SECTION 6B1-2 - ENGINE COOLING - V6

SUPERCHARGED ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

1. GENERAL INFORMATION

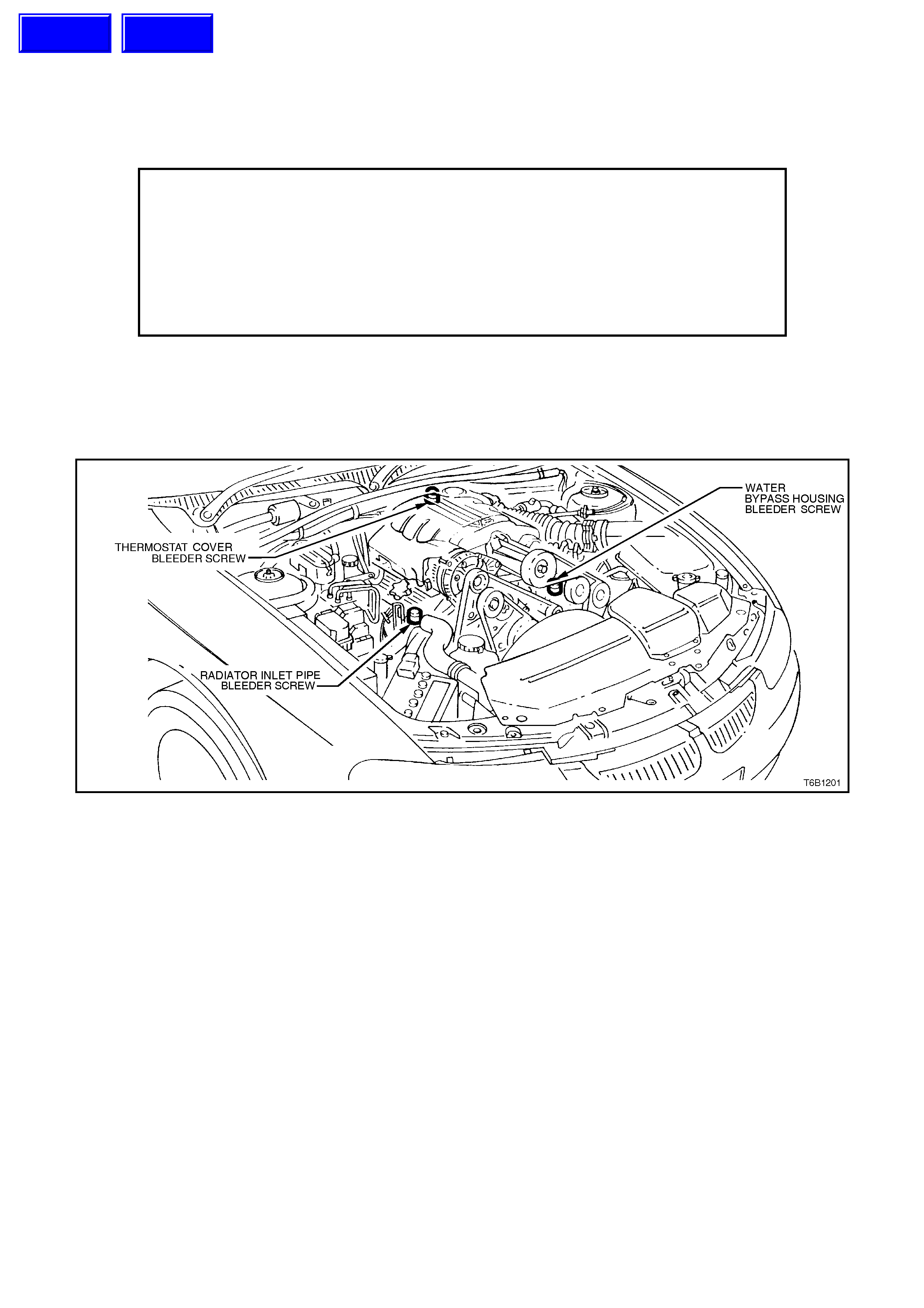

The cooling system for VT V6 Supercharged engine differs from normally aspirated V6 engines with revised

plumbing and additional bleeder points.

Figure 6B1-2-1

Techline

Techline

2. SERVICE OPERATIONS

Cooling system service operations carry over in general from those described in Section 6B1-1 ENGINE

COOLING - V6 ENGINE, except for the following operations.

