SECTION 2B - SERVICE OPERATIONS - VT SEDAN

WITH ACCESSORY FITTED LPG

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt pre-

tensioners and a driver's and front passenger's side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

IMPORTANT:

When any LPG system component has been replaced or overhauled, or when the engine assembly has

been replaced or overhauled, the adaptive learn drive cycle procedures must be carried out as described in

2.23, ADAPT IVE DIGITAL PROCESSOR SET -UP PROCEDURE under VT Sedan With Production LPG of the

VT Series Service Information CD. This is because the values stored in the Adaptive Digital Processor

operational cells apply only to the previous condition of the engine or components.

2.1 LEAK TESTING

The procedure for leak testing the LPG system high pressure components on VT Series Model Sedans with

Accessory fitted LPG is the same as detailed in Section 2.3 LEAK TESTING under VT Sedan With Production

LPG of the VT Series Service Information CD, noting the following.

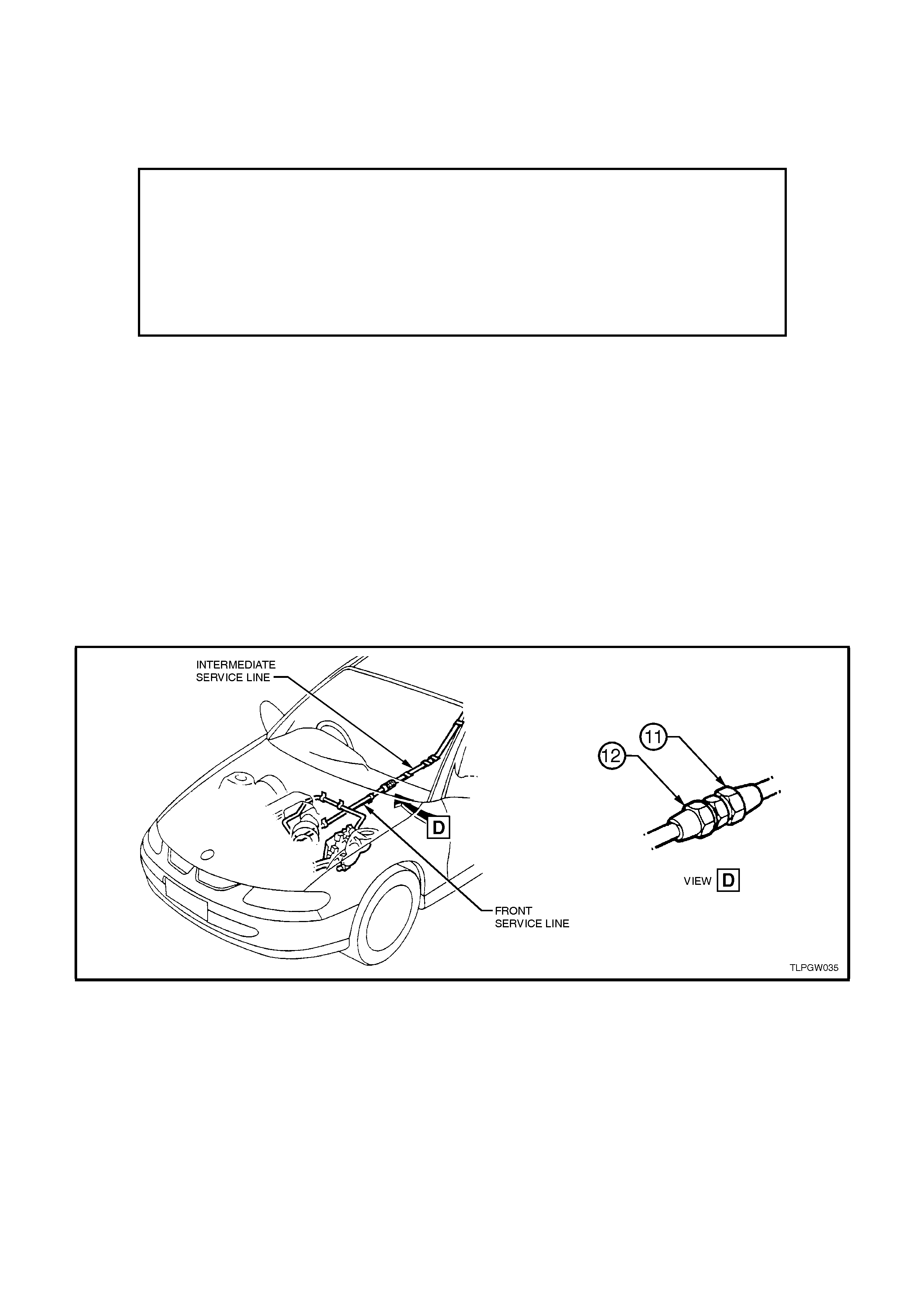

The front and intermediate service line joiner is located on the underbody on VT Sedans with accessory LPG.

