SECTION 6B2 ENGINE COOLING - V8 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag, o r seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

The cooling system for VT Series Models with V8

engine consists of two 2-speed electric cooling

fans mounted behind the radiator. The fan

operation is dependent on engine coolant

temperature, vehicle speed, A/C request (where

fitted) and A/C system pressure. Refer to

Section 6C2 POWERTRAIN MANAGEMENT - V8

ENGINE for further information.

1.1 GENERAL INFORMATION

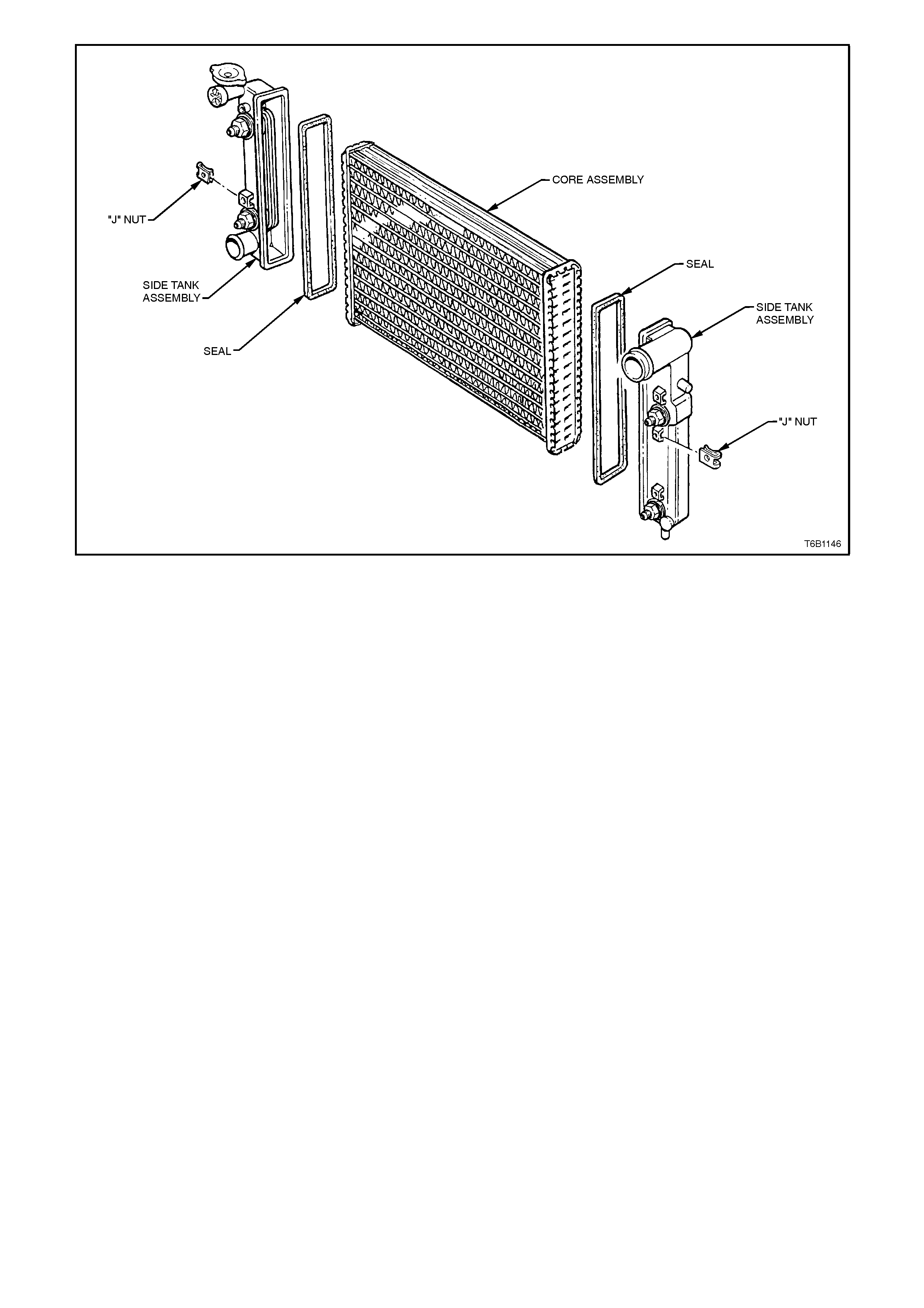

The radiator utilises an aluminium core and is of

the crossflow design, with a radiator cap situated

on the left hand side tank. Plastic side tanks are

attached to the core by the use of clinch tabs. The

clinch tabs are formed as part of the core

assembly.

A high temperature rubber seal is used to seal the

mating surface between the core and each side

tank. The seal/s must be replaced any time the side

tank is removed from the core.

For vehicles with automatic transmission,

transmission oil coolers are located in both left

hand and right hand side tanks.

Pegs are attached to the lower frame and the upper

area of each side tank. These pegs are used to

support the radiator in four rubber mounts. The

assembly is held in position by two spring clips at

the upper mounting locations. Figure 6B2-1

Techline

Techline

Figure 6B2-2

The radiator core, side tanks or transmission oil cooler CANNOT be replaced separately. If there is a fault with any

of these components, the radiator assembly must be replaced. Small core repairs can be made using an

‘Aluminised Silicon’ based liquid repair agent, refer to 2.12 RADIATOR - RADIATOR REPAIR PROCEDURE in this

Section.

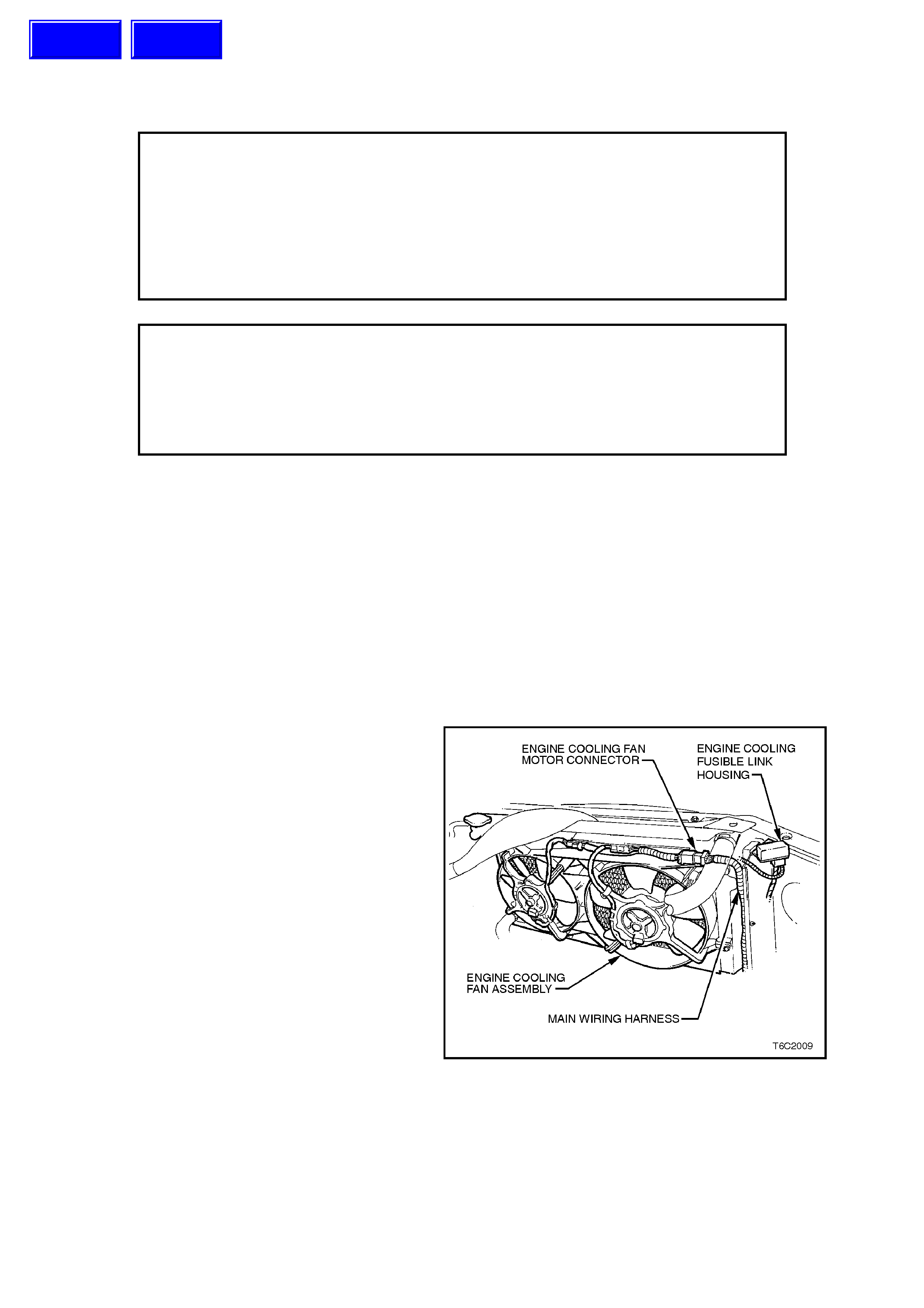

The cooling fan and electric motor assembly is supported in a polypropylene mounting bracket. The mounting

bracket and fan shroud are moulded as a one piece assembly. The mounting bracket is attached to the radiator

side tanks.

ENGINE COOLING FAN LOW SPEED

The PCM determines operation of the two speed engine cooling fan based on A/C request, A/C system pressure

(where fitted), engine coolant temperature and vehicle speed signal inputs.

The engine cooling fan low speed relay is energised by the BCM. The PCM determines when to enable the low

speed fan based on inputs from the BCM serial data, Engine Coolant Temperature (ECT) sensor and the Vehicle

Speed Sensor (VSS). The cooling fan speed relay will be turned “ON” when:

• The A/C request indicated (YES) and either

• The vehicle speed is less than 30 km/h.

or

• A/C pressure is greater than 1500 kPa.

or

• The coolant temperature is greater than 95 degrees C.

• If the coolant temperature is greater than 117 degrees C. when the ignition is switched off, the relay is energised

for up to approx. 4 minutes.

If an engine coolant temperature sensor fault is detected, such as DTC 14, 15, 16 or 17.

The cooling fan low speed relay will be turned “OFF” when the following conditions have been met:

• A/C request is not indicated (NO).

• The A/C request is indicated (YES) and the vehicle speed is greater than 50 km/h and A/C pressure is less than

1170 kPa.

ENGINE COOLING FAN HIGH SPEED

The engine cooling fan high speed relay is

controlled by the PCM based on input from the

Engine Coolant Temperature (ECT) sensor. The

PCM will only turn “ON” the engine cooling f an high

speed relay if the engine cooling fan low speed

relay has been “ON” for 2 seconds and the

following conditions are satisfied.

• There is a BCM message response fault which

will cause a DTC 92.

• An engine coolant temperature sensor failure is

detected such as DTC 14, 15, 16 or 17.

• Coolant temperature greater than

104 degrees C.

The engine cooling fan high speed relay can also

be enabled by the A/C Refrigerant Pressure

Sensor. When the A/C Refrigerant Pressure

Sensor determines the A/C system pressure is to

high, greater than 2600 kPa., and this will instruct

the PCM to enable the high speed fan.

If the low speed fan was “OFF” when the criteria

was met to turn the high speed fan “ON”, the high

speed fan will come “ON” 5 seconds after the low

speed fan is turned “ON” . If both the engine c ooling

fan relays are “ON”, the PCM will turn “OFF” the

high speed relay when:

• The engine coolant temperature is less than 99

degrees C.

• A/C request not indicated (NO).

• A/C request indicated (YES) and A/C pressure

is less than 2300 kPa.

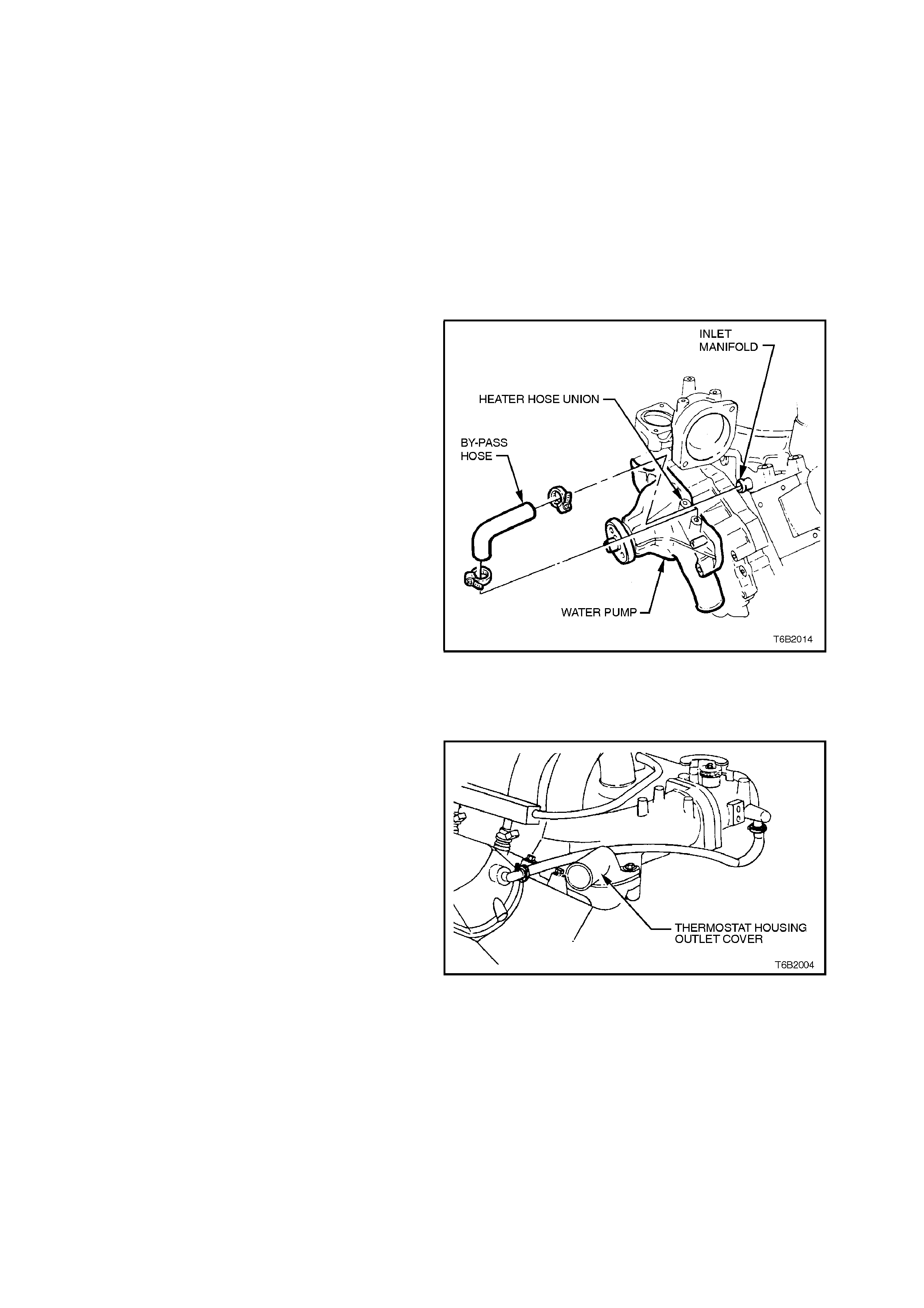

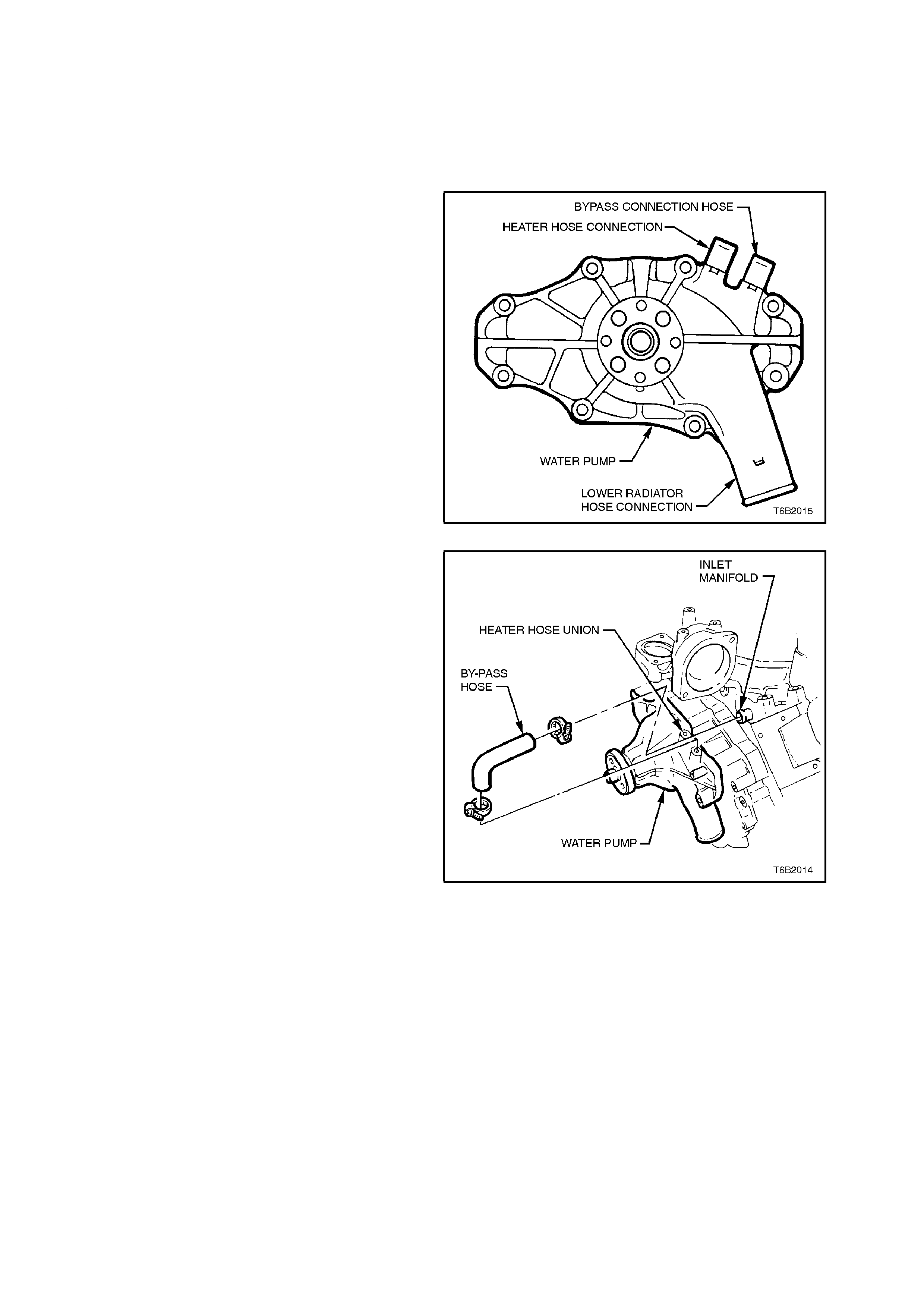

The water pump is mounted to the engine front

cover and is driven by the V-belt. Coolant passes

through the engine from the water pump inlet at the

engine front c over and exits via the therm ostat and

coolant outlet at the front of the inlet manifold.

