SECTION 6C1-1 GENERAL INFORMATION

CAUTION

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS

will consist of either seat belt pre-ten sioners and a driv er’s side air bag, or seat belt

pre-tensioners and a driver’s and front passenger’s side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resulting in possible personal injury or

unnecessary SRS system repairs.

CAUTION

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests

of safety, the LPG fuel system should be isolated by turning 'OFF' the manual

service valve and then draining the LPG service lines, before any service work is

carried out on the vehicle. Refer to the LPG leaflet included with the Owner's

Handbook for details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

The engines used in this vehicle uses a Powertrain Control Module (PCM) with both an automatic transmission and a

manual transmission to control exhaust emissions while maintaining excellent driveability and fuel economy. The PCM

maintains a desired air/fuel ratio of precisely 14.7 to 1 by monitoring electrical signals from dual oxygen sensors

mounted in the exhaust stream and optimising the amount of fuel flow from the injectors. This method of "feed back"

fuel control is called CLOSED LOOP.

In addition to fuel control, the PCM also controls ignition dwell and timing, idle speed, EGR, electric engine cooling fan,

electric fuel pump, instrument panel "Check Powertrain" lamp and on vehicles so equipped, the A/C compressor clutch.

The PCM also controls the automatic transmission functions. The PCM also interfaces through the serial data line with

other vehicle control or information modules, such as the trip computer, Body Control Module (BCM), ABS/ETC module,

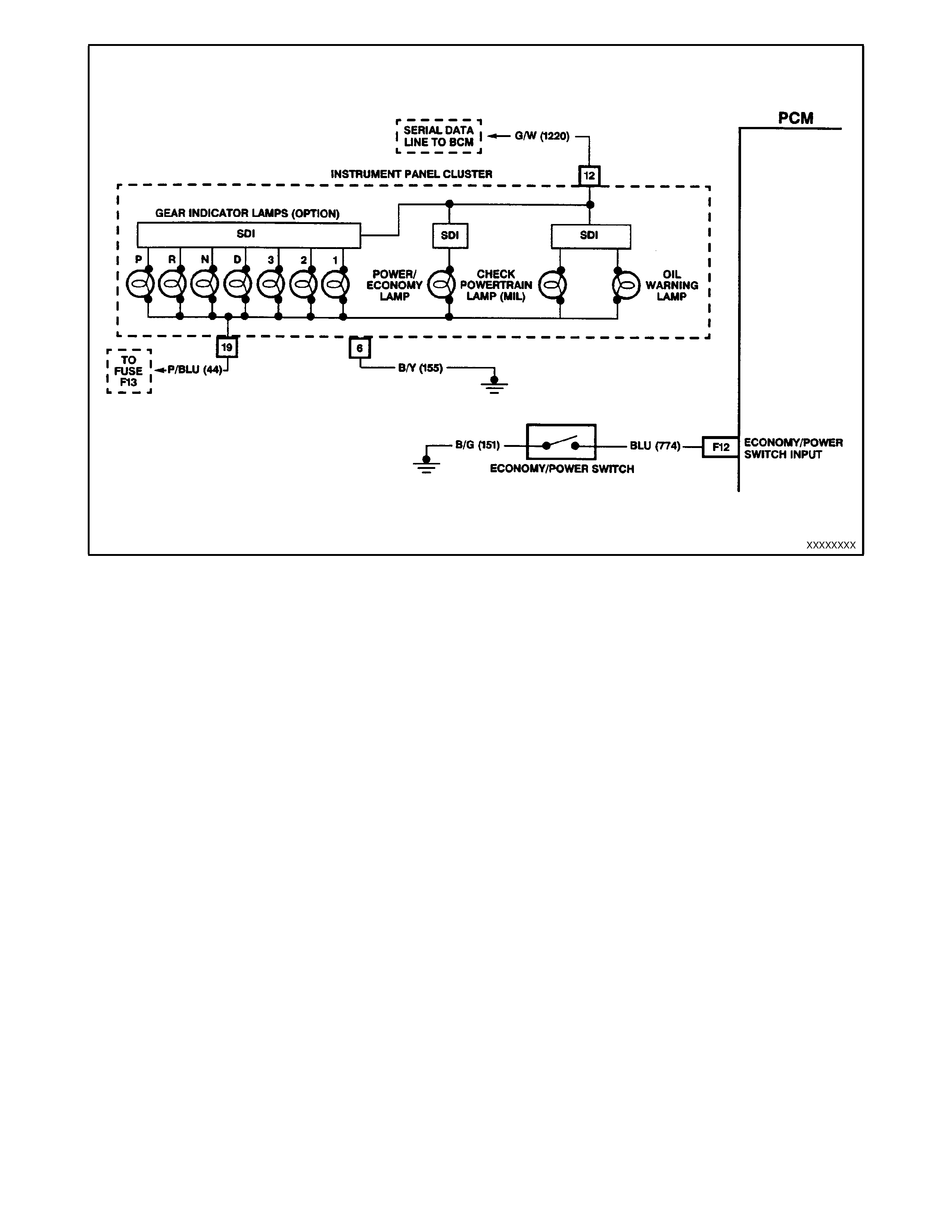

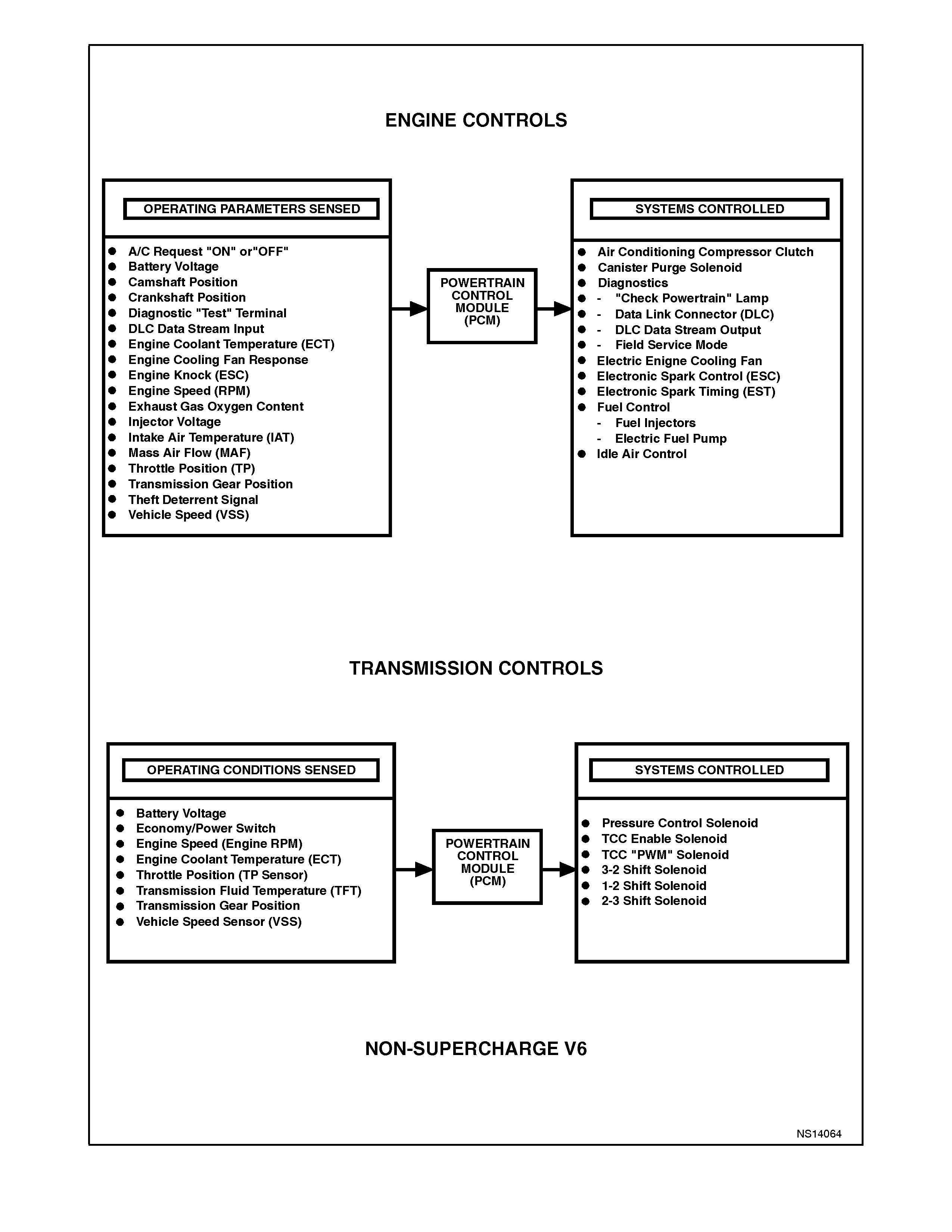

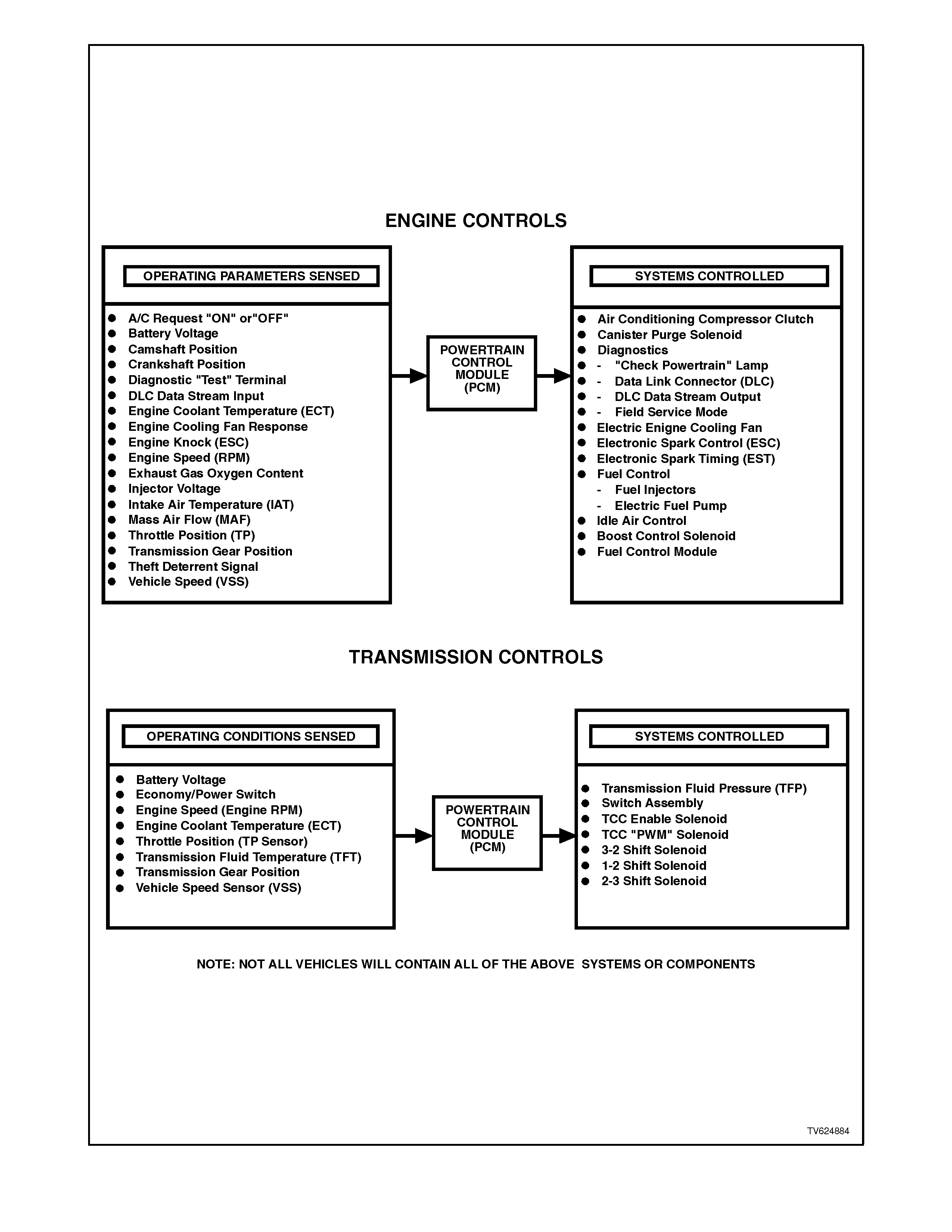

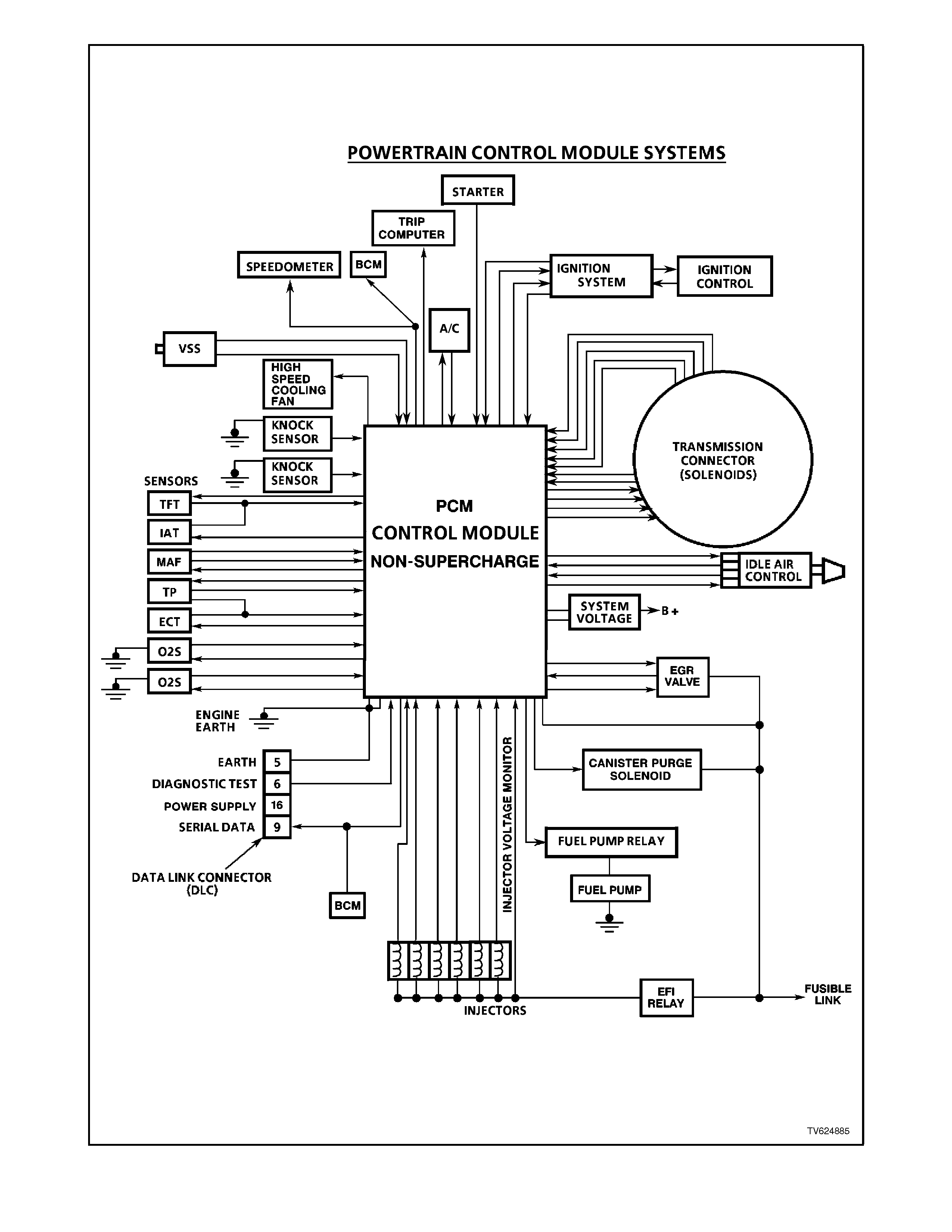

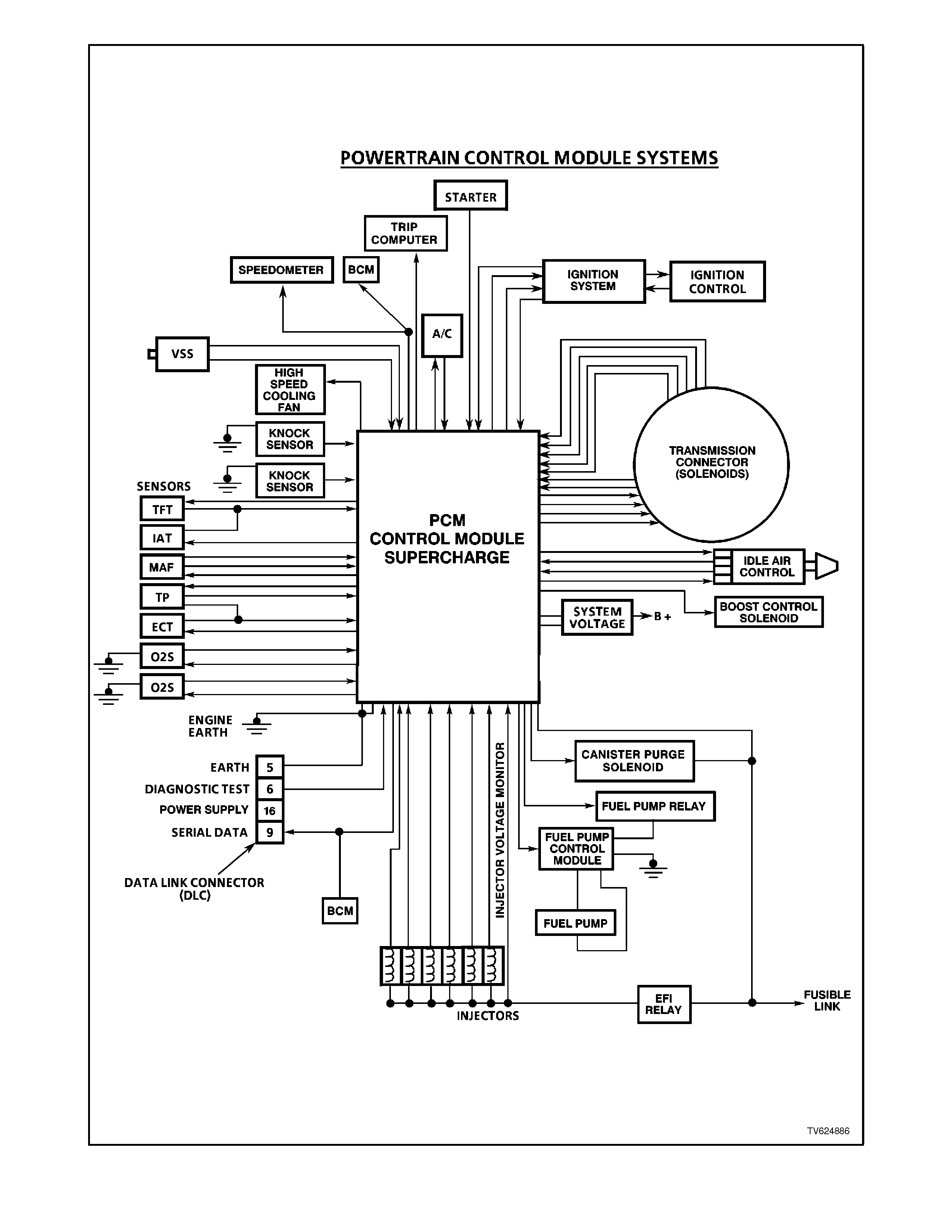

ECC module, SRS module, and theft deterrent system. Figures 6C1-1-1 through 6C1-1-4 contain a list of the various

operating conditions sensed by the PCM on the left, and the various systems controlled on the right. Details of basic

operation, diagnosis, and service are covered in this and other relevent Sections.

The PCM has a built-in diagnostic system that recognises and identifies possible operational problems and alerts the

driver by illuminating the "Check Powertrain" lamp/Malfunction Indicator Lamp (MIL) on the instrument panel. If the

lamp comes "ON" while driving, it does not mean that the engine should be stopped immediately, but the cause of the

lamp coming "ON" should be checked as soon as is reasonably possible. The PCM has built-in backup systems that in

all but the most severe failures will allow the vehicle to operate in a near normal manner until repairs can be made.

Below the instrument panel to the left of the steering column is a Data Link Connector (DLC) which is used by the

assembly plant for a computer "check-out" of the system. This connector is used in service along with a scan tool to

help diagnose the system. Refer to Section 6C1-2, DIAGNOSIS for further details.

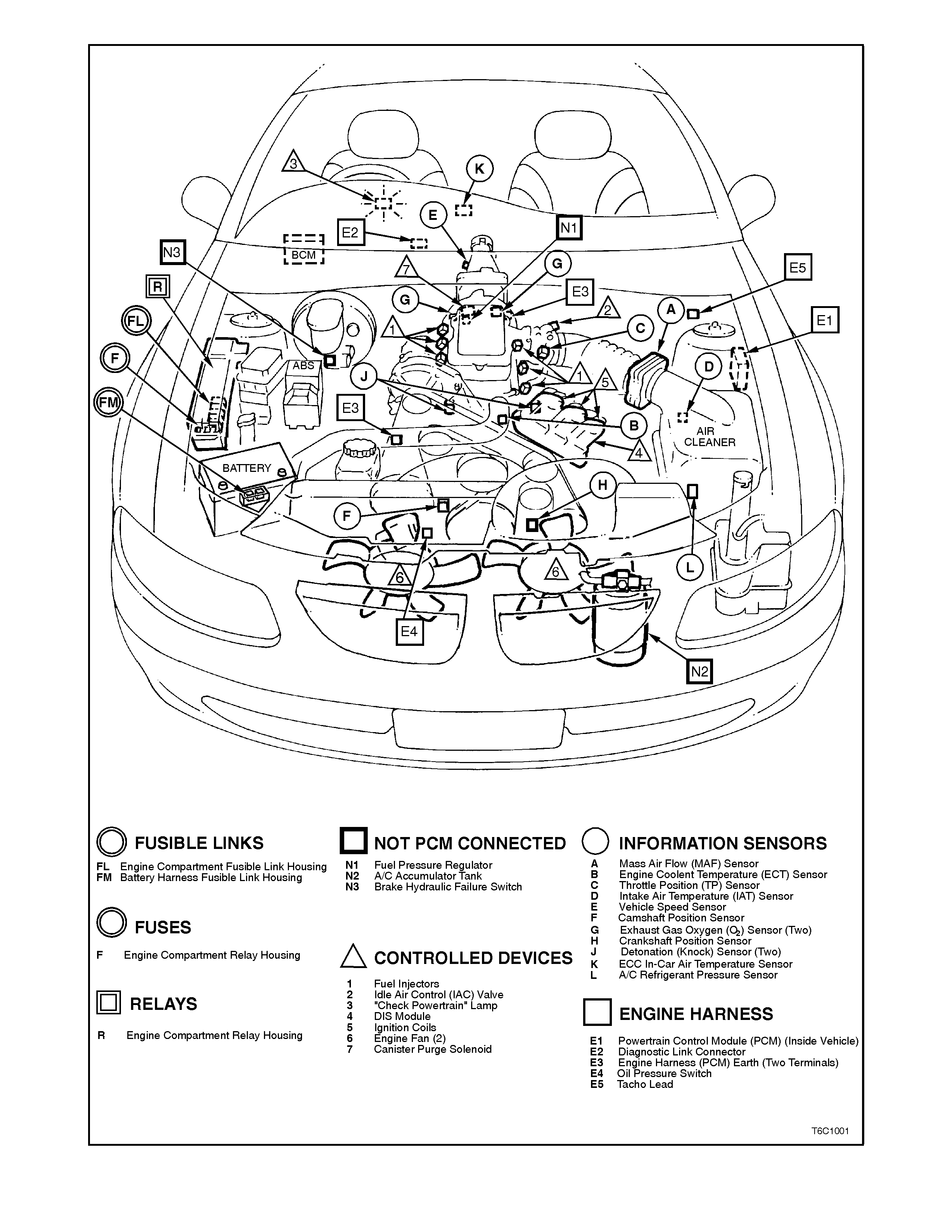

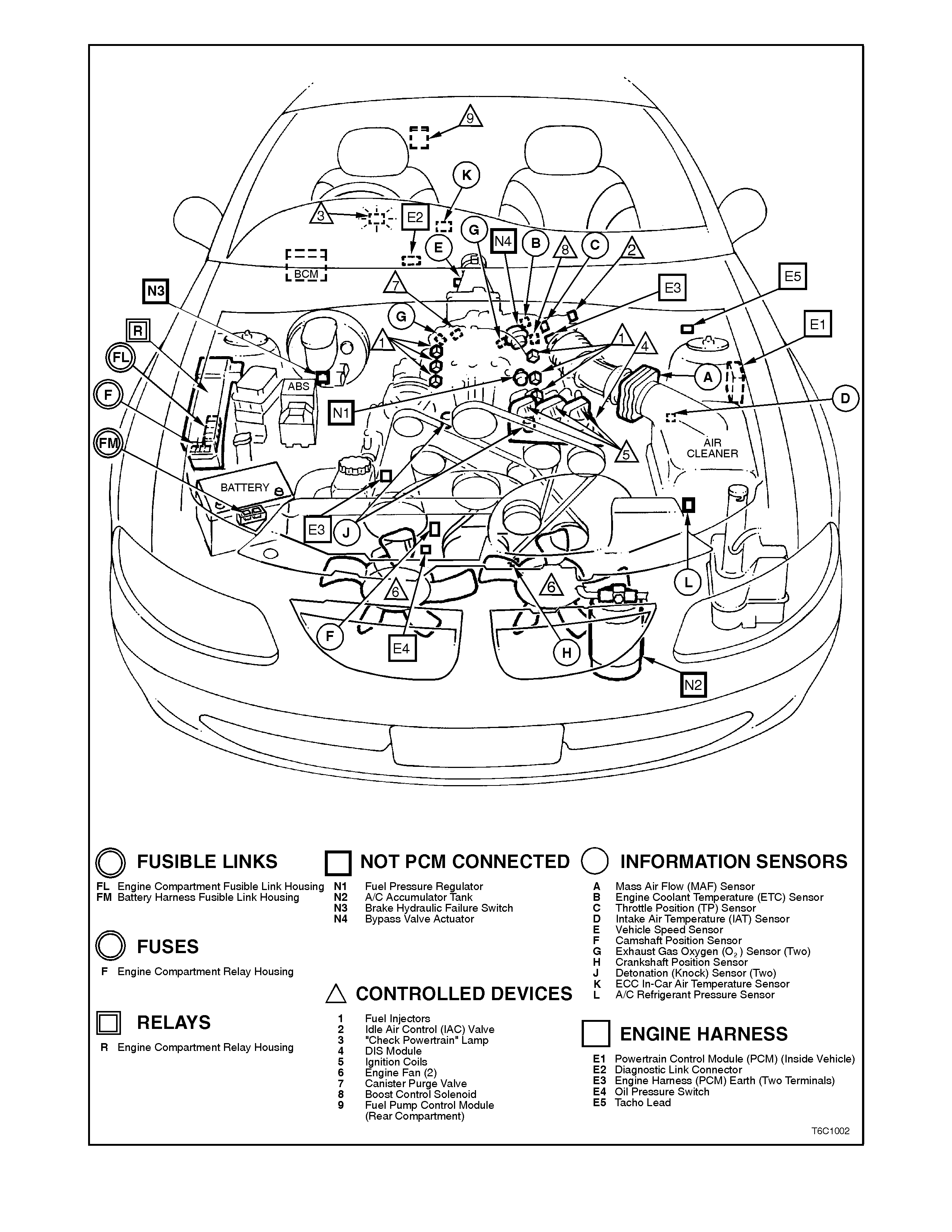

The locations of the Engine Management System (EMS) components of the system are shown in the following

Figures 6C1-1-5 through 6C1-1-13.

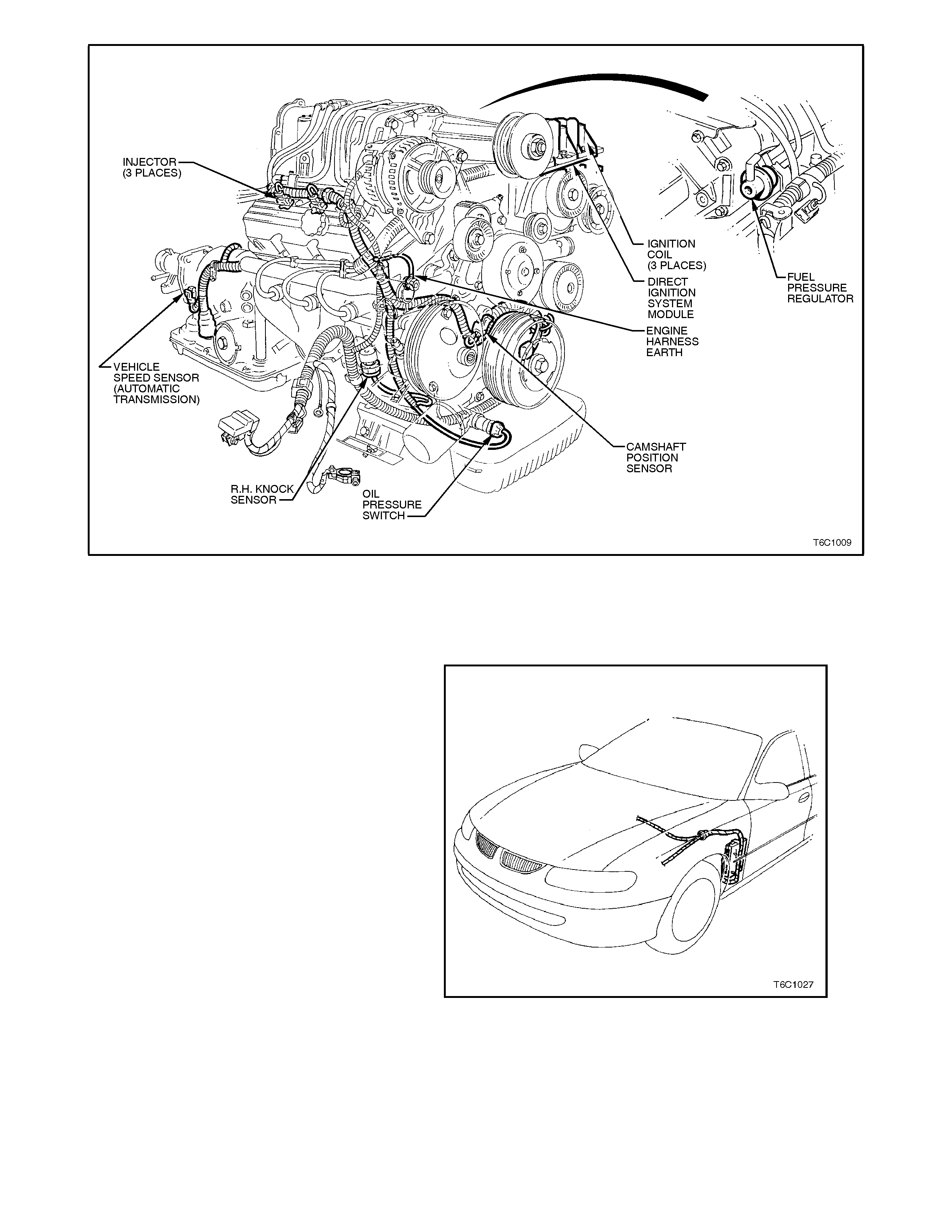

For the Transmission Management System components and their locations, refer to Figure 6C1-1-60 in this Section.

Techline

Figure 6C1-1-1 Non-Supercharged Engine Powertrain Control Module Systems

Figure 6C1-1-2 Supercharged Engine Powertrain Control Module Systems

Figure 6C1-1-3 Non-Supercharged Engine Powertrain Control Module Systems

Figure 6C1-1-4 Supercharged Engine Powertrain Control Module Systems

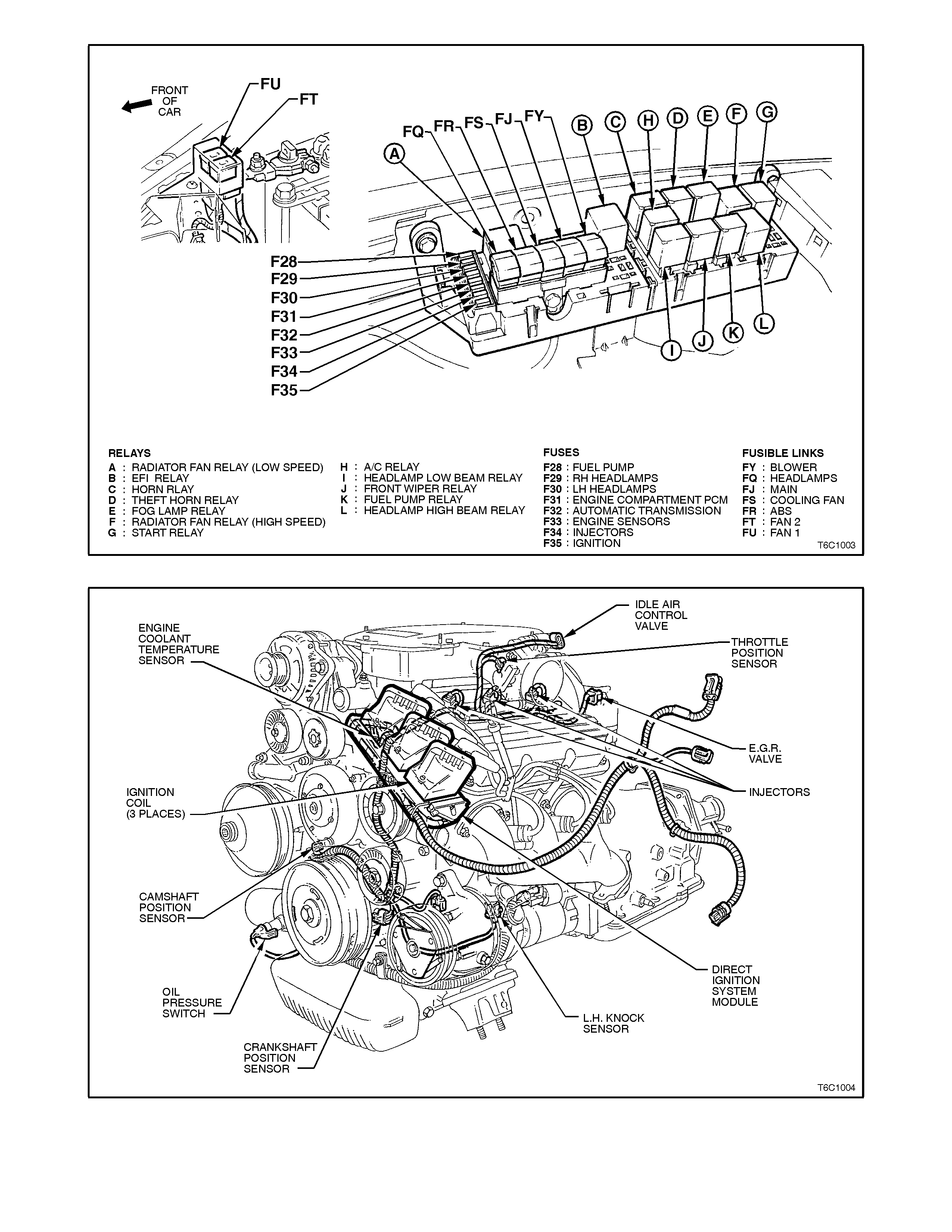

Figure 6C1-1-5 Non-Supercharged Engine Compartment Component Locations

Figure 6C1-1-6 Supercharged Engine Compartment Component Locations

Figure 6C1-1-7 Engine Compartment Relay Locations

Figure 6C1-1-8 Non-Supercharged Engine Component Locations

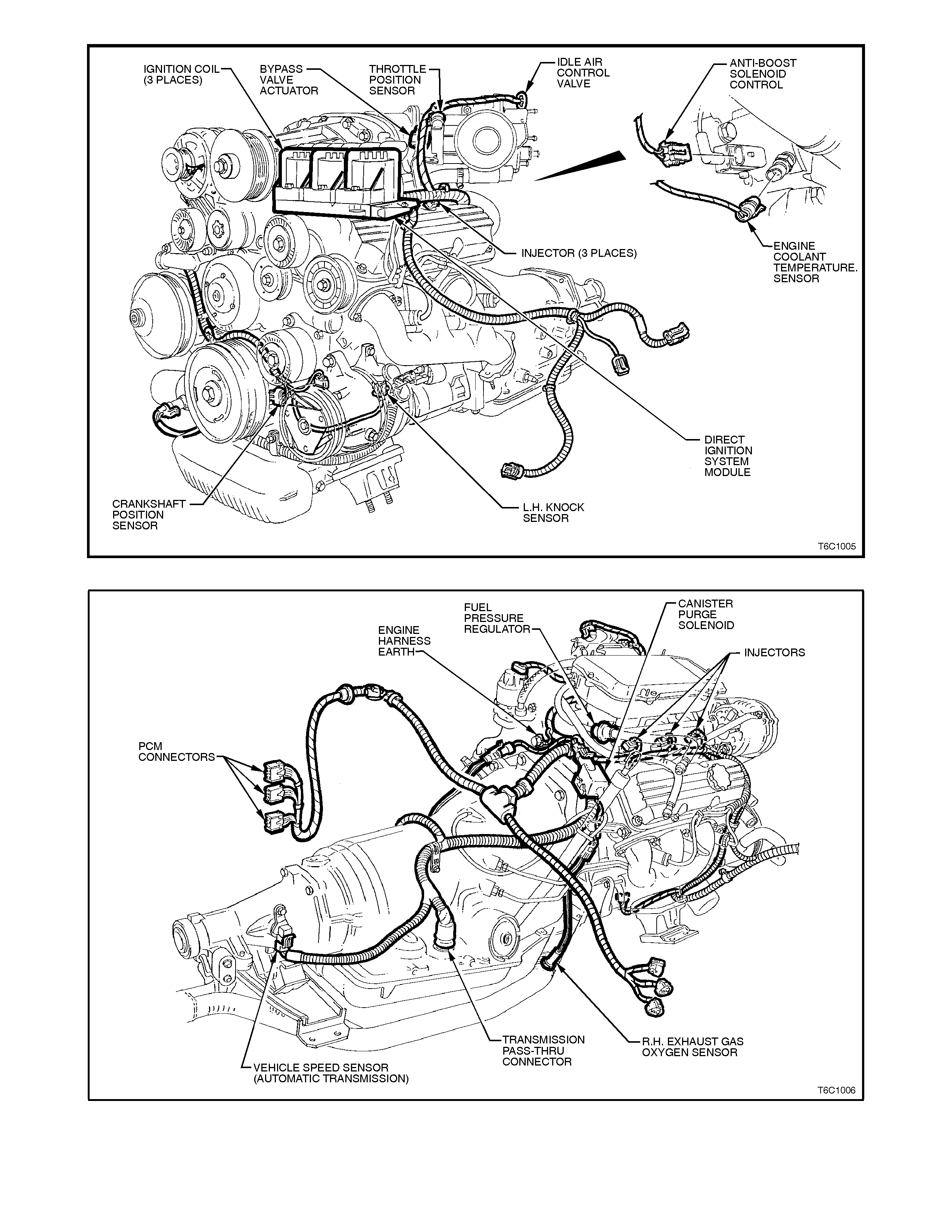

Figure 6C1-1-9 Supercharged Engine Component Locations

Figure 6C1-1-10 Non-Supercharged Engine Component Locations

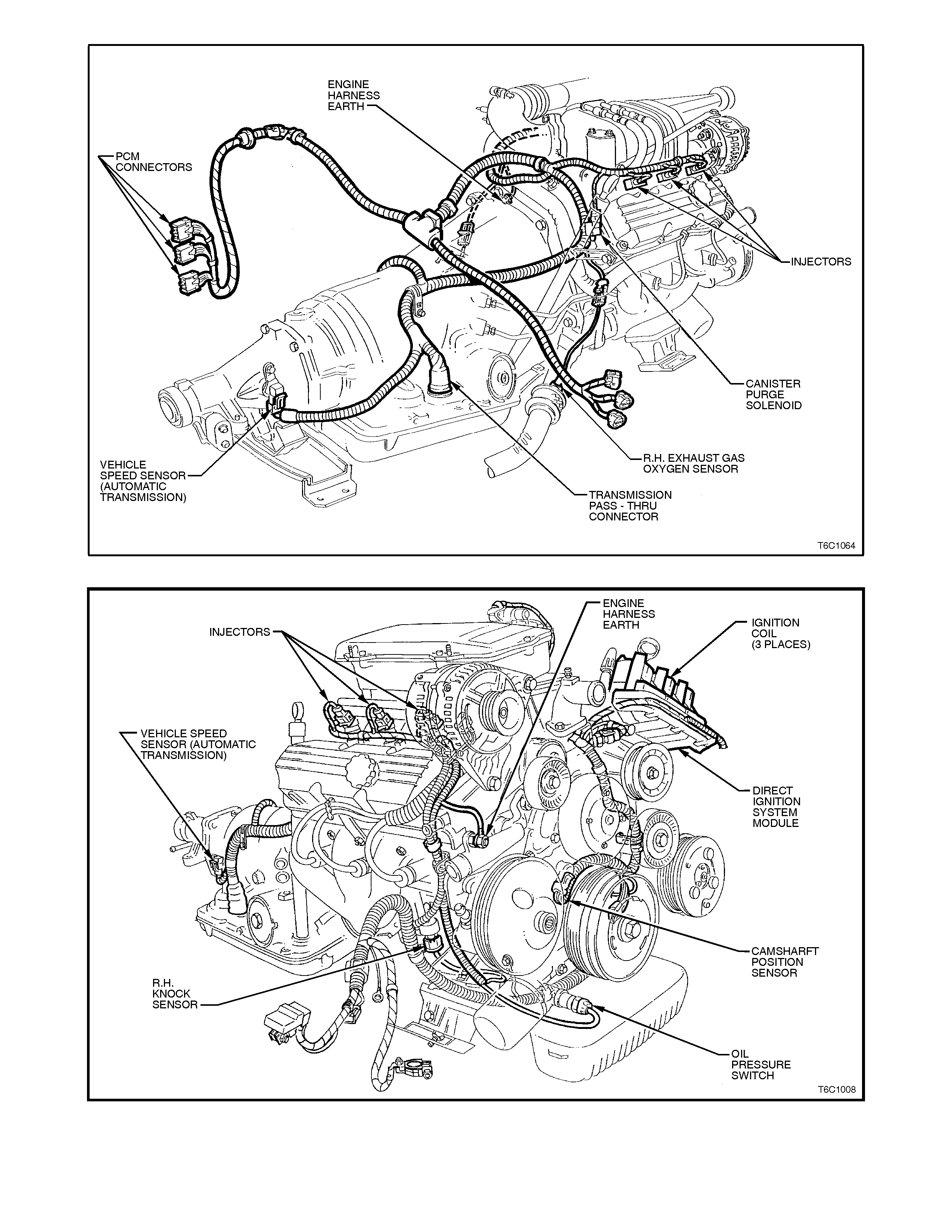

Figure 6C1-1-11-Supercharged Engine Component Locations

Figure 6C1-1-12 Non-Supercharged Engine Component Locations

Figure 6C1-1-13 Supercharged Engine Component Locations

1.1 POWERTRAIN CONTROL MODULE (PCM)

POWERTRAIN CONTROL MODULE (PCM)

