SECTION 2A - SERVICE OPERATIONS - VT WAGON

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

IMPORTANT:

When any LPG system component has been replaced or overhauled, or when the engine assembly has

been replaced or overhauled, the adaptive learn drive cycle procedures must be carried out as described in

2.23, ADAPT IVE DIGITAL PROCESSOR SET - UP PRO CEDURE under VT Sedan With Production LPG, of the

VT Series Service Information CD. This is because the values stored in the Adaptive Digital Processor

operational cells apply only to the previous condition of the engine or components.

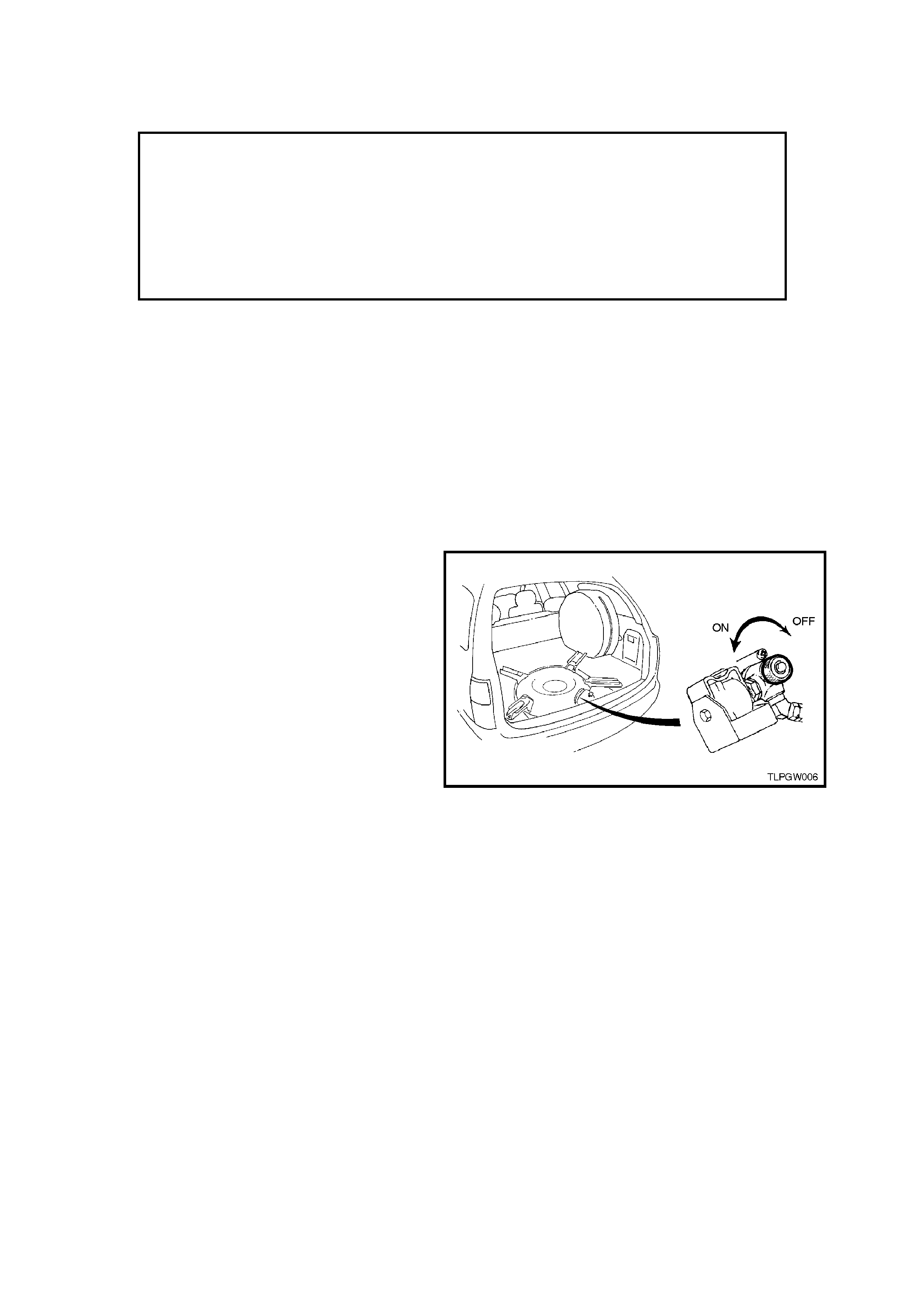

2.1 DRAINING THE SERVICE LINES

The procedure f or draining the ser vice lines on VT

Series Wagon is the same as VT Series Sedans

with exception to the location of the m anual service

valve. Theref ore when draining the service lines on

VT Series Wagon, refer to 2.1 DRAINING THE

SERVICE LINES under VT Sedan W ith Production

LPG of the VT Series Service Information CD,

noting the location of the manual service valve for

VT Series wagons.

