SECTION 4B – FINAL DRIVE AND DRIVE SHAFTS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air b ags or seat belt pre- tensioners, driv er’s and front passenger’s air bag and left and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC,

VT Series I Service Information (V6) or VT Series II Service Information (GEN III V8).

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning ‘OFF’ the manual service valve and then draining the LPG

service lin es, b efo re any serv ice work is carried o ut on th e v ehi cle. Refer t o t he L PG leaf let in clud ed with

the Owner's Handbook for details or the appropriate Section of this Service Information CD for more

specific servicing information.

1. GENERAL INFORMATION

A local sourc e of rear suspens ion trailing arm s is to be f itted to VT Ser ies II vehicles f rom an antic ipated break point

in late January, 2000.

As the new trailing arm requires new special tools to service the trunnion and/or bearing, should work be required

on these components, then correct identification of the trailing arm will be required. Refer to

2.2 TRAI LING ARM IDENTIFICATION, in this Section for details.

Service operations relating to the removal and reinstallation procedures for the final drive assembly have been

included, that reflect revised procedures, some torque specification revisions and upgraded illustrations.

Apart from this change, all other service operations remain as detailed in 4B FINAL DRIVE AND DRIVESHAFTS

of the VT Series I Service Information.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

IMPORTANT SERVICE REQUIREMENTS

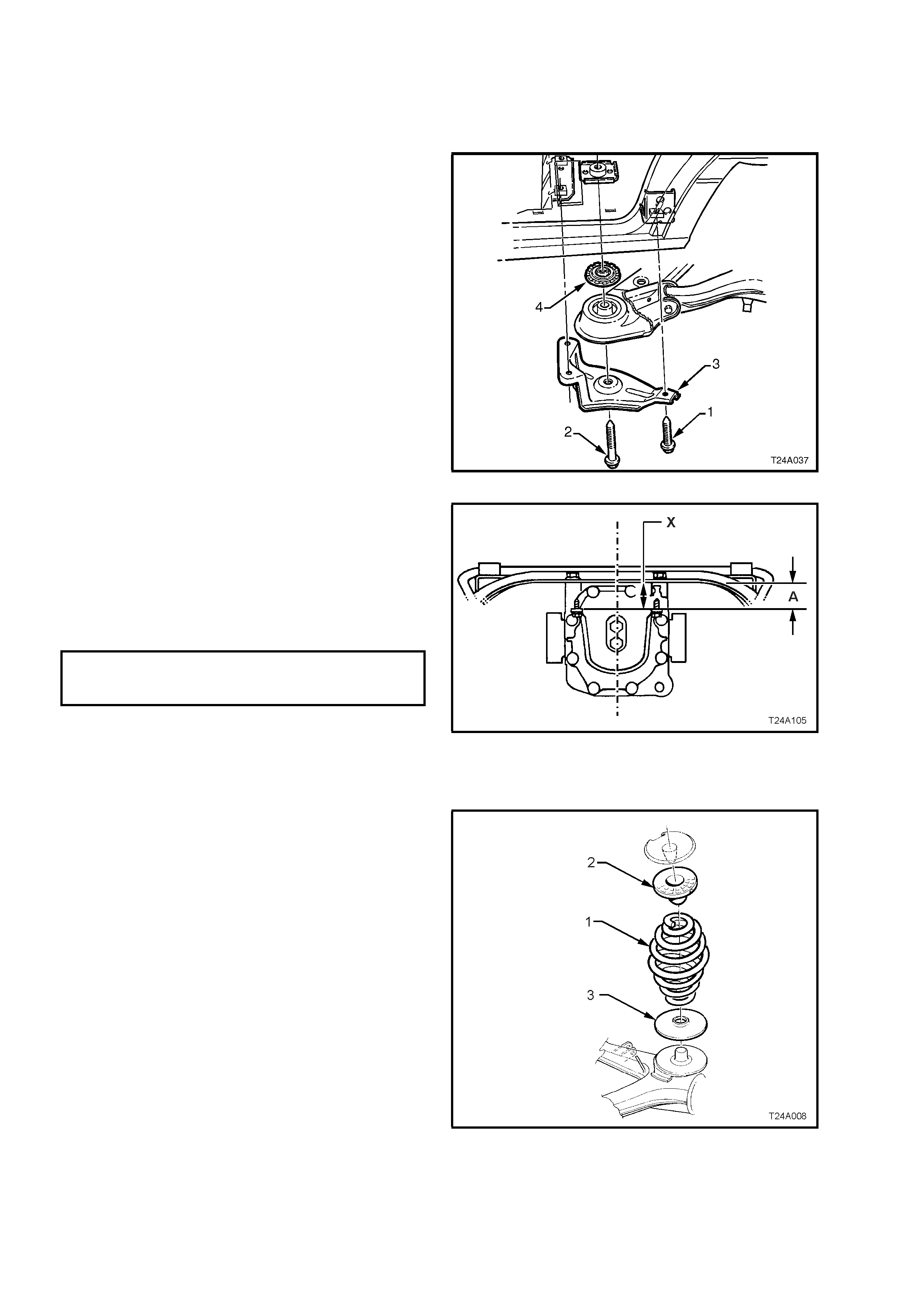

1. Whenever a road wheel and/or brake disc is

removed from the vehicle, the relationship of

the road wheel to the hub and the disc to the

hub MUST be marked with a felt tipped pen or

similar, in order for those parts to be reinstalled

in their original positions. This is critical to

maintain the brake disc and road wheel runout

dimension to a minimum.

2. When reinstalling road wheels, do not use an

impact gun to tighten wheel nuts, unless it is

fitted with a torque limiter socket (Tool No

AU534). Failure to correctly tighten wheel nuts

to the correct torque specification and in the

correct order, may result in a distorted brake

disc, that may lead to the development of

brake shudder.

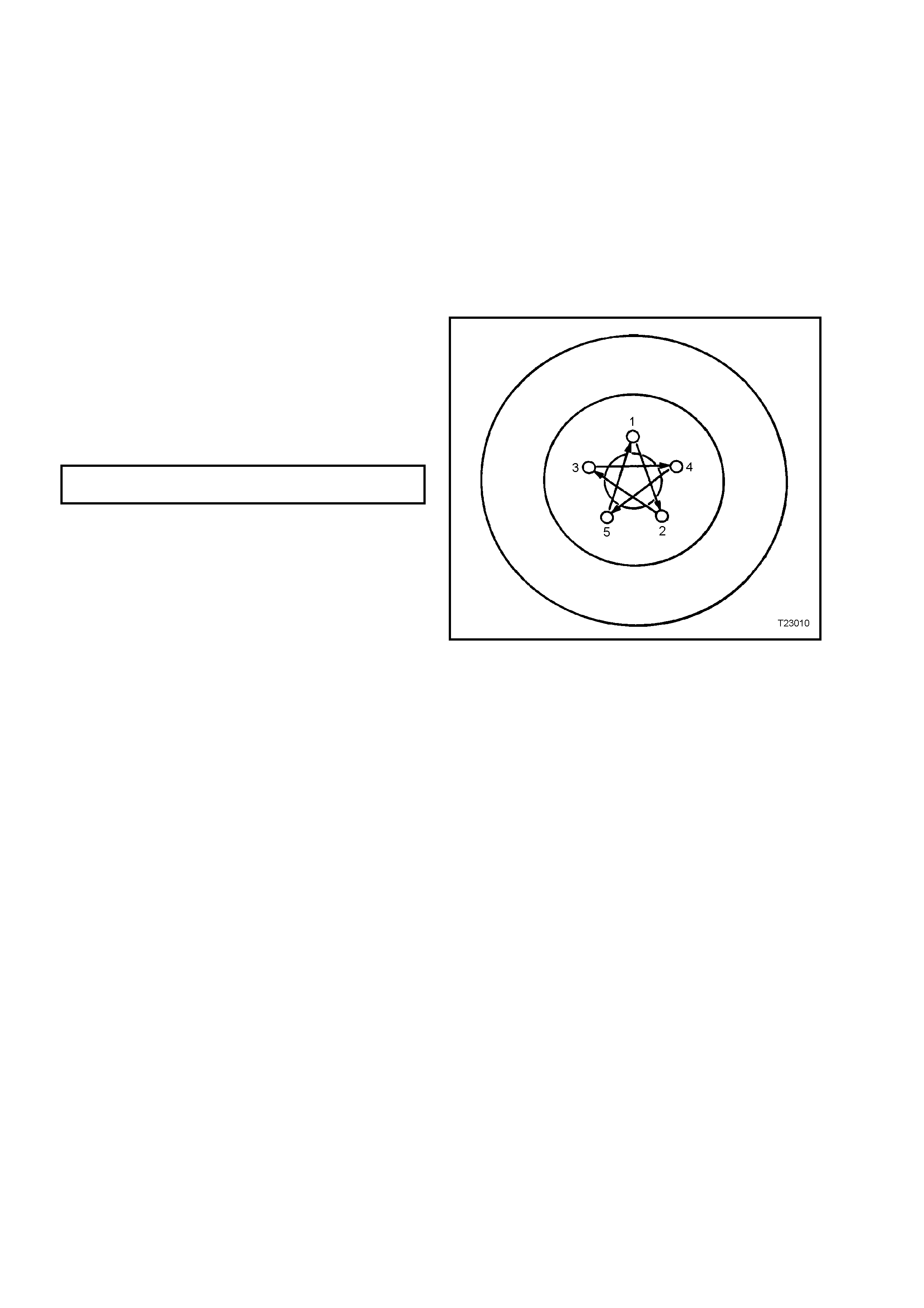

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

For a complete description of the method used to

measure both brake disc and trunnion assembly

runout and correction, refer to

2.2 REAR BRAKE DISC, Brake Disc and Hub

Indexing Procedure, in 5A STANDARD BRAKES,

of the VT Series II Service Information.

Figure 4B-1

3. All rear suspension fasteners are important

attaching parts because they affect the

performance of vital components and/or could

result in major repair expense. Where

specified in this Section, fasteners MUST be

replaced with ones of the s ame par t number or

with an equivalent part. Do not use a

replacem ent part of inf erior quality or substitute

design.

4. Torque values must be used as specified

during reassembly to ensure proper retention

of all rear suspension components.

2.2 TRAILING ARM IDENTIFICATION

CAUTION: Whenever any component that

forms part of the ABS (if fitted) is disturbed

during Service Operations, it is vital that the

complete ABS system be checked, using the

procedure as detailed in DIAGNOSIS, ABS

FUNCTION CHECK, in Section 12L ABS &

ABS/ETC, VT Series I Service Information

(V6 engine) or Section 12L ABS & ABS/ETC, VT

Series II Service Information (GEN III V8

engine).

As the introduction of the changed source of

trailing arm manufacturer has been on a ‘staged’

basis over a period of tim e, identific ation of the two

types is necessary if service work is to be carried

out on the trunnion and/or bearing.

The most effective way of identifying the locally

sourced trailing arm is a visual inspection, that can

be achieved by the following procedure.

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle and place saf ety

stands under body rear jack ing points. Ref er to

Section 0A GENERAL INFORMATION of the

VT Series I Service Information for location of

jacking points.

2. Remove wheel cover (steel wheels) or centre

cap ( alloy wheels) from the requir ed side of the

vehicle.

3. Mark relationship of road wheel to hub (e.g.

end of wheel stud), with a felt tipped pen or

similar. Loosen then remove road wheel

attaching nuts. Remove the road wheel.

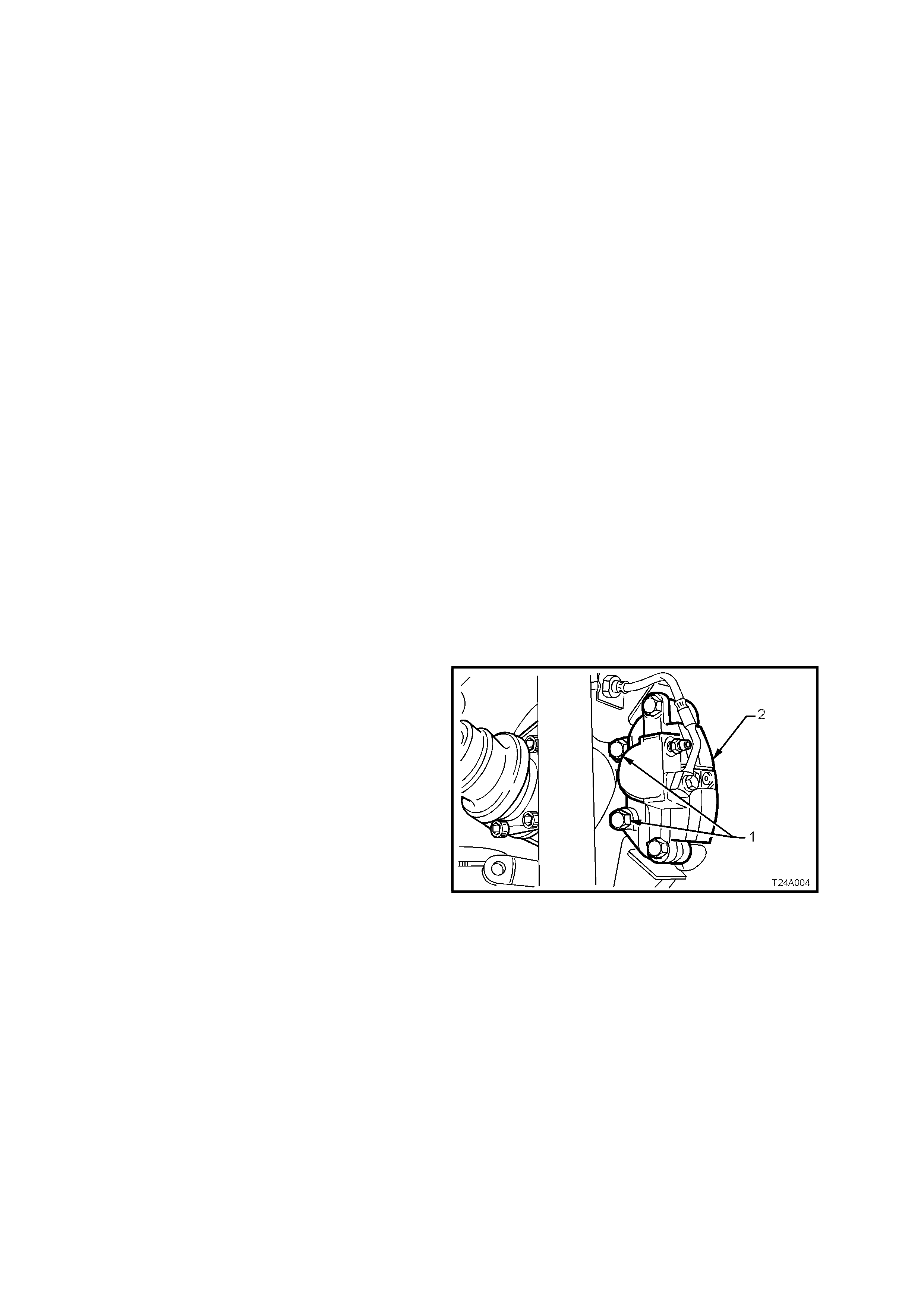

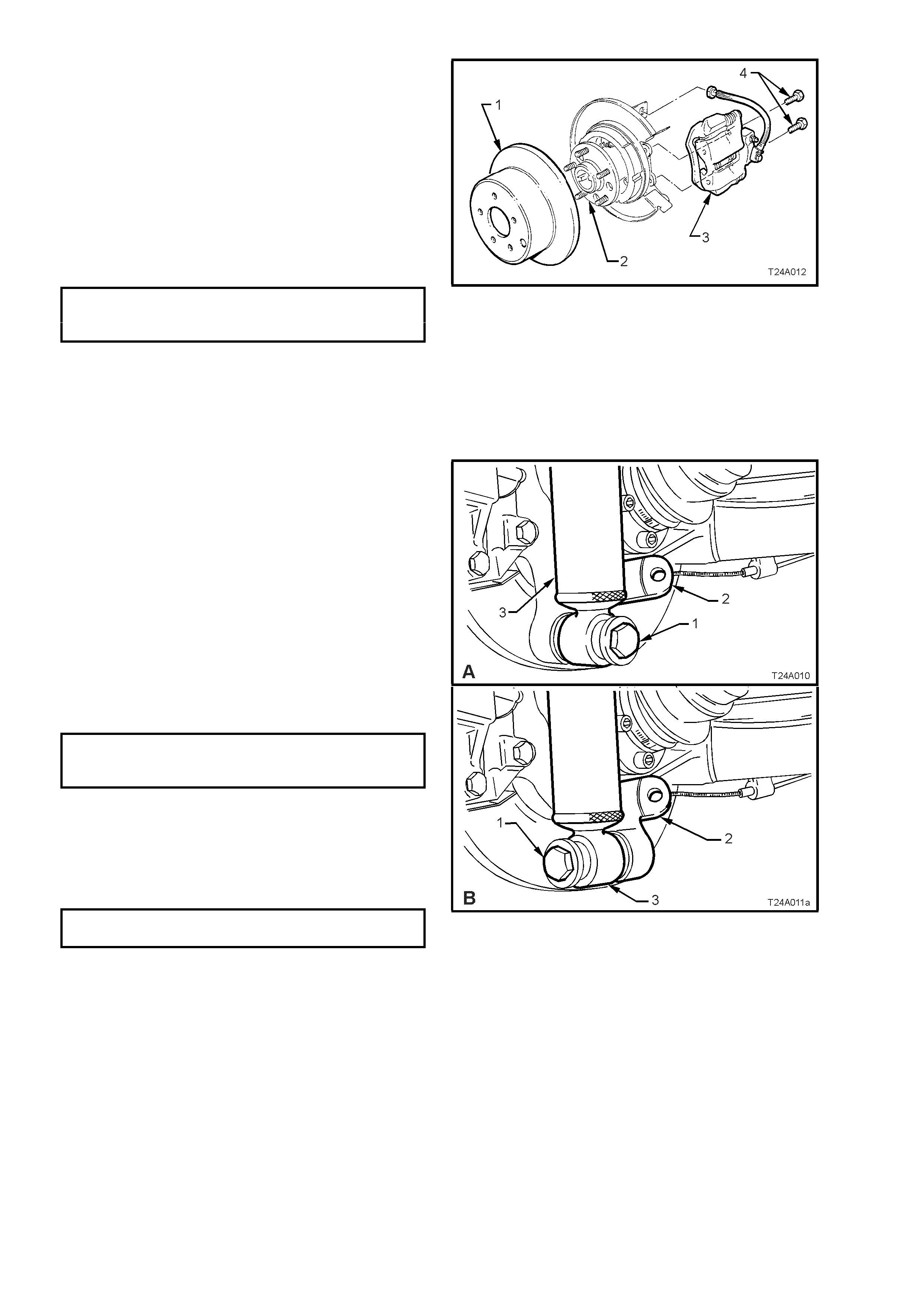

4. Remove brake caliper anchor plate to trailing

arm attaching bolts (1) and remove caliper (2)

