SECTION 1E - COCKPIT MODULE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag, o r seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL INFORMATION

The cockpit module panel is clearly visible in the engine bay, the panel is painted gloss black and the glue track is

apparent where the panel joins to the floor and A-pillars.

The module consists of a sub-assembly comprising the dashboard, air conditioner (where fitted), radio, pedals,

steering column, instruments etc. After completion of the-sub assembly, the operation of the electrical components

is tested before fitting to the vehicle.

The sub-assembly is retained in a channel (glue track) filled with a Special Silicone Adhesive in the front floor

extension and inner shroud panels of the body shell. Refer to 1.2 GENERAL PRECAUTIONS, as under repair

conditions the glue track must be free of refinishing paint.

The module locates on self-centering dimples, two bolts, installed through the A-pillar, and two bolts, installed in the

plenum area. These points maintain the location until the adhesive cures. After installation and when the adhesive is

fully cured, the module becomes an integral part of the body structure.

Prior to removal of the module, the vehicle should be mounted in a jigging system to ensure that the body structure

is fully supported and cannot move.

The upper section of the module forms the base for the front windshield, which is bonded to the module using a

urethane adhesive.

The Vehicle Identification Number (VIN) plate is secured to the left side of the module by unique rosette headed

rivets. As a theft deterrent, the VIN number is visible through the front windshield.

The Silicone Adhesive in the glue track is suited for the high temperature conditions generated in the engine

compartment. The silicone also has excellent bonding, sealing and longevity characteristics.

1.2 GENERAL PRECAUTIONS

Unless repairing a crack or tear in the glue track, only two part silicone adhesive should be used when refitting the

cockpit module.

NOTE:

Remove as much of the old adhesive as possible from the glue track before installing the cockpit module.

As the cockpit module panel forms part of the vehicle structure, where the module panel has any damage or cracks

in the sheet metal, or if fire damage has occurred, the module must be removed and replaced.

Tears, separation or splitting in the adhesive exceeding 300 mm in length require removal and complete reglueing

of the module.

The Silicone Adhesive, Part Number M39998 used in the glue track must not be replaced with any other type of

adhesive or sealant other than that which is recommended by GMHAL; urethanes, epoxies, acrylic etc. are not

suitable for use in this application. Failure to correctly seal the cockpit module panel to the vehicle may allow

exhaust, fuel or other fumes to enter the passenger compartment.

INSTALLATION PRECAUTIONS

IMPORTANT:

To obtain a satisfactory bond between the two parts, the following procedures must be observed.

1. Remove as much of the remaining adhesive as possible from the glue track prior to reinstallation of the panel.

2. After repairing the sheet metal work, if all the remaining adhesive has been thoroughly removed, apply a coat

of primer inside the glue track. Do not apply primer over any remaining adhesive.

NOTE:

The finish on the front floor extension and shroud panel service parts will not require priming before applying the

adhesive to the glue track.

3. When reinstalling a module after a repair, ensure that no refinishing paint or overspray is in the glue track or on

the remaining adhesive.

Apply a layer of masking tape to the track before painting, and install the module after oven baking the paint

(where appropriate).

4. Do not use an adhesive other than that which is recommended by GMHAL.

5. Body shell assemblies are available (at the time of publication) in white enamel finish with or without the cockpit

module installed.

6. Before commencing installation of the module, thoroughly read 2.1 COCKPIT MODULE - MIXING SILICONE

ADHESIVE in this Section.

7. Although the cockpit module is installed as an assembly on the production line, this method is not practical for

repairing the vehicle. Service Operation 2.1 COCKPIT MODULE in this Section describes the cockpit module

disassembly and reassembly in the vehicle.

SAFETY PRECAUTIONS

The Silicone Adhesive used in the glue track, once cured requires no special precautions. However, when mixing

the adhesive compound with the catalyst, the Precautions listed below should be observed.

1. Do not swallow–the catalyst is a Toxic substance, keep away from children.

2. Safety glasses should be worn to avoid contact with eyes. If eye contact occurs, wash the area in clean water

only, and seek immediate medical advice.

3. Wear protective gloves when handing the adhesive and catalyst, as they may cause skin irritation. If irritation

occurs, wipe the adhesive/catalyst off with a clean cloth and wash the affected area thoroughly in clean water.

4. Vapour produced by the adhesive and catalyst may cause breathing difficulties, use only in a well ventilated

area.

5. The catalyst is combustible, keep away from sparks and flame.

2. SERVICE OPERATIONS

2.1 COCKPIT MODULE

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to DISABLING

THE SRS, Section 12M SRS.

NOTE:

This procedure describes the minimum

disassembly required to remove the components

attached to the cockpit module. Where replacement

of individual parts is necessary refer to appropriate

Section.

IMPORTANT:

As a theft deterrent, VT series vehicles are fitted

with a security coded audio system. Af ter the power

supply is interrupted, the radio will remain

inoperative after reinstallation until the pin number

is entered into the system. The procedure is

described in the glove box literature accompanying

the Owner’s Handbook.

1. Disconnect the negative and positive cables

from the battery to isolate the electrical

equipment, and prevent damage to the

components.

2. Drain cooling system, refer to

Section 6B1-1 ENGINE COOLING - V6

ENGINE or 6B1-2 ENGINE COOLING - V6

SUPERCHARGED or 6B2 ENGINE COOLING

- V8 ENGINE.

3. Where fitted discharge the air conditioning

system, refer to

Section 2C AIR CONDITIONING -

SERVICING AND DIAGNOSIS .

4. Depressurise the fuel system as described in

Section 6C1 POWERTRAIN MANAGEMENT

- V6 ENGINE or 6C2 POWERTRAIN

MANAGEMENT - V8 ENGINE.

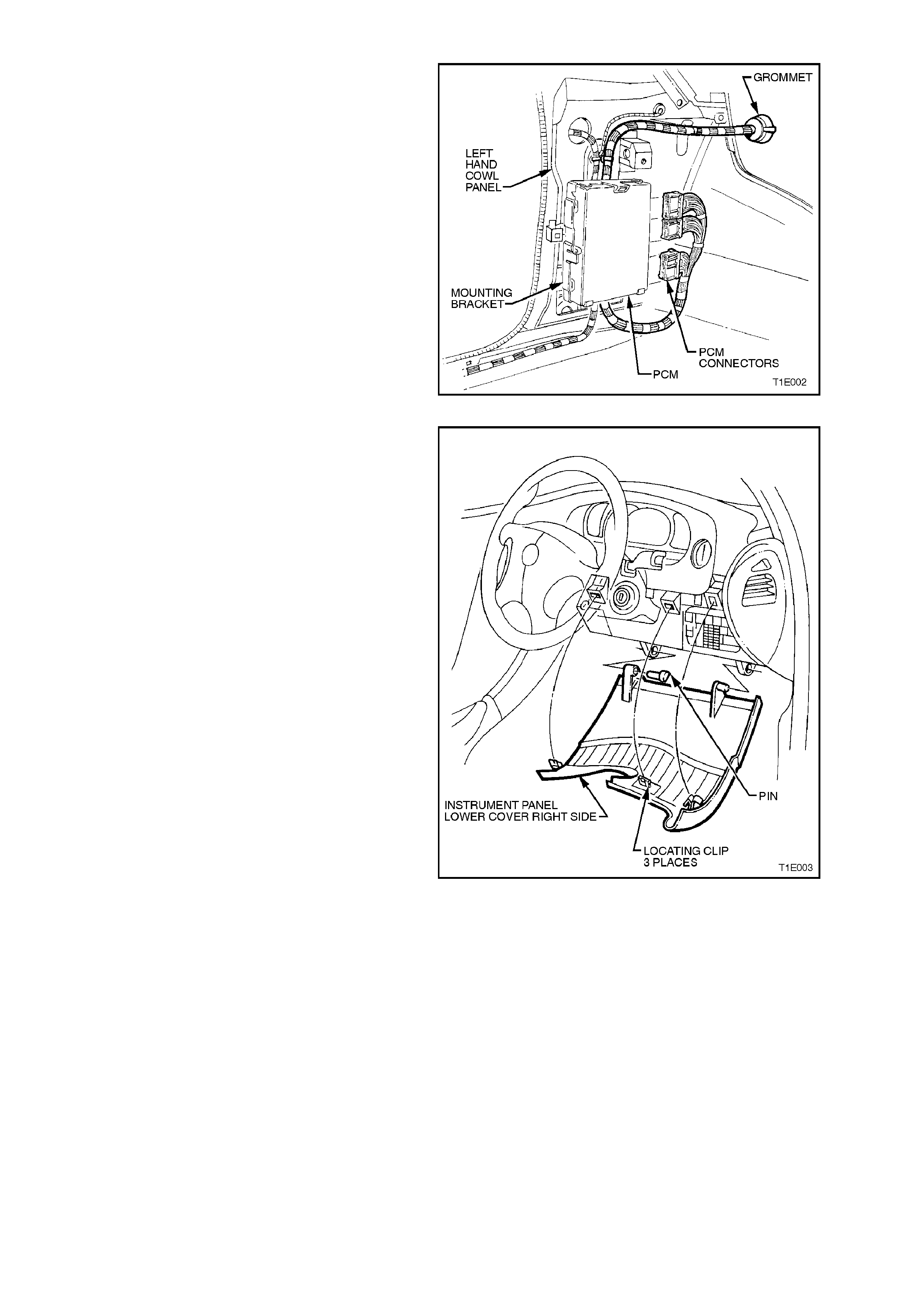

5. Locate powertrain control module in the

passenger footwell.

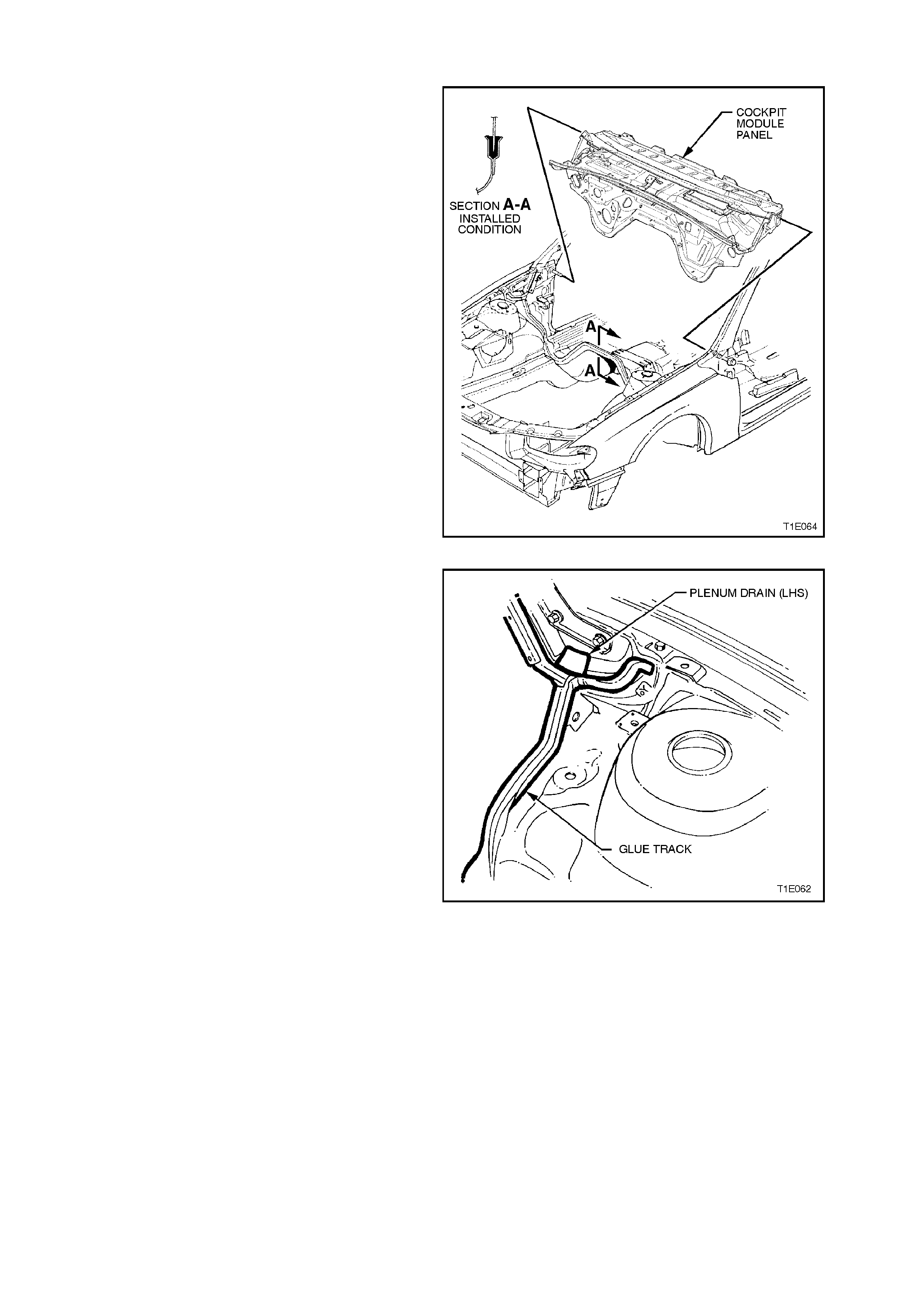

Figure 1E-1

6. Unclip duct cover flap on right hand side of

footwell upper closing panel left side and

disengage locating lugs to passenger side

shroud lower. Grasp closing panel firmly and

detach by pulling left side down first, then

disengage right side clip and remove panel.

Figure 1E-2

7. Remove passenger side shroud lower trim

assembly, refer to Section 1A2 BODY

DIMENSIONS.

Techline

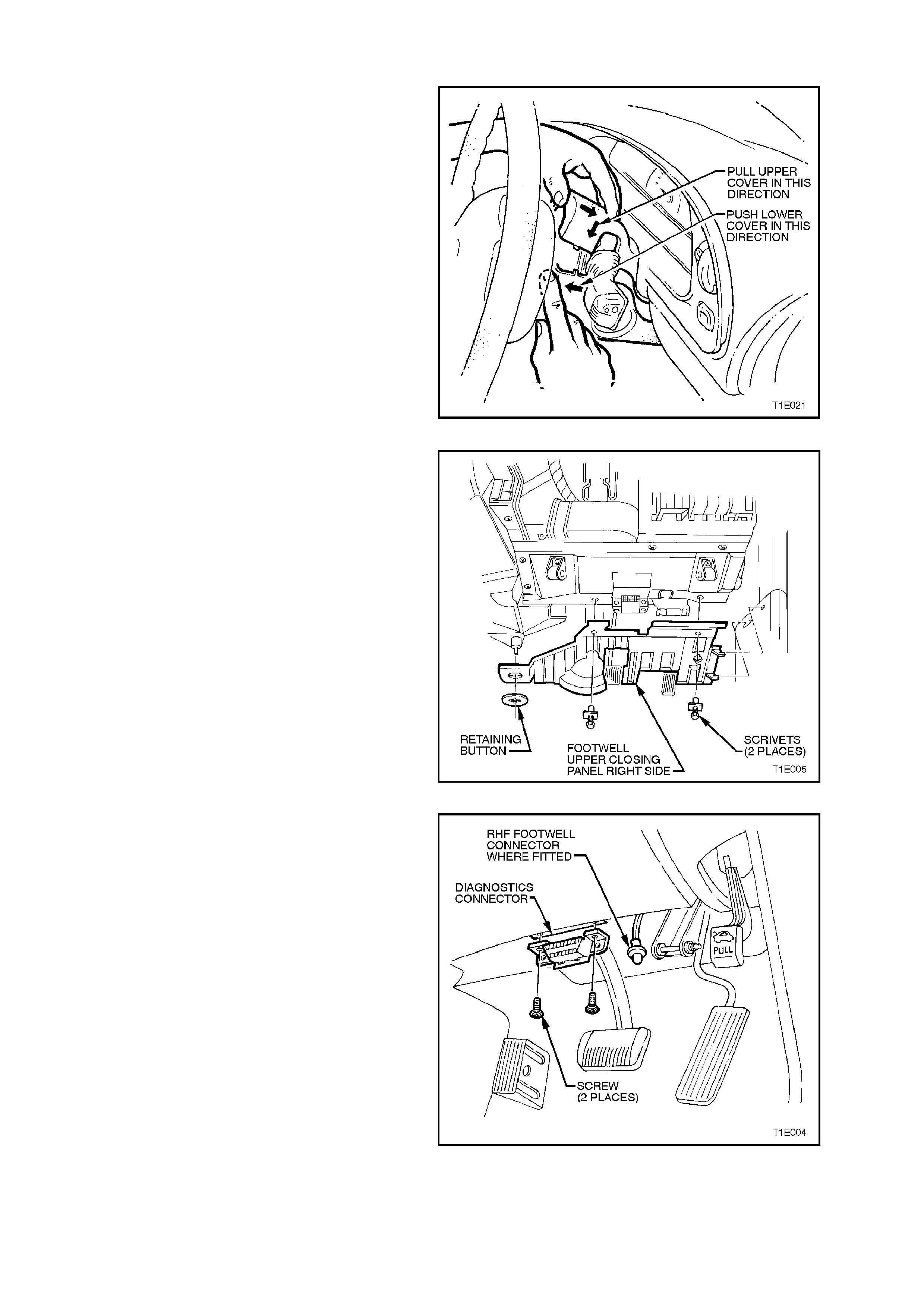

8. Disconnect the harness from the powertrain

control module, refer to Section 6C1

POWERTRAIN MANAGEMENT - V6 ENGINE

or 6C2 POWERTRAIN MANAGEMENT - V8

ENGINE. The module should be removed from

the vehicle to prevent damage occurring.

Figure 1E-3

9. Adjust steering wheel to upper most position.

Grasp right hand side of lower cover panel

right side firmly and pull towards rear of

vehicle. Repeat procedure f or left hand side of

cover. Prise out the left hand hinge pin using a

flat blade screwdriver.

Tilt the cover down on the left side and

disengage the right hand hinge pin and

remove panel.

Figure 1E-4

10. Adjust steering column to lower most position.

Remove steering column to facia screen.

Remove single screw from the lower steering

column shroud and remove upper and lower

steering column shroud.

Figure 1E-5

11. Remove two scrivets and on vehicles fitted

with automatic transm ission, prise off retaining

button and detach the footwell upper closing

panel right side.

Where fitted disconnect front footwell lamp

from footwell upper closing panel, refer to

Section 12B LIGHTING SYSTEM.

