SECTION 2B - HEATING & AIR CONDITIONING

- REMOVAL AND INSTALLATION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bag s or seat belt pre- tensio ners, d riv er’s and fron t p asseng er’s air bag and lef t and rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Section of this Service Information CD for more

specific servicing information.

1. GENERAL INFORMATION

This Section details only the Service Operations (rem oval and installation operations) that have changed since the

publication of this Service Information CD. Therefore, for Service Operations not covered in this Section, refer to

Section 2B AIR CONDITIONING - REMOVAL & INSTALLAT ION of this Service Inf ormation CD. If the removal of

any ECC components is warranted, reference to Section 2E AIR CONDITIONING - ECC - REMOVAL &

INSTALLATION of this Service Information CD should be made.

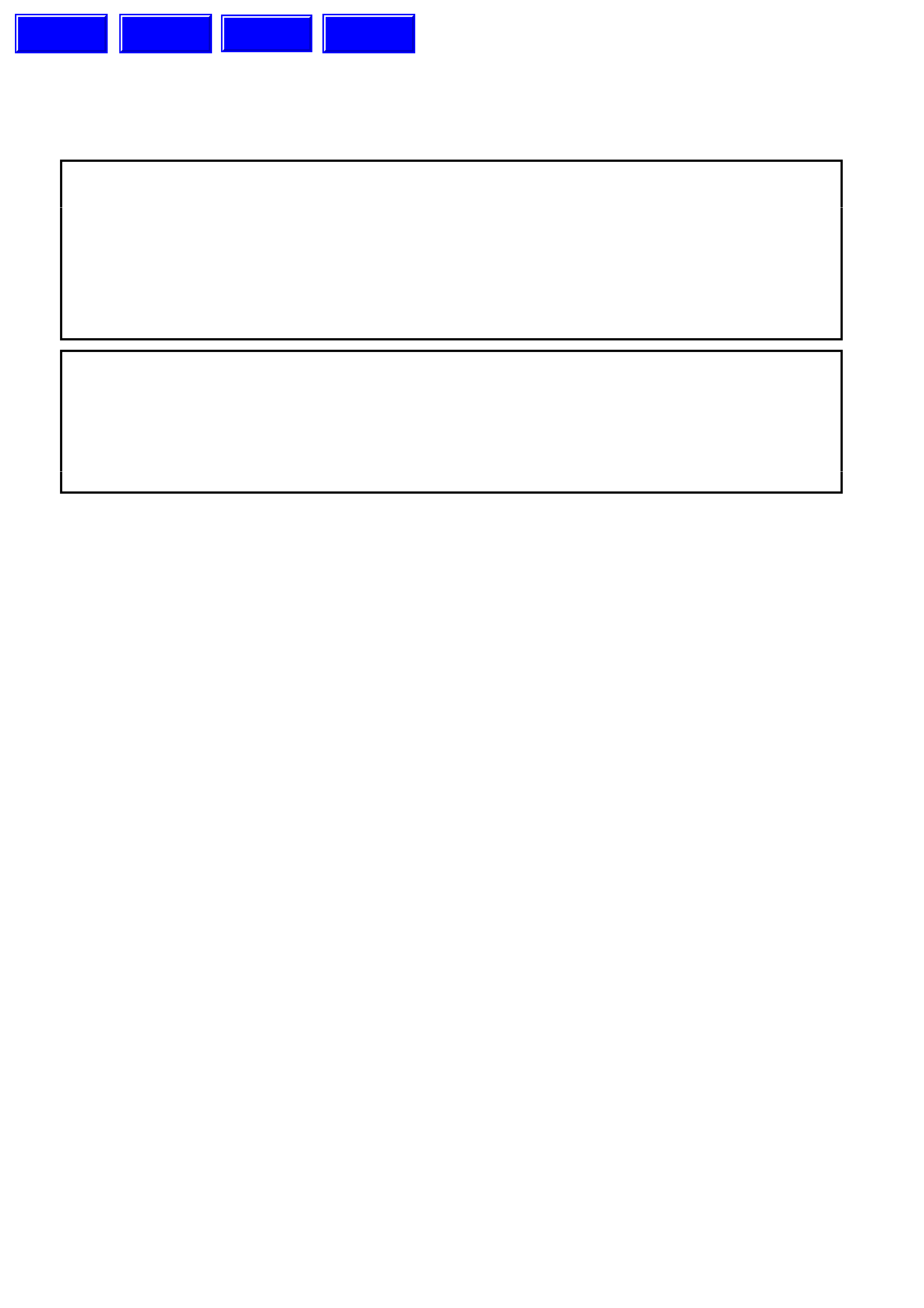

Figure 2B-1 details the air conditioning hose and line layout for VT Series Models with GEN III V8 engine

Techline

Techline

Techline

Techline

Figure 2B-1 GEN III V8 engine air conditioning hose and line layout

1. Thermal Expansion Valve (or block valve) 7. Discharge tube 13. Discharge hose/tube

2. 0-Ring 8. Discharge tube retaining clip 14. Retaining nut

3. Suction hose 9. Discharge tube retaining nut 15. Compressor

4. Liquid tube 10. Condenser

5. Retaining screw 11. Filter Drier Receiver (FDR)

6. Suction tube retaining clip 12. Retaining clamp

2. SERVICE OPERATIONS

2.1 HEATING, VENTILATION AND AIR CONDITIONING (HVAC) UNIT

REMOVE & REINSTALL

Removal and reinstallation of the HVAC unit on a

vehicle with a GEN III V8 engine is as detailed in

Section 2B AIR CONDITIONING - REMOVAL &

INSTALLATION of this Service Information CD,

noting the following:

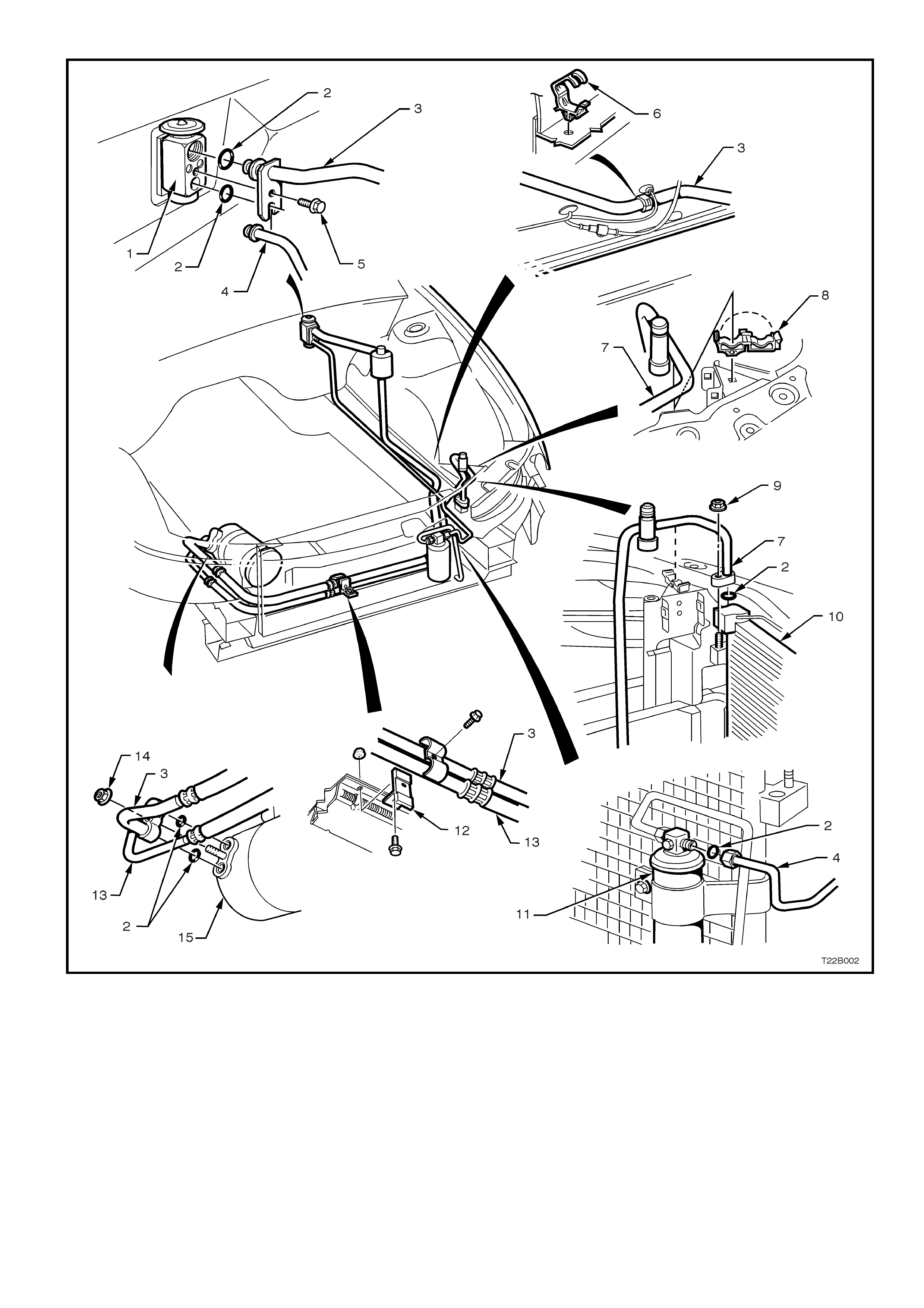

Figure 2B-2 shows the location of the heater

hoses and HVAC vacuum hoses in the engine

compartment. Before these hoses are removed,

they should be marked to ensure the correct

replacement position.

Figure 2B-2

2.2 CONDENSER - GEN III V8 ENGINE

REMOVE

1. Recover refrigerant from the air conditioning

system, refer to Section 2C AIR

CONDITIONING - SERVICING AND

DIAGNOSIS of this Service Information CD.

2. Remove the r adiator assem bly, refer to Section

6B3 ENGINE COOLING - GEN III V8 ENGINE

in the VT Series II Service Information.

3. Remove the two screws securing the left hand

side grille insert to the front bumper assembly

and lift grille out and up.

Figure 2B-3

4. Through the opening in the front bumper facia,

(where the left hand grille insert was removed)

unscrew the liquid tube fitting (1) from the Filter

Drier Receiver (FDR) (2) outlet.

T22B004

2

1

Figure 2B-4

5. Gently prise open the discharge tube retaining

clip (1).

6. Remove the nut ( 2) retaining the discharge tube

pad fitting (3) to the condenser (4).

7. Cap all open tubes/hoses to avoid moisture

from entering the system.

8. Discard O - ring (5).

T22B005

123

5

4

Figure 2B-5

9. ECC vehicles only: disconnect the ambient

temperature sensor electrical connector from

the front right hand side of the condenser.