from disc. Support the brake caliper with tie

wire secured to the vehicle underbody. THE

CALIPER IS NOT TO HANG BY THE BRAKE

HOSE.

Figure 4B-2

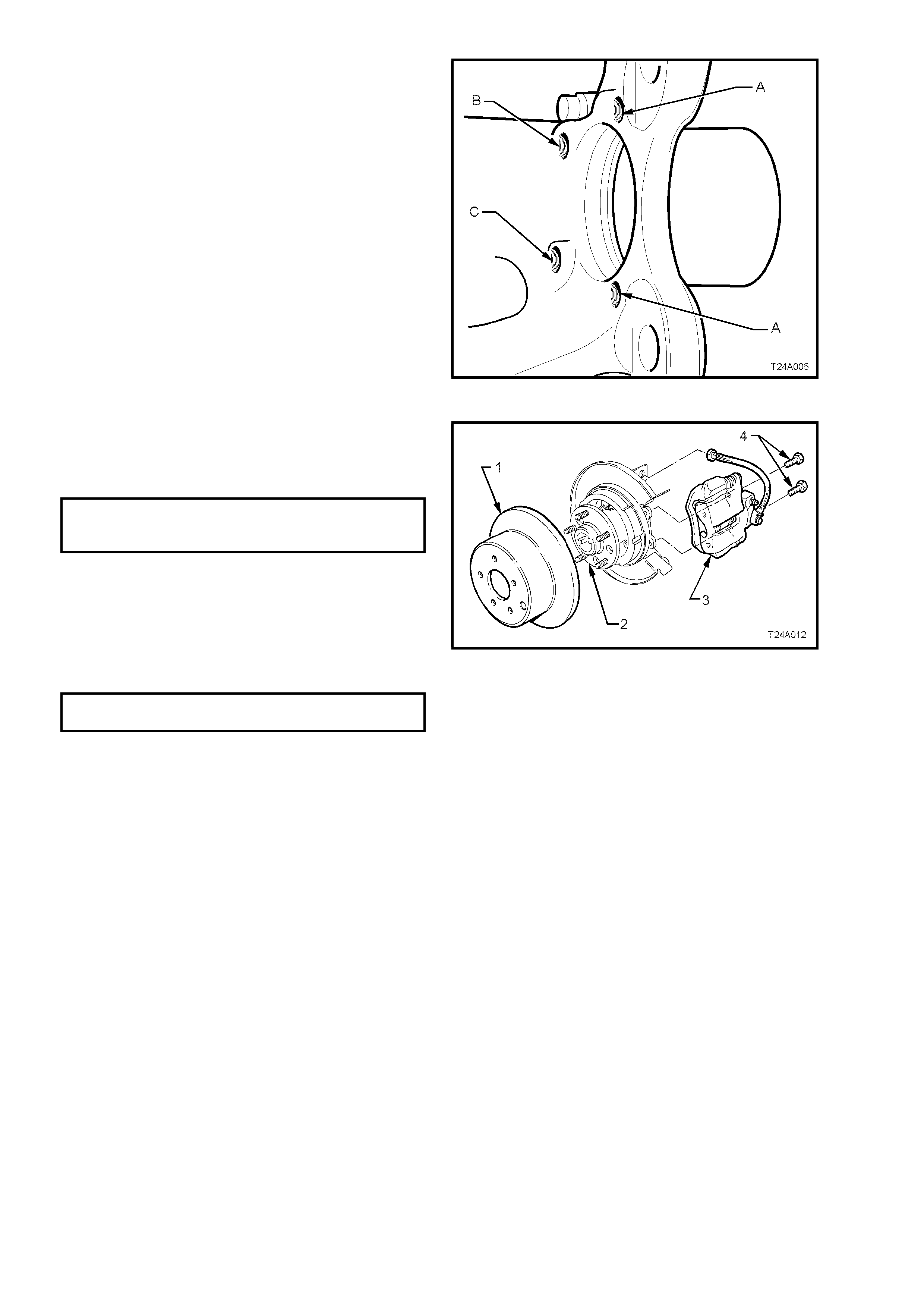

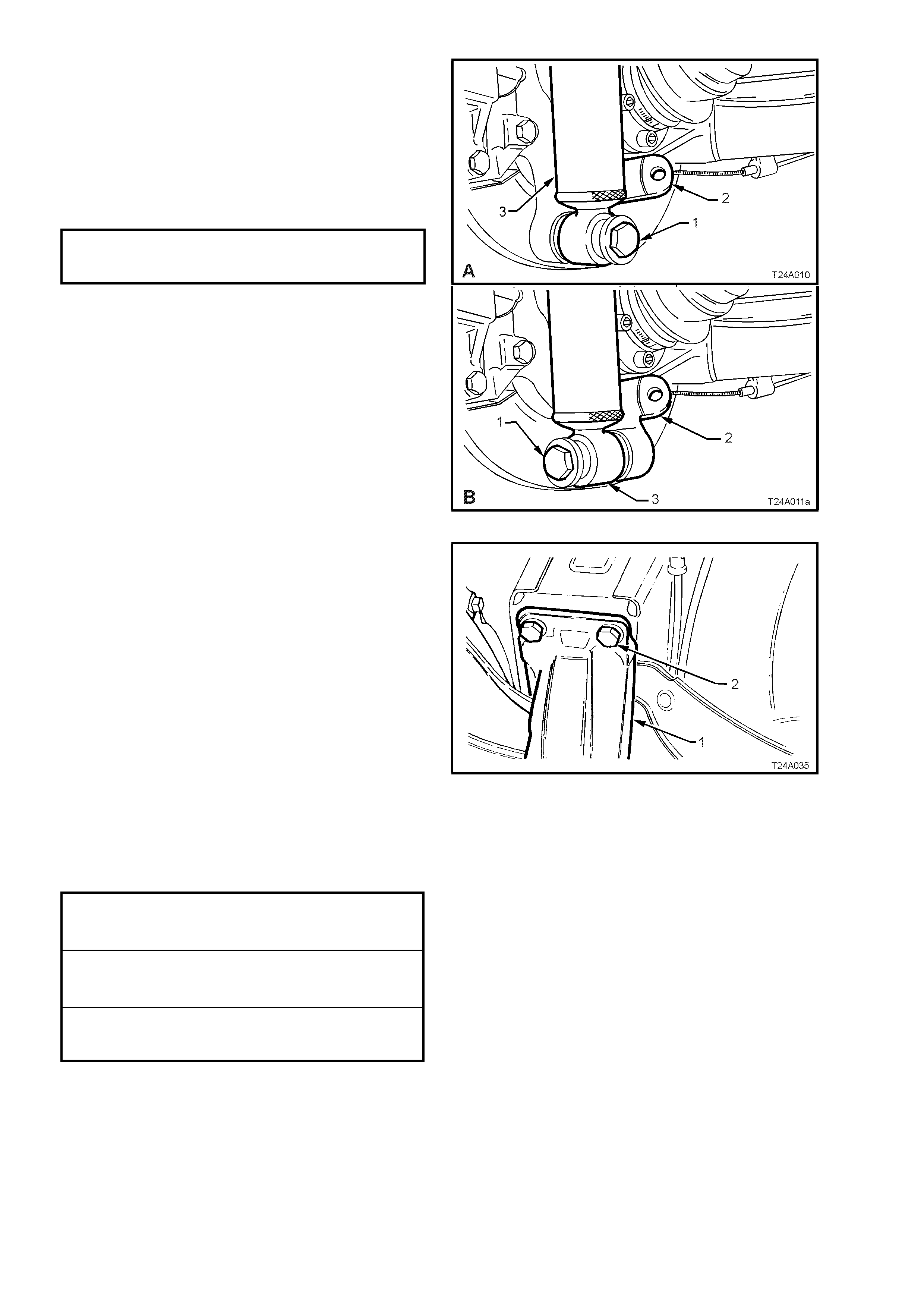

5. Visually observe the protrusions from the rear

of the trunnion housing. If the two inner

protrusions (B and C) are higher than the outer

two (A) and each are of differing heights to

each other (as shown in Fig. 4B-3), then the

trailing arm is of local manufacture.

The service operations relating to the trunnion

and/or bearing are included in this Section.

Should the protrusions all be of the same

height, then the trailing arm is of the earlier

design. For service operations on this

trunnion/bearing assembly, refer to

2.5 TRAILING ARM, in Section 4B FINAL

DRIVE AND DRIVESHAFTS, of the VT Series

I Service Information.

NOTE: The view shown does not include the brake

backing plate, trunnion or inner trunnion flange, to

more clearly show the protrusion differences.

Figure 4B-3

6. Reinstall the brake caliper (3) to the trailing

arm, reinstall brake caliper anchor plate to

trailing arm attaching bolts (4) and tighten to

the correct torque specification.

BRAKE CALIPER ANCHOR PLATE

TO TRAILING ARM ATTACHING 70 - 100 Nm

BOLT TORQUE SPECIFICATION

7. Reinstall road wheel, aligning marks made

before removal and reinstall attaching nuts.

8. Lower vehicle to the ground and tighten road

wheel attaching nuts to the correct torque

specification, working in a ‘star’ pattern. Refer

2.1 SERVICE NOTES in this Section for more

details.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

9. Refit wheel cover/centre cap.

Figure 4B-4

3. MAJOR SERVICE OPERATIONS

3.1 TRAI LING ARM TRUNNION FLANGE, TRUNNION ASSEMBLY AND/OR

WHEEL BEARING

The following procedure involves the removal of

the trunnion flange, trunnion and/or wheel bearing

with the trailing arm installed on the vehicle.

A similar procedure is included in

Section 4A REAR SUSPENSION – Early

Production Trailing Arms or Section 4A REAR

SUSPENSION – Local Production T railing Arms of

the VT Series II Service Information, involving the

trailing arm removed from the vehicle.

For this operation, a new lock plate and collar nut

must be used on reassembly.

NOTE: The rear wheel bearing should only be

rem oved if it is faulty, or if the trunnion ass embly is

to be removed.

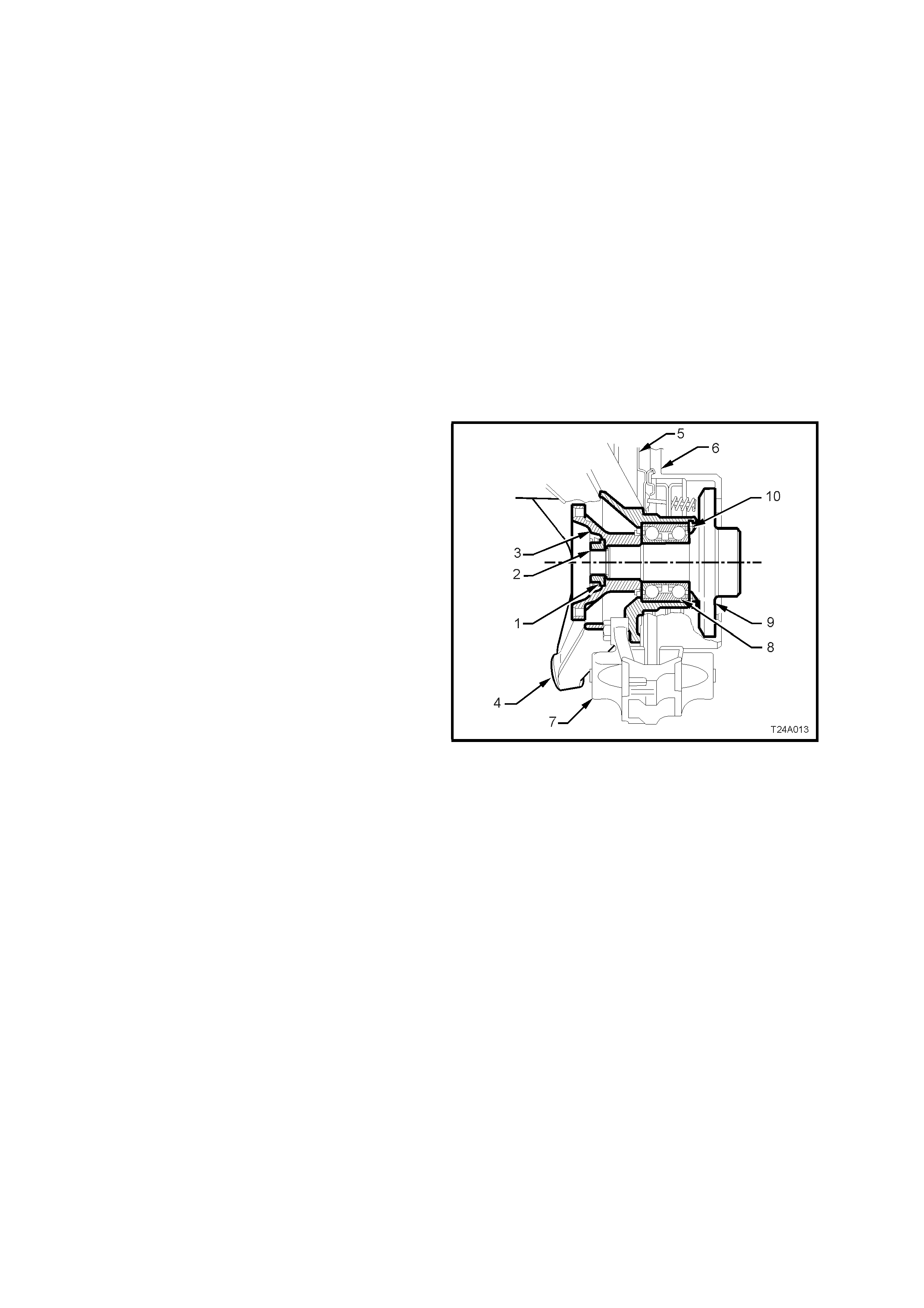

Trunnion Assembly – Sectioned View

Legend

1. Collar Nut Lock Plate.

2. Collar Nut.

3. Trunnion Flange.

4. Trailing Arm.

5. Brake Backing Plate.

6. Brake Disc.

7. Brake Caliper.

8. Rear Wheel Bearing.

9. Trunnion Assembly.

10. Rear Wheel Bearing Retaining Ring.

Figure 4B-5

REMOVE

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle and place saf ety

stands under body rear jack ing points. Ref er to

Section 0A GENERAL INFORMATION of the

VT Series I Service Information for location of

jacking points.

