SECTION 7C1 – HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION: GENE RAL INFORMATI ON

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenge r's air bags or seat b elt pre-t ensio ners, d river’s and f ront p asseng er’s a ir bag and lef t and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System

before performing any service operation on, or around any SRS components, the steering mechanism o r

wiring. Failure to follow the SAFETY PRECAUTIONS could result in SRS deployment, resulting in

possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, (V6

Engine) or (GEN III V8 Engine) of this Service Information CD.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning ‘OFF’ the manual service valve and then draining the LPG

service lines , before an y serv ic e work is car ried o ut on t he v eh icl e. R ef er t o t he L PG le aflet inclu ded wit h

the Owner's Handbook for details or the appropriate Section of this Service Information CD for more

specific servicing information.

1. GENERAL INFORMA T ION

1.1 SECTION DE SCRIPTIONS

The Multi-Section approach to th e Hydra-matic 4L60-E Autom atic Transm ission has been continued f or VT Series

II vehicles.

SECTION 7C1: HYDRA-MATIC AUTOMATIC TRANSMISSION: GE NERAL INFORMATION

The purpose of this Section is to provide an overview of this automatic transmission, by briefly describing what

each of the various sub-sections contains.

In addition, an overview of the changed features for the 1999 model year transmission is provided.

SECTION 7C2 HYDRA-MATIC AUTOMATIC TRANSMISSION:- ELECTRICAL DIAGNOSIS

As the electrical systems and diagnosis for this transmission are controlled by the Powertrain Control Module

(PCM), this material has now been included in the appropriate sections relating to the PCM; namely

Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE of the VT Series I Service Information and

Section 6C3 POW ERT RAIN MANAGEM ENT – GEN III V8 ENGINE of the VT Series II Service Information.

SECTION 7C3 HYDRA-MATIC AUTOMATIC TRANSMISSION:- GENERAL DIAGNOSIS

As distinct from the previous Section, 7C3 contains information that will assist in the diagnosis of the mechanical

and hydraulic components in the 4L60-E automatic transmission, with the unit installed in the vehicle.

Only those diagnostic procedures that have modified information will be published here. Therefore, this Section

should be read in conjunction with Section 7C3 - HYDRA-MATIC AUTOMATIC TRANSMISSION - GENERAL

DIAGNOSIS, of the VT Series I Service Inf or mation.

Techline

Techline

Techline

SECTION 7C4 HYDRA-MATIC AUTOMATIC TRANSMISSION:-ON-VEHICLE SERVICING

Again, this Section only covers on-vehicle servicing items that differ to those detailed in

Section 7C4 - HYDRA-MATIC AUTOMATIC TRANSMISSION -ON-VEHICLE SERVICING of the VT Series I

Service Information. As a result, this information should also be read in conjunction with that information.

SECTION 7C5 HYDRA-MATIC AUTOMATIC TRANSMISSION:-UNIT REPAIR

This sec tion c ont ai ns the proced ures nec ess ary for the d isas s embly, inspecti on, over hau l a nd assembly op erati ons

of the mechanical components, once the transmission is removed from the vehicle. As the unit repair procedures

remain essentially unchanged, refer to Section 7C5 - HYDRA-MATIC AUTOMATIC TRANSMISSION -UNIT

REPAIR of the VT Series I Service Information.

