SECTION 9A - STEERING

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

1. GENERAL INFORMATION

A driver’s side Supplemental Restraint System (SRS) and an energy absorbing steering column incorporating a

Tilt/Reach feature, is fitted as standard equipment on all VT models.

The variable ratio, power steering gear, is fitted as standard equipment to all VT models except Calais.

For servicing information on the speed sensitive power steering fitted to this model, refer to Section 9B SPEED

SENSITIVE POWER STEERING.

1.1 GENERAL DESCRIPTION - POWER STEERING

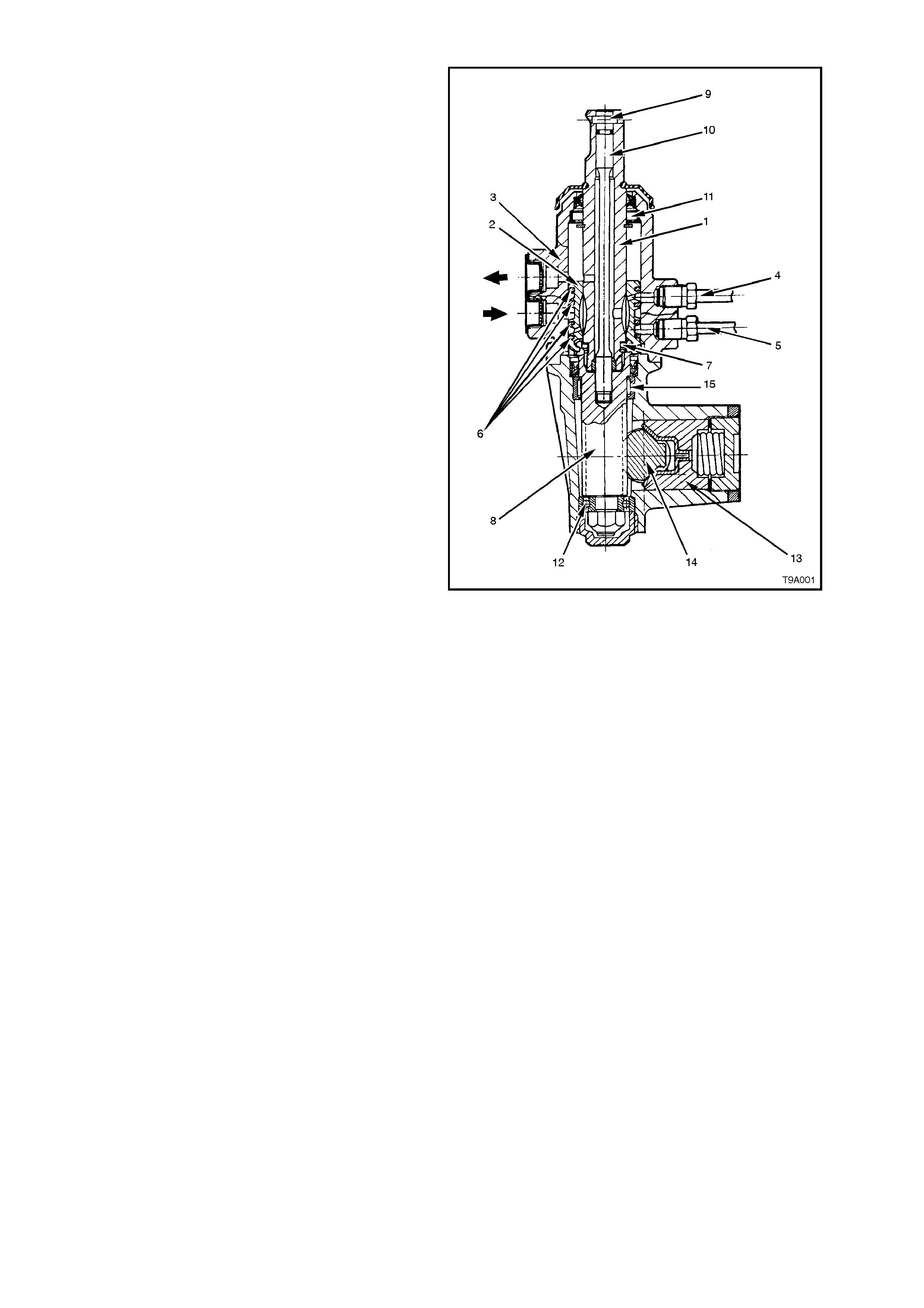

POWER STEERING RACK AND PINION

The power steer ing gear features a variable ratio rack and pinion that is m ade possible by the unique design of the

rack teeth. This means that the effective pitch radius of the pinion is less in the straight ahead position than on

turns.

This results in less tur ns being r equired from lock to loc k . F or ex ample, 3.5 tur ns would be requir ed if the 'on c entre'

ratio was used from lock to lock, whereas only 2.7 turns are required with this rack design.

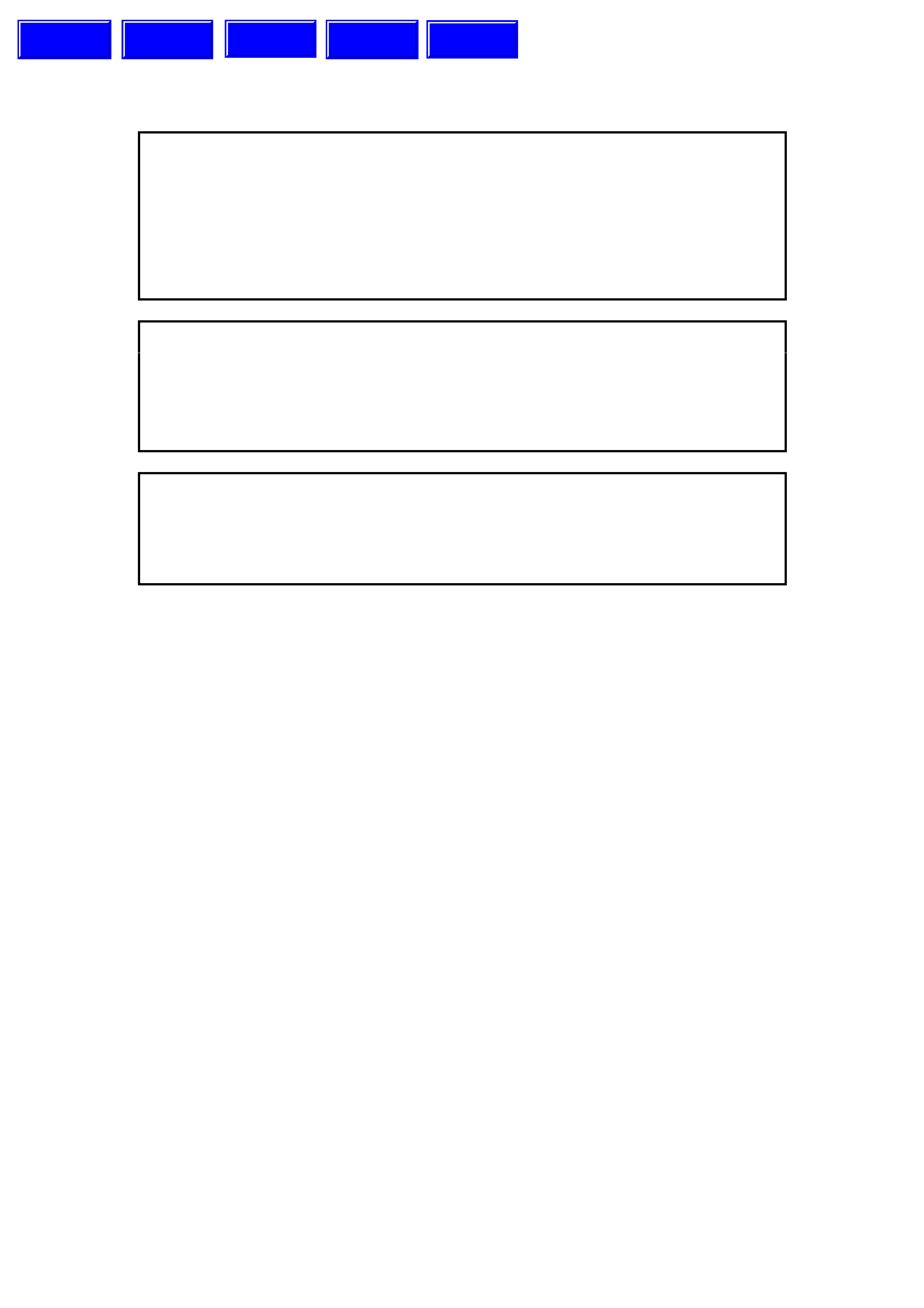

Referring to Figure 9A-1, the helical toothed pinion (8) is supported in the steering gear housing (3) by a needle

roller bearing (11) at the upper end, a ball race (12) at the lower and a roller bearing (15) at the upper end of the

pinion teeth.

The rack operates within the housing and is supported at one end by a rack bearing and at the other end by the

pinion (8) and a spring loaded pad (13), which maintains slack free adjustment of the rack (14) with the pinion (8).

The tie rods are connected to eac h end of the rack by pre-as sem bled ball joints and to the steering ar ms by tie rod

end ball joints.

Techline

Techline

Techline

Techline

Techline

PRINCIPLES OF OPERATION

With the engine running and the steering wheel in

the neutral position (straight ahead), fluid flows

continuously from the power steering pump to the

steering gear and back to the pump, via the fluid

reservoir. In this steering mode, very little pressure

is required to maintain the high fluid flow rate that

occurs at this time. As a result, little engine power

is required to operate the system.

When turning the steering wheel to either s ide, f luid

flow from the pump is directed by a rotary control

valve fitted to the steering gear, to whichever side

of the rack piston is appropriate, as indicated by the

steering wheel position. The fluid pressure then

increases as necessary, to provide the required

steering assistance.

This rotary control valve assembly, is located

between the input shaft (1) and the pinion (8), in the

steering gear.

As shown, the rotary valve assem bly consists of an

inner member (1) which forms part of the input

shaft and a surrounding sleeve member (2). The

whole valve, rotates in the steering gear housing

(3) as the steering wheel is turned, but it is the

slight relative movement of the inner and the sleeve

members that controls and directs the power

steering fluid flow.

Fluid is fed to the valve ( ) and from there, to the

left (4) and right (5) sides of the power piston via

circum f erential grooves in the outer sleeve, that are

sealed by PTFE seals (6). Excess fluid is returned

to the reservoir.

The outer sleeve is coupled by a stepped pin (7) to

the rack pinion (8), while the input shaft (1) is

coupled to the rack pinion by a pinned (9), flexible,

torsion bar (10) that provides a mechanical but

flexible link between the two members.

In the straight ahead position, the valve remains

centred. As steering effort requirements increase,

the torsion bar flexes, causing slight relative

rotation between the input shaft and sleeve,

directing fluid and providing power assistance as

needed.

Figure 9A-1

Power Steering Gear - Figure 9A-2

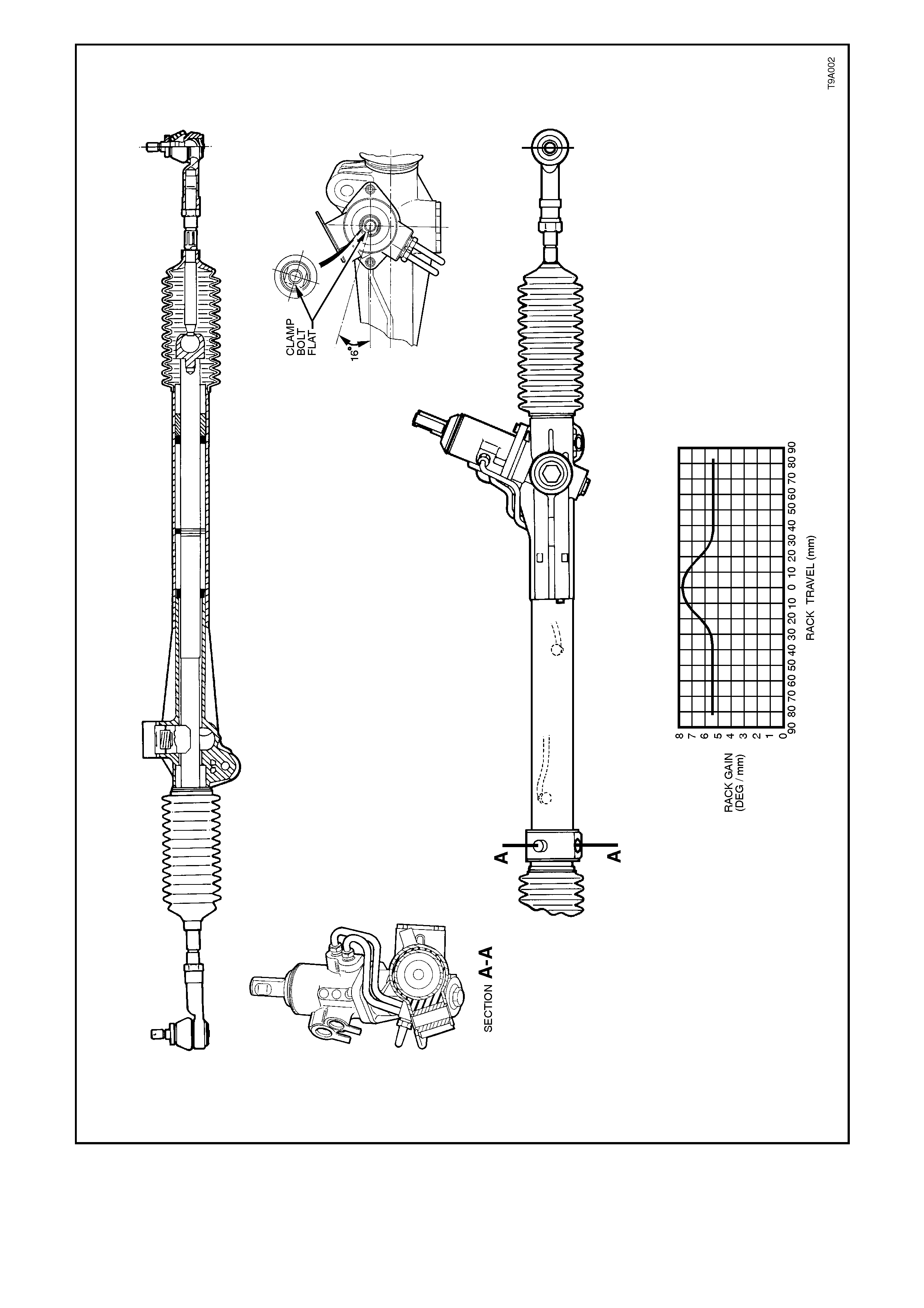

NEUTRAL POSITION (STRA IGHT AHEAD)

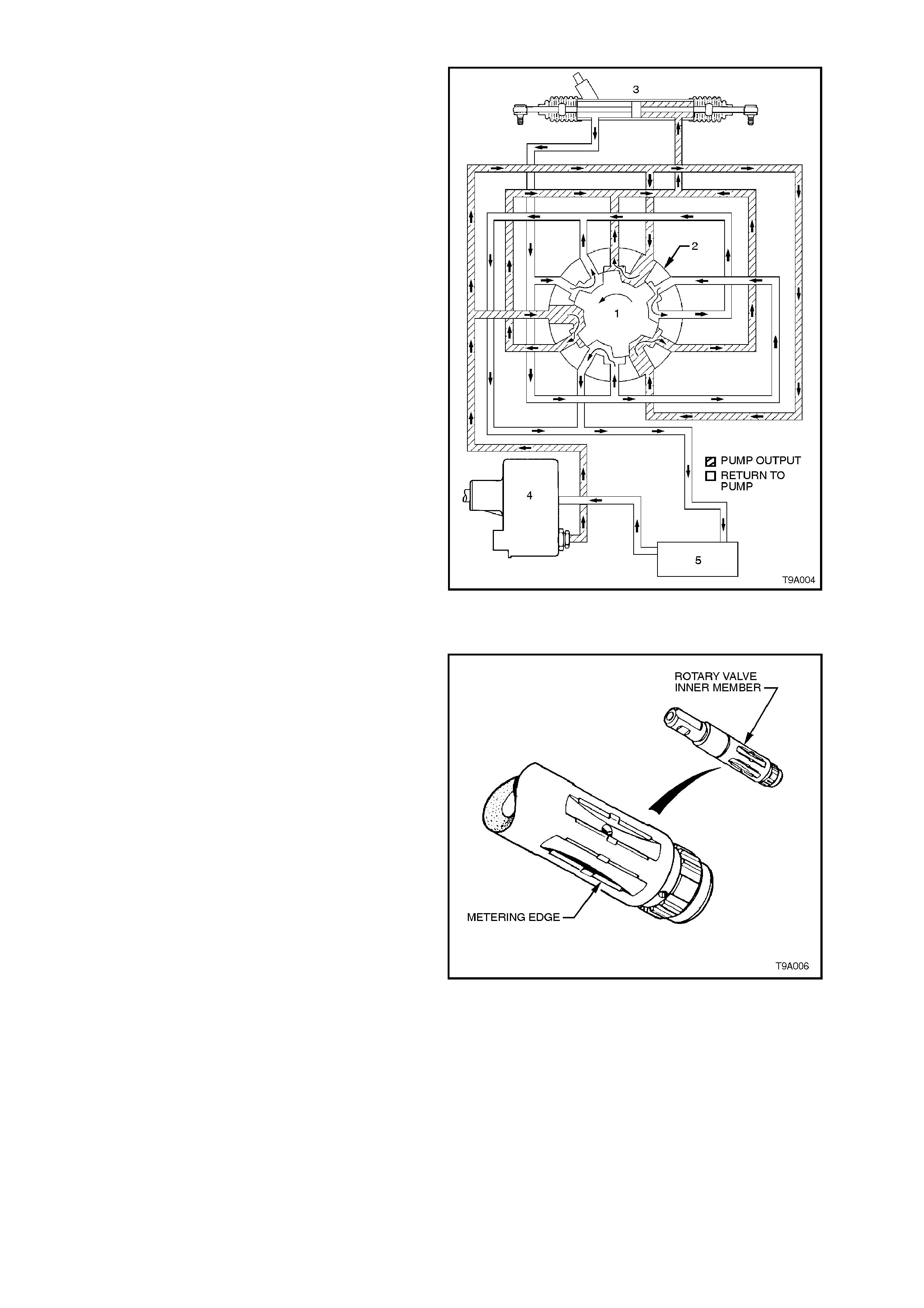

From the stylised cros s-s ec tioned view of the rotary

valve shown in Figure 9A-3, it can be seen that in

this attitude, fluid f low from the pum p ( 4) is dir ected

into the cavities (Shown as ‘A’). of the inner valve

assembly (1) and out through a number of drilled

holes in the outer sleeve (2) (Shown as ‘B’). In this

steering position, the inner valve (1) allows fluid to

pass equally to both sides of the rack (3) piston

(shown as 'Static' because no fluid actually flows to

and from the steering gear). The bypassed fluid

returns to the fluid reservoir (5) through holes

drilled in the longitudinal grooves of the inner valve.

W ith an equal pr essure applied to both sides of the

rack piston, no power assistance is provided.

Figure 9A-3

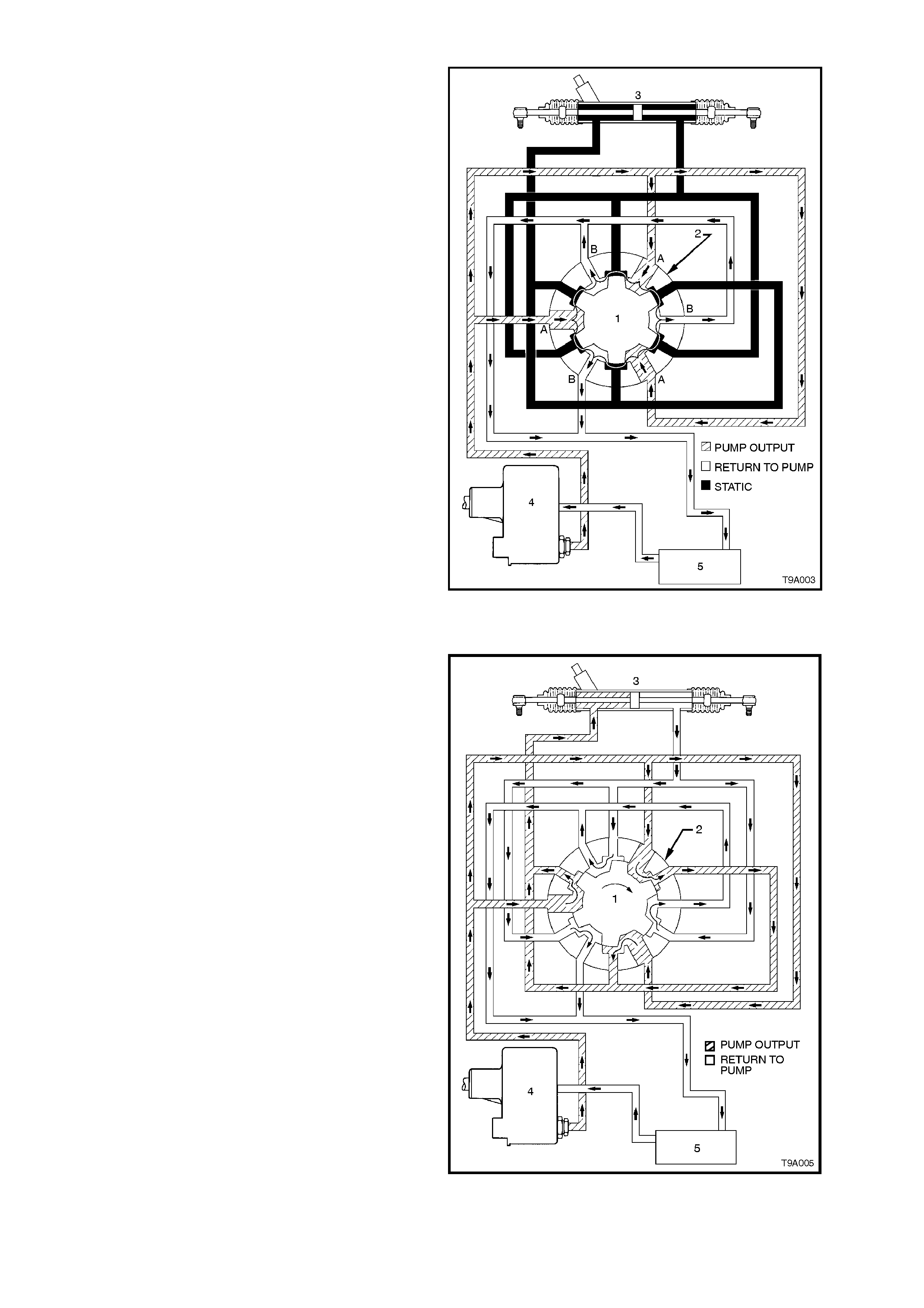

TURNING RIGHT

When turning to the right, as soon as relative

motion between the inner rotating valve (1) and

outer sleeve (2) occurs, fluid is restricted in its f ree

return to the pump and is routed to the right hand

side of the rack piston. At the same time, fluid on

the opposite side of the piston is directed to the

return circ uit, leading to the reservoir (5) and pump

(4). This action is slight at first, providing only a

small amount of driver assistance, but becomes

progressively greater with a higher steering load

that causes the torsion bar in the rotary valve

assembly, to twist.

Figure 9A-4

TURNING LEFT

When turning left, the opposite situation occurs.

That is, once the relative m otion between the inner

valve (1) and the outer sleeve (2) causes a return

restric tion, fluid is r outed to the left hand s ide of the

rack piston (3), providing the required assistance.

Also, fluid on the opposite side of the piston is free

to flow back to the reservoir (5) and the pump (4),

through the return circuit. As before, the amount of

assistance provided by the fluid, is determined by

the restric tion caused by the interaction of the inner

valve and outer rotary sleeve. This is controlled by

the twisting of the torsion bar connected between

these two valve members.

Figure 9A-5

INNER VALVE MEMBER

W hen parking, more than 90% of the work is done

by the fluid. In order to achieve a balance between

this graduated increase of assistance and maintain

a realistic 'feel' with good response as the road

speed increases, the grooves of the inner rotating

valve are precisely shaped to meter the flow of oil.

Note that under extreme load conditions or when

for any reason, the hydraulic system is inoperative,

the torsion bar is able to deflec t suffic iently to allow

the input shaft to drive the steering pinion directly.

This is achieved by having a loose fitting spline

between the lower end of the input shaft and the

surrounding upper end of the pinion. Under these

operating conditions, steering loads will be high and

a noticeable amount of slack will develop because

of the flexing of the torsion bar. W hile the steering

gear remains entirely operable, in the interest of

safety, the vehicle should be operated in this

manner only for the minimum distance needed to

reach a point where the system can be serviced. Figure 9A-6

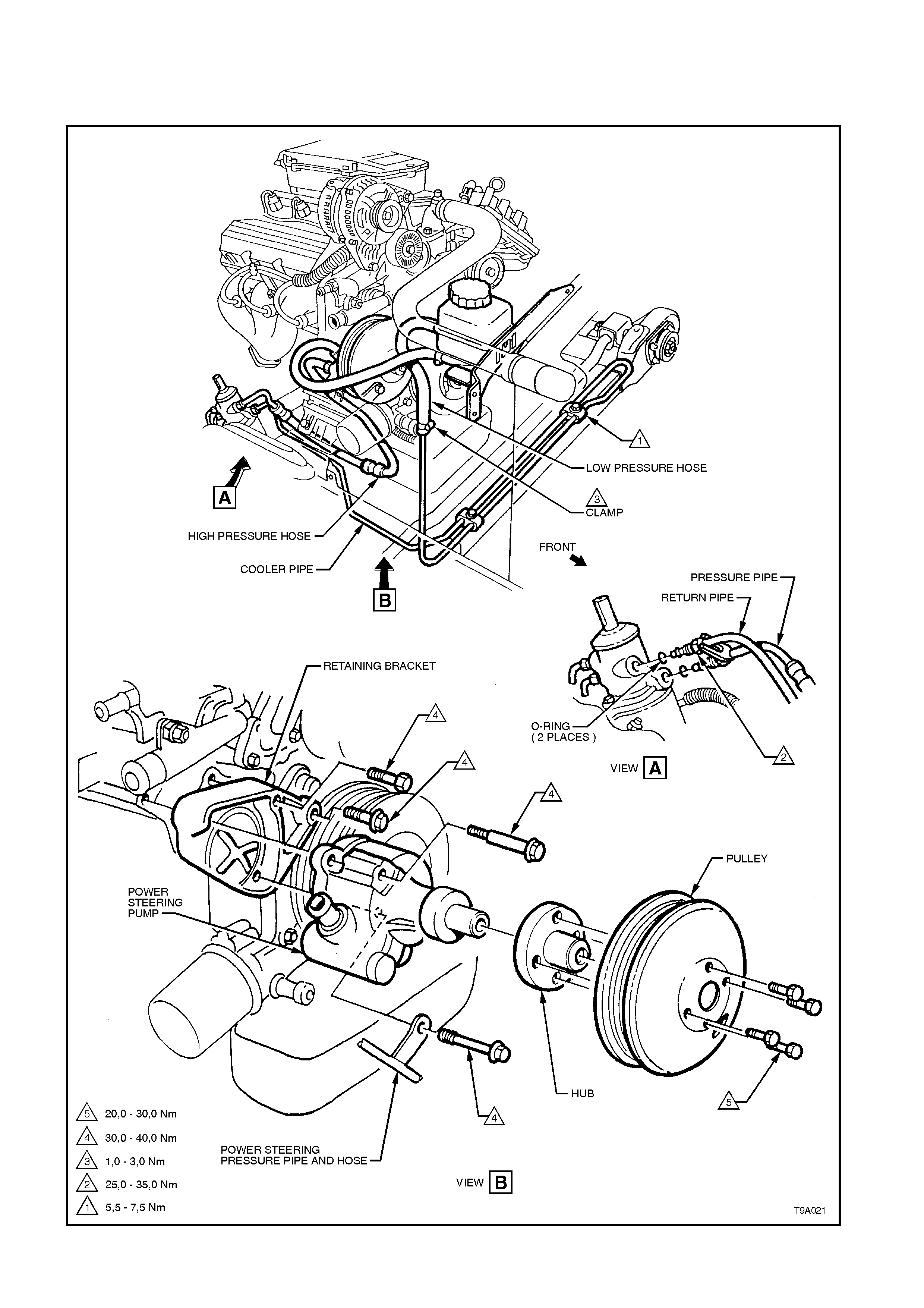

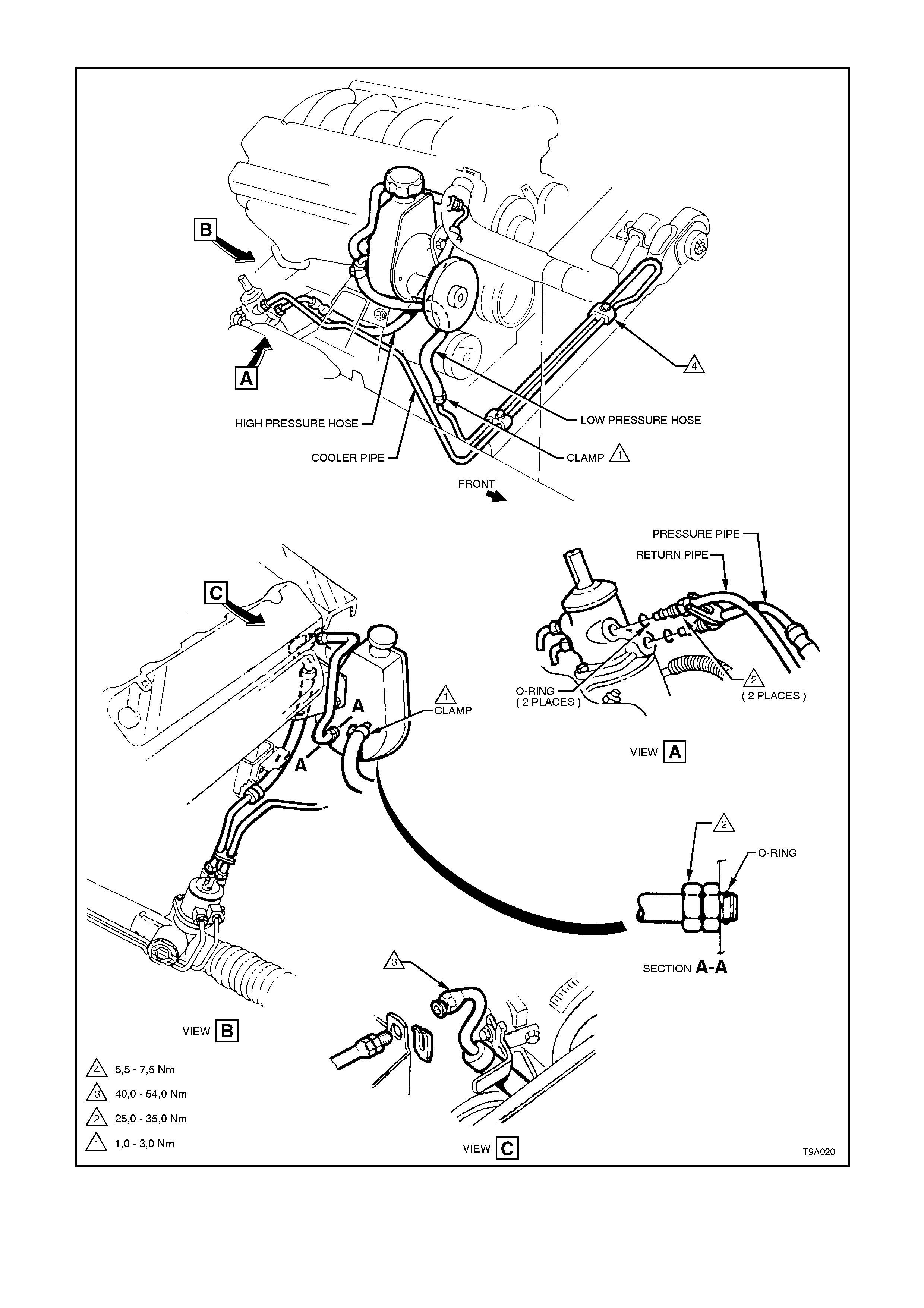

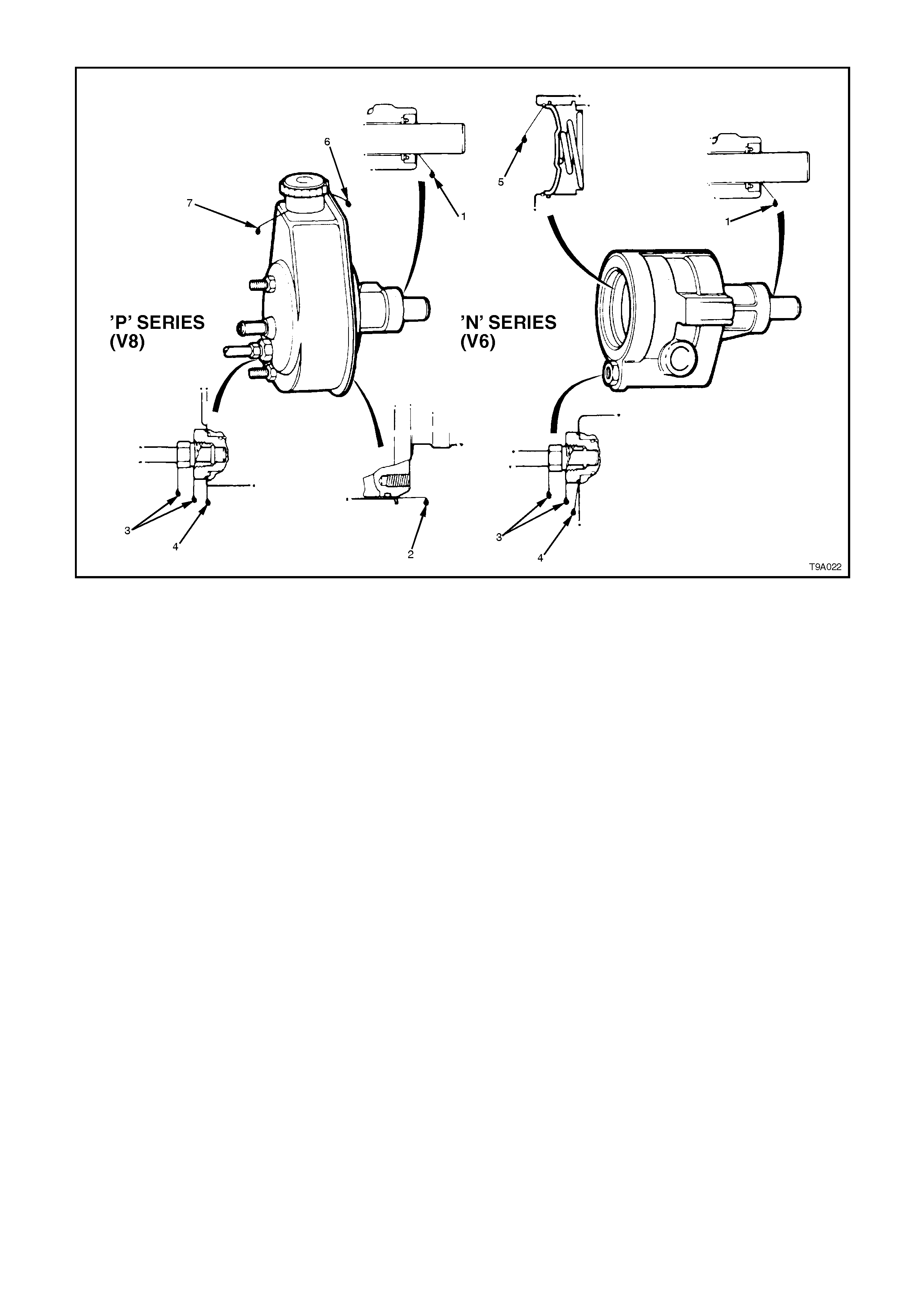

POWER STEERING PUMPS

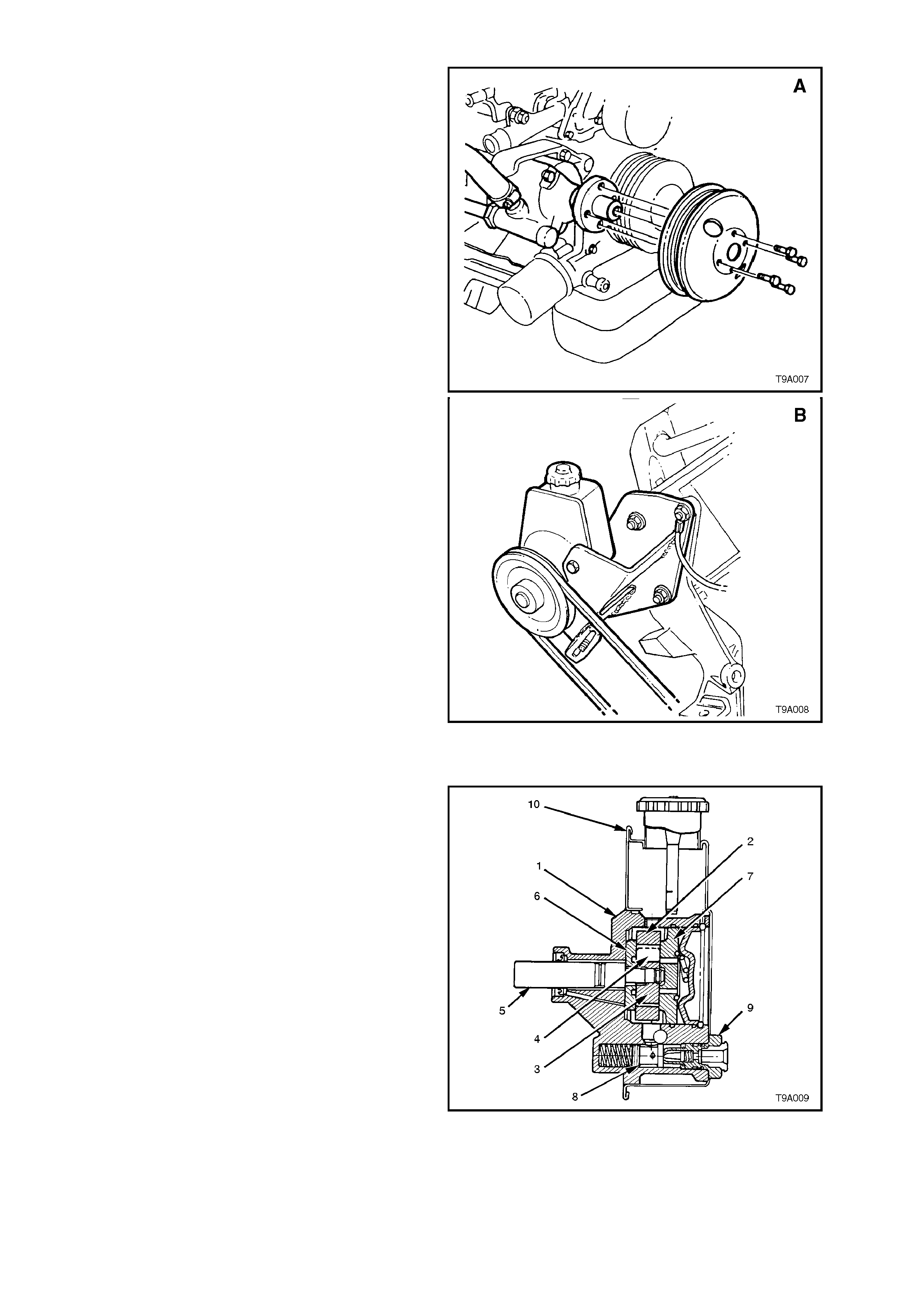

Hydraulic pressure for the V6 engined, power

steering system is provided by a SAGINAW 'N'

Series, droop flow, vane type pump [A]. The pump

is mounted to a retaining bracket, attached to the

right hand side of the cylinder block. The remote

fluid reservoir is mounted to a bracket attached to

the radiator.

