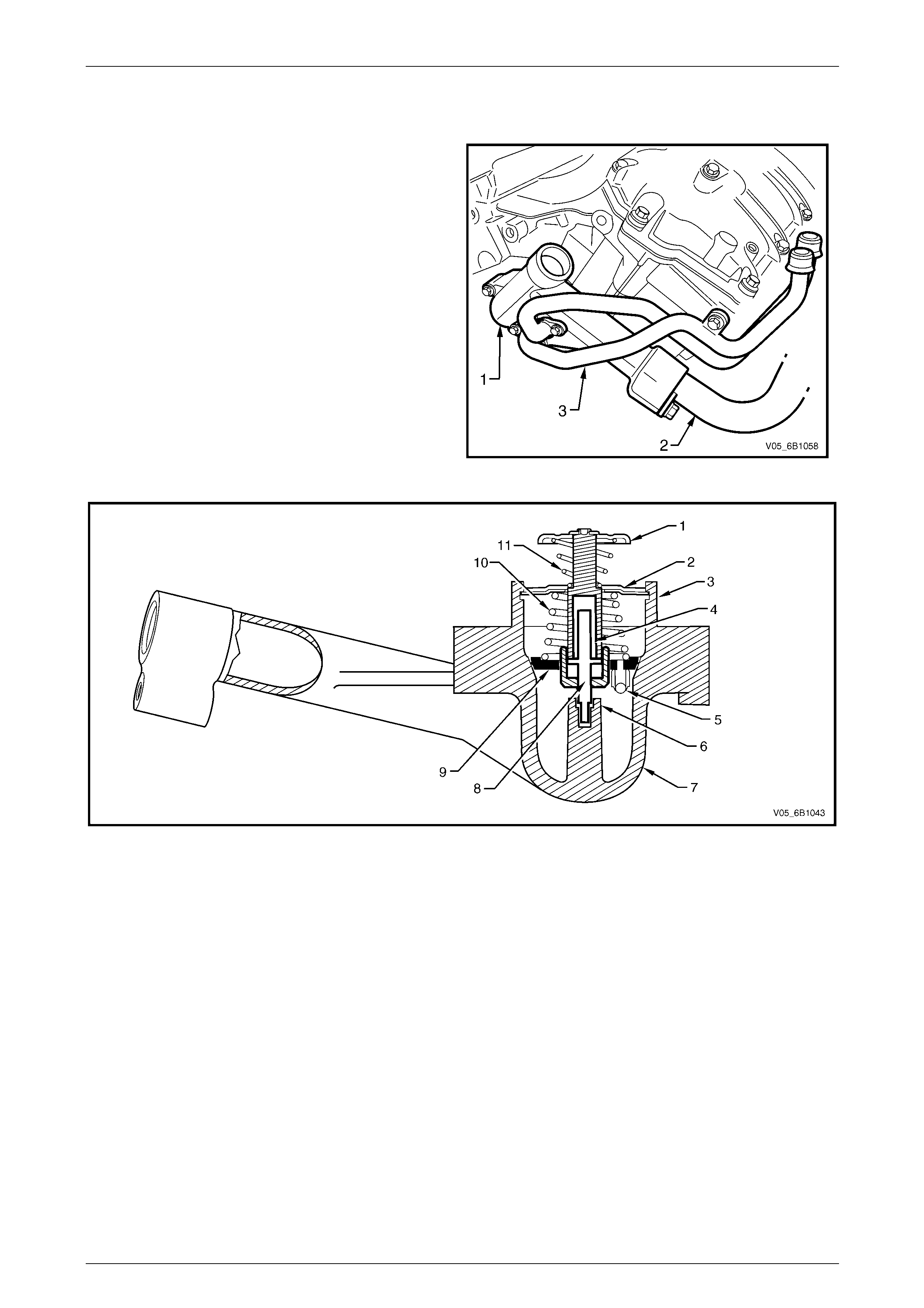

2.5 Thermostat

The thermostat housing (1) is located between the coolant

inlet pipe (2) and the rear of the intake manifold,

underneath the heater pipe as sembly (3).

Figure 6B1 – 12

Figure 6B1 – 13

Legend

1 Bypass Valve

2 Thermostat Retaining Bar

3 Thermostat Assembly Retaining Lugs

4 Wax Pellet

5 Air Bleed Valve

6 Piston Centre Support

7 Thermostat Housing

8 Piston

9 Rubber Diaphragm

10 Thermostat Spring

11 Bypass Spring

A wax pellet type thermostat is used in the coolant inlet passage to control the flow of coolant, providing fast engi ne

warm up and regulating coolant temperature. The wax pellet or power element in the thermostat expands when heated

and contracts when cooled. The wax pellet is connected through a piston to a valve and when the pe llet is heated,

pressure is exerted against a metal valve, which is forced to open.

As the pellet is cooled, the contraction allows a spring to close the valve. Thus, the valve remains closed whil e the

coolant is cold, preventing circulation of coolant through the radiator, but allowing the coolant to circulate throughout the

engine to warm it quickly and evenly. As the engine becomes warm, the pellet expands and the thermostat opens,

permitting the coolant to flow through to the radiator where heat is transferred to the surrounding air, through the ra diator

walls.

This opening and closing of the thermostat valve permits enough coolant to enter the radiator to keep the engine within

specified temperature limits.

The thermostat also provides a restriction in the cooling system, even after it has opened. This restriction creates a

pressure difference, which prevents cavitation at the coolant pump and forces coolant to circulate through the engine

block.

Engine Cooling – V6 Engine Page 6B1–17

Page 6B1–17

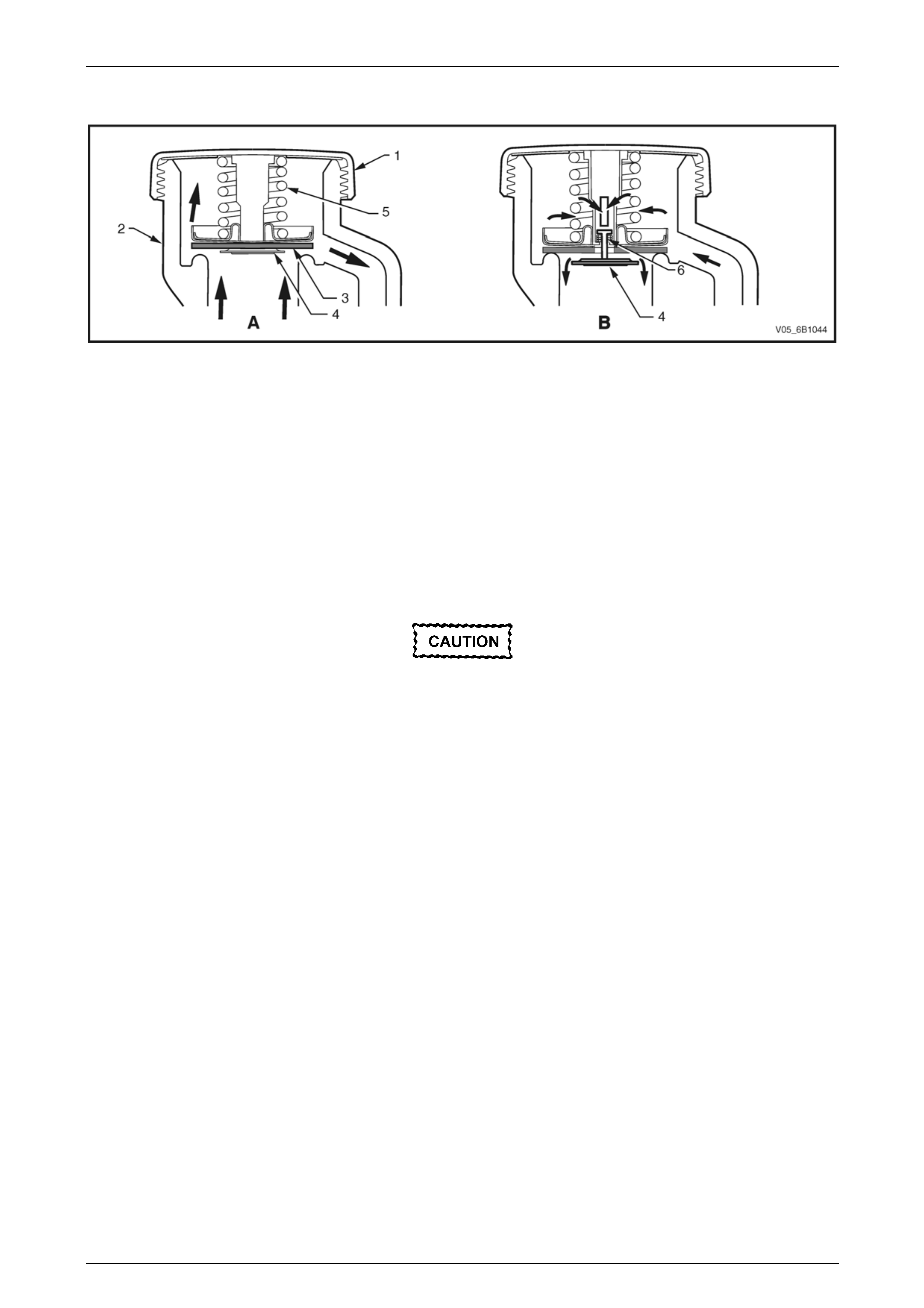

2.6 Coolant Filler Cap

Figure 6B1 – 14

The pressurised coolant filler cap (1), fitted to the filler neck (2) on the coolant outlet housing, causes the cooling system

to operate at higher than atmospher ic pressure. The higher pressure raises the boiling point of the coola nt, resulting i n

increased engine coolin g efficiency. The cool ant filler cap contains a pressure valve (3) and a vacuum (atmospheric)

valve (4).

Referring to view ‘A’, the pressure valve is hel d against its seat by a spring (5), which determines the maximum operating

pressure of the cooling system (135 kPa for the Allo ytec V6 engine).

Referring to view ‘B’, the vacuum valve (4) is held against its seat by a light spring (6) and opens during cool down

because of the drop in pressure with contract ion of the coolant volume. This pressure drop over-comes the spring force

and the vacuum valve is opened, preventing the radiator hoses from collapsin g. In additi on, coolant can also flow back

into the cooling system from the coolant recovery reservoir while this valve is open maintaining a full volume of coolant

within the engine and radiator.

Should the radiator pressure cap require

replacement, only fit the correct cap (w ith the

correct pressure-rating) for this engine. Refer

to the current release of Partfinder™ for this

information.

Engine Cooling – V6 Engine Page 6B1–18

Page 6B1–18

2.7 Coolant Recovery Reservoir

The coolant is maintained at the ideal l evel in the radiator by the coolant filler cap and the coolant recovery reservoir,

resulting in increased coo ling efficiency.

The coolant recovery reservoir is located on the left-hand side front of the engine compartment, between the radiator

support panel and air cleaner assembly. The coolant recover y reservoir is connected to the radiator overflow connection

by a small diameter hose.

As the engine temperature rises, the coolant is heated and expands. The fluid displaced by expansion flows from the

radiator into the recovery reservoir.

When the engine is turned OFF, the coolant contracts as it cools. Coolant is then drawn back into the radiator through

the coolant filler cap atmospheric valv e.

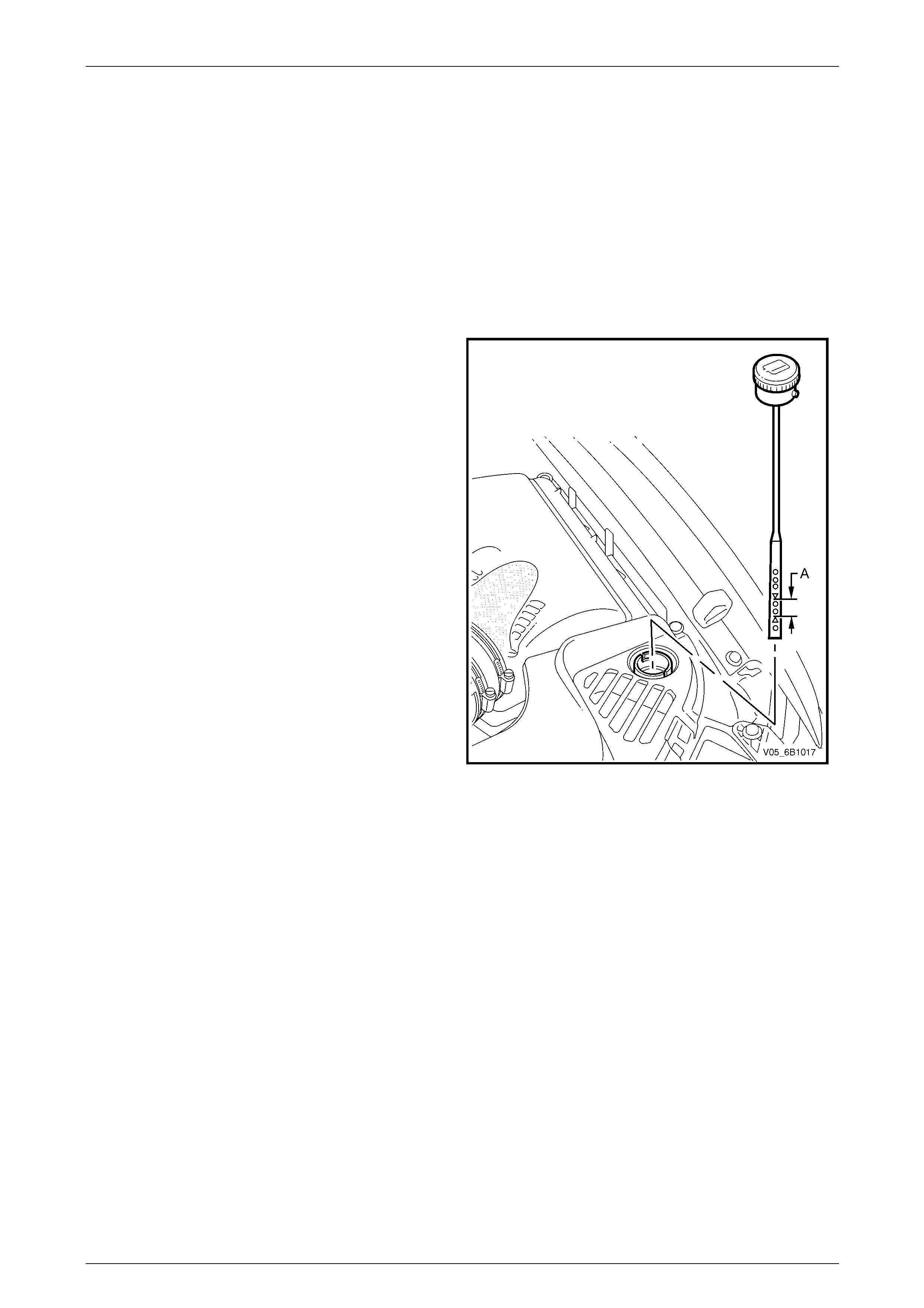

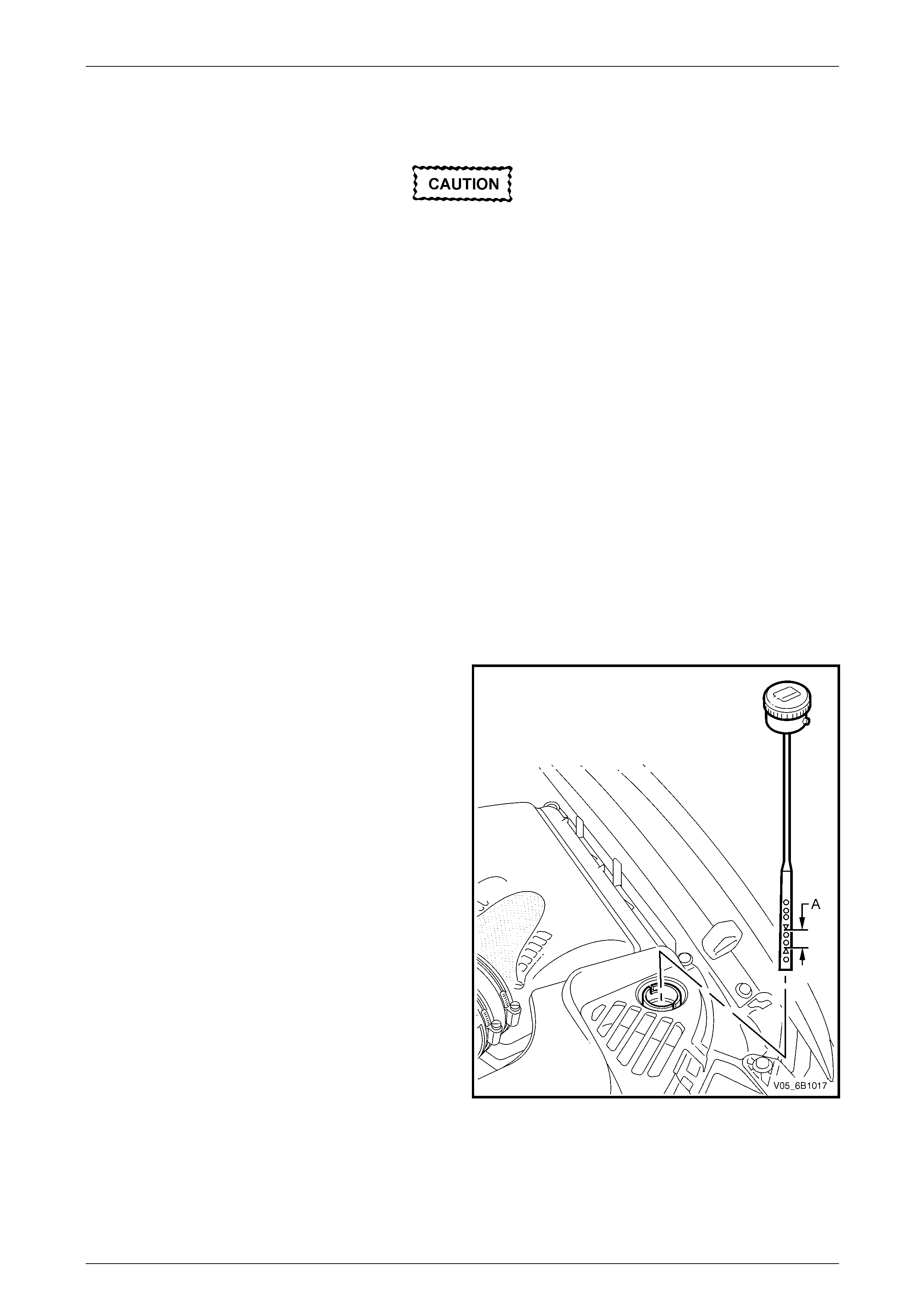

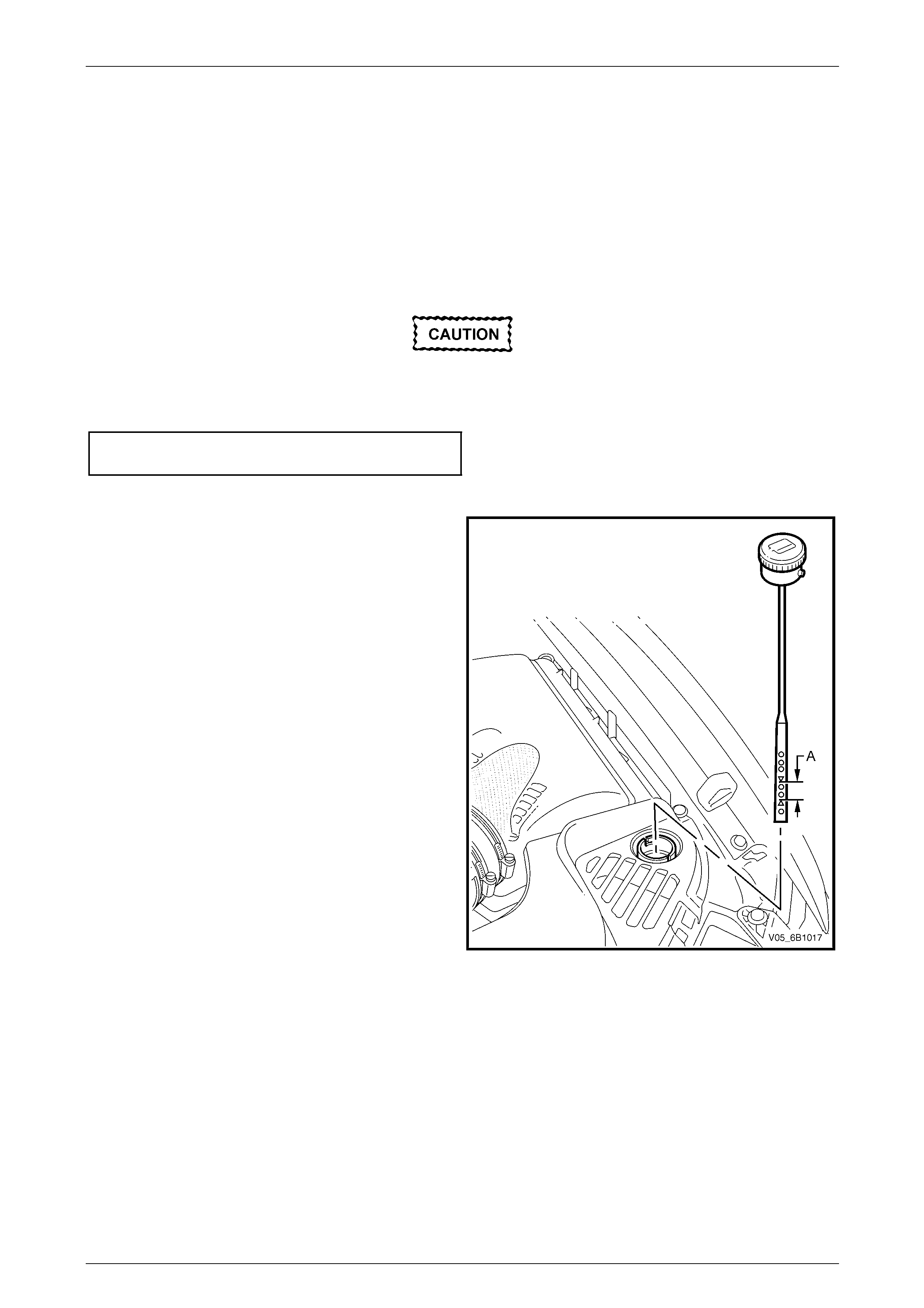

Coolant level should be maintained between indicator

arrows (‘A’) on the coolant recovery reservoir dipstick, as

shown in Figure 6B1 – 15, when the e ngine is cold.

