SECTION 7B1 - MANUAL TRANSMISSION -

V6 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas. In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the LPG serv ice lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & A BS/ETC.

1. GENERAL INFORMATION

With the introduction of VT Series vehicles, the manual transmission fitted with the V6 engine, is the five speed,

Getrag, Type 260 (production option M35).

This manual transmission is standard equipment on V6 powered Executive models and is optional on Berlina.

The ‘260’ manual transmission is a fully synchronised unit, including reverse gear, with baulk ring type

synchronisers. The transmission primarily consists of a two piece transmission case, with the clutch housing

integrated with the front case section. During disassembly, the gear train and shift mechanism remain in the

transmission case rear section.

1.1 GENERAL DESCRIPTION

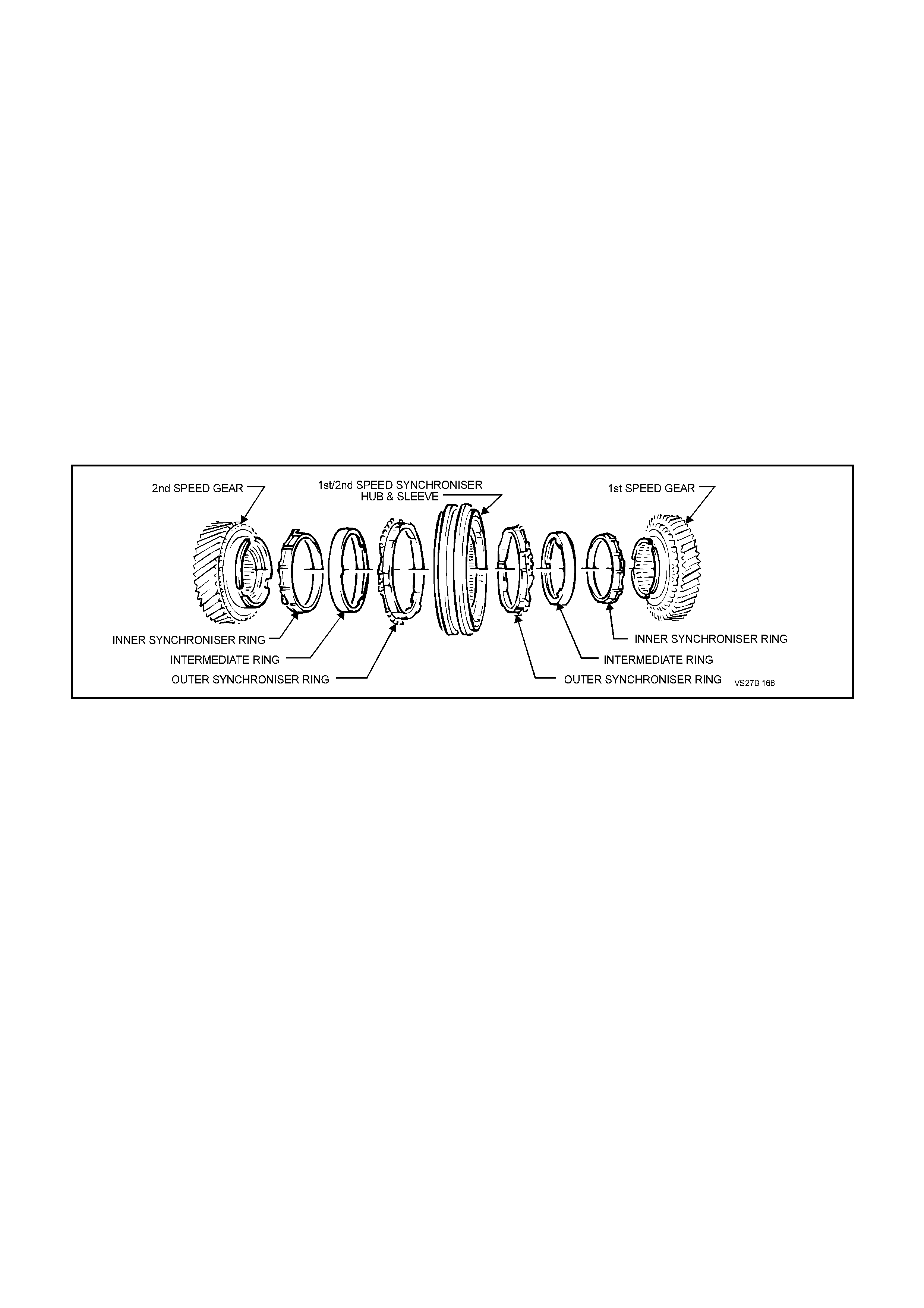

SYNCHRONISER ASSEMBLIES

Each of the three synchroniser hubs are an interference fit, splined to the mainshaft and fixed by selective snap

rings to accommodate manufacturing tolerances. Sintered, double cone blocking rings are fitted to 1st and 2nd

gears, while those for 3rd, 4th, 5th and reverse gears are brass, with a molybdenum coating on their inner surface.

The purpose of the synchroniser assemblies is to permit clutching to the required gear, that is in constant mesh with

the cluster gear.

Synchroniser Action

During synchroniser operation, the synchroniser sleeve is moved into engagement by the appropriate fork, carrying

with it three sy nchroniser inserts and spring loaded balls, located in slots in the synchroniser hub.

The synchroniser sleeve, together with the inserts, is moved along the hub, placing a load on the three lugs of the

blocking ring.

This initial force is sufficient to seat the blocking ring and start pre-synchronisation because of the friction between

the cone on the constant mesh gear and the blocking ring/s.

At this stage, gear engagement is prevented as long as there is a difference in speed between the mating surfaces

of the blocking ring and cone of the constant mesh gear. As the speeds between the blocking ring and the gear

cone become synchronised, the teeth on the blocking ring and gear cone line up with the internal splines of the

sleeve, allowing the sleeve to engage the teeth on the mainshaft gear, completing gear selection.

Figure 7B1-1 shows an exploded view of the three piece synchromesh unit, used for 1st and 2nd gears.

Figure 7B1-1

REVERSE GEAR

The reverse idler gear is in constant mesh with the cluster gear and the reverse gear that is mounted on the

mainshaft. When reverse gear is engaged, the 5th/reverse synchromesh sleeve engages the reverse constant

mesh gear, completing the selection.

BEARING SUPPORT

The maindrive gear runs on a single row ball race in the front of the transmission case and supports the front end of

the mainshaft via a caged needle roller bearing. The mainshaft runs on a single row ball race, mounted in the rear

transmission case .

The maindrive gear and mainshaft bearings are located in their respective housings by an interference fit and the

use of snap rings or a bolted plate. Shims are used to accommodate manufacturing tolerances in each bearing

bore.

The cluster gear runs on two parallel roller bearings, one at each end, with end float being controlled by a shim

located between the cluster gear front bearing cup and the front circlip.

Each of the mainshaft constant mesh gears run on caged needle roller bearings, while the reverse idler gear is

supported by two caged needle roller bearings running on the idler gear shaft.

LUBRICATION

Lubrication of all internal components is by splash feed, provided by the rotating cluster gear assembly.

SELECTOR MECHANISM

The floor mounted, gearshift control lever operates a single rail mechanism which extends into the rear

transmission case. The first/second, third/fourth and fifth/reverse shift forks are all supported at each end, in the two

transmission case s.

A shift interlock system, prevents engagement of more than one gear at a time. The system consists of an interlock

pin located in the third/fourth selector shaft and two interlock balls, that locate in a neutral position groove in each of

the remaining two rails. These components, together with the shift detent balls and springs are all located in the end

of rear transmission housing.

When either the first/second or fifth/reverse selector shaft is moved to engage a gear, one of the interlock balls is

moved across, displacing the interlock pin, effectively locking the remaining two shafts. Moving the third/fourth

selector shaft, moves each of the two balls firmly into their respective shafts, allowing a third/fourth shift to take

place, with the interlock pin being carried with the shaft.

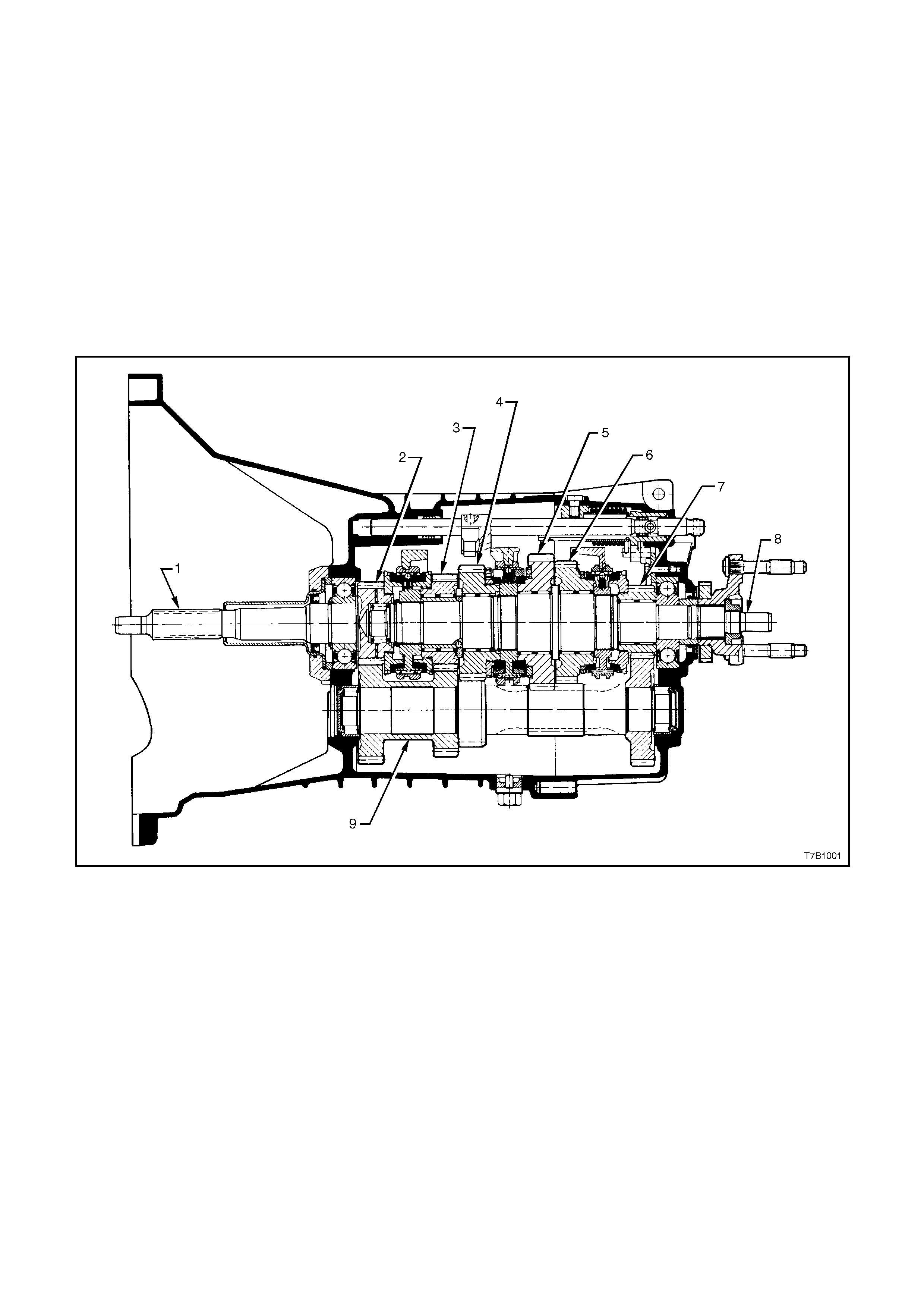

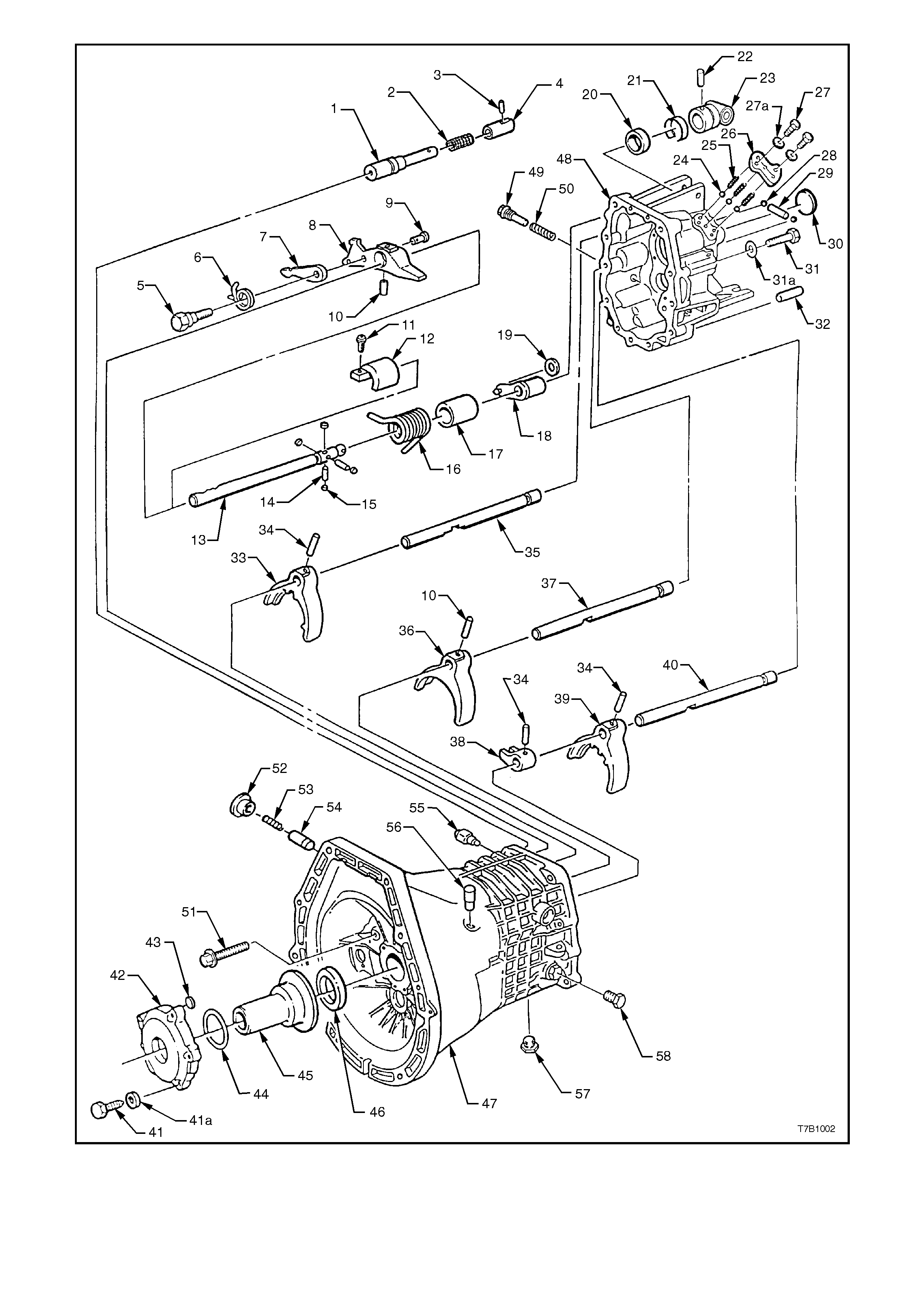

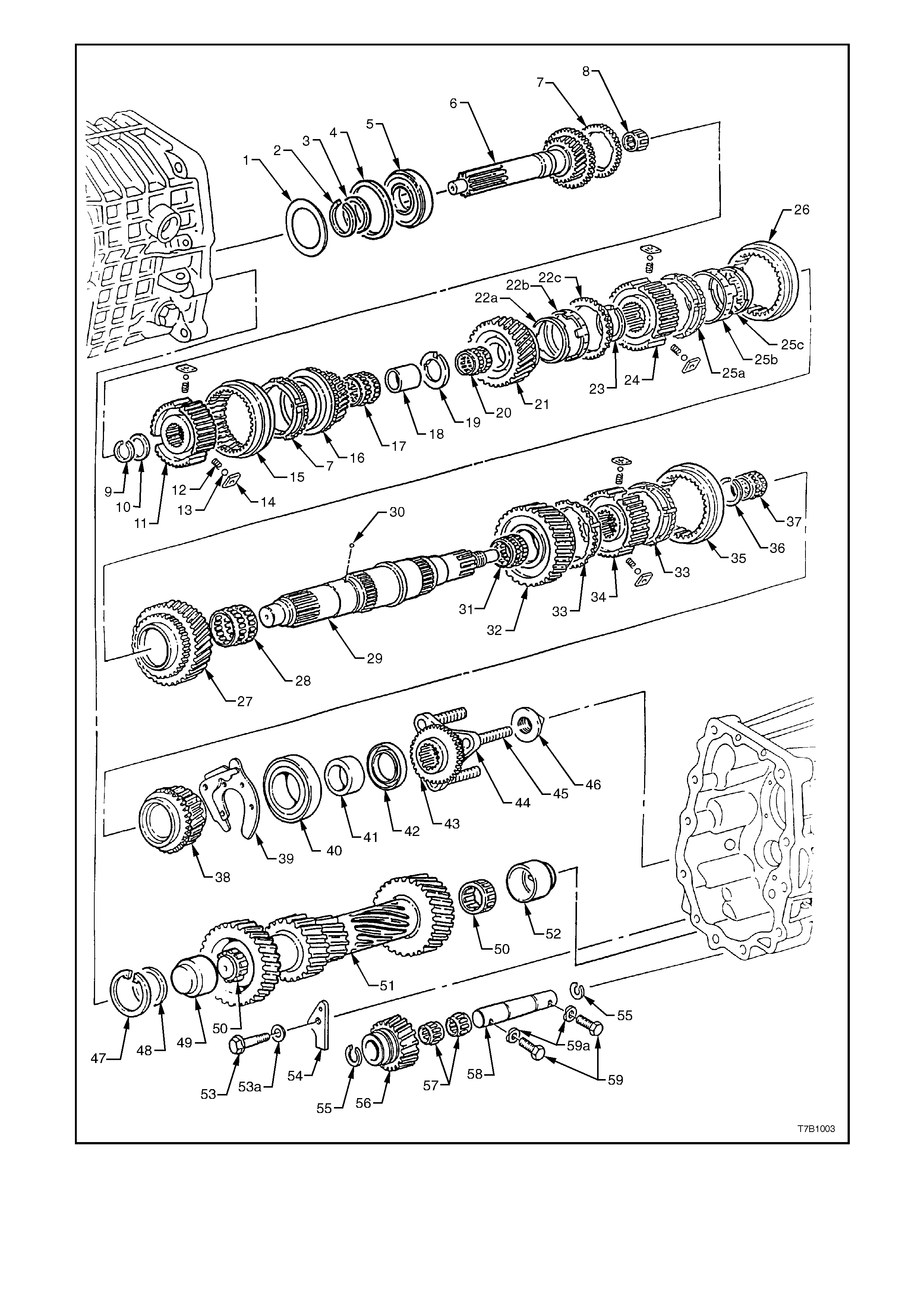

See Figure 7B1-2 for a sectioned view of the type ‘260’ transmission (production option M35). Figure 7B1-3 shows

an exploded view of the two case halves and selector components, while figure 7B1-4 shows an exploded view of

the gear train components.

1. Input Shaft

2. Maindrive Gear

3. Third Speed Gear

4. Second Speed Gear

5. First Speed Gear

6. Reverse Gear

7. Fifth Speed Gear

8. Mainshaft

9. Cluster Gear

Figure 7B1-2 - Type ‘260’ Transmission, Sectioned View

Figure 7B1-3 - Transmission Shift Mechanism and Case Components

REF No. PART NAME REF No. PART NAME

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24

25.

26.

27.

27a.

28.

29.

Reverse blocker pin

Helical compression spring

Reverse blocker bushing,

retainer pin

Reverse blocker bushing

Cap bolt

Cylindrical torsion spring

Reverse lock plate

Shift finger

Pin

Roll pin

Allen key head cap screw

Shift shaft support

Selector rod shift shaft

Dowel pin

Roller

Cylindrical torsion spring

Bushing

Select lever

Roller

Oil seal - shift shaft

Spring retaining clip

Selector rod trunnion pin

Selector rod trunnion

Detent ball - 3 places

Helical compression spring -

3 places

Cover plate

Bolt

Wave washer

Interlock ball - 2 places

Interlock pin

30.

31.

31a.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

41a.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

Welsh plug

Bolt

Wave washer

Dowel pin

Shift fork, 5th/Reverse

Roll pin

Selector shaft, 5th/Reverse

Shift fork, 3rd/4th

Selector shaft, 3rd/4th

Shift yoke, 1st/2nd

Shift fork, 1st/2nd

Selector shaft, 1st/2nd

Bolt

Wave washer

Front housing cover

Disc

O-ring

Clutch throwout bearing guide

Oil seal

Front transmission housing

Rear transmission housing

Plug

Spring

Reverse blocker pin bolt

Plug

Spring

Detent plunger assembly

Back-up lamp switch

Breather plug

Drain plug with magnet

Filler plug

Figure 7B1-4 - Transmission Gear Components

REF No. PART NAME REF No. PART NAME

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21

22a

22b

22c.

23.

24.

25a.

25b.

25c.

26.

27.

28.

29.

30.

31.

Selective spacer washer

Snap ring

Selective spacer washer

Front bearing spacer ring

Front bearing

Input shaft and maindrive gear

Synchromesh ring

Caged, spigot needle roller

bearing

Snap ring

Selective spacer washer

Synchromesh hub

Spring

Ball

Sliding key

Synchromesh outer sleeve

3rd speed gear

Caged, needle roller bearing

Needle roller inner sleeve

Thrust washer

2nd gear, needle roller bearing

2nd speed gear

Cone ring

Friction ring

Synchromesh ring

Snap ring

1st/2nd speed synchromesh

hub

Synchromesh ring

Friction ring

Cone ring

Synchromesh outer sleeve

1st speed gear

1st speed, needle roller bearing

Mainshaft

Locating ball

Reverse gear, needle roller

bearing

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

53a.

54.

55.

56.

57.

58.

59.

59a.

Reverse gear

Synchromesh ring

5th/Reverse speed synchromesh

hub

Synchromesh outer sleeve

Selective snap ring

5th speed, needle roller bearing

5th speed gear

Rear mainshaft bearing retainer

plate

Rear mainshaft bearing

Spacer

Oil seal

Speed sensor toothed ring

Output flange

Knurled stud

Flanged retaining nut

Circlip

Support washer

Front cluster gear needle roller

bearing cup

Cluster gear needle roller bearing

Cluster gear

Rear cluster gear needle roller

bearing cup

Bolt

Wave washer

Thrust plate

Snap ring

Reverse idler gear

Caged needle roller bearings

Reverse idler gear shaft

Bolt

Wave washer

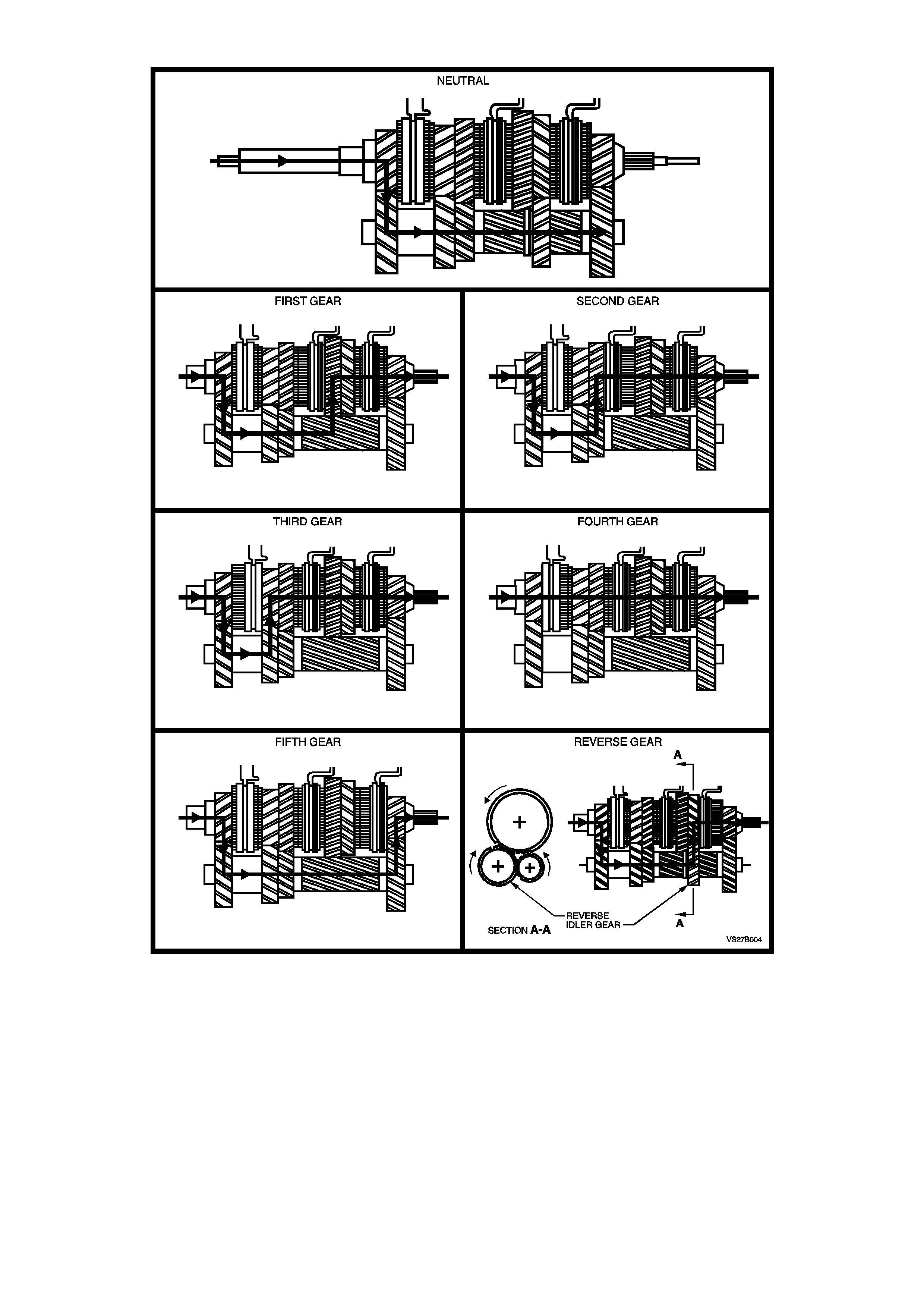

1.2 POWER FLOWS

The maindrive gear, fifth, third, second, first speed and reverse gears are in constant mesh with the cluster gear.

Therefore, when the engine is running with the clutch engaged, torque is imparted to the maindrive gear and

through the cluster gear to the fifth, third, second, first speed and reverse gears at all times.

Refer to Figure 7B1-6 for illustrations relating to the following descriptions:

NEUTRAL

In neutral, with the clutch engaged, the maindrive gear turns the cluster gear. The cluster gear turns the constant

mesh gears because no synchroniser assemblies are engaged. As all constant mesh gears are supported on roller

bearings, they will also rotate with the cluster gear.

FIRST GEAR

In first gear, the first/second speed synchroniser sleeve is moved rearward to engage the first speed gear, which is

being turned by the cluster gear. Because the first/second speed synchroniser hub is splined to the mainshaft,

torque is imparted to the mainshaft from the first speed gear through the sy nchroniser sleeve and hub.

SECOND GEAR

In second gear, the first/second speed synchroniser sleeve is moved forward to engage the second speed gear,

which is being turned by the cluster gear. Because the first/second speed synchroniser hub is splined to the

mainshaft, torque is imparted to the mainshaft from the second speed gear through the synchroniser sleeve and

hub.

THIRD GEAR

In third gear, the first/second speed synchroniser sleeve assumes a neutral position. The third/fourth speed

synchroniser sleeve is moved rearward to engage the third speed gear, which is being turned by the cluster gear.

The engagement of the sleeve with the third speed gear, imparts torque to the mainshaft because the third/fourth

speed synchroniser hub is splined to the mainshaft.

FOURTH GEAR

In fourth gear, the third/fourth speed synchroniser sleeve is moved forward to engage the maindrive gear. This

engagement of the maindrive gear with the third/fourth synchroniser sleeve and hub assembly, imparts torque

directly to the mainshaft. While the cluster gear is still rotating, it does not impart torque to any component but

continues to lubricate the internal transmission components by the ‘splash’ method.

FIFTH GEAR

In fifth or overdrive gear, the first/second and third/fourth speed synchroniser sleeves assume neutral positions. The

fifth speed/reverse synchroniser sleeve is moved rearward to engage the fifth speed constant mesh gear, supported

on the mainshaft by a caged needle roller bearing. This engagement of the sleeve with the fifth speed constant

mesh gear, imparts torque from the cluster gear to the mainshaft, via the splined synchromesh hub.

REVERSE GEAR

In reverse gear, the fifth speed/reverse synchroniser sleeve is moved forward to engage the mainshaft reverse gear

and the cluster reverse gear, via the reverse idler gear. This imparts torque from the cluster reverse gear through

the idler gear (reversing direction of rotation) to the mainshaft reverse gear. Because the fifth speed/reverse

synchromesh hub is splined to the mainshaft, this causes the mainshaft to rotate in the opposite direction to the

maindrive gear.

MANUAL TRANSMISSION POWER FLOWS

Figure 7B1-6

1.3 TRANSMISSION SERIAL NUMBER

The transmission serial number is located on a self-adhes ive decal attached to the lef t s ide of the trans miss ion f r ont

housing.

This number pr ovides coded infor mation which c ould be significant to parts interpretation and should be ref erred to

when ordering replacement parts.

Figure 7B1-5

2. SERVICI NG I NFORMATION

2.1 RECOMMENDED LUBRICANT

The recommended lubricant for the ‘260’ manual transmission is an 80W gear oil to Holden’s Specification HN1855,

such as Castrol VMX80W or equivalent.

The transmission lubricant capacity is approximately 1.2 litres.

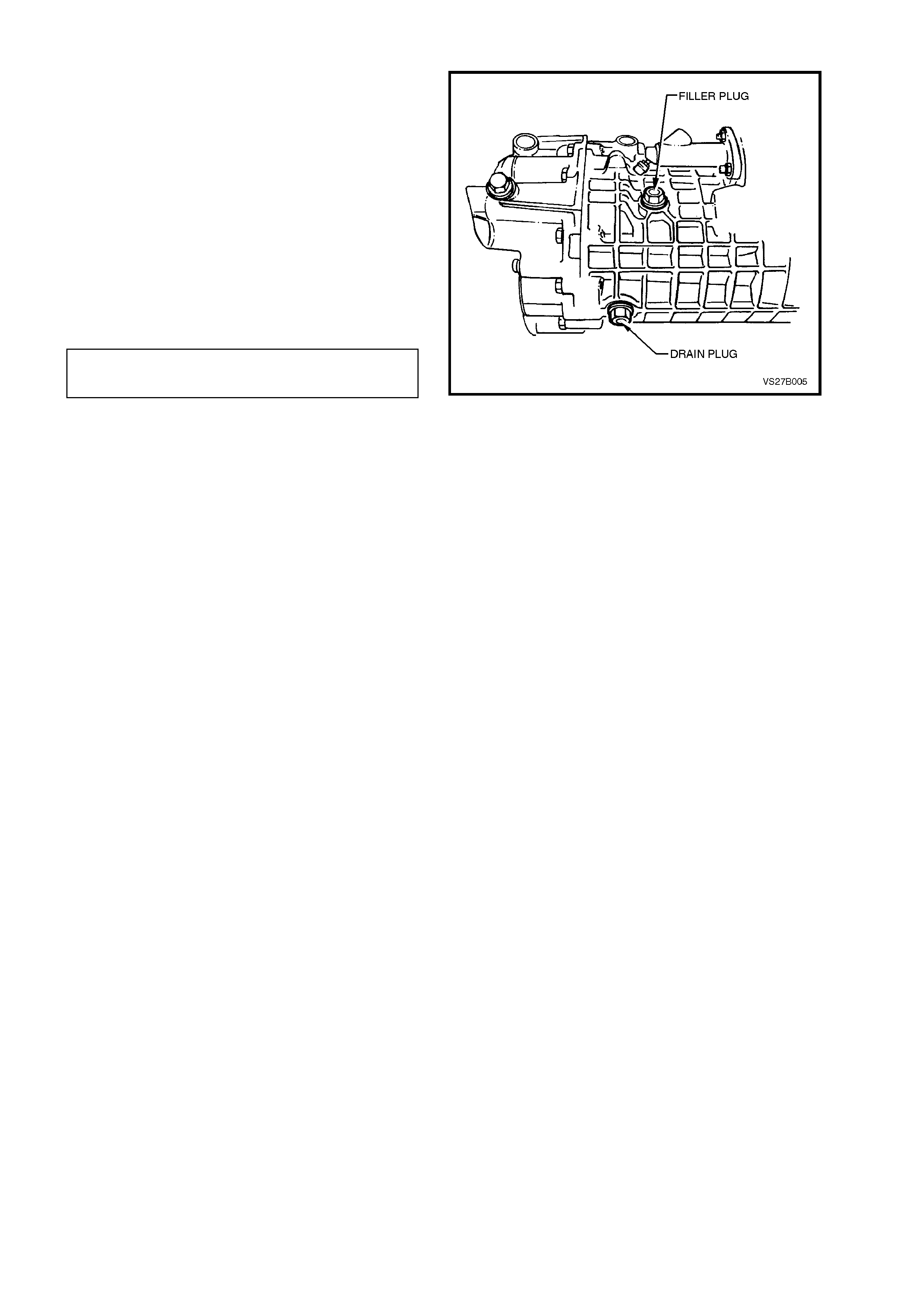

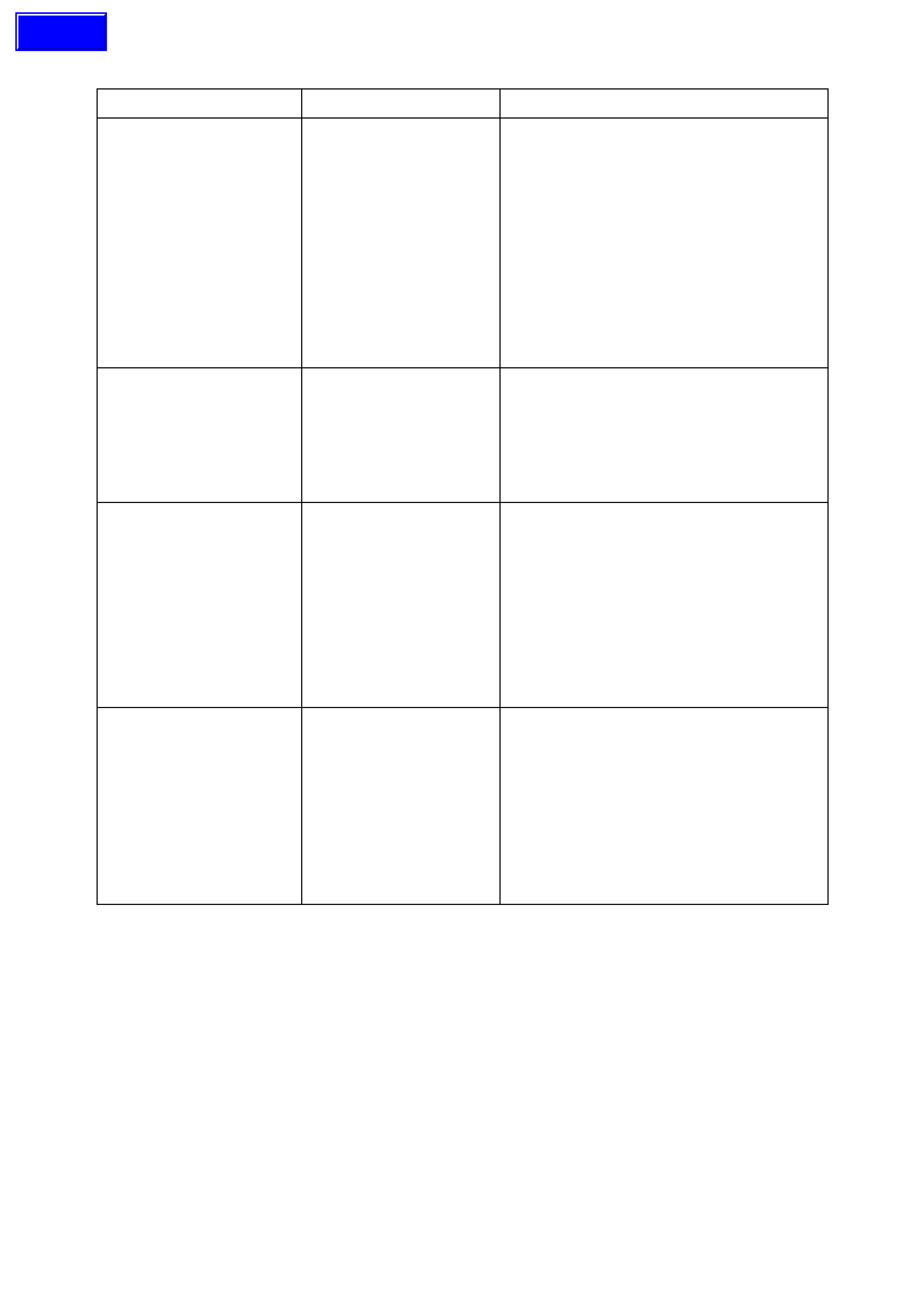

2.2 CHECKING TRANSMISSION LUBRICANT LEVEL

To check transmission lubricant level, remove

transmission filler plug, using a 17 mm ring

spanner, from right hand side of transmission case.

The level is correct when lubricant is level with the

filler plug threads.

NOTE:

Ensure that the vehicle is on level ground and

transmission is cold.

If necessary, add lubricant to bring to the correct

level.

Reinstall filler plug and tighten to the correc t torque

specif ic ation. Do not apply thread sealant or tape to

the plug threads.

TRANSMISSION FILLER PLUG 40 - 60

TORQUE SPECIFICATION Nm

Lubricant level is to be checked at the time or

distance intervals detailed in the VT Ser ies Owner's

Handbook.

Figure 7B1-7

2.3 DRAINING AND REFILLING TRANSMISSION

While the initial fill of transmission lubricant is

specif ied as a ‘fill for lif e’, s hould a lubr icant c hange

be required, then the following procedure should be

adopted.

1. To drain transmission, jack up vehicle front

and rear and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION for the location of jacking

points.

2. Place a drain tray beneath transmission and

remove filler plug and then drain plug using a

17 mm ring spanner.

3. When transmission has fully drained, insert

drain plug and tighten to the correct torque

specification. Do not apply thread sealant or

tape to the plug threads.

TRANSMISSION DRAIN PLUG 40 - 60

TORQUE SPECIFICATION Nm

4. Refill transmission to correct level, refer

2.2 CHECKING TRANSMISSION

LUBRICANT LEVEL in this Section.

3. MI NOR SERVICE OPERATIONS

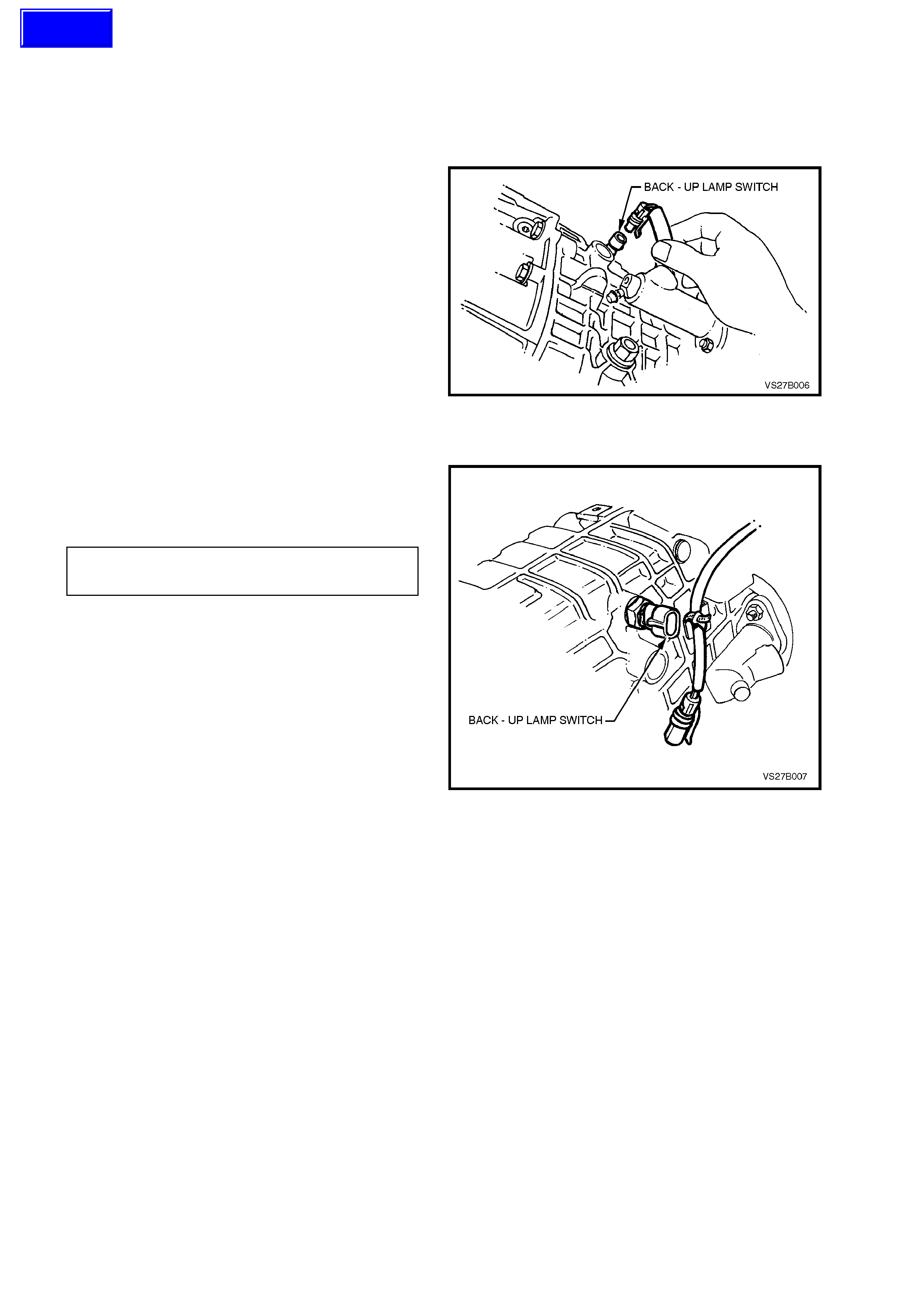

3.1 BACK-UP LAMP SW ITCH

REMOVE

1. Raise front of vehicle and support on safety

stands.

