SECTION 12C - INSTRUMENTS, WIPERS/

WASHERS & HORN

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

Instrumentation for VX Series Models carries over from VT Series II Models noting the following:

• The instrument cluster now features a coloured instrumentation background (coloured keyed to the interior trim) on

SS models.

• Electronic T raction Control (ET C) is available on VX Series models with manual tr ansm iss ion. In this situation, the

traction control switch (TRAC CTRL) is mounted in the instrument panel on the lower right-hand side.

For all service information relating to the instrument panel mounted traction control switch, refer to

Section 12L ANTI-LOCK BRAKING & ELECTRONIC TRACTION CONTROL in this service information. The

traction control switch continues to be fitted on the console adj acent to the trans m ission s elector f or vehicles fitted

with an automatic transmission.

For inform ation relating to the ser vice pr ocedures and specif ications for the ins trum ents as f itted to VX Series Models ,

refer to Section 12C INSTRUMENTS, WIPERS/WASHERS AND HORN in the VT Series II Service Information, in

conjunction with Section 12C INSTRUMENTS, WIPERS/WASHERS AND HORN in the VT Series I Service

Information.

The wipers/washers as fitted to VX Series Models carry over from VT Series I Models, noting the following:

• A new front wiper motor and linkage assembly w as introduced as a running change to all VX Series Models.

• A new rear wiper motor and rear wiper arm were introduced as a running change to all VX Series Wagon Models.

For information relating to the wipers/washers as fitted to VX Series Models not covered in this Section, refer to

Section 12C INSTRUMENTS, WIPERS/WASHERS AND HORN in the VT Series I Service Information.

NOTE: Information has been provided in this Section to assist the technician in identifying which type of front or rear

wiper components have been used on a particular vehicle. For details regarding the actual timing for the above

changes, refer to the appropriate area in the Holden spare parts information.

The horn c omponents as f itted to VX Ser ies Models c arr y over from VT Ser ies I Models . For infor mation relating to the

horn components as fitted to VX Series Models, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS AND

HORN in the VT Series I Service Information.

Techline

Techline

Techline

Techline

1.1 WIPERS AND WASHERS

FRONT WIPER MOTOR AND LINKAGE

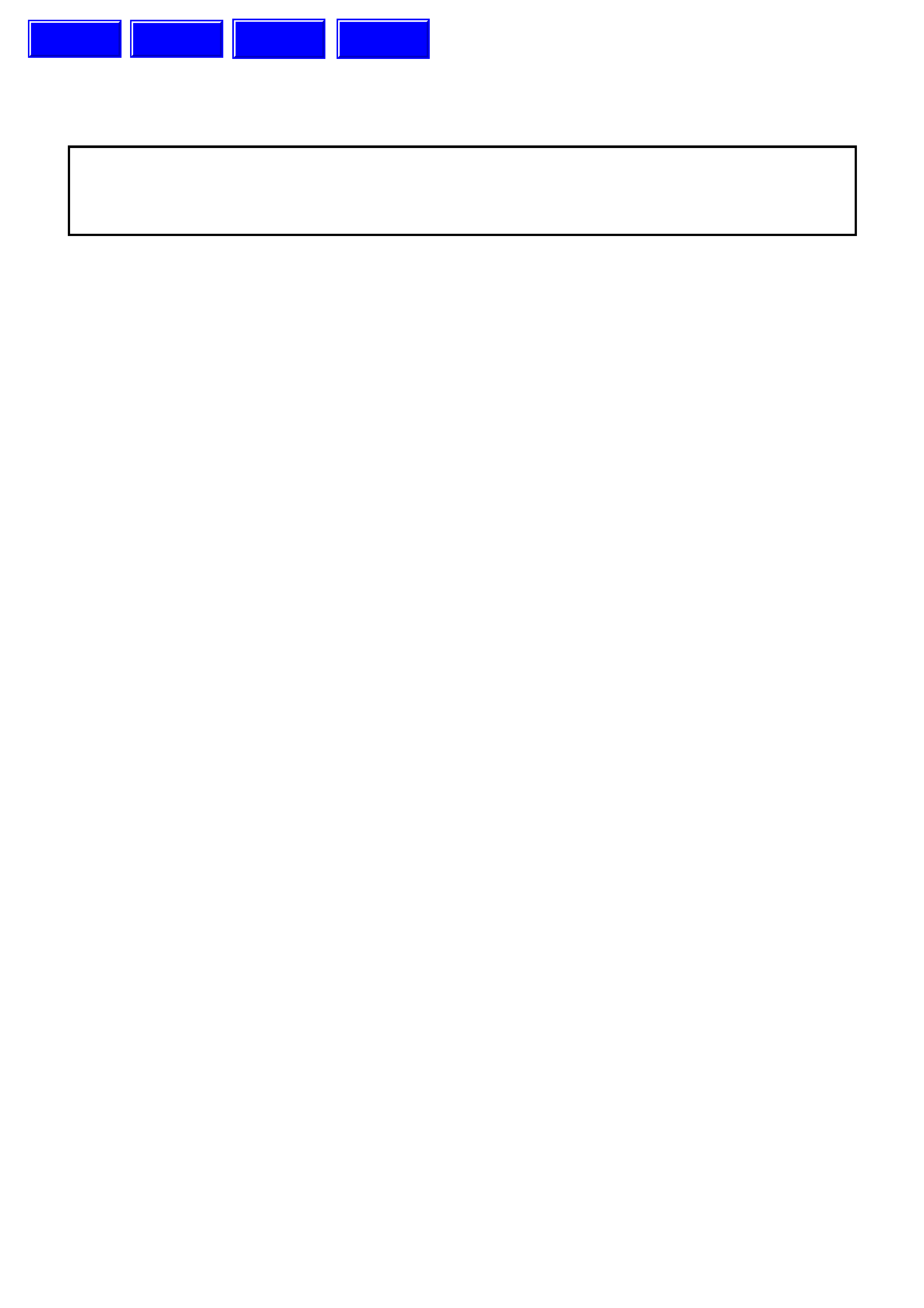

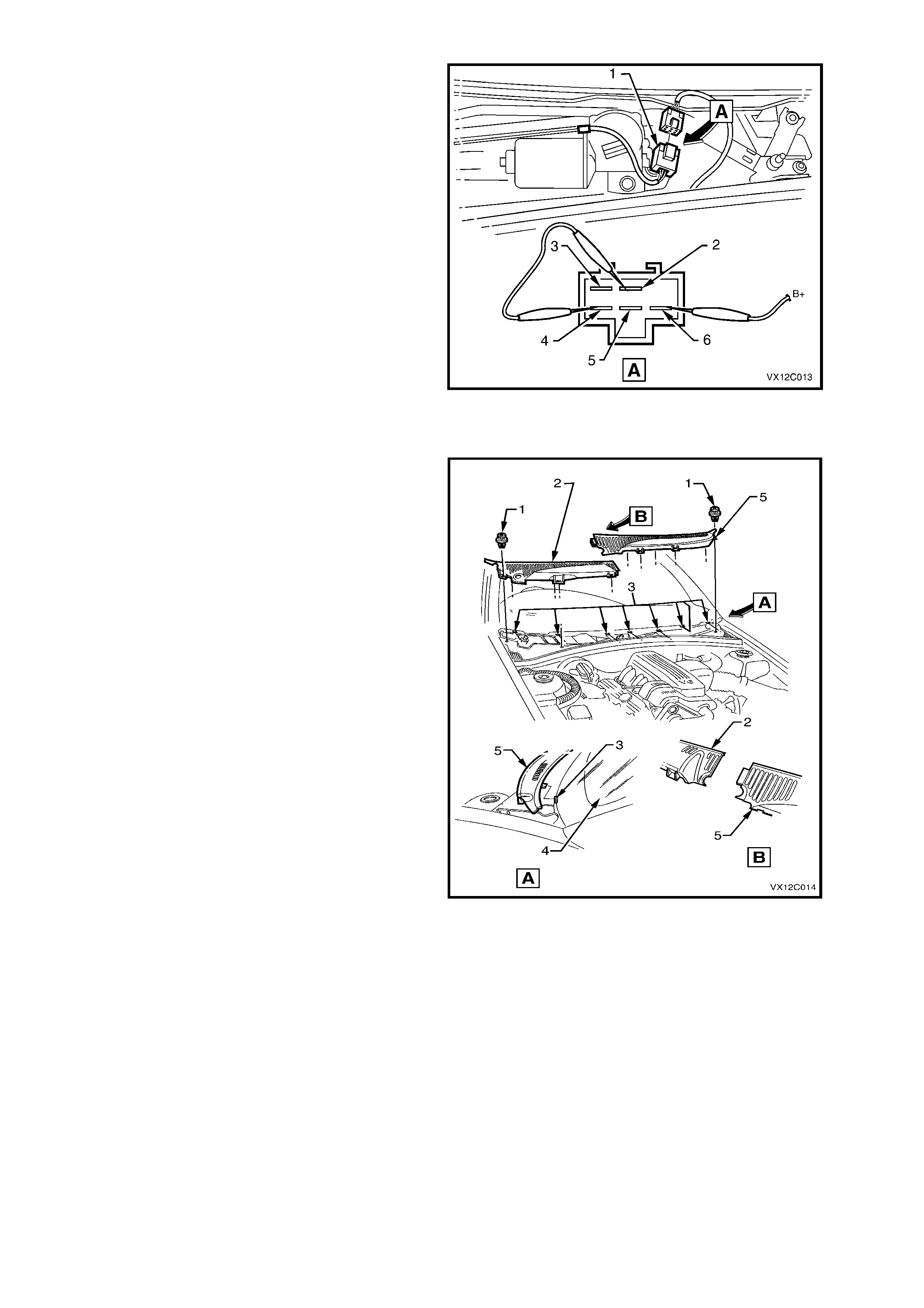

Two fr ont wiper motor and linkage ass emblies have

been used in VX Series Models. One was

manufactured by Preslite (early type) while the

other was manufactured by Trico (late type).

