SECTION 2B - ELECTRONIC CLIMATE CONTROL -

REMOVAL AND INSTALLATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

This Section details the Service Operations necessary for maintenance of the ECC system. Care should be taken to

ensure that whenever any component is disconnected that plugs are immediately inserted into any open

connections. Failure to follow these precautions could render the components unserviceable.

Whenever any diagnosis or repairs to the electrical connectors and wiring is required, reference to the ECC wiring

diagrams, connecter terminal assignments or diagnosis procedures should be made. Refer to the appropriate

Sections in this Service Information Supplement.

Techline

Techline

Techline

Techline

Techline

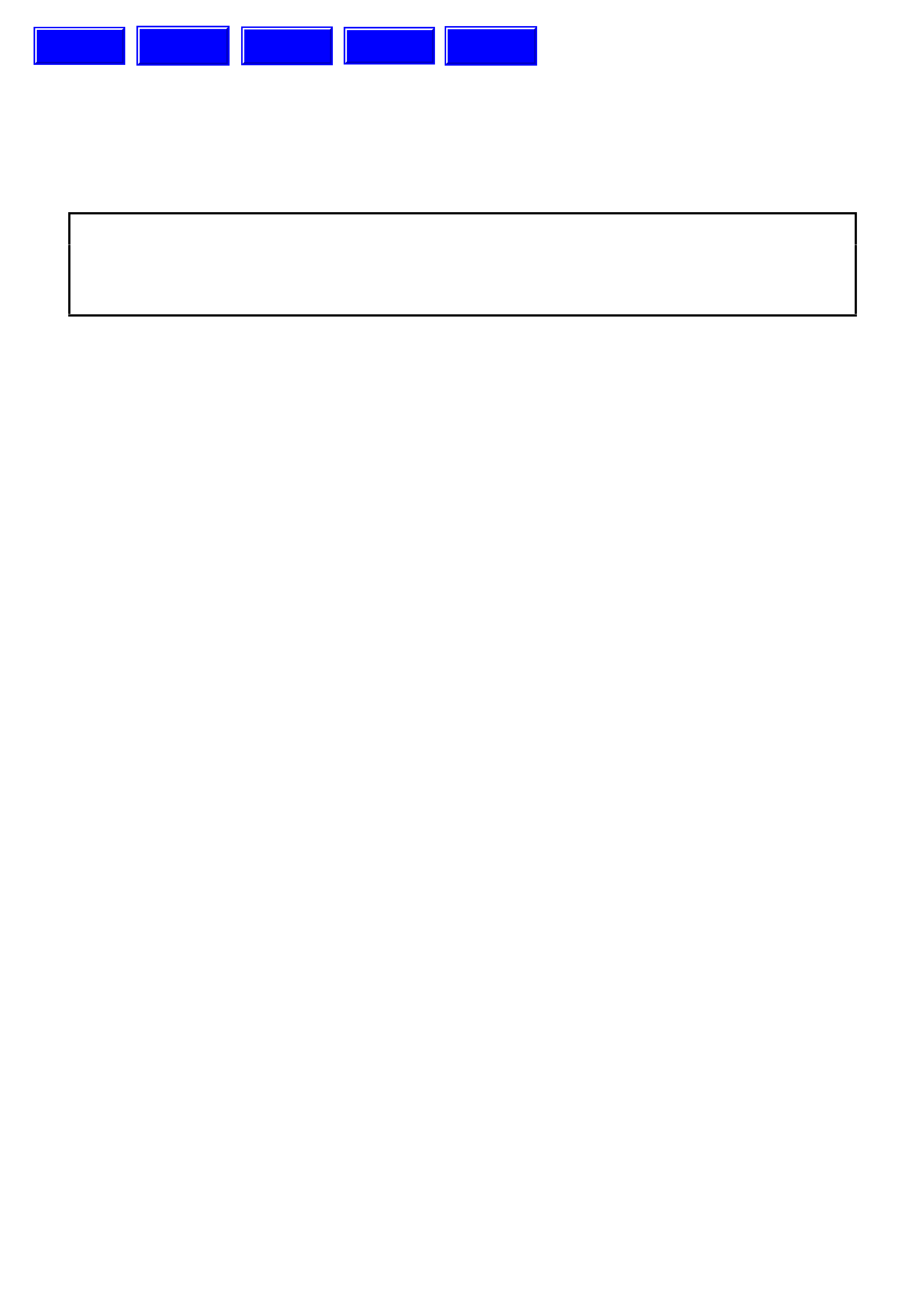

HOSE LAYOUT V6

Figure 2B-1

Legend

1. Thermal expansion valve (or block valve)

2. O-Ring 6.07 X 1.78 mm

3. O-Ring 15.54 X 2.62 mm

4. Liquid tube

5. Retaining screw

6. Suction tube/hose

7. Compressor

8. Bonded sealing washers

9. Retaining nut

10. Discharge hose

11. Liquid tube retaining clip

12. Discharge tube retaining clip

13. Discharge tube

14. Discharge tube retaining nut

15. O-Ring 9.19 X 2.62 mm

16. Condenser

17. Filter Dryer Receiver (FDR)