Figure 1E-6

12. Remove two screws securing the diagnostic

connector to instrument panel lower trim right

side assembly.

Figure 1E-7

13. Slide the passenger compartment relay and

fuse block to the left, push through support

panel and withdraw towards front of vehicle.

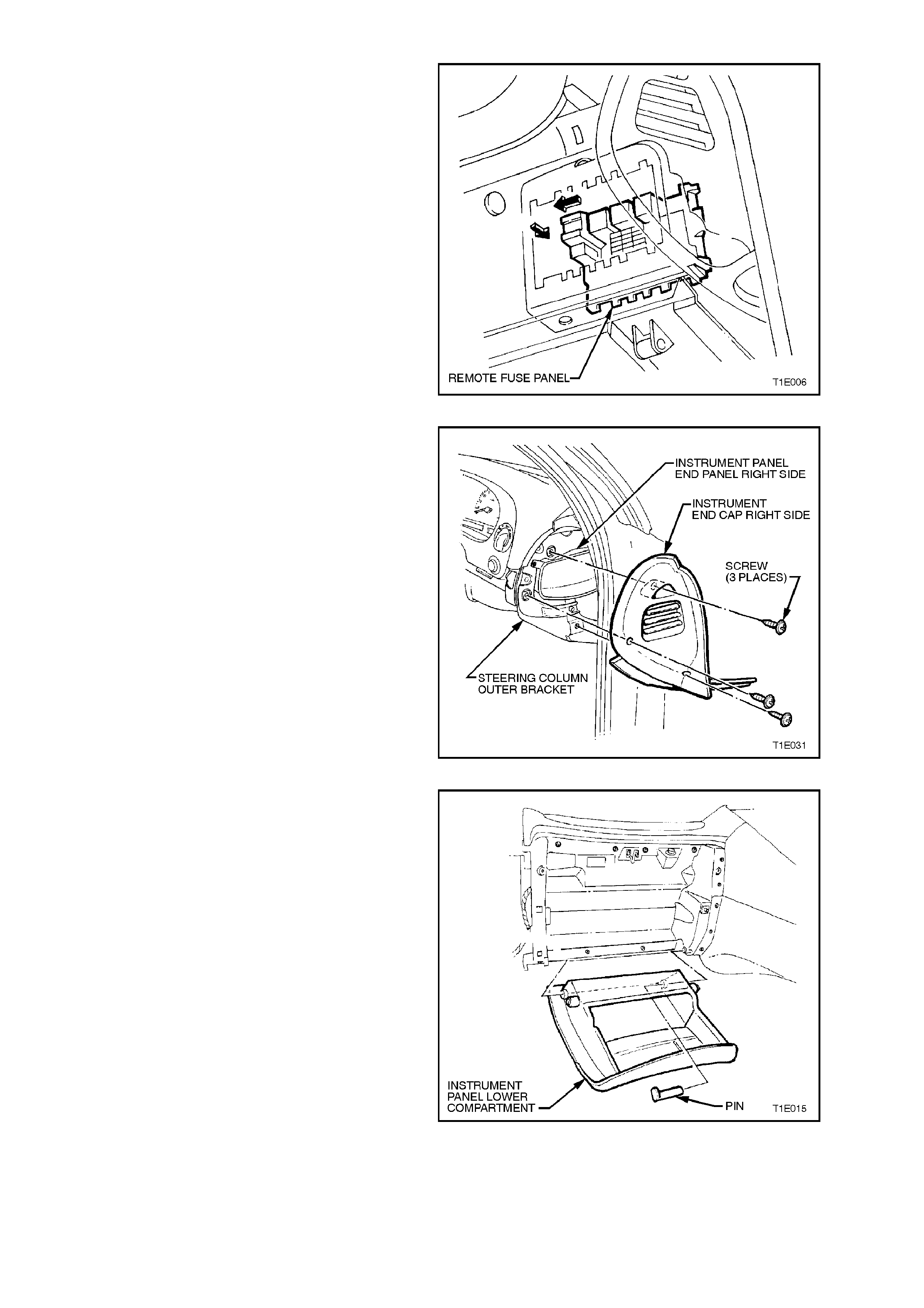

Figure 1E-8

14. Remove the three screws and remove

instrument panel end cap cover right hand

side.

Figure 1E-9

15. Open the instrument panel lower

com partment, and lever the hinge pin f rom the

right side. Lower compartment and withdraw

the pin. Disengage right hand travel limiting

peg from slot in instrument panel roof by

deforming plastic tang..

Figure 1E-10

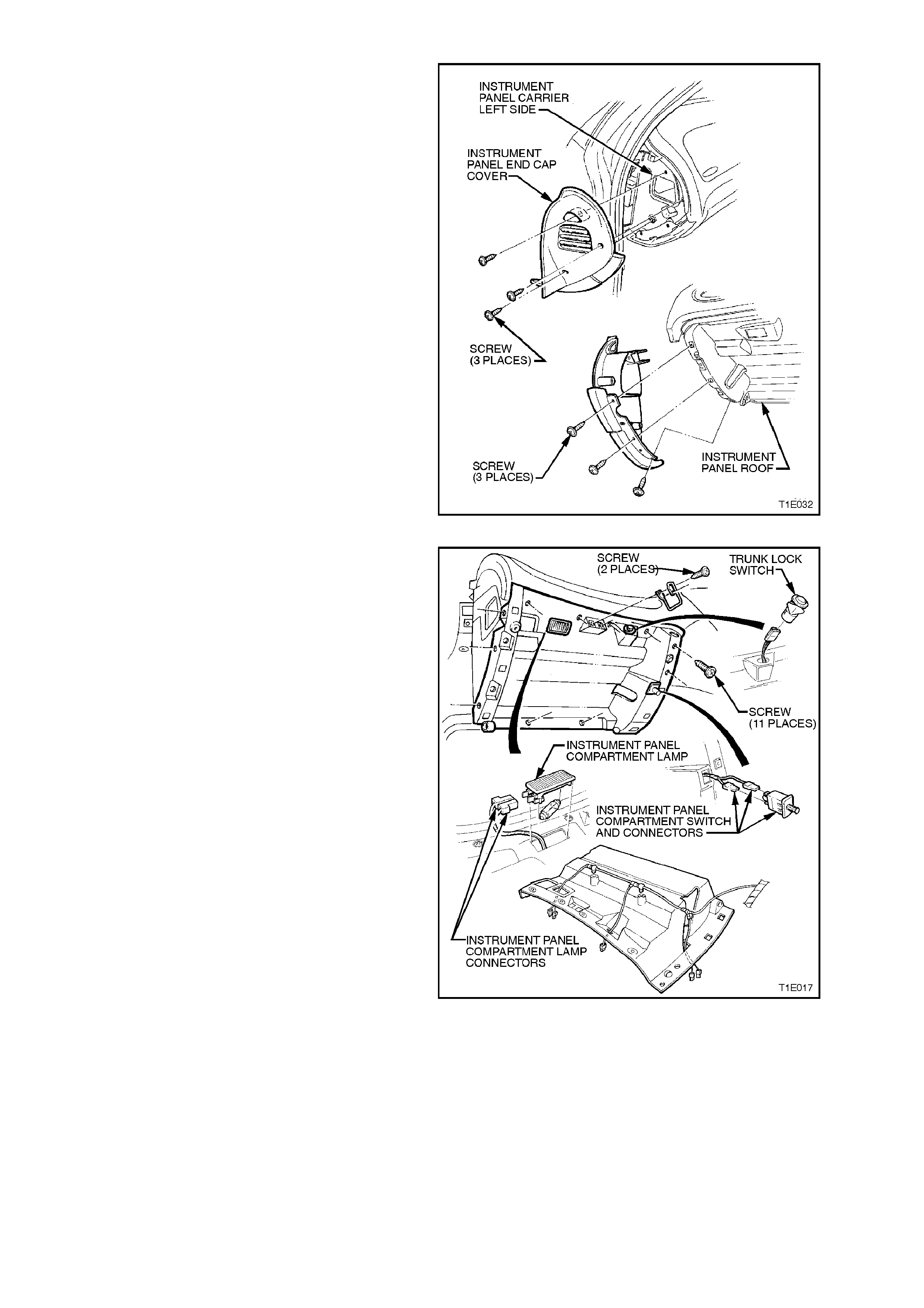

16. Remove the six retaining screws for instrument

panel end cap cover left hand side.

Figure 1E-11

17. Remove 11 retaining screws from instrument

compartment roof, disconnect glove box lamp

connectors, trunk lock switch connector, glove

box switch connectors and unclip glove box

wiring harness.

Figure 1E-12

18. Remove driver’s side shroud lower trim

assembly, refer to Section 1A2 BODY

DIMENSIONS.

Figure 1E-13

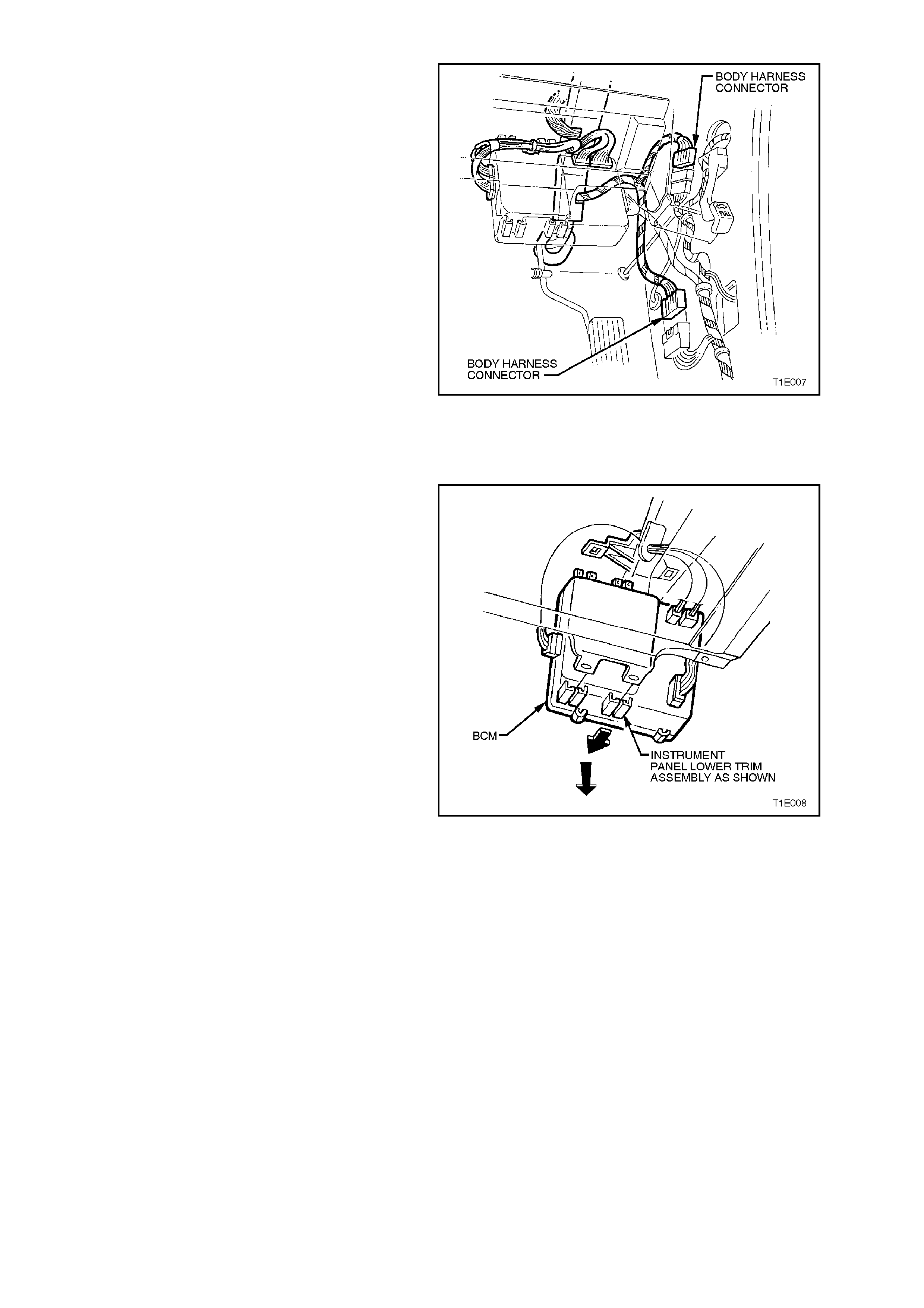

19. Disconnect body harness to main wiring

harness connectors at the right hand cowl

panel.

20. Remove Body Control Module (BCM) from

mounting brackets by pushing the bottom of

the BCM towards the front of the vehicle until

the BCM disengages from the lower mounting

bracket.

NOTE:

The wiring harnesses are still connected.

Then grasp the BCM, and gently pull the BCM

down disengaging it from the upper mounting

bracket.

Figure 1E-14

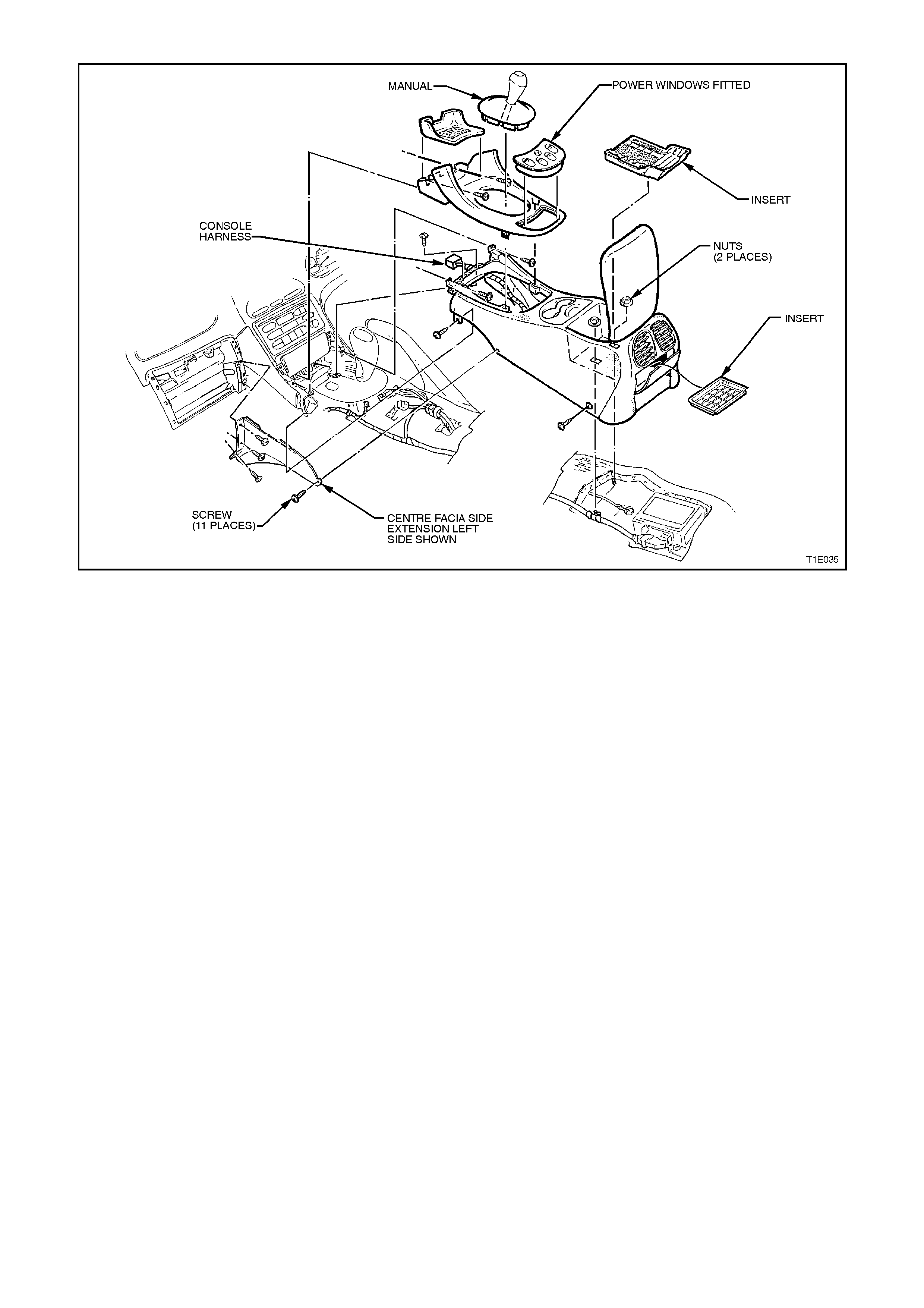

21. Remove the transmission console and detach

console wiring harness, refer to

Section 1A3 INSTRUMENT PANEL &

CONSOLE.

