SECTION 7B3 - MANUAL TRANSMISSION –

GEN III V8 ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

The 6 speed manual transmission available as an option for VX Series models equipped with the GEN III V8

engine, remains unchanged from the assembly used for VT Series II models, except for the minor change to the

remote shifter mechanism described in this Section.

Apart fr om this change, r efer to Section 7B3 MANUAL TRANSMISSION – GEN III V8 ENGINE, in the VT Series II

Service Information, for all information relating to this transmission.

Techline

Techline

Techline

2. SERVICE OPERATIONS

2.1 REMOTE CONTROL SHIFT MECHANISM

REMOVE

Refer 4.3 TRANSMISSION DISASSEMBLE, in the

VT Series II Service Information.

DISASSEMBLE

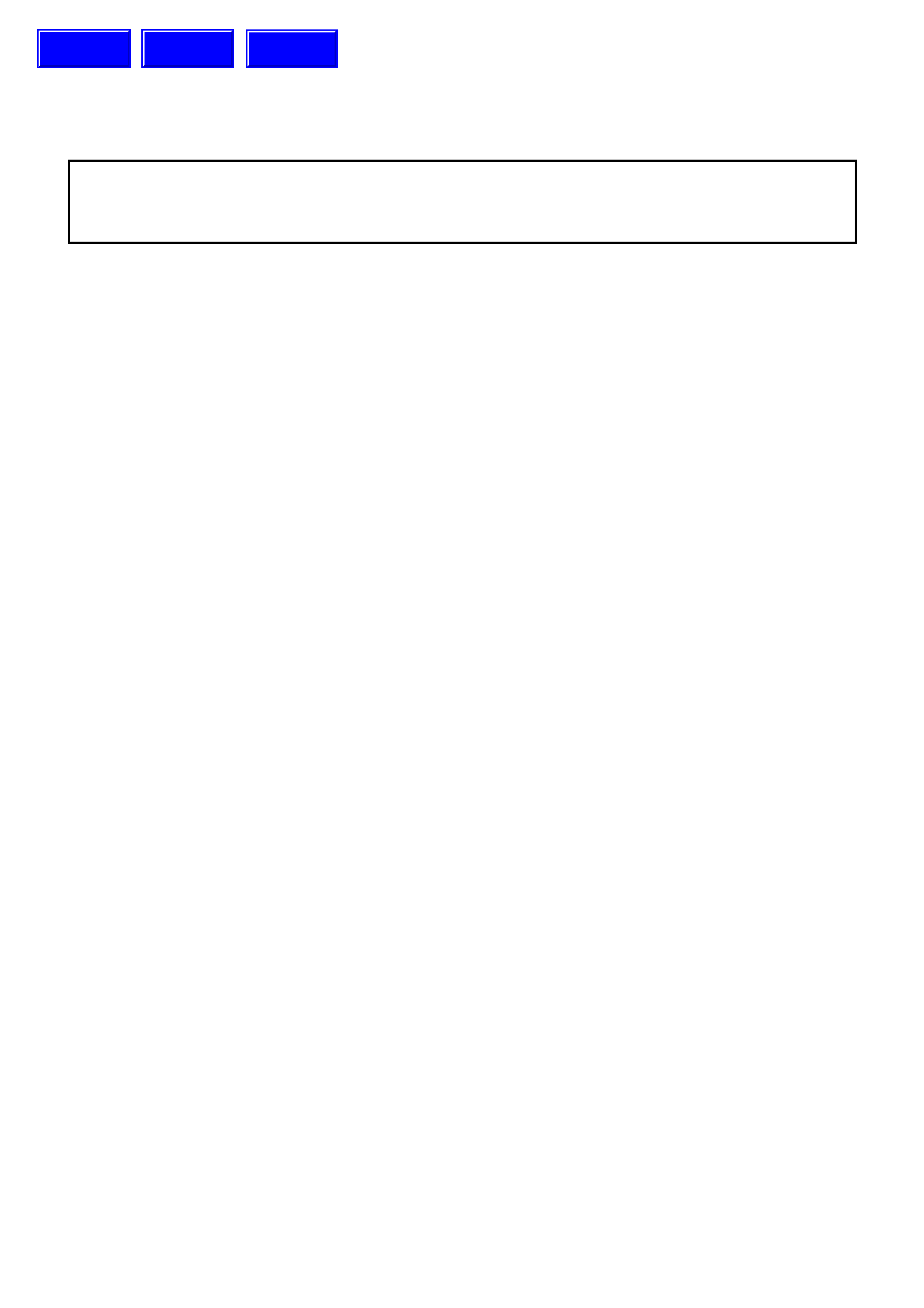

1. With the boot and dust cover removed, use a

small screwdriver to remove both ‘E’ clips (1).

CAUTION: Wear safety glasses to avoid

possible eye injury.

