SECTION 3 - FRONT SUSPENSION

IMPORTANT

Before p erforming any Serv ice Operation or other procedu re described in this Section , refer to Section

00 CAUTIONS AND NOTES of the VX Series Service Information for correct workshop practices with

regard to safety and/or property damage.

1. GENERAL DESCRI PTI O N

The front suspension for VX models, carries over from VT Series II vehicles, except for the minor changes

described in this Section. For all remaining service operations and specifications, refer to

Section 3. FRONT SUSPENSION, of the VT Series I and SECTION 3 - FRONT SUSPENSION - BEFORE

PRODUCTION SERIAL NUMBER L 492505 or SECTION 3 - FRONT SUSPENSION - AFTER PRODUCTION

SERIAL NUMBER L 492505 of the VT Series II Service Information.

New, light weight front struts and a re-designed stabiliser bar spacer stud, insulating bushes, retainers and

attaching nuts, form the changes made to the front suspension for VX models. The lower end of the spacer stud

now has a ball joint, attached to the stabiliser bar with a ball joint stud and nut.

Minor revisions have also been made to the wheel alignment specification range to improve vehicle tracking, that

applies to earlier build vehicles. Therefore, refer to VT Series II Service Information for the relevant changes that

also apply to VX Series vehicles.

The front suspension fitted to VX models with the revised components, continues to operate on the MacPherson

strut princ iple. The assem bly cons ists of the fr ont crossm ember, control arm s, tension rods, stabiliser bar and strut

assemblies (Refer to Fig. 3-1).