2.1 SERVICE NOTES

WARNING:

To avoid serious personal injury, never remove the r adiator cap or open the air vent bleeder on the coolant

outlet when the engine is hot, even if the cooling system should require filling. Sudden release of cooling

system pressure is very dangerous.

When removing radiator cap allow engine to cool, place a shop rag over the radiator cap and slowly turn the cap

anti-clockwise (without pressing down) until the cap reaches the first ‘stop’. This is the pressure relief stop, which

will allow any remaining pressure within the system to escape. Press down on cap and continue to rotate anti-

clockwise until cap can be removed.

The vehicle is fitted with a radiator electric cooling fan. When working around the engine compartment with the

engine running or with the ignition ‘ON’, keep clear of the fan as it may start operating without warning.

The cooling system requires little care except for maintaining the coolant to the correct level in the cooling recovery

tank. Periodic servicing of the cooling system is required at the time or distance intervals as outlined in the VT

Series Owner’s Handbook.

Techline

2.2 CHECKING AND FILLING COOLING SYSTEM

During any service operation that requires the

cooling system to be partly or completely drained,

the following instructions must be followed when

refilling the cooling system to ensure that all air is

bled from system.

The following procedure requires the use of Tool

No. AU 425 to fill the cooling system.

1. Set heater control to maximum.

2. Mix a coolant m ixtur e consis ting 50% ethylene

glycol antifreeze/inhibitor (Specification HN

2043) with 50% clear, clean water.

Ethylene glycol conforming to Holden Specification

HN 2043 is named New Formula Long Life All

Seasons Coolant, and is available in the following

quantities:

1 litre, P/N M40236

5 litre, P/N M40307

20 litre, P/N M40238

NOTE:

Do not mix different types of anti-freeze or

corros ion inhibitors as they m ay be incom patible. If

a different type has been used in the cooling

system, flush the system with clean water, refer to

Section 6B1 ENGINE COOLING - V6 ENGINE -

2.4 CLEANING COOLING SYSTEM.

3. If cooling s ystem was com pletely drained, add

a pack of pellets (thr ee pellets) P/N M40124 to

cooling system by disconnecting radiator

upper hose from engine coolant outlet and

placing pellets inside radiator hose.

Refit hose to coolant outlet and tighten hose clamp.

4. Remove radiator cap and install Tool No. AU

425 to radiator filler neck.