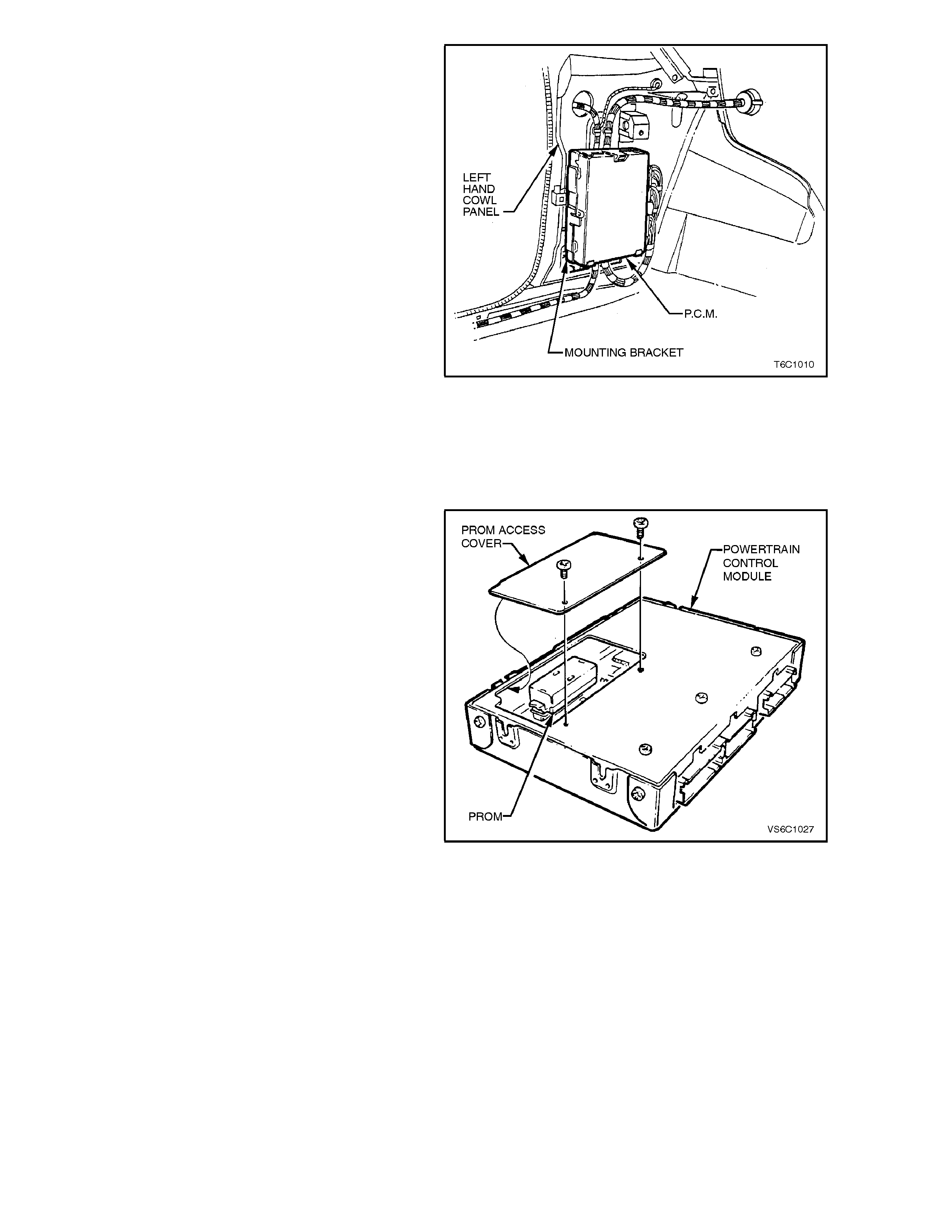

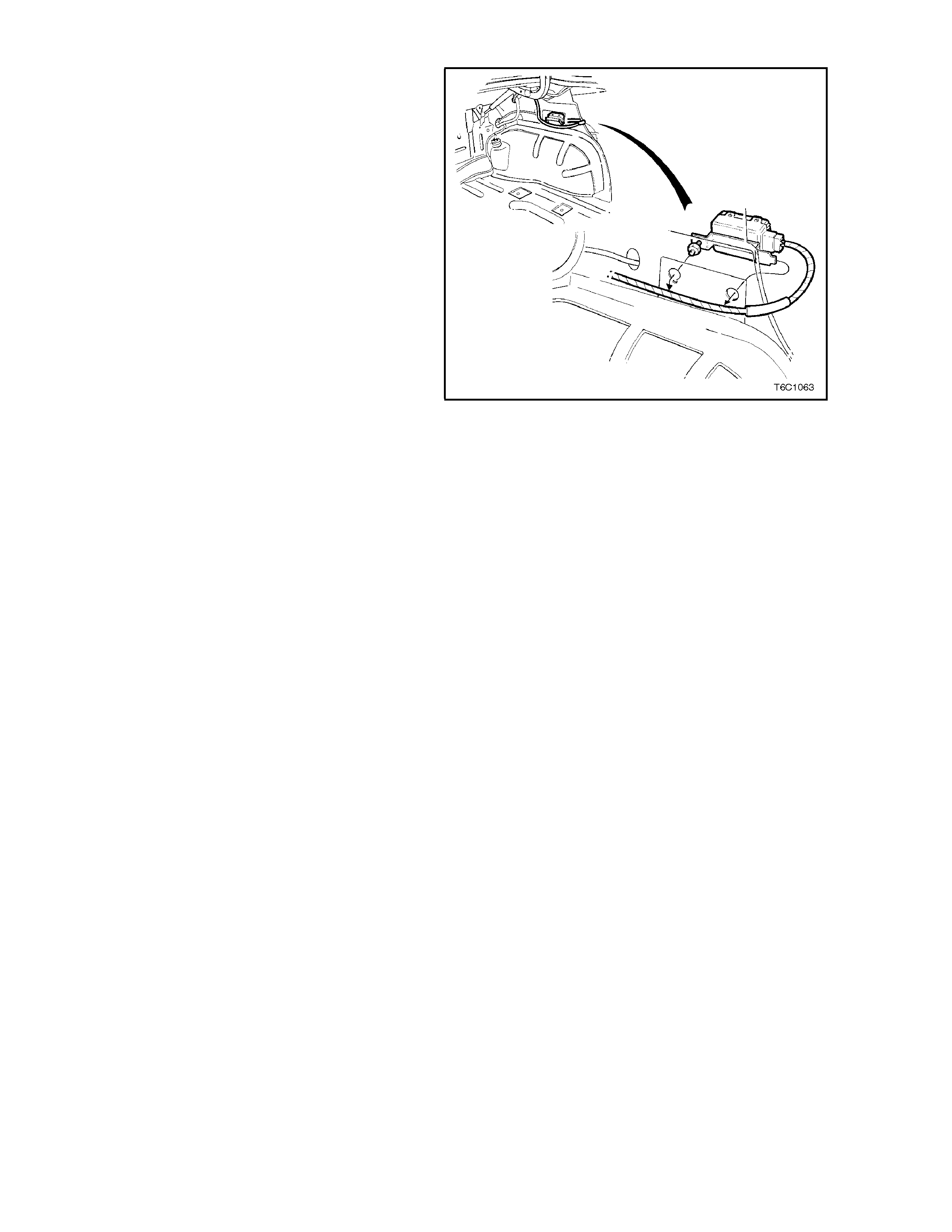

The Powertrain Control Module (PCM), located

behind the front left hand cowl trim panel, and is

the control center of the fuel injection and

transmission management systems. It constantly

monitors information from various sensors, and

controls the systems that affect exhaust emissions

and vehicle performance. The PCM performs the

diagnostic function of the system. It can recognise

operational problems, alert the driver through a

Malfunction Indicator Lamp (MIL) "Check

Powertrain" lamp and store a diagnostic code(s)

that will identify problem areas to aid the technician

in making repairs. Refer to Section 6C1-2

DIAGNOSIS for more information on using the

diagnostic functions of the PCM.

The PCM s upplies either a buf fer ed 5 or 12 volts to

power various sensors or switches. This is done

through resistance's in the PCM which are so high

in value that a test light will not light when

connected to the circuit. In some cases, even an

ordinary voltmeter will not give an ac curate reading

because the meter's internal resistance is too low.

Figure 6C1-1-14 Powertrain Control Module Location

A 10 Megaohm input impedance digital voltmeter is

required to assure accurate voltage readings.

The PCM controls output circuits such as the

injectors, IAC, and various relays, etc. by

controlling the earth circuit through transistors or a

device called a "Q uad-Driver" m odule (QDM) in the

PCM. The two exceptions to this are the fuel pump

relay control circuit and the autom atic transmission

Pressure Control Solenoid (PCS). The fuel pump

relay is the only PCM controlled circuit where the

PCM controls the +12 volts sent to the coil of the

relay. The earth side of the fuel pump relay coil is

connected to engine earth. The PCM supplies

current to the PCS and m onitors how m uch curr ent

returns to the PCM on a separate terminal.

PCM SECURITY LINK

Once the PCM and or BCM have been replaced,

the new PCM and or BCM must be security linked

to each other. If this procedure is not performed,

the vehicle will not crank.

There are two different types of procedures that

may be perform ed to ac com plish this tas k. Ref er to

Section 6C1-3 SERVICE OPERATIONS for this

procedure.

Figure 6C1-1-15 PCM Mounting

PROM

To allow one model of PCM to be used for many

diff erent vehicles, a device called a PROM is used.

The PROM is located inside the PCM and has

information on the vehicle's weight, engine,

transmission, axle ratio and several other factors.

While one PCM part number m ay be used by m any

different vehicles, a PROM is specific. For this

reason, it is very important to chec k the latest par ts

catalogue and Technical Information Bulletins for

the correct part number when replacing a PROM.

A replacement PCM (called a controller) is

supplied without a PROM. The PROM from the old

PCM must be carefully removed and installed in the

new PCM. For details refer Section 6C1-3

SERVICE OPERATIONS.

Figure 6C1-1-16 PROM Location

PCM MEMORY FUNCTIONS

There ar e three types of mem ory storage within the

PCM: RAM, EPROM and EEPROM.

RAM

Random Access Memory (RAM) is the

microprocessor "scratch pad." The processor can

write into, or read from this memory as needed.

This memory is volatile and needs a constant

supply of voltage to be retained. If the voltage is

lost, the memory is lost.

EPROM

Erasable Programmable Read Only Memory

(EPROM) is the portion of the PCM which means

that the program can be erased. This is also the

portion of the PCM that contains software and the

different engine and transmission calibration

information that is specific to year, model and

emis sions. T his m emor y is erased by exposing it to

high intensity ultra violet radiation for several

minutes.

The service Programmable Read Only Memory

(PROM) which is used by technicians in the field to

update calibrations in the PCM is actually an

EPROM. T he service PROM is r emovable fr om the

PCM. The PROM should be retained with the

vehicle following PCM replacement.

EEPROM

Electronically Erasable Programmable Read Only

Memory (EEPROM) is the portion of the PCM that

means the program can only be erased

electronically. This type of memory cannot be

erased by disconnecting the vehicle's battery. The

only way to erase this type of memory is by a

special electronic tool, such as the Tech 2 scan

tool. This type of memory is used to store the

Diagnostic Trouble Codes (DTC). DTC history data

is stored in EEPROM and will be saved even after

the vehicle's battery has been disconnected. For

this reason, the only way that the DTC history data

can be cleared is with the Tech 2 scan tool.

1.2 ENGINE INFORMATION SENSORS AND SIGNALS

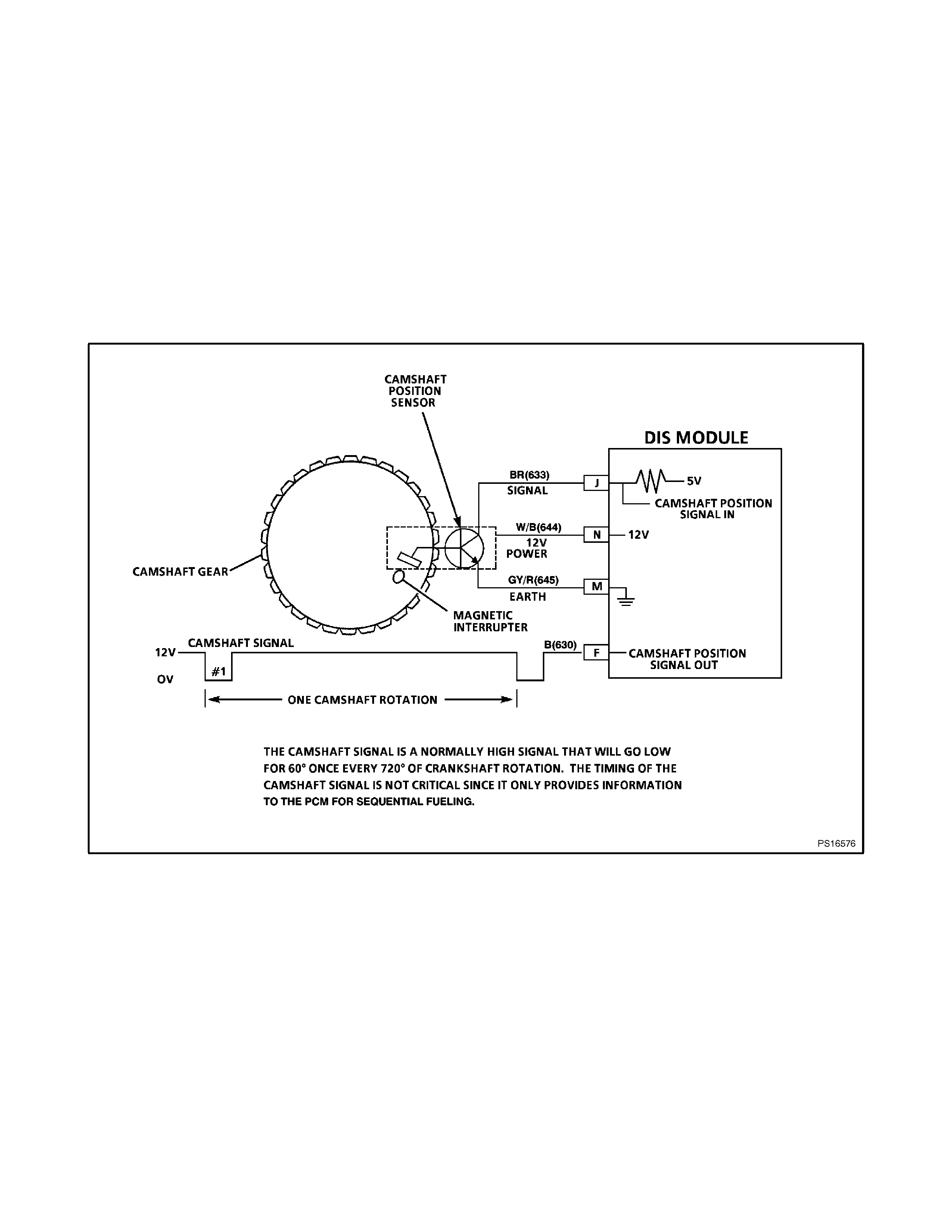

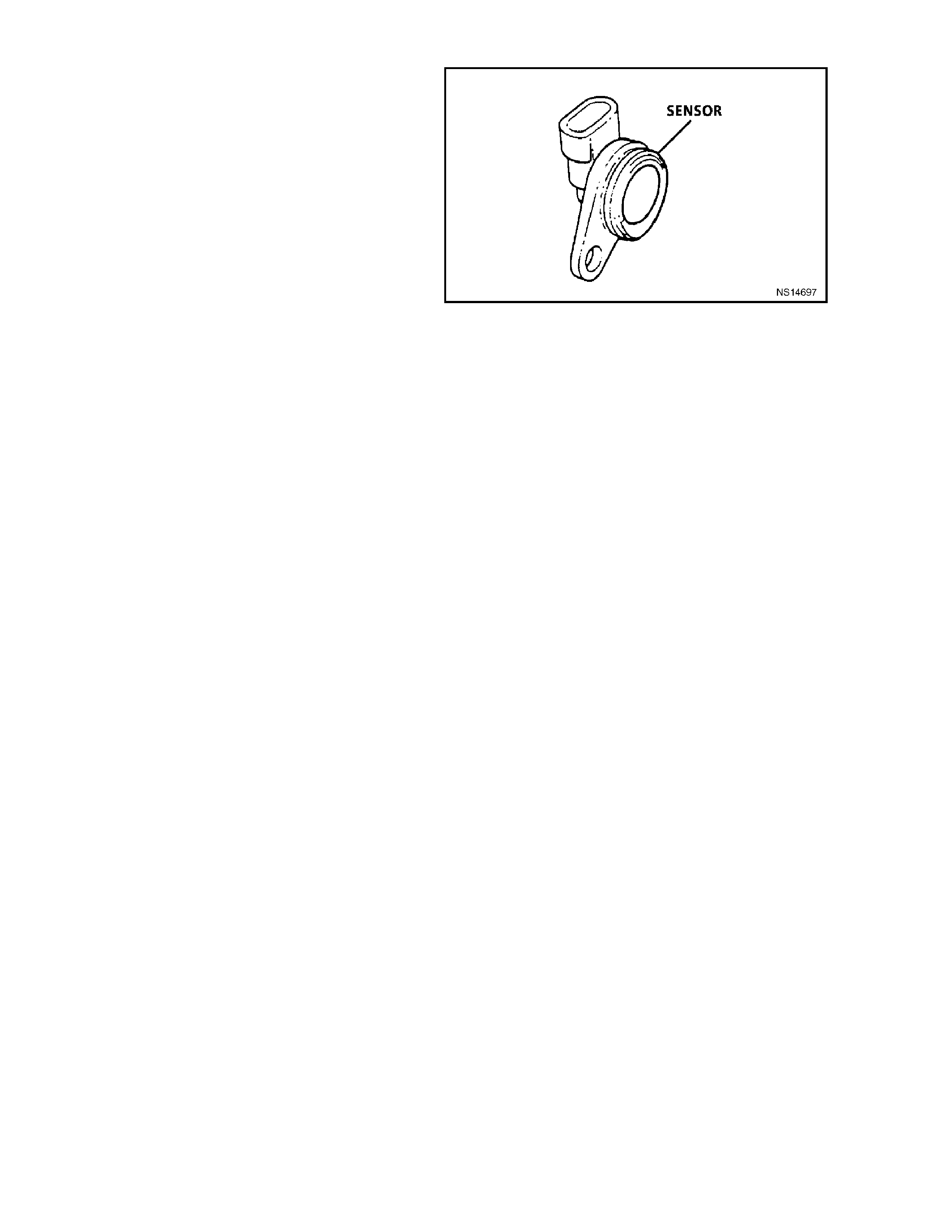

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the

engine front cover, behind and below the water

pump, near the camshaft sprocket.

As the camshaf t spr ock et turns, a m agnet m ounted

on it activates the Hall Ef f ec t s witch in the c ams haf t

position sensor. When the Hall Effect switch is

activated, it earth's the signal line to the DIS

module, pulling the camshaft position signal line's

applied voltage low. This is interpreted as a

camshaft position signal (Synchronisation Pulse).

Because of the way the signal is created by the

camshaft position sensor, the signal circuit is

always either at a high or low voltage (square wave

signal).

While the camshaft sprocket continues to turn, the

Hall Eff ect switch turns "OFF" as the m agnetic f ield

passes the camshaft position sensor, resulting in

one signal each time the camshaft makes one

revolution.

The camshaft position signal, which actually

represents camshaft position due to the sensor's

mounting location, is used by the PCM to properly

time its sequential fuel injection operation.

Figure 6C1-1-17 Camshaft Position Sensor

Figure 6C1-1-18 Camshaft And Crankshaft Position Sensor Locations

CAMSHAFT POSITION SIGNAL

The PCM uses the camshaft position signal to

determine the position of the No. 1 piston on its

power stroke. This signal is used by the PCM to

calculate sequential fuel injection operation. If the

camshaft position signal is lost while the engine is

running, the fuel injection mode will be based on

the last fuel injection pulse, and the engine will

continue to run. The engine can be restarted and

will run in the synchronous (all six inj ectors inject at

once) mode as long as the fault is present.

When the camshaft position signal is not received

by the PCM, a DTC 48 will be set. An intermittent

camshaft position signal will set a DTC 49. If either

of these DTC's are set, the fuel system will not be

in sequential fuel injection mode.

Figure 6C1-1-19 Camshaft Position Signal

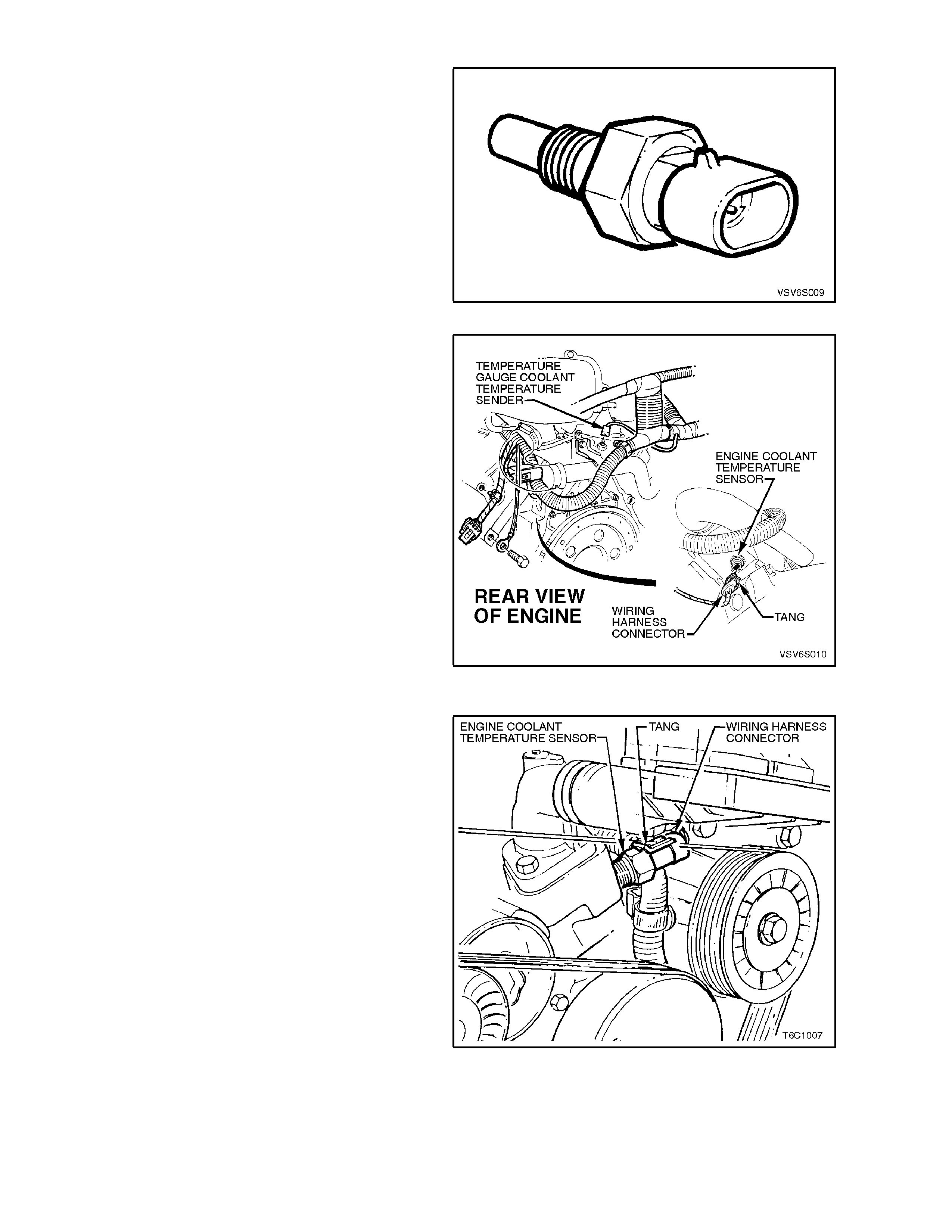

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

The Engine Coolant Temperature (ECT) sensor is a

thermistor (a resistor that changes value based on

temperature) mounted in the engine coolant stream

and is specifically for the PCM. A different sensor is

used for instrument panel functions. Low coolant

engine temperature produces a high sensor

resistanc e (28,939 ohms at - 20 degrees C) while high

engine coolant temperature causes low sensor

resistance (180 ohms at 100 degrees C).

Figure 6C1-1-20 ECT Sensor

The location of the sensor for the Supercharged

application is at the rear of the engine. Both sensor

application are located near the thermostat housing.

Figure 6C1-1-21 ECT Sensor Location (Supercharged

Engine)

The Engine Coolant Temperature location on the

Non-Supercharged application is at the front of the

engine

Figure 6C1-1-22-A ECT Sensor Location (Non-

Supercharged Engine)

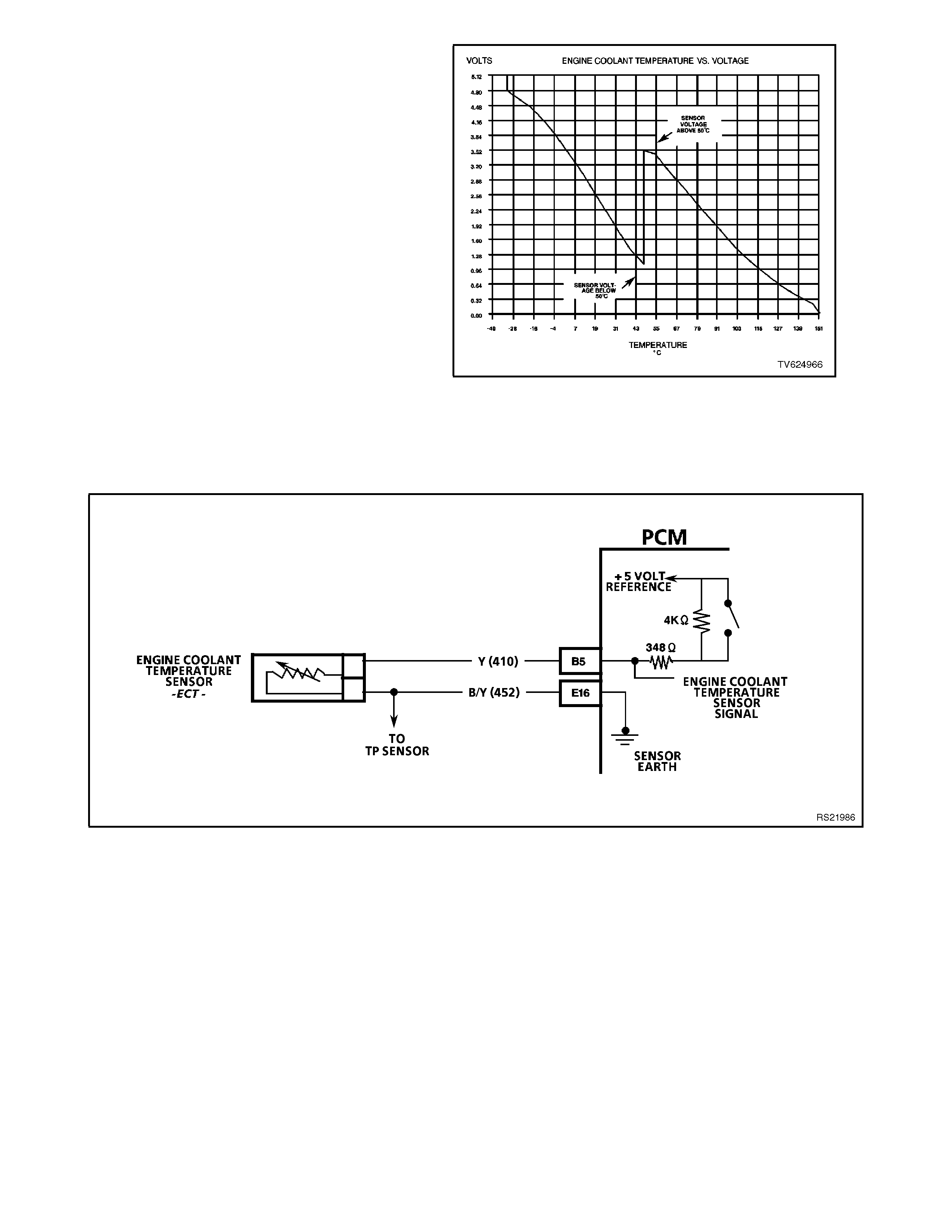

The PCM:

1. Supplies a 5 volt signal voltage to the sensor

through a resistor in the PCM, and

2. Monitors the circuit voltage, which will change

when connected to the sensor.

The circuit voltage will vary depending on the

resistance of the engine coolant temperature sensor.

The circuit voltage will be close to the 5 volt level

when the sensor is cold, and will decrease as the

sensor warms. Engine coolant temperature affects

most systems controlled by the PCM.

A failure in the engine coolant temperature sensor

circuit should set either a Diagnostic Trouble Code

(DTC) 14 or DTC 15. An intermittent open or a short

failure s hould set DTC 16. T he PCM supplies a 5 volt

signal to the engine coolant temperature sensor

through one of two resistors in the PCM. When the

engine coolant is cold the PCM will operate on one

resistor then switch over to another resistor at

approximately 50 degrees C. The circuit voltage will

change at this time but the Tech 2 scan tool will still

read the correct temperature value and will not

suddenly jump. A f ailure in one of these two resistor s

will set DTC 17.

Figure 6C1-1-23 ECT Temperature vs Voltage

Figure 6C1-1-24 ECT Sensor Circuit

EXHAUST GAS OXYGEN SENSOR

The exhaust gas oxygen sensors are the key to

closed-loop f uel contr ol. The PCM us es inform ation

from the oxygen sensors to precisely fine-tune its

fuel injector pulse width calculations, based on the

unused, "left-over" oxygen content in the exhaust.

The Non-Supercharged V6 engine use two

unheated oxygen sensors, one oxygen sensor is

located in each exhaust pipe. This is done so that

the PCM can better control the engine's fuelling

requirements. By monitoring the exhaust oxygen

content of each bank of cylinders, the PCM can

better control the fuel injector pulse width to the

individual fuel injectors on each bank.

The Supercharged V6 engine uses two heated

oxygen sensors. These heated oxygen sensors

have a internal heater element that is used to heat

the Zirconia element faster inside the sensors,

thereby decreasing the amount of time the fuel

control system can begin running in closed loop

fuel control.

Both type of oxygen sensors have a zirconia

element that, when heated to temperatures above

360 degrees C, produce voltages based on the

amount of oxygen content surrounding the tip, as

compared to oxygen in the atmosphere.

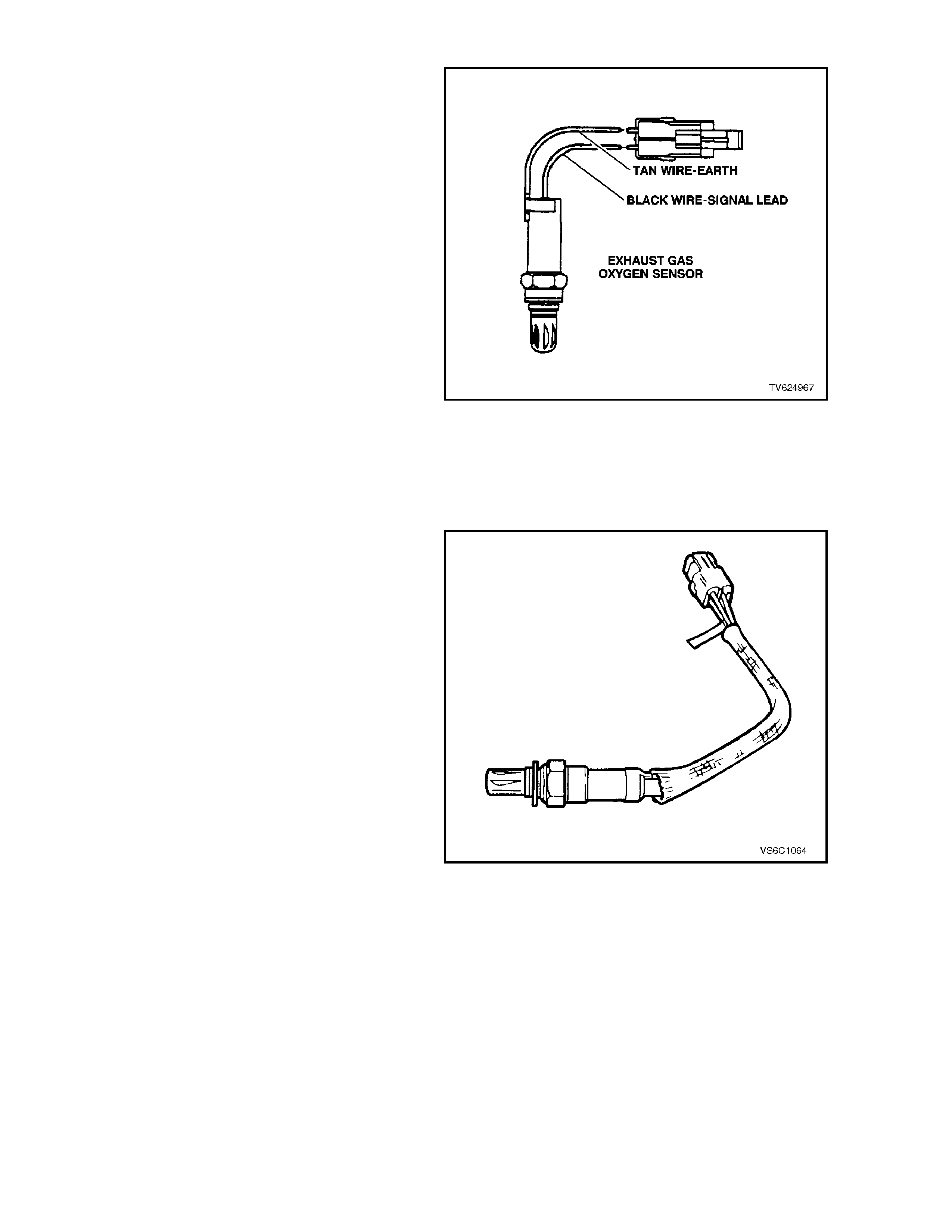

Figure 6C1-1-25 Two Wire Oxygen Sensor

The sensor is mounted in the exhaus t pipe with the

sensing portion exposed to the exhaust gas

stream. When the sensor has reached an operating

temper ature of m ore than 360 degrees C, it ac ts as

a voltage generator, producing a rapidly changing

voltage of between 10 - 1000 millivolts. This voltage

output is dependent upon the oxygen content in the

exhaust gas, as compared to the sensor's

atmospheric oxygen reference cavity. This

reference cavity is exposed to the atmosphere

through the air that passes between the wire

strands and insulation.

When the sensor is cold, it produces either no

voltage, or an unusable, slowly changing one. Also

when cold, its internal electrical resistance is

extremely high - many million ohms. The PCM

always supplies a steady 450 millivolt, very low

current called "bias" voltage to the oxygen sensor

circuit. W hen the sensor is cold and not producing

any voltage, the PCM "detects" only this steady

bias voltage. As the sensor begins heating, its

internal resistance decreases and it begins

producing a rapidly changing voltage that will

overshadow the PCM's supplied steady bias

voltage.

Figure 6C1-1-26 Four Wire Heated Oxygen Sensor

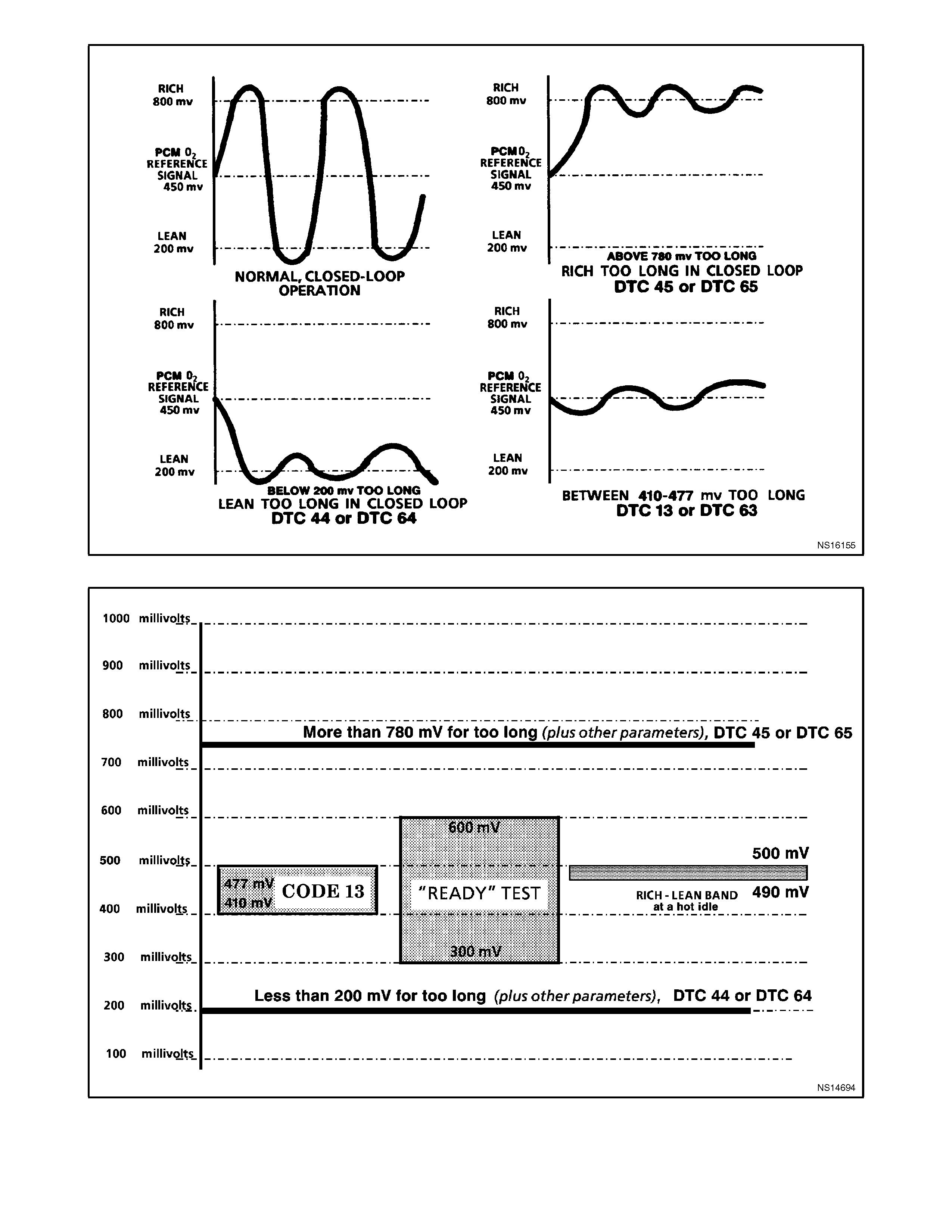

When the PCM "detects" the changing voltage, it

knows the oxygen sensor is hot and its output

voltage can be used for the "fine-tuning" the fuel

injector pulse width. T he PCM monitors the oxygen

sensor's "changing voltage" for going above and

below a mid-range voltage band (approximately

300 - 600 millivolts), to help dec ide when to operate

in the closed-loop mode. (refer "READY TEST,"

Figure 6C1-1-29.)

W hen the fuel system is correctly operating in the

closed-loop mode, the oxygen sensor voltage

output is rapidly changing several times per

second, going above and below a rich/lean band.

The PCM monitors the changing voltage, and

decides the needed fuel mixture correction. (refer

"NORMAL, CLOSED-LOOP OPERATION,"

Figure 6C1-29).

An open sensor signal circuit or earth circuit, or a

defective, contaminated, or cold sensor could

cause the voltage to stay within a 350-550 millivolt

band too long, keeping the fuel control system in

open-loop and setting a DTC 13 or DTC 63. (refer

"DTC 13 or DTC 63", Figure 6C1-28).

Figure 6C1-1-27 Oxygen Sensor Zirconia Element

If the PCM monitors a low voltage for too long

(indicating a "lean" exhaust), a DTC 44 or DTC 64

will store in memory. If the PCM monitors a high

oxygen sensor circuit voltage for too long

(indicating a "rich" exhaust), a DTC 45 or DTC 65

will store in m e mory (refer "DTC 44 or DTC 64" and

"DTC 45 or DTC 65", Figure 6C1-28).

RESPONSE TIME

Not only is it necessary for the oxygen sensor to

produce a voltage signal for rich or lean exhaust, it

is also important to respond quickly to changes.

The PCM senses the response times and displays

this on the Tech 2 scan tool as the "rich-lean

status" and as "cross counts" If the oxygen sensor

responds slowly, the customer may complain of

poor fuel economy, rough idle or lack of

performance. It may also set false PCM DTCs

because the PCM uses oxygen sensor voltages for

system checks.

OXYGEN SENSOR CONTAMINANTS

CARBON

Black carbon or soot deposits result from over-rich

air/fuel mixtures. However, carbon does not harm

an oxygen sensor. Deposits can be burned off in

the vehicle by running it at least part thr ottle for two

minutes.

SILICA

Certain RTV silicone gasket materials give off

vapour as they cure that may contaminate the

oxygen sensor. This contamination is usually

caused by the vapours being pulled from the PCV

system, into the combustion chamber and passed

on to the exhaust system. The sand like particles

from the RTV silica embed in the molecules of the

oxygen sensor element and plug up the surface.

With the outside of the oxygen sensor element not

able to sense all of the oxygen in the exhaust

system it results in "lazy" oxygen sensor response

and engine control. The oxygen sensor will have a

whitish appearance on the outside if it has been

contaminated.

There is also a possibility of silica contamination

caused by silicone in the fuel. Some oil companies

have used silic one to rais e the oc tane rating of their

fuel. Careless fuel handling practices with transport

containers can result in unacceptable

concentrations of silicone in the fuel at the pump.

There is also a possibility of silica contamination

caused by silicon in lubricants used to install

vacuum hoses on fittings. Do not use silicone

sealers on gaskets or exhaust joints.

LEAD

Lead glazing of the sensors can be introduced

when regular, or leaded fuel is burned. Fuel

containing large amounts of methanol will also

result in lead contamination.

The methanol dissolves the terne coating of the fuel

tank, which introduces lead into the fuel system,

and into the exhaust after combustion. It is difficult

to detect lead contamination by visual inspection.

OTHER SUBSTANCES

Oil deposits will ultimately prevent oxygen sensor

operation. The sensor will have a dark brown

appearance. Causes of high oil consumption

should be checked.