The cooling system is design ed to use a coolant, DEX-

COOL® long-life coolant or equival ent to GM specification

6277M (a mixture of ethylene glycol antifreeze and

corrosion inhibitors and water), rather than plain water to

maintain the integrity of the cooling system, and to prevent

oxidation occurring within the engine.

NOTE

Some vehicle markets call for DEX-COOL®

long-life coolant and others for its equivalent,

known as Extended Life Anti-freeze Coolant,

conforming to GM specification 6277M. If in

doubt regarding the correct coolant to be us ed,

refer to the Owner’s Handbook.

Figure 6B1 – 15

Engine Cooling – V6 Engine Page 6B1–19

Page 6B1–19

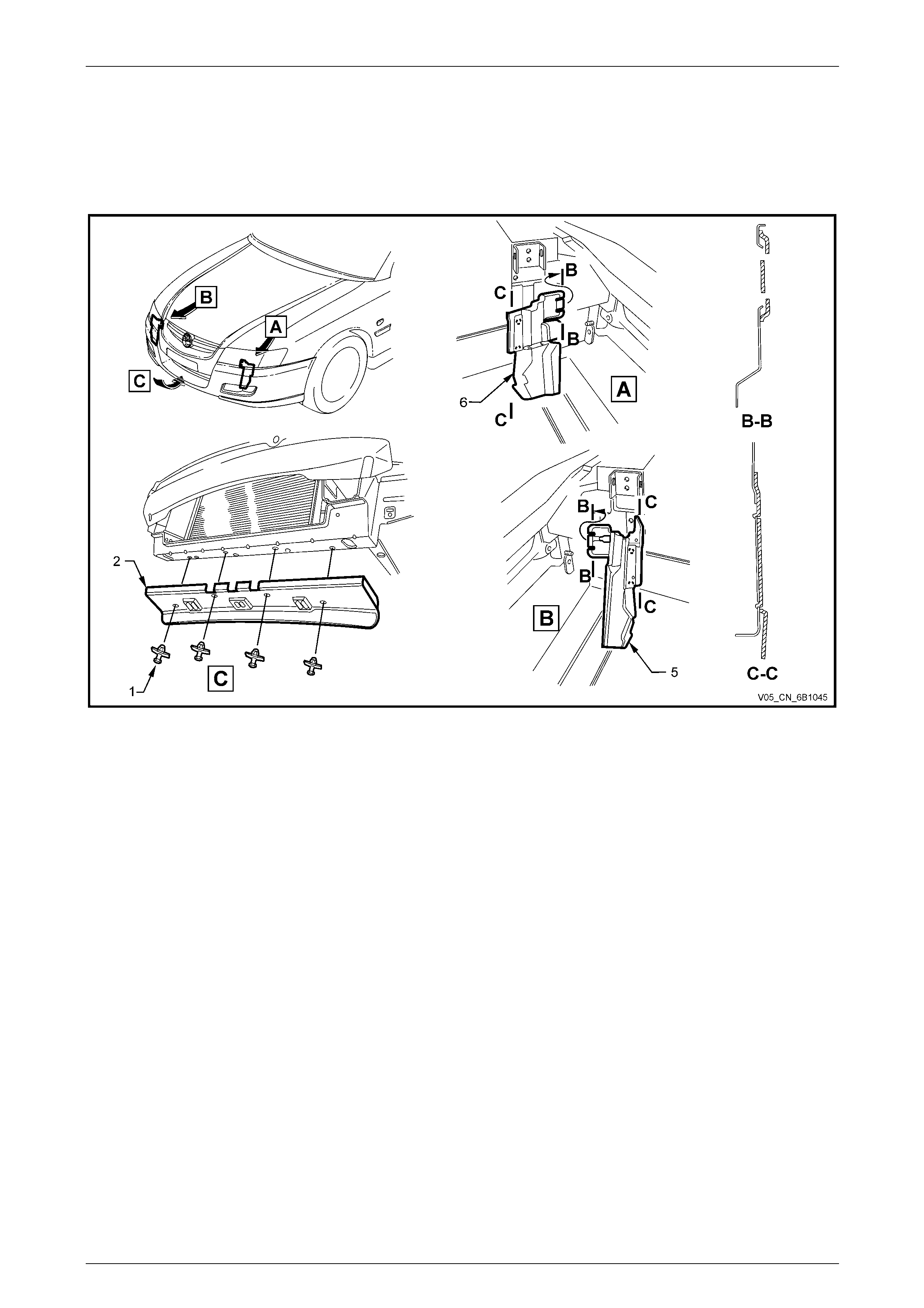

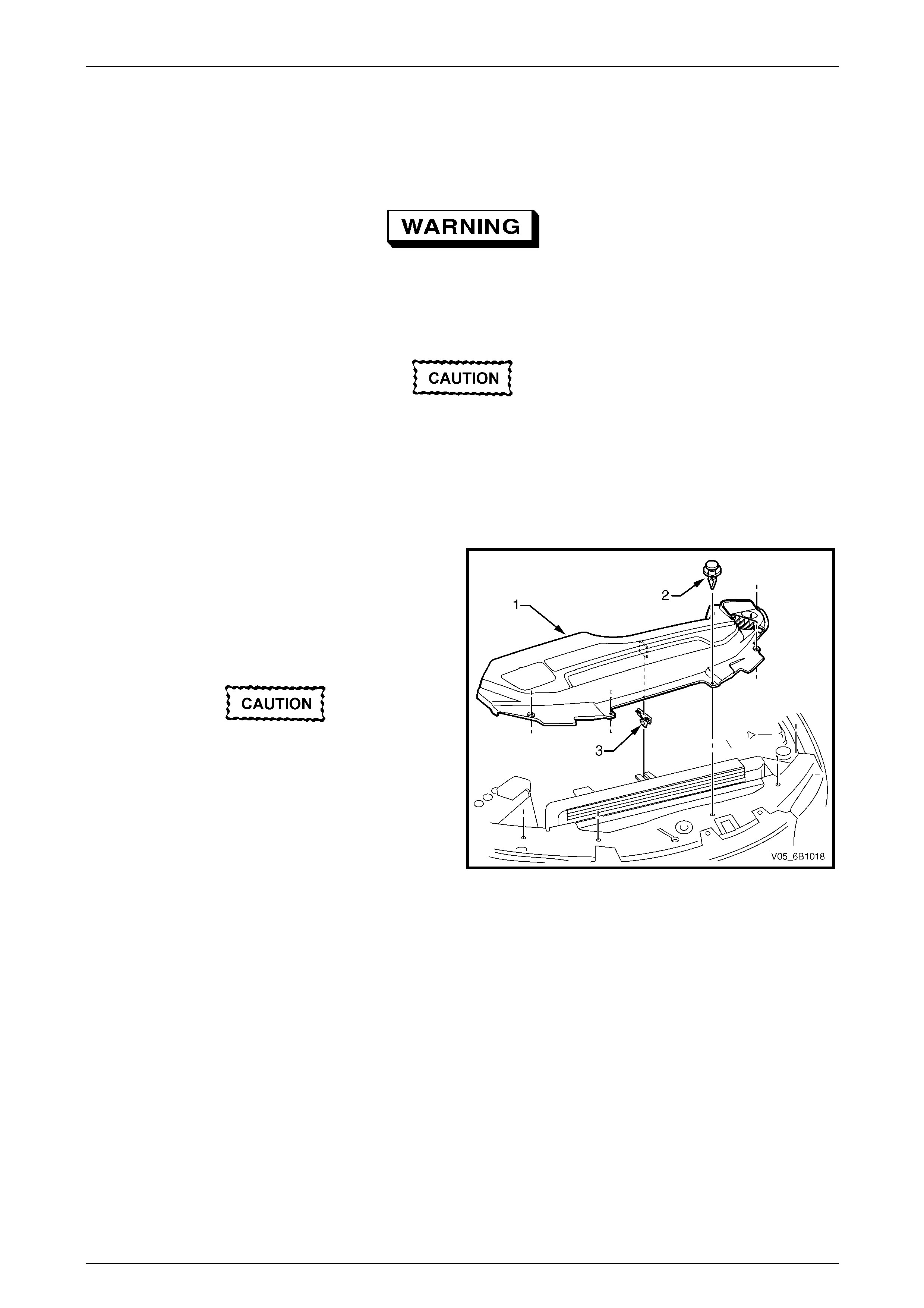

2.8 Air Baffle, Chutes and Shroud

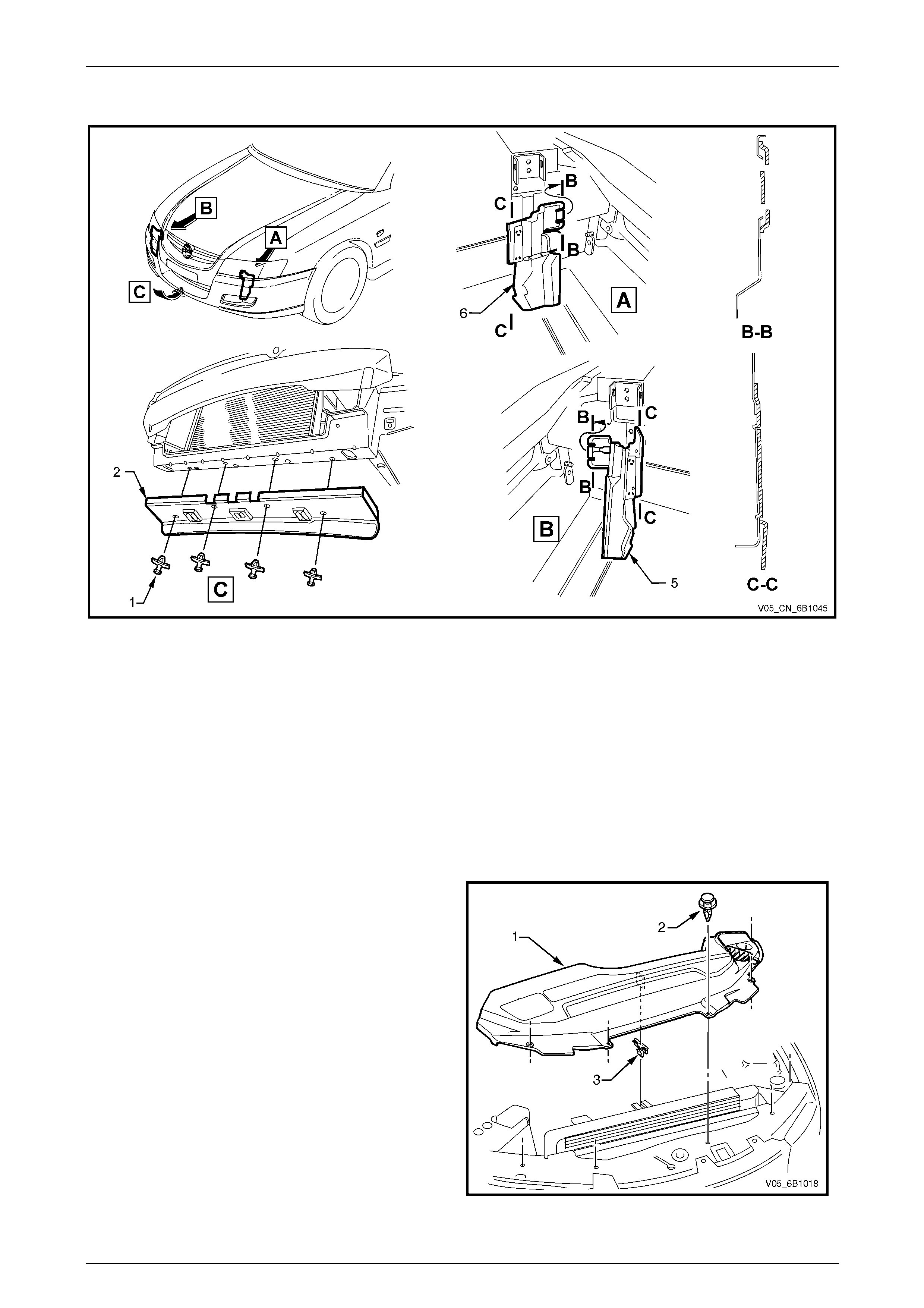

Figure 6B1 – 16

Legend

1 Plastic Fasteners (4 places)

2 Lower Air Chute Baffle 3 Lower Air Chute Extension Duct

4 Plastic Fasteners (2 places) 5 Right-hand Side Air Chute

6 Left-hand Side Air Chute

A lower air chute baffle and side chutes are fitted to the front end of the vehicle to direct and promote airflow through the

radiator to provide maximum cooling.

The purpose of the lower air chute baffle is to create a low-pressure area behind the radiator whilst the vehicle is at

speed. This enables additional airflow through the radiator core to maintain the desired engine cooling.

The air baffle or chutes should only be removed for service work. If either the air baffle or chutes are damaged, this will

reduce the cooling system efficiency, and therefore they must be replaced.

An upper radiator shroud (1) is fitted between the upper

radiator support panel and the radiator assembly to

minimise the recirculation of hot air from the rear of the

radiator back over the core and to direct cool incoming air

from the front of the vehicle through the radiator core. The

shroud is held in place by five plastic scrivets (2) and a

retaining clip (3).

Figure 6B1 – 17

Engine Cooling – V6 Engine Page 6B1–20

Page 6B1–20

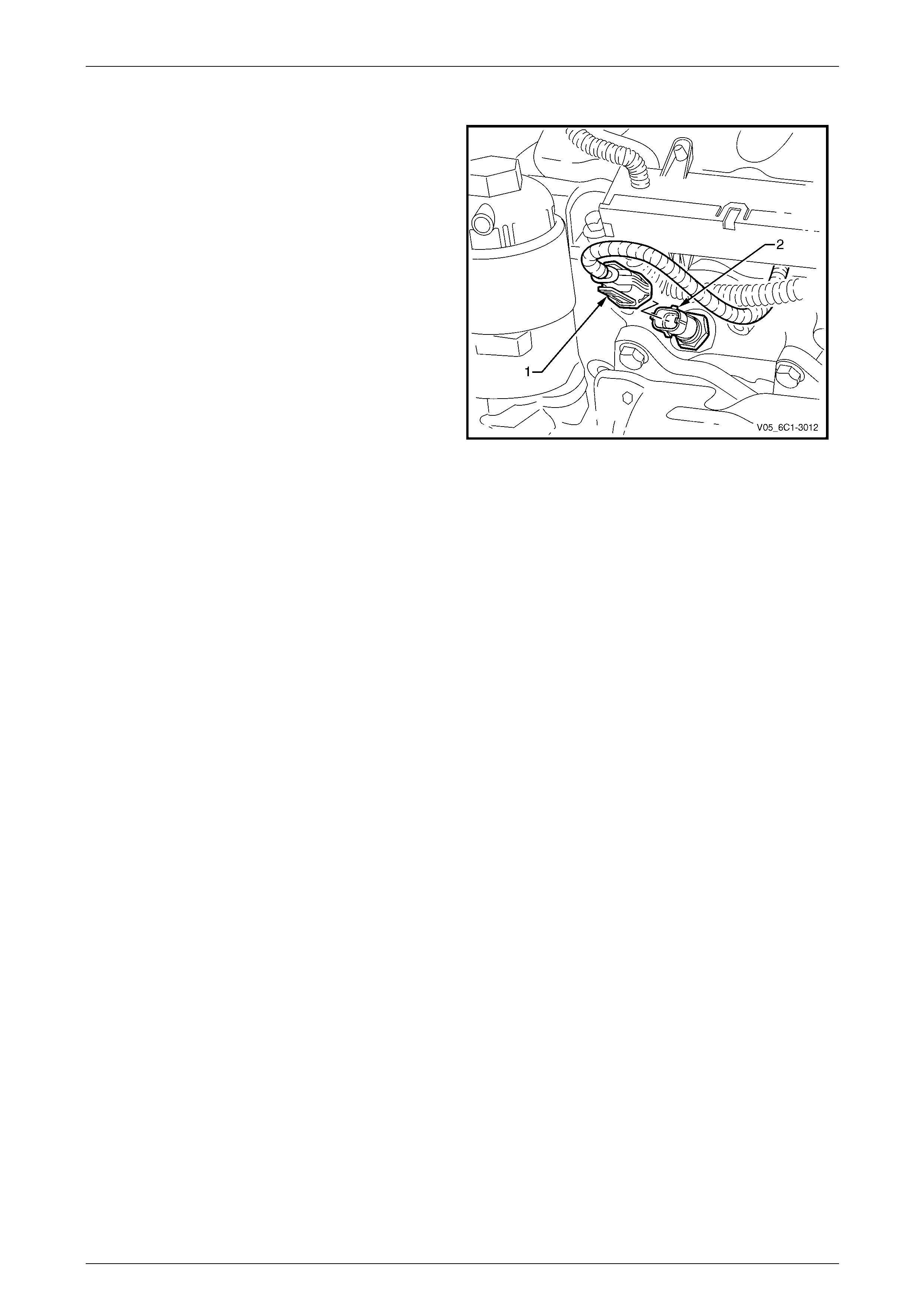

2.9 Engine Coolant Temperature Sensor

An Engine Coolant Temperatur e (ECT) sensor (2) is

mounted in the left-hand side c ylinder he ad, just behind

the oil filter housing. The ECT sensor is used in

conjunction with the instrument panel tempe r ature gauge.

