SECTION 5A - BRAKES

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL INFORMAT ION

The VU Series Models braking system carries over from VX Series Models with the addition of a load sensing

proportioning valve which is coupled to the rear suspension. Because VU Series Models are equipped with a load

sensing proportioning valve, the brake master cylinder does not have the standard proportioning valve installed.

The normal master cylinder proportioning valve is replaced by a pressure differential spool valve. The spool valve

provides warning in the event of a loss of front or rear system pressures and allows equal system pressure to the

load sensing proportioning valve.

The load sensing proportioning valve fitted to VU Series Models is not a serviceable item and if found to be faulty,

must be replaced as an assembly.

For inf orm ation not co ver ed in this Sect ion, ref er to S ection 5A BR AKE S in th e VT Serie s I and VT Series II Ser vice

Information.

1.1 MASTER CYLINDER - PRINCIPLES OF OPERATION

DESCRIPTION

A master cylinder with a 25.4 mm (1 inch) diameter main bore is used on all VU Series Models, regardless of the

braking system fitted. The only difference being the master cylinder used with ABS has a screw in blanking plug

installed into the lower of the two front brake outlets in the master cylinder.

The m aster cylinder is a tandem , c entre valve des ign, incor porati ng a 3 1.75 m m fast fill bore and va lve that prov ides

a reduce d p eda l travel. T he m as ter cylinder is mounted to the vac u um brak e boos t er , whic h i n t ur n is mounte d to th e

engine side of the dash panel.

CONSTRUCTION

This tandem m aster cylinder configuration provides separate hydraulic circuits for the application of the br akes, in a

front to rear split arrangement.

Both of these circuits are fed by separate fluid feed and compensating ports, through a common fluid reservoir,

sealed by a diaphragm fitted inside the reservoir cover. This diaphragm provides an effective seal against any

atmos pheric m oisture com ing into co ntact with t he hygros copic brak e fluid. T his prov ision m aintains the brak e fluid's

boiling point for a maximum period of time.

The interna l parts of the m aster cylinder comprises of a stepped di ameter prim ary pist on with an L type s eal and an

‘O’ ring, a secondary piston (which incorporates a centre valve, a caged spring and two L type seals), a return spring,

a secondary piston stop pin and a fast fill valve.

In all v ehicles , a load s ensi ng pr oport ioning valv e is loc ated at t he r ear of t he veh icle. T he prop orti oning v alv e that is

usually located in the second bor e of the master cylinder, is replaced with a pressure differentia l spool valve, which

can move within the m aster cylinder body to operate t he brake fail warning light switch. The s witch then illuminates

the brake fail warning light in the instrument cluster, should a pressure loss occur in either the front or rear brake

systems.