Refer to Section 0A GENERAL

INFORMATION for the location of jacking

points.

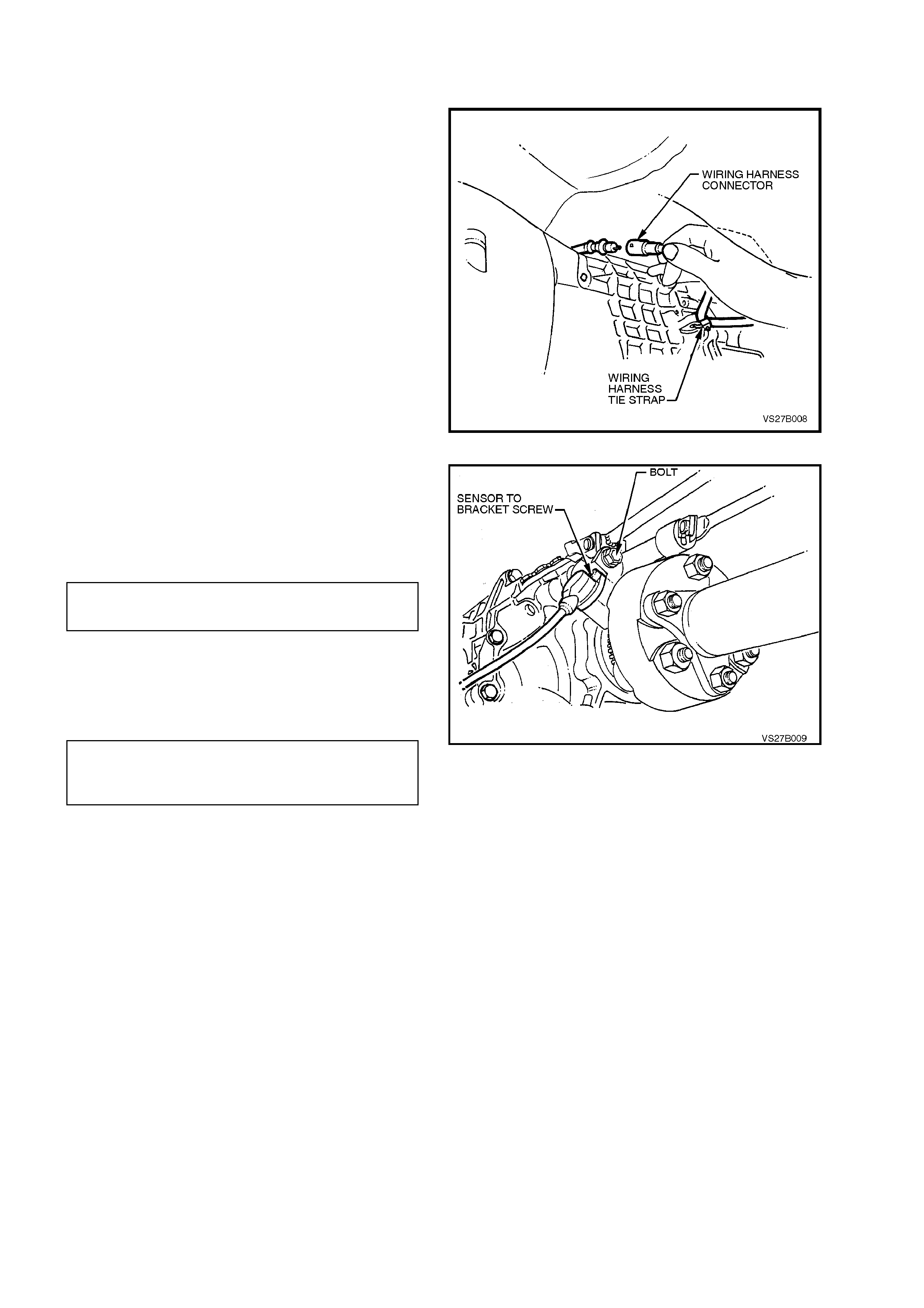

2. Remove wiring harness connector from

switch, located on the right hand side of the

transmission case.

3. Loosen, then remove switch from the

transmission case.

Figure 7B1-8

REINSTALL

1. Ensure that the switch threads are clean.

2. Install switch to transmission case and tighten

to the correct torque specification.

BACK-UP LAMP SWITCH 20

TORQUE SPECIFICATION Nm

3. Install wiring harness connector to switch.

4. Remove safety stands and lower vehicle to

ground.

5. Check back-up lamp operation.

Figure 7B1-9

Techline

3.2 SPEED SENSOR AND/OR BRACKET

REPLACE

1. Jack up vehicle front and rear and support on

safety stands. Refer to

Section 0A GENERAL INFORMATION for

the location of jacking points.

2. Disconnect speed sensor wiring harness

connector.

3. Cut the speed sensor wiring harness strap

from the lug on the transmission case.

4. Remove speed sensor mounting bracket bolt

from the rear of the transmission housing.

5. Remove the bracket and sensor assembly

from the rear transmission housing.

6. Remove the sensor to bracket mounting

screw, then disconnect the sensor by a

twisting and pulling motion to free the O-ring

seal from the bracket.

Figure 7B1-10

7. Installation is the reverse of removal except for

the following points;

a. Tighten the speed sensor to mounting

bracket retaining screw to the correct

torque specification.

SPEED SENSOR TO BRACKET 6 - 14

SCREW TORQUE SPECIFICATION Nm

b. Tighten the sensor bracket to

transm iss ion housing m ounting bolt to the

correct torque specification.

SPEED SENSOR BRACKET TO

TRANSMISSION HOUSING BOLT 15 - 20 Nm

TORQUE SPECIFICATION

c. Connect the speed sensor lead to the

wiring harness connector, ensuring that

the connection is positive and secure.

d. Secure the speed sensor wiring harness

to the lug on the transmission using a

new tie strap.

Figure 7B1-11

3.3 GEARSHIFT LEVER KNOB AND BOOT ASSEMBLY

NOTE:

The gearshift lever knob and console boot are

manufactured as a single component. Do not

attempt to remove the gearshift lever knob

separately to the boot.

REMOVE

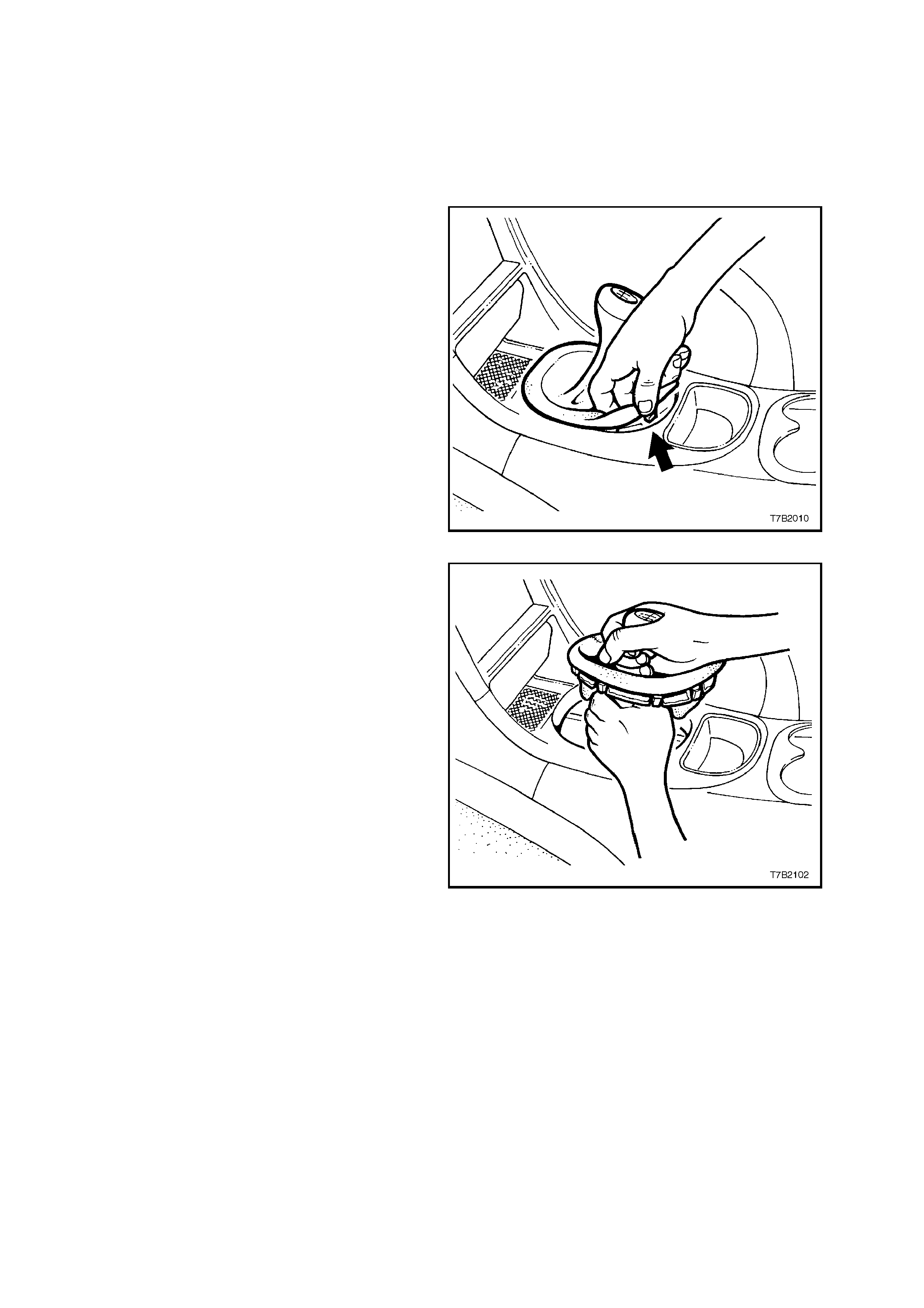

1. With the fingers of one hand hooked under the

edge of the gearshift lever boot as shown,

caref ully release each of the 8 plas tic retainer s

and free the gearshift lever boot from the

console cap.

Figure 7B1-12

2. Lift the gears hif t lever boot enough to enable a

firm grasp to be made on the gearshift lever

with the left hand, then grasp the gearshift

knob with the right.

3. W hile rocking the knob sideways, and with an

upward force applied, dislodge the knob

retaining claws from the lever.

4. Remove the gearshift lever knob and boot

assembly, from the gearshift lever.

Figure 7B12-13

REINSTALL

1. Reinstall the knob and boot as sem bly over the

gearshift lever, align the knob in the correct

attitude and then bump the knob onto the

gearshif t lever until the retaining claws engage

with the groove in the lever.

2. Align the boot retaining clips with the hole in

the console cap, then carefully seat the boot

retainers into the console cap until each clip

engages correctly.

3.4 GEARSHIFT LEVER

REMOVE

1. Remove the gearshift lever knob and boot

assembly, from the gearshift lever. Refer

3.3 GEARSHIFT LEVER KNOB AND BOOT

ASSEMBLY, for the necessary procedure.

2. Raise vehicle front and rear and support

on safety stands. Refer to

Section 0A GENERAL INFORMATION for

the location of jacking points.

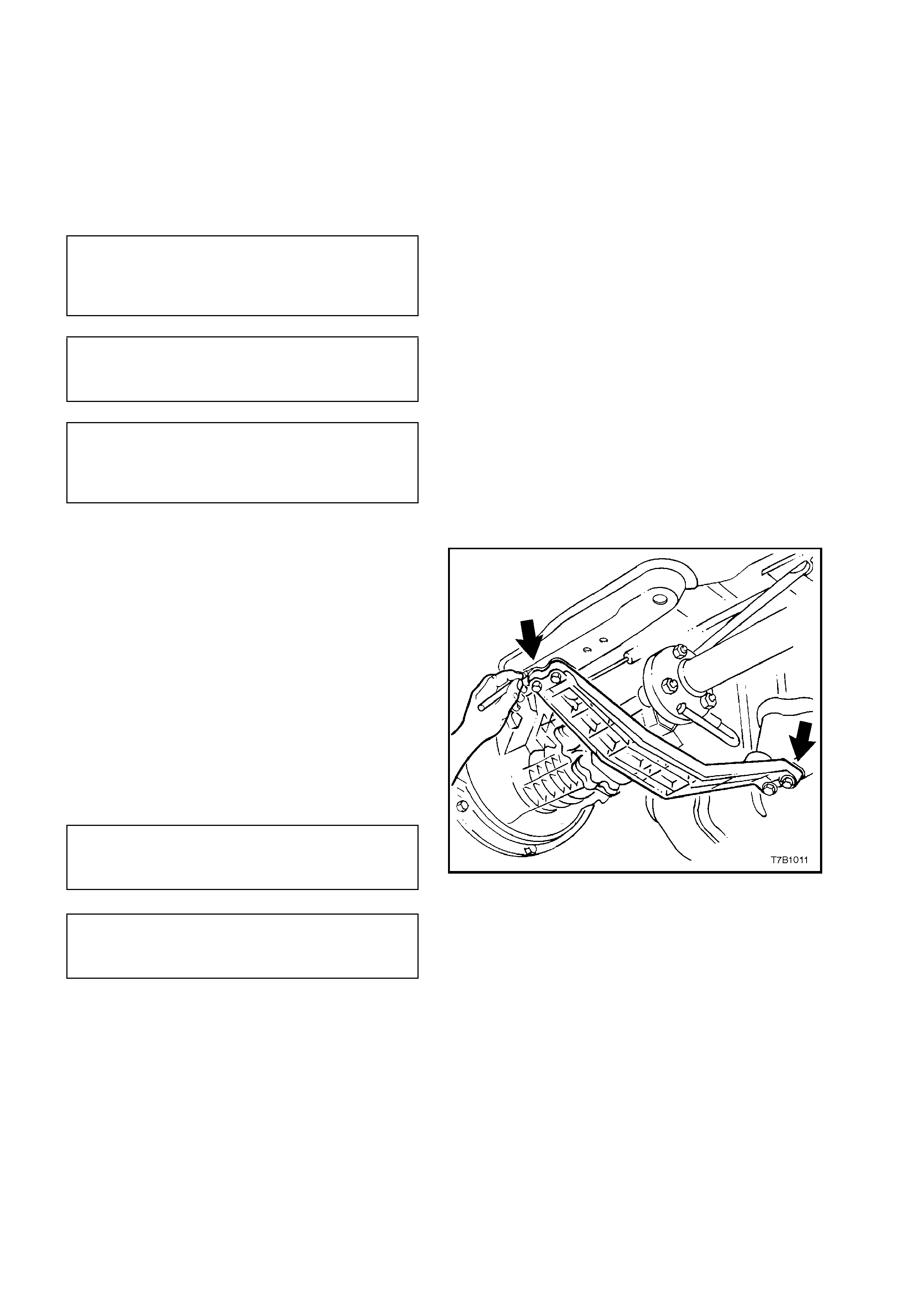

3. Scribe around each of the rear engine

mounting c r oss member mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

IMPORTANT:

This step is critical to the correct powertrain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems will

result!

NOTE:

For clarity, the exhaust system is shown as being

removed.

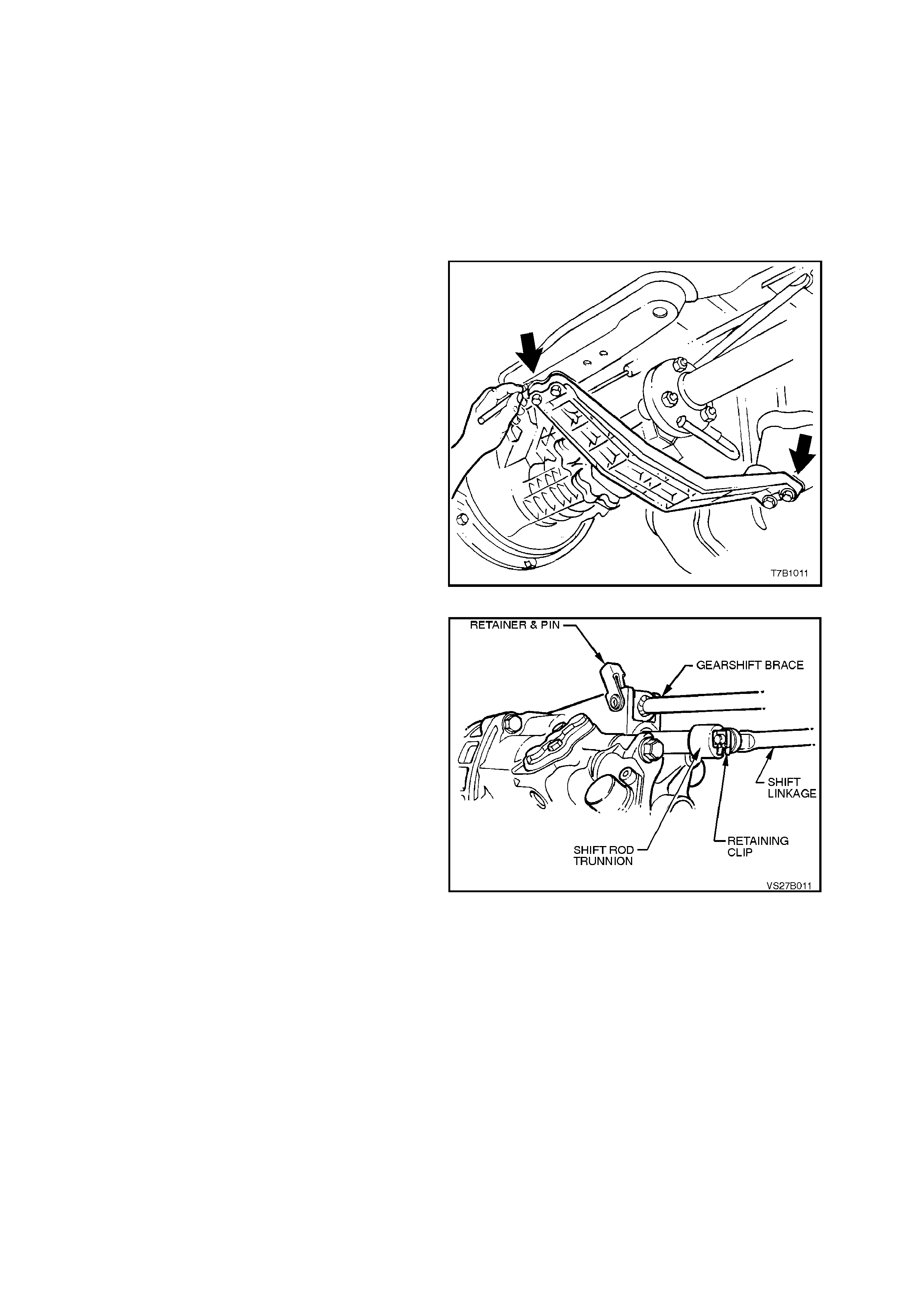

4. Support the rear of the transmission with a

floor jack, then remove the four rear engine

mounting crossmember bolts.

Figure 7B1-14

5. Lower the rear of the transmission, sufficient

to gain access to the front end of the shift

linkage brace.

6. From under vehicle, prise the shift linkage

brace retainer loose, at the transmission end,

using a screwdriver or suitable lever.

7. Remove the retainer and pin from the

transmission case lugs.

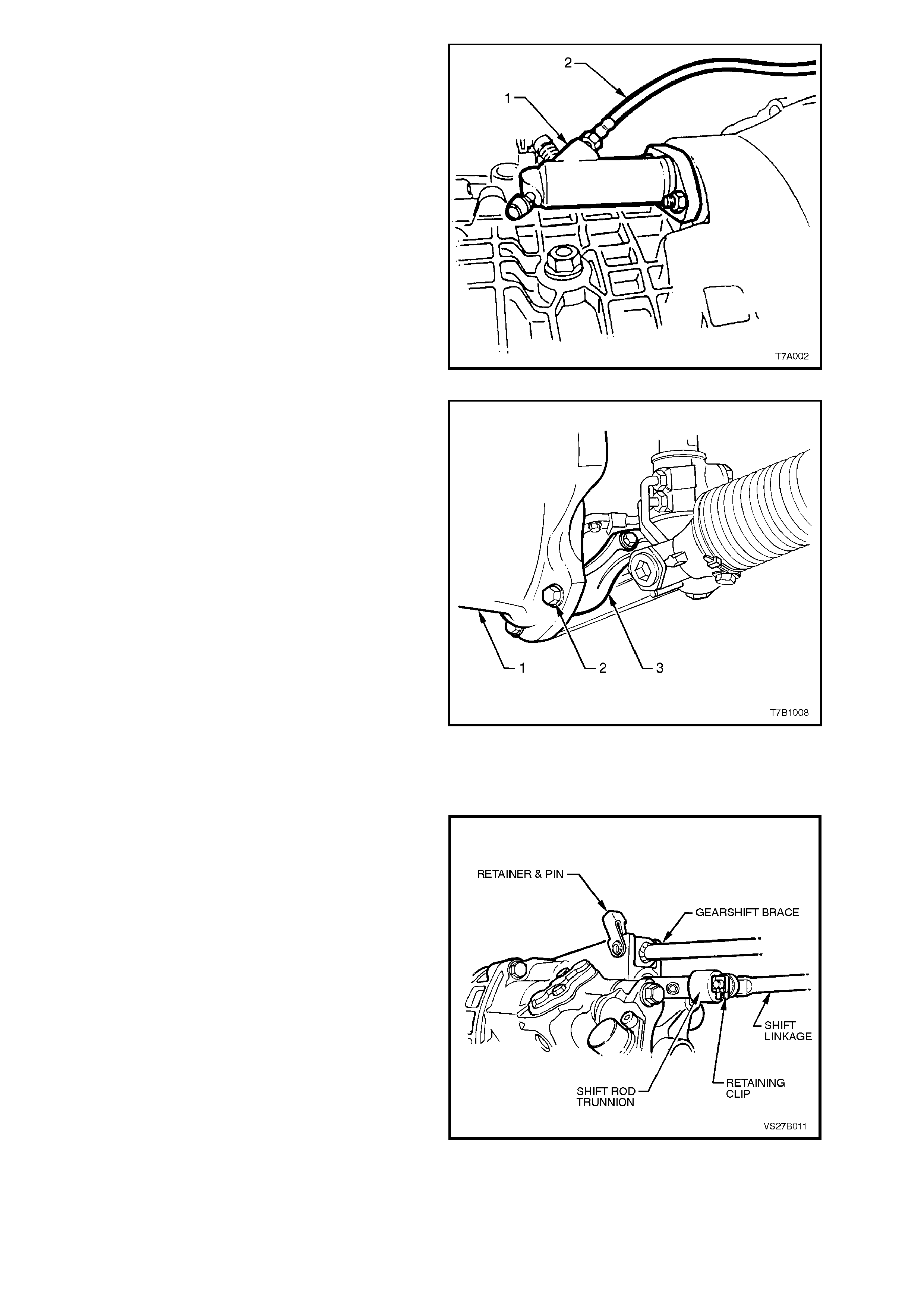

Figure 7B1-15

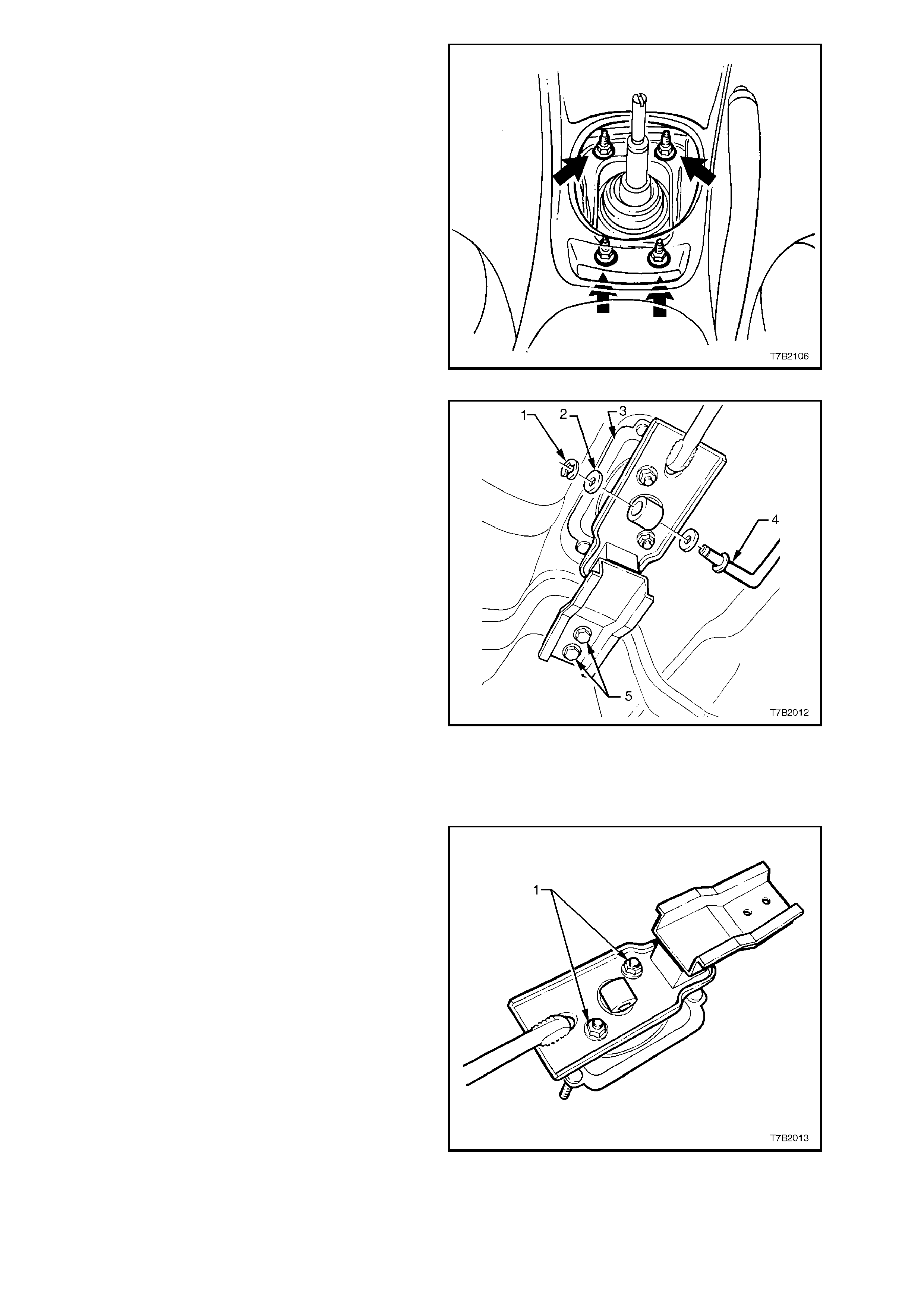

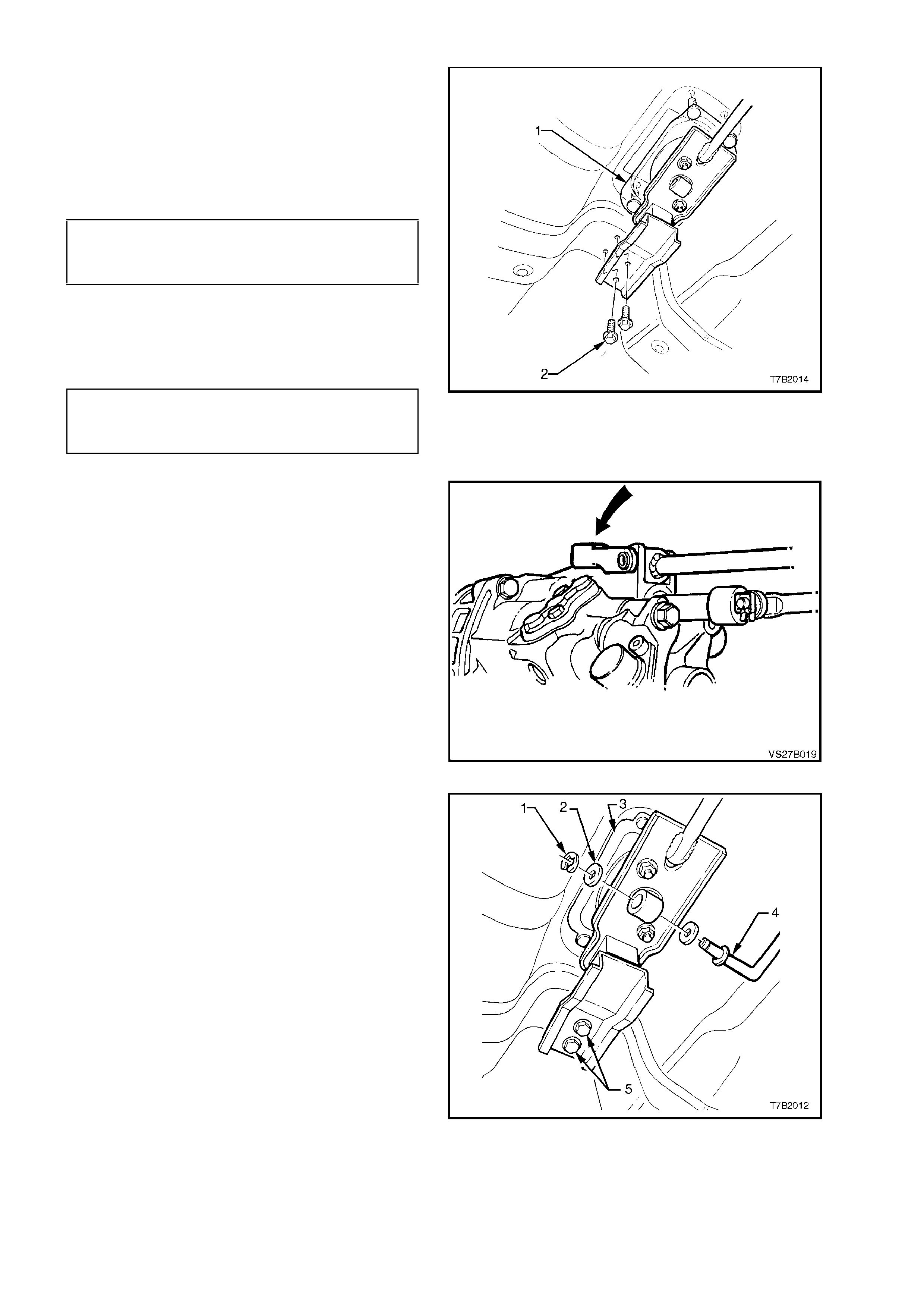

8. Remove the four gearshift lever bracket,

mounting nuts (arrows) from inside the

vehicle.

Figure 7B1-16

9. Remove the retaining C-clip (1) and washer

(2) from the transmission shift rod coupling

(4), at the gearshift lever end.

10. Remove two gearshift lever support mounting

bolts (5) from underfloor bracket.

11. Remove gearshift lever bracket (3), with

rubber boot and the complete br ace as s embly,

from below the vehicle.

NOTE 1:

If the shift rod is disconnected from the

transmission end and removed from the vehicle

with the brace assem bly, take particular note of the

rod’s orientation f or correc t installation. Do not lose

the washer fitted at the inner end of the shift rod

coupling (4).

NOTE 2:

W hile the illustration shows the propeller shaft and

exhaust removed for clarity, removal of the brace

assembly from the vehicle, is possible without first

removing these items.

Figure 7B1-17

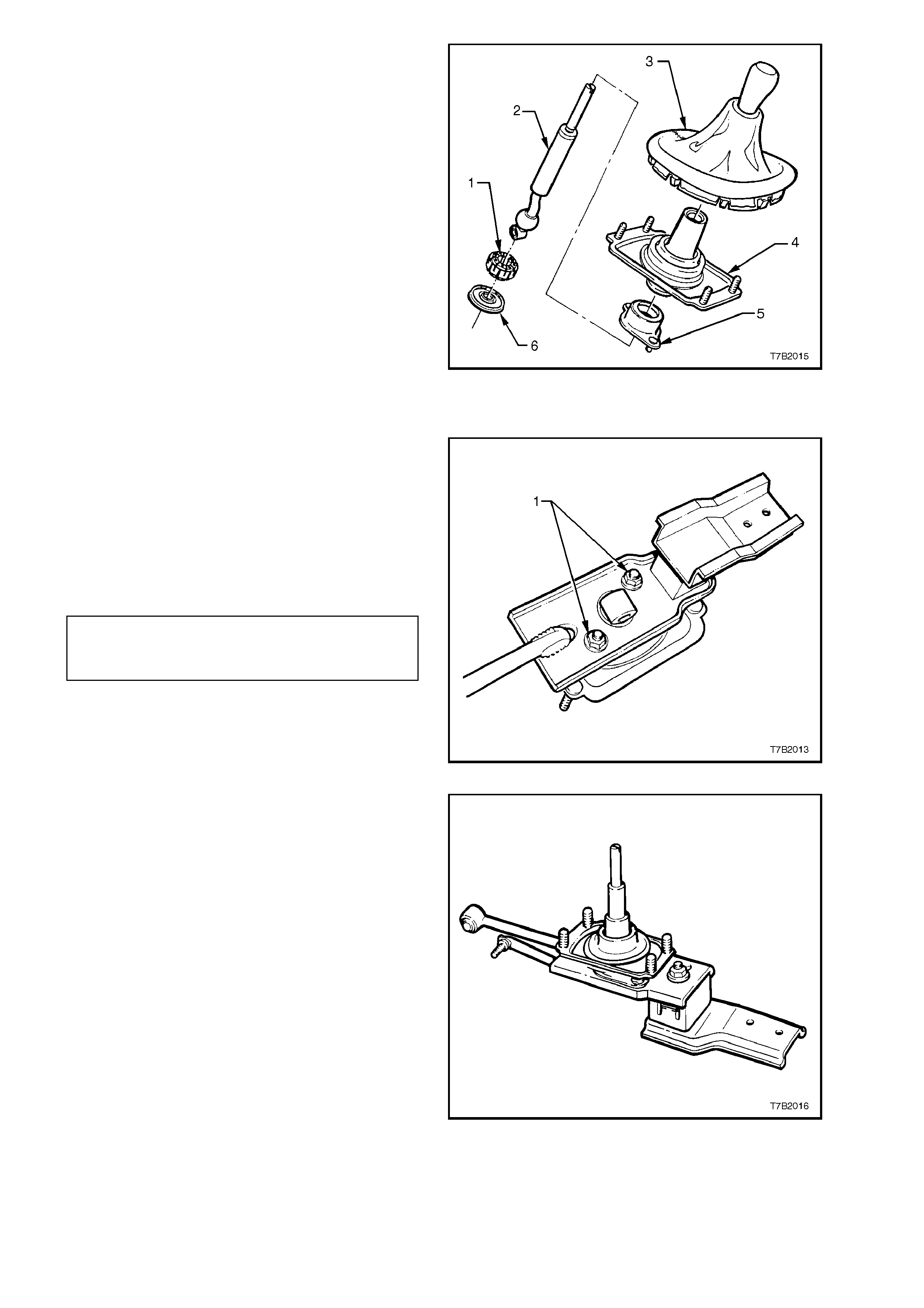

DISASSEMBLE

1. Remove both nuts (1) securing the gearshift

lever ball socket retainer, to the mounting

brace.

2. Remove retainer and gearshift lever assem bly

from the brace.

Figure 7B1-18

3. Remove the boot and mounting bracket

assembly (4), from the gearshift lever (2).

4. Separate the assem bly by holding the bearing

cover (5) and gently bump the end of the

gearshif t lever (2), to displace the end plate ( 6)

and bearing (1) from the ball of the gearshift

lever.

5. Inspect all components for wear and/or

damage, replacing parts as required.

Figure 7B1-19

REASSEMBLE

Reassembly operations are the reverse of

disassembly, except for the following items.

1. Lubricate the gearshift lever ball and socket

with Lithium grease NLGI No. 4 EP.

2. Install the gearshift lever ball and socket

retainer to the brace, fit the two retaining nuts

(1) and tighten to the correct torque

specification.

GEARSHIFT BALL SOCKET

RETAINER PLATE NUTS 6 - 14 Nm

TORQUE SPECIFICATION

Figure 7B1-20

3. Install the rubber gearshift boot over the

gearshift lever as shown.

Figure 7B1-21

REINSTALL

1. Install gearshift lever assembly into position,

aligning studs with the holes in the floor pan

and the bolt holes in the rubber m ounting, with

the captive nuts on the underbody.

2. Install gearshift lever brace rubber mounting

bolts (2) and tighten to the correct torque

specification.

SHIFT LEVER BRACE, RUBBER

MOUNTING BRACKET BOLT 6 - 14 Nm

TORQUE SPECIFICATION

3. From inside the vehicle, install and tighten the

four, brace (1) to underfloor retaining nuts,

tightening to the correct torque specification.

SHIFT LEVER BRACE TO

UNDERFLOOR RETAINING NUT 6 - 14 Nm

TORQUE SPECIFICATION

Figure 7B1-22

4. Install gearshift brace pin and retainer to the

transmission end, ensuring that the security

lug is firmly in place.

Figure 7B1-23

5. Install gearshif t linkage to the lower end of the

gearshift lever, then install the washer (2) and

C-clip (1).

NOTE:

Ensure that the linkage is only assembled in the

attitude shown. If fitted in the reverse direction, the

linkage may foul, resulting in diff iculty with 2nd gear

selection that can cause damage to the

transmission.

6. Remove safety stands and lower vehicle to

ground.

7. Disconnect battery ground cable.

8. Reinstall gearshift lever knob/boot assembly.

Refer to 3.3 GEARSHIFT LEVER KNOB AND

BOOT ASSEMBLY in this Section, f or spec ific

details.

9. Road test vehicle to check gearshift operation. Figure 7B1-24

ADJUST

No adjustment of the gearshift linkage is required.

3.5 SHIFT LINKAGE BRACE RUBBER MOUNTING AND/OR BUSH

REPLACE

1. Remove the gearshift lever and brace

assembly from the vehicle, as detailed in

3.4 GEARSHIFT LEVER in this Section.

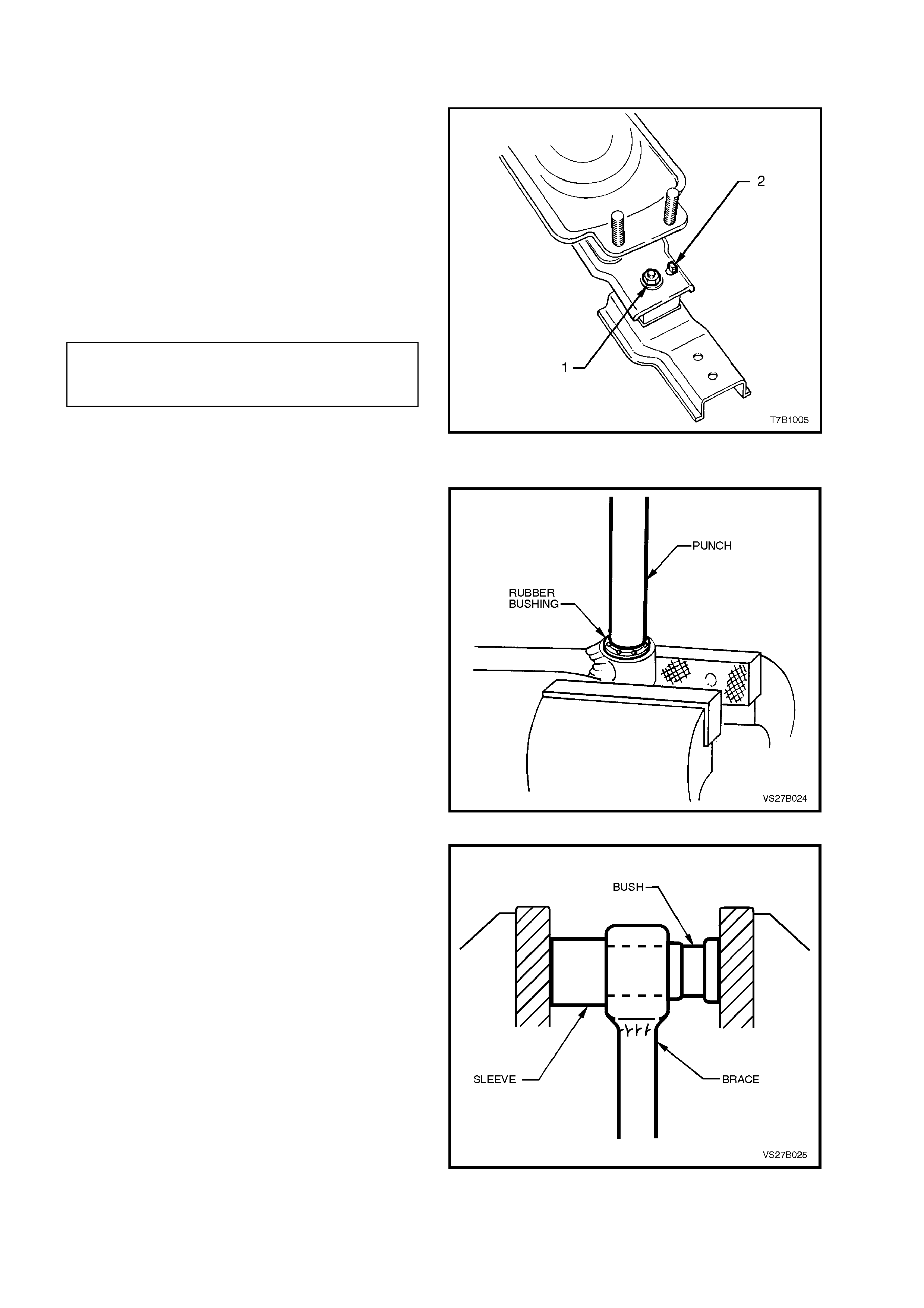

Brace Mounting

2. Remove the rubber mounting from the rear of

the gearshift lever support after removing the

retaining nut (1).

3. Fit the rear mounting to the brace, inserting

the locating tang (2) in the hole provided.

Install the retaining nut (1) and tighten to the

correct torque specification.

REAR GEARSHIFT LINKAGE

RUBBER MOUNTING NUT 22 Nm

TORQUE SPECIFICATION

Figure 7B1-25

Brace Bush

4. Using a suitable sized pin punch and ham m er,

remove the rubber bushing from the

transmission end of the brace assembly,

clamping the eye of the brace between

protected vice jaws.

Figure 7B1-26

5. Using a suitable sized piece of tubing (or

sock et) , over the end of the brac e eye, use the

clamping effect of a bench vice to install the

replacement rubber bush.

NOTE:

Dip the replacement bushing in a soap solution to

assist in the installation process.

6. Reinstall the brace and gearshift assembly into

the vehicle, as detailed in

3.4 GEARSHIFT LEVER in this Section.

Figure 7B1-27

4. MAJOR SERVICE OPERATIONS

4.1 SPEED SENSOR TOOTHED RING OR TRANSMISSION CASE REAR SEAL

REMOVE

1. Disconnect battery earth lead.

2. Raise front and rear of vehicle, supporting

on safety stands. Refer to

Section 0A GENERAL INFORMATION for

the location of jacking points.

