SECTION 7C3 - HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION - HYDRAULIC/MECHANICAL

DIAGNOSIS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas. In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

1. GENERAL INFORMATION

1.1 HOW TO USE THIS SECTION

This section contains a description of the HYDRA-MATIC 4L60-E operation and the procedures for diagnosing the

hydraulic/mechanical aspects of this transmission. When diagnosing any condition on the 4L60-E HY DRA-MATIC

transmission, begin with the "HYDRA-MATIC 4L60-E Functional Test Procedure" detailed in this Section.

After the cause of a condition is determined, refer to Section 7C4 ON-VEHICLE SERVICING or

Section 7C5 UNIT REPAIR, for the necessary procedures. Alternatively, if the condition is considered to be

electrical/electronic in nature, then refer to either Section 6C1, POWERTRAIN MANAGEMENT - V6 ENGINE or

Section 6C2, POWERTRAIN MANAGEMENT - V8 ENGINE.

1.2 TRANSMISSION GENERAL DESCRIPTION

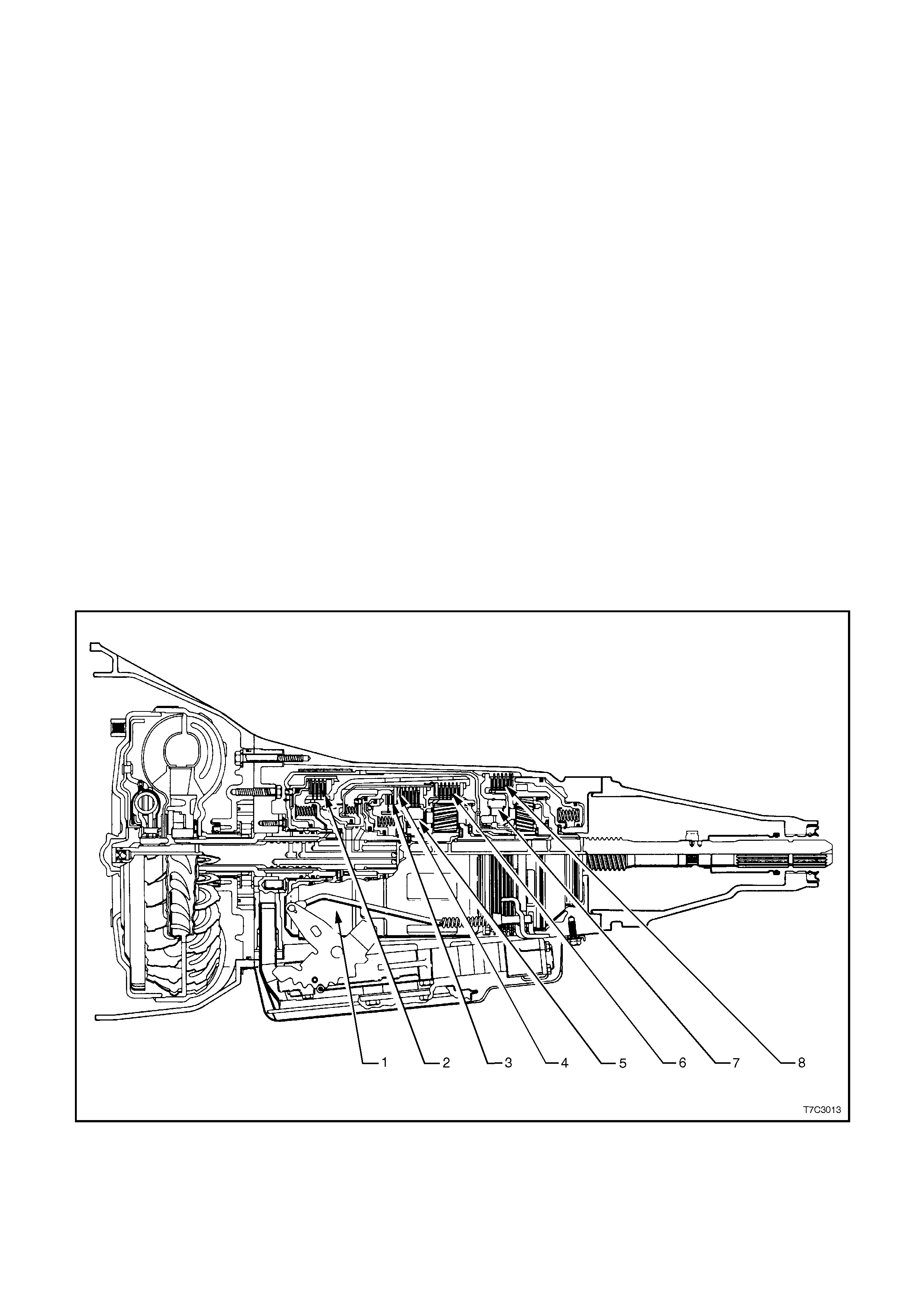

The Hydra-matic 4L60-E is a fully automatic, four speed, rear wheel drive transmission. It consists primarily of a four

element torque converter, two planetary gear sets , various clutches, an oil pump and a control valve body.

The four element torque converter contains a pump, a turbine, a pressure plate splined to the turbine and a stator

assembly. The torque converter acts as a fluid coupling to transmit power smoothly from the engine to the

transmission. It also provides additional hydraulic torque multiplication when required. The pressure plate, when

applied, provides a mechanical 'direct drive' coupling of the engine to the transmission.

The two planetary gear sets provide the four forward gear ratios and reverse. Changing of the gear ratios is fully

automatic and is accomplished through the use of various electronic sensors that provide input signals to the

Powertrain Control Module (PCM). The PCM interprets these signals to send current to the various solenoids inside

the transmission.

By using electronics, the PCM controls shift points, shift feel and torque converter clutch apply and release, to

provide proper gear ranges for maximum fuel economy and vehicle performance.

Five multiple-disc clutches, one roller clutch, a sprag clutch and a brake band provide the friction elements required

to obtain the various ratios with the planetary gear sets.

An hydraulic system (the control valve body), pressurised by a vane type pump, provides the working pressure

needed to operate the friction elements and automatic controls.

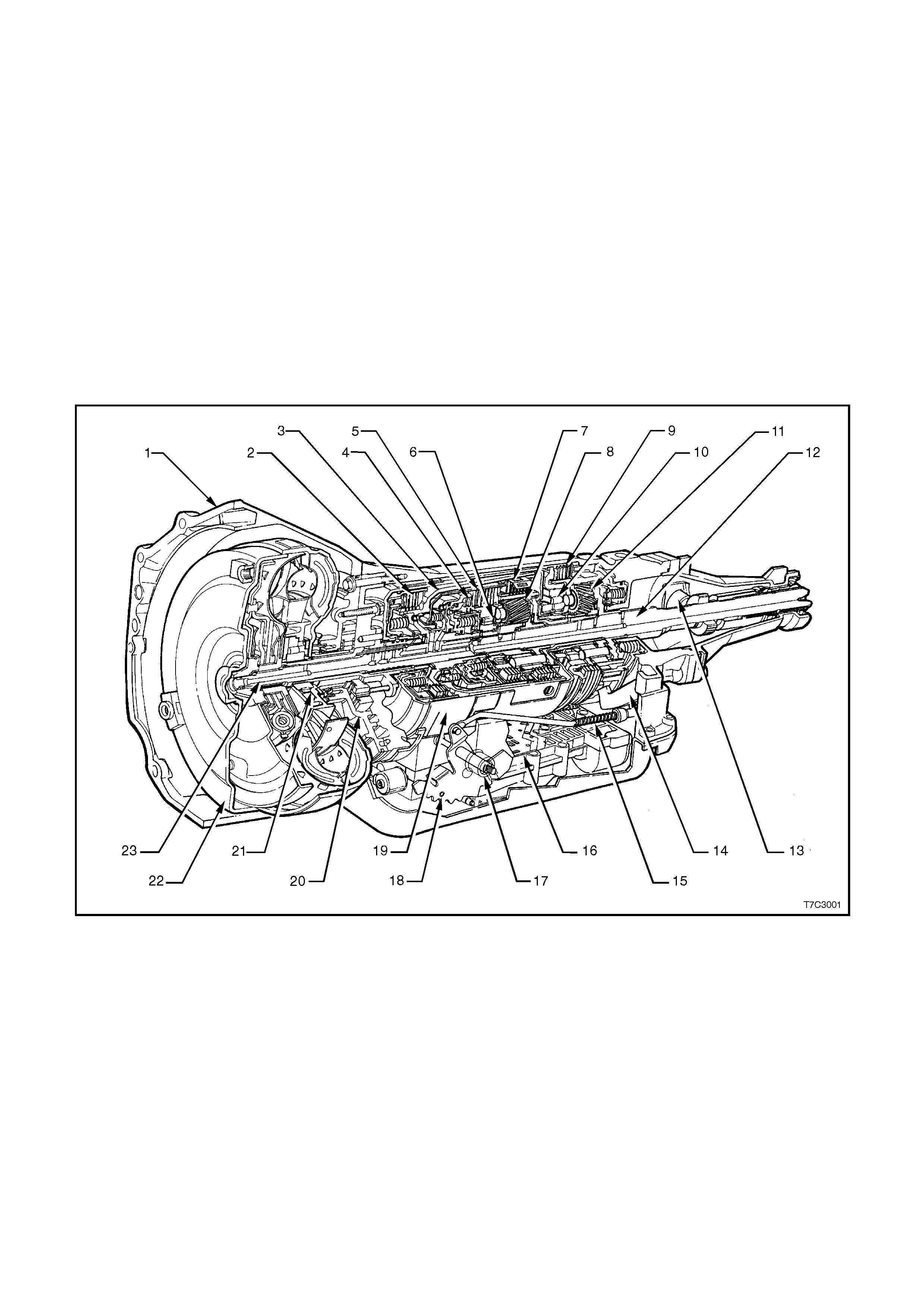

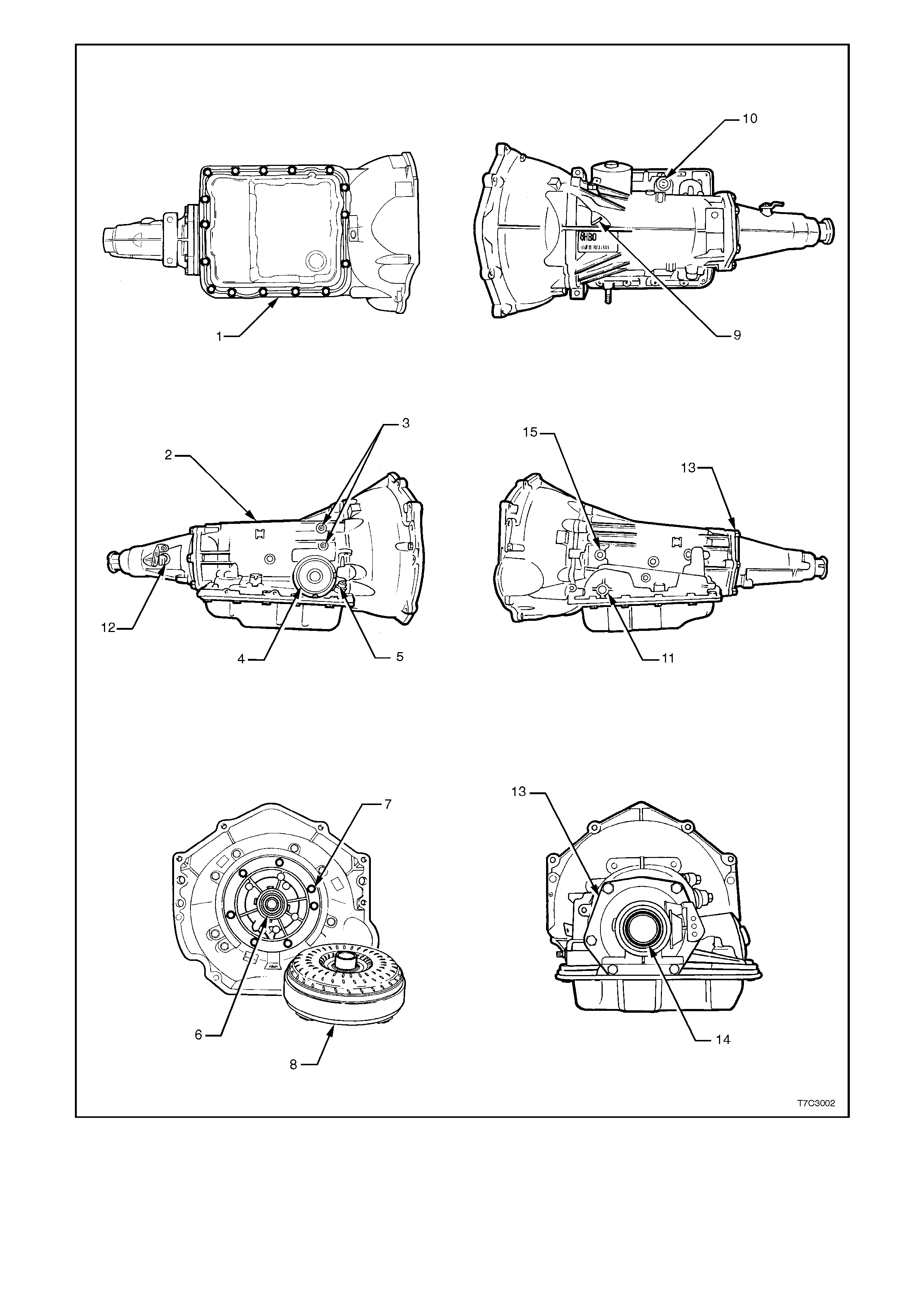

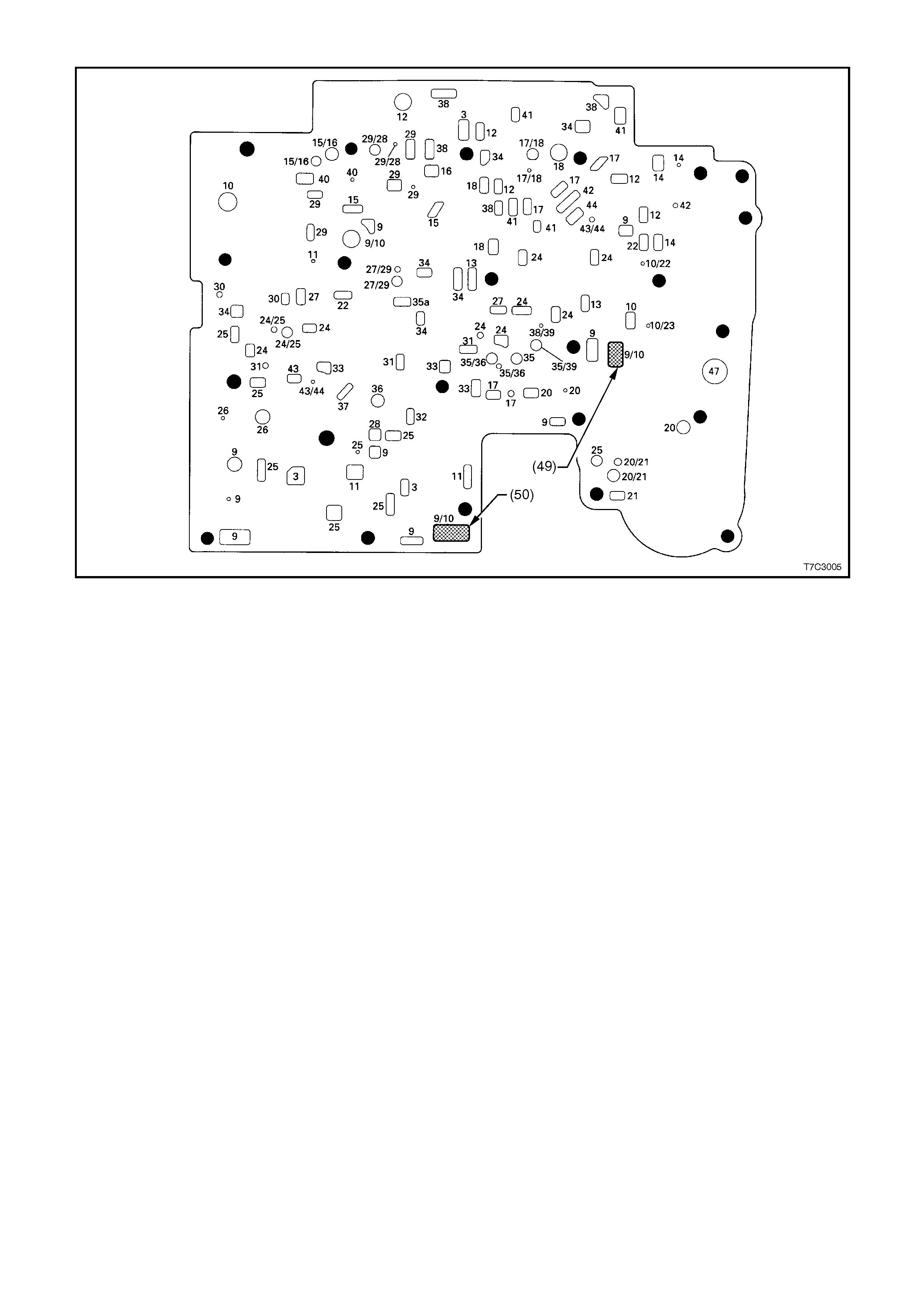

The general arrangement of both the majority of mechanical and hydraulic components is as shown.

1. Case Assembly 9. Low and Reverse Clutch 17. Manual Shaft

2. Reverse Input Clutch 10. Low Roller Clutch Assembly 18. Inside Detent Lever

3. Input Clutch Housing 11. Reaction Planetary Gear Set 19. 2 - 4 Band Assembly

4. Overrun Clutch 12. Output Shaft 20. Pump Assembly

5. Forward Clutch 13. Speed Sensor 21. Stator Roller Clutch

6. Forward Clutch Sprag Assembly 14. Parking Pawl 22. Torque Converter Assembly

7. 3 - 4 Clutch 15. Parking Lock Actuator Assembly 23. Turbine Shaft

8. Input Planetary Gear Set 16. Control Valve Assembly

Figure 7C3-1

1.3 TRANSMISSION DEFINITIONS AND ABBREVIATIONS

The following Definitions and Abbreviations are provided to establish a common language for describing

transmission related conditions.

Taking the few minutes required to read this information may easily overcome unnecessary waste of time by being

familiar with the terminology used within this Diagnosis Section.

THROTTLE POSITIONS

Minimum Throttle - the least amount of throttle opening required for an upshift.

Light Throttle - approximately 1/4 of accelerator pedal travel (25% Throttle Position).

Medium Throttle - approximately 1/2 of accelerator pedal travel (50% Throttle Position).

Heavy Throttle - approximately 3/4 of accelerator pedal travel (75% Throttle Position).

Wide Open Throttle (WOT) - full travel of the accelerator pedal ( 100% Throttle Position).

Full Throttle Detent Downshift - a quick apply of the accelerator pedal to its full travel, forcing a downshift.

Zero Throttle Coastdown - a full release of the accelerator pedal while the car is in motion and in drive range.

Engine Braking - a condition where the engine is used to slow the car by manually downshifting during a zero

throttle coastdown.

SHIFT CONDITIONS

Bump - a sudden and forceful apply of a clutch or band.

Chuggle - a bucking or jerking may be most noticeable when the converter clutch is engaged; similar to the feel of

towing a trailer.

Delayed - a condition where a shift is expected but does not occur for a period of time. Examples of this could be

described as clutch or band engagement that does not occur as quickly as expected during a part throttle or

wide open throttle apply of the accelerator or, when manually downshifting to a lower range. Also defined as

"LATE" or "EXTENDED".

Double Bump (Double Feel) - two sudden and forceful applications of a clutch or band.

Early - a condition where the shift occurs before the car has reached proper speed. Tends to labour the engine

after the upshift.

End Bump - a firmer feel at the end of a shift, compared to the feel at the start of the shift. Also defined as "END

FEEL" or "SLIP BUMP".

Firm - a noticeably quick apply of a clutch or band that is considered normal with a medium to heavy throttle.

Should not be confused with "HARSH" or "ROUGH".

Flare - a quick increase in engine rpm along with a momentary loss of torque. This most generally occurs during a

shift. Also defined as 'SLIPPING''.

Harsh (Rough) - a more noticeable apply of a clutch or band as compared with "FIRM". This condition is

considered undesirable at any throttle position.

Hunting - a repeating quick series of upshifts and downshifts that causes a noticeable change in engine rpm. An

example could be described as a 4-3-4 shift pattern. Also defined as "BUSYNESS".

Initial Feel - a distinct firmer feel at the start of a shift as compared to the finish of the shift.

Late - a shift that occurs when the engine is at a higher than normal rpm for a given amount of throttle.

Shudder - a repeating jerking condition similar to "CHUGGLE" but more severe and rapid. This condition may be

most noticeable during certain ranges of car speed.

Slipping - a noticeable increase in engine rpm without a car speed increase. A slip usually occurs during or after

initial clutch or band apply.

Soft - a slow, almost unnoticeable clutch or band apply with very little shift feel.

Surge - a repeating engine related condition of acceleration and deceleration that is less intense than "CHUGGLE".