The additives in ethylene glycol can also affect

oxygen sensor performance. This produces a

whitish appearance. If antif reeze enters the ex haus t

system, you will likely encounter other, more

obvious, symptoms of cooling system trouble. If for

example the engine had a head gasket failure

where coolant did enter the combustion chamber it

would be a good idea to check the oxygen sensor

operation after the head gasket was repaired.

MULTIPLE FAILURES

Leaded fuel, silica contamination from uncured,

low-grade (unapproved) RTV sealant, and high oil

consumption are possible.

A problem in the oxygen sensor circuit or fuel

system should set a DTC 13 or DTC 63 (open

circuit), DTC 44 or DTC 64 (lean indication), or

DTC 45 or DTC 65 (rich indication). Refer to

applicable diagnostic chart if any of these DTCs

were stored in memory.

Figure 6C1-1-28 Oxygen Sensor Voltage Curves

Figure 6C1-1-29 Normal Oxygen Sensor Voltages, and Abnormal Trends

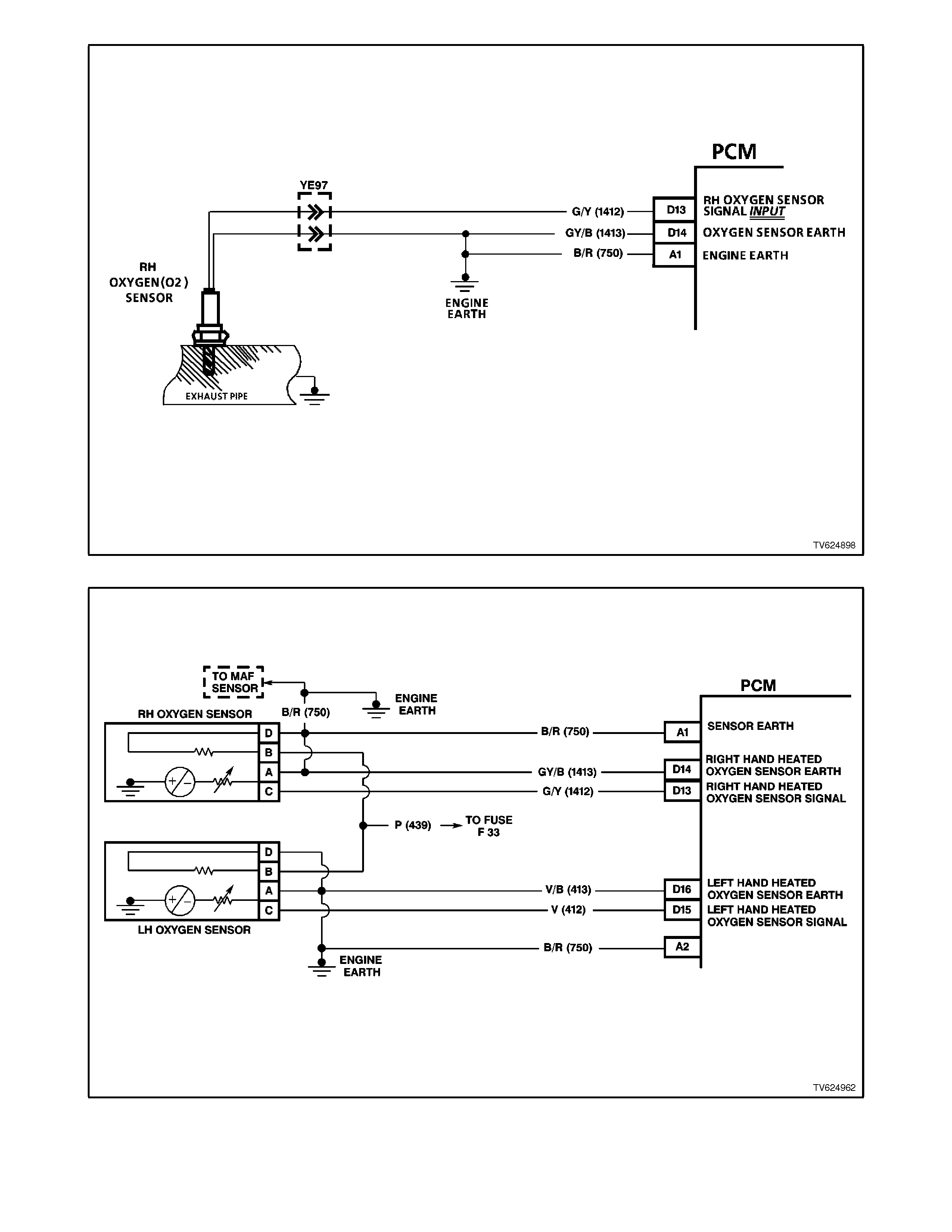

Figure 6C1-1-30 Two Wire Oxygen Sensor Circuit

Figure 6C1-1-31 Four Wire Heated Oxygen Sensor Circuit

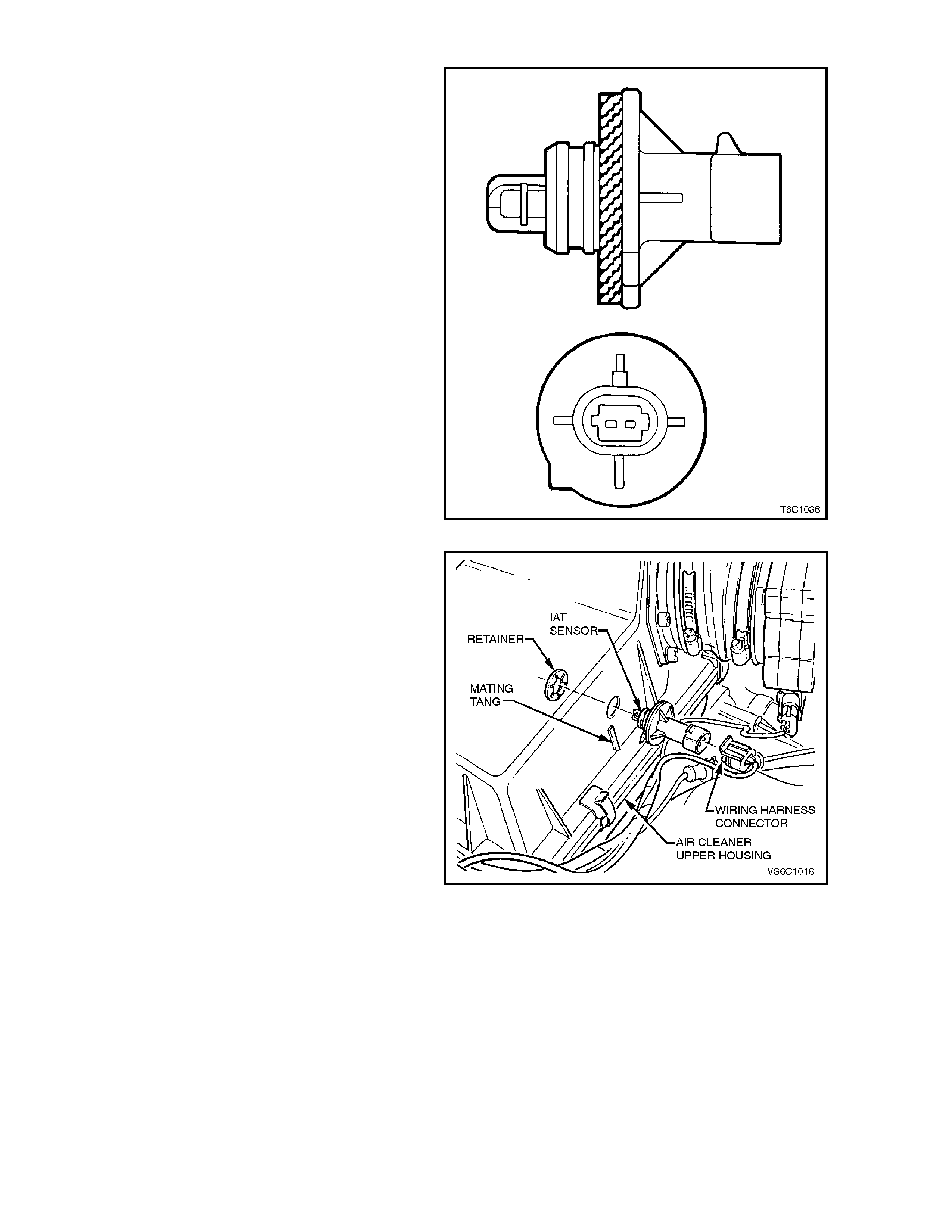

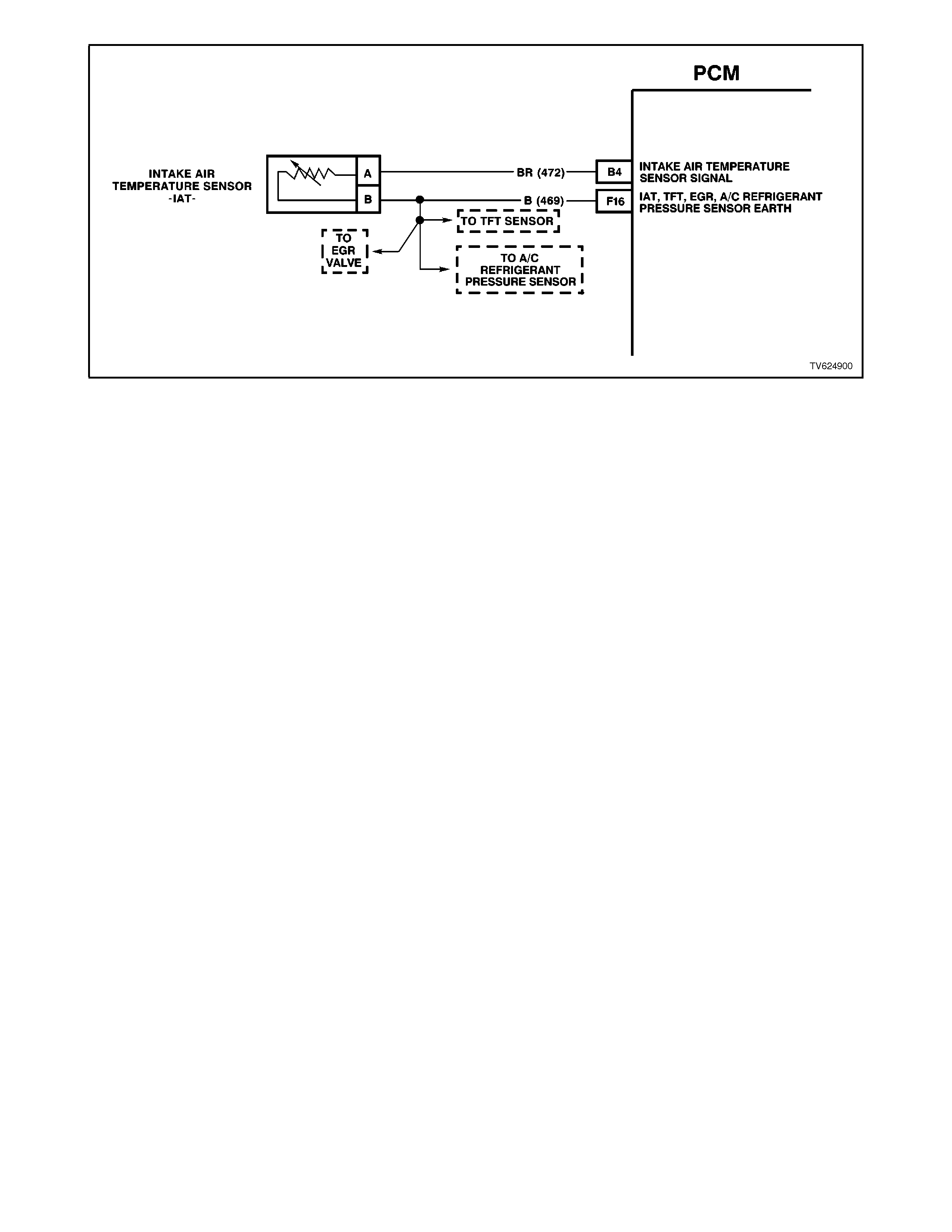

INTAKE AIR TEMPERATURE (IA T) SENSOR

The Intake Air Temperature (IAT) sensor is a

thermistor (a resistor that changes resistance with

changes in tem perature) mounted in an air cleaner

housing of the intake system. Low intake air

temper atur e produces high res istanc e in the sens or

(100,866 ohm s at -40 degr ees C), while high intak e

air temperature causes low sensor resistance (78

ohms at 130 degrees C).

The PCM:

1. Supplies a 5 volt signal voltage to the sensor

through a resistor in the PCM, and

2. Monitors the intake air temperature circuit

voltage, which will change when connected to

the intake air temperature sensor.

The circuit voltage will vary depending on the

resistance of the IAT sensor. The voltage will be

close to the 5 volt level when the sensor is cold,

and will decrease as the sensor warms.

The input intake air temperature signal voltage is

used by the PCM to assist in calculating the fuel

injector pulse width.

A failure in the IAT sensor circuit should set either a

Diagnostic Trouble Code (DTC) 23 or DTC 25. An

intermittent failure in the IAT sensor circuit should

set DTC 26. Figure 6C1-1-32 IAT Sensor

Figure 6C1-1-33 IAT Sensor Location

Figure 6C1-1-34 IAT Sensor Circuit

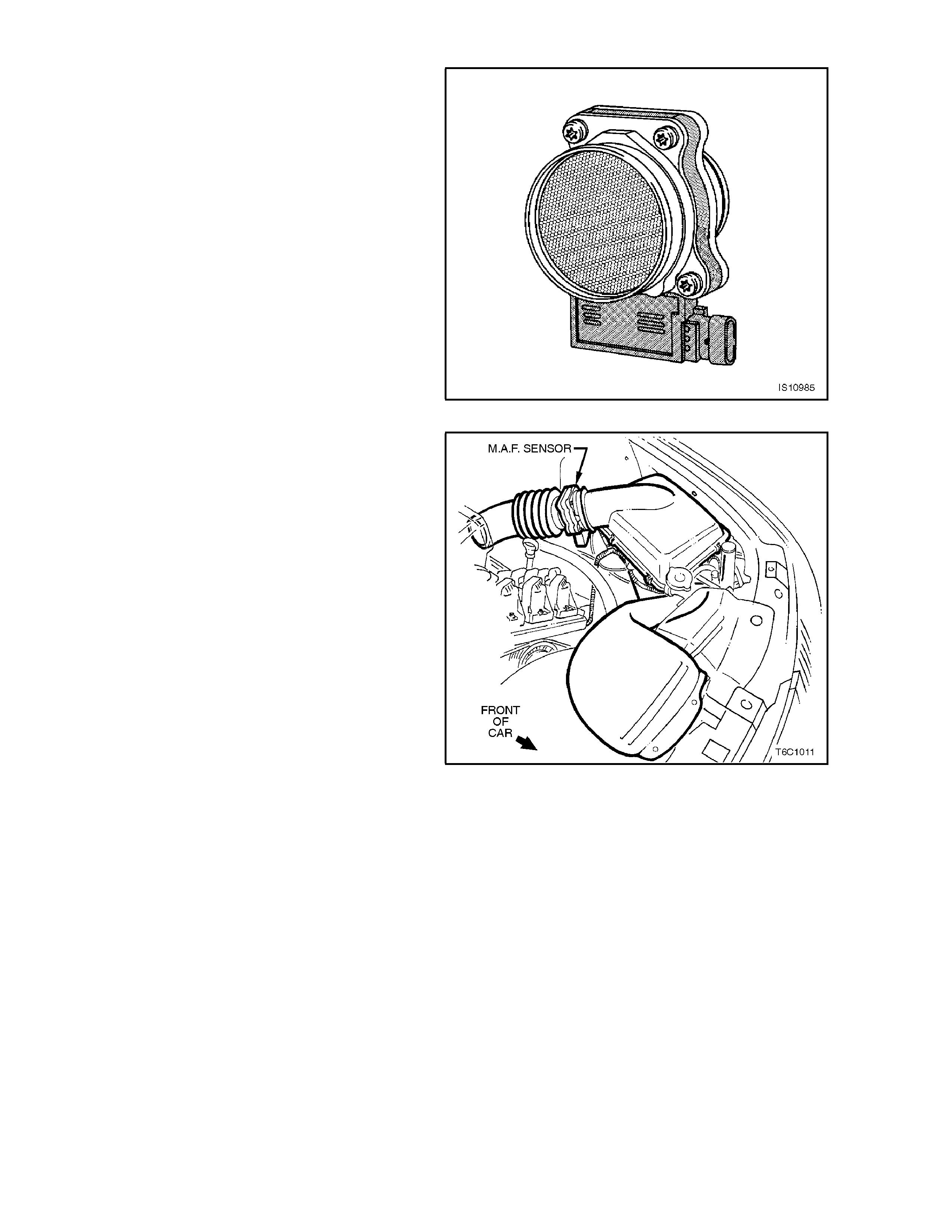

MASS AIR FLOW (MAF) SENSOR

The Mass Air Flow (MAF) sensor used on these

engines utilises a heated element type of operation.

A heated element in the MAF is placed in the air

flow stream of the engine intake system. The

heating element is maintained at a constant

temperature differential above the air temperature.

The am ount of elec trical power r equired to m aintain

the heated element at the proper temperature is a

direct function of the mass flow rate of the air past

the heated element.

Figure 6C1-1-35 Mass Air Flow Sensor

Figure 6C1-1-36 MAF Sensor Location

Non-Supercharged Engine

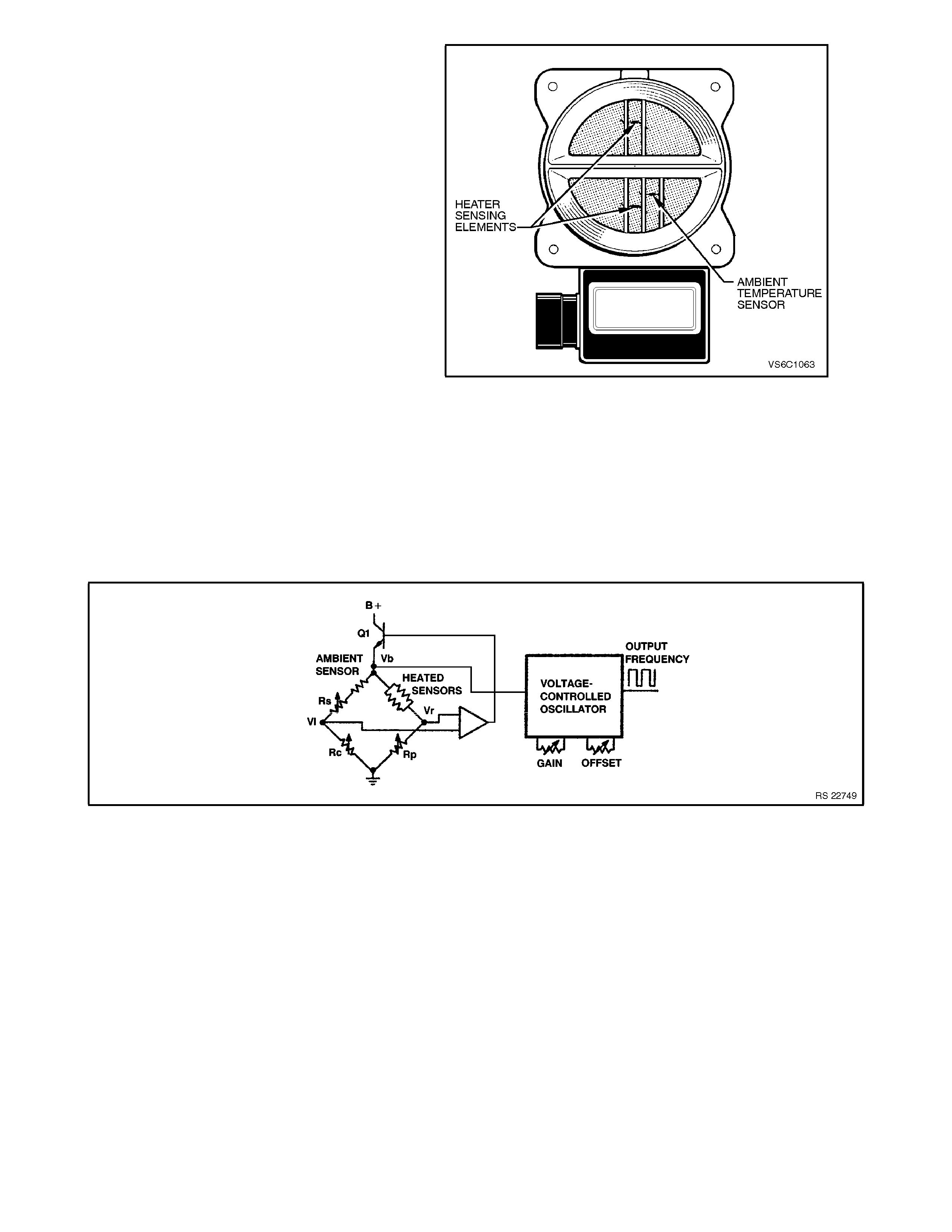

Three sensing elements are used in this system.

One senses ambient air temperature and uses two

calibratable resistors to establish a voltage that is

always a function of ambient temperature. This

ambient sensor is mounted in the lower half of the

sensor housing. The other two sensing elements

are heated to a predetermined temperature that is

significantly above ambient air temperature. The

two heated elements are connected electrically in

parallel and mounted directly in the air flow stream

of the sensor housing. O ne sensor is in the top and

one sensor is in the bottom of the sensor housing.

This is done so that the air meter is less sensitive to

upstream ducting configurations that could skew

the flow of air through the housing.

As air passes over the heated elements during

engine operation they begin to cool. By measuring

the amount of electrical power required to m aintain

the heated elements at the predetermined

temperature above ambient temperature the mass

air flow rate can be determined.

Once the mass air flow sensor has developed an

internal signal related to the mass air flow rate, it

must send this information to the PCM. In order to

preserve the accuracy and resolution of the small

voltage signal in the mass air flow sensor, it is

converted to a frequency signal by a voltage

oscillator and sent to the PCM.

Figure 6C1-1-37 Sensing Elements

Figure 6C1-1-38 MAF Sensor Simplified Schematic

The signal that is sent from the mass air flow

sensor is sent in the form of a frequency output. A

large quantity of air passing through the sensor

(such as when accelerating) will be indicated as a

high frequency output. A small quantity of air

passing through the sensor will be indicated as a

low frequency output (such as when decelerating or

at idle). The T ech 2 scan tool displays MAF sens or

information in frequency, and in grams per second

and calculated in mg per cylinder. At idle the

readings should be low and increase with engine

RPM.

As the PCM receives this f requency signal from the

Mass Air Flow sensor, it searches its pre-

program med tables of inform ation to determine the

pulse width of the fuel injectors required to match

the Mass Air Flow signal.

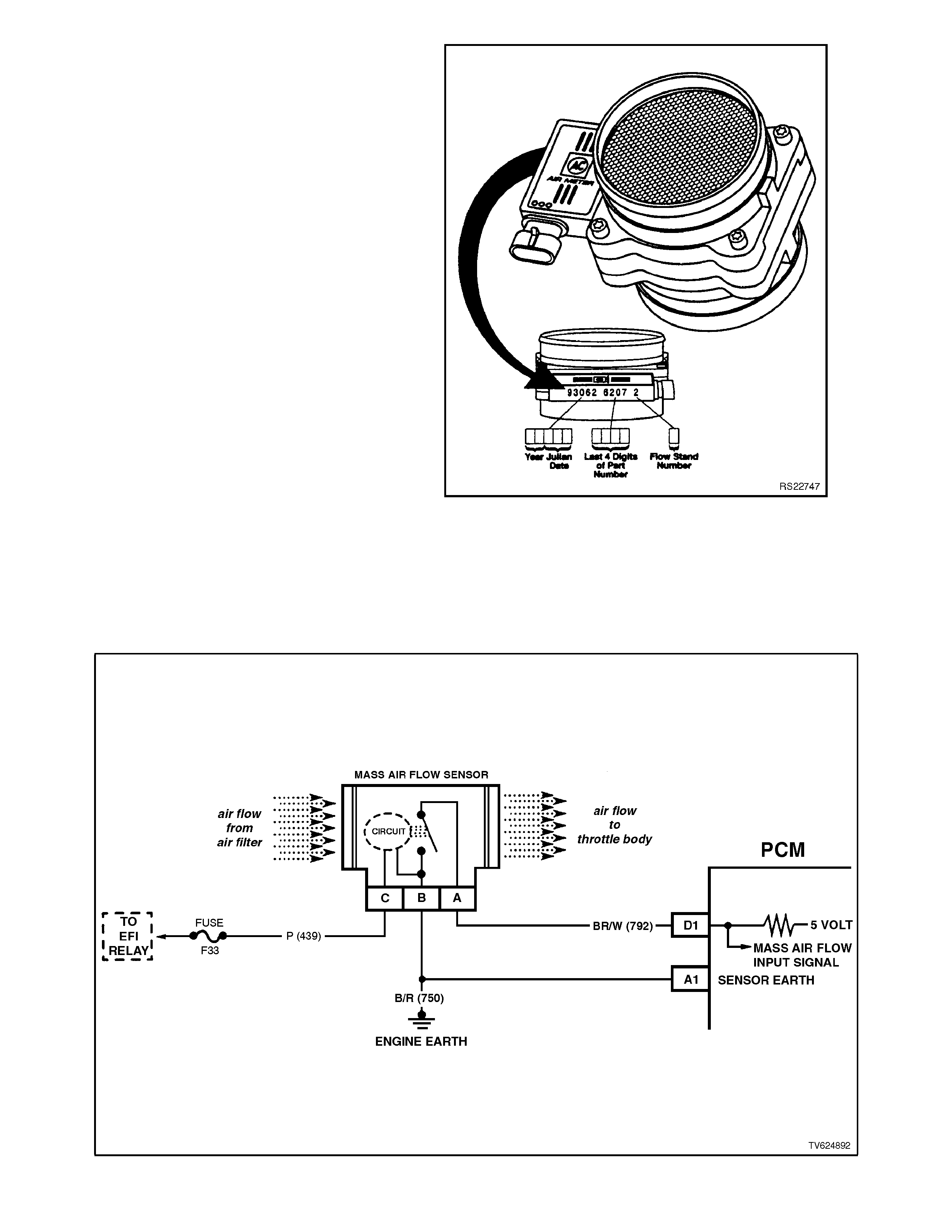

If a problem occurs in the Mass Air Flow sensor

circuit, after a period of time, the PCM will store a

DTC in its memory. The PCM will turn "ON" the

"Check Powertrain" lamp Malfunction indicator

Lamp (MIL) indicating there is a problem. If this

occurs, the PCM will calculate a "substitute" Mass

Air Flow signal based on engine speed and Throttle

Position (TP) sensor signal.

No field service adjustment is necessary or

possible with this Mass Air Flow sensor.

A failure in the Mass Air Flow sensor circuit should

set a DTC 32. Remember, this code indicates a

failure in the circuit, so pr oper use of the diagnos tic

chart will lead to either repairing a wiring problem or

replacing the MAF Sensor, to properly repair a

problem.

Figure 6C1-1-39 Mass Air Flow Sensor Identification

Figure 6C1-1-40 MAF Sensor Circuit

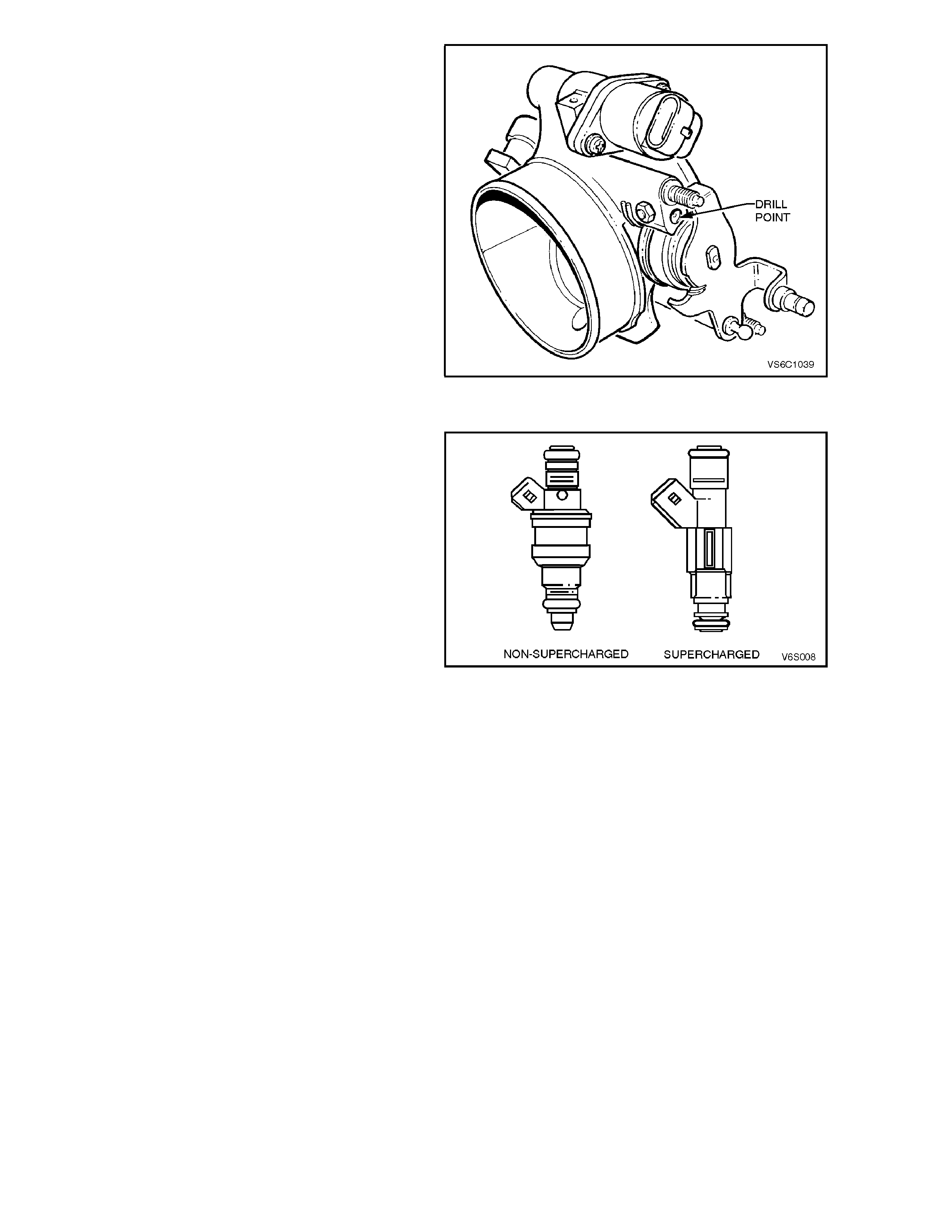

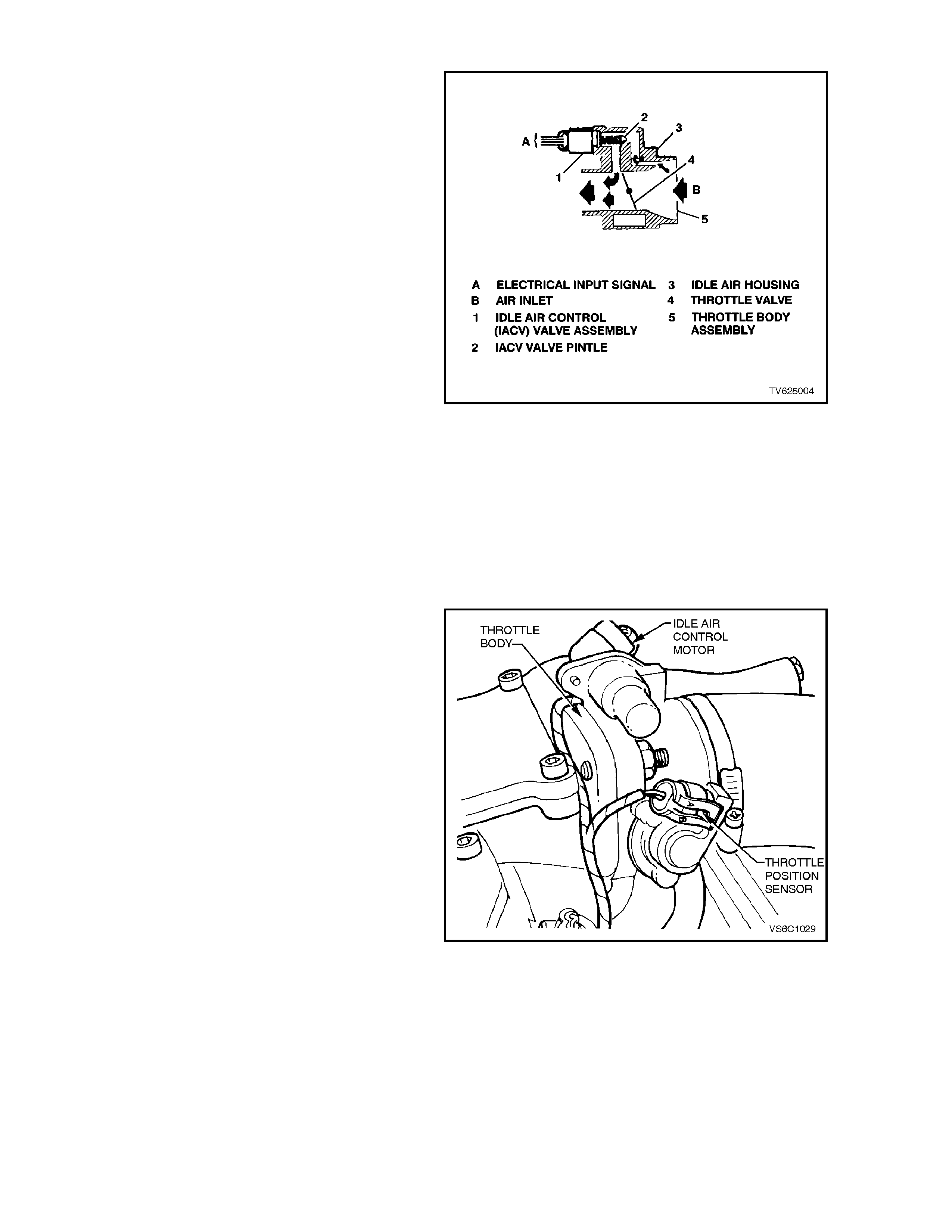

THROTTLE POSITION (TP) SENSOR

The Throttle Position (TP) sensor is connected to

the throttle shaft on the throttle body unit. It is a

potentiometer with one end connected to 5 volts

from the PCM and the other end to PCM earth. A

third wire connects from a sliding contact in the TP

sensor to the PCM allowing the PCM to measure

the voltage from the TP sensor. As the throttle is

moved ( acceler ator pedal m oved), the output of the

TP sensor changes. At a closed throttle position,

the output of the TP sensor is below 1.25V. As the

throttle valve opens, the output increases so that, at

wide-open throttle (WOT), the output voltage

should be about 4 volts.

By monitoring the output voltage from the TP

sensor, the PCM can determ ine fuel delivery based

on throttle valve angle (driver demand). A broken or

loose TP sensor can cause intermittent bursts of

fuel from the injectors, and an unstable idle,

because the PCM interprets the throttle is moving.

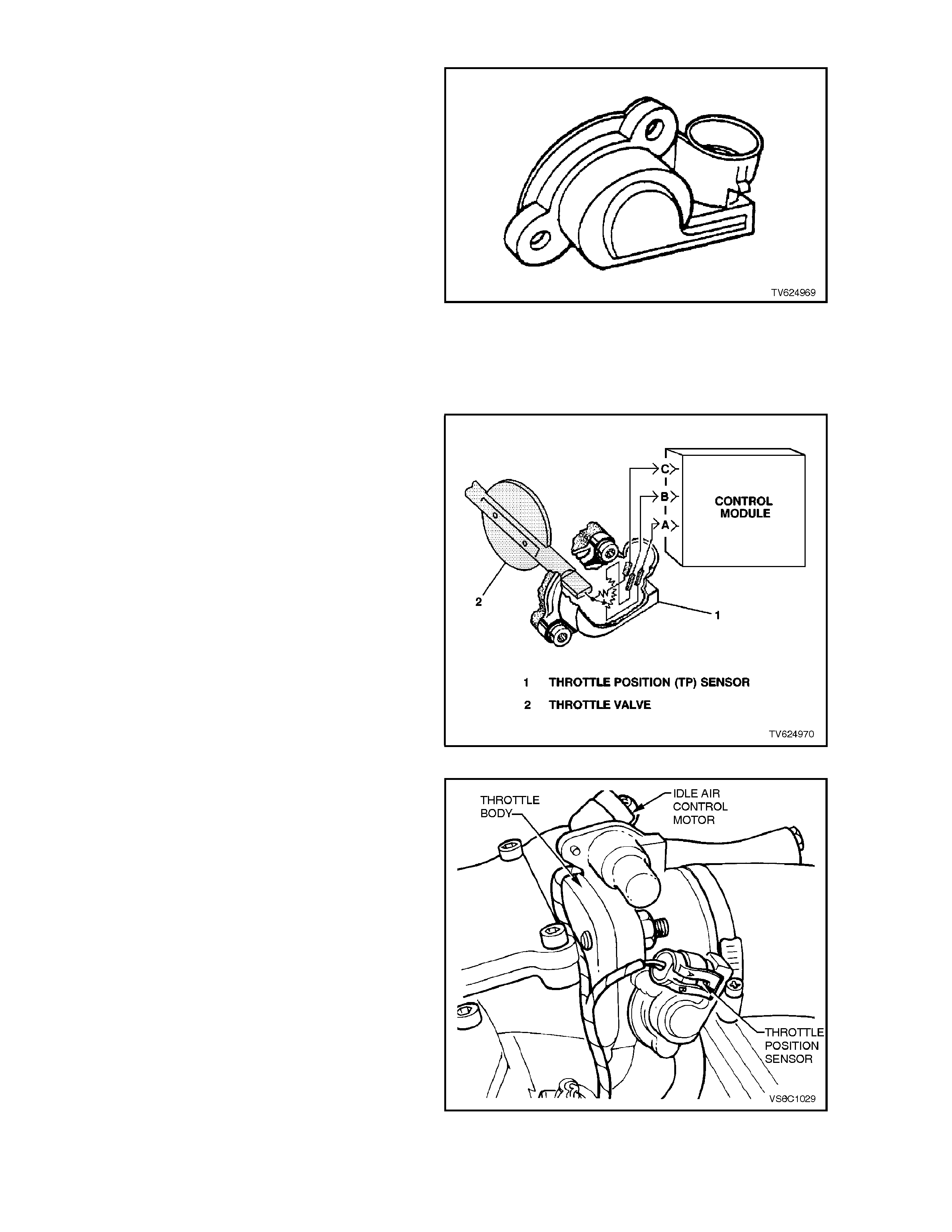

Figure 6C1-1-41 TP Sensor

The TP sensor is not adjustable and there is not a

set value for voltage at closed throttle because the

actual voltage at closed throttle can vary from

vehicle to vehicle due to tolerances. The PCM has

a special progr am built into it that can adjus t for the

tolerances in the T P sensor voltage reading at idle.

The PCM uses the reading at clos ed throttle idle for

the zero reading (0% throttle) so no adjustment is

necessary. Even if the TP sensor voltage reading

was to be change by: tampering, throttle body

coking, sticking cable or any other reason, the TP

sensor will still be 0%. The PCM will learn what the

closed throttle value is every time the throttle

comes back to closed throttle. The new closed

throttle value will be used by the PCM and no

driveability complaint will be present because the

PCM learned a new setting.

A failure in the TP sensor circuit problem will set

DTC 21 or DTC 22. If the internal spring in the TP

sensor should fail, the T P sensor will be stuck high.

A sticking TP sensor should set DTC 19. Figure 6C1-1-42 TP Sensor - Typical

Figure 6C1-1-43 TP Sensor Location

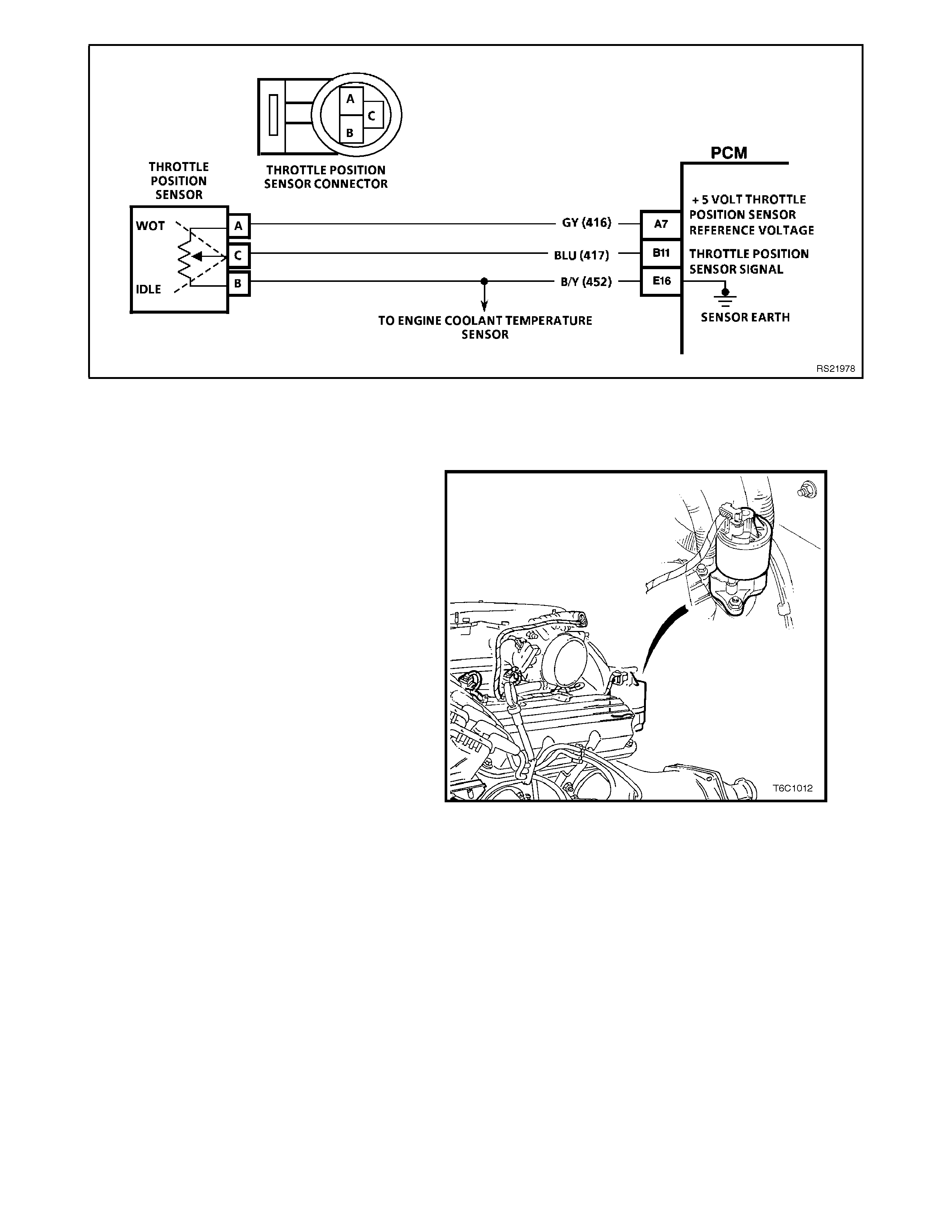

Figure 6C1-1-44 TP Sensor Circuit

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

NON-SUPERCHARGED ENGINE APPLICATION ONLY

PURPOSE

The Exhaust Gas Recirculation (EGR) system is

used to lower Oxides of Nitrogen (NOx) emission

levels caused by high combustion temperatures. It

does this by decreasing combustion temperature.

