SECTION 12M - SUPPLEMENTAL RESTRAINT

SYSTEM (VERSIONS 8.0 AND 8.1)

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

The Supplemental Restraint System (SRS) used on VX Series Models carries over from the systems that were

introduced for VT Series Models in August 1998; versions 8.0 and 8.1, noting the following:

Since the introduction of SRS versions 8.0 and 8.1, there have been numerous changes and corrections:

• Introduction of the GEN III V8 engine, resulting in a new PCM (from VT Series II).

• Introduction of a new PCM for vehicles with a V6 engine on VX Series Models.

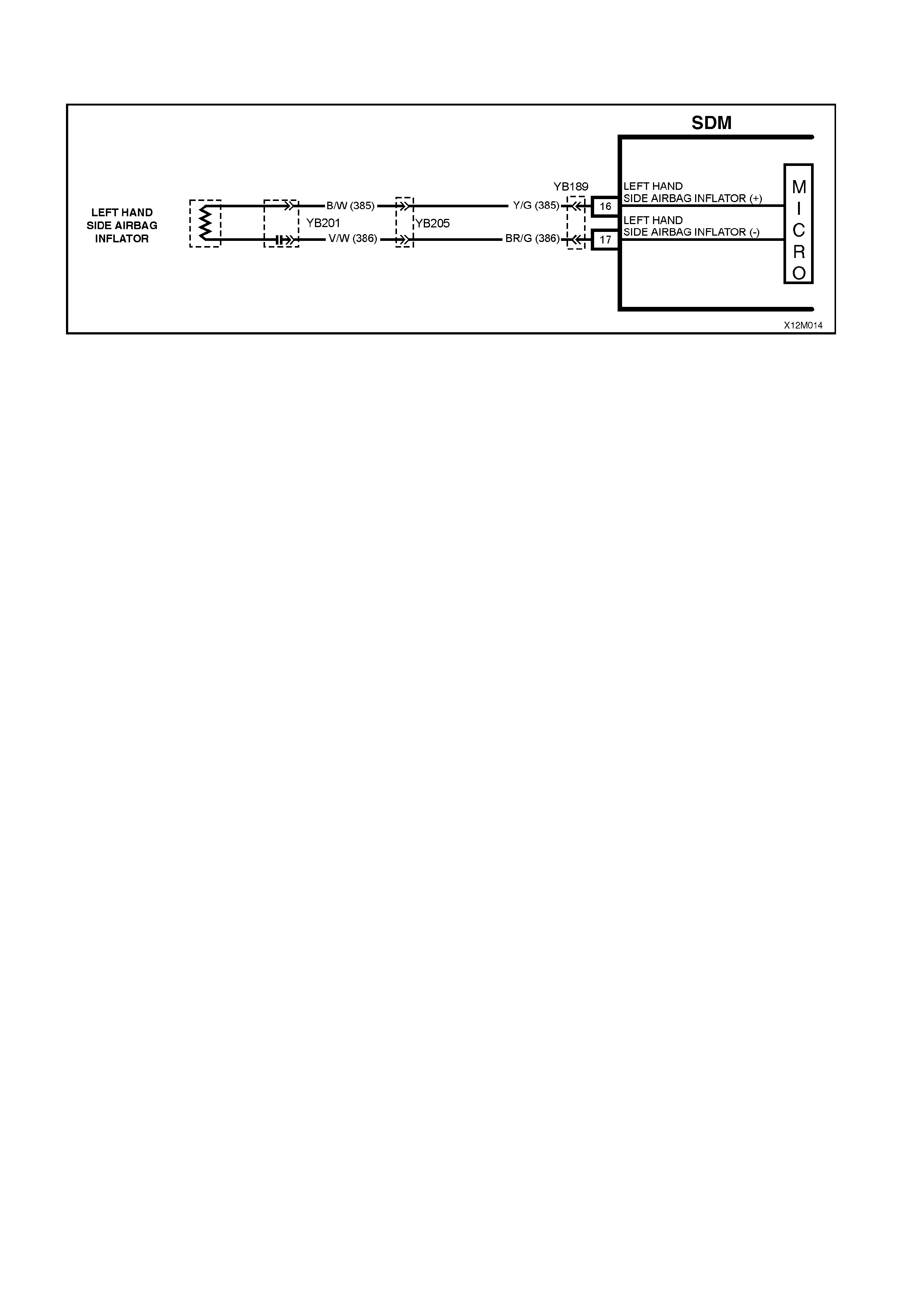

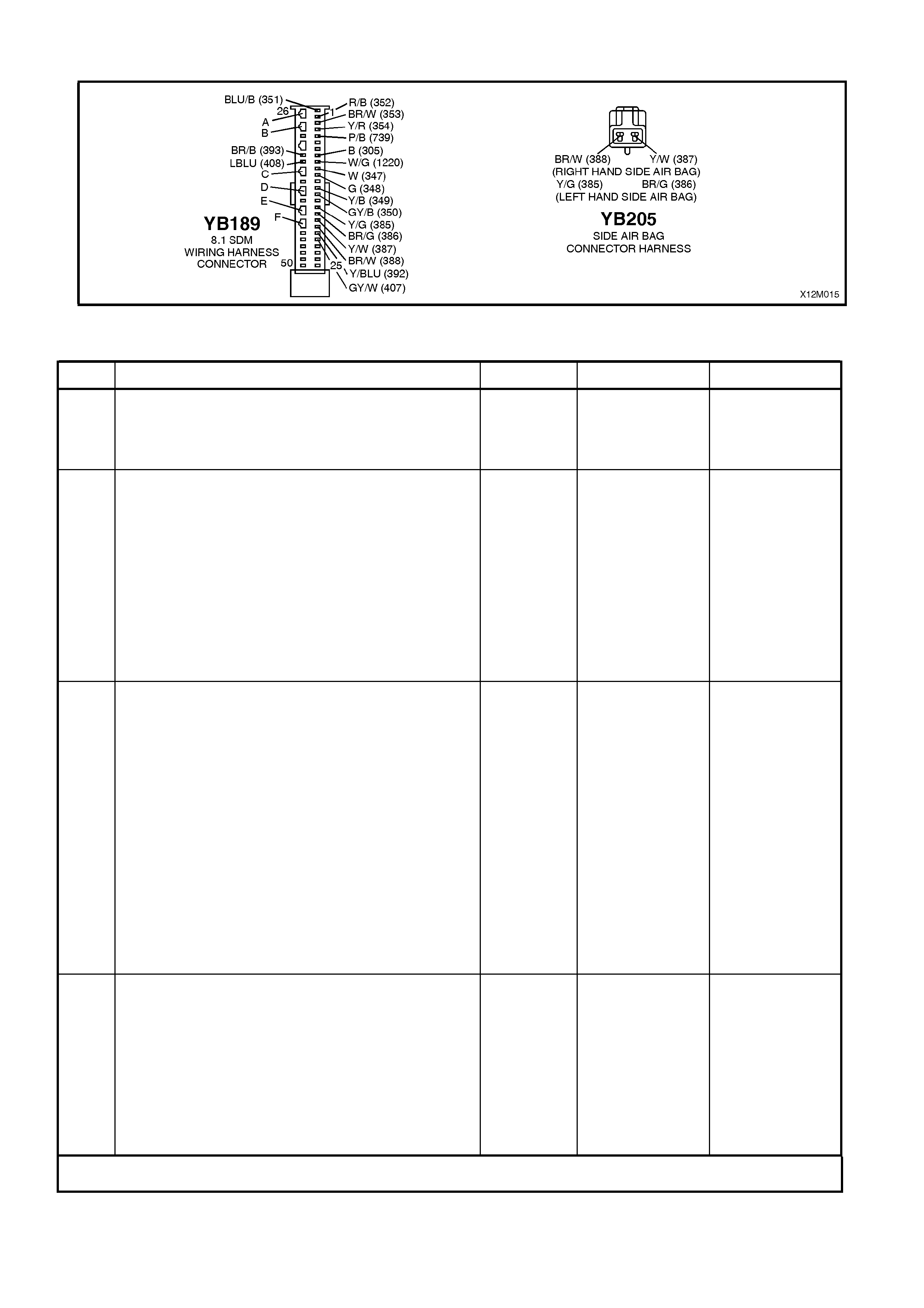

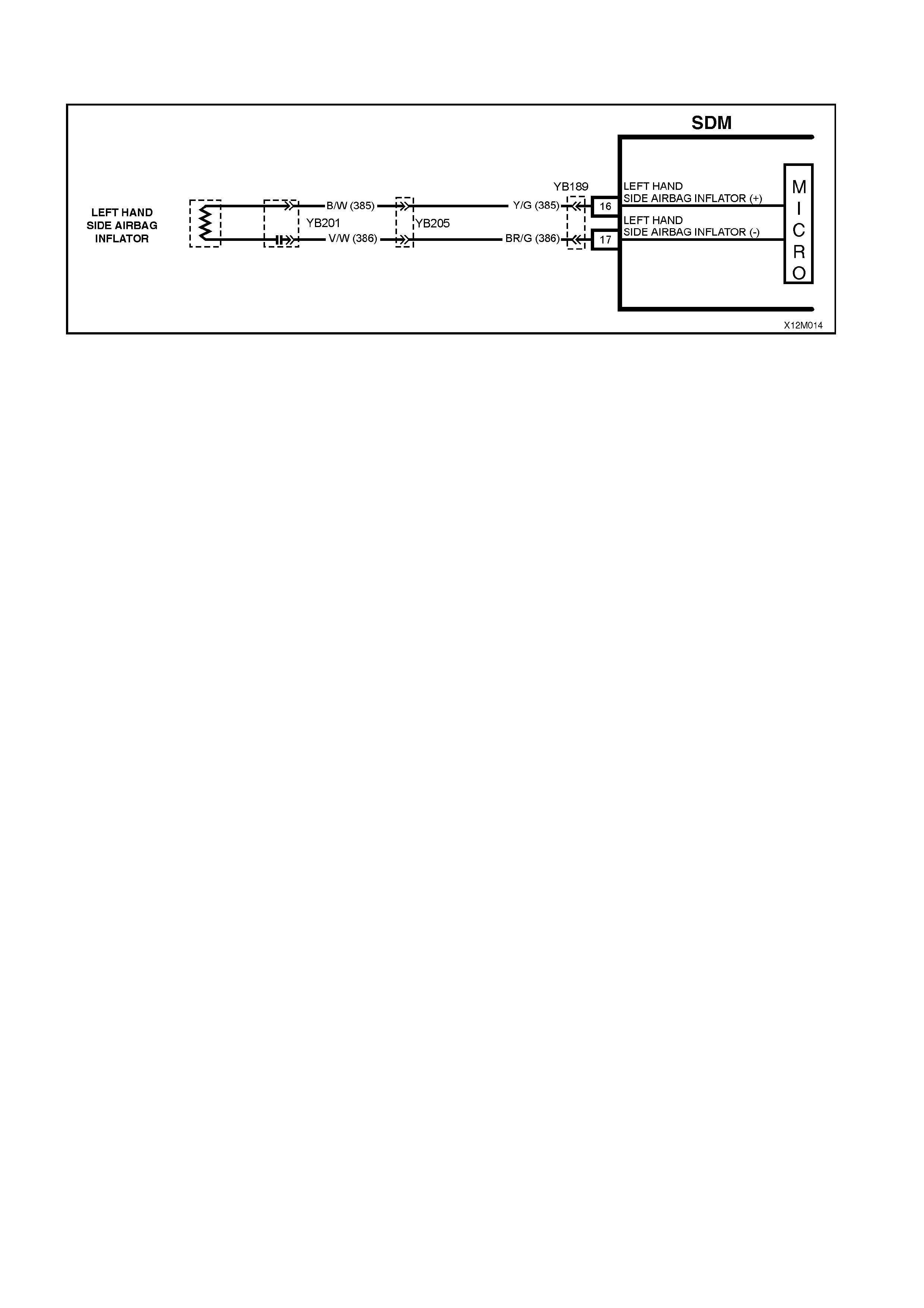

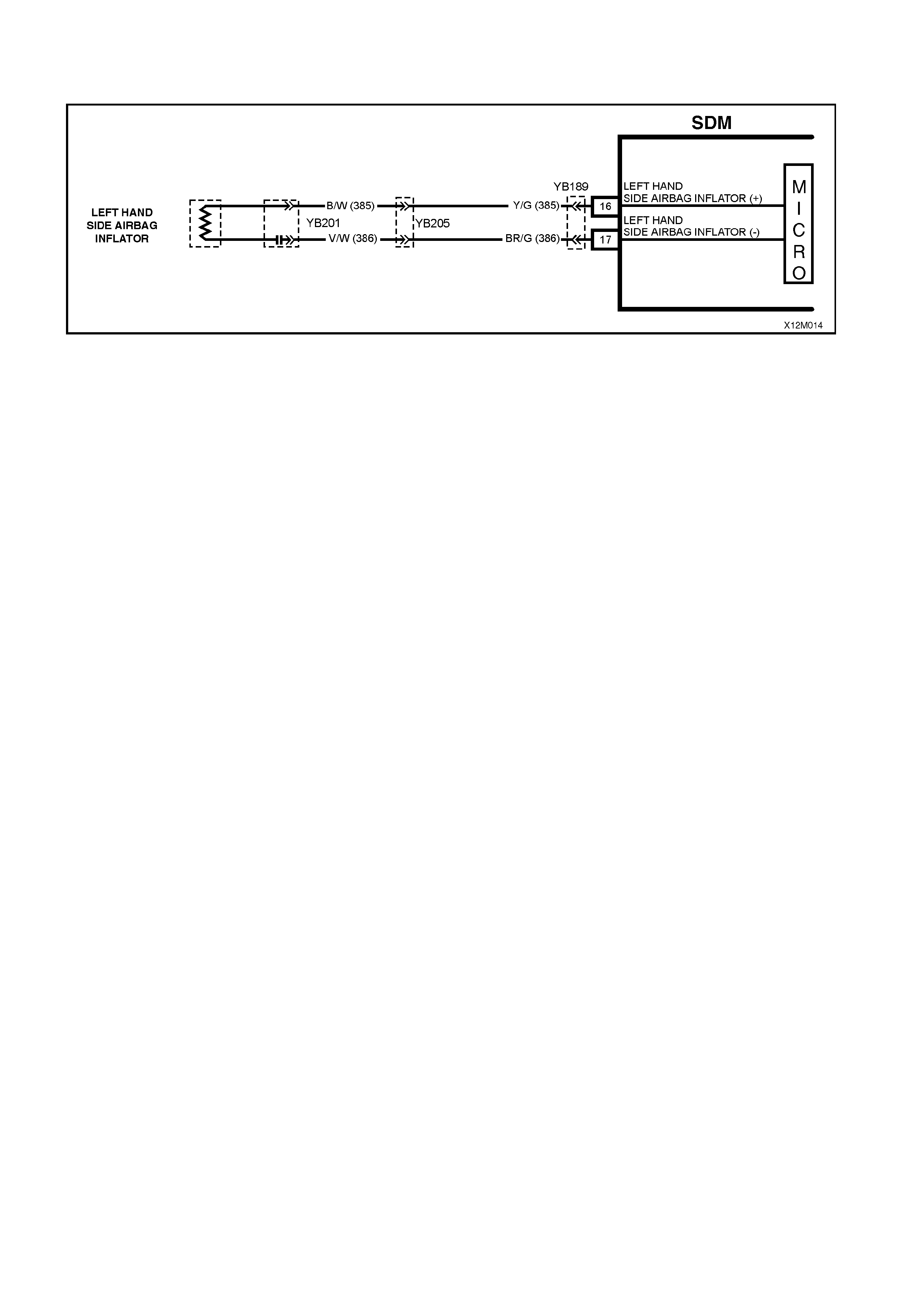

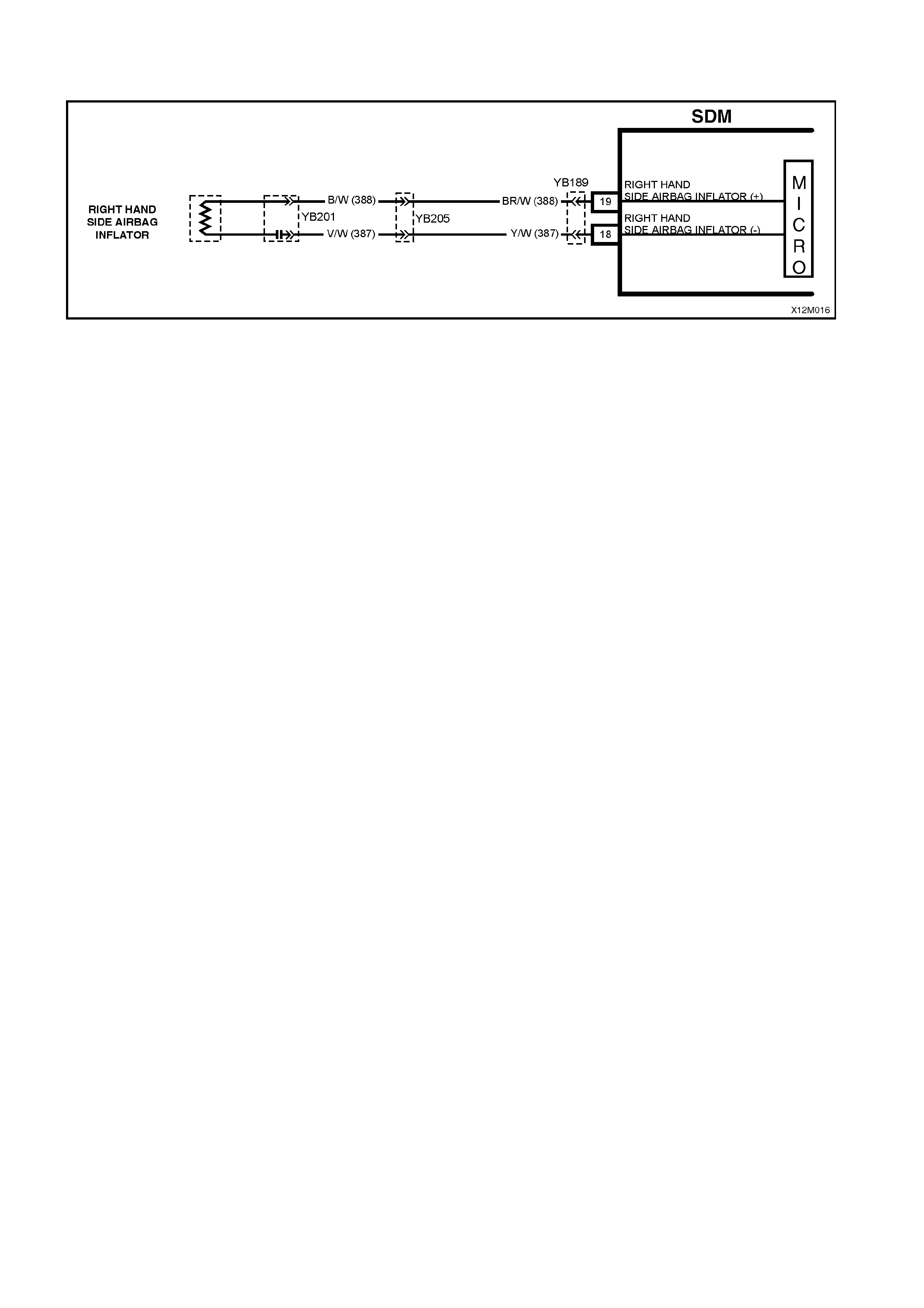

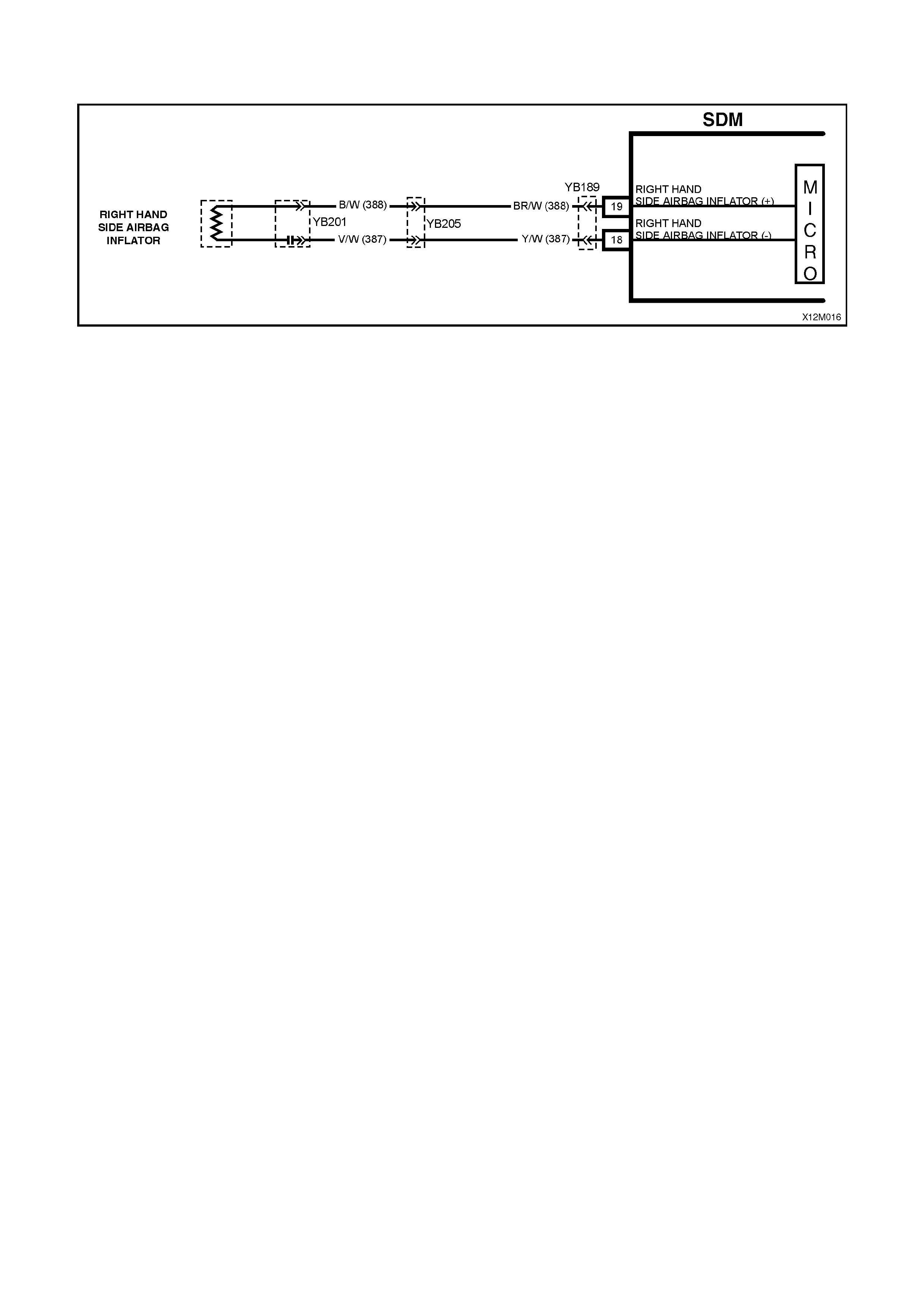

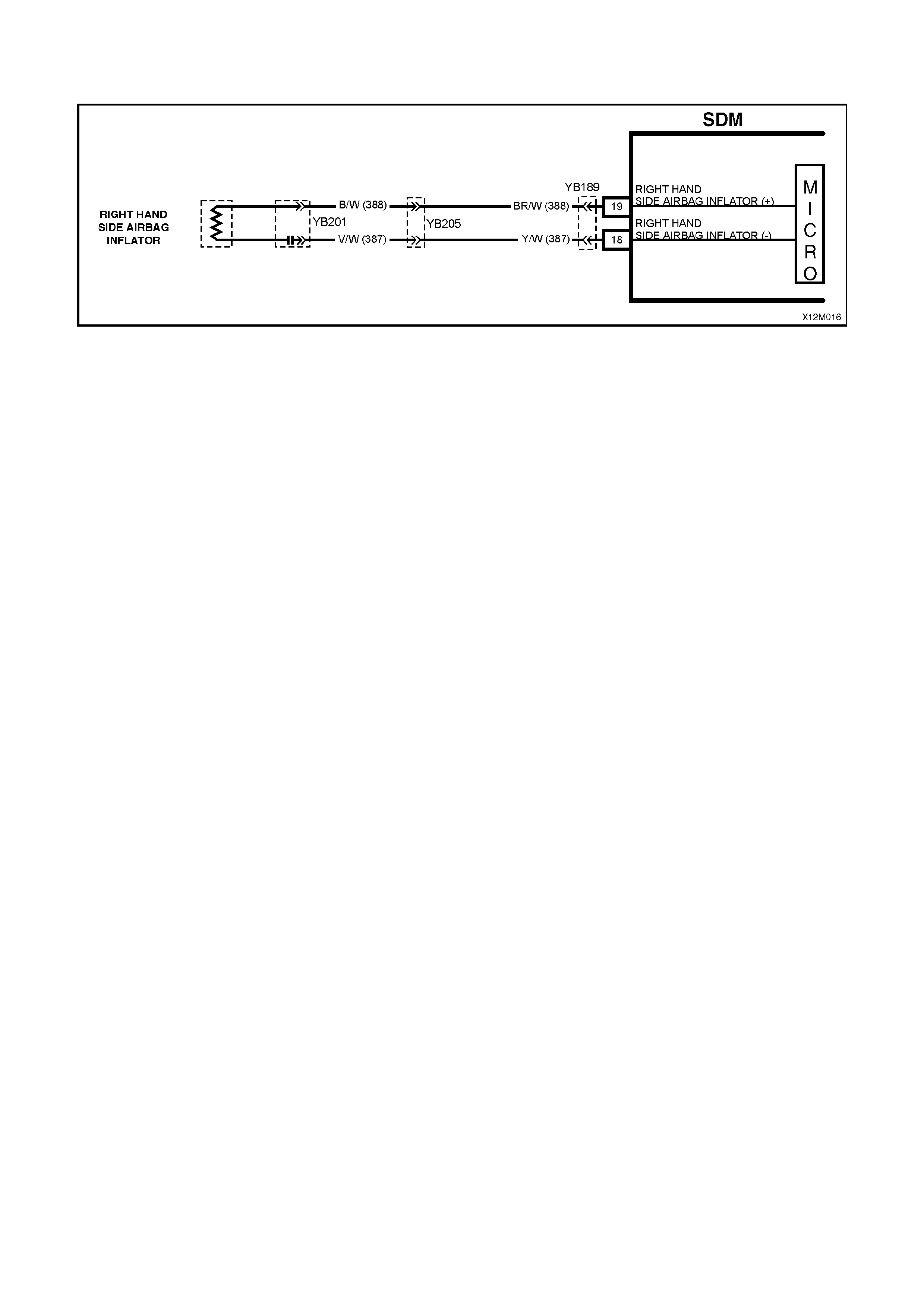

• Minor changes to the side air bag wiring circuits – terminal assignment of connector YB205 being swapped

around (from VT Series II).

• Incorrect identification of the wire colour for circuit 1220 (from introduction of VT Series).

• Emittance of recognition of a shorting link busbar in connector YB189 (from VT Series II).

These changes and corrections do not effect the SRS Operation or Service Operations, however, to avoid any

confusion, the Diagnostic Charts for SRS versions 8.0 and 8.1 have been updated and republished in full in this

Section.

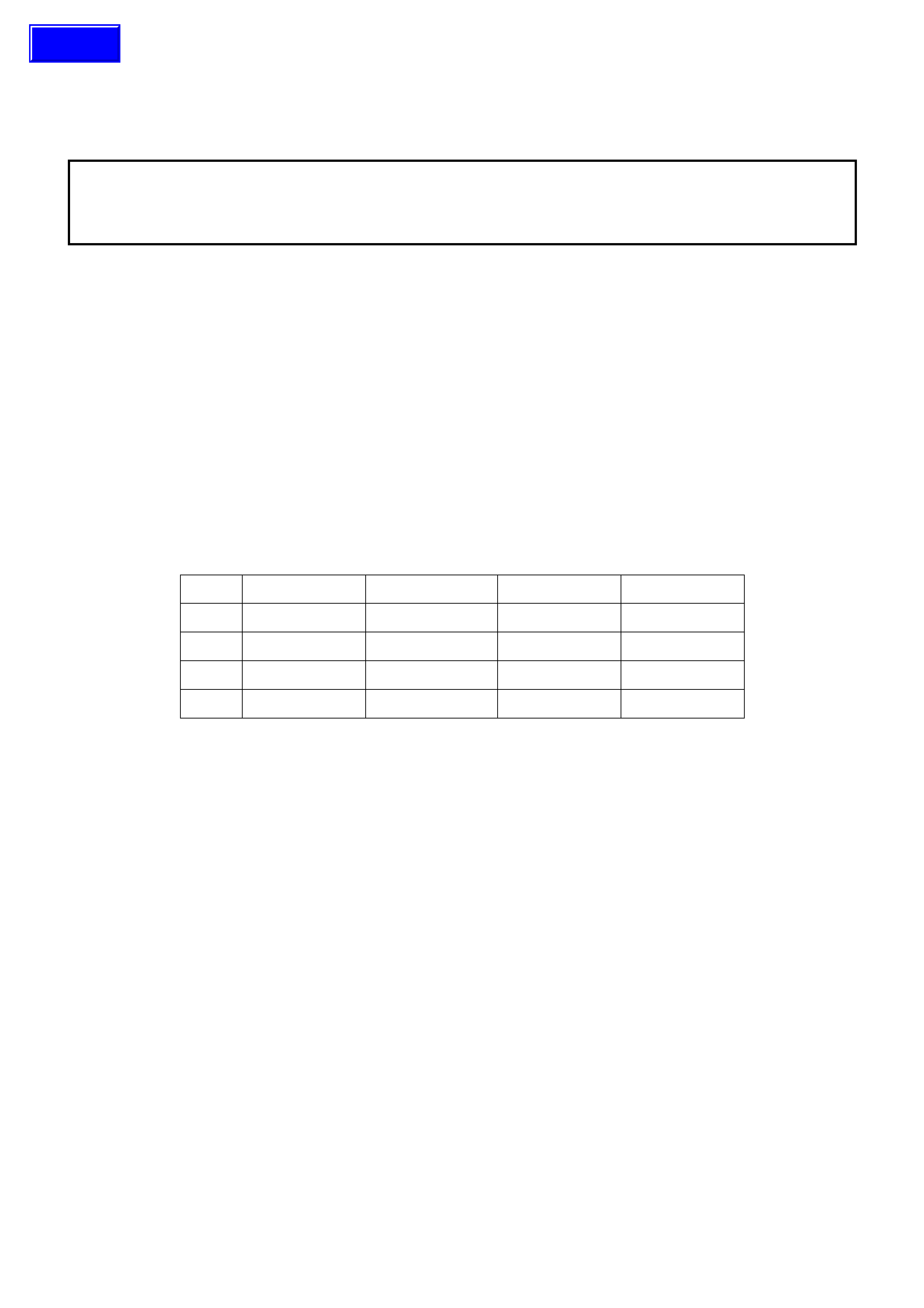

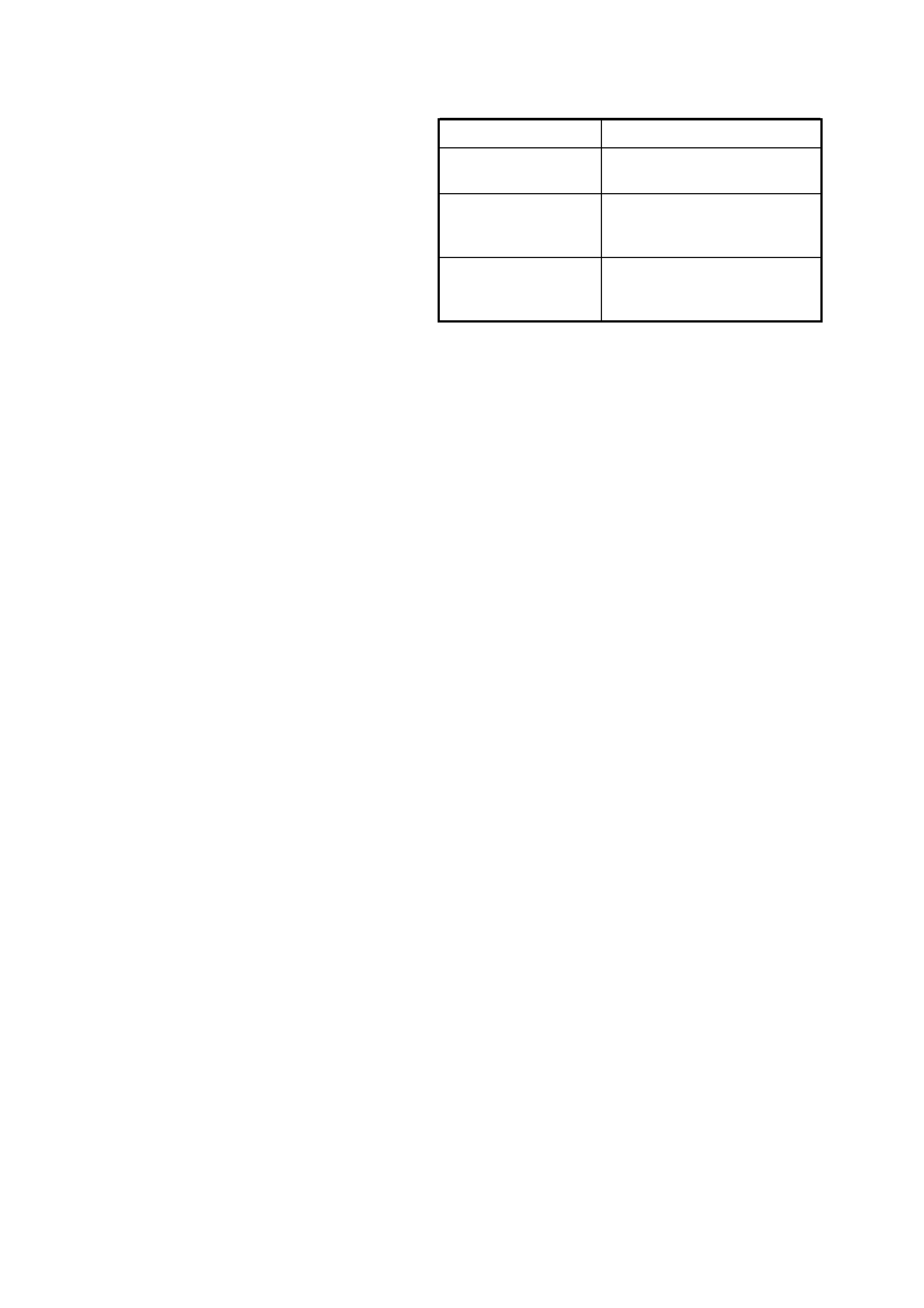

The following table summarises the version usage on VX Series Models.

SDM Pre-tensioner Driver’s Air bag Pass.Air bag Side Air bags

8.0 ✷

8.0 ✷ ✷

8.0 ✷ ✷ ✷

8.1 ✷ ✷ ✷ ✷

(SDM – Sensing and Diagnostic Module)

NOTE: Refer to the latest sales information for Model Option availability.

For all information relating to the SRS used on VX Series Models that is not covered in this Section, refer to:

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2) or

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information.

NOTE: Information in these two Sections should be read in conjunction with each other.

Techline

2.2 PRELIMINARY SYSTEM DIAGNOSIS

When investigating any complaint of an SRS problem or malfunction, always begin diagnosis with a circuit check,

refer to 2.5 DIAGNOSTICS CHARTS, CHART A - DIAGNOSTIC CIRCUIT CHECK in this Section.

The diagnostic circuit check is a preliminary procedure that checks to ensure the SDM is communicating on the

serial data line as well as helping to identify the problem and directing the technician to the appropriate diagnostic

chart in this Section.

2.4 TECH 2 DIAGNOSTICS, TEST MODES AND DISPLAYS FOR SRS DIAGNOSIS

All information relating to TECH 2, in regards to the SRS for VX Series Models, is as detailed in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Inform ation,

noting the following:

When using TECH 2 on a VX Series Model, ensure the correct Model Year and Vehicle Type is selected:

(Y) 2000

(1) 2001 VX Commodore

(2) 2002

2.5 DIAGNOSTIC CHARTS

The following diagnos tic charts are designed to provide f ast and ef ficient f ault location of the SRS for vehicles f itted

with an 8.0 or 8.1 SDM only. The diagnostic charts contain: a ‘diagnostic chart’, pertinent information, circuit

diagrams, and where necessary, the steps are explained by the corresponding numbered paragraphs.