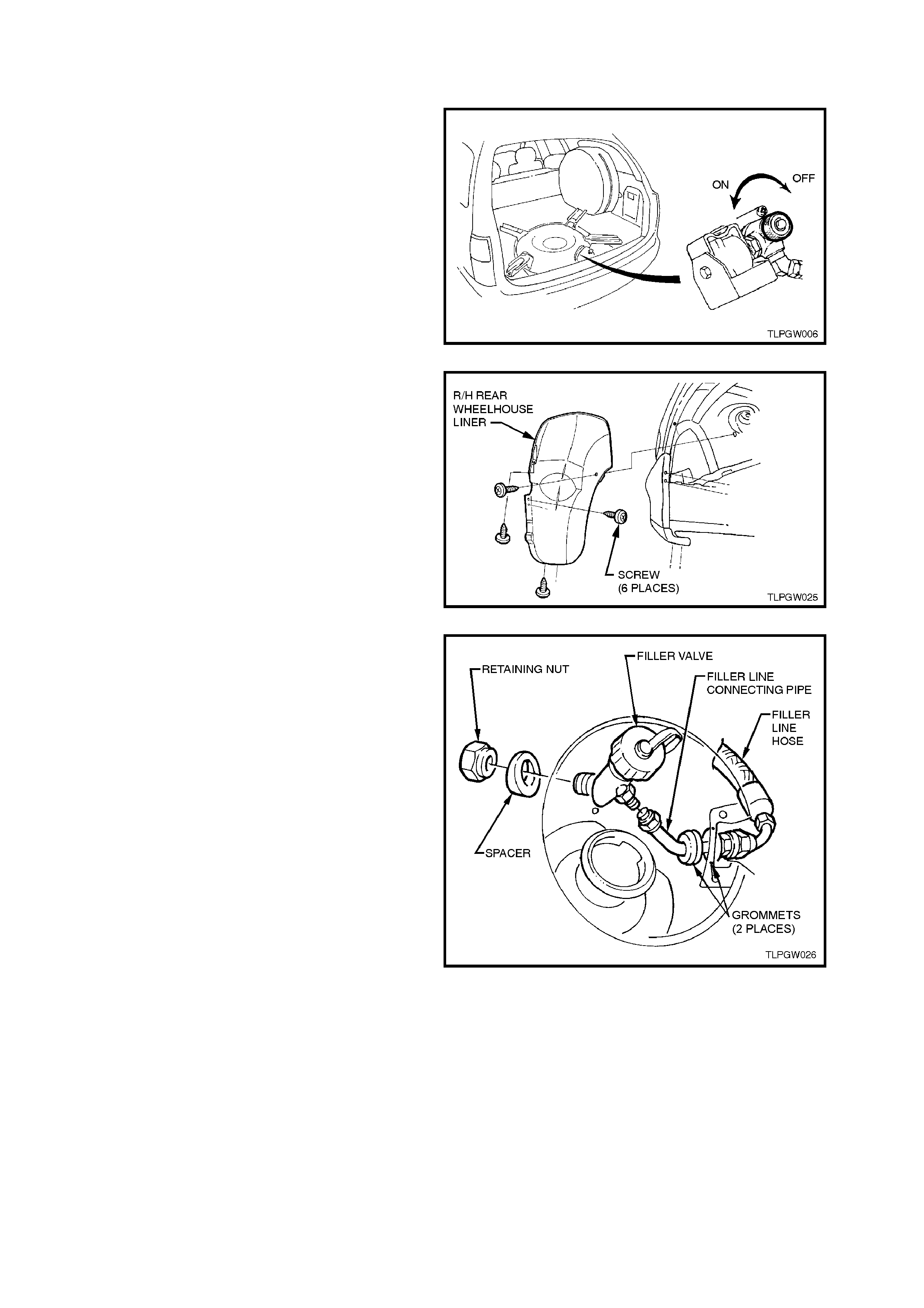

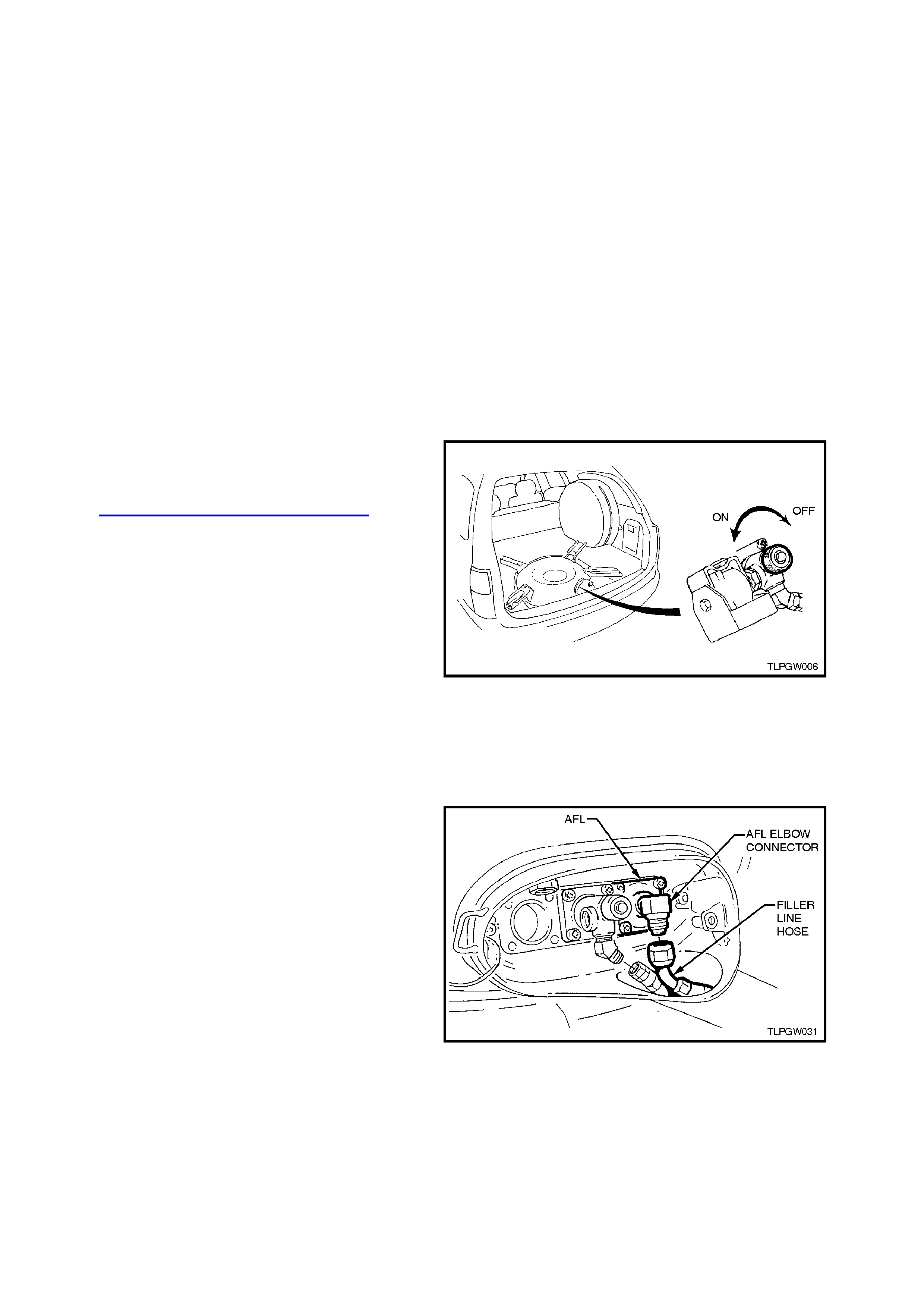

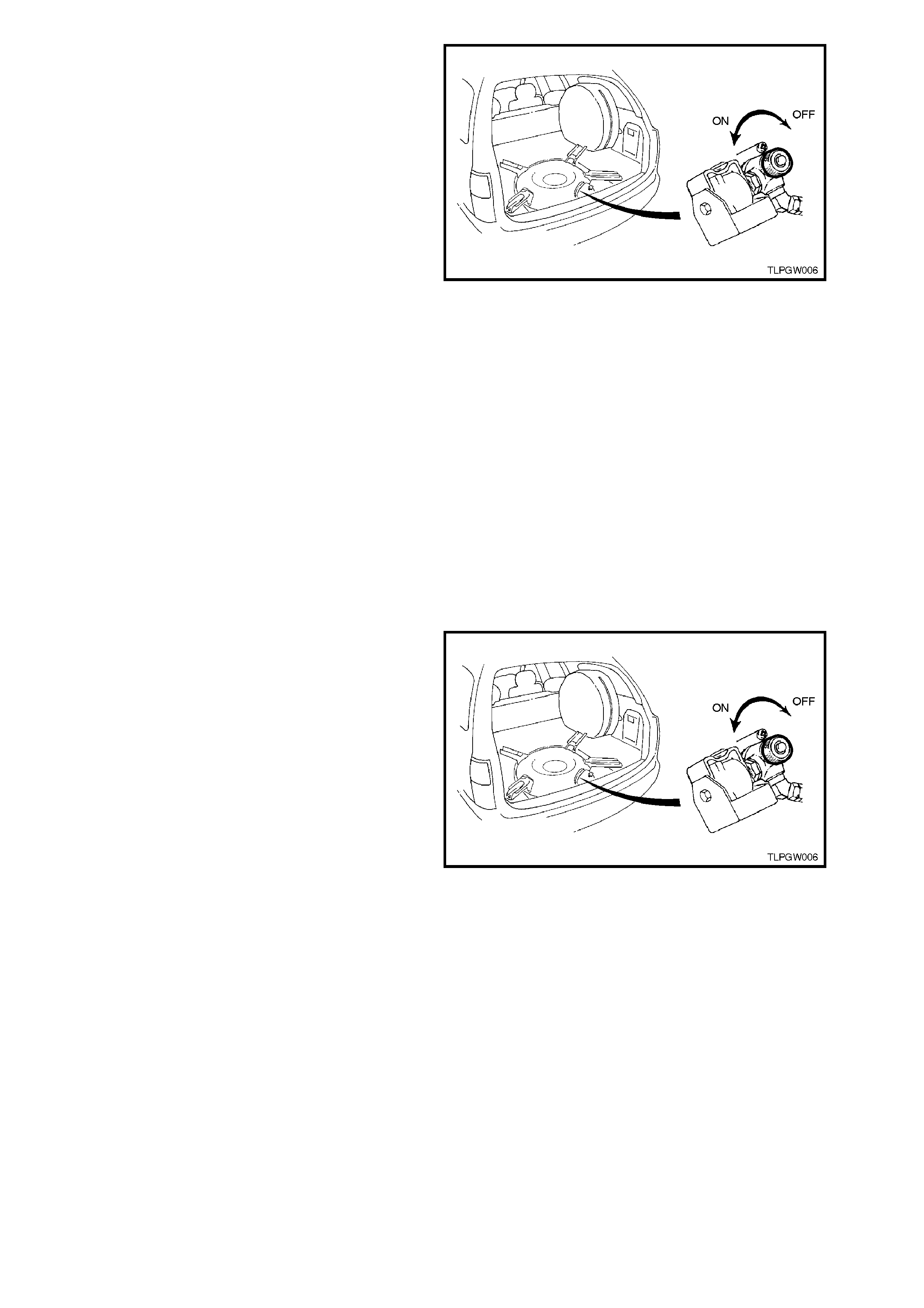

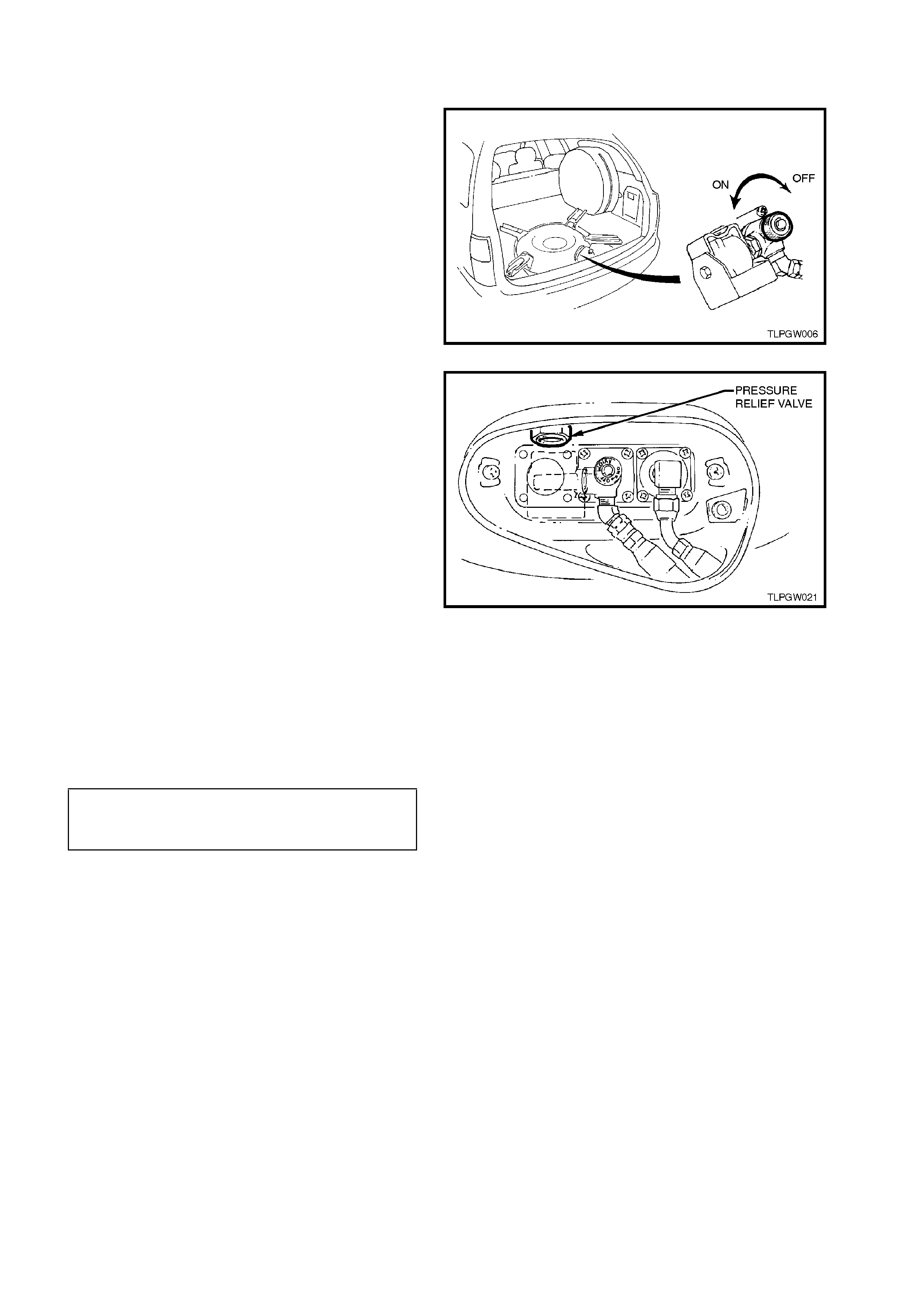

The manual service valve is located on the upper

rear of the LPG tank which is m ounted in the spare

wheel compartment, refer Fig. 2A-1.

Figure 2A-1

2.2 LPG TANK UNLOADING PROCEDURE

The procedure for unloading the LPG tank on VT

Series wagons is essentially the same as the VT

Series Sedan, therefore refer to

2.2 LPG TANK UNLOADING PROCEDURE under

VT Sedan With Production LPG of the VT Series

Service Information CD, noting the following:

Due to a flexible rear s ervic e line (hos e) being used

on Wagon Models , it is not neces s ary to com pletely

remove the rear service line. Therefore, only

disconnect the rear service line at the manual

service valve.

To remove the tank fuel gauge, it will be necessary

to remove the smart unit and solenoid sleeve to

gain access to the four tank fuel gauge retaining

screws. Refer to 2.8 SMART UNIT AND

SOLENOID VALVE in this Section.

CAUTION:

AFTER ANY VALVE OR COMPONENT HAS

BEEN REMOVED AND REINSTALLED TO THE

LPG TANK, THE LPG TANK MUST BE

PRESSURE AND LEAK TESTED IN

ACCORDANCE WITH THE CURRENT

AUSTRALIAN STANDARD AS2030.1 BEFORE

THE LPG T ANK IS PUT BACK INTO SERVICE IN

THE VEHICLE.

Figure 2A-2

2.3 LEAK TESTING

The following leak test procedure is to be carried

out on the LPG system high pressure components

and is to be performed as part of the LPG After

Installation Check as well as each normal

maintenance service.

The leak test is to be carried out in the open air in a

well-ventilated area, away from any ignition source

and PRIOR to bringing the vehicle into the

workshop.

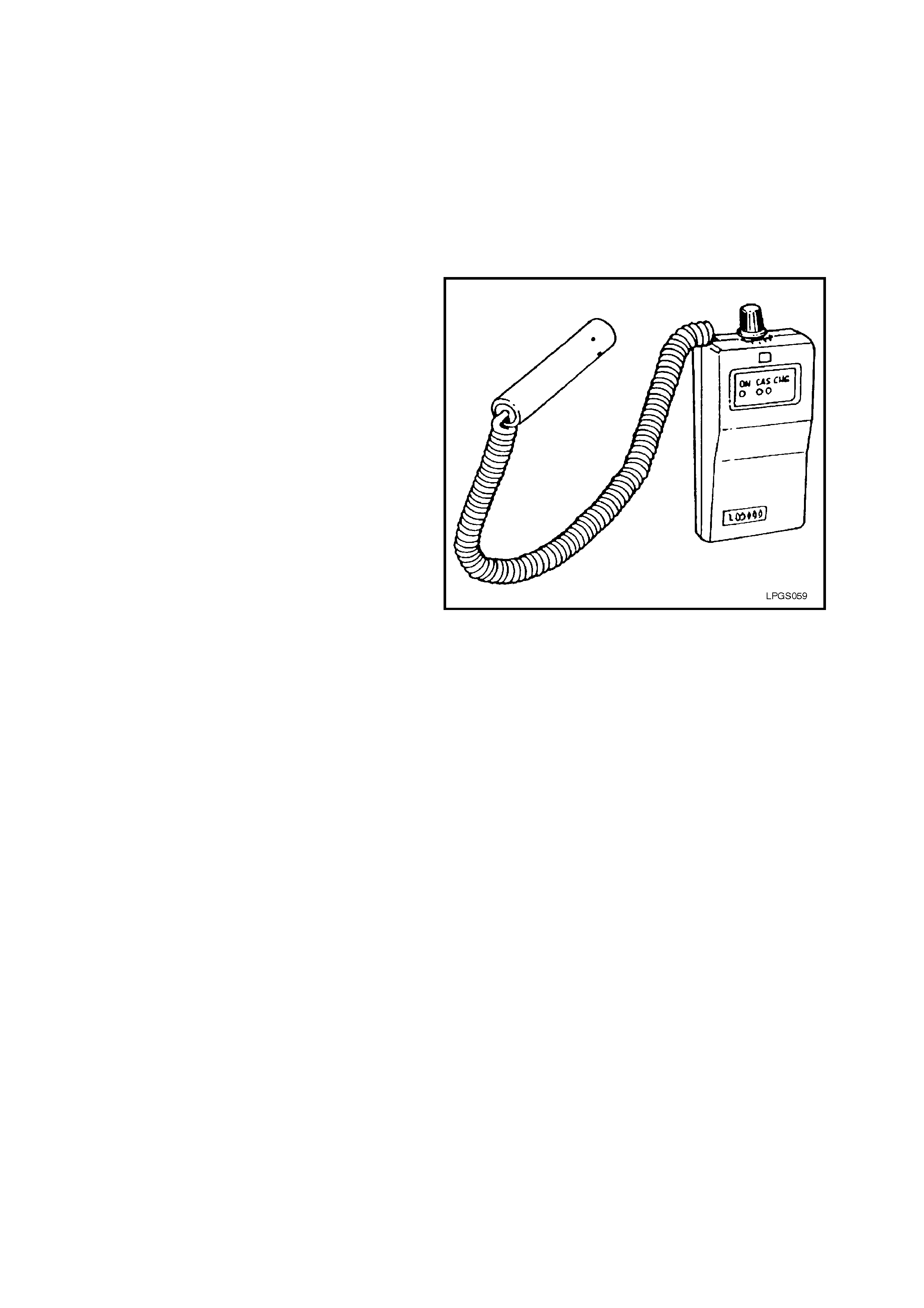

COMBUSTIBLE GAS DETECTORS

If a com bustible gas detector is to be used for leak

testing of the LPG system, the combustible gas

detector should be capable of detecting 25 parts

per million (P.P.M.) of LPG in air. A detector such

as a LD-9001 LP Gas Leak Detector or equivalent

is recommended.

Whichever leak detector is used, it is important to

follow the manufacturer's instructions in regard to

adjustment and setting the instrument prior to

conducting the leak test.

Care in interpretation is necessary, as the detector

can respond to the presence of any of several

vapours that are combustible, some of which may

not be LPG, such as oil smears, joining

compounds, etc. They may also detect residual

LPG vapours that are present for reasons other

than leakage, and which must be cleared before a

valid test for leakage can be made.

If a leak is present, a detector will signal its

existence but not its size, and will indicate its

general location, but may not be able to locate it

exactly. So, a proving or follow up check with foam

is often desirable.

Figure 2A-3

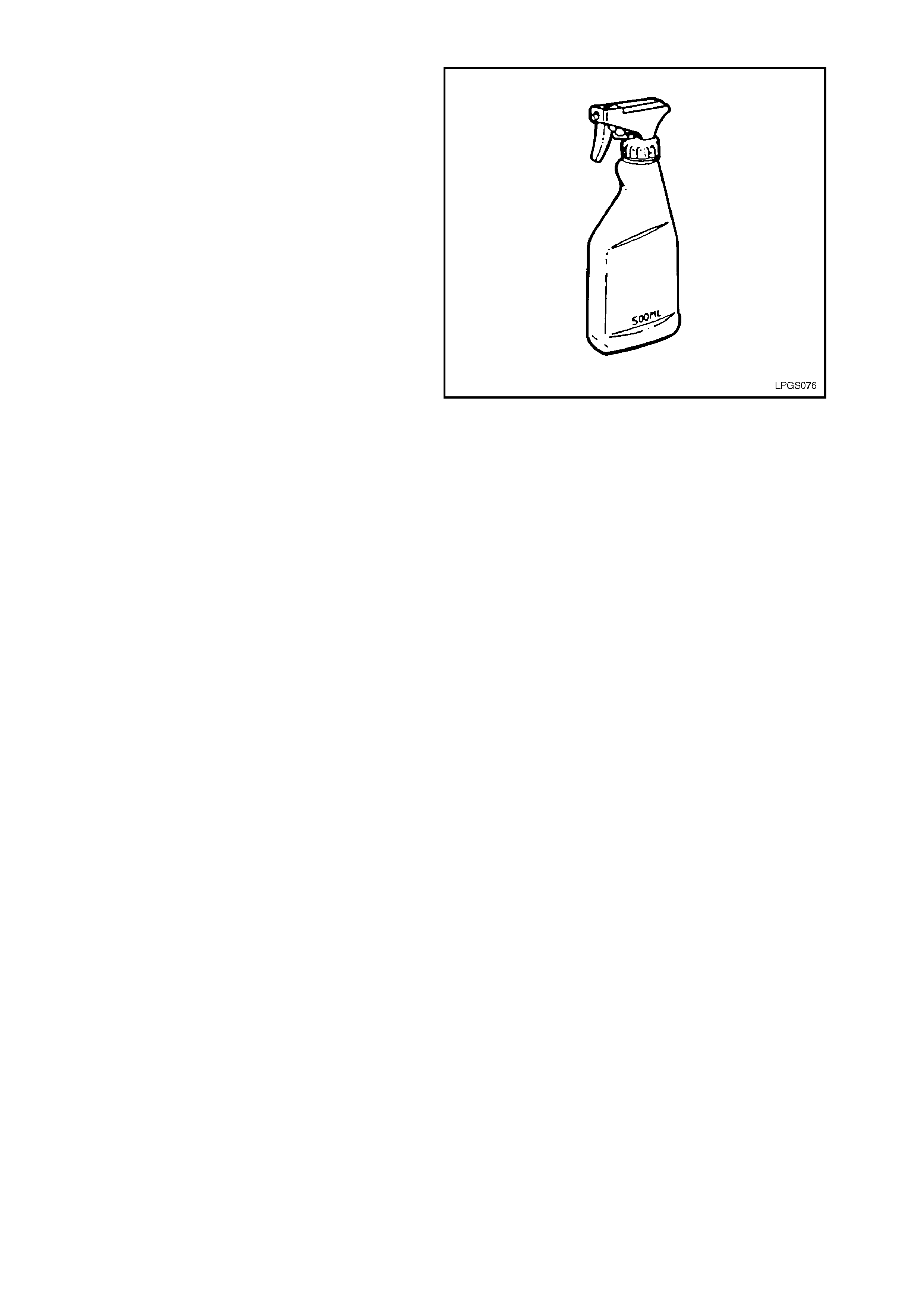

FOAM

If foam is to be used, the f oaming agent should be

a propriety leak test solution, f or mulated spec if ic ally

for the purpose, s uch as G am eco Leak Check TM or

a similar solution. T he solution should be fresh and

the whole of the area to be tested should be

coated, and time allowed for bubbles to form. All

areas under test must be able to be observed

during the leak test.

W hichever foaming agent is used, it is impor tant to

follow the manufacturer's instructions.

Foam testing is more effective for small leaks.

Large leak s tend to blow the solution away from the

leak without forming a bubble, so care in

application is necessary.

The leak test is performed by directing a spray of

solution at each of the possible leak points in the

high pressure side of the system.

After applying the solution, look c ar ef ully for no les s

than 15 seconds.

A leak is indicated by the presence of gas bubbles

(foaming) in the solution at the leak source.

NOTE:

LPG IS HEAVIER THAN AIR SO TEST

THOROUGHLY BELOW ALL COMPONENTS

AND FITTINGS.

If a leak is detected at a joint, the relevant

component/s must be rem oved as described in the

appropriate component service operation in this

Section, all mating threads thoroughly cleaned,

then resealed using the specified sealant and

tightened to the correct torque specification. Once

installed, thoroughly leak test the component/s

again.

At the completion of each test, dry the leak test

area of the foaming agent with low pressure

compressed air or shop cloths and spray

imm ediate area with a water dispersing agent such

as WD40 or RP7, etc.

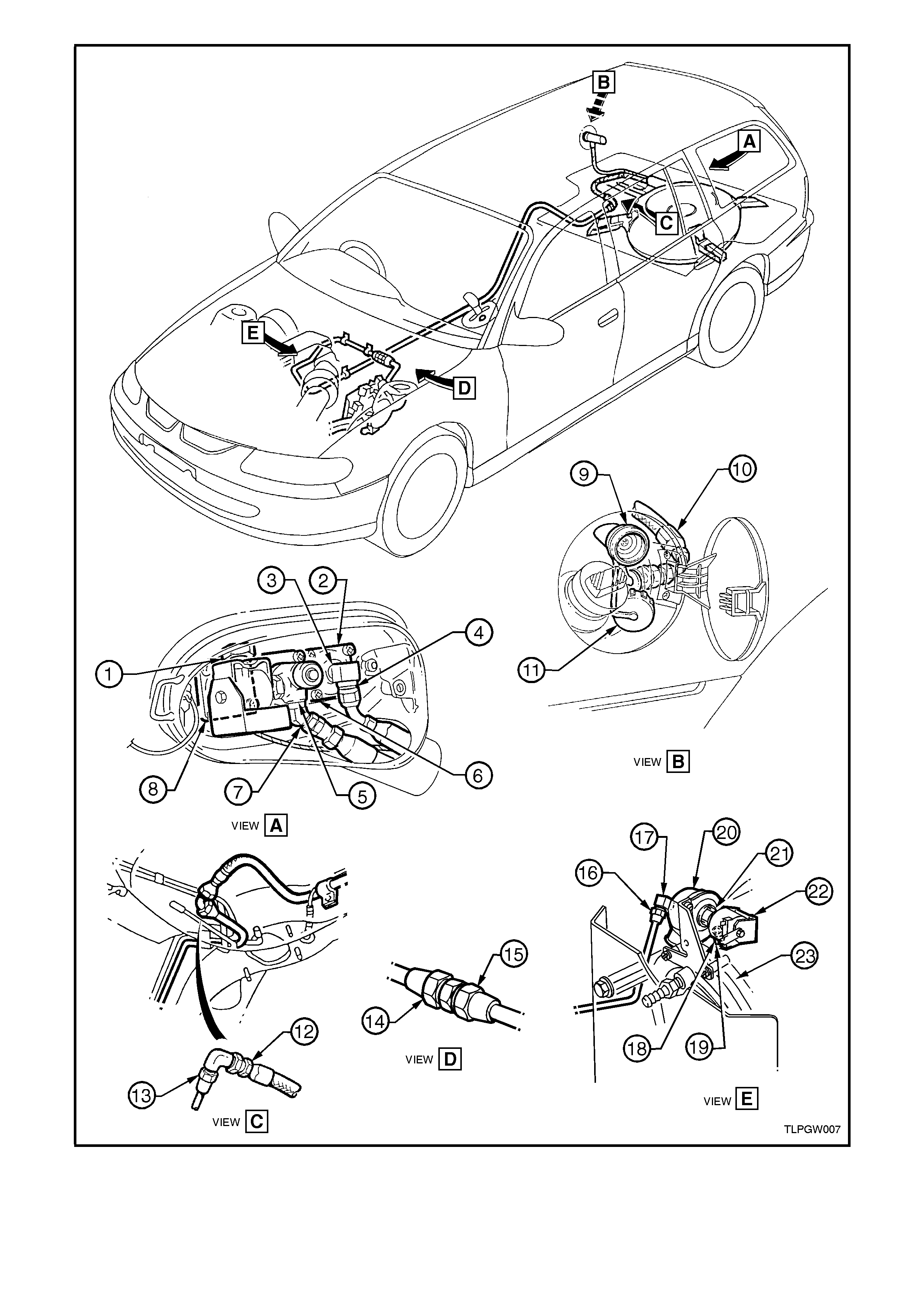

Figure 2A-4

LEAK TEST PROCEDURE

With at least 3 litres of LPG in the LPG tank, leak test the complete LPG system following the instructions below

1. Park the vehicle in a dry, well ventilated area.

DO NOT SMOKE OR ALLOW NAKED FLAMES OR ANY IGNITION SOURCE NEAR THE VEHICLE DURING THE

TESTING OPERATIONS.