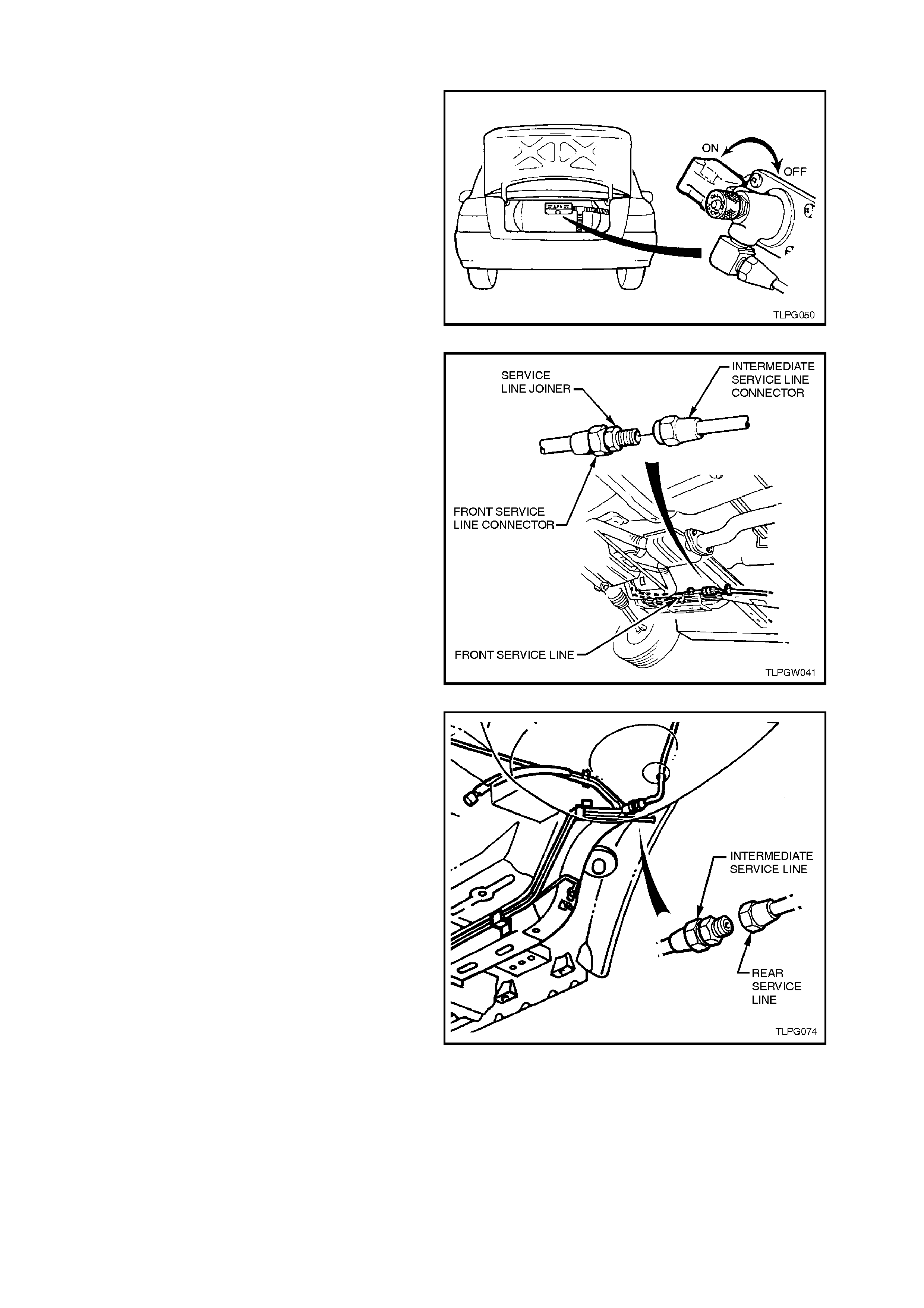

Figure 2B-1

2.2 SERVICE LINES

FRONT SERVICE LINE

REMOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES under

VT Sedan With Production LPG of the VT

Series Service Information CD.

