MAIN DATA AND SPECIFICATIONS

Exhaust system

Pipe outside diameter × thickness

Front pipe mm (in)

Middle pipe (4 × 4) mm (in)

Silencer & Tail pipe

Type

Pipe outside diameter × thickness

Tail pipe mm (in)

Length mm (in)

Mounting

Number of suspension points

Type

50.8 × 1.6 (2.0 × 0.063)

50.8 × 1.6 (2.0 × 0.063)

Circular section-shell construction

of double skin and end plates,

internal construction of baffles

and perforated tubes.

50.8 × 1.6 (2.0 × 0.063)

Approximately 1335 (52.6)

4

Rubber

GENERAL DESCRIPTION

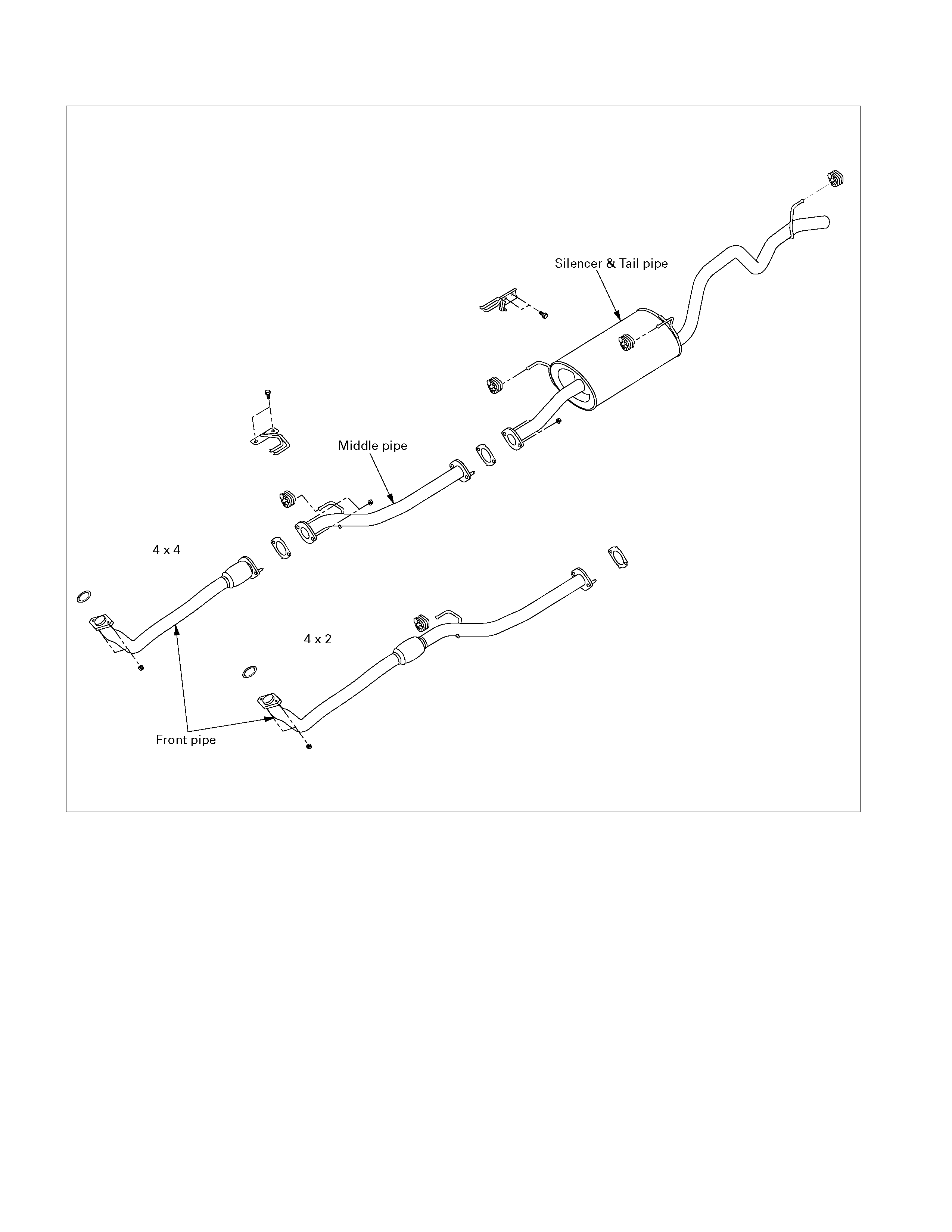

150R300002

The exhaust pipe layout is described in the above illustration.

The catalytic converter is installed between the turbocharger and the front pipe.

