SECTION 3 – FRONT SUSPENSION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air b ags or seat belt pre- tensioners, driv er’s and front passenger’s air bag and left and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning ‘OFF’ the manual service valve and then draining the LPG

service lin es, b efo re any serv ice work is carried o ut on th e v ehi cle. Refer t o t he L PG leaf let in clud ed with

the Owner's Handbook for details or the appropriate Section of this Service information CD for more

specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ET C FUNCTION CHECK, in Section 12L ABS & ABS/ET C, in either

VT Series I Service Information (V6) or VT Series II Service Information (GEN III V8).

1. GENERAL DESCRIPTI ON

Introduced as a running change in the production of VT Series II vehicles, with a build date after August 12, 1999

and production serial number L 492505, the steering knuckle design and material was changed, which has also

resulted in a design change to the control arm ball joint. As a further result of the changed steering knuckle, the

taper angle of the steering rack outer tie rod ends has also changed.

The new/changed components will not service back to earlier build VT and VT Series II vehicles, unless the

following components are all changed as a group:

• Steering knuckle

• Control arm ball joint

• Outer tie rod end.

Planned for introduction in late January, 2000, the two front crossmember to side frame member bolts are to be

changed to incorporate a tapered boss at the head end to provide a self aligning feature for the front suspension

crossmember. This change affects the alignment procedure for the crossmember.

Only those ser vice pr ocedures af fec ted by the above changes, are descr ibed in this Section and s hould be ref erred

to for vehicles produced after the expected and stated breakpoint production serial number.

Introduced during the life of VT Series II production, minor changes to the front suspension alignment tolerance

range, results in an increased vehicle directional stability . Details are included in this Section.

Those service operations not described in this Section remain unchanged from the procedures detailed in

3. FRONT SUSPENSION, of the VT Series I Service Information and/or modified in 3. FRONT SUSPENSION of

the VT Series II Service Information.

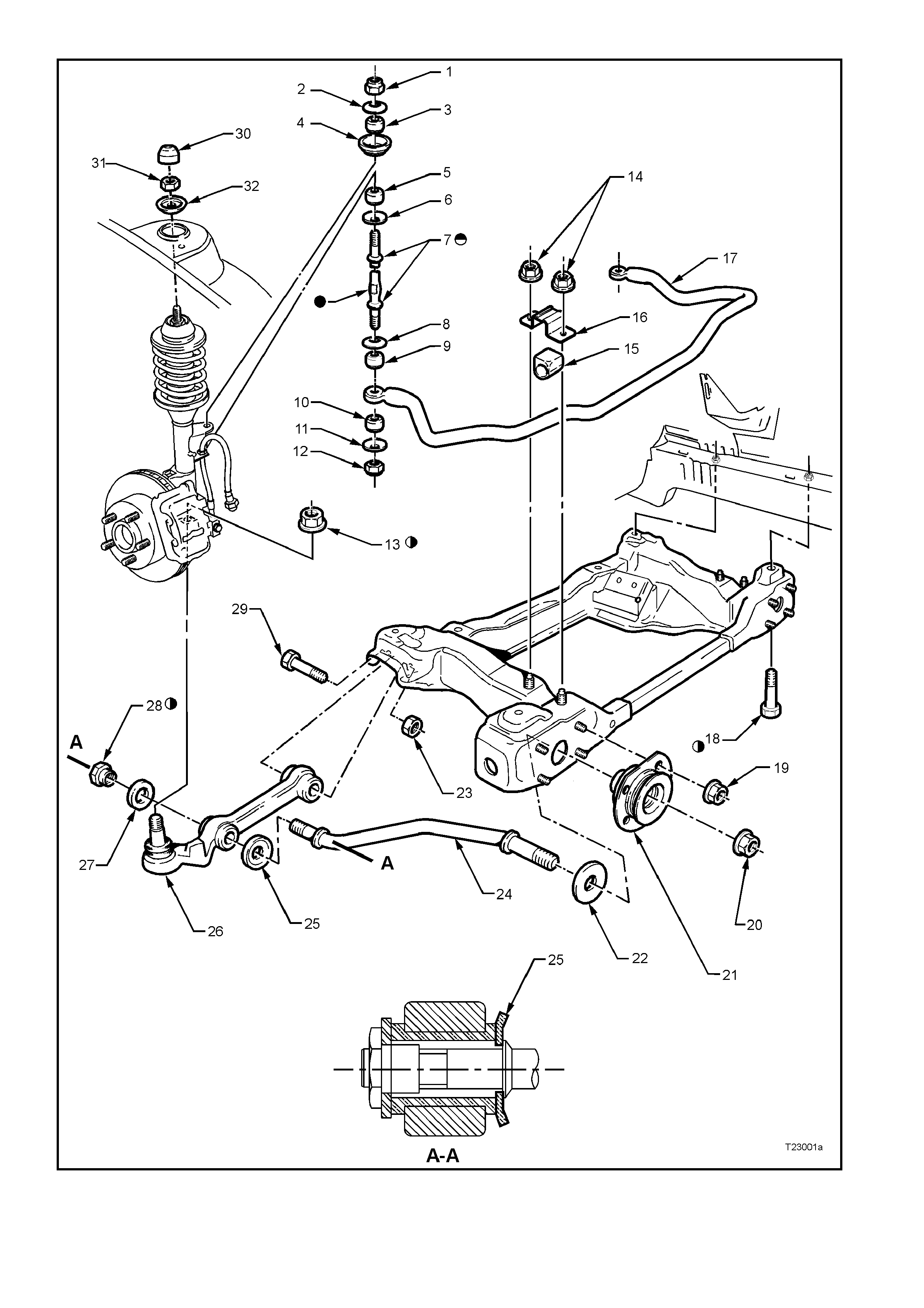

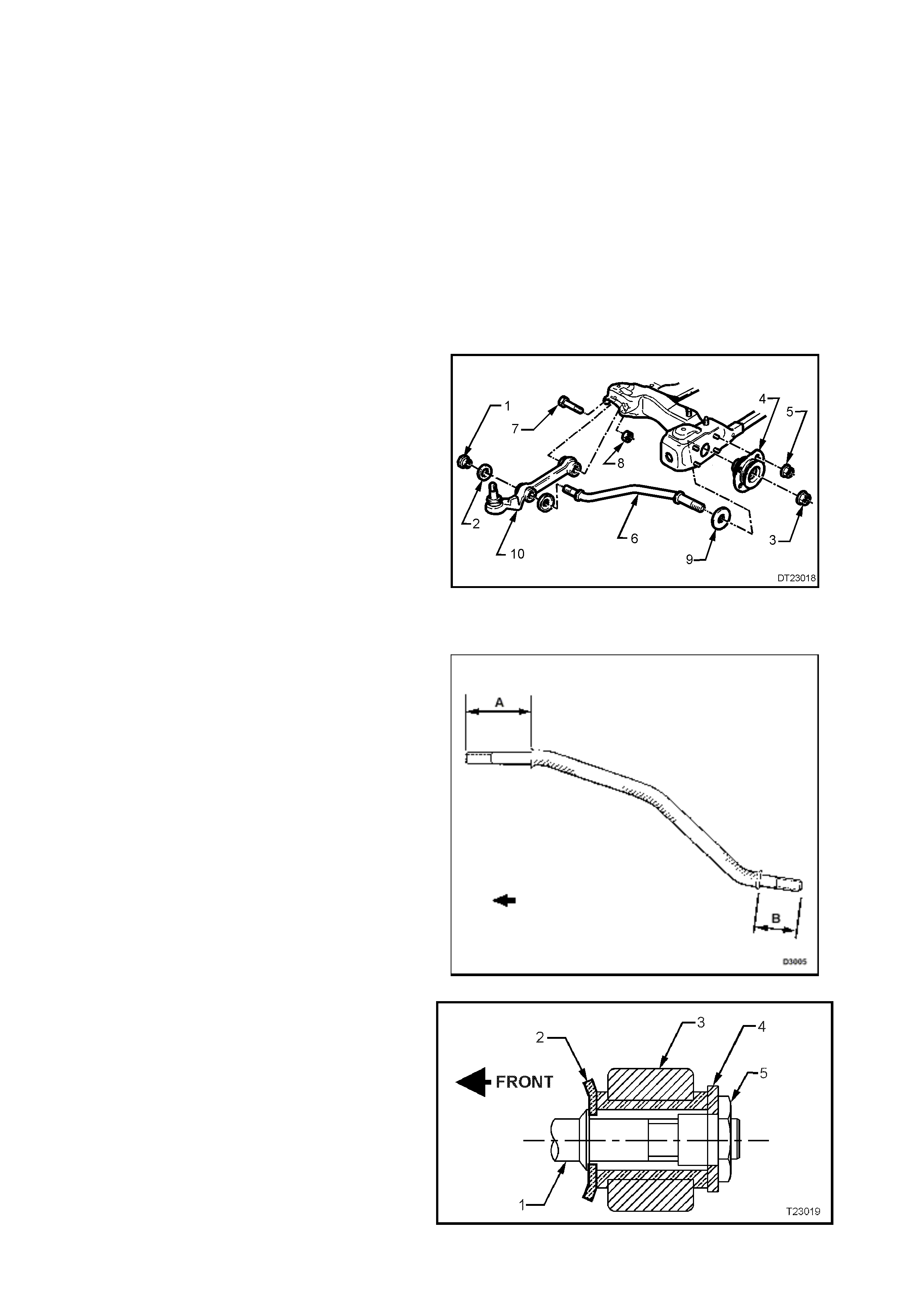

The f ront suspension f itted to VT Series II m odels with the revised components, operates on the MacPherson strut

principle. The assembly consists of the front crossmember, control arms, tension rods, stabiliser bar and strut

assemblies (Refer to Fig. 3-1).

The c rossm ember is bolted to both longitudinal f rame s ide mem bers, while the inner pivots of the contr ol arms ar e

rubber bushed and are attached to the crossmember by bolts and nuts. The outer end of each control arm is

connected to the knuckle on the strut assembly through a ball joint tapered stud and nut.

The strut assembly incorporates a hydraulic wet sleeve type damper inside the strut tube, a rubber dust boot with

air filter and compression rubber, a coil type suspension spring mounted between the strut housing and upper

spring seat collar, a bearing assembly and an upper strut support.

The strut assembly is located at the upper end to the body structure by an upper strut support and secured by a

self-locking nut and locating disc, while the lower end of the strut tube is fastened to the steering knuckle by two

bolts and nuts.

Positioning of the control arm assemblies is controlled by tension rods connecting the control arms to the front

suspension crossmember. The tension rods are m ounted in a rubber bush at the control arm end and a fluid filled

damper at the other.

Techline

Techline

A stabiliser bar is mounted to the side members of the crossm ember by two brackets and insulating rubbers, and

attached to each strut tube by a spacer stud, insulating bushes, retainers and attaching nuts.

Legend for Fig. 3-1

Flattened end toward

stabiliser Stud to be held while nuts are

torqued to specification Fastener must be new and

assembled dry.

1. Nut (2 places) 12. Nut (2 places) 23. Nut (2 places)

2. Washer (2 places) 13. Nut (2 places) 24. Rod – Tension (2 places)

3. Bush (2 places) 14. Nuts (4 places) 25. Washer – Cupped (2 places)

4. Seat (2 places) 15. Insulator (2 places) 26. Control Arm – Lower (2 places)

5. Bush (2 places) 16. Bracket (2 places) 27. Washer (2 places)

6. Washer (2 places) 17. Bar – Stabiliser 28. Nut (2 places)

7. Spacer Stud (2 places) 18. Bolt (4 places) 29. Bolt (2 places)

8. Washer (2 places) 19. Nut (8 places) 30. Dust Cover (2 places)

9. Bush (2 places) 20. Nut (2 places) 31. Nut (2 places)

10. Bush (2 places) 21. Bush (2 places) 32. Locating Disc (2 places)

11. Washer (2 places) 22. Washer (1 place on driver’s

side ONLY) ‘A-A’ - Assemble washer ‘25’ as

shown

Figure 3-1

2. WHEEL ALIGNMENT

2.1 WHE EL ALIGNMENT CHECKING AND ADJUSTMENT

PRELIMINARY INSPECTION

Before any attempt is made to check camber,

caster or toe-in, these preliminary checks should

be carried out.

1. Check tyre and tyre mountings. Always check

cam ber and toe-in at the m ean r un-out position

on the tyre or rim.

2. Check and adjust tyre pressures to

recommended values.

3. Front wheel bearing end float is to be checked

to ensure it is within specification, as detailed

in 2.4 FRONT WHEEL BEARING HUB - END

FLOAT CHECKING PROCEDURE, FRONT

SUSPENSION, of the VT Series I Service

Information.

4. Control arm ball joints and inner bushes should

be checked for wear.

5. Check steering gear mounting bolts for

tightness and tie rod ball joints for wear.

6. The vehicle should be at curb weight, fuel tank

full, without driver, passengers or luggage etc.

7. Check for improperly operating front struts or

rear shock absorbers.

8. Check for loose or missing stabiliser bar or

tension rod attachments.

9. Before checking the front wheel alignment,

refer to 4A REAR SUSPENSION of the VT

Series I Service Information for rear wheel

alignment details.

CASTER ADJUSTMENT

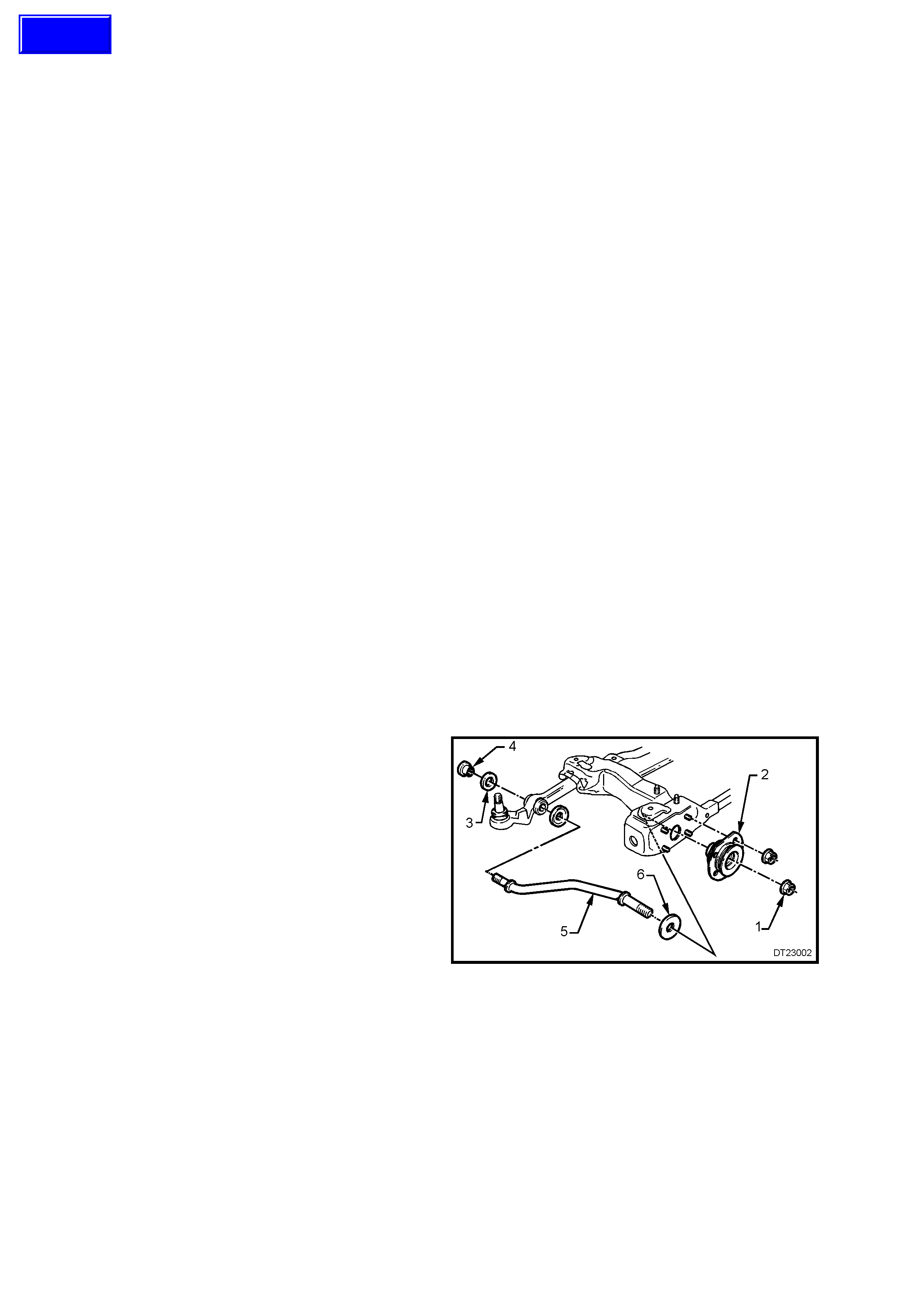

W hile one bright f inished spaced washer (6) will be

fitted to the driver’s s ide tension rod (5), the f itment

of an additional washer is permitted to correct

minor caster adjustments

Only one spacer washer is to be fitted and is to be

added to the side with the higher caster reading.

Figure 3-2

Techline

CAMBER ADJUSTMENT

1. Raise front of vehicle and support on safety

stands under front side members. Refer to

Section 0A GENERAL INFORMATION of the

VT Series I Service Information for location of

jacking and support points.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels) and mark relationship of

wheel to hub stud, using a felt tipped pen or

similar.

3. Remove wheel attaching nuts and remove

wheel.

4. Loosen, remove and discard the two lower

strut attaching bolts and nuts (2).

Reinstall NEW lower strut attaching bolts and

nuts (2) but do not tighten fully to

specification until after the camber has been

adjusted to the recommended specification.