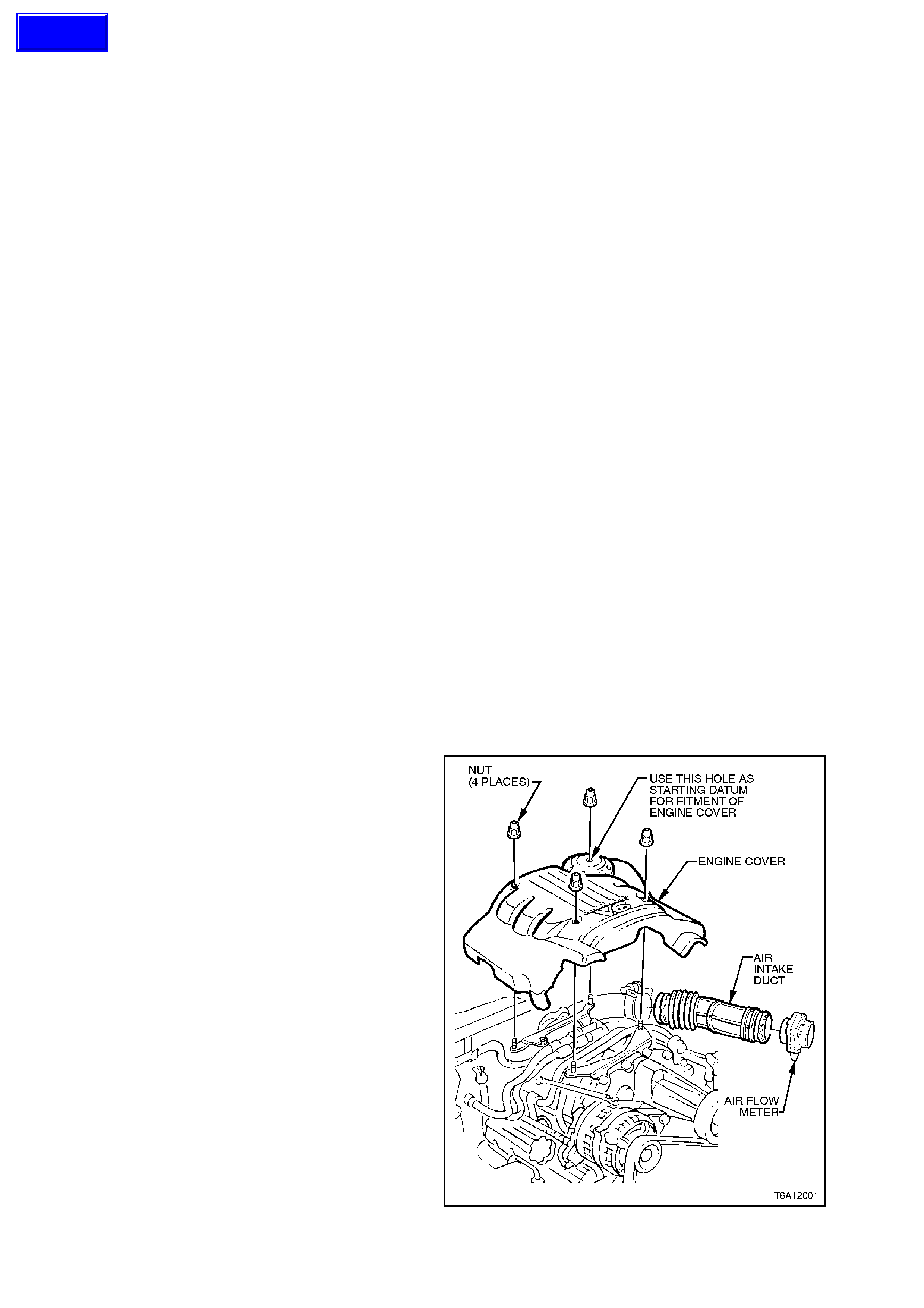

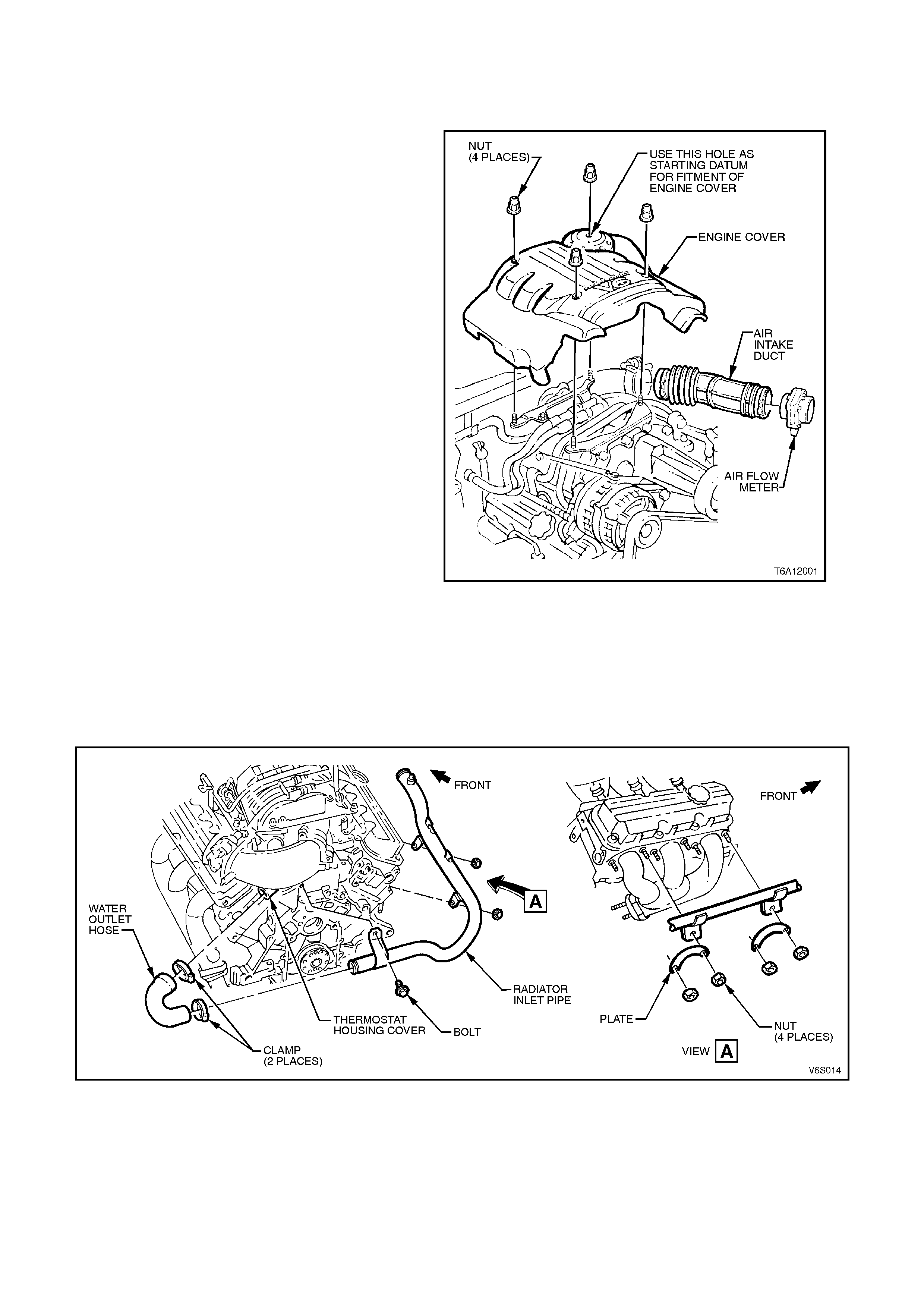