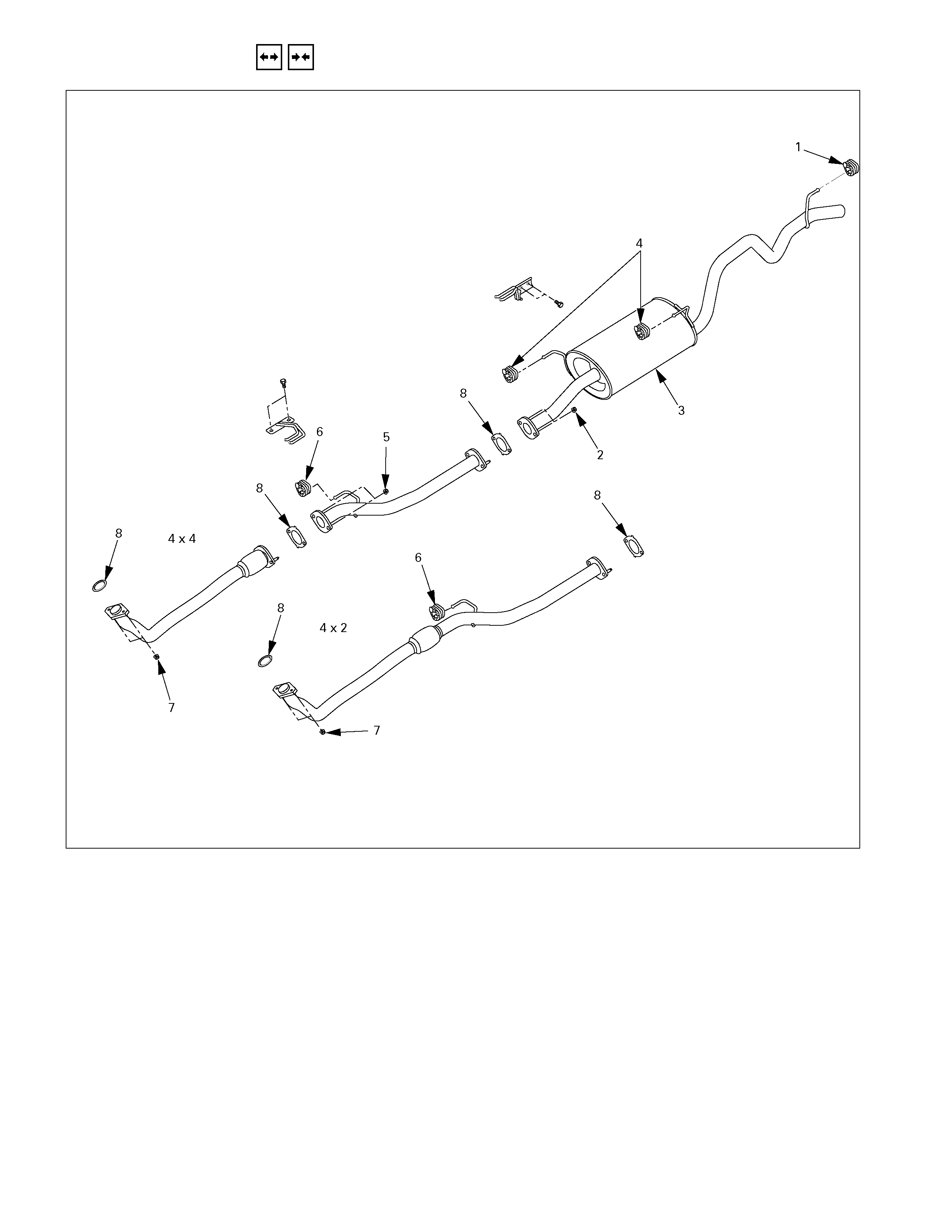

REMOVAL AND INSTALLATION

150L300001

Removal Steps

1. Rear hanger rubber

2. Silencer front nut

3. Exhaust silencer

4. Silencer hanger rubber

5. Middle pipe nut

6. Front hanger rubber

7. Front pipe nut

8. Exhaust pipe gasket

Important Operations – Installation

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

1. Front Pipe Nut

Connect the exhaust pipe to the catalytic converter.

Torque N⋅m (kg⋅m/lb⋅ft)

67 (6.8/49)

2. Middle pipe Nut (4×4 only)

Connect the middle pipe to the front pipe.

Torque N⋅m (kg⋅m/lb⋅ft)

43 (4.4/32)

3. Silencer Front Nut

Connect the silencer to the front or middle pipe.

Torque N⋅m (kg⋅m/lb⋅ft)

43 (4.4/32)

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Front Exhaust Pipe and Exhaust Silencer

Check the pipes for corrosion, cracking, damage or misalignment and repair as required.

Check the rubber rings for deterioration or damage and repair as required.

