SECTION 8A2 - LPG SYSTEM

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL INFORMA TION

1.1 VX SERIES II MODELS

Liquef ied P etrol eum Gas (LPG ) Pro duc ti on O ption KL7 as f itte d t o VX S eries II Mo dels c arr ies o ver f rom VX S eries

I Models noting the following:

• The remote filler assembly has been revised in sedan models.

• The filler line f rom the rem ote fil ler as sem bl y to the LPG c ylinder has been re-r outed in s edan m odels and no w

enters the load compartment through the same point as the rear service line.

• The convoluted tube in the load compartment that contained the filler line has been deleted in sedan models.

• The convoluted tube from the elbow at the LPG cylinder to the load compartment floor that previously

contained the rear service line also contains the filler line for Sedan Models.

• The elbow for the convoluted tubes connection to the LPG cylinder in VX Series I Sedan Models, has been

removed from VX Series II Sedan Models. B oth filler line and rear service line (LPG cylinder to floor) are now

contained in one convoluted tube.

For information relating to the LPG system as fitted to VX Series II Models not covered in this section, refer to

Section 8A2 LPG SYSTEM in the VX Series I Service Information, in conjunction with SEDAN LPG SYSTEM or

WAGON AND SEDAN ACCESSORY LPG SYSTEM in the VT Series I and VT Series II Service Information.

1.2 VU SERIES II MODELS

Liquef ied Petro le um Gas ( LPG) Prod uc tio n O pti on KL7 as f itted to VU S eries II Mo dels car ries o ver f r om VU Series

I Models For information relating to the LPG system as fitted to VU Series II Models not covered in this section,

refer to Section 8A2 LPG SYSTEM in the VU Series I Service Information, in conjunction with Section 8A2 LPG

SYSTEM in the VX Series I Service Information, in conjunction with SEDAN LPG SYSTEM or WAGON AND

SEDAN ACCESSORY LPG SYSTEM in the VT Series I and VT Series II Service Information.

NOTE: Liquified Petroleum Gas (LPG) is not available for WH Series Models.

2. SERVICE OPERATIONS

2.1 REMOTE FILLER VALVE AND CONNECTOR PIPE - SEDAN

REMOVE

CAUTION: Ensure that there are no naked flames or

other sources of ignition in the vicinity.

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. From inside the rear load compartment, remove

the cylinder valve box cover.

3. Ensure the manual service valve is turned 'OFF'

and the battery earth lead is disconnected.

4. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in Section

2 LPG SYSTEM, VT SEDAN WITH

PRODUCTION LPG in the VT Series II Service

Information.

WARNING: The vehicle CANNOT be run on LPG in

the workshop unless the w orkshop is a “Specia list

Gas Workshop” (in accordance with the current

Australian Standards AS2746 – 1985) and LPG is

specifically required for testing.

Theref ore, the vehic le ma y only enter t he work shop at

the completion of the service line draining procedure,

with the manual service valve closed, all LPG in the

service lines exhausted and the vehicle running on

petrol. Then, and only then, can the vehicle enter the

workshop.