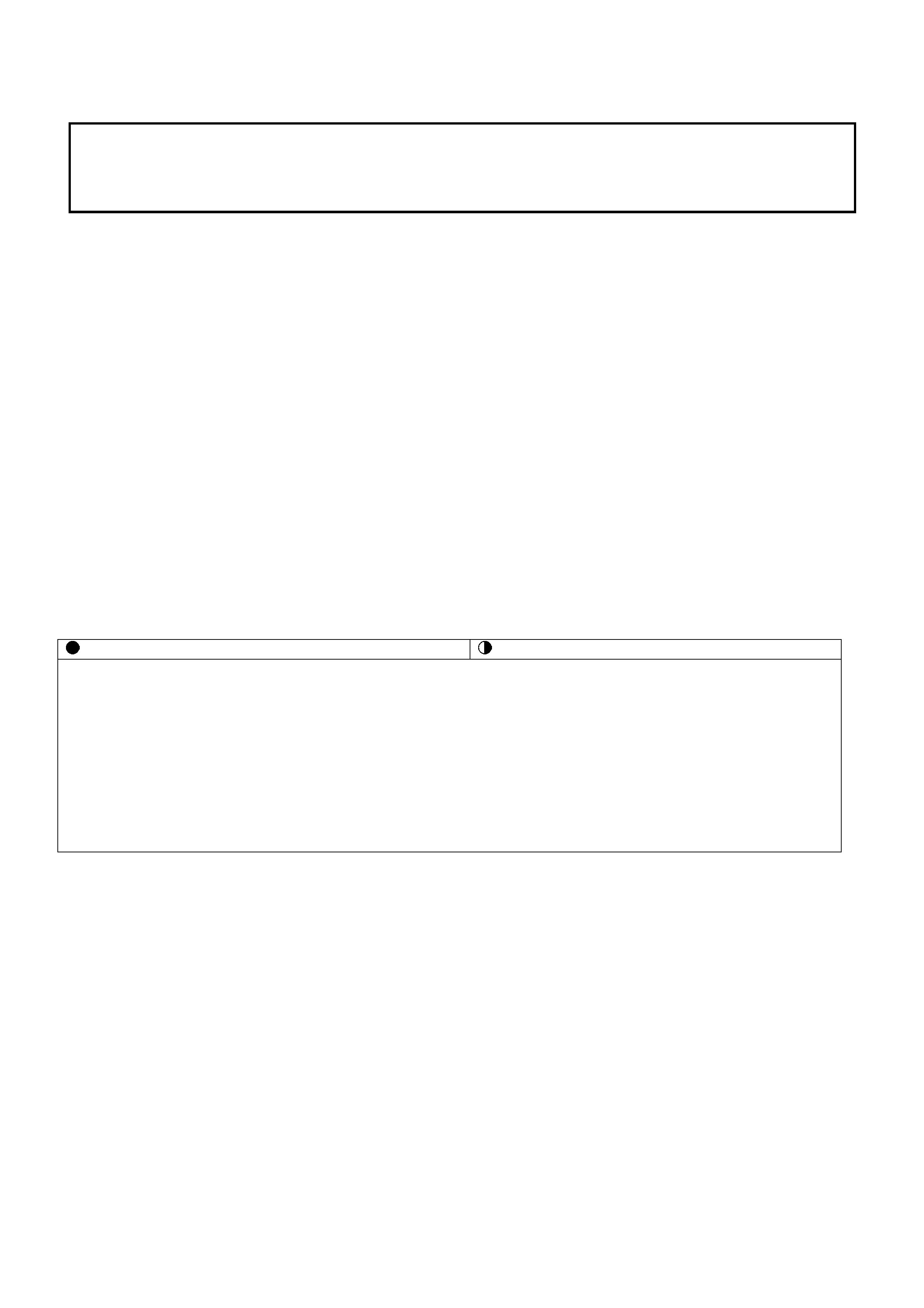

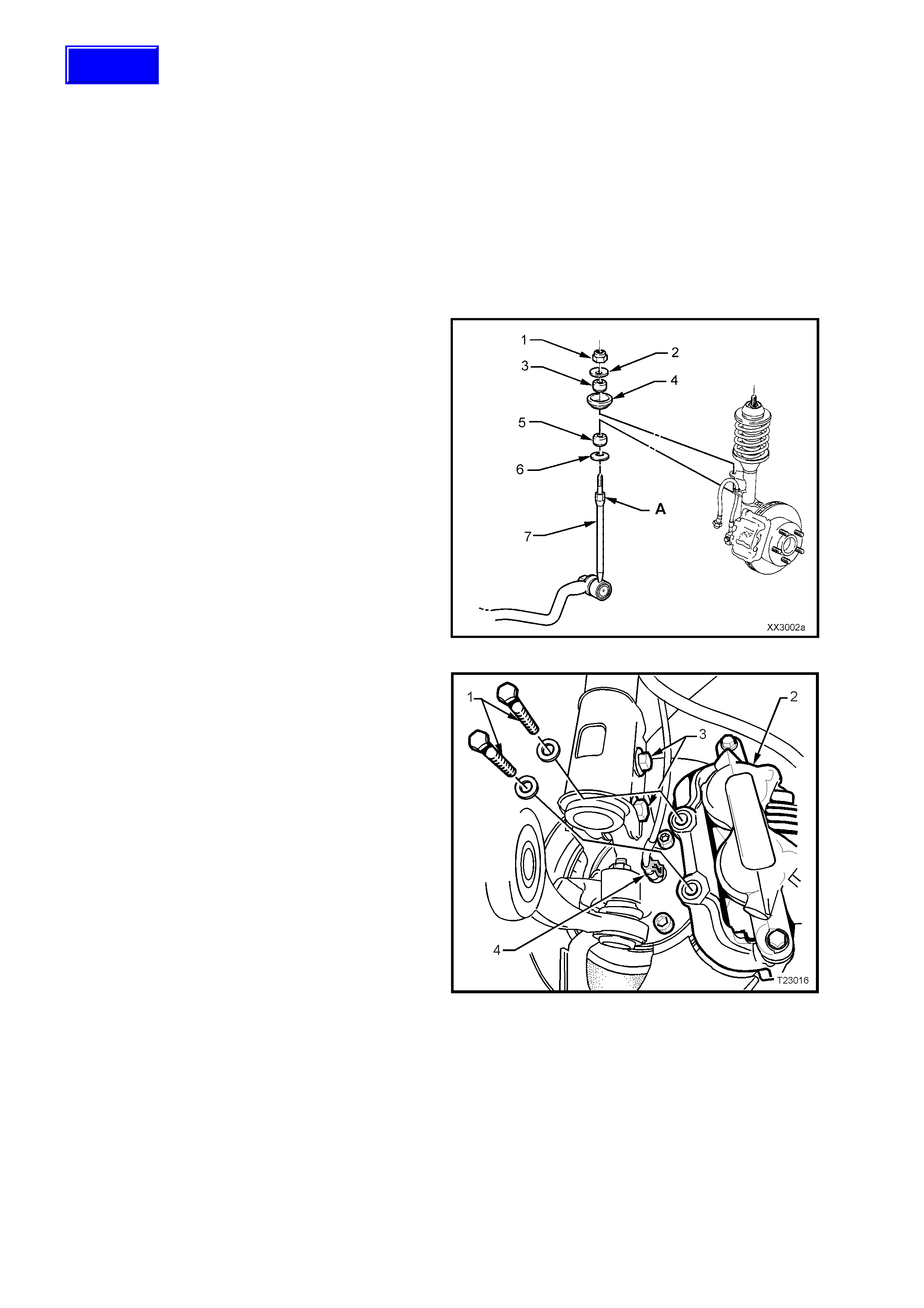

Legend for Fig. 3-1

Stud to be held while nuts are torqued to specification Fastener must be new and assembled dry.

1. Nut (2 places) 11. Insulator (2 places) 20. Washer – Cupped (2 places)

2. Washer (2 places) 12. Bar – Stabiliser 21. Control Arm (2 places)

3. Bush (2 places) 13. Bolt – Front, Flanged (2 places) 22. Washer (2 places)

4. Seat (2 places) 13a. Bolt – Rear, Plain (2 places) 23. Nut - Stepped (2 places)

5. Bush (2 places) 14. Nut (8 places) 24. Bolt (2 places)

6. Washer (2 places) 15. Nut (2 places) 25. Cover - Dust (2 places)

7. Stabiliser Bar Spacer Stud (2 places) 16. Bush – Tension Rod (2 places) 26. Nut (2 places)

8. Nut (2 places) 17. Washer (1 on driver’s side only) 27. Locating Disc (2 places)

9. Nuts (4 places) 18. Nut (2 places) 28. Crossmember

10. Bracket (2 places) 19 Rod – Tension (2 places) ‘A-A’ - Assemble washer ‘20’ as shown

Figure 3-1

2. SERVICE OPERATIONS

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC is disturbed during Service Operations, it

is vital that the complete ABS or ABS/ETC system is checked, using the procedure as detailed in 4.

DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, of the VT Series I

Service Information (V6) or of the VT Series II Service Information (GEN III V8).

2.1 STABILISER BAR LINK

REPLACE

1. Jack up f ront of vehicle and place s afety stands

under side frame members. Observe jacking

precautions as outlined in

2.3 JACKING PRECAUTIONS in VT Series I,

3. FRONT SUSPENSION.

2. Remove decorative road wheel retaining nut

caps, if fitted.

3. Mar k relationship of wheel to hub. Loos en, then

remove road wheel attaching nuts. Remove

road wheel.

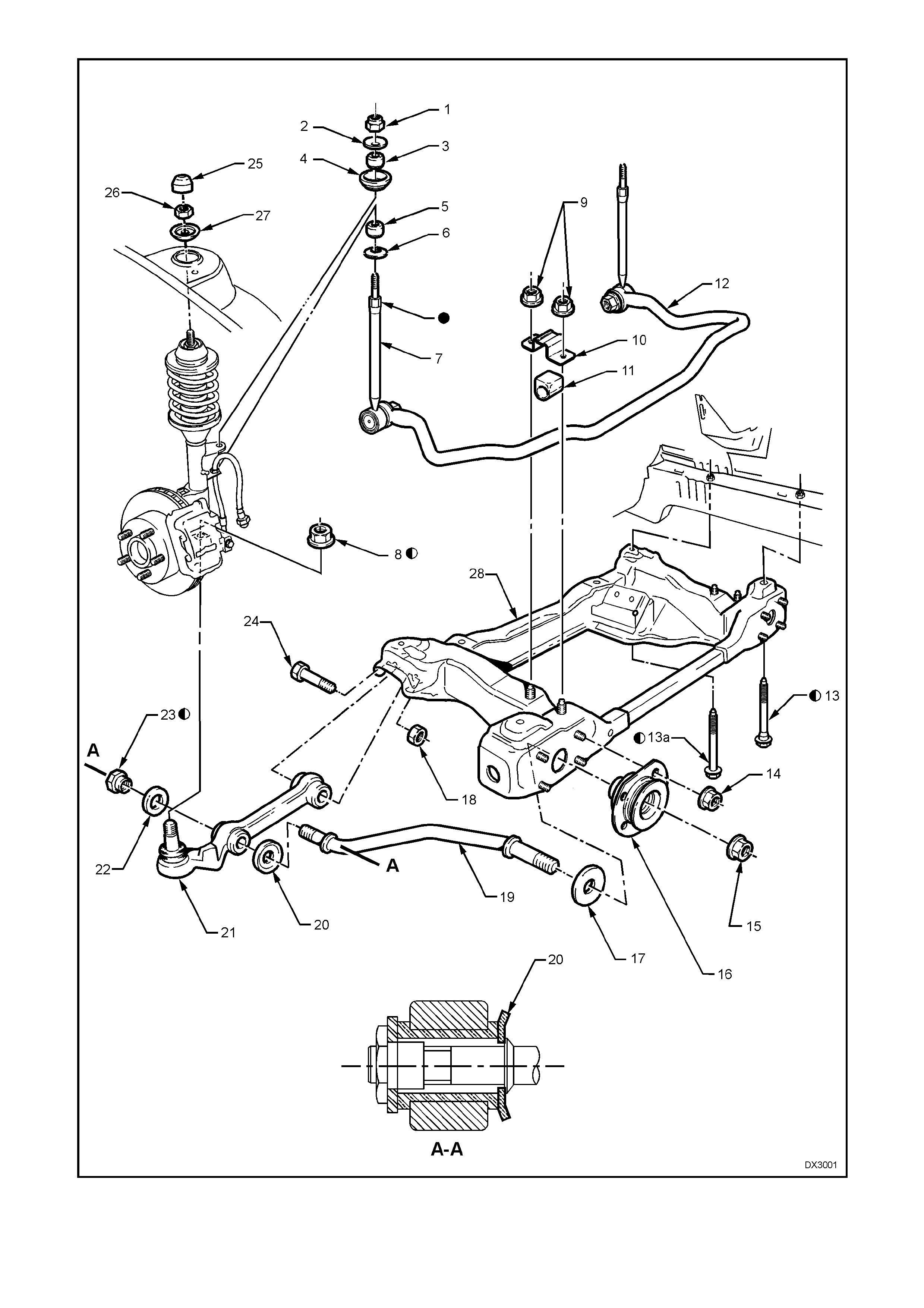

4. Using a suitable size spanner, hold the

stabiliser bar spacer stud (7) at ‘A’, then use

another spanner to loosen and remove the

stabiliser bar spacer stud nut (1).