3. Scribe around each of the rear engine

mounting c r oss member mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

IMPORTANT:

This step is critical to the correct powertrain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems will

result!

4. Support the rear of the transmission with a

floor jack, then remove the four rear engine

mounting crossmember bolts.

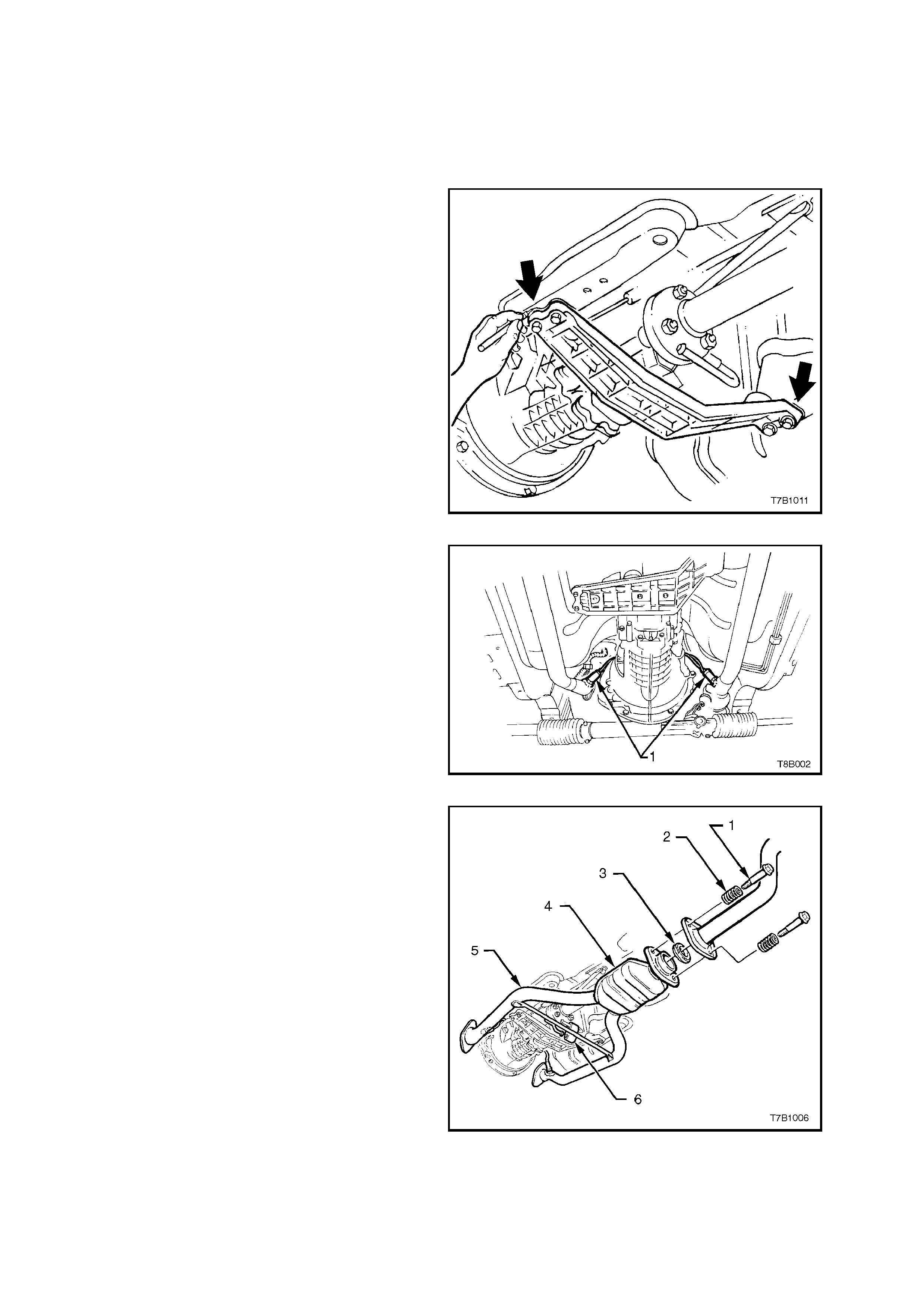

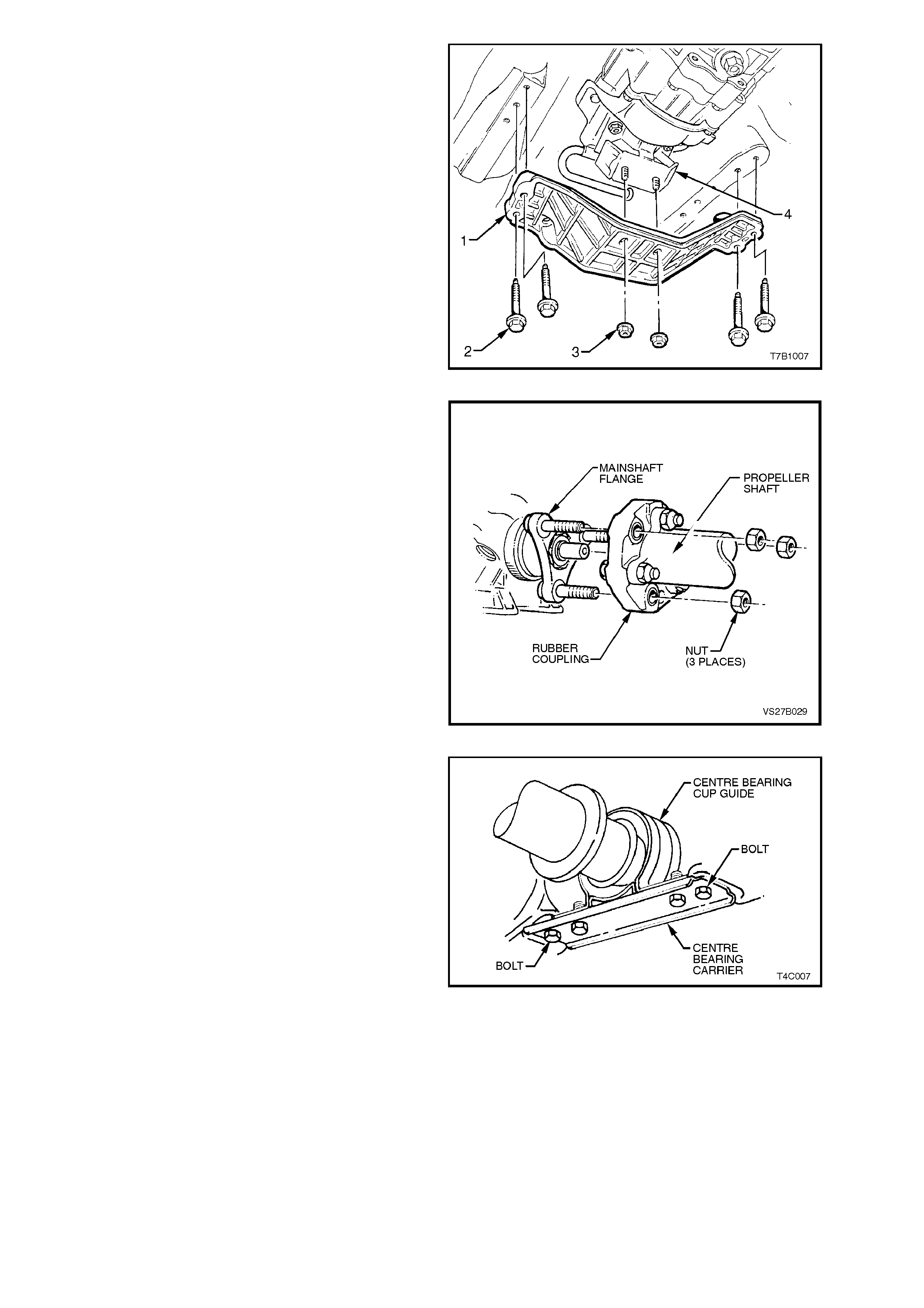

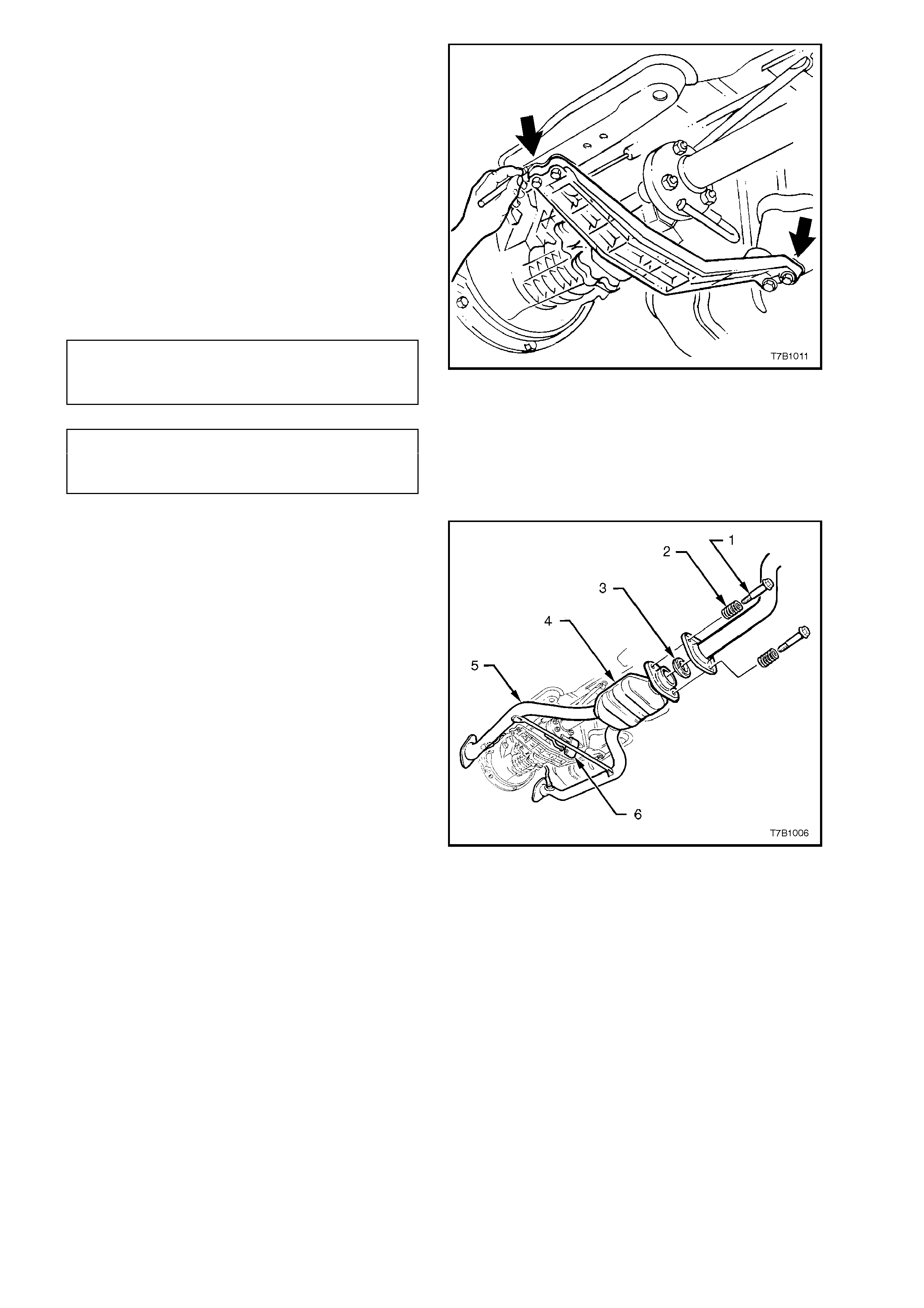

Figure 7B1-28

4. Disconnect wiring harness connectors from

each of the two oxygen sensors (1).

Figure 7B1-29

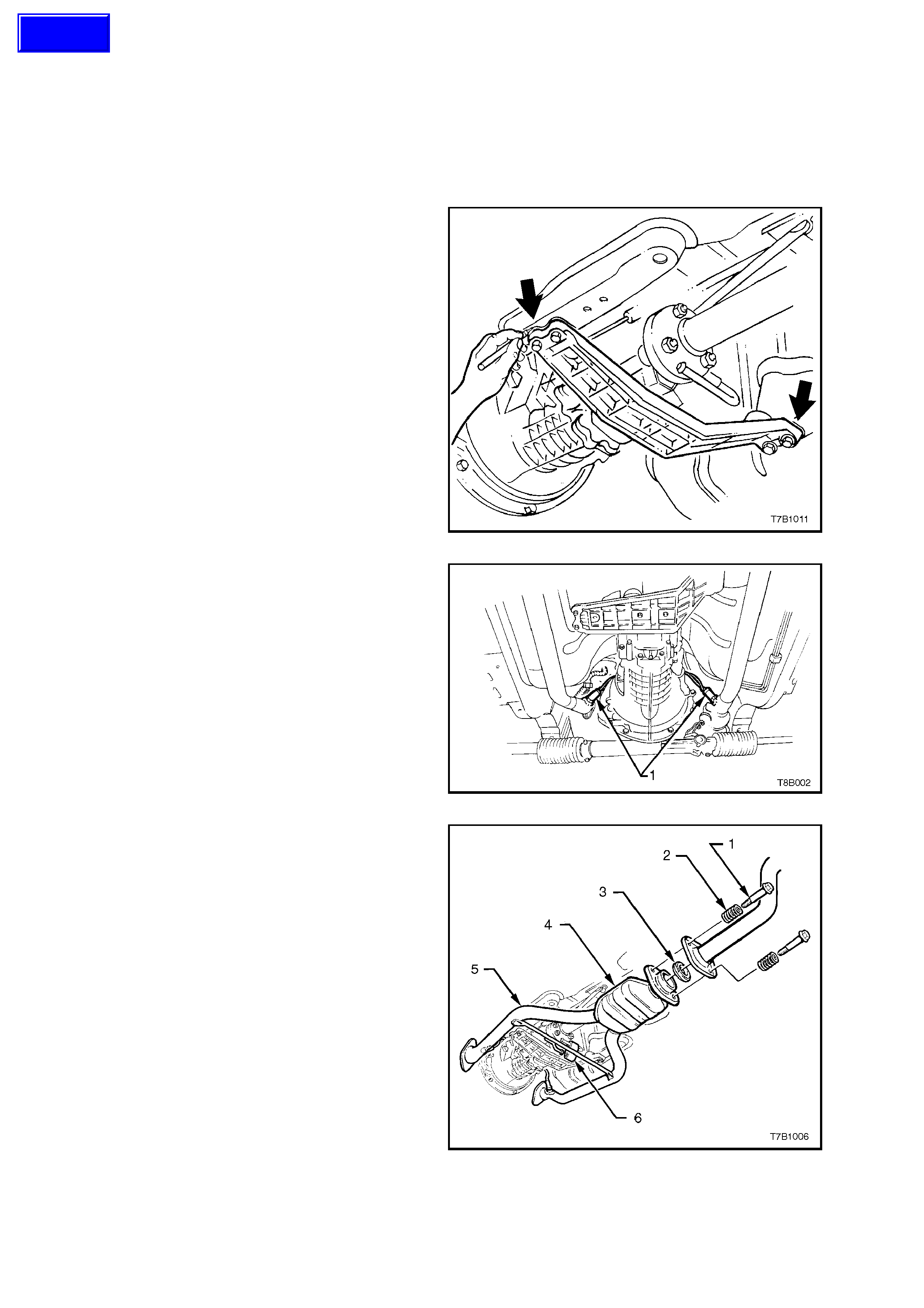

5. Then remove the twin exhaust pipe (5) and

catalytic converter (4) from the exhaust

manif olds, the s upport rubber (6) at the rear of

the transm ission and the interm ediate exhaust

pipe, after removing the two bolts (1), springs

(2) and seal ring (3).

Figure 7B1-30

6. Support weight of transm ission as sembly on a

transmission jack.

7. Remove engine rear crossmember to side

frame attaching bolts (2).

8. Remove crossmember to rear mounting

attaching nuts (3) from the reaar engine

mounting (4), then remove crossmember (1)

from the vehicle.

NOTE:

Illustration does not show transmission jack in

position, for clarity of the crossmember orientation.

Figure 7B1-31

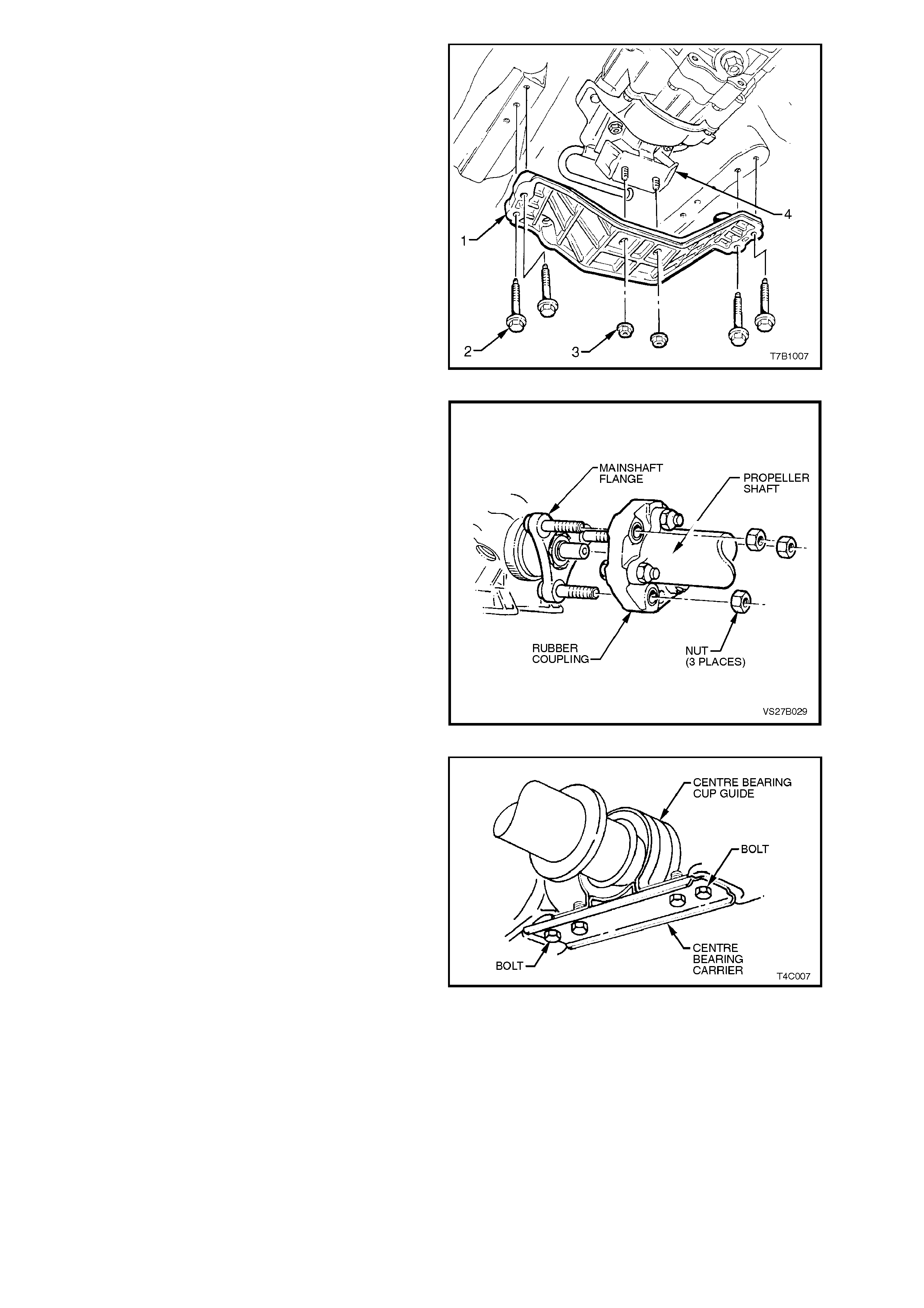

8. Remove propeller shaft flexible rubber

coupling to mainshaft flange attaching nuts.

Figure 7B1-32

9. Remove centre bearing carrier to underbody

reinforcement bolts and spacers.

NOTE:

For correct reassembly, take particular note of any

spacer arrangement that may be fitted, observing

any side to side variations and the orientation of the

bracket offset.

Figure 7B1-33

10. Remove bolts and nuts holding propeller shaft

rear universal joint flange to pinion flange.

Disengage rear universal joint flange from

pinion flange.

NOTE:

The two flanges have paint alignment marks that

are assem bled as c lose together as pos sible. If the

marks are not visible, scribe a mark on both

flanges so that they may be reinstalled in their

correct position.

11. Remove propeller shaft by pulling it toward

rear of vehicle to disengage rubber coupling

from mainshaft flange.

Figure 7B1-34

12. Remove the speed sensor bracket retaining

bolt from the rear of the transmission, remove

the sensor and bracket and secure to the

underbody with a piece of tie wire.

Figure 7B1-35

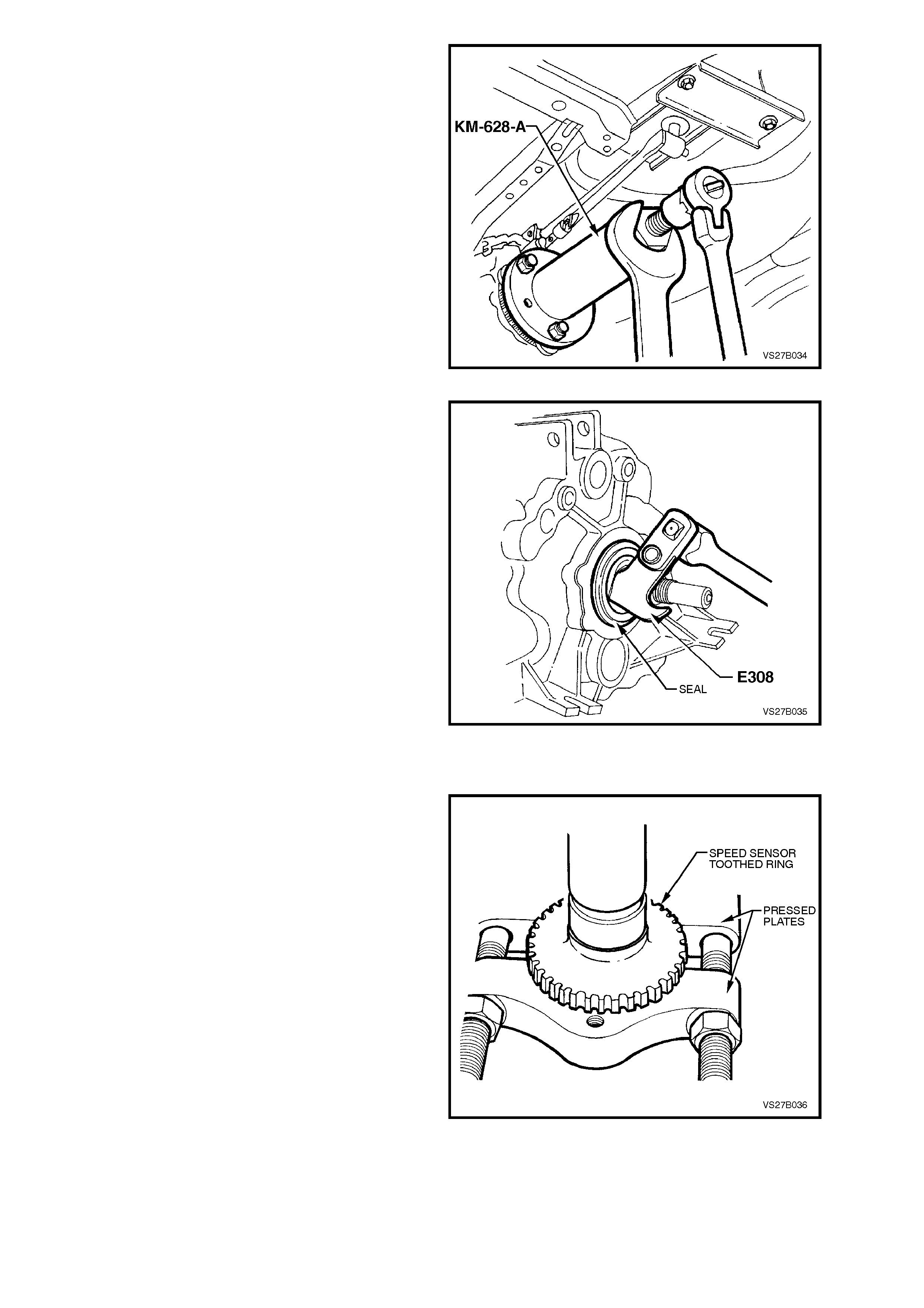

13. To use the previously released, Tool No. KM-

620-1-A to hold the flange, it must first be

modified by redrilling the three holes stamped

‘B’ (on the Tool) to 13 mm.

Fasten the modified tool to the flange using

the three discarded nuts. Then, using a

suitable length of pipe on the tool, loosen and

remove flange nut, using a commercially

available, 30 mm deep socket.

Figure 7B1-36

14. Place a drain tray beneath transmission.

15. Install extractor, Tool No. AKM-628-A to output

shaft flange.

16. Tighten extractor forcing bolt and remove

flange and speed sensor toothed ring, from

output shaft.

17. Inspect the sealing surface of the flange for

damage. Replace as necessary.

NOTE:

Tak e care that no tooth dam age takes place to the

speed sensor toothed ring while the flange is

removed.

Figure 7B1-37

18. Using a seal remover such as Tool No. E308

or a suitable lever, remove the seal from the

transmission case .

Figure 7B1-38

SPEED SENSOR TOOTHED RING - REPLACE

NOTE:

Only perform this operation if the speed sensor

toothed ring is damaged or the flange is being

replaced.

1. Use press plates such as J22912-01

(previously released as E6673) or commercial

equivalent, fitted under the speed sensor

toothed ring, with the flat side against the

toothed ring, then press from the mainshaft

flange.

NOTE:

A new toothed ring must be fitted after removal,

because of the risk of tooth dam age. To achieve an

accurate speed sens or reading, it is abs olutely vital

that no tooth damage is evident.

2. Using a suitable diameter and length of pipe,

carefully press the replacement toothed ring

onto the mainshaft output flange.

NOTE:

Ensure that the mainshaft output flange is

supported on the machined inner boss and not on

the three studs, during the installation process.

Figure 7B1-39

REINSTALL

1. Lubricate seal surface of spacer with

transmission lubricant and install over the

mainshaft.

2. After lubricating the seal lip with transmission

lubricant, use previously released Tool No. J-

21426 (or similar ) and ins tall the new seal over

the sleeve and into the transmiss ion rear case

housing.

Figure 7B1-40

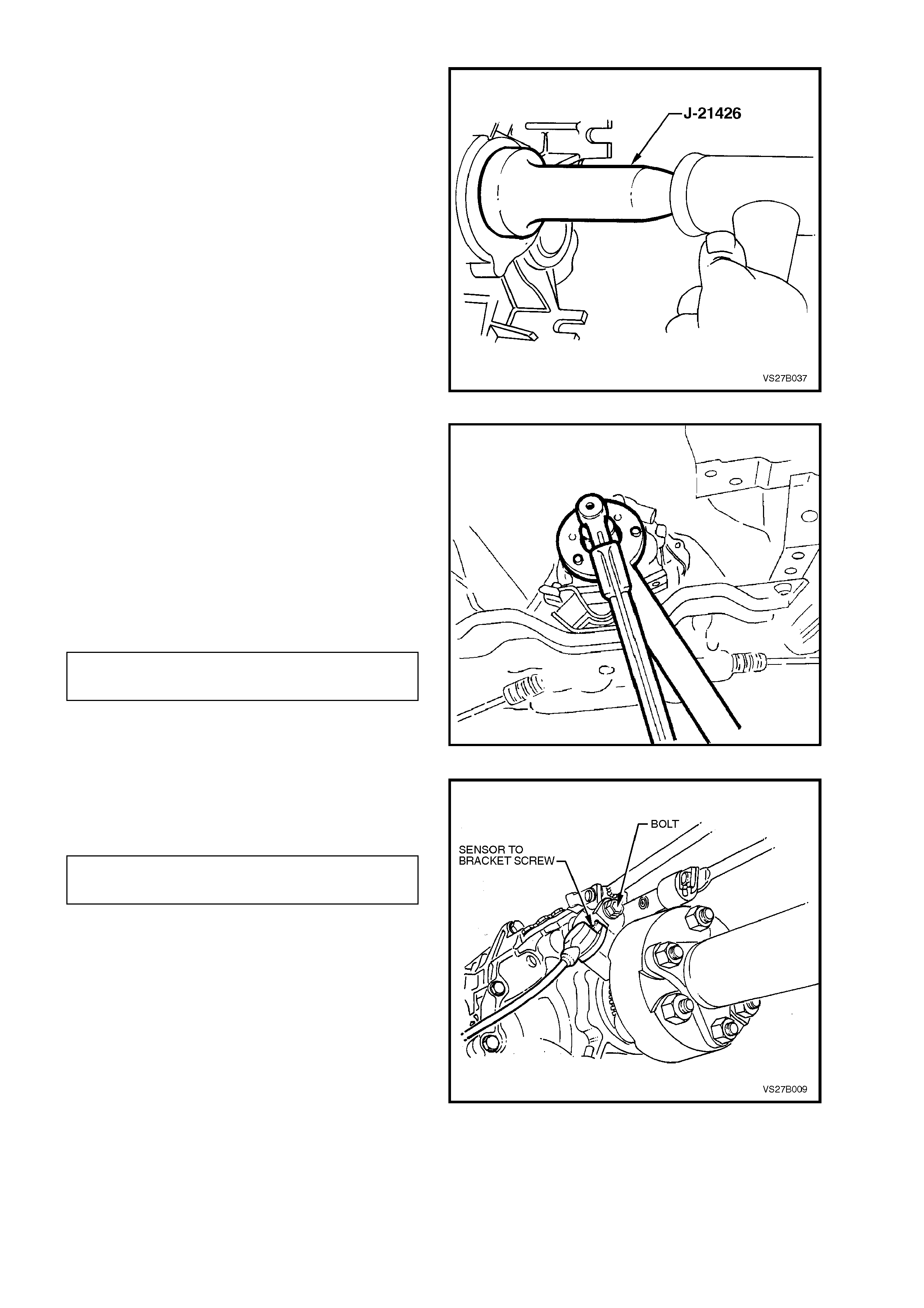

3. Install flange and toothed ring onto mainshaft,

using the original flange nut to pull the

assembly fully into place. Use Tool No. KM-

620-1-A to hold the flange during this process.

4. Remove the original nut and replace with a

new nut that has had thread sealant such as

Loctite 242 or 243 (or equivalent to Holden’s

Specification HN1256) applied to the threads.

5. Again using modified Tool No. KM-620-1-A to

hold flange, tighten the new flange nut to the

correct torque specification.

MAINSHAFT FLANGE NUT 100

TORQUE SPECIFICATION Nm

Figure 7B1-41

6. Reinstall speed sensor and bracket assembly,

tightening the retaining bolt to the correct

torque specification.

SPEED SENSOR RETAINING 6 - 14

SCREW TORQUE SPECIFICATION6 Nm

Figure 7B1-42

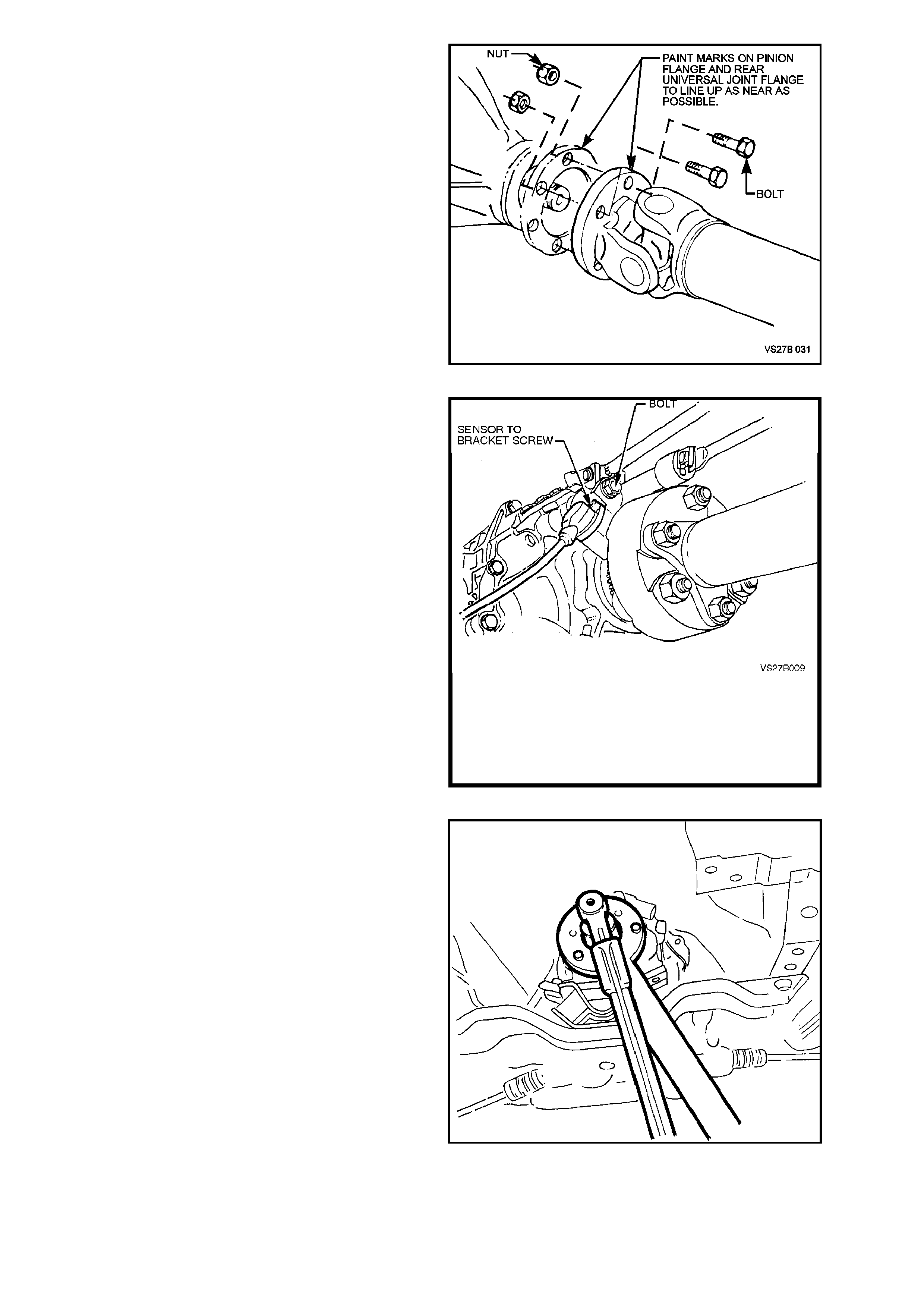

7. Install propeller shaft rubber coupling to

transmission mainshaft flange and loosely

install NEW attaching nuts.

8. Lift propeller shaft upward and install centre

bearing carrier to underbody reinforcement,

ensuring that any spacers are placed in the

same positions, noted on removal. Install

retaining bolts.

9. Assemble propeller shaft rear universal joint

flange to pinion flange and install attaching

bolts and nuts.

10. Tighten all propeller shaft attaching bolts to

the correct torque specification.

PROPELLER SHAFT RUBBER

COUPLING TO TRANSMISSION

OUTPUT FLANGE NUT, 74 - 80 Nm

TORQUE SPECIFICATION

CENTRE BEARING CARRIER

TO UNDERBODY REINFORCEMENT 20 - 25 Nm

BOLT, TORQUE SPECIFICATION

PROPELLER SHAFT REAR

UNIVERSAL JOINT FLANGE TO

PINION FLANGE BOLT 55 - 60 Nm

TORQUE SPECIFICATION

11. Install rear crossmember to rear mounting,

install washers and attaching nuts.

12. Loosely install rear crossmember to side

frame member bolts.

13. Carefully align the scribed marks made prior to

rem oval, then tighten the four cross mem ber to

side frame bolts.

IMPORTANT:

This step is critical to the correct powertrain

alignment. If not carried out, then vehicle vibration

and/or handling problems will result!

14. Remove transmission jack.

15. After checking to see that the crossmember

position has not changed, tighten the four

crossmember to side frame bolts and the rear

mounting nuts to the correct torque.

REAR CROSSMEMBER TO REAR

MOUNTING ATTACHING NUT 20 - 30 Nm

TORQUE SPECIFICATION

REAR CROSSMEMBER TO SIDE

FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

Figure 7B1-43

16. Reinstall exhaust system, tightening fasteners

as detailed in Sections 8B EXHAUST

SYSTEM.

17. Check transmission lubricant level and top up

as necessary, refer 2.2 CHECKING

TRANSMISSION LUBRICANT LEVEL in this

Section.

18. Remove jack stands and lower vehicle to the

ground.

19. Reconnect battery ground lead.

4.2 TRANSMISSION ASSEMBLY

REMOVE

1. Disconnect battery ground lead.

2. Raise vehicle front and rear and support on

safety stands. Refer to Section 0A

GENERAL INFORMATION for the location of

jacking points.

3. Use a sharp s criber to m ark the exac t location

of the crossm ember to the side fram e, before

loosening any of the four cr ossm em ber to side

frame attaching bolts.

IMPORTANT:

This step is critical to the correct powertrain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems will

result!

Figure 7B1-44

3. Disconnect wiring harness connectors from

each of the two oxygen sensors (1).

Figure 7B1-45

4. Then remove the twin exhaust pipe (5) and

catalytic converter (4) from the exhaust

manif olds, the s upport rubber (6) at the rear of

the transm ission and the interm ediate exhaust

pipe, after removing the two bolts (1), springs

(2) and seal ring (3).

5. Depending on the reason for removal, it might

be opportune to drain the transmission

lubricant into a clean container. Refer to the

procedure detailed in 2.3 DRAINING AND

REFILLING TRANSMISSION in this Section.

NOTE:

Regardless of the reasons for the transmission

being removed, if the lubricant is drained prior to

rem oval, then it is good pr actice to car efully inspect

the magnet in the drain plug and the fluid for

foreign matter such as metal particles, etc.

Figure 7B1-46

Techline

6. Support weight of transm ission as sembly on a

transmission jack.

7. Remove engine rear crossmember to side

frame attaching bolts (2).

8. Remove crossmember to rear mounting

attaching nuts (3) from the rear engine

mounting (4), then remove the crossmember

(1) from the vehicle.

NOTE:

Illustration does not show transmission jack in

position, for clarity of the crossmember orientation.

Figure 7B1-47

9. Remove propeller shaft flexible rubber

coupling to mainshaft flange, crimped

attaching nuts. Discard the nuts.

Figure 7B1-48

10. Remove centre bearing carrier to underbody

reinforcement bolts and spacers.

NOTE:

For correct reassembly, take particular note of any

spacer arrangement that may be fitted, observing

any side to side variations and the orientation of the

bracket offset.

Figure 7B1-49

11. Remove bolts and nuts holding propeller shaft

rear universal joint flange to pinion flange.

Discard the crimped nuts.

Disengage rear universal joint flange from

pinion flange.

NOTE:

The two flanges have paint alignment marks that

are assembled as close together as possible.

If the marks are not visible, scribe a mark on both

flanges so that they may be reinstalled in their

correct position.

12. Remove propeller shaft by first disengaging

the shaft assembly from the pinion flange,

then pull toward rear of vehicle to disengage

rubber coupling from mainshaft flange.

Remove the complete assembly from the

vehicle. Figure 7B1-50

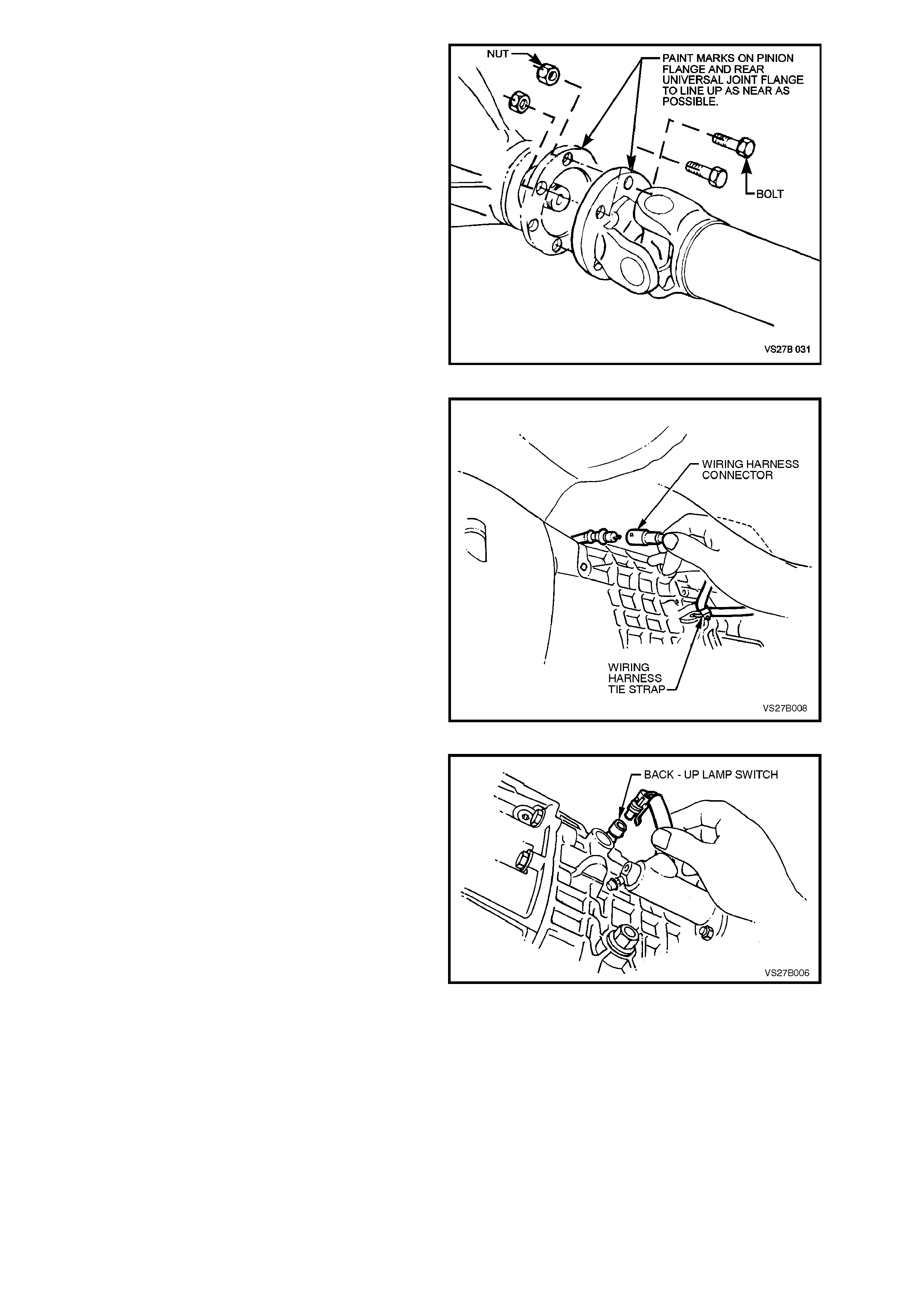

13. Disconnect the speed sensor wiring harness

connector on the left hand side of the

transmission.