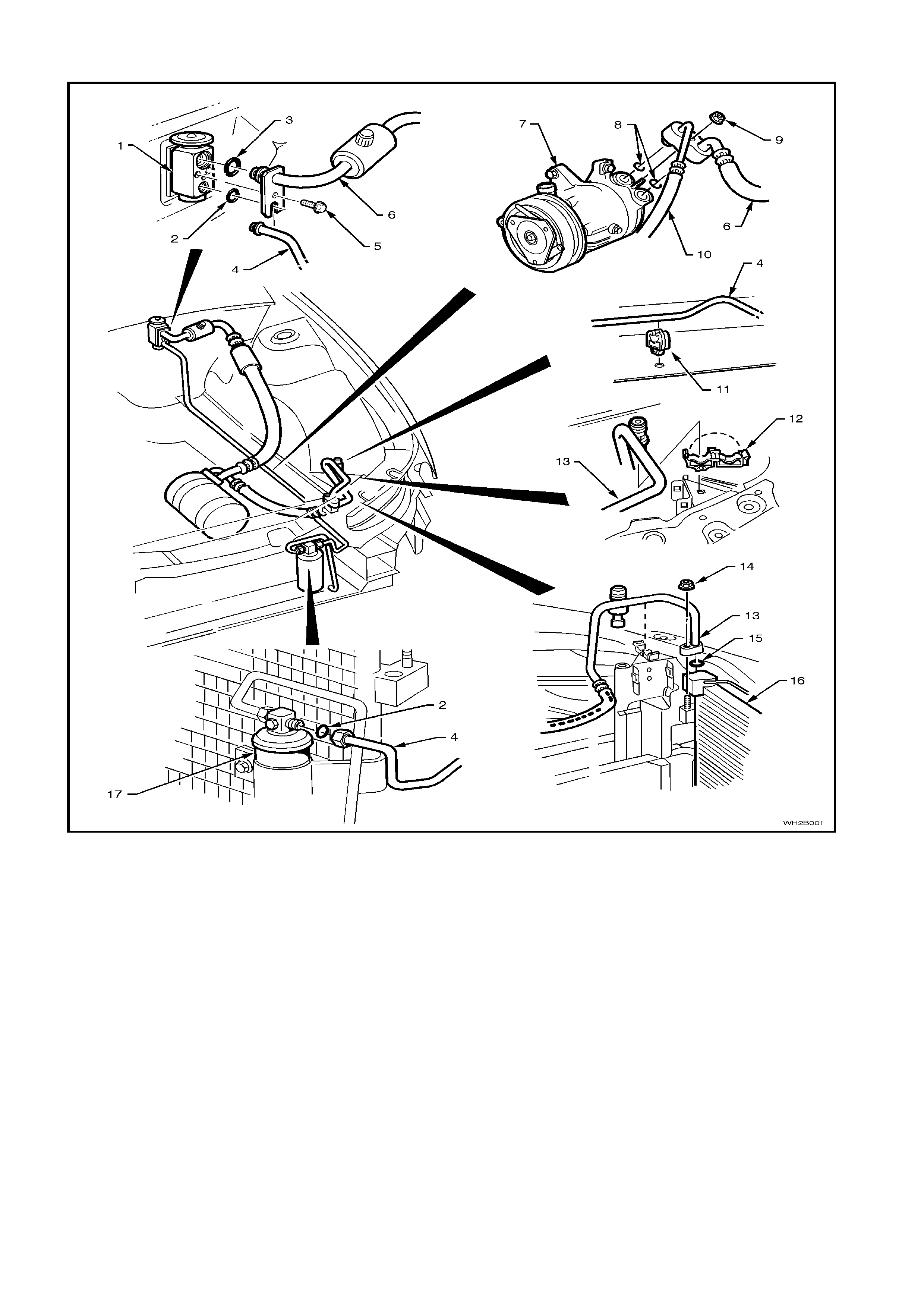

HOSE LAYOUT GEN III V8

Figure 2B-2

Legend

1. Thermal expansion valve (or block valve)

2. O-Ring

3. Suction hose

4. Liquid tube

5. Retaining screw

6. Suction tube retaining clip

7. Discharge tube

8. Discharge tube retaining clip

9. Discharge tube retaining nut

10. Condenser

11. Filter Dryer Receiver (FDR)

12. Retaining clamp

13. Discharge tube/hose

14. Retaining nut

15. Compressor

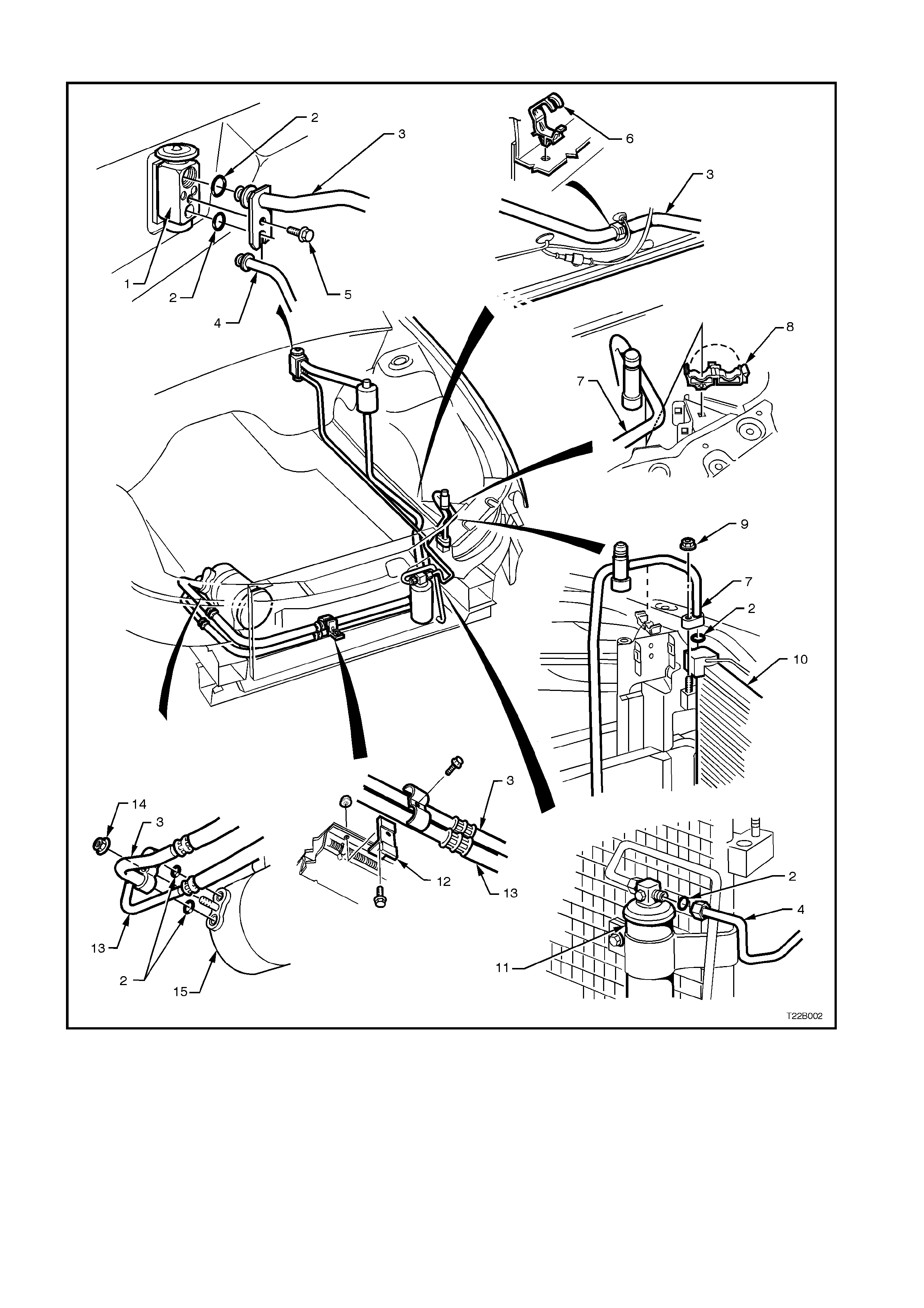

ECC ELECTRICAL CONNECTORS

Figure 2B-3

2. SERVICE OPERATIONS

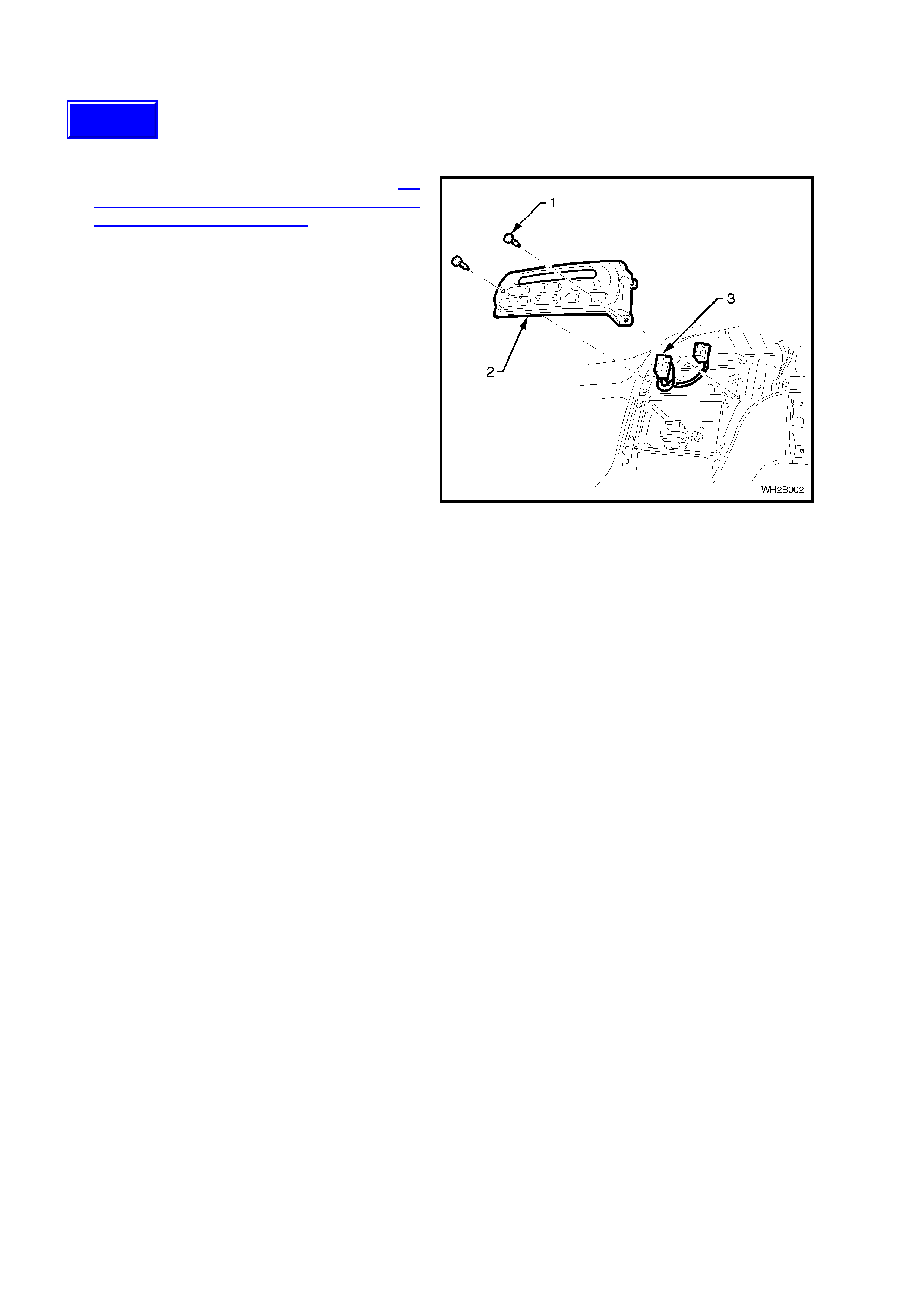

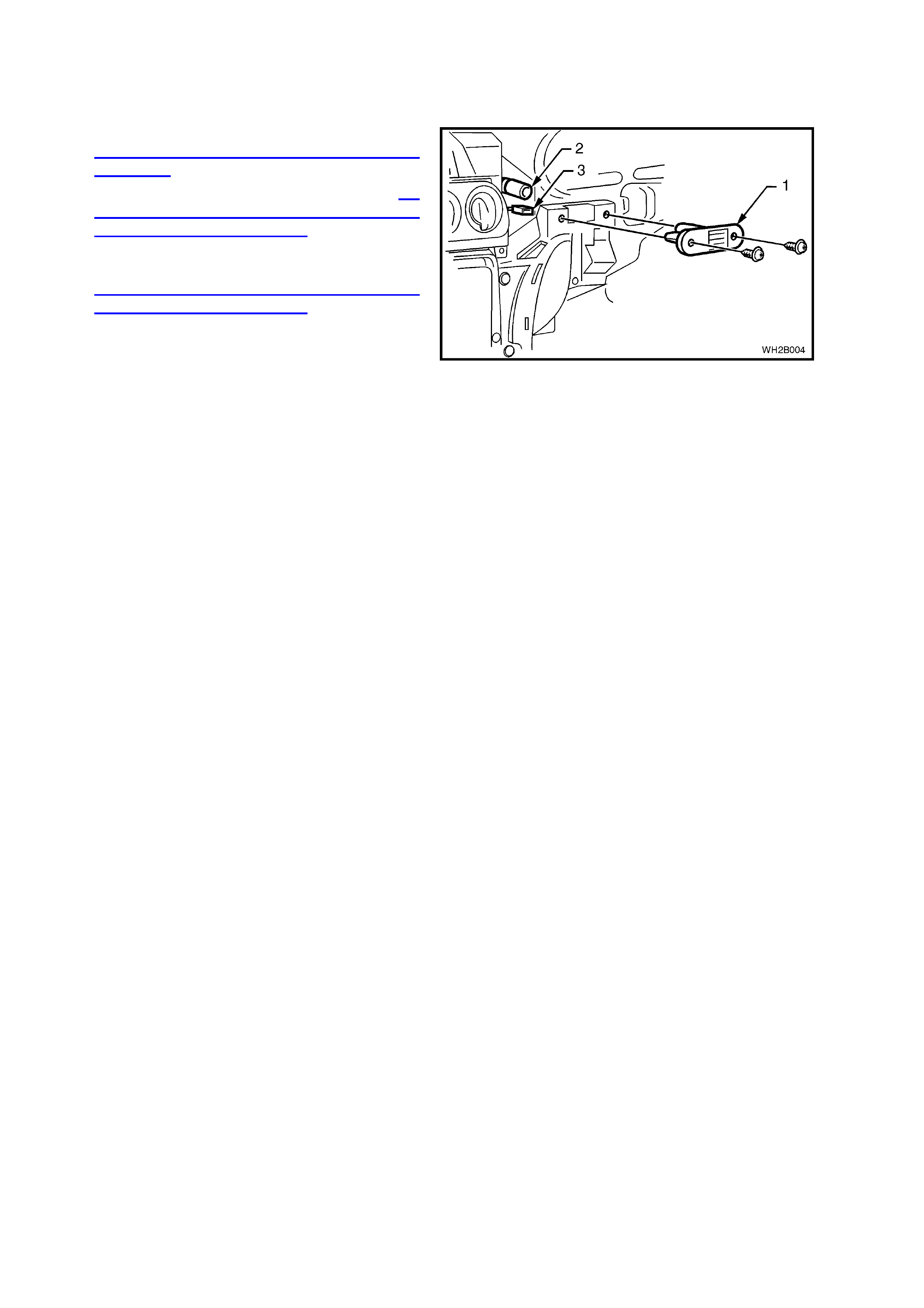