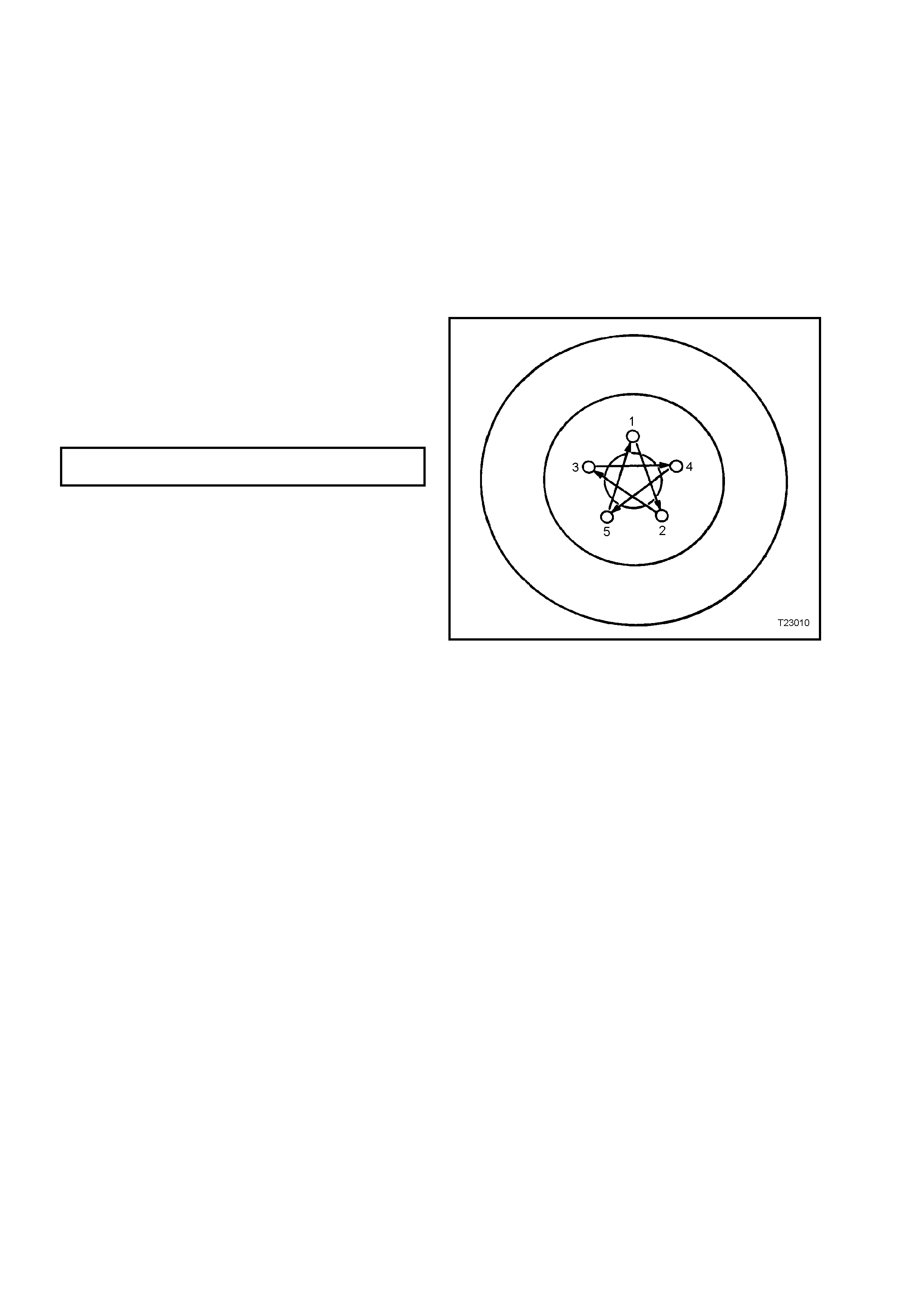

5. Reinstall road wheel, aligning previously made

marks. Install wheel nuts and tighten to the

correct torque specification, working in a ‘star’

pattern. Do not over-tighten!

ROAD WHEEL ATTACHING NUT 110 - 140

TORQUE SPECIFICATION Nm

6 Lower the vehicle to the ground and bounce

vehicle several times to settle suspension.

Figure 3-3

7. Check the camber angle.

8. If required, adjust camber by turning the

camber adjusting screw (1) in the required

direction; clockwise to reduce negative

camber, anti-clockwise to reduce positive

camber.

NOTE: The camber adjusting screw has thread

sealant applied in the form of micro-encapsulation

and does not require a lock nut.

9. Raise vehicle once again, support on safety

stands and remove the front road wheels.

10. Tighten both steering k nuckle bolts and nuts to

the correct torque specification.

NOTE: New bolts and nuts MUST be used!

STEERING KNUCKLE TO STRUT Stage 1 85 Nm

ATTACHING BOLTS & NUTS Stage 2 100 Nm

TORQUE SPECIFICATION Stage 3 Turn

through 90°

11. Reinstall road wheels, aligning the marks

made prior to removal.

12. Remove jack stands and lower vehicle.

13. Install wheel nuts and tighten to the correct

torque specification, working in a ‘star’ pattern.

Do not over-tighten!

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

14. Refit wheel cover/centre cap.

15. Check the c amber angle again to ensure that it

is still within specification (refer to Fig. 3-6).

TOE ADJUSTMENT

Toe of both front wheels, is checked with the

wheels in the straight ahead position.

Adjustm ent is achieved by winding the tie rods in or

out of the tie rod ends, thus increasing or

decreasing their length and thereby altering the

toe-in setting.

1. Set steering gear and wheels in straight ahead

position.

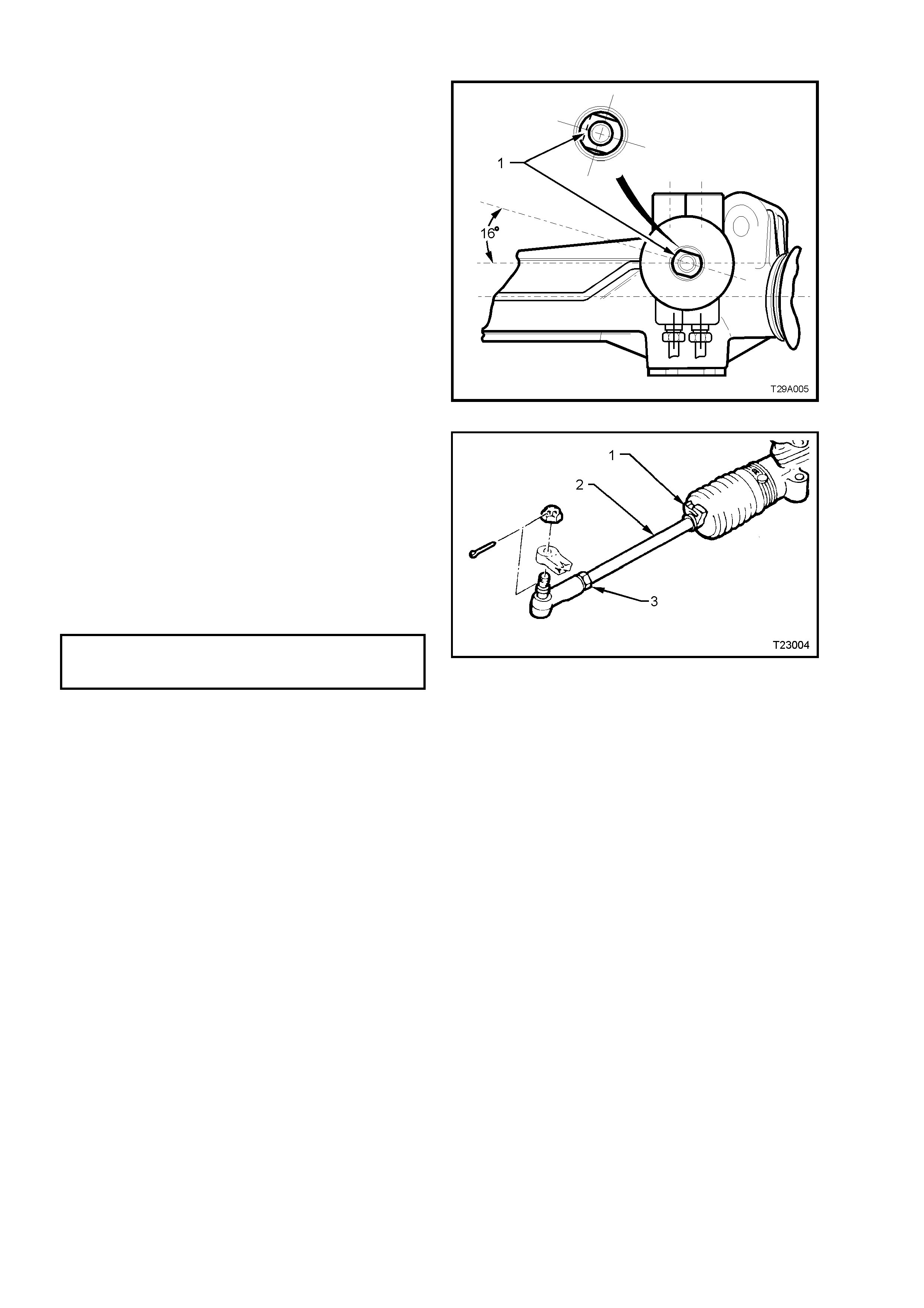

2. To check if steering gear is in straight ahead

position (on-centre), the pinion (input) shaft (1)

should be aligned as shown.

NOTE: While the one-piece steering rack housing

is shown, the on-centre position is the same for all

steering racks.

Figure 3-4

3. Before adjusting tie rods (2), disconnect

steering gear outer bellows clips (1).

4. Loosen lock nut (3) at end of each tie rod.

5. Turn each tie rod as required, until the correct

toe is obtained.

NOTE: During toe adj ustment, ensur e that steering

wheel is held in the straight ahead position.

6. Tighten lock nuts (3), to the correct torque

specification, ensuring that tie rod ends are in

alignment with their ball studs.

TIE ROD TO TIE ROD BALL

JOINT LOCK NUT 40 – 60 Nm

TORQUE SPECIFICATION

7. Tighten outer bellows clips securely, making

sure that convolutions of the boots are not

distorted.

Figure 3-5

8. With steering gear in straight ahead position,

ensure that st eering wheel is c entralis ed. If not,

remove steering wheel (refer to

Section 9 STEERING of the VT Series I

Service Information) and reposition.

FRONT WHEEL ALIGNMENT AT KERB WEIGHT

Wheel Alignment Angle Specification – All Sedan and Station Wagon

Camber -0° 12' ± 0° 18'

Caster 7° 45' ± 1° 15'

Toe-in Degrees Total 0° 10’ ± 0° 10'

Degrees per Wheel 0° 5’ ± 0° 5’

Toe-out on Turns 1° 42’ @ 20 ° turn angle ± 1° 30'

Steering Axis Inclination Angle 12° 52’ ± 1° 30'

Included Angle 12° 40’ ± 1° 30'

SERVICE INFORMATION

• The adjusting values for camber, caster and toe-in must remain

within the tolerances specified. The difference between left and

right must not exceed the following:

CASTER ............ 0° 36'

CAMBER ........... 0° 48'

TOE-IN............... 0° 10'

• The specifications listed are the nominal value, with acceptable

variance from this c entral point. Wher e poss ible, an attempt should

always be made to achieve the nominal settings when changing.

• Front wheel camber alters as a function of front suspension height.

• Camber adjusting bolt: After loosening both lower strut to steering

knuc kle bolts and nuts, adjust c amber by turning the adjusting bolt

clockwise to decrease negative camber and anti-clockwise to

increase negative camber. After adjustment, both bolts and nuts

MUST be replaced with new parts and tightened to the

recommended torque setting.

• The rear wheel alignment should be checked and corrected if

necessary (refer to Section 4. REAR SUSPENSION in Volume 1)

before checking front wheel alignment.

Fuel Mass with Full Tank - All Models 56 kg

Figure 3-6

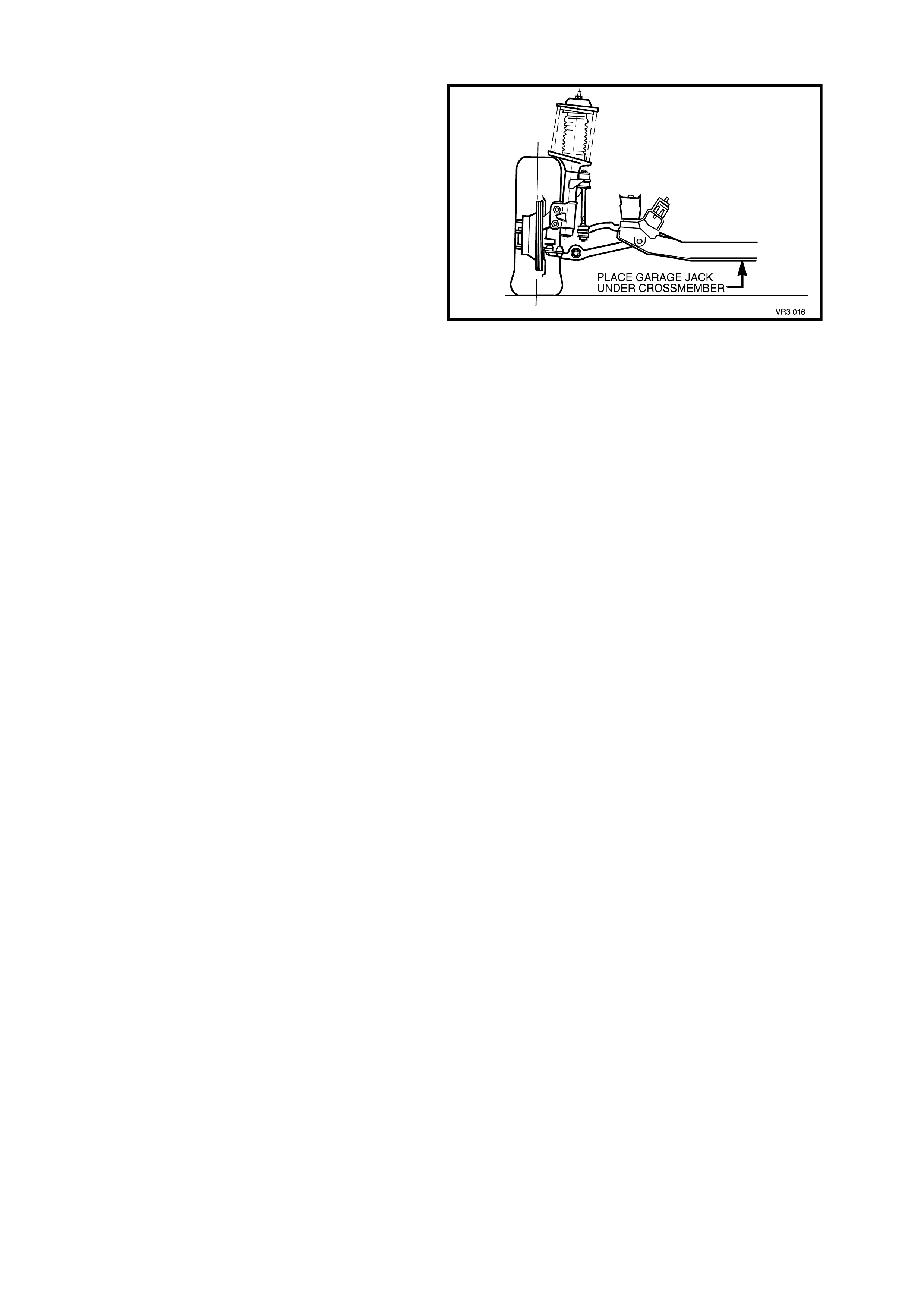

2.2 JACKING PRECAUTIONS

When raising the front of the vehicle with a jack,

the jack should be placed under the front

crossmember. THE WEIGHT OF THE VEHICLE

MUST NOT BE LIFTED UNDER THE CONTROL

ARMS.

When the vehicle is raised on the jack, it must be

firm ly supported on safety stands located under the

fram e s ide m embers before any work is attem pted.

If a vehicle is not correctly supported by safety

stands, serious injury can result if the vehicle

should slip off the jack.

Figure 3-7

3. SERVICE OPERATIONS

3.1 GENERAL

IMPORTANT SERVICE REQUIREMENTS

NOTE 1: Whenever a road wheel and/or brake

disc is removed from the vehicle, the relationship

of the road wheel to the hub and the disc to the

hub MUST be marked with a felt tipped pen or

similar, in order for those parts to be reinstalled in

their original positions. This is critical to maintain

the brake disc and road wheel runout dimension to

a minimum.

NOTE 2: When reinstalling road wheels, do not

use an impact gun to tighten wheel nuts, unless it

is fitted with a torque limiter socket (Tool AU534).

Failure to correctly tighten wheel nuts to the correct

torque specification and in the correct order, may

result in a distorted brake disc, that may lead to the

development of brake shudder.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

Figure 3-8

3.2 FRONT WHEEL HUB AND STEERING KNUCKLE

As stated in 1. GENERAL DESCRIPTION, the new knuckle will only service back to earlier ‘V’ series vehicles, if

the following components are all changed as a group:

• Steering knuckle

• Control arm ball joint

• Outer tie rod end.

Apart fr om wheel stud replacem ent, ther e are no ser viceable item s in the front wheel hub assem bly. As the unit is a

‘sealed for life’ assembly, neither bearing adjustment nor lubrication maintenance is required. Should a non-

standard condition develop, then the assembly must be replaced as a complete unit.

As with the earlier design hub, this design has zero axial free play or ‘end float’ but some angular movement may

be evident when a rocking force is applied to the mounted wheel and tyre assembly. Before a hub is replaced for

an excessive free play condition, refer to the checking procedure, detailed in Operation 2.4 in 3, FRONT

SUSPENSION, of the VT Series I Service Information.

Techline

3.3 SUSPENSION & TRIM HEIGHT, CHECK

The suspension and trim height dimensions for standard vehicles with base equipment only, are provided in

5. SPECIFICATIONS in this Section.

The dimensions are for a new vehicle built to standard specification and only intended as a guide when

check ing suspens ion and trim height dim ensions at norma l curb weight. Norm al curb weight is defined as a vehicle

with a full tank of fuel, all fluids at the specified levels, spare tyre included, tyre pressures as specified and no

passengers. Accumulated dirt, mileage, etc., must also be taken into consideration when checking vehicle heights.

The following procedure should be followed before checking any suspension or trim height.

1. All c hec ks must be c ar ried out on a LEVEL s ur f ac e, af ter the vehic le's tyre pressures have been c hec k ed and it

has been confirmed that the vehicle has not suffered accident damage.

2. On average, all VT Series II vehicles will sit approxim ately 4 mm lower at the right hand side front, because of

the vehicle's battery weight.

3. Push vehicle up and down several times at the front bumper bar with a decreasing force and then gently

remove hands, allowing vehicle to settle on its own. Carry out vehicle front trim and suspension height check.

4. Push vehicle up and down several times at the rear bumper bar with a decreasing force and then gently

remove hands, allowing vehicle to settle on its own. Carry out vehicle rear trim and suspension height check.

As shown in the specification listing (refer to 5. SPECIFICATIONS in this Section), there are two different

dimensions that must be checked and the location for the measurements to be taken is critical to correctly

establishing a st andard vehicle condition. When chec king a vehicle's r ide height, the following tolerances must also

be taken into account, before any spring is replaced.

RIDE HEIGHT VARIATIONS FROM SPECIFICATION

FRONT TO REAR..............................± 20 mm

SIDE TO SIDE ...................................± 10 mm

NORMAL SPRING SETTLING ..........± 5 mm

NOTE: Ride height variation may also be due to any one or a combination of the following:

a. Spring seat location on the suspension/body.

b. Incorrect springs; Check spring identification against the table shown in 5. SPECIFICATIONS in this

Section.

c. Non-standard, additional vehicle weight, such as a tow bar and/or after-market LPG fitment.

d. Any combination of the above.

CAUTION: Good judgement must be exercised before replacing a spring or springs from a vehicle whose

height is within the limits quoted. Even should a vehicle's dimensions prove to be slightly outside these

tolerances, the vehicle could well be in a serviceable condition.

Spring replacement under conditions of excessive weight due to non standard fittings, undercoating, road

dirt, etc; will assist very little in restoring the vehicle to its specified height.

3.4 FRONT WHEEL HUB, BRAKE DISC OR BRAKE SHIELD

NOTE 1: Apart f rom wheel stud r eplacem ent, there

are no serviceable items in the front wheel hub

assembly. As the unit is a 'sealed for life'

assembly, neither bearing adjustment nor

lubrication maintenance is required. Should a non-

standard condition develop, then the hub ass embly

must be replaced as a complete unit.