Construction of the 'P' series V8 engine power

steering pump [B], is slightly different in that the

housing and internal parts are mounted inside the

reservoir so the pump parts always operate,

submerged in oil. The pump is mounted to a

bracket attached to the front of the right hand

cylinder head.

Figure 9A-7

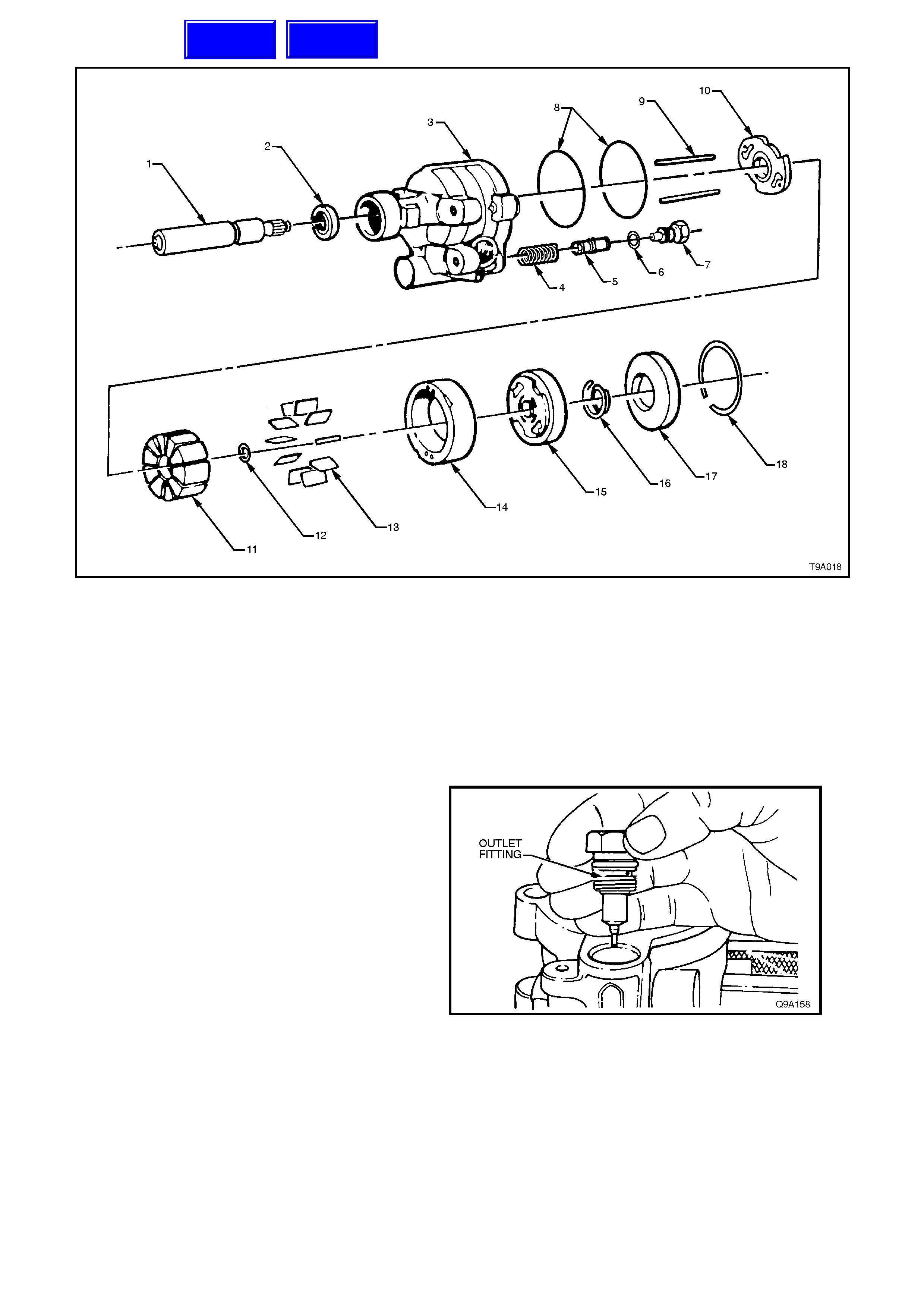

PUMP CONSTRUCTION

Shown is a sectioned view of a 'P' series pump

assembly. As both the 'N' and 'P' Series power

steering pum ps are sim ilar in c onstruc tion, the view

shown will suffice for both pumps. Essentially the

only difference between them being the manner in

which the fluid reservoir (10) is arranged, and the

drive pulley designs.

In each pump assembly there is a large cavity in

the rear of the pump housing (1) that contains the

following parts: pump ring (2), pump rotor (3) and

vanes (4), splined to the drive shaft (5) and thrust

(6) and pressure plates (7).

A smaller cavity, below the larger one , contains the

flow control assembly (8), which consists of a

control valve assembly and pump outlet fitting (9)

with control needle and spring.

Figure 9A-8

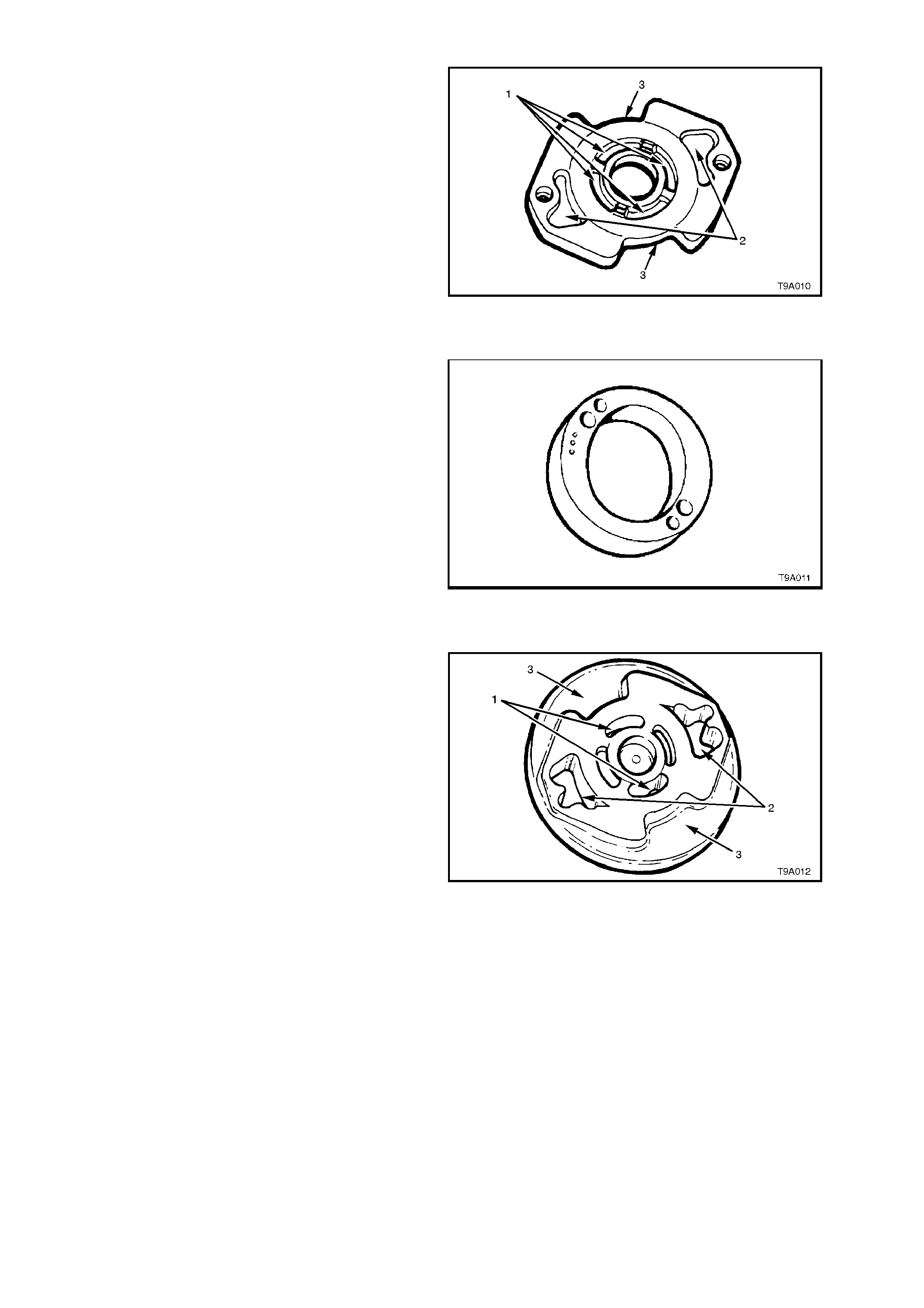

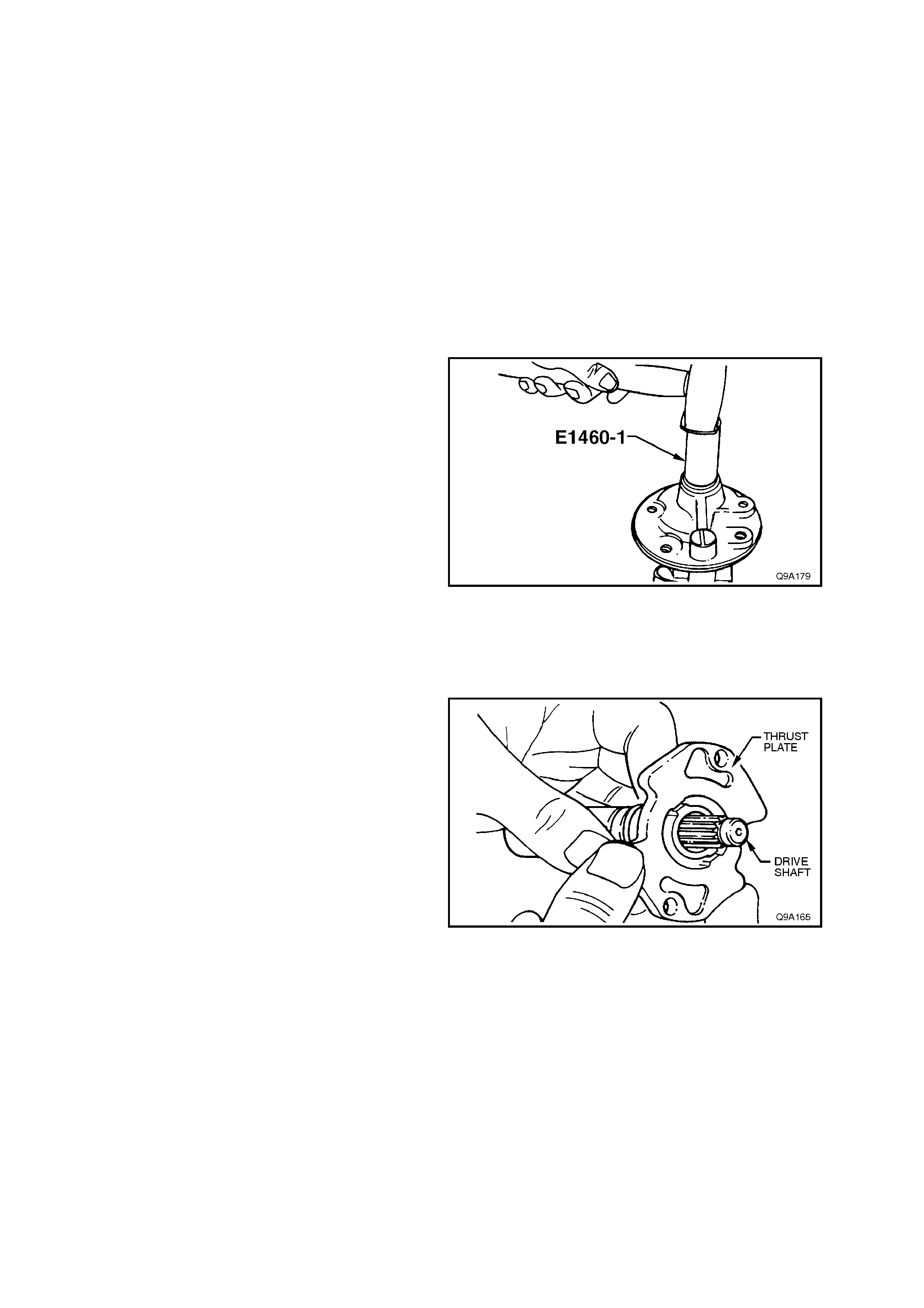

THRUST PLATE

The thrust plate is located on the inner face of the

housing by two dowel pins. This plate has six

cavities; the four central cavities (1) supply under-

vane fluid pressure, and the two outer cavities (2)

direct discharge pressure through the cross-over

holes in the pump ring, through to the pressure

plate and then on to the steering gear. The outside

slots (3) are for fluid intak e from the suction part of

the pump to the rotor.

Figure 9A-9

PUMP RING

The end faces of the pum p ring are ground f lat and

parallel. The centre hole is a two lobed cam in

which the rotor and vanes operate, providing two

cycles per revolution. T he ring is placed next to the

thrust plate and located with the same two dowel

pins.

Figure 9A-10

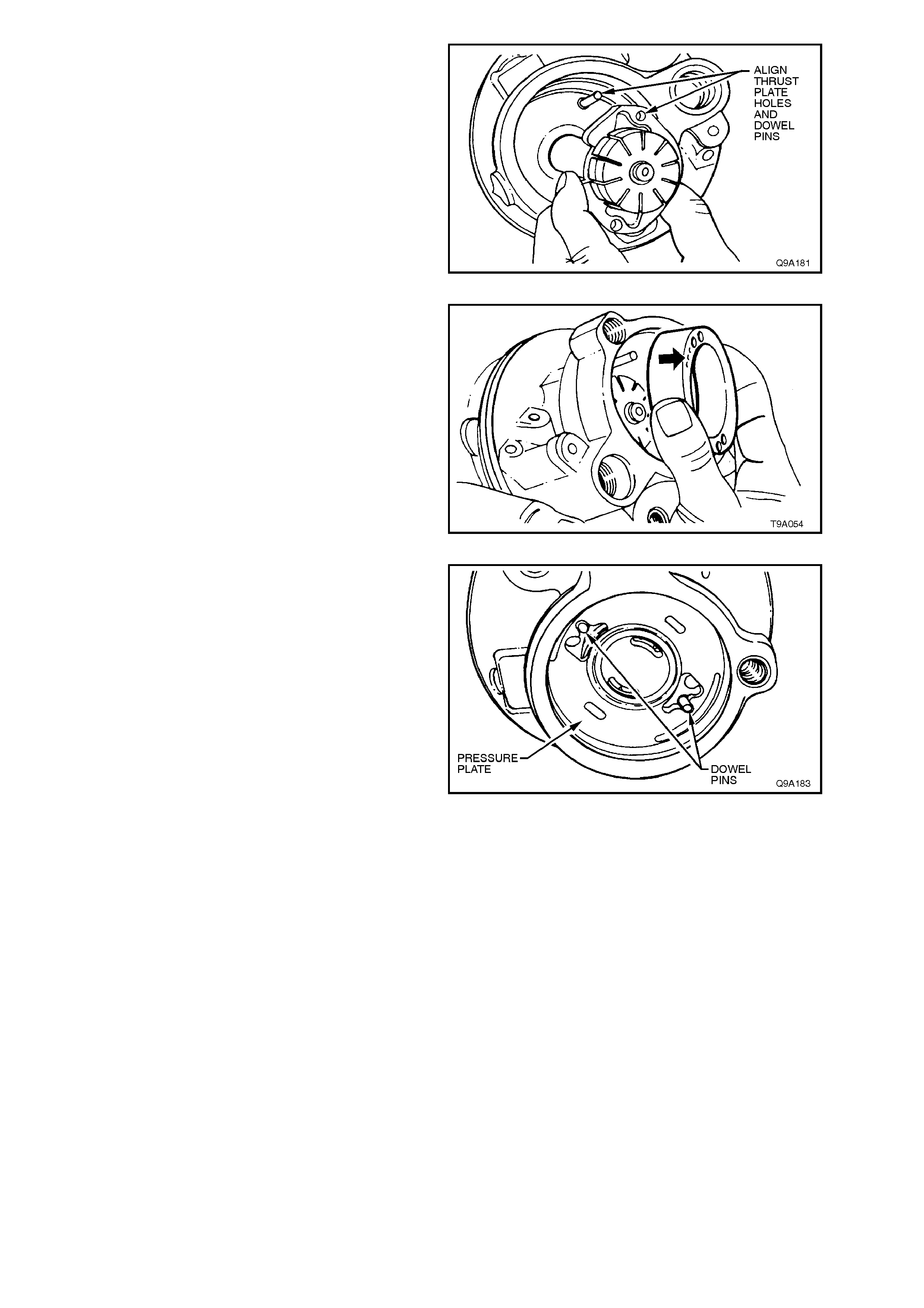

PRESSURE PLATE

The pressure plate is fitted against the pump ring

and located with the same two dowel pins. This

plate has two central ports (1) for under-vane fluid

pressure. The two outer ports (2) pass fluid under

discharge pr es sur e thr ough the contr ol valve, to the

steering gear.

The two outer slots (3) in the press ure plate ar e for

intake of the fluid from the suction part of the pump.

Figure 9A-11

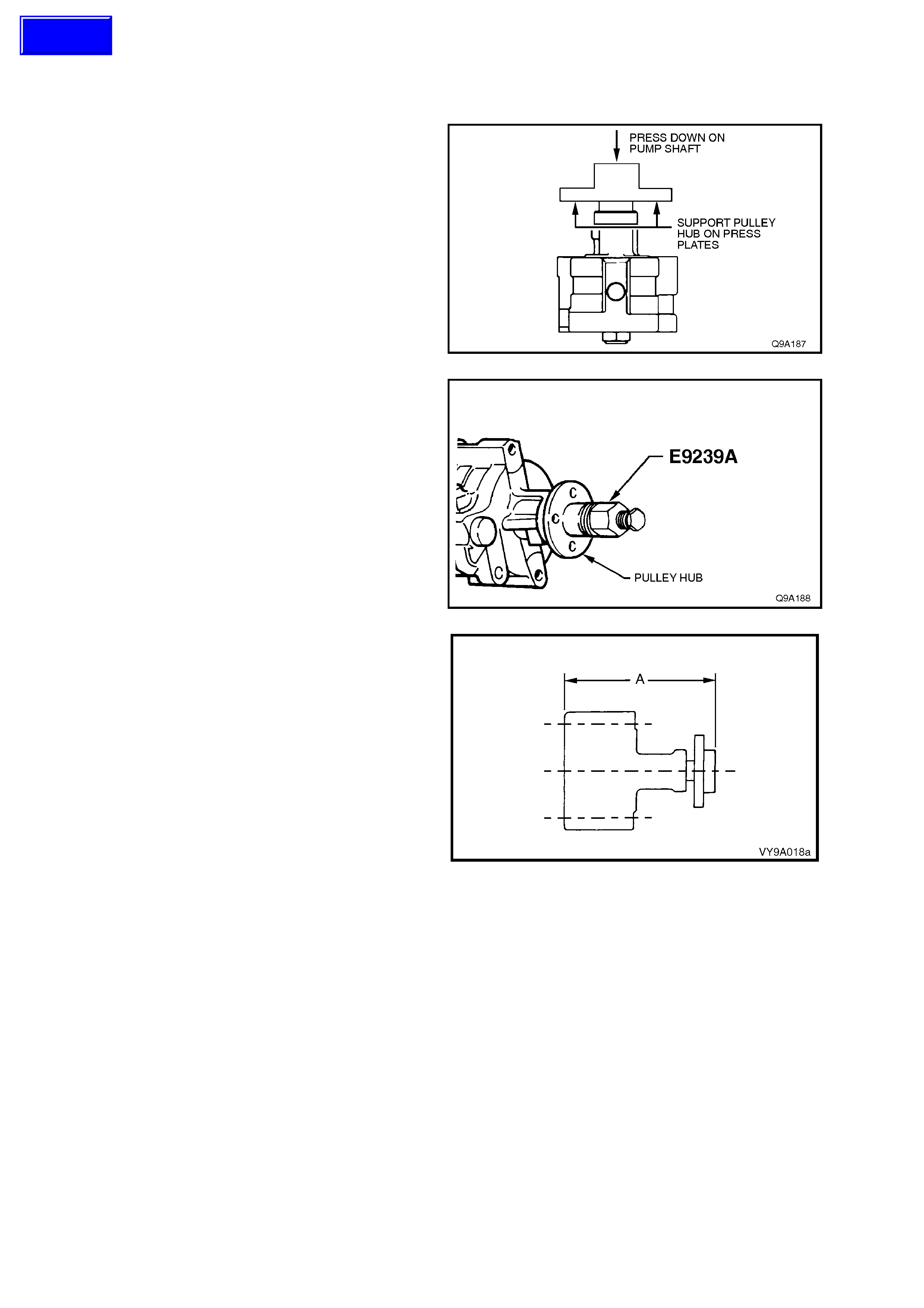

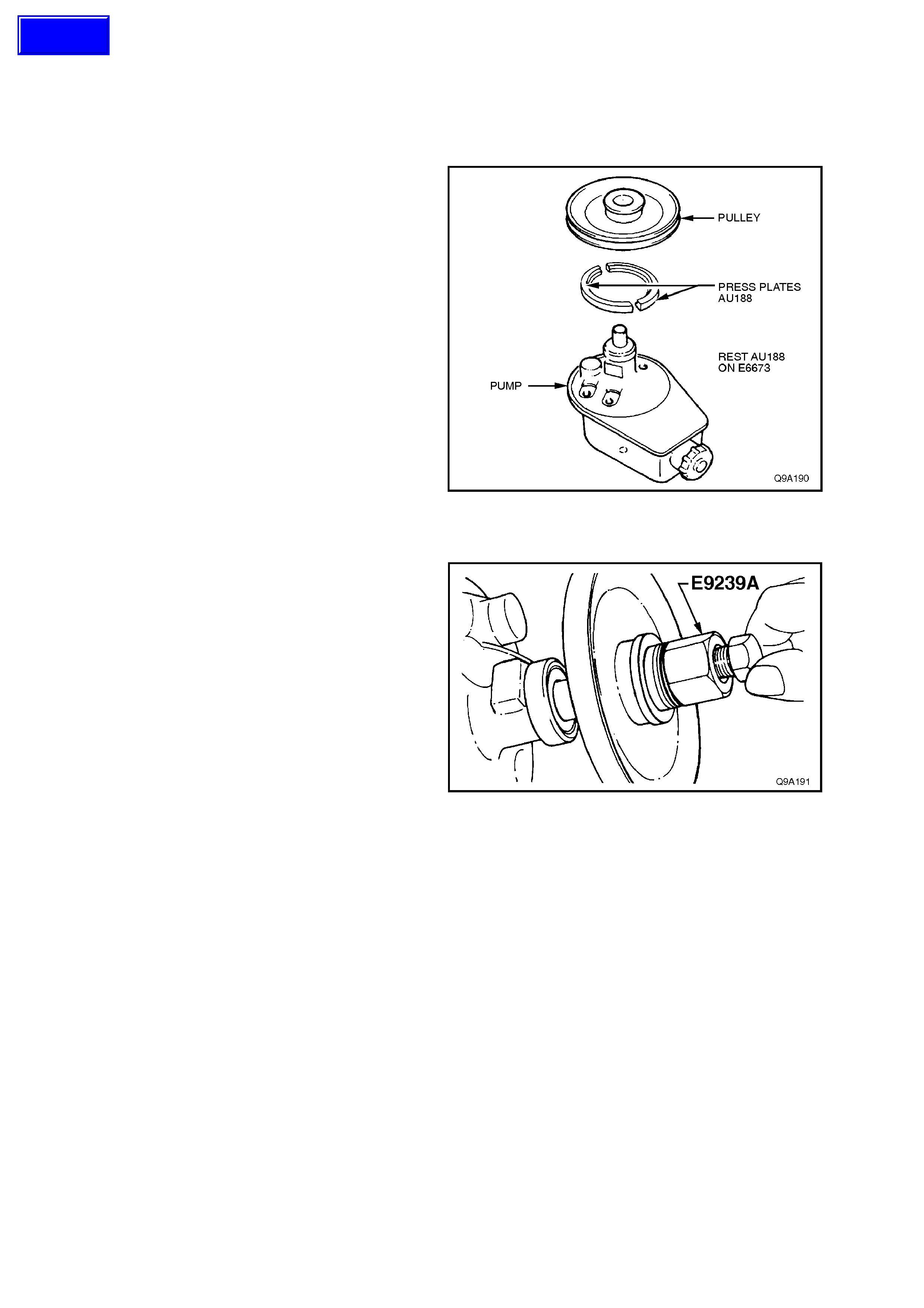

DRIVE SHAFT AND ROTOR

The drive shaft is fitted with a belt driven pulley

from the engine crankshaft. The pump rotor is

splined to the drive shaft and is located within the

pump ring between the thrust and pressure plates.

Ten vanes are mounted in radial slots around the

rotor. The shaft is supported by a bush, pressed

into the front of the pump housing.

CONTROL VALVE ASSEMBLY

The purpose of the control valve assem bly fitted to

droop flow design pum ps, is to vary power steering

system pressure and fluid flow to the steering gear

as required, under various operating conditions.

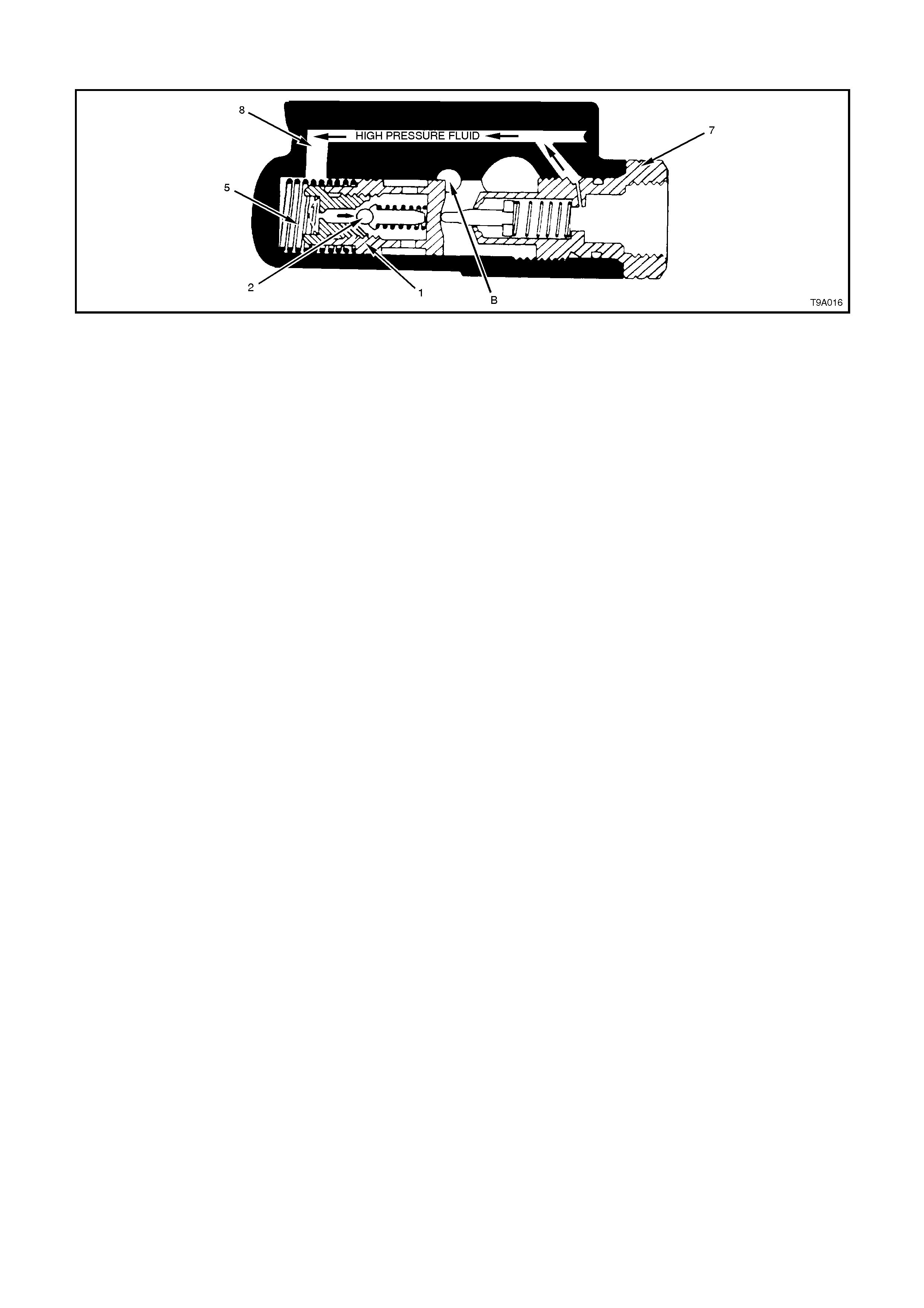

The control valve assembly consists of the control

valve plunger (1), an internal pressure relief ball

check (2), ball check guide and ball check guide

spring (3) . A scr een (4) in the end of the plunger, is

designed to keep dirt and foreign material out of the

ball check area.

Movem ent of the c ontrol valve as s embly under fluid

pressure and spring (5) force, acts upon a fluid

control needle and spring (6), in the pump outlet

fitting (7). The needle is tapered and movement

within the outlet fitting orifice hole, changes the

amount of fluid flow to the steering gear.

Figure 9A-12

FILLING THE PUMP

When the pump and power steering gear are

completely empty of fluid, adding fluid to the

reservoir will fill the pump housing assembly.

Suction and gravity draw fluid into the intake

section of the pump, causing it to flow through a

drilled passage in the housing, leading to the large

cavity around the rotor ring. The fluid fills this area

and also the two intake openings on the pressure

and thrust plates, f illing the space between the ring

and rotor assembly. Any air that might enter the

system is automatically removed by the circulating

fluid, from the pump, through the fluid circuit to the

steering gear and then to the reservoir, where it

vents to atmosphere, via the reservoir cap.

PRINCIPLES OF OPERATION

The m ode of oper ation of the power steering pum p

is based upon the demand of the power steering

gear.

The various major modes of operation are:

1. Slow cornering.

2. Moderate to high speed straight ahead driving.

3. Cornering against the wheel stop.

The pump is designed to recognise these

conditions and compensate for them internally .

As the pump drive shaft turns the rotor, the vane

tips follow the inner cam surface of the pump ring,

moving outward and inward twice during each

revolution. This results in a complete pumping

cycle every 180° of rotation. Fluid is moved in the

spaces between the vanes. As the vane tips move

outward, fluid enters the inter -vane spaces through

four suction ports in the pressure and thrust plates .

As the vane tips m ove inwards, the pres sure of the

fluid is raised and the fluid is discharged from the

pump ring. High pressure discharges into a cavity,

behind the pressure plate. A portion of this fluid is

circulated through the central port system in the

pressure plate, forcing the vanes to follow the cam

surface of the ring.

Fluid is discharged from the high pressure cavity,

through the outlet fitting to the steering gear. As the

fluid passes through the outlet fitting, the fluid

pressure drops. This reduced pressure is

transmitted to the spring end of the control valve.

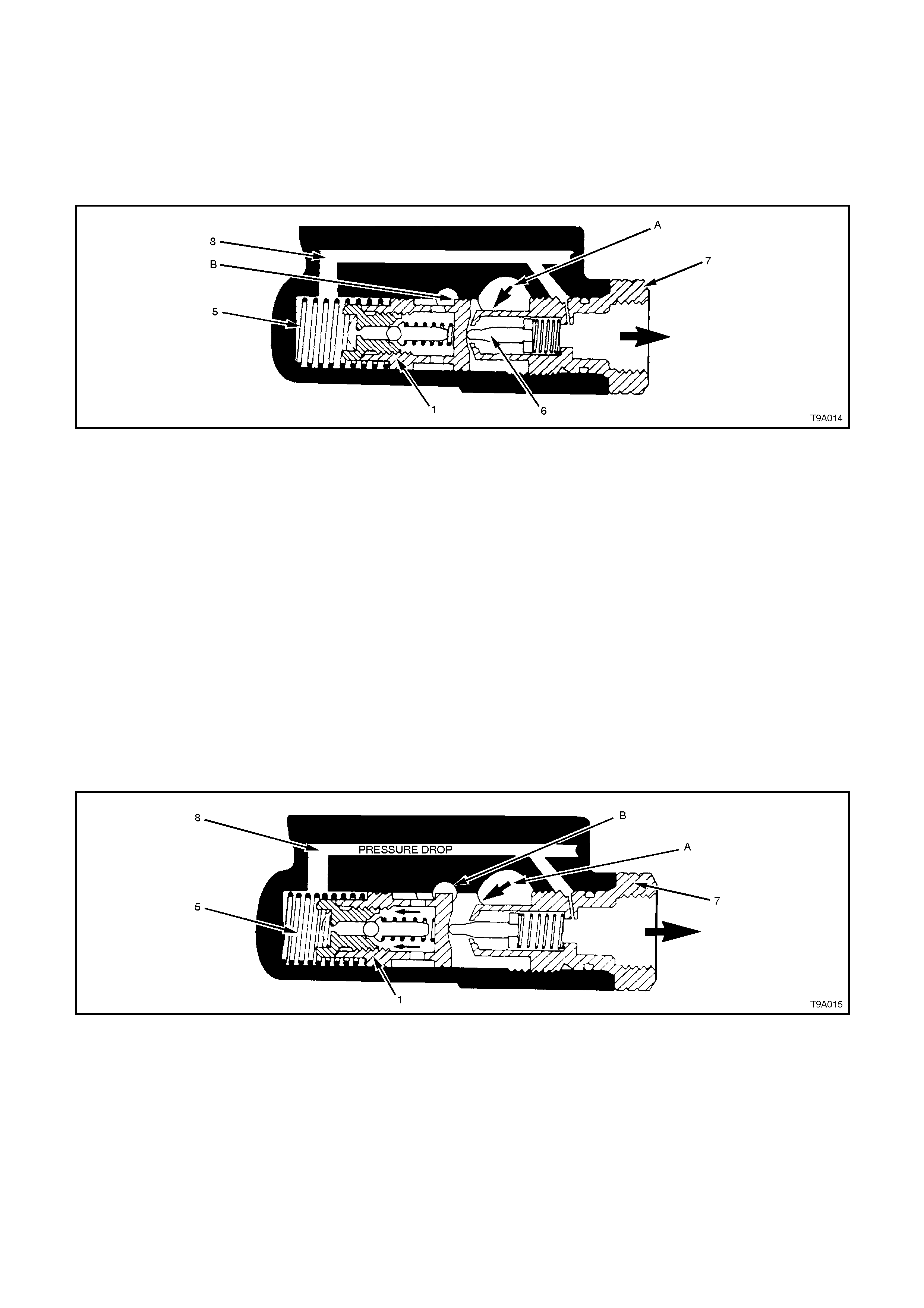

SLOW CORNERING

Pump speeds during slow cornering or parking are normally low, as are demands for fluid flow due to slower

steering manoeuvres.

The fluid is pressurised to approximately 3,400 kPa to 4,800 kPa and directed to the high pressure cavity behind the

pressure plate (arrow ‘A’). Discharge ports direct this fluid to the outlet fitting (7) and then to the steering gear.

The discharge fluid pressure from the outlet fitting (7), is slightly lower in pressure than the internal high pressure

coming from the pump ring. This drop in pressure occurs as the fluid flow passes the needle (6) and orifice in the

outlet fitting.

Figure 9A-13

This lower pressure is transmitted to the spring (5) end of the control valve (1) by a fluid passage (8), connecting the

control valve to the outlet fitting (7).

This results in a pressure unbalance on the valve itself.

The control valve (1) moves away from the outlet fitting (7), but due to the force of the control valve spring (5), the

valve remains closed to the fluid by-pass hole (B). The movement of the control valve (1), controls the needle valve

(6) in the outlet fitting (7) and this controls the fluid flow to the steering gear.

Because fluid pressure is not high enough to cause the pressure relief ball check to actuate, the external circuit

through the steering gear, allows fluid to recirculate through the entire system.

MODERATE TO HIGH SPEED OPERATION

System pressures in this mode are normally low (approximately 260 kPa) due to the lack of steering manoeuvres.

Fluid is discharged from the high pressure cavity through the outlet fitting (7) to the steering gear. As fluid passes

through the fitting, a pressure drop occurs across the needle valve (6) and orifice. This reduced pressure is

transmitted to the spring (5) end of the control valve (1), via the fluid passage (8).

This pressure differential, causes the control valve (1) to move and open up the fluid by-pass passage (B) to the

pump inlet. The movement of the control valve (1) also controls the movement of the flow control needle (6) in the

outlet fitting (7). The needle closes in the orifice and fluid flow to the steering gear is reduced.

Figure 9A-14

CORNERING AGAINST WHEEL STOPS

When the steering wheel is turned to full lock and held in that position, the steering rack power piston chamber

becomes fully pressurised and fluid flow stops. The resulting high pressure is then transmitted to the spring (5) end

of the control valve (1) by connecting fluid passage (8) from the outlet fitting.

When the pressure relief ball check (2) within the control valve opens, a small amount of fluid passes through the

pressure relief orifice, creating a pressure drop, acting on the spring end of the control valve.

The control valve then moves back against spring force (5), opening the fluid by-pass passage (B). Fluid then

returns to the pump inlet. Pre-determined relief pressure is thus maintained while the steering gear is turned and

held on full lock.

NOTE:

This condition should not be maintained for long periods of time due to excessive fluid temperature rise.

Figure 9A-15

1.2 GENERAL DESCRIPTION - STEERING COLUMN

All steering columns include a combination ignition/steering lock, are of an energy absorbing design and will

progressively compress under impact from either direction.