1.2 TRANSMISSION CHANGES FOR 1999 MY

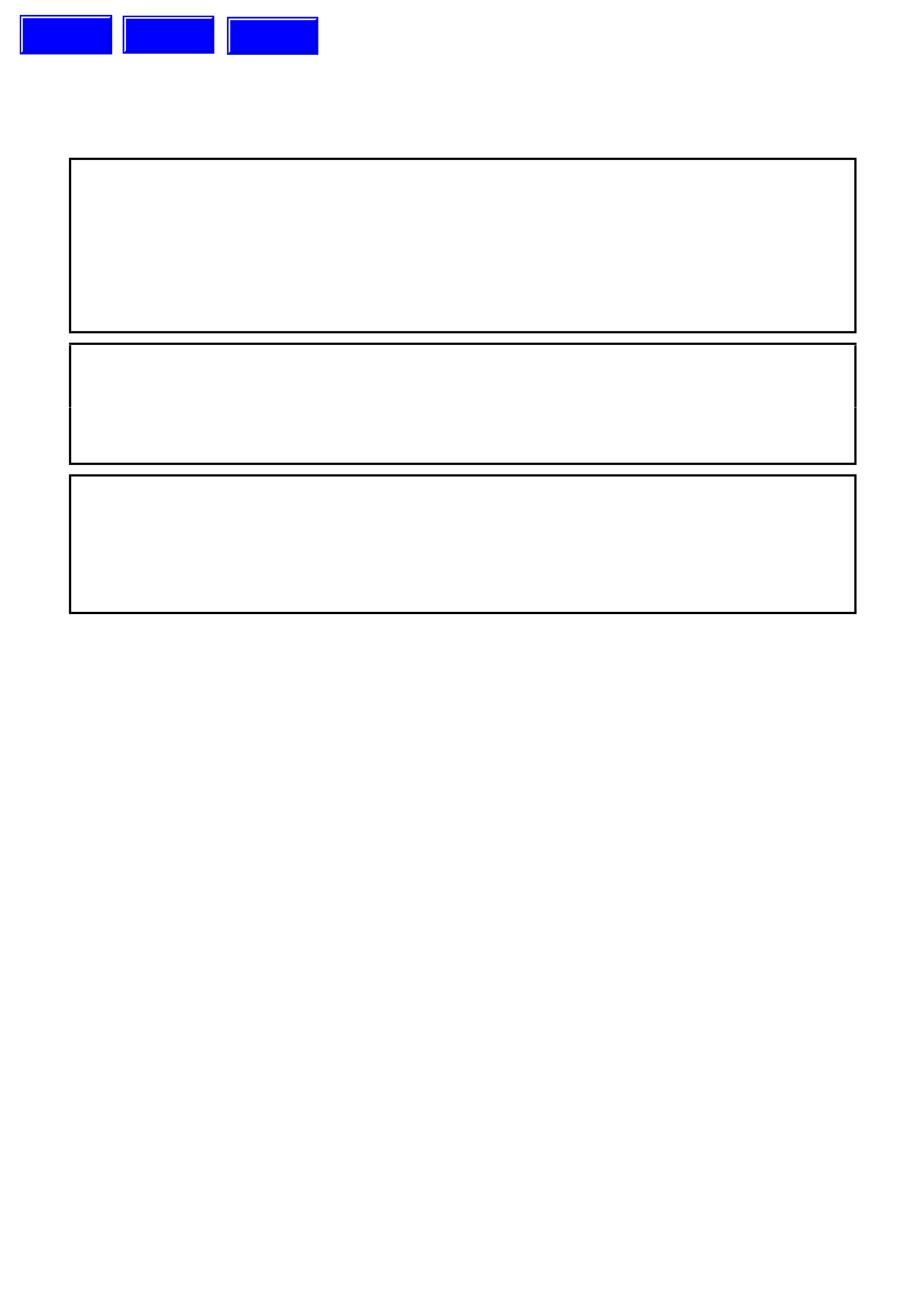

1-2 ACCUMULATOR PISTON AND SP RING

Introduced into production on May 11, 1998,

(Julian date 131), the 1-2 accumulator piston

changed from an aluminium piston to a composite

material.

At this time the accumulator outer spring also

changed f r om a round wire spr in g to a s prin g made

from oval shaped wire.

The 1-2 accumulator pistons and outer springs are

not inter-cha nge ab le.