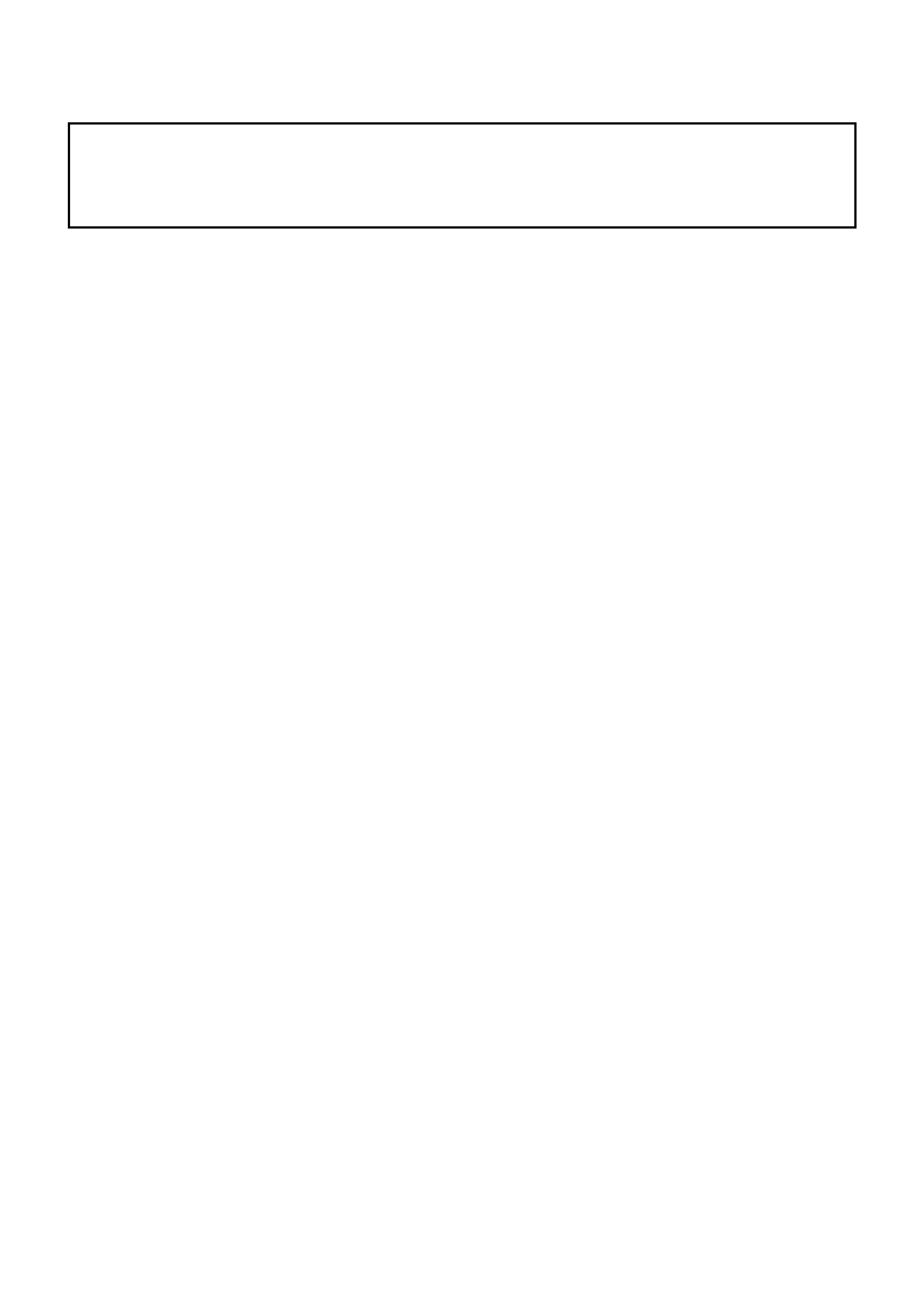

Figure 8A2-1

5. From inside the LPG valve box, (while holding AFL

elbow) crack open filler line to AFL elbow

connector (1) and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure. Once all the LPG in the line has

dispersed, unscrew filler line connector

completely from AFL elbow.