5. Remove the washer (2), upper bush (3) and

seat (4).

6. If requir ed, repeat steps 4 and 5 f or the second

side.

NOTE: If both sides are disconnected from the

strut brackets, the spacer stud can be disengaged

from the strut bracket, by pushing down on the

stabiliser bar. Otherwise proceed as in step 7.

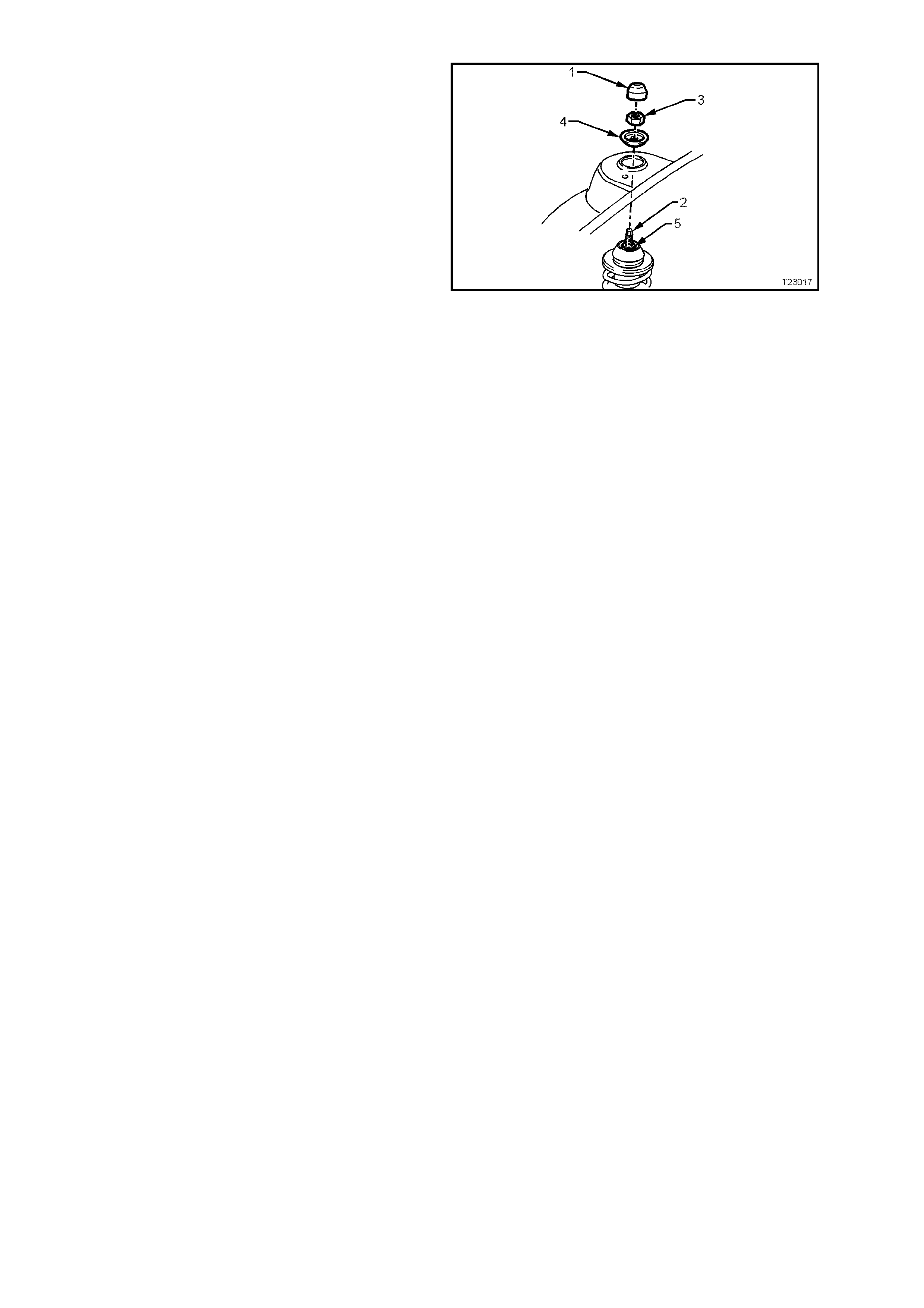

Figure 3-2

Techline

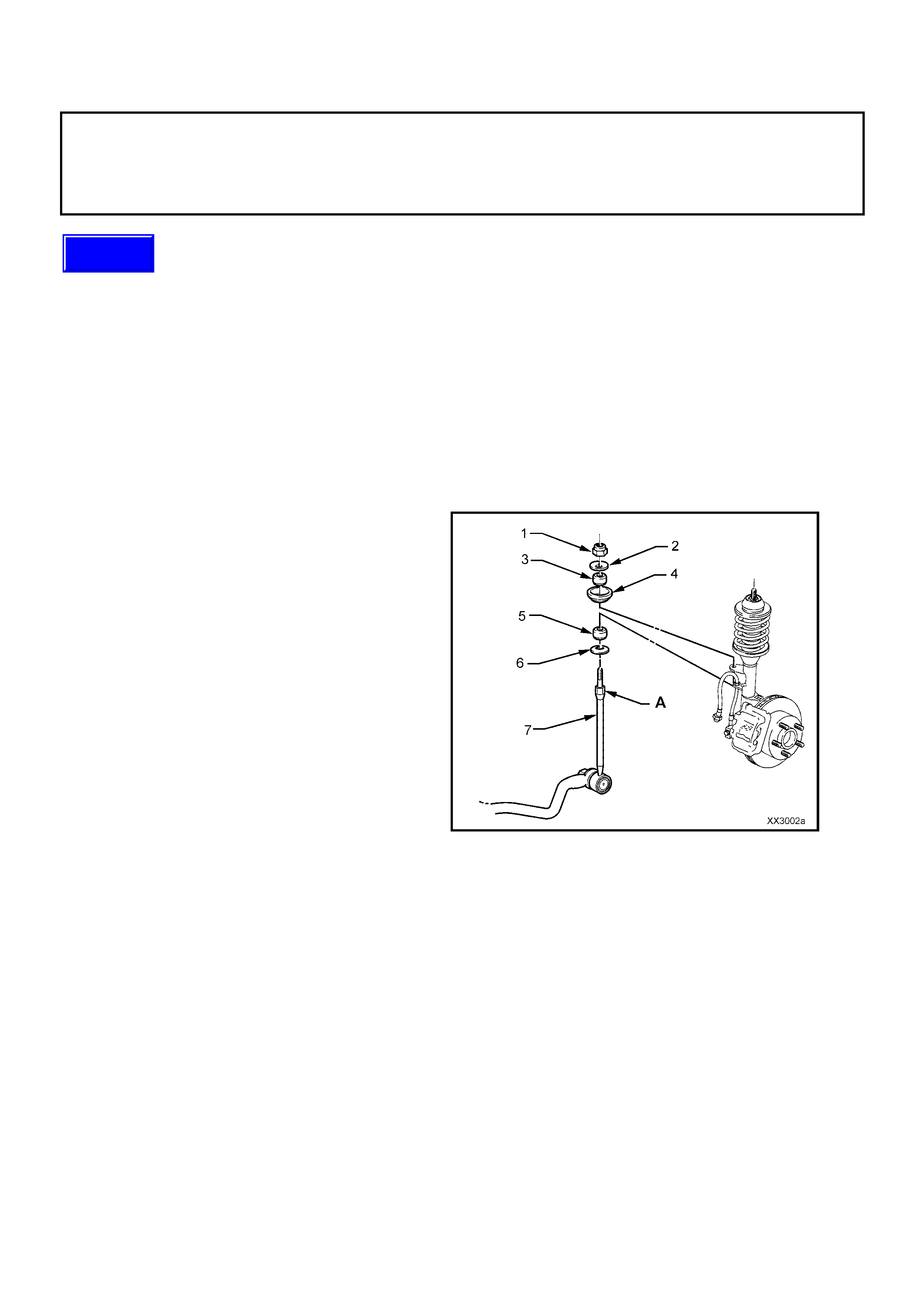

7. With a backing set spanner holding the

stabiliser bar link inner stud hexagon (3), use a

second spanner to loosen then remove the

retaining nut (4).