Figure 7B3-1

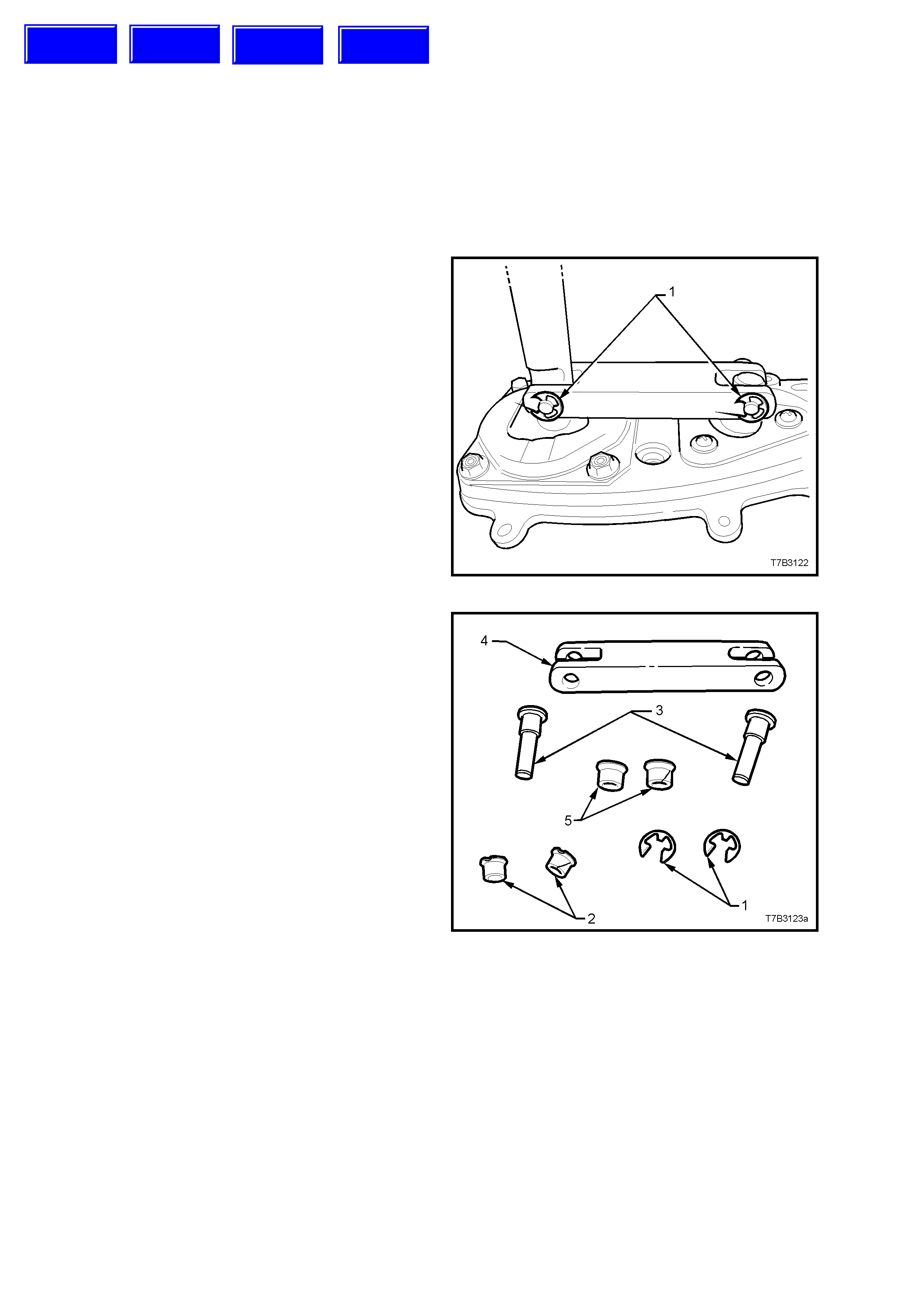

2. Tap the two pins (3) free from the bridging

piece (4). T hese two pins ar e an interference fit

into each of the two pivot pieces and must be

replaced after removal.

3. Remove both the smaller (2) and larger (5)

bushes from the bridging piece (4).