Figure 7B1-51

14. Disconnect wiring harness connector from

back up lamp switch.

Figure 7B1-52

15. Remove clutch actuating cylinder retaining

nuts, remove the cylinder (1) from the

transm ission case and s ecure to one side with

tie wire or similar.

Figure 7B1-53

16. Remove transmission to engine brace

attaching bolts (2) from the clutch housing (1).

Braces (3) can remain bolted to the engine oil

pan but the front lower cover cannot be

removed until the transmission is removed.

17. Remove two screws securing the lower

flywheel cover plate to the transmission clutch

housing.

NOTE:

The right hand side screw also has a wiring

harness clip.

18. Lower transmission slowly on jack, still

supporting weight of transmission.

Figure 7B1-54

19. Disconnect wiring harness from two retaining

clips; one on top of the transm ission case, the

other on the right hand side.

20. Using a screwdriver, remove retainer from

shift rod at the transmission end.

21. Using a suitable lever, prise the shift linkage

brace retaining bracket from the transmission

lug, then remove retainer and pin assembly

from brace and transmission.

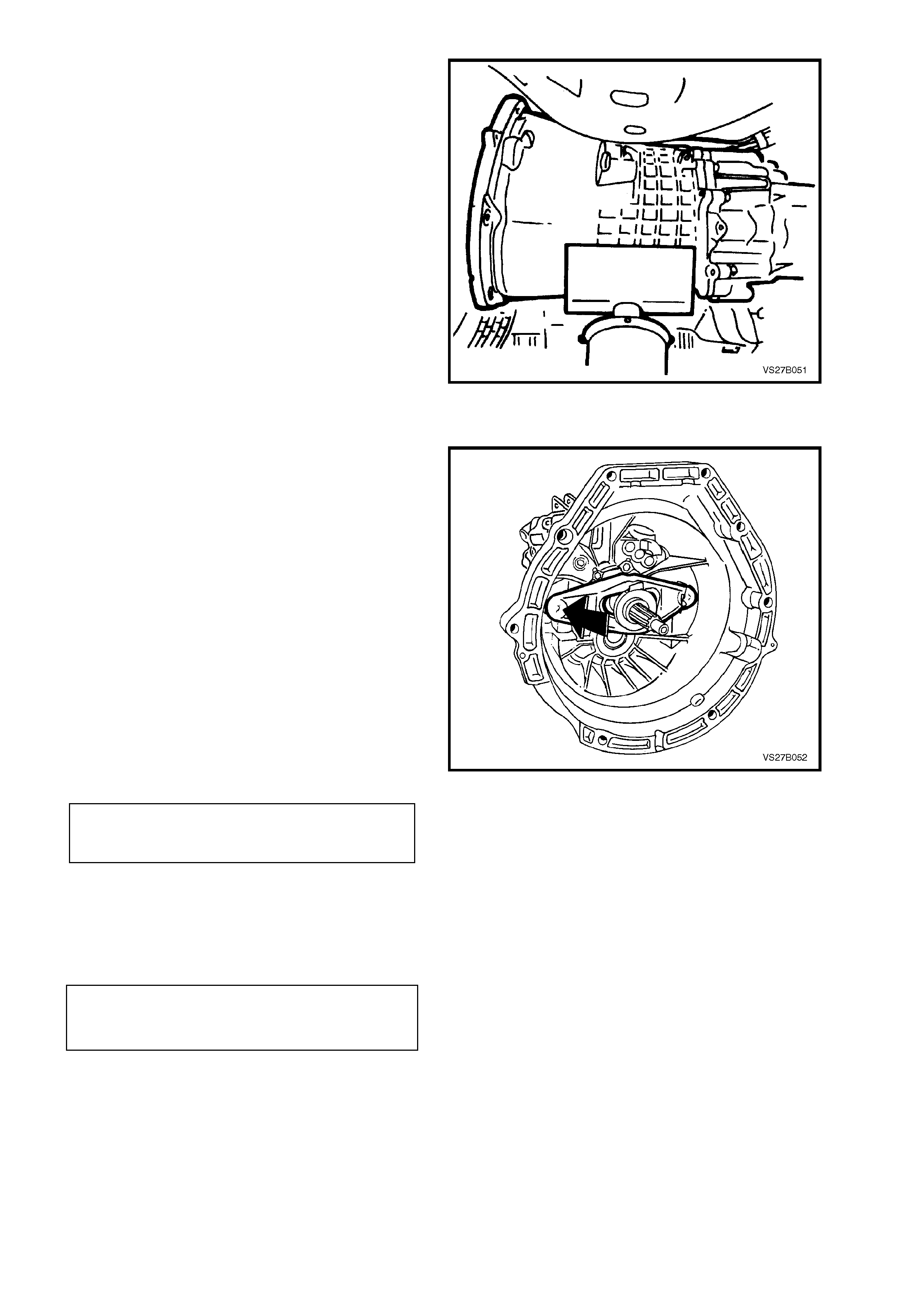

Figure 7B1-55

22. Remove transmission case to engine block

attaching bolts.

23. Withdraw transmission from the engine block

and clutch driven plate.

NOTE:

Keep the transmission assembly supported so that

it does not tilt in relation to the engine, until the

maindrive gear splines are clear of the clutch

driven plate. If the transmission is allowed to hang

on the splines, the clutch driven plate will be

damaged.

Figure 7B1-56

REINSTALL

1. Put transmission into 4th gear.

2. Apply a thin coating of Special High

Tem per ature grease ( to Holden's Spec ification

HN1227) to maindrive gear splines. Push the

clutch throwout bearing into the fully released

position (toward the transmission), ensuring

that placement with the throwout fork, is

correct. Lubricate the spigot end of the

transmission input shaft with a smear of SAE

90 Gear Oil

3. Raise transmission on jack and install

maindrive gear into splines of clutch driven

plate and push transmission toward engine

block . It may be necessary to rotate the output

flange to assist in spline alignment.

4. Install flywheel lower cover plate before

pushing the transmission fully home on to the

guide pins, then install the two retaining

screws and tighten to the correct torque.

FLYWHEEL LOWER

COVER PLATE SCREW 5 - 10 Nm

TORQUE SPECIFICATION

5. Install and tighten clutch housing to engine

block attaching bolts and nut. Also install the

two clutch housing to beaming brace bolts,

tightening all to the correct torque

specification.

CLUTCH HOUSING TO ENGINE

BLOCK AND BEAMING BRACE 50 - 85 Nm

BOLT TORQUE SPECIFICATION

6. Using transmission jack, support transmission

in a lower than installed position.

7. Install wiring harness into retaining clips.

Figure 7B1-57

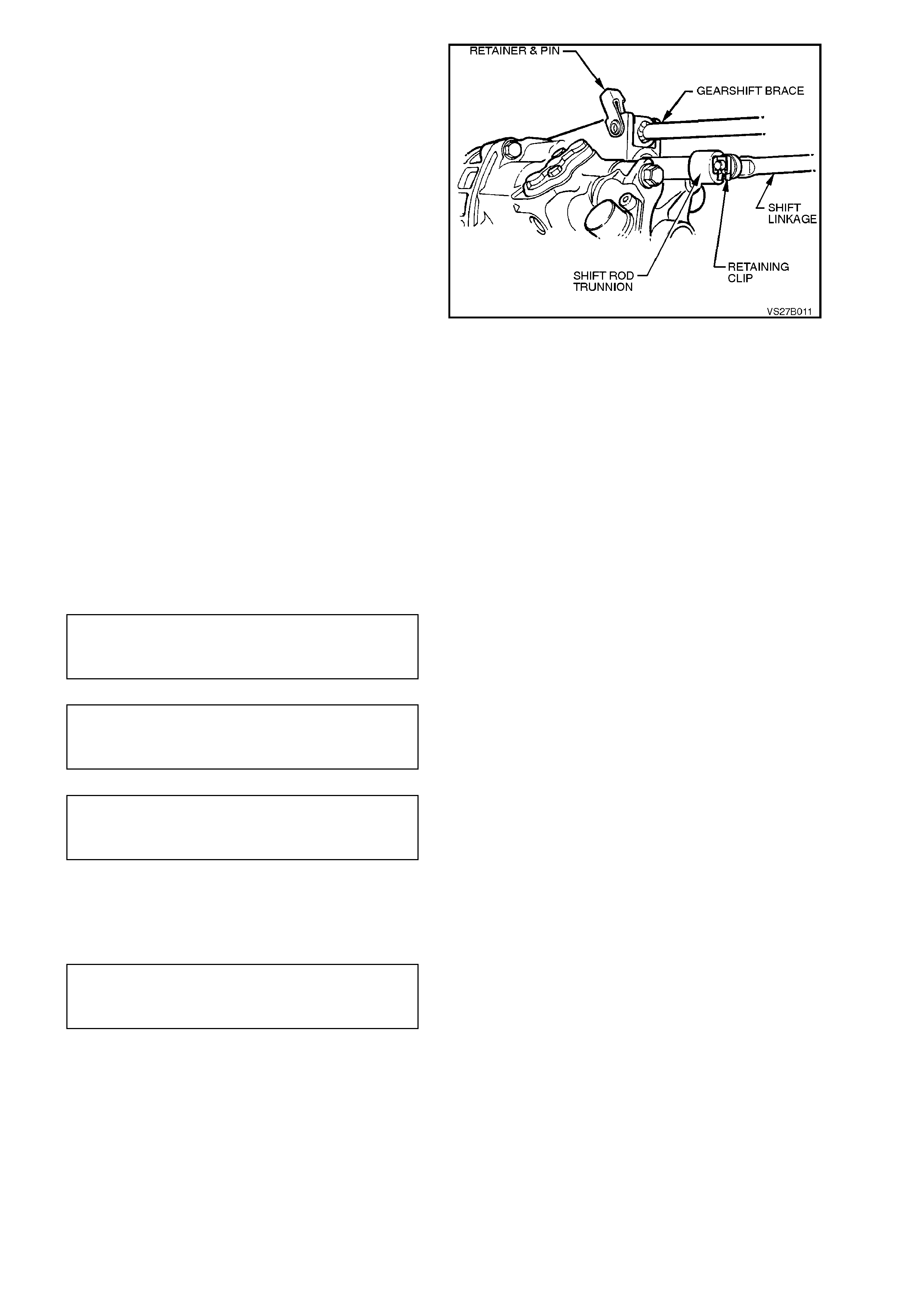

8. Align the shift linkage brace/bush and the

transm ission lug holes. Install the pin from the

left hand side, then rotate, to engage the

retaining clip with the transmission lug. Tap to

fully engage the clip with the lug.

9. Raise the transmission assembly into the

installed position.

10. Fit a washer to the inner end of the shift

linkage pin, apply a small amount of

Molybdenum Disulphide grease (Holden’s

Specification HN1461) to the pin, then install

into the transmission shift rod trunnion. Install

a second washer to the shift linkage pin, then

secure with the retaining clip.

11. Install wiring harness connector to back up

lamp switch and to the speed sensor.

12. Assemble propeller shaft flexible rubber

coupling to transmission mainshaft flange and

loosely install NEW attaching nuts.

13. Lift propeller shaft upward and install centre

bearing carrier to underbody reinforcement,

ensuring that all spacers are replaced in the

same positions, noted on removal. Install

retaining bolts.

Figure 7B1-58

14. Assemble propeller shaft rear universal joint

flange to pinion flange and install attaching

bolts and nuts.

15. Tighten all propeller shaft attaching bolts to

the correct torque specification.

PROPELLER SHAFT RUBBER

COUPLING TO OUTPUT FLANGE 74 - 80 Nm

NUT TORQUE SPECIFICATION

CENTRE BEARING CARRIER TO

UNDERBODY REINFORCEMENT 20 - 25 Nm

BOLT TORQUE SPECIFICATION

PROPELLER SHAFT REAR

UNIVERSAL JOINT FLANGE BOLT 55 - 60 Nm

TORQUE SPECIFICATION

16. Install clutch actuating cylinder to transm iss ion

case, install the nuts and tighten to the correc t

torque specification.

CLUTCH ACTUATING CYLINDER

RETAINING NUT 22 Nm

TORQUE SPECIFICATION

NOTE:

When the actuating cylinder is engaged with the

mounting studs, the internal spring will hold the

flange out from the fully installed position, by

approximately 25 mm. Hold the cylinder in against

this spring force, to start the retaining nuts.

17. Install rear crossmember to rear mounting,

install washers and attaching nuts.

18. Loosely install rear crossmember to side

frame member bolts.

19. Carefully align the scribed marks (arrows)

made prior to removal, then tighten the four

crossmember to side frame bolts.

IMPORTANT:

This step is critical to the correct powertrain

alignment. If not carried out, then vehicle vibration

and/or handling problems will result!

20. Remove transmission jack.

21. After checking to see that the crossmember

position has not changed, tighten the four

crossmember to side frame bolts and the rear

mounting nuts to the correct torque.

REAR CROSSMEMBER TO REAR

MOUNTING ATTACHING NUT 20 - 30 Nm

TORQUE SPECIFICATION

REAR CROSSMEMBER TO SIDE

FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

Figure 7B1-59

22. Inspect catalytic converter to intermediate

exhaust pipe seal ring (3) for deterioration or

damage, replacing if required.

23. Reinstall exhaust system components. Refer

to Section 8B EXHAUST SYSTEM, for the

necessary procedures and clearances.

Tighten all fasteners to the correct torque

specifications, as detailed in that Section.

24. If transmission fluid was drained during the

removal operation, then refill, as described in

2.3 DRAINING AND REFILLING

TRANSMISSION in this Section.

25. Remove safety stands and lower vehicle.

26. Reconnect battery earth lead.

27. Road test vehicle and check transmission,

clutch and gearshift operations.

Figure 7B1-60

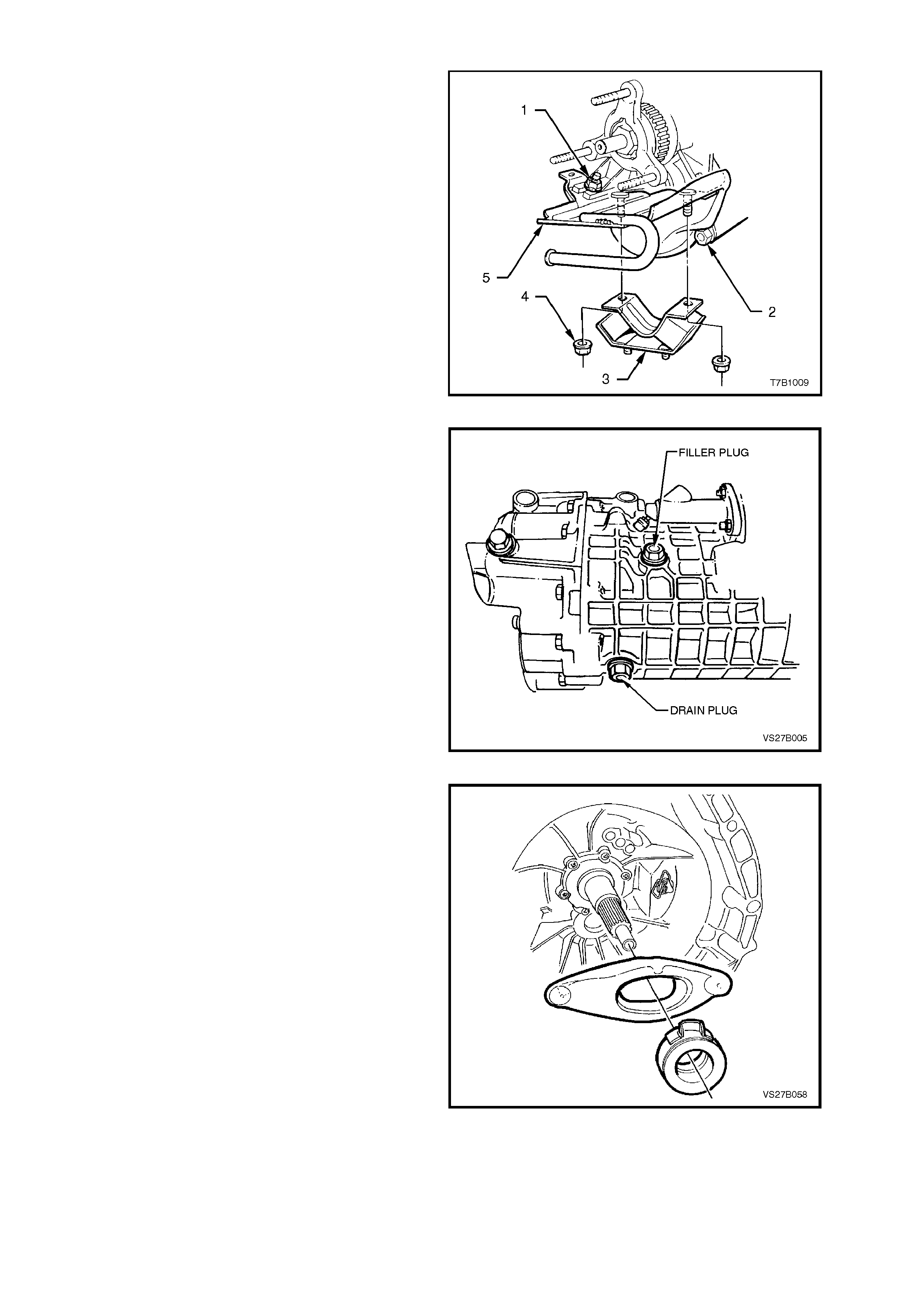

4.3 TRANSMISSION DISASSEMBLE

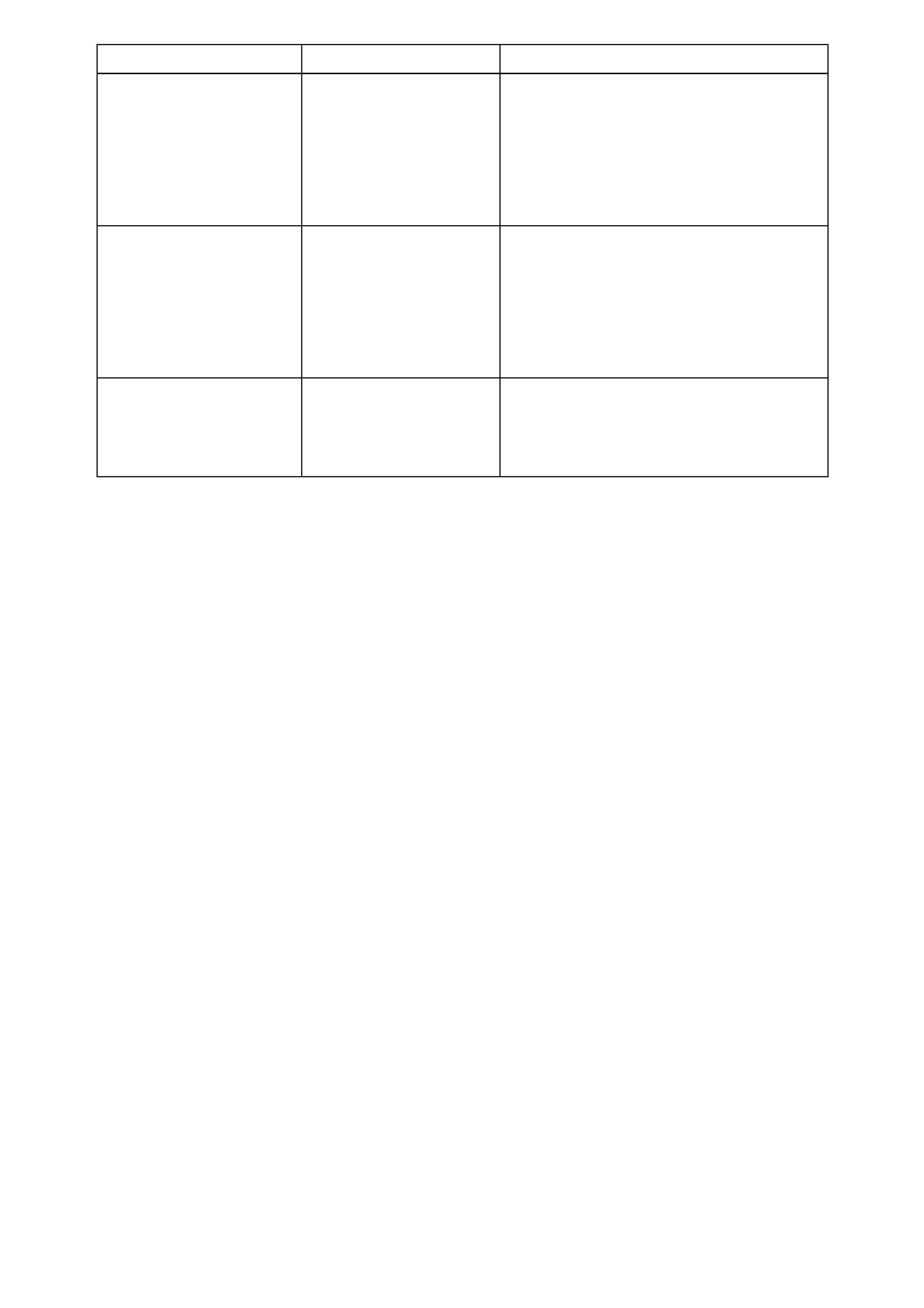

1. Remove rear engine mounting nuts (4) from

the transmission adaptor bracket (5).

2. Remove both nuts (1) and the two Allen key

headed bolts (2) securing the rear engine

mounting adaptor bracket (5) to the rear

transmission housing. Set to one side.

Figure 7B1-61

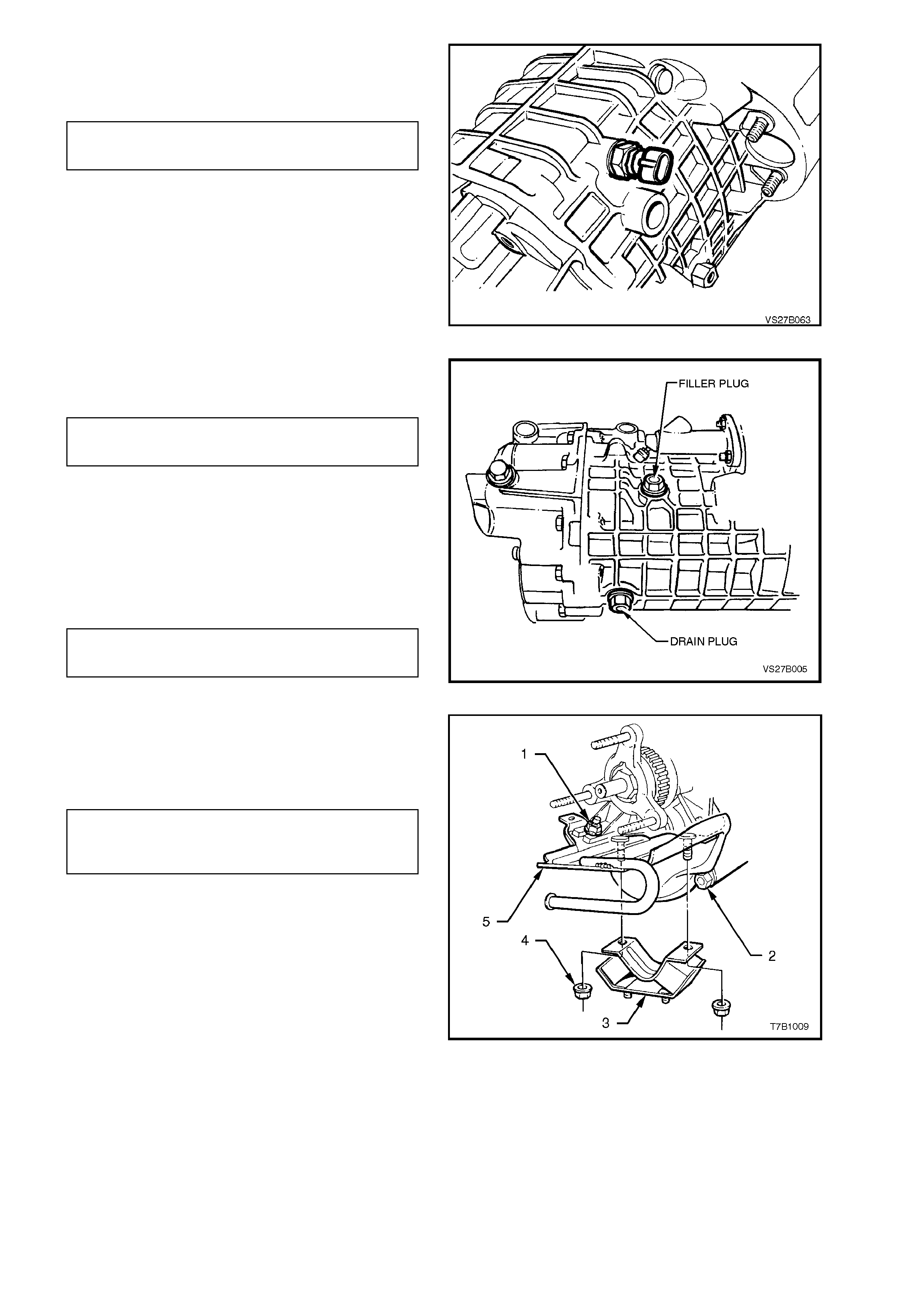

3. If not carried out during the transmission

rem oval procedure, us e a 17 m m ring spanner

and remove transmission filler plug from right

hand side of transmission case.

4. Remove trans miss ion drain plug with a 17 ring

spanner and allow transmission lubricant to

drain into a suitable clean, drain tray.

NOTE:

At this time, car efully inspect the drain plug m agnet

and the drained fluid for foreign matter such as

metal particles, etc.

Figure 7B1-62

5. Release clutch releas e lever from the wire clip

and remove lever from transmission case,

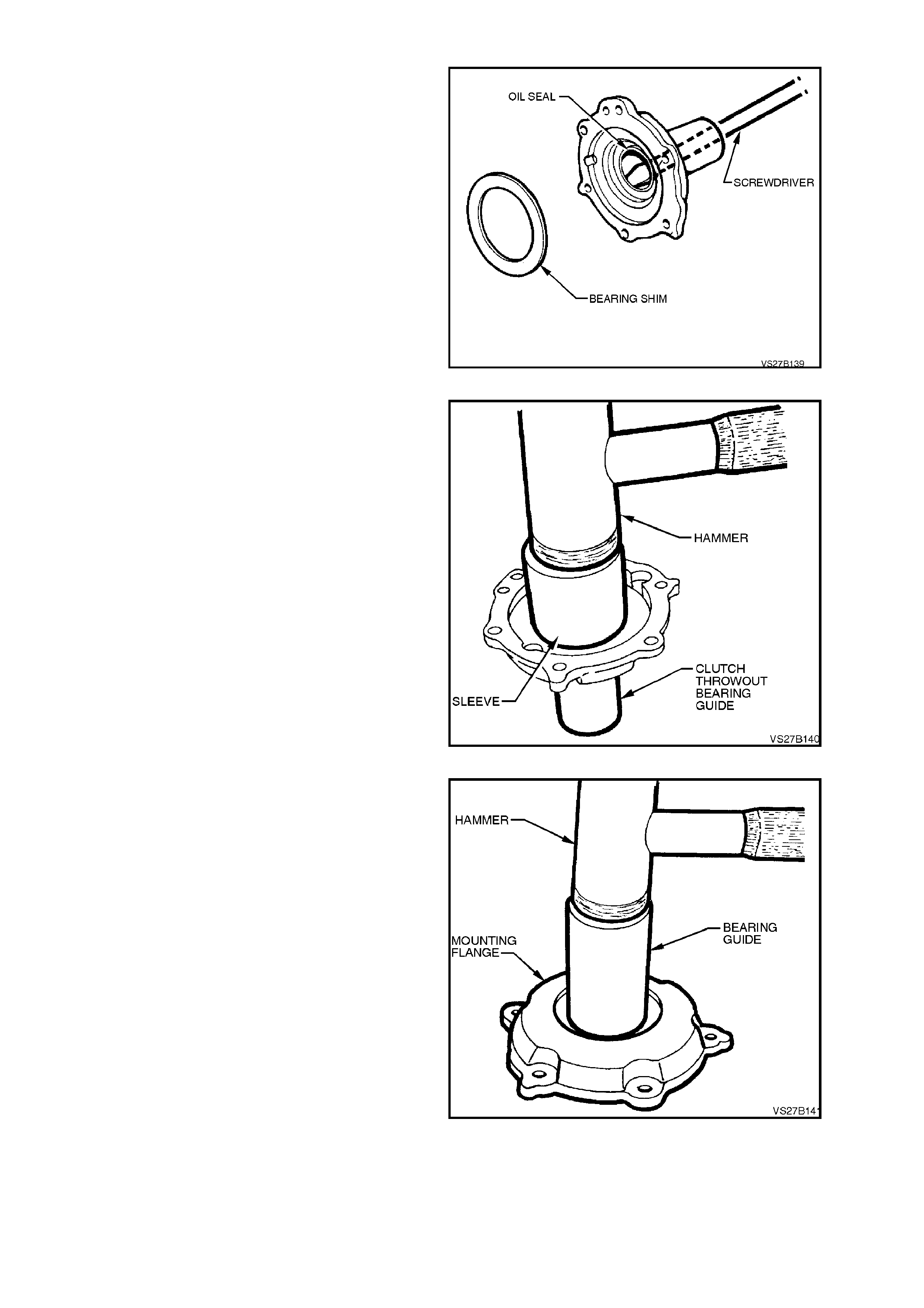

together with the thrust bearing.

Figure 7B1-63

6. Remove bolts attaching throwout bearing

guide assembly. Gently tap sideways with a

soft faced hammer to break the seal, then

remove the assembly from the transmission

maindrive gear shaft.

Figure 7B1-64

7. Remove shim washer and distance spacer

ring from the front bearing. Using suitable

snap ring pliers, remove the snap ring and

spacer washer from maindrive gear.

Figure 7B1-65

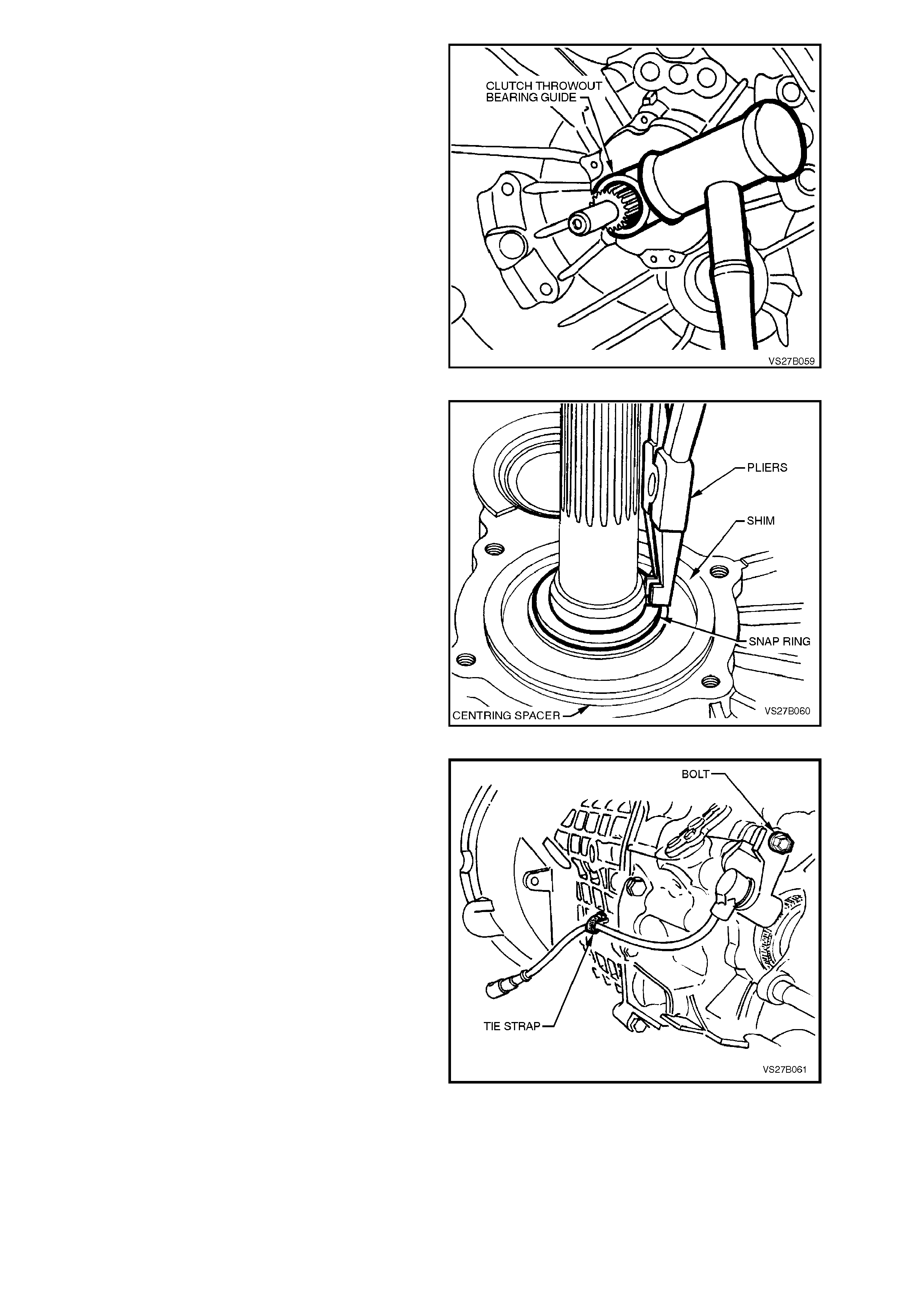

8. Remove the speed sensor bracket retaining

bolt from the rear transmission case. Cut the

wiring harness retaining strap from the

transmission case lug and remove the sensor

and bracket assembly.

Figure 7B1-66

9. Lever the spring steel retaining ring forward

from selector rod trunnion, to expose the

connecting pin.

While pushing the trunnion in to the

transmission, use a suitable punch and push

the pin from the trunnion. Remove trunnion

and retaining ring from the selector rod.

Figure 7B1-67

10. Remove back-up lamp switch and spacer

washer.

Figure 7B1-68

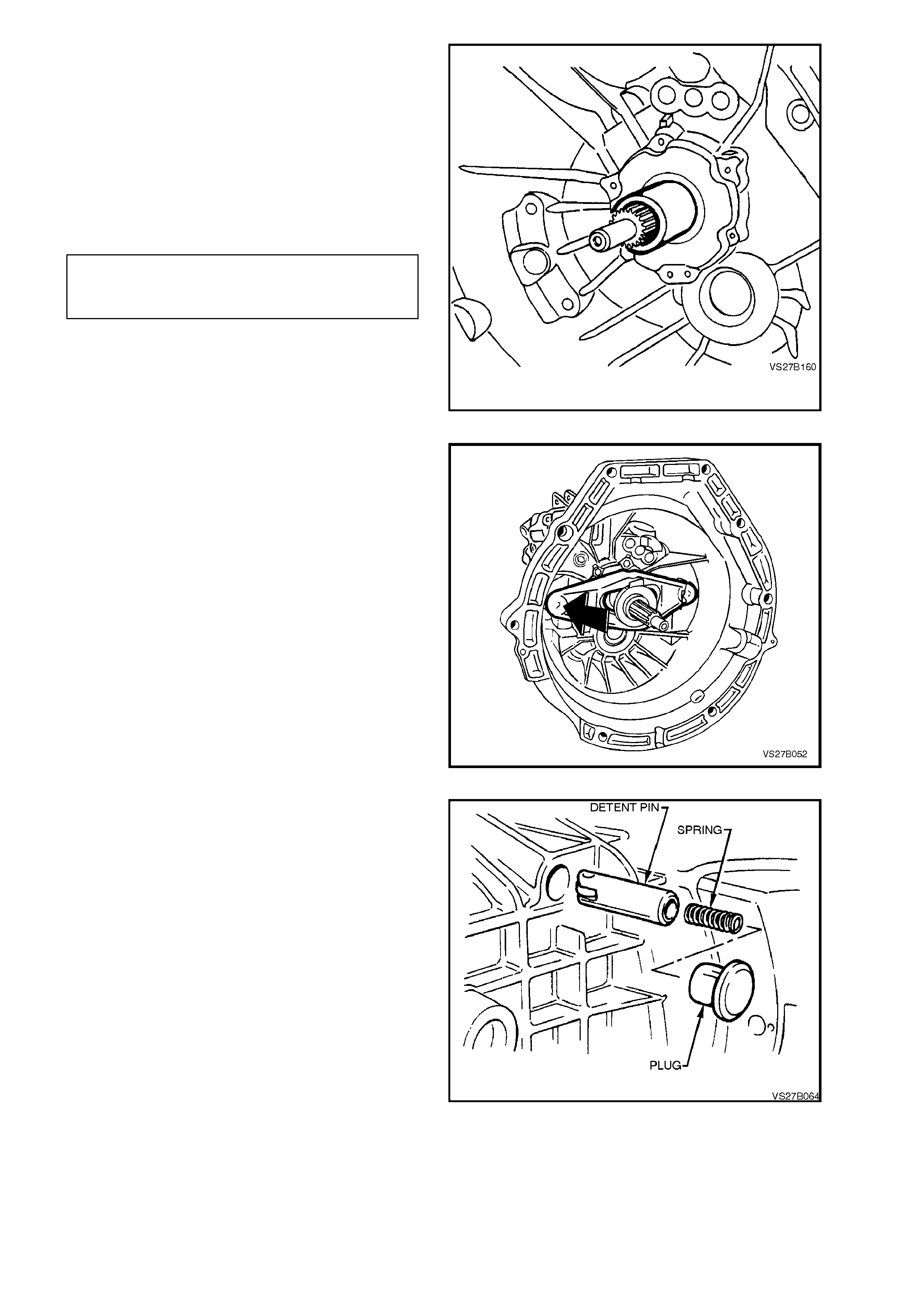

11. Using suitable lever, remove detent plug from

front section of transmission case.

12. Remove detent pin, pressure spring and plug.

Figure 7B1-69

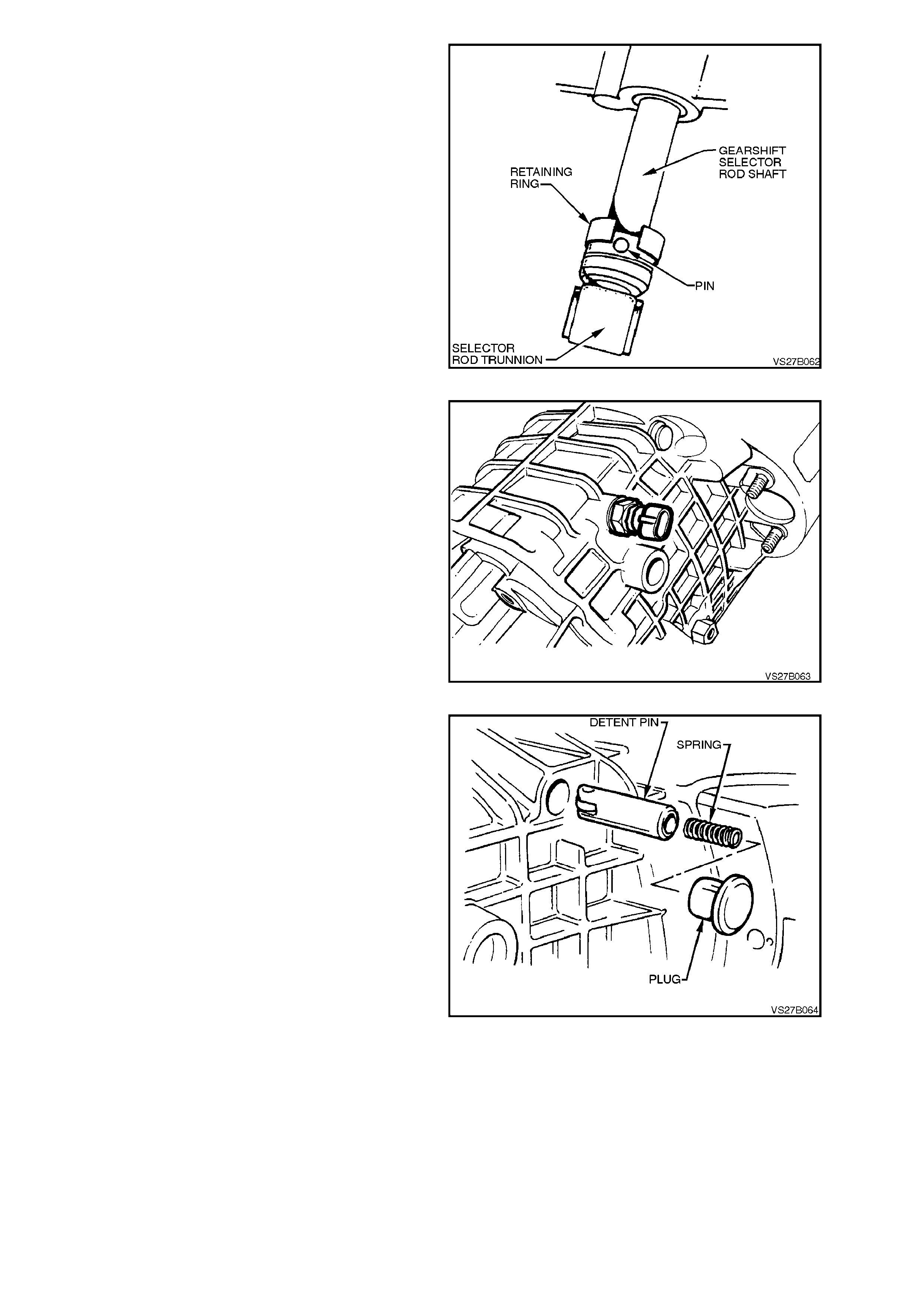

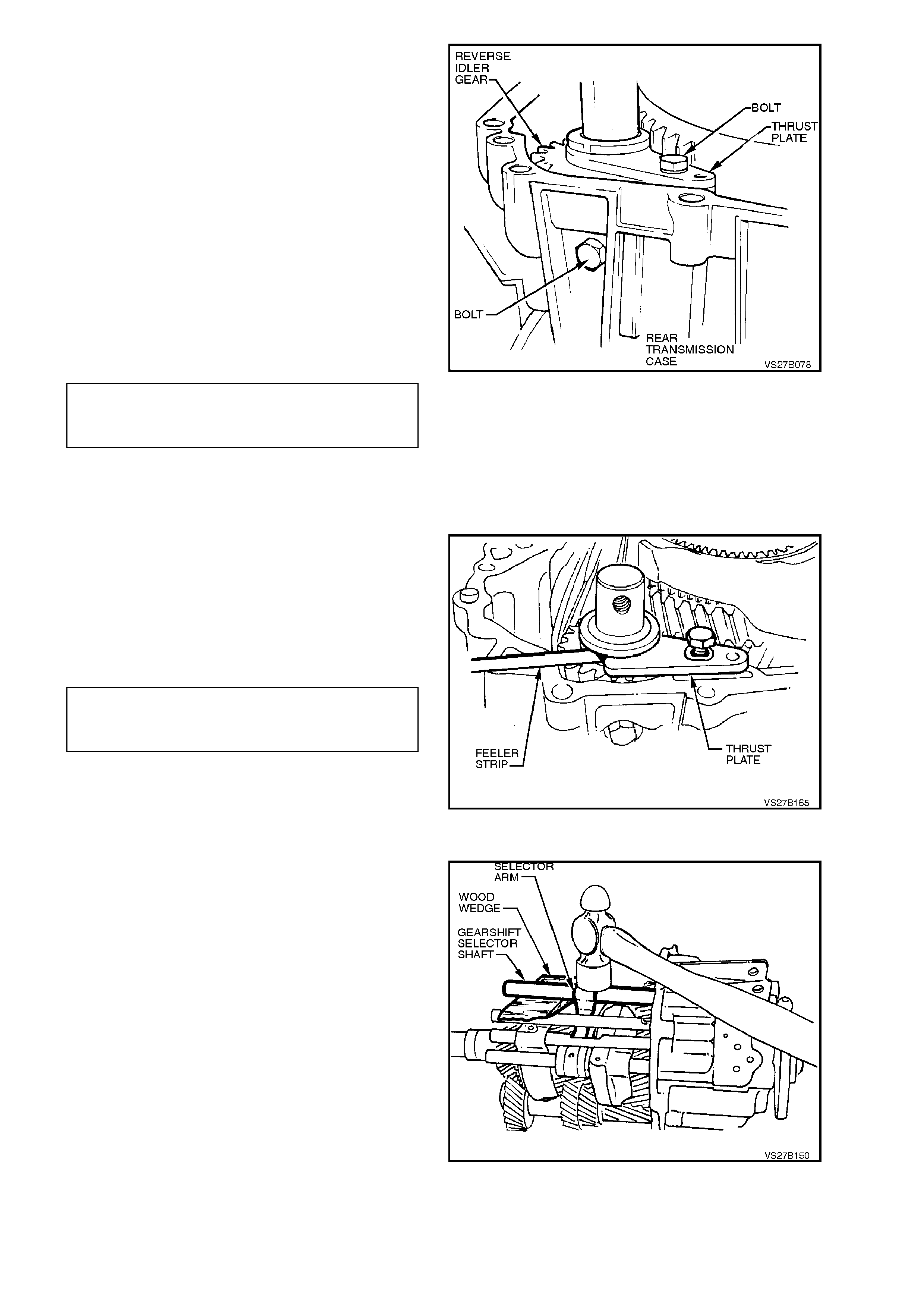

13. Remove front bolt fastening the reverse idler

gear shaft to the left side of transmission case.