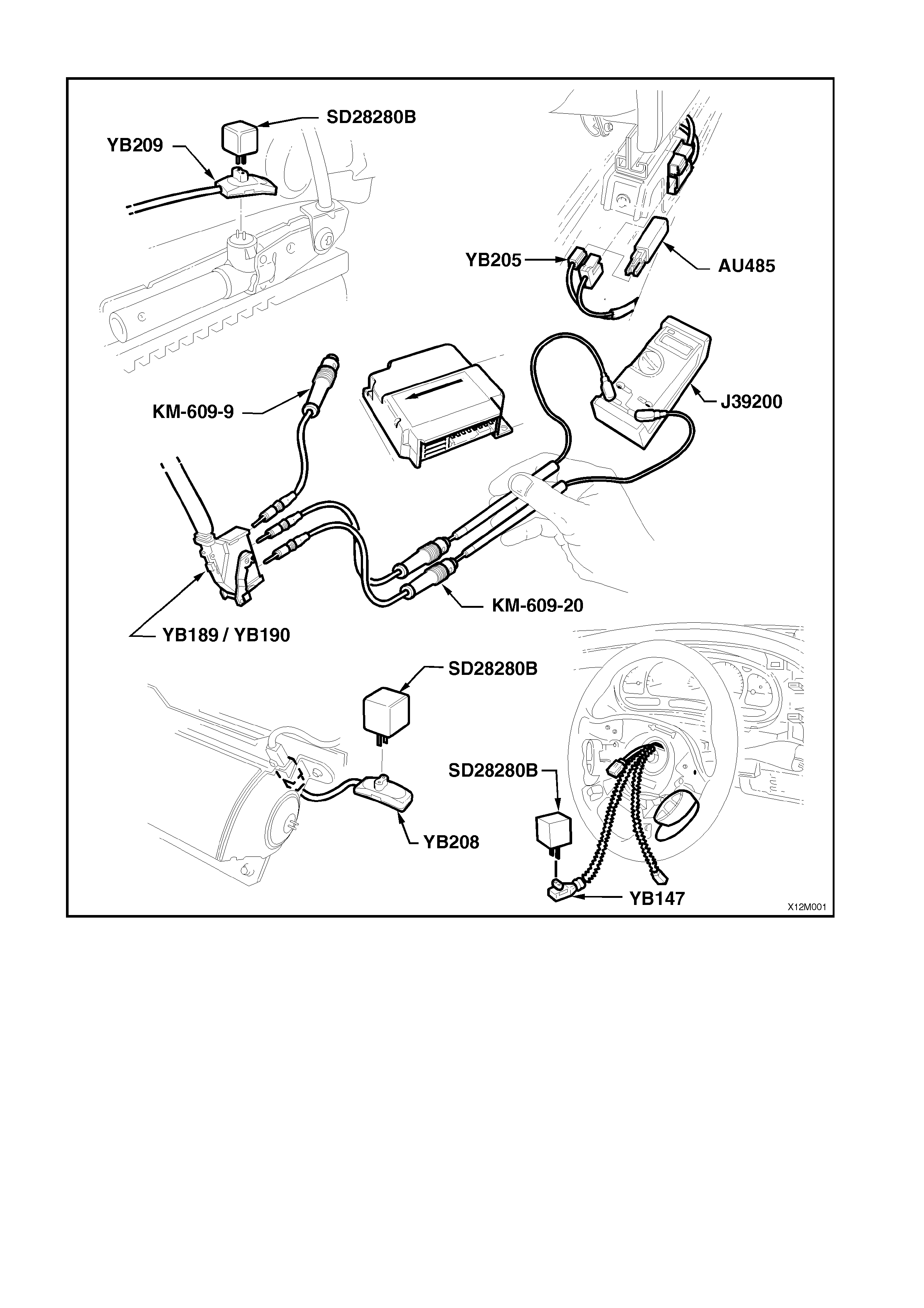

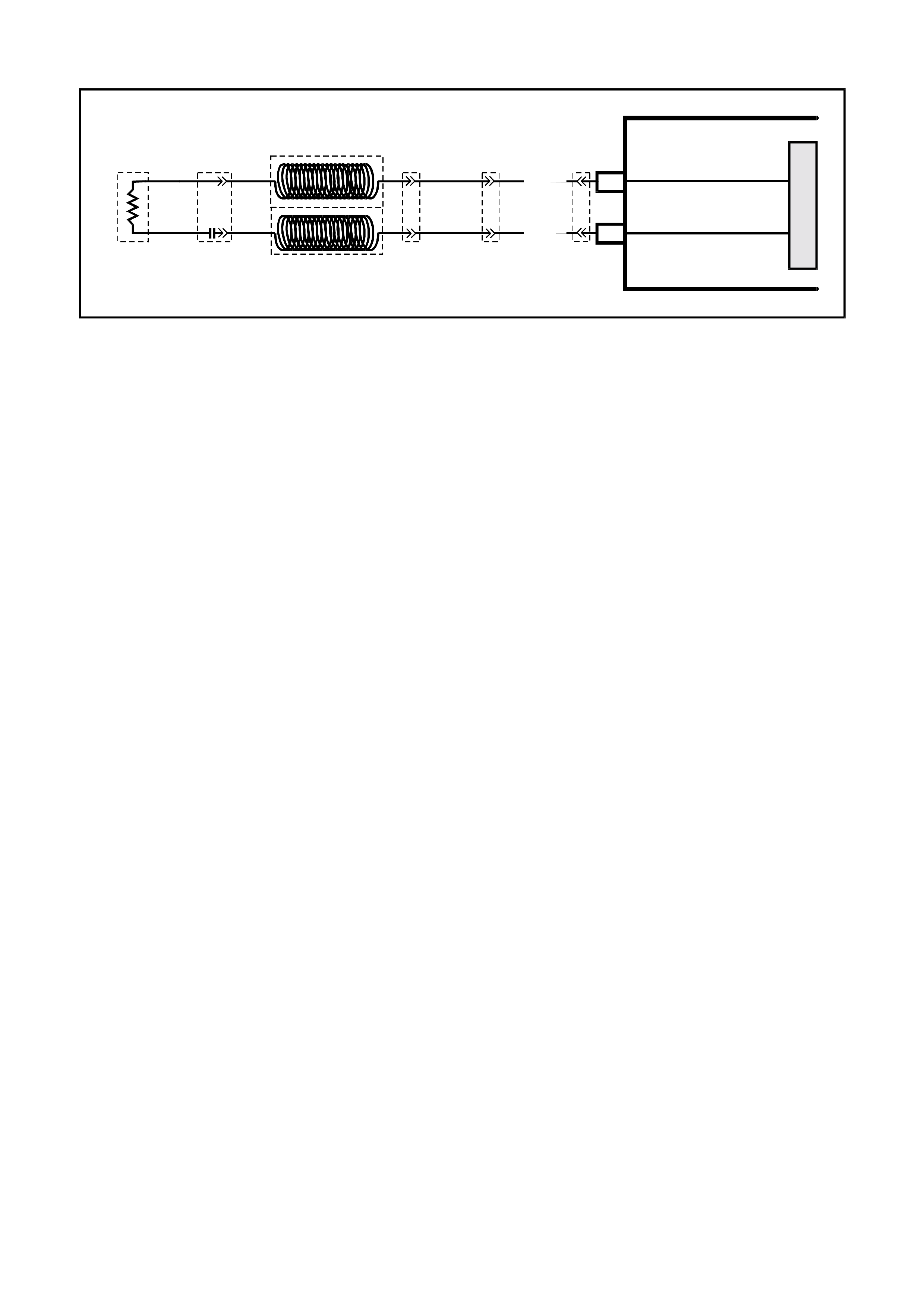

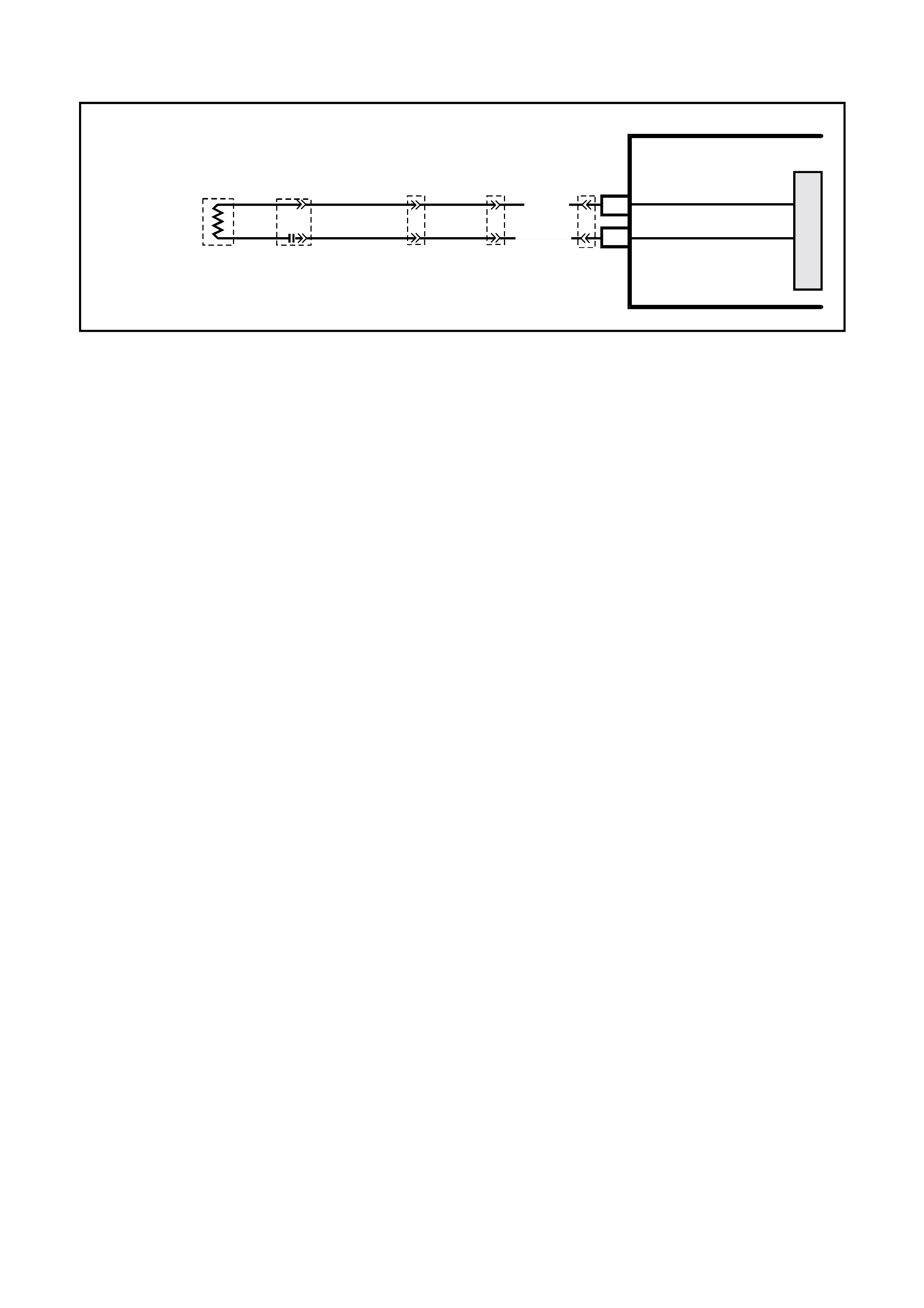

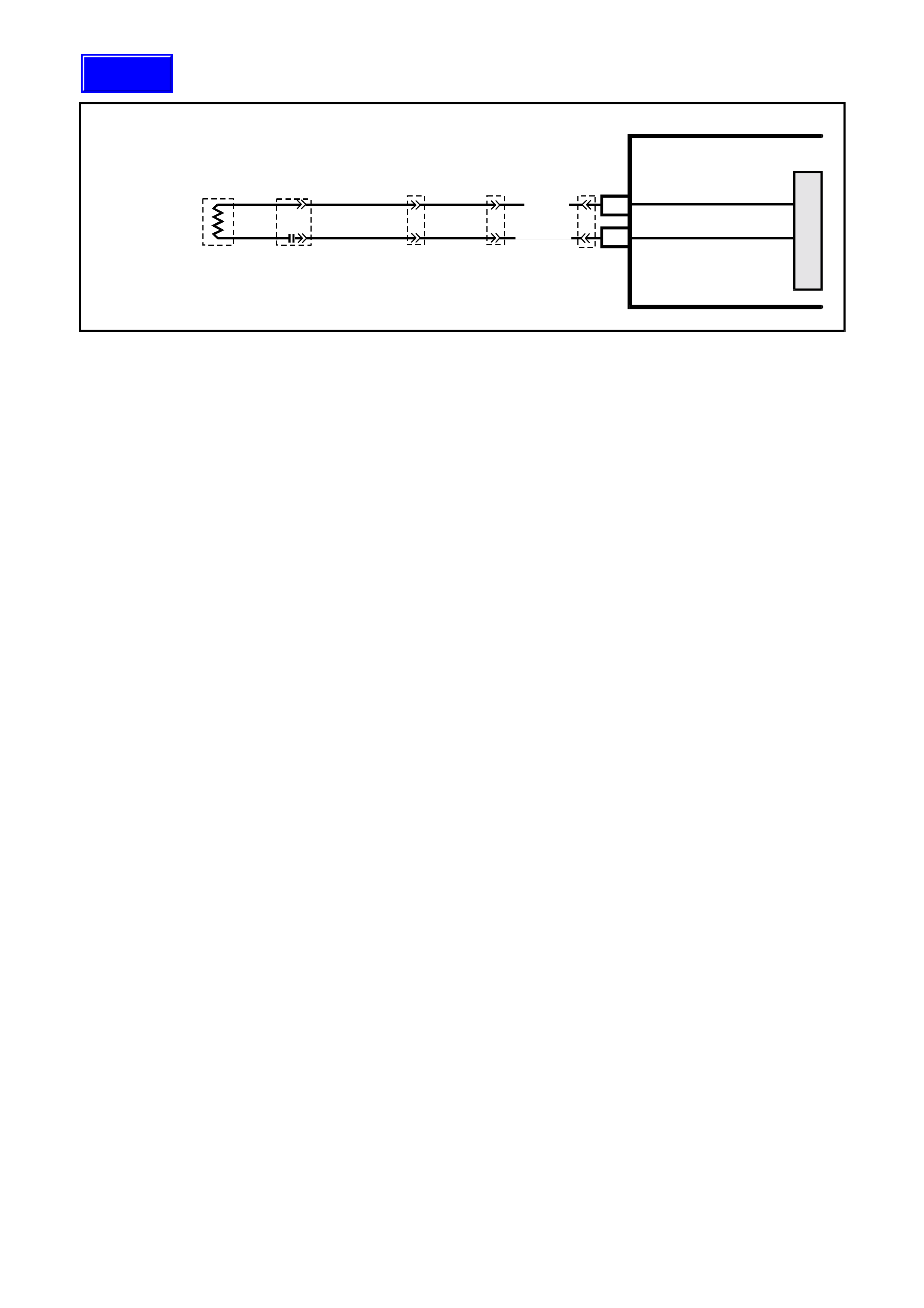

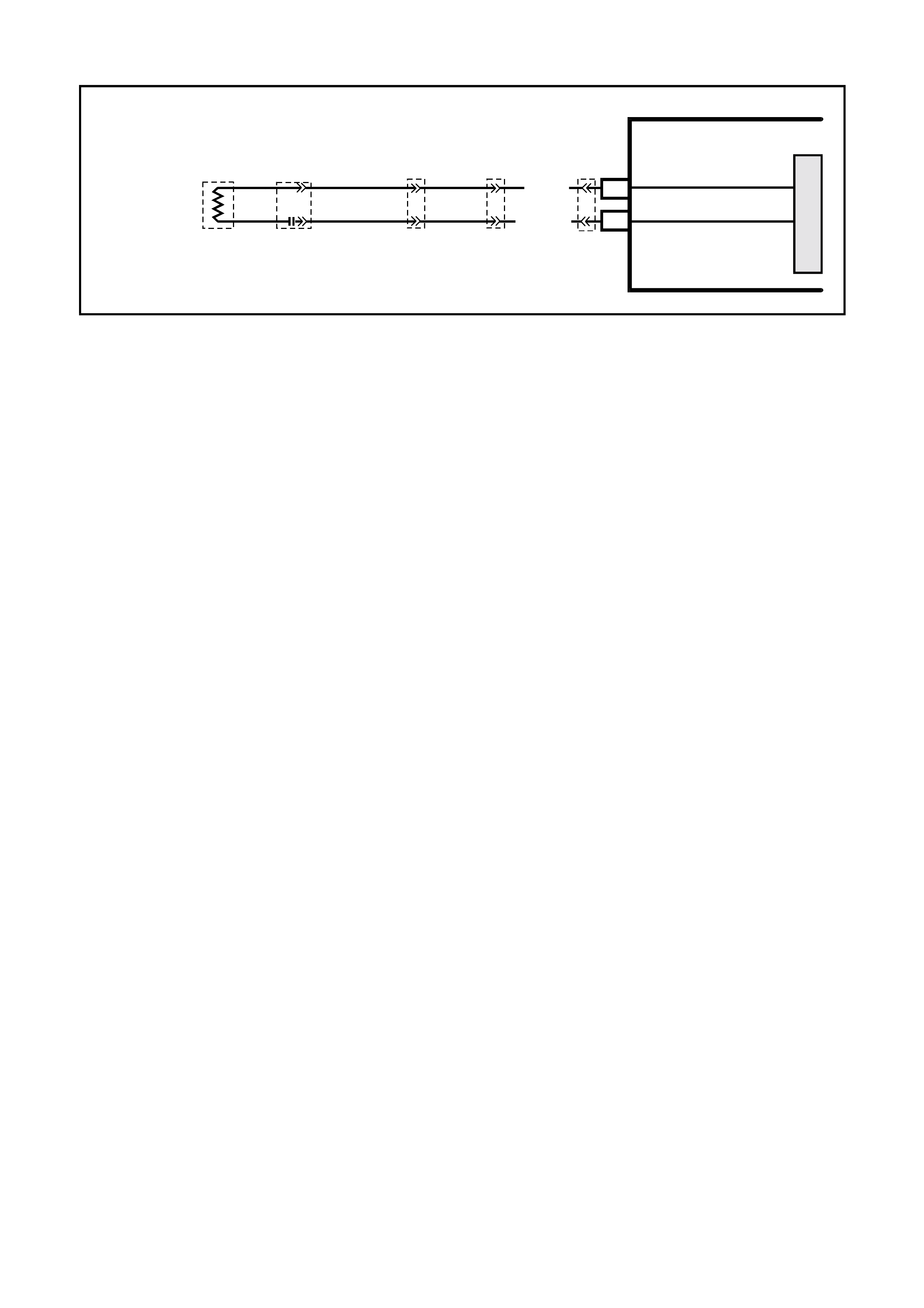

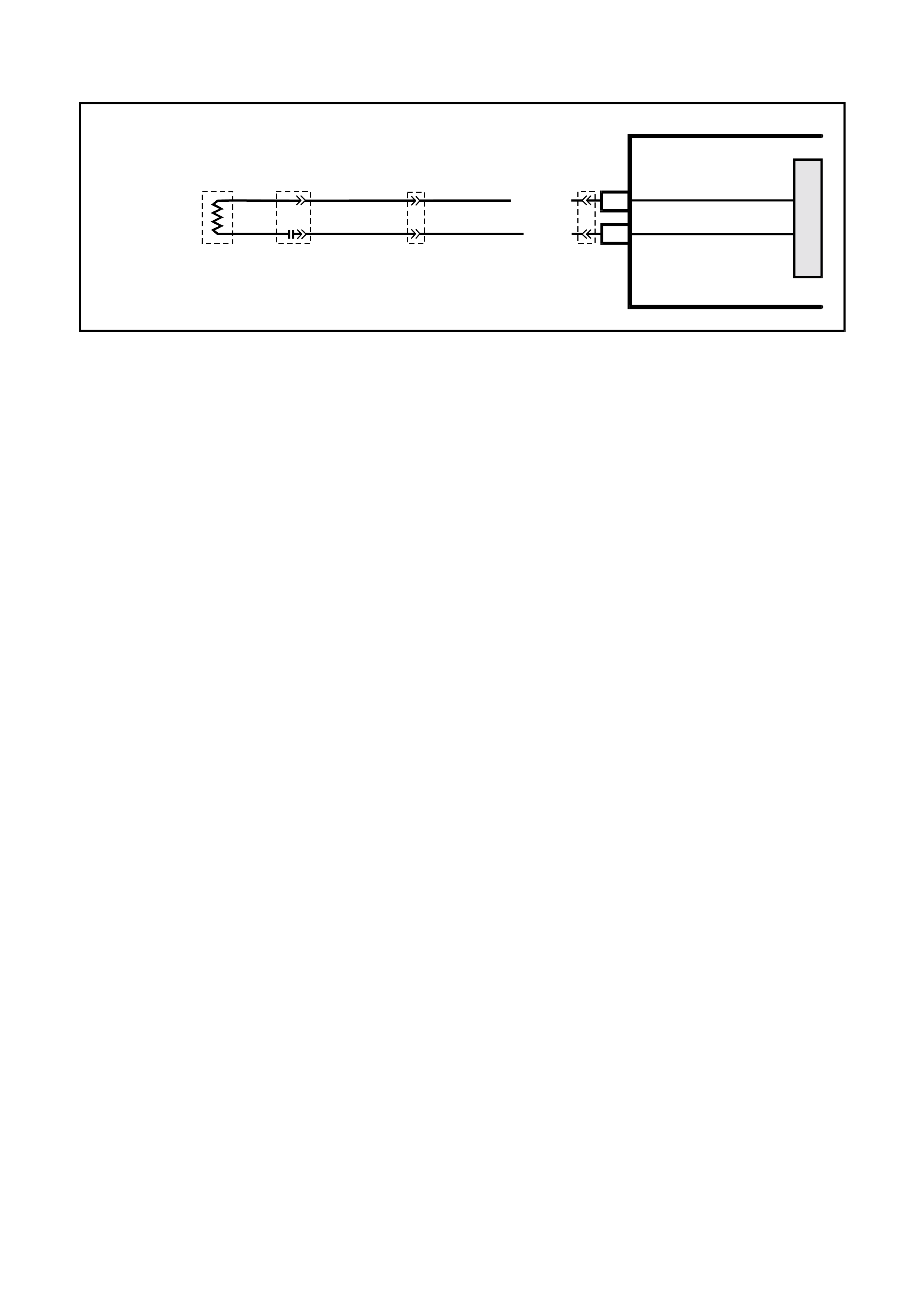

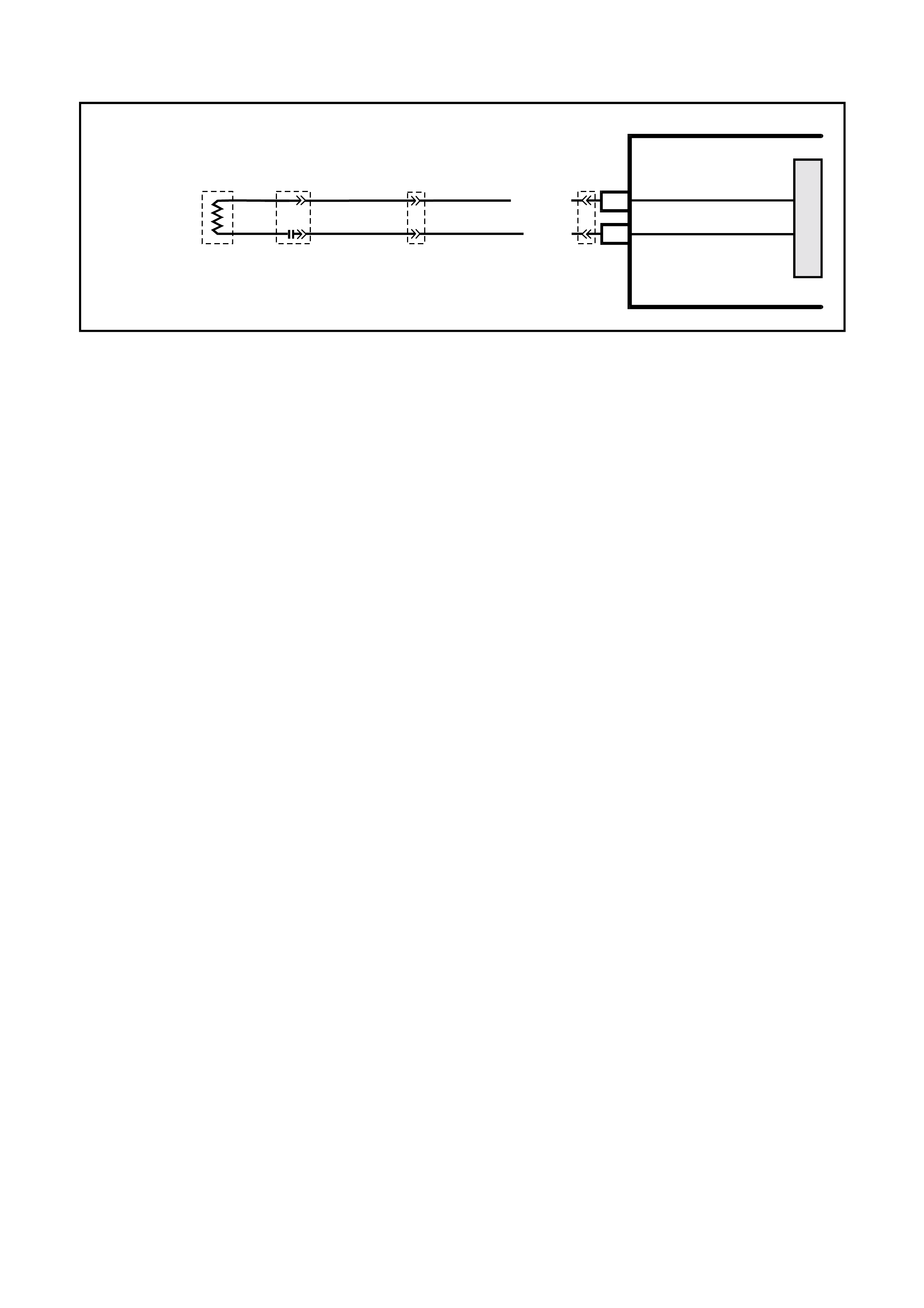

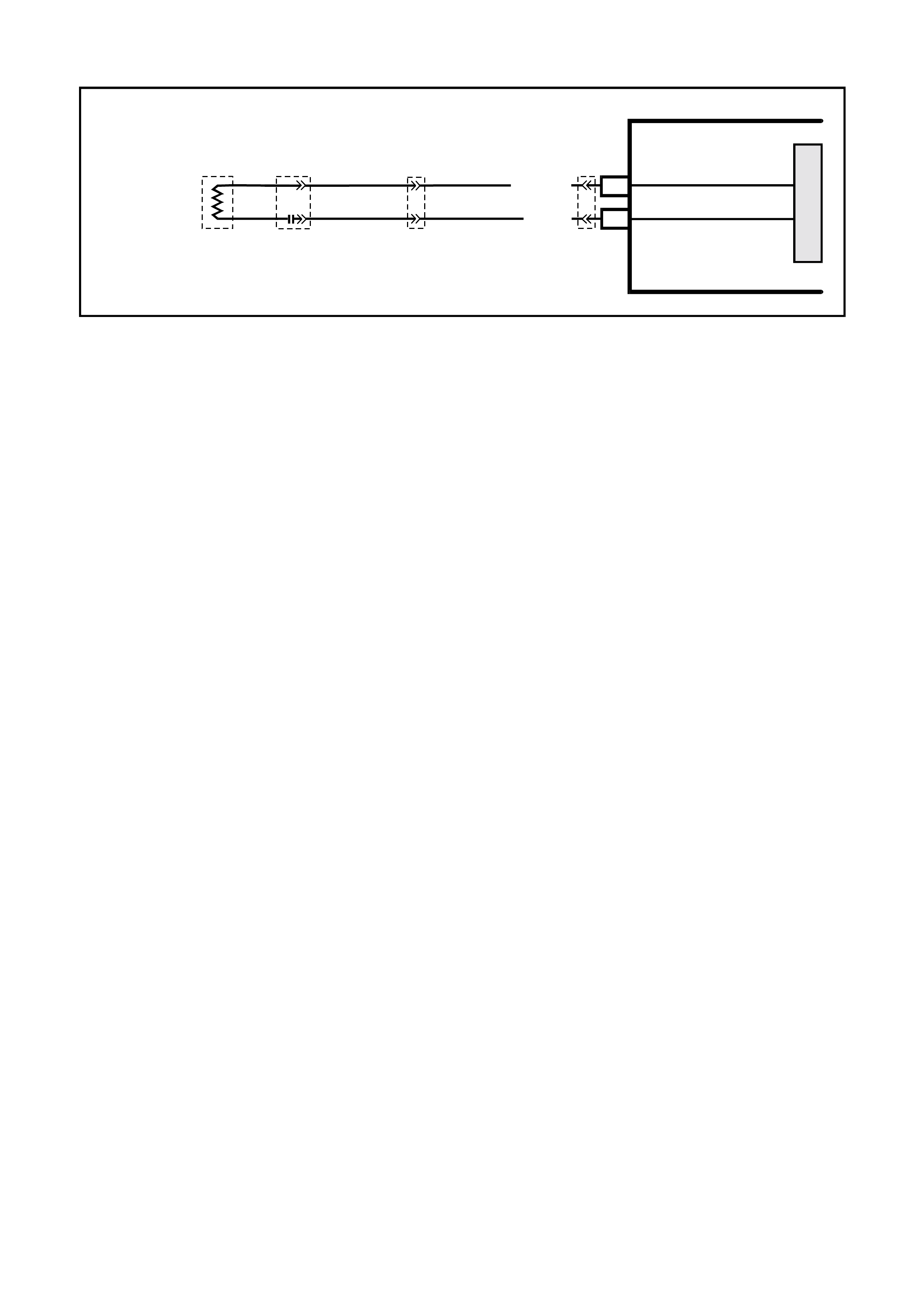

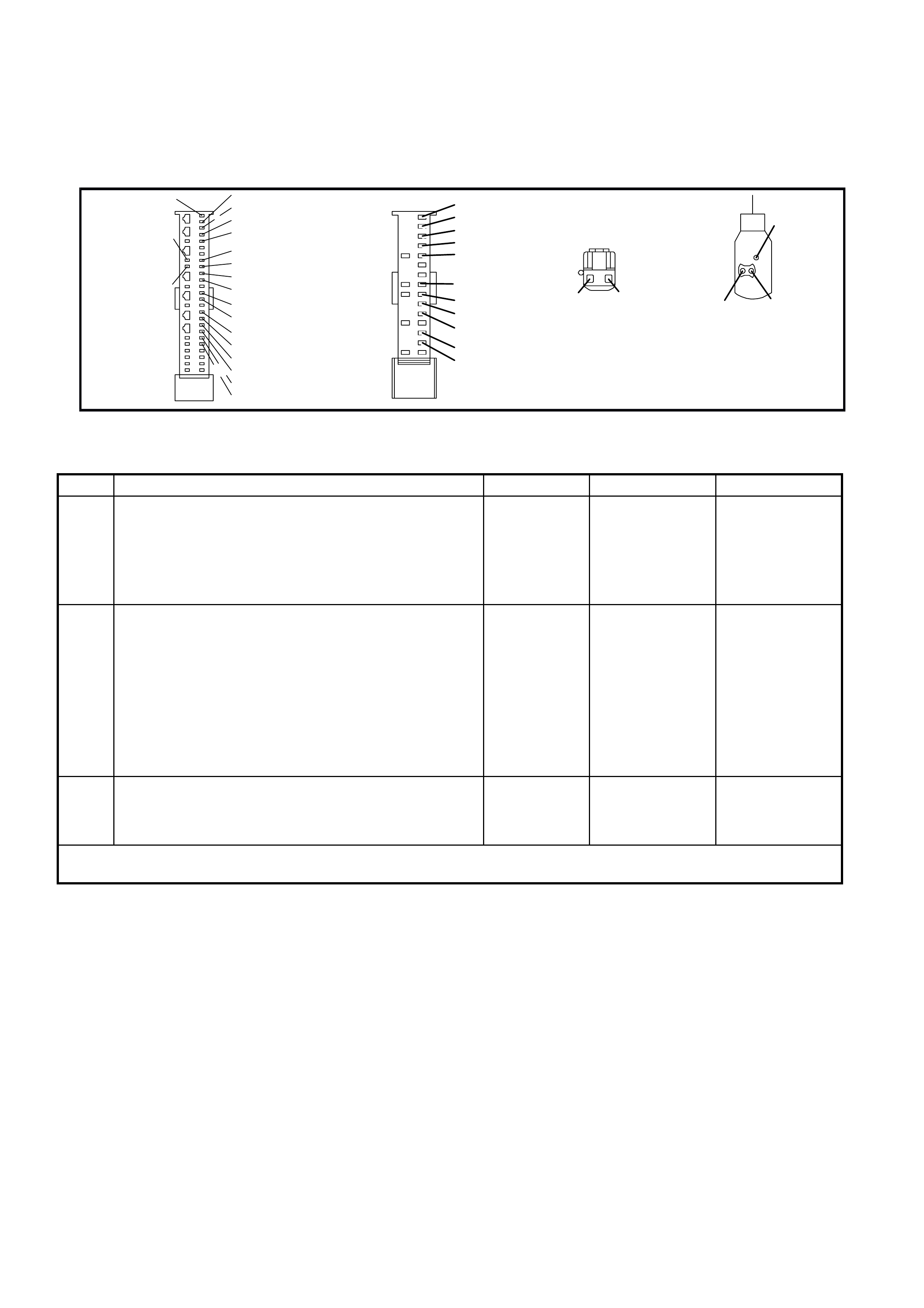

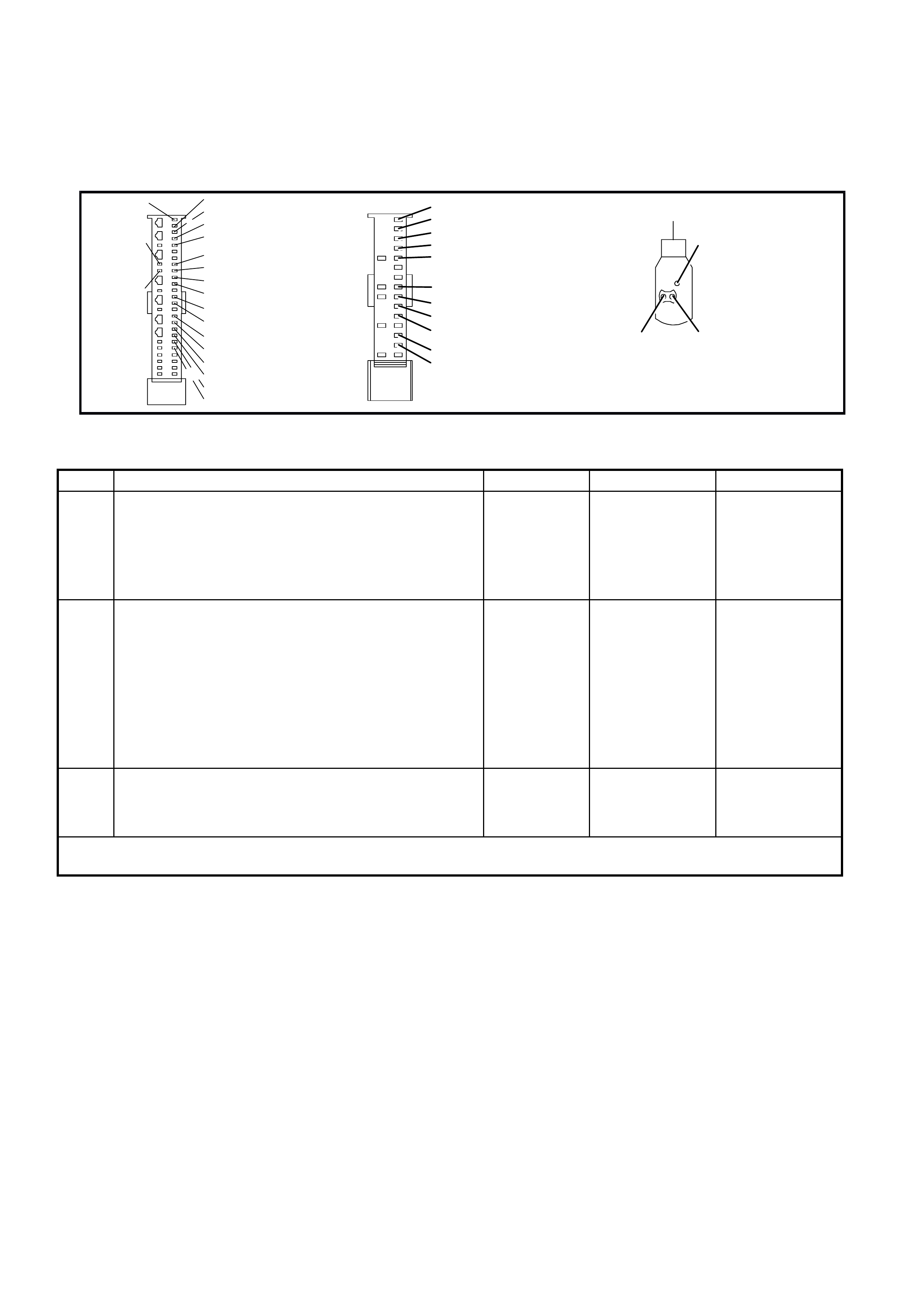

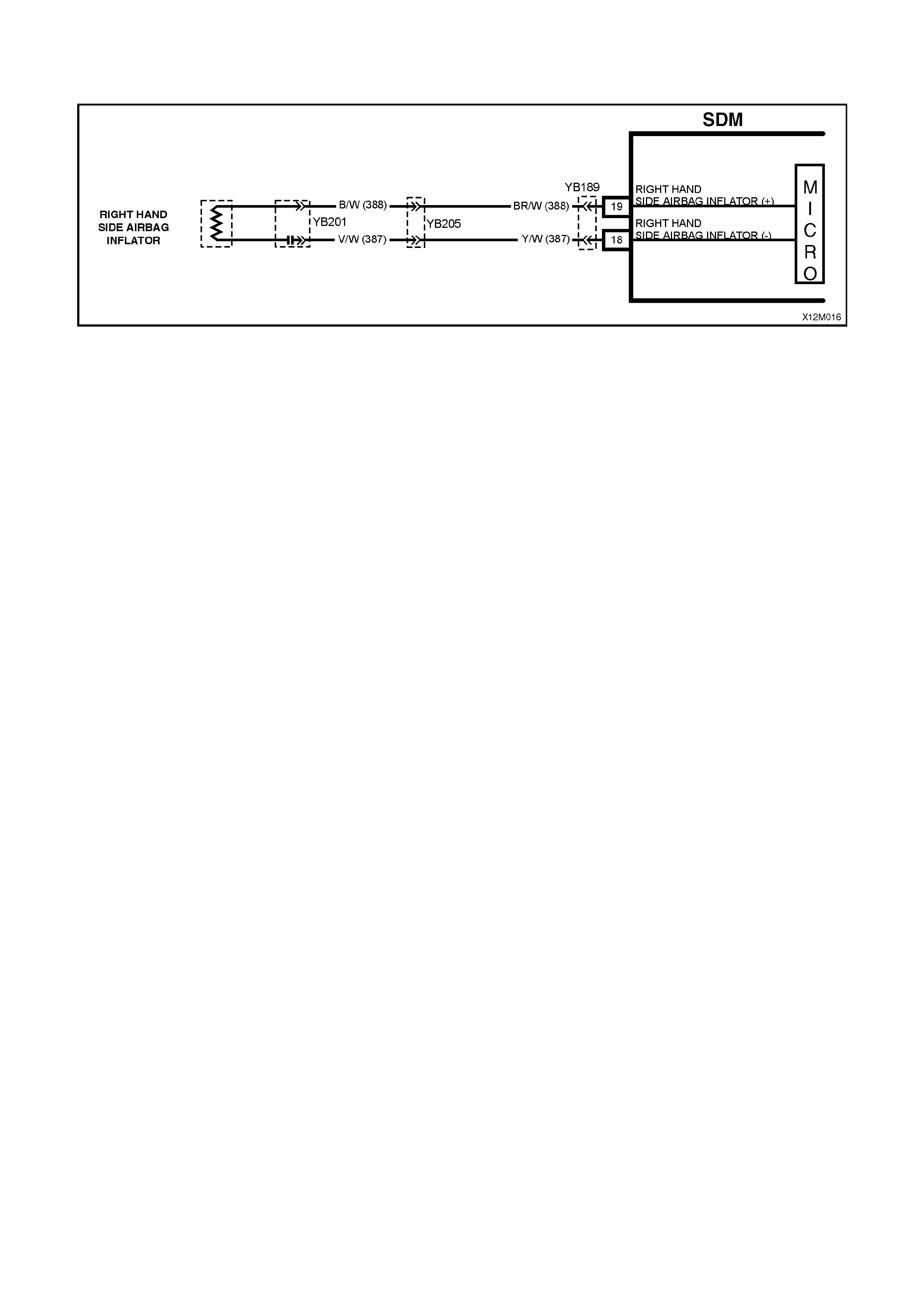

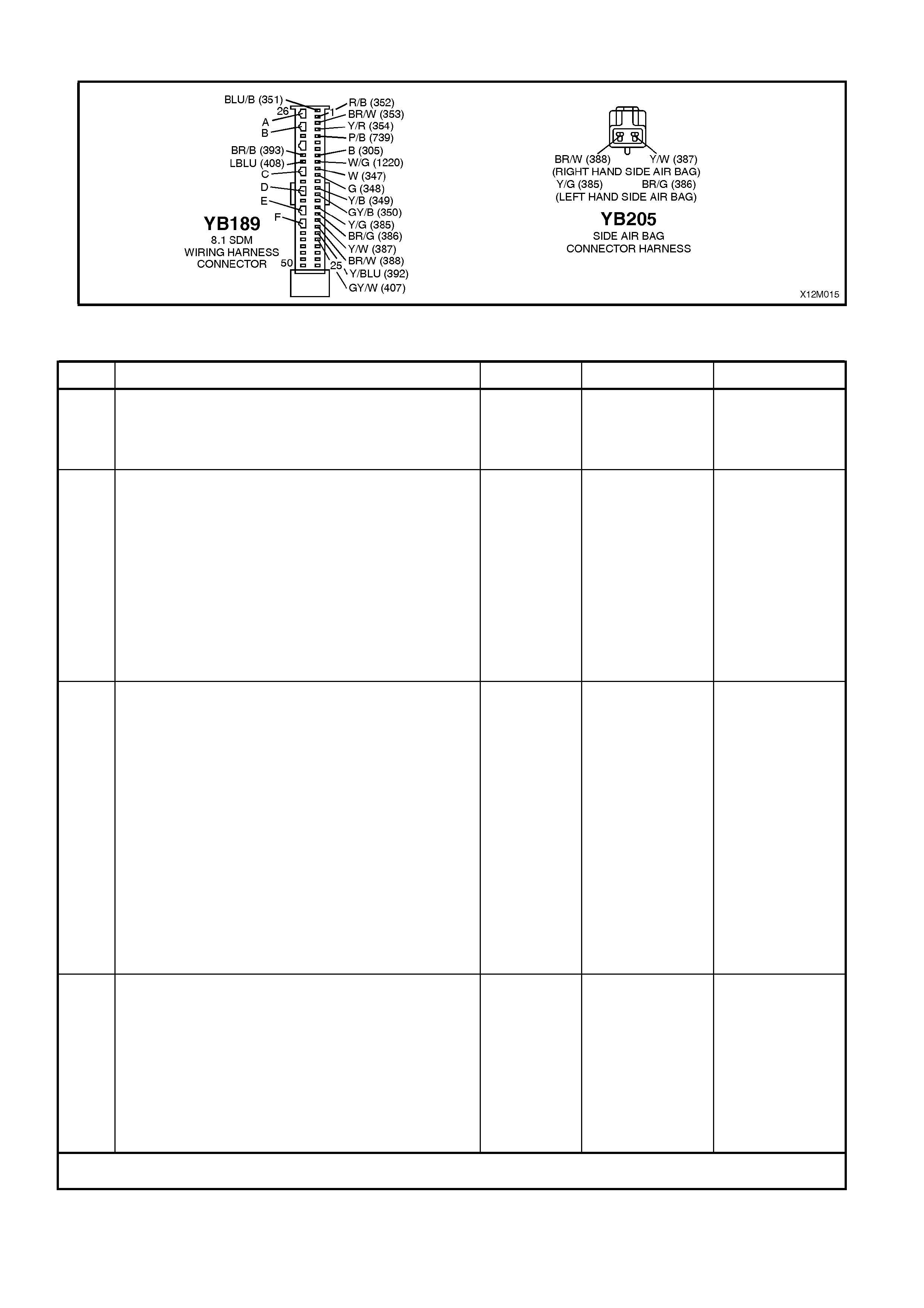

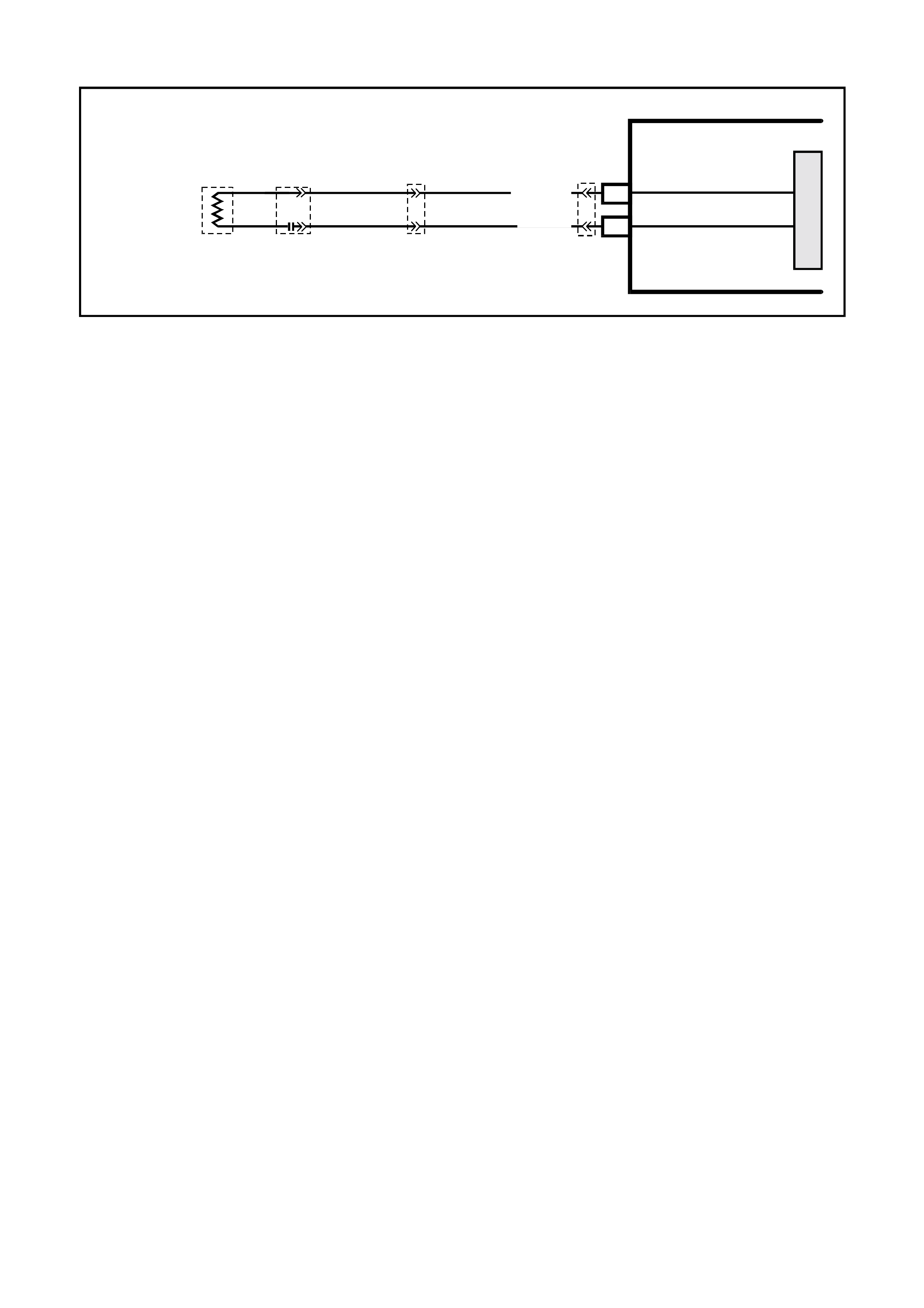

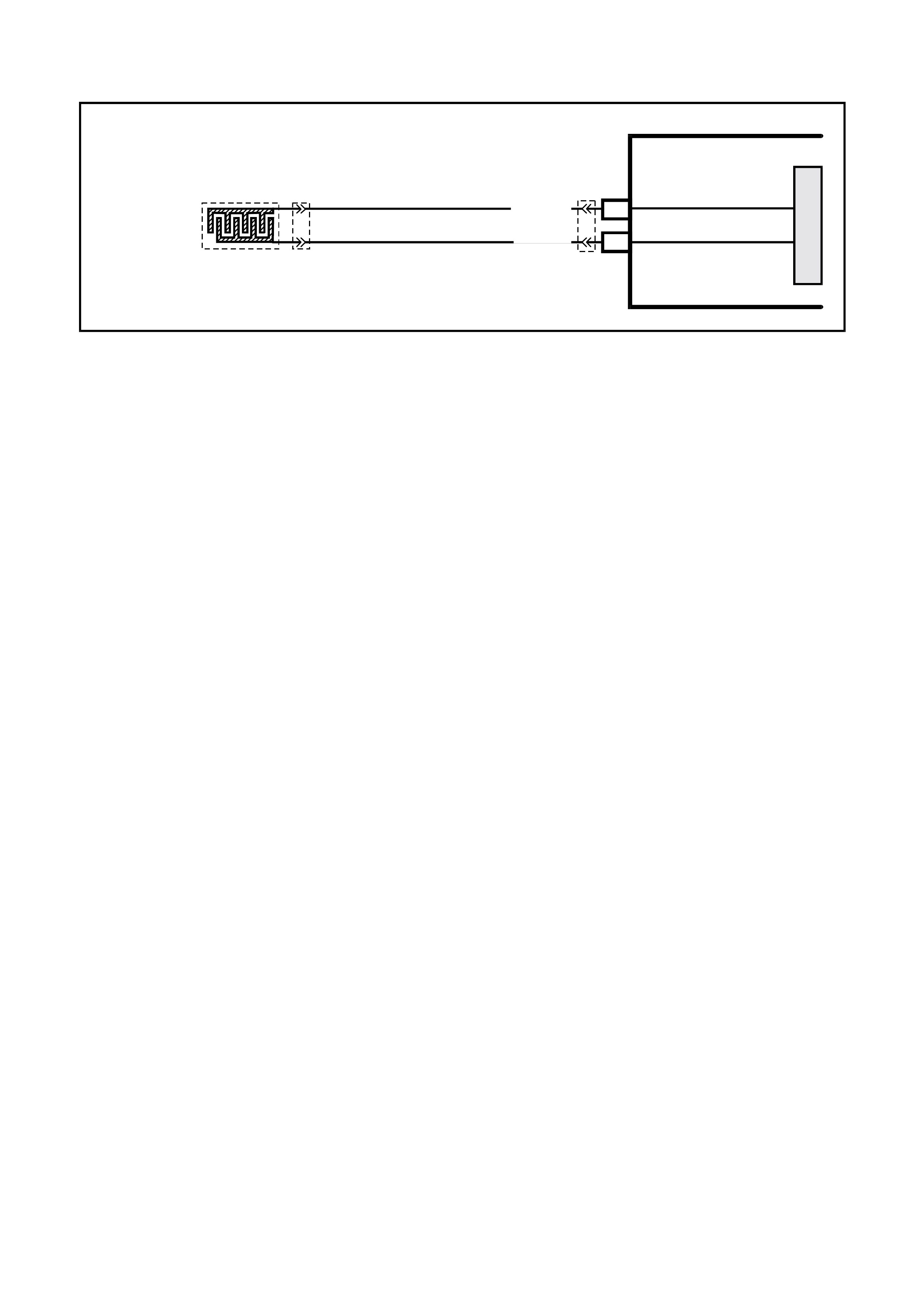

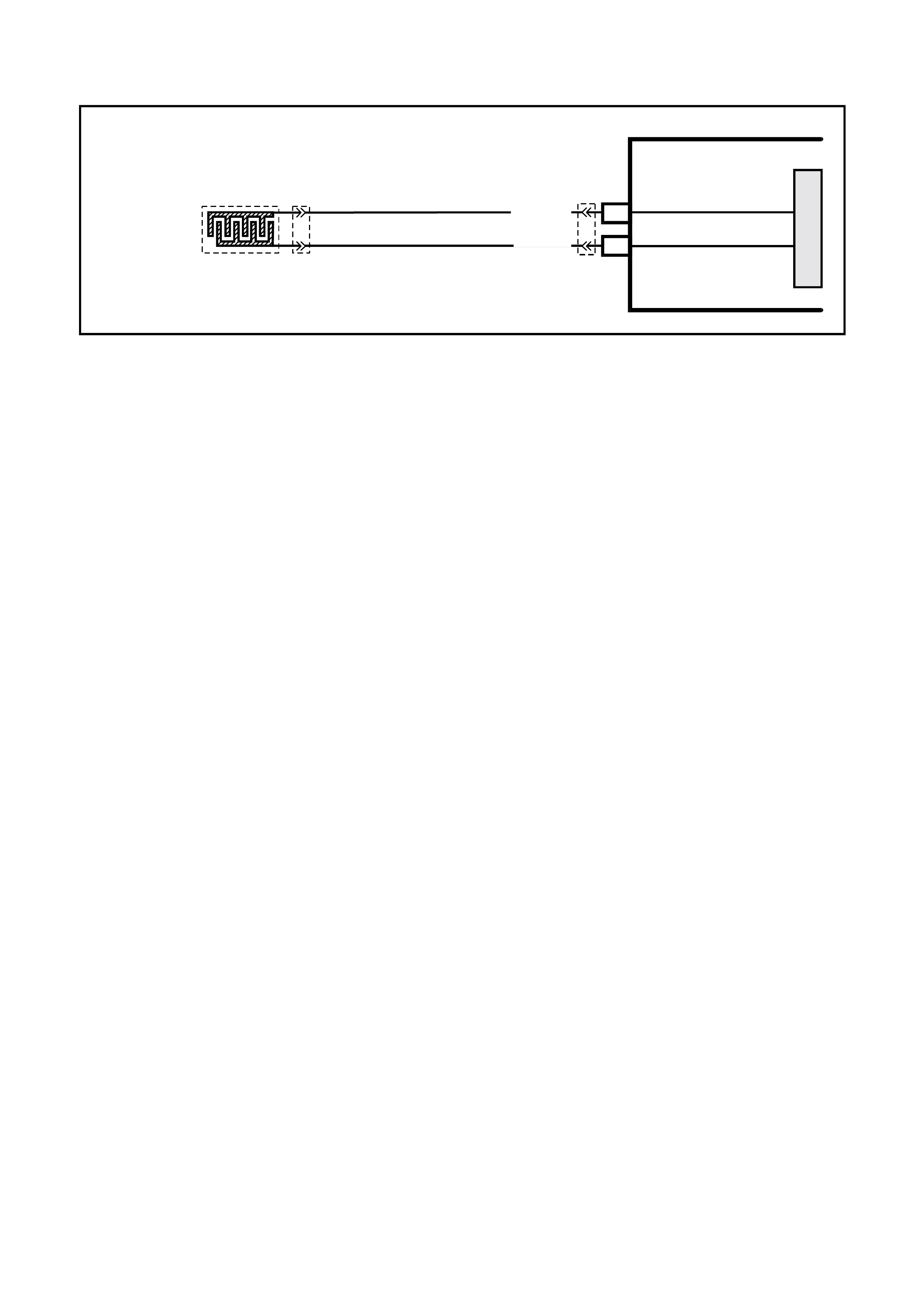

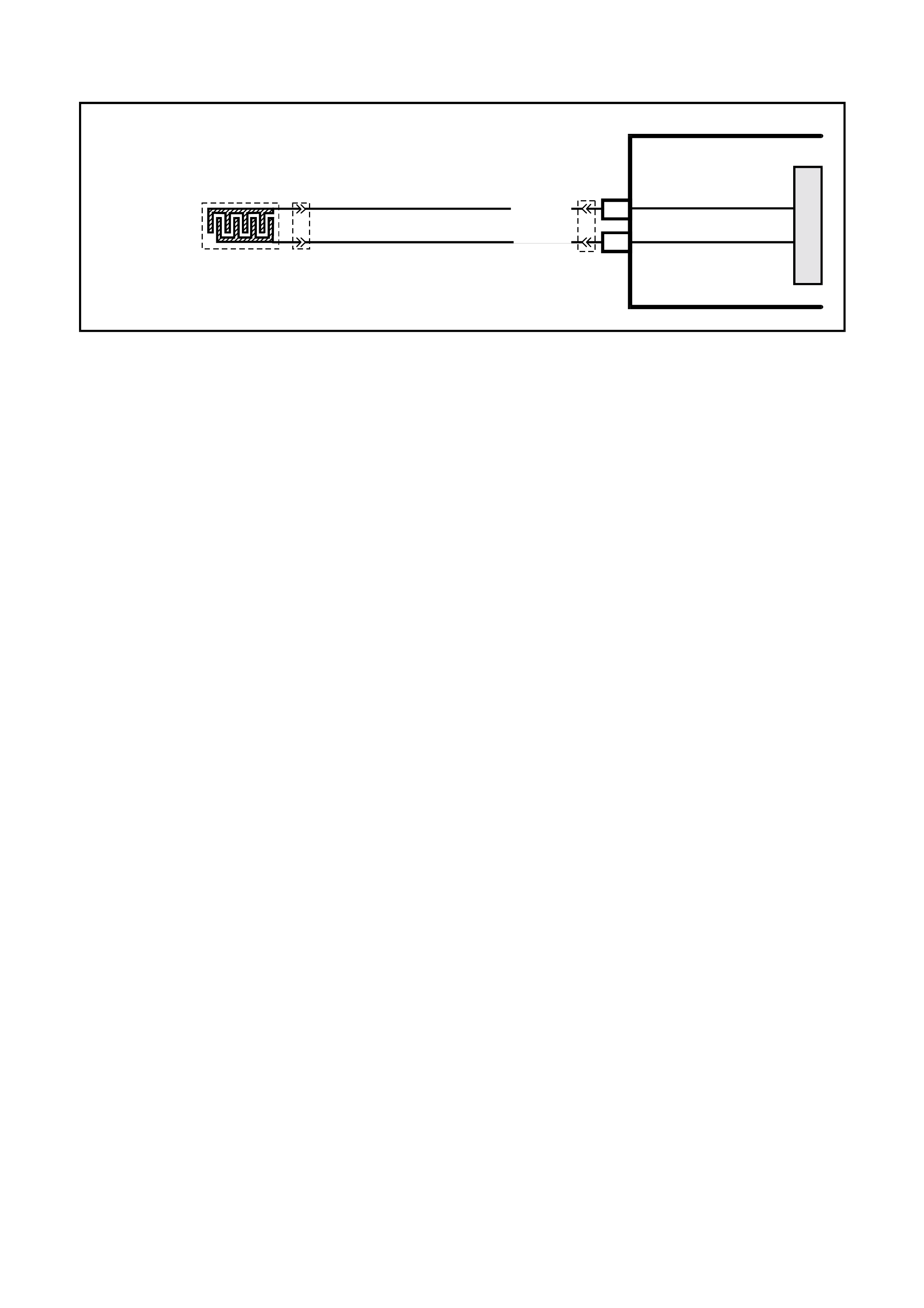

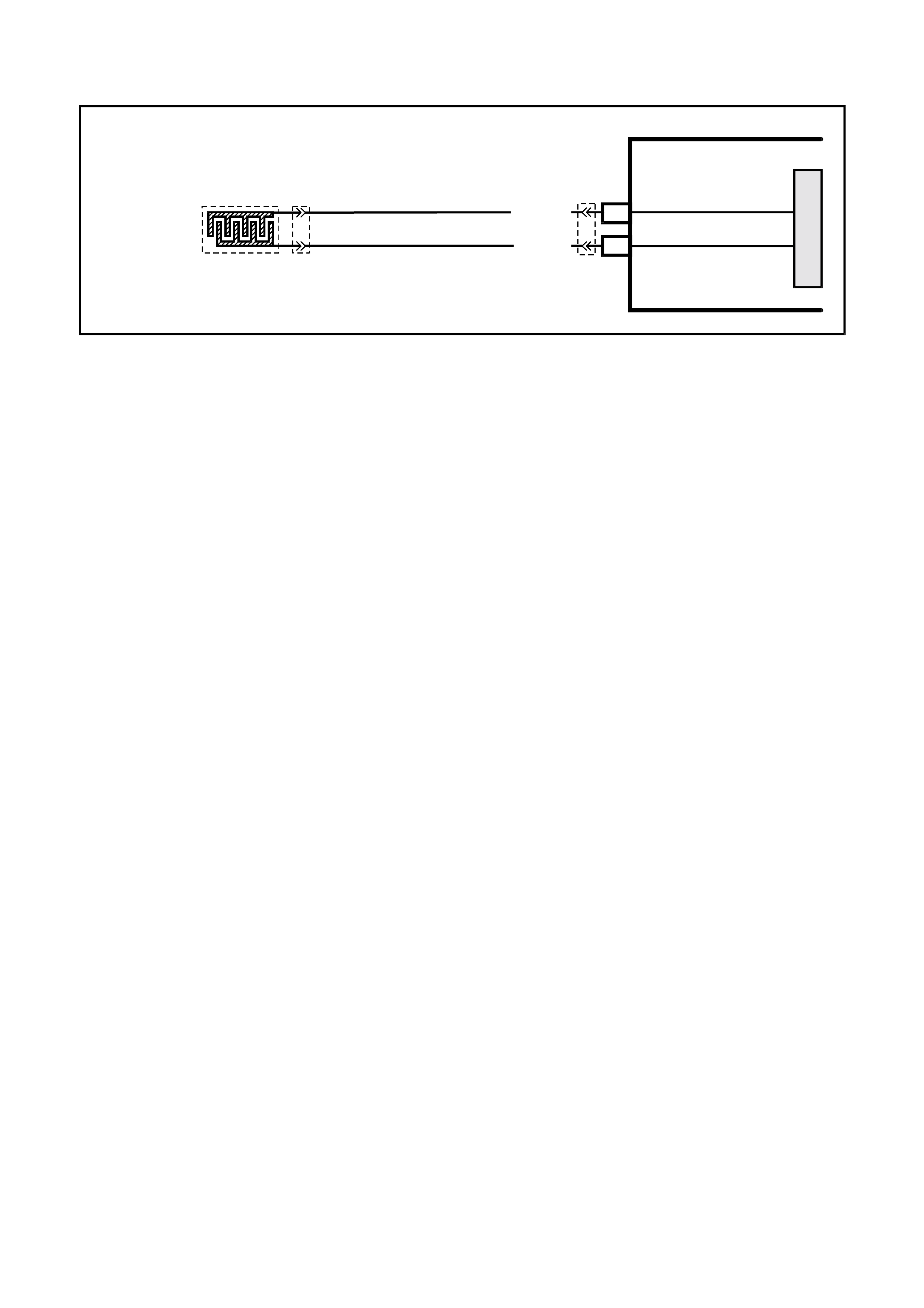

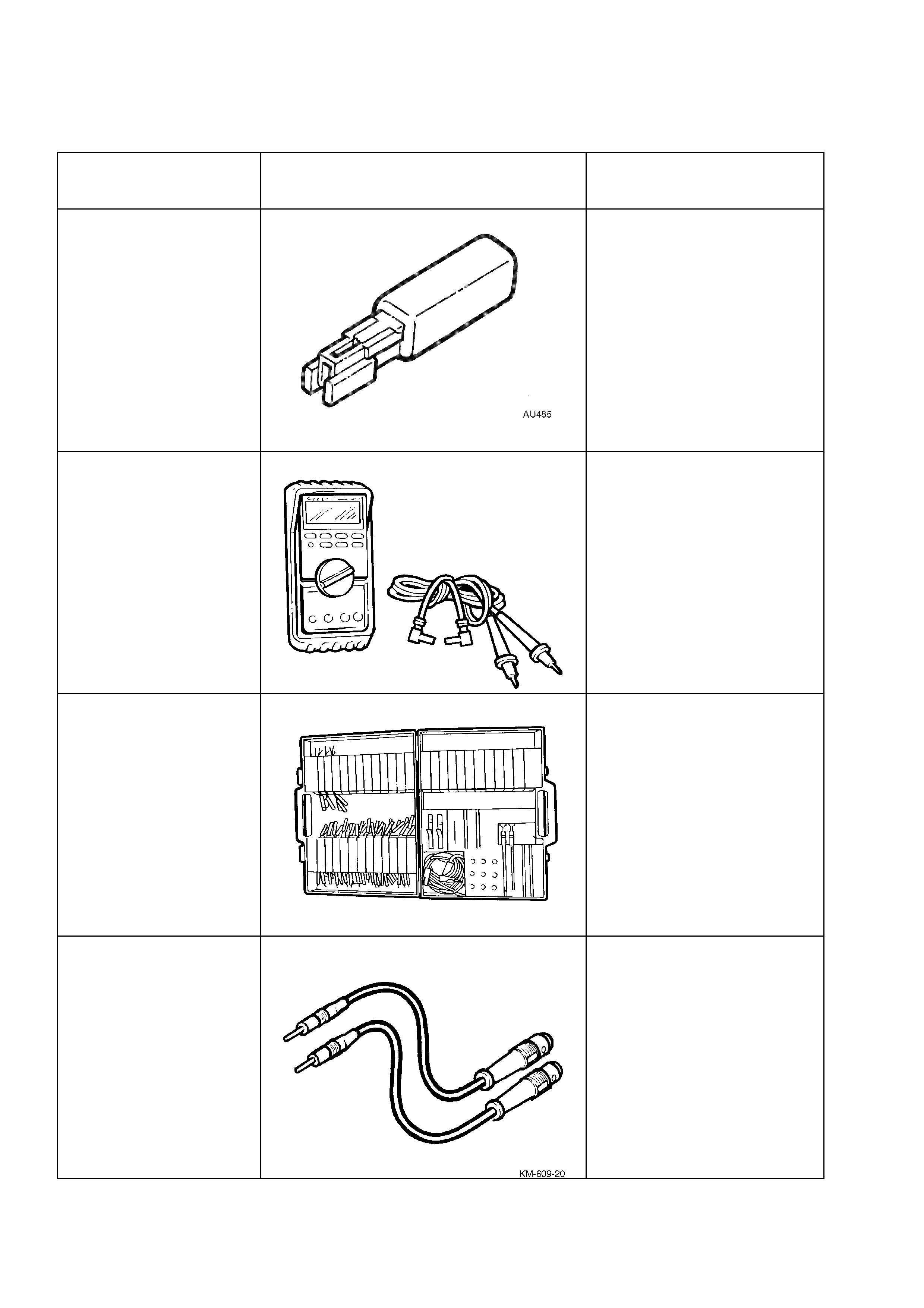

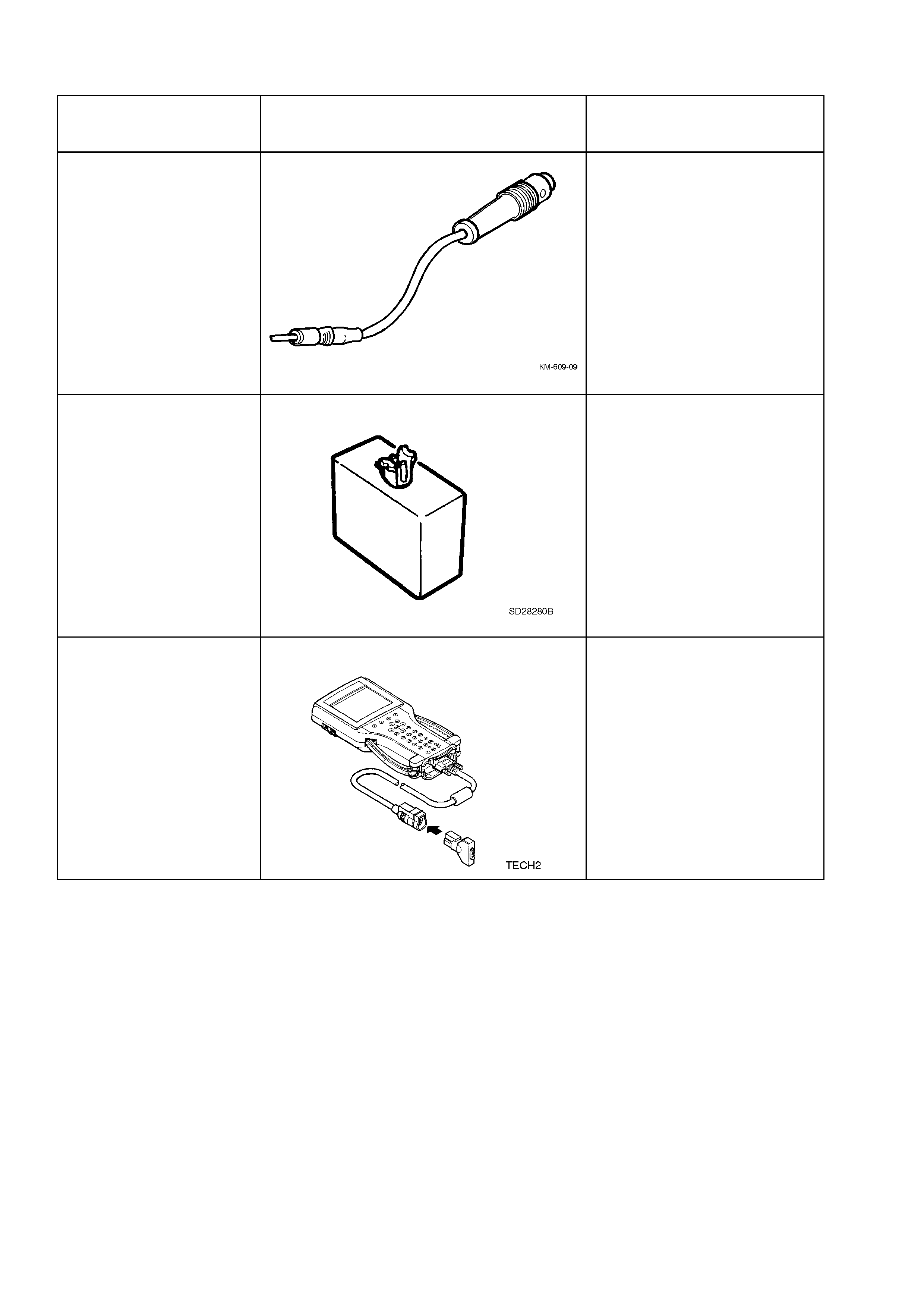

Figure 12M-2 illustrates the correct use and installation of the various SRS diagnostic service tools (SD28280B &

AU485) and test lead set (KM-609-20) which are called up in the various diagnostic charts.