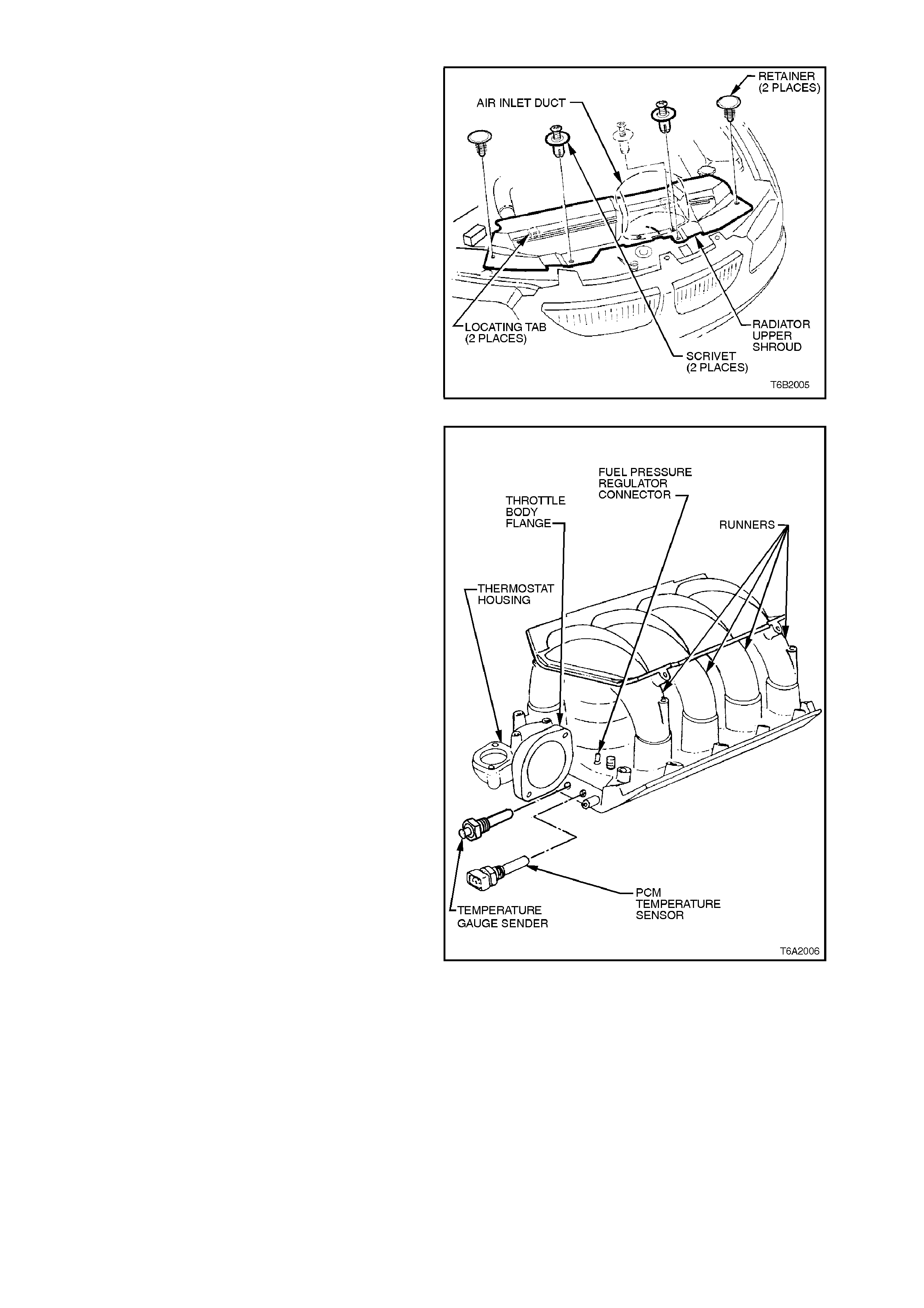

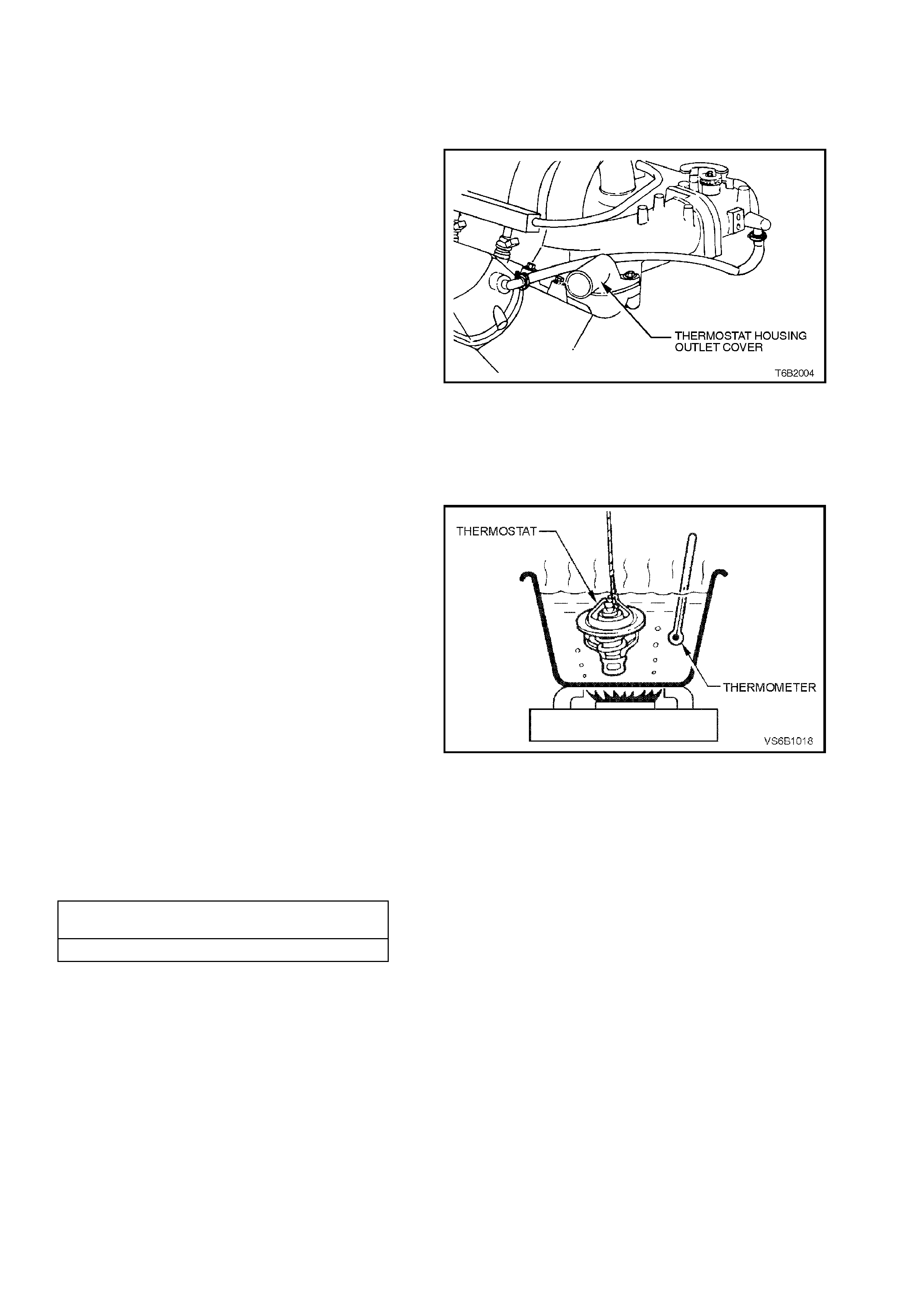

Figure 6B2-3

The c oolant outlet is located at the front of the inlet

manifold.

The thermostat is housed between the coolant

outlet and the inlet manifold.

Figure 6B2-4

A wax pellet type thermostat is used in the coolant

outlet passage to control the flow of coolant,

providing fast engine warm up and regulating

coolant temperature. The wax pellet or power

element in the thermostat, expands when heated

and contracts when cooled. The wax pellet is

connected through a piston to a valve and when the

pellet is heated, pressure is exerted against a metal

valve which is forced to open. As the pellet is

cooled, the contraction allows a spring to close the

valve. Thus, the valve remains closed while the

coolant is cold, preventing circulation of coolant

through the radiator, but allowing the coolant to

circulate throughout the engine to warm it quickly

and evenly.

As the engine becomes warm, the pellet expands

and the therm ostat opens, perm itting the coolant to

flow through the radiator where heat is passed

through the radiator walls. This opening and c los ing

of the thermostat valve permits enough coolant to

enter the radiator to keep the engine within

specified temperature limits.

Figure 6B2-5

A radiator cap, fitted to the radiator filler neck,

causes the cooling system to operate at higher

than atmospheric pressure. The higher pressure

raises the boiling point of the coolant, resulting in

increased engine cooling efficiency.

The radiator cap contains a pressure valve and a

vacuum (atm ospheric) valve. T he pressure valve is

held against its seat by a spring, which determines

the maximum operating pressure of the cooling

system (100 kPa for V8 engine) The vacuum valve

is held against its seat by a light spring. The

vacuum created during cool down over-comes the

spring force and opens the valve, preventing the

radiator hoses from collapsing. Figure 6B2-6

NOTE:

Due to the cooling system pressure on vehicles

with V6 engine being greater than vehicles with V8

engine, a specific radiator cap is used on vehicles

fitted with V6 engines and will not fit onto the V8

type radiator neck.

The radiator cap for V6 is stamped with a 135 kPa

pressure rating.

The coolant is maintained at the ideal level in the

radiator by the radiator cap and the coolant

recovery reservoir, resulting in increased cooling

efficiency.

The c oolant recover y reservoir is located on the lef t

hand front of the engine com partm ent, between the

radiator support panel and air cleaner assembly.

The coolant recovery reservoir is connected to the

radiator overflow connection by a hose.

As the engine temperature rises, the coolant is

heated and expands. The fluid displaced by

expansion flows from the radiator into the recovery

reservoir. When the engine is turned “OFF”, the

coolant contracts as it cools. Coolant is then drawn

back into the radiator through the radiator cap

atmospheric valve.

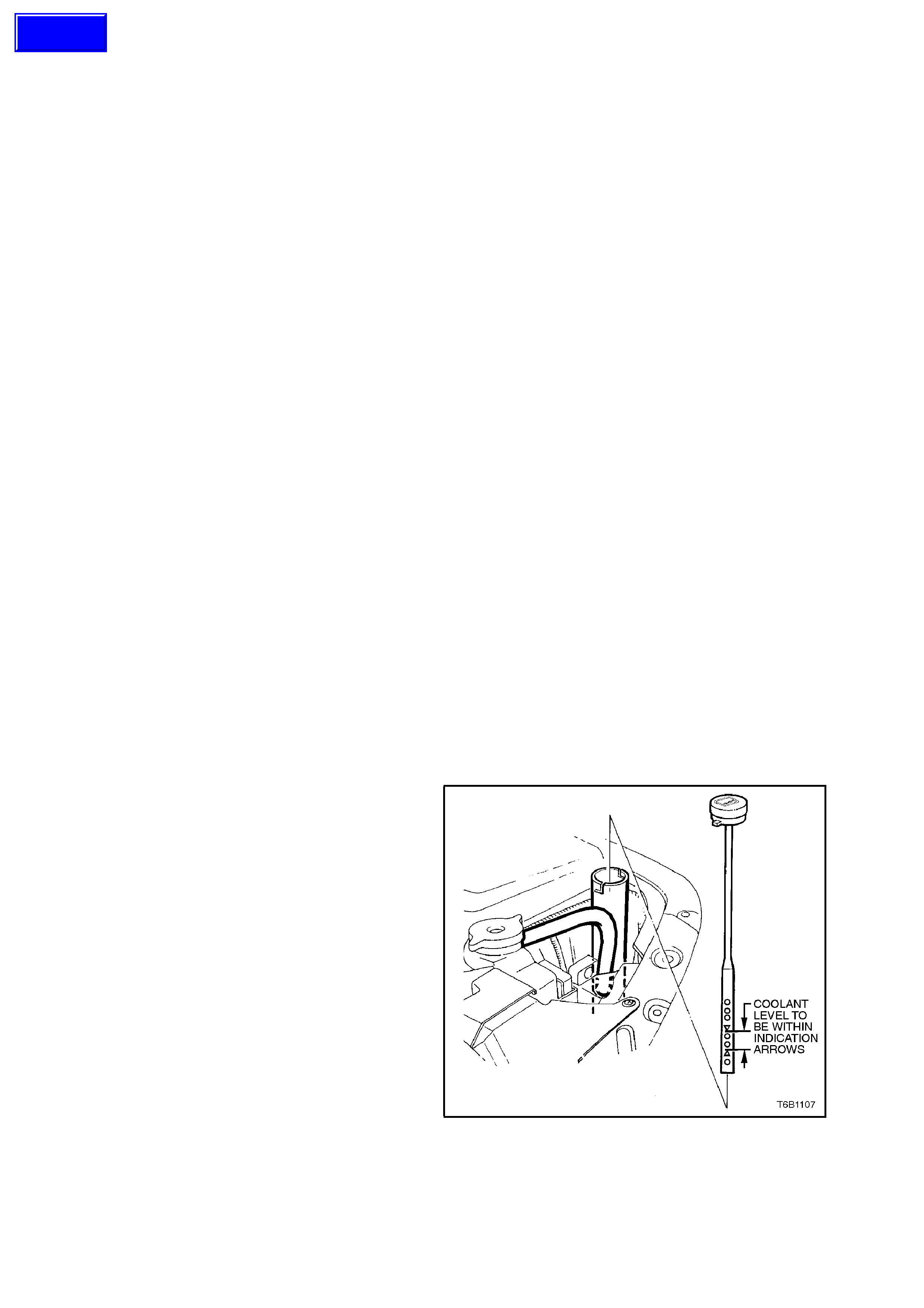

Coolant level should be maintained between

indicator arrows on the coolant recovery reservoir

dipstick when the engine is cold. Figure 6B2-7

The c ooling system is designed to us e a coolant (a

mixture of ethylene glycol antifreeze with inbuilt

corrosion inhibitors, and water), rather than plain

water to maintain the integrity of the cooling

system, and to prevent oxidation occurring within

the engine.

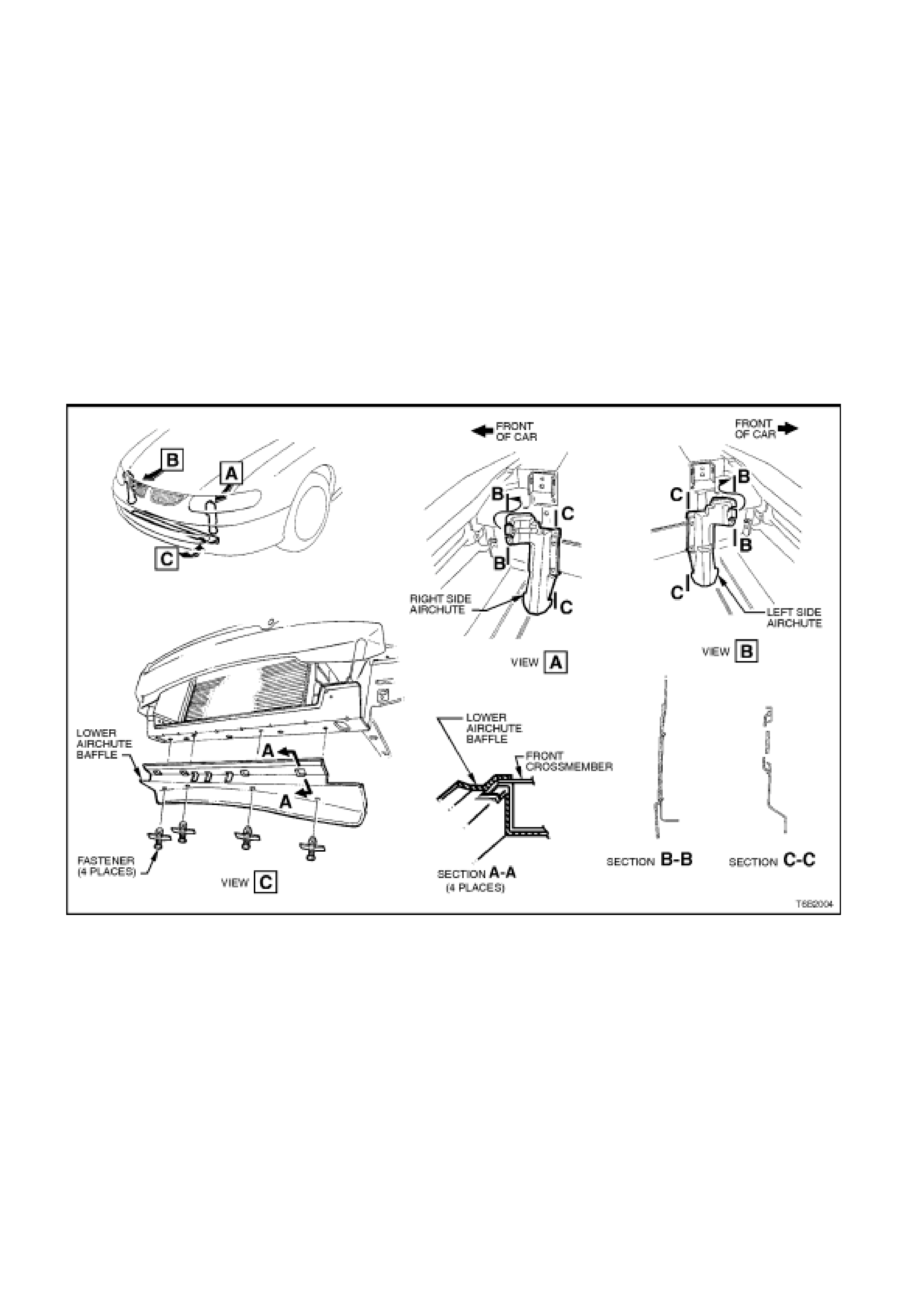

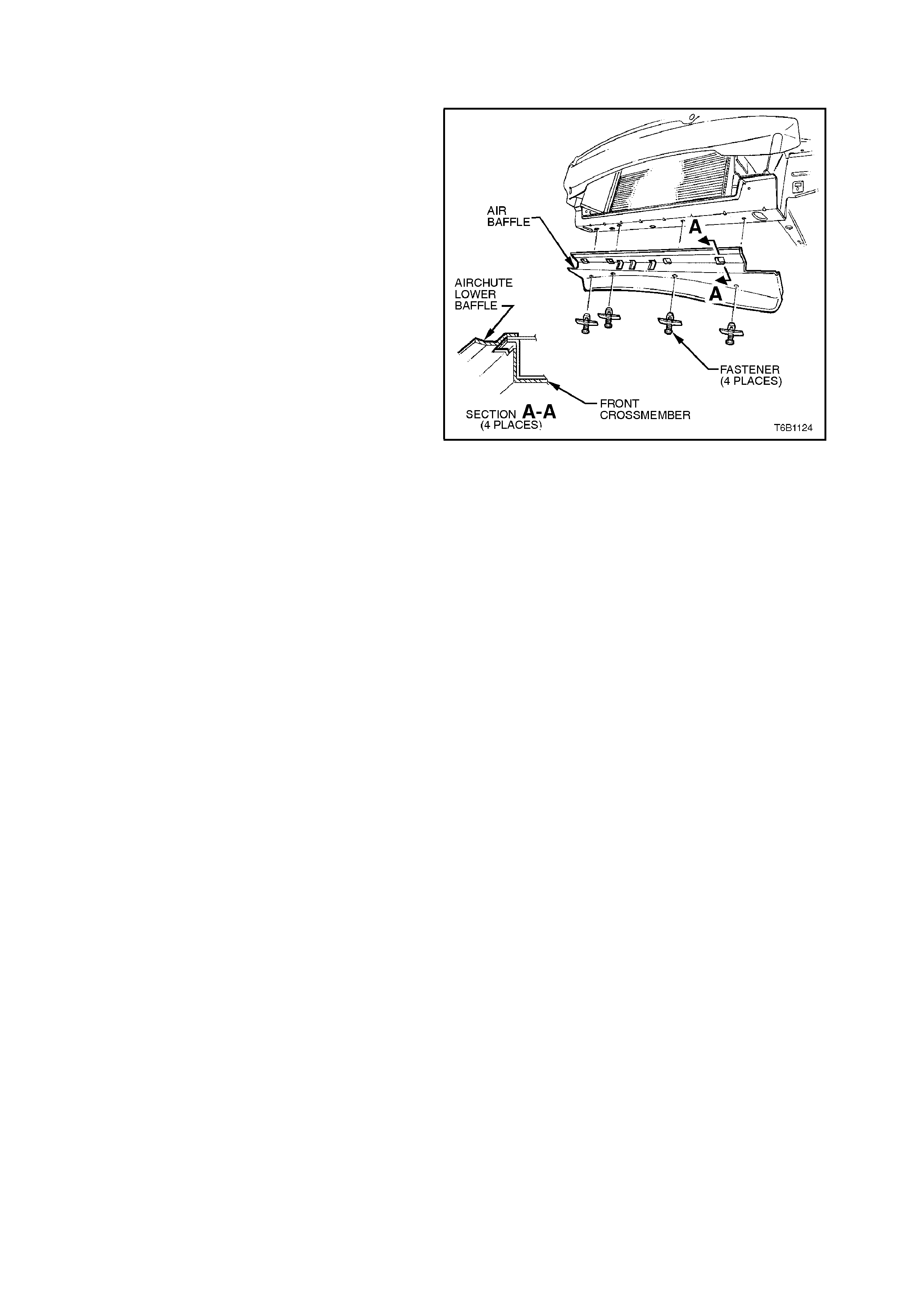

An air baffle and side chutes are fitted to the front

end of the vehicle to direct and promote air flow

through the radiator to provide maximum cooling.