NOTE 2: While the front wheel hub is designed to

have zero axial free play or ‘end-float’, some

angular m ovement m ay be evident when a rock ing

force is applied to the mounted wheel and tyre

assembly. Before a hub is replaced, refer to

check ing procedur e, detailed in Operation 2.4 in 3.

FRONT SUSPENSION, of the VT Series I Service

Information.

REMOVE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as

outlined in 2.2 JACKING PRECAUTIONS in

this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of road wheel to hub or brake

disc. Loosen then remove road wheel

attaching nuts. Remove the road wheel.

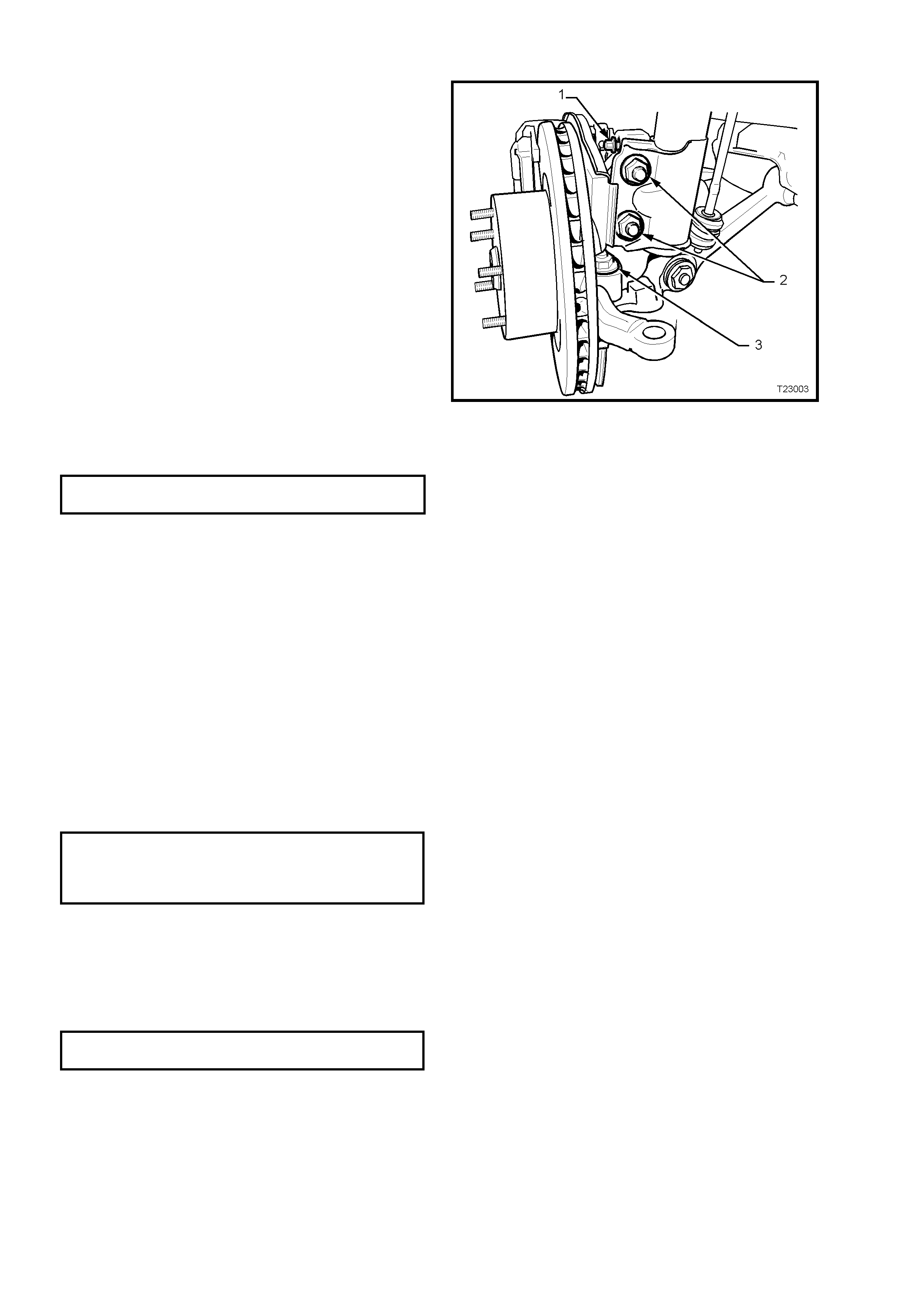

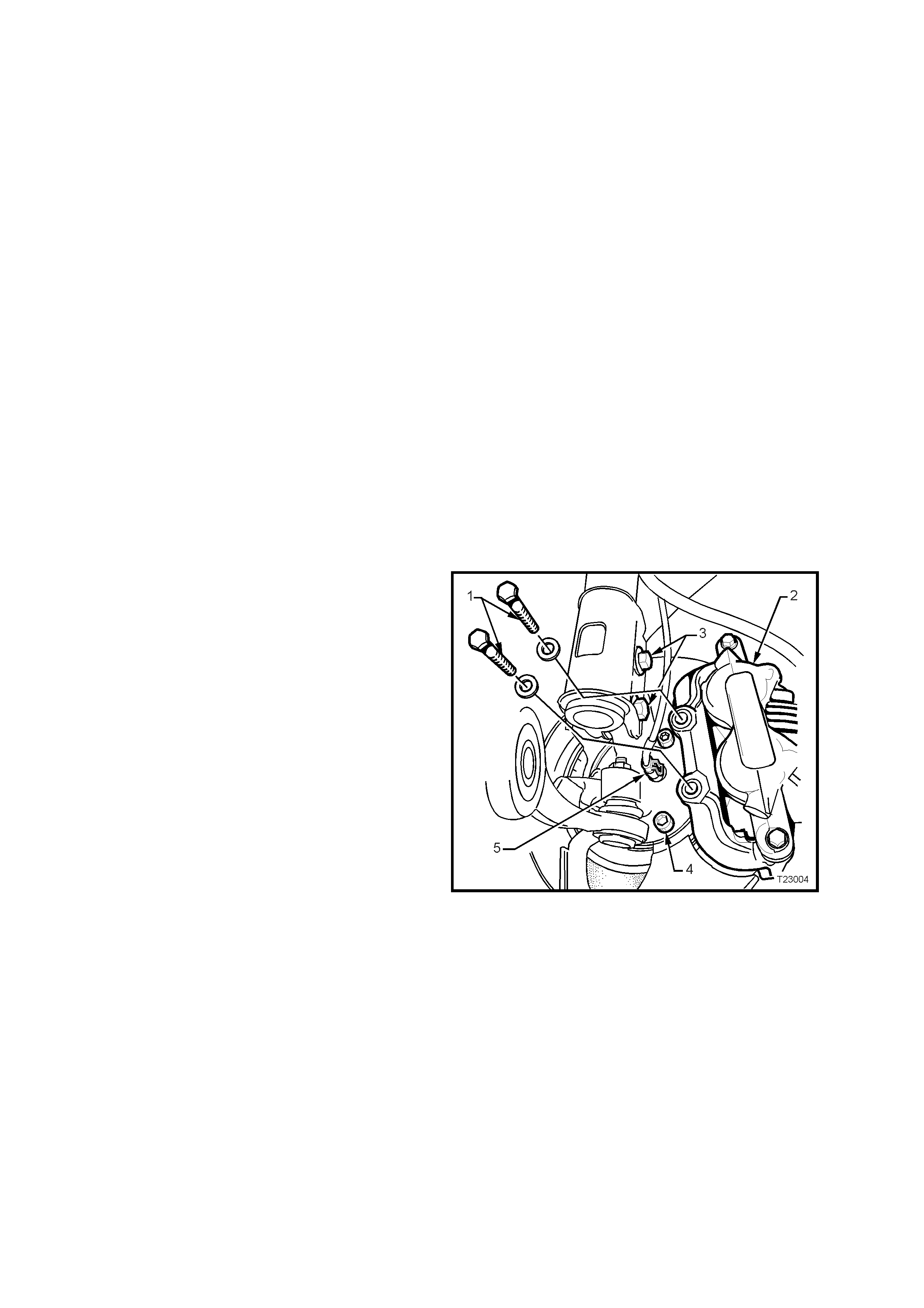

4. Remove brake caliper anchor plate retaining

bolts and washers (1), lift caliper assembly (2)

from brake disc. Position caliper (2) in such a

way that no strain is placed on the brake hose.

If necessary, tie caliper to the suspension

spring with a piece of wire. THE CALIPER IS

NOT TO HANG BY BRAKE HOSE.

5. W hile the brake disc to hub location is marked

in production, ensure that the disc to hub

position is carefully marked.

NOTE: This is necessary to overcome the

possibility of inducing a brake shudder condition

after reassembly.

6. Remove brake disc from the wheel bearing

hub.

NOTE: For vehicles equipped with ABS,

disconnect the wheel speed sensor connector (5)

from the hub sensor connector, by lifting the

connector locking tab and pulling on the connector

to disconnect.

7. Using a commercially available 10 mm Allen

key socket and a suitable socket bar, loosen

each of the three bolts (4) holding the hub to

the steering knuckle.

NOTE 1: If the Allen key socket is too long to fit

into the front, upper hub bolt, then the lower strut to

steering knuckle nut (and bolt) will need to be

loosened and removed. Discard the removed bolt

and nut, as they must be replaced on reassembly.

NOTE 2: For the front lower hub bolt, turn wheel

outwards to provide sufficient clearance.

Figure 3-9

8. If the hub is a tight fit to the knuckle, it may be

necessary to loosen the three loosened bolts

and tap on the heads. DO NOT STRIKE THE

HUB.

9. Remove the three bolts and then the hub from

steering knuckle.

10. If rem oval of the brak e s hield is neces sary, drill

the heads from the three rivets securing the

shield to the steering knuckle support.

11. After shield removal, carefully drill out the

remainder of the rivets, using a suitable sized,

sharp drill.

INSPECT

1. Check wheel studs to ensure threads are not

damaged, and that studs are pressed firmly

into the front wheel hub.

If one or more wheel studs require

replacement, refer to operation

3.3 FRONT HUB WHEEL STUD of the VT

Series I Service Information, for details.

2. Examine brake disc for scores or damage. If

either of these conditions exist, the brake disc

should be machined. Refer to

Section 5A BRAKES of the VT Series II

Service Information for details.

3. Check for damage to the shield that m ay cause

fouling of any rotating parts and if suspect, the

shield should be replaced.

REINSTALL

Reinstallation of the fr ont wheel hub and brak e dis c

is the reverse of removal procedures, except for

the following points:

All Models:

1. If the brake shield has been removed, install

three, common pop rivets (1), using a

commercially available pop rivet gun.

NOTE: Install the first rivet in the brake shield hole

with the round hole. This will ensure that the

clearance to brake caliper is correct.

2. Before installing the hub, inspect both mating

surfaces to make sure that they are clean and

free from burrs that could prevent correct

alignment of both parts, once installed.

Figure 3-10

Without ABS:

3. Install the hub assembly to the steering

knuckle.

4. Install the three attaching bolts (4) and tighten

to the correct torque specification.

FRONT HUB TO STEERING

KNUCKLE ATTACHING BOLT 100 - 115 Nm

TORQUE SPECIFICATION

NOTE: The three hub attaching bolts are micro-

encapsulated with thread sealant and are not to be

re-used more than three times. If in doubt, the bolts

should be replaced.

WITH ABS:

5. Carefully align the sensor connection on the

hub, with the hole in the steering knuckle, then

install the three hub attaching bolts (4) and

tighten to the correct torque specification.

FRONT HUB TO STEERING

KNUCKLE ATTACHING BOLT 100 - 115 Nm

TORQUE SPECIFICATION

6. Fit the wheel speed sensor connector (5),

ensuring that the locking tang is in place.

ALL MODELS:

7. If removal of the lower strut to steering knuckle

bolt and nut (3) was necessary, the bolt and

nut, must be replaced with new parts. Tighten

the bolt and nut to the correct torque

specification.

Figure 3-11

STEERING KNUCKLE TO STRUT Stage 1 85 Nm

ATTACHING BOLTS & NUTS Stage 2 100 Nm

TORQUE SPECIFICATION Stage 3 Turn

through 90°

8. Reinstall brake disc, aligning the marks made

before removal.

NOTE: If the hub was replaced, then runout

checks must be carried out on the installed brake

disc. Refer to 5A STANDARD BRAKES, of the VT

Series II Service Information for important

information regarding these checks.

9. Reinstall the brake caliper and attaching bolts,

tightening bolts to the correct specification.

BRAKE CALIPER ANCHOR 80 - 90 Nm,

PLATE RETAINING BOLTS then turn through

TORQUE SPECIFICATION 40° - 50°

10. Reinstall road wheel, aligning the marks made

prior to removal and secure with the attaching

nuts.

11. Remove jack stands and lower vehicle.

12. Tighten road wheel attaching nuts to correct

torque specification, working in a ‘star’ pattern,

as indicated in Fig. 3-8, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

13. Refit wheel cover/centre cap.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCT ION CHECK, in Section 12L ABS & ABS/ET C, VT Series I

Service Information (V6) or VT Series II Service Information (GEN III V8).

4. MAJOR SERVICE OPERATIONS

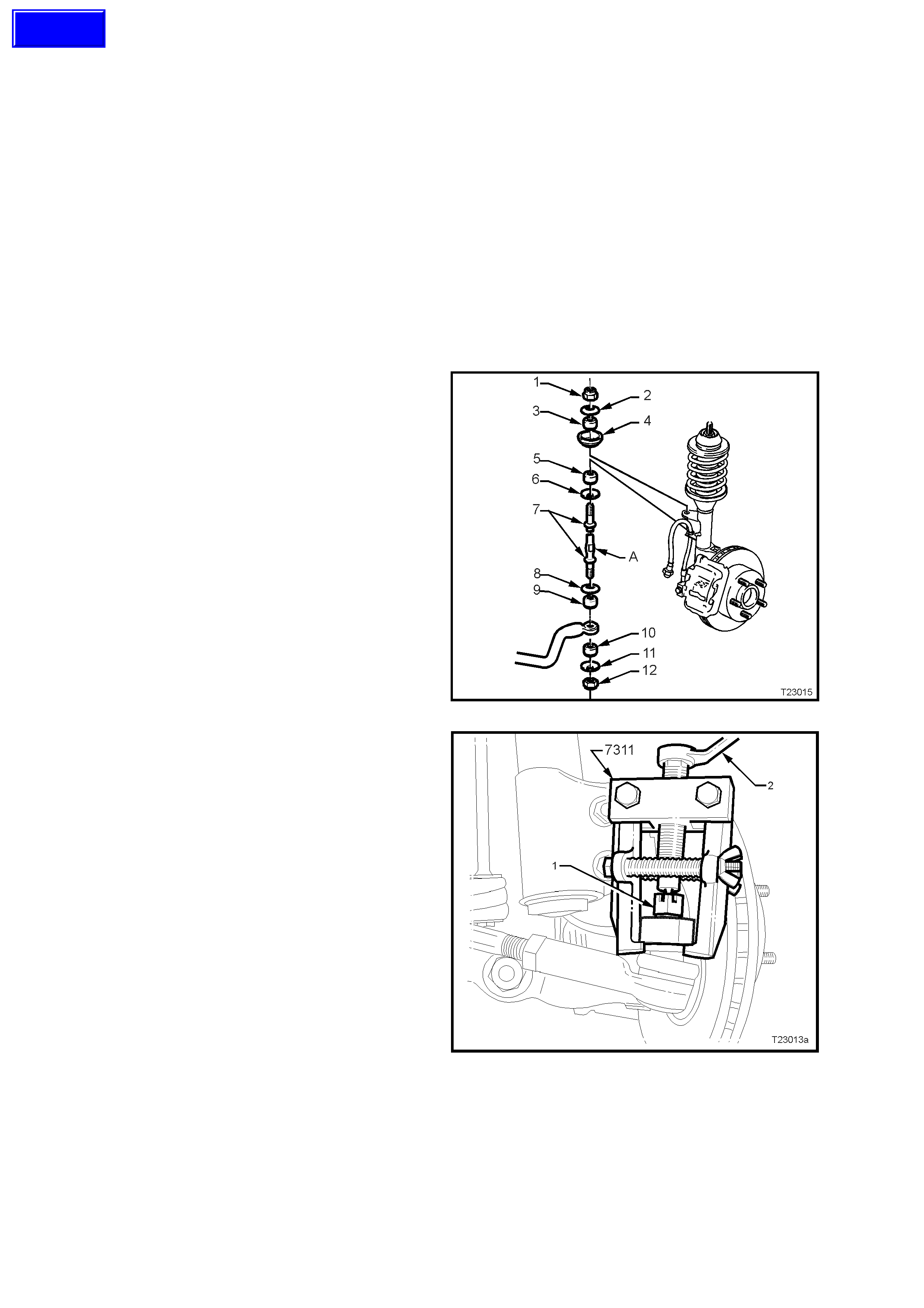

4.1 FRONT STRUT ASSEMBLY

REMOVE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as

outlined in 2.2 JACKING PRECAUTIONS in

this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of road wheel to hub or brake

disc. Loosen then remove road wheel

attaching nuts. Remove road wheel.

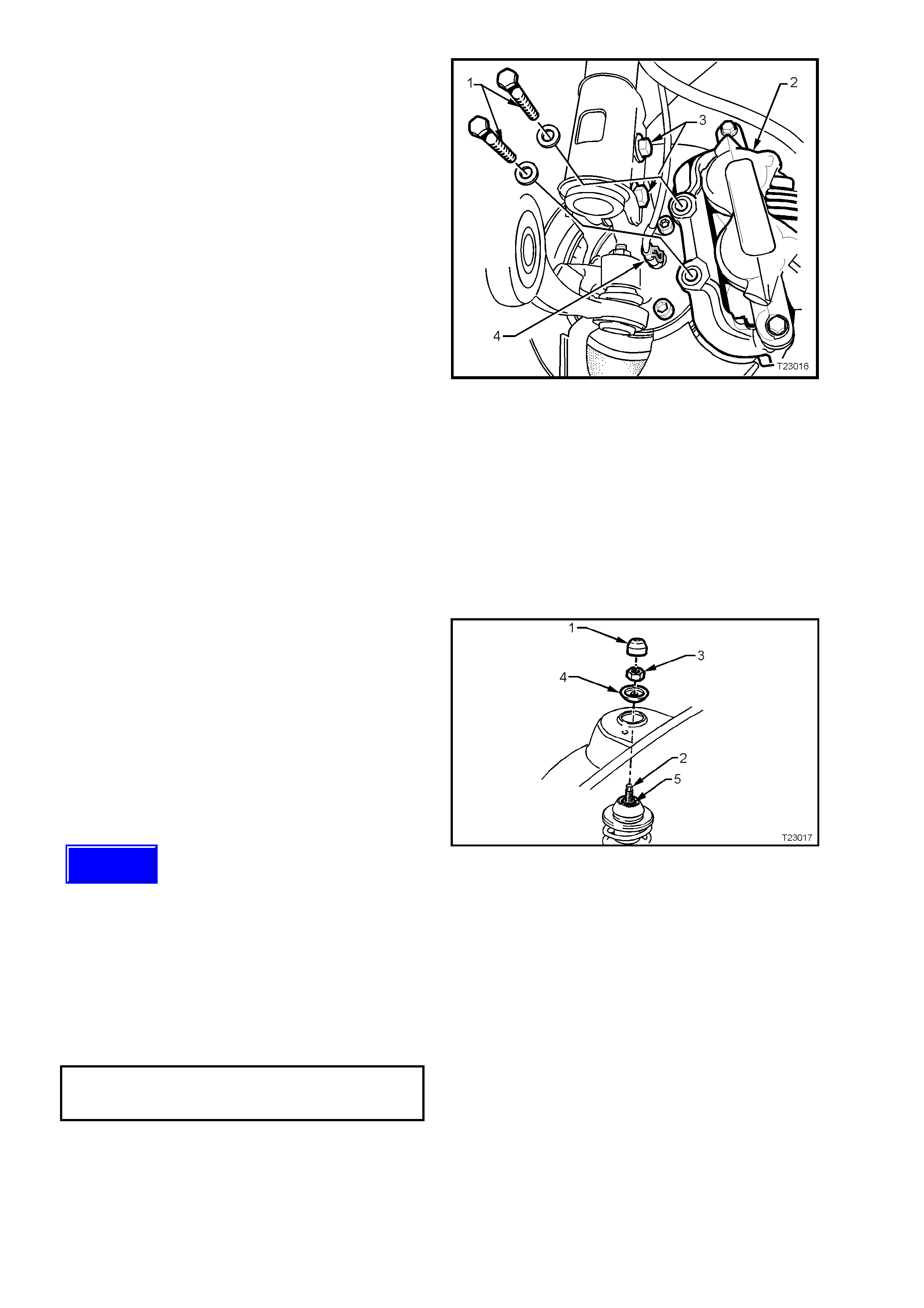

4. Position a suitable size open end spanner over

flat ‘A’ in stabiliser bar spacer stud (7), remove

upper nut (1), washer (2), bush (3) and seat

(4).

