SECTION 2B - HEATING & AIR CONDITIONING –

REMOVAL & INSTALLATION

IMPORTANT

Before perfo rming any Service O peration or oth er procedu re described in t his Sectio n, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL INFORMATION

1.1 AIR-CONDITIONING HOSE LAYOUTS

V6 ENGINES

GEN III V8 ENGINE

2. SERVICE OPERATIONS

2.1 CONDENSER – V6 ENGINES

REMOVE

REINSTALL

2.2 CONDENSER – GEN III V8 ENGINES

REMOVE

REINSTALL

2.3 FILTER DRIER RECEIVER

REMOVE

REINSTALL

3. TORQUE WRENCH SPECIFICATIONS

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL I NFORMATION

The removal and installation procedures for the heating and air conditioning system as fitted to VX and WH Series II

Models carries over from the information provided for VT Series Models, noting the following:

• A new condenser, radiator and fan module (CRFM) was introduced into WH Series II Models as a running

change during August 2002.

The information provided in this Section only applies to WH Series II Models fitted with the revised CRFM. For

information regarding either the earlier type CRFM or the unchanged portion of the heating and air conditioning

system, refer to Section 2B – HEATING AND AIR CONDITIONING – REMOVAL AND INSTALLATION in the

VT Series I and VT Series II Service Information.

NOTE: Information in these two Sections should be read in conjunction with each other.

The rem oval and inst allation procedures for the heating and air conditioning s ystem as f itted to VU Series II Models

carries over from the information provided for VU Series I Models.

For information relating to the removal and installation of the heating and air conditioning system as fitted to VU

Series II Models, refer to Section 2B HEATING AND AIR CONDITIONING – REMOVAL AND INSTALLATION in

the VU Series I in conjunction with Section 2B HEATING AND AIR CONDITIONING – REMOVAL AND

INSTALLATION in the VT Series I and VT Series II Service Information.

NOTE: Information in these three Sections should be read in conjunction with each other.

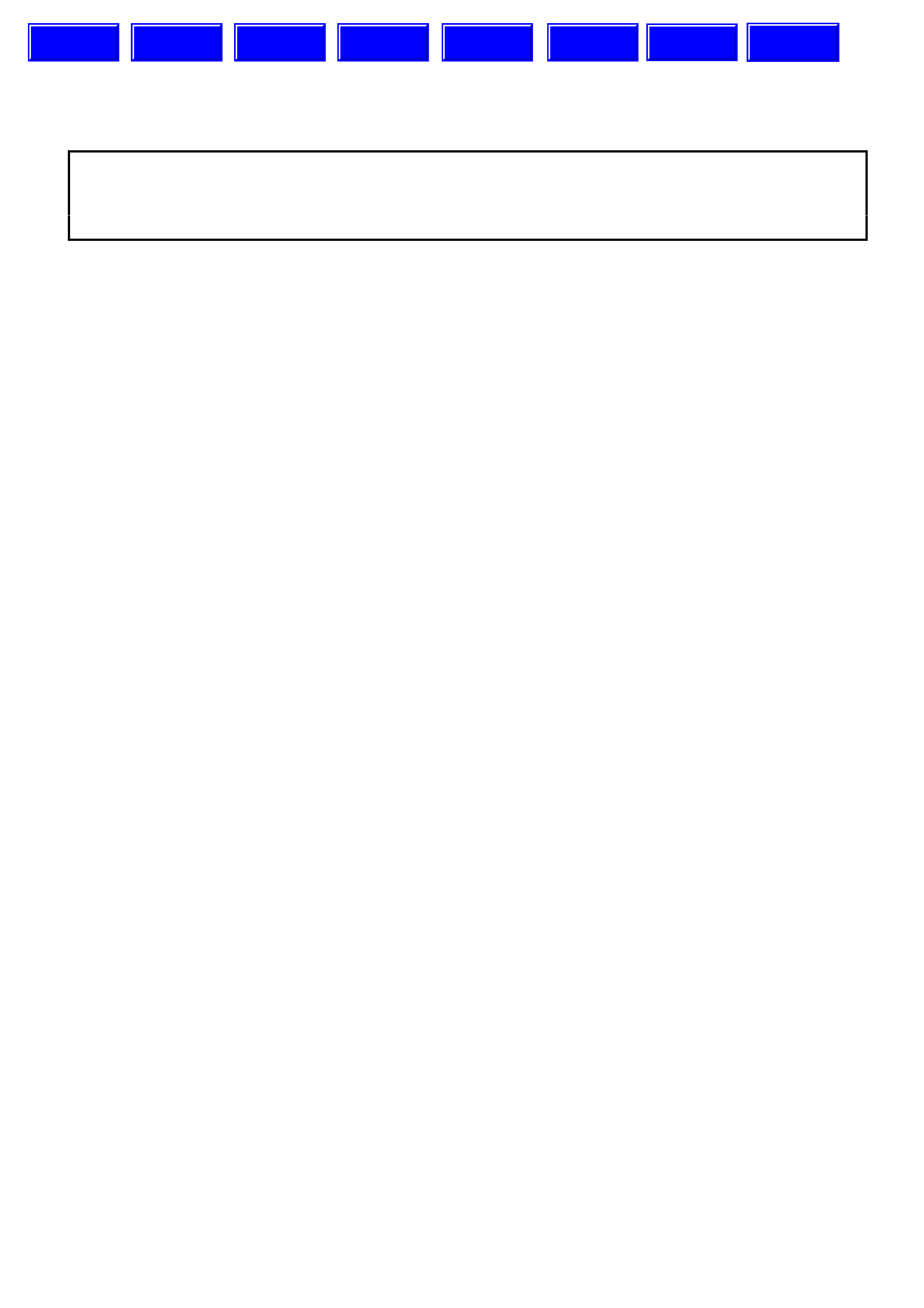

1.1 AIR-CONDITIONING HOSE LAYOUTS

Due to the intr oduction of a revised CRF M, several air -conditioning hos es and the position of the filter drier r eceiver

(FDR) have also been revised. Figures 2B-1 and 2B-2 show the air conditioning hose layouts for WH Series II

Models fitted with the revised CRFM.

V6 ENGINES

Figure 2B-1

Legend

1. Thermal Expansion Valve

2. O-ring

3. Suction Tube

4. Screw

5. Liquid Tube

6. O-ring

7. Compressor

8. Bonded Sealing Washer

9. Nut

10. Suction Hose

11. Discharge Hose

12. Liquid Tube Clip

13. Discharge Tube Clip

14. Discharge Tube

15. Nut

16. O-ring

17. Condenser

18. O-ring

19. Filter Drier Receiver (FDR)

GEN III V8 ENGINE

Figure 2B-2

Legend

1. Thermal Expansion Valve

2. O-ring

3. Suction Tube

4. Liquid Tube

5. Retaining Screw

6. Suction Tube Retaining Clip

7. Discharge Tube

8. Discharge Tube Retaining Clip

9. Discharge Tube Retaining Nut

10. Condenser

11. Filter Drier Receiver (FDR)

12. Retaining Clamp

13. Discharge Hose/Tube

14. Retaining Nut

15. Compressor

2. SERVICE OPERATIONS

2.1. CONDENSER – V6 ENGINES

REMOVE

1. Recover the refrigerant from the A/C system,

refer to 2.1 SYSTEM CHARGING AND

EVACUATION in Section 2C HEATING AND

AIR CONDITIONING – SERVICING AND

DIAGNOSIS in the VT Series I Service

Information.