The purpose of the air baffle is to create a low

pressur e area behind the radiator whilst the vehic le

is at speed.

This enables additional air flow through the radiator

core to maintain the desired engine cooling.

The air baffle or side chutes should never be

removed unless for service work. If either the air

baffle or side chutes are damaged, this will reduce

the cooling system efficiency, and therefore, they

must be replaced.

Figure 6B2-8

A radiator shroud is fitted between the upper

radiator support panel and the radiator assembly, to

minim is e the recirc ulation of hot air from the r ear of

the radiator back over the core.

Figure 6B2-9

A coolant temperature sensor is mounted in the

front of the inlet manifold. T he coolant temperature

sensor is used in conjunction with the instrument

panel temperature gauge. T he coolant temperatur e

sensor generates a signal which is used by the

engine management PCM/BCM for calculation of

the various engine management functions.

Figure 6B2-10

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

WARNING:

TO AVOID SERIOUS PERSONAL INJURY, NEVER REMOVE THE RADIATOR CAP OR OPEN THE AIR VENT

VALVE ON THE COOLANT OUTLET WHEN THE ENGINE IS HOT, EVEN IF THE COOLING SYSTEM SHOULD

REQUIRE FILLING. SUDDEN RELEASE OF COOLING SYSTEM PRESSURE IS VERY DANGEROUS.

Before removing the radiator cap, allow the engine to cool, then place a shop rag over the radiator cap and then

slowly turn the cap anti-clockwise, without pressing down until the cap reaches the first ‘stop’. This is the pressure

relief stop, which will allow any remaining pressure within the system to escape. Then press down on cap and

continue to rotate it anti-clockwise until it can be removed.

The vehicle is fitted with a radiator electric cooling fan. When working around the engine compartment with the

engine running or with the ignition ‘ON’, keep clear of the fan as it may start operating without warning.

The cooling system requires little care except for maintaining the coolant to the correct level in the recovery

reservoir and periodic servicing at the time or distance intervals as outlined in the VT Owner’s Handbook.

Periodic servicing includes

1. Checking coolant level, refer to 2.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

2. Checking coolant concentration, refer to 2.2 GLYCOL COOLANT MAINTENANCE - TESTING COOLANT

CONCENTRATION this Section.

3. Pressure test cooling system and radiator cap, refer to 2.6 PRESSURE TESTING in this Section.

4. Tighten hose clamps and inspect all hoses, refer to 2.5 COOLANT HOSES in this Section. Replace hoses if

swollen or deteriorated.

CAUTION:

Always wear protective safety glasses when working with spring type hose clamps. Failure to do so could

result in eye injury.

5. Clean out cooling system, refer to 2.4 CLEANING COOLING SYSTEM - REVERSE FLUSHING in this

Section and refill cooling system, refer to 2.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

Techline

2.2 GLYCOL COOLANT MAINTENANCE

The cooling system is designed to use a coolant

(a mixture of ethylene glycol antifreeze with inbuilt

corrosion inhibitors, and water), rather than plain

water.

The use of glycol also raises the boiling point and

increases the cooling system efficiency.

For this reason, it is of the utmost importance to

ma intain the correct c oncentration level of ethylene

glycol in the cooling system.

Addition of plain water into the cooling system

when ‘topping-up’ may dilute the coolant mix ture to

a point where the antifreeze/anti-boil and corrosion

inhibitor properties of ethylene glycol become

ineffective.

The coolant should comprise of a mixture 50%

ethylene glycol antifreeze/inhibitor (Holden’s

Specification HN2043) with 50% clear, clean water.

Ethylene glycol conforming to Holden’s

Specific ation HN2043 is named New For mula Long

Life All Seasons Coolant, and is available in the

following quantities:

1 litre, P/N M40236

5 litre, P/N M40307

20 litre, P/N M40238

NOTE:

Do not mix different types of anti-freeze or

corros ion inhibitors as they m ay be incompatible. If

a different type has been used in the cooling

system, flush the system with clean water, refer to

2.4 CLEANING COOLING SYSTEM - REVERSE

FLUSHING in this Section and ref ill cooling system

with the correct coolant, refer to 2.3 CHECKING

AND FILLING COOLING SYSTEM in this Section.

TOPPING UP THE COOLING SYSTEM

Under normal operating conditions, the cooling

system should not be topped up at the radiator

filler. The level can be checked at the coolant

recovery reservoir, and coolant (in the correct

concentration with clear, clean water) added as

necessary to bring the level to between the

indicator arrows on the coolant recovery reservoir

dipstick when the engine is cold .

Figure 6B2-11

Techline

TESTING COOLANT CONCENTRATION

To ensure the specified ethylene glycol

concentration is maintained in the engine coolant,

the coolant concentration must be checked at the

time or distance intervals outlined in the VT

Owner’s Handbook.

Check coolant concentration as follows:

1. Cooling system should be at or close to

ambient temperature.

2. Remove radiator cap and insert nozzle of

coolant tester, Tool No. AU435 into coolant, and

by squeezing the rubber bulb, draw sufficient

coolant into the tester to float hydrometer bulb

freely.

NOTE:

The coolant recovery reservoir is not part of the

dynamic coolant system and therefore coolant

concentration measurements must not be made via

the recovery reservoir.

3. Hold tester at eye level and read scale on

hydrometer bulb at coolant level.

The reading shows the percentage of ethylene

glycol antifreeze contained in the engine

coolant.

4. The hydrometer reading should show 50% if the

coolant concentration is correct.

If a reading of less than 50% is achieved, the

cooling system requires topping up with ethylene

glycol antifreeze to Holden’s Specification

HN2043.

Refer to the following chart to determine how

much ethylene glycol antifreeze is required to

add to the cooling system to bring the coolant to

the specified concentration.

Figure 6B2-12

HYDRO-

METER

READING %

LITRES OF ANTIFREEZE TO BE

ADDED FOR CORRESPONDING

HYDROMETER READING

06.0

55.7

10 5.3

15 4.9

20 4.5

25 4.0

30 3.4

35 2.8

40 2.0

45 1.1

50 0

5. Drain sufficient quantity of coolant from

cooling system to allow top-up with ethylene

glycol antifreeze.

6. Add required amount of ethylene glycol

antifreeze to radiator and reinstall radiator cap.

2.3 CHECKING AND FILLING COOLING SYSTEM

During any service operation that requires the

cooling system to be partly or completely drained,

the following instructions must be followed when

refilling the cooling system so as to ensure that all

air is bled from system.

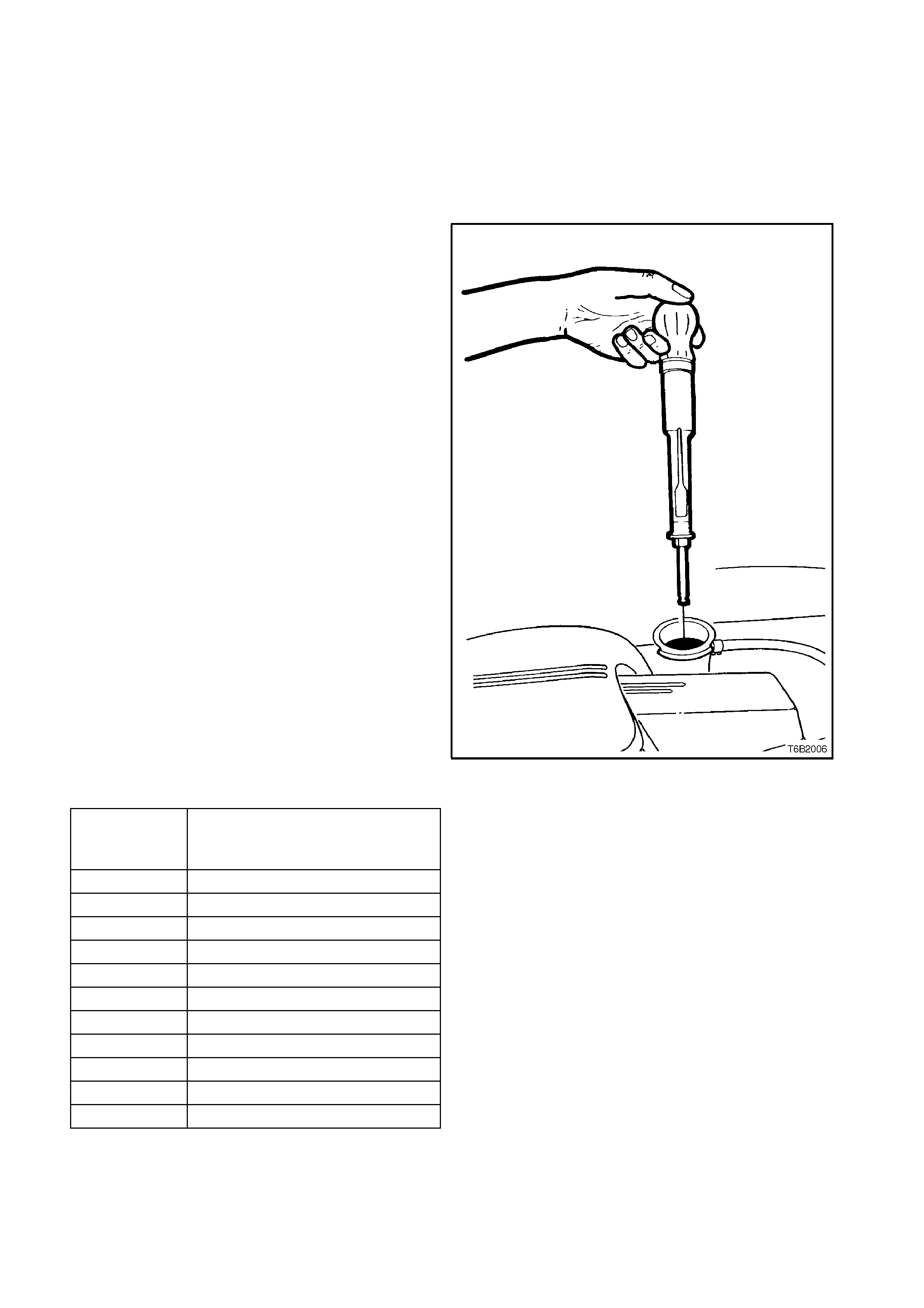

FILLING COOLING SYSTEM WITH TOOL AU425

The following procedure requires the use of Tool

No. AU425 to fill the cooling system . An alternative

procedure for filling the cooling system is also

given should Tool No. AU425 not be available.

1. Set heater control to maximum.

2. Mix a coolant m ixtur e consis ting 50% ethylene

glycol antifreeze/inhibitor (Holden’s

Specification HN2043) with 50% clear, clean

water.

Ethylene glycol conforming to Holden’s

Specific ation HN2043 is named New For mula Long

Life All Seasons Coolant, and is available in the

following quantities:

1 litre, P/N M40236

5 litre, P/N M40307

20 litre, P/N M40238

NOTE:

Do not mix different types of anti-freeze or

corros ion inhibitors as they m ay be incompatible. If

a different type has been used in the cooling

system, flush the system with clean water, refer to

2.4 CLEANING COOLING SYSTEM - REVERSE

FLUSHING in this Section.

3. If cooling s yst em was com pletely dr ained, add

a pack of pellets (three pellets), P/N M40124

to cooling system by disconnecting radiator

upper hose from engine coolant outlet and

placing pellets inside radiator hose. If cooling

system was only partially drained, add one

pellet for every four litres of coolant replaced.

CAUTION:

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

Refit hose to coolant outlet and tighten hose

clamp.

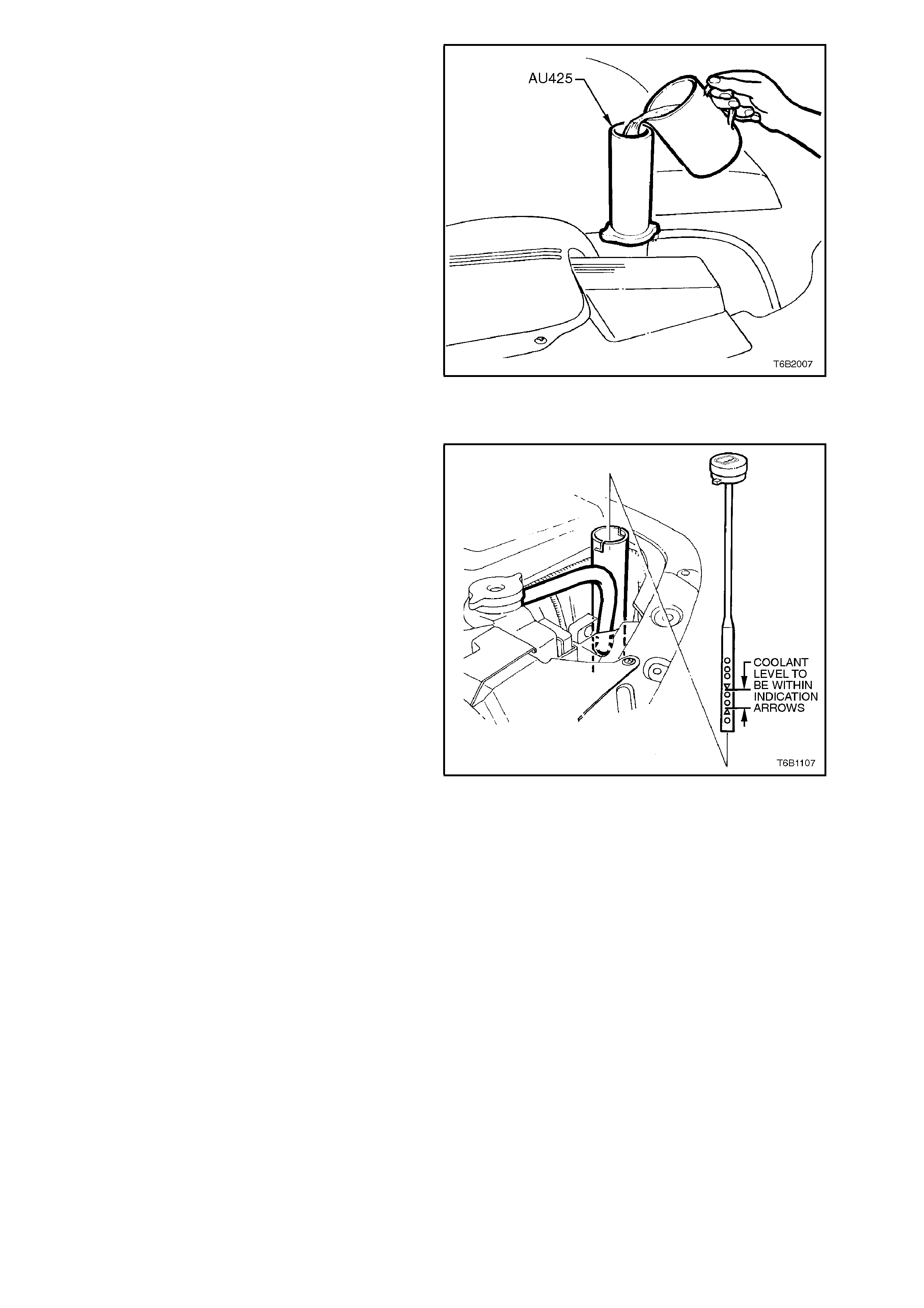

4. Remove radiator cap and install Tool No.

AU425 to radiator filler neck.

5. Fill cooling system using coolant mixture via

Tool No. AU425 until coolant flows from air

vent opening and all air is expelled.