Figure 7B1-70

14. Remove transmission case attaching bolts

from case rear section. Take note of the

longer bolt (60 mm) position (arrow) for

reassembly.

15. Drive the upper locating dowel pin into the

front transmission case.

NOTE:

The output flange is shown as being removed, to

enable the bolts to be more clearly shown.

Figure 7B1-71

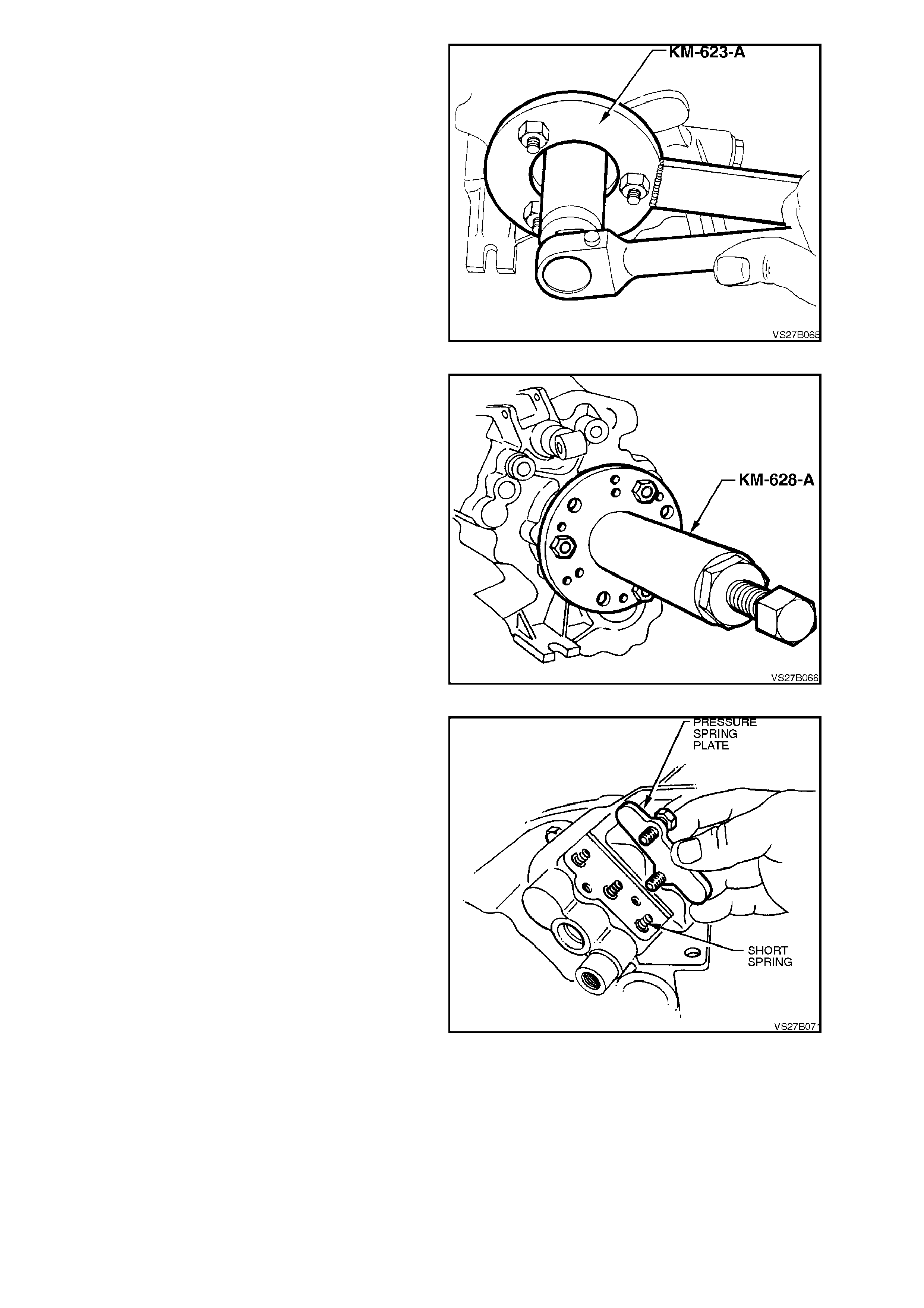

16. Install extractor, Tool No. AKM-628-A, to front

of transm ission case using all six of the clutch

throwout bearing guide bolts.

17. Tighten extractor forcing bolt to separate

transmission case sections.

NOTE:

While the forcing bolt of Tool AKM-628-A has

torque applied, it may be necessary to use a

suitable block of wood and hammer at the two lug

locations provided on the rear transmission case, to

assist in the separation process.

18. Carefully remove the front transmission case

section and place to one side.

NOTE 1:

The maindrive gear bearing and cluster gear front

bearing cup remain in the transmission case front

section. Take care that the cluster gear roller

bearing does not fall out of the front case

immediately after splitting the cases. The

remainder of the transmission assembly is

removed with the transmission case rear section.

NOTE 2:

When the transmission cases have been

separated, do not manipulate the position of the

transmission rear section by using the maindrive

gear as a lever or handle. If this is done, then the

mainshaft spigot bearing will suffer brinelling and

be permanently damaged.

Figure 7B1-72

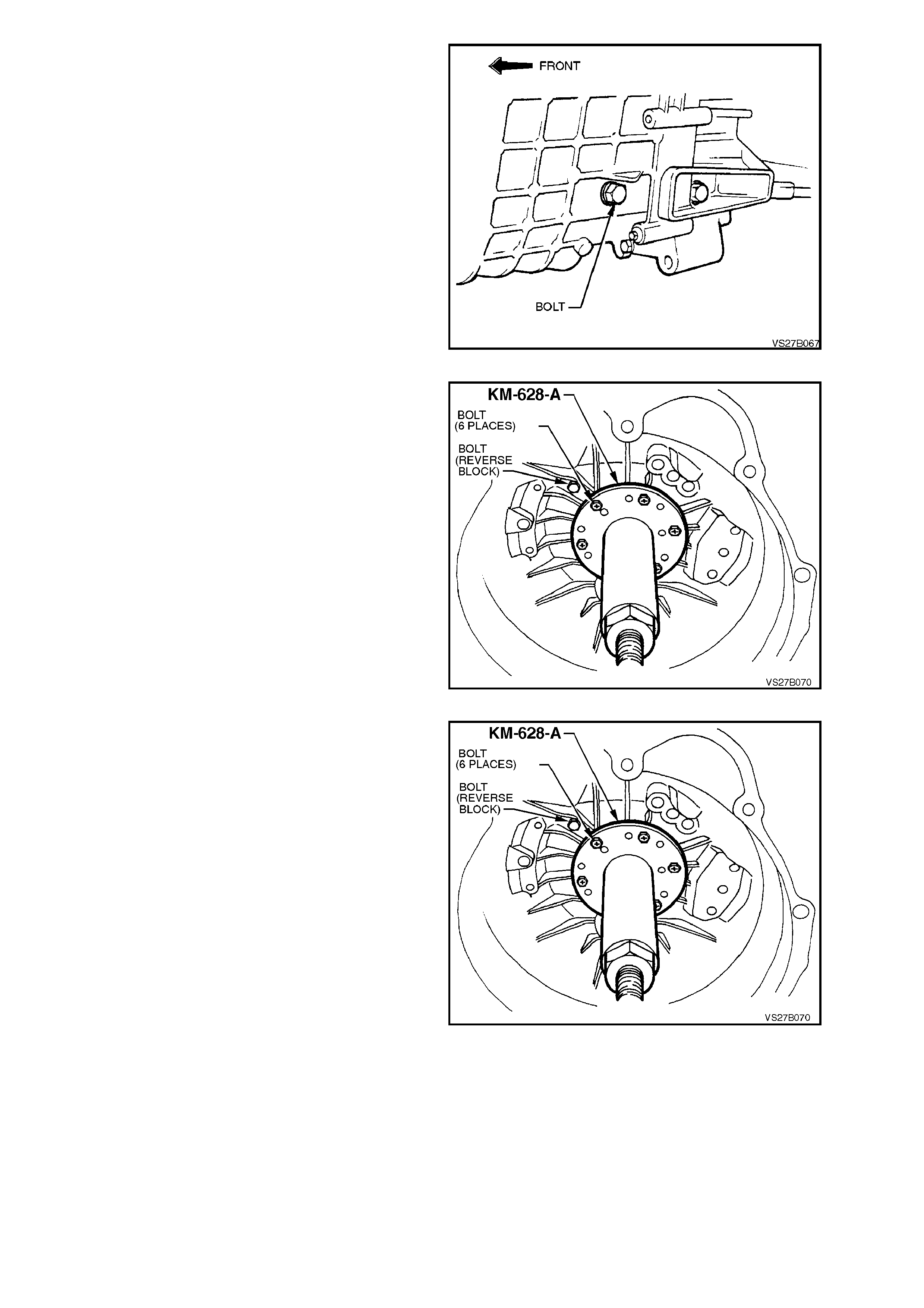

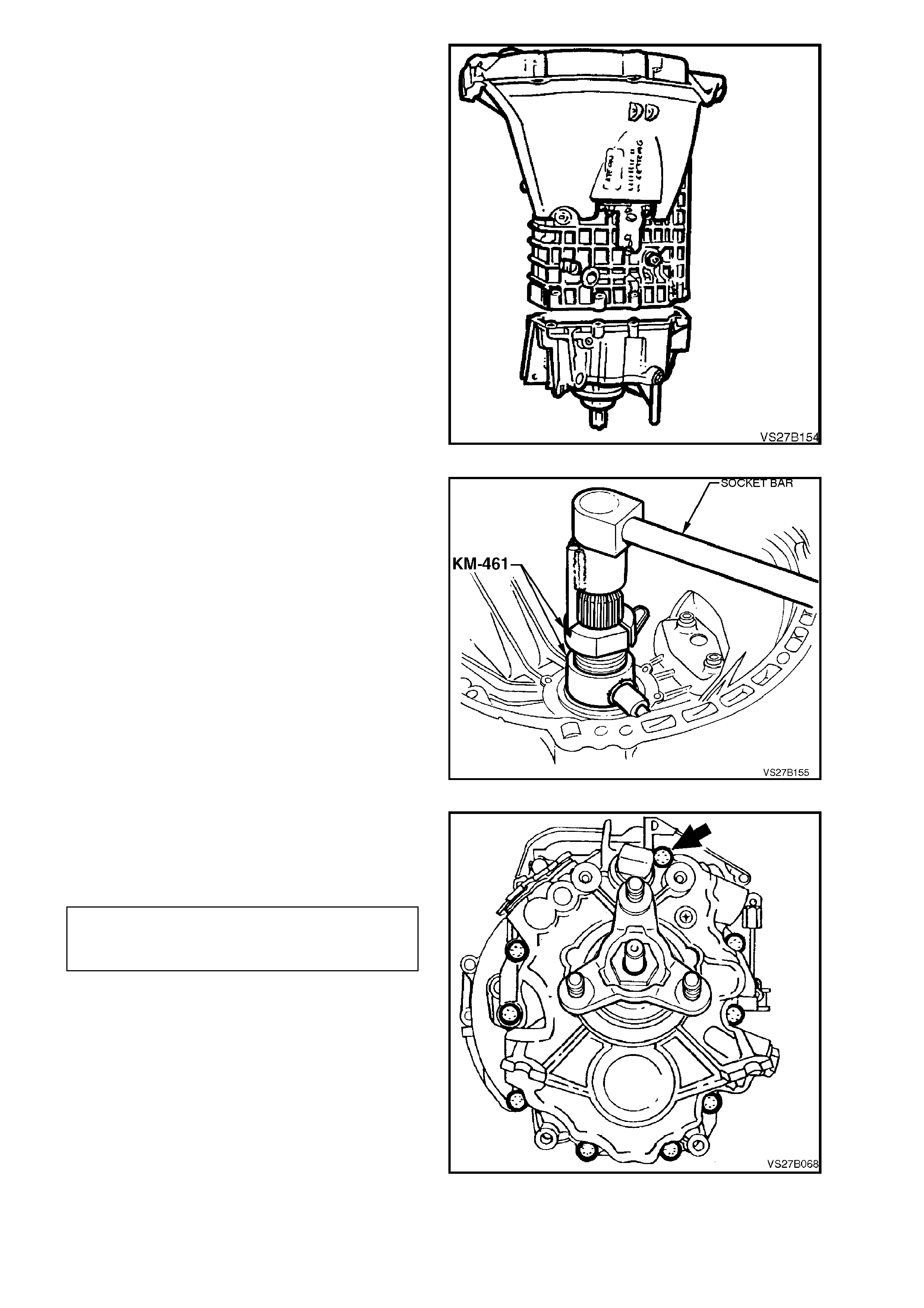

19. Before using the previously released, Tool No.

KM-620-1-A to hold the flange, it must first be

modified by redrilling the three holes stamped

‘B’ (on the Tool) to 13 mm.

Fasten the modified tool to the flange using

the three discarded nuts. Then, using a

suitable length of pipe on the tool handle,

loosen and remove flange nut, using a

commercially available, 30 mm deep socket.

Figure 7B1-73

20. Install extractor, Tool No. AKM-628-A to

mainshaft output flange studs. Use the

removed nuts to secure the extractor tool to

the flange.

21. Tighten ex tractor forc ing bolt to remove flange

from mainshaft.

Figure 7B1-74

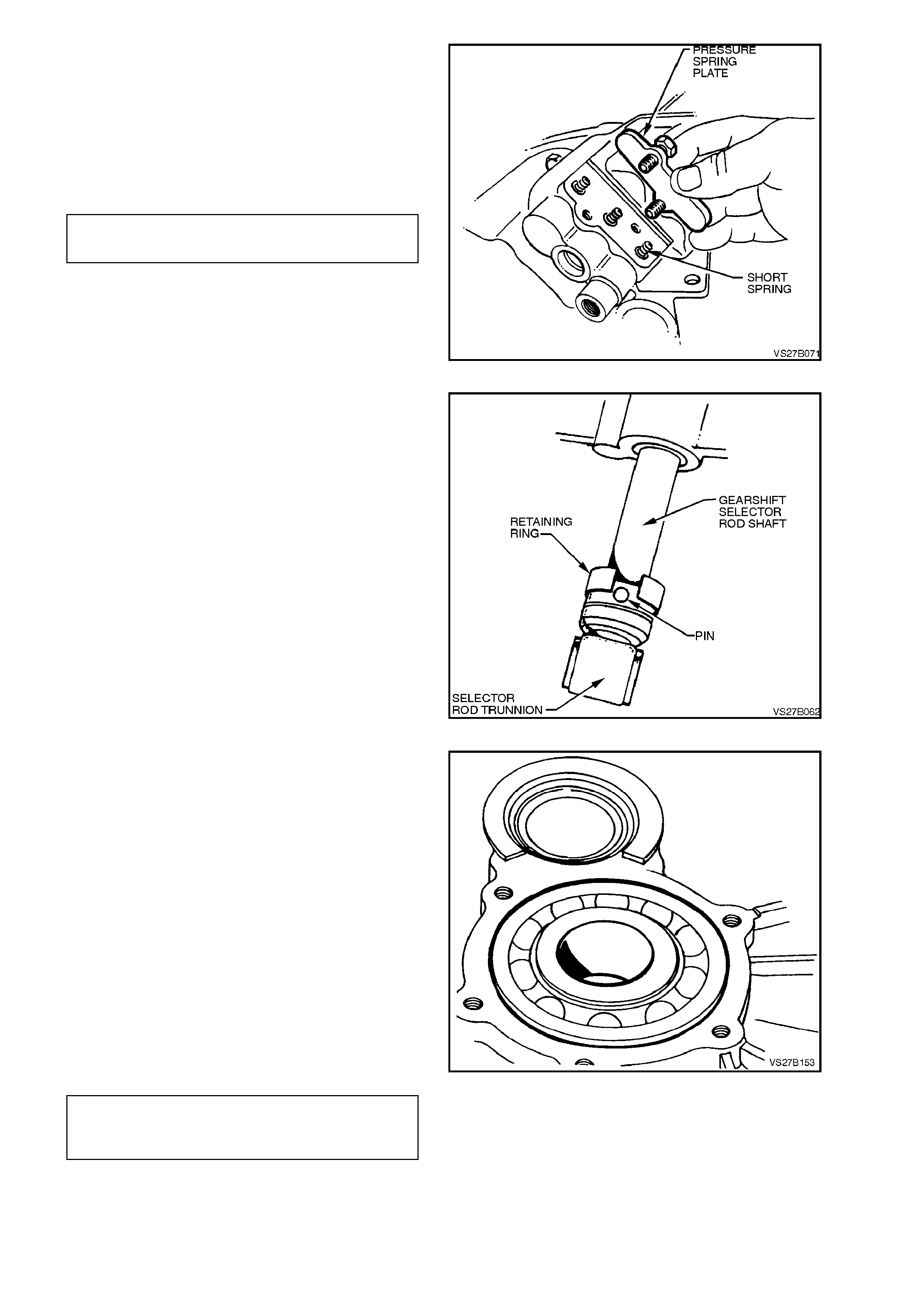

22. Remove bolts attaching pressure spring cover

plate to transmission case rear section.

23. Remove three detent ball springs.

24. Using a pencil magnet, remove three detent

balls from under the springs.

Figure 7B1-75

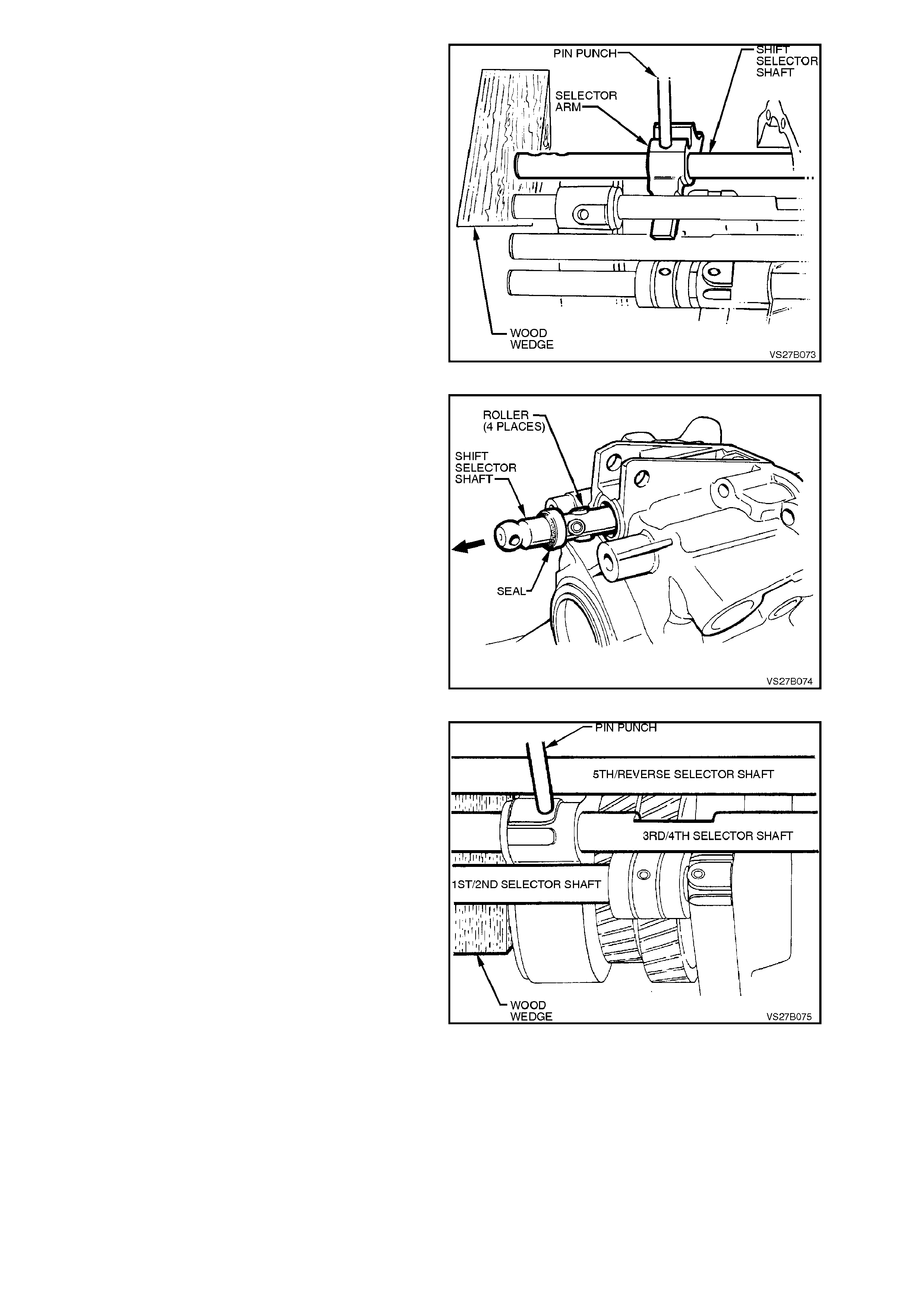

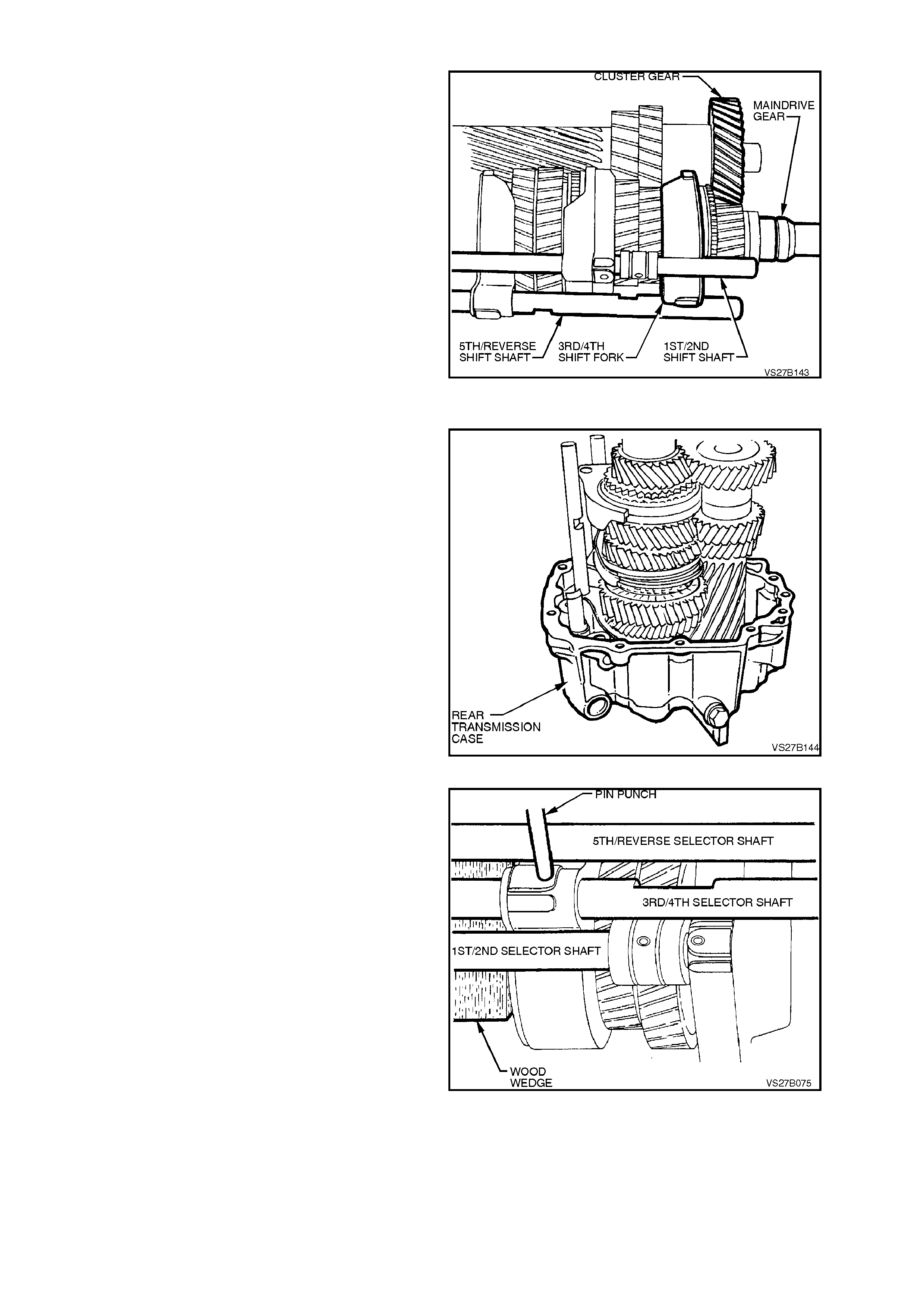

25. Select 4th gear, s upport the s hif t s elec tor s haf t

with a wooden wedge, then remove the roll pin

from the gearshift selector arm, using a

suitable sized pin punch. When in 4th gear,

the roll pin will not foul on gear teeth during the

removal process.

Figure 7B1-76

26. Using a soft faced hammer, tap the shift shaft

rearwards through the bearing support,

removing the seal in the same operation.

NOTE:

As the shift shaft is removed, there are four rollers

that can be dislodged from the pins in the shaft.

Take care not to lose them.

Figure 7B1-77

27. While supporting the selector shaft with a

suitable wedge of wood, drive the selec tor f ork

roll pin out, just s uf ficient to enable the shaf t to

be removed.

Figure 7B1-78

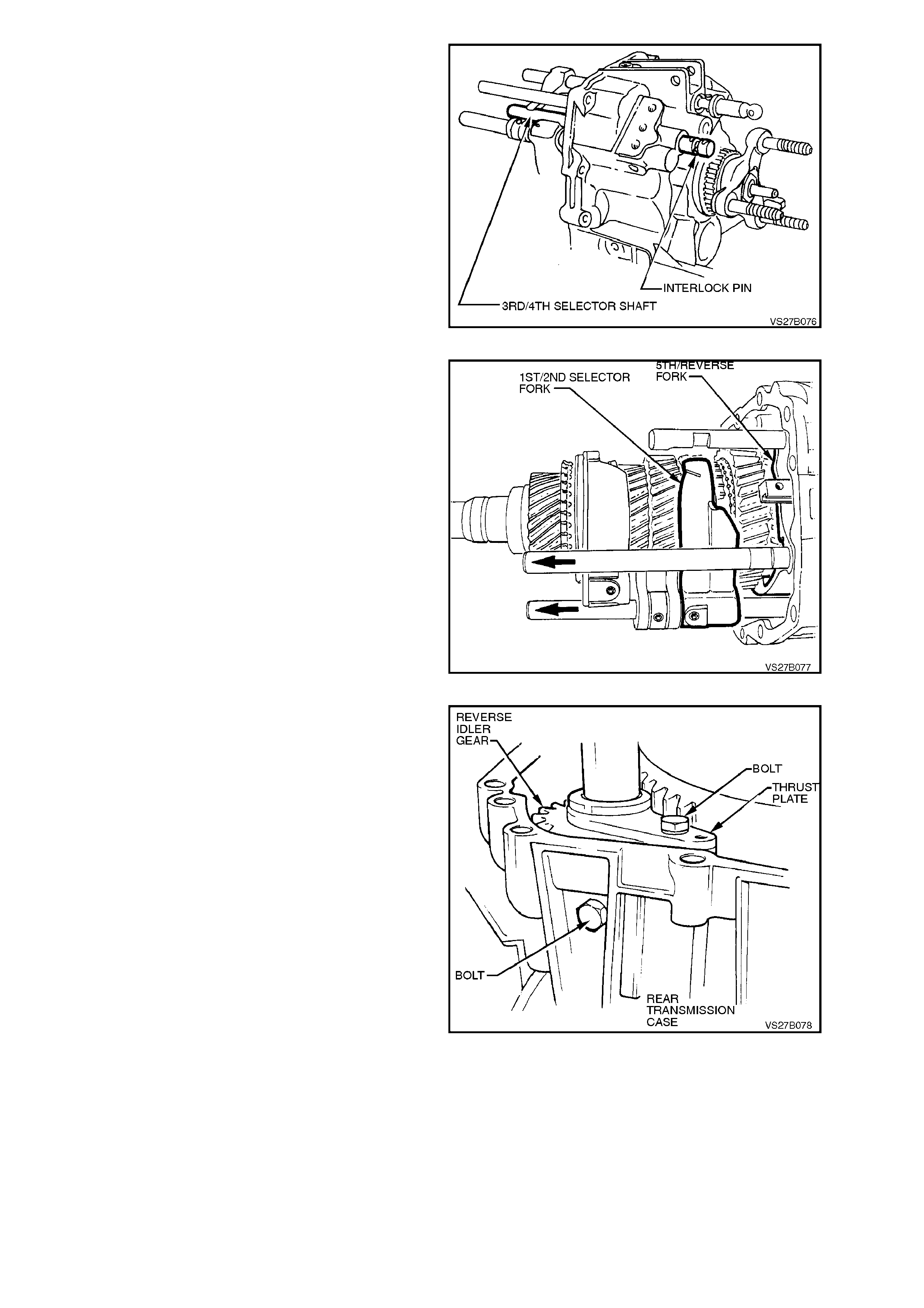

28. While supporting the 3rd/4th shift fork, use a

soft faced hammer to gently tap the shaft

rearward, displacing the expansion plug in the

rear transmission housing. This will allow

rem oval of the inter lock pin and the shaf t from

the rear, which overcomes the risk of the

interlock pin becoming dis lodged and jamm ing

the shaft.

Figure 7B1-79

29. Move the 1st/2nd synchromesh ring forward

into the 2nd gear position and the 5th/Revers e

synchromesh ring forward, into the Reverse

position.

Figure 7B1-80

30. Remove the rear bolt securing the reverse

idler gear to the transmission case and the

bolt securing the thrust plate. Remove the

reverse idler gear shaft and r oller bearing f rom

the rear case section. Remove the idler gear.

Figure 7B1-81

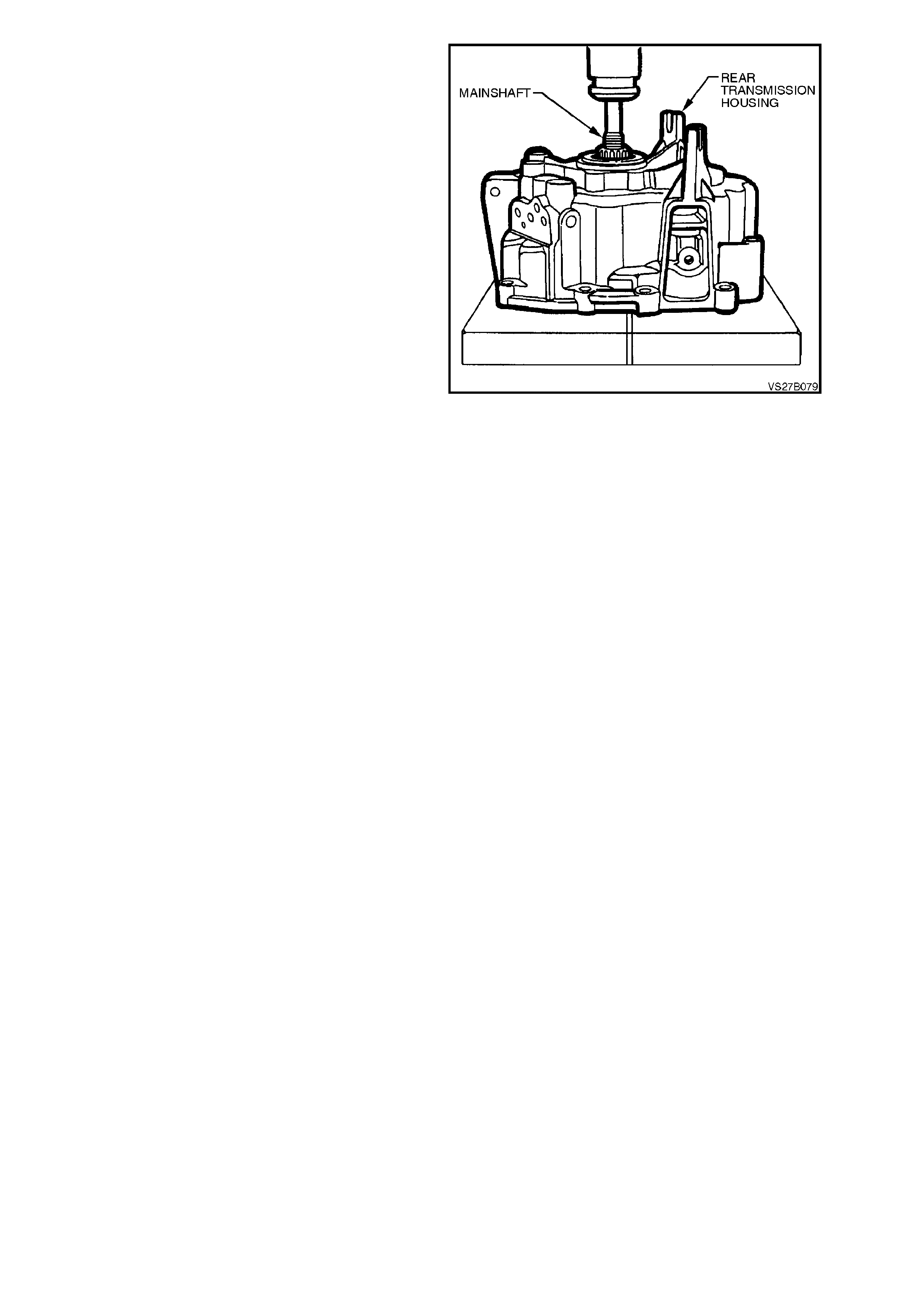

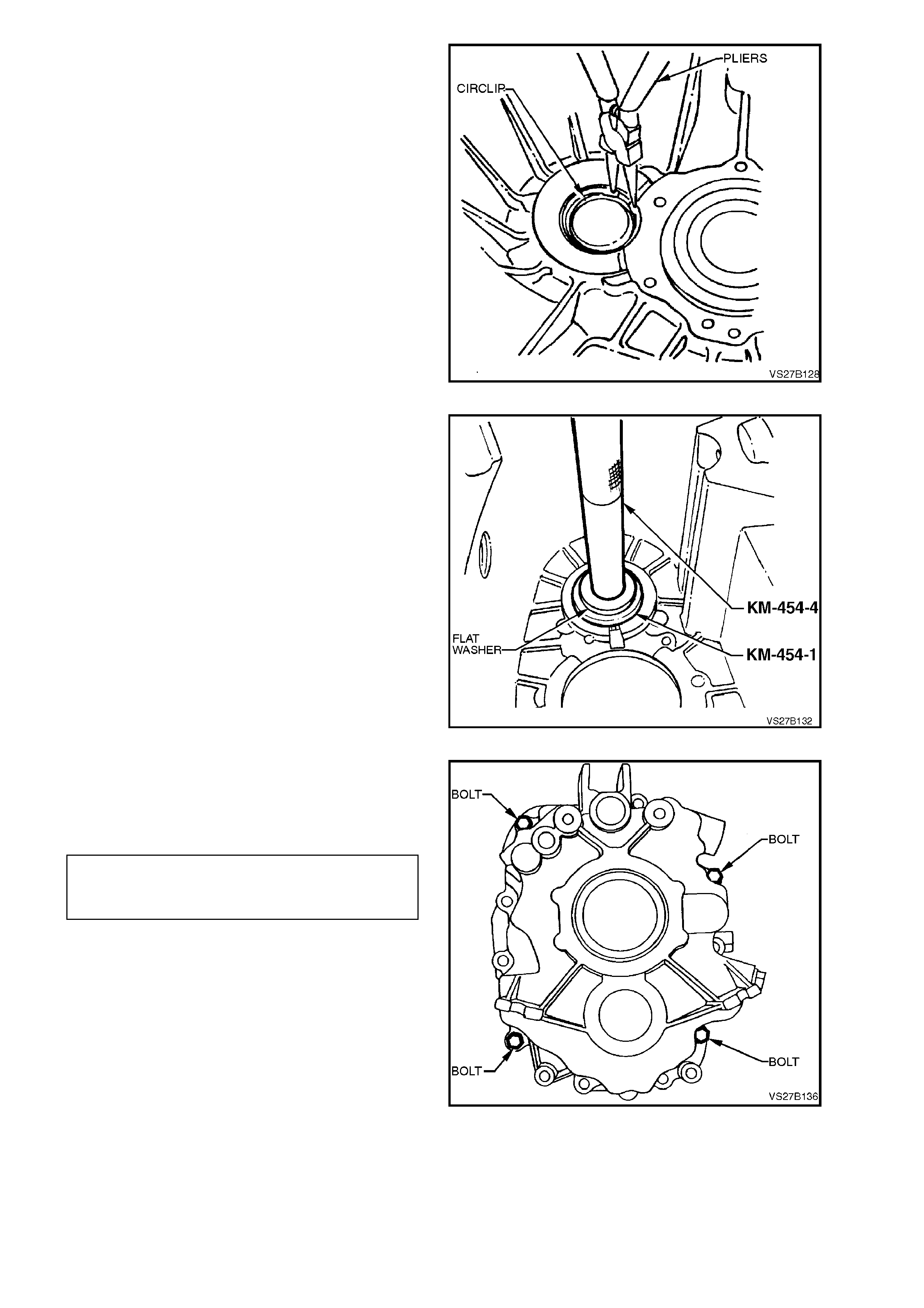

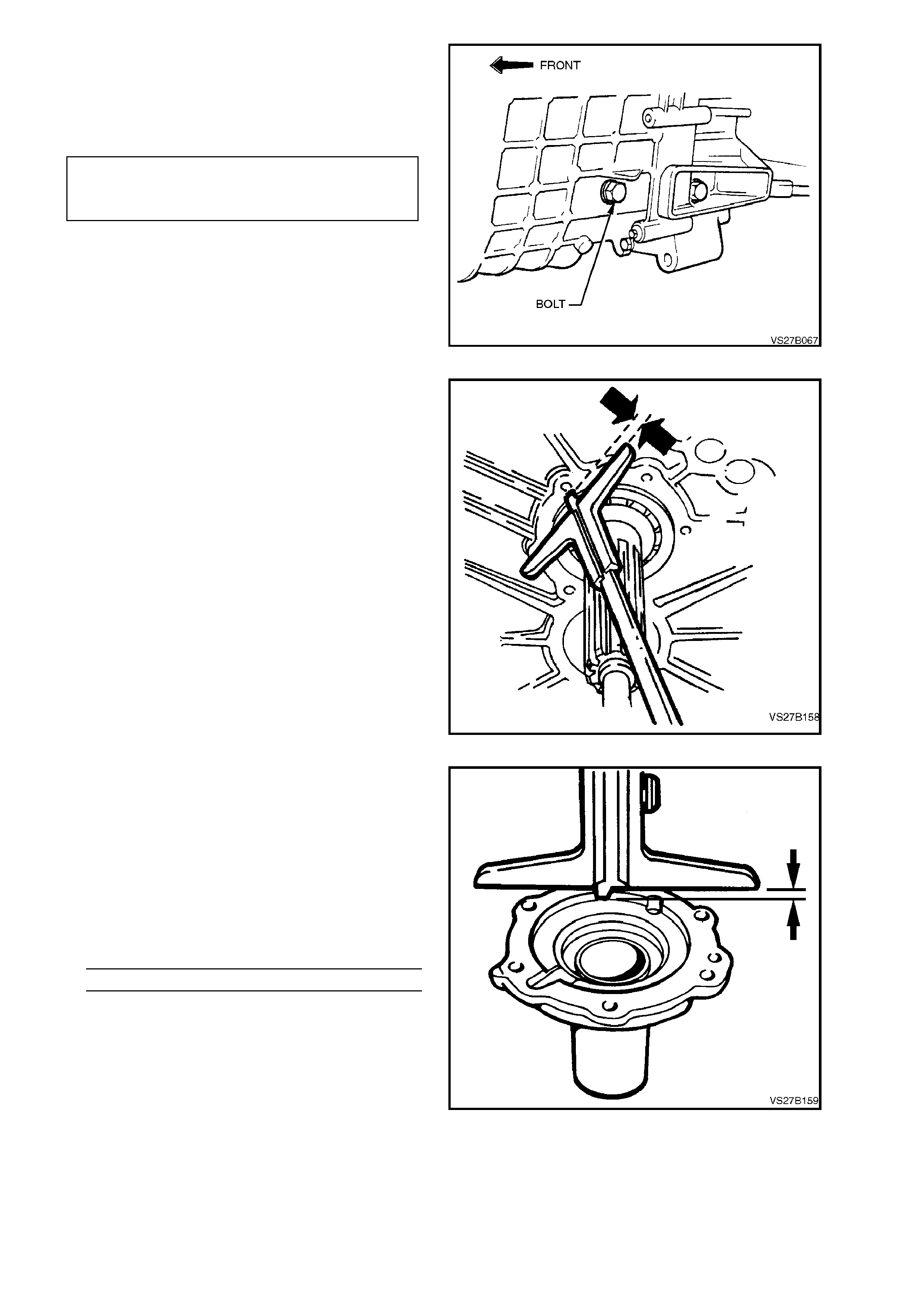

31. To remove mainshaft and cluster gear

assemblies, together with the selector shafts

and forks from rear transmission case,

support the case on suitable press plates , then

press the mainshaft from the rear mainshaft,

sealed ball race.

