Automatic Transmission – 4L60E – General Information Page 7C1–1

Page 7C1–1

Section 7C1

Automatic Transmission – 4L60E –

General Information

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 Section Descriptions..............................................................................................................................2

1.1 7C1 Automatic Transmission – 4L60E – General Information........................................................................... 2

Recommendations................................................................................................................................................. 3

Oil Cooler Pipes..................................................................................................................................................... 3

Clean and Inspect.................................................................................................................................................. 3

1.2 7C2 Automatic Transmission – 4L60E – Electrical Diagnosis........................................................................... 4

1.3 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis...............................................5

1.4 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.......................................................................... 6

1.5 7C5 Automatic Transmission – 4L60E – Unit Repair.......................................................................................... 7

2 General information ...............................................................................................................................8

2.1 Transmission Identification .................................................................................................................................. 8

2.2 Economy, Power and Cruise Modes.................................................................................................................... 9

Economy Mode ...................................................................................................................................................... 9

Power Mode............................................................................................................................................................ 9

Cruise Mode ........................................................................................................................................................... 9

2.3 Engine Torque Management............................................................................................................................... 10

2.4 System Protection Devices................................................................................................................................. 11

2.5 Self Diagnosis...................................................................................................................................................... 12

2.6 PCM Sensors and Actuators ............................................................................................................................... 13

3 Transmission Definitions and Abbreviations....................................................................................14

3.1 Throttle Position Related Definitions................................................................................................................. 14

3.2 Noise Condition Related Definitions.................................................................................................................. 15

3.3 General Definitions.............................................................................................................................................. 16

3.4 Abbreviations....................................................................................................................................................... 19

4 Service Notes........................................................................................................................................20

Fasteners.............................................................................................................................................................. 20

General Workshop Practice................................................................................................................................ 20

5 Torque Specifications..........................................................................................................................21

6 Transmission Specifications...............................................................................................................22

7 Special Tools ........................................................................................................................................25

Techline

Techline

Techline

Techline

Automatic Transmission – 4L60E – General Information Page 7C1–2

Page 7C1–2

1 Section Descriptions

Service information for the Hydra-matic 4L60E Automatic transmission has been divided into five Sections to assist the

tecnician to quickly locate the correct service, maintenance and diagnostic information.

The following provides a brief outline of each of the Sections.

Section 7C1 Automatic Transmission – 4L60E – General Information

Section 7C2 Automatic Transmission – 4L60E – Electrical Diagnosis

Section 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Section 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing

Section 7C5 Automatic Transmission – 4L60E – Unit Repair

The following provides a brief outline of each of the Sections.

1.1 7C1 Automatic Transmission – 4L60E –

General Information

This section provides general informati on ab out the automatic transmission, including:

A glossary of terms,

Transmission identification information,

Some notes that address safe workshop practices,

Service notes relating to fasteners and consumable items used at various stages throughout this section,

Special tools required to work on the transmission,

Fastener torque specifications, and

Transmission specifications.

For all information relating to the mechanical construction and function of the 4L60E automatic transmission, refer to the

General Motors Powertrain Group Electronically Controlled Automatic Transmission Tech nician’s Guide.

This guide includes suc h information as:

Transmission Cutaway Views,

Principles of Operation,

Power Flow,

Complete Hydraulic Circuits,

Bushing and Bearing Locations,

Seal Locations and

Illustrated Parts List.

NOTE

Specifications quoted in this General Motors

Powertrain Group Electronically Controlled

Automatic Transmission Technician Guide

may not be for the vehicle you are working

on. For correct specifications refer to

6 Transmission Specifications.

Automatic Transmission – 4L60E – General Information Page 7C1–3

Page 7C1–3

Recommendations

When servicing the transmission, all parts should be cleaned and insp ected. Individual units should be reassembled

before disassembly of other units to avoid confusion and interchanging of parts.

a Thoroughly clean the transmission exterior before removal of any component.

b Disassembly and reassembly must be made on a clean work bench. Clean liness is of the utmost importance, the

bench tools and parts must be kept clean at all times.

c Before installing screws and other fasteners into alum inium parts, dip screw threads into transmission fluid to

prevent galling aluminium threads and to prevent screws from seizing.

d To prevent thread stripping, alwa ys use a torque wrench when installing screws or nuts.

e If threads in aluminium parts are stripped or damaged, the parts can be made serviceable by the use of

commercially availabl e thread inserts.

f Protective tools must be used when assembling seals to prevent damage. The slightest flaw in the sealing surface

of the seal can cause an oil leak.

g Aluminium castings and valve parts are very susceptible to nicks, burrs, etc. and should be handled with care.

h Expand Internal snap rings and compress e xternal snap rings if they are to be re-used to ensure proper seating

when reinstalled.

i Do not re-use removed O-rings, gaskets and oil se als.

j Teflon oil seal rings shoul d not be removed unless damaged.

k During assembly of each unit, all internal moving parts must be lubricated with transmission fluid.

Oil Cooler Pipes

Should any transmission fluid cooling pipe suffer accidental damage, a genuine rep lacement pipe must be fitted. Refer to

the current release of PartFinder™ to determine the correct part number for the particul ar engine and pipe involved.

Reworking of damaged pipes or hand made replacements are not permitted.

Clean and Inspect

Do not use solvents on neoprene seals,

composition faced clutch plates or thrust

washers as damage to parts may occur.

After complete disassembly of a component, wash all metal parts in a clean solvent and dry with compressed air. Blow

oil passages out and check to make sure they are not obstr ucted, small passages shou ld be checked with tag wire. All

parts should be inspected to determine if replacement is required.

Pay particular attention to the follo wing:

Inspect linkage and pivot points for excessive wear.

Bearing and thrust surfaces of all parts shou ld be checked for excessive wear and scorin g.

Check for broken seal rings, damaged ring la nds and damaged threads.

Inspect seals for damage.

Mating surfaces of castings should be check ed for burrs. Irregularities ma y be removed by lapping the surface with

emery paper laid on a flat surface, such as a piece of plate glass.

Castings should be checked for cracks and porosity.

Automatic Transmission – 4L60E – General Information Page 7C1–5

Page 7C1–5

1.3 7C3 Automatic Transmission – 4L60E –

Hydraulic and Mechanical Diagnosis

Information contained in Section 7C3 Autom atic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis will assist

in the diagnosis of the mechanical and hydraulic components in the 4L60E automatic transmission, while the

transmission remains installed on the vehicle.

Examples of the type of diagnostic information contained within this section are:

transmission functional test,

line pressure information,

transmission fluid diagnosis,

symptom diagnosis and

shift speed charts.

Automatic Transmission – 4L60E – General Information Page 7C1–6

Page 7C1–6

1.4 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Information in Section 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing covers transmission fluid level

checking, as well as specific information for servicing some components while the transmission remains installed on the

vehicle. This Section also covers the transmission removal and reinstallation to the vehicle.

Automatic Transmission – 4L60E – General Information Page 7C1–7

Page 7C1–7

1.5 7C5 Automatic Transmission – 4L60E –

Unit Repair

Section 7C5 Automatic Transmission – 4L60E – Unit Repair contains the procedures necessary for the inspection and

overhaul of the mechanical components once the transmission is removed from the vehicle. Also included is informati on

relating to the measurement of clearances and the correct use of special tools.

Automatic Transmission – 4L60E – General Information Page 7C1–8

Page 7C1–8

2 General information

The hydra-matic 4L60E automatic transmission fitted to vehicles with GEN III V8 engine is controlled using the

powertrain control module (PCM).

For information on the mechanical operation of the transmission, refer to General Motors Powertrain Group

Electronically Controlled Automatic Transmission Technician's Guide.

For information on the PCM, refer to Section 6C3-1 Powertrain Management – GEN III V8 – General Info rmation.

2.1 Transmission Identification

The 4L60E automatic transmission application and identification can be d etermined from the stamping at the rear of the

transmission , in the location (7) as shown in Figure 7C1 – 1, where:

1= Model year,

(4=2004)

2 = Model,

5.7 litre GEN III V8 (HAD).

3 = Transmission model identif ier,

('D' = 4L60E).

4 = Julian date (day of the year).

5 = Shift Build,

'A','B','J' = First shift.

'C','H','W' = Second shift,

6 = Individual transmission serial number.

7 = Transmission identificatio n number.

Figure 7C1 – 1

Automatic Transmission – 4L60E – General Information Page 7C1–9

Page 7C1–9

2.2 Economy, Power and Cruise Modes

The programming in the powertrain control module (PCM) for GEN III V8 allows for different shift patterns, which are

driver controllable through the use of the power (PWR) button, located in the centre console.

Economy Mode

The calibration for this mode is for maximum comfort, with minimal intrusion of engine noise and smooth shifts under all

driving conditions. When ad ditional power is required for acceleration, full throttle upshifts are similar to those calibrated

for the power mode.

Power Mode

When activated, the PCM modifies the transmission cali bration in the following ways:

1 When the throttle is less than 80% o pe n, later upshift points are provided.

2 Shift time is reduced.

3 The torque converter clutch (TCC) will be applied in both the third and fourth speed ranges.

Cruise Mode

When the driver activates the cruise control (where fitted), the power icon in the instrument clusters multi-function display

(MFD) will be deactivated (provided the vehicle was operating in power mode) and the transmission shift pattern will

switch to the cruise control pattern. When in this mode, the PCM modifies the shift pattern so that earlier downshift and

later upshift points are provided.

Through the electronic progra mming of the logic processes contained in the PCM, the frequency of gear shifting and

torque converter clutch application and release is minimised. The end result of these logic processes, is that a quick

series of upshifts and downshifts (e.g. a '4 – 3 – 4' shift pattern) is minimised.

Automatic Transmission – 4L60E – General Information Page 7C1–10

Page 7C1–10

2.3 Engine Torque Management

When a GEN III V8 engine is fitted with the 4L60E transmission, torque management is a function of the PCM which

reduces engine power under certain conditions, including transmission upshifts and downshifts.

Torque management is perform ed for the following reasons:

prevent overstress of the powertrain components,

prevent damage to the vehicle durin g certain abusive manoeuvres, and

reduce engine speed when the idle air control system is out of the normal operating r ange.

The PCM monitors the following sensors and engine parameters to calculate en gine output torque:

air/fuel ratio,

mass air flow,

manifold absolute pressure,

intake air temperature,

spark advance,

engine speed,

engine coolant temperature and

A/C clutch status.