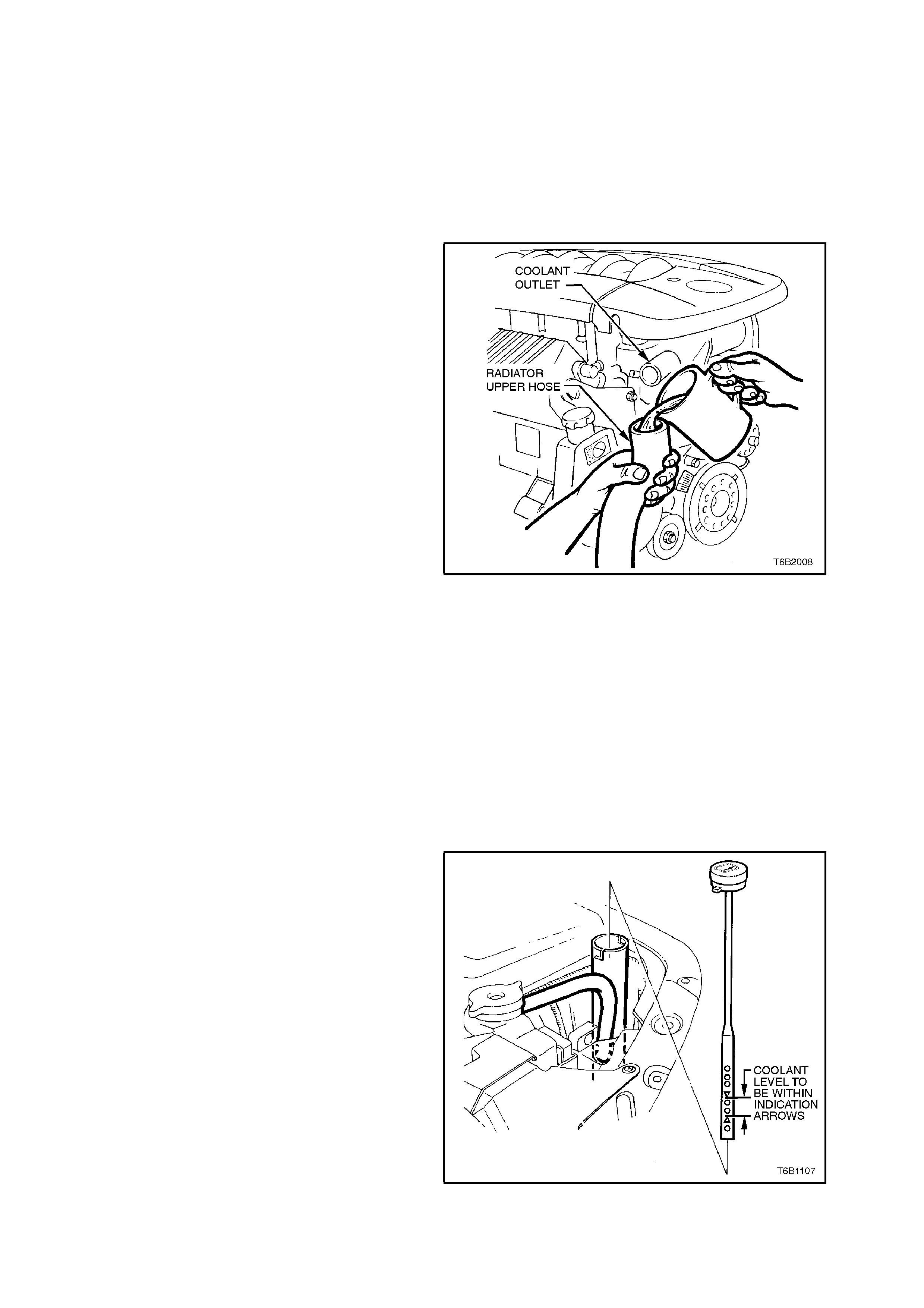

Figure 6B2-13

6. Close air vent valve and remove AU425 from

radiator.

7. If necessary, remove cap from coolant

recovery reservoir and fill to between the

indicator arrows on the coolant recovery

reservoir dipstick when the engine is cold.

Figure 6B2-14

8. Pressure test cooling system, refer to

2.6 PRESSURE TESTING in this Section.

9. Refit radiator cap.

FILLING COOLING SYSTEM WITHOUT TOOL AU425

As an alternative to filling the cooling system

should Tool No. AU425 not be available, perform

the following procedure.

1. Set heater control to maximum.

2. Mix a coolant m ixtur e consis ting 50% ethylene

glycol antifreeze/inhibitor (Holden’s

Specification HN2043) with 50% clear, clean

water.

Ethylene glycol conforming to Holden’s

Specific ation HN2043 is named New For mula Long

Life All Seasons Coolant, and is available in the

following quantities:

1 litre, P/N M40236

5 litre, P/N M40307

20 litre, P/N M40238

NOTE:

Do not mix different types of anti-freeze or

corros ion inhibitors as they m ay be incompatible. If

a different type has been used in the cooling

system, flush the system with clean water, refer to

2.4 CLEANING COOLING SYSTEM - REVERSE

FLUSHING in this Section.

3. Remove radiator cap and fill cooling system

with as much coolant mixture as possible.

4. Replace radiator cap.

5. Loosen radiator upper hose clamp at coolant

outlet and remove hose from engine coolant

outlet.

CAUTION:

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

6. Holding disconnected end of radiator upper

hose upward, fill cooling system using coolant

mixture via open end of radiator upper hose

until coolant starts to flow from coolant outlet.

Figure 6B2-15

7. If cooling s yst em was com pletely dr ained, add

a pack of pellets (three pellets), P/N M40124

by placing pellets inside radiator hose. If

cooling system was only partially drained, add

one pellet for every four litres of coolant

replaced.

8. Quick ly install r adiator upper hos e onto engine

coolant outlet, trying not to allow pellets or a

large amount of coolant to spill from hose.

Install hose clamp at coolant outlet

connection.

9. Pressure test cooling system, refer to

2.6 PRESSURE TESTING in this Section.

10. Remove cap from recovery reservoir and fill

with coolant to a level approximately 25 mm

ABOVE the indicator arrows on the coolant

recovery reservoir dipstick, refit dipstick.

NOTE:

This condition only applies when the cooling

system is first being filled, after a major loss of

coolant.

The level of coolant will subsequently drop in the

reservoir and the level should then be kept at the

correct level.

Figure 6B2-16

2.4 CLEANING COOLING SYSTEM

A cleaning solution should be used to loosen the

rust and scale before performing a cooling system

flush.

Use radiator cleaner, Holden’s Part No. M39304

(500 ml). Follow the instructions on the container.

REVERSE FLUSHING

Before reverse flushing, clean the cooling system

with Holden’s Radiator Cleaner (Part Number

M39304), following the instructions on the package.

Reverse flushing is accomplished by forcing water

through the system in the direction opposite to

normal flow.

Reverse flush the cooling system as follows:

RADIATOR

1. Allow the engine to cool to ambient

temperature (less than 50° C). Remove the

radiator cap, then disconnect the upper and

lower radiator hoses at the engine. Allow the

cooling system to drain, then reinstall radiator

cap.

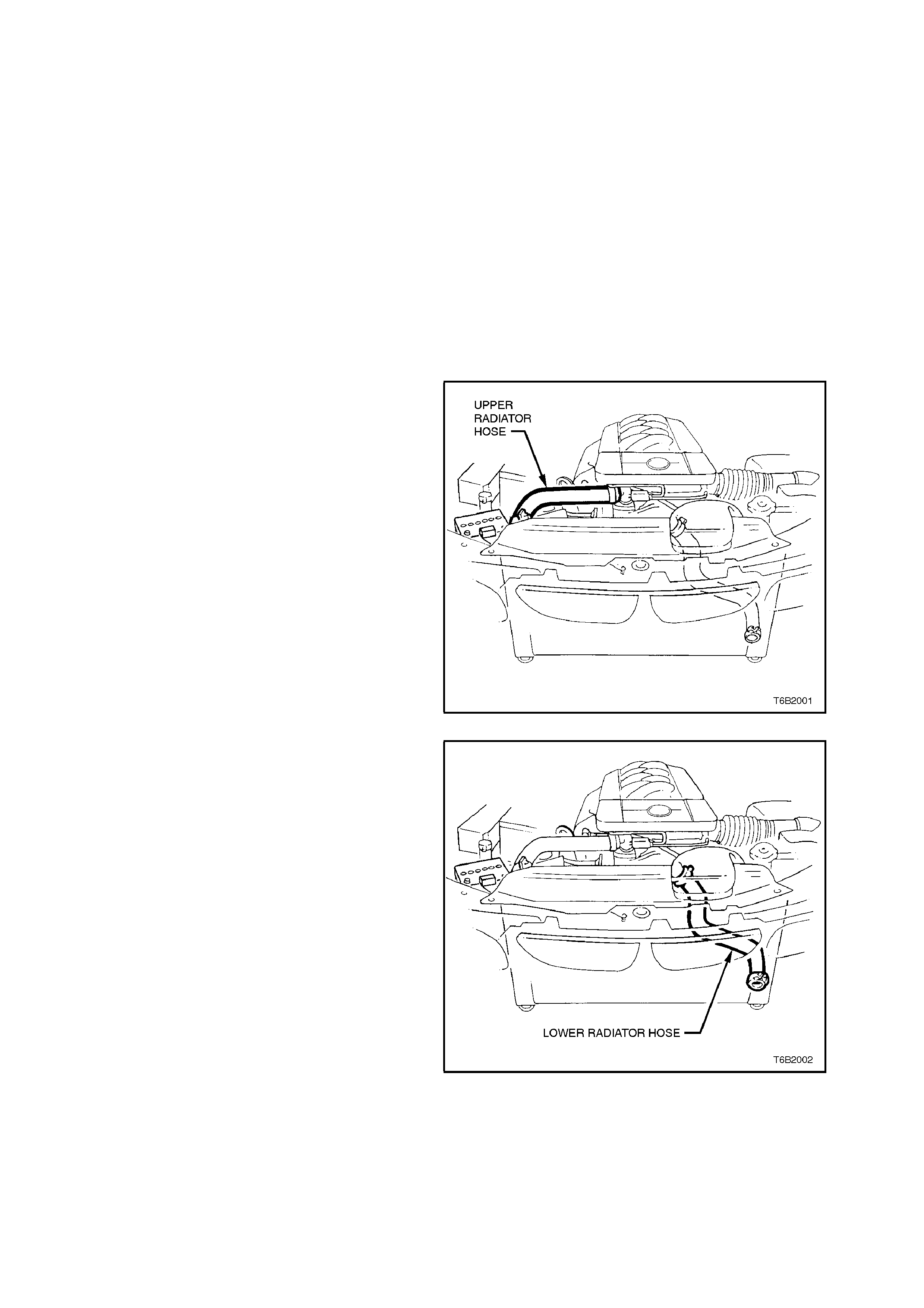

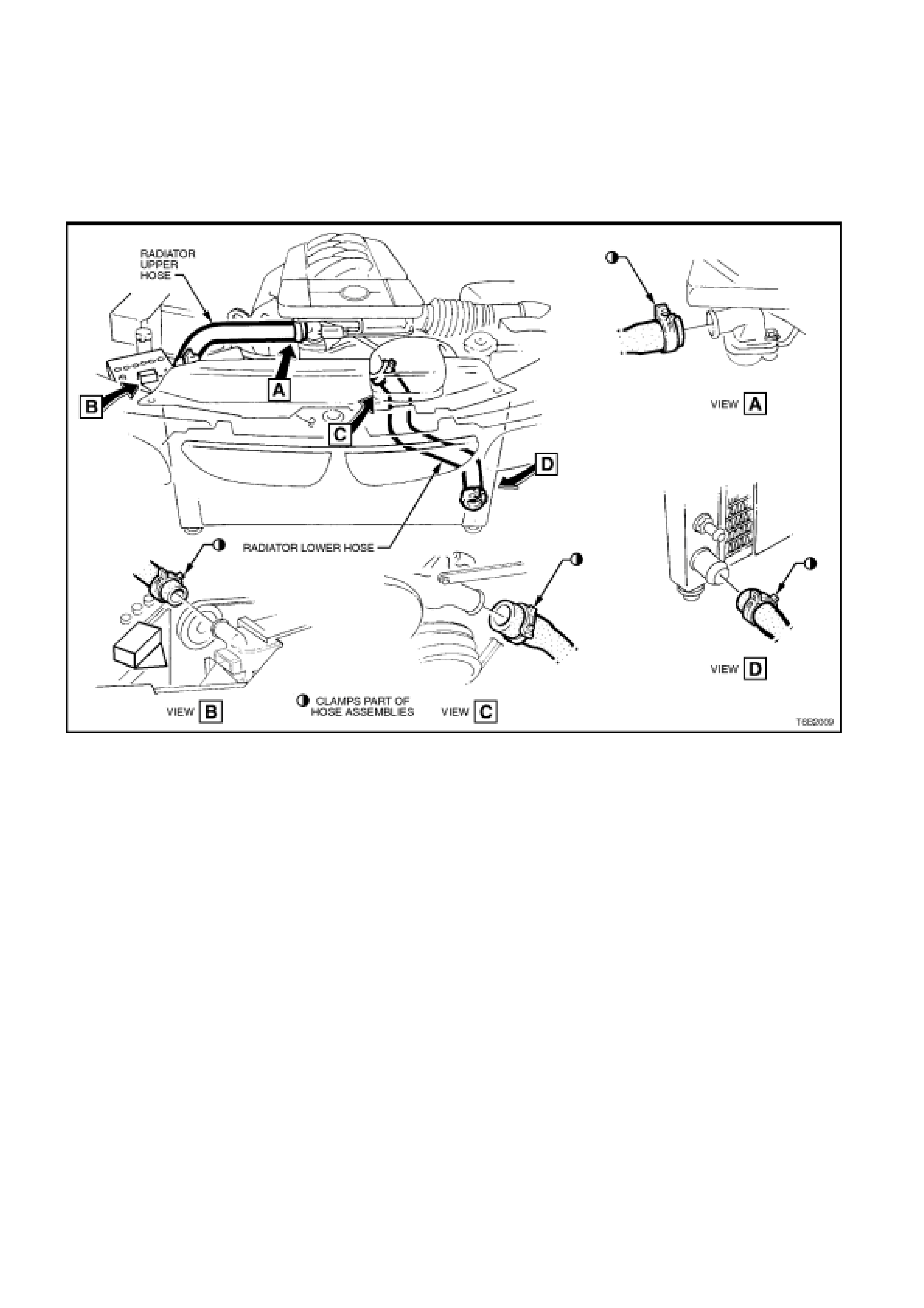

Figure 6B2-17

Figure 6B2-18

2. Attach a lead-away hose at the upper radiator

connection.

3. Attach a piece of hose between the flushing

gun and lower radiator connection.

4. Connect the flushing equipment in ac cordance

with the manufacturer’s recommendations.

CAUTION:

Apply air gradually as the radiator will only

withstand a maximum pressure of 135 kPa

pressure.

5. Operate the f lushing equipment in accordance

with the manufacturer’s recommendations.

6. Continue flushing until the water from the lead-

away hose runs clear.

CYLINDER BLOCK AND CYLINDER HEADS

1. Allow the engine to cool to ambient

temperature (less than 50° C). Remove the

radiator cap, then disconnect the upper and

lower radiator hoses at the engine. Allow the

cooling system to drain.

2. Remove the thermostat, refer to Operation

2.7 THERMOSTAT - REMOVE in this Section.

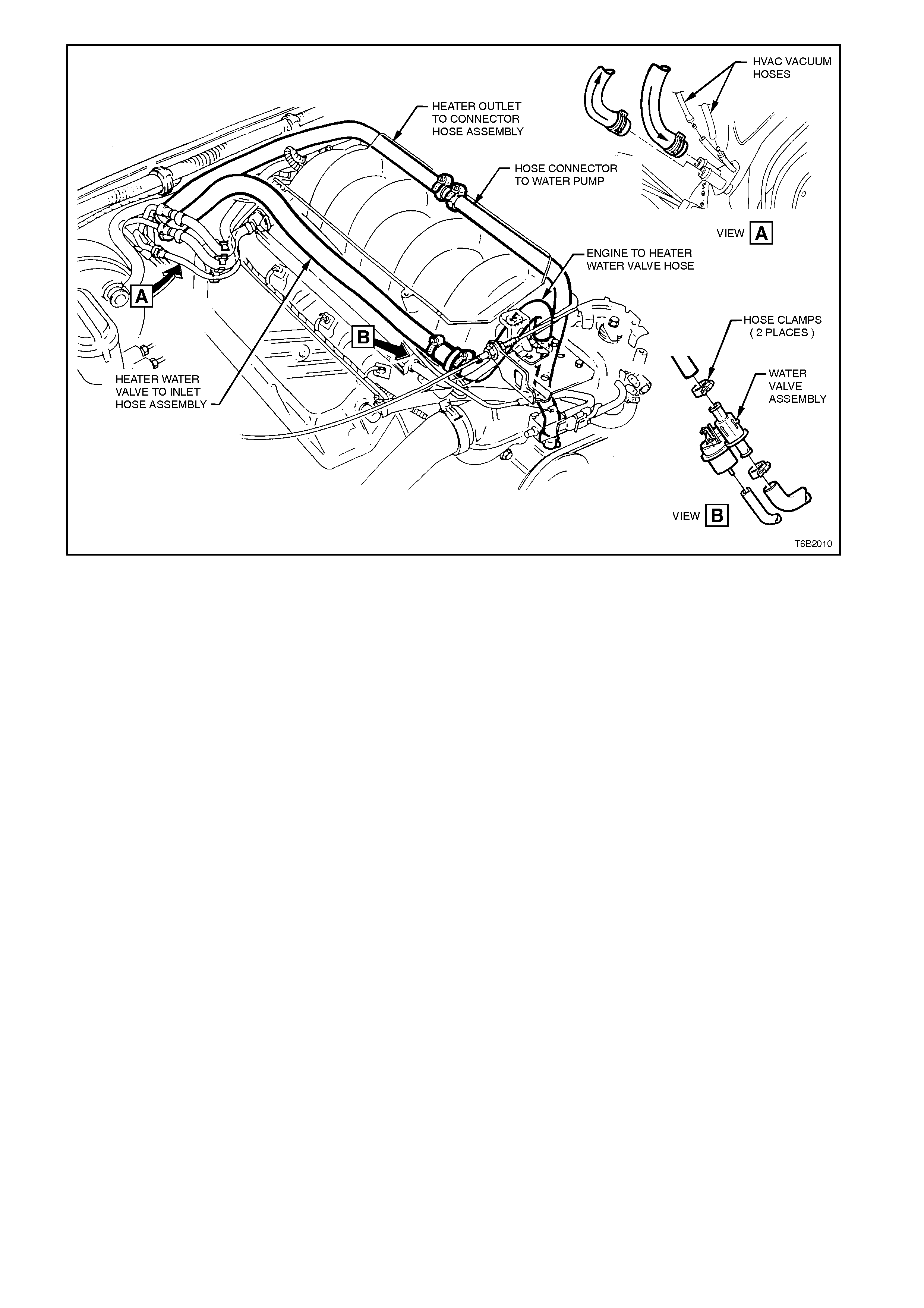

3. Disconnect the heater hoses and seal the

connections at the water pump.

4. Attach a lead-away hose to the water pump

inlet and a length of hose between the

thermostat housing outlet and the flushing

gun.

5. Operate the f lushing equipment in accordance

with the manufacturer’s recommendations.

6. Continue flushing until the water from the lead-

away hose runs clear.