Techline

Techline

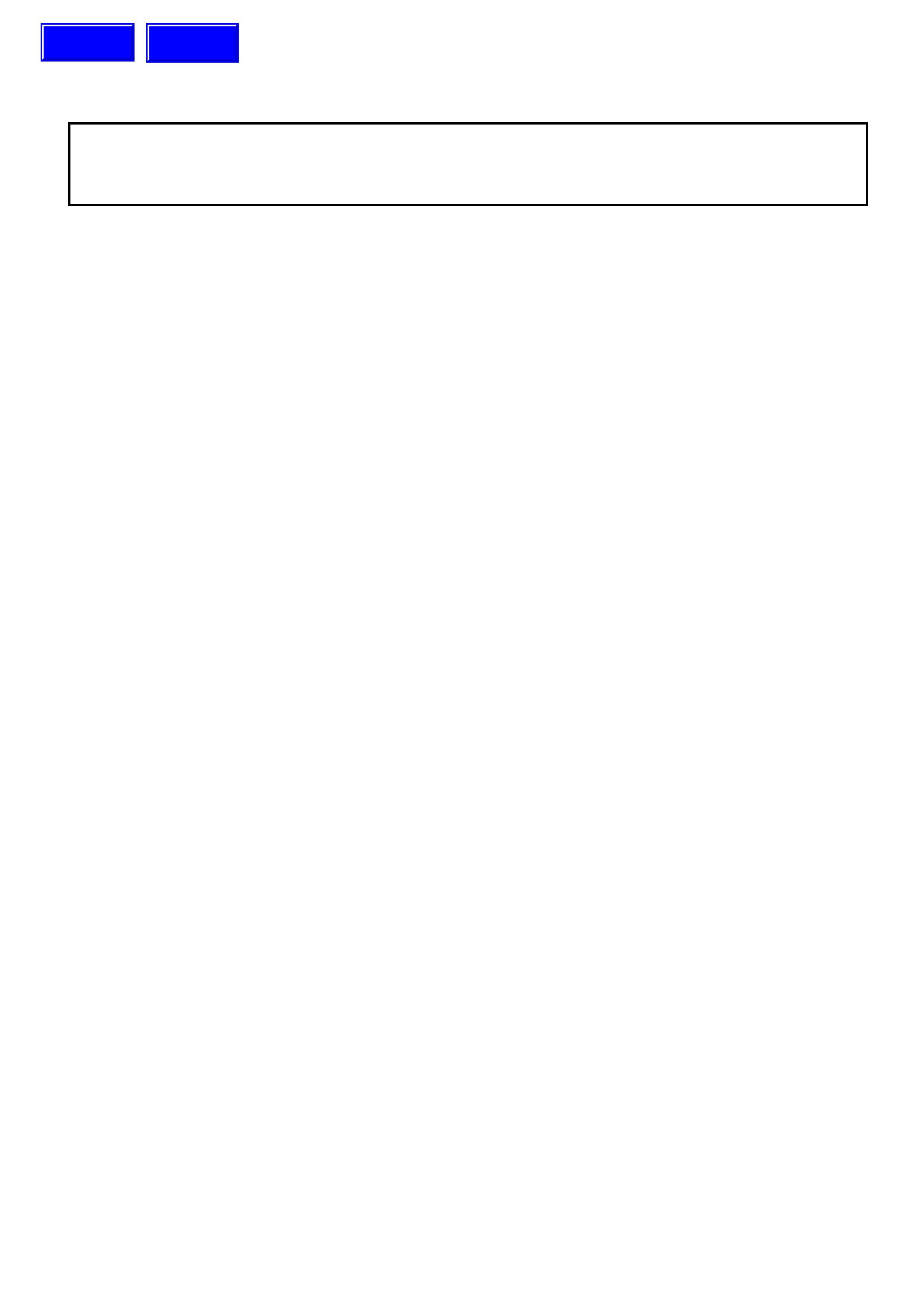

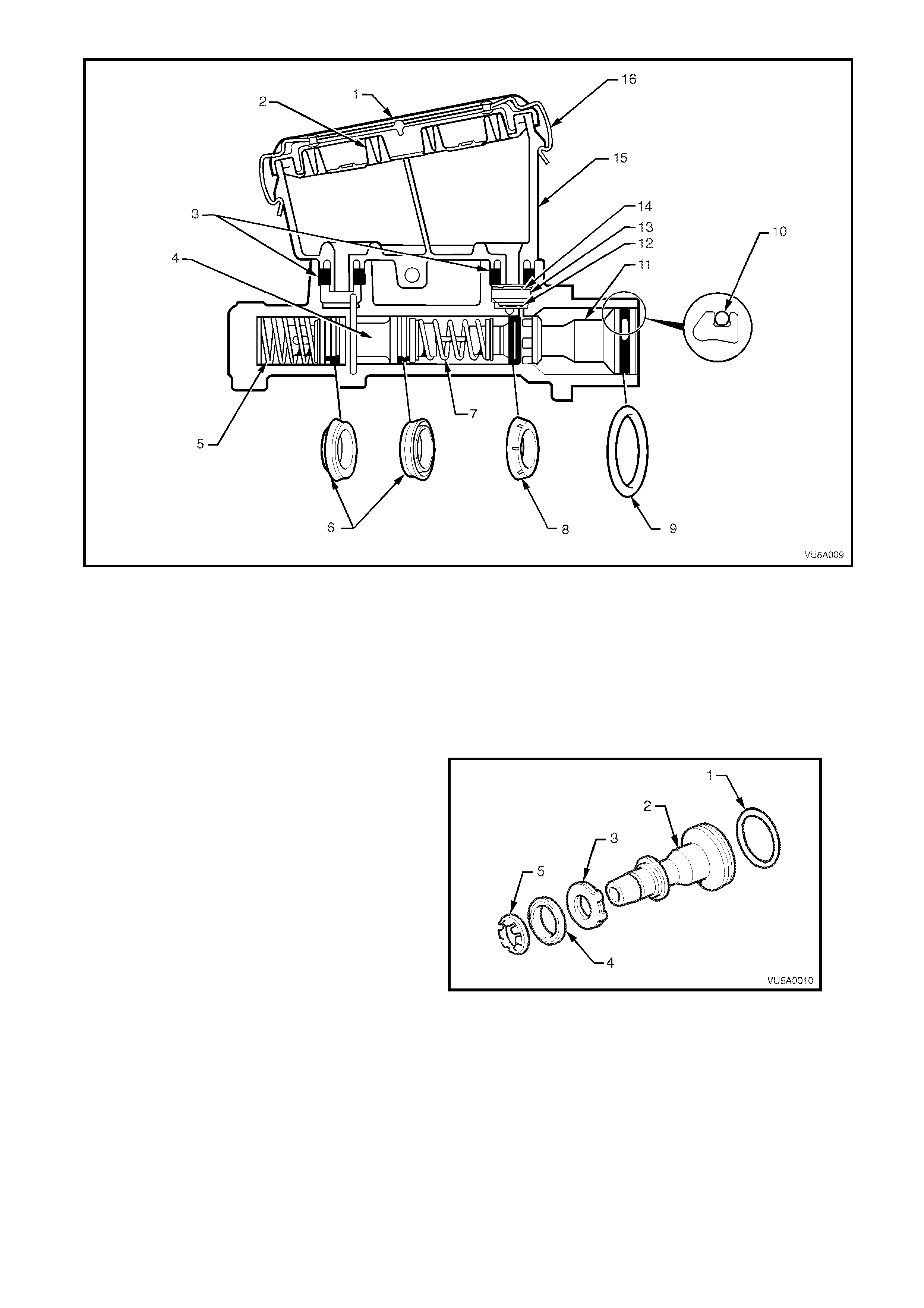

Figure 5A-1

Legend

1. Reservoir cap

2. Reservoir cap se al

3. Reservoir sealing grommets

4. Secondary piston

5. Return spring

6. Secondary seals (L type)

7. Caged spring

8. Primary seal (L type)

9. Primary piston 'O' ring

10. End plug

11. Primary piston

12. Fast fill valve 'O' ring

13. Fast fill valve

14. Fast fill valve circlip

15. Brake fail warning li ght switch

16. Primary seal retainer

17. Secondary piston stop pin

18. Recuperating guide

19. Reservoir retaining sc rew

20. Differential spool valve

21. Spool valve sleeve

22. Spool valve sleeve 'O' ring

23. End plug 'O' ring

OPERATION

The fast fill (fast pressure build up) valve

incorporated into the master cylinder provides

reduced pedal travel by rapidly overcoming the

large low pressure displacements, such as the

advancement of brake pads against the disc with

minimal primary piston travel.

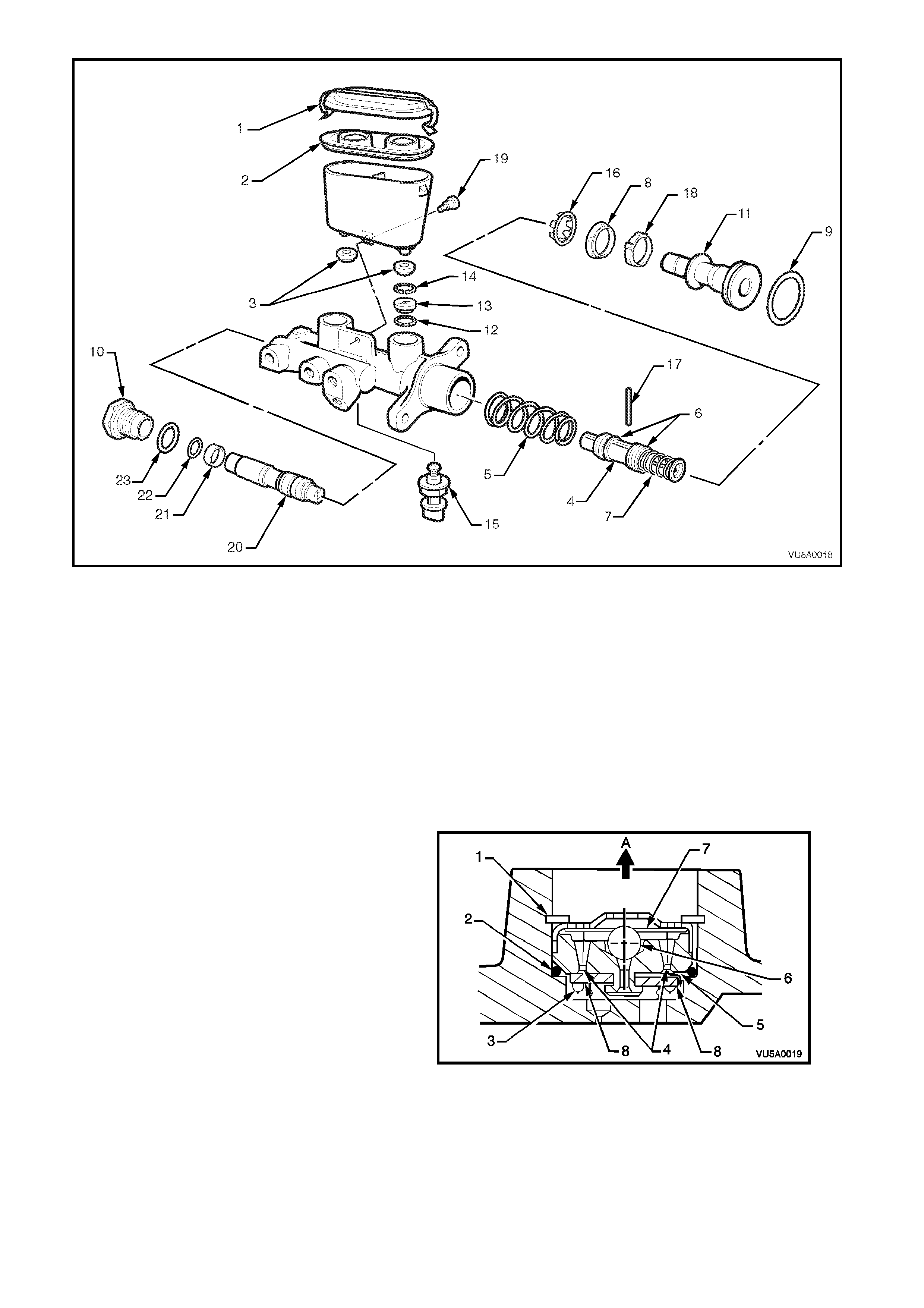

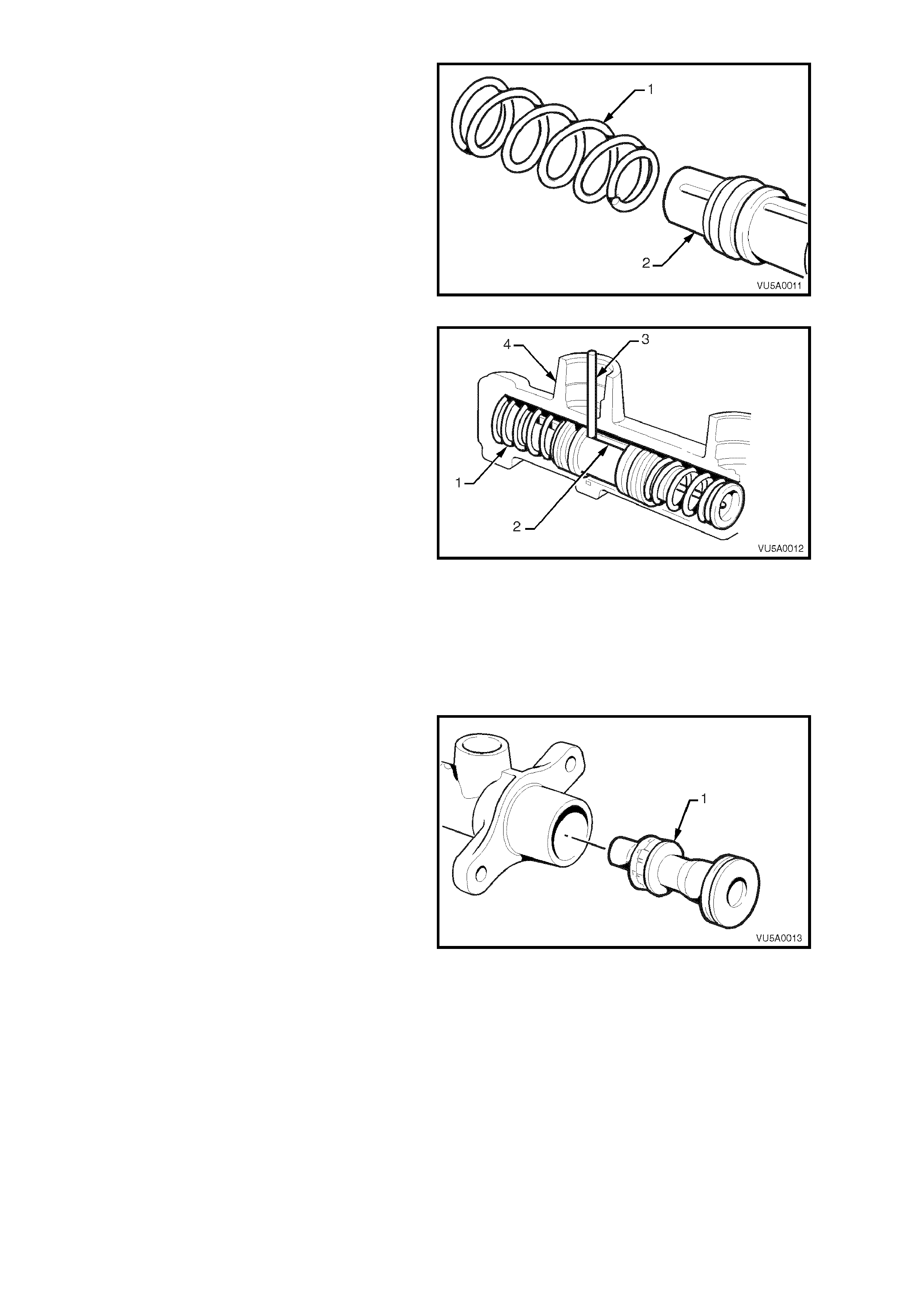

Legend

1. Retaining circlip for fast fill valve

2. Fast fill valve 'O' ring

3. One way rubber flapper valve

4. Replenishing holes

5. Compensating passage

6. Ball valve and seat

7. Ball valve pre lo ad disc spr i ng

8. Rubber flaps

A. To reservoir

Figure 5A-2 FAST FILL VALVE

Initial primary piston movement produces pressure

in the larger bore of the master cylinder which

forces closed the flap on the fast fill valve and

prevents fluid from entering the reservoir port.