The PCM monitors the torque converter status, the transmission gear ratio and the engine speed in order to determine if

torque reduction is required. If torque reduction is require d, the PCM retards the ignition a s appropriate to reduce engine

torque output. The PCM also shuts off the fuel to certain injectors to reduce the engin e p ower in the case of an abusive

manoeuvre.

Instances when engine po wer reductio n is likely to be experienced:

during transmission upshifts and do wnshifts,

heavy acceleration from a standi ng start,

the intake air control valve is out of the normal operating range and

when the driver is performing stress-inducing (abusive) manoeuvres, such as shifting into gear at high throttle

opening, or shifting the transmission from r everse to drive to create a rocking motion.

The driver is unlikely to notice the torqu e management actions in the first two instances. The engine power output will be

moderate at full throttle in the other two cases.

The PCM calculates the amount of igniti on retard necessary to reduce the engine power and cuts off spark to certain

cylinders. For example, the PCM disables the fuel injectors and retards spark for cylinders 1, 4, 6, and 7 in the case of a

series of abusive manoeuvres.

Automatic Transmission – 4L60E – General Information Page 7C1–11

Page 7C1–11

2.4 System Protection Devices

Should 1st gear be selected and left in that rang e, the PCM will prot ect the engine from an over-speeding condition by

upshifting to 2nd gear at a pre-determi ned point. Similarly, the PCM provides high speed, downshift protection by

preventing a manual shift into 1st gear above pre-determined engine speeds.

Under severe operating conditions such as towing in high ambient temperatures, fluid temperatures can rise to a poin t

where lubrication breakd own can occur. In addition to having an oil cooler fitted to the vehi cle, the 4L60E transmission is

also fitted with a transmission fluid temperature sensor located in the Transmission Range (TR) Pressure Switch

Assembly (PSA).

When fluid temperatures in excess of 135C a r e sensed, the torque converter clutch is applied as programmed, in 3rd or

4th gear. This action reduces further the fluid temperature d uring normal operation of the torque converter. While these

high fluid temperatures are se nsed however, torque converter clutch apply is not avai lable when the throttle opening is

above 50%.

Similarly, when the fluid temperature is below 29C, the PCM prevents torque converter clutch apply.

If a condition occurs, preventing electronic control of the transmission' s functions, a 'Fail Safe' mode will default the

transmission to 3rd gear when either Drive or 3 is selected, applying also maximum line pressure. While in this mode, the

vehicle operator can still manually select 2, 1, Reverse, Park or Neutral, should the need arise.

Automatic Transmission – 4L60E – General Information Page 7C1–12

Page 7C1–12

2.5 Self Diagnosis

If any transmission operation controlled by the PCM begins to operate outside its pre-set parameters, the PCM has the

ability to store a range of diagnostic codes which can be accessed by the servicing technician, thereby localising the

problem.

Automatic Transmission – 4L60E – General Information Page 7C1–13

Page 7C1–13

2.6 PCM Sensors and Actuators

As indicated earlier, there are a number of sensors and switches providing input information for the PCM programming

that will allow the PCM to change the shift pattern, shift feel and torque converter clutch operation.

The PCM does this by comparing this input information with its predetermined values on shift pattern, fluid pressure

maps, shift duration parameters, extreme he at protection programming and adaptive controls.

In addition, each input signal and output actuator operation is also monitored and if outside its pre-set parameters, a

diagnostic code is logged for future reference by the servicing technici an.

Automatic Transmission – 4L60E – General Information Page 7C1–14

Page 7C1–14

3 Transmission Definitions and

Abbreviations

The following definitions and abbreviations are provided to establis h a common language and assist the user in

describing transmission related cond itions. The use of these terms and/or conditions can be foun d in the various parts of

the automatic transmission sections of the MY2005 Service Information, but more particularly in

Section 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis.

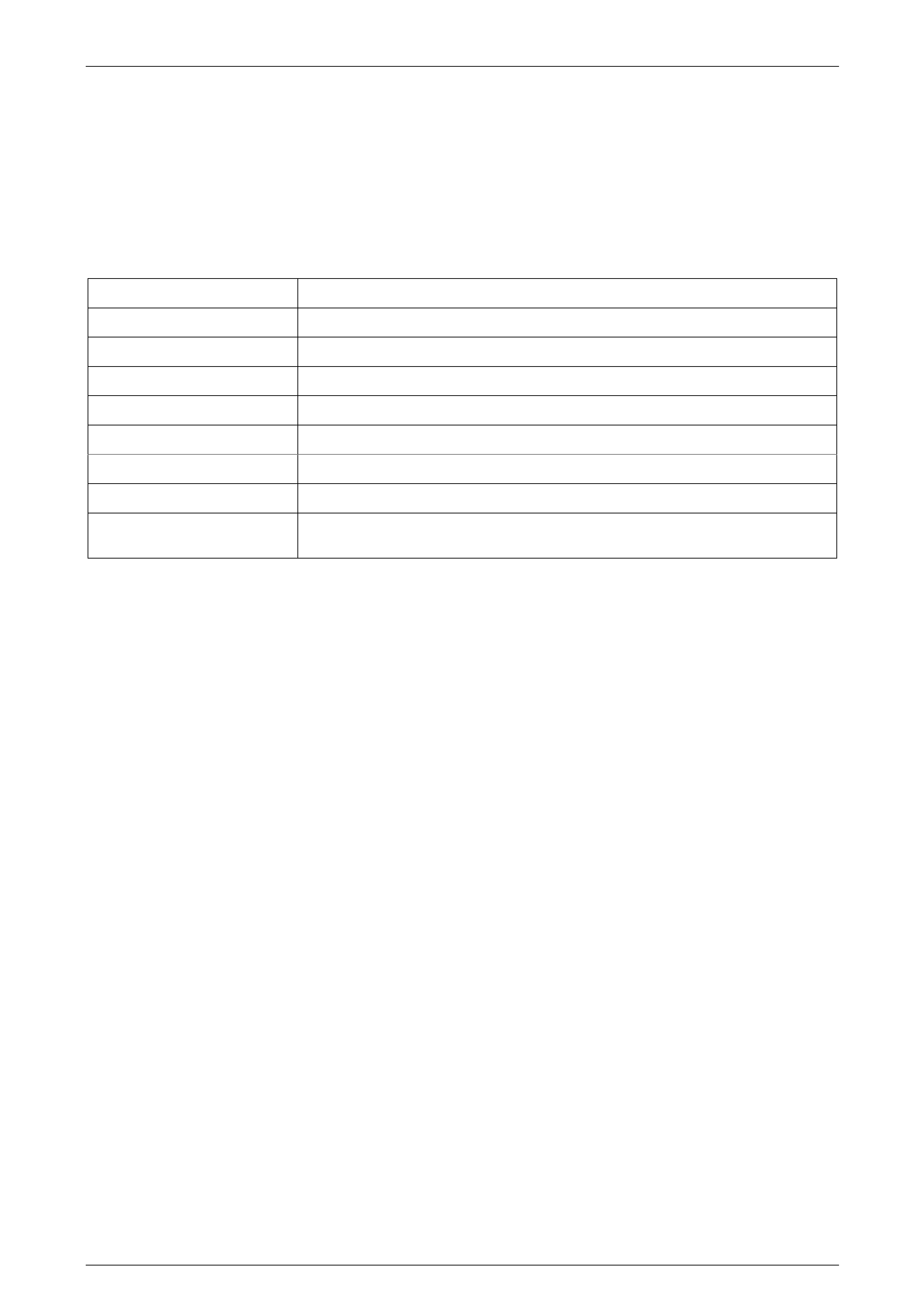

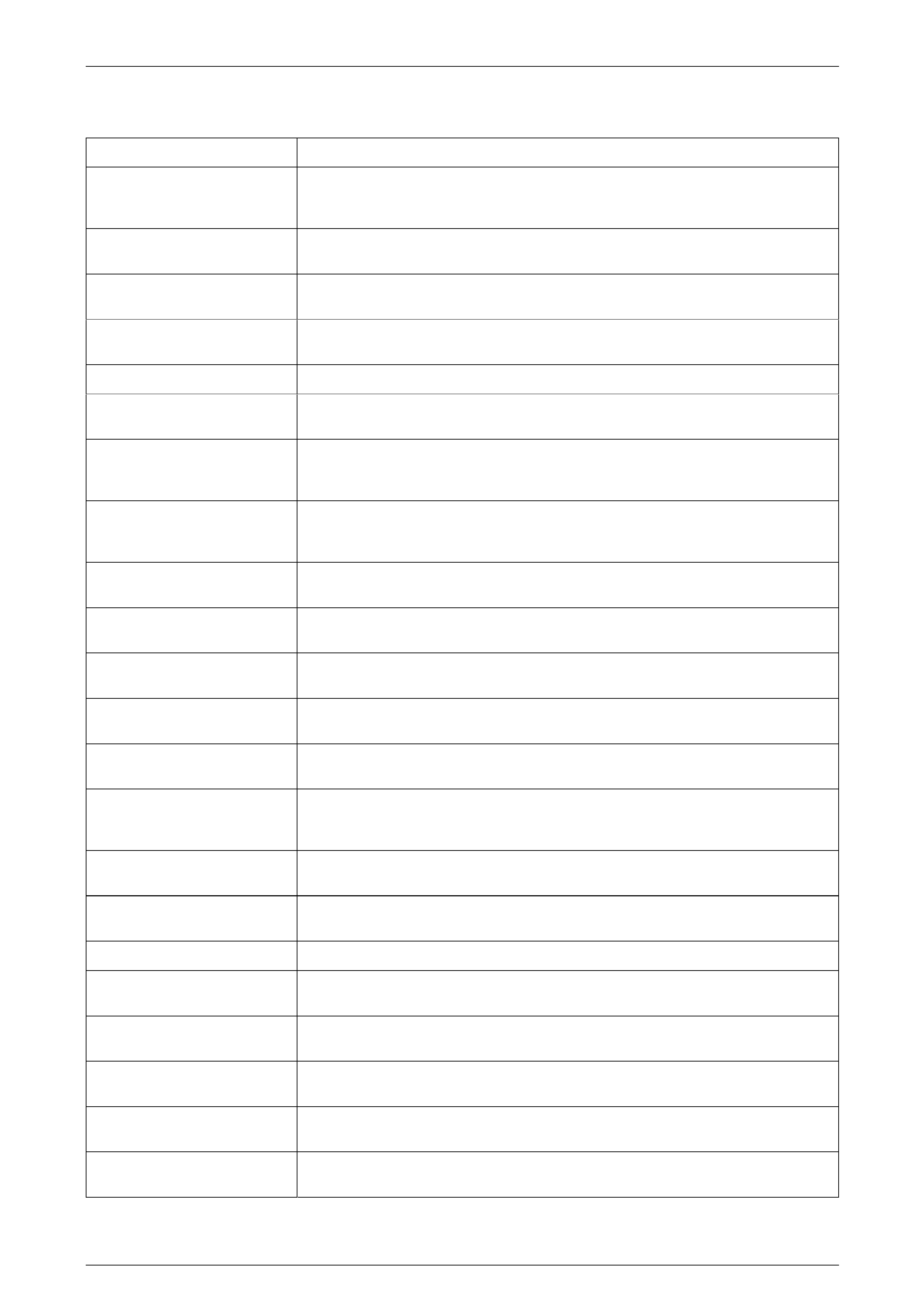

3.1 Throttle Position Related Definitions

Throttle Position Definition

Minimum Throttle The least amount of throttle opening required for an upshift.