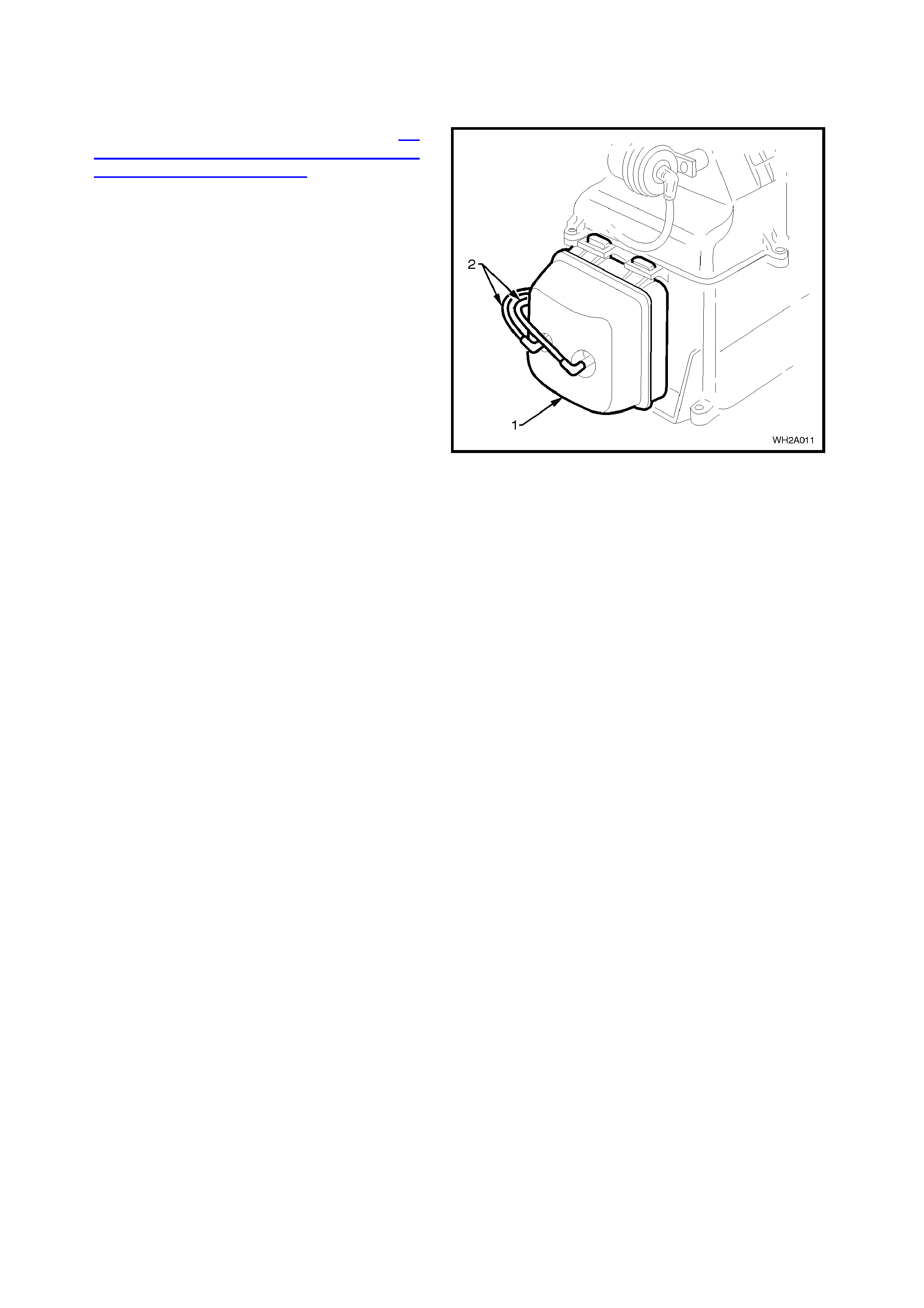

2.1 ECC MODULE

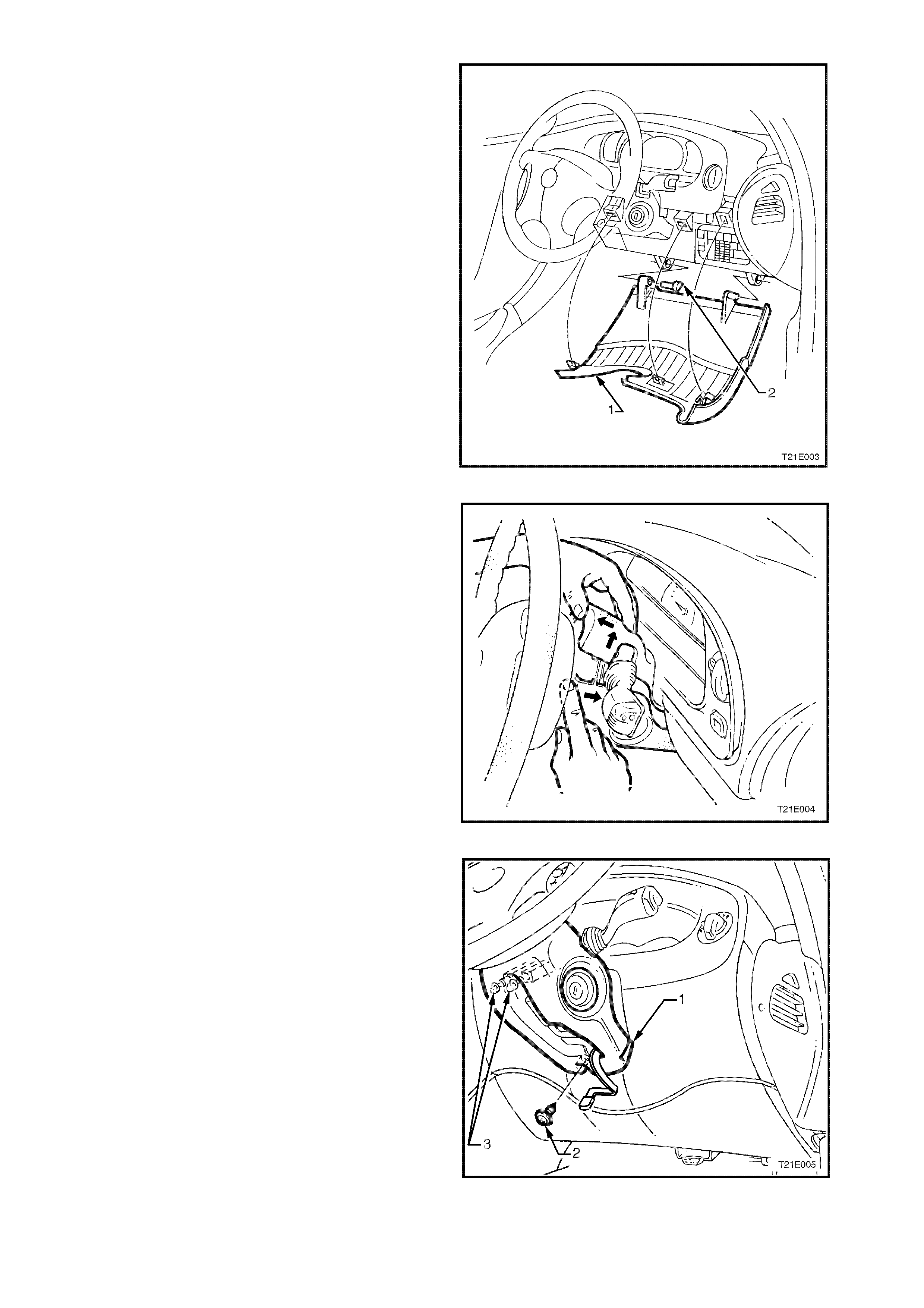

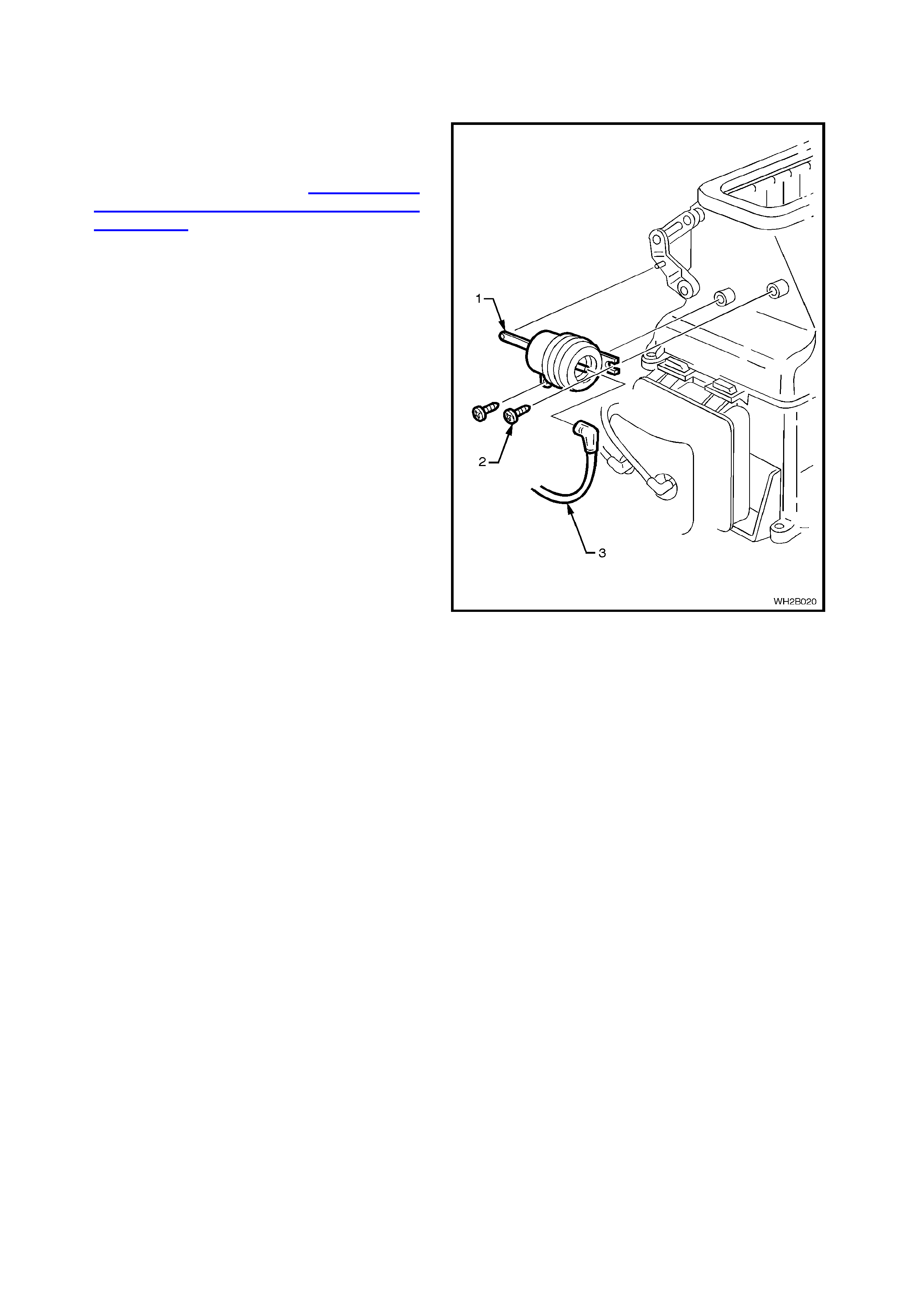

REMOVE

1. Detach the instrument facia panel, refer to 2.7

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

2. Locate and rem ove the two s elf-t apping sc rews

(1) used to retain the ECC Module (2) to the

instrument panel carrier.

3. Disconnect the two ECC Module electrical

connectors (3).

REINSTALL

Reinstallation is the reverse order of removal.

NOTE: If installing a new ECC module, ensure the

most current software version is loaded in module.