This high volume low pressure fluid flows over the

primary piston primar y L type seal, into the sm aller

bore and out to the brake calipers, catering for

most of the low pressure brake system

displacement with minimal primary piston travel.

Figure 5A-3 INITIAL PISTON MOVEMENT

Further primary piston movement increases the

pressure in the larger bore, and at a pre-

determined pressure, the ball and seat feature

incorporated in the fast fill valve unloads,

preventing additional pressure rise and allowing

fluid to flow from the larger bore into the reservoir

port.

At this point, the small bore section of the master

cylinder functions as a conventional master

cylinder, producing high operating line pressures

with minimal primary piston travel.

Figure 5A-4 FAST FILL VALVE UNLOADING

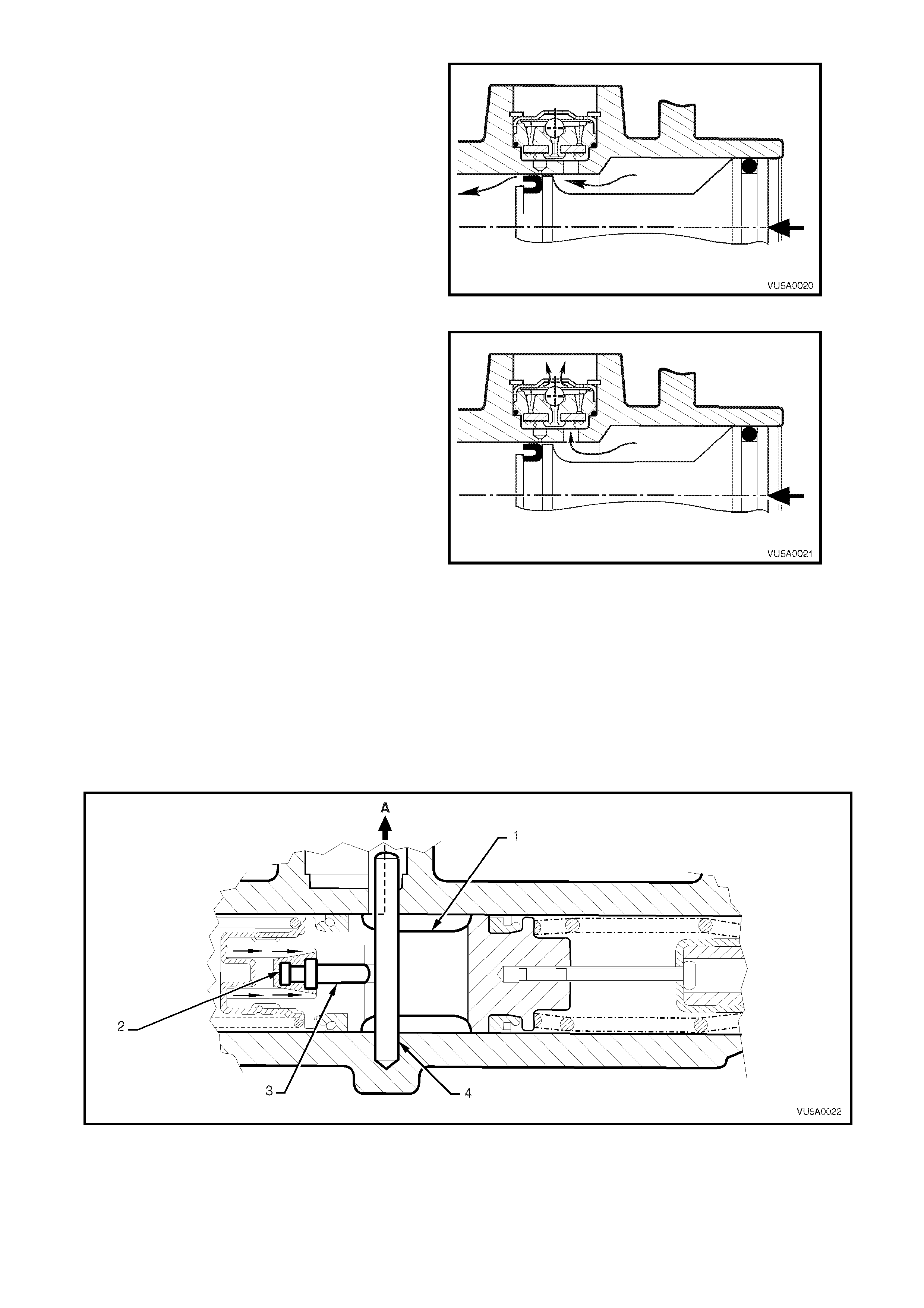

The combination of hydraulic pressure and the force of the primary piston acting on the secondary piston spring

causes the secondary piston to move forward.

This action on the secondary piston moving forward releases the centre valve pin from contact with the secondary

piston stop pin. With the force of the centre valve spring and the release of the centre valve pin, the rubber centre

valve seal is pushed against the front of the secondary piston inner bore, effectively blocking off the fluid from the

rear brake system compensating port.

At the sam e tim e, the prim ary pist on L t ype seal pass es the f ront br ake s ystem compensating p ort, c losing it off fr om

the reservoir and thus the high operating fluid pressure is produced.

The high operating fluid pressure influence is then registered on either side of the pressure differential spool valve,

then to the front and rear brake calipers (via the load sensing proportioning valve) where the brakes are applied.

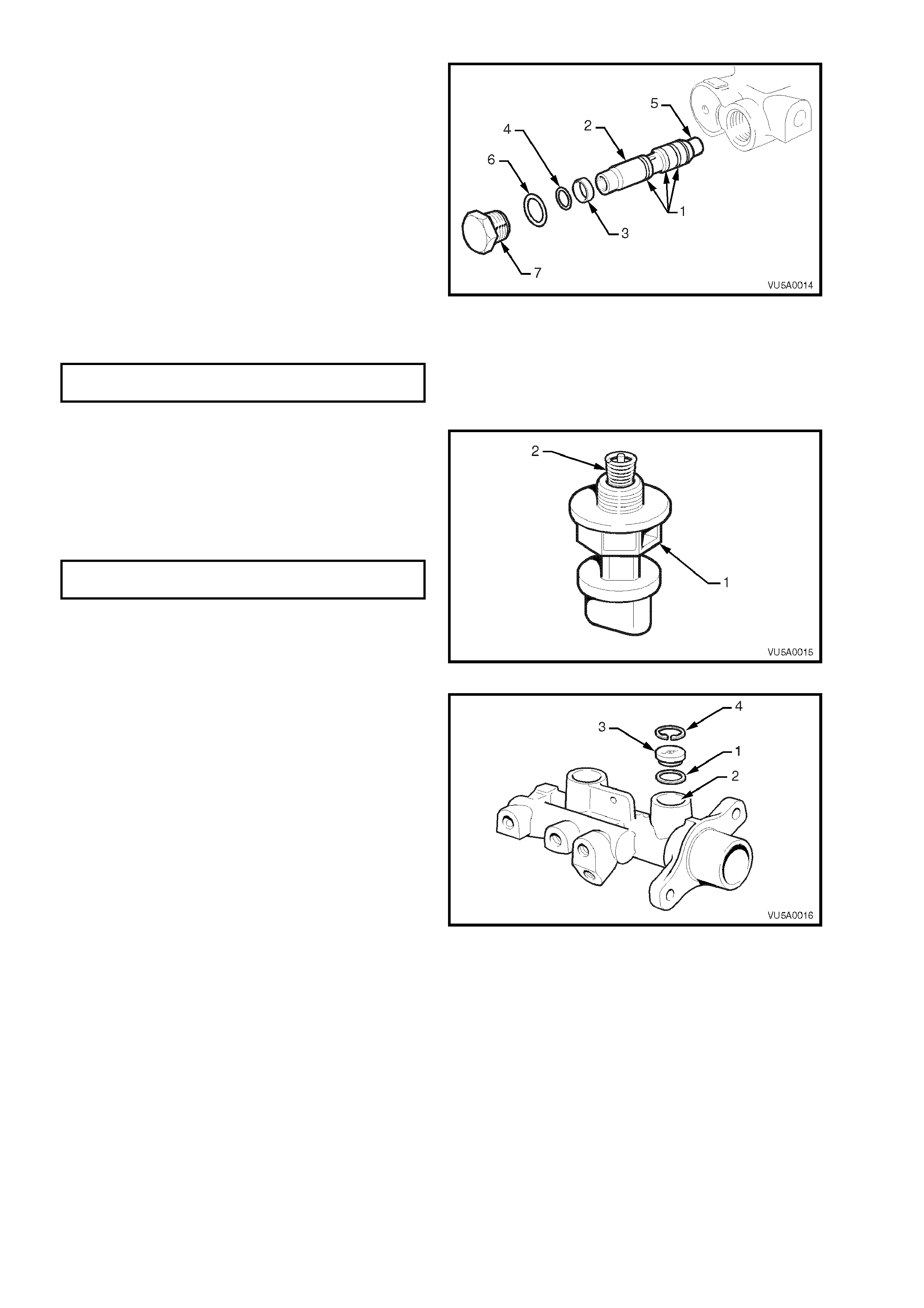

Figure 5A-5 CENTRE VALVE CLOSED

Legend

1. Secondary piston

2. Centre valve seal 3. Centre valve pin

4. Secondary stop pin A. To reservoir

FRONT BRAKE SYSTEM: When the brake pedal

is released and the primary piston returns, fluid

recuperation will occur from the reservoir through

the reple nishing ho les in the f ast fill val ve, over the

rubber flap and into the larger and smaller piston

bores.

