SECTION 3B - DIAGNOSIS - VT SEDAN WITH

ACCESSORY FITTED LPG

3.1 PREREQUISITES TO DIAGNOSIS AND TROUBLESHOOTING

PRELIMINARY SYSTEM REQUIREMENTS

Prerequisites before proceeding with system checks are:

Ensure that sound earth connections are available for all functioning components, particularly at the body earth

connection (fender panel inner stud, adjacent to the battery).

Ensure the battery is in good condition and adequately charged (above 12.5 volts) before carrying out any

electrical checks.

SAFETY REQUIREMENTS

Disconnect the battery when carrying out work which involves the risk of an electrical short circuit.

Do not touch mechanical components during function checks, to avoid the risk of a hand being caught in the

mechanism.

CHECKING EQUIPMENT

TECH 2 scan tool.

A digital multimeter, with a minimum 10 Megohm impedance MUST be used when undertaking any electrical

checks on these systems.

Exercise care when taking readings from wiring harness connectors. It is preferred that the back probing method

with individual connectors is employed wherever possible, to avoid terminal damage and subsequent connection

failure.

When carrying out wiring checks as directed to by the diagnostic charts, rather than probe terminals and connectors

with incorrect sized multimeter connections, use the adaptors contained in connector test adaptor kit KM-609. This

will prevent any possibility of spreading or damaging wiring harness terminals.

IMPORTANT:

ENSURE THAT THE IGNITION IS TURNED OFF AND THE BATTERY EARTH LEAD IS DISCONNECTED

BEFORE ANY TEST THAT REQUIRES DISCONNECTION OR RECONNECTION OF ANY OF THE PCM

CONNECTORS.

When checking the complete system, the exact order of the test steps should be observed.

If the required nominal value is not achieved in any stage, then the problem must be rectified before

proceeding further.

Unless the multimeter being used has an auto ranging function, check that the correct range, as specified, is

selected before the test is carried out.

Testing of the system will involve gaining access to specific wiring harness connectors. For the location of

these connectors, refer to Section 4 WIRING DIAGRAMS.

Techline

3.2 GENERAL INFORMATION

The procedures outlined in the LPG VEHICLE PRELIMINARY DIAGNOSTIC CHART MUST be carried out first

whenever diagnosing a problem in a LPG vehicle.

The LPG system is designed to operate in LPG mode when LPG has been selected via the fuel mode switch. When

diagnosing the LPG system, unless otherwise directed. Ensure that the LPG mode has been selected, there is LPG

in the LPG cylinder and the manual service valve is turned 'ON'.

When LPG has been selected via the fuel mode switch the PCM will operate in the LPG mode if the operating

parameters sensed by the PCM permit the switching to the LPG mode.

Before any diagnostic procedures are carried out on the LPG system you must first confirm that the vehicle

operates on petrol without any problems and there are NO DIAGNOSTIC TROUBLE CODES stored in the PCM

memory. This can be achieved by following the LPG VEHICLE PRELIMINARY DIAGNOSTIC CHART in this

Section.

After the LPG vehicle preliminary diagnostic procedure has been carried out, an ON-BOARD DIAGNOSTIC

SYSTEM CHECK must be performed and any diagnostic trouble code that has been logged in the PCM memory

must be rectified and all diagnostic trouble codes cleared before you confirm any problem with the LPG system.

When carrying out the diagnostic procedures refer the to the fold out wiring diagrams, refer Section 4 WIRING

DIAGRAMS in this Section.

3.3 LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. If the Check Powertrain Lamp illuminates, the PCM is being powered up. If the Check Powertrain Lamp does

not illuminate you should refer to the ON-BOARD DIAGNOSTIC SYSTEM CHECK, in the VT Series Service

Information CD.

2. Ensures TECH 2 is functioning correctly.

3. Checks if TECH 2 can communicate with the PCM. If Tech 2 cannot communicate with the PCM you should

refer to PCM DIAGNOSTICS in the VT Series Service Information CD.

4. Checks if the PCM can operate in the LPG mode.

5. Checks if the LPG switch is operating correctly.

6. Checks the operation of the LPG lamp.

7. Checks if the engine will operate on petrol.

8. Checks if the engine will crank when LPG has been selected.

9. Checks if the engine will run when LPG has been selected.

10. If the engine backfires when operating on LPG, go to the 3.9 ENGINE BACK FIRES ON LPG diagnostic chart

in this Section.

11. If the engine lacks power, is sluggish or has poor performance, refer Diagnostic Chart 3.10 POOR

PERFORMANCE, SLUGGISH OR POOR FUEL CONSUMPTION WHEN OPERATING ON LPG in this

Section.

12. If the fuel gauge does not operate correctly on when petrol or LPG has been selected via the fuel mode switch,

refer Diagnostic Chart 3.12 FUEL GAUGE DOES NOT OPERATE in this Section.