5. If the vehicle is fitted with ABS, disconnect the

wheel speed sensor cable by pulling the

insulator from the strut bracket.

Figure 3-12

Techline

6. Remove the brake caliper anchor plate

retaining bolts and washers (1), lift the caliper

assembly (2) from the brake disc and support

in such a way that no strain is placed on the

brake hose. THE BRAKE CALIPER IS NOT

TO HANG BY THE BRAKE HOSE.

NOTE: T his step is nec essary to provide access to

the lower strut mounting bolts and nuts (3).

7. If required, remove brake disc from the wheel

bearing hub. While the brake disc to hub

relationship is marked during production,

ensure that the disc to hub position is carefully

marked.

NOTE: This is necessary to overcome the

possibility of inducing a brake shudder condition

after reassembly.

8. Remove brake hose from the strut housing

bracket by turning plastic sleeve on the hose

until flats on sleeve align with bracket opening.

9. Using a suitable floor jack fitted with a block of

wood, position under the control arm, just

sufficient to support the weight.

10. Loosen, remove and DISCARD the two lower

strut to knuckle attaching bolts and nuts (3).

11. To avoid placing str ain on the ABS sensor lead

(if fitted), release the connector locking tang

and pull on the sensor lead connector (4) to

remove from the sensor.

12. Pull the steering knuckle clear of the strut.

Figure 3-13

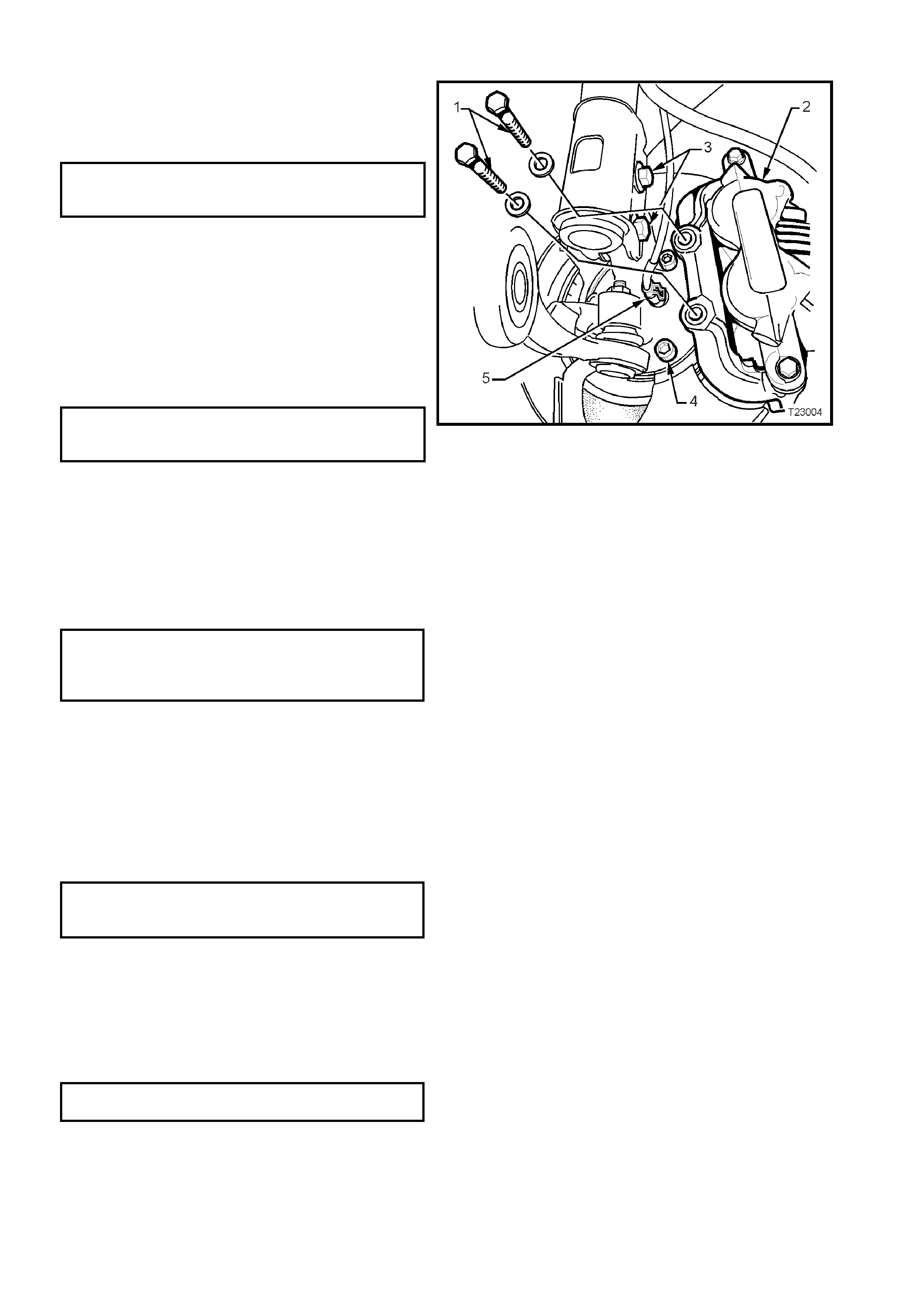

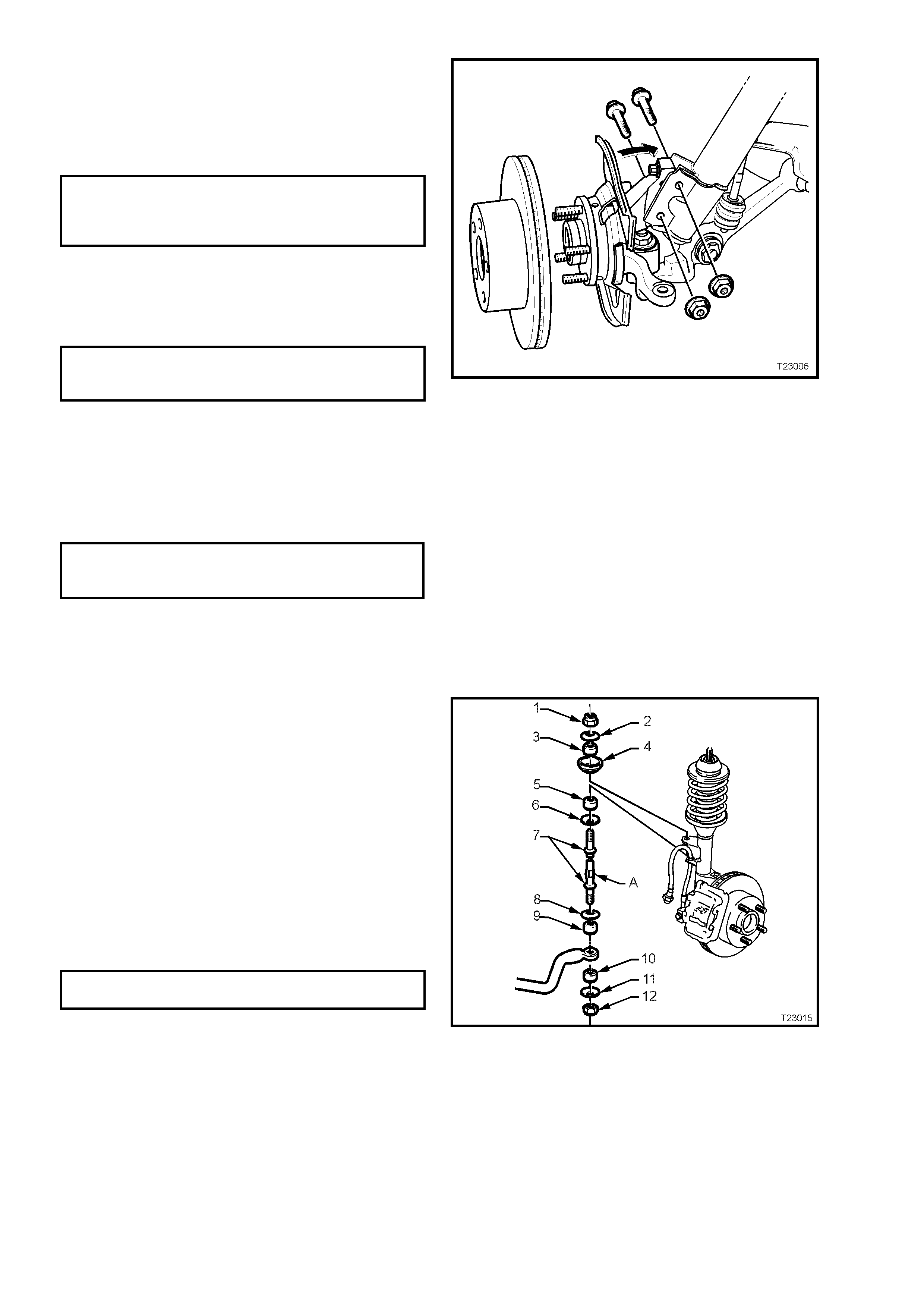

13. Rem ove the dust cover ( 1) fr om the upper str ut

support, in the engine compartment.

14. While holding the strut rod shaft (2) with a 10

mm socket, remove the self-locking nut (3),

using a 24 mm (15/16") ring spanner, then

remove the locating disc (4). DISCARD THE

STRUT ROD NUT.

15. Carefully lower the strut from the tower,

manipulate the strut to remove the stabiliser

stud from the bracket on the strut and remove

the assembly from the vehicle.

Figure 3-14

REINSTALL

NOTE: In the interests of vehicle safety, it is

important that fasteners are replaced with new

parts where stated dur ing the reinstallation process

described here.

Important: The torque of the strut bearing

retaining n ut (‘5’ in Fig . 3-14) M UST be checked

for correct tightness BEFORE installing the

strut into the vehicle!

UPPER STRUT BEARING

RETAINING NUT 70 - 85 Nm

TORQUE SPECIFICATION

1. Manipulate the strut assembly so that the

stabiliser bar stud is located in the strut

bracket, then locate strut assembly into the

spring stru t tower.

2. After installing the locating disc, partially install

a NEW upper nut to the strut rod. Do not

tighten at this time.

Techline

3. Pivot the hub and steering knuckle assemblies,

sufficient to line up the bolt holes in the

steering knuckle and the lower end of the strut

assembly.

4. Install NEW retaining bolts and nuts, and

tighten in stages to the specified torque values.

STEERING KNUCKLE TO STRUT Stage 1 85 Nm

ATTACHING BOLTS & NUTS Stage 2 100 Nm

TORQUE SPECIFICATION Stage 3 Turn

through 90°

5. While holding the strut rod from turning, with a

10 mm socket, tighten the upper strut rod

retaining nut (‘3’ in Fig. 3-14) to the correct

torque specification, using a 24 mm (15/16")

ring spanner with a torque wrench attached.

UPPER STRUT LOCATING

PLATE RETAINING NUT 50 - 60 Nm

TORQUE SPECIFICATION

6. Install the brake hose to the strut bracket by

turning plastic sleeve on the hose until the flats

on the sleeve align with the bracket opening.

7. If removed, install the brake disc, aligning

marks made prior to removal.

8. Reinstall the brake caliper, tightening the

attaching bolts to specification.

Figure 3-15

BRAKE CALIPER ANCHOR 80 - 90 Nm,

PLATE RETAINING BOLTS then turn through

TORQUE SPECIFICATION 40° - 50°

9. If the vehicle is fitted with ABS, fit the wheel

speed sensor connector, pushing firmly onto

the sensor until the retaining tang is secure.

Then, reinstall the sensor lead into the strut

mounting bracket.

10. Reinstall stabiliser bar spacer stud nut (1) after

ensuring that all components are assembled as

shown. While holding the spacer stud (7) with a

suitable open end spanner at ‘A’, tighten the

upper retaining nut (1) until the end of the

thread on the stud.

NOTE: Do not use power tools for this tightening

operation, otherwise thread damage will result.

11. Install road wheel, aligning the marks made

prior to removal.

12. Remove safety stands and lower vehicle.

13. Tighten road wheel attaching nuts to the

correct torque specification, working in a ‘star’

pattern, as indicated in Fig. 3-8, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

14. Refit wheel cover/centre cap.

15. Bounce vehicle up and down several times to

settle suspension.

16. Check wheel alignment, as detailed in

2.1 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

Figure 3-16

4.2 STEE RING KNUCKLE

REMOVE

1. Remove front brake disc, wheel hub assembly

and brake shield, as detailed in

3.4 FRONT WHEEL HUB, BRAKE DISC OR

BRAKE SHIELD in this Section.

2. Remove the s plit pin and loosen the castellated

nut (1) until the nut is flush with the end of the

tie rod ball joint stud.

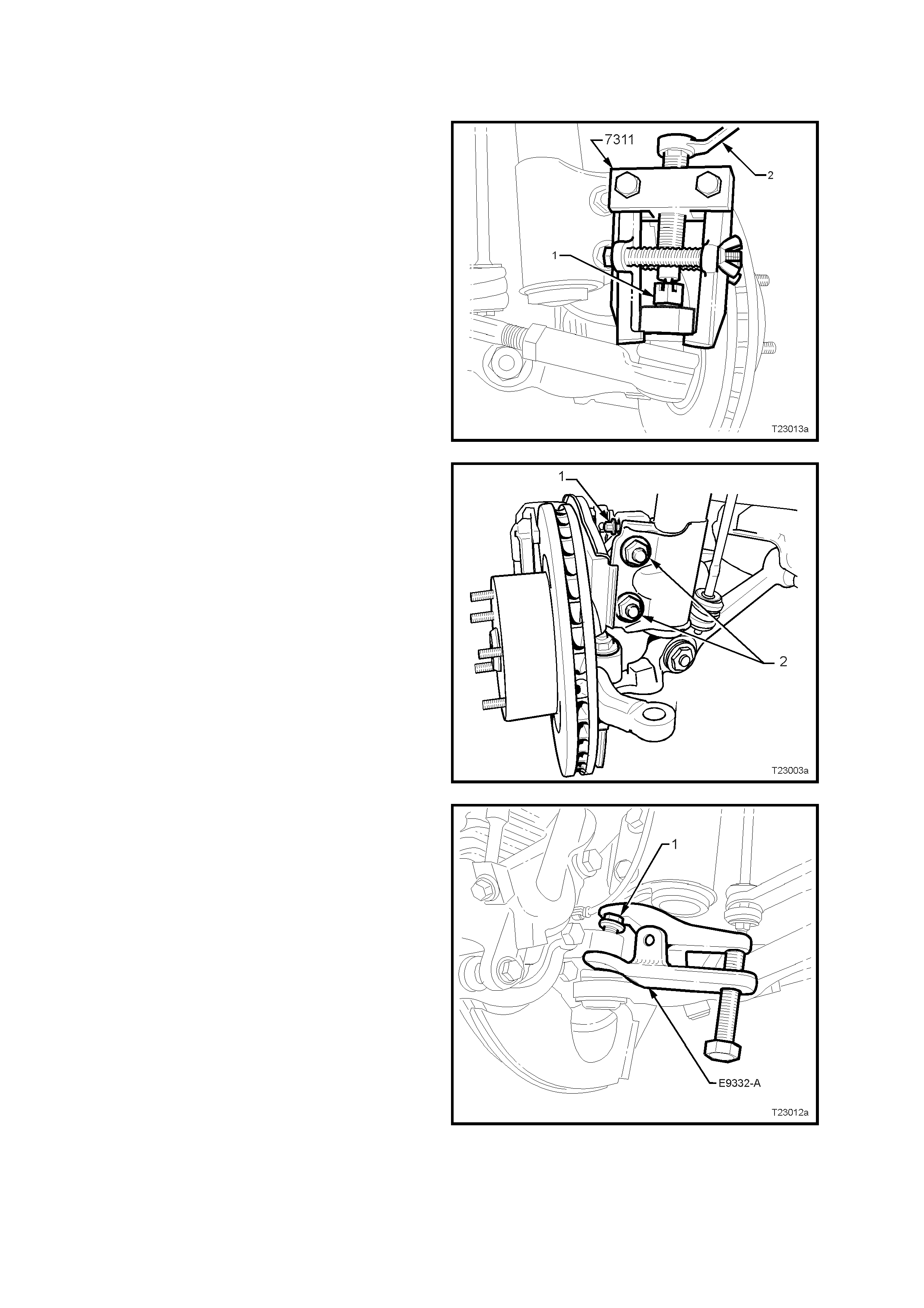

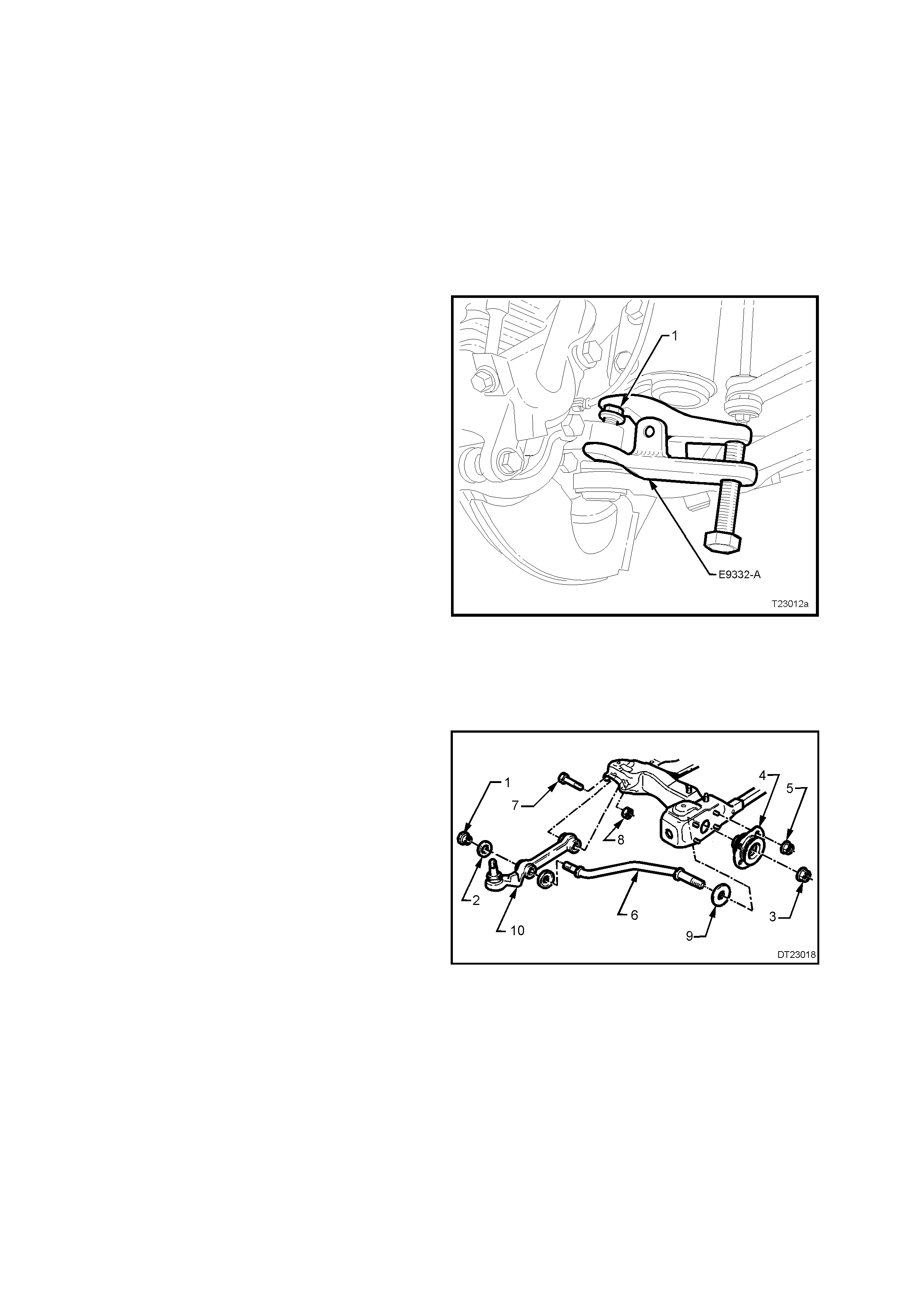

3. Install Tool No. 7311 as shown and, using a

ring spanner (2), press stud out from steering

knuckle.