When the primary piston has fully returned, the

compensating hole in the master cylinder will be

uncovered. This allows fluid returning from the

brake calipers to f low into t he reservoir via the f ast

fill valve compensating passage, thus relieving all

pressur e in the brak e s ystem.

Figure 5A-6 FLUID REPLENISHMENT THROUGH FAST

FILL VALVE

REAR BR AKE SYSTE M: W hen the brake peda l is releas ed and the seco ndary pist on returns, f luid recuperatio n will

occur f r om the r eser vo ir a n d thr o ugh th e c en tre va lv e when the c entre val ve rub ber seal bec omes uns ea ted f r om the

secondary piston bore.

Figure 5A-7 FLUID REPLENISHMENT THROUGH CENTRE VALVE

Legend

1. Centre valve seal.

2. Centre valve pin. 3. Secondary piston.

4. Secondary piston stop pin. A. Compensating port to

reservoir.

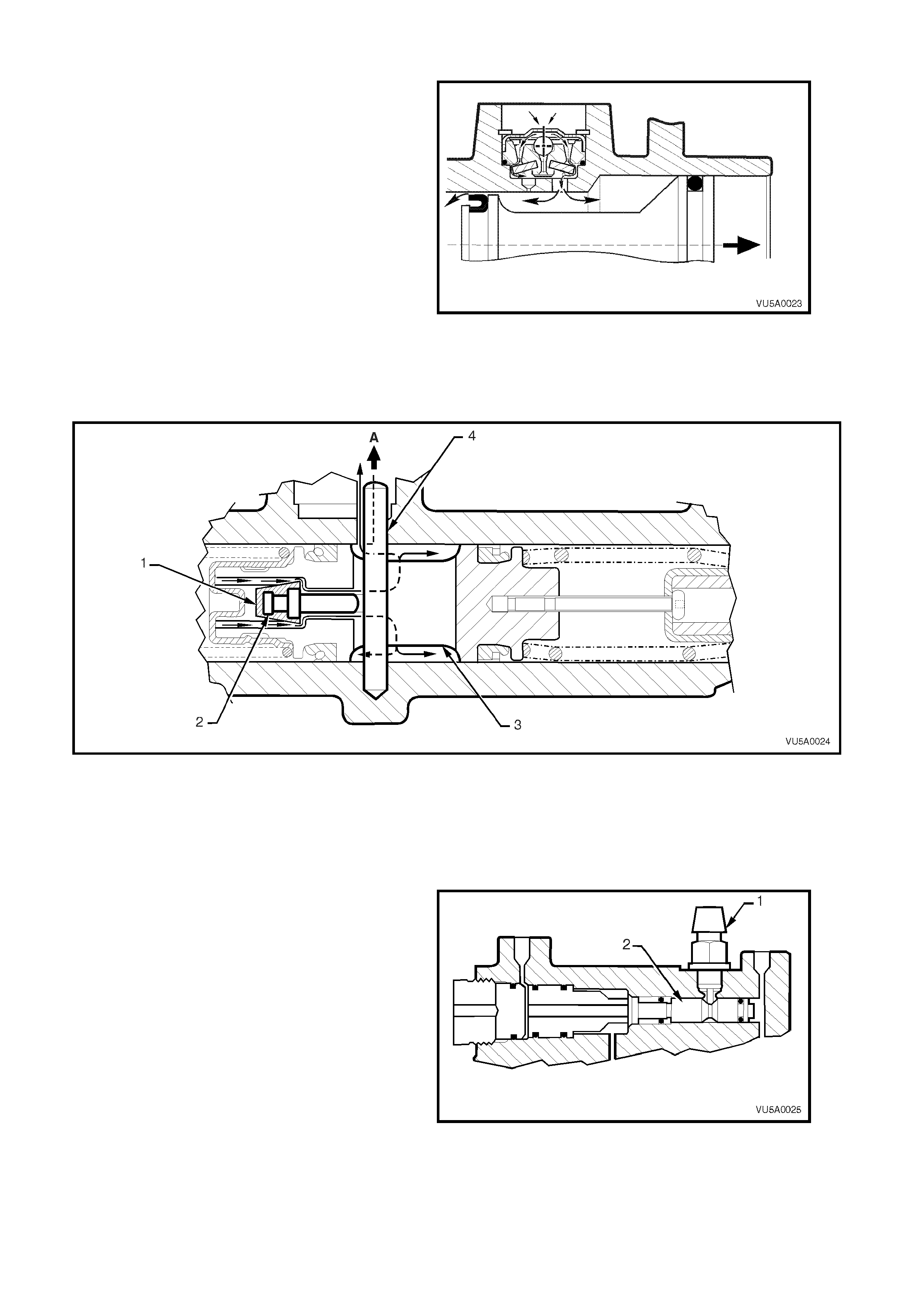

PRESSURE DIFFERENT IAL SPOOL V ALVE OPERATION

The brake fail warning light switch (1) is mounted in

the spool valve body with the spring loaded plunger

fitting into a tapered groove in the centre of the

spool valve (2). With the spool in a centralised

position, the switch contacts remain open.

Should there be a loss of pressure in either the

front or rear brak e s ystem, when t he br ak e pedal is

applied, the spool valve will move off centre,

closing the switch contacts and turning on the

warning light on the instrument panel.

After repairs have been made and the brake

system has been bled, the pressure in the front

and rear brake systems will equalise (when the

brakes are applied), centralising the spool and

opening the switch contacts, thus switching off the

brak e fail warni ng li ght.

Figure 5A-8

1.2 LOAD SENSING PROPORTIONING VALVE - PRINCIPLES OF OPERATION

CONSTRUCTION

The loa d sens ing propor tio ning va lve is att ached to

the right hand frame, above the final drive

assembly. The valve torsion spring lever is

attached to the right hand trailing arm rod with a

bracket, cable and hook.

The load sensing proportioning valve senses load

by monitoring the rear suspension ride height, to

regulate the pressure applied to the rear brake

calipers. Maximum line pressure is supplied to the

rear brakes when the vehicle is fully laden, while

lightly loaded conditions provide minimum line

pressure; i.e. line pressure varies in relation to the

weight of the load.