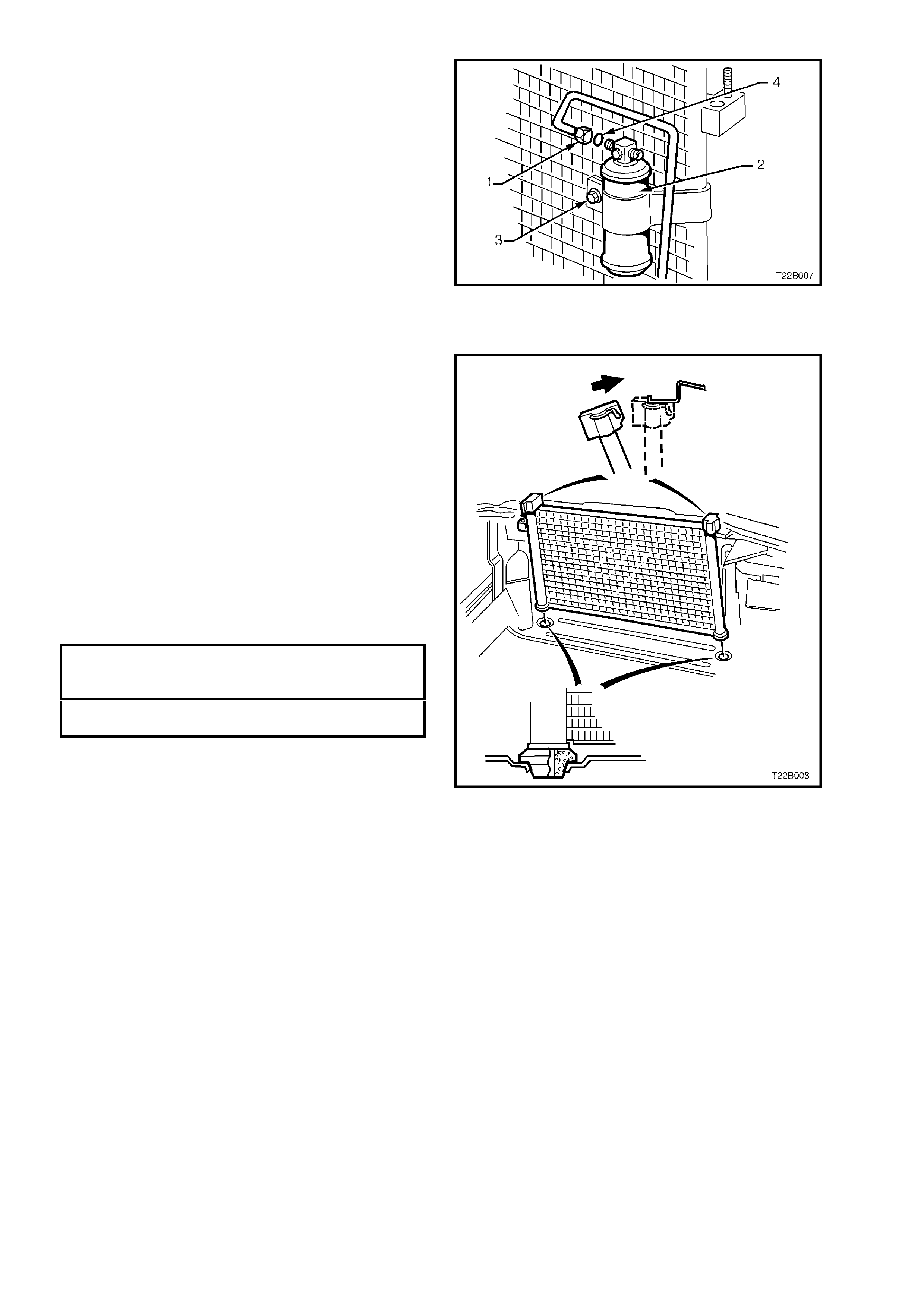

10.Tilt the condenser towards engine and lift

upwards.