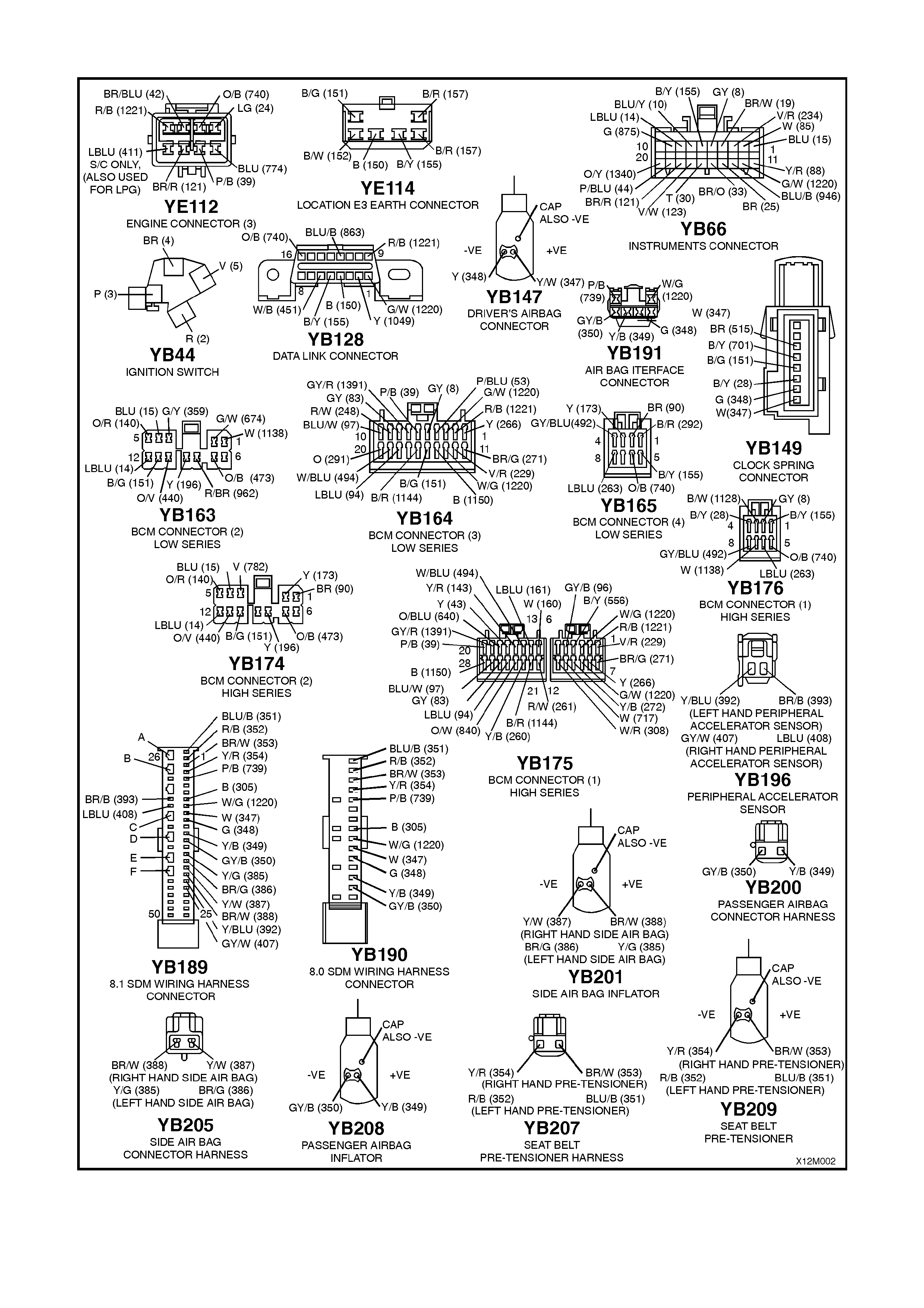

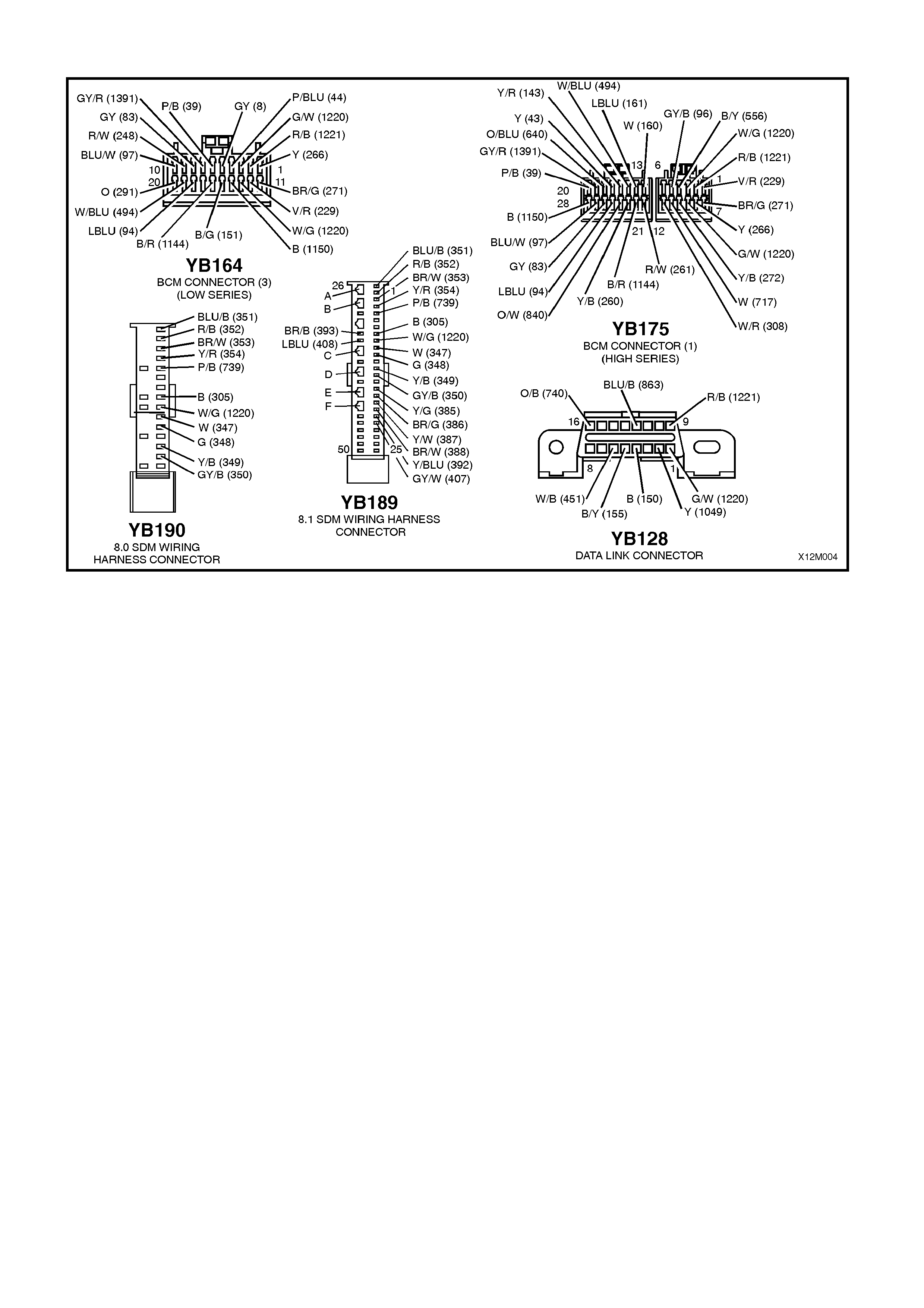

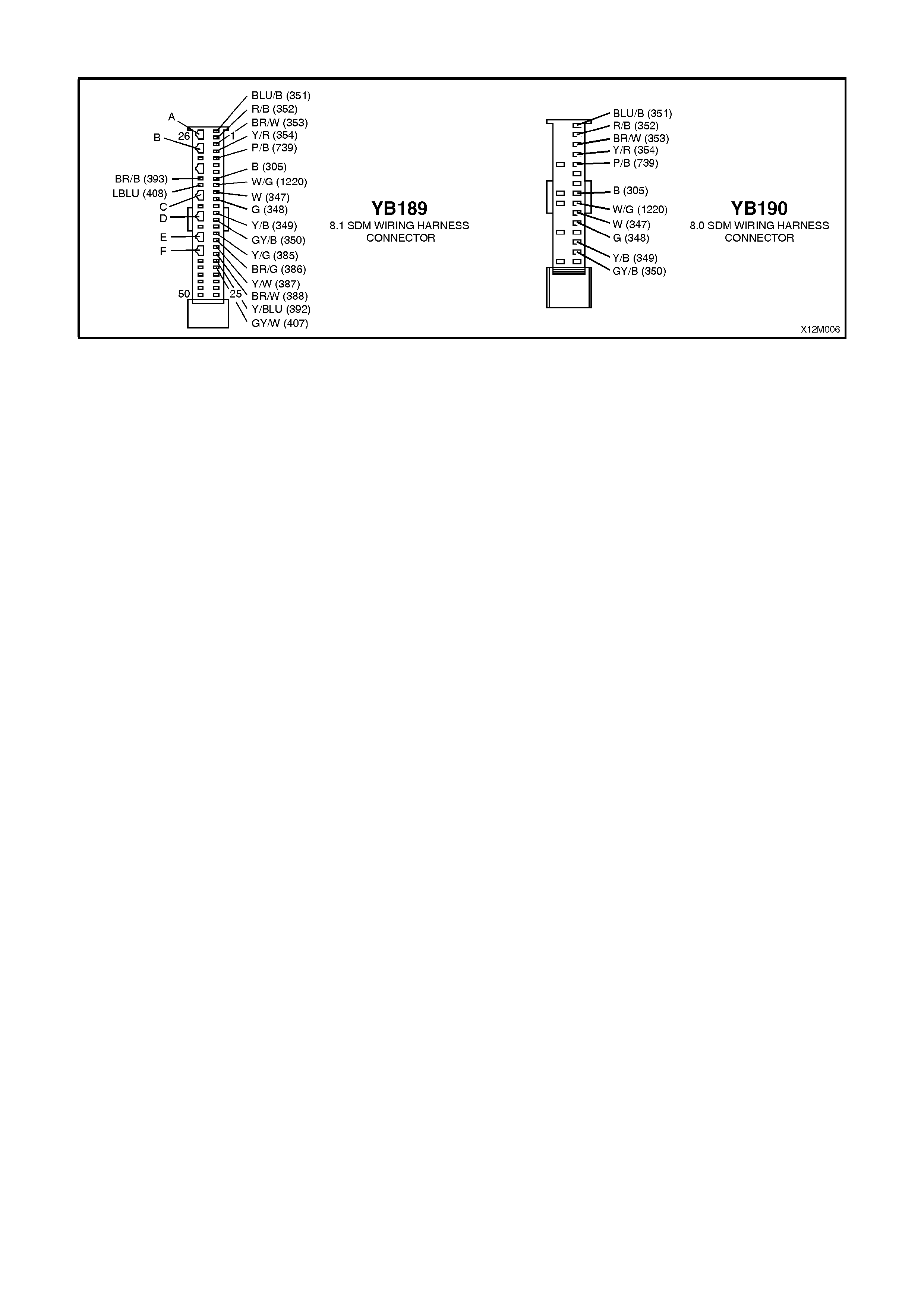

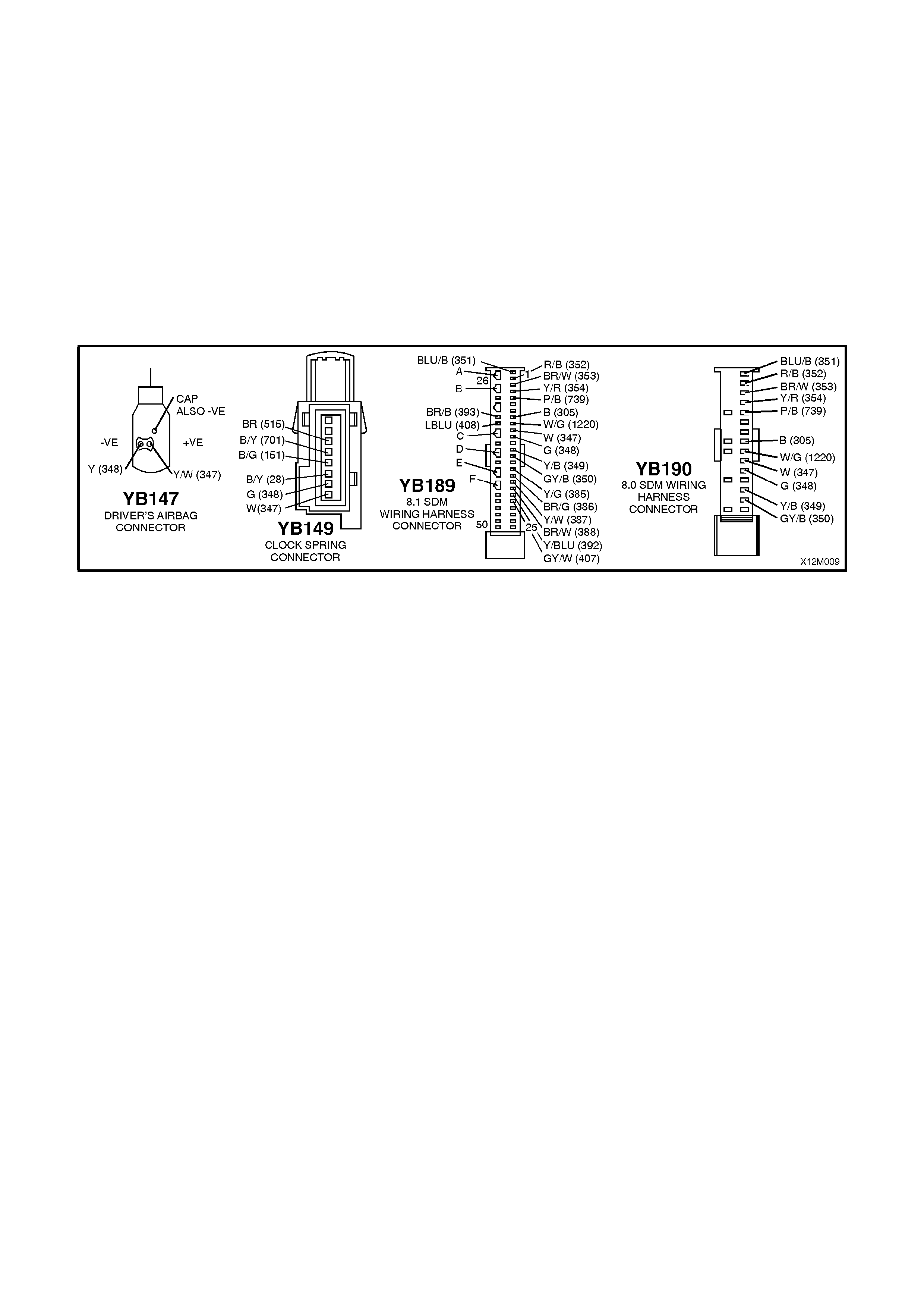

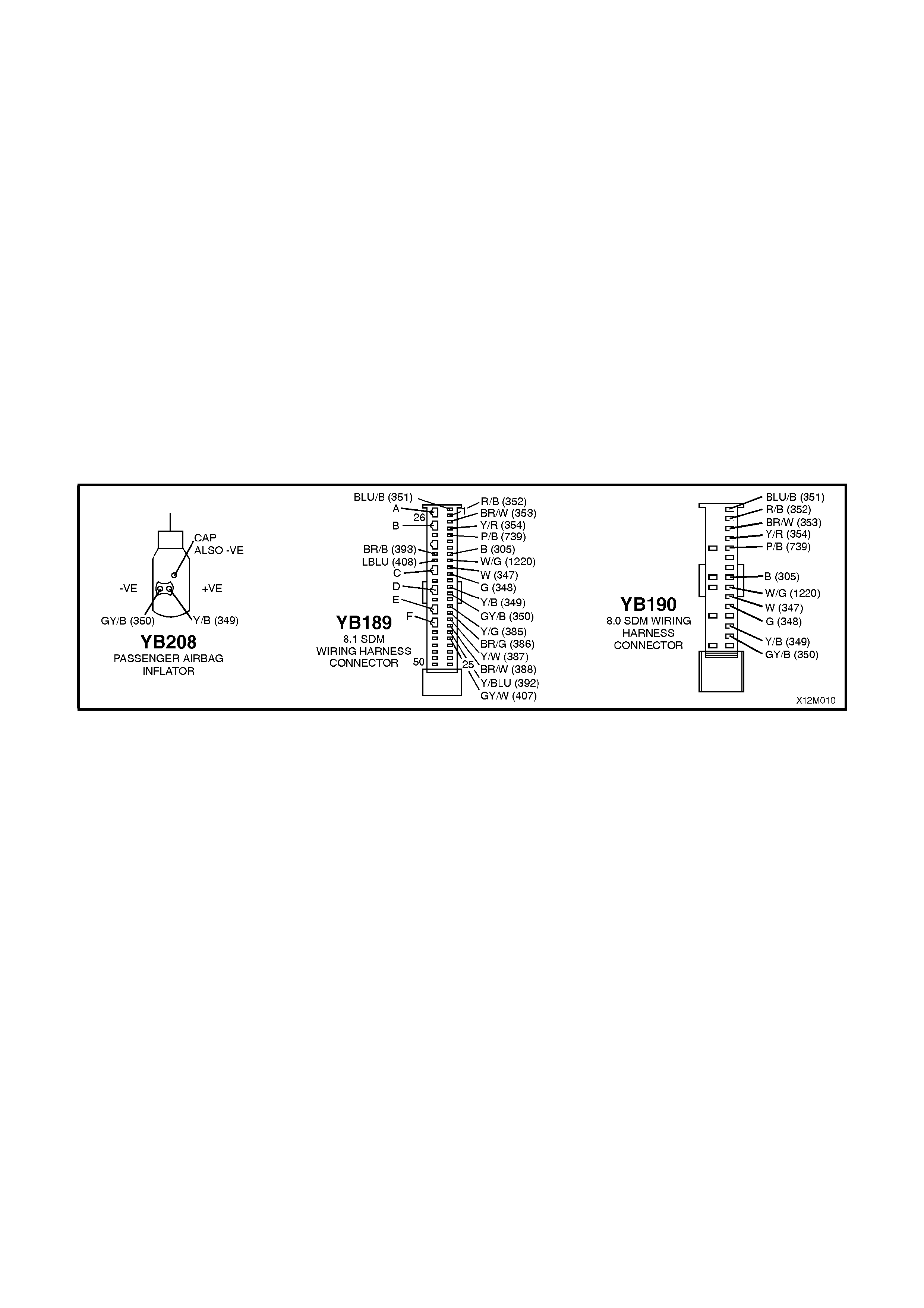

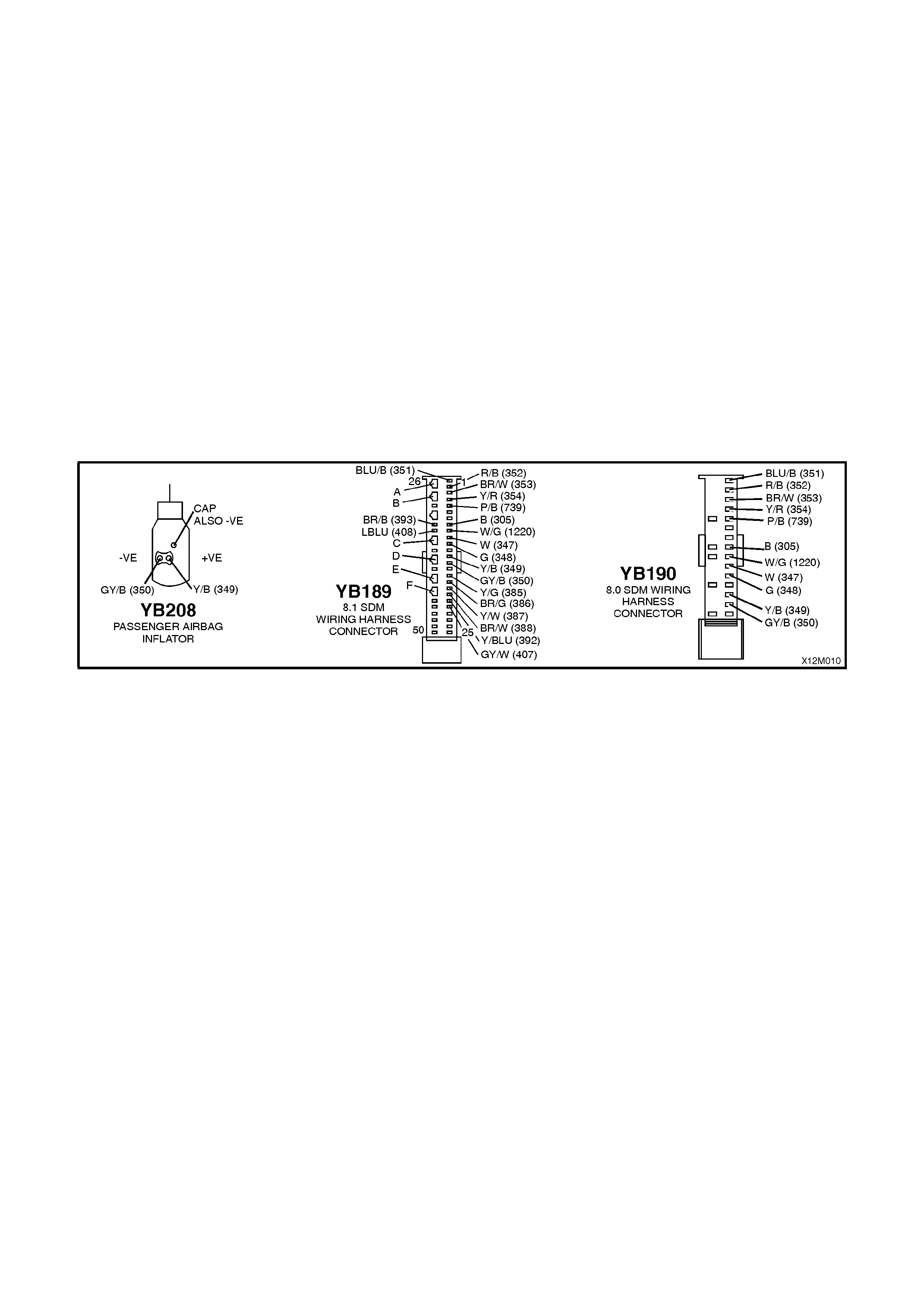

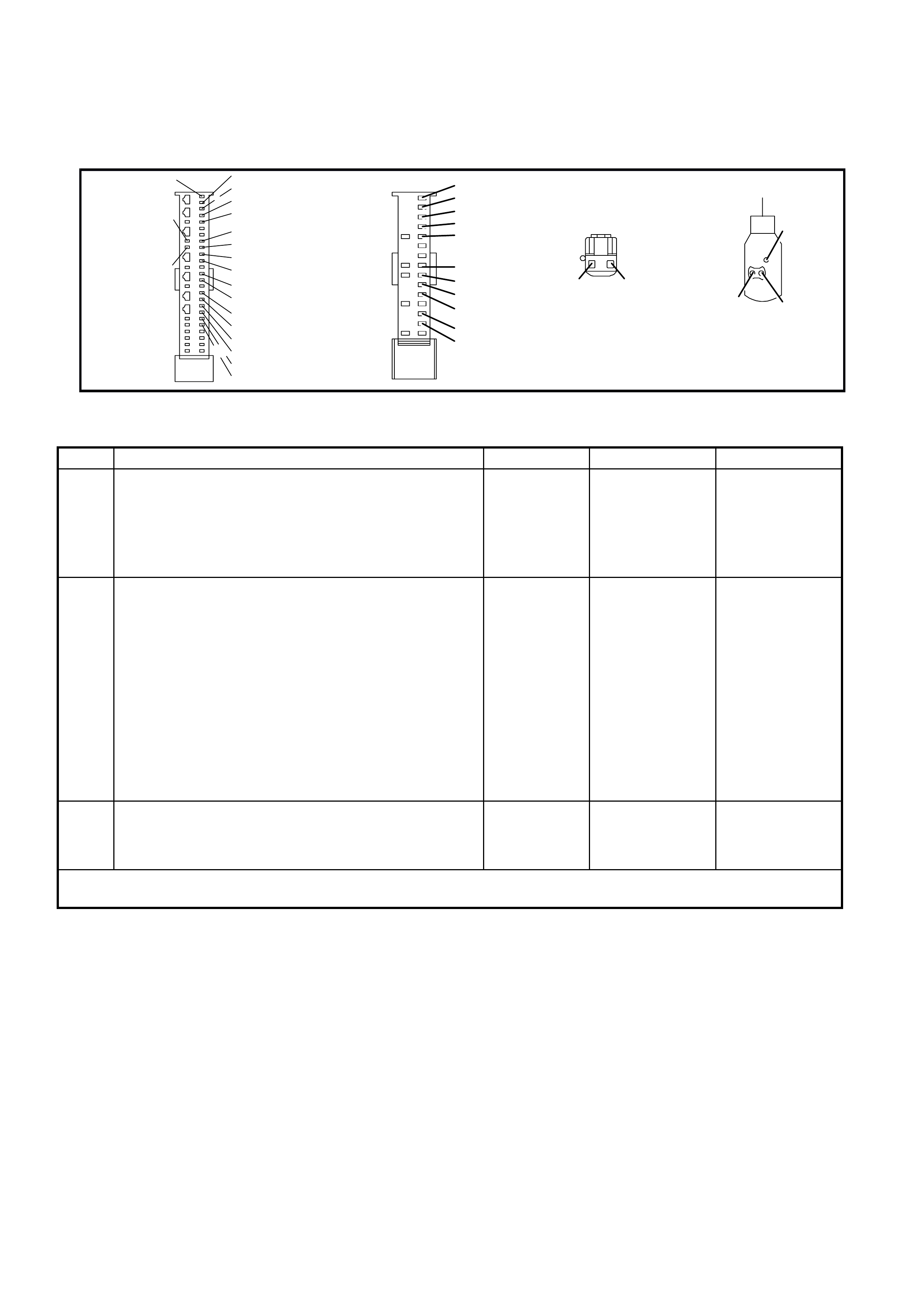

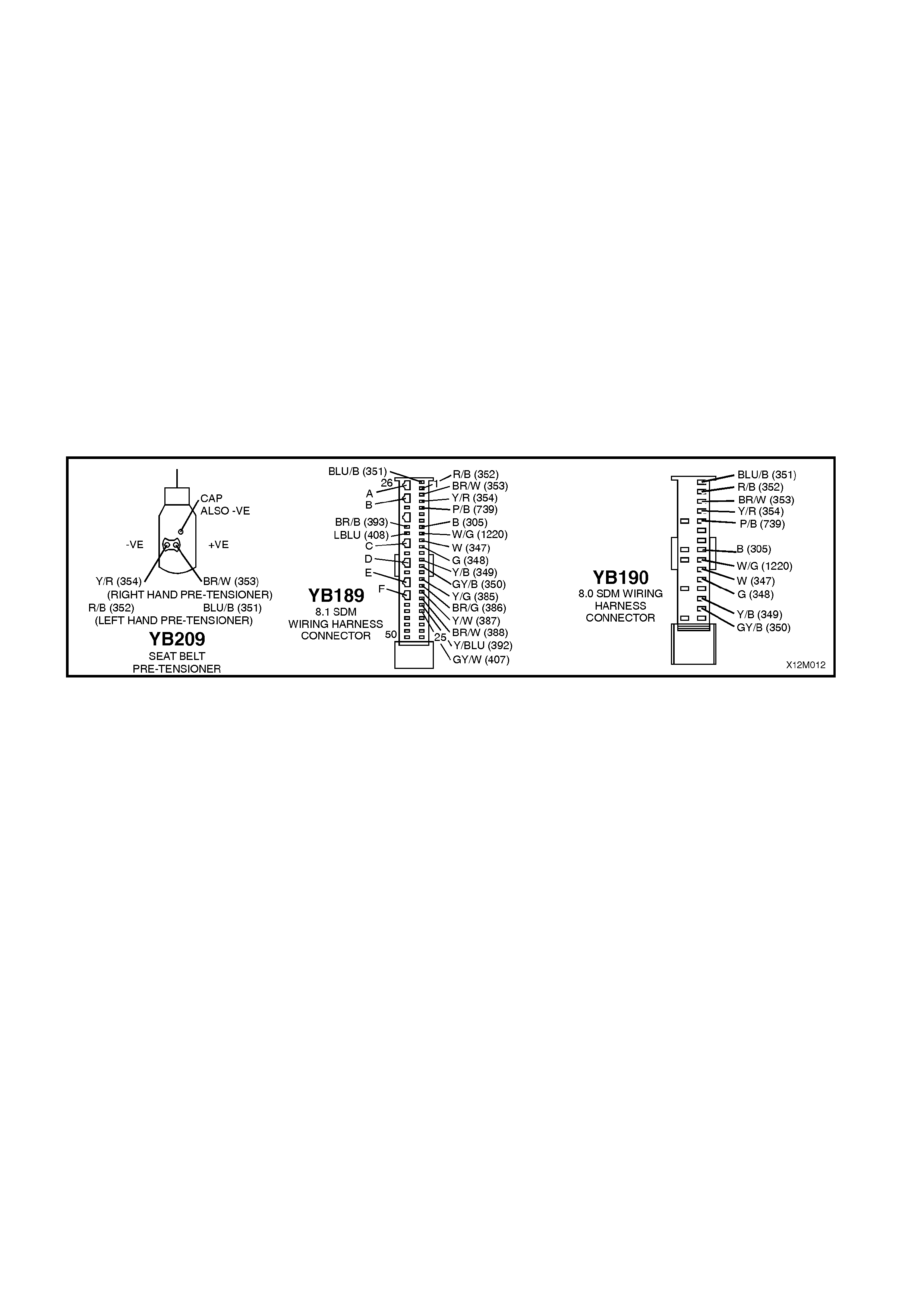

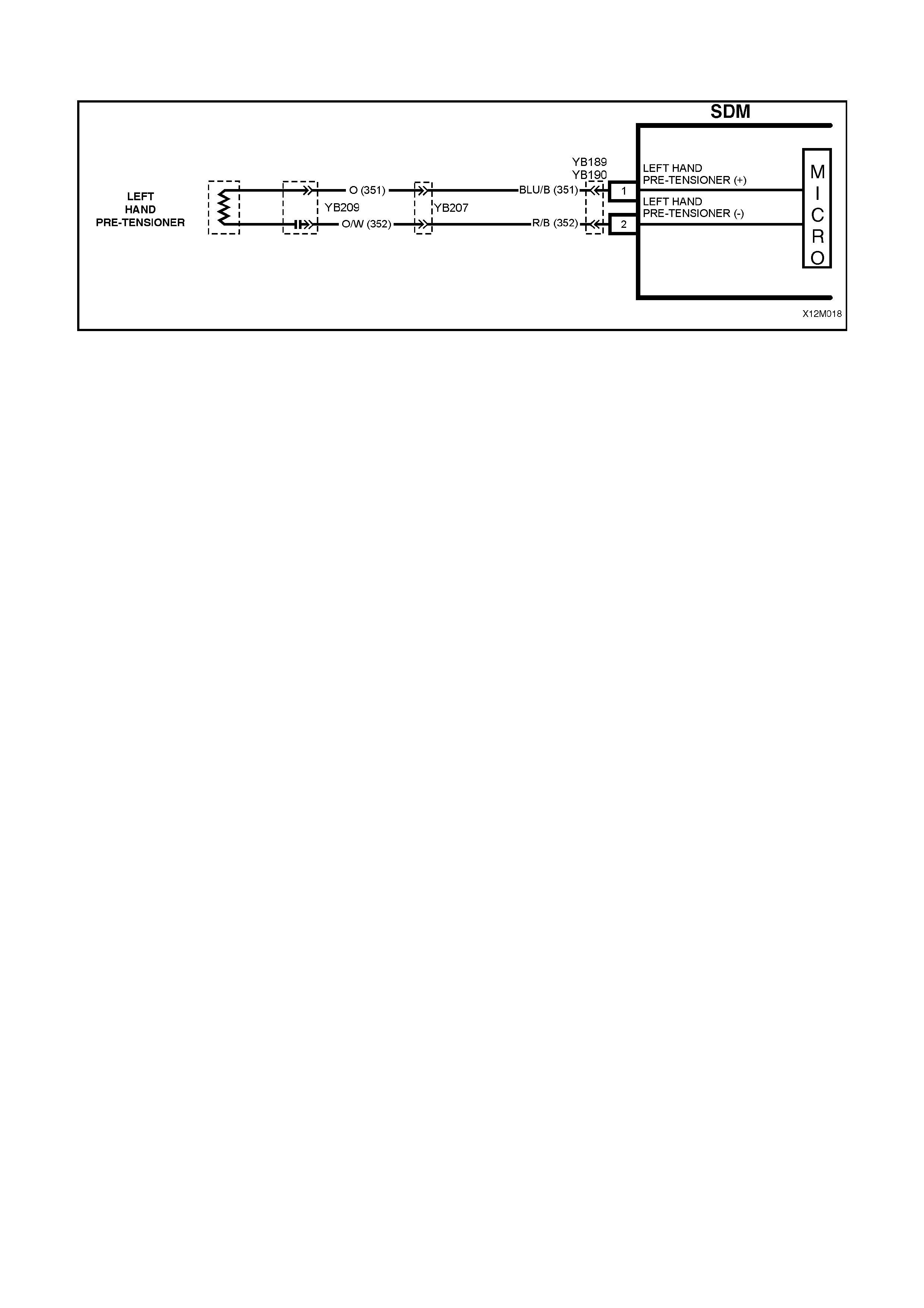

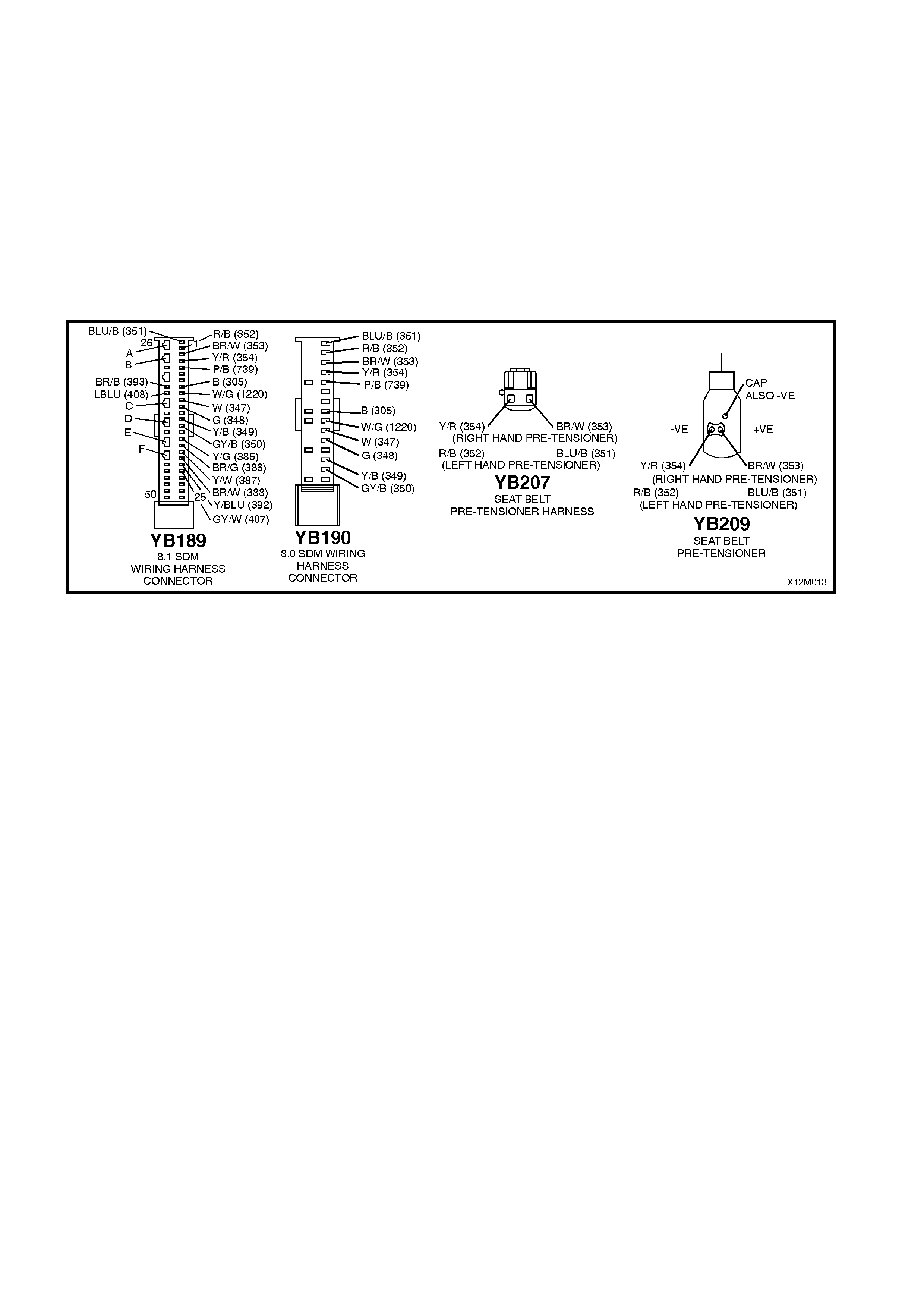

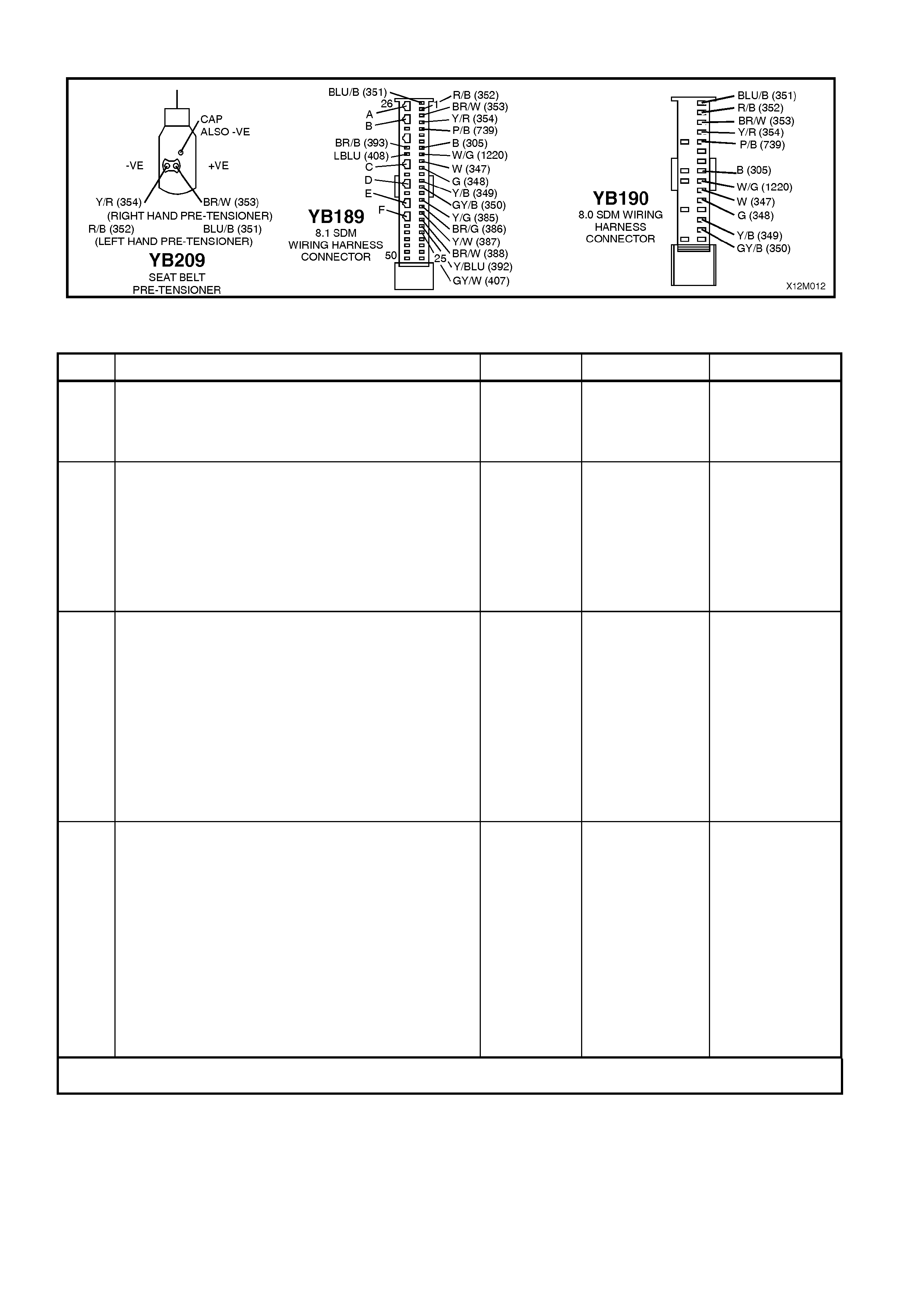

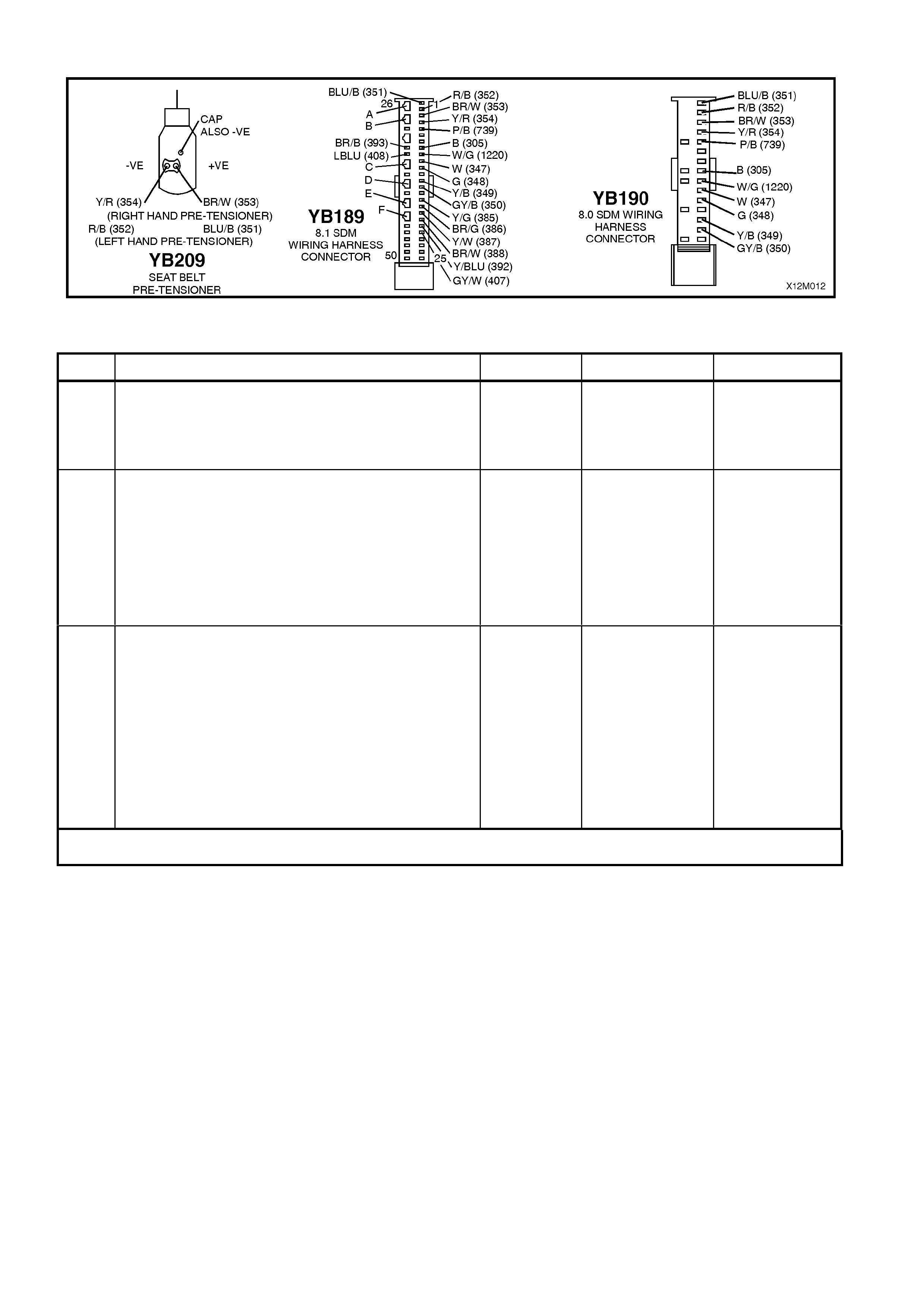

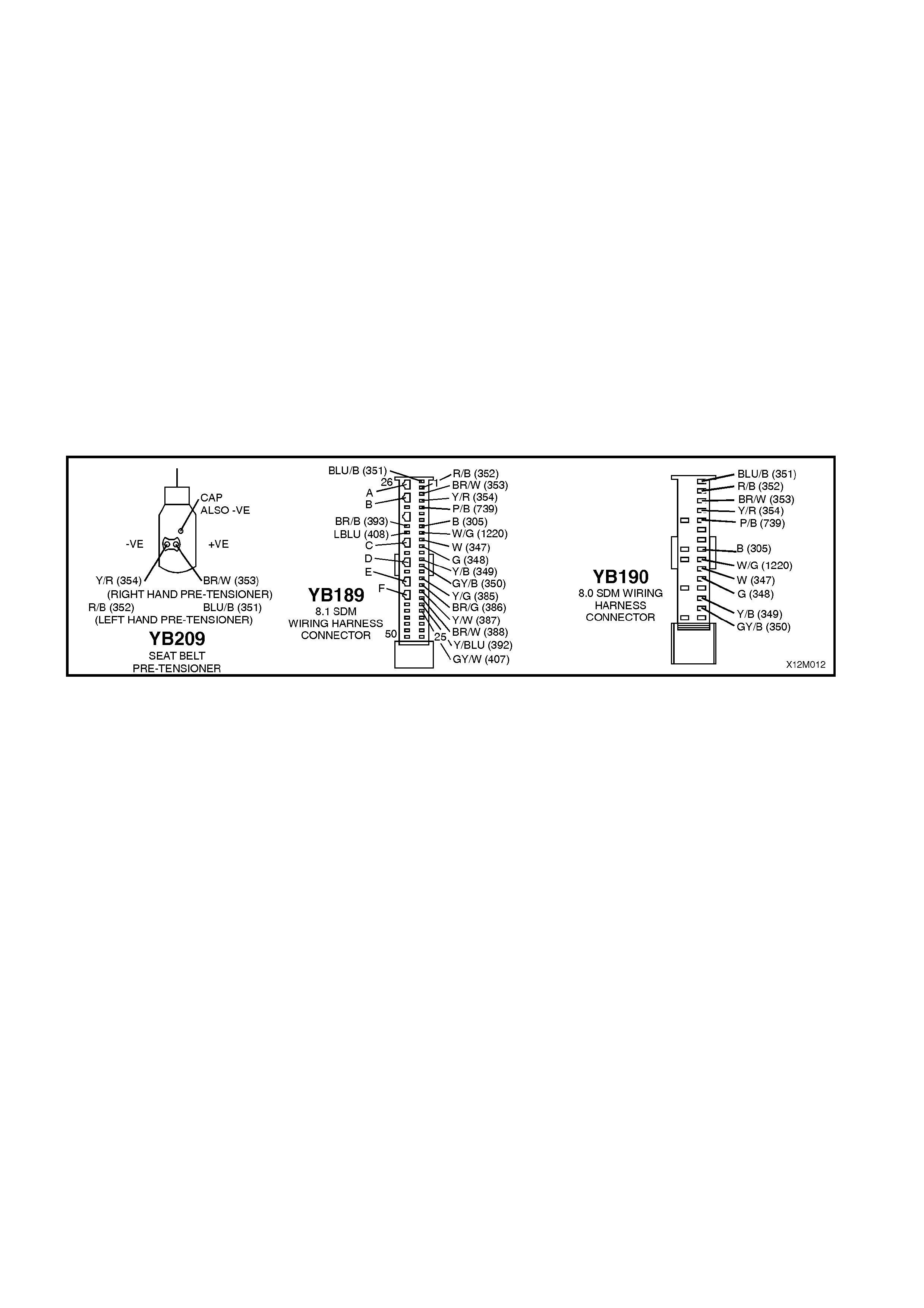