The early type f ront wiper motor and linkage can be

identified by the clamp type attachment of the

motor to the linkage (1) and the position of the

wiper motor harness connector (2).

For all information relating to the early type front

wiper motor and linkage, refer to

Section 12C INSTRUMENTS, WIPERS/

WASHERS AND HORN in the VT Series I Service

Information.

Figure 12C-1

The later type front wiper m otor and linkage c an be

identified by the three bolts (1) attaching the wiper

motor to a bracket (2) spot welded to the wiper

linkage and the pos ition of the wiper m otor harness

connector (3).

This Section provides all the relevent information

relating to the later type front wiper motor and

linkage.

Figure 12C-2

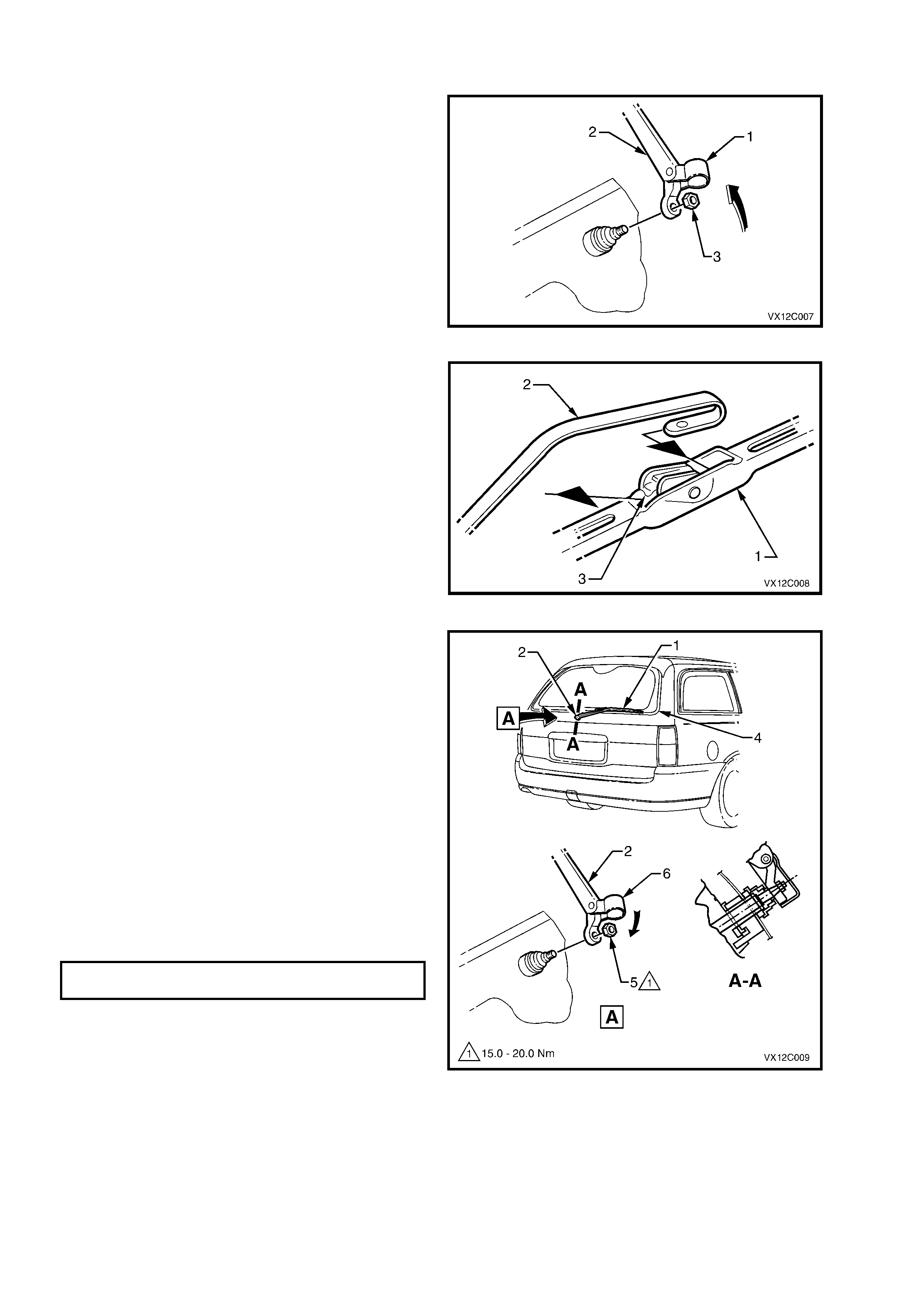

REAR WIPER MOTOR

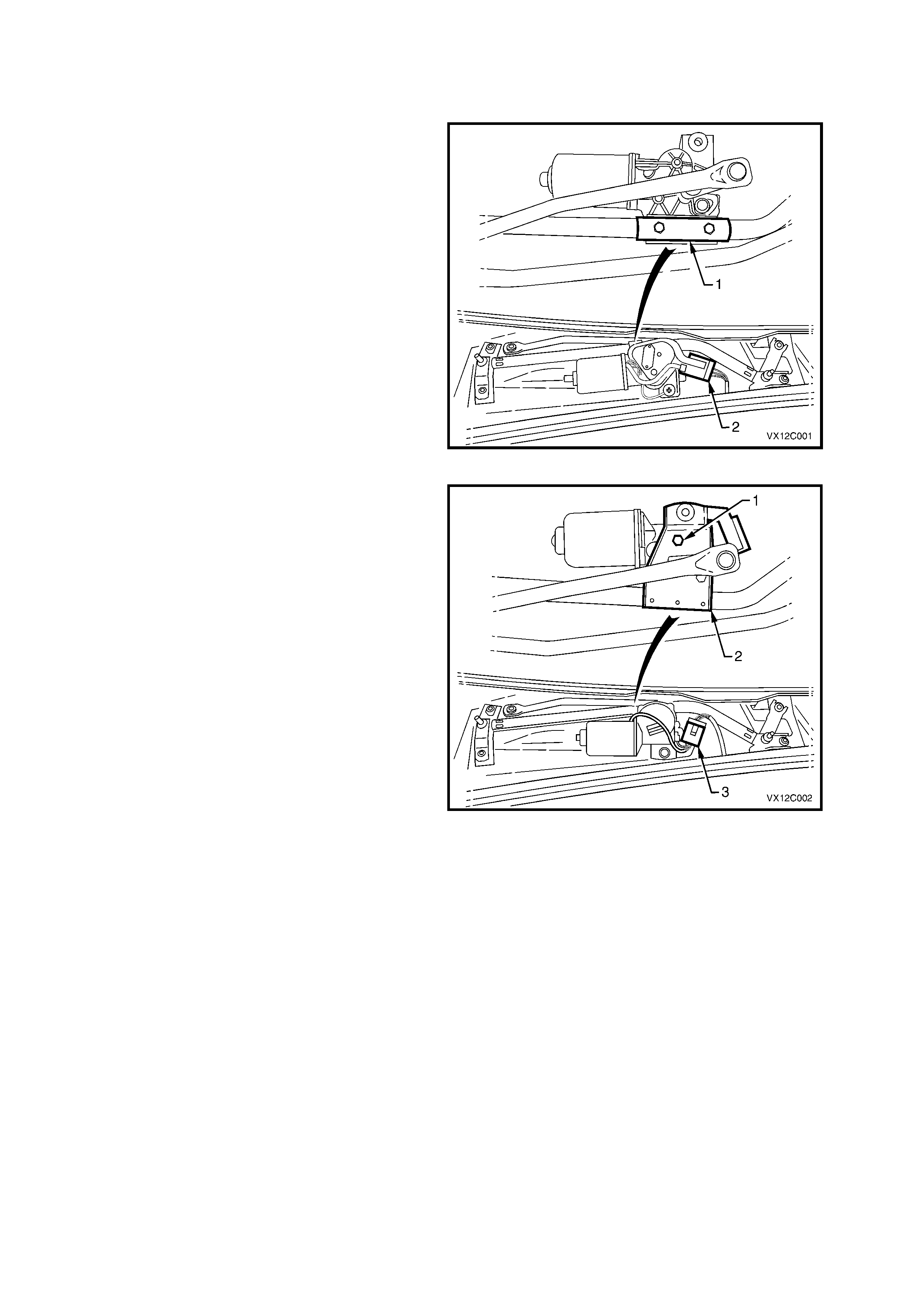

There has been three rear wiper m otor assemblies

used in VX Series Wagon Models. One was

manufactured by Preslite (early type) while the

other two were manufactured by Trico (interim and

late type).

The early type rear wiper motor can be identified by

the size of the nut (1) attaching the rear wiper arm

(2) to the r ear wiper motor shaf t (3). The early type

uses an 11 m m nut, while the interim and late type

use a 13 mm nut for the rear wiper arm to motor

attachment. To inspect the nut, lift the rear wiper

arm pivot trim cap (4).

NOTE: T he early type rear wiper motor can also be

identified by the location of the hole in the tailgate

for the wiper motor shaft. For the early type motor,

the hole in the tailgate is aligned with the centreline

of the vehicle. For the interim and late type rear

wiper motor, the hole in the tailgate is offset

approximately 50 mm towards the passenger side

from the vehicle centre line.

For all information relating to the early

type rear wiper motor, refer to

Section 12C INSTRUMENTS, WIPERS/

WASHERS AND HORN in the VT Series I Service

Information.