Figure 1E-15

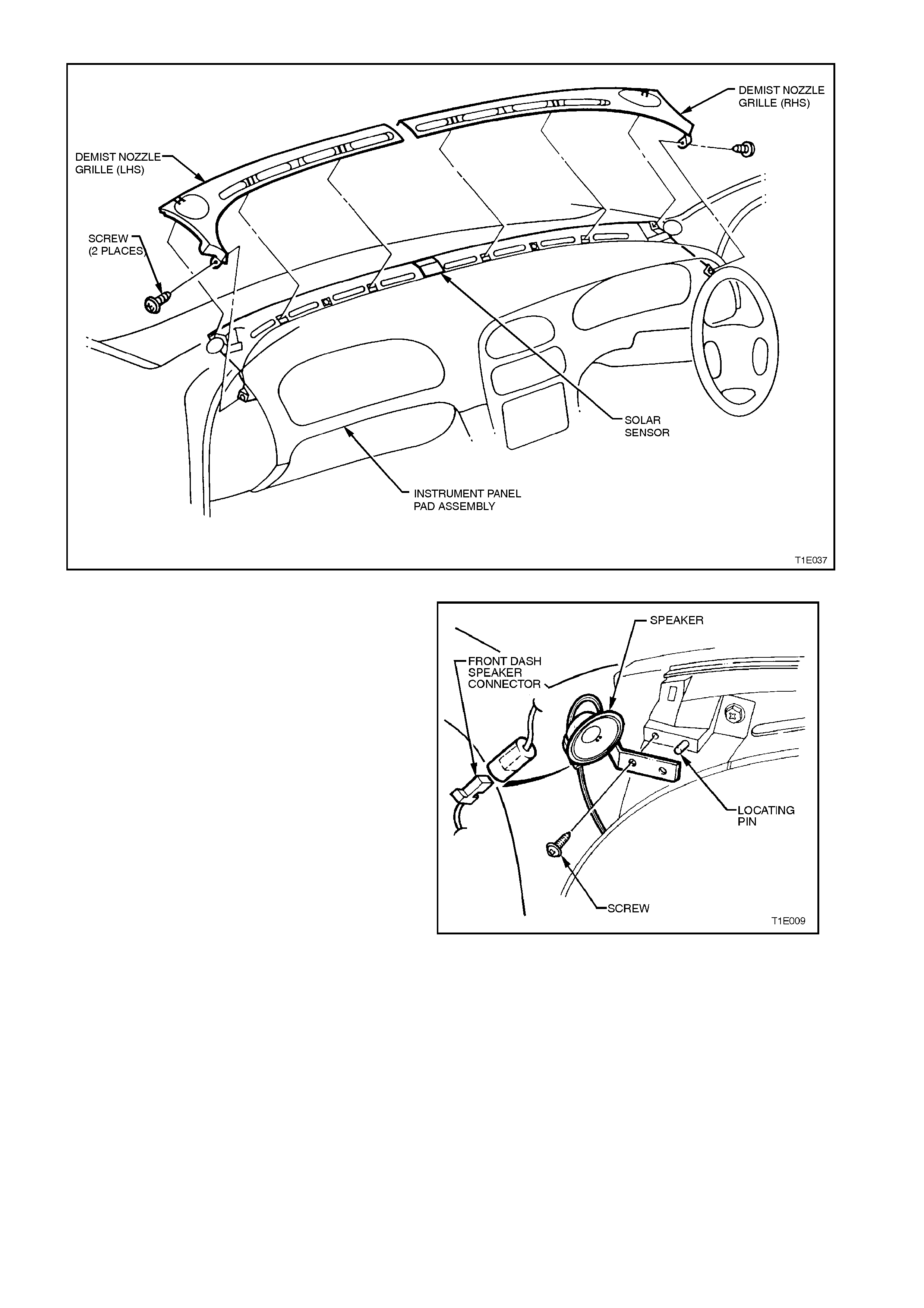

22. Remove retaining screw from the demist

nozzle right-hand and remove.

23. Remove retaining screw from the demist

nozzle left-hand and remove.

NOTE:

On all vehicles, care must be taken to avoid

damage to the solar sensor.

Figure 1E-16

24. Disconnect left and right front dash speaker

harness connectors. Using a Phillips screw

driver, remove screw attaching front dash

speakers and remove both speakers.

Figure 1E-17

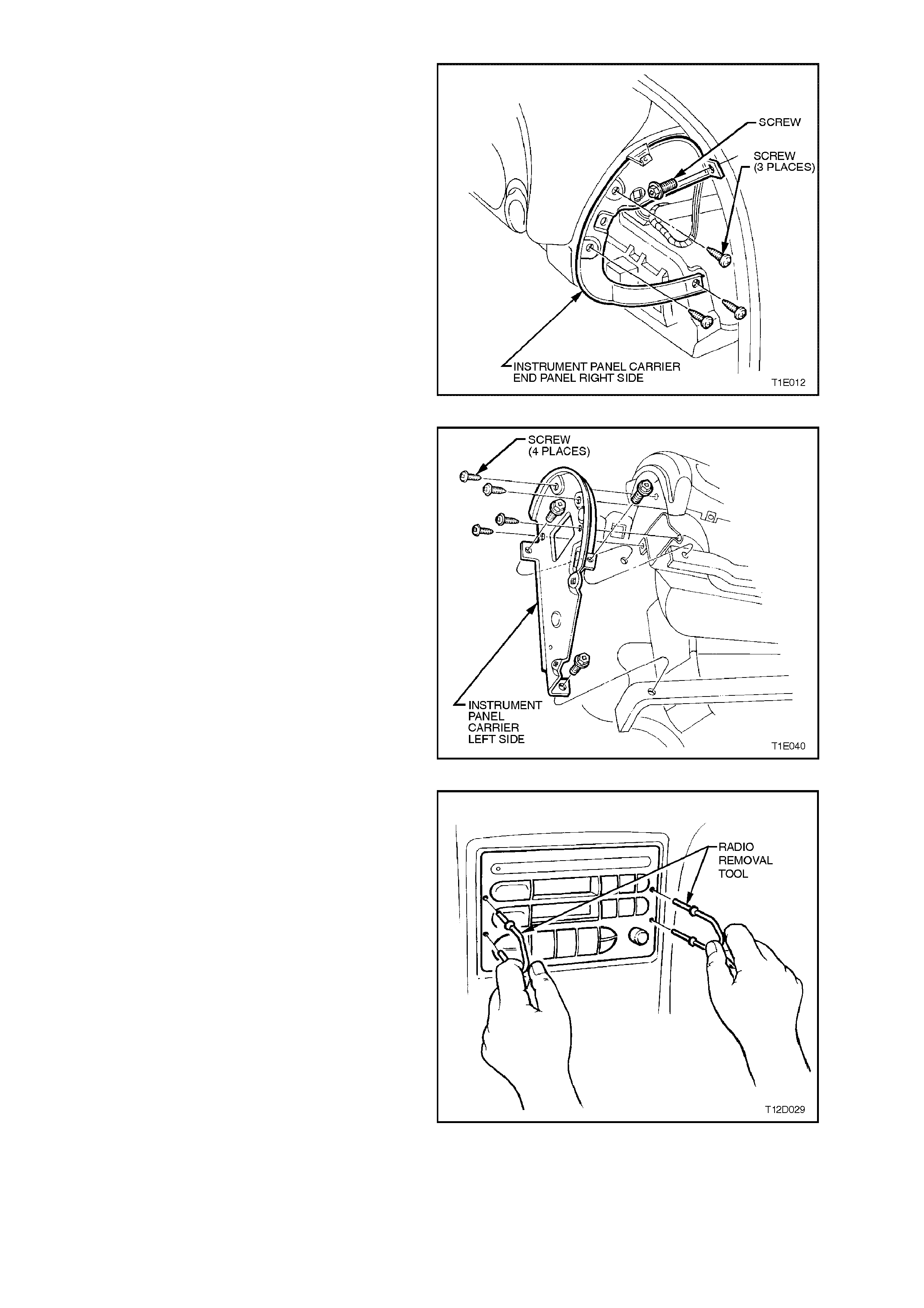

25. Remove the four retaining screws from

instrument panel carrier end panel right side

and remove panel.

Figure 1E-18

26. Remove four attaching screws securing

instrument panel carrier end panel left side

and three bolts attaching passenger airbag

support rail, lower left side rail, and remove

panel.

Figure 1E-19

27. Remove radio/cassette/CD from instrument

panel, use service tool 179 1308 000 to assist

in removal. Refer to Section 12D AUDIO

SYSTEMS.

Figure 1E-20

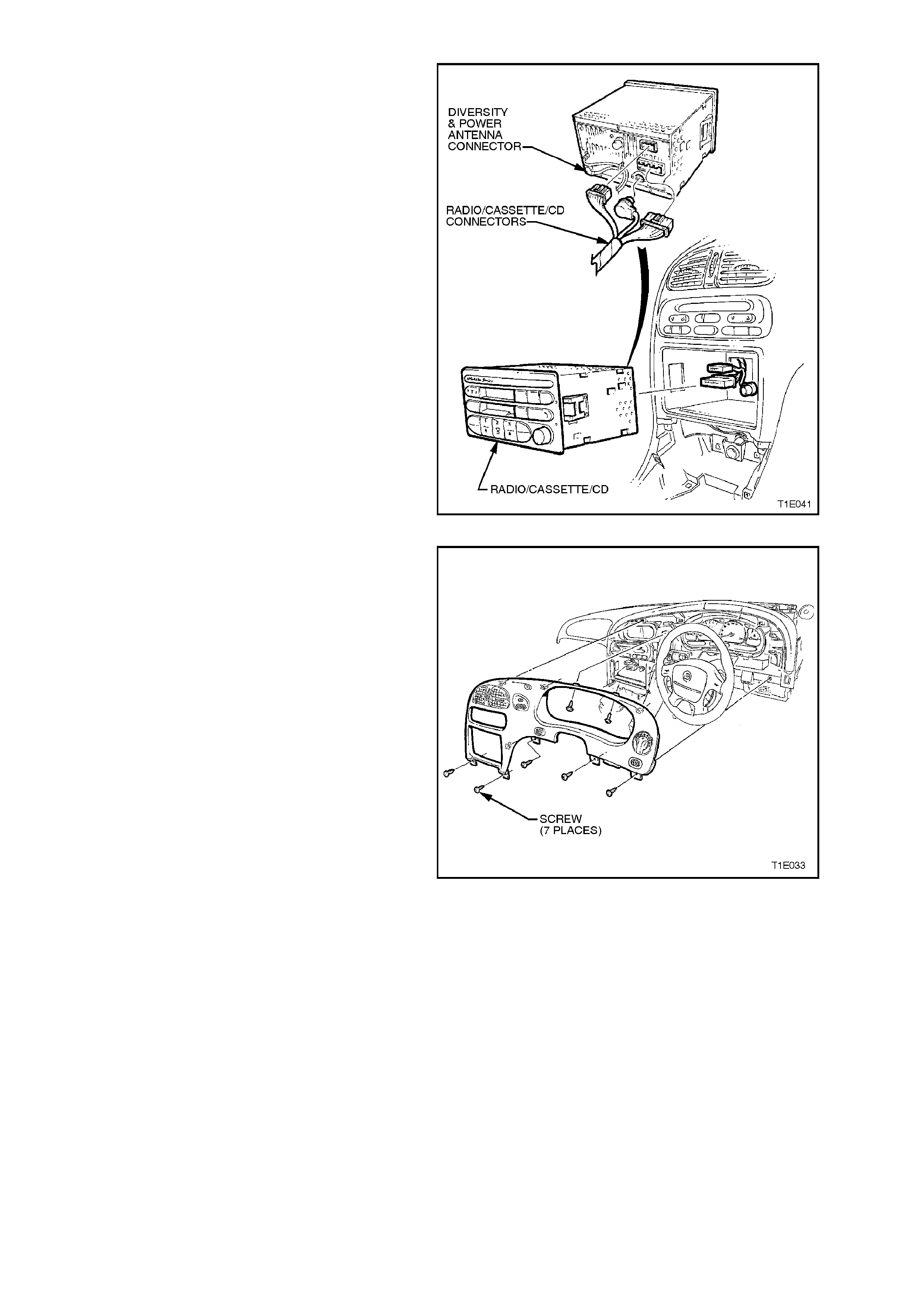

28. Disconnect radio/cassette harness and if fitted

CD connector. Disconnect antenna and if fitted

diversity and power antenna.

Figure 1E-21

29. Remove the seven screws retaining the

instrument facia assembly, and pull facia from

retaining clips (5 clips).

NOTE:

Care must be taken to disconnect the headlamp

switch connector, fog lamp switch connector (if

fitted), trip computer switch connector (if fitted),

hazard switch connector from main wiring harness.

Figure 1E-22

30. Remove the two attaching screws securing in-

car sensor (if fitted) and disconnect harness

connector, refer to Section 2E AIR

CONDITIONING.

31. Remove the 13 screws securing centre facia

assembly, refer to

Section 1A3 INSTRUMENT PANEL &

CONSOLE.

Figure 1E-23

NOTE:

The steering column is designed as an energy

absorbing unit. Avoid hammering, jarring dropping

or applying force to any portion of the steering

column.

IMPORTANT:

TO MAINTAIN SAFETY STANDARDS DO NOT

REUSE DAMAGED COMPONENTS OR

REPLACEMENT PARTS OF LESSER QUALITY

OR SUBSTITUTE DESIGN.

32. Disconnect the wiring harness connectors

from the ignition switch, horn, turn signal

switch and ignition key reader and lamp.

33. Remove four retaining screws securing Airbag

and disconnect horn connector, airbag

connector and if fitted remote radio connector.

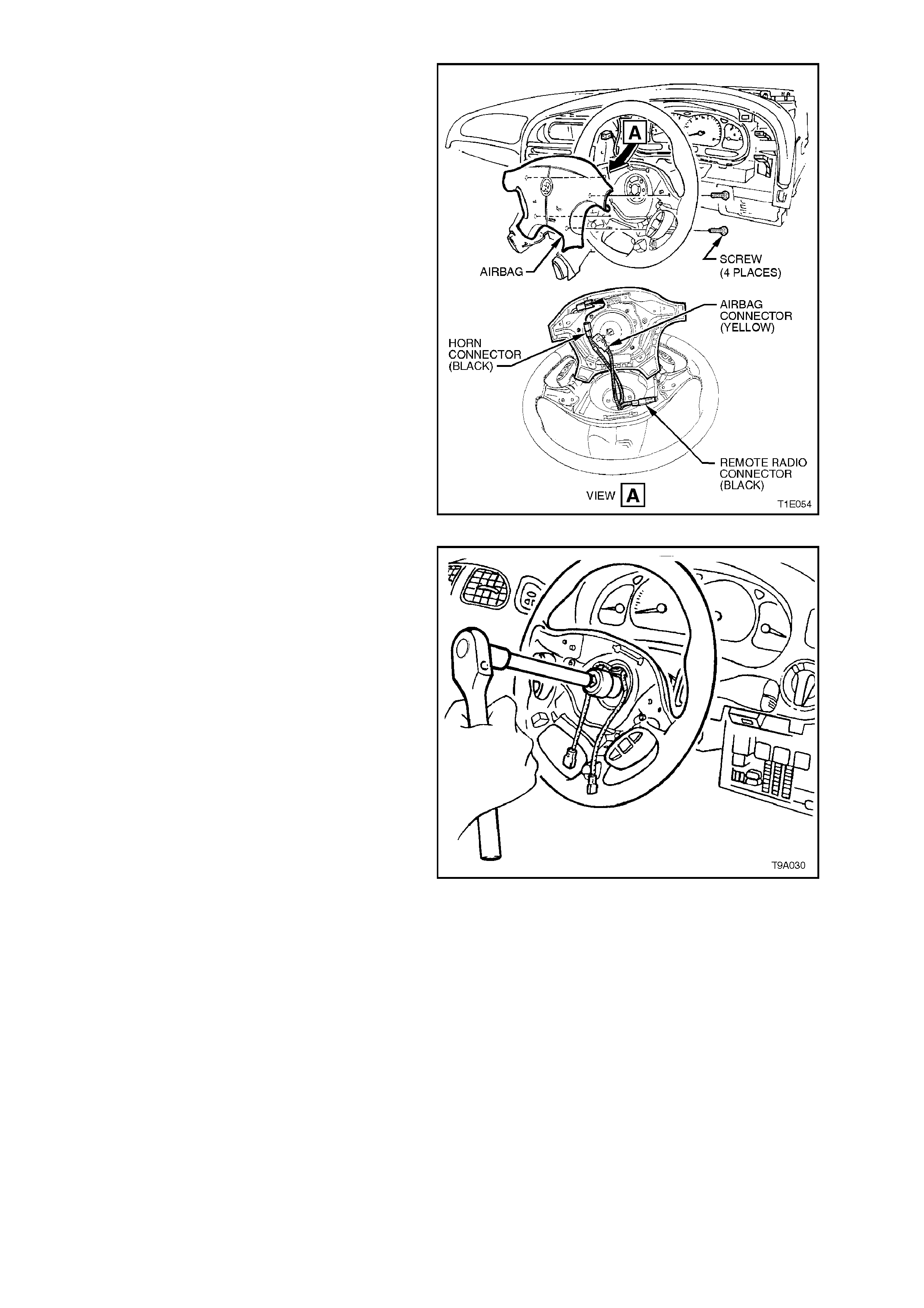

Figure 1E-24

34. Use Torx driver to remove single screw

securing steering wheel to steering column,

and remove steering wheel.

Figure 1E-25

35. Remove the screws securing the heater and

air conditioning controls and disconnect the

electrical connections.

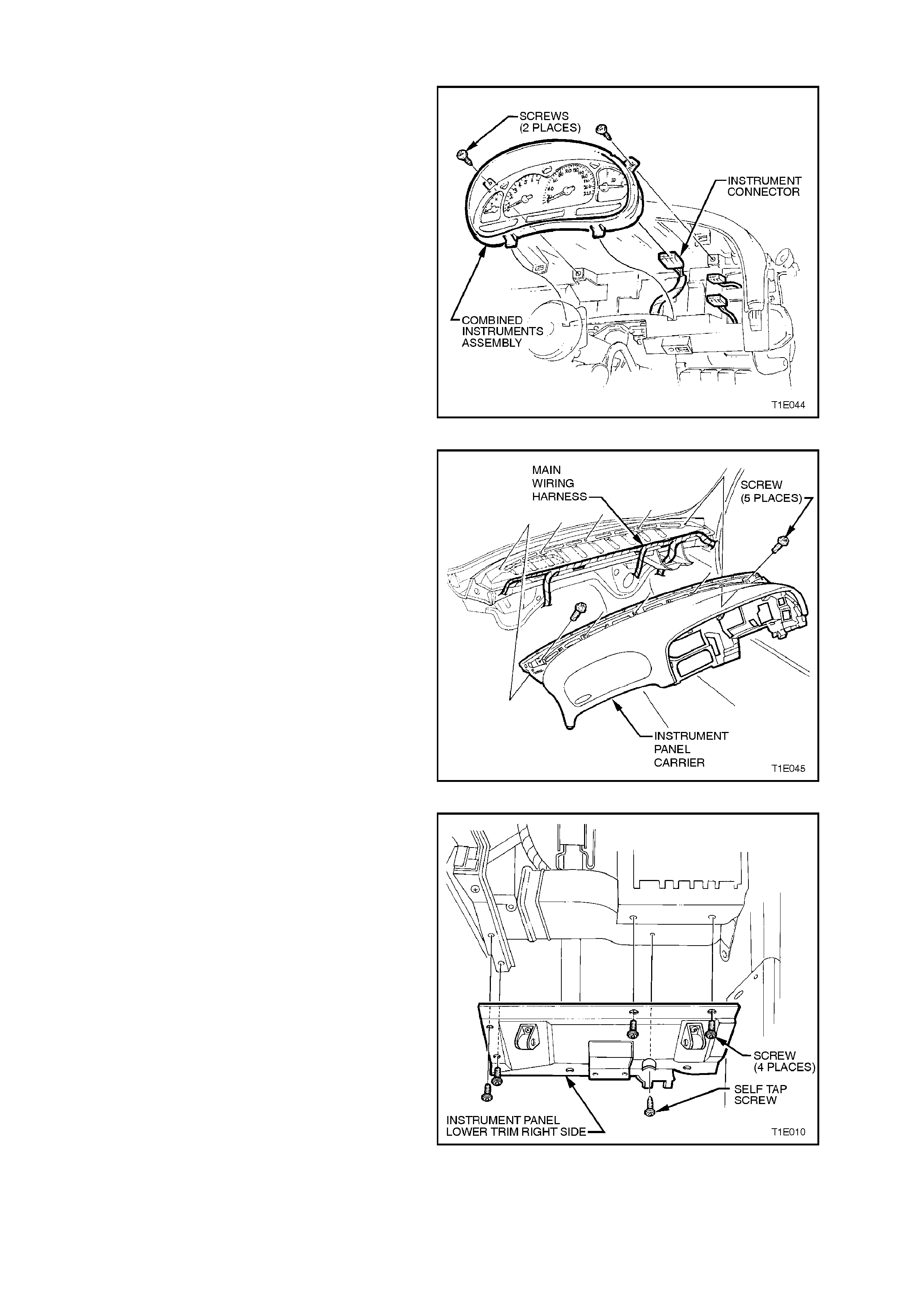

36. Remove the screws securing the combined

instruments assembly and disconnect

instrument connector.