As this change was introduced during the 1998

model year build, the composite piston and oval

wire outer spring is the on l y on e to be f itt ed t o 1 999

model year transmissions. Figure 7C1-1

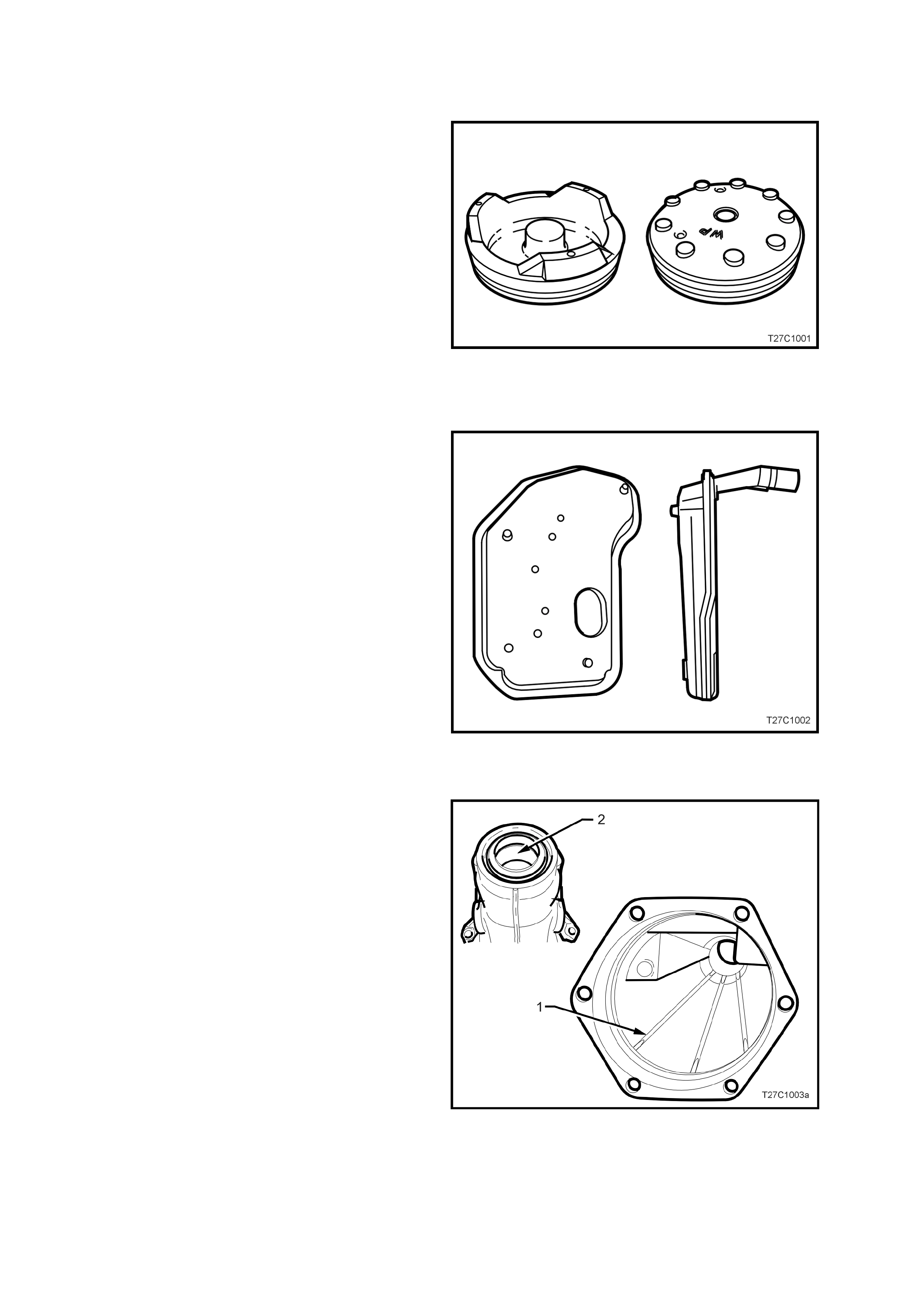

DEEP PAN OIL FILTER

The oil filter used with the deep oil pan, is now a

black, all-plastic component and must be fitted to

all 1999 model year transmissions.

Important: Do not use a shallow pan filter in a

4L60-E automatic transmission that is fitted with a

deep oil pan.