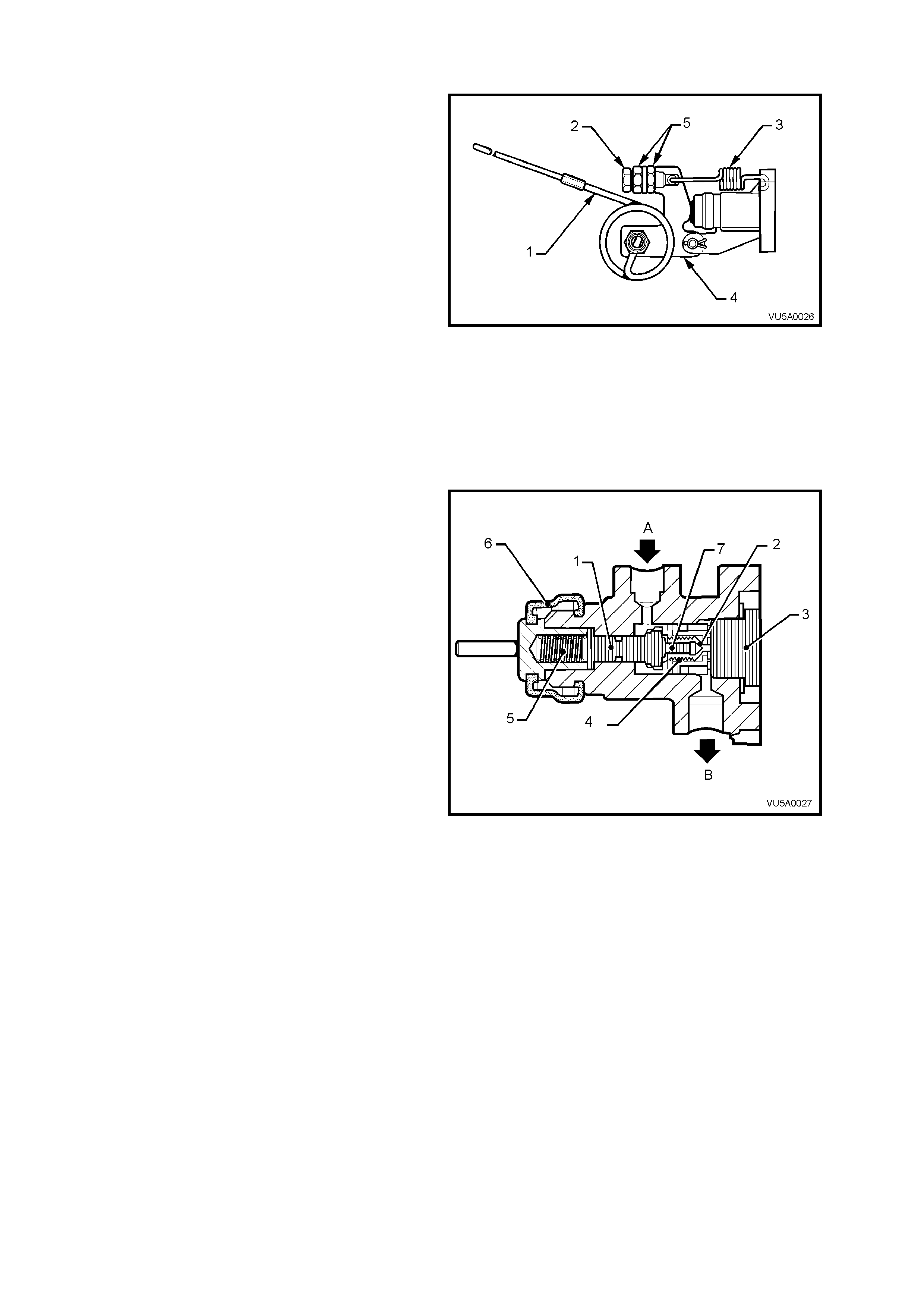

Legend

1. Sensing torsion spring

2. Adjusting screw

3. Static spring

4. Torsion spring lever

5. Adjusting screw lock nuts

Figure 5A-9

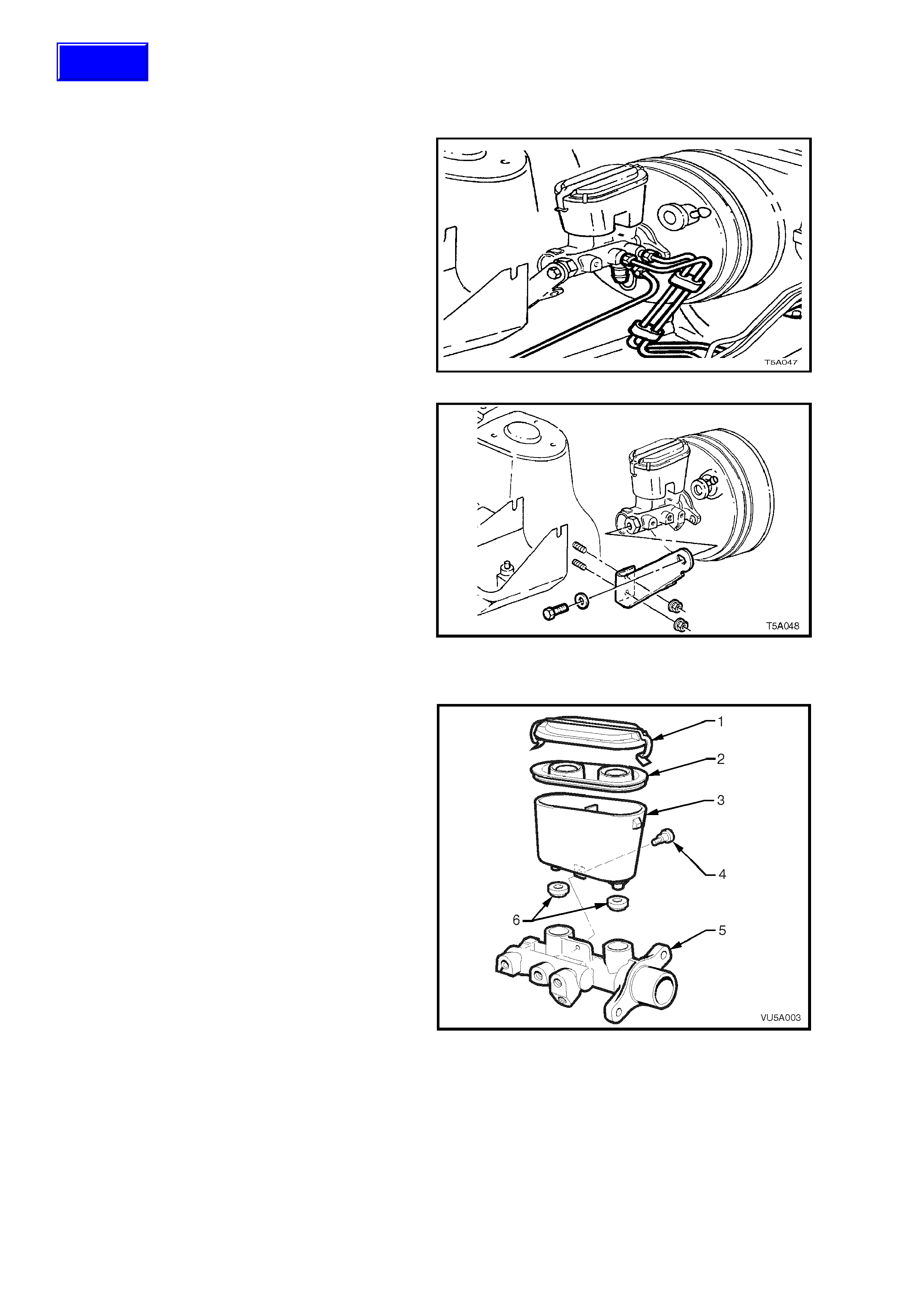

OPERATION

The static spring exerts a force on the end of the

spool by means of a lever, while a torsion type

sensing spring attached to the right-hand trailing

arm rod modifies this applied force, depending on

the axle load.

When the vehicle is unladen or lightly loaded, the

torsion spring has the maximum effect and,

together with the static spring force, the total apply

force on the plunger and piston is lowest. This

apply force is able to position the load sensing

piston to restrict the flow of fluid through the outlet

port to the rear brakes.

However, when the vehicle is loaded, the spool is

positioned so that fluid can flow unrestricted

through the inlet port, through the spool sub-

assem bly, around th e poppet valve and out via th e

spool sub assembly sealing seat and outlet port to

the rear wheel calipers.

When the brake pedal is released, inlet pressure

drops, allowing the higher pressure on the rear

wheel side of the sensing valve to force upon the

poppet valve, such that the brake fluid can flow

almost unrestricted, back to the master cylinder.

Eventually, the spool is forced into its released

position by the external spring set up, to fully open

the passage between the front and rear circuit.

NOTE: The static spring tension is pre-set and

should not be adjusted.