IMPORTANT:

Take care when the gear assemblies come free

from the ball race, as they are heavy. Do not allow

them to drop to the floor when gear tooth damage

could occur.

NOTE:

Do not lose any of the selector interlock balls that

will come away when the shafts are removed.

There are two of them, both of equal size.

Once free, the cluster gear assembly and

selector shafts and forks can be easily

separated from the mainshaft assembly.

Figure 7B1-82

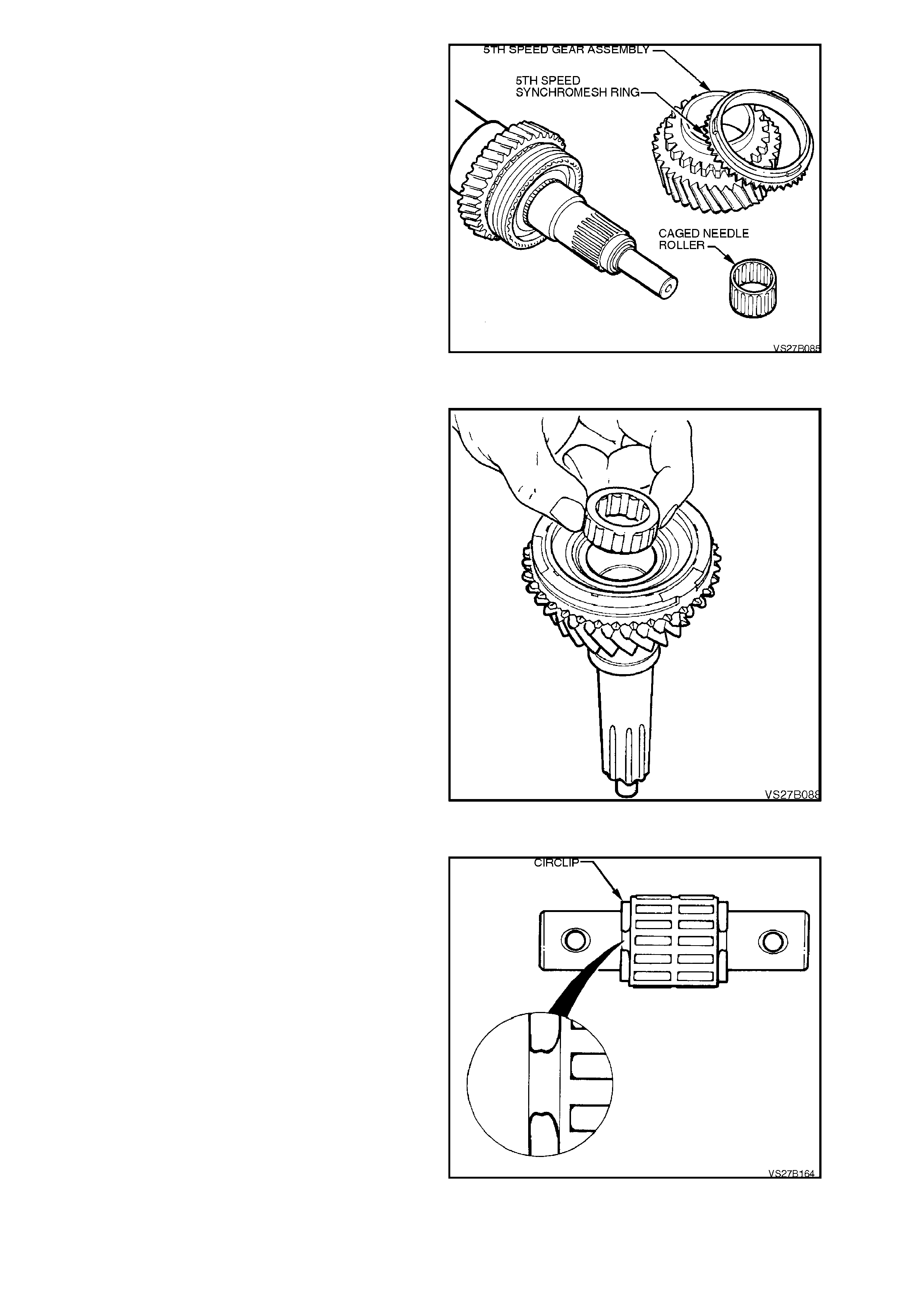

4.4 TRANSMISSION SUB-ASSEMBLIES

DISASSEMBLE

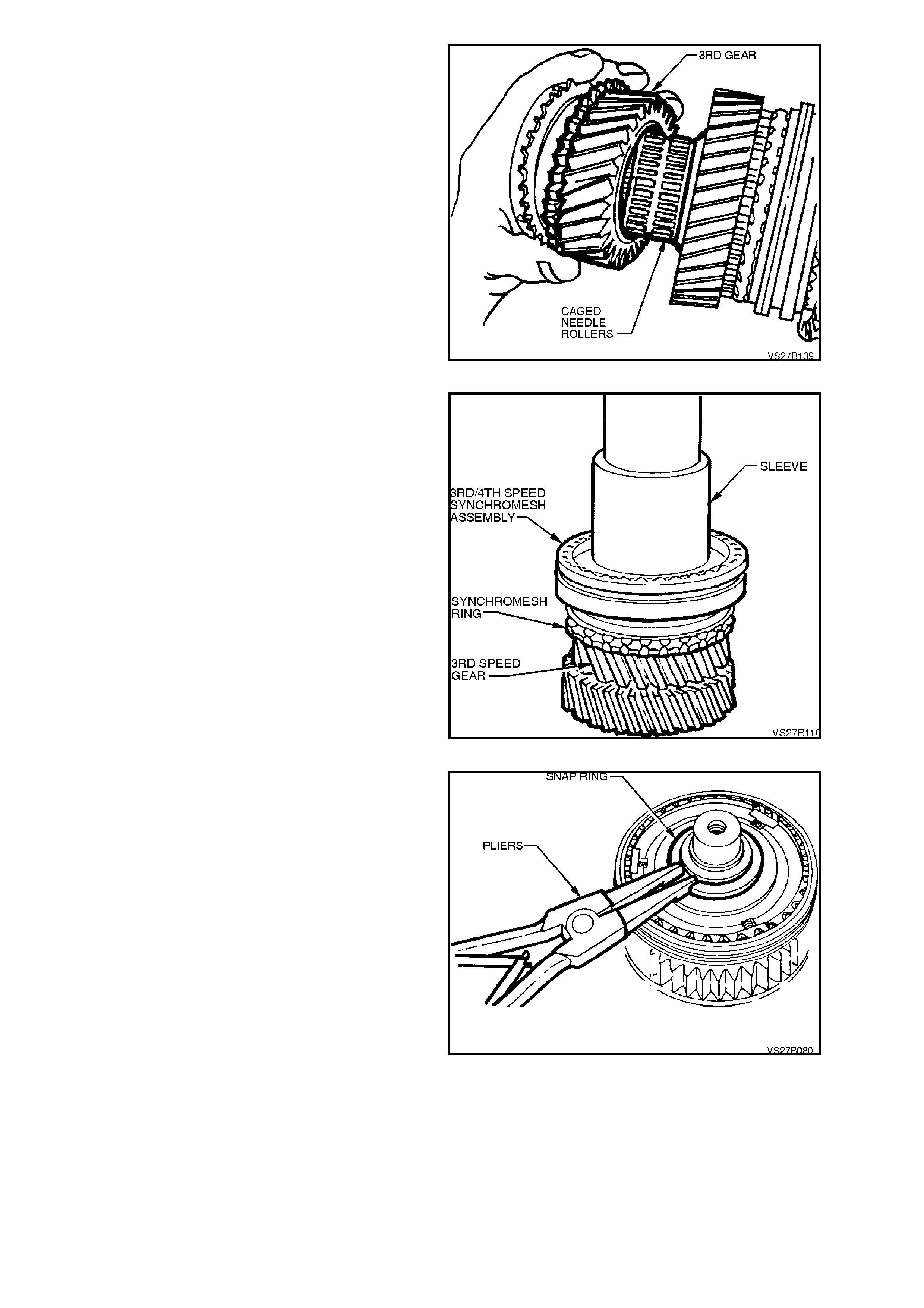

Mainshaft

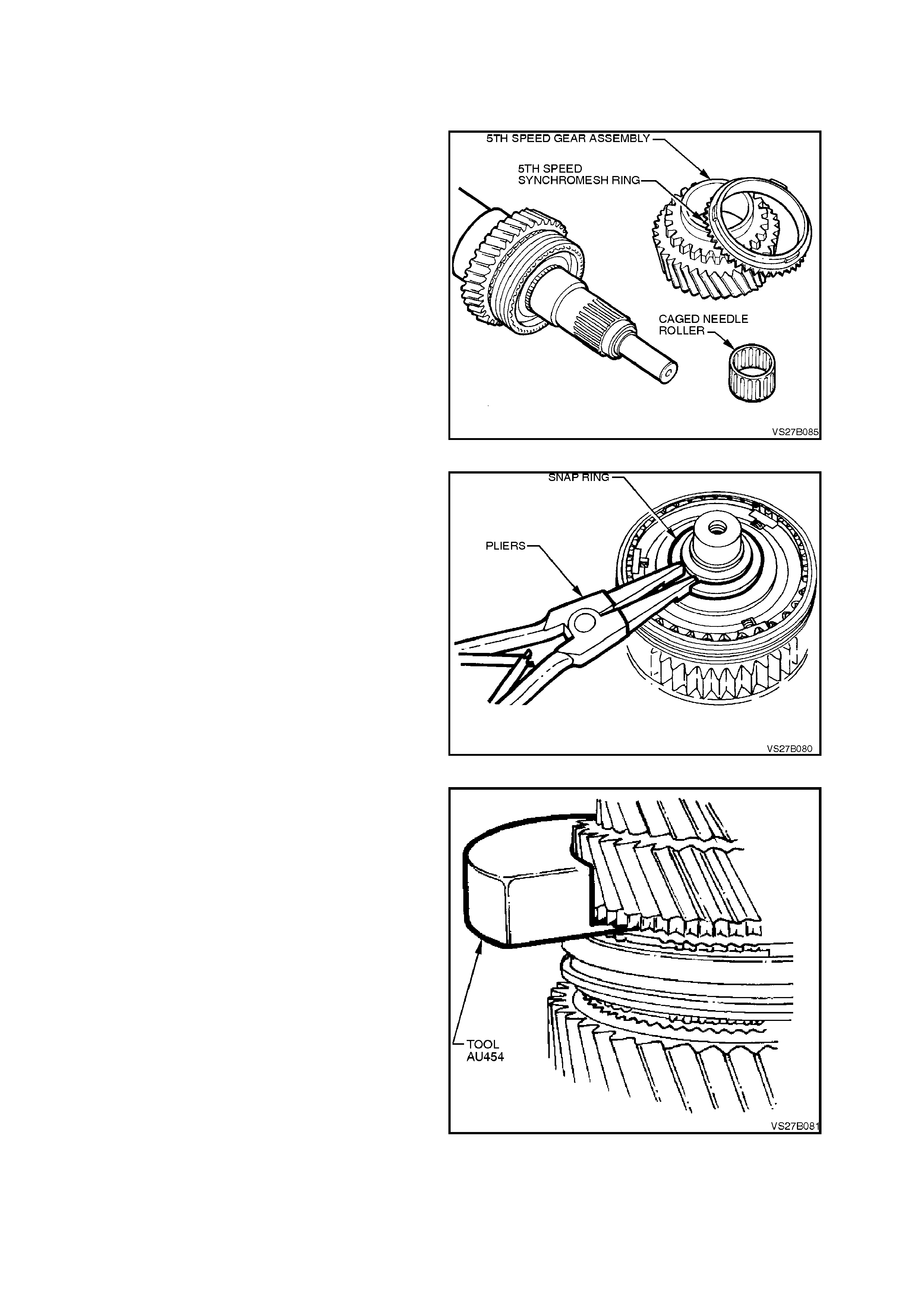

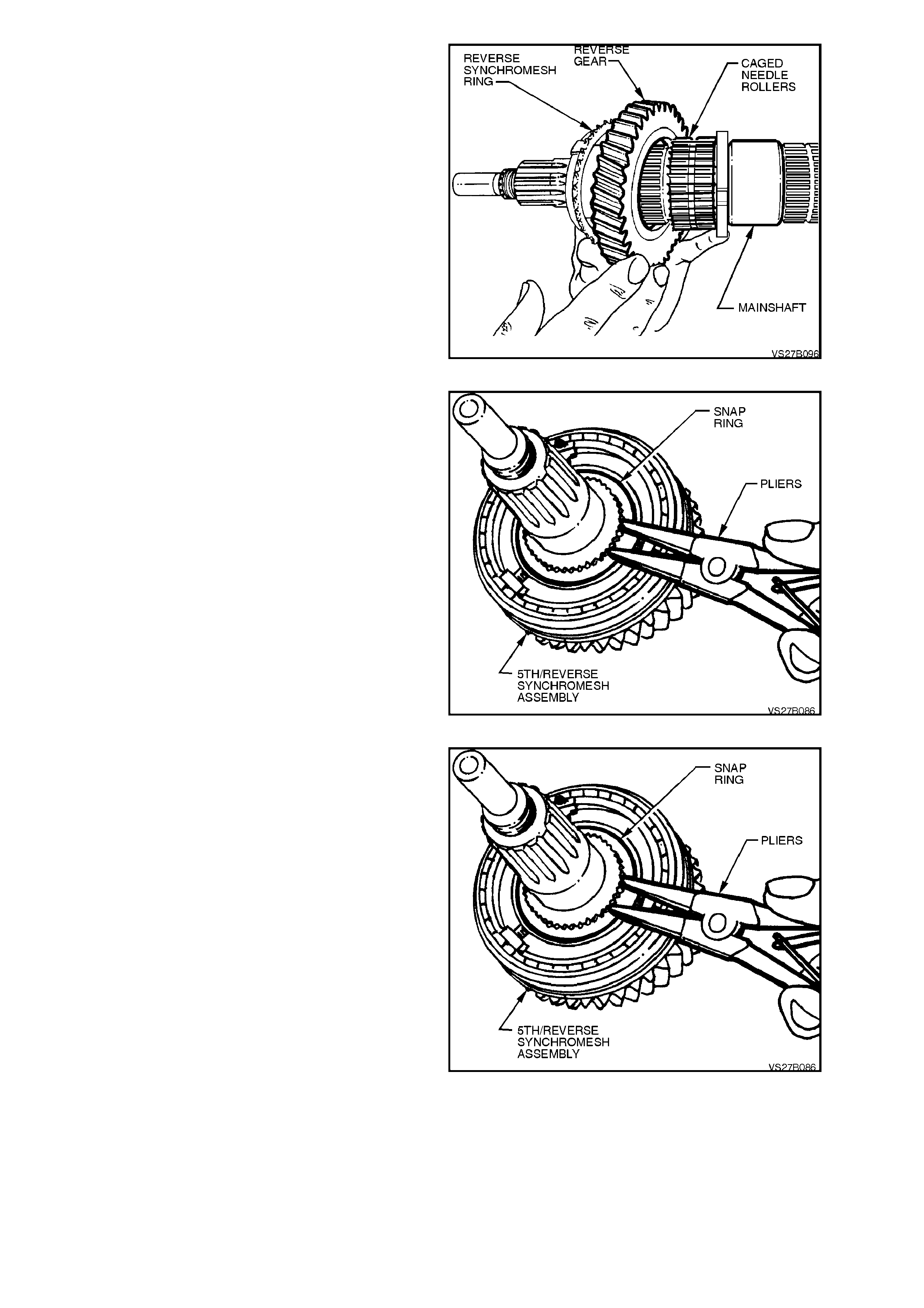

1. Remove the 5th speed constant mesh gear,

synchromesh ring and caged needle roller

bearing from the rear of the mainshaft.

Figure 7B1-83

2. Remove maindrive gear and fourth speed gear

synchromesh ring from mainshaft.

3. Remove snap ring and washer from front end

of mainshaft.

Figure 7B1-84

4. Insert each half of Tool No. AU454 under the

dog clutch teeth of 2nd speed gear, ensuring

that both halves are fully installed.

Figure 7B1-85

5. Support both halves of Tool No. AU454 under

suitable press plates and press the mainshaft

from the following components;

•3rd/4th gear synchromesh assembly.

•3rd speed gear and synchromesh ring.

•3rd speed gear, caged needle roller

bearing.

•3rd speed gear, roller bearing sleeve.

•2nd speed gear thrust washer.

•Thrust washer locating ball.

•2nd speed gear.

•2nd speed gear, caged needle roller

bearing.

NOTE:

As the synchromesh hub and roller bearing sleeve

are both interference fits on the mainshaft, some

forc e will be required to rem ove thes e com ponents.

Also, take care not to lose the thrust washer

locating ball, as it may fall out during the pressing

operation.

6. Remove the three part synchromesh rings

from the 1st/2nd synchromesh assembly.

Figure 7B1-86

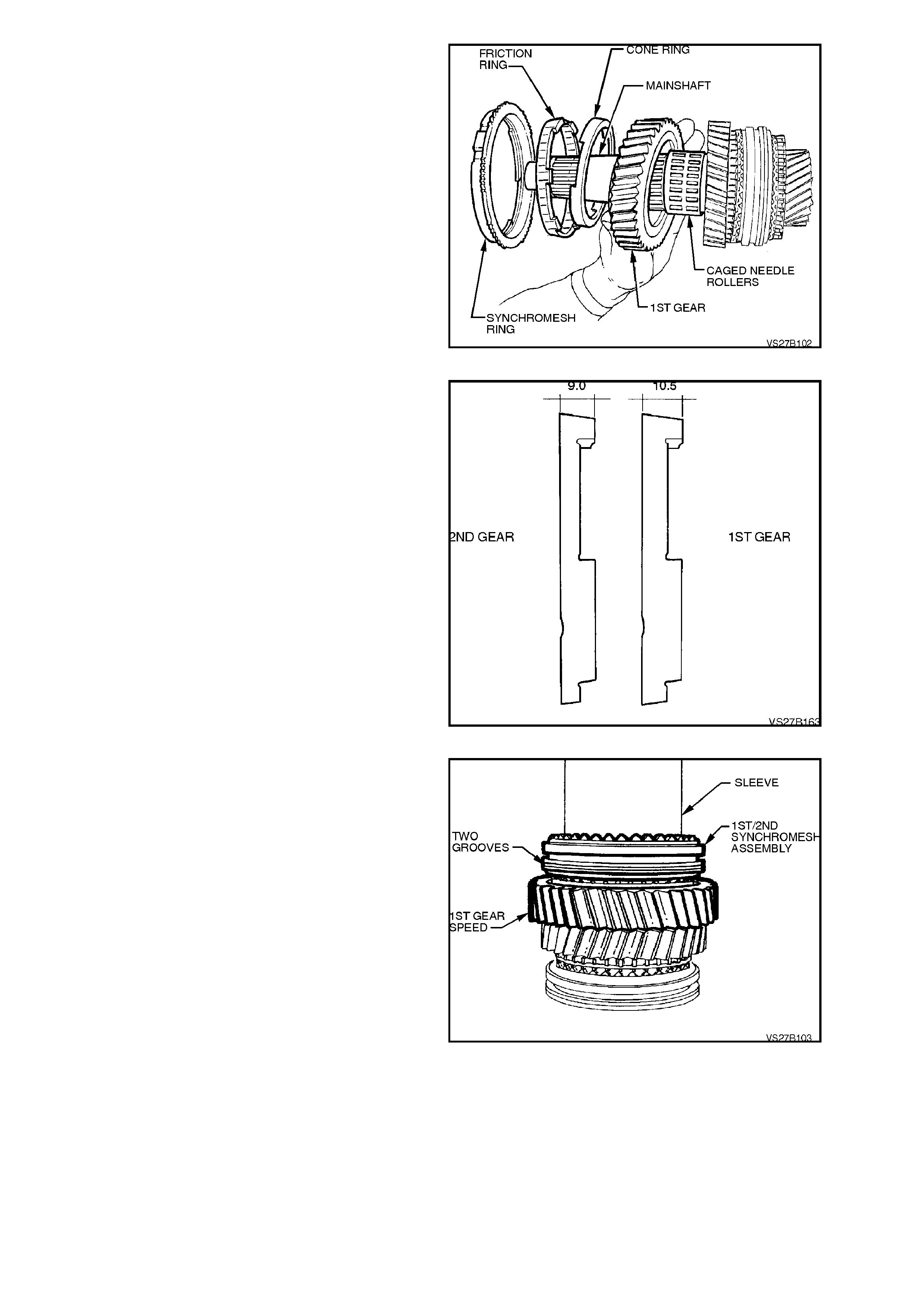

7. Remove snap ring from the 1st/2nd gear

synchromesh hub.

Figure 7B1-87

8. Using suitable press plates, positioned with

the flat side under first speed gear, press

mainshaft from 1st/2nd speed synchromesh

assembly, 1st speed synchromesh ring, cone

ring, friction ring, first speed gear and needle

roller bearing.

Figure 7B1-88

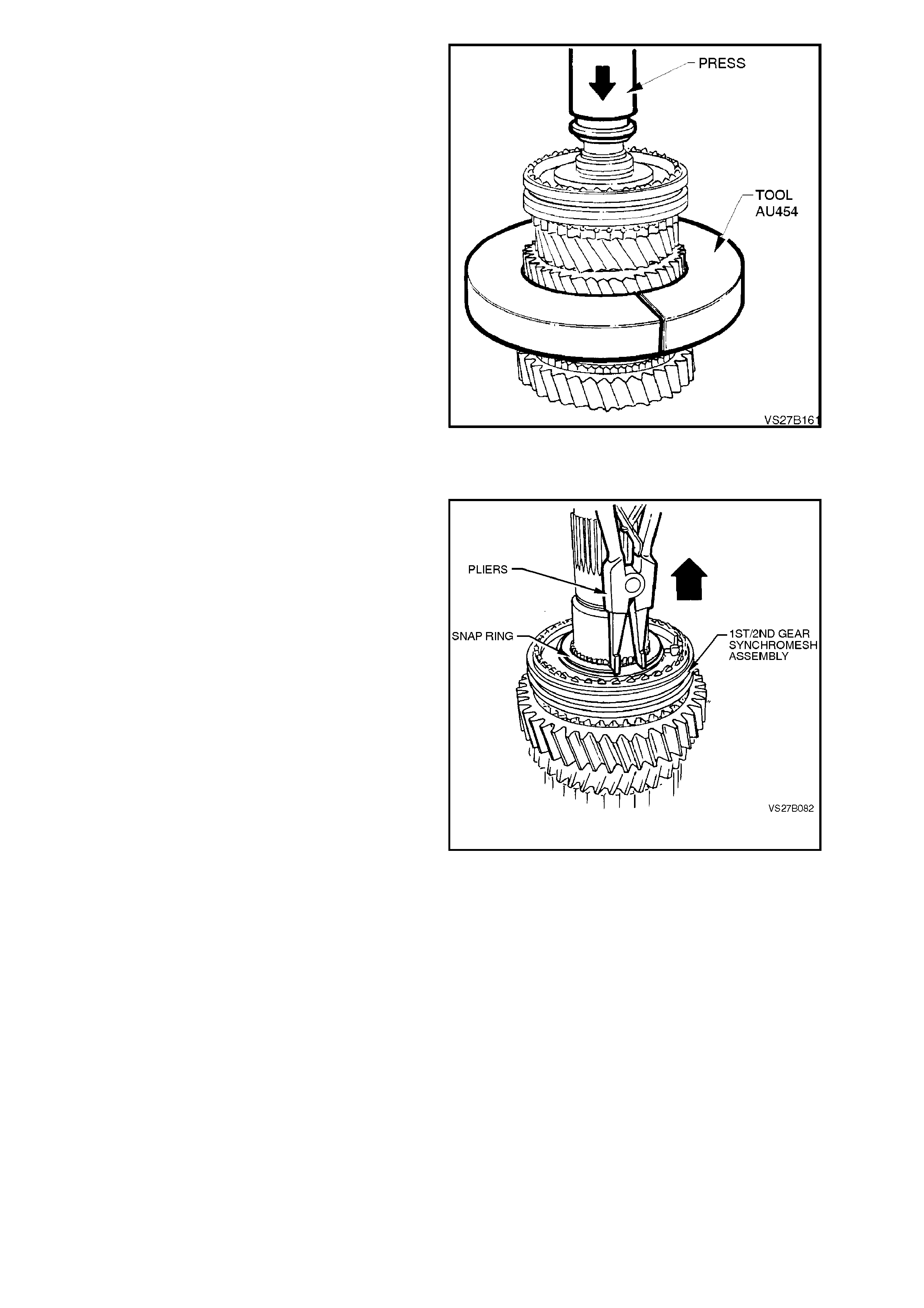

9. Remove 5th/Rever se speed synchrom esh hub

snap ring from mainshaft.

Figure 7B1-89

10. Press mainshaft from 5th/Reverse speed

synchromes h assembly, reverse synchrom esh

ring and reverse constant mesh gear, using

suitable press plates, with the flat side

positioned under Reverse speed gear.

11. Remove reverse speed gear and selective,

caged needle roller bearing from mainshaft.

Figure 7B1-90

MAINDRIVE GEAR

1. Remove the caged needle roller bearing from

the maindrive gear.

Figure 7B1-91

CLUSTER GEA R

While the cluster gear is made up from three

separate components, it is only serviced as a

complete assembly. It should therefore, not be

dismantled. The assembly of the components is

precise and cannot be duplicated.

REVERSE IDLER GEAR SHAFT

When removing the two snap rings securing the

two caged needle roller bearings to the idler shaft,

take par ticular note of the orientation of each to the

bearings.

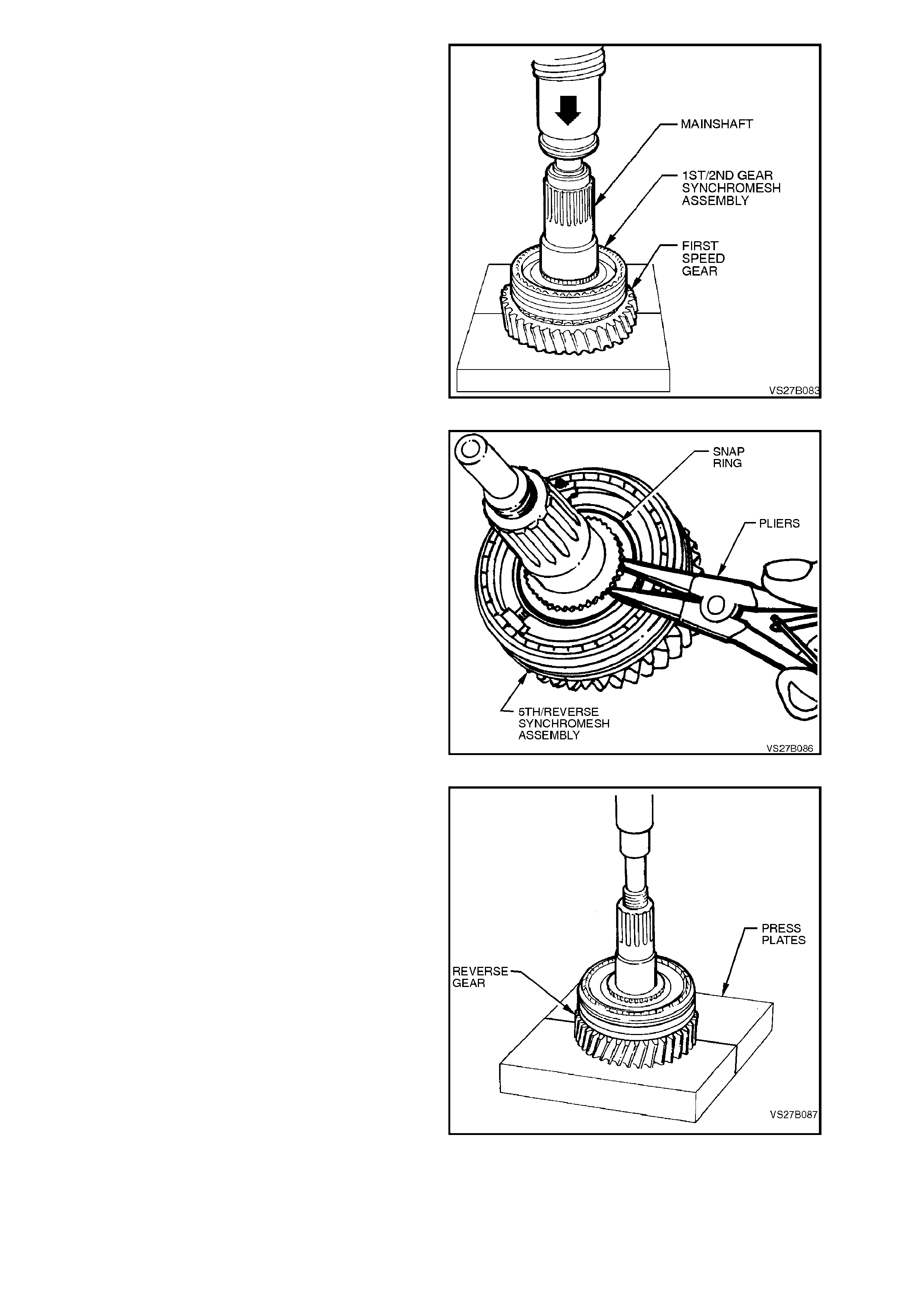

SYNCHROMESH ASSEMBLIES

With the index finger and thumb of the left hand

circling the synchromesh hub, slide the outer

sleeve from the assem bly, using the r ight hand. Be

careful that the pressure springs do not cause any

of the three balls to be ejected and lost. Note the

relationship of the outer sleeve to the synchrom esh

hub.

NOTE:

While the synchromesh assembly shown is for the

1st/2nd speed ranges, the disassembly process is

the same for each of the remaining two

assemblies.

Figure 7B1-92

INSPECT COMPONENTS

1. Check synchromesh rings for cracks and for

deformation. Inspect rings for excessive wear

in the areas shown.

2. Check synchromesh hubs, outer sleeves,

sliding blocks and synchromesh springs for

damage.

Figure 7B1-93

3. Check each synchromesh ring for wear by

mounting the ring on the respective gear and

measuring the gap, as indicated.

NOTE:

To obtain an accurate measurement, the

synchromesh ring must be held squarely and fully

installed on its gear, as shown. Then, using feeler

gauges, measure the gap in at least three places

around the circumference. Average the readings

and use this f igure to asse ss the synchr omesh ring

wear.

Specifications for each synchromesh ring are as

follows and correspond to the synchromesh

assemblies indicated in the sectioned view.

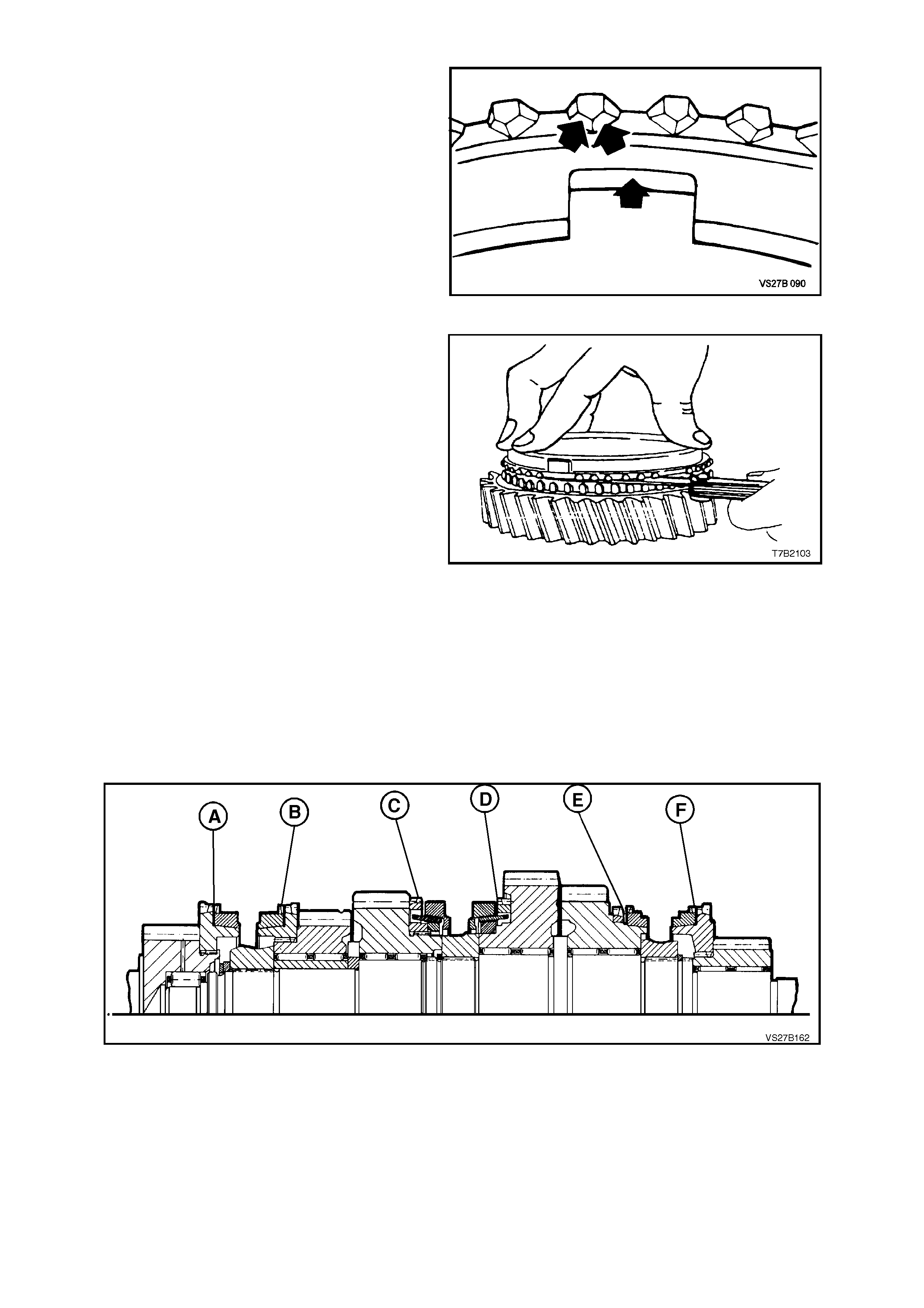

Position Gear Serviceable Wear Limit

(A) 4th 0.82 - 1.35 mm

(B) 3rd 0.82 - 1.35 mm

(C) 2nd 0.85 - 2.25 mm

(D) 1st 0.95 - 2.35 mm

(E) Reverse 0.5 - 0.98 mm

(F) 5th 0.82 - 1.35 mm

Figure 7B1-94

Figure 7B1-95

4. Inspect all gears, sleeves, hubs, rings and

shafts for wear, scoring, pitting, c hips, nick s or

burrs. Slight s cores or bur rs m ay be honed off

with a fine stone, however if a gear is chipped

or unduly worn it must be replaced.

5. Inspect all needle roller bearings for wear or

damage.

NOTE:

As needle roller wear can be difficult to see, it is

good practice to r eplace all roller bear ings where a

substantial distance has been covered by the

transmission.

6. Inspect the mainshaft surfaces, roller bearing

inner sleeves and internal surfaces of the

gears where the needle bearings come into

contact.

NOTE:

The needle roller bearing assembly used with the

mainshaft Reverse gear, is a selective fit. Should

any component associated with this gear and/or

the mainshaft need to be replaced, then the

following procedure must be adopted, to ensure

that the correct replacement part/s are fitted.

SYNCHROMESH ASSEMBLIES

Identification

Identification or particular installation position of

each of the synchromesh assembly components is

described as follows:

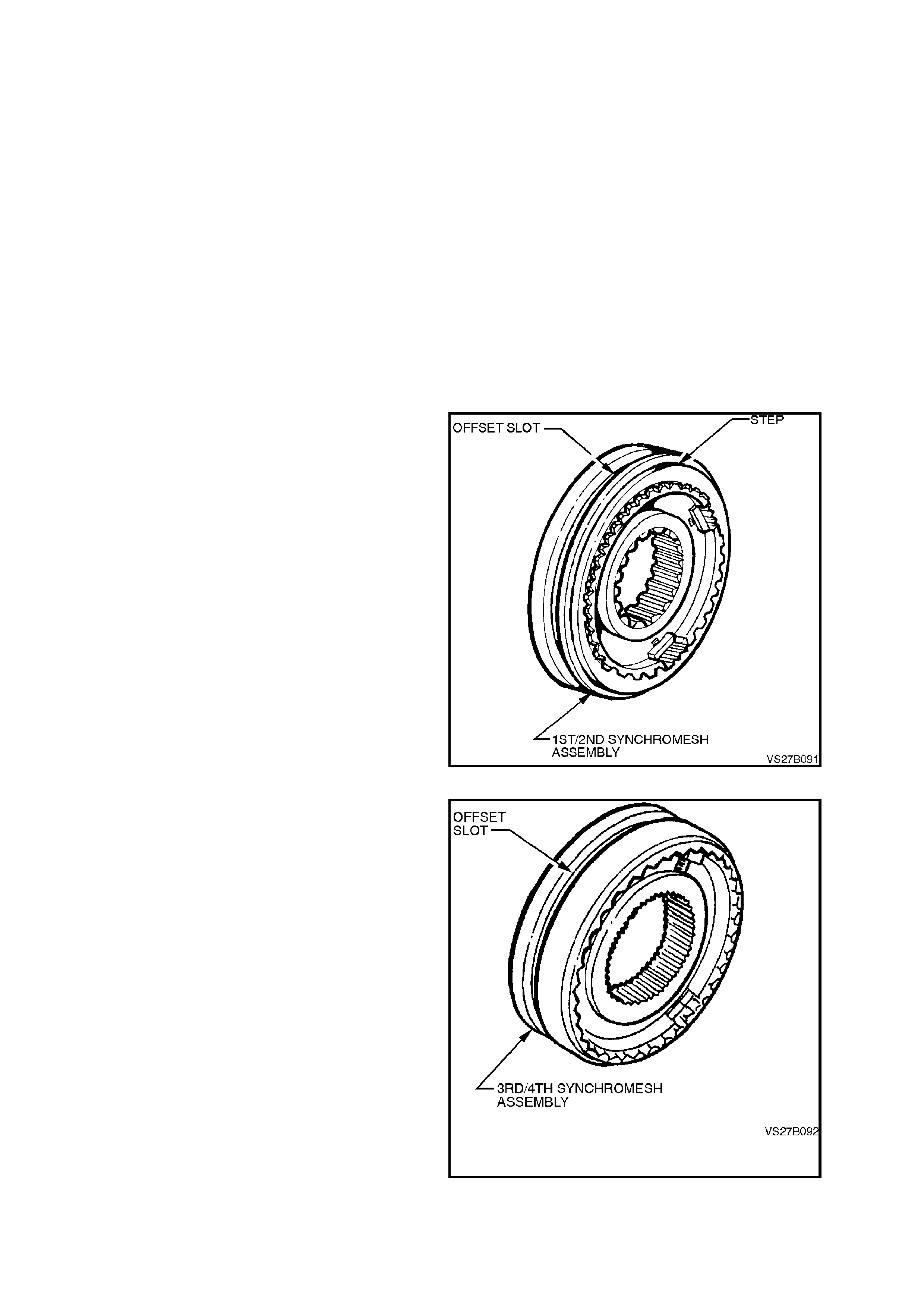

1. The 1st/2nd speed synchromesh assembly

can be recognised by the larger diameter

splined hole in the hub, when com pared to the

3rd/4th synchromesh assembly.

The stepped edge on the outer sleeve is

another identification feature.

Figure 7B1-96

2. Identification of 3rd/4th speed synchromesh

assembly is by the offset selector slot in the

outer sleeve and smaller diameter s plined hole

in the hub.

Figure 7B1-97

3. Identification of the 5th/Reverse synchromesh

assembly is by a single groove on the outer

sleeve and the larger diameter splined hole in

the hub, when compared to the 3rd/4th speed

synchromesh assembly.