Figure 7B3-2

Techline

Techline

Techline

Techline

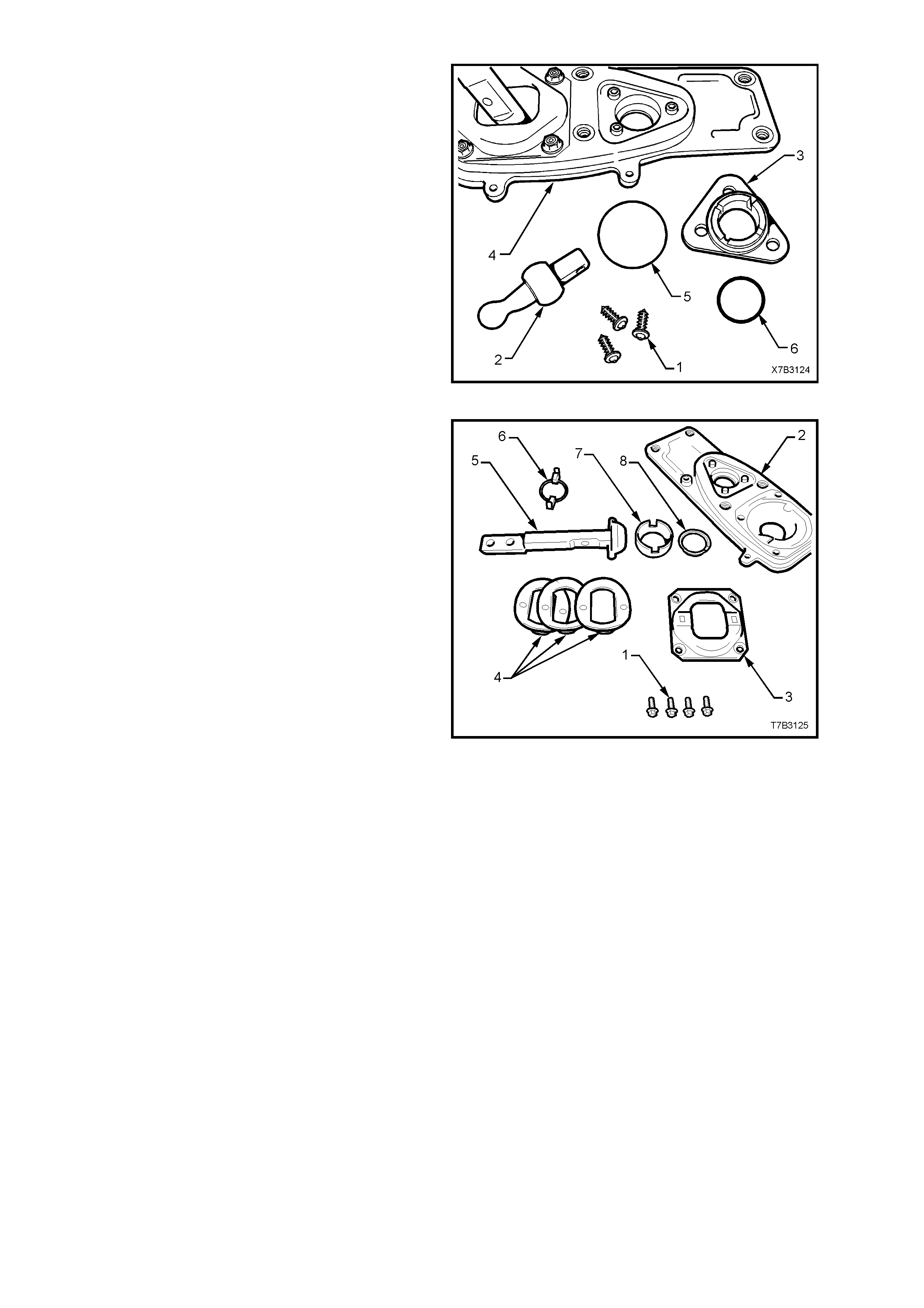

4. To disassemble the front pivot assembly,

unscrew the three self tapping screws (1),

using a Phillips No. 2 screwdriver.

5. By grasping the remote selector pivot (2), pull

the pivot (2) and seat assembly (3) from the

baseplate (4).

6. Remove the O-ring seals (5 and 2) from the

seat (3).

7. Separate the selector pivot (2) from the seat

assembly (3) by supporting the seat assembly

over the open jaws of a vice assembly, then tap

the ball end of the selector pivot (2) free from

the seat (3).

Figure 7B3-3

8. The rear remote shifter assembly can be

disassembled by first removing the four plate

(3) retaining bolts (1) from the baseplate (2).

9. Remove the wave springs (4), remote shifter

shaft (5) and guide (6), from the base plate (2).

10. Finally, remove the ball seat (7) and seat

support ring (8) from the base plate (2).

Figure 7B3-4

CLEAN AND INSPECT

Clean

After removing rubber insulating bushes and seal to the

extension housing, thoroughly was h all com ponents in a

suitable cleaning solvent. Dry all parts with clean, dry

compressed air.

CAUTION: Wear safety glasses to avoid eye injury.

Inspect

1. Inspect pins, bushes, ball seats and other

components for wear or damage, replacing as

required.

2. Inspect the O-ring seal at the front pivot assembly,

the cover plate insulating r ubber bushes and seal to

the extension housing, for deterioration or damage,

replacing as required.

REASSEMBLE

While reassembly is the reverse to disassembly,

there are some specific procedures such as;

1. Apply 10% molybdenum disulphide grease

such as Moybond GA 10 or equivalent (to

Holden’s Specification HN 1271) to all moving

parts in the rear remote shifter assembly.

2. Reassemble all parts in the reverse order of

disassem bly.