Light Throttle Approximately 1/4 of accelerator pedal travel (25% Throttle Position).

Medium Throttle Approximately 1/2 of accelerator pedal travel (50% Throttle Position).

Heavy Throttle Approximately 3/4 of accelerator pedal travel (75% Throttle Position).

Wide Open Throttle (WOT) Full travel of the accelerator pedal (100% Throttle Position).

Full Throttle Detent Downshift A quick apply of the accelerator pedal to its full travel, forcing a downshift.

Zero Throttle Coast Down A full release of the accelerator pedal while the car is in motion and in drive range.

Engine Braking A condition where the engi ne is used to slow the car by manually downshifting

during a zero throttle coast down.

Automatic Transmission – 4L60E – General Information Page 7C1–15

Page 7C1–15

3.2 Noise Condition Related Definitions

Noise Condition Definition

Planetary Gear Noise A whine related to car speed most noticeable in first gear or reverse. Becomes less

noticeable after an upshift.

Pump Noise A high pitch whine increasing wit h en gine r.p.m.

Automatic Transmission – 4L60E – General Information Page 7C1–16

Page 7C1–16

3.3 General Definitions

General Definition

Accumulator A component of the transmission that absorbs hydraulic pressure during the apply of a

clutch or band. Accumulators are designed to control the quality of a shift from one

gear range to another.

Adaptive Learning Programming within the PCM that automatically adjusts hydrau lic pressures in order to

compensate for changes in the transmission (i.e. component wear).

Applied An 'Applied Component' is one that is holding another component to which it is splined

or assembled to. Also referred to as "engag ed"

Apply Components Hydraulically operated clutches, servo’s, ba nds and mechanical one-way roller or

sprag clutches that drive or hold members of a pla netary gear set.

Apply Plate A steel clutch plate in a clutch pack, located next to the (apply) piston.

Backing Plate A steel plate in a clutch pack that is usually the last plate in that clutch assembly

(furthest from the clutch piston).

Band An apply component that consists of a flexible strip of steel and friction material that

wraps around a drum. When applied, it tightens around the drum and prevents the

drum from rotating.

Brake Switch An electrical device that provides sig nals to the powertrain control module or

transmission control module, (PCM), based on the positio n of the brake pedal. The

PCM uses this information to apply or release the torque converter clutch (TCC).

Centrifugal Force A force that is imparted on an object (due to rotation) that increases as that object

moves further away from a centre-point of rotation.

Check Ball A spherical, hydraulicall y controlled component (usually of steel) that either seals or

opens fluid circuits. It is also referred to as a check valve.

Clutch Pack An assembly of components generally consisting of clutch plates, an apply plate and a

backing plate.

Clutch Plate A hydraulically activated component that has two basic designs: (1) all steel, or (2) a

steel core with friction material bonded to one or two sides of the plate.

Control Valve Body A machined metal casting that contains valve trains and other hydraulically controlled

components that shift the transmission.

Coupling Speed The speed at which a vehicle is travelling and no longer requires torque multiplication

through the torque converter. At this point, the stator 'free wheels' to allow fluid leaving

the turbine to flow directly to the pump. (Also see Torque Converter).

De-energise(d) To interrupt the electrical current that flows to an electronically controll ed device,

making it electrically inoperable.

Direct Drive A condition in a gears set where the input speed and input torque equals the output

speed and output torque. The gear ratio through the gear set is 1:1.

Downshift A change in a gear ratio where both input speed and torque increases.

Duty Cycle In reference to an electronically controlled solenoid, it is the amount of time (expressed

as a percentage) that current flows through the solenoid coil.

Energise(d) To supply a current to an electronica lly controlled device, enablin g it to perform its

designed function.

Engine Compression Brakin g A condition where compressi on from the engine is used with the transmission to

decrease vehicle speed.

Exhaust The release of fluid pressure from a hydraulic circuit. (The words 'exh austs' and

'exhausting' are also used and have the same intended meaning.)

Fail-safe Mode A condition whereby a component (i.e. engine or transmission) will partially function

even if its electrical circuit is disabled.

Automatic Transmission – 4L60E – General Information Page 7C1–17

Page 7C1–17

General Definition

Fluid In this Section of the Service Manual, 'fluid' refers primarily to automatic transmission

fluid (or ATF) and, for the Hydra-matic 4L60E transmission, the only recommended

fluid is Dexron III.

Fluid Pressure A pressure that is consistent throughout a given fluid circuit.

Force A measurable effort that is exerted on an object (componen t).

Freewheeling A condition where power is lost through a driving or holding device (i.e. roller or sprag

clutches).

Friction Material A heat and wear resistant fibrous material, bonded to clutch plates and ba nds.

Gear A round, toothed device that is used for transmitting torque through other components.

Gear Range A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear,

2nd gear etc.).

Gear Ratio Revolutions of an input gear as compared to the revolutions of an outp ut ge ar. It can

also be expressed as the nu mber of teeth on a gear as c ompared to the number of

teeth on a gear that it is in mesh with.

Hydraulic Circuit A fluid passage which often includes the mechanical compone nts in that circuit

designed to perform a specific function.

Input A starting point for torque, revolutions or energ y into another component of the

transmission.

Internal Gear The outermost member of a gear set that has gear teeth in constant mesh with the

planetary pinion gears of the gear set.

Land (Valve Land) The larger diameters of a spool valve that contact the valv e bore or bushing.

Line Pressure The main fluid pressure in a hydraulic system created by the pump and pressure

regulator valve.

Manual Valve A spool valve that distributes fluid to various hydraulic circuits and is mechanically

linked to the gear selector lever.

Orifice A restricting device (usually a hole in the sp acer plate) for controlling pressure build up

into another circuit.

Overdrive An operating condition in the gear set allowing output speed to be higher than input

speed and output torque to be lower than input torque.

Overrunning The function of a one-way mechan ical clutch that allows the clutch to freewheel during

certain operating conditi ons of the transmission.

Pedal Position The percentage angle of the accelerator pedal as displayed by Tech 2.

Pinion Gears Pinion gears (housed in a carrier) that are in constant mesh with a circumferential

internal gear and centralised sun gear.

Planetary Gear Set An assembly of gears that consists of an internal gear, planet pinion gears with a

carrier, and a sun gear.

Powertrain Control Module

(PCM) An electronic device that manages the vehicle's engine and automatic transmission

functions.

Pressure A measurable force that is exerted on an area and e xpr essed as kilopascals (kPa).

Pulse Width Modulated (PWM) An electronic signal that continuously cycles the On and Off time of a device (such as

a solenoid) while var ying the amount of On time.

Race (Inner or Outer) A highly polished steel surface that contacts bearings or sprag or roller elements.

Reduction (Gear Reduction) An operating condition in the gear set allowing output speed to be lower than input

speed and output torque to be hig her than input torque.

Residual Fluid Pressure Excess pressure contained within an area after the supply pressure has been

terminated.

Automatic Transmission – 4L60E – General Information Page 7C1–18

Page 7C1–18

General Definition

Roller Clutch A mechanical clutch (holding device) consisting of roller bearings assembled between

inner and outer races.

Servo A spring loaded device consisting of a piston in a bore that is operated (stroked) by

hydraulic pressure to appl y or release a band.

Spool Valve A round hydraulic control valve often containing a variety of land an d valley diameters.

Sprag Clutch A mechanical clutch (holding device consisting of "figure eight" like elements

assembled between inner and outer races.

Staking The effect of deforming, peening over or riveting a shaft to provide a solid mounting.

Throttle Position The travel of the throttle plate that is expressed in percentages and measured by

Tech 2.

Torque A measurable twisting force expressed in terms of Newton metres (Nm).

Torque Converter A component of an automatic transmission, (attached to the engine flex plate) that

transfers torque from the engine to the transmission through a fluid coupling.

Torx Plus Bit A special tool used for the removal of the b ell housing. Precision tip fit means that cam

out of the bolt head is virtually eliminated.

NOTE

Torx Plus Bits are different from normal Torx Bits

Variable Capacity Pump The device that provides fluid for operating the hydraulic circuits in the transmission.

The amount of fluid supplied varies depending on vehicle operating con ditio ns.