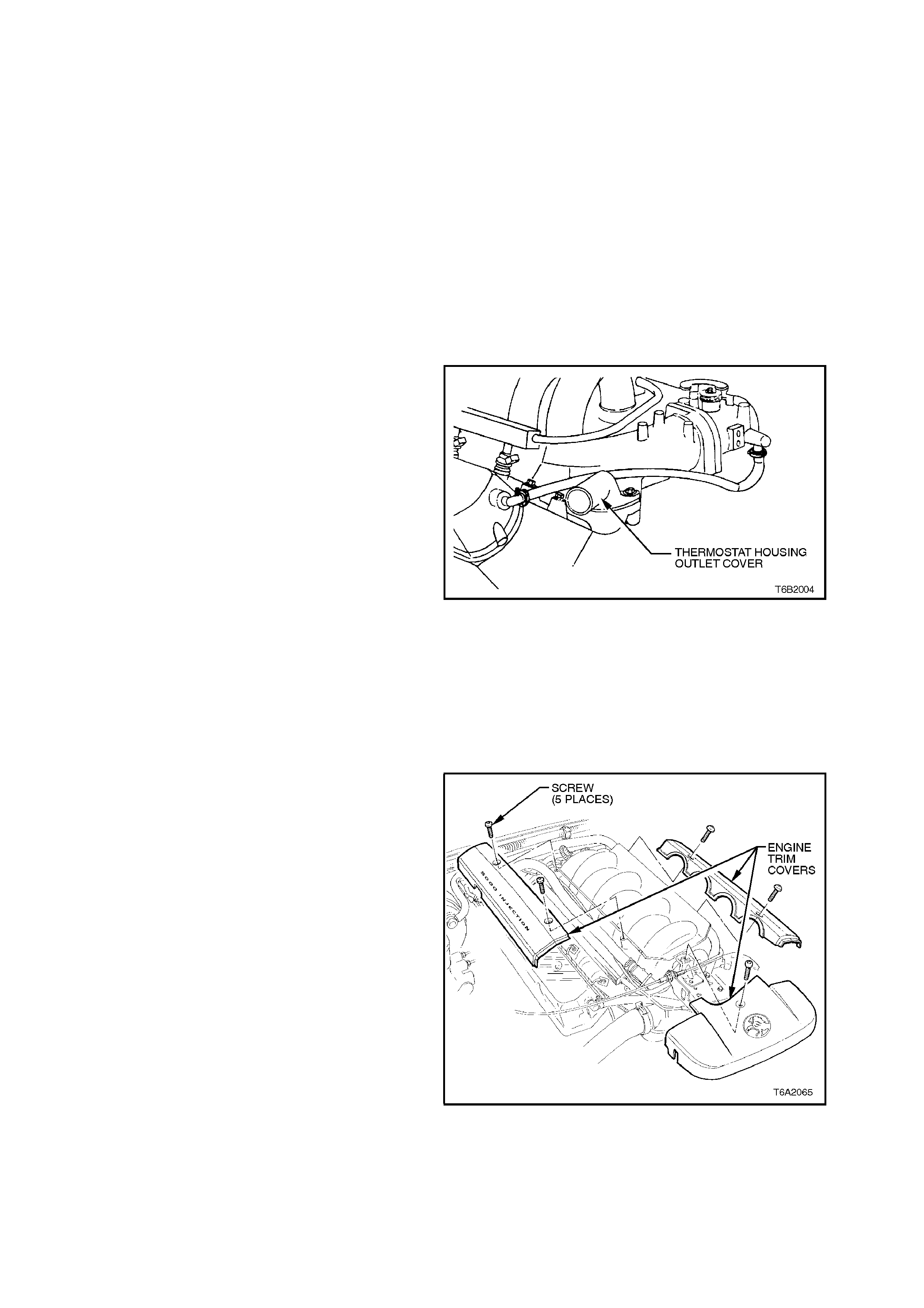

Figure 6B2-19

HEATER CORE

1. Allow the engine to cool to ambient

temperature (less than 50° C).

2. Remove engine trim covers. Refer to

Section 6A2 ENGINE MECHANICAL - V8

ENGINE.

3. Disconnect the heater hoses from under the

inlet manifold trim covers.

4. If necessary, attach a lead-away hose to

heater core inlet and a length of hose between

the outlet hose and flushing gun.

5. Operate flushing equipment in accordance

with the manufacturer’s recommendations.

6. Continue flushing until the water from the lead-

away hose runs clear.

Figure 6B2-20

Figure 6B2-21

2.5 COOLANT HOSES

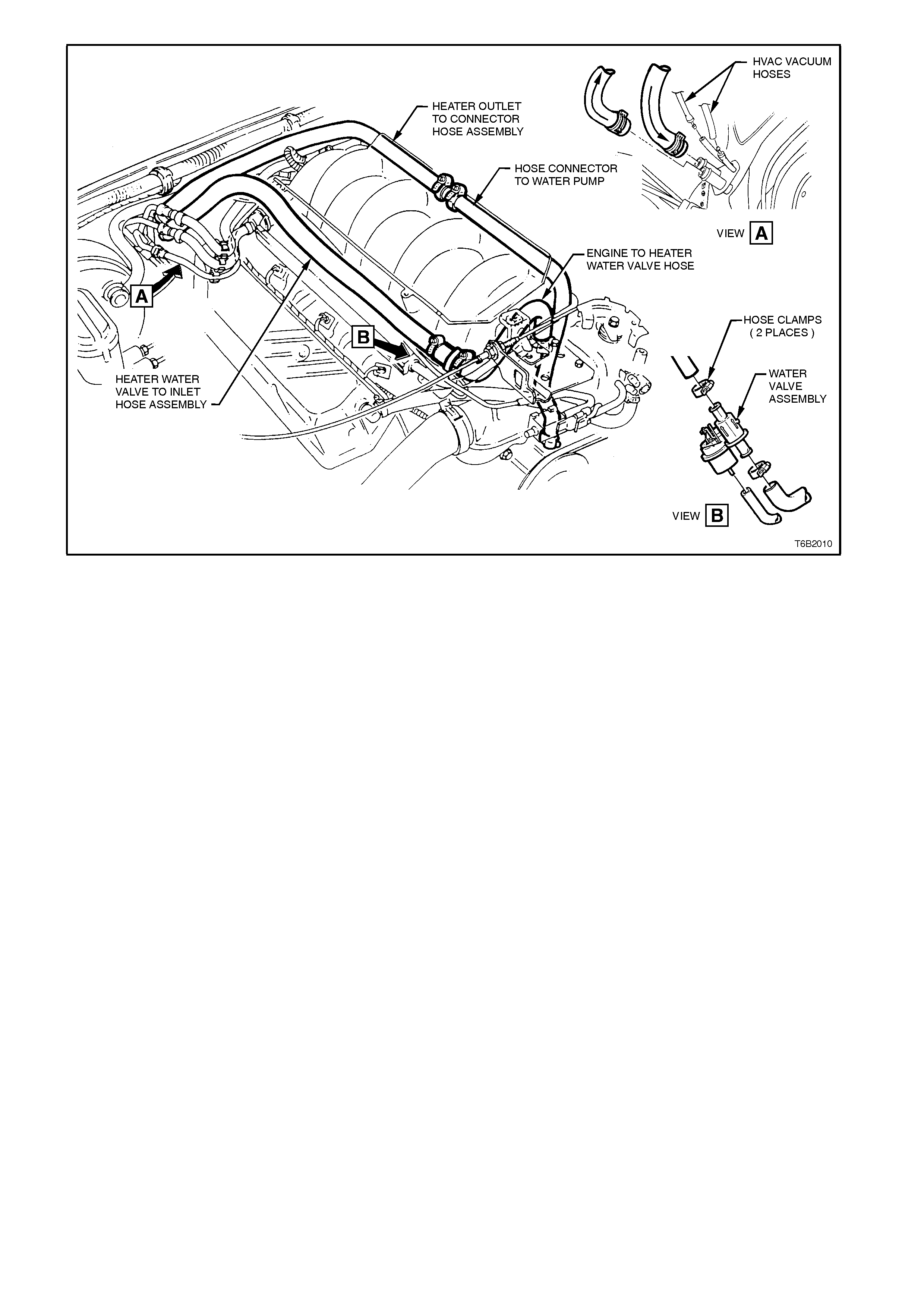

Coolant hoses are installed as shown in the following illustrations.

Hose connections should be thoroughly cleaned before installing any new hose.

After hose is fitted, always refill the cooling system with correct concentration of coolant, refer 2.3 CHECKING AND

FILLING COOLING SYSTEM and pressure test cooling system, refer 2.6 PRESSURE TESTING in this Section.

CAUTION:

Always wear protective safety glasses when working with spring type hose clamps. Failure to do so could

result in eye injury.

Figure 6B2-22

Figure 6B2-23

2.6 PRESSURE TESTING

RADIATOR CAP TESTING

1. Allow engine to cool to ambient temperature

(less than 50° C), then remove radiator cap.

CAUTION:

Do not remove radiator cap while the engine

coolant t emperature is above 50°

°°

°C, as personal

injury may result.

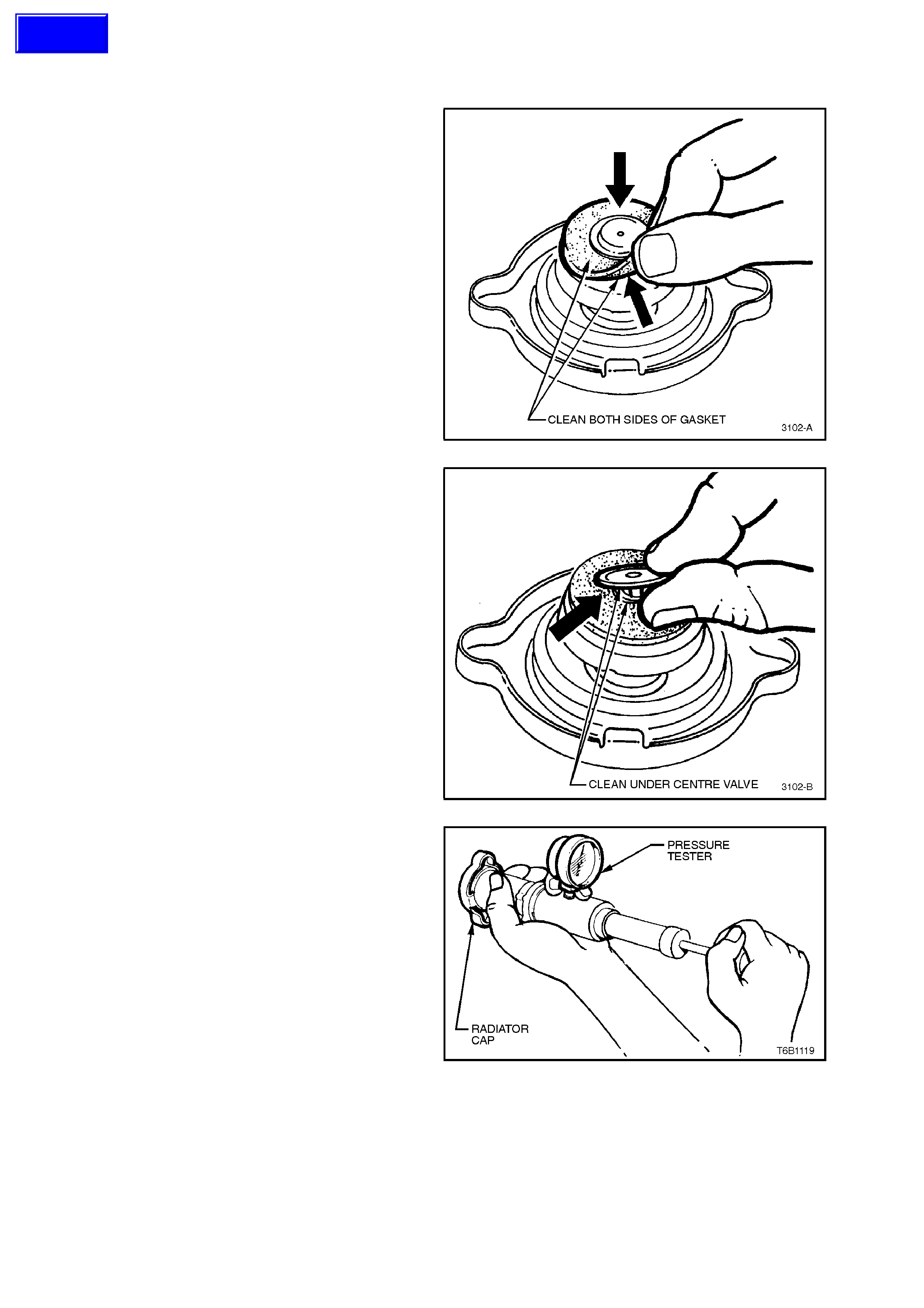

2. Clean both sides of radiator cap gasket with a

wet cloth.

NOTE:

Use only water to wet cleaning cloth.

Figure 6B2-24

3. Lift centre valve and clean gasket area under

valve.

Figure 6A1-25

4. Attach radiator c ap to a c ommerc ially available

cooling system pressure tester. Slowly

pressurise cap to 120-150 kPa. The cap is

serviceable if it unloads slightly above this

pressure range and holds pressure at 120

kPa. Should cap fail to reach or hold the

specified pressure, replace cap.

Figure 6B2-26

Techline

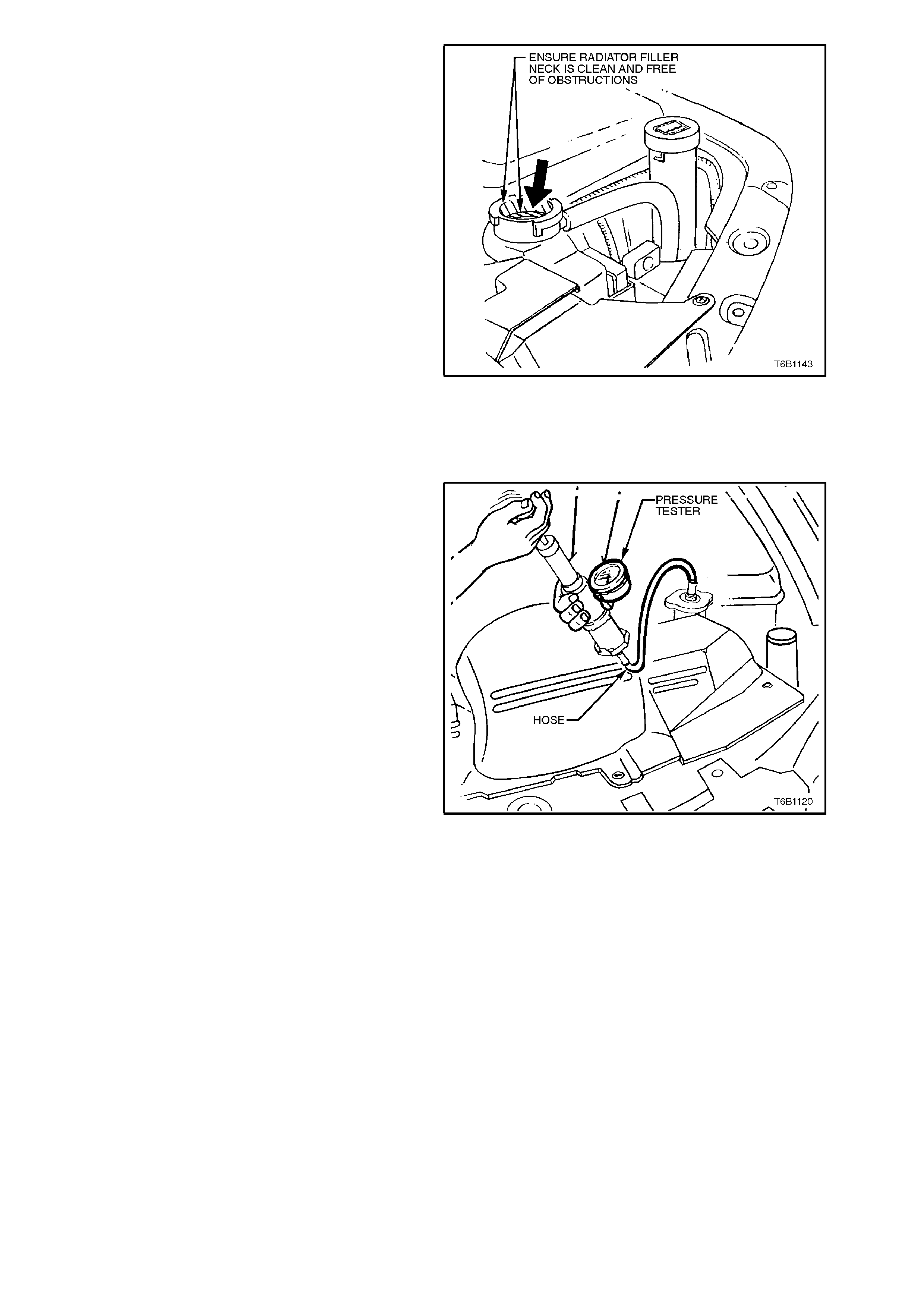

5. Prior to reinstalling radiator cap ensure

radiator f iller neck cap s eating sur face is clean

and free from obstruction, damage and

surface irregularities.

Figure 6A1-27

COOLING SYSTEM PRESSURE TESTING

1. Allow engine to cool to ambient temperature

(less than 50°C), then remove radiator cap.

CAUTION:

Do not remove radiator cap while the engine

coolant t emperature is above 50°

°°

°C, as personal

injury may result.

2. Ensure coolant level is correct.

3. Connect a commercially available cooling

system pressure tester to radiator filler neck

and using compressed air, blow dry any

residual coolant around radiator filler neck.

Pressur ise c ooling s ystem to 120-150 kPa and

check for leaks at the following points;

a. All hoses and hose connections.

b. Overflow hose connection at radiator.

c. Radiator seams and core.

d. Corroded or faulty engine welsh plugs or

drain plugs.

e. Water pump and gasket.

f. Vehicle heater system.

g. Check engine oil dipstick for evidence of

engine oil contamination with coolant.

Figure 6B2-28

4. If pressure will not hold, there is a leak in the

cooling system. Repair as necessary.

2.7 THERMOSTAT

REMOVE

1. Drain cooling system, refer to

2.1 SERVICE NOTES in this Section.

2. Remove engine trim covers. Refer to

Section 6A2 ENGINE MECHANICAL - V8

ENGINE.

NOTE:

Both inlet manif old trim c overs need to be rem oved

before the front cover can be removed.

3. Disconnect radiator upper hose from

thermostat housing.

4. Remove the two bolts securing thermostat

housing outlet cover to inlet manifold.