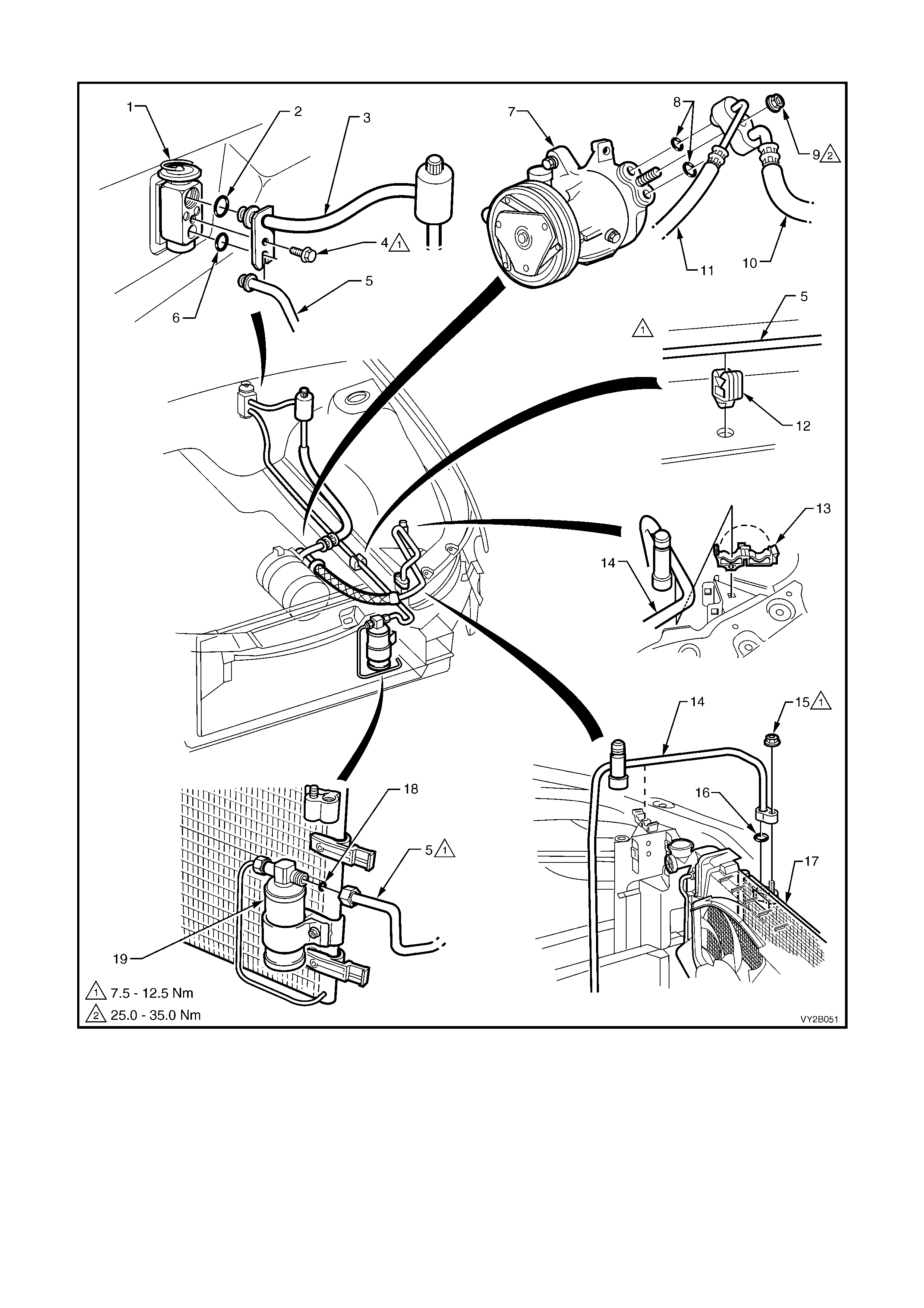

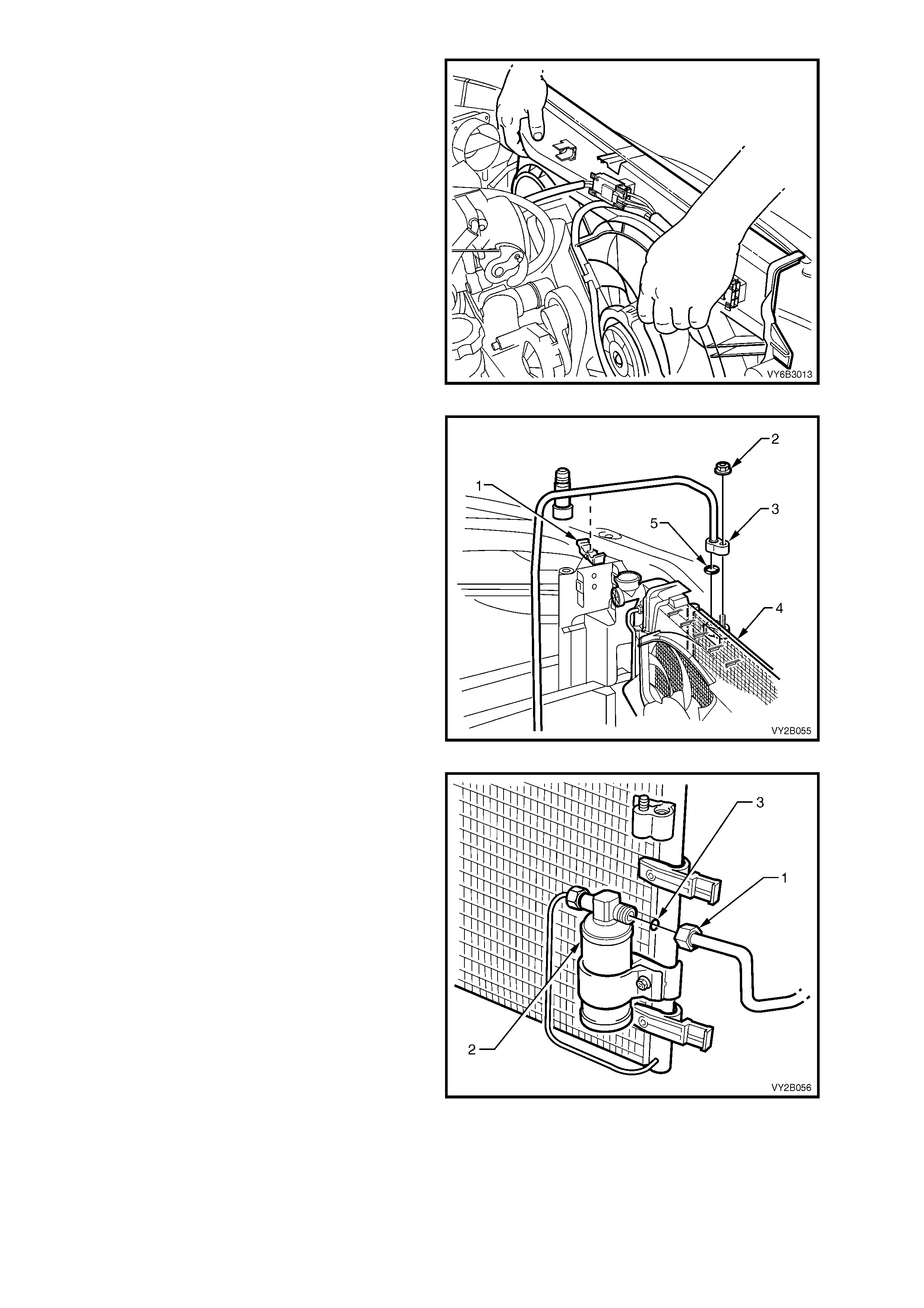

2. Remove the cold air intake duct and radiator

upper shroud retainers (1 and 2). Remove the

cold air intake duct (1), then disengage the

shroud locating tabs (4) by pulling the shroud

(3) towards front of vehicle, prior to removal.

Figure 2B-3

3. Release each of the automatic transmission

cooling pipes (if fitted) (1) from the integral clips

(2) on the fan shroud.

Figure 2B-4

4. Depress the tang on the main wiring harness-

to-cooling fan motor wiring harness connector

(1) and separate the connector.