Automatic Transmission – 4L60E – General Information Page 7C1–19

Page 7C1–19

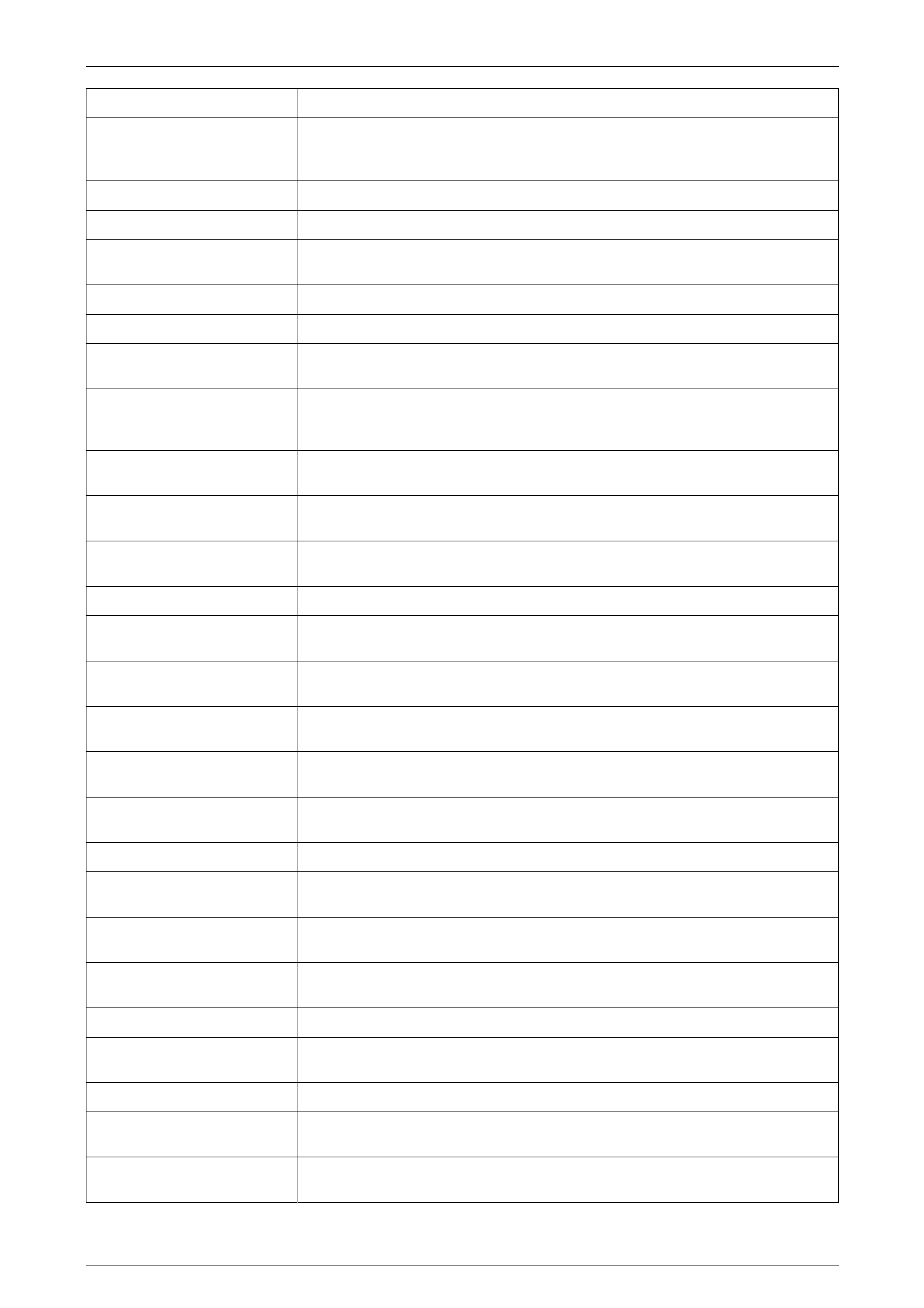

3.4 Abbreviations

Abbreviation Definition

2WD Two Wheel Drive.

AC Alternating Current

A/C Air Conditioning

AFL Actuator Feed Limit

DC Direct Current

D.C Duty Cycle

DLC Diagnostic Link Connector

DTC Diagnostic Trouble Code

ECM Engine Control Module

ECT Sensor Engine Coolant Temperature Sensor.

ETC Electronic Throttle Control

N.C Normally Closed

N.O. Normally Open

PCM Powertrain Control Module.

PCS Pressure Control Solenoid (or Force Motor)

PIM Powertrain Interface Module

PWM Pulse Width Modulated

RWD Rear Wheel Drive.

TCC Torque Converter Clutch.

TFP Switch Transmission Fluid Press ure Manual Valve Position Switch

TFT Transmission Fluid Temperature Sensor.

TP Sensor Throttle Position Sensor.

VS Sensor Vehicle Speed Sensor.

Automatic Transmission – 4L60E – General Information Page 7C1–20

Page 7C1–20

4 Service Notes

In the interests of safety to personnel, equipment and to the vehicle and its components, the following notes should be

read and adhered to whenever servicing operations are to be carried out o n the H ydra-m atic 4L6 0E automatic

transmission. In addition, some of this information also refers to sound workshop practices and, to achieve the design lif e

of affected components.

Fasteners

Always reinstall fasteners in the same locations as they were removed.

If a fastener requires replacement, al ways use a part of the correct part number or of equal size and strength or

stronger.

General Workshop Practice

Keep work area and tools clean.

To avoid unnecessar y conta mination, always clean the exterior of the transmission before removi ng any parts.

Do not use wiping cloths or rags because of the risk of lint being trapped in the transmission.

Do not use solvents on:

neoprene seals,

composition faced clutch plates, or

thrust washers.

Always wear eye protection when using compressed air.

Blow out all passages with compressed air. Only probe small passages with soft, thin wire.

Handle parts with care to avoid nicks and scratches.

Do not remove Teflon oil seal rings unless damaged or performing a complete overhaul.

Expand internal snap rings and compress external snap rings to maximise retention and security.

Lubricate all internal parts with transmission fluid (only use Dexron® III), as they are being installed.

When installing cap screws into aluminium castings:

always use a torque wrench and

stripped or damaged threads in aluminium castings may be reconditioned by using commercially available

thread inserts.

Once removed, replace all ga skets, seals and O-rings with new parts.

Always use seal protectors where indicated and do not use gasket cement or sealant on any joined face unless

specified to do so.

Automatic Transmission – 4L60E – General Information Page 7C1–21

Page 7C1–21

5 Torque Specifications

Oil pan attaching bolt............................................................................12.0 Nm

Manual shaft linkage attaching nut ...........................................15.0 – 35.0 Nm

Selector rod locking bolt ........................................................... 15.0 – 35.0 Nm

Selector knob attaching Torx screw ..............................................1.0 – 3.0 Nm

Selector knob bezel attaching screw.............................................1.0 – 2.0 Nm

Selector base attaching nut ......................................................12.0 – 18.0 Nm

Neutral start and back-up lamp switch attaching screw.............15.0 – 35.0 Nm

Vehicle speed sensor attaching bolt...........................................11.0 - 14.0 Nm

Transmission mount attaching bolt ...........................................50.0 – 65.0 Nm

Transmission support attaching bolt .........................................50.0 – 65.0 Nm

Transmission mount attaching nut ............................................20.0 – 30.0 Nm

Extension housing attaching bolt...............................................42.0 – 48.0 Nm

1 – 2 Accumulator cover attaching bolt.................................................12.0 Nm

TCC solenoid attaching bolt .................................................................12.0 Nm

Control valve body attaching bolt .........................................................12.0 Nm

Transmission fluid pressure (TFP) manual valve

position switch attaching bolt................................................................12.0 Nm

Manual detent spring attaching bolt......................................................23.0 Nm

Spacer plate support plate attaching bolt .............................................12.0 Nm

Filler tube bracket attaching bolt................................................20.0 – 30.0 Nm

Vent pipe attaching bolt...............................................................7.5 – 12.0 Nm

Radiator cooler hose / line assembly flare nut...........................20.0 – 25.0 Nm

Transmission fluid lines bracket attaching nut...........................19.0 – 25.0 Nm

Torque converter to flexplate attaching bolt...............................60.0 – 70.0 Nm

Torque converter housing attaching bolt ...................................50.0 – 60.0 Nm

Torque converter cover attaching bolt.........................................5.0 – 10.0 Nm

Oil Cooler Pipe Quick Connect Fitting to Transmission Case...............38.0 Nm

Oil Pump Cover to Pump Body Attaching Bolt......................................25.0 Nm

Pressure Control Solenoid Retainer Attaching Bolt..............................12.0 Nm

Forward Accumulator Cover Attaching Bolt..........................................12.0 Nm

Manual Shaft Inner Detent Lever Attaching Nut...................................30.0 Nm

Park Pawl Bracket Attaching Bolt.........................................................30.0 Nm

Oil Pump to Transmission Case Attaching Bolt....................................30.0 Nm

Torque Converter Housing to

Transmission Case Attaching Bolt.............................................65.0 – 75.0 Nm

