SECTION 7C4 - HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION ON-VEHICLE SERVICING

IMPORTANT

Before p erforming any Serv ice Operation or other procedu re described in this Section , refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL I NFORMATI ON

Information in this Section, details service operations that can be carried out on a transmission while it is still

installed in the vehicle.

Introduced as a running change in VT Series II m odels a revised des ign autom atic trans m ission f luid cooler with an

increased heat tr ans f er ef ficiency was fitted, from a production s erial num ber of L579900 and date of April 10, 2000.

On V6 naturally aspirated engined vehicles, this cooler design change m eans that the external cooler the can now

been deleted.

Those VX Series models fitted with the V6 Supercharged engine retains the single in-tank radiator cooler and

external cooler intr oduced as a r unning c hange in VT Ser ies II vehic les from a pr oduc tion ser ial number of L518684

and date of October 18, 1999. Refer Section 7C4 ON-VEHICLE SERVICING in the VT Series II Service Information.

The automatic transm ission oil cooler design f or those VX Series m odels f itted with the GEN III V8 engine remains

unchanged from the original. For information relating to this oil cooler package, refer to

Section 7C4 ON-VEHICLE SERVICING in the VT Series II Service Information.

As a change in procedure, a tool has been released that allows the replacement of the manual shaft oil seal, without

requiring the removal of the oil pan, control valve body and manual shift shaft.

Only these items ar e detailed here. T heref ore, for on-vehicle s ervice operations not included in this Section, ref er to

7C4 AUTOMATIC TRANSMISSION ON-VEHICLE SERVICING in the VT Series I and VT Series II Service

Information.

A minor change to the cooling fan wiring has been im plemented, involving a single, sealed connector . T his change

however, does not affect the operation of the cooling fans. For additional information, refer to

Sections 12N FUSES, RELAYS & WIRING HARNESSES and Sections 12P WIRING DIAGRAMS in the VX

Series Service Information.