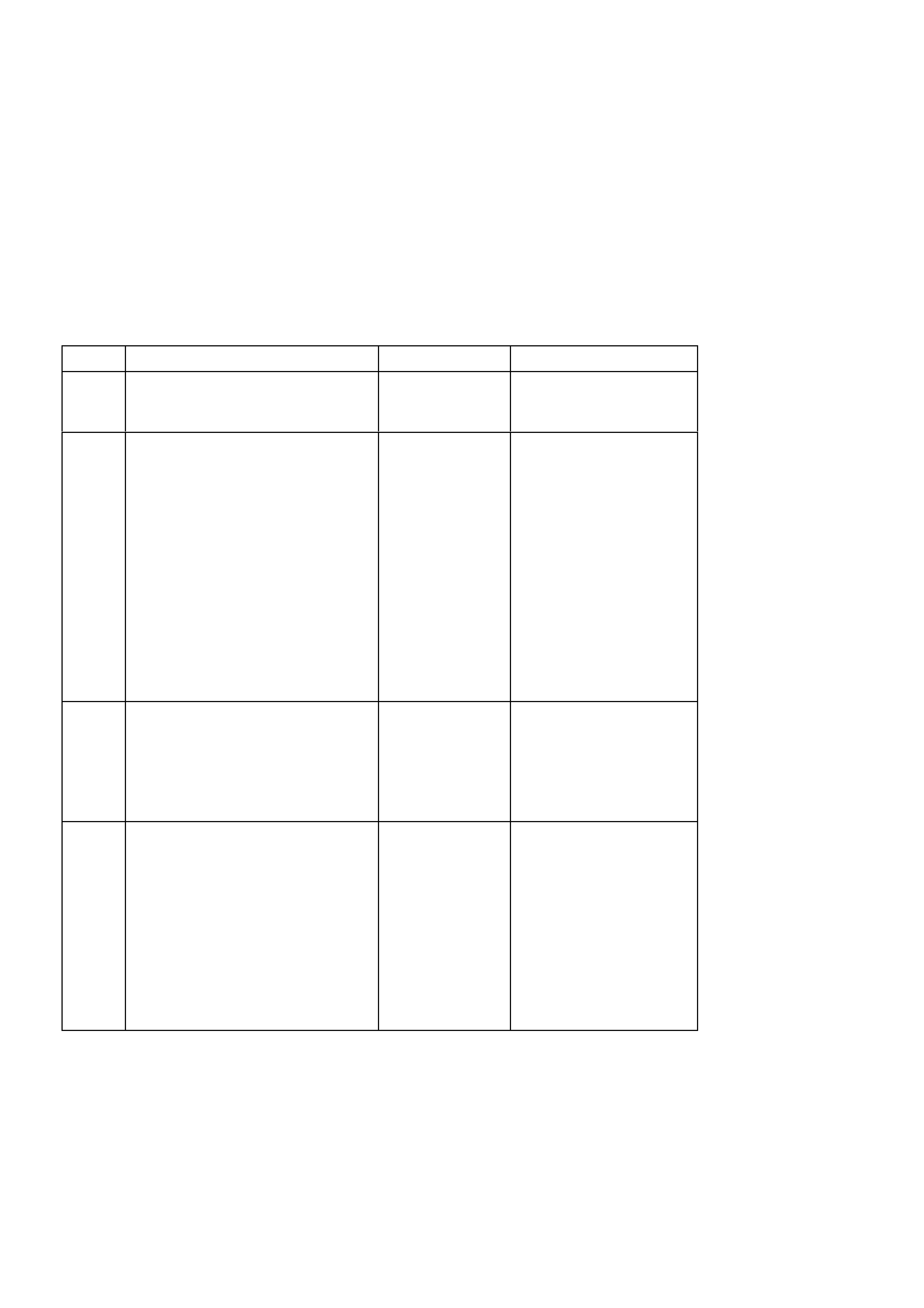

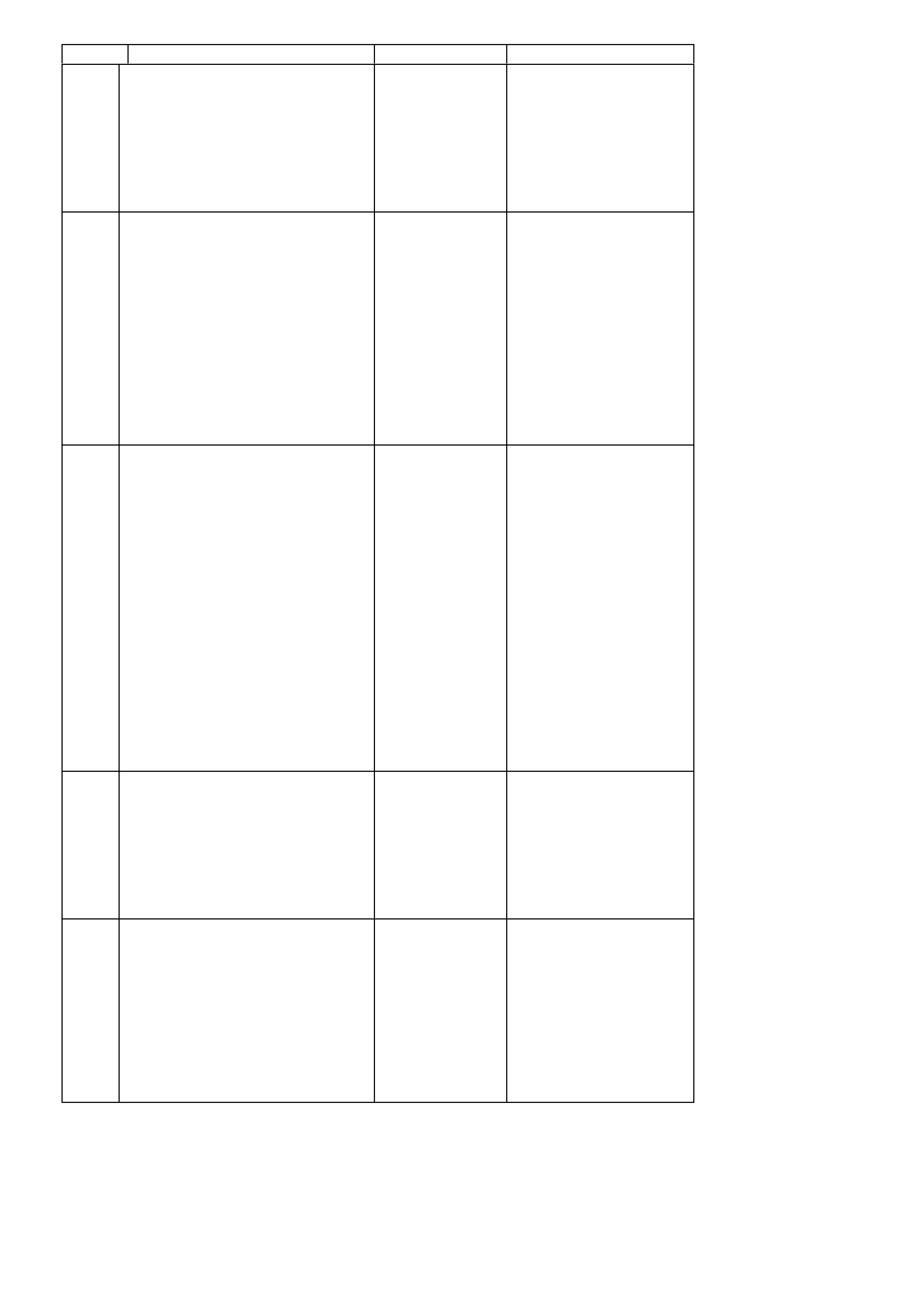

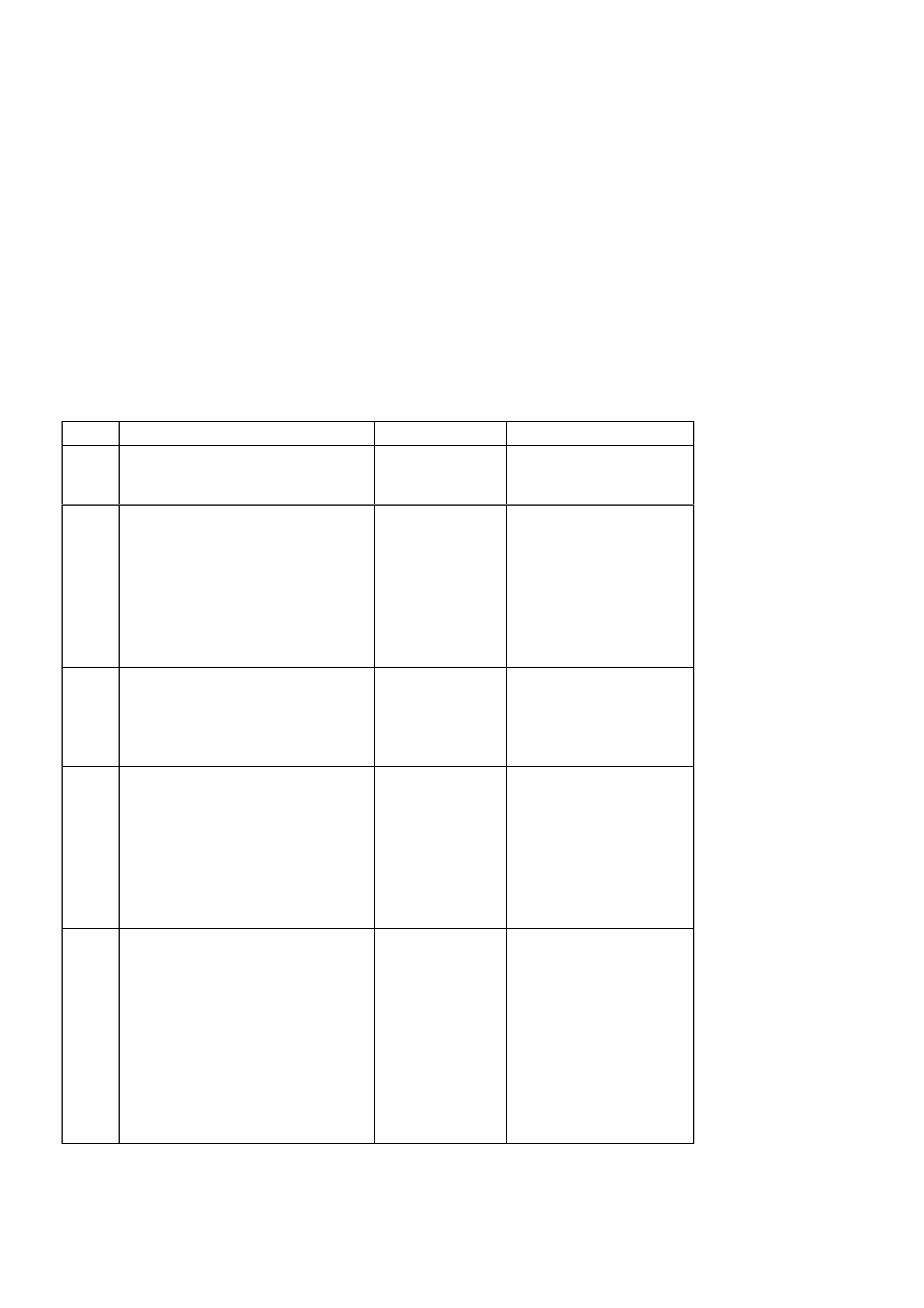

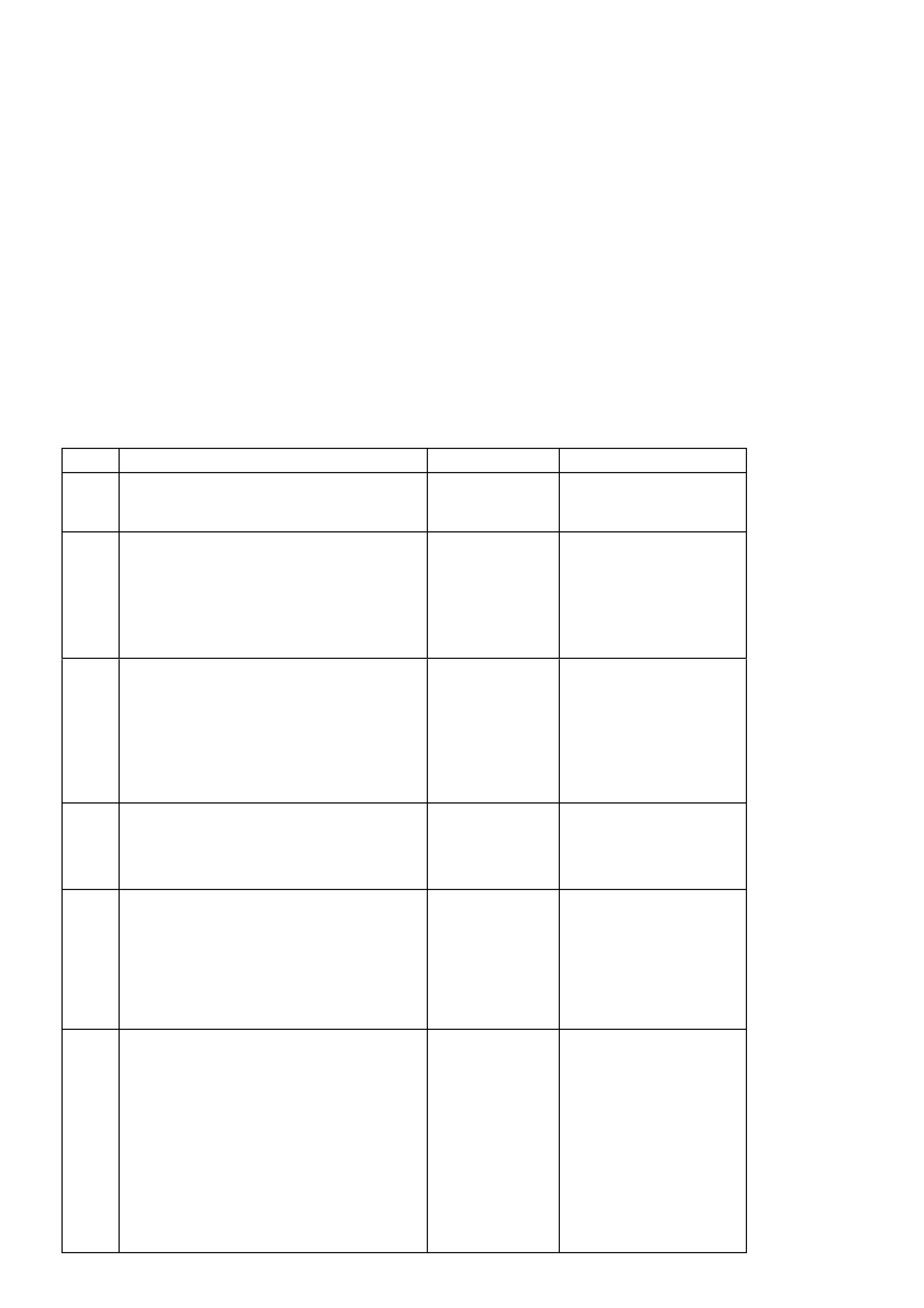

STEP ACTION YES NO

1. 1. Turn ignition ON.

2. Does the Check Powertrain

Lamp illuminate?

Go to Step 2. Refer ON-BOARD

DIAGNOSTIC SYSTEM

CHECK, Section 6C1-2A

in this Service

Information CD.

2. 1. Turn ignition OFF.

2. Install TECH 2 to DLC.

3. Turn ignition ON.

4. Push power button on TECH

2.

5. Does TECH 2 power up

(screen will illuminate display

TECH 2)?

Go to Step 3. Refer TECH 2

DIAGNOSIS,

Section 0C TECH 2

in this Service

Information CD.

3. 1. With TECH 2 still connected

and ignition on, press the

ENTER key then select

Diagnostics / model year / VT

Commodore / Engine / V6

LPG, follow the instructions

on the Tech 2 screen.

2. Does TECH 2 display PCM

system identification

information (PROM ID)?

Go to Step 4. Refer ON-BOARD

DIAGNOSTIC SYSTEM

CHECK, Section 6C1

in this Service

Information CD.

4. 1. With TECH 2 still connected

and ignition on,

select / F2: Data Display / F0:

All Data / Scroll to LPG Fuel

Enabled.

2. Does TECH 2 display LPG

Fuel Enabled YES?

Go to Step 5. Refer 3.4 DOES NOT

OPERATE ON LPG, in

this Section.

STEP ACTION YES NO

5. 1. With TECH 2 still connected,

scroll to Fuel.

2. Select LPG via the fuel mode

switch.

3. Does Fuel display on TECH 2

change from Petrol to LPG?

Go to Step 6. Refer 3.5 FUEL MODE

SWITCH DOES NOT

OPERATE, in this

Section.

6. 1. Ignition ON, select LPG via

the fuel mode switch.

2. Does the LPG lamp in the

switch illuminate?

Go to Step 7. Refer 3.6 LPG LAMP

DOES NOT OPERATE in

this Section.

7. 1. Select Petrol via the fuel

mode switch.

2. Will the engine crank and

start immediately the key is

turned from off to start (no

delay)?

Go to Step 8. Refer ON-BOARD

DIAGNOSTIC SYSTEM

CHECK, Section 6C1

in this Service

Information CD.

8. 1. Select LPG via the fuel mode

switch.

2. Will the engine crank

immediately the key is turned

from off to start (no delay)?

Go to Step 9. Refer 3.7 ENGINE DOES

NOT CRANK in this

Section.

9. 1. Does engine crank and run

on LPG? Go to Step 10. Refer 3.8 ENGINE

CRANKS DOES NOT

START ON LPG in this

Section.

10. 1. Does engine backfire when

operated on LPG? Refer Diagnostic

Chart 3.9

ENGINE

BACKFIRES ON

LPG in this

Section.

Go to Step 11.

11. 1. Does engine lack power,

sluggish or have poor

performance when operating

on LPG?