Tie-Up - a condition where two opposing clutches and/or bands are attempting to apply at the same time causing

the engine to labour with a noticeable loss of engine rpm.

NOISE CONDITIONS

Planetary Gear Noise - a whine related to car speed most noticeable in first gear or reverse. Becomes less

noticeable after an upshift.

Pump Noise - a high pitch whine that increases with engine rpm.

ABBREVIATIONS

PCM -Powertrain Control Module.

TCC - Torque Converter Clutch.

TP Sensor - Throttle Position Sensor.

ECT Sensor - Engine Coolant Temperature

VS Sensor - Vehicle Speed Sensor.

TFP VAL. POSITION SW. - Transmission Fluid Pressure Manual Valve Position Switch

PSA - Transmission Range (TR) Pressure Switch Assembly.

TTS - Transmission Fluid Temperature Sensor.

2. DIAGNOSIS

2.1 BASIC KNOWLEDGE REQUIRED

You must be familiar with some basic electronics to use this section. They will help y ou to follow diagnostic

procedures.

NOTE:

A lack of basic knowledge of this powertrain when performing diagnostic procedures, could result in incorrect

diagnostic performance or damage to powertrain components. Do not, under any circumstances, attempt to

diagnose a powertrain problem without this basic knowledge.

SPECIAL TOOLS

You should be able to use a break out box, a Digital Volt Meter (DVM), a circuit tester, jumper wires or leads and a

line pressure gauge set. Having access to and the ability to use the TECH 2 scan tool would also be a distinct

advantage, as many aspects of transmission diagnosis requires the use of this instrument.

The Functional Test Procedure detailed in Section 2.2, is designed to verify the correct operation of components in

the transmission and to identify whether a condition is electrical in nature, or not. This will eliminate the unnecessary

removal of transmission components and time loss in rectification.

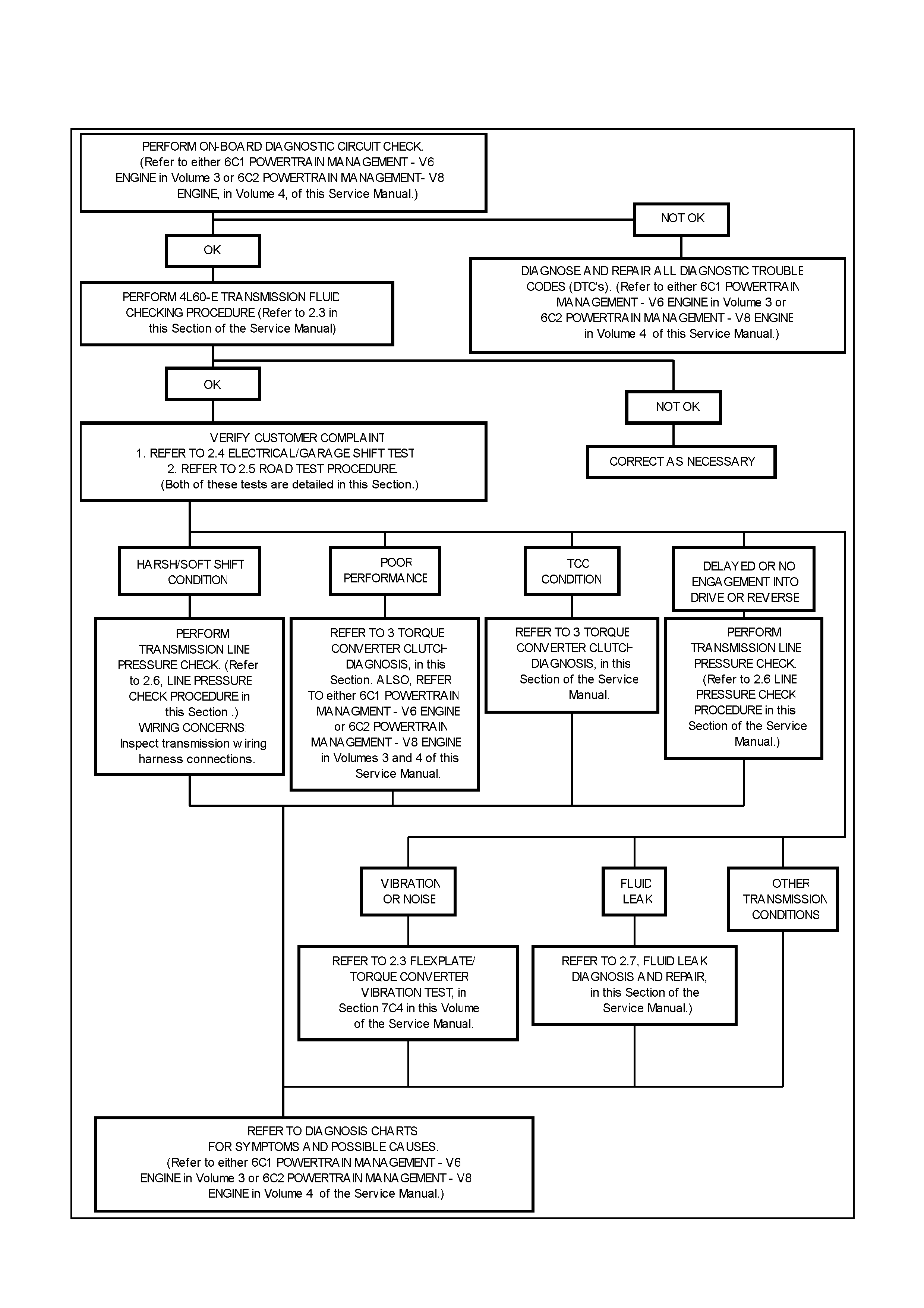

2.2 FUNCTIONAL TEST PROCEDURE

When diagnosing any HYDRA-MATIC - 4L60-E related condition, always begin with the Functional Test Procedure

detailed in Figure 7C3-2. This procedure will indicate the proper path of diagnosing the transmission, by describing

the basic checks and then referencing the locations of specific checks.

Figure 7C3-2

2.3 TRANSMISSION FLUID CHECKING PROCEDURE

1. Start engine and drive vehicle for a distance of 24 km, or until transmission normal operating temperature (82 -

94° C) is reached.

NOTE:

As temperature affects transmission fluid levels, this operation must only be carried out with the transmission at

normal operating temperature. If the vehicle is not at normal operating temperature, and the proper checking

procedures are not followed, the result could be a false reading of the fluid level on the dipstick.

2. Park vehicle on level ground.

3. Move gear selector to 'PARK' position.

4. Apply park brake.

5. Let engine idle for 3 minutes with accessories turned off.

6. Lift the coloured dipstick locking lever, remove dipstick and check fluid colour, condition and level.

7. If the fluid level is low, add only enough Dexron® III to bring the level into the “HOT” area.

*Inaccurate fluid level readings will result if checked immediately after the vehicle has been operated under any

or all of the following conditions:

a. In high ambient temperatures above 32° C.

b. At sustained high speeds.

c. In heavy city traffic during hot weather.

d. Towing.

e. In commercial use (e.g. taxi).

*If the vehicle has been operated under these conditions, switch the engine off and allow the vehicle to 'cool' for

approximately thirty minutes. After the cool-down period, re-start the vehicle and continue from step 2, above.

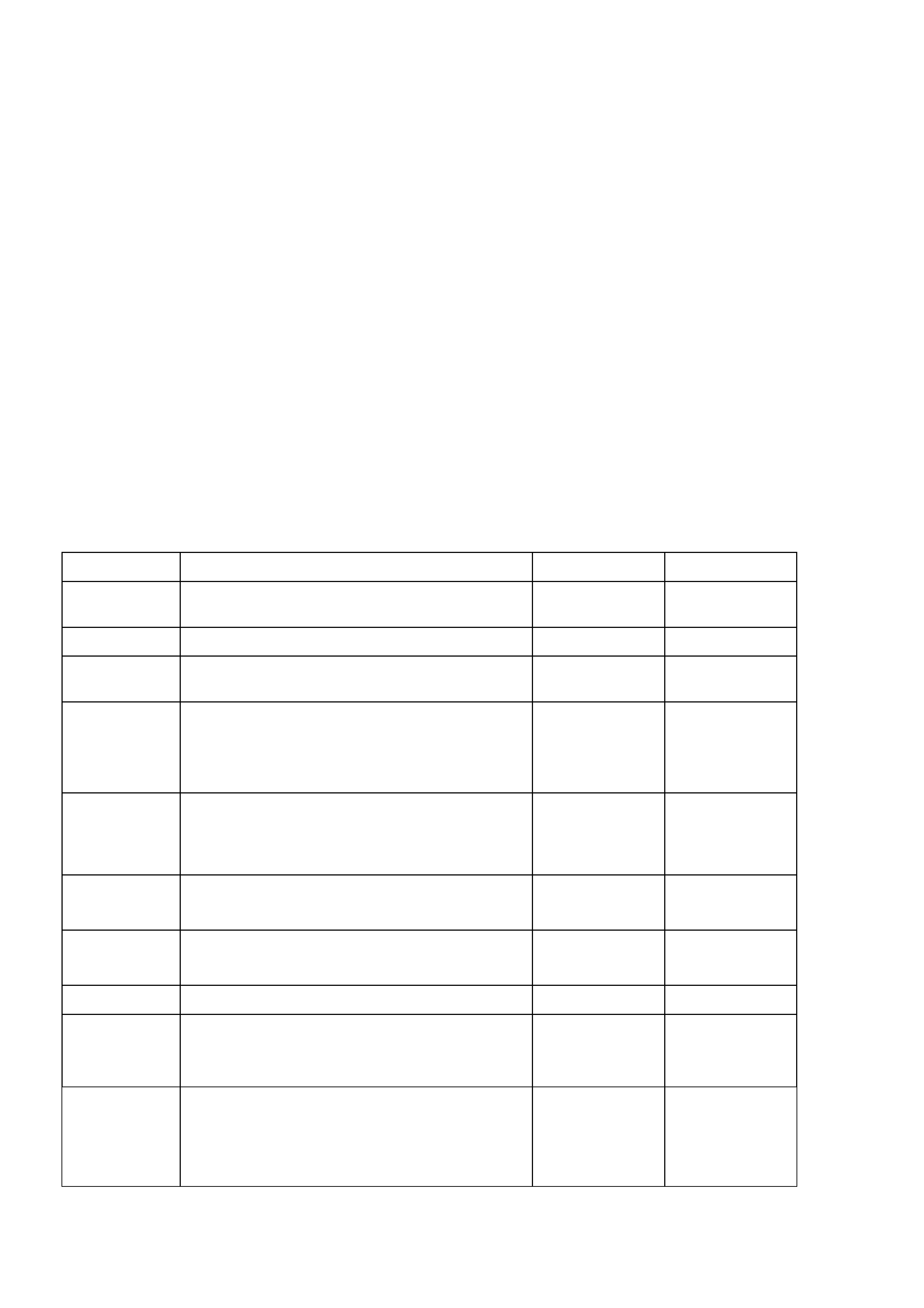

STEP ACTION YES NO

1. Check the fluid colour.

Is the fluid colour red? Go to Step 2 Go to Step 11

2. Is the fluid level satisfactory? Go to Step 20 Go to Step 3

3. Check the fluid.

Is the fluid foamy? Go to Step 8 Go to Step 4

4. Check the fluid level. The correct fluid level

should be in the middle of the cross-hatch on the

dipstick.

Is the level high?

Go to Step 9 Go to Step 5

5. Fluid will be low.

Add fluid to the correct fluid level.

Is the fluid level satisfactory?

Go to Step 6 Go to Step 1

6. Check for external leaks.

Were any leaks present?

Go to Step 7 Go to Step 20

7. Correct the fluid leak condition.

Is action complete?

Go to Step 20

8. Is the fluid level too high? Go to Step 9 Go to Step 10

9. Remove excess fluid to adjust to the correct fluid

level.

Is action complete?

Go to Step 20

10.

1. Check for contaminants in the fluid.

2. Drain the fluid to determine the source of

contamination.

3. Is action complete?

Go to Step 15

STEP ACTION YES NO

11. Is the fluid colour a non-transparent pink? Go to Step 12 Go to Step 13

12. Replace the leaking cooler.

Is the action complete?

Go to Step 15

13. The fluid colour should be light brown.

Transmission fluid may turn dark with normal use.

This does not always indicate oxidation or

contamination.

Is the fluid colour light brown?

Go to Step 14 Go to Step 1

14. Drain the fluid to determine if the fluid is

contaminated. A very small amount of material in

the bottom of the oil pan is a normal condition, but

larger pieces of metal or other material in the

bottom of the oil pan are not and the transmission

requires an overhaul.

Was the fluid contaminated?

Go to Step 15 Go to Step 18

15. Overhaul the transmission or fit a SRTA unit.

Refer to Section 7C5 Unit Repair.

Is action complete?

Go to Step 16

16. Flush the coolers.

Is action complete?

Go to Step 17

17. Add new fluid.

Is action complete?

Go to Step 19

18. Change the fluid and filter.

Is action complete?

Go to Step 19

19. Is the fluid level satisfactory? If not, correct as

necessary.

Is action complete?

Go to Step 20

20. Refer to 2.2 Functional Test Procedure, in this

Section.

Is action complete?

Fluid Checking

Procedure

Completed

2.4 ELECTRICAL/GARAGE SHIFT TEST

This preliminary test should be performed before a hoist or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked before operating the transmission, a simple electrical

condition could be misdiagnosed as a major transmission condition.

The TECH 2 scan tool provides valuable information and must be used on the HYDRA-MATIC 4L60-E transmission

for accurate diagnosis.

1 Move gear selector to "Park" (P) and set the park brake.

2. Connect scan tool to DLC terminal.

3. Start engine.

4. Connect power to scan tool.

5. Verify that the following signals are present:

•ENGINE SPEED

•TRANS OUTPUT SPEED

•VEHICLE SPEED

•A/B/C RNG

•PRNDL SELECT

•DESIRED PCS

•ACTUAL PCS

•PCS DUTY CYCLE

•ENG COOLANT TEMP

•TRANS FLUID TEMP

•THROTTLE ANGLE

•SYSTEM VOLTS

6. Monitor the PRNDL SELECT signal and move the gear selector through all the ranges.

•Verify that the PRNDL SELECT value matches the gear range indicated on the instrument panel or

console.

•Gear selections should be immediate and not harsh.

7. Move gear selector to neutral and monitor the THROTTLE ANGLE signal while increasing and decreasing

engine RPM with the accelerator pedal.

•THROTTLE ANGLE should increase with engine RPM.

UPSHIFT CONTROL AND TORQUE CONVERTER CLUTCH (TCC) APPLY

The PCM calculates upshift points based primarily on two inputs: THROTTLE ANGLE and VEHICLE SPEED. When

the PCM says a shift should occur, an electrical signal is sent to the shift solenoids which in tum moves the valves

to perform the upshift.

The shift speed charts reference THROTTLE ANGLE instead of "min throttle" or "wot" to make shift speed

measurement more uniform and accurate. The TECH 2 scan tool should be used to monitor THROTTLE ANGLE.

The TECH 2 scan tool also has the advantage of being able to record shift point information. Check the instruction

manual for the required procedures.

With gear selector in D4:

1. Look at the shift speed chart (See in this section) and choose a throttle angle of 50%.

2. Set up the scan tool to monitor THROTTLE ANGLE and VEHICLE SPEED

3. Accelerate to the chosen throttle angle and hold the throttle steady.

4. As the transmission upshifts, note the shift speed and commanded gear changes for:

•2nd gear.

•3rd gear.

•4th gear

IMPORTANT:

Shift speeds may vary due to slight hydraulic delays responding to electronic controls. A change from the original

equipment tyre size also affects shift speeds.

Note when TCC applies. This should occur in third or fourth gear. If the apply is not noticed by a drop in engine

speed, refer to the "Functional Check Procedure", in 3 TORQUE CONVERTER CLUTCH DIAGNOSIS, in this

Section.

The TCC should not apply unless the transmission has reached a minimum operating temperature of 18°C TRAN

TEMP and engine coolant temp of 60°C.

5. Repeat steps 1-4 using several different throttle angles.

PART THROTTLE DETENT DOWNSHIFT

1. At vehicle speeds of 64 to 88 km/h in fourth gear, quickly increase throttle angle and verify that:

•TCC releases.

•Transmission downshifts to 3rd gear immediately.

•1-2 Shift Solenoid turns off.

FULL THROTTLE DETENT DOWNSHIFT

1. At vehicle speeds of 64 to 88 km/h in fourth gear, quickly increase throttle angle to its maximum position and

verify that::

•TCC releases.

•Transmission downshifts to 2nd gear immediately.

•1-2 Shift Solenoid is off, 2-3 Shift Solenoid is on.

MANUAL DOWNSHIFTS

The shift solenoids do not control the initial downshift during 4-3 and 3-2 manual downshifts. All manual downshifts

are hydraulic except the 2-1. The solenoid states will change during, or shortly after a manual downshift is selected.

1. At vehicle speeds of 64 to 88 km/h in fourth gear, release the accelerator pedal while moving the gear selector

to ‘3’. Observe that:

•TCC releases.

•Transmission downshifts to 3rd gear immediately.

•Engine slows vehicle down.

2. Move gear selector back to D4 and accelerate to 64 to 72 km/h. Release the accelerator while moving the gear

selector to ‘2’ and observe that:

3. Move gear selector back to D4 and accelerate to 48 km/h. Release the accelerator pedal while moving the

gear selector to ‘1’ and observe that:

•TCC releases.

•Transmission downshifts to 1st gear immediately.

•Engine slows vehicle down.

COASTING DOWNSHIFTS

1. With the gear selector in D4, accelerate to 4th gear with TCC applied.

2. Release the accelerator pedal and lightly apply the brakes, and observe that:

•TCC releases.

•Downshifts occur at speeds shown on the Shift Speed Chart, in this Section.

MANUAL GEAR RANGE SELECTION

Upshifts in the manual gear ranges are controlled by the shift solenoids. Perform the following tests by accelerating

at 10-15° TP Sensor:

Manual Third (3)

1. With vehicle stopped, move the gear selector to D3 and accelerate to observe:

•1-2 shift.

•2-3 shift.

Manual Second (2)

1. With vehicle stopped, move gear selector to D2 and accelerate to observe:

Transmission starts and remains in second gear.

2. Accelerate to 40 km/h and observe:

•2-3 shift does not occur.

•TCC does not apply.

Manual First (1)

1. With vehicle stopped, move gear selector to D1. Accelerate to 32 km/h (20 mph) and observe:

•No upshifts occur.

•TCC does not apply.

Reverse (R)

1. With vehicle stopped, move gear selector to R and slowly accelerate to observe:

•1-2 and 2-3 Shift Solenoids are on.

Use the TECH 2 scan tool to see if any transmission trouble codes have been set. Refer to

Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE or Section 6C2, POWERTRAIN MANAGEMENT -

V8 ENGINE for the required procedures and suggested action required After repairing the vehicle, verify that the

code does not set again.

If the transmission is not performing well and no trouble codes have been set, there may be an intermittent

condition. Check all electrical connections for damage or a loose fit. TECH 2 has a snapshot mode that can help

catch an intermittent condition that does not occur long enough to set a code. Refer to Section 0C, TECH 2 for the

necessary procedure.

If no trouble codes have been set and the condition is suspected to be hydraulic, take the vehicle on a road test.

2.5 ROAD TEST PROCEDURE

IMPORTANT NOTES:

1. Shift points will vary with actual throttle position and driver habits.

2. Compare the results of the test with speed shift chart information. Use these results with the diagnosis

information contained in this Section to evaluate the transmission.

3. This test should only be performed when traffic and road conditions permit.

4. Observe all traffic safety regulations.

5. Perform the road test using a scan tool.

Drive and Reverse Engagement Shift Check

1. Start engine.

2. Depress brake pedal.

3. Move gear selector:

•'P' (Park) to 'R' (Reverse).

•'R' (Reverse) to 'N' (Neutral) to 'D' (Drive).

Gear selections should be immediate and not harsh.

Upshifts and Torque Converter Clutch (TCC) Application

With gear selector in 'D' (Economy Mode):-

1. Accelerate using a steady increasing throttle application.

2. Note the shift speed point gear engagements for:

•1st to 2nd gear.

•2nd - 3rd gear.

•3rd - Overdrive 4th.

3. Note the speed shift point for Torque Converter Clutch (TCC) application. This should occur while in third gear

(Power Mode) or overdrive (Economy Mode).

IMPORTANT:

The TCC will not engage if engine coolant temperature is below 45° C or road speed is less than;

88 km/h in 4th Economy Mode

65 km/h in 3rd Power Mode.

Part Throttle Downshift

At a speed of 70 - 90 km/h, quickly depress the accelerator to half open throttle position and observe:

•TCC releases.

•Transmission immediately causes a 4-3 downshift.

Full Throttle (Detent) Downshift

Operate the vehicle at 70 - 90 km/h in 'D', then quickly depress the accelerator to wide open throttle position and

observe:

TCC releases.

Transmission immediately causes a 4-2 downshift.

Manual Downshift

1. Operate the vehicle at 70 - 90 km/h in 'D', then release the accelerator pedal (closed throttle position) and

move the gear selector to '3' (Third) gear position at the same time and observe:

•TCC release occurs at zero throttle.