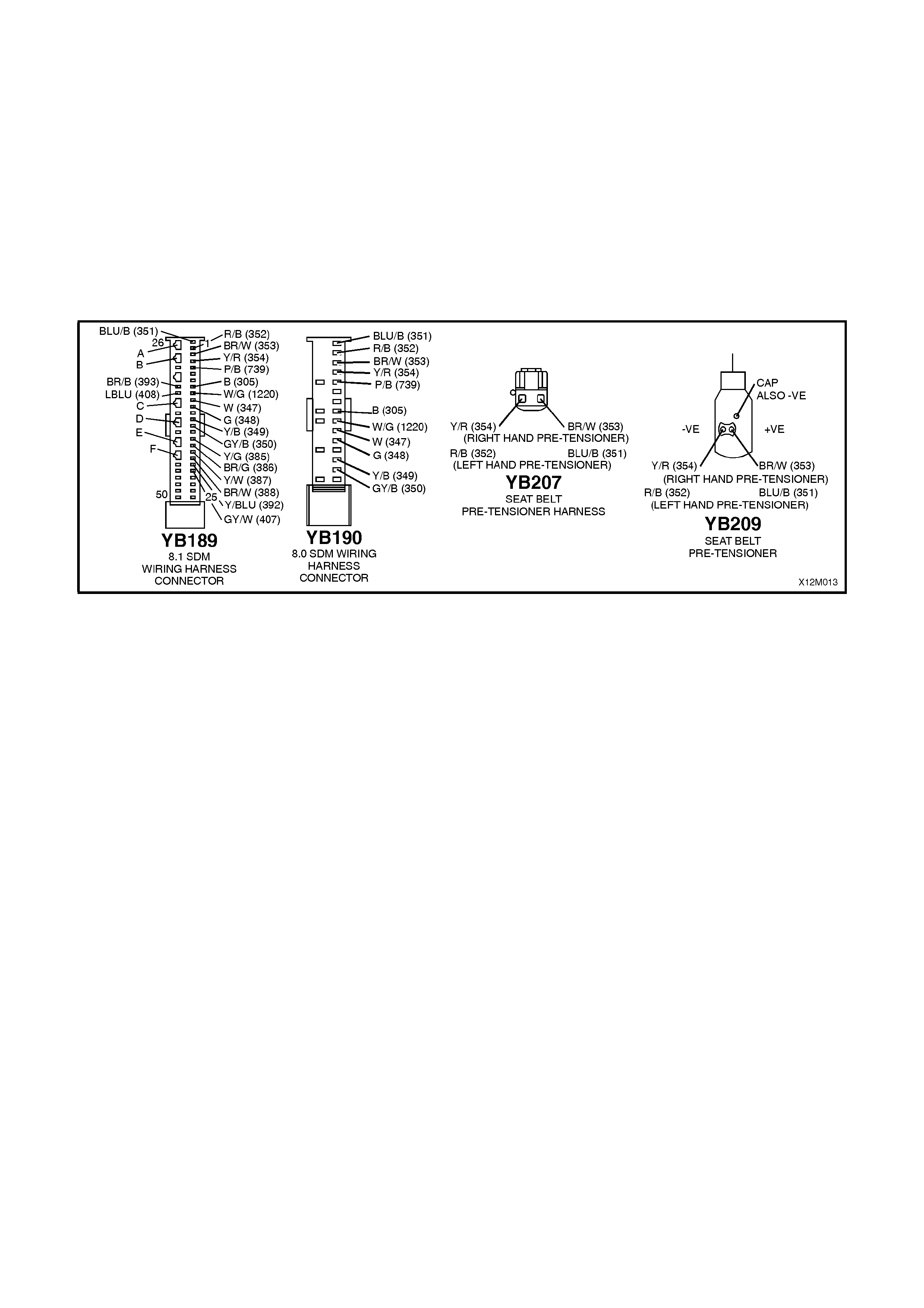

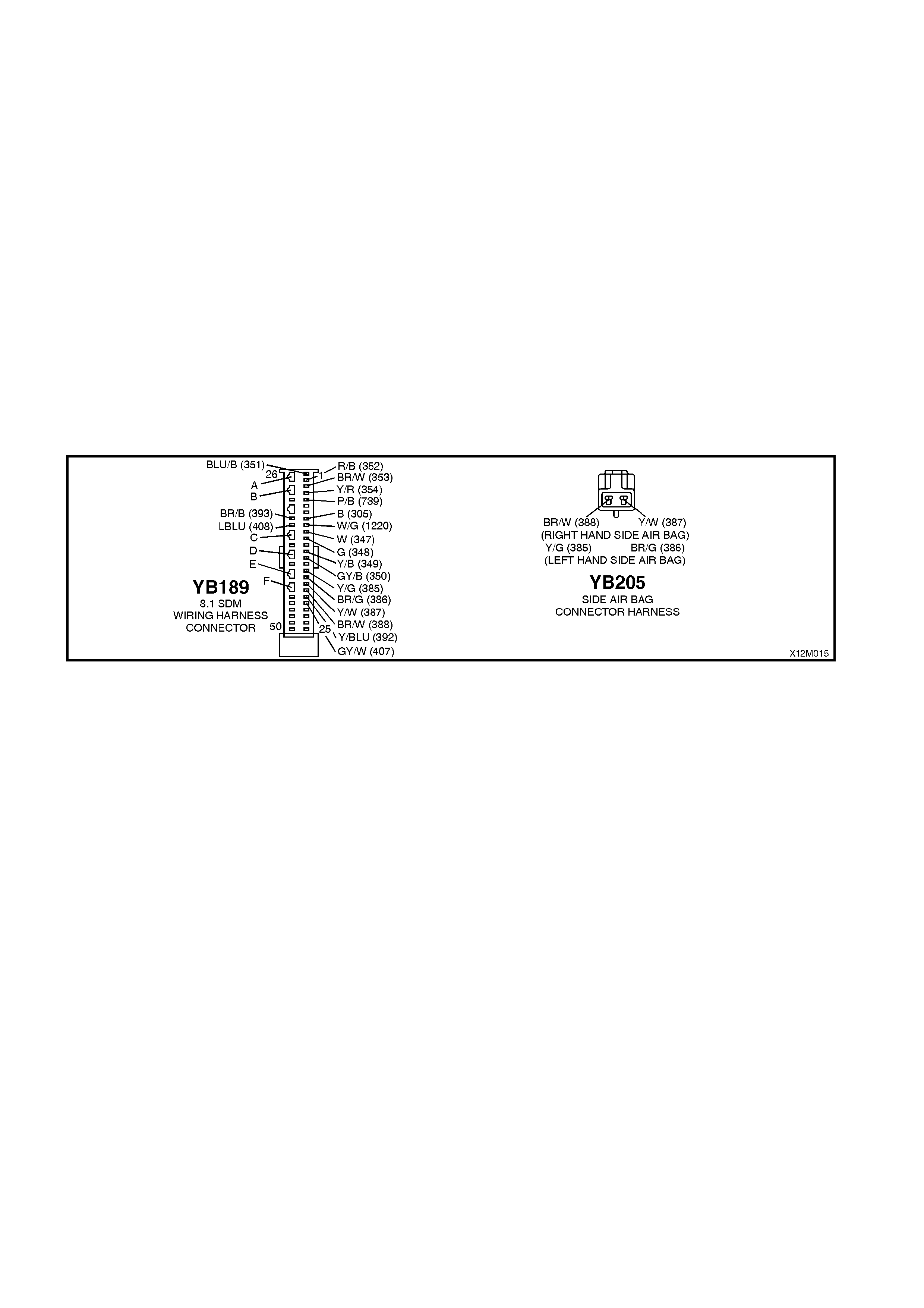

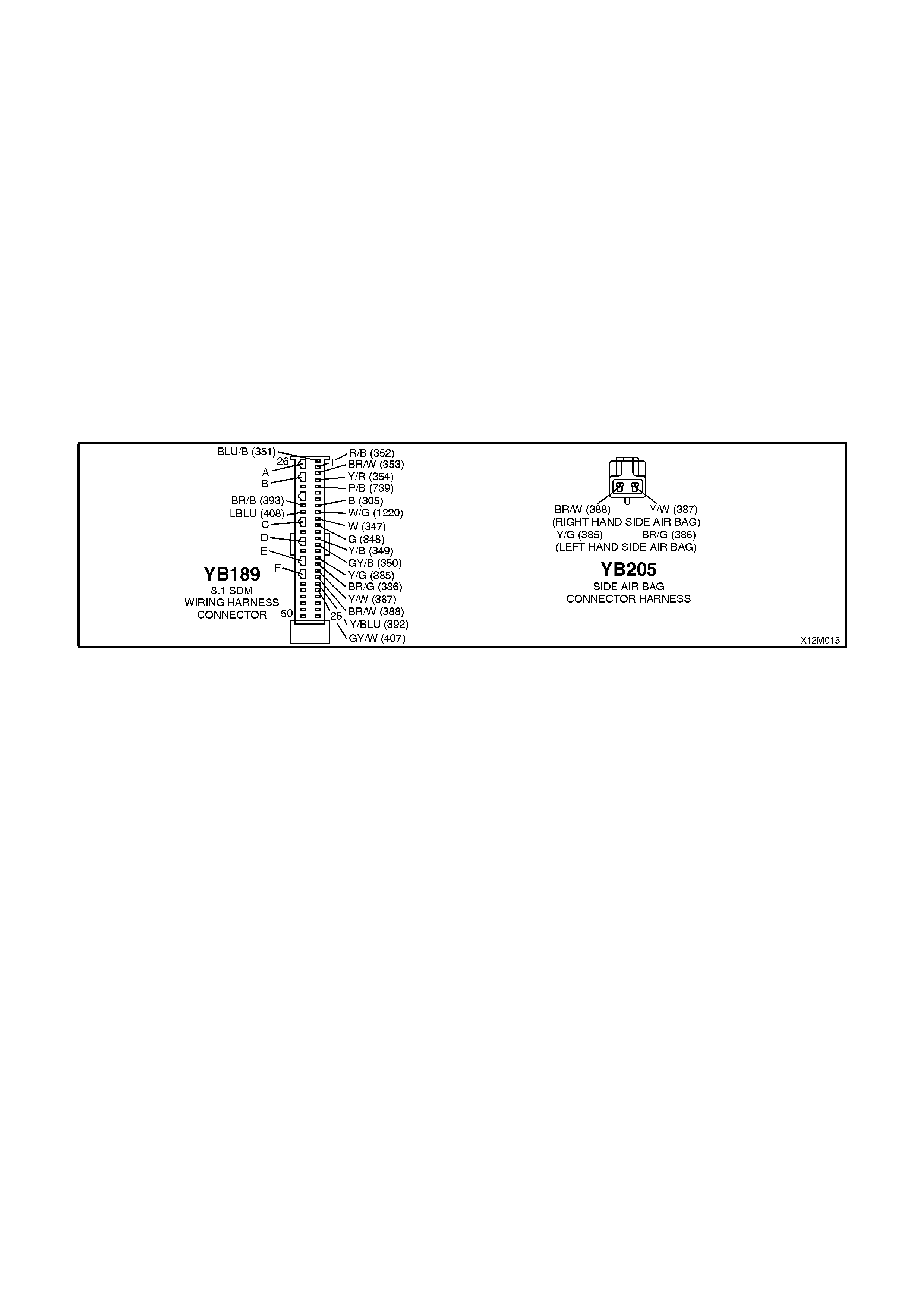

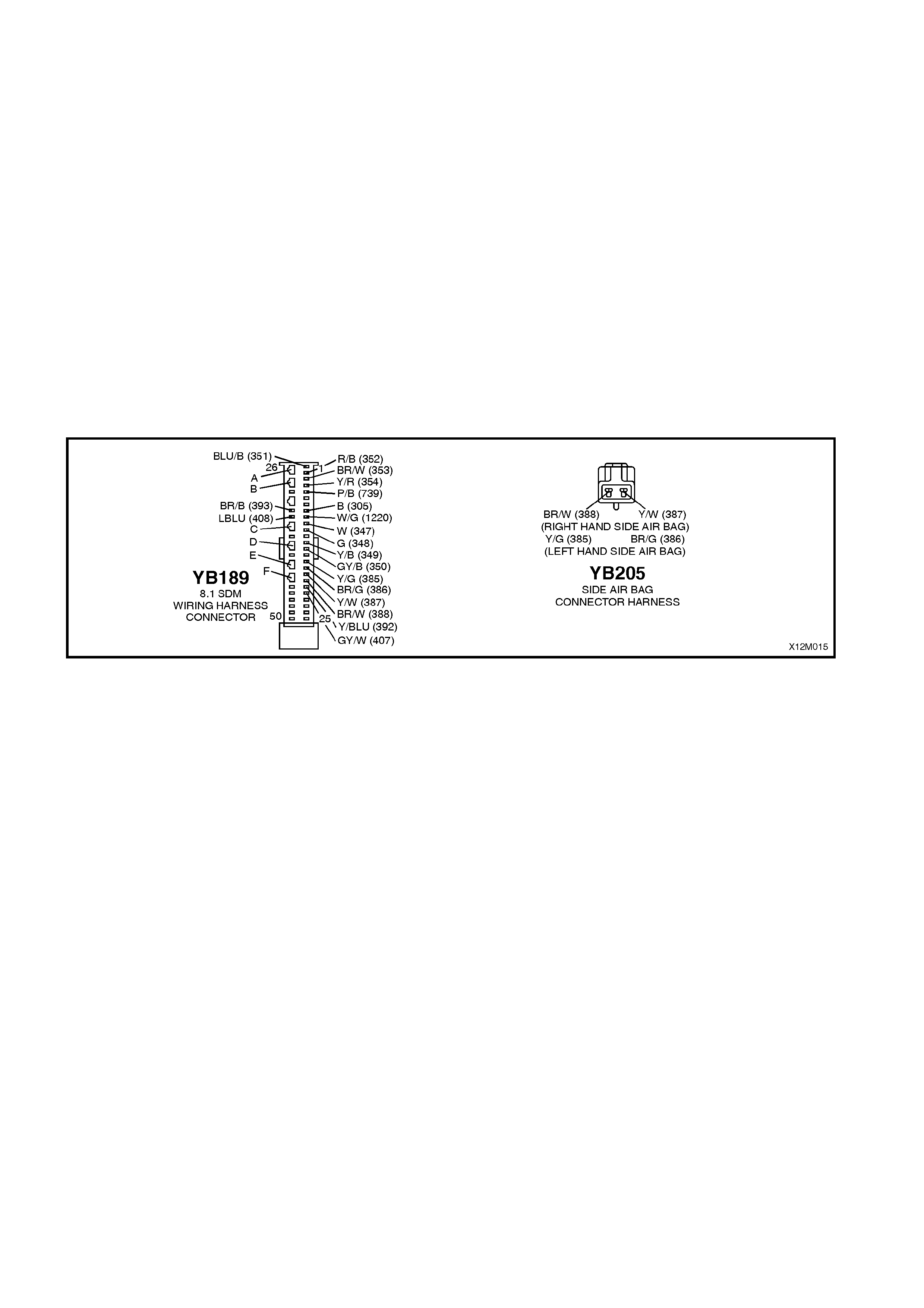

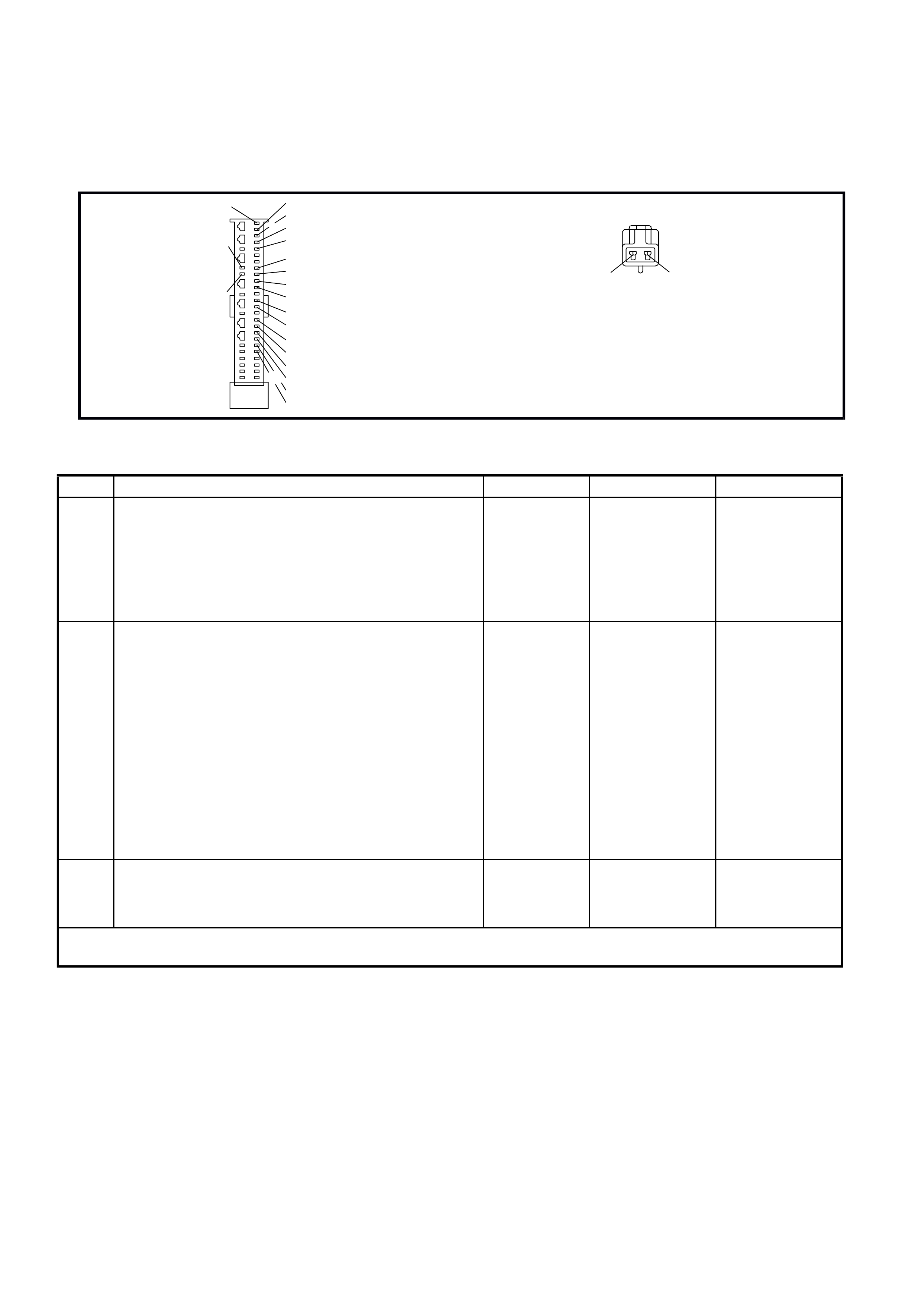

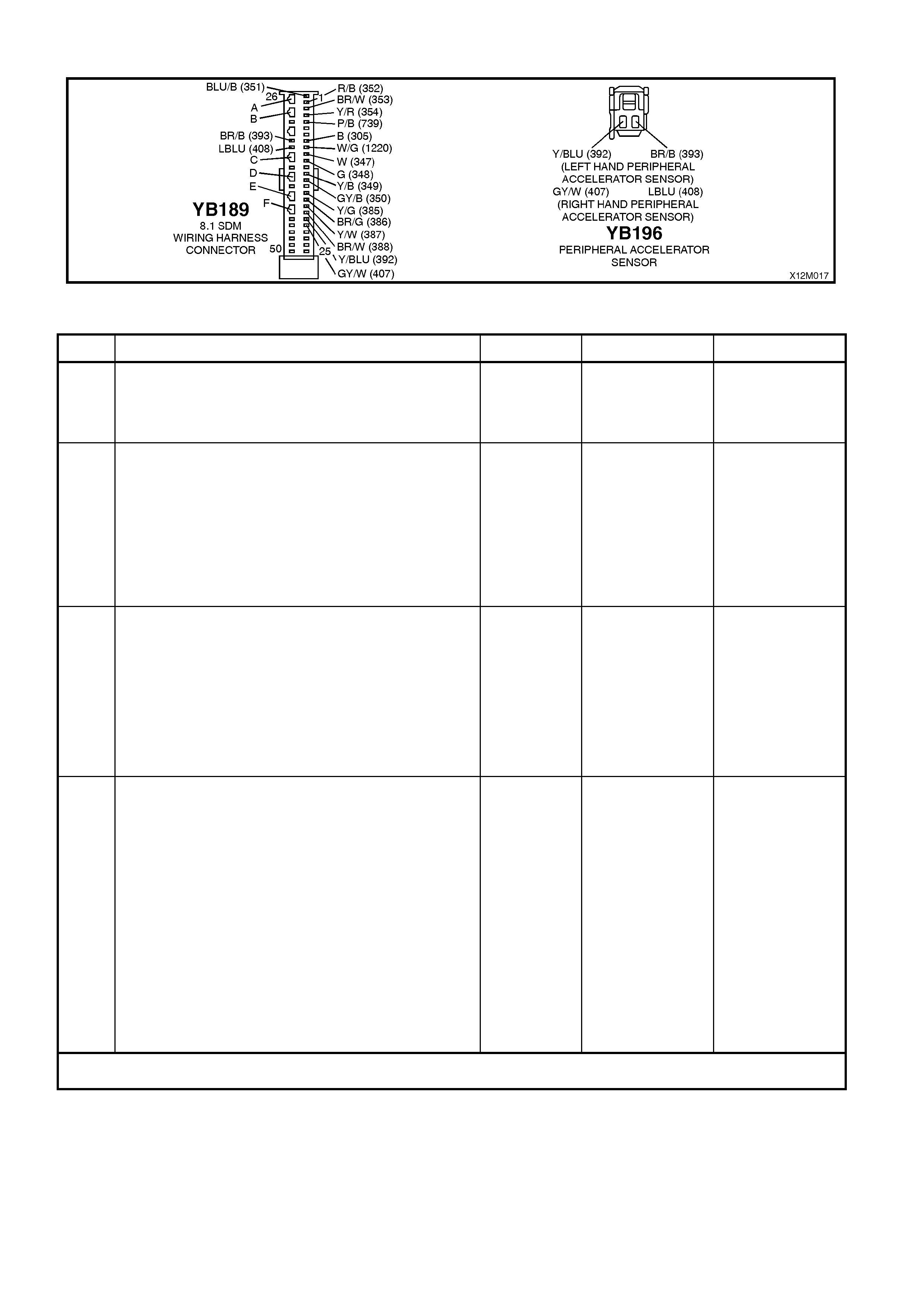

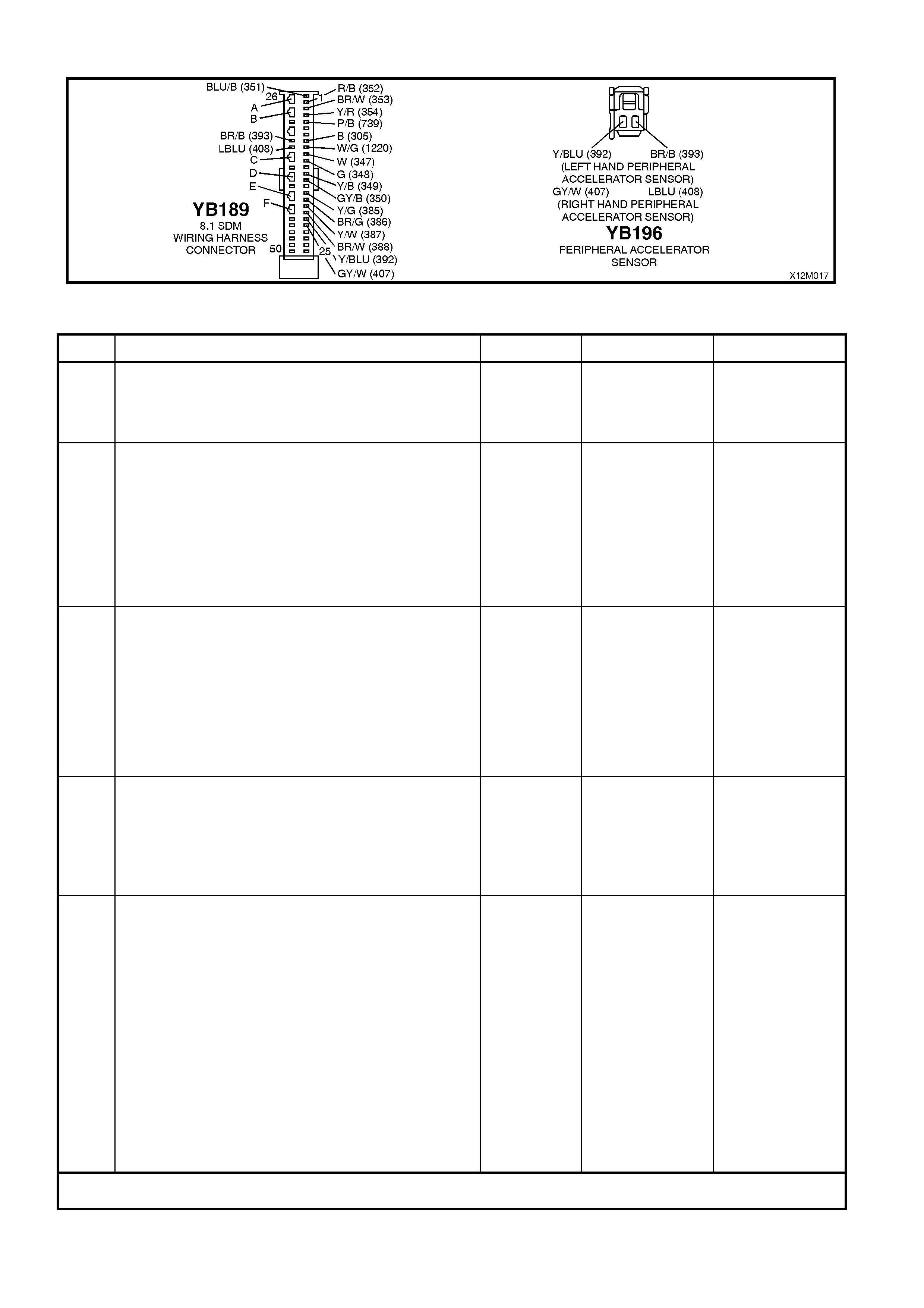

Figure 12M-3 illustrates the terminal layout of the various connectors used in the 8.0 and 8.1 systems. This

illustration should be used in conjunction with the diagnostic chart circuit diagram s when checking circuit faults if a

connector diagram is not included in the chart.