2. Ensure the vehicle is operating on LPG and run the engine for at least 30 seconds to fully pressurise the

system, then stop the engine.

3. The recommended sequence of testing is as follows:

A. Referring to Figure 2A-5, View A, lift the rear part of the floor trim in the luggage compar tment to acc es s the

valve box, remove the valve box cover and leak test at and around the:

Pressure relief v alve (1).

AFL to LPG tank (2).

AFL inlet elbow to AFL (3).

Rear service line to AFL inlet elbow connection (4).

Solenoid and manual service valve assembly (5).

Solenoid and manual service valve assembly to LPG tank (6).

Rear service line to solenoid and manual service valve assembly connection (7).

Tank fuel gauge assembly (8).

B. Referring to Figure 2A-5, View B: remove the right hand rear wheelhouse liner to gain access to the inner

side of the f iller valve as s embly, refer to Section 1A1 BODY of the VT Series Servic e Manual. Leak tes t at

and around the filler valve connecting pipe to filler line hose (10).

Open filler box door and leak tes t at and around the filler valve c heck ball (11) and f iller line c onnec ting pipe

to the filler valve connection (9).

C. Referring to Figure 2A-5, View C, raise rear of vehicle and support on safety stands, refer to Section 0A

GENERAL INFORMATION of the VT Series Servic e Inform ation CD f or the loc ation of jac k ing points. Leak

test at and around the:

Rear service line (hose) to intermediate service line joiner connection (12).

Intermediate service line to rear service line joiner connector (13).

D. Referring to Figure 2A-5, View D, leak test in the engine compartment at and around the:

Intermediate service line to front service line joiner connection (14).

Front service line to intermediate service line joiner connection (15).

E. Referring to Figure 2A-5, View E, leak test in the engine compartment at and around the:

Front service line to lockoff inlet connection (16).

Lockoff inlet connection to lockoff (17).

Lockoff to lockoff outlet connection (18).

Lockoff outlet connection to converter (19).

Lockoff (20, 21, 22).

Converter mounting faces (23).

At the completion of the leak test, close the manual service valve, start the engine and run the engine until all the

LPG in the service line is exhausted. W ith the engine stopped, switch to ‘petrol’ and start the engine. The vehicle

can now be driven into the workshop.

NOTE:

The vehic le cannot be oper ated on LPG in the workshop unles s the work s hop is a “Spec ialis t Gas Work s hop” , refer

to Australian Standard AS 2746 - 1985.

Figure 2A-5

2.4 FILLER VALVE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2A-6

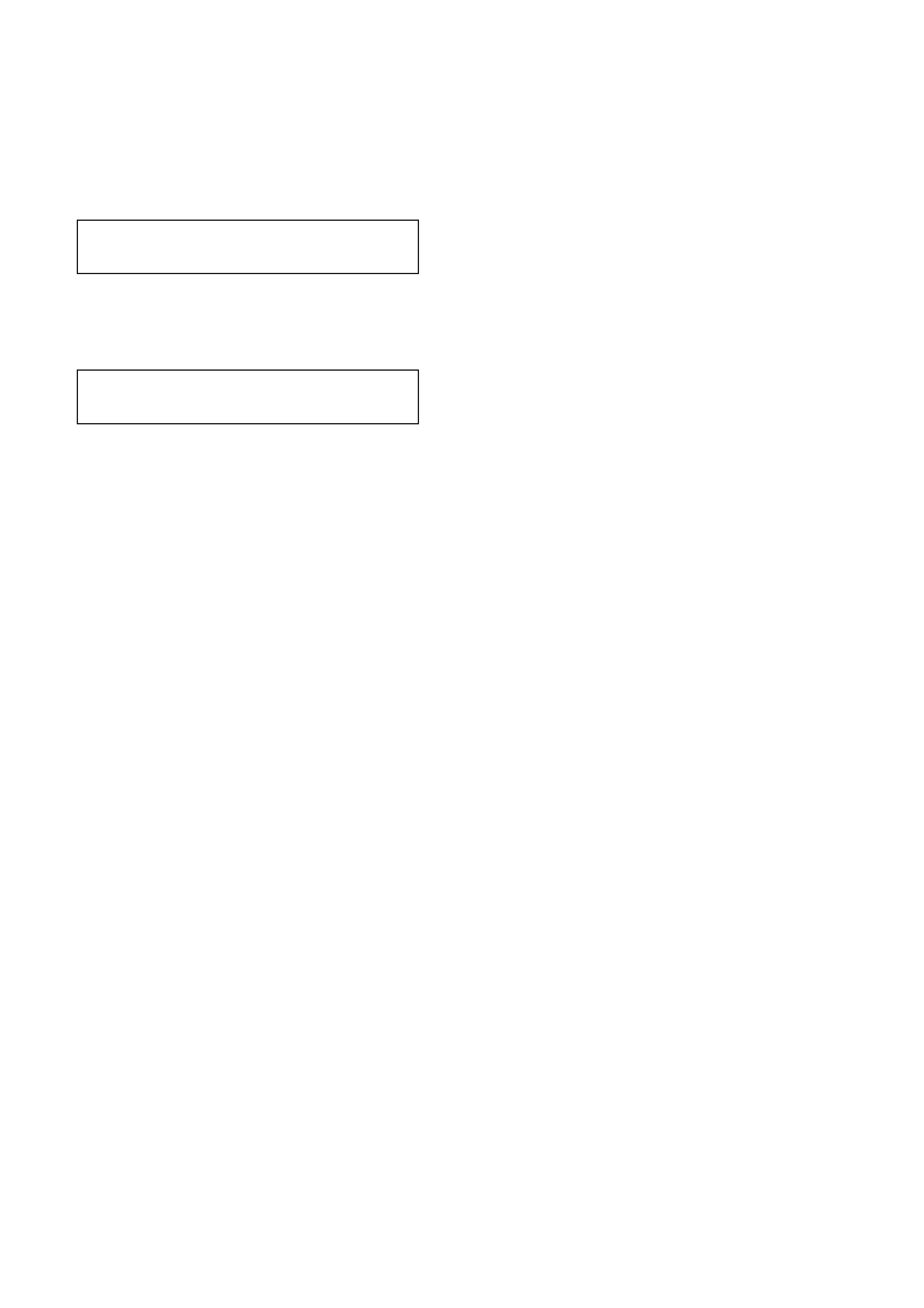

4. Remove the right hand rear wheelhouse liner.

Figure 2A-7

5. Crack open the filler line connecting pipe at

the filler valve and allow the residual gas to

escape.

CAUTION:

The filler line will contain LPG under pressure.

6. Unscrew the filler line connecting pipe from the

filler valve and m ove is away fr om contac t with

the filler valve.

7. From inside the right hand rear wheelhouse,

loosen and remove the f iller valve retaining nut

and spacer.

8. Remove the filler valve.

NOTE:

During installation of the LPG system, silicone

adhesive is applied to the vehicle body m ating face

of the filler valve.

Figure 2A-8

REINSTALL

1. Clean filler valve and f iller line c onnecting pipe

mating threads.

2. Apply silcone sealer, to Holden Specification

HN1886, to the filler valve mating surface

(between vehicle body and filler valve). Install

filler valve, spacer and retaining nut and

tighten to the correct torque specification.

FILLER VALVE

RETAINING NUT

TORQUE SPECIFICATION 50.0 - 60.0 Nm

3. Connect filler line connecting pipe to filler

valve and tighten to the correct torque

specification.

FILLER LINE

CONNECTING PIPE

TORQUE SPECIFICATION 12.0 - 18.0 Nm

4. Reconnect battery earth lead.

5. Carry out LPG system leak test, refer

2.3 LEAK TESTING in this Section.

6. Ensure the two filler line connecting pipe

grommets are installed correctly.

7. Reinstall right hand rear wheelhouse liner.

2.5 FILLER LINE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF'.

4. De-pressur ise the fuel (petrol) system , refer to

Section 6C1 POWERTRAIN MANAGEMENT

of the VT Series Service Information CD.

5. Ensure the battery earth lead is disconnected.

6. Remove the fuel (petrol) tank assembly, refer

to Section 8A FUEL TANK of the VT Series

Service Information CD. Figure 2A-9

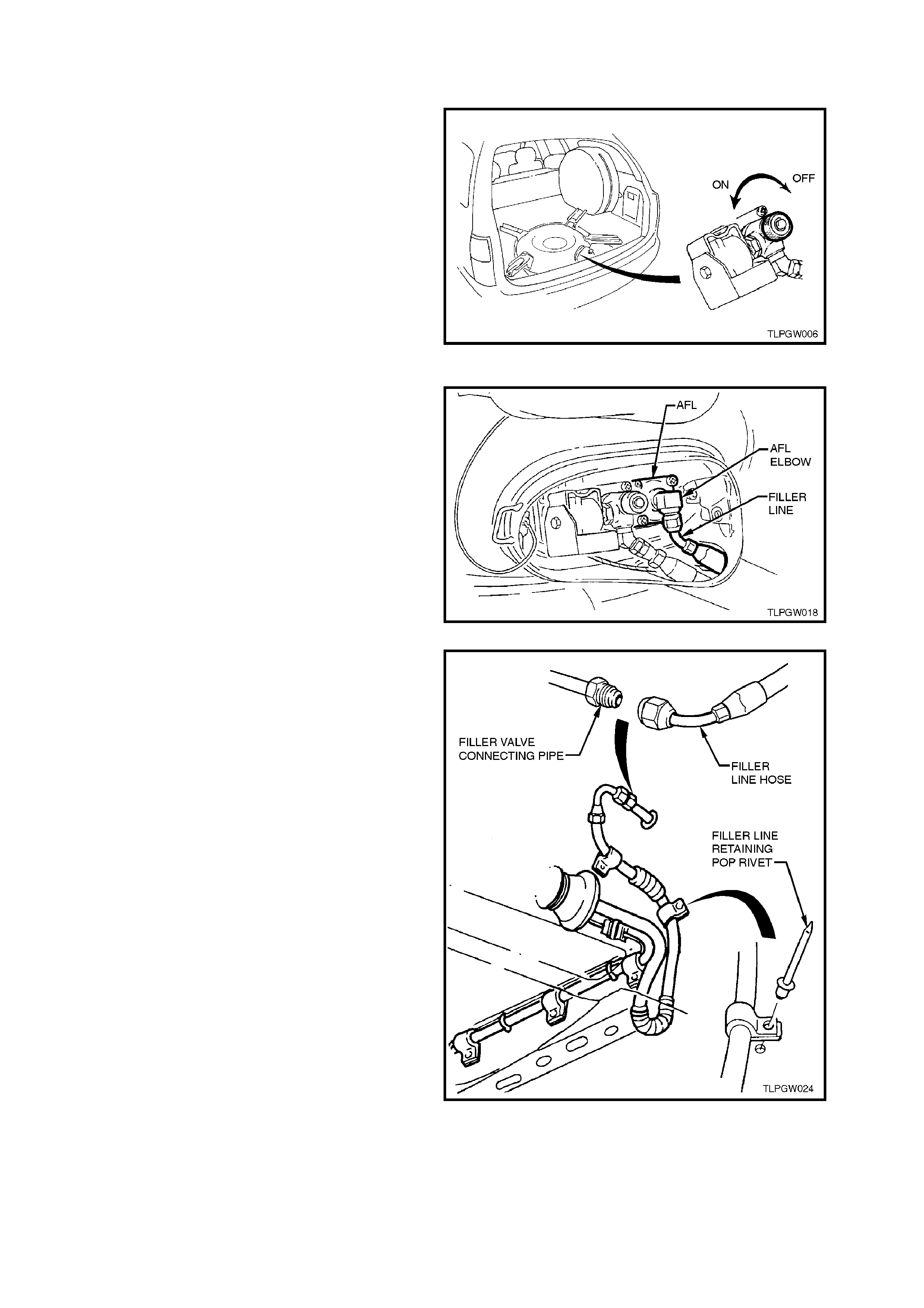

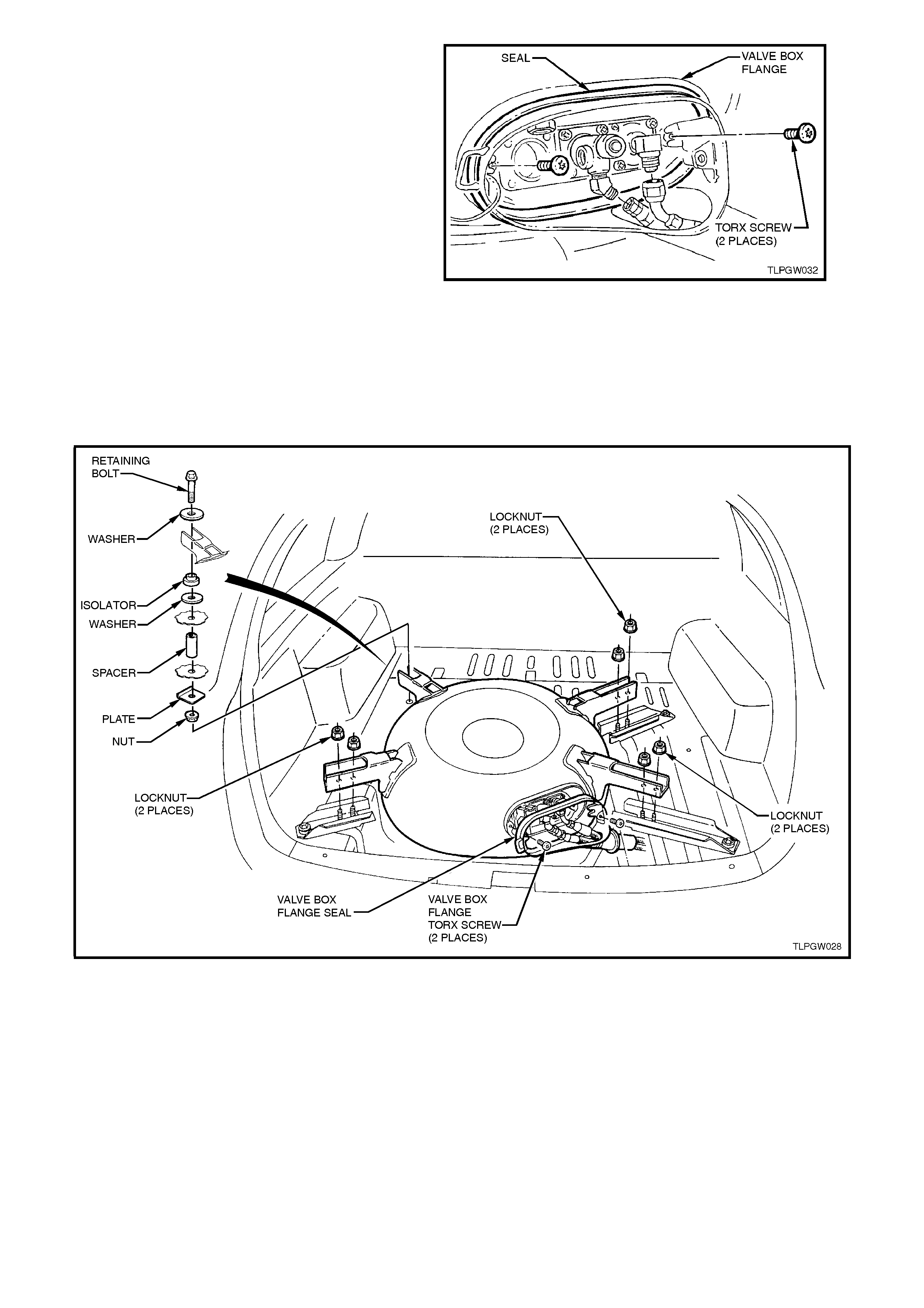

7. From inside the LPG tank valve box, while

holding AFL elbow, crack open filler line hose

to AFL elbow connector and allow residual

LPG to escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line hose connector completely

from AFL elbow.