Figure 7C1-2

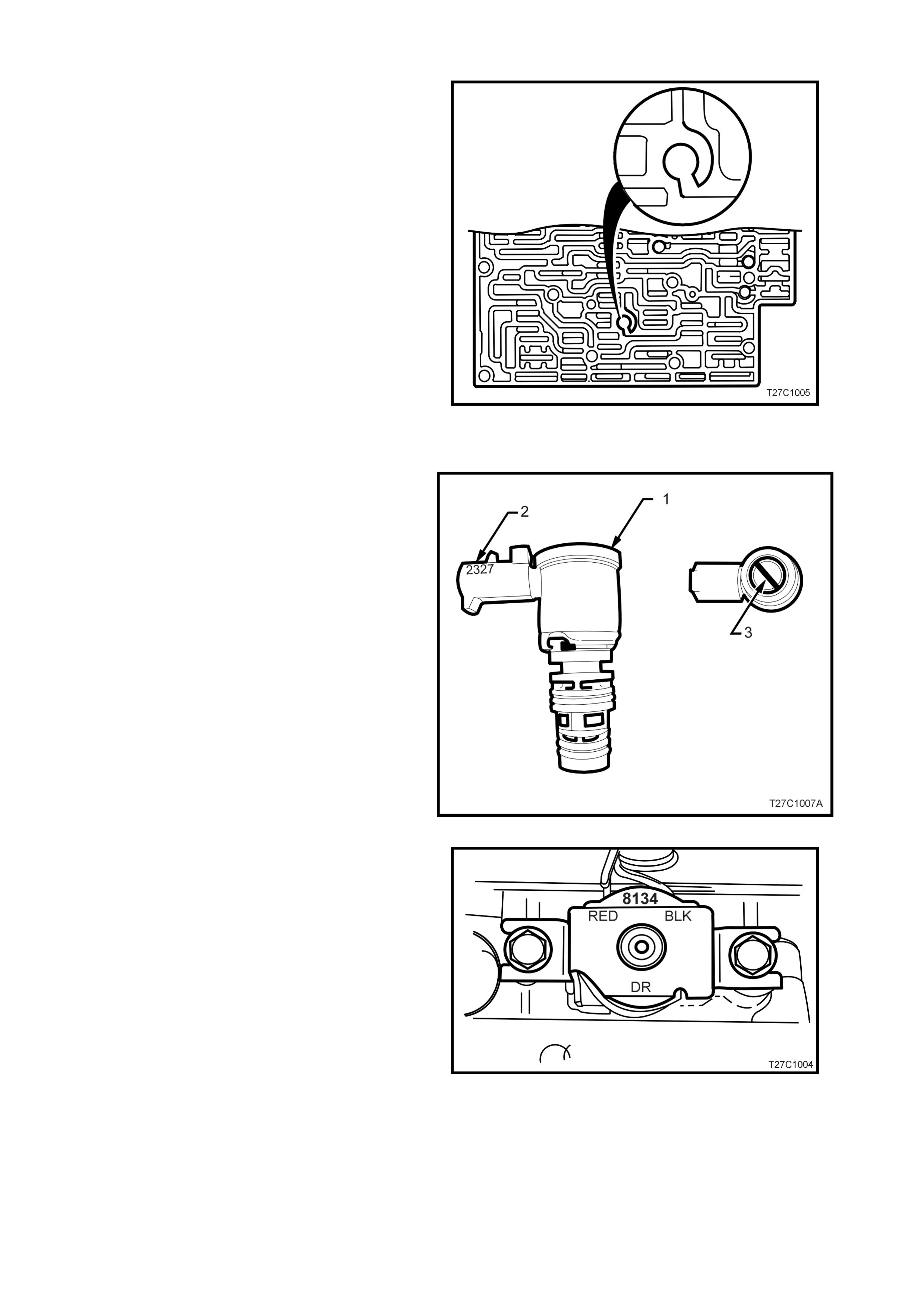

EXTENSION HOUSING AND BUSH

The extension housing for 1999 model year

transm issions has three inter nal ribs (1) added and

the propeller shaft slip yoke bush material has

changed from a bronze bushing to one made with

a Teflon ® (2) coating.

The new bushing can be identified as a smooth

bushing with no lubricant holes previously used

with the bronze bus h and is grey/green in colo ur .

While the new extension housing and Teflon®

bush will service back to earlier, two-piece case

transmissions, the bush and extension are not

inter-changeable.