The main element of the system is the linear EGR

valve. The EGR valve feeds small amounts of

exhaust gas back into the compression chamber.

With the air/fuel mixture thus diluted, combustion

temperatures are reduced.

Figure 6C1-1-45 Linear EGR Valve Location

OPERATION

The linear EGR valve is designed to accurately

supply EGR to an engine independent of intake

manifold vacuum. The valve controls EGR flow

from the exhaust to the intake m anifold through an

orifice with a PCM controlled pintle. During

operation, the PCM controls pintle position by

monitoring the pintle position feedback signal. The

feedback signal can be monitored with a scan tool

as "EGR POS. FEEDBACK". "EGR POS.

FEEDBACK" should always be near the

commanded EGR position ("EGR POS.

COMMANDED"). If a problem with the EGR system

will not allow the PCM to control pintle position

properly, DTC 29 should set. The PCM also tests

for EGR flow; if incorrect flow is detected, DTC 18

should set. If DTC 29 and/or DTC 18 are

encountered, refer to appropriate DTC chart in

section.

The Linear EGR valve is usually activated under

the following conditions:

• Warm engine operation

• Above idle engine speed

• Vehicle not in Park or Neutral

• Fuel Control Is In Closed Loop Mode

LINEAR EGR CONTROL

The PCM monitors EGR feedback position and

adjust pintle position accordingly. The PCM uses

information from the following sensors to control

the pintle position:

• Engine Coolant Temperature (ECT) sensor.

• Mass Air Flow (MAF).

• Engine RPM.

RESULTS OF INCORRECT EGR SYSTEM

OPERATION

Too much EGR flow at idle, cruise, or cold

operation may cause any of the following conditions

to occur:

• Engine stalls after cold start.

• Engine stalls at idle after deceleration.

• Vehicle surge during cruise.

• Rough idle.

• Misfire.

Too little or no EGR flow may allow combustion

temperatures to get too high. This could cause:

• Spark knock (detonation).

• Engine overheating.

• High emissions.

• Poor fuel economy.

• DTC 18.

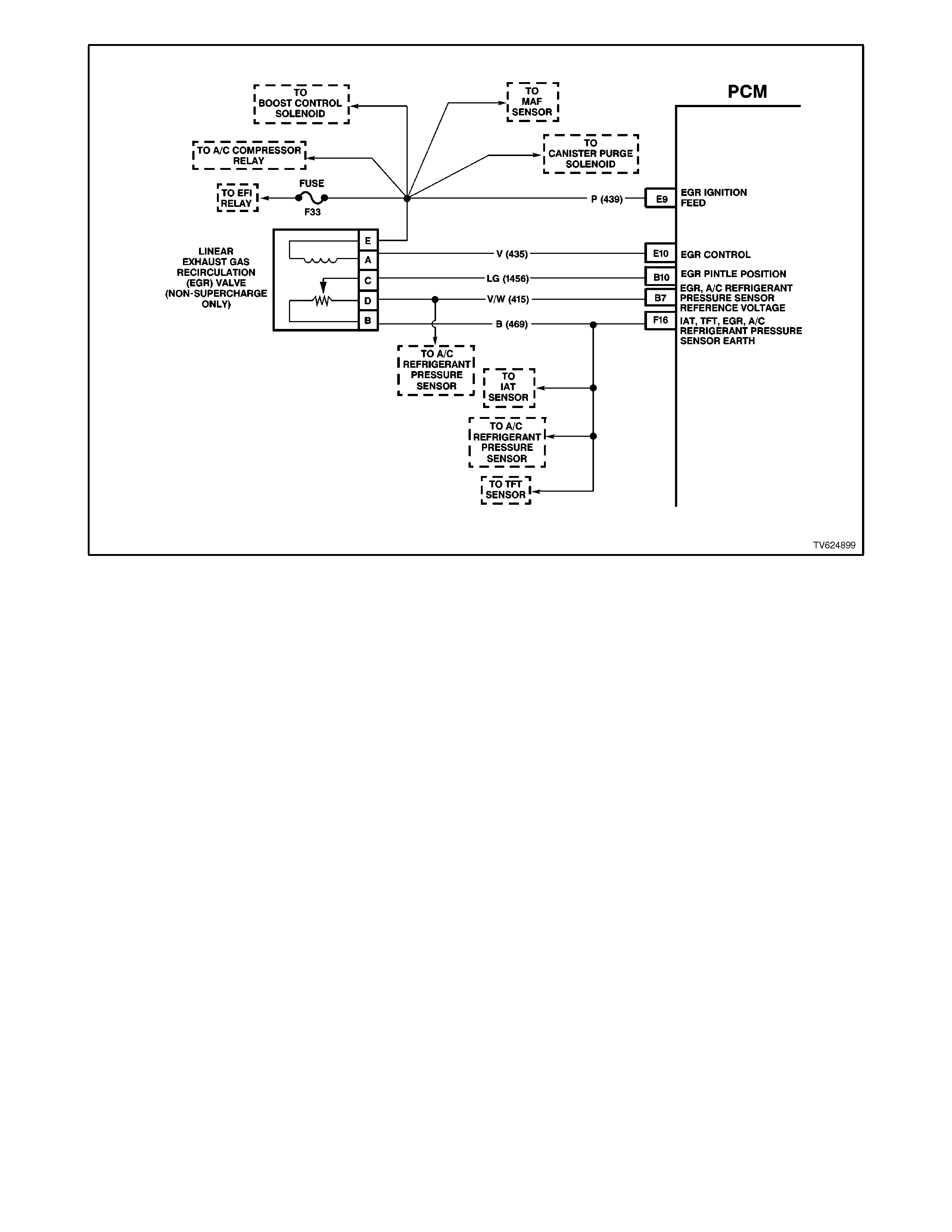

Figure 6C1-1-46 Linear EGR Valve Circuit

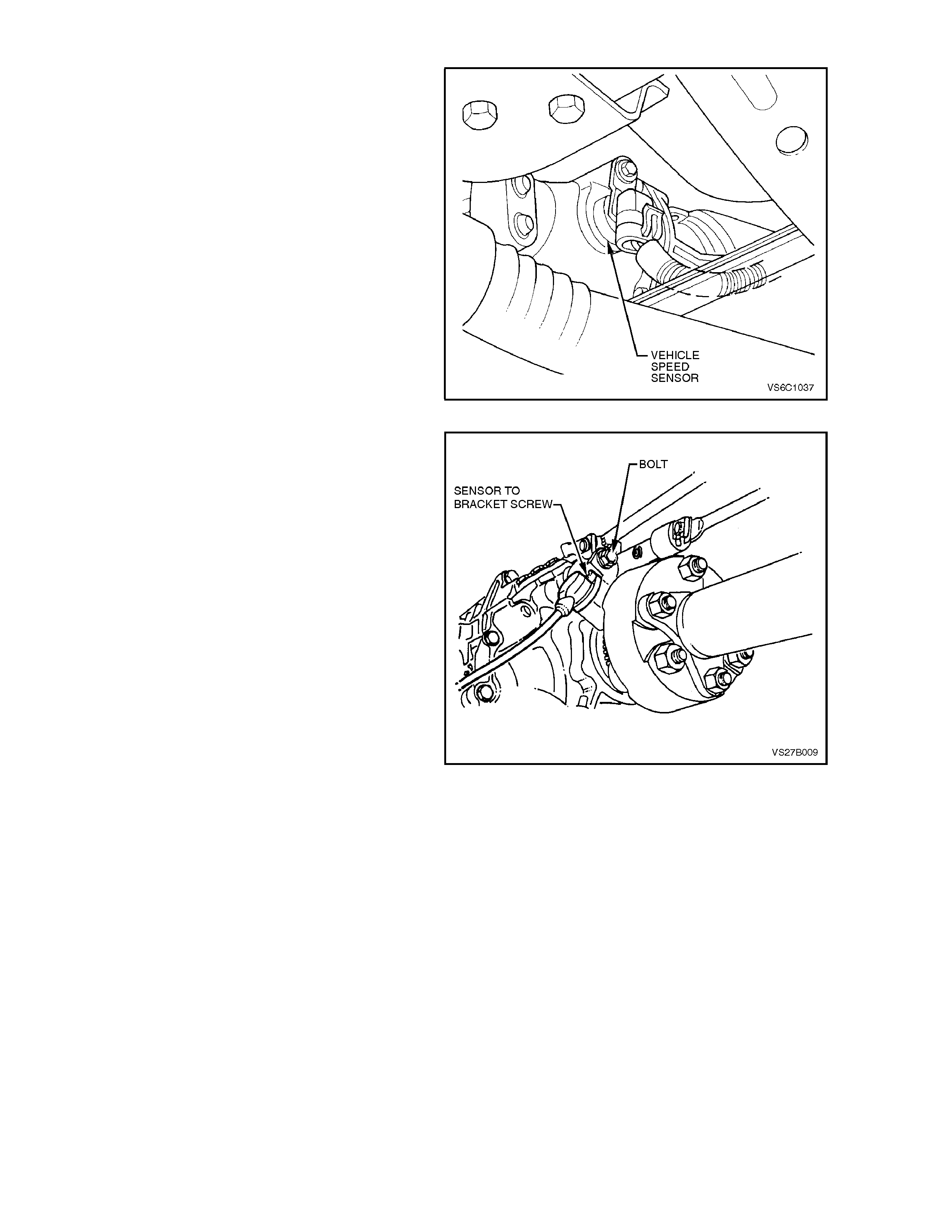

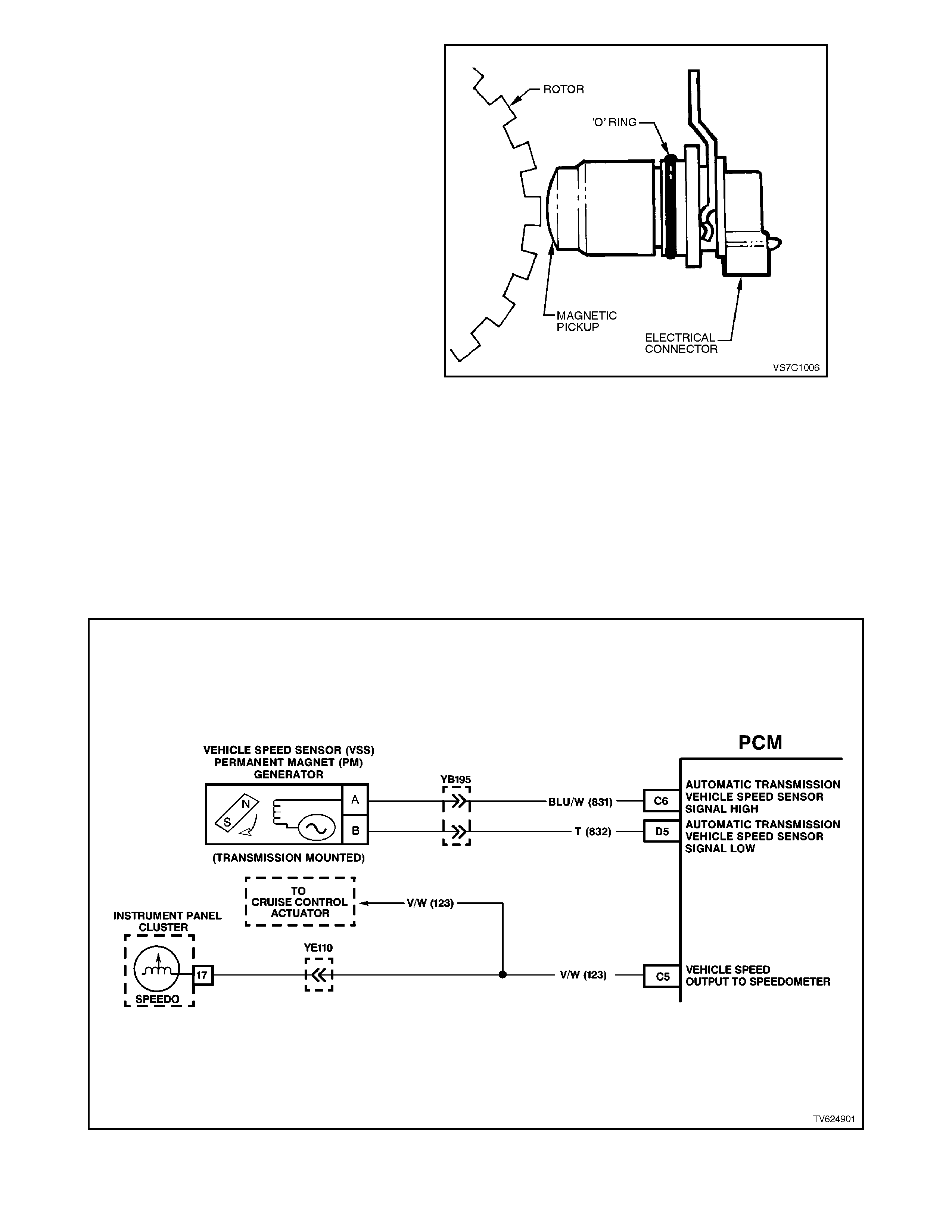

VEHICLE SPEED SENSOR (VSS)

The Vehicle Speed Sensor (VSS) is located on the

transm iss ion. Refer to Figure 6C1-1- 47 for the VSS

Location - Automatic Transmission and 6C1-1-48

for the VSS Location - Manual Transmission.

The VSS provides an indication of road speed to

the PCM. The sensor is mounted to the

transmission where it is gear driven by the

transmission output shaft. The sensor is an

electronic Hall effect switch that pulses to earth a

voltage signal com ing from the PCM. T hese pulses

occur 10 tim es per sensor revolution, and ar e used

by the speedometer for driver information.

The PCM also uses information from the VSS for

IAC valve operation and some of the engine fuelling

modes. If the PCM receives no pulses on the

vehicle speed sensor input while certain conditions

exist, a DTC 24 (Automatic Transmission) or DTC

94 (Manual Transmission) will be set.

Diagnostic Trouble Code (DTC) 24 or 94 will set if a

fault exis ts in the vehicle s peed sensor circ uit when

the vehicle is decelerated, and the VSS signal is

constant, or not pulsing. DTC 24 or 94 will set and

a default value will be substituted by the PCM. As

long as the fault r emains and the diagnostic trouble

code is set. If the fault is removed, normal

operation will resume after the next ignition cycle

Figure 6C1-1-47 VSS Location - Automatic Transmission

Figure 6C1-1-48 VSS Location - Manual Transmission

The vehicle speed sensor contains a coil that has

continuous magnetic field. A voltage signal is

induced in the vehicle speed s ens or by teeth on the

output shaft that rotate past the sensor and break

the magnetic field. Eac h break in the field s ends an

electrical pulse to the PCM. T his voltage output will

vary with transmission output shaft speed from a

minim um of 0.5 volts AC at 100 RPM to more than

100 volts AC at 8000 RPM with no load on the

circuit on the vehicle, with the engine at 4,000 RPM

in fourth gear the voltage will be approximately 10-

12 Volts AC.

The PCM uses speed information from this sensor

to determine the following:

• Vehicle speed.

• Control shift points (Auto Trans).

• Calculate transmission slip (Auto Trans).

• Engine fuelling modes.

Diagnostic Trouble Code (DTC) 24 or 94 will set if a

fault exists in the vehicle speed sensor circuit

indicating the vehicle is not moving. For the

automatic transmission, as the vehicle is

accelerated the PCM shifts the transmission to

second gear at approximately 50 km/h. If the

vehicle speed signal is still not present while in

second gear, DTC 24 is set, the transmission will

have maximum line pressure, 2 ND gear only and

have no TCC and a def ault value will be s ubs tituted

by the PCM.

Figure 6C1-1-49 VSS

Figure 6C1-1-50 VSS Circuit

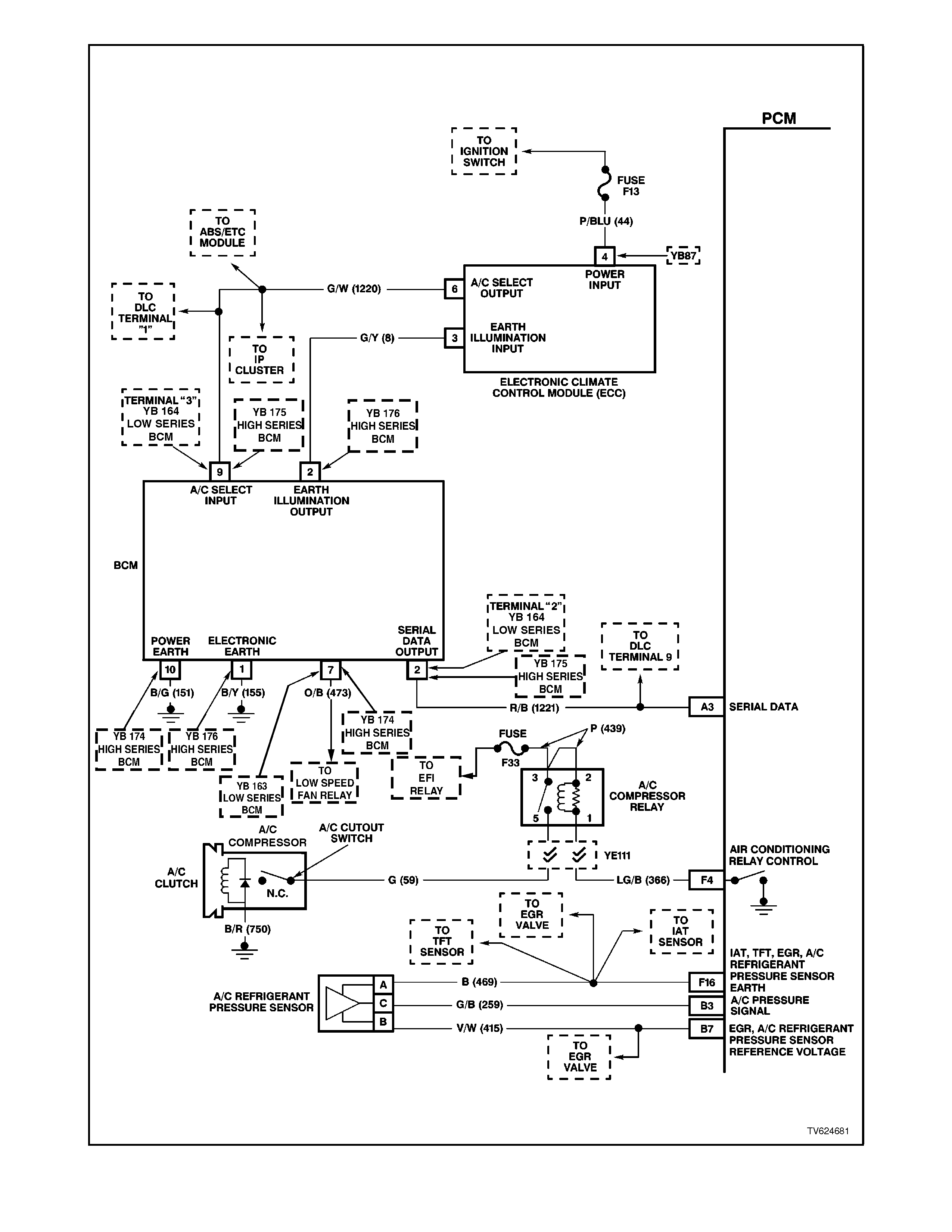

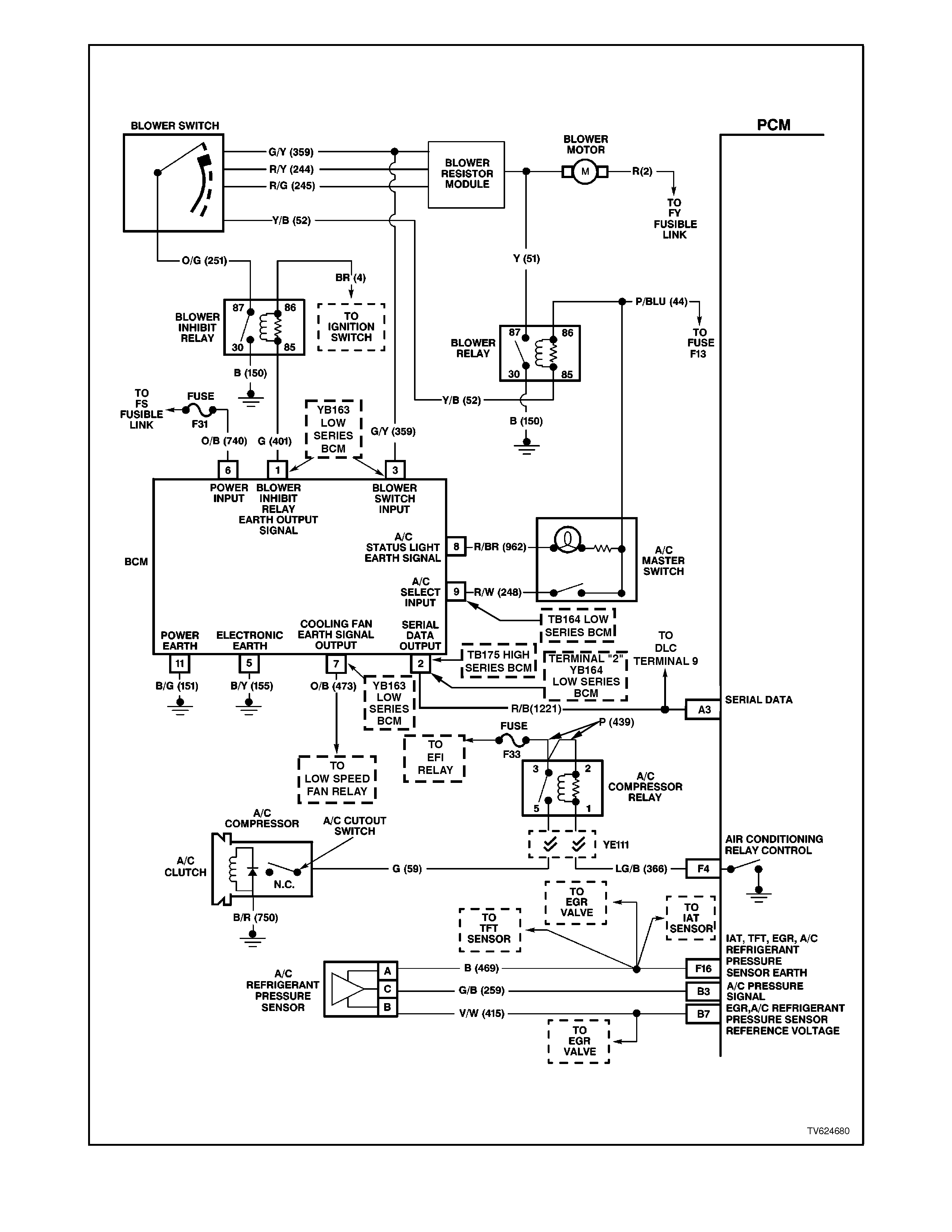

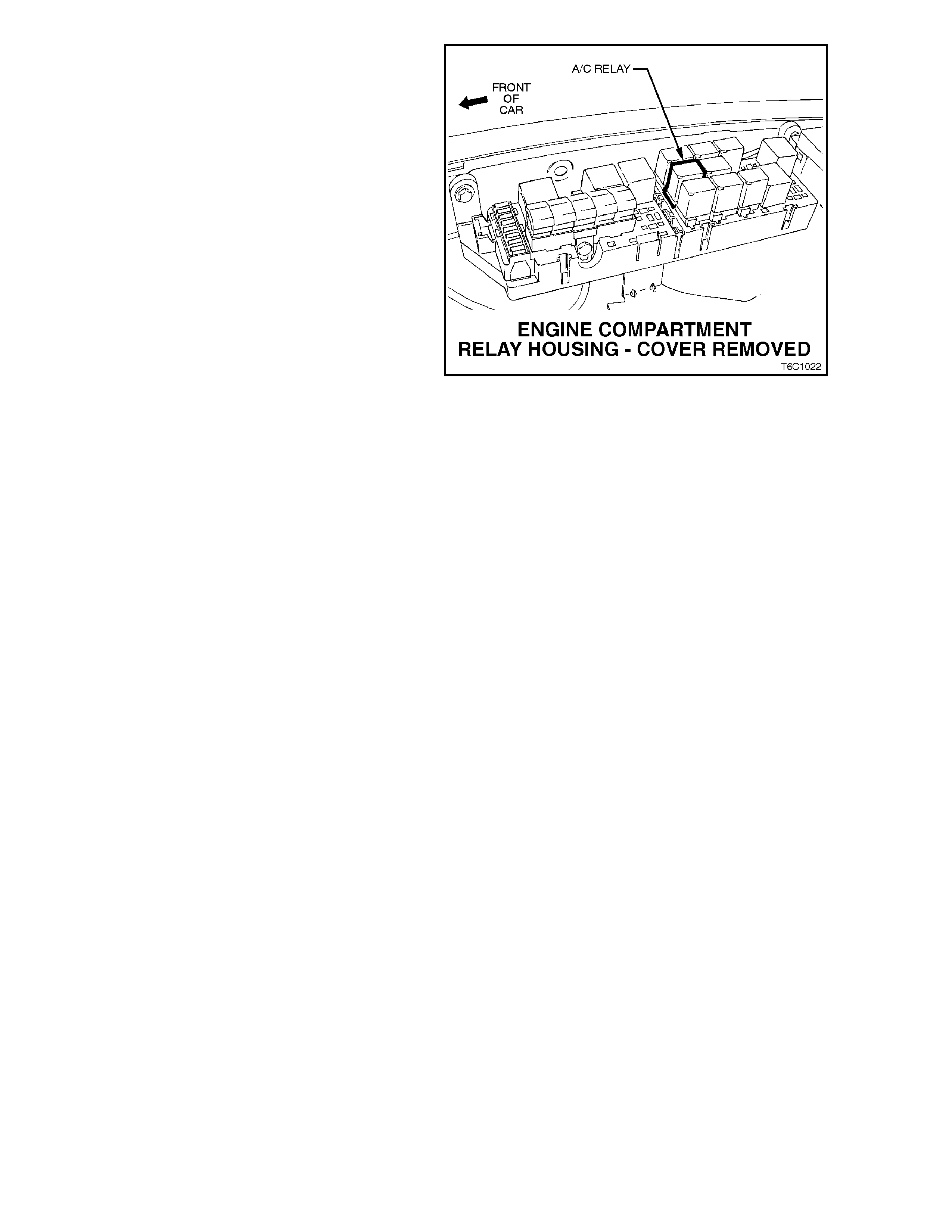

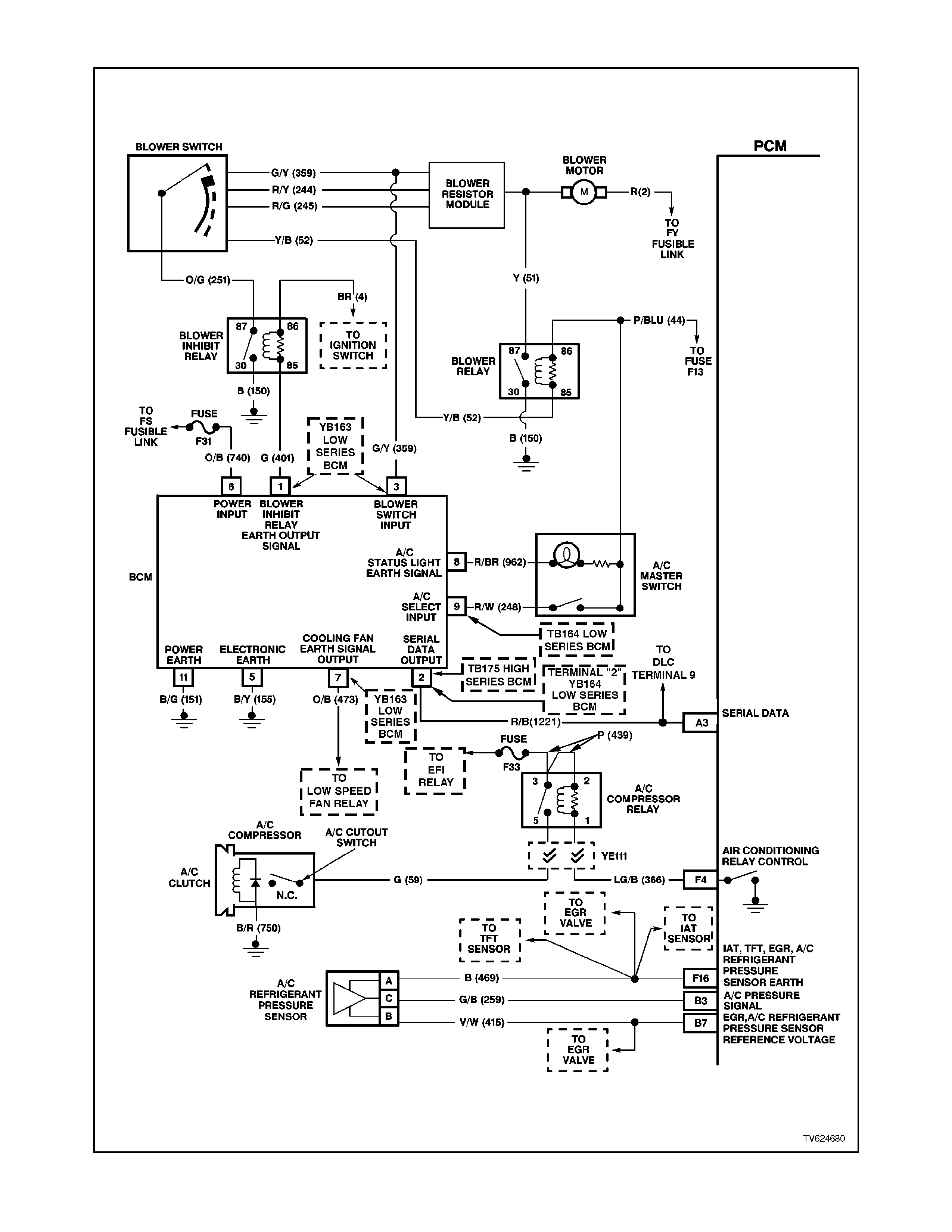

A/C REQUEST SIGNAL

When A/C is requested from the dash master A/C switch, the A/C request signal is sent to the BCM. The BCM will then

send a command via the serial data line to the PCM. The PCM will then supply a earth signal to the A/C compressor

relay, to energise the A/C compressor.

The PCM uses this BCM serial data command to:

1. Adjust the Idle Air Control (IAC) position to compensate for the additional load placed on the engine by the air

conditioning compressor, and then

2. Energises the A/C compressor relay, to operate the A/C compressor.

Figure 6C1-1-51 A/C Request Signal Circuit With ECC

Figure 6C1-1-52 A/C Request Signal Circuit Without ECC

BATTERY VOLTAGE

The PCM continually monitor s battery voltage. W hen the battery voltage is low, the ignition system may deliver a weak

spark and the injector mechanical movement takes longer to open the injector. The Powertrain Control Module will

compensate by:

1. Increasing the ignition coil dwell time if the battery voltage is less than 12 volts.

2. Increasing the engine idle RPM if battery voltage drops below 10 volts.

3. Increasing the injector pulse width if the battery voltage drops below 10 volts.

On vehicles equipped with automatic transmissions, Diagnostic Trouble Code (DTC) 53 will set when the ignition is

"ON'' and PCM terminal "A4'' voltage is more than 19.5 volts for about 2 seconds.

Diagnostic Trouble Code (DTC) 54 will set when the ignition is "ON'' and PCM terminal "A4'' voltage changed more than

2.5 volts in 100 milliseconds.

Diagnostic Trouble Code (DTC) 75 will set when the ignition is "ON'' and PCM terminal "A4'' voltage is less than 8.6

volts for about 4 seconds. Minimum voltage allowed for Diagnostic Trouble Code 75 to set is on a graduated scale and

will change with the temperature. Minimum voltage at -40 degrees C is 7.3 volts, minimum voltage at 90 degrees C is

8.6 volts., minimum voltage at 152 degrees C is 11.4 volts.