In addition, all steering columns are equipped with a Tilt/Reach feature, as an integral part of their design.

The ignition/steering lock is located to the right of the column assembly. The body of the lock assembly forms an

integral part of the column outer tube and cannot be removed/replaced as a separate component.

The steering lock is activated when the 'lock' position is s elected and the lock m echanism is released and engages

into a slot in the steering shaft (when the slot is facing the lock mechanism).

The ignition switch is attached to the left hand end of the ignition/steering lock housing.

The end of the ignition barrel ass embly shaft is s tepped and engages with the ignition switch. T he ignition s witch is

activated as the lock cylinder is rotated.

Connecting the steering shaft to the steering gear, is an integral steering coupling, which features two universal

joints and a vibration damper.

The following features determine the steering column assembly collapse behaviour in the event of a collision.

A. Upper End of the Steering Column

The upper end of the steering column is fastened to the instrument panel by a bracket with two inserts at the

mounting point, and held in pos ition by two bolts. Under c ollision conditions , should the vehic le operator not be

wearing a seat belt, and suf ficient f orce be exerted by the person against the steer ing wheel and the deployed

air bag, the bracket is able to m ove away from the inserts, the am ount being controlled by a coiled spring on

each side. This enables the upper end of the steering colum n to move down, within a specified load range, in

this extreme and illegal situation.

Collapse load control is achieved prim arily by the break ing away of the mounting bracket f rom the two inserts

and the tension applied by the two control springs.

B. Telescoping Shaft Assembly

The shaf t assembly consists of an upper tube that s lides over a lower shaft, thus allowing the shaft to transm it

torque but still collapse during impact.

C. Supplemental Restraint System (SRS)

This s ystem is des igned to supplement the lap/sash seat belt, dr iver rest raint system als o fitted to the vehicle.

Under no circumstances is the SRS system expected to replace the need for the driver to wear a seat

belt.

CAUTION:

Before any servicing operations are considered, that could in any way impinge on the operation of the SRS

and/or the personal safety of the individual working on the vehicle, the cautionary notes detailed under

2.1 STEERING COLUMN ASSEMBLY SERVICE NOTES AND PRECAUTIONS, in this Section, must be read

and complied with, in all respects!

Figure 9A-16

2. STEERING COLUMN ASSEM BLY SERVICE OPERATIONS

2.1 STEERING COLUMN ASSEMBLY SERVICE NOTES AND PRECAUTIONS

CAUTION:

Disable the SRS (Air Bag). Refer to 'DISABLING THE SRS’, in this Section.

CAUTIONARY NOTES:

1. The outer jacket, steering shaft and instrument panel mounting bracket are designed as energy absorbing

units. Because of the design of these components, it is absolutely vital that the steering column assembly is

handled with care when performing any of the required service operations. Avoid hammering, jarring, dropping

or leaning on any portion of the column.

2. All steering wheel and column fasteners are important parts in that they could affect the performance of other

vital parts and systems.

3. Fasteners must be replaced with those of the same part number or with an equivalent part, if replacement is

required. Do not use a replacement part of lesser quality or substitute design.

4. Torque values must be used where specified during reassembly to assure proper retention of the part.

Techline

2.2 SRS DISABLING AND ENABLING PROCEDURE

DISABLING THE AIR BAG

IMPORTANT:

While simply disconnecting the battery earth

lead from the battery terminal is sufficient to

disable the air bag/s fitted to VT Series

vehicles, this wo uld also mean losing radio PIN

setting (if the battery were to remain

disconnected for more than approximately 8

hours) and BCM programming. The procedure

detailed here then, describes an approach that

disables the driver’s air bag, rendering it safe

to work on steering components but allowing

all pre-sets to remain intact.

1. Disconnect the battery earth lead from the

battery terminal.

2. Turn the steering wheel so that the vehicle’s

front wheel are pointing straight ahead.

3. Rotate the ignition switch to the ‘LOCK’

position and remove key from the ignition

switch.

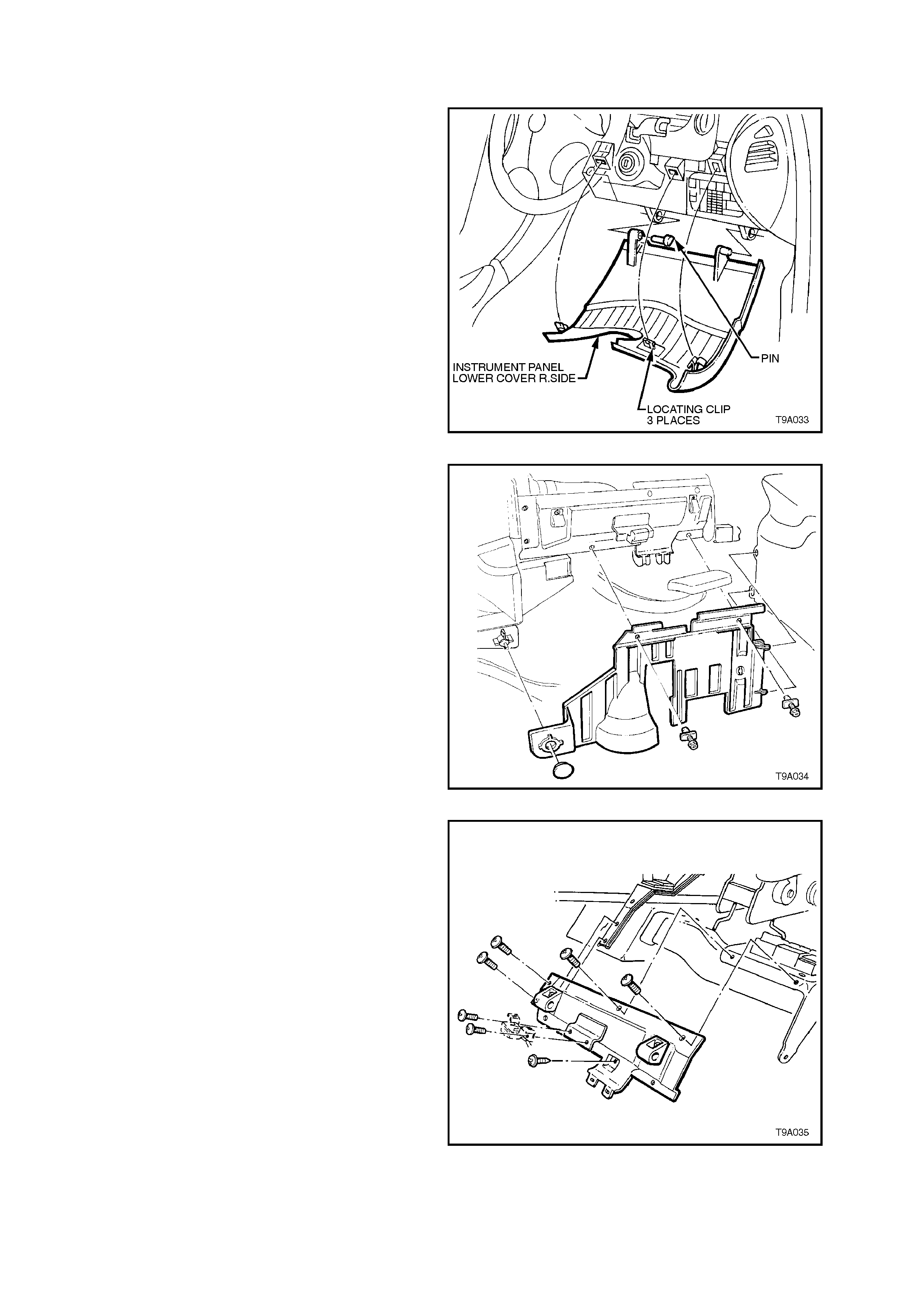

4. Lower the instrument panel right hand cover

assembly by grasping the top edge on each

side of the s teering column with the finger tips

and pulling the top edge out, to free the

retaining lugs from the clips.

5. Release steering column tilt/reach clamp

lever, lower the column and lock the clamp

lever in this position to retain column in the

lowered position.

Figure 9A-17

6. Remove mini fuse F26 (arrow) from fuse

panel, using the removal tool provided.

Figure 9A-18

7. Insert finger between the steering wheel and

the lower cover as shown and apply a small

amount of force, pus hing the cover toward the

instrument cluster.

8. Remove the upper cover by lifting upwards,

then rearwards.

Figure 9A-19

9. Disconnect the wiring harness connector from

the clock spring assembly, by first pulling the

yellow connector lock to the left hand side as

shown, then pull the connector from the clock

sprin g assembly.

NOTE:

The steering wheel is shown removed to more

clearly illustrate the connector.

IMPORTANT:

This procedure is only suitable for disabling the

driver’s side air b ag. For the passenger side air

bag (where fitted), disconnecting the battery

earth lead from the battery terminal is the most

practical method.

THIS PROCEDURE IS ONLY SUITABLE FOR

THE SRS (AIR BAG/S) FITTED TO VT SERIES

VEHICLES. DO NOT USE THIS PROCEDURE ON

ANY OTHER VEHICLE APART FROM THESE

MODELS! Figure 9A-20

ENABLING THE DRIVER’S SIDE AIR BAG

1. Ensure the ignition is switched to the ‘LOCK’

position.

2. Install the wiring harness connector to the

clock spring assembly, then push the yellow

connector lock in the direction shown. When

fully engaged a ‘click’ will be heard.

NOTE 1: The steering wheel is shown removed to

more clearly illustrate the connector.

3. To enable the remainder of the driver’s side

SRS:

Raise the instrument panel right-hand lower

cover and locate each tang in its respective

clip before firmly pushing home to secure.

Install the retaining screw.

Reinstall the upper steering column cover in

the reverse way to removal, ensuring the two

locating lugs at the front end of the upper

cover, engage with the retaining lugs on the

lower.

Reinstall fuse F26 to fuse panel.

Close the instrument panel lower cover by

locating each tang in its respective clip, then

pushing firmly to secure.

4. Connect battery earth lead to battery earth

terminal.

5. Switch ignition ON and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approxim ately 5 seconds. During this period of

time the SDM performs a wiring and self-

check.

If no system faults are detected, the SRS

warning lamp will be switched OFF. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates 2 seconds after it was originally

switched off, an SRS fault is present. Ref er to

3, DIAGNOSTICS, in Section 12M, SRS, to

rectify fault.

Figure 9A-21

2.3 HORN BAR & AIRBAG ASSEMBLY

If conducting this operation on an air bag that has

been deployed, ensure that safety glasses and

gloves are worn to protect eyes and hands from

possible irritation when handling the deployed horn

bar and air bag inflator module assembly.

After deployment of the horn bar and air bag

inflator m odule as sembly, the surfac e of the air bag

may contain a powdery residue that consists

primarily of corn starch (used to lubricate the bag

as it inflates) and by the products of the chemical

reaction. Sodium hydroxide dust is produced as a

by-product of air bag deployment reaction, which

then quickly reacts with atmospheric moisture and

is converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikely

that sodium hydroxide will be present after

deployment.

REMOVE

1. Disable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE

in this Section.

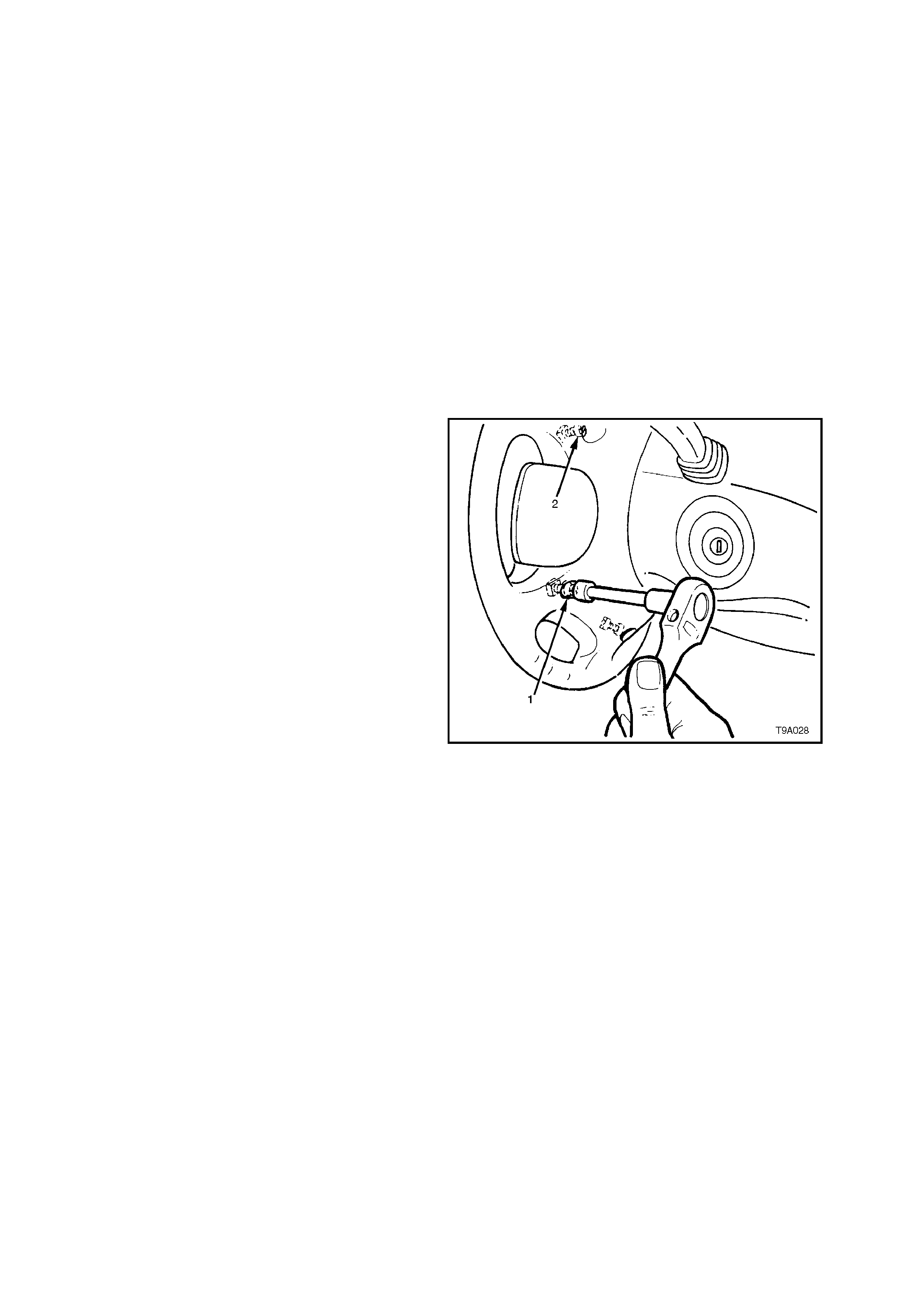

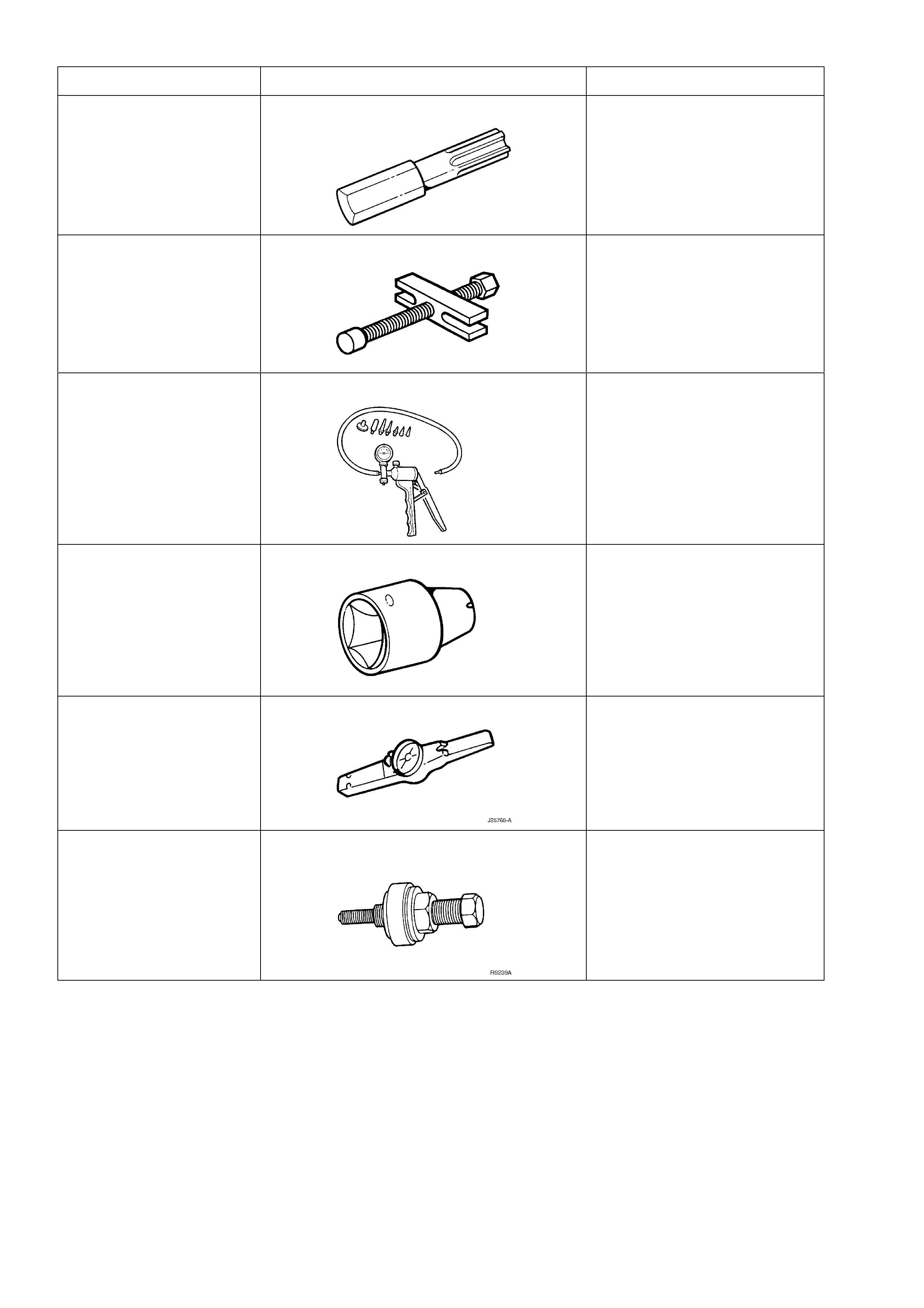

2. Using a number T30H Torx bit (commercially

available), or Tool No. ETX30H and a suitable

holder such as Tool No. J25359-8 (1), loosen

then remove the horn bar and air bag inflator

module assembly retaining screws (2) from

four places on the rear of the steering wheel.

Figure 9A-22

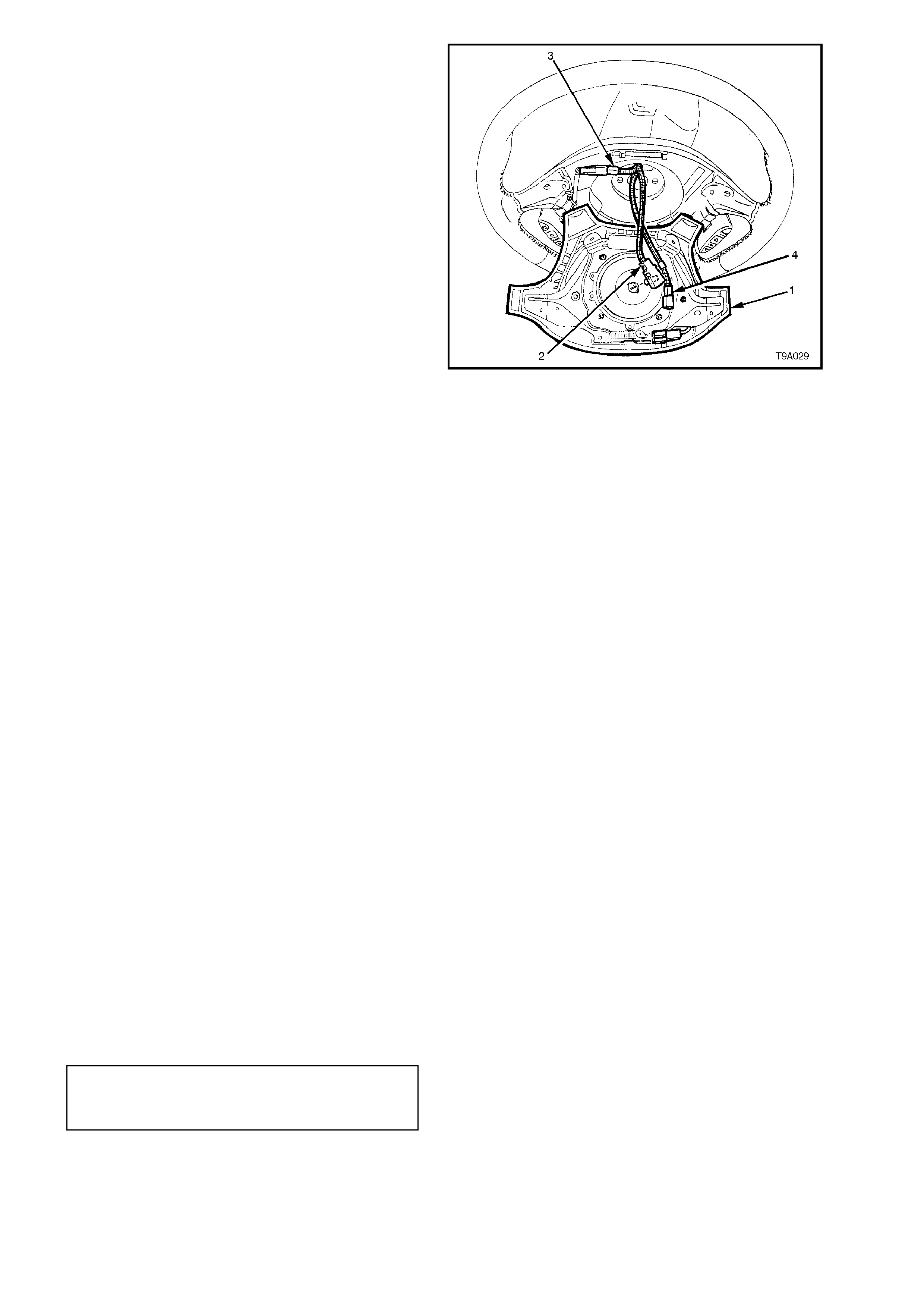

2. Lift up the horn bar and air bag inflator module

assembly (1) from the steering wheel, remove

the yellow clock spring to inflator assembly

connection (2) and disconnect wiring harness

connectors (3 and 4) from rear of assembly.

NOTE:

If removing a horn bar and air bag inflator module

assembly from a steering wheel fitted with stereo

controls (as shown), take extreme care when

disconnecting the left hand horn pad connector (3)

from the stereo control wiring connector.

Otherwise, damage to the stereo control wiring

could result.

Remove the horn bar and air bag inflator

module assembly (1) from the steering wheel.

CAUTION:

When carrying a live (undeployed) horn bar and

air bag inflator module assembly, make sure

the bag opening is facing away from the body.

Never carry the horn bar and air bag inflator

module assembly by the horn bar wires or

connectors on the underside of the assembly.

In case of accidental deployment, the bag will

then deploy with a minimal chance of injury.

When placing a live horn bar and air bag

inflator module assembly on a bench or other

surface, always face the bag and horn bar

facing up, away from the surface. Never rest the

horn bar and air bag inflator module assembly

with the horn bar face down. This is necessary

so that a free space is provided to allow the air

bag to expand, in the unlikely event of

accidental deployment. Otherwise, personal

injury may result.

Figure 9A-23

REINSTALL

1. Lift horn bar and air bag inflator module

assembly up to steering wheel and reconnect

all wiring harness connec tors to the r ear of the

assembly.

2. Seat the horn bar and air bag inflator module

assembly on steering wheel, ensuring wiring

and connectors are not caught between the air

bag inflator module and the steering wheel

hub.

3. Using a number T30H Torx bit, Tool No.

ETX30H and a suitable holder such as Tool

No. J25359-8, install then tighten the four

screws into the rear of the steering wheel to

secure the horn bar and air bag inflator

module assembly to the steering wheel.

Tighten screws to the correct torque

specifications. DO NOT OVER-TIGHTEN.

HORN BAR AND AIRBAG MODULE

ASSEMBLY TO STEERING WHEEL 10 - 14 Nm

SCREW TORQUE SPECIFICATION

4. Enable the SRS (Air Bag). Refer 2.2 SRS

DISABLING AND ENABLING PROCEDURE,

in this Section.

5. Switch ignition ON and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approximately 5 seconds. During this period of

time the SDM performs a wiring and self-

check.

If no system faults are detected, the SRS

warning lamp will be switched OFF. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates 2 seconds after it was originally

switched off, an SRS fault is present. Refer to

3, DIAGNOSTICS, in Section 12M, SRS, to

rectify fault.

2.4 STEERING WHEEL

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to in 2.2 SRS

DISABLING AND ENABLING PROCEDURE, in

this Section.

1. Remove the horn bar and air bag inflator

assembly, as described in 2.3 HORN BAR

AND AIRBAG MODULE ASSEMBLY,

Remove, in this Section.

2. Ensure that the front wheels and the steering

wheel are in the straight ahead position.

NOTE:

This is im por tant to ens ure that the c loc k s pr ing coil

is locked, when the steering wheel is removed.

3. To aid installation of the steering wheel to its

original position, scribe an aligning mark on

the steering wheel centre section and steering

shaft. A felt tipped pen could also be used.

NOTE:

Do not use a centre punch for this operation. See

'CAUTIONARY NOTES’, in 2.1, in this Section.

4. Using a commercially available, Torx E20

socket, remove the steering wheel retaining

bolt.

NOTE:

Do not use a conventional, 12 pointed socket for

this operation.

7. Remove the steering wheel from the steering

shaft splines and feed the clock spring wiring

and connectors through the steering wheel

aperture.

NOTE:

When the steering wheel is removed, check that

the green coloured tang has engaged the inner

clock spring member to lock it in the centralised

position.

Figure 9A-24

NOTE:

With the increased diameter of the steering shaft

and the angle of the locating bevel, it is not usually

necessary to require a puller to remove the steering

wheel. However, if one is required, use puller, Tool

No. J1859-A (1) and legs (2), Tool No. E1408.

9. Install legs (2) to the steering wheel.

10. After turning the lugged feet on each of the

legs in an outward direction, tighten the

puller forcing screw to pull the steering wheel

from the mating splines on the steering shaft.

Remove the puller (1) from the steering wheel.

Figure 9A-25

REINSTALL

1. Install steering wheel to steering shaft,

aligning marks made prior to removal and

ensuring the drive tang of the clock spring is

aligned with the steering wheel aperture.

NOTE:

This action automatically releases the clock spring

centralising lock.

2. After cleaning the threadlock residue from the

bolt threads, apply Loctite '242' (or equivalent

to Holden’s Specification HN1256 Class 2,

Type2) to bolt threads. Install and tighten

steering wheel retaining bolt to the correct

torque specification, using a commercially

available, Torx E20 socket.

STEERING WHEEL RETAINING 40 - 50

BOLT TORQUE SPECIFICATION Nm

3. Reinstall the horn bar and air bag inflator

assembly, as described in 2.3 HORN BAR

AND AIRBAG MODULE ASSEMBLY in this

Section. Tighten the four scr ews to the correct

torque specification. DO NOT OVER-

TIGHTEN.

HORN BAR AND AIRBAG MODULE

ASSEMBLY TO STEERING WHEEL 10 - 14 Nm

SCREW TORQUE SPECIFICATION

6. Enable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE,

in this Section.

7. Check horn and turn indicator operation.

2.5 IGNITION BARREL LOCK CYLINDER

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE, in

this Section.

1. Disconnect battery earth lead.

2. Remove ignition keys from ignition switch.

3. Lower the instrument panel right hand cover

assembly by grasping the top edge on each

side of the s teering column with the finger tips

and pulling the top edge out, to free the

retaining lugs from the clips.

4. Release the steering column tilt/reach clamp

lever, lower the column and lock the clamp

lever in this position.

Figure 9A-26

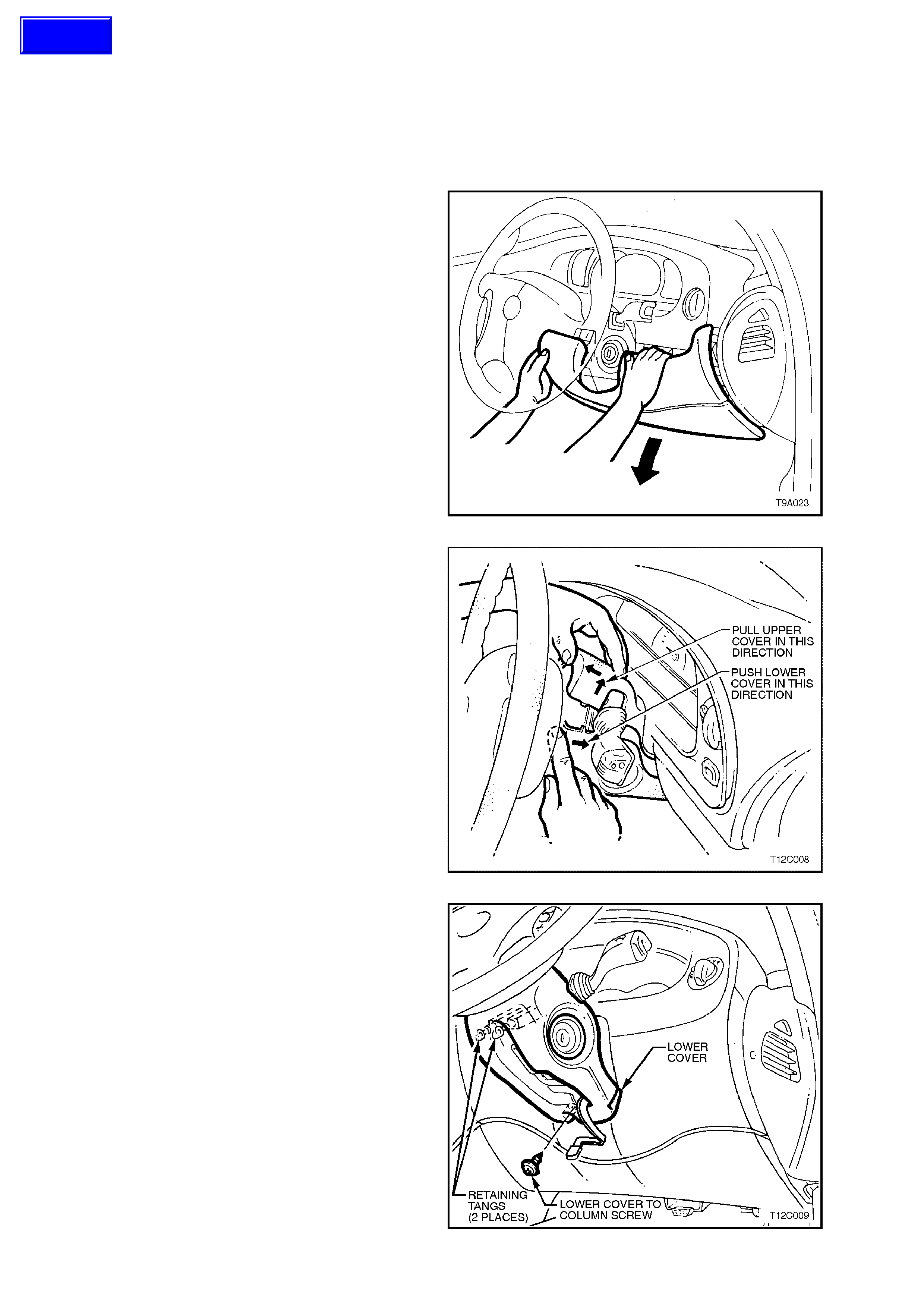

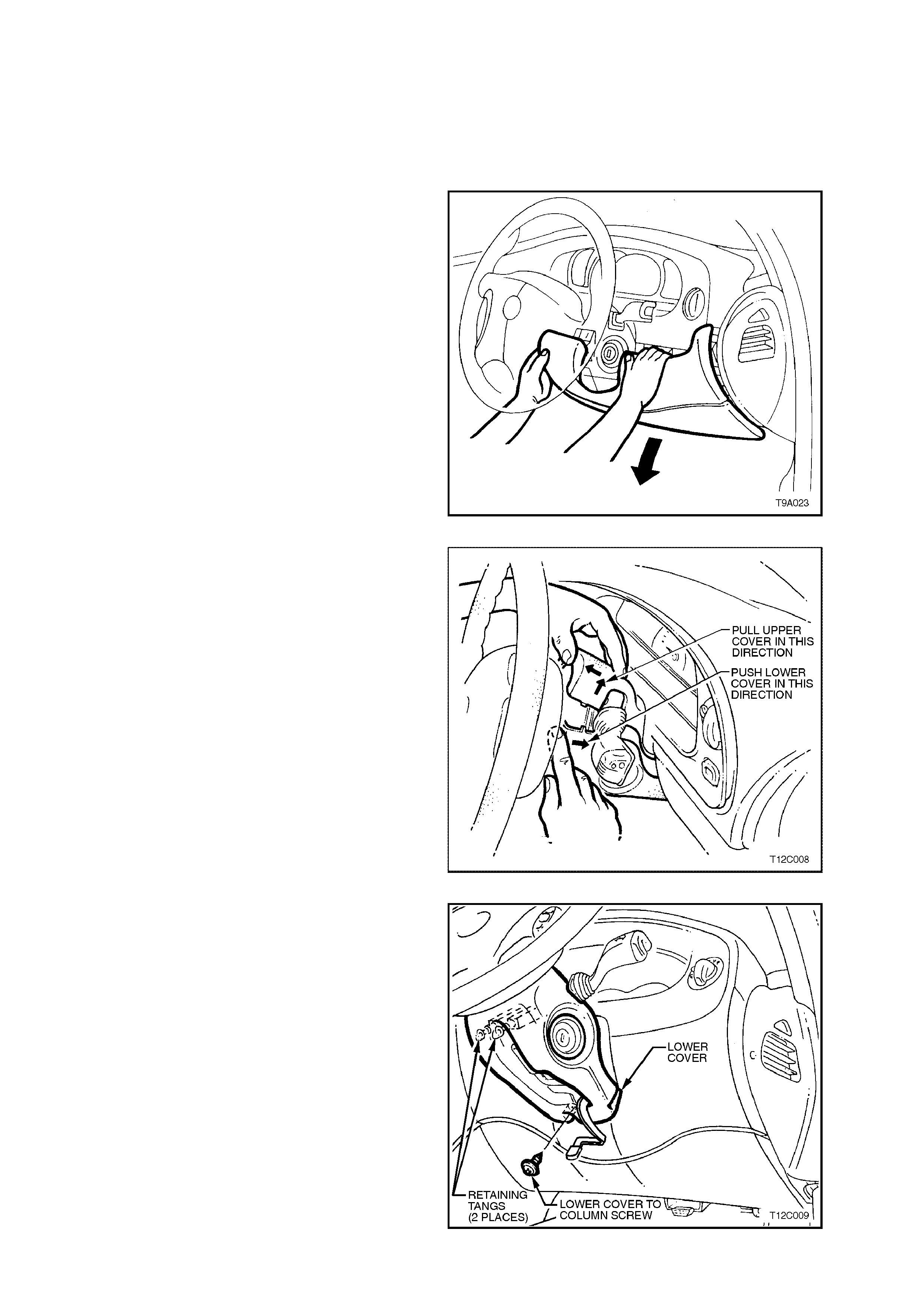

5. Insert finger between the steering wheel and

the lower cover as shown and apply a small

amount of force, pushing the c over toward the

instrument cluster.

6. Remove the upper cover by lifting upwards,

then rearwards.

Figure 9A-27

7. Remove the screw securing the lower cover to

the steering column.

8. Push the lower cover up towards the steering

wheel to release the cover from the two

retaining tangs on the steering column.

9. While feeding the key reader outer surround

from the lower cover, remove the lower cov er.