Refer Diagnostic

Chart 3.10 POOR

PERFORMANCE

, SLUGGI SH OR

POOR FUEL

CONSUMPTION

WHEN

OPERATING ON

LPG in this

Section.

Go to step 12

12. 1. Does fuel gauge operate

correctly? LPG system

operating

correctly.

Refer Diagnostic Chart

3.12 FUEL GAUGE

DOES NOT OPERATE in

this Section.

3.4 DOES NOT OPERATE ON LPG

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. The PCM will not operate in the LPG mode if it is fitted with the incorrect PROM. Refer to the latest technical

publications or spare parts information (PartFinderΤΜ) for the correct PROM application.

3. When the ignition is turned on, battery voltage is applied to terminal E11 of the PCM. This enables the PCM to

operate in either the Petrol or LPG mode. If battery voltage is not applied to PCM terminal E11 the PCM will

only operate in the Petrol mode.

4. This test confirms that the PCM connector terminal retention is not causing the problem. The terminal retention

should always be checked before a PCM is replaced.

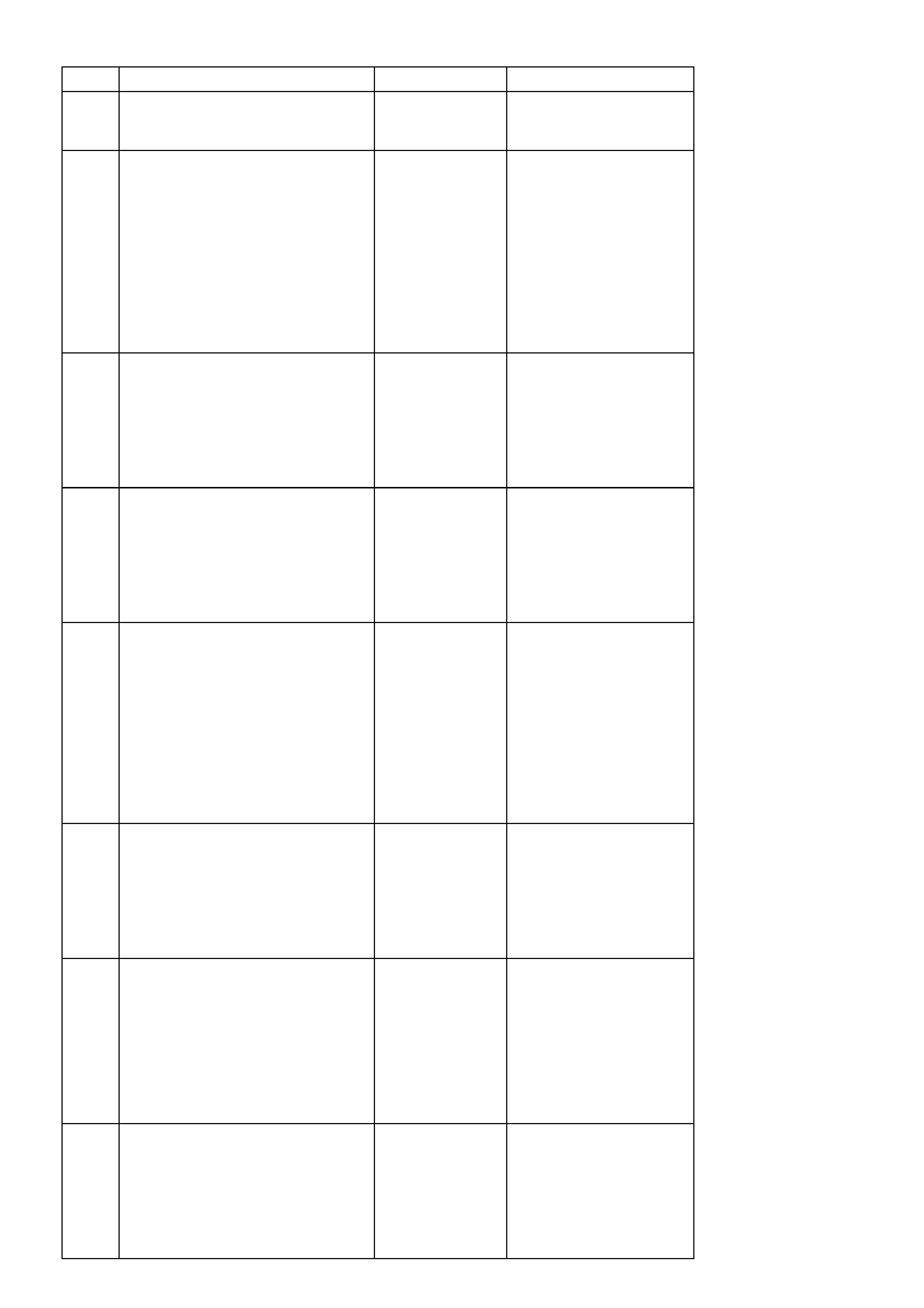

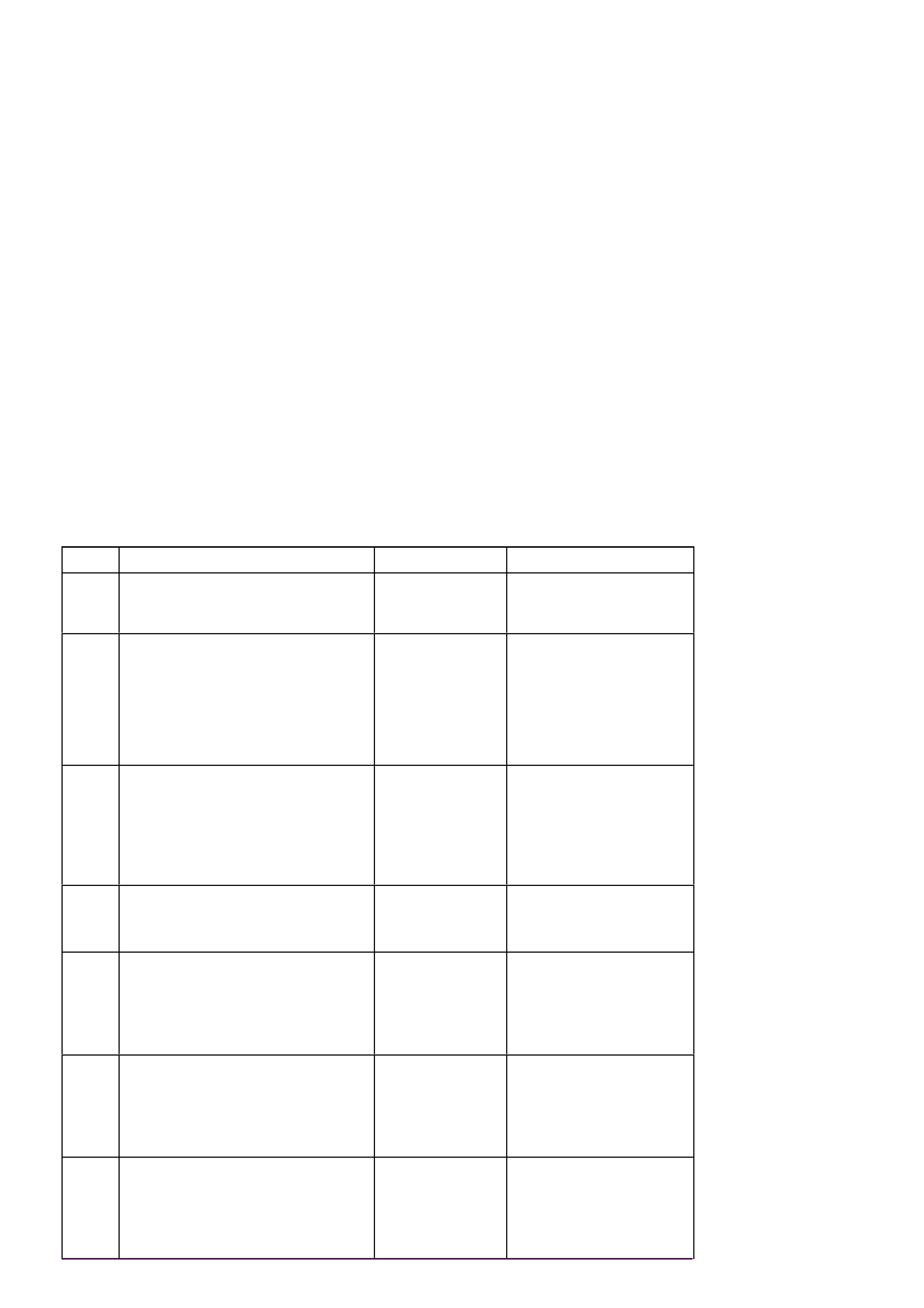

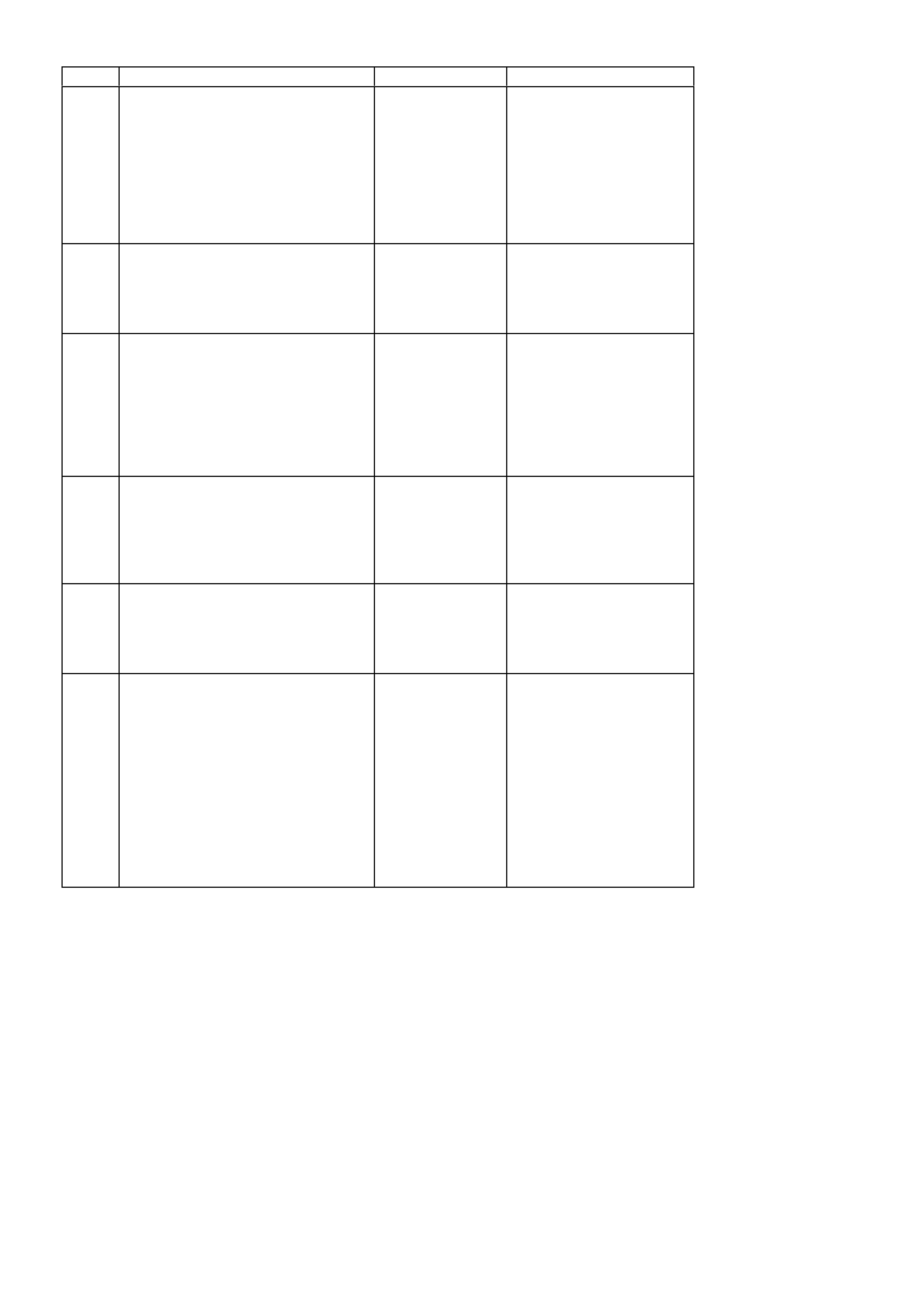

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Is the PCM fitted with the

correct LPG PROM? (Refer

2.19 PROM in Section 2 of, VT

Sedan With Production LPG).