Figure 7C1-3

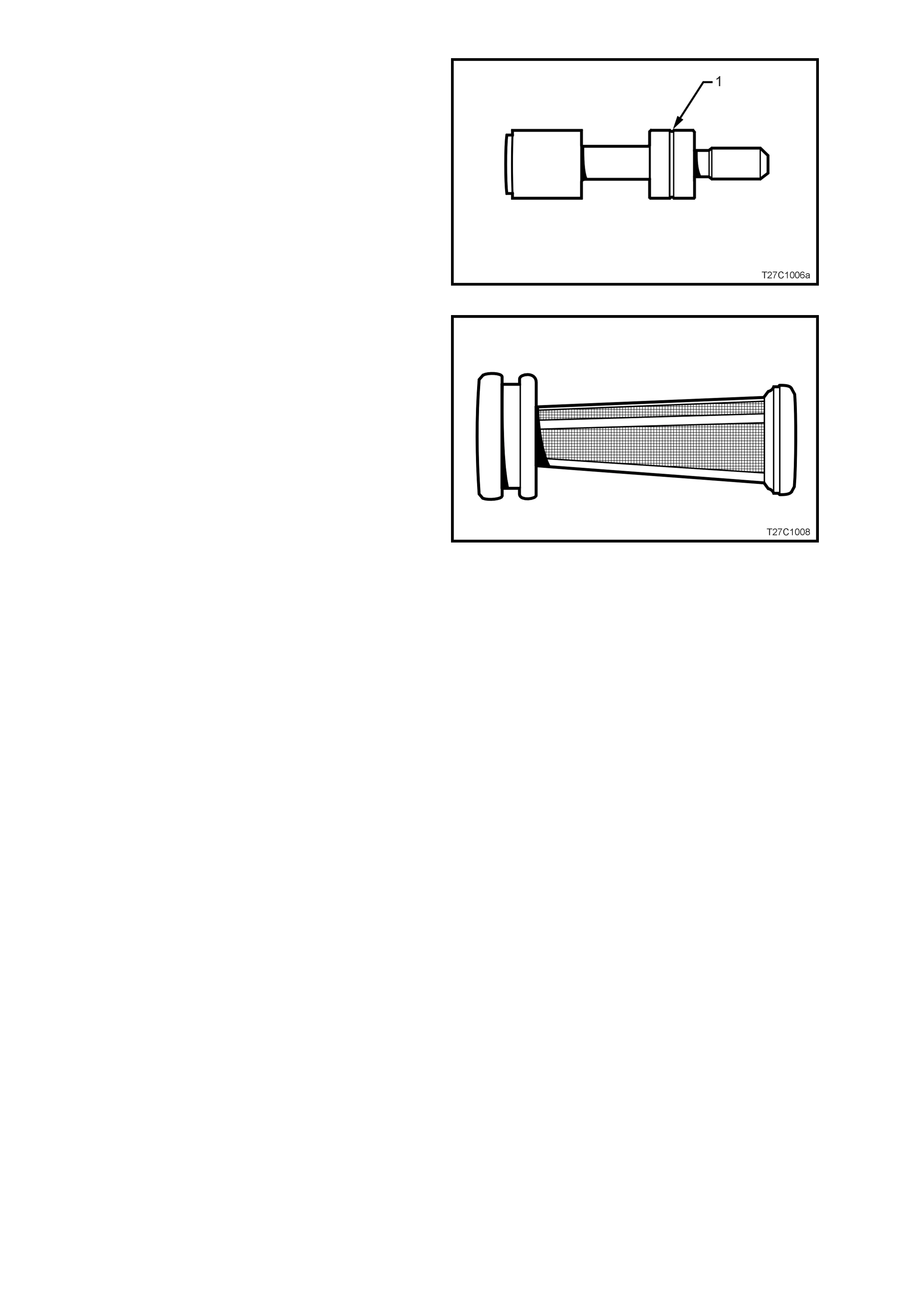

CONTROL VALVE BODY

To improve durability, the check ball hole as

indicated, has been changed from an oval to a

round shape.

This revised contr ol valve bod y must be us ed in all

1999 model year transmissions.

Figure 7C1-4

3-2 CONTROL SOLENOID

A revised 3-2 control solenoid (1) is fitted and can

be identified by the number ‘2327’ (2) (previously

‘9127’) and the inclusion of a black plastic support

(3) on the bottom of the filter screen.

This revised part m ust be fitted to 199 9 m odel year

transmissions.

Figure 7C1-5

TCC SOLENOID

The torque converter clutch solenoid has been

revised for the 1999 model year transmission, to

reduce the converter drain back.

As sho wn, the rev is ed s o len o id ca n be id ent if ied by

the silver coloured bracket (previously gold) and

with the number ‘8134’ on the wiring bobbin

(previously ‘8128’).

The revised solenoid must be used on all 1999

model year transmissions.

Figure 7C1-6

REGUL ATOR APPLY VALVE

A revised design regulator apply valve is now used,

that im proves durabilit y by lessening the possibility

of the valve wearing the control valve body bore.

The revised design can be recognised by the

groove (1) and must be used on all 1999 model

year transmissions.

Figure 7C1-7

PUMP FILTER SCREEN

The mesh on the pump filter screen is now more

coarse than the previous screen, to improve

transmission fluid flow under cold operating

conditions.

This screen must be used in all 1999 model year

transmissions.