Figure 2B-5

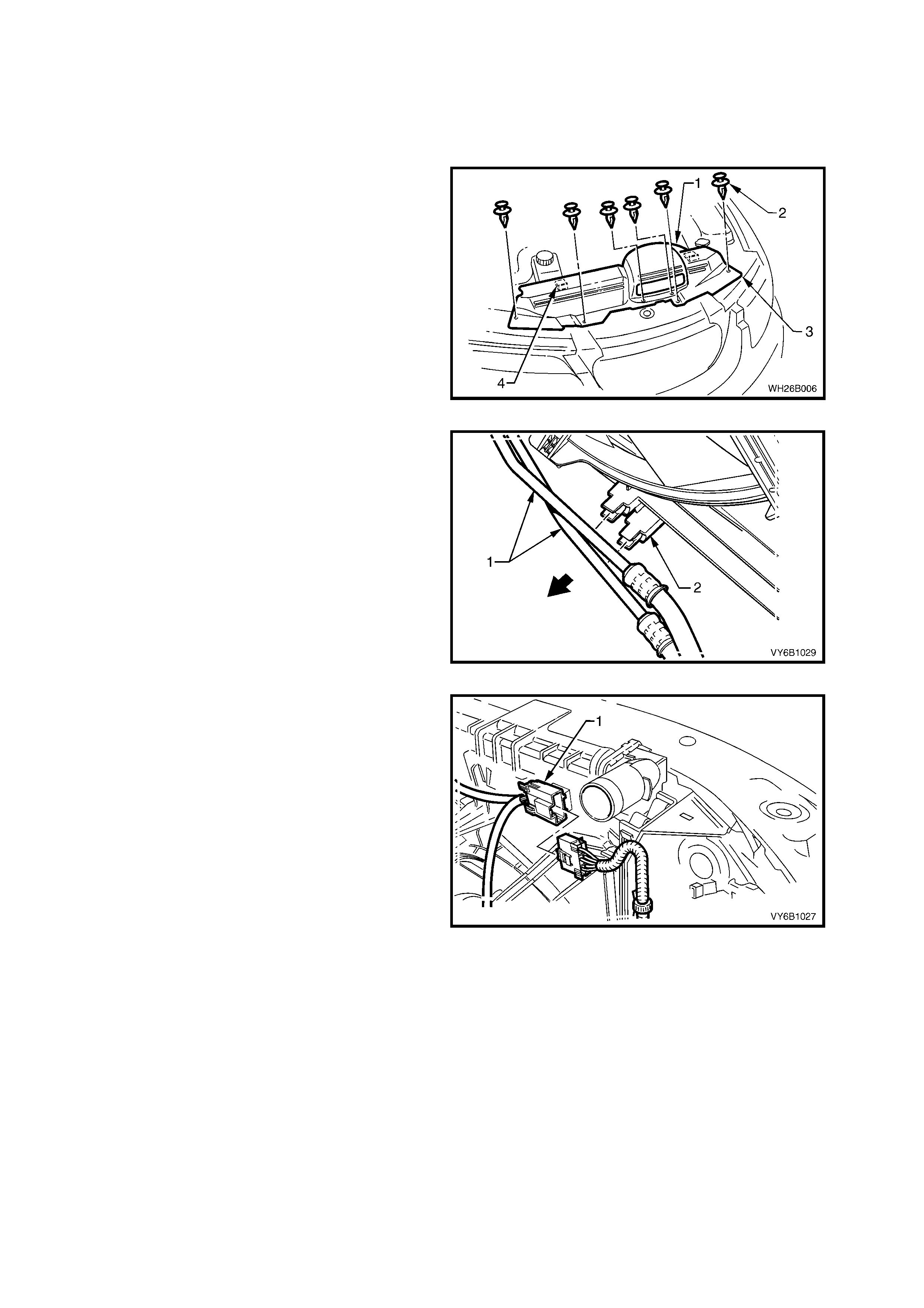

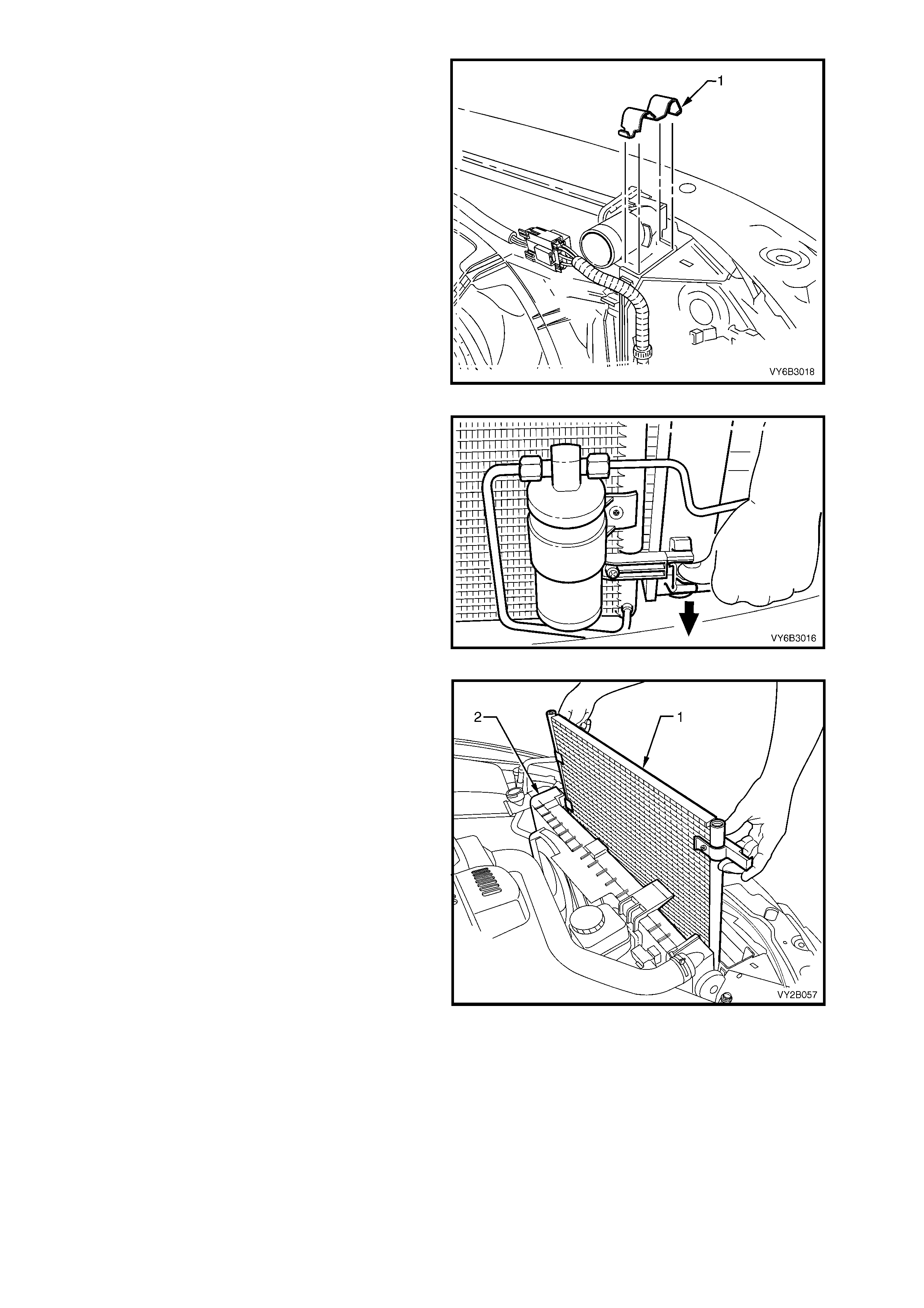

5. Release the discharge tube retaining clip (1).

6. Remove the nut (2) retaining the discharge

hose pad fitting (3) to the condenser (4).

7. Cap all open tubes/hoses to avoid moisture

from entering the system.

8. Discard the O-ring (5).

Figure 2B-6

9. Remove the liquid tube union (1) from the

FDR (2) and discard the O-ring (3).