Catalytic Converter

1. Inspect outside the catalytic converter for any hitting mark.

2. Visual check inside the catalytic converter for crack or break converter element.

3. If find any problem during the inspection, replace the catalytic converter assembly.

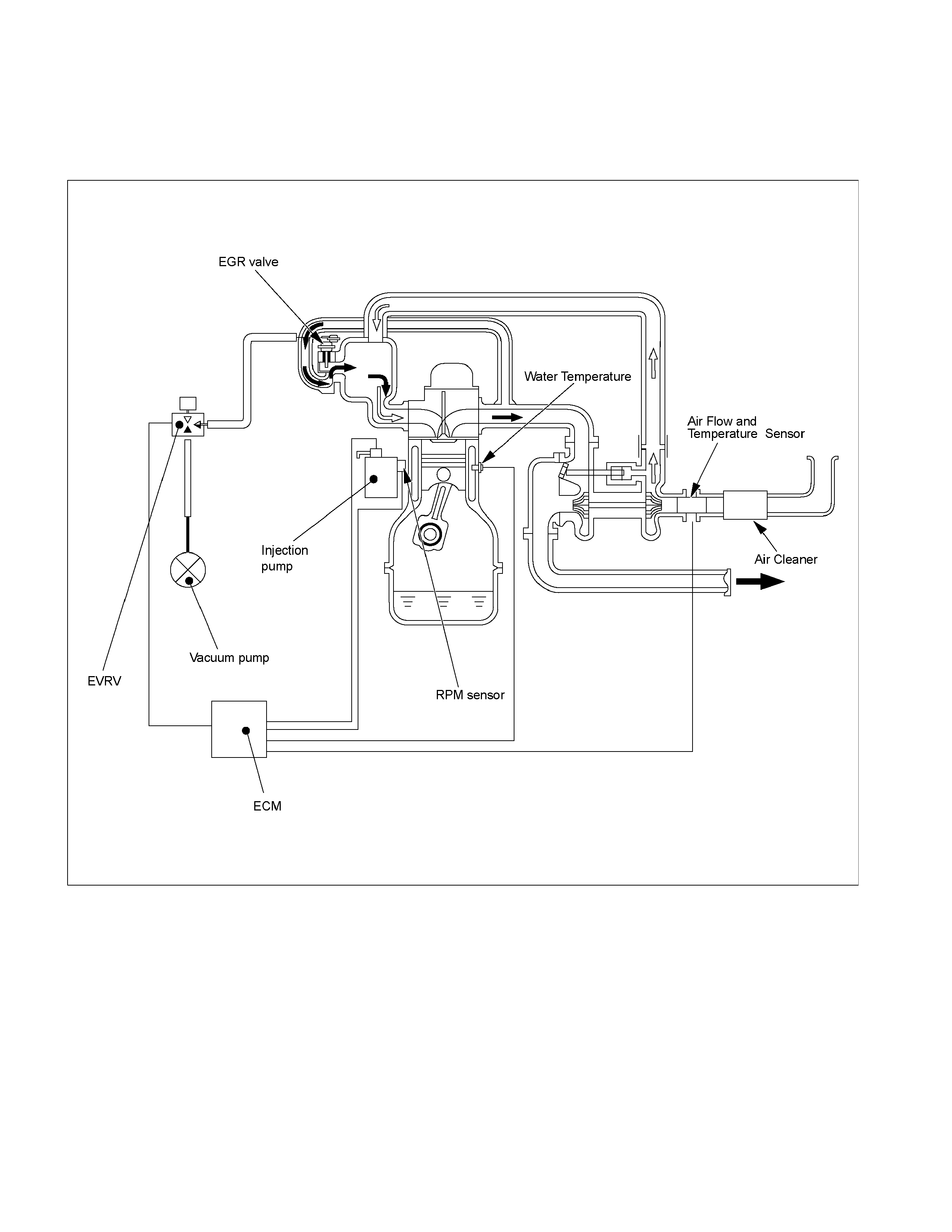

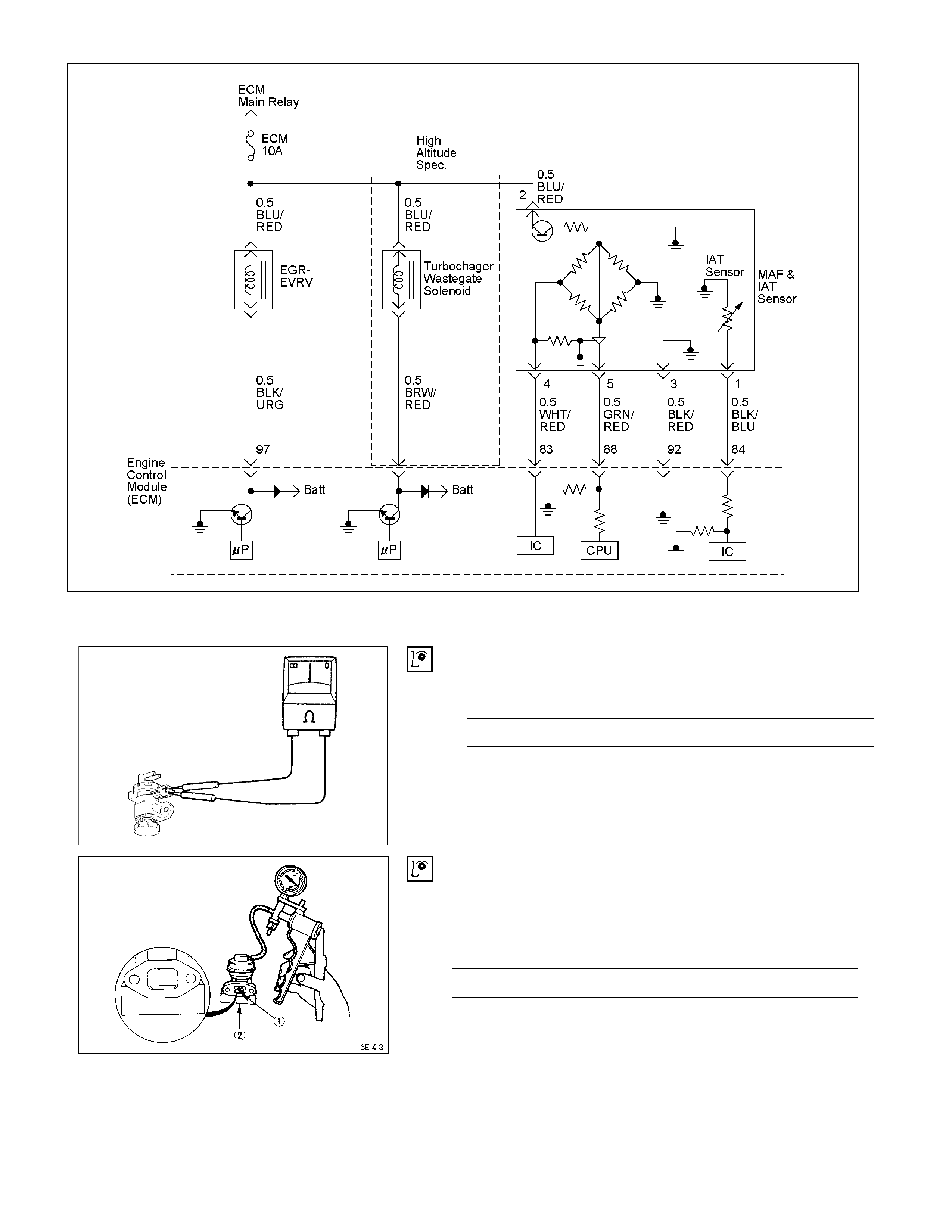

The EGR system is controlled by the ECM. Refer to “Engine Driveability and Emissions” section for details.

RTW46EMF000701

INSPECTION

RTW46ESH000301

EVRV

Use a circuit tester to measure the EVRV resistance.

EVRV Resistance Ω at 20°C

14

If the resistance is not within specification, replace the

EVRV.

EGR Valve

Apply vacuum to the EGR valve and check the valve

operation.

Negative Pressure

Less than 250 mm Hg No operation

More than 300 mm Hg Operation

TURBOCHARGER

MAIN DATA AND SPECIFICATI O NS

Engine Model 4JA1L 4JA1T, 4JB1T,

4JA1TC 4JG2T 4JH1TC

Turbocharger Model IHI RHF 4H IHI RHB 52W

or RHF5 RHF5H

Turbine Type Radial Inflow

Compressor Type Radial Outflow

Maximum Permissible Speed rpm – 180,000 172,000 180,000

Boost Set Value mmHg 440 – – –

Wastegate Opening Pressure mmHg – 189 – 887

Safety Valve Opening Pressure mmHg – 850 – 910

Weight kg (lb) 4.1 (9.0) 4.2 (9.3) 4.6 (10.1)

IHI: Ishikawajima Harima Heavy Industries., Ltd.