The ECT sensor generates a signal, which is used by the

engine management system for calculatio n of the various

engine management function s.

Figure 6B1 – 18 shows the wiring harness connector (1)

and the ECT sensor (2).

Refer to Section 6C1-1 Engine Management – V6 –

General Information for further information on the ECT

sensor.

Figure 6B1 – 18

Engine Cooling – V6 Engine Page 6B1–21

Page 6B1–21

3 Service Operations

3.1 Service Notes

Safety

• To avoid serious personal injury, never

remove the coolant filler pressure cap on

the coolant outlet housing when the

engine is hot, even if the cooling system

should require filling. Sudden release of

cooling system pressure is very

dangerous.

• The vehicle is fitted with twin electric

radiator cooling fans. When working

around the engine compartment, keep

clear of the fans as they may start without

warning.

Before removing the coolant filler cap, allow the engine to cool, then place a shop rag over the coolant filler cap and then

slowly turn the cap anticlockwise, approximately 1½ turns, until the pressure relief position is reached. The pressure

relief position will allow any remaining pressure within the system to escape into the coolant recovery reservoir. Continue

to rotate the cap anticlockwise until the cap can be safely removed.

Periodic Servicing

The cooling system requires little attention except for maintaining the coolant to the correct level in the recovery reservoir

and periodic servicing at the time or distance intervals as outlined in Section 0B Lubricati on and Service.

Periodic servicing includ es:

1 Checking coolant level. Refer to 3.3 Draining and Filling Co oling System in this Section.

2 Checking coolant concentration. Refer to 3.2 Coolant Maintenance – Testing Coolant Concentration in this Section.

3 Pressure test cooling system and coolant filler cap. Refer to 3.7 Pressure Testing in this Section.

4 Tighten hose clamps and ins pect all hoses. Refer to 3.6 Coolant Hoses in this Section. R eplace hoses if swollen or

deteriorated.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

5 Clean out cooling system, refer to 3.4 Cleaning Cooling System – Cooling System Reverse Flush in this Section.

6 Refill the cooling system. Refer to 3.3 Drainin g and F illing Cooling S ystem in this Section.

Engine Cooling – V6 Engine Page 6B1–22

Page 6B1–22

Environmental Issues

To reduce environmental impact and maintenance cost, whenever the coolant is drained from any engine, the service

records are to be checked to determi ne when the coolant was last changed. If more than six months life is left before the

next coolant change, then the following procedure is to be followed:

1 When draining the coolant from the engine, use a clean co ntainer to hold at least 12 litres of coolant and ensure

that the coolant is not contaminated in the draining process.

2 After repairs have been completed, refill the engine cooling system with the drained coolant.

3 Top up as required, using a 50 / 50 mix of clean water and the recommended cool ant, which is either DEX-COOL®

long-life coolant or its equivale nt, known as Extended Life Anti-freeze Coolant conforming to GM specification

6277M. Refer to 3.2 Coolant Maintenance and 3.3 Draini ng and Filling Cooling System in this Section, for the

necessary procedures and further information.

Engine Cooling – V6 Engine Page 6B1–23

Page 6B1–23

3.2 Coolant Maintenance

Do not mix different types of anti-freeze

or corrosion inhibitors, as they

may be incompatible. If a different type

has been used in the cooling system, flush

the system with clean water, refer to

3.4 Cleaning Cooling System –

Cooling System Reverse Flush in this

Section and refill cooling system with

the correct coolant. Refer to

3.3 Draining and Filling Cooling System in

this Section.

The cooling system is design ed to use a coolant (a mixture of ethylene glycol antifreeze with added corr osion inhibitors,

and water), rather than plain water. T he use of glycol also raises the boiling point and incr eases the cooling system

efficiency. For this reason, it is of the utmost importance that the correct concentration level of ethylene glycol in the

cooling system is maintained.

Addition of plain water into the cooling system when 'topping-up' ma y dilute the coolant mixture to a point where the

antifreeze / anti-boil and corrosion inhibitor properties of ethylene glycol become ineffective.

The coolant should comprise of a mixture 50% ethylene gl ycol antifreeze / inhibitor with 50% clear, clean water.

Ethylene glycol conforming to the correct specificatio n is eith er named DEX-COOL® long-life coolant or its equivalent,

known as Extended Life Anti-freeze Coolant conforming to GM specification 6277M. Both are available in a number of

different quantities. Check the current release of Partfinder ™ for specific details.

Topping Up the Cooling System

Under normal operating conditions, the cooling system

should not be topped up at the coolant filler cap. The level

can be checked at the coolant recover y reservoir, and

coolant (in the correct concentration with clear, clean

water) added as necessary to bring the level to between

the indicator arrows (‘A’) on the coolant recovery reservoir

dipstick, as shown in Figure 6B1 – 19, when the engine is

cold.

Figure 6B1 – 19

Engine Cooling – V6 Engine Page 6B1–24

Page 6B1–24

Testing Coolant Concentration

To ensure the specified ethylene glycol concentration is maintained in the engine coolant, the coolant concentration must

be checked at the time or distance intervals outlined in the Owner’s Handbook or Service Booklet in the glove box.

NOTE

• While a number of coolant concentration

measuring devices are available, the two

preferred types are as described.

• The procedures detailed, apply to either

coolant type used.

Method 1 – Refractometer

NOTE

• Coolant tester, Tool No. J26568,

automatically compensates for temperature.

• Ensure that the eyepiece of the tester is free

of coolant before looking through it.

• Before each use, swing back the plastic cove r

at the slanted end of the coolant tester,

exposing the measuring window and the

bottom of the plastic cover. Carefull y wipe the

measuring window dry with a tissue or clean,

soft cloth. Close the plastic cover.

1 Check the calibration of the coolant tester as follows:

a Place a few drops of distilled water (between 21 and 29° C) onto the measuring window, then close the

plastic cover.

b Point the tester toward any light source, look into the eyepiece and check that the indicated reading is zero. If

not, then re-calibrate the tester as detailed at the end of this Test Method, Calibrating the Tester.

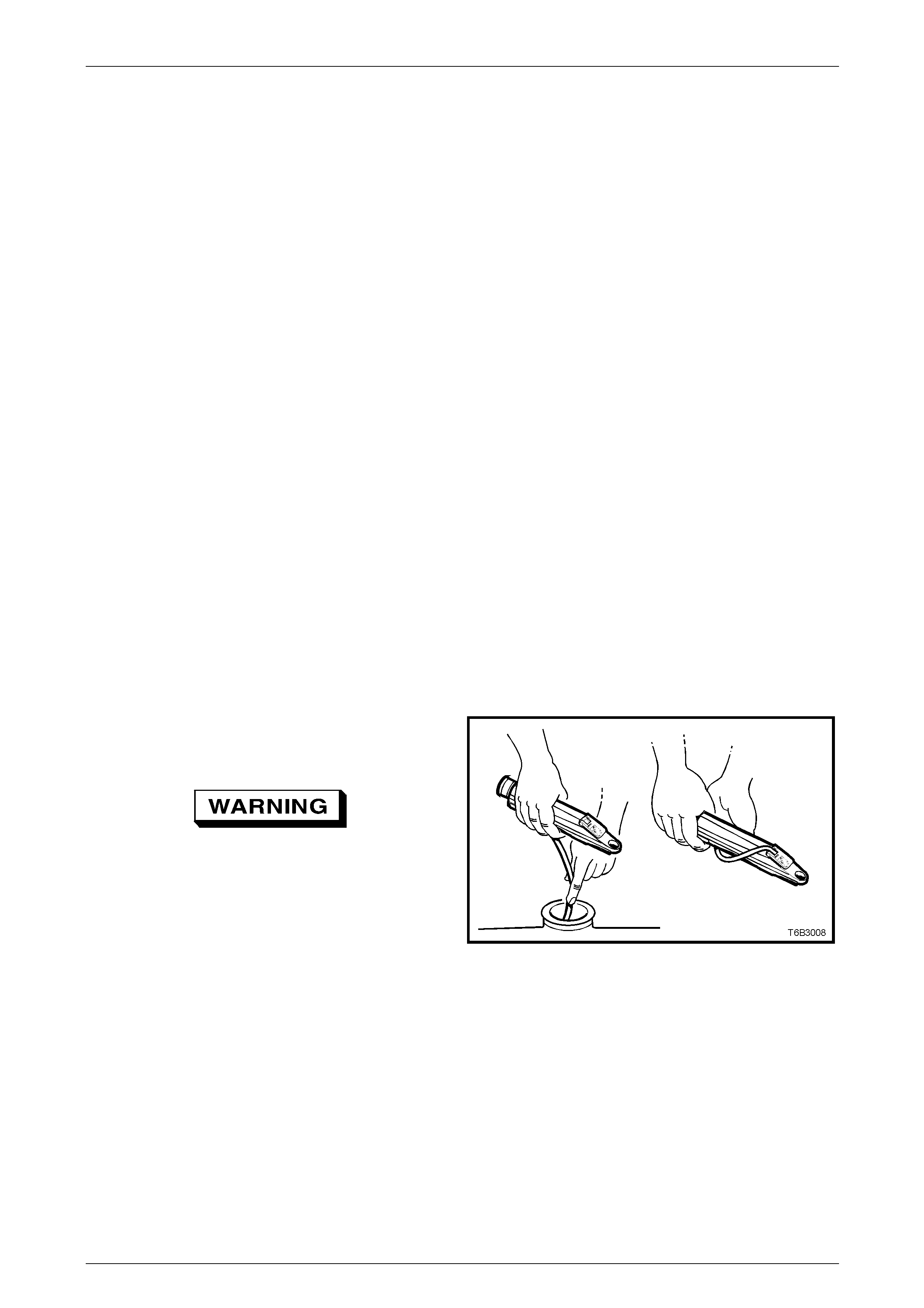

2 Release the tip of the bulb pump from under the

refractometer body. It is not necessary to remove the

complete pump from the tool.

Refer to 3.1 Service Notes in this Section,

for important safety items.

3 Carefully remove the coolant filler cap.

4 Insert the tube of the pump into the coolant, and

then press the bulb to obtain a sample.

5 Bend the tube around and insert the end into the

cover plate opening.

Figure 6B1 – 20

6 Press the pump bulb to deposit a few drops of coolant onto the measuring surface. Do not open the plas tic cover

when taking readings, as moisture evaporation will change the reading obtained.

Engine Cooling – V6 Engine Page 6B1–25

Page 6B1–25

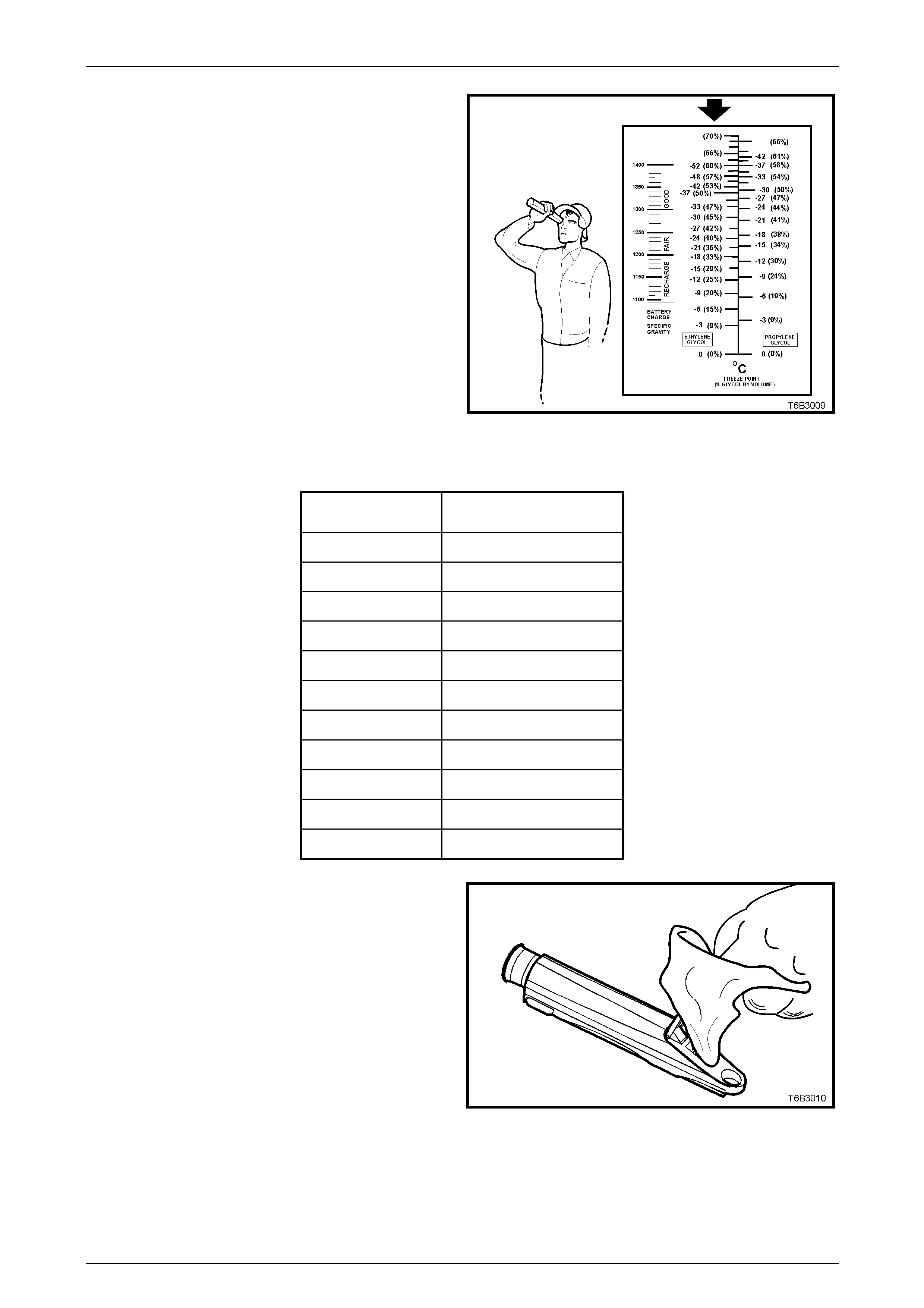

7 Point the coolant tester toward any light source,

looking into the eyepiece.

a The coolant protection read ing is at the point

where the dividing line between the light and

dark, crosses the scale.

b The scale for ethylene glycol (bold arrow) is

the reference scale for either DEX-COOL®

long-life coolant or its equivale nt, known as

Extended Life Anti-freeze Co olant conforming

to GM specification 6277M.

NOTE

The temperature scale is reversed from that of

a conventional thermometer. Below zero

readings are on the upper half of the scale.

8 A reading between – 30 and – 52° C (corresponding

to a coolant concentration between 45 to 60%), is

satisfactory for the Alloytec V6 engine cooling

system. Figure 6B1 – 21

COOLANT CONCENTRATION

Concentration

Reading % Litres Of Coolant To Be

Added

0 4.95

5 4.46

10 3.96

15 3.47

20 2.97

25 2.48

30 1.98

35 1.48

40 0.99

45 0.50

50 0

NOTE

If the reading is not clear, then properly clean

and dry the measuring surface, then conduct

another test. Also ensure that there is

sufficient fluid on the measuring prism.

9 If the reading shows that the concentration level of

the coolant is inadequate, refer to the Coolant

Concentration table to determine the amount of

coolant that needs to be added to the coolant

recovery reservoir.

10 Start and run the engine until normal operating

temperature is reached, to allow the adde d coolant

to be distributed throughout the engin e cooling

system. Figure 6B1 – 22

Engine Cooling – V6 Engine Page 6B1–26

Page 6B1–26

Calibrating the Tester

The coolant tester calibration is checked at manufacture. If however, the calibration check detailed in Step 1 of this

method shows that the instrument is not reading correctly, then conduct the following recalibration procedure:

1 Remove the sealant covering the adjustme nt screw on the underneath of the tester.

2 With a distilled water sample on the measur ing surface, carefully adjust the screw until a zero reading is obtained.

NOTE

DO NOT completely remove the screw.

3 After recalibration, reseal the screw with a small amount of silicone sealant.

Method 2 – Hydrometer

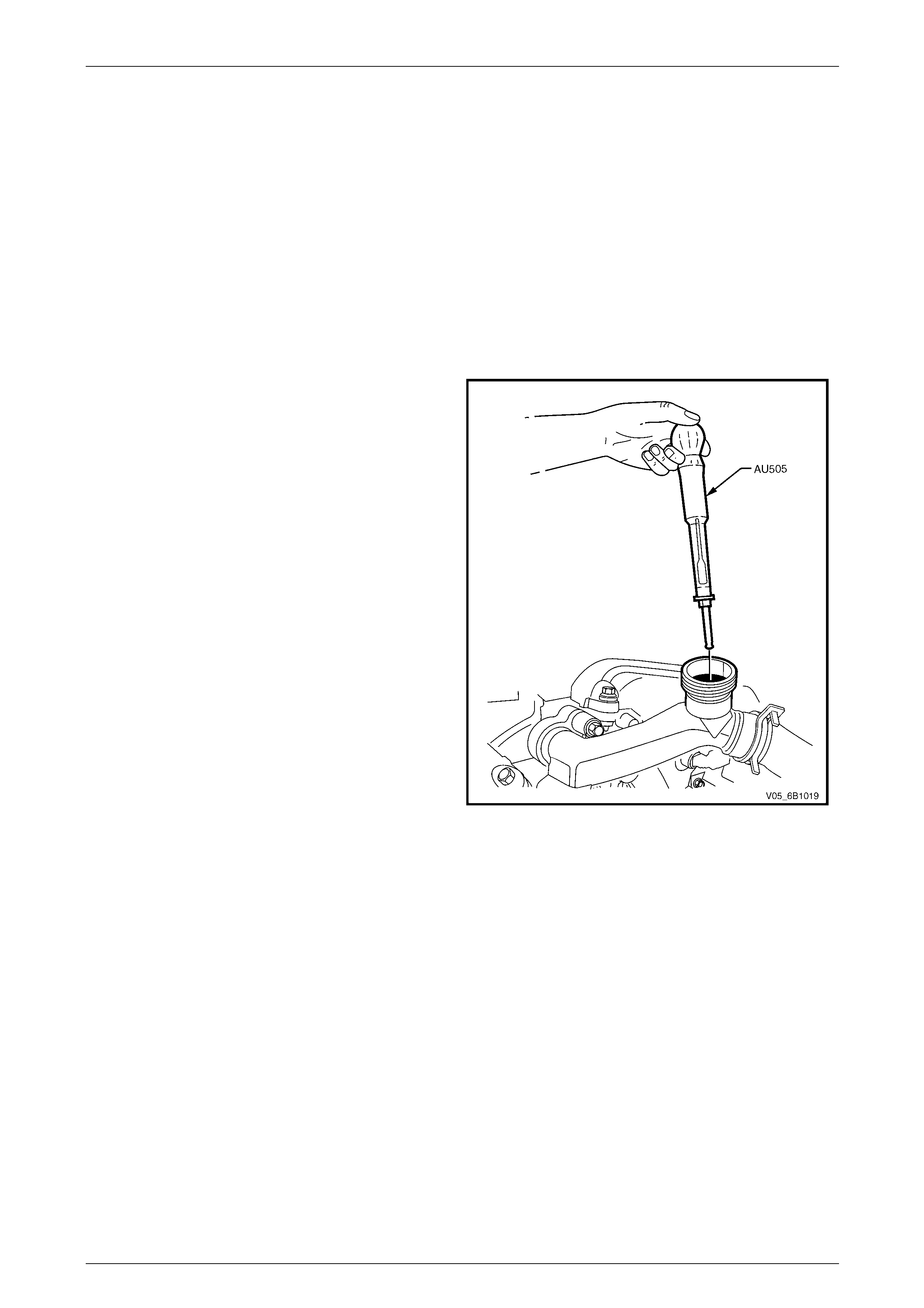

1 The cooling system should be at or close to ambient

temperature.