Figure 9A-28

Techline

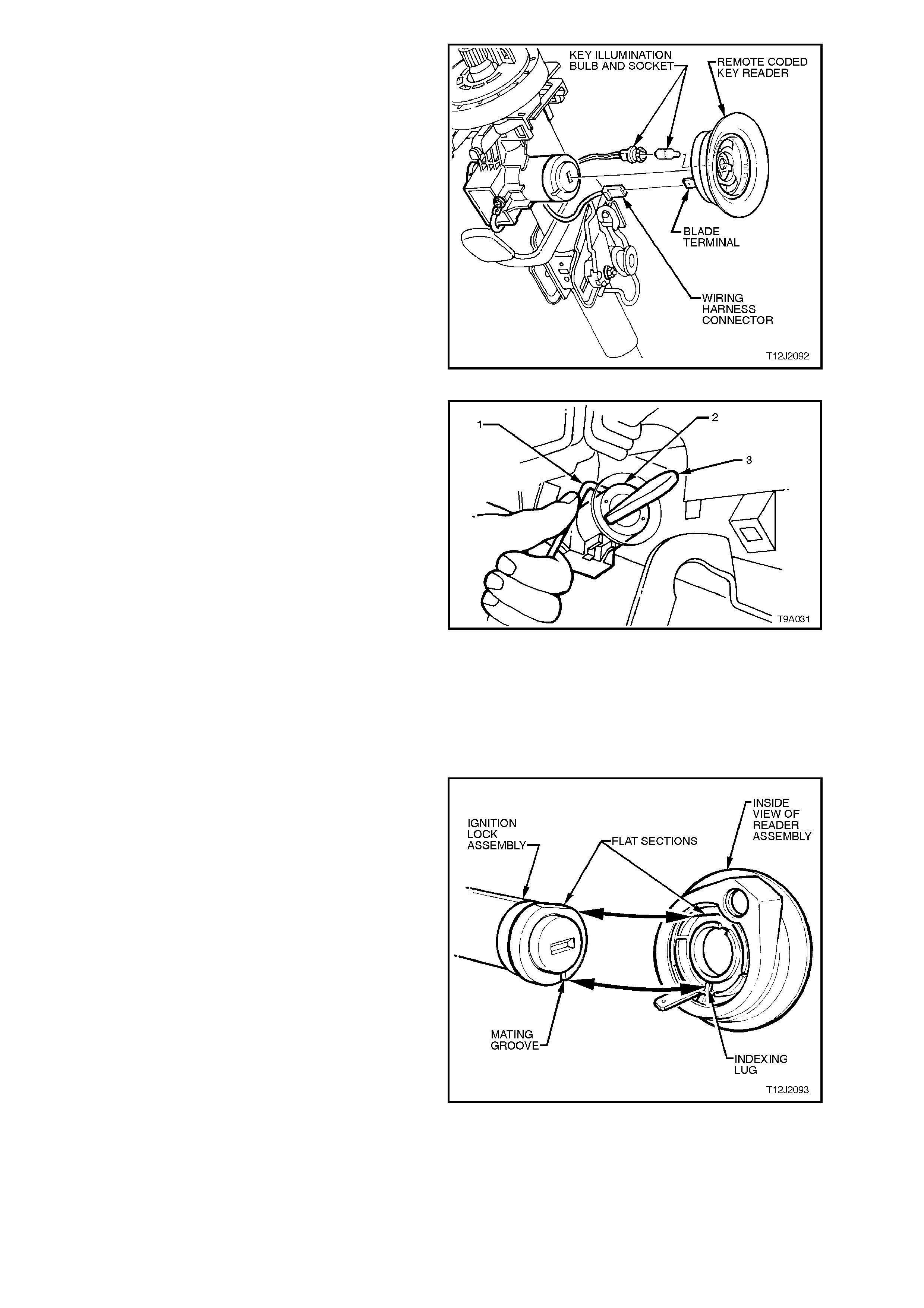

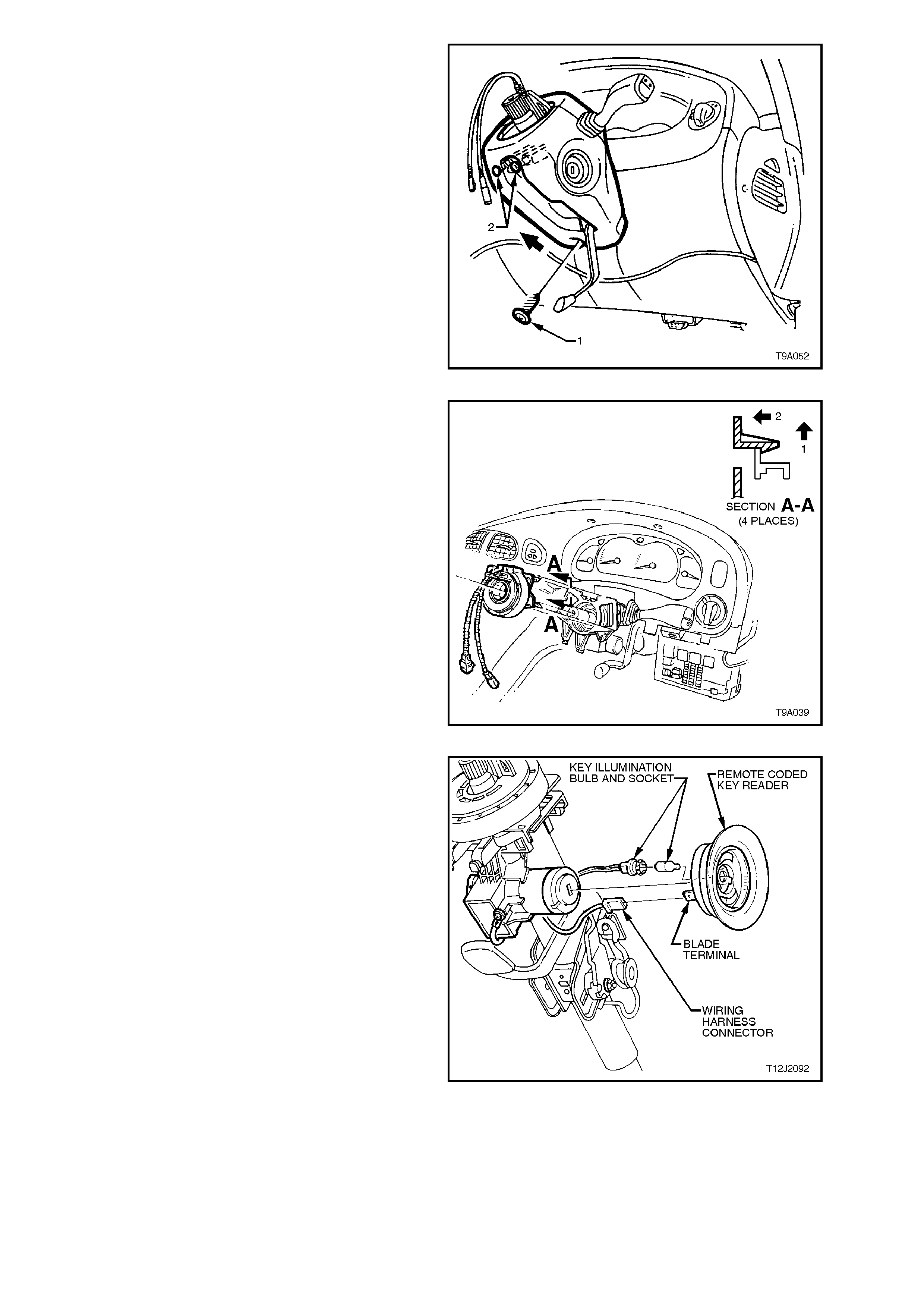

10. Disconnect the wiring harness connector and

ignition lock illumination socket and bulb from

the key reader assembly.

11. Carefully pull the key reader from the ignition

lock assembly housing.

Figure 9A-29

12. Insert ignition key into barrel and turn to the

'ON' position.

13. Insert a 2.5 mm diameter pin (an Allen key is

suitable) (1), into locking pin hole, depress

spring loaded barrel locking latch to release

lock cylinder.

14. Remove pin and pull barrel (2) from lock

housing.

Figure 9A-30

REINSTALL

1. Install key into ignition barrel, and turn key to

the ignition 'ON' position.

2. Insert barrel into lock housing until latch locks

into the housing.

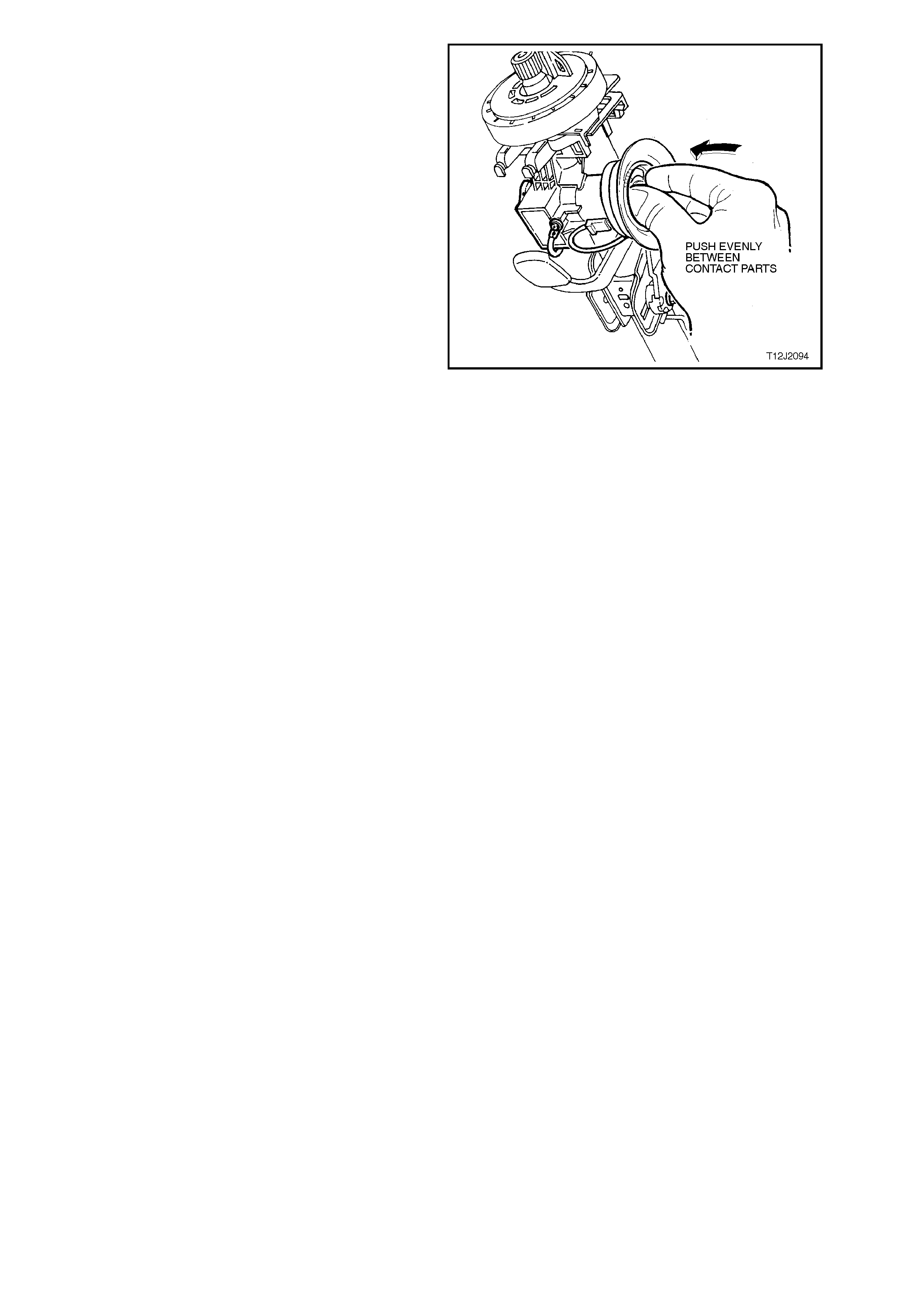

3. To reinstall the ignition key reader, align the

flat section of the remote key reader

assembly, with the ignition lock assembly.

Figure 9A-31

4. Gently press the key reader assembly onto the

ignition lock by pushing evenly between the

two key reader seats, until the reader

assembly seats onto the ignition lock.

5. Ensure that the wiring harness connector and

ignition lock illumination bulb and socket are

securely fitted to the key reader assembly.

6. Reinstall steering column lower cover, by

engaging the two retaining tangs before

pushing the cover towards the instrument

cluster to engage. When the holes are aligned,

install the lower cover attaching screw.

7. Install the upper cover in the reverse manner

to removal.

8. Raise the instrument panel right hand cover

assembly and locate each tang in its

respective clip before firmly pushing home to

secure.

9. Reconnect battery earth lead.

10. Insert the ignition key and check ignition

switch lock and barrel operations.

IMPORTANT:

Enable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE, in

this Section.

Figure 9A-32

2.6 IGNITION SWITCH

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE in

this Section.

1. Disconnect battery earth lead.

2. Remove ignition keys from ignition switch.

3. Lower the instrument panel right hand cover

assembly by grasping the top edge on each

side of the s teering column with the finger tips

and pulling the top edge out, to free the

retaining lugs from the clips.

4. Release the steering column tilt/reach clamp

lever, lower the column and lock the clamp

lever in this position.

Figure 9A-33

5. Insert finger between the steering wheel and

the lower cover as shown and apply a small

amount of force, pushing the c over toward the

instrument cluster.

6. Remove the upper cover by lifting upwards,

then rearwards.

Figure 9A-34

7. Remove the screw securing the lower cover to

the steering column.

8. Push the lower cover up towards the steering

wheel to release the cover from the two

retaining tangs on the steering column.

9. While feeding the key reader outer surround

from the lower cover, remove the lower cov er.

Figure 9A-35

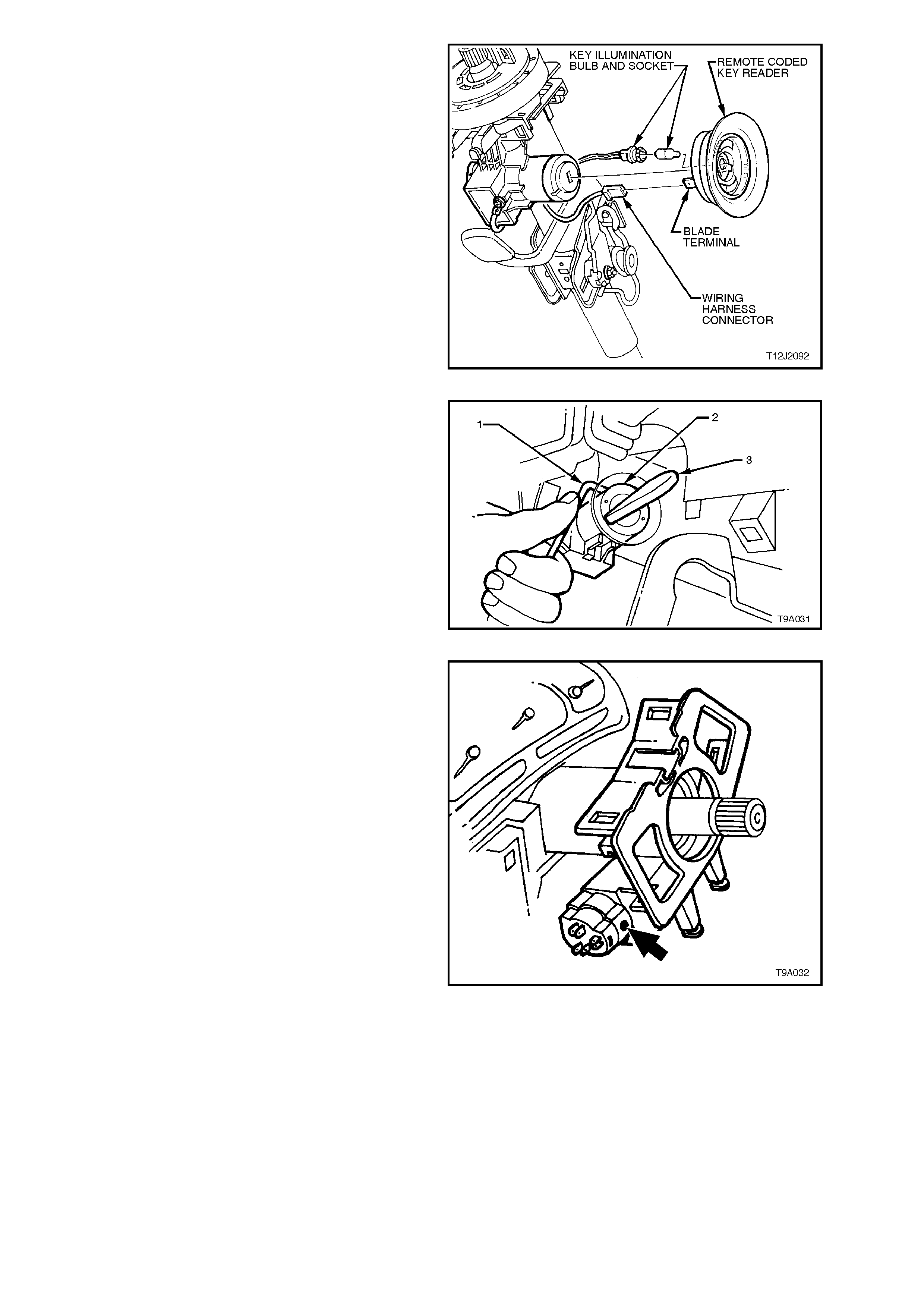

10. Disconnect the wiring harness connector and

ignition lock illumination socket and bulb from

the key reader assembly..

11. Carefully pull the key reader from the ignition

lock assembly housing.

Figure 9A-36

12. Insert ignition key into barrel and turn to the

'ON' position.

13. Insert a 2.5 mm diameter pin (an Allen key is

suitable) (1), into locking pin hole, depress

spring loaded barrel locking latch to release

lock cylinder.

14. Remove pin and pull barrel (2) from lock

housing.

Figure 9A-37

15. Disconnect wiring harness connector from the

ignition switch.

16. Using a fine bladed screwdriver, remove

ignition switch to steering lock housing

retaining grub screw (arrow).

17. Pull switch from steering lock housing,

disengaging the roll pin f rom the side oppos ite

the grub screw.

Figure 9A-38

REINSTALL

Installation of the ignition switch is the reverse of

removal procedure, noting the following points:

1. When installing ignition switch into housing,

ensure that the switch body engages the

locating roll pin in the housing and that the s lot

in end of switch aligns with stepped end of

ignition barrel shaft and

2. Once fitted, retain the switch by tightening the

grub screw.

3. After installing the wiring harness connector to

the ignition switch, reconnect battery earth

lead and check ignition switch operation.

IMPORTANT:

Enable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE, in

this Section.

2.7 STEERING LOCK

As the steering lock is an integral part of the steering column assembly, the steering lock is not a separately

serviceable component. If found to be faulty, the entire steering column assembly must be replaced.

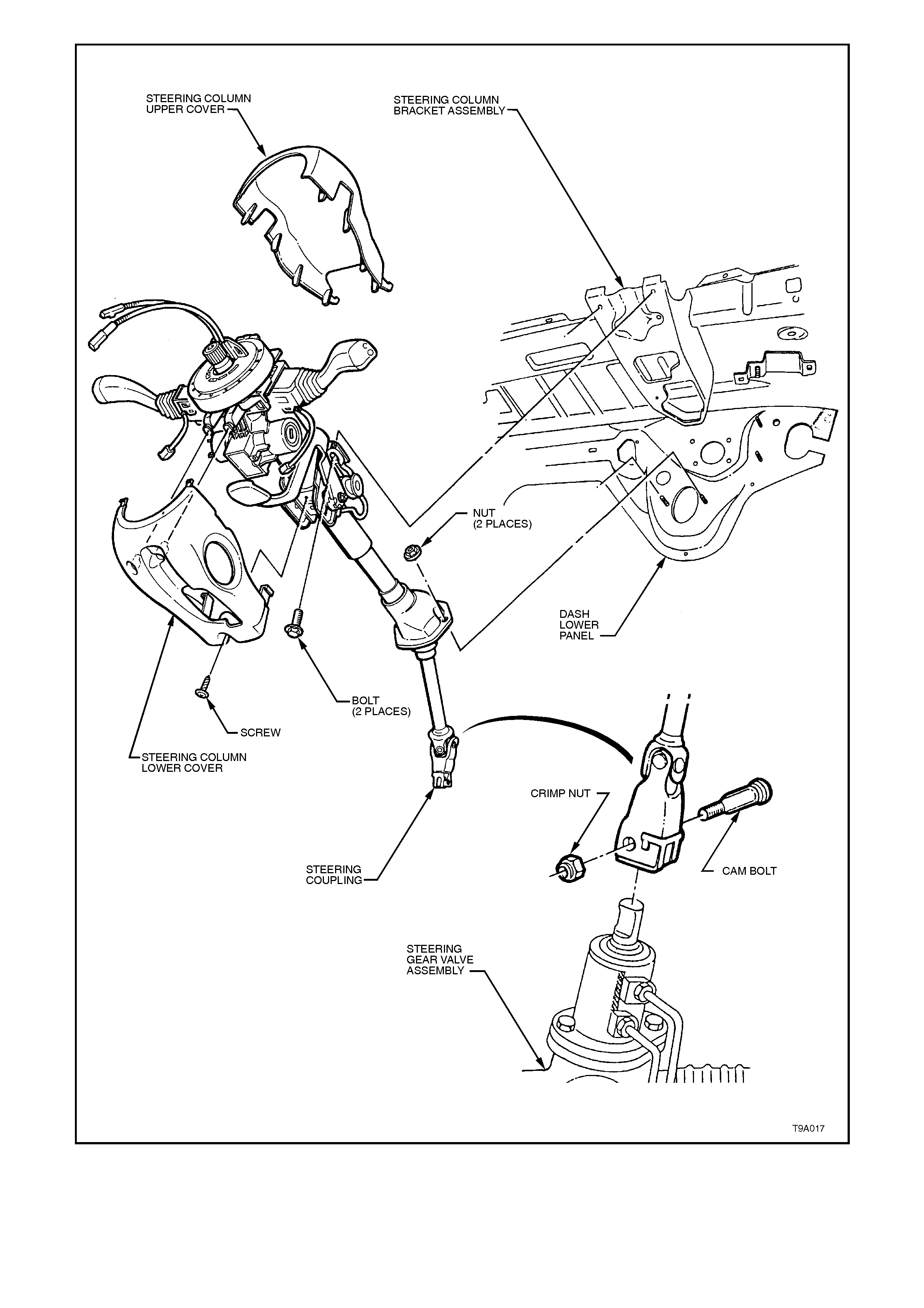

2.9 STEERING COLUMN ASSEMBLY

REMOVE

CAUTION:

Disable the SRS (Air Bag). Refer to 2.2 SRS

DISABLING AND ENABLING PROCEDURE in

this Section.

1. Disconnect battery earth lead.

2. Lower the instrument panel right hand cover

assembly by grasping the top edge on each

side of the s teering column with the finger tips

and pulling the top edge out, to free the

retaining lugs from the clips.

3. Using a screwdriver or similar, lever out the

left hand hinge pin, lower the cover at the left

hand end, then remove cover from the

instrument panel.

4. Remove steering wheel, refer to

2.4 STEERING WHEEL in this Section.

Figure 9A-39

5. Remove the instrument panel lower trim by

removing the two fasteners and retainer.

Lower the trim, then twist the footwell

illumination lamp holder to remove.

Figure 9A-40

6. Remove the screws attaching the fuse and

body control module panel to the dash panel.

Leaving the Data Link Connector (DLC)

attached to the panel, swing the panel to one

side and secure with tie wire or similar.

Figure 9A-41

7. After removing the upper steering column

cover, remove the screw (1) securing the

lower cover to the steering column.

8. Push the lower cover up towards the top of the

steering column (arrow) to release the two

retaining tangs (2) on the steering column.

9. While feeding the key reader outer surround

from the lower cover, remove the lower cover.

Figure 9A-42

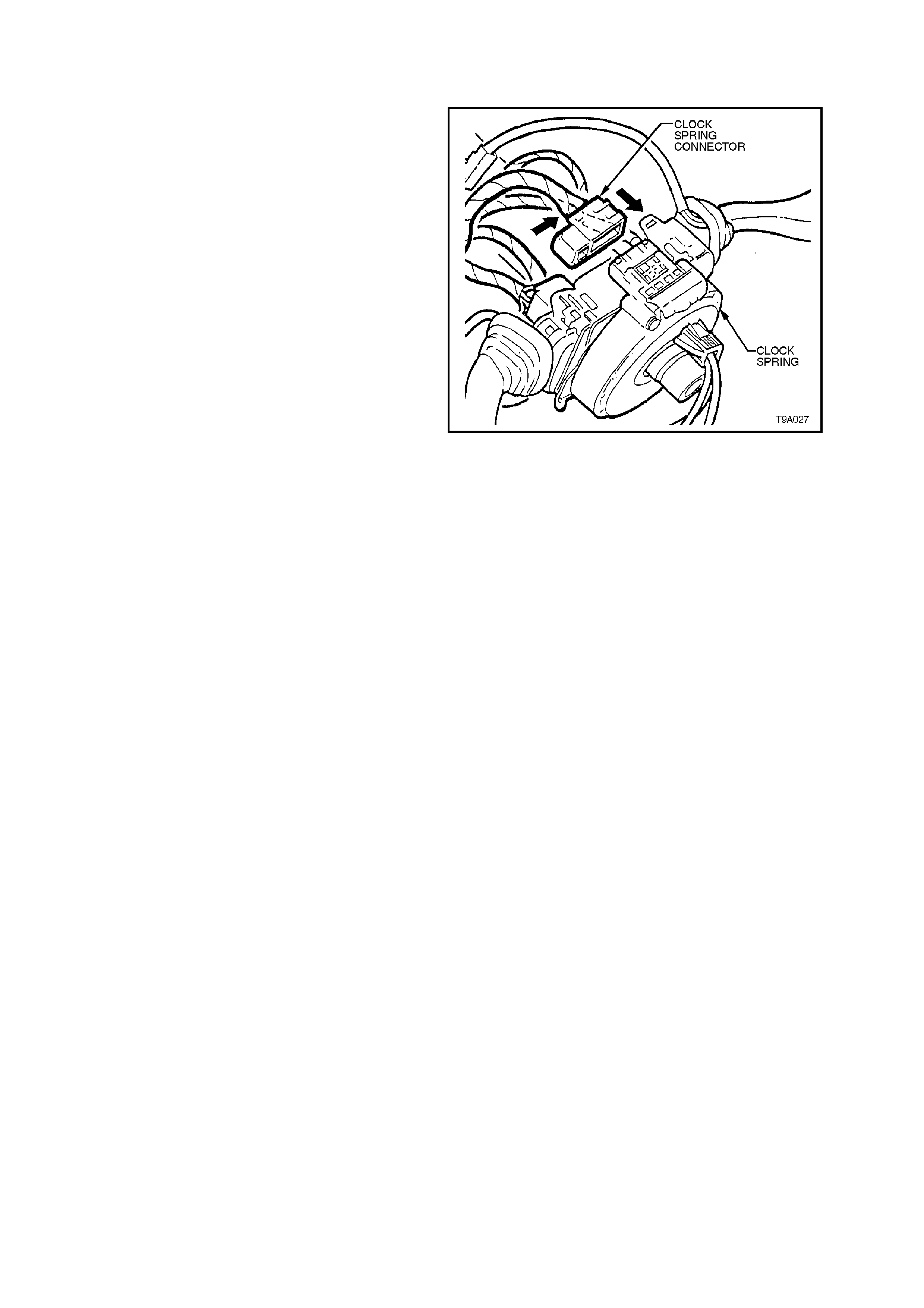

10. To remove the clock spring assembly,

disengage the two top locking tangs by lifting

first in direction (1) then pulling the clock

spring assembly in direction (2) to disengage

each tang. Repeat for the lower two tangs,

then remove the assembly from the steering

column.

Figure 9A-43

11. Disconnect the wiring harness connector and

ignition lock illumination socket and bulb from

the key reader assembly.

12. Carefully pull the key reader from the ignition

lock assembly housing.

13. Remove the screw holding the earth lead to

the ignition lock housing and remove the

wiring harness connector from the ignition

switch assembl y.

Figure 9A-44

14. Remove both the turn s ignal and wiper/washer

switch assemblies by depressing the switch

retaining tangs (2), then pull each switch from

the upper bearing suppor t as sem bly (3). While

removal of the turn signal switch assembly is

shown (1), the retention method for both

switches is the same.

15. Using a screwdriver or similar, depress the

tangs of the wiring harness retaining clip and

remove.

16. Carefully lift the wiring harness to one side and

secure.

Figure 9A-45

17. Loosen but do not remove steering column to

instrument panel mounting bolts.

18. Raise front of vehicle and place on safety

stands. Refer to Section 0A, GENERAL

INFORMATION for location of jacking points.

19. Remove steering coupling to steering rack

pinion shaft cam bolt nut. Remove the cam

bolt, then disengage the retaining clip and

slide the coupling away from the steering rack

pinion shaft.

Figure 9A-46

20. From inside the vehicle, remove the two nuts

(2) securing the lower housing ass embly (1) to

the floorpan.

21. W hile supporting the steering colum n, remove

the previously loosened upper column

retaining bolts.

22. Remove the steering column assembly from

the vehicle.

Figure 9A-47

REINSTALL

Installation of the steering column assembly is the

reverse of r emoval pr ocedur es , noting the f ollowing

points:

1. Inspect the foam seal stuck to the lower

housing to ensure it is intact. If the sealing

ability of the flattened seal is suspect, apply a

continuous bead of silicone sealant such as

RTV 732 or equivalent to Holden’s

Specification HN 1373 to the seal material.

2. After installing the steering column coupling

through the floor pan, install the two lower

housing retaining nuts but do not tighten at

this stage.

3. Lift the column assembly and loosely install

the two upper support bracket retaining bolts.

NOTE:

Only use bolts that were originally used, or replace

with genuine parts, as these parts are an inherent

part of this vital safety feature of the vehicle.

4. Engage the lower coupling with the steering

rack input shaft, install cam bolt and a new

'crimp' nut to the lower coupling and tighten

the nut to the specified torque.

LOWER STEERING COUPLING

TO RACK PINION, CAM BOLT 23 - 30 Nm

NUT TORQUE SPECIFICATION

Figure 9A-48

5. Tighten the lower housing retaining nuts from

inside the vehicle, to the specified torque.

STEERING COLUMN LOWER

HOUSING RETAINING NUTS 15 - 30 Nm

TORQUE SPECIFICATION

6. Tighten the two upper bracket to instrument

panel mounting nuts to the correct torque

specification.

UPPER STEERING COLUMN

MOUNT ATTACHING NUTS 15 - 30 Nm

TORQUE SPECIFICATION

7. The remainder of the installation process is

the reverse of the removal steps, with the

exception of the following important points:

8. Reinstall the clock spring assembly as follows:

a. To avoid irreparable dam age to the clock

spring coil ribbon wire, ensure that the

steering gear is in the centralised

position. Refer to 3.6 POWER

STEERING GEAR in this Section for the

required details.

b. W ith the clock spring assembly locked in

the centralised position, install over the

steering shaf t, indexing the lower loc ating

pins on the clock spring, with matching

holes in the switch housing.

c. Push the clock spring assembly onto the

switch housing until the four locking tangs

fully engage.

NOTE:

If the clock spring assembly was removed without

being centred, refer to the following procedure.

9. Reinstall steering wheel, refer to 2.4

STEERING WHEEL in this Section.

10. Connect battery earth lead and check the

operation of all affected electrical items.

CENTRING THE CLOCK SPRING COIL

1. The steering gear MUST be in the centralised

position before the installation of the coil

spring assembly, otherwise irreparable

damage to the clock spring coil may result.

Refer to 3.6 POWER STEERING GEAR in

this Section for details regarding centralising

the steering gear.

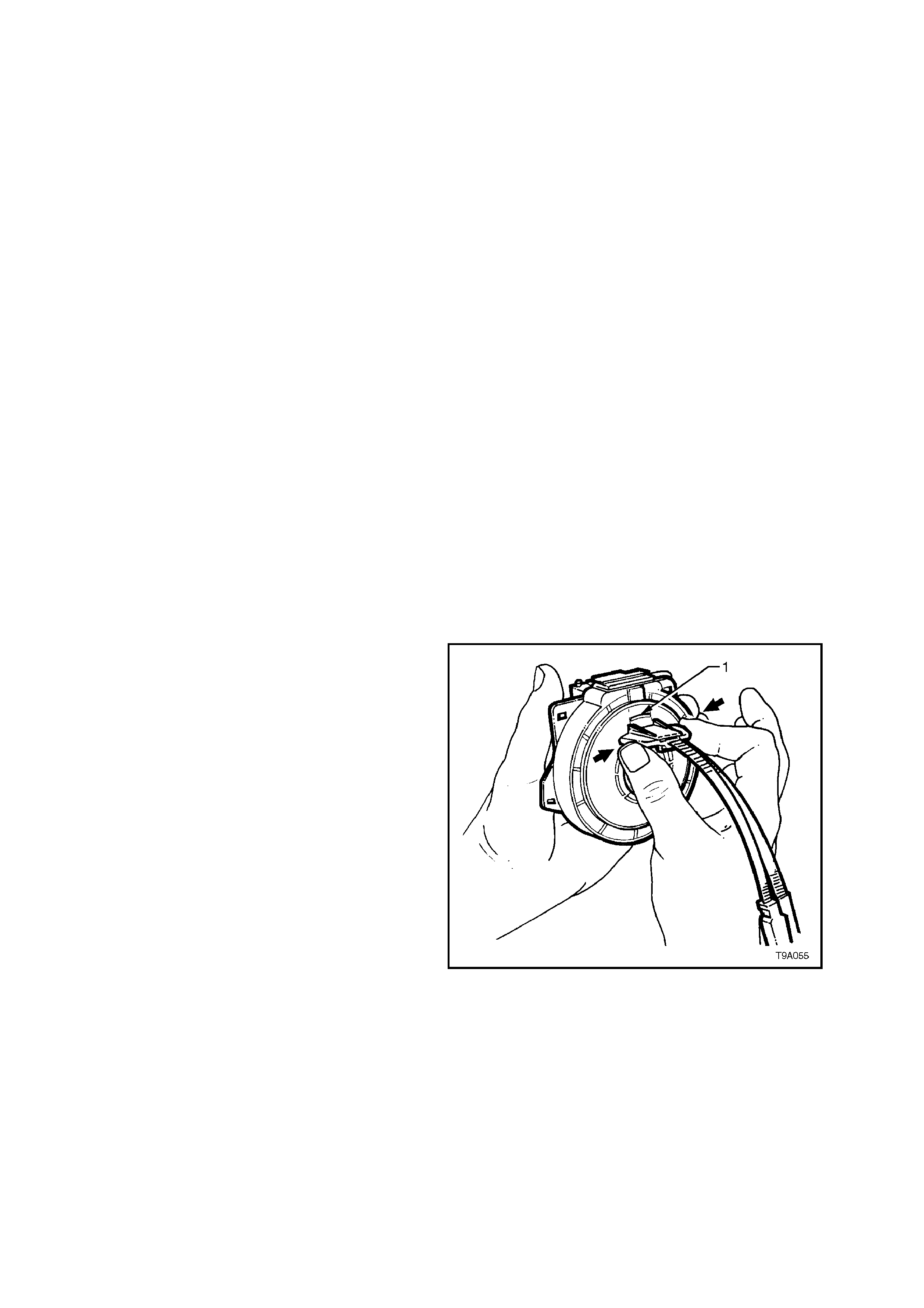

2. To centralise the clock spring prior to

installation:

a. Hold the clock spring coil outer housing

with the left hand.

b. Then, while holding each of the two

locking lugs inward as shown, rotate the

inner member in a clockwise direction

until a mechanical stop is felt.

c. While still holding the locking lugs as

before, rotate the inner member of the

clock spring assembly in the opposite

direction, approximately 2.5 turns, until

the green indexing tab (1) is seen full

width in the upper window.

NOTE:

It is possible to have a partial view of the green tab

without the clock spring coil being in the correct,

centred position.

d. Release the locking lugs and the inner

rotor should now be locked to the outer

member with the clock spring in the

centralised position.

Figure 9A-49

2.10 CHECKING S TEERING COLUMN FOR ACCIDENT DAMAGE

IMPORTANT:

Vehicles involved in accidents resulting in major body

or sheet metal damage or where the steering column

has been impacted, column damage or misalignment

may also have occurred.

INSPECT:

1. Check visually to see that either or both of the

two mounting lugs have been dislodged from the

column bracket and that the control springs are

undamaged.

2. Visually check for any damage to the column

and/or shaft that causes binding or jamming.

Should any component of the steering column

assembly show signs that distortion has occurred,

then the column must be replaced as an assembly.

For steering column assembly replacement

procedures, refer to 2.9 STEERING COLUMN

ASSEMBLY in this Section.

2.11 TILT/RE ACH HANDLE

REPLACE

NOTE:

While replacement of this component is not

recommended, the handle is serviced separately.

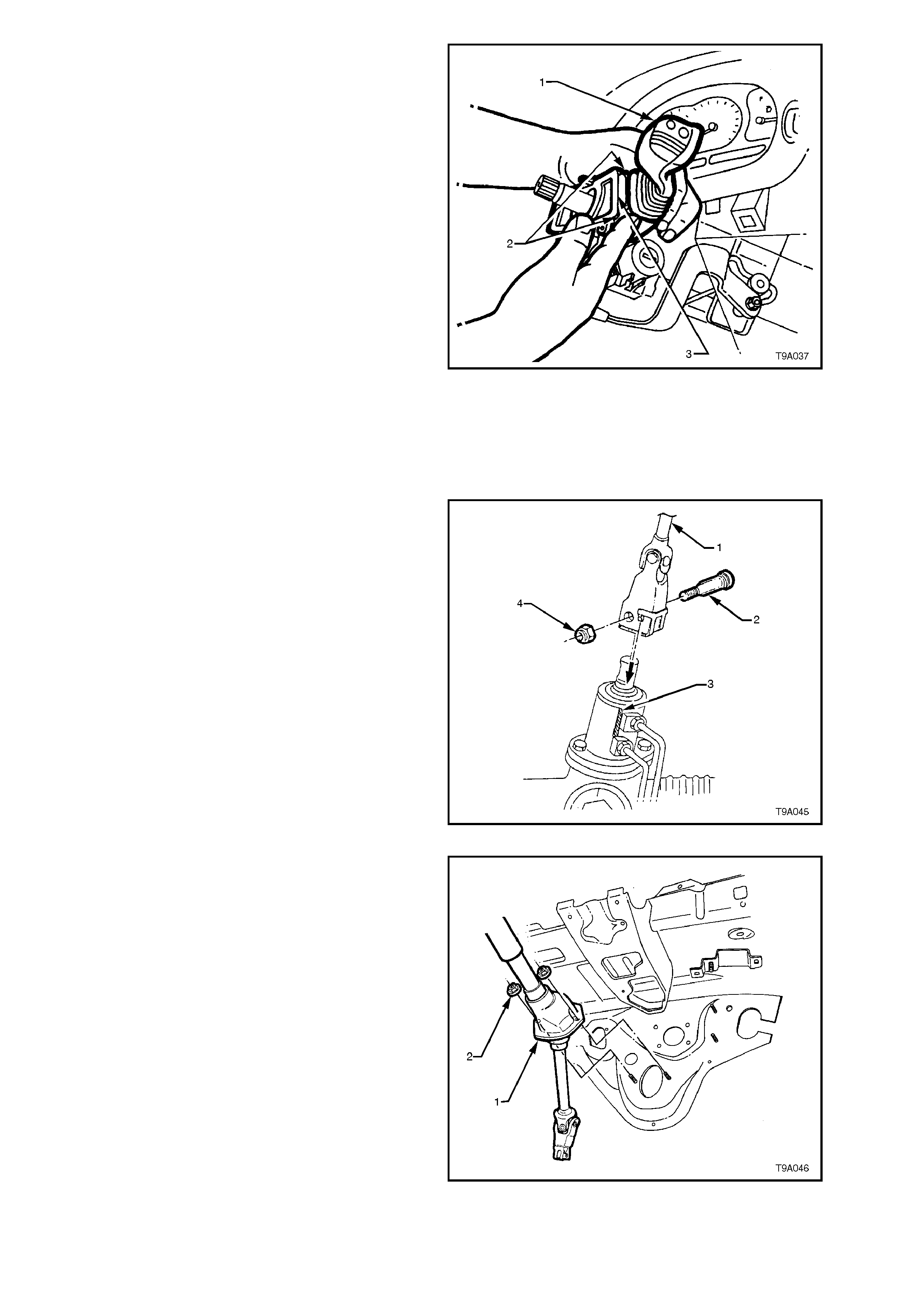

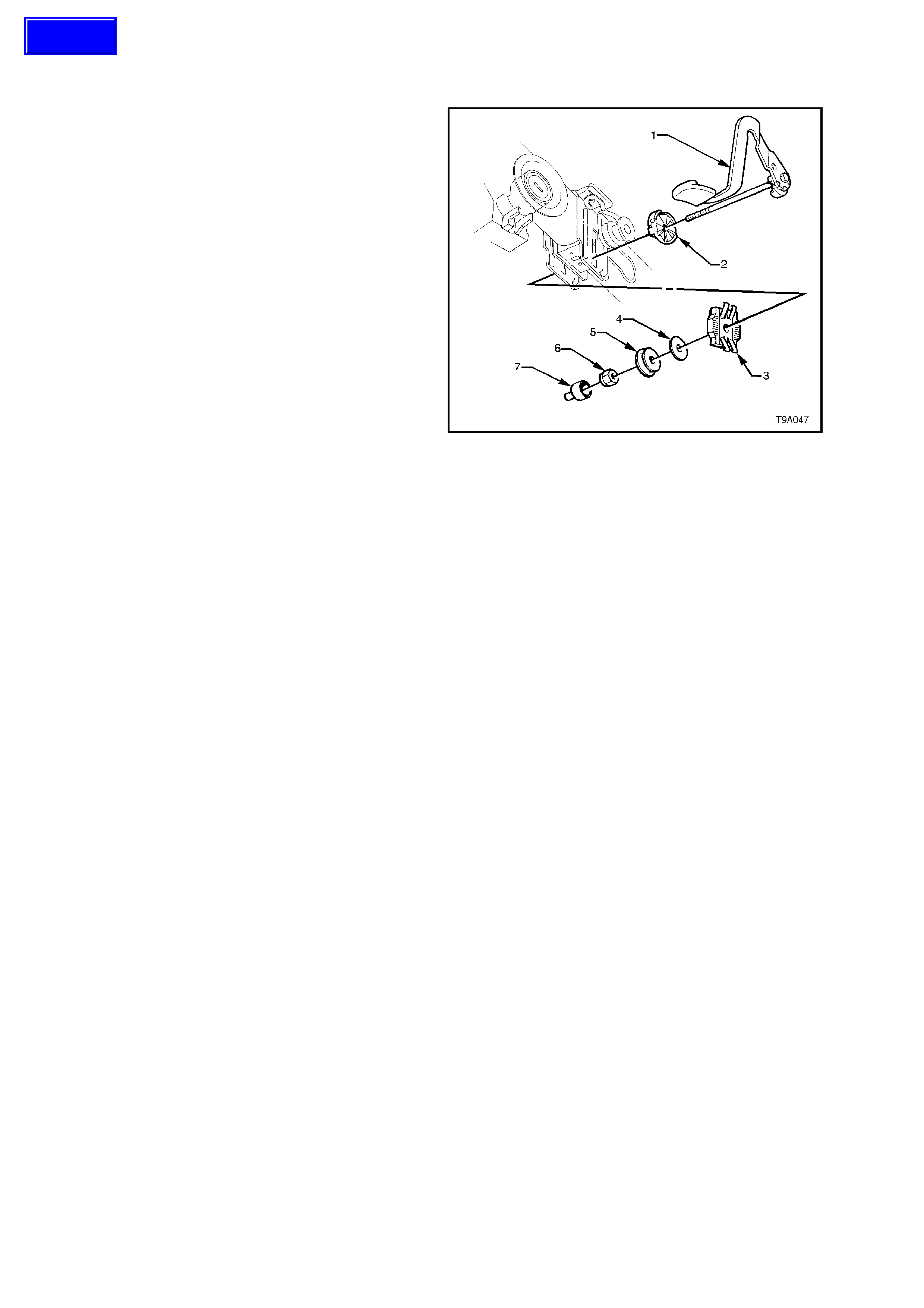

1. Release the tilt/reach handle (1) and, while

supporting it with one hand, remove the

through bolt, nut cover (7) and retaining nut

(6).