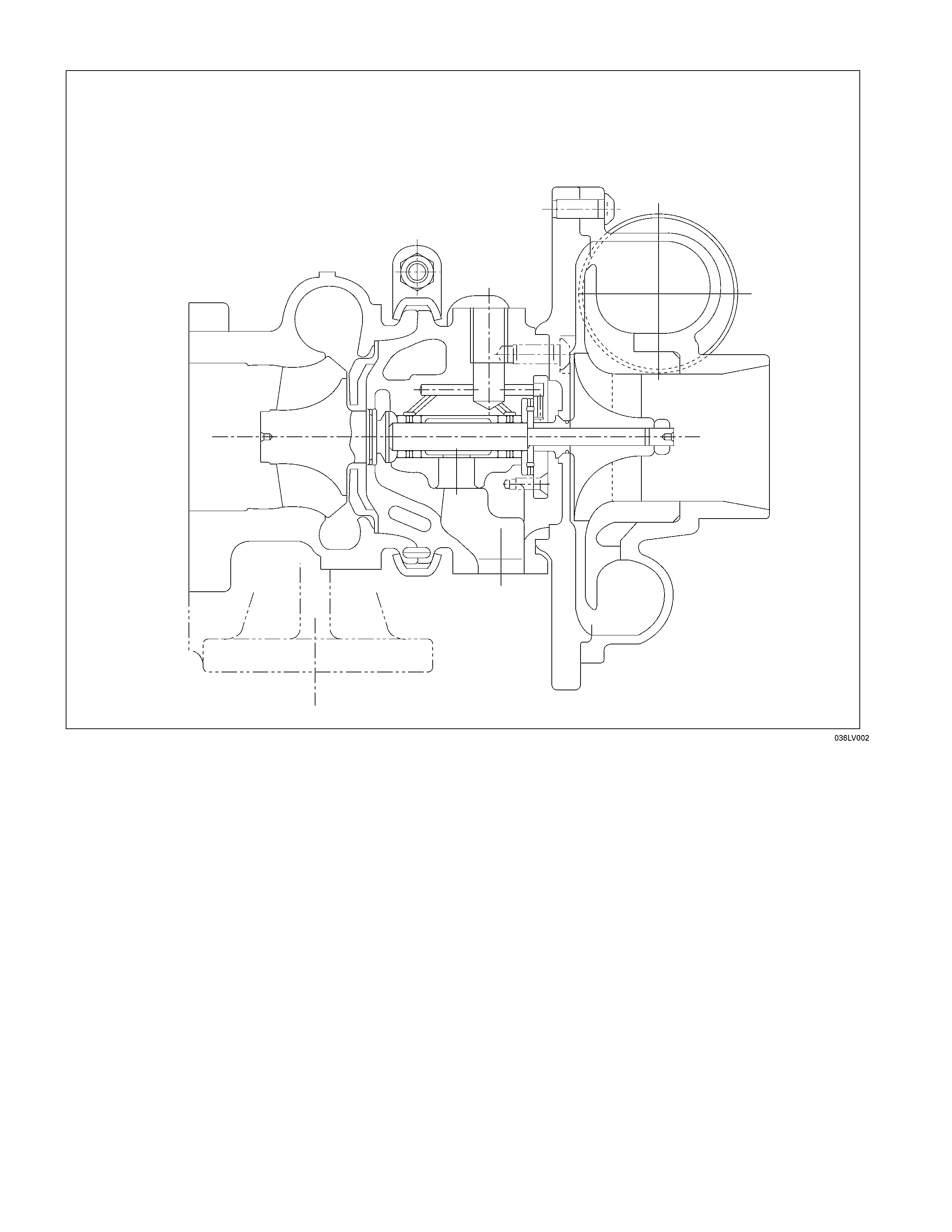

GENERAL DESCRIPTION

The turbocharger internal mechanism consists of the turbine wheel, the compressor wheel, and the radial bearings.

These parts are supported by the bearing housing.

The turbocharger external mechanism consists of the compressor housing air intake port and the turbine housing air

exhaust port.

The turbocharger increases air intake efficiency. This results in increased engine power, reduced fuel consumption,

and minimal engine noise.

The turbocharger operates at very high speeds and temperatures. Part materials have been carefully selected and

machined to extremely high precision.

Turbocharger servicing requires great care and expertise.

If reduced performance is noted, check the engine for damage or wear. If there is no apparent engine damage or wear,

trouble with the turbocharger is indicated.

INSPECTION AND REPAIR

Make the necessary adjustments, re pairs, and part replacements if excessive wear or damage is discovere d during

inspection. Note that the quoted pressures ar e Absolute Pressure.

