SECTION 6D2-1CHARGING SYSTEM - V8 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

1. GENERAL DESCRIPTI ON

A 120 amp generator is fitted to all VT Series Models with the 5.0 Litre engine.

The generator construction consists of a stator, which is of a three phase star connected output winding

construction on a ring shaped lamination pack. A rotor, which is of a twelve pole construction, carries a slip ring fed

field winding. The rotor is supported by ball bearings in both the drive and slip ring end housings.

The output of the stator is rectified by six diodes which are contained within the slip ring end plate. An additional two

diodes, in conjunction with the hybrid circuit, are connected to the star point of the stator windings. The purpose of

this circuit is to increase the generator assembly output to 120 amps. Excitation current is supplied to the rotor field

coil via the voltage regulator, brushes and slip rings. The electronic voltage regulator requires no adjustment in

service.

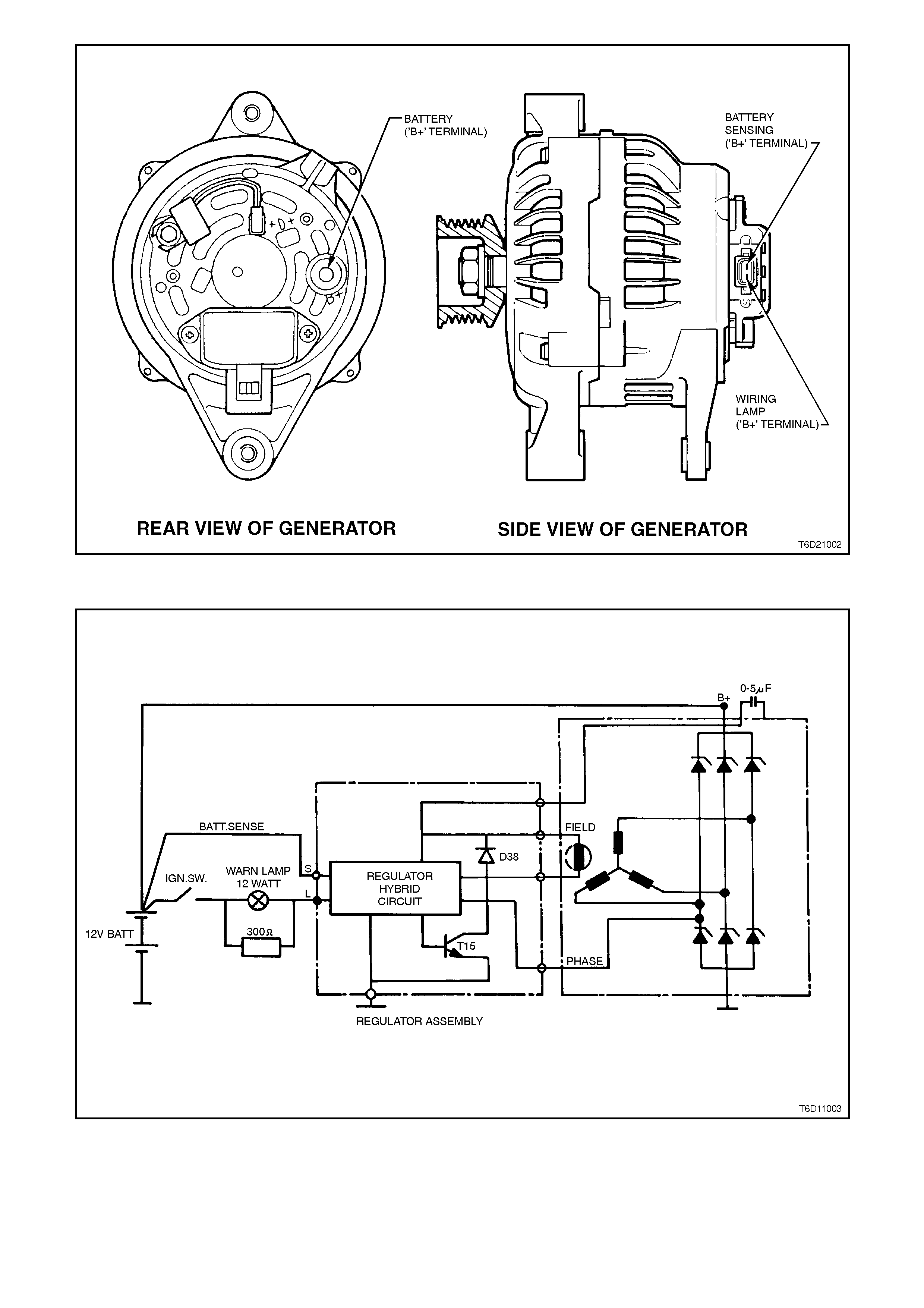

The generator has four external connections; the B+ lead to the battery positive terminal, the L lead to the generator

warning lamp, the S lead for battery voltage sensing and an earth connection.

The diodes and stator windings are cooled by air flow through the generator induced by a ventilating fan mounted

on rotor shaft within the drive end housing.

The internal circuitry of the generator illuminates the warning lamp in the event of the following;

1. Disconnected generator to battery sensing lead.

2. Disconnected generator to battery charging lead.

3. Battery overcharging.

4. Generator not charging.

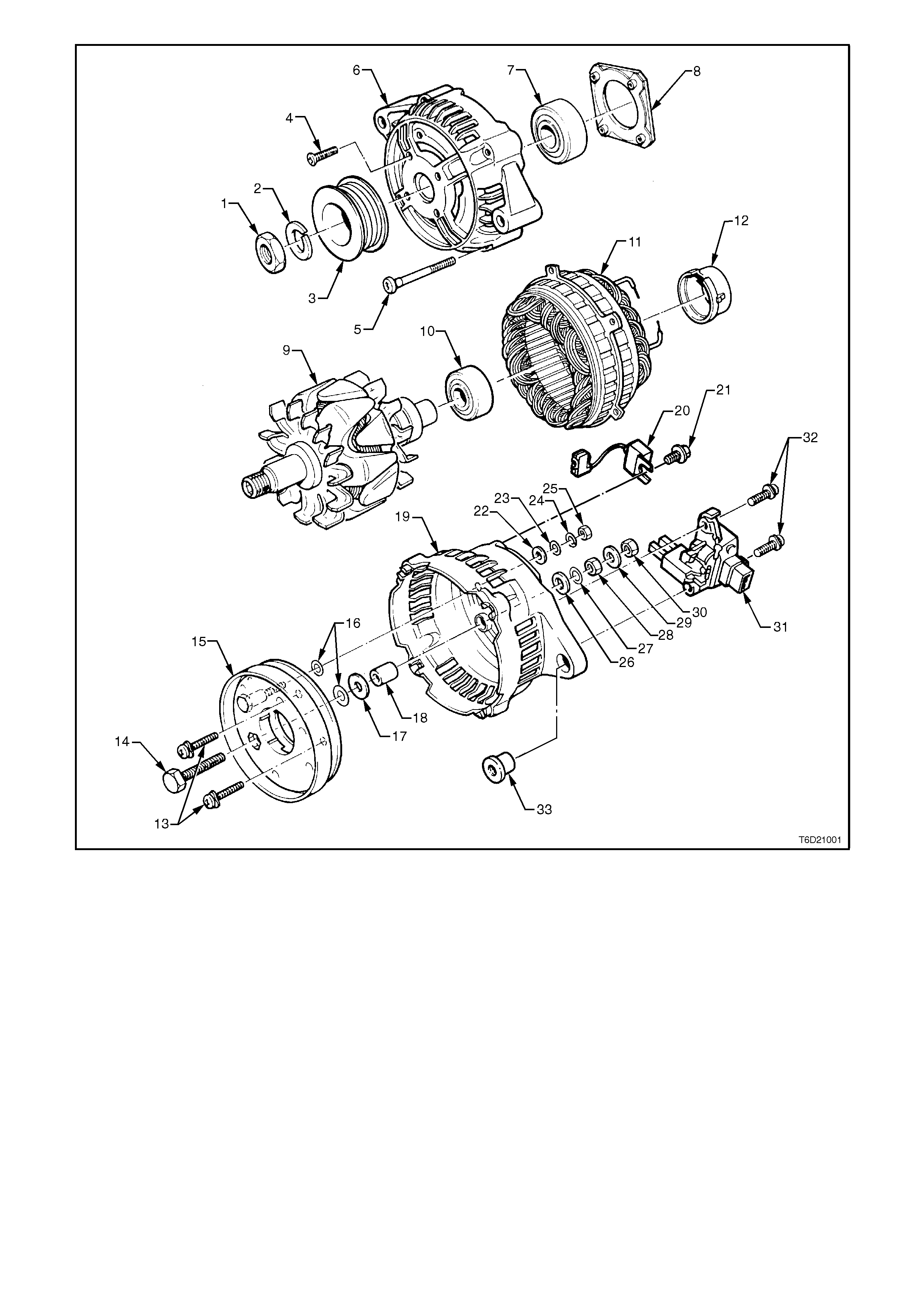

Fig. 6D2-1-1 shows an exploded view of the 120 amp generator.