Figure 12C-3

If the vehicle uses a 13mm nut for the rear wiper

arm to motor attachment, to identify whether the

vehicle is fitted with the interim or late type rear

wiper, first remove the tailgate interior trim panel,

refer to Section 1A4 REAR COMPARTMENT LID

& TAILGATE in the VT Series I Service

Information.

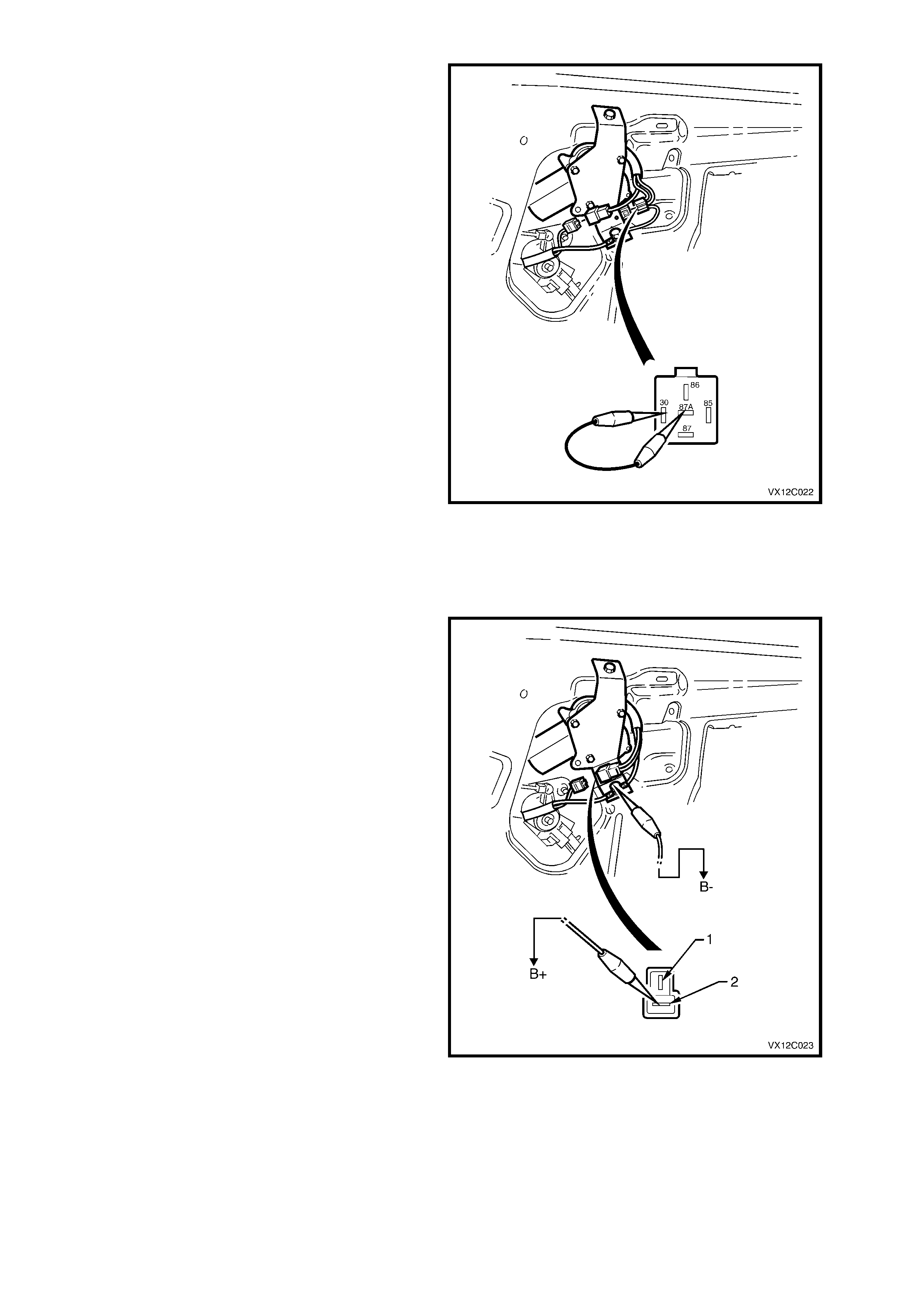

If the rear wiper motor has an external relay (1)

rivetted to the mounting bracket, it is an interim

type (2). If the rear wiper motor is not fitted with an

external relay, it is the late type (3).

This Section provides all the relevent information

relating to the interim and late type rear wiper motor

and linkage.