Go to step 3. Install the correct LPG

PROM.

Verify repair.

3. 1. Ignition ON.

2. Check for voltage at PCM

terminal E11 connector YB194

circuit 39 (Pink/Blue wire).

3. Is battery voltage present?

Go to step 4. Repair open in circuit 39

between fuse F14 and

PCM terminal E11.

Verify repair.

4. 1. Check PCM connector

terminal retention.

2. Is terminal retention OK?

Replace PCM

refer to Section

6C1-3 SERVICE

OPERATIONS -

V6 ENGINE in

this Service

Information CD.

Verify repair.

Repair terminals.

Verify repair.

3.5 FUEL MODE SWITCH DOES NOT OPERATE

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. Tests operation of fuel mode switch.

3. Checks for voltage at the fuel mode switch. If voltage is not present, circuit 39F is open between the fuel mode

switch and fuse F14. If voltage is present there is an open circuit between the fuel mode switch and PCM

terminal A9.

4. This test checks for an open in the fuel mode switch circuit 2.

5. This test confirms that the PCM connector terminal retention is not causing the problem. The terminal retention

should always be checked before a PCM is replaced.

STEP ACTION YES NO

1. 1. Has an LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform an LPG

VEHICLE PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Test fuel mode switch.

Refer 2.22 FUEL MODE

SWITCH TEST in Section 2 of,

VT Sedan With Production

LPG.

(Note: refer 2.4 FUEL MODE

SWITCH in Section 2B of this

Section to remove switch).

2. Is the fuel mode switch OK?

Go to step 3. Replace fuel mode

switch.

3. 1. Ignition ON.

2. Check for voltage at the fuel

mode switch connector LP5

circuit 39F (Pink/Blue wire).

3. Is battery voltage present?

Go to step 4. Repair open in circuit 39

between fuse F14 and

fuel mode switch.

4. 1. Check for open in circuit 2

(Violet wire) between fuel

mode switch and PCM

terminal A9.

2. Is circuit open?

Repair open in

circuit 2 between

fuel mode switch

and PCM

terminal A9.

Go to step 5.

5. 1. Check PCM connector

terminal retention.

2. Is terminal retention OK?

Replace PCM

refer to Section

6C1-3 SERVICE

OPERATIONS -

V6 ENGINE in

this Service

Information CD.

Verify repair.

Repair terminals.

Verify repair.

3.6 LPG LAMP DOES NOT OPERATE

NOTE:

The LPG lamp on VT Series Models with accessory fitted LPG systems is located in the fuel mode switch, not the

instrument cluster.

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. Checks for voltage at the fuel mode switch. If voltage is not present, circuit 39G is open between the fuel mode

switch and the splice joint.

3. This test checks the continuity of the fuel mode switch earth circuit for an open in the fuel mode switch circuit 2.

4. This test confirms that the PCM connector terminal retention is not causing the problem. The terminal retention

should always be checked before a PCM is replaced.

STEP ACTION YES NO

1. 1. Has an LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform an LPG

VEHICLE PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Ignition ON, LPG selected.

2. Ignition OFF

3. Remove instrument panel

facia to gain access to the fuel

mode switch, refer 1A3

INSTRUMENT PANEL AND

CONSOLE in this Service

Information CD.

4. Ignition ON

5. Check voltage at fuel mode

switch connector LP6, circuit

39G (Pink/Blue wire).

6. Is battery voltage present?

Go to Step 3 Repair open in circuit 39G

between connector LP6

and splice joint.

Verify repair.

3. 1. Check continuity of fuel mode

switch lamp earth circuit 935C

between fuel mode switch

connector and a known good

earth.

2. Is there continuity?

Got to Step 4 Repair open in circuit

935C between connector

LP6 and splice joint.

Verify repair.

4. 1. Remove bulb and socket

assembly from fuel mode

switch, refer INSTRUMENT

FACIA AND CENTRE FACIA

ESCUTCHEON SWITCH

ILLUMINATION BULBS in

Section 12B LIGHTING

SYSTEM, of this VT Series

Service Information CD.

2. Is bulb and socket assembly

OK?

Replace fuel

mode switch,

refer 2.4 FUEL

MODE SWITCH

in Section 2B of

this Section

Replace fuel mode

switch bulb and

socket assembly.

Verify repair

3.7 ENGINE DOE S NOT CRANK

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. The Theft Deterrent System must be disarmed before the engine will crank. If the Theft Deterrent System

cannot be disarmed, refer to Theft Deterrent Diagnostics in Section 12J-1, for vehicles fitted with Low Series

BCM’s or Section 12J-2 for vehicles fitted with High Series BCM’s, of this Service Information CD.

3. When PETROL is selected the engine should crank immediately the ignition switch is turned from off to start. If

the engine does not crank immediately, then refer to ON-BOARD DIAGNOSTIC SYSTEM CHECK,

Section 6C1 in this Service Information CD.

4. When LPG is selected, the engine should crank immediately the ignition Switch is turned from off to start. If the

engine cranks immediately the system is operating correctly .

5. When LPG is selected the PCM will prevent the engine from cranking if the PCM determines the throttle is

open more than approximately 5%. This tests uses TECH 2 to monitor the Throttle Position Sensor operation.