Automatic Transmission – 4L60E – General Information Page 7C1–22

Page 7C1–22

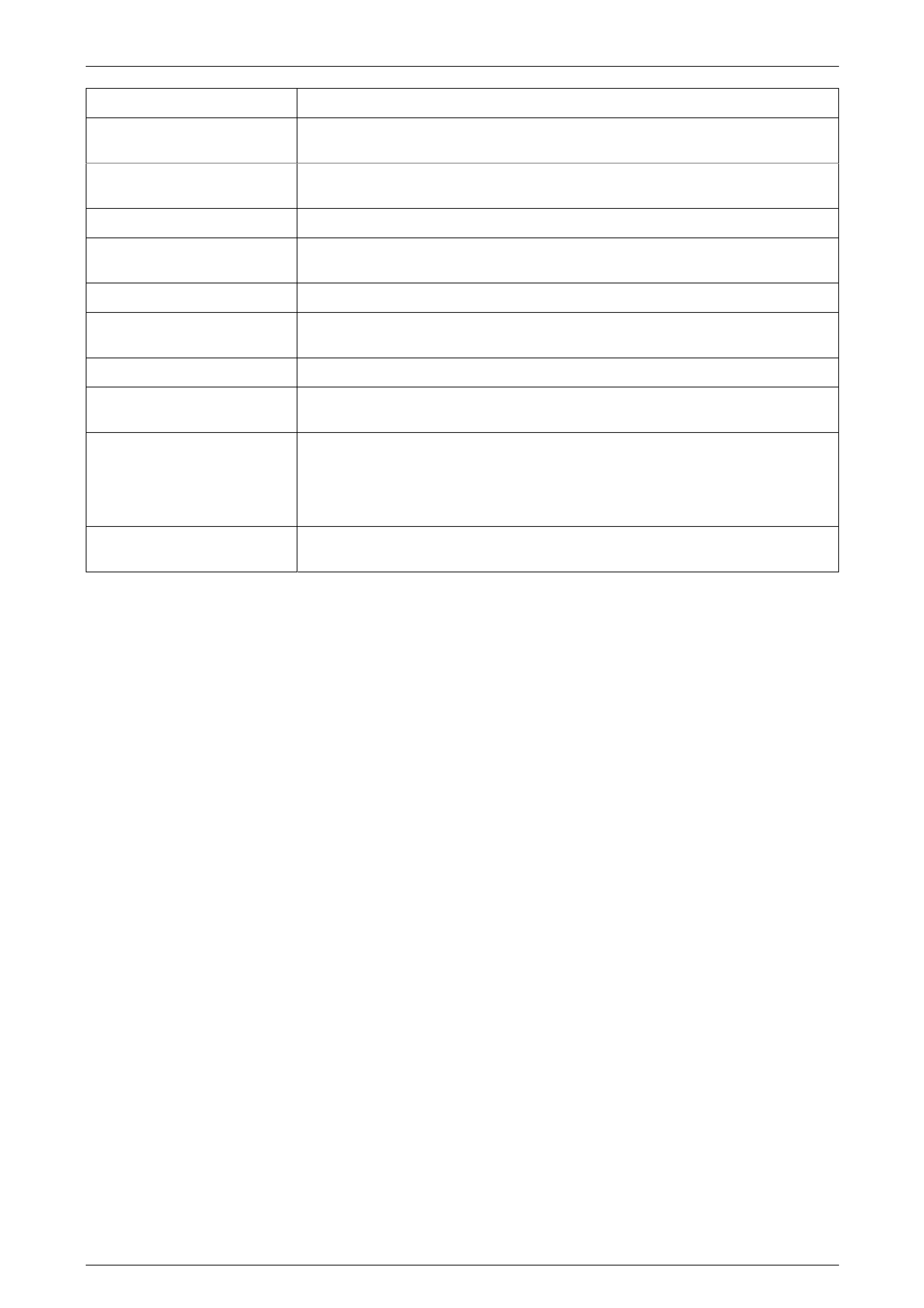

6 Transmission Specifications

Type Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operatio n

Overdrive 4th speed range

Selector Location................................................................................. Floor mounted console

Gear Ratios

Park (P) ..................................................................................................................................–

Reverse (R) ..................................................................................................................2.294:1

Neutral (N)..............................................................................................................................–

Drive (D – 4) .................................................................................................................0.696:1

Drive (D – 3) .................................................................................................................1.000:1

Second (2)....................................................................................................................1.625:1

First (1).........................................................................................................................3.059:1

Shift Speeds

Refer to Section 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Dia gnosis

Oil Pressure

Refer to Section 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Dia gnosis

Torque Converter

Number of Elements..................................................................3 plus torque converter clutch

Torque Converter Diameter

V6................................................................................................................................258 mm

GEN III V8 Engine .......................................................................................................300 mm

End Play – (All Engines)......................................................................................0.1 – 0.5 mm

Lubricant

Type recommended................................................................................................Dexron® III

Capacity.........................Nominal only. Check when transmission is at operating temperature

Refill........................................................................................................V6 Engine – 4.8 litres

.....................................................................................................GEN III V8 Engine – 5.0 litre

Total (Dry)

................................................................................................................V6 Engine – 7.9 litres

.................................................................................................GEN III V8 Engine – 10.6 litres

Fluid Cooling.................................... Transmission fluid to engine coolant in one radiator tank

Clutches and Band

2 – 4 Band:

Type...........................................................................................Composition lined, steel band

Operation:....................................................................................................................... Servo

Adjustment:................................................................................................Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm......................................................................................................1 Groove

67.23 – 67.53 mm......................................................................................................2 Groove

68.64 – 68.94 mm....................................................................................................No Groove

Techline

Automatic Transmission – 4L60E – General Information Page 7C1–23

Page 7C1–23

Reverse Input Clutch

Type................................................................................................................Multiple wet disc

Backing plate........................................................................................................(1) Selective

Clutch plate (numbers):

Steel .......................................................................................................................................4

Composition............................................................................................................................4

Belleville .................................................................................................................................1

Backing Plate........................................................................................................1 (Selective)

Backing plate, identification and thickness:

'2'.....................................................................................................................7.25 – 7.41 mm

'3'.....................................................................................................................6.52 – 6.68 mm

'4'.....................................................................................................................5.79 – 5.95 mm

Backing plate travel .........................................................................................1.02 – 1.94 mm

Forward Clutch

Type................................................................................................................Multiple wet disc

Clutch plate, (number):

Flat steel plates.................................................................................................................... (5)

Composition plates..............................................................................................................(5)

Waved steel plate................................................................................................................ (1)

Backing plate........................................................................................................(1) Selective

Backing plate, identification and thickness:

'A'.....................................................................................................................6.97 – 7.07 mm

'B'.....................................................................................................................6.38 – 6.48 mm

'C'.....................................................................................................................5.79 – 5.89 mm

'D'.....................................................................................................................5.20 – 5.30 mm

'E'.....................................................................................................................4.61 – 4.71 mm

Backing plate travel – All engines....................................................................0.87 – 1.88 mm

Overrun Clutch

Type................................................................................................................Multiple wet disc

Clutch plates, (number):

Flat steel.............................................................................................................................. (2)

Composition......................................................................................................................... (2)

3 – 4 Clutch

Type................................................................................................................Multiple wet disc

Clutch plates, (number):

Flat steel.............................................................................................................................. (5)

Composition......................................................................................................................... (6)

Stepped apply plate.............................................................................................................(1)

Backing plate........................................................................................................(1) Selective

Backing plate, identification and thickness:

'A'.....................................................................................................................5.88 – 5.68 mm

'B'.....................................................................................................................4.99 – 4.76 mm

'C'.....................................................................................................................4.10 – 3.90 mm

Backing plate travel .........................................................................................2.10 – 0.90 mm

Automatic Transmission – 4L60E – General Information Page 7C1–24

Page 7C1–24

Low and Reverse Clutch

Type................................................................................................................Multiple wet disc

Clutch plates (number):

Flat steel.............................................................................................................................. (5)

Composition......................................................................................................................... (5)

Waved flat steel................................................................................................................... (1)

Selective flat steel plate........................................................................................(1) Selective

Selective plate, (identific ation) and thickness,

measured dimension:

28.06 – 27.54 mm (identification NONE).........................................................1.68 – 1.83 mm

28.59 – 28.07 mm (identification '0')................................................................1.17 – 1.31 mm

27.54 – 27.03 mm (identification '1')................................................................2.20 – 2.34 mm

Transmission End Play Check

Transmission end play check specification......................................................0.13 – 0.92 mm

Identification and washer thickness:

67.....................................................................................................................1.87 – 1.97 mm

68.....................................................................................................................2.04 – 2.14 mm

69.....................................................................................................................2.21 – 2.31 mm

70.....................................................................................................................2.38 – 2.48 mm

71.....................................................................................................................2.55 – 2.65 mm

72.....................................................................................................................2.72 – 2.82 mm

73.....................................................................................................................2.89 – 2.99 mm

74.....................................................................................................................3.06 – 3.16 mm

Torque Converter End Play Inspection

258 mm diameter converter.................................................................................0.1 – 0.5 mm

300 mm diameter converter.................................................................................0.1 – 0.5 mm

Automatic Transmission – 4L60E – General Information Page 7C1–25

Page 7C1–25

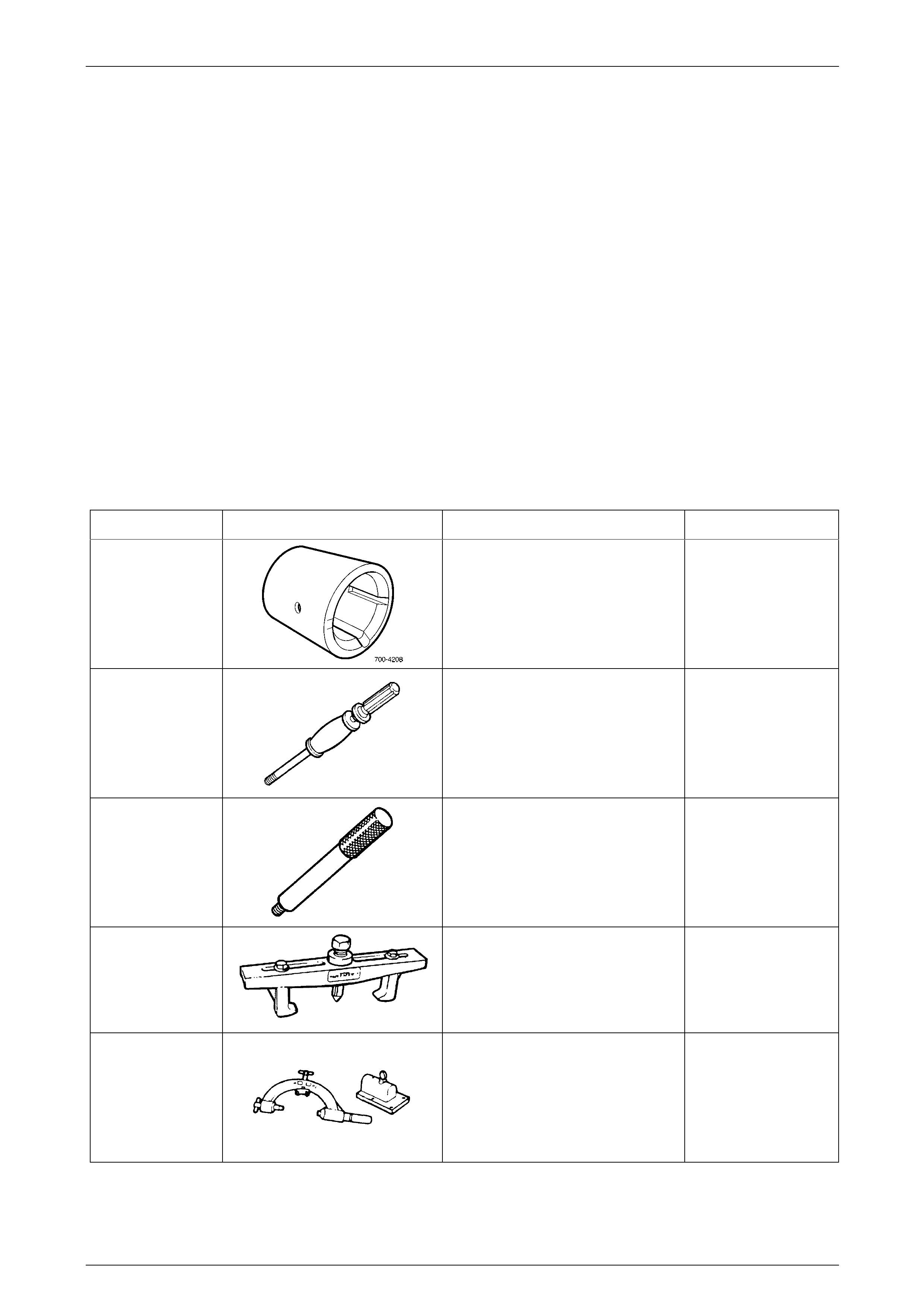

7 Special Tools

The following pages list and illustrate the special service tools required. The tools are classified into the following

categories:

Mandatory: When required to perform routine maintenance operations and adj ustmen ts, or are required to carry out

fault diagnosis procedures.