Figure 12C-4

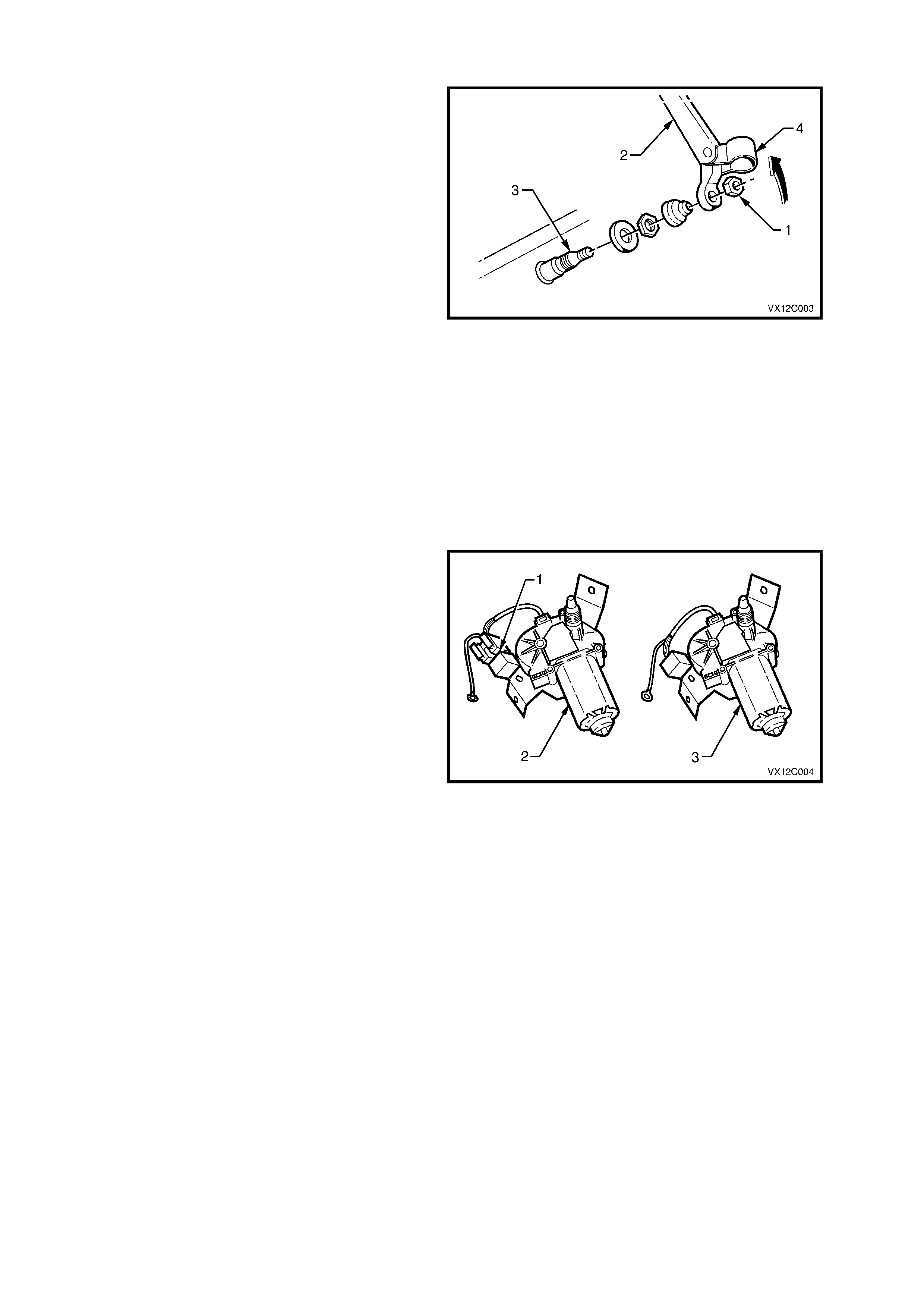

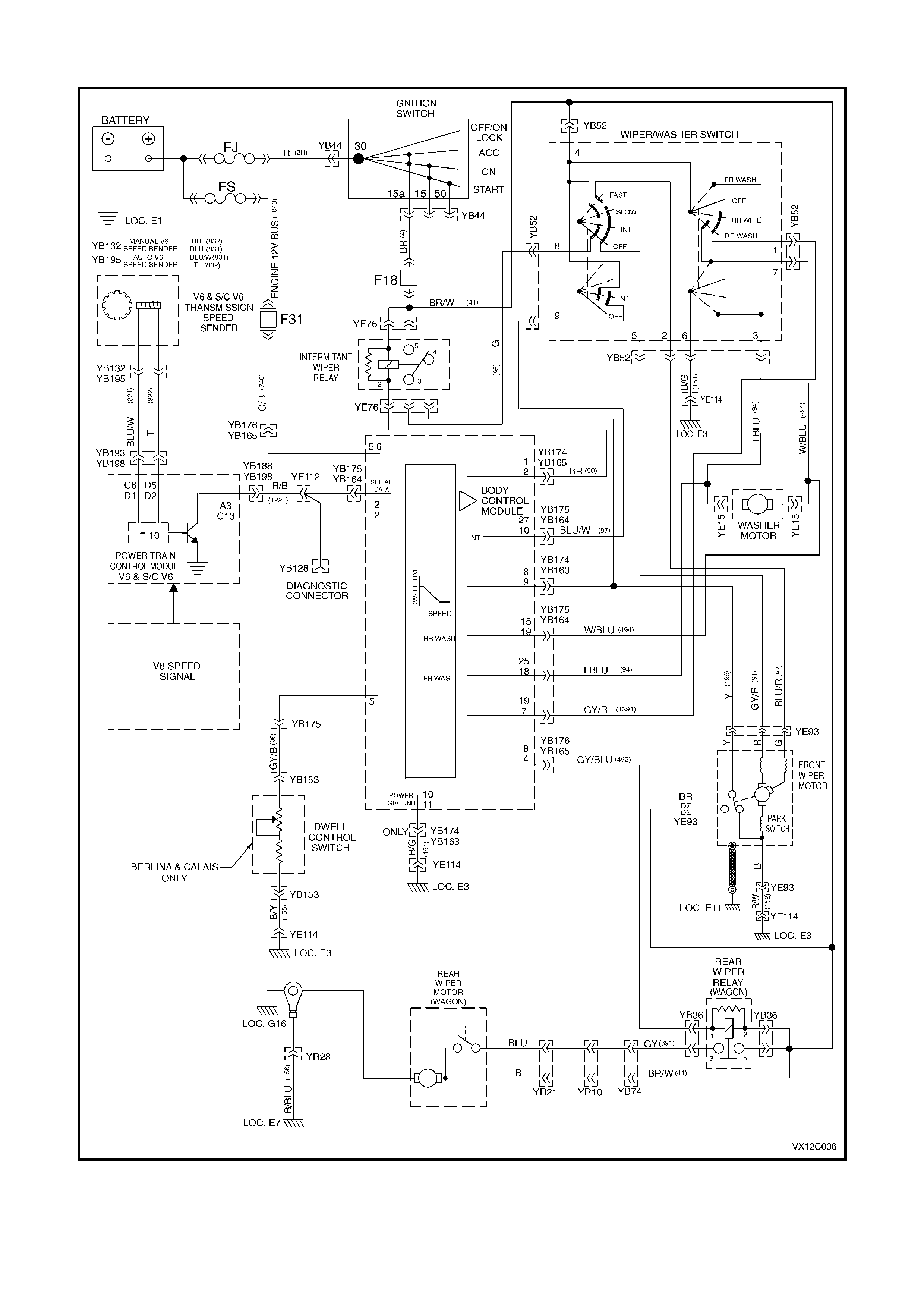

CIRCUIT DIAGRAMS

Figure 12C-5 shows the circuit for the wiper/washer system f or vehicles with the late type (Trico) front wiper motor

and linkage assembly and interim type rear wiper motor. Figure 12C-6 shows the circuit for the wiper/washer

system for vehicles with the late type (Trico) front wiper motor and linkage assembly and late type rear wiper motor.

INTERIM TYPE REAR WIPER MOTOR

Figure 12C-5

LATE TYPE REAR WIPER MOTOR

Figure 12C-6

2. WIPERS AND WASHERS SERVICE OPERATIONS

2.1 FRONT WIPER ARM

The front wiper arm s as fitted to VX Series Models carry over from VT Series I Models. For inform ation relating to

the f ront wiper arm as fitted to VX Series Models, r ef er to Sectio n 12C INSTRUM ENTS, WIPERS/W ASHERS AND

HORN in the VT Series I Service Information.

Techline

2.2 REAR WIPER ARM

REMOVE

1. Lift up trim cap (1) from wiper motor drive

spindle end of wiper arm (2).

2. Remove wiper arm to drive spindle securing

nut (3) and remove wiper arm.

Figure 12C-7

3. If required, remove wiper blade (1) from the

arm (2) by lifting up the retainer (3) on the

wiper blade and pulling blade from arm.

Figure 12C-8

REINSTALL

1. If rem oved, slide wiper blade (1) into wiper arm

(2) until the wiper blade retainer locks into

position.

2. Ensure the wiper motor is in the PARKED

position.

3. Reinstall wiper arm assembly onto drive

spindle (3) so that the wiper blade rests on the

glass moulding (4).

NOTE: To ensure arm will not wipe over moulding

in the park position, push arm onto wiper spindle

with the arm in the vertical position and then rotate

wiper arm clockwise until blade rests on glass

moulding.

4. Reinstall the nut (5) securing the wiper arm to

the drive spindle and tighten to the correct

torque specification.

REAR WIPER ARM NUT

TORQUE SPECIFICATION 15 – 20 Nm

5. Push trim cap (6) onto wiper arm.

Figure 12C-9

2.3 FRONT AND REAR WIPER BLADES/INSERTS

The fr ont and rear wiper blades and ins erts c arry over from VT Series I Models. For information r elating to the front

and rear wiper blades as fitted to VX Series Models, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS

AND HORN in the VT Series I Service Information.

2.4 FRONT WIPER MOTOR AND LINKAGE

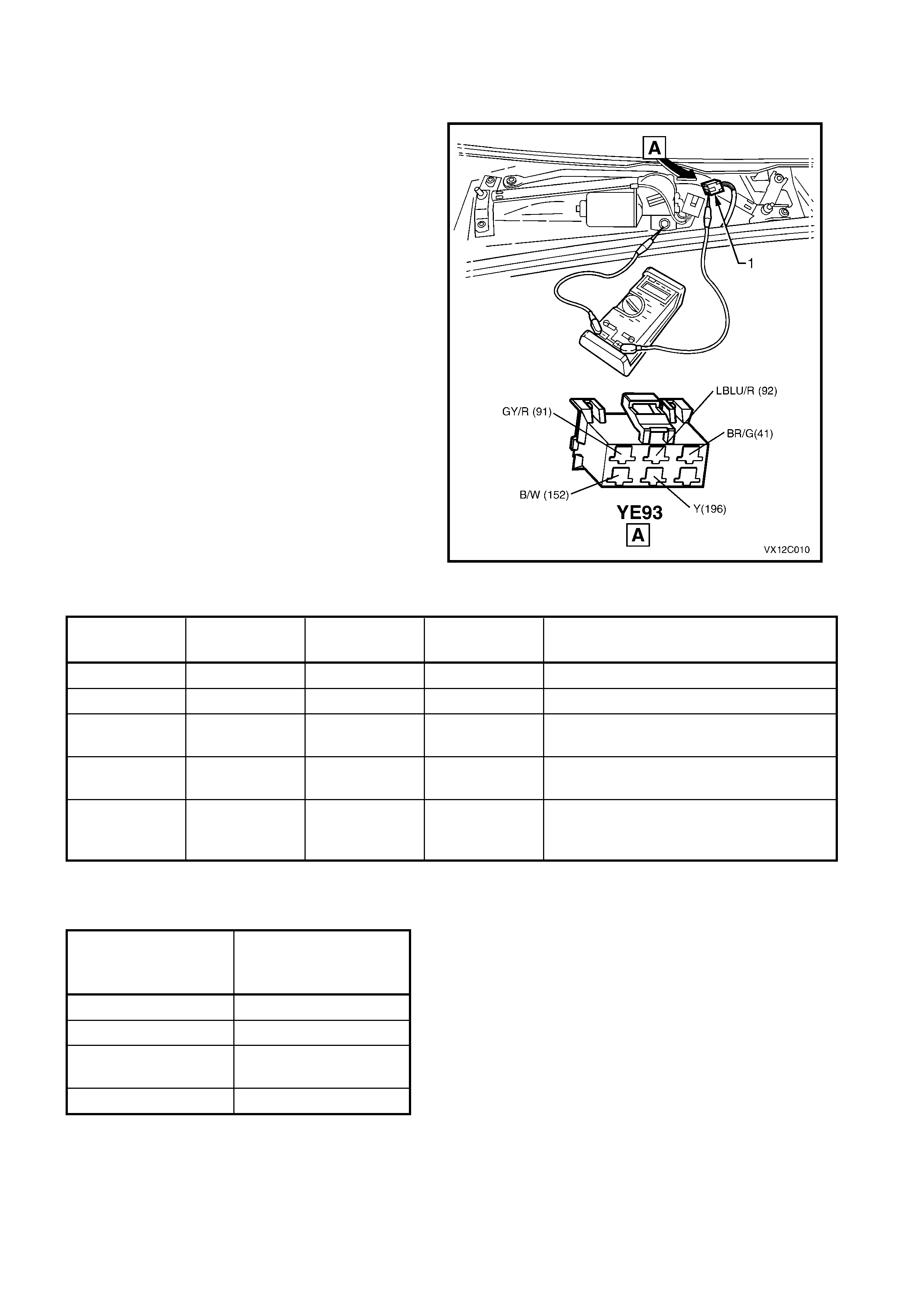

CHECKING WIPER MOTOR WIRING

The following operation checks the wiper motor

wiring at the wiper motor connec tor YE93 (1) as an

aid to diagnosing a fault in the wiper motor system.

NOTE: On vehicles with a High Series BCM,

operation of the intermediate dwell control can be

checked with TECH 2, refer Section 12J-2 HIGH

SERIES BCM in the VT Series I Service

Information.

1. Remove wiper arms, plenum covers, water

deflector and disconnect wiring harness

connector YE93, refer to Steps 1 - 6 in the

following wiper motor removal procedure.

2. Us ing a multimeter connec ted with the negative

lead to the black wire terminal of the wiring

harness connector and the positive lead to the

main wiring harness connector wire terminal

nominated in the following chart, check wiper

motor wiring as follows:

Figure 12C-10

WIRE

COLOUR CIRCUIT No. CIRCUIT MULTIMETER

SETTING RESULT IF WIPER MOTOR WIRING

IS OK

Black/White 152 Earth Resistance 0 ohms (approximately).

Brown/Green 41 Power source Voltage B+ with ignition in ACC or ON position.