T22B006

Figure 2B-6

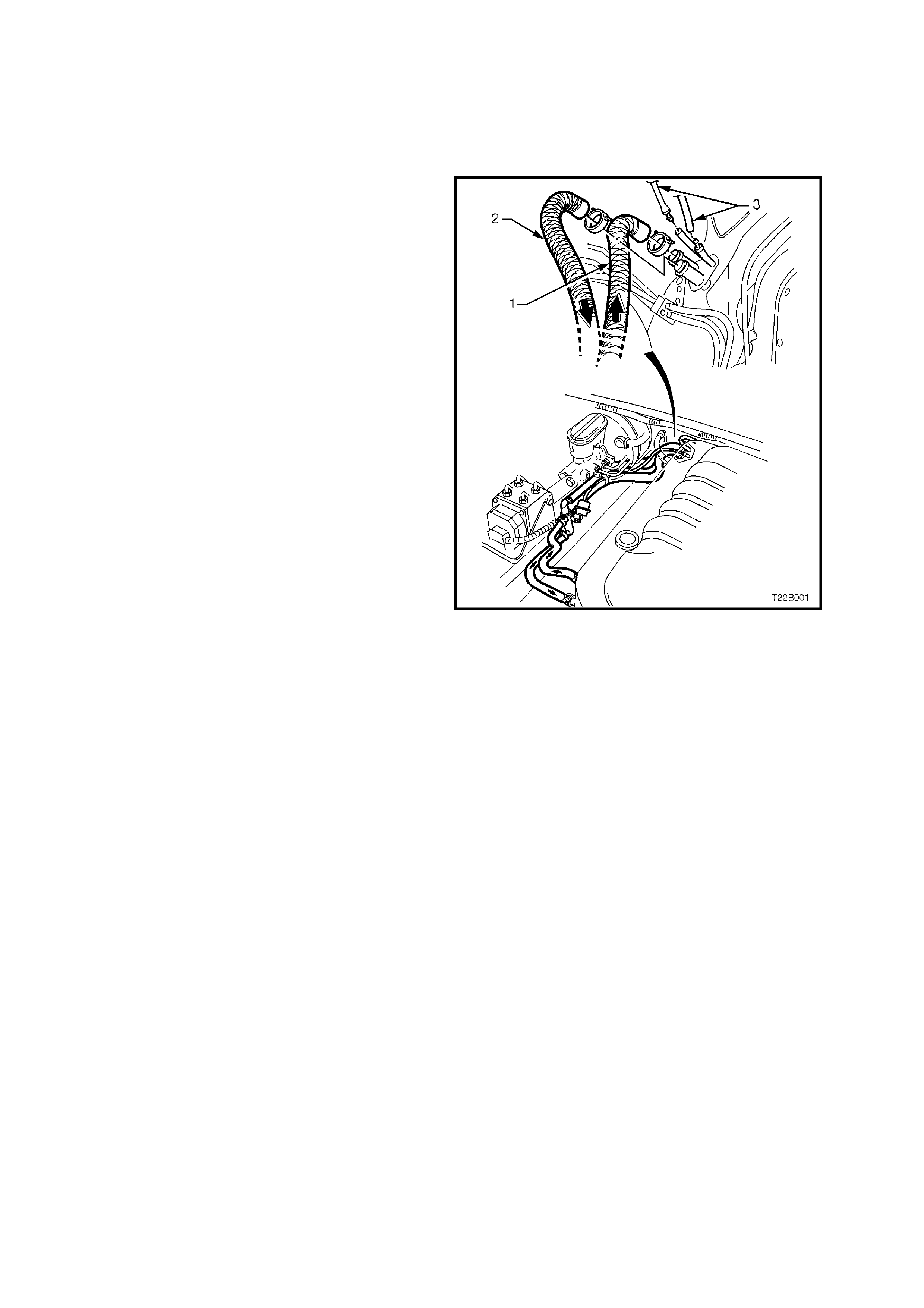

11.Mark mounting position of FDR for correct

reinstallation.

12.Unscrew the FDR inlet fitting (1), loosen the

FDR mounting bracket bolt (3) and remove the

FDR (2).

13.Discard O-ring (4).

Figure 2B-7

REINSTALL

Reinstallation of the c ondens er is the r evers e of the

removal procedure, noting the following:

1. Always use new O-r ings and lubricate with PAG

refrigerant oil (part number 12345923) before

fitting.

CAUTION: Do not allow PAG refrigerant oil to

contact bare skin or vehicle paint work. If contact

occurs to either, wash PAG refrigerant oil off

immediately.

2. When reinstalling the FDR, ensure the FDR inlet

tube is connected to the fitting on the FDR with

the word ‘IN’ on it (refer to markings on FDR

before removal).

3. Tighten all air conditioning fittings to the correct

torque specifications.