Figure 7C1-8

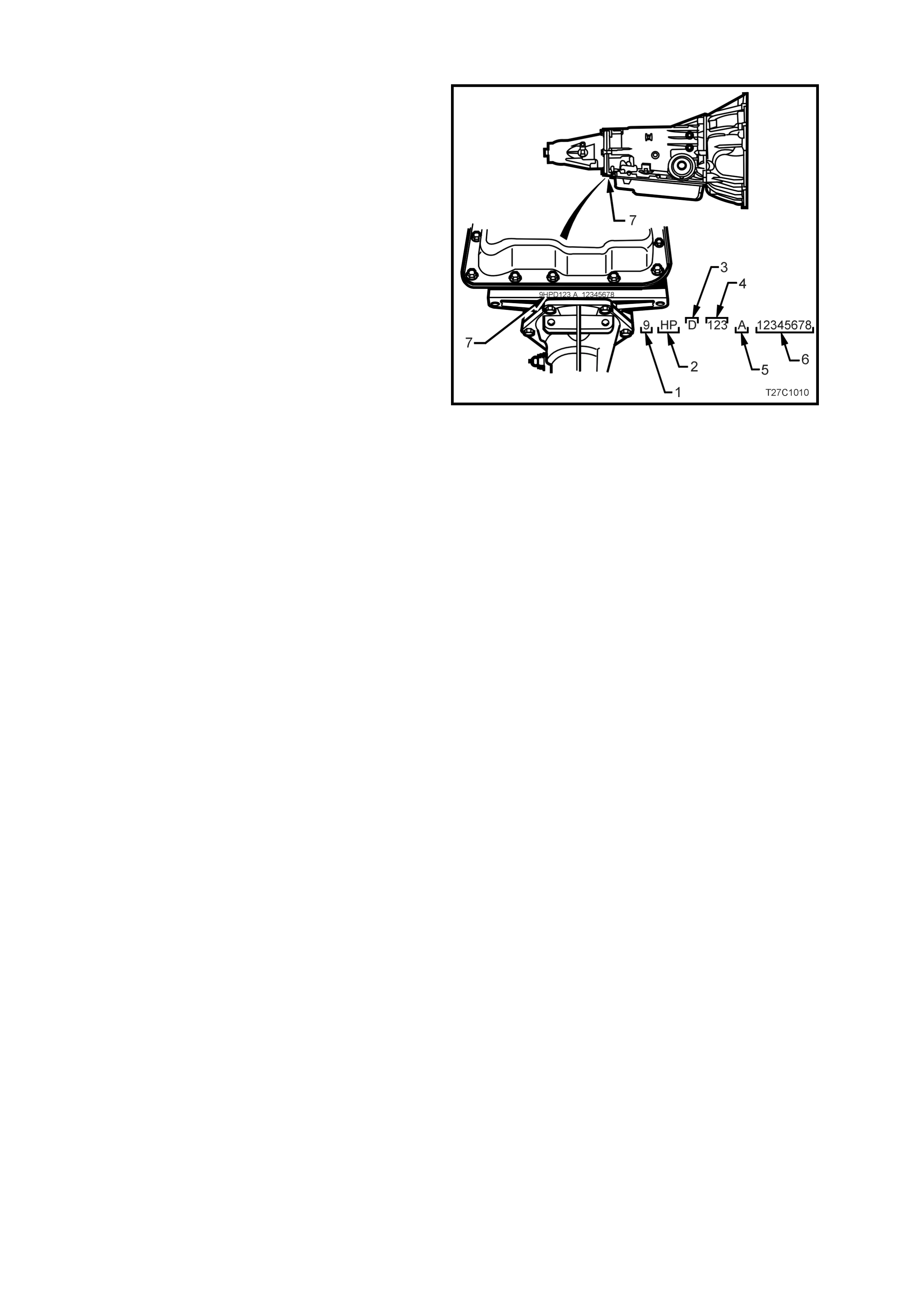

1.3 TRANSMISSION IDENTIFICATION

The 4L60-E automatic tr ansmiss ion app lication an d

identification can be determined from the stamping

in the rear of the transmission case at the rear, in

the location shown (7).

The coded number can be interpreted from the

follo wing breakdown;

1. Model Year (‘9’ = 1999)

2. Model: 3.8 litre V6 (LN3) HF

3.8 litre V6 S/C (L67) HN

5.7 litre GEN III V8 (LS1) HP

3. Transmission Model Identifier (‘D’ = 4L60-E)

4. Julian Date (Day of the Year)

5. Shift Build ‘A’, ‘B’, ‘J’ = First Shift;

‘C’, ‘H’, ‘W’ = Second Shift

6. Individual Transmission Serial Number

Figure 7C1-9

1.4 TORQUE CONVERTE R CHANGE

The size of the torque converter fitted to the V6 engine (production option LN3) automatic transm ission has been

increased from 245 mm to 258 mm, which now becomes common with the V6 supercharged engine (production

option L67). The reasons for the change are to reduce operating temperatures and improve fuel consumption

This running change, introduced with the 9HFD transmission, became effective from a vehicle build date of

Februar y 26, 1999.