5. Remove thermostat housing outlet cover, O -

ring and thermostat. Figure 6B2-29

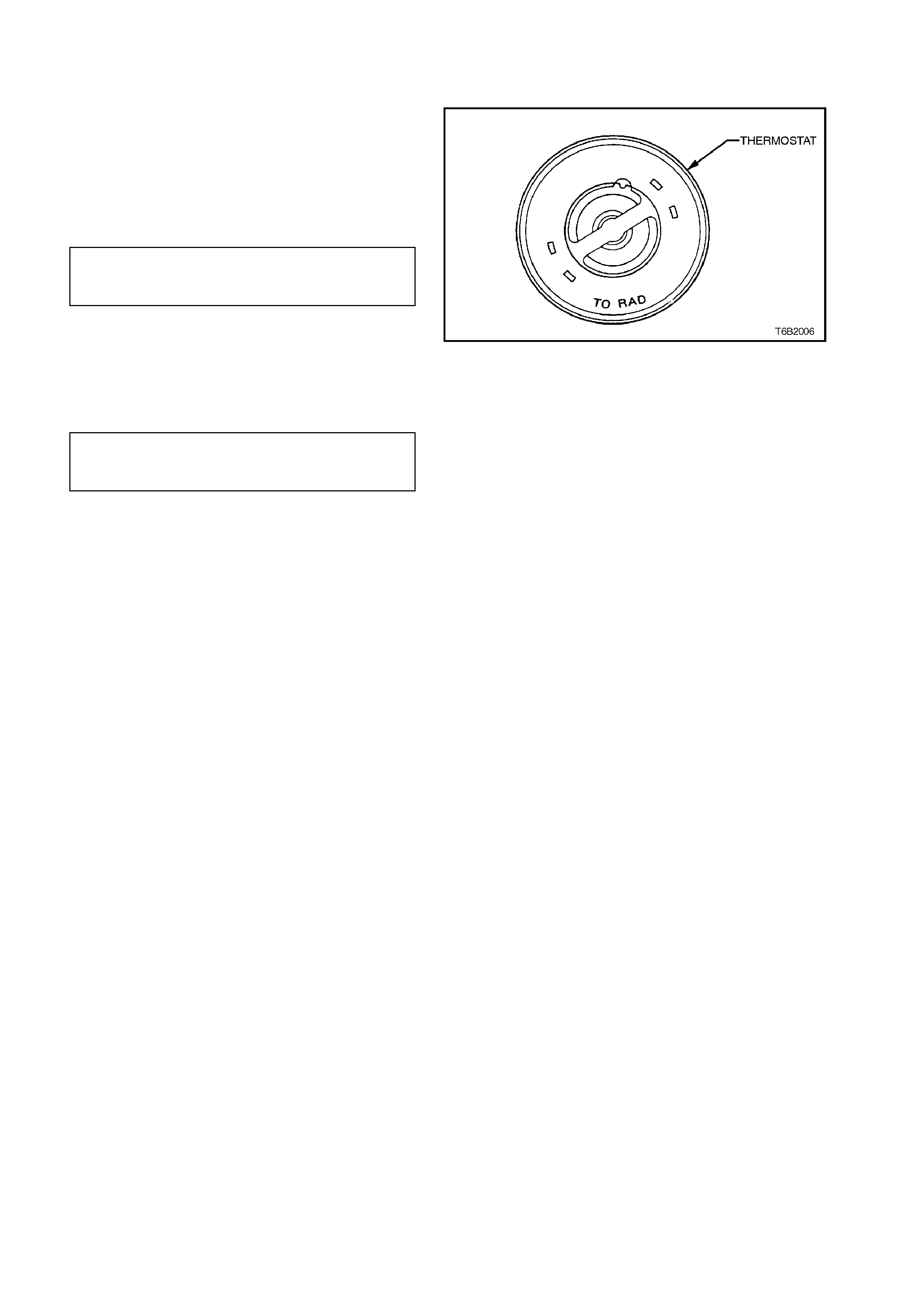

TEST

1. Suspend thermostat and a suitable

thermometer in a container of 50/50

glycol/water.

2. Heat container, agitating solution to ensure

uniform temperature until ther mostat begins to

open. Note temperature and ensure

thermostat opens within specif ied temperature

range.

3. Replace thermostat if it does not meet these

operating conditions.

Figure 6B2-30

NOTE:

Neither the thermostat or thermometer should rest

on the bottom of the container because of uneven

concentration of heat at this point when the

container is heated.

THERMOSTAT OPENING

TEMPERATURE 89° - 93° C

THERMOSTAT FULLY OPEN 103° C

REINSTALL

1. Clean mating surfaces of inlet manifold,

thermostat and thermostat housing.

2. Reinstall thermostat in inlet manifold with ‘TO

RAD’ inscription positioned towards radiator,

Figure 6B2-31.

3. Install new O - ring into housing cover.

4. Reinstall thermostat housing outlet cover and

progressively tighten bolts to specified torque.

THERMOSTAT HOUSING

ATTACHING BOLTS 20 - 27 Nm

TORQUE SPECIFICATION

5. Reconnect radiator upper hose to thermostat

housing.

6. Reinstall engine trim covers and tighten

fasteners to the specified torque.

ENGINE COVER

RETAINING SCREWS 6 - 14 Nm

TORQUE SPECIFICATION

NOTE The inlet manifold covers are specific to

each side. Reinstall with the correct orientation.

7. Refill cooling system with specified coolant

(refer to 2.3 CHECKING AND FILLING THE

COOLING SYSTEM in this Section) and

check for leaks.

Figure 6B2-31

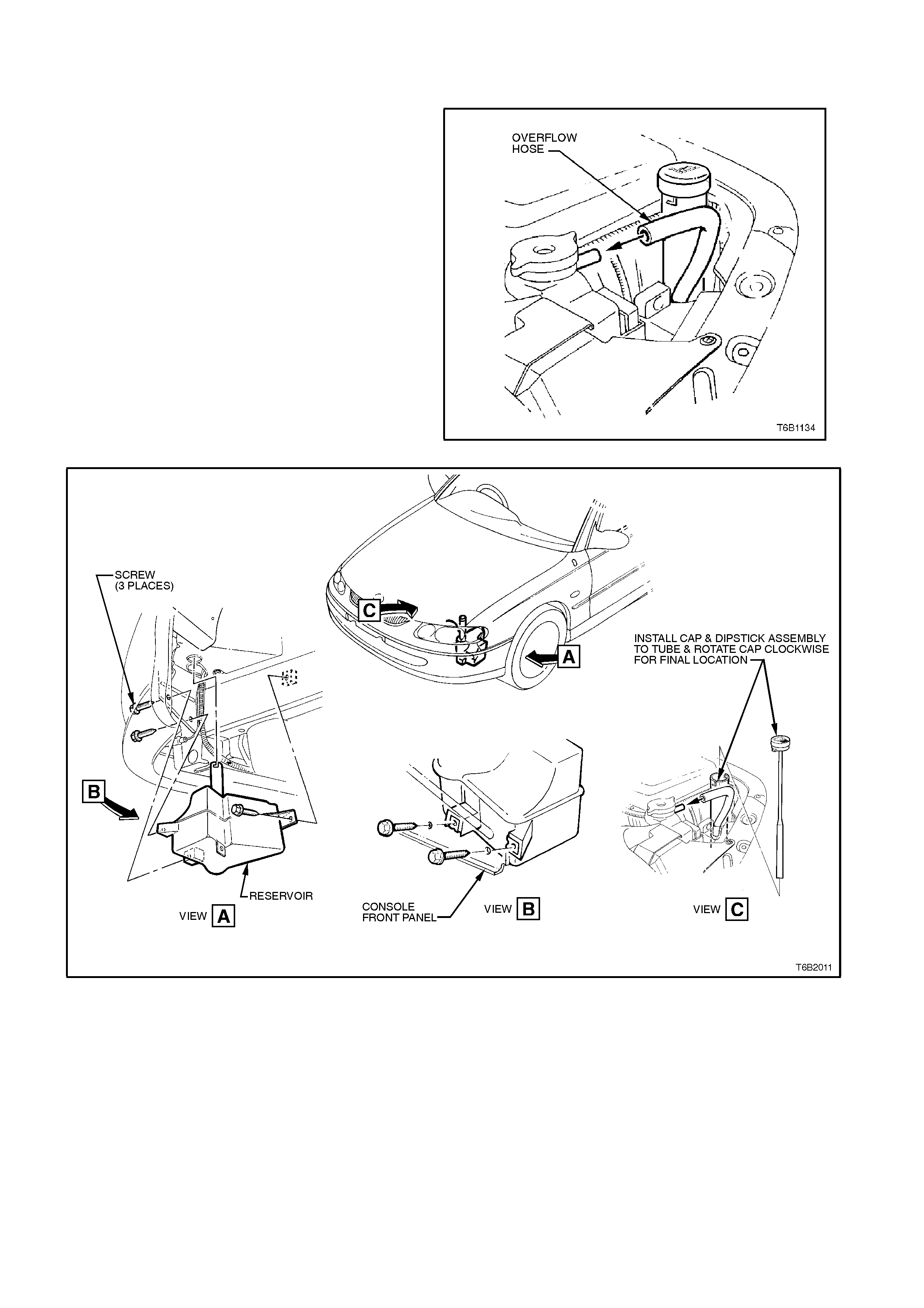

2.8 COOLANT RECOVERY RESERVOIR

REMOVE

1. Remove hose from the coolant recovery

reservoir to radiator assembly .

2. Remove the three screws securing the

assembly to console front panel and chassis,

refer to Figure 6B2-1-33.

Figure 6B2-32

Figure 6B2-33

INSPECT

1. Drain contents from reservoir assembly.

2. Clean reservoir assembly with water and dry using compressed air.

3. Check reservoir and assembly for damage, e.g. abrasions, cracks, leaks or distortion. Replace if required.

REINSTALL

Reinstallation of the reservoir assembly is the reverse of removal procedures, noting the following points:

1. Refill cooling recovery reservoir and cooling system with the correct concentration of coolant, refer to

2.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

2. Check cooling system for leaks.

2.9 AI R BAFFLE

REMOVE

1. Jack up front of vehicle and place on safety

stands. Refer to Section OA GENERAL

INFORMATION for location of jacking points.

2. Remove air baffle to radiator support panel

fasteners and remove baffle.

Figure 6B2-34

REINSTALL

Reinstallation of the air baffle is the reverse of

removal procedures.

2.10 WATER PUMP

REMOVE

CAUTION:

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

NOTE:

The water pump cannot be overhauled, and is

serviced only as an assembly.

1. Drain cooling system, refer to

2.1 SERVICE NOTES in this Section.

2. Remove engine trim covers, refer to

Section 6A2 ENGINE MECHANICAL - V8

ENGINE.

3. Disconnect heater and by-pass hoses from

water pump.

4. Loosen and rem ove the water pump dr ive belt,

refer to Section 6A2 ENGINE MECHANICAL

- V8 ENGINE.

5. Remove water pump drive belt pulley.

Figure 6B2-35

6. Remove water pump attaching bolts, and

withdraw water pump and gasket (refer to

Figure 6B2-36).

Figure 6B2-36

REINSTALL

Installation is the reverse of removal procedure,

except that the attaching bolts are to be tightened

to the specified torque.

WATER PUMP

ATTACHING BOLT

TORQUE SPECIFICATION 23 - 30 Nm

7. Tighten water pump pulley attaching bolts to

the correct torque specification.

WATER PUMP PULLEY TO

HUB ATTACHING BOLT

TORQUE SPECIFICATION 10 - 16 Nm

8. Refit radiator lower hose and clamp to front

cover connection.

9. Refill cooling system, refer to

2.3 CHECKING AND FILLING COOLING

SYSTEM in this Section.

10. Check for coolant leaks, refer to

2.6 PRESSURE TESTING in this Section.

11. Reconnect battery earth lead.

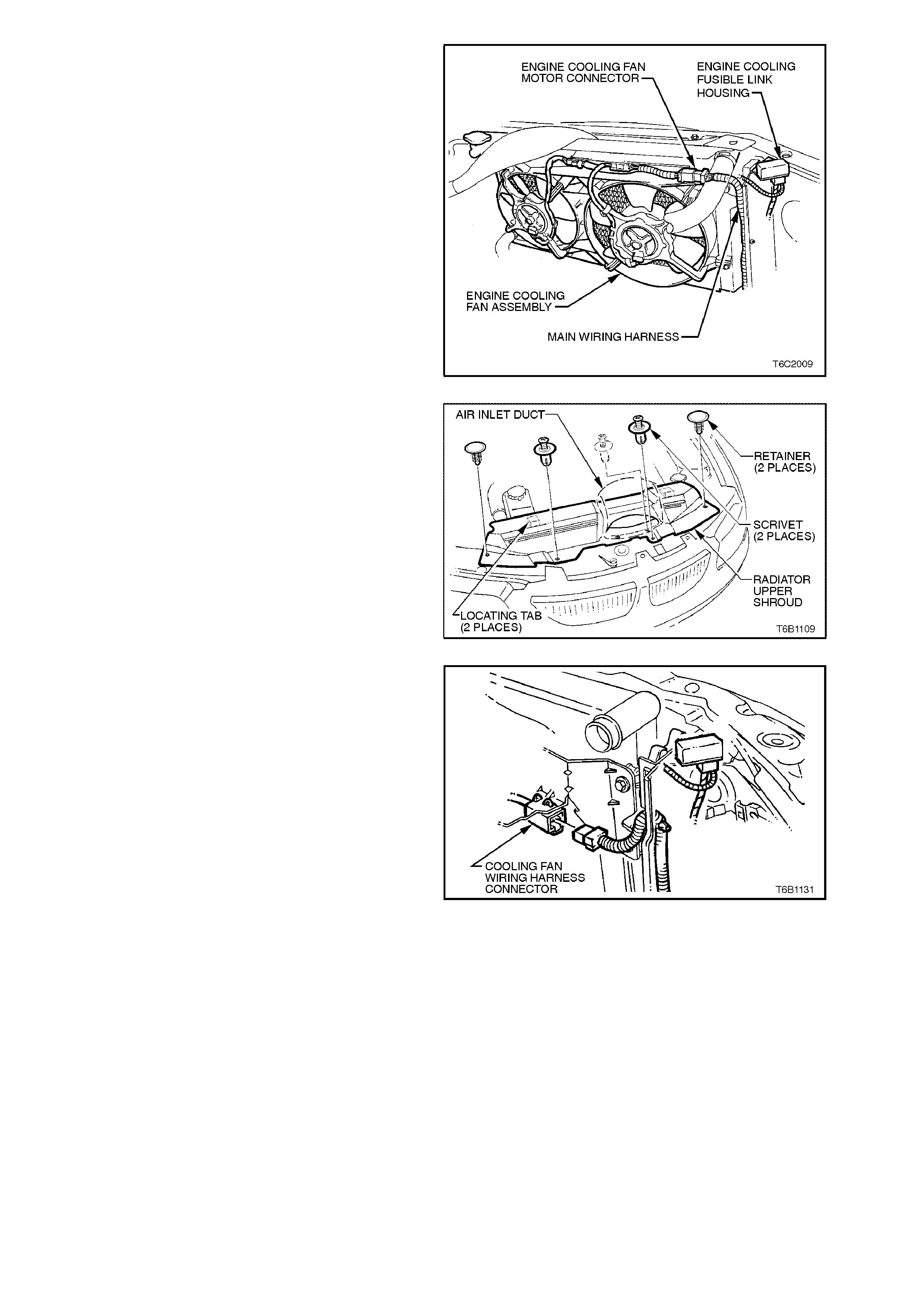

2.11 COOLING FAN AND SHROUD ASSEMBLY

REMOVE

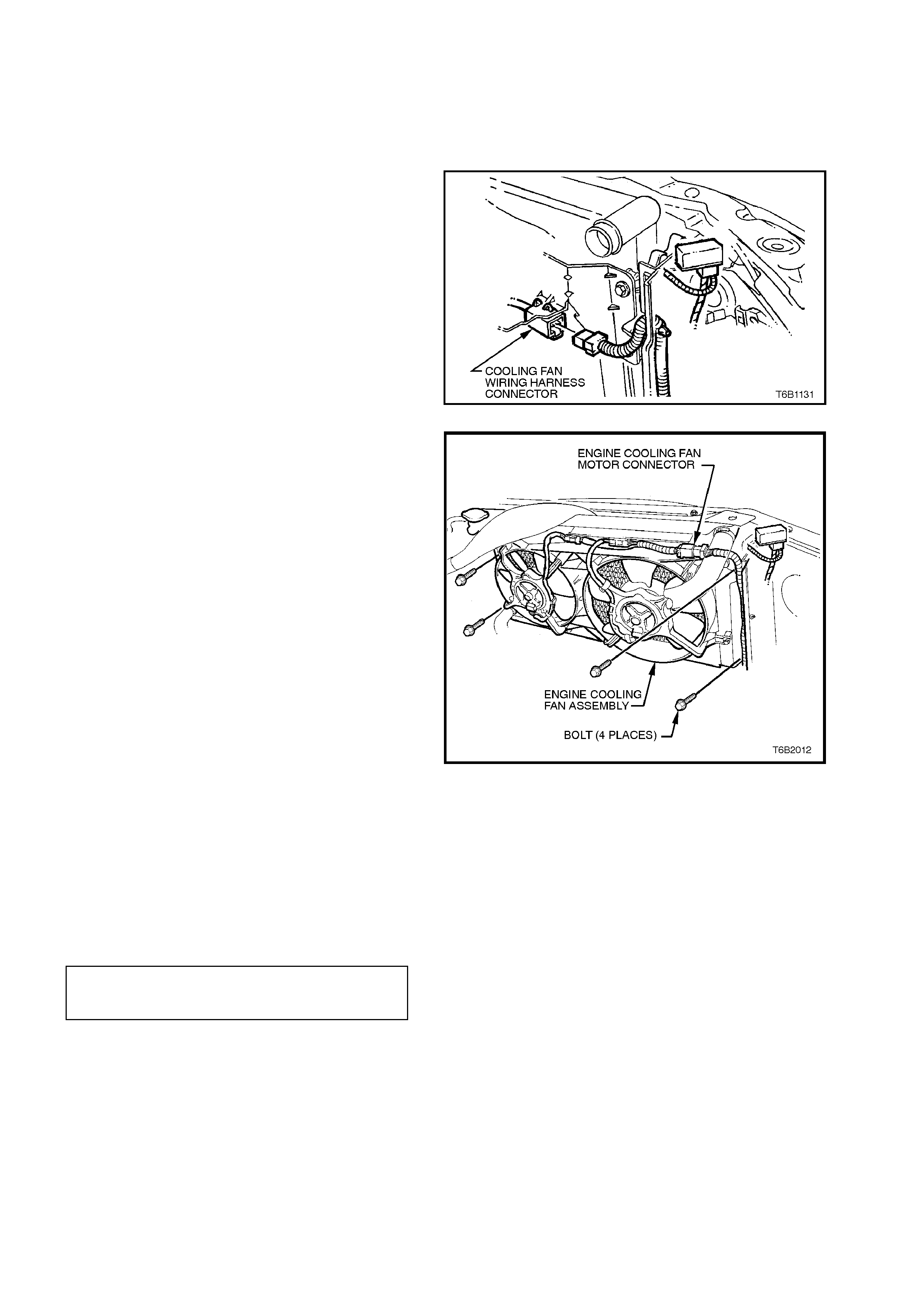

1. Disconnect battery earth lead.

2. Remove the power steering pump reservoir,

refer to Section 9A STEERING.

3. Depress tang on main wiring harness to

cooling fan motor wiring harness connector

and separate connector.

Figure 6B2-37

4. Remove cooling fan and shroud to radiator

attaching bolts, remove fan and shroud

assembly from engine compartment.

Figure 6B2-38

REINSTALL

Reinstallation of the cooling fan and shroud

assembly is the reverse of removal procedures,

noting the following points:

1. Ensure that fan and shroud assembly to

radiator attaching bolts are tightened to the

correct torque specification.

COOLING FAN AND SHROUD TO

RADIATOR ATTACHING BOLT

TORQUE SPECIFICATION 3 - 4.5 Nm

2. Check cooling fan operation, refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE. Check rotation direction of

cooling fan.