Figure 2A-10

8. From under vehicle, while holding the filler

valve connecting pipe f r om turning, loos en and

unscrew the filler line hose, refer Fig 2A-11.

9. Using a suitable sized drill bit, drill into the

head of the two filler line hose retaining pop

rivets, refer Fig. 2A-11, and remove the filler

line hose .

10. Using a suitable size pin punch and hammer,

knock out remains of the filler line hose

retaining pop rivets from vehicle underbody.

Figure 2A-11

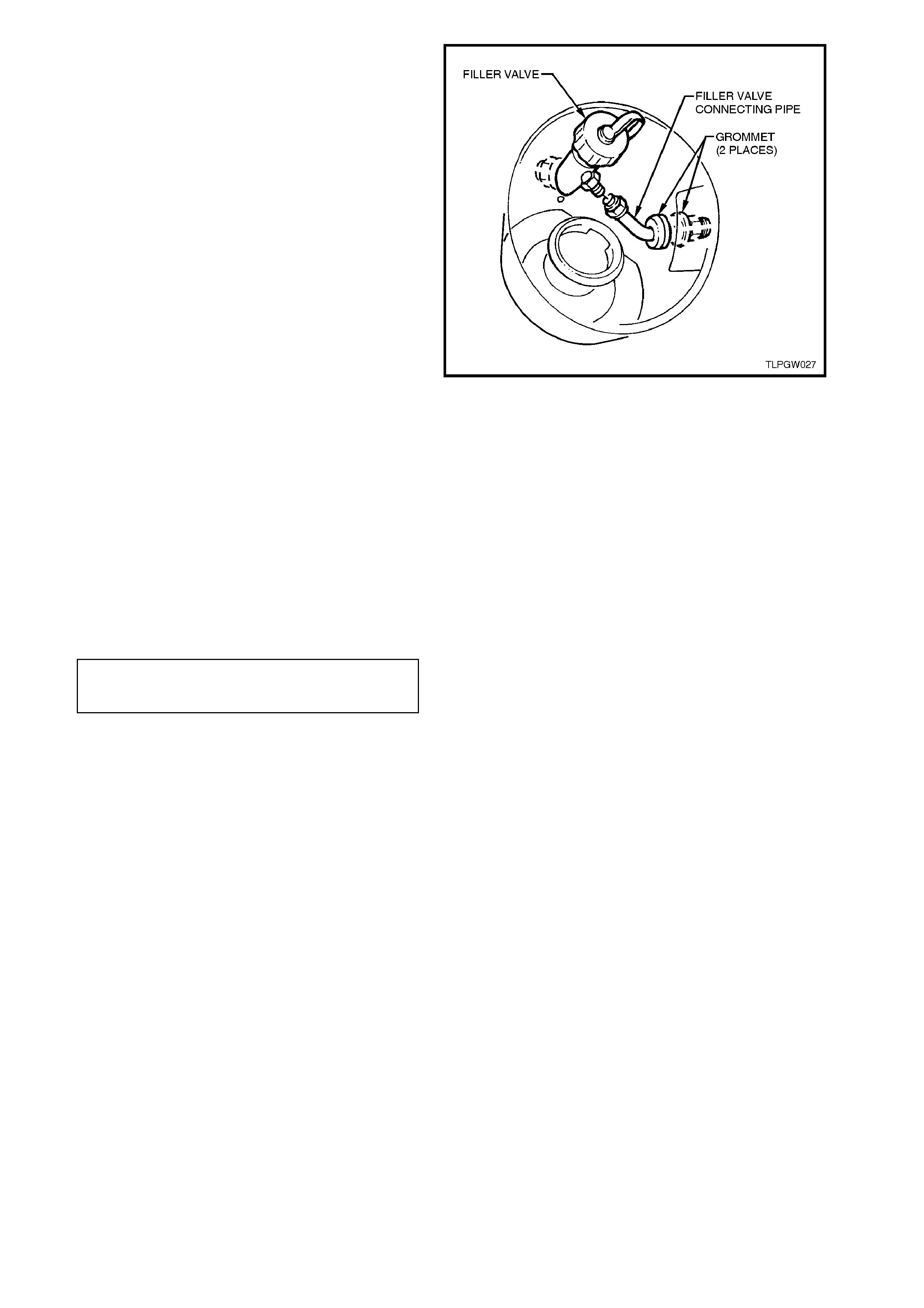

11. From inside fuel filler box, while holding the

filler valve connection f rom turning, loos en and

unscrew the filler line connecting pipe, refer

Fig. 2A-12.

12. Using a suitable screwdriver, push/lever the

two grommets into the fuel filler box and

rem ove the filler valve c onnecting pipe thr ough

the filler box opening.

Figure 2A-12

REINSTALL

Reinstallation of the filler line is the reverse of the

removal procedure, noting the following:

1. Clean filler line mating threads on filler valve,

filler valve c onnecting pipe, filler line hos e and

AFL.

2. Ensuring that flared surfaces are free of

sealant and contaminants, tighten filler line

connections to the correct torque

specifications.

FILLER LINE

CONNECTORS

TORQUE SPECIFICATION 12.0 - 18.0 Nm

3. Secure filler line hose using a new pop rivets

before the fuel (petrol) tank is reinstalled.

4. Ensure the two filler line connecting pipe

grommets are installed correctly.

5. Before starting vehicle or opening the manual

service valve, carry out a fuel (petrol) system

leak test as detailed in

Section 6C1 POWERTRAIN MANAGEMENT

- V6 ENGINE of the VT Series Service

Information CD.

6. Carry out LPG system leak test, refer

2.3 LEAK TESTING in this Section.

2.6 LPG TANK

CAUTION:

AFTER ANY VALVE OR COMPONENT HAS

BEEN REMOVED AND REINSTALLED TO THE

LPG TANK, THE LPG TANK MUST BE

PRESSURE AND LEAK TESTED IN

ACCORDANCE WITH CURRENT AUSTRALIAN

STANDARD AS2030.1 BEFORE THE LPG TANK

IS REFI TTED TO THE VEHICLE.

NOTE:

THE LPG TANK MUST BE PRESSURE AND

LEAK TESTED ACCORDING TO THE LAWS OF

THE STATE IN WHICH THE VEHICLE IS

REGISTERED. THIS TESTING MUST ONLY BE

DONE BY A LICENSED INSTALLER OR

TESTING STATION.

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

‘OFF’ and the battery earth lead is

disconnected.

4. Remove the luggage com partm ent f loor cover,

refer 2.15 LUGGAGE COMPARTMENT

FLOOR COVER in this Section.

5. Unload the LPG tank of LPG. Refer to notes in

operation 2.2 LPG TANK UNLOADING

PROCEDURE in this Section, then follow the

cylinder unloading procedure, steps 4 - 10

only, in operation 2.2 LPG CYLINDER

UNLOADING PROCEDURE in VT Sedan

W ith Pr oduction LPG of the VT Series Ser vice

Information CD.

Figure 2A-13

6. From inside the LPG tank valve box, while

holding the AFL elbow, crack open filler line

hose to AFL elbow connector and allow

residual LPG to escape.

CAUTION:

The filler line will contain LPG under pressure.

7. Once all the LPG in the line has dispersed,

unscrew filler line hose connector completely

from AFL elbow.

Figure 2A-14

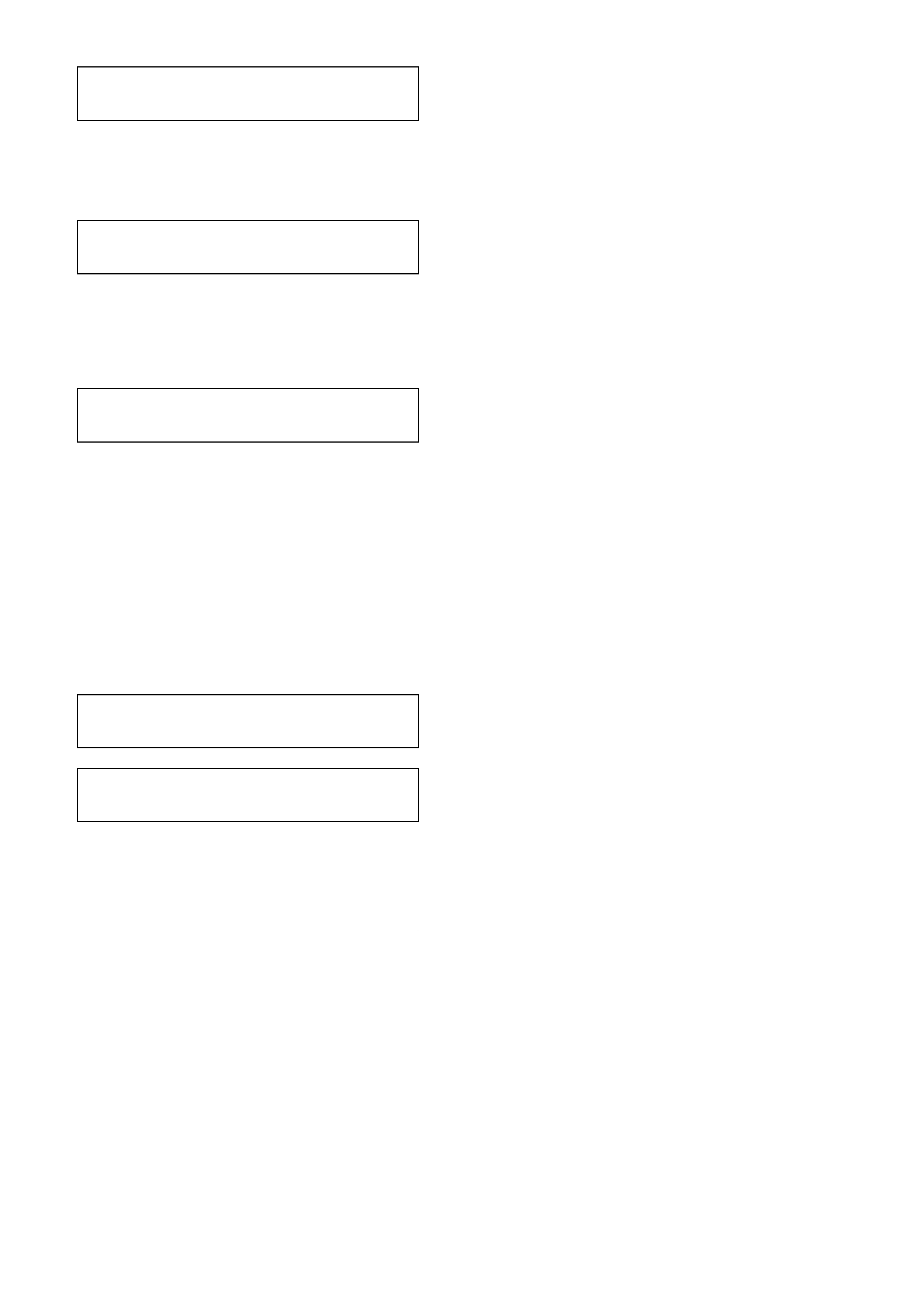

8. Loosen and remove the two torx screws

retaining the valve box flange to the LPG tank.

9. Pull valve box flange and s eal away from LPG

tank so that there is sufficient clearance to

remove the LPG tank.

Figure 2A-15

10. With the aid of an assistant, loosen and

remove the left hand front LPG tank retaining

bolt and nut, refer Fig. 2A-16.

11. Loosen and remove the six locknuts retaining

the LPG tank to the rem aining three LPG tank

brackets, refer Fig. 2A-16.

12. Lift the LPG tank up and remove.

Figure 2A-16

REINSTALL

1. If the LPG tank fuel gauge has not already

been reinstalled, reinstall LPG tank fuel gauge

assembly, refer 2.12 TANK FUEL GAUGE

ASSEMBLY in this Section.

2. Seat tank onto the LPG tank bracket studs

(six places).

3. With the aid of an assistant, install the left

hand front retaining bolt and nut, ensuring

spacers, isolators, washers and reinforcement

plates are installed correctly, refer

Fig. 2A-16. While holding the retaining bolt,

tighten retaining nut to the correct torque

specification.

LPG TANK

RETAINING NUT

TORQUE SPECIFICATION 40 - 50 Nm

4. Install the six locknuts retaining the LPG tank

to the LPG tank brackets and tighten locknuts

to the correct torque specification.

LPG TANK

RETAINING LOCKNUT

TORQUE SPECIFICATION 40 - 50 Nm

5. Install the valve box f lange, ensuring the valve

box seal is seated correctly. Tighten the two

valve box flange retaining torx screws to the

correct torque specification.

VALVE BOX FLANGE

RETAINING TORX SCREW

TORQUE SPECIFICATION 7.0 Nm

6. Reinstall the smart unit and solenoid valve,

refer 2.8 SMART UNIT AND SOLENOID

VALVE in this Section.

7. Clean rear service line mating threads on

solenoid and manual service valve assembly

and the filler line hose mating surface on the

AFL elbow.

8. Ensuring the flared surfaces are free of

sealant and contaminants, tighten filler line

hose and service line connections to the

correct torque specification.

FILLER LINE HOSE

CONNECTION TO AFL ELBOW

TORQUE SPECIFICATION 12.0 - 18.0 Nm

SERVICE LINE CONNECTION

TO MANUAL SERVICE VALVE

TORQUE SPECIFICATION 12.0 - 18.0 Nm

10. If the LPG tank has not alr eady been pressure

tested, pressure and leak test LPG tank in

accordance with the current Australian

Standard AS2030.1

11. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

12. Reinstall valve box cover.

13. Reinstall the luggage compartment floor cover,

refer 2.15 LUGGAGE COMPARTMENT

FLOOR COVER in this Section

2.7 SOLENOID AND MANUAL SERVICE VALVE ASSEMBLY

CAUTION:

If at any time the manual service valve

becomes stuck, no service operations on the

system will be possible. Should for any reason

the valve stick, the LPG tank will have to be

returned to the tank manufacturer (APA) to

arrange a replacement tank.

Contact: APA Industries

190 Colchester Road

Kilsyth

Victoria 3137

Phone - (03) 9720 2855

Fax - (03) 9761 4495

NOTE:

The m anual service valve is three valves in one. A

manual shut off valve, an electrically operated

solenoid valve and an excess flow valve.

EXCESS-FLOW VALVE TEST

CAUTION:

ENSURE THERE ARE NO NAKED FLAMES OR

OTHER SOURCES OF IGNITION IN THE

VICINITY.

ENSURE ALL SAFETY PRECAUTIONS LISTED

AT THE FRONT OF THIS MANUAL ARE

ADHERED TO WHILE PERFORMING THIS

TEST.

DO NOT PERFORM THIS TEST ON A VEHICLE

WITH A HOT ENGINE.