Desirable: T hese tools should be considered for purchase since their use will greatly facilitate perform ing designated

tasks and permit achievement of standard times.

Unique: These tools are those that must be employed when over hauling major assemblies or performing r elatively

large tasks.

Available: Are those tools that are of a general nature for which commercially available equivalents exist, or tools

which have had previous application.

Unless otherwise specified, al l tools are available from:

SPX Australia PTY. LTD.

Service Solutions

28 Clayton Road

Notting Hill, Victoria, 3168

Telephone: (03) 9544 6222

Facsimile: (03) 9544 5222

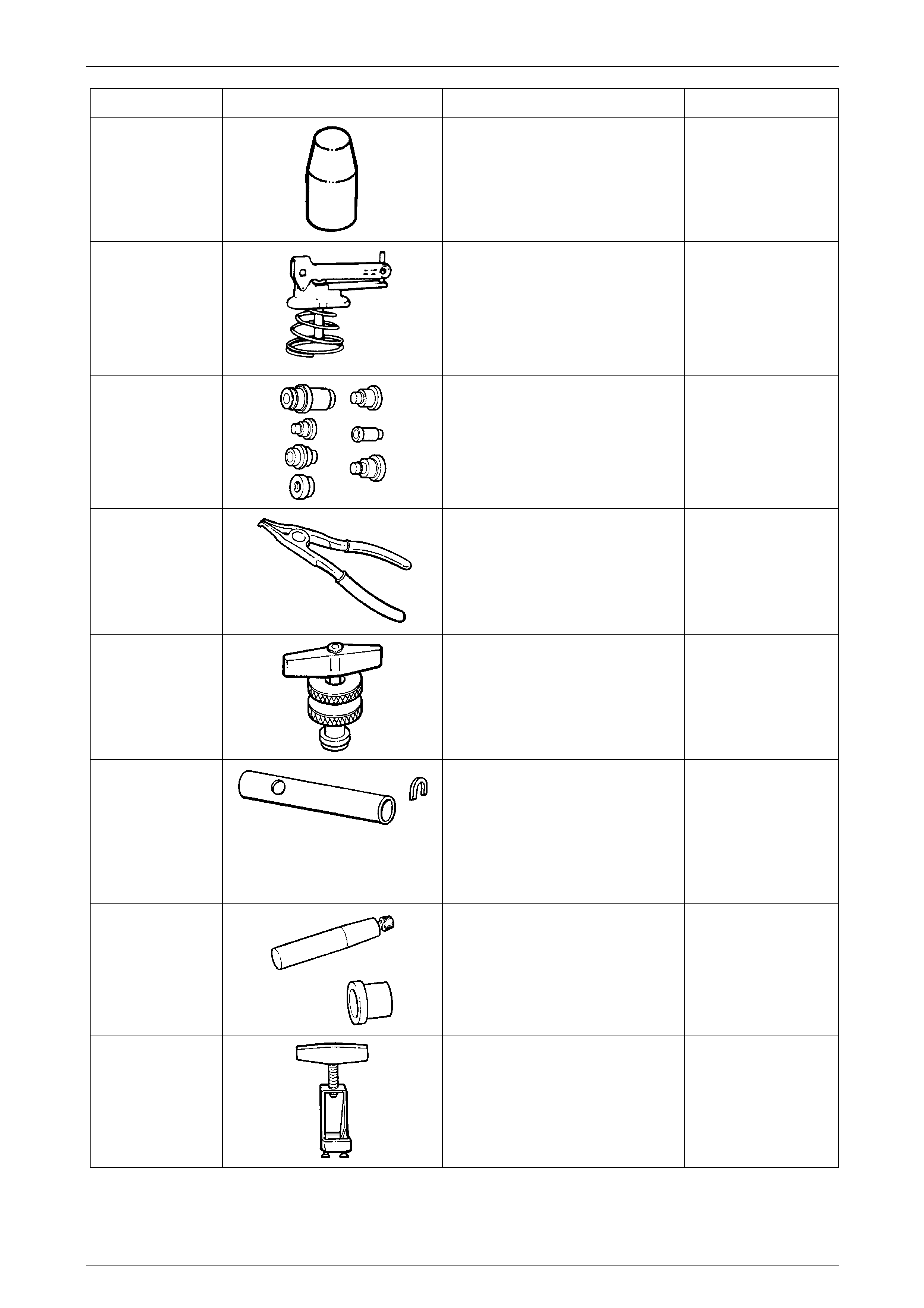

Tool Number Illustration Description Tool Classification

700-4208

Pass-Thru Connector Remover

Used to release the four locking tangs

on the Pass-Thru connector from the

transmission case.

Previously released

Desirable

J6125-1B

Slide Hammer

Used for a number of bush removal

operations.

Previously released

Unique

J8092

Driver Handle

Used for a number of bush installation

operations.

Previously released

Unique

J8433

Puller

Used with J21427-01 to remove the

output speed sensor ring from the

main shaft.

Previously released

Unique

J8763-02

Holding Fixture

Used in conjunction with holding

fixture base J3289-20 to ho ld

automatic transmission.

Previously released.

Unique

Automatic Transmission – 4L60E – General Information Page 7C1–26

Page 7C1–26

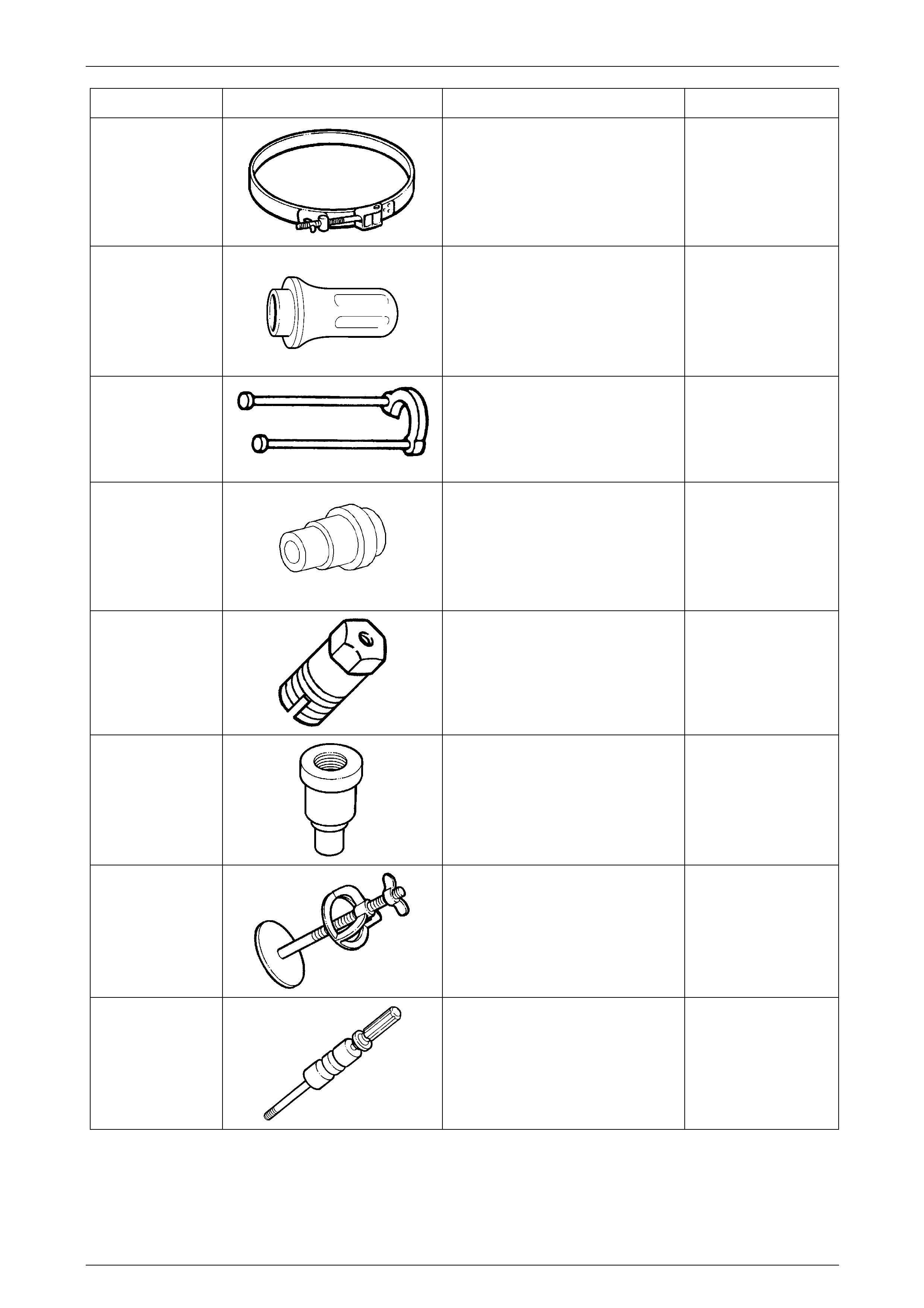

Tool Number Illustration Description Tool Classification

J21368

Oil Pump Alignment Band

Used to align the two oil pump

sections before tightening the

securing bolts.

Previously released

Unique

J21426

Rear Seal Installer

Used to install the extension housi ng

oil seal.

Previously released

Unique

J21427-01

Puller Adaptor

Used with J8433 to remove the output

speed sensor ring from the main

shaft.

Previously released

Unique

J21465-2

Installer

Used with driver J8092 to ins t all the

front stator shaft bush.

Previously released

Unique

J21465-15

Remover

Used in conjunction with slide

hammer J6125-1B to remove the

stator shaft front bushing.

Previously released

Unique

J23062-14

Bush Remover

Used in conjunction with driver handle

J8092.

Previously released

Unique

J23327-1

Clutch Spring Compressor

Needed to compress the clutch,

before dismantling.

Plate J42628 is also required.

Previously released

Unique

J23907

Slide Hammer

Used with J29369-2 to remov e the

reaction carrier shaft bushes.