DISCHARGE TUBE PAD

RETAINING NUT 7.5 - 12.5 Nm

TORQUE SPECIF ICATION

AIR CONDITIONING TUBE FITTING 7.5 - 12.5

TO FDR TORQUE SPECIFICATION Nm

4. Recharge air conditioner system, refer to

Section 2C AIR CONDITIONING - SERVICING

& DIAGNOSIS of this Service Information CD. Figure 2B-8

2.3 AIR CONDITIONING DRIVE BELT- GEN III V8 ENGINE

REMOVE

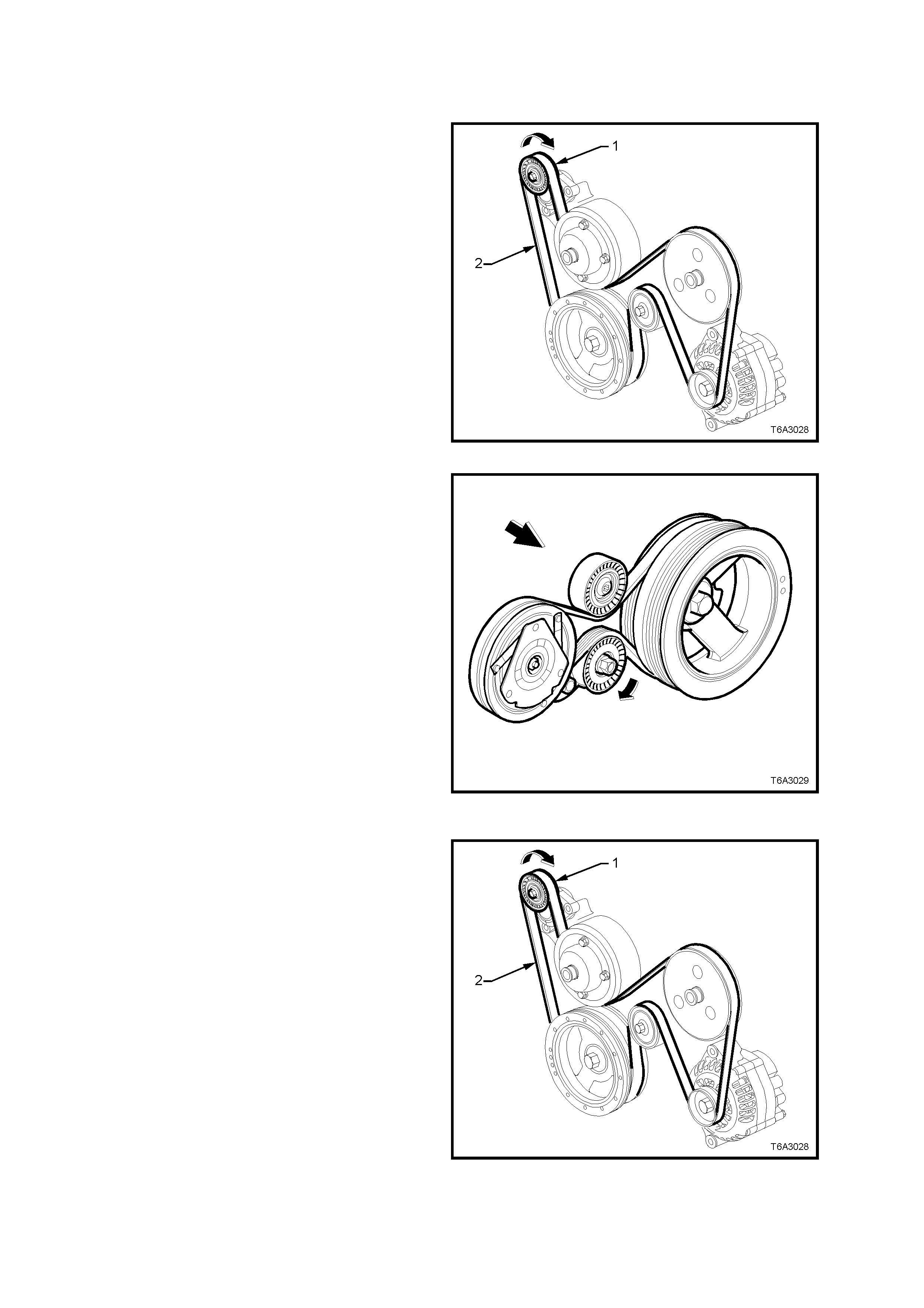

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the engine

accessory drive belt tensioner (1), in the

direction indicated, to reduce belt tension.

2. Remove the engine dr ive belt (2), taking note of

the belt routing.

Figure 2B-9

3. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown, to

relieve belt tension.

4. Remove the air conditioning drive belt from the

pulleys.

5. Inspect belts for damage and replace if

necessary.

REINSTALL

1. Clean the engine acces sory and air conditioning

drive belt running surfaces

2. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown, install

the drive belt over the pulleys, routing the belt

correctly , as shown.

3. Inspect the installation to ensure that the belt is

correctly aligned on all pulleys. Figure 2B-10

4. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the engine

accessory drive belt tensioner (1), in the

direction indicated, install the engine accessory

drive belt (2) over the pulleys, routing the belt

correctly , as shown.

5. Inspect the installation to ensure that the belt is

correctly aligned on all pulleys.