Figure 6D2-1-1

1 Nut 13 Rectifier Attaching Screws 25 D+ Terminal Attaching Nut

2 Lock Washer 14 B+ Terminal Bolt 26 Insulating Washer

3 Drive Pulley 15 Rectifier Assembly 27 Flat Washer

4 Bearing Retaining Plate Screw

(4) 16 Mica Insulating Washers 28 Nut

5 Through Bolt (4) 17 Insulating Washer 29 Flat Washer

6 Drive End Housing 18 Spacer 30 B+ Terminal Retaining Nut

7 Drive End Bearing 19 Slip Ring End Housing 31 Regulator and Brush

Assembly

8 Bearing Retaining Plate 20 Suppressor 32 Regulator and Brush Screws

9 Rotor 21 Suppressor Attaching Screw 33 Slip Ring End Housing Lug

Sleeve

10 Slip Ring End Bearing 22 Insulating Washer

11 Stator 23 Flat Washer

12 Slip Ring End Bearing Support

Ring 24 Wave Washer

Figure 6D2-1-2

Figure 6D2-1-3

2. MI NOR SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

Since the generator and voltage regulator are designed for use only on a negative earth system, the following

precautions must be observed. Failure to observe these precautions will result in serious damage to the generator.

1. Do not reverse the polarity of the battery connections as the generator and voltage regulator are designed for

use only on a negative earth system.

2. When installing a battery, ensure that the ignition switch is in the OFF position.

3. Fit positive (+) cable to battery positive (+) terminal first, then fit negative (-) cable to battery negative (-)

terminal.

4. When a slave battery is utilised for starting purposes, ensure both batteries are connected in parallel, i.e.

positive terminals together and negative terminals together.

5. When charging battery, disconnect both battery cables from the battery, thus isolating battery and external

charging equipment from the vehicle electrical system.

NOTE:

It is important to isolate the battery during a charging operation, as some charging equipment may produce

Transient Voltage that will damage the PCM (Powertrain Control Module) or ECM (Electronic Control Module).

6. Do not operate the generator open circuit (any terminal disconnected), or disconnect the battery cable/s while

the engine is operating.

7. Do not attempt to polarise generator.

8. Do not use a generator warning lamp bulb of more than 2 Watts (1.2 - 2.0 Watts is necessary).

9. Do not bridge, ground or cross connect the L and S terminals at the voltage regulator.

10. Do not connect the voltage regulator L terminal to the battery or ignition circuit (12 volts).

NOTE:

Always ensure that generator warning lamp illuminates when ignition switch is turned to the ON position.

2.2 MAINTENANCE AND ON VEHICLE TESTING

At regular intervals, inspect the terminals of the

generator for corrosion, loose connectors and the

wiring for damaged insulation.

Check the generator drive belt tension and

condition at the intervals specified in the VT

Owner's Handbooks.

The drive belt adjustment for the generator/water

pump is effected by pivoting the generator.

Periodically check the mounting bolts for specified

torque and rectify if necessary, refer to Section

6A2 ENGINE MECHANICAL - V8 ENGINE.

LUBRICATION

The ball bearings used in this NC-A generator are

a high tolerance type, only fully sealed bearings of

the same specification are to be used as

replacements. It is recommended that the

bearings be replaced during the reconditioning

process to restore the unit to its original

configuration.

TESTING THE GENERATOR OUTPUT AND VOLTAGE REGULATOR

NOTE:

Do not reverse the S and L connections or put the

12 volt supply to L terminal, this connection must

not be used as a supply source other than to

supply the requirements of the warning lamp (2

watts). Such action will destroy the regulator

warning lamp circuit.

Before testing the generator output, make certain

that the generator circuit is thoroughly checked for

loose or dirty connections. The generator must

always be connected to the battery during testing,

otherwise damage to the diodes could result. The

battery should be fully charged. The generator

warning light, in addition to indicating that the

generator is charging, is also necessary for initial

field excitation.

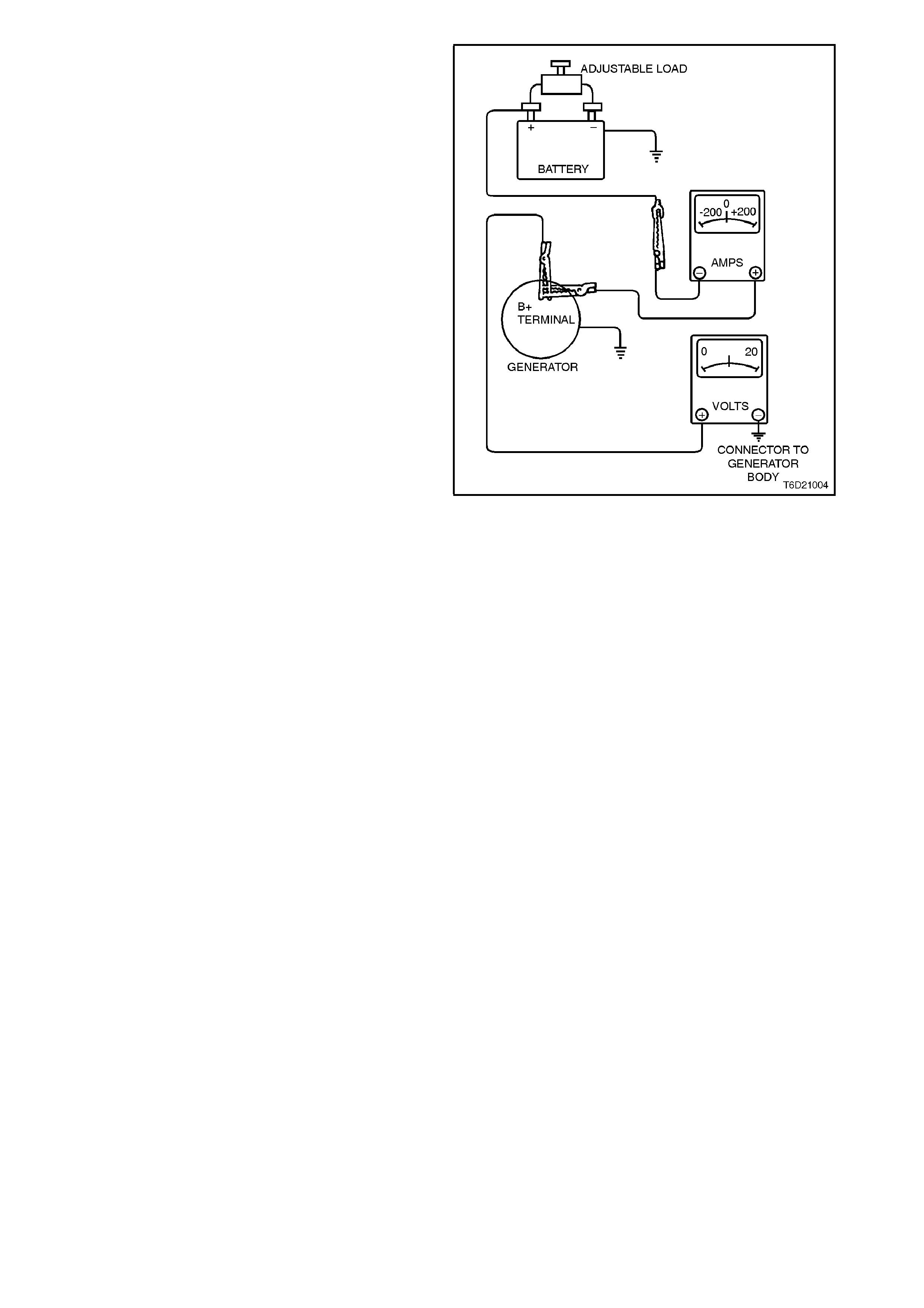

TESTING GENERATOR OUTPUT

NOTE:

Keep the duration of this test to a minimum to

avoid undue heating and high engine speed. The

battery should be fully charged to perform this

check.

RATED OUTPUT

TEMP VOLTAGE

SETTING AMPS ALTERNATOR RPM

20°C 13.5

CONSTANT 120 6000

1. Ensure that all the electrical equipment is

turned OFF, and the ignition switch is in the

OFF position.

2. Disconnect battery earth cable at battery.

3. Disconnect the generator positive lead (red

wire) from the B+ generator terminal.

4. Connect the positive lead of an ammeter (0 - 100

Amp s cale) to the gener ator B+ term inal, and the

negative ammeter lead to the disconnected

generator positive lead (red wire).

5. Connect positive lead of a voltmeter (0 - 20 Volt

scale minimum) to the generator B+ terminal,

and negative voltmeter lead to a good ground on

generator body.

CAUTION:

Insulate the generator positive lead (red wire)

terminal to prevent contact w ith any metal part of

the vehicle. If the terminal is grounded, damage to

the charging circuit will result w hen the battery is

reconnected.

6. Reconnect the battery earth cable. Fit a loading

device across battery terminals (if sufficient

electrical loads are not available a carbon pile

resistance can be connected across the battery).

NOTE:

Loading device must have a minimum power

consumption of 1000 watts.

7. Start engine and increase engine speed until the

alternator is running at 6000 rpm.

8. Switch on electrical loads until the alternator

voltage drops to 13.5 volts. An output of 120

Amps should be achieved under these

conditions.