Figure 2B-4

Techline

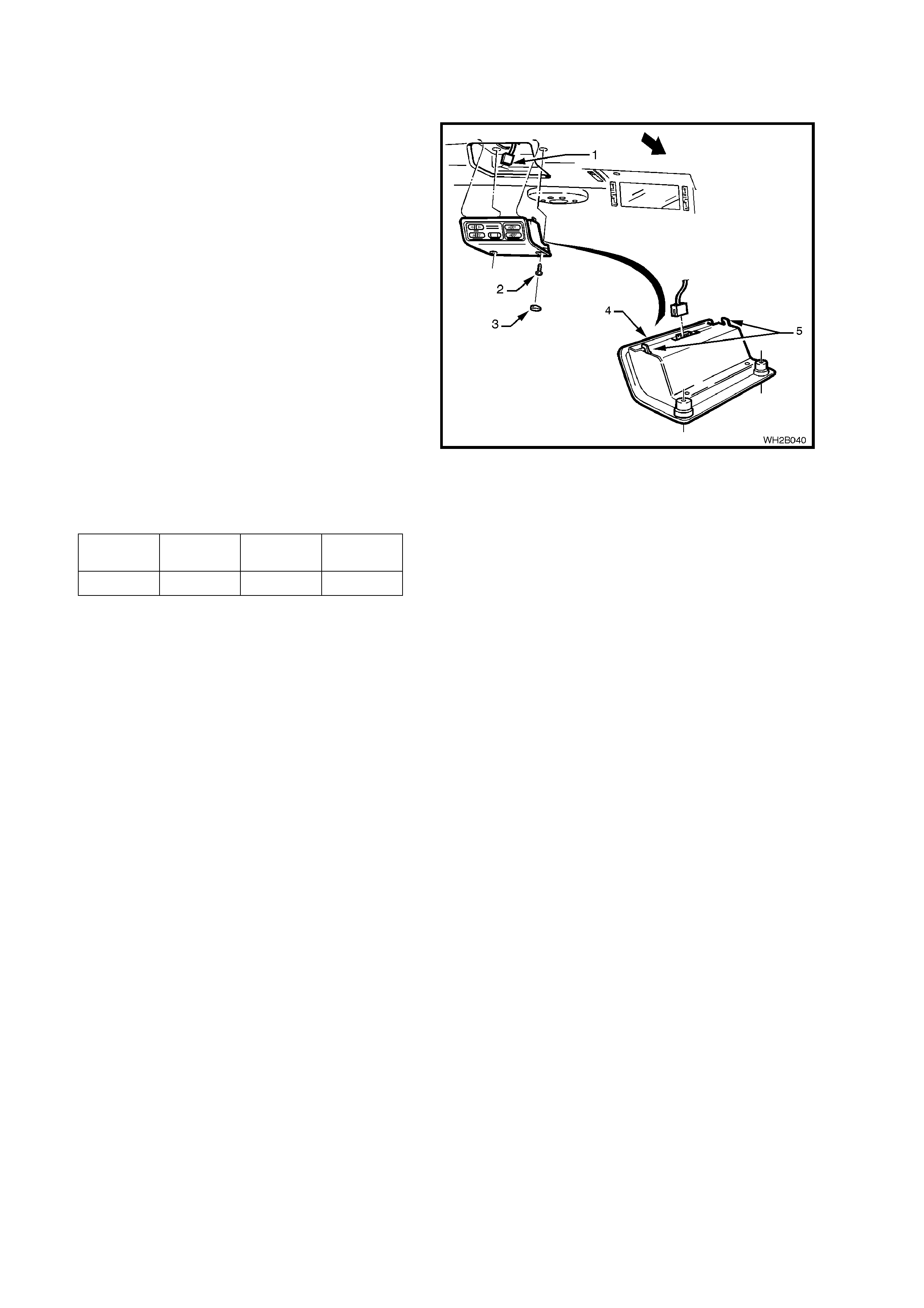

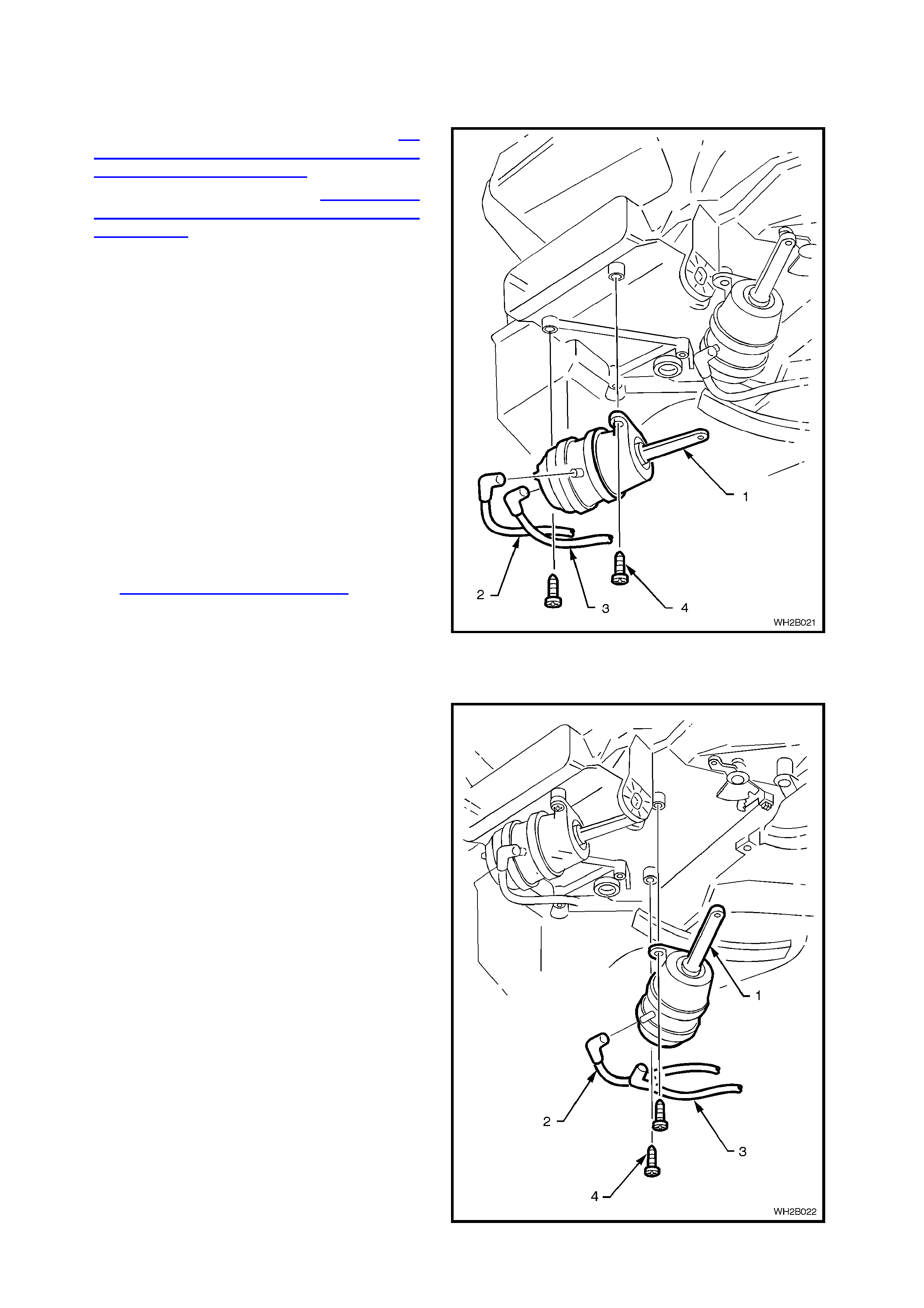

2.2 REAR REMOTE CONTOL

REMOVE

1. Remove the plugs (3) concealing the remote

control retaining screws (2) and remove the

retaining screws.

2. Lower the front of the remote control assembly

(4) disengaging the support lugs (5).

3. Disconnect the body wiring harness electrical

connector (1) and remove the remote control

assembly.

REINSTALL

Reinstallation is the reverse of removal operations.

TEST

The rear remote control is a non-serviceable unit

and as such can only be tested for switch

resistance values which are listed in the following

table.

1. Connect an ohmmeter to the two terminals on

the side of the connector corresponding to the

climate controls. Press each button and check

for the following readings.

Figure 2B-5

TEMP

DOWN TEMP UP FAN

DOWN FAN UP

47Ω120Ω330Ω560Ω

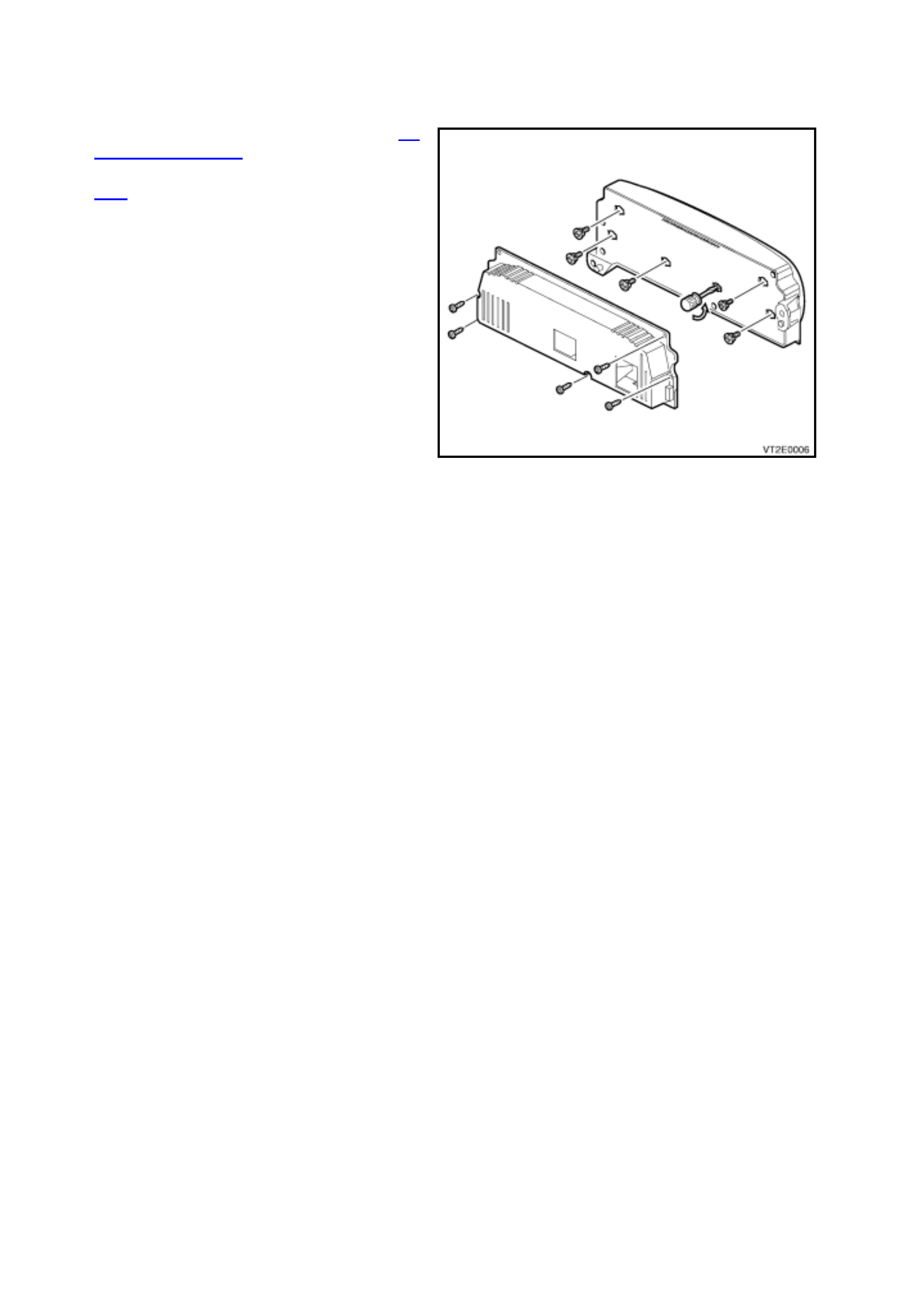

2.3 CONTROL ILLUMINATION

REMOVE

1. Remove the ECC Module refer to 2.1

CONTROL MODULE in this Section.

2. Disconnect the two electrical connectors, Fig.

2B-4.

3. Unscrew the five self tapping screws retaining

the rear housing of the ECC Module.

4. Insert a flat blade screwdriver in the plastic

globe holder slot (as shown) then twist anti-

clockwise until the holder stops. Gently ease

globe holder out of the front housing.

REINSTALL

Reinstallation is the reverse order of removal.