•Transmission immediately downshifts to 3rd gear.

•Engine should moderately slow vehicle.

2. Operate the vehicle at 70 - 80 km/h in 'D'. Release the accelerator pedal and simultaneously move the gear

selector to '2' (Second) gear position, and observe:

•TCC release occurs at zero throttle.

•Transmission immediately downshifts to 2nd gear.

•Engine should slow vehicle.

3. Move gear selector to 'D' and accelerate from zero to 40 km/h, with 1-2 and 2-3 upshifts at light throttle.

Release the accelerator pedal (closed throttle position) and simultaneously move the gear selector to '1' (First)

gear position and observe:

•Transmission immediately downshifts to 1st gear.

•Engine should significantly slow vehicle.

Coastdown Downshift

1. With the gear selector in 'D', accelerate to engage 4th gear with TCC applied (approximately 75 km/h).

2. Release the accelerator pedal (closed throttle position) and lightly apply the brakes to observe:

•TCC release occurs at zero throttle.

•The point at which downshift occurs. This will only be noticeable with the assistance of a TECH 2 scan

tool display.

MANUAL GEAR RANGE SELECTION.

Manual Third '3'

With vehicle stopped, place gear selector in '3' and accelerate to observe:

•The first to second gear shift point.

•The second to third gear shift point.

•TCC apply/release (in Economy/Power modes).

Manual Second '2'

1. With vehicle stopped, place gear selector in '2' (Second) and accelerate to observe:

•The first to second gear shift point.

2. Accelerate to 60 km/h and observe:

•That no second to third gear shift occurs.

•That TCC does not engage.

Manual First '1'

1. With vehicle stopped, place gear selector in '1' (First), accelerate to 40 km/h and observe:

•That no upshift occurs. (PCM protection will cause a 1-2 upshift near maximum engine speed.)

•That TCC does not engage.

Reverse.

1. With vehicle stopped, selecte 'R' (Reverse), slowly accelerate and observe reverse gear operation.

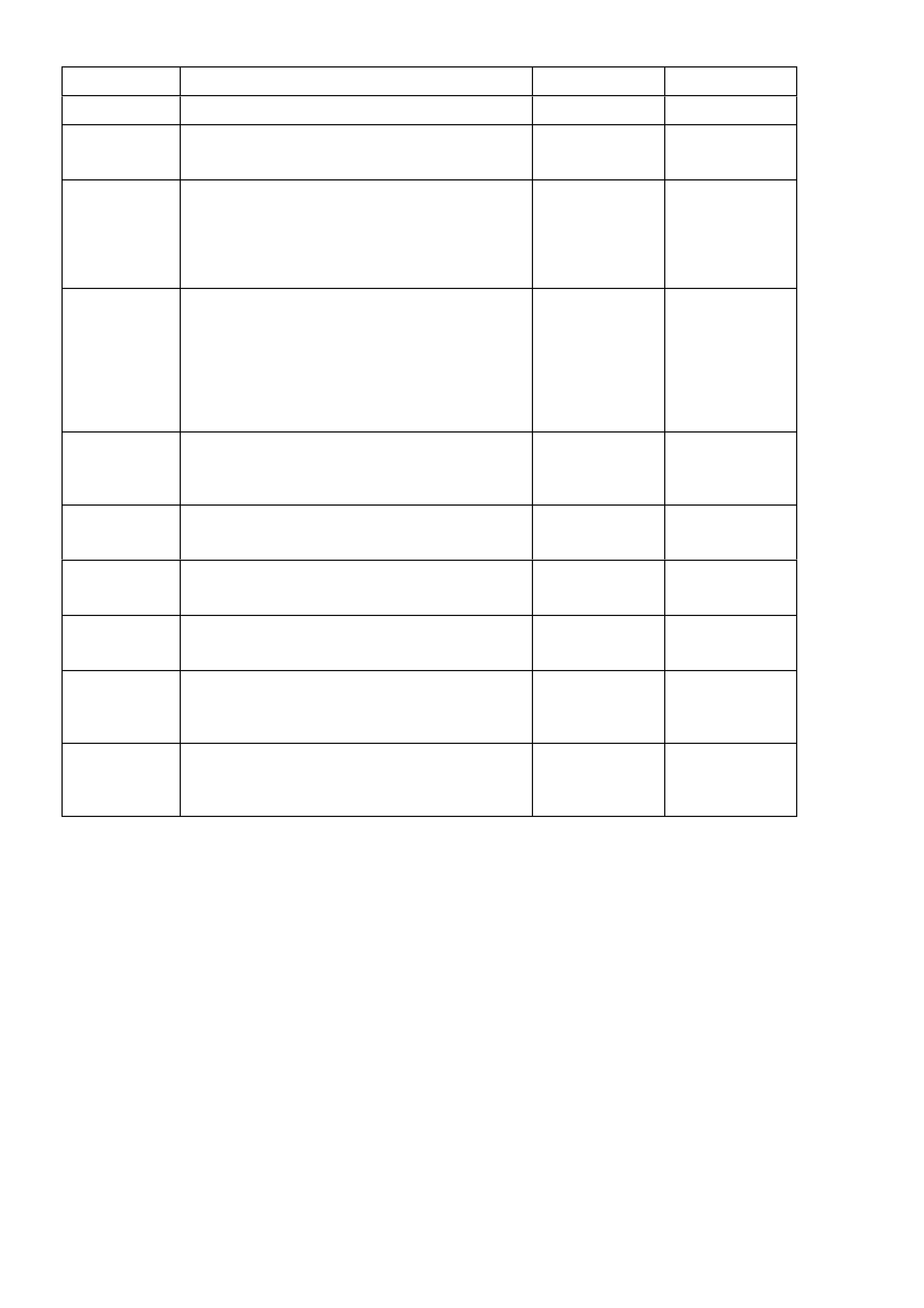

1998 MY HYDRA-MATIC 4L60-E SHIFT SPEED CHART

UPSHIFTS

SHIFT CLOSED THROTTLE -

6.25% - (km/ h ) PART THROTTL E -

50% - (km/h ) WID E OPEN THRO TTLE -

100% - (km/h )

MODE 1 - 22 - 33 - 41 - 22 - 33 - 41 - 22 - 33 - 4

ECONOMY 19 32 73 43 72 205 64 118 205

HFD

(V6 ENGINE ) POWER 21 35 89 52 92 205 64 119 205

CRUISE N/A 35 81 N/A 84 205 N/A 119 205

HND ECONOMY 19 33 71 45 81 200 65 122 200

(V6

SUPERCHARGED POWER 21 35 93 55 97 200 84 121 200

ENGINE CRUISE N/A 34 93 N/A 97 200 N/A 119 200

ECONOMY 19 29 71 39 72 185 61 116 185

HBD

(V8 ENGINE ) POWER 21 34 89 50 81 186 61 116 185

CRUISE N/A 35 81 N/A 87 185 N/A 113 185

DOWNSHIFTS

SHIFT CLOSED THROTTLE -

6.25% - (km/ h ) PART THROTTL E -

50% - (km/h ) WID E OPEN THRO TTLE -

100% - (km/h )

MODE 4 - 33 - 22 - 14 - 33 - 22 - 14 - 33 - 22 - 1

ECONOMY68291684481620410946

HFD

(V6 ENGINE ) POWER79321897611820410946

CRUISE 72 32 N/A 93 67 N/A 204 109 N/A

HND ECONOMY64311677561618811351

(V6

SUPERCHARGED POWER 85 34 18 101 64 18 188 113 51

ENGINE) CRUISE 65 32 N/A 101 64 N/A 188 105 N/A

ECONOMY66191680531617710546

HBD

(V8 ENGINE ) POWER79191884612417710646

CRUISE 72 32 N/A 113 57 N/A 177 105 N/A

MISCELLANEOUS SHIFTS

MANUAL LOW WOT MIN TCC APPLY Coastdown Information

2-1 Downshift 3-1 Downshift 3rd Gear 3-1 3-2

HFD (V6 ENGI NE) 58 46 53 N/A 32

HND (V6 SUPE RCHARGED ENGINE) 56 46 55 N/A 33

HBD (V8 ENGINE) 58 46 53 17 N/A

NOTE 1.

This publication does not include all possible

throttle positions and the corresponding shift point

information.

NOTE 2.

All speeds are indicated in kilometres per hour

(km/h).

NOTE 3.

Actual shift points may vary in accordance with

transmission build variations.

2.6 LINE P RE SSURE CHECK PROCEDURE

Line pressures are calibrated for two sets of gear

ranges - Drive/Park/Neutral and Reverse. This

allows the transmission line pressure to be

appropriate for two different pressure needs in

different gear ranges:

Gear Range Line Pressure Range

Drive, Park or Neutral 379 - 1,303 kPa

Reverse 441 - 2,234 kPa

Before perf orm ing a line pressur e check , ver ify that

the pressure control solenoid is receiving the

correct electrical signal from the PCM, as follows:

1. Install the TECH 2 scan tool. Refer to

Section 0C TECH 2 for the necessary

procedure.

2. Start the engine and firmly apply the park

brake.

3. Check for a stored pressure control solenoid

Diagnostic T rouble Code (DT C) and any other

stored codes.

4. Rectify as necessary.

NOTE:

The transmission may experience harsh, soft or

mushy shifts for up to two days afterwards.

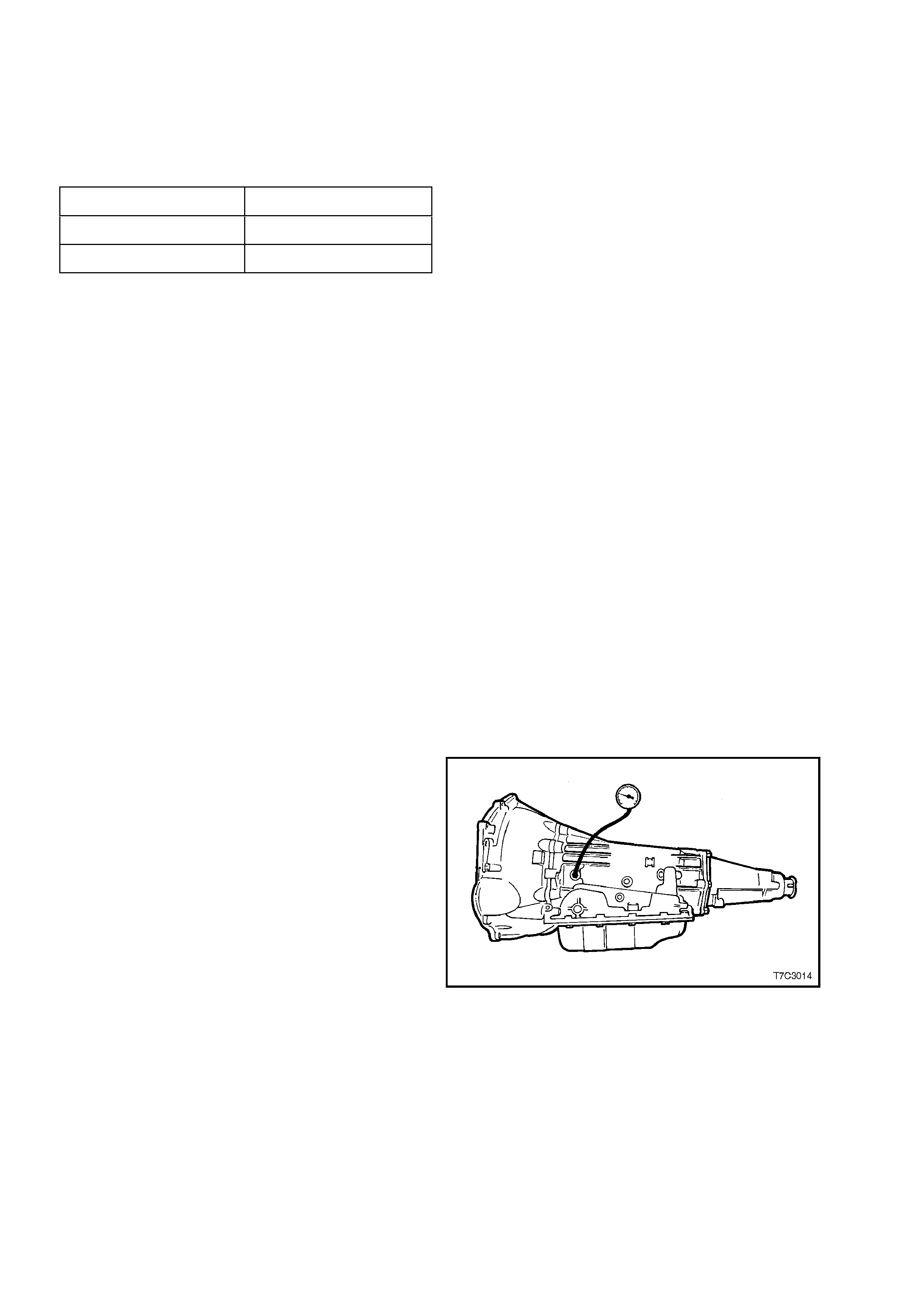

PROCEDURE

1. Check engine and transmission fluid levels.

2. Check manual linkage for correct adjustment

and wear.

3. If not previously carried out, install a TECH 2

scan tool to the vehicle. Refer to

Section 0C, TECH 2 for the necessary

procedure.

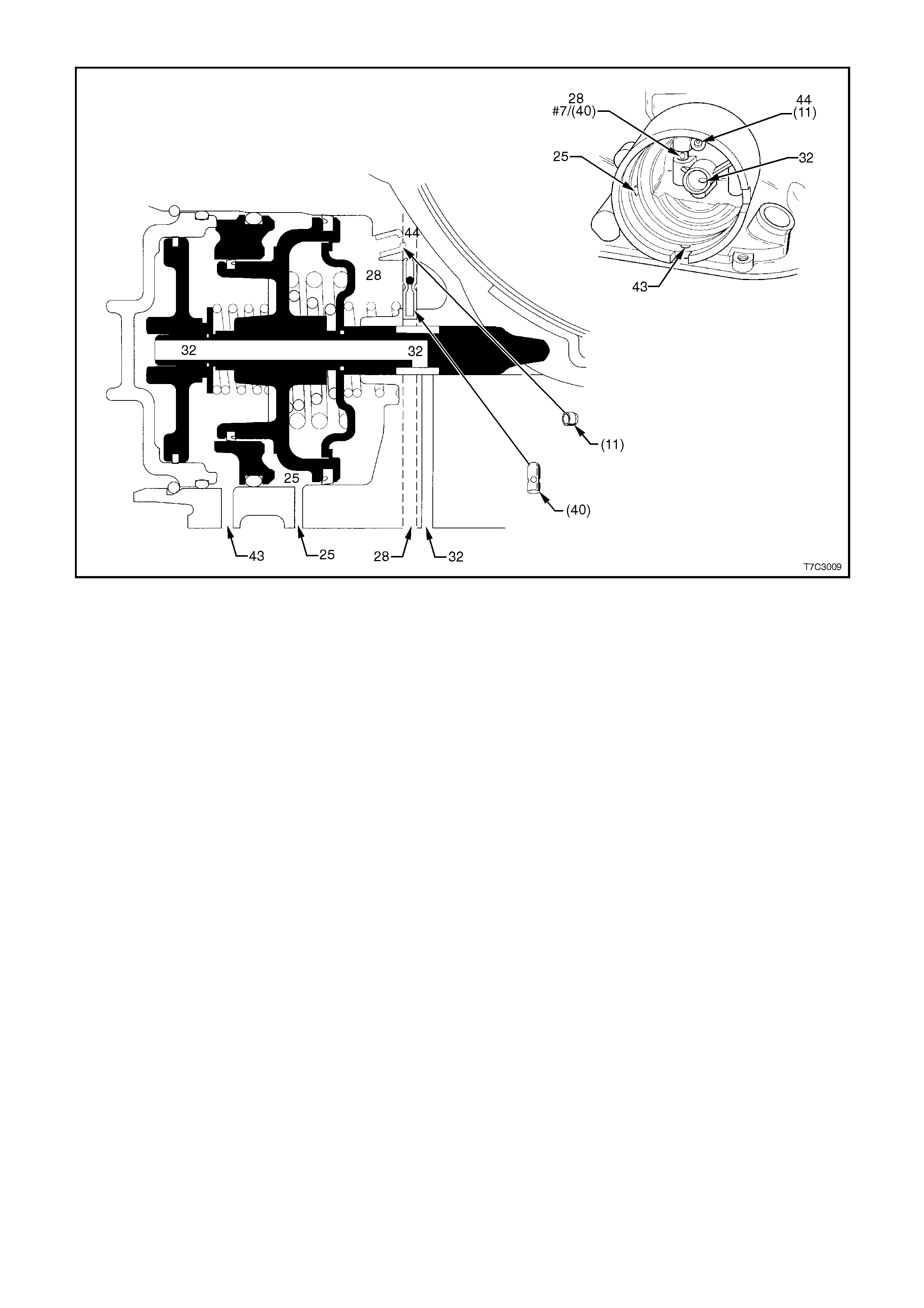

4. Install an oil pressure gauge such as Tool

J21867 or commercial equivalent, to the line

pressure tapping point on the transmission, as

shown.

5. Select ‘P’ (Park) range and firmly apply the

park brake.

6. Start the engine and allow to warm up, at idle.

7. Access the “PCS CONTROL” test on the

TECH 2 scan tool.

8. Increase “DESIRED PCS” in 0.1 Amp

increm ents on the TECH 2 scan tool and read

the corres ponding line press ure reading on the

fluid pressure gauge. (Allow the pressure to

stabilise for 5 seconds after each current

change.

9. Compare the pressure readings against the

chart shown next.

IMPORTANT:

Total test running time should not exceed 2 minutes

or transmission damage could occur.

Figure 7C3-3

NOTE 1:

Pressures are to be taken at an engine speed of 1,500 rpm and a temperature of 66° C. Line pressure drops as

temperature increases.

NOTE 2:

If pressure readings differ greatly from the line pressure chart, refer to the Diagnostic Section in 6C1

POWERTRAIN MANAGEMENT - V6 ENGINE or 6C2 POWERTRAIN MANAGEMENT - V8 ENGINE.

NOTE 3:

The TECH 2 scan tool is only able to control the pressure control solenoid in Park, and Neutral, with the vehicle

stopped. This protects the clutch packs from extremely high or low pressures in Drive or Reverse ranges

Pressure Control Solenoid

Current (Amp) Line Pressure

(kPa)

0.02 1,172 - 1,310

0.10 1,138 - 1,275

0.20 1,103 - 1,241

0.30 1,069 - 1,206

0.40 1,020 - 1,158

0.50 965 - 1,103

0.60 896 - 1,000

0.70 758 - 896

0.80 620 - 793

0.90 448 - 620

0.98 379 - 448

Figure 7C3-4

2.7 FLUID LEAK DIAGNOSIS AND REPAIR

The cause of most external leaks can usually be located and repaired with the transmission installed in the vehicle.