8. Separate the stabiliser bar link (1) from the

stabiliser bar (2) and remove from the vehicle.

The reinstallation procedure is the reverse to

removal, except for the following points.

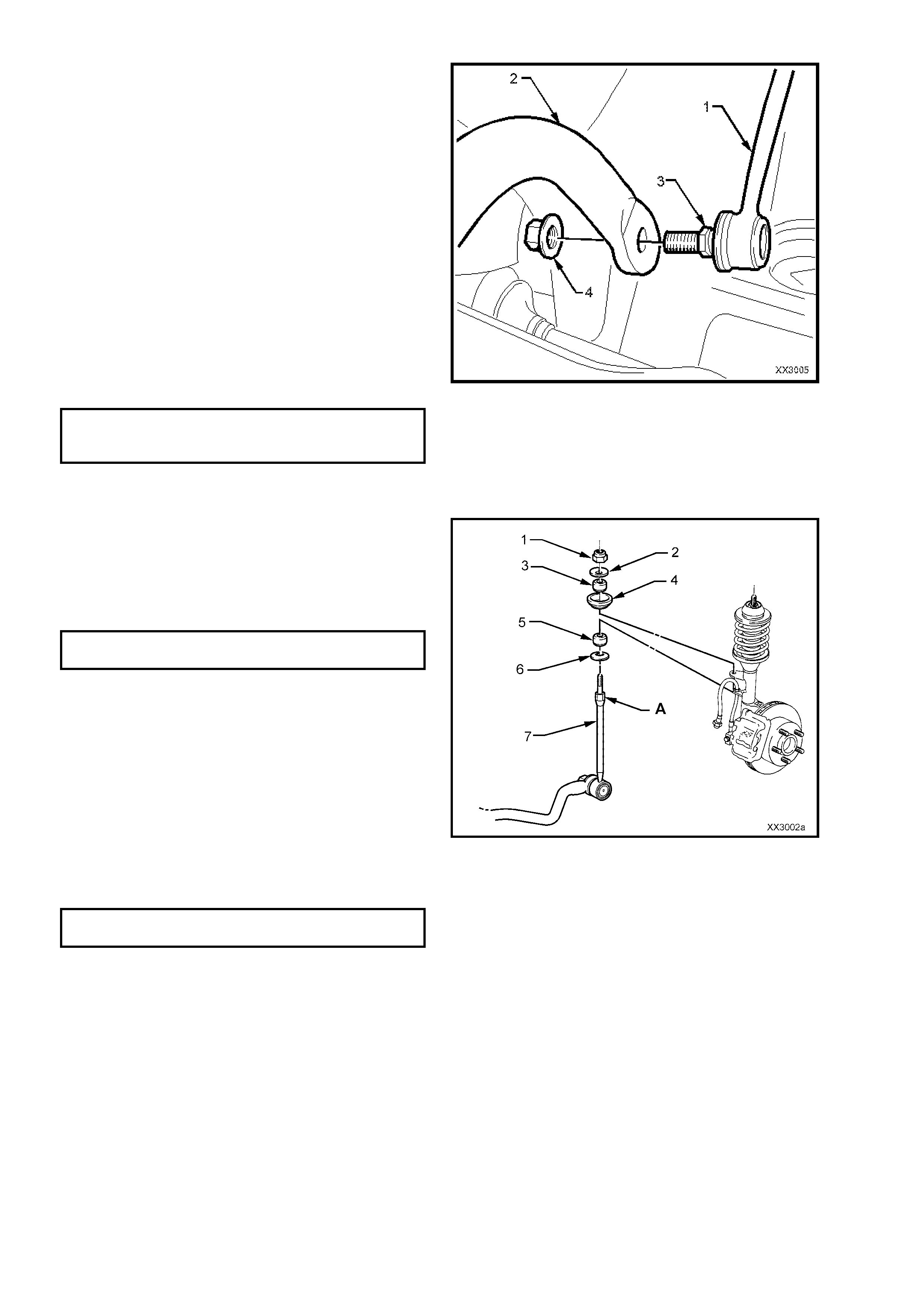

9. As required, the lower link bush (5) and washer

(6) may be replaced (refer to Fig. 3-3).

10. Before reinstallation of the stabiliser bar link (1)

to the stabiliser bar (2), insert the upper

threaded end of the link (1) into the strut

mounting bracket.

11. Reinstall the link ball joint stud to the stabiliser

bar (2), tighten the retaining nut (4) to the

correct torque specification, while holding the

inner stud hexagon (3) with a backing spanner.

STABILISER BAR LINK BALL

JOINT STUD RETAINING NUT 45 – 55 Nm

TORQUE SPECIFICATION

Figure 3-3

12. Reinstall the seat (4), upper bush (3) and seat

(2).

13. Reinstall the upper link retaining nut (1) and

tighten to the correct torque specification, while

holding the link at the upper hexagonal section

(A). DO NOT over-tighten.

STABILISER BAR LINK UPPER

NUT TORQUE SPECIFICATION 13 – 18 Nm

14. Reinstall road wheels, aligning marks made

prior to removal.

15. Remove safety stands and lower vehicle.

16. Tighten road wheel attaching nuts to the

correct torque specification, working in a ‘star’

pattern, as indicated in 3. FRONT

SUSPENSION, in SECTION 3 - FRONT

SUSPENSION - Before Production Serial

Number L 492505 or SECTION 3 - FRONT

SUSPENSION - After Production Serial

Number L 492505 of the VT Series II Service

Information.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

17. Reinstall decorative road wheel retaining nut

caps, as required.

18. Bounce vehicle up and down several times to

settle suspension.