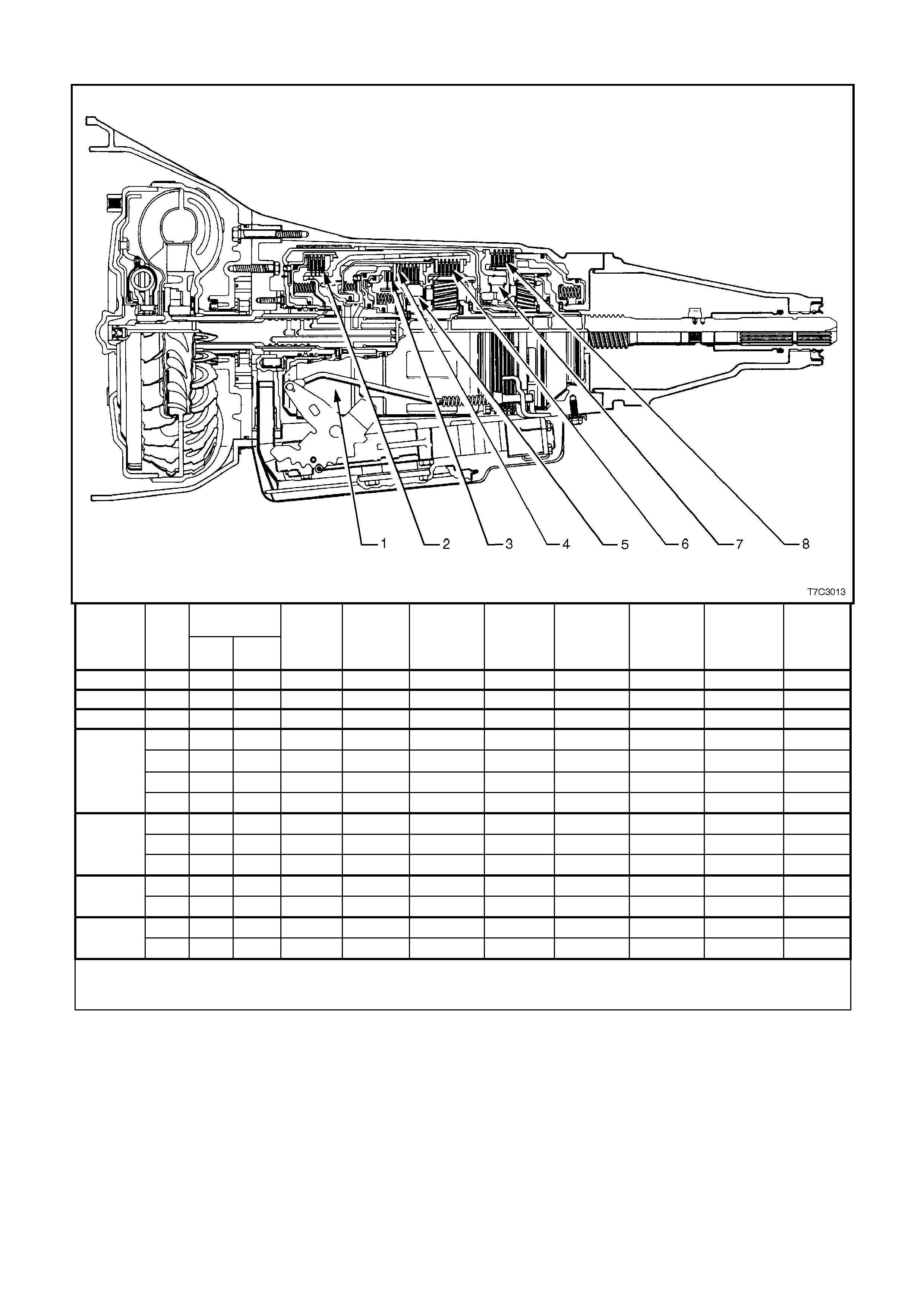

1.5 RANGE RE FERENCE CH ART

RANGE GEAR SHIFT

SOLENOID 2-4 BAND REVERSE

INPUT OVERRUN

CLUTCH FORWARD

CLUTCH FORWARD

SPRAG CL. 3-4 CLUTCH LOW/

ROLLER LOW/

REVERSE

1 - 2 2 - 3 (#1) CL UTCH

(#2) (#3) (#4) ASSEMBLY

(#5) (#6) CLUTCH

(#7) CLUTCH

(#8)

PARK On * On * APPLIED

REVERSE On * On * APPLIED APPLIED

NEUTRAL On * On *

1ST On On APPLIED HOLDING HOLDING

D2ND OFF On APPLIED APPLIED HOLDING

3RD OFF OFF APPLIED HOLDING APPLIED

4TH On OFF APPLIED APPLIED APPLIED

1ST On On APPLIED HOLDING HOLDING

32ND OFF On APPLIED APPLIED HOLDING

3RD OFF OFF APPLIED APPLIED HOLDING APPLIED

21ST On On APPLIED APPLIED HOLDING HOLDING

2ND OFF On APPLIED APPLIED APPLIED HOLDING

11ST On On APPLIED APPLIED HOLDING HOLDING APPLIED

2ND ** OFF On APPLIED APPLIED APPLIED HOLDING

* SHIFT SOLENOID STATE IS A FUNCTION OF VEHICLE SPEED A ND MAY C HANGE IF A VEHI CLE SPEED INCREASES SUFFICIENTLY IN PARK, REVERSE

OR NEUTRAL. HOWEVER, tHIS DOES NOT AFFECT TRANSMISSION OPERATION.