6. Start the engine to ensure correct operation.

Figure 2B-11

2.4 AIR CONDITIONING DRIVE BELT IDLER PULLEY - GEN III V8 ENGINE

REPLACE

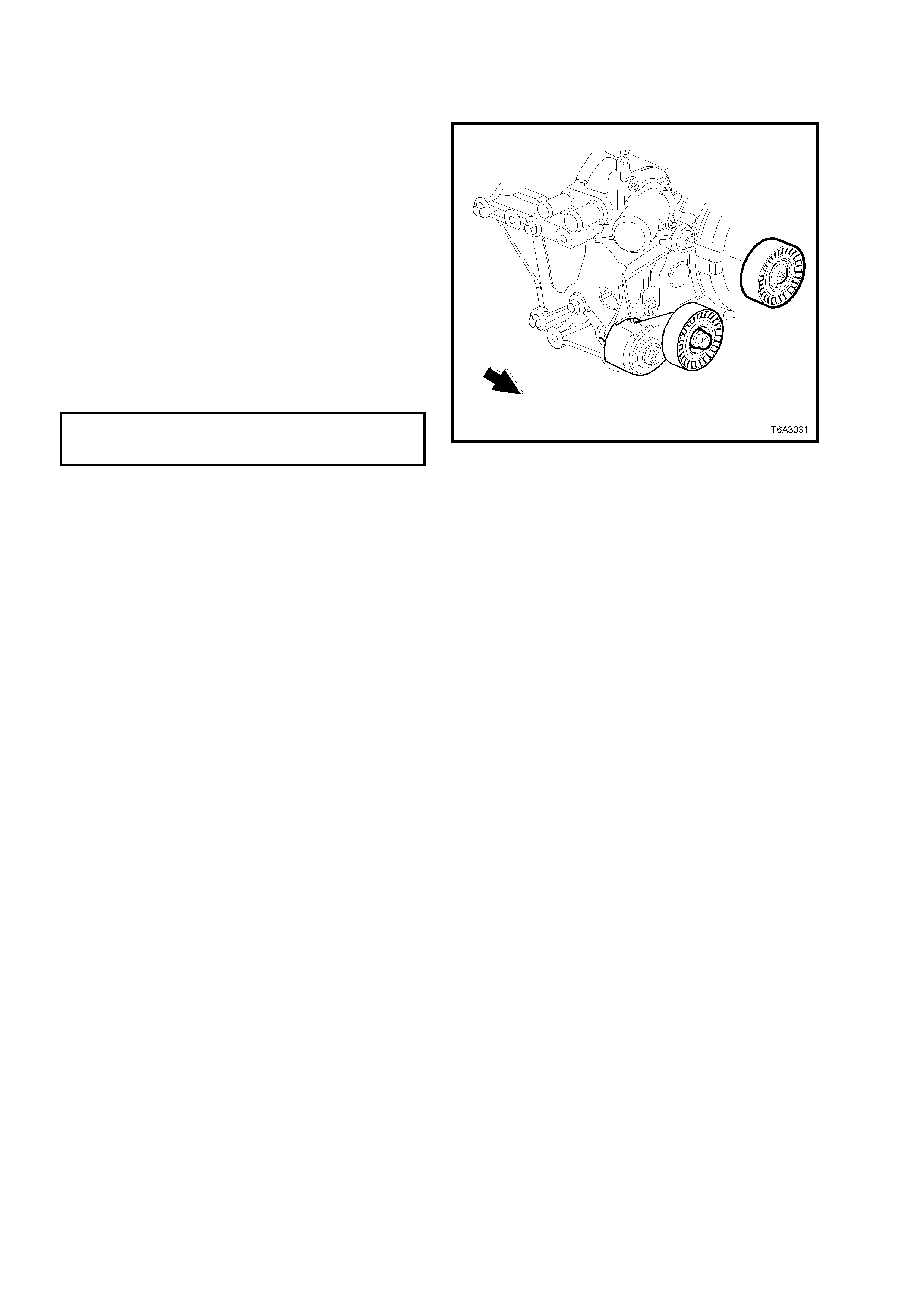

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown in

Figure2B-10, to relieve belt tension.

2. Remove the air conditioning drive belt from the

pulleys but leave hanging on the crankshaft

pulley.

3. Using a commercially available, Torx bit T50,

remove the bolt securing the air conditioning

com pr es s or drive belt idler pulley to its mounting

boss on the water pump housing, then remove

the pulley assembly.

4. Install the idler pulley to its mounting boss.

5. Install the idler pulley retaining bolt and tighten

to the correct torque specification.

AIR CONDITIONING COMPRESSOR

DRIVE BELT IDLER PULLEY BOLT 40.0 - 60.0 Nm

TORQUE SPECIFICATION

6. Reinstall the air conditioning compressor drive

belt. Refer 2.3 AIR CONDITIONING DRIVE

BELT _ GEN III ENGINE – REINSTALL in this

Section for the necessary procedure.