Figure 7B1-98

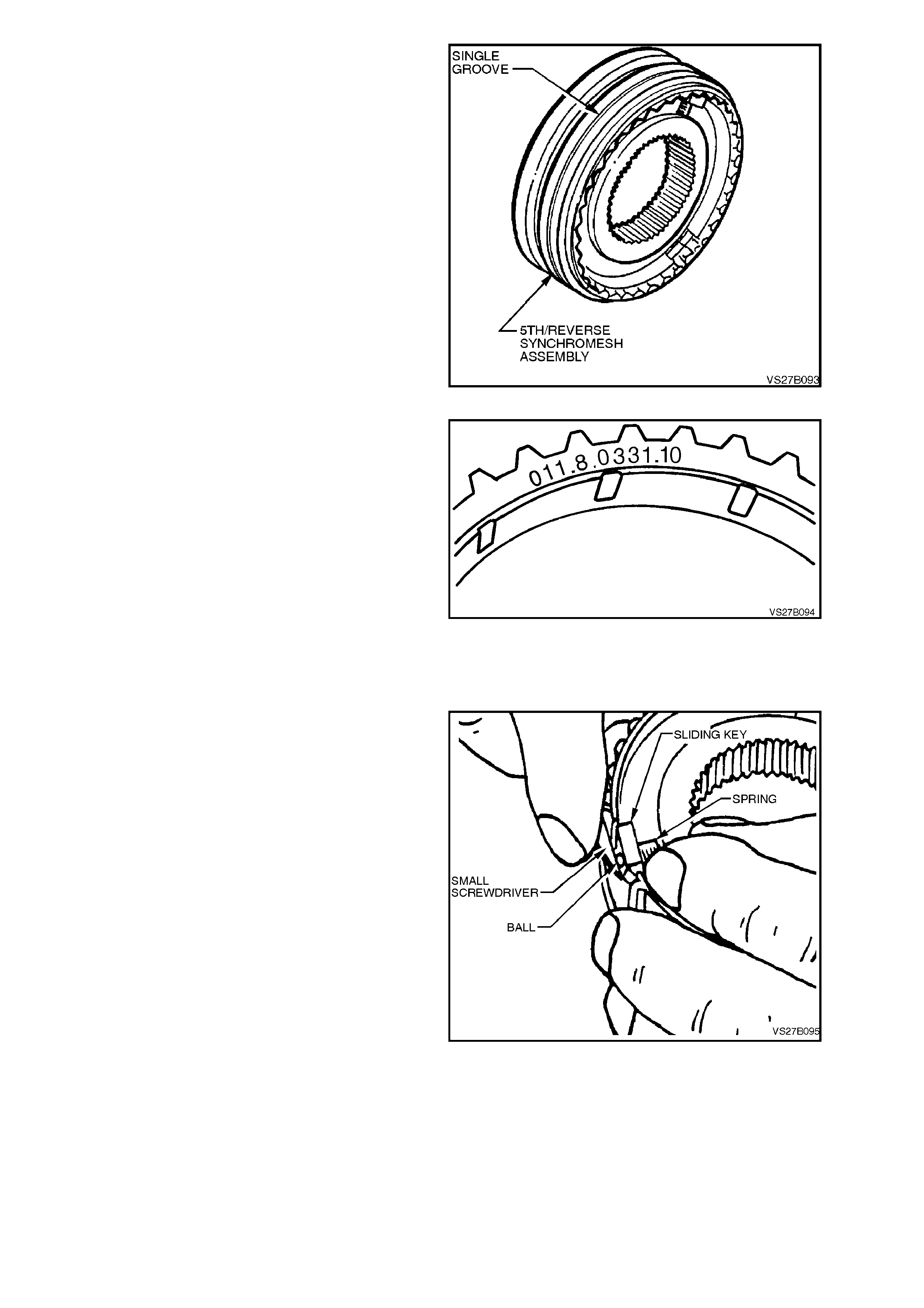

The synchromesh rings can be identified by the

number stamped on the flat face of each one.

Applications are as follows;

1st/2nd 040.8.0001.00

3rd/4th 002.8.0301.00

5th/Reverse 011.8.0331.10

(optional) 011.8.0331.11

Figure 7B1-99

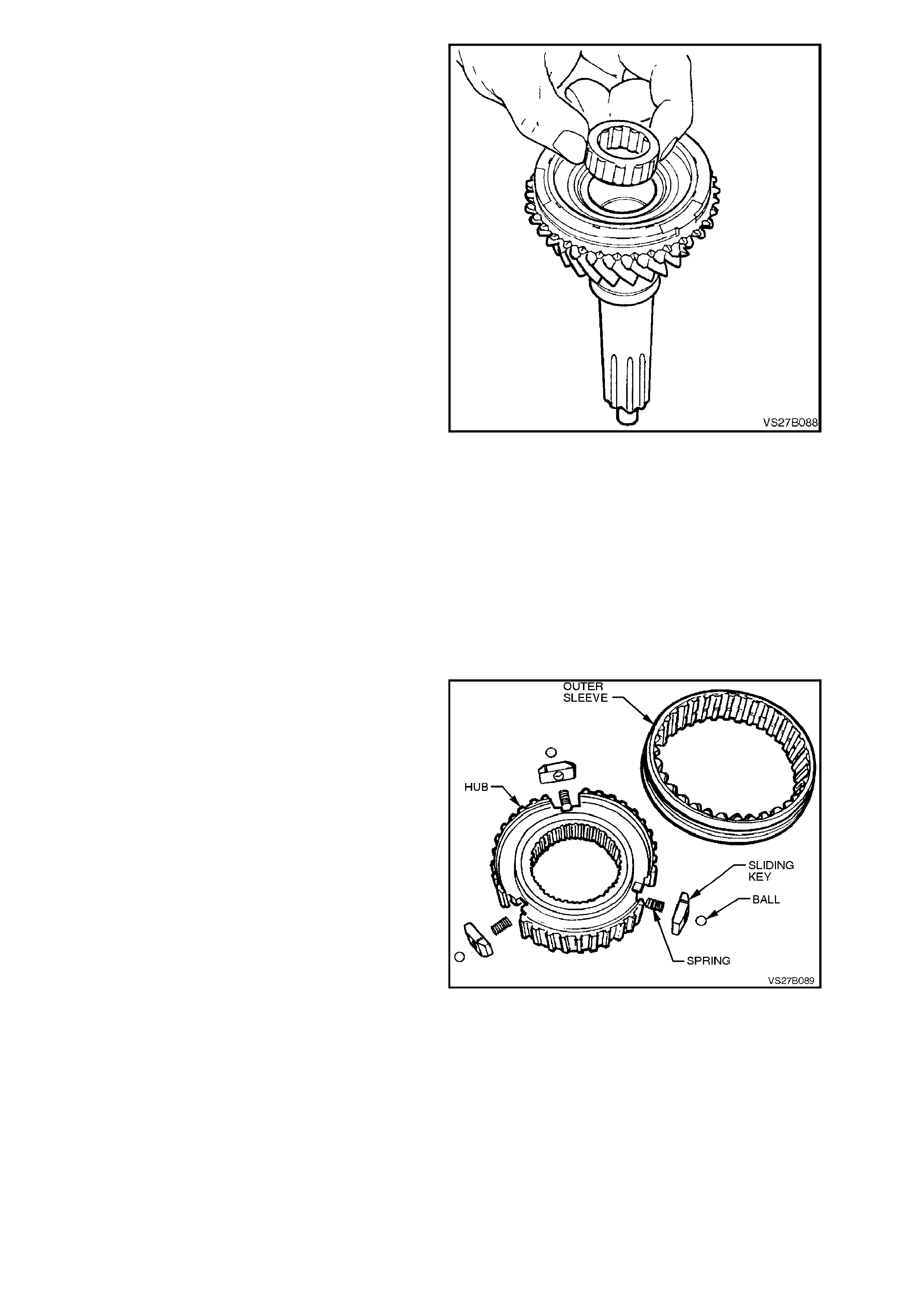

REASSEMBLE

Synchromesh Assemblies

The respective synchromesh assemblies are to be

assembled before pressing onto the mainshaft.

Only one synchromesh assembly is described in

the following operations, since reassembly is

similar for all units.

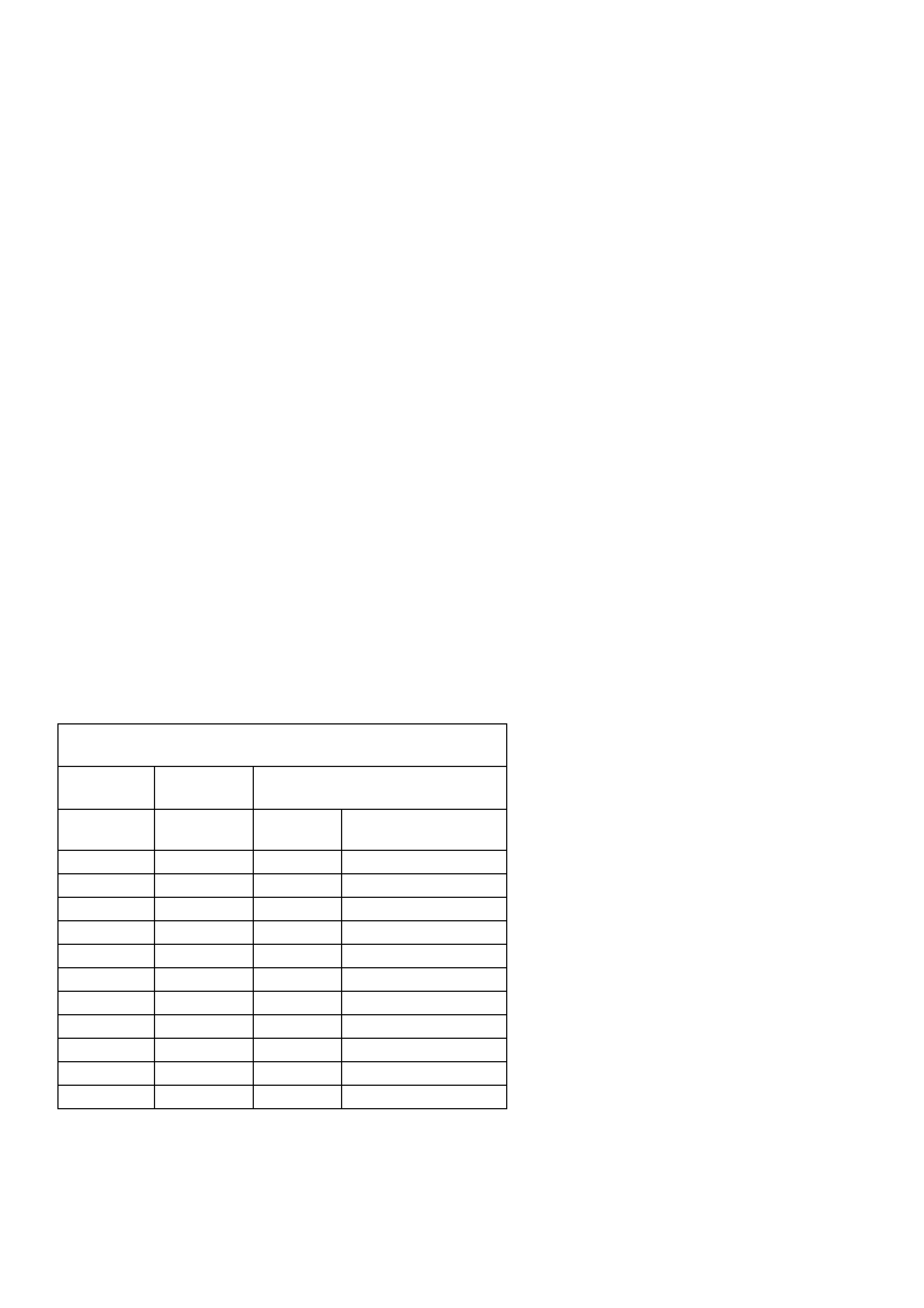

1. Support the synchromesh hub over a suitable

disc to raise it from the bench surface and

install the outer sleeve over the synchromesh

hub.

2. Insert sliding keys (with the chamfered ends

facing outwards) and the pressure springs,

into each of the locations in the synchromesh

hub. Use petroleum jelly to hold parts in place.

3. Using a small screwdriver, prise each key

upwards, just sufficient to enable a ball to be

inserted. While holding the ball inwards, push

the key down to capture the ball. Repeat for

the remaining two key/spring combinations.

Figure 7B1-100

Assembly Notes:

a. The thicker boss of the 3rd/4th

synchromesh hub faces 3rd gear. The

offset of the 3rd/4th selector fork groove

faces 4th gear.

b. The offset groove and the step in the

outer sleeve of the 1st/2nd gear

synchromesh assembly, faces 1st gear.

c. The single groove on the outer sleeve of

the 5th/Reverse synchromesh outer

sleeve, faces 5th gear.

MAINSHAFT

Reverse Gear Needle Roller Bearing

NOTE:

The mainshaft reverse gear, caged needle roller

bearing is a selective fit, with the various sizes

identified by different colour needle roller bearing

cages.

Both the mains haft and r everse gear are accurately

measured after manufacture and the size recorded

by using different colour paint daubs on each

component.

Depending on the combination of the two different

colours (and therefore, sizes), the correct needle

roller bearing can then be selected, also by a colour

coding of the cage.

Examples of the selection process, using the

opposite table, are;

1. With a white paint daub on the mainshaft and

a green daub on the reverse gear, the correct

needle roller selec tion would be one that had a

red cage.

2. A yellow daub on the mainshaft with a yellow

daub on the reverse gear , indicates the correc t

needle roller selection as being one with a

white cage.

3. Those combinations marked ‘*‘ are non-

preferred combinations. If possible, an

alternative mainshaft or reverse gear colour

would be preferred. However, is this is not

possible, then the choices as listed, can be

used.

TABLE 1

Relationship of the Mainshaft, Reverse Gear and Reverse

Gear Needle Roller Bearing

Mainshaft Reverse

Gear Needle Roller Bearing

Paint Daub

Colour Paint Daub

Colour Cage

Colour Undersize Dimension

White Yellow Green -0.5 to -0.7 mm

White White White -0.3 to -0.5 mm

White Green Red 0 to -0.2 mm

Yellow Orange Green -0.6 to -0.7 mm

Yellow Yellow White -0.3 to -0.5 mm

Yellow White Blue -0.1 to -0.3 mm

*Yellow Green Red 0 to -0.2 mm

Orange Blue Green -0.5 to -0.7 mm

Orange Orange White -0.3 to -0.5 mm

Orange Yellow Blue -0.1 to -0.3 mm

* Orange White Red 0 to -0.2 mm

1. Coat mainshaft, all gear bores and needle

bearings with transmission lubricant.

2. Assem ble the colour c oded, selec tive Reverse

gear needle bearing, gear and synchromesh

ring to mainshaft.

3. Preheat assembled 5th/Reverse speed

synchromesh hub to approximately 100 °C.

NOTE:

Use Faber Castell Thermochrom 2815/100 °C to

indicate temperature.

Apply therm ochrom around the inner s urface of the

synchromesh hub.

Figure 7B1-101

4. Using a heat proof glove, position

synchromesh assembly onto mainshaft, with

the groove in the outer sleeve facing 5th gear

and aligning mainshaft and hub splines.

5. Using suitable sleeve and press plates, press

mainshaft into synchromesh hub, ensuring

that synchromesh ring slots align with sliding

keys in the synchromesh assembly.

6. Remove mainshaft from press, and if

necessar y, lever up the Reverse s ynchrom esh

ring with a screwdriver so that it is not jam m ed

on the gear cone.

Figure 7B1-102

7. Install synchromesh assembly selective snap

ring onto mainshaft, ensuring that no gap

exists between the synchromesh hub and the

installed snap r ing. Mak e sure the snap ring is

seated correctly in groove.

Snap rings are available in thicknesses of 1.8, 1.85,

1.9, 1.95 and 2 mm.

Figure 7B1-103

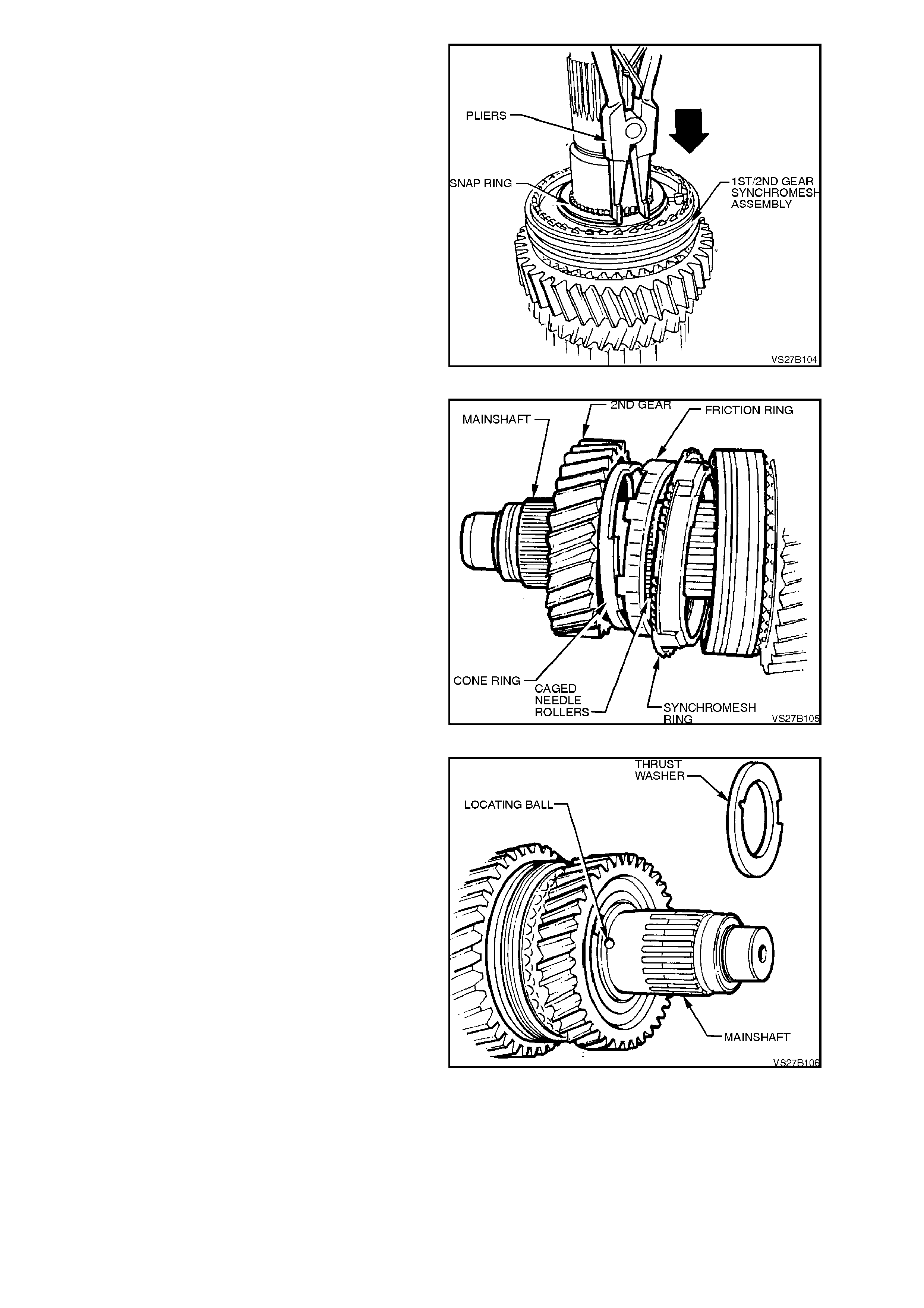

8. Install 1st speed gear, caged needle roller

bearing, 1st speed gear , f r iction r ing, cone r ing

and synchromesh ring onto mainshaft.

NOTE:

The 1st and 2nd gear synchromesh cone rings

have different dimensions. See the next illustration.

Figure 7B1-104

IMPORTANT:

Ensure that the correct cone ring is f itted. The c one

rings for 1st and 2nd gears have different

dimens ions, as shown. T he m anufac turer’s num ber

on each ring is as follows;

1st gear cone ring 040.8.0069.00

2nd gear cone ring 040.8.0059.00

Figure 7B1-105

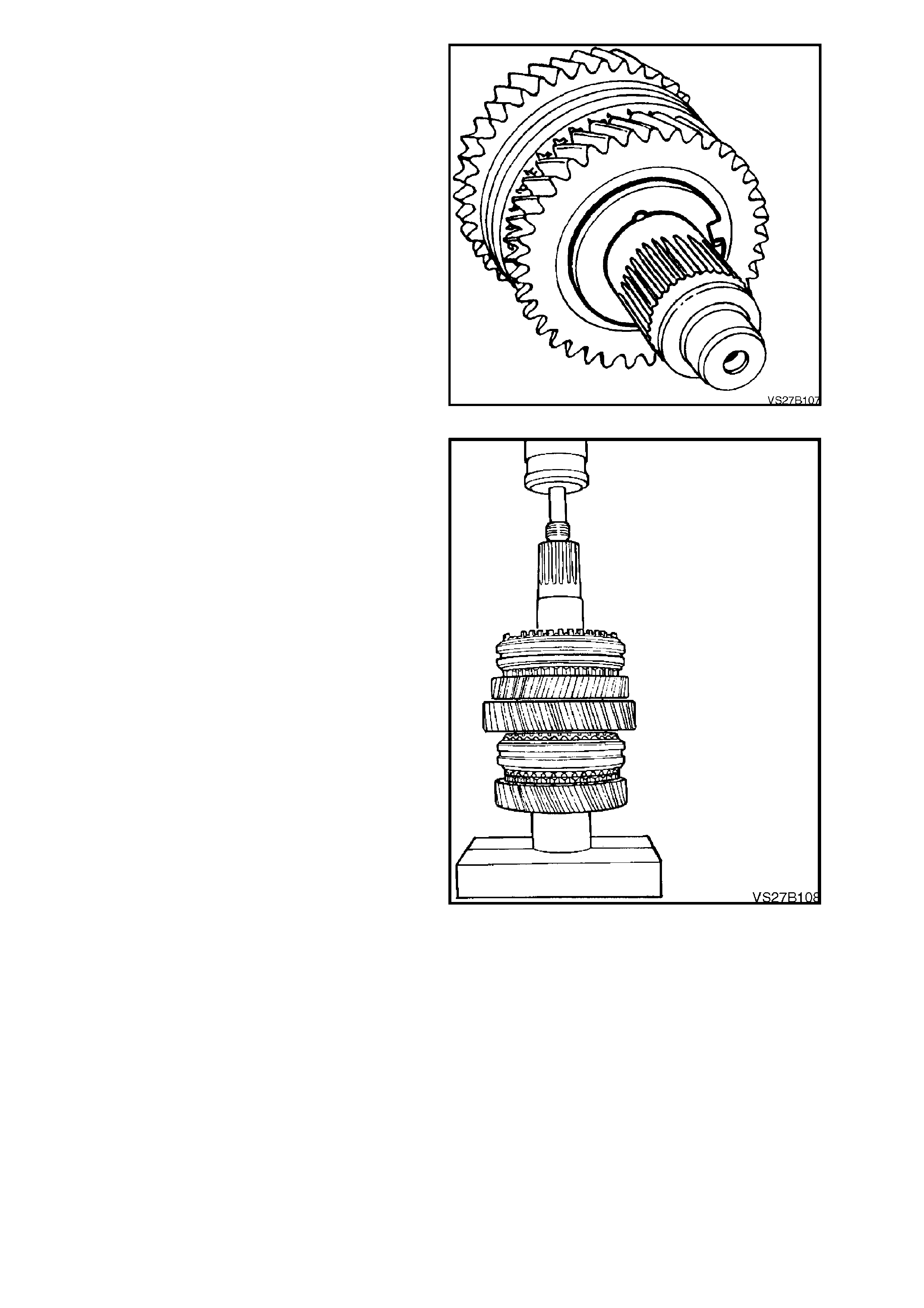

9. Preheat assembled 1st/2nd speed

synchromesh hub on a hot plate to

approximately 100° C.

NOTE:

Use Faber Castell Thermochrom 2815/100° C to

indicate temperature. Apply thermochrom around

synchromesh hub.

10. Using a heat proof glove, position

synchromesh assembly onto mainshaft,

aligning mainshaft and hub splines.

NOTE:

The side with the smaller outer surface and the

step, faces 1st gear.

11. Using suitable sleeve, pres s synchrom esh hub

onto mainshaft, ensuring that synchromesh

ring slots align with sliding keys.

12. Remove mainshaft from press, and if

necessary, lever up 1st speed synchromesh

ring with a screwdriver so that it is not jam m ed

on the gear cone.

Figure 7B1-106

13. Mount rear end of mainshaft in vice with soft

metal jaws.

14. Install synchromesh assembly, selective snap

ring onto mainshaft, ensuring that snap ring is

correctly seated in groove, without any end

clearance.

NOTE:

Snap rings are available in thicknesses of 1.8, 1.85,

1.9, 1.95 and 2 mm.

Figure 7B1-107

15. Install 2nd speed gear with caged needle roller

bearing, friction cone, cone ring and

synchromesh ring onto mainshaft, ensuring

that the friction ring, cone ring and

synchromesh ring are correctly located in the

synchromesh assembly.

NOTE:

Ensure that the correct synchromesh cone ring is

fitted. Refer to Figure 7B-105 for correct

identification details.

Figure 7B1-108

16. Install small, locating ball in mainshaft,

securing with petroleum jelly.

Figure 7B1-109

17. Install thrust washer over locating ball.

Figure 7B1-110

18. Preheat 3rd speed gear roller bearing

sleeve on a hot plate to approximately 80° C.

NOTE:

Use Faber Castell Thermochrom 2815/80° C to

indicate temperature.

19. Using a heat proof glove, position bearing

sleeve onto mainshaft and press home using

suitable press plates. When pressing

mainshaft into the sleeve, ensure that the

thrust washer remains in place over the

retaining ball.

Figure 7B1-111

20. Install caged needle roller bearing, 3rd speed

constant mesh gear and synchromesh ring,

onto mainshaft.

21. Preheat assembled 3rd/4th speed

synchromesh assembly on a hot plate to

approximately 100° C.

NOTE:

Use Faber Castell Thermochrom 2815/100° C

around synchromesh hub, to indicate temperature.

22. Using a heat proof glove, position

synchromesh assembly onto mainshaft,

aligning mainshaft and hub splines.

NOTE:

The 3rd/4th selector fork offset in the outer sleeve

faces away from 3rd gear.

Figure 7B1-112

23. Using suitable sleeve, pres s synchrom esh hub

assembly onto mainshaft, ensuring that

synchromesh ring slots align with sliding keys.

24. Remove mainshaft from press, and if

necessary, lever up 3rd speed synchromesh

ring with a screwdriver so that it is not jam m ed

on the gear cone.

Figure 7B1-113

25. Install washer and snap ring to mainshaft,

ensuring that snap ring is correctly seated in

groove with no clearance between the snap

ring and the washer.

Snap rings are available in thicknesses of 2.0, 2.1,

2.2, 2.3, 2.4 and 2.5 mm.

Figure 7B1-114

26. Install 5th speed caged needle roller bearing

onto mainshaft. Then install the synchromesh

ring, engaging ring slots with sliding blocks of

the synchrom esh assem bly and f inally, the 5th

speed gear.

Figure 7B1-115

Maindrive Gear

1. Coat maindrive gear needle bearing with

petroleum jelly.

2. Insert bearing assembly into the maindrive

gear.

Figure 7B1-118

Reverse Idler Gear Shaft

1. Lubricate the reverse idler gear shaft with

clean transmission fluid, then install the two

caged needle roller bearings.

2. Locate the roller bearings by installing new

snap rings to eac h groove on the reverse idler

gear shaft.

IMPORTANT:

Snap rings must be installed with the curved out

portion of each snap ring end, AWAY from the

roller bearing as shown.

As the reverse idler gear is in constant mesh with

the cluster gear, if the snap rings are not installed

as shown, then a transmission noise will be

created.

Figure 7B1-119

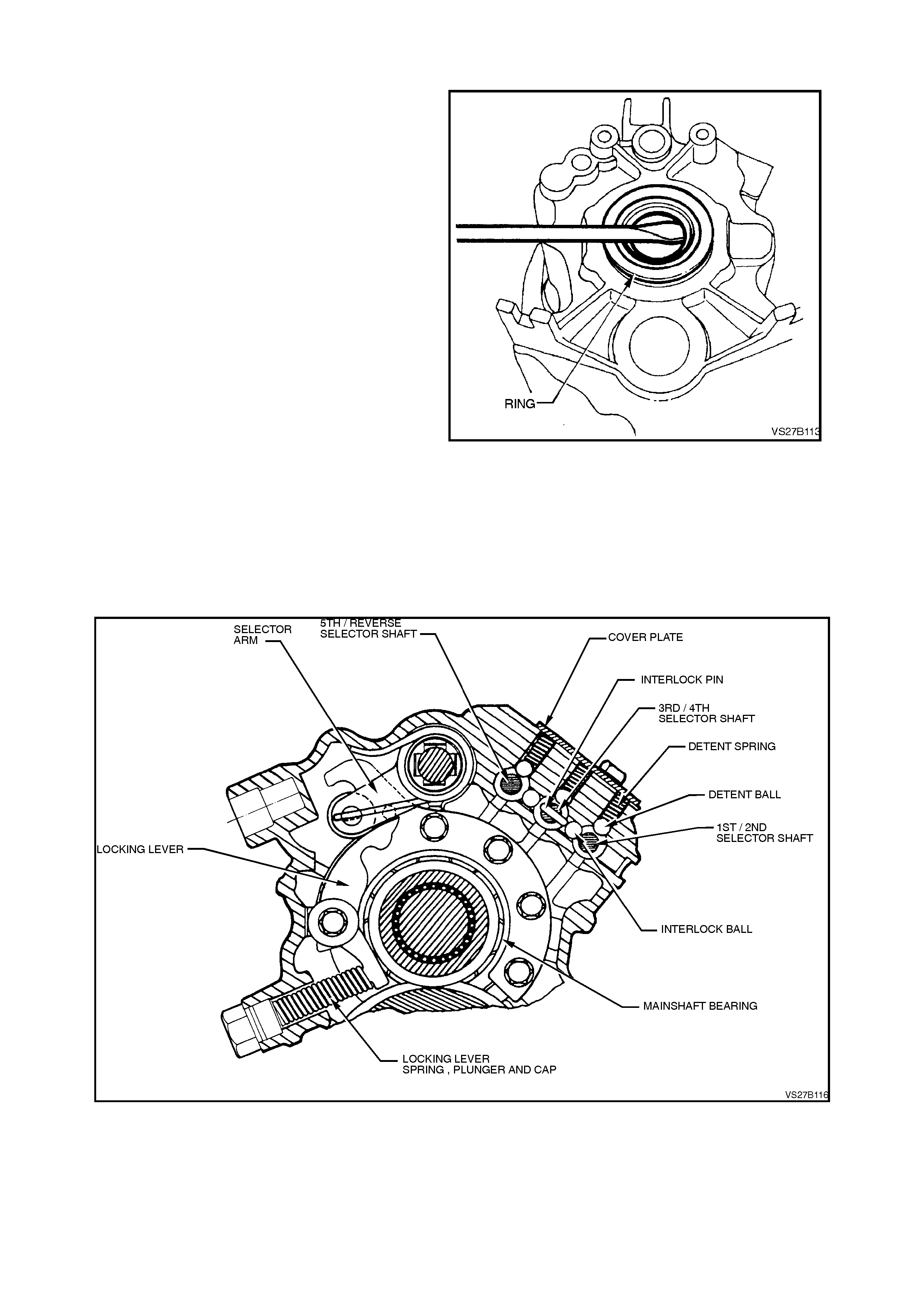

TRANSMISSION CASE, REAR SECTION

Disassemble

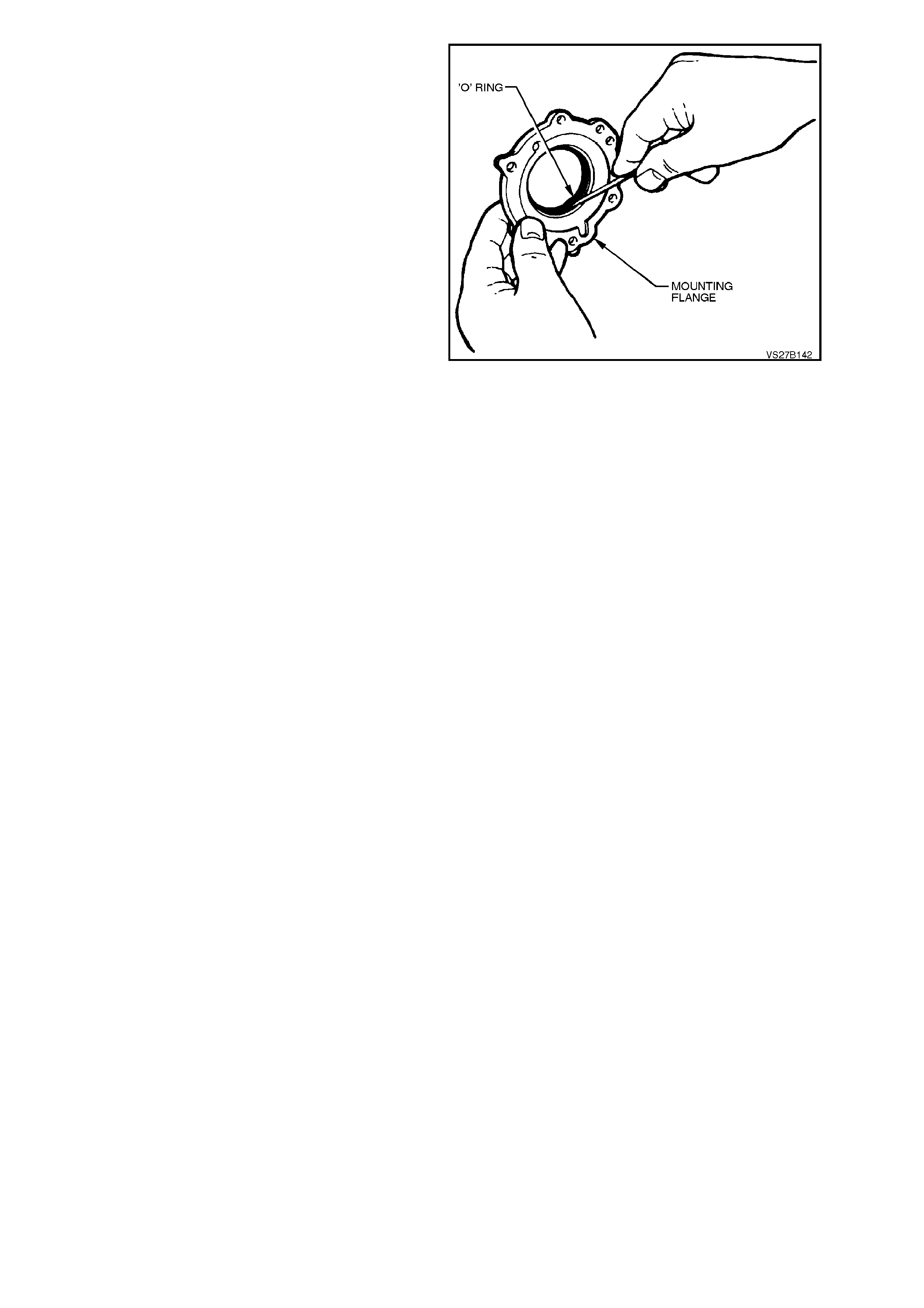

1. To remove the rear oil seal, use the distance

spacer ring f rom the fr ont m ainshaf t bearing to

protect the transmission rear housing, then

use a screwdriver to lever out the seal from

the rear transmission case.

NOTE:

Take extreme care not to scratch the seal surface

in the rear transmission case. If damaged, a

subsequent fluid leak may occur.

Figure 7B1-120

2. Remo ve the locking lever sc rew plug from the

rear housing, using a 19 mm ring spanner,

noting that sealant is applied to the threads.

CAUTION:

Take care that the plug does not fly out under

spring force, when the plug is unscrewed.

3. Remove the spring from the rear housing.

Figure 7B1-121

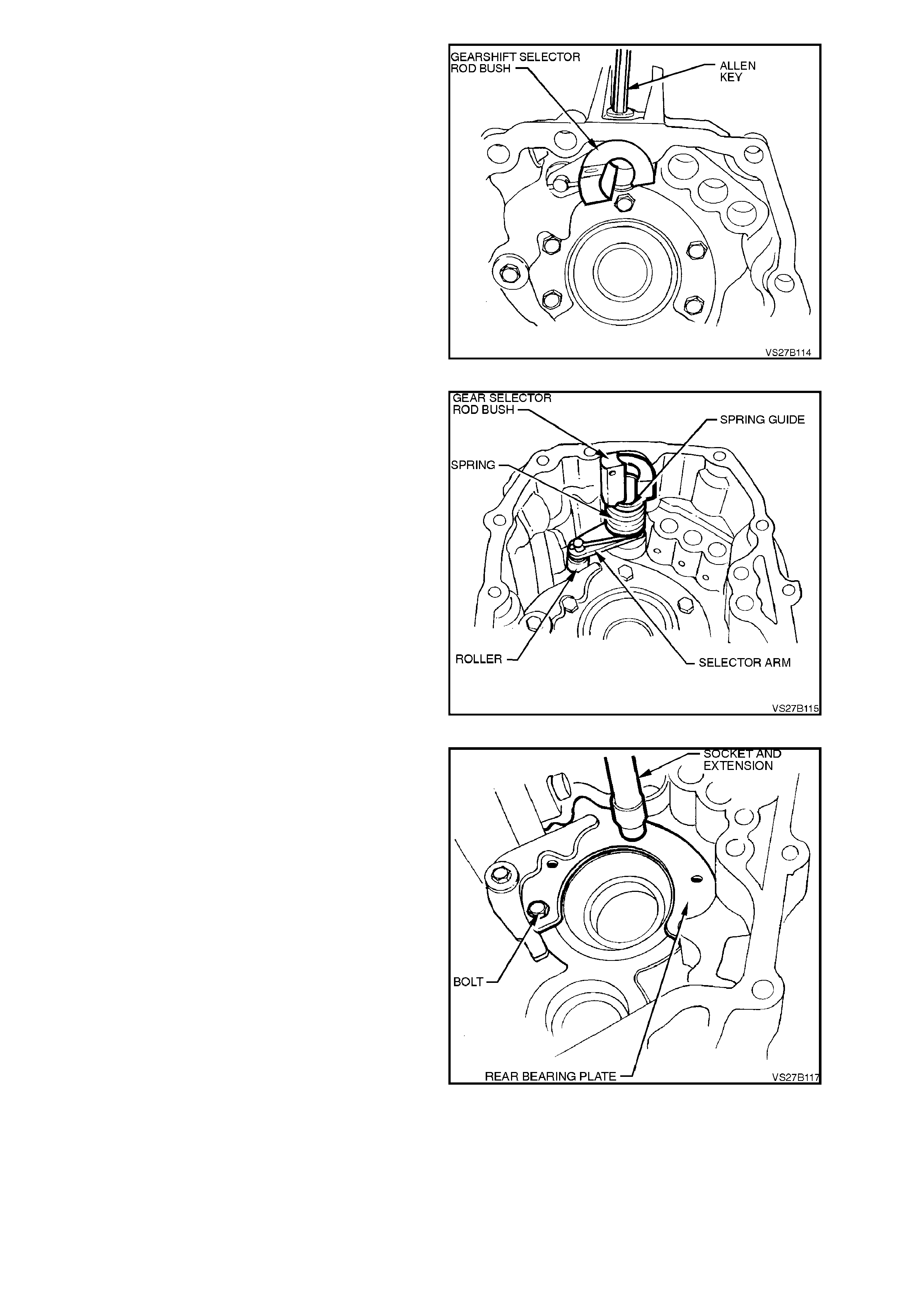

4. Using a 6 mm, Allen key socket, remove the

gearshift selector rod bush lock bolt from the

rear case section.

NOTE 1:

The loc k bolt has sealant applied to the thread and

will be difficult to remove, if a hot air gun is not

used to soften the sealant prior to bolt removal.

NOTE 2:

As the Allen key screw is removed, support the

gearshif t selector rod bush against rotational s pring

force.

Figure 7B1-122

5. From inside case, remove the spring, spring

guide and selector arm with roller. Be careful

as spring force can easily eject these parts,

uncontrolled.

Figure 7B1-123

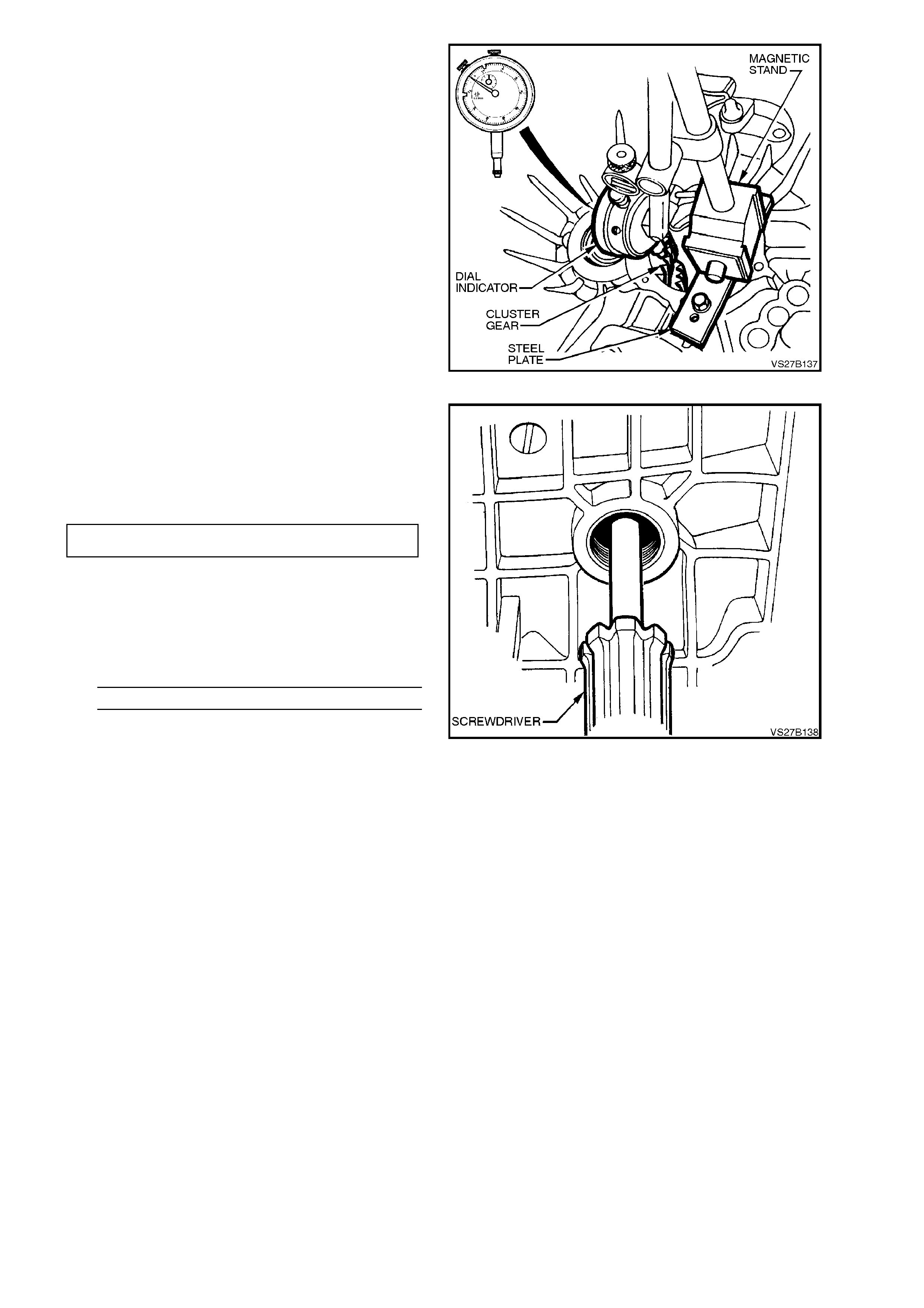

6. Remove the f ive bolts holding the rear bear ing

plate and locking lever support, then remove

the plate and locking lever as an assembly.