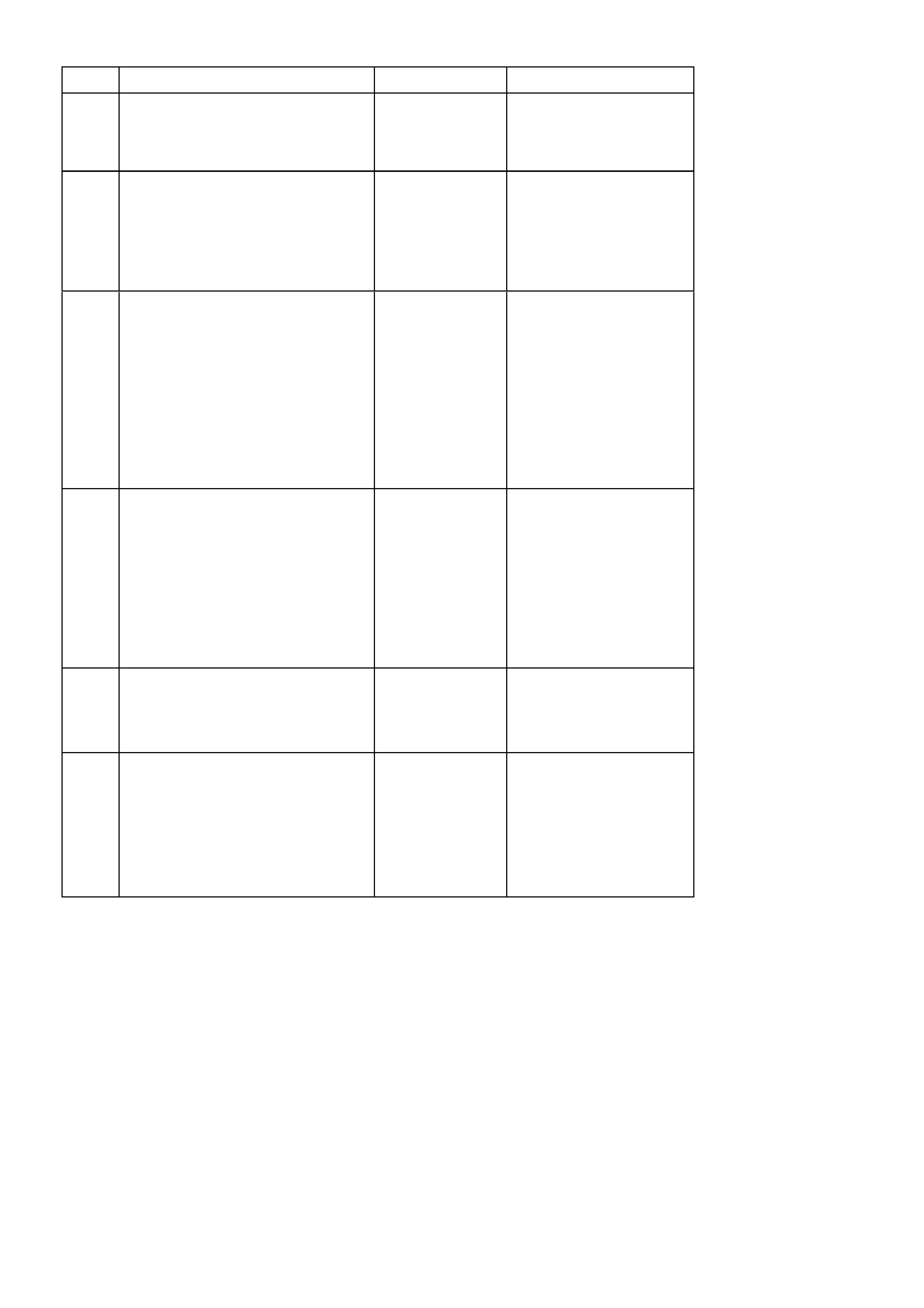

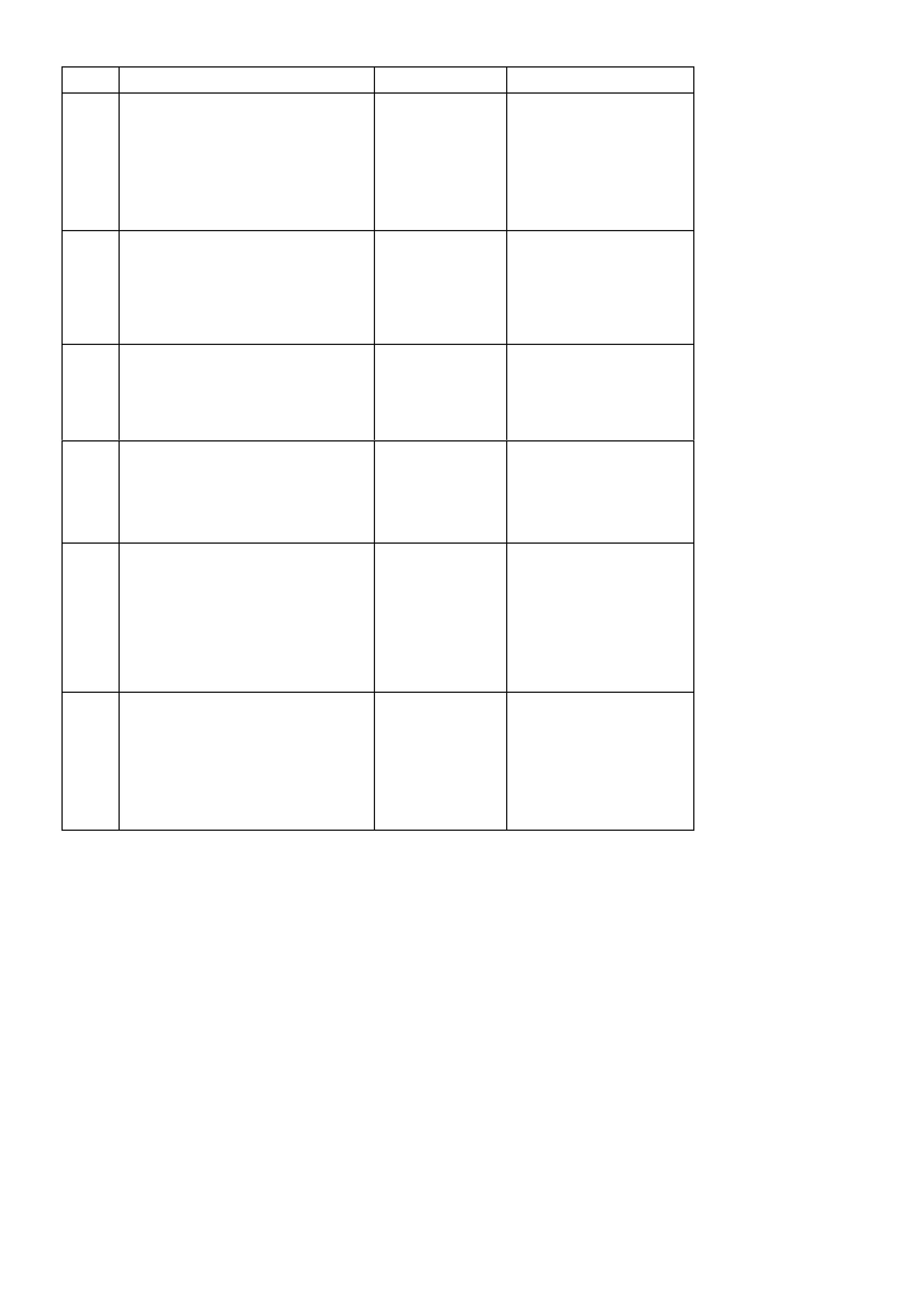

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Disarm theft deterrent system

(LED not flashing).

2. Ignition OFF.

3. Is theft deterrent system

disarmed?

Go to Step 3. Refer Section 12J-1 Low

Series BCM or

Section 12J-2 High

Series BCM in this

Service Information CD.

3. 1. Ignition ON, select Petrol via

the fuel mode switch.

2. Turn ignition switch to

“START” for a maximum of

five seconds or until engine

starts to crank.

3. Does engine crank

immediately (less than one

second)?

Go to Step 4. Refer ON-BOARD

DIAGNOSTIC

SYSTEM CHECK,

Section 6C1-2A in this

Service Information CD.

4. 1. Ignition ON, select LPG via the

fuel mode switch.

2. Turn ignition switch to

“START” for a maximum of

five seconds or until engine

starts to crank.

3. Does engine crank

immediately (less than one

second)?

System operating

correctly.

Check for

intermittent

connections.

Go to Step 5.

5. 1. Ignition OFF.

2. Install TECH 2 to DLC.

3. Ignition ON.

4. Push power button on TECH 2.

5. Select ENGINE / ENGINE

TYPE V6 LPG / Data List / All

Data.

6. Scroll to Throttle Angle.

7. Is Throttle Position Sensor

displaying 0%?

Refer ON-

BOARD

DIAGNOSTIC

SYSTEM

CHECK, Section

6C1-2A in this

Service

Information CD.

Refer Chart A-6.2

TP SENSOR

OUTPUT CHECK,

Section 6C1-2A in this

Service Information CD.

3.8 ENGINE CRANKS BUT WILL NOT START ON LPG

SHEET 1

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. These initial checks are designed to verify that the engine is capable of operating on LPG.

3. Voltage is supplied to the LPG lockoff from the smart unit when the ignition is first turned on and when the

engine is cranking or running. If voltage is not present at these times the lockoff will not be energised and LPG

will not flow to the converter.

4. This test confirms correct converter operation. Incorrect converter pressures can cause the engine not to start.

5. This test determines if the ADP is causing the no start condition.

6. All hoses and vacuum lines should be checked as vacuum leaks or blockages can cause a variety of system

operating problems

7. This tests confirms correct mixer operation.

8. This tests confirms correct A DP set up.

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2. Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. INITIAL CHECKS:

1. Has LPG been selected via the

fuel mode switch?

2. Is correct LPG PROM installed

in the PCM?

3. Is the manual service valve

open?

4. Is there any LPG present in the

LPG cylinder, check contents

gauge?

If yes to all,

go to Step 3. Repair any faults.

Recheck starting

on LPG.

3. 1. Check for voltage at LPG

lockoff connector YE2 circuit

601 (Red wire).

2. Is voltage above 9 volts for 3

seconds when the ignition is

first turned on or while the

engine is cranking?

Go to Step 4. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (SHEET 2) on the

following chart in this

Section.

4. 1. Test for presence of LPG in

system by checking converter

pressures. (Refer 2.15

CONVERTER in Section 2 of,

VT Sedan With Production

LPG).

2. Are converter pressures OK?

Go to Step 5. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (SHEET 3) in this

Section.

5. 1. Ignition ON, select Petrol via

the fuel mode switch.

2. Start engine and bring to 2000

RPM.

3. Select the LPG mode via the

fuel mode switch.

4. Does the engine continue to

run?

Set up ADP and

adjust LPG

mixture. Refer

2.23 ADP

SET-UP

PROCEDURE in

Section 2 of,

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to Step 6.

6. 1. Check for vacuum leaks in

vacuum or vapour feed lines

between mixer and converter,

or a blocked balance line, FCV

or Regulator Check Valve.

2. Are there any leaks or

blockages?

Repair vacuum

leaks or

blockages.

Recheck starting

on LPG.

Go to Step 7.

7. 1. Test mixer operation (refer

2.18 MIXER in Section 2 of,

VT Sedan With Production

LPG).

2. Is mixer operating correctly?

Go to Step 8. Check and repair any air

leaks between mixer and

throttle body, if no leaks

overhaul mixer. Refer

2.18 MIXER in Section 2

of, VT Sedan With

Production LPG.

Recheck starting

on LPG.

8. 1. Set up ADP and adjust LPG

mixture (refer 2.23 ADP SET-

UP PROCEDURE in Section 2

of, VT Sedan With Production

LPG) and recheck starting on

LPG.

2. Does engine start on LPG?

System OK. Go to Diagnostic Chart

ENGINE CRANKS BUT

WILL NOT START ON

LPG (2) on the following

chart in this Section.

SHEET 2

TEST DESCRIPTION

1. The smart unit and the ADP receive voltage from the LPG relay smart unit inline fuse. If this fuse is blown the

smart unit will not operate.

2. This test checks the continuity of the smart unit earth circuit. If the smart unit does not have a good earth then

it will not operate.

3. This test checks to see if the smart unit is supply ing voltage to the LPG lockoff. If voltage is present at the

smart unit then the circuit between the smart unit and the LPG lockoff is open or shorted to earth.

NOTE:

The smart unit has a current protection device on this circuit. If circuit 601 is shorted to earth the smart unit will

shutdown. The ignition must be cycled from on to off to reset the smart unit.

4. With the ignition on and LPG selected battery voltage should be supplied to circuit 905 (Pink/Green wire) when

the LPG relay is energised by the PCM.

5. This test checks if the LPG relay is operating correctly.

6. With Petrol selected via the fuel mode switch, battery voltage should be present at PCM terminal E1 circuit 935

(Pink/Black wire).

7. When LPG is selected via the fuel mode switch the PCM earths terminal E1 causing circuit 935 (Pink/Black

wire) to be pulled low, less than 0.2 volts.

8. When operating in the LPG mode, the PCM pulses the 5 volt pull up in the smart unit to earth via circuit 1 at a

50% duty cycle. Therefore the voltage at PCM terminal E5 should be 2 to 3 volts when the ignition is first turned

on or when the engine is cranking.

9. This test checks the continuity of circuit 1 (White/Green wire).

10. This test checks if circuit 1 (White/Green wire) is shorted to earth.

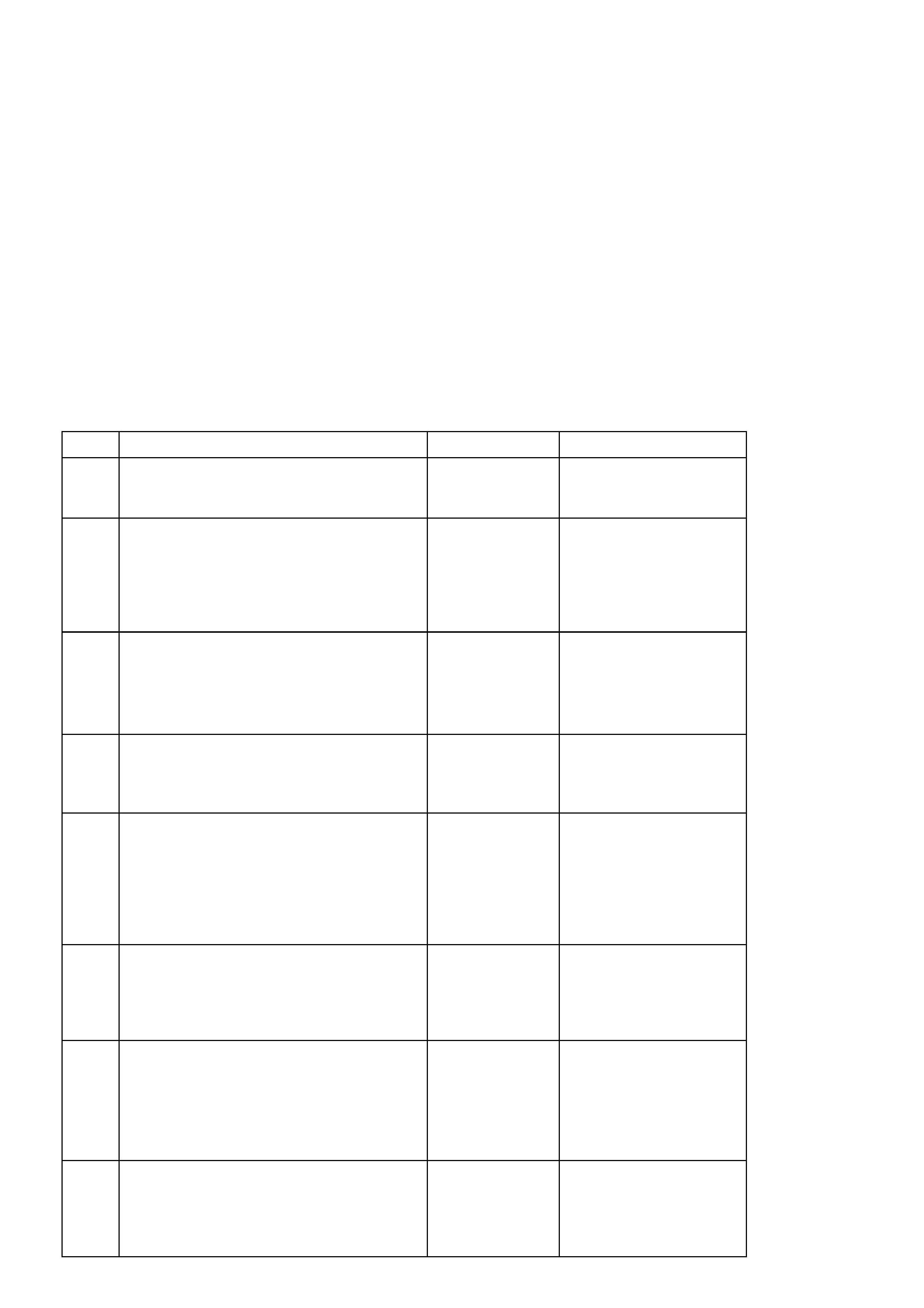

STEP ACTION YES NO

1. 1. Is the smart unit in line fuse

(located below the steering

column) OK?