NOTE:

It may be necessary to adjust engine speed to

maintain alternator speed.

Figure 6D2-1-4

If generator does not pr ovide rated output, it s hould

be disassem bled and inspected for f aults, refer to

3.1 GENERATOR in this Section.

CAUTION:

On completion of the Generator OUTPUT CHECK, to prevent excessive battery discharge occurring, the

engine should be returned to idle speed and the loading device disconnected from battery terminals.

9. Disconnect the battery earth cable at battery. Remove the volt and ammeters, then reconnect the generator

positive lead (red wire) to the generator B+ terminal. Reconnect the battery earth cable to the battery.

TESTING THE VOLTAGE REGULATOR

1. Connect a voltmeter to the alternator, the positive lead to the B+ terminal and the negative lead to the

alternator casing. Select an appropriate voltage range on the meter. i.e. 20 volt range.

2. Connect an ammeter in series with the main output cable from the B+ terminal on the alternator. Select a

range which will be capable of reading 120 Amps from the alternator.

3. Note the voltmeter reading before starting the engine, this reading should increase when the engine is running,

indicating alternator output.

4. Start the engine and increaser the engine speed until the alternator is running at 4000 rpm.

5. Switch on vehicle loads of 5 - 10 Amps. (indicated on ammeter). The voltmeter should read 14.0 - 14.2 volts.

6. If voltage reading is not to specification, replace voltage regulator. Refer to 3.1 GENERATOR in this Section.

3. MAJOR SERVICE OPERATIONS

3.1 GENERATOR

REMOVE

1. Disconnect battery earth lead.

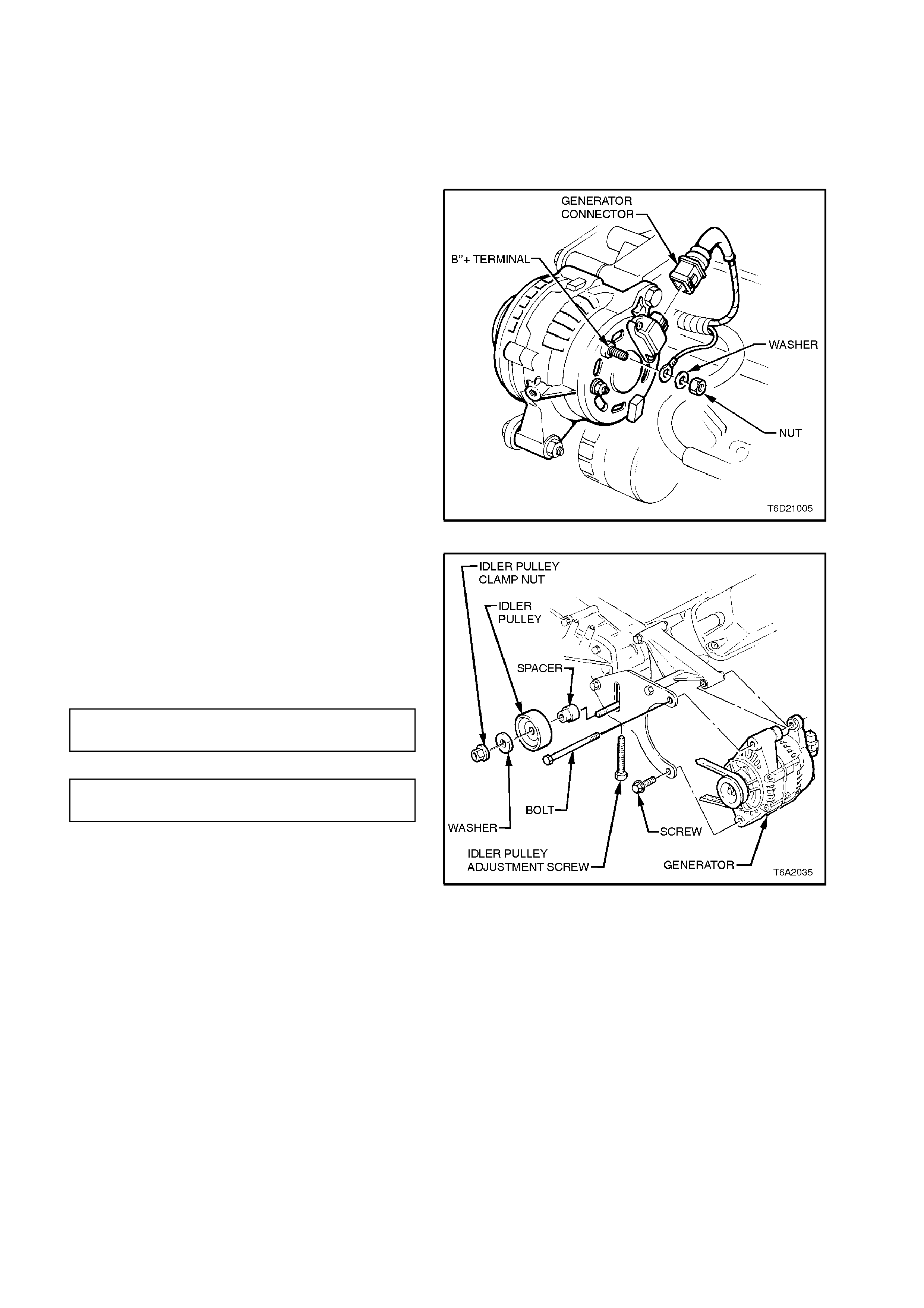

2. Remove wiring harness connector from

generator terminal block by depressing

connector retainer and pulling connector from

generator.

3. Pull back cap from the generator B+ terminal,

remove nut, washer and generator positive

lead (red wire).

Figure 6D2-1-5

4. Loosen generator drive belt idler pulley clamp

nut.

5. Use the idler pulley adjusting bolt to achieve

specified belt tension, then tighten clamp nut

to specified torque. Belt tension can be

checked by using Tool No. BT 3373-F, or

similar.

GENERATOR BELT 64 kg Ne w

TENSION SPECIFICATION 43 kg Used

IDLER PULLEY CLAMP NUT 35 - 65

TORQUE SPECIFICATION Nm

Figure 6D2-1-6

6. While supporting weight of generator,

withdraw generator drive end plate to

mounting bracket bolt and nut.

DISASSEMBLE

1. Mark relative positions of slip ring end plate,

stator and drive end plate. Use a permanent

marking pen, do not use a centre punch as

this can cause misalignment of the housing.

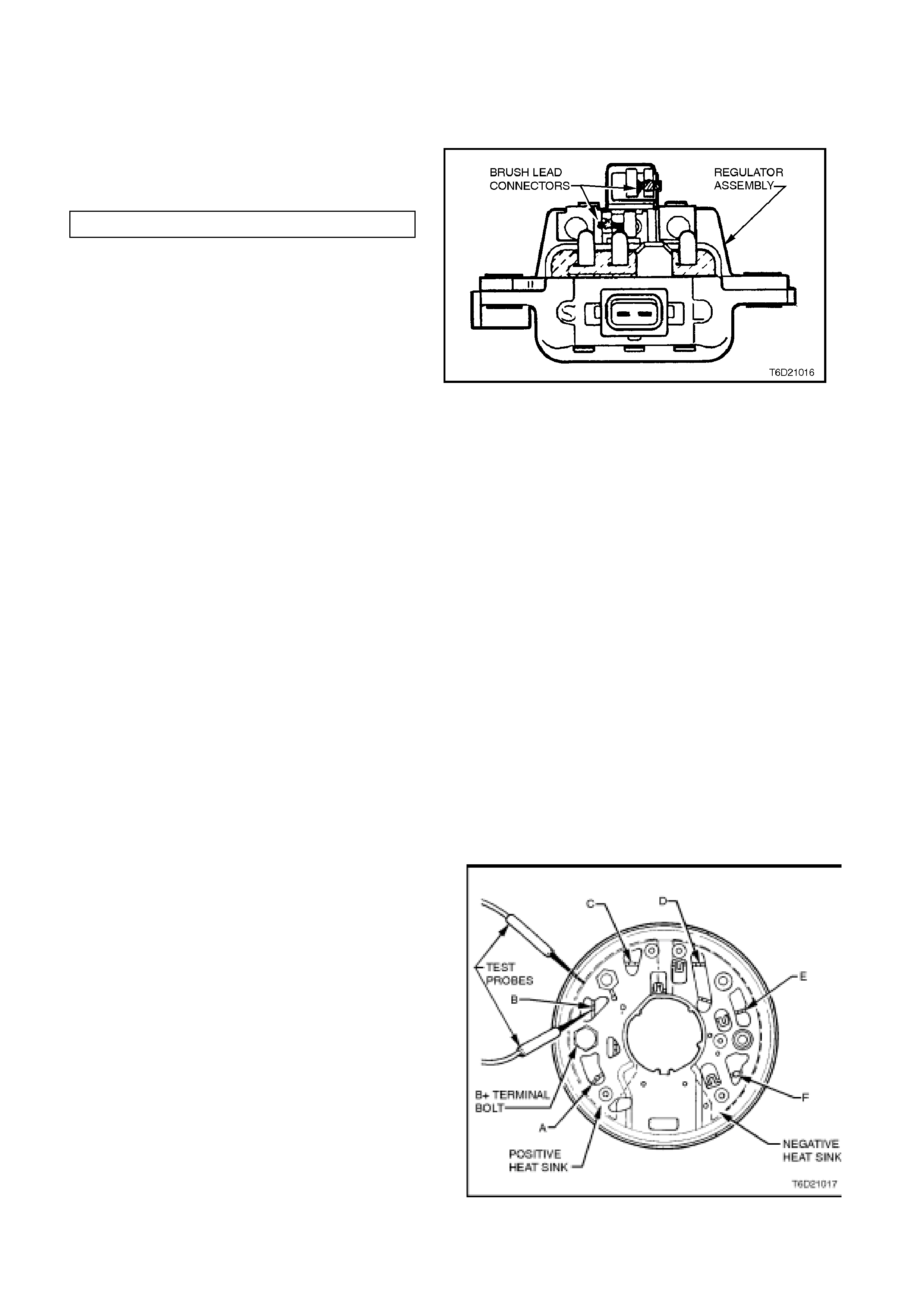

Figure 6D2-1-7

2. Remove two screws securing regulator and

brush assembly to slip ring end plate. Tilt the

regulator slightly from the plug connec tion until

the regulator clears the housing and withdraw

assembly, taking care not to damage the

brushes.