Figure 2B-7

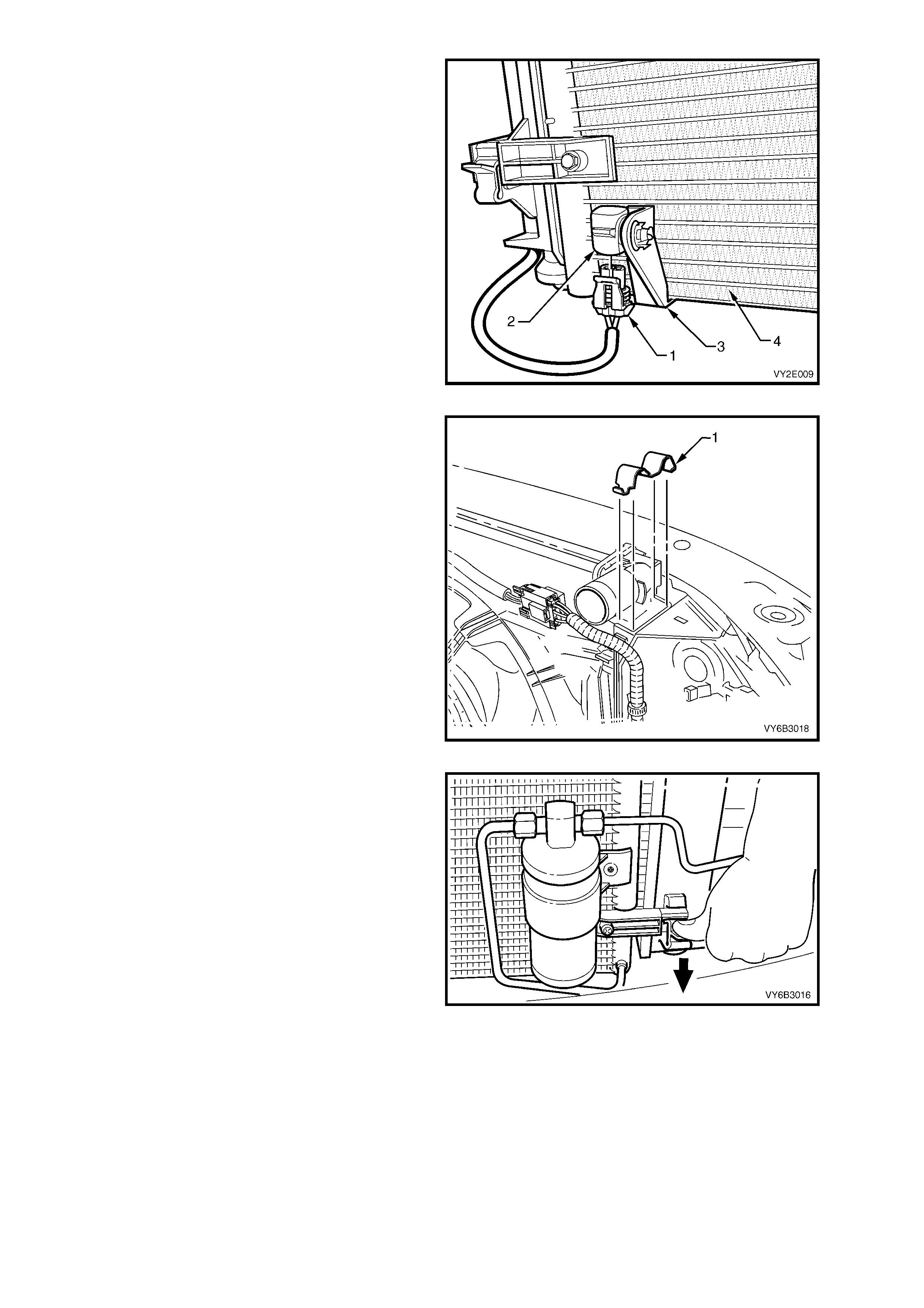

10. Disconnect the harness connector (1) from the

ambient temperature sensor (2). Do not

attempt to remove the bracket (3) from the

condenser (4).

Figure 2B-8

11. Using a screwdriver, compress and lever out

the radiator retaining clips (1) from the radiator

upper mounting brackets.

IMPORTANT: Do not lift the radiator assembly by

lifting on the fan rings as this will bend the fan

motor shaft and create an unnecessary vibration.

12. Lift the radiator assembly upwards out of the

lower insulators. Slant the upper section of the

assembly behind the radiator support sheet

metal work and allow it to remain there.

Figure 2B-9

13. Release one of the clips securing the

condenser to the radiator (bold arrow) by

pressing down on the locking retainer while

lifting the condenser assembly. Repeat for the

other side.

Figure 2B-10

14. Lift the condenser assembly (1) upwards

suff ic iently to clear the mounts moulded to f ront

of the radiator (2). Rem ove the condenser from

engine bay with the FDR attached.

NOTE: If the FDR is to be removed from the

condenser mark the mounting position of the FDR

in relation to the mounting bracket for correct

positioning when installing, and note the IN mar king

on the filter head for the correct flow direction. For

FDR installation information, refer to 2.3 FILTER

DRIER RECEIVER in this Section.

Figure 2B-11

REINSTALL

Installation of the condenser is the reverse of removal procedures, noting the following points:

1. Before installing the radiator, inspect the core to ensure that there is no foreign matter in the core fins. Clean out

between the core fins with compressed air, blowing from rear to front.

2. Ensure that the radiator lower mounting insulators are correctly located in the radiator support panel.

3. Ensure that the upper ins ulators are installed on each of the upper m ounting pins and the radiator retainer s are

correctly installed on each side of the radiator by checking that the clips engage on both sides of the channel

support bracket

4. If rem oved, install the FDR, ens uring that the union thread with the word IN is connected to the condenser side

of the FDR. Tighten the FDR unions and the FDR mounting bracket screw.

5. Install the liquid tube and the disc harge hose us ing new lubricated O-r ings to the condens er. T orque the unions

to specification.

FDR TUBE UNION

TORQUE SPECIFICATION ......................7.5 - 12.5 Nm

6. Evacuate and c harge the A/C system with 775 – 825 g of R134a ref rigerant, refer to 2.1 SYST EM CHARGING

AND EVACUATION in Section 2C HEATING AND AIR CONDITIONING – SERVICING AND DIAGNOSIS in

the VT Series I Service Information.

7. Ensure that fan and shroud assembly-to-radiator attaching clips are all fully engaged and that the two locking

tangs on the upper clips are securing the shroud correctly.

8. Check the cooling fan operation and direction of rotation.

2.2 CONDENSER – GEN III V8 ENGINE

REMOVE

1. Allow the engine to cool to ambient

temperature (less than 50°C), slowly loosen the

screw-on pressure cap at the coolant surge

tank to relieve any residual coolant pressure,

then remove.

CAUTION: Do not remove the screw-on

pressure cap while the engine coolant

temperature is above 50°

°°

°C, as personal injury

will most likely occur.

2. Disconnect the battery ground lead.

IMPORTANT: Disconnection of the battery affects

certain vehicle electronic systems. Refer to

BATTERY DISCONNECT CAUTION in Section 00

CAUTIONS AND NOTES in the VX Series II Service

Information before disconnecting the battery.