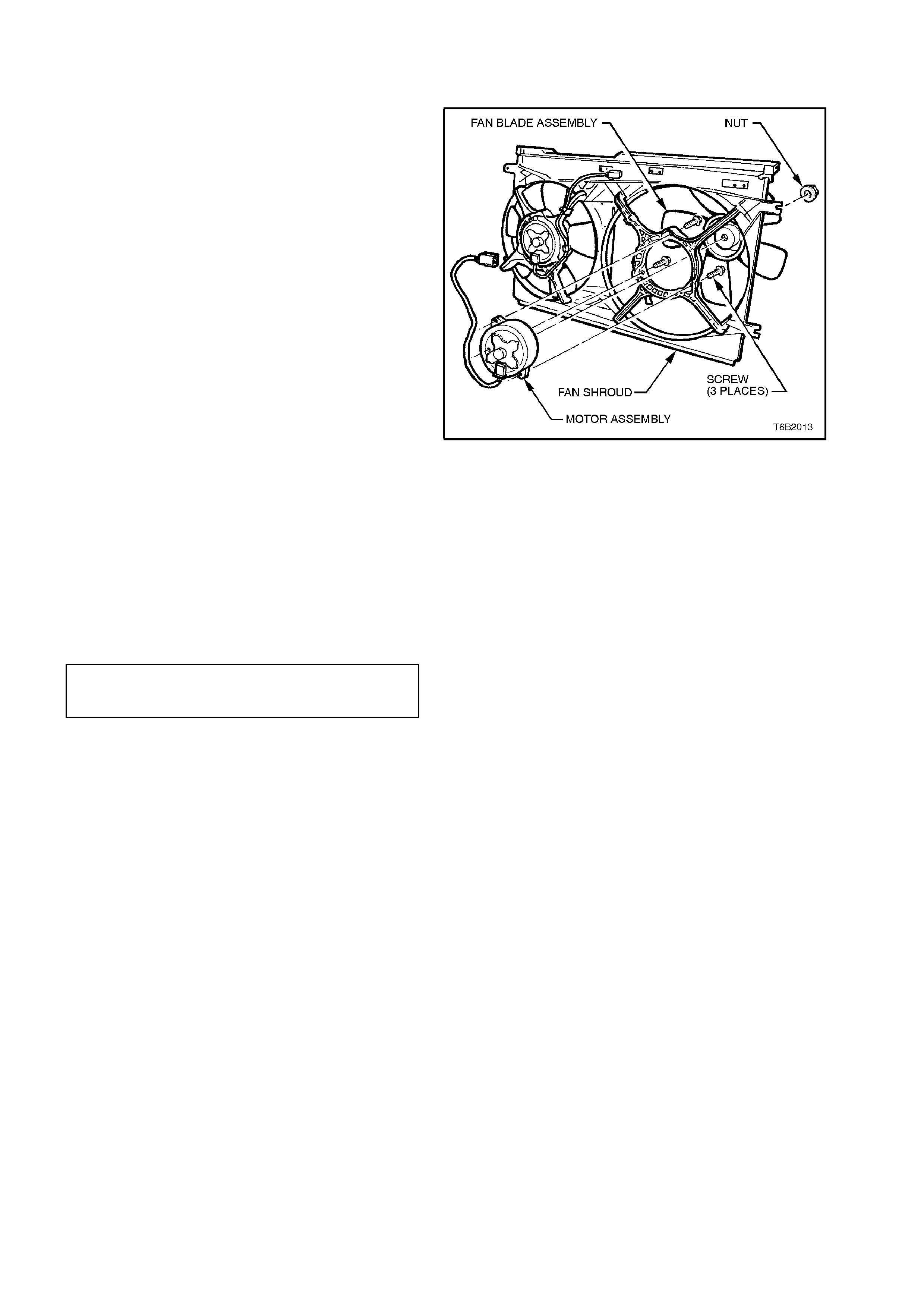

DISASSEMBLE

1. Remove cooling fan and shroud assembly as

previously described.

2. Holding fan blade assembly, remove fan to

motor shaft attaching nut and remove fan.

NOTE:

If the fan blade assembly is a tight fit on motor

shaft, reinstall attaching nut and leave loose.

Holding fan blade assembly up, tap on end of

motor shaft with a soft faced hammer. Remove

attaching nut and fan blade assembly.

3. Remove motor assembly wiring harness to

shroud attaching straps

4. Remove motor assembly to shroud attaching

screws, remove motor.

Figure 6B2-39

REASSEMBLE

Reassembly is the reverse of disassembly

procedures, noting the following points:

1. Tighten motor to shroud attaching screws

securely.

2. Install fan blade assembly to motor shaft and

tighten attaching nut to the correct torque

specification.

FAN TO MOTOR SHAFT

ATTACHING NUT

TORQUE SPECIFICATION 1.5 - 2.5 Nm

3. Install new motor wiring harness to shroud

attaching straps.

4. Reinstall cooling fan and shroud assembly as

previously described.

2.12 RADIATOR

REMOVE

1. Allow engine to cool to ambient temperature

(less than 50°C), then remove radiator cap.

CAUTION:

Do not remove radiator cap while the engine

coolant t emperature is abov e 50°

°°

°C, as personal

injury may result.

2. Disconnect battery earth lead.

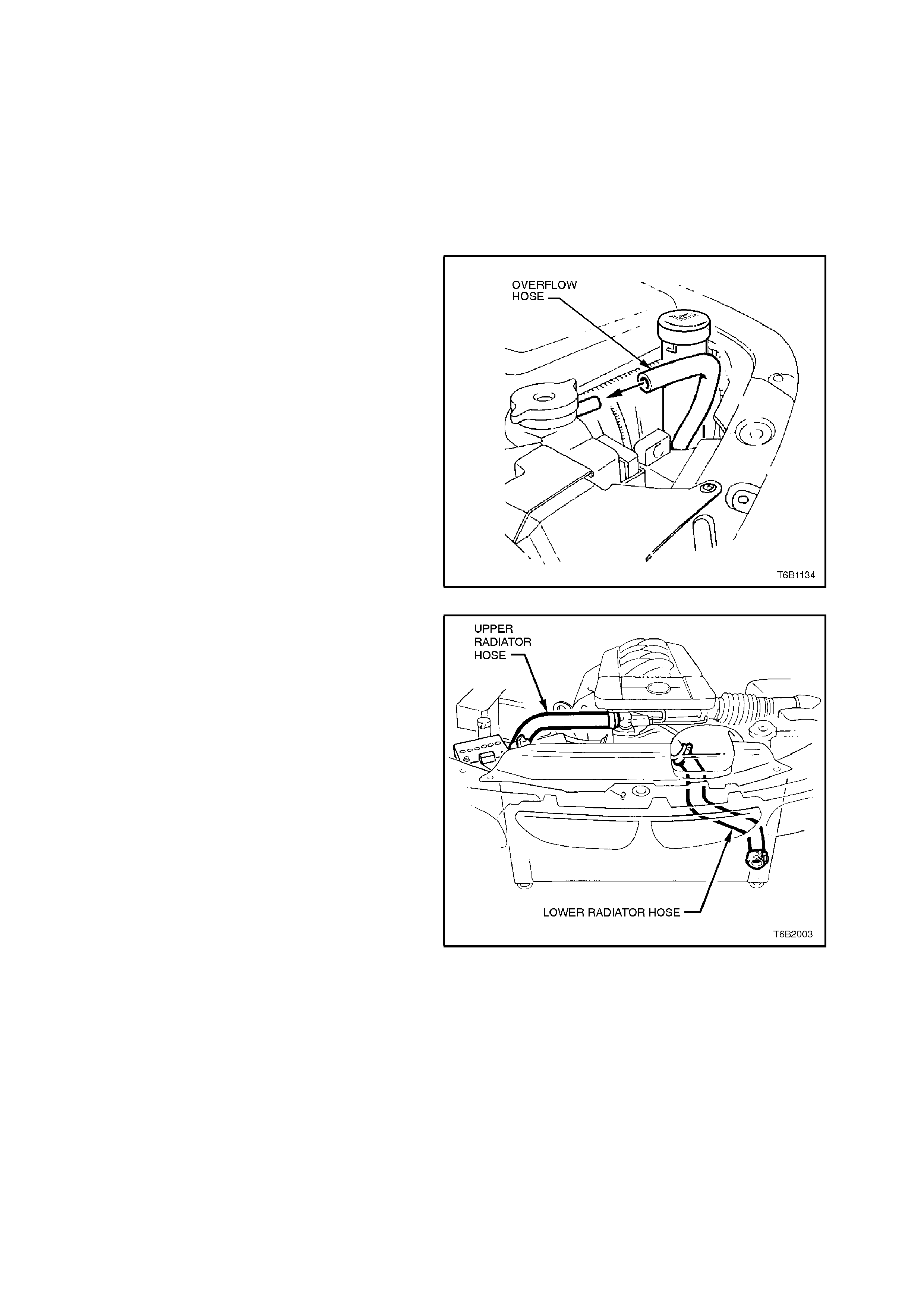

3. Remove coolant overflow hose from radiator

filler neck connection.

Figure 6B2-40

4. Remove radiator lower hose from radiator

connection and allow coolant to drain into a

suitable splash tray.

CAUTION:

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

5. Remove radiator upper hose from radiator.

Figure 6B2-41

6. If vehicle is equipped with automatic

transmission, loosen transmission oil cooler

line hose clamps and disconnect hoses from

radiator oil cooler unions.

Plug hoses and oil cooler unions to prevent

foreign matter entry.

7. Remove the power steering pump reservoir,

refer to Section 9A STEERING.

Figure 6B2-42

8. Remove the cold air intake duct and radiator

shroud retainers, disengage locating tabs by

pulling shroud towards front of vehicle prior to

removing the shroud.

Figure 6B2-43

9. Depress tang on main wiring harness to

cooling fan motor wiring harness connector

and separate connector.

Figure 6B2-44

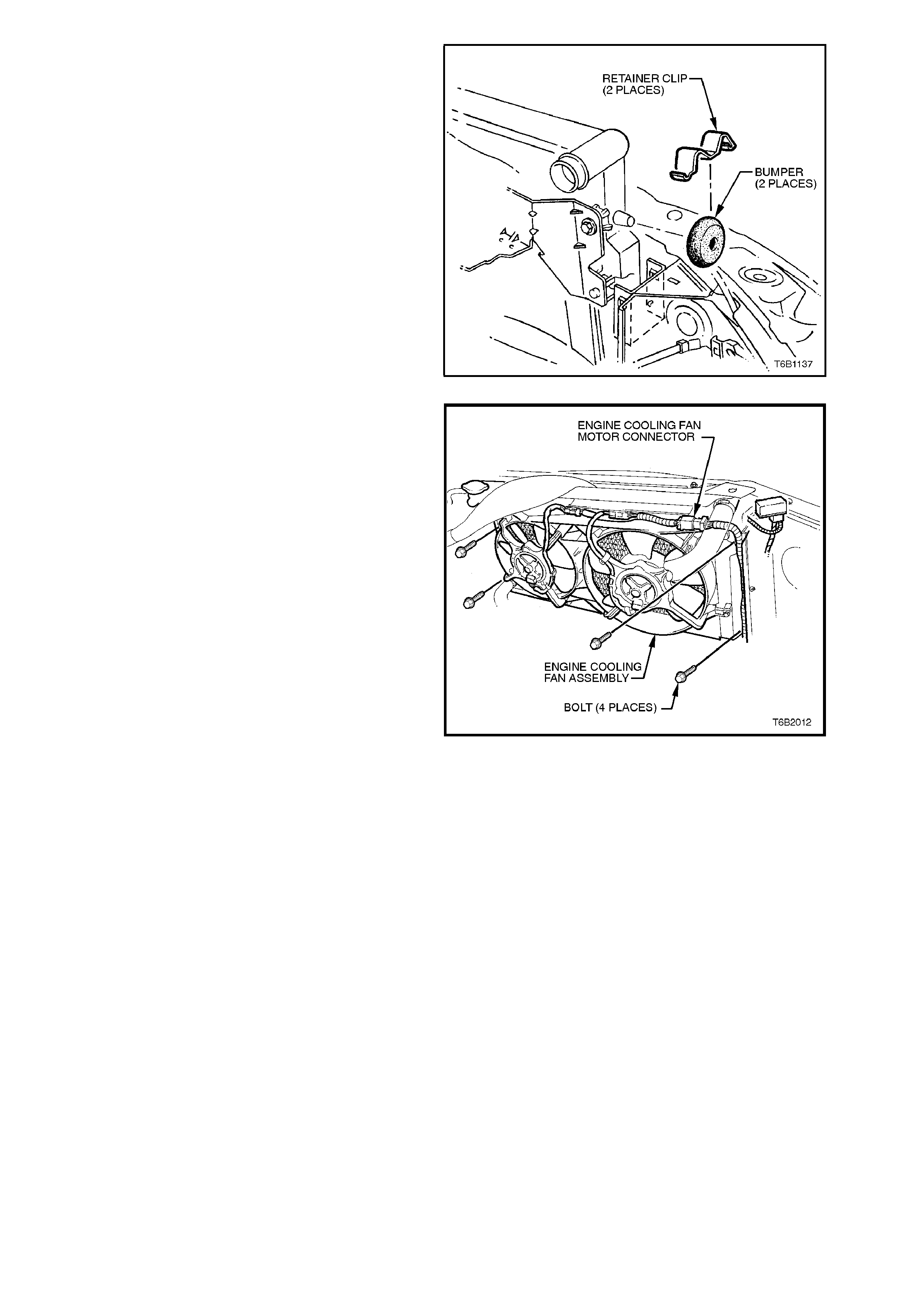

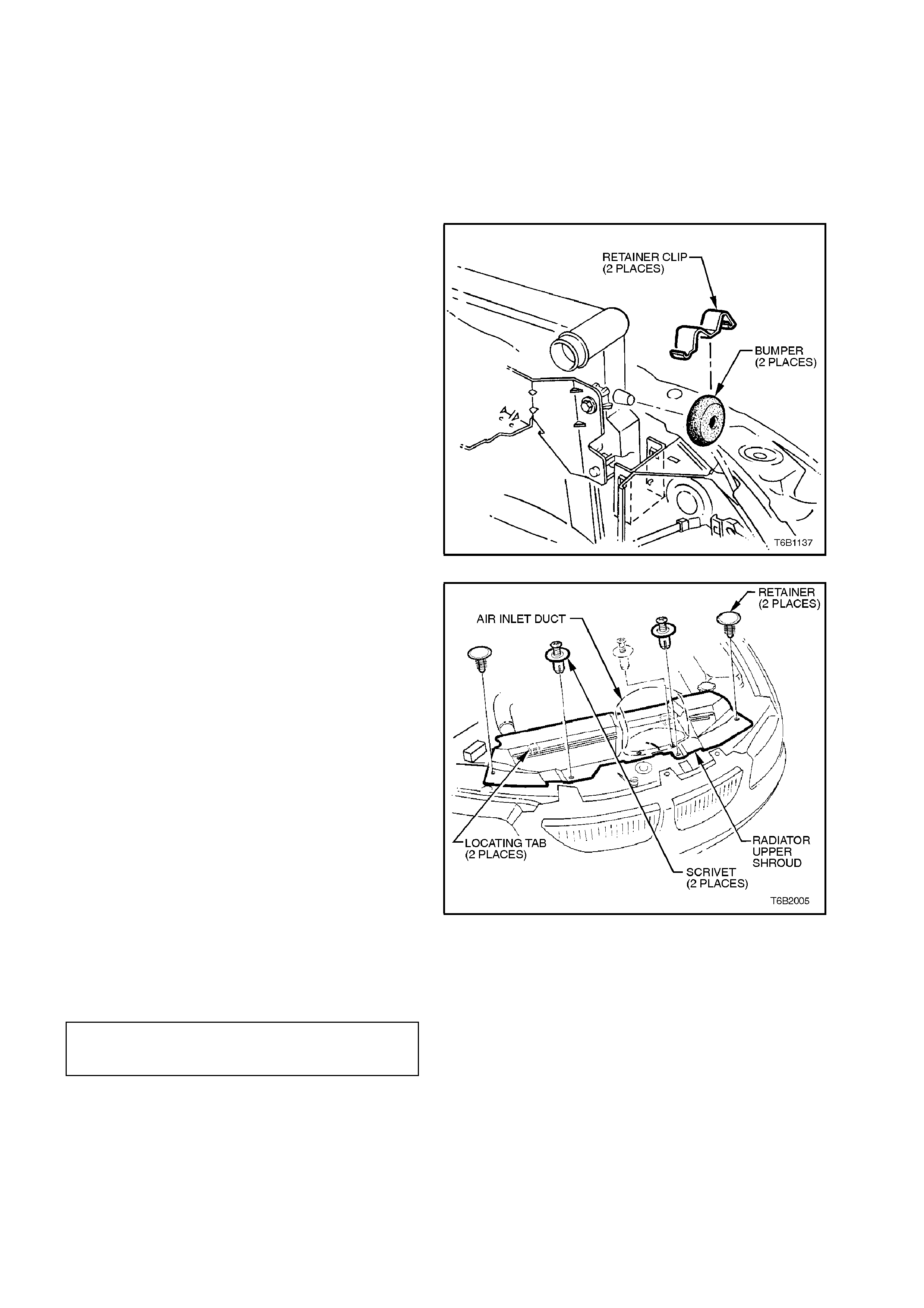

10. Using a screwdriver, compress and lever out

radiator retaining clips from radiator upper

mounting brackets.

11. Lift radiator upwards out of lower insulators

and remove radiator from vehicle.

Remove upper insulators from radiator upper

mounting pins.

Figure 6B2-45

12. If necessary, remove cooling fan and shroud

assembly to radiator attaching bolts and

remove fan and shroud assembly.

Figure 6B2-46

REINSTALL

Reinstallation of the radiator is the reverse of

removal procedures, noting the following points:

1. Before installing radiator, inspect core to

ensure that there is no foreign matter in core

fins. Clean out between core fins with

compressed air.

2. Ensure that radiator lower mounting pins are

correctly located in lower insulators.

3. Ensure that upper insulators are installed on

upper m ounting pins and radiator retainer s ar e

installed.

Figure 6B2-47

4. Reinstall cold air intake duct and front end

panel radiator shroud.

Figure 6B2-48

5. If removed, tighten cooling fan and shroud

assembly to radiator attaching bolts to the

correct torque specification.

COOLING FAN AND SHROUD TO

RADIATOR ATTACHING BOLT

TORQUE SPECIFICATION 3 - 4.5 Nm

6. Refill cooling system, refer to

2.3 CHECKING AND FILLING COOLING

SYSTEM in this Section.

7. Check for coolant leaks, refer to

2.6 PRESSURE TESTING in this Section.

8. Check cooling fan operation, refer to

Section 6C1 POWERTRAIN MANAGEMENT

- V8 ENGINE.