Figure 3-17

4. Loosen, remove and discard the two lower

strut attaching bolts and nuts (2).

5. If the steering knuckle is to be replaced,

remove the camber adjusting bolt (1) from the

arm.

Figure 3-18

6. Loosen the ball joint retaining nut (1) until the

nut is flush with the end of the ball joint stud

thread.

NOTE: Because the nut has micro-encapsulated

sealant applied to the threads, it must be replaced

after removal.

7. Install separation Tool No. E9332-A as shown,

then apply force to the top of the ball joint stud

by tightening the forcing bolt on the tool,

separating the ball joint from the knuckle.

NOTE: Once load is applied by the release tool

loading bolt, a sharp tap on the nut end of the tool

will lessen the apply force required.

8. Temporarily jam the ball joint stud taper into

the knuckle to hold the stud, before fully

removing the retaining nut. Discard the

removed nut as it has micro-encapsulation

sealant applied and must be replaced on

reassembly.

9. Separate the knuckle from the ball joint stud

and remove from the vehicle.

Figure 3–19

REINSTALL

Reinstallation is the reverse of removal procedures

except for the following:

1. Reinstall the steering knuckle over the ball joint

stud, then install NEW lower strut to steering

knuckle, bolts and nuts but do not tighten fully

at this stage.

2 Using a suitable floor jack fitted with a block of

wood, position under the control arm, just

sufficient to support the weight and jam the ball

joint stud taper into the knuckle.

3. Install a NEW self-locking nut to the ball joint

stud and tighten the nut to the correct torque

specification.

BALL JOINT STUD NUT

TORQUE SPECIFICATION 50 - 70 Nm

4. Install steering tie rod end ball joint stud to the

steering knuckle and tighten the castellated

attaching nut to the correct torque

specification. Install new split pin.

TIE ROD BALL JOINT STUD

CASTELLATED NUT 50 – 80 Nm

TORQUE SPECIFICATION

5. Reinstall brake shield, wheel hub assembly

and front brake disc, as detailed in

3.4 FRONT WHEEL HUB, BRAKE DISC OR

BRAKE SHIELD in this Section.

NOTE: the brake disc must be reinstalled, aligning

the marks made prior to removal.

6. Temporarily install road wheel/s and lower

vehicle to the ground.

7. Bounce vehicle up and down several times to

settle suspension.

8. Check wheel alignment, as detailed in

2.1 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

9. Following wheel alignment operations, it will be

necessary to raise the vehicle and tighten the

NEW steering knuckle to strut bolts and nuts to

the correct torque specification.

STEERING KNUCKLE TO STRUT Stage 1 85 Nm

ATTACHING BOLTS & NUTS Stage 2 100 Nm

TORQUE SPECIFICATION Stage 3 Turn

through 90°

10. After reinstalling the road wheel and aligning

the marks made prior to removal, install the

nuts, lower the vehicle to the ground and

tighten road wheel attaching nuts to the correct

torque specification, working in a ‘star’ pattern,

as indicated in Fig. 3-8, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

11. Refit wheel cover/centre cap.

4.3 CONTROL ARM

REMOVE

1. Raise front of vehicle and place safety stands

under side frame members. Observe jacking

precautions as outlined in

2.2 JACKING PRECAUTIONS in this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub. Loosen,

then remove road wheel attaching nuts and

remove wheel.

4. Turn the steering out on full lock.

5. Loosen the ball joint retaining nut (1) until the

top of the nut is flush with the top of the ball

joint stud thread.

6. Install separation Tool No. E9332-A as shown,

then apply force to the top of the ball joint stud

by tightening the forcing bolt on the tool,

separating the ball joint from the knuckle.

NOTE: Once load is applied by the release tool

loading bolt, a sharp tap on the nut end of the tool

will lessen the apply force required.

7. Temporarily jam the ball joint stud taper into

the knuckle to hold the stud, before fully

removing the retaining nut. Discard the

removed nut as it has micro-encapsulation

sealant applied and must be replaced on

reassembly.

8. Separate the ball joint stud from the knuckle.

9. Hold the steering knuckle away from the

control arm by using a suitable length prop.

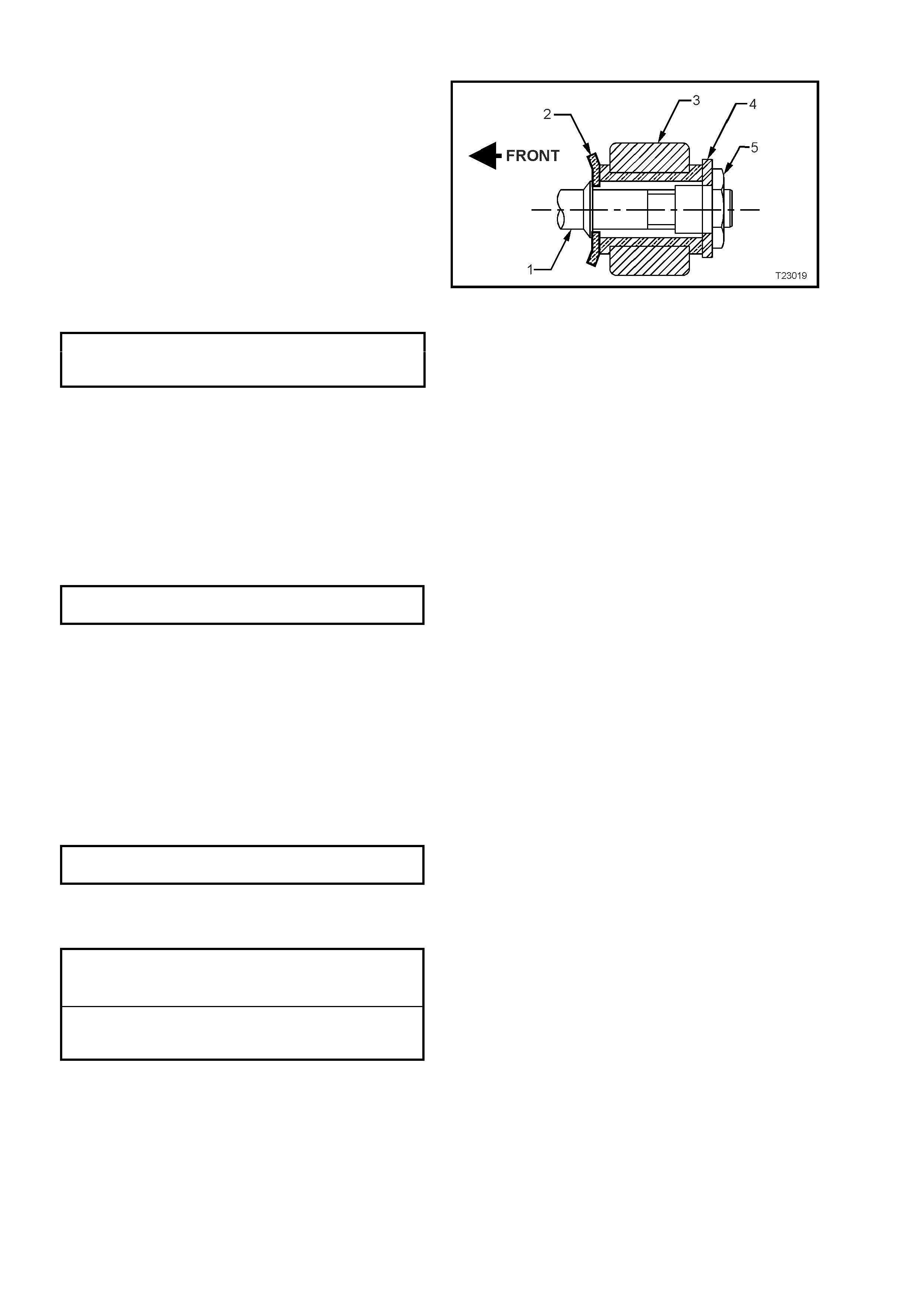

Figure 3-20

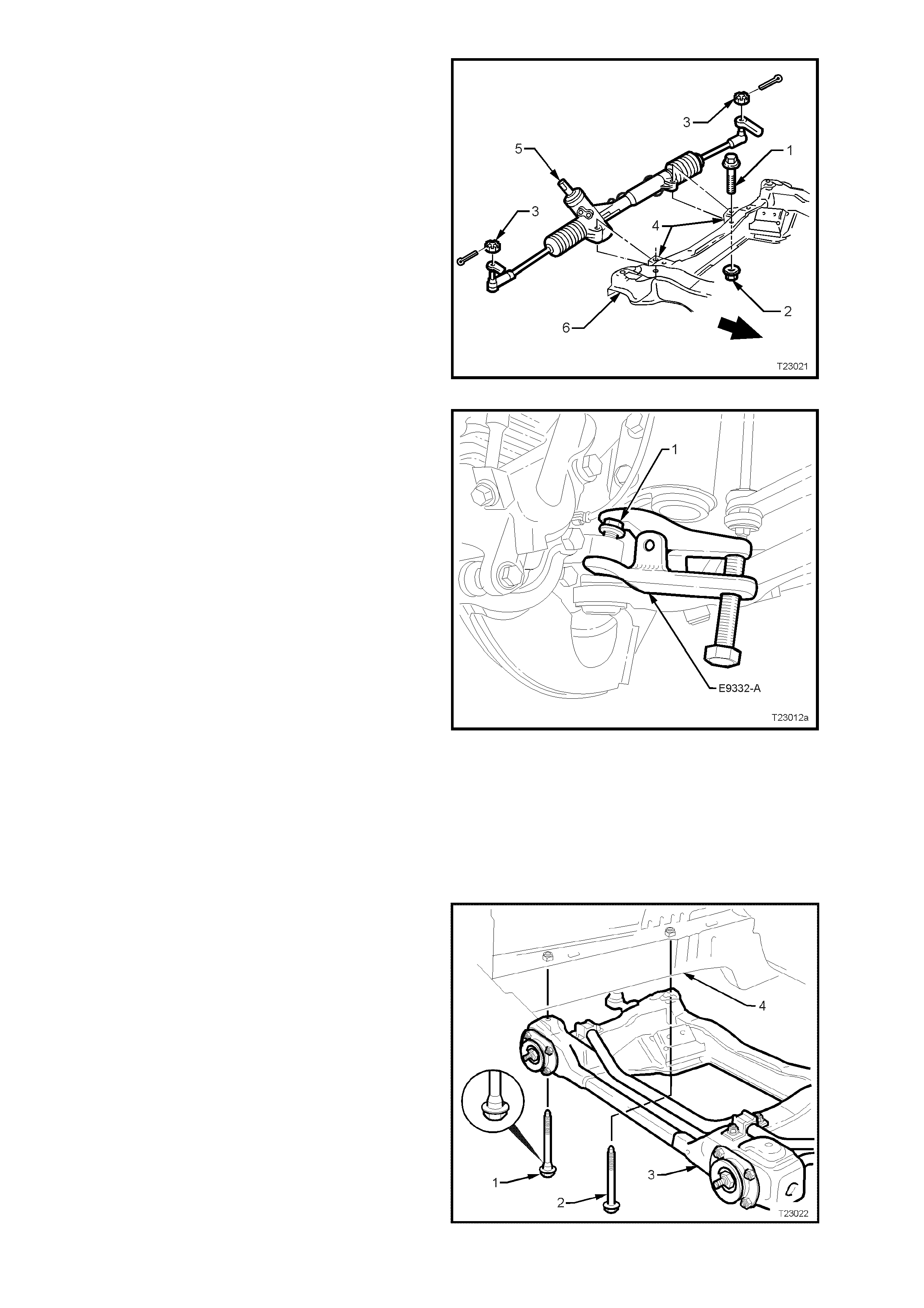

10. Loosen the tension rod front nut (3) at the

tension rod bush assembly (4).

11. Remove tension rod to control arm attaching

nut (1) and washer (2). Discard nut (1).

12. Remove the four nuts (5) securing the tension

rod, bush assembly (4) to the crossmember,

then remove the tension rod (6) from the

control arm, outer bush.

13. Rem ove contr ol arm inner pivot bolt (7) and nut

(8). Discard nut (8).

14. Remove control arm (10) and bright finished

washer (9) from the vehicle.

Figure 3-21

REINSTALL

1. Install control arm to the crossmember, install

bolt (‘7’ in Fig. 3-21), then install a NEW nut (‘8’

in Fig. 3-21), but do not fully tighten at this

stage.

2. Install tension rod (1) to control arm (3) with

convex side of cupped washer (2) toward

control arm bush, as shown.

3. Install tension rod to control arm washer (4)

with a NEW attaching nut (5) but do not fully

tighten at this stage.

4. Install tension rod, front bush assembly to the

crossmember, install the four retaining nuts

and tighten to the correct torque specification.

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY ATTACHING 20 – 26 Nm

NUT TORQUE SPECIFICATION

NOTE: Ins tall a NEW tens ion rod nut to the fr ont of

the tension rod but do not tighten at this stage.

Figure 3-22

5 Using a suitable floor jack fitted with a block of

wood, positioned under the control ar m, lift jus t

sufficient to support the weight of the strut

assembly and jam the ball joint stud taper into

the knuckle.

6. Install a NEW self-locking nut to the ball joint

stud and tighten the nut to the correct torque

specification.

BALL JOINT STUD NUT

TORQUE SPECIFICATION 50 - 70 Nm

7. Install road wheel, aligning marks made prior

to removal. Tighten the wheel nuts

progressively, working in a ‘star’ pattern. Do

not overtighten.

8. Remove safety stands and lower vehicle.

9. Bounce vehicle up and down several times to

settle suspension.

10. With the weight of the vehicle on the

suspension components, tighten control arm

inner pivot bolt to the correct torque

specifications.

CONTROL ARM INNER PIVOT

BOLT TORQUE SPECIFICATION 95 – 110 Nm

11. Tighten the tension rod nuts, both at the

control arm and the tension rod hydraulic

damper, to the correct torque specifications.

TENSION ROD TO CONTROL

ARM ATTACHING NUT 95 – 110 Nm

TORQUE SPECIFICATION

TENSION ROD TO

HYDRAULIC DAMPER 140 – 155 Nm

TORQUE SPECIFICATION

Important: The weight of the vehicle must be on

all four wheels before tightening the tension rod to

specification. Otherwise the tension rod hydraulic

damper will be incorrectly preloaded, reducing the

life of the damper and affecting ride and handling.

12. Tighten road wheel attaching nuts to the

correct torque specification, working in a ‘star’

pattern, as indicated in Fig. 3-8, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

13. Refit wheel cover/ centre cap.

14. Check wheel alignment, as detailed in

2.1 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.4 CONTROL ARM BALL JOINT

INSPECT

The following procedure should be used when

checking the ball joint for wear.

1. Jack up vehicle under crossmember.

2. Holding the road wheel at top and bottom,

check for play in the ball joint by rocking wheel.

3. If any up or down movem ent of s tud in ball j oint

housing is detected, the control arm and ball

joint assembly must be replaced, as the ball

joint is not serviced separately.