Techline

Techline

Techline

Techline

2. ON-VEHICLE SERVICE OPERATIONS

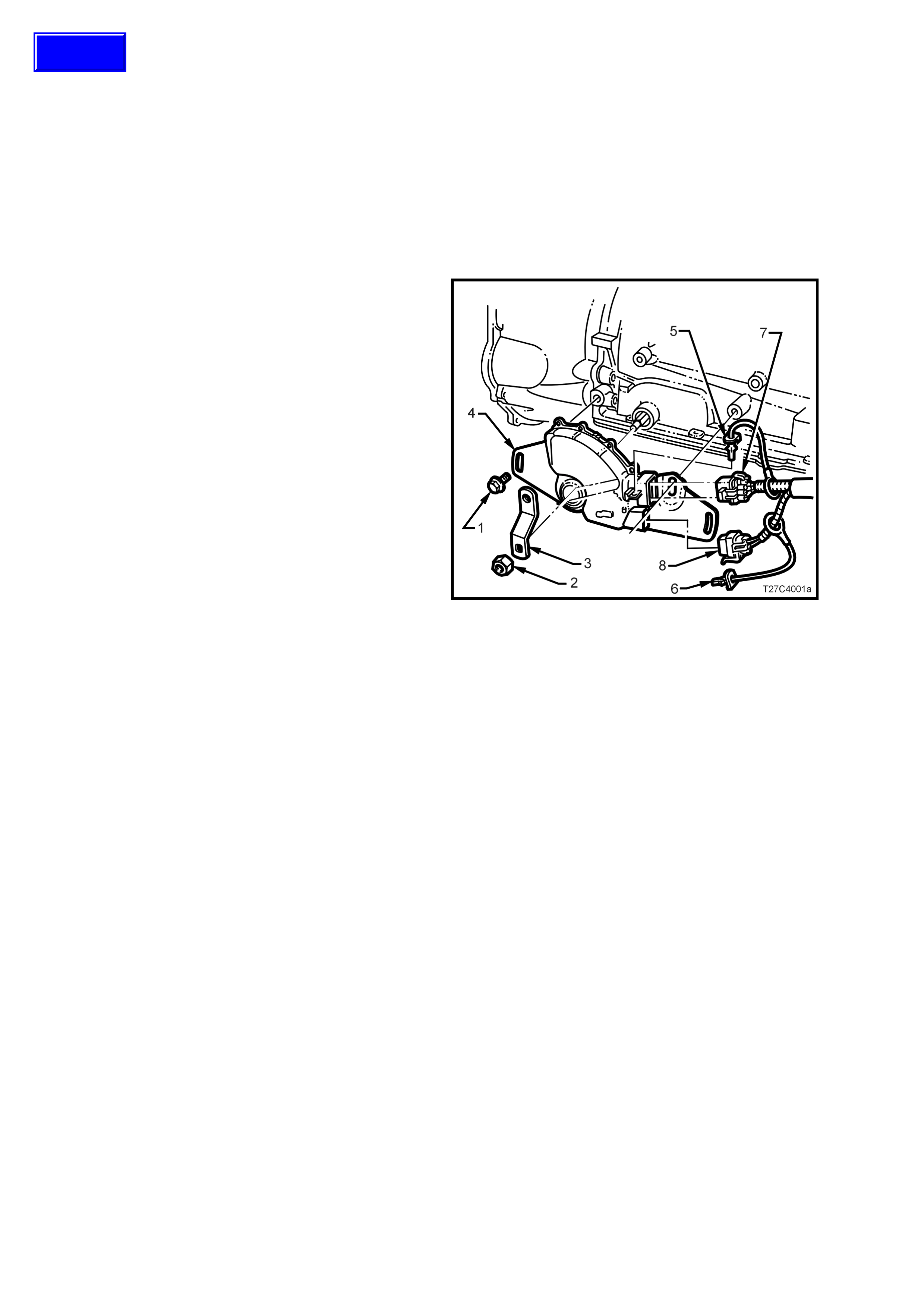

2.1 NEUTRAL START AND BACK-UP LAMP SWITCH

REMOVE

1. Raise the front of the vehicle and place on

safety stands. Refer

Section 0A, GENERAL INFORMATION in the

VT Series I Service Information for the location

of recommended jacking points.

2. While holding the lower selector lever (3) with

an adjus table wr ench, remove the retaining nut

(2).

3. Carefully remove the lever (3) from the

transmission manual shaft.

4. Prise the wiring harness connector CPA

(Connector Position Assurance) securing pins

(5 and 6) from the neutral start and back-up

lamp switch (4), taking care not to break the

pins in the process. Disconnect the two wiring

harness connectors (7 and 8) from the switch

assembly (4).

5. Remove the two switch retaining screws (1),

then slide the switch assembly (4) over the

manual shaft and remove from the vehicle.

Figure 7C4-1

Techline

REINSTALL

Reinstallation of the neutral start and back-up lamp

switch is the reverse of the removal procedure

except for the following:

1. W hen installing the two switch sec uring screws,

leave them finger tight, until the adjustment

process has been completed.

2. After installing the selector lever and retaining

nut, hold the lever with an adjustable wrench

and tighten the nut to the correct torque

specification.

SELECTOR LEVER RETAINING

NUT TORQUE SPECIFICATION..................... 15 - 35 Nm

3. Check the selector linkage adjustment. Refer

3.2 SELECTOR LINKAGE, in 7C4

AUTOMATIC TRANSMISSION ON-VEHICLE

SERVICING in the VT Series I Service

Information.

4. On completion of the neutral start and back-up

lamp switch adjustment procedure that follows,

check that the engine can only be started when

the gearshift lever is either in the ‘P’ (Park) or

‘N’ (Neutral) positions.

ADJUST

1. With the vehicle raised, rotate the neutral start

and back-up lamp switch back and forth until a

central position is attained, then lightly tighten

the front bolt to retain.

2. With the ignition switched to the ON position,

check that the engine can only be started in

both the Park and Neutral selector positions. A

further minor adjustment may be required to

achieve this state.

Also check that the Reverse lamps illuminate

when Reverse range is selected.

3. After switch adjustment, tighten the switch

retaining bolts to the correct torque

specification.

NOTE: To gain access to the rear bolt, it will be

necessary to remove the wiring harness connector.

NEUTRAL START & BACK-UP

LAMP SWITCH RETAINING BOLT

TORQUE SPECIFICATION ............................. 15 - 35 Nm

4. Following the bolt tightening pr ocedure, reinstall

the connector/s and the CPA securing pin/s.