Figure 2B-6

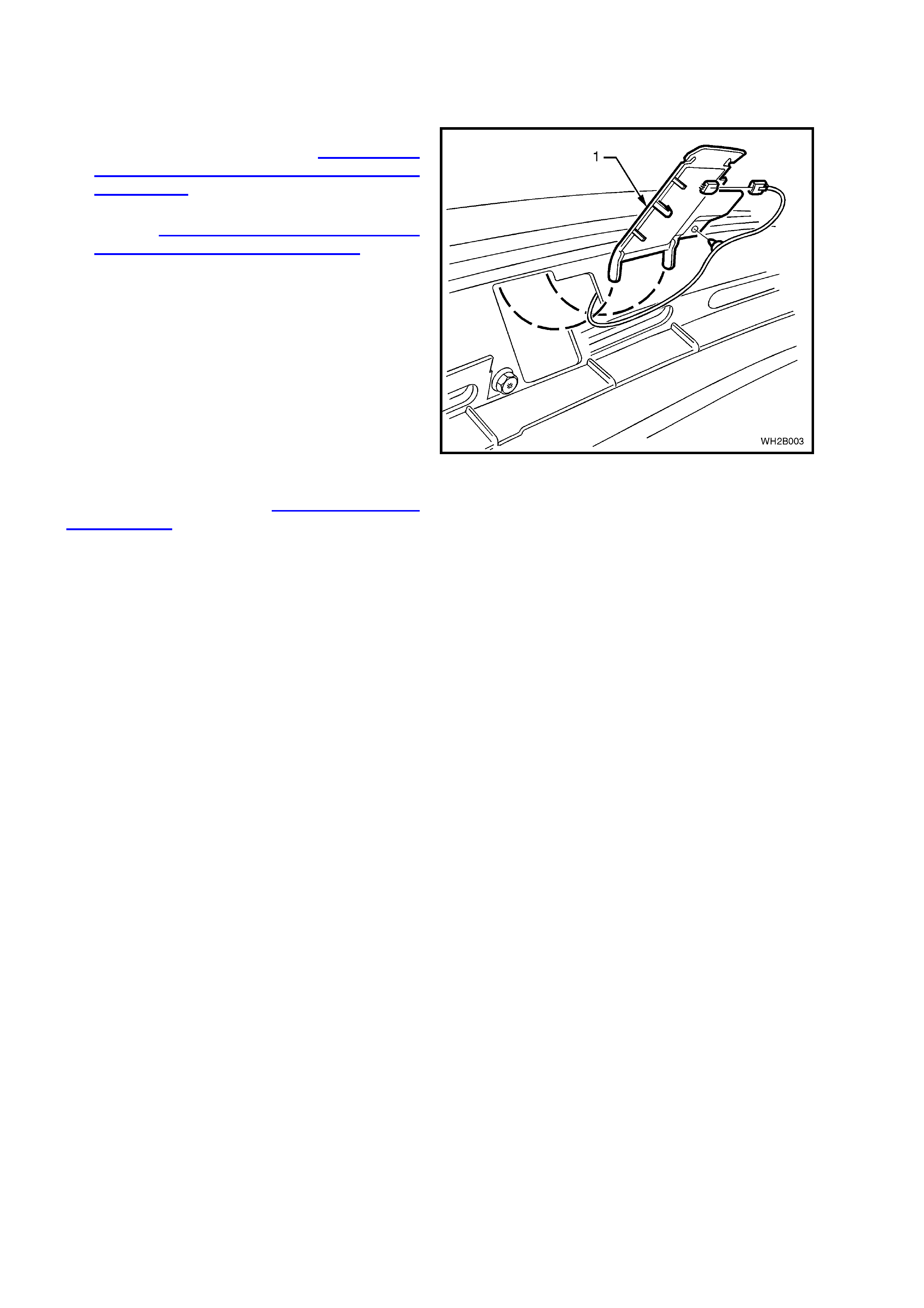

2.4 SUN SENSOR/REMOTE RECEIVER MODULE

REMOVE

1. Remove the right and lef t hand side instrum ent

panel end cap covers, refer to 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT in this Section.

2. Remove the right and left hand demist panels,

refer to 2.8 HEATING, VENTILATION AND

AIR CONDITIONING (HVAC) UNIT in this

Section.

3. Unclip the Sun Sensor/Remote Receiver

Module (1) from the dash panel by lifting from

the bottom then pulling downward to disengage

the locking legs. Disconnect the electrical

connector and unclip wiring.

REINSTALL

Reinstallation is the reverse order of removal.

NOTE: Sun Sensor/Remote Receiver Module

diagnostics can be found in Section 12J-2 HIGH

SERIES BCM, of the VT Series II Service

Information.

Figure 2B-7

2.5 IN-CAR TEMPERATURE SENSOR

REMOVE

1. Remove the transmission console, refer to

Section 1A3 INSTRUMENT PANEL AND

CONSOLE of the WH Service Information.

2. Remove the radio from the dash, refer to 2.8

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

3. Remove the instrum ent panel lower cover right

side and the instrument facia assembly, refer to

2.8 HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

4. Remove the in-car temperature sensor (1) two

self tapping screws.

4. Disconnect the electrical connector (3) and

aspirator tube (2) and remove the sensor.

REINSTALL

1. Reinstallation takes place in reverse order of

removal.

2. Reset radio security code, refer to the Owner’s

Handbook.

Figure 2B-8

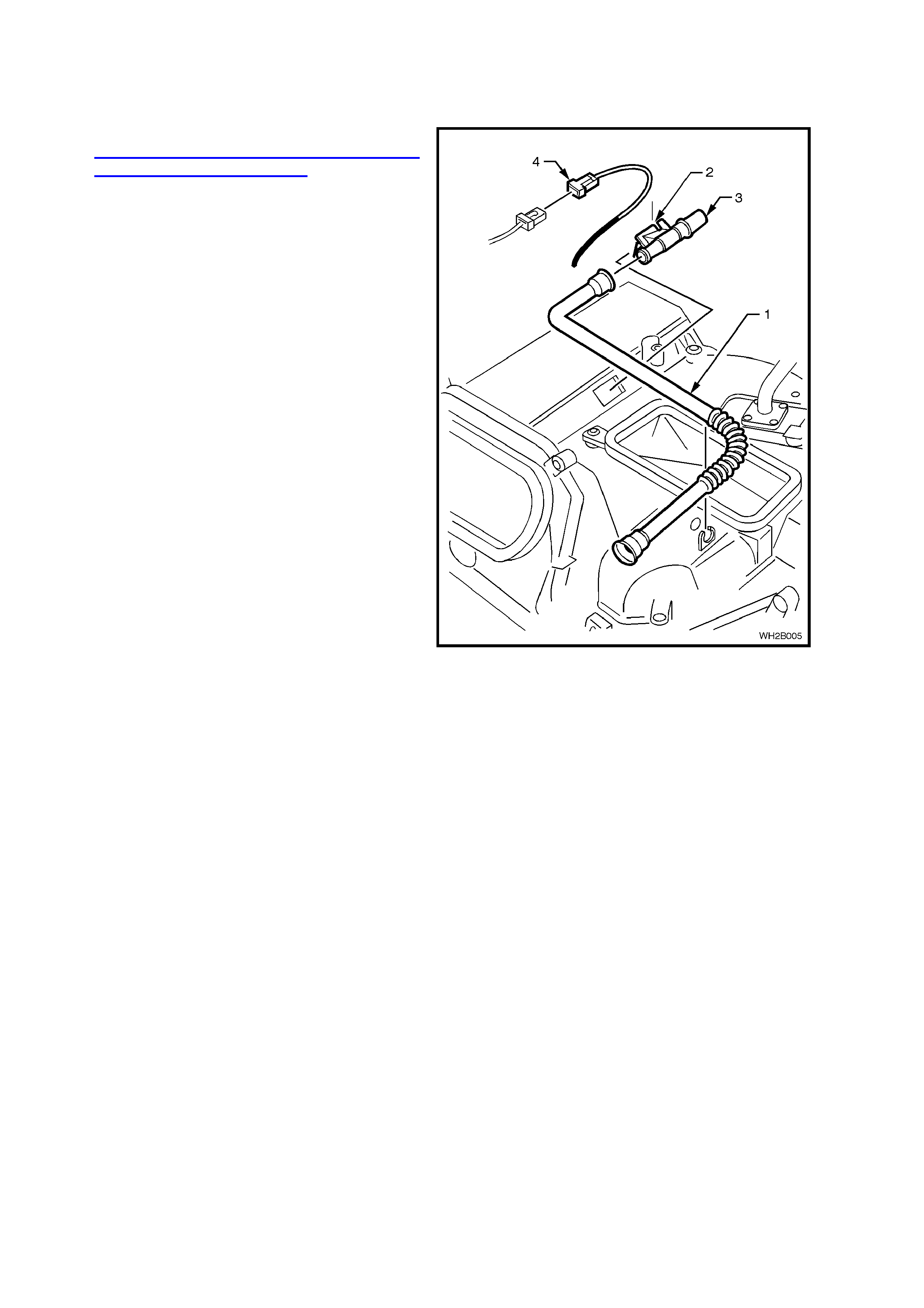

2.6 INTAKE AIR TEMPERATURE SENSOR AND AS PIRATOR TUBE

REMOVE

1. Remove the instr ument f acia as s embly, refer to

2.8 HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

2. The intake air temperature sensor (4), venturi

(3) and aspirator tube (1) is located on top of

the HVAC unit.