2. On the side of the vehicle where the trailing

arm is to be removed, mark relationship of

road wheel to hub (e.g. end of wheel stud),

with a felt tipped pen or similar. Loosen then

remove road wheel attaching nuts. Remove

the road wheel.

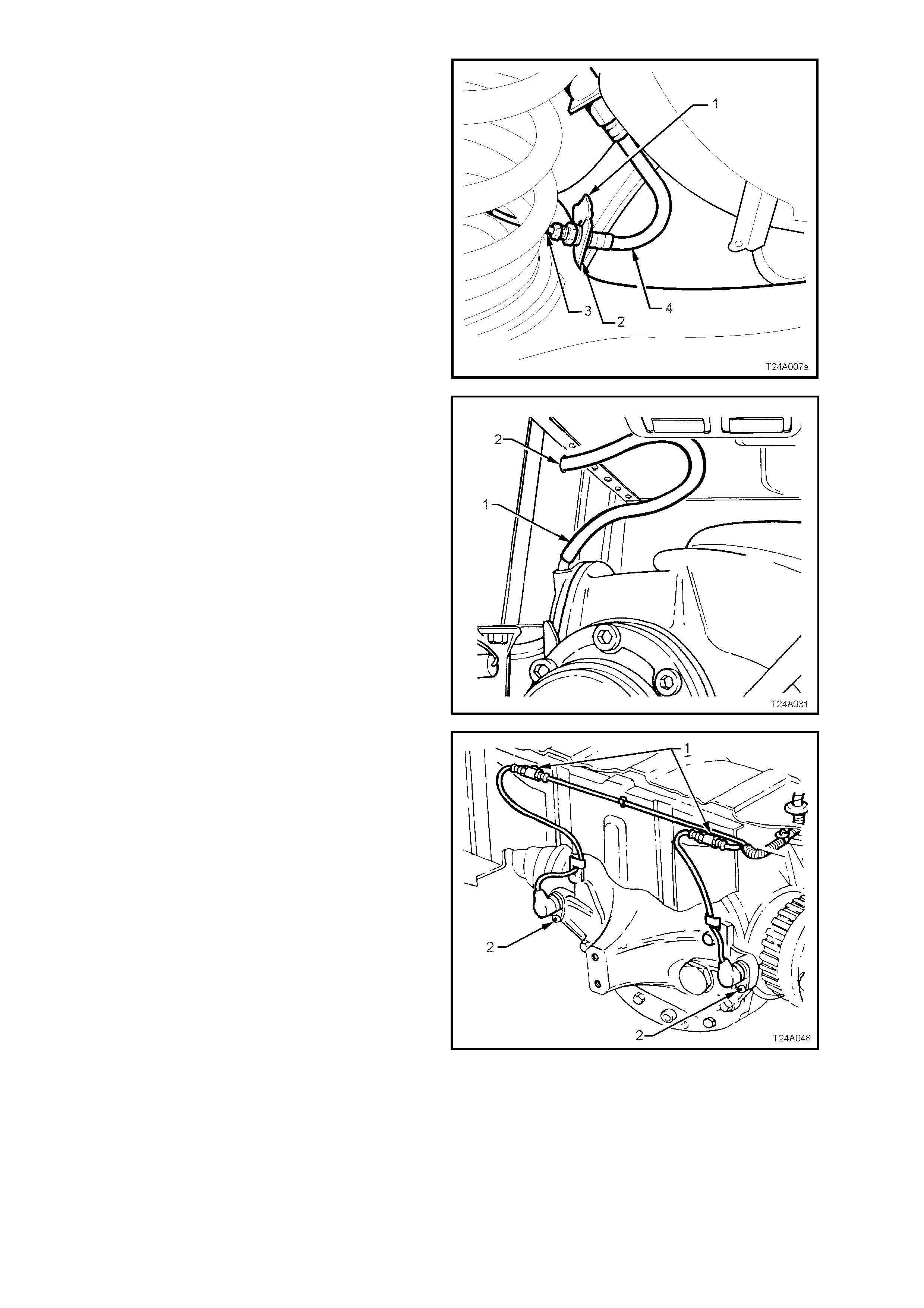

3. Remove brake hose retaining clip (1) from

brake backing plate bracket (2). Disconnect

rear caliper brake hose (3) from brake pipe (4)

and disconnect pipe f rom bac k ing plate bracket

(2).

Plug open ends of brake pipe (4) and hose (3)

to prevent fluid loss and foreign matter entry.

Figure 4B-6

4. Remove brake caliper anchor plate to trailing

arm attaching bolts (1) and remove caliper (2)

from disc.

Important: If the brake pipe to hose is not

disconnected, the br ak e caliper m ust be s ecured to

the vehicle underbody. THE CALIPER IS NOT TO

HANG BY THE BRAKE HOSE.

5. Remove brake disc from the wheel bearing

hub.

NOTE 1: While the brake disc to hub location is

marked in production, ensure that the disc to hub

position is carefully marked (e.g. disc to end of

wheel stud), with a felt tipped pen or s im ilar. T his is

necess ary to overcome the pos sibility of inducing a

brake shudder condition after reassembly.

NOTE 2: Should it be necessary to adjust the park

brake shoe to allow the brake disc to be removed,

refer to 5A STANDARD BRAKES, of the VT

Series I Service Information, for the necessary

procedure.

Figure 4B-7

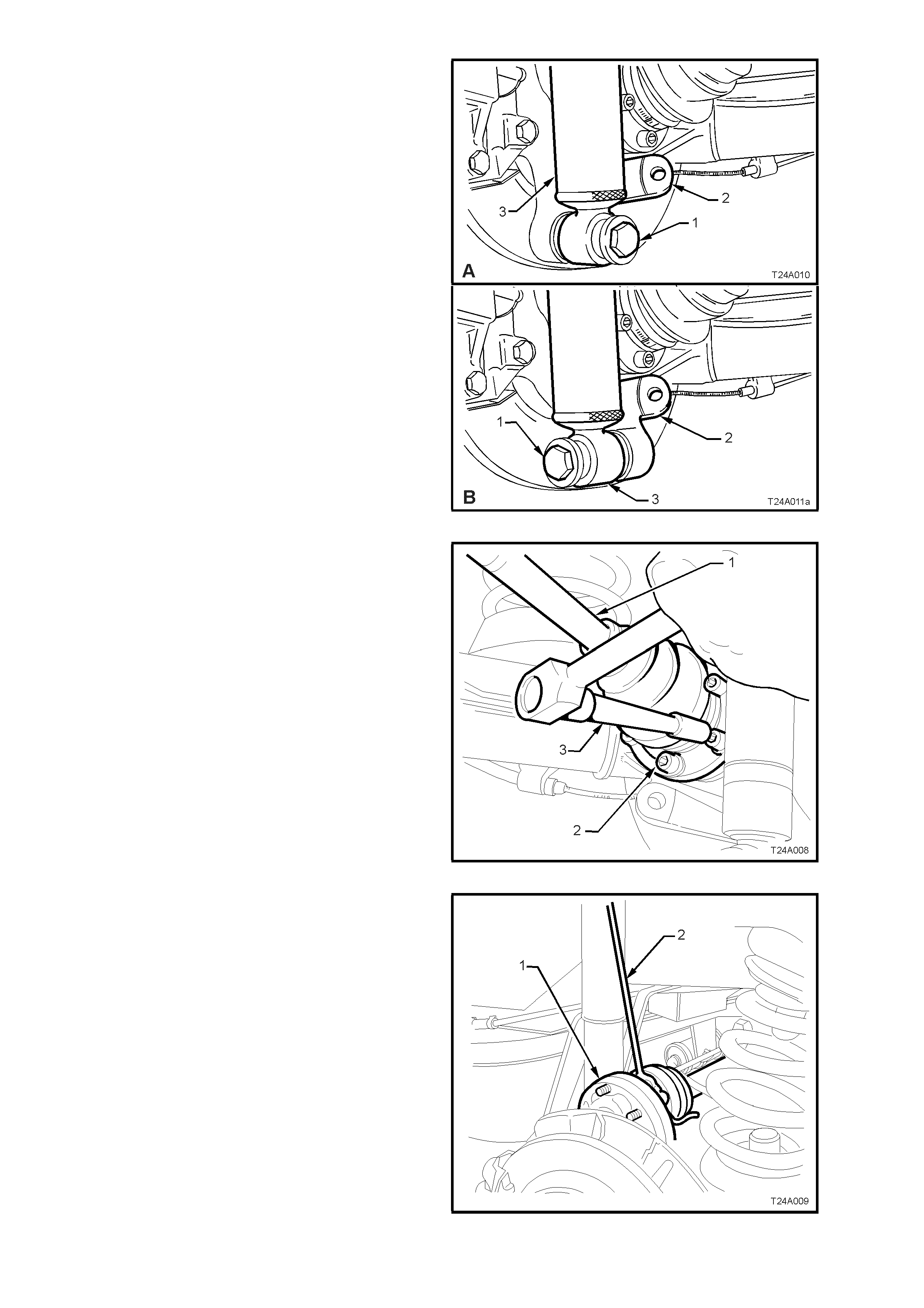

6. Position floor jack with a block of wood under

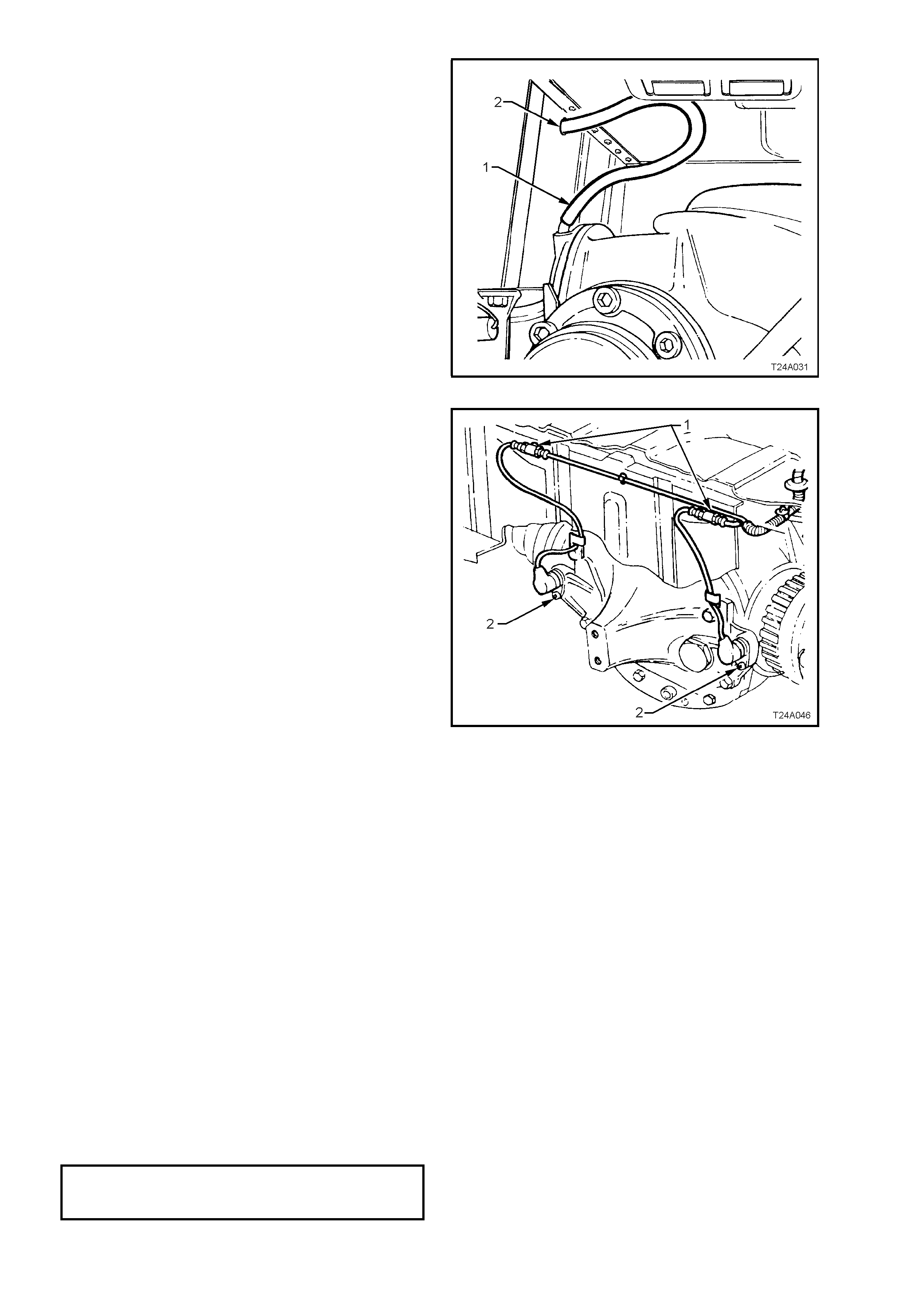

the trailing arm (2). Raise jack slightly to take

spring load off trailing arm.

7. Disconnect rear shock absorber lower

mounting bolt ( 1) f rom trailing ar m (2), then pull

the lower end of shock absorber (3) from

trailing arm (2).

‘A’ – Sedan

‘B’ – Station Wagon

NOTE: Leave the supporting jack and wooden

block in position.

Figure 4B-8

8. Using holding bar, Tool No. KM468 over the

wheel studs to hold trunnion assembly from

rotating, loosen and remove the six drive shaft

(1) constant velocity joint to trunnion flange

attaching bolts (2) and plates, using an 8 mm

Allen key socket and suitable socket

equipment (3).

Figure 4B-9

9. Separate drive shaft from flange and lift

upward. While keeping the outer constant

velocity joint (1) in the same plane as the

driveshaft, use a piece of wire (2) and tie up

the drive shaft assembly to lower end of shock

absorber upper mounting.

NOTE: Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the trailing

arm is lowered. This will lead to premature failure

of the boot and eventual failure of the joint if left

unchecked.

10. The supporting jack may now be lowered and

the wooden block removed.

Figure 4B-10

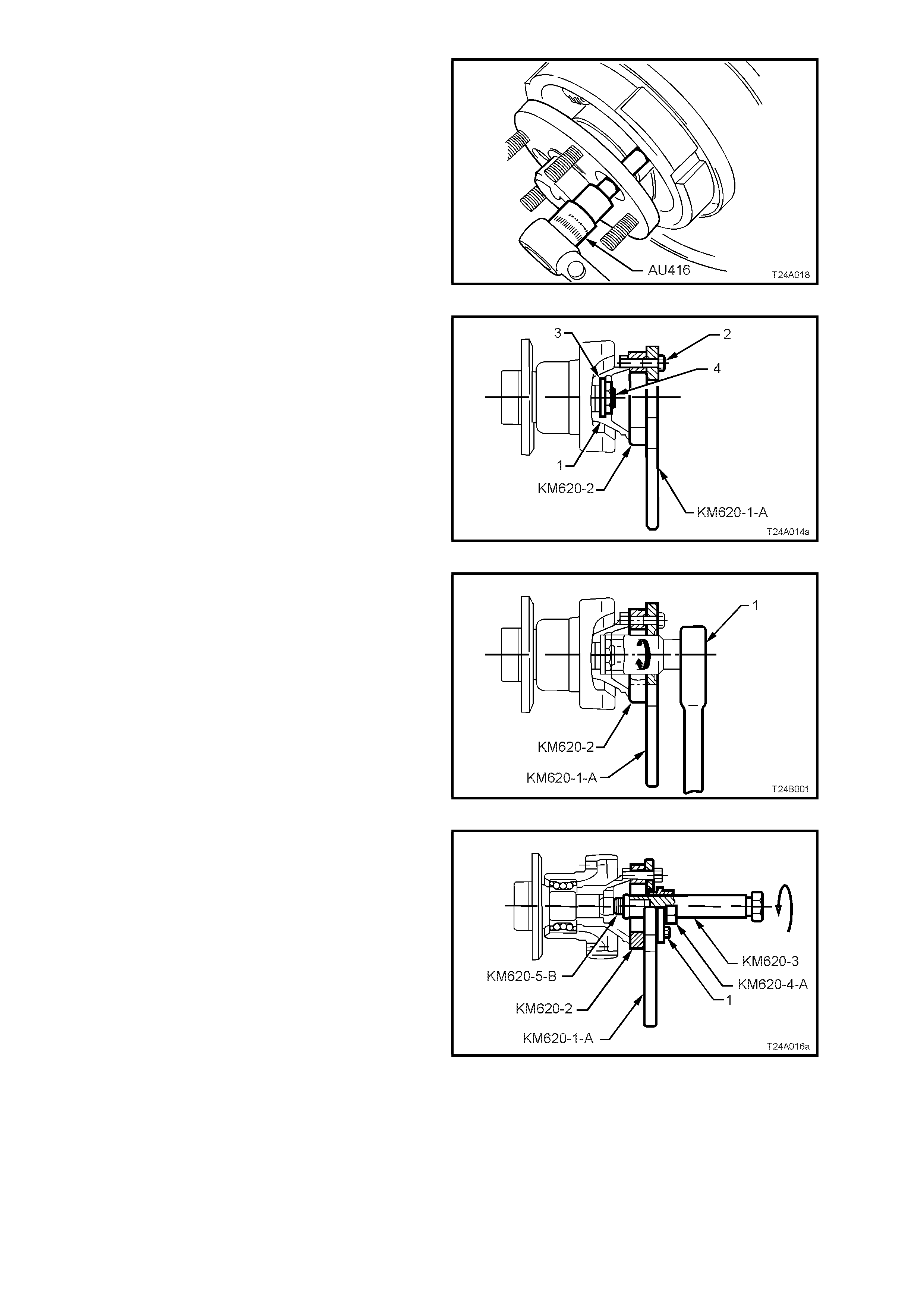

11. Using T orx bit s ocket, T ool No. AU416, remove

brake backing plate to trailing arm, two upper

attaching bolts. Then, using suitable socket

equipment, remove the two longer, hexagonal

headed, lower bolts.