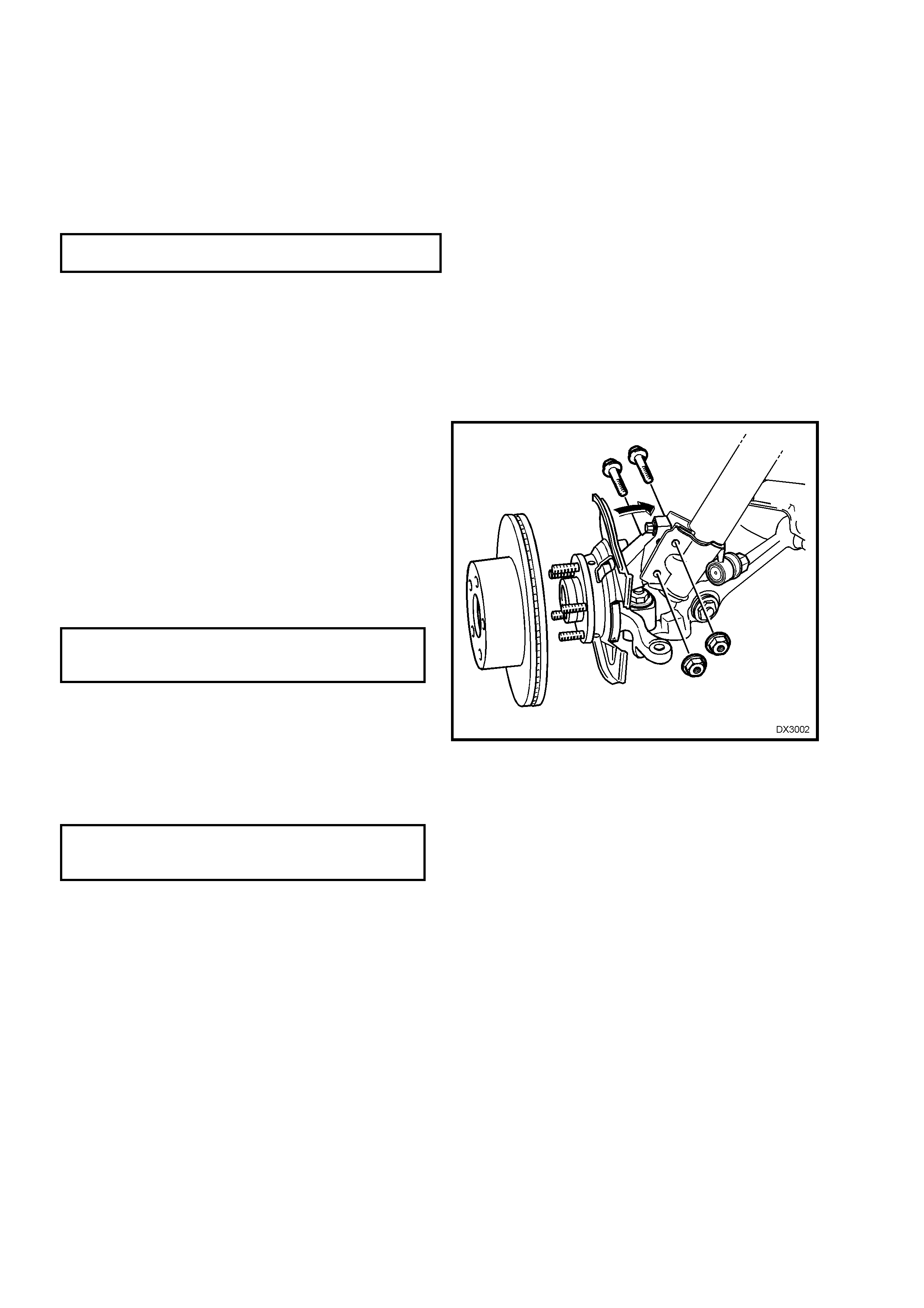

Figure 3-4

2.2 FRONT STRUT ASSEMBLY

REMOVE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as outlined

3. FRONT SUSPENSION,

2.3 JACKING PRECAUTIONS in VT Series I,

Service Information.

2. Remove decorative road wheel retaining nut

caps, if fitted.

3. Mark relationship of road wheel to hub or brake

disc. Loosen then remove road wheel attaching

nuts. Remove road wheel.

4. Position a suitable size open end spanner to

hold the stabiliser bar spacer stud (7) at ‘A’,

use another spanner to loosen and remove

upper nut (1), washer (2), bush (3) and seat

(4).

5. Disconnect the wheel speed sensor cable and

insulator from the strut bracket.

Figure 3-5

6. Remove the brake caliper anchor plate

retaining bolts and washers (1), lift the caliper

assembly (2) from the brake disc and support

in such a way that no strain is placed on the

brake hose. THE BRAKE CALIPER IS NOT

TO HANG BY THE BRAKE HOSE.

NOTE: T his step is nec essary to provide access to

the lower strut mounting bolts and nuts (3).

7. If required, remove brake disc from the wheel

bearing hub. While the brake disc to hub

relationship is marked during production,

ensure that the disc to hub position is carefully

marked.

NOTE: This is necessary to overcome the

possibility of inducing a brake shudder condition

after reassembly.

8. Remove brake hose from the strut housing

bracket by turning plastic sleeve on the hose

until flats on sleeve align with bracket opening.

9. Using a suitable floor jack f itted with a block of

wood, position under the control arm, just

sufficient to support the weight.

10. Loosen, remove and DISCARD the two lower

strut to knuckle attaching bolts and nuts (3).

11. To avoid placing strain on the ABS sensor

lead, release the connector locking tang and

pull on the sens or lead c onnec tor ( 4) to remove

from the sensor.

12. Pull the steering knuckle clear of the strut.

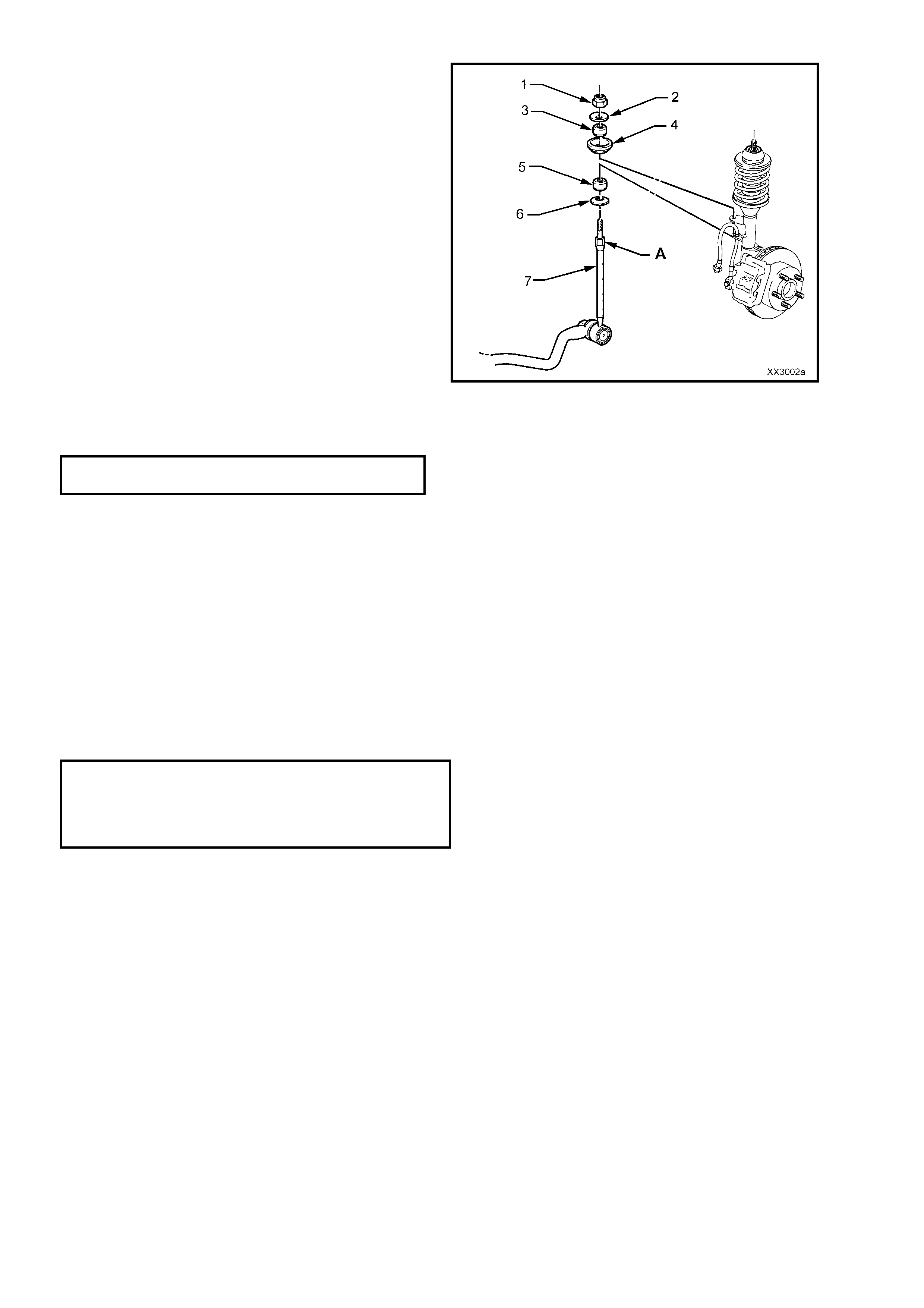

Figure 3-6

Techline

13. Remove the dus t c over (1) f rom the upper strut

support, in the engine compartment.