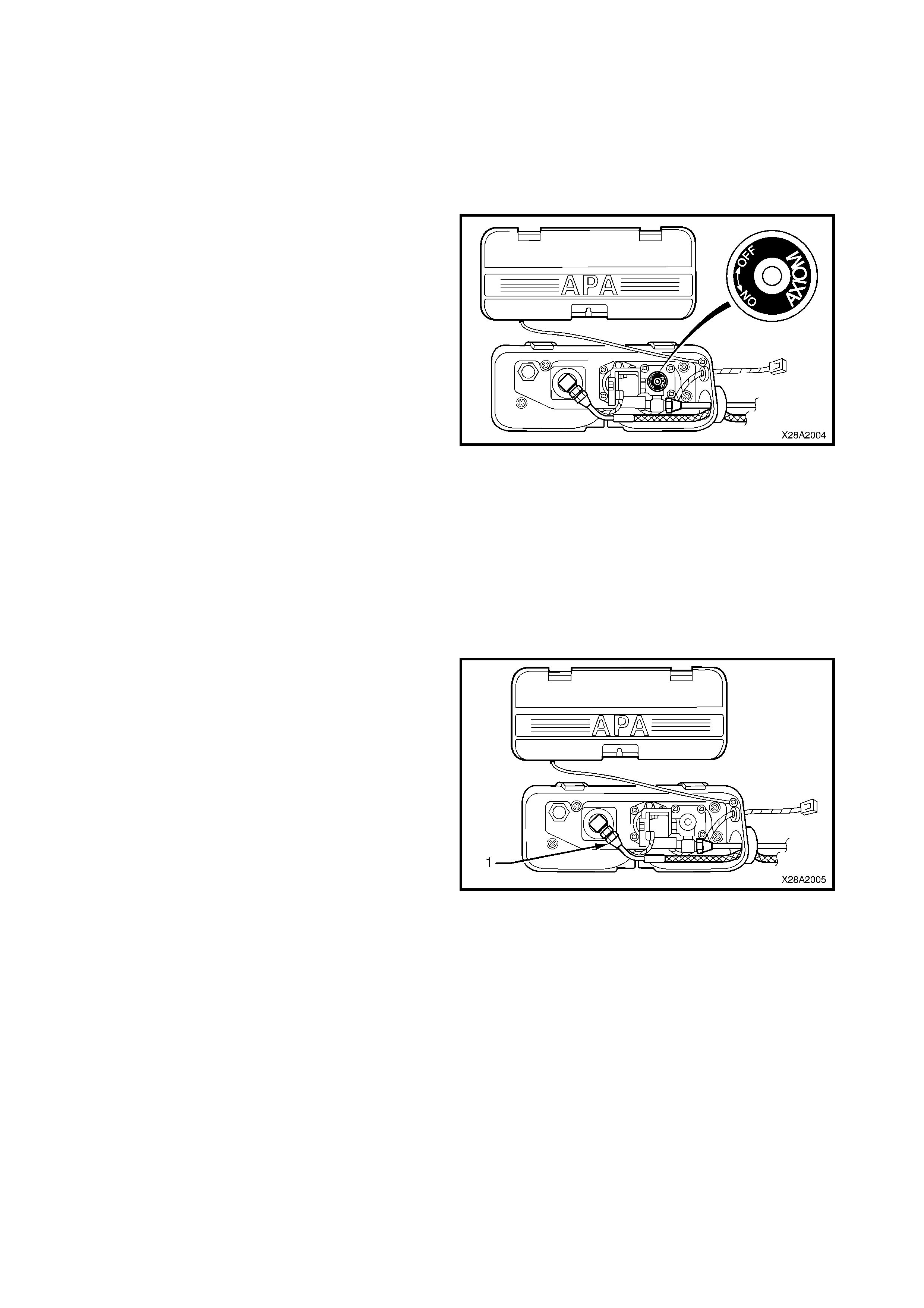

Figure 8A2-2

6. Remove the six screws (2) retaining the RH rear

wheelhouse liner (1) and remove liner from

wheelhouse.

Figure 8A2-3

7. From inside the rear wheel house, disconnect the

rear filler line hose (1) from the filler valve

connector pipe (2).

8. Disconnect the connector pipe from the remote

filler v al ve (3) a nd car ef ul l y moneuvre the pi pe an d

two grommets (4) into fuel filler recess.

9. From inside the rear wheelhouse, remove the nut

(5) and spacer (6) retaining the remote filler to th e

fuel filler recess.