5. Lower the vehicle to the ground and check the

operation of the neutral start and back-up lamp

switch. T he vehicle should only start in either ‘P’

(Park) or ‘N’ (Neutral) ranges and the reverse

lamps should only illuminate when the ‘R’

(Reverse) range is selected.

2.2 MANUAL SHAFT OIL SEAL

REPLACE

1. Raise the front of the vehicle and place on

safety stands. Refer to

Section 0A, GENERAL INFORMATION in the

VT Series I Service Information for the location

of recommended jacking points.

2. Remove the Neutral Start and Back-Up Lamp

Switch. Refer to

2.1 NEUTRAL START AND BACK-UP LAMP

SWITCH in this Section.

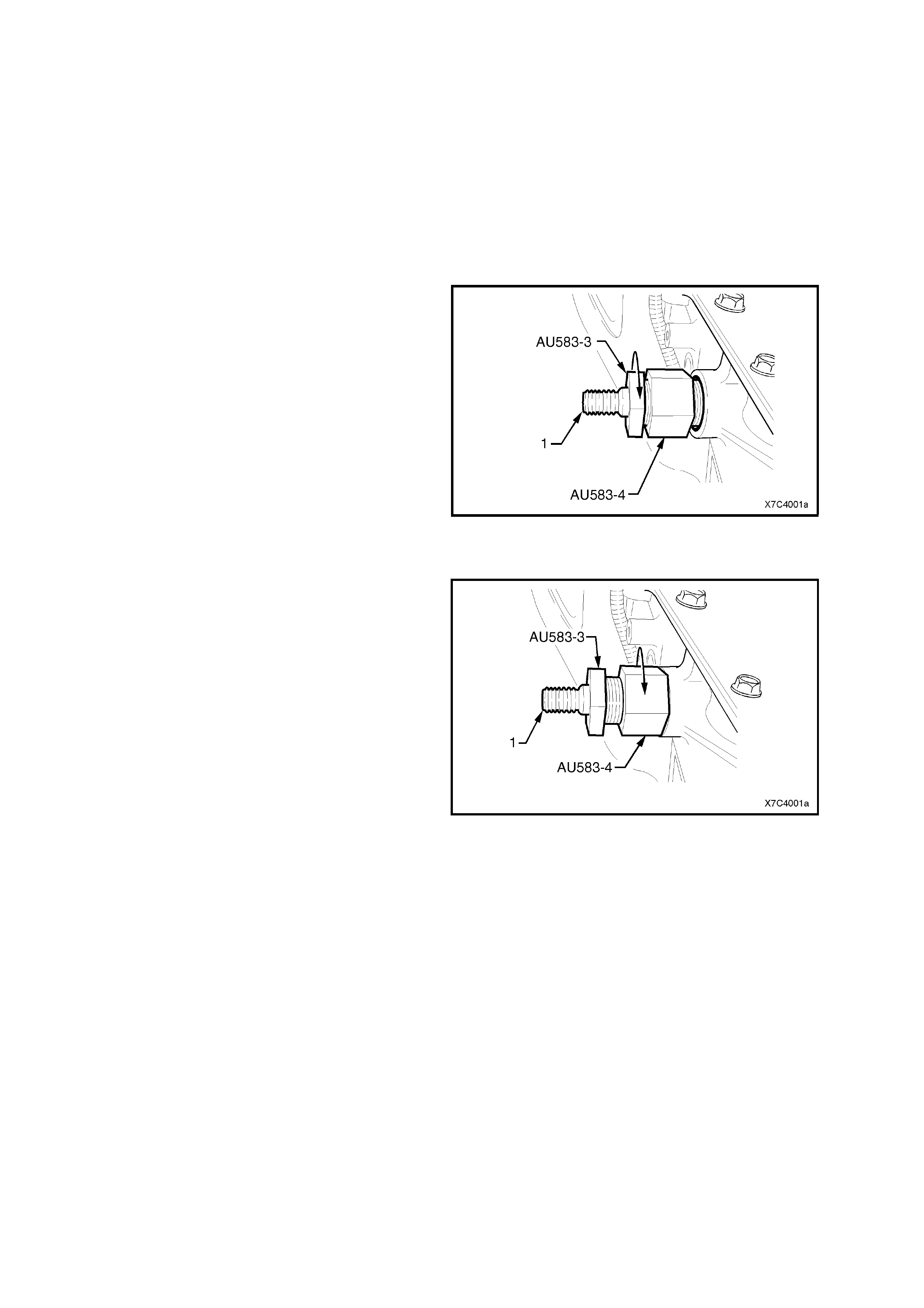

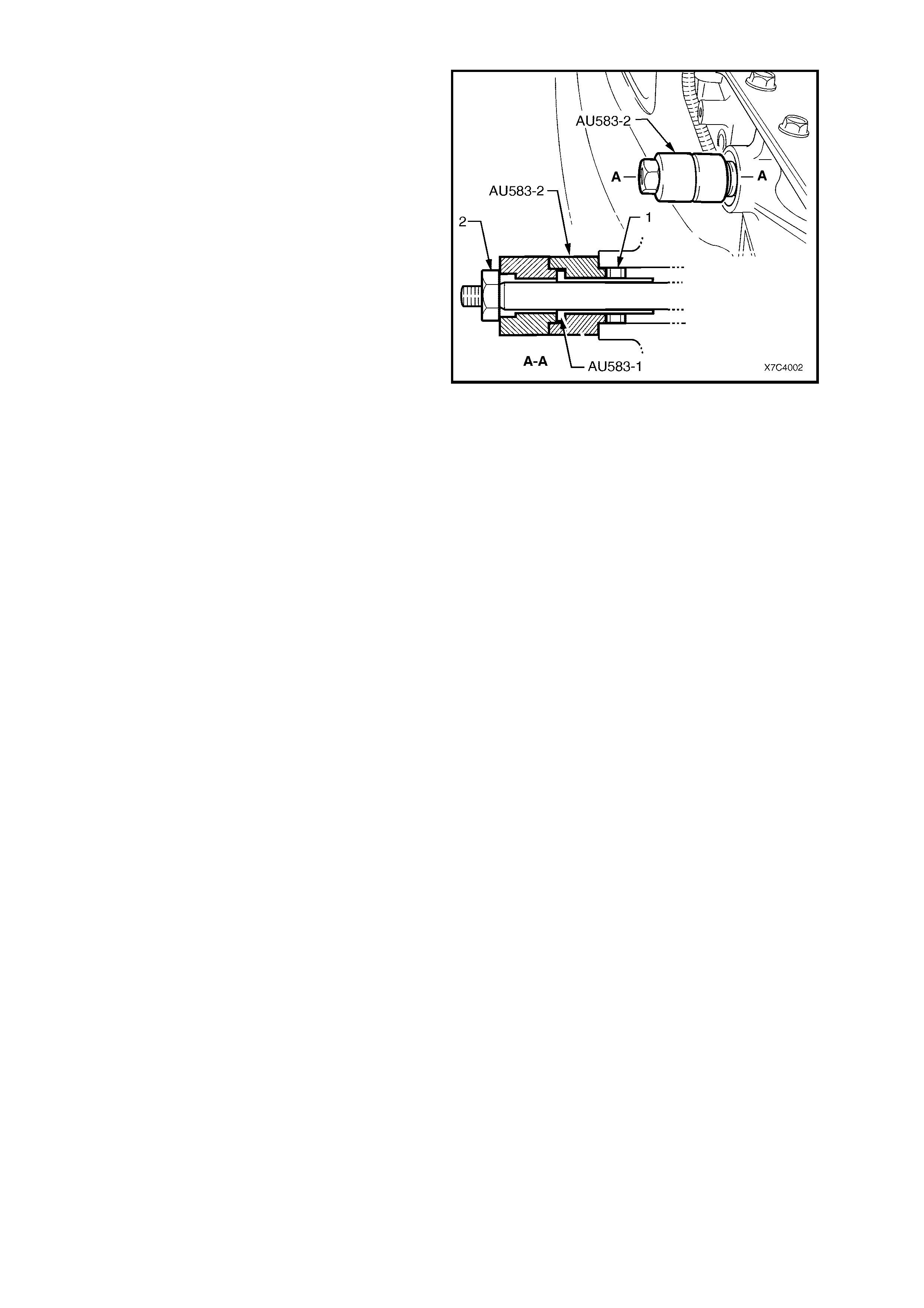

3. Assemble the remover nut (Tool No. AU583-4)

with the threaded section closest to the

hexagonal head of the seal remover AU583-3.