Grey/Red 91 Low speed Voltage B+ with ignition in ACC or ON position

and wiper switch in low speed position.

LBlue/Red 92 High speed Voltage B+ with ignition in ACC or ON position

and wiper switch in high speed position.

Grey/Red 91 INT Position Voltage B+ cycling with ignition in ACC or ON

position and wiper switch in INT

position.

3. With wiring harness connector YE93 disconnected, check for continuity between the Yellow wire, circuit 196 and

the Grey/Red wire, circuit 91, as per the following table:

SWITCH POSITION RESULT IF WIPER

MOTOR WIRING IS

OK

OFF Continuity

INTERMITTENT Continuity

LOW Continuity (low

resistance)

HIGH Open circuit

NOTE: If any of the readings are not as specified, check and repair faulty circuit as necessary.

CHECKING WIPER MOTOR OPERATION

The following operation checks the various

functions of the wiper motor. If there is a fault

in the wiper system, and the following operation

proves that the wiper motor is OK, check

|the wiper/washer switch or wiring as described

in this Section, or check the BCM control,

depending on model variant, refer to

either Section 12J-1 LOW SERIES BCM or

Section 12J-2 HIGH SERIES BCM in the VT

Series I Service Information.

If the following operation proves that the wiper

motor is faulty, replace the wiper motor assembly.

1. Remove wiper arms, plenum covers, water

deflector and disconnect wiring harness

connector (1), refer to Steps 1 - 6 in the

following wiper motor removal procedure.

2. Connect a lead from vehicle battery positive

terminal to the Red wire of the wiper motor

connector. The wiper motor should operate on

low speed.

3. Connect a lead from vehicle battery positive

terminal to the Green wire of the wiper motor

connector. The wiper motor should operate on

high speed.

Figure 12C-11

4. To check wiper motor PARK operation,

connect a jumper lead from vehicle positive to

Red wire of motor connector (1) and allow

motor to turn linkages approximately 1/4 of a

turn past the PARK position.

To check if the wiper motor is off the parked

position, connect a test lamp between battery

positive and the Yellow wire of the wiper motor

connector. The lamp should NOT illuminate. If

the lamp does illuminate, contacts within the

wiper motor are faulty or check for Yellow wire

shorted to earth.

Figure 12C-12

Using a second jumper wire, connect the Red

and Yellow wires of the wiper motor connector

together.

Using jumper leads from battery positive,

connect to Brown wire of wiper motor

connector and the wiper motor should turn the

wiper linkages to the PARK position and stop. If

the wiper motor does not turn the linkages or

the linkages do not stop at the PARK position,

the contacts within the wiper motor are faulty

and therefore, the wiper motor must be

replaced.

5. Reconnect wiring harness connector (1) to

wiper motor.

6. Reinstall water deflector, plenum chamber

covers and wiper arm assemblies, refer to the

following removal and reinstallation procedure

of the wiper motor in this Section.

Figure 12C-13

REMOVE

1. Remove wiper arms, refer to

Section 12C INSTRUMENTS, WIPERS/

WASHERS AND HORN in the VT Series I

Service Information.

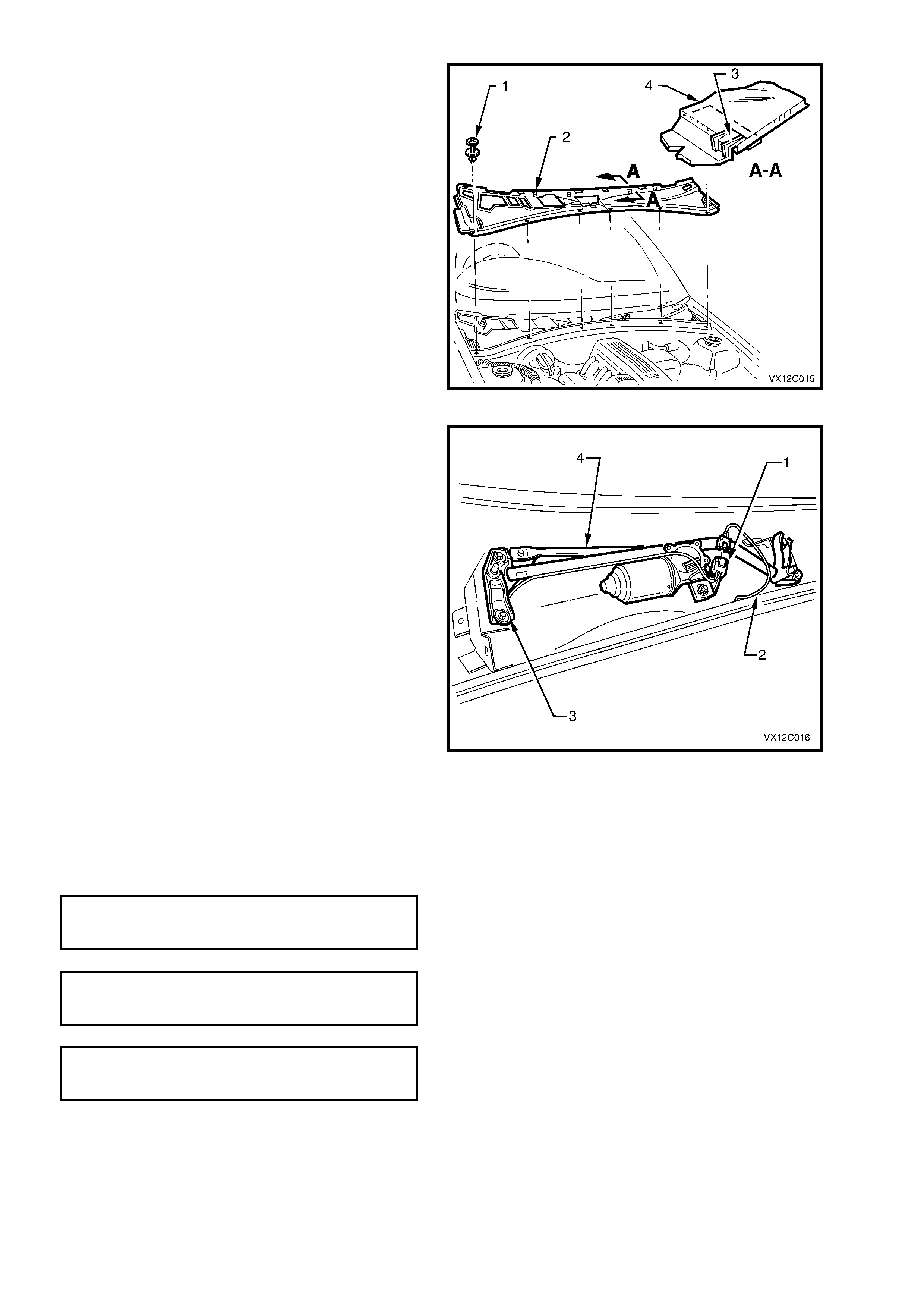

2. Remove the six fasteners (1) securing the

plenum chamber covers to the plenum

chamber.

3. Pull the right-hand plenum chamber cover (2)

forward to release the three retaining tabs (3)

securing it to the winds creen (4), then lift c over

upwards while manoeuvring the cover away

from the engine hood hinge.

4. Pull the left-hand plenum chamber cover (4)

forward to release the four retaining tabs

securing it to the windscreen, then lift cover

upwards while manoeuvring the cover away

from the engine hood hinge.

NOTE: The right-hand plenum chamber cover

must be removed first.

Figure 12C-14

4. Rem ove the 6 fasteners (1) securing the water

deflector (2) to the plenum chamber.

5. Pull the water deflector forward to release the

four retaining tabs (3) securing it to the

windscreen (4).

6. Remove the water deflector.

Figure 12C-15

7. Squeeze the tang at the m ain wiring harness to

wiper motor harness connector and disconnect

wiring harness.