METHODS FOR LOCATING LEAKS

General Method

1. Verify that the leak is in fact, transmission fluid.

2. Thoroughly clean the suspected leak area.

3. Operate the vehicle for about 24 km or until normal operating temperatures are reached.

4. Park the vehicle over clean paper or cardboard.

5. Switch the engine off and look for fluid spots on the paper.

6. Make necessary repairs.

Powder Method

1. Thoroughly clean the suspected leak area with a suitable cleaning agent.

2. Apply an aerosol type powder (eg foot powder) to the suspected leak area.

3. Operate the vehicle for about 24 km or until normal operating temperatures are reached.

4. Switch the engine off.

5. Inspect the suspected leak area and trace the leak path through the powder to find the source.

6. Make necessary repairs.

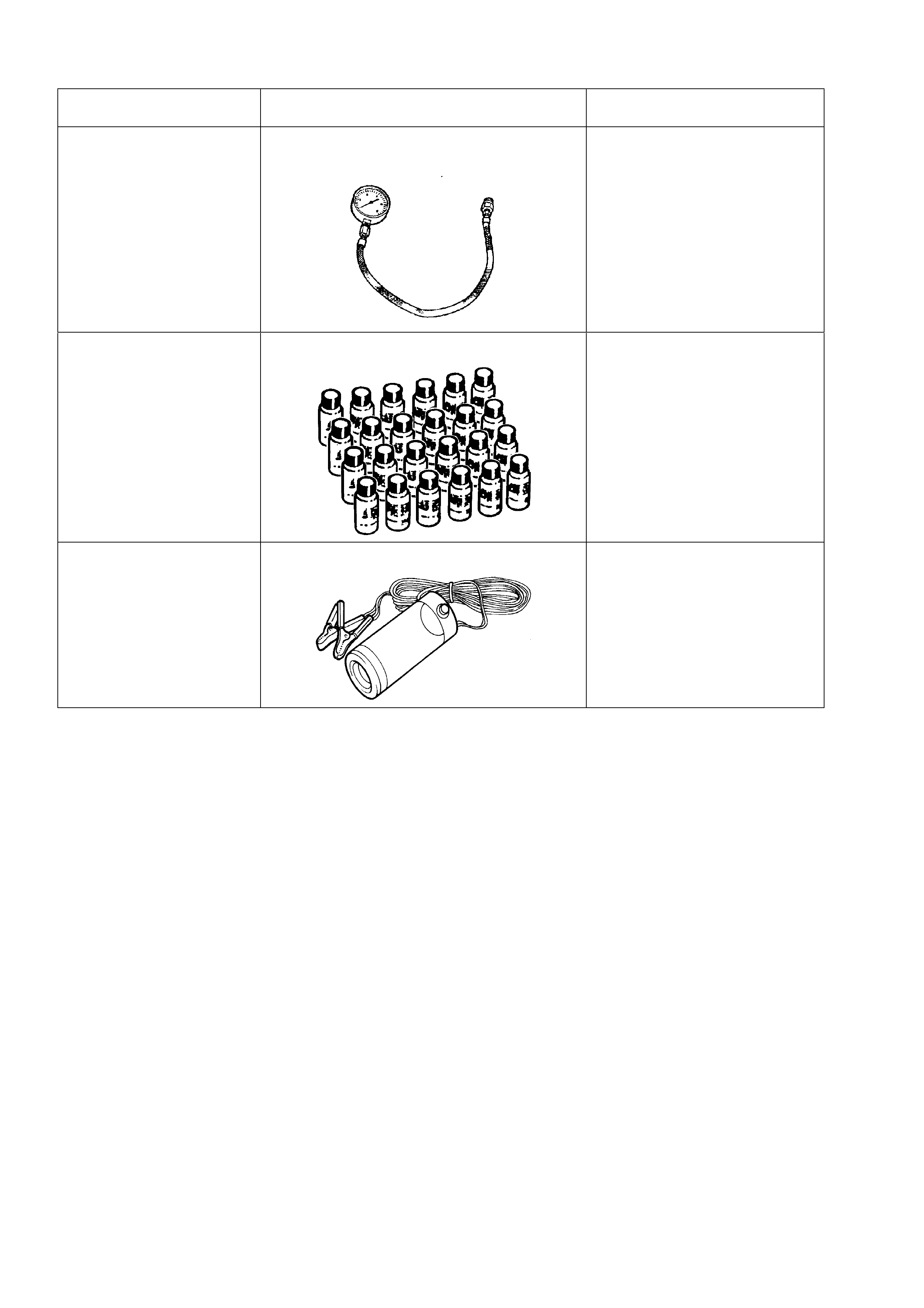

Dye and Black Light Method

While the following can be used as a guide, always follow the manufacturer’s recommendations for use of this

equipment.

1. Pour the manufacturer's recommended amount of dye (such as J28431-B) into the transmission.

2. Road test the vehicle under normal operating conditions.

3. Direct the black light (Tool No. J42220) to the suspect area. Any fluid leak will appear as a brightly coloured

path, leading to the source.

NOTE:

The colour of the dyed fluid can be checked on the transmission dipstick.

4. Make the necessary repairs, then re-check that the leak has been rectified.

REPAIRING THE LEA K

NOTE 1:

Once the leak has been located and traced back to its source, the CAUSE of the leak must be determined, for the

repair to be satisfactory .

NOTE 2:

If a gasket is replaced, but the sealing flange is distorted or bent (eg oil pan flange), the new gasket will not stop the

leak. Obvious damage such as this must be rectified before fitting new gaskets, if a satisfactory repair is to be

expected.

NOTE 3:

Before attempting to repair a leaking seal and/or gasket, check to make sure that the following conditions do not

apply:

Gaskets:

Fluid level or pressure is too high.

Blocked or partially blocked vent or drain back holes.

Incorrectly torqued fasteners or dirty/damaged threads.

Warped/bent flanges or sealing surface.

Scratches, burrs or other damage to the sealing surface.

Damaged or worn gasket.

Cracking or porosity of the component or adjacent part.

Improper sealant used (where applicable).

Techline

Seals:

Fluid level or pressure is too high.

Blocked or partially blocked vent or drain back holes.

Damaged seal bore (Scratched burred or nicked).

Damaged or worn seal.

Incorrect previous installation.

Cracks in the component.

Manual or output shaft is scratched, nicked or worn.

Loose or worn bearing, causing excess seal wear.

POSSIBLE POINTS OF FLUID LEAKS

1. Transmission and Oil Pan:

Attaching bolts not torqued correctly.

Improperly installed or damaged gasket.

2. Case Leak:

Filler tube multi-lip seal damaged or missing.

Filler tube bracket misaligned.

Speed sensor seal damaged.

Manual shaft seal worn or damaged.

Oil cooler connector fittings loose or damaged.

Propeller shaft oil seal worn or damaged.

Line pressure plug loose or thread damage has occurred.

Porous casting.

3. Leak at End of Converter:

Converter seal damaged.

•Seal lip cut (Check converter hub for damage).

•Bushing has moved forward and/or is damaged.

•Garter spring is missing from seal.

Converter leak in the weld area.

Porous casting (case or pump).

4. Fluid Comes from Vent or Fill Tube:

Overfilled.

Water or coolant in fluid (milky/pink fluid colour).

Case porous.

Incorrect fluid level indicator.

Blocked or partially blocked vent.

Drain back holes blocked.

The alignment of the oil pump to case gasket is incorrect.

CASE POROSITY REPAIR

1. Clean the area with epoxy manufacturer's recommended solvent and air dry .

CAUTION:

Epoxy adhesives may cause skin irritations and eye damage. Read and follow all information on the

product label, as provided by the manufacturer.

2. Mix sufficient amount of epoxy adhesive ('Araldite' or an equivalent product), following the manufacturer's

recommendations.

3. While the transmission case is hot, apply epoxy adhesive with a clean, dry stiff brush.

4. Allow the adhesive to dry for the recommended time before starting the engine and checking the results of the

repair.

5. Repeat the fluid leak diagnosis procedure previously detailed.

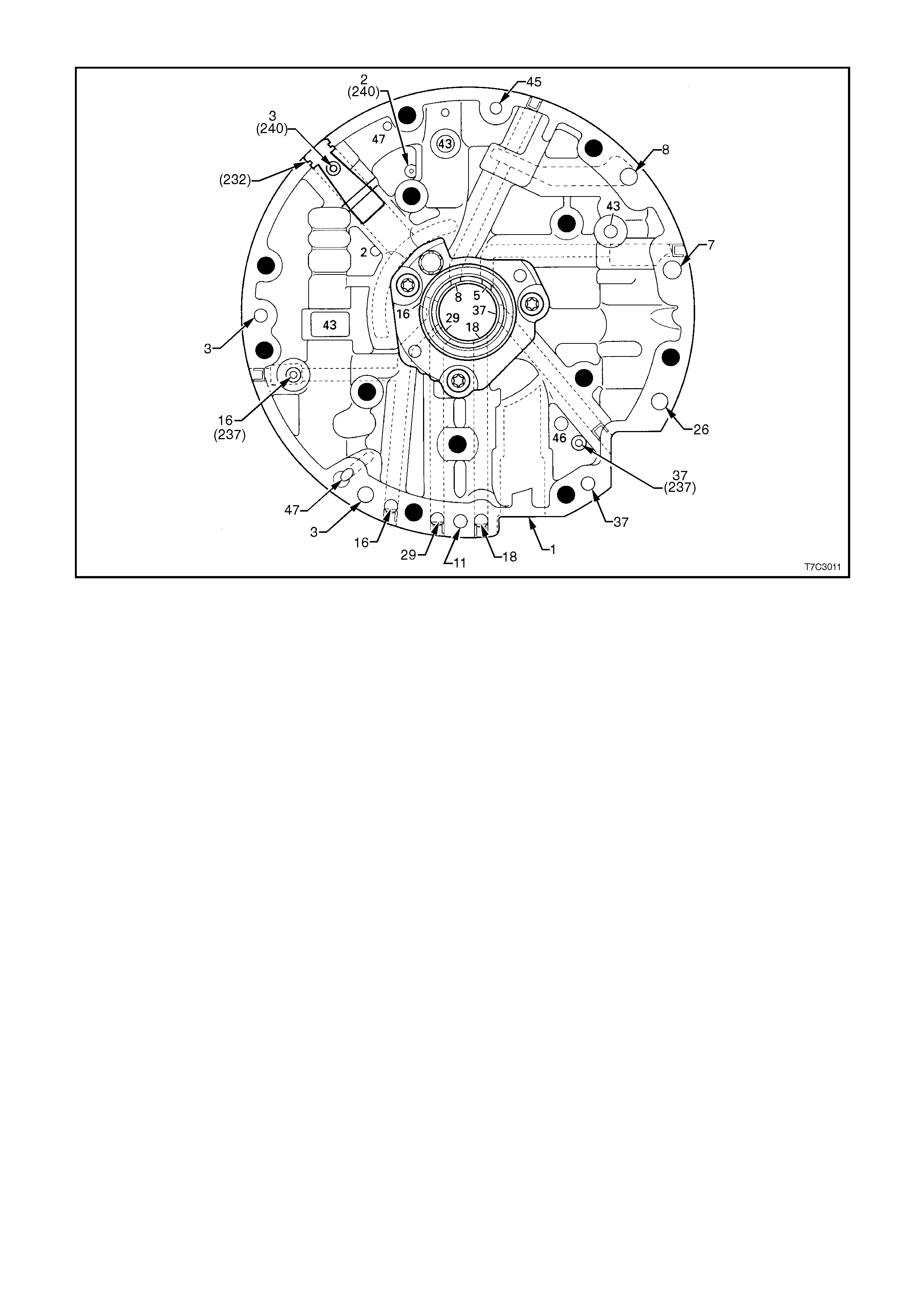

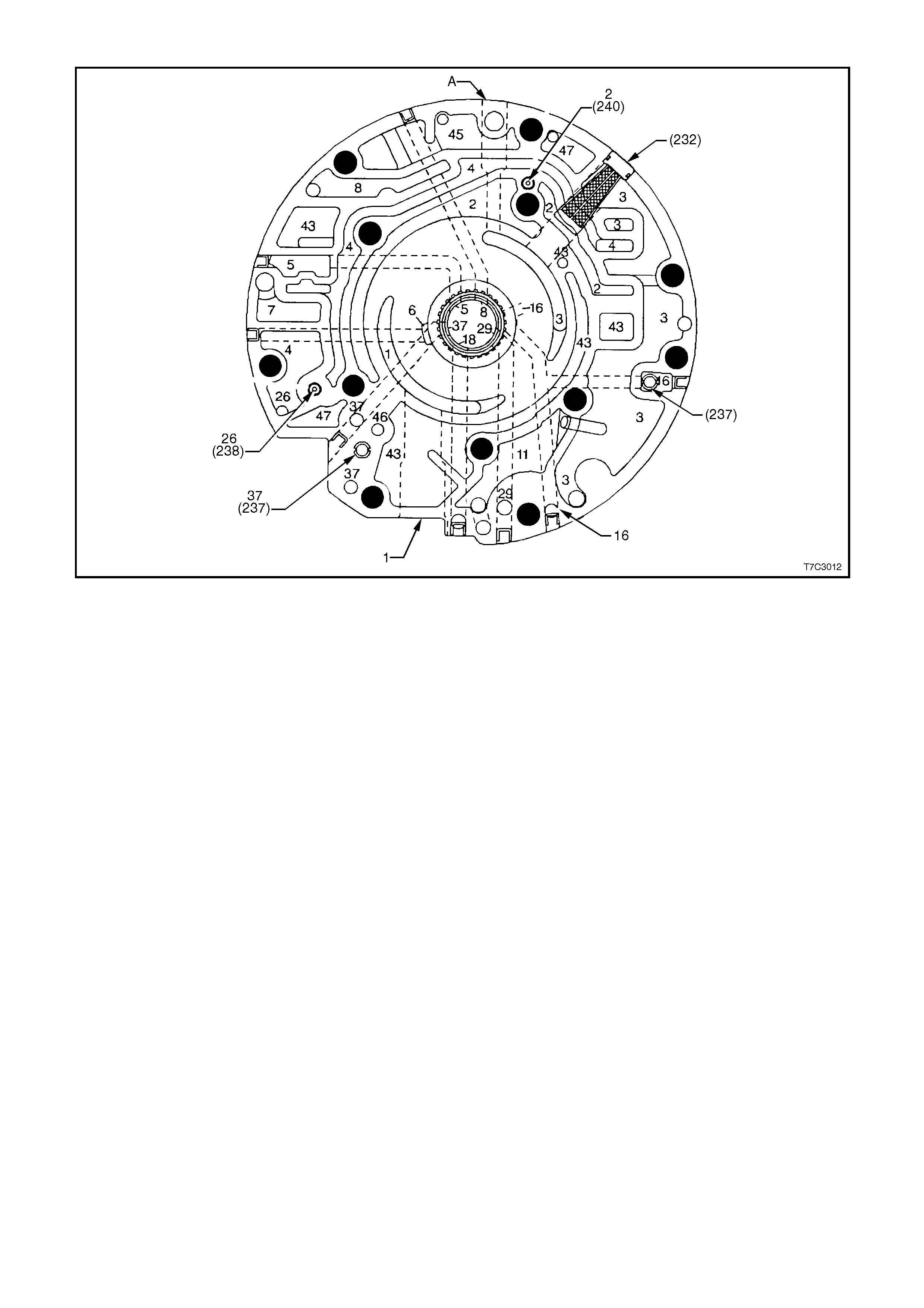

1. Oil Pan Gasket

2. Transmission Main Case

3. Cooler Connections

4. 2-4 Servo Cover Seal

5. Oil Filler Tube Seal

6. Oil Pump Seal Assembly

7. Oil Pump to Case Seal

8. Torque Converter

9. Transmission Vent

10. Pass-through Connector O-ring

11. Manual Shaft Oil Seal

12. Vehicle Speed Sensor O-ring

13. Extension Housing to Case Seal

14. Extension Housing Oil Seal

Assembly

15. Line Pressure Plug

Figure 7C3-5 Possible Points of External Leaks

3. TORQUE CONVERTER CLUTCH (TCC) DIAGNOSIS

To properly diagnose the Torque Converter Clutch (TCC) system, perform all electrical testing first and then the

hydraulic testing.

The TCC is applied by fluid pressure, that is controlled by solenoids located inside the automatic transmission

assembly. For a detailed description of this control function, refer to Section 7C1 GENERAL INFORMATION.

3.1 FUNCTIONAL CHECK PROCEDURE

INSPECT

1. Install a tachometer or TECH 2 scan tool.

2. Operate the vehicle until proper operating temperature is reached.

3. Drive the vehicle at 80 to 88 km/h with a light throttle (road load).

4. Maintaining throttle, lightly touch the brake pedal and check for release of the TCC and a slight increase in

engine speed (RPM).

5. Release the brake, slowly accelerate and check for a re-apply of the converter clutch and a slight decrease in

engine speed (RPM).

3.2 TORQUE CONVERTE R EVALUATION

TORQUE CONVERTER STATOR

The torque converter stator roller clutch can have one of two different type malfunctions:

A. Stator assembly freewheels in both directions.

B. Stator assembly remains locked up at all times.

Condition A - Poor Acceleration Low Speed

The car tends to have poor acceleration from a standstill. At speeds above 50 to 55 km/h, the car may act normally.

If poor acceleration is noted it should first be determined that the exhaust system is not blocked, and the

transmission is in first (1st) gear when starting out.

If the engine freely accelerates to high RPM in "NEUTRAL" (N), it can be assumed that the engine and exhaust

system are normal. Checking for poor performance in "Drive" and "Reverse" will help determine if the stator is

freewheeling at all times.

Condition B - Poor Acceleration High Speed

Engine RPM and car speed limited or restricted at high speeds. Performance when accelerating from a standstill is

normal. Engine may over-heat. Visual examination of the converter may reveal a blue colour from over-heating.

If the converter has been removed, the stator roller clutch can be checked by inserting two fingers into the splined

inner race of the roller clutch and trying to tum the race in both directions. The inner race should turn freely

clockwise, but not turn or be very difficult to turn anti-clockwise.

Noise

Torque converter whine is usually noticed w hen the vehicle is stopped and the transmission is in "Drive" or

"Reverse". The noise will increase when engine RPM is increased. The noise will stop when the vehicle is moving or

when the torque converter clutch is applied because both halves of the converter are turning at the same speed.

Perform a stall test, as detailed next, to make sure the noise is actually coming from the converter:

1. Place foot on brake.

2. Put gear selector in "Drive".

3. Depress accelerator to approximately 1200 RPM for no more than six seconds.

NOTE:

If the accelerator is depressed for more than six seconds, damage to the transmission may occur.

A torque converter noise will increase under this load.

IMPORTANT:

This noise should not be confused with pump whine noise which is usually noticeable in "Park", "Neutral" and all

other gear ranges. Pump whine will vary with pressure ranges.

The torque converter should be replaced under any of the following conditions:

•External leaks in the hub weld area.

•Converter hub is scored or damaged.

•Converter pilot is broken, damaged or fits poorly into crankshaft.

•Steel particles are found after flushing the cooler and cooler lines.

•Pump is damaged or steel particles are found in the converter.

•Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses have

been made. (Converter clutch material may be glazed.)

•Converter has an imbalance which cannot be corrected. (Refer to Converter Vibration Test Procedure.)

•Converter is contaminated with engine coolant containing antifreeze.

•Internal failure of stator roller clutch.

•Excess end play.

•Heavy clutch debris due to overheating (blue converter).

•Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are worn

or damaged - indicates that lining material came from converter.

The Torque Converter Should Not Be Replaced If:

•The oil has an odour, is discoloured, and there is no evidence of metal or clutch facing particles.

•The threads in one or more of the converter bolt holes are damaged. Correct with thread insert.

•Transmission failure did not display evidence of damage or worn internal parts, steel particles or clutch plate

lining material in unit and inside the fluid filter. Vehicle has been exposed to high mileage (only). The

exception may be where the torque converter clutch damper plate lining has seen excess wear by vehicles

operated in heavy and/or constant traffic, such as taxi, delivery or police use.

3.3 TCC SHUDDER

The key to diagnosing Torque Converter Clutch (TCC) shudder is to note when it happens and under what

conditions.

TCC Shudder should only occur during the APPLY and/or RELEASE of the converter clutch; SELDOM after the

TCC plate is fully applied.

While TCC Is Applying Or Releasing:

If the shudder occurs while TCC is applying, the problem can be within the transmission or torque converter.

Something is not allowing the clutch to become fully engaged, not allowing clutch to release, or is trying to release

and apply the clutch at the same time. This could be caused by leaking turbine shaft seals, a restricted release

orifice, a distorted clutch or housing surface due to long converter bolts, or defective friction material on the TCC

plate.

Shudder Occ urs After TCC Has Applied:

In this case, most of the time there is nothing wrong with the transmission! As mentioned above, once the TCC has

been applied, it is very unlikely that it will slip. Engine problems may go unnoticed under light throttle and load, but

become noticeable after TCC apply when going up a hill or accelerating, due to the mechanical coupling between

engine and transmission.

NOTE:

Once TCC is applied there is no torque converter (fluid coupling) assistance. Engine or driveline vibrations could be

unnoticeable before TCC engagement.

Inspect the following components to avoid misdiagnosis of TCC Shudder and possibly disassembling a

transmission and/or replacing a torque converter unnecessarily:

•Spark plugs - Inspect for cracks, high resistance or broken insulator.

•Plug wires - Look in each end. If there is red dust (ozone) or black substance (carbon) present, then the wires

are bad. Also look for a white discolouration of the wire indicating arcing during hard acceleration.

•Distributor cap and rotor (V8 engine) - Look for broken, cracked parts and carbon tracking.

•Ignition coil (V8 engine) - Look for carbon tracking on tower, indicating arcing while engine is misfiring.

•Fuel injector - Filter may be plugged.

•Vacuum leak - Engine won't get correct amount of fuel. May run rich or lean depending on where the leak is.

•MAP sensor - Like a vacuum leak, engine won't get correct amount of fuel for proper engine operation.

•Carbon on intake valves - Restricts proper flow or air/fuel mixture into cylinders.

•Flat cam - Valves don't open enough to let proper fuel/air mixture into cylinders.

•Oxygen sensor - May command engine too rich or too lean for too long.

•Fuel pressure - May be too low.

•Engine mounts - Vibration of mounts can be multiplied by TCC engagement.

•Propeller shaft universal joints - Check for vibration.

•TPS - TCC apply and release depends on TPS in many engines. If TPS is out of specification, TCC may

remain applied during initial engine acceleration.

•Cylinder balance - Bad piston rings or poorly sealing valves can cause low power in a cylinder.

•Fuel contamination - Causes poor engine performance.

3.4 RANGE REFERENCE CHART

RANGE GEAR SHIFT

SOLENOID 2-4 BAND RE V ERS

E INPUT OVERRU

N

CLUTCH

FORWAR

D

CLUTCH

FORWARD

SPRAG

CL.