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

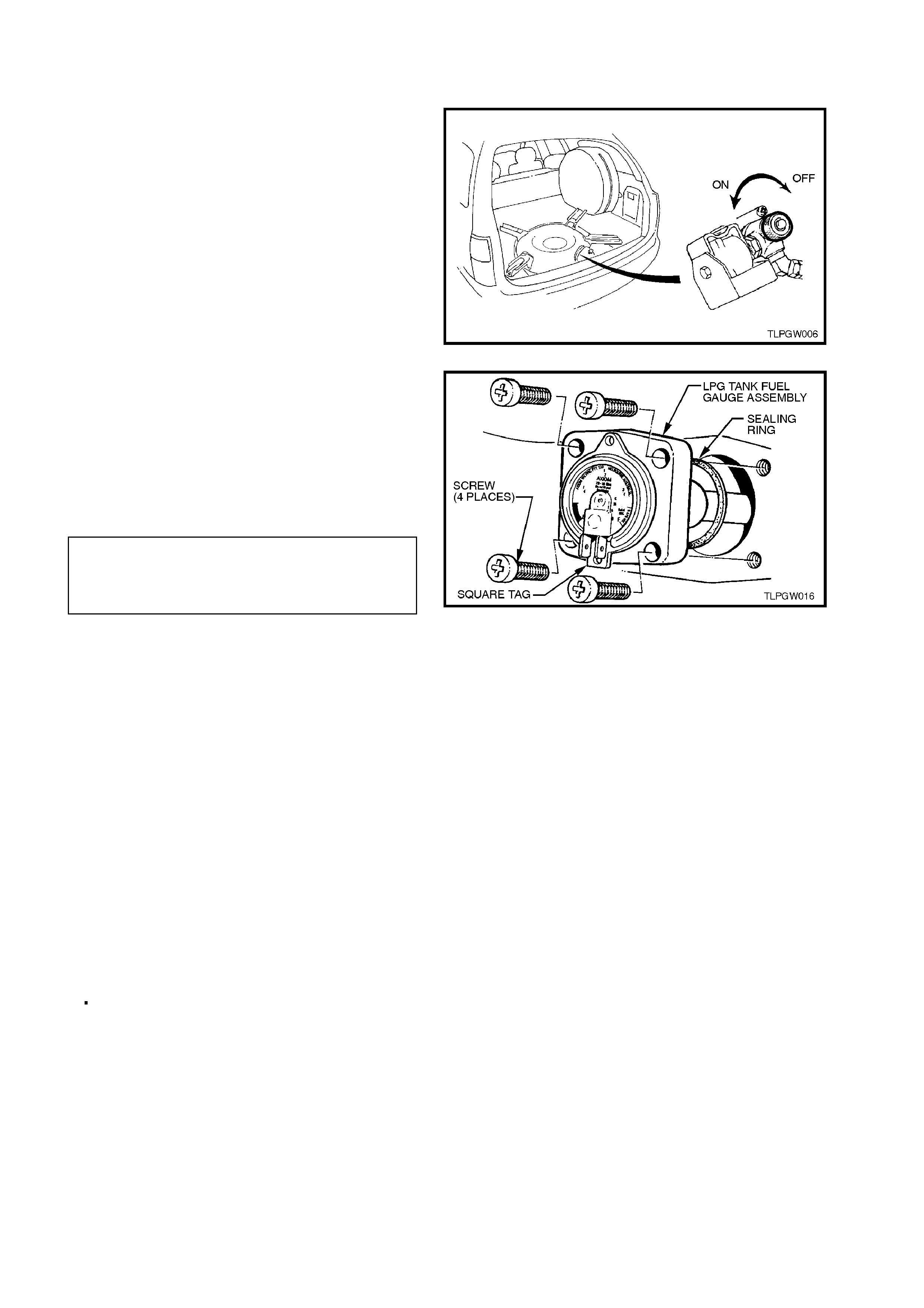

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

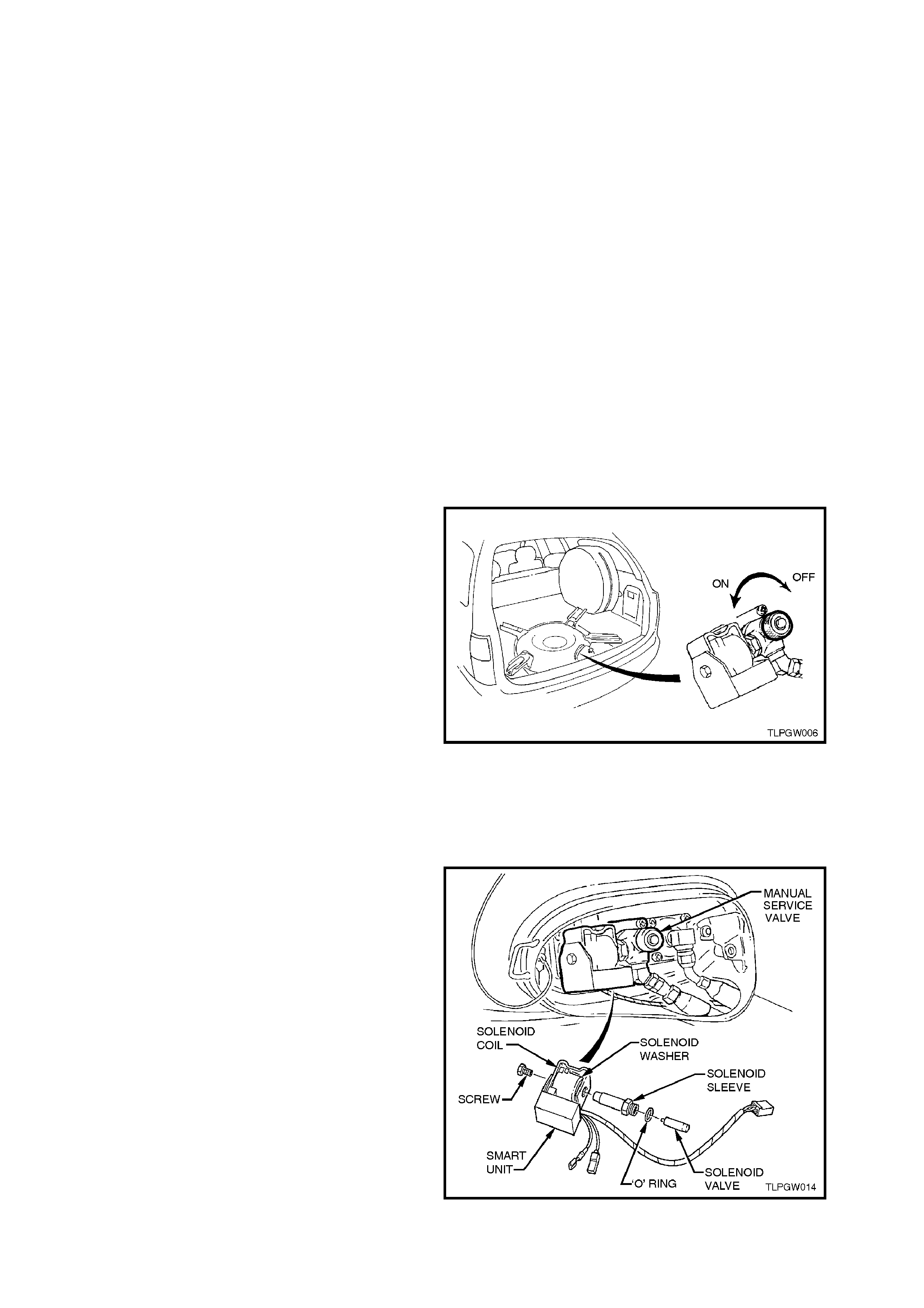

Figure 2A-17

4. Remove the smart unit and solenoid

assembly, including the solenoid valve, r ef er to

2.8 SMART UNIT AND SOLENOID VALVE in

the Section.

NOTE:

It is not necessary to completely remove the smart

unit from the vehicle, ie. leave the harness routed

through the valve box vent tube.

5. Reinstall the solenoid sleeve (with O-ring)

WITHOUT the solenoid valve.

6. Disconnect the front service line at the lockoff

valve to allow LPG to flow from this line when

the manual service valve is opened, refer to

operation 2.13 SERVICE LINES under VT

Sedan With Production LPG of the VT Series

Service Information CD.

Figure 2A-18

7. Quickly open the manual service valve and

listen for the sound of the excess-flow valve

operating.

8. If the excess flow valve is operating correctly,

it can be heard to click shut when the manual

service valve is opened quickly.

CAUTION:

TO ENSURE THAT THE LEAST AMOUNT OF

LPG ESCAPES INTO TH E ATMO SPHERE, O NLY

OPEN THE M ANUAL SERVICE VALVE FOR T HE

MINIMAL TIME POSSIBLE TO PERFORM THIS

TEST.

Figure 2A-19

9. Reinstall the front service line to the lockoff

valve as per the reinstallation procedure

detailed in operation 2.13 SERVICE LINES

under VT Sedan With Production LPG of the

VT Series Service Information CD.

10. Remove the solenoid sleeve from the manual

service valve. Reinstall the solenoid valve,

solenoid sleeve and smart unit as per the

reinstallation procedure in

2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

11. Leak test LPG system, refer

2.3 LEAK TESTING in this Section.

12. Once installed, check vehicle operation on

LPG and petrol.

REPLACE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG tank of LPG. Refer to notes in

operation 2.2 LPG TANK UNLOADING

PROCEDURE in this Section, then follow the

cylinder unloading procedure, steps 4 - 10

only, in operation 2.2 LPG CYLINDER

UNLOADING PROCEDURE under VT Sedan

W ith Pr oduction LPG of the VT Series Ser vice

Information CD.

Figure 2A-20

5. Pull the rear service line thr ough the valve box

vent tube.

6. Loosen and remove the two screws securing

the valve box vent tube to the LPG tank.

Loosen the hose clam p securing the grommet

to the valve box vent tube.

7. From under the vehicle, disconnect LPG body

harness connector from LPG tank harness

connector, refer to Fig 2A-21.

From inside the luggage compartment, gently

pull LPG tank harness through the valve box

vent tube towards the LPG tank, refer to Fig

2A-21.

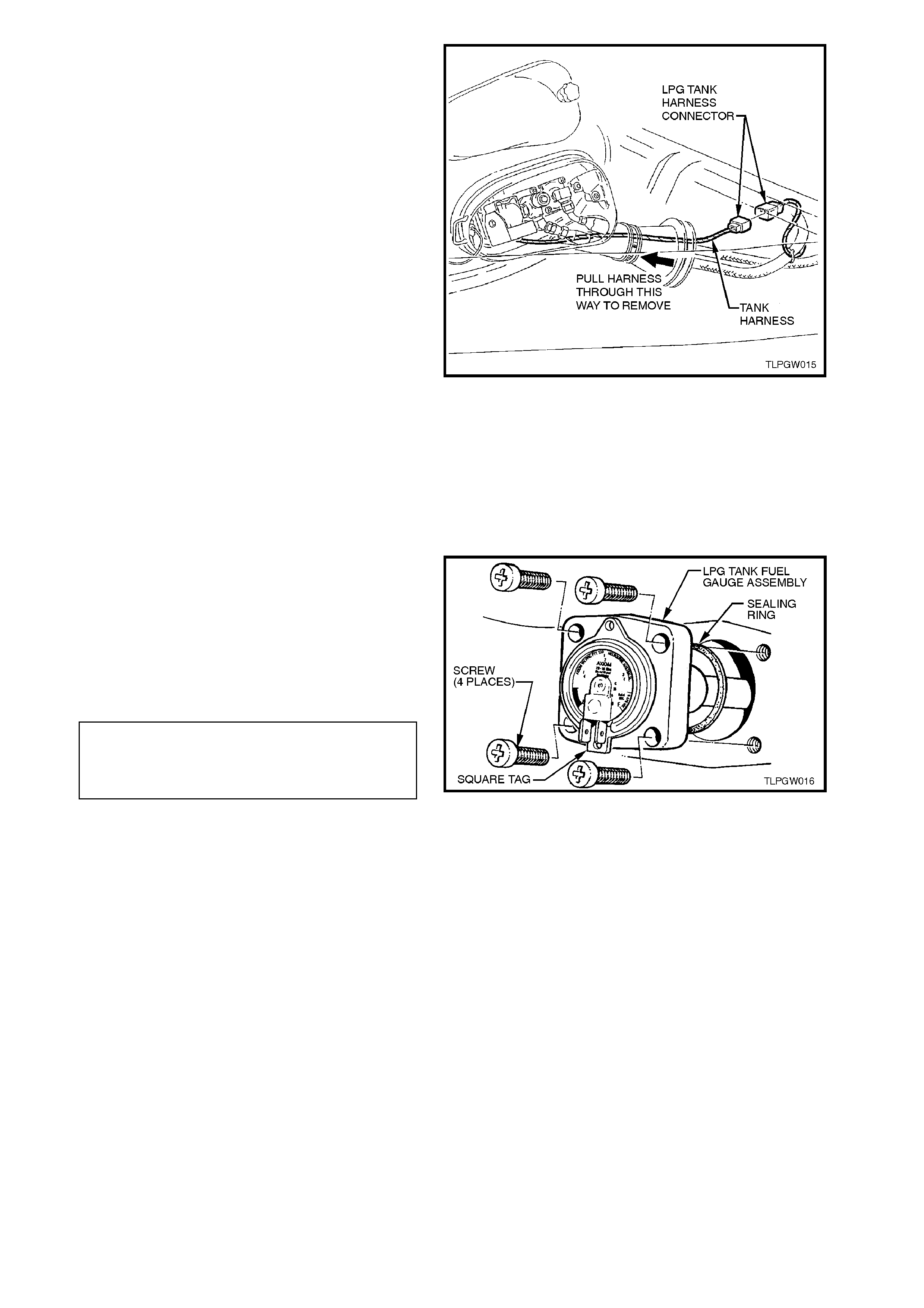

Figure 2A-21

8. If not already removed, r em ove sm art unit and

solenoid valve assembly from the manual

valve, refer 2.8 SMART UNIT AND

SOLENOID VALVE in this Section.