Figure 4B-11

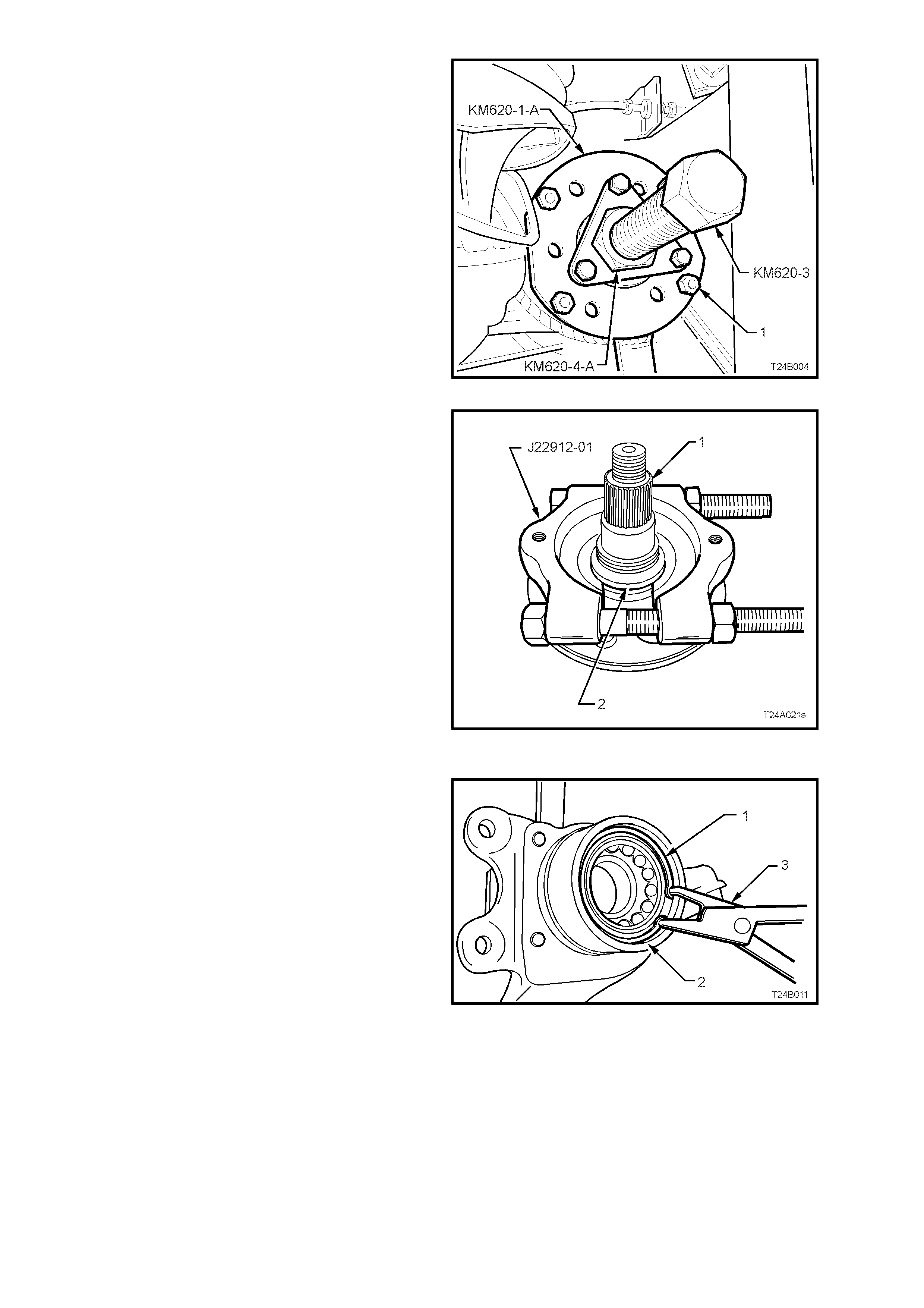

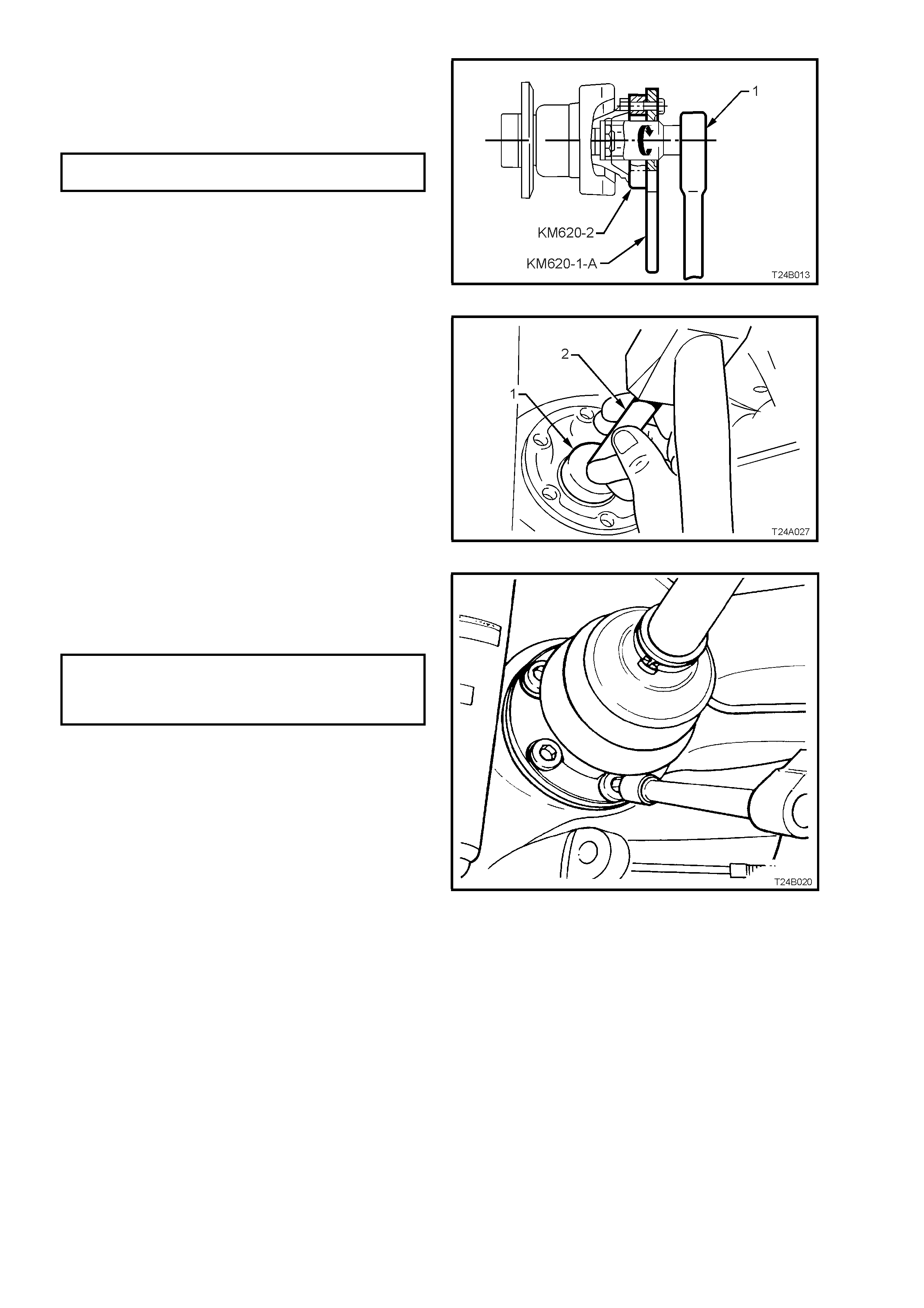

12. Secure flange holding tool, KM620-1-A and

trunnion flange ring tool KM620-2 to trunnion

flange (1) with three of the removed drive s haft

constant velocity joint to trunnion flange

attaching bolts (2).

NOTE: Align holes marked ‘B' on the flange

holding tool KM620-1-A and KM620-2 with holes in

the trunnion flange before installing and tightening

bolts.

Figure 4B-12

13. Install a suitable length and diam eter steel tube

over handle of KM620-1-A to stop it from

rotating, then use suitable socket equipment

(1) to loosen and remove the collar nut and

lock plate.

NOTE: Once collar nut and lock plate have been

removed, they must be discarded as they are only

to be used once.

Figure 4B-13

14. Lubricate the threads of forcing screw KM620-

3, then install to adaptor KM620-4-A. Apply

grease to ball end of plunger, T ool No. KM620-

5-B, then install that, into the end of forcing

screw KM620-3.

15. Install the whole sub-assembly through the

central opening of flange holding tool KM620-

1-A. Secure the adaptor KM620-4-A to the

flange holding tool KM620-1-A, using three

suitable bolts (1).

NOTE: Adjust the position of the forcing screw

KM620-3 in the adaptor KM620-4-A, to allow

adaptor to be in full contact with the flange holding

tool KM620-1-A.

Figure 4B-14

16. While holding KM620-1-A from rotating, turn

the screw KM620-3, forcing the flange free

from the trunnion.

Separate components from flange once it has

been removed.

Figure 4B-15

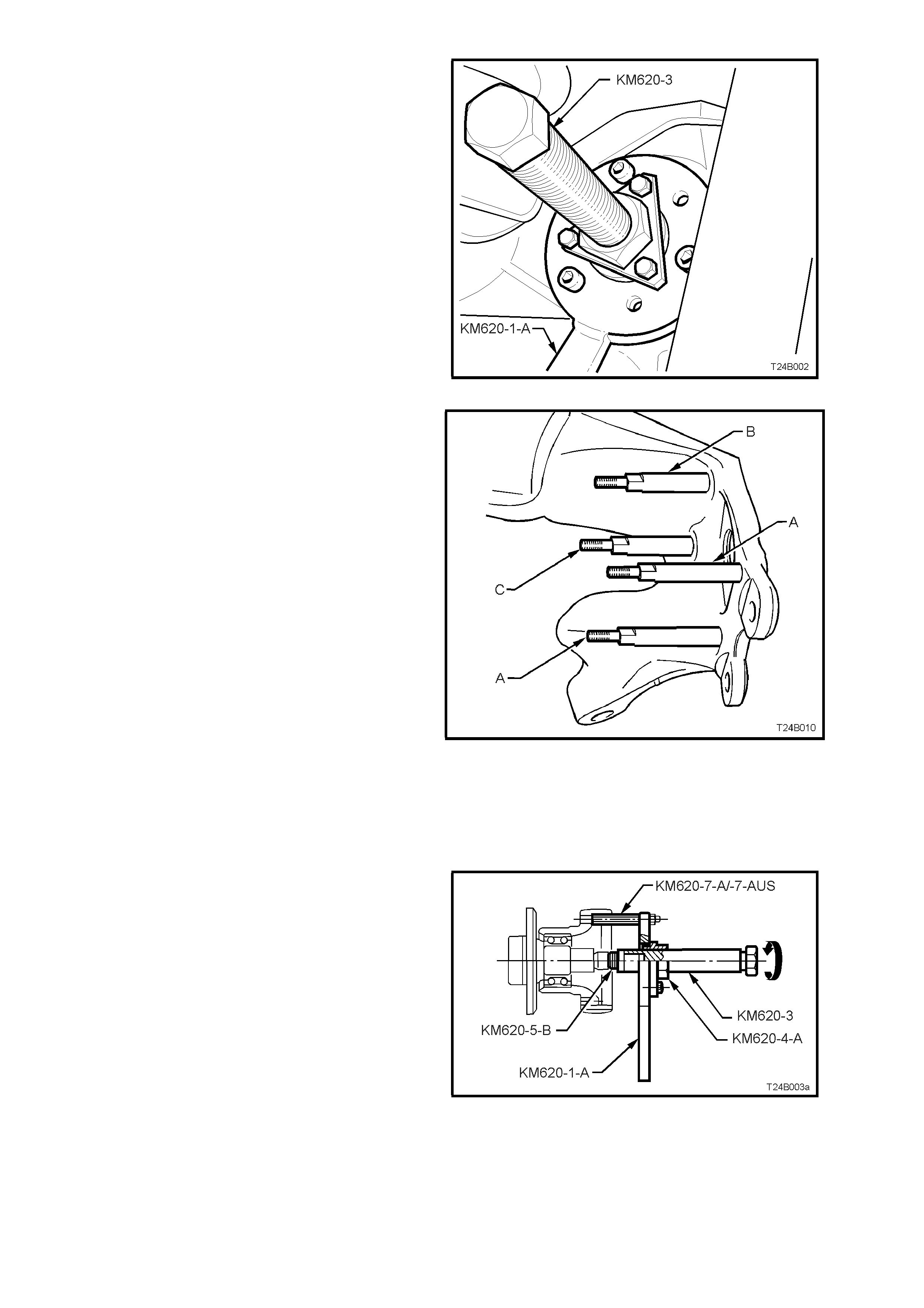

17. Preparatory to removing the trunnion assembly

and rear wheel bearing from the trailing arm,

use a commercially available M10 x 1.25

bottoming tap and clean the four backing plate

to trailing arm bolt threads, using a suitable

lubricant and working from the trunnion

assembly side.

NOTE: This step is necessary to clear any dried

mud, dirt etc, from the exposed portion of the

threads on the inboard side of the trailing arm.

Also, the deepest thread (position ‘C’) may not be

completely formed through to the inboard side.