Figure 5A-10

Legend

1. Load sensing valve spool

2. Load sensing valve spool sealing seat

3. Load sensing valve end plug

4. Secondary spring

5. Primary spring

6. Load sensing valve boot

7. Load sensing valve poppet and valve

A. Brake fluid inlet

B. Brake fluid outlet

2. SERVICE OPERATIONS

2.1 MASTER CYLINDER

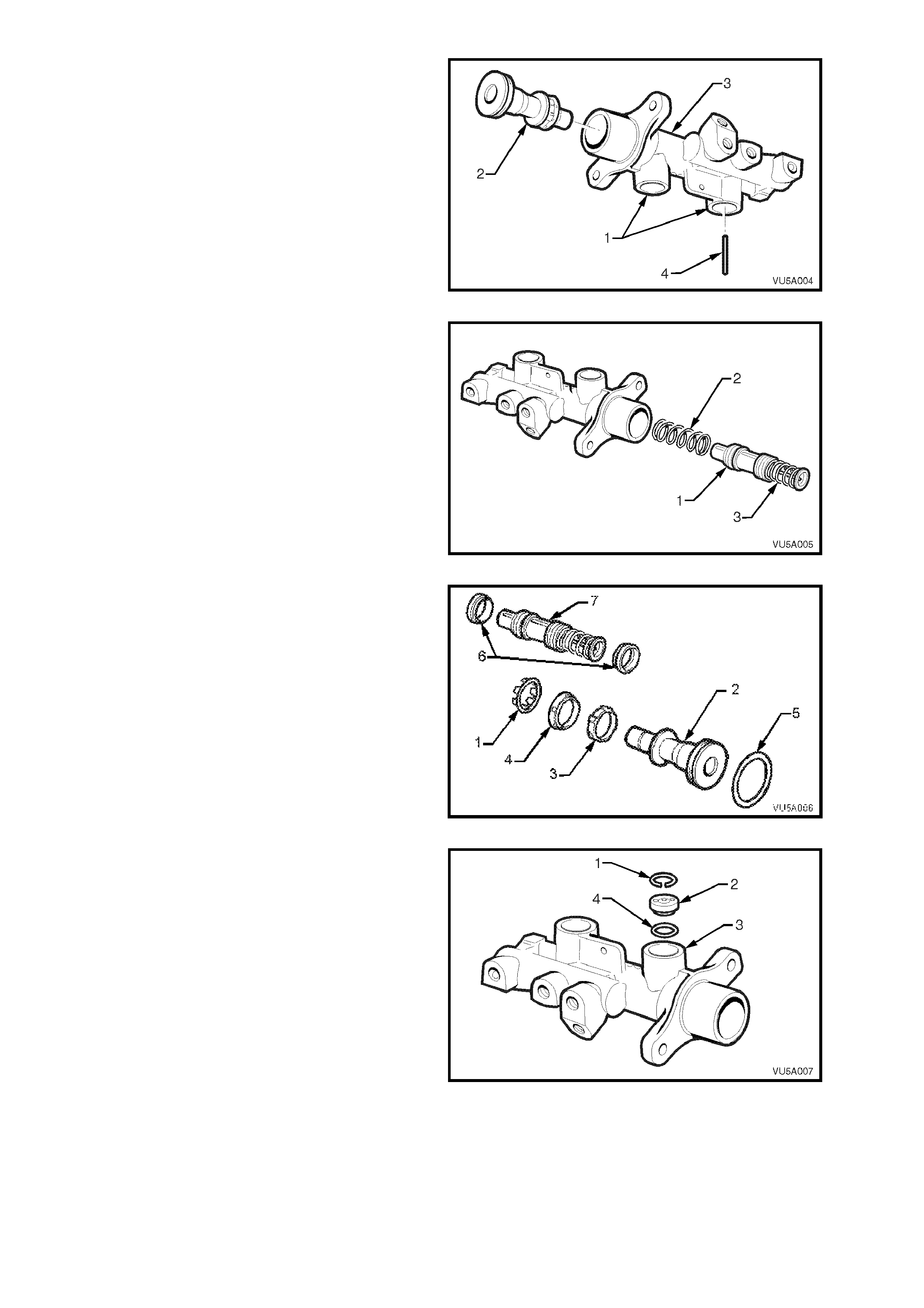

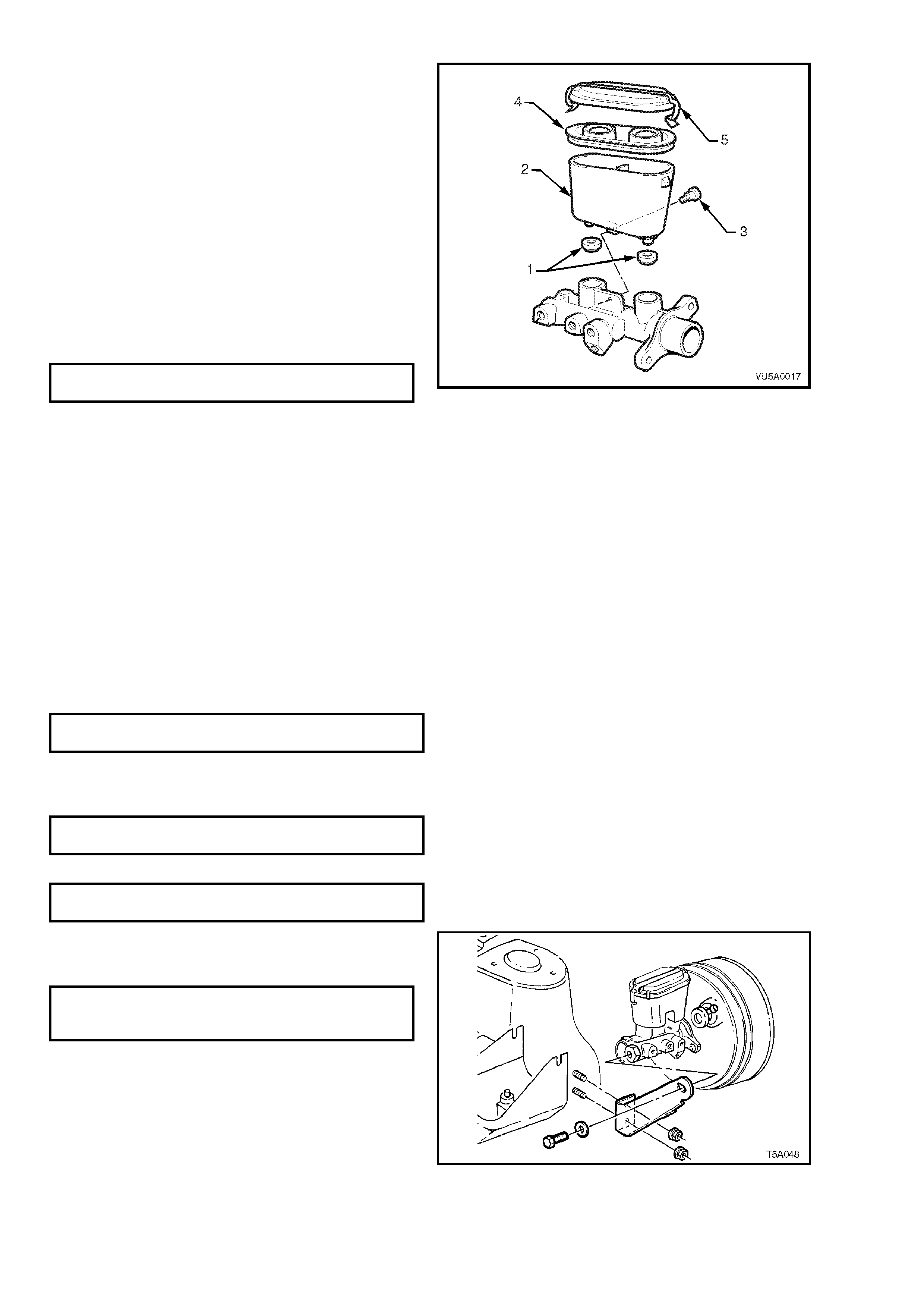

REMOVE

1. Remove master cylinder reservoir cap

temporarily and syphon brake fluid from the

reservoir. Reinstall reservoir cap.

2. Disconnect electrical connector from brake

warning differential switch.

3. Disconnect brake lines from master cylinder

and plug the lines and master cylinder

apertures, to prevent foreign matter entry.

Figure 5A-11

4. Remove bolt and nuts securing the bracket to

master cylinder and front suspension strut

tower, remove bracket.

5. Remove nuts s ecuring master c ylin der t o br ake

booster and remove master cylinder.

NOTE: DO NOT disturb brake booster push rod

and DO NOT depress brake pedal with master

cylinder r em oved or the int ernal r eact ion disc in the

booster may become dislodged.

Figure 5A-12

DISASSEMBLE

1. Clean the outside of the master cylinder.

2. Remove reservoir cap (1) and seal (2). Discard

any fluid left in reservoir (3).

3. Unscrew the reservoir to body retaining screw

(4), located at the base of the reservoir.

4. Separate the plastic reservoir, by hand, from

the body (5).

5. Remove the two reservoir sealing grommets

(6) from the body.

Figure 5A-13

Techline

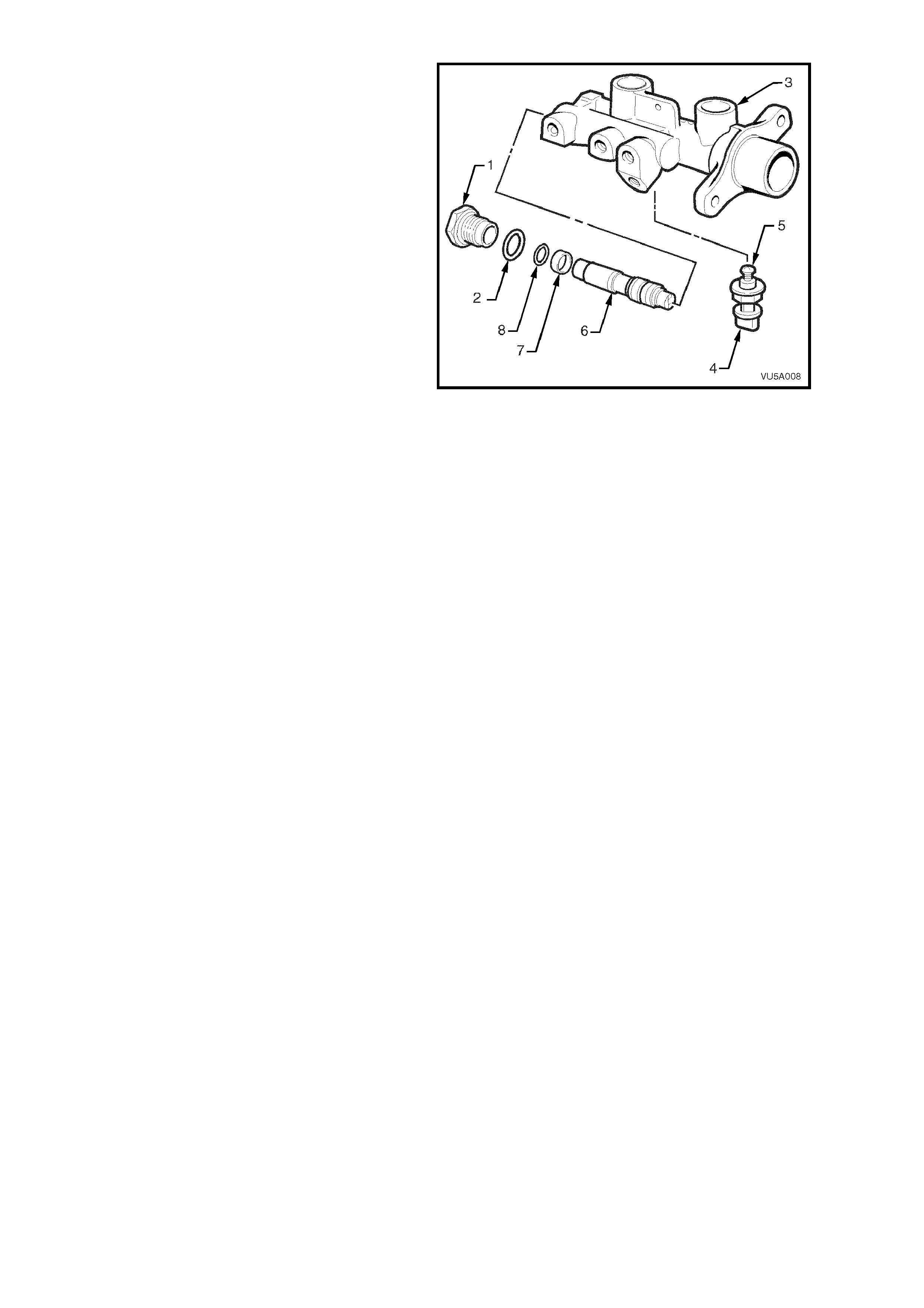

6. Invert master cylinder body so that the

reservoir ports (1) face downwards. Depress

the primary piston (2) with a wood dowel or

brass r od u nti l t he pis t on b ottoms in the bor e of

the master cylinder body (3). The secondary

piston stop pin (4) should fall out freely.

7. Carefully remove primary piston from the main

bore of the master cylinder.

Figure 5A-14

8. Remove s ec ond ar y pis to n (1) and retur n s prin g

(2) by lightly tapping the open end of the

master cylinder b ore squar ely onto a sof t piece

of wood.

NOTE 1: The caged spring (3) of the secondary

piston has been set to a predetermined length. Do

not attempt to adjust or remove the caged spring.

NOTE 2: The centre valve is part of the secondary

piston assembly and is not serviced as a separate

part.

Figure 5A-15

9. Remove the seal retainer (1) from the primary

piston (2) by using a small screwdriver to

caref ull y pry apart the seal retain er legs.

10. Remove the recuperating guide (3) and seal

(4) from the primary piston (2).