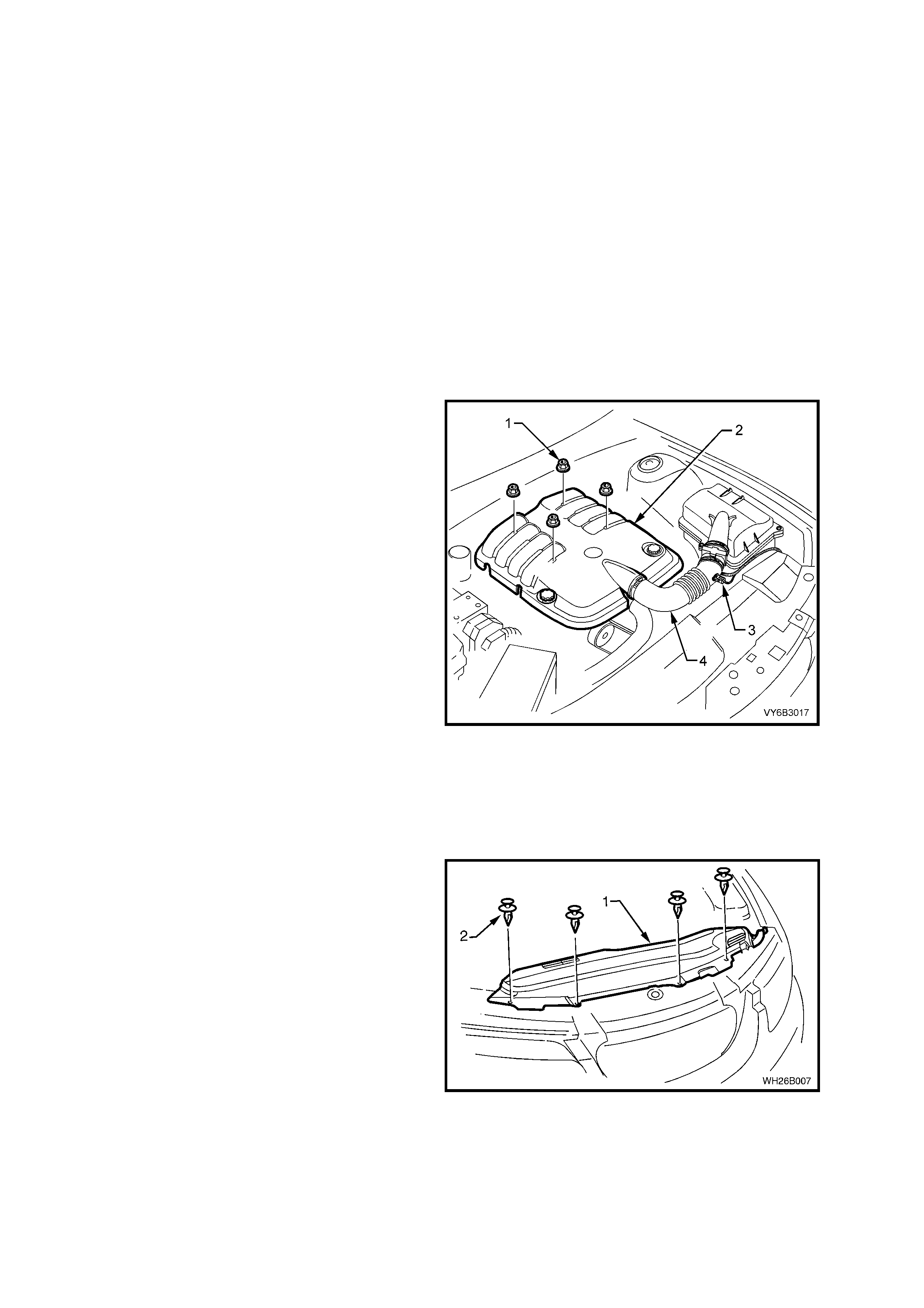

3. Remove engine dress cover decorative nuts

(1), then remove the cover (2).

4. Lift the locking lever on the Intake Air

Temperature (IAT) sensor wiring harness

connector (3), then remove the connector.

5. Lift the locking lever on the Mass Air Flow

(MAF) sensor, then remove the connector.

6. Loosen the two intake duct clamps, one at the

throttle body and the other at the MAF sensor

to air c leaner c onnection. Remove the duc t and

MAF sensor as an assembly and carefully set

to one side.

7. Drain the engine coolant into a suitable, clean

container. Refer to 2.3 DRAINING AND

FILLING COOLING SYST EM in Sect ion 6B3 –

ENGINE COOLING – GEN III V8 ENGINE in

the VT Series II Service Information.

8. Release the vapour hose from the radiator fan

shroud clips, remove the clamp securing the

hose to the radiator, remove the hose and

route to one side.

9. Remove the c lamp sec ur ing the vapour hose to

the surge tank at the radiator end. Remove the

hose and route to one side.

Figure 2B-12

10. Remove the four retainers (2) securing the

radiator upper shroud (1) by carefully lifting the

inner stud with a small screwdriver. Lift the

upper shroud, on the right side first, to allow

release of the locating tab on the left-hand end.

Figure 2B-13

11. Remove the clamps from the upper hose on

the radiator, then remove the hose (1) and set

to one side.

CAUTION: Wear eye protection when working

with spring type hose clamps.

Figure 2B-14

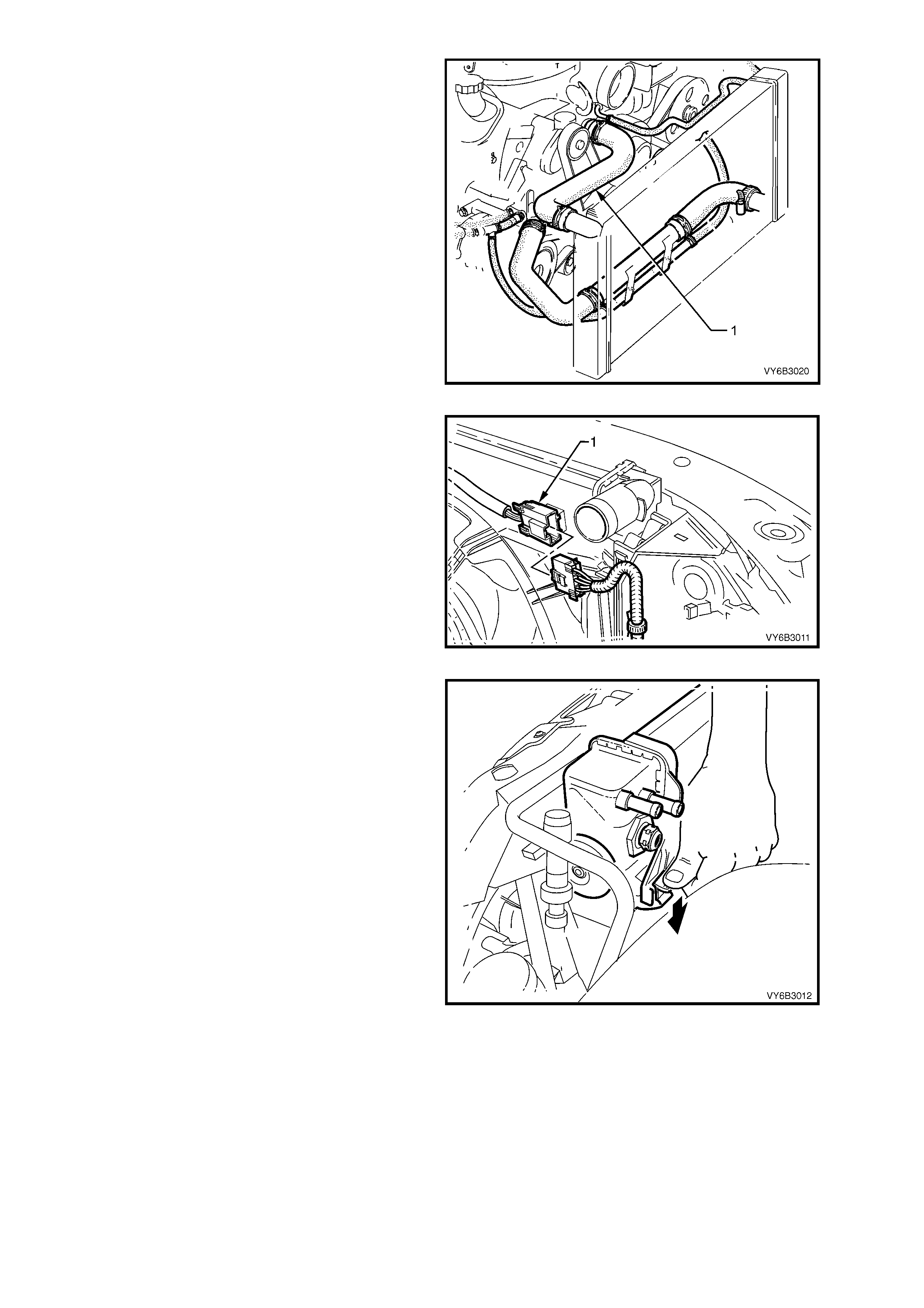

12. Press the retaining tang on the wiring harness-

to-cooling fan motor wiring harness connector

(1), then separate the connector halves.

Figure 2B-15

13. While holding the shroud locking tang in the

release position, lift the shroud and fan

assembly upwards. Repeat for the second side.

NOTE: While the automatic transmission fluid

cooling pipe is shown removed, this is not a

mandatory requirement for shroud removal. Pipe

has been shown rem oved to m ore clearly show the

shroud release method.

Figure 2B-16

14. Lift the shr oud and fan as sem bly clear from the

engine bay, grasping the fan motor mounting

brackets.

IMPORTANT: Do not lift the assembly clear by

lifting on the fan rings as this will bend the fan

motor shaft and create an unnecessary vibration.