Previously released

Unique

Automatic Transmission – 4L60E – General Information Page 7C1–27

Page 7C1–27

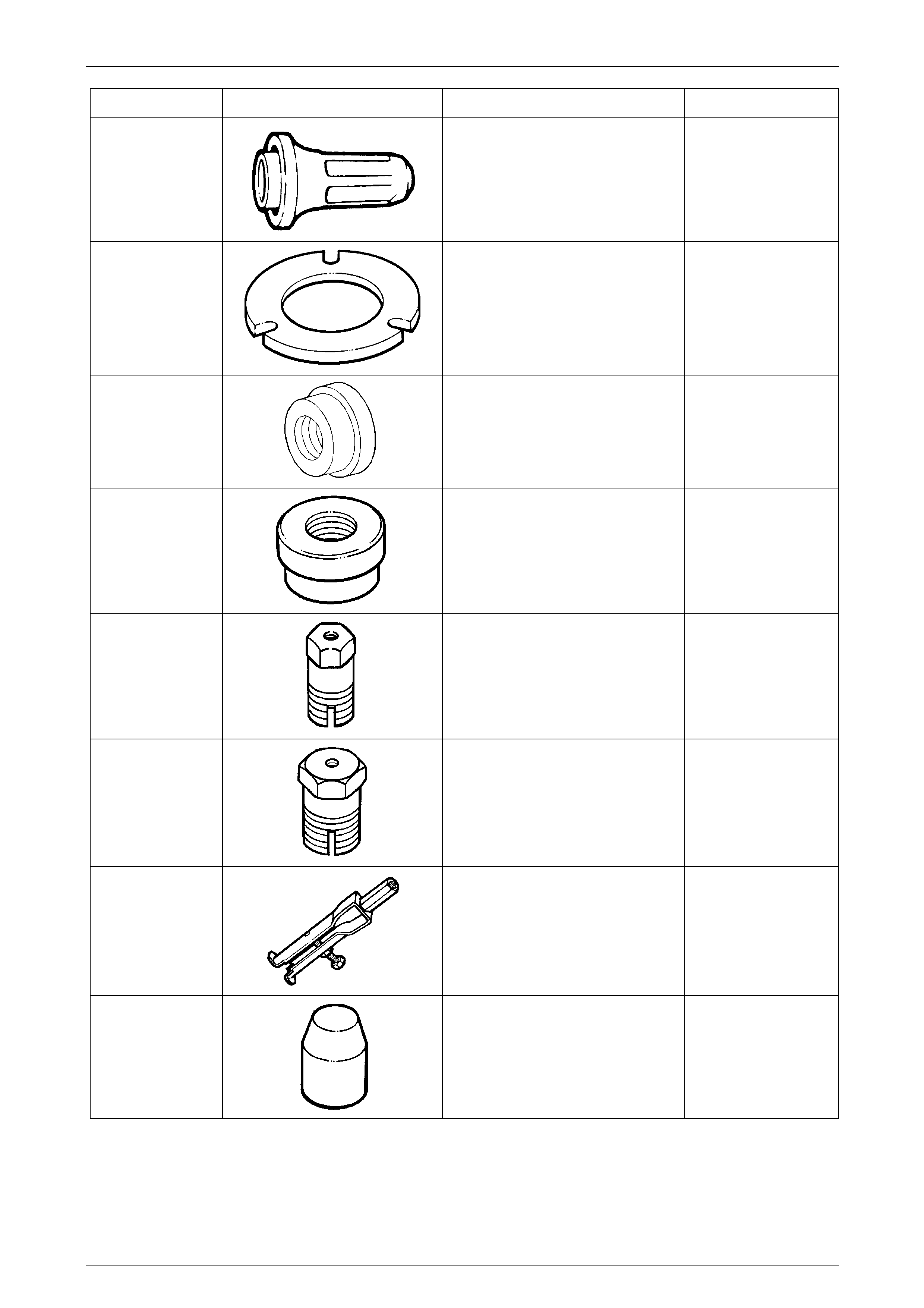

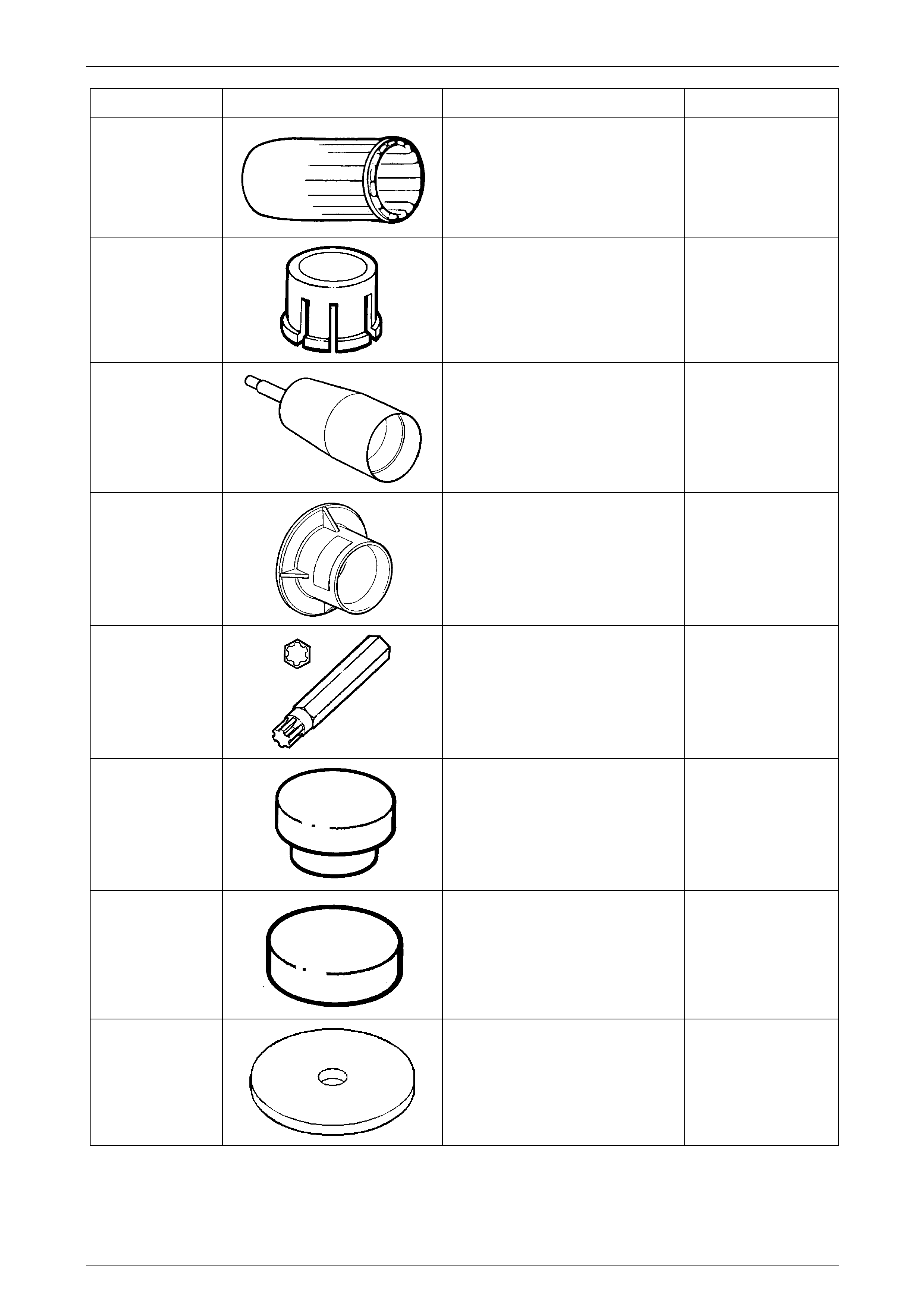

Tool Number Illustration Description Tool Classification

J25016

Oil Pump Seal Installer

Used to install the oil pump oil seal.

Previously released

Unique

J25018-A

Clutch Spring Compressor Adaptor

Used with compressor J23327 to

compress the reverse input clutch

during disassembly.

Previously released

Unique

J25019-4

Bush Installer

Used in conjunction with J8092

Installer Handle.

Previously Released

Unique

J25019-9

Bush Installer

Used in conjunction with driver handle

J8092.

Previously released

Unique

J25019-14

Bush Remover

Used with slide hammer J6125-1B.

Previously released

Unique

J25019-16

Bush Remover

Used with slide hammer J6125-1B.

Previously released

Unique

J29369-2

Universal Bush Remover

Used with slide hammer J23907.

Previously released

Unique

J29882

Inner Overrun Clutch Seal

Protector

Used to protect the inner, overrun

clutch piston seal from damage during

installation.

Previously released

Unique

Automatic Transmission – 4L60E – General Information Page 7C1–28

Page 7C1–28

Tool Number Illustration Description Tool Classification

J29883

Inner Forward Clutch Seal

Protector

Used to protect the inner, forward

clutch piston seal from damage during

installation.

Previously released

Unique

J33037

2 – 4 Band Apply Pin Tool

Used to check the selective apply pin

length.

Previously released

Unique

J34196-B

Bush Remover/Installer Set

Used for various applications,

described in the text.

Previously released

Unique

J34627

Snap Ring Pliers

Specific purpose is to assist in the

removal/replacement of the output

shaft snap ring.

Previously released

Unique

J35138

Torque Converter End Play

To be used in conjunctio n with

commercially available magnetic

stand and dial indicator.

Previously released

Unique

J36352

Speed Sensor Installer &

Gauging Tool

Needed to correctly install the output

speed sensor ring to the main shaft.

Comprises sleeve, J36352-6 and C-

washer J36352-4.

Previously released

Unique

J36418-B

Turbine Shaft Seal Installer &

Resizer

Used to install and re-size the turbine

shaft seal. Comprises J36418-1B

installer and J36418-2A resizer.

Previously released

Unique

J37789-A

Oil Pump Remover

Used with J39119 to remove the oil

pump assembly.

Previously released

Unique

Automatic Transmission – 4L60E – General Information Page 7C1–29

Page 7C1–29

Tool Number Illustration Description Tool Classification

J38735-3

Stator Shaft Sealing Ring Installer

Used with J39855-1 to install the

stator shaft seal.

Previously released

Unique

J39119

Oil Pump Remover Adaptor

Used with J37789-A to remove the oil

pump assembly.

Previously released

Unique

J39855-1

Stator Shaft Seal Expander

Used to expand the stator shaft seal

prior to installation.