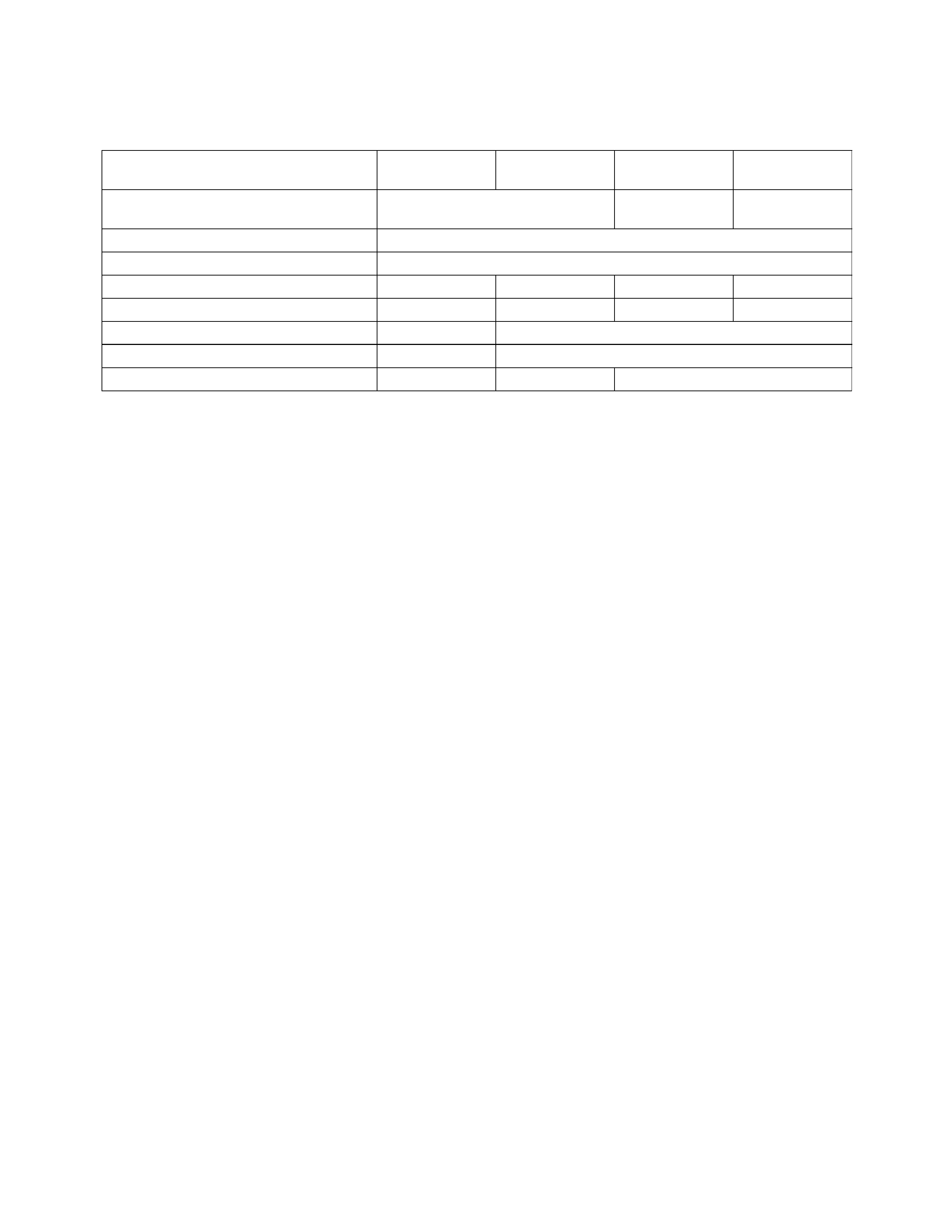

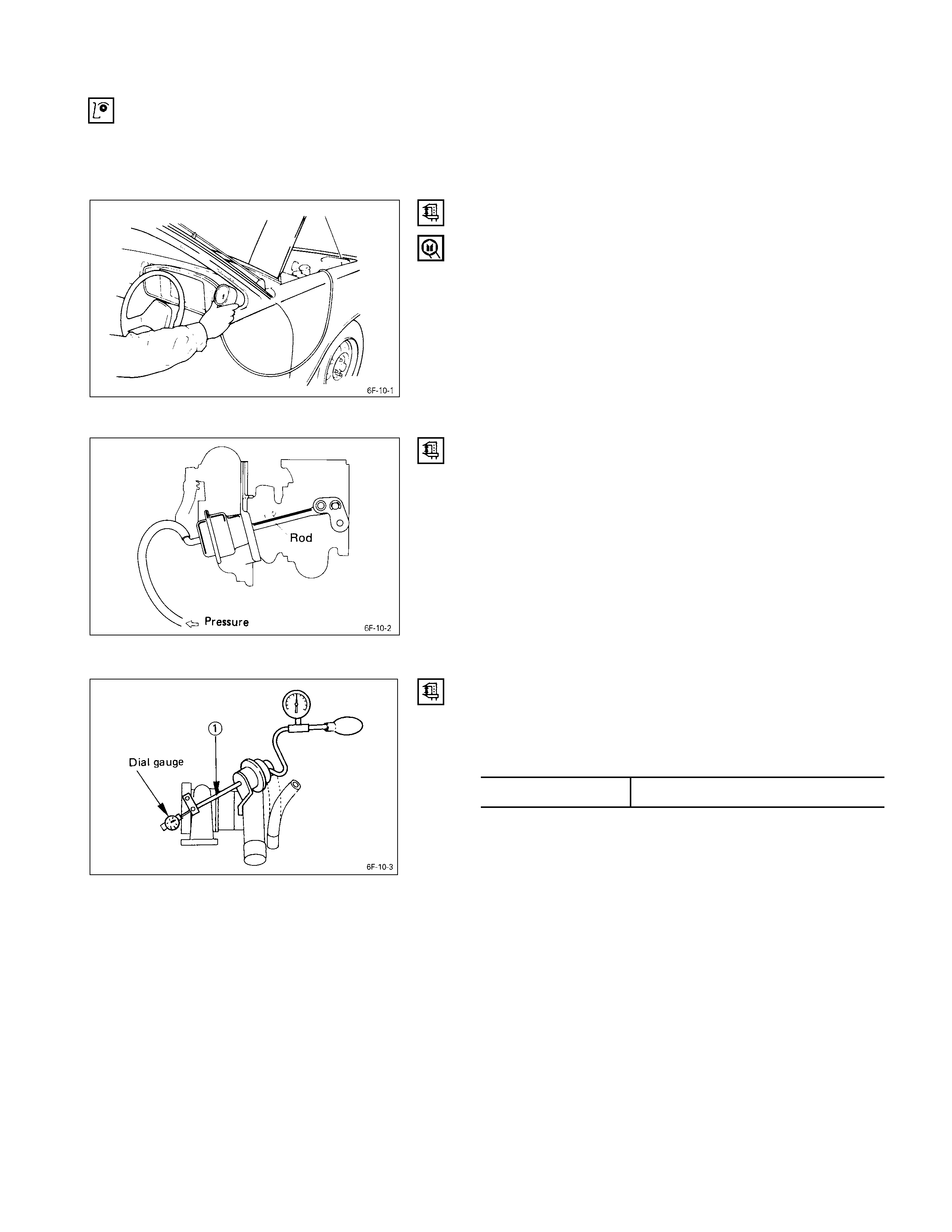

Turbocharger pressure check

(1) Remove the pressure switch conn ecting hose from

intake duct.

(2) Connect the pressure gau ge.

(3) Start the engine and gradually increase the engine

speed (the vehicle must be stationary with no load

applied to the engine).

(4) Check to see that turbocharger pressure rises to

approximately 141.3 kPa (1060 mmHg).

Pressure Gauge : 5-8840-0075-0

Waste gate operation check

(1) Remove the hose between the waste gate and the

intake pipe.

(2) Connect the pressure gau ge.

(3) Check to see that the rod begins to move when a

pressure of approximately 118 kPa (885 mm Hg) is

applied to the waste gate.

Note:

Do not apply a pressure greater than 150 kPa (1125

mm Hg) to the wastegate during this check.