Figure 6C1-1-53 PCM Battery Feed

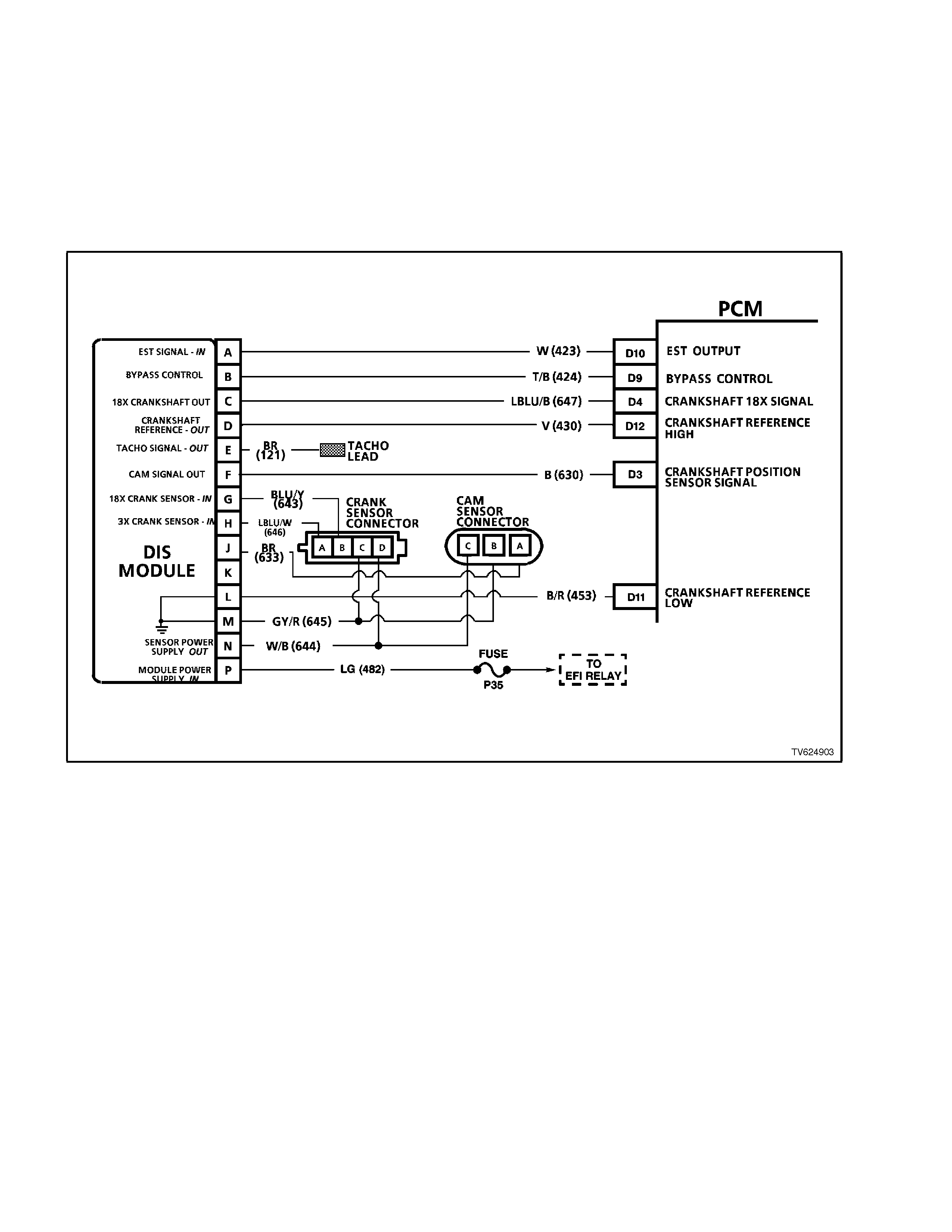

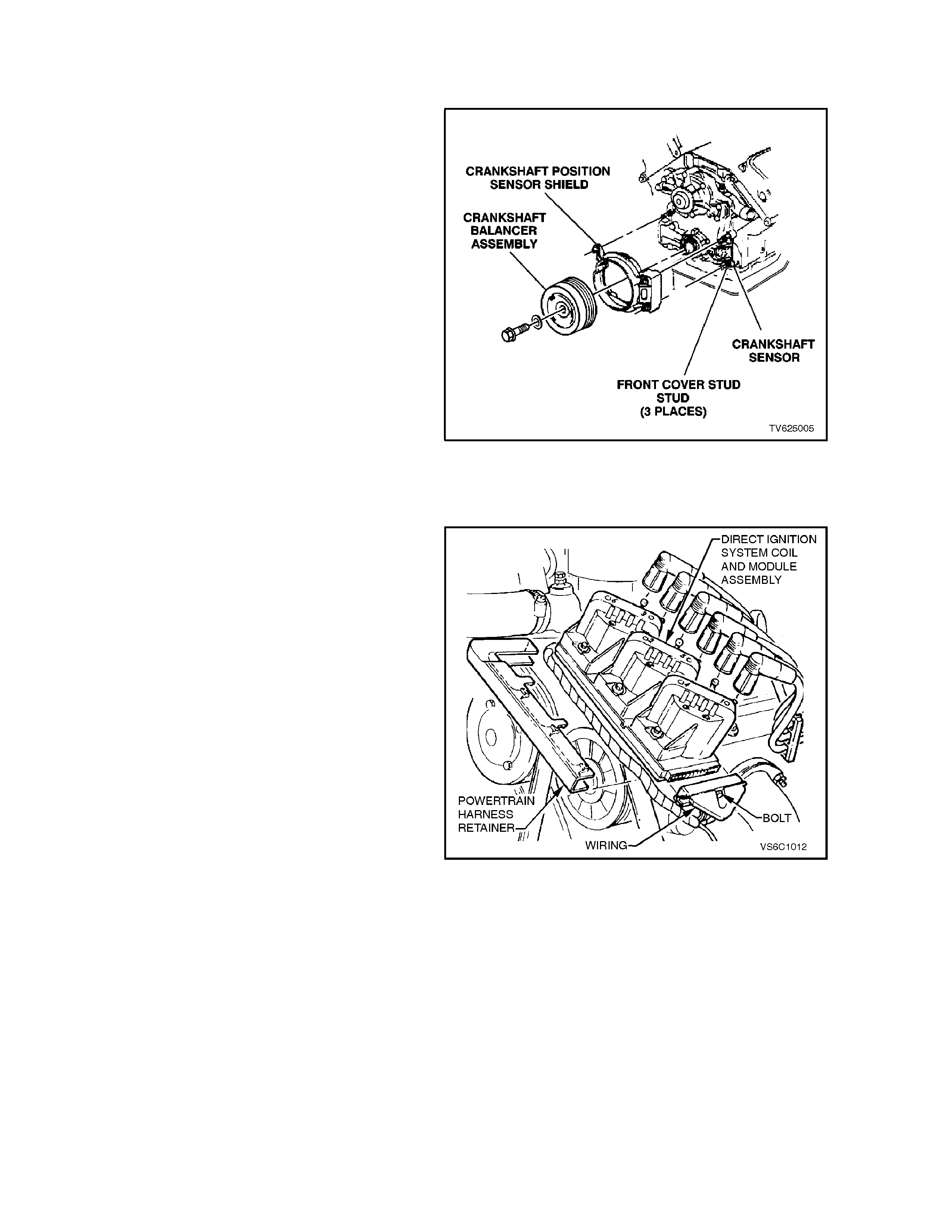

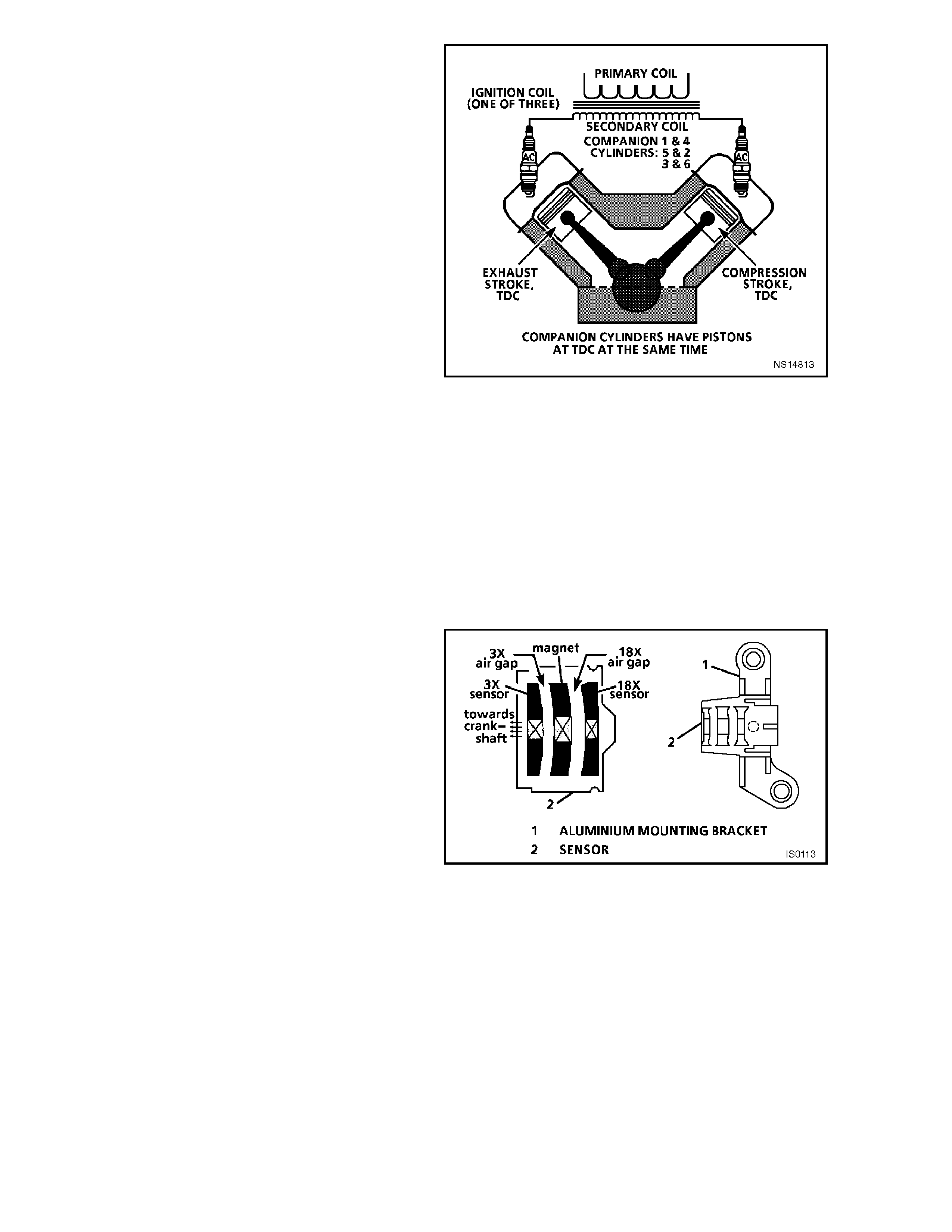

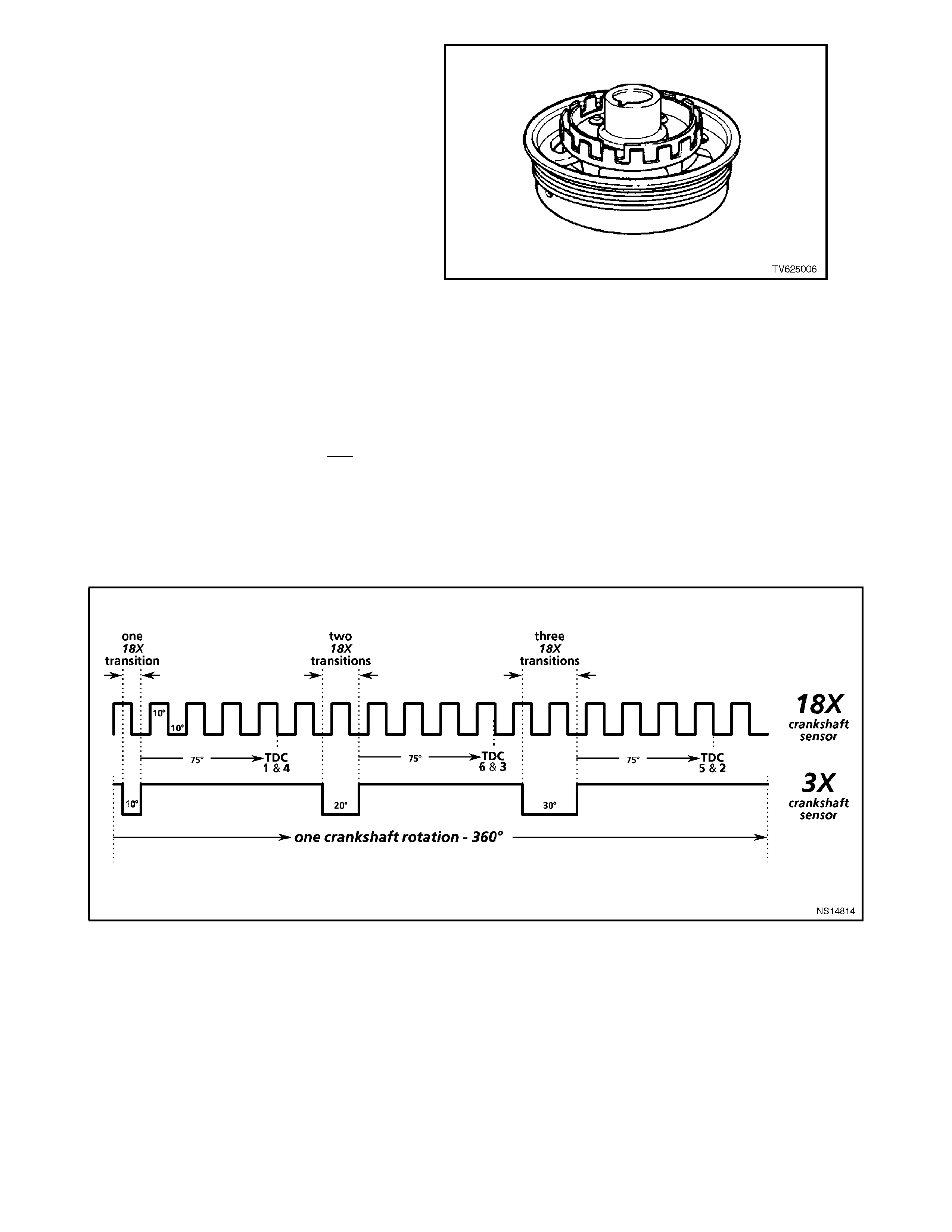

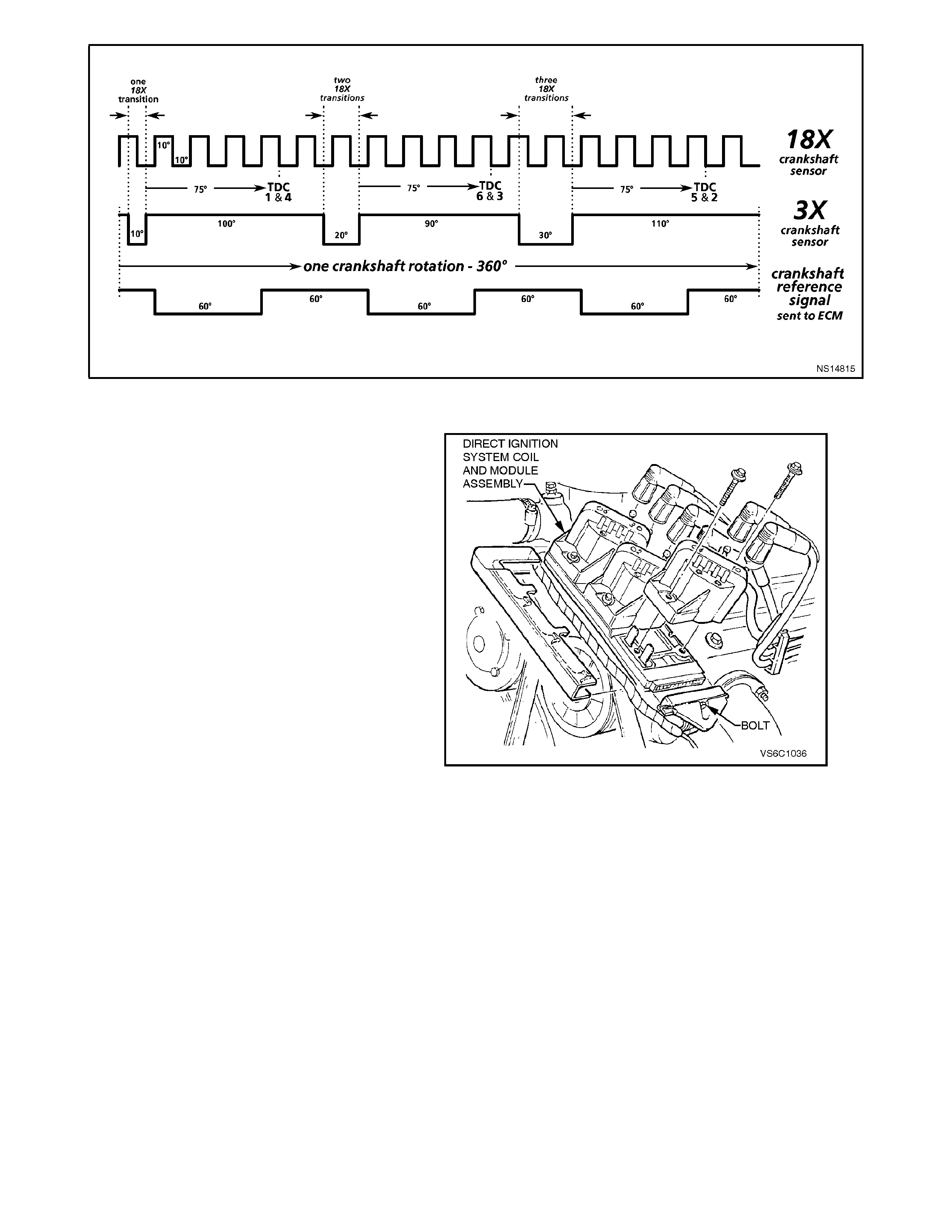

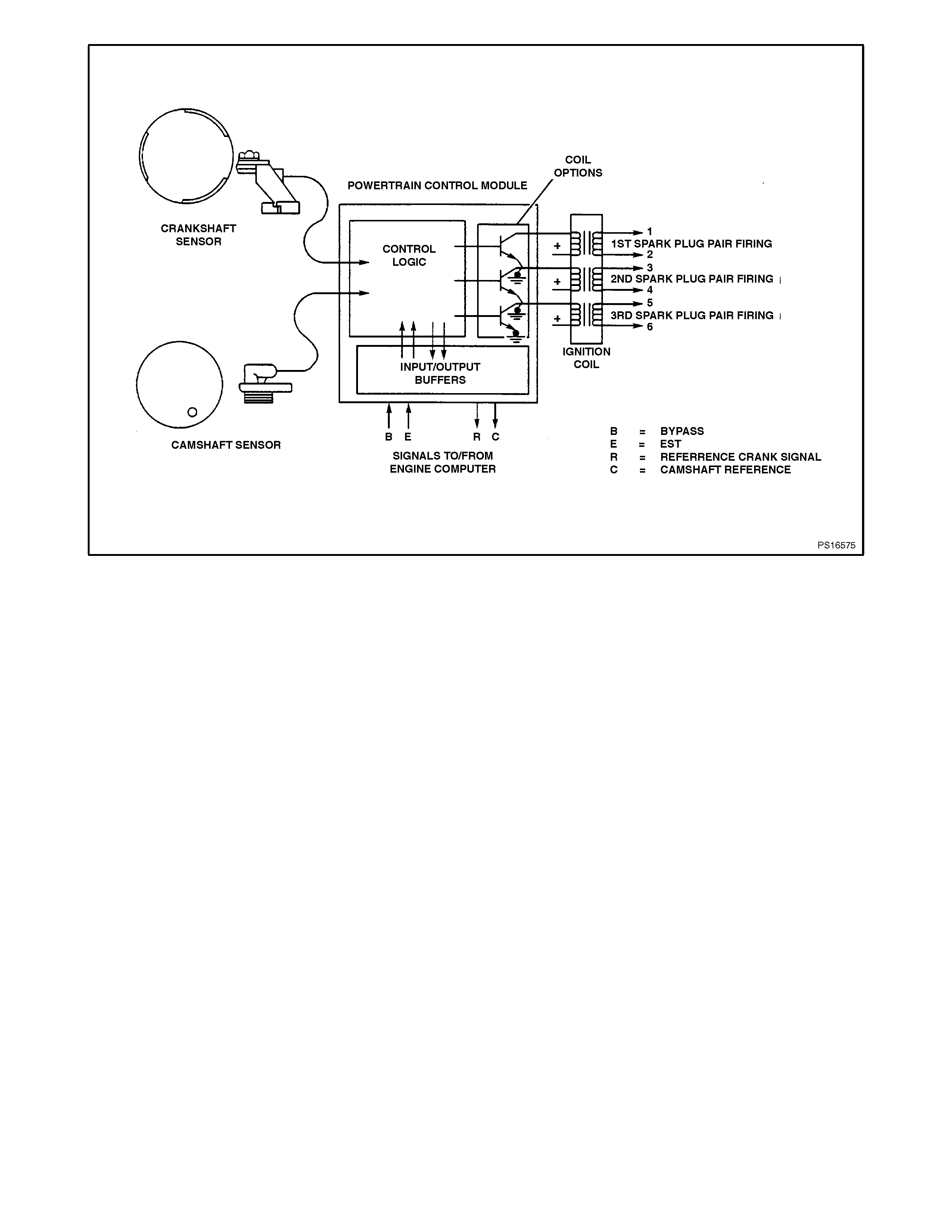

CRANKSHAFT REFERENCE SIGNAL

This also uses the camshaft position sensor signal to synchronise the fuel injector circuits for sequntial fuel injection.

The PCM also uses these reference pulses for Electronic Spark Timing (EST) operation.

For a full description of the ignition system operation refer to Section 1.7 DIRECT IGNITION SYSTEM (DIS) in this

Section.

The Direct Ignition System (DIS) sends this signal to the PCM to tell it engine RPM and crankshaft position. This signal

is a repeating series of low voltage electrical pulses generated by the ignition module. The PCM initiates fuel injector

pulses based upon receiving these crankshaft reference signal pulses.

Figure 6C1-1-54 Crankshaft Reference Signal

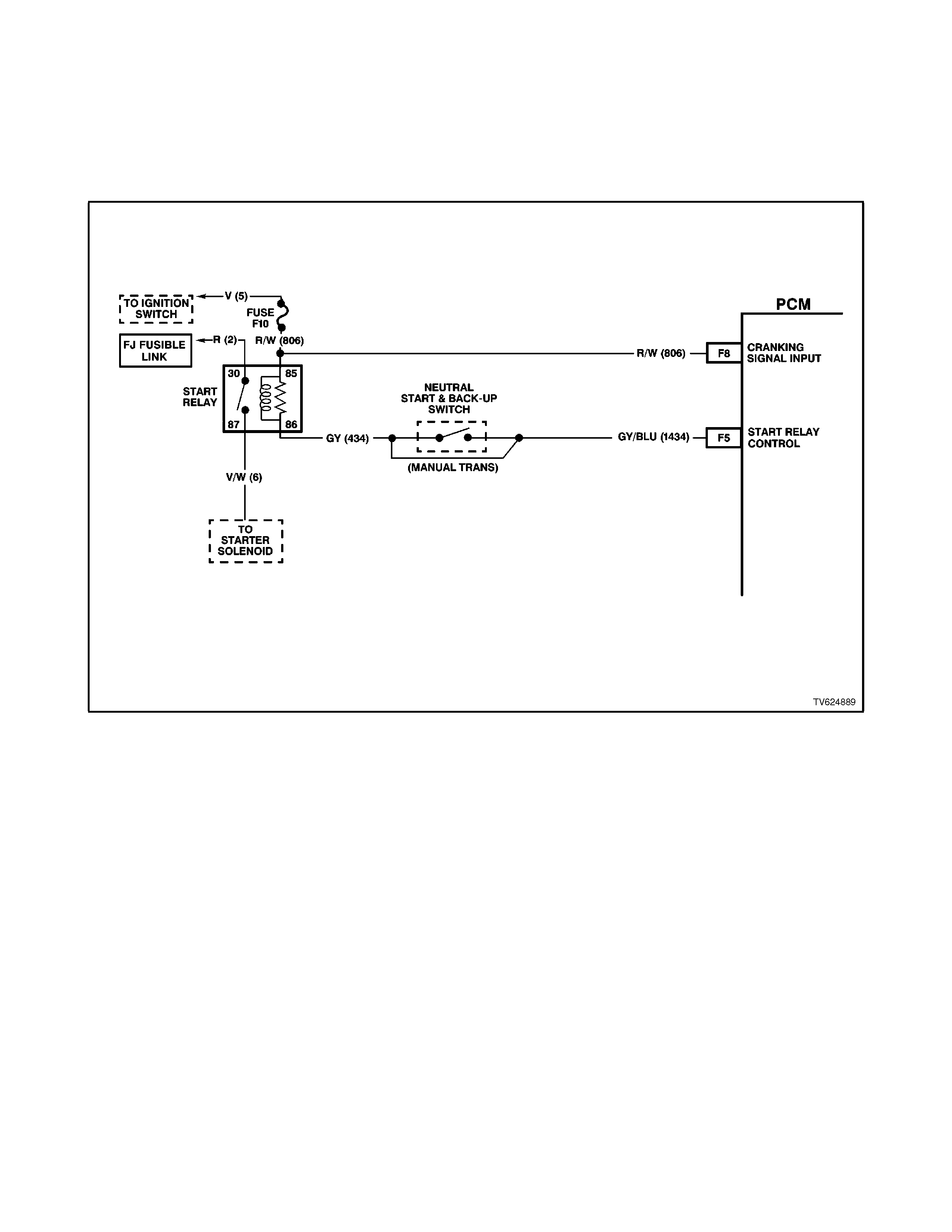

CRANKING SIGNAL

The cranking circuit provides an input for enabling fuel cut off during a possible backfire situation. During an engine

start, when the ignition switch is r eleas ed f r om the cr ank position bef or e the engine is running, the engine may back fire.

The Powertrain Control Module stops all injection pulses when the engine speed is less than 450 RPM, coolant

temperature is greater than -4 degrees C, a cranking signal is not received, but was received with the previous 12.5

milliseconds.

The Powertrain Control Module monitors the voltage on the cranking signal input terminal. This terminal is a voltage

sensing input.

Figure 6C1-1-55 Cranking Signal Circuit

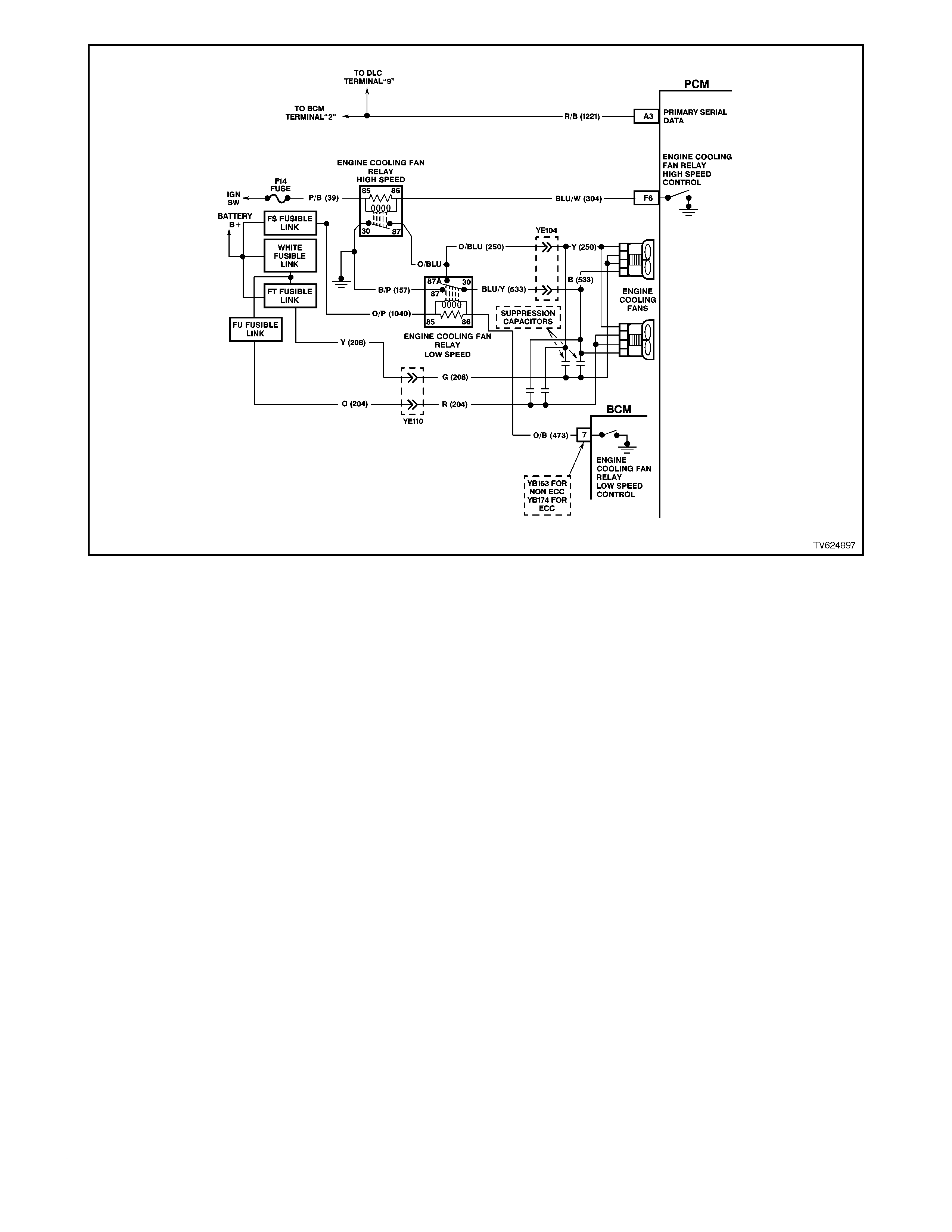

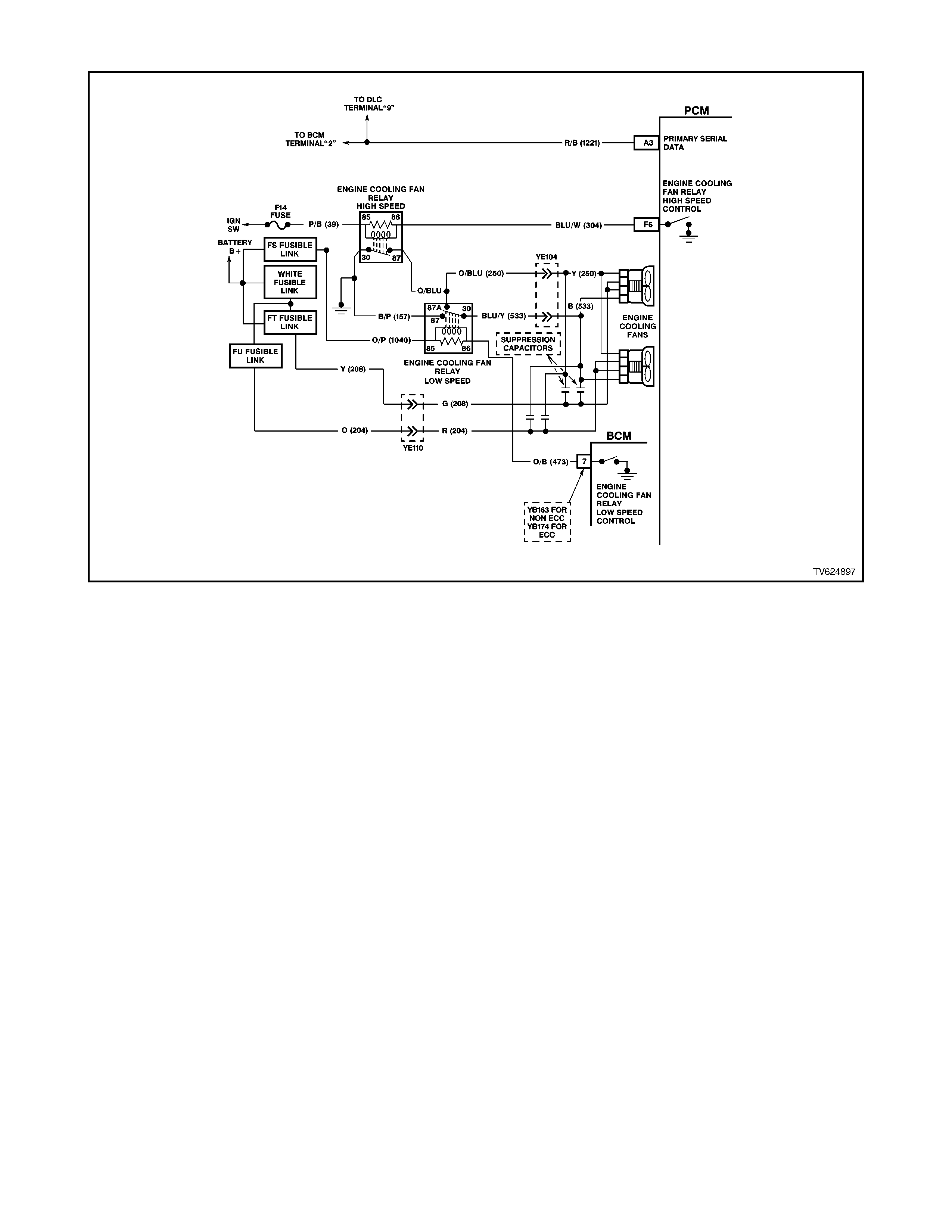

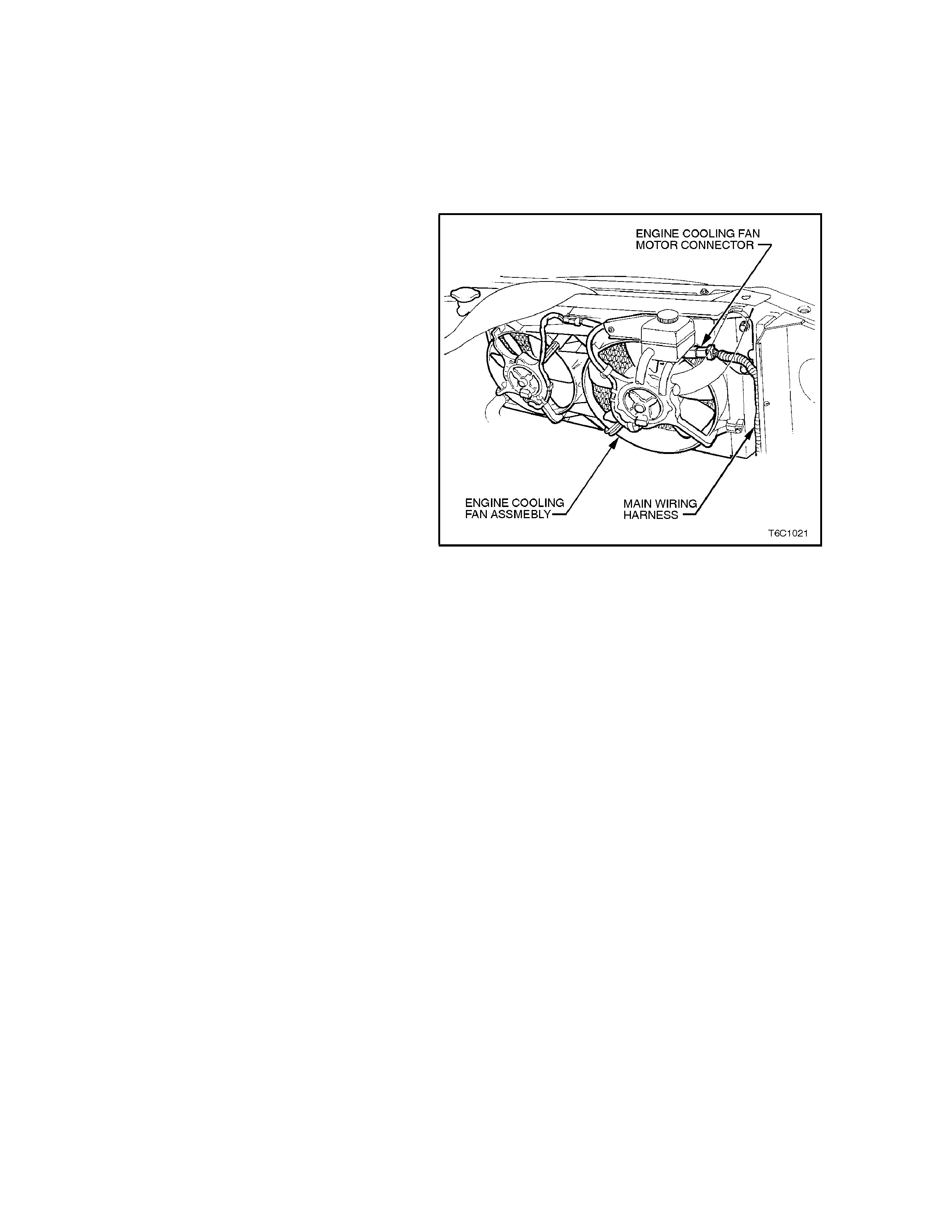

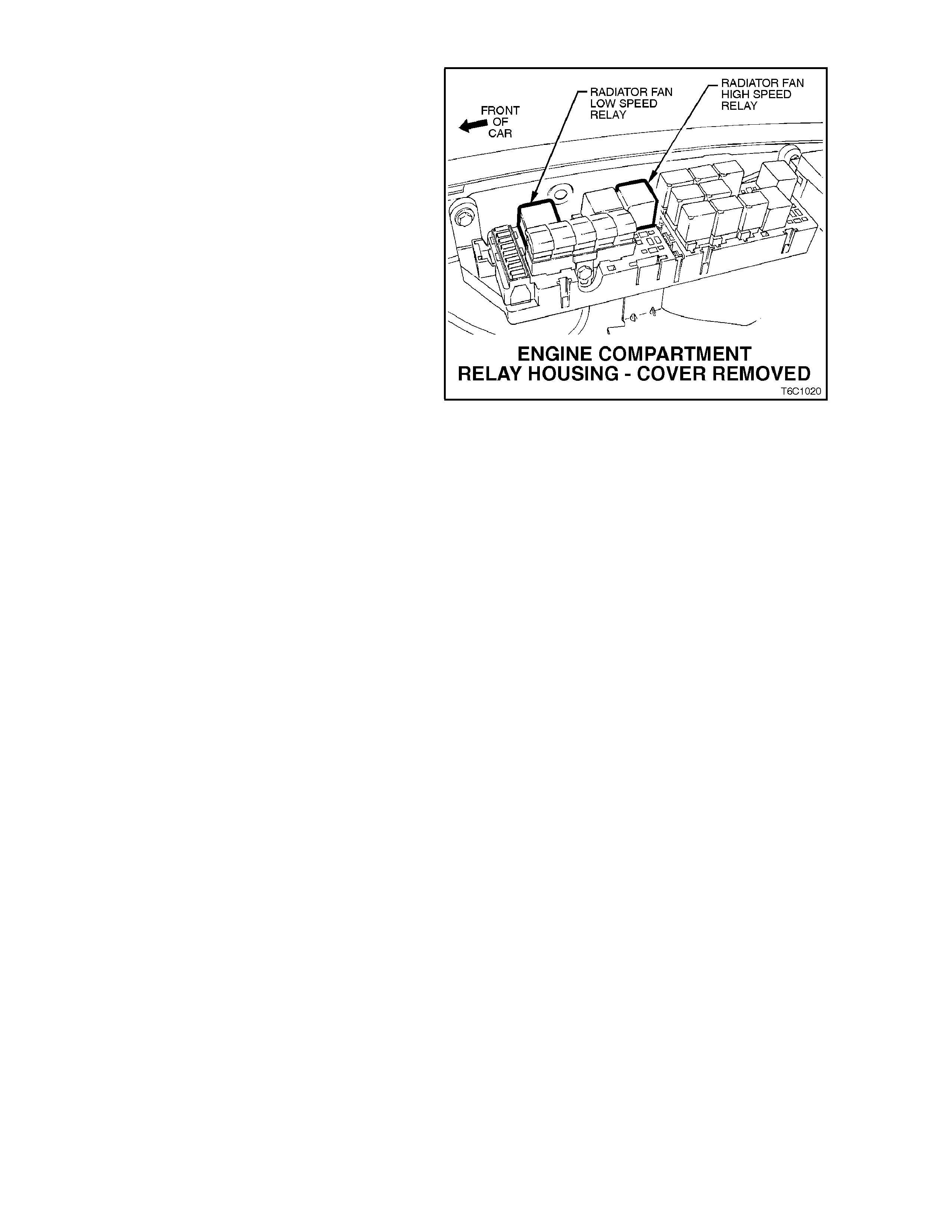

ENGINE COOLI NG FAN SIGNAL

(LOW SPEED RESPONSE)

The V6 engine has two (2), two speed electric cooling fans which provides the primary means of moving air through the

engine radiator. These fan are placed between the radiator and the engine and has its own shroud. These fans are

used on all vehicles whether or not it is equipped with air conditioning. There is no fan in front of the A/C condenser.

The two (2), two speed electric fan's low speed can only be enabled when the engine cooling fan low speed relay is

energised by the BCM. The PCM will request low speed fan enable and disable via the serial data communication to the

BCM. After the PCM requests a change in the engine cooling fan low speed relay , the BCM will send a serial data

response message back to the PCM confirming it received the message. A failure in this response communication will

set a DTC 92. There are also four (4) suppression capacitors incorporated into the fan motor wiring circuits. These

suppression capacitors help eliminate fan motor noise through the radio speakers. If these capacitors are open, then

noise will be present through the radio speakers. If shorted to earth, the fan motors could continuously run, or the fuse

or fusible link could fail.

Figure 6C1-1-56 Engine Cooling Fan Signal

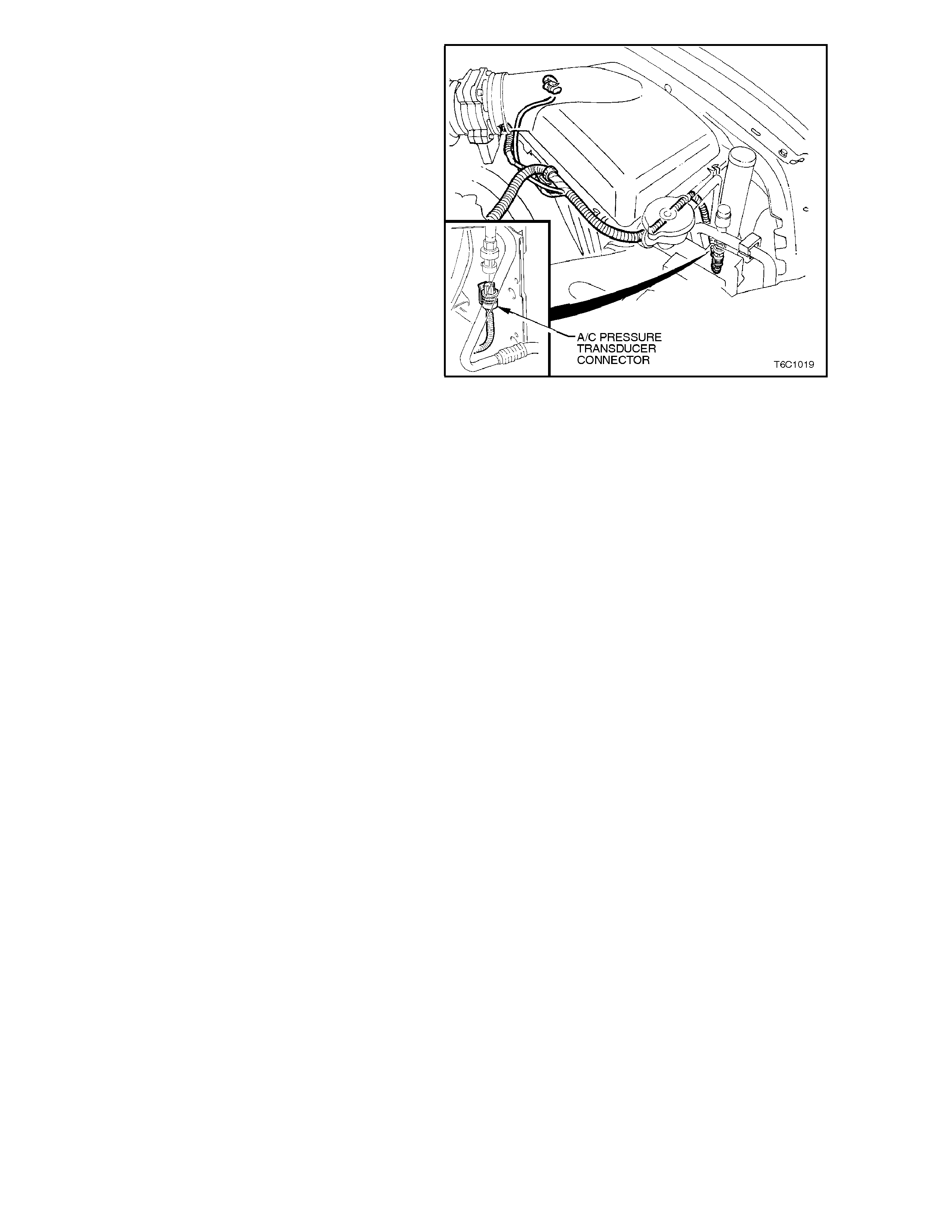

ENGINE COOLING FAN HIGH SPEED

The engine cooling fan high speed is controlled by the PCM based on input from the Engine Coolant Temperature

Sensor (ECT). The PCM will only turn "ON" the engine cooling fan high speed if the engine cooling low speed fans have

been "ON" for 2 seconds and the following conditions are satisfied.

• There is a BCM message response fault which will cause a DTC 92.

• An engine coolant temperature sensor failure is detected, such as DTC 14,15,16,17.

• Coolant temperature greater than 109 degrees C.

If the fan low speed was "OFF" when the criteria was met to turn the fan high speed "ON", the fan high speed will come

"ON" 5 seconds after the fan low speed is turned "ON". The high speed engine cooling fan relay can also be enable by

the A/C Refrigerant Pressure Sensor. The A/C Refrigerant Pressure Sensor will enable high speed cooling fan, if the

A/C system pressure becomes to high.

If a failure occurs in the PCM Engine Cooling Fan Relay High Speed Control circuit, a DTC 91 will set.

There are also four (4) suppression capacitors incorporated into the fan motor wiring circuits. These suppression

capacitors help eliminate fan motor noise through the radio speakers. If these capacitors are open, then noise will be

present through the radio speakers. Is shorted to earth, the fan motors could continuously run, or the fuse or fusible link

could fail.

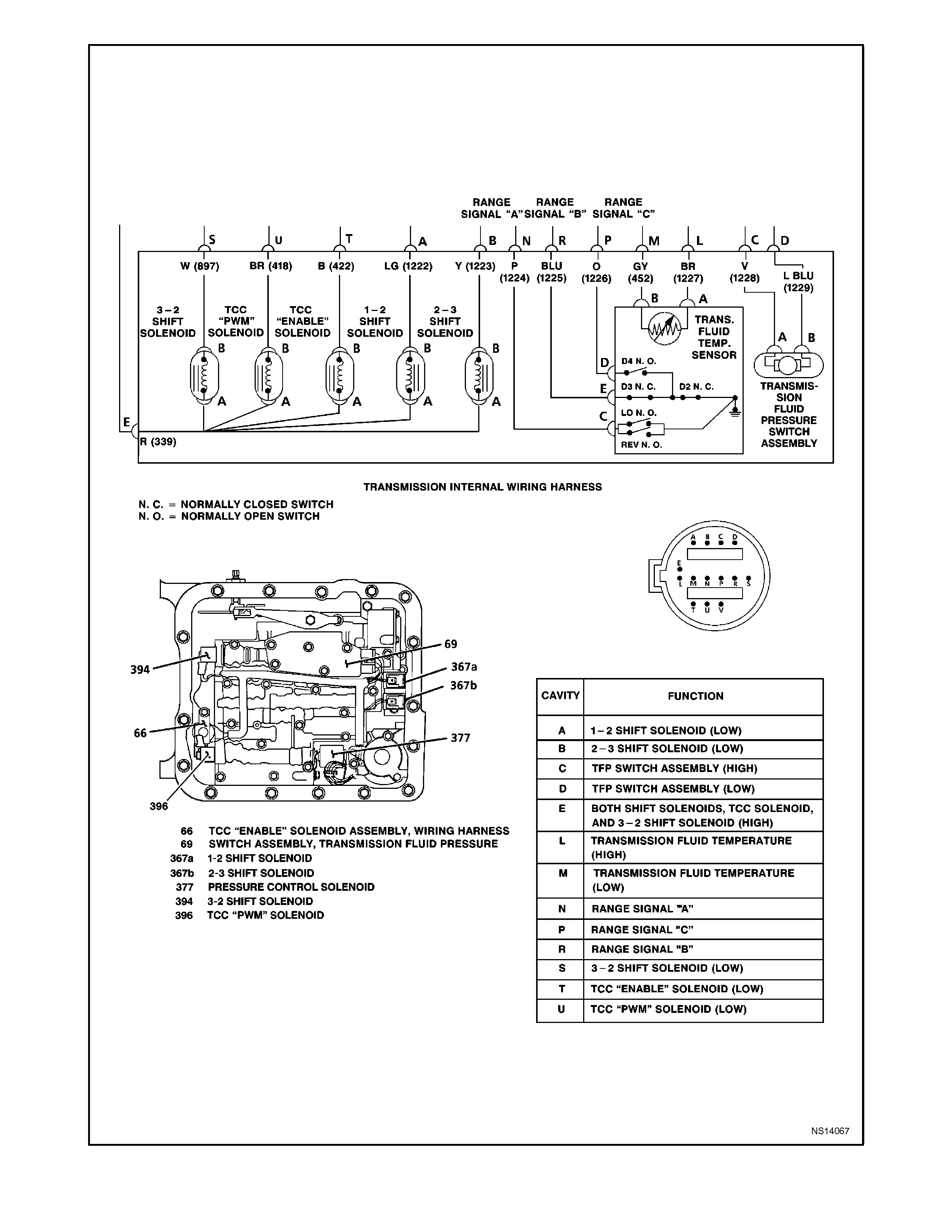

TRANSMISSION FLUID PRESSURE (TFP) SWITCH ASSEMBLY

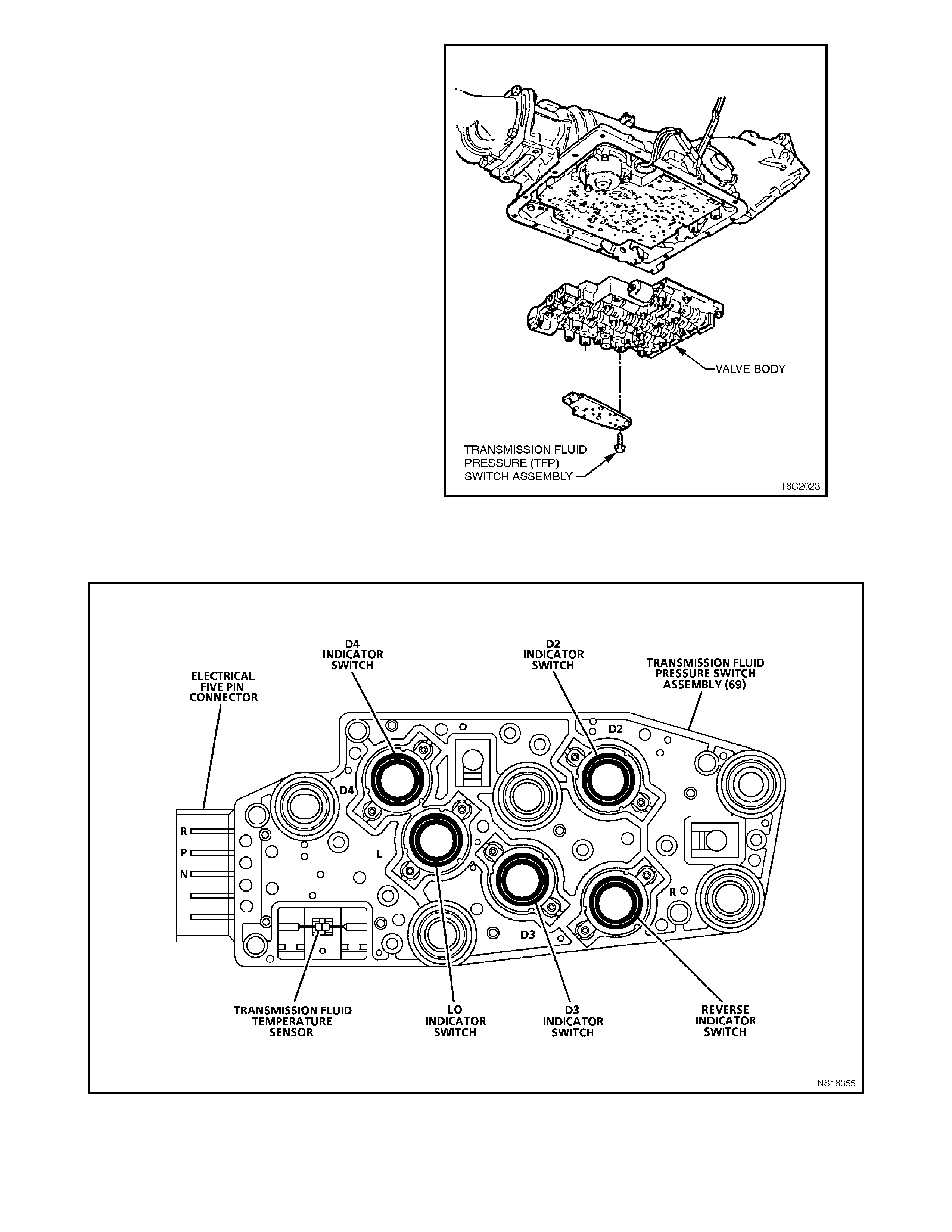

The Transmission Fluid Pressure Switch Assembly (TFP) is used by the PCM to sense what gear range has been

selected by the vehicle operator. The TFP is located on the transmission valve body and consists of five pressure

switches, 2 normally closed fluid pressure switches and 3 normally open fluid pressure switches combined into one unit.