5. Remove the four engine dress cover dome

nuts and remove the cover.

Figure 6B1-2

Techline

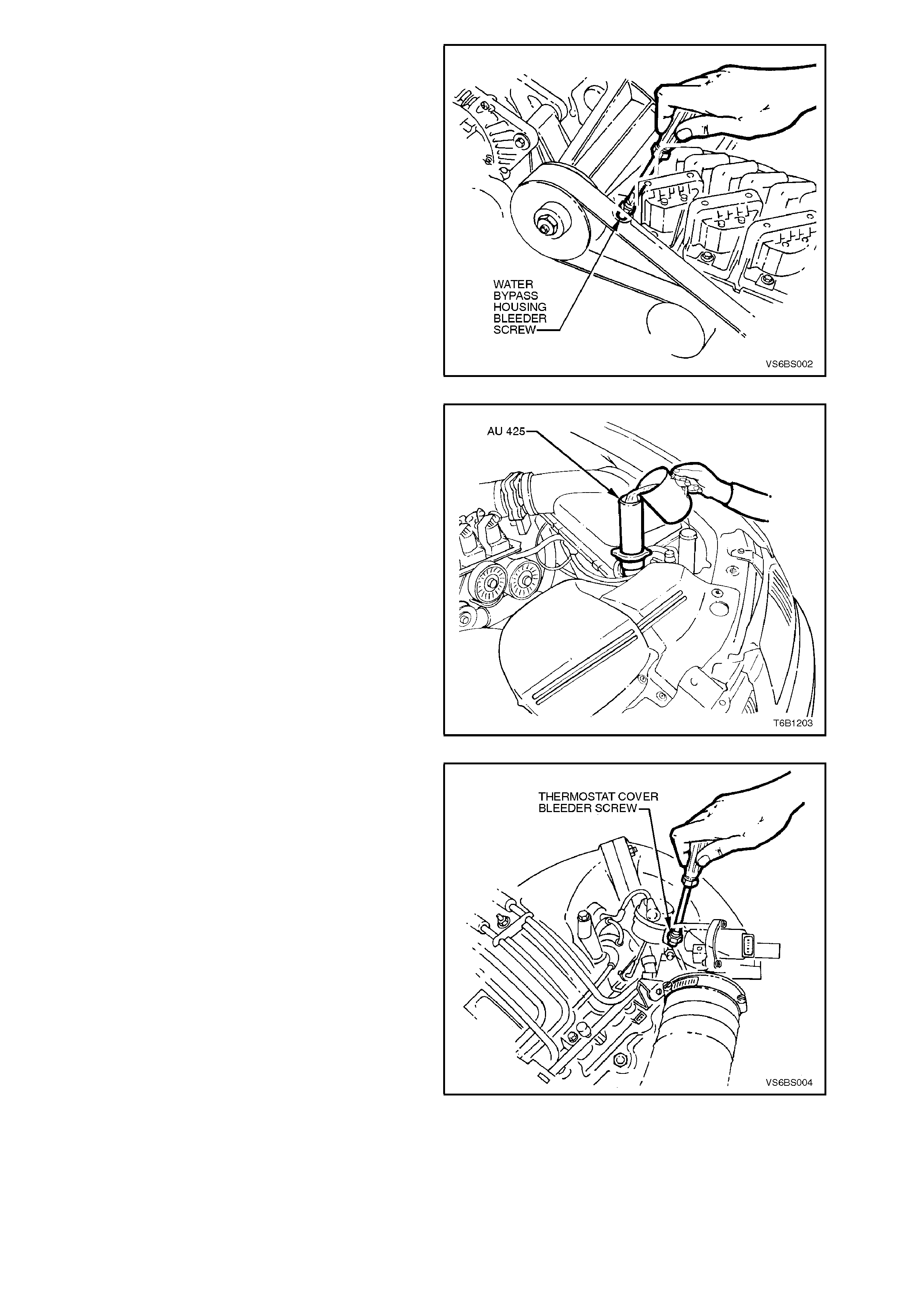

NOTE:

Commence bleeding the cooling system using the

air vent bleeder screw located in the water bypass

housing.

6. Using a screwdriver, open air vent bleeder

screw at water bypass housing.

Figure 6B1-2-3

7. Fill cooling system using coolant mixture via

Tool No. AU 425 until coolant flows from air

vent bleeder screw at water bypass housing

and all air is expelled. Close air vent bleeder

screw.

Figure 6B1-2-4

8. Continue bleeding cooling system from air

vent bleeder screw located in thermostat

housing cover until indications of air stop.

Close air vent bleeder screw.

Figure 6B1-2-5

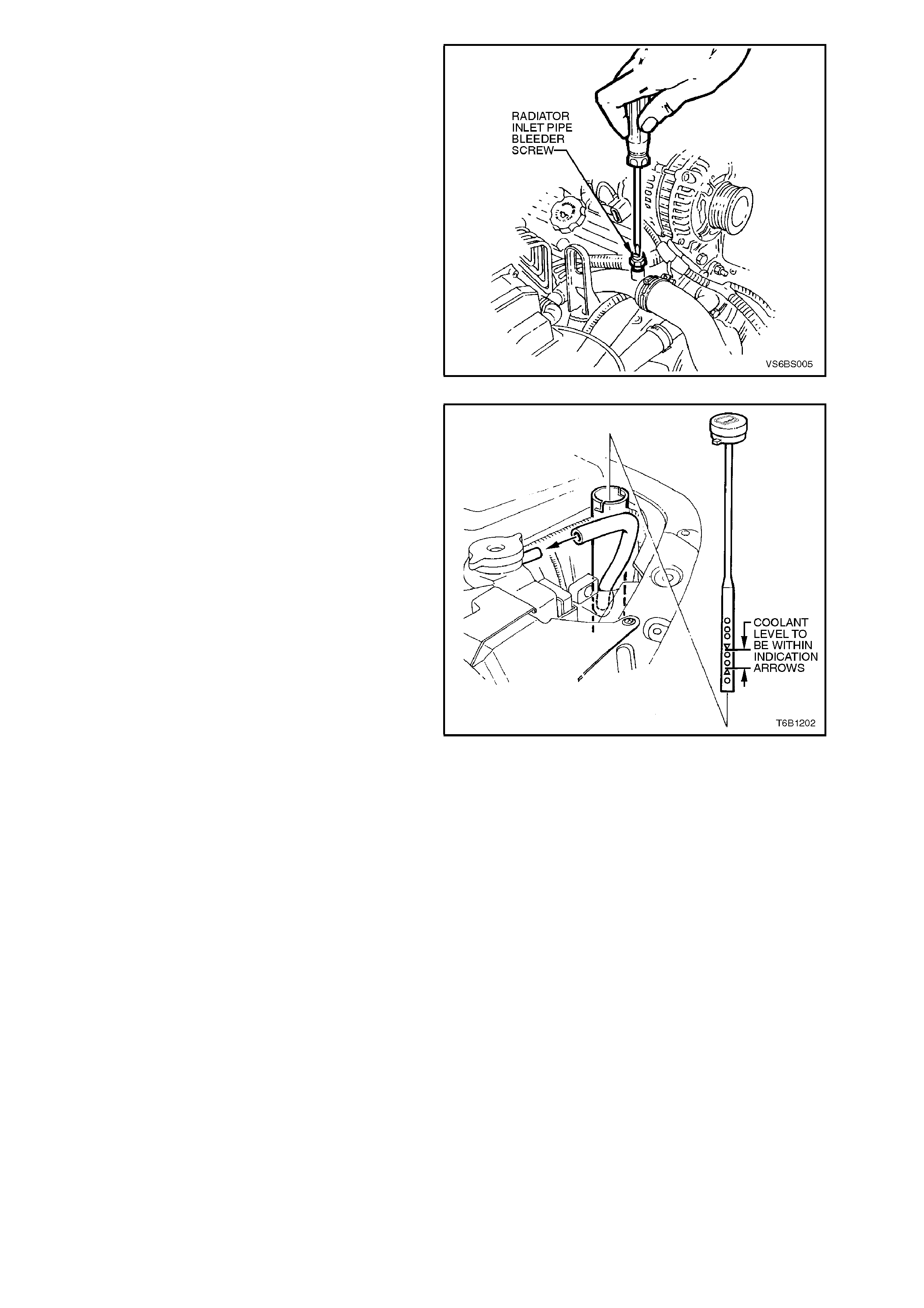

9. Commence bleeding system from radiator inlet

pipe air vent bleeder screw until indications of

air stop. Close air vent bleeder screw.

Repeat operations 6 to 9 until all air is exhausted

from cooling system.

Figure 6B1-2-6

10. Ensure air vent bleeder scr ews are closed and

remove AU 425 from radiator.

11. If necessary, remove coolant dipstick from

recovery tank and fill tank to between the

indicator arrows, re fit recovery tank dipstick.

12. Pressure test cooling system, refer to Section

6B1 ENGINE COOLING - V6 ENGINE -

2.7 PRESSURE TESTING.

13. Refit radiator cap.

14. Start engine and run at idle until operating

temperature is reached (thermostat is open).

15. Repeat bleeding procedure as outlined in

steps 6- 9 until all air is ex hausted from cooling

system.

16. Top up cooling system using coolant mixture

as described in step 2 and refit radiator cap.

Figure 6B1-2-7

2.3 THERMOSTAT

REMOVE

1. Remove the four engine dress cover dome

nuts and remove the cover.