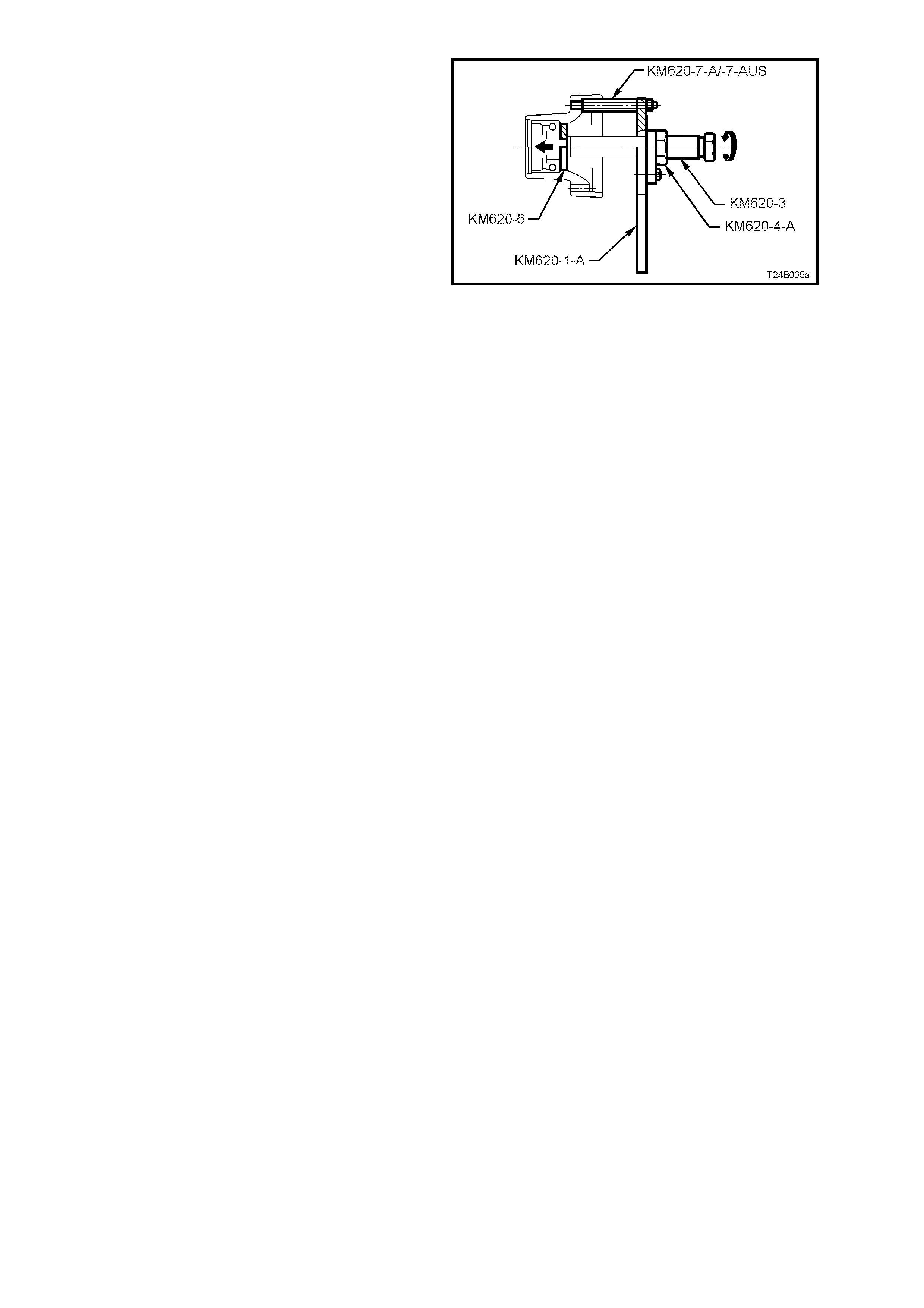

18. Install two supports KM620-7-A in positions ‘A’

and two KM620-7-AUS to ‘B’ and ‘C’ in the

trailing arm, as indicated.

As a guide, the two longest supports (KM620-

7-A) are to be installed at the brake caliper

mounting side (position ‘A’). The longer of

KM620-7-AUS supports is installed at position

‘B’ and the shorter is installed at position ‘C’.

19. After installing all four supports in the correct

positions, tighten with a set spanner.

Figure 4B-16

20. Install flange holding tool KM620-1-A over the

four supports, KM620-7-A (2 places) and

KM620-7-AUS (2 places), install four suitable

nuts (1) and tighten to secure.

21. Pre-assemble lubricated forcing screw KM620-

3 to adaptor KM620-4-A. Apply grease to ball

end of plunger KM620-5-B, then install that,

into the end of forcing screw KM620-3.

22. Install this sub-assembly through the central

opening of holding tool KM620-1-A. Secure the

adaptor KM620-4-A to the flange holding tool

KM620-1-A, using three suitable bolts (2).

NOTE: Adjust the position of the forcing screw

KM620-3 into the adaptor KM620-4-A, to allow full

contact of the adaptor to the flange holding tool

KM620-1-A.

Figure 4B-17

23. Insert a suitable length of tube over the handle

of holding tool KM620-1-A to stop it from

rotating and turn the forcing screw KM620-3 to

press trunnion from rear wheel bearing.

24. W hen the trunnion has been removed, remove

nuts (1) holding KM620-1-A assembly to the

distance pieces, KM620-7-A and KM620-7-

AUS. Remove KM620-1-A, and remove

KM620-5-B from KM620-3.

25. Unscrew the forcing screw (KM620-3), as this

same arrangement is used to press the rear

wheel bearing from the trailing arm.

NOTE: The rear wheel bearing inner cone will

separate from the bearing assembly and be

retained on the trunnion assembly.

26. Remove the brake backing plate and park

brak e assem bly from the trailing ar m and set to

one side.

Figure 4B-18

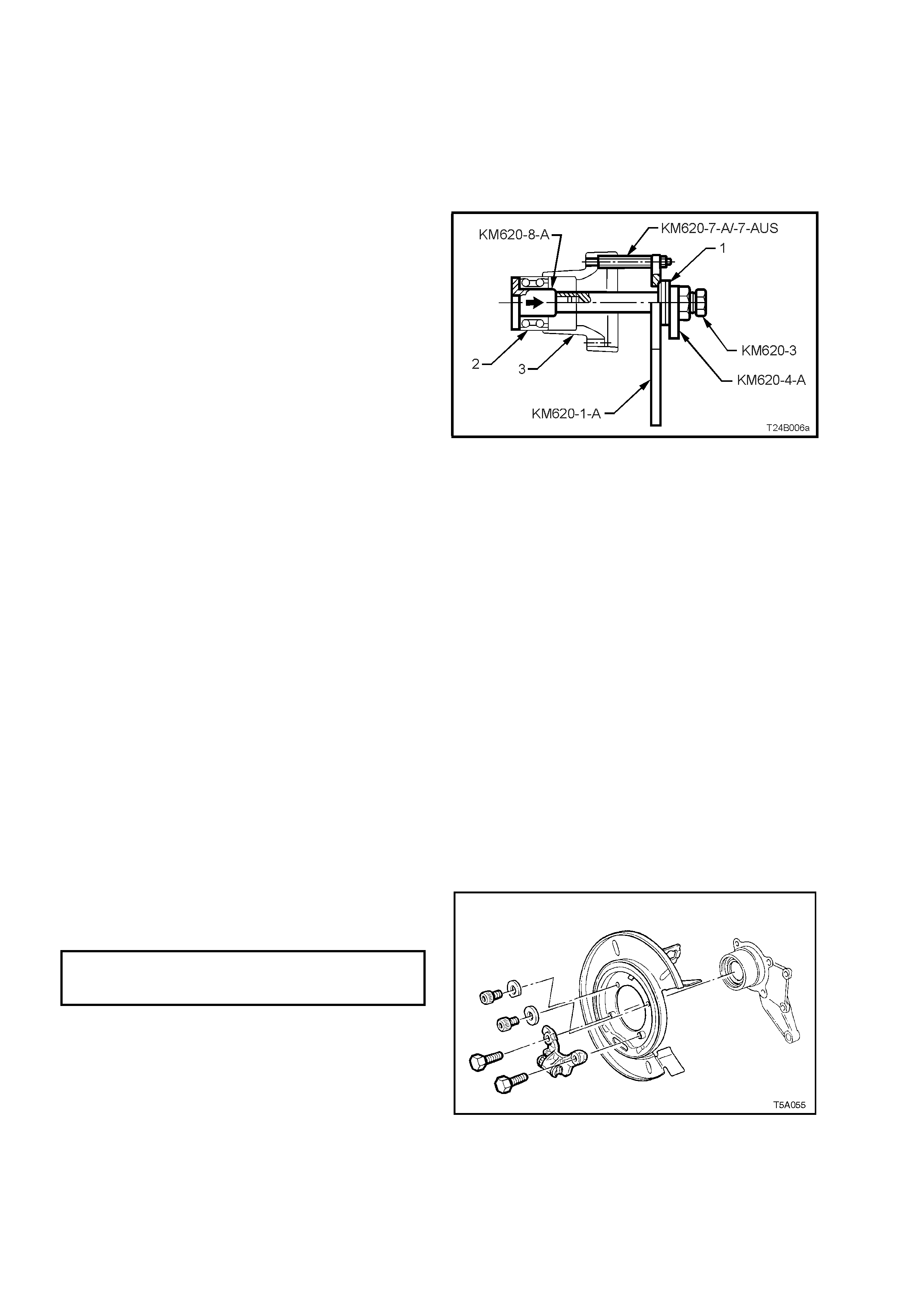

27. If the trunnion assem bly (1 ) is to be reinstalled,

then the outer half of the inner rear wheel

bearing cone (2) will need to be removed from

the trunnion assembly (1).

a. Install press plates J22912-01 over the

bearing cone (2) and tighten the press

plate bolts to grip the bearing cone.

b. Press the trunnion assembly (1) from the

bearing cone (2) and discard bearing cone.

NOTE 1: If the trunnion is to be r eplaced, then step

26 will not be required.

NOTE 2: A new trunnion assembly is supplied with

wheel studs already installed.

Figure 4B-19

28. Remove wheel bearing retaining ring (1) from

trailing arm (2), using suitable circlip pliers (3).

Figure 4B-20

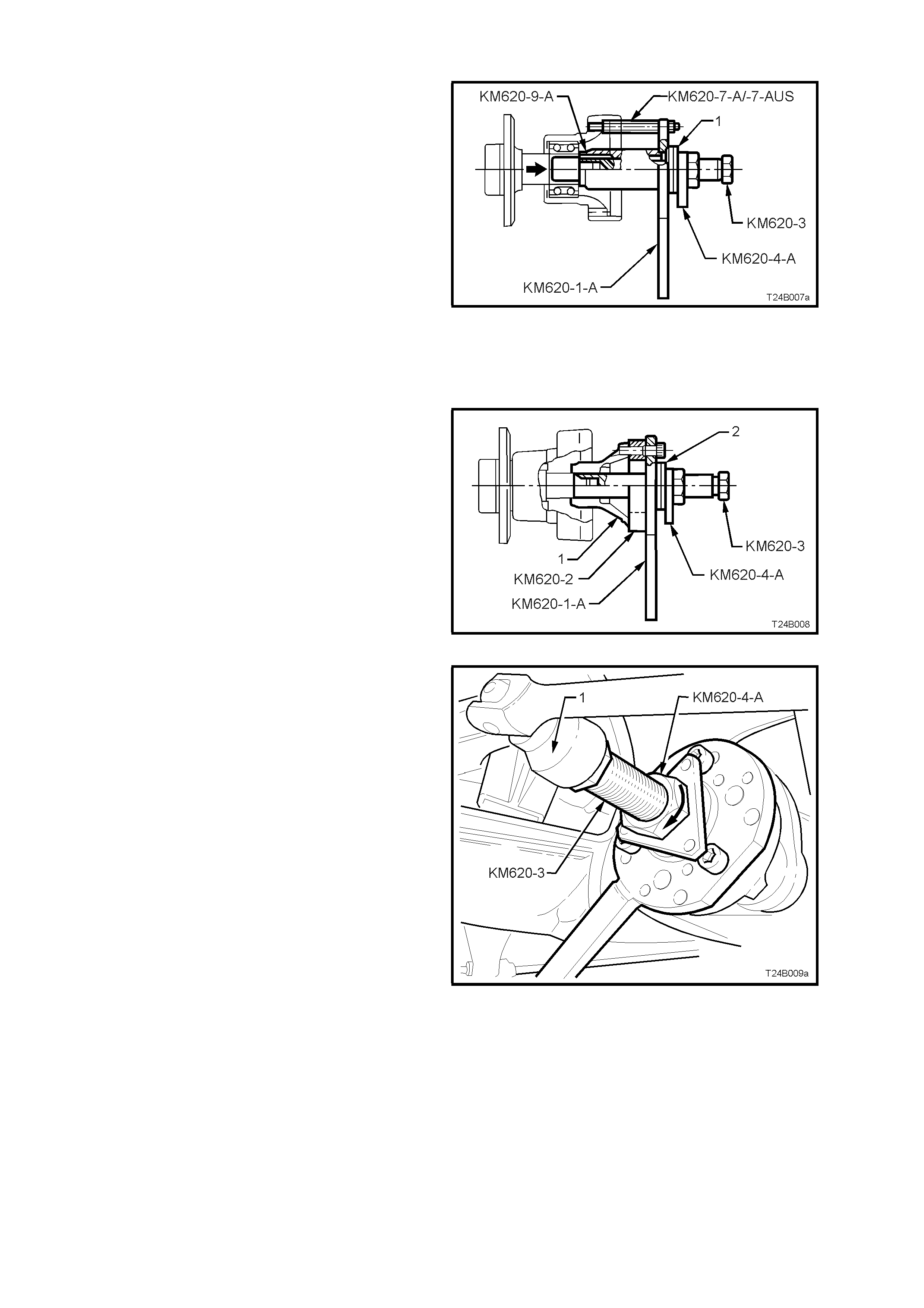

29. With the tool components set up in the same

arrangement as for step 20 (and as shown in

Fig. 4B-21), install rear axle bearing removing

plate KM620-6 to rear of the axle bearing.

Reposition the forcing screw KM620-3 to hold

the removing plate KM620-6 in place.

30. Insert a suitable length of tube over the handle

of holding tool KM620-1-A to stop it from

rotating, then turn the forcing screw KM620-3

to press the wheel bearing from the trailing

arm.

31. If installing a replacement trailing arm without

bushes, install new bushes. Refer to

2.6, TRAILING ARM BUSHES in 4A REAR

SUSPENSION of the VT Series I Service

Information.

Figure 4B-21

REINSTALL

To Install a New Bearing:

1. Ensure that bearing bore of trailing arm is

clean and free of any foreign matter.

2. Coat outside diameter of new wheel bearing

and bore of trailing arm with lubricant such as

Molybond HE50, or equivalent (to Holden's

Specification HN1326).

3. Remove bolts securing adaptor KM620-4-A to

the holding tool KM620-1-A, then remove the

adaptor and forcing screw KM620-3 from the

holding tool KM620-1-A.

4. Lubricate the thrust ball bearing race (1) (part

of KM620-A) with lubricant such as Molybond

HB50, or equivalent (to Holden's Specification

HN1326), then assemble the bearing onto the

flanged end of adaptor KM620-4-A.

5. Reinstall the f orcing sc rew and adaptor/bearing

assembly to the flange holding tool KM620-1-

A. Do not reinstall the adaptor (KM620-4-A) to

holding tool (KM620-1-A) attaching bolts.

6. Install bearing installer KM620-8-A into a new

bearing (2) and install both into the trailing arm

(3).

7. Join the forcing screw (KM620-3), and bearing

installer (KM620-8-A) by engaging the screw

thread of the forcing screw (KM620-3) with

installer (KM620-8-B) and tightening the f orc ing

screw to engage at least eight full threads.

8. While holding the forcing screw (KM620-3)

from turning by using suitable socket

equipment (4), rotate the adaptor KM620-4-A

in a clockwise direction, using a suitable 40

mm wrench to draw the new bearing (2) fully

into position.

Figure 4B-22

9. When the bearing is fully installed, separate

installer KM620-8-A from the forcing screw

KM620-3, then rem ove the installer and for cing

screw (KM620-3), adaptor (KM620-4-A) and

bearing, from the holding tool (KM620-1-A).

Leave remaining tools installed.

10. Using suitable circlip pliers, install a new

bearing retaining ring into trailing arm,

ensuring that the ring is seated correctly.

11. Install rear disc brake shield to trailing arm

bolts and tighten to the correct torque

specification.

REAR DISC BRAKE SHIELD TO Upper: 70 - 80 Nm

TRAILING ARM ATTACHING

BOLT TORQUE SPECIFICATION Lower: 85 - 90 Nm

NOTE 1: The two upper bolts have washers that

are to be installed with the cut-out surface facing

around the trailing arm hub outer surface.

NOTE 2: Apply Loctite 242 thread sealant or

equivalent (to Holden's Specification HN1256,

Class 2 Type 1) to the threads of the two longer,

lower hexagon headed bolts, before installation.

Figure 4B-23

To Reinstall Trunnion:

1. Remove KM620-1-A from distance pieces,

KM620-7-A and KM620-7-AUS. Install KM620-

9-A over KM620-3, with the stepped shoulder

facing away from the trunnion bearing.

Reinstall KM620-1-A to KM620-7-A and

KM620-7-AUS, tightening the attaching nuts.

2. Screw the threaded end of the trunnion into

KM620-3. While holding KM620-3 f rom turning,

rotate KM620-4-A to draw trunnion into wheel

bearing.

3. Unscrew f orcing s crew KM620-3 from trunnion,

then remove the nuts holding tool KM620-1-A

to the distance pieces KM620-7-A and KM620-

7-AUS.

4. Remove the distance pieces KM620-7-A and

KM620-7-AUS from the trailing arm.

Figure 4B-24

5. Assemble KM620-2 and KM620-1-A to

trunnion flange using thr ee drive shaft cons tant

velocity joint to flange bolts.

6. Lubricate trunnion flange splines and trunnion

threads with the recommended differential

carrier lubricant.

7. With KM620-4-A, thrust ball bearing race (2)

and KM620-3 assem bled to KM620-1-A, screw

the internal thread of KM620-3 onto the

trunnion assembly.