7. If required, remove the locking lever pivot bolt

and nut from the rear bearing retaining plate.

Figure 7B1-124

NOTE:

Unless the rear mainshaft bearing is to be

replaced, there is no need for this next operation.

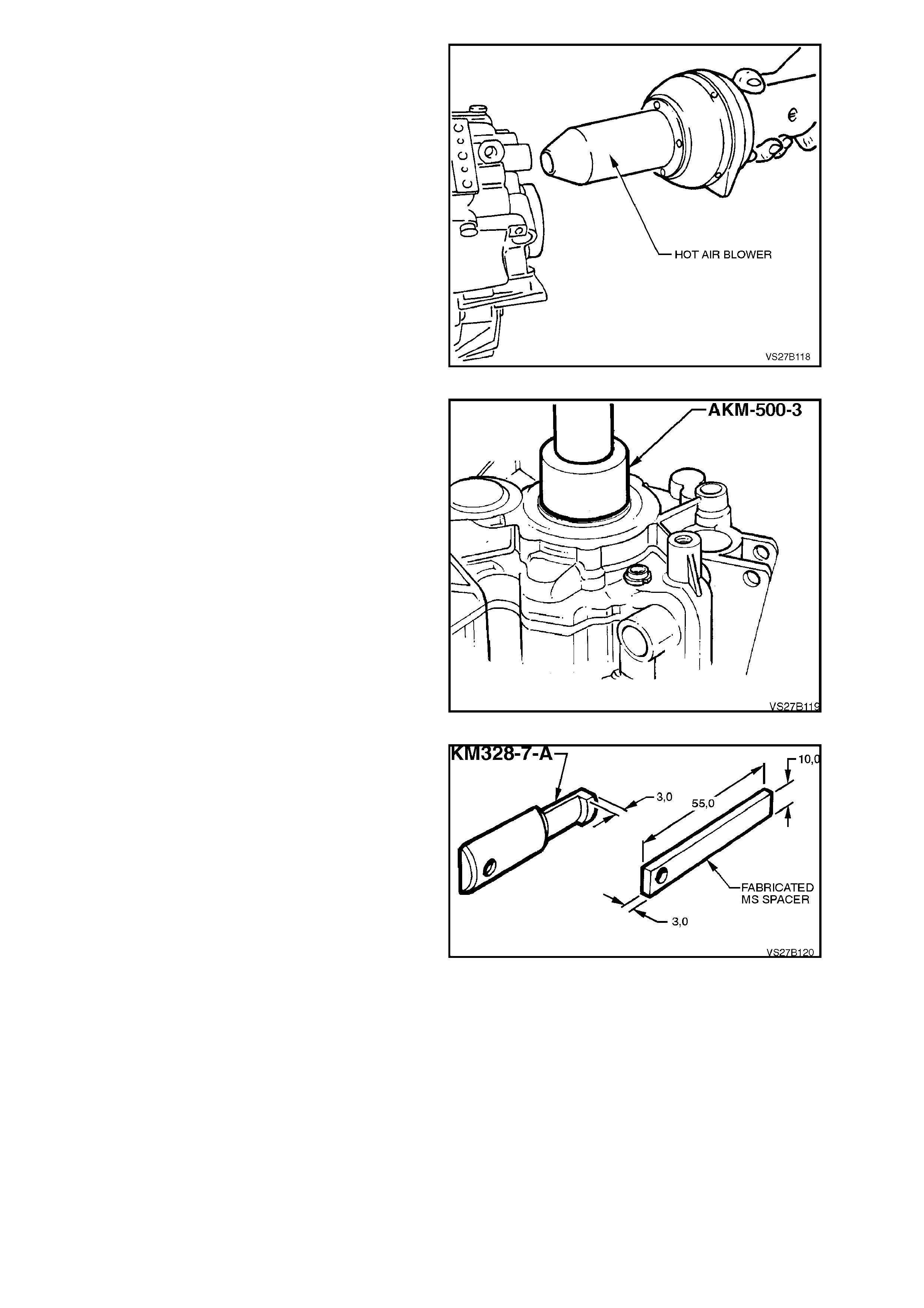

8. Preheat the transmission housing in the rear

bearing area, to approximately 80° C using a

commercially available hot air blower.

NOTE:

Use Faber Castell Thermocrom 2815/80° C, to

ensure that an excessive temperature is not

reached.

Figure 7B1-125

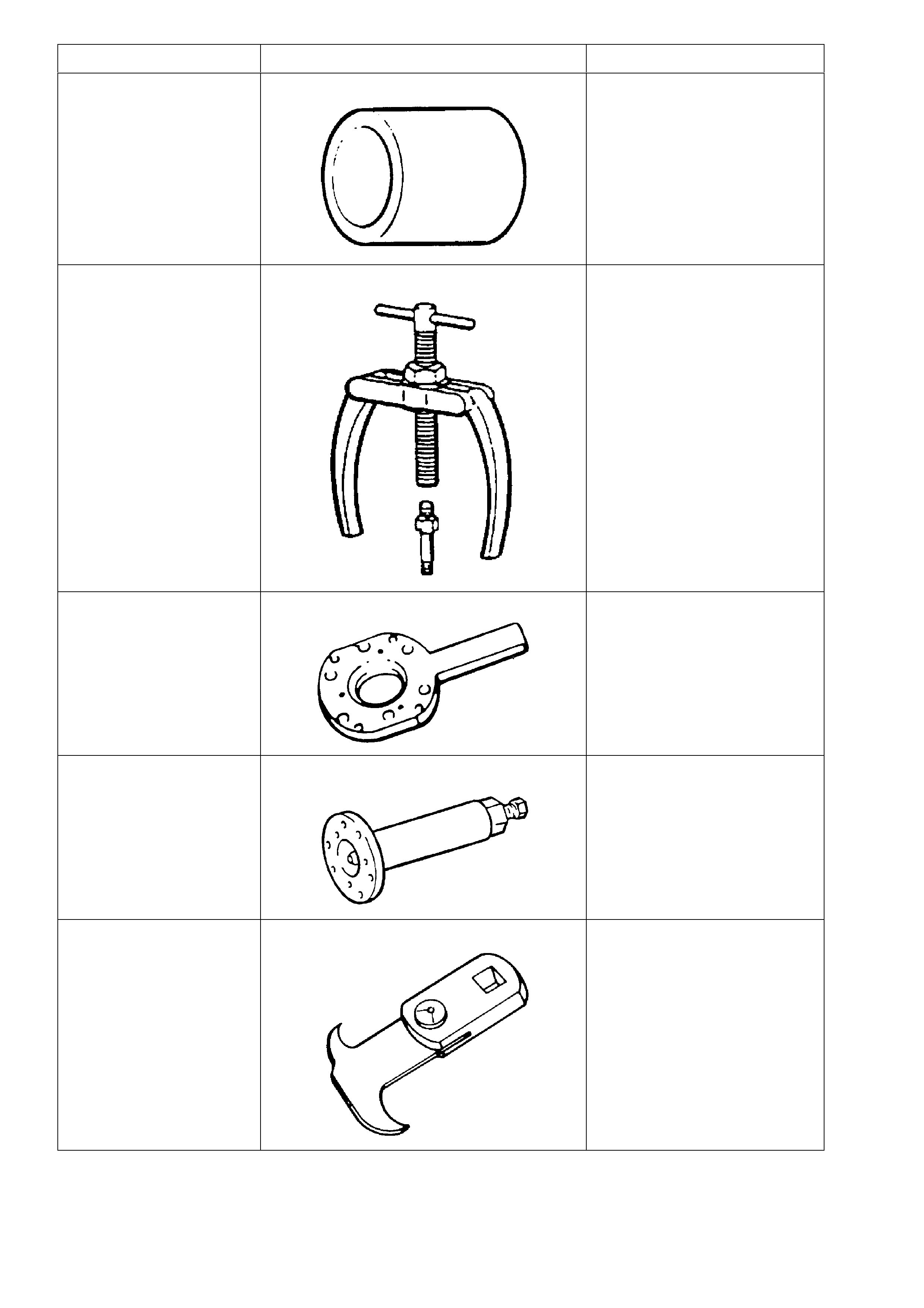

9. Use a suitable sleeve such as AKM- 500-3 and

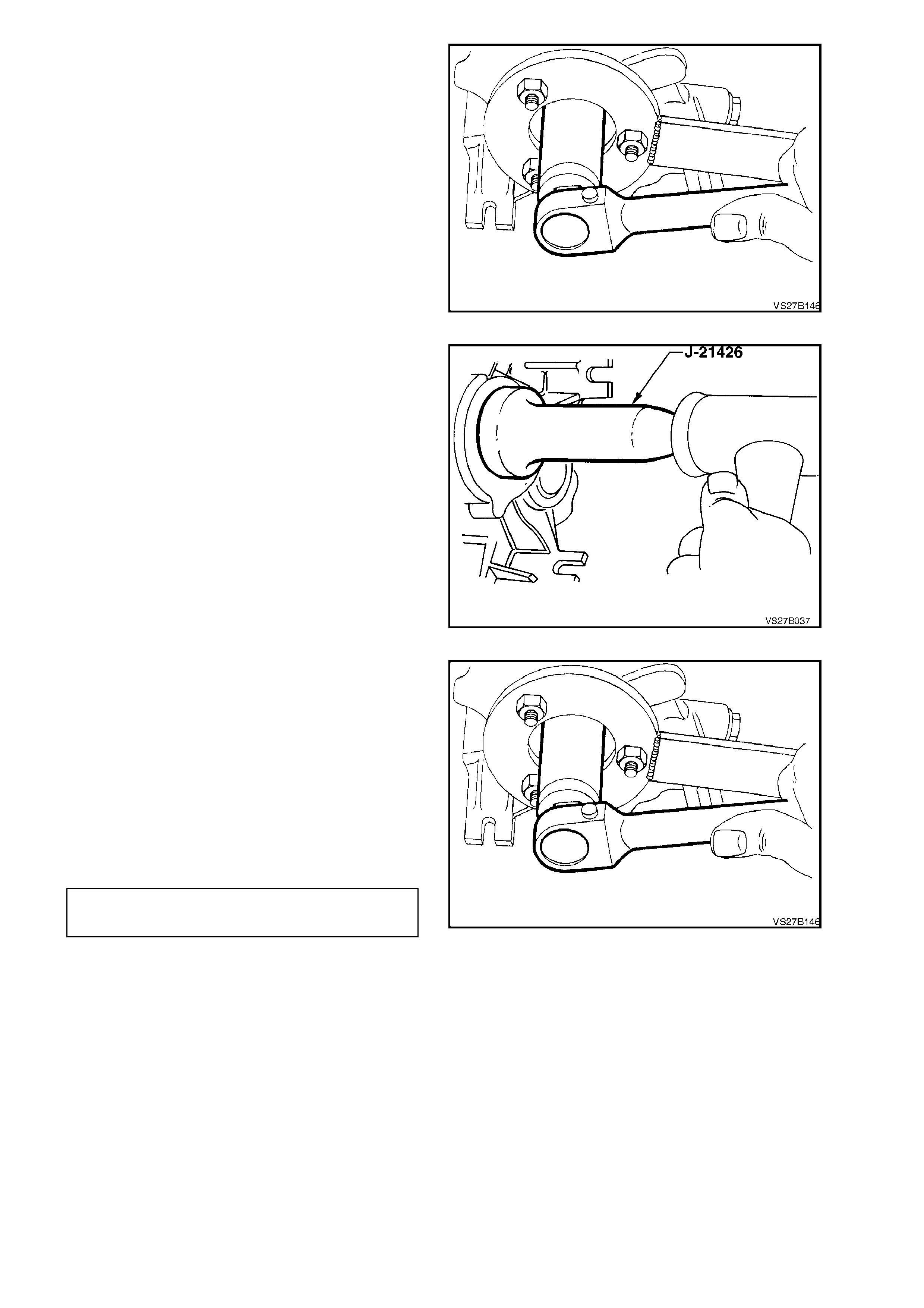

press the mainshaft rear bearing from the

transmission housing.

IMPORTANT:

Because of ball brinelling, the bearing MUST be

replaced, after removal.

Figure 7B1-126

10. To remove the rear cluster gear bearing cup,

use the following method;

a. Grind the legs of Tool KM-328-7-A down

to approximately 3 mm , s uf ficient to inser t

under the bearing cup.

b. Fabricate a spacer as shown, to insert

between the two legs, using 3 mm

thickness, mild steel stock.

Figure 7B1-127

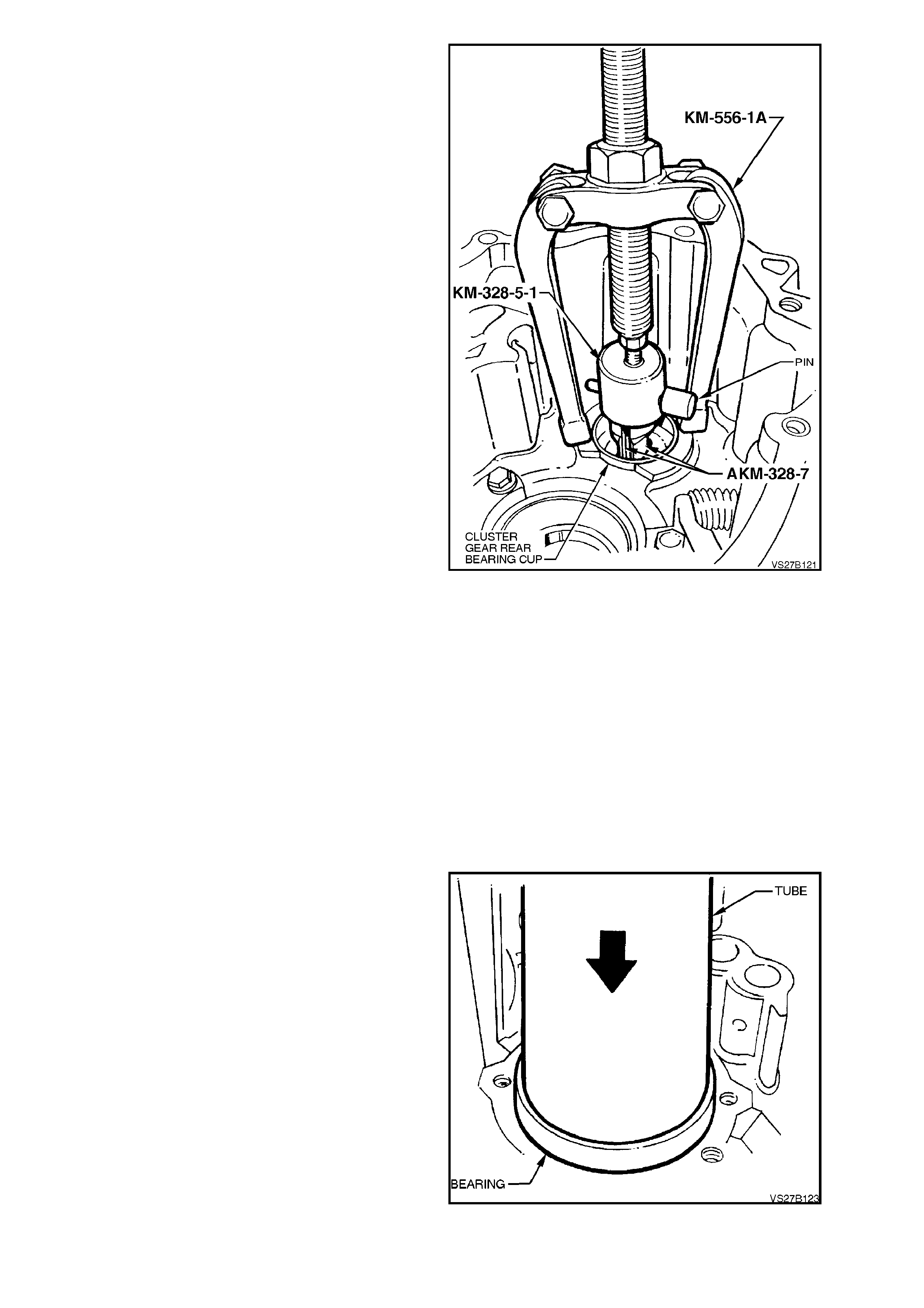

c. Install each of the modified legs of Tool

KM-328-7-A under the bearing cup, then

insert the fabricated spacer in between

them.

d. Use the cup, Tool KM-328-5-A and pin

from slide hammer, Tool KM-328-B to

secure the legs and spacer assembly.

e. Screw threaded adaptor into cup and

install puller KM-556-1A.

f. Use the puller to extract the bearing cup

from the rear transmission case.

NOTE:

To aid in rem oval of bearing, it will be necessar y to

preheat case area of bearing to 80° C, using a

commercially available, hot air blower.

Use Faber Castell Thermocrom 2815/80° C, to

ensure that an excessive temperature is not

reached.

Figure 7B1-128

INSPECT

1. Inspect rear transm ission cas e for any defects

or cracks that may cause oil leaks.

2. Check all machined surfaces for burrs, and if

present, dress them off with a fine cut file.

3. Check bearing bores for damage or scoring.

4. Inspect all shift control component contact

surfaces and sliding surfaces for wear,

scratches, projections or other damage.

5. Check all springs for damage or distortion.

6. Check the selector inter-lock pin and balls for

damage.

REASSEMBLE

1. Using a suitable length and diameter pipe,

press a new, sealed ball race into the rear

transmission case, ensuring that force is only

applied to the outer bearing ring.

NOTE 1:

To assist in the installation of the bearing, heat the

rear transmission housing with a commercially

available hot air gun to approximately 80° C.

Use Faber Castell Thermocrom 2815/80° C, to

ensure that an excessive temperature is not

reached.

NOTE 2:

The of fset on the inner bear ing cone faces the rear

of the transmission.

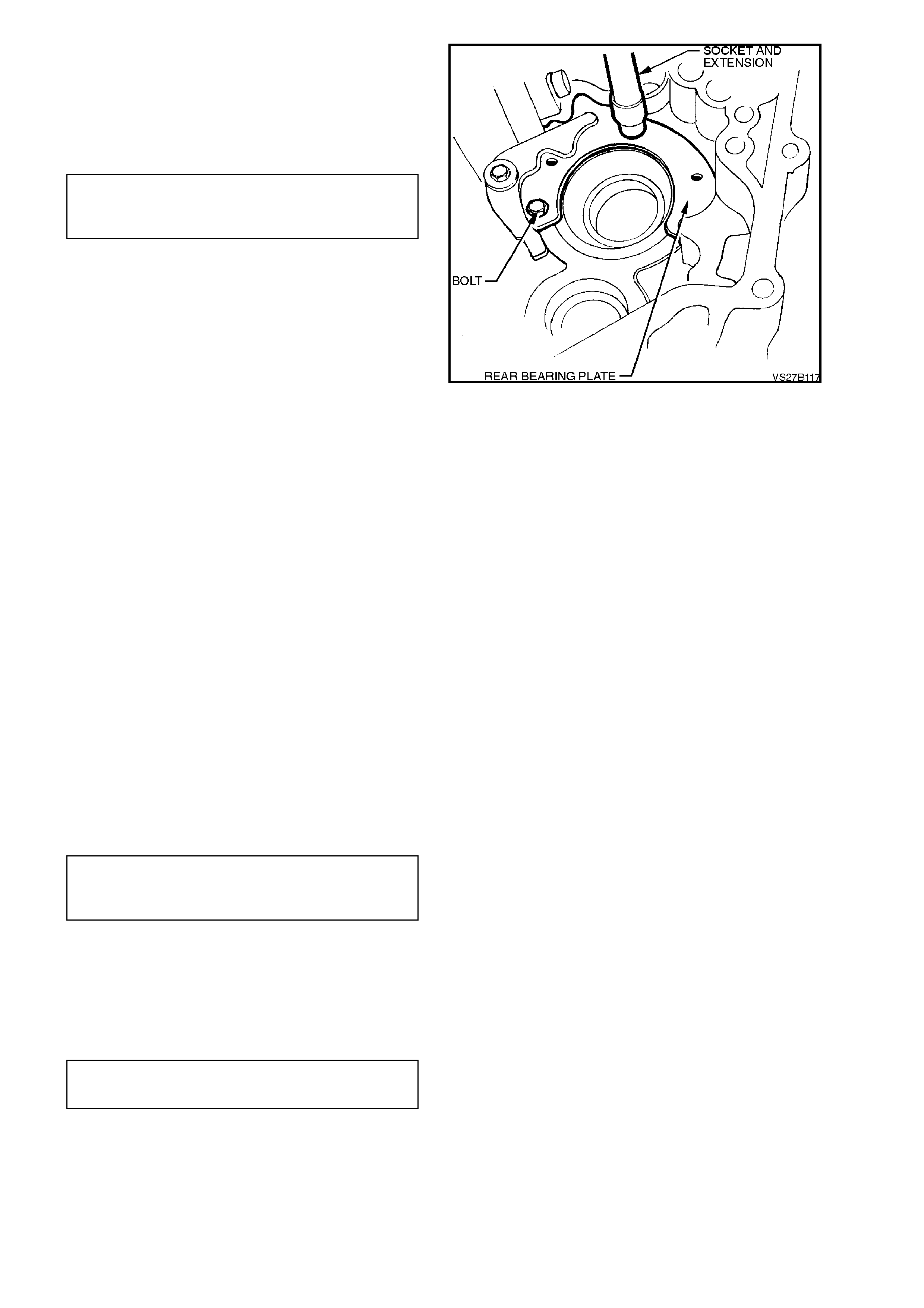

Figure 7B1-129

2. Apply thread sealant such as Loctite 242 or

243 (or equivalent, to Holden’s Specification

HN1256) to the cleaned threads of the rear

bearing plate retaining bolts. Install the rear

bearing plate and tighten the bolts to the

correct torque specification.

REAR BEARING PLATE AND

LOCKING LEVER BOLT 10 Nm

TORQUE SPECIFICATION

Figure 7B1-130

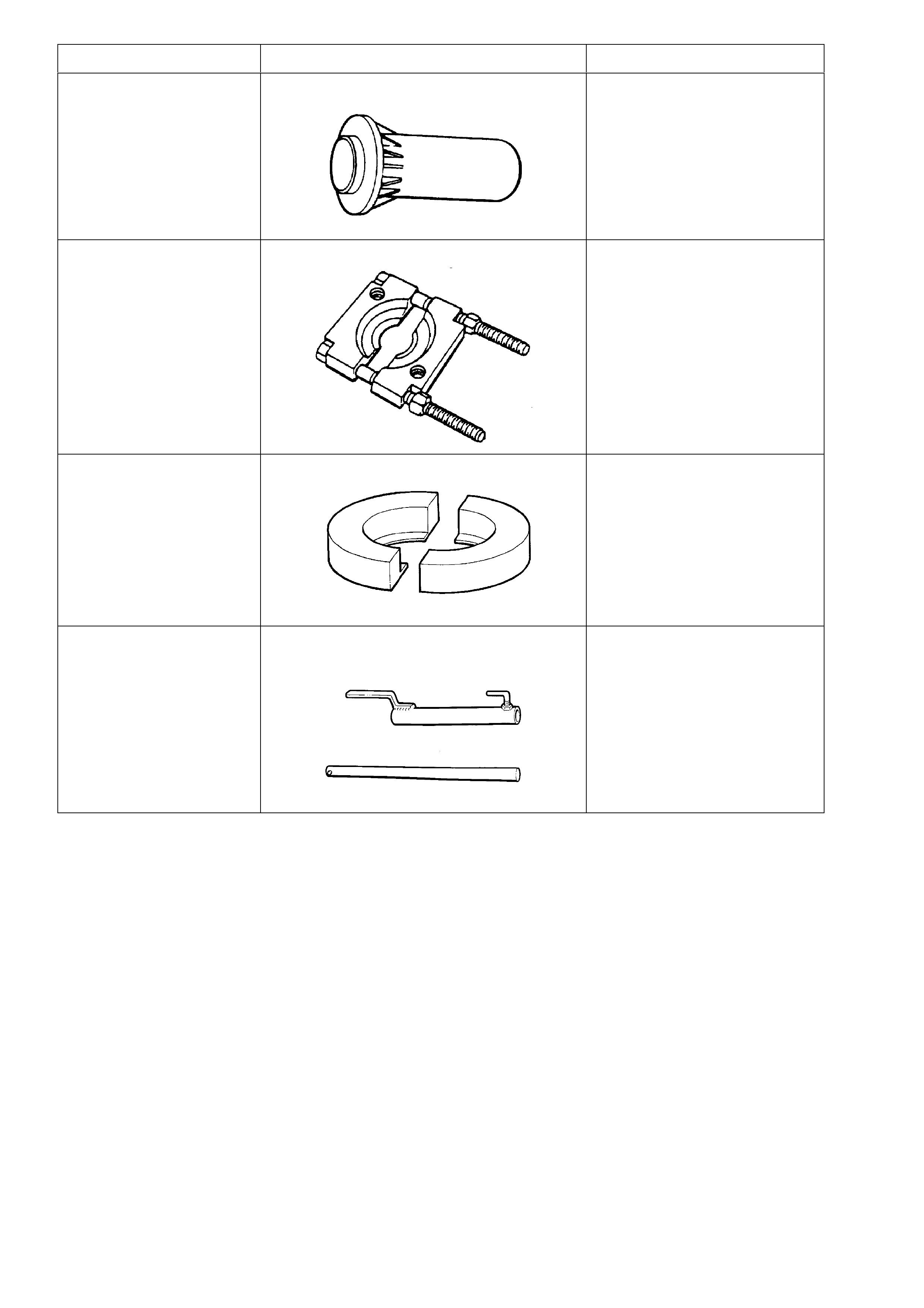

3. Preassemble the selector arm, spring, bush

and sleeve, by first inserting the shaft of Tool

AU462 into the rear of the selector arm,

engaging the lugs with those in the arm (2).

Then, install the straight end of the spring (5)

into the selector arm pin hole and insert the

sleeve and bush (4) over the shaft. Insert the

sleeve of Tool AU462 over the protruding s haf t

and engage the leg with the free end of the

spring.

While holding the selector lever (2) in one

hand, rotate the sleeve of the holding Tool

AU462 counter-clockwise, loading the spring.

Tighten the locking screw (3) to retain the

assembly in the loaded state.

4. Use petroleum jelly to sec ure the selector arm

roller (1), to the pin, then install the assembly

to the rear transmission case. Install the bush

locating screw, after applying sealant such as

Loctite 242 or 243 (or equivalent to Holden’s

Specification HN1256) to cleaned screw

threads and tighten with an Allen key headed

socket to the correct torque specification.

GEARSHIFT SELECTOR

ROD BUSH SCREW 20 Nm

TORQUE SPECIFICATION

5. Apply thread sealant such as Loctite 242 or

243 (or equivalent, to Holden’s Specification

HN1256) to the cleaned threads of the locking

lever screw plug. Install the spring and plug,

tightening to the correct torque specification.

LOCKING LEVER SCREW PLUG 48

TORQUE SPECIFICATION Nm

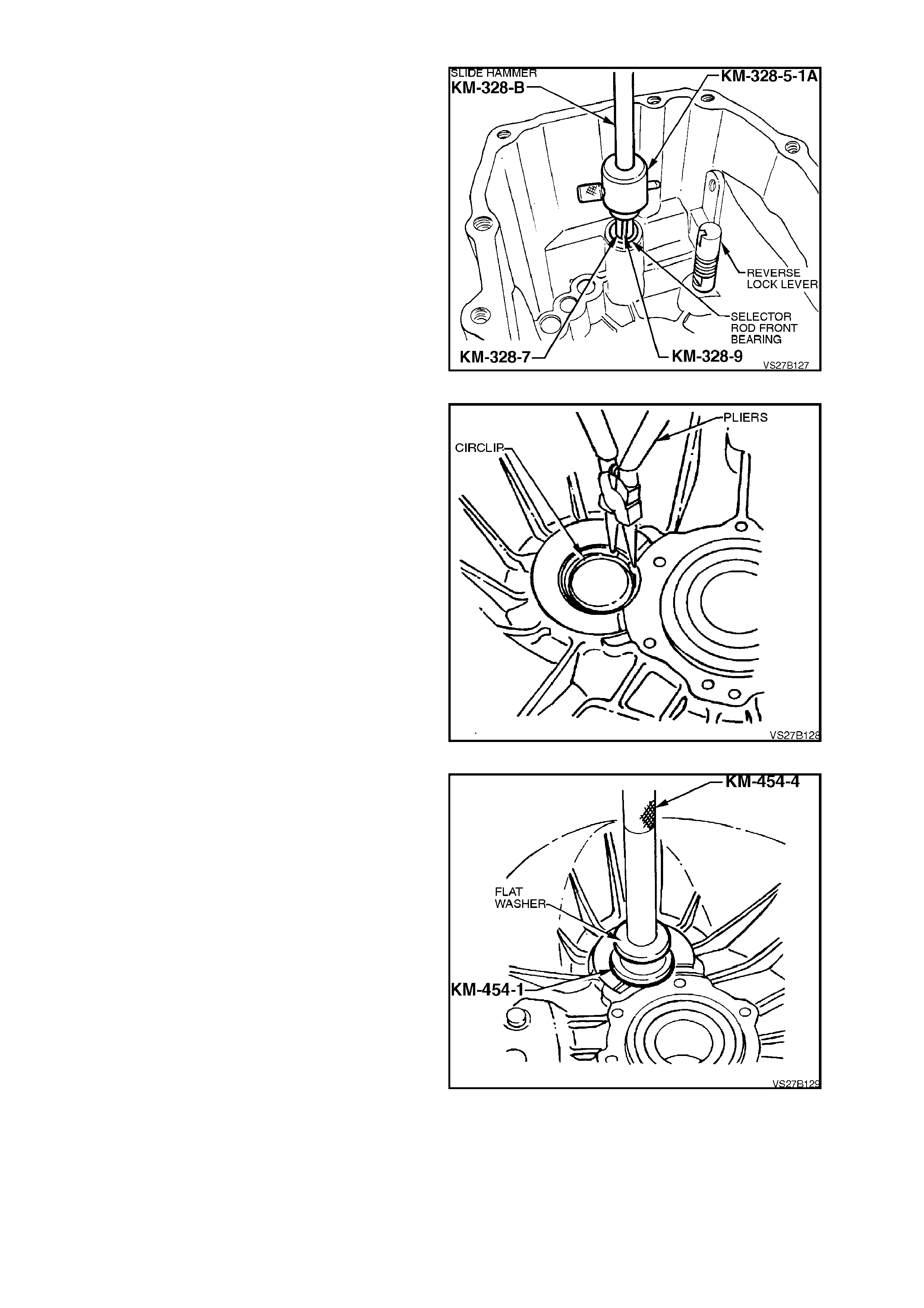

TRANSMISSION CASE, FRONT SECTION

DISASSEMBLE

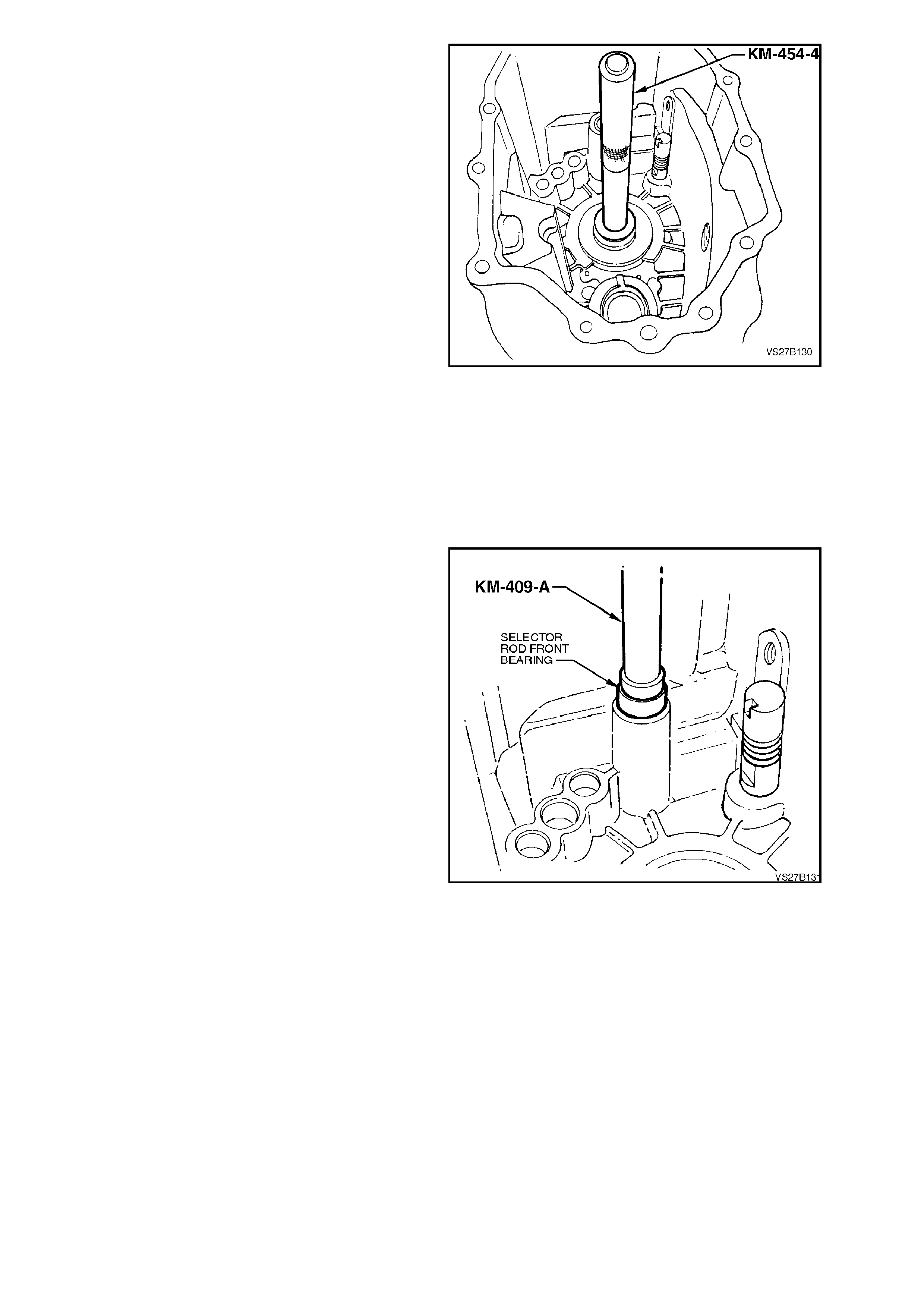

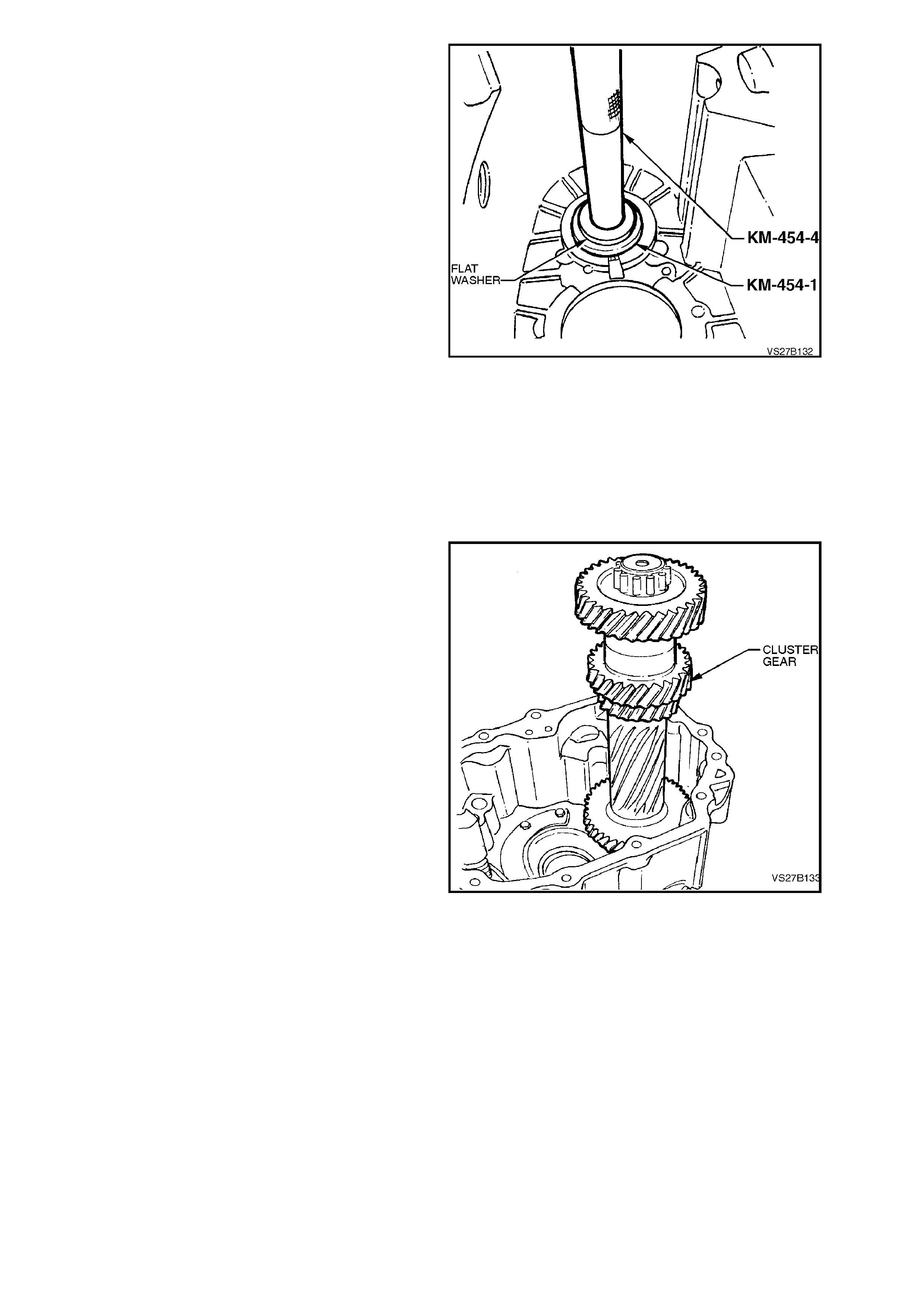

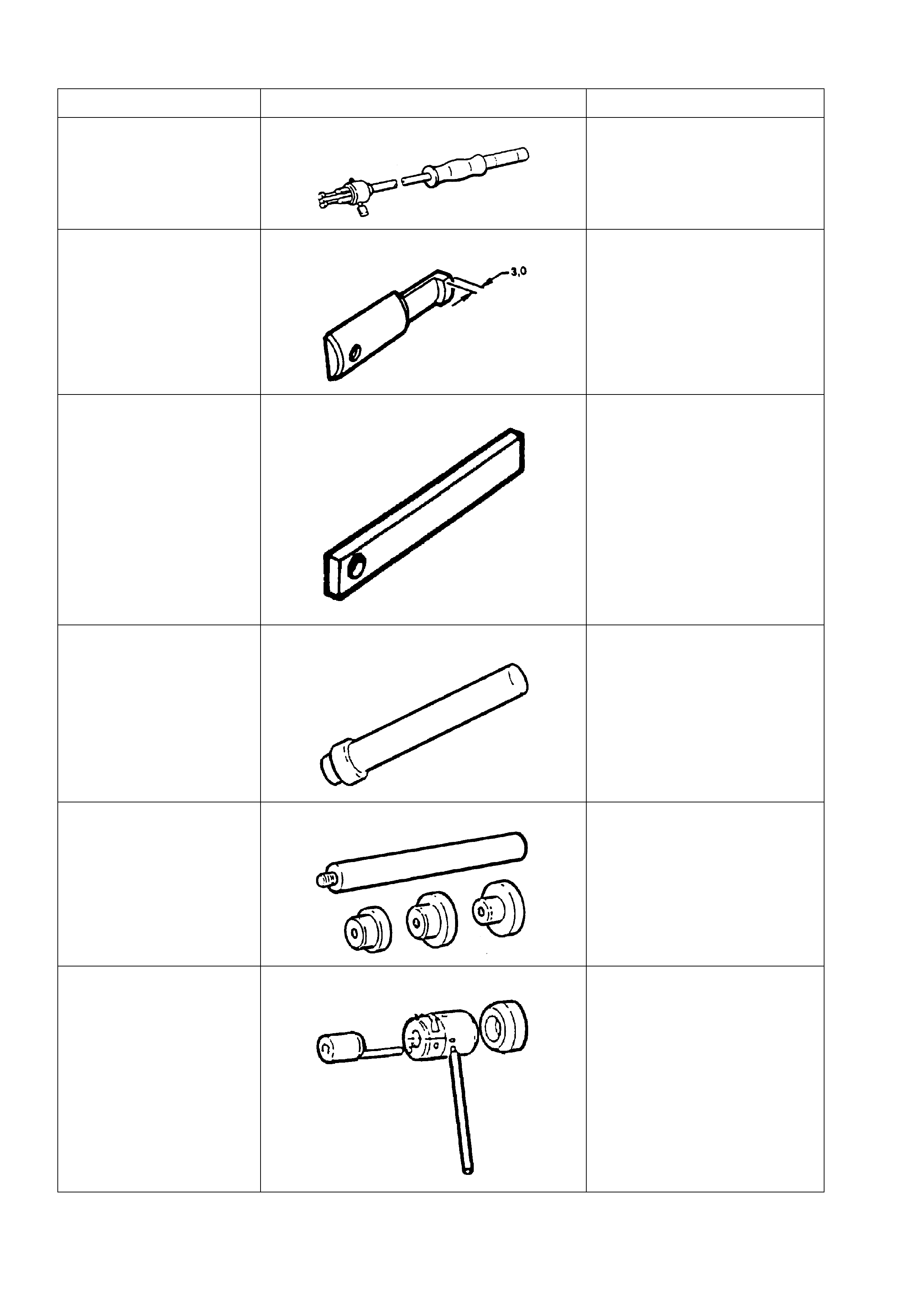

1. Insert the legs of Tool KM328-7-A into the

bearing and hold in position with spacer. Tool

KM-328-9. Slip the cup of Tool KM-328-5-1A

over the legs and secure with the pin.

2. Screw the thread of slide hammer, Tool No.

KM-328-B into the cup and remove the

gearshift selector rod front bearing from case.

NOTE:

When carrying out this operation, the bearing will

be damaged and must be replaced.

3. From inside the transmission bell housing,