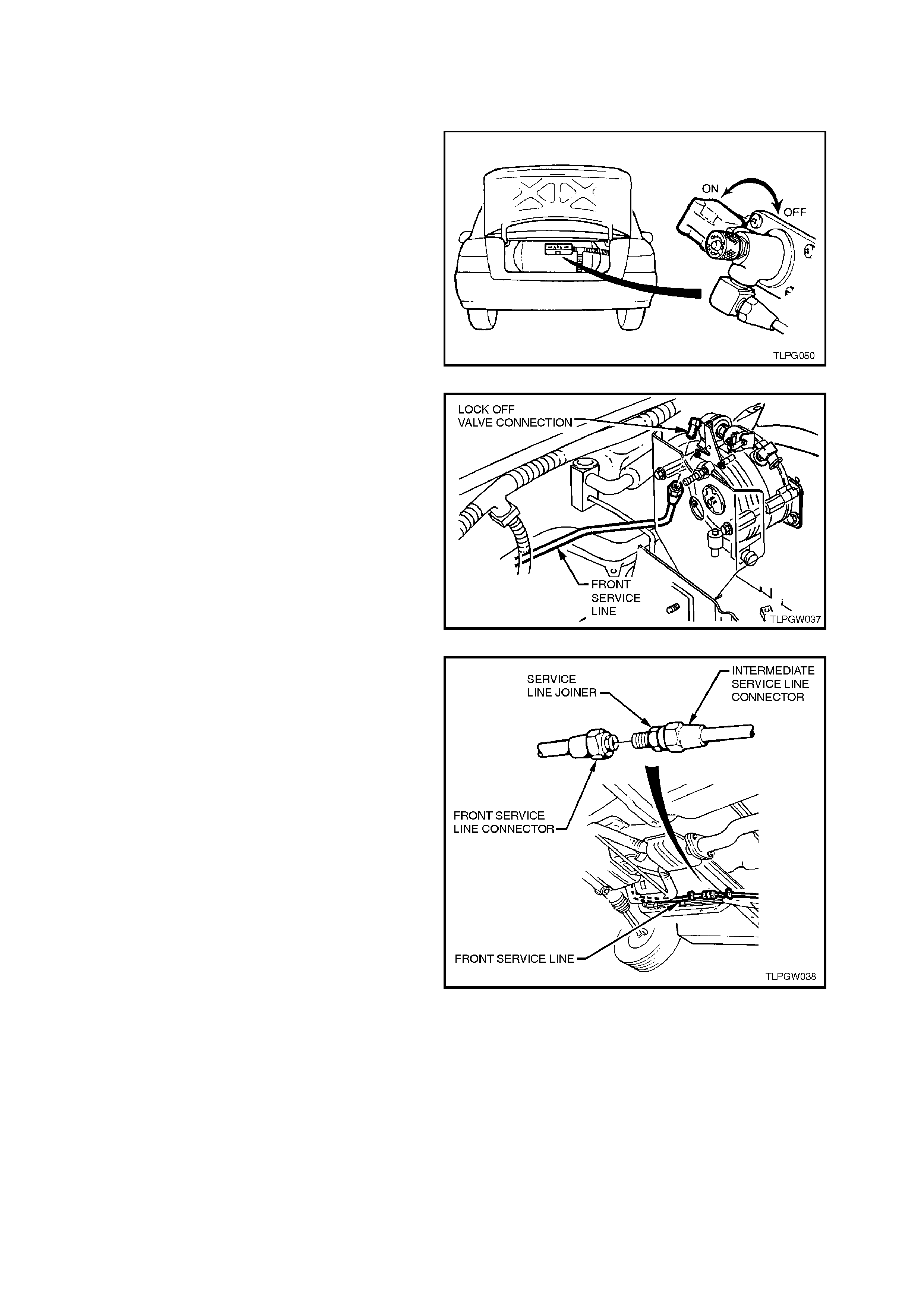

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2B-2

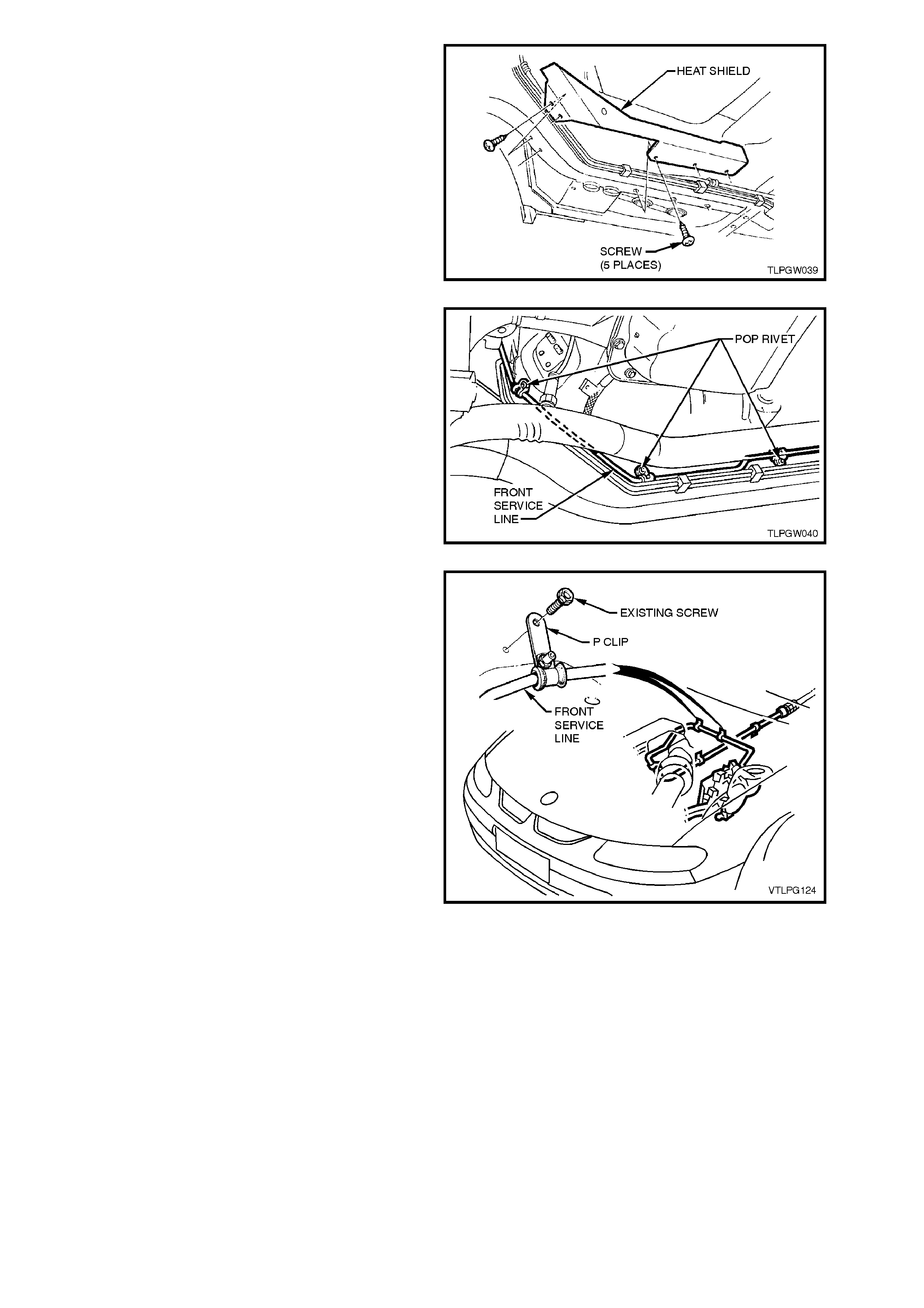

4. Loosen and disconnect front service line

connector from LPG lockoff connection.

Figure 2B-3

5. W hile holding f ront to inter mediate service line

joiner from turning, loosen and disconnect

front service line connector from joiner and

remove front service line.