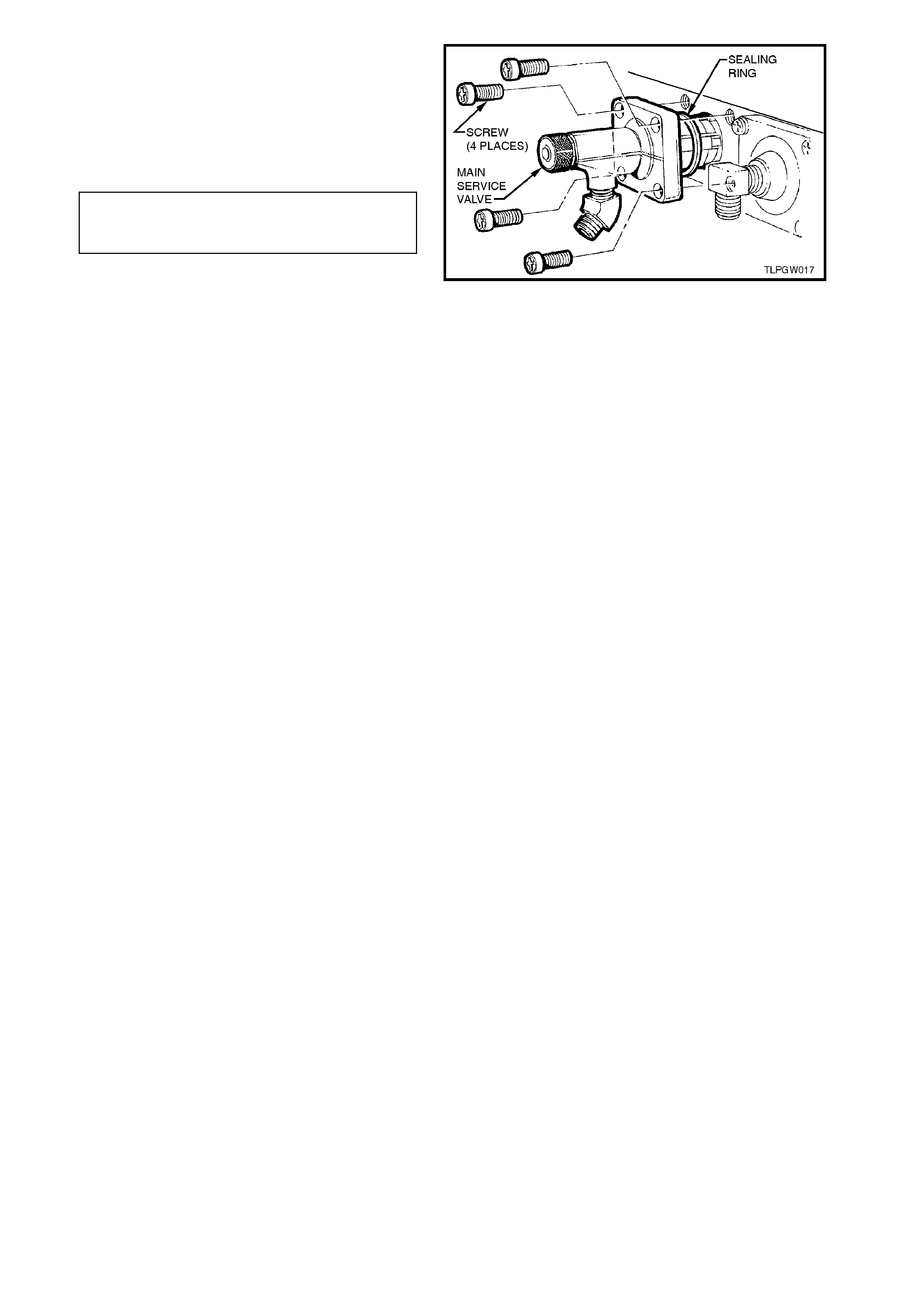

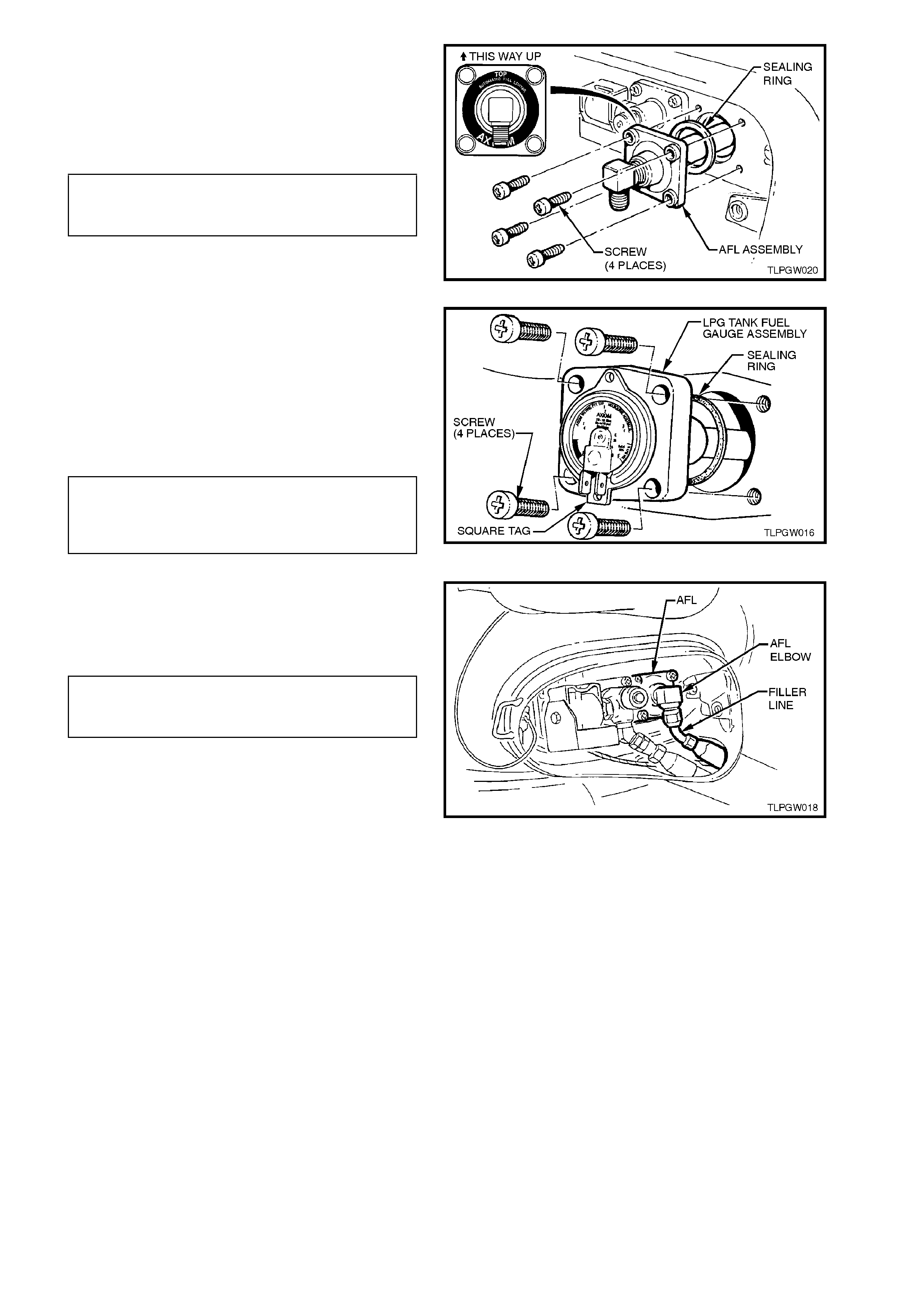

9. Unscrew the four manual service valve

attaching screws and remove the manual

service valve from LPG tank, refer to Fig. 2A-

23.

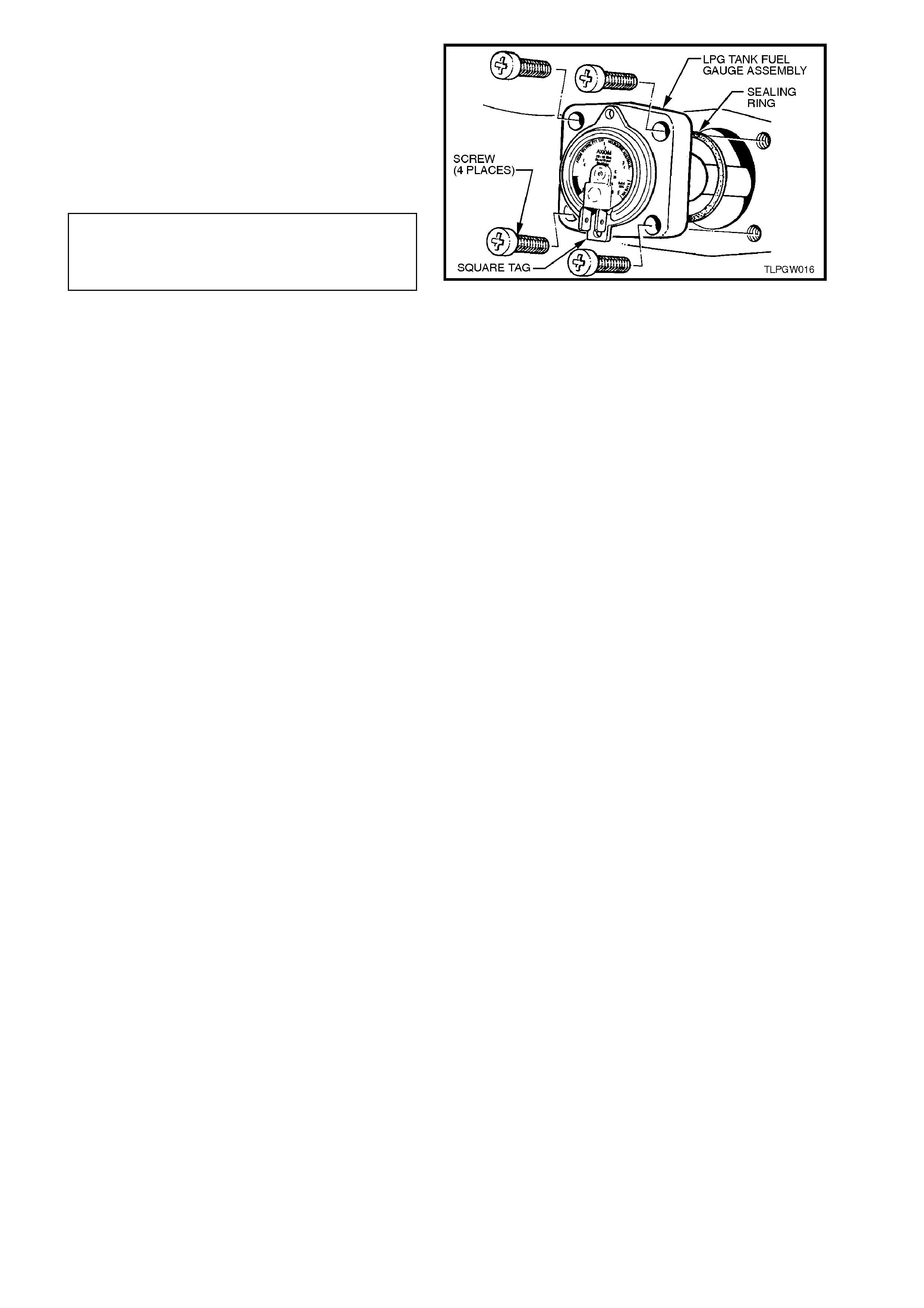

10. Install new LPG tank fuel gauge assembly to

LPG tank sealing ring, install LPG tank fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten LPG tank fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

LPG TANK FUEL GAUGE

ASSEMBLY TO LPG TANK 5.0 - 7.0

ATTACHING SCREW Nm

TORQUE SPECIFICATION

Figure 2A-22

11. Install new manual service valve to LPG tank

sealing ring and the new manual s ervice valve

assembly. Take care to install the valve so that

the valve elbow for the service line connection

is pointing In the correct direction. Install and

tighten the four m anual ser vice valve attaching

screws to the correct torque specification.

MANUAL SERVICE VALVE TO

LPG TANK ATTACHING SCREW 5.0 - 7.0 Nm

TORQUE SPECIFICATION

12. Reinstall the smart unit and solenoid valve,

refer 2.8 SMART UNIT AND SOLENOID

VALVE in this Section.

13. Reconnect LPG body wiring harness

connector to LPG tank harness connector.

14. Reconnect rear service line to manual service

valve and tighten to the correct torque

specification, refer 2.13 SERVICE LINES in

this Section.

15. Tighten valve box vent tube retaining screws

and hose clamp.

16. Pressure and leak test LPG tank in

accordance with the current Australian

Standard AS2030.1

17. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2A-23

2.8 SMART UNIT AND SOLENOID VALVE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

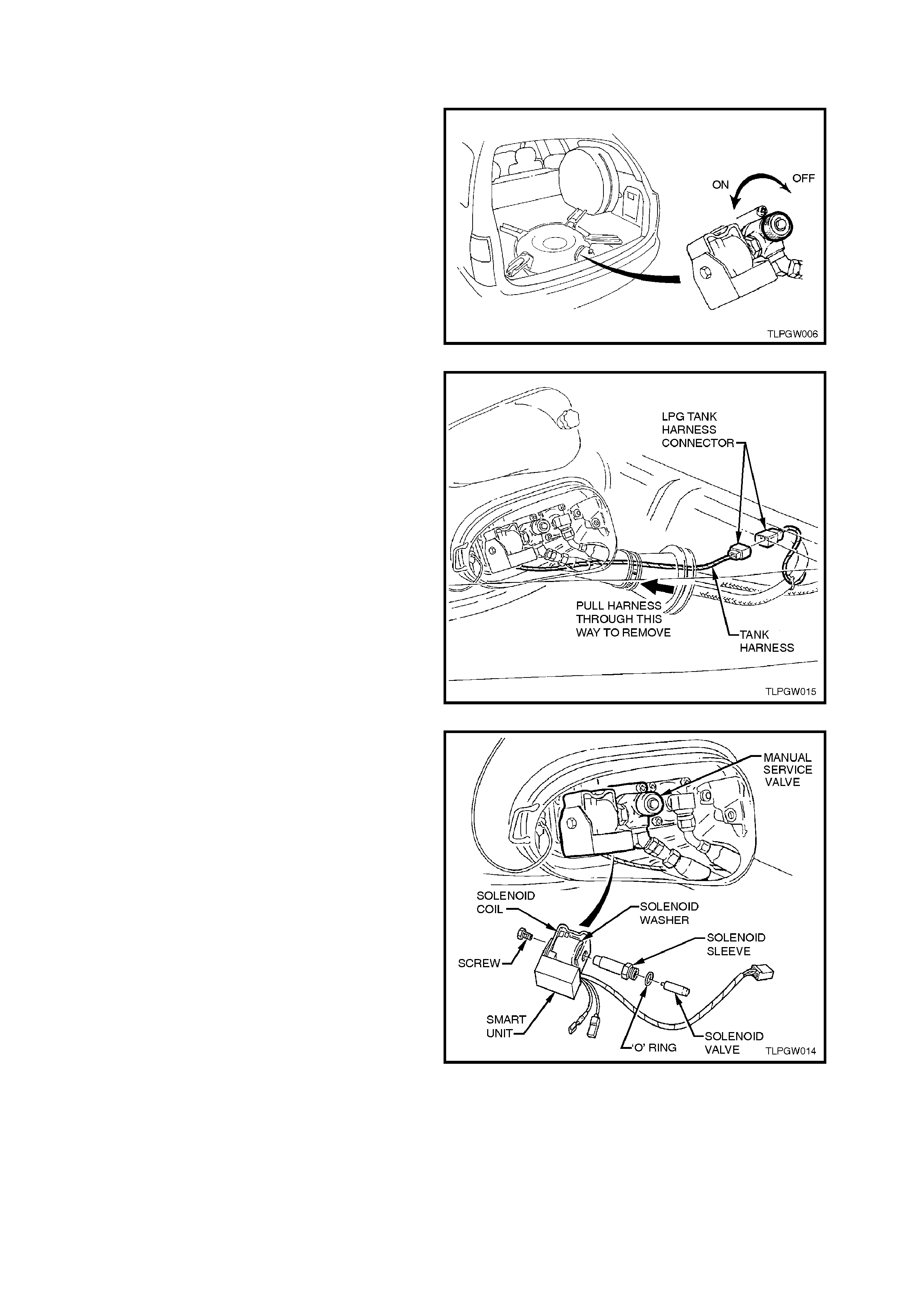

Figure 2A-24

4. Disconnect the rear service line to the tank

and pull rear ser vic e line through the valve box

vent tube.

5. Loosen and remove the two screws securing

the valve box vent tube to the LPG tank.

Loosen the hose clam p securing the grommet

to the valve box vent tube.

6. From under the vehicle, disconnect LPG body

harness connector from LPG tank harness

connector 2A-25.

From inside the luggage compartment, gently

pull LPG tank harness through the valve box

vent tube towards the tank valves.

Figure 2A-25

7. Remove smart unit retaining screw from end

of the assembly.

8. Slide the smart unit and solenoid coil from the

solenoid sleeve and manual service valve.

9. Loosen and remove solenoid sleeve from

manual service valve, ensuring that solenoid

valve is also removed.

Separate solenoid valve from the sleeve.

Discard the solenoid sleeve to m anual service

valve 'O' ring.

10. Disconnect LPG tank harness connectors

from tank fuel contents gauge terminals.

Figure 2A-26

REINSTALL

Reinstallation of the smart unit and solenoid coil to

the manual service valve is the reverse of removal

procedures, noting the following points:

1. Ensure new 'O' ring is fitted to solenoid sleeve.

2. Tighten solenoid sleeve to the manual service

valve to the correct torque specification.

SOLENOID SLEEVE TO

MANUAL SERVICE VALVE

TORQUE SPECIFICATION 15 - 18 Nm

3. Once installed, ensure that the smart unit

retaining screw is tightened to the correct

torque specification.

SMART UNIT

RETAINING SCREW

TORQUE SPECIFICATION 1 - 3 Nm

4. Reconnect rear service line to manual service

valve and tighten to the correct torque

specification, refer 2.13 SERVICE LINES in

this Section.

5. Leak test LPG system, refer to

2.3 LEAK TESTING in this Section.

6. Once installed, check vehicle operation on

LPG and petrol.

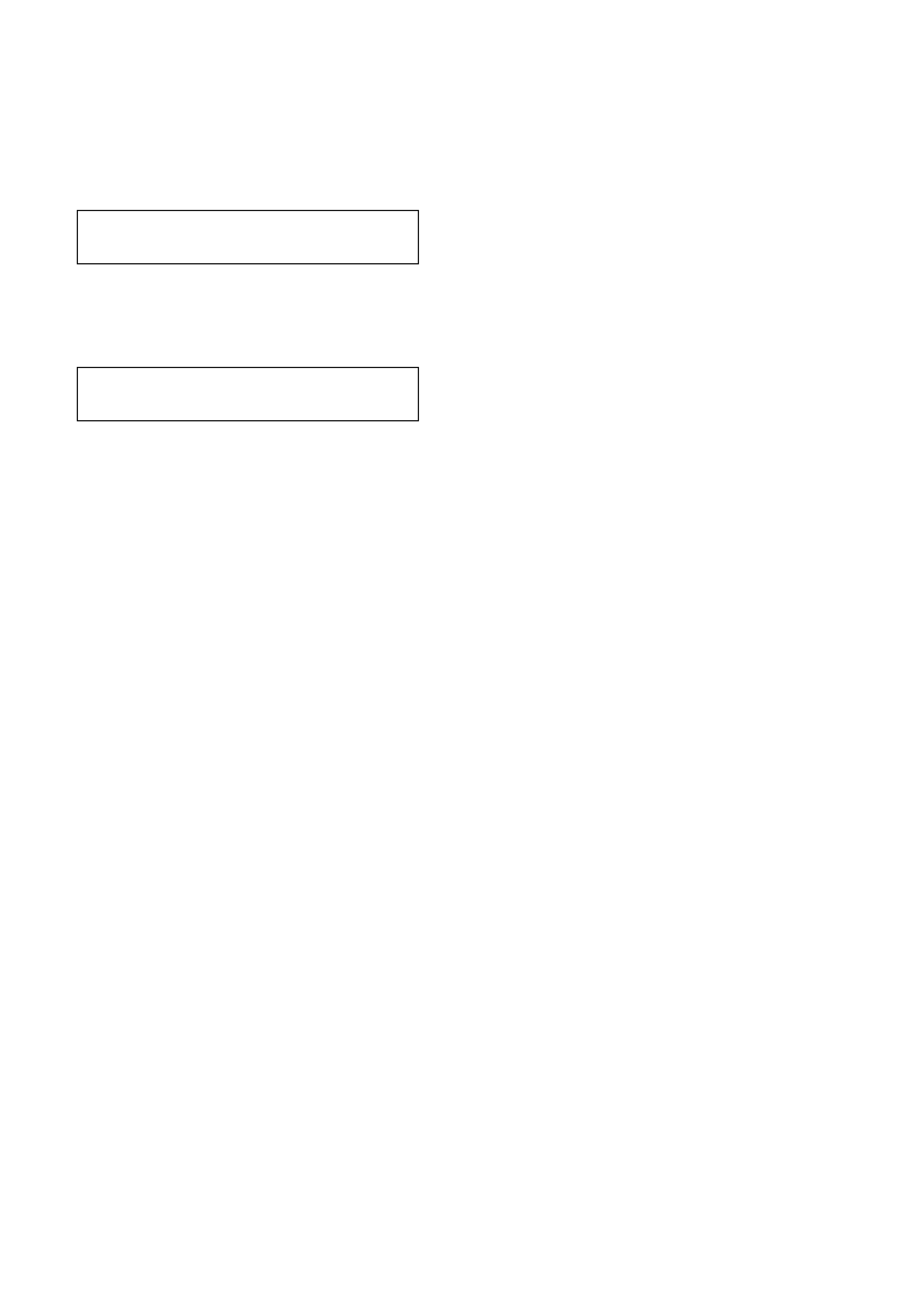

2.9 PICK-UP PIPE AND STRAINER

REMOVE

Remove the solenoid and manual service valve,

refer 2.7 SOLENOID AND MANUAL SERVICE

VALVE ASSEMBLY in this Section.