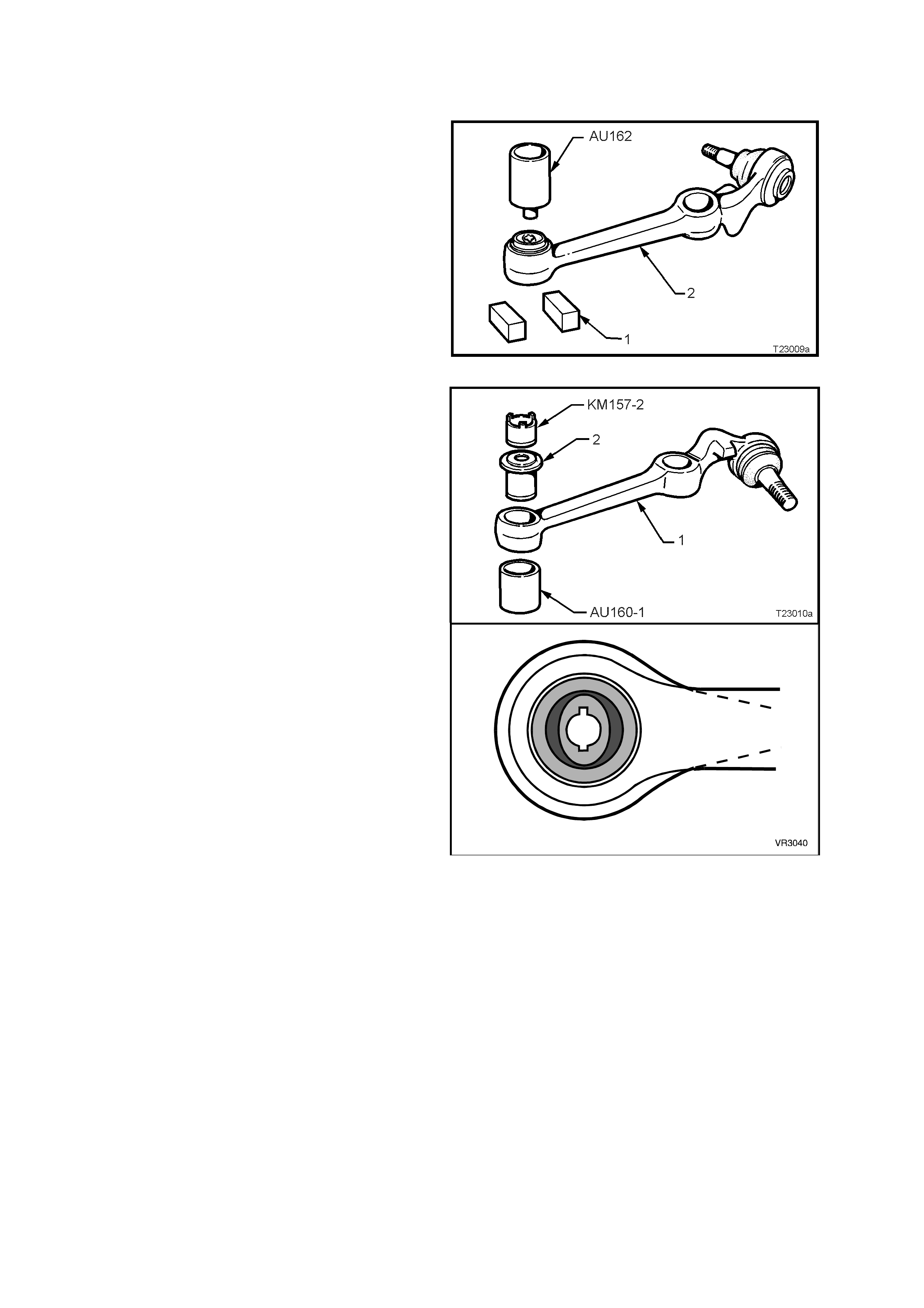

4.5 CONTROL ARM INNER PIVOT BUSH

REPLACE

1. Remove control arm (2) as detailed in

4.3 CONTROL ARM in this Section.

2. Support the control arm (2) with two pieces of

square scrap (1) and press the bush from the

arm, using Tool No. AU162.

Figure 3-23

3. Using T ool Nos. AU160-1 and KM157-2, install

new bush from front side of control arm, until

flange on outer sleeve is flush with control arm.

NOTE 1: The bush MUST be aligned, as shown.

NOTE 2: The bush may be lubricated with a soapy

water solution to ease the installation process.

NOTE 3: Tool No KM157-2 is used in the reverse

direction to some previous ‘V’ car models.

4. Reinstall control arm as detailed in

4.3 CONTROL ARM in this Section.

Figure 3-24

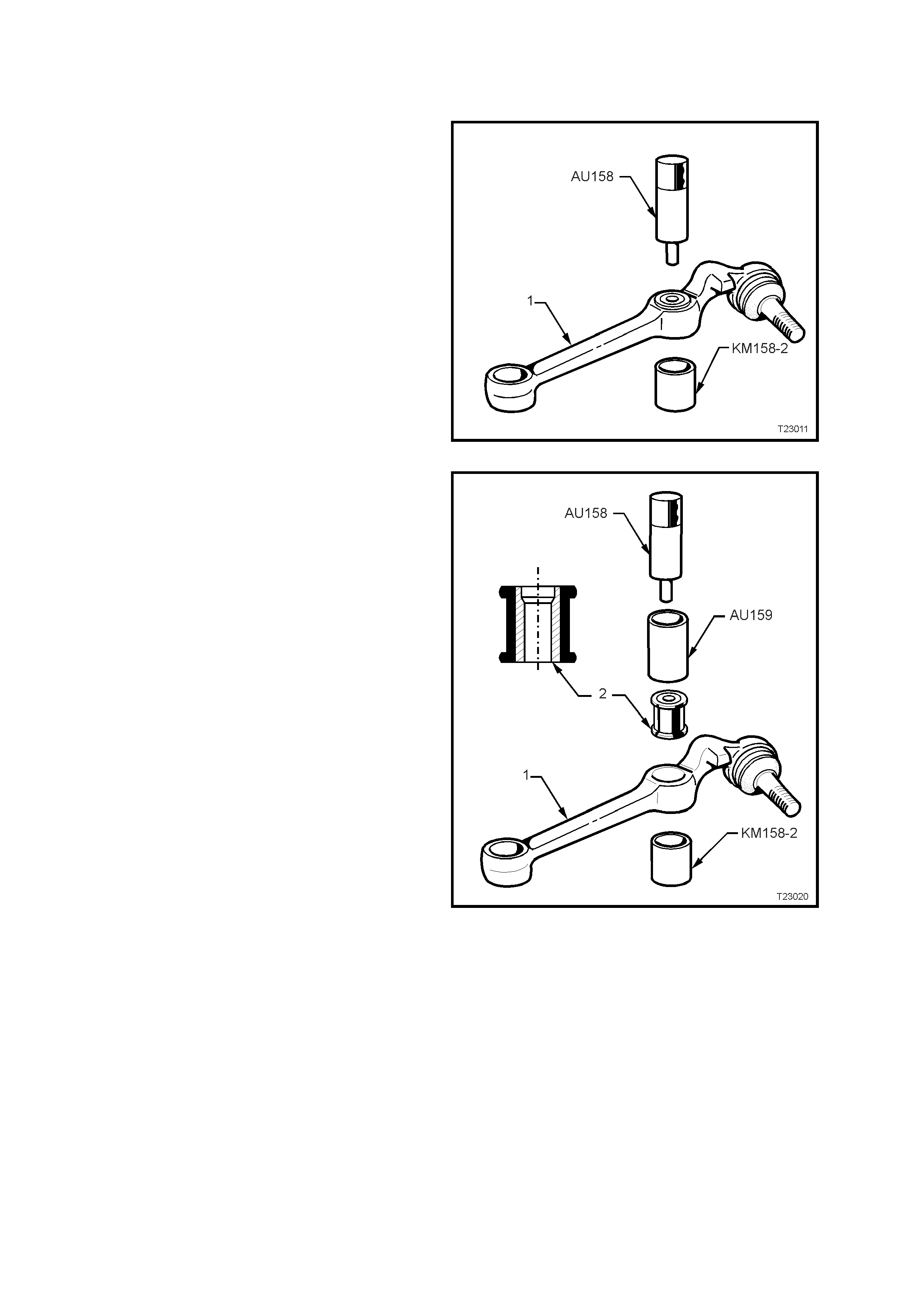

4.6 CONTROL ARM TENSION ROD BUSH

REPLACE

1. Remove control arm as detailed in

4.3 CONTROL ARM in this Section.

2. Press out tension rod bush from control arm

using Tool No AU158 and KM158-2 as shown.

Figure 3-25

3. Pr ess in a new tension r od bush (2) using T ool

No’s AU158, AU159 and KM158-2 as shown.

To as sist in installation, dip bush (2) in a soapy

water solution. Install bus h with larger diameter

of stepped tension rod mounting hole toward

rear of control arm (1).

NOTE: Press the bush (2) in until it is centrally

located in the control arm(1).

4. Reinstall control arm (1) as detailed in

4.3 CONTROL ARM in this Section.

Figure 3-26

4.7 CONTROL ARM TENSION ROD

REMOVE

1. Before raising the vehicle, loosen the front

tension rod nut (‘3’ in Fig. 3-29).

2. Raise front of vehicle and place safety stands

under side frame members. Observe jacking

precautions as outlined in 2.2 JACKING

PRECAUTIONS in this Section.

3. Remove wheel cover (steel wheels) or centre

cap (alloy wheels) on the side where the tension

rod is to be removed.

4. Mark relationship of road wheel to hub. Loosen,

then rem ove road wheel attaching nuts. Rem ove

road wheel.

5. Remove tension rod to control arm attaching

nut (1) and washer (2). Discard the nut (1).

6. Rem ove four nuts (5) attaching the tension rod

hydraulic damper assembly (4) to the

crossmember outrigger.

7. Remove tension rod (6) and tension rod

damper assembly (4) from control arm and out

through the crossmember outrigger.

8. Secure the tension rod (6) in protected vice

jaws, then remove the tension rod to tension

rod dam per assem bly retaining nut (3). Discar d

the nut (3).

9. Remove bright finished washer (9), from

tension rod (6), on the driver’s side.

Figure 3-27

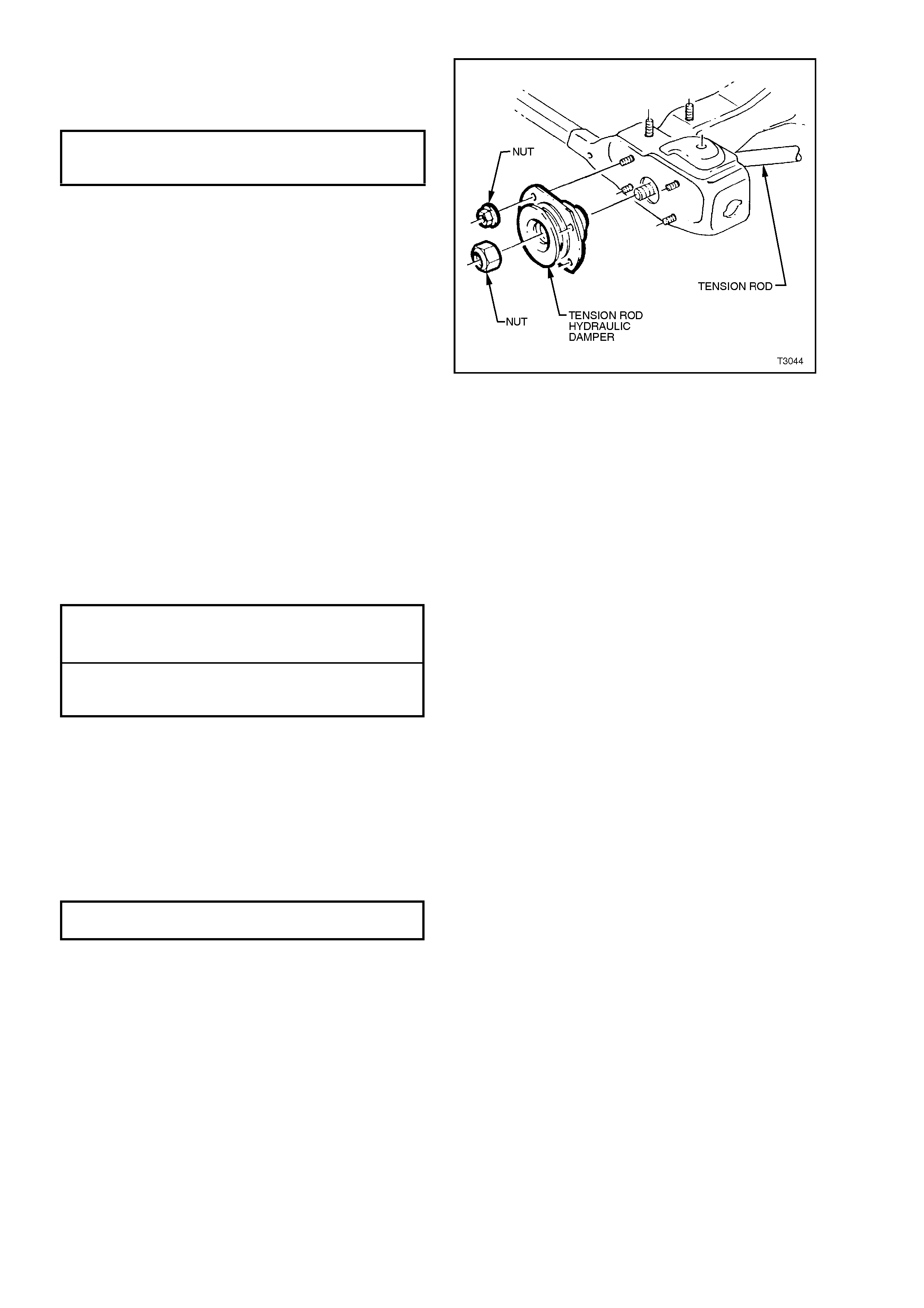

REINSTALL

1. Install bright finished inner washer to front end

of tension rod (A), on the driver’s side ONLY.

NOTE: T he f ront end of the tension rod is identified

by the longer length of the shouldered ends (‘A’

compared to ‘B’).

Figure 3-28

2. Install tension rod (1) into the hole in the

crossmember outrigger and then into the

control arm (3), with the cupped washer (2)

installed as shown. Reinstall tension rod to

control arm washer (4) with a NEW attaching

nut (5) but do not fully tighten at this stage.

Figure 3-29

3. Install tension rod, hydraulic damper assembly,

over the tension rod and install four retaining

nuts to the crossmember outrigger studs.

Tighten to the correct torque specification.

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY ATTACHING 20 – 26 Nm

NUT TORQUE SPECIFICATION

4. Install a NEW tension rod retaining nut but do

not fully tighten at this stage.

NOTE: If fitted, ensure that the spacer washer is

installed over the tension rod and then the flat

washer, before fitting the tension rod damper.

Figure 3-30

5. Reinstall road wheel, aligning the marks made

prior to removal and secure with the attaching

nuts, tightening progressively in a ‘star’

pattern. Do not overtighten.

6. Remove safety stands and lower vehicle to the

ground.

7. Bounce vehicle up and down several times to

settle suspension.

8. With the vehicle at curb position, tighten both

the tension rod to hydraulic damper and the

tension rod to control arm attaching nuts to the

correct torque specifications.

TENSION ROD TO HYDRAULIC

DAMPER ATTACHING NUT 140 – 155 Nm

TORQUE SPECIFICATION

TENSION ROD TO CONTROL

ARM ATTACHING NUT 95 – 110 Nm

TORQUE SPECIFICATION

Important: The weight of the vehicle must be on

all four wheels before tightening each end of the

tension rod to specification. Otherwise the fluid

filled tension rod bush will be incorrectly preloaded,

reducing the life of the bush and effect ride and

handling.

9. Tighten road wheel attaching nuts to the

correct torque specification, working in a ‘star’

pattern, as indicated in Fig. 3-8, in this

Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

10. Refit wheel cover/centre cap.

11. Check wheel alignment, as detailed in

2.1 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.8 FRONT SUSPENSION CROSSMEMBER

IMPORTANT: The service procedure detailed here, is only applicable to those vehicles fitted with the

revised design front crossmember to side frame bolts. While the bolts w ill service back to earlier VT series

vehicles, unless they are used, then the procedure detailed in 3. FRONT SUSPENSION, of the VT Series I

Service Information must be followed.

REMOVE

1. Jack up front of vehicle and place safety

stands under side frame members. Observe

jacking precautions as outlined in

2.2 JACKING PRECAUTIONS in this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub. Loosen,

then remove road wheel attaching nuts.

Remove road wheel.

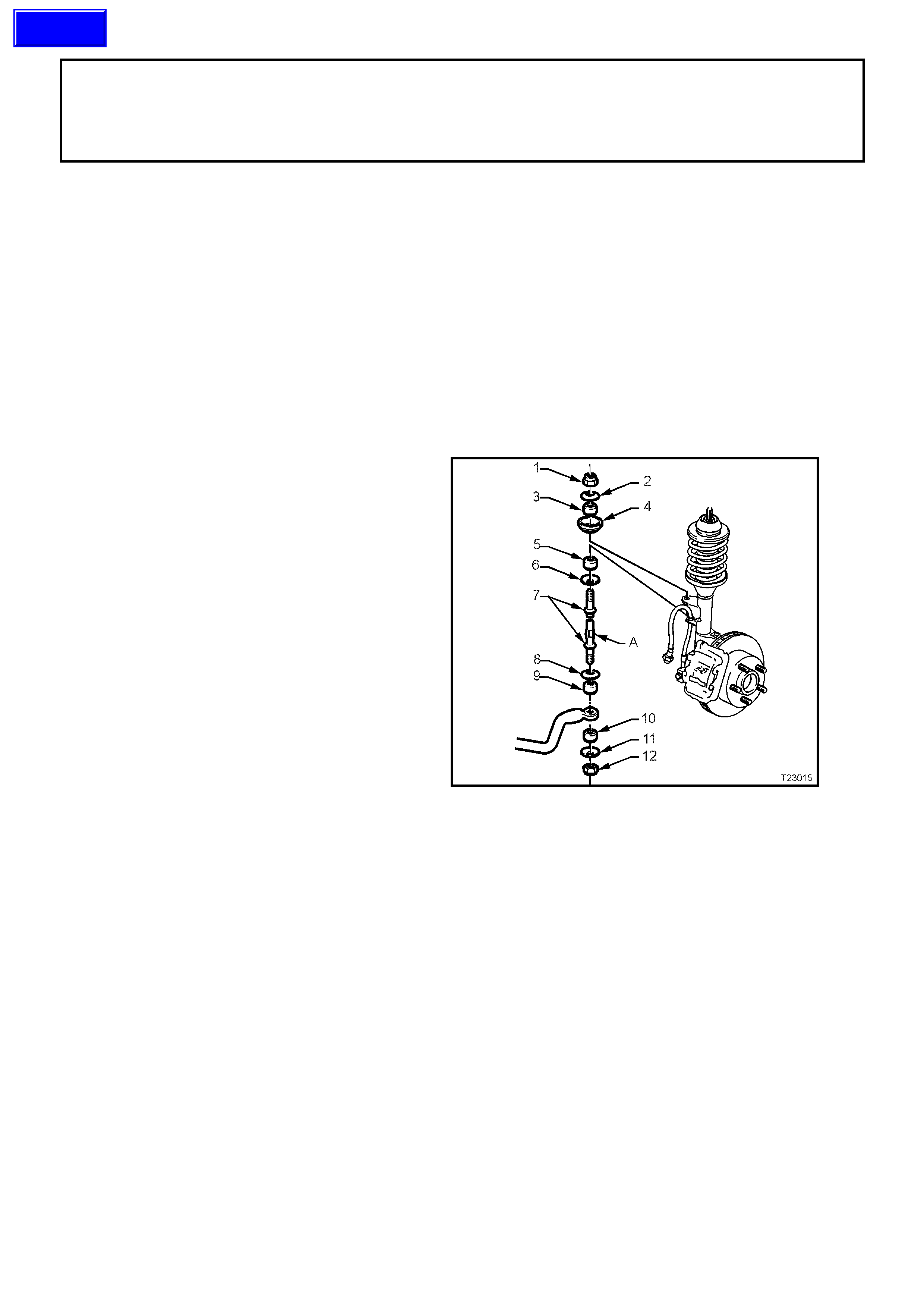

4. Using a suitable size open end spanner, hold

the stabiliser bar spacer stud (7) at ‘A’ and

remove the lower nut (12), washer (11) and

bush (10) from each side.

NOTE: The illustration shows an exploded view of

the complete assembly, for convenience only.

Figure 3-31

5. Remove the split pin from the tie rod ball joint

castellated nut (1), then loosen the nut until the

top of the nut is level with the top of the tie rod

end stud.

6. Install Tool No. 7311 and use a ring spanner

(2) to separate the tie rod ball joint stud from

the steering knuckle.

Figure 3-32

Techline

7. Remove steering gear housing (5) to

crossmember (6) mounting bolts (1) and nuts

(2). Remove steering gear housing (5) from

crossmember mountings (4).