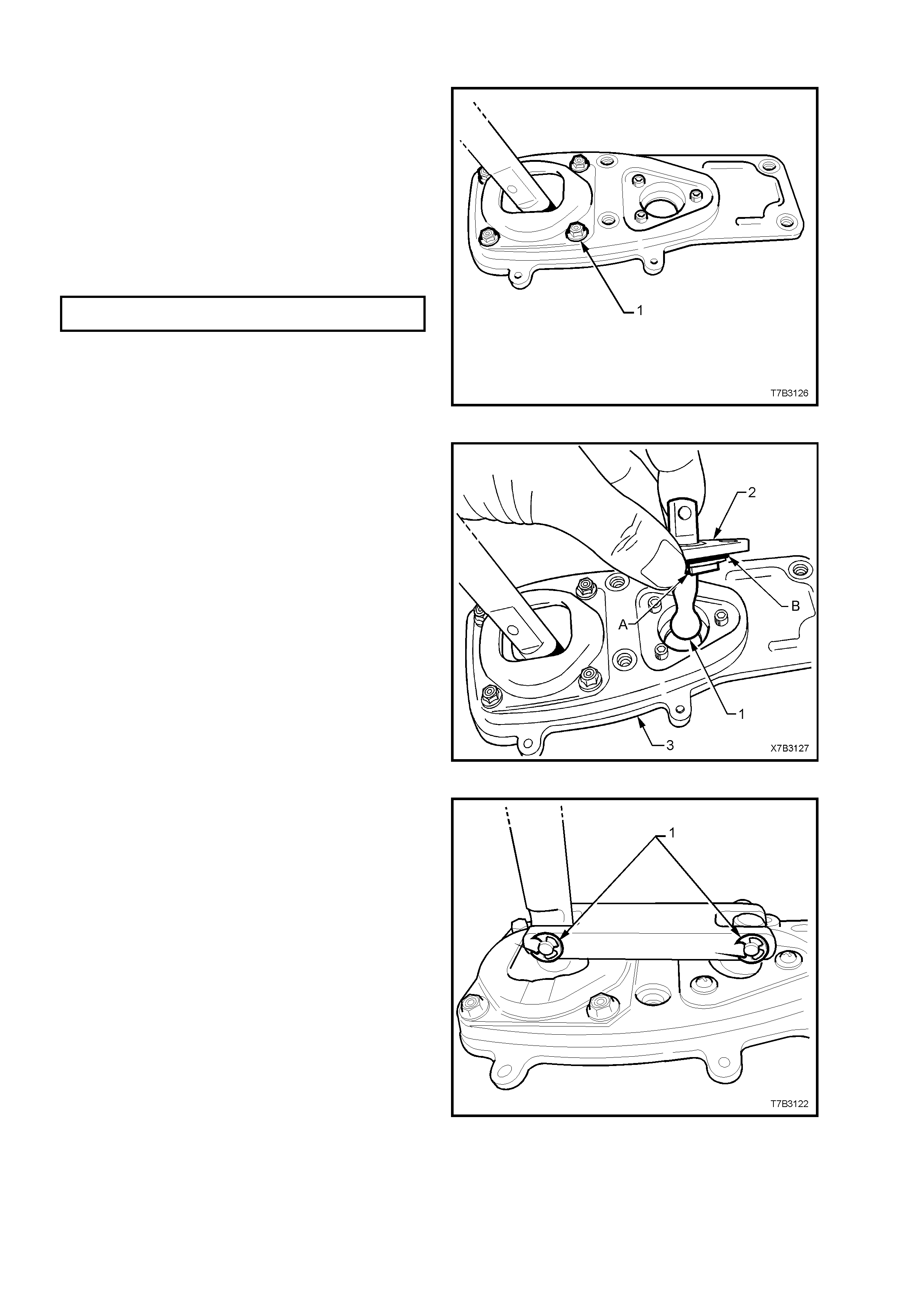

3. Install the four bolts (1) securing the plate to

baseplate, tightening to the correct torque

specification.

REAR REMOTE SHIFT LEVER COVER

BOLT TORQUE SPECIFICATION.................. 10 - 12 Nm

Figure 7B3-5

4. Apply NLGI No. 4 EP grease to the ball socket

of the front selector pivot (2), then reassemble

by tapping the front selector pivot (1) into the

plastic ball socket (2).

5. Install the O-ring seals ‘A’ and ‘B’ to the ball

socket (2), replacing with new parts if the

originals are damaged.

6. Reinstall the front selector pivot assembly to

the baseplate (3), install the three retaining

screws and tighten securely.

Figure 7B3-6

7. Install the bridging piece to the two remove

lever assemblies.

8. Install new bushes to the bridging piece after

lubricating with NLGI No. 4 EP grease.

9. Install NEW pivot pins to each location and tap

home with a hammer.

NOTE: These pins are designed to be an

interference fit to the front and rear remote shifter

levers and not be free floating.

10. Fit NEW ‘E’ clips (1) to secure each pin.

CAUTION: Wear safety glasses to avoid eye

injury.

NOTE: the dust cover and boot assembly will be

installed after the remote shifter assembly is

installed to the transmission extension housing.

Figure 7B3-7

REINSTALL

Refer 4.7 TRANSMISSION REASSEMBLE, Extension

Housing, in the VT series II Service Information.