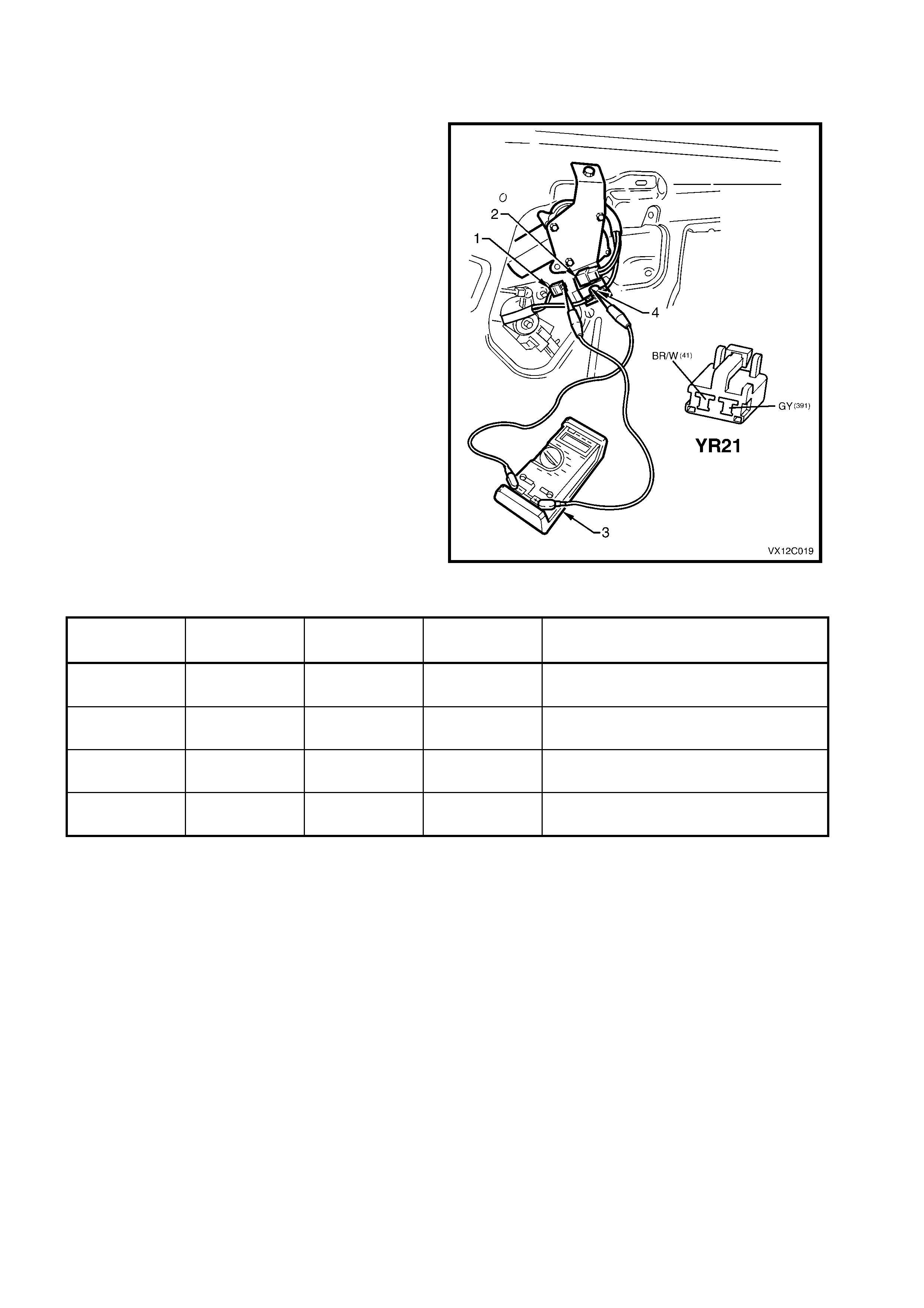

8. Remove the five screws securing the wiper

motor and linkage assembly to the plenum

chamber and remove wiper motor and linkage

assembly.

NOTE: The bolt sec uring the wiper m otor and earth

strap (5) is secured to the strap by a spacer and

cannot be seperated.

9. If necess ary, rem ove the nut sec uring the wiper

linkages to the wiper motor pivot and the three

bolts securing the wiper motor to the bracket

on the wiper linkages and separate the wiper

motor from the wiper linkages.

Figure 12C-16

REINSTALL

Installation of the wiper motor is the reverse of the

removal procedure, noting the following:

1. Ensure all fasteners are tightened to the

correct torque specification.

WIPER MOTOR TO LINKAGE

SECURING SCREWS

TORQUE SPECIFICATION 7 – 9 Nm

WIPER MOTOR CRANK ARM TO

WIPER MOTOR ATTACHING NUT

TORQUE SPECIFICATION 16 – 20 Nm

WIPER MOTOR AND LINKAGE

ASSEMBLY SECURING SCREW S

TORQUE SPECIFICATION 4 – 6 Nm

NOTE 1: If the wiper motor has been removed from

the linkages. The wiper motor pivot must be installed in

the park position, by aligning the wiper motor pivot

within the lines on the mounting bracket marked R (1)

for right-hand drive, or L (2) for left-hand drive models.

NOTE 2: Ensure that the wires from the connector do

not get caught or foul the wiper motor linkages.

2. Operate wiper motor before installing the wiper

arms to ensure it is in the correct PARK position.

3. When installing the water deflector and plenum

covers, ensure that the retaining tabs engage

under the windscreen.

Figure 12C-17

2.5 REAR WIPER MOTOR ASSEMBLY

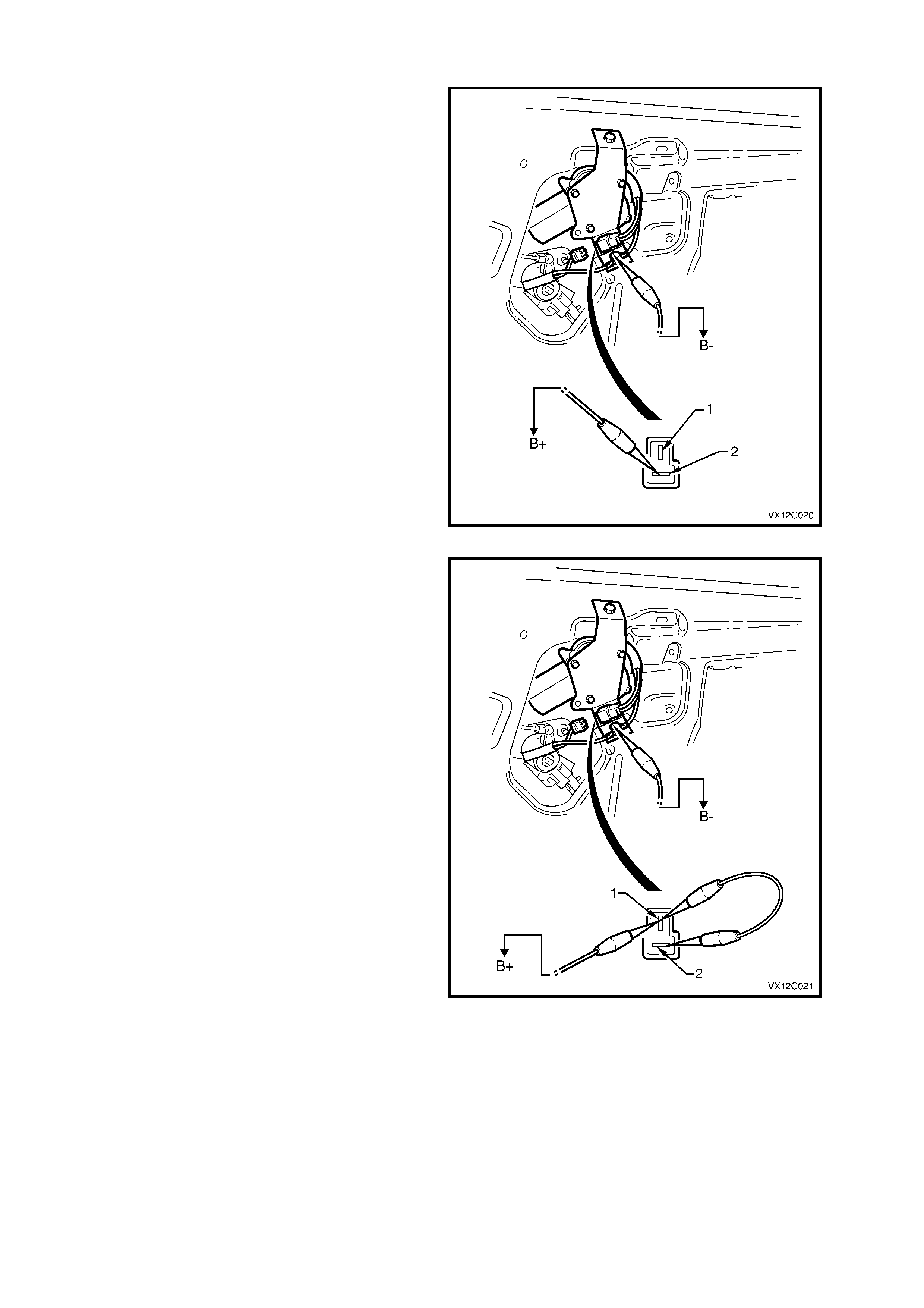

CHECKING WIPER MOTOR WIRING

1. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE in the VT Series I Service

Information.

2. Depress retaining tang on rear compartment

harness connector (1) and disconnect from

rear wiper motor connector (2).

3. Using a multimeter (3) connected between the

lower wiper motor bracket securing screw (4)

and the rear compartment harness connector,

check wiper motor wiring as per the following

chart.