3-4

CLUTCH LOW/

ROLLER LOW/

REVERSE

1 - 22 - 3 (#1) CLUTCH

(#2) (#3) (#4) ASSEMBL

Y

(#5)

(#6) CLUTCH(

#7) CLUTCH

(#8)

PARK On * On * APPLIED

REVERSE On * On * APPLIED APPLIED

NEUTRAL On * O n *

1ST On On APPLIED HOLDING HOLDING

D2ND OFF On APPLIED APPLIED HOLDING

3RD OFF OFF APPLIED HOLDING APPLIED

4TH On OFF APPLIED APPLIED APPLIED

1ST On On APPLIED HOLDING HOLDING

32ND OFF On APPLIED APPLIED HOLDING

3RD OFF OFF APPLIED APPLIED HOLDING APPLIED

21ST On On APPLIED APPLIED HOLDING HOLDING

2ND OFF On APPLIED APPLIED APPLIED HOLDING

11ST On On APPLIED APPLIED HOLDING HOLDING APPLIED

2ND ** OFF On APPLIED APPLIED APPLIED HOLDING

*SHIFT SOLENOID STATE IS A FUNCTION OF VEHICLE SPEED AND MAY CHANGE IF A VEHICLE SPEED INCREASES

SUFFICIENTLY IN PARK, REVERSE OR NEUTRAL.. HOWEVER, tHIS DOES NOT AFFECT TRANSMISSION OPERATION.

** IN MANUAL FIRST, SECOND GEAR IS ONLY AVAILABLE ABOVE APPROXIMATELY 70 KM/H TO PREVENT ENGINE

OVERSPEEDING.

Figure 7C3-6

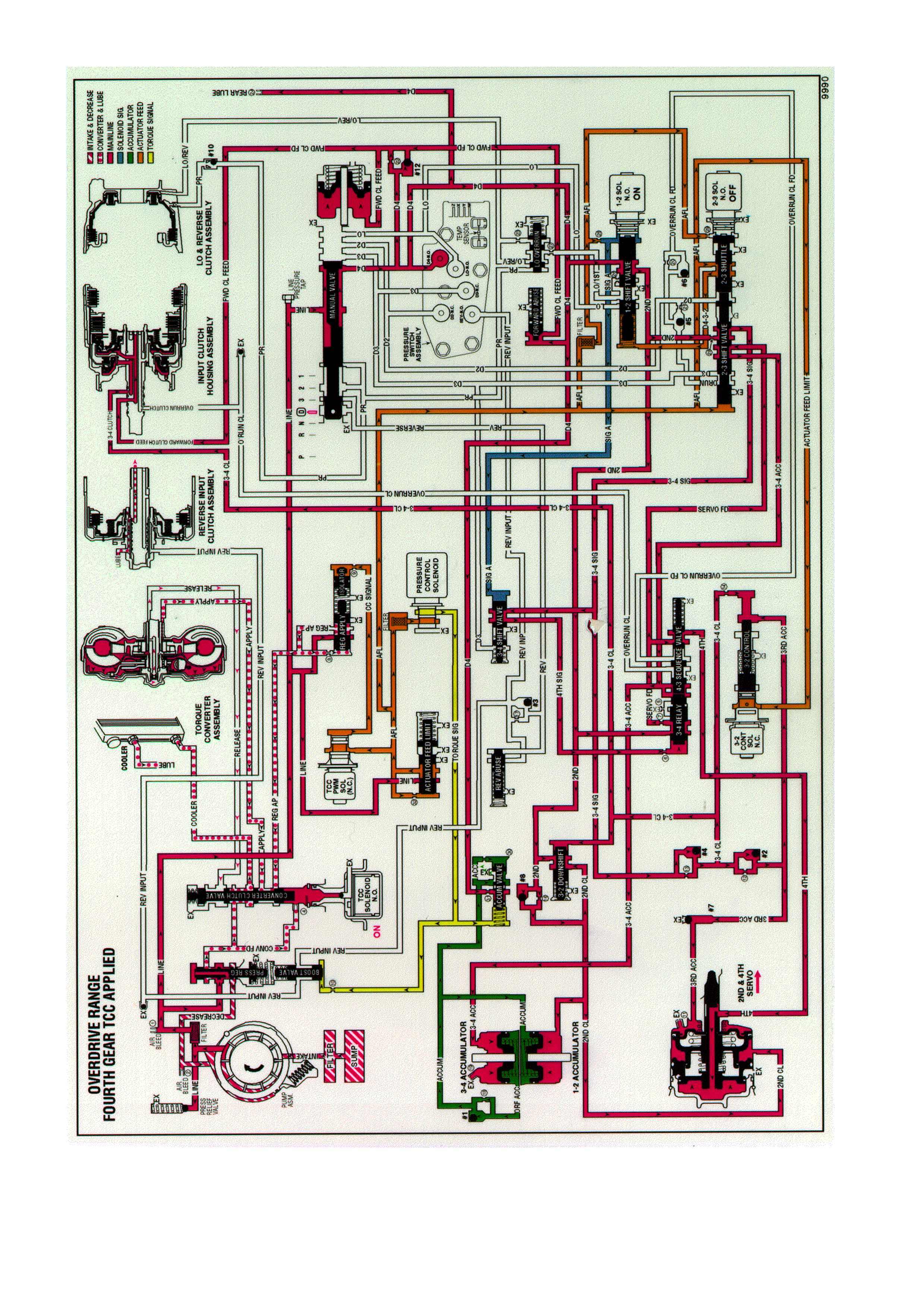

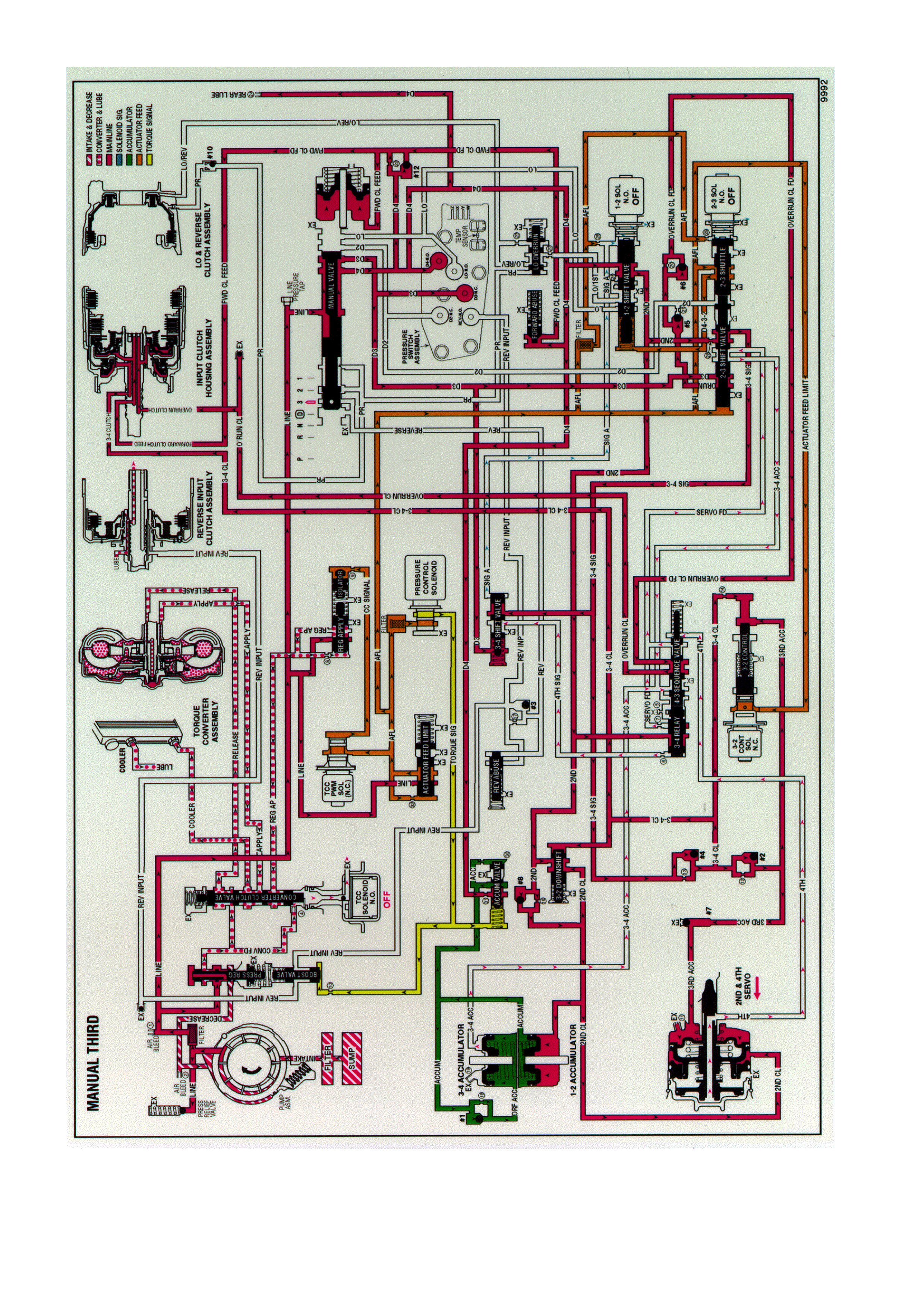

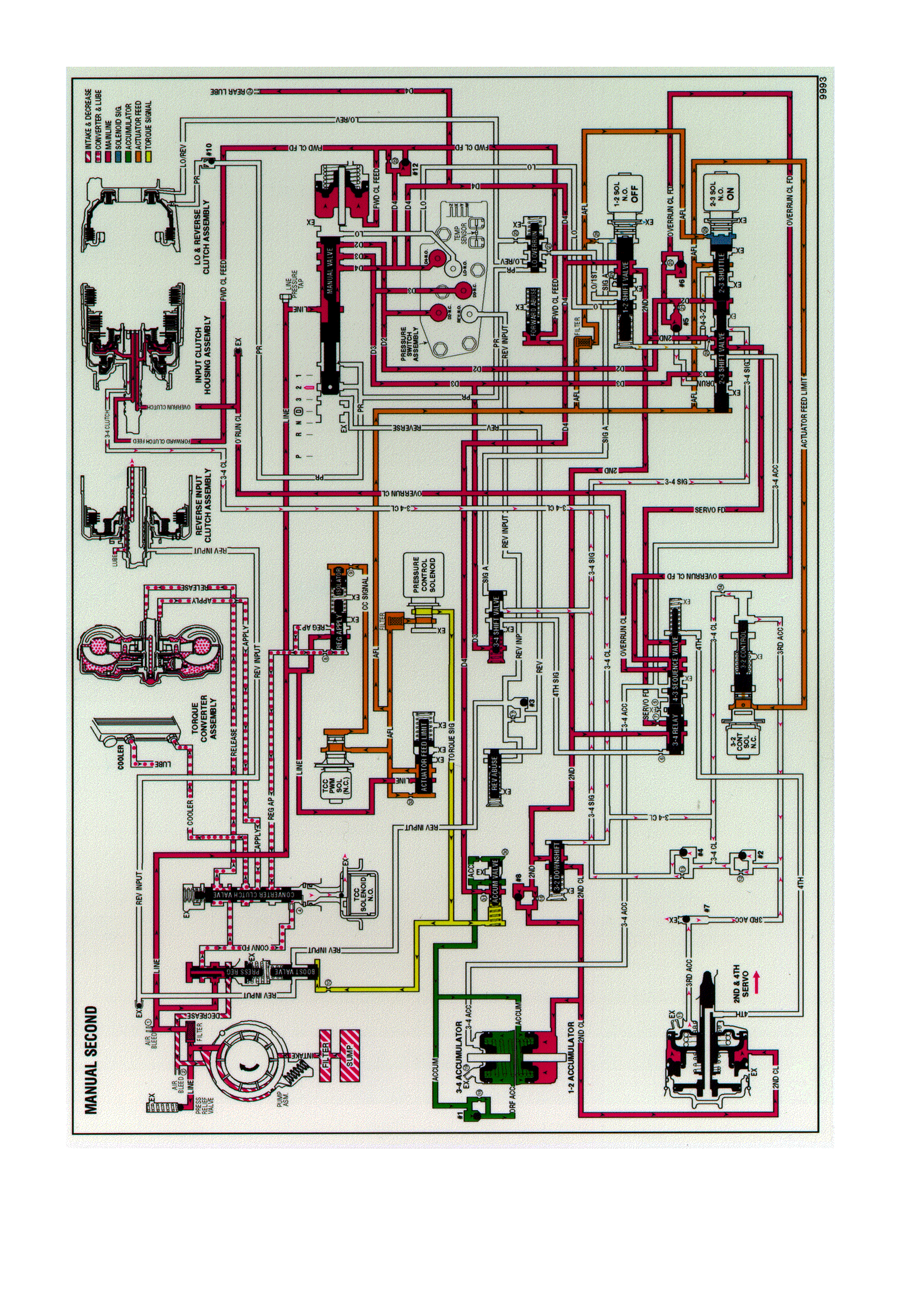

4. FLUID FLOW AND CIRCUIT DESCRIPTI ONS

PARK (ENGINE RUNNING)

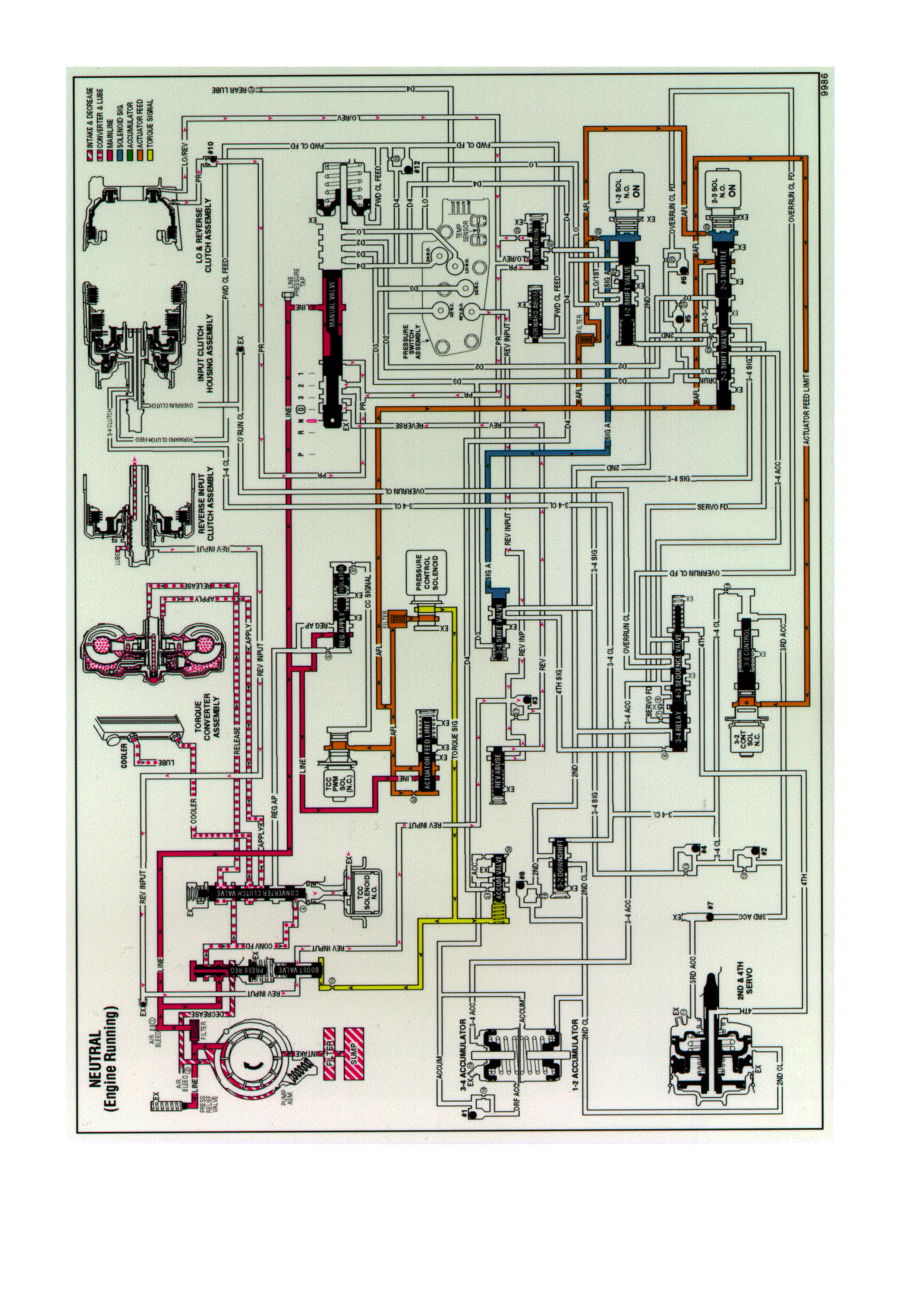

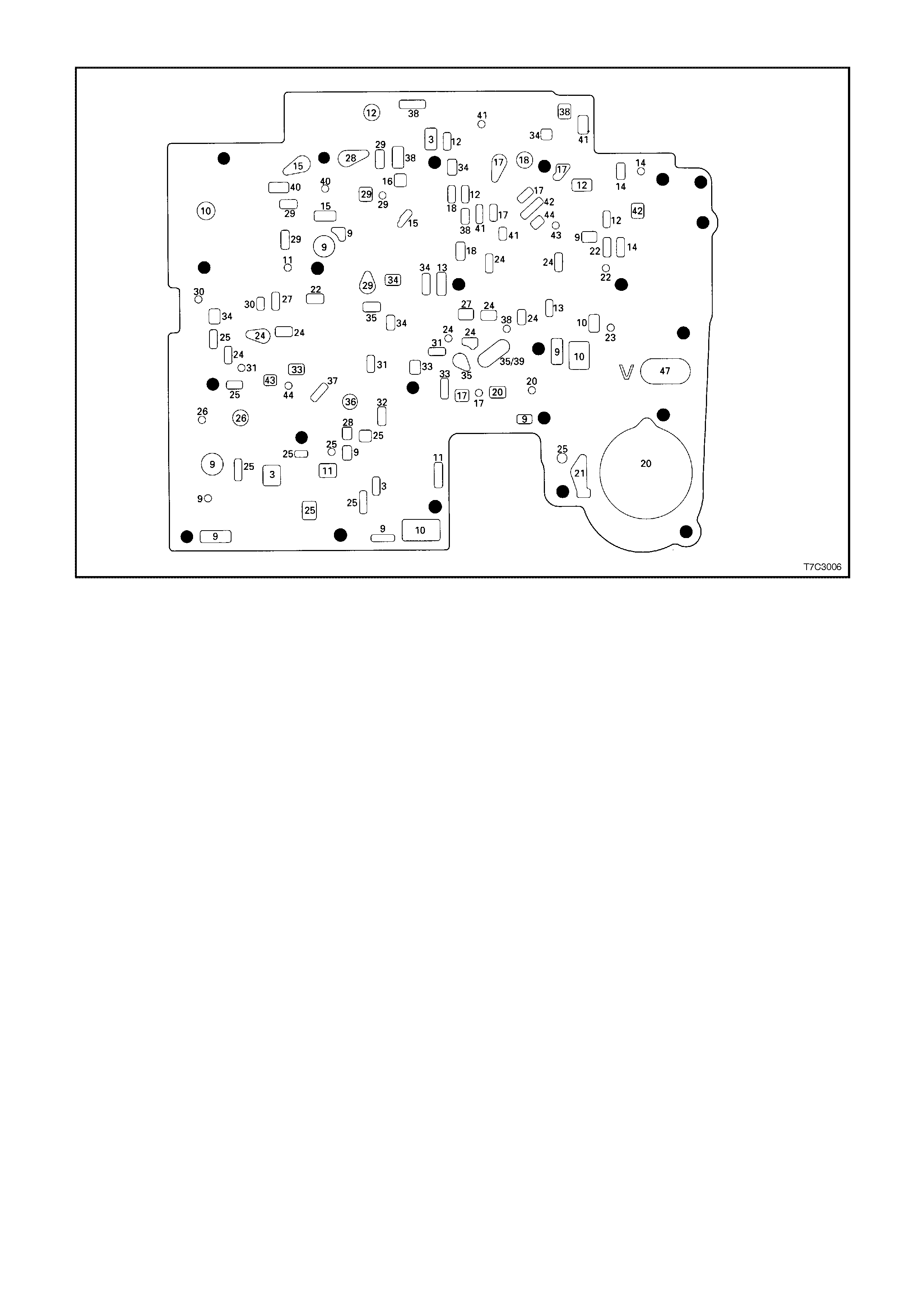

Figure 7C3-7 Park Engine Running

With the gear selector lever in the PARK (P) position and the engine running, the line pressure from the oil pump

assembly is directed to various components in the valve body and the oil pump.

PRESSURE REGULATOR

Pressure Regulator Valve

The pressure regulator valve regulates the oil pump output (line pressure) in response to the signal fluid pressure,

the spring force and the line pressure acting on the end of the valve. The line pressure is routed through the valve

and into both the converter feed and the decrease fluid circuits. Regulated line pressure is also directed to the

manual valve, the converter clutch signal valve and the actuator feed limit valve.

Pressure Relief Valve

Controlled by spring force, this checkball limits the maximum value of the line pressure. When the line pressure

reaches this limiting value, fluid is exhausted past the ball and returns to the sump.

Line Pressure Tap

The line pressure tap provides a location to measure the line pressure with a fluid pressure gauge.