Figure 6D2-1-8

3. Remove four through bolts and washers.

4. Separate slip ring end plate and stator (as an

assembly) from rotor and drive end plate,

taking care not to put strain on the stator

wires.

Figure 6D2-1-9

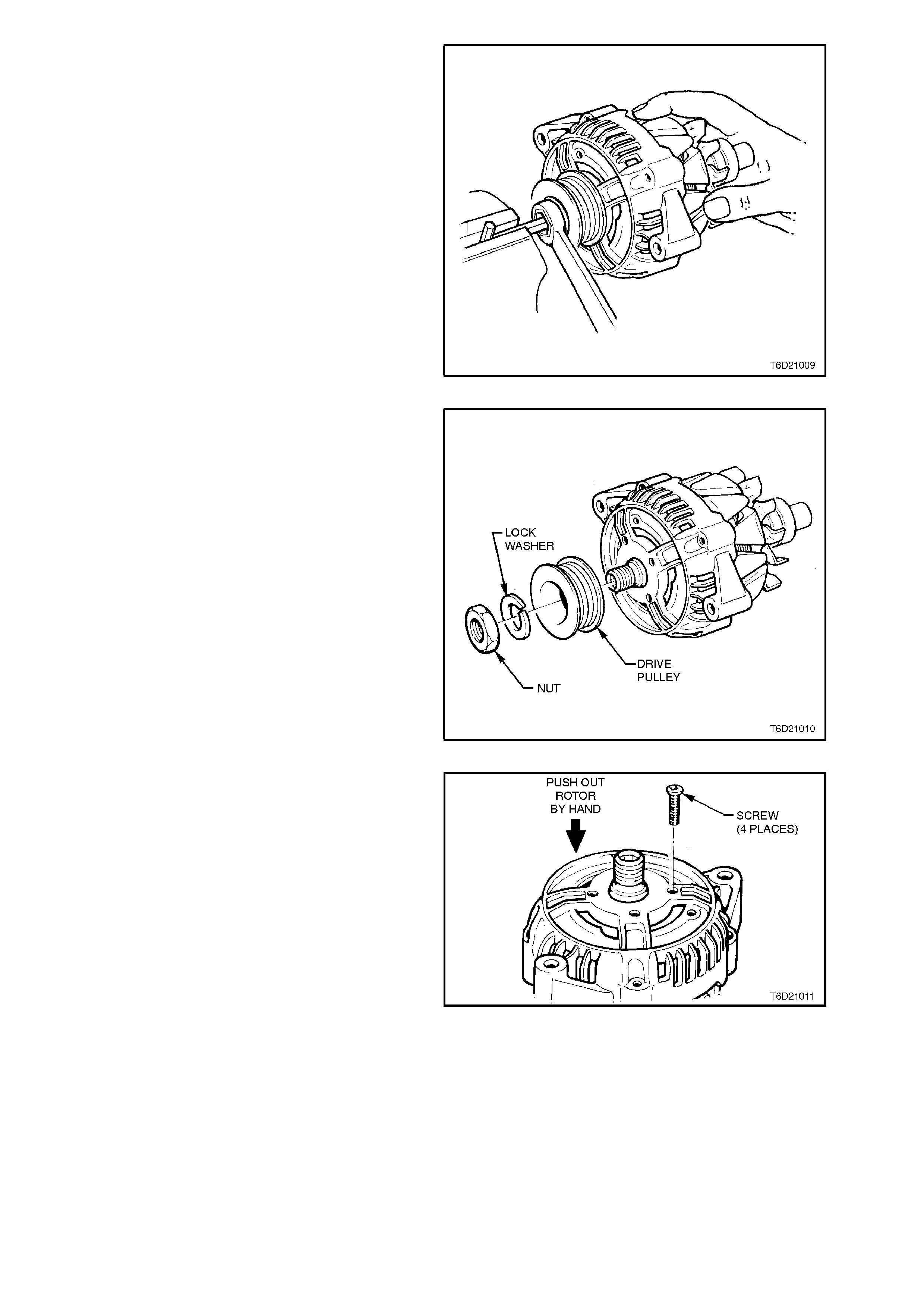

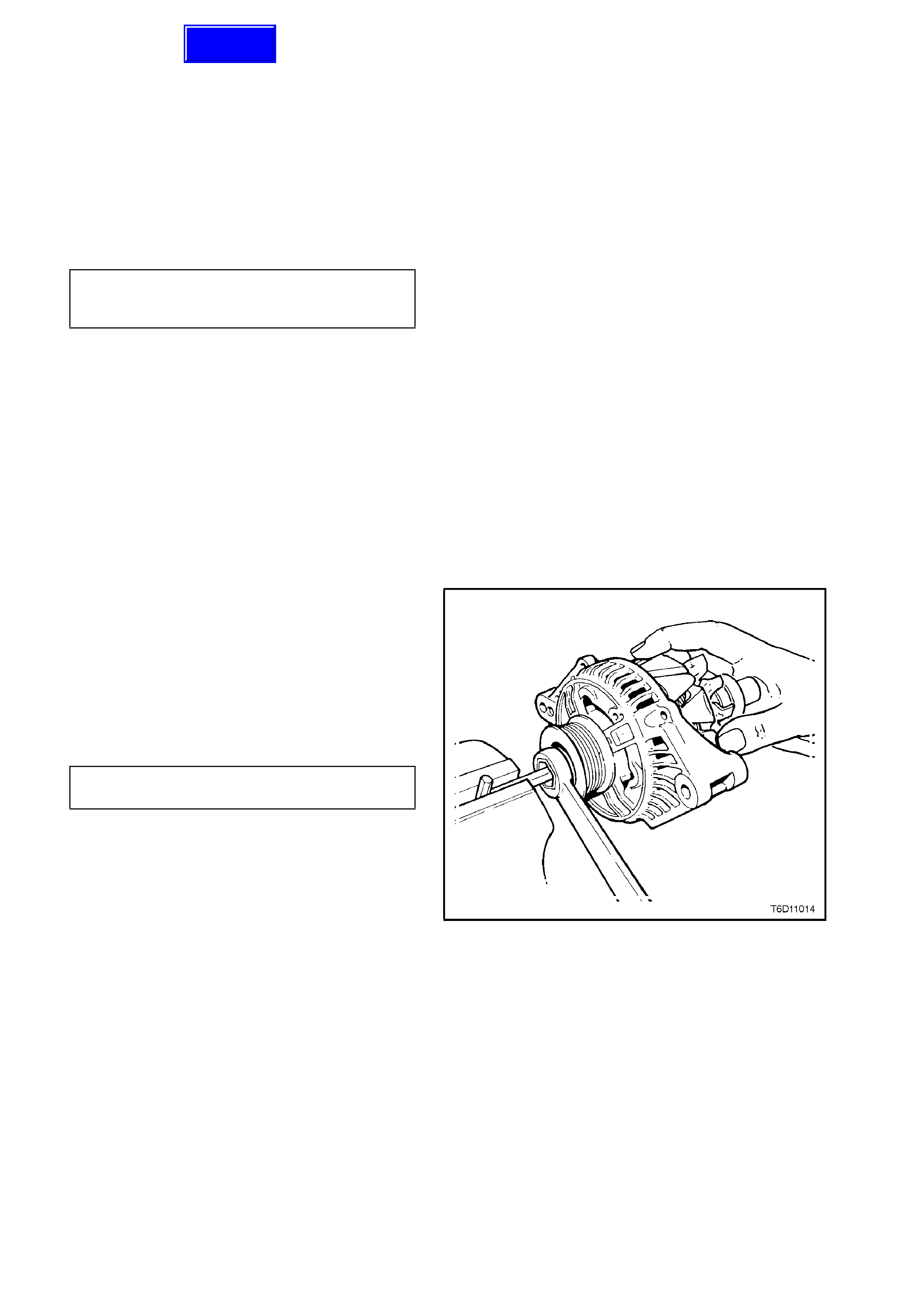

5. To remove the drive pulley, mount an 8mm.

Allen key in a vice with the long end pointing

out from the side of the vice.