3. Gently unclip the venturi (3) from the

evaporator top cover.

4. Work ing through ventur i opening, us e a thin f lat

blade screwdriver to gently pry the sensor wire

from the plastic retaining clip.

NOTE: Avoid dam aging the evaporator c oil surf ace

when removing sensor wire.

REINSTALL

1. Reinstallation is the reverse order of removal.

2. When installing the intake air temperature

sensor wire, ensure that the wiring runs in the

recess (2) provided in the venturi housing.

IMPORTANT: Ensure the evaporator air sensor

probe clip is re-affixed in exactly the same position

as when removed.

Figure 2B-9

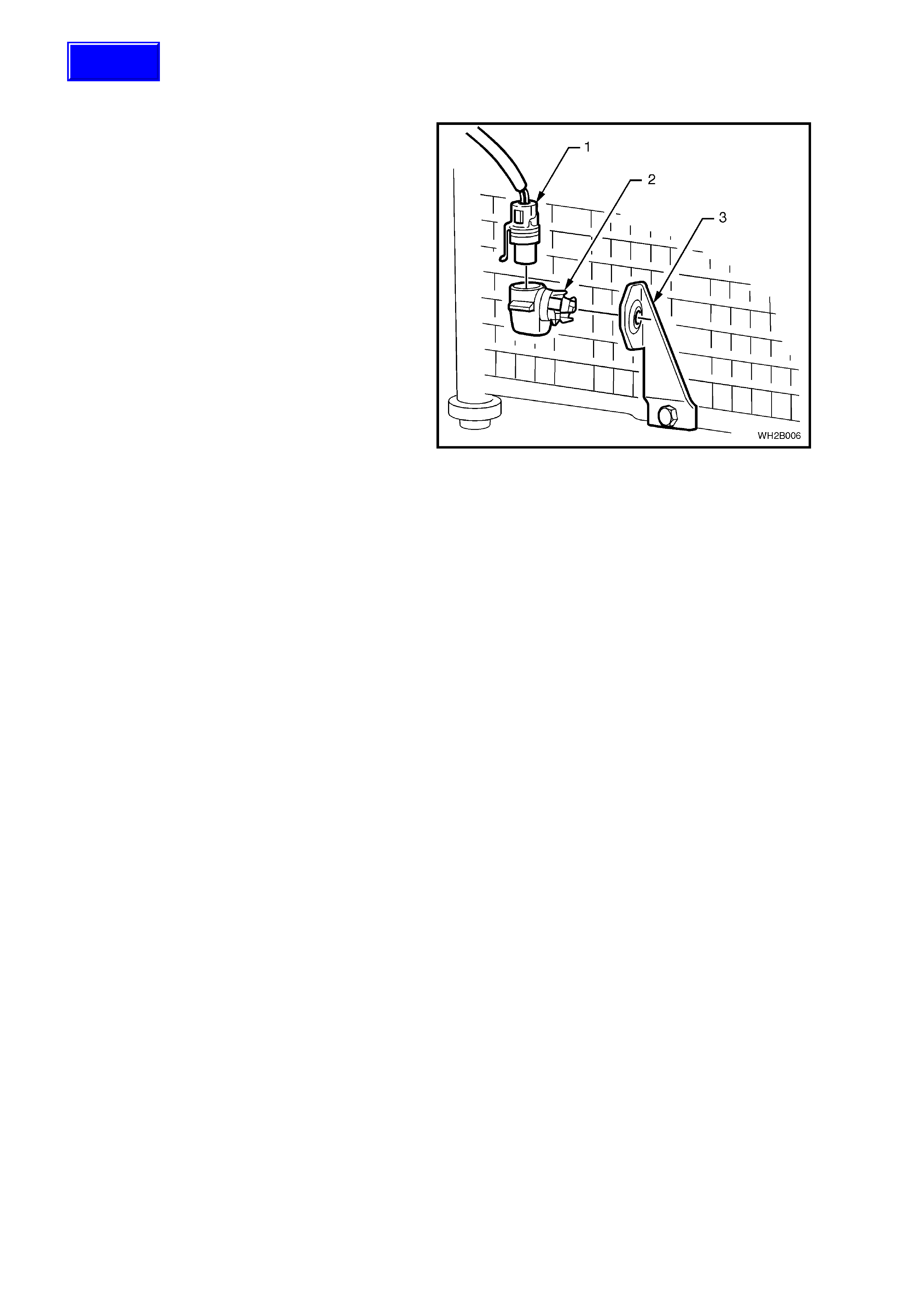

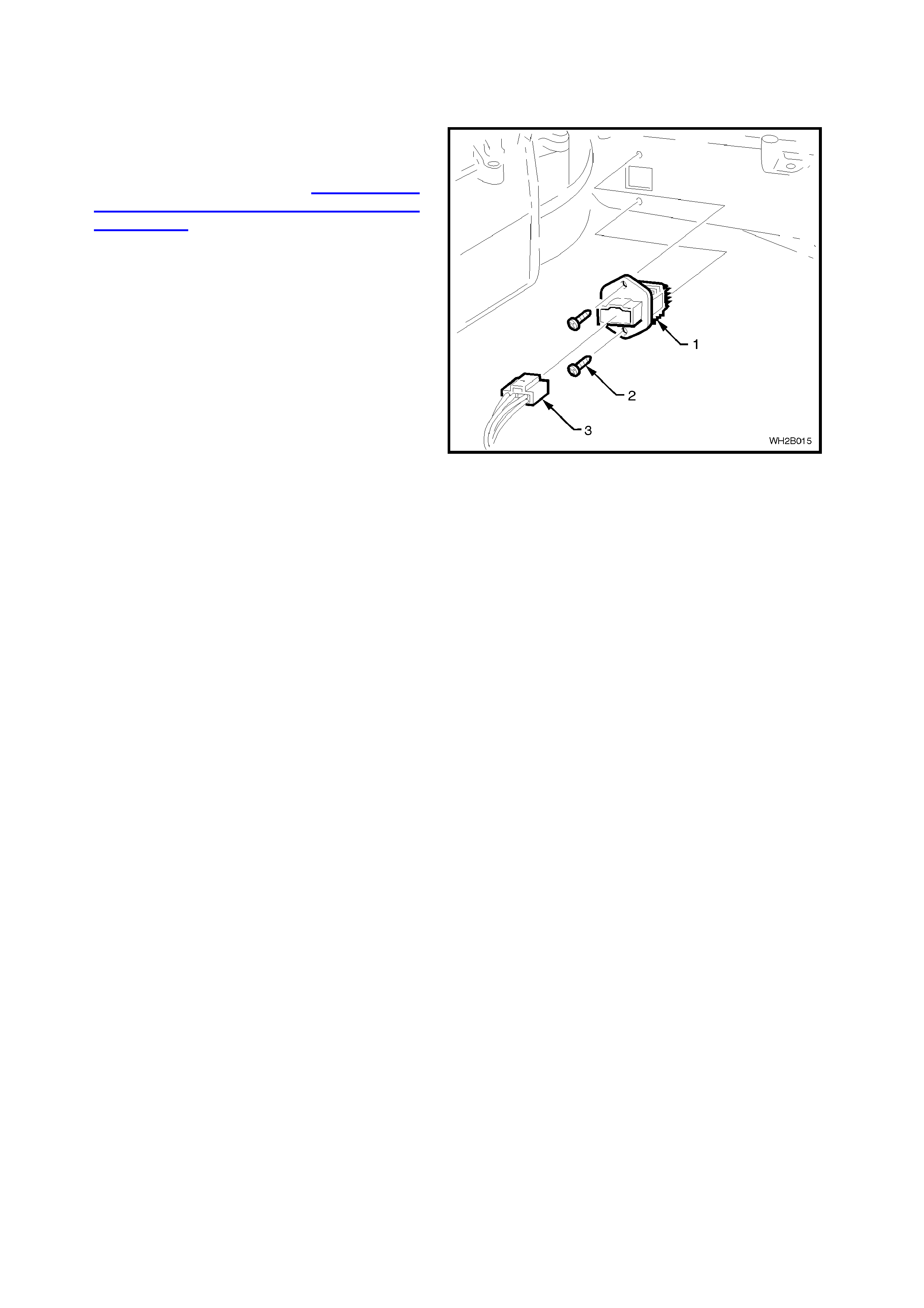

2.7 AMBIENT TEMPERATURE SENSOR

REMOVE

1. Through the front bumper bar opening, detach

the ambient temperature sensor electrical

connector (1).

3. Using a flat blade screwdriver gently pry the

sensor (2) away from the retaining bracket (3).

The sensor is clipped into position.

REINSTALL

Reinstallation is the reverse order of removal.