Figure 12C-18

WIRE

COLOUR CIRCUIT No. CIRCUIT MULTIMETE

R SETTING RESULT IF WIPER MOTOR IS OK

Brown/White 141 Power source Voltage B+ with ignition in ACC or ON position

and wiper/washer switch OFF

Grey 391 Motor drive Voltage 0 volt with ignition in ACC or ON

position and wiper/washer switch OFF

Brown/White 141 Power source Voltage B+ with ignition in ACC or ON position

and wiper/washer switch ON

Grey 391 Motor drive Voltage B+ with ignition in ACC or ON position

and wiper/washer switch ON

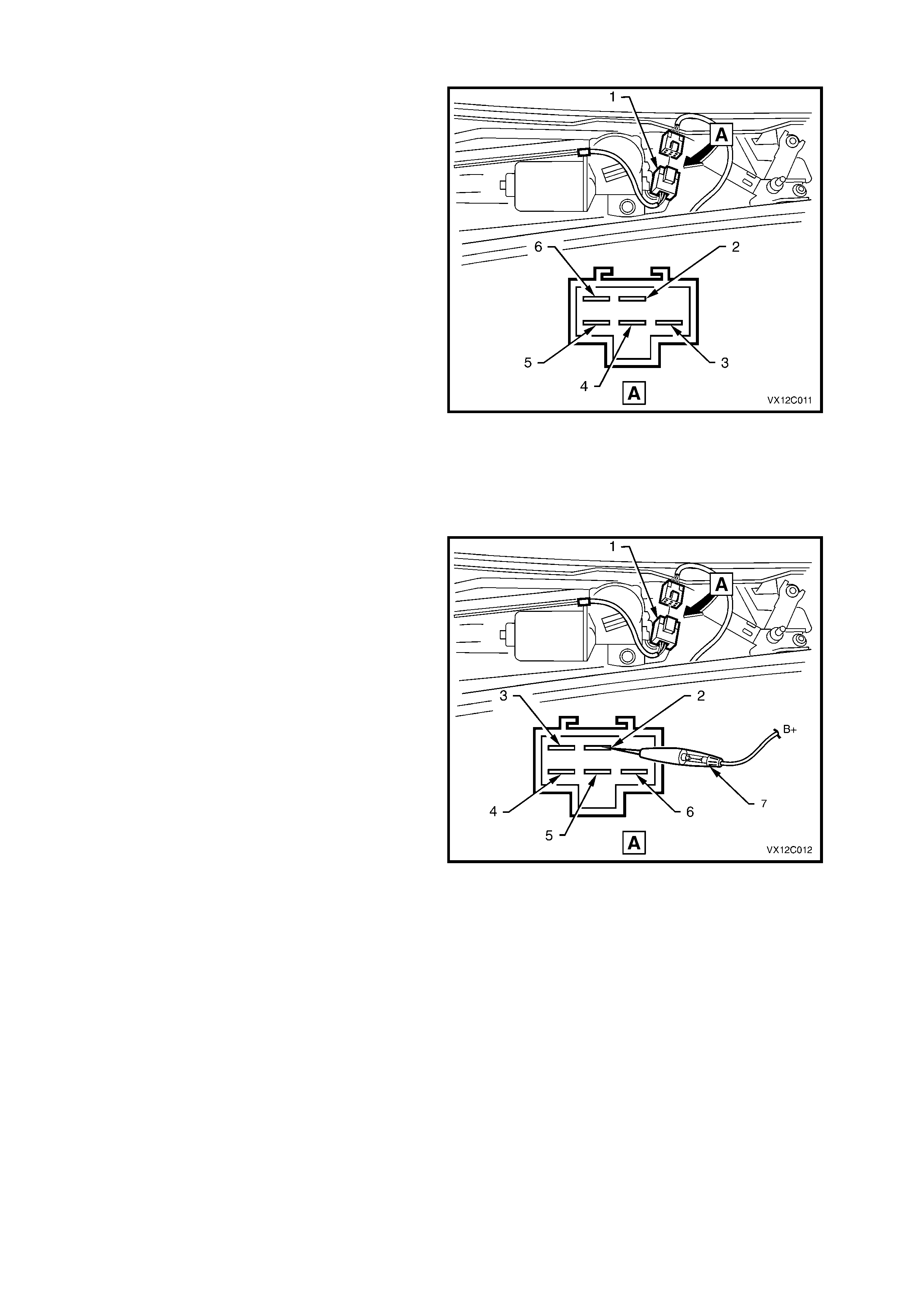

CHECKING WIPER MOTOR OPERATION – INTERIM TYPE MOTOR

1. Remove rear wiper arm, refer to

2.2 REAR WIPER ARM in this Section.

2. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE in the VT Series I Service

Information.

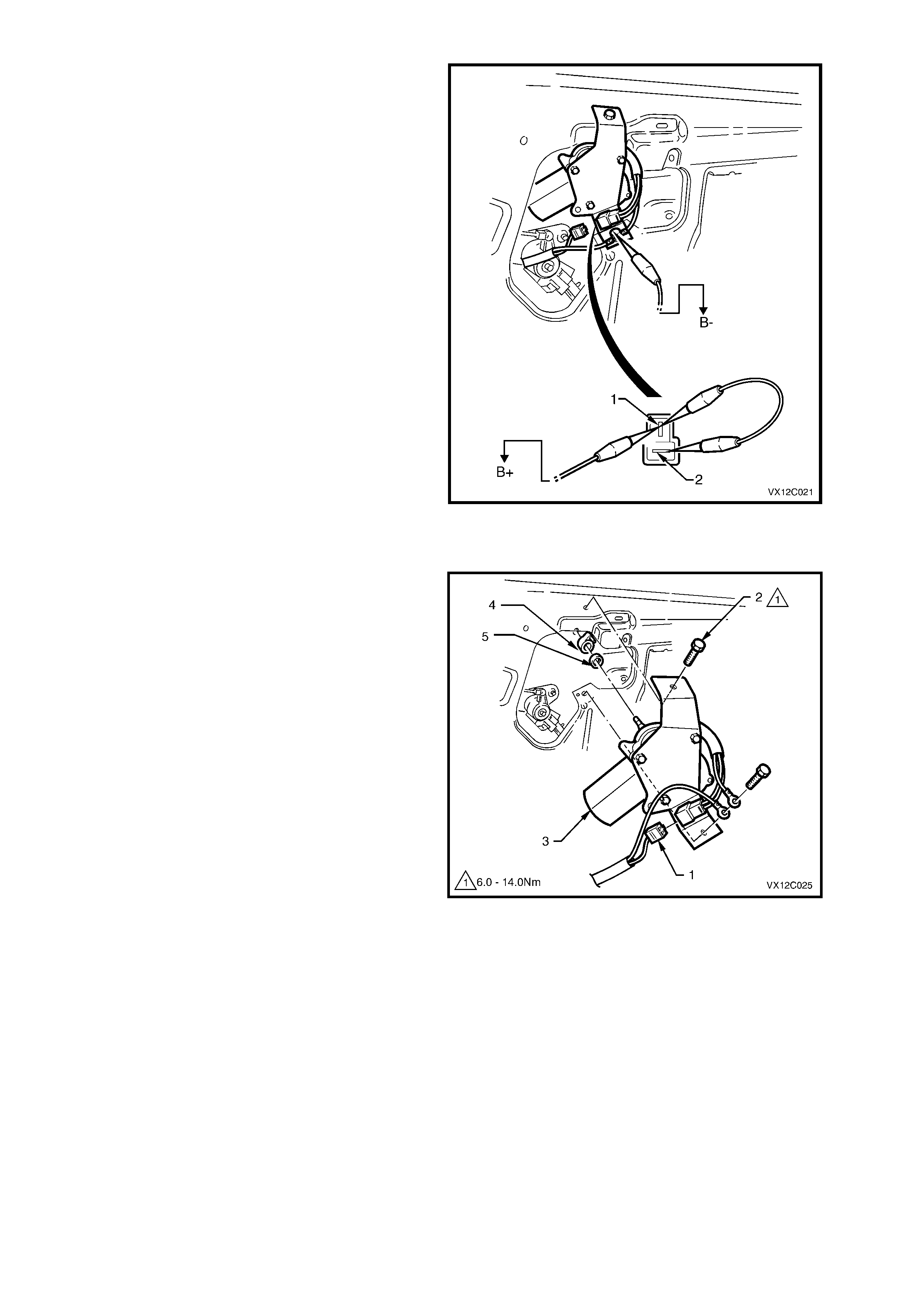

3. Use a jumper lead connected between battery

earth and the wiper mounting br ac k et and earth

lead (Brown wire).

4. Using a second jumper lead connected to

battery positive, touch jumper lead terminal to

Blue wire terminal of wiper motor connector.

Drive spindle of motor should rotate. If drive

spindle does not rotate, motor is faulty and

must be replaced.

Figure 12C-19

5. To check wiper motor PARKED operation,

connect a bridging wire between the Black and

Blue wires of the wiper motor connector.

Connect a jumper wire from battery positive to

Black wire to wiper motor connec tor, and wiper

motor spindle should rotate.

Disconnect bridging wire from Blue wire and

wiper motor should continue to rotate until it

reaches the PARK position.

Figure 12C-20

7. If the motor does not park, remove all jumper

wires and reconnect the rear wiper motor

harness connector.

8. Replace the rear wiper park relay with a known

good relay. If the wiper arm returns to the park

position and stops, the rear wiper park relay is

faulty and must be replaced. If the wiper arm

does not return to the park position and stop,

the rear wiper m otor inter nal contacts are f aulty

and the motor must be replaced.

NOTE: If a known good relay is not available,

continue with steps 9 through to 13.

9. Turn the ignition switch to the OFF position with

the rear wiper arm in the centre of its stroke.

10. Remove the connector block from the rear

wiper park relay on the rear wiper motor

mounting bracket.

11. Connect a jumper wire between terminal 30

and terminal 87a.

12. Turn the ignition to the on position.

13. If the wiper arm returns to the par k position and

stops, the rear wiper park relay is faulty and

must be replaced. If the wiper arm does not

return to the park position and stop, the rear

wiper motor inter nal contacts are faulty and the

motor must be replaced.

Figure 12C-21

CHECKING WIPER MOTOR OPERATION – LATE TYPE MOTOR

1. Remove rear wiper arm, refer to

2.2 REAR WIPER ARM in this Section.

2. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE in the VT Series I Service

Information.