14. While holding the strut rod shaft (2) with a 10

mm socket, remove the self-locking nut (3),

using a 24 mm (15/16") ring spanner, then

remove the locating disc (4). DISCARD THE

STRUT ROD NUT.

15. Carefully lower the strut from the tower,

manipulate the strut to remove the stabiliser

stud from the bracket on the strut and remove

the assembly from the vehicle.

Figure 3-7

REINSTALL

NOTE: In the interests of vehicle safety, it is

important that fasteners are replaced with new parts

where stated during the reinstallation process

described here.

Important: The torque of the strut bearing

retaining nut (‘5’ in Fig. 3-6) MUST be checked

for correct tightness BEFORE installing the strut

into the vehicle!

UPPER STRUT BEARING RETAINING

NUT TORQUE SPECIFICATION 70 - 85 Nm

1. Manipulate the strut assembly so that the

stabiliser bar stud is located in the strut bracket,

then locate strut assembly into the spring strut

tower.

2. After installing the locating disc, partially install a

NEW upper nut to the strut rod. Do not tighten at

this time.

3. Pivot the hub and steering knuck le assem blies,

sufficient to line up the bolt holes in the

steering knuckle and the lower end of the strut

assembly.

4. Install NEW retaining bolts and nuts, and

tighten to a preliminary torque of 85 Nm.

5. Use a 10 mm socket to hold the strut rod from

turning, then tighten the upper strut rod

retaining nut (‘3’ in Fig. 3-6) to the correct

torque specification, using a 24 mm (15/16")

ring spanner with a torque wrench attached.

UPPER STRUT LOCATING

PLATE RETAINING NUT 50 - 60 Nm

TORQUE SPECIFICATION

6. Install the brake hose to the strut bracket by

turning plastic s leeve on the hose until the flats

on the sleeve align with the bracket opening.

7. If removed, install the brake disc, aligning

marks made prior to removal.

8. Reinstall the brake caliper, tightening the

attaching bolts to specification.

BRAKE CALIPER ANCHOR 80 - 90 Nm,

PLATE RETAINING BOLTS then turn through

TORQUE SPECIFICATION 40° - 50°

9. Reinstall the wheel speed sensor connector,

pushing firmly onto the sensor until the

retaining tang is secure. Then, reinstall the

sensor lead and insulator into the strut

mounting bracket.

Figure 3-8

10. Reinstall stabiliser bar spacer stud nut (1) after

ensuring that all components are assembled as

shown. While holding the spacer stud (7) with a

suitable open end spanner at ‘A’, use another

spanner to tighten the upper retaining nut (1)

until the end of the thread on the stud is

contacted.

NOTE: Do not use power tools for this tightening

operation, otherwise thread damage will result.

11. Install road wheel, aligning the marks made

prior to removal.

12. Remove safety stands and lower vehicle.

13. Tighten road wheel attaching nuts to

the correct torque specification, working

in a ‘star’ pattern, as indicated

in 3. FRONT SUSPENSION,

SECTION 3 - FRONT SUSPENSION - Before

Production Serial Number L 492505 or

SECTION 3 - FRONT SUSPENSION - After

Production Serial Number L 492505 of the VT

Series II Service Information.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

14. Reinstall decorative road wheel retaining nut

caps, as required.

15. Bounce vehicle up and down several times to

settle suspension.

16. Check wheel alignment, as detailed

in 2.1 WHEEL ALIGNMENT CHECKING

AND ADJUSTMENT, SECTION 3 - FRONT

SUSPENSION - Before Production Serial

Number L 492505 or SECTION 3 - FRONT

SUSPENSION - After Production Serial

Number L 492505 of the VT Series II Service

Information.

17. Tighten the steering knuckle to strut bolts and

nuts to the specified torque values.

Figure 3-9

STEERING KNUCKLE TO STRUT

ATTACHING BOLTS & NUTS..

TORQUE SPECIFICATION ..... Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn through 90°

3. SPECIFICATIONS

SUSPENSION

Type ........................................................................ MacPherson Wet Strut

Application............................................................... All VX Models

Travel

Compression (2/3compression of bumper)