Go to Step 2. Replace fuse. Check for

short in circuit 905.

Recheck starting

on LPG

2. 1. Check continuity of smart unit

earth circuit 151C

(Black/Yellow wire) between

smart unit connector YR50 and

a known good earth.

2. Is there continuity?

Go to step 3. Repair open in circuit 151

(Black/Yellow wire).

Recheck starting

on LPG.

3. 1. Ignition ON, LPG selected.

2. Check voltage at smart unit

connector YR50 circuit 601

(Blue/Orange wire).

3. Is voltage above 9 volts for

three seconds when the

ignition is first turned on or

while the engine is being

cranked? (REFER NOTE

ABOVE)

Repair open or

short to earth in

LPG lockoff

circuit 601

between smart

unit and lockoff.

Recheck starting

on LPG.

Go to Step 4.

4. 1. Ignition ON, LPG selected.

2. Check for voltage at smart unit

connector YR50 circuit 905

(Pink/Green wire).

3. Is battery voltage present for

three seconds when the

ignition is first turned on or

while the engine is being

cranked?

Go to Step 8. Got to Step 5.

5. 1. Is LPG relay OK.

Refer 2.3 LPG RELAY in

Section 2B of this Section for

LPG relay location.

Go to step 6. Replace LPG Relay.

Recheck starting

on LPG.

6. 1. Turn ignition ON and select

Petrol Mode via the fuel mode

switch.

2. Check voltage at PCM terminal

E1 circuit 935 (Pink/Black

wire).

3. Is battery voltage present?

Go to step 7. Repair open in circuit 935

(Pink/Black wire) between

the LPG relay and PCM.

Recheck starting

on LPG.

STEP ACTION YES NO

7. 1. Turn ignition ON and select

Petrol Mode via the fuel mode

switch.

2. Check voltage at PCM terminal

E1 circuit 935 (Pink/Black

wire).

3. Does voltage drop from battery

voltage to less than 0.2 volts

for 3 seconds when LPG is

selected via the fuel mode

switch and ignition is switched

on?

Go to step 8. Check PCM connector

terminal retention, if OK,

Replace PCM.

Recheck starting

on LPG.

8. 1. Select LPG via the fuel mode

switch.

2. Check voltage at PCM

terminal E5 circuit 1

(/White/Green wire).

3. Turn the ignition ON. Is voltage

between approx 5 volts for

three seconds when the

ignition is first turned on or

when the engine is cranking?

Check smart unit

connector

terminal

retention. If OK,

replace smart

unit.

Verify repair.

Go to step 9.

9. 1. Check continuity of circuit 1

(White/Green wire) between

smart unit connector YR50 and

PCM connector YB194

terminal E5.

2. Is there continuity?

Go to step 10. Repair open in circuit 1

(White/Green wire).

Verify repair.

10. 1. Check for a short to earth in

circuit 1 (White/Green wire)

between smart unit connector

YR50 and PCM connector

YB194 terminal E5.

2. Is there a short to earth?

Repair short to

earth in circuit 1

(White/

Green wire).

Verify repair.

Check PCM connector

terminal retention. If OK,

Replace PCM.

Recheck starting

on LPG.

SHEET 3

TEST DESCRIPTION

1. Low primary converter pressure can be caused by low supply pressure or a faulty converter.

2. If the primary converter pressure is too high the converter will have to be overhauled.

3. If the primary converter pressure is within specification but the secondary converter is out of specification, the

converter will have to be overhauled.

4. This test checks if the solenoid valve is restricting the flow of LPG.

5. This test checks the flow of LPG from the LPG cylinder to the LPG lockoff.

6. This test determines if the LPG lockoff or the converter is causing the problem.

7. This test checks if the service line is blocked. If the service line is not blocked then the manual service valve or

the LPG cylinder pick up must be blocked.

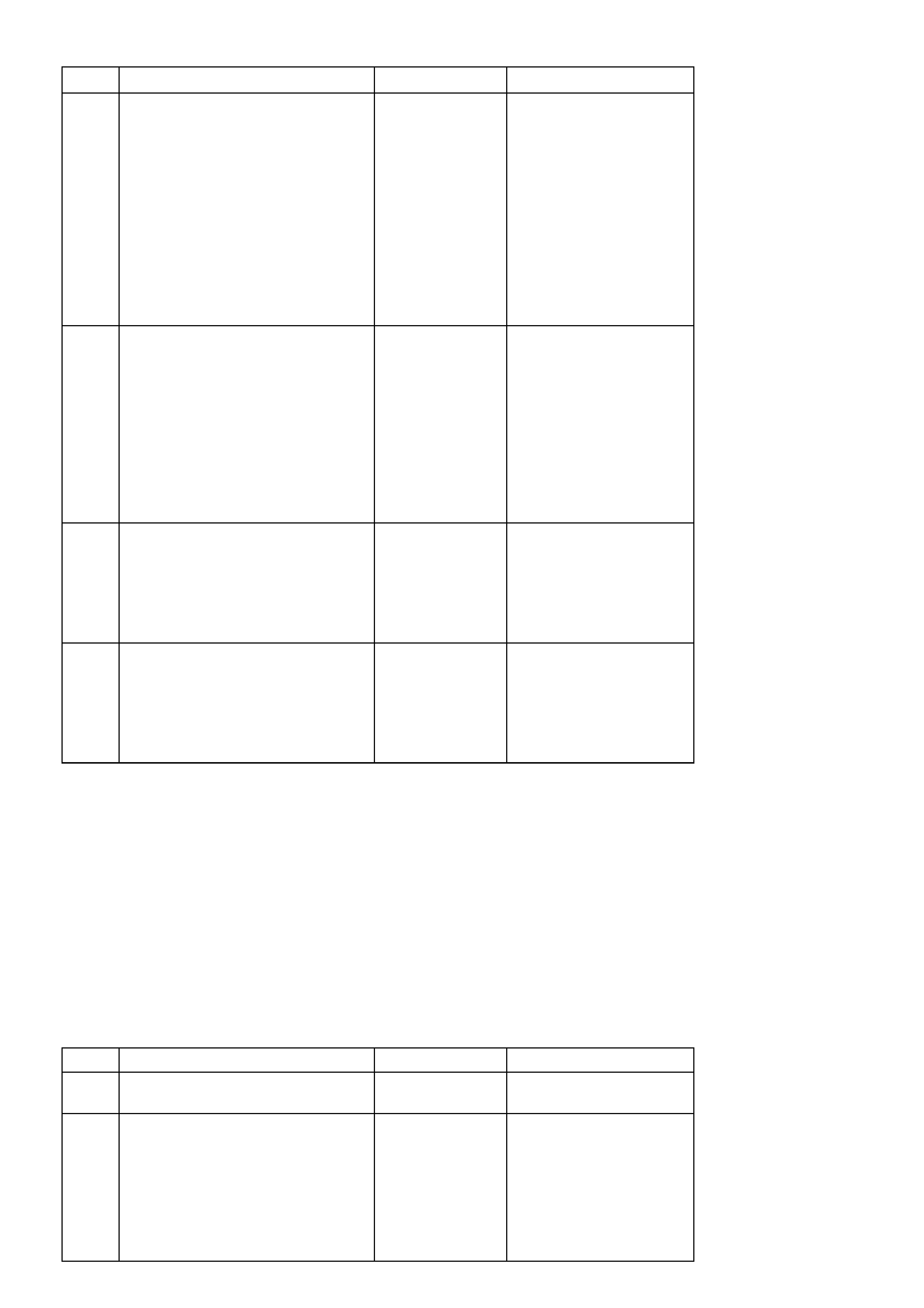

STEP ACTION YES NO

1. 1. Is primary converter pressure

below specification? Go to Step 4. Got to Step 2.

2. 1. Is primary converter pressure

above specification? Repair converter,

refer 2.15

CONVERTER in

Section 2 of,

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to Step 3.

STEP ACTION YES NO

3. 1. If primary converter pressure is

within specification, is the

secondary converter pressure

out of specification?

Repair converter,

refer 2.15

CONVERTER

Section 2 of,

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Go to step 4.

4. 1. Ignition OFF.

2. Close manual service valve.

3. Remove the solenoid valve

from the manual service valve

assembly and reinstall

solenoid sleeve, refer 2.8

SMART UNIT AND

SOLENOID VALVE in Section

2 of, VT Sedan With

Production LPG.

4. Does engine start and run on

LPG?

Replace smart

unit and solenoid

valve.

Recheck starting

on LPG.

Go to Step 5.

5. 1. Ignition OFF.

2. Close manual service valve.

3. With the solenoid valve still

removed from the manual

service valve assembly,

disconnect the front service

line at the LPG lockoff.

4. In accordance with AS-1425,

have a second technician open

the manual service valve

(slowly so that the excess flow

valve doesn’t shut LPG flow

off). If a click is heard at the

manual service valve, the

excess flow valve has closed.

5. Does LPG flow from the front

service line?

Go to Step 6. Go to Step 7.

6. 1. Test LPG lockoff (refer 2.14

LPG LOCKOFF in Section 2

of, VT Sedan With Production

LPG).

2. Is LPG lockoff OK?

Repair converter,

refer 2.14

CONVERTER in

Section 2 of,

VT Sedan With

Production LPG.

Recheck starting

on LPG.

Repair LPG lockoff, refer

2.14 LPG LOCKOFF in

Section 2 of,

VT Sedan With

Production LPG.

Recheck starting

on LPG.

7. 1. Disconnect rear service line at

manual service valve.

2. With front service line still

disconnected, blow air through

service line to check for

blockages

3. Does air flow through service

line?

Check for manual

service valve or

LPG cylinder fuel

pick-up blockage

or fault. Repair or

replace blocked

or damaged

components.

Recheck starting

on LPG.

Check for damaged or

blocked service lines.

Repair or replace blocked

or damaged components.

Recheck starting

on LPG.

3.9 ENGINE BACKFIRES ON LPG

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

NOTE:

Whenever a engine backfire has occurred the complete intake system including the mixer should be checked for

damage.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. An ON BOARD DIAGNOSTIC SYSTEM CHECK should be performed to confirm that a problem with the

Powertrain Management System is not causing the engine to backfire when operating on LPG?

3-7 An ignition system that is not operating at it’s full potential can cause an engine to backfire when operating on

LPG. Ignition leads that operate quite well when operating on petrol, can still cause problems when operating

on LPG. Therefore, all ignition system components must be at here optimum when operating on LPG.