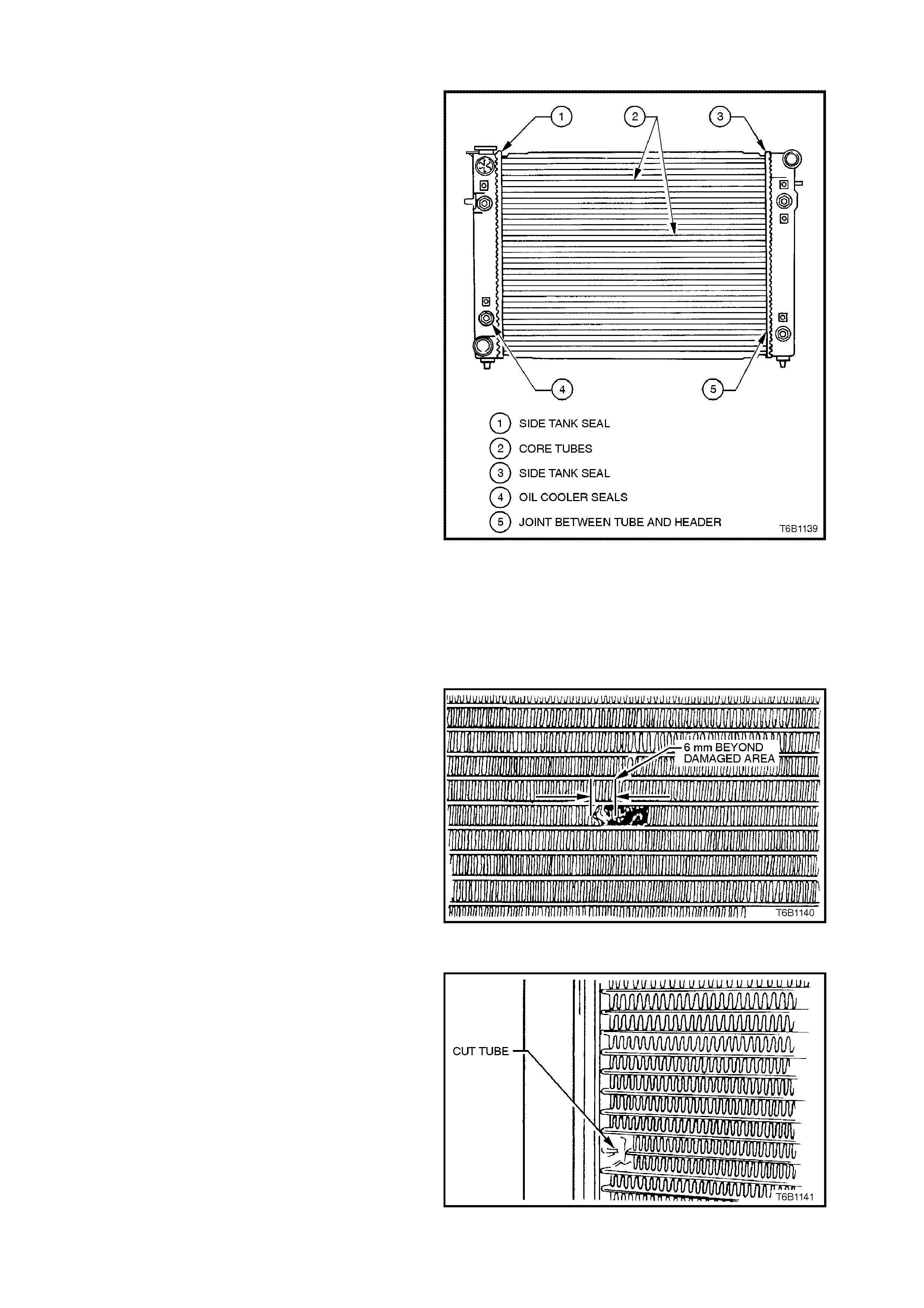

RADIATOR REPAIR PROCEDURE

REPAIRABLE LEAKS

There are two types of leaks that can be repaired

on the aluminium-plastic radiator; core leaks and

automatic transmission oil cooler seal leaks. Leak s

in the plastic tanks or the seals between the side

tanks and the headers cannot be repaired,

therefore the radiator must be replaced.

Core leaks may occur in a tube or in the joints

between the tubes and the headers. Seal leaks

may occur in the joints between the plastic tanks

and the headers or in the joints between the oil

cooler fittings and the tank (vehic les with autom atic

transmission).

Some leaks can be repaired while the radiator is

installed in the vehicle, however f or best r esults it is

recommended to remove the radiator from the

vehicle.

Figure 6B2-49

NOTE:

Minor damage to tubes, or tube to header joint

(holes up to 1m m diameter m ax.) can be repaired.

Core replacement is necessary if damage is any

greater.

REPAIR METHOD

Repairs to the alum inium r adiator c ore s hould only

be made using the recommended ‘Aluminised

Silicon’ based liquid repair agent, in accordance

with the recommended procedure outlined in

General Core Repair in this Section. Refer to VT

Parts Information for Alum inised Silicon base liquid

part number.

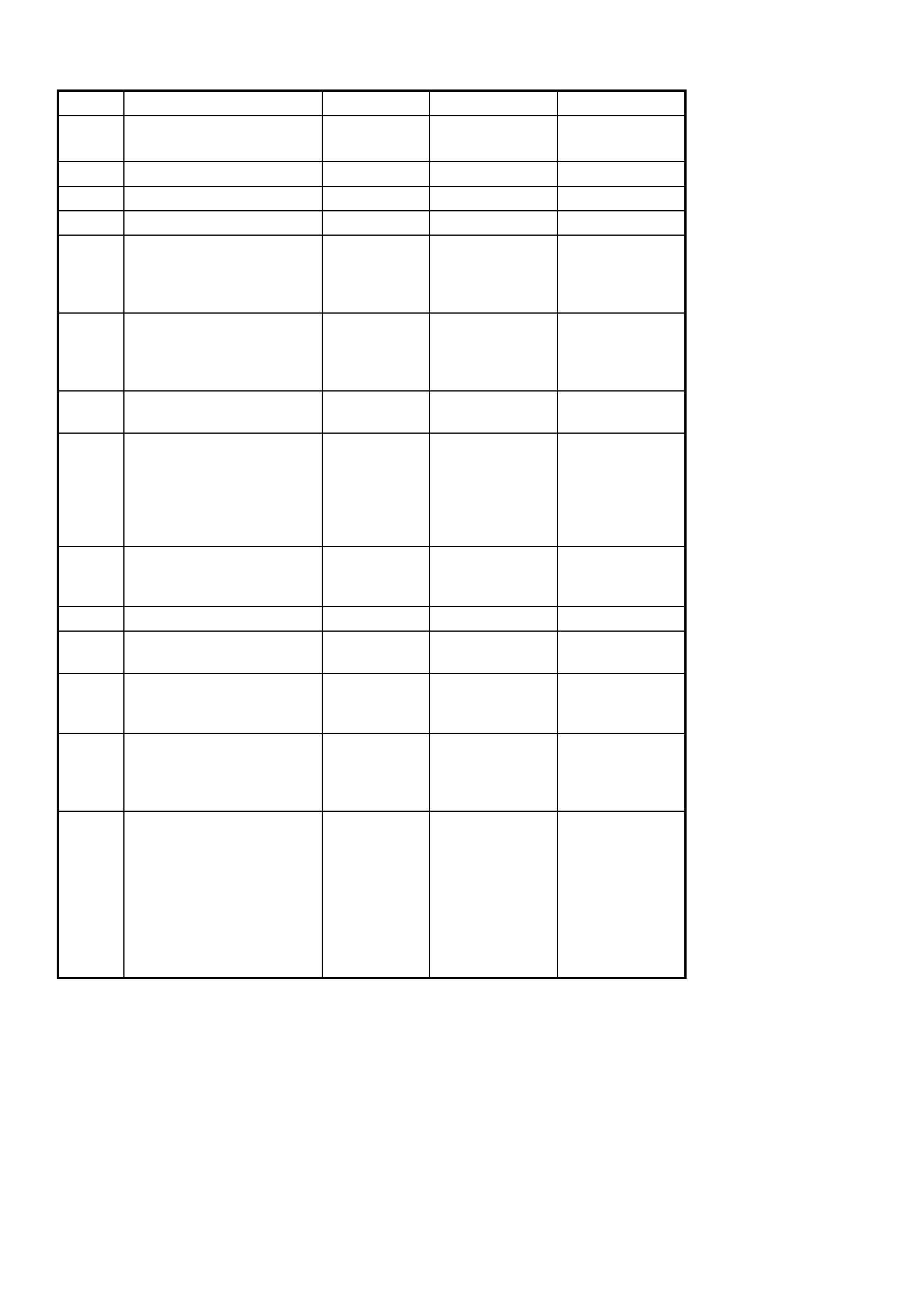

For damaged areas that are between the cooling

fins, it may be necessary to remove some of the

fins. Do not remove more fins than is necessary.

Usually 6mm beyond the leak or damage area, up

to a maximum of 25mm of total fin material, is

enough to make an effective repair. Figure 6B2-50

TUBE BLOCKING

If a tube is severely damaged, it can be blocked off.

NOTE:

Do not block off more than two tubes in a radiator.

Blocking off more than two tubes will reduce the

cooling capacity of the system.

The tube should be cut off 6 mm from the header

and pinched shut before it is cleaned and sealed,

refer General Core Repair in this Section.

Figure 6B2-51

HEADER REPAIR

If the header or a tube near the header requires a

repair, the side tank does not have to be removed.

GENERAL CORE REPAIR

The need for careful preparation of the surface in the repair area cannot be over-emphasised. If the leak area

surface is not clean, the repair material will not adhere to the surface.

1. Remove and drain radiator, refer to 2.12 RADIATOR - REMOVE in this Section.

2. If necessary, carefully cut away fins to expose the damaged area.

NOTE:

Do not cut away more than 25 mm total fin material.

3. Clean away dirt etc. with water. Dry the affected area using hot air from a hair drier.

NOTE:

Do not apply flame to dry damaged area.

4. Clean affected area with petrol to remove any traces of oil.

5. Thoroughly stir contents of repair agent.

In cases of extended shelf life, the silicon in solution may separate from the thinner base. Should this occur,

mix contents well until agent is again homogeneous.

6. Apply repair agent sparingly to damaged area. Do not apply excessive amount, as this will cause blockage of

the radiator tube.

Use a clean, dry wooden applicator to ‘DRIP’ agent onto damaged area of radiator.

7. Allow radiator to stand in a clean, dry area for a minimum of 3 hours (at ambient temperature of 20 - 30°C) with

adequate ventilation.

NOTE:

Do not apply heat or flame to promote drying.

8. Refit radiator, refer to 2.12 RADIATOR - REINSTALL in this Section.

TRANSMISSION OIL COOLER LEAK TEST

If the transmission oil cooler is suspected of leaking oil, test it before removal as follows:

1. Disconnect oil cooler lines from radiator connections.

2. Plug one of the connections and attach an air supply to the other connection.

3. Remove radiator cap.

4. APPLY AIR PRESSURE GRADUALLY, increasing it up to a maximum of 1030 kPa.

If bubbles appear in radiator neck, oil cooler is leaking and the radiator assembly must be replaced.

TRANSMISSION OIL COOLER SEAL REPLACEMENT.

The oil cooler seal can be replaced without

removing the side tank.

1. Remove radiator, refer to 2.12 RADIATOR -

REMOVE in this Sect ion, and lay radiator on a

flat surface.

2. Remove oil cooler to side tank nuts and

washers.

3. Press oil cooler into the side tank and remove

seal using a small wire hook.

Figure 6B2-52

4. Blow dry all surfaces on side tank and oil

cooler.

5. Install new seals WITHOUT ANY

LUBRICANT. Be sure they are seated

correctly on the flanges of the oil cooler

connections.

6. Pull oil cooler into position against side tank

and assemble washers and nuts to oil cooler

connections. Tighten oil cooler to side tank

nuts to the correct torque specification.

NOTE:

Do not over tighten, as damage to the seals could

result.

OIL COOLER TO SIDE TANK NUT

TORQUE SPECIFICATION 20 Nm

7. Reinstall radiator, refer to

2.12 RADIATOR - REINSTALL and pressure

test refer to

2.6 PRESSURE TESTING in this Section.

3. ENGINE COOLING SYSTEM DIAGNOSIS

Little or no heat coming from the heater, especially at idle, could be an indication of a cooling system problem.

As the coolant level begins to get lower than normal, air enters the system to replace the missing coolant. The

heater core is one of the highest parts of the cooling system and therefore, the first area to lose coolant.

At first, with a small amount of coolant loss, lack of heat will be most noticeable at idle. As driving speed increases,

the engine pumps more coolant and more heat is now able to pass through the heater core.

If coolant level drops even lower, heater operation will become less effective, even during normal driving. Cooling

and engine systems can be adversely affected if problem is not corrected.

The combustion gases can also force coolant out of the system and into the coolant recovery reservoir.

Air bubbles in the coolant or an overflow condition of the recovery reservoir are indications of a cylinder head gasket

leak.

To avoid needless time and cost in diagnosing cooling system complaints, the customer should be questioned

about driving conditions that place abnormal loads on the cooling system.

1. IS OVERHEATING OCCURRING AFTER PROLONGED IDLE, IN GEAR, AIR CONDITIONING SYSTEM

OPERATING?

If answer is YES - instruct owner on driving techniques that would avoid overheating such as:-

a. Idle in neutral as much as possible - increase engine rpm to get higher air flow (due to increase in voltage to

the fan) and water flow through radiator.

b. Turn air conditioning system off during extended idling periods if overheating is indicated on temperature

gauge. Further diagnostic checks should not be required.

2. IS OVERHEATING OCCURRING AFTER PROLONGED DRIVING IN SLOW CITY TRAFFIC, TRAFFIC

JAMS, PARADES, ETC?

If answer is YES - instruct owner on driving technique that would avoid overheating - same as for prolonged

idle - No.1. Further diagnostic checks should not be required.

If none of the above conditions apply, refer to the following Diagnosis Chart.

To effectively use this chart, question the customer to determine which of the following three categories apply to the

complaint:-

a. Hot indication on temperature gauge.

b. Boiling.

c. Coolant loss.

A. IF COMPLAINT IS HOT INDICATION ON TEMPERATURE GAUGE

Was temperature reading accompanied by boiling? If answer is YES, go to overheating on diagnosis chart. If

answer is NO, check temperature gauge and sender.

B. IF COMPLAINT IS BOILING

Go to overheating on diagnosis chart.

C. IF COMPLAINT IS COOLANT LOSS

Determine if customer is filling the system correctly.

If incorrect filling is not the problem, go to coolant loss in the diagnosis chart.

WARNING:

THE COOLING SYSTEM IS DESIGNED TO OPERATE AT 120-150 kPa AND TEMPERATURES NOT

EXCEEDING 130°

°°

°C.

Refer to the WARNING in 2.1 SERVICE NOTES in this Section before removing the radiator cap or servicing the

system.

Techline

COOLING SYSTEM DIAGNOSIS

STEP ACTION RESULT IF YES IF NO

1. • Check Temperature

gauge reading High Temp.

Low Temp. Go to Step 3

Go to Step 6

2. • Check drive belt Belt Present Go to Step 3

3. • Check coolant Boiling Go to Step 4 Go to Step 5

4. • Check coolant level Low Go to Step 10 Go to Step 6

5. • Check Radiator cap.

Refer to 2.6

PRESSURE TESTING

in this Section

OK? Go to Step 8 Replace

Radiator cap

6. • Check thermostat.

Refer to 2.7

THERMOSTAT in this

Section

OK? Go to Step 9 Go to Step 13

7. • Check Temperature

Gauge Faulty Replace Go to Step 12

8. • Check cooling fan

operation. Refer

Section 6C1

POWERTRAIN

MANAGEMENT - V6

ENGINE.

Operational Go to Step 10 Repair

9. • Check for collapsed

upper or lower radiator

hose.

Collapsed Replace Go to Step 13

10. • Visual system check Leaks Go to Step 13 Go to Step 11

11. • Check Antifreeze

/Antiboil protection To

Specification Go to Step 12 Add Antifreeze

/Antiboil

12. • Check radiator core for

bent fins, dirt, bugs or

other obstructions.

Obstructed Clean or

straighten Go to Step 14

13. • Pressure Test cooling

system, Refer 2.6

PRESSURE TESTING

in this section.

Leaks Repair System OK

14. • If none of the above

require repair, the

problem is out of

ordinary or of a major

nature. Listed below

are two groups of

problem areas that

should be checked in

the order as shown.

A. PROBLEMS NOT REQUIRING DISASSEMBLY OF COOLING SYSTEM

1. Large obstructions blocking radiator or condenser airflow.

a. Auxiliary oil coolers.

b. License plate.

c. Obstruction of radiator grille, i.e. mud.

2. Loose, damaged or missing air chute side panels.

3. Missing or damaged air baffle.

4. Cracked or loose coolant recovery system hose.

B. PROBLEMS REQUIRING DISASSEMBLY OF COOLING SYSTEM

1. Damaged cooling fan or faulty motor operation.

2. Pressure test cooling system.

3. Defective water pump.

a. Eroded or broken impeller vanes.

b. Failed bearing or seal - check for shaft or bearing end play.

4. Internally blocked radiator core.

5. Obstruction of coolant recovery system.

6. Internal system leaks.

a. Head gaskets.

b. Cracked cylinder block.

c. Engine front cover.

d. Intake manifold gaskets.

7. Blocked coolant passages in cylinder heads or engine block - remove cylinder heads and check.

BLACK LIGHT AND DYE LEAK DIAGNOSIS METHOD

Holden strongly recommends the use of the black light and dye method to diagnose fluid leaks. This method of leak

detection is a proven, reliable method that identifies the specific leak source and/or location. The black light kit can

be used for various types of leak detection and when used with the appropriate tracer dye it can be used for

detecting water leaks, engine and transmission fluid leaks, R12, R134A leaks and coolant leaks. The following is a

summary of the steps involved in detecting a cooling system fluid leak using black light and dye.

4. SPECIFICATIONS

GENERAL

Radiator cap pressure rating 100 kPa

Cooling system capacity 12 Litres

Coolant corrosion inhibitor HN2043, approx. 6.0 litres

required when changing coolant.

THERMOSTAT

Type Power element (wax pellet)

Start to open at 89° - 93° C

Fully open at less than 103° C

WATER PUMP

Type Centrifugal

Drive V-belt

Bearing Type Double Row Ball Bearing

RADIATOR

Core type Aluminium crossflow core

Overall width 663 mm

Core width 546 mm

Overall height 462 mm

Core height 418 mm

Core thickness 25 mm

Plastic tanks Nylon 6,6

RADIATOR HOSES

LowerNumber and ty pe One, Moulded

Inside diameter 38.5 mm

UpperNumber and type One, Moulded

Inside diameter 34.0 mm

ENGINE COOLING FAN (1)

Number of blades 5

Spacing Uneven

Material Polypropylene (20% glass filled)

Diameter 340 mm

Electric motor drive 200 watts (nominal)

ENGINE COOLING FAN (2)

Number of blades 7

Spacing Uneven

Material Polypropylene (20% glass filled)

Diameter 300 mm

Electric motor drive 160 watts (nominal)

5. TORQUE WRENCH SPECIFI CATIONS

Nm

Cylinder Block Drain Plugs 27 - 35

Coolant Outlet To Inlet Manifold

Attaching Bolts 20 - 34

Water Pump To Front Cover Bolts 14 - 18

Water Pump To Cylinder Block Bolts 20 - 30

Water Pump Pulley Attaching Bolts 10 - 16

Cooling Fan And Shroud To Radiator

Attaching Bolts 3 - 4.5

Fan To Motor Shaft Attaching Nut 1.5 - 2.5

Oil Cooler To Side Tank Nuts 20

6. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

AU425 COOLING SYSTEM FILLER TUBE