Install the nut up to the hexagonal end.

4. Install the pre-assembled remover (Tool Nos.

AU583-3 and AU583-4) over the manual shaft

(1) and engage the tapered thread end of the

seal remover into the seal. Tighten the seal

remover until the tool thread grips the steel

shell of the seal.

NOTE: Do not overtighten the seal remover in the

seal.

Figure 7C4-2

5. While holding the seal remover (AU583-3),

screw the remover nut (AU583-4) up to the

transmission case.

6. Continue tightening the remover nut until the

seal is removed into the remover nut cavity.

7. Discard the removed seal.

Figure 7C4-3

8. Pre-as sem ble the s eal protector (AU583-1) into

one of the plastic seal installers (AU583-2), as

shown in the sectioned view.

9. Lubricate the seal lip of a new seal (1) with

Dexron® III automatic transmission fluid, then

install it (with the steel seal casing facing the

installer) over the seal protector sleeve

(AU583-1).

10. Install the seal protector (AU583-1), seal

installer (AU583-2) and seal (1), over the

manual shaft and up to the transmission case.

NOTE: If the s leeve jams on the m anual shaf t, then

the shaf t will be bur red over the f lats that locate the

selector lever. Use a fine file to remove burrs, then

proceed.

11. Install the second plastic seal installer over the

manual shaft until it seats against the first

installer.

12. Install the manual shaft lever retaining nut (2)

and tighten it to install the seal fully into place in

the transmission case.

NOTE: Two plastic seal installers (AU583-2) are

required, because of the restricted space between

the end of the manual shaft and the floor pan.

13. Remove installer tools, AU583-2 (two pieces)

and seal protector AU583-1 from the manual

shaft.

Figure 7C4-4

14. Reinstall the Neutral Safety and Back -Up Lamp

Switch and adjust as detailed in 2.1 NEUTRAL

START AND BACK-UP LAMP SWITCH

REINSTALL AND ADJUST, in this Section.

15. Lower the vehicle to the ground, check and top

up the automatic transmission fluid level, as

required. Refer 2.1 FLUID LEVEL CHECK, in

the VT Series II Service Information.

2.3 TRANSMISSION COOLER PIPES/HOSES

REMOVE (V6 NON SUPERCHARGED ENGINE ONLY)