The Transmission Fluid Pressure Switch Assembly is one of the inputs used by the PCM to control:

• Idle Air Control (IAC) and,

• Transmission Operation.

A failure in the TFP circuits will set a DTC 28 (Transmission Fluid Pressure Switch Assembly (TFP) circuit fault) if:

• The PCM detects an "illegal" TFP combination for five seconds.

For a full description of the TFP operation refer to

Section 1.3 TRANSMISSION INFORMATION INPUT SENSORS AND SIGNALS .

Figure 6C1-1-57 Transmission Fluid Pressure Switch Assembly Circuit

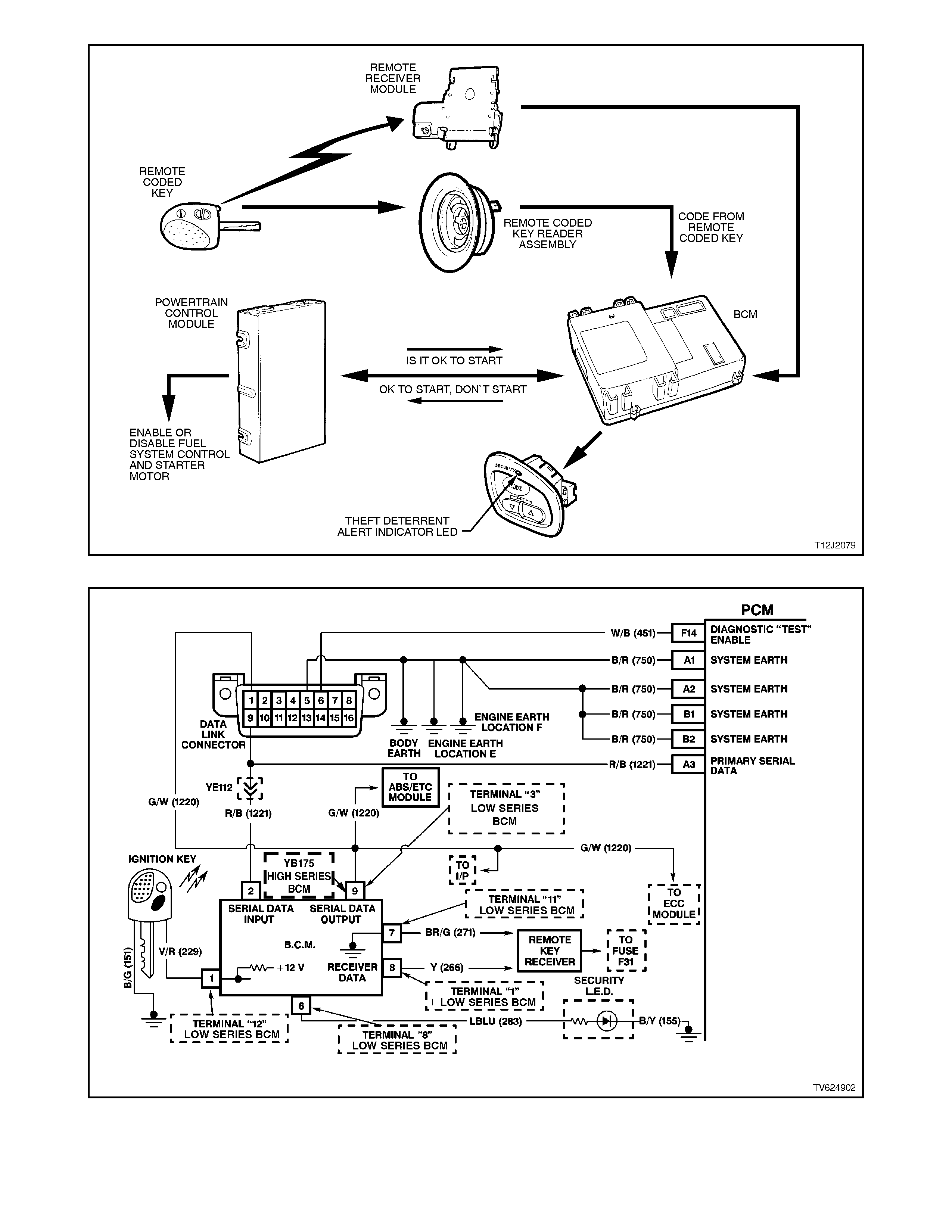

THEFT DETERRENT INPUT

When the ignition switch is turned to the “ON” position, the BCM polls the PCM and sends an encrypted BCM / key

security code. The security code is received by the BCM, via the remote key reader (slip ring) or via the remote receiver

in the event of no slip ring communication.

The PCM compares the received security code with its stored security code and if matched, the PCM will continue to

enable injector fuelling and engine crank.

The PCM will return a Valid Code message (OK TO START), which tells the BCM to jump to the short loop mode to the

long loop mode.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the PCM

for antitheft purposes. If the BCM does not receive the message OK TO START from the PCM within 0.5 seconds of

the ignition being switched on, the auxiliary bus is isolated via switching within the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the BCM

or PCM causing a problem on the bus and inhibiting antitheft communications.

This period is known as “Short Loop Time”, and continues until the PCM responds with an acknowledgment or a

maximum of 5 seconds, after which the BCM will switch to the standard poling sequence.

Following successful antitheft communications, the BCM begins sequential poling of devices on the bus and normal

system operation is established.

Figure 6C1-1-58 Theft Deterrent System

Figure 6C1-1-59 Theft Deterrent Serial Data Circuit

1.3 TRANSMISSION INFORMATION INPUT SENSORS AND SIGNALS

The computer used with Sequential Fuel Injected (SFI) petrol engine is called a Powertrain Control Module (PCM) and

controls a number of engine functions such as: fuel control, and ignition timing, in addition to the transmission functions.

The diagnosis of this transmission requires the availability of a Tech 2 scan tool to interface with the Powertrain Control

Module (PCM).

The transmission control system of the electronic control module has software and hardware that monitors a number of

engine and vehicle functions then uses the data to control the following operations:

• Transmission Converter Clutch (TCC) engagement.

• Upshift pattern.

• Downshift pattern.

•Line pressure to control shift quality.

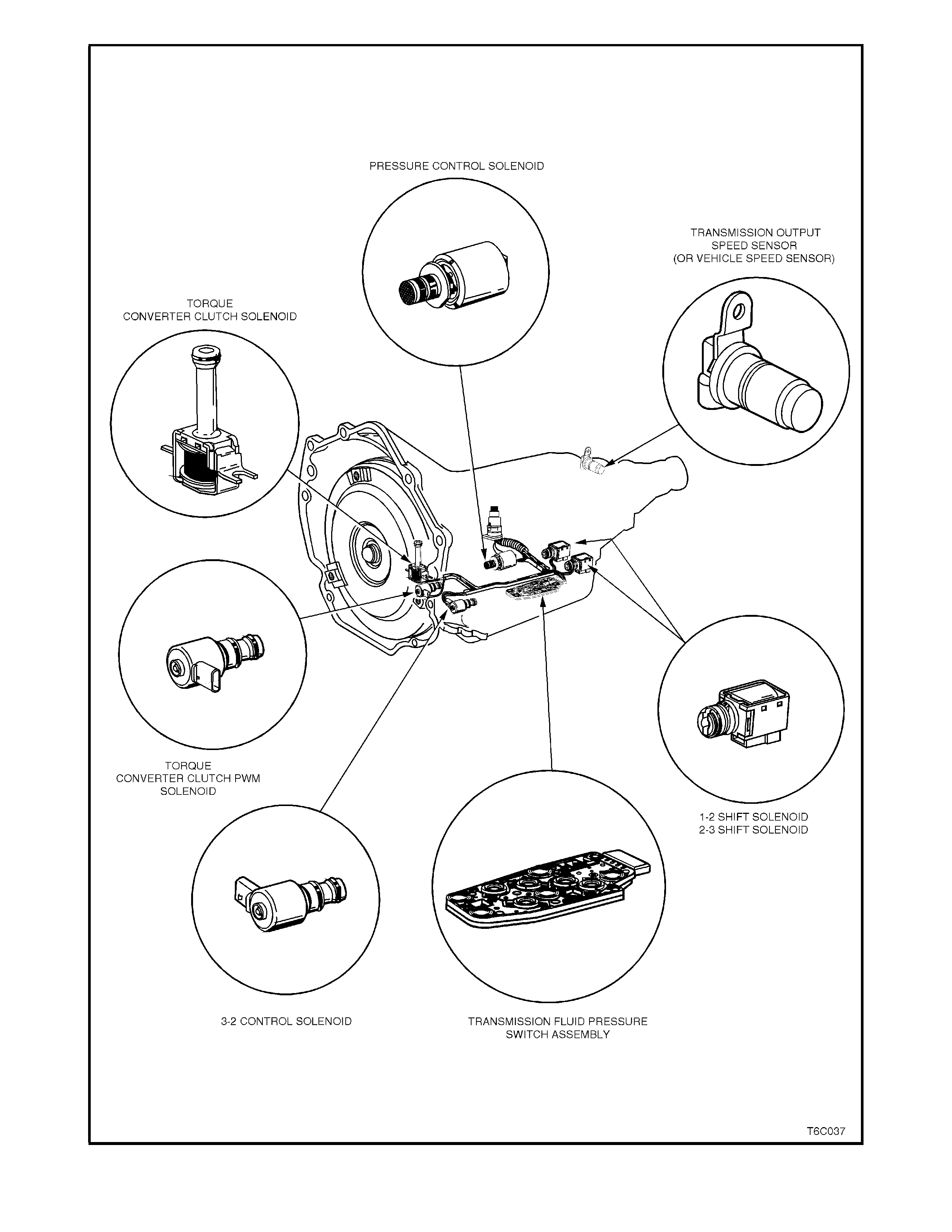

Figure 6C1-1-60 Transmission Electronic Component Location View

Figure 6C1-1-61 Transmission Wiring

INFORMATION SENSORS

The PCM uses the following information sensors and switches to gather data for electronically controlling transmission

functions.

• Engine Coolant Temperature (ECT) sensor.

• Engine Speed.

• Fluid Pressure Switch Assembly.

• Throttle Position (TP) Sensor.

• Transmission Fluid Temperature (TFT) sensor.

• Transmission Economy/Power Switch.

•Vehicle Speed Sensor (VSS).

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

ECT sensor information is also used for engine functions as well as for the transmission management system. For ECT

details, refer to 1.2 ENGINE INFORMATION SENSORS AND SIGNALS in this Section.

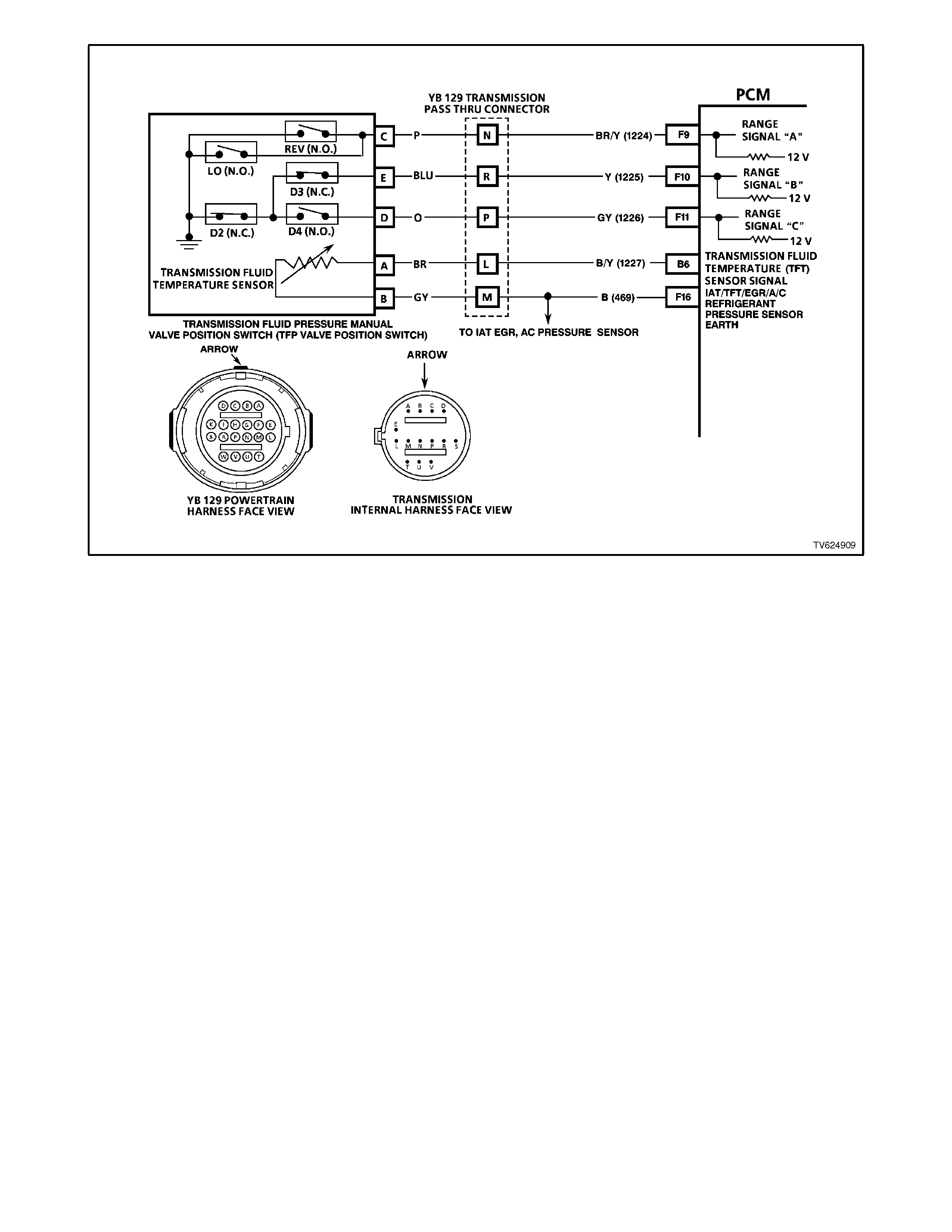

TRANSMISSION FLUID PRESSURE (TFP) SWITCH ASSEMBLY

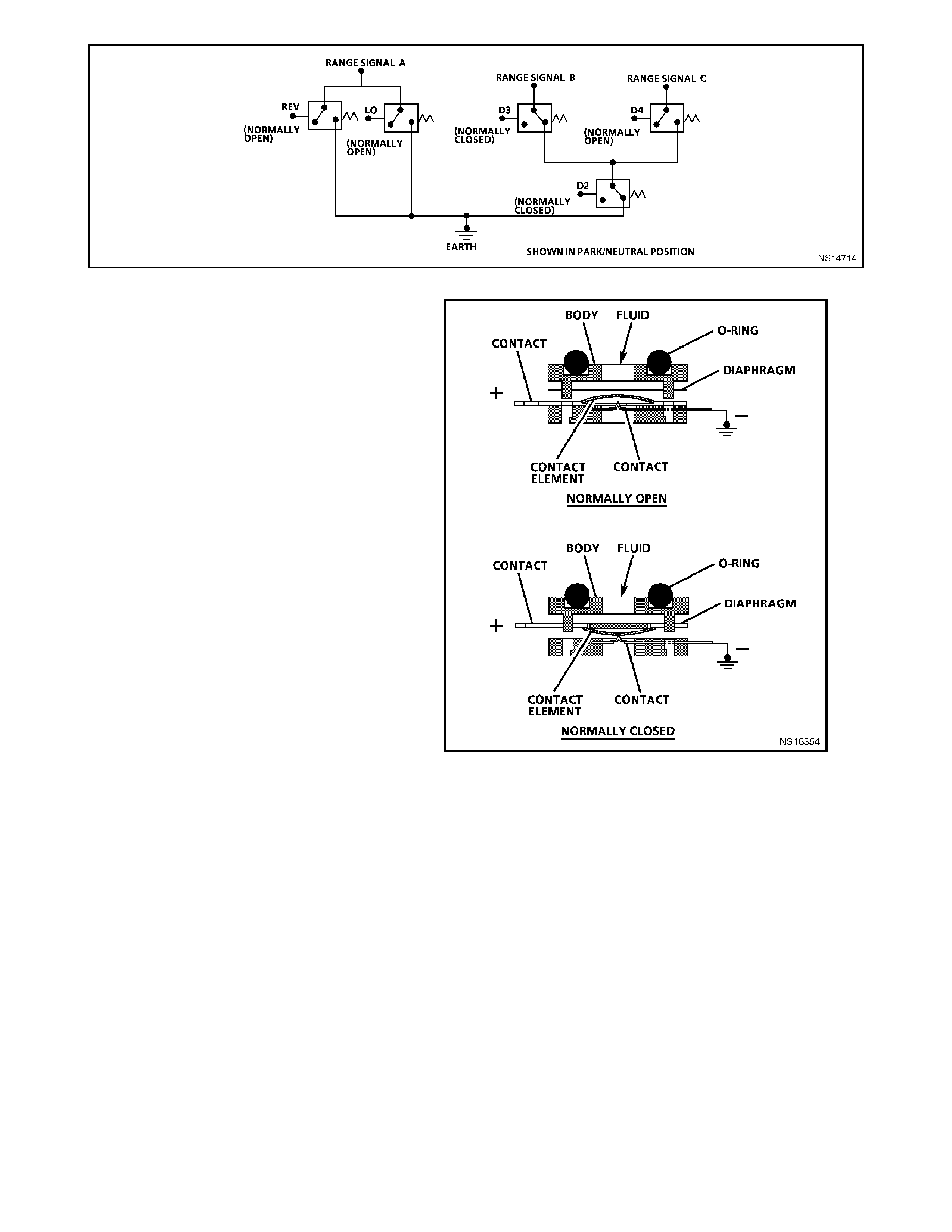

Figure 6C1-1-62 Transmission Fluid Pressure Switch Assembly (TFP) and Transmission Fluid Temperature Sensor

Figure 6C1-1-63 Transmission Fluid Pressure Switch Assembly (TFP) Switches

This gear range sensing device called a

Transmission Fluid Pressure Switch Assembly

(TFP) is used by the PCM to sense what gear

range has been selected by the vehicle operator.

The T FP is located on the valve body and consists

of five pressure switches, 2 normally closed and 3

normally open, combined into one unit.

The normally open fluid pressure switches are the

"D4", "LO" and "Reverse" fluid pressure switches.

They are normally open and electrical current is

stopped at these switches when no fluid pressure is

present. Fluid pressure moves the diaphragm and

contact element until the contact element touches

both the positive contact and the earth contact.

This creates a closed circuit and allows current to

flow from the positive contact, through the switch

and to earth. The normally closed fluid pressure

switches are the "D2" and "D3" fluid pressure

switches. They are normally closed and electrical

current is free to flow from the positive contact to

the earth contact when no f luid pressur e is pres ent.

Fluid pressure moves the diaphragm to disconnect

the positive and earth contacts. This opens the

switch and stops current from flowing through the

switch.

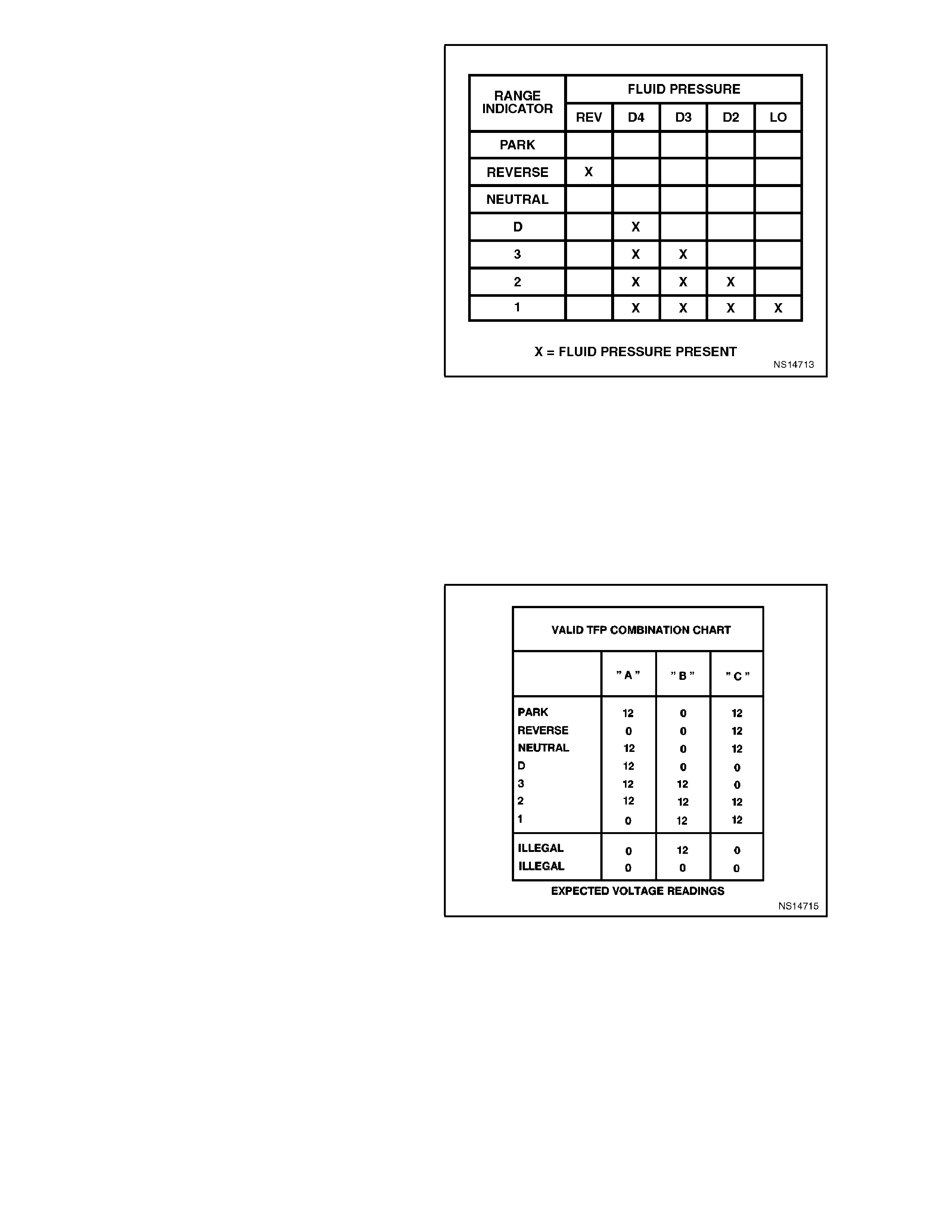

The PCM applies system voltage to the TFP on

three separate wires. An open circuit measures 12

volts while an earthed circ uit m easures 0 volts. T he

switches are opened or closed by fluid pressure.

The combination of which switches are open and

closed is used by the PCM to determine actual

manual valve position. The TFP however cannot

distinguish between park and neutral because the

monitored valve body pressures are identical in

both cases.

L -This switch will have hydraulic pressure

applied to it in m anual 1st gear only and will be

closed.

R -This switch will have hydraulic pressure

applied to it in reverse only and will be closed.

Figure 6C1-1-64 Transmission Fluid Pressure Switch

Assembly (TFP)

D2 -This switch will have hydraulic pressure

applied to it in manual 1st and 2nd gear and

will be open.

D3 -This switch will have hydraulic pressure

applied to it in manual 1st, 2nd and 3r

d

gear

and will be open.

D4 -This switch will have hydraulic pressure

applied to it in all drive gears except reverse

and will be closed.

TFP assembly signal voltage can be measured with

a high impedance digital volt ohmmeter by back

probing the PCM then taking measurements from

each terminal to earth, and comparing it to the

combination chart. On the transmission wiring

harness, pin N is "Range Signal A", pin R is "Range

Signal B", and pin P is "Range Signal C". With the

wiring harness connected and engine operating, a

voltage measurement of these three lines will

indicate a "high" reading (near 12 volts) when a

circuit is open, and a low (zero volts) when the

circuit is switched to earth.

These TFP inputs are used to help control line

pressure, torque converter clutch apply and shift

solenoid operation. To monitor TFP assembly

operation, the PCM compares the actual voltage

combination of the switches to a TFP combination

chart stored in its mem ory. If the PCM detects one

of two "illegal" voltage combinations a Diagnostic

Trouble Code 28 will result.

Figure 6C1-1-65 Pressure Applied to TFP Switches

There are two possible combinations of the

switches within the pressure switch assembly that

do not represent an actual gear range. If either of

these combinations are detected by the PCM for 5

seconds or longer, Diagnostic Trouble Code 28 will

set. Diagnostic Trouble Code 28 will also set if a

valid gear range combination appears at the wrong

time.

While Diagnostic Trouble Code 28 is present, the

PCM will take the following action:

1. Assume D4 for shift pattern control.

2. Use D2 pressure table.

3. Inhibit 4th gear operation in hot mode only.

4. Inhibit TCC operation.

If the TFP resumes normal functioning, the

transm ission will resum e norm al operation after the

next ignition cycle.

DTC 28 will not detect an open circuit in either

range signal "B" or "C". An open circuit in either of

these signals will not be an illegal T FP com bination

but a legal TFP combination at the wrong time, so

that the PCM interprets wrong information.

Figure 6C1-1-66 TFP Chart

There ar e two failures in the T FP that will cause an

unusual complaint. If the range signal "B" is open

the PCM will interpret this PRNDL select as "2"

gear in park or neutral with the ignition "ON" or

engine idling. The customer will probably complain

that when "D" range is selected the transmission

never shif ts into 4th gear. T his is becaus e the PCM

only controls shif ts in "D" range, but because of the

open circuit in range signal "B" the PCM interprets

this as "3" gear and the tr ans miss ion will never s hif t

to fourth gear because this "3" gear input is a

normal condition.

The other condition to cause an unusual complaint

is an open in the range signal "C". When the dr iver

selects "3" gear range, the PCM will interpret this

PRNDL select as "2" gear and will provide 1st and

2nd gears only. If the driver selects "D" range, the

transmission will have all gears and TCC, but the

Tech 2 scan tool will read P-N all the time.

Figure 6C1-1-67 Transmission Fluid Pressure Switch

Assembly (TFP) Location

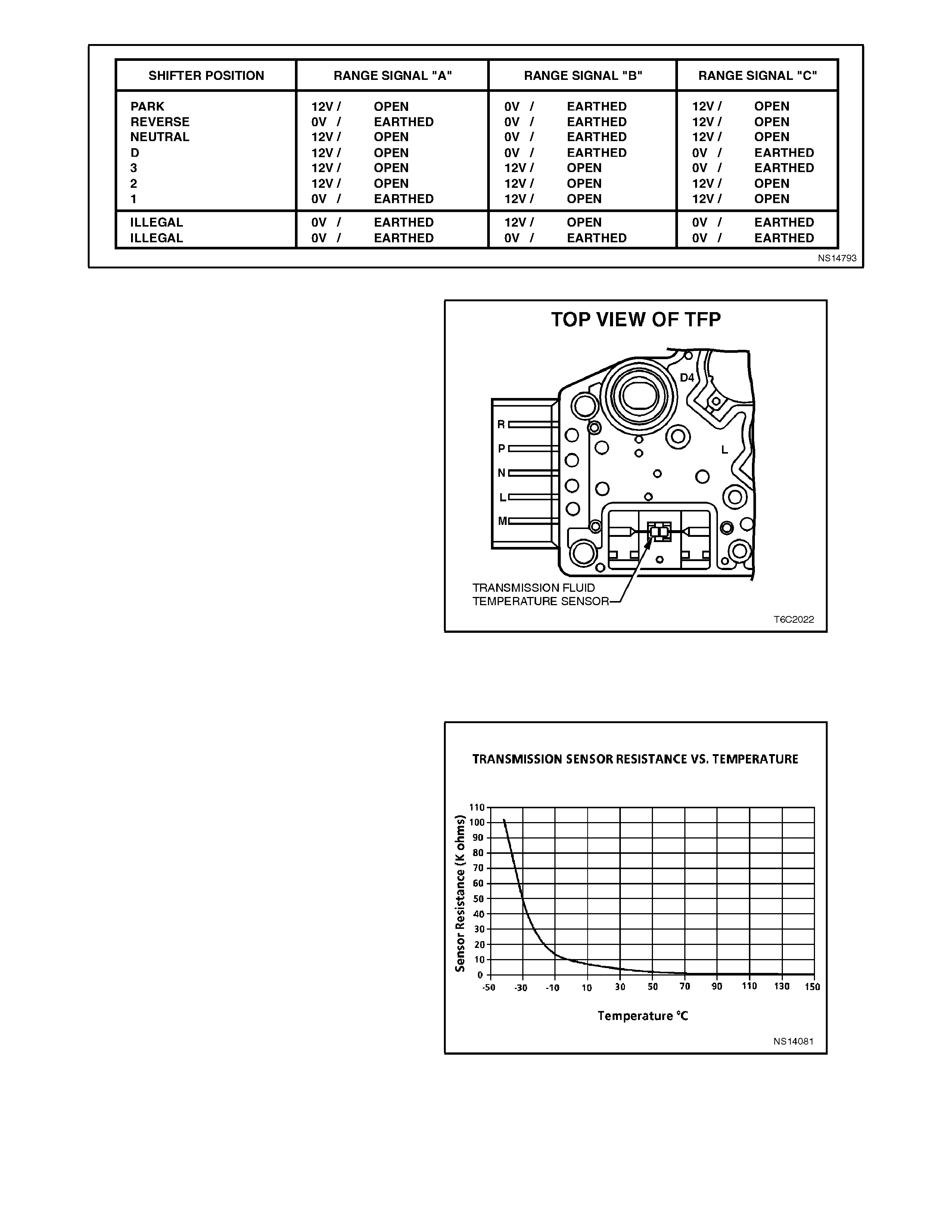

TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR

Figure 6C1-1-68 Transmission Fluid Pressure Switch Assembly (TFP) and Transmission Fluid Temperature Sensor

Figure 6C1-1-69 Transmission Fluid Pressure Switch Assembly (TFP) Switch Voltages

The Transm ission Fluid Temperature (T FT) sensor

is a thermistor (a res istor that changes value based

temperature) that is part of the transmission fluid

Pressure Switch Assembly (TFP). Low

transmission fluid temperature produces high

resistance and high transmission fluid temperature

produces low resistance. The PCM supplies a 5

volt signal to the Transmission Fluid Temperature

(TFT) sensor through an internal resistor then

measures the voltage drop in the circuit. Voltage

will be high when the transmission fluid is cold and

low when the transmission fluid is hot.

The PCM uses the Transmission Fluid

Temperature (TFT) Sensor to regulate torque

converter clutch apply, as well as shift quality.

Diagnostic T rouble Code 58 and 59 indic ate a fault

in the Transmission Fluid Temperature (TFT)

sensor circuit. The Tech 2 scan tool will display

transmission fluid temperature in degrees Celsius.

After the vehicle has been started, transmission

fluid temperature should rise steadily and stabilize

between 82 and 94 degrees Celsius, depending on

load.

Figure 6C1-1-70 Transmission Fluid Temperature Sensor

Both diagnostic trouble codes will cause the PCM

to use a default value of 130 degrees Celsius thus

reacting as if the transmission were hot in either

case. W hen Diagnostic Trouble Code 58 or 59 are

set the torque converter clutch is enabled in

second, third and forth and will apply early. Some

driveability symptoms will be noticed especially

when cold.

DTC 79 is used to identify if the transmission fluid

has been overheated to the point that the f luid is no

longer useable for the transmission. DTC 79 will set

if the transmission fluid temperature exceeds 146

degrees C and does not go lower than 137 degrees

C for 30 minutes.

The PCM m onitors the TFT sensor for determ ining

DTC 79. An electrical failure in the TFT sensor

circuit will not set a DTC 79. DTC 79 will only be set

if the fluid actually did exceed the temperature or if

the TFT sensor is skewed high or stuck above the

temperature threshold.

Temperature to Resistance specification chart

found at DTC 58 and DTC 59.

Figure 6C1-1-71 TFT Sensor Temperature to Resistance

Relationship

THROTTLE POSITION (TP) SENSOR

TP sensor information is also used for engine

functions as well as for the transmission

management system. For TP details, refer to

1.2 ENGINE INFORMATION SENSORS AND

SIGNALS in this Section.

TRANSMISSION ECONOMY/POWER SWITCH

The economy/power switch is used to modify

upshifts and shift times slightly. The driver can

select two transmission modes, "Economy" or

"Power" with a dash or centre console mounted

switch. The "OUT" position enables the "Power"

mode. A green indicator lamp of 1.2 watts at 12

volts is located on the right side of the instrument

cluster and displays "PWR" when illuminated to

inform the driver that the "Power" mode is now

enabled.

The PCM sends out a voltage signal, about 12

volts, and monitors the status of this circuit. In the

"Economy" position, the switch is open and the

PCM voltage status signal remains high, about 12

volts. The PCM does not allow shift point changes

in the economy mode. When the transmission

switch is pressed to "Power" position the switch is

closed and the PCM voltage status signal is pulled

low, about 0.5 volts. The PCM senses this voltage

drop and enables "power" mode (alternate shift

pattern "tables" to be utilised).

In the "Power" mode, TCC can be applied in 3rd

and 4th gears. W hen TCC is applied in 3rd gear it

will stay applied until the normal 4th gear upshift

criteria are met, when the 3-4 upshift occurs the

TCC will not be released momentarily. Also, in the

"Power" mode, while in "D" gear select position the

PCM will delay the 1-2 and 2-3 shift while under

light throttle. The shift patterns will be the same in

the "Economy" and "Power" modes if the TP sensor

is between 94% - 100%. The "Power" m ode should

be used when towing as applying the TCC in 3rd

and 4th gear reduces slippage in the T CC and thus

heat build up.

Figure 6C1-1-72 Transmission Economy/Power Switch

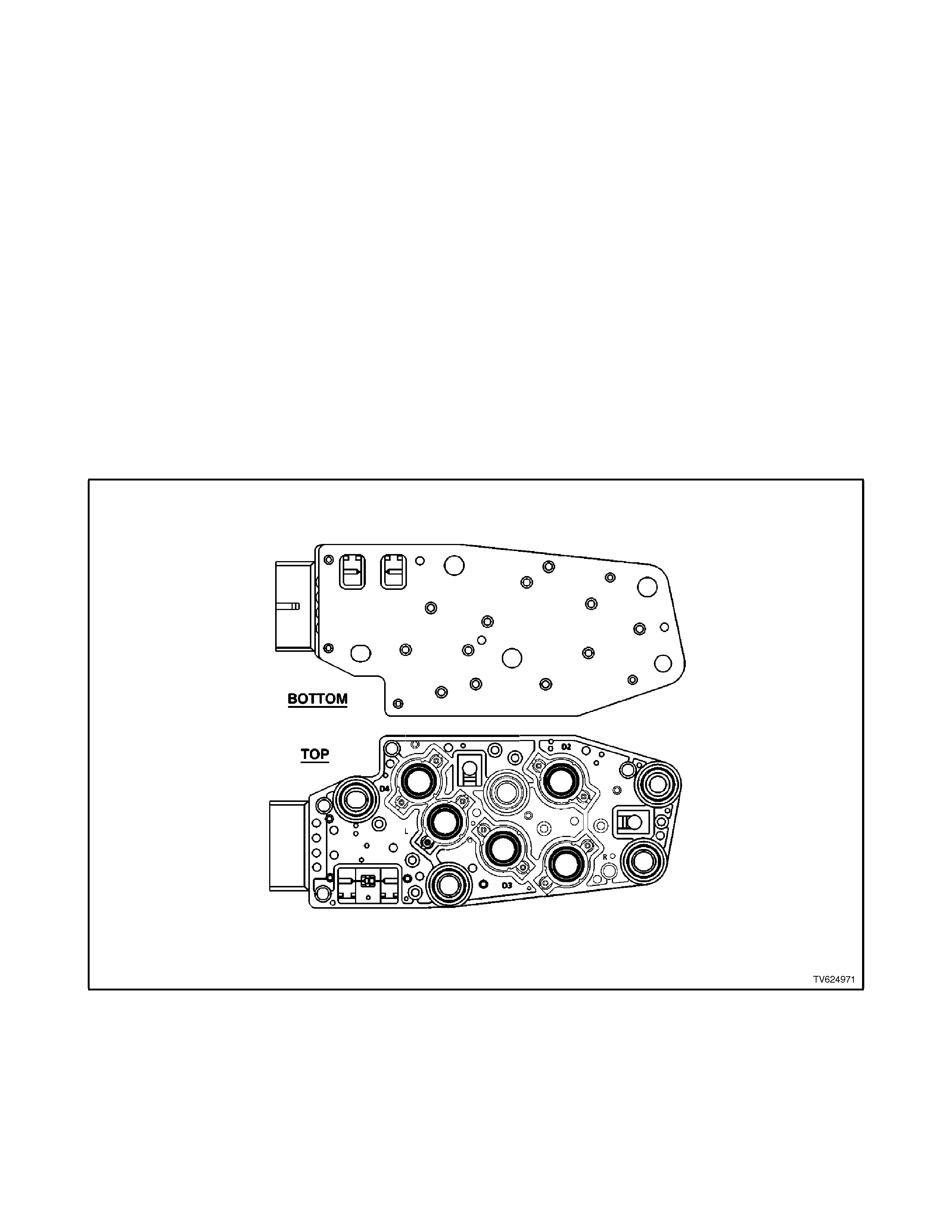

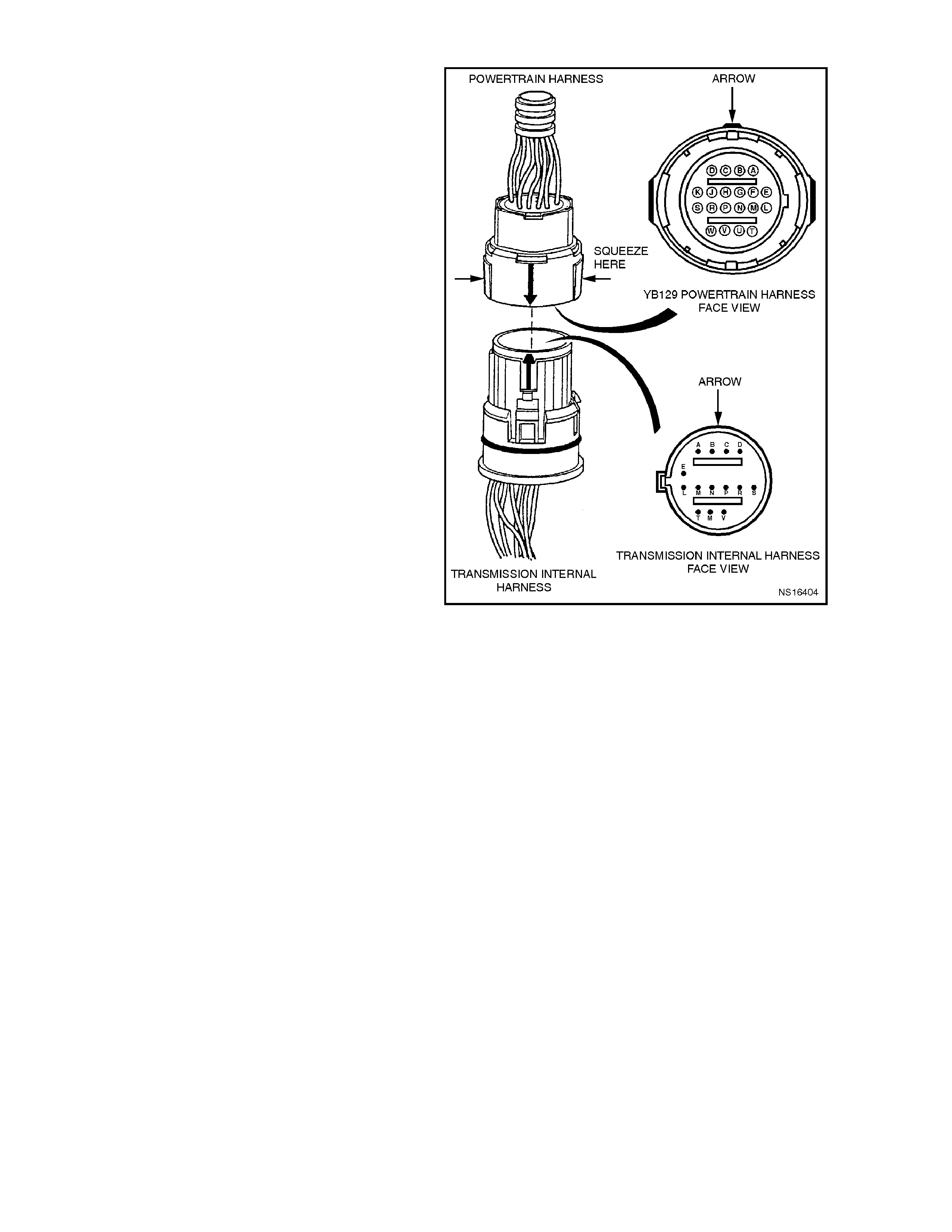

TRANSMISSION PASS-THRU CONNECTOR

The transmission electrical pass-thru connector is a

very important part of the HYDRA-MATIC 4L60-E

operating system.

A wiring harness electrically connects the PCM to

various sensors, solenoids, and relays within the

transmission management system. Many of the

connectors used are environmentally protected

because of the systems low voltages and low

current levels. Anything that interferes with the

electrical connec tion can cause the transm ission to

set diagnostic trouble codes and/or operate

incorrectly.

The following items can affect the electrical

connection:

• Bent pins in the connector from rough handling

during connection and disconnection.