Standard and V5W........................................... 90 mm

FE2................................................................... 80 mm

Rebound

Standard and V5W........................................... 110 mm

FE2................................................................... 120 mm

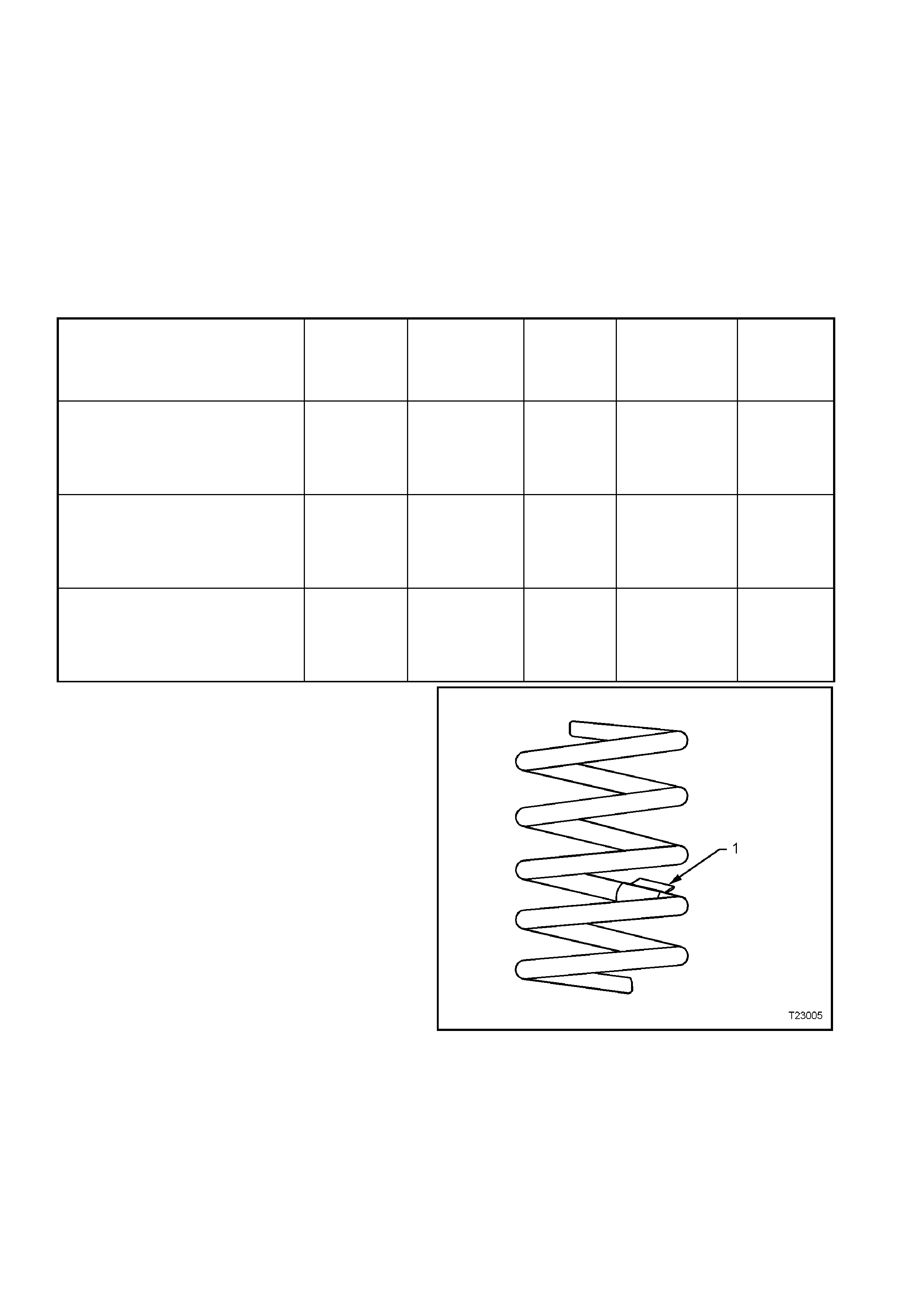

FRONT SPRING SPECIFICATIONS

SEDAN & STATION WAGON

MODELS

Approximat

e

Number

COILS

Approximate

FREE

LENGTH

(mm)

INSIDE

DIAMETE

R

(mm)

PROD. I.D.

CODE

(Tag on

spring)

SPRING

TYPE &

RATE

STANDARD SUSPENSION –

ALL ENGINE S and BODY S T Y LES 6.05 444 136 ± 1.5 HN VARIABLE

19 - 23

N/mm

(3700 ± 110 N

@ 210 mm)

FE2 SPORTS SUSPENSION –

ALL ENGINE S and BODY S T Y LES 5.25 341 136 ± 1.5 HJ VARIABLE

24 – 31

N/mm

(3660 ± 110 N

@ 200 mm)

V5W COUNTRY PACK SUSPENSION –

ALL ENGINE S and BODY S T Y LES 6.05 444 136 ± 1.5 HN VARIABLE

19 - 23

N/mm

(3700 ± 110 N

@ 210 mm)

Legend

1. Production Identification Code Tag

Figure 3-10

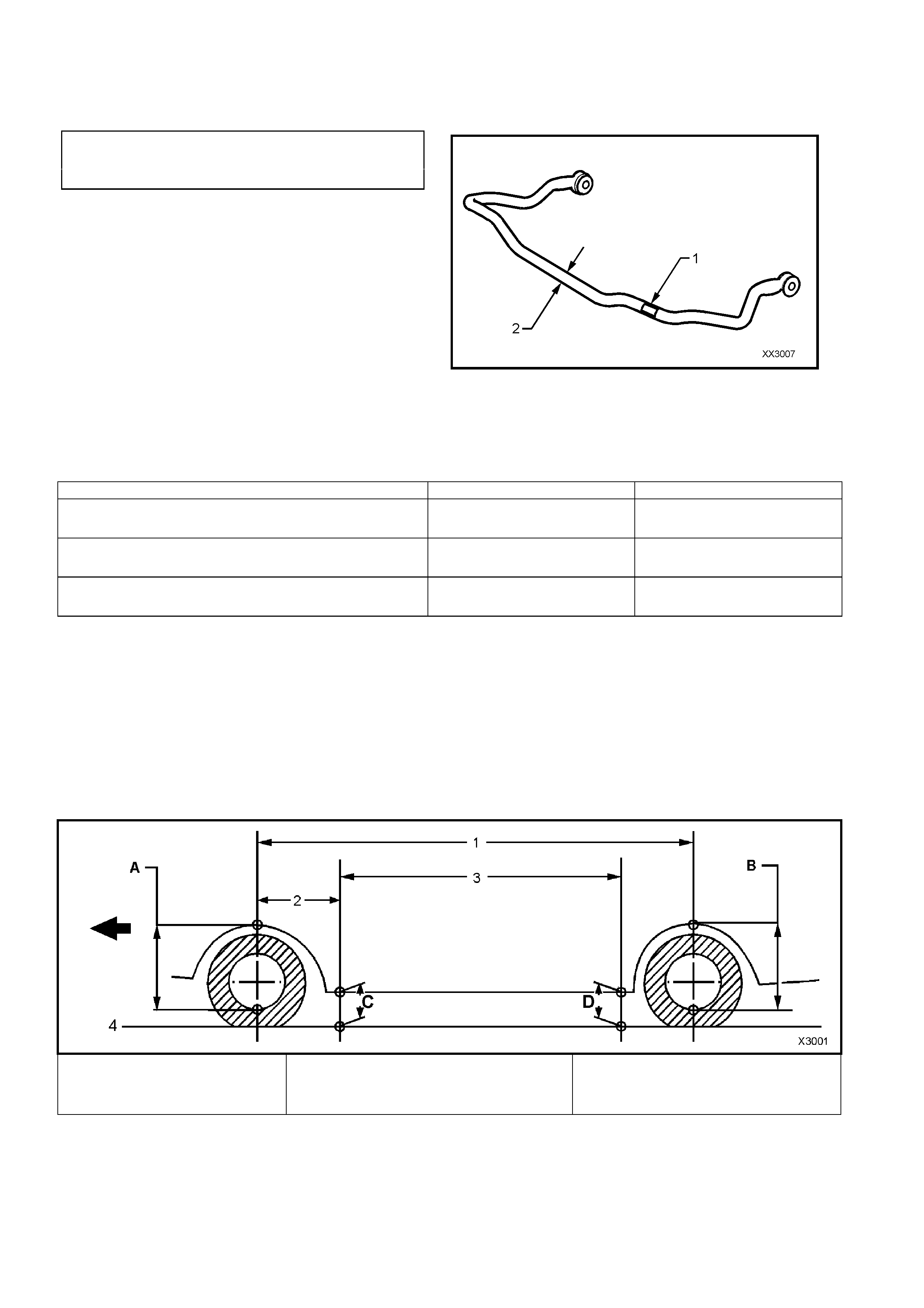

STABILISER BAR (FRONT)

Type .................................................................. Decoupled

STABILISER BAR IDENTIFICATION

I.D. Diameter

MODELS CODE mm

(1) (2)

All VX Models and Suspensions

except for Vehicles with FE2 YB 26.0

All VX Models with the FE2

Sports Suspe ns io n YA 27.0

Legend

1. Production Identification Code Tag

2. Stabiliser Bar Diameter

Figure 3-11

FRONT STRUT

Type ................................................................. Wet strut – non-serviceable

FRONT STRUT IDENTIFICATION

Suspension and Application Right Hand Side Left Hand Side

STANDARD SUSPENSION –

ALL BODY STYLES AND ENGINES ZM ZN

SPORTS SUSPENSION –

ALL BODY STYLES AND ENGINES ZP ZR

COUNTRY PACK SUSPENSION –

ALL BODY STYLES AND ENGINES ZS *ZT

CONTROL ARM

Type ................................................................. Forged with rubber bushes for attachment to front

crossmember and tension rod. Ball joint is a press fit

into the control arm. The ball joint is not serviced separately.