2 Carefully remove the coolant filler cap from the

coolant outlet housing and, while holding the rubber

bulb squeezed, insert nozzle of coolant tester

hydrometer, Tool No. AU505 into coolant. Re leasing

the rubber bulb will then draw sufficient coolant into

the tester to float hydrometer bulb freely.

3 Hold tester at eye level and read scale on

hydrometer bulb at coolant level.

The reading shows the percentage of ethylene

glycol antifreeze contained in the engine coolant.

4 The hydrometer reading should show 50% if the

coolant concentration is correct.

• If a reading of less than 50% is achieved, the

cooling system requires topping up with either

DEX-COOL® long-life coola nt or its equiva lent,

known as Extended Life Anti-freeze Coolant

conforming to GM specification 6277M.

• Refer to the Coolant Concentration table

shown for the previous method to determine

how much coolant additive of either type is

required to be added to the cooling system to

bring the coolant to the specified

concentration.

Figure 6B1 – 23

5 Drain sufficient quantity of coolant from cooling system to allow top-up with coolant additive, then add the required

amount of the correct additive. Reinstall coolant filler cap to the coolant outlet housing.

6 Start and run the engine until normal operating temperature is reache d. This will allow the added coo lant to be

distributed throughout the engine cooling system.

Engine Cooling – V6 Engine Page 6B1–27

Page 6B1–27

3.3 Draining and Filling Cooling System

Draining

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50° C), then remove the coolant filler cap (located near the

front left-hand side of the engine throttle body).

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes,

before removing the ground lead.

2 Disconnect the battery ground lead. Refer to Section 12A B attery.

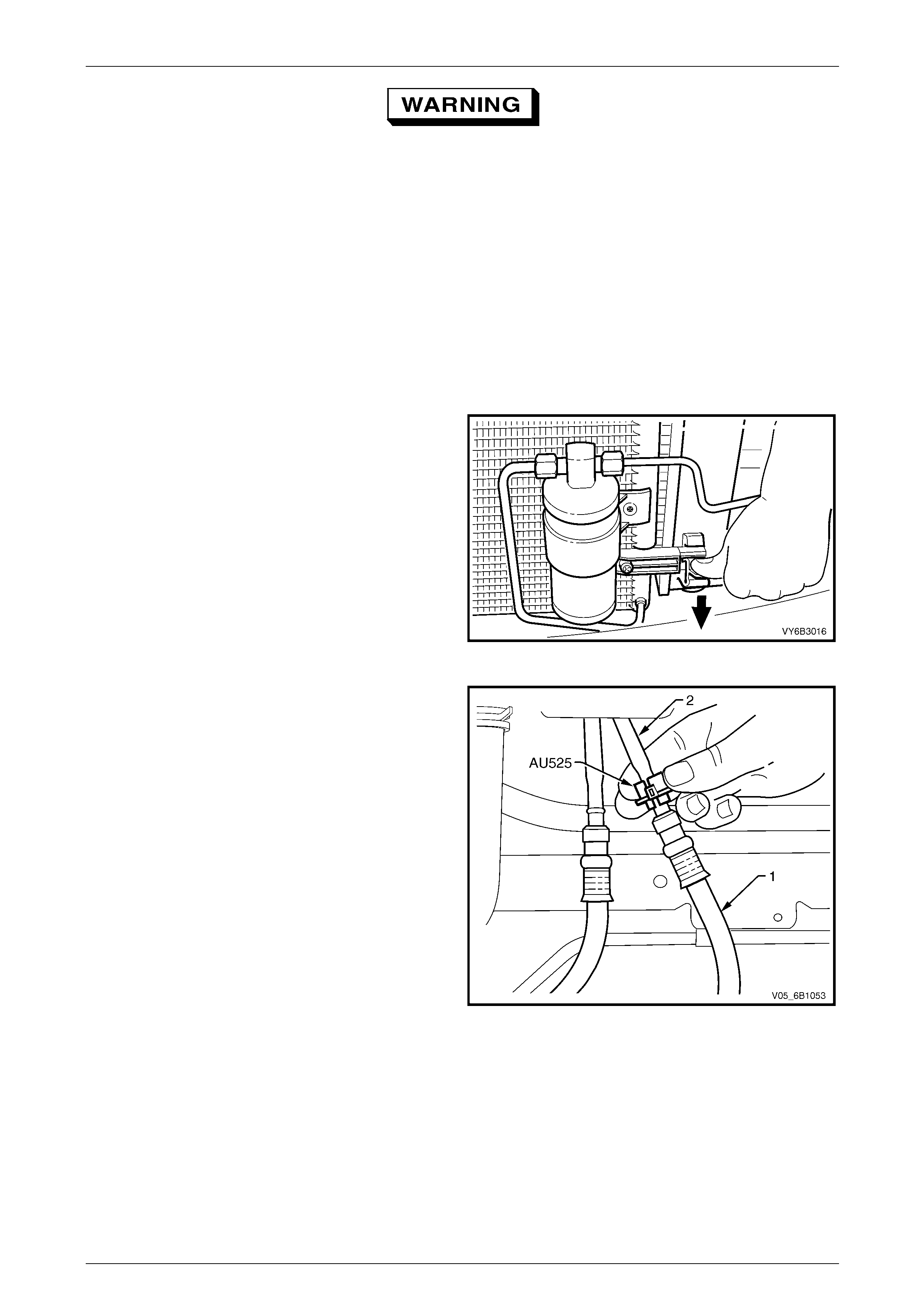

3 Drain the coolant from the system via the radiator drain tap on the lower LHS of the radiator. Attach a suitable piece

of rubber tubing to the tap outlet to help direct the flow of the coolant into a suitable container (capacity at least

12 litres).

Filling

During any service op eration that requires the cooling s ystem to be partly or completely drained, the following

instructions must be followed when refilling the cooling system, to ensure that all air is ble ed from system.

• Refer to 3.1 Service Notes in this Section,

for important safety items.

• Before opening the radiator bleed screw,

the cooling system must first be

completely depressurised with the engine

coolant filler cap removed.

Do not mix different types of anti-freeze or

corrosion inhibitors, as they may be

incompatible. Always check which coolant is

to be added to the particular vehicle being

serviced. If a different type has been used in

the cooling system (or is added accidentally),

flush the system with clean water. Refer to

3.4 Cleaning Cooling System – Cooling

System Reverse Flush in this Section.

NOTE

Ensure that the radiator drain tap located at the

bottom of left-hand side radiator tank is closed

before proceeding.

Engine Cooling – V6 Engine Page 6B1–28

Page 6B1–28

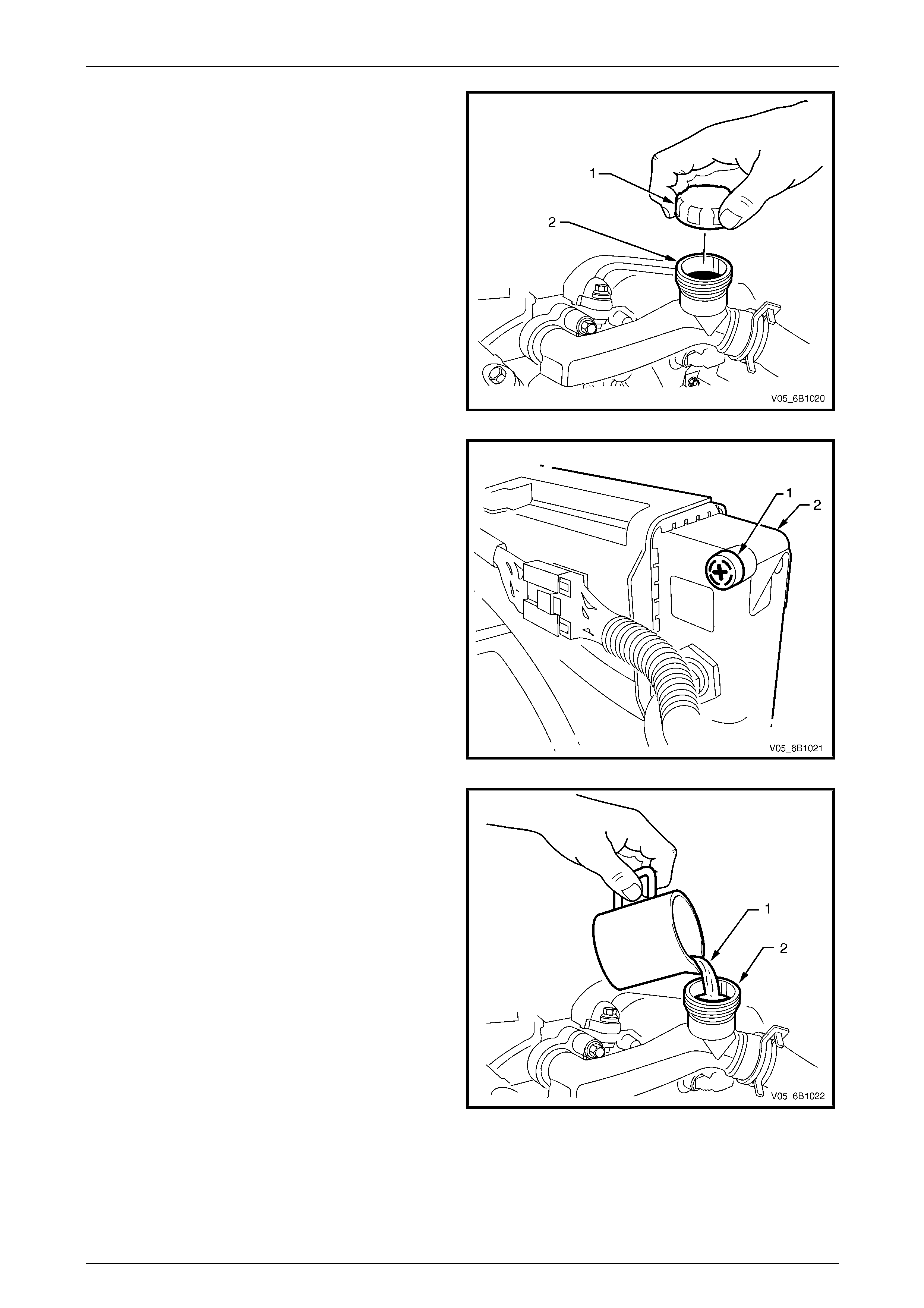

1 With the engine stopped, remove the co olant filler cap

(1) on the coolant outlet housing (2), located at the

front left-hand side of the engine.

Figure 6B1 – 24

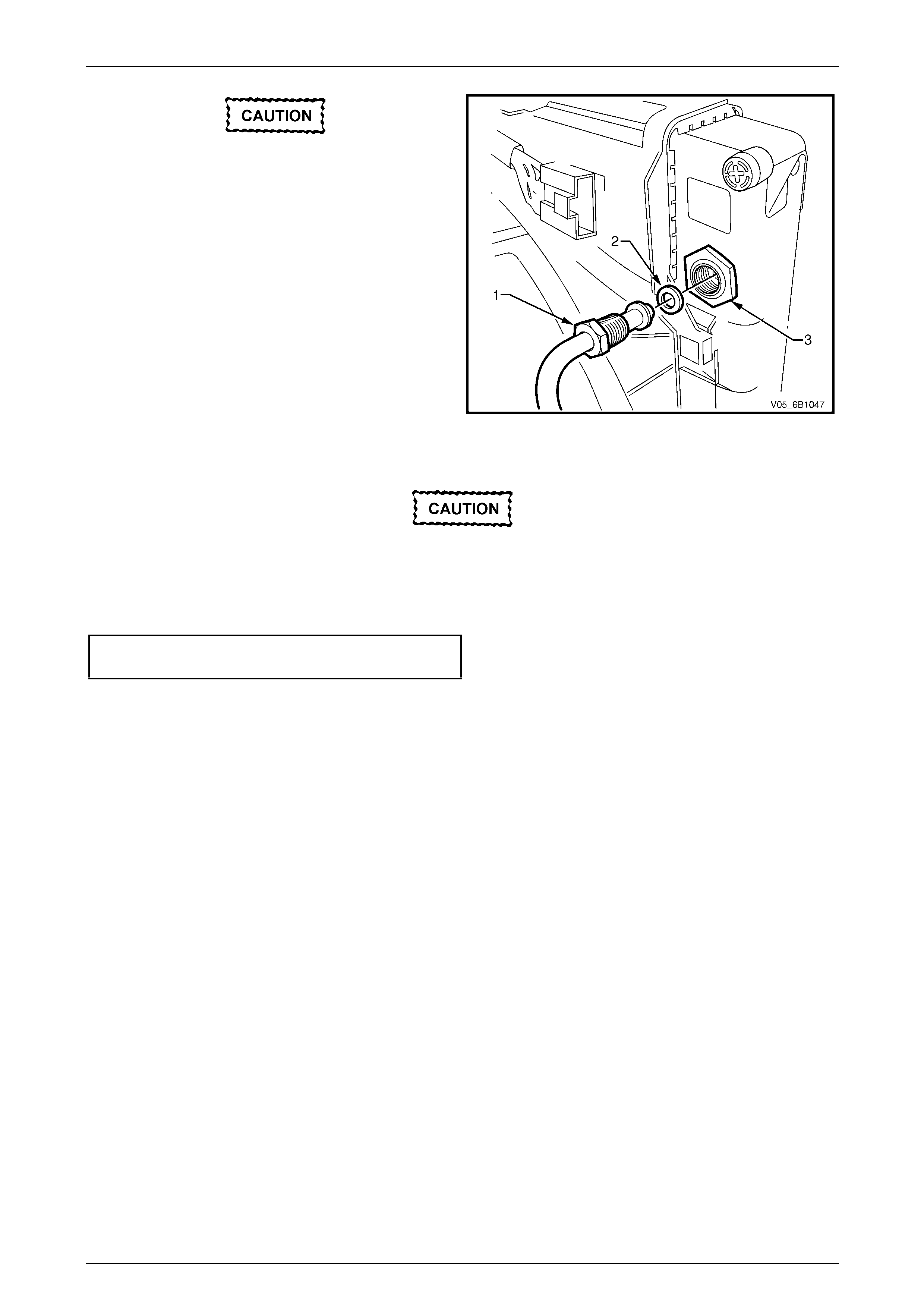

2 Use a Phillips screwdriver (+ type) to open the radiator

bleed screw (1) on the top of the right-hand side

radiator tank (2).

Figure 6B1 – 25

3 If filling a completely empty cooling system, mix

approximately 5 litres of clean water with 5 litres of the

recommended coolant.

4 Add coolant (1) via the engine coolant filler neck (2) on

the coolant outlet housing until it leaks from the

radiator bleed scre w.

5 When the coolant leaks from the bleed screw hole,

close the bleed screw and continue filling until full.

NOTE

Do not replace the coolant filler cap before

starting the engine (in step 6). Leaving the filler

cap off allows the engine to warm up without

pressurising.

6 Reconnect battery ground lead.

Refer to Section 12A Battery.

7 Start the engine and set the HVAC controls to:

• Full hot.

• Low fan.

• A/C OFF. Figure 6B1 – 26

Engine Cooling – V6 Engine Page 6B1–29

Page 6B1–29

8 Run the engine at approximatel y 2,00 0 rpm to warm up the engine.

9 Continue to run the engine until the radiator fans switch on.

10 When the radiator fans have switched on, let the engine rpm return to idle.

11 Turn the engine off when the radiator fans switch off.

12 Open the radiator bleed screw.

13 Add coolant until it leaks past the radiator bl eed screw.

14 Close the radiator bleed screw.

Do not over-tighten the radiator bleed screw

as the radiator assembly would have to be

replaced if the screw hole thread is damaged.

Radiator bleed scre w

torque specification.............................................1.5 N.m

15 Top up the coolant until full an d fit the coolant filler cap to the coolant outlet housing.

16 Top up the radiator coolant recovery reservoir to the

top mark on the dipstick.

17 Reinstall the coolant recovery reservoir cap.

NOTE

This condition only applies when the cooling

system is first being filled after draining or a

major loss of coolant. The level of coolant in the

reservoir will then drop, once the engine is

started and normal operating temperature is

reached. The coolant level should then be

maintained at the correct level (between the two

dipstick arrows ‘A’).

Figure 6B1 – 27

Engine Cooling – V6 Engine Page 6B1–30

Page 6B1–30

3.4 Cleaning Cooling System

NOTE

• Before carrying out reverse flushing

procedures, it is recommended that a

cleaning solution be use d to loosen scale and

corrosion. Only use a GM approved radiator

cleaner following the instructions on the

container label.

• This operation should only be carried out

when the engine and radiator are at ambient

temperature.

• When using specialised cooling system

flushing equipment, conn ect the equipment as

recommended by the manufacturer.

Cooling System Reverse Flush

Radiator

Refer to ‘Environmental Issues’ in 3.1 Service

Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draini ng and Filling Coolin g System – Draining in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

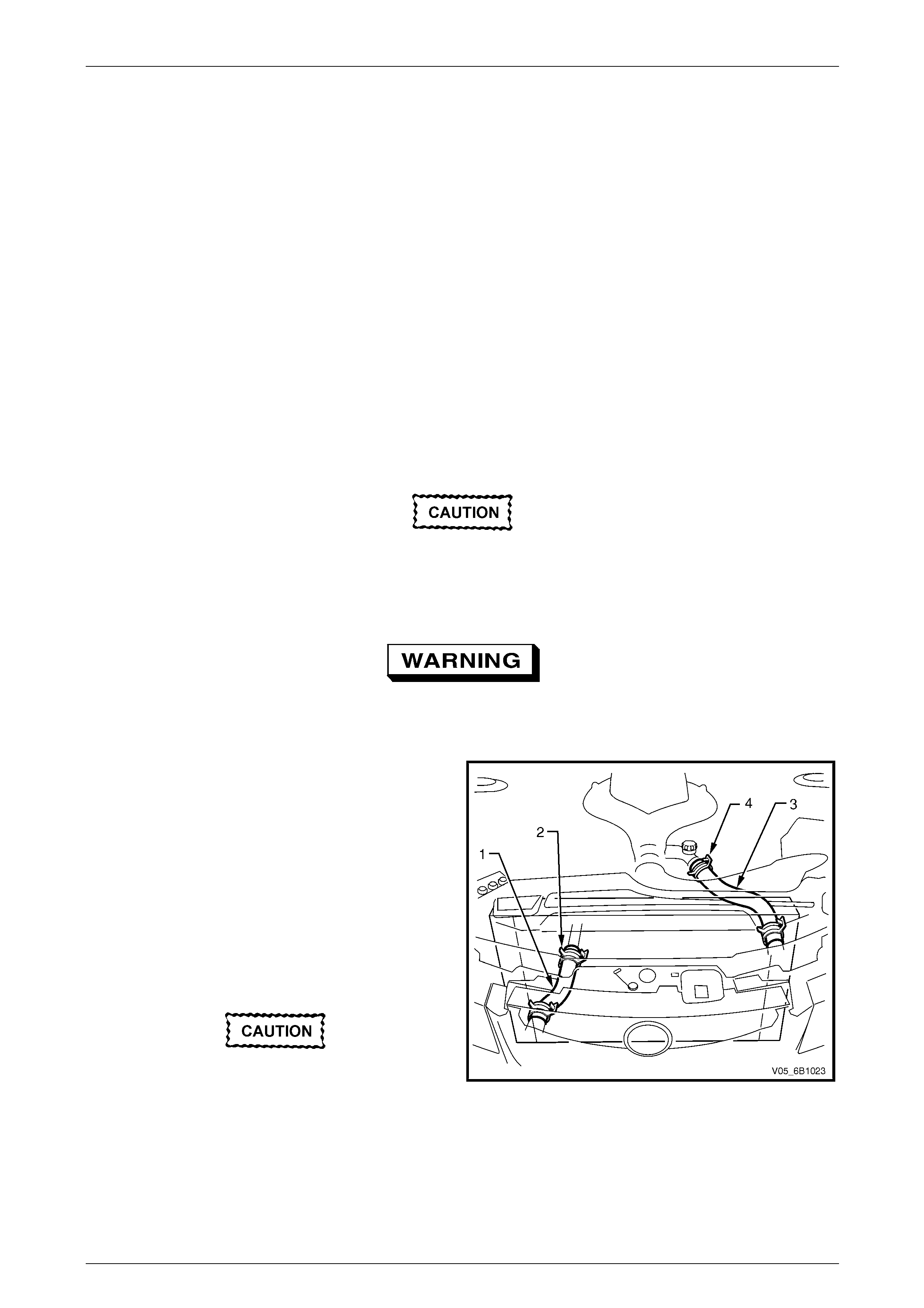

2 Remove the lower radiator outlet hose (1) at the

coolant inlet pipe connection (2).