IMPORTANT: UNDER NO CIRCUMSTANCES IS 12 VOLTS TO BE APPLIED TO THE DUMMY LOAD;

SD28280B OR AU485, AS THIS WILL DAMAGE THE INTERNAL RESISTOR IN THE LOAD, RENDERING THE

DUMMY LOAD USELESS FOR ANY FURTHER DIAGNOSTIC WORK.

ENSURE THAT AT THE COMPLETION OF ANY DIAGNOSTIC PROCEDURE, ALL DIAGNOSTIC TOOLS ARE

REMOVED AND ALL SRS COMPONENTS ARE CORRECTLY RECONNECTED.

When carrying out wiring checks as dir ec ted to by the diagnostic charts, rather than probe ter minals and connectors

with incorrect sized multimeter connections, use the adaptors contained in connector test adaptor kit KM-609 and

test lead set KM-609-20. This will prevent any possibility of spreading or damaging wiring harness terminals and

later on causing a system intermittent failure.

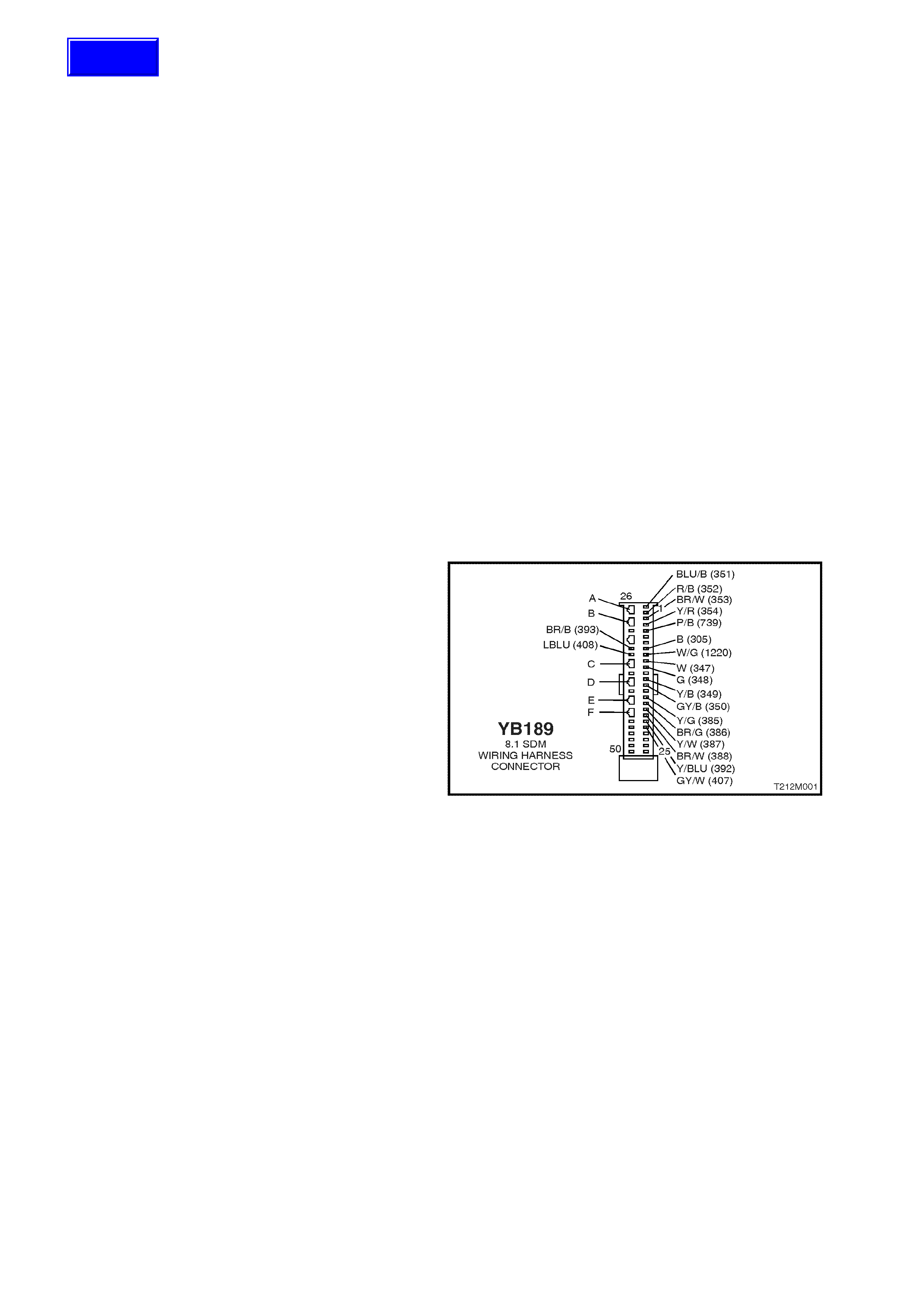

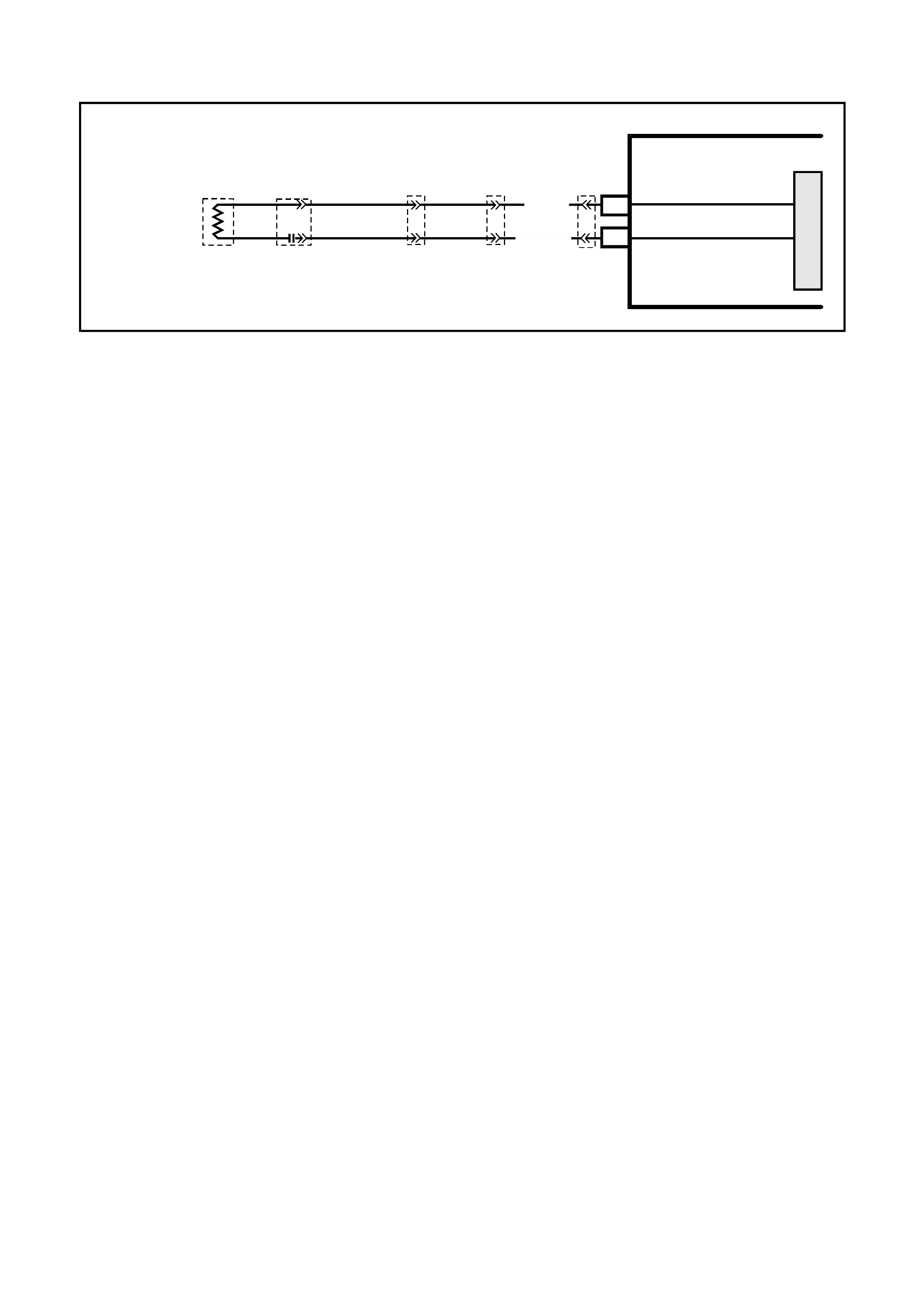

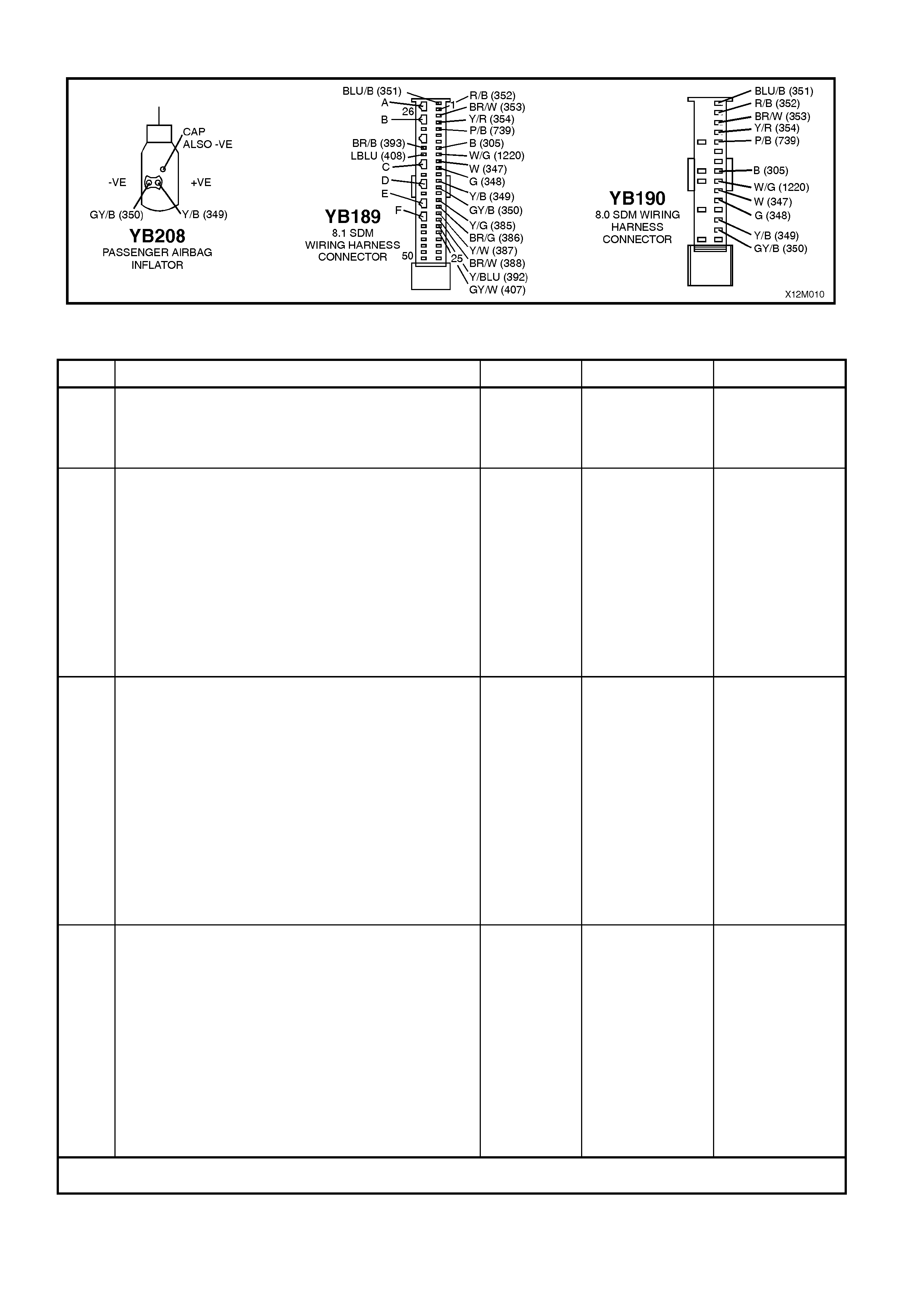

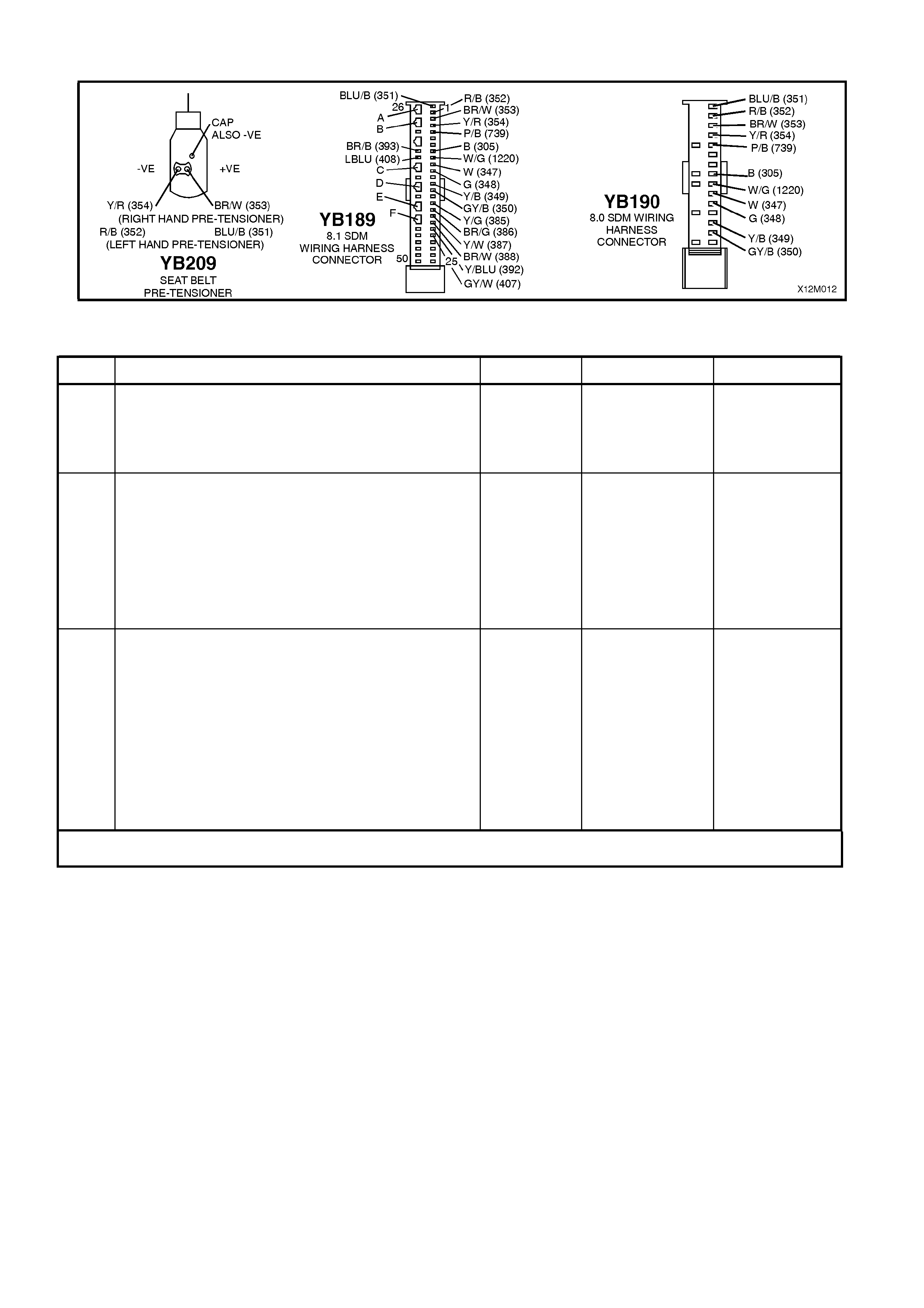

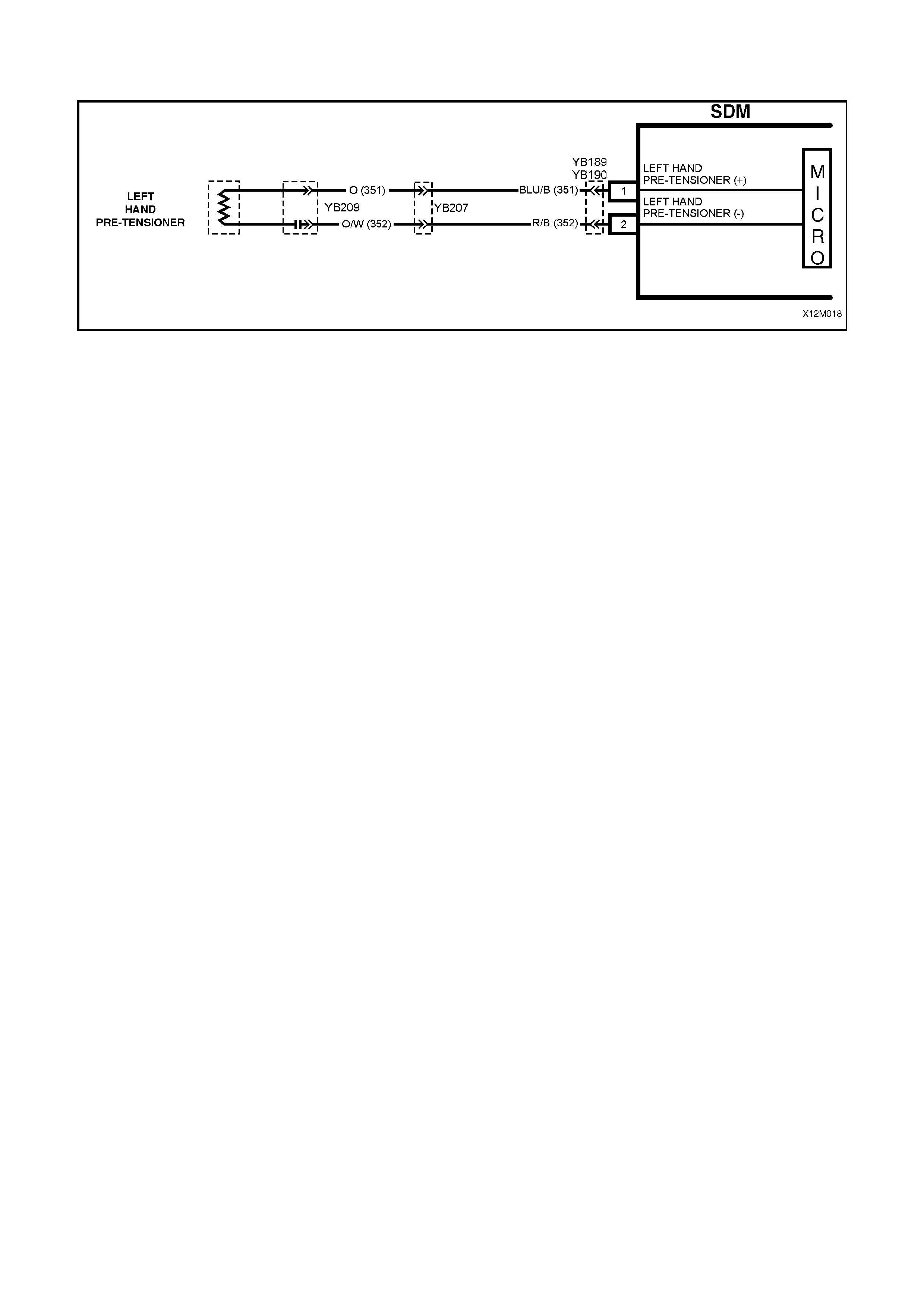

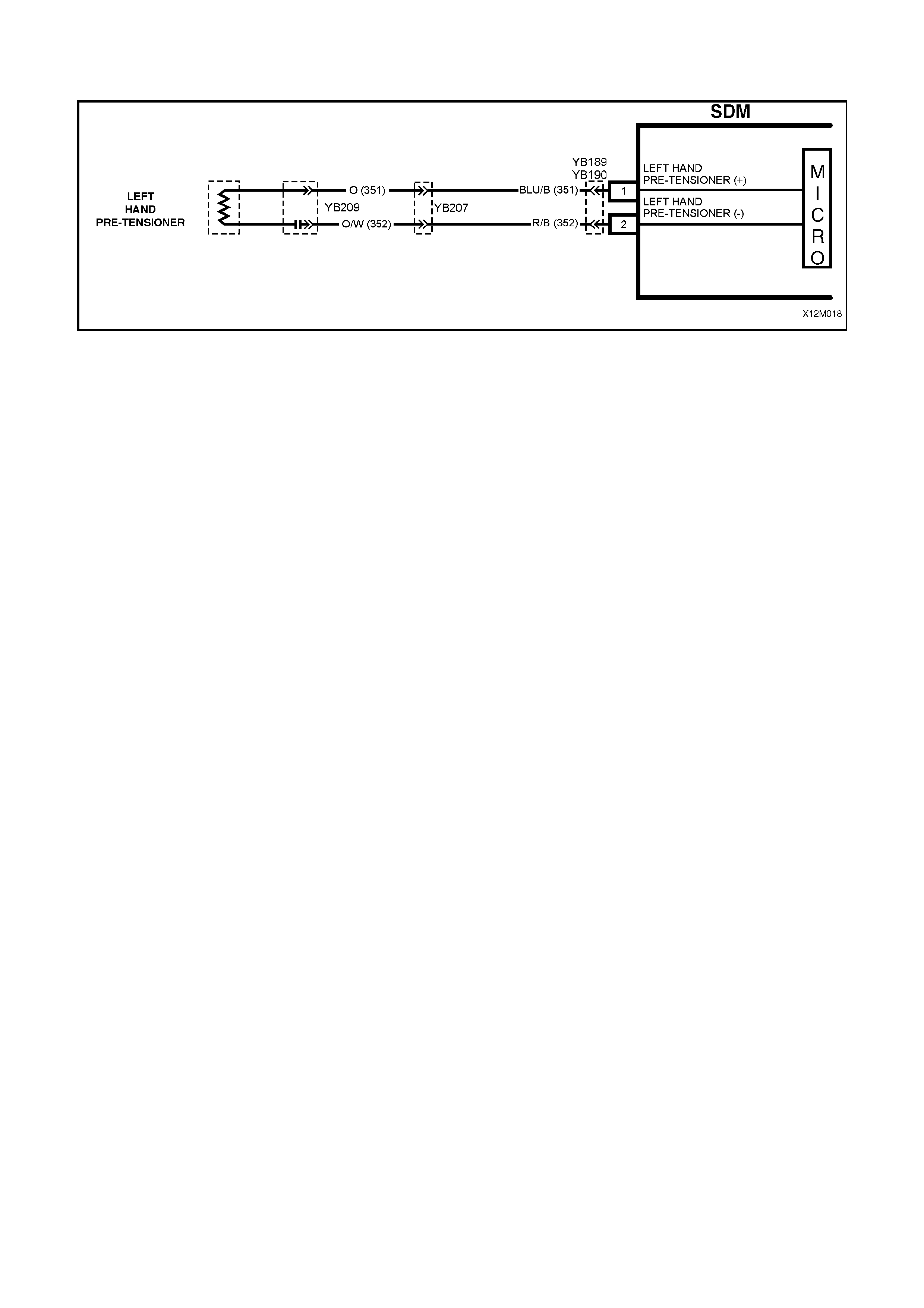

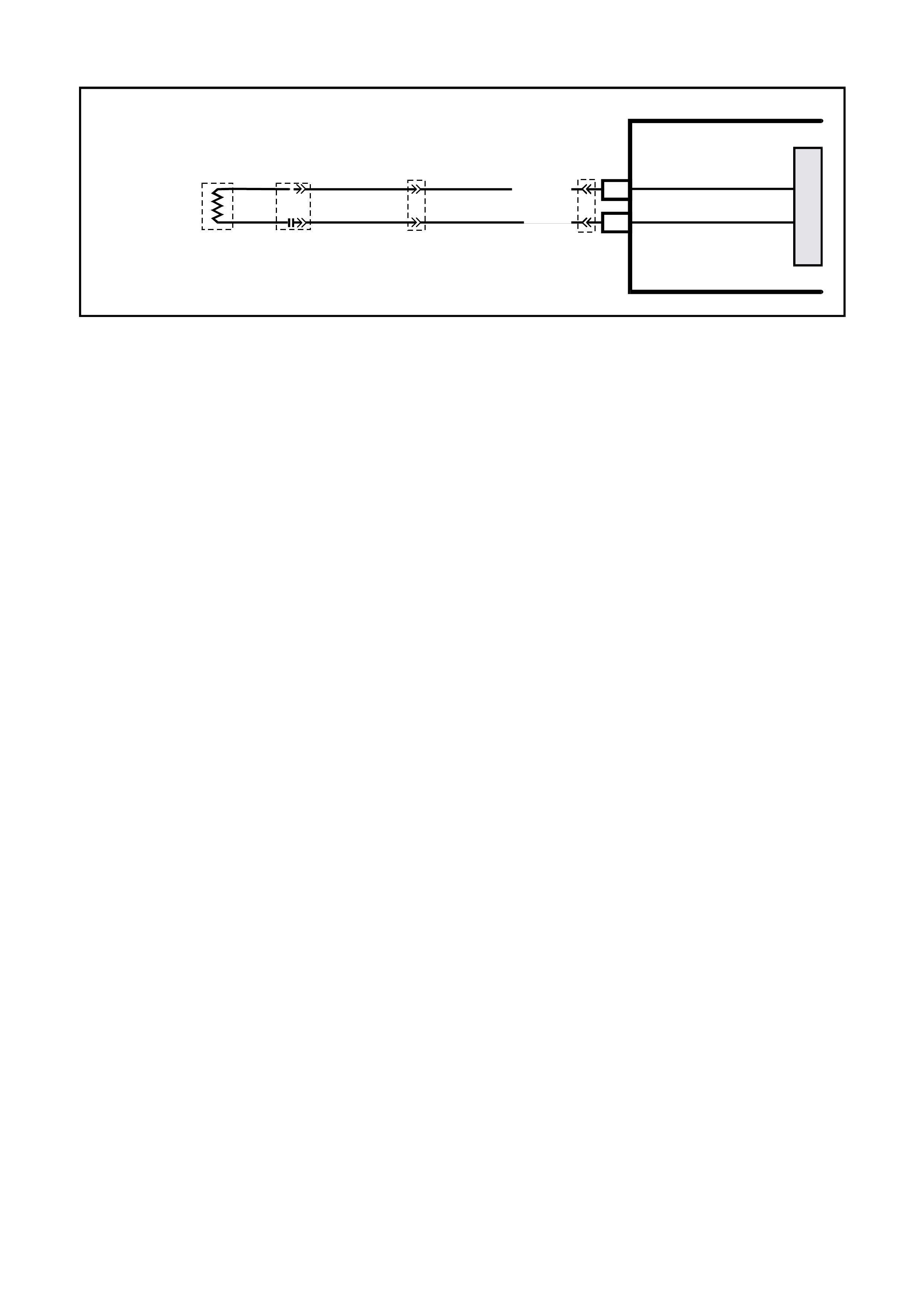

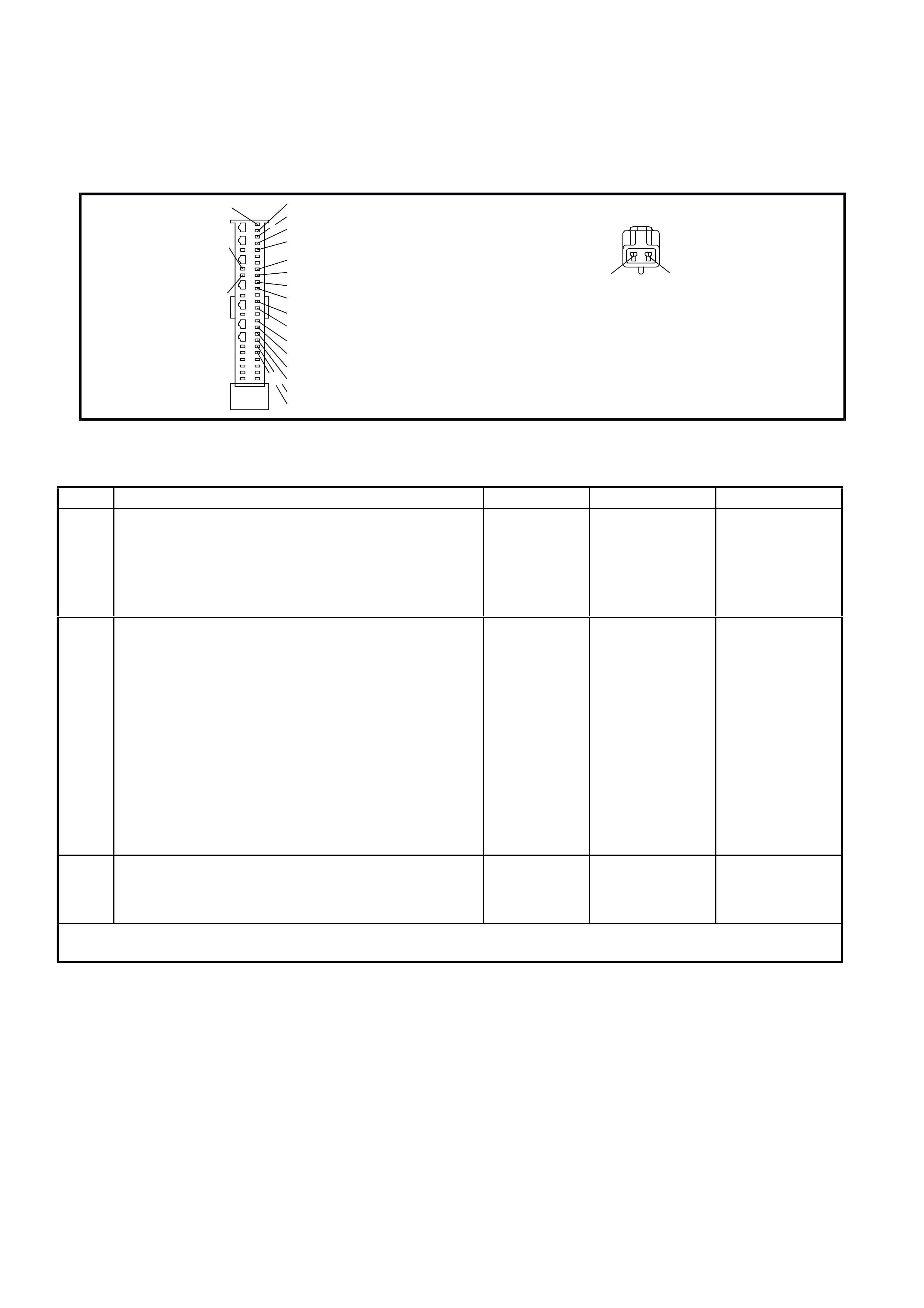

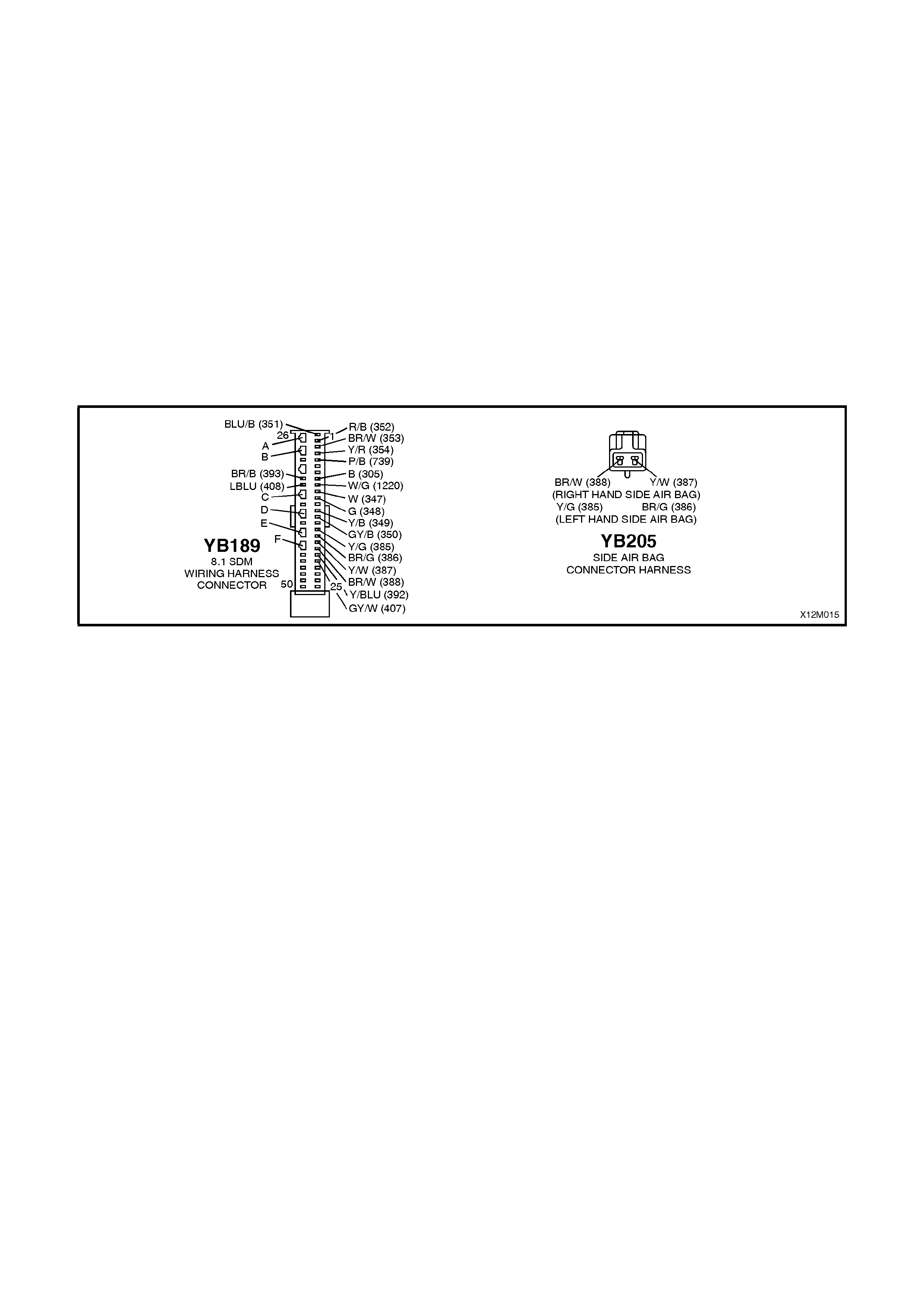

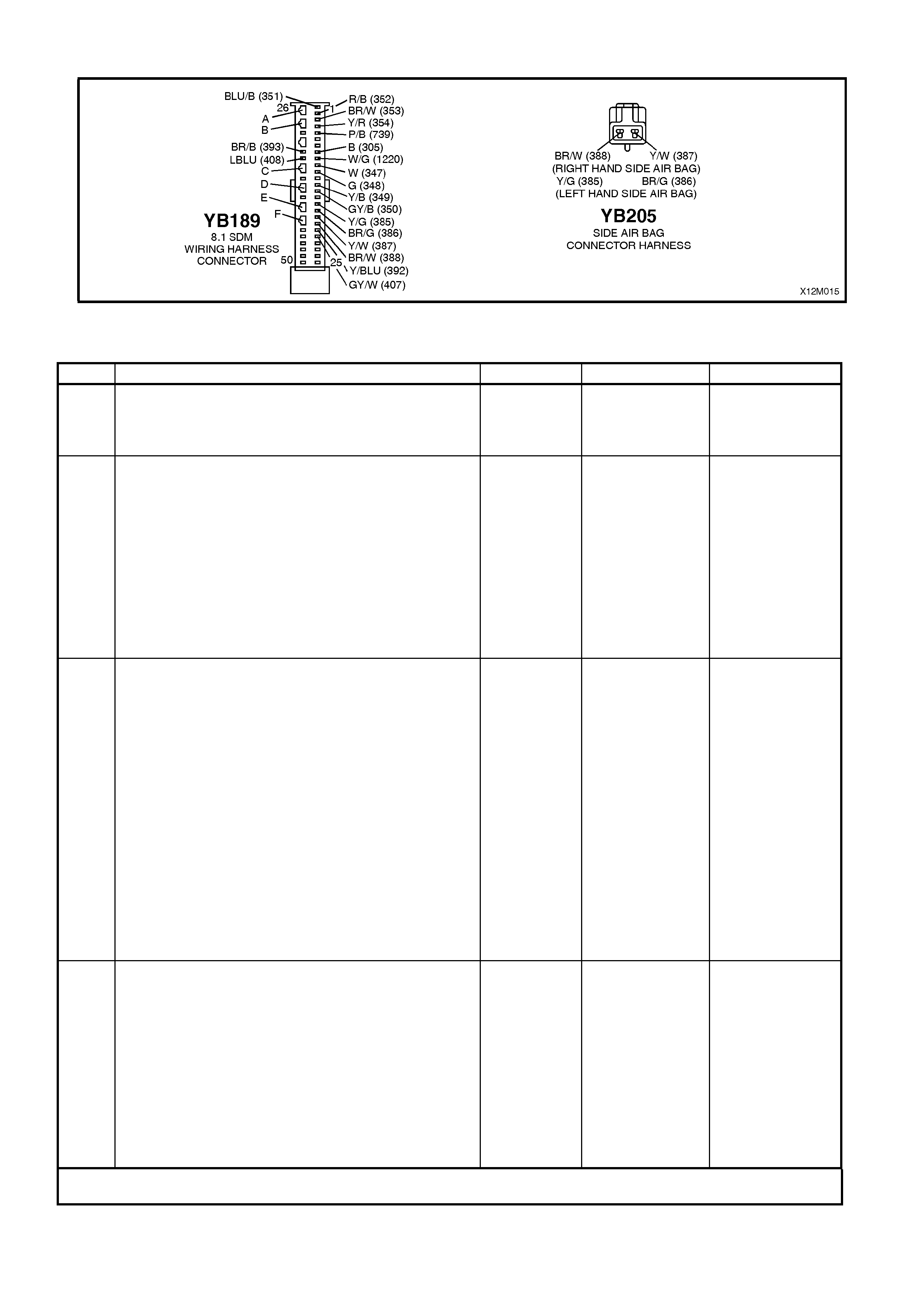

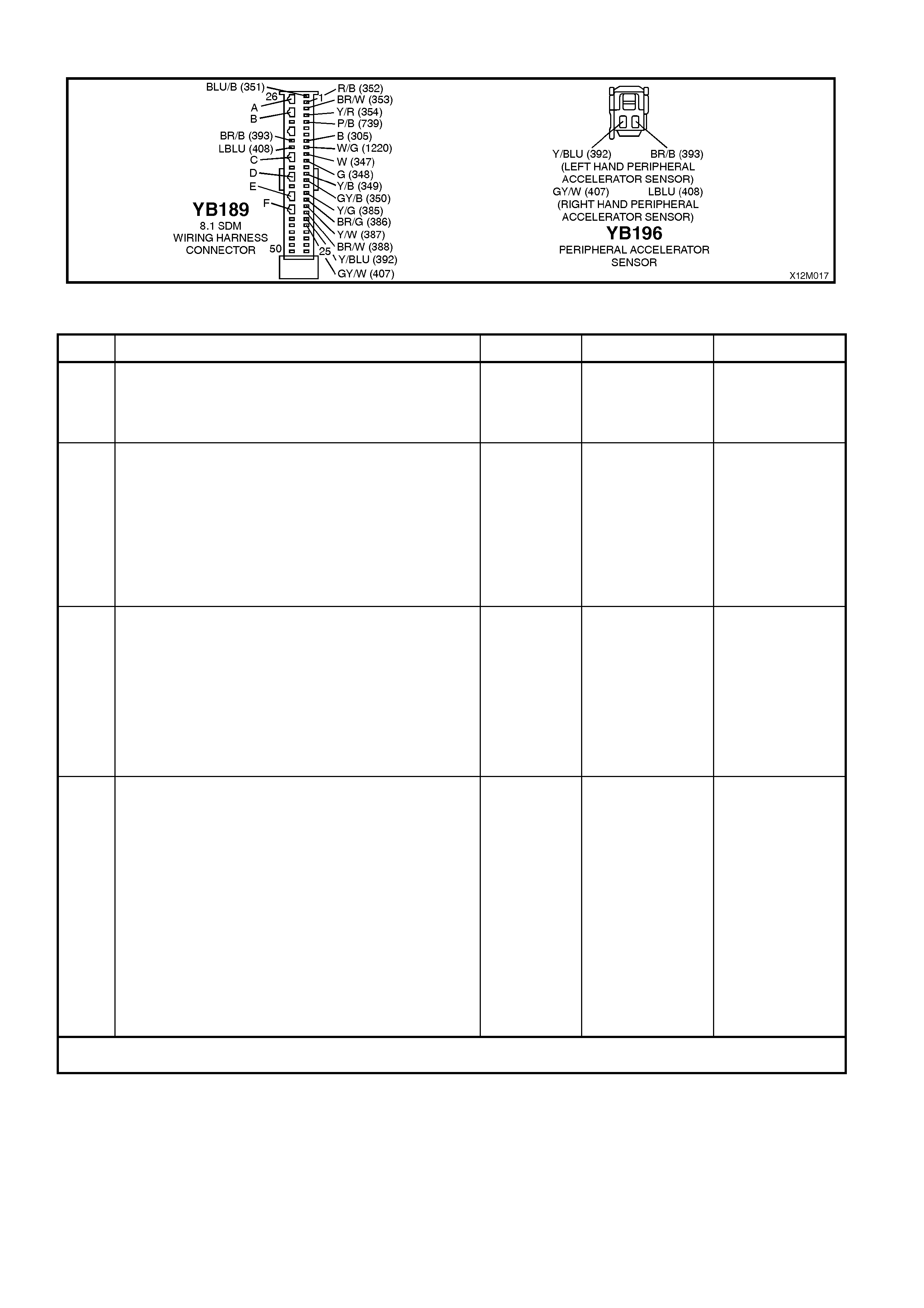

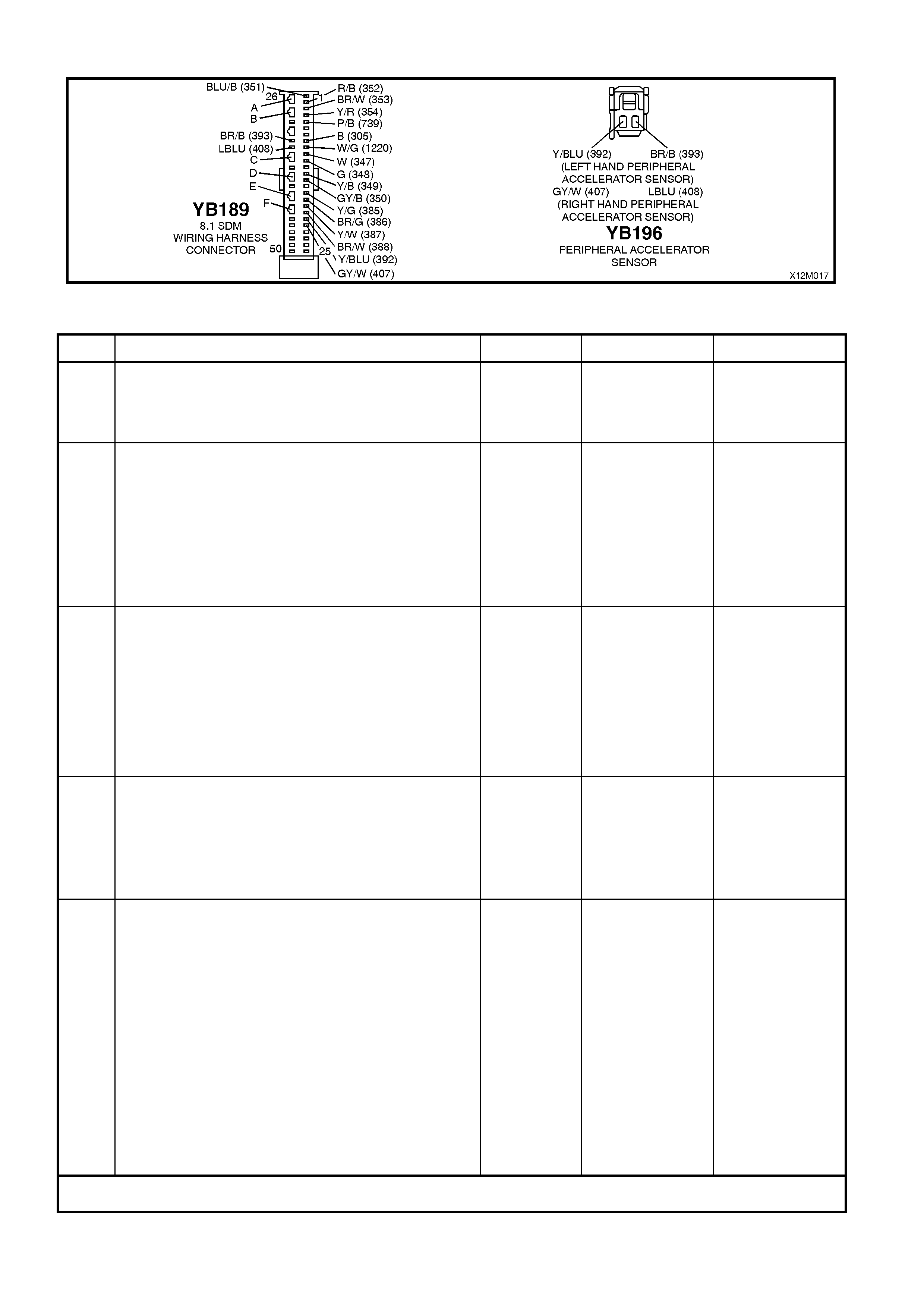

SDM connector YB189 is equipped with shorting link busbar. Whenever a diagnostic procedur e ask s a technician to

check a circuit for an open or short while SDM connector YB189 is disconnected, the technician will need to open

the shorting link busbar for that particular circuit.