Figure 2B-4

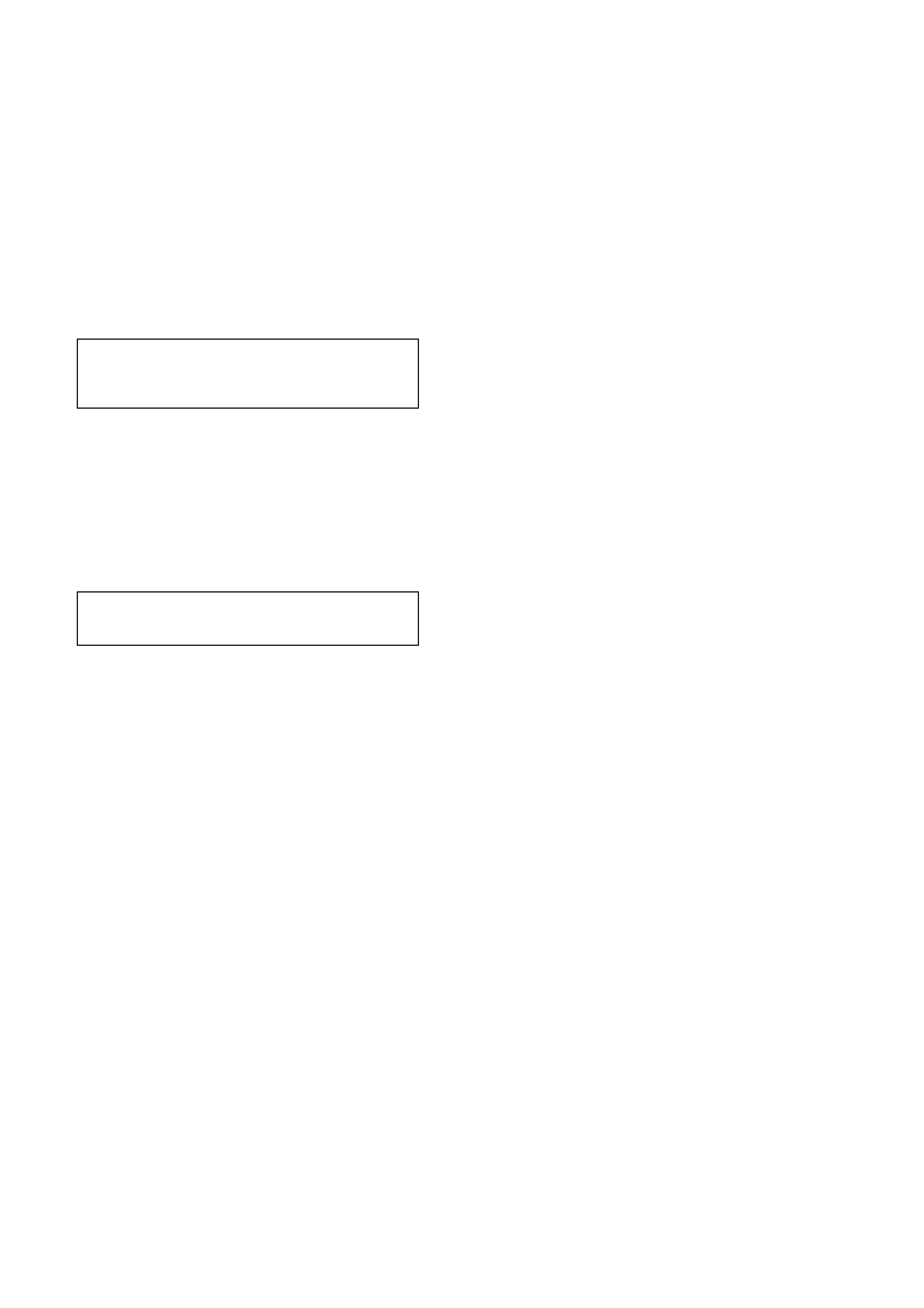

6. Remove the five screws securing the front

service line heat shield to the underbody and

remove heat shield.

7. Remove the longitudinal to front floor brace,

refer Section 1A1 BODY of the VT Series

Service Information CD.

Figure 2B-5

8. From under the vehicle, and using a suitable

sized drill bit, drill into the heads of the three

front service line retaining pop rivets.

9. Using a suitable size pin punch and hammer,

knock out remains of the three front service

line retaining pop rivets.

Figure 2B-6

10. From inside the engine compartment, remove

the two screws securing the front service line

to the cockpit module.

11. Remove the front service line from beneath

the vehicle.

Figure 2B-7

REINSTALL

1. Clean mating threads of front service line,

LPG lockoff connection and front to

intermediate service line joiner connector.

2. From under vehicle, feed the f ront service line

into the engine compartment.

3. From above, position the front service line

across the engine compartment to the LPG

lockoff.

4. Ensuring that flared surfaces are free of

sealant and contaminants, assemble front

service line connectors to LPG lockoff

connection and service line joiner and tighten

to the correct torque specification.

FRONT SERVICE LINE

TO LOCKOFF CONNECTOR

AND JOINER

TORQUE SPECIFICATION

12.0 - 15.0

Nm

5. Using new pop rivets and existing clamps,

secure the front service line to the underbody.

6. Reinstall the two screws securing the front

service line to cockpit module.

7. Reinstall the longitudinal to front floor brace

and tighten the four nuts to the correct torque

specification.

LONGITUDINAL TO FRONT

FLOOR BRACE NUT

TORQUE SPECIFICATION 25.0 - 35.0 Nm

8. Assemble the front service line heat shield to

the underbody and install securing screws.

9. Leak test LPG system, refer

2.1 LEAK TESTING in this Section.

INTERMEDIATE SERVICE LINE

MOVE

1. Park the vehic le in a well ventilated area, away

from any ignition source.

2. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES under

VT Sedan With Production LPG of the VT

Series Service Information CD.

3. Ensure the manual service valve is turned

'OFF' and the battery earth lead is

disconnected.

Figure 2B-8

4. W hile holding f ront to inter mediate service line

joiner from turning, loosen and disconnect

intermediate service line connector from

joiner.

Figure 2B-9

5. While holding the intermediate to rear service

line joiner from turning, loosen and unscrew

the rear service connector from the service

line joiner.