2. Withdraw the through bolt and handle (1),

inner cam (2), outer rack (3), washer (4) and

bearing (5).

3. Reinstall through bolt and replacement handle

(1), through the inner cam (2).

4. Apply Loctite 242 (or equivalent to Holden’s

Specification HN1256 Class 2, Type 2) to the

bolt thread.

5. Reinstall the remaining components in the

reverse order to removal and install a NEW

retaining nut (6).

Important:

The final tension on the through bolt determines the

security of the upper steering column assembly and

the final nut tension must be determined by

adopting the following procedure.

6. Tighten the nut until a f orc e of 80 N is r equired

to push the lever closed.

7. With the lever releas ed, check that the c olum n

is free to slide up and down. If the rack (3)

grates, loosen the nut just sufficient to allow

free movement of the column.

8. Install the nut cover (7).

Figure 9A-50

Techline

2.13 STEE RING COUPLING

Because the steering coupling forms an integral part of the steering shaft assembly, should the coupling be found to

require replacement, the complete column assembly must be replaced. For steering column assembly replacement

procedures, refer to 2.9 STEERING COLUMN ASSEMBLY in this Section.

3. POWER STEERING SERVICE OPERATIONS

3.1 FLUID LEVEL CHECK

NOTE:

The recommended fluid for use in all VT series

vehicles, is Dex r on® III autom atic trans m ission f luid

to Holden’s Specification HN2126.

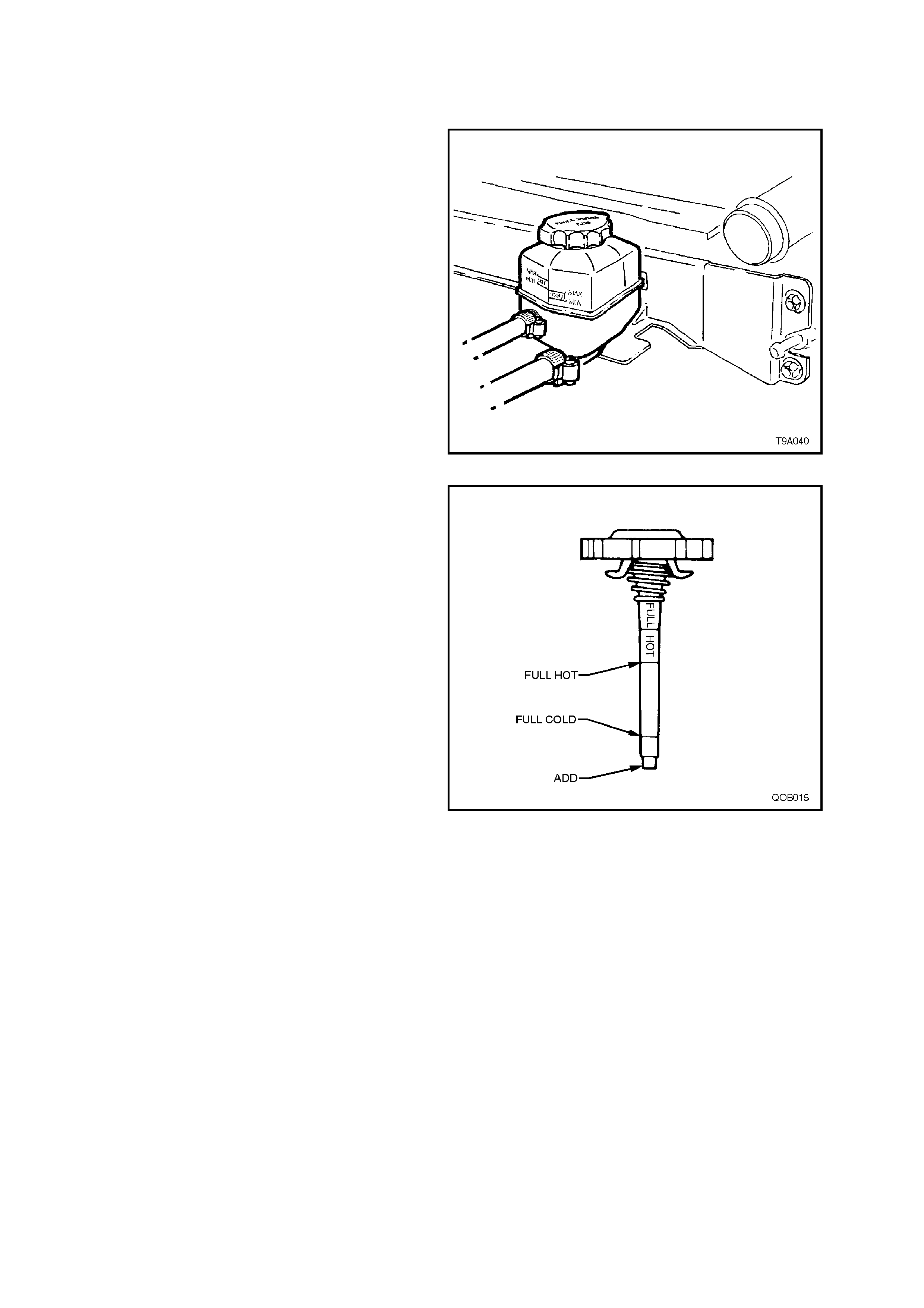

V6 Engine

The power steering fluid level can be checked by

viewing the level through the translucent plastic

side of the reservoir.

If the fluid is cold, the level should be in the ‘COLD’

range. Sim ilar ly, if it is hot, the fluid s hould be in the

‘HOT’ range. If the fluid level is at the low side of

either range, new fluid should be added to br ing the

level into the correct range and the system checked

for the cause of the leakage and corrected as

necessary.

Figure 9A-51

V8 Engine

The power steering fluid level is checked by using

the dipstick attached to the reservoir filler cap.

The fluid level should be in the range between the

‘ADD’ and ‘FULL HOT’ indicator marks on the

dipstick , depending on the temperature of the fluid.

If the power steering fluid is at or below the ‘ADD’

mark, new fluid should be added to bring the level

into the correct range and the system checked for

the cause of the leakage and corrected as

necessary.

Figure 9A-52

3.2 DRIVE BELT ADJUSTMENT

V6 ENGINE

For vehicles with V6 engine, the power steering

pump is driven by the engine serpentine drive belt.

The belt is self adjusting within tensioner operating

limits. For details, refer to Section 6A1, ENGINE

MECHANICAL.

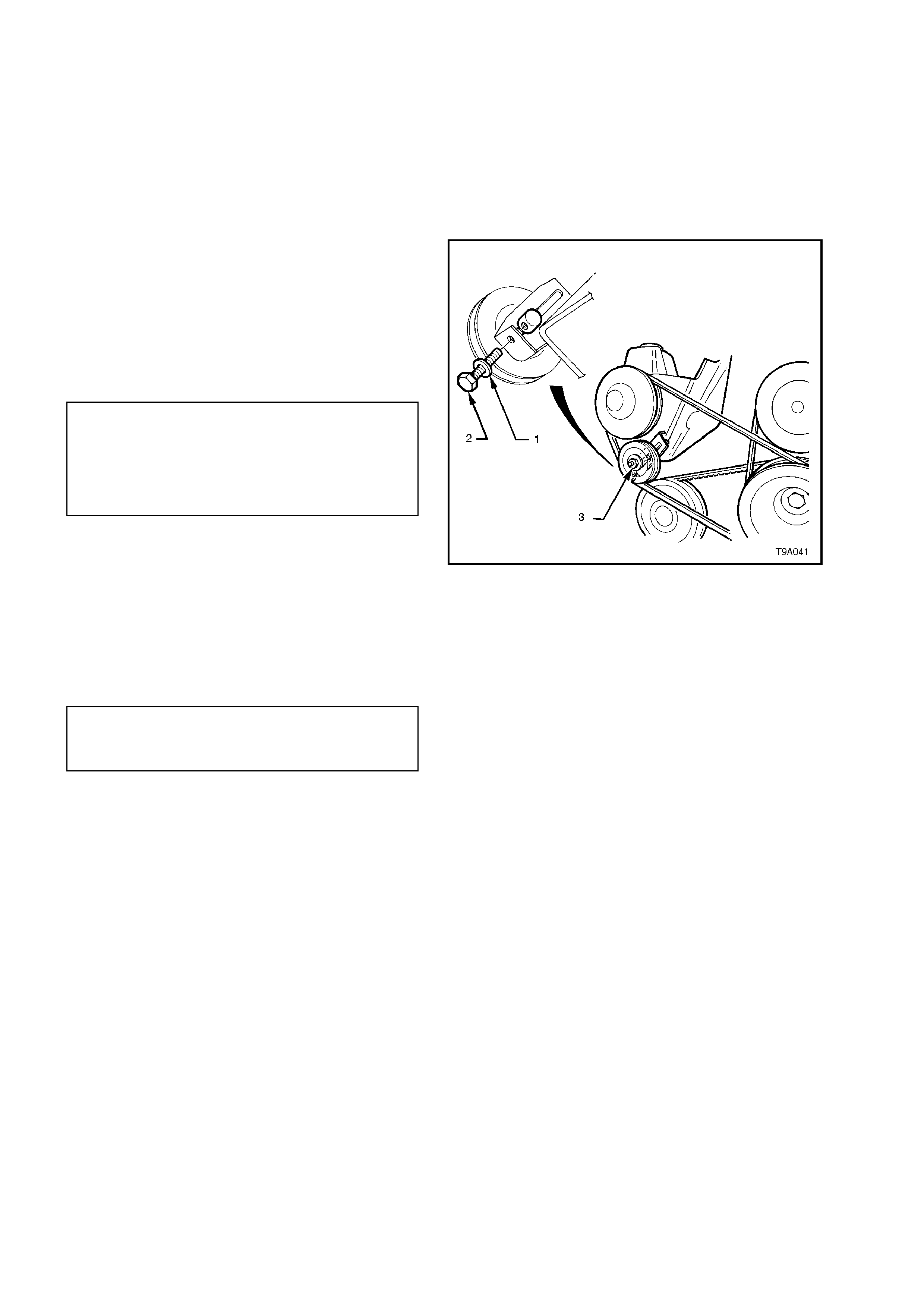

V8 ENGINE

For this engine, check drive belt tension as follows:

1. Inspect drive belt condition.

2. Check belt for correct tension using belt

tension gauge, Tool No. BT3373-F (or

J23600-B).

Refer to the following chart for the correct belt

tension specifications.

POWER STEERING PUMP DRIVE 57 kg

New

BELT TENSION SPECIFICATION 34 kg

Used *

* A drive belt is considered used after

10 minutes of running.

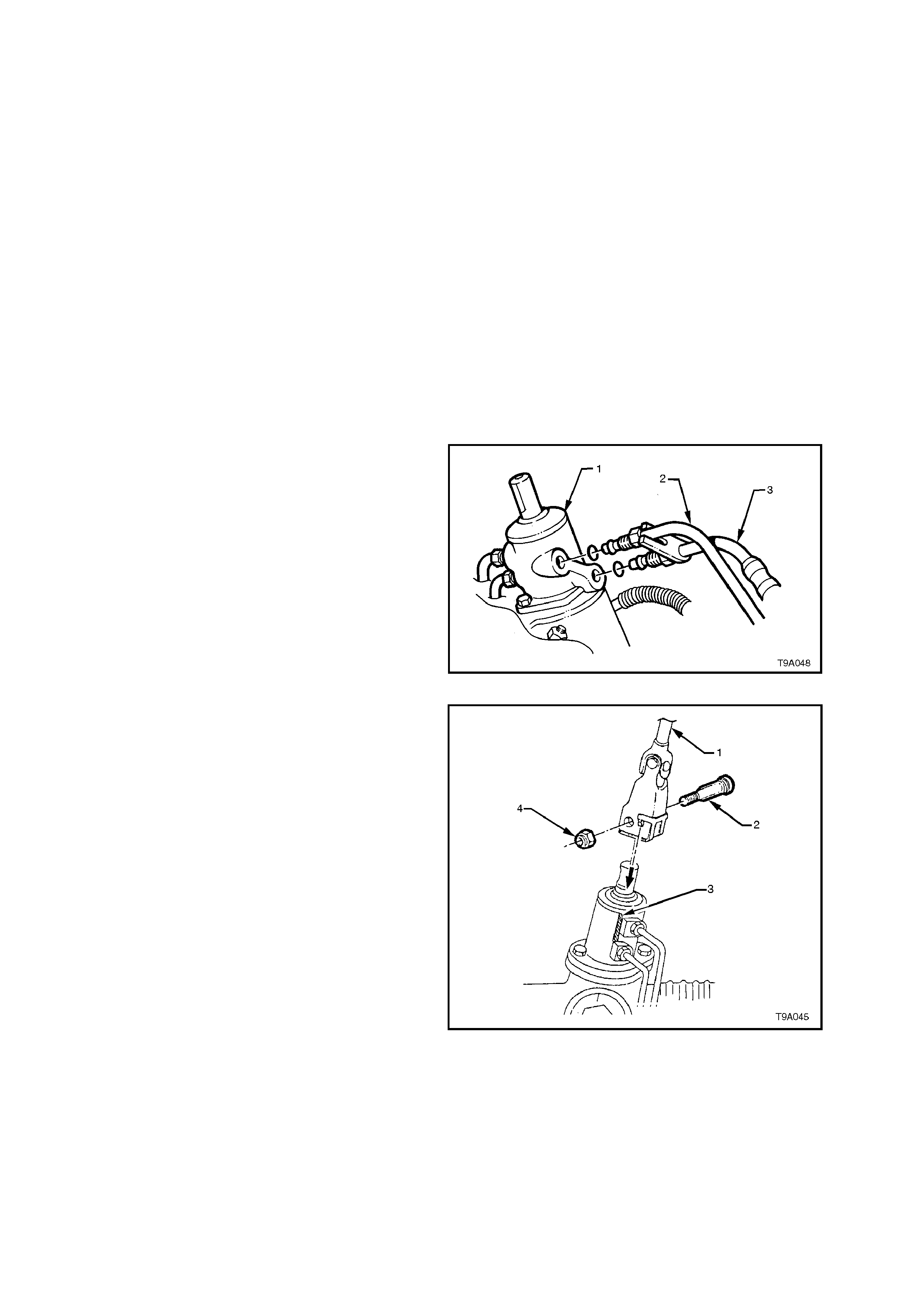

To Adjust the Drive Belt Tension:

1. Loosen power steering pump idler pulley nut

(3).

2. Adjust the bolt (2) to move the idler pulley

position, to achieve the specified belt tension.

3. Tighten power steering pump idler pulley nut

(3) to the correct torque specification.

POWER STEERING PUMP

IDLER PULLEY NUT 35 - 65 Nm

TORQUE SPECIFICATION

Figure 9A-53

3.3 HYDRAULIC SYSTEM, BLEEDING/REFILLING PROCEDURE

CAUTIONARY NOTES:

1. If the fluid level is low in the fluid reser voir, air will be drawn in and m ixed with the fluid in small bubbles . If the

pump is allowed to continue operation, an increasing am ount of air will be drawn into the system , causing the

fluid volume to increase to a point where the r es ervoir will overf low. Sudden releases in pres s ure that will occur

when the steering is suddenly taken off a 'full lock' condition, will cause dramatic eruptions of fluid from the

reservoir. The separation of air entrapped under these conditions will be extr emely difficult to r emove and m ay

take several days.

2. If the steering rack assembly requires replacement, a large volum e of air will be required to be purged, which

means that the reservoir fluid level will fall rapidly when the engine is started.

3. During bleeding, it is important that the front wheels are clear of the ground and that the steering is not held

forcibly against the steering stops.

BLEEDING/REFILLING PROCEDURE

1. Raise front of vehicle and place on safety stands. Refer to Section 0A, GENERAL INFORMATION.

2. With engine not running, add fluid to reservoir to the maximum mark (or greater, if it is known that the steering

gear is empty).

3. Start engine and allow to run for only 2-3 seconds. Do not turn the steering wheel at this point.

4. Continue with Steps 2 and 3 until the fluid level remains constant.

5. Start and run the engine at idle speed, turning the steering wheel from lock to lock, without holding at the full

lock positions (this will build up high pressures, atomising any entrapped air). Repeat this procedure from six to

eight times. Stop the engine, check the fluid level and top up to the maximum level, as required.

6. Start and run the engine at idle speed. Again turn the steering wheel from lock to lock but now slowly build up

the pressure levels by holding against the full lock position from 1-2 seconds. Repeat this procedure from four

to six times. Stop the engine and top up the fluid level to the maximum mark, as required.

NOTE:

While the majority of entrapped air will be removed by the above process, a small amount may remain, which can

only be removed by alternate circulation and settling of the fluid for a prolonged period. This is usually achieved

automatically after two to three days, with daily driving and settling overnight.

7. Turn the steering wheel to the straight ahead position, lower vehicle to the ground and turn ignition 'OFF'.

3.4 HYDRAULIC SYSTEM, CHECK

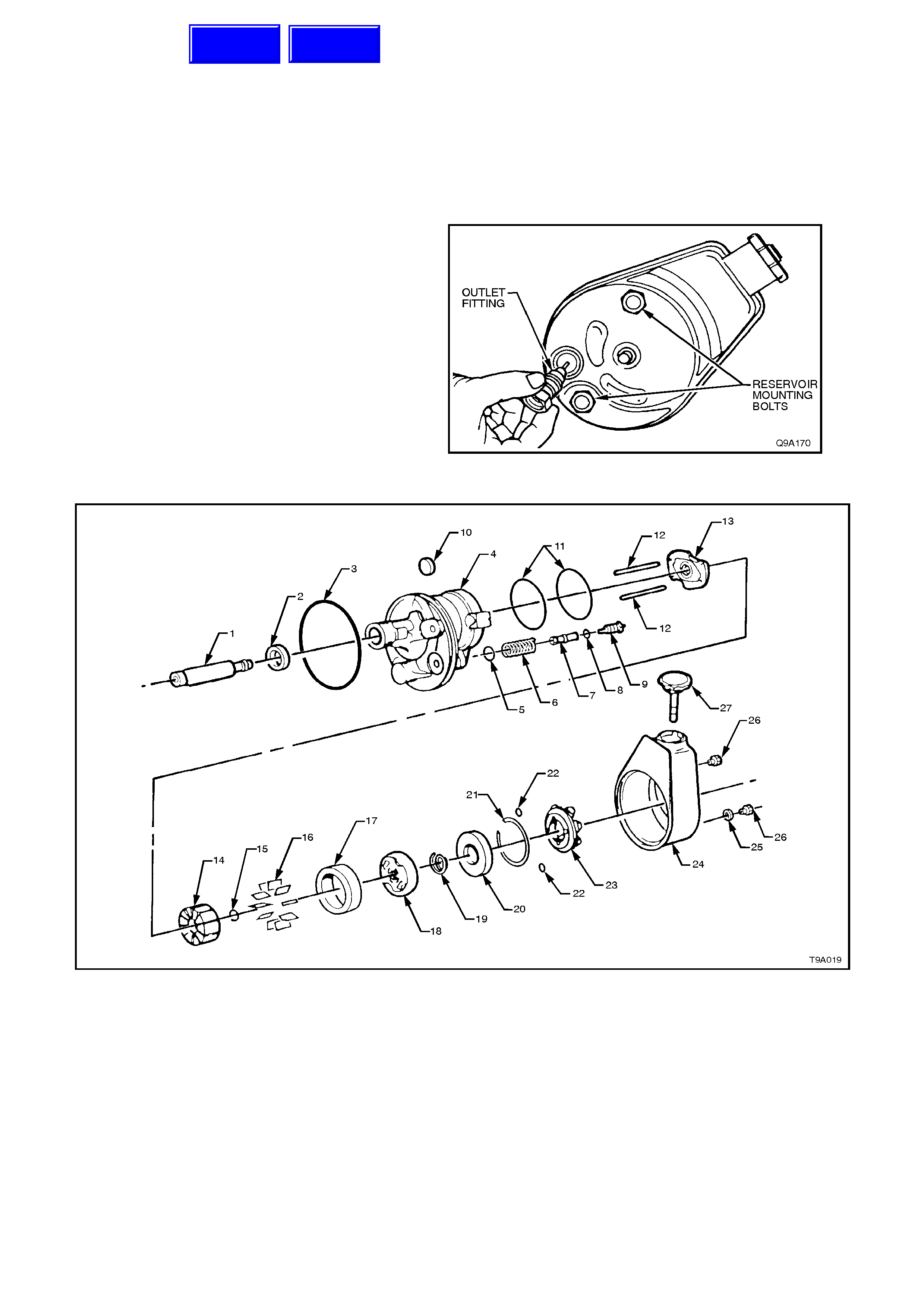

The following procedures outline methods to

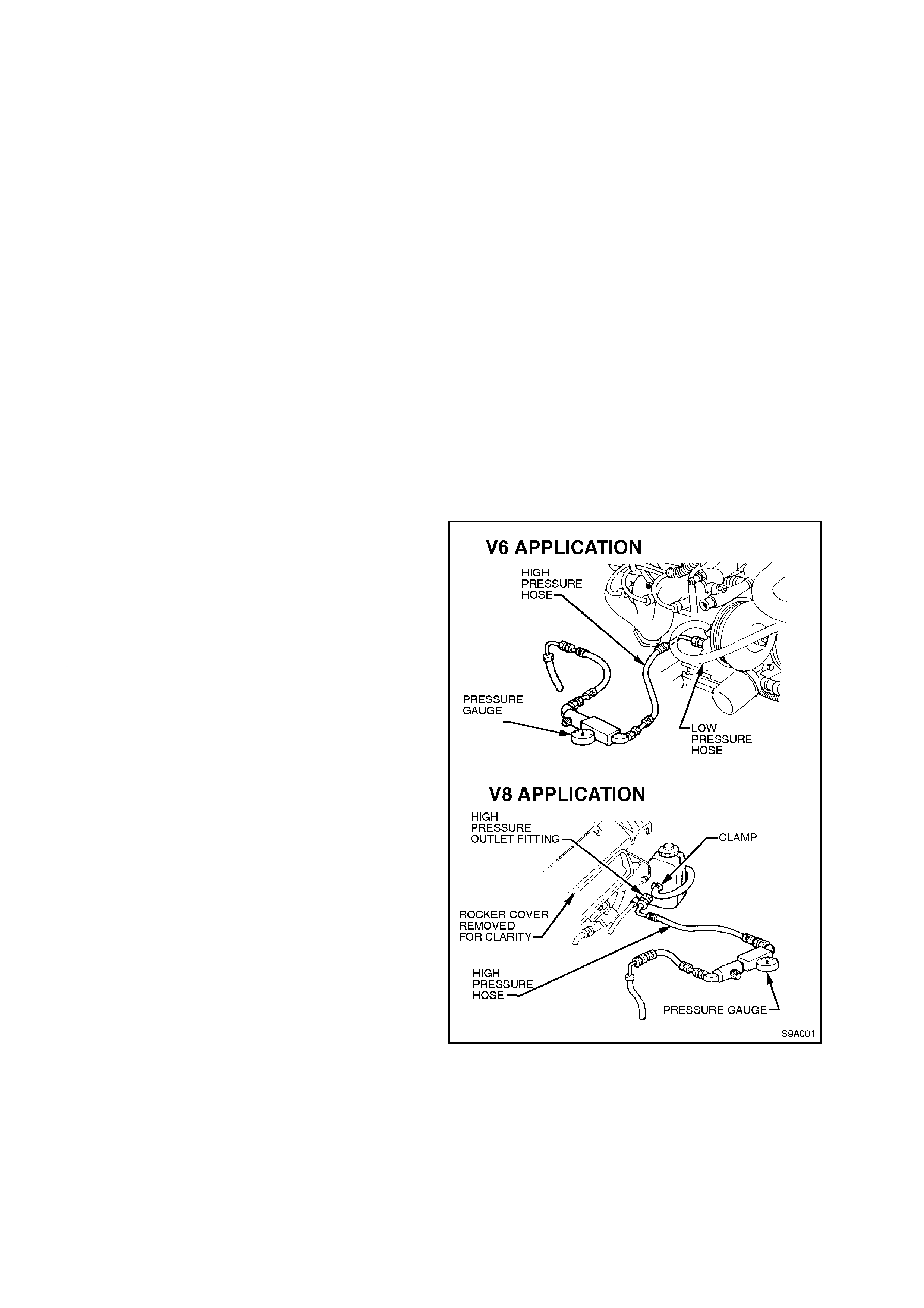

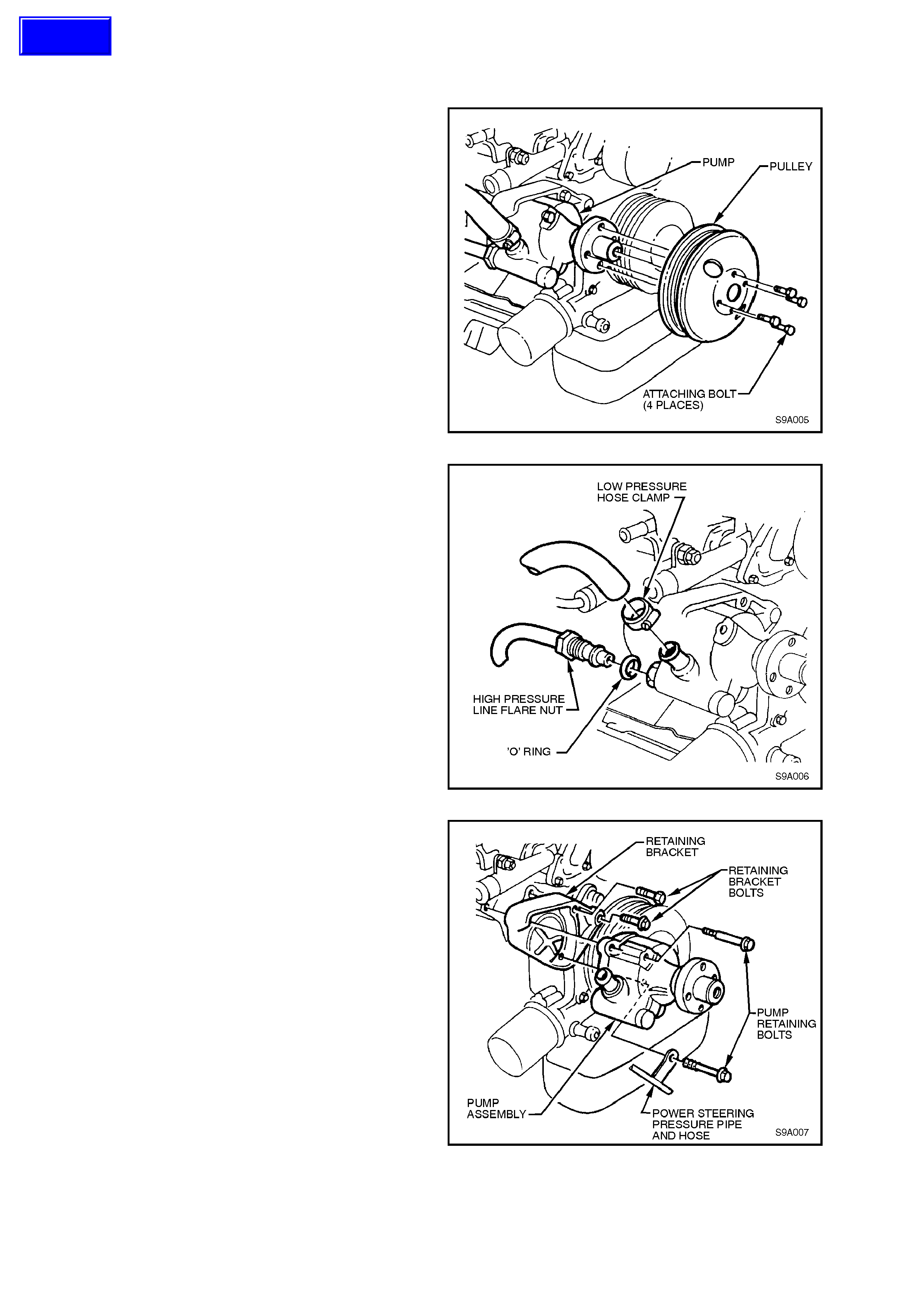

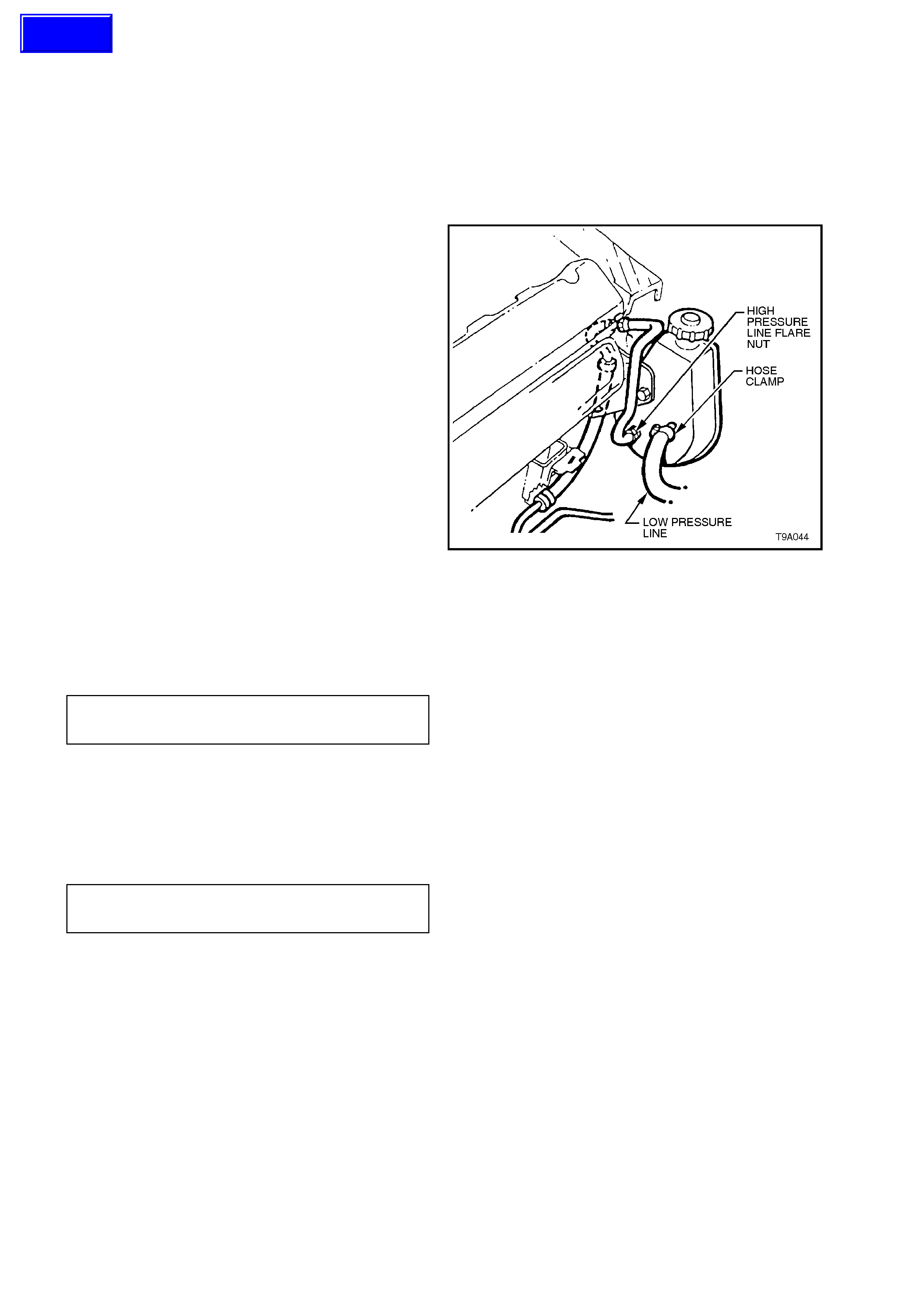

identify and isolate power steering hydraulic circuit

difficulties. This test is divided into two parts. Test

number one provides a means of determining

whether the power steering system hydraulic parts

are faulty. If test number one results in readings

indicating faulty hydraulic operation, test number

two will identify the faulty part.

Before performing the hydraulic circuit test,

carefully check the fluid level, drive belt condition

and tension, idler and driving pulleys for smooth

operation.

The engine must be at normal operating

temperature and the front tyres inflated to the

correct pressure. All tests are made with engine

idling.

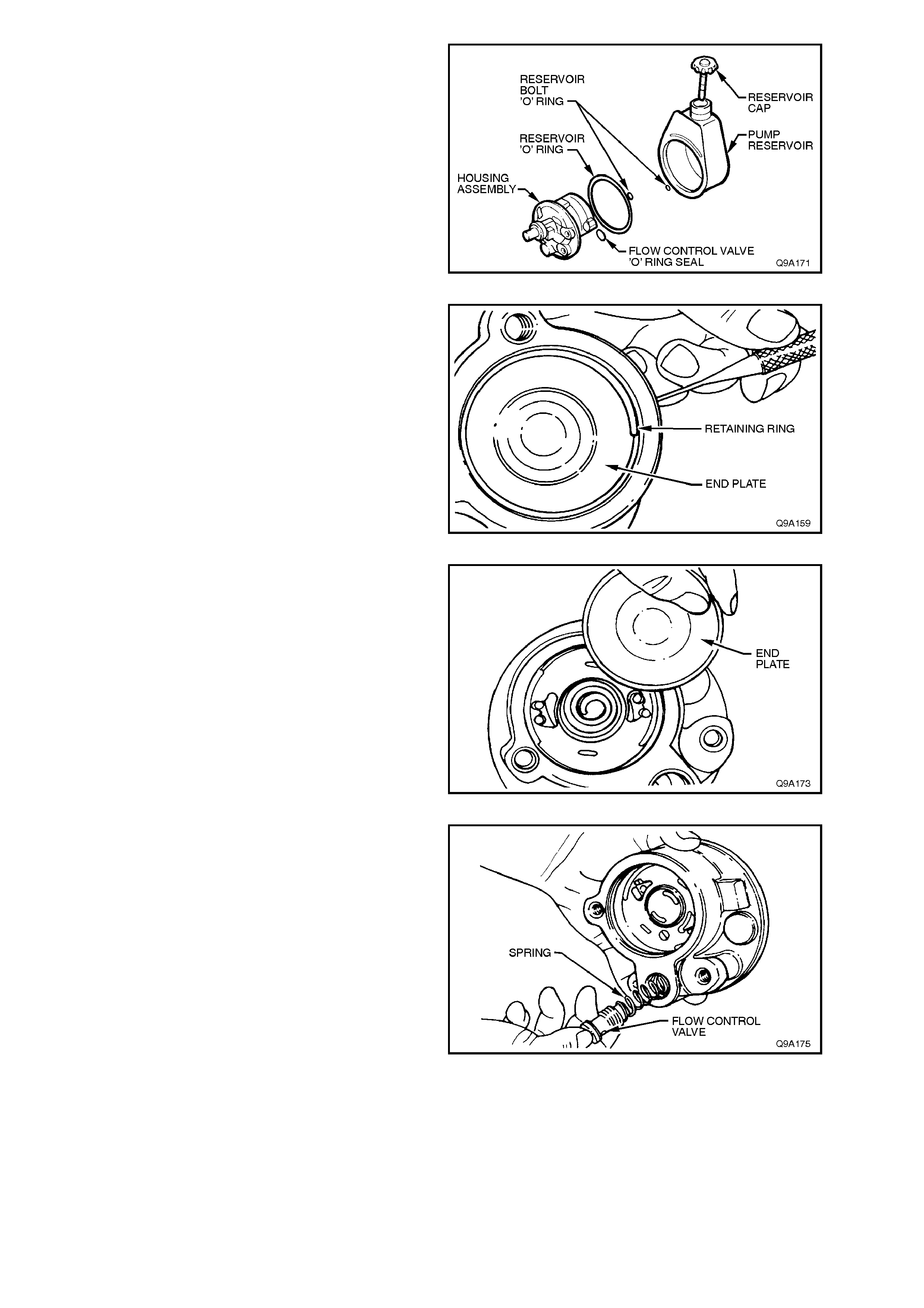

To perform the two pressure checks, it is

necessary to connect a pressure gauge assembly

into the hydraulic line between the pump and

steering gear.