To open the shorting link busbar for a particular circuit, insert a spade type terminal, approximately 3 mm in

diameter (or alternatively, use tool KM-609-9 fr om the KM- 609 kit) into the openings (nominated as A, B, C, D, E or

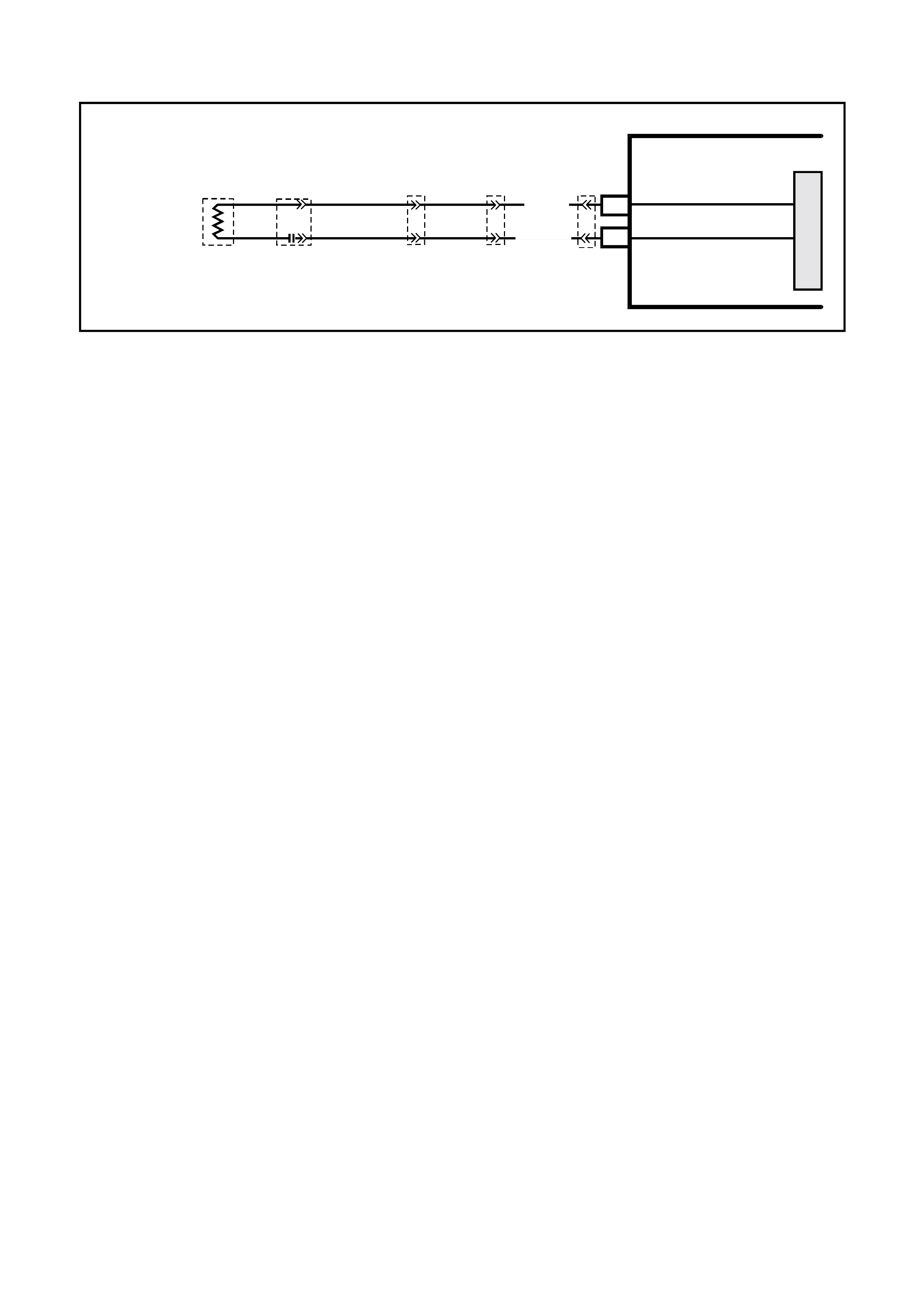

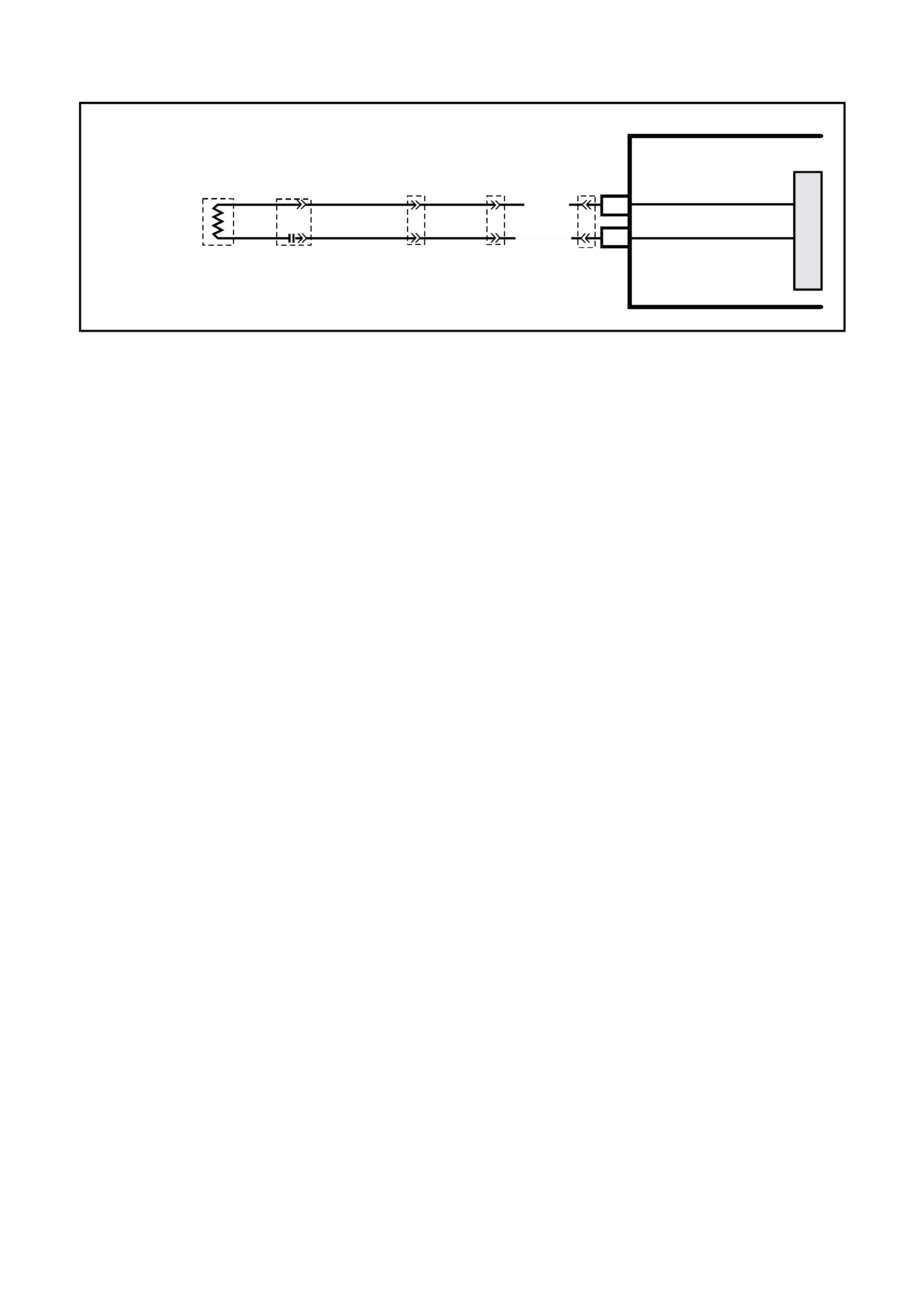

F in the following diagram) opposite the circuits terminal, refer Fig. 12M-1.

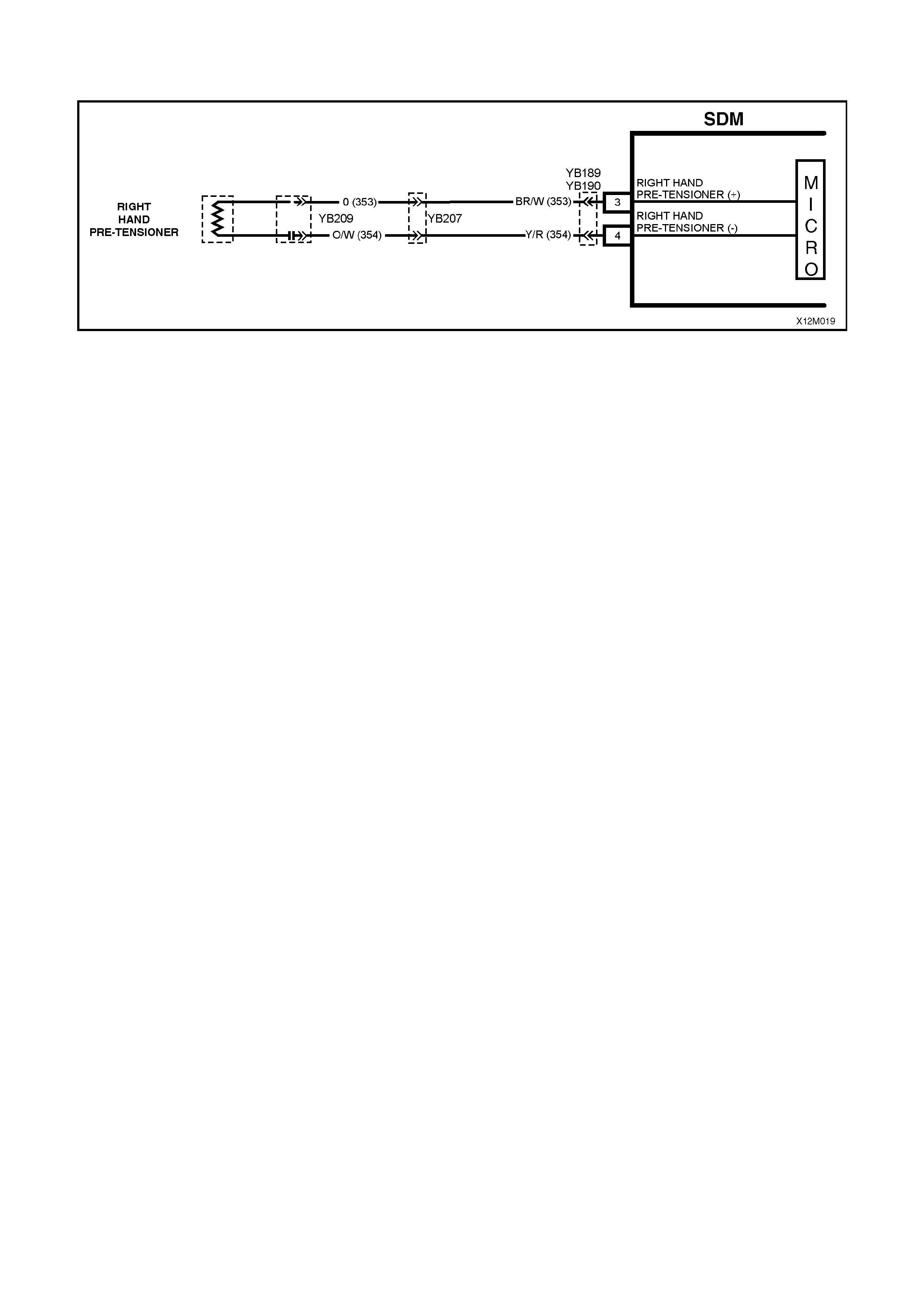

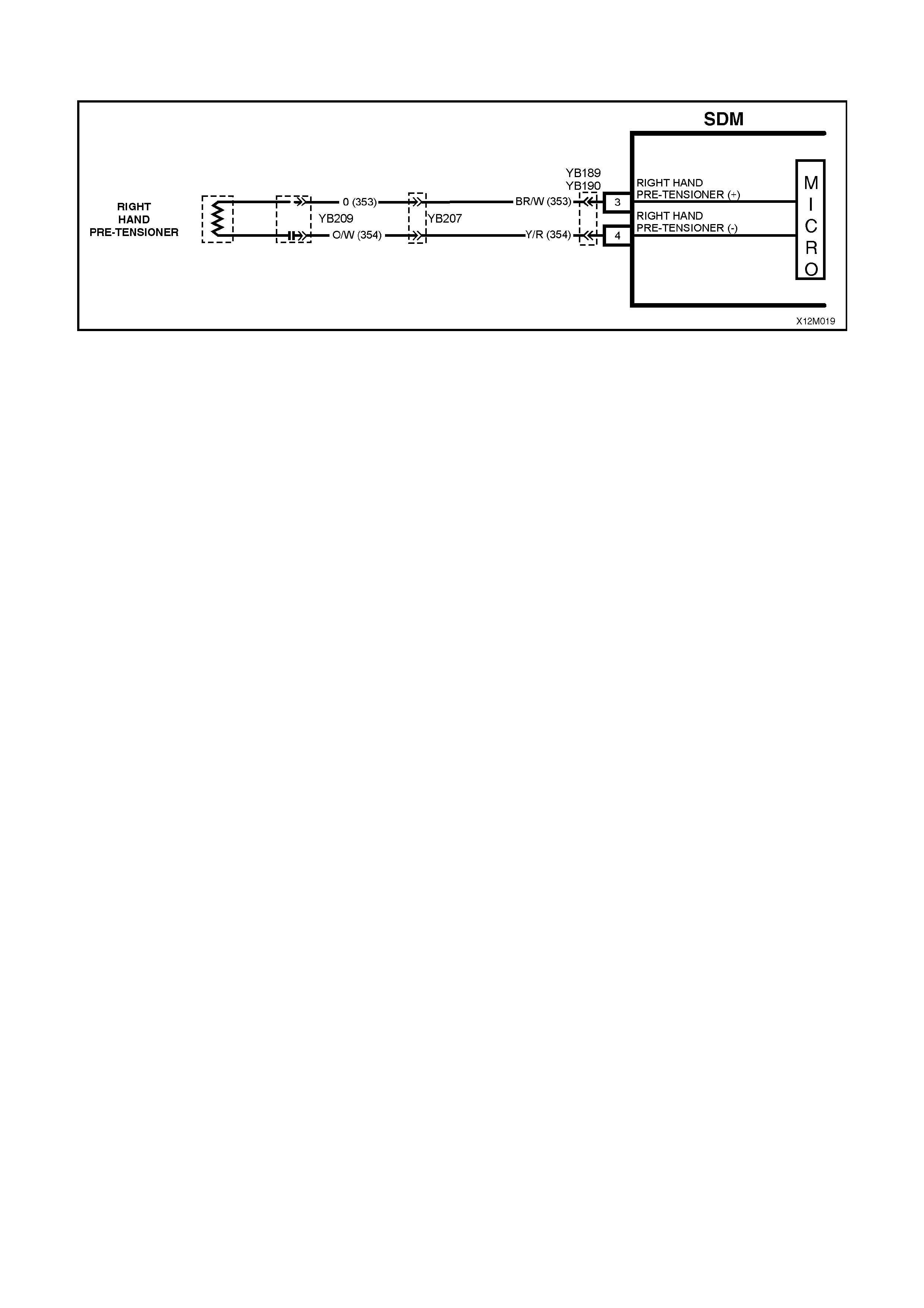

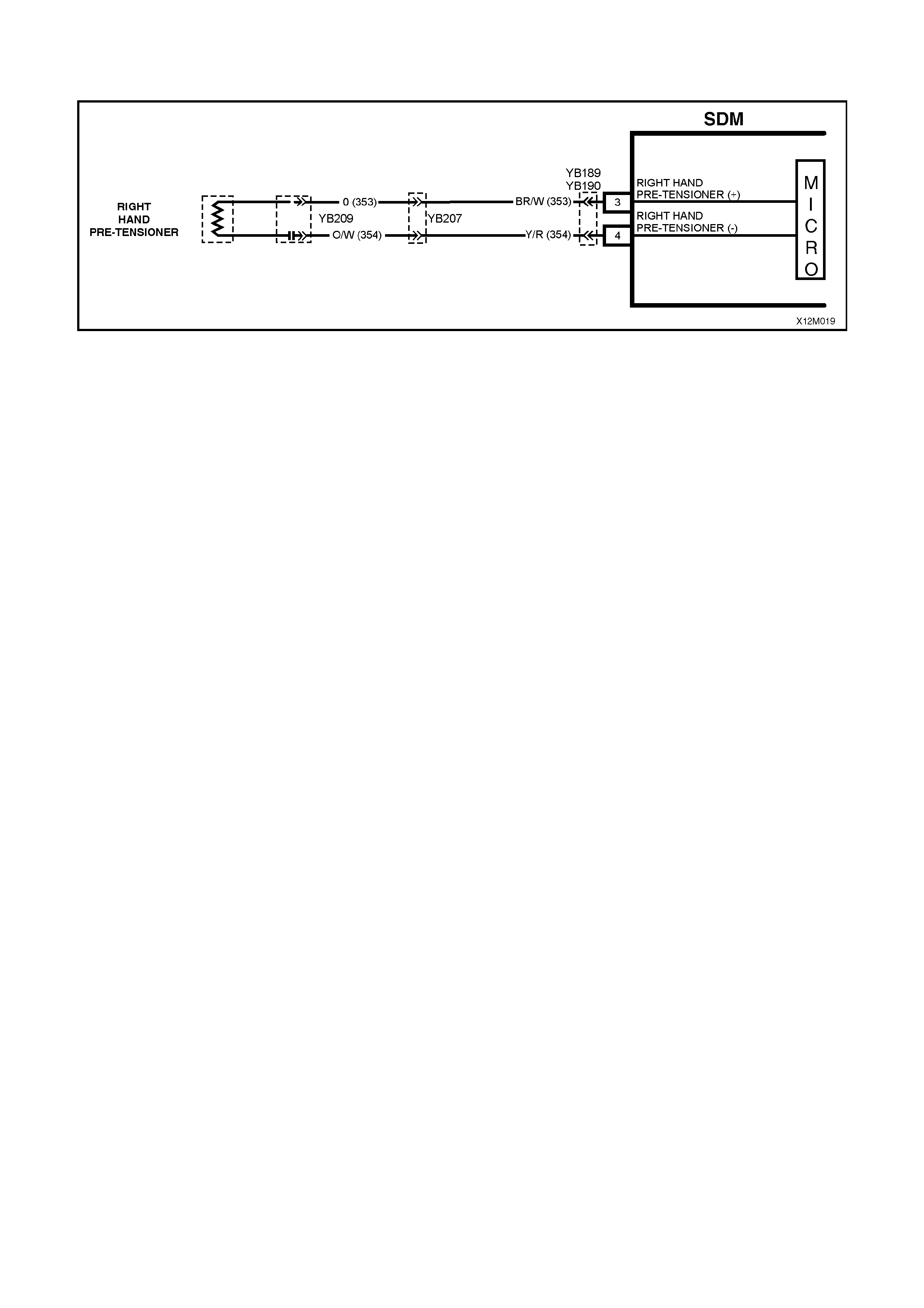

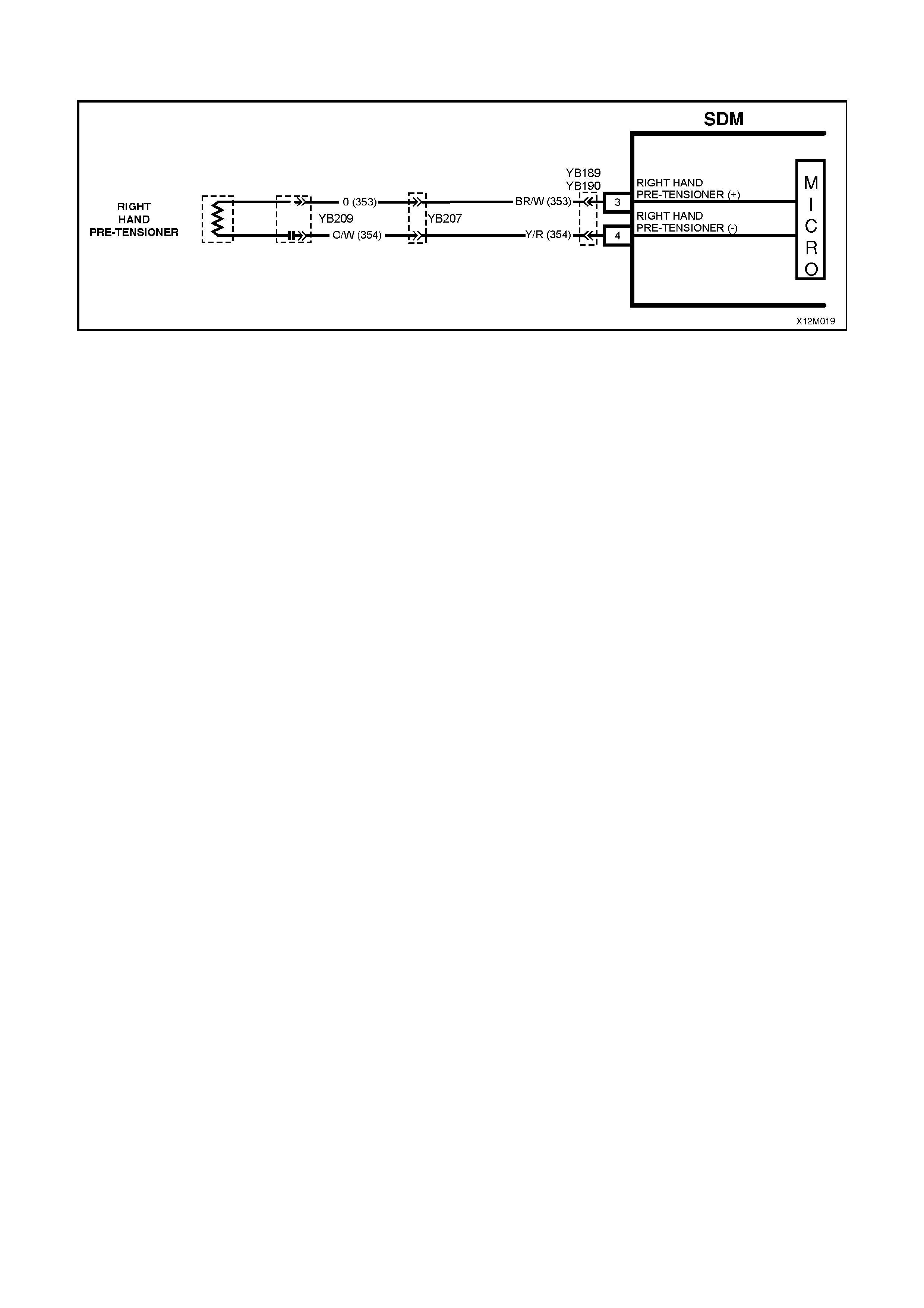

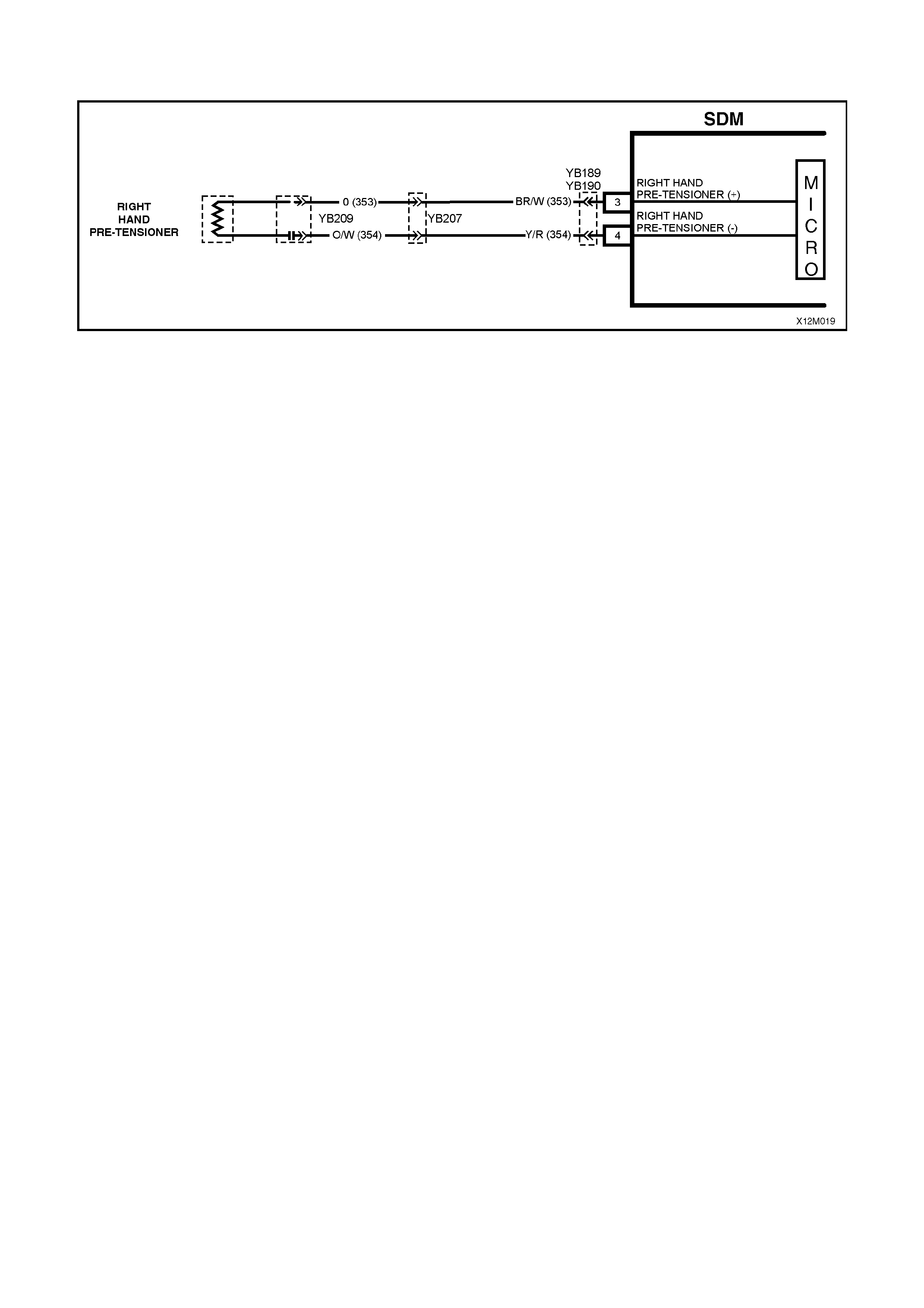

SHORTING LINK BUSBAR

A Terminals 1 and 2 – left hand pre-tensioner circuit

B Terminals 3 and 4 – right hand pre-tensioner circuit

C Terminals 10 and 11 – drivers air bag circuit

D Terminals 13 and 14 – passenger’s air bag circuit

E Terminals 16 and 17 left hand side air bag circuit

F Terminals 18 and 19 right hand side air bag circuit

Figure 12M-1

Techline

Figure 12M-2

Figure 12M-3

CHART A - DIAGNOSTIC CIRCUIT CHECK

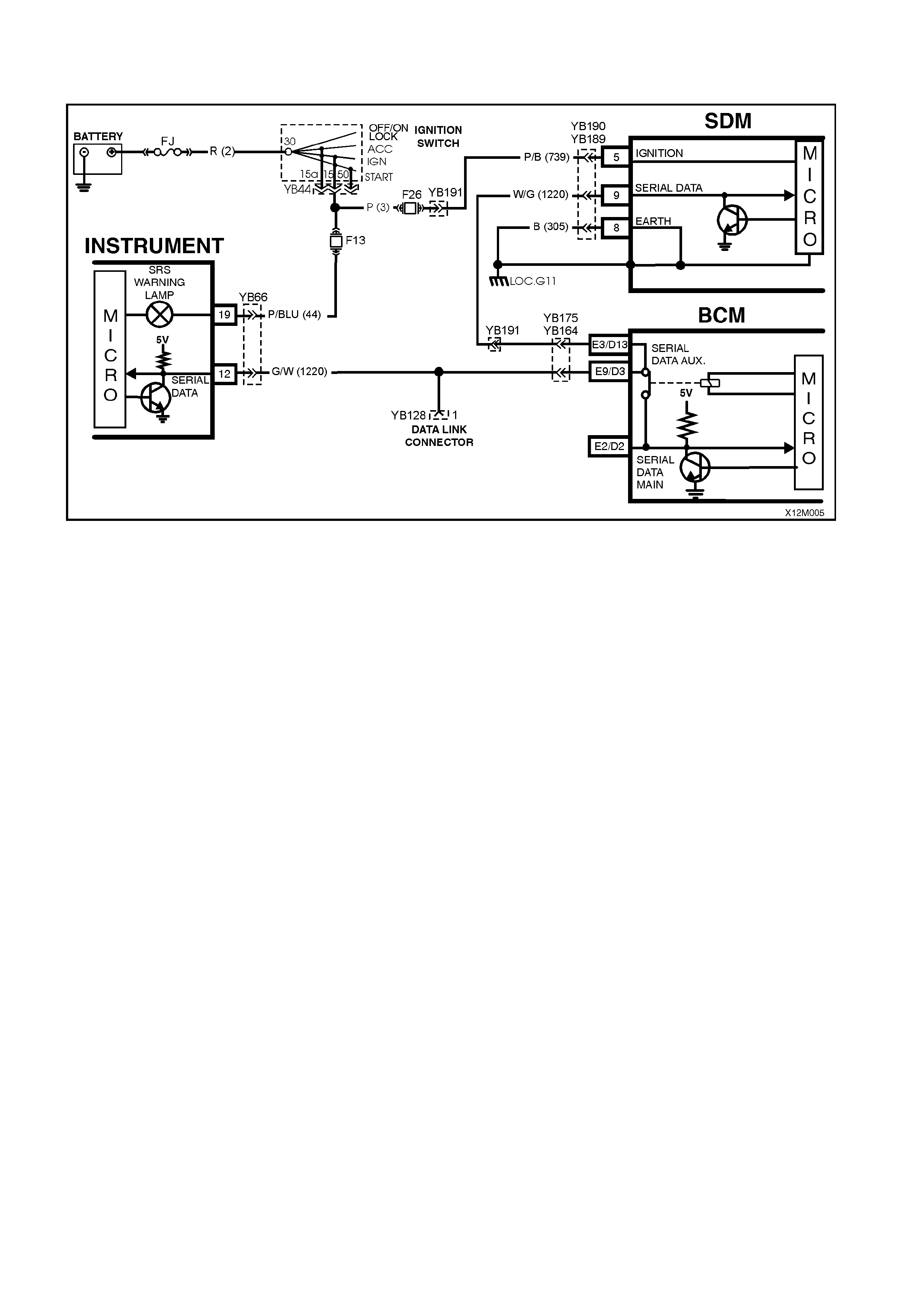

Figure 12M-4

CIRCUIT DESCRIPTION

When investigating any complaint of an SRS problem or malfunction, always begin diagnosis with the following

diagnostic circ uit check . T his c heck is a pr elim inary procedure that check s to ensure the SDM is com m unic ating on

the serial data line as well as helping to identify a problem or malfunction and directing the technician to the

appropriate diagnostic chart in this Section.

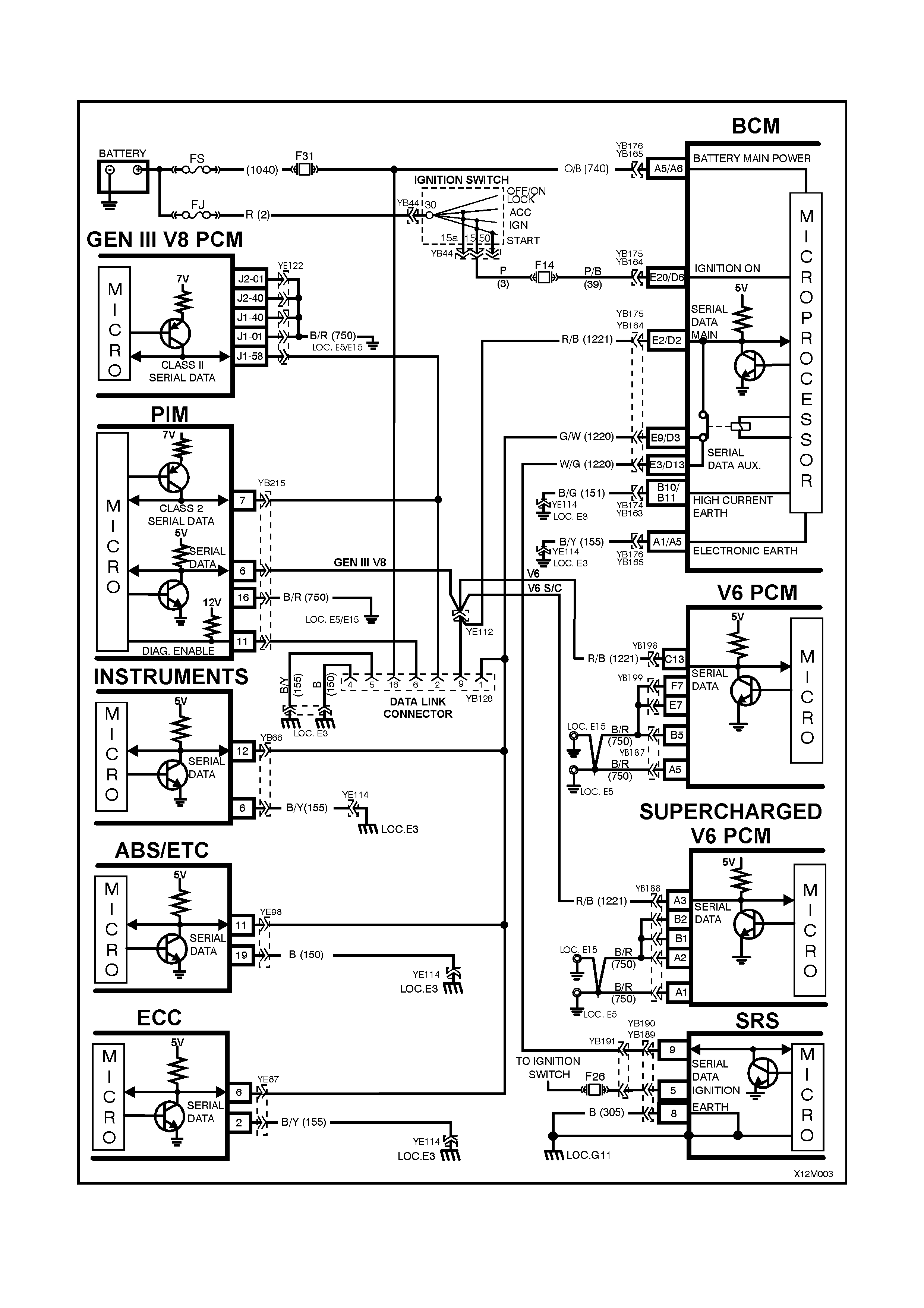

With TECH 2 connected to the DLC and the ignition switched on, TECH 2 should display serial data

communication. If TECH 2 does not display serial data, the serial data circuit maybe open or shorted.

There are several other control modules that are connected to the serial data line (PCM, BCM, ABS/ETC, ECC,

instruments and SDM). ANY one of these control modules could cause a fault on the serial data line. This fault

could result in TECH 2 not being able to display serial data.

Notes on Diagnostic Chart:

1. Refer to TECH 2 DIAGNOSTICS in Sec tion 12M SUPPLEMENTAL REST RAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

2. Refer to Section 12P WIRING DIAGRAMS of the VT Series I Service Informationfor procedures on checking

wiring faults.

To ensure none of the other control modules on the serial data circuit are causing this voltage problem, unplug each

control module, one at a time, to isolate the short to voltage.

SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit. Refer to 2.5 DIAGNOSTIC CHARTS in this Section for additional information.

Test Description:

The following numbers refer to step numbers in diagnostic chart ‘A’

1-2. This test is a functional check of the SRS warning lamp during a system self check.

3. Checks to see if TECH 2 can communicate with the SDM.

4. Uses TECH 2 to check for DTCs.

5. If TECH 2 is unable to communicate with the BCM and PCM, there is a fault (short to earth) in the serial data

communication circuit (circuits 1220 or 1221).

6. Checks fuse F26 and circuit 739 for short to earth.

7. Checks for power to SDM.

8. Checks continuity of earth circuit 305.

9. Checks earth connection at SDM.

10. Checks for continuity in circuit 1220 between SDM and BCM to determine if SDM is faulty.

11. Checks if fault is with BCM or open in circuit 1220 between BCM and SDM.

CHART A - DIAGNOSTIC CIRCUIT CHECK

STEP ACTION VALUE YES NO

1. • Turn ignition on while monitoring the SRS warning

lamp in the instrument cluster.

• Does the SRS warning lamp illuminate? Go to Step 2. Go to CHART B -

‘SRS’ WARNING

LAMP

INOPERATIVE,

in this Section.

2. • After five seconds of the ignition being switched on,

does the SRS warning lamp turn off and remain off? Fault not present. Go to Step 3

3. • Connect TECH 2 to DLC (refer to NOTE 1 on this

page) and turn ignition on.

• Select Body / SRS and confirm.

• Does TECH 2 display System Identification (ie.

SDM part number)?

Go to Step 4. Go to Step 5.

4. • With TECH 2 connected, select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information.

• Are there any DTCs set? Check and repair

fault causing DTC

to set, refer to

relevant diagnostic

chart in this

Section.

Go to CHART C

‘SRS’ WARNING

LAMP

ILLUMINATED

(NO DTC’S

STORED), in this

Section.

5. • With TECH 2 connected and ignition on, select

Body / DTC Check / F0: DTC Check and press the

‘Confirm’ soft key as instructed.

• Can TECH 2 communicate with the BCM and PCM

(or PIM – GEN III V8) of the vehicle (if NO DATA is

displayed next to a control module, then there is no

communication between TECH 2 and that particular

control module)?

Go to Step 6. Go to BCM

diagnostics in

Section 12J-1

LOW SERIES

BCM or 12J-2

HIGH SERIES

BCM in this

Service Manual.

6. • Check SDM fuse F26 in instrument panel

compartment.

• Is fuse OK? Go to Step 7. Check and repair

short to earth in

circuit 739,

replace fuse F26.

Recheck and

verify repair.

7. • Turn Ignition off.

• Disconnect SDM connector YB189/YB190.

• Turn the ignition on and , using SRS test lead set

KM-609-20, measure voltage between the SDM

connector YB189/YB190, terminal 5, circuit 739

(Pink/Black wire) and earth (refer to NOTE 2 & 4 on

previous page).

• Is voltage as specified?

Battery + Go to Step 8. Check and repair

open in circuit

739. Recheck

and verify repair.

8. • Turn ignition off.

• With SDM connector YB189/YB190 disconnected,

and using SRS test lead set KM-609-20, check for

continuity between SDM connector YB189/YB190,

terminal 8, circuit 305 (Black wire) and earth at

location G11 (refer to NOTE 2 & 4 on previous

page).

• Does continuity exist?

Go to Step 9. Repair open in

earth circuit 305

as necessary.

Recheck and

verify repair.

9. • Turn ignition OFF.

• Check for continuity between SDM earth (location

G11) and a known good earth (refer to NOTE 2 & 4

on previous page).

• Does continuity exist?

Go to Step 10. Repair earth as

necessary.

Recheck and

verify repair.

10. • Disconnect SDM connector YB189/YB190.

• Check for continuity in circuit 1220 (White/Green –

Green/W hite wire) between BCM and SDM by back

probing BCM connector YB164, terminal 3 (Low

Series BCM) or YB175, terminal 9 (High Series

BCM) and, using SRS test lead set KM-609-20,

probe SDM connector YB189/YB190, terminal 9

(refer to NOTE 2 & 4 on previous page).

NOTE: Use SRS test lead set KM-609-20 to probe

terminals on connector YB189/YB190.

• Does continuity exist?

Replace SDM, refer

Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the VT

Series I Service

Information.

Recheck circuit to

verify repair.

Go to Step 11.

11. • Disconnect BCM connector YB164 (Low Series

BCM) or YB175 (High Series BCM).

• With SDM connector YB189/YB190 disconnected,

check for continuity between BCM connector

YB164, terminal 13 or YB175, terminal 3 and SDM

connector YB189/YB190, terminal 9 (refer to NOTE

2 and 4 on previous page).

NOTE: Use SRS test lead set KM-609-20 to probe

terminals on connector YB189/YB190.

• Does continuity exist?

Replace BCM, refer

to 12J-1 LOW

SERIES BCM or

12J-2 HIGH

SERIES BCM of

the VT Series II

Service

Information.

Repair open in

circuit 1220

between SDM

and BCM.

Recheck and

verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

Figure 12M-5

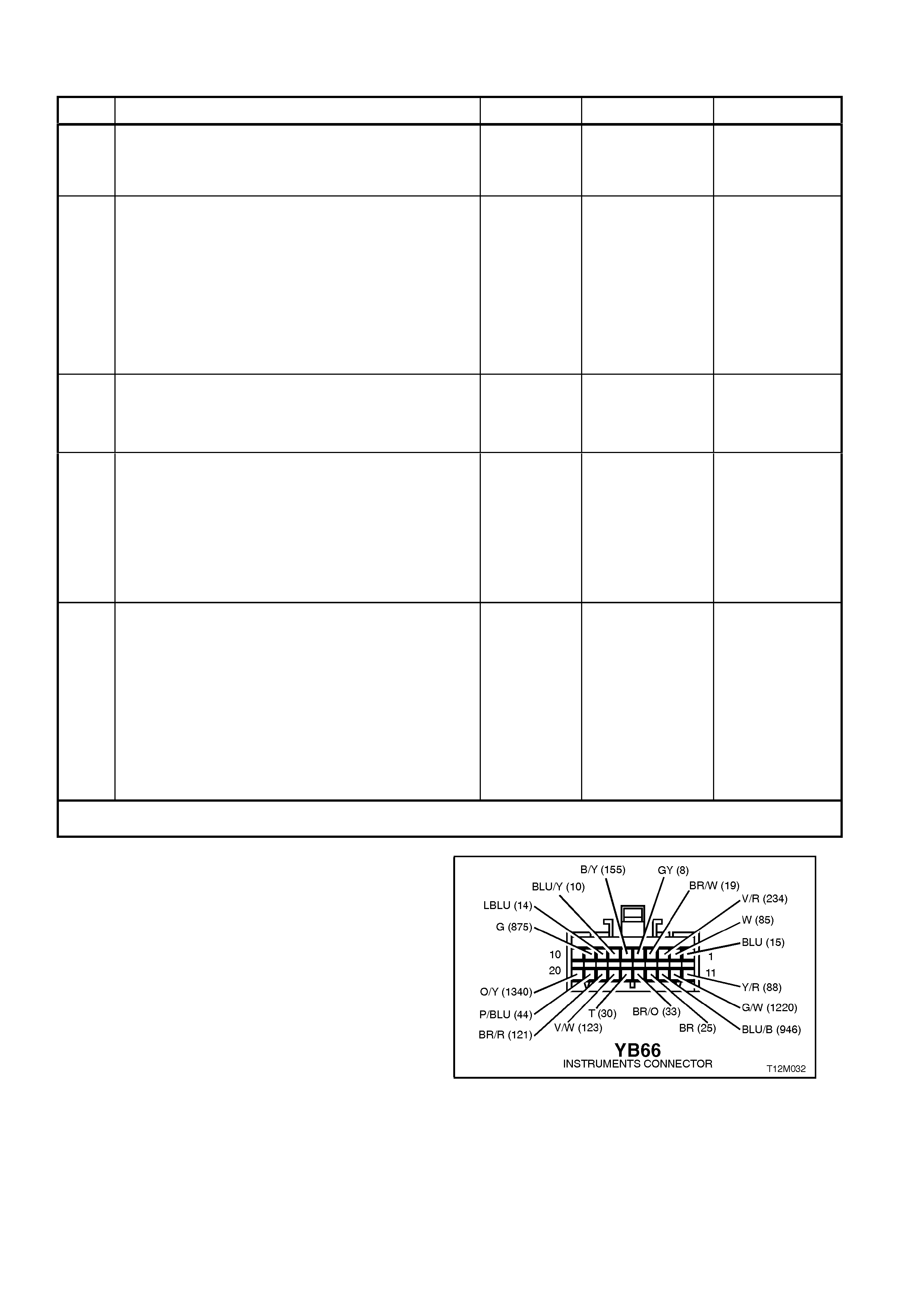

CHART B - SRS WARNING LAMP INOPERATIVE

Figure 12M-6

CIRCUIT DESCRIPTION

Battery voltage is supplied to the SRS warning lamp with the ignition switch in the IGN or START positions through

fuse F13 (located in the passenger compartment fuse panel). To illuminate the lamp, the SDM sends a serial data

message to the instrument cluster, requesting the SRS lamp to illuminate.