Place a deep 24mm. Socket with external hex

(commercially available) onto the pulley

attaching nut and place a suitable size

spanner over socket hex.

Position drive end housing and rotor ass embly

with the internal hexagon of the rotor shaft

onto the Allen key.

Loosen drive pulley attaching nut. Remove

drive end housing from Allen key .

NOTE:

Under no circums tances is the rotor to be m ounted

in the vice as the rotor and or cooling fan will be

damaged.

Figure 6D2-1-10

6. Withdraw the pulley assembly.

NOTE:

The pulley has an integral boss which locks up

against the ball race, therefore no thrust collar is

provided.

Figure 6D2-1-11

7. Remove four screws securing bearing

retaining plate to drive end plate, remove

retaining plate.

8. Push the rotor shaf t and fr ont bearing fr om the

drive end housing

NOTE:

The rotor must not be pressed from the drive end

housing. If the rotor is pressed out, the bearing

retaining plate and drive end housing will be

damaged or distorted. Parts removed in this way

MUST be replaced if the integrity of the generator is

to be maintained.

Figure 6D2-1-12

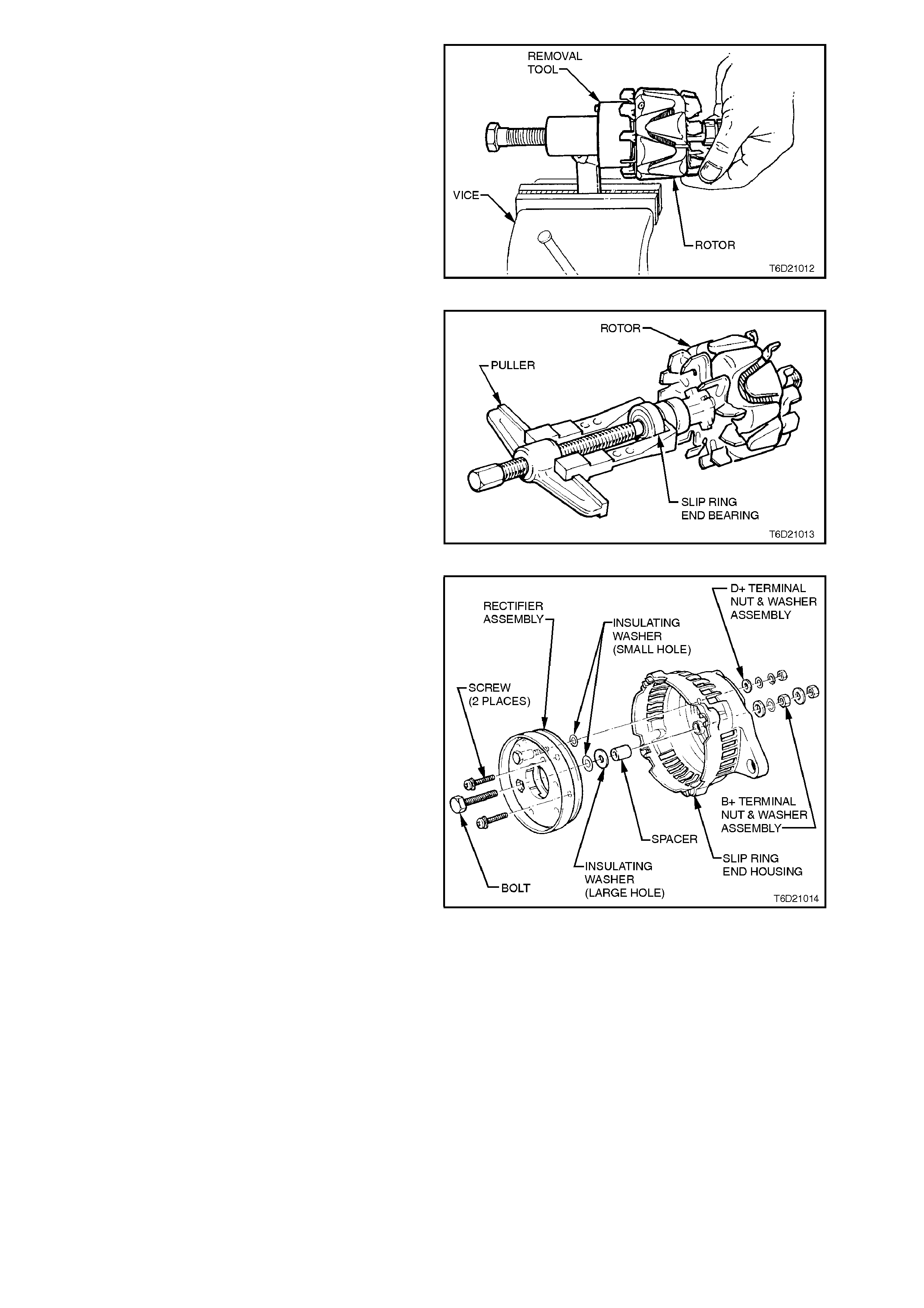

9. Using the drive end housing bearing removal

tool (Bosch tool 9981 066 601), remove drive

end bearing from rotor shaft.

NOTE:

This process will damage the bearing retaining

plate and must be replaced. As the bearings are

fine tolerance, high speed, noiseless design they

must also be replaced.

Figure 6D2-1-13

10. Using a commercially available puller, remove

slip ring end bearing from rotor shaft, taking

care not to distort the rear fan during the

process.

Figure 6D2-1-14

11. Remove nut, wave washer, flat washer and

insulating washer from the B+ terminal stud.

12. Remove suppressor lead connection from

rectifier + terminal.

13. Remove three screws and washers attaching

rectifier assembly to slip ring end plate.

Remove the stator and rectifier as an

assem bly. Remove spacer and m ica ins ulating

washer from B+ terminal stud.

NOTE:

Discard the mica insulating washers as new

washers and heat sink com pound mus t be used on

reassembly.

Figure 6D2-1-15

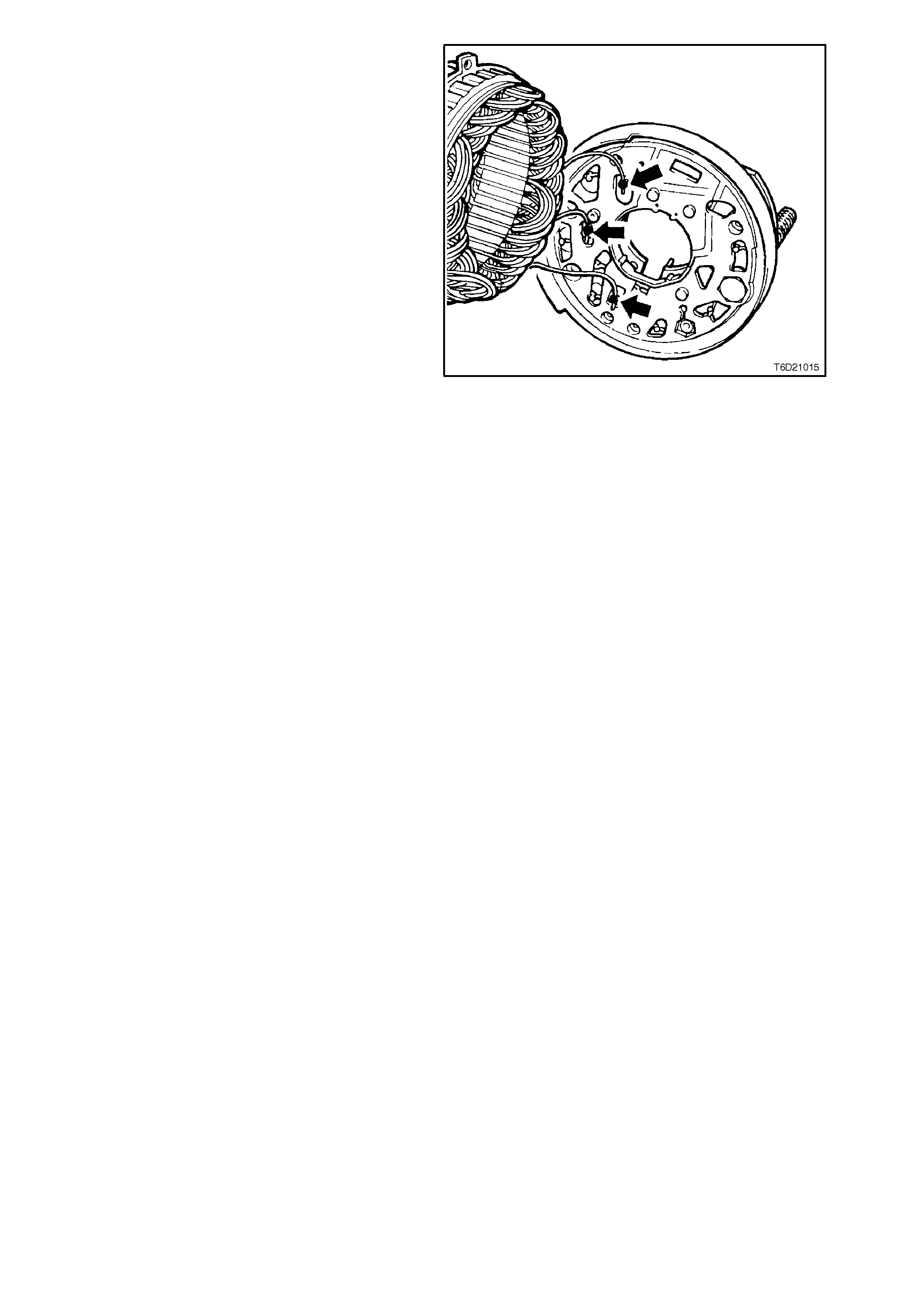

14. To separate the s tator from rectifier assembly,

grasp the stator wires close to the wire loop

with a pair of long nosed pliers, heat the joint

with a soldering iron, when the point becomes

plastic apply a slight twisting motion to the

wires, then pull up to release the wires.