Figure 1E-26

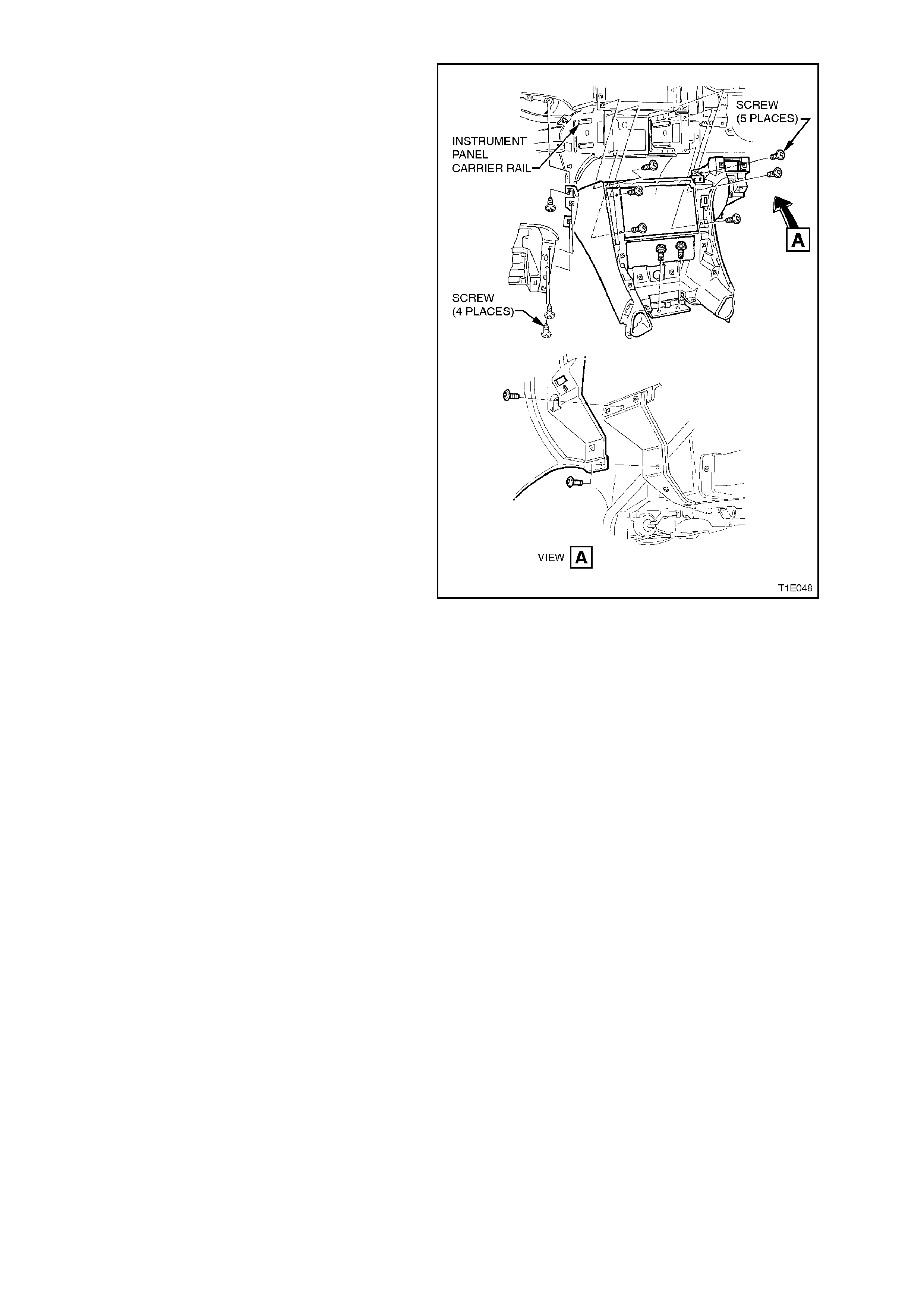

37. Remove the five retaining screws along top

edge of instrument panel carrier.

Figure 1E-27

38. Remove the five screws and withdraw

instrument panel lower trim right side rail

assembly.

39. Remove HVAC unit to door outer right hand

side and HVAC unit to door vent inner right

hand side. Refer to

Section 2B AIR CONDITIONING - REMOVAL

AND INSTALLATION .

Figure 1E-28

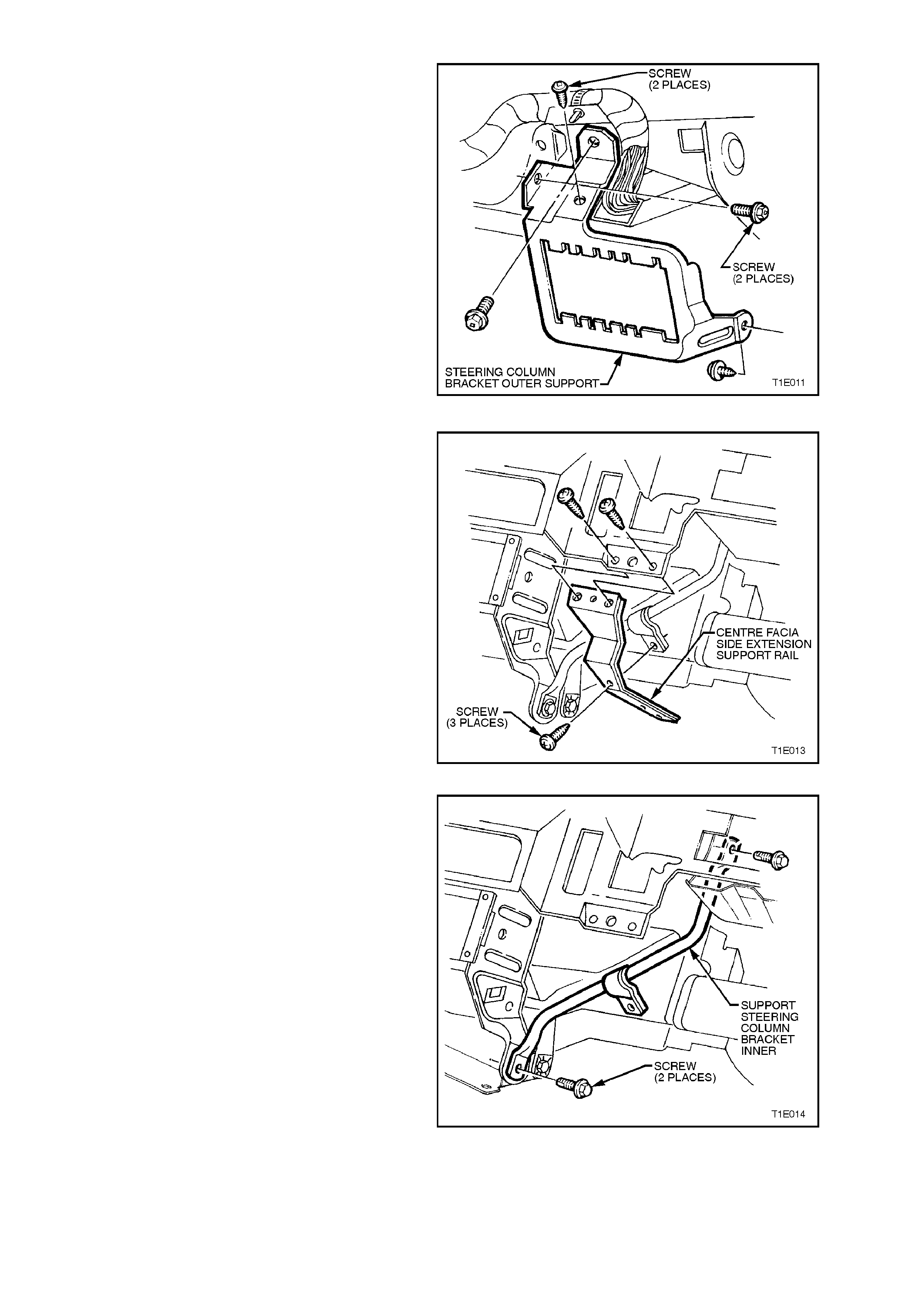

40. Remove four screws securing the steering

column bracket outer support and remove.

Figure 1E-29

41. Remove centre facia side extension support

rail (3 screws).

Figure 1E-30

42. Remove the two screws and remove support

steering column bracket inner.

Figure 1E-31

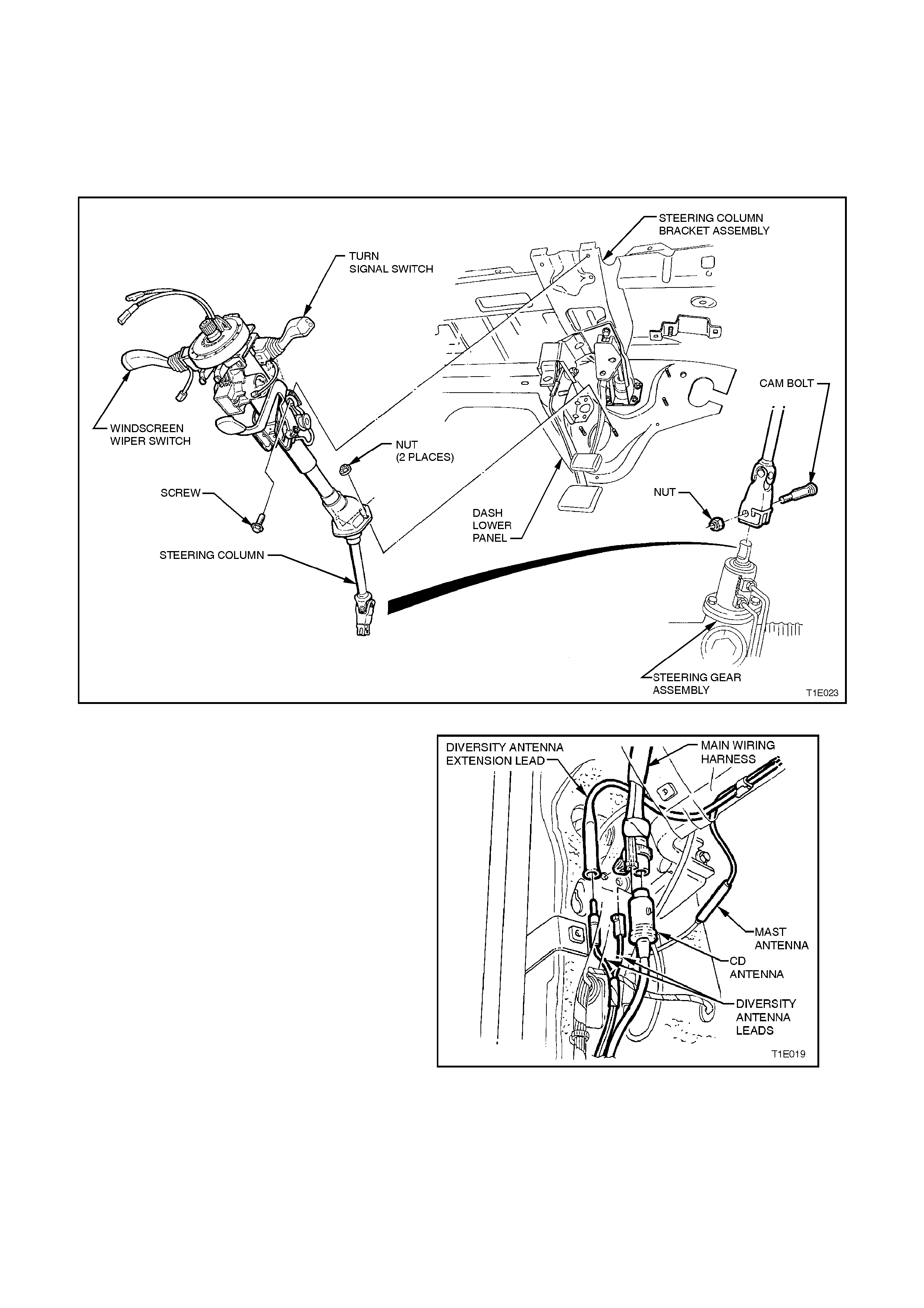

43. Remove cam bolt and nut from steering

column clevis located at the steering rack.

From inside vehicle remove two nuts at base

of steering column, remove two upper

mounting screws, and carefully remove

steering column assembly from vehicle.

Figure 1E-32

44. Disconnect the main wiring harness from the

antenna, power, and where fitted CD

connector located on the left side of

passenger footwell.

Figure 1E-33

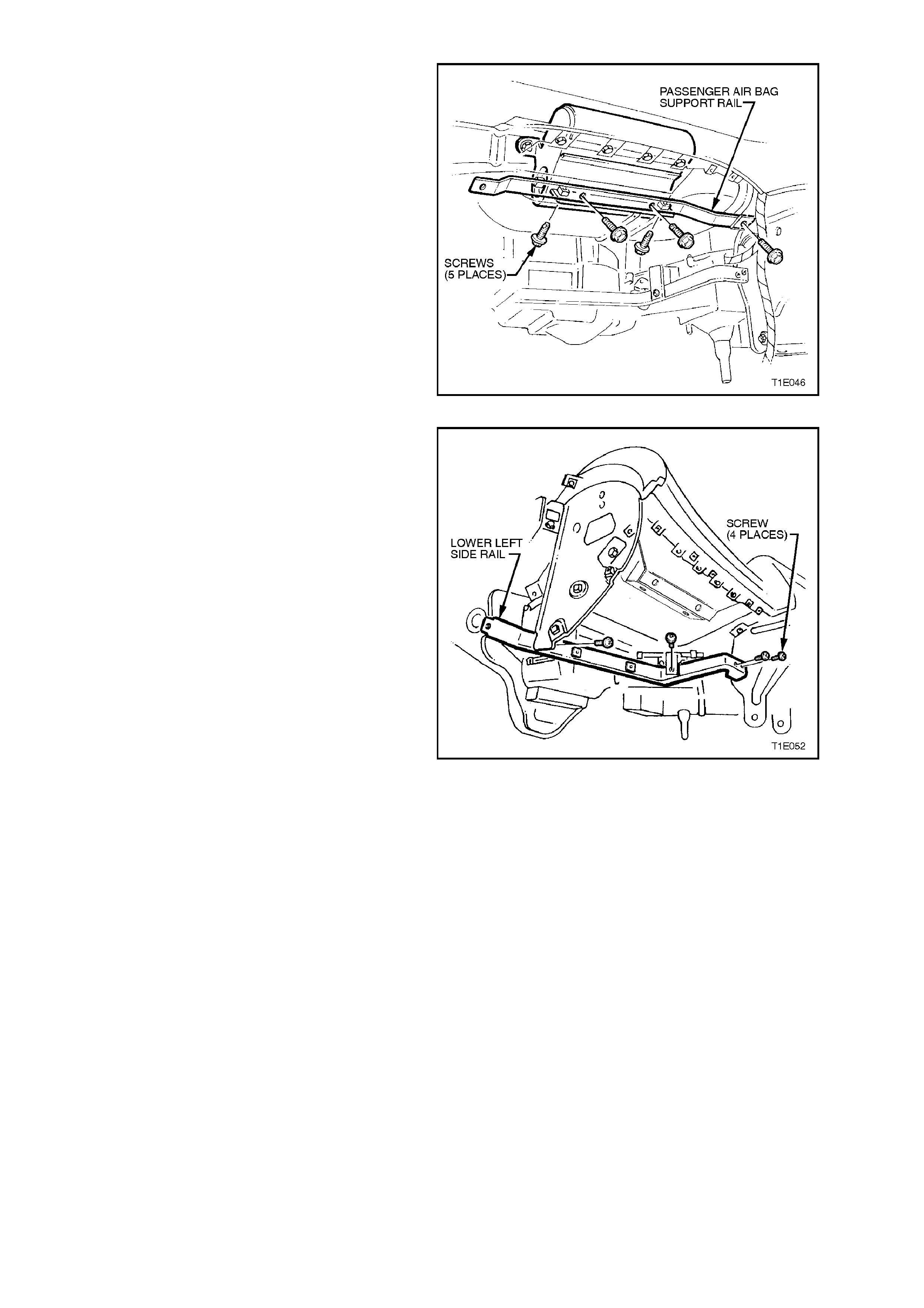

45. Remove five screws securing passenger

airbag support rail assembly left side and

remove rail.

Figure 1E-34

46. Rem ove two screws connecting lower lef t side

rail to instrument panel carrier rail assembly.

Remove single screw connecting lower left

side rail to instrument panel carrier end panel

left side. Remove single screw connecting

lower left side rail to body mount.