Figure 2B-17

15. Release the discharge tube retaining clip (1).

16. Remove the nut (2) retaining the discharge

hose pad fitting (3) to the condenser (4).

17. Cap all open tubes/hoses to avoid moisture

from entering the system.

18. Discard the O-ring (5).

Figure 2B-18

19. Remove the liquid tube union (1) from the

FDR (2) and discard the O-ring (3).

Figure 2B-19

20. Disconnect the harness connector (1) from the

ambient temperature sensor (2). Do not

attempt to remove the bracket (3) from the

condenser (4).

Figure 2B-20

21. Using a screwdriver, compress and lever out

the radiator retaining clips (1) from the radiator

upper mounting brackets.

IMPORTANT: Do not lift the radiator assembly by

lifting on the fan rings as this will bend the fan

motor shaft and create an unnecessary vibration.

22. Lift the radiator assembly upwards out of the

lower insulators. Slant the upper section of the

assembly behind the radiator support sheet

metal work and allow it to remain there.

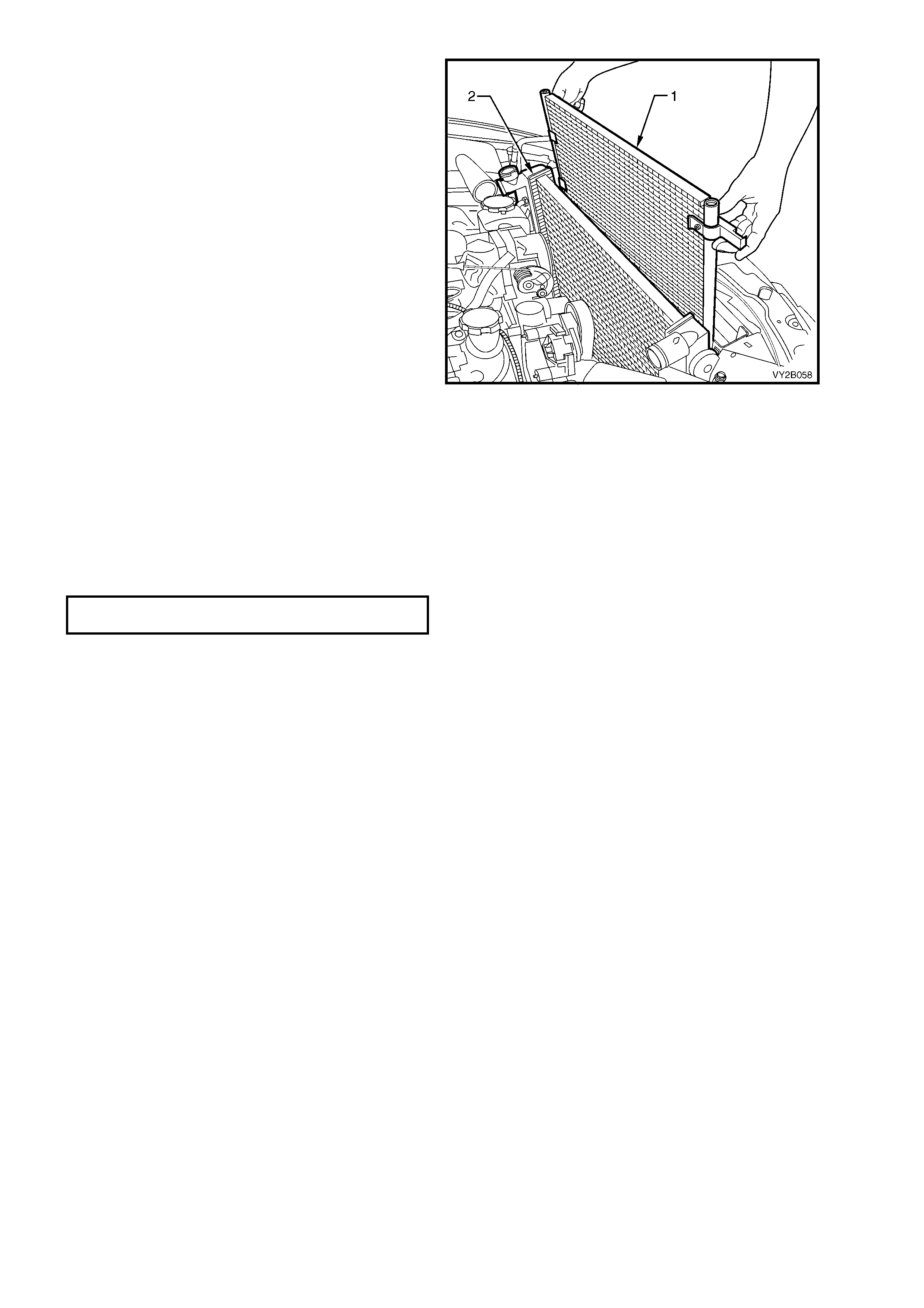

Figure 2B-21

23. Release one of the clips securing the

condenser to the radiator (bold arrow) by

pressing down on the locking retainer while

lifting the condenser assembly. Repeat for the

other side.

Figure 2B-22

24. Lift the condenser assembly (1) upwards

suff ic iently to clear the mounts moulded to f ront

of the radiator (2).

25. Remove the condenser from the engine bay

with the FDR attached.

NOTE: If the FDR is to be removed from the

condenser, mark the mounting position of the FDR

in relation to the mounting bracket for correct

positioning when installing, and note the IN mar king

on the filter head for the correct flow direction. For

FDR installation information, refer to 2.3 FILTER

DRIER RECEIVER in this Section.

Figure 2B-23

REINSTALL

Installation of the condenser is the reverse of removal procedures, noting the following points:

1. Before installing the radiator, inspect the core to ensure that there is no foreign matter in the core fins. Clean out

between the core fins with compressed air, blowing from the rear to the front.

2. If rem oved, install the FDR, ens uring that the union thread with the word IN is connected to the condenser side

of the FDR. Tighten the FDR unions and the FDR mounting bracket screw.

3. Install the liquid tube and the discharge hose, together with new lubricated O-rings into the condenser.

4. Torque the unions to specification.

FDR TUBE UNION

TORQUE SPECIFICATION ......................7.5 - 12.5 Nm

5. Evacuate and charge the A/C system with 775 – 825 g of R134a ref rigerant, refer to 2.1 SYST EM CHARGING

AND EVACUATION in Section 2C HEATING AND AIR CONDITIONING – SERVICING AND DIAGNOSIS in

the VT Series I Service Information.

6. Ensure that the fan and shroud assembly-to-radiator attaching clips are all fully engaged and that the two

locking tangs on the upper clips are securing the shroud correctly.

7. Refill the cooling system and test the concentration levels. Refer to 2.3 DRAINING AND FILLING COOLING

SYSTEM in Section 6B3 – ENGINE COOLING – GEN III V8 ENGINE in the VT Series II Service Information

and TESTING COOLANT CONCENTRATION, 2.2 COOLANT MAINTENANCE in Section 6B3 – ENGINE

COOLING – GEN III V8 ENGINE in the VT Series II Service Information.

8. Check the cooling fan operation and direction of rotation.

2.3 FILTER DRIER RECEIVER

REMOVE

1. Recover the refrigerant from the A/C system,

refer to 2.1 SYSTEM CHARGING AND

EVACUATION in Section 2C HEATING AND

AIR CONDITIONING – SERVICING AND

DIAGNOSIS in the VT Series I Service

Information.