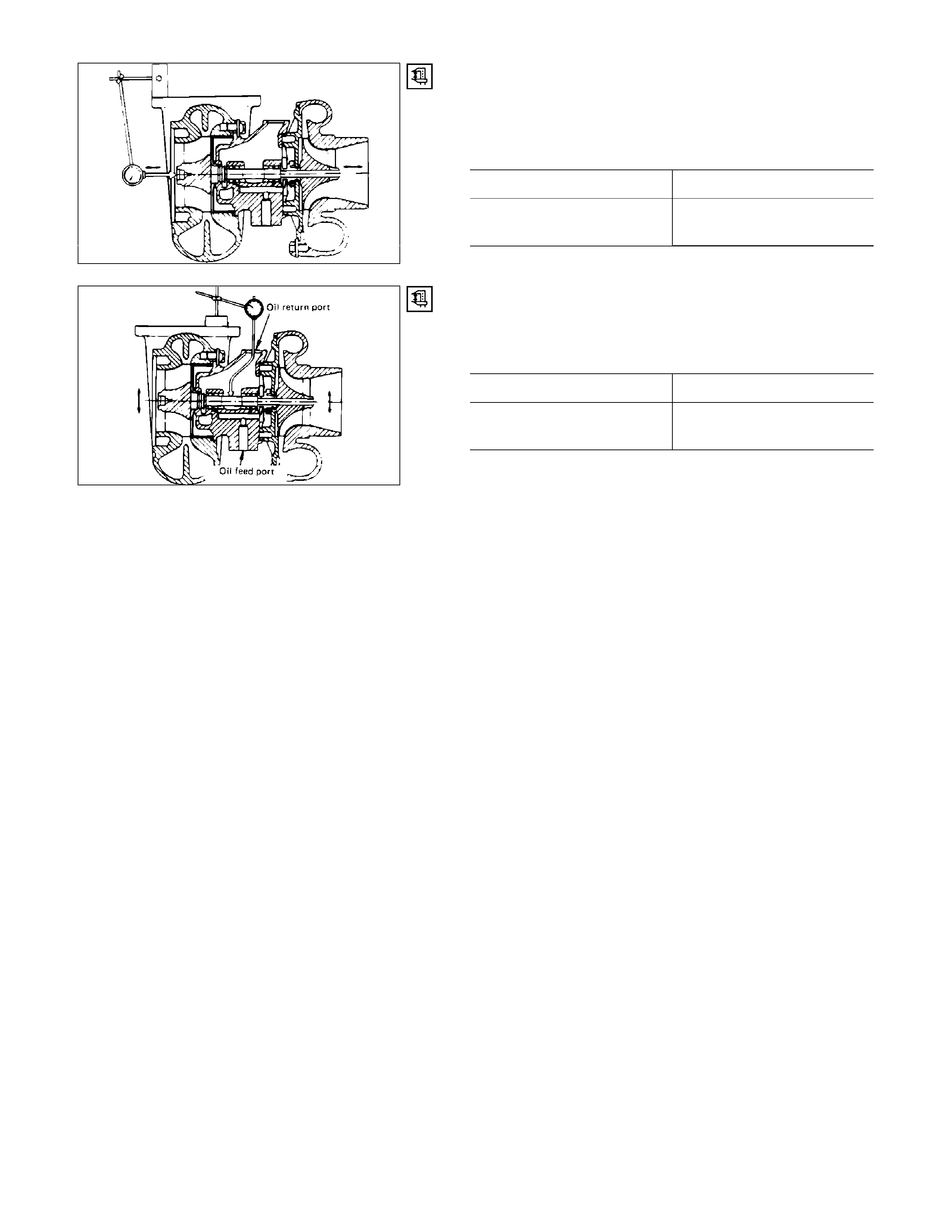

Unit Inspection (Remove Turbo. from engine)

Check that the pressure required to stroke the control rod

c is at the correct value. kPa / mm Hg

4JH1-TC 134.8 / 1101

Contact the “ISUZU MOTORS LIMITED” Dealer service

department or “IHI SERVICE FACILITY” for major repairs

and maintenance.

Important wheel shaft end play and bearing clearance

standards and limits are included below for your

reference.

Wheel Shaft End Play

Use a dial indicator to measure the wheel shaft end play.

Apply a force of 11.8 N (1.2 kg/2.6 lb) alternately to the

compressor wheel end and the turbine wheel end.

Wheel Shaft End Play mm (in)

Standard Limit

0.03 - 0.06

(0.001 - 0.002) 0.09 (0.004)

150RY00034

Wheel Shaft and Bearing Clearance

Use a dial indicator to measure the wheel shaft and

bearing clearance.

Wheel Shaft and Bearing Clearance mm (in)

Standard Limit

0.056 - 0.127

(0.0022 - 0.0050) 0.127 (0.0050)

150RY00036

SPECIAL TOOLS

ILLUSTRATION TOOL NUMBER TOOL NAME

901RX00143

5-8840-0075-0 Pressure Gauge

IHI SERVICE NETWORK

For inquiries relating to turbochargers, please contact your ISUZU distributor or the nearest IHI Turbocharger Service

Facility.

HEADQUARTERS

ISHIKAWAJIMA HARIMA HEAVY INDUSTRIES CO., LTD.(IHI)

General Machinery Division

Tokyo Chuo Building 1-6-2 Marunouchi Chiyoda-ku

Tokyo 100-0005 JAPAN

TEL: 81-(3)-3286-2405 to 2407 (3 lines)

FAX: 81-(3)-3286-2430

CHINA

IHI BEIJING OFFICE

Room 705, China World Trade Centre, No. 1 Jian Guo Men Wai Avenue

Beijing, People’s Republic of CHINA

TEL: 86-(1)-505-4997, 0408

FAX: 86-(1)-505-4350

TLX: 210343 IHIPK CN

TAIWAN

IHI TAIPEI OFFICE

Room 1202, Chia Hsin Building, No. 96 Chung Shan

North Road, Section 2, Taipei, TAIWAN

TEL: 886-(2)-542-5520, 5521, 5523

FAX: 886-(2)-542-4362

TLX: 11320 IHICO

THAILAND

IHI BANGKOK OFFICE

8th Floor, Thaniya Building, 62 Silom Road, Bangkok, THAILAND

TEL: 66-(2)-236-3490, 7356, 9099

FAX: 66-(2)-236-7340

TLX: 82375 IHICO TH

MALAYSIA

IHI KUALA LUMPUR OFFICE

Letter Box No. 52, 22nd Floor, UBN Tower,

10 Jin. P. Ramlee 50250 Kuala Lumpur, MALAYSIA

TEL: 60-(3)-232-1255, 1271

FAX: 60-(3)-232-1418

TLX: IHI KLMA 20257

INDONESIA

IHI JAKARTA OFFICE

9th Floor, Skyline Building JI. M. H. Thamrin, No. 9, Jakarta, INDONESIA

TEL: 62-(21)-32-2147, 390-2211

FAX: 62-(21)-32-3273

TLX: 44175 IHIJKT