3 Remove the upper radiator inlet hose (3) at the coo la nt

outlet housing connectio n (4).

4 Attach a lead-away hose to the open end of the upper

radiator hose.

5 Attach a suitable piece of hose or ada ptor between the

flushing gun and the open end of the lower radiator

hose.

6 Connect and operate the flus hing equipment as

recommended by the manufacturer.

Apply air pressure gradually and not in

excess of 120 kPa, otherwise radiator

damage will result. Figure 6B1 – 28

7 Continue flushing until the water from the lead-away hose runs clean and clear.

8 Reinstall all disconn ected hoses, ensuring that they are correctly positi oned and securely clamped.

9 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System – Filling in this Section.

10 Pressure test the cooling system. Refer to 3.7 Pressure Testing in this Section.

Engine Cooling – V6 Engine Page 6B1–31

Page 6B1–31

Engine

Refer to ‘Environmental Issues’ in 3.1 Service

Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draini ng and Filling Coolin g System – Draining in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove the upper and lo wer radiator hoses from the coolant outlet housing and coola nt inlet pipe connections.

Refer to Figure 6B1 – 28.

3 Remove the thermostat housing from the rear of the intake manifold. Refer to 3.8 Thermostat in this Section.

4 Remove the thermostat from the thermostat housing and reinstall the housing to the rear of the intake manifold.

Refer to 3.8 Thermostat in this Section.

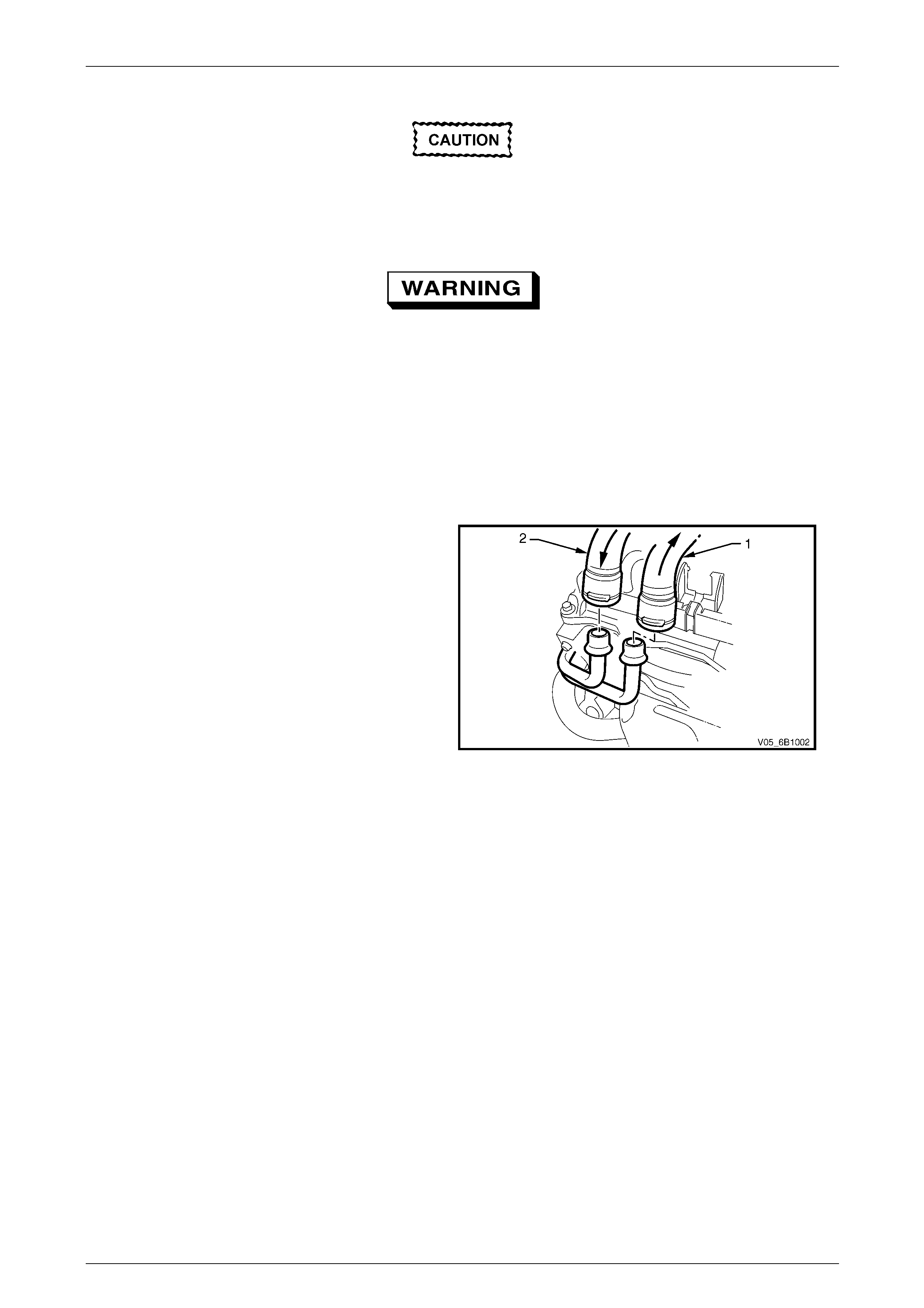

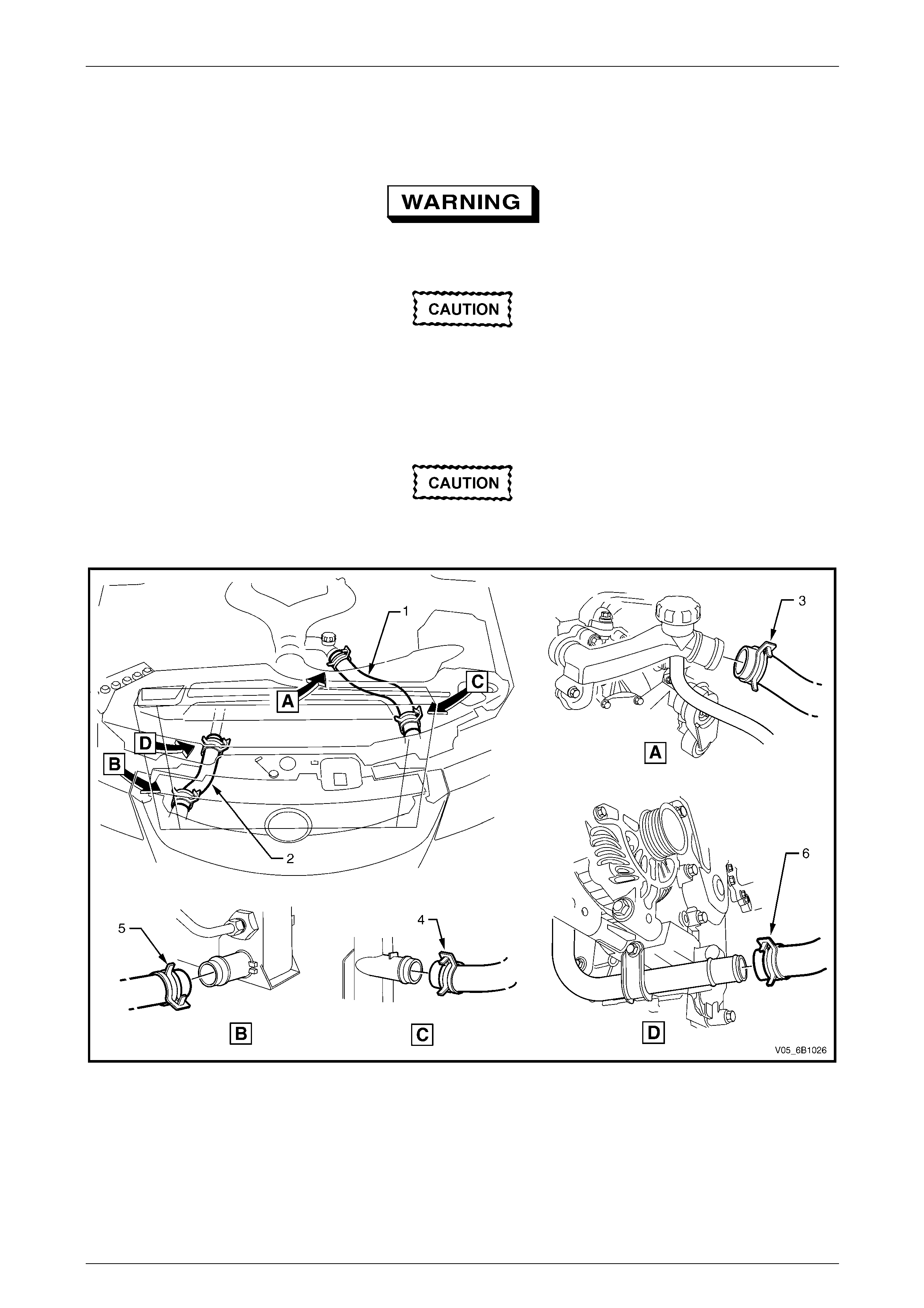

5 Remove both heater hoses (1) and (2) from their

connections at the heater pipe assembly, noting

which hose was connected to which conn ection.

Seal the heater pipe assembly connections by

using a suitable piece of tube and two hose clamps

to loop the heater inlet connection to the outl et

connection .

6 Reinstall a lead-away hose to the coolant inlet pipe

connection and a length of suitable hose between

the coolant outlet housing connection and the

flushing equipment.

7 Connect and operate the flus hing equipment as

recommended by the manufacturer.

Figure 6B1 – 29

8 Continue flushing until the water from the lead-away hose runs clear.

9 Remove the coolant recovery reservoir, flush it out with clean water and reinstall.

Refer to 3.9 Coolant Recovery Reservoir in this Section.

10 Reinstall the thermostat. Refer to 3.8 Thermostat in this Section.

11 Reinstall all disconn ected hoses, ensuring that they are correctly positioned and securely clamped.

12 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System – Filling in this Section.

13 Pressure-test the cooling system. Refer to 3.7 Pressure Testing in this Section.

Engine Cooling – V6 Engine Page 6B1–32

Page 6B1–32

Heater Hoses and Core

Refer to ‘Environmental Issues’ in 3.1 Service

Notes, before draining the coolant

1 Drain the cooling system. Refer to 3.3 Draini ng and Filling Coolin g System – Draining in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove both heater hoses (1) and (2) from their

connections at the heater pipe assembly, noting

which hose was connected to which conn ection.

3 Direct the hose (1) that was connected to the

heater pipe assembly’s front connection into a

suitable container.

4 Attach the hose (2) from the rear-most connection

to the flushing gun.

5 Turn the heater switch to ensure that the water

valve is open.

Figure 6B1 – 30

6 Connect and operate the flus hing equipment as recommended by the manufacturer.

Apply air pressure gradually and not in

excess of 120 kPa, otherwise heater core

damage will result.

7 Reinstall all disconn ected hoses, ensuring that they are correctly positi oned and securely clamped.

NOTE

For heater hose routing, refer to Figure 6B1 – 34.

8 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System, Filling in this Section.

9 Pressure test the cooling system. Refer to 3.7 Pressure Testing in this Section.

Engine Cooling – V6 Engine Page 6B1–33

Page 6B1–33

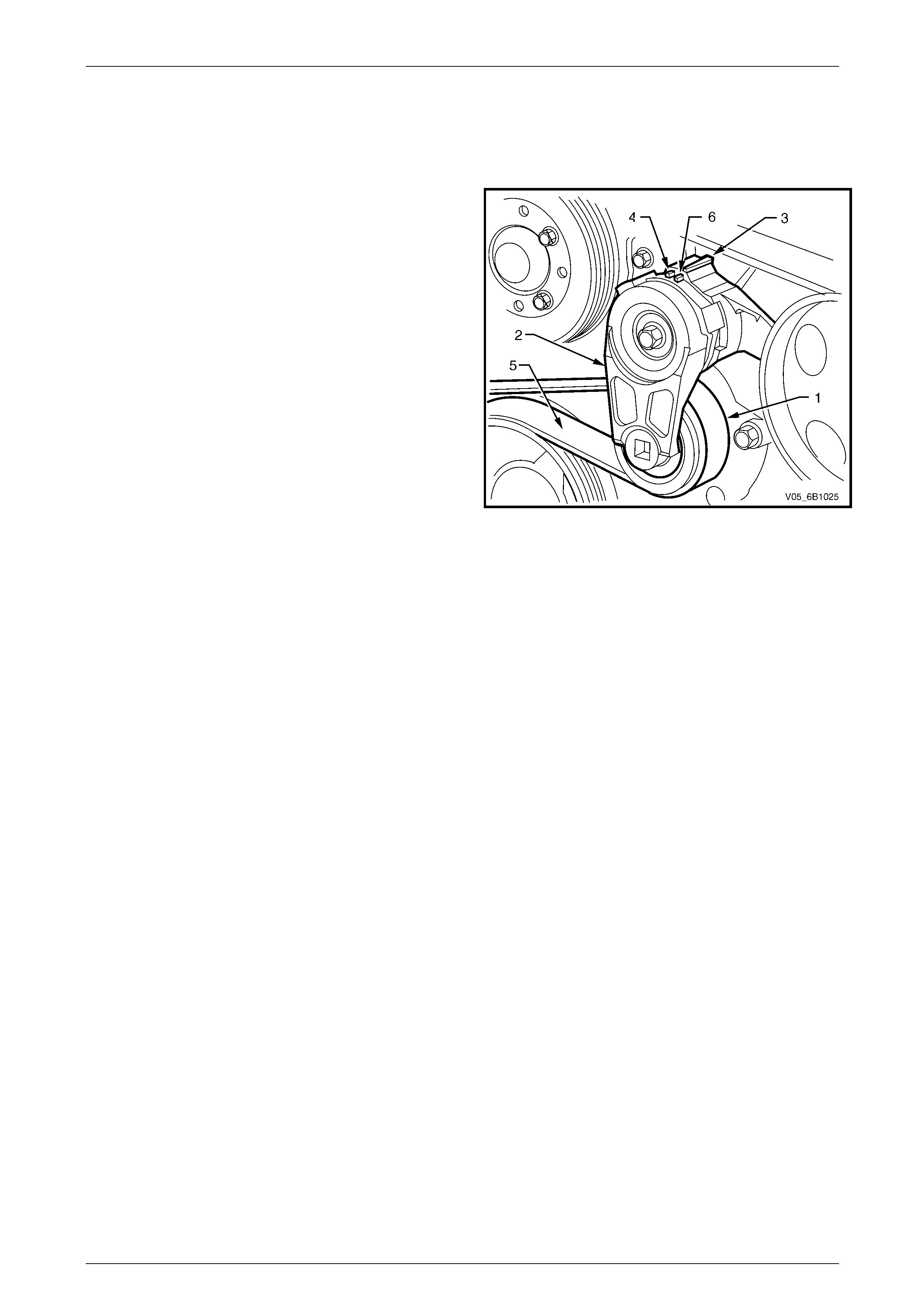

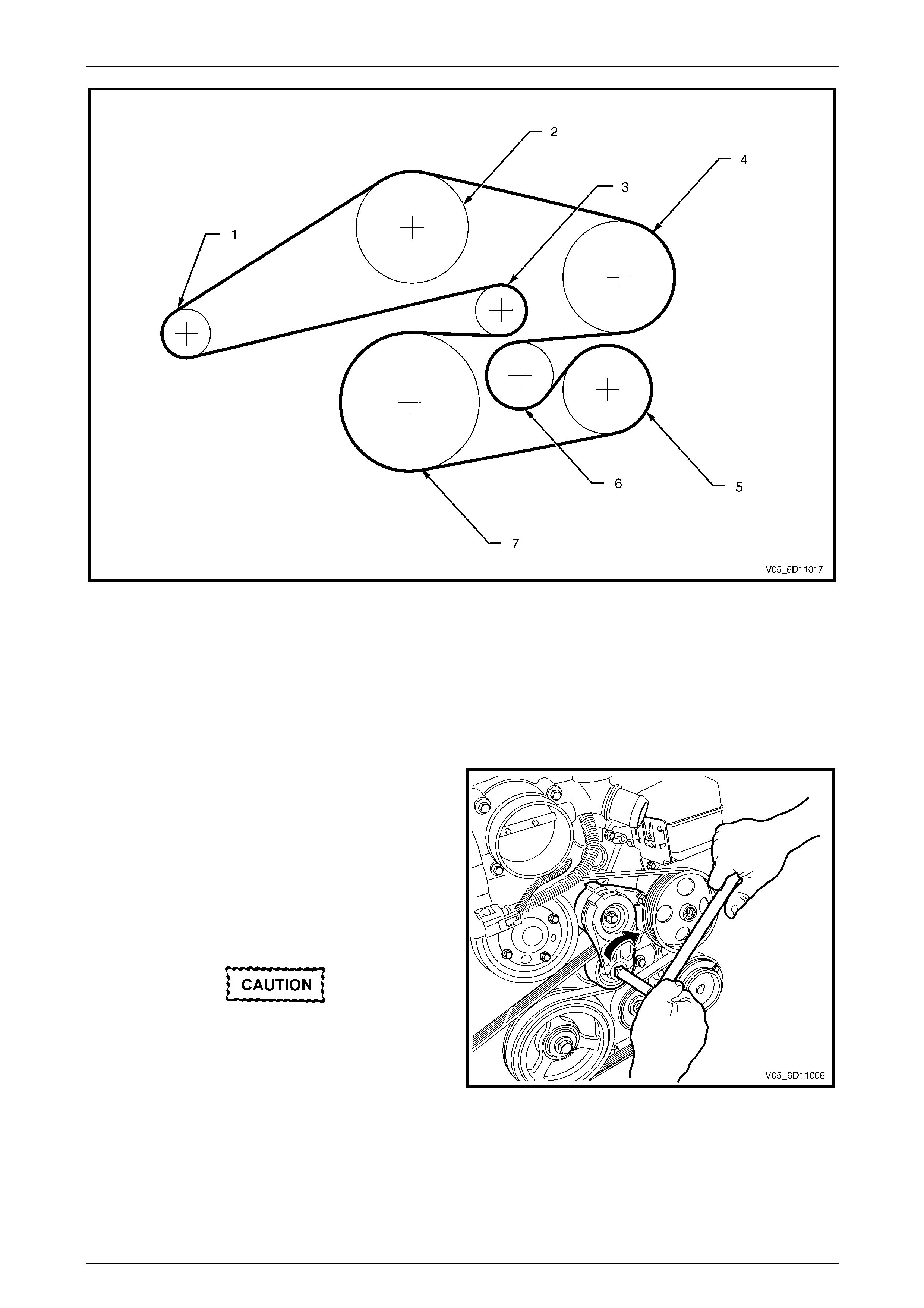

3.5 Drive Belt Tension

An automatic tensioner asse mbly provides drive belt tension. The tensioner is an i dler pulley mounted on a spring-loaded

arm that maintains the drive belt at the prope r tension, without imposing undue loads on the various components.