PROCEDURE

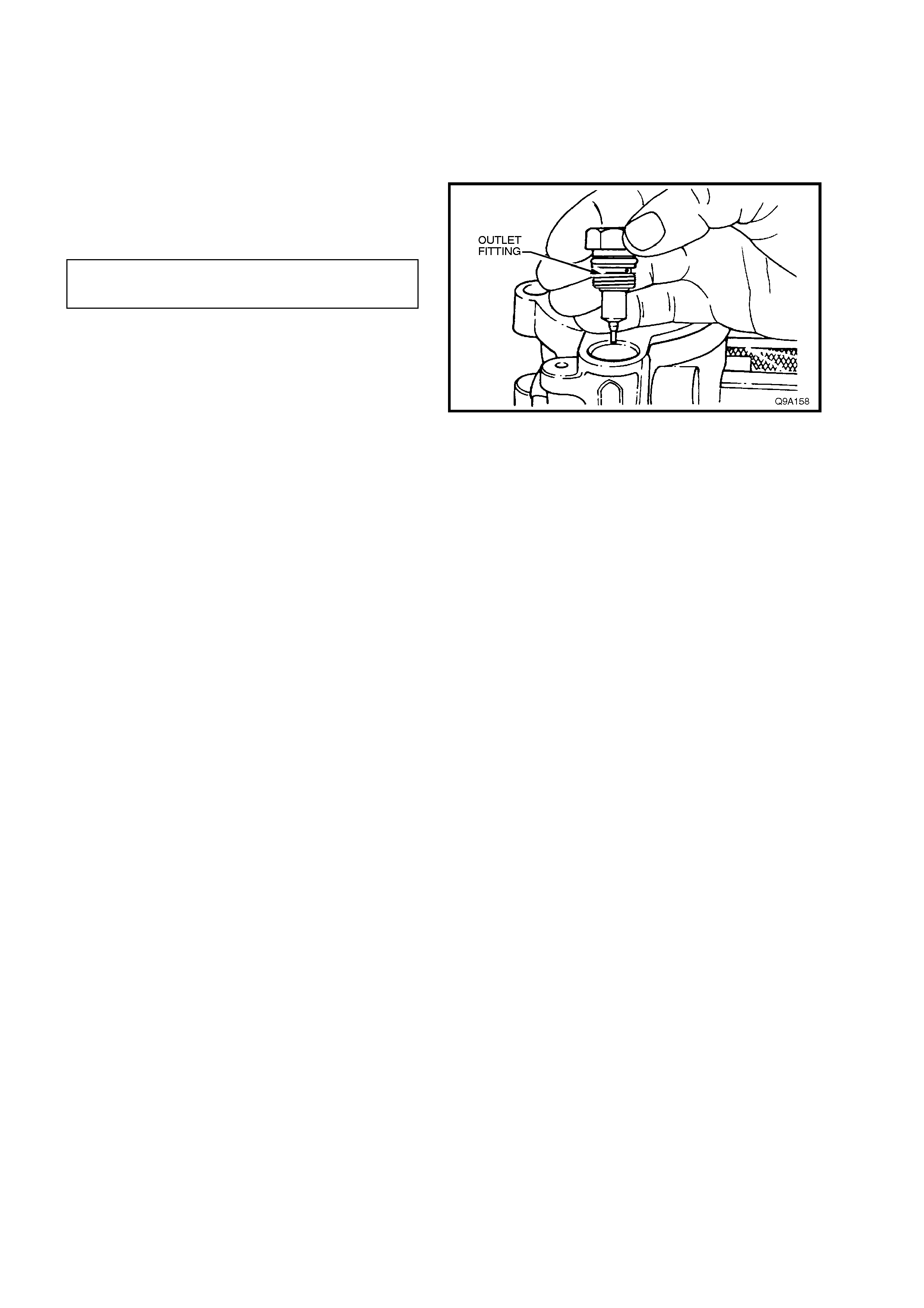

1. Place a drain tray beneath the power steering

pump assembly.

2. Loosen and remove the high pressure

hydraulic line fitting and O-r ing from the power

steering pump.

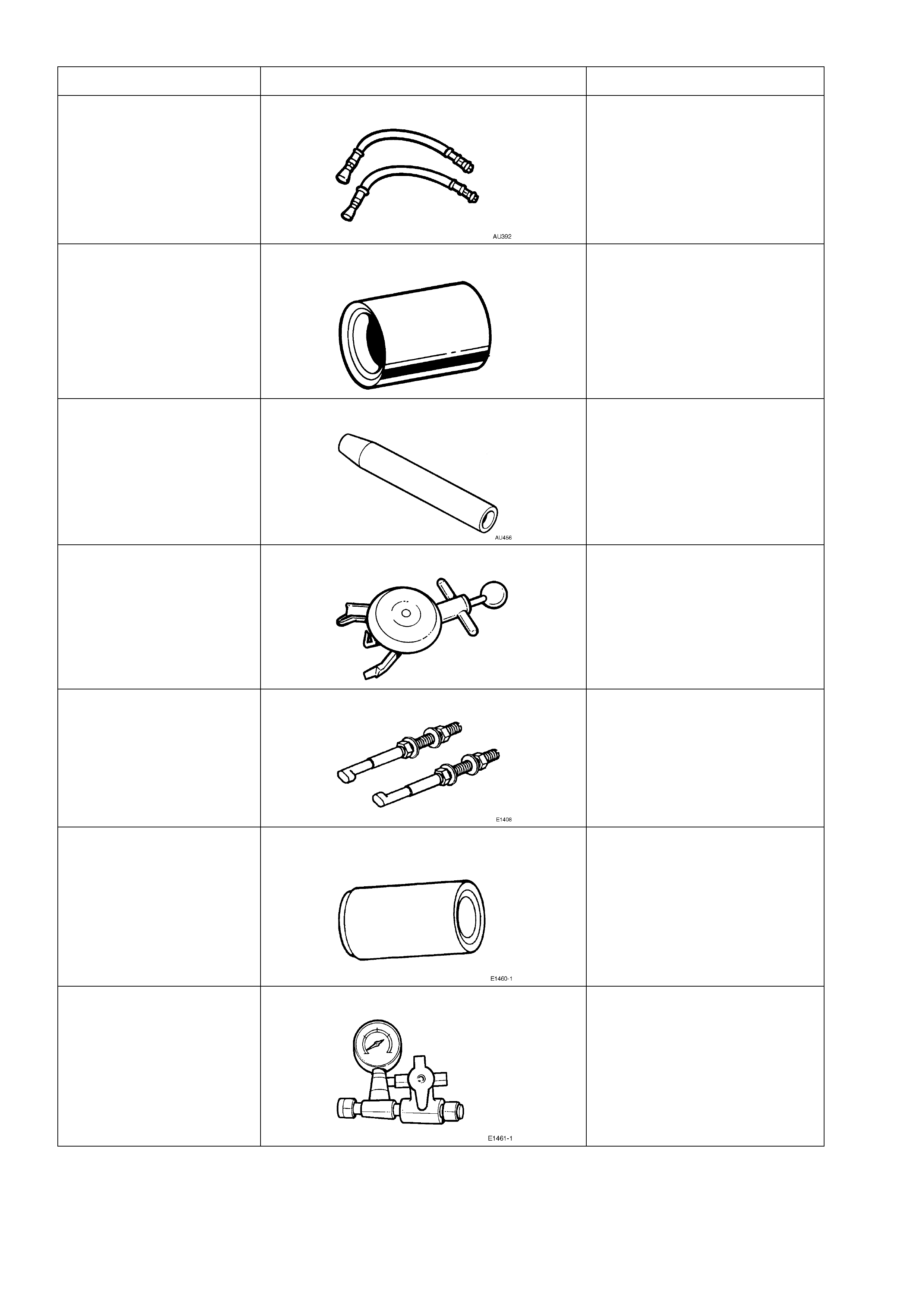

3. Install pressure gauge assembly (Hose set

AU392 and Gauge assembly E1461-1 (or 9A7-

1) into the outlet fitting of the pump and the

disconnected high pressure hose fitting.

4. Refill system with fluid to the correct level,

refer to 3.1 FLUID LEVEL CHECK in this

Section. Ensure that there are no leaks at

either the hose or gauge connections.

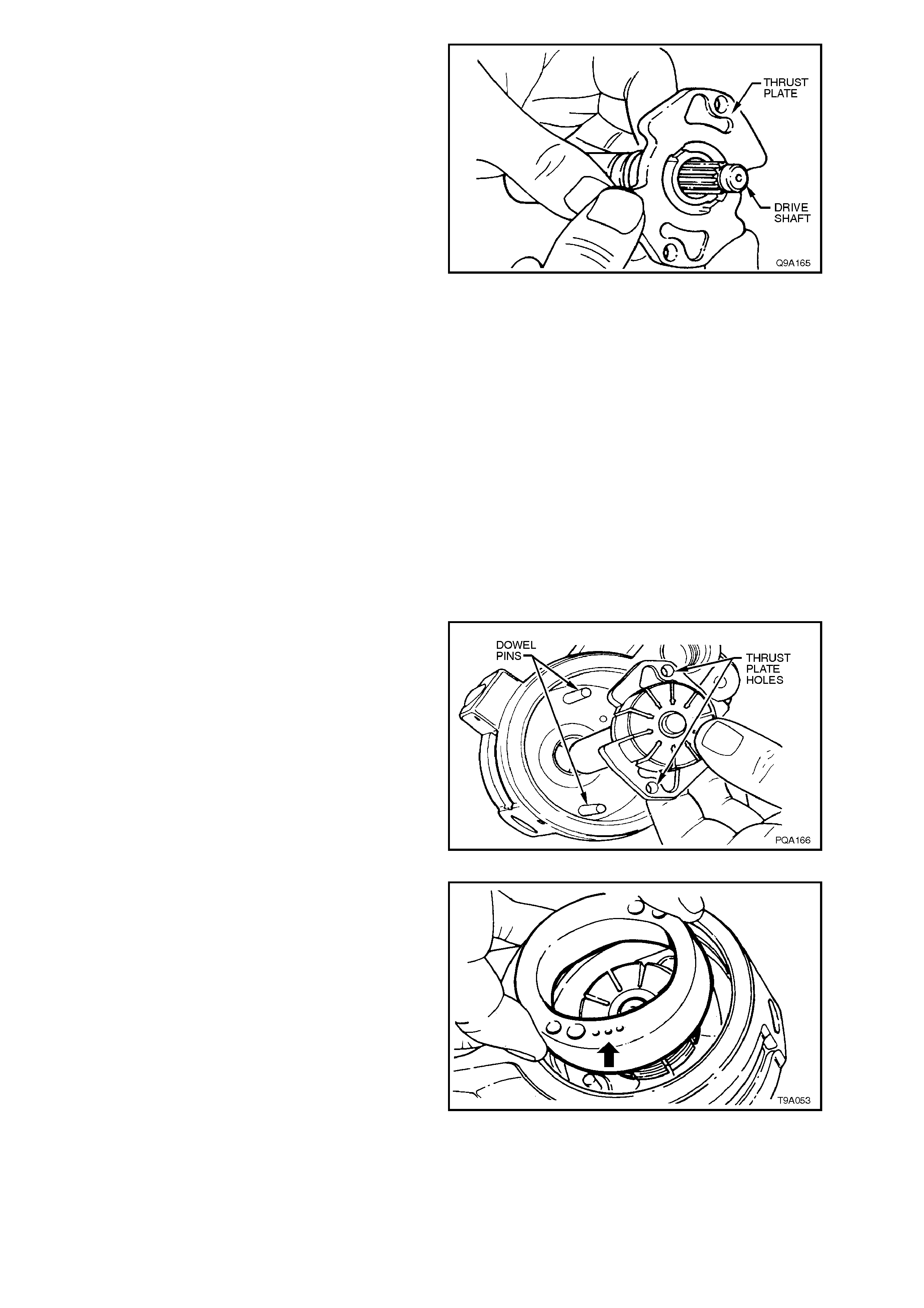

5. Bleed air from the system, as described in the

Bleeding/Refilling Procedure, just detailed.

Figure 9A-54

TEST 1 - HYDRAULIC CIRCUIT OPEN

1. With valve open, start engine, allow to idle and with steering LIGHTLY on full lock, check connections for

leakage.

2. Insert thermometer into reservoir filler opening and move steering from lock to lock until fluid reaches 75°

Celsius.

3. Turn steering to full lock momentarily, if pressure is below 7,580 kPa (V6 application) or 8,270 kPa (V8

application), a faulty hydraulic circuit is indicated.

TEST 2 - HYDRAULIC CIRCUIT CLOSED

1. Slowly turn valve on Tool E1461-1 (or 9A7-1) to the closed position, note pressure, and quickly re-open valve

to avoid pump damage.

2. If pressure was less than 7,580 kPa (V6 application) or 8,270 kPa (V8 application), the pump may be

considered to be faulty.

3. If pressure was between 7,580 - 8,270 kPa (V6 application) or 8,270 - 8,960 kPa (V8 application), steering

gear, external hoses or connections may be considered faulty.

NOTE:

If pump proves faulty, retest after overhaul to check repairs and condition of steering gear.

4. At the completion of tests, remove pressure gauge, hoses and connectors.

5. While LIGHTLY holding the steering wheel on full lock, have an observer check for fluid leaks from the hose

connections.

The following flow chart, details an alternative procedure for checking the power steering hydraulic system.

POWER STEERING HYDRAULIC SYSTEM CHECK

STEP ACTION YES NO

1Start engine and allow to idle.

Is fluid level correct? Go to Step 2. Top up as required

and check for leaks.

Go to Step 2.

2Check fluid condition. Is fluid condition OK? Go to Step 3. Drain, flush system

and refill with fluid.

Go to Step 3.

3With valve on test gauge fully open, check pressure reading.

Is the pressure reading for standard power steering

approximately 350 kPa or:

With speed sensitive power steering, is the pressure reading

approximately 700 kPa?

Go to Step 4. Check hoses/pipes

for restriction. Repair

or replace as

necessary.

Go to Step 4.

4Is system pressure now to specification? Go to Step 5. Replace steering rack

valve assembly.

Go to Step 3.

5Close then open valve fully three times, noting the highest

pressure reading each time.

NOTE:

Do not leave valve closed for more than 5 seconds, as pump

damage could result.

Are all readings between 7,580 - 8,270 kPa (V6) or 8,270 -

8,960 kPa (V8) and within 340 kPa of each other?

Hydraulic system

is operating to

specification.

Go to Step 6.

6Are pressures within specified range but not within 340 kPa of

each other? Go to Step 7. Go to Step 9.

7Remove flow control valve and remove any burrs with crocus

cloth or fine hone.

Repeat Step 4. Are pressure readings now OK?

Hydraulic system

is now operating

to specification.

Go to Step 8.

8Remove pump, disassemble clean, reassemble and reinstall.

Repeat Step 4. Are pressure readings now within 340 kPa of

each other?

Hydraulic system

is now operating

to specification.

Go to Step 10.

9Are pressures within 340 kPa of each other but below

specified maximum range? Go to Step 10. Go to Step 5.

10 Replace flow control valve, then repeat

Step 4.

Are pressure readings now OK?

Hydraulic system

is now operating

to specification.

Overhaul or replace

power steering pump.

Go to Step 5.

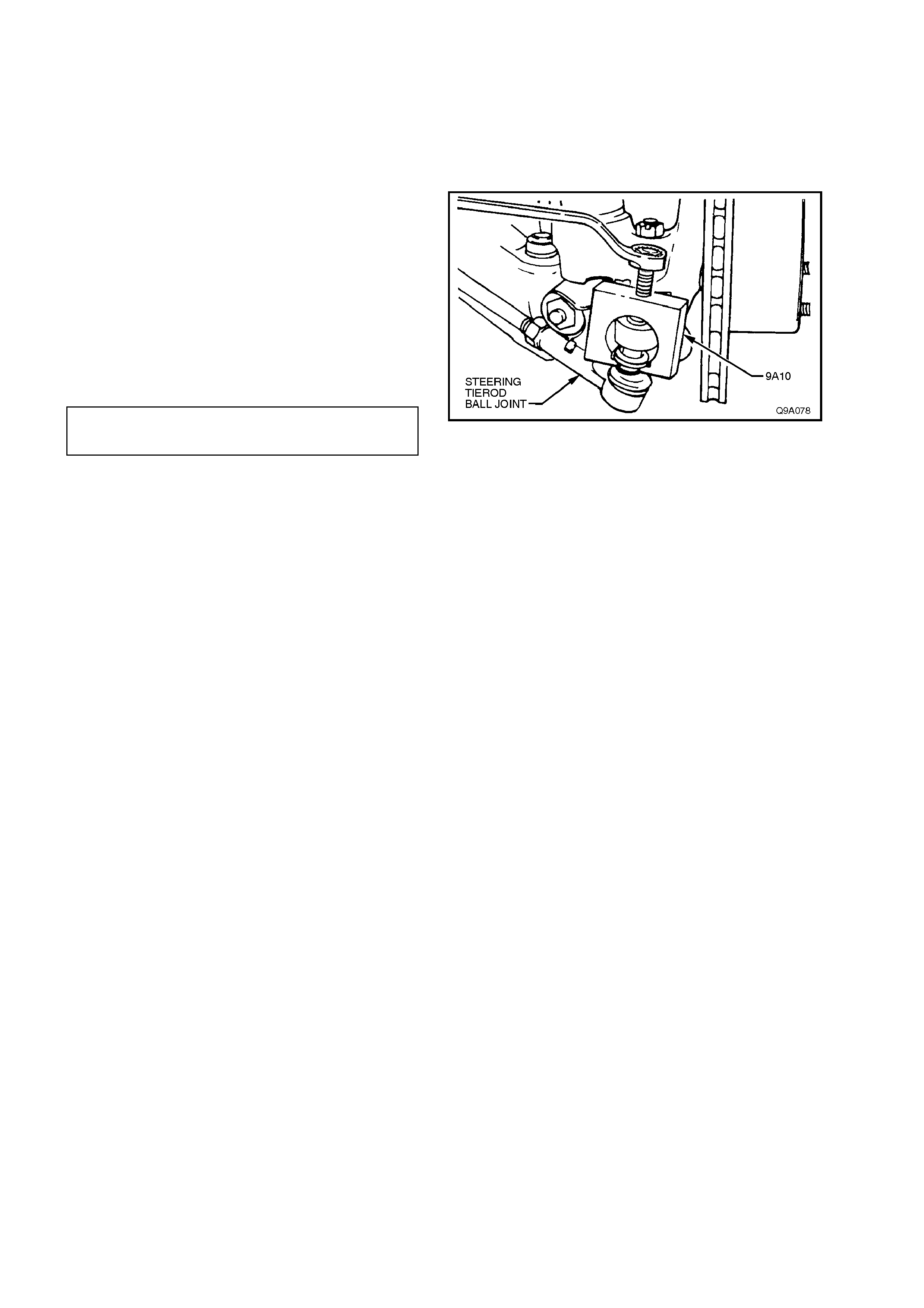

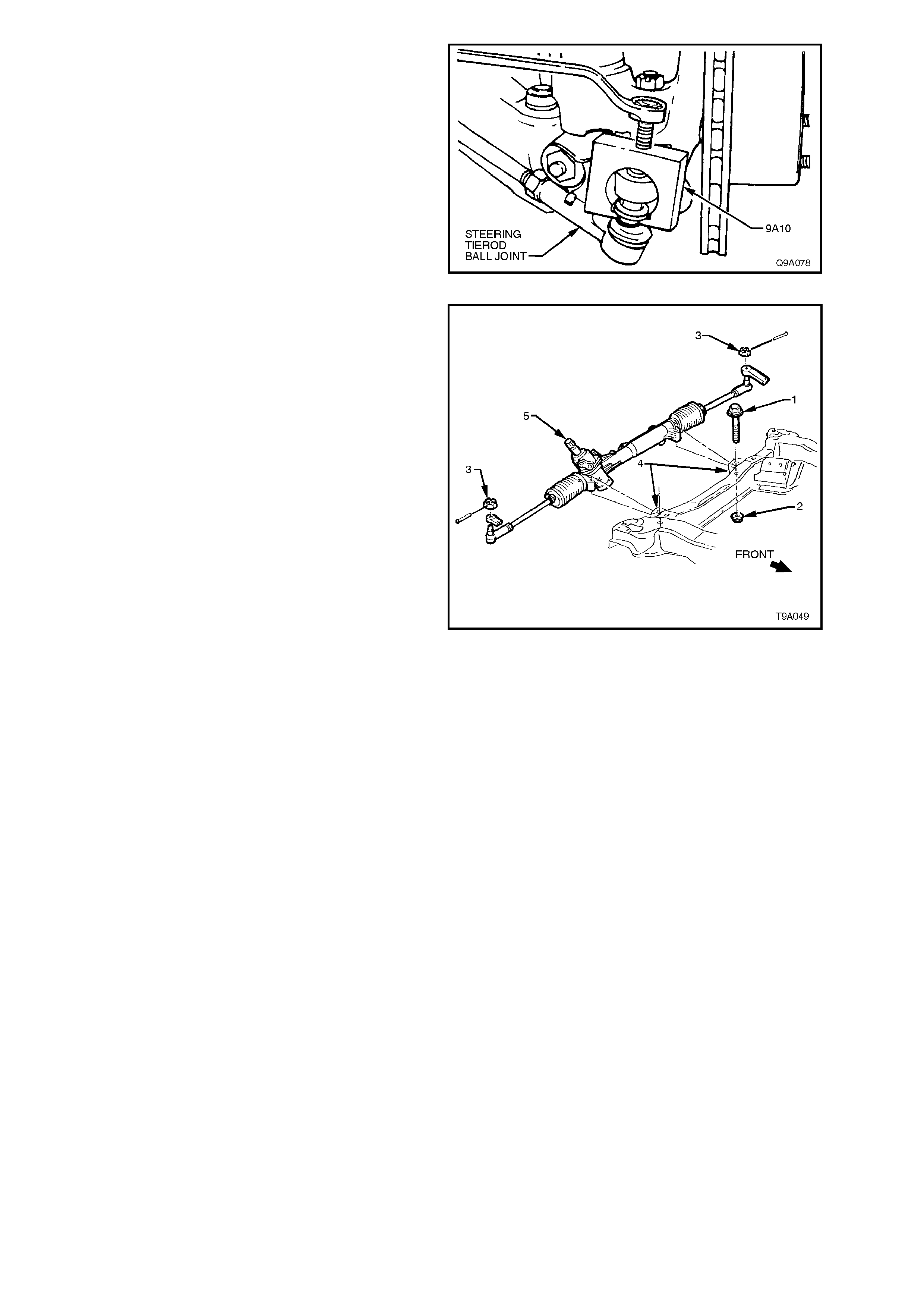

3.5 TIE ROD BALL JOINT

REPLACE

Tie rod ball j oints are ser viced as an ass embly and

must be replaced when excessive up or down

movement is evident, or if any lost motion or end

play exists at the ball end of the stud.

1. Remove split pin and nut from tie rod ball stud.

2. Using Tool No. 9A10 or similar, tighten centre

screw to force stud from taper in steering arm.

3. Loosen tie rod lock nut. Unscrew ball joint

from tie rod, counting the number of turns to

wind ball joint from tie rod.

4. Install new ball joint onto tie rod and wind on

the same number of turns as in Step 3.

5. Install ball joint to steering arm. Install

castellated nut and tighten to the correct

torque specification.

TIE ROD BALL JOINT STUD 50 - 85

TORQUE SPECIFICATION Nm

NOTE:

Ensure that the nylon spacer is positioned on the

tie rod ball joint stud before installing into steering

arm.

6. Install new split pin.

7. Check front wheel toe-in. Refer to

Section 3 FRONT SUSPENSION.

Figure 9A-55

3.6 POWER STEERING GEAR

IMPORTANT:

Remove the ignition key from the ignition lock

and ensure that the steering column is locked.

If this operation is not carried out and the

steering wheel is spun while the steering gear

is removed from the vehicle, the clock spring

coil in the upper end of the steering column will

be destroyed!

REMOVE

1. Disconnect battery earth lead.

2. Raise front of vehicle and place on safety

stands. Refer to Section 0A GENERAL

INFORMATION.

3. Remove front wheel cover (steel wheels) or

centre caps (alloy wheels)

4. Mark relationship of each wheel to hub/brake

disc. Remove road wheel attaching nuts and

remove wheels.

5. Place a drain tray beneath steering gear.

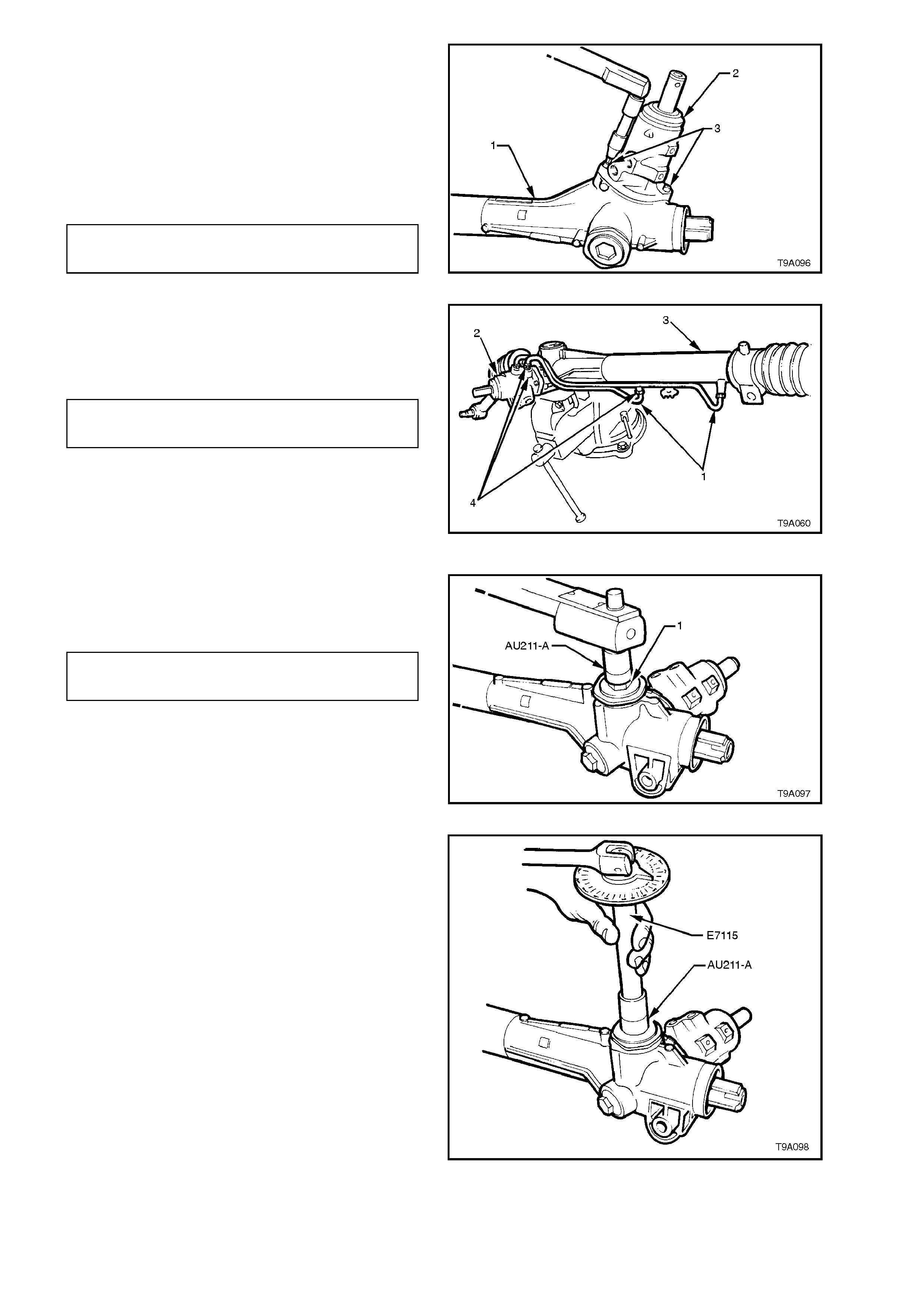

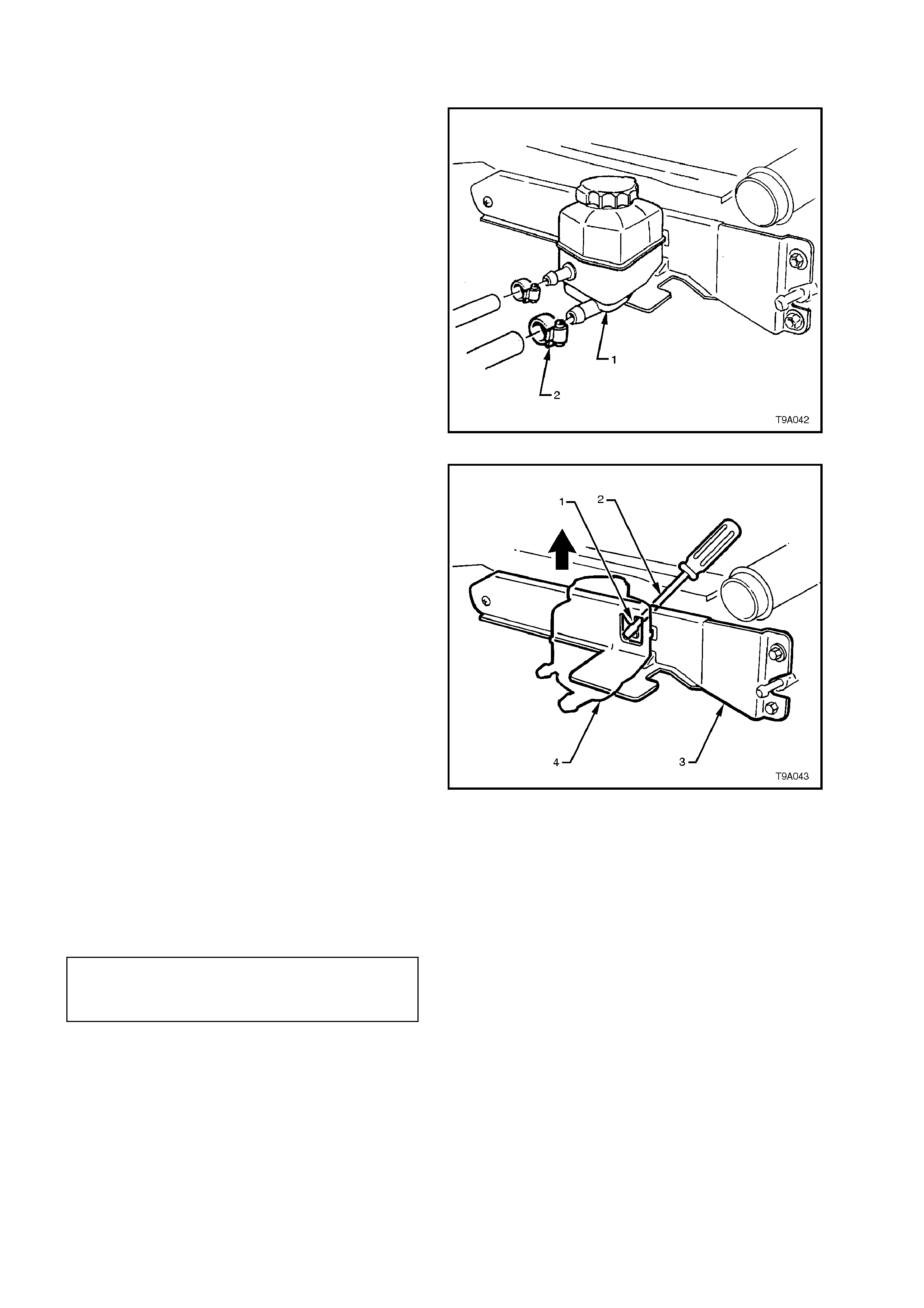

6. Loosen and remove hydraulic lines (2 and 3)

from steering gear valve housing ( 1) and allow

fluid to drain into a suitable container. While

the V6 engine application is shown, the V8

engined arrangement is similar.

Figure 9A-56

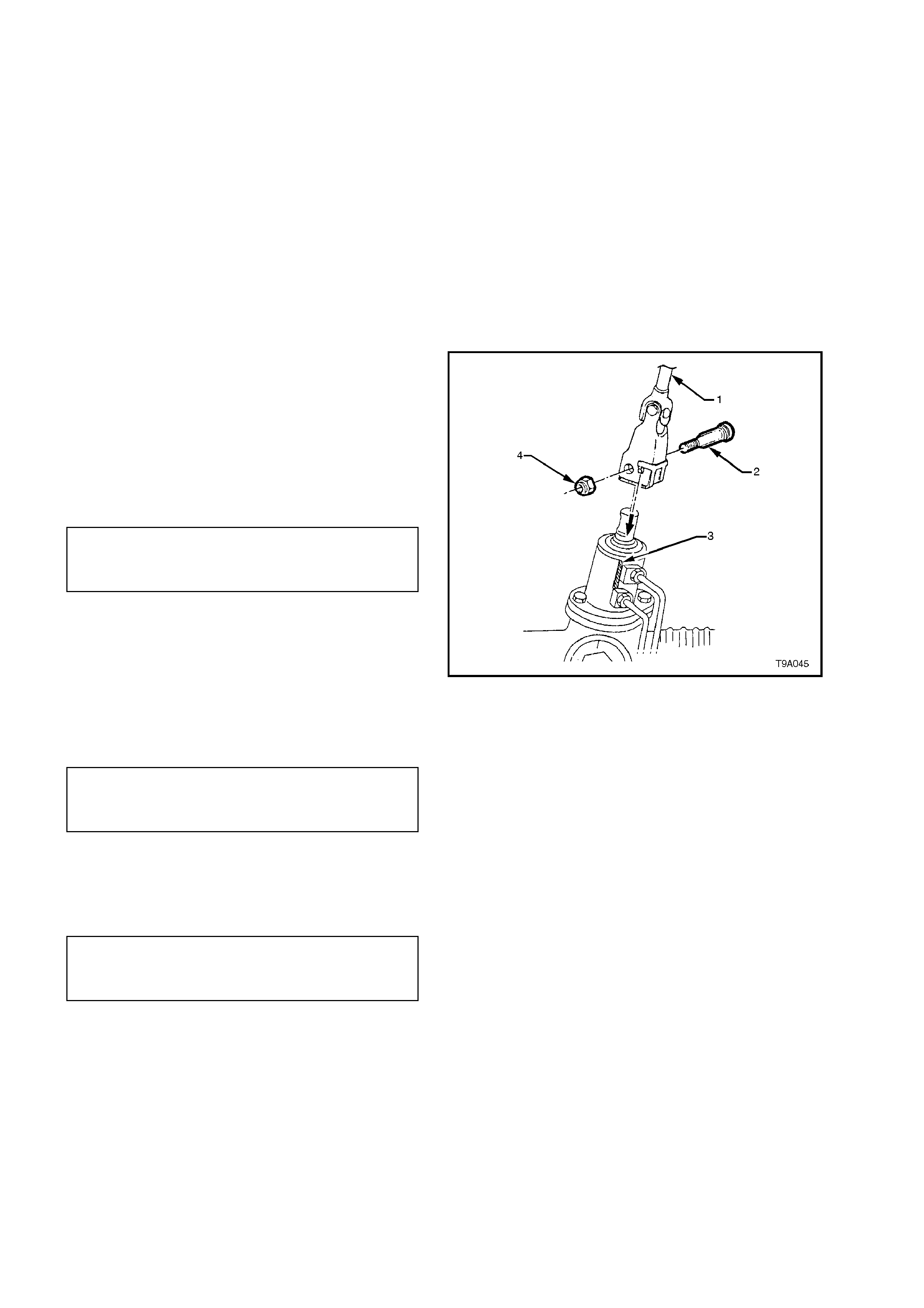

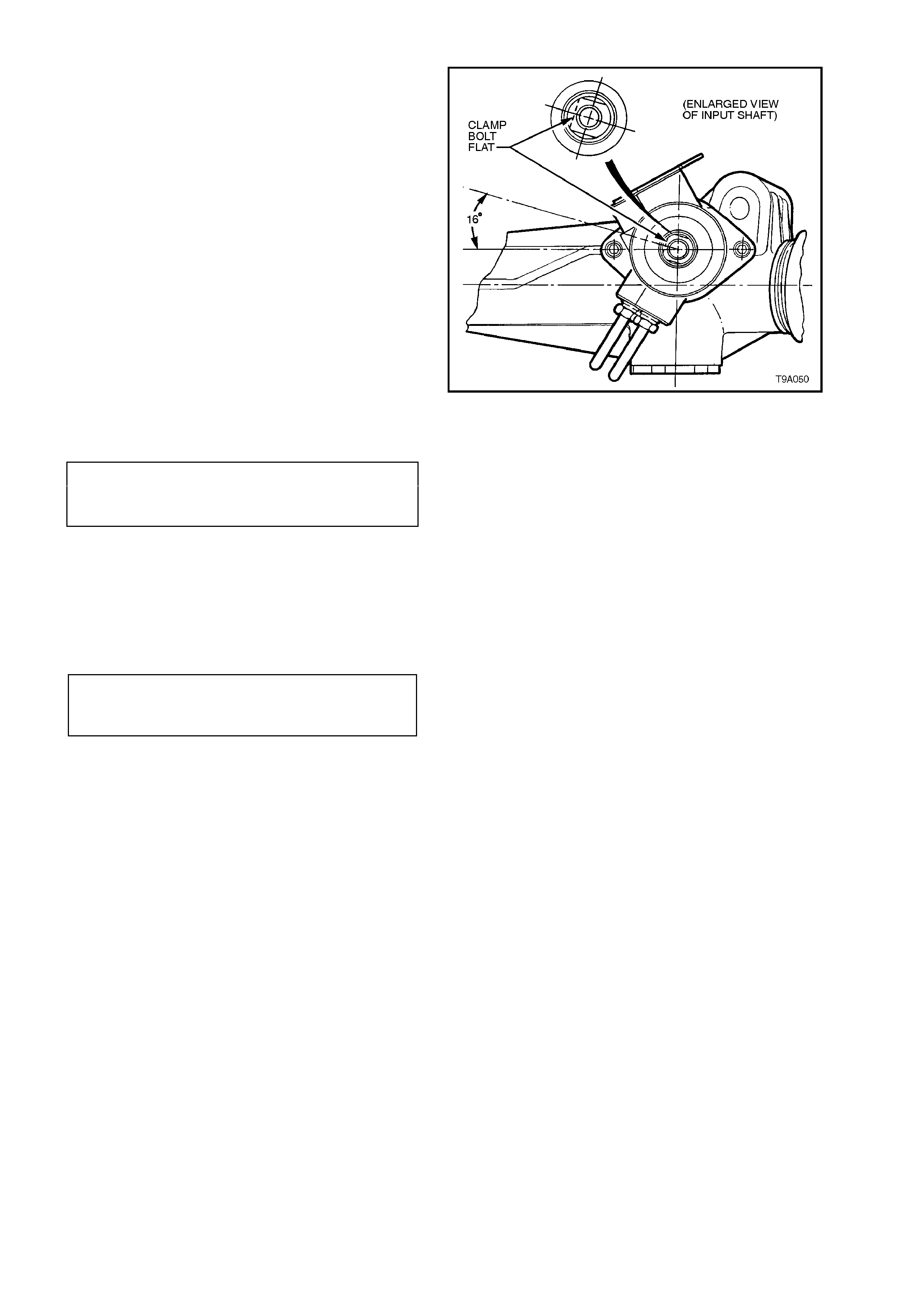

7. Remove steering coupling lower cam bolt (2)

nut (4), and slide coupling (1) away from

steering gear (3).