Remove the s tator. This proc edure opens the

wire loop to release the stator connections

easily.

CAUTION:

Use only as much heat as required to melt the

solder. Excessive heat may damage the diodes.

Figure 6D2-1-16

CLEANING AND INSPECTION

With generator completely disassembled,

components should be cleaned and inspected.

Wash all components except stator, rotor, rectifier

and regulator in a suitable cleaning solvent.

CAUTION:

Do not clean stator or rotor windings with

cleaning solvent or damage to the insulation

could result.

WARNING:

CLEAN ALL PARTS OTHER THAN THOSE

PREVIOUSLY NOMINATED USING A NON

VOLATILE OR LOW INFLAMMABLE AGENT IN

A WELL VENTILATED AREA.

IT IS IMPORTANT THAT ALL PARTS ARE

THOROUGHLY DRIED BEFORE ASSEMBLY,

TAKING CARE NOT TO BREATH IN ANY

VAPOURS.

OBSERVE THE SAFETY REGULATIONS AND

PRECAUTIONS ISSUED BY THE

MANUFACTURER OF THE CLEANING AGENT

IN USE.

CAREFULLY CLEAN ROTOR AND STATOR

WITH COMPRESSED AIR.

COMPONENT CHECKING

BRUSH GEAR

1. Unsolder brush leads from regulator

connections and bend back the retaining lugs.

Remove brushes and springs.

2. Measure length of brushes, replace if less

than specified minimum length.

MINIMUM BRUSH LENGTH 3.8 mm

3. Inspect brushes for damage.

4. Inspect brush springs for discolouration or

breakage. If either condition exists, replace

springs.

5. Install brush springs over brush leads, install

brushes into regulator and solder leads to

connections. Figure 6D2-1-17

6. Check that brushes m ove smoothly in and out

of holder by pushing on end of brushes, and

then releasing.

DIODES

NOTE:

The rectifier assembly is not repairable and should be

replaced if diodes prove to be faulty.

The following commercially available test equipment is

essential for correctly testing the diodes within the

rectifier assembly.

A. A diode tester or multimeter with a diode test

feature where the DC output at the test probes

does not exceed 14 volts, or in the case of AC

testers, 12 volts RMS.

This is necessary so as to ensure that when testing

the diodes, the for ward and rever se voltage c hec ks

are completed and are not masked by the diode

turning on due to zener breakdown voltage.

B. A zener diode tester with a DC output in excess of

30 volts. The tester should also incorporate internal

current limiting set to five mA to prevent high

currents during testing.

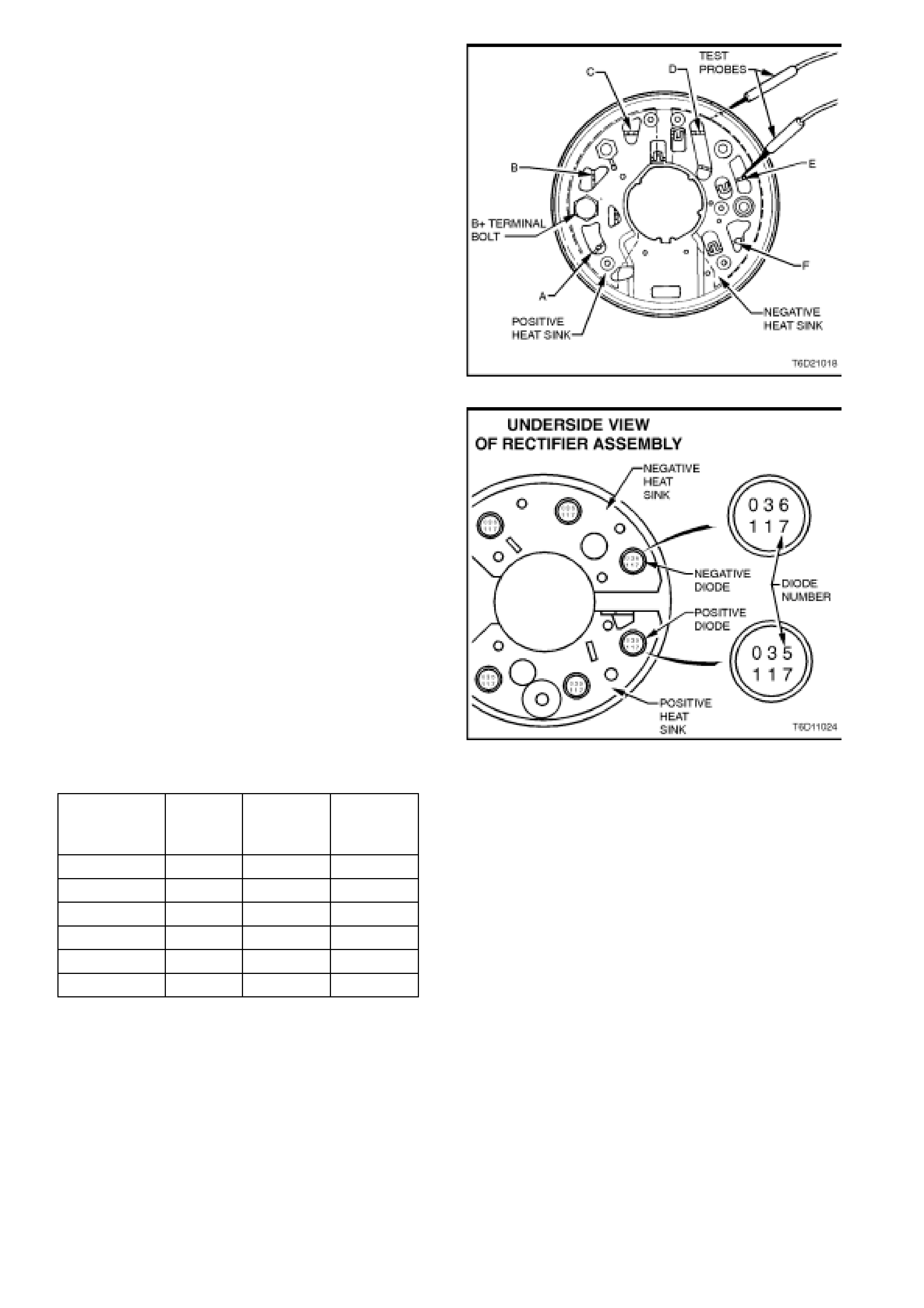

1. Attach negative test probe of diode tester or

multimeter with diode test function to the positive

heat sink of the rectifier assembly and the positive

probe alternatively to positive diode c onnections A,

B and C shown in Fig. 6D2-1-18.

A low resistance reading, or the forward voltage

drop across the diode should be obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction only

(high resistance reading or higher reverse voltage

should be obtained).

Figure 6D2-1-18

2. Repeat procedure on negative heat sink by

attaching positive test probe to the negative heat

sink and the negative probe alternatively to

negative diode connections D, E and F shown in

Fig. 6D2-1-19.

A low resistance reading, or the forward voltage

drop across the diode should be obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction only

(high resistance reading or higher reverse voltage

should be obtained).

NOTE:

In steps 1 and 2, ensure that the reverse voltage

applied is less than 14 volts DC, or 12 volts RMS when

using an AC tester.

Figure 6D2-1-19

3. Ensure that steps 1 and 2 are carried out before

the diodes zener voltage is tested. The diodes are

grouped together according to their zener voltage,

ie. all diodes within a rectifier must have the same

zener voltage.

To identif y the zener voltage of the diodes, ref er to

the numbers stamped into the base of each diode

and to the following chart.

Figure 6D2-1-20

Diode Zener

Voltage

at 5mA

Positive

Diode

Number

Negative

Diode

Number

Forward

Current

Rating

17.8 - 19.2 031 032 35A

18.8 - 20.2 033 034 35A

19.8 - 21.2 035 036 35A

20.8 - 22.2 037 038 35A

21.8 - 23.2 038 040 35A

22.8 - 24.2 041 042 35A

ROTOR

INSULATION TEST

Using an ohmmeter, or powered test lamp (up to

110V), check insulation between slip rings and

rotor core or shaft. Test light should not glow or

ohmmeter should indicate an open circuit (or

resistance of greater than 1 megohm). If an open

circuit does not exist replace rotor.