Throughout its functional travel, the tensio ner mechanism

will maintain correct belt tension, using a pulley (1) mounted

to a spring-loaded arm (2), which compensates for increases

in belt wear and stretch.

When the indicator pointer (3) on the tensioner has reached

minimum tension range (4), the tensioner has reach ed the

full extent of its travel and replacement of the belt (5) is

necessary.

The maximum tension ran ge is shown as (6).

Drive belt tension can be checked usi ng Tool No. BT3373-F.

Refer to Section 6A1 Engine Mechanical – V6.

Figure 6B1 – 31

Inspect

The four views in Figure 6B1 – 32 show the various stages of drive belt wear, to assist in belt replacement decisions.

NOTE

Condition of the belt ribs can be better assessed

if the belt is wrapped over the coolant pump drive

pulley.

Engine Cooling – V6 Engine Page 6B1–34

Page 6B1–34

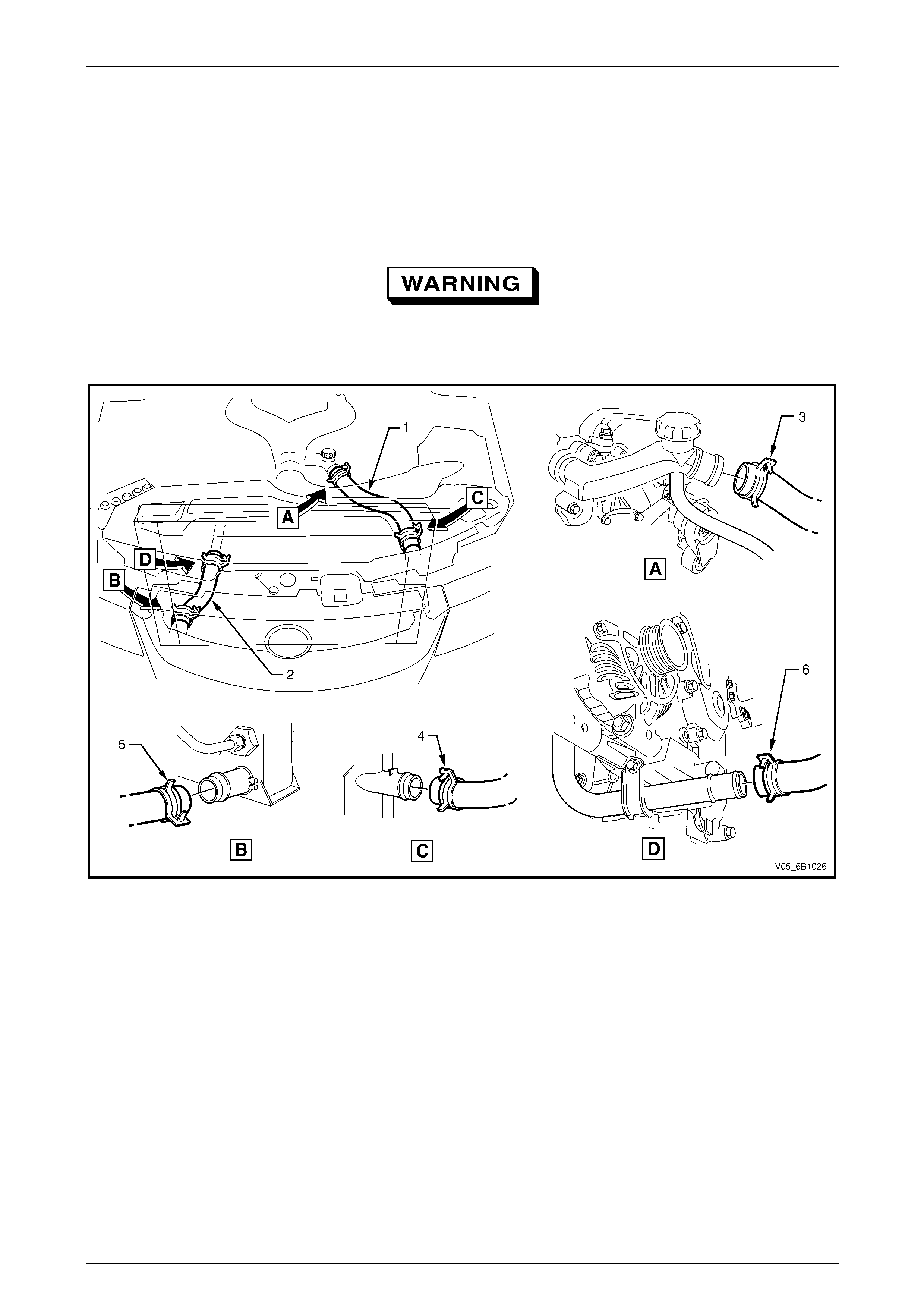

3.6 Coolant Hoses

Coolant hoses are to be installed as shown in the following ill ustrations.

Hose connections should be thoroughly cleaned before installing any new hose.

After all hoses are installed, always refill the cooling system with correct concentration of cool ant, refer to

3.3 Draining and Filling Co oling System and pressure test cooling system, refer to 3.7 Pressure Testing in this Section.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

Figure 6B1 – 32 – Eng ine Coolant Ho ses

Legend

1 Radiator Hose – Upper

2 Radiator Hose – Lower

3 Hose Clamp – Upper Hose to Engine Outlet Housing

4 Hose Clamp – Upper Hose to Radiator Inlet

5 Hose Clamp – Lower Hose to Radiator Outlet

6 Hose Clamp – Lower Hose to Engine Coolant Inlet Pipe

Engine Cooling – V6 Engine Page 6B1–35

Page 6B1–35

Figure 6B1 – 33 – Heater Hose Layout

Legend

1 Heater Hose from Cabin

2 Water Valve Actuator

3 Heater Hose Connectors (2 places)

4 Vacuum Hose to Water Valve Actuator

5 Heater Hose to Water Valve

6 Water Valve

7 Heater Hose to Cabin

8 Vacuum Check Valve

9 Vacuum Hose to HVAC Vacuum Tank

10 Vacuum Hose to Check Valve

11 Vacuum Hose to Inlet Manifold

12 Inlet Manifold Connection

13 Hose Clamps Water Valve (2 places)

14 Heater Pipes

15 Hose Clamps HVAC Unit (2 places)

16 Vacuum Hose to Water Valve Vacuum Switch

Engine Cooling – V6 Engine Page 6B1–36

Page 6B1–36

3.7 Pressure Testing

Coolant Filler Cap Pressure Testing

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50° C), then remove coolant filler cap.

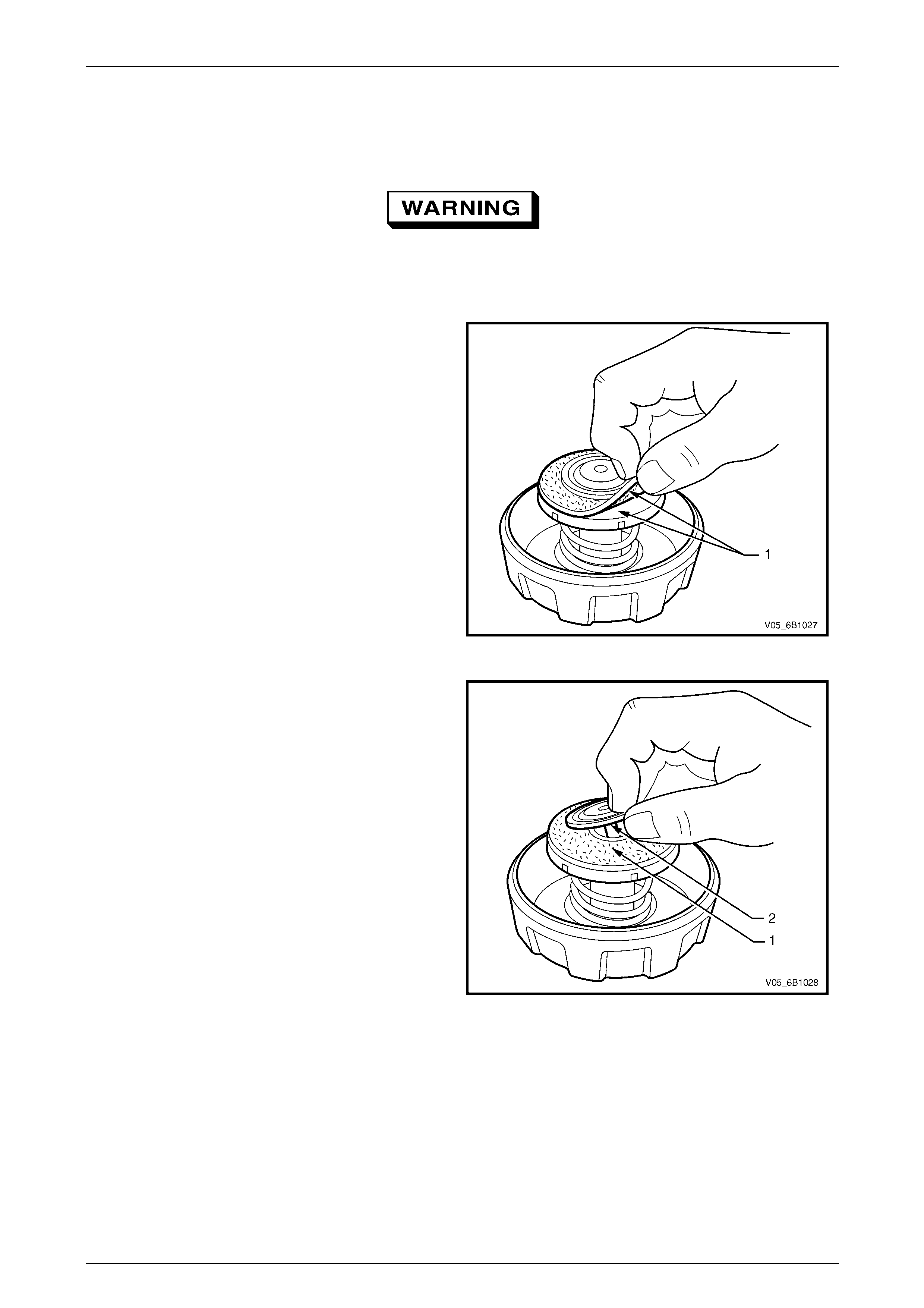

2 Inspect and clean both sides (1) of coolant filler cap

gasket with a wet cloth.

NOTE

Use only water to wet the cleaning cloth.

Figure 6B1 – 34

3 Lift centre vacuum valve. Clean and inspect the

gasket (1) and sealing surface of the under

valve (2).

Figure 6B1 – 35

Engine Cooling – V6 Engine Page 6B1–37

Page 6B1–37

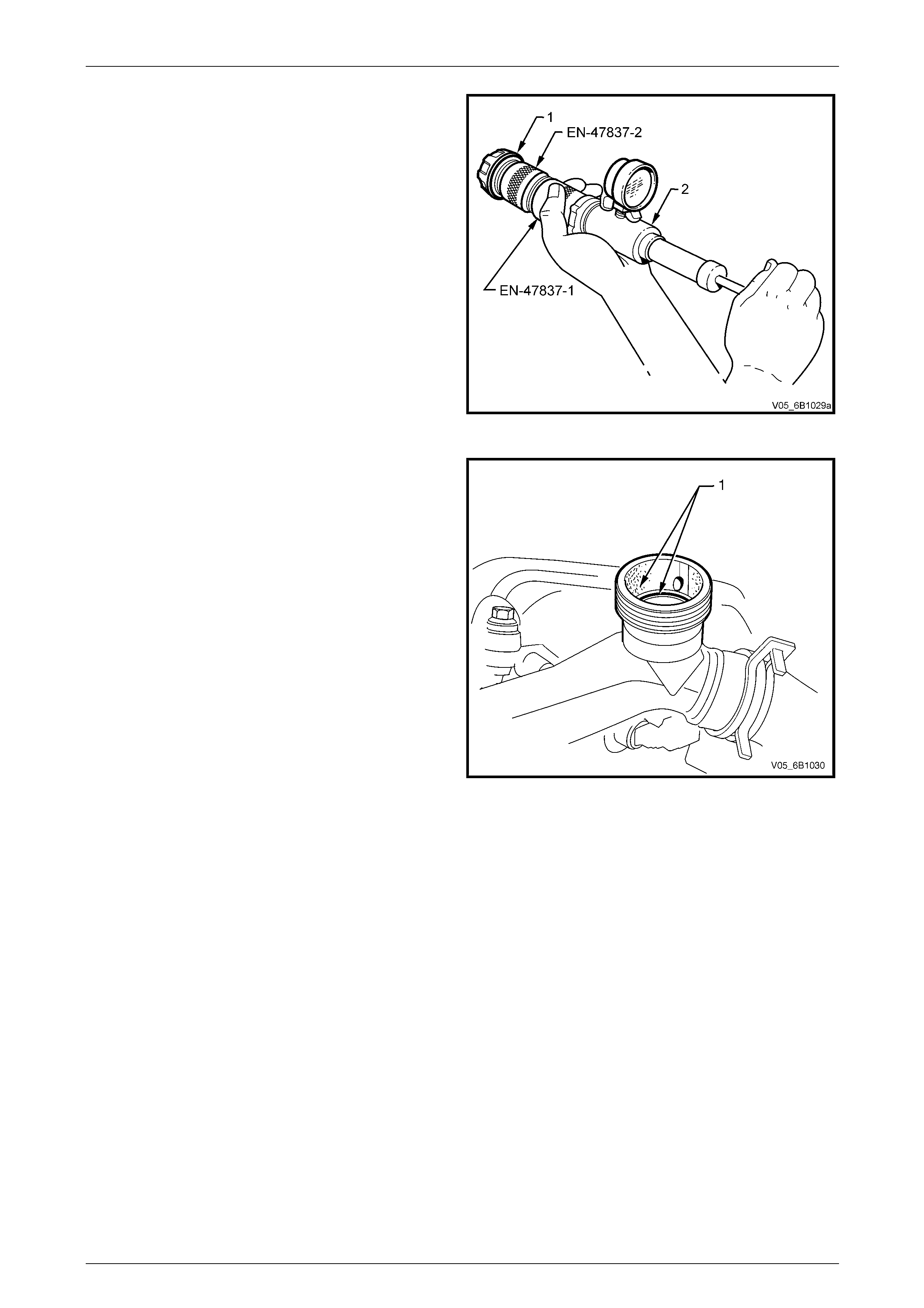

4 Attach coolant filler cap (1) to a commercially available

cooling system pressure tester (2), using the pressure

cap adaptor, Tool No. EN-47837-2, and the pressure

tester adaptor, Tool No. EN-47837-1.

5 Slowly pressurise cap to 120 – 130 kPa. The cap is

serviceable if it unloads slightl y above this pressure

range and holds pressure at 120 kPa.

NOTE

Should the cap fail to reach or hol d the specified

pressure, replace the cap.

Figure 6B1 – 36

6 Prior to installing coolant filler cap ensure that the

coolant filler neck cap seating surface (1) is clean and

free from obstruction.

Figure 6B1 – 37

Engine Cooling – V6 Engine Page 6B1–38

Page 6B1–38

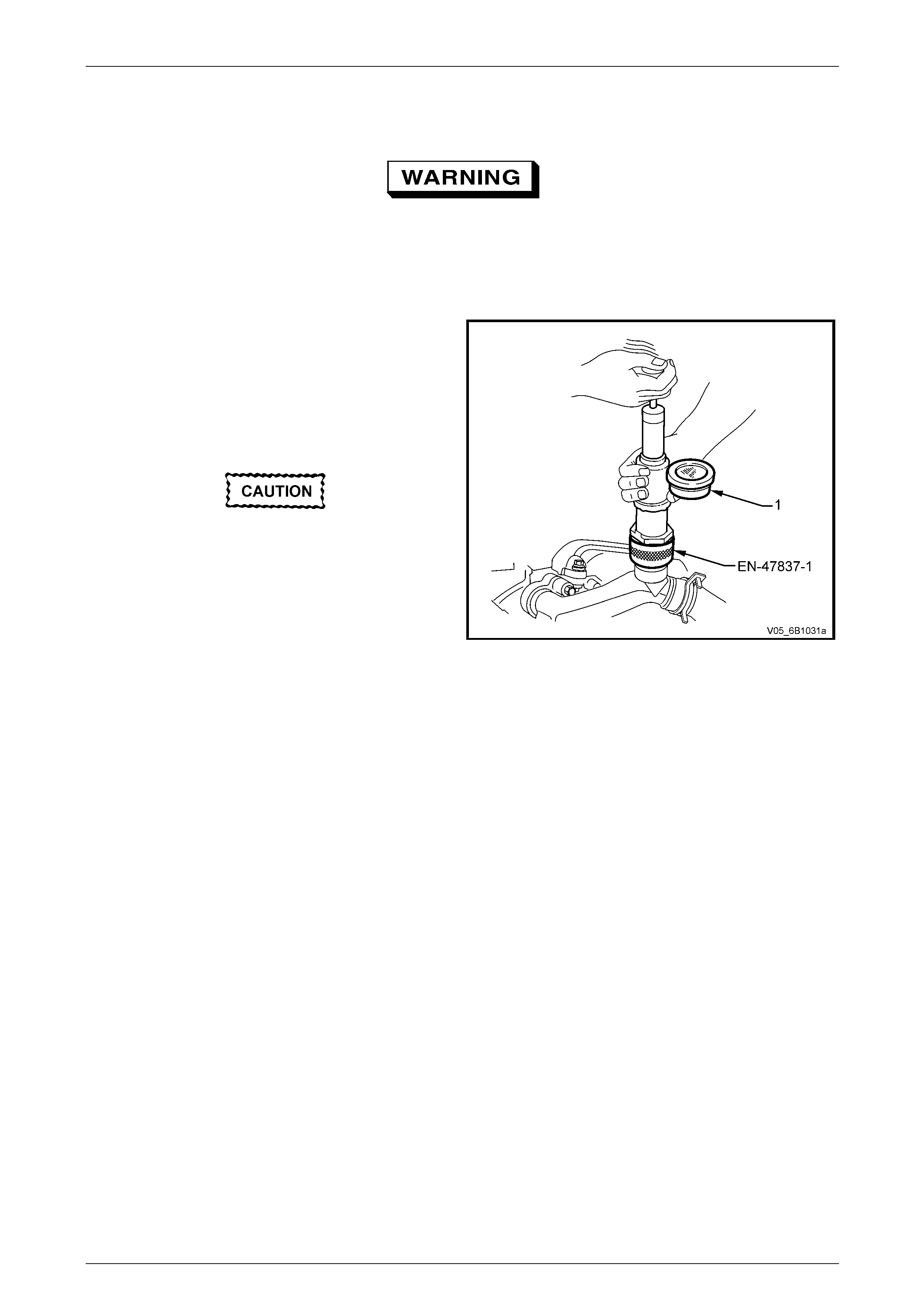

Cooling System Pressure Testing

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow the engine to cool to ambient temperature (less than 50° C), then remove coolant filler cap.

2 Ensure that the coolant level is correct.

3 Reinstall the coolant filler n eck adaptor, Tool No. EN-

47837-1 to a commercially available coolin g system

pressure tester (1),.

4 Reinstall the assembly to the eng ine coolant filler

neck.

5 Using compressed air, blow dry any spilled coolant

around coolant filler neck.

Do not exceed the stated pressure, as

damage to the cooling system could

otherwise result.

6 Using the cooling system pressure tester pump,

pressurise cooling system to 130 kPa maximum and

check for leaks at the following points:

• All hoses and hose connectio ns.

• Overflow hose connection at coolant outlet

housing connection.

Figure 6B1 – 38

• Radiator seams and core.

• Corroded or faulty engine welch plugs.

• Coolant pump and gasket.

• Thermostat housing and coolant inlet pipe connection.

• Radiator drain tap and bleed screw.

• Vehicle heating system (e.g. heater cor e an d water valve).