Figure 3-33

8. Turn each wheel out in turn.

9. Loosen the ball joint retaining nut (1) until the

top of the nut is flush with the top of the ball

joint stud thread.

10. Install separation Tool No. E9332-A as shown,

then apply force to the top of the ball joint stud

by tightening the forcing bolt on the tool,

separating the ball joint from the knuckle.

NOTE: Once load is applied by the release tool

loading bolt, a sharp tap on the nut end of the tool

will lessen the apply force required.

11. Temporarily jam the ball joint stud taper into

the knuckle to hold the stud, before removing

the retaining nut. Discar d the removed nut as it

has micro-encapsulation sealant applied and

must be replaced on reassembly.

12. Separate the knuckle from the ball joint stud.

Figure 3-34

13. Mark hood hinge positions with felt tipped pen

and remove engine hood.

14. Support engine on a suitable lifting hook and

remove engine mounts to crossmember bolts

or nuts, refer to Sections 6A1 (V6) of the VT

Series I Service Information or Section 6A3

(GEN III V8) of the VT Series II Service

Information, for details.

15. Support crossmember (3) on a jack and

remove four bolts (1 and 2) securing the

crossmember to side frame members (4).

16. Lower, then remove crossmember assembly

(3) from vehicle.

17. As required, remove the control arms, tension

rod hydraulic dampers, tension rods and

stabiliser bar from the crossmember.

Figure 3-35

REINSTALL

While the majority of the reinstallation process is

the reverse of removal procedures, note the

following points:

1. Install the stabiliser bar insulating rubbers and

brackets to the crossmember, tightening

retaining nuts to the correct torque

specification.

STABILISER BAR SUPPORT

BRACKET RETAINING NUT 24 - 30 Nm

TORQUE SPECIFICATION

2. W hen reinstalling the crossmember, install the

two front, black coloured and stepped bolts (‘1’

in Fig. 3-37) and tighten to the correct torque

specification. This will correctly align the

crossmember to the side frames.

3. Reinstall the two rear, silver coloured, plain

shanked bolts (‘2’ in Fig. 3-37) to the two rear

positions and tighten them to the cor rec t torque

specification.

CROSSMEMBER TO SIDE

MEMBER BOLT (ALL) 120 – 125 Nm

TORQUE SPECIFICATION

4. Reinstall the two control arms to the

cross member, inst alling the pivot bolts fr om the

rear to the front. Install NEW nuts but do not

fully tighten at this stage.

5. If the control arms were removed with the

crossmember, install the ball joint stud into

each steering knuckle, install a NEW nut and

tighten to the correct torque specification.

BALL JOINT STUD NUT

TORQUE SPECIFICATION 50 – 70 Nm

6. If Rem oved, reinstall both tension rods, loos ely

installing washers and NEW retaining nuts, as

detailed in 4.7 CONTROL ARM TENSION

ROD in this Sec tion. Do not tighten at this time.

However, the tension rod hydraulic damper

mounting nuts can be tightened to the correct

torque specification.

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY ATTACHING 20 - 26 Nm

NUT TORQUE SPECIFICATION

7. Refit steering gear housing to crossmember,

tighten mounting nuts to the correct torque

specification.

STEERING GEAR HOUSING TO

CROSSMEMBER MOUNTING 70 - 85 Nm

NUT TORQUE SPECIFICATION

8. Reconnect engine mounts to crossmember,

refer to Sections 6A1 (V6) of the VT Series I

Service Information or Section 6A3 (GEN III

V8) of the VT Series II Service Inform ation, for

details.

9. Reinstall road wheels, aligning marks made

prior to removal .

10. Refit engine hood.

11. Remove safety stands and lower vehicle.

12. Bounce vehicle up and down several times to

settle suspension.

13. Tighten control arm , inner pivot bolt nuts to the

correct torque specification.

CONTROL ARM INNER PIVOT

BOLT TORQUE SPECIFICATION 95 - 100 Nm

14. With the vehicle at curb position, tighten the

tension rod attaching nuts at the control arm

and the hydraulic dam per, to the corr ect torque

specifications.

TENSION ROD TO CONTROL

ARM ATTACHING NUT 95 - 110 Nm

TORQUE SPECIFICATION

TENSION ROD TO HYDRAULIC

DAMPER ATTACHING NUT 140 - 155 Nm

TORQUE SPECIFICATION

Important: The weight of the vehicle must be on

all four wheels before tightening the tension rod to

specification. If not, the f luid filled tension rod bush

will be ruptured, once the vehicle is put back into

service.

15. Check wheel alignment, as detailed in

2.1 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

5. SPECIFICATIONS

SUSPENSION

Type MacPherson Wet Strut

Application All VT Models

Travel

Compression

(2/3compression of bumper)

Rebound

Standard and V5W

90 mm

110 mm

FE2

80 mm

120 mm

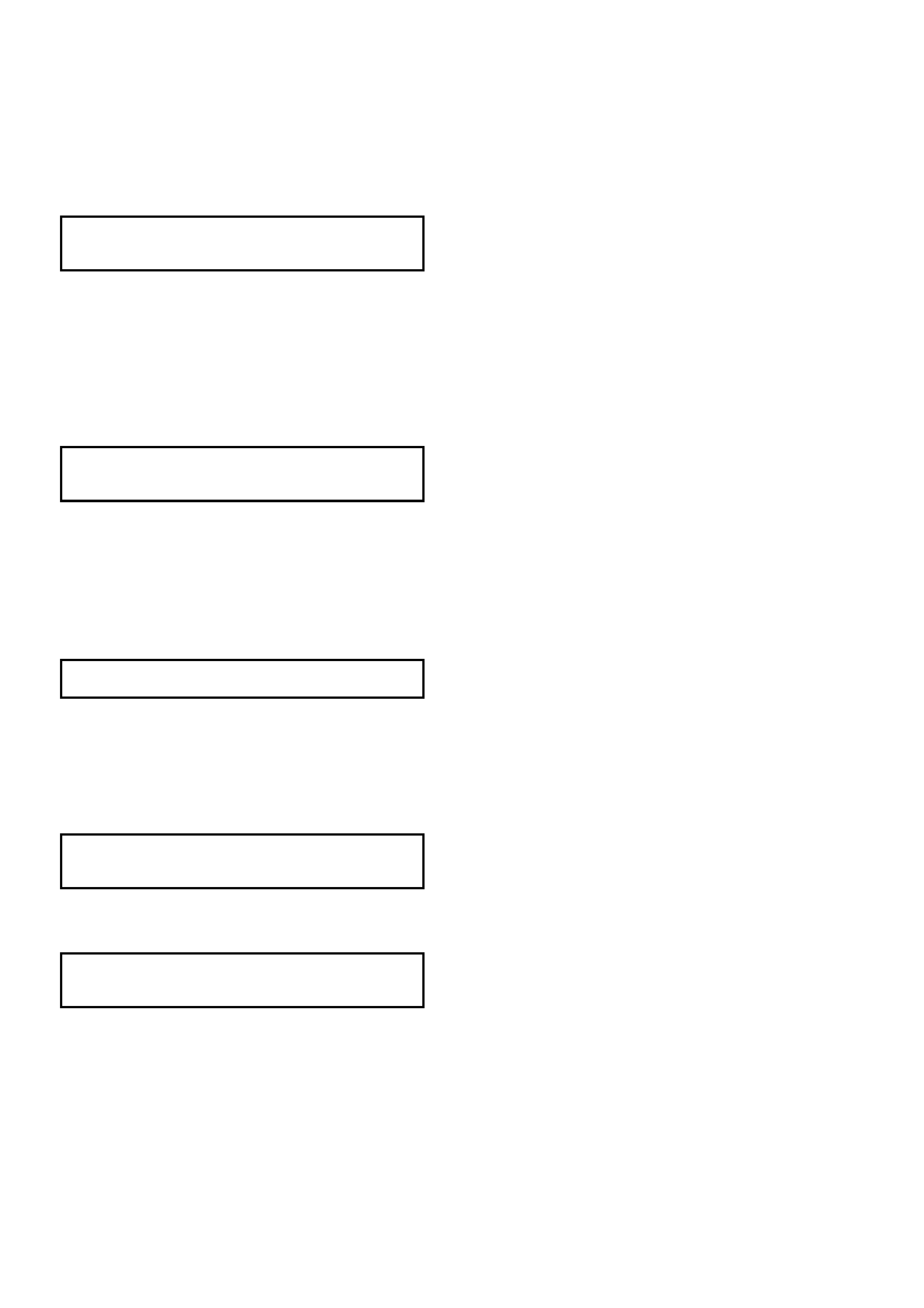

FRONT SPRING SPECIFICATIONS

SEDAN & STATION WAGON

MODELS

Approximat

e

Number

COILS

Approximate

FREE

LENGTH

(mm)

INSIDE

DIAMETE

R

(mm)

PROD. I.D.

CODE

(Tag on

spring)

SPRING

TYPE &

RATE

STANDARD SUSPENSION –

ALL ENGINES 6.05 444 136 ± 1.5 HN VARIABLE

19 - 23

N/mm

(3700 ± 110 N

@ 210 mm)

FE2 SPORTS SUSPENSION –

ALL ENGINES 5.25 341 136 ± 1.5 HJ VARIABLE

24 - 31

N/mm

(3660 ± 110 N

@ 200 mm)

V5W COUNTRY P ACK SUS PENS ION

– V6 ENGINE 6.12 376 136 ± 1.5 HS VARIABLE

24 - 31

N/mm

(3660 ± 110 N

@ 230 mm)

Figure 3-36

Legend

1. Production Identification Code Tag

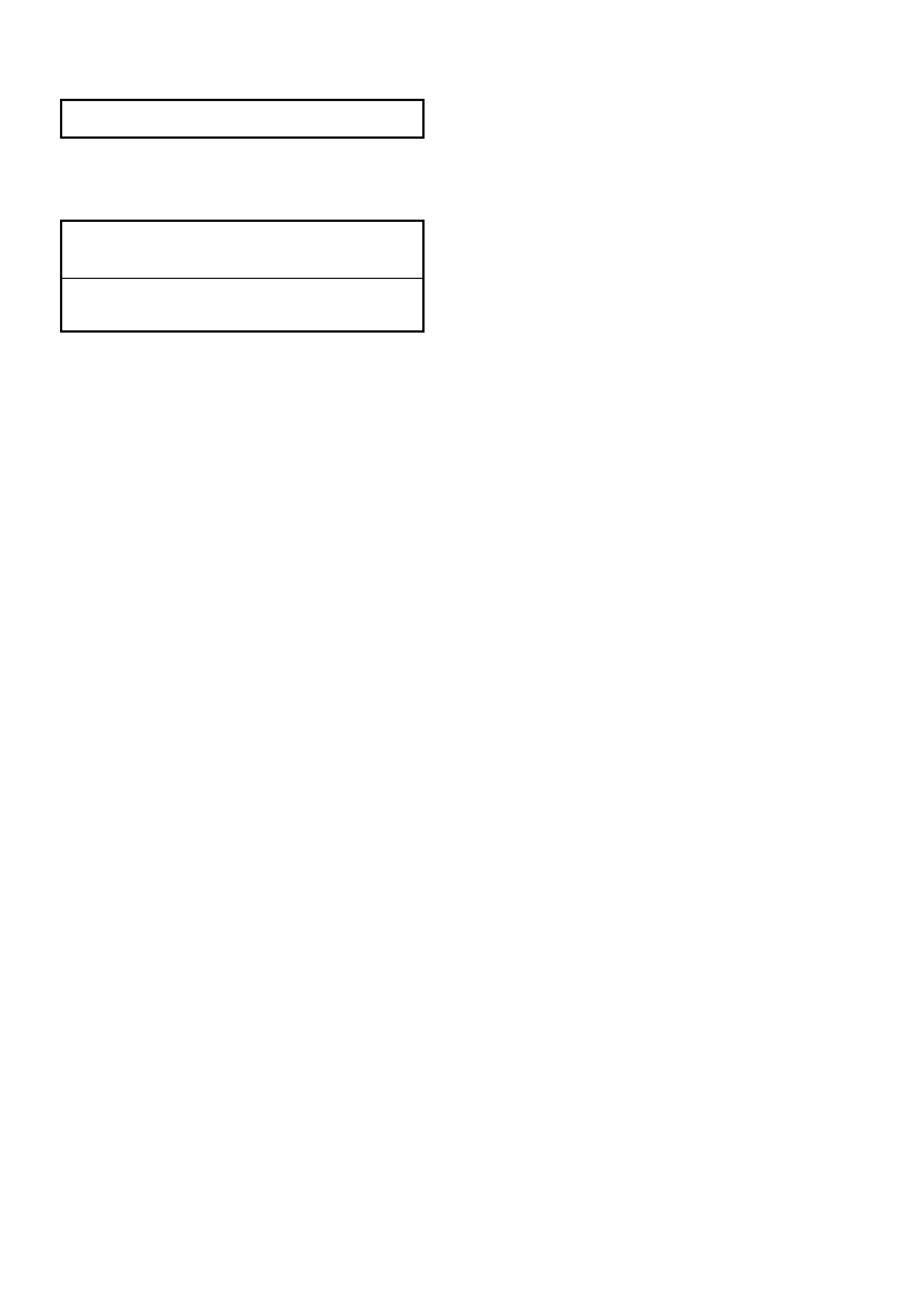

STABILISER BAR (FRONT)

Type ......................................................................... Decoupled

STABILISER BAR IDENTIFICATION

Diameter I.D.

MODELS mm CODE

(2) (1)

All VT Series II Models and

Suspensions, except for

Sedan with FE2 26.0 GE

Sedan Models and

FE2 Suspension 27.0 GH

Figure 3-37

Legend

1. PRODUCTION IDENTIFICATION CODE TAG

2. Stabiliser Bar Diameter

FRONT STRUT

Type ........................................................................ Wet strut – non-serviceable

Piston Diameter....................................................... 30 mm

Fluid Type................................................................ Hydraulic fluid to Holden Specification HN 1588

Capacity............................................................. 350 ml

FRONT STRUT ID ENTIFICATION

Suspension and Application Right Hand Side Left Hand Side

STANDARD SUSPENSION –

SEDAN AND STATION WAGON RS LS

SPORTS SUSPENSION (FE2) –

SEDAN AND STATION WAGON RT LT

COUNTRY PACK SUSPENSION –

SEDAN AND STATION WAGON RU LU

CONTROL ARM

Type ........................................................................ Forged with rubber bushes for attachment to front

crossmember and tension rod. Ball joint is a press fit

into the control arm.

FRONT WHEEL BEARINGS

Type ........................................................................ Double row ball bearing

Lubricant.................................................................. Sealed for life: non-adjustable