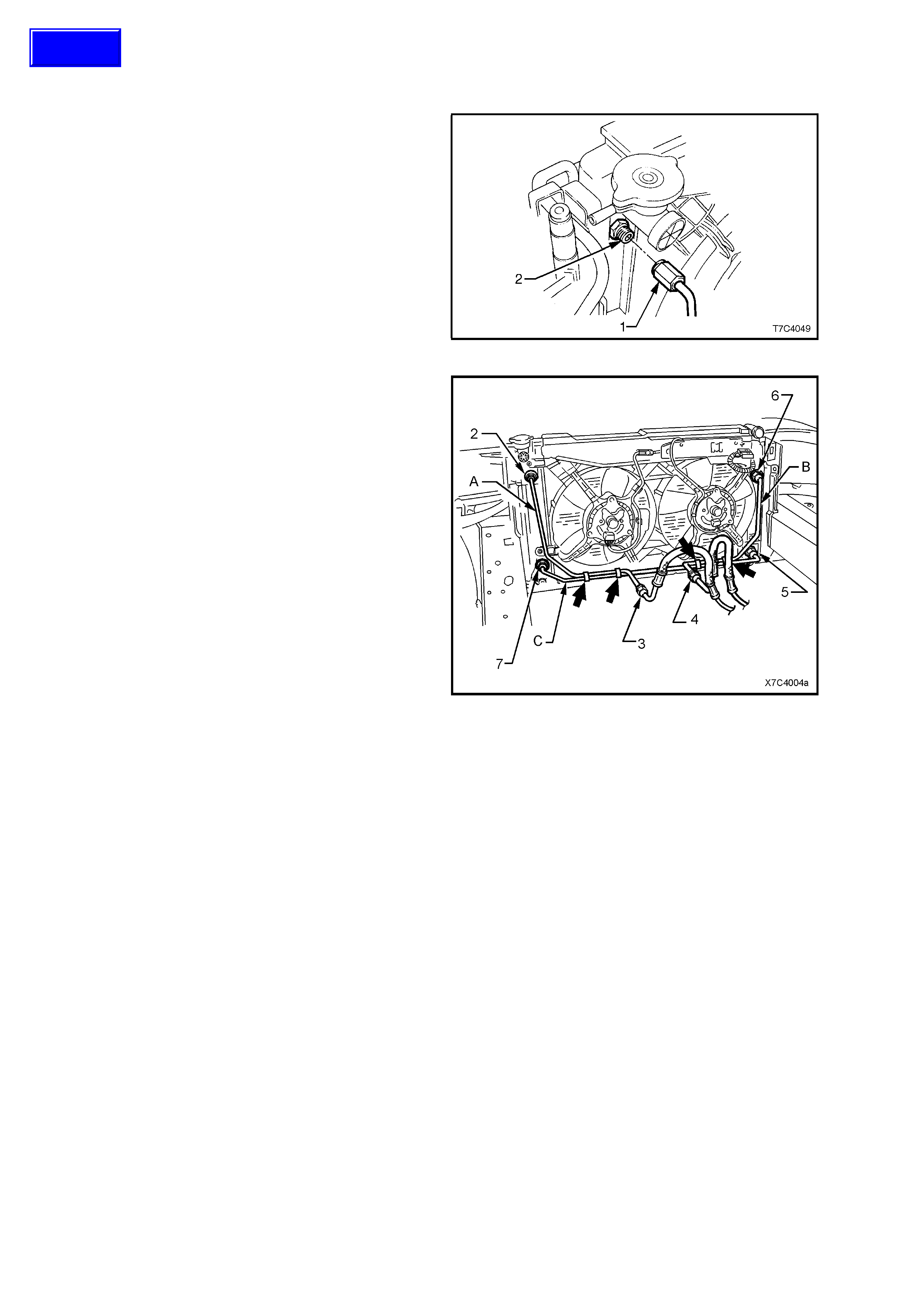

1. Hold the radiator flare nut fitting (2) with a back-

up spanner, then loosen and disconnect the

outlet oil cooler pipe (1) from that location.

Figure 7C4-5

2. Remo ve the clips (bold arr ows) securing the oil

cooler pipes to each other.

3. While us ing a bac k-up spanner on the fitting (3)

at the oil cooler hose end, loosen then

disconnect the transmission outlet line pipe,

flare nut.

4. Remove the inlet cooler pipe (A) from the

vehicle.

5. Repeat steps 1 and 3 to 4 for the return oil

cooler pipe (B) and the crossover pipe (C).