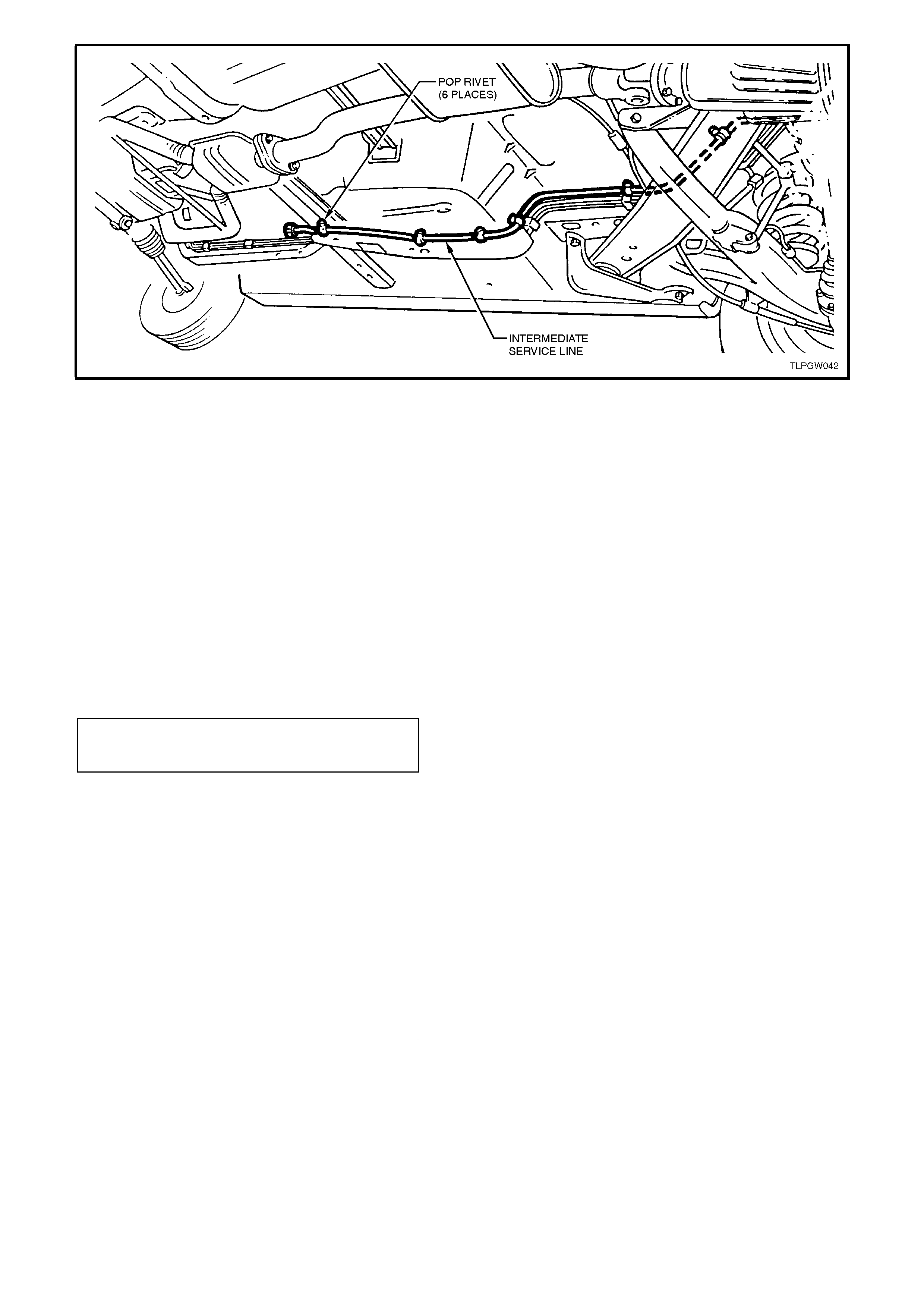

6. From under the vehicle, and using a suitable

sized drill bit, drill into the heads of the six

intermediate service line retaining pop rivets.

7. Remove the intermediate service line, by

feeding the service line towards the front of the

vehicle.

8. Using a suitable size pin punch and hammer,

knock out remains of the six intermediate

service line retaining pop rivets.

Figure 2B-10

Figure 2B-11

REINSTALL

1. Clean mating threads of front to intermediate

and intermediate to rear service line joiner

connectors.

2. From under vehicle, place the intermediate

service line in position, by feeding the line

from the front of the vehicle, over the

handbrake cable, rear suspension and axle

components.

3. Ensuring that flared surfaces are free of

sealant and contaminants, assemble front to

intermediate and intermediate to rear service

line joiner connectors and tighten to the

correct torque specification.

INTERMEDIATE SERVICE

LINE CONNECTION

TORQUE SPECIFICATION 12.0 - 15.0 Nm

4. Using new pop rivets and existing clamps,

secure the intermediate service line to the

underbody (6 places), refer Fig. 2B-11.

5. Leak test LPG system, refer 2.1 LEAK

TESTING in this Section.

REAR SERVICE LINE

The procedure for removing and reinstalling the

rear service line on VT Series Sedan Models with

accessory LPG systems is the same as the

procedure published for VT Sedan Models with

production fitted LPG system s. Therefore, refer to

Section 2.13 SERVICE LINES - REAR SERVICE

LINE under VT Sedan W ith Production LPG of the

VT Series Service Information CD.

2.3 LPG RELAY

REMOVE

1. Disconnect battery earth lead.

2. Remove left hand front shroud panel lower

trim (cowl panel trim), refer

Section 1A2 UNDERBODY of the VT Series

Service Information CD.

3. Disconnect LPG interior patch harness from

LPG relay.