Actuator Feed Limit Valve

Biased by spring force and orificed AFL fluid, it limits the maximum value of line pressure entering the AFL fluid

circuit. Below this limiting value, the AFL fluid pressure equals the line pressure. The AFL fluid is routed to the

pressure control solenoid, the 3-2 control solenoid, the 1-2 and 2-3 shift solenoids, and the 2-3 shift valve train.

Pressure Control Solenoid

Controlled by the Powertrain Control Module (PCM) the pressure control solenoid regulates the filtered AFL fluid

into the torque signal fluid pressure. The PCM controls this regulation by varying the current value to the solenoid in

relation to the throttle position and other vehicle operating conditions.

TORQUE CONVERTER CLUTCH (TCC)

Torque Converter Clutch Signal Valve

The valve may be in a position to allow the line pressure to enter the converter clutch (CC) signal fluid circuit. If this

occurs with the 2nd clutch fluid circuit empty, the CC signal fluid pressure orificed to the end of the CC signal valve

will close the valve and block line pressure. Any fluid in the CC signal fluid circuit will exhaust through the normally

open TCC solenoid.

Converter Clutch Apply Valve

Held in the release position by spring force, it directs converter feed fluid into the release fluid circuit. Also, fluid

returning from the converter in the apply fluid circuit is routed through the valve and into the cooler fluid circuit.

Torque Converter

Release fluid pressure unseats the TCC apply checkball (#9), keeps the pressure plate released from the converter

cover and fills the converter with fluid. Fluid exits the converter between the converter hub and the stator shaft in the

apply fluid circuit.

Cooler and Lubrication System

Cooler fluid from the converter clutch apply valve is routed through the transmission fluid cooler and into the

lubrication fluid circuits.

MANUAL VALVE

Controlled by the selector lever and the manual shaft, the manual valve is in the Park (P) position and directs the

line pressure into the PR (Park/Reverse) fluid circuit. Line pressure is blocked from entering any other fluid circuit at

the manual valve.

LOW AND REVERSE CLUTCH APPLIES

Lo and Reverse Clutch Piston

The PR fluid seats the low and reverse clutch checkball (#10) and is orificed to the outer area of the piston. Orificing

the PR fluid around the #10 checkball helps control the low and reverse clutch apply. Also, Lo/Reverse fluid

pressure from the low overrun valve acts on the inner area of the low and reverse clutch piston in order to increase

the clutch holding capacity.

Low Overrun Valve

The PR fluid pressure moves the valve against the spring force and fills the low/reverse fluid circuit. Lo/Reverse

fluid is orificed (323) back to the low overrun valve in order to assist the PR fluid in moving the valve against the

spring force. The spring force provides a time delay for the PR fluid filling the Lo/Reverse fluid circuit. The

Lo/Reverse fluid is routed to the inner area of the low and reverse clutch piston in order to increase the holding

capacity of the clutch.

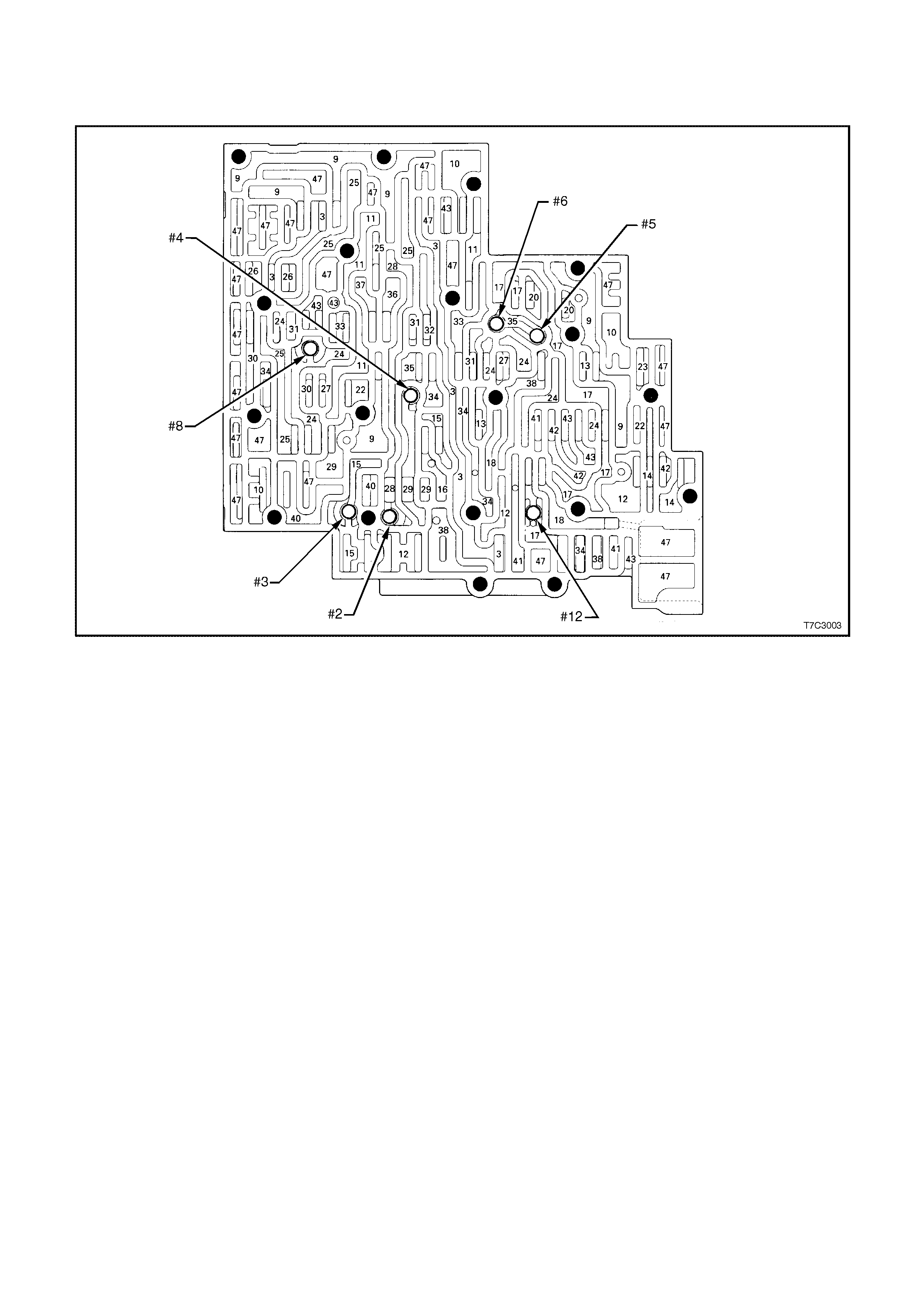

TRANSMISSION FLUID PRESSURE MANUAL VALVE POSITION SWITCH (TFP VAL. POSITION SW.)

ASSEMBLY

The TFP Val. Position Sw. consists of five fluid pressure switches: D2 and D3 are normally closed and D4, Low and

Rev are normally open. All fluid circuits routed to the assembly are empty and the TFP Val. Position Sw. signals the

PCM that the transmission is in either Park or Neutral.

Shift Solenoids (1 -2 and 2-3)

Both shift solenoids, which are normally open, are energised by the PCM and block fluid from exhausting. This

maintains the signal A fluid pressure at the 1-2 shift solenoid and signal B fluid pressure at the 2-3 shift solenoid.

Shift Valves (1-2, 2-3 and 3-4)

Signal A fluid pressure holds the 1-2 shift valve in the downshift position and the 3-4 valve in the upshift (first and

fourth gear) position. The signal B fluid pressure from the 2-3 shift solenoid holds the 2-3 shift train in the downshift

position.

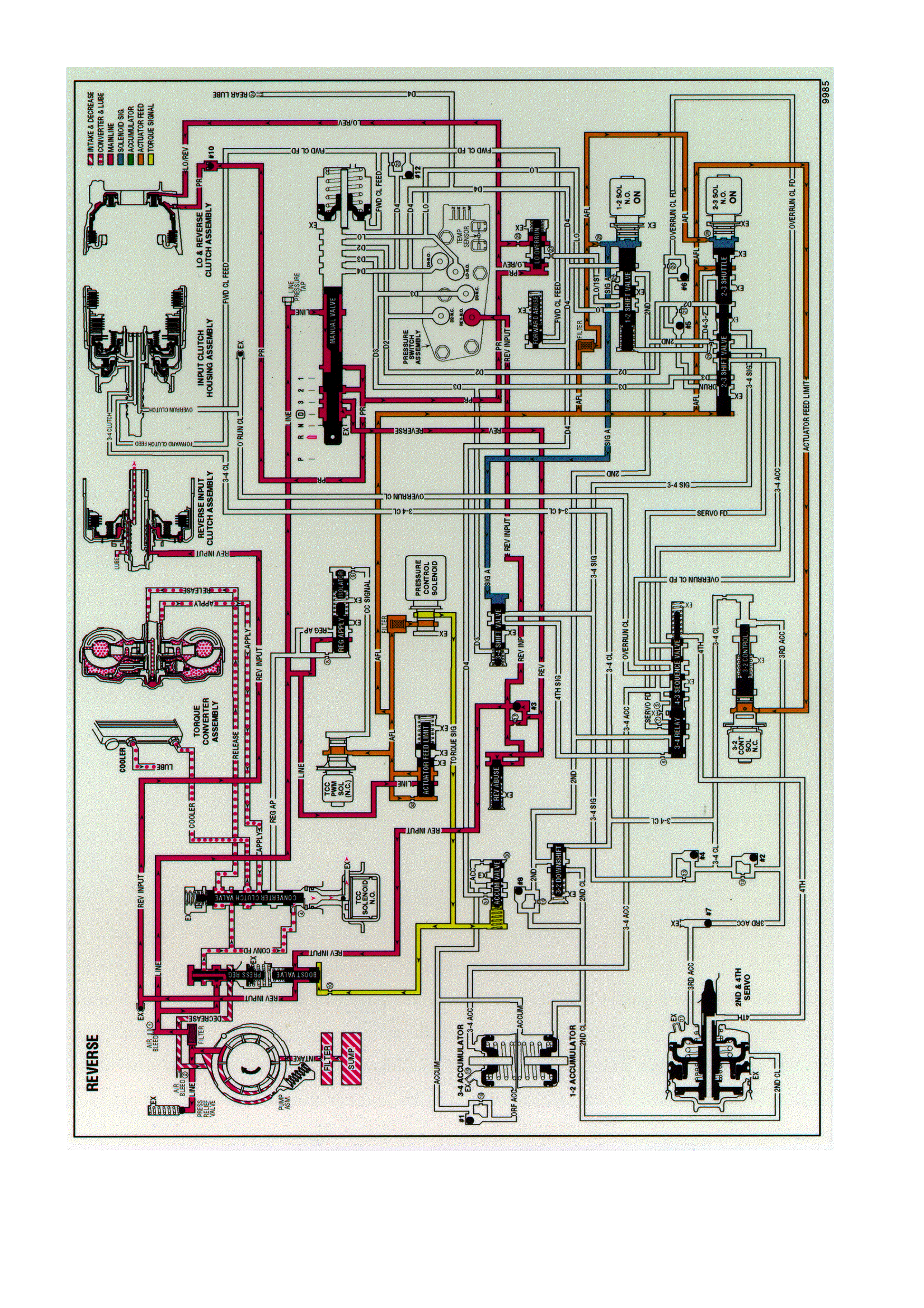

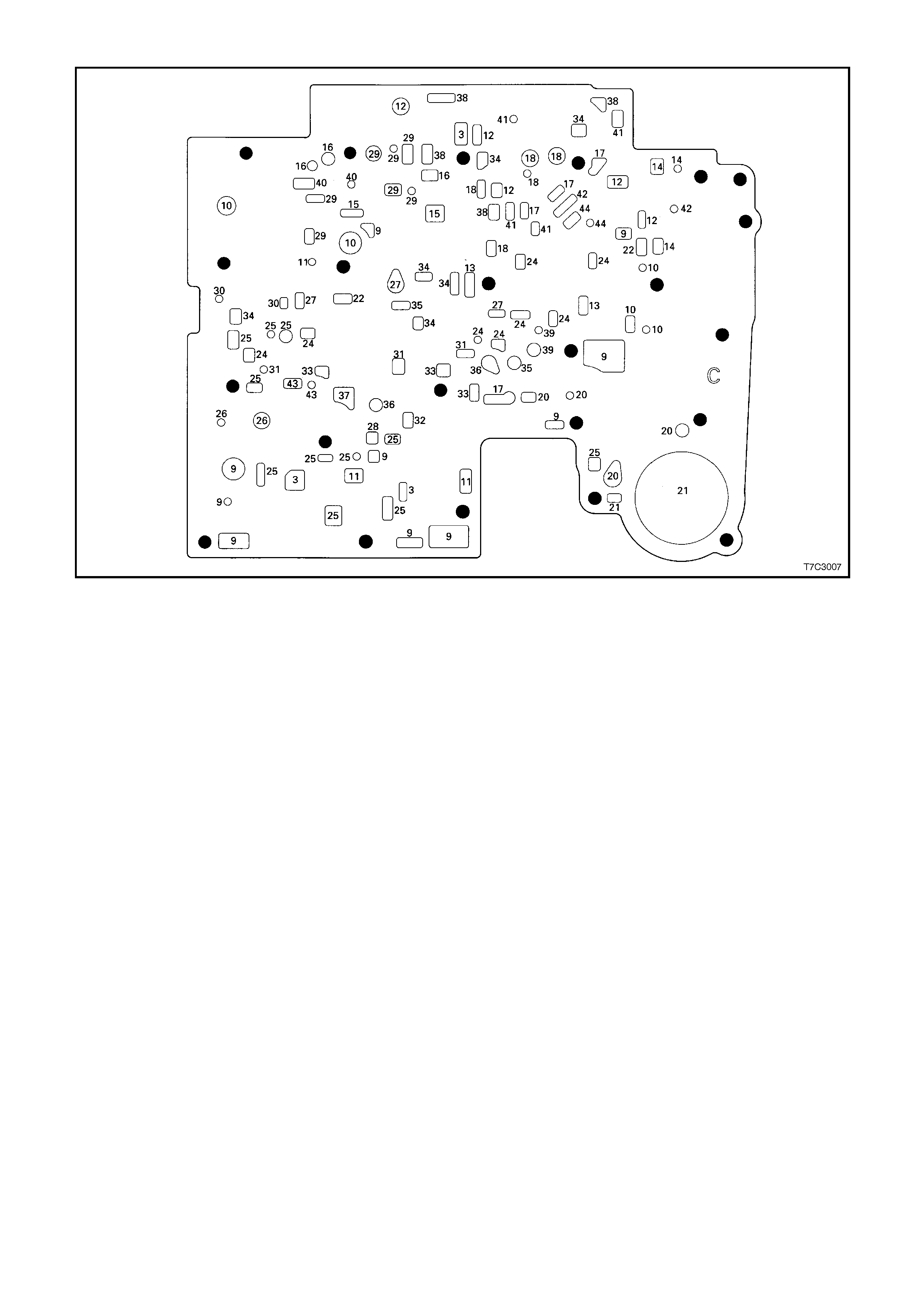

NEUTRAL - ENGINE RUNNING

Figure 7C3-8 Neutral Engine Running

When the gear selector lever is moved to the Neutral (N) position from the Reverse position, the following changes

occur to the transmission hydraulic and electrical systems.

MANUAL VALVE

In the Neutral position, the manual valve blocks the line pressure from entering any other fluid circuits. Reverse and

PR fluids exhaust past the manual valve.

LO AND REVERSE CLUTCH RELEASES

Lo and Reverse Clutch Piston

PR and Lo/reverse fluids exhaust from the piston, thereby releasing the lo and reverse clutch plates. Exhausting PR

fluid unseats the lo and reverse clutch checkball (#10) for a quick exhaust.

LO OVERRUN VALVE

Spring force closes the valve when the PR fluid pressure exhausts. Lo/reverse fluid exhausts through the valve, into

the Lo/1st fluid circuit, past the 1-2 shift valve, into the Lo fluid circuit and through an exhaust port at the manual

valve.

REVERSE INPUT CLUTCH RELEASES

Reverse Input Clutch Piston

Reverse input fluid pressure exhausts from the piston, through the boost valve, past the #3 checkball and to the

manual valve. With the reverse input fluid exhausted, the reverse input clutch plates are released and the

transmission is in Neutral.

REVERSE ABUSE VALVE

Reverse fluid pressure exhausts and spring force closes the valve.

BOOST VALVE

Reverse input fluid pressure exhausts and line pressure returns to the normal operating range as in the Park and

Overdrive positions.

REVERSE INPUT CHECKBALL (#3)

Exhausting reverse input fluid unseats the ball for a quick exhaust through the reverse fluid circuit and past the

manual valve.

TRANSMISSION FLUID PRESSURE MANUAL VALVE POSITION SWITCH (TFP VAL. POSITION SW.)

ASSEMBLY

IMPORTANT:

In Park, Reverse and Neutral the shift solenoids are shown energised. This is the normal operating state when the

vehicle is stationary or at low vehicle speeds. However, the PCM will change the shift solenoid states depending on

the vehicle speed.

For example, if Neutral is selected when the transmission is operating in Second Gear, the shift solenoids will

remain in a Second Gear state. However, with the manual valve blocking line pressure, the shift solenoid states do

not affect transmission operation in Park, Reverse and Neutral.

Reverse input fluid exhausts from the TFP Val Position Sw. With no other fluid routed to it, the TFP Val Position Sw.

signals the PCM that the transmission is operating in either Park or Neutral.