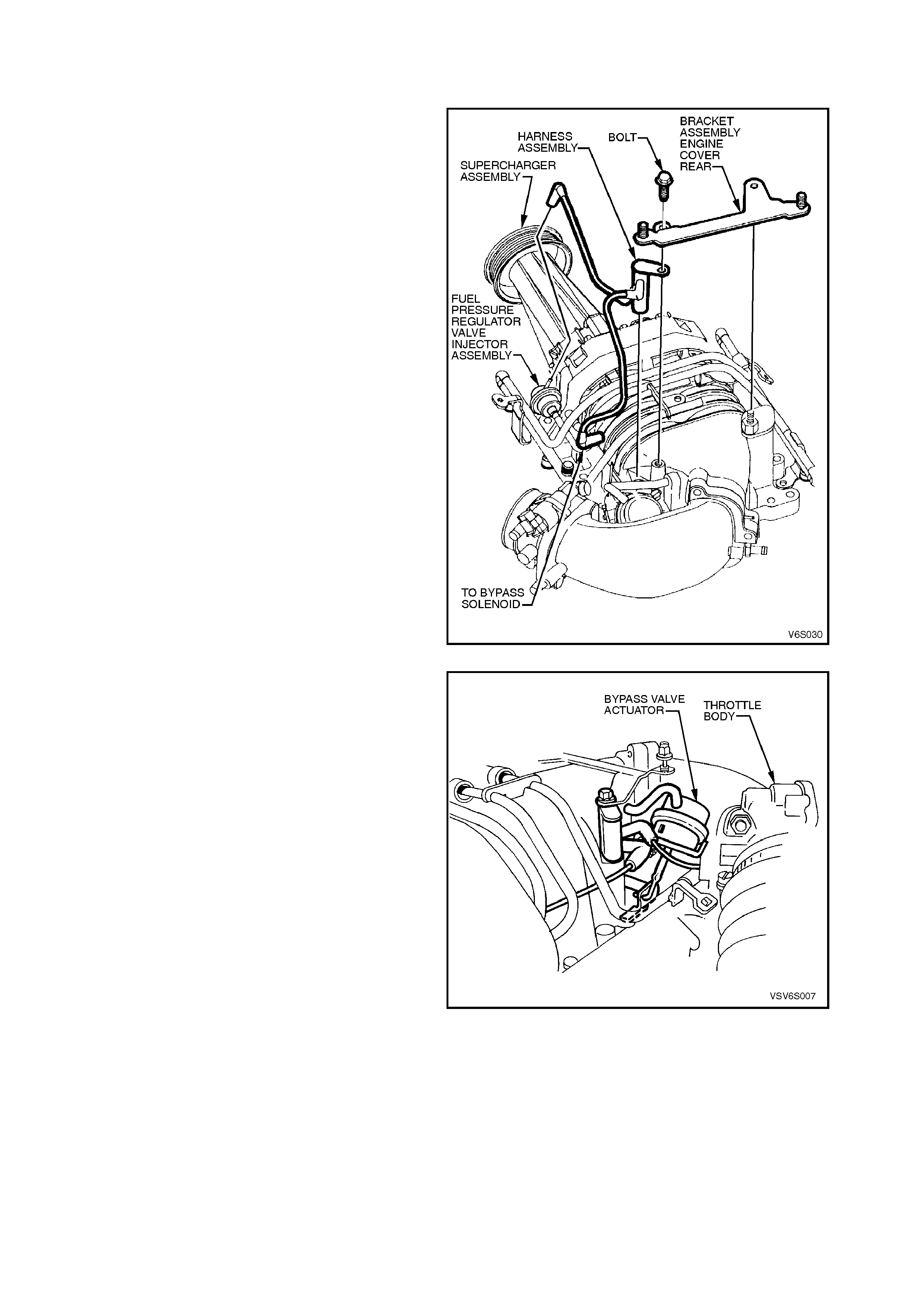

2. Remove 2 bolts securing rear engine cover

bracket assembly and remove bracket.

3. Tag and dis connect vacuum connections from

fuel pressure regulator and bypass solenoid,

lift out harness assembly.

Figure 6B1-2-8

4. Remove bolts attaching bypass valve actuator

and swing actuator to one side to gain access

to thermostat front bolt refer to Figure 6B-12-9.

6. Remove air intake duct, throttle body and

throttle cable mounting bracket, refer to

Section 6A1-2 ENGINE MECHANICAL - V6

SUPERCHARGED ENGINE.

7. Remove the water outlet hose from the

thermostat housing cover.