8. Vacuum leaks or blocked vacuum lines can cause incorrect system operation, causing engine backfire.

9. An incorrect mixer operation can cause incorrect air/fuel ratios. Incorrect air/fuel ratios can cause engine

backfire.

10. An incorrect ADP set-up can cause incorrect system operation, causing engine backfire.

11. Incorrect converter operation can cause incorrect air/fuel ratios. Incorrect air/fuel ratios can cause engine

backfire.

12. This test confirm correct Regulator Check Valve (RCV) operation. Incorrect RCV operation can cause slow

converter response causing engine backfire.

13. The engine must be in optimum operating condition to prevent any possibility of the engine backfiring when

operating on LPG.

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Has an ON BOARD

DIAGNOSTIC SYSTEM

CHECK been performed?

Refer ON-BOARD

DIAGNOSTIC SYSTEM

CHECK, Section 6C-2A in this

Service Information CD.

Go to Step 3. Perform ON-BOARD

DIAGNOSTIC SYSTEM

CHECK. Refer Section

6C1-2A in this Service

Information CD.

Recheck for engine

backfire.

3. 1. Check spark plug leads for

tracking or cracks in insulation

and resistance (refer Section

6D1-3 in this Service

Information CD).

2. Are the spark plugs leads OK?

Go to Step 4. Replace spark plug leads.

Recheck for engine

backfire.

4. 1. Remove and inspect spark

plugs for fowling.

2. Are the spark plugs OK?

Go to Step 5. Replace spark plugs.

Recheck for engine

backfire.

5. 1. Re-gap spark plugs to

minimum specification.

2. Have spark plugs been re-

gaped to minimum

specification?

Go to Step 6. Re-gap spark plugs to

minimum specification

Recheck for engine

backfire.

6. 1. Check coil resistance (refer

Section 6D1-3 in this Service

Information CD).

2. Is the ignition coil resistance

within specification?

Go to Step 7. Replace faulty

ignition coil.

Recheck for engine

backfire.

7. 1. Check PCM, Direct Ignition

System (DIS) module and

Crank Angle Sensor terminal

retention.

2. Is terminal retention OK?

Go to Step 8. Resize terminals.

Recheck for engine

backfire.

STEP ACTION YES NO

8. 1. Check for vacuum leaks in

vacuum or vapour feed lines

between mixer and converter,

or a blocked balance line, FCV

or Regulator Check Valve.

2. Are there any leaks or

blockages?

Repair vacuum

leaks or

blockages.

Recheck for

engine backfire.

Go to Step 9.

9. 1. Test mixer operation (refer

2.18 MIXER in Section 2 of,

VT Sedan With Production

LPG).

2. Is mixer operating correctly?

Go to Step 10. Overhaul mixer. Refer

2.18 MIXER in Section 2

of, VT Sedan With

Production LPG.

Recheck for engine

backfire.

10. 1. Is the ADP set-up correct?

(refer 2.23 ADP SET-UP

PROCEDURE in Section 2 of,

VT Sedan With Production

LPG).

Go to Step 11. Carry out ADP set-up

procedure.

Recheck for engine

backfire.

11. 1. Test converter pressures.

(Refer 2.15 CONVERTER in

Section 2 of, VT Sedan With

Production LPG).

2. Are converter pressures OK?

Go to Step 12. Overhaul converter.

Refer 2.15 CONVERTER

in Section 2 of, VT Sedan

With Production LPG.

12. 1. Test Regulator Check Valve

operation (refer 2.16

REGULATOR CHECK VALVE

in Section 2 of, VT Sedan With

Production LPG).

2. Is Regulator Check Valve

operating correctly?

Go to Step 13. Replace Regulator Check

Valve. Refer 2.16

REGULATOR CHECK

VALVE in Section 2 of,

VT Sedan With

Production LPG.

Recheck for engine

backfire.

13. 1. Check engine mechanical

condition by checking

compression, valve timing,

intake and exhaust valves and

manifolds for casting flash.

2. Is the engine mechanical

condition OK?

Check for

incorrectly routed

harnesses,

ignition leads

or non genuine

accessories.

Repair any faults.

Recheck for engine

backfire.

3.10 POOR PERFORMANCE, FLAT SPOTTING, SLUGGISH OR POOR FUEL

CONSUMPTION WHEN OPERATING ON LPG

Because of the nature of LPG, a minimal loss of power may be experienced under heavy acceleration, this

is expected and quite normal.

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. An ON BOARD DIAGNOSTIC SYSTEM CHECK should be performed to confirm that a problem with the

Powertrain Management System is not causing the engine to backfire when operating on LPG?

3. These symptoms checks this the most common causes of engine drivability problems.

4. Incorrect ADP operation can cause incorrect air/fuel ratios.

5. Incorrectly tensioned air valve to diaphragm attaching screws can cause incorrect mixer operation.

6. Correct mixer operation is required so that the correct air/fuel ratio is achieved.

7. A regulator check valve that is blocked or opening at the wrong vacuum can cause incorrect converter

operation.

8. The converter is one of the key components in the control of the delivery of LPG. Incorrect converter operation

can cause rich or lean mixtures.

STEP ACTION YES NO

1. 1. Has an LPG VEHICLE PRELIMINARY

DIAGNOSIS CHECK been

performed?

Go to step 2 Perform an LPG

VEHICLE PRELIMINARY

DIAGNOSIS CHECK.

2. 2. Has an ON BOARD DIAGNOSTIC

SYSTEM CHECK been performed?

Refer ON-BOARD DIAGNOSTIC

SYSTEM CHECK, Section 6C1-2A in

this Service Information CD.

Go to Step 3. Perform ON-BOARD

DIAGNOSTIC SYSTEM

CHECK. Refer Section

6C1-2A in this Service

Information CD.

Recheck performance.

3. 1. Carry out SYMPTOMS CHECK (refer

Section,

6C1-2B in this Service Information

CD).

2. Are all checks OK?

Go to Step 4. Repair any faults.

Recheck performance.

4. 1. Is the ADP set-up correctly?

(refer 2.23 ADP SET-UP

PROCEDURE in Section 2 of,

VT Sedan With Production LPG).

Go to Step 5. Carry out ADP set-up

procedure.

Recheck performance.

5. 1. Check air valve to diaphragm

attaching screws for correct torque.

(refer 2.18 MIXER in Section 2 of , VT

Sedan With Production LPG).

2. Are screws tightened to the correct

torque?

Go to Step 6. Tension Screws to the

correct torque

specification, refer 2.18

MIXER in Section 2 of,

VT Sedan With

Production LPG.

Recheck performance.

6. 1. Test mixer operation (refer 2.18

MIXER in Section 2 of,

VT Sedan With Production LPG).

2. Is mixer operating correctly?

Go to Step 7. Overhaul mixer. Refer

2.18 MIXER in Section 2

of, VT Sedan With

Production LPG.

Recheck performance.

7. 1. Test Regulator Check Valve operation

(refer 2.16 REGULATOR CHECK

VALVE in Section 2 of, VT Sedan With

Production LPG).

2. Is Regulator Check Valve operating

correctly?

Go to Step 8. Replace Regulator

Check Valve.

Recheck performance.

8. 1. Test converter operation (refer 2.16

CONVERTER in Section 2 of, VT

Sedan With Production LPG).

2. Is converter operating correctly?

System OK Repair converter, refer

2.16 CONVERTER in

Section 2 of, VT Sedan

With Production LPG.

Recheck performance.

3.11 FUEL CONTROL VALVE DOES NOT OPERATE

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. These initial checks are designed to verify that the engine is capable of operating on LPG.

3. If the FCV can be heard operating the ADP is being powered up and pulsing the FCV.

4. This test checks that the ADP is pulsing the FCV.

5. This test checks if power is being supplied to the FCV.

6. This test checks if the ADP is supplying power to circuit 107 (Yellow wire).

7. This test checks the continuity of circuit 105 Yellow/Black wire.

8. This test checks that battery voltage is being supplied from the LPG relay to the ADP via circuit 905

(Pink/Green wire).

9. This test checks the continuity of both of the ADP earth circuits.

10. In this test step, circuit 105 (Yellow/Black wire) is checked for a short to earth?

11. This test checks the operation of the FCV.

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed.

Go to step 2. Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. INITIAL CHECKS:

1. Has LPG been selected via the

fuel mode switch?

2. Is correct LPG PROM installed

in the PCM?

3. Is smart unit in line fuse

(located under steering

column) OK?

If YES to all,

go to Step 3. Repair any faults.

Verify repair.

3. 1. Ignition ON, LPG selected via

fuel mode switch.

2. Can fuel control valve be heard

operating for three seconds

when ignition first switched on?

Go to Step 10. Go to step 4

4. 1. Remove connectors from FCV.

2. Ignition ON.

3. Check voltage between FCV

circuits 107 (Yellow wire) and

105 (Yellow/Black wire).

4. Is voltage at least 9 volts for

three seconds when ignition

first switched on?

Go to step 10. Go to Step 5.

5. 1. Remove connectors from FCV

terminals.

2. Ignition ON, LPG selected via

fuel mode switch.

3. Check for voltage between

FCV connector YE2 circuit 107

(Yellow wire) and a known

good earth.

4. Is battery voltage present for

three seconds when ignition

first switched on?

Go to Step 7. Go to Step 6.

STEP ACTION YES NO

6. 1. Ignition ON, LPG selected via

fuel mode switch.

2. Check for voltage at ADP

connector LP4 circuit 107

(Yellow wire).

3. Is battery voltage present for

three seconds when ignition is

first switched on?

Repair circuit 107

(Yellow wire).

Verify repair.

Go to Step 7.

7. 1. Check continuity of circuit 105

(Yellow/Black wire) between

FCV terminal YE2 and ADP

connector LP4.

2. Is there continuity?

Go to Step 8. Repair open in circuit 105

(Yellow/Black wire)

Verify repair.

8. 1. Ignition ON, LPG selected via

fuel mode switch.

2. Check for voltage at ADP

connector LP4 circuit 905

(Pink/Green wire).

3. Is battery voltage present for

three seconds when ignition

first switched on?

Go to Step 9. Repair open circuit 905

(Pink/Green wire).

Verify repair.

9. 1. Check continuity of ADP earth

circuits 151 (Black /Yellow

wire) and circuit 3 (Black/Red

wire) from ADP connector LP4

and a known good earth.

2. Is there continuity?

Check ADP

connector

terminal retention

if OK, replace

ADP.

Verify repair.

Repair faulty ADP

earth circuit 151

(Black/Yellow w ire)

and 3 Black/Red Wire.

Verify repair.

10. 1. Check for a short to earth in

circuit 105 (Yellow/Black wire).

2. Is circuit 105 (Yellow/Black

wire) shorted to earth?

Repair short to

earth in circuit

105 (Yellow/

Black wire). Verify

repair.

Go to step 11.

11. 1. Test operation of FCV, (refer

2.17 FUEL CONTROL

VALVES in Section 2 of,

VT Sedan With Production

LPG).

2. If FCV operating correctly?

Perform ADP set

up procedure.

Refer 2.23

ADAPTIVE

DIGITAL

PROCESSOR

SET-UP

PROCEDURE in

Section 2 of,

VT Sedan With

Production LPG.

Verify repair.

Check FCV connector

terminal retention if OK,

replace FCV.

Verify repair.

3.12 FUEL GAUGE DOES NOT OPERATE

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. In this test TECH 2 is used to test the operation of the instrument cluster fuel gauge.