Figure 2B-12

2.5 AIR CONDITIONING DRIVE BELT TENSIONER - GEN III V8 ENGINE

REPLACE

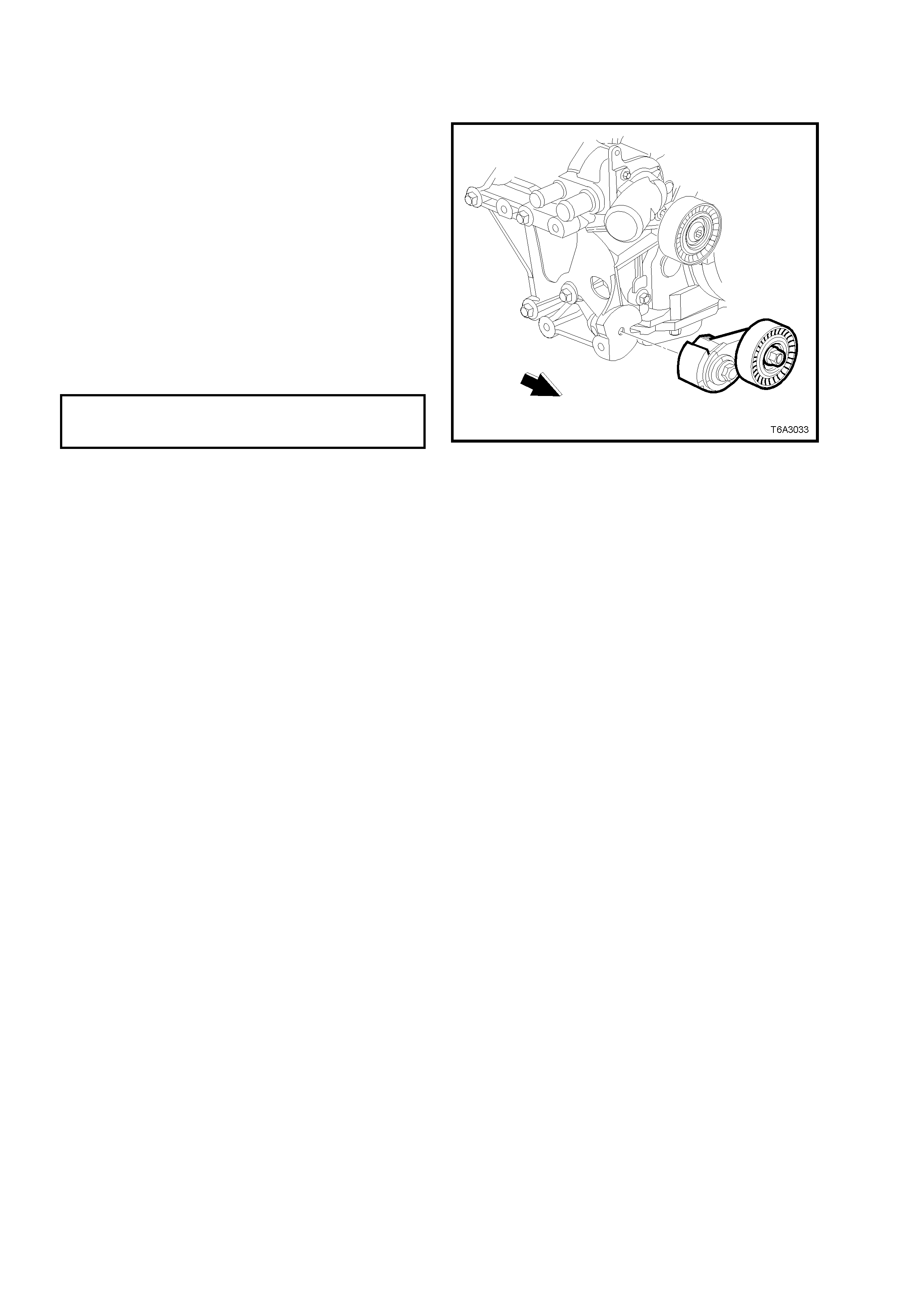

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown in

Figure 2B-10, to relieve belt tension.

2. Remove the air conditioning drive belt from the

pulleys but leave hanging on the crankshaft

pulley.

3. Remove the bolt securing the air conditioning

compressor drive belt tensioner, then remove

the assembly.

4. Install the tensioner as sembly and the mounting

bolt.

5. Tighten the tensioner mounting bolt to the

correct torque specification.

AIR CONDITIONING DRIVE BELT

TENSIONER BOLT 21.0 - 29.0 Nm

TORQUE SPECIFICATION

6. Reinstall the air conditioning compressor drive

belt. Refer 2.3 AIR CONDITIONING DRIVE

BELT - REINSTALL in this Section for the

necessary procedure.

Figure 2B-13

2.6 COMPRESSOR - GEN III V8 ENGINE

REMOVE

1. Disconnect the battery ground cable.

2. Drain coolant and rem ove the heater hoses and

lower radiator coolant hose from the cylinder

block , refer to Section 6B3 ENGINE COOLING

- GEN III V8 ENGINE in the VT Series II Servic e

Information.

3. Recover refrigerant charge, refer to

Section 2C AIR CONDIT IONING - SERVICING

AND DIAGNOSIS of this Service Information

CD.