• Wires backing away from the pins or coming

uncrimped (in either the transmission or

powertrain wiring harness).

• Dirt contamination entering the connector when

it is disconnected.

• Pins in the connector backing out of the

connector or pushed out during connection.

• Excessive transmission fluid leaking into the

connector, wicking up into the powertrain wiring

harness and degrading the wire insulation.

• Water/moisture intrusion in the connector.

• Low pin retention from excessive connection

and disconnection of the wiring harness.

• Pin corrosion from contamination.

The presence of transmission fluid in the

transmission connector is not harmful.

The fluid only affects the vehicle harness wiring

insulation if the fluid wicks up that far.

Points to remember when working with the

transmission electrical connector:

• To rem ove the connector, squeeze the two tabs

towards each other and pull straight up.

• Carefully limit twisting or wiggling the connector

during removal. This can bend pins.

• DO NOT pry the connector off with a

screwdriver or other tool.

• To install the connector, first orient the pins by

lining up the arrows on each half of the

connector. Push the connector straight down

into the transmission without twisting or angling

the mating parts.

• The connector should click into place with a

positive feel and/or noise.

• Whenever the trans mis sion pass thru connec tor

is disconnected from the transmission and the

ignition is switched "ON" or the engine is

started, numerous DTC's will be set.

Figure 6C1-1-74 YB129 Powertrain Harness Connector

1.4 TRANSMISSION OUTP UTS CONTROLLED BY THE PCM

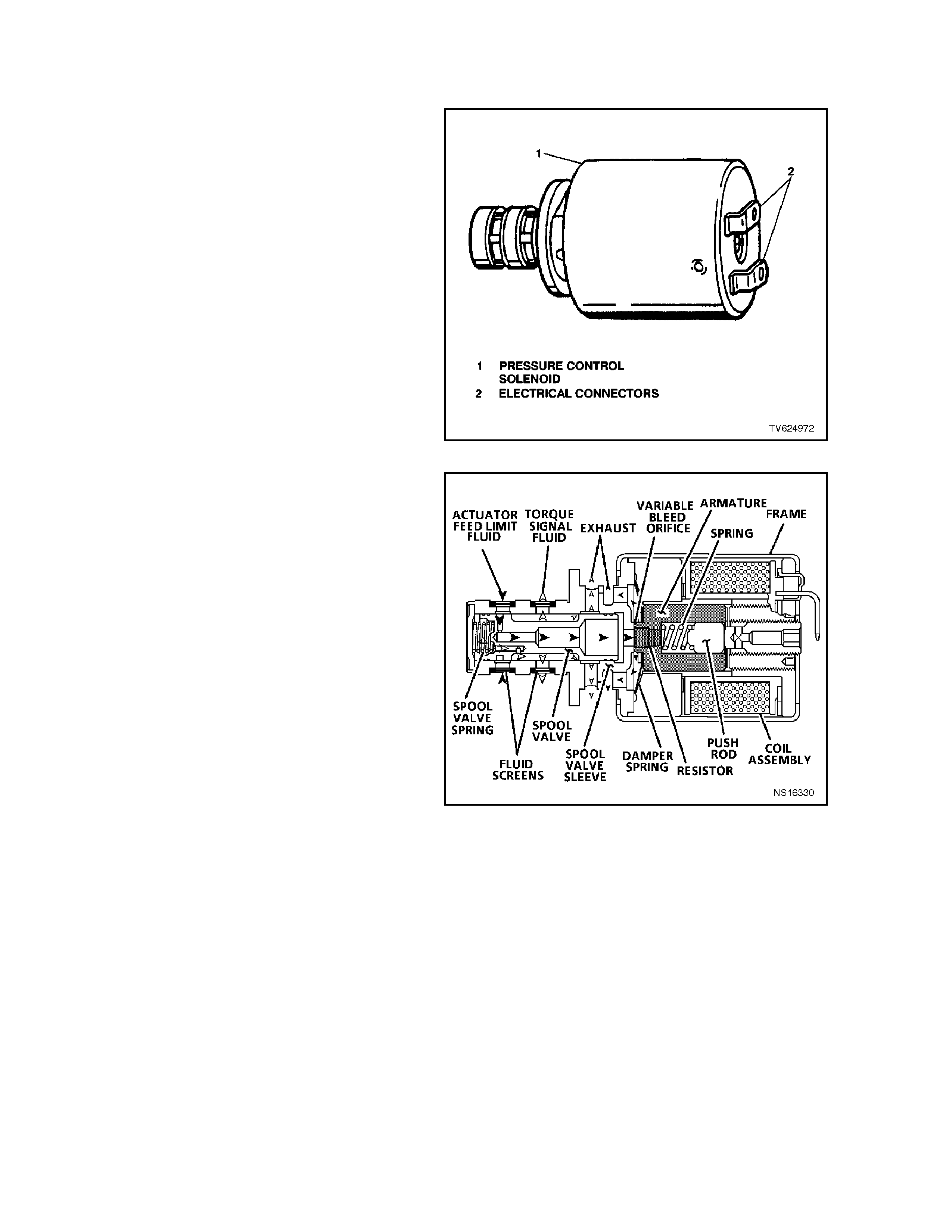

PRESSURE CONTROL SOLENOID

The transmission Pressure Control Solenoid (PC

SOL) is an electronic pressure regulator that

controls pressure based on current flow through its

coil winding. The magnetic field produced by the

coil moves the solenoid's internal valve that varies

pressure to the pressure regulator valve.

The pressure control solenoid takes the place of

the throttle valve used on past model 4L60

transmissions, used in previous "V" car models.

The PCM varies line pressure based on engine

load. Engine load is calculated from various inputs

including the TP and MAF sensors. The

transmission line pressure is actually varied by the

PCM's control of the pressure control solenoid and

its ability to change the amperage applied to the

pressure control solenoid from 0 amps (high line

pressure) to 1.1 amps (low line pressure). This

changes the duty cycle of the solenoid, which can

range between 0% and 100%. Figure 6C1-1-75 Pressure Control Solenoid

There is one Diagnostic Trouble Code associated

with the pressure control solenoid Diagnostic

Trouble Code (DTC) 73. Diagnostic Trouble Code

73 will set when the PCM detects a difference of

0.16 amp or more between the amperage

commanded and actual amperage. While the

Diagnostic Trouble Code 73 is set, the pressure

control solenoid will be turned "OFF" creating

maximum line pressure. Recovery can occur after

the next ignition cycle. Diagnostic Trouble Code 73

will not sense a stuck valve.

Figure 6C1-1-76 Pressure Control Solenoid Cutawa y View

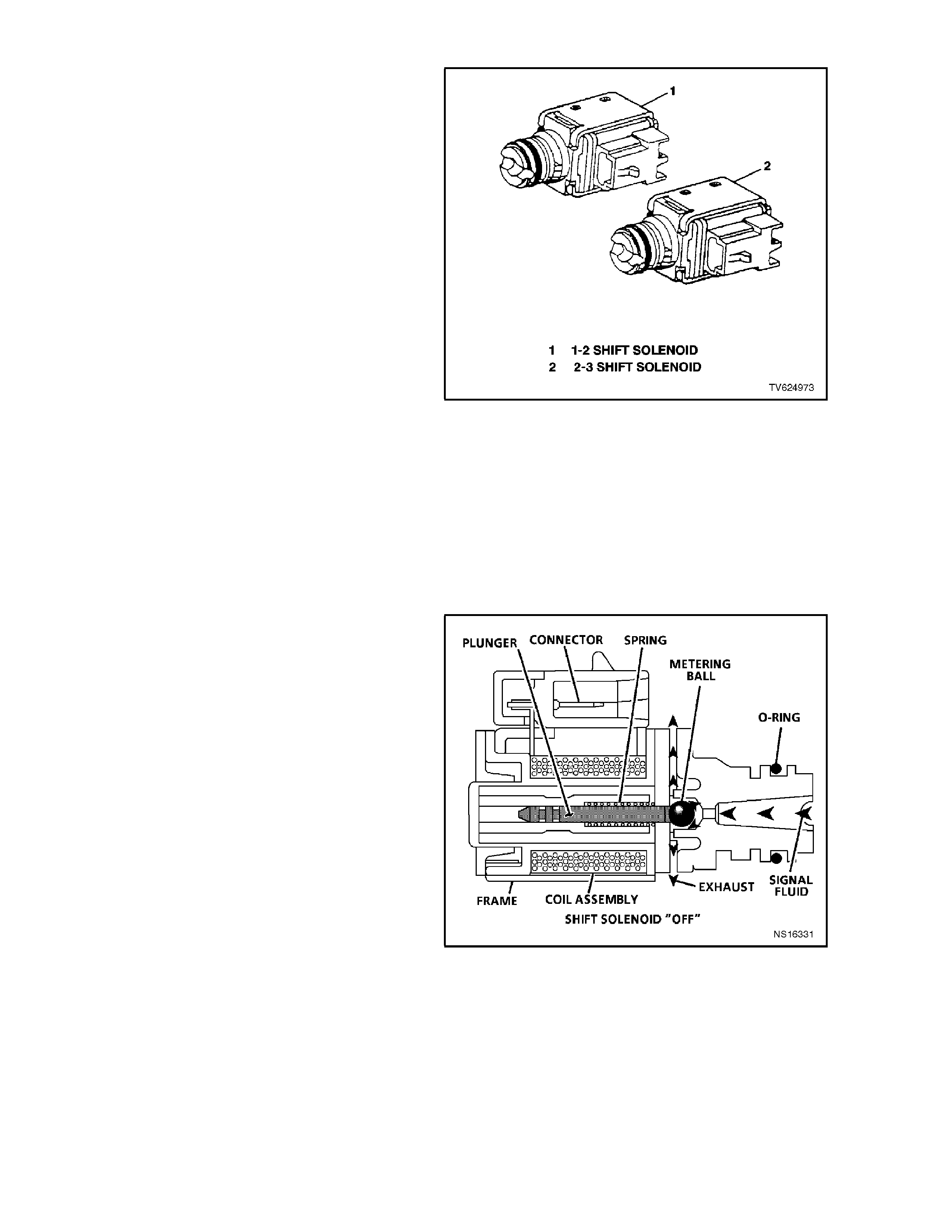

SHIFT SOLENOIDS

The 1-2 Shift Solenoid and 2-3 Shift Solenoid are

identical in operation solenoid devices that control

the movement of the 1-2 and 2-3 shift valves (the

3-4 shift valve is not directly controlled by a shift

solenoid). The solenoids are normally open

exhaust valves that work in four combinations to

shift the transmission into different gears. PCM

controlled shift solenoids eliminate the need for

Throttle Valve (TV) and governor pressures to

control shift valve operation.

IMPORTANT:

The PCM does NOT have total control of shifting

the transmission. The manual valve can

hydraulically override the shift solenoids. Only in

"D" are the PCM and shift solenoids totally

determ ining what gear the transm ission is in. In the

manual positions "3", "2", and "1", the transm ission

manual valve position will change fluid direction in

the valve body. The transmission will shift on its

own hydraulically, the PCM will have limited control

and will respond to the hydraulic changes of the

manual valve. The PCM will change the shift

solenoids when the pressure switch assembly

(TFP), throttle position and vehicle speeds fall into

the correct ranges for PCM control. In other words

the PCM "catches up" to what happened

hydraulically. This is impor tant to rem ember , as the

Tech 2 scan tool will only display the commanded

state of the shift solenoids not the actual gear the

transmission is in.

Figure 6C1-1-77 Shift Solenoids

1-2 SHIFT SOLENOID

The 1-2 shift s olenoid is attached to the valve body

and is a normally open exhaust valve. The PCM

activates the solenoid by earthing it through an

internal Quad Driver Module (QDM). The 1-2 shift

solenoid is "ON" in 1st and 4th gear, and "OFF" in

2nd and 3rd gears. When "ON," the solenoid

redirects fluid to act on the shift valves.

There is one Diagnostic Trouble Code associated

with the 1-2 shift Solenoid, Diagnostic Trouble

Code 82. The PCM continually monitors the 1-2

shift solenoid circuit for expected voltage ("OFF"

high "ON" low). If the voltage r eading is not what is

expected on the circuit, Diagnostic Trouble Code

82 will set. While Diagnostic Trouble Code 82 is

present, high line pressure will be set and the

vehicle will have 2nd or 3rd gear only or 1st and 4th

gears only. When the fault is removed, recovery will

occur on the next ignition cycle. Figure 6C1-1-78 Shift Solenoid Cutaway View

2-3 SHIFT SOLENOID

The 2-3 shift s olenoid is attached to the valve body

and is a normally open exhaust valve. The PCM

activates the solenoid by earthling it through an

internal Quad Driver Module (QDM). The 2-3 shift

solenoid is "ON" in 1st and 2nd gear and "OFF" in

3rd and 4th gear. When "ON," the shift solenoid

redirects fluid to act on the shift valves.

There is one Diagnostic Trouble Code (DTC)

associated with the 2-3 shift Solenoid, DT C 81. 2-3

shift solenoid circuit fault. The PCM continually

monitors the 2-3 shift solenoid circuit for expected

voltage ("OFF" high "ON" low). If the voltage

reading is not what is expected, DTC 81 will set.

While DTC 81 is present, TCC operation will be

inhibited, line pressure will be high and the

transmission will have 2nd or 3rd gear only. When

the fault is r emoved, rec overy will occur at the nex t

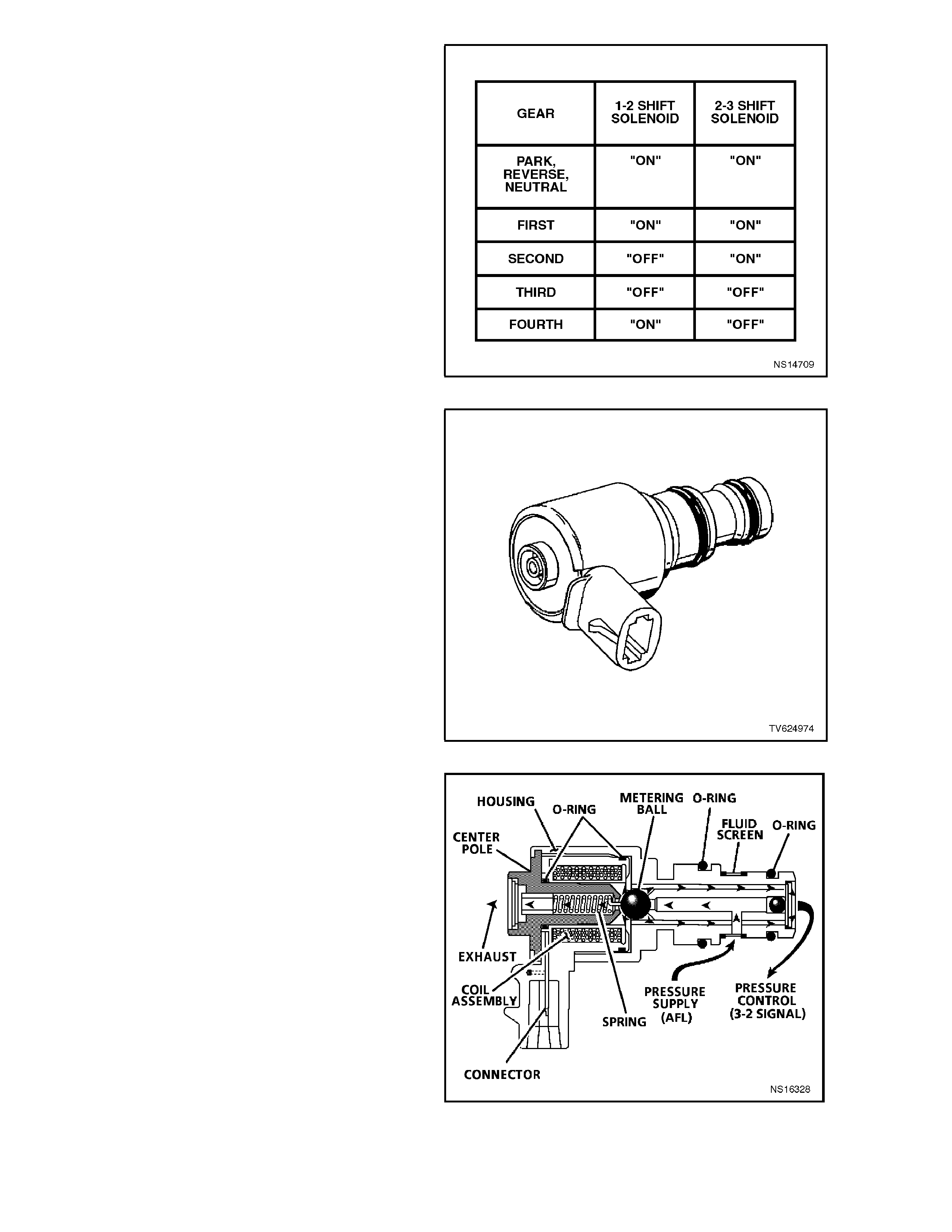

ignition cycle. Figure 6C1-1-79 Solenoid Status

3-2 SHIFT SOLENOID VALVES

The 3-2 shift solenoid is either "ON" or "OFF" and

is used to improve the 3-2 downshift. The 3-2 shift

solenoid uses "ON" or "O FF" to contr ol press ure so

that the release of the 3-4 clutch and the apply of

the 2-4 band are smooth. The 3-2 shift solenoid is

normally "OFF" in first gear and "ON" in all other

drive gears, except during a 3-2 downshift when the

solenoid is "OFF". The amount of "OFF" time is

determined by throttle position, vehicle speed, and

the commanded gear.

There is one Diagnostic Trouble Code (DTC)

associated with the 3-2 Shift Solenoid, DTC 66.

DTC 66 will set when the PCM detects either high

voltage when the 3-2 Shift Solenoid is com manded

"ON" or if low voltage exists on the feed back line

when the solenoid is com m anded "OFF". While the

3-2 Shift Solenoid DTC 66 is set, the solenoid will

be "OFF", When DTC 66 is set, the transmission

will have a soft landing into 3rd gear, high line

pressure and 3rd gear. W hen the fault is removed

recovery can occur after the next ignition cycle.

Figure 6C1-1-80 3-2 Shift Solenoid

Figure 6C1-1-81 3-2 Shift Solenoid Cutaway View

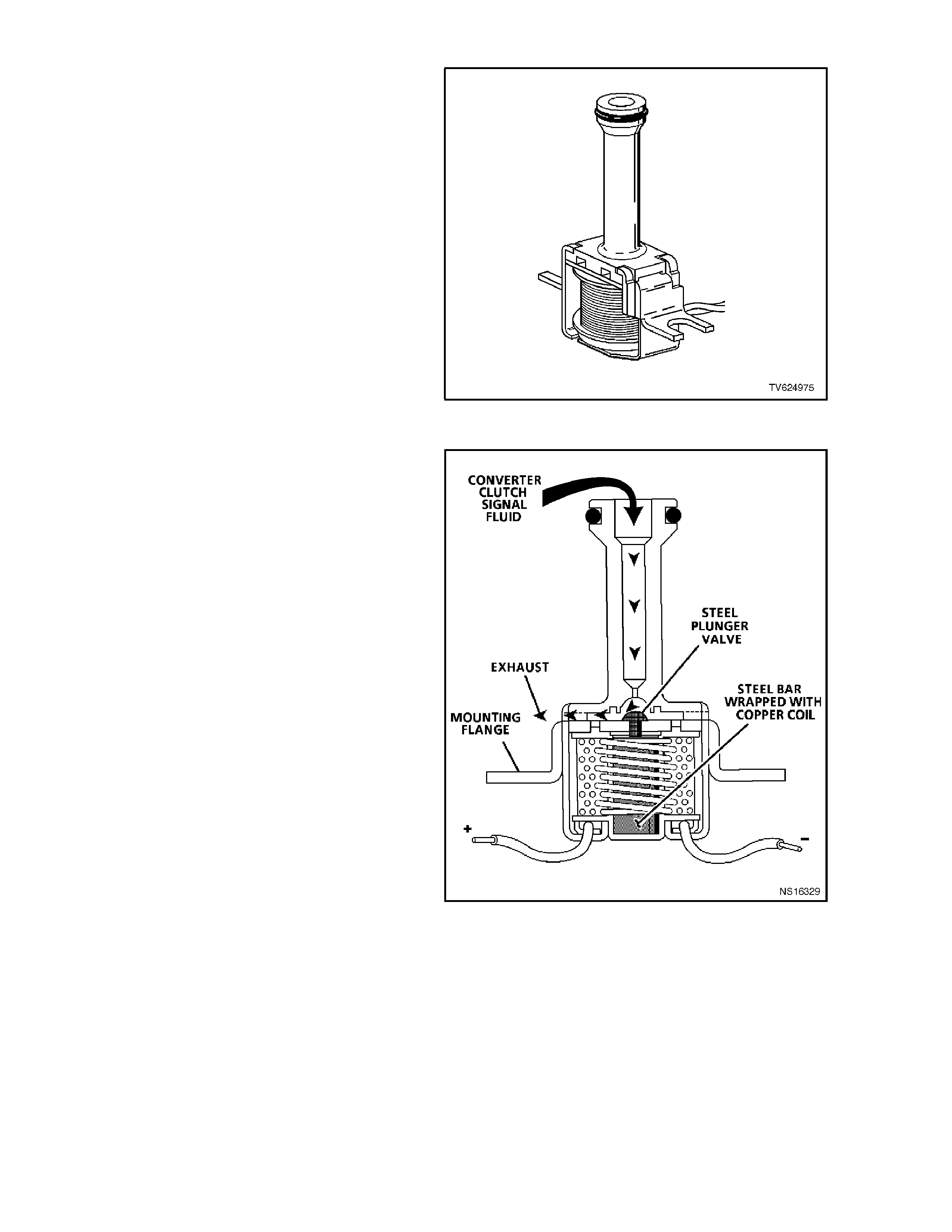

TORQUE CONVERTER CLUTCH (TCC) SOLENOIDS

This transmission uses two Torque Converter

Clutch (TCC) solenoids valves that are used to

control torque converter clutch apply and release.

The TCC enable solenoid has priority in applying

and releasing the torque converter clutch. "The

Torque Converter Clutch enable solenoid is a

normally open exhaust valves that is commanded

either "ON" or "OFF" by the PCM. When earthed

(energised "ON"), by the PCM, the TCC solenoid

stops converter feed from exhausting. This causes

converter feed pressure to increase and shift the

TCC valve into the apply position. This pressure

allows the TCC to couple the transm ission with the

engine for a near 100% engagement.

There are two Diagnostic Trouble Codes (DTC's)

associated with the TCC enable solenoid. The first

DTC is 67, T CC enable Solenoid Cir cuit F ault. DT C

67 is designed to detect a fault in the TCC enable

solenoid electrical circuit. While DTC 67 is set the

PCM will inhibit 4th gear if the trans miss ion is in the

hot mode, and no TCC operation. Figure 6C1-1-82 Torque Converter Clutch (TCC) Enable

Solenoid

The second DTC associated with the TCC enable

solenoid is DTC 69, TCC stuck "ON". DTC 69 is

designed to detect TCC enable solenoid that does

not disengage. It does this by monitoring engine

RPM when the TCC solenoid is com manded "ON."

If the engine speed does not rise when the TCC

solenoid is disengaged the DTC 69 is set. While

DTC 69 is set the TCC will be "ON" in all gears or

2nd, 3rd, and 4th depending upon the failure, and

the transmission will have an early shift pattern.

When the fault is removed recovery will occur on

the next ignition cycle.

Figure 6C1-1-83 TCC Solenoid Cutaway View

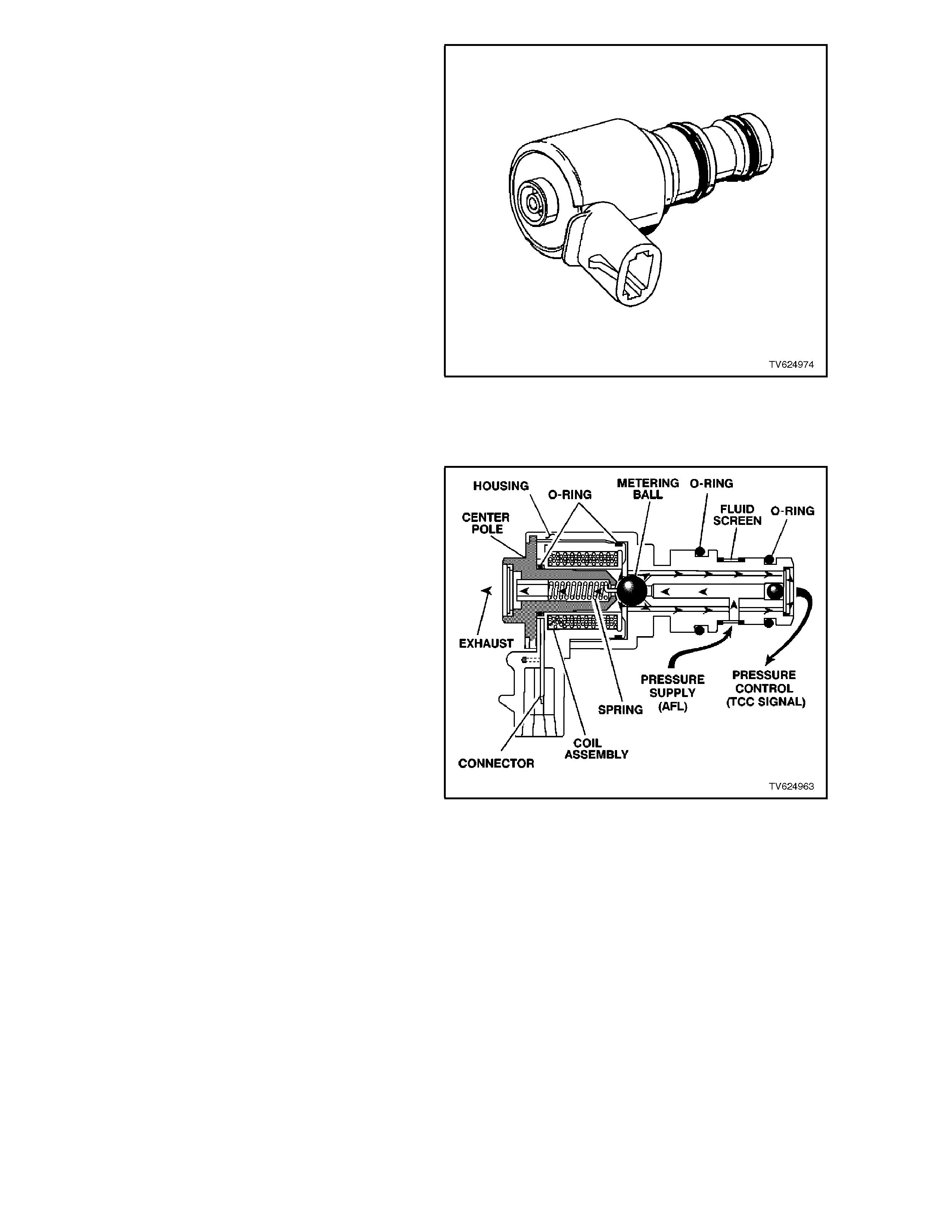

The Torque Converter Clutch "Pulse Width

Modulated" (PWM) solenoid is used to control the

fluid acting on the converter clutch control valve,

which then controls the TCC apply and release.

This solenoid is attached to the control valve body

assem bly within the transmiss ion. The T CC "PWM"

solenoid does not have total control over TCC

engagement. The TCC "PW M" solenoid is used as

a supplement to the TCC enable solenoid. The

TCC "PWM" solenoid is used to provide smooth

engagement of the torque converter clutch by

operating on a negative duty percent of "ON" time,

which means that the earth (negative or low) side

of the solenoid circuit is controlled by the PCM.

Therefore, the TCC "PWM" solenoid is constantly

fed approximately 12 volts to the high (positive)

side and the PCM controls the length of time the

electrical circuit path to earth is closed (i.e. duty

cycle).

When the PCM closes the solenoid earth circuit,

current flows through the TCC "PWM" solenoid,

and the earth circuit (or negative side) is at low

voltage state (0 volts and solenoid energised).

Figure 6C1-1-84 Torque Converter Clutch (TCC) "PWM"

Solenoid

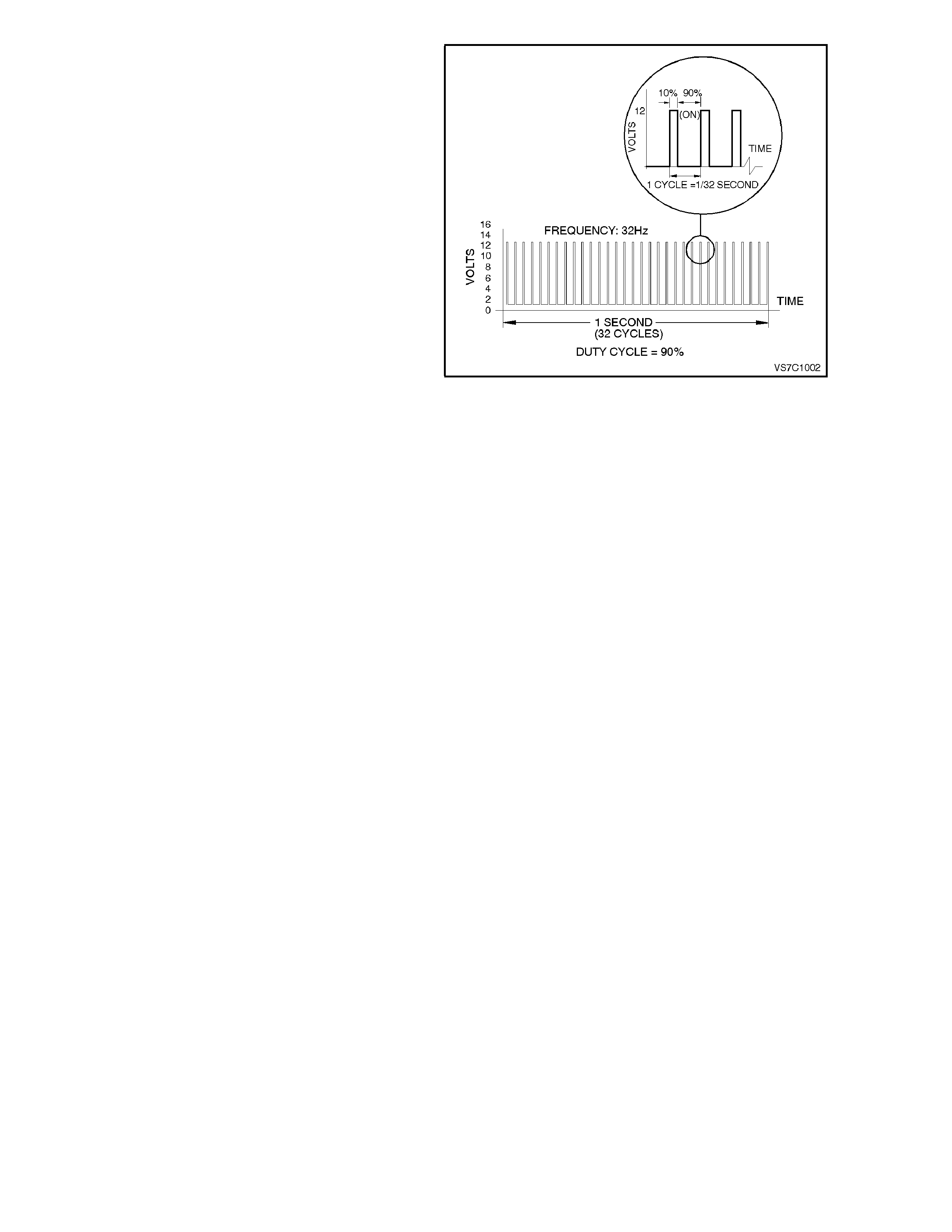

Fig. 6C1-1-86 illustrates an example of the TCC

"PWM" solenoid operating with a 90% negative

duty cycle at a constant operating frequency of 32

Hz (cycles per second). The frequency means that

the solenoid is puls ed (energised) with current fr om

the PCM 32 times per second. The 90% negative

duty cycle means that during each of these 32

cycles the solenoid is energis ed (ON) and 0 volts is

measured on the low (negative) side of the circuit,

90 % of the time.

At road speeds below approximately 13 km/h, the

negative duty cycle will be 0%, which means that

no current will flow through the TCC "PWM"

solenoid, deactivating it. When in this condition,

spring force will move the plunger seating the

metering ball and blocking the filtered Actuator

Feed Limit (AFL) fluid from entering the Converter

Clutch Signal (CC SIGNAL) circuit. This action

opens the Converter Clutch Signal fluid circuit to

exhaust through the solenoid.

Above road speed of approximately 13 km/h, the

TCC "PWM" solenoid will be operating at about a

90% duty cycle. T his action will cause the m etering

ball to close off the path to exhaust, most of the

time and allow AFL fluid to flow past the metering

ball and into the CC SIGNAL circuit, in readiness

for the apply of the torque converter clutch.

Figure 6C1-1-85 Torque Converter Clutch (TCC) "PWM"

Solenoid Cutaway View

When the PCM signals TCC apply, the TCC

"PWM" solenoid operates with a variable, negative

duty cycle, ranging from 90% to 0%, with an

operating fr equency of 32 Hz. This allows the PCM

to control the current flow through the solenoid coil

according to the duty cycle it sets. This has the

effect of creating a variable magnetic field, that

magnetises the solenoid core, attracting the

metering ball to seat against spring force. A high

percentage duty cycle keeps the metering ball

seated more often, thereby creating higher TCC

signal fluid pressures.

Figure 6C1-1-86 Torque Converter Clutch (TCC) "PWM"

Solenoid Duty Cycle

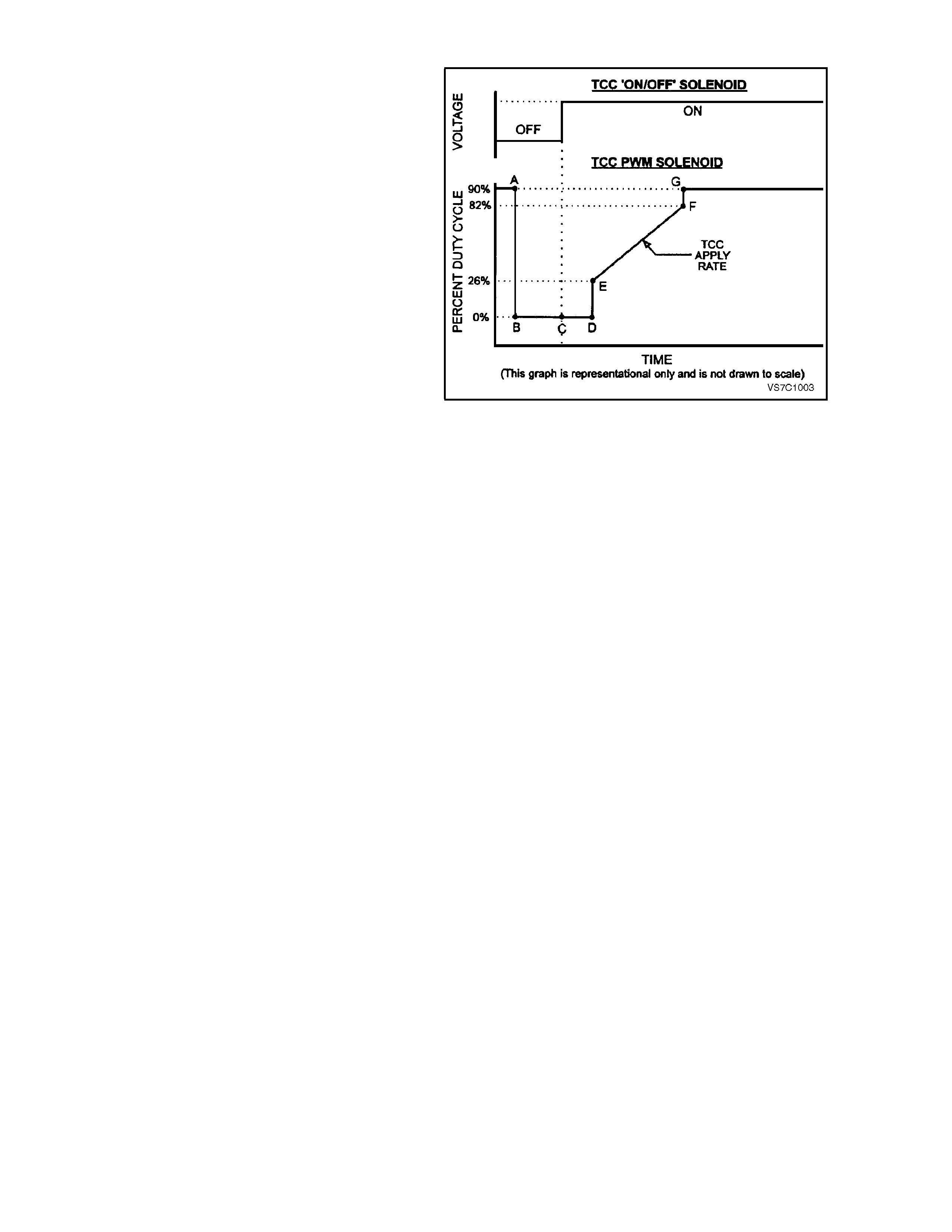

TCC "PWM" SOLENOID OPERATION

When vehicle road speed rises above about 13

km/h, the PCM causes the TCC "PWM" solenoid

duty cycle to change from 0% to 90% (point "A"), in

readiness for an apply of the torque converter.

To apply the torque converter clutch, the process

the PCM adopts, is as follows;

The duty cycle is dropped to 0% (point "B") and a

measurable amount of time is allowed for the TCC

enable solenoid to turn "ON". This is shown as the

time between points "B" and "C" in Fig. 6C1-1-84

Note that, at point "C", the TCC enable solenoid is

activated.

The time from point "C" to "D" is used to allow

converter (CONV FD) f luid to build in pressure and

move the Converter Clutch Valve into the apply

position.

At this point, with the TCC enable solenoid applied,

the PCM then increases the duty cycle to about

26% (point "E"). From this point, the duty cycle is

'ramped' to around the 82% point ("E" to "F"). The

rate at which the duty cycle is increased over this

period of tim e, determ ines how quickly the value of

the regulated apply fluid increases and therefore,

how quickly the torque converter clutch is applied.

This rate of change also affects the converter

clutch apply 'feel'.

As soon as the duty cycle reaches the 82% value, it

is then immediately increased to the maximum of

90%, to achieve full apply pressur e in the regulated

apply fluid circuit (point "G").

NOTE:

that the duty cycle and apply pressure will

continually vary, depending on vehicle specif ication

and operating conditions.

The two TCC solenoids work together so that TCC

apply or releas e rate can be calibrated f or a variety

of situations.

If a fault is detected by the PCM, in the TCC

"PW M" solenoid electrical circuit, a DTC 83 will be

set. When DTC 83 is set, the PCM will inhibit 4th

gear and TCC operation if in hot mode.

Figure 6C1-1-87 Torque Converter Clutch Solenoid

Operation

1.5 FUEL CONTROL SYSTEM

PURPOSE

The purpose of closed loop fuel control is to control tailpipe emissions consisting of hydrocarbons (HC), Carbon

Monoxide (CO), and Oxides of Nitrogen (NOx). At the sam e time, the system m ust achieve good engine perform ance

and good fuel economy.

The closed loop system regulates exhaust emissions by controlling the air/fuel ratio at an optimum level during various

driving conditions. The most efficient air/fuel ratio to minimise exhaust emissions is 14.7 to 1, this allows the 3-way

catalytic converter to operate at maximum efficiency to control exhaust pollutants. Because of the constant measuring

of the exhaust gases by the oxygen sensors, and adjusting of the fuel injector pulse width by the PCM, the fuel injection

system is called a "closed-loop" control system.