3. This test confirms correct operation of the cylinder fuel gauge assembly.

4. If the TECH 2 instrument LPG sender signal is displaying 5 volts, the LPG sender circuit is open circuited.

5. If the TECH 2 instrument LPG sender signal is displaying 0 volts, the LPG sender circuit is short circuited.

6. This test step checks the continuity of the cylinder fuel gauge earth circuit.

7. In this test step, circuit 5 (Yellow wire) is checked for a short to earth.

8. This test step checks the continuity of the LPG sender earth circuit 5.

9. This test checks for continuity on circuit 5, between LPG body harness connector YR50 and instrument cluster

assembly connector YB66.

10. In this test step, the cylinder fuel gauge assembly is removed from the LPG cylinder and checked for correct

operation.

CAUTION:

All safety precautions listed in 2.12 CYLINDER FUEL GAUGE ASSEMBLY in Section 2 of, VT Sedan With

Production LPG must be observed.

DIAGNOSTIC AIDS

On VT Series Models built before L326280 (Executive) and L327258 (Berlina), fitted with accessory LPG systems, it

was a requirement to replace the instrument cluster assembly to obtain interface capabilities with the LPG system

(for additional information, refer to Holden Newsline NL156 (15/4/98)).

Instrument clusters with LPG interface capabilities can be identified by a sticker on the housing; labelled “EE

Version 15” or latter (ie. EE 15, EE 16, EE 17, etc.).

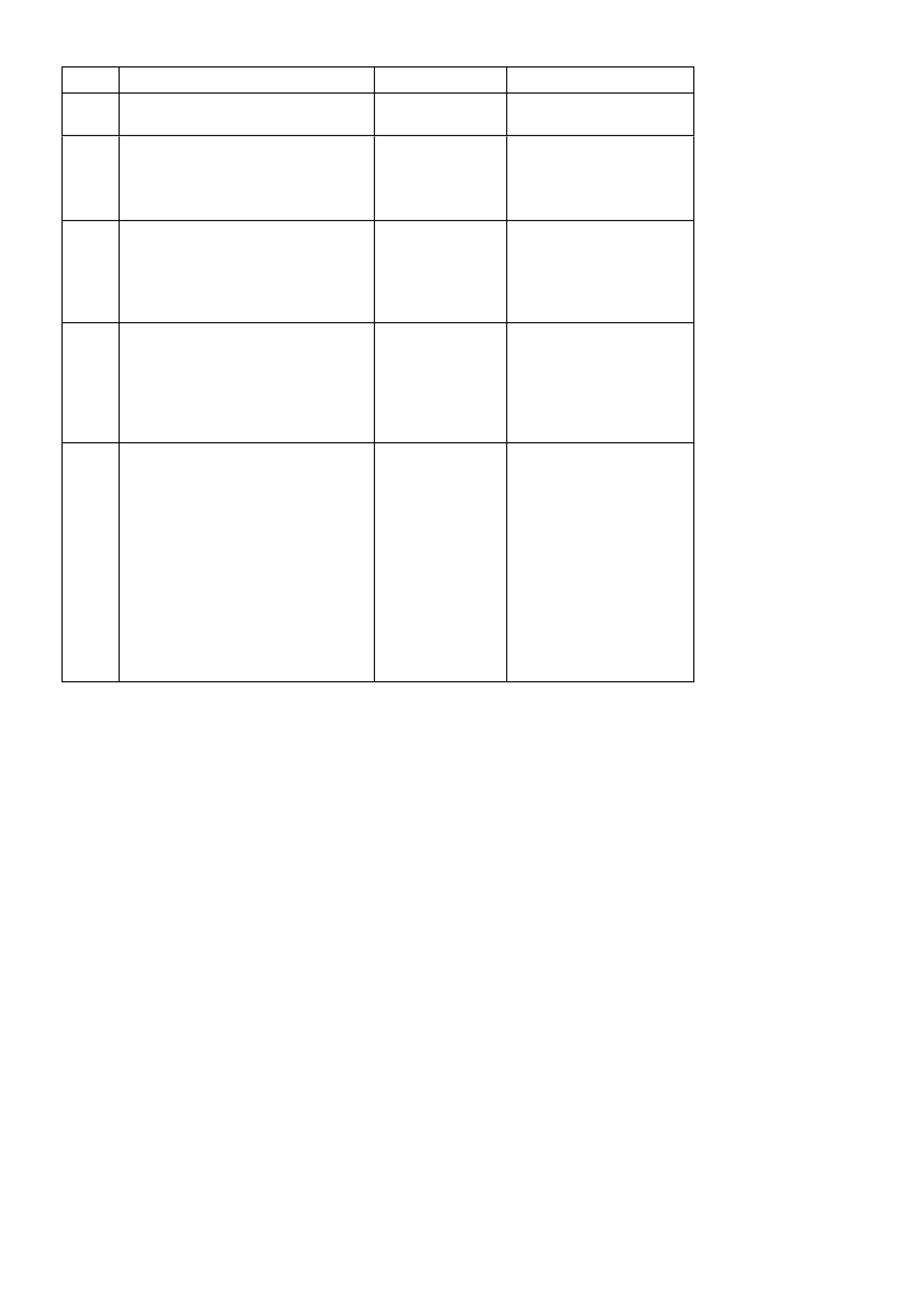

STEP ACTION YES NO

1. 1. Has LPG VEHICLE

PRELIMINARY DIAGNOSIS

CHECK been performed?

Go to step 2 Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Install TECH 2 to DLC.

2. Select Body / Instruments /

Miscellaneous Tests / Control

Tests / Fuel Gauge Level

3. Run Fuel Gauge Level test.

4. Does fuel gauge operate

correctly?

Go to Step 3. Replace instrument

cluster, refer to Section

12C INSTRUMENTS,

WIPERS / WASHERS

AND HORNS in this

Service Information CD

3. 1. Does fuel gauge operate when

petrol is selected via the fuel

mode switch?

Go to step 4. Refer 3.13 FUEL GAUGE

DOES NOT OPERATE

WHEN PETROL

SELECTED in this

Section.

4. 1. Test operation of cylinder fuel

gauge. (refer 2.12 CYLINDER

FUEL GAUGE ASSEMBLY in

Section 2 of, VT Sedan With

Production LPG).

2. Is cylinder fuel gauge

operating correctly?

Go to step 5. Replace cylinder fuel

gauge. (refer 2.12

CYLINDER FUEL

GAUGE ASSEMBLY in

Section 2 of, VT Sedan

With Production LPG).

5. 1. Install TECH 2 to DLC and

select Body/ Instruments /

Data Display / Instrument.

2. Scroll to LPG Sender Signal.

3. Is the LPG Sensor Signal 5

Volts.

Go to step 7. Go to step 6.

STEP ACTION YES NO

6. 1. In test step 5, is the LPG

Sender Signal 0 Volts? Go to step 7. Go to step 10.

7. 1. Check circuit 5 (Yellow wire)

for short to earth.

2. Is circuit 5 (Yellow wire)

shorted to earth?

Repair short to

earth in circuit 5

(Yellow wire).

Verify Repair.

Go to step 10.

8. 1. Check continuity of earth

circuit 3, (Black/Red wire)

between LPG body harness

connector YR50 and earth.

2. Is there continuity?

Go to step 9. Repair open in earth

circuit 3 (Black/Red wire).

Verify repair.

9. 1. Check continuity of circuit 5,

(Yellow wire) between LPG

body harness connector YR50

and instrument cluster

assembly connector YB66.

2. Is there continuity?

Go to step 10. Repair open in circuit 5

(Yellow wire).

Verify repair.

10. 1. Remove cylinder fuel gauge

assembly, refer 2.12

CYLINDER FUEL GAUGE

ASSEMBLY in Section 2 of,

VT Sedan With Production

LPG.

2. Check operation of cylinder

fuel gauge assembly.

3. Check for binding, jammed &

smooth operation).

4. Does cylinder fuel gauge asm.

operate correctly?

Check all

connector

terminal

retention. Monitor

TECH 2

Instrument Data

List while

manipulating

wiring harness to

check for an

intermittent

connection.

Replace cylinder fuel

gauge assembly, refer

2.12 CYLINDER FUEL

GAUGE ASSEMBLY in

Section 2 of, VT Sedan

With Production LPG.

Verify repair.

3.13 FUEL GAUGE DOES NOT OPERATE WHEN PETROL SELECTED

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. The LPG VEHICLE PRELIMINARY DIAGNOSIS CHECK must be the first step when diagnosing any LPG

system problem.

2. In this test, TECH 2 is used to check the signal from the fuel gauge sender.

3. In this test, TECH 2 is used to check circuit 30 (Tan wire), if the fuel gauge sender unit signal is not 0 volts

circuit 30 is open.

4. In this test, TECH 2 is used to check circuit 30 (Tan wire), if the fuel gauge sender unit signal is not 5 volts

circuit 30 is shorted to earth.

5. In this test step, circuit 155 (Black/Yellow wire) is checked for open circuit.

6. This test confirms correct fuel gauge sender unit operation.

DIAGNOSTIC AIDS

On VT Series Models built before L326280 (executive) and L327258 (Berlina), fitted with accessory LPG systems, it

was a requirement to replace the instrument cluster assembly to obtain full interface capabilities with the LPG

system (for additional information, refer to Holden Newsline NL156 (15/4/98)).

Instrument clusters with full LPG interface capabilities can be identified by a sticker on the housing; labelled “EE

Version 15” or latter (ie. ‘EE 15’, ‘EE 16’, ‘EE 17’, etc.).

STEP ACTION YES NO

1. 1. Has LPG VEHICLE PRELIMINARY

DIAGNOSIS CHECK been

performed?

Go to step 2 Perform LPG VEHICLE

PRELIMINARY

DIAGNOSIS CHECK.

2. 1. Install TECH 2 to DLC.

2. Select Body/ Instruments / Data

Display / Instrument.

3. Scroll to Fuel Gauge Sender Signal.

4. Is the Fuel Gauge Sensor Signal 5

Volts?

Go to step 3. Go to step 4.

3. 1. With TECH 2 connected to DLC.

2. Disconnect fuel gauge sender unit

connector YR44.

3. Jumper circuit 30 (Tan wire) to a

known good earth.

4. Is the Fuel Gauge Sensor Signal 0

Volts?

Go to step 6. Repair open in circuit 30

(Tan wire).

Verify repair.

4. 1. With TECH 2 connected to DLC.

2. Disconnect fuel tank connector YR44.

3. Is the Fuel Gauge Sensor Signal 5

Volts?

Go to step 5. Repair short to earth in

circuit 30 (Tan wire).

Verify repair.

5. 1. Disconnect fuel gauge sender unit

connector YR44.

2. Check continuity of fuel gauge sender

unit earth circuit 155 (Black/Yellow

wire) between fuel tank connector

YR44 and a known good earth.

3. Is there continuity?

Go to step 6. Repair open in earth

circuit 155

(Black/Yell ow wire).

Verify repair.

6. 1. Test operation of fuel gauge sender

unit. (refer 2.3 SENDER UNIT in

Section 12C ).

2. Is fuel gauge sender unit operating

correctly?

Check all

connector

terminal

retention.

Monitor TECH 2

Instrument Data

List while

manipulating

wiring harness to

check for an

intermittent

connection.

Replace fuel gauge

sender unit.

(Refer 2.3 FUEL

SENDER ASSEMBLY

in Section 8A ).