10. Remove the remote filler valve

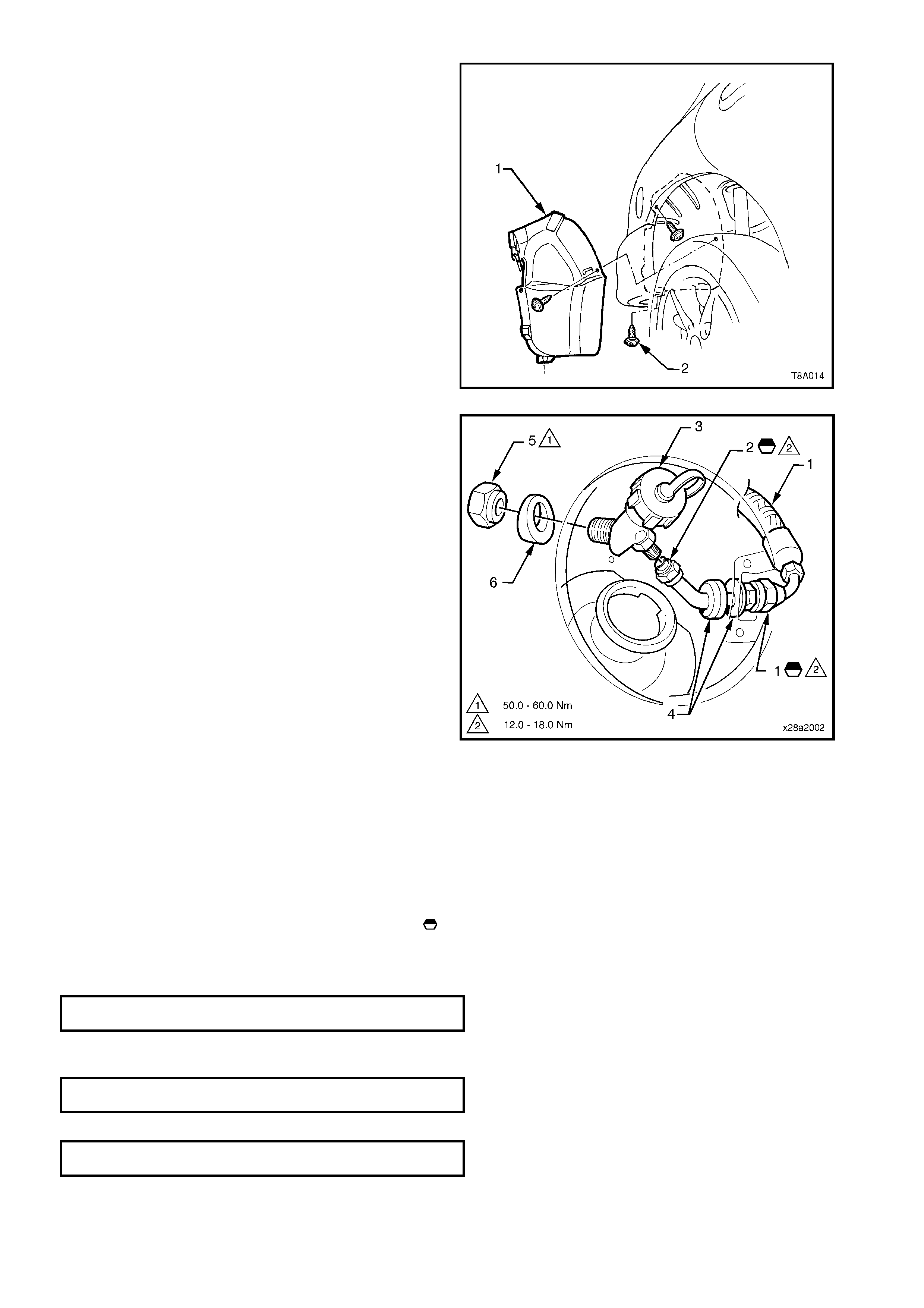

Figure 8A2-4

REINST ALL

Reinstallation if the remote filler valve and connector

pipe is the reverse of the removal procedur e, noting the

following:

1. Clean the mating threads on filler line, connector

pipe and remote filler valve.