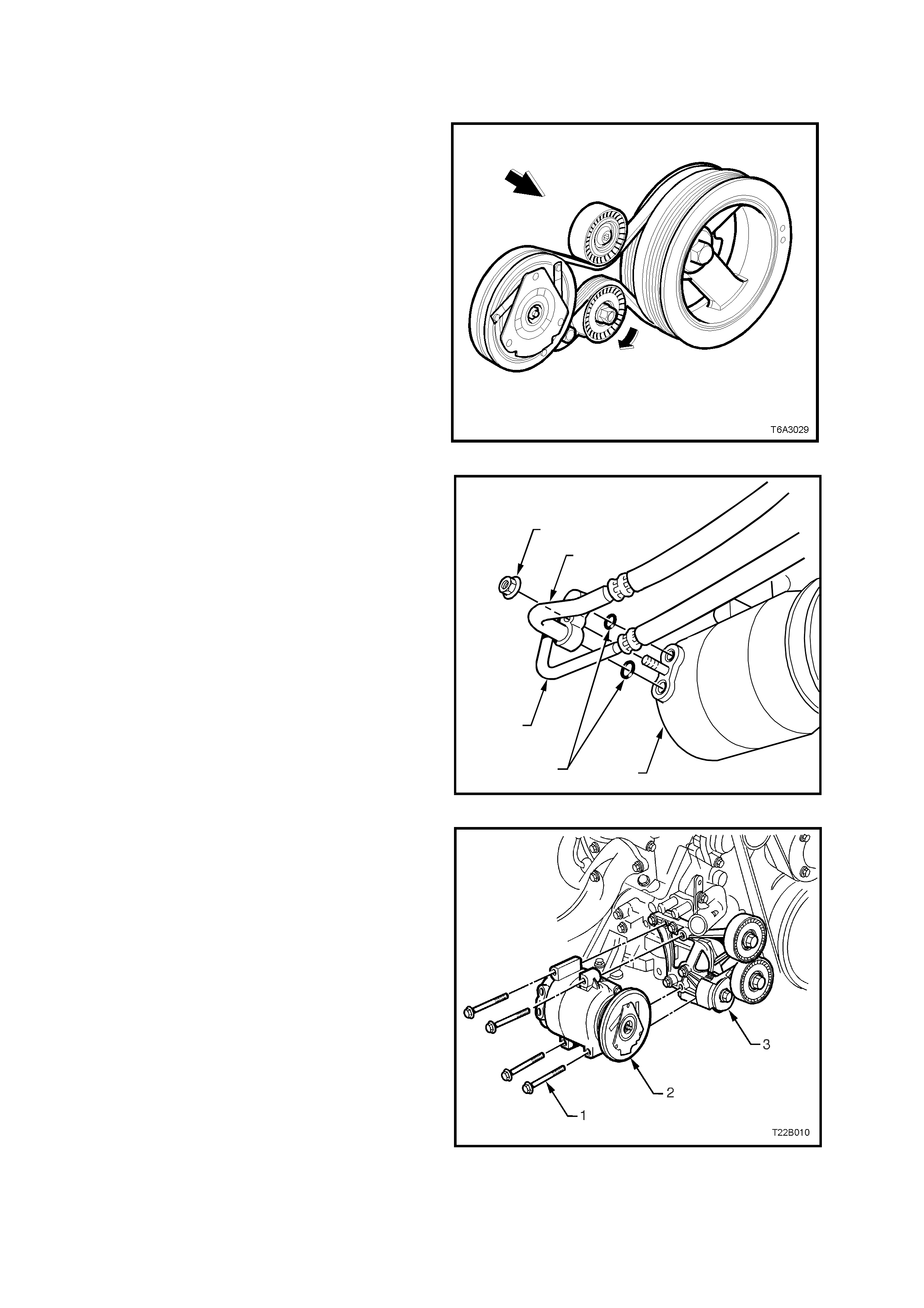

4. Using a 15mm socket attached to the centre

bolt of the air conditioning drive belt tensioner,

rotate the tensioner in the direction shown in

Figure 2B-10, to relieve belt tension.

5. Remove the air conditioning drive belt from the

pulleys but leave hanging on the crankshaft

pulley. Figure 2B-14

6. Loosen and remove the nut (1) retaining the

suction (2) and discharge (3) hoses to the

com press or (4). Rem ove the hoses (2 & 3) f rom

the compressor.

7. Discard O-rings (5).

8. Cap or plug the ports immediately to prevent

entry of moisture from the atmosphere.

9. Disconnect the compressor clutch electrical

connector.

T22B009

1

2

3

54

Figure 2B-15

10.Remove the four bolts (1) retaining the

compressor (2) to the mounting bracket (3).

NOTE: Figure 2B-16 shows several components

removed for clarity only (i.e. heater and coolant

hoses). To remove the compressor, it is not

necessary to remove these components.

11.Remove compressor.

12. If necess ary, remove the f our bolts retaining the

compressor mounting bracket to the cylinder

block and remove the mounting bracket.

Figure 2B-16

REINSTALL

1. If removed, reinstall the compressor mounting

bracket and tighten the four retaining bolts to

the correct torque specification.

COMPRESSOR MOUNTING BRACKET

RETAINING BOLT 40.0 - 60.0 Nm

TORQUE SPECIFICATION

NOTE: If replacing with a new compressor refer to

Section 2C AIR CONDITIONING - SERVICING

AND DIAGNOSIS of this Service Information CD

for lubrication requirements/specifications.

2. Fit the compressor to the com pressor mounting

bracket, install the four retaining bolts and

tighten to the correct torque specification.

COMPRESSOR RETAINING BOLT 40.0 - 60.0

TORQUE SPECIFICATION Nm

3. Reinstall the air conditioning compressor drive

belt. Refer 2.3 AIR CONDITIONING DRIVE

BELT – GEN III V8 ENGINE - REINSTALL in

this Section for the necessary procedure.

4. Remove c aps f r om compres sor ports and ins tall

new sealing washers.

5. Using new O-rings lubricated with PAG

refrigerant oil (part number 12345923) install

the air conditioning suction and discharge hose

pad fitting onto the compressor.

CAUTION: Do not allow PAG refrigerant oil to

contact bare skin or vehicle paint work. If contact

occurs to either, wash PAG refrigerant oil off

immediately.

6. Install the suction and discharge hose pad

retaining nut and tighten to the correct torque

specification.

SUCTION AND DISCHARGE HOSE

PAD RETAINING NUT 28.0 - 42.0 Nm

TORQUE SPECIFICATION

7. Connect the compressor clutch electrical

connector.

8. Connect heater and lower radiator coolant

hoses, refill coolant system with correct coolant

and pressure test coolant system, refer to

Section 6B3 ENGINE COOLING - GEN III V8

ENGINE in VT Series II Service Information.

9. Recharge air conditioner system, refer to

Section 2C AIR CONDITIONING - SERVICING

& DIAGNOSIS of this Service Information CD.

3. TORQUE WRENCH SPECIFI CATIONS

For torque wrench specifications not listed below, refer to Section 2B HEATING AND AIR CONDITIONING -

REMOVAL AND INSTALLATION, of this Service Information CD.

GEN III V8 ENGINE Nm

Air conditioning compressor drive belt idler pulley bolt......... 40.0 - 60.0

Air conditioning compressor drive belt tensioner bolt ........... 21.0 - 29.0

Air conditioning tube fittings to FDR...................................... 7.5 - 12.5

Compressor mounting bracket retaining bolt........................ 40.0 - 60.0

Compressor retaining bolt..................................................... 40.0 - 60.0

Compressor suction and discharge hose pad retaining nut.. 28.0 - 42.0

Condenser discharge tube pad retaining nut........................ 7.5 - 12.5

V6 ENGINE Nm

Compressor retaining bolt..................................................... 20.0 - 30.0

Compressor retaining nut...................................................... 40.0 - 55.0

Compressor suction and discharge hose pad retaining nut.. 28.0 - 42.0

NOTE: The V6 compressor torque wrench specifications listed above were

either omitted or incorrectly quoted in Section 2B HEATING AND AIR

CONDITIONING - REMOVAL AND INSTALLATION, of this Service

Information CD.