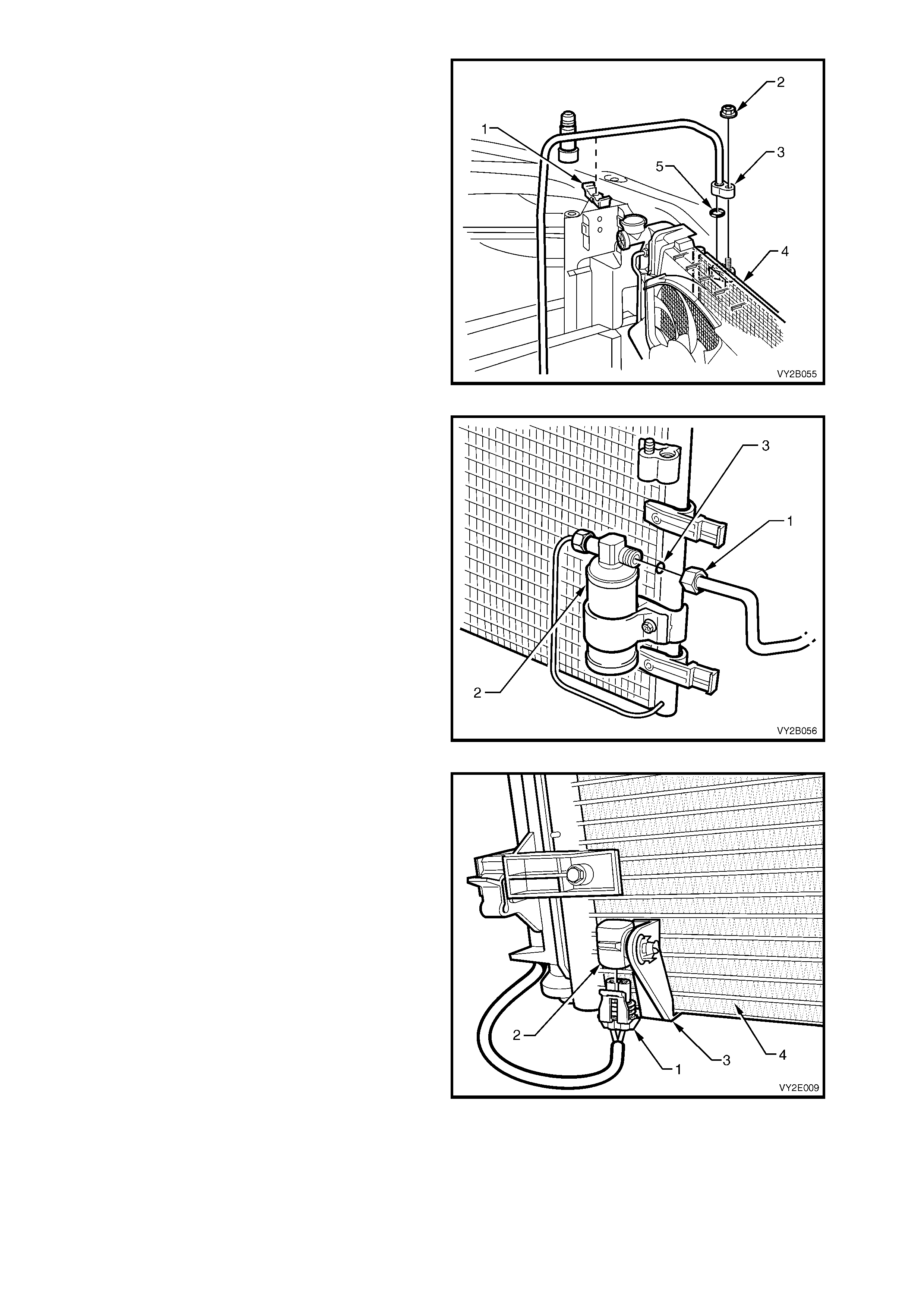

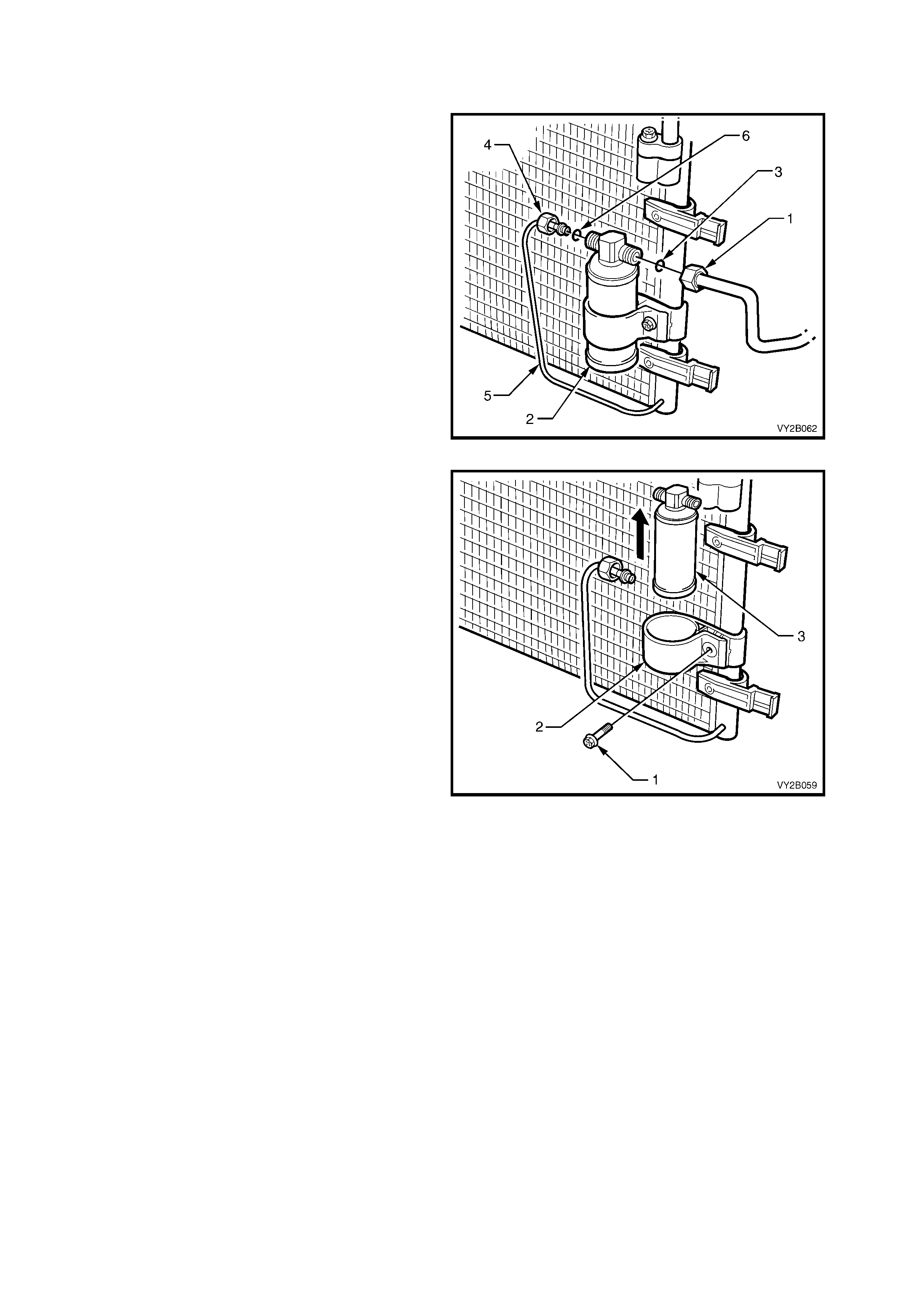

2. Remove the liquid tube union (1) from the

FDR (2) and discard the O-ring (3).

3. Remove the discharge pipe union (4) from the

FDR and caref ully flex the discharge pipe ( 5) to

the left clear of the FDR. Discard the O-ring (6).