Figure 7C4-6

Techline

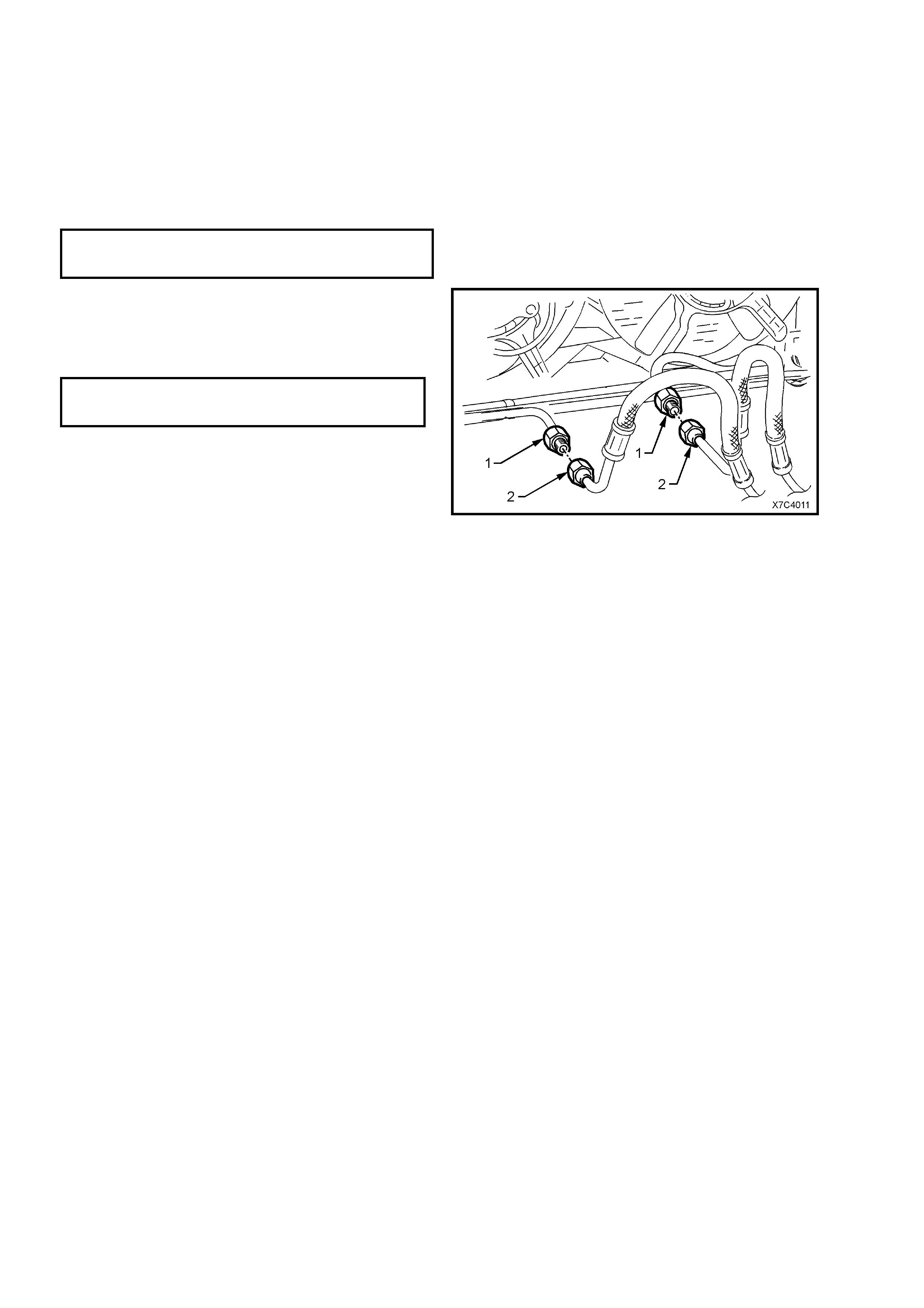

REINSTALL

Referr ing to Figure 7C4- 5, the reinstallation proc ess

of the oil cooler pipes, is the reverse to removal,

except for the following:

1. When tightening oil cooler pipes to the radiator

fittings (2, 5, 6 and 7), ALW AYS use a back-up

spanner on the radiator flare nut fitting BEFORE

tightening the flare nuts to the correct torque

specification.

TRANSMISSION COOLER PIPE

FLARE NUT TO RADIATOR FITTING

TORQUE SPECIFICATION............................. 25 – 30 Nm

2. Before tightening the transmission oil cooler

pipe fittings (1) to the cooler hose fittings (2), a

back-up spanner MUST be used on the oil

cooler hose fittings (2) BEFORE tightening to

the correct torque specification.

TRANSMISSION COOLER PIPE

FLARE NUT TO COOLER HOSE

TORQUE SPECIFICATION............................. 25 – 30 Nm

3. Check and top up the automatic transmission

fluid level, as required. Refer

Section 7C4 ON-VEHICLE SERVICING, 2.1

FLUID LEVEL CHECK, in the VT Series II

Service Information.

Figure 7C4-7

NOTE: For the remainder of the oil cooler pipe

removal and reinstallation procedures, refer

Section 7C4 ON-VEHICLE SERVICING in the VT

Series II Service Information.

3. TORQUE WRENCH SPECIFICATIONS

NOTE: For a complete listing of specifications as they apply to com ponents not discussed in this Section, refer to

Section 7C4 HYDRA-MATIC 4L60- E AUTO MATIC T RANSMISSION: ON-VEHICLE SERVICING in the VT Series I

and VT Series II Service Information and Section 7C5 HYDRA-MATIC 4L60-E AUTOMATIC TRANSMISSION:

UNIT REPAIR, in the VX Series Service Information. Nm

Neutral Start and Back-Up Lamp Switch Retaining Bolt................................. 15 – 35

Selector Lever Retaining Nut.......................................................................... 15 – 35

Transmission Cooler Pipe Flare Nut to Radiator Fitting................................. 25 – 30