Previously released

Unique

J39855-2

Stator Shaft Seal Resizer

Used to re-size the stator shaft seal

after installation.

Previously released

Unique

J41510

T50 Torx Plus Bit

Used to loosen and tighten the torque

converter housing to transmission

case bolts.

Also released as 6194.

Previously released

Unique

J41778-1

Oil Pump Bush Installer

Used with a bench press.

Previously released

Unique

J41778-2

Support Plate

Used to support the oil pump during

bush installation.

Previously released

Unique

J42628

Plate

Used with clutch spring compressor,

J23327-1.

Previously released

Unique

Automatic Transmission – 4L60E – General Information Page 7C1–30

Page 7C1–30

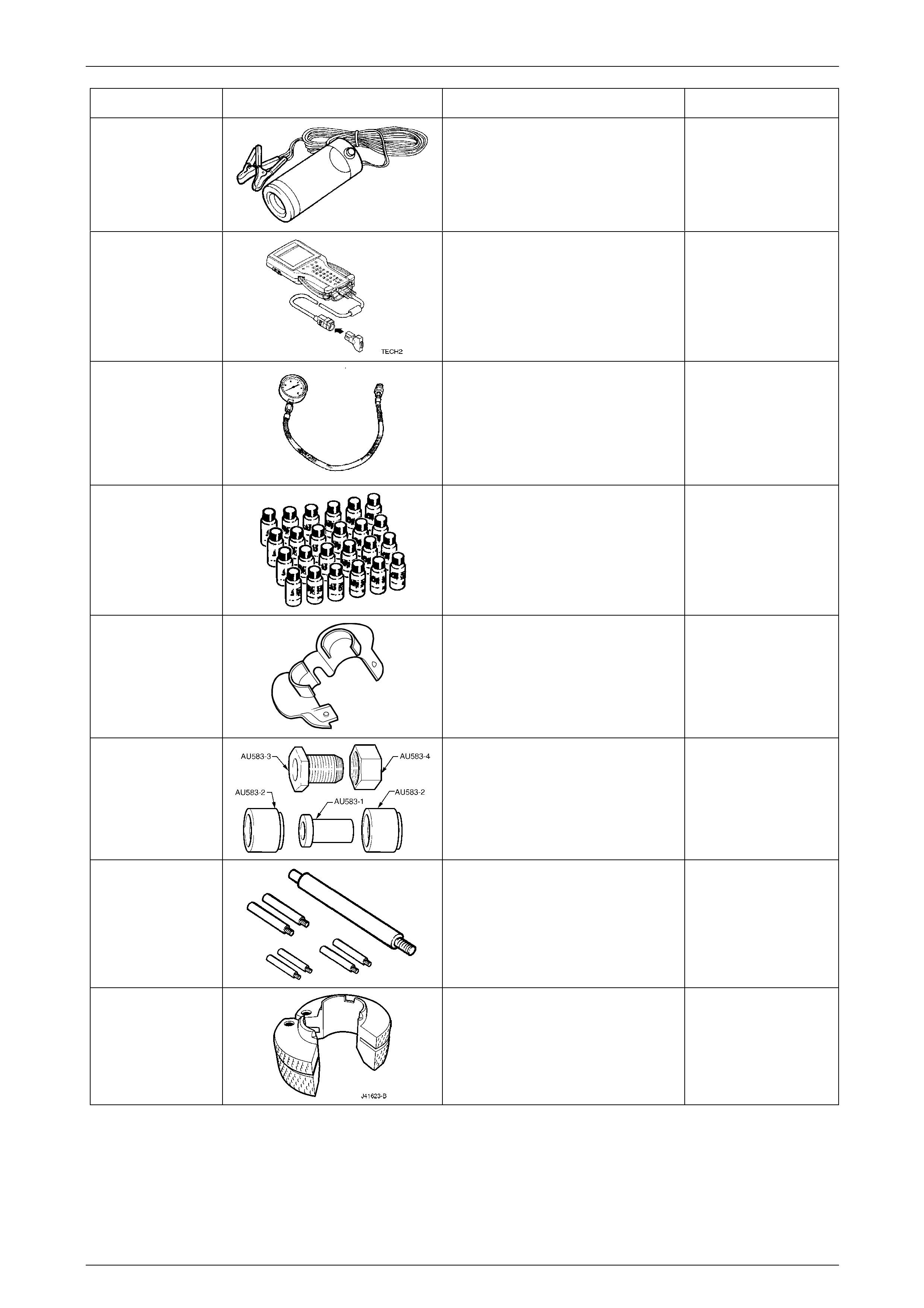

Tool Number Illustration Description Tool Classification

16296

12 Volt Black Light

Used with special, fluorescent dyes

for tracing a variety of fluid leaks.

Also previously released as J42220

Desirable

70000861

Tech 2 Diagnostic Tool

Previously released

Mandatory

J21867

Pressure Gauge And Hose

Assembly

Previously released

Mandatory

J28431-B

Fluorescent Oil Dye

Supplied in packs of 24, 1 oz bottles.

Suitable for black light tracing of

engine, transmission and power

steering fluid leaks.

Previously released

Desirable

AU525

A

U525

Quick-Connect Release Tool

This tool is used on all engines with

automatic transmission.

Previously released

Mandatory

AU583

Selector Shaft Seal Remo ver/

Installer

Use to remove and install the manual

shaft oil seal, with the transmission

installed in the vehicle.

Previously released

Unique

J25025-B

Dial Indicator Stand and

Guide Pin Set

Used for the guide pins for aligning

the control valve body sp acer plate.

Previously released

Unique

J41623-B

Cooler Line Disconnect Tool

Used to disconnect cooler line s at the

transmission end, Quick-Connects.

Previously released

Mandatory

Automatic Transmission – 4L60E – General Information Page 7C1–31

Page 7C1–31

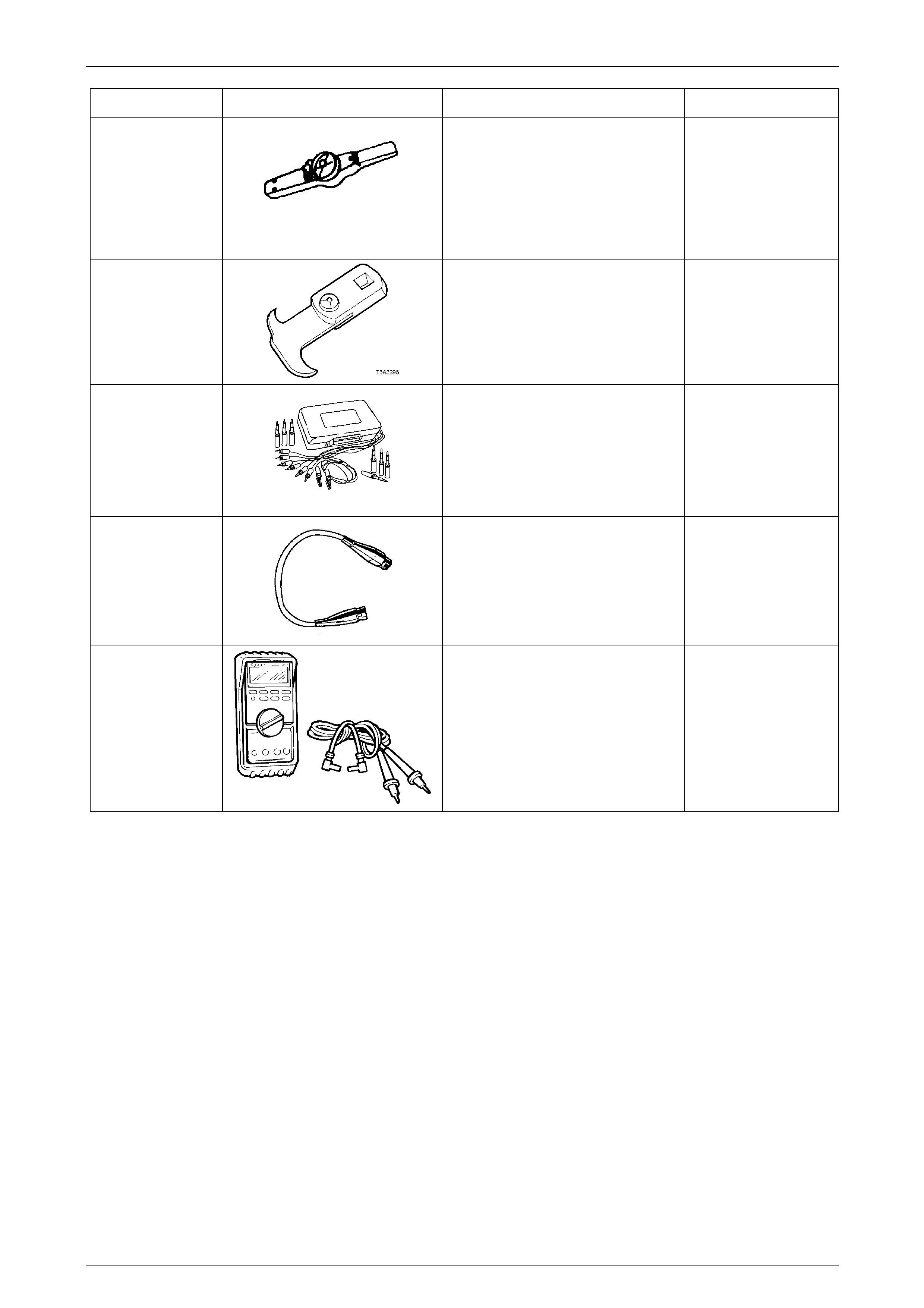

Tool Number Illustration Description Tool Classification

7380

(J25765-A)

Pre-load gauge

(3/8” drive)

Used in several applications. In 7C5 it

is used in conjunction with J33037 to

measure selective apply pin length.

(0-17 Nm.)

Previously released

Mandatory

E308

(56750)

(49V012001)

Seal Remover

Used as a universal seal remover.

Previously released

Available

J35616-C

Electronic Kit

Used in conjunction with a multimeter

for measuring voltages and

resistances without damaging wiring

harness connectors.

Previously released

Desirable

J44152

Jumper Harness

Used for checking automatic

transmission during diagnostic

checks.

Previously released

Mandatory

J39200

Digital Multimeter

Tool no. J39200 previously released,

or use commercially available

equivalent. Must have 10 meg ohm

input impedance.

Previously released

Available