Figure 1E-35

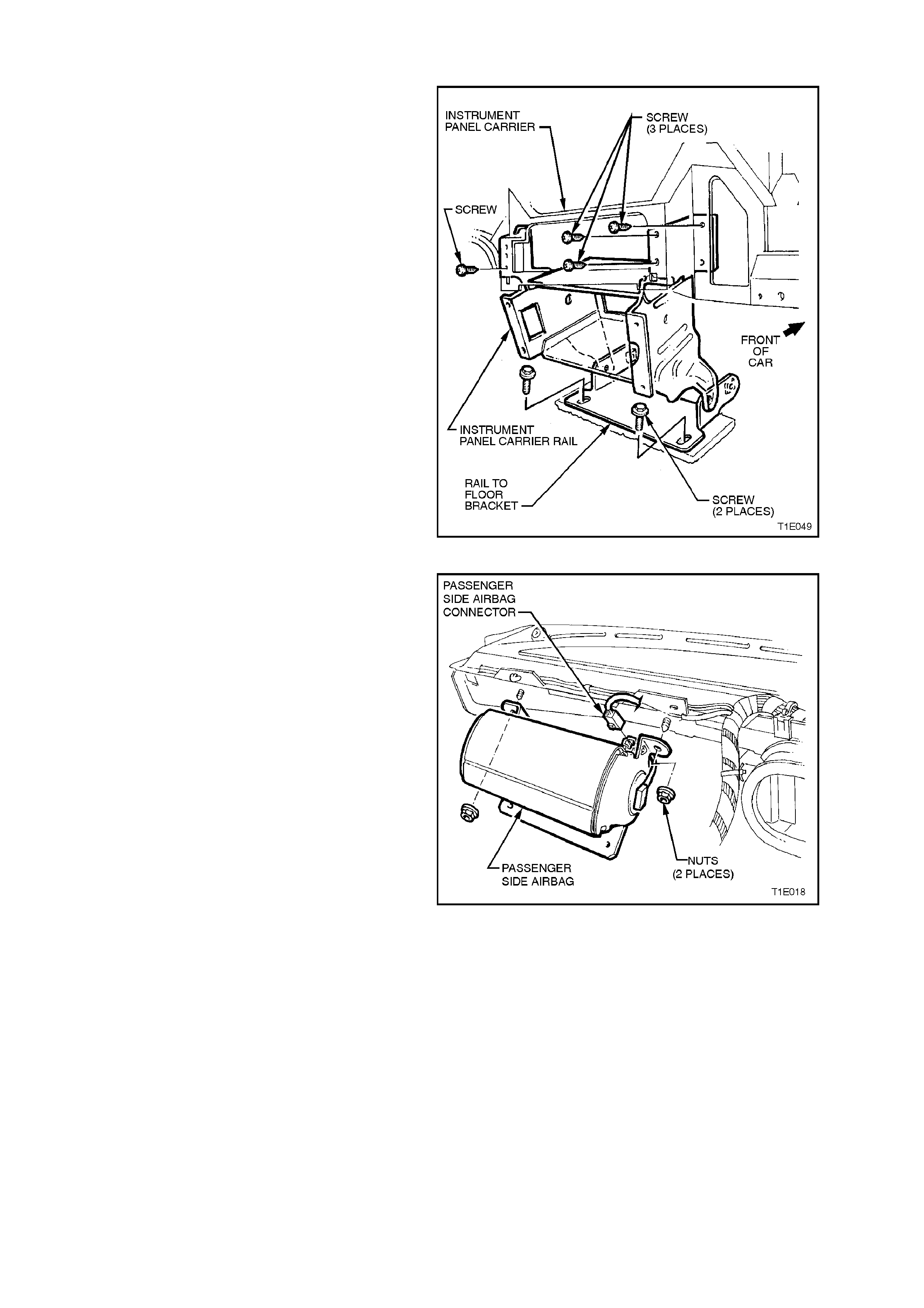

47. Remove instrument panel carrier rail

assembly.

Figure 1E-36

48. Where fitted remove passenger side airbag

connector located on the right hand side of

airbag. Remove two nuts attaching airbag to

dash lower panel assembly

Figure 1E-37

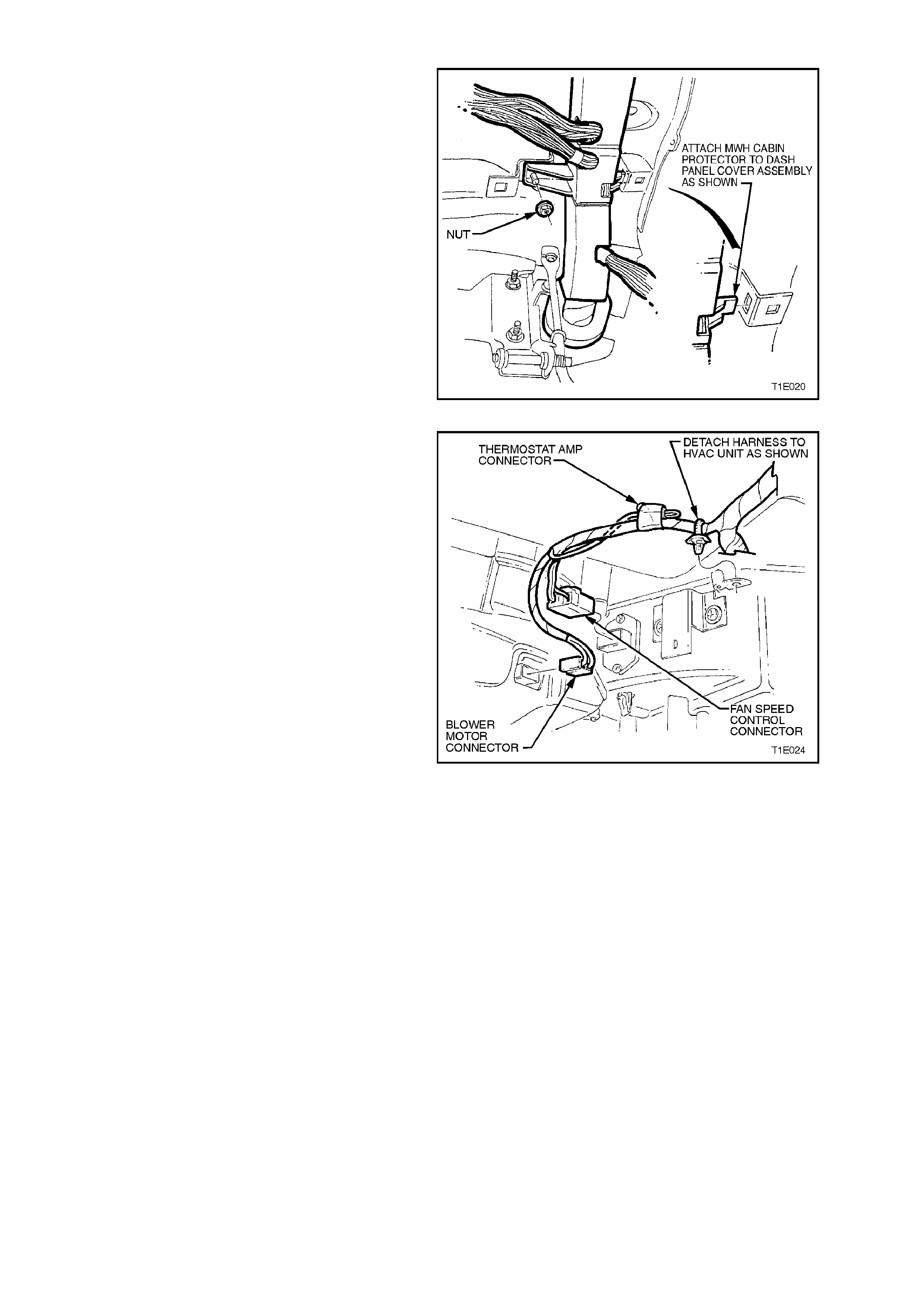

49. Remove main wiring harness former

retaining screw accessed from above and

single nut accessed from underneath.

Unclip main wiring harness former from

upper retaining bracket.

50. Disconnect the throttle cable from the

accelerator pedal and throttle body lever,

then remove the cable from the vehicle.

NOTE: Throttle cable remove is described in

Section 6C1 POWERTRAIN MANAGEM ENT – V6

Engine or 6C2 POWERTRAIN MANAGEMENT –

V8 Engine in the VT Series I Service Information.

Figure 1E-38

51. Disconnect the blower motor connector and

fan speed control connector from the HVAC

unit and detach harness.

Figure 1E-39

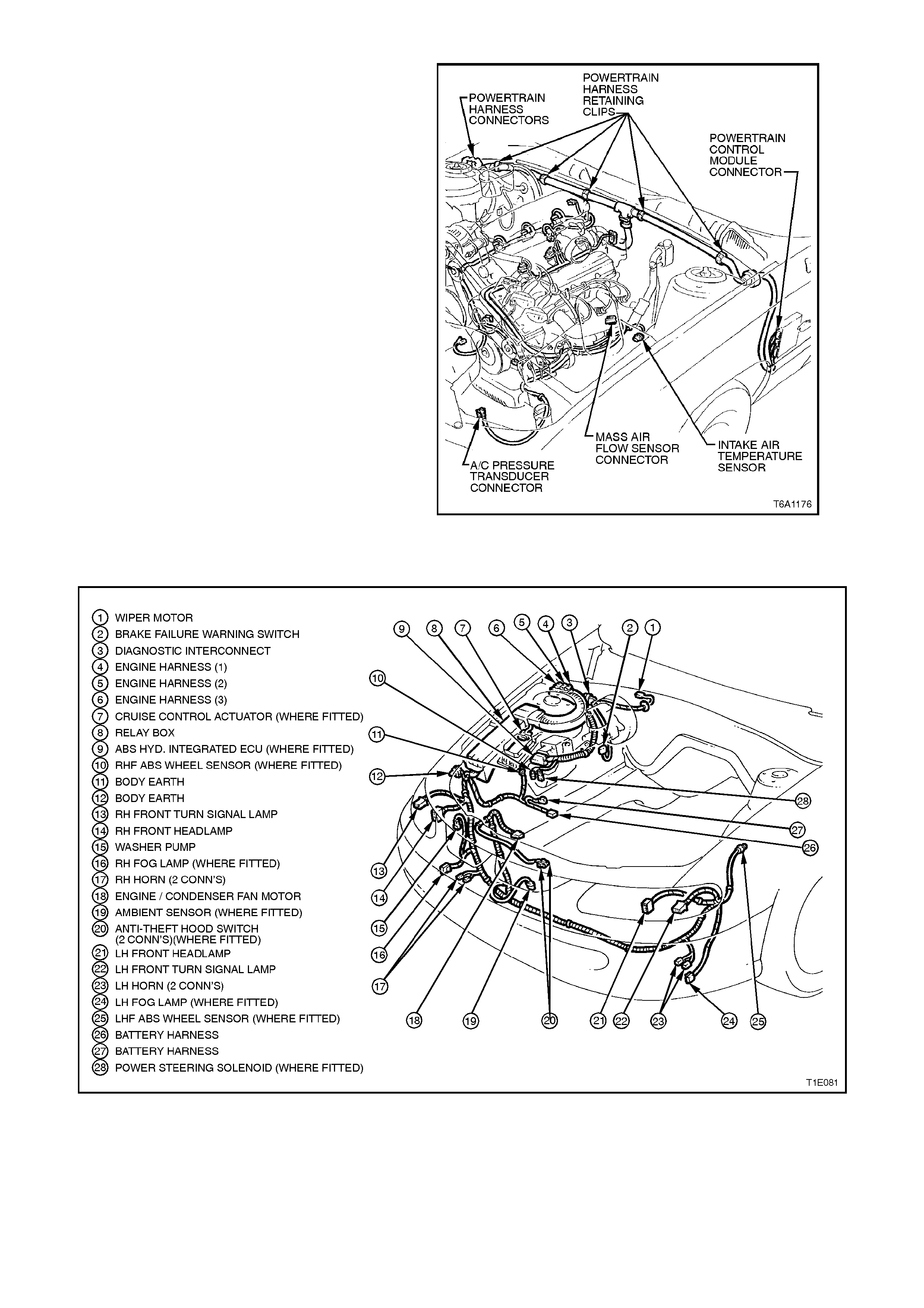

52. From engine compartment release powertrain

harness to dash panel retaining clips.

Disconnect mass air flow sensor, idle air

control motor connector, powertrain control

module connector. Disconnect intake air

temperature sensor at air cleaner and air

conditioning pressure transducer connector at

air conditioning condenser, lay wiring harness

on top of engine.

Figure 1E-40

53. Disconnect the main wiring harness from the

engine compartment electrical equipment.

Figure 1E-41

54. With engine hood adequately supported,

remove clips securing upper end of struts to

hood pivots. Disengage struts from hood

pivots and lay strut down on fender inner

panel.

With the aid of an assistant hold hood

assembly, remove engine hood bracket to

hinge attaching screws, and remove hood.

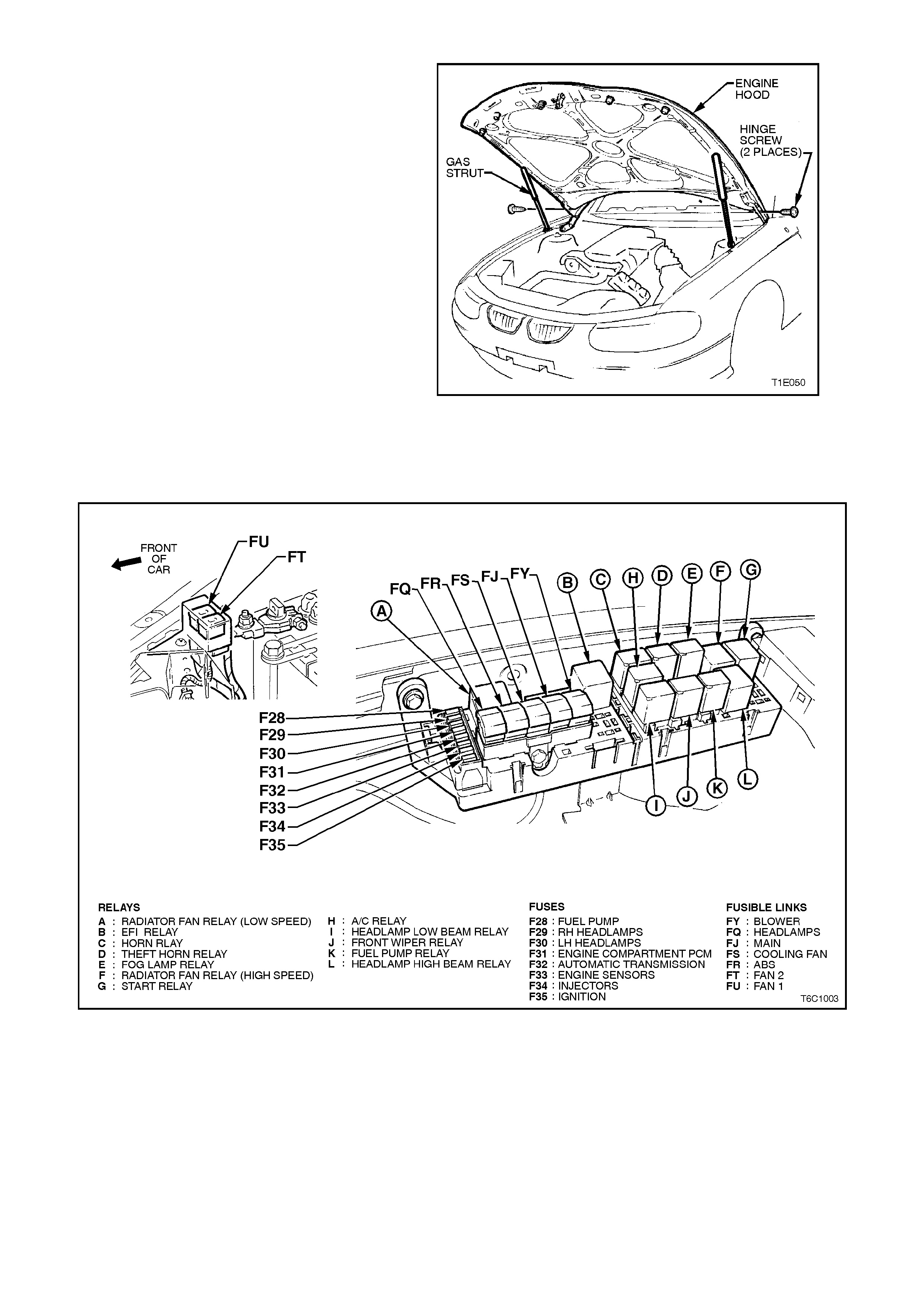

Figure 1E-42

55. Tag and remove all relays, fusible links, and

fuses from the relay housing in the engine

compartment. If fitted, disconnect Cruise

Control Actuator Connector.