The SRS warning lamp will be illuminated when:

• The ignition is switched on ( system wiring and self chec k) and if no f aults are detected, the SRS warning lam p

will be turned off.

• If communication is lost between the SDM and the instrument cluster.

• If the instrument cluster has not been programmed for the vehicle configuration; 2, 3, 4 or 6 loop system

(configuration problem).

• If battery voltage is below eight volts or above 21.2 volts.

• If the SRS is deployed.

• If one or more current or history Diagnostic Trouble Codes (DTCs) are detected when the ignition is switched

on.

• During an ignition cycle, if the SDM detects a current DTC, the SRS warning lamp will be illuminated.

• If the energy reserve in the SDM is switched on (battery voltage less than 7.5 volts).

• If commanded by TECH 2.

Test Description:

The following numbers refer to step numbers in diagnostic chart ‘B’.

1. This test checks for any DTCs that may cause the SRS warning lamp to be inoperative.

2. This test determines if the SDM is faulty by using TECH 2 to drive the warning lamp on.

3. This is a simple test to determ ine if power is being supplied to the instrument cluster warning lamps (the SRS

and ABS warning lamps share a common power source).

4. This step determines if the warning lamp bulb or socket is defective.

5. This test checks for a faulty voltage supply to the warning lamp.

Notes on Diagnostic Chart:

1. Refer to TECH 2 DIAGNOSTICS in Sec tion 12M SUPPLEMENTAL REST RAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

2. Refer to Section 12P WIRING DIAGRAM S of the VT Series I Service Information f or procedures on checking

wiring faults.

CHART B - SRS WARNING LAMP INOPERATIVE

STEP ACTION VALUE YES NO

1. • Install TECH 2 to DLC and select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information

(refer to NOTE 1 on previous page).

• Are any DTCs set?

Repair conditions

which set DTCs.

Recheck and

verify repair.

Go to Step 2.

2. • With TECH 2 still connected, select Body /

Instruments / Miscellaneous Tests / Lamps and

command the SRS warning lamp on.

• Does SRS warning lamp illuminate?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

Go to Step 3.

3. • Disconnect TECH 2 from DLC.

• Turn ignition on whilst observing ABS warning

lamp.

• Does ABS warning lamp illuminate for

approximately five seconds then turn off?

Go to Step 4. Go to Step 5.

4. • Remove instrument cluster, refer to Section 12C

INSTRUMENTS, W IPERS/W ASHERS AND HORN

of the VT Series I Service Information.

• Remove SRS warning lamp bulb and socket from

instrument cluster and check warning lamp bulb

condition.

• Is bulb and socket OK?

Replace

instrument cluster,

refer to 12C

INSTRUMENTS,

WIPERS /

WASHERS AND

HORNS of the VT

Series I Service

Information.

Replace SRS

warning lamp

bulb and/or

socket. Recheck

and verify repair.

5. • Remove instrument cluster, refer to Section 12C

INSTRUMENTS, W IPERS/W ASHERS AND HORN

of the VT Series I Service Information.

• Switch ignition on and measure voltage between

instrument cluster connector YB66, terminal 19,

circuit 44 (Pink/Blue wire) and earth (refer to NOTE

2 on previous page).

• Is voltage as specified?

Battery + Fault not present.

Check all system

wiring harness

connectors and

terminals. Repair

as necessary and

recheck system to

verify repair.

Check fusible link

FJ and fuse F13.

Check wiring

between ignition

switch and

instrument

cluster connector

YB66. Check

ignition switch

contacts.

Recheck circuit

to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

Figure 12M-7

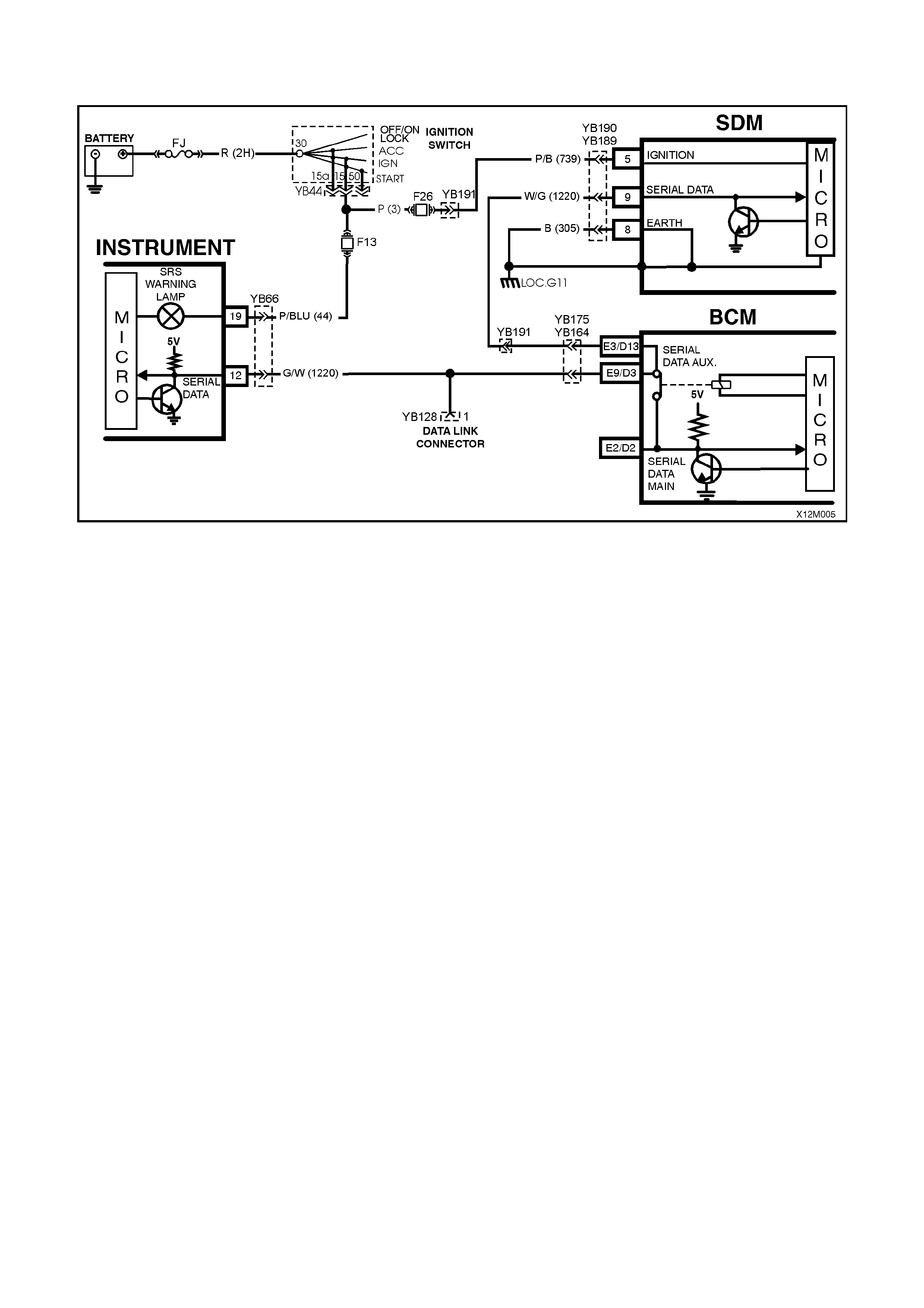

CHART C - SRS WARNING LAMP ILLUMINATED (NO DTC’S STORED)

Figure 12M-8

CIRCUIT DESCRIPTION

Battery voltage is s upplied to the SRS warning lamp with the ignition switch in the IG N or START positions through

fuse F13 (located in the passenger compartment fuse panel). To illum inate the lamp, the SDM sends a serial data

message to the instrument cluster (circuit 1220), requesting the SRS lamp to illuminate.

When the ignition is switched on, the SRS warning lamp should illuminate f or appr ox imately f ive seconds to indicate

the system start up sequence / system wiring and self check. If no system faults are detected, the SRS warning

lamp will be switched off.

If a fault is detected (either during this system check or during the ignition cycle), the SRS warning lamp will either

remain on until the fault is remedied or if a DTC is set, until it is cleared. If a fault is remedied during an ignition

cycle, unless the fault caused a DTC to set, the SRS warning lamp will turn off immediately.

The SRS SDM will send a serial data message to the instrument cluster requesting the lamp to be illuminated if it

detects any of the following: If battery voltage is below eight volts or above 21.2 volts. If the energy reserve in the

SDM is switched on (batter y voltage less than 7.5 volts). If the SRS is deployed. If the SDM does not receive a poll

from the BCM. If one or more current or history DTCs are detected when the ignition is switched ON. During an

ignition cycle, if the SDM detects a current DTC, the SRS warning lamp will be illuminated.

The SRS warning lamp will also be illuminated if com munication is lost (no serial data) between the SDM and the

instrument cluster.

Notes On Diagnostic Chart:

1. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

2. Refer to Section 12P WIRING DIAGRAMS of the VT Series I Service Information for procedures on checking

wiring faults.

3. Refer to Section 6D1-1 CHARGING SYSTEM - V6 ENGINE of the VT Series I Service Information or

Section 6D3-1 CHARGING SYSTEM – GEN III V8 ENGINE of the VT Series II Service Information for

generator testing details.

4. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

5. Fault Interm ittent; c onnect T ECH 2 to DLC, select F 3 Body / SRS / DATA DISPLAY and monitor the following to

see if TECH 2 display changes state while wiggling circuit wires and/or road testing vehicle:

BATTERY VOLTAGE (AFTER 3 SEC)

MODULE DEPLOYED

ENERGY RESERVE

CONFIGURATION FROM INSTRUMENTS

BCM POLL

Repair fault as necessary, recheck circuit to verify repair.

Test Description:

The following numbers refer to step numbers in diagnostic chart ‘C’

1. Ensures the Diagnostic Circuit Check was perform ed which determines if there is a serial data com munication

fault and checks if any DTCs are set.

2. Checks if fault is current or intermittent.

3. Using TECH 2, this step checks the voltage supply to the SDM. If battery voltage to the SDM falls below

eight volts or above 21.2 volts for more than three seconds, the SRS warning lamp is switched on.

4. Checks generator output.

5. Determines if the ignition input voltage at the SDM is approximately the same as what the generator output

voltage was during Step 5.

6. Checks continuity of earth circuit 305.

7. Checks earth connection at SDM, location G11.

8. Using TECH 2, this step checks if the energy reserve has been switched on. If the voltage supply to the SDM

falls below 7.5 volts, the energy reserve in the SDM is switched on.

9. Using TECH 2, this step checks if the SDM has deployed the SRS.

10. If TECH 2 is unable to drive the SRS warning lamp on and off, it indicates fault is within the instrument cluster.

CHART C - SRS WARNING LAMP ILLUMINATED (NO DTC’S SET)

STEP ACTION VALUE YES NO

1. • Was the Diagnostic Circuit Check preformed?

Go to Step 2. Go to CHART A -

DIAGNOSTIC

CIRCUIT CHECK in

this Section.

2. • Turn ignition on.

• Does SRS warning lamp remain illuminated after

five seconds? Go to Step 3. Fault intermittent,

refer to NOTE 5 on

previous page.

3. • Install TECH 2 to DLC and select Body / SRS / Data

Display and scroll to BATTERY VOLTAGE (AFTER

3 SEC)(refer to NOTE 1).

• Does TECH 2 display battery voltage (after three

sec) is OKAY?

Go to Step 8. Go to Step 4.

4. • Carry out checks of generator output (refer to NOTE

3 on previous page).

• Is generator output OK?

Go to Step 5. Repair generator as

necessary.

Recheck and verify

repair.

5. • Disconnect SDM connector YB189/YB190.

• Start engine, turn headlamps on and raise engine

idle speed to approximately 2500 RPM.

• Using Tool KM-609-20, check voltage between SDM

wiring harness connector YB189/YB190, terminal 5,

circuit 739 and a known good earth (refer to NOTE 2

& 4 on previous page).

• Is the voltage measured approximately the same as

measured during Step 4 (generator output tests)?

Go to Step 6. Check and repair

circuit 739 as

necessary.

Recheck and verify

repair.

6. • Turn ignition off.

• With SDM connector YB189/YB190 disconnected,

and using SRS test lead set KM-609-20, check for

continuity between SDM connector YB189/YB190,

terminal 8, circuit 305 (Black wire) and earth at

location G11 (refer to NOTE 2 & 4 on previous

page).

• Does continuity exist?

Go to Step 7. Repair open in

earth circuit 305 as

necessary.

Recheck and verify

repair.

7. • Check for continuity between SDM earth location

G11 and a known good earth (refer to NOTE 2 & 4

on previous page).

• Does continuity exist?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the VT

Series I Service

Information.

Recheck circuit to

verify repair.

Repair earth as

necessary.

Recheck and verify

repair.

8. • With TECH 2 connected, and Body / SRS / Data

Display selected, scroll to ENERGY RESERVE.

• Does TECH 2 display energy reserve off?

Go to Step 9. Go to Step 4.

9. • With TECH 2 connected, and Body / SRS / Data

Display selected, scroll to MODULE HAS

DEPLOYED.

• Does TECH 2 display MODULE HAS DEPLOYED

YES?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the VT

Series I Service

Information.

Recheck circuit to

verify repair.

Go to Step 10.

10. • Wi th TECH 2 connected, select Body / Instruments /

Miscellaneous Tests / Lamps / SRS Lamp.

• Using the soft keys on TECH 2, drive the SRS

warning lamp on and off.

• Is TECH 2 able to drive the SRS warning lamp on

and off?

Replace SDM, refer

Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the VT

Series I Service

Information.

Recheck circuit to

verify repair.

Replace instrument

cluster assembly,

refer Section 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

Figure 12M-9

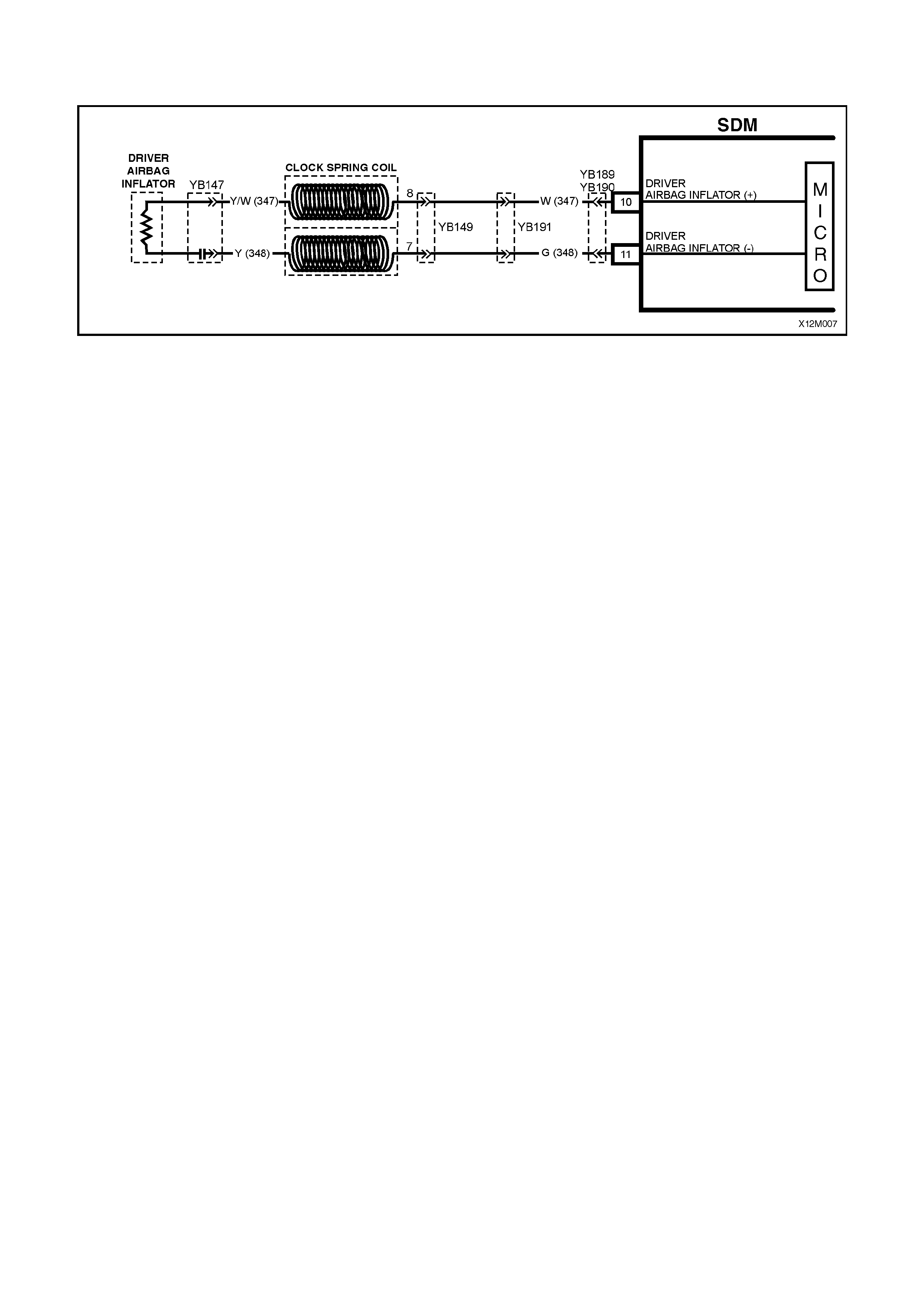

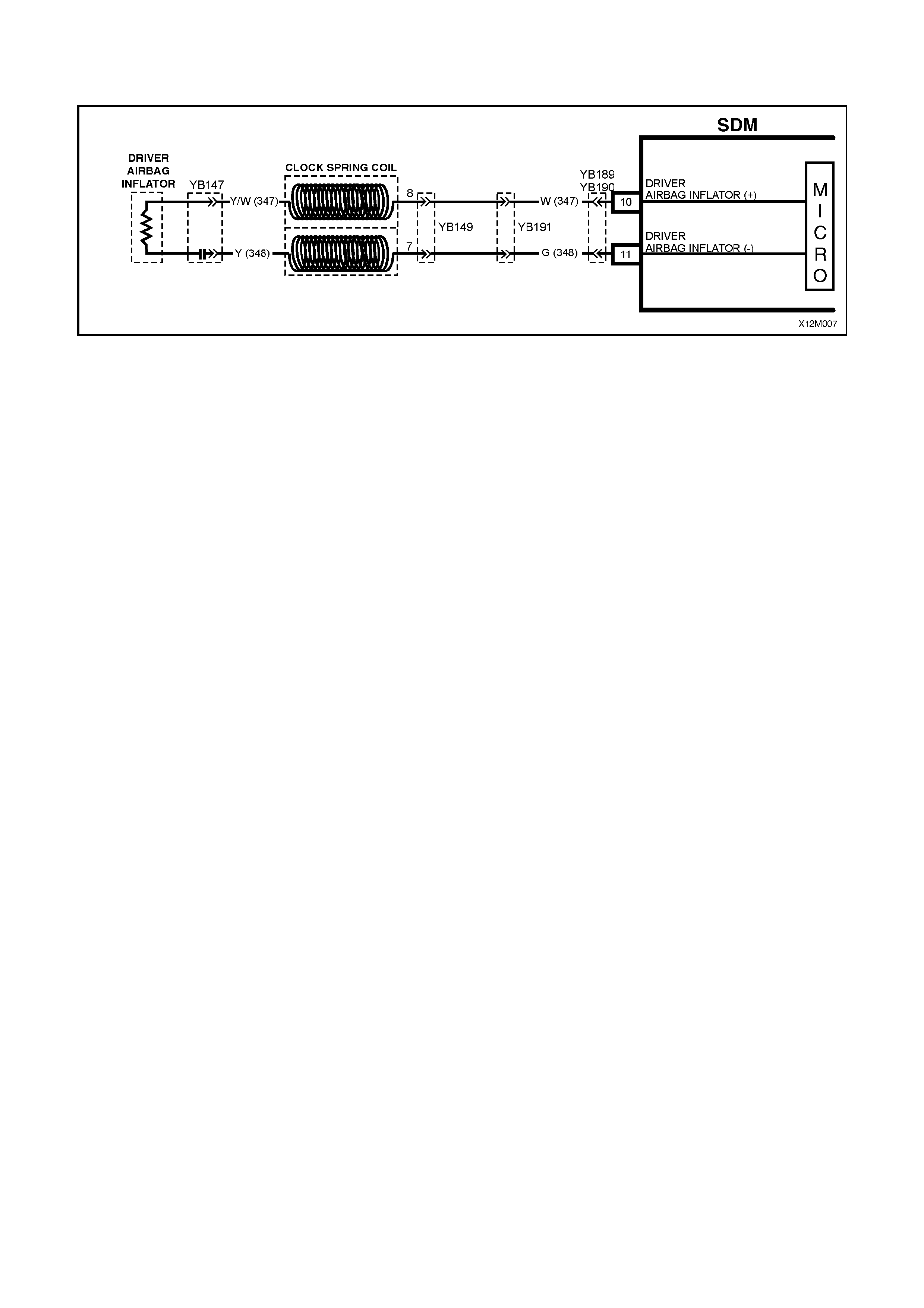

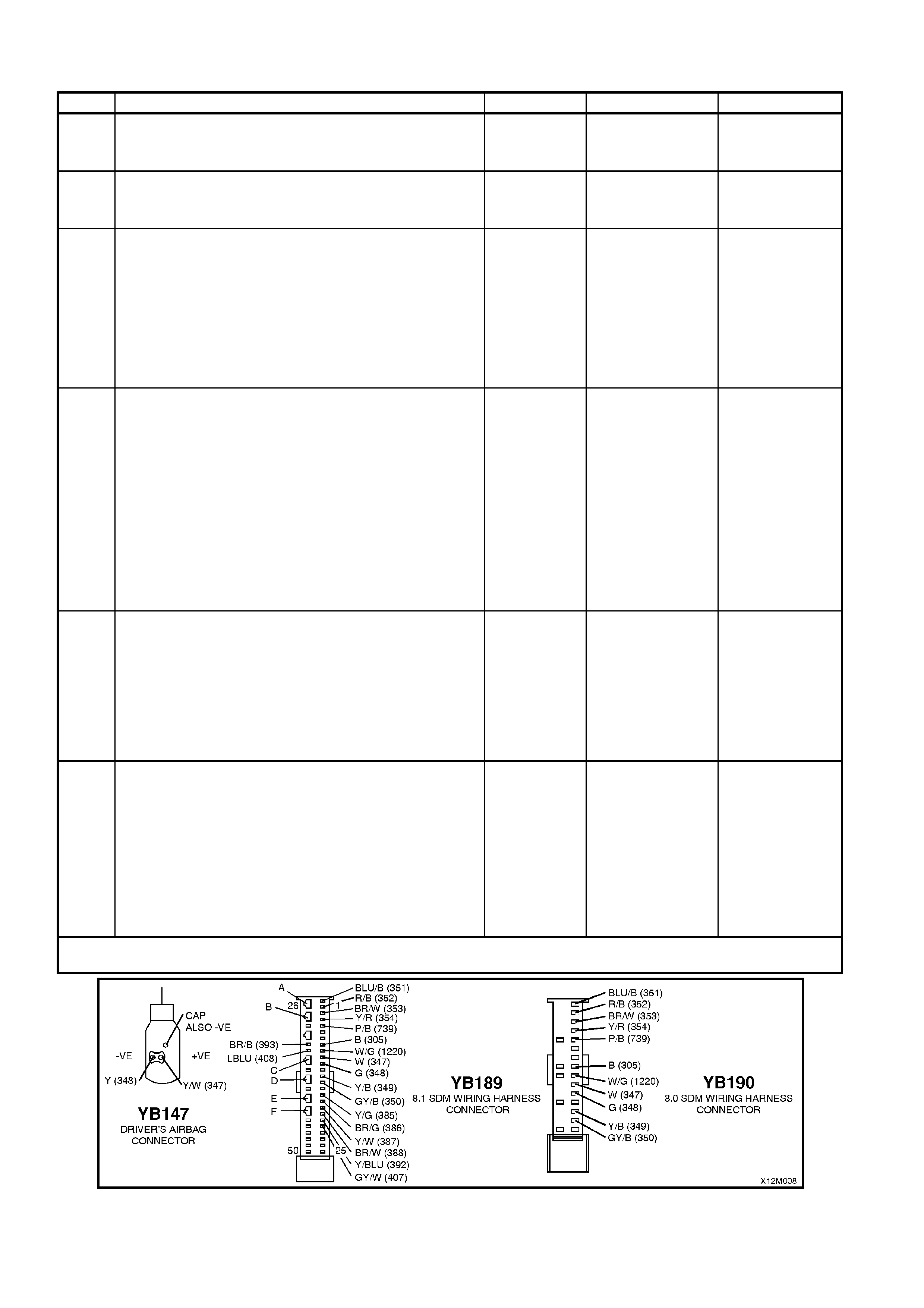

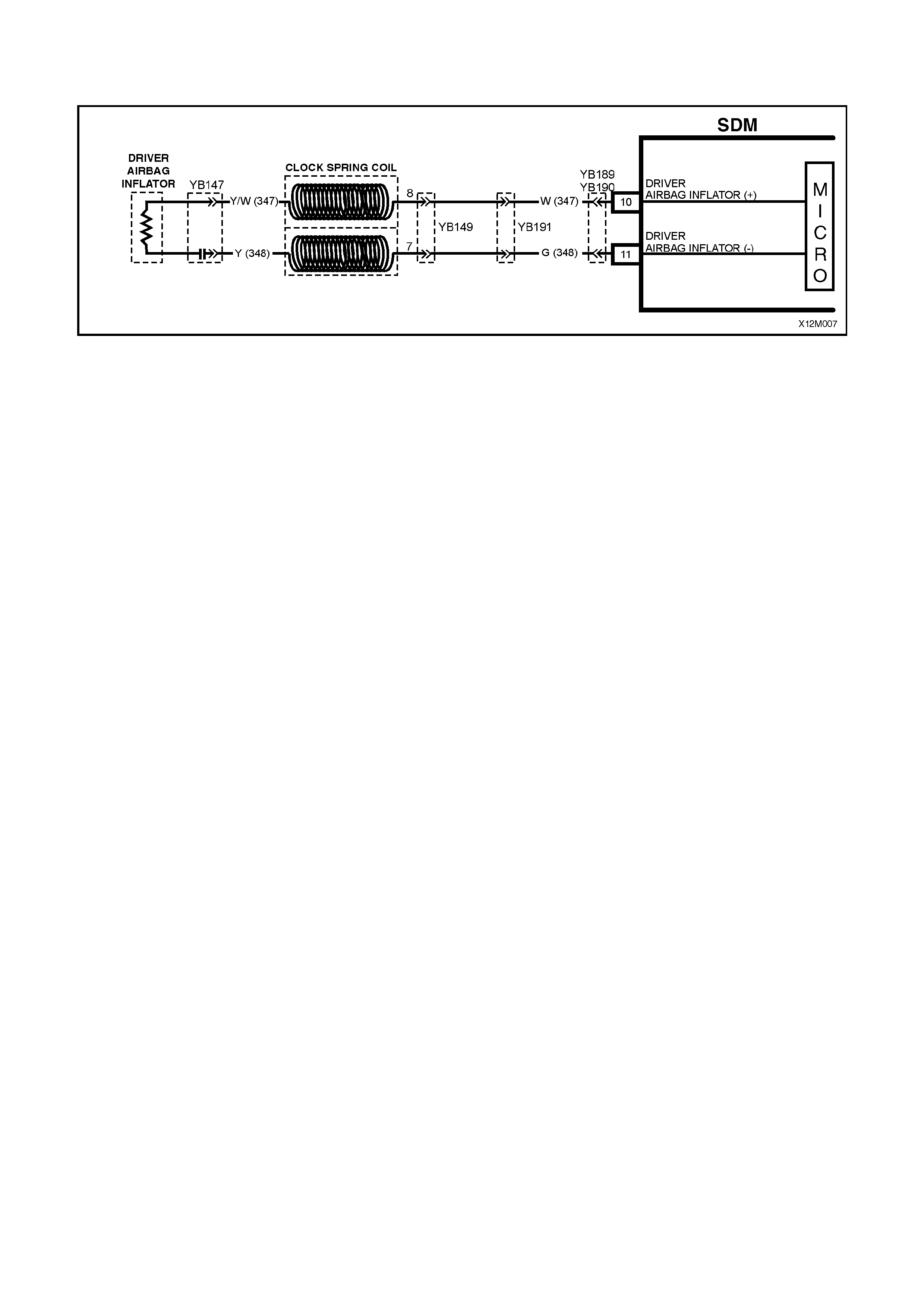

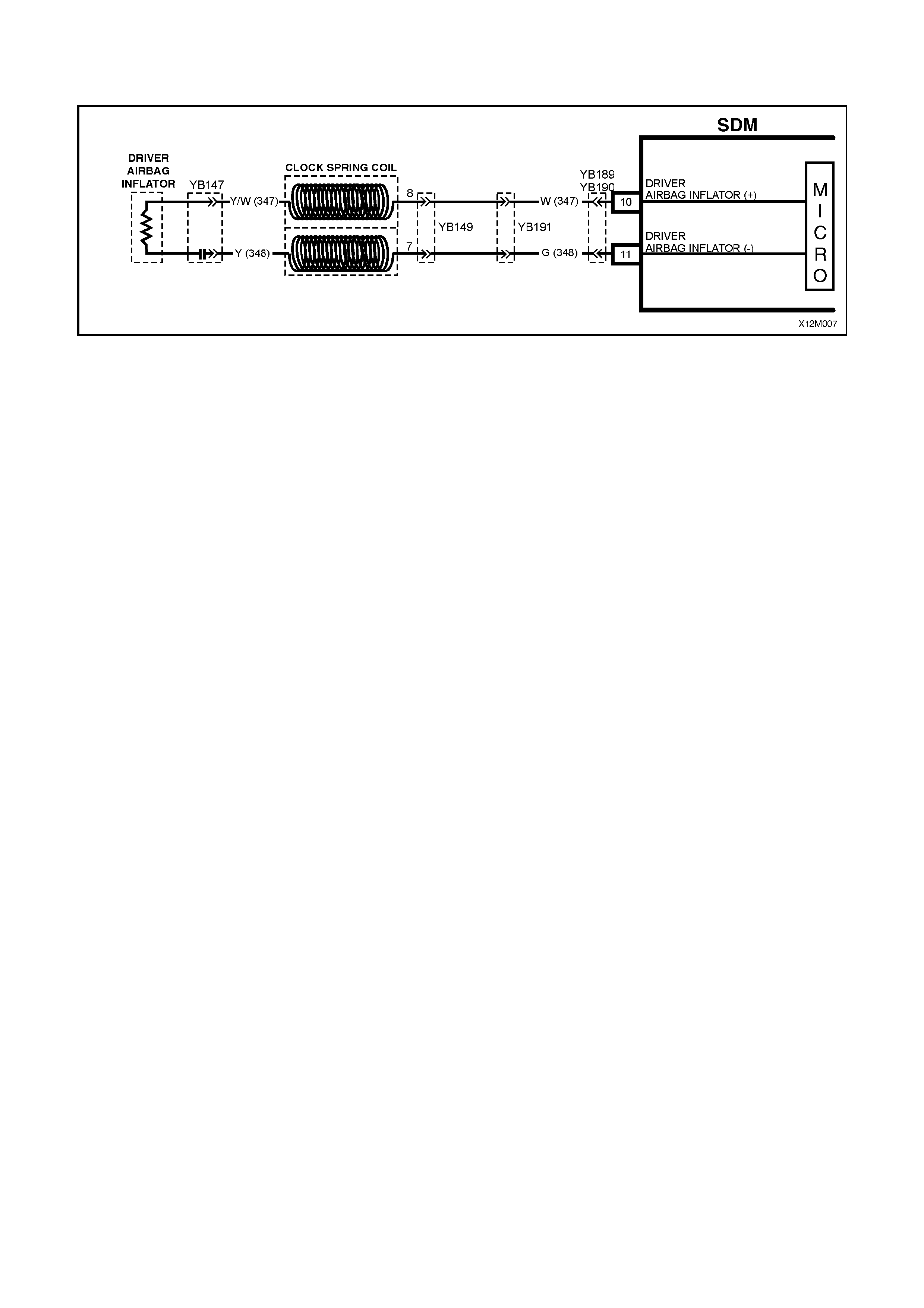

DTC 17 - DRIVER AIR BAG CIRCUIT SHORT TO BATTERY

Figure 12M-10

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

perfor ms a s ystem s elf c hec k. If the SDM detec ts a r esis tanc e to battery supply is less than f ive kohm s in either the

positive and/or negative circuit for more than 3 - 5 seconds, a current DTC 17 will set (refer to

SRS SELF DIAGNOSTICS in Sect ion 12M SUPPLEMENTAL RESTRAINT SYST EM (Version 8.0 & 8.1) of the VT

Series I Service Information for more details).

DTC 17 will set if circuits 347 (driver’s air bag positive side) and/or 348 (driver’s air bag negative side) are shorted to

battery +.

When DTC 17 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 17. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 17. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 17 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 17 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 17 is set, the SRS, including the driver’s air bag, will still be operational.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1. Uses TECH 2 to check if DTC 17 is current or history.

2. Checks for intermittent fault by monitoring TECH 2 screen display. If screen display changes during a ‘wiggle’

test, a fault with the wiring is at that location.

3. Checks circuits 347 and 348 for a short to battery +.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS WIRING REPAIR in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2), of

the VT Series I Service Information before conducting any SRS wiring harness repairs.

3. Resistance cannot be m easured between the two term inals in connector YB147 as the in-built capacitor block s

measurement. Therefore, a ‘service hole’ is incorporated into the connector for fault tracing. Refer to

1.1 SYSTEM COMPONENTS, WIRING HARNESS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM

(Version 6.2) of the VT Series I Service Information for more details on this type of connector.

4. Wiring should be checked at the point where TECH 2 screen display changed status. If necessary, split open

harness.

5. If the fault can not be identified, the harness should be replaced.

6. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

7. Refer to TECH 2 DIAGNOSTICS in Sec tion 12M SUPPLEMENTAL REST RAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

DTC 17 - DRIVER AIR BAG CIRCUIT SHORT TO BATTERY

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information (refer to NOTE 7 on

previous page).

• Is DTC 17 current ?

Go to Step 3. Go to Step 2.

2. • Remove steering column upper and lower cover.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear

all (if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the clock spring

coil and monitor TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

NOTE 2 & 4 on

previous page).

Clear DTC and

recheck system to

verify repair.

Fault not present.

Check all system

wiring harness

connectors and

terminals, refer to

NOTE 5 on

previous page.

Clear DTC and

recheck system.

3. • Dis able the SRS, refer to 2.2 SYSTEM DISABLING

AND ENABLING PROCEDURE in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the VT

Series I Service Information.

• Remove horn bar and driver's air bag inflator

module, refer to 2.3 HORN BAR AND AIR BAG

MODULE ASSEMBLY in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM, of the VT

Series I Service Information.

• Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• Reconnect battery.

• Using Tool KM-609-20, check wiring between SDM

wiring harness connector YB189/YB190, terminals

10 and 11 and driver's air bag connector YB147,

circuits 347 (White wire) and 348 (Green wire) for

short to battery + (refer to NOTES 1, 3 and 6 on the

previous page).

• Is all OK?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

Figure 12M-11

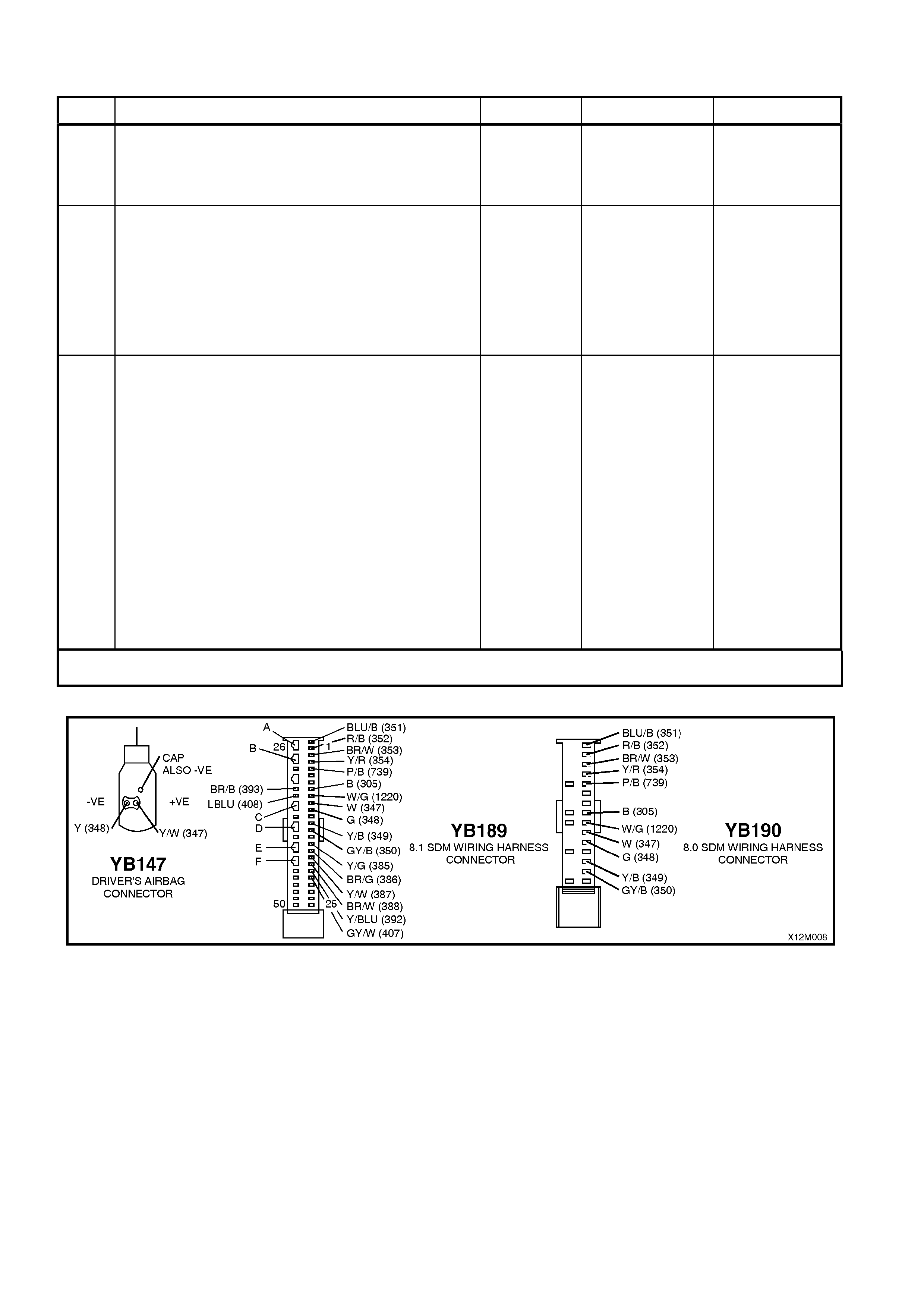

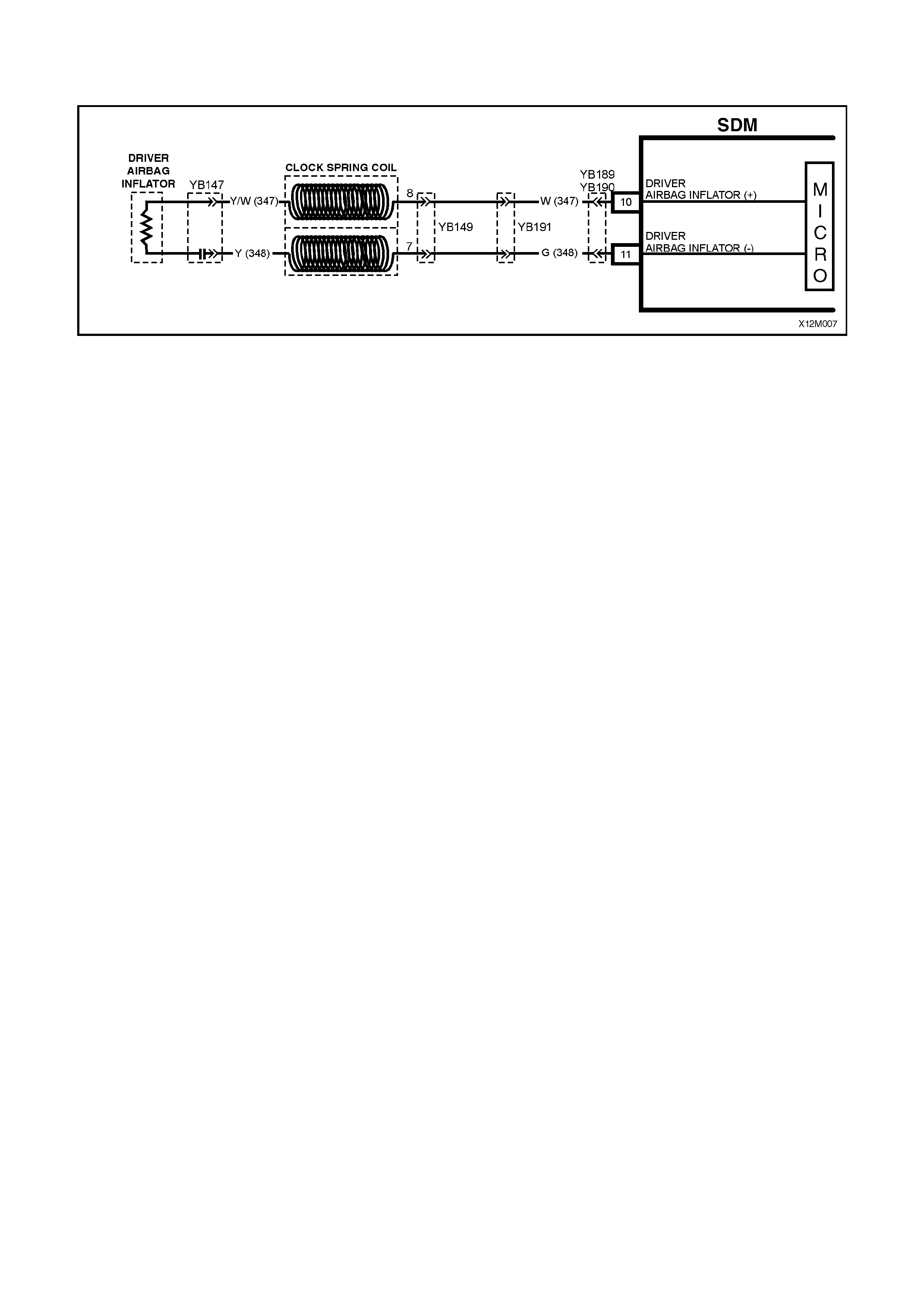

DTC 18 - DRIVER AIR BAG CIRCUIT SHORT TO EARTH

Figure 12M-12

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check. If the SDM detects a resistance to earth of less than three kohms in either the

positive or negative inflator circuit for more than 3 - 5 seconds, a current DTC 18 will set (refer to

SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENT AL RESTRAINT SYST EM (Version 8.0 & 8.1) of the VT

Series I Service Information for more details).

DTC 18 will set if circuits 347 (driver’s air bag positive side) and/or 348 (driver’s air bag negative side) are shorted to

earth.

When DTC 18 sets, the SDM illuminates the SRS warning lamp and sets a ‘current’ DTC 18. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 18. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 18 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 18 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 18 is set, the SRS, including the driver’s air bag, will still be operational.

Test Description

The following numbers refer to Step numbers in the following diagnostic chart.

1. Uses TECH 2 to check if DTC 18 is current or history.

2. TECH 2 in this mode should display approximately 2.0 - 6.4 ohms if the driver's air bag loop circuit is OK.

3. If screen display changes during a wiring 'wiggle' test, a fault with the wiring is at that location.

4. Tool SD28280B is a dum m y load taking the place of the horn bar and driver's air bag inflator m odule. If T ECH 2

displays the cor rect resis tance of the dum m y load, the system f ault is in the horn bar and driver's air bag inflator

module assembly.

5. T his test check s the wiring between the SDM wiring harnes s connector YB189 (8.1 SDM) or YB190 (8.0 SDM) ,

terminal 10 and the horn bar and driver's air bag inflator module connector YB147 for faults.