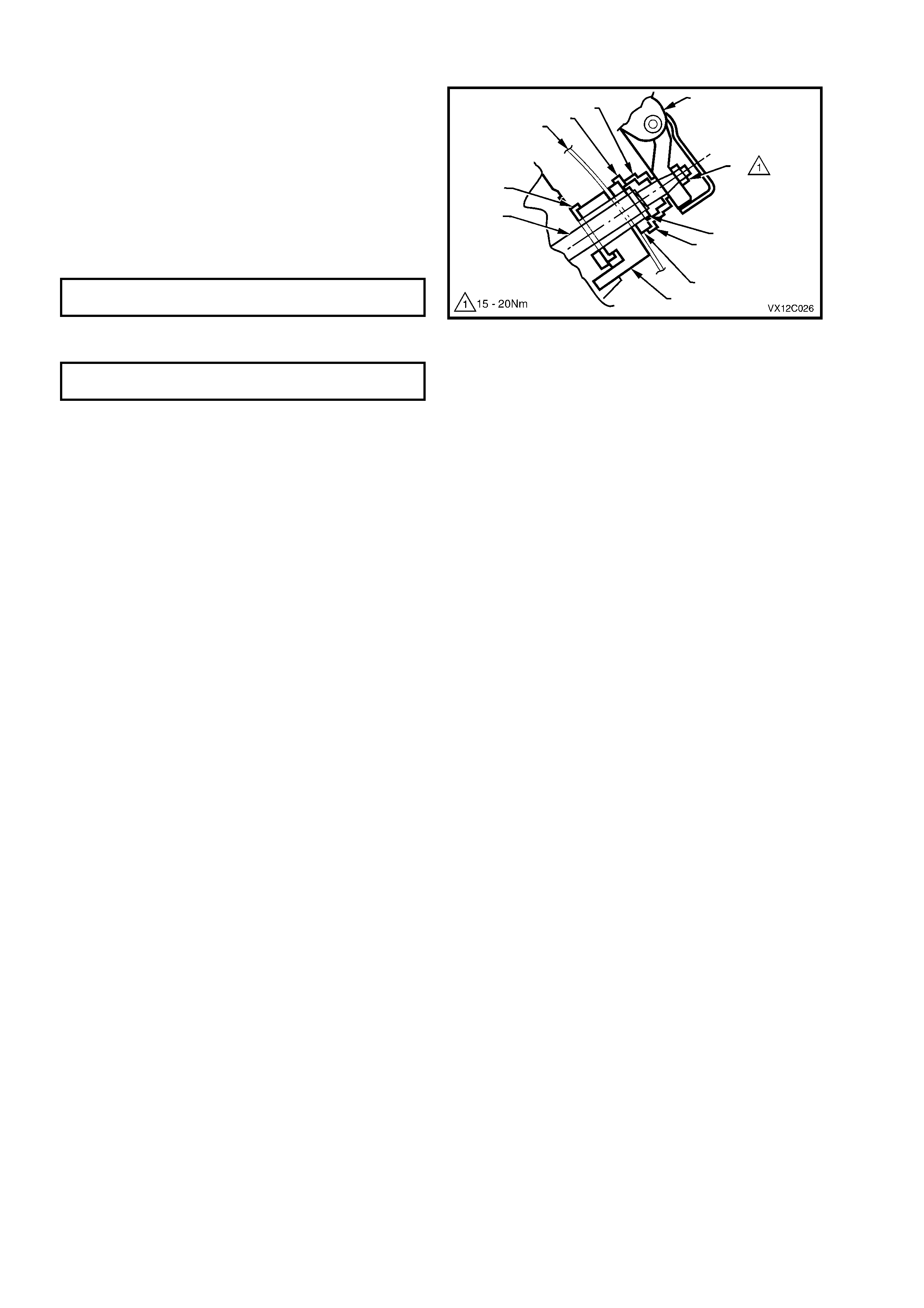

3. Use a jumper lead connected between battery

earth and the wiper mounting br ac k et and earth

lead (Brown wire).

4. Using a second jumper lead connected to

battery positive, touch jumper lead terminal to

Blue wire terminal of wiper motor connector.

Drive spindle of motor should rotate. If drive

spindle does not rotate, motor is faulty and

must be replaced.

Figure 12C-22

5. To check wiper motor PARKED operation,

connect a bridging wire between the Black and

Blue wires of the wiper motor connector.

Connect a jumper wire from battery positive to

Black wire to wiper motor connec tor, and wiper

motor spindle should rotate.

Disconnect bridging wire from Blue wire and

wiper motor should continue to rotate until it

reaches the PARK position.

If motor does not park, the contacts within the

motor are faulty and therefore, the motor must

be replaced.

Figure 12C-23

REMOVE

1. Remove rear wiper arm, refer

2.2 REAR WIPER ARM in this Section.

2. Remove the rubber seal, nut, cap and spacer

from the wiper motor shaft.

3. Remove tailgate interior trim panel, refer

Section 1A4 REAR COMPARTMENT LID &

TAILGATE in the VT Series I Service

Information.

4. Depress retaining tang on rear compartment

harness connector (1) and disconnect from

rear wiper motor connector.

5. Remove the two screws (2) securing the rear

wiper motor to the tailgate, r em ove wiper m otor

and bracket assembly (3).

6. Remove inner spacer (4) and cap (5) from

wiper motor shaft.

Figure 12C-24

REINSTALL

Installation of the rear wiper motor is the r everse of

the removal procedure, noting the following points

1. Ensure that the inner spacer (1), outer spacer

(2), washers (3), shaft seal (4) and nut (5) are

fitted onto the wiper shaft (6) correctly.

2. To ensure the earth connection, the wiper

motor earth lead must be installed before the

tailgate harness earth lead.

3. Tighten wiper motor securing screws to the

correct torque specification.

WIPER MOTOR SECURING SCREW

TORQUE SPECIFICATION 6 – 14 Nm

4. Tighten rear wiper arm attaching nut (7) to the

correct torque specification.

REAR WIPER ARM ATTACHING NUT

TORQUE SPECIFICATION 15 – 20 Nm

Figure 12C-25

3. TORQUE WRENCH SPECIFICATIONS

Nm

Front Wiper Arm Attaching nut .............................................20 - 25

Rear Wiper Arm Attaching nut..............................................15 - 20

Rear Wiper Motor Attaching Screw ......................................6 - 14

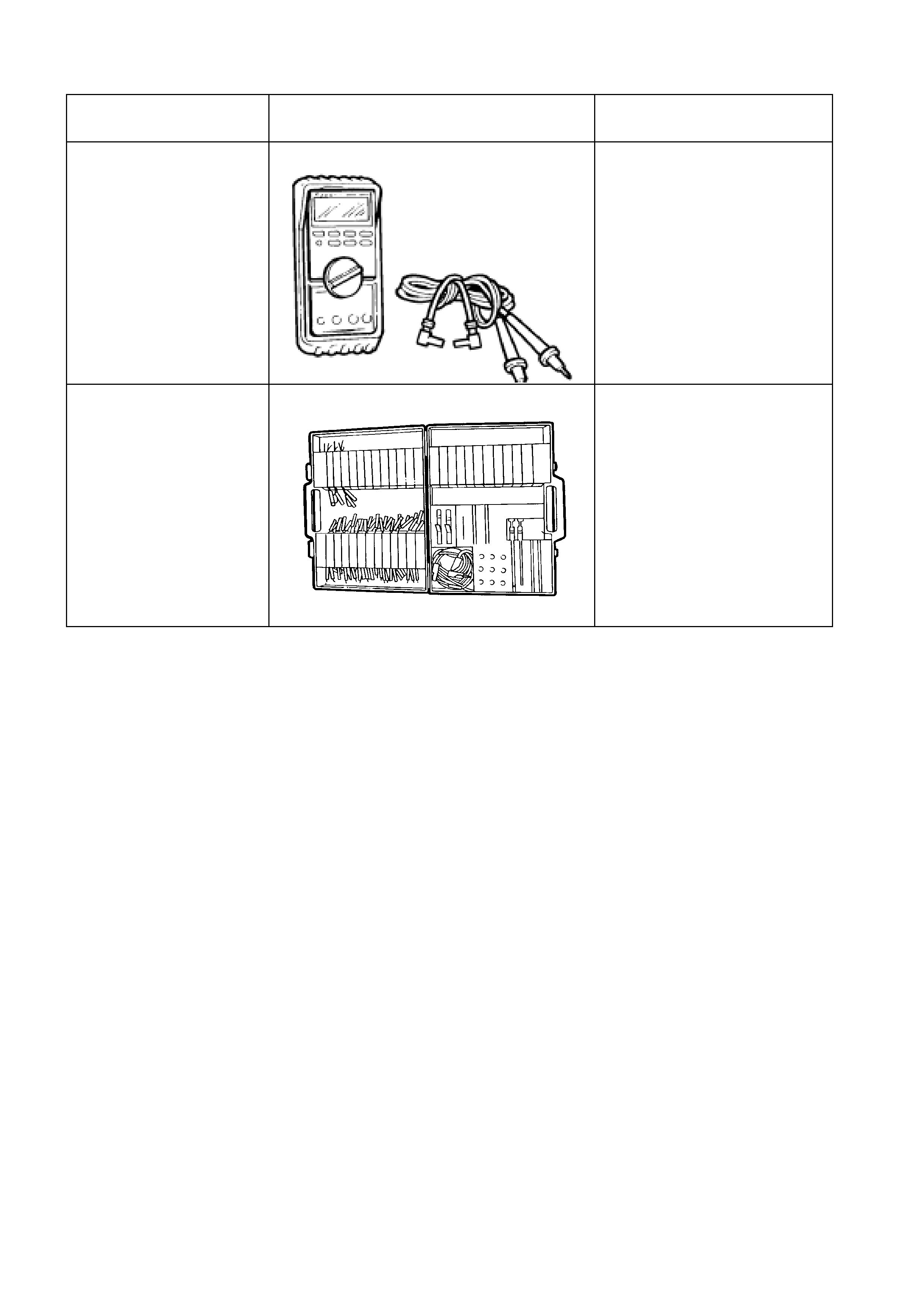

4. SPECIAL TOOLS

TOOL NO. REF

IN TEXT TOOL DESCRIPTION COMMENTS

J39200

DIGITAL MULTIMETER TOOL NO. J39200

PREVIOUSLY RELEASED, OR

USE COMMERCIALLY

AVAILABLE EQUIVALENT.

MUST HAVE 10 MEG OHM

INPUT IMPEDANCE

KM-609 CONNECTOR TEST ADAPTOR KIT

PREVIOUSLY RELEASED

FOR V CAR. USED IN

CONJUNCTION WITH A

MULTIMETER FOR

MEASURING VOLTAGES AND

RESISTANCES WITHOUT

DAMAGING WIRING

HARNESS CONNECTORS