Remove the two screws retaining the LPG pick-up

pipe and strainer to the manual valve ass embly and

twist the pick -up pipe and strainer out from the rear

of the manual service valve.

REINSTALL

Reinstallation of the LPG pick-up pipe and strainer

is the reverse of the rem oval procedure, noting the

following point:

Ensure the O-r ing on the end of the pick -up pipe is

installed correctly.

Figure 2A-27

2.10 AUTOMATIC FILL LIMITER

TEST

The proc edure for testing the Autom atic Fill Limiter

(AFL) on VT Wagon Models is the same as the

procedure detailed in oper ation 2.10 AUTOM AT IC

FILL LIMITER under VT Sedan With Production

LPG of the VT Series Service Information CD,

noting the following:

The LPG tank ‘fillable’ capacity for VT Wagon

Models is 60 litres ± 2 litres.

REPLACE

The automatic fill limiter should only be replaced if

it proves to be faulty.

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

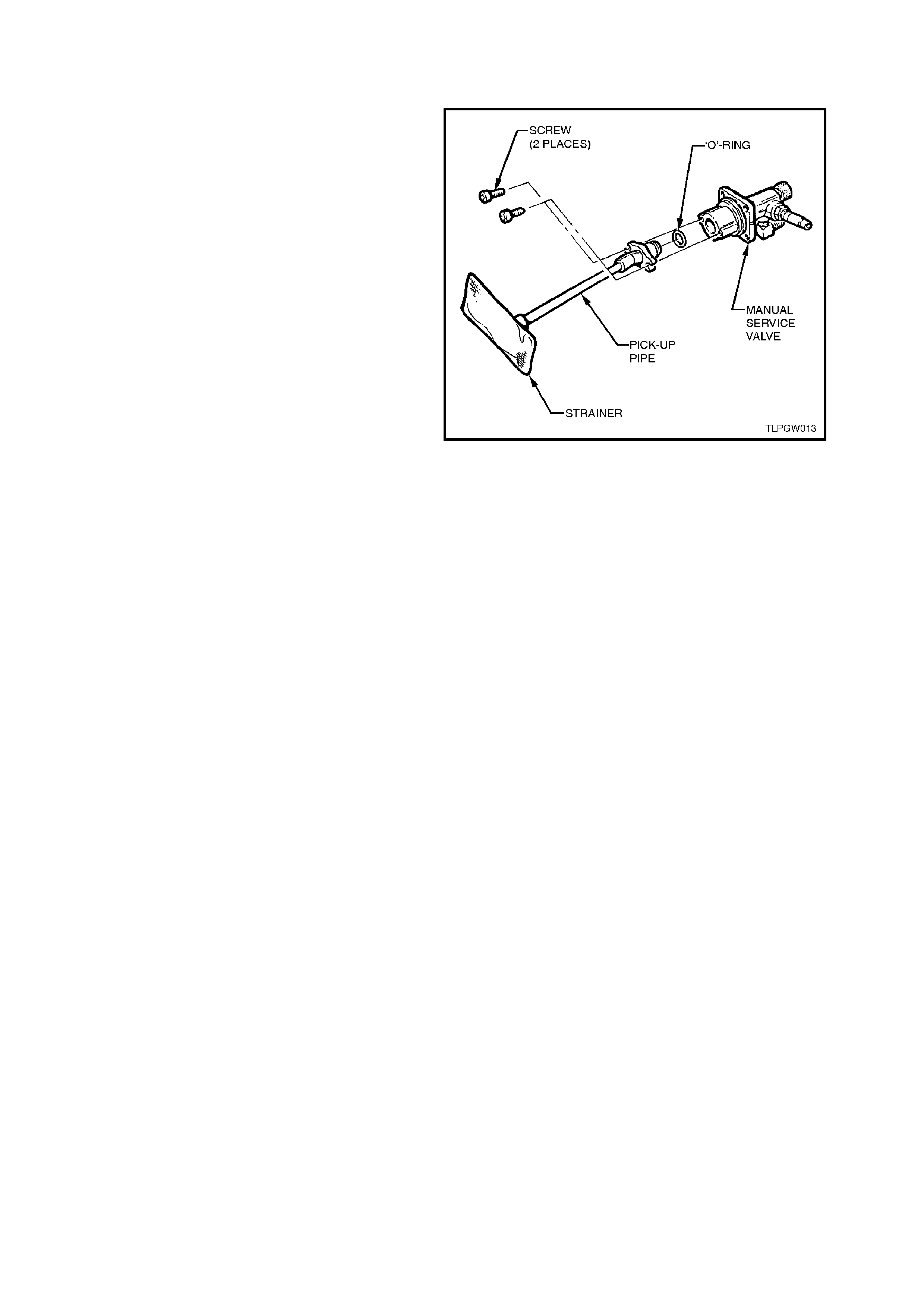

Figure 2A-28

4. Unload the LPG tank of LPG, refer

2.2 LPG TANK UNLOADING PROCEDURE

in this Section.

5. From inside the LPG tank valve box, while

holding AFL elbow, crack open filler line hose

to AFL elbow connector and allow residual

LPG to escape.

CAUTION:

The filler line will contain LPG under pressure.

Once all the LPG in the line has dispersed,

unscrew filler line hose connector completely

from the AFL elbow.

Figure 2A-29

6. Unscr ew the four autom atic fill lim iter retaining

screws and remove automatic fill limiter from

the LPG tank.

Figure 2A-30

7. Install new automatic fill limiter to LPG tank

sealing ring and the autom atic fill limiter. Take

care to install the automatic fill lim iter the right

way up. Install and tighten the four automatic

fill limiter attaching screws to the correct

torque specification.

AUTOMATIC FIL L LIMITER TO

LPG TANK ATTACHING SCREW 5.0 - 7.0 Nm

TORQUE SPECIFICATION

Figure 2A-31

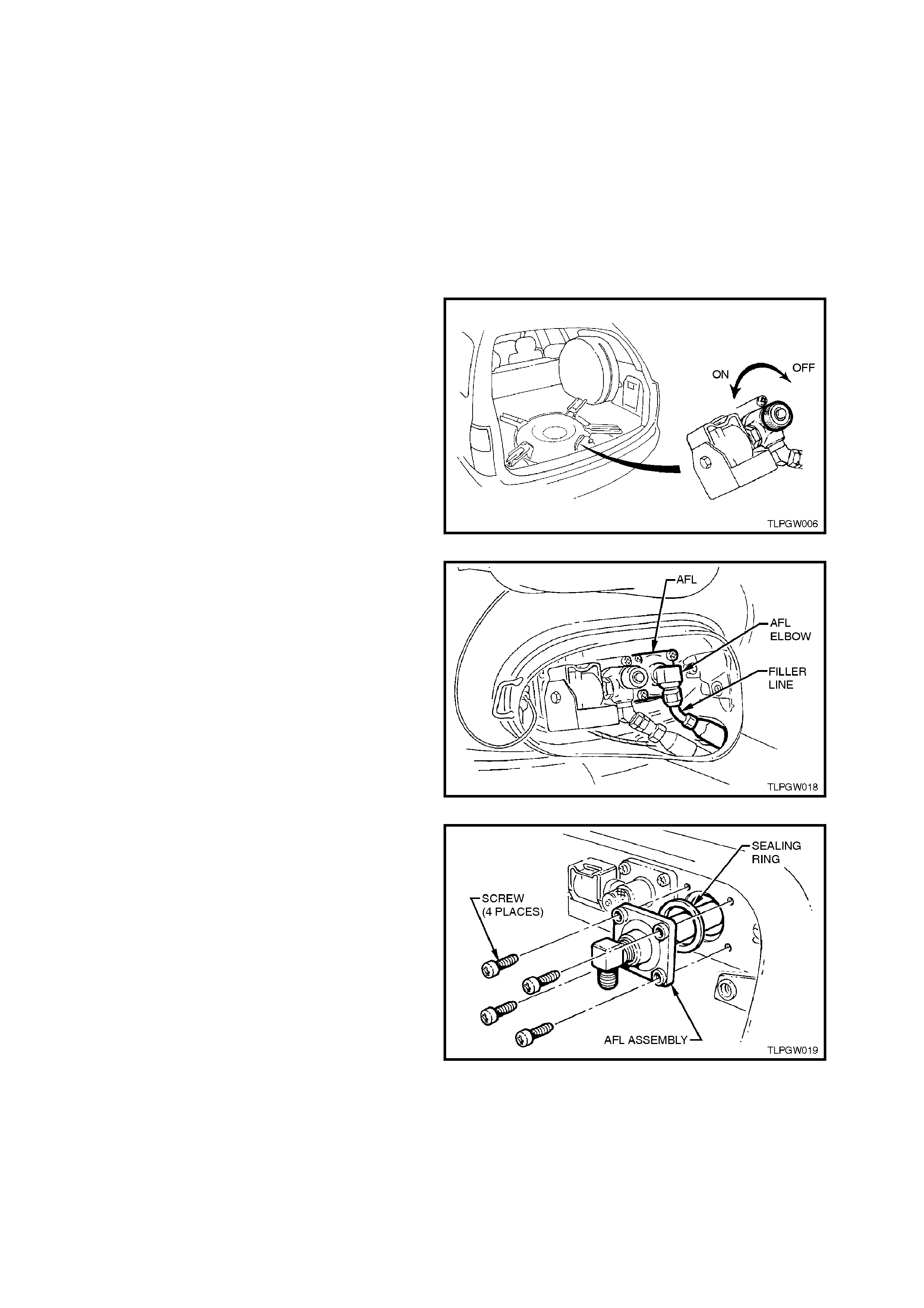

8. Install new LPG tank fuel gauge assembly to

LPG tank sealing ring, install LPG tank fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten LPG tank fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

LPG TANK FUEL GAUGE

ASSEMBLY TO LPG 5.0 - 7.0

TANK ATTACHING SCREW Nm

TORQUE SPECIFICATION

Figure 2A-32

9. Ensuring that flared surfaces are free of

sealant and contaminants, connect filler line

hose to AFL elbow and tighten to the correct

torque specification.

FILLER LINE HOSE CONNECTOR

TO AFL ELBOW SCREW 12.0 - 18.0 Nm

TORQUE SPECIFICATION

10. Pressure and leak test LPG tank in

accordance with the current Australian

Standard AS2030.1.

11. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section. Figure 2A-33

2.11 PRESSURE RELIEF VALVE

REPLACE

NOTE:

The pr essure re lief valve should only be r eplaced if

it proves to be leaking.

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2A-34

4. Unload the LPG tank of LPG, refer

2.2 LPG TANK UNLOADING PROCEDURE

in this Section.

NOTE:

The smart unit and solenoid valve is removed

during the unloading procedure.

5. Using a 1 1/16 inch socket and breaker bar,

loosen and remove the pressure relief valve

from the LPG tank.

NOTE:

It may be necessary to install a tube over the end of

the breaker bar to enable greater leverage to be

applied for loosening the valve.

6. Ensure that new relief valve and LPG tank

mating threads are clean.

Apply Loctite 577 sealant to the valve threads

and a small amount to the tank mating

threads.

7. Tighten pressure relief valve to the correct

torque specification.

PRESSURE RELIEF VALVE

TO LPG TANK 60 Nm

TORQUE SPECIFICATION

Figure 2A-35

8. Install new LPG tank fuel gauge assembly to

LPG tank sealing ring, install LPG tank fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten LPG tank fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

LPG TANK FUEL GAUGE

ASSEMBLY TO LPG 5.0 - 7.0

TANK ATTACHING SCREW Nm

TORQUE SPECIFICATION

9. Reinstall the smart unit and solenoid valve,

refer 2.8 SMART UNIT AND SOLENOID

VALVE in this Section.

10. Pressure and leak test LPG tank in

accordance with the current Australian

Standard AS2030.1

11. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2A-36

2.12 TANK FUEL GAUGE ASSEMBLY

REPLACE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

4. Unload the LPG tank of LPG, refer

2.2 LPG TANK UNLOADING PROCEDURE

in this section.

Figure 2A-37

5. Install new LPG tank fuel gauge assembly to

LPG tank sealing ring, install LPG tank fuel

gauge assembly taking care to install

assembly with gauge up the right way. Install

and tighten LPG tank fuel gauge assembly

attaching screws to the correct torque

specification. Reconnect wiring harness

connectors to gauge terminals.

LPG TANK FUEL GAUGE

ASSEMBLY TO LPG 5.0 - 7.0

TANK ATTACHING SCREW Nm

TORQUE SPECIFICATION

6. Reinstall the smart unit and solenoid valve,

refer 2.8 SMART UNIT AND SOLENOID

VALVE in this Section.

7. Pressure and leak test LPG tank in

accordance with the current Australian

Standard AS2030.1

8. Carry out system leak testing, refer

2.3 LEAK TESTING in this Section.

Figure 2A-38

CONTENTS GAUGE

The procedure for removing, testing and

reinstalling the LPG contents gauge is as detailed

in Section 2.12 CYLINDER FUEL GAUGE

ASSEMBLY under VT Sedan With Production LPG

of the VT Series Service Information CD, noting the

following:

To r einstall the smar t unit and solenoid valve, refer

to 2.8 SMART UNIT AND SOLENOID VALVE in

this Section.

2.13 SERVICE LINES

FRONT SERVICE LINE

The procedure for removing and reinstalling the

front s er vice line on VT Wagon Models is the s ame

as the procedure published for VT Sedan Models.

Theref ore, ref er to Section 2.13 SERVICE L INES

- FRONT SERVICE LINE under VT Sedan With

Production LPG of the VT Series Service

Information CD.

INTERMEDIATE SERVICE LINE

The intermediate service line is incorporated into

the fuel and brake pipe harness assembly and,

therefore, not serviced separately. For additional

information, refer to Section 8A FUEL TANK of

the VT Series Service Information CD.

NOTE:

Ensure heat protective shield is installed over

intermediate service line near the exhaust

manifold.

REAR SERVICE LINE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer

2.1 DRAINING THE SERVICE LINES in this

Section.

3. Ensure the manual service valve is turned

'OFF'.

4. De-pressur ise the fuel (petrol) system , refer to

Section 6C1 POWERTRAIN MANAGEMENT

of the VT Series Service Information CD.

5. Ensure the battery earth lead is disconnected.

6. Remove the fuel (petrol) tank assembly, refer

to Section 8A FUEL TANK of the VT Series

Service Information CD. Figure 2A-39

7. From inside the LPG tank valve box, loosen

and unscrew the rear service line connector

from solenoid and manual service valve

assembly, refer to Fig. 2A-40.