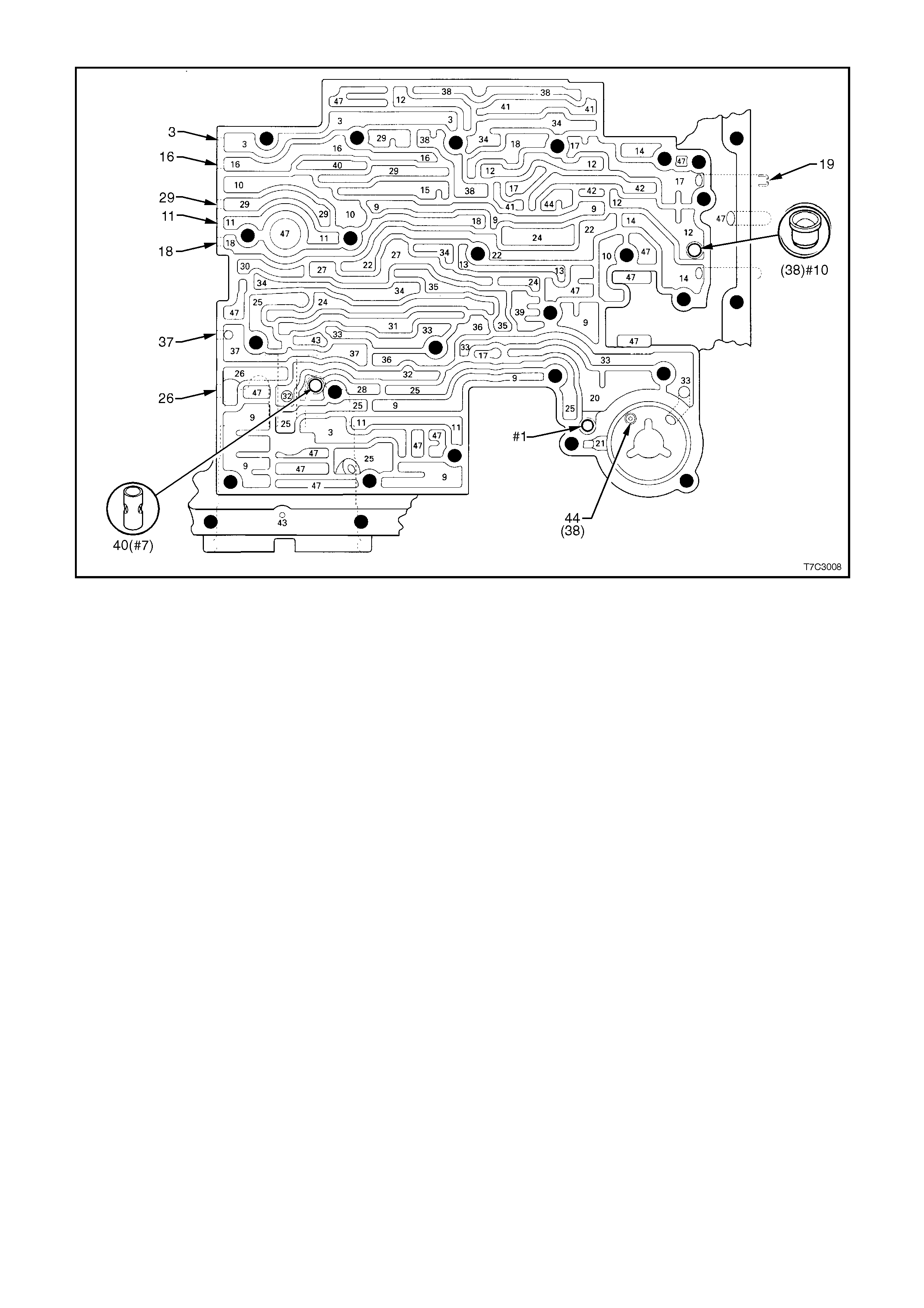

DRIVE (OVERDRIVE) RANGE, FIRST GEAR

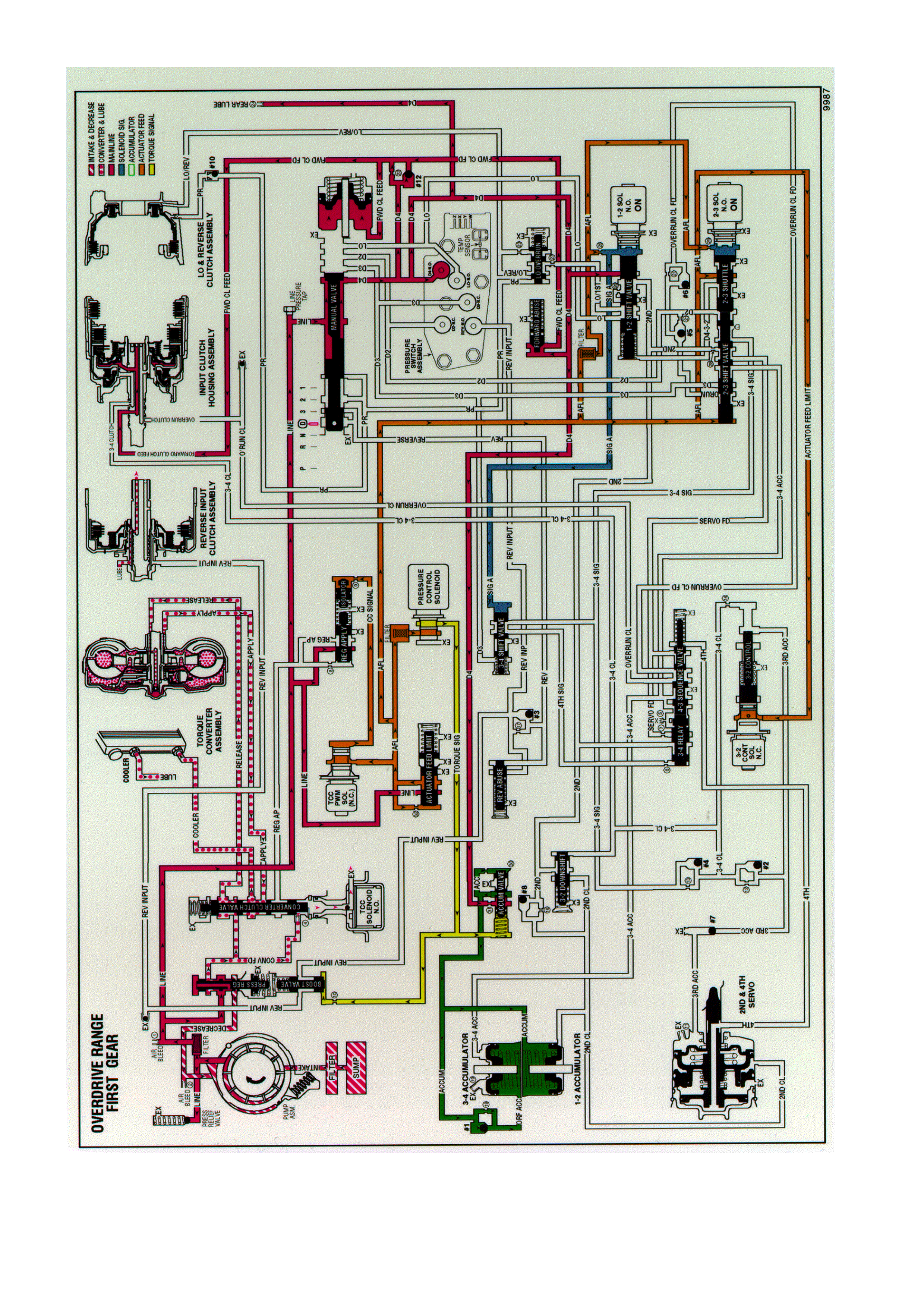

Figure 7C3-9 Drive Range, First Gear

When the gear selector lever is moved to the Overdrive position, from the neutral position, the following changes

occur to the transmission’s hydraulic and electrical sy stems:

MANUAL VALVE

Line pressure flows through the manual valve and fills the D4 fluid circuit. All other fluid circuits remain empty w ith

the manual valve in the Overdrive position.

FORWARD CLUTCH APPLIES

Forward Clutch Accumulator Checkball (#12)

D4 fluid pressure seats the checkball and is orificed (#22) into the forward clutch feed fluid circuit. This orifice helps

control the forward clutch apply rate.

Forward Clutch Accumulator Piston

Forward clutch feed fluid pressure moves the piston against spring force. This action absorbs some of the initial

increase of forward clutch feed fluid pressure to cushion the forward clutch apply.

Forward Clutch Abuse Valve

D4 fluid pressure acts on the valve opposite of spring force. At engine speeds greater than idle, D4 fluid pressure

increases and moves the valve against spring force (as shown). D4 fluid can then quickly fill the forward clutch feed

fluid circuit, thereby bypassing the control of orifice #22 and providing a faster apply of the forward clutch.

Otherwise, with increased throttle opening and engine torque, the clutch may slip during apply .

TRANSMISSION FLUID PRESSURE MANUAL VALVE POSITION SWITCH (TFP VAL. POSITION SW.)

ASSEMBLY

D4 fluid pressure is routed to the TFP Val. Position Sw. and closes the normally open D4 fluid pressure switch. This

signals the PCM that the transmission is operating in Overdrive range.

1-2 SHIFT SOLENOID

Energised (ON) as in Neutral, the normally open solenoid is closed and blocks signal A fluid from exhausting

through the solenoid. This maintains pressure in the signal A fluid circuit.

2-3 SHIFT SOLENOID

Energised (ON) as in Neutral, the normally open solenoid is closed and blocks signal B fluid from exhausting

through the solenoid. This maintains signal B fluid pressure at the solenoid end of the 2-3 shift valve.

2-3 Shift Valve Train

Signal B fluid pressure at the solenoid end of the 2-3 shift valve holds the valve train in the downshifted position

against AFL fluid pressure acting on the 2-3 shift valve. In this position, the 2-3 shuttle valve blocks AFL fluid from

entering the D432 fluid circuit. The D432 fluid circuit is open to an exhaust port past the valve.

1-2 SHIFT VALVE

Signal A fluid pressure holds the valve in the downshifted position against spring force. In the First gear position, the

valve blocks D4 fluid from entering the 2nd fluid circuit.

ACCUMULATOR VALVE

Biased by torque signal fluid pressure, spring force and orificed accumulator fluid pressure at the end of the valve,

the accumulator valve regulates D4 fluid into accumulator fluid pressure. Accumulator fluid is routed to both the 1-2

and 3-4 accumulator assemblies in preparation for the 1-2 and 3-4 upshifts respectively.

REAR LUBE

D4 fluid is routed through an orifice cup plug (#24) in the rear of the transmission case to feed the rear lube fluid

circuit.

PRESSURE CONTROL SOLENOID

Remember that the pressure control solenoid continually varies torque signal fluid pressure in relation to throttle

position and vehicle operating conditions. This provides a precise control of line pressure.

3-2 CONTROL SOLENOID

The PCM keeps the solenoid OFF in First gear and the normally closed solenoid blocks filtered AFL fluid from

entering the 3-2 signal fluid circuit.

DRIVE (OVERDRIVE) RANGE, SECOND GEAR

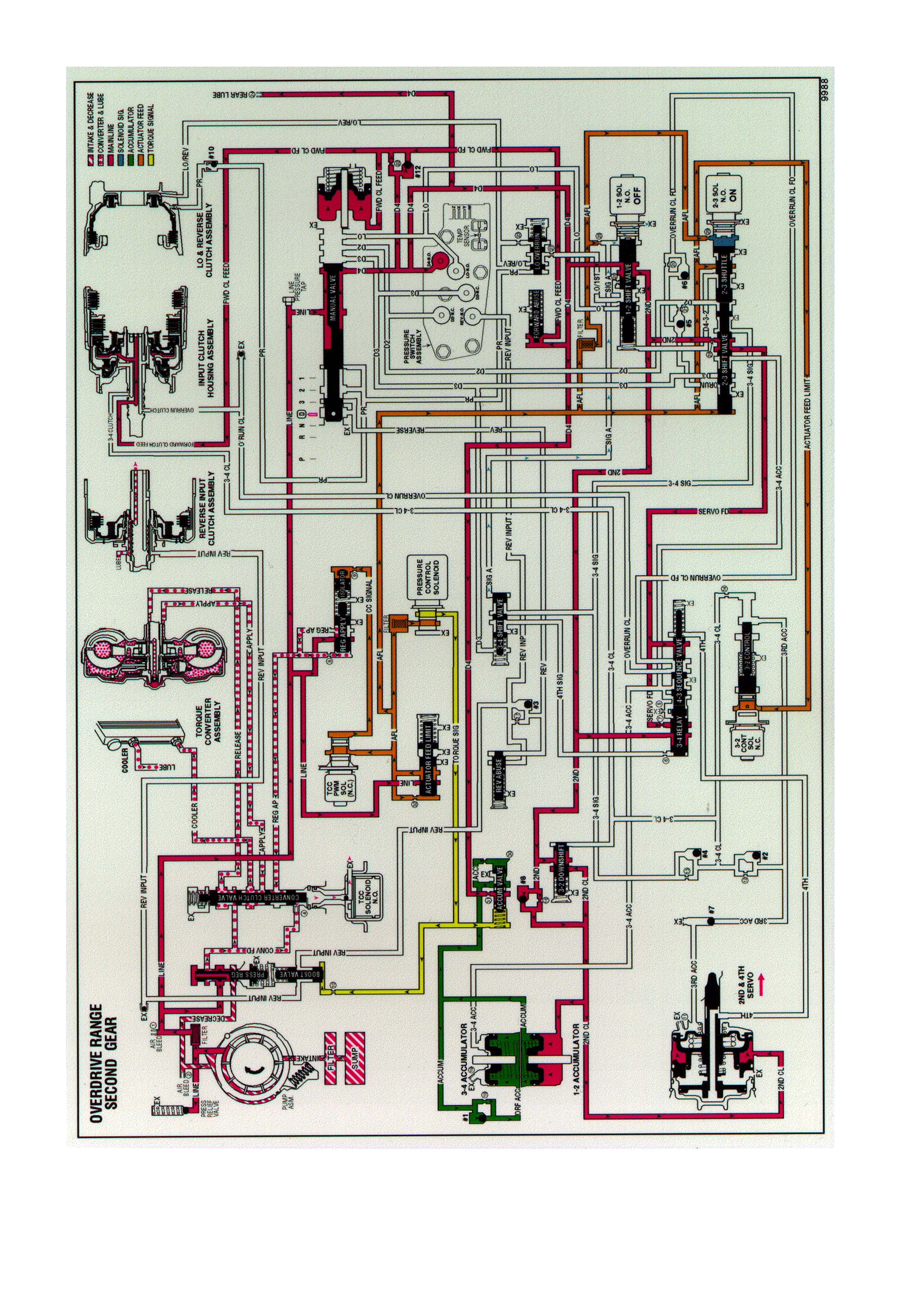

Figure 7C3-10 Drive Range, Second Gear

As vehicle speed increases and other operating conditions are appropriate, the PCM de-energises the 1-2 shift

solenoid in order to shift the transmission to second gear.

1-2 SHIFT SOLENOID

De-energised (turned OFF) by the PCM, the normally open solenoid opens and signal A fluid exhausts through the

solenoid.

2-3 SHIFT SOLENOID

IMPORTANT:

The actuator feed limit (AFL) fluid continues to feed the signal A fluid circuit through orifice #25. However, the

exhaust port through the solenoid is larger than orifice #25 in order to prevent a pressure build-up in the signal A

fluid circuit. Exhausting signal A fluid is represented by the blue arrows.

Energised (ON) as in first gear, the 2-3 shift solenoid blocks signal B fluid from exhausting through the solenoid.

This maintains signal B fluid pressure at the solenoid end of the 2-3 shift valve.

1-2 SHIFT VALVE

Without signal A fluid pressure, spring force moves the valve into the upshift position. D4 fluid is routed through the

valve and fills the 2nd fluid circuit.

1-2 SHIFT CHECKBALL (#8)

The 2nd fluid pressure seats the #8 checkball, flows through orifice #16, and fills the 2nd clutch fluid circuit. This

orifice helps control the 2-4 band apply rate.

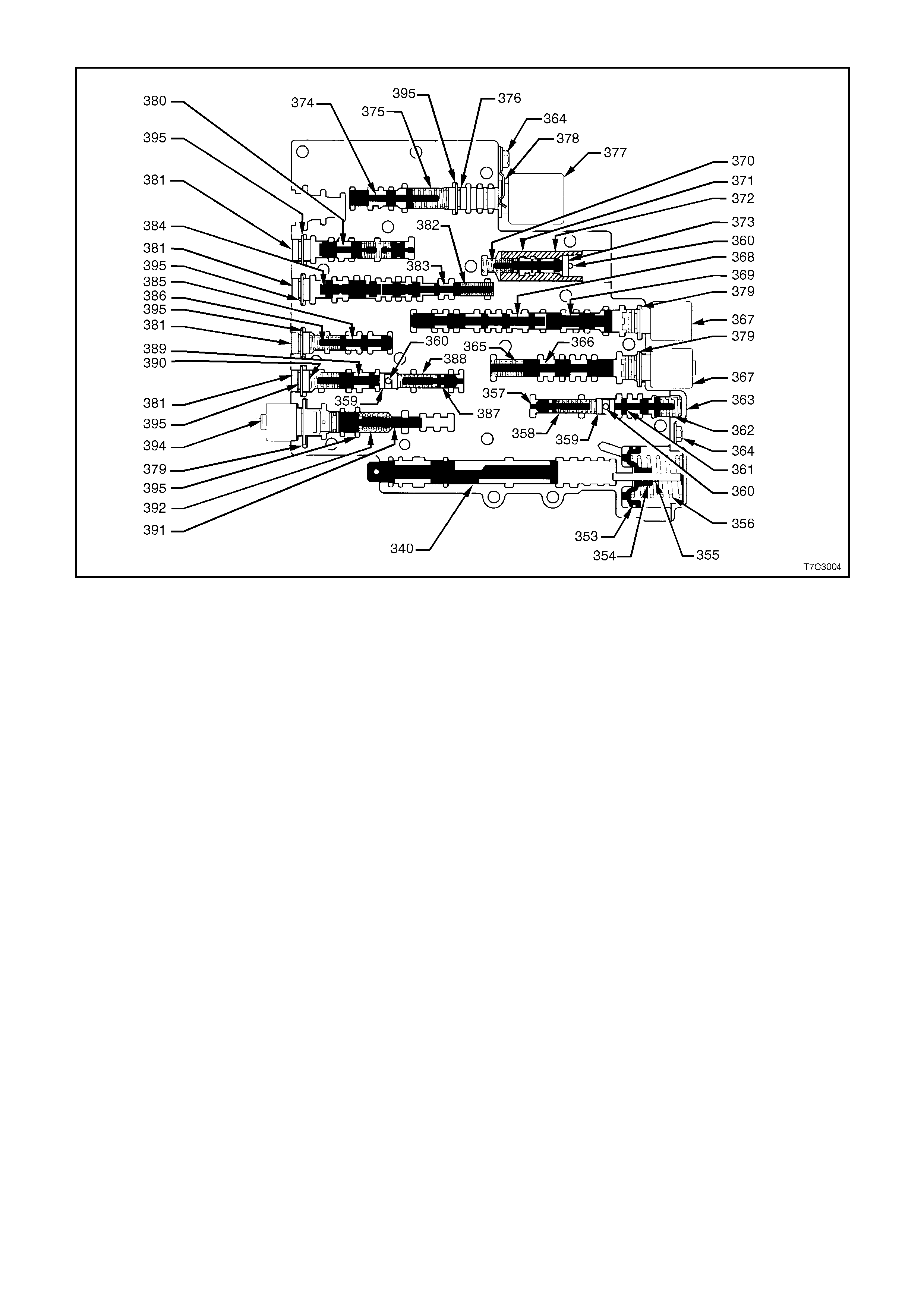

2-4 SERVO ASSEMBLY

The 2nd clutch fluid pressure moves the #8 checkball, flows through orifice #16 and fills the 2nd clutch fluid circuit.

This orifice helps to control the 2-4 band apply rate.

1-2 ACCUMULATOR

The 2nd clutch fluid pressure also moves the 1-2 accumulator piston against the spring force and the accumulator

fluid pressure. This action absorbs the initial 2nd clutch fluid pressure in order to cushion the 2-4 band apply rate.

Also, the movement of the 1-2 accumulator piston forces some accumulator fluid out of the accumulator assembly.

This accumulator fluid is routed back to the accumulator valve.

ACCUMULATOR VALVE

The accumulator fluid forced out of the 1-2 accumulator is orificed (#30) to the end of the accumulator valve. This

pressure moves the valve against the spring force and the torque signal fluid pressure in order to regulate the

exhaust of excess accumulator fluid. This regulation provides additional control for the 2-4 band apply rate. The fluid

circuit shows the exhaust of the accumulator fluid during the shift by the arrow directions in the accumulator fluid

circuit.

2-3 SHIFT VALVE TRAIN

The signal B fluid pressure from the 2-3 shift solenoid holds the valve train in the downshift position. The 2nd fluid is

routed through the 2-3 shuttle valve and fills the servo feed fluid circuit.

3-4 RELAY VALVE AND 4-3 SEQUENCE VALVE

Spring force holds these valves in the downshift position (first, second and third gear positions). The 2nd fluid is

blocked by the 3-4 relay valve and the servo feed fluid is blocked by both valves in preparation for a 3-4 upshift.

3-2 DOWNSHIFT VALVE

Spring force holds the valve closed, blocking the 2nd fluid and the 2nd clutch fluid. This valve is used in order to

help control the 3-2 downshift.

3-4 SHIFT VALVE

Signal A fluid pressure exhausts and spring force moves the valve into the downshift position (second and third

gear positions).

CONVERTER CLUTCH SIGNAL VALVE

The 2nd clutch fluid pressure opens the valve and the line pressure feeds the converter clutch (CC) signal fluid

circuit. The TCC signal fluid is orificed (#8) to the end of the CC signal valve and opposes the 2nd clutch fluid

pressure. The TCC signal fluid is routed through a filter and orificed (#4) to the TCC solenoid.

TCC SOLENOID

IMPORTANT:

The orifice cup plug (#4) in the CC signal fluid circuit is smaller than the exhaust through the TCC solenoid.

Therefore, fluid pressure does not build up at the end of the converter clutch apply valve.

Under normal operating conditions in second gear, the PCM keeps the normally open TCC solenoid de-energised

(OFF). CC signal fluid exhausts through the open solenoid and spring force keeps the converter clutch apply valve

in the release position.

DRIVE (OVERDRIVE) RANGE, THIRD GEAR - TCC APPLIED

Figure 7C3-11 Drive Range, Third Gear

As vehicle speed increases further and other vehicle operating conditions are appropriate, the PCM de-energises

the normally open 2-3 shift solenoid in order to shift the transmission into Third gear.

2-3 SHIFT SOLENOID

De-energised (turned OFF) by the PCM, the solenoid opens and actuator feed limit signal B fluid exhausts through

the solenoid.

NOTE:

AFL fluid continues to feed signal B fluid to the solenoid through orifice #29. However, the exhaust port through the

solenoid is larger than orifice #29 to prevent a build-up of pressure in the signal B fluid circuit at the solenoid end of

the 2-3 shift valve. Exhausting signal B fluid is represented by the arrows through the solenoid.

2-3 SHIFT VALVE TRAIN

AFL fluid pressure at the 2-3 shift valve moves the valve train toward the solenoid. In the upshifted position, the

following changes occur:

AFL fluid is routed through the 2-3 shift valve and fills the D432 fluid circuit.

2nd fluid is blocked from entering the servo feed fluid circuit and is orificed (#28) into the 3-4 signal fluid circuit. This

orifice helps control the 3-4 clutch apply rate.

Servo feed fluid exhausts past the valve into the 3-4 accumulator fluid circuit and through an exhaust port at the 3-4

relay valve.

3-4 CLUTCH EXHAUST CHECKBALL (#4)

3-4 signal fluid unseats the ball and enters the 3-4 clutch fluid circuit.

3-4 CLUTCH PISTON

3-4 clutch fluid pressure moves the piston to apply the 3-4 clutch plates and obtain 3rd gear. However, the 2-4 band

must release as the 3-4 clutch applies.

3RD ACCUMULATOR CHECKBALL (#2)

3-4 clutch fluid pressure unseats the ball and fills the 3rd accumulator fluid circuit.

3RD ACCUMULATOR EXHAUST CHECKBALL (#7)

3rd accumulator fluid seats the ball against the orificed exhaust and is routed to the released side of the 2nd apply

piston. Before the #7 checkball seats air in the 3rd accumulator fluid circuit is exhausted through the orifice.

2-4 SERVO ASSEMBLY

3rd accumulator fluid pressure acts on the release side of the 2nd apply piston and assists servo return spring

force. The surface area on the release side of the piston is greater than the surface area on the apply side.