Figure 4B-25

8. While holding the forcing screw (KM620-3)

from turning with suitable socket equipment

(1), use a suitable 40 mm wrench to rotate the

adaptor KM620-4-A in the direction shown, to

install the trunnion flange onto trunnion.

9. Unscrew KM620-3 from the trunnion, then

remove it and adaptor KM620-4-A from the

holding tool KM620-1-A. Leave the holding tool

KM620-1-A and trunnion flange ring tool

KM620-2 installed to the trunnion flange.

Figure 4B-26

10. Inst all NEW collar nut to the trunnion assem bly

and, using a suitable length and sized pipe

over the handle of KM620-1-A to hold trunnion

assembly from turning, tighten collar nut to the

correct torque specification.

COLLAR NUT TO TRUNNION

ASSY TORQUE SPECIFICATION 295 - 305 Nm

11. Remove the holding tool KM620-1-A and

trunnion flange ring tool KM620-2 from the

trunnion flange.

Figure 4B-27

12. Using a 1.25 inch socket (1), 150 mm socket

bar (2) and a soft faced hammer, install new

lock plate over collar nut.

Figure 4B2-28

13. Assemble driveshaft outer constant velocity

joint to trunnion flange, aligning bolt holes.

14. Reinstall attaching bolts with plates and tighten

bolts to the correct torque specification.

DRIVESHAFT CONSTANT

VELOCITY JOINT TO TRUNNION 50 Nm, then

FLANGE ATTACHING BOLT 60° - 75 turn angle

TORQUE SPECIFICATION

Figure 4B-29

15. Reinstall brake disc (1) to trunnion, aligning the

marks made before removal.

NOTE: If the trunnion has been replaced, then

runout checks must be carried out on the trunnion

flange and the installed brake disc (1). Refer to

5A STANDARD BRAKES, of the VT Series II

Service Information for important information

regarding these checks.

16. Reinstall the brake caliper (3) to the trailing

arm, reinstall brake caliper anchor plate to

trailing arm attaching bolts (4) and tighten to

the correct torque specification.

BRAKE CALIPER ANCHOR PLATE

TO TRAILING ARM ATTACHING 70 - 100 Nm

BOLT TORQUE SPECIFICATION

17. After reconnecting the brake line to the caliper

hose and installing the brake hose retaining

clip, bleed the rear brakes and check for leaks.

For the recommended procedure, refer to

5A STANDARD BRAKES, of the VT Series I

Service Information.

Figure 4B-30

18. Support the trailing arm with a floor jack and

wooden block, sufficient to enable the shock

absorber to be reinstalled.

19. Reinstall shock absorber to trailing arm, install

the lower mounting bolt but do not torque to

specification at this stage.

20. Install road wheel, aligning marks made before

removal and reinstall attaching nuts.

21. Remove safety stands and lower vehicle to the

ground and bounce the rear of the vehicle

several times to settle the suspension

components.

22. Tighten the lower shock absorber bolt to the

correct torque specification.

SHOCK ABSORBER LOWER

MOUNTING BOLT 105 - 125 Nm

TORQUE SPECIFICATION

NOTE: Vehicle must be at curb weight and on all

four wheels before this torque is applied.

23. Tighten road wheel attaching nuts to the

correct torque specification, working in a ‘star’

pattern. Refer 2.1 SERVICE NOTES in this

Section for more details.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

24. Refit wheel cover/centre cap.

Figure 4B-31

3.2 FINAL DRIVE ASSEMBLY

CAUTION: Whenever any component that

forms part of the ABS (if fitted) is disturbed

during Service Operations, it is vital that the

complete ABS system be checked, using the

procedure as detailed in DIAGNOSIS, ABS

FUNCTION CHECK, in Section 12L ABS &

ABS/ETC, VT Series I Service Information

(V6 engine) or Section 12L ABS & ABS/ETC, VT

Series II Service Information (GEN III V8

engine).

Important: Before disturbing the rear suspension

crossmember mounting bolts, an alignment

procedure is required on reinstallation and a

special tool is required for this purpose. If this tool

is not available, then the crossmember cannot be

correctly aligned and steering and/or handling

abnormalities will result.

NOTE: Fo r this s ervice operation, new trailing ar m -

to-crossmember lock nuts, rear crossmember rear

mount-to-vehicle underbody attaching bolts,

differential carrier-to-rear crossmember attaching

bolts and intermediate muffler support retainers

must be used on reassembly.

REMOVE

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle and place saf ety

stands under body rear jack ing points. Ref er to

Section 0A GENERAL INFORMATION of the

VT Series I Service Information for location of

jacking points.

2. Remove wheel covers (steel wheels) or centre

caps (alloy wheels).

3. Mark relationship of road wheels to hubs (e.g.

end of wheel stud), with a felt tipped pen or

similar. Loosen then remove road wheel

attaching nuts. Remove the road wheel.

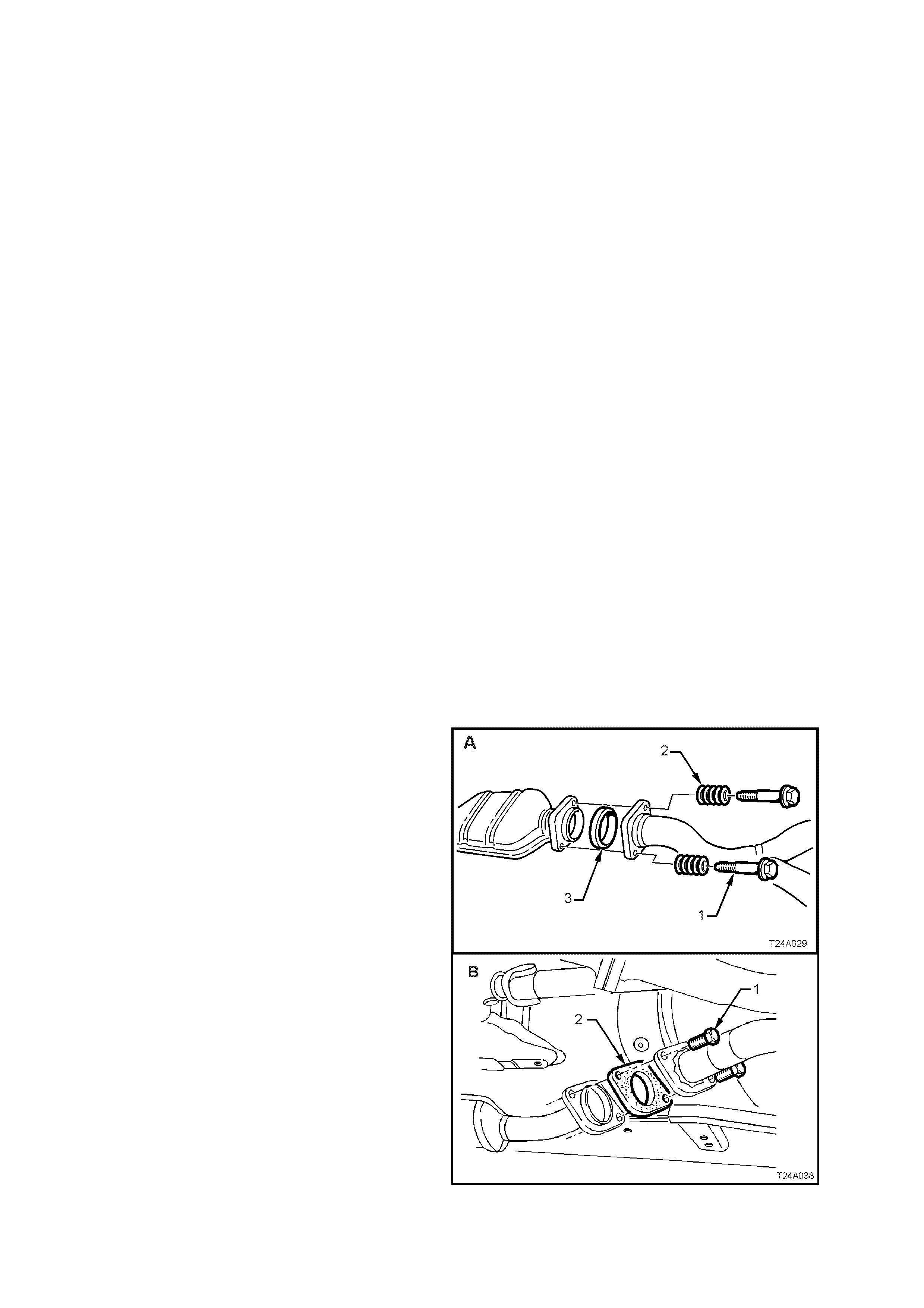

4. Disconnect exhaust system from rear of

catalytic converte r/s:

V6 Engined Vehicles (A):

a. Remove both flange bolts (1) and springs

(2). After separation remove the retaining

ring (3).

V6 Supercharged and GEN III V8 Engined

Vehicles (B):

b. Remove both flange bolts (1), then the

sealing gasket (2).

NOTE: Only one side of the V6

Supercharged/GEN III V8 engine arrangement is

shown.

Figure 4A-32

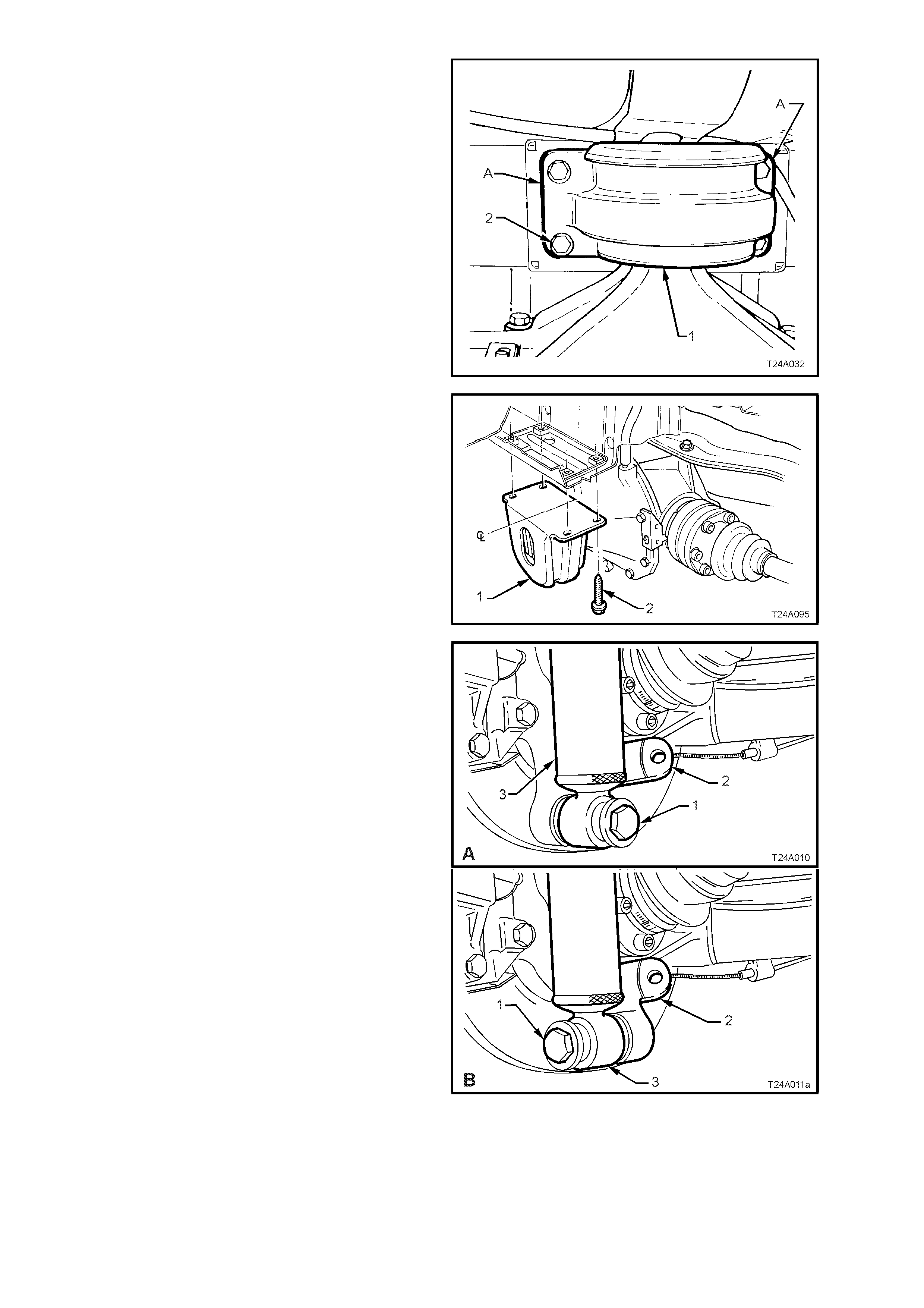

5. Remove the two retainers (1) from the top

posts and discard. Disconnect exhaust system

support rings (2) from rear hanger of rear

muffler assembly. Both V6 and GEN III V8

engine arrangements are similar.

Figure 4A-33

6. Remove muffler support to rear crossmember

hanger retainers (1).

NOTE: There are two retainers for V6 engined

vehicles (as shown) and four retainers for V6

Supercharged and GEN III V8 engined vehicles.

7. Support intermediate section of exhaust

system and remove support rings (2) from

muffler and crossmember hangers.

8. Remove intermediate and rear sections of

exhaust system from vehicle.

Figure 4A-34

9. Remove propeller shaft, refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS VT Series I Service

Information (V6 engines) or

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS VT Series II Service

Information (GEN III V8 engine).