4. Remove LPG relay retaining screw, remove

relay.

REINSTALL

Reinstallation of the LPG relay is the reverse of the

removal procedure. Figure 2B-12

2.4 FUEL MODE SWITCH

REMOVE

1. Disconnect the battery earth lead.

2. Remove instrument panel facia far enough to

gain access to switch connectors (fuel mode,

headlamp, fog lam p, trip computer and hazard

switches) attached to instrument panel facia,

refer Section 1A3 INSTRUMENT PANEL

AND CONSOLE of the VT Series Service

Information CD.

3. Disconnect wiring harness connectors from

instrument panel facia and remove facia.

4. From behind instrument panel facia, squeeze

together fuel mode switch to instrument panel

facia retaining tangs and push switch out from

facia.

TEST

The procedure for testing the f uel mode switch on

VT Series Models with accessory fitted LPG is the

same as the procedure detailed for VT Series

Sedans with production fitted LPG systems.

Therefore, refer to operation 2.22 FUEL MODE

SWITCH under VT Sedan With Production LPG of

the VT Series Service Information CD.

Figure 2B-13

REINSTALL

Reinstallation of the fuel mode switch is the reverse

of the removal procedure.

2.16 AFTER INSTALLATION CHECK (FOR ACCESSORY FITTED LPG SYSTEMS ONLY)

GENERAL INFORMATION

On completion of the LPG installation and at the 1,500 km (or 1 month) first service, it is a requirement of Holden

Ltd. A.B.N. 84 006 893 232 that a copy of the following ‘After Installation Check’ list be completed and filled out by the

fitting dealer to ensure a high quality installation standard. Be advised that Holden Ltd. reserves the right at any time

to audit any ‘After Installation Check’ list sheet.

All items in this check list must be checked to ensure they have been installed, adjusted or reinstalled as outlined in

the Fitting Instructions, or applicable Service Manual.

DATE: ____________________________________ VEHICLE: _____________________________________

VIN No. REGISTRATION No. ______________________ REGISTRATION No. ________________________

Kit No. _____________________________________________________________________________________

AUTHORISED DEALER: _______________________________ LICENCE No: _________________________

FITTER: ____________________________________________ LICENCE No. _________________________

UNDERBODY (Tick the appropriate boxes)

CHECK OK REPAIR

1. Rear service line and intermediate service line

connected to joiner (near grommet in rear

longitudinal) and connectors tightened to the

correct torque specification.

!!!

2. Front and intermediate service lines connected

to joiner, just forward of brake/fuel pipe harness

cover, and connectors tightened to the correct

torque specification.

!!!

3. Front and intermediate service lines are not

chafing or in contact with brake, petrol or

evaporative lines, body or any other component.

!!!

4. Front and intermediate service lines correctly

routed and retaining clips installed. !!!

5. LPG cylinder correctly installed and attaching

nuts tightened to the correct torque specification. !!!

6. Rear springs installed and rear shock absorber

mounting bolts tightened to the correct torque

specification.

!!!

7. Drive shafts and constant velocity joint to

trunnion flange attaching bolts are tightened to

the correct torque specification.

!!!

VEHICLE INTERIOR (Tick the appropriate boxes)

CHECK OK REPAIR

1. All the following LPG body harness connections

are installed. !!!

a. LPG body harness fuel mode switch

connector to fuel mode switch. !!!

b. 3 Amp fast blow fuse installed in LPG main

wiring harness (under RHF lower instrument

panel).

!!!

c. LPG body harness 10 pin connector to LPG

engine harness connector. !!!

d. LPG body harness 9 pin ADP connector to

ADP. !!!

e. LPG body harness single lead PCM terminals

are inserted to PCM connector as follows:

Violet lead into cavity A9 of connector 2,

YB188.

Pink/Black lead into cavity E1, White/Green

lead into cavity E5 and Pink/Blue lead into

cavity E11 of connector 3, YB194.

Anti-backout combs reinstalled.

!!!

2. LPG body harness routed along rocker panel

from RHF shroud lower trim (kick panel) and tie

strapped to existing wiring harness.

!!!

3. Rear seat cushion and RHR seat back

reinstalled. !!!

4. RH rocker panel cover installed. !!!

5. RHF instrument panel lower trim assembly and

instrument panel facia reinstalled with fuel mode

switch installed and connected to LPG main

harness.

!!!

6. LPG body harness routing not impairing heater

valve.

Operate heater controls to ensure the harness

routing does effect their operation.

!!!

7. ADP installed and retaining screws tightened to

the correct torque specification. ADP vacuum

supply hose is connected to ADP without any

kinks in the vacuum hose.

!!!

8. PCM connectors are installed correctly. !!!

9. LH shroud lower trim (kick panel) assembly and

rocker panel cover installed. !!!