11. Remove the rubber 'O' ring (5) from the

primary piston, taking EXTREME CARE not to

damage the piston

12. Remove both rubber seals (6) from the

secondary piston (7), taking EXTREME CARE

not to damage the piston.

Figure 5A-16

13. Using suitable circlip pliers, remove the circlip

(1) retaining the fast fill valve (2) located in the

primary reservoir port of the master cylinder

body (3).

14. Face the master cylinder reservoir ports

downwards to allow the fast fill valve to fall out.

If the valve is stuck, lightly tap the master

cylinder on a piece of wood to assist removal.

15. Remove the valve sealing 'O'-ring (4) from the

bottom of the reservoir port.

Figure 5A-17

16. Unscrew and remove the end plug (1) and 'O'

ring (2) from the master cylinder body (3).

17. Remove the brake fail warning light switch (4)

from the master cylinder, ensuring that the

electrical earthing spring (5) remains on the

switch plunger.

18. Remove the pressure differential spool valve

assembly (6), spool valve sleeve (7) and 'O'

ring (8) by lightly tapping the 'end plug' end of

the cylinder bore squarely onto a soft piece of

wood to dislodge the spool valve assembly.

Important: Do not damage the pressure

differential spool valve assembly by attempting to

pull it out of the bore with pliers.

Figure 5A-18

CLEAN AND INSPECT

NOTE: Ensure work area is clean and f r ee of dus t or other c ontaminants. These can af f ec t the per f ormance of all the

seals in the master cylinder.

1. Wash master cylinder body, reservoir and cap in clean methylated spirits.

2. Wash all internal parts in brake fluid.

3. Check all recesses, openings and passages to ensure they are open and free of foreign matter.

4. Place all parts on a clean surface.

5. Inspect the master cylinder bores for signs of etching, pitting, scoring or rust. If in poor condition, replace the

cylinder.

IMPORTANT:

Do not hone the master cylinder bore.

6. Discard all rubber parts together with the secondary piston assembly (the secondary piston assembly

incorporates the secondary piston, the centre valve and the caged spring). Only new parts from the genuine

service kit should be used to reassemble the master cylinder.

REASSEMBLE

NOTE 1: Before assembly, lubricate internal parts and master cylinder bores with clean, recommended brake fluid

from a sealed container.

NOTE 2: Prior to assembly, ensure that the primary piston, without seals fitted to it, is free to move the full piston

stroke in the large bore.

NOTE 3: The three 'L' type seals must be assembled in the directions and positions shown in Fig. 5A-19.

Figure 5A-19

Legend

1. Reservoir cap

2. Reservoir cap seal

3. Reservoir sealing grommets

4. Secondary piston

5. Return spring

6. Secondary seals (L type)

7. Caged spring

8. Primary seal (L type)

9. Primary piston 'O' ring

10. Primary piston (Sectional

view)

11. Primary piston

12. Fast fill valve 'O' ring

13. Fast fill valve

14. Fast fill valve circlip

15. Reservoir

16. Reservoir cap re taining clip

1. Install ‘O’ ring seal (1) into the groove at the

end of the primary piston (2).

2. Install the recuperating guide (3) followed by

the primary L type seal (4) onto the end of the

primary piston. The sealing face of the L type

seal must face away from the recuperating

guide.

NOTE: The primary L type seal for the primary

piston can be identified by the six shallow grooves

around the seal’s outer surface.

3. Ass em ble the seal re tain er (5) onto the prim ar y

piston. Using a small screwdriver, clip the

retainin g legs of the retai ner into the groov e on

the primary piston. Care should be taken to

avoid damage to the piston or seal.

Figure 5A-20

4. Ass em ble the sm all en d of the ret urn spr ing (1)

over the end of the secondary piston (2). This

should be a slight interference fit.

Figure 5A-21

5. Carefully insert the secondary piston, caged

spring end las t, throug h the large bor e and into

the sm aller bor e of the mas ter c ylinder un til th e

return spring (1) 'bottoms'. Ensure the return

spring does not dislodge from the secondary

piston assembly during this operation.

NOTE: To assemble the secondary piston

assembly into the body, align the slot in the

secondary piston (2) with the hole in the reservoir

ports. This must be done so that the secondary

piston stop pin can be inserted into secondary

reservoir port in the master cylinder.

6. Fully stroke the secondary piston using a soft

dowel and while h eld at the bottom of the bor e,

install the sec on dary pisto n s top pi n (3) in to th e

secondary reservoir port (4). The piston stop

pin should easily fit through the larger hole of

the two holes located in the secondary

reservoir port. The top of the secondar y piston

stop pin should not protrude more than 6 mm

above the bottom of the reservoir port.

Figure 5A-22

7. Inser t the pr im ary pist on (1) into the m ain bore,

against t he secondar y piston a nd caged spr ing

assembly. Carefully push both pistons down

the bore until the primary piston is flush with

the bore opening.

8. Stroke pistons and check that the primary

piston re turns to the end of the bore after eac h

stroke. Ensure movement is not sticky.

Figure 5A-23

9. Fit new O-rings (1) onto the pressure

differential spool valve (2).

10. Ensure spac er (3) and O-ring ( 4) are f itted over

the spool valve and that they are installed the

right way (spacer first followed by the O-ring).

11. Inser t spool val ve into the b or e, c app ed e nd (5)

first. Extreme care should be taken when

inserting the spool valve to ensure that the O-

rings are not damaged. If O-rings are

damaged, the master cylinder will not function

correctly and will leak brake fluid. The spool

valve assembly must be bottomed in the bore

of the master cylinder.

12. Assemble a new O-ring (6) onto the end plug

(7), and screw the end plug into the master

cylinder body.

END PLUG 25 - 30

TORQUE SPECIFICATION Nm

Figure 5A-24

13. Reinstall differential switch (1) and spring (2).

Do not over tighten.

NOTE: Ensure the earthing spring on the

differential switch is installed on the plunger as

shown. If necessary, the small end of the spring

may need to be closed down slightly to give the

required attachment.

DIFFERENTIAL SWITCH 2

TORQUE SPECIFICATION Nm

Figure 5A-25

14. Carefully install the fast fill valve O-ring (1) in

the bottom shoulder of the primary reservoir

port (2).

15. Fit the fast fill valve (3) into the primary

reservoir port, ensuring the rubber base with

six dimples is faced downwards. Secure valve

with circlip (4).

Figure 5A-26

16. Lightly smear the bores of the reservoir ports

and sealing grom mets with clean brake fluid.

17. Carefully assemble sealing grommets (1) into

the bores of the reservoir ports to locate them

against the shoulder in each bore.

18. Reins tall res ervoir (2 ) by pus hing reser voir into

the sealing grommets until the hole for the

retaining screw in the reservoir aligns with the

m aster cylinder bo d y. Ins ta l l re ta in in g s cr ew ( 3)

and tighten to the specified torque. The

retaining screw should just protrude from the

hole in the master cylinder body when

tightened.

NOTE: Both reservoir and master cylinder holes

must be aligned when installing the reservoir

retaining screw to avoid cross threading.

RESERVOIR SCREW 4.0 - 5.0

TORQUE SPECIFICATION Nm

19. Fill the master cylinder with fresh,

recommended brake fluid and bleed on the

bench prior to installation to the vehicle. After

bleeding, block master cylinder outlet ports to

prevent fluid escaping.

20. Assemble new reservoir seal (4) into reservoir

cap (5). Lubricate inside of the reservoir lips

with clean brake fluid to accept the reservoir

cap seal.

21. Install cap seal and cap.

Figure 5A-27

REINSTALL

1. Install master cylinder assembly on brake

booster, tak ing care not to disturb brak e booster

push rod. Tighten master cylinder nuts to

specified torque.

MASTER CYLINDER ATTACHING 15 - 20

NUT TORQUE SPECIFICATION Nm

2. Install bracket securing master cylinder to

adjacent spring tower. Tighten nuts and bolt to

specified torque.

MASTER CYLINDER TO BRACKET 6 - 11

BOLT TORQUE SPECIFICATION Nm

MASTER CYLINDER BRACKET 6 - 11

NUT TORQUE SPECIFICATION Nm

3. Unplug brake lines and master cylinder outlet

ports, install pipes to master cylinder and

tighten to specified torque.

BRAKE PIPE TO MASTER

CYLINDER FLARED NUT 8 - 11 Nm

TORQUE SPECIFICATION

4. Reconnect electrical connector to differential

switch.

5. Bleed brake system, refer to

Section 5 A BR AK ES of the VT Series Service

Information.