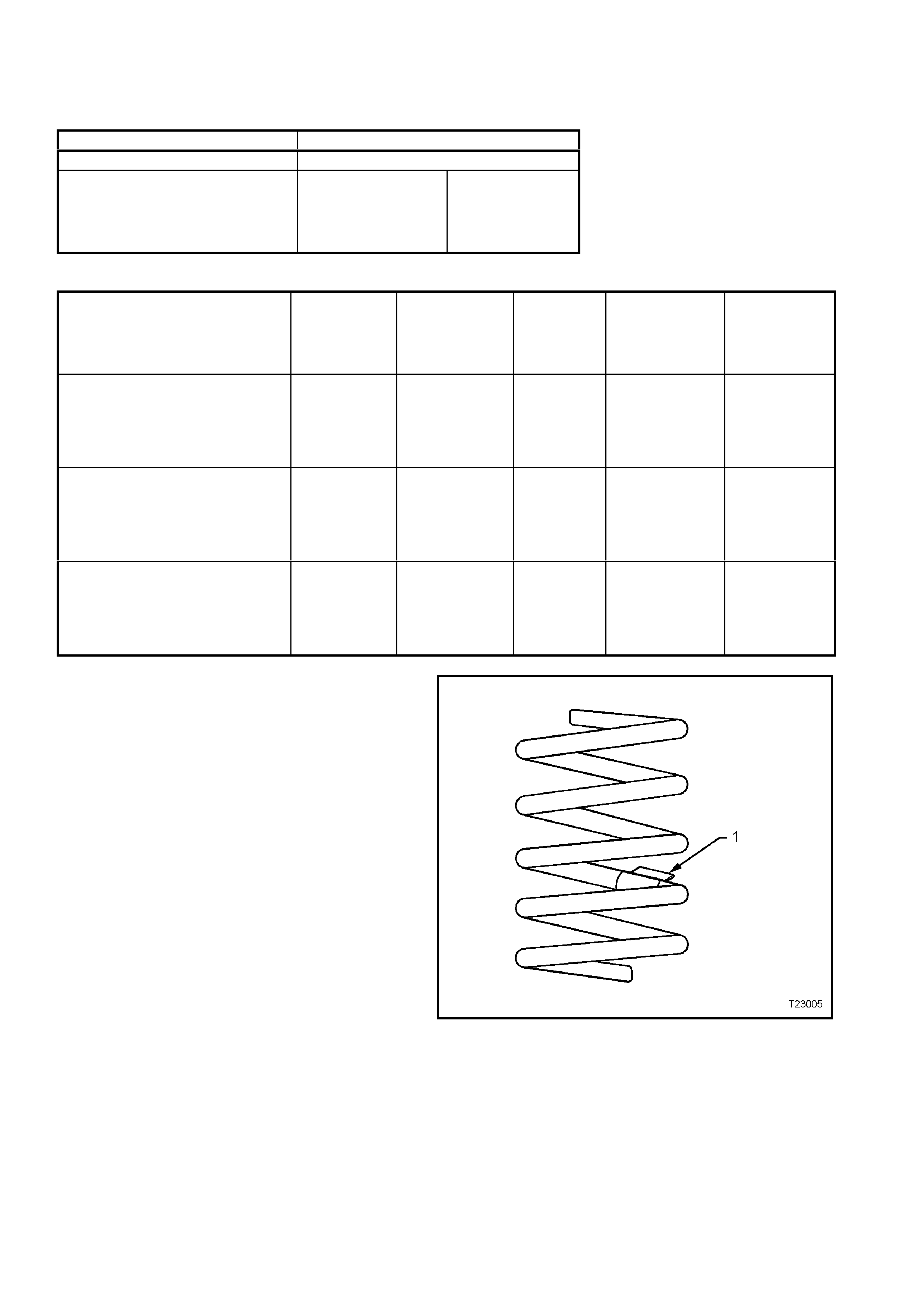

SUSPENSION and TRIM HEIGHT SPECIFICATIONS

A Front Suspension Height

B Rear Suspens i on Hei ght

C Trim Hei ght Checking Locations

1. Wheelbase: All VT S edan – 2798 mm

All Station Wagon – 2935 mm

2. Reference Point: All Models – 584.5 mm

3. Trim Height Spacing:

All Sedan – 1615 mm

All Station Wagon – 1765 mm

4. Ground Line

Figure 3-38

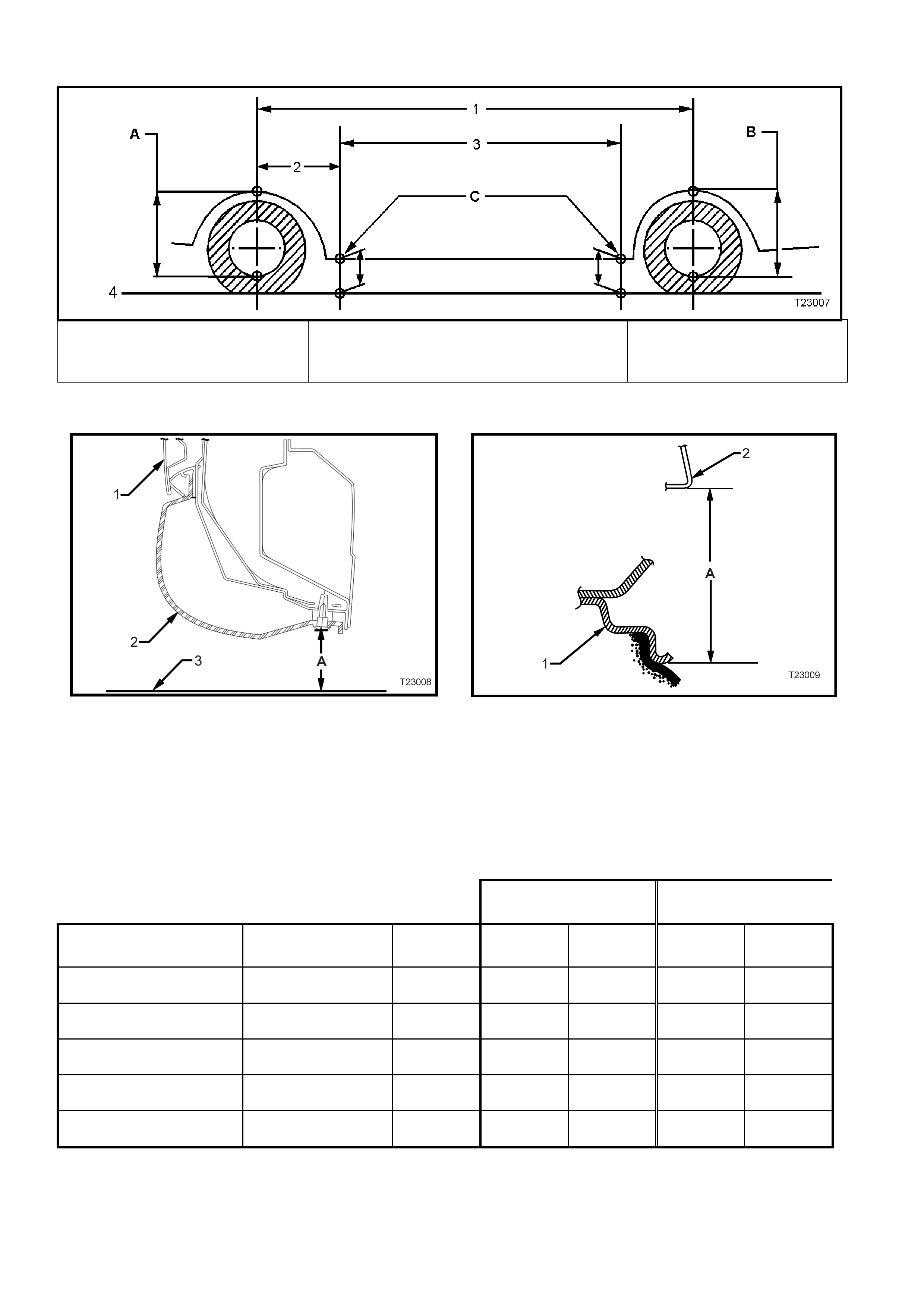

1. Door 2. Trim 3 Ground Li ne ‘ A’ Trim Hei ght 1. Wheel Rim 2. Fender Opening ‘A’ Sus pension Height

Figure 3-39 – Rear Trim Height Checking Location (Front

Similar) Figure 3-40 – Front and Rear Suspension Height

Checking Location

NOTE: The following suspensi on/trim height dimensions ar e intended for refe rence and ar e intended to be

a guide only (Refer to 3.3 SUSPENSION AND TRIM HEIGHT CHECK, in this Section).

VT SERIES II MODELS WITH V6 ENGINE AND STANDARD SUSPENSION

SUSPENSION HEIGHT

(mm) TRIM HEIGHT

(mm)

VEHICLE

DESCRIPTION TRANSMISSION MODEL FRONT REAR FRONT REAR

Executive Sedan Manual Base 593 583 192 201

Berlina Sedan Automatic Base 593 583 192 201

Calais Sedan Automatic Base 593 583 192 201

Executive Station Wagon Manual Base 603 573 192 210

Berlina Station Wagon Automatic Base 598 582 192 210

6. TORQUE SPECIFICATIONS

NOTE: For Those Torque Specifications Not Listed Here, Refer To: Section 3 FRONT SUSPENSION or

Section 9A STEERING of the VT Series I Service Information and Section 9A STEERING of the VT Series II

Service Information.

Nm

Ball Joint Stud Nut........................................................................ 50 - 70

Brake Caliper Anchor Plate Retaining Bolts.............Stage 1....... 80 - 90

Stage 2....... Turn through 40° - 50°

Control Arm Inner Pivot Bolt......................................................... 95 – 110

Crossmember to Side Member Bolt Torque................................. 120 – 125

Front Hub to Steering Knuckle Attaching Bolt .............................. 100 - 115

Road Wheel Attaching Nut........................................................... 110 - 140

Stabiliser Bar Support Bracket Retaining Nut............................... 24 - 30

Steering Gear Housing to Crossmember Mounting Nut............... 70 - 85

Steering Knuckle to Strut Attaching Bolts and Nuts Stage 1....... 85

Stage 2....... 100

Stage 3....... Turn through 90°

Tension Rod Hydraulic Damper Assembly Attaching Nut............ 20 – 26

Tension Rod to Control Arm Attaching Nut .................................. 95 – 110

Tension Rod to Hydraulic Damper Attaching Nut......................... 140 – 155

Upper Strut Bearing Retaining Nut............................................... 70 - 85

Upper Strut Locating Plate Retaining Nut..................................... 50 - 60

Tie Rod Ball Joint Stud Castellated Nut ....................................... 50 – 80

Tie Rod to Tie Rod Ball Joint Lock Nut ........................................ 40 – 60

7. SPECIAL TOOLS

TOOL No. REFERENCE

IN TEXT TOOL DESCRIPTION COMMENTS

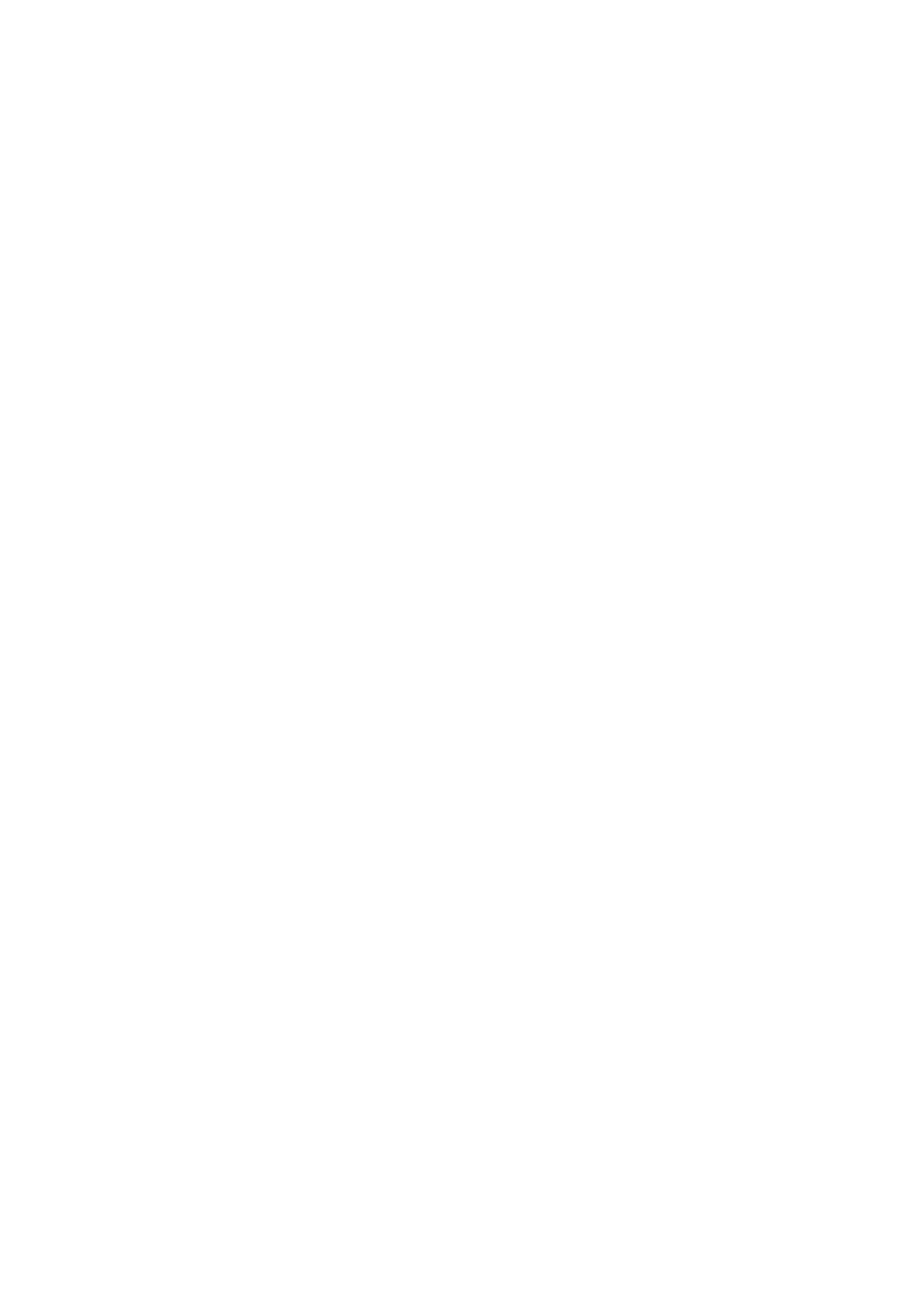

3A8-6 SUPPORT

Previously released.

Used to support control arm during

ball joint replacement operations.

7311 TIE ROD BALL JOINT REMOVER

Previously released.

Can also be used on earlier ‘V’ cars

for the same purpose.

7A42 PRESS PLATES

Previously released.

AKM500-3 PRESS TUBE

Previously released.

Used to install a new ball joint into

the control arm.

TOOL NO. REF

IN TEXT TOOL DESCRIPTION COMMENTS

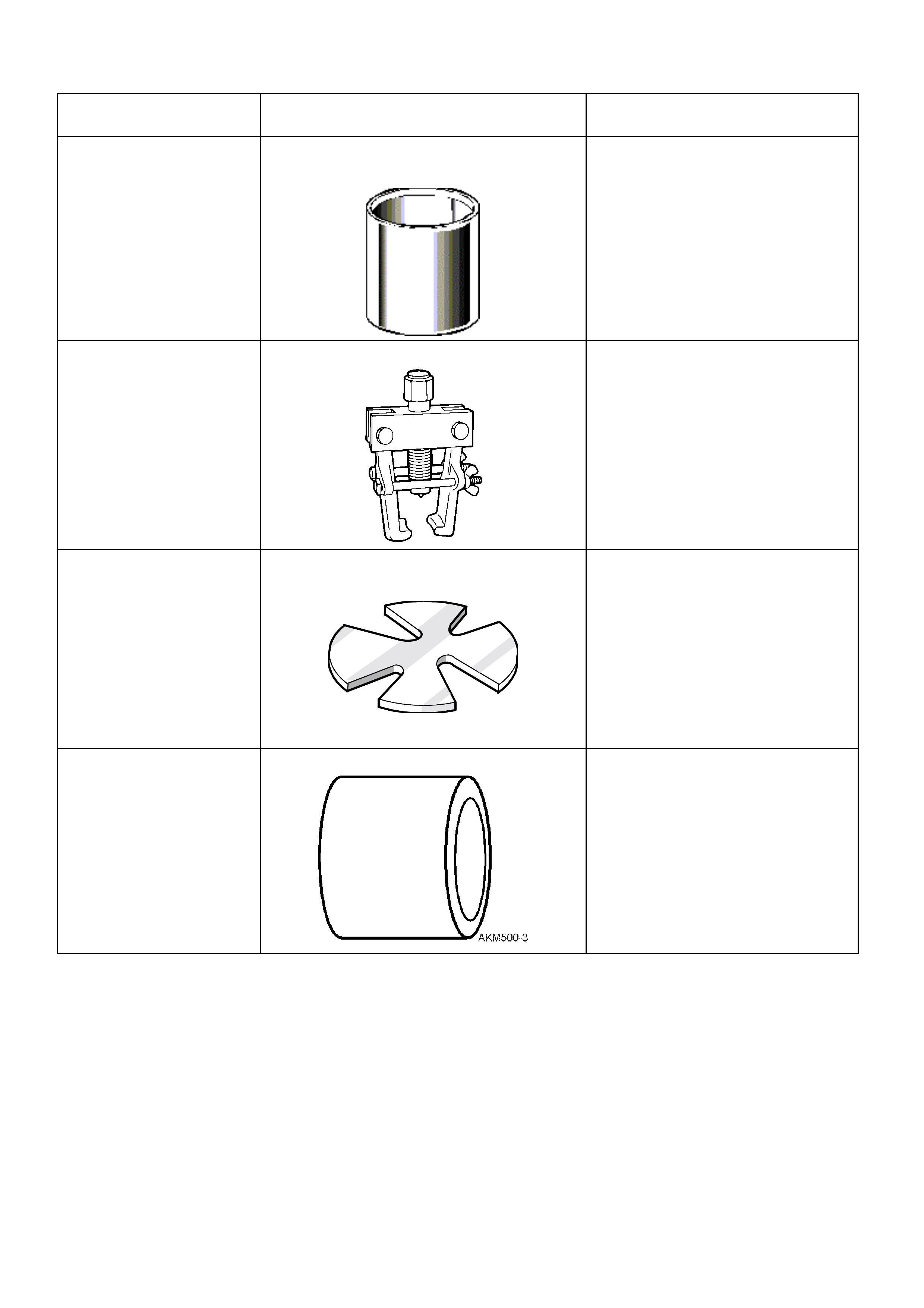

AU158 CONTROL ARM TENSION ROD BUSH

REMOVER AND INSTALLER MANDREL

Previously released for "V" car.

Used with KM158-2 for removing

bush and AU159 and KM157-2 for

installing.

AU159 CONTROL ARM TENSION ROD BUSH

REPLACER SLEEVE

Previously released for "V" car.

AU160-1 SUPPORT

Previously released.

Used to support control arm when

installing a new inner bush.

AU162 CONTROL ARM INNER PIVOT BUSH

REMOVAL MANDREL

Used with AU160-1 and KM157-2.

Previously released for "V" car..

AU534 TORQUE LIMITING SOCKET

Previously released.

Used in conjunction with an impact

gun to tighten wheel nuts.

This is a mandatory tool.

TOOL NO. REF

IN TEXT TOOL DESCRIPTION COMMENTS

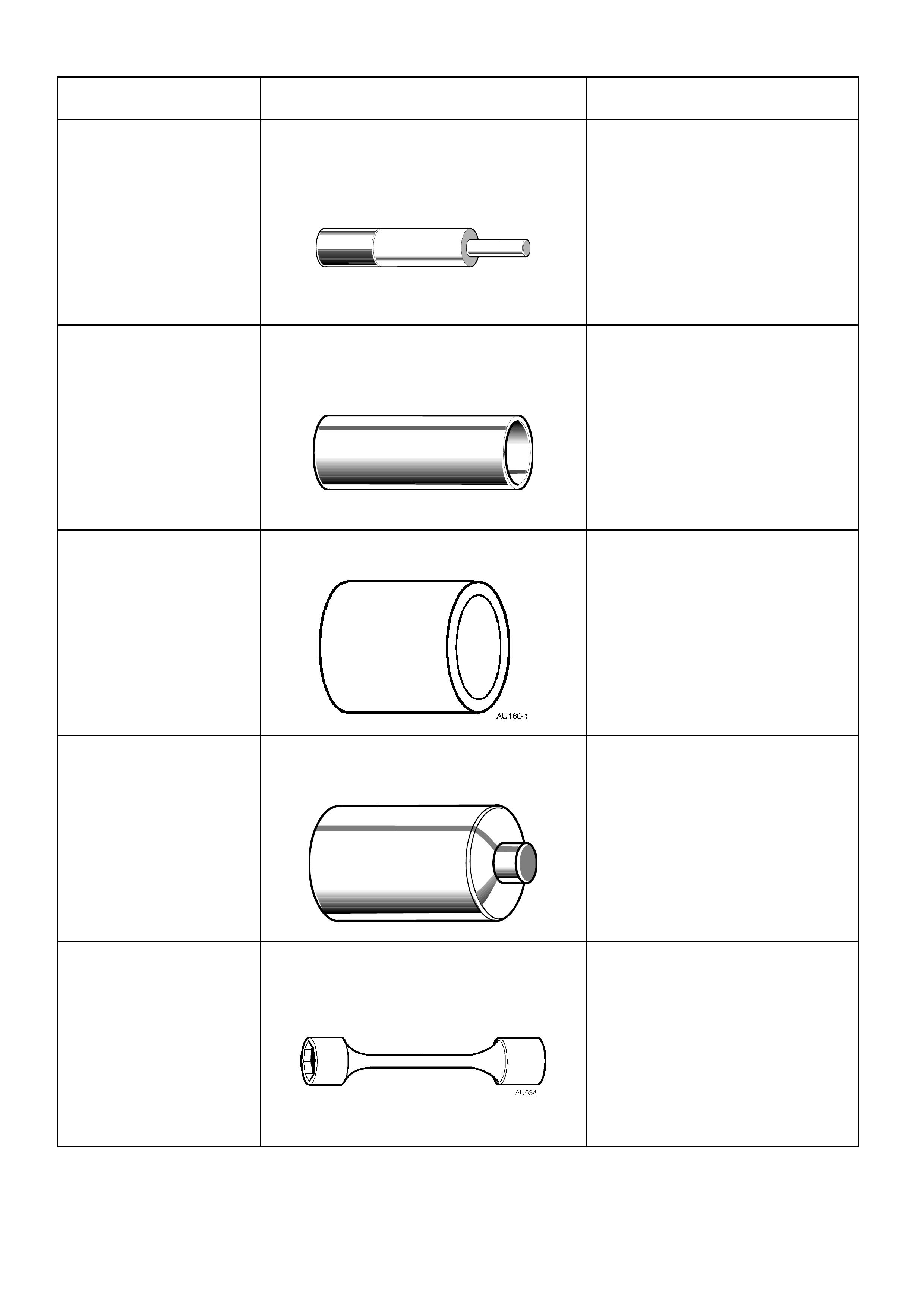

E7115 ANGLE WRENCH

Previously released for 'J' and 'V'

cars.

Used to tighten component fasteners

when angle torque is required.

E9332-A BALL JOINT RELEASE TOOL

Previously release.

Used to release the control arm ball

joint from the steering knuckle.

KM157-2 CONTROL ARM BUSH INSTALLER

Previously released for "V" car.

Used with AU158 and AU159.

KM158-2 CONTROL ARM TENSION ROD BUSH

INSTALLING SUPPORT SLEEVE

Previously released for "V" car.

Used with AU158 and AU159.