7 Check engine oil dipstick for evid ence of engine oil contamination with coolant.

8 If pressure will not hold, there is a leak in the cooling s ystem . Repair as necessary.

NOTE

If visible loss of coolant is not evident

from pressure testing, then the use of a dye

and black light, may be necessary. Refer to

4.7 Black Light and Dye Leak Diagnosis Method,

in this Section.

Engine Cooling – V6 Engine Page 6B1–39

Page 6B1–39

3.8 Thermostat

Remove

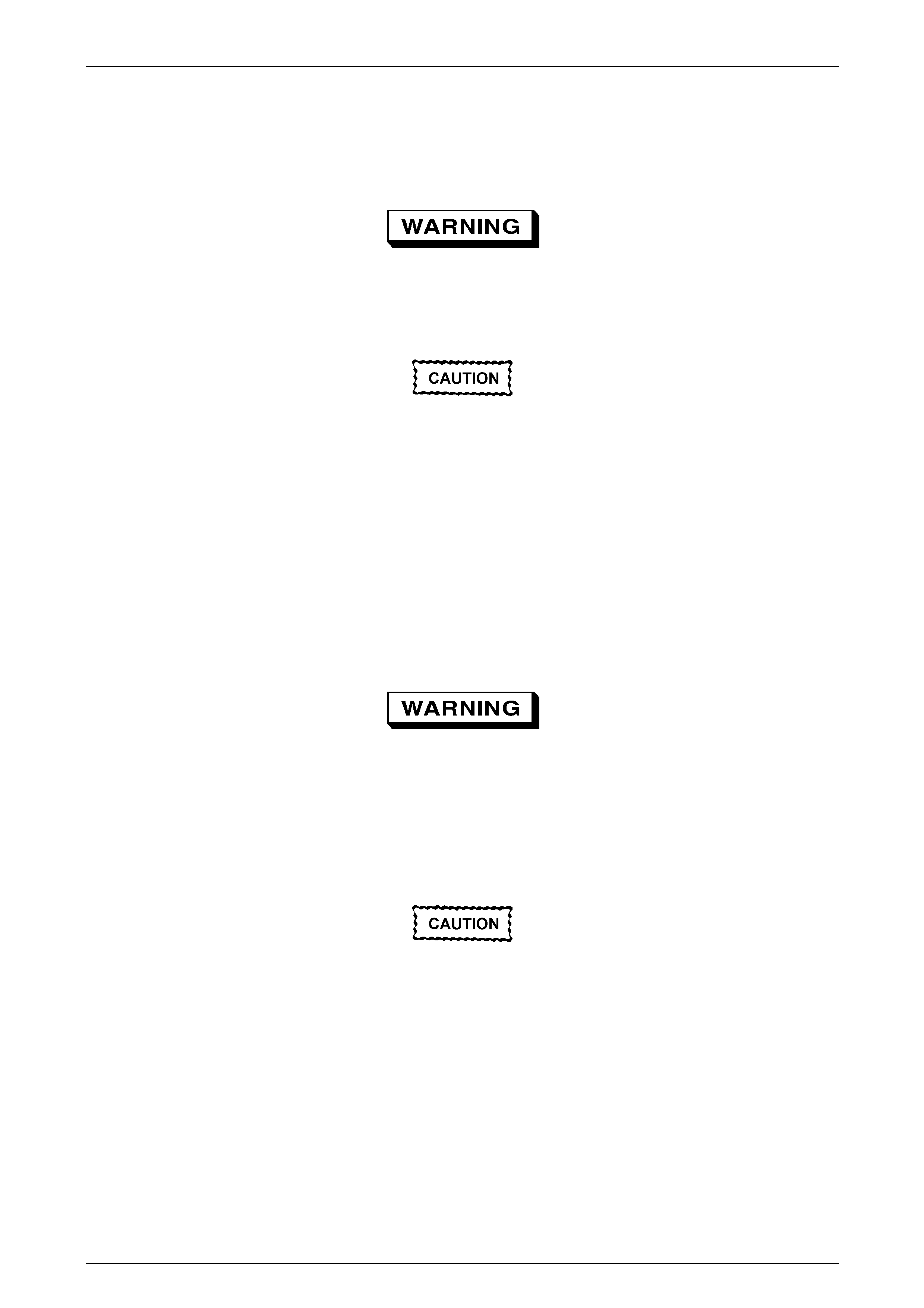

Do not remove coolant filler cap while the

engine coo lant temperature is ab ove 50° C, as

personal injury may result.

1 Allow engine to cool to ambient temperature (less than 50° C), then remove the coolant filler cap (located at the

front left-hand side of the engine).

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes,

before removing the ground lead.

2 Disconnect the battery ground lead. Refer to Section 12A B attery.

3 Remove the engine dress covers. Refer to Section 6A1 Eng ine Mechanical – V6.

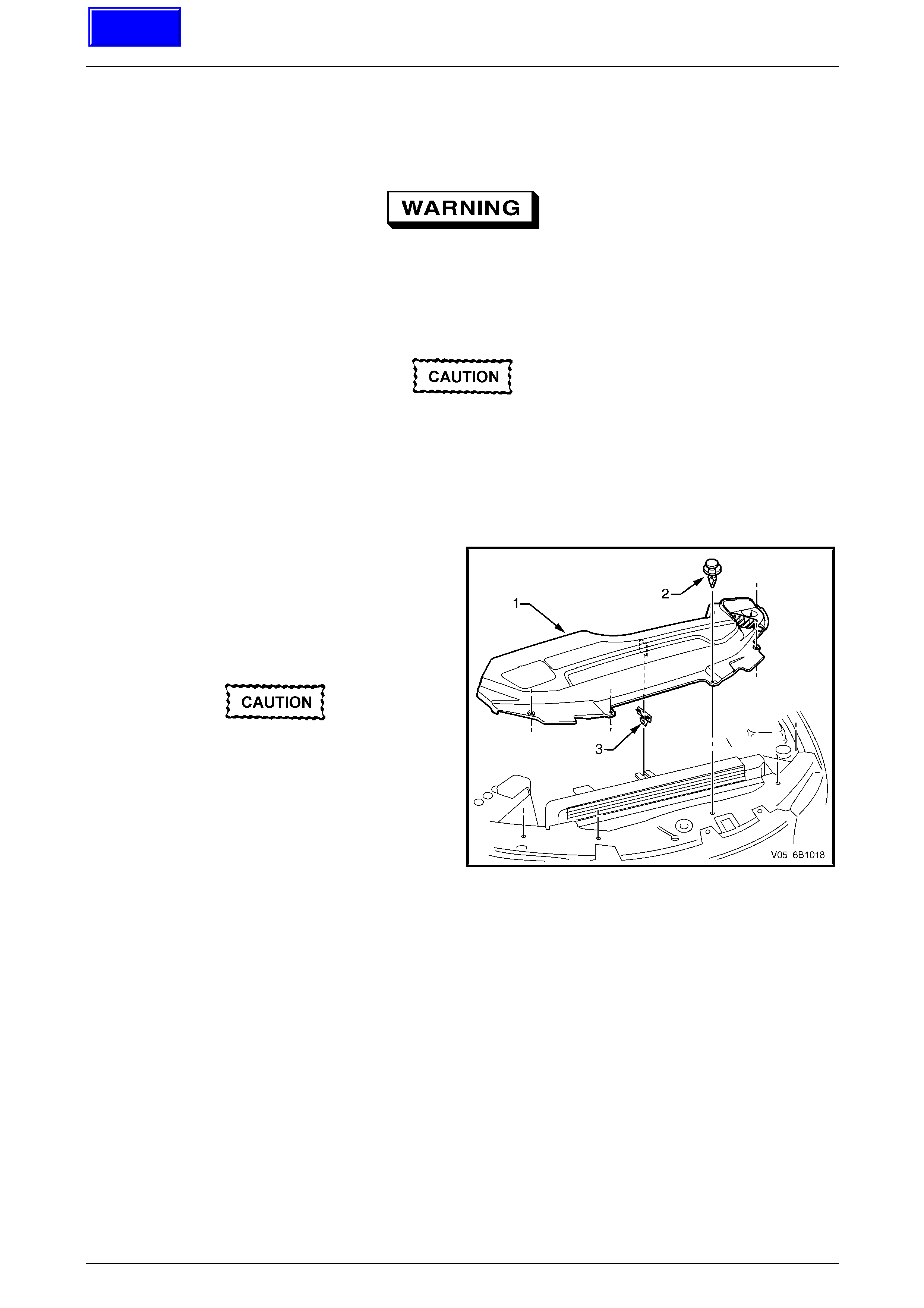

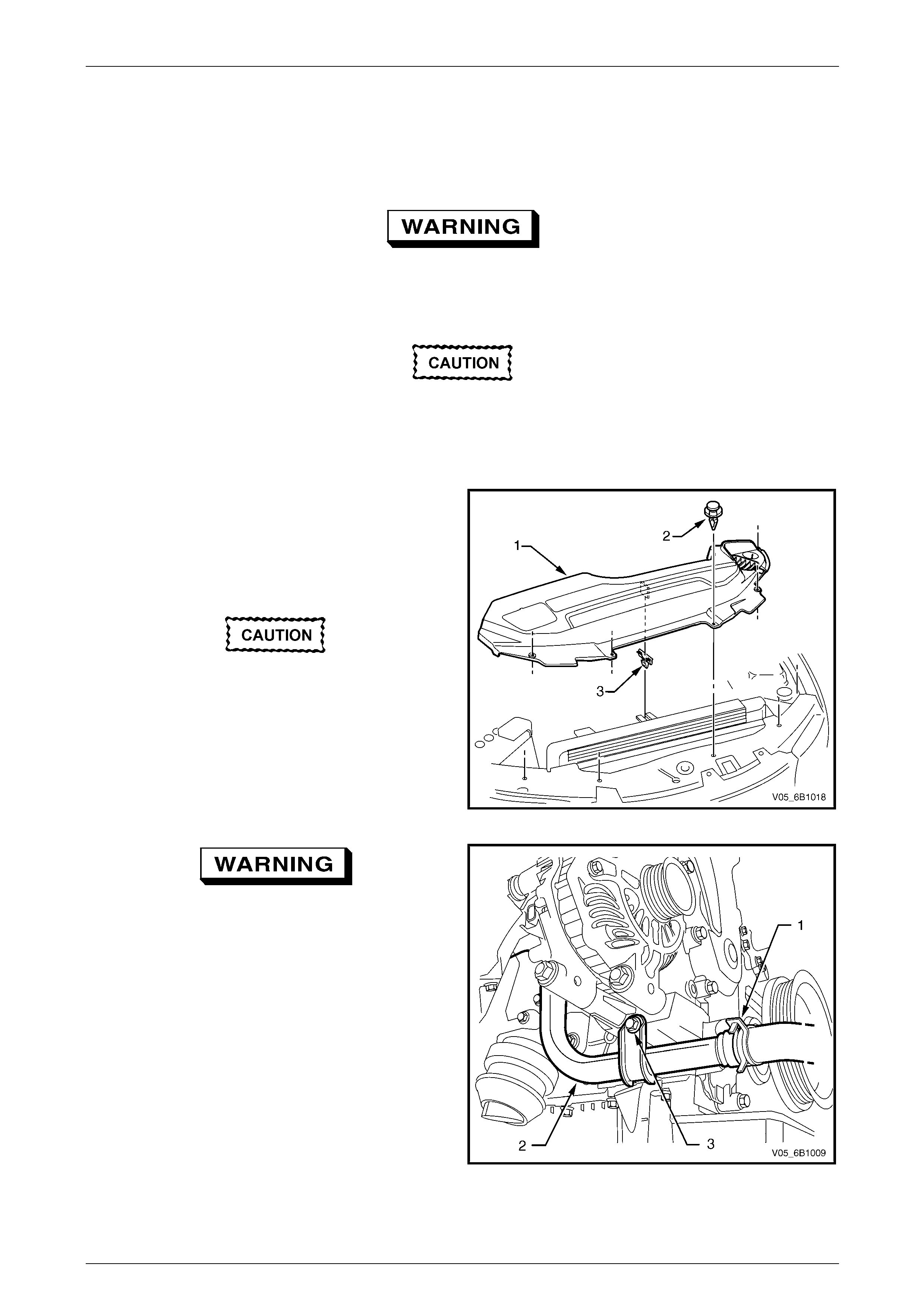

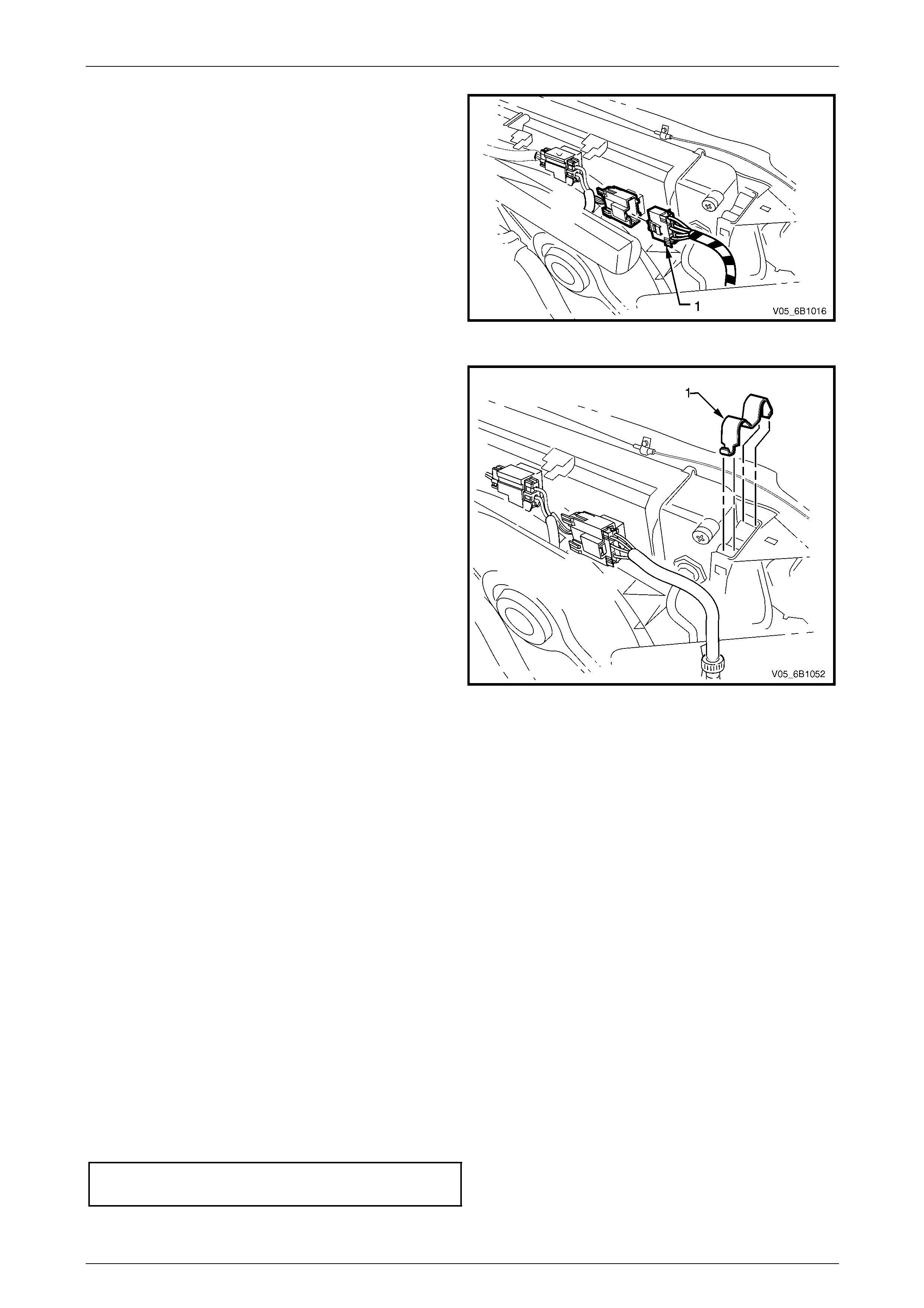

4 Remove the upper radiator shroud (1) as fol lows:

a Using a fine, flat-blade screwdriver to prise the

centre pin of the scrivet (2) upward, then remove

the scrivet, in five places.

b Lift up the radiator shroud to disengage the

retaining clip (3), then remove the shroud.

Refer to ‘Environmental Issues’ in 3.1 Service

Notes, before draining the coolant.

5 Drain the coolant from the system. Refer to

3.3 Draining and Filling Co oling System in this

Section.

6 Remove the complete intake manifold assembly.

Refer to Section 6A1 Engine Mechanical – V6.

7 Plug each of the exposed intake ports with lint free

cloth to prevent the entry of foreign matter.

8 Remove the coolant inlet pipe.

Refer to 3.13 Coolant Inlet Pipe in this Section.

Figure 6B1 – 39

Techline

Engine Cooling – V6 Engine Page 6B1–40

Page 6B1–40

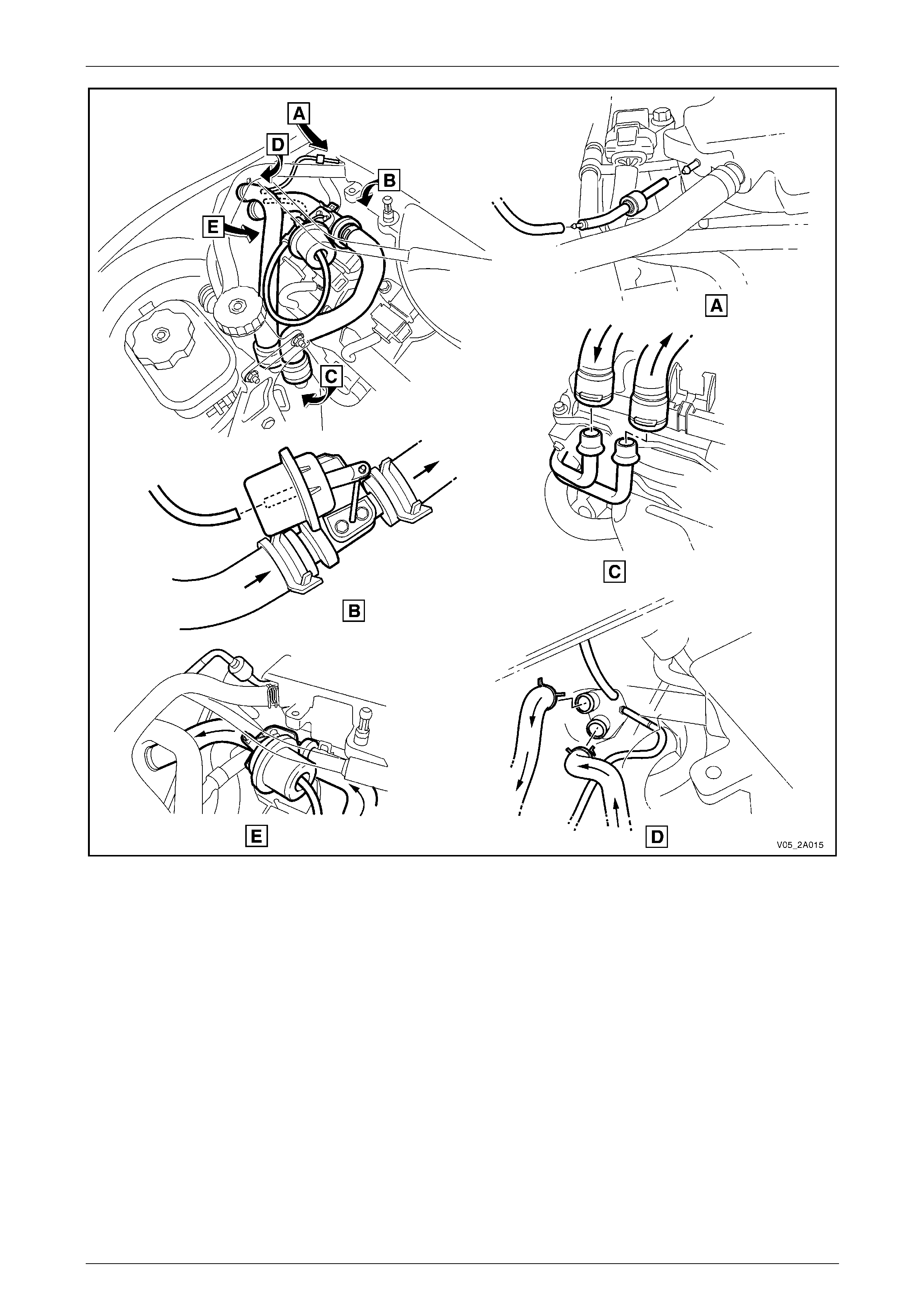

Always wear protective safety glasses when

working with spring type hose clamps.