Figure 2A-40

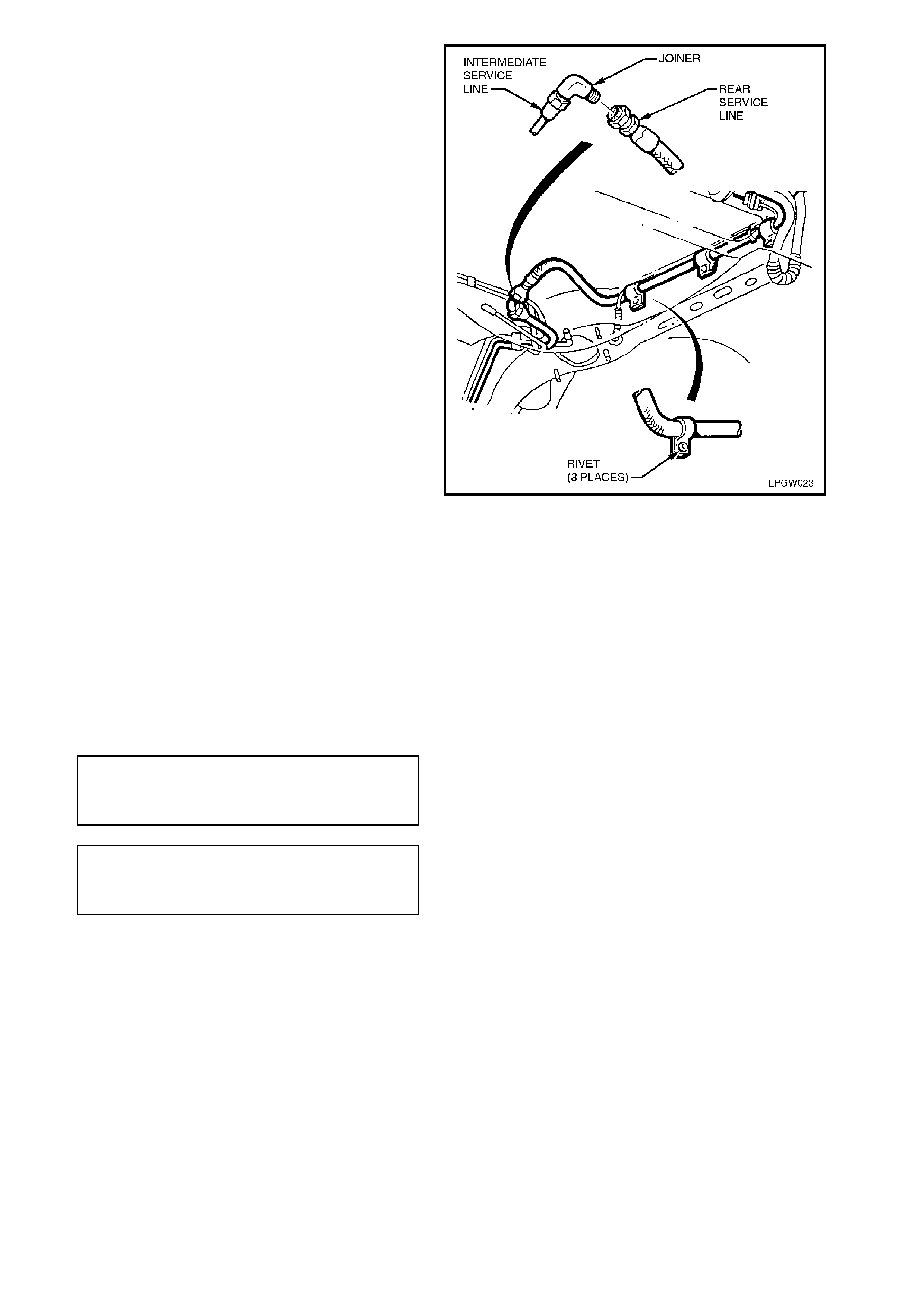

8. From under vehicle, while holding the

intermediate to rear service line joiner from

turning, loosen and unscrew the rear service

connector fr om the s ervic e line joiner , r ef er Fig

2A-41.

9. Using a suitable sized drill bit, drill into the

heads of the rear service line retaining pop

rivets (refer Fig. 2A-41) and remove the rear

service line.

10. Using a suitable size pin punch and hammer,

knock out remains of the rear service line

securing pop rivets from vehicle underbody.

Figure 2A-41

REINSTALL

Reinstallation of the r ear service line is the reverse

of the removal procedure, noting the following:

1. Clean rear service line mating threads on

solenoid and manual service valve assembly,

intermediate to rear service line joiner, and

both rear service line connectors.

2. Ensuring that flared surfaces are free of

sealant and contam inants, tighten rear service

line connections to the correct torque

specifications.

REAR SERVICE LINE

CONNECTION TO SERVICE

LINE JOINER VALVE

TORQUE SPECIFICATION

12.0 - 15.0

Nm

REAR SERVICE LINE

CONNECTION TO SOLENOID

AND MANUAL SERVICE VALVE

TORQUE SPECIFICATION

12.0 - 18.0

Nm

3. Secure rear service line using new pop rivets

before fuel (petrol) tank is reinstalled.

4. Before starting vehicle or opening the manual

service valve, carry out a fuel (petrol) system

leak test as detailed in

Section 6C1 POWERTRAIN MANAGEMENT

- V6 ENGINE of the VT Series Service

Information CD.

5. Carry out LPG system leak test, refer

2.3 LEAK TESTING in this Section.

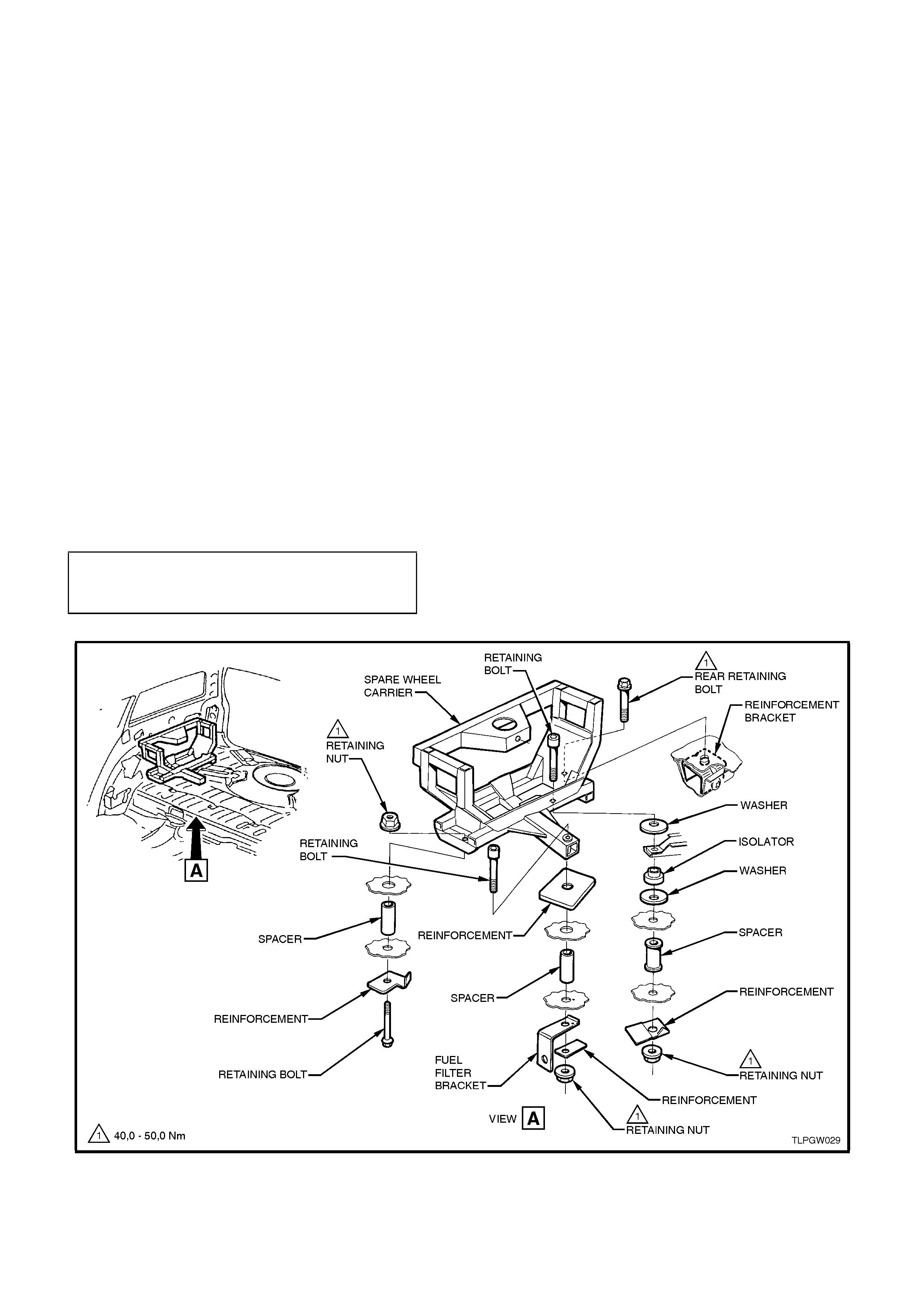

2.14 SPARE WHEEL CARRIER

REMOVE

1. Remove spare wheel cover and spare wheel

from the spare wheel carrier.

2. Remove the luggage com partm ent f loor cover,

refer 2.15 LUGGAGE COMPARTMENT

FLOOR COVER in this Section.

3. With the aid of an assistant, loosen and

remove the four bolts and three nuts securing

the spare wheel carrier to the rear

compartment floor, refer Fig. 2A-42.

NOTE:

The rear spare wheel carrier retaining bolt screws

into a reinforcement bracket with a captive nut.

REINSTALL

Reinstallation of the spare wheel carrier is the

reverse of the removal procedure, noting the

following:

1. Ensure spacer, isolator and reinforcement

plates are installed correctly, refer Fig. 2A-42.

2. Ensure all fasteners are tightened to the

correct torque specification.

SPARE WHEEL CARRIER

RETAINING BOLT AND NUT 40.0 - 50.0 Nm

TORQUE SPECIFICATION

Figure 2A-42

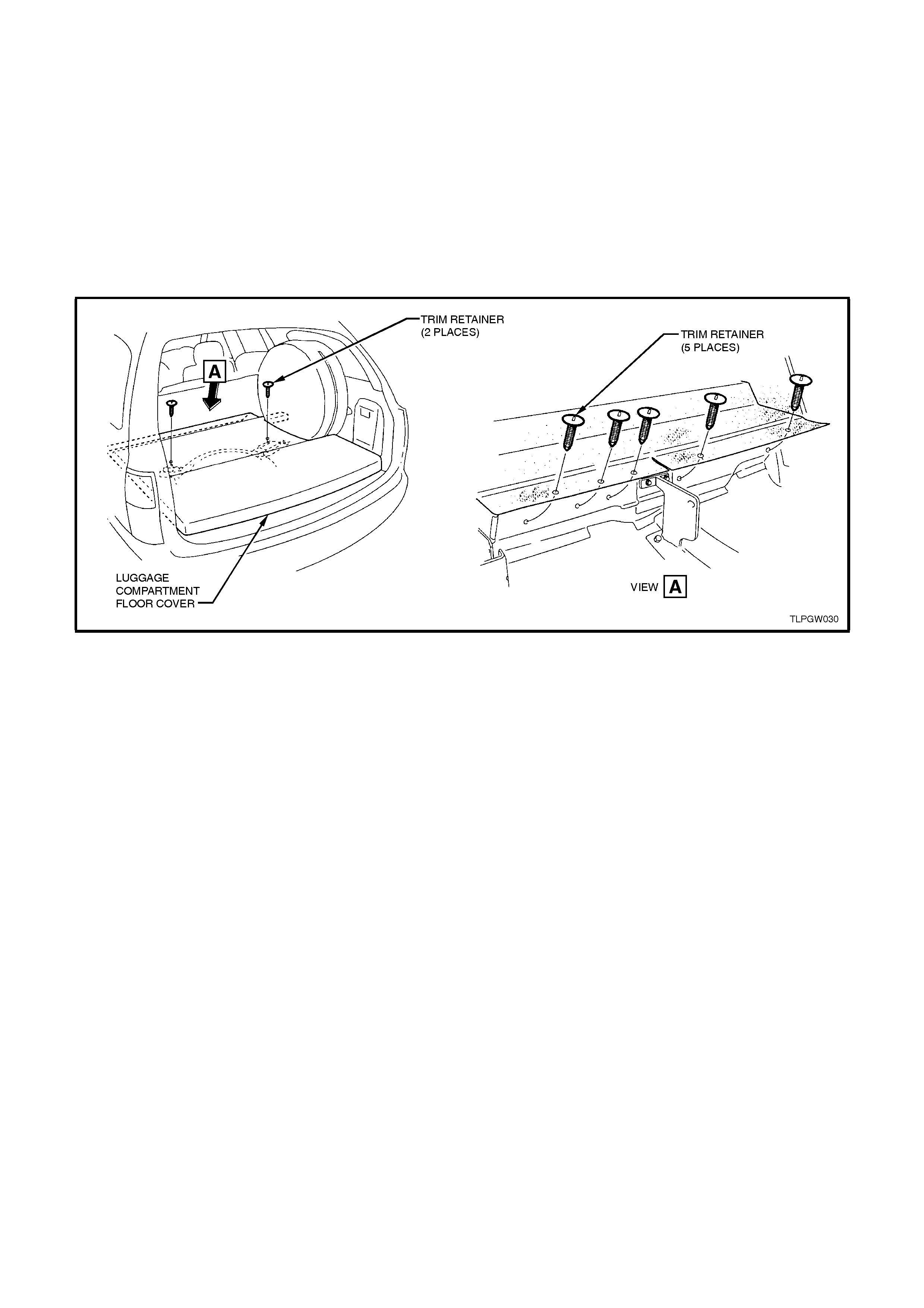

2.15 LUGGAGE COMPARTMENT FLOOR COVER

REMOVE

1. Lower the rear seat back assemblies.

2. Remove the five trim retainers from the rear of the luggage compartment floor cover.

3. Remove the two trim retainers from the centre of the luggage compartment floor cover.

4. Lifting the left hand side of the luggage compartment floor cover up 45°, remove the floor cover from the

luggage compartment.

REINSTALL

Reinstallation of the luggage compartment floor cover is the reverse of the removal procedure.

Figure 2A-43

2.16 AFTER INSTALLATION CHECK (FOR PRODUCTION FITTED LPG SYSTEMS ONLY)

GENERAL INFORMATION

At the 1,500 km (or 1 month) first service, it is a requirement of Holden Ltd. A.B.N. 84 006 893 232 that the following

‘After Installation Check’ be performed.

All items in this check list must be checked to ensure they have been adjusted or installed as outlined in this Service

Information CD.

UNDERBODY (Tick the appropriate boxes)

CHECK OK REPAIR

1. Rear service line and intermediate service line

connected to union (under vehicle) and

connectors tightened to the correct torque

specification.

!!!

2. Service lines correctly routed and retaining clips

installed. !!!

3. LPG tank/cylinder correctly installed and

attaching nuts tightened to the correct torque

specification.

!!!

REAR COMPARTMENT (Tick the appropriate boxes)

CHECK OK REPAIR

1. Floor flange installed and silicone sealer applied.

(Sedan Only) !!!

2. Service line vent tube installed to floor flange and

retaining clamps tightened. (Sedan Only) !!!

3. Service line vent tube installed to joiner and

retaining clamp tightened (Sedan Only).

Ensure vent tube grommet is installed correctly

in its location. (Wagon Only).

!!!

4. Filler line connected to joiner and LPG

tank/cylinder high pressure inlet elbow and filler

line connectors tightened to the correct torque

specification.

!!!

5. Filler installed correctly and retaining cap screws

tightened to the correct torque specification.

(Sedan Only)

Filler installed correctly and retaining nut

tightened to correct torque specification (Wagon

Only).

!!!

6. Filler lid operates without binding and shuts

flush, AFL sticker is affixed to inside of filler lid. !!!

7. Rear service line connected to solenoid and

manual service valve assembly and connector

tightened to the correct torque specification.

!!!

8. LPG tank/cylinder level sender and smart unit

harness connector is connected to LPG body

harness connector (YR50).

!!!

9. Rear compartment carpet and quarter trim

carpet have been reinstalled and are positioned

correctly.

!!!

10. Check spare wheel retainer is hand tight (Wagon

Only). !!!

11. Check spare wheel carrier is correctly installed &

nuts tightened to the correct torque specification

(Wagon Only).

!!!

UNDER BONNET (Tick the appropriate boxes)

CHECK OK REPAIR

1. The vapour line to mixer and vapour line to

converter retaining clamps are installed and

tightened.

!!!

2. The vapour line and vacuum hoses are

connected and routed correctly. !!!

3. Converter and converter bracket installed and

retaining bolts are tightened to the correct torque

specification.

!!!

4. Coolant pipe hose clamps fitted and tightened.

Coolant and vapour hoses correctly routed to

avoid contact with engine or body parts.

!!!

5. Fuel control valve (FCV) installed and FCV

retaining bolt tightened to the correct torque

specification.

!!!

6. Air intake tube installed, clamps and mounting

screw tightened to the correct torque

specification.

!!!

7. Air cleaner assembly and MAF sensor installed. !!!

8. Intermediate LPG line P clamps installed on

cockpit module and tightened to the correct

torque specification.

!!!

LEAK CHECK

With at least 3 litres of LPG in the cylinder/tank, leak test the complete LPG system as outlined in 2.3 LEAK

TESTING in this Service Information CD.(Tick the appropriate boxes)

Note: The following points must be tested. CHECK OK REPAIR

1. Pressure relief valve. !!!

2. Solenoid and manual service valve assembly to

LPG tank/cylinder. !!!

3. Solenoid and manual service valve assembly. !!!

4. Rear service line to solenoid and manual service

valve assembly connector. !!!

5. LPG tank/cylinder fuel gauge assembly. !!!

6. AFL inlet elbow to LPG tank/cylinder. !!!

7. Rear service line to AFL inlet elbow connector. !!!

8. AFL to LPG tank/cylinder. !!!

9. Filler valve to filler line and on Wagon Models,

filler line connector to filler line hose. !!!

10. Filler valve check ball. !!!

11. Rear service line to intermediate service line

joiner connection. !!!

12. Intermediate service line to rear service line

joiner connection. !!!

13. Intermediate service line to front service line

joiner connection. !!!

14. Front service line to intermediate service line

joiner connection. !!!

15. Front service line to LPG lockoff inlet connection. !!!

16. LPG lockoff inlet connection to LPG lockoff. !!!

17. LPG lockoff. !!!

18. LPG lockoff to LPG lockoff outlet connection. !!!

19. LPG lockoff outlet connection to converter. !!!