2. Apply Loctite 577 sealant to filler line, connector

pipe and remote filler valve threads marked in

Figs. 8A2-4 and 8A2-7.

3. Tighten remote filler valve retaining nut to the

specified torque specification.

FILLER VALVE RETAINING NUT

TORQUE SPECIFICATION 50 - 60Nm

4. Tighten filler line connectors to the specified torque

specification.

CONNECTOR PIPE TO FILLER VALVE

TORQUE SPECIFICATION 12 - 18Nm

CONNECTOR PIP E TO FILLER L INE

TORQUE SPECIFICATION 12 - 18Nm

2.2 FILLER LINE - SEDAN

REMOVE

CAUTION: Ensure that there are no naked flames or

other sources of ignition in the vicinity.

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. With the rear decklid cover open, remove the

cylinder valve box cover.

3. Ensure the manual service valve is turned 'OFF'

and the battery earth lead is disconnected.

4. Drain the service lines of LPG, refer

2.1 DRAINING THE SERVICE LINES in Section

2 LPG SYSTEM, VT SEDAN WITH

PRODUCTION LPG in the VT Series II Service

Information.

WARNING: The vehicle CANNOTbe run on LPG in

the workshop unless the w orkshop is a “Specia list

Gas Workshop” (in accordance with the current

Australian Standards AS2746 – 1985) and LPG is

specifically required for testing.

Theref ore, the vehic le ma y only enter t he work shop at

the completion of the service line draining procedure,

with the manual service valve closed, all LPG in the

service lines exhausted and the vehicle running on

petrol. Then, and only then, can the vehicle enter the

workshop.