** IN MANUAL FIRST, SECOND G EAR IS ONLY AVAILABLE ABOVE APPROXIMATELY 48 – 56 KM/H TO PREVENT ENGINE OVERSPEEDING.

Figure 7C1-10

1.6 ENGINE TORQUE MANAGEMENT

W ith the GEN III V8 engine, Tor que Man agement is a f unc tion of the PCM that r educes engin e p ower under c ert ain

conditions, included in which, is the transmission upshifts and downshifts.

Torque Management is performed for the following reasons:

1. To prevent overstress of the powertrain components.

2. To prevent damage to the vehicle during certain abusive manoeuvres.

3. To reduce engine speed when the IAC is out of the normal operating range.

The PCM monitors the following sensors and engine parameters to calculate engine output torque;

• Air/Fuel ratio

• Mass Air Flow

• Manif old Absolute Pressure

• Intake Air Temperature

• Spark Advance

• Engine Speed

• Engine Coolant Temperature

• A/C Clutch Status

The PCM monitors the torque converter status, the transmission gear ratio, and the engine speed in order to

determine if torque reduction is required. The PCM retards the spark as appropriate to reduce engine torque

output if torque reduction is required. The PCM. also shuts off the fuel to certain injectors to reduce the engine

power In the case of an abusive manoeuvres.

Instances when eng in e power red uc tio n is likely to be experienc ed, ar e:

a. During transmission upshifts and downshifts.

b. Heavy acceleration from a standing start.

c. The IAC is out of the normal operating range.

d. W hen the dri ver is perfo rming str ess-inducing (ab usive) m anoeuvres suc h as shiftin g into gear at high thr ottle

angles or shifting the transmission from reverse to drive to create, a rocking motion.

The driver is unlikely to notice the torque managem ent actions in the first two instances. The engine power output

will be moderate at full throttle in the other two cases.

The PCM calcul ates the am ount of spark retard nec essar y to re duce t he eng ine powe r b y the des ired am ount. For

example the PCM disables the fuel injectors for cy linders 1, 4, 6, and 7 in the case of an abusive manoeuvres.

2. SE RVICE NOTE S

In the inter ests of s af et y to per son ne l, e qu ipment and to t he vehic l e an d i ts com ponents , th e f oll o wing notes s ho ul d

be read and a dhered to whene ver servici ng operations are to be car ried out on the H ydra-m atic 4L60-E aut omatic

transmission.

In addit ion, s ome of this information a lso refers to the adherenc e to sound work shop practices a nd, to achieve the

design life of affected components, it is also recommended that these points are taken into account.

2.1 FASTENERS

• Always reinstall fasteners at the same locations as they were removed.

• If a fastener requires repl acement, always use a part of th e correct part number or of equal size and strengt h

or stronger.

• Tighten fasteners to correct torque value when required. Torque values are specified for dry, unlubricated

fastener threads.

2.2 GENERAL WORKSHOP PRACTICE

• Keep work area and tools clean.

• To avoid unnecessary contamination, always clean the exterior of the transmission before removing any parts.

• Do not use wiping cloths or rags because of the risk of lint being trapped in the transmission.

• Do not use solvents on:

− neoprene seals.

− composition faced clutch plates.

− thrust washers.

• Always use protective eye wear when using compressed air on components.

• Blow out all passages with compressed air. Only probe small passages with soft, thin wire.

• Handle parts with care to avoid nicks and scratches.

• Do not remove Teflon oil seal rings unless damaged or performing a complete overhaul.

• Expand internal snap rings and compress external snap rings to maximise retention and security.

• Lubricate all internal parts with transmission fluid (Only use Dexron® III), as they are being installed.

• When installing cap screws into aluminium castings:

− always use a torque wrench.

− always dip screw threads in transmission fluid (Only use Dexron® III).

− Stripped or damaged threads in aluminium castings may be reconditioned by using commercially

available thread inserts.

• Once removed, replace all gaskets, seals and O-rings with new parts and:

− always use seal protect ors where indicated and do not use gask et cement or sealant on any joined face

unless specified to do so.