Figure 2B-24

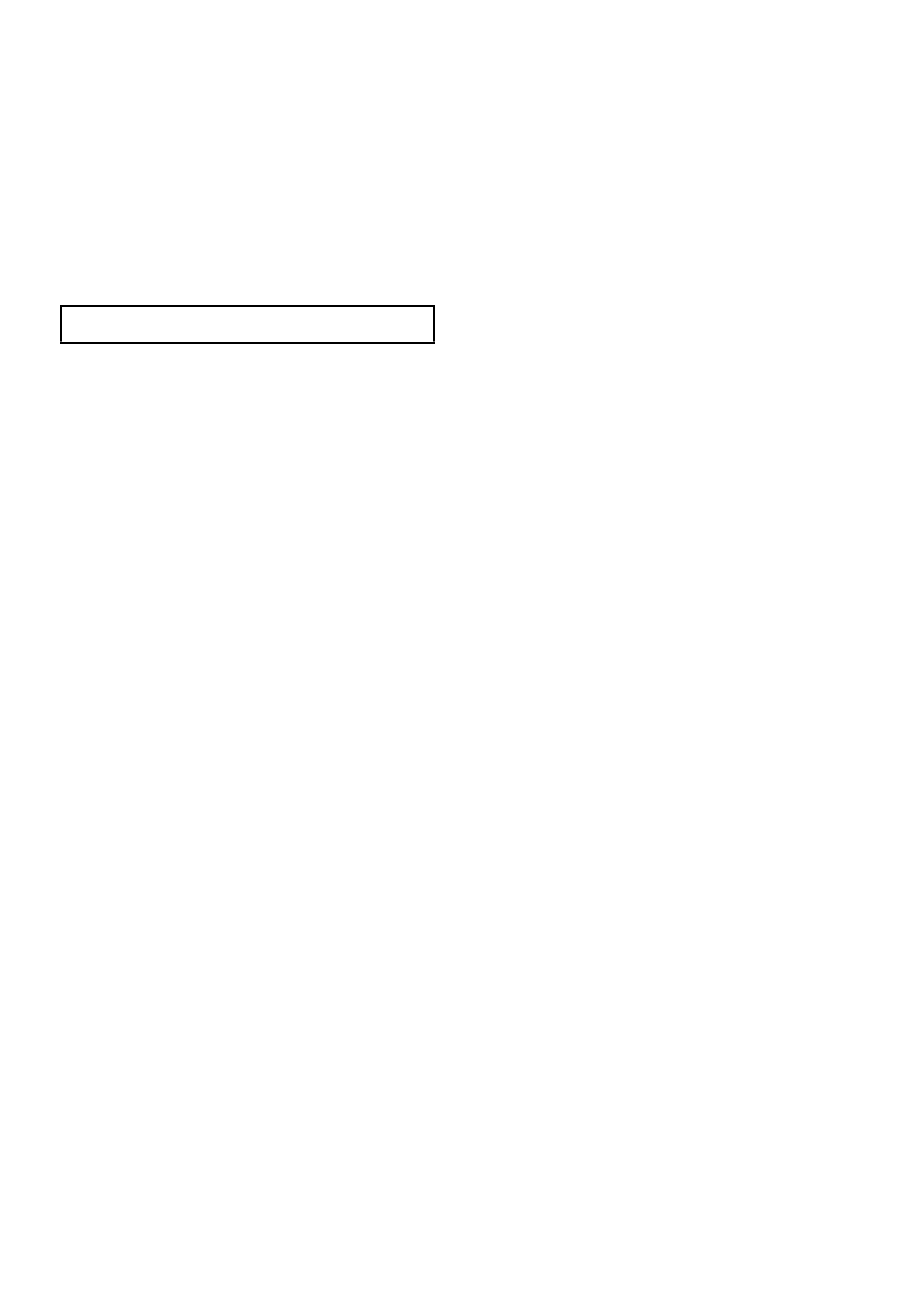

4. Remove the screw (1) on the FDR mounting

bracket (2).

5. Cap all open tubes/hoses to avoid moisture

from entering the system.

6. Expand the bracket and remove the FDR (3) by

lifting it upwards clear of the bracket.

7. Rem ove the F DR (1) through the grille aperture

(2).

Figure 2B-25

REINSTALL

Installation of the filter drier receiver is the reverse

of removal procedures, noting the following points:

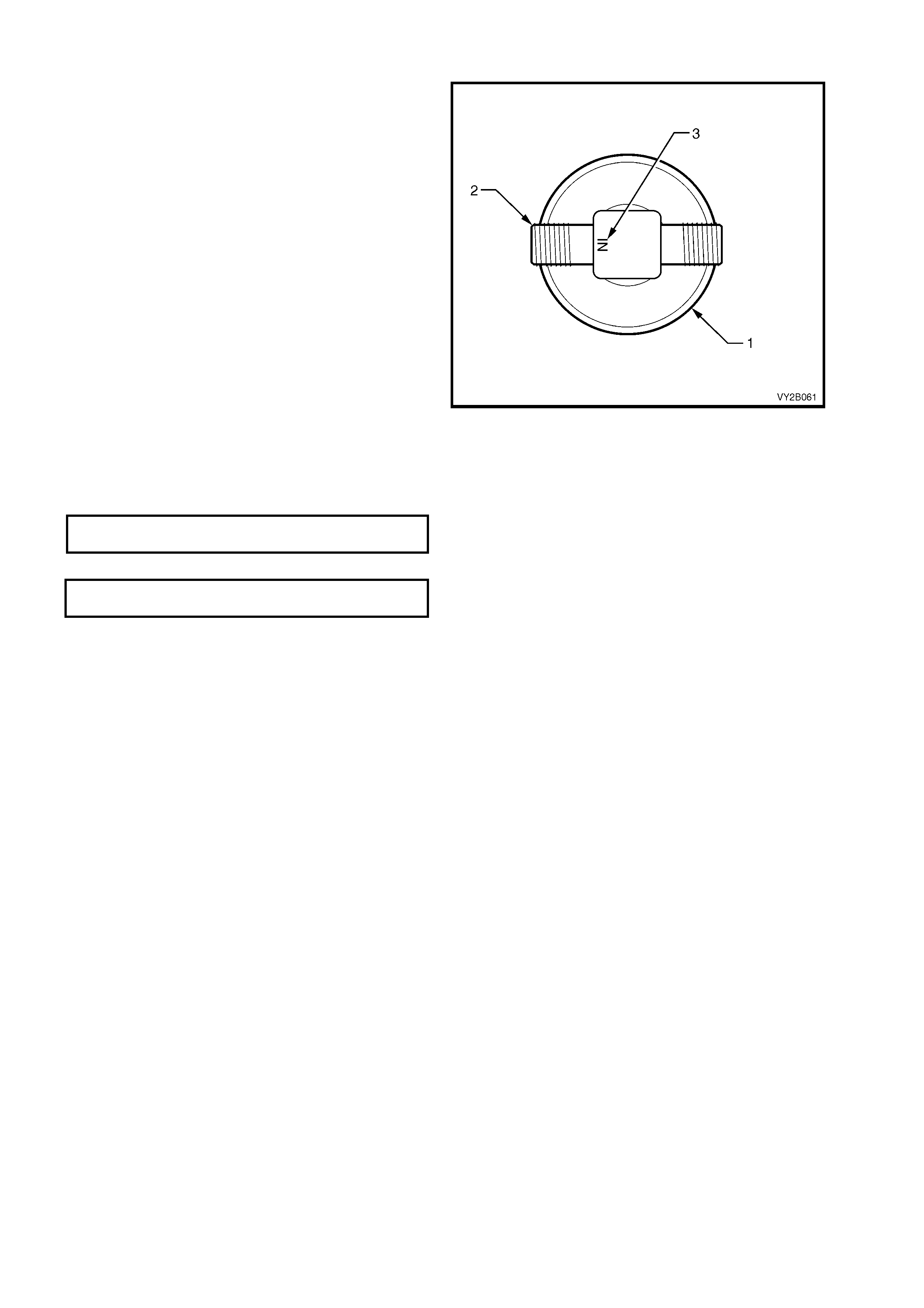

1. Install the FDR (1), ensuring that the condenser

union is connected to the thread (2) adjacent to

the word IN (3) stamped on the head of the

FDR.

Figure 2B-26

2. Install the liquid tube and the discharge hose,

together with new lubricated O-rings, into the

condenser. Torque the mounting screw and

unions to specification.

FDR MOUNTING BRACKET SCREW

TORQUE SPECIFICATION ...................7.5 – 12.5 Nm

FDR TUBE UNION

TORQUE SPECIFICATION ...................7.5 – 12.5 Nm

3. Evacuate and charge the A/C system with

775 – 825 g of R134a refrigerant, refer to

2.1 SYSTEM CHARGING AND EVACUATION

in Section 2C HEATING AND AIR

CONDITIONING – SERVICING AND

DIAGNOSIS in the VT Series I Service

Information.

3. TORQUE WRENCH SPECIFICATIONS

Nm

FDR Tube Union.............................................................................7.5 – 12.5

FDR Mounting Bracket Screw......................................................... 7.5 – 12.5