Figure 1E-43

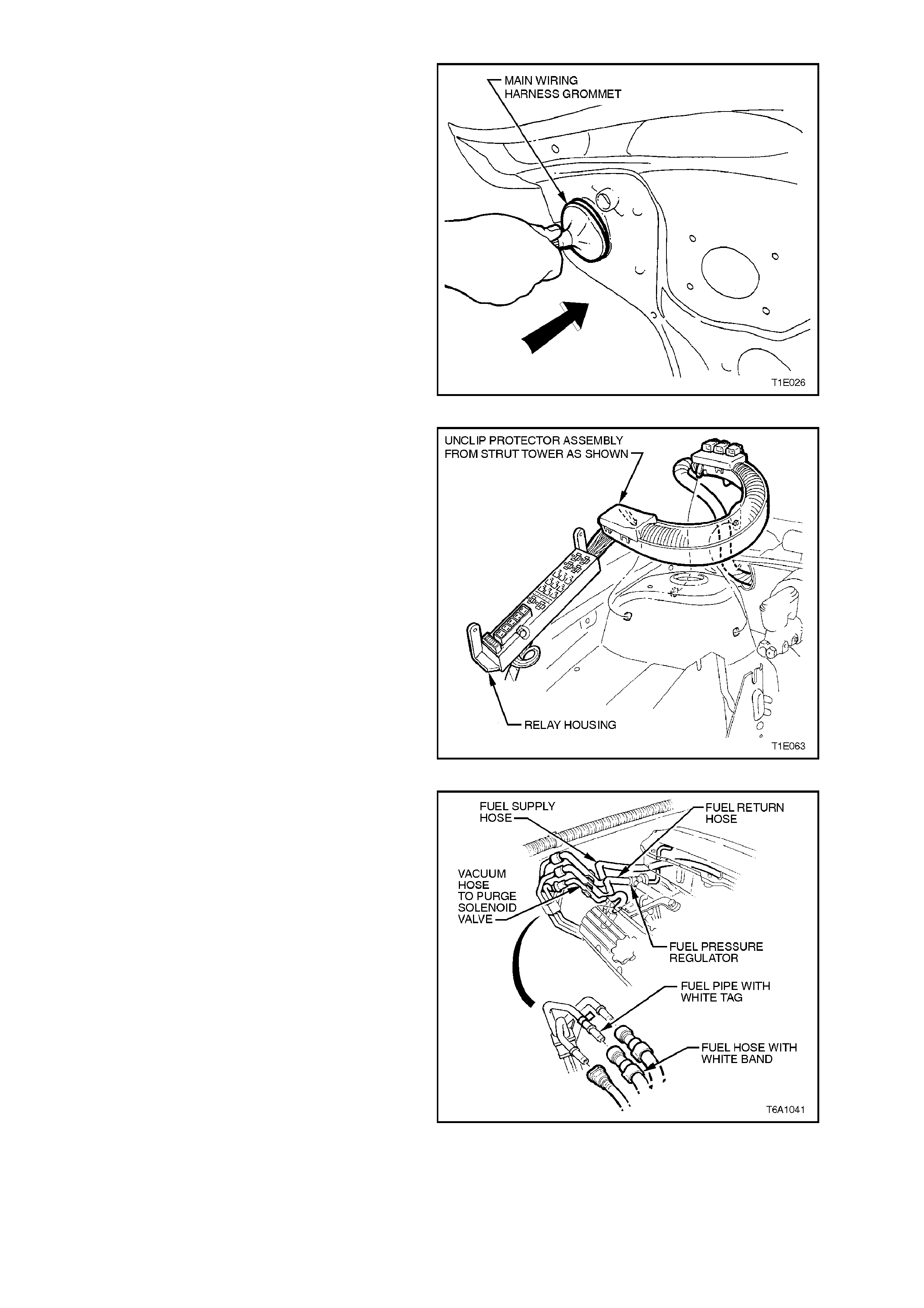

56. Release engine compartment harness tie

down clips, then push the main wiring harness

grommet into the cabin.

Figure 1E-44

57. Pass engine compartment relay block and

harness through cockpit module panel

opening.

CAUTION:

This operation is extremely difficult and should

be carried out with the utmost care, as damage

to wiring harness may occur.

Figure 1E-45

58. Disconnect the fuel feed and return hoses at

quick connects. Plug all openings to prevent

foreign matter entry.

NOTE:

Do not attempt to remove hoses from fuel rail

connections. Once removed from fuel rail

connection hoses require replacement.

Figure 1E-46

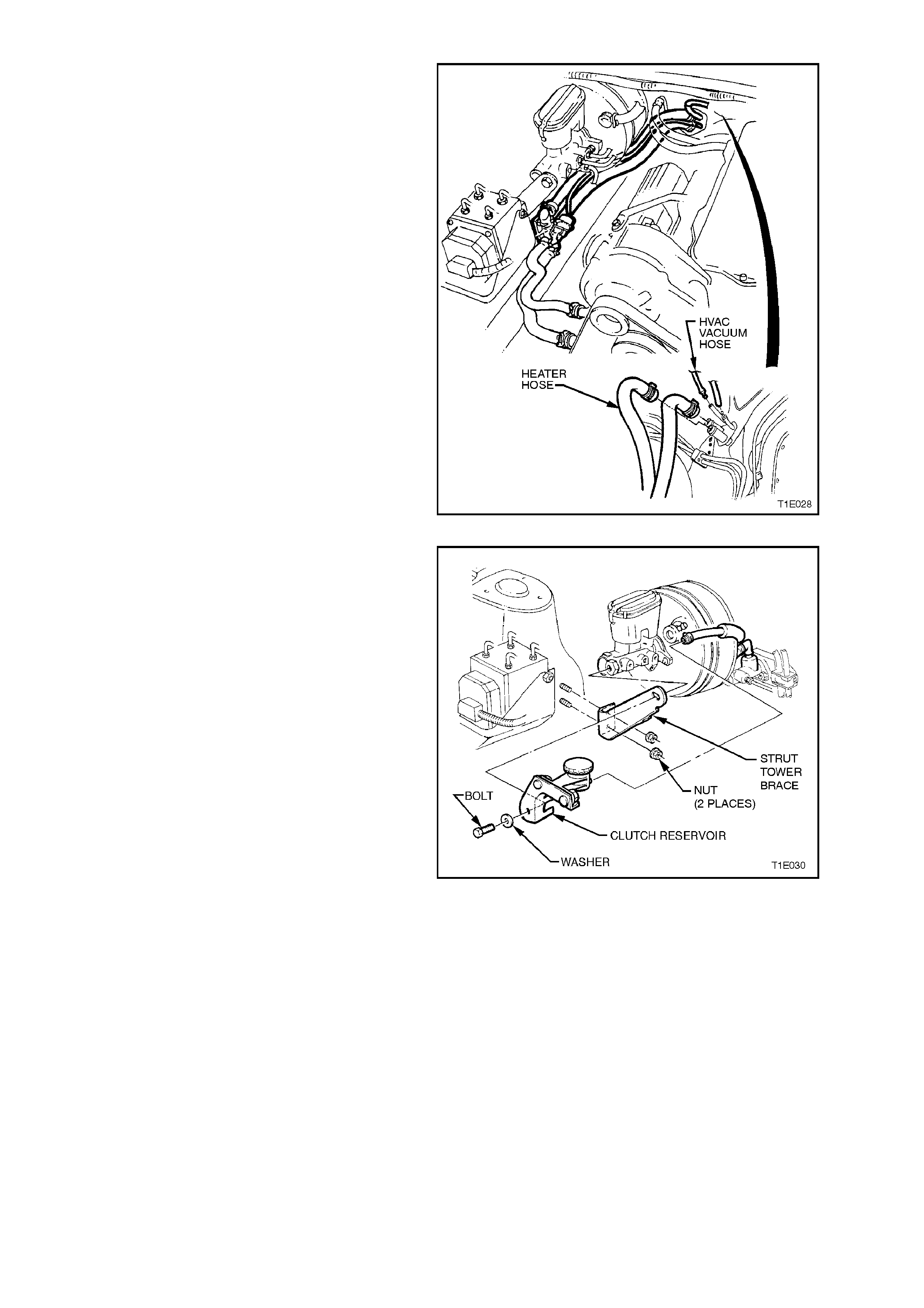

59. Tag and disconnect the heater hoses and

vacuum lines.

60. Remove the bolt retaining the fuel pipe clip to

the module panel.

Figure 1E-47

61. Where f itted, disconnec t fluid hose f rom clutch

ma ster c ylinder and using a suitable container,

collect fluid.

62. Remove retaining screw from the clutch fluid

reservoir located at the brake master cylinder.

63. Remove the master cylinder to strut tower

brace.

Figure 1E-48

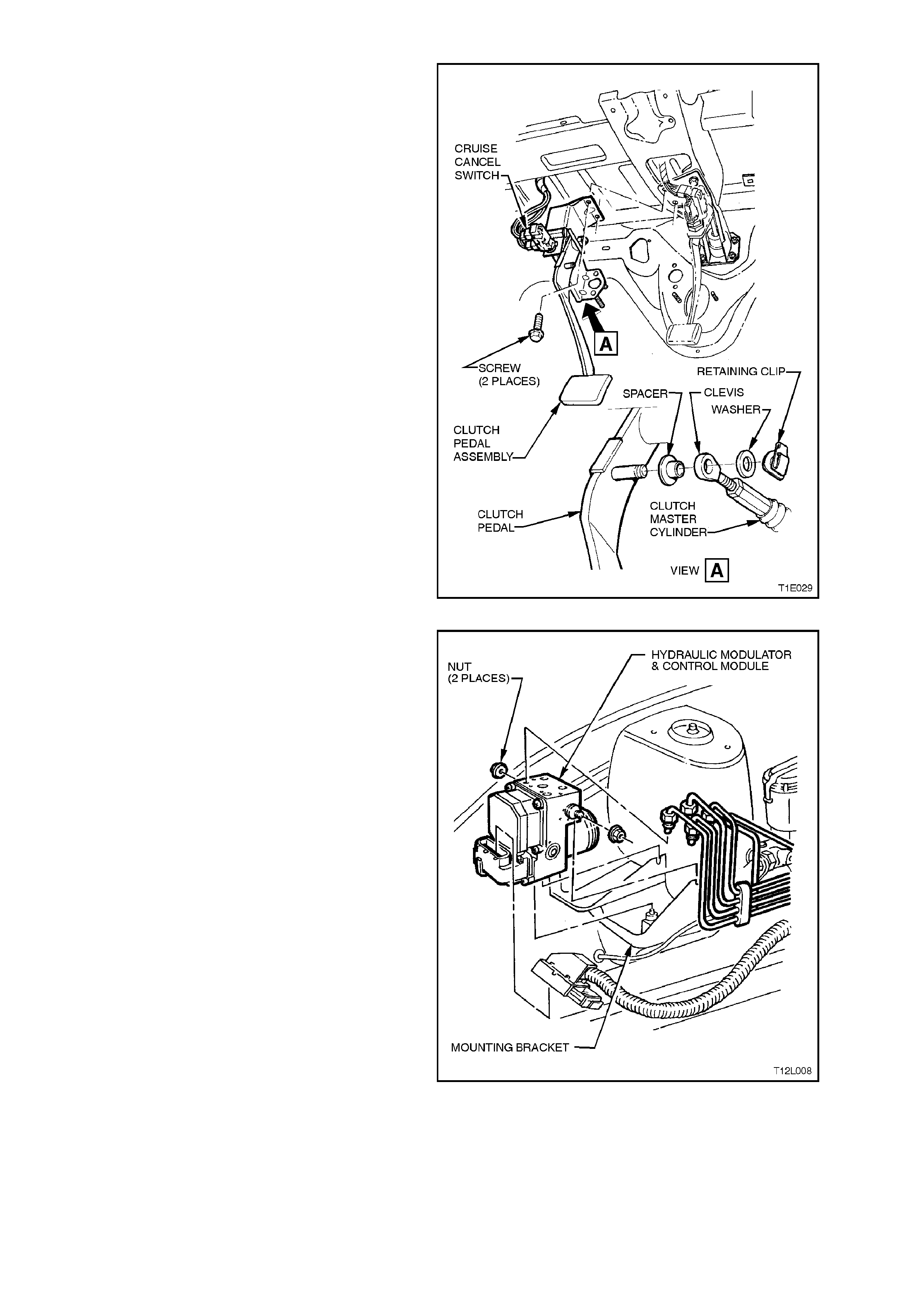

64. Rem ove two retaining nuts from clutch master

cylinder, and from inside vehicle, remove

clevis from clutch pedal assembly.

65. From inside vehicle, remove the two retaining

screws attaching clutch pedal assembly to

cockpit module panel and remove pedal

assembly from vehicle.

66. If fitted, remove the cruise control electrical

release harness connector from brake pedal

electrical release switch.

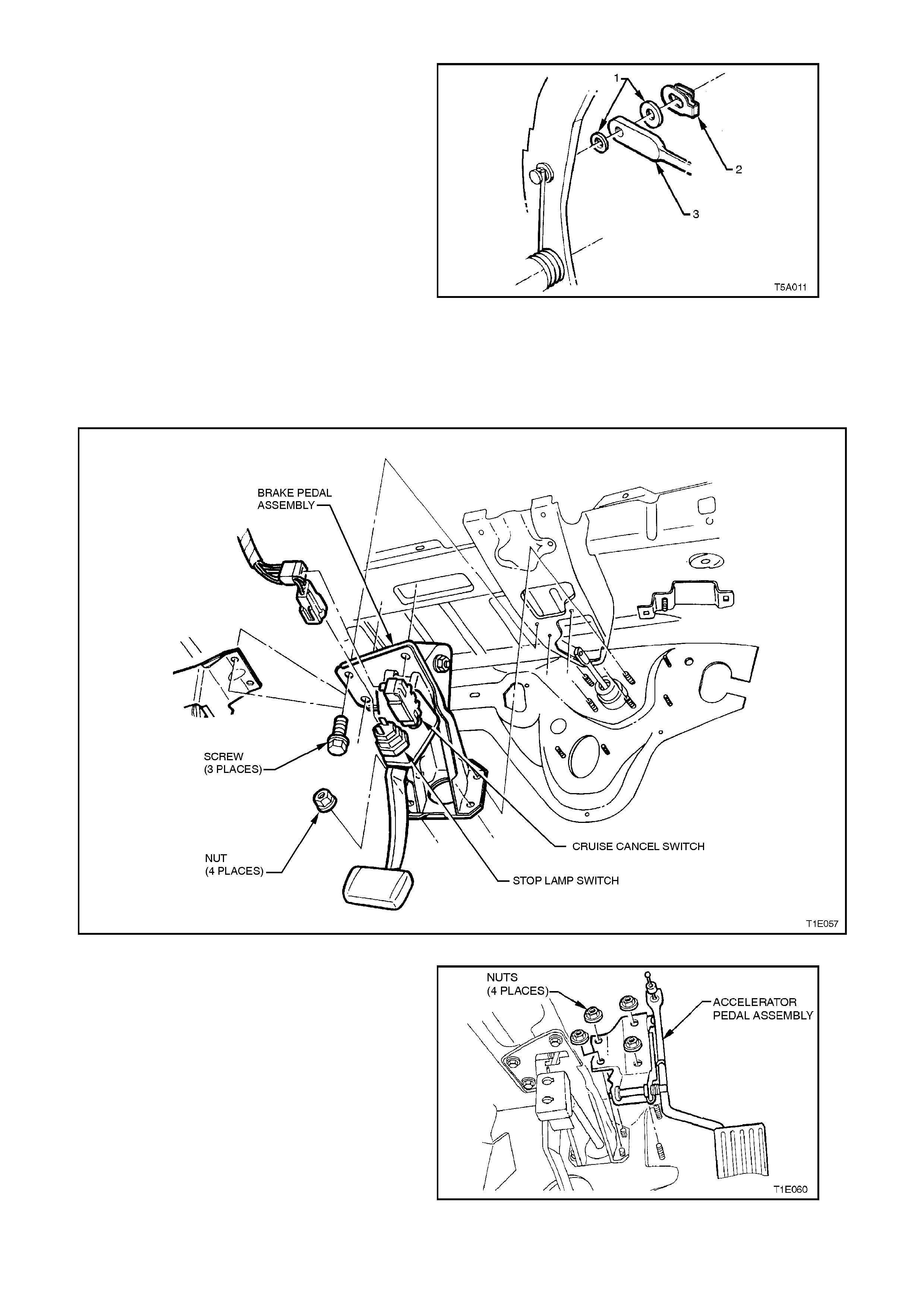

Figure 1E-49

67. Tag and disconnect the brake lines, vacuum

hose and electrical harness from the brake

booster, ABS modulator (where fitted) and

master cylinder assembly. Seal all apertures

with suitable plastic plugs.

68. On vehicles with automatic transmission

remove the nuts from the blanking plate

adjacent to the brake booster.

69. Tag and disconnect the vacuum control hose

at the throttle body (V6) or inlet manifold (V8).

Figure 1E-50

70. Rem ove the retaining clip (2), washers ( 1) and

brake booster pushrod (3) from the brake

pedal.

Figure 1E-51

71. Remove stop lamp switch harness connector

and if fitted, cruise control cancel switch

harness connector.

72. Remove the three screws securing the brake

pedal assembly to the module.

Figure 1E-52

73. Remove the four nuts secur ing the accelerator

pedal bracket, then remove the assembly,

refer to Fig. 1E-53.

74. Remove the remaining two nuts from brake

pedal assembly and remove assembly from

vehicle.

Figure 1E-53

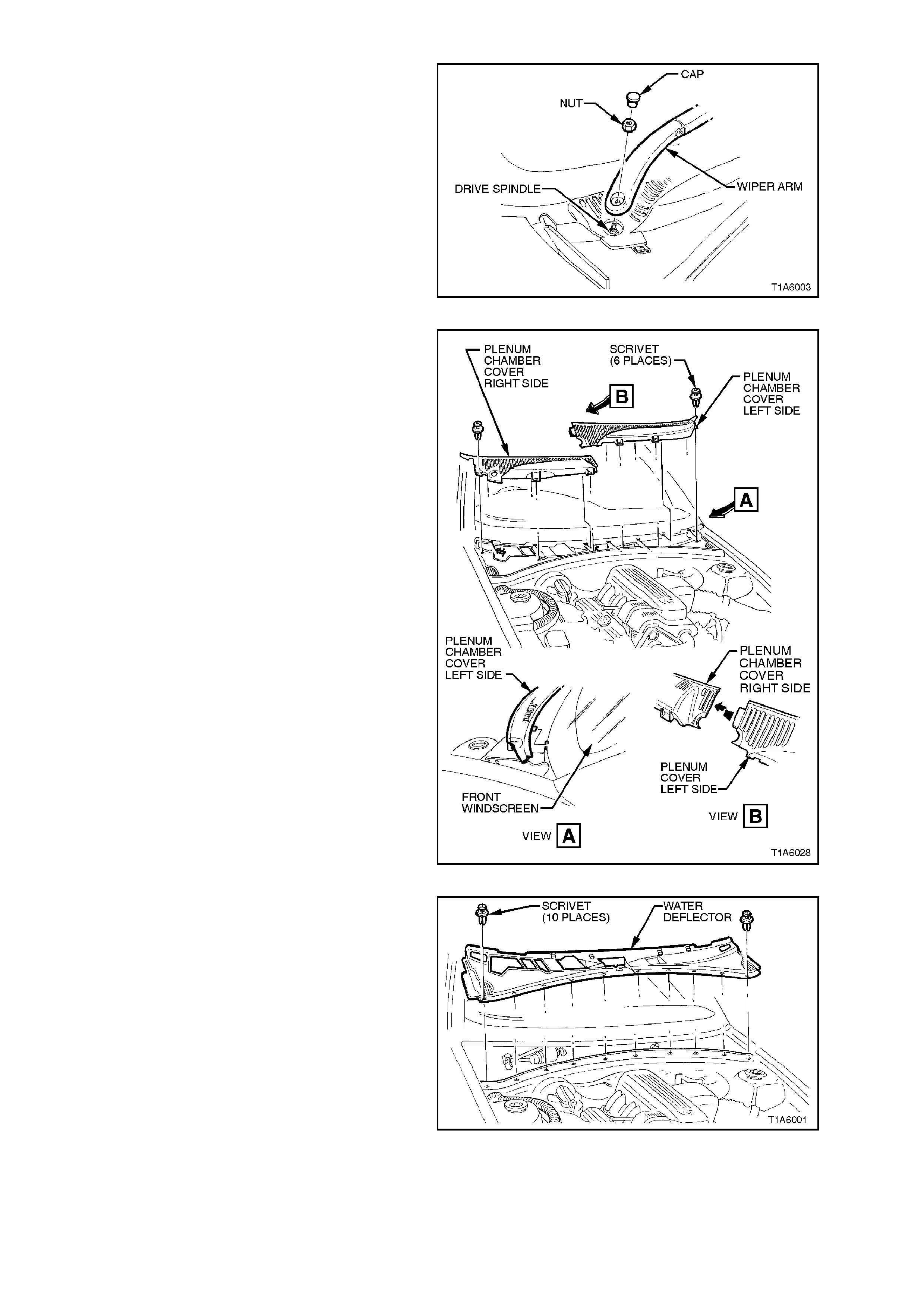

75. Remove the windscreen wiper arm and blade

assemblies. For further information refer to

Section 12C INSTRUMENTS, WIPERS,

WASHERS & HORN .