FRONT WHEEL BEARINGS

Type ................................................................. Double row ball bearing

Lubricant........................................................... Sealed for life: non-adjustable

SUSPENSION and TRIM HEIGHT SPECIFICATIONS

A Front Suspension Height Locati on

B Rear Suspension Height Location

C Front Trim Height Check Locati on

D Rear Trim Hei ght Check Location

1. Wheelbase:

All VX Sedan – 2788 mm

All Station Wagon – 2938 mm

2. Ref erence Point : All Models – 584.5 mm

3. Trim Hei ght Spacing:

All Sedan – 1615 mm

All Station Wagon – 1765 mm

4. Ground Line

Figure 3-12

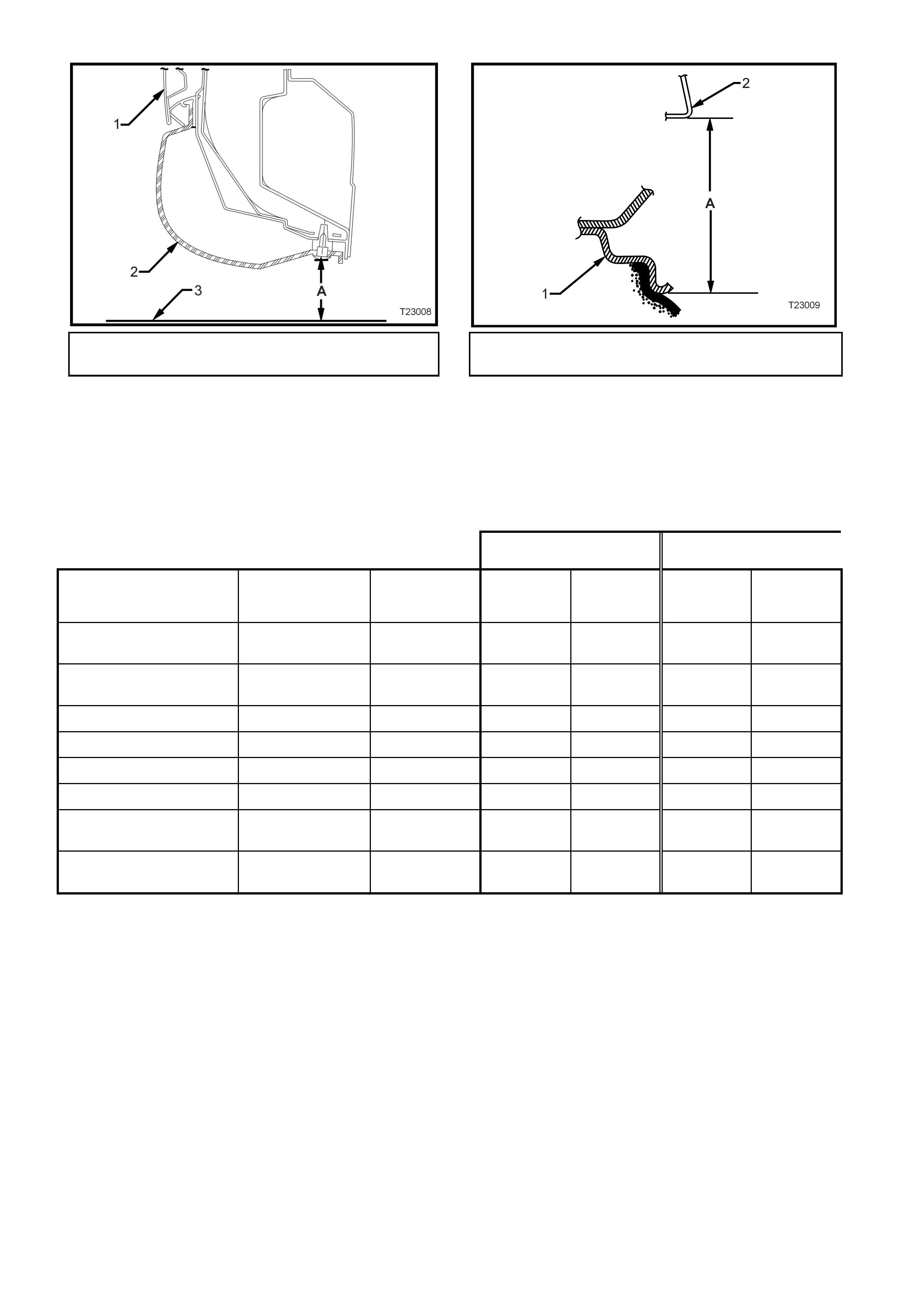

1. Door 2. Trim

3 Ground Line ‘A’ Trim Height 1. Wheel Rim

2. Fender Opening ‘A’ Suspension Height

Figure 3-13 – Rear Trim Height Checking Location (Front

Similar) Figure 3-14 – Front and Rear Suspension Height

Checking Location

NOTE: The following suspension/trim height dimensions are intended for reference only and are

intended to be a guide only. Refer to 3.3 SUSPENSION AND TRIM HEIGHT, CHECK

SECTION 3 - FRONT SUSPENSION - BEFORE PRODUCTION SERIAL NUMBER L 492505 or

SECTIO N 3 - FRONT SUSPENSION - AFT ER PRODUCTION SERIAL NUMBER L 492505 in VT Series II Service

Information for ride height variations and additional procedures.

VX MODELS SUSPENSION HEIGHT

(mm) TRIM HEIGHT

(mm)

VEHICLE

DESCRIPTION TRANSMISSION SUSPENSION FRONT

(‘A’ in

Fig. 3-12)

REAR

(‘B’ in

Fig. 3-12)

FRONT

(‘C’ in

Fig. 3-12)

REAR

(‘D in

Fig. 3-12)

Executive/Acclaim/Berlina

Sedan Manual/Automatic Standard/V5W 605 594 192 201

Executive/Acclaim/Berlina

Sedan Manual/Automatic FE2 583 581 172 186

‘S’ Pack Sedan Manual/Automatic FE2 605 603 172 186

‘SS’ Sedan Manual/Automatic FE2 611 609 172 186

Calais Sedan Automatic Standard/V5W 618 607 192 201

Calais Sedan Automatic FE2 596 608 172 186

Executive/Acclaim/Berlina

Wagon Manual/Automatic Standard/V5W 601 583 192 210

Executive/Acclaim/Berlina

Wagon Manual/Automatic FE2 586 568 177 195

4. TORQUE SPECIFICATIONS

NOTE: For those torque specifications not listed here, refer to 3 FRONT SUSPENSION in VT Series I and

Section 3 - FRONT SUSPENSION - Before Production Serial Number L 492505 or Section 3 - Front

Suspension - After Production Serial Number L 492505 of the VT series II Service Information.

Nm

Brake Caliper Anchor Plate Retaining Bolts.............Stage 1....... 80 - 90

Stage 2....... Turn through 40° - 50°

Road Wheel Attaching Nut........................................................... 110 – 140

Stabiliser Bar Link Ball Joint Stud Retaining Nut.......................... 45 – 55

Stabiliser Bar Link Upper Nut....................................................... 13 – 18

Steering Knuckle to Strut Attaching Bolts and Nuts Stage 1....... 85

Stage 2....... 100

Stage 3....... Turn through 90°

Upper Strut Bearing Retaining Nut............................................... 70 - 85

Upper Strut Locating Plate Retaining Nut..................................... 50 - 60