Therefore, 3rd accumulator fluid pressure and servo return spring force move the 2nd apply piston against 2nd

clutch fluid pressure. This action serves two functions:

1. Move the apply pin to release the 2-4 band.

2. Act as an accumulator by absorbing initial 3-4 clutch fluid to cushion the 3-4 clutch apply rate. Remember that

the 3rd accumulator fluid circuit is fed by 3-4 clutch fluid.

3-2 DOWNSHIFT VALVE

3-4 clutch fluid pressure moves the valve against spring force. This opens the valve and allows 2nd fluid to feed the

2nd clutch fluid circuit through the valve.

1-2 SHIFT SOLENOID AND 1-2 SHIFT VALVE

The 1-2 shift solenoid remains de-energised and signal A fluid is exhausted through the solenoid. Also, D432 fluid

pressure from the 2-3 shift valve assists spring force to hold the 1-2 shift valve in the upshifted position.

3-4 SHIFT VALVE

Spring force holds the valve in the downshifted position, blocking 3-4 clutch fluid in preparation for a 3-4 upshift.

TORQUE CONVERTER CLUTCH

TCC Solenoid

Under normal operating conditions in Overdrive Range-Third Gear, the PCM keeps the normally open TCC solenoid

de-energised. CC signal fluid exhausts through the open solenoid and spring force keeps the converter clutch apply

valve in the release position. However, at speeds above approximately 121 km/h, the PCM will command TCC

apply in Third gear.

DRIVE (OVERDRIVE) RANGE, FOURTH GEAR - TCC APPLIED

Figure 7C3-12 Drive Range, Fourth Gear

At higher vehicle speeds, the Hydra-matic 4L60-E transmission uses an overdrive gear ratio (fourth gear) in order

to increase fuel economy and in order to maximise engine performance. When vehicle operating conditions are

appropriate, the PCM energises the 1-2 shift solenoid to shift the transmission into fourth gear.

1-2 SHIFT SOLENOID

Energised (turned ON) by the PCM, the normally open solenoid closes and blocks signal A fluid from exhausting

through the solenoid. This creates pressure in the signal A fluid circuit.

2-3 SHIFT SOLENOID

De-energised (OFF) as in third gear, the 2-3 shift solenoid exhausts signal B fluid through the solenoid.

1-2 SHIFT VALVE

D432 fluid pressure from the 2-3 shift valve and spring force hold the valve in the upshift position against signal A

fluid pressure.

3-4 SHIFT VALVE

Signal A fluid pressure moves the valve into the upshift position against the spring force. In this position, the valve

routes 3-4 signal fluid into the 4th signal fluid circuit.

3-4 RELAY VALVE AND 4-3 SEQUENCE VALVE

4th signal fluid pressure moves both valves into the upshift (fourth gear) position against the spring force acting on

the 4-3 sequence valve. This causes the following changes:

Orificed (#7) 2nd fluid is routed through the 3-4 relay valve and into the servo feed fluid circuit.

Servo feed fluid is routed through the 4-3 sequence valve and into the 4th fluid circuit.

3-4 accumulator fluid routed from the 2-3 shuttle valve is blocked by both valves.

2-4 SERVO ASSEMBLY

4th fluid is routed through the center of the servo apply pin and acts on the apply side of the 4th apply piston. 4th

fluid pressure moves the 4th apply piston against the apply pin spring force acting on the release side of the 4th

apply piston. This action moves the apply pin and applies the 2-4 band in order to obtain fourth gear.

2-4 BAND APPLY ACCUMULATION

2-3 Shift Valve Train

The valve train remains in the upshift position with the AFL fluid pressure acting on the 2-3 shift valve. In addition to

its operation third gear, the 2-3 shift valve directs servo feed fluid into the 3-4 accumulator fluid circuit.

3-4 ACCUMULATOR ASSEMBLY

3-4 accumulator fluid pressure moves the 3-4 accumulator piston against spring force and orificed accumulator fluid

pressure, This action absorbs initial 4th clutch apply fluid pressure in order to cushion the 2-4 band apply.

Remember that both of the 3-4 accumulator and 4th fluid circuits are fed by servo feed fluid.

As 3-4 accumulator fluid fills the accumulator, any air in the system will exhaust through orifice #19. This piston

movement forces some orificed accumulator fluid out of the 3-4 accumulator assembly.

3-4 ACCUMULATOR CHECKBALL (#1)

The accumulator fluid forced from the accumulator unseats the #1 checkball and enters the accumulator fluid

circuit. This fluid is routed to the accumulator valve. This is shown by the arrow directions in the fluid circuit.

ACCUMULATOR VALVE

Accumulator fluid forced from the 3-4 accumulator is orificed to the end of the accumulator valve. This fluid

pressure, in addition to spring force and torque signal fluid pressure, regulates the exhaust of excess accumulator

fluid pressure through the middle of the valve. This regulation helps control the 2-4 band apply feel.

TORQUE CONVERTER CLUTCH APPLIES

TCC Solenoid

When operating conditions are appropriate, the PCM energises the normally open TCC solenoid. This closes the

solenoid, blocks the converter clutch signal fluid from exhausting and creates pressure in the converter clutch signal

fluid circuit.

CONVERTER CLUTCH APPLY VALVE

Converter clutch signal fluid pressure moves the valve against spring force and into the apply position. In this

position, release fluid is open to an exhaust port and converter feed fluid fills the apply fluid circuit. Converter feed

fluid also feeds the cooler fluid circuit through orifice #3.

TORQUE CONVERTER

Release fluid from behind the pressure plate exhausts through the end of the turbine shaft. Apply fluid pressure is

routed between the converter hub and stator shaft where it enters the torque converter. This fluid applies the

converter clutch against the converter cover and keeps the converter filled with fluid.

TCC Apply Checkball (#9)

Release fluid, exhausting from the converter, seats the #9 checkball located in the end of the turbine shaft, and is

orificed around the ball. Orificing the exhausting release fluid controls the converter clutch apply rate.

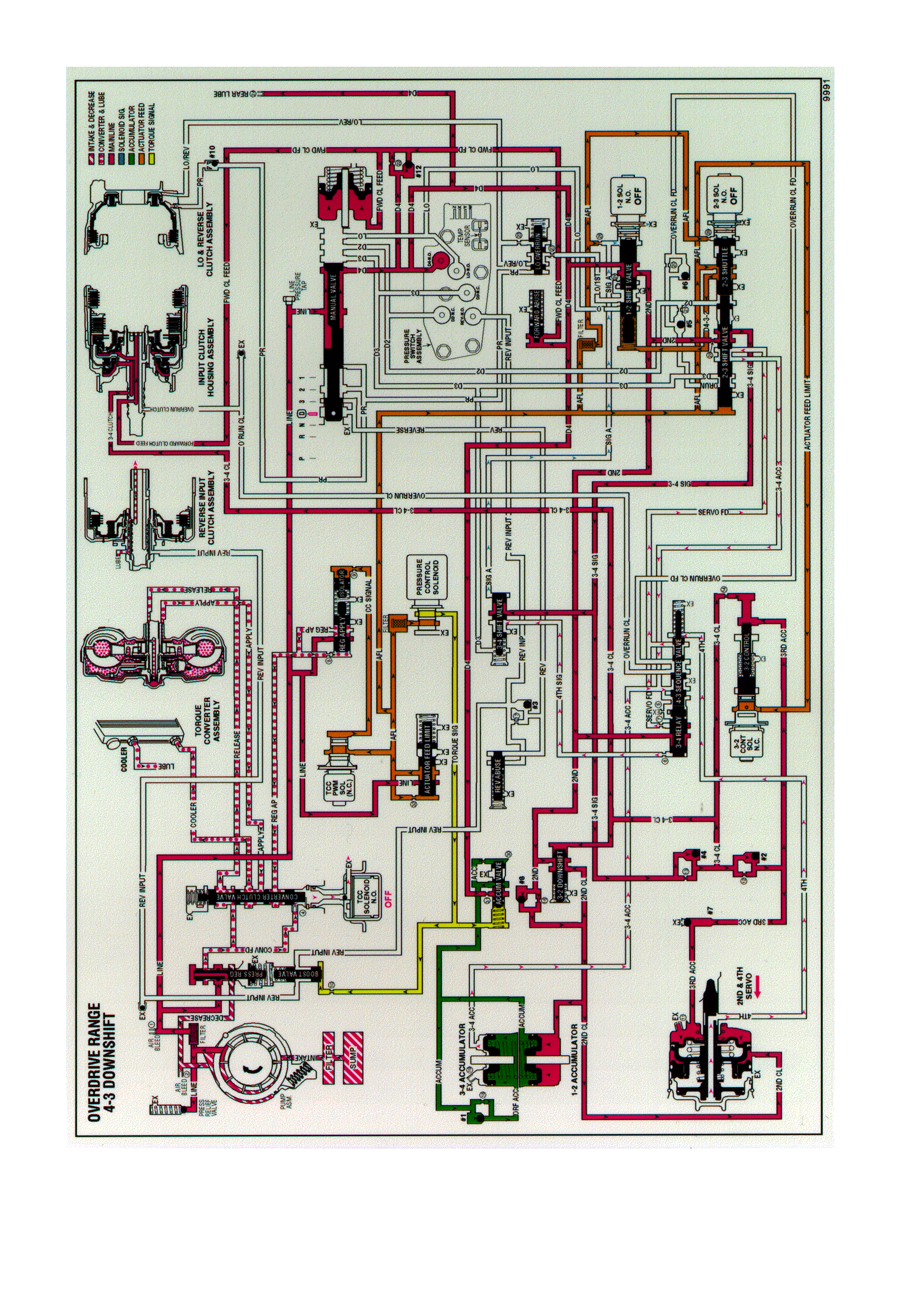

DRIVE (OVERDRIVE) RANGE, 4-3 DOWNSHIFT

Figure 7C3-13 Drive Range, 4-3 Downshift

When the transmission is operating in fourth gear, a forced 4-3 downshift occurs if there is a significant increase in

throttle position. At minimum throttle, the vehicle speed decreases gradually (coastdown) and the PCM commands

a 4-3 downshift.

The PCM also initiates a forced 4-3 downshift when the throttle position remains constant but engine load is

increased, such as driving up a steep incline. To achieve a 4-3 downshift, the PCM de-energises the 1-2 shift

solenoid and the following changes occur to the transmission's electrical and hydraulic systems:

1-2 SHIFT SOLENOID

De-energised by the PCM, the normally open solenoid opens and signal A fluid exhausts through the solenoid.

1-2 SHIFT VALVE

As in Fourth gear, D432 fluid pressure and spring force hold the valve in the upshift position.

2-4 BAND RELEASES

3-4 Shift Valve

With the signal A fluid pressure exhausted, the spring force moves the valve into the downshift position. In this

position, the valve blocks the 3-4 signal fluid and the 4th signal fluid exhausts past the valve.

3-4 RELAY VALVE AND 4-3 SEQUENCE VALVE

These valves control the timing of the 2-4 band release. With the 4th signal fluid pressure exhausted, the 3-4

accumulator fluid pressure moves the 3-4 relay valve into the third gear position. This opens the 3-4 accumulator

fluid to an orificed exhaust (#5) past the 3-4 relay valve (shown by red arrows). Because the exhaust is orificed, the

3-4 accumulator fluid pressure momentarily holds the 4-3 sequence valve against spring force before completely

exhausting.

When the exhausting 3-4 accumulator fluid pressure decreases sufficiently, the spring force moves the 4-3

sequence valve into the third gear position as shown. This opens both the 3-4 accumulator and the 4th fluid circuits

to a quick exhaust past the 4-3 sequence valve. In this position the valve blocks the 2nd fluid from entering the

servo feed fluid circuit.

2-4 SERVO ASSEMBLY

The 4th fluid exhausts from the 4th apply piston in the servo assembly. The apply pin spring moves the 4th apply

piston and the apply pin in order to release the band from the reverse input drum and shift the transmission into

third gear.

3-4 ACCUMULATOR ASSEMBLY

The 3-4 accumulator fluid exhausts from the 3-4 accumulator piston. The orificed accumulator fluid pressure and

the spring force move the piston into a third gear position.

3-4 ACCUMULATOR CHECKBALL (#1)

As the accumulator fluid fills the 3-4 accumulator, it seats the #1 checkball and is forced through orifice #18. This

orifice controls the rate at which accumulator fluid pressure fills the 3-4 accumulator and the 3-4 accumulator fluid

exhausts from the accumulator assembly.

ACCUMULATOR VALVE

Biased by torque signal fluid pressure and spring force, the accumulator valve regulates the drive fluid into the

accumulator fluid circuit.

2-3 SHIFT SOLENOID

This solenoid remains de-energised as in fourth gear and the signal B fluid exhausts through the solenoid.

2-3 SHIFT VALVE TRAIN

The AFL fluid pressure at the 2-3 shift valve holds the valves in the upshift position. This allows the servo feed fluid

to exhaust through the valve, into the 3-4 accumulator fluid circuit and past the 4-3 sequence valve.

TORQUE CONVERTER CLUTCH

The PCM releases the converter clutch prior to initiating the 4-3 downshift. However, if the vehicle speed is above

approximately 121 km/h, the PCM commands the TCC to apply in third gear.

Pressure Control Solenoid

Remember that the pressure control solenoid continually adjusts the torque signal fluid pressure in relation to the

various PCM input signals (mainly the throttle position).

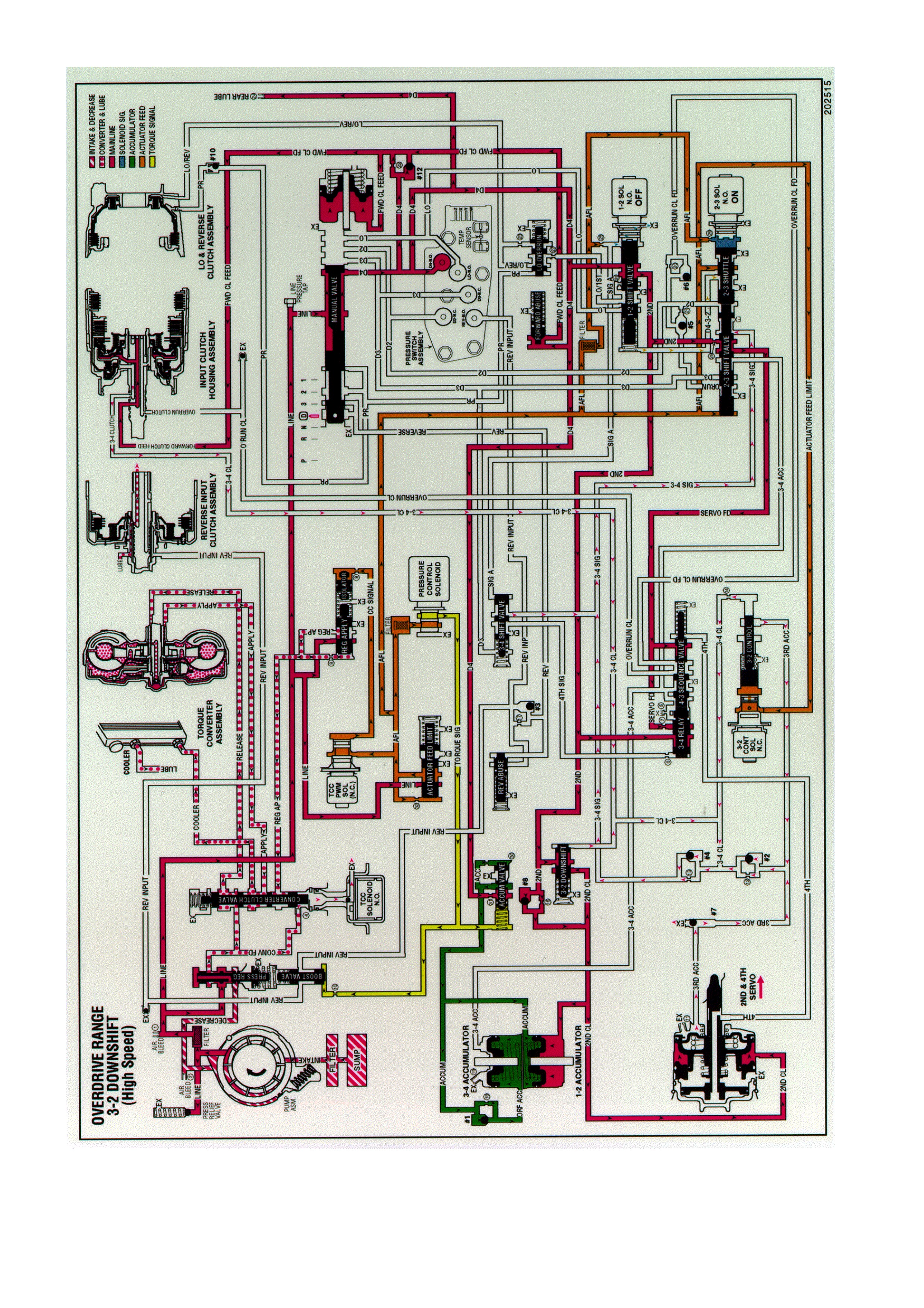

DRIVE (OVERDRIVE) RANGE, 3-2 DOWNSHIFT

Figure 7C3-14 Drive Range, 4-3 Downshift

Similar to a forced 4-3 downshift, a forced 3-2 downshift can occur because of minimum throttle (coastdown

conditions), heavy throttle or increased engine load. In order to achieve a forced 3-2 downshift, the PCM energises

the 2-3 shift solenoid and the following changes occur:

Energised by the PCM, the normally open solenoid closes and blocks the signal B fluid from exhausting through the

solenoid. This creates pressure in the signal B fluid circuit at the solenoid end of the 2-3 shift valve.

2-3 SHIFT VALVE TRAIN

The signal B fluid pressure from the shift solenoid moves both valves to the downshift position against AFL fluid

pressure acting on the 2-3 shift valve. This causes the following changes:

The AFL fluid is blocked from the D432 fluid circuit and the D432 fluid exhausts past the 2-3 shuttle valve.

The 2nd fluid is blocked from feeding the 3-4 signal fluid circuit and the 2nd fluid is routed into the servo feed fluid

circuit.

The 3-4 signal fluid is exhausted past the valve. The 3-4 clutch fluid and the 3rd accumulator fluid, which were fed

by the 3-4 signal fluid, also exhaust.

3-4 CLUTCH RELEASES AND 2-4 BAND APPLIES

3-4 Clutch Piston

The 3-4 clutch fluid exhausts from the piston and the 3-4 clutch plates are released.

3-4 Clutch Exhaust Checkball (#4)

Exhausting the 3-4 clutch fluid seats the #4 checkball and is forced through orifice #13. This orifice controls the 3-4

clutch fluid exhaust and the 3-4 clutch release rate.

2-4 SERVO ASSEMBLY

The 3rd accumulator fluid exhausts from the servo assembly. The 2nd clutch fluid pressure moves the 2nd apply

piston against the servo return spring force in order to move the apply pin and apply the 2-4 band.

3-2 DOWNSHIFT VALVE AND 1-2 UPSHIFT CHECKBALL (#8)

The 3-2 clutch fluid exhausts from the valve and the spring force moves the valve into the second gear position.

However, before the spring force overcomes exhausting the 3-4 clutch fluid pressure, the 2nd fluid feeds the 2nd

clutch fluid circuit through the valve. This bypasses the control of orifice #16 at the #8 checkball and provides a

faster 2-4 band apply. Remember that the #8 checkball and orifice #16 are used to help control the 2-4 band apply

during a 1-2 upshift.

DOWNSHIFT TIMING AND CONTROL

At higher vehicle speeds, the 2-4 band apply must be delayed to allow the engine speed RPM to increase

sufficiently for a smooth transfer of engine load to the 2-4 band. Therefore, exhaust of the 3rd accumulator fluid

must be delayed. However, at lower speeds the band must be applied quickly. In order to provide for the varying

requirements for the 2-4 band apply rate, the exhausting 3rd accumulator fluid is routed to both the 3rd accumulator

checkball (#2) and the 3-2 control valve.

3RD ACCUMULATOR CHECKBALL (#2)

The exhausting 3rd accumulator fluid seats the #2 checkball and is forced through orifice #12. This fluid exhausts

through the 3-4 clutch and the 3-4 signal fluid circuits and past the 2-3 shift valve. Orifice #12 slows the exhaust of

the 3rd accumulator fluid and delays the 2-4 band apply rate.

3-2 CONTROL SOLENOID AND 3-2 CONTROL VALVE

These components are used to increase the exhaust rate of 3rd accumulator fluid, as needed, depending on the

vehicle speed.

The 3-2 control solenoid is a normally closed On/Off solenoid controlled by the PCM. The PCM controls the

solenoid state during a 3-2 downshift according to vehicle speed.

Low Speed

At lower vehicle speeds, the PCM operates the 3-2 control solenoid in the Off position.

In the Off position the solenoid blocks actuator feed limit fluid pressure from the 3-2 control valve.

With no actuator feed limit fluid pressure, the 3-2 control valve spring force keeps the valve open to allow a faster

exhaust of 3rd accumulator fluid through orifice #14 into the 3-4 clutch fluid circuit.