Figure 6D2-1-21

OPEN CIRCUIT TEST

Connect ohmmeter probes across slip rings and

measure resistance of rotor windings.

Rotor winding resistance values are given in the

following chart.

NOTE:

If the resistance of the rotor winding is not to

specification, replace the rotor.

ROTOR WINDING 2.3 ±

RESISTANCE @ 20°C 0.115 W

Figure 6D2-1-22

SLIP RINGS

If the slip rings are worn or out of round they must

be re-m achined to a m inimum diam eter of 26.7m m

and should have a runout not exceeding 0.45mm.

If the slipring is below these limits it must be

replaced with a new one.

WARNING:

EXTREME CARE MUST BE TAKEN WHEN

MACHINING THE SLIPRING AS IT IS POSSIBLE

FOR THE TURNING TOOL TO FOUL THE FAN.

BEARINGS

The bearings in this alternator are a special low

noise, high speed type and must only be replaced

by Bosch original equipment bearings. Bosch part

No’s 9 900 069 006 for drive end bearing, 1 900

905 275 for slip ring end bearing.

CAUTION:

Failure to use these bearings will result in

noisy operation and reduced s ervice life.

Check bearing bores in drive end and slip ring end

housings for wear. If bearing outer race is allowed

to rotate in its bore, it will cause ovality of the bore

and a lip will form in the bore.

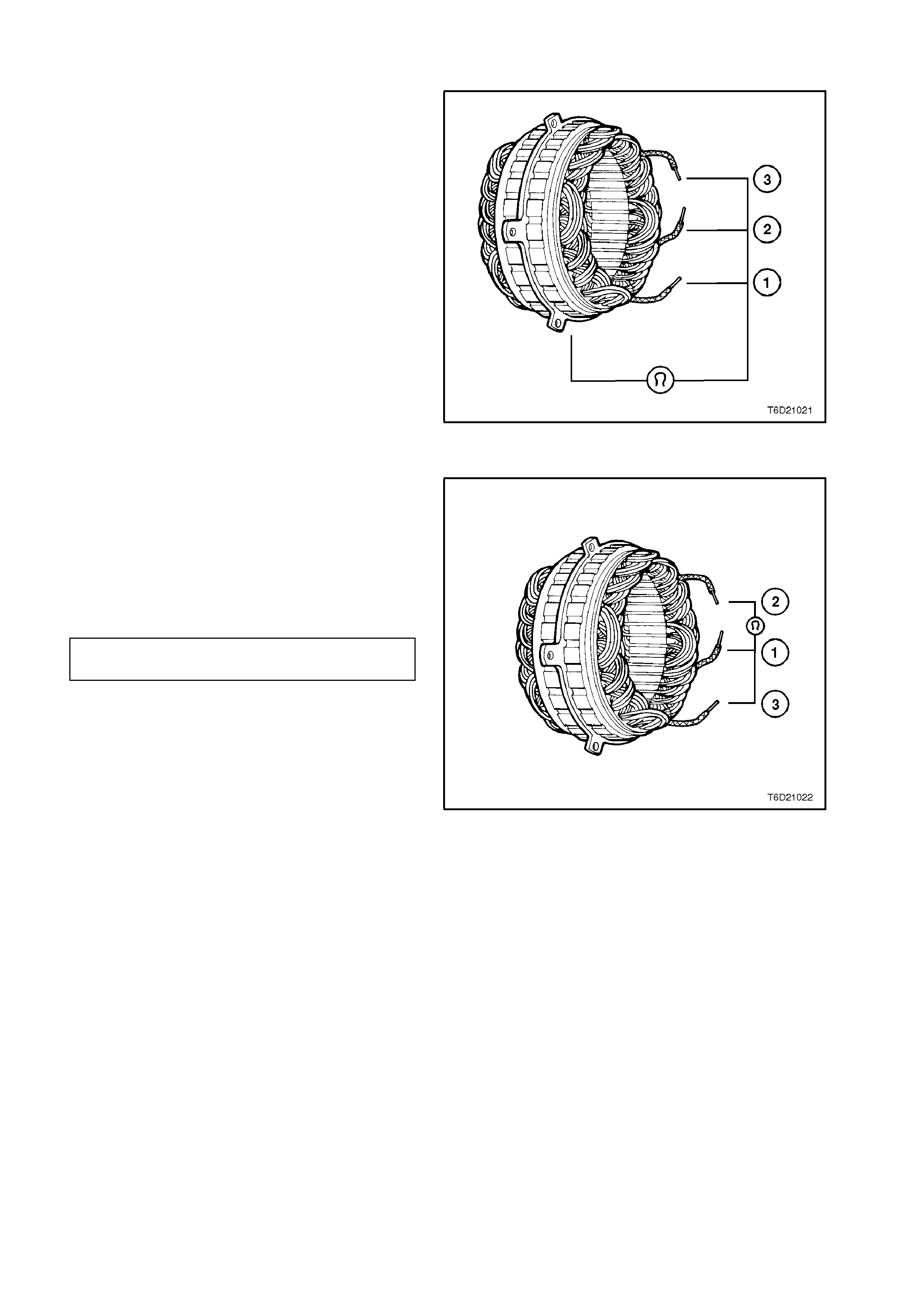

STATOR

INSULATION TEST

Connect a powered test lamp (up to 110 V) or an

ohmmeter between any stator lead and stator

frame. The insulation resistance must be greater

than 1 megohm. If test lamp glows or ohmmeter

reading is low indicating that an open circuit does

not exist, replace stator.

Figure 6D2-1-23

OPEN CIRCUIT TEST

1. Connect ohmmeter to any two stator leads.

Ohmmeter should not register any significant

resistance.

2. Repeat test on remaining stator leads. If

resistances are high, replace the stator.

The stator winding resistance is given in the

following chart.

STATOR WINDING 0.015 ±

RESISTANCE @ 20°C 0.00015 W

Figure 6D2-1-24

REASSEMBLE

Refer to Fig. 6D2-1-1 for identification of

components.

NOTE:

Special assembly tool (Bosch tool 9122 067 037)

fits both ball races at one operation which reduces

noise and provides extended lifetime.

1. Attach new Drive End Bearing into Drive End

Housing with bearing plate. Tighten retaining

screws to the correct torque specification.

DRIVE END HOUSING BEARING

PLATE RETAINING SCREW 2.1 - 3.0 Nm

TORQUE SPECIFICATION

2. Insert new Slip Ring Bearing into recess in

Bearing Assembly Fixture. (Bosch tool 9122

067 037)

3. Insert Rotor into Bearing Assembly Fixture so

that rotor shaft at Slip Ring end is seated in

Slip Ring Bearing.

4. Place Drive End Housing onto Bearing

Assembly Fixture.

5. Insert mandrel into Drive End Housing and

press bearings into position.

6. Assem ble drive pulley, washer and nut to rotor

shaft.

7. Mount an 8 mm Allen key in a vice with the

long end pointing out from the side of the vice.

Place socket used for pulley nut removal

(24mm) onto nut. Position drive end housing

with the internal hexagon of the rotor shaft

onto the Allen key.

Tighten drive pulley attaching nut. to the

correct torque specification.

DRIVE PULLEY ATTACHING NUT 54 - 68

TORQUE SPECIFICATION Nm

NOTE:

Under no circums tances is the rotor to be m ounted

in the vice as the rotor and or cooling fans will be

damaged.