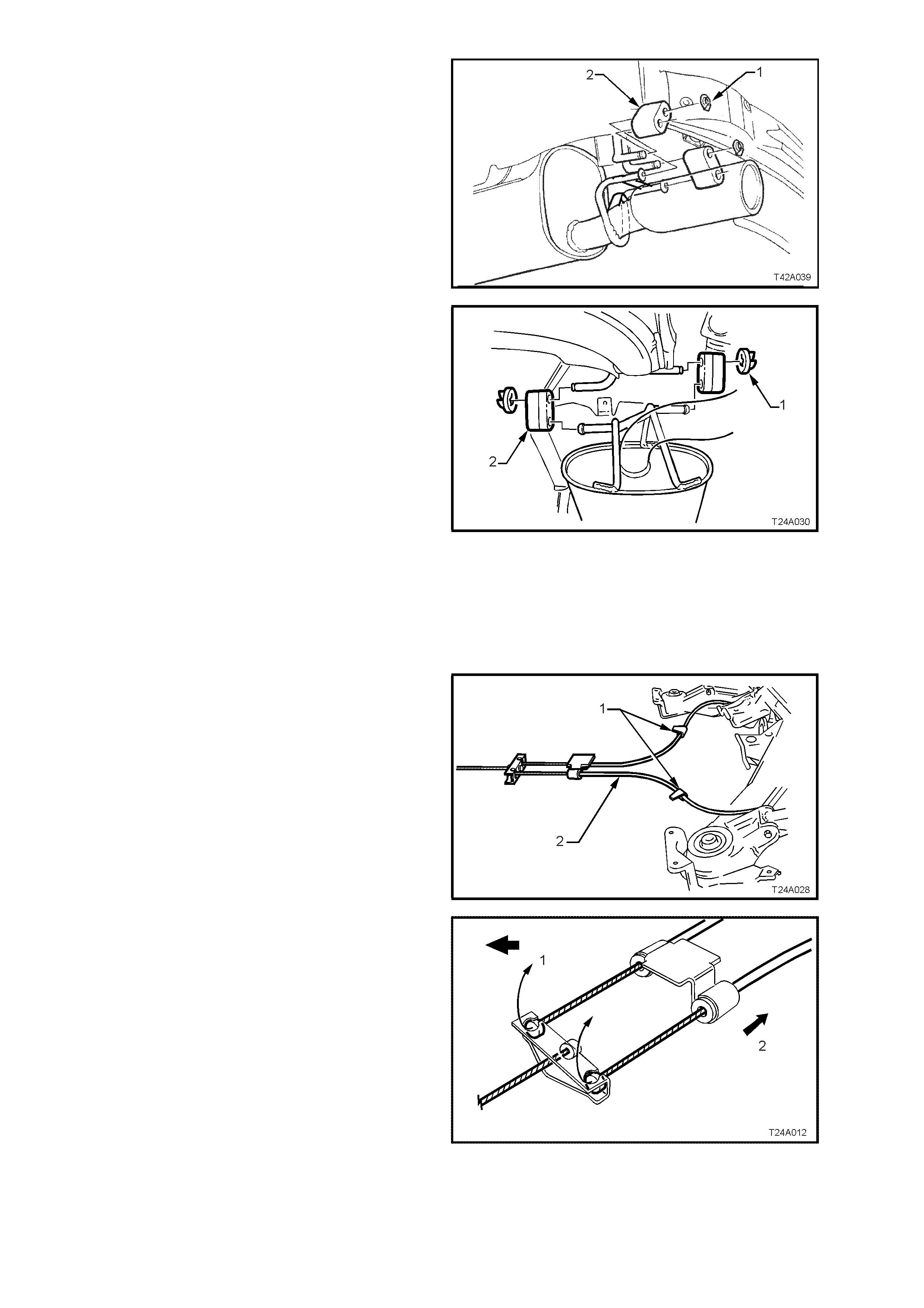

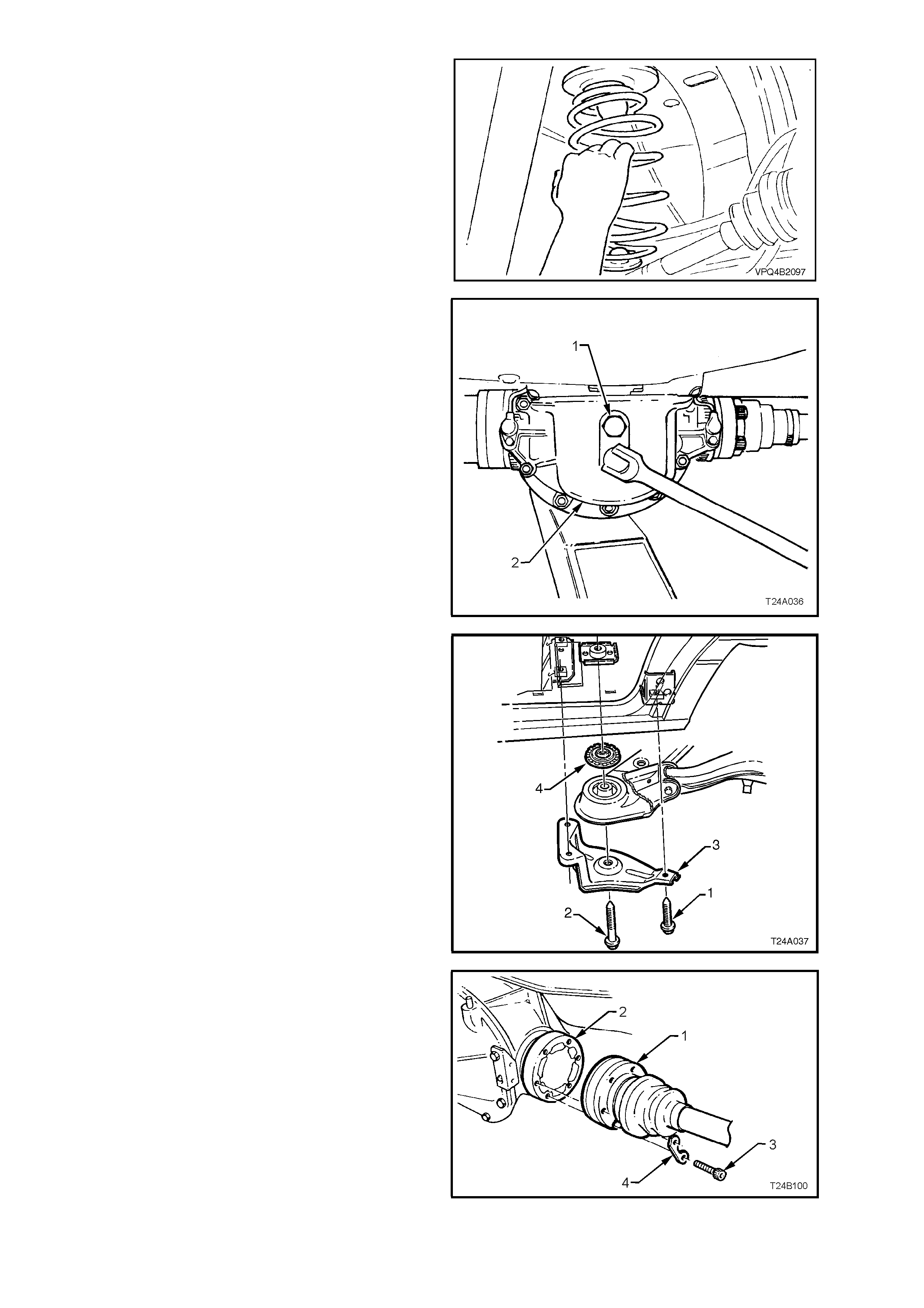

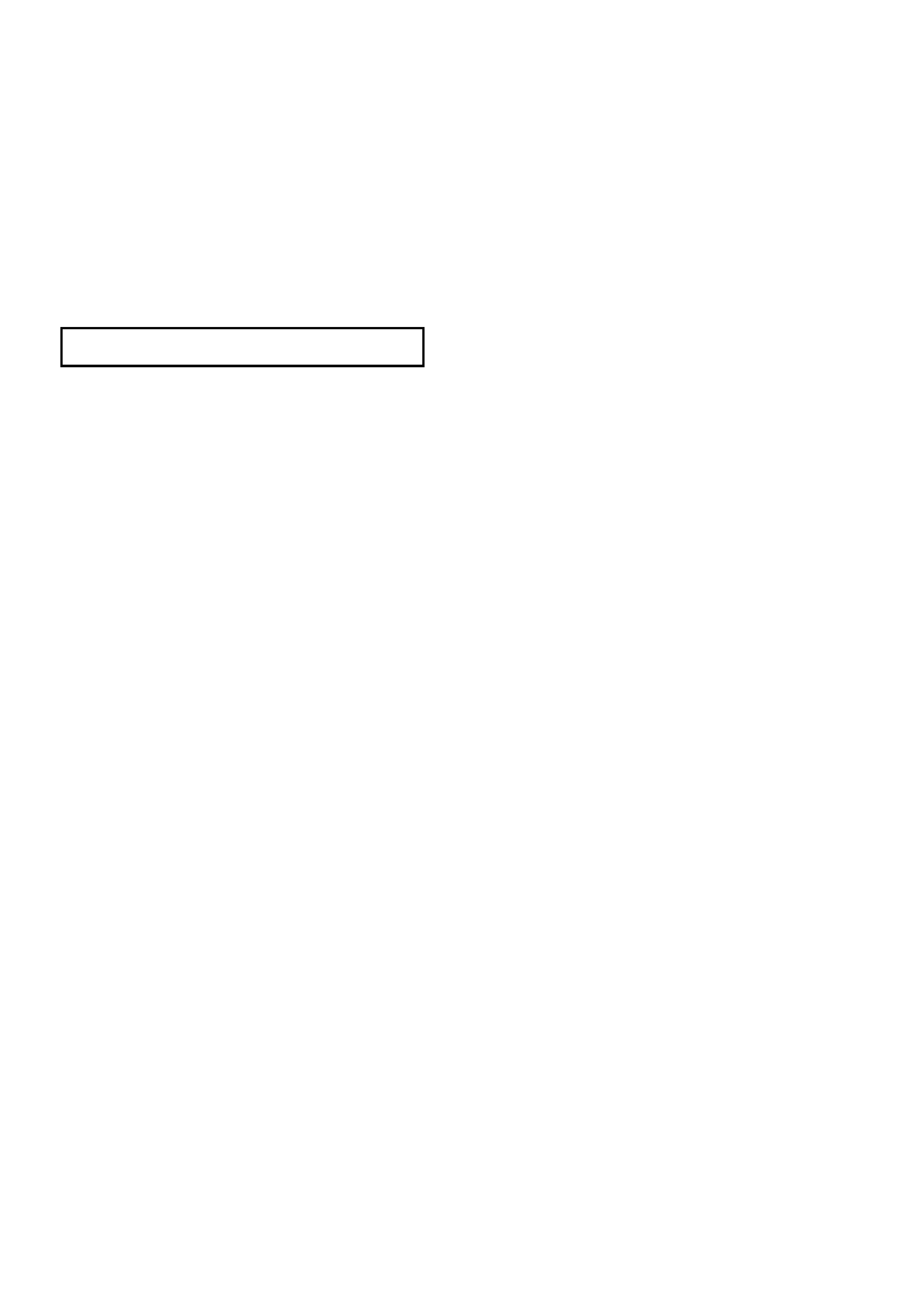

10. Set park brake in fully released position, then

release each of the underbody to park brake

cable (1) retaining clips (2) and free cables (1).

Figure 4A-35

11. Remove park brake outer cable retaining

bracket bolt (underbody bracket and bolt are

not shown) from the vehicle underbody.

12. Pull each park brake inner cable forward and

up, (1) out of the cable retainer to release each

cable.

13. Pull the outer cable rearward (2) to remove

from the underbody retainer.

Figure 4A-36

14. Disconnect brake pipe (3) from brake hose (4)

at trailing arm bracket (2) and remove the

brake hose retaining clip (1).

Plug the open ends of both pipes and hoses to

prevent unnecessary fluid loss and/or dirt

entry.

15. Repeat for the other side.

Figure 4A-37

16. Pull out differential carrier breather hose (1)

from vehicle underbody crossmember hole (2).

Figure 4A-38

17. If vehicle is fitted with ABS, pull both sensor

lead connectors from the underbody retaining

clips (1). Separate the sensor connectors from

the body harness connectors by levering with a

screwdriver.

Figure 4A-39

18. Using a scriber, m ark rear m ount (1) to vehicle

under body location (A). This will assist in rear

crossmember alignment on reinstallation.

19. Support weight of differential carrier with floor

jack.

Figure 4A-40

20. Remove rear mount (1) to vehicle underbody

attaching bolts (2) and discard removed bolts.

Lower differential carrier and rear

crossmember assembly by at least 60 mm.

Figure 4A-41

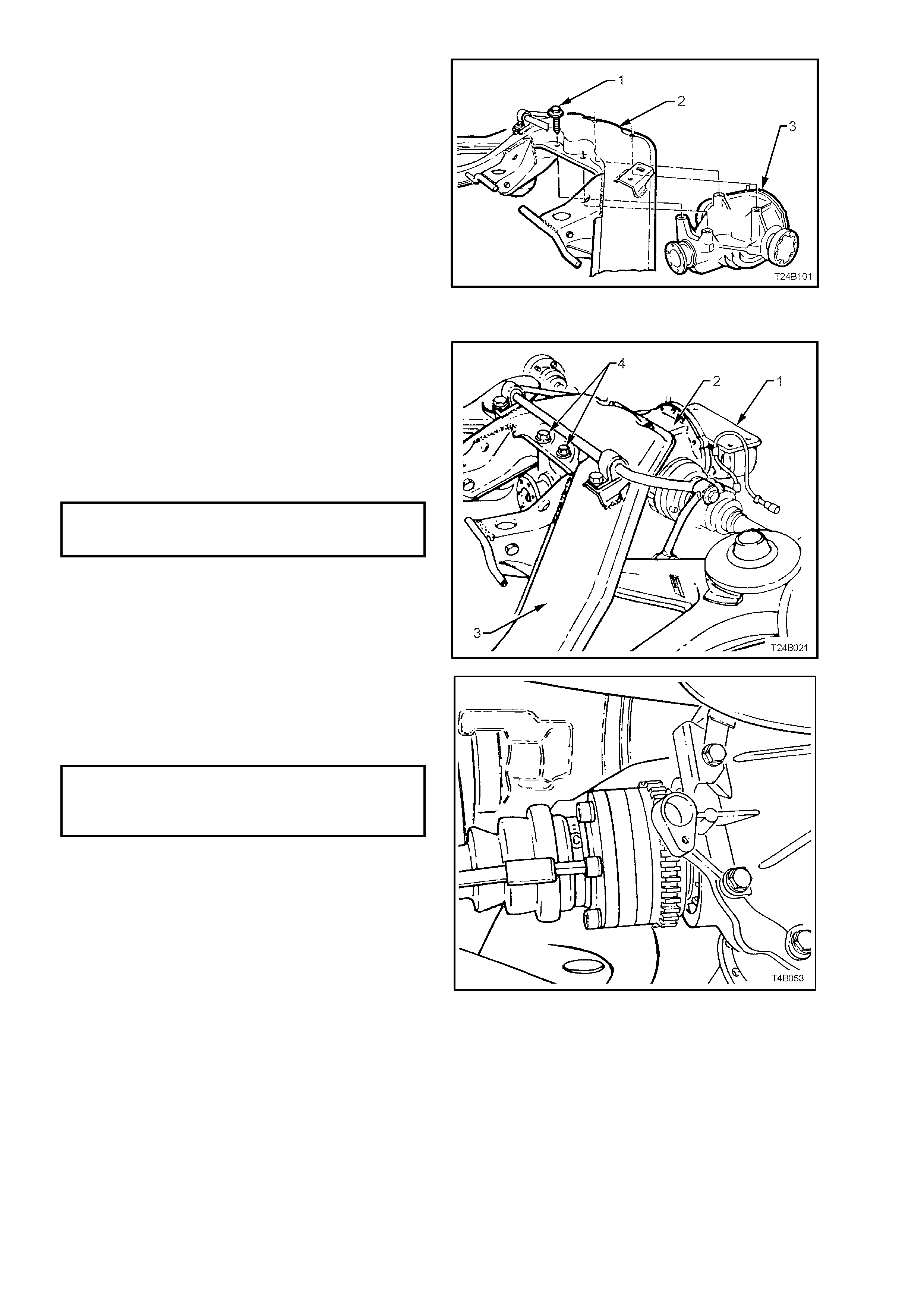

21. Position floor jack with a block of wood under

trailing arm. Raise jack slightly to take spring

load off trailing arm. Disconnect rear shock

absorber lower mounting bolt (1) from trailing

arm (2), then pull the lower end of shock

absorber (3) from trailing arm (2).

‘A’ – Sedan

‘B’ – Station Wagon

NOTE: Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the shock

absorber is disconnected from the trailing arm

before the rear of the differential carrier and

crossmember assembly has been lowered by at

least 60 mm. Bruising of the boot will lead to

prem ature f ailure of the boot and eventual failure of

the joint if left unchecked.

Figure 4A-42

22. Remove rear springs and insulators from

vehicle underbody and trailing arms.

23. Raise differential c arrier and rear cr ossm em ber

on floor jack until rear mount contacts

underbody.

Figure 4A-43

24. If replacing differential carrier assembly, rear

cover or rear mount, loosen and remove rear

mount to r ear cover attac hing bolts (1), rem ove

rear mount (2) and discard attaching bolts (1).

Figure 4A-44

25. Use a floor jack and block of wood to support

differential carrier and crossmember assembly.

26. Remove brace to underbody bolts (1) (3

places) and crossmember to vehicle

underbody attaching bolt (2) from each side.

27. Remove the braces (3) from the vehicle.

28. With an assistant supporting front end of rear

crossmember, lower assembly on jack and

remove from beneath vehicle.

NOTE: If the vehicle is fitted with the GEN III V8

engine and manual transmission, take care not to

lose the is olating r ubbers (4 ) loc ated on top of eac h

front crossmember bush.

Figure 4A-45

29. Using an 8 m m Allen key socket, remove drive

shaft inner constant velocity joint (1) to inner

axle shaft (2) attaching bolts (3) and plates (4).

Disconnect joints from inner axle shafts.

NOTE: Support drive shafts with suitable tie wire

so that they do not hang on one end. Drive shaft

joint def lection should be kept to within the angular

movement of an installed drive shaft.

Figure 4B-46

30. Remove differential carrier (3) to rear

crossmember (2) attaching bolts (1), remove

rear crossmember assembly from differential

carrier and discard attaching bolts(1).

31. If not carried out in step 24, rem ove rear m ount

to rear cover attaching bolts, remove mount

and discard attaching bolts.

Figure 4B-47

REINSTALL

Installation is the reverse of removal procedure

except for the following items:

1. If necessary, install rear mount (1) to rear

cover using NEW bolts but leave bolts finger

tight at this stage.

2. Line up mounting holes in differential

carrier (2) and rear crossmember (3). Install

NEW attaching bolts (4) (four places) and

tighten to the correct torque specification.

DIFFERENTIAL CARRIER TO REAR 90 Nm, then

CROSSMEMBER ATTACHING BOLT 30° - 45°

TORQUE SPECIFICATION turn angle

Figure 4B-48

3. Inspect drive shaft constant velocity joint boots

for damage, replace as necessary.

4. Tighten drive shaft inner constant velocity joint

to inner axle shaf t attaching bolts to the correct

torque specification.