Transmission Cooler Pipe Flare Nut to Cooler Hose...................................... 25 – 30

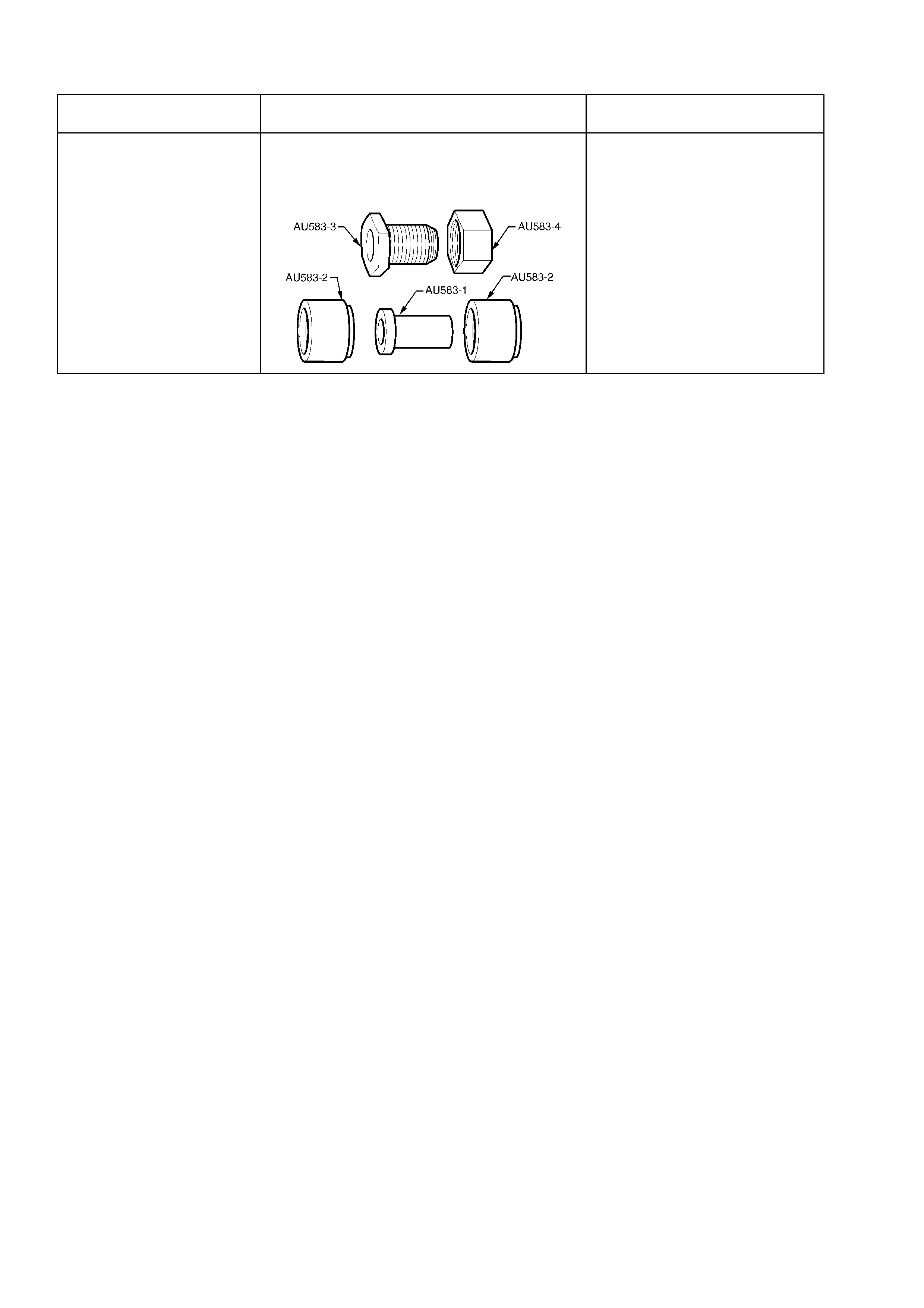

4. SPECIAL TOOLS

TOOL No. REF. in TEXT TOOL DESCRIPTION COMMENTS

AU583 SELECTOR SHAFT SEAL REMOVER/

INSTALLER

New release.

Use to remove and install the

manual shaft oil seal, with the

transmission installed in the

vehicle.