Failure to do so could result in eye injury.

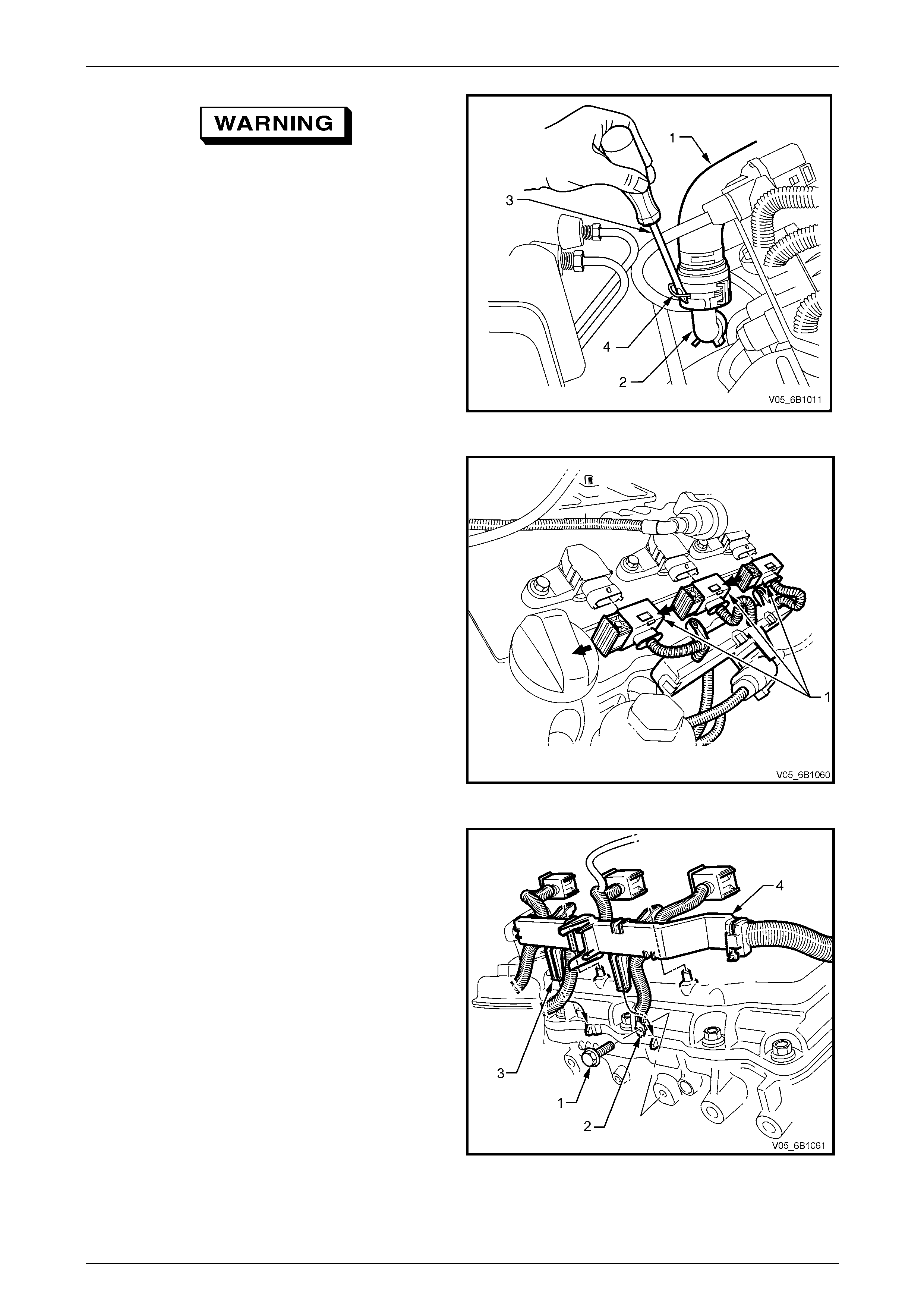

9 Use a straight-blade screwdriver (3) to releas e the

heater hose quick connect clips (4).

10 Disconnect the heater hoses (1) from the hea ter pipes

(2) in two places.

Figure 6B1 – 40

11 To gain easier access to the heater pipe flange and

thermostat housing bolts, disconnect the engine

harness and lay back on the right side of the engine

bay. Apart from those harness connectors removed

during the intake manifold removal, this involves the

removal of wiring harness connectors and fasteners,

from the following:

a Pull out the release bar on each of the ignition

coil packs (1) on cylinders 2, 4 and 6, before

disconnecting each connector.

b The coolant temperature sen sor.

c The left side Pre-O2 sensor connector, 2, 4 & 6.

NOTE

Refer to Section 12O Fuses and Wiring

Harnesses for the location of harness

connectors, not shown.

Figure 6B1 – 41

12 Remove the bolt (1) securing the engine harness

ground terminal (2), to the cylinder block.

13 Prise both locking legs of the left side engin e harn ess

former (4) free, then lift up on the harness former to

release.

Figure 6B1 – 42

Engine Cooling – V6 Engine Page 6B1–41

Page 6B1–41

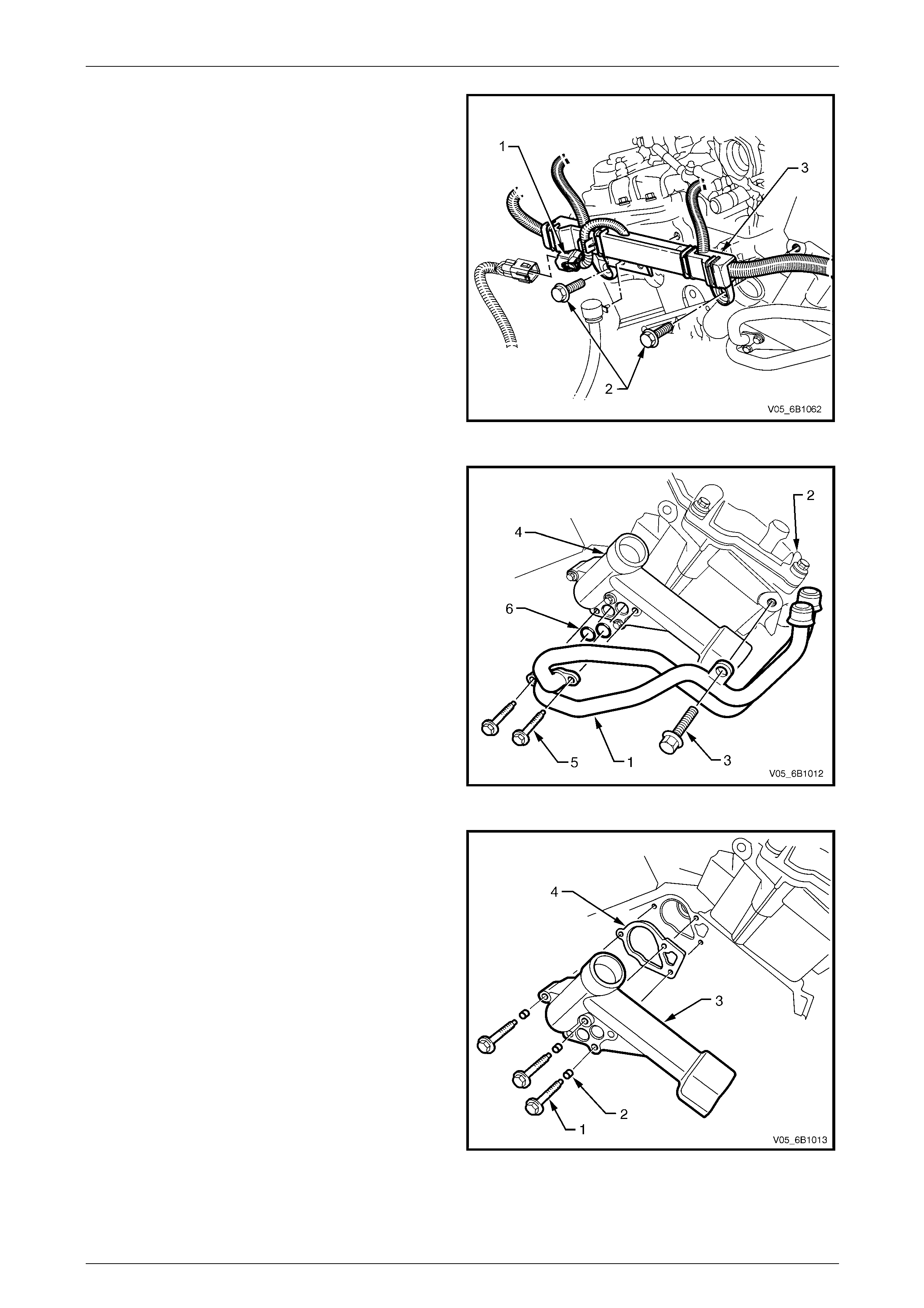

14 Working at the rear of the engine, disconnect the

engine harness to transmission harness connector (1).

15 Remove the two bolts (2) securing the engine harness

former (3) to the rear of the engine.

16 Carefully lift the engine harness free and drape on the

right side of the engine.

Figure 6B1 – 43

17 Remove the heater pipe assembly (1) to right-hand

side cylinder head (2) attaching bolt (3).

18 Remove the heater pipe assembly to thermostat

housing (4) attaching bolts (5 ), then remove the heater

pipe assembly.

19 Remove and discard the heater pipe assembly to

thermostat housing O-ring seals (6).

Figure 6B1 – 44

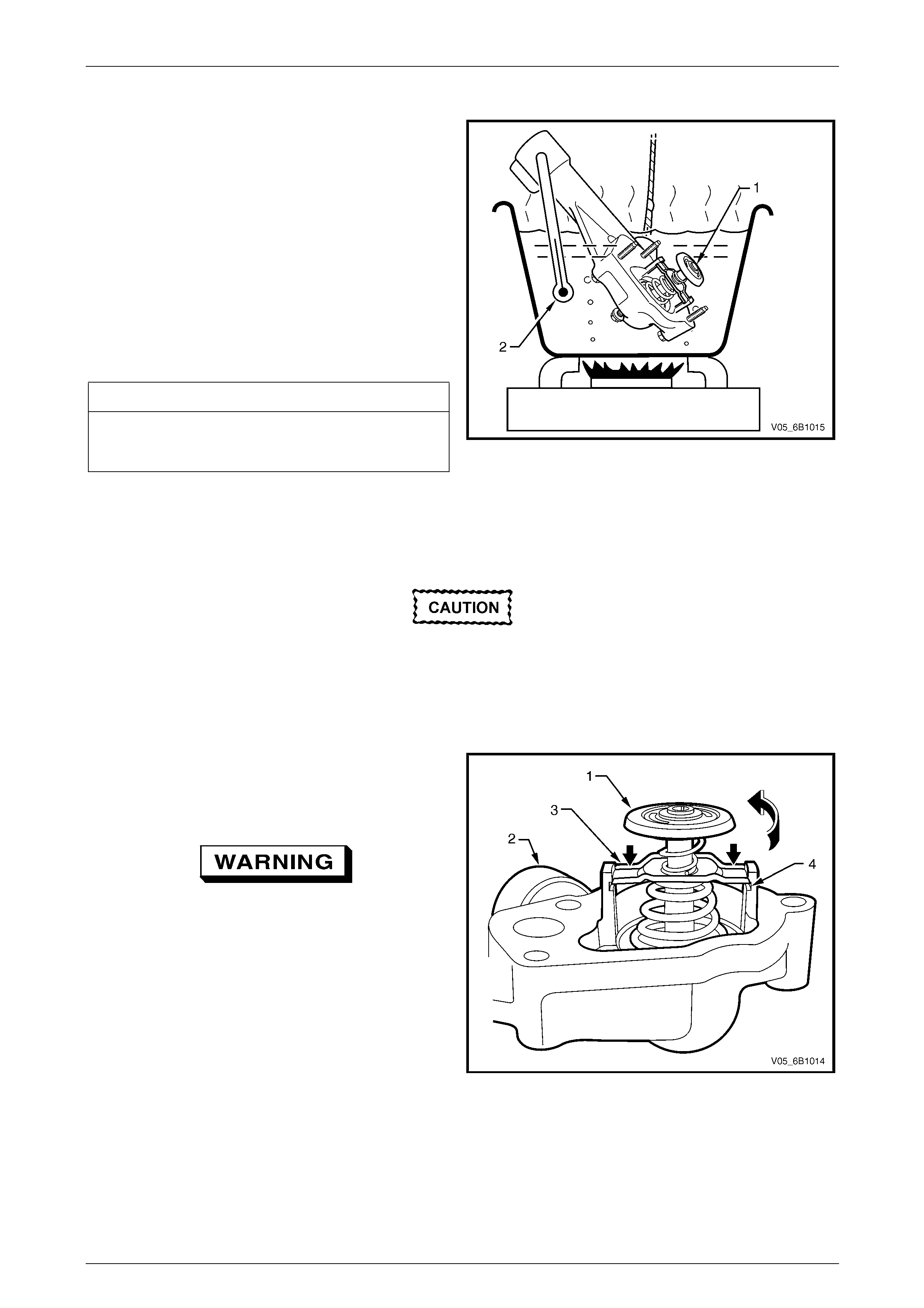

20 Remove the three thermostat housing attaching bolts

(1), rubber grommets (2), then remove the thermostat

housing (3).

NOTE

The upper thermostat housing attaching bolt is

longer than the two lower bolts.

21 Remove and discard the thermostat housing to engine

block gasket (4).

Figure 6B1 – 45

Engine Cooling – V6 Engine Page 6B1–42

Page 6B1–42

Test

1 With the thermostat (1) installed in the housing,

suspend it and a suitable thermometer (2) in a

container of 50% clean fresh water and 50% Dexron ®

long life coolant, (conforming to GM 6277M).

NOTE

Neither the thermostat assembly (1) nor the

thermometer (2) should rest on the bottom of the

container because of uneven concentration of

heat at this point when the container is heated.

2 Heat container until thermostat begins to open. Agitate

solution to ensure uniform temperature. Note

temperature and ensure t hermostat opens within

specified temperature range.

Thermostat Opening Specifications

Opening Temperature........................................82° C

Fully Open Temperature.................................... 95° C

3 Replace thermostat if it does not meet these operating

conditions.

Figure 6B1 – 46

Dismantle

Only dismantle the thermostat if a reverse

flushing operation of the cylinder block is to

be carried out. If the testing operation

indicates that the thermostat is faulty, then

the housing and thermostat are only serviced

as an assembly.

1 Remove thermostat (1) from thermostat housing (2) as

follows:

a Secure the thermostat housing by gripping in a

vice fitted with soft jaws.

Always wear protective safety glasses when

working with spring-loaded devices. Failure

to do so could result in eye injury.

b Depress the retaining bar (3) on both si des of

the thermostat and rotate the thermostat until it

clears the retaining lugs (4) on the thermostat

housing (2).

c Release the thermostat spring force.

d Remove the thermostat assembly from the

thermostat housing. Figure 6B1 – 1

Engine Cooling – V6 Engine Page 6B1–43

Page 6B1–43

Reassembly

The reassembly process is the reverse to that used for disassembly, with the following exceptions:

1 Check that the valve sealing surface is un damaged.

2 Wipe the valve sealing surface to ensure a clean surface.

Reinstall

Always wear protective safety glasses when

working with sprin g-lo aded de vices. Fail ure to

do so could result in eye injury.

1 Reinstall the thermostat into the housing (reverse to removal procedure).

2 Ensure that the engine block and thermostat housing mating surfaces are clean and dry.

3 Reinstall a new gasket to the thermostat hou s ing.

4 Reinstall the thermostat housi ng to the engine block and secure with the attaching bo lts (wit h rubber grommets

installed). Tighten all bolts to the correct torque specification.

Thermostat housing to engine

block bolt torque specification..............................10 N.m

5 Ensure that the heater pipe assembly and the rmostat housin g mating surfaces are clean and dry.

6 Reinstall new O-rings to the heater pipe assembly.

7 Reinstall heater pipe assembly to thermostat housing and secure with the attaching bolts. Tighten all bolts to the

correct torque specification.

Heater pipe assembly to thermostat

housing bolt torque specification..........................10 N.m

8 Reinstall heater pipe assembly to right-hand cylinder head bolt. Tighten bolt to the correct torque specification.

Heater pipe assembly to cylinder

head bolt torque specification ..............................35 N.m

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

9 Reinstall the engine wiring harness, securing the rear harne ss former to the rear of the engine with the two

retaining bolts, tightened to the correct torque specific ation.

Rear engine harness former

retaining bolts torque specification.......................15 N.m

Engine Cooling – V6 Engine Page 6B1–44

Page 6B1–44

10 Reinstall the left side engine harness former to the two locating pegs, then push inward to secure.

11 Reinstall the bolt securing the engine harness ground termi nal, to the left side of the cylinder block and tighten to

the correct torque specification.

Engine harness ground terminal

attaching bolt torque specification........................12 N.m

12 Reinstall each wiring harness connector to its correct location, ensuring that all security clips are installed correctly.

13 Connect the heater hoses to the heater pipe assembly.

14 Reinstall the coolant inlet pipe. Refer to 3.13 Coolant Inlet Pipe in this Section.

15 Close the radiator drain tap on the lower LHS of the radiator and remove the piece of rubber tubing to the tap

outlet.

16 Reinstall the complete intake manifold assembly. Refer to Section 6A1 Engine Mechanical – V6.

17 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

18 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

19 Reinstall the radiator shroud.

20 Reinstall the engine dress c overs. Refer to Section 6A1 Engine Mechanical – V6.

21 Reconnect battery ground lead. Refer to Section 12A Battery.

22 Road test the vehicle to check for correct operation.

Engine Cooling – V6 Engine Page 6B1–45

Page 6B1–45

3.9 Coolant Recovery Reservoir

Remove

Figure 6B1 – 47

Legend

1 Screw (3 places)

2 Reservoir 3 Coolant Dipstick

4 Console Front Panel 5 Scrivet Fastener

6 Wheelhouse Liner

1 Remove the coolant recovery hose from the underside of the coolant outlet housing, and then remove the hose

from the fan shroud retaining clip.

2 Raise front of vehicle and support on safet y stands. Refer to Section 0A General Information, for the location of

jacking and support points.

3 Remove the scrivet fastener attaching the wheelhous e liner to the coolant recovery reservoir.

4 Remove reservoir assembly attaching screws, and remove reservoir assembly from under the vehicle.

Inspect

1 Drain contents from reservoir assembly.

2 Clean the reservoir assembly with water and dry using compressed air.

3 Check reservoir and assembly for damage (for example; abrasions, cracks or distortion). Repl ace if required.

Reinstall

Reinstallation of the reservoir assembly is the reverse of removal procedures, noting the following points:

1 For ease of access, it may be necessary to remove the upper radiator shroud.

2 Refill cooling recovery reservoir and cooling system with the correct concentration of coolant.

Refer to 3.3 Draining and Filling Cooling System in this Section.

3 Check coolant recovery system for leaks.

Engine Cooling – V6 Engine Page 6B1–46

Page 6B1–46

3.10 Air Baffle and Chutes

Remove