Figure 9A-57

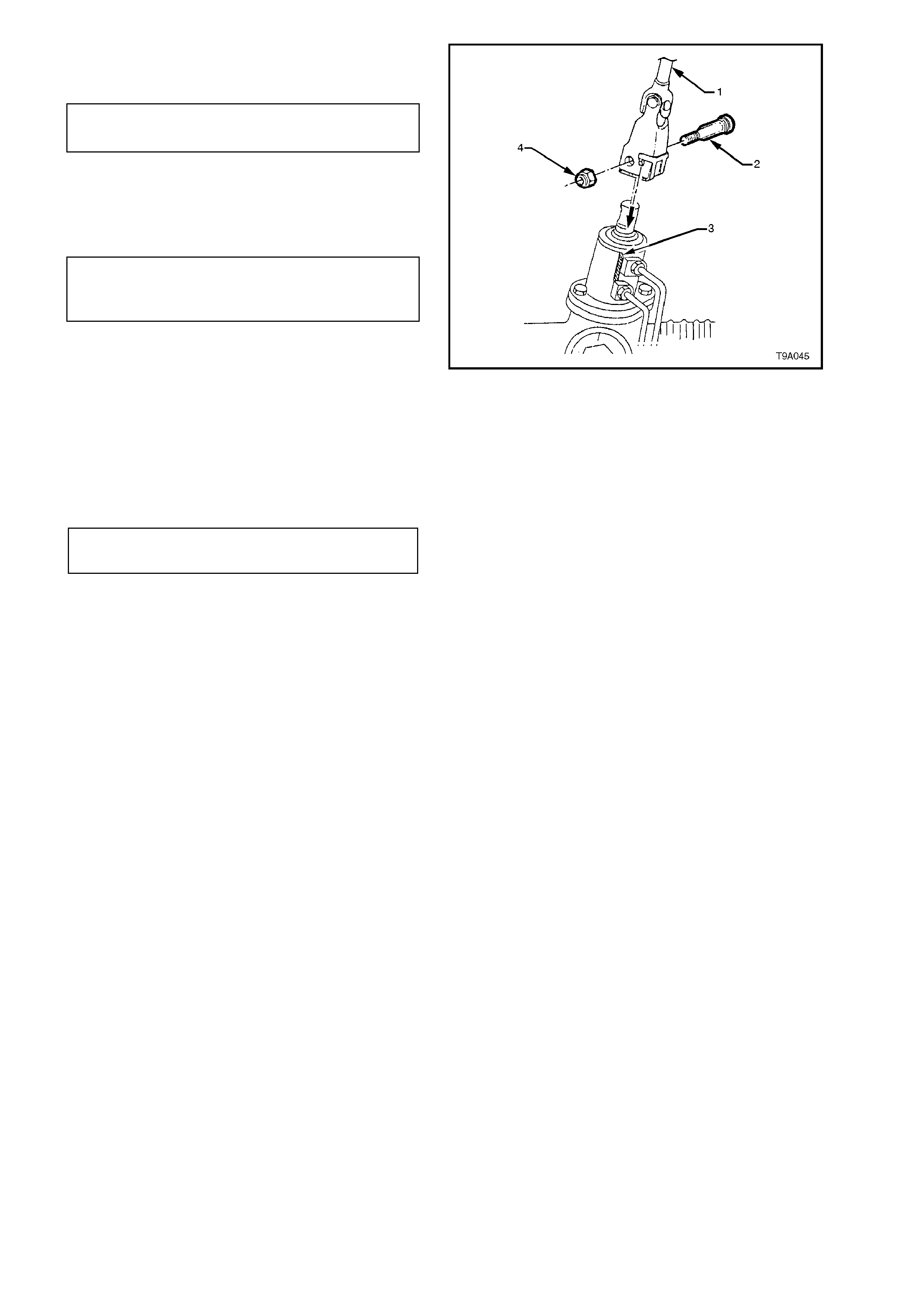

8. Remove tie rod end split pins and castellated

nuts (’3’ in Figure 9A-59).

9. Separate tie rod end ball studs from steering

arm tapers using a suitable remover, such as

Tool No. 9A10.

Figure 9A-58

10. Remove steering gear housing to front

suspension crossmember mounting bolts (1)

and nuts (2).

11. Remove steering gear by pulling it out from

front suspension crossmember mounting (4)

and slide pinion (input) shaft (5) from steering

coupling lower clamp.

Figure 9A-59

REINSTALL

1. Ensure steering gear is centralised.

NOTE 1:

This is achieved by rotating the pinion to the

halfway position of its total lock to lock rotation.

W hen the r ack is in the stra ight ahead position, the

pinion (input) shaft will be aligned as shown.

NOTE 2:

Alternatively, remove both inner boot clamps, slide

the boots back and measure the exposed portion of

each end of the rack from the housing. W hen both

measurements are equal, the rack is centralised.

2. Ensure steering wheel is in straight ahead

position.

3. Slide steering gear pinion (input) shaft into

steering coupling lower flange.

4. Position steering gear housing into

crossmember mounting points. Install

mounting bolts, washers and nuts and tighten

nuts to the correct torque specification.

STEERING GEAR HOUSING TO

CROSSMEMBER MOUNTING 70 - 85 Nm

TORQUE SPECIFICATION

5. Inspect condition of steering gear hydraulic

line O-rings. Replace as necessary.

6. Refit hydraulic lines to steering gear valve

housing. Tighten flare nuts to the correct

torque specification.

HYDRAULIC LINE TO VALVE

HOUSING FLARE NUT 25 - 35 Nm

TORQUE SPECIFICATION

Figure 9A-60

7. Install lower cam bolt (2) and a new nut (4).

Tighten to the correct torque specification.

STEERING COUPLING CAM BOLT 23 - 30

NUT TORQUE SPECIFICATION Nm

8. Reinstall tie rod end ball studs into steering

arms. Reinstall castellated nuts and tighten to

the correct torque specification.

TIE ROD BALL JOINT STUD

CASTELLATED NUT 50 - 85 Nm

TORQUE SPECIFICATION

9. Install new split pins into tie rod ball studs.

NOTE:

Ensure plastic spacers are positioned on tie rod

end ball studs and that they are in good condition

before fitting studs into steering arms. Replace

spacers if damaged.

10. Install wheels, aligning marks made on

removal. Tighten wheel attaching nuts to the

correct torque specification.

ROAD WHEEL ATTACHING NUT 110 - 140

TORQUE SPECIFICATION Nm

11. Lower vehicle to ground and reconnec t battery

earth lead.

12. Refill and bleed hydraulic system, refer

3.3, HYDRAULIC SYSTEM,

BLEEDING/REFILLING in this Section.

13. Check front wheel toe-in setting, refer to

Section 3, FRONT SUSPENSION for details.

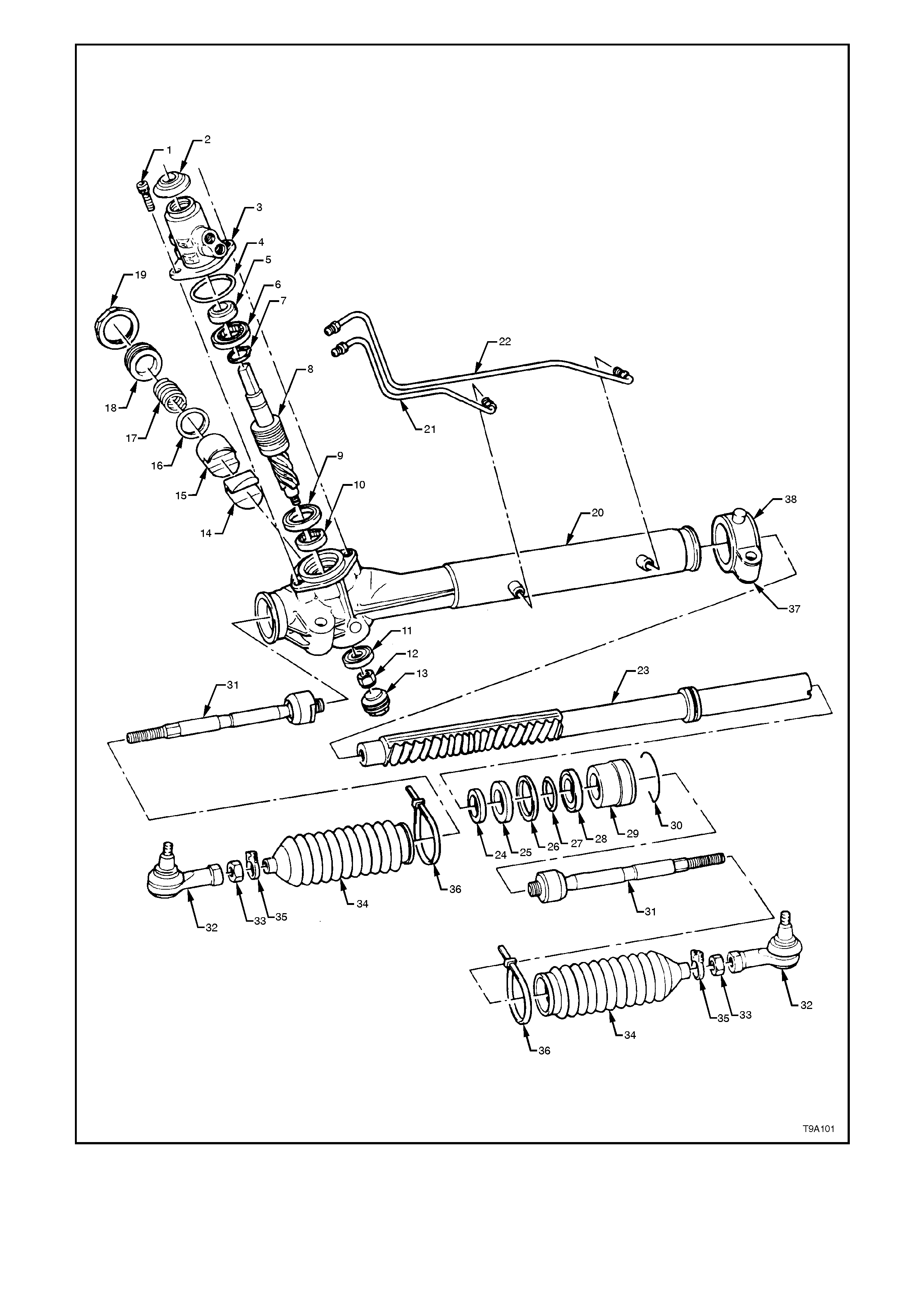

Figure 9A-61

1. Screw - Valve Housing Attaching

(2 places)

2. Cover - Dust

3. Housing - Valve

4. O-ring

5. Seal

6. Bearing - Roller

7. Circlip

8. Valve Assembly - Rotary

9. Seal

10. Bearing - Roller

11. Bearing - Ball

12. Nut - Pinion

13. Plug - Sealing

14. Insert - Rack Pad

15. Pad - Rack

16. Washer

17. Spring

18. Plug - Rack Pad

19. Nut - Lock

20. Housing - Steering Gear

21. Pipe - Rack Piston Fluid - Short

22. Pipe - Rack Piston Fluid - Long

23. Rack and Piston Assembly

24. Spacer - Inner Rack Seal

25. Seal - Inner Rack

26. Seal - Rack Piston

27. O-ring - Rack Piston

28. Seal - Outer Rack

29. Bushing - Rack Outer

30. Wire - Retaining

31. Rod - Tie

32. End - Tie Rod

33. Nut - Lock

34. Bellows

35. Clip - Bellows Outer

36. Strap - Bellows Inner Tie

37. Bracket - Mounting

38. Insulator - Mounting Bracket

Figure 9A-62 - Rack and Pinion Power Steering Gear

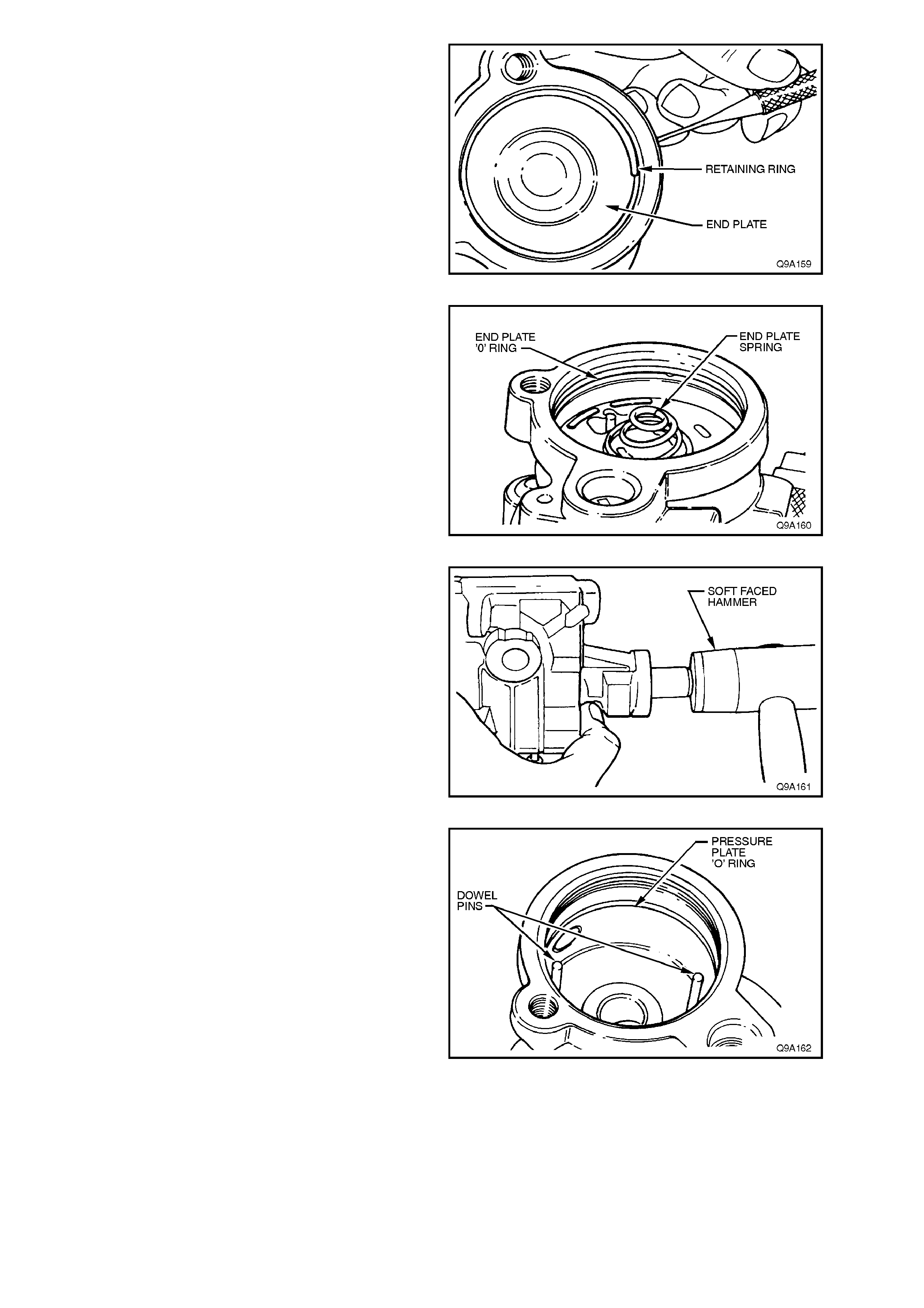

DISASSEMBLE

For identification of components, refer to Figure

9A-62.

1. Clean all dirt and foreign matter from exterior

of steering gear assembly.

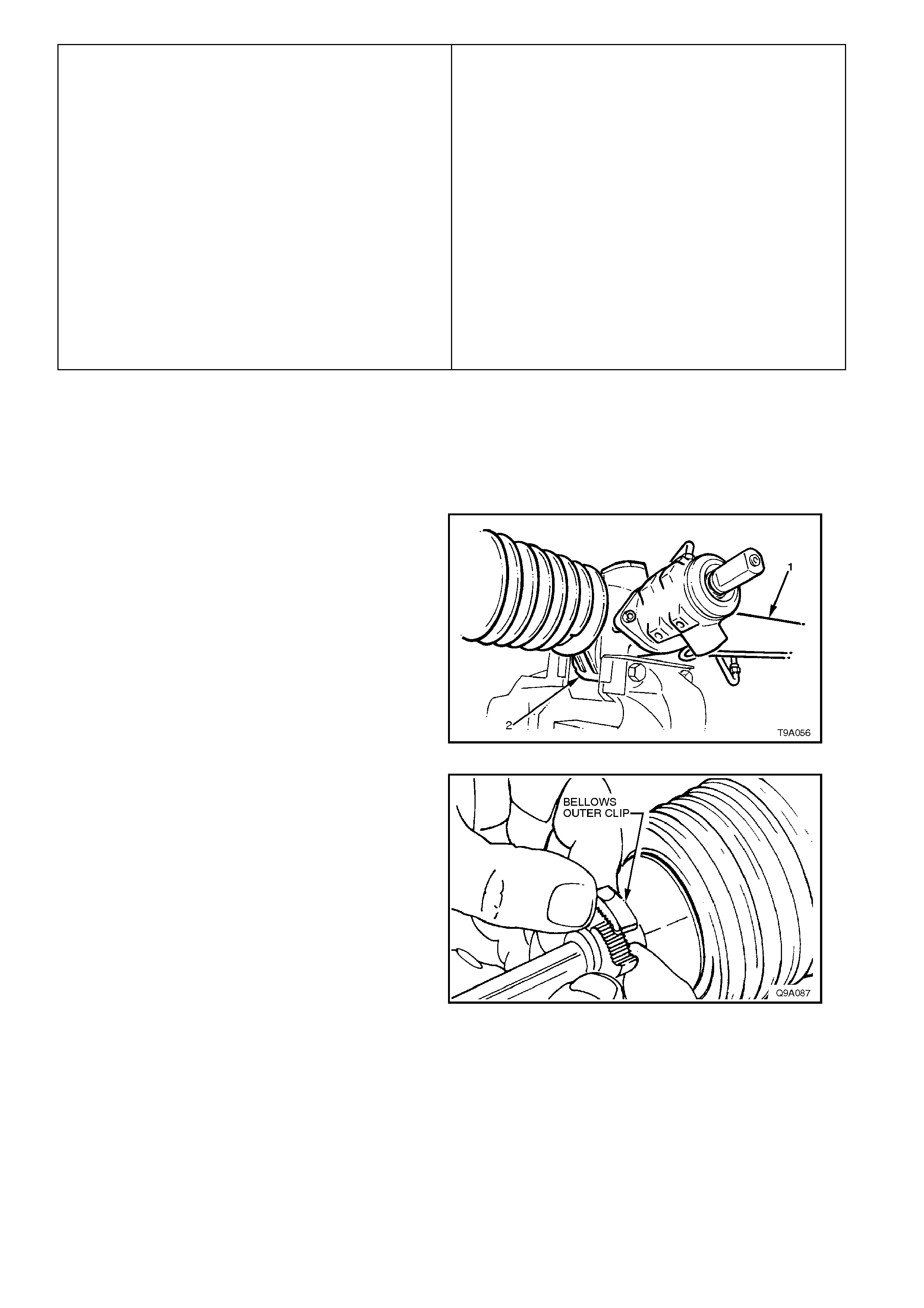

2. Mount steering gear housing (1) by gripping

right hand mounting boss (2) in a vice fitted

with soft jaws.

3. Place a drain tray beneath steering gear.

Figure 9A-63

4. Unclip and remove all bellows clips.

a. To r emove outer c lips : Move ends of c lips

sideways until they disengage.

Figure 9A-64

b. To remove inner clips: Push out the pin

retaining the clip ends together using a

fine pin punch.

Figure 9A-65

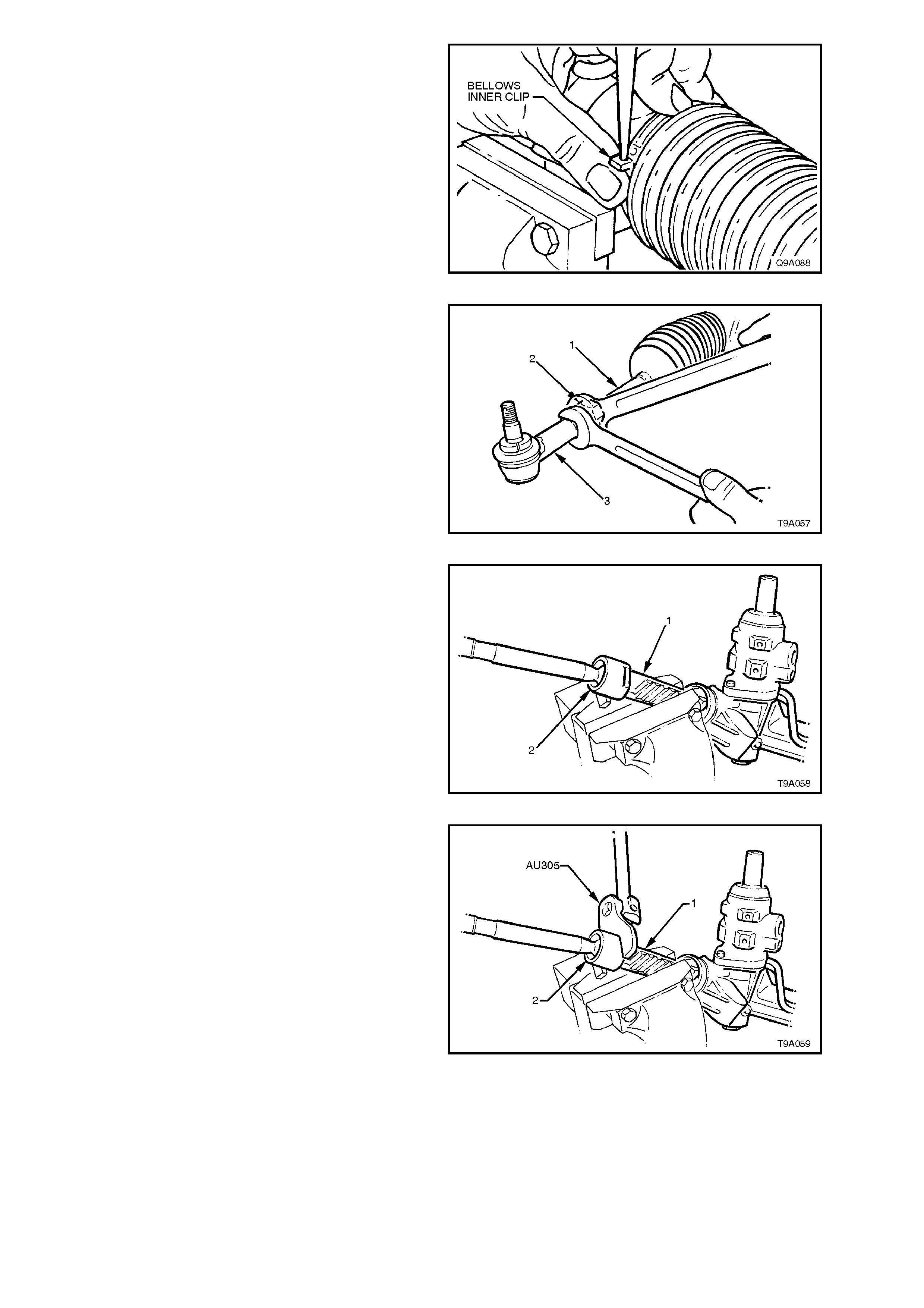

5. Loosen tie rod lock nuts (2). Remove tie rod

ball joints (3) and lock nuts (2) from tie rods

(1).

6. Slide bellows from steering gear housing and

tie rods.

7. Rotate pinion (input) shaft fully counter-

clockwise (full left lock).

Figure 9A-66

8. Remove steering gear housing from vice and

grip exposed tooth end of rack (1) in vice with

soft jaws.

Figure 9A-67

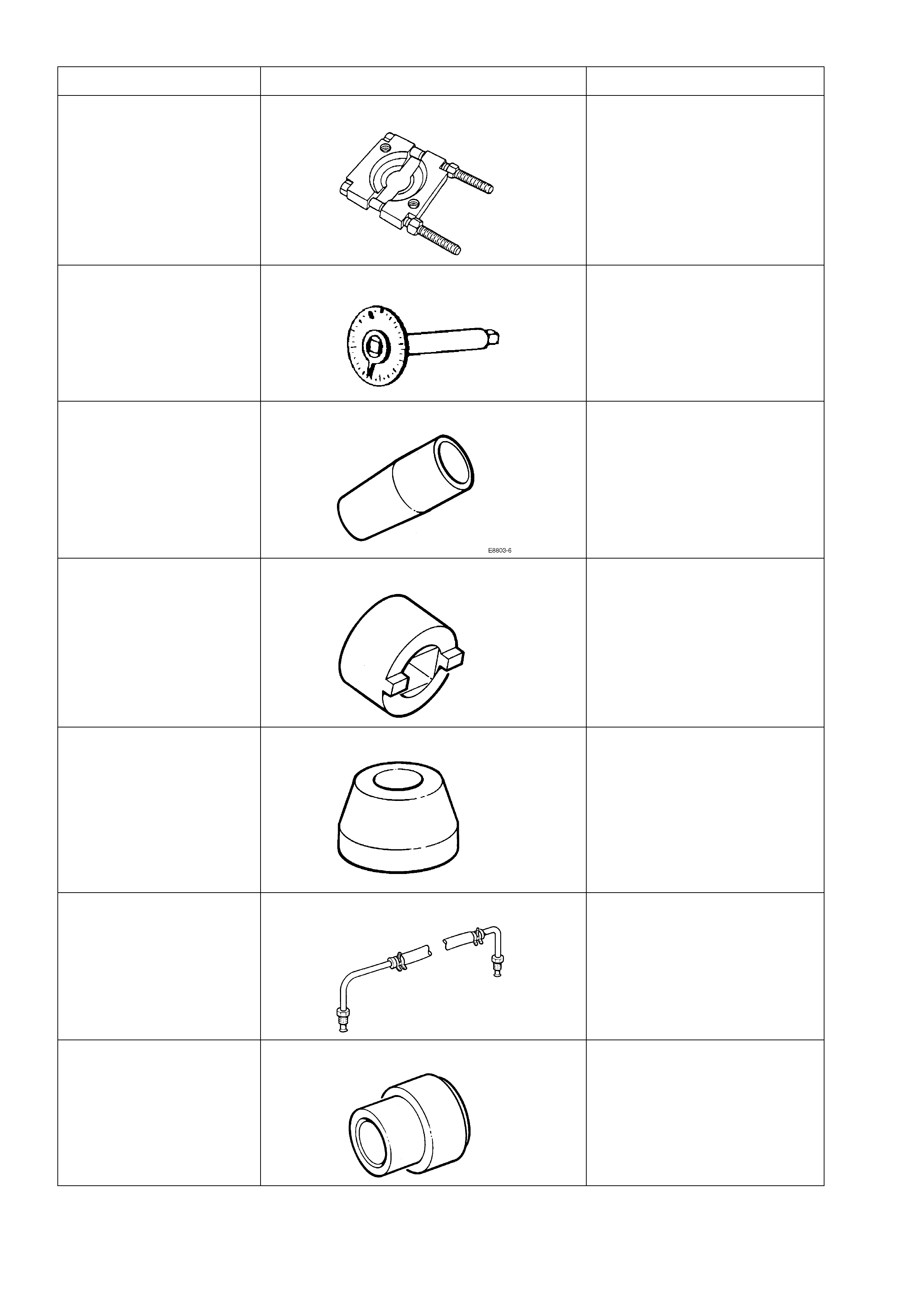

9. Using Tool No. AU305, loosen then tighten tie

rod ball joint housing to break the staking, then

unscrew housing from end of rack

Figure 9A-68

10. Remove housing assembly from vice and

ensure that there is no foreign matter on rack

teeth. Rotate pinion (input) shaft clockwise,

just enough to expose left hand tab washer

and tie rod.

11. Remount steering gear in vice, gripping

around exposed teeth of rack.

12. Remove left-hand tie rod assembly as in

step 9.

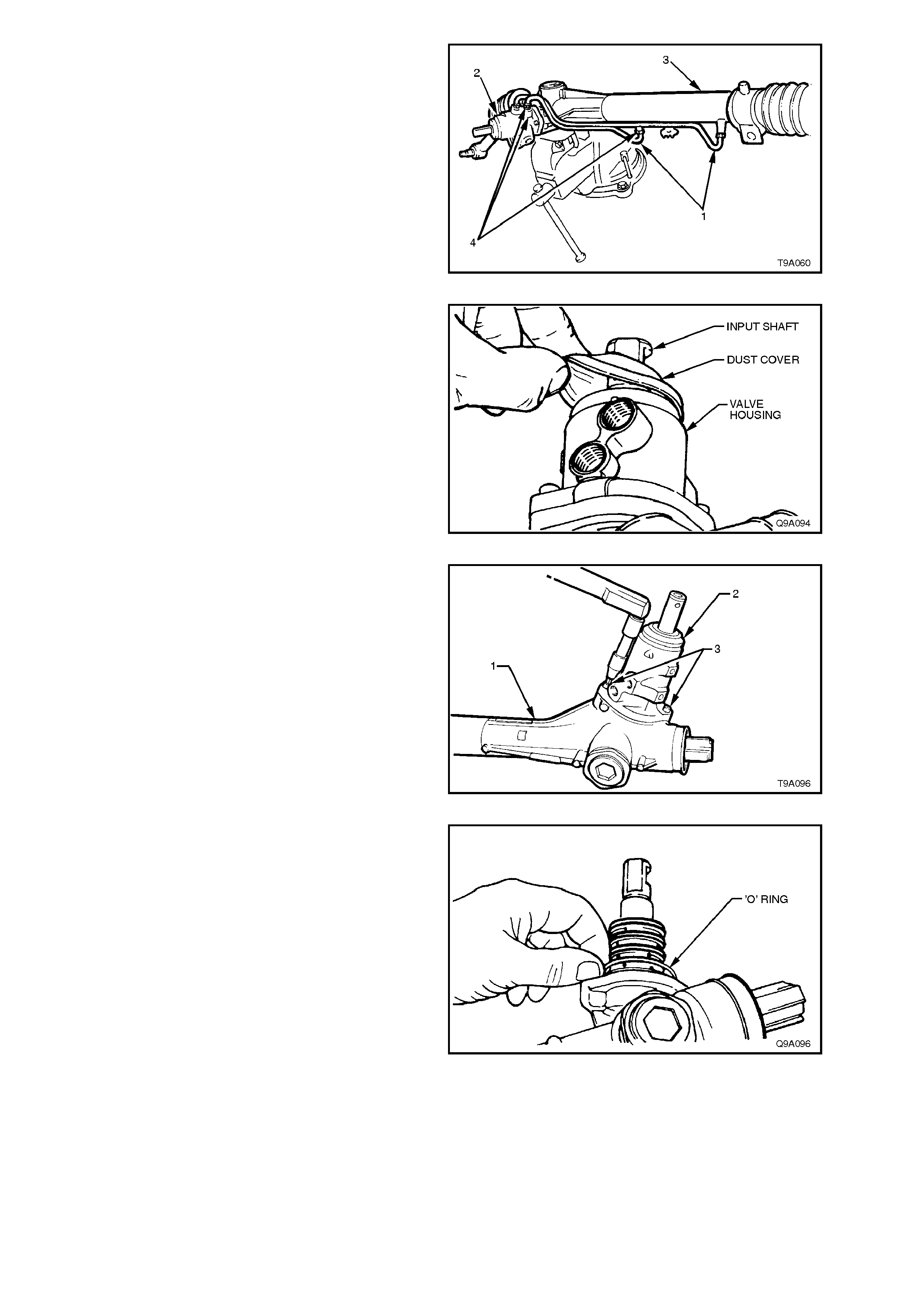

13. Remount steering gear housing (3) in vice

fitted with protective jaws, gripping right-hand

mounting boss.

14. Disconnect feed pipes (1 and 4) from valve

housing (2) and steering gear tubing (3).

Figure 9A-69

15. Remove dust cover from valve housing and

input shaft.

Figure 9A-70

16. Using a 5 mm Allen key, remove valve

housing attaching screws (3). Withdraw valve

housing (2) from input shaft.

Figure 9A-71

17. Rem ove and discard valve hous ing to steering

gear housing O-ring.

Figure 9A-72

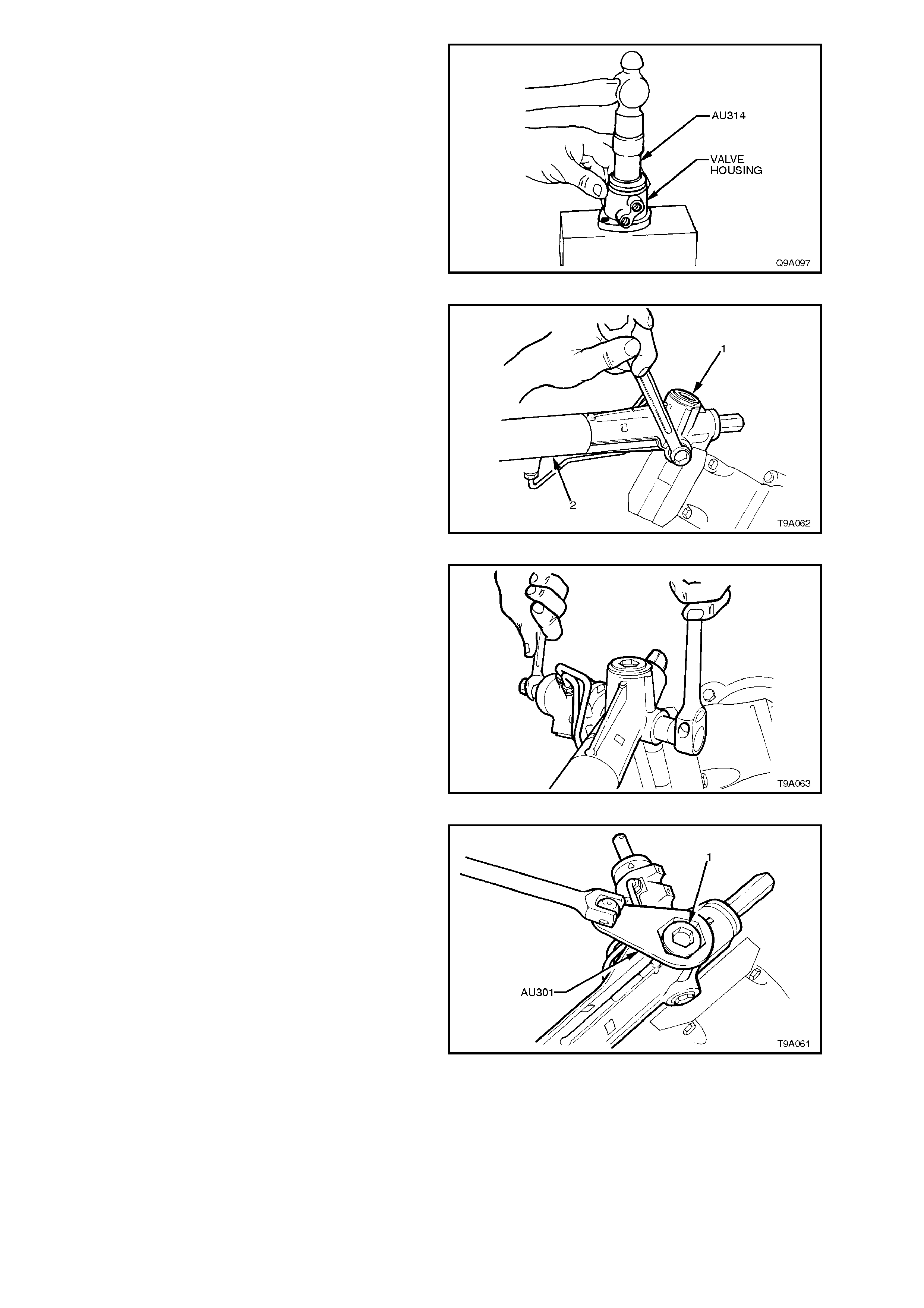

18. Place flange face of valve housing onto a

wooden block and, using Tool No. AU314,

drive valve seal and bearing from valve

housing.

NOTE:

As there is no inner race, to support them, the

needle rollers may fall out during this operation.

Figure 9A-73

19. Remove pinion lower bearing screw plug (1)

from housing.

Figure 9A-74

20. While holding the input pinion with a set

spanner across the flats, remove pinion lower

bearing retaining nut from pinion.