DRIVE SHAFT CONSTANT

VELOCITY JOINT TO TRUNNION 50 Nm, then

FLANGE ATTACHING BOLT 60° - 75°

TORQUE SPECIFICATION turn angle

Figure 4B-49

5. With the aid of two assistants, place the

differential carrier and rear crossmember

assembly onto a floor jack.

6. Position assem bly under vehicle, raise with the

jack and, with the aid of the assistants, guide

the crossmember front mounting points into

position.

NOTE 1: When raising the assembly take car e that

the rear mount does not foul on the fuel tank or

fuel hoses.

NOTE 2: During this operation, ensure that trailing

arms are also supported on safety stands, to keep

the drive shafts as near to horizontal as possible.

Otherwise, bruising to the insides of the constant

velocity joint boots will result, leading to boots

splitting and eventually joint failure, if left

unchecked.

7. If the vehicle is fitted with the GEN III V8

engine and manual transmission, an isolating

rubber (4) must be fitted at the top of each

crossmember front bush as shown, before

raising the assembly into place.

8. Install crossm ember front mounting braces (3),

attaching bolts (‘1’ - three places) and rear

crossmember, front mounting bolt (4) but do

not fully tighten any of these bolts at this

stage.

Figure 4A-50

9. Lower rear of the final drive assembly to gain

access to the rear mount to cover attaching

bolts. Tighten attaching bolts to the correct

torque specification. At the same time, ensure

that mount does not twist, as the mount to

vehicle underbody mating surface should be

parallel to the rear crossmember, to within 1

mm (‘X’).

REAR MOUNT TO REAR COVER

ATTACHING BOLT 85 – 105 Nm

TORQUE SPECIFICATION

NOTE: Use a spirit level on rear mount to

underbody surface and top surface of

crossmember to ensure that both surfaces are

parallel. Dimension ‘A’ is to be 56.7 mm.

Figure 4A-51

10. Lower differential carrier and rear

crossmember assembly on floor jack and

safety stands. Install rear springs (1) and the

two insulators, (2 and 3).

NOTE: During this operation, the differential c arrier

and rear crossmember assembly rear mount must

be lowered at least 60 mm from the vehicle

underbody, or else damage to the drive shaft

constant velocity joint boots will occur.

Figure 4A-52

11. After installing springs and insulators, use a

second floor jack to raise each trailing arm (2)

up far enough to allow shock absorber (3)

lower mounting to be installed to the trailing

arm (2).

12. Install washers and bolts (1) to the shock

absorber lower mount and tighten bolts to the

correct torque specification. Repeat for the

other side.

SHOCK ABSORBER LOWER

MOUNTING BOLT 105 – 125 Nm

TORQUE SPECIFICATION

NOTE 1: The torque specification for Sedan (A)

and Station Wagon (B) are the same.

NOTE 2: vehicle m ust be at curb weight and on all

four wheels before this torque is applied.

Figure 4A-53

13. Raise assembly until rear mount contacts

vehicle underbody.

14. Align rear mount (1) with marks on underbody,

made on disassembly, then loosely install new

attaching bolts (2) but do not fully tighten at

this stage.

15. The rear crossmember MUST now be aligned

to the vehicle centreline, using the special tool

and procedure as detailed in

Section 1A2 BODY DIMENSIONS of the VT

Series I Service Information.

CAUTION: Failure to correctly align the rear

crossmember to the centreline of the vehicle

will result in steering abnormalities and uneven

tyre wear!

Figure 4A-54

16. Tighten all cros smember mounting f ast eners to

the correct torque specification.

REAR MOUNT TO VEHICLE 30 – 40 Nm, plus

UNDERBODY ATTACHING BOLT 55° – 65 °

TORQUE SPECIFICATION turn angle

REAR CROSSMEMBER FRONT 125 Nm, plus

MOUNTING BOLT 30° – 40°

TORQUE SPECIFICATION turn angle

REAR CROSSMEMBER FRONT

MOUNTING BRACE BOLT 60 – 85 Nm

TORQUE SPECIFICATION

17. Install differential carrier breather hose into

vehicle underbody crossmember hole. Ensure

that end of hose is pushed into hole

approximately 25 mm.

Figure 4B-55

18. If equipped with ABS, reconnect wheel sensor

wiring harness connectors. Reinstall into the

retaining clips.

19. Reinstall park brake inner cables to the front

retainer, install and secure outer cables in the

underbody retainers, then install the outer

cable retaining bracket bolt to the vehicle

underbody.

20. Check and fill dif ferential c arrier to co rrect level

with specified lubricant, refer to

2.1 CHECKING DIFFERENTIAL CARRIER

LUBRICANT LEVEL in 4B FINAL DRIVE AND

DRIVE SHAFTS, of the VT Series I Service

Information.

21. Check park brake adjustment and bleed brake

hydraulic system, refer to

Section 5A STANDARD BRAKES of the VT

Series I Service Information.

22. Reinstall propeller shaft. Refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS VT Series I Service

Information (V6 Engines) or

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS VT Series II Service

Information (GEN III V8 Engine).

23. Reinstall exhaust system, by first installing the

front of the intermediate pipe to the catalytic

converter (V6 engine) or converters (V6

Supercharged and GEN III V8 engines). Use

new gaskets at the flanges on V6

Supercharged and GEN III V8 converters.

24. While supporting the exhaust system, install

the exhaust hanger rubbers to the rear of the

intermediate muffler/s and secure with new

retainers

25. Install rear muffler support rings to the rear of

the rear muffler and secure with new retainers.

26. Tighten intermediate exhaust pipe to catalytic

converter bolts to the correct torque

specification.

Figure 4B-56

INTERMEDIATE EXHAUST PIPE TO All Engines

CATALYTIC CONVERTER B OL T 40 – 50 Nm

TORQUE SPECIFICATION

27. Check exhaust clearances as detailed in

Section 8B EXHAUST SYSTEM VT Series I

Service Information (V6 engines) or

Section 8B EXHAUST SYSTEM VT Series II

Service Information (GEN III V8 engine).

28. Reinstall road wheel/s, aligning the marks

made prior to removal and secure with the

attaching nuts.

29. Remove safety stands and lower vehicle.

30. Bounce the rear of the vehicle several times to

settle suspension then, tighten road wheel

attaching nuts to correct torque specification,

working in a ‘star’ pattern, as indicated in Fig.

4B-1, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

31. Refit wheel cover/centre cap.

32. Start vehicle and check for exhaust leaks.

Repair as necessary.

4. TORQUE WRENCH SPECIFICATIONS

NOTE: Only those torque wrench specifications relative to the service procedures contained in this Section are

detailed here. For all remaining torque specifications, refer to 4B FINAL DRIVE AND DRIVESHAFTS of the VT

Series I Service Information.

Nm

Brake Caliper Anchor Plate to Trailing Arm Attaching Bolt .................... 70 – 100

Collar Nut to Trunnion Assembly............................................................ 295 – 305

Differential Carrier to Rear Crossmember Attaching Bolt ...................... 90, then

30° – 45° turn angle

Driveshaft Constant Velocity Joint to Trunnion Flange Attaching Bolt ... 50, then

60° – 75° turn angle

Intermediate Exhaust Pipe to Catalytic Converter Bolt (All Engines) ..... 40 – 50

Rear Crossmember Front Mounting Bolt ............................................... 125, then

30° – 40° turn angle

Rear Crossmember Front Mounting Brace Bolt..................................... 60 – 85

Rear Mount to Rear Cover Attaching Bolt .............................................. 85 - 105

Rear Mount to Vehicle Underbody Attaching Bolt .................................. 30 – 40, then

55° – 65° turn angle

Rear Disc Brake Shield to Trailing Arm Attaching Bolt - Upper ............ 70 – 80

- Lower ............ 85 – 90

Road Wheel Attaching Nut..................................................................... 110 – 140

Shock Absorber Lower Mounting Bolt.................................................... 105 - 125

5. SPECIAL TOOLS

NOTE: Only those special tools relative to the service procedures contained in this Section are detailed here. For

all remaining special tools, refer to 4B FINAL DRIVE AND DRIVESHAFTS of the VT Series I Service Information.

TOOL No. REF. IN TEXT TOOL DESCRIPTION COMMENTS

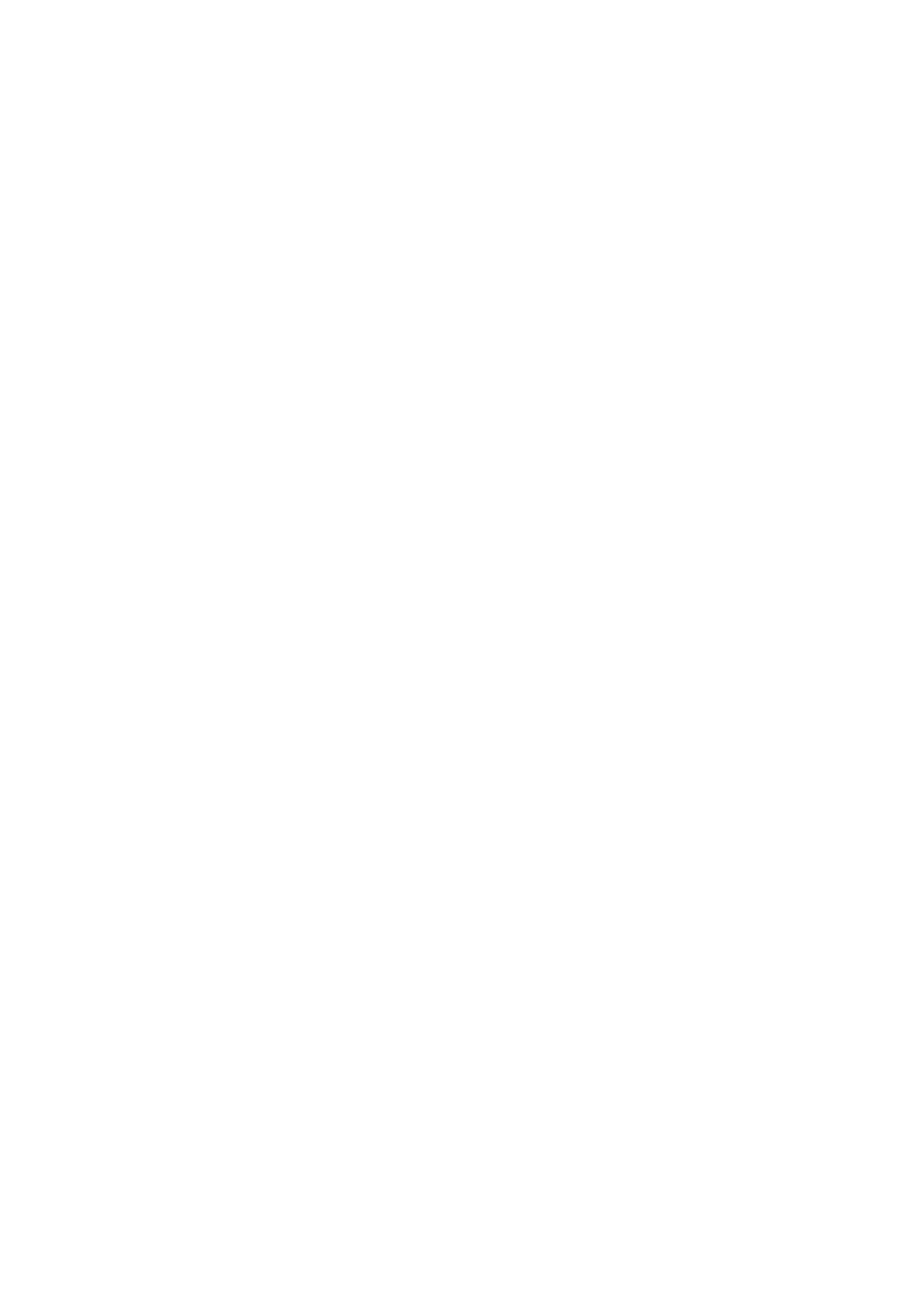

AU416 TORX BIT

Previously released.

Used to loosen/tighten the two

upper rear brake disc shield

bolts to the trailing arm.

AU534 TORQUE LIMITING SOCKET

New release.

Used in conjunction with an

impact gun to tighten wheel

nuts.

This is a mandatory tool.

E7115 ANGLE WRENCH

Previously released.

Used to tighten any fastener

where a torque angle is

specified in addition to and

initial torque specification.

J22912-01 PRESS PLATES Previously released.

Used for various pressing

support operations.

KM468 HOLDING BAR

Previously released.

Used to hold trunnion assembly

hub from rotating.

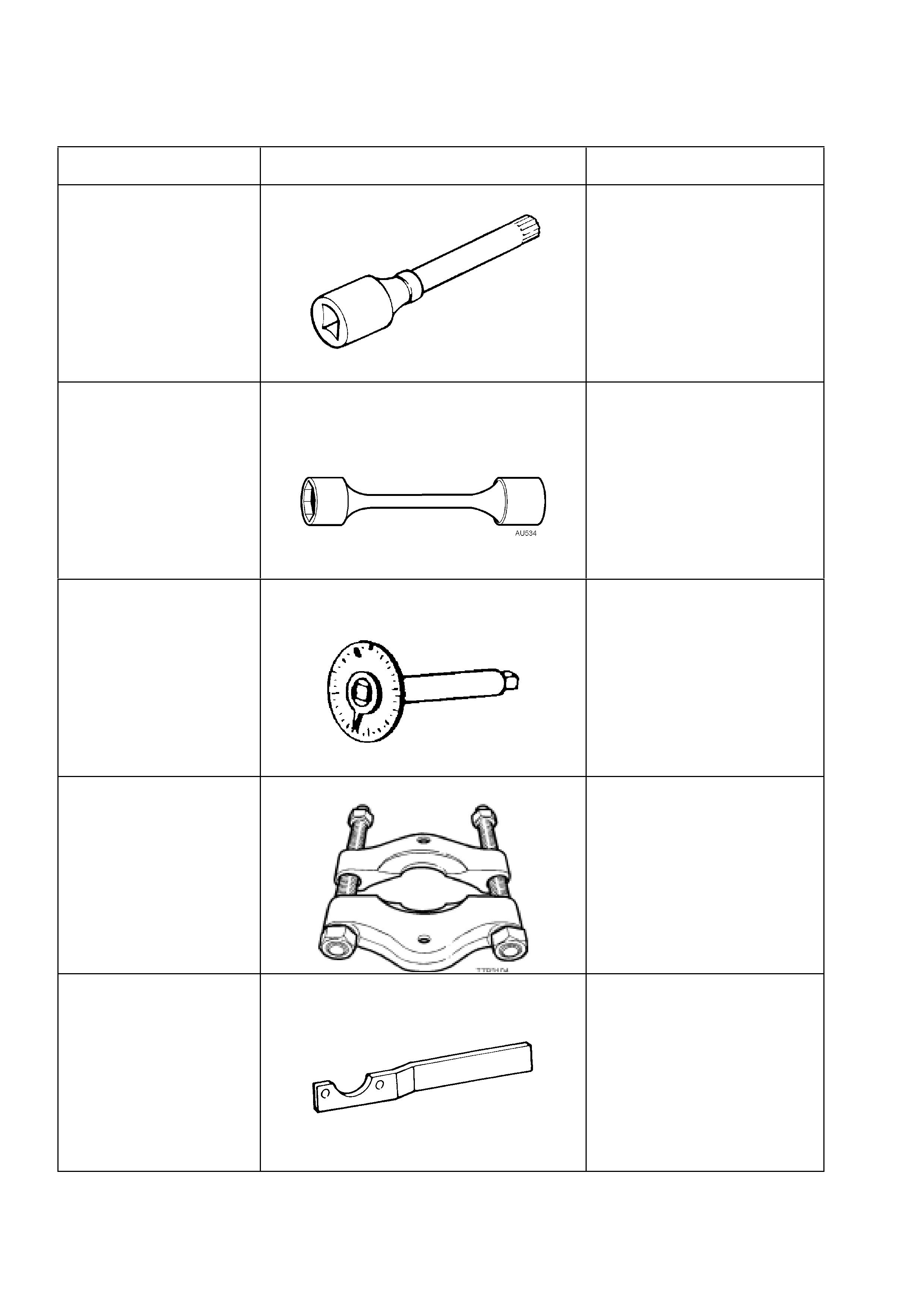

TOOL No. REF. IN TEXT TOOL DESCRIPTION COMMENTS

KM620-A REMOVER/INSTALLER

Previously released.

Used to remove and install

trunnion flange, rear wheel

bearing and trunnion assembly.

KM620-7-AUS SUPPORTS

New release.

The two revised length supports

are required when undertaking

any of the following service

operations on the locally

sourced trailing arm assembly:

• Rear trunnion flange

• Rear wheel bearing

• Rear trunnion assembly

• Rear brake disc shield.