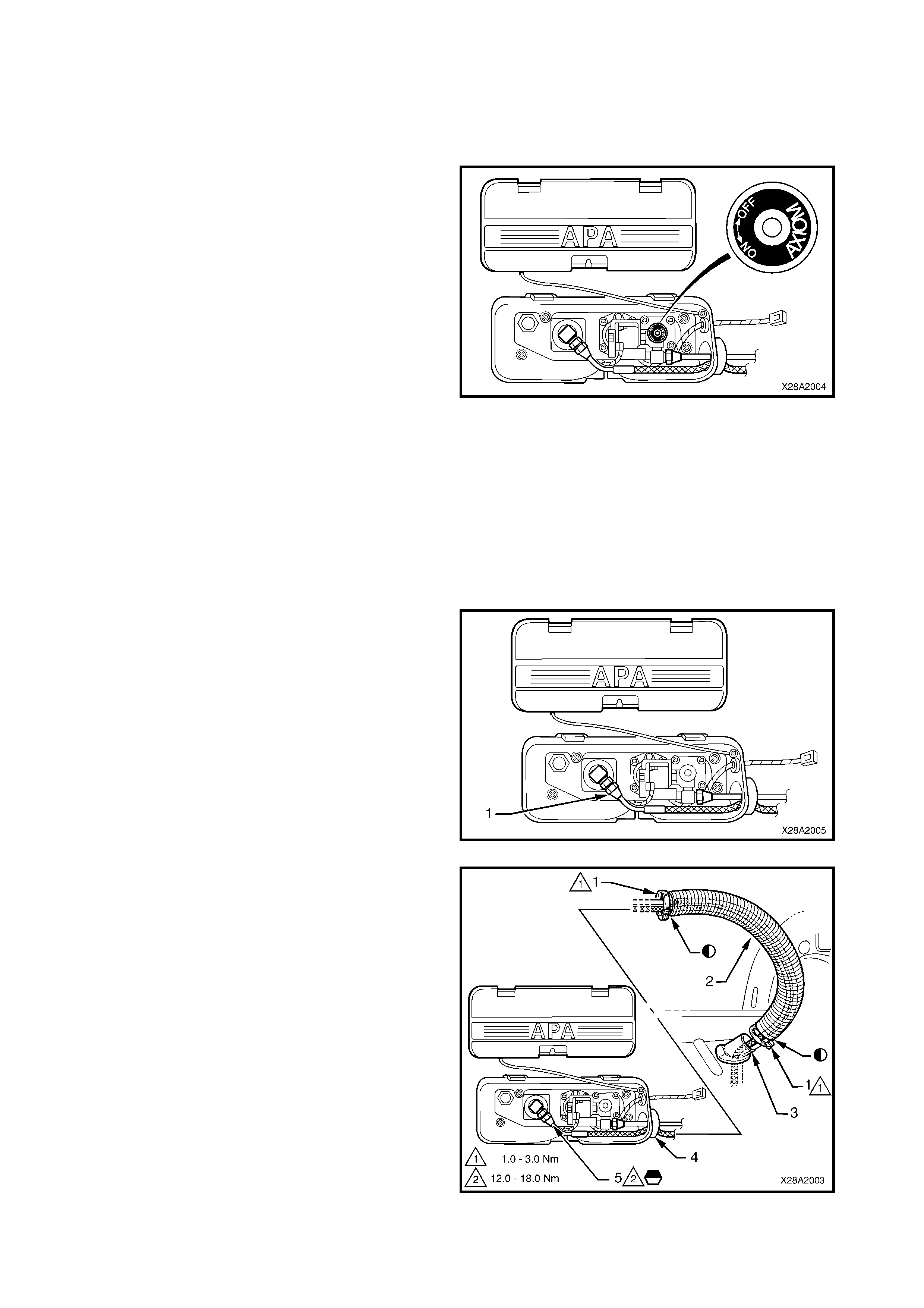

Figure 8A2-5

5. Remove th e cylinder valve box cov er. From inside

the LPG valve box, (while holding AFL elbow)

crack open filler line to AFL elbow connector (1)

and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure. Once all the LPG in the line has

dispersed, unscrew filler line connector

completely from AFL elbow.

6. Using a suita ble sp ann er to pr eve nt th e AFL el bo w

rotating, disconnect the filler line (1) from the AFL

valve.

Figure 8A2-6

7. Remove the two hose clamps (1) securing the

convoluted tube (2) to the fitting on the load

compartment floor (3) and the LPG valve box (4).

8. Remove the rear fender liner, refer Fig 8A2-3 in

this Section.

9. Disconnect filler line from remote filler connector

pipe and remove the LPG filler line from within

convoluted tube, refer to Fig 8A2-4 in this Section.

10. From inside the rear load compartment, withdraw

the filler line (5) through convoluted tube and

remove.

Figure 8A2-7

REINST ALL

Reinstallation of the filler line is the reverse of the

removal procedure, noting the following:

1. Clean mating threads on LPG cylinder AFL elbow,

filler line and filler valve connector pipe.

2. Apply Loctite 577 sealant to LPG cylinder AFL

elbow and remote filler pipe connector threads

marked in Figs. 8A2-4 and 8A2-7, ensuring that

flared surfaces are free of sealant and

contaminants.

3. Apply silicone sealer to Holden Specification

HN1886 to mating surfaces on convoluted tubing

marked . in Fig.8A2-7.

4. Tighten filler line connectors to the specified torque

specification.

FILLER LINE CONNE CT O RS

TORQUE SPECIFICATION 12 - 18Nm

5. Leak test LPG s ystem , refer 2.3 LEAK TESTING in

Section 2 LPG SYSTEM, VT SEDAN WITH

PRODUCTION LPG in the VT Series II Service

Information.

6. Apply silicon sealer to convoluted tube mating

surfaces,. Tighten convoluted tube hose clamps to

specified torque.

CONVOLUTED TUBE HOSE CLAMPS

TORQUE SPECI FI CAT ION 1 - 3Nm

3. TORQUE WRENCH SPECIFIC ATIONS

LPG service line connectors................................................. 12-18 Nm

LPG service line retaining clamp bolt ................................... 12-15 Nm

LPG filler line connectors...................................................... 12-18 Nm

Convoluted tube hose clamps .............................................. 2-3 Nm