Figure 9A-75

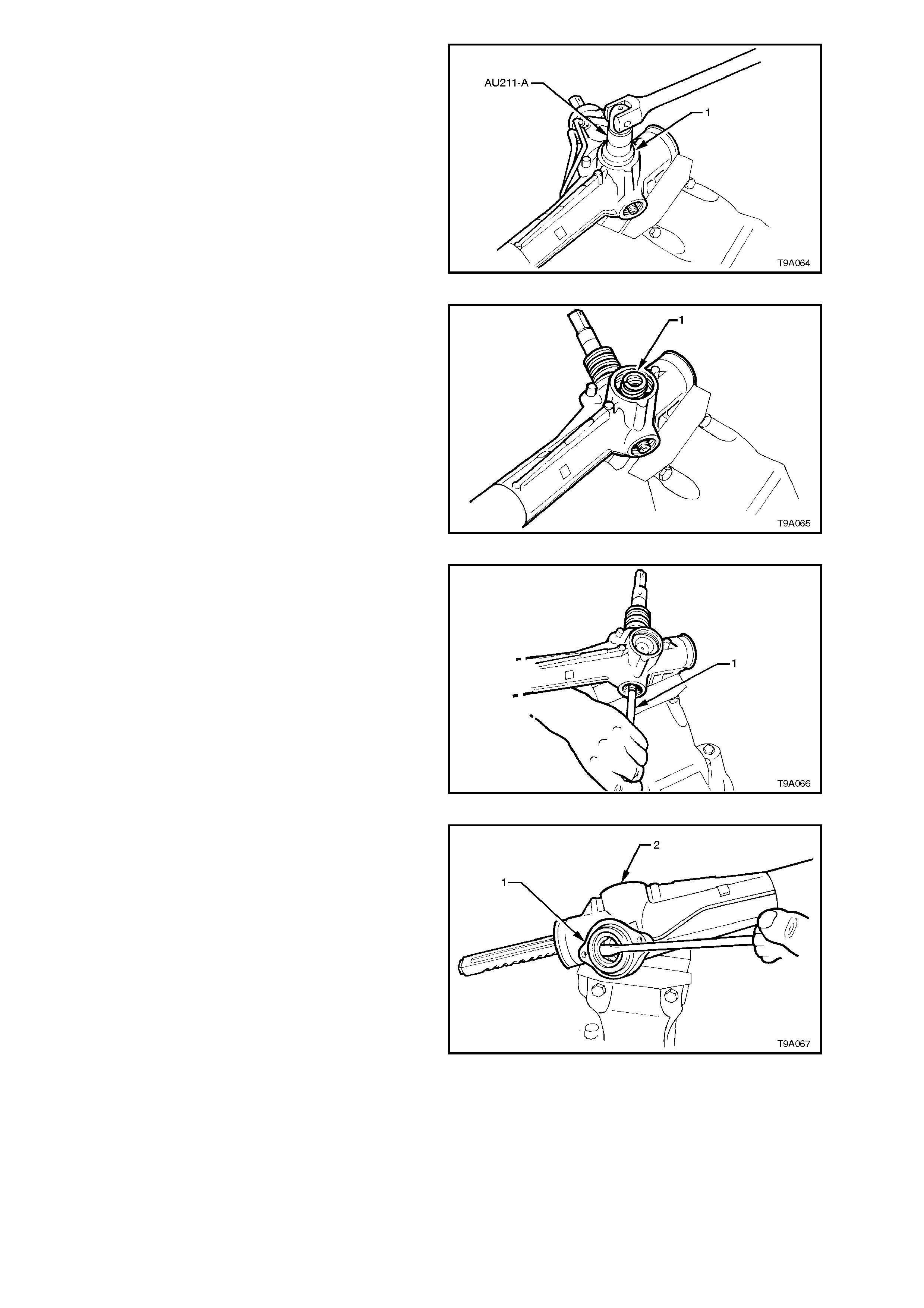

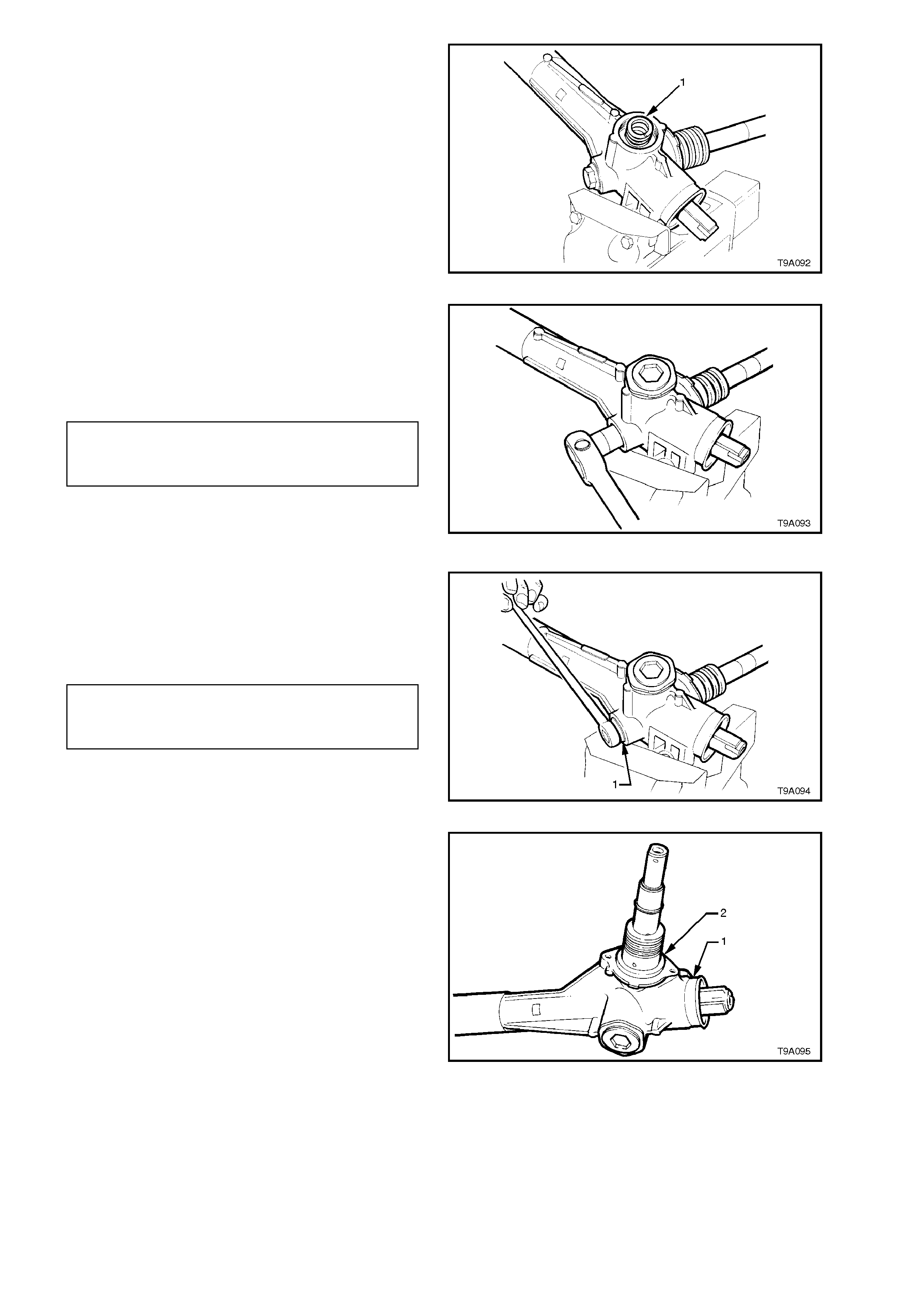

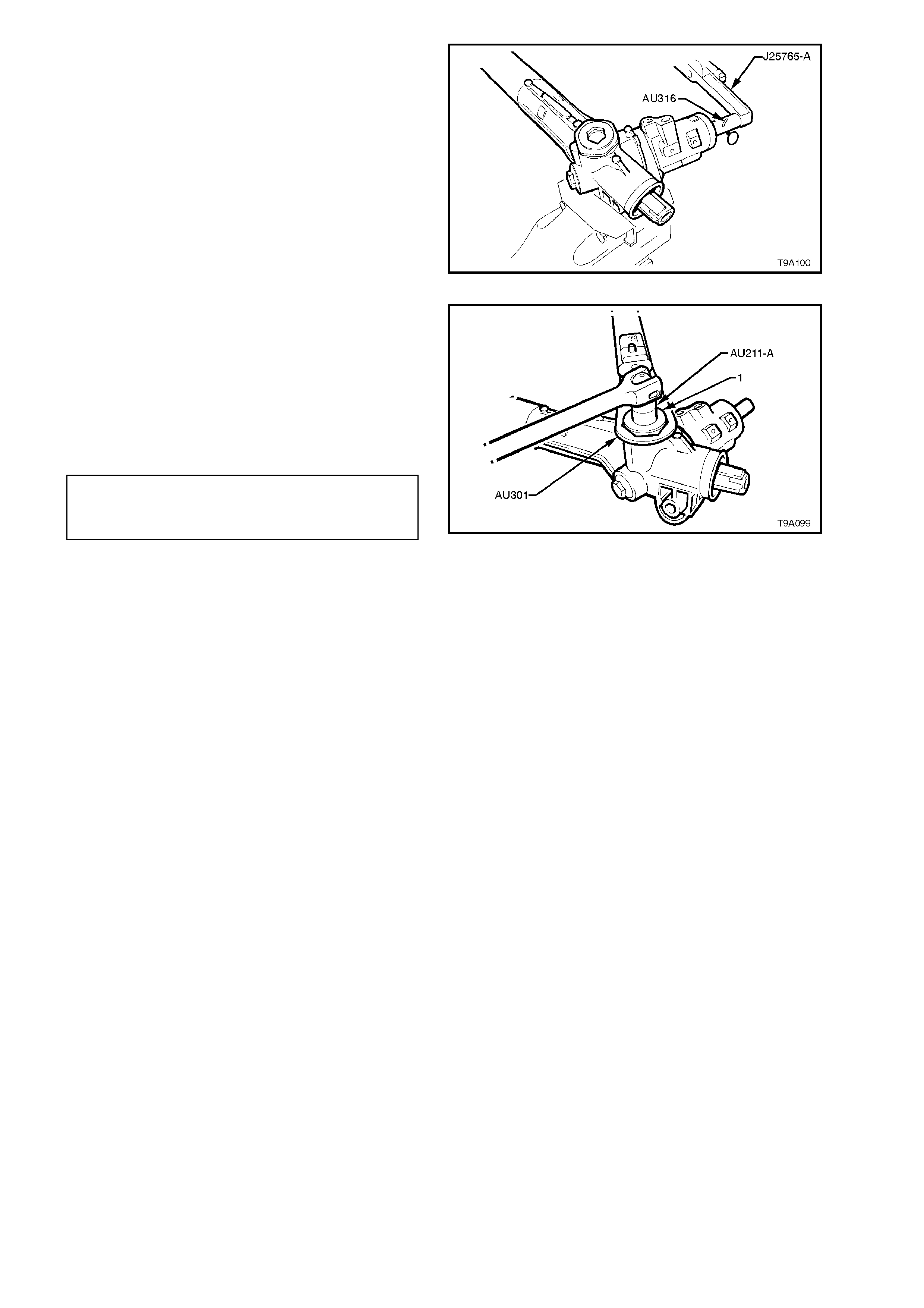

21. Remove rack pad adjuster lock nut (1) using

Tool No. AU301.

22. Rotate input shaft fully clockwise (full right

lock).

Figure 9A-76

23. Loosen and remove rack pad adjuster screw

(1), using Tool No. AU211-A.

Figure 9A-77

24. Remove rack pad spring (1) and rack pad

assembly from steering gear housing.

NOTE:

It may be necessary to remove the housing from

the vice and tap gently on a wooden block to

dislodge the rack pad assembly .

Figure 9A-78

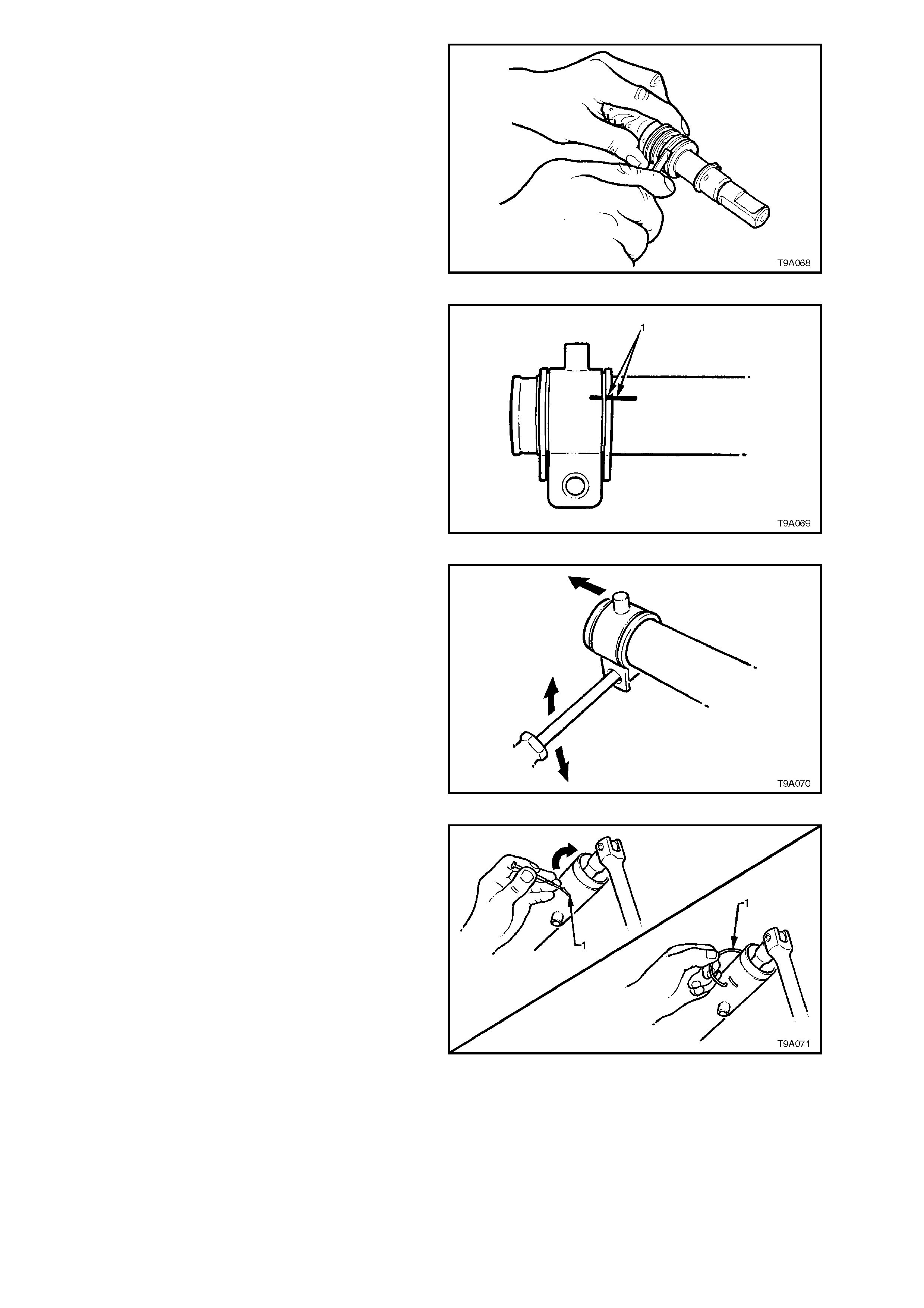

25. Using a brass drift (1) and a soft faced

hammer, gently knock on lower end of pinion

to remove pinion assembly from housing.

Figure 9A-79

26. Using a screwdriver, lever out pinion seal (1)

from housing (2). Discard seal.

NOTE:

Take care not to damage housing lip.

Figure 9A-80

27. Remove and discard PTFE rings from rotary

valve outer sleeve.

The seals are best removed by cutting

diagonally with a sharp knif e, but car e m ust be

taken to avoid scratching the sides of the

grooves otherwise subsequent leakage will

result.

NOTE:

Because of component matching that is critical to

the safe operation of the sleeve and valve

assembly, THE PINION ASSEMBLY MUST NOT

BE FURTHER DISMANTLED.

Figure 9A-81

28. Using a white marker pen or sim ilar, mark the

relative position of the left hand mounting

bracket and the steering rack tube (1).

Figure 9A-82

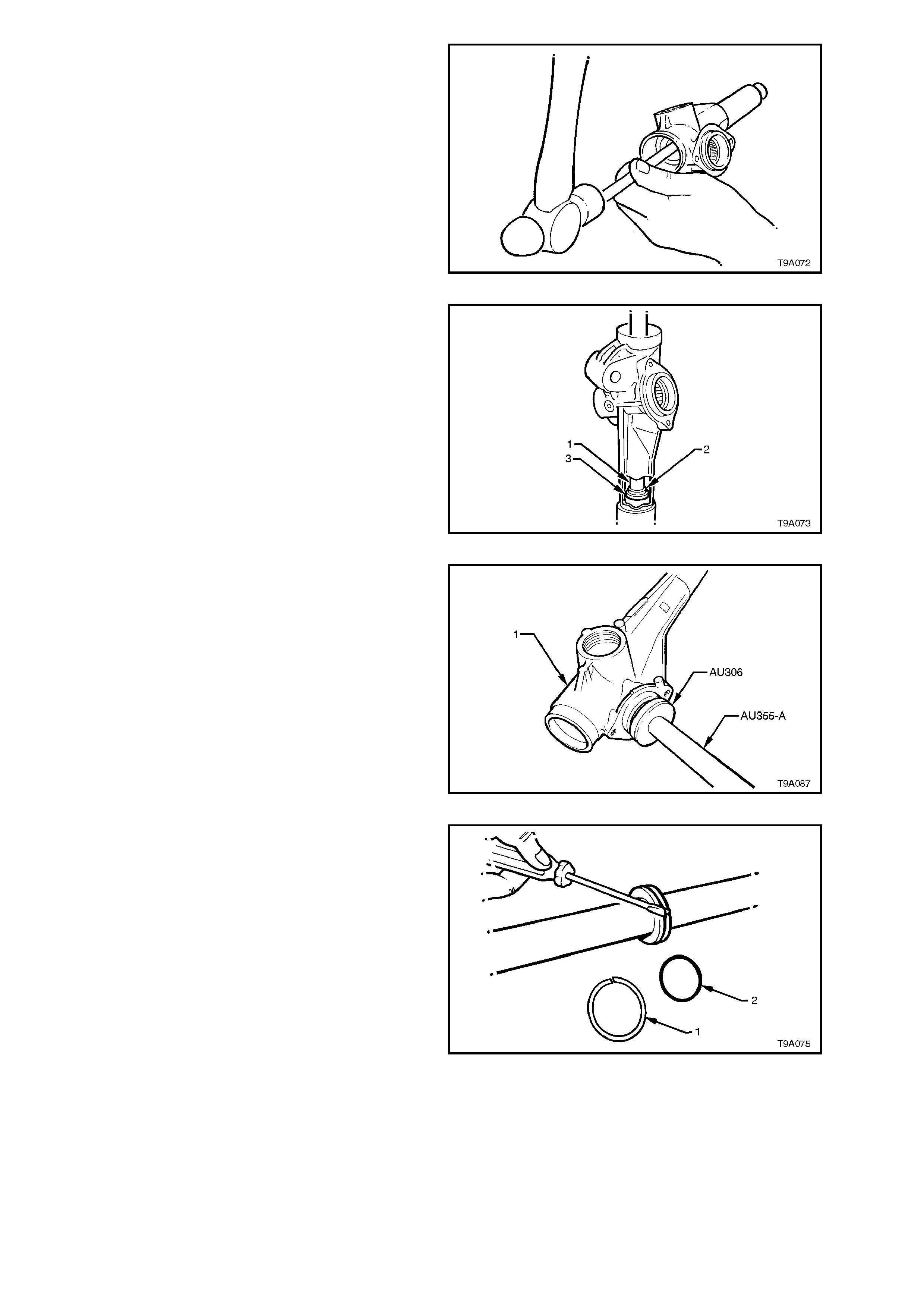

29. Remove the left hand mounting bracket, by

using a round bar inserted through the

mounting holes and rotating the bushing and

bracket, back and forth while pulling at the

same time.

Figure 9A-83

30. Remove the rack end bushing retaining wire,

as follows:

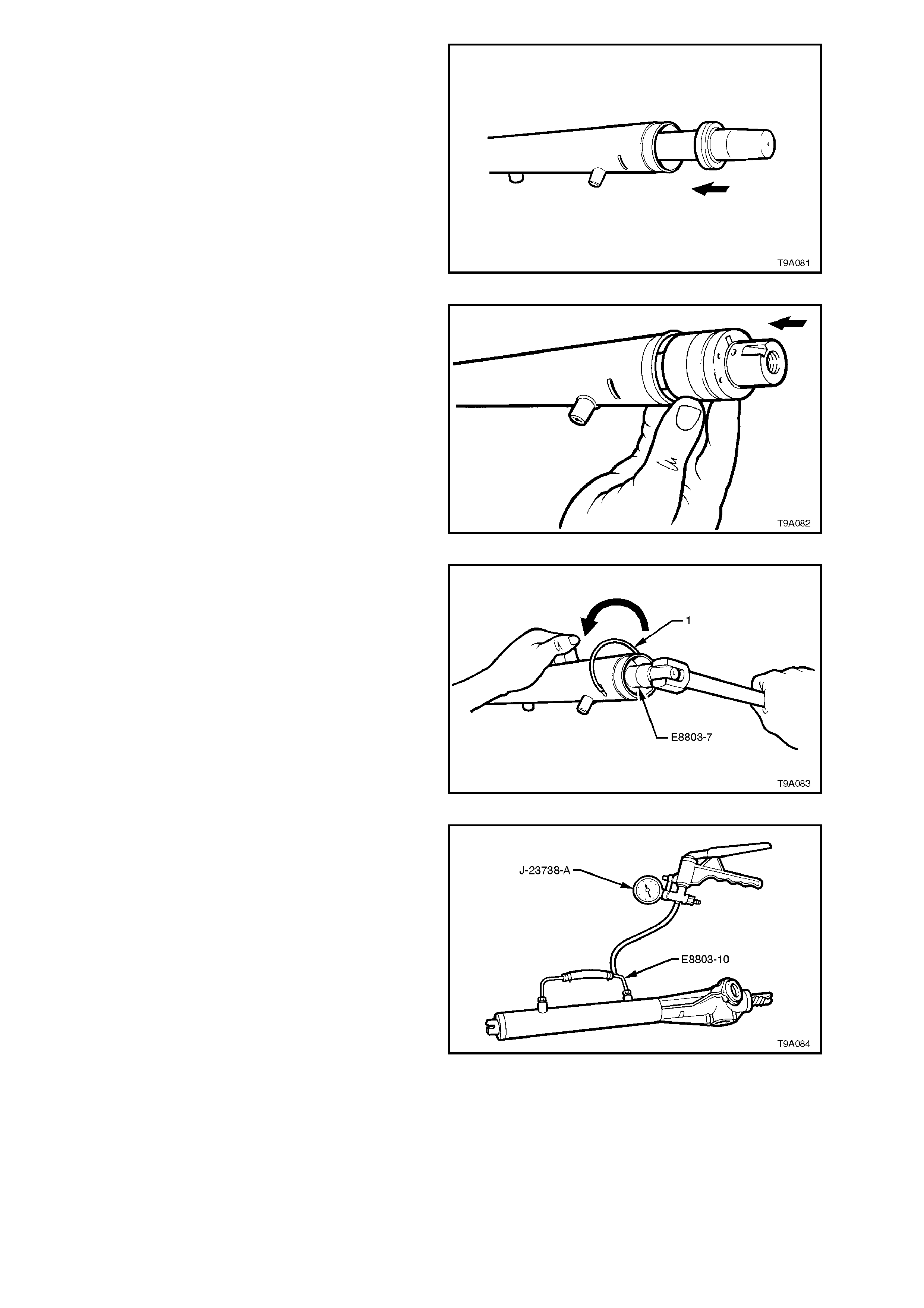

a. Using Tool No. E8803-7 with a socket

extension and bar, rotate the rack end

bush anti-clockwise, until the end of the

retainer (1) appears in the slot.

b. Carefully prise the end of the retainer wire

free of the rack tube as shown, then

rotate the end bushing with Tool No,

E8803-7, in a clock wise direction (arrow),

winding the retainer out of the tube.

c. Continue unwinding the retainer until the

end of the retainer (1) appears, then lift it

from the slot in the rack tube. Figure 9A-84

31. Remove the rack from the housing by inserting

a brass drift into the right threaded end of the

rack and driving the rack from the tube end of

the rack housing.

NOTE:

As this action will remove the rack end bush and

the outer piston rod seal from the steering tube,

some resistance will be encountered.

Figure 9A-85

32. Insert a suitable length of tubing or mild steel

stock (1), 30 mm in diameter into the housing

from the pinion end, then use a hammer to

drive the spacer (2) and inner piston rod seal

(3) and from the rack housing.

Figure 9A-86

33. Remove pinion lower bearing using Tool No.

AU306 and driver handle AU355-A.

NOTE:

The pinion upper bearing cannot be removed from

the steering gear housing. If the upper bearing is

found to be damaged or has failed, then the

housing and bearing assembly must be replaced.

Figure 9A-87

34. Remove rack piston seal (1) and O-ring (2)

from the rack piston.

NOTE:

The s eal (1) c an be more eas ily rem o ved by cutting

diagonally with a sharp knife, but take care not to

scratch the sides of the seal groove, during this

process.

Figure 9A-88

CLEAN AND INSPECT

Thor oughly wash all m etal parts in cleaning solvent

and blow dry with compressed air.

1. Inspect rubber bellows for damage or

deterioration, replace if necessary.

2. Inspect pinion bearings for signs of brinelling,

damage or wear.

NOTE:

The pinion upper bearing cannot be removed from

the steering gear housing. If the upper bearing is

found to be damaged, replace the housing and

pinion upper bearing assembly.

3. Inspect pinion for signs of tooth wear or

damage.

4. Inspect rack for signs of wear or damage to

teeth, rack pad faces and rack bearing journal.

NOTE:

A light polish on teeth and rack rear face is norm al

and should not be confused with wear.

5. Inspect housing for wear or damage in pinion

bearing bores, seal bores, rack piston and

lock stop faces.

6. Inspect rack pad for damage or excessive

wear.

7. Inspect m ajor components of pinion assem bly

(pinion, valve, sleeve and torsion bar) for

damage or wear.

NOTE:

Thes e parts cannot be serviced individually as they

are hydraulically balanced at the pinning stage of

assembly to equalise the steering efforts in right

and left directions.

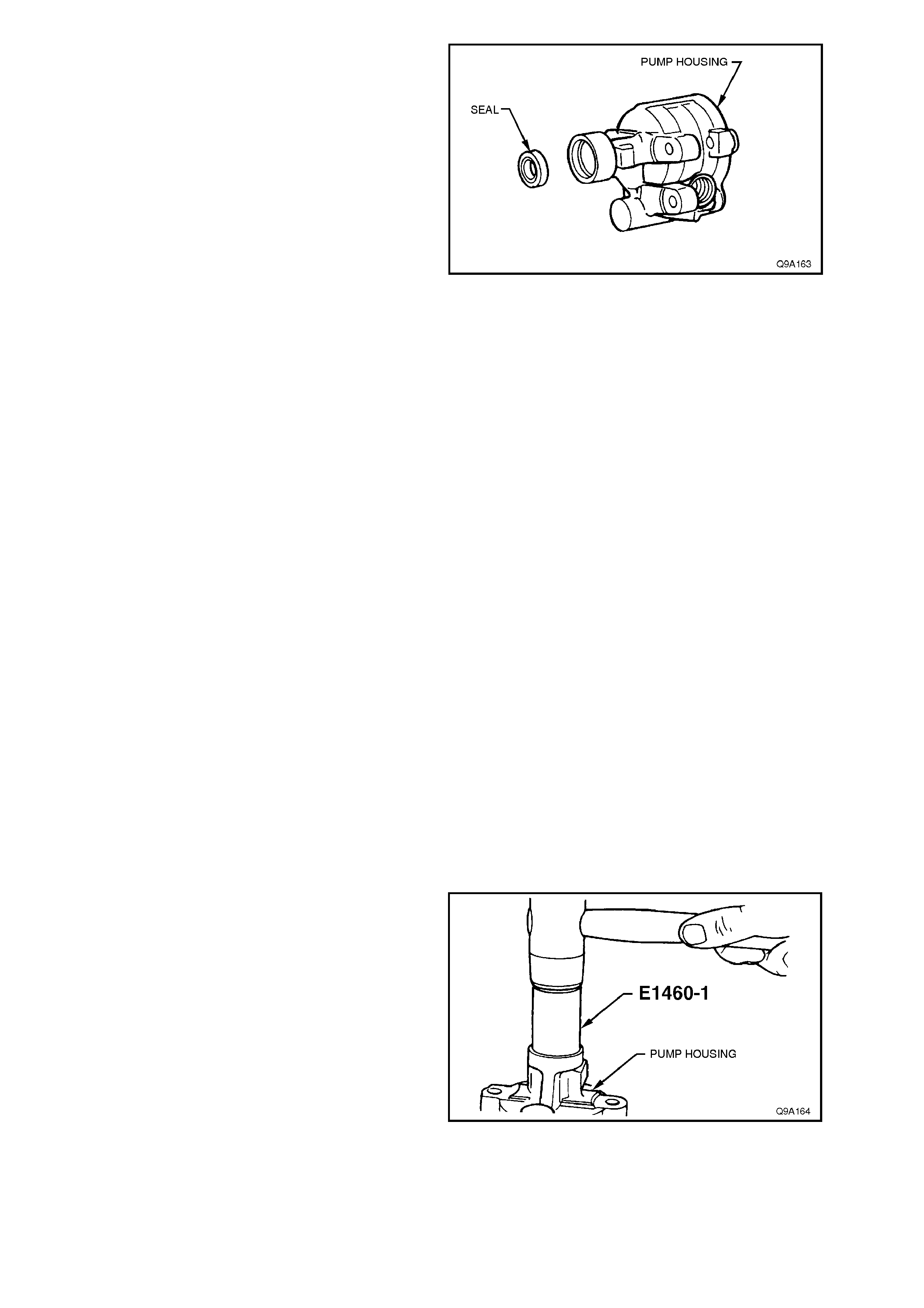

REASSEMBLE

1. Check that each of the rack seals have a

circular, plastic insert ring fitted to each, on the

opposite side to the spring loaded seal lip, with

the tapered edge of the ins ert facing in toward

the seal. Ensure the taper ed ends of the rings

seat correctly.

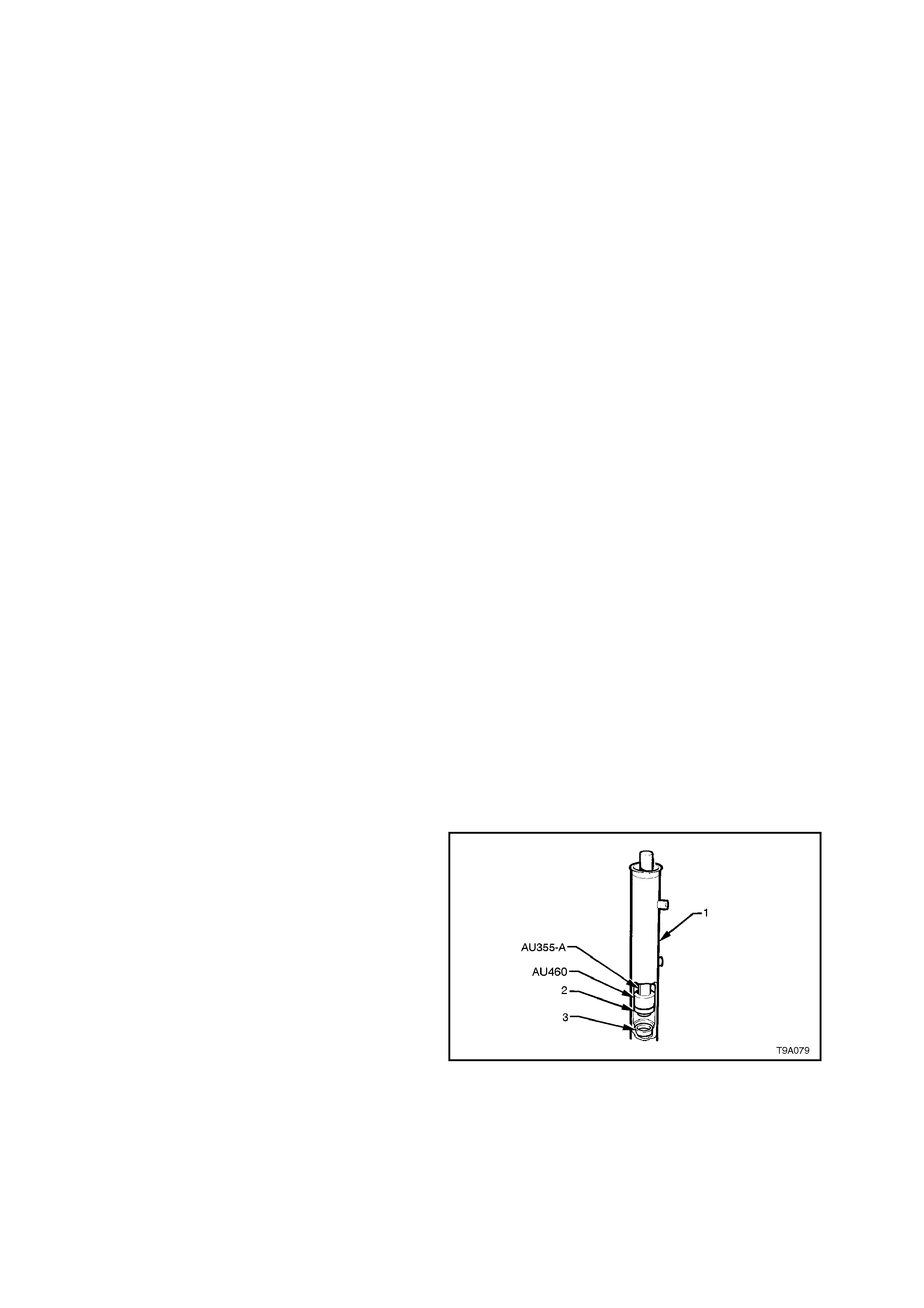

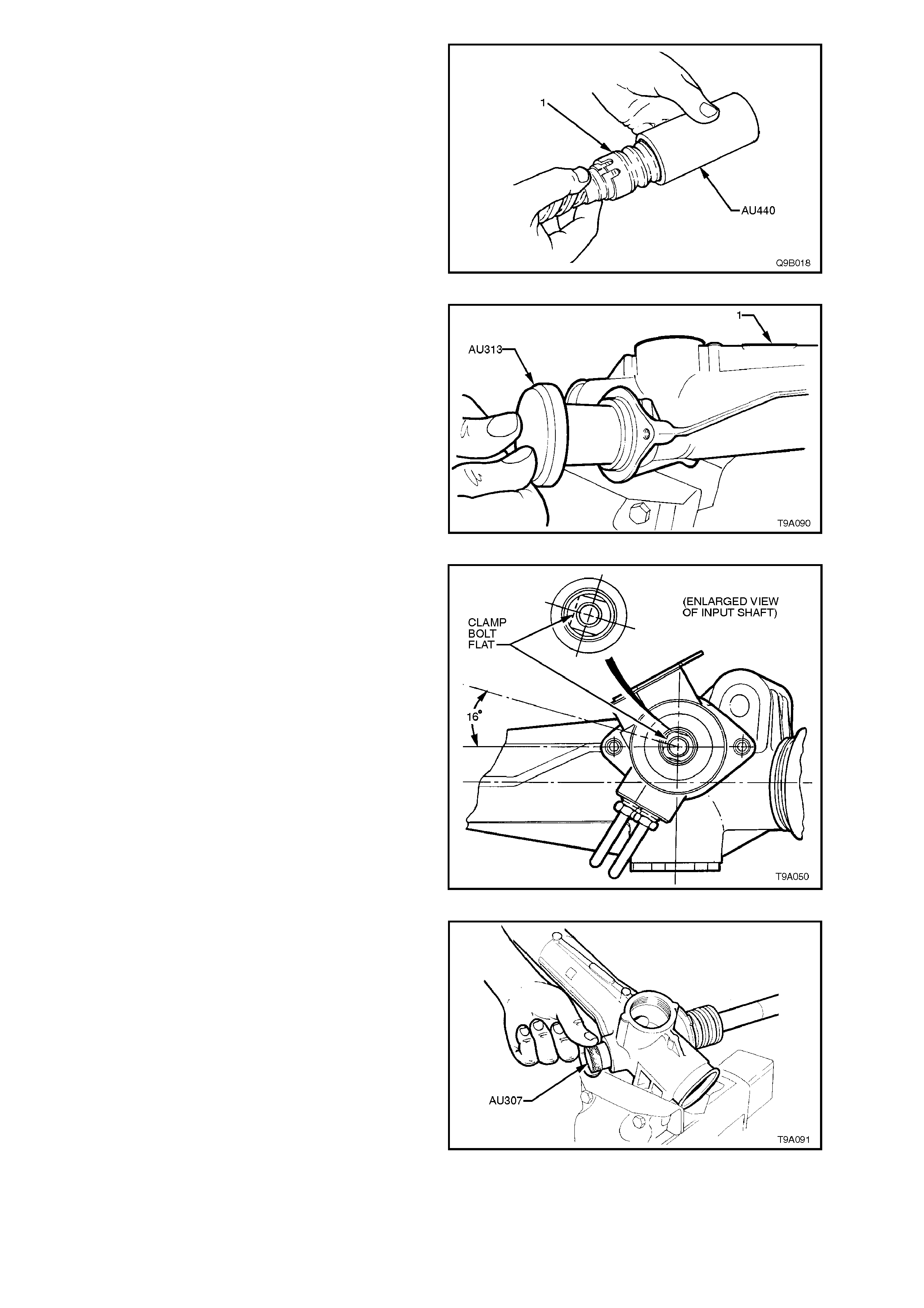

2. Screw Tool No. AU460 onto driver handle Tool

No. AU355-A with the O-ring end facing out.

Install the inner seal spacer (3) onto Tool No.

AU355-A, using the O-ring to hold the spacer

in place. Insert the tools and spacer into the

rack tube.

3. Using tool combination AU460/AU355-A,

press the seal s pacer (3) into the rack hous ing

(1), until the end of Tool No. AU355-A

protrudes f rom the rac k tube by approxim ately

53 mm . This m easurement will ensur e that the

spacer has been fully installed.

4. Reverse the fitment of Tool No. AU460 to the

driver handle Tool No. AU355-A.

5. Lubricate a new rack inner seal (2) with

Dexron® III autom atic trans miss ion f luid. Install

the seal (2) over the spigot of T ool No. AU460,

ensuring that the spring loaded sealing lip is

facing Tool No. AU460.

6. Press seal into the rack housing (1) on top of

the spacer (3). The seal will be fully installed

when the end of Tool No. AU355-A protrudes

from the rack tube by approximately 60 mm.

Figure 9A-89

7. Install a new O-ring to groove in rack piston.

8. After dipping a new Teflon seal ring in clean

power steering fluid, install the seal ring over

expander Tool No. E8803-9.

Figure 9A-90

9. With the seal ring still installed on Tool No.

E8803-9, slide the ass em bly over the rack and

up to the piston. Slide the seal ring (1) off the

expansion tool and into the piston groove (2),

over the O-ring.

Figure 9A-91

10. Ensure that the seal is seated correctly in the

groove, by wrapping fingers around the seal,

as shown.

Figure 9A-92