Figure 1E-54

76. Unscrew scrivets at six locations and remove

plenum chamber cover left and right side.

Figure 1E-55

77. Unscrew scrivets at ten locations and remove

plenum chamber water deflector.

Figure 1E-56

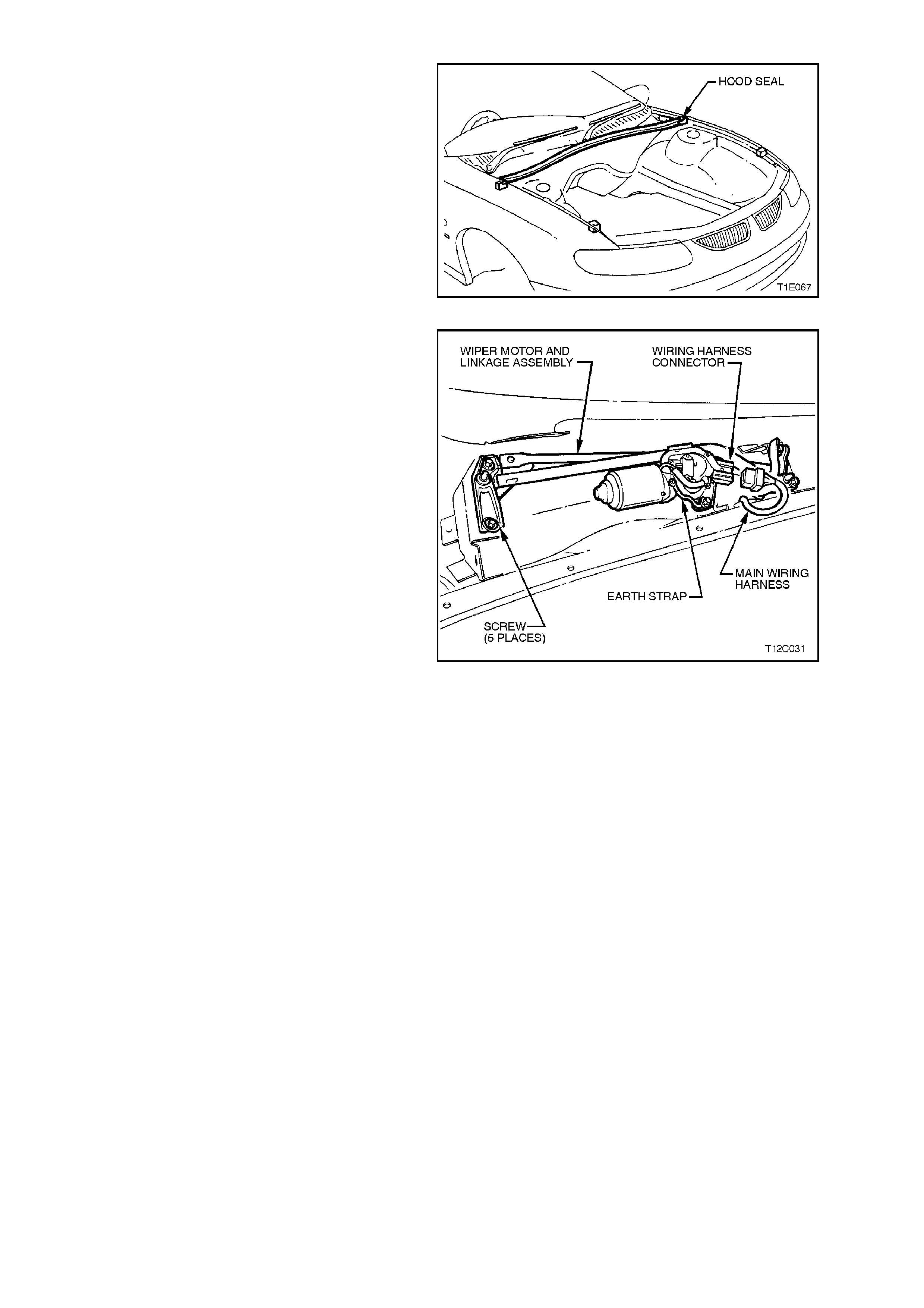

78. Remove Hood Seal.

Figure 1E-57

79. Disconnect wiper motor wiring harness and

push back through hole, then remove the five

mounting bolts and earth strap from the

windshield wiper assembly, and remove

assembly from vehicle.

Figure 1E-58

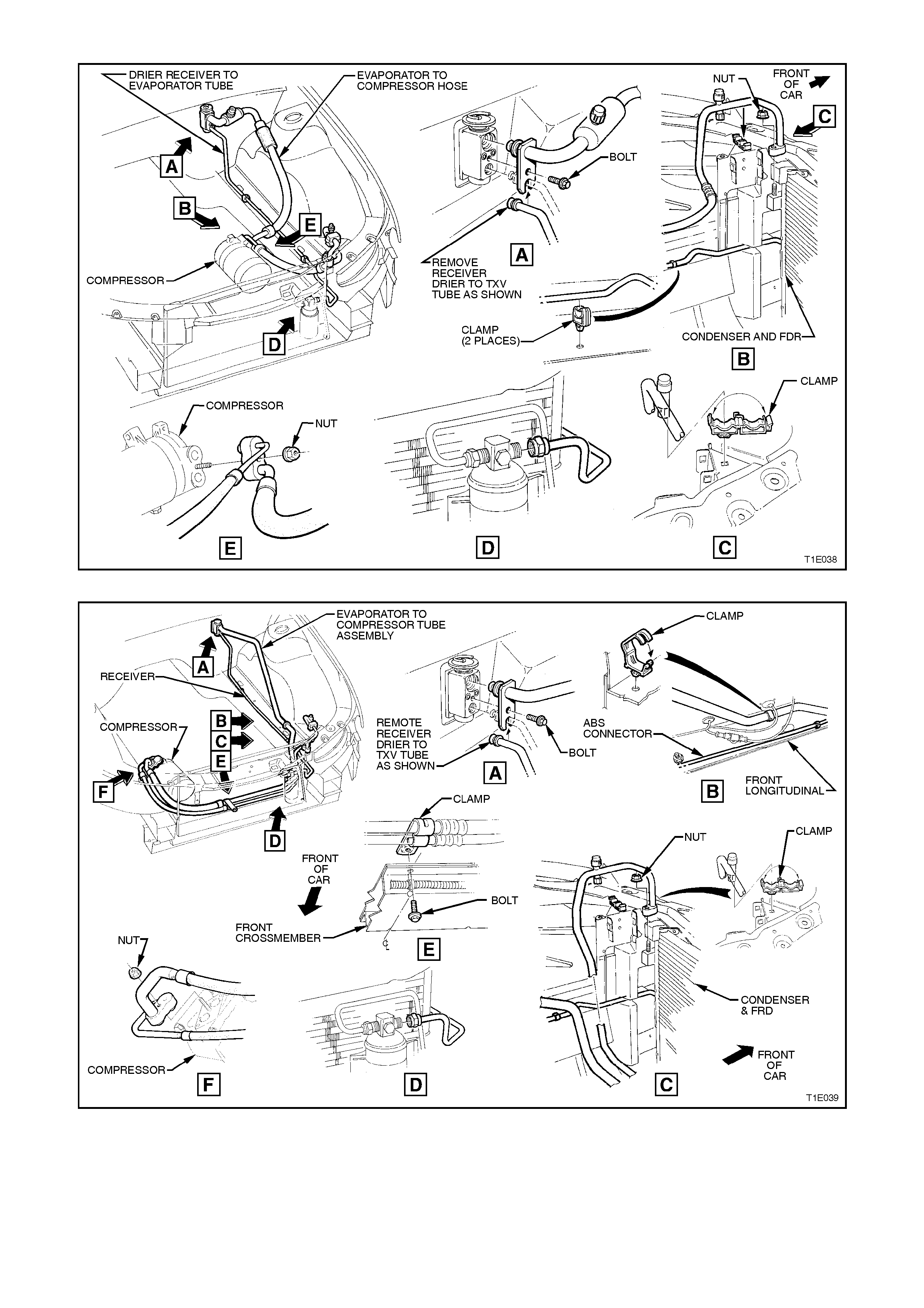

80. Where fitted, disconnect the air conditioning

lines at the evaporator bloc k valve, then cap or

plug connections.

81. Disconnect the evapor ator to c ondens er line at

the condenser, plug the f ittings then unclip the

line and remove.

82. Remove the compressor to evaporator line

and hose, then plug the fittings, refer to Fig.

1E-59 (V6 Engines) and Fig. 1E-60 (V8

Engines).

Figure 1E-59

Figure 1E-60

83. Remove the brake booster and master

cylinder assembly. If fitted, remove ABS

hydraulic modulator and control module, refer

to Section 12L ANTI-LOCK BRAKING

SYSTEM/TRACTION CONTROL .

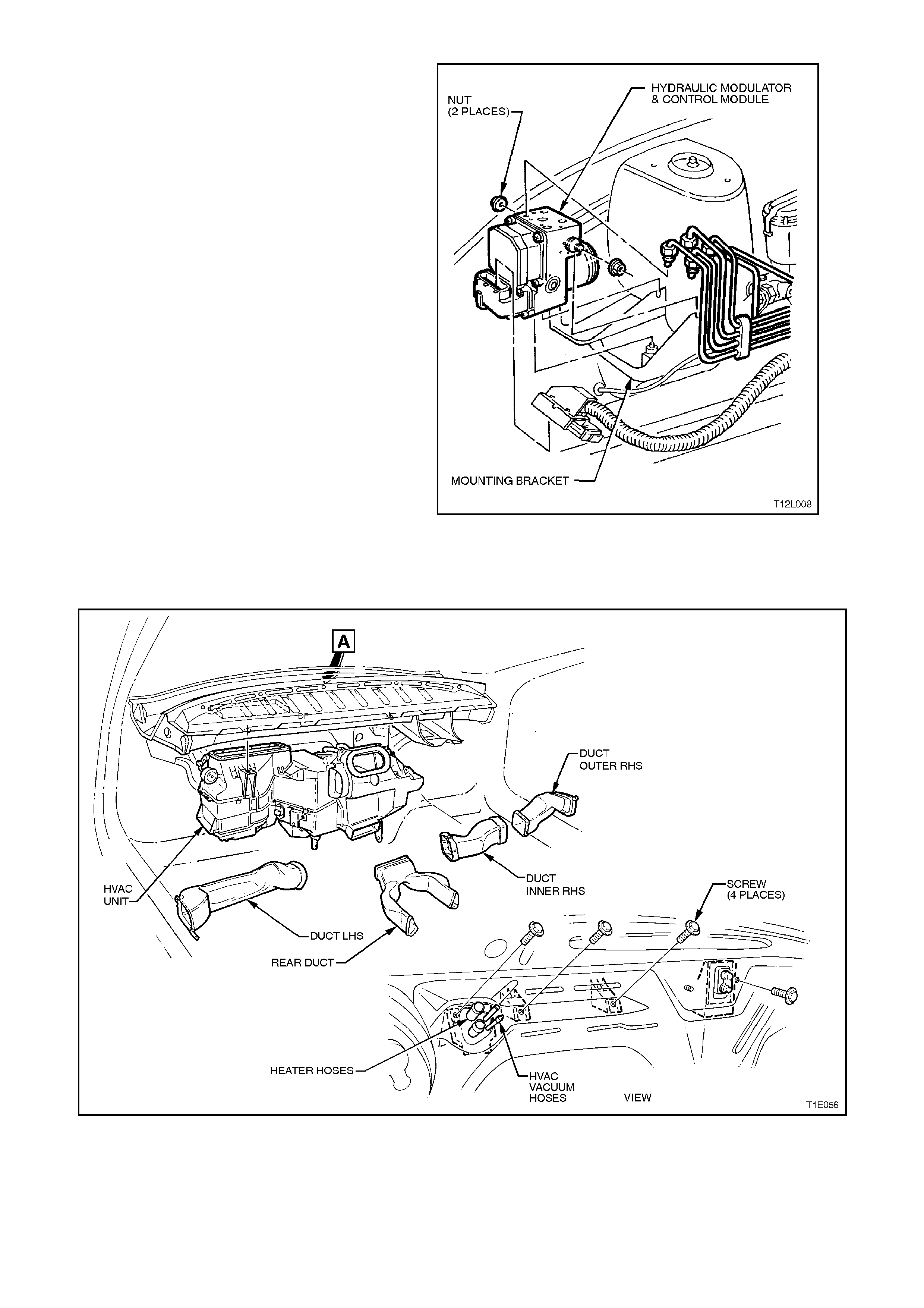

Figure 1E-61

84. Disconnect the front and rear door harnesses.

85. Remove the screws securing the heater case

assembly to the module panel.

Figure 1E-62

86. Remove the case from the vehicle by

disengaging the drain grommet and easing the

assembly from the vehicle taking care not to

strain the heater core tubes.

Figure 1E-63

87. Remove the grommets and insulation panels.

88. Remove the front windshield, refer to

Section 1A6 STATIONARY GLASS.

89. The cockpit module should be disassembled

prior to removing the panel, the procedure is

described in 2.1 COCKPIT MODULE in this

Section.

90. Remove the front doors, refer to

Section 1A5 FRONT AND REAR DOOR

ASSEMBLIES.

91. Remove engine, refer to

Section 6A1-1 ENGINE MECHANICAL - V6

ENGINE or 6A1-2 ENGINE MECHANICAL -

V6 SUPERCHARGED or 6A2 ENGINE

MECHANICAL - V8 ENGINE.

92. Remove module retaining bolts: Two from the

A-pillar area (1 bolt each side).

Figure 1E-64

93. Remove module retaining bolts: Two from the

plenum area (1 bolt each side).

Figure 1E-65

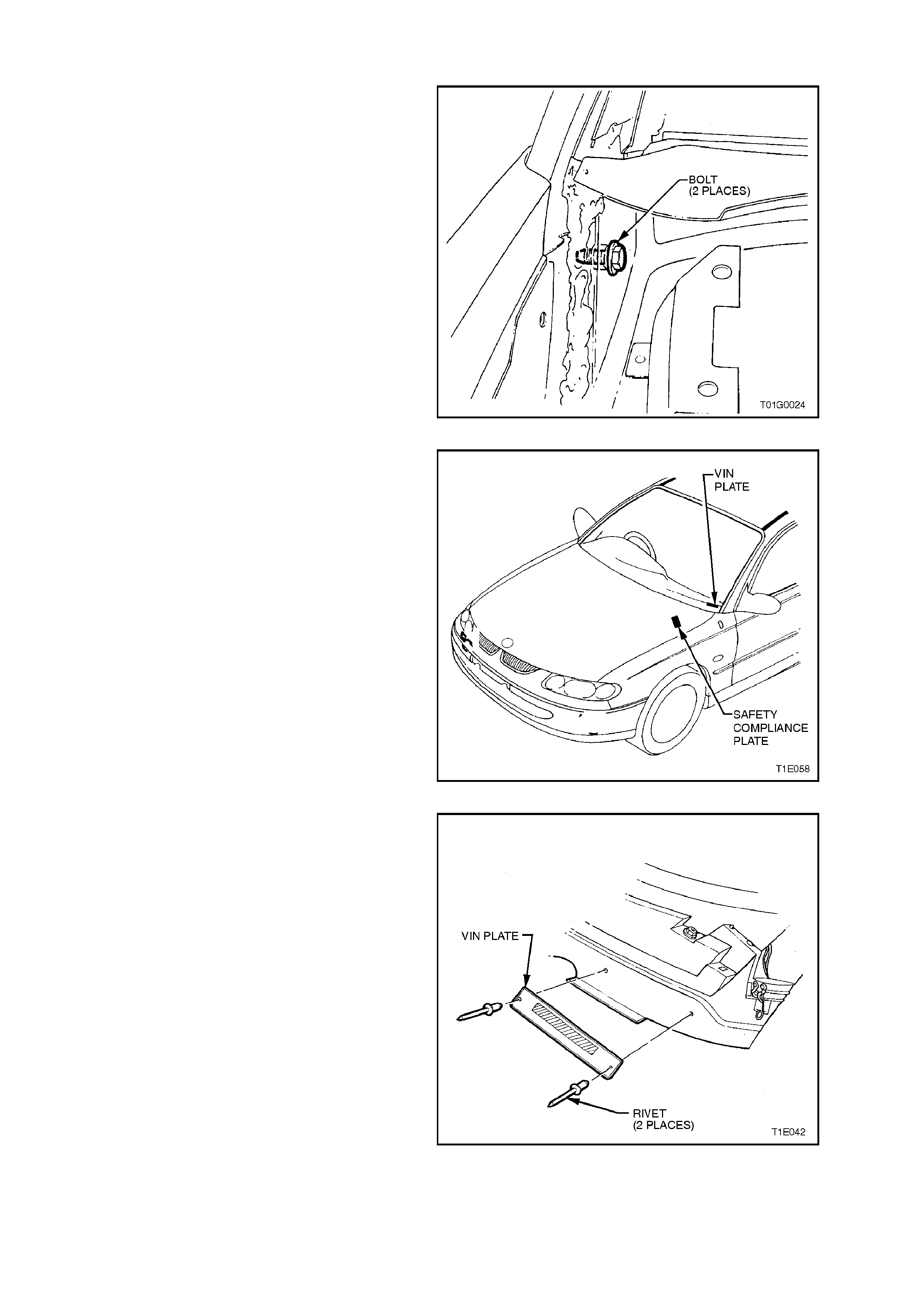

94. Locate VIN plate and compliance plate on

passenger side of cockpit module panel, and

using a drill and suitable drill bit, drill out

retaining rivets.