FUNCTION

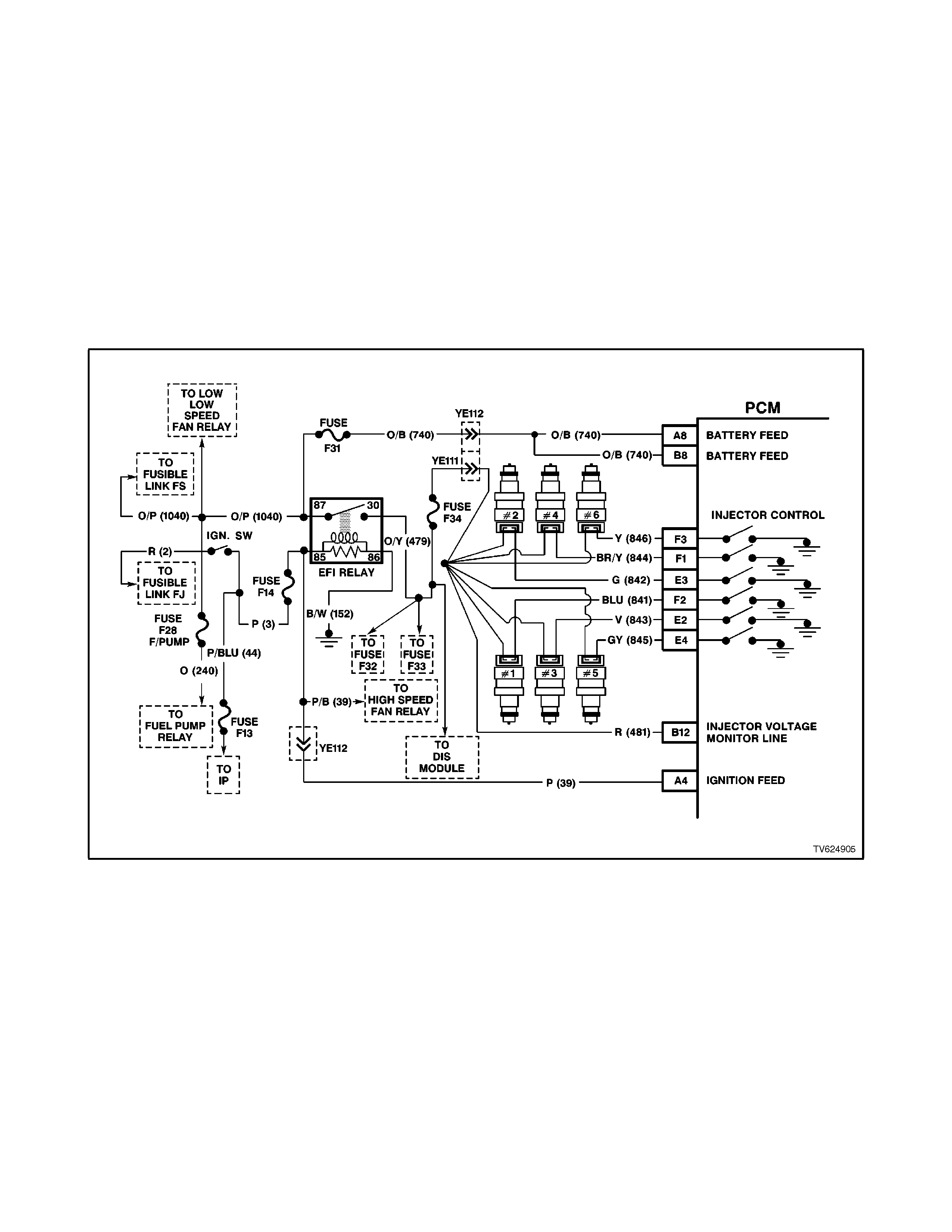

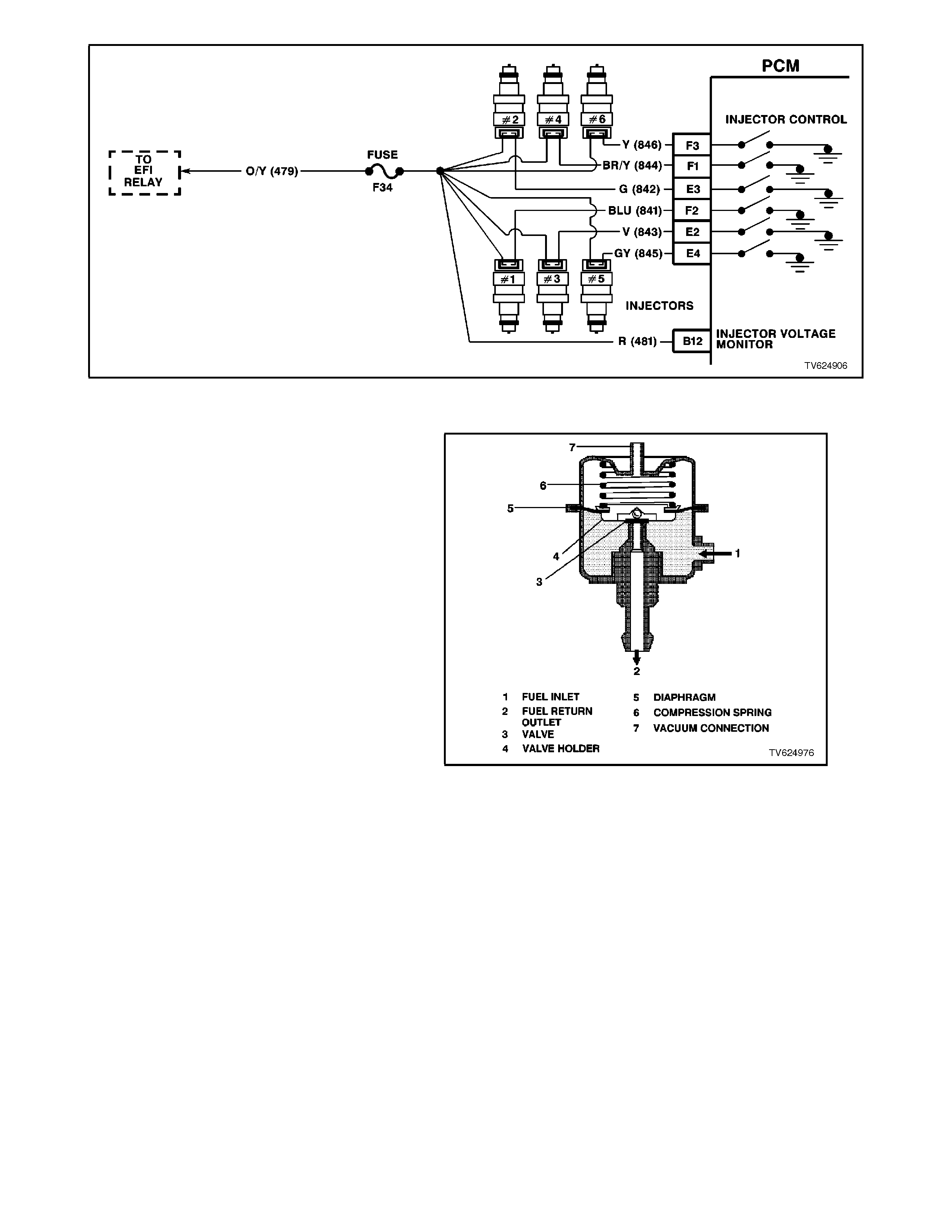

The f uel supply system delivers fuel at a r egulated pressur e to the fuel rail. T he fuel injec tors, located dir ectly ahead of

each inlet port of the cylinder head, act as fuel flow control valves, "spraying" atomised fuel into the inlet ports when

they are electrically "pulsed" by the PCM. On this engine, all injectors are wired individually so they are pulsed

individually. This type of fuel injection is referred to as sequential injection because pulsation of the injectors are

individually controlled and in a specific order.

The PCM controls the amount of fuel injected into the engine by controlling the length of time the injectors are held

open. This "length-of-time" is called PULSE WIDTH. To increase the amount of fuel injected, the pulse width is

lengthened, and vice versa. The pulse width is calibratable and varies between 0 - 11 milliseconds with the engine

running at idle, and injection pulses normally occur once every crankshaft revolution.

MASS AIR FLOW SYSTEM

The Holden/Delco Fuel Injection system is a Mass Air Flow system. The system is based upon an Air Meter that

measures the mass air flow rate of the engine directly.

Advantages of Mass Air Flow:

• Base engine components can be changed.

• Automatically compensates for engine aging.

• No air measurement lag time.

• Excellent idle stability.

Two spec ific data s ensors provide the PCM with the basic inf orm ation for the fuel m anagem ent por tion of its operation.

That is, two specific signals; cr ankshaf t reference signal f rom the ignition s ystem , and the Mass Air Flow (MAF) sensor

signal. Both of these signals to the PCM establish the engine speed and m ass of air ingested by the engine. Due to the

additional temperature compensation sensor in the MAF sensor, this system does not require a manifold absolute

pressure sensor.

The engine speed signal comes from the ignition module to the PCM on the crankshaft reference signal input circuit.

The PCM uses RPM information to calculate the best fuel injector pulse width and spark timing for a given operating

RPM band.

The mass of air ingested by the engine is sent as a signal from the mass air flow sensor to the PCM.

When the engine is started, the PCM will immediately look at the Engine Coolant Temperature sensor to determine how

much fuel is required to start the engine. After the engine is started, the PCM will constantly monitor the MAF sensor

values to determine both the spar k advanc e and engine f uelling r equirements . The Mass Air Flow s ens or meas ures the

mass of air ingested into the engine. The PCM then calculates how much fuel that must be injected to maintain an

air/fuel ratio of 14.7 to 1. An engine started in cold weather will require more fuel and spark advance than an engine

started hot, which requires less fuel and less spark advance.

One sensor is used to m easur e the density fac tor, the Mass Air F low (MAF) sensor. T he m ass air f low sensor used on

this engine utilises a heated element type of operation. Three sensing elements are used in this system.

As air passes over the heated elements during engine operation they begin to cool. By measuring the amount of

electrical power required to maintain the heated elements at the predetermined temperature above ambient

temperature mass air flow rate can be determined.

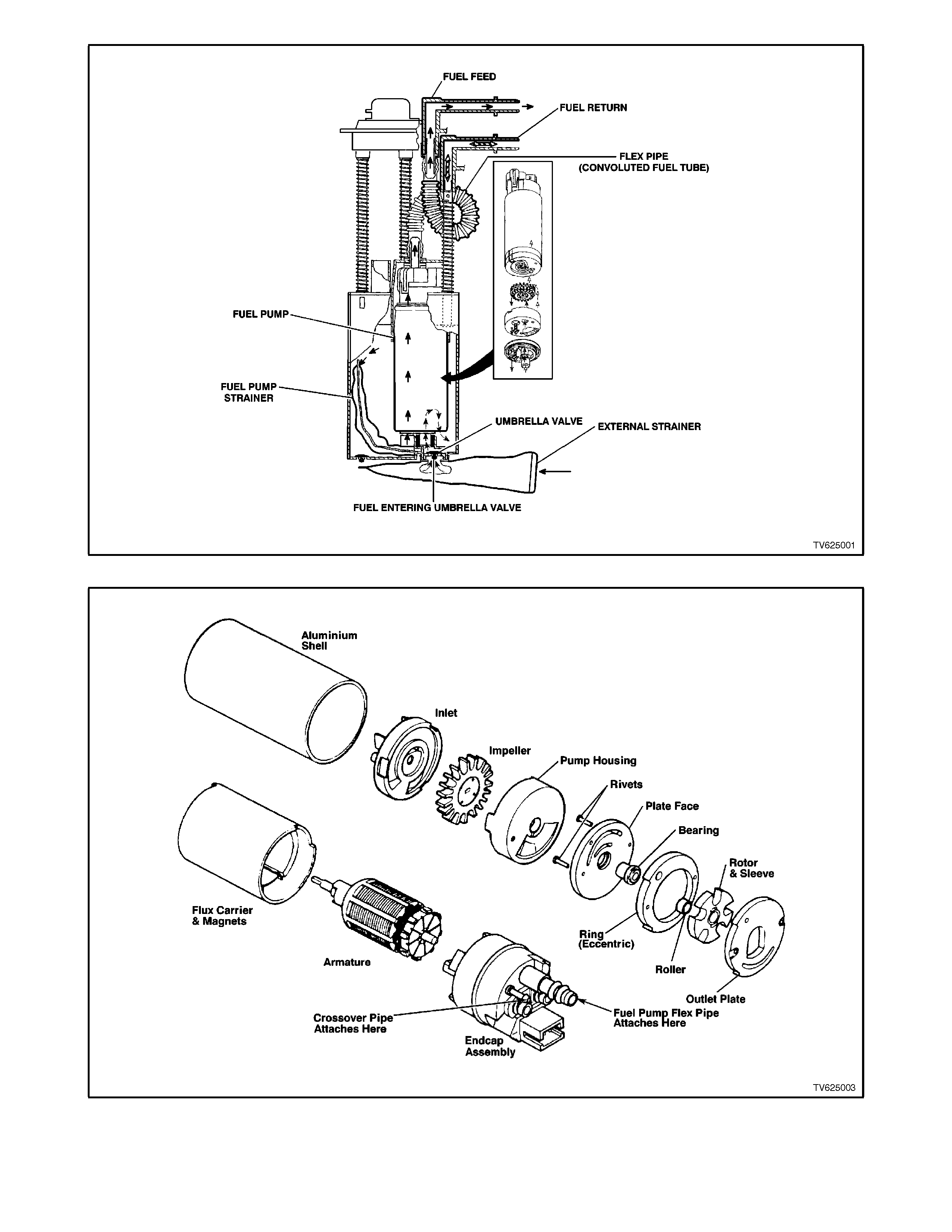

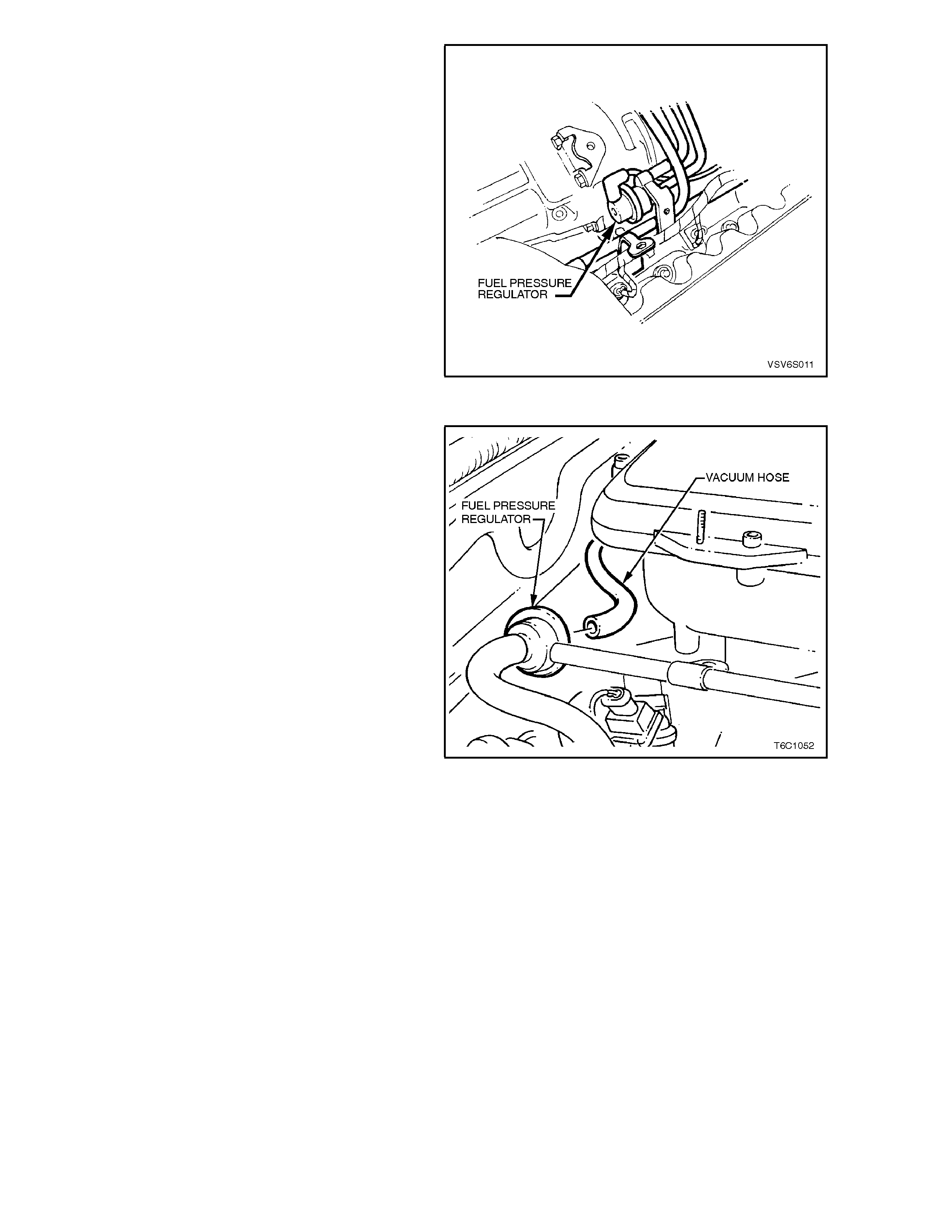

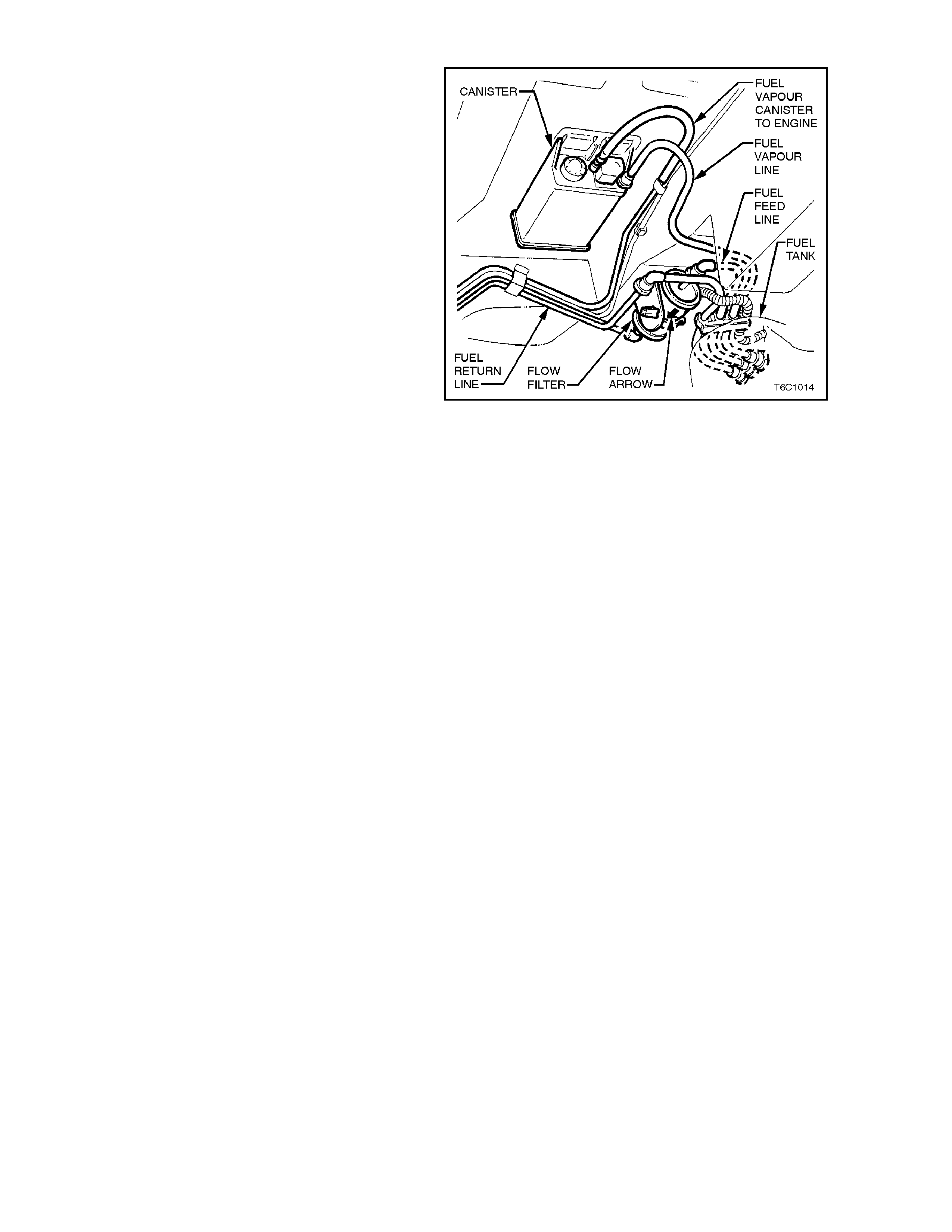

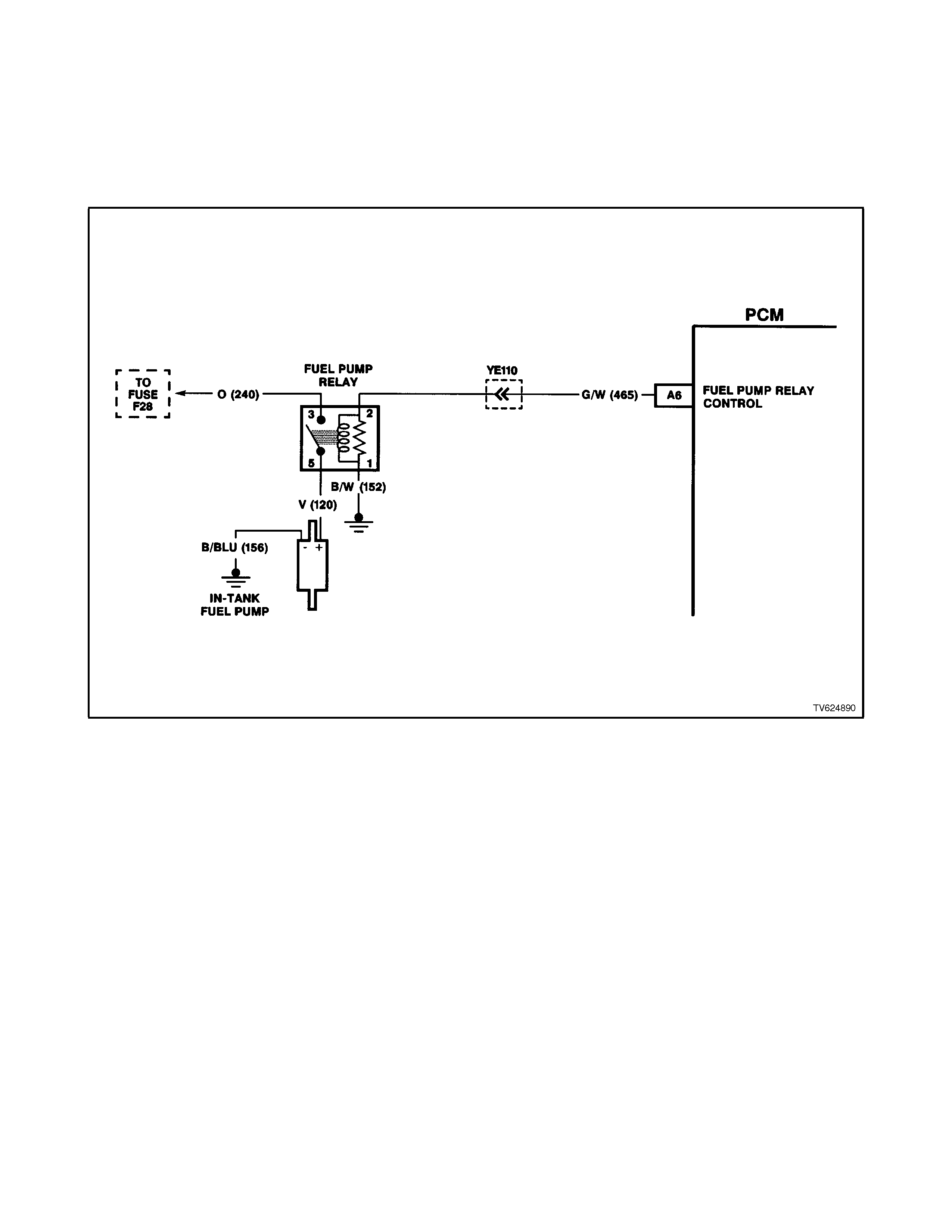

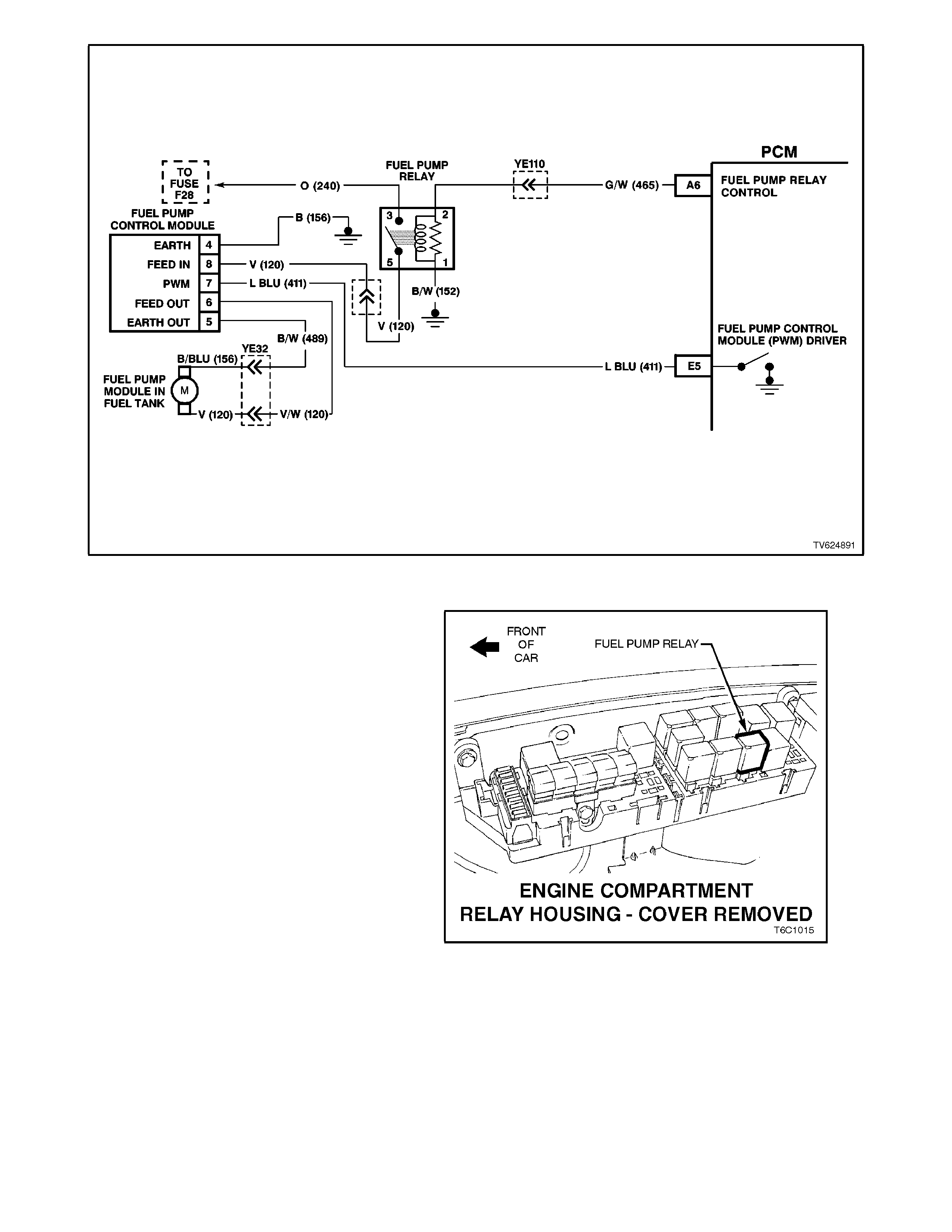

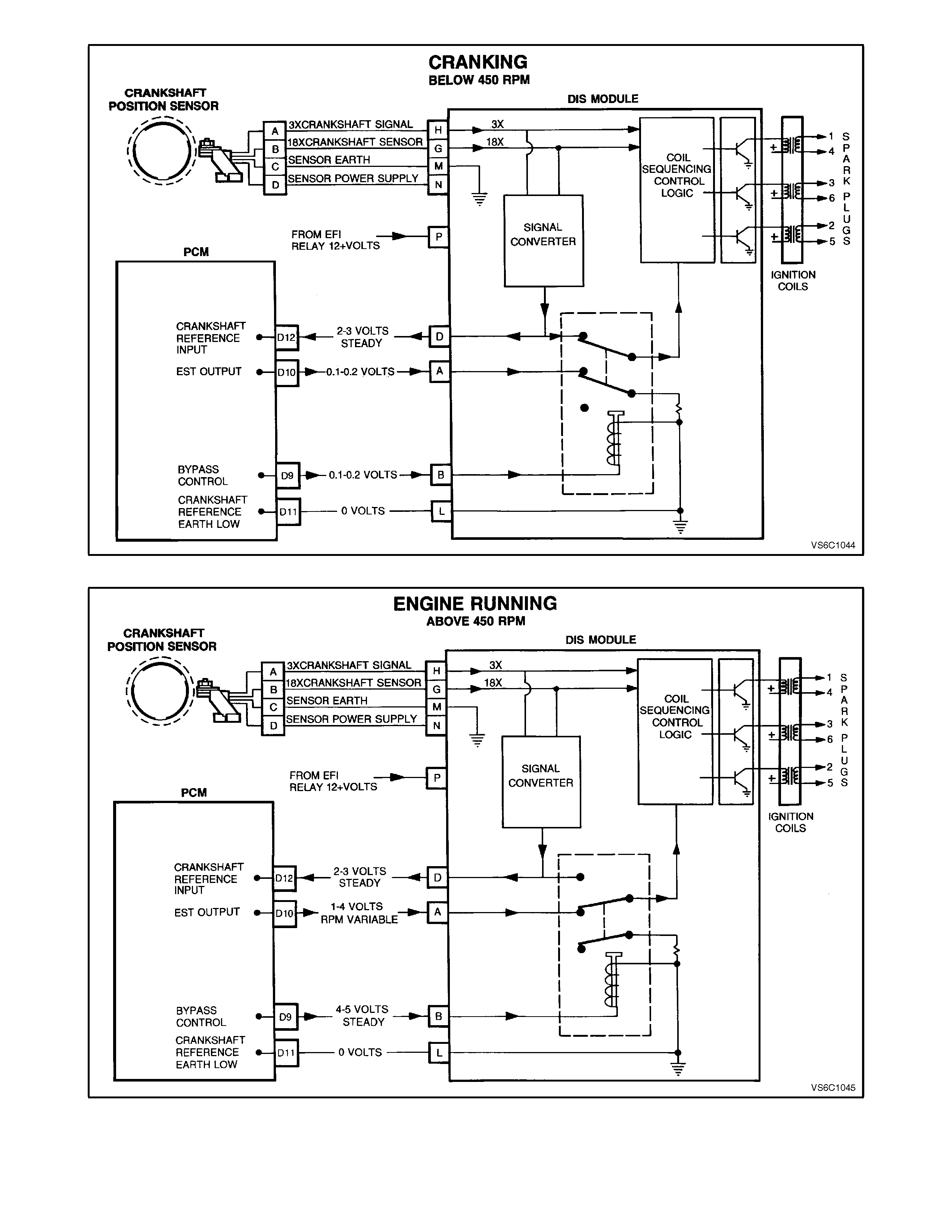

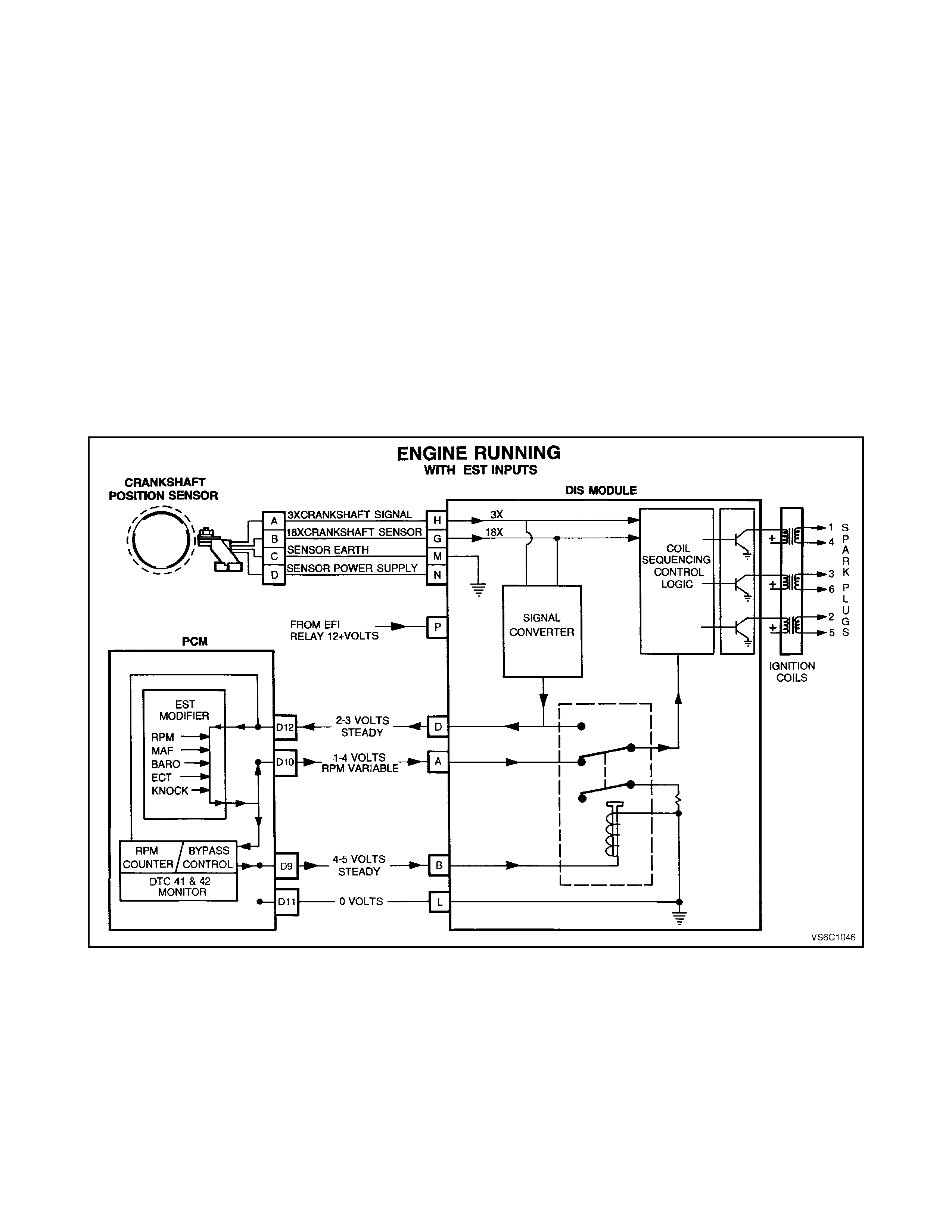

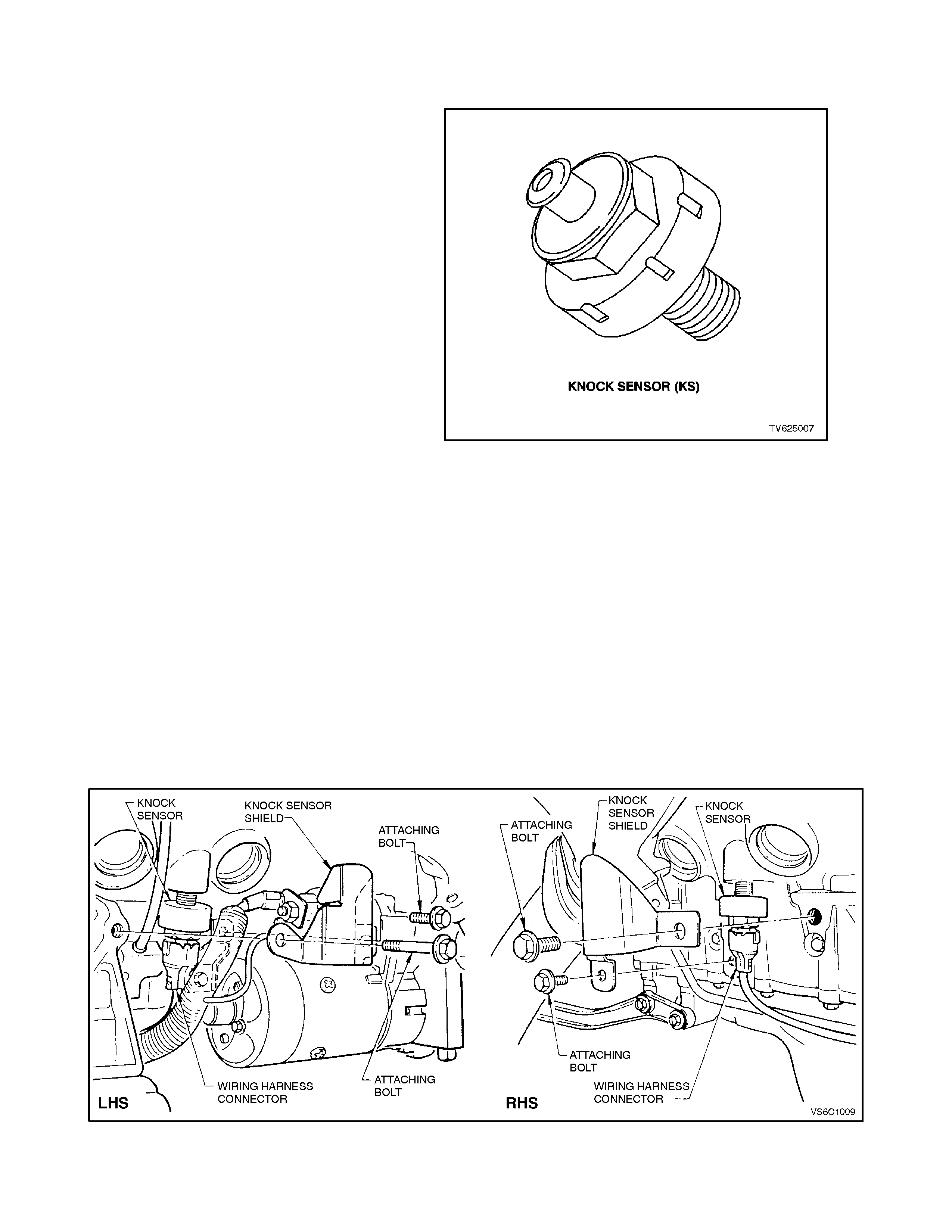

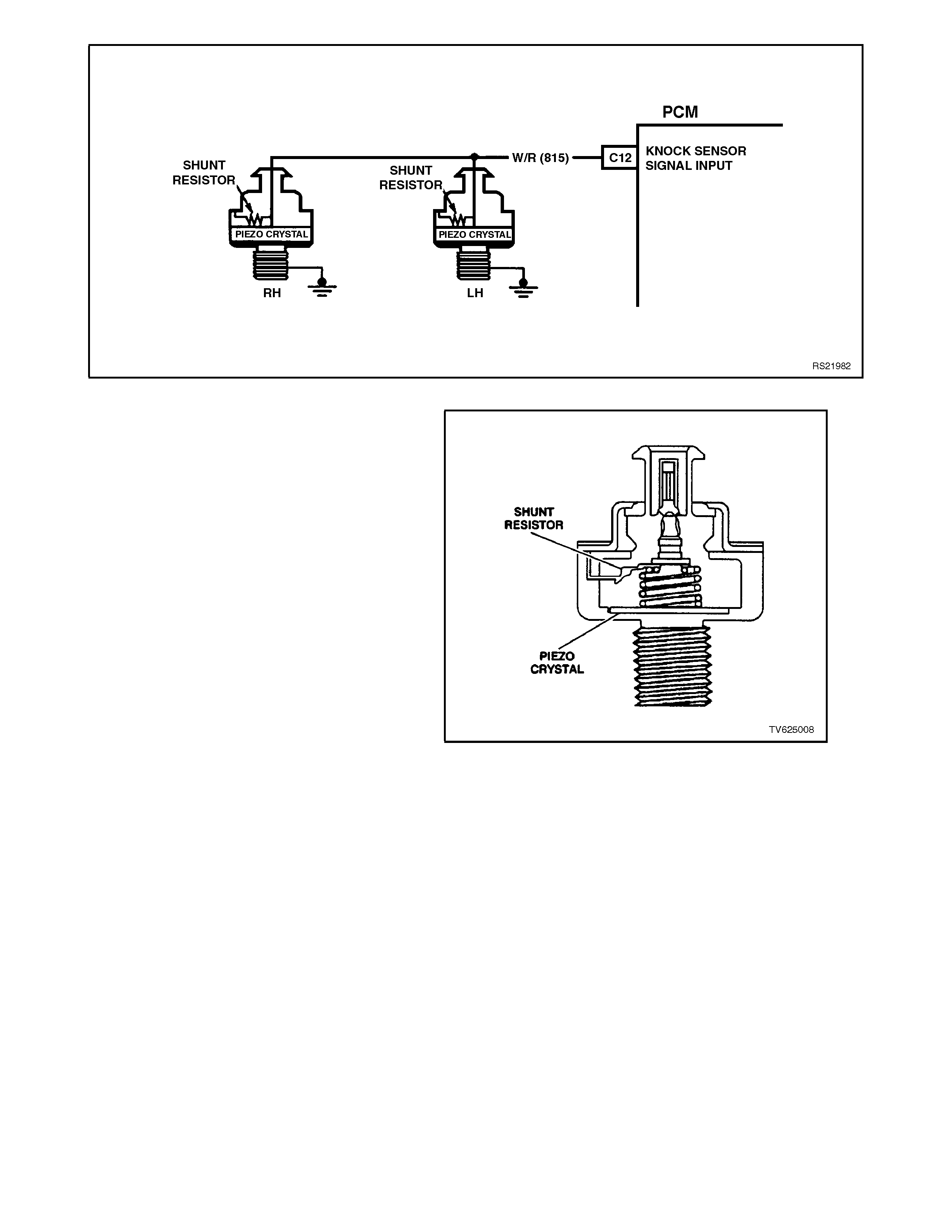

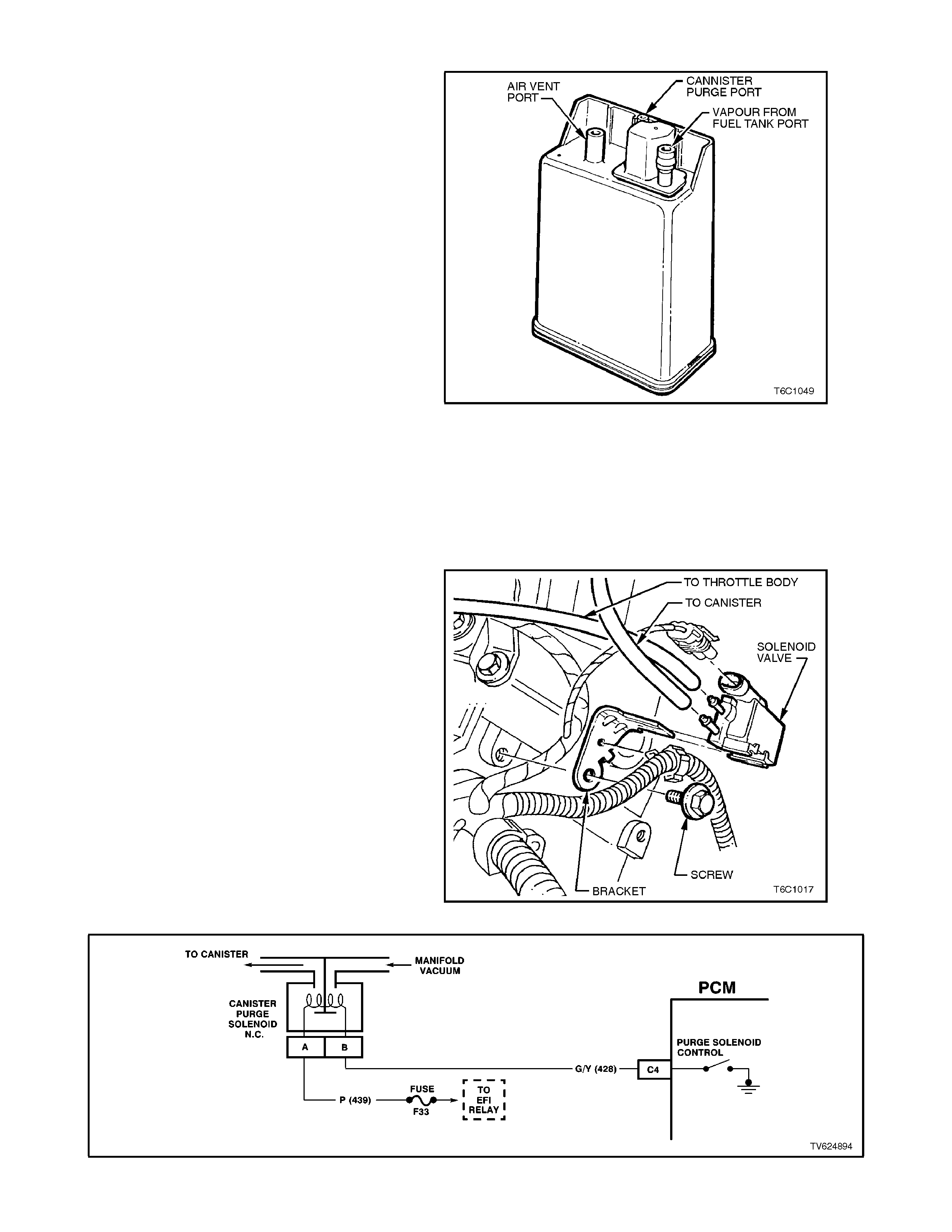

As the PCM receives this frequency signal from the mass air flow sensor, it searches its pre-programmed tables of