Figure 6B1-2-9

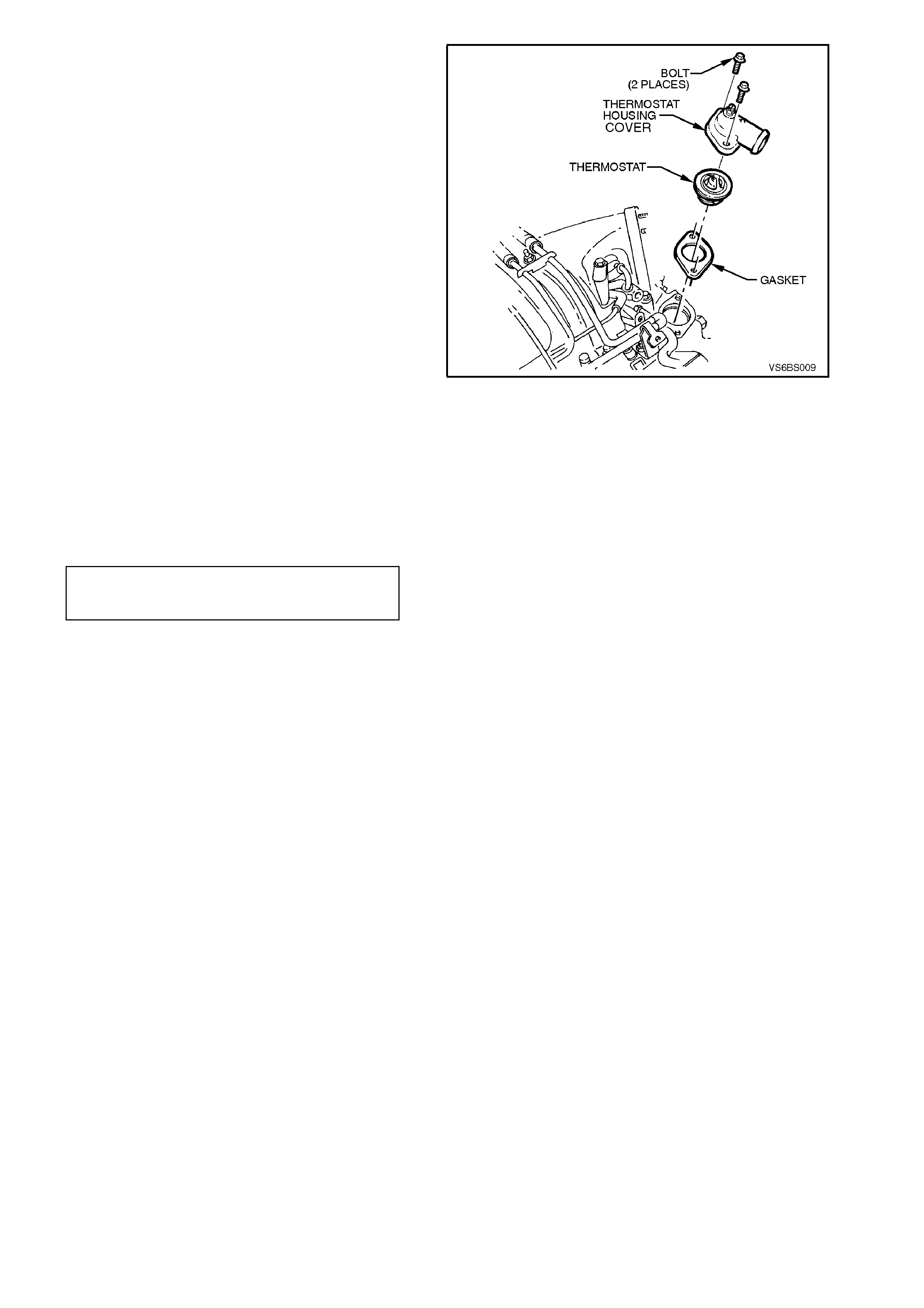

8. Remove the two bolts securing the thermostat

housing cover, remove cover, thermostat and

gasket. The rear bolt can be removed by

reaching around from behind supercharger

(using short open-ended spanner) and the

front bolt removed by using a socket ratchet

with extension. W iring harnes s located in fr ont

of the rear firewall may need to be temporar ily

shifted in order to gain access to rear bolt.

Figure 6B1-2-10

REINSTALL

Reinstallation of the thermostat is the reverse of

removal procedures noting the following.

1. Ensure all gasket surfaces are clean.

2. Tighten thermostat housing cover screws to

correct torque specification.

THERMOSTAT HOUSING

COVER SCREWS

TORQUE SPECIFICATION 20-34 Nm

3. Ensure the cooling system is bled correctly,

refer to 2.2 CHECKING AND FILLING

COOLING SYSTEM in this Section.

4. If the wiring harness was moved during

removal, reposition to original location.

2.4 RADIATOR INLET PIPE

REMOVE

1. Disconnect the negative cable from the

battery.

2. Remove the lower radiator hose and drain the

cooling system.

3. Remove the four engine dress cover dome

nuts and remove the cover.

Figure 6B1-11

4. Remove the water outlet hose from the

radiator inlet pipe.

5. Disconnect the wiring harness from the

retainer brackets on the radiator inlet pipe.

6. Remove the screws securing the radiator inlet

pipe to the engine assembly removing the

pipe.

Figure 6B1-2-12

REINSTALL

Reinstallation of the radiator inlet pipe is the

reverse of removal operations noting the following

points.

1. Ensure the cooling system is bled correctly,

refer to 2.2 CHECKING AND FILLING

COOLING SYSTEM in this Section.

3. SPECIFICATIONS

GENERAL

Radiator cap pressure rating 135 kPa

Cooling system capacity 12 Litres

Coolant corrosion inhibitor HN 2043, approx. 6.0 litres

required for service fill.

THERMOSTAT

Type Power element (wax pellet)

Start to open 89° - 93° C

Fully open at 106° C max

WATER PUMP

Type Centrifugal

Drive V-belt

Bearing type Double Row Ball Bearing

RADIATOR

Core type Aluminium crossflow core

Overall width 663 mm

Core width 546 mm

Overall height 462 mm

Core height 418 mm

Core thickness 25 mm

Plastic tanks Nylon 6,6

RADIATOR HOSES

Lower

Number and ty pe One, Moulded

Inside diameter 38.5 mm

Upper

Number and ty pe One, Moulded

Inside diameter 34.0

ENGINE COOLI NG FAN 1

Number of blades 5

Spacing Uneven

Material Polypropylene (20% glass

filled)

Diameter 340 mm

Electric motor drive 200 watts (nominal)

ENGINE COOLI NG FAN 2

Number of blades 7

Spacing Uneven

Material Polypropylene (20% glass

filled)

Diameter 300 mm

Electric motor drive 160 watts (nominal)

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Thermostat housing cover retaining bolts 20-34

Radiator inlet pipe retaining bolts 20-27

Water Outlet Hose 2-5

Engine dress cover attaching nut 4-6

Rear engine cover bracket assembly securing bolts 15 - 20

5. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

AU 425 COOLING SYSTEM FILLER TUBE