Figure 6D2-1-27

Techline

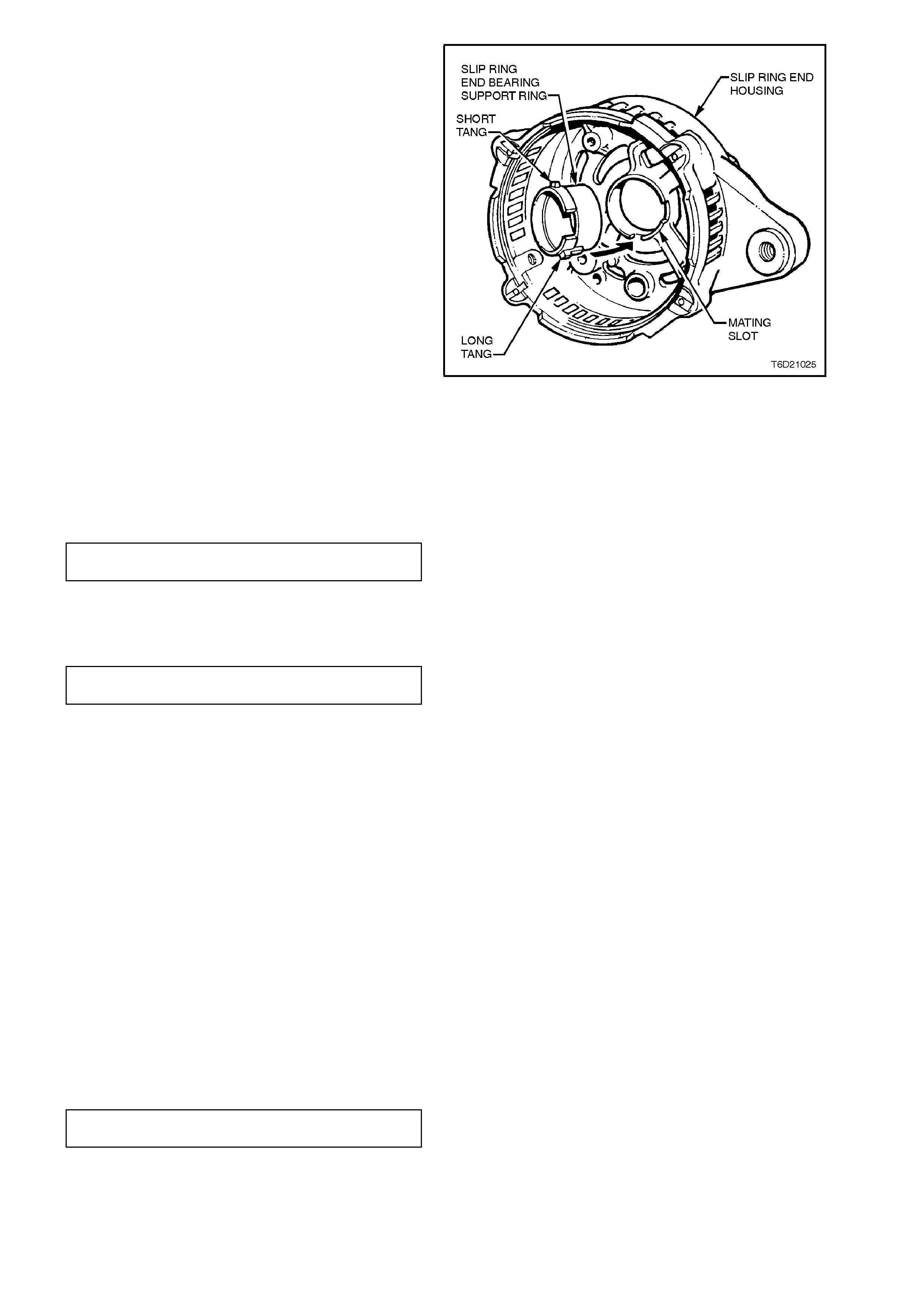

8. Inspect the slip ring end bearing support ring

for signs of damage, especially cracks. If in

any doubt replace the ring by pressing it into

the slip ring end housing by hand. DO NOT

USE EXCESSIVE FORCE.

IMPORTANT:

The slip ring end bearing support ring will only

locate correc tly into the slip ring end housing in one

location, i.e. with the long tang on its outer diam eter

locating into the mating slot in the slip ring end

housing.

9. Apply heat sink compound to both sides of

new rectifier positive heat sink mica washers.

Assemble mica washers to positive heat sink

with washer having largest hole fitted over the

B+ terminal bolt. The other mica washer is

fitted on the positive heat sink , ar ound the hole

for the retaining screw.

10. Install spacer over B+ terminal bolt and

assemble rectifier into slip ring end housing.

Assemble ins ulating washer, f lat washer , wave

washer and nut to B+ terminal, leaving nut

finger tight.

Figure 6D2-1-28

11. Install and tighten rectifier retaining screws to

the correct torque specification.

RECTIFIER RETAINING SCREW

TORQUE SPECIFICATION 2.2 - 3.2 Nm

Tighten B+ terminal nut to the correct torque

specification.

B+ TERMINAL NUT

TORQUE SPECIFICATION 7.5 - 8.5 Nm

12. To refit the stator, ensure that the mating

surfaces of the stator frame, drive end and slip

ring end housings are clean and free from

damage.

Fit the stator into the slip ring end housing,

noting the correct lead positioning. Fit the

stator leads into the wire loops in the rectifier.

Using a pair of pointed nose pliers, squeeze

the loops to retain the stator leads prior to

soldering. Solder the leads into position using

60/60 resin cored solder.

Once completed, ensure the leads will clear

the internal fan when the rotor is assembled

into the stator.

13. Assem ble rotor and dr ive end housing into the

stator and slip ring end plate assembly,

aligning marks made during disassembly.

14. Reinstall through bolts and tighten evenly, and

to the correct torque specification.

THROUGH BOLT

TORQUE SPECIFICATION 3.8 - 5.5 Nm

NOTE:

Ensure that the slip ring housing and drive end

housing are seated squarely on the stator frame.

This ensur es that the air gap between the rotor and

stator windings is equal at all points.

15. Reinstall the regulator and brush assembly to

the slip ring end housing, ensuring that the

regulator engages with the spring connectors

on the rectifier. Ensure the brushes are

located correctly onto the slip rings.

Install the regulator and brush assembly

securing screws and tighten to the correct

torque specification.

REGULATOR AND BRUSH

ASSEMBLY SECURING SCREW

TORQUE SPECIFICATION 1.6 - 3.2 Nm

16. Reconnect suppressor lead to rectifier +

terminal.

REINSTALL

1. Place generator into mounting bracket,

aligning drive end plate and mounting bracket

bolt holes. Install mounting bracket bolt and

nut, leave finger tight.

2. Install generator positive lead (red wire),

washer and nut on B+ term inal. Tighten nut to

the correct torque specification, then refit cap

over B+ terminal.

B+ TERMINAL NUT

TORQUE SPECIFICATION 7.5 - 8.5 Nm

3. Connect wiring harness at the generator

terminal block.

4. Install the generator brace and brace bolt to

generator drive end plate, leave bolt finger

tight.

5. Install drive belt onto generator drive pulley,

ensuring that drive belt is correctly fitted to

crankshaft balancer and water pump pulley

and that all drive pulleys are aligned.

6. Use generator to achieve specified

generator/water pump belt tension. For

details, refer to Section 6A2 ENGINE

MECHANICAL - V8 ENGINE. Tighten the

generator mounting bolts to the correct torque

specification.

GENERATOR TO MOUNTING

BRACKET NUT

TORQUE SPECIFICATION 20 - 45 Nm

GENERATOR TO BRACE BOLT

TORQUE SPECIFICATION 15 - 35 Nm

BRACE TO FRONT COVER BOLT

TORQUE SPECIFICATION 23 - 30 Nm

GENERATOR/WATER PUMP

DRIVE BELT

TENSION SPECIFICATION

57 kg NEW

34 kg USED

7. Reconnect battery earth cable at battery.

8. Start engine and check generator warning

lamp operation, drive belt alignment,

generator output and regulated voltage.

4. DIAGNOSIS

1. UNDERCHARGED BATTERY

a. Defective battery

b. Loose connection in charging system

c. Corroded connections in charging circuit

d. Defective wiring

e. Faulty generator

f. Faulty voltage regulator

2. OVERCHARGED BATTERY

a. Shorted battery cell

b. Faulty voltage regulator

c. Short circuit in rotor winding

d. Voltage drop in sense wire

3. FAULTY INDICATOR LIGHT OPERATION

(LIGHT DOES NOT GLOW)

a. Burnt out bulb

b. Defective bulb socket

c. Defective wiring

d. Defective rectifier

e. Defective regulator

4. FAULTY INDICATOR LIGHT OPERATION

(LIGHT REMAINS ON)

a. Negative diode failure

b. Defective voltage regulator

c. Faulty generator

d. B+ cable off or broken

e. S cable off or broken

f. Battery overcharged

g. Open circuit in rotor winding

5. NOISY GENERATOR OPERATION

a. Normal magnetic hum

b. Badly discharged battery

c. Generator mounting brackets loose or bolts loose

d. Worn or frayed drive belt

e. Worn bearings

f. Loose drive pulley attaching nut

g. Open or shorted diodes

h. Open or shorted stator winding

5. SPECIFICATIONS

Earth Polarity Negative

Nominal Voltage 12V

Nominal Output 120 Amps

Stator Phases 3

Stator Winding Connections Star

Number Of Poles 12

Resistance of Rotor Winding ohms @ 20°C 2.3 ±0.115 W

Resistance of Stator Winding ohms @ 20°C 0.015 ± 0.00015 W

Voltage Regulator Setting 14.25-14.55V

Brush Length 9.3 mm (new) 3.8 mm (min)

Generator Belt Tension 64 kg (new) 43 kg (used)

6. TORQUE WRENCH SPECIFI CATIONS

Nm

Through Bolts 3.8 - 5.5

Front Bearing Retainer Plate Screws 2.1 - 3.0

Drive Pulley Retaining Nut 54 - 68

Regulator and Brush Assembly Securing

Screws 1.6 - 3.2

'B+' Terminal Stud Nut 7.5 - 8.5

Battery Harness Terminal to 'B+' Terminal

Stud Nut 5 - 12

Rectifier Plate Retaining Screw 2.2 - 3.2

Capacitor Fixing Screw 2.7 - 3.8

Generator to Mounting Bracket Nut 20 - 45

Brace to Generator Bolt 15 - 35

Brace to Front Cover Bolt 23 - 30

Generator Mounting Bracket to Cylinder

Head Bolts 46 - 60

Idler Pulley Clamp Nut 35 - 65

7. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

9981 066 601 ROTOR BEARING REMOVAL TOOL

9122 067 037 BEARING ASSEMBLY FIXTURE

BT3373-F BELT TENSION GAUGE