Figure 5A-28

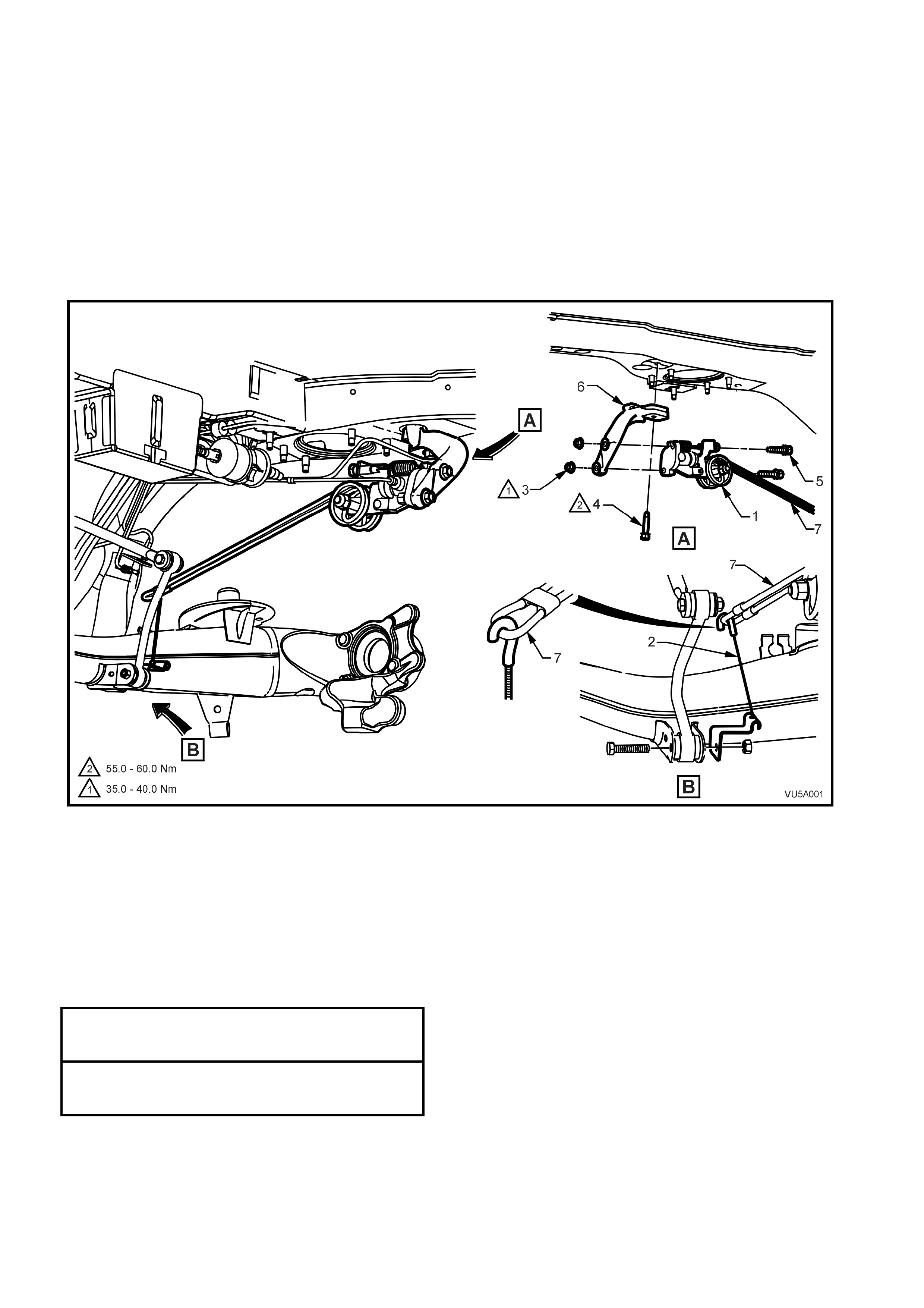

2.2 LOAD SENSING PROPORTIONING VALVE

REMOVE

1. Raise the rear wheels and place the vehicle on suitable safety stands.

2. Disconnect the brake lines from the load sensing proportioning valve. Seal the openings and lines with suitable

plugs.

3. Unhook the load sensing proportioning valve connector cable from the load-sensing arm by moving the arm

downward to relieve the tension. Slowly release the arm.

NOTE: T he arm ma y sprin g up slight ly when the hook is

released.

4. Support the loa d sensing proporti oning valve, then r emove the nuts f rom the two retaining b olts and rem ove the

bolts removing the valve assembly.

Figure 5A-29

Legend

1. Load sensing proportioning

valve

2. Connector cable assembly

3. Nut (2 places)

4. Mounting bracket bolt

5. Bolt (2 places)

6. Mounting bracket

7. Load sensing arm

REINSTALL

The installation procedure is the reverse of the removal procedure, noting the following:

1. Position valve on bracket, then install and secure the two bolts. Tighten the bolts or nuts to the correct torque

specification.

LOAD SENSING VALVE

MOUNTING NUT 35 - 40 Nm

TORQUE SPECIFICATION

LOAD SENSING VALVE

MOUNTING BRACKET BOLT 55 - 60 Nm

TORQUE SPECIFICATION

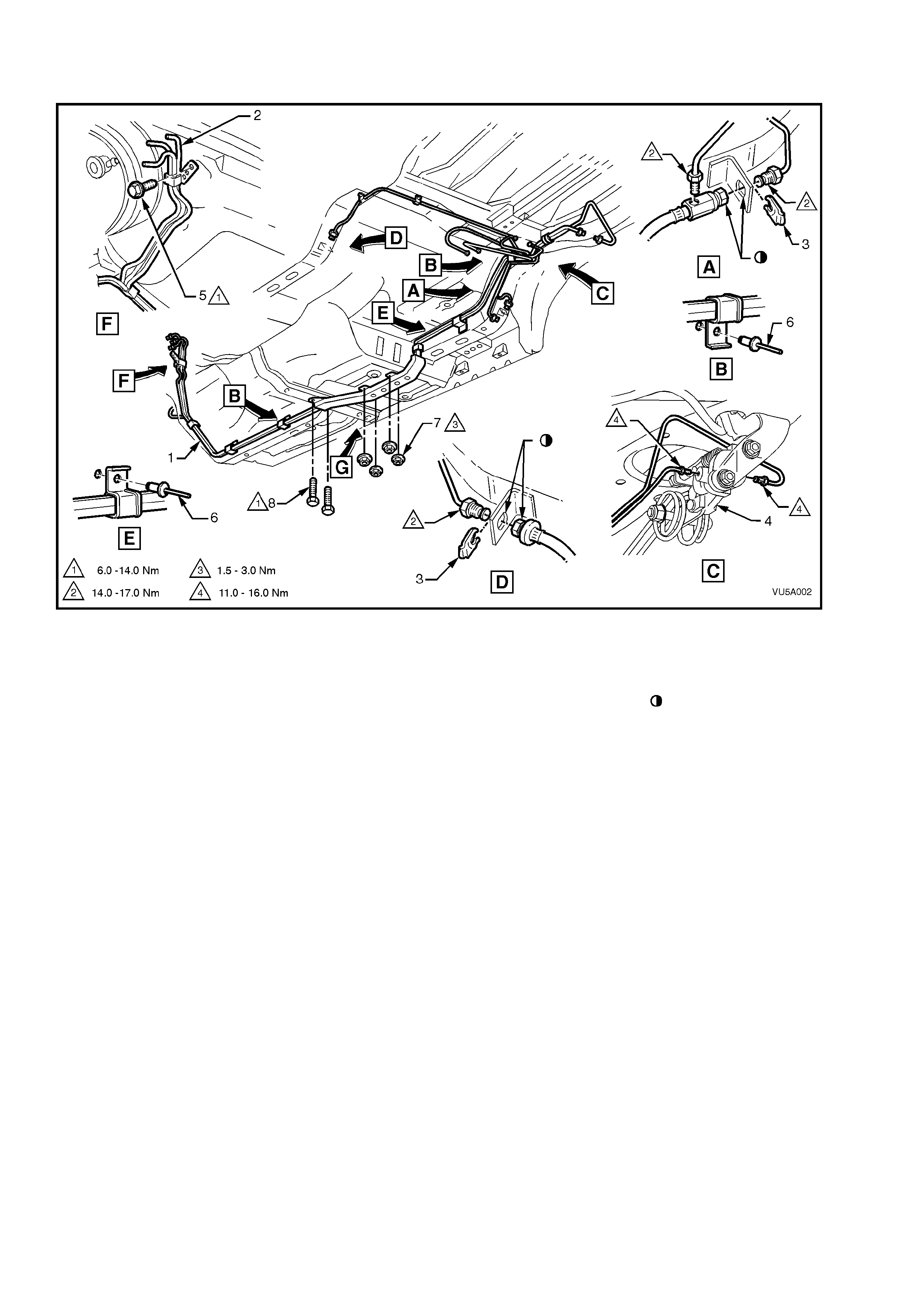

2. Ensure all pipes are secured and routed correctly, refer to Fig. 5A-30.

3. Bleed the brake system refer Section 5A STANDARD BRAKES of the VT Series Service Information.

NOTE 1: T he load se nsing propor tioning valve se tting is

preset and should not be adjusted.

NOTE 2: The c able hook mus t be connec ted to the t or sion s pring l ever in th e corr ect orien tat ion, ref er Vie w B in F ig.

5A-29.

Figure 5A-30

Legend

1. Brake and fuel line harne ss

2. Fuel feed and return line

3. Brake hose clip

4. Load sensing proportioning valve

5. Brake pipe clamp to dash panel

bolt

6. Rivet (5 places)

7. Nut (4 places)

8. Screw (2 places)

Flats aligned on hose

and bracket

3. TORQUE WRENCH SPECIFICATIONS

Nm

Master Cylinder End Plug..................................................... 25 - 30

Master cylinder attaching nuts................................................. 15 - 20

Differential Switch.................................................................... 2

Master Cylinder Reservoir Retaining Screw............................ 4 - 5

Master Cylinder Bracket Retaining Nut ................................... 6 - 11

Master Cylinder Bracket To Master Cylinder Bolt ................... 6 - 11

Brake Pipe To Master Cylinder Flared Nut.............................. 8 - 11

Load Sensing Proportioning Valve Mounting Nut.................... 35 - 40

Load Sensing Proportioning Valve Mounting Bracket Bolt...... 3 5 - 60

Brake Pipe To Load Sensing Proportioning Valve.................. 11 - 16

Rear Brake Pipes To Flexible Hose ........................................ 14 - 17

Front Brake Pipe Clamp To Dash Panel Bolt.......................... 6 - 14

Lower Brake Pipe Shield To Floor Bolt ................................... 6 - 14

Lower Brake Pipe Shield To Floor Nut.................................... 1.5 - 3