10. All instrument panel controls function correctly. !!!

REAR COMPARTMENT (Tick the appropriate boxes)

CHECK OK REPAIR

1. Floor flange installed and silicone sealer applied. !!!

2. Service line vent tube installed to floor flange and

retaining clamps tightened. !!!

3. Service line vent tube joiner installed and

retaining clamp tightened. !!!

4. Filler line connected to joiner and LPG cylinder

high pressure inlet elbow and filler line

connectors tightened to the correct torque

specification.

!!!

5. Filler valve flange installed correctly and retaining

cap screws tightened to the correct torque

specification.

!!!

6. Filler lid operates without binding and shuts

flush, AFL sticker is affixed to inside of filler lid. !!!

7. Rear service line connected to solenoid and

manual service valve assembly and connector

tightened to the correct torque specification.

!!!

8. LPG cylinder level sender and smart unit

harness connector is connected to LPG body

harness connector.

!!!

9. Rear compartment carpet and quarter trim

carpet have been reinstalled and are positioned

correctly.

!!!

UNDER BONNET (Tick the appropriate boxes)

CHECK OK REPAIR

1. All the following LPG engine harness

connections are installed. !!!

a. LPG engine harness 8 pin connectors are

connected to main harness and engine harness

connectors (YE112) located near RH strut tower.

!!!

b. Earth lead is installed to rear of LH cylinder head

and retaining bolt is tightened to the correct

torque specification.

!!!

c. LPG engine harness oxygen sensor connectors

are connected to vehicle engine harness and

oxygen sensor connectors (YE97).

!!!

d. LPG engine harness lockoff connector is

connected to LPG lockoff. !!!

e. LPG engine harness fuel control valve connector

connected to fuel control terminals. !!!

2. Oxygen sensor wiring correctly routed and cable

tie installed. !!!

3. The vapour line to mixer and vapour line to

converter retaining clamps are installed and

tightened.

!!!

4. The vapour line and vacuum hoses are

connected and routed correctly. !!!

5. Converter and converter bracket installed and

retaining bolts are tightened to the correct torque

specification.

!!!

6. Coolant pipe hose clamps fitted and tightened.

Coolant and vapour hoses correctly routed to

avoid contact with engine or body parts.

!!!

7. Fuel control valve (FCV) installed and FCV

retaining bolt tightened to the correct torque

specification.

!!!

8. Air intake tube installed, clamps and mounting

screw tightened to the correct torque

specification.

!!!

9. Air cleaner assembly and MAF sensor installed. !!!

10. Front service line P clamps installed on cockpit

module and tightened to the correct torque

specification.

!!!

LEAK CHECK

With at least 3 litres of LPG in the cylinder/tank, leak test the complete LPG system, refer 2.1 LEAK TESTING in

this Service Information CD.

Note:

The following points must be tested. (Tick the appropriate boxes)

CHECK OK REPAIR

1. Pressure relief valve. !!!

2. Solenoid and manual service valve assembly to

LPG tank/cylinder. !!!

3. Solenoid and manual service valve assembly. !!!

4. Rear service line to solenoid and manual service

valve assembly connector. !!!

5. LPG tank/cylinder fuel gauge assembly. !!!

6. AFL inlet elbow to LPG tank/cylinder. !!!

7. Rear service line to AFL inlet elbow connector. !!!

8. AFL to LPG tank/cylinder. !!!

9. Filler valve to filler line. !!!

10. Filler valve check ball. !!!

11. Rear service line to intermediate service line

joiner connection. !!!

12. Intermediate service line to rear service line

joiner connection. !!!

13. Intermediate service line to front service line

joiner connection. !!!

14. Front service line to intermediate service line

joiner connection. !!!

15. Front service line to LPG lockoff inlet connection. !!!

16. LPG lockoff inlet connection to LPG lockoff. !!!

17. LPG lockoff. !!!

18. LPG lockoff to LPG lockoff outlet connection. !!!

19. LPG lockoff outlet connection to converter. !!!

FILLING

After the leak test has been completed and there are NO LEAKS, fill the LPG cylinder and record the number of

litres taken.

NOTE:

Don't forget the three litres you put into the LPG cylinder to conduct the Leak Test.

The LPG cylinder capacity of 74 litres is the 'fallible' capacity .

Automatic Fill Limiter (AFL) operation.

Total Litres Taken: __________________________________ Litres.

COMMISSIONING OF VEHICLE (Tick the appropriate boxes)

CHECK OK REPAIR

1. ADP fuel adjustment. Confirm with fuel system

analyser. !!!

2. Glove box installed, key and lock operate

correctly. !!!

3. Vehicle's fuel changeover operation. !!!

4. Number plate LPG stickers affixed. !!!

5. LPG compliance plate affixed. !!!

6. Windscreen label affixed. !!!

7. Owners handbook LPG supplement. !!!

8. Road test vehicle. !!!

9. Warranty card filled out. !!!