Figure 1E-66

95. Transfer VIN plate onto new cockpit panel.

Using commercially available hand rivet tool

and new rosette headed rivets (two off each

plate) secure to new cockpit module panel.

Figure 1E-67

96. Transfer compliance plate onto new cockpit

panel. Using com merc ially available hand rivet

tool and new rosette headed rivets (two off

each plate) secure to new cockpit module

panel.

Figure 1E-68

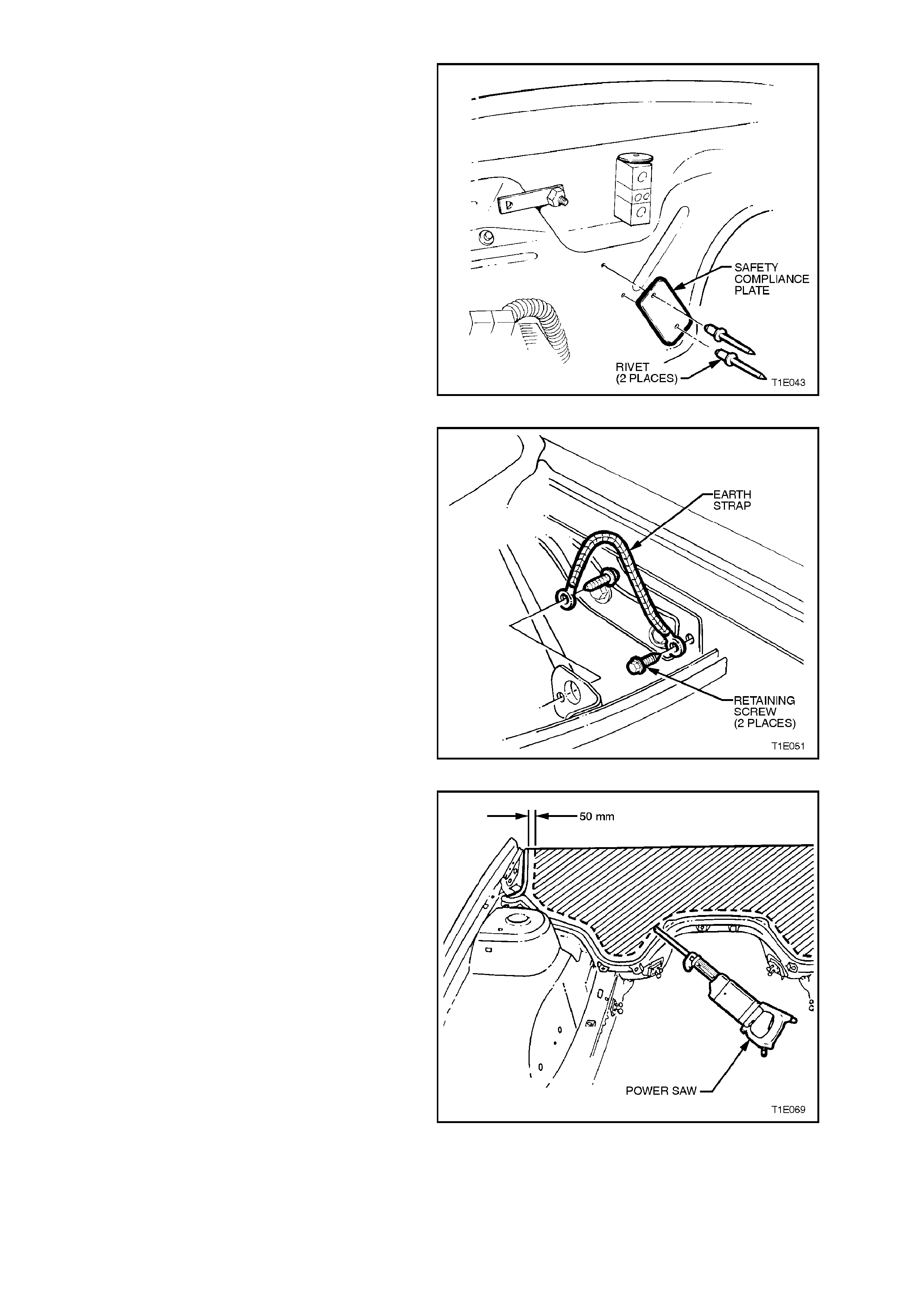

97. Remove the two screws retaining cockpit

module to body earth strap and remove from

vehicle.

Figure 1E-69

98. Using a power saw, cut the module panel

approximately 50 mm above the glue track.

CAUTION:

Sparks may ignite petrol in the fuel or emission

control lines if due precautions are not taken.

Figure 1E-70

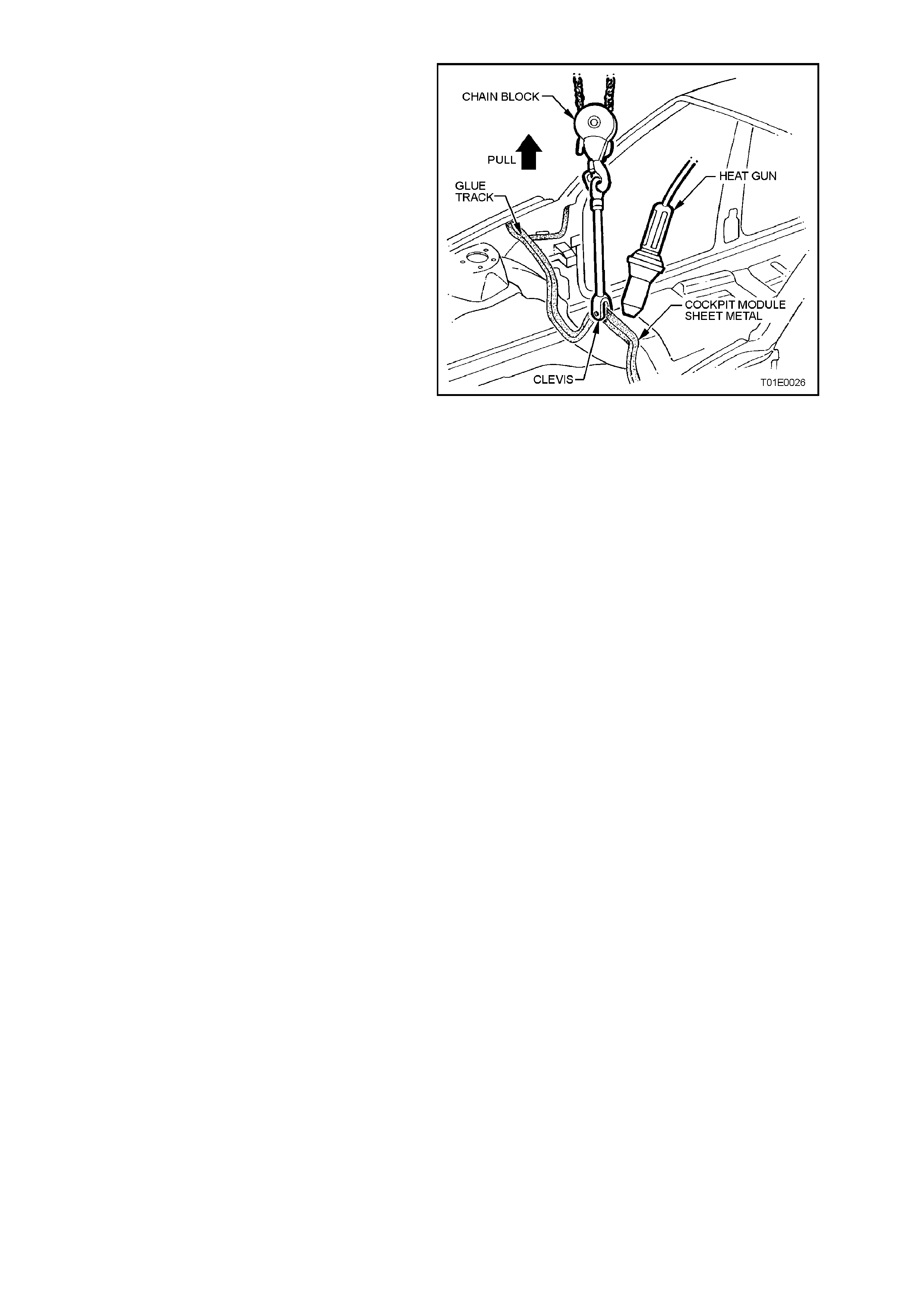

99. Drill a hole in the flange above the

transmission tunnel, and attach a chain block

and a clevis.

100.Apply and maintain a light tension to the

module. Heat the adhesive using a heat gun

and pull the panel from the glue track.

Alternatively cut the adhesive with a hot knife.

101.Clean the excess adhesive f rom the glue tr ack

using a hot knife or a heat gun and tool.

CAUTION:

To avoid fire, Do NOT attempt to burn the

remaining adhesive from the glue track using an

“oxy” torch.

Figure 1E-71

MIXING SILICONE ADHESIVE

Surface Preparation

Clean any remaining adhesive from the glue track

using a hot knife or heat gun and tool if necessary.

The vehicle should be painted before installation of

the cock pit module. Bef ore painting the vehicle apply

masking tape to prevent paint entering the glue track.

The adhesive will not properly adhere to paint,

overspray, oils, grease etc. The glue track must be

free of dirt, dust, grease, oils and paint or over spray.

Wipe the glue track with a suitable cleaning agent

such as “Prepsol”, then clean any residue from the

area with a clean, dry, lint free cloth.

Avoid fitment problems by temporarily installing the

cockpit module panel, prior to mixing the adhesive,

rectify any faults found, then remove the panel from

the vehicle.

Before mixing the adhesive it is necessary to have

the application gun available. All par ts m ust be clean

of any previous adhesive.

Refer to the VT Series Parts Inf orm ation, Section 12-

430 for details of where to obtain an applicator gun.

Mixing Adhesive and Catalyst

IMPORTANT:

This is a two-part mix, fast cure adhesive, ensure

that the panel is ready for installation before mixing

the adhesive. The working time is less than 20

minutes.

Part A:

The Adhesive compound, yellow in colour and

supplied in a 1.4 kilogram container.

Part B:

The Catalyst, used to accelerate the “Cure” time of

the of the adhesive compound and is supplied in a

120 gram tube.

The contents of the Adhesive Kit, Part Number

M39998 is sufficient to install the module panel in a

vehicle.

CAUTION:

The vapour from the adhesive may cause

breathing difficulties, use only in a well ventilated

area. In case of eye contact, flush immediately

with clean water.

Combustible – keep away from spark and flame.

Refer to Safety Precautions in

1.2 GENERAL PRECAUTIONS in this Section.

1. Remove the lid from the Adhesive Compound

container.

2. Remove the cap from the Catalyst and pierce

the end of the tube, then squeeze the entire

contents of the tube into the Adhesive

Compound container.

3. Hold the container sec urely, and mix the catalyst

into the adhesive using a paint mixer or a flat

clean wooden utensil.

4. Continue to mix until the adhesive is a

consistent grey colour without any streaks.

5. Place the follower plate supplied with the

applicator gun into the adhesive container.

6. Remove the front end cap and disposable

nozzle from the applicator gun.

7. Cut the tip from the nozzle.

8. Place the applicator gun front end over the hole

in the follower plate.

NOTE:

The easiest method of drawing the adhesive into the

gun is to proceed slowly, allow the downward

pressure on the plate and the suction of the gun to

draw the compound.

9. Simultaneous ly push down on the gun and plate

with maximum pressure, press the gun’s release

plate inward and slowly pull the T-bar (piston)

outwards. This procedure will slowly suck the

mixed adhesive into the applicator gun.

10. Wipe any excess adhesive from the applicator

gun, screw the end cap onto the applicator gun,

then reinstall the nozzle.

11. Proceed immediately with installing the panel.

IMPORTANT:

After mixing the silicone adhesive, installation of the

cockpit module panel should be completed within 15

- 20 minutes. Under normal conditions, the adhesive

will begin to cure in about 25 - 30 minutes. After

installation, the module panel should not be moved or

disturbed until the adhesive is fully cured (about 3

hours).

Check List

Before m ixing the adhesive and installing the cockpit

module the following items should be checked:

• Familiarise yourself with the precautions in

1.2 GENERAL PRECAUTIONS in this Section.

• Ensure the adhesive being used is the material

recommended by GMHAL.

• The vehicle surface should be finished and the

paint fully dry.

• Clean any overspray, grease, oil, dirt, etc. from

the glue track using Prepsol and A CLEAN,

DRY, LINT FREE CLOTH.

• Test fit the module panel in the glue track

BEFORE MIXING THE ADHESIVE.

• Is the adhesive applicator gun clean and ready

for use?

• Install the main wiring harness plate in position

on the module panel.

• Are the cockpit module bolts readily accessible?

MODULE PANEL INSTALLATION

1. Clean any remaining adhesive from the glue

track using a hot knife or heat gun and tool if

necessary.

2. Temporarily install the cockpit module without

adhesive to check fit. Panel should sit in the

centre of the glue track. Rectify any faults

found, then remove from vehicle.

3. Install the harness side plate onto the right

hand side of the module panel.

4. Check each item in the Check List in

MIXING SILICONE ADHESIVE in this Section.

5. Mix the silicone adhesive and f ill the applicator

gun as described in ‘Mixing Silicone Adhesive’

in this Section.

6. Begin filling the glue track from the lowest

points to prevent air bubbles forming in the

adhesive. Completely fill the channel in a

continuous bead.

7. Apply a patch of adhesive approximately

50 mm diameter to the base or the windshield

pillar.

Figure 1E-72

IMPORTANT:

The glue track or any adhesive remaining within,

must be thoroughly clean and free of grease, dirt,

dust, paint overspray or other foreign material.

NOTE:

Do not attempt to install a fully built-up cockpit

module assembly.

8 Have an assistant help install the cockpit

module panel.

9. Push the panel firmly into the glue track

channel until mounting bolt holes align. Check

to ensure that the section above the main

wiring harness hole is correctly installed.

10. Replace 2 bolts into plenum area (torque

setting 15,0 - 35,0 Nm). Replace 2 bolts into

A-pillar area (torque setting 35,0 - 65,0 Nm)

11. Wipe any excess adhesive from the plenum

drain holes and shroud panel areas (LHS

plenum drain shown).

12. After installing the cockpit module panel,

immediately wipe the excess adhesive from

the applicator gun and follower plate.

Figure 1E-73

REINSTALL

Reverse removal operations noting the following.

IMPORTANT:

If vehicle is equipped with SRS (Air Bag),

enable the system. Refer to ENABLING THE

SRS, Section 12M SRS.

NOTE:

Use new O - rings when installing air conditioning

components.

1. Install the rubber grommets and insulation

materials onto the module panel.

2. Ensure that air conditioner drain tube is

correctly installed.

3. Ensure that all wiring is correctly clipped in

location.

4. Charge air conditioning system and leak test,

refer to Section 2C AIR CONDITIONING -

SERVICING AND DIAGNOSIS.

3. TORQUE WRENCH SPECIFI CATIONS

Nm

Lower steering column shroud screw 0.5 - 2.0

Diagnostics connector attaching screws 1.0 - 2.0

Instrument panel end cap cover attaching screws 1.0 - 3.0

Instrument panel compartment attaching screws 1.0 - 3.0

Instrument panel compartment lock striker attaching

screws 1.0 - 3.0

Centre console securing screws 1.0 - 3.0

Centre console bin retaining nuts 1.0 - 3.0

Transmission console retaining screws 1.0 - 3.0

Storage compartment securing screws 1.0 - 3.0

Demist nozzle retaining screws 1.0 - 3.0

Front dash speaker connecting screws 1.0 - 2.0

Instrument panel carrier end panel attachment

screws 1.0 - 3.0

Instrument panel carrier end panel attaching bolts 3.0 - 5.0

Instrument facia assembly retaining screws 1.0 - 3.0

Cent re facia assembly securing screws 1.0 - 3.0

Airbag securing screws 8.0 - 11.3

Steering wheel securing screw 40.0 - 50.0

Heater and air conditioning controls securing screws 1.0 - 3.0

Combined instruments assembly securing screws 1.0 - 3.0

Instrument panel carrier retaining screws 7.0 - 12.0

Instrument panel lower trim right side rail assembly

retaining screws 1.0 - 3.0

Steering column bracket outer support securing

screws 3.0- 5.0

Centre facia side extension support rail attaching

screws 1.0 - 3.0

Support steering column bracket inner securing

screws 3.0 - 5.0

Steering column clevis cam bolt 23.0 - 30.0

Steering column upper mounting screws 15.0 - 30.0

Nuts at base of steering column 15.0 - 30.0

Passenger air bag support rail securing screws 2.5 - 5.0

Lower left side rail connecting screws 1.0 - 3.0

Instrument panel carrier rail assembly securing

screws 1.0 - 3.0

Passenger side air bag securing nuts 15 - 25.0

Main wiring harness cabin protector securing nut

Engine hood bracket retaining screws 6.0 - 14.0

Fuel pipe clip retaining bolt 10.0 - 25.0

Clutch fluid reservoir attachment screw

Strut tower brace attachment nuts 15.0 - 20.0

Clutch master cylinder retaining nuts

Clutch pedal assembly retaining screws 20.0 - 30.0

Blanking plate securing nuts 20.0 - 30.0

Brake pedal assembly securing screws

Brake pedal assembly securing nuts 20.0 - 30.0

Accelerator pedal bracket securing nuts 20.0 - 30.0

Windshield wiper assembly mounting bolts 20.0 - 30.0

Receiver drier to TXV connecting bolt - V6 4.0 - 6.0

Hose to condenser and FRD connecting nut V6/V8 7.5 - 12.5

Hose to compressor connecting nut V6/V8 7.5 - 12.5

Front crossmember securing bolt - V8 7.5 - 12.5

ABS hydraulic modulator and control module

securing nuts 7.5 - 12.5

Heater case assembly securing screws 5.0 - 12.0

A-pillar area module retaining bolts 6.0 - 14.0

Module retaining bolts from the plenum area 35.0 - 65.0

Retaining earth strap screw to cockpit module 15.0 - 35.0

2.0 - 4.0

4. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

179 1308 0000 RADIO REMOVAL TOOL