6. T his test check s the wiring between the SDM wiring harnes s connector YB189 (8.1 SDM) or YB190 (8.0 SDM) ,

terminal 11 and the horn bar and driver's air bag inflator module connector YB147 for faults.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS W IRING REPAIR in Sect ion 12M SUPPLEMENTAL REST RAINT SYSTEM of the VT Ser ies I

Service Information before conducting any SRS wiring harness repairs.

3. Resistance cannot be measured between the two terminals in connector YB147 as the in-built capacitor blocks

measurement. Therefore, a ‘service hole’ is incorporated into the connector for fault tracing. Refer to

1.1 SYSTEM COMPONENTS, WIRING HARNESS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM

(Version 8.0 & 8.1) of the VT Series I Service Information for more details on this type of connector.

4. Wiring should be checked at point where TECH 2 screen display changed. If necessary, split open wiring

harness.

5. If the fault cannot be identified, the wiring harness should be replaced.

6. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

7. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

8. To enable or disable the SRS system, refer to 2.2 SYSTEM DISABLING AND ENABLING PROCEDURE in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service

Information.

DTC 18 - DRIVER AIR BAG CIRCUIT SHORT TO EARTH

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to DLC and select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information

(refer to NOTE 7 on previous page).

• Does TECH 2 display DTC 18 as a Current DTC?

Go to Step 2. Go to Step 3.

2. • With TECH 2 still connected, select Body / SRS /

Data Display and scroll to DRIVER AIR BAG LOOP

RESISTANCE.

• Is value displayed on TECH 2 as specified?

Approx.

2.0 - 6.4

Ohms

Go to Step 3. Go to Step 4.

3. • Remove steering column upper and lower cover.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear all

(if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the clock spring coil

and monitor TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

to NOTES 2 & 4

on previous

page).

Clear DTC and

recheck system to

verify repair.

Fault not

present. Check

all system wiring

harness

connectors, and

terminals, refer

to NOTE 5 on

previous page.

Clear DTC and

recheck system.

4. • Disable the SRS (refer NOTE 8 on previous page).

• Remove horn bar and driver's air bag inflator

module, refer to 2.3 HORN BAR AND AIR BAG

MODULE ASSEMBLY in Section 12M

SUPPLEMENT RESTRAINT SYSTEM, of the VT

Series I Service Information.

• Connect Tool No. SD28280B to SRS wiring harness

connector YB147.

• Enable the SRS (refer NOTE 8 on previous page).

• With TECH 2 still connected, select Body / SRS /

Data Display and scroll to DRIVER AIR BAG LOOP

RESISTANCE.

• Is value displayed on TECH 2 as specified?

Approx.

3.0 Ohms Replace horn bar

and driver air bag

inflator module

assembly, refer to

2.3 HORN BAR

AND AIR BAG

MODULE

ASSEMBLY in

Section 12M, Vol.

7 of the VT Series

Service Manual.

Clear DTC and

recheck system to

verify repair.

Go to Step 5.

5. • Disable the SRS (refer NOTE 8 on previous page).

• Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• Remove Tool SD28280B from YB147.

• Using Tool KM-609-20, check wiring between SDM

wiring harness connector YB189/YB190, terminals

10 and driver's air bag inflator module connector

YB147, circuit 347 for short to earth (refer to NOTE

1 & 6 on previous page).

• Is all OK?

Go to Step 6. Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

6. • With system disabled, SDM wiring harness

connector YB189/YB190 disconnected and using

Tool KM-609-20, check wiring between SDM wiring

harness connector YB189/YB190, terminal 11 and

driver's air bag inflator module connector YB147,

circuit 348 for a short to earth (refer to NOTES 1, 3

and 6 on previous page).

• Is all OK?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

Figure 12M-13

DTC 19 - DRIVER AIR BAG CIRCUIT CAPACITANCE TOO HIGH

Figure 12M-14

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check.

If the SDM detects the capacitanc e in the driver’s air bag circ uit is too high (gr eater than 550 nF) f or longer than 3 -

5 seconds, a current DTC 19 will set (refer to SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information for more details).

DTC 19 will set if the in-built capacitor in the SRS wiring harness connector YB147 is faulty.

When DTC 19 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 19. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 19. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 19 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 19 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

ACTION REQUIRED

If DTC 19 is set, the driver’s air bag may not operate and therefore, the clock spring coil assembly must be replaced

(connector YB147 with the in-built capacitor is part of the clockspring coil assembly). Refer to

2.6 CLOCK SPRING COIL in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2), of the VT Series

I Service Information for the correct procedure on replacing the clock spring coil assembly .

After the clock spring coil ass embly has been replaced, ensure all SRS c omponents are r econnected, clear DTCs ,

enable the SRS and verify the correct operation of the system (i.e. warning lamp not illuminated after five seconds

of ignition being switched ON).

DTC 20 - DRIVER AIR BAG CIRCUIT CAPACITANCE TOO LOW

Figure 12M-15

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check.

If the SDM detects the capacitance in the driver’s air bag circuit is too low (less than 390 nF) for longer than 3 - 5

seconds, a current DTC 20 will set (refer to SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information for more details).

DTC 20 will set if the in-built capacitor in the SRS wiring harness connector YB147 is faulty.

When DTC 20 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 20. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 20. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 20 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 20 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

ACTION REQUIRED

If DTC 20 is set, the driver’s air bag may not operate and therefore, the clock spring coil assembly must be replaced

(connector YB147 with the in-built capacitor is part of the clockspring coil assembly). Refer to

2.6 CLOCK SPRING COIL in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2), of the VT Series

I Service Information for the correct procedure on replacing the clock spring coil assembly .

After the clock spring coil assembly has been replaced, ensure that all SRS components are reconnected, clear

DTCs, enable the SRS and verify the correct operation of the system (i.e. warning lamp not illuminated after five

seconds of ignition being switched ON).

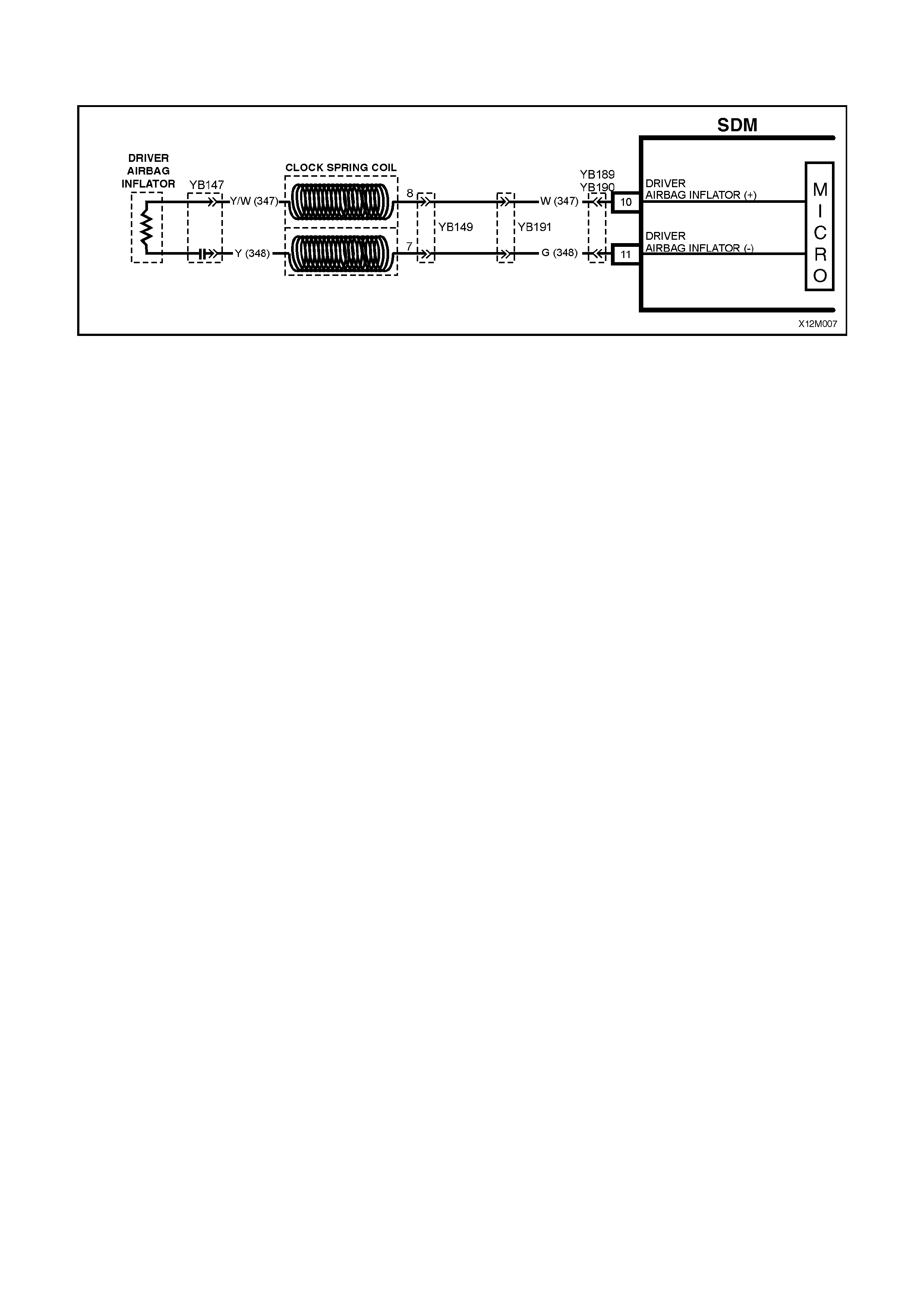

DTC 21 - DRIVER AIR BAG CIRCUIT RESISTANCE TOO HIGH

Figure 12M-16

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check.

If the SDM detects a resistance in the driver’s air bag circuit that is too high (greater than 10 ohms) for longer than 3

- 5 seconds, a current DTC 21 will set (refer to SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information for more details).

DTC 21 will set if circuits 347 or 348, (including the horn bar and air bag assembly and the clock spring coil) are

open circuited.

When DTC 21 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 21. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 21. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 21 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 21 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 21 is set, dependent on where the fault is, the driver’s air bag may not operate.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS WIRING REPAIR in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2) of

the VT Series I Service Information before conducting any SRS wiring harness repairs.

3. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

4. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

5. To enable or disable the SRS system, refer to 2.2 SYSTEM DISABLING AND ENABLING PROCEDURE in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service

Information.

Test Description

The following numbers refer to Step numbers in the following diagnostic chart.

1. Uses TECH 2 to check if DTC 21 is current or history.

2. Checks for intermittent fault by monitoring TECH 2 screen. If screen display changes during a wiring 'wiggle'

test, a fault with the wiring is at that location.

3. Tool SD28280B is a dummy load taking the place of the driver’s horn bar and air bag assembly. If DTC 21

becomes a history DTC with dummy load connected, the system fault is in the driver’s horn bar and air bag

assembly.

4. Checks if open circuit is in the clock spring coil. If the clock spring coil is disconnected from the system, and

term inals 7 & 8 in connector YB149 bridged together, DT C 21 will becom e a histor y DT C if the clock spr ing coil

is faulty.

5. Checks circuit 347 for open circuit.

6. Checks circuit 348 for open circuit.

Figure 12M-17

DTC 21 - DRIVER AIR BAG CIRCUIT RESISTANCE TOO HIGH

STEP ACTION VALUE YES NO

1. • Install TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information (refer NOTE 4 on previous

page.

• Is DTC 21 current?

Go to Step 3. Go to Step 2.

2. • Remove steering column upper and lower cover.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear all

(if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the clock spring coil

while monitoring the TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system to

verify repair.

Fault not present.

Check all system

wiring harness

connectors, and

terminals.

Clear DTC and

recheck system.

3. • Disable the SRS (refer NOTE 5 on previous page).

• Remove horn bar and driver's air bag inflator

module, refer to 2.3 HORN BAR AND AIR BAG

MODULE ASSEMBLY in Section 12M

SUPPLEMENT RESTRAINT SYSTEM, of the VT

Series I Service Information.

• Connect Tool No. SD28280B to SRS wiring harness

connector YB147.

• Enable the SRS (reconnect battery).

• Connect TECH 2 to DLC and select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information.

• Is DTC 21 still current?

Go to Step 4. Replace horn bar

and driver's air

bag inflator

module

assembly, refer

to 2.3 HORN

BAR AND AIR

BAG MODULE

ASSEMBLY in

Section 12M, Vol

7 of the VT

Series Service

Manual. Clear

DTC and recheck

system to verify

repair.

4. • Disable the SRS (refer NOTE 5 on previous page).

• Disconnect SRS wiring harness connector YB149

from clock spring coil assembly.

• Enable the SRS (reconnect battery).

• Using a suitable jumper wire from KM-609, bridge

connector YB149, terminals 7 and 8 together.

(NOTE: This step may set a current DTC 22).

• With TECH 2 still connected, select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information.

• Does DTC 21 become history?

Replace clock

spring coil

assembly, refer to

2.6 CLOCK

SPRING COIL in

Section 12M, of

the VT Series I

Service

Information. Clear

all DTCs and

recheck system to

verify repair.

Go to Step 5

5. • Disable the SRS, (refer NOTE 5 on previous page).

• Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• Using Tool KM-609-20, check wiring between SDM

wiring harness connector YB189/YB190, terminal

10 and clock spring coil connector YB149, terminal

8, circuit 347 (White wire) for open circuit (refer to

NOTES 1 & 3 on previous page).

• Is all OK?

Go to Step 6. Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

6. • With system disabled, SDM wiring harness

connector YB189/YB190 disconnected and using

Tool KM-609-20, check wiring between SDM wiring

harness connector YB189/YB190, terminal 11 and

clock spring coil connector YB149, terminal 7,

circuit 348 (Green wire) for open circuit (refer to

NOTES 1 & 3 on previous page).

• Is all OK?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

DTC 22 - DRIVER AIR BAG CIRCUIT RESISTANCE TOO LOW

Figure 12M-18

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check.

If the SDM detects a r es istanc e in the dr iver’s air bag cir cuit that is too low (less than one ohm) f or longer than 3 - 5

seconds, a current DTC 22 will set (refer to SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information for more details).

DTC 22 will set if circuits 347 or 348, (including the horn bar and air bar assembly and the clock spring coil) are

shorted together.

When DTC 22 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 22. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 22. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 22 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 22 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 22 is set, dependent on where the fault is, the driver’s air bag may not operate.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1. Uses TECH 2 to check if DTC 22 is current or history.

2. Checks for intermittent fault by monitoring TECH 2 screen. If screen display changes during a wiring 'wiggle'

test, a fault with the wiring is at that location.

3. Tool SD28280B is a dummy load taking the place of the driver’s horn bar and air bag assembly. If DTC 22

becomes a history DTC with dummy load connected, the system fault is in the driver’s horn bar and air bag

assembly.

4. Check s if shor t circuit is in the clock spring coil. If the clock spr ing coil is disconnected fr om the system , a DT C

21 (open circuit) will set and DT C 22 will become histor y. If DTC 21 s ets and DT C 22 bec omes his tory, the c lock

spring coil is faulty.

5. This test checks the wiring between the SDM harness connector YB189 (8.1 SDM) or YB190 (8.0 SDM) and

SRS connector YB149 for a short circuit.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS WIRING REPAIR in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 &

8.1) of the VT Series I Service Information before conducting any SRS wiring harness repairs.

3. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

4. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

5. To enable or disable the SRS system, refer to 2.2 SYSTEM DISABLING AND ENABLING PROCEDURE in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service

Information.

Figure 12M-19

DTC 22 - DRIVER AIR BAG CIRCUIT RESISTANCE TOO LOW

STEP ACTION VALUE YES NO

1. • Install TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information (refer to NOTE 4 on previous

page).

• Is DTC 22 current?

Go to Step 3. Go to Step 2.

2. • Remove steering column upper and lower cover.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear all

(if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the clock spring coil

while monitoring the TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

Fault not present.

Check all system

wiring harness

connectors, and

terminals.

Clear DTC and

recheck system.

3. • Disable the SRS (refer NOTE 5 on previous page).

• Remove horn bar and driver's air bag inflator

module, refer to 2.3 HORN BAR AND AIR BAG

MODULE ASSEMBLY in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the VT

Series I Service Information.

• Connect Tool No. SD28280B to SRS wiring harness

connector YB147.

• Enable the SRS (reconnect battery).

• Connect TECH 2 to DLC and select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information.

• Is DTC 22 still current?

Go to Step 4. Replace horn bar

and driver's air

bag inflator

module assembly,

refer to 2.3 HORN

BAR AND AIR

BAG MODULE

ASSEMBLY in

Section 12M, Vol.

7 of the VT Series

Service Manual.

Clear DTC and

recheck system to

verify repair.

4. • Disable the SRS (refer NOTE 5 on previous page).

• Disconnect SRS wiring harness connector YB149

from clock spring coil assembly.

• Enable the SRS (reconnect battery).

• With TECH 2 still connected, select Body / SRS /

Diagnostic Trouble Codes / Read DTC Information.

• Is DTC 21 current and DTC 22 history?

Replace clock

spring coil

assembly, refer

to 2.6 CLOCK

SPRING COIL in

Section 12M, of

the VT Series I

Service

Information.

Clear all DTCs

and recheck

system to verify

repair.

Go to Step 5

5. • Disable the SRS (refer NOTE 5 on previous page).

• Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• With SRS wiring harness connector YB149

disconnected, and using Tool KM-609-20, check for

continuity between SDM wiring harness connector

YB189/YB190, terminal 10, circuit 347 (White wire)

and terminal 11, circuit 348 (Green wire)(refer to

NOTES 1 & 3 on previous page).

• Does continuity exist?

Repair short in

circuits 347 and

348, between

SDM wiring

harness

connector

YB189/YB190

and YB149 as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

DTC 247 - DRIVER’S AIR BAG CIRCUIT POWER STAGE ERROR

T12M126

M

I

C

R

O

YB147

YB149

7

8

YB191

YB189

YB190

DRIVER

AIRBAG

INFLATOR

DRIVER

A

IRBAG INFLATOR (+)

DRIVER

A

IRBAG INFLATOR (-)

10

11

CL OCK SPR ING CO IL

W (347)

G (348)

SDM

Figure 12M-20

CIRCUIT DESCRIPTION

At ignition on, the SDM perfor ms an initial system self check of the SDM power s tages. If during this initial self test

the SDM detects a fault with the driver’s air bag power stage a current DTC 247 Driver’s Air Bag Circuit Power

Stage Error will set. On completion of the initial system self test the SDM then performs a test of the Driver’s Air Bag

Circuit. If the SDM detects a pr oblem with this circuit the as sociated Driver ’s Air Bag Cir cuit DT C will be set and the

DTC 247 Driver’s Air Bag Circuit Power Stage Error will become a history DTC.

DTC 247 Driver’s Air Bag Circuit Power Stage Error will set if a fault occurs in the driver’s air bag circuit, clock

spring coil assembly with the in-built capacitor connector YB147, connector YB149, connector YB191, the SRS

wiring harness, connector YB189/YB190 or SDM.

When a history DTC 247 Driver’s Air Bag Circuit Power Stage Error sets, the SDM illuminates the SRS warning

lamp. Should the fault conditions detected by the SDM clear during the same ignition cycle the code will remain a

history DTC 247 Driver’s Air Bag Circuit Power Stage Error for all ignition cycles until cleared. The SRS warning

lamp will remain on for the remainder of the ignition cycle.

W hen a DTC 247 Driver’s Air Bag Circuit Power Stage Error sets, the SDM illum inates the SRS warning lamp for

the rem ainder of the ignition cycle. Should the fault conditions detected by the SDM clear during the sam e ignition

cycle the code will remain a history DTC 247 Driver’s Air Bag Circuit Power Stage Error for all ignition cycles until

cleared. T he SRS warning lam p will also rem ain illum inated until the history DTC 247 Driver ’s Air Bag Circuit Power

Stage Error is cleared.

If a DTC 247 Driver’s Air Bag Circuit Power Stage is set, dependent on where the fault is, the driver’s air bag may

not operate.

ACTION REQUIRED

If DTC 247 Driver’s Air Bag Circuit Power Stage Error and any other DTC is set then the diagnostics for the other

DTC s hould be car r ied out f ir st. F or ex ample if a DT C 247 Dr iver’s Air Bag Circ uit Power Stage Err or and a DTC 21

Driver’s Air Bag Circuit Resistance High are set, the diagnostics for a DTC 21 Driver’s Air Bag Circuit Resistance

High should be carried out first.

If only a DTC 247 Driver’s Air Bag Circuit Power Stage Error is set then the SDM should be replaced.

NOTE: An intermittent in the driver’s air bag circuit may cause a DTC 247 Driver’s Air Bag Circuit Power Stage

Error to set.

After the fault has been rectified, ensure that all SRS components are reconnected, clear DTCs, enable the SRS

and verify the correct operation of the system (i.e. warning lamp not illum inated after five seconds of ignition being

switched ON).

Test Description

The following numbers refer to Step numbers in the following diagnostic chart.

1. Us es T ECH 2 to chec k if a DT C 247 Driver’s Air Bag Circ uit Power Stage Error is history code, and if any other

driver’s air bag circuit current or history DTCs are set. If any other DTCs are set refer to these DTCs first.

2. Checks for intermittent fault by monitoring TECH 2 screen during ignition on cycle. If screen display changes

during a wiring 'wiggle' test, a fault with the wiring is at that location.

3. If no other DTCs are set and there are no intermittents in the driver’s air bag circuit then the SDM should be

replaced.

Notes On Diagnostic Chart

1. For all wiring harness checking procedures, refer to VT Series 1 Service Information, WIRING DIAGRAMS,

SECTION 12P.

2. Refer to VT Series 1 Service Information Section 12M, SRS VERSION 6.2, 2.8 SRS WIRING REPAIR before

conducting any SRS wiring harness repairs.

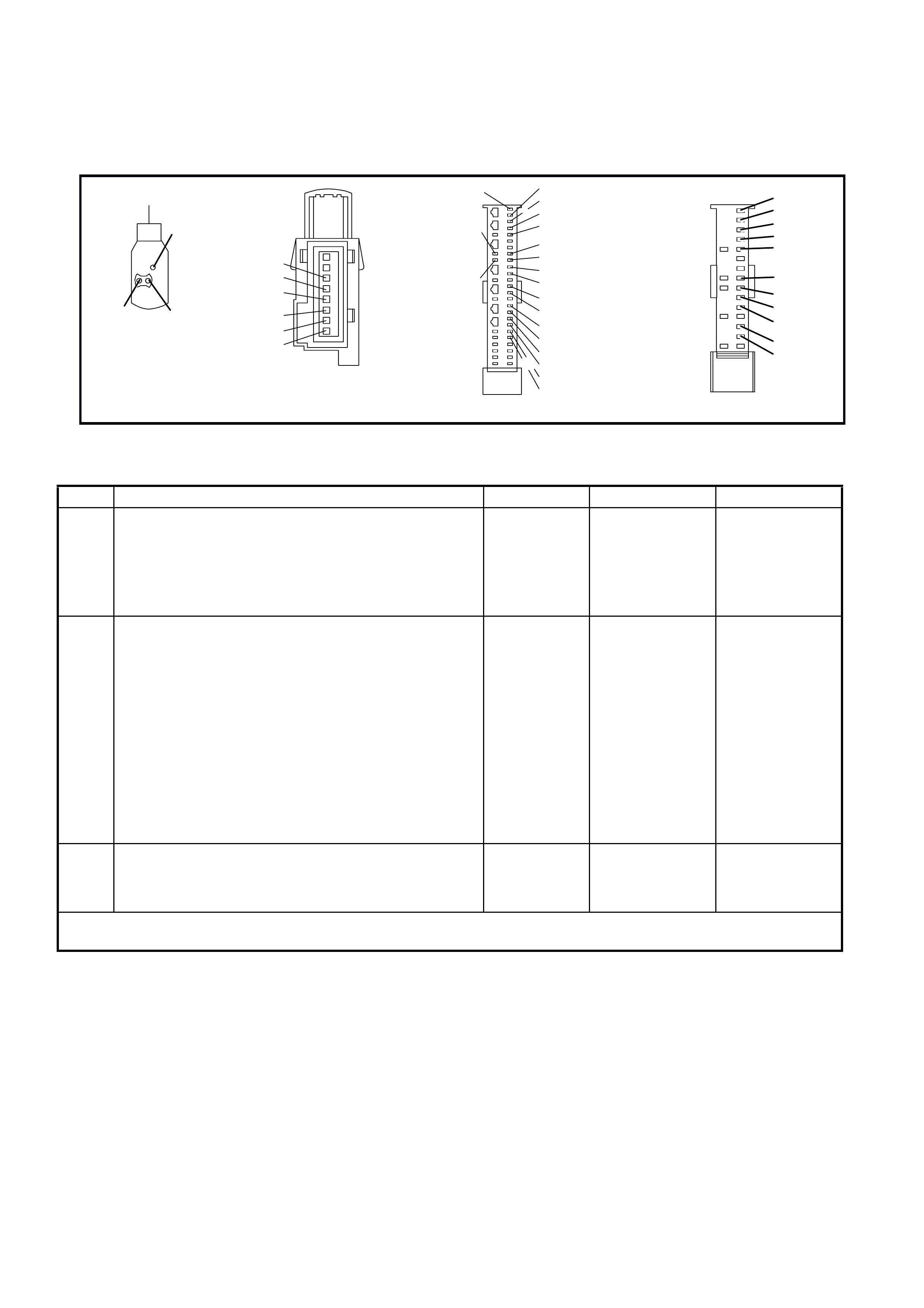

T12M170

YB189

8.1 SDM

WIRING HARNESS

CONNECTOR

BR/B (393)

26

50 25

1

BL U/ B (351) R/B (3 52)

BR/W ( 353)

Y/R (354)

P/B (739)

B (305)

B (3 05)

G/W (1220)

W (3 4 7 )

G (3 48 )

Y/B (349)

GY / B (350 )

Y/G (385)

BR/G (386)

Y/W (387)

BR/W ( 388)

Y/BLU (392)

GY / W ( 407 )

LBLU (408)

BLU/B ( 351)

R/B (352)

BR/W (353)

Y/R (354)

P/B (739)

G/W (1220)

W (3 4 7)

G (348)

Y/B (349)

GY/ B (350)

YB190

8.0 SDM WIRING

HARNESS

CONNECTOR

+VE-VE

G (348) W (3 47 )

CAP

ALSO -VE

YB147

DRIVER'S AIRBAG

CONNECTOR

B/Y (701)

B/Y (28)

G (348)

W(347)

BR (515)

B/G (151 )

YB149

CLOCK SP RING

CONNECTOR

Figure 12M-21

DTC 247 - DRIVER’S AIR BAG CIRCUIT POWER STAGE ERROR

STEP ACTION VALUE YES NO

1. • Install TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information.

• Is a DTC 247 Driver’s Air Bag Circuit Power Stage

Error a history DTC, and are any other driver’s air

bag circuit DTCs set?

Go to other

driver’s air bag

circui t DTC

diagnostic chart

in this Section.

Go to Step 2.

2. • Remove steering column upper and lower cover.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear all

DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the clock spring coil

while monitoring the TECH 2 screen display.

• Jack up the front of the vehicle and turn the steering

wheel from lock to lock while monitoring the TECH 2

screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Go to applicable

DTC chart in this

Section.

Go to step 3.

3 • Replace SDM, refer to VT Series 1 Service

Information Section 12M, SRS VERSION 8.0 & 8.1,

2.4 SENSING AND DIAGNOSTIC MODULE (SDM).

Recheck circuit to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

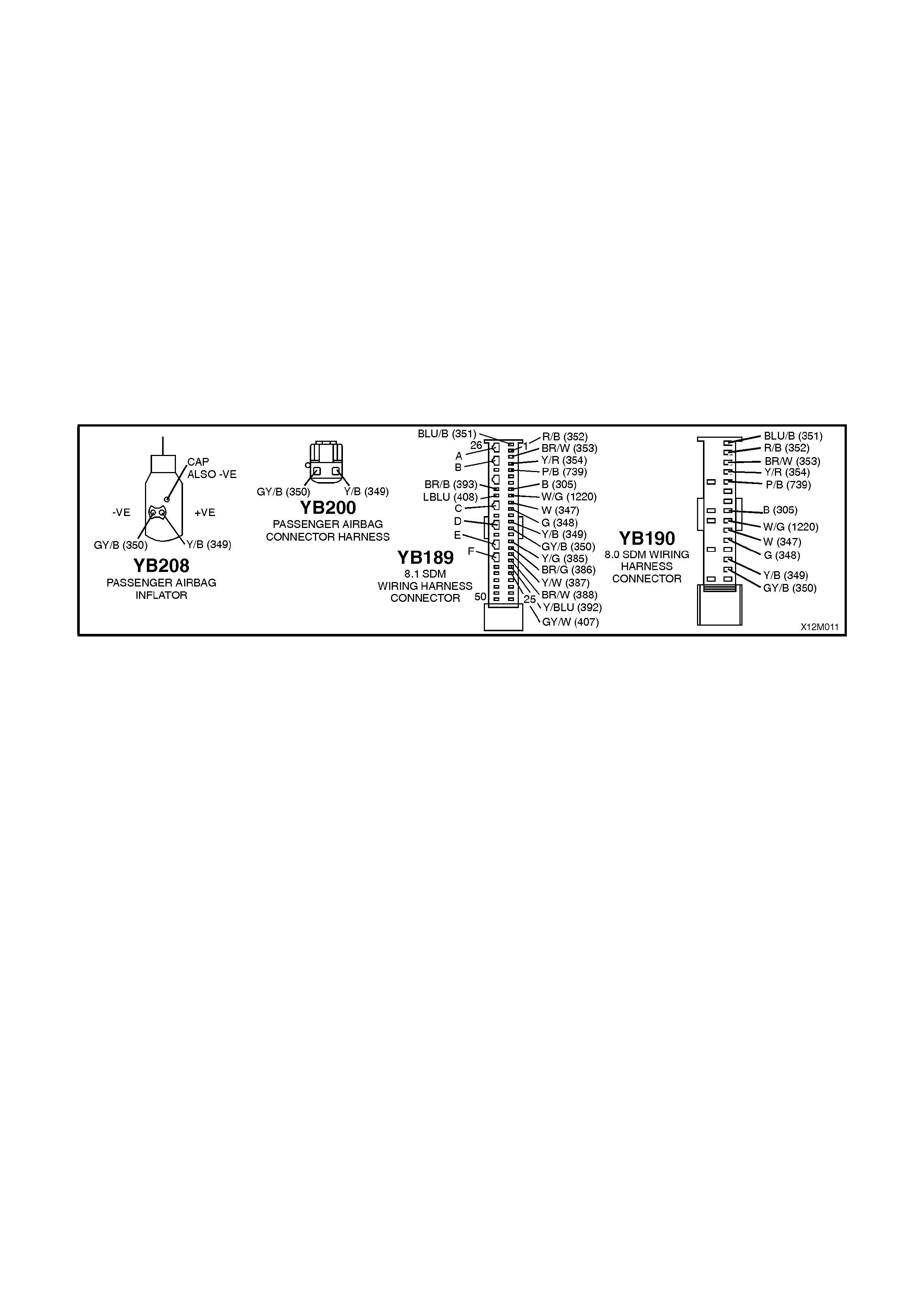

DTC 33 - PASSENGER AIR BAG CIRCUIT SHORT TO BATTERY

T12M127

SDM

M

I

C

R

O

YB191

YB189

YB190

YB200

YB208

PASSENGER

AIRBAG

INFLATOR

PASSENGER

AIRBAG INFLATOR (+)

PASSENGER

AIRBAG INFLATOR (-)

13

14

Y/B (3 49)

GY/B (350)

Figure 12M-22

CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check.

If the SDM detects a r esis tanc e to battery supply is les s than f ive kohms in either the pos itive and/or negative c irc uit

for more than 3 - 5 seconds, a current DTC 33 will set (refer to SRS SELF DIAGNOSTICS in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service Information for more

details).

DTC 33 will set if circ uits 349 (pas senger’s air bag positive s ide) and/or 350 (pass enger’s air bag negative side) are

shorted to battery +.

When DTC 33 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 33. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 33. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 33 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 33 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 33 is set, the SRS, including the passenger’s air bag, will still be operational.

Test Description

The following numbers refer to step numbers in the following diagnostic chart:

1. Uses TECH 2 to check if DTC 33 is current or history.

2. Checks for intermittent fault by monitoring TECH 2 screen display. If screen display changes during a ‘wiggle’

test, a fault with the wiring is at that location.

3. Checks circuit 349 and 350 for a short to battery +.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS WIRING REPAIR in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2), of

the VT Series I Service Information before conducting any SRS wiring harness repairs.

3. Resistance c annot be m easured between the two term inals in connector YB208, as the in-built capacitor block s

measurement. Therefore, a ‘service hole’ is incorporated into the connector for fault tracing. Refer to

1.1 SYSTEM COMPONENTS, WIRING HARNESS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM

(Version 8.0 & 8.1) of the VT Series I Service Information for more details on this type of connector.

4. Wiring should be checked at point where TECH 2 screen display changed status. If necessary, split open the

harness.

5. If the fault can not be identified, the harness should be replaced.

6. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

7. To enable or disable the SRS system, refer to 2.2 SYSTEM DISABLING AND ENABLING PROCEDURE in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service

Information.

8. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

Figure 12M-23

DTC 33 – PASSENGER AIR BAG CIRCUIT SHORT TO BATTERY

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information (refer NOTE 6 on previous

page).

• Is DTC 33 current ?

Go to Step 3. Go to Step 2.

2. • Remove instrument panel compartment to gain

access to passenger’s air bag, refer to Section 1A3

INSTRUMENT PANEL AND CONSOLE of the VT

Series I Service Information.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear all

(if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, ‘wiggle’ SRS wiring harness at all

locations between the SDM and the passenger’s air

bag wiring harness connector YB208, while

monitoring TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

to NOTES 2 & 4

on previous

page).

Clear DTC and

recheck system to

verify repair.

Fault not present.

Check all system

wiring harness

connectors, and

terminals (refer to

NOTE 5 on

previous page).

Clear DTC and

recheck system.

3. • Disable the SRS (refer NOTE 7 on previous page).

• Disconnect passenger’s air bag inflator module

wiring harness connector YB208.

• Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• Reconnect battery.

• Using Tool KM-609-20, check wiring between SDM

wiring harness connector YB189/YB190, terminals

13 and 14 and passenger’s air bag connector

YB208, circuits 349 (Yellow/Black wire) and 350

(Grey/Black wire) for short to battery + (refer to

NOTES 1, 3 and 8 on previous page).

• Is all OK?

Replace SDM,

refer Section 12M

SUPPLEMENTAL

RESTRAINT

SYSTEM (Version

8.0 & 8.1) of the

VT Series I

Service

Information.

Recheck circuit to

verify repair.

Make repairs as

necessary (refer

to NOTE 2 on

previous page).

Clear DTC and

recheck system

to verify repair.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, ENSURE ALL SRS COMPONENTS ARE

RECONNECTED, CLEAR ALL DTC’S, ENABLE THE SRS AND VERIFY CORRECT OPERATION

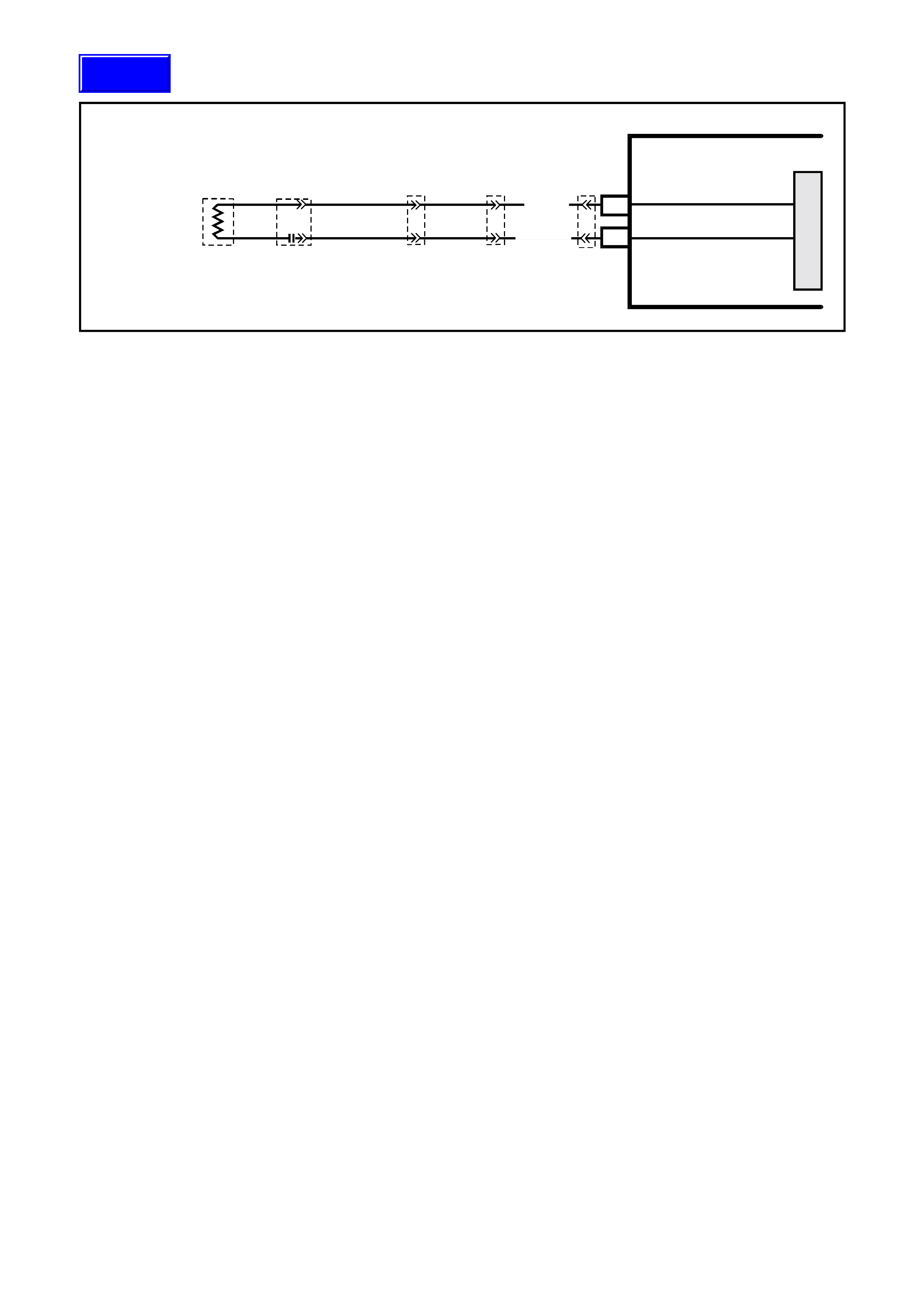

DTC 34 - PASSENGER AIR BAG CIRCUIT SHORT TO EARTH

T12M127

SDM

M

I

C

R

O

YB191

YB189

YB190

YB200

YB208

PASSENGER

AIRBAG

INFLATOR

PASSENGER

AIRBAG INFLATOR (+)

PASSENGER

AIRBAG INFLATOR (-)

13

14

Y/B (3 49)

GY/B (350)

Figure 12M-24 - CIRCUIT DESCRIPTION

At ignition on, and on a constant monitoring cycle of every 500 milliseconds during the ignition cycle, the SDM

performs a system self check. If the SDM detects a resistance to earth of less than three kohms in either the

positive or negative inflator circuit for more than 3 - 5 seconds, a current DTC 34 will set (refer to

SRS SELF DIAGNOSTICS in Section 12M SUPPLEMENT AL RESTRAINT SYST EM (Version 8.0 & 8.1) of the VT

Series I Service Information for more details).

DTC 34 will set if circ uits 349 (pas senger’s air bag positive s ide) and/or 350 (pass enger’s air bag negative side) are

shorted to earth.

When DTC 34 sets, the SDM illuminates the SRS warning lamp and sets a current DTC 34. Should the fault

conditions detected by the SDM clear during the same ignition cycle, the current code will clear and become a

history DTC 34. The SRS warning lamp will remain on for the remainder of the ignition cy cle.

If a DTC 34 is set, the SRS warning lamp is illuminated on each ignition cycle, even if the DTC is set as a history

DTC, until the f ault conditions for s etting DTC 34 are rectif ied and the DTC (curr ent or history) can then be cleared

from the SDM via TECH 2.

If DTC 34 is set, the SRS, including the passenger’s air bag, will still be operational.

Test Description

The following numbers refer to step numbers in the following diagnostic chart:

1. Uses TECH 2 to check if DTC 34 is current or history.

2. TECH 2 in this mode should display approximately 1.6 - 6.4 ohms if the passenger’s air bag loop circuit is OK.

3. If screen display changes during a wiring 'wiggle' test, a fault with the wiring is at that location.

4. Tool SD28280B is a dummy load taking the place of the passenger ’s air bag inflator module. If TECH 2 displays

the correct resistance of the dummy load, the system fault is in the passenger's air bag inflator module

assembly.

5. T his test c heck s the wiring between the SDM wiring harnes s connec tor YB189 (8.1 SDM) or YB190 (8.0 SDM),

terminal 13 and the passenger's air bag inflator module connector YB208 for faults.

6. T his test c heck s the wiring between the SDM wiring harnes s connec tor YB189 (8.1 SDM) or YB190 (8.0 SDM),

terminal 14 and the passenger's air bag inflator module connector YB208 for faults.

Notes on Diagnostic Chart

1. For all wiring harness checking procedures, refer to Section 12P WIRING DIAGRAMS of the VT Series I

Service Information.

2. Refer to 2.8 SRS WIRING REPAIR in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 6.2) of

the VT Series I Service Information before conducting any SRS wiring harness repairs.

3. Refer to TECH 2 DIAGNOSTICS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1)

of the VT Series I Service Information for connecting and using TECH 2.

4. Resistance cannot be measured between the two terminals in connector YB208 as the in-built capacitor blocks

measurement. Therefore, a ‘service hole’ is incorporated into the connector for fault tracing. Refer to

1.1 SYSTEM COMPONENTS, WIRING HARNESS in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM

(Version 8.0 & 8.1) of the VT Series I Service Information for more details on this type of connector.

5. Wiring should be checked at point where TECH 2 screen display changed. If necessary, split open wiring

harness.

6. If fault cannot be identified, the wiring harness should be replaced.

7. To enable or disable the SRS system, refer to 2.2 SYSTEM DISABLING AND ENABLING PROCEDURE in

Section 12M SUPPLEMENTAL RESTRAINT SYSTEM (Version 8.0 & 8.1) of the VT Series I Service

Information.

8. SDM connector YB189 is equipped with a shorting link busbar which needs to be opened before checking the

circuit, re fer to 2.5 DIAGNOSTIC CHA RTS in this Section for additional information.

Figure 12M-25

DTC 34 - PASSENGER AIR BAG CIRCUIT SHORT TO EARTH

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to DLC.

• Select Body / SRS / Diagnostic Trouble Codes /

Read DTC Information (refer NOTE 3 on previous

page).

• Does TECH 2 display DTC 34 as a Current DTC?

Go to Step 2. Go to Step 3.

2. • W ith TECH 2 still connected to DLC, select Body /

SRS / Data Display and scroll to PASSENGER’S

AIR BAG LOOP RESISTANCE'.

• Is value displayed on TECH 2 as specified?

Approx.

1.6 - 6.4

ohms

Go to Step 3. Go to Step 4.

3. • Remove instrument panel compartment to gain

access to passenger’s air bag, refer to Section 1A3

INSTRUMENT PANEL AND CONSOLE of the VT

Series I Service Information.

• With TECH 2 still connected, select Diagnostic

Trouble Codes / Clear DTC Information and clear

all (if any) DTCs.

• Select Diagnostic Trouble Codes / Read DTC

Information, 'wiggle' SRS wiring harness at all

locations between the SDM and the passenger’s air

bag wiring harness connector YB208, while

monitoring TECH 2 screen display.

• Does TECH 2 screen display change status from

No Diagnostic Trouble Codes?

Make repairs as

necessary (refer

to NOTE to 2 & 5

on previous

page).

Clear DTC and

recheck system to

verify repair.

Fault not present.

Check all system

wiring harness

connectors, and

terminals (refer to

NOTE 6 on

previous page).

Clear DTC and

recheck system.

4. • Disable the SRS (refer NOTE 7 on previous page).

• Disconnect passenger’s air bag inflator module

wiring harness connector YB208.

• Connect Tool No. SD28280B to SRS wiring

harness connector YB208.

• Re-connect battery.

• With TECH 2 still connected, select Body / SRS /

Data Display and scroll to PASSENGER’S AIR

BAG LOOP RESISTANCE'.

• Is value displayed on TECH 2 as specified?

Approx.

3.0 ohms Replace

passenger air bag

inflator module

assembly, refer to

2.4 FRONT

PASSENGER’S

AIR BAG

MODULE

ASSEMBLY in

Section 12M, Vol

7 of the VT Series

Service Manual.

Clear DTC and

recheck system to

verify repair.

Go to Step 5.

5. • Disconnect SDM wiring harness connector

YB189/YB190 from the SDM.

• Remove Tool SD28280B from YB208.

• Using Tool KM-609-20, check wiring between SDM

wiring harness connector YB189/YB190, terminals

13 and passenger’s air bag inflator module

connector YB208, circuit 349 (Yellow/Black wire)

for short to earth (refer to NOTES 1 & 8 on

previous page).

• Is all OK?

Go to Step 6. Make repairs as

necessary (refer

to NOTE 2 on

previous page).