Figure 2B-10

Techline

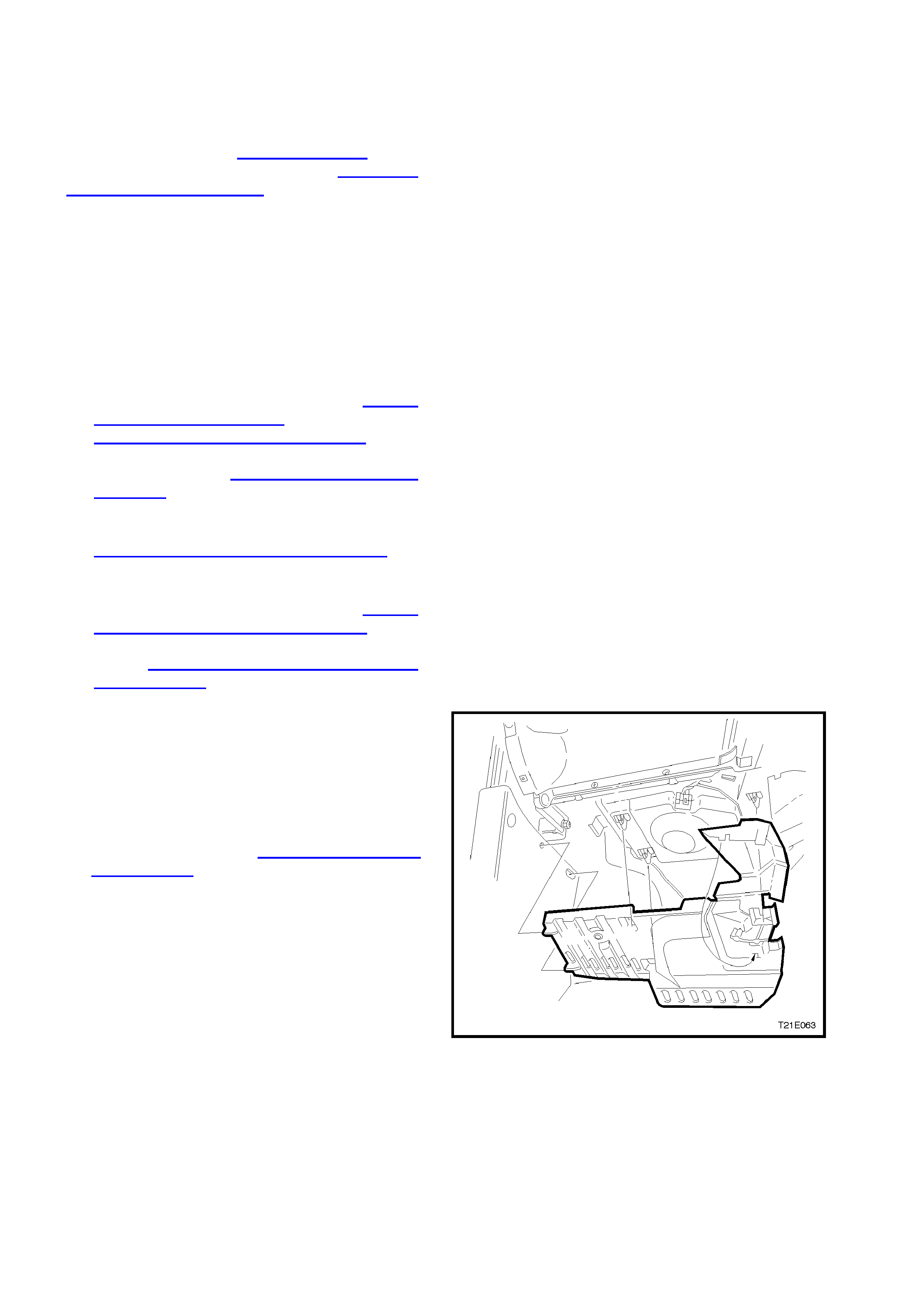

2.8 HEATING, VENTILATION AND AIR CONDITIONING (HVAC) UNIT

REMOVE

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M SRS of the

VT Series I Service Information or Section 00

CAUTIONS AND NOTES of this WH Service

Supplement.

IMPORTANT: As a theft deterrent, WH series

vehicles are fitted with a security coded audio

system. After the power supply is interrupted, the

radio will rem ain inoperative af ter reinstallation until

the pin number is entered into the system. The

procedure is described in the glove box literature

accompanying the Owner’s Handbook.

1. Disconnect the battery negative and positive

cables.

2. Drain engine cooling system, refer to Section

6B1 ENGINE COOLING - V6 ENGINE,

Section 6B1-1 ENGINE COOLING - V6

SUPERCHARGED of the VT Series I Service

Information or Section 6B3 ENGINE

COOLING - GEN III V8 ENGINE of the VT

Series II Service Information.

3. Discharge the air conditioning system, refer to

Section 2C AIR CONDITIONING -

SERVICING AND DIAGNOSIS of this Service

Information CD.

4. Depressurise the fuel system, refer to Section

6C1 POWERTRAIN MANAGEMENT - V6

ENGINE of the VT Series I Service Inform ation

or Section 6C3 POWERTRAIN

MANAGEMENT - GEN III V8 ENGINE of the

VT Series II Service Information.

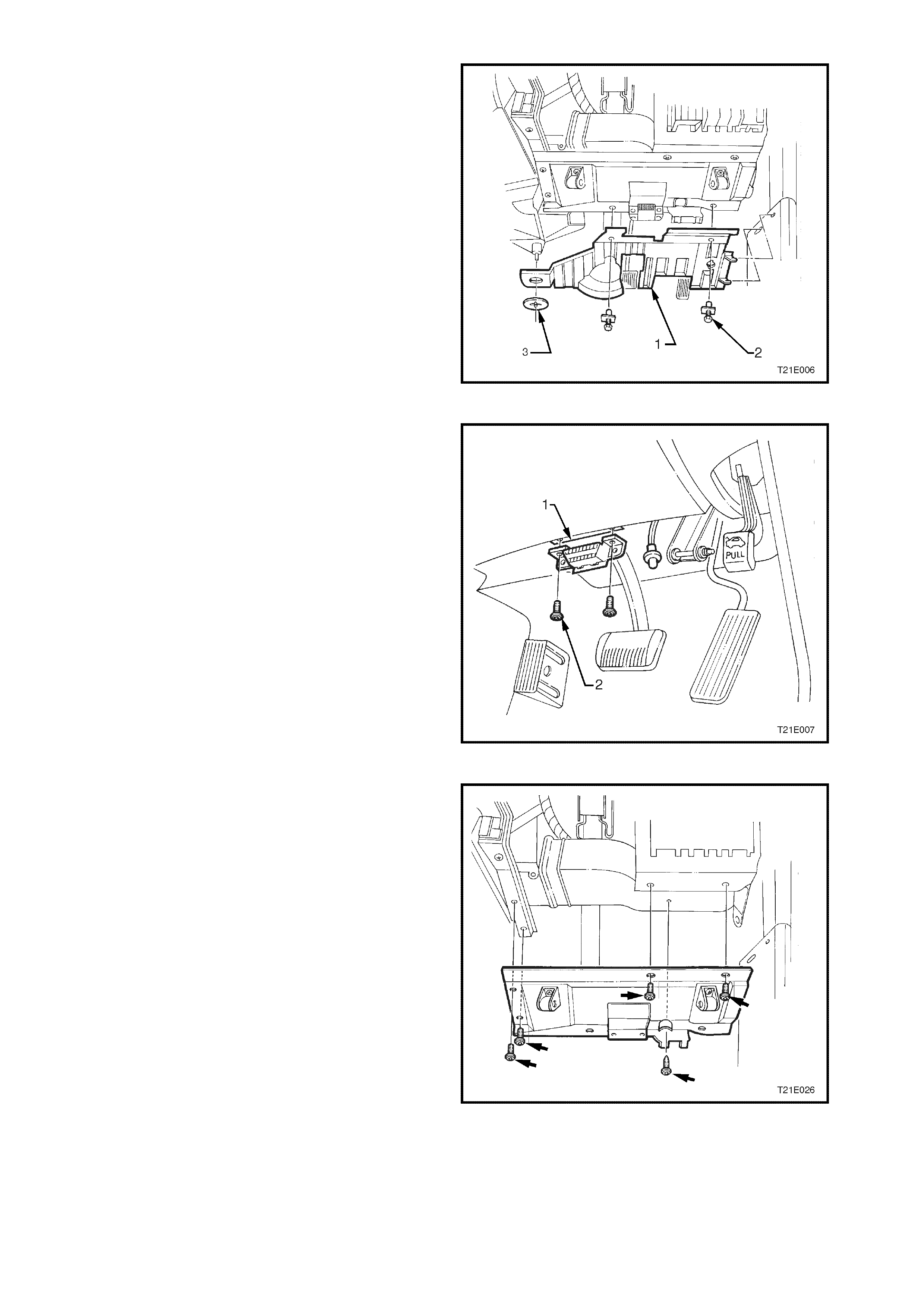

5. Unclip duct cover flap on right hand side of foot

well upper closing panel left side. Disengage

the locating lugs to passenger side shroud

lower. Grasp closing panel firm ly and detach by

pulling left side down first, then disengage right

side clip and remove panel.

6. Remove passenger side shroud lower trim

assembly, refer to Section 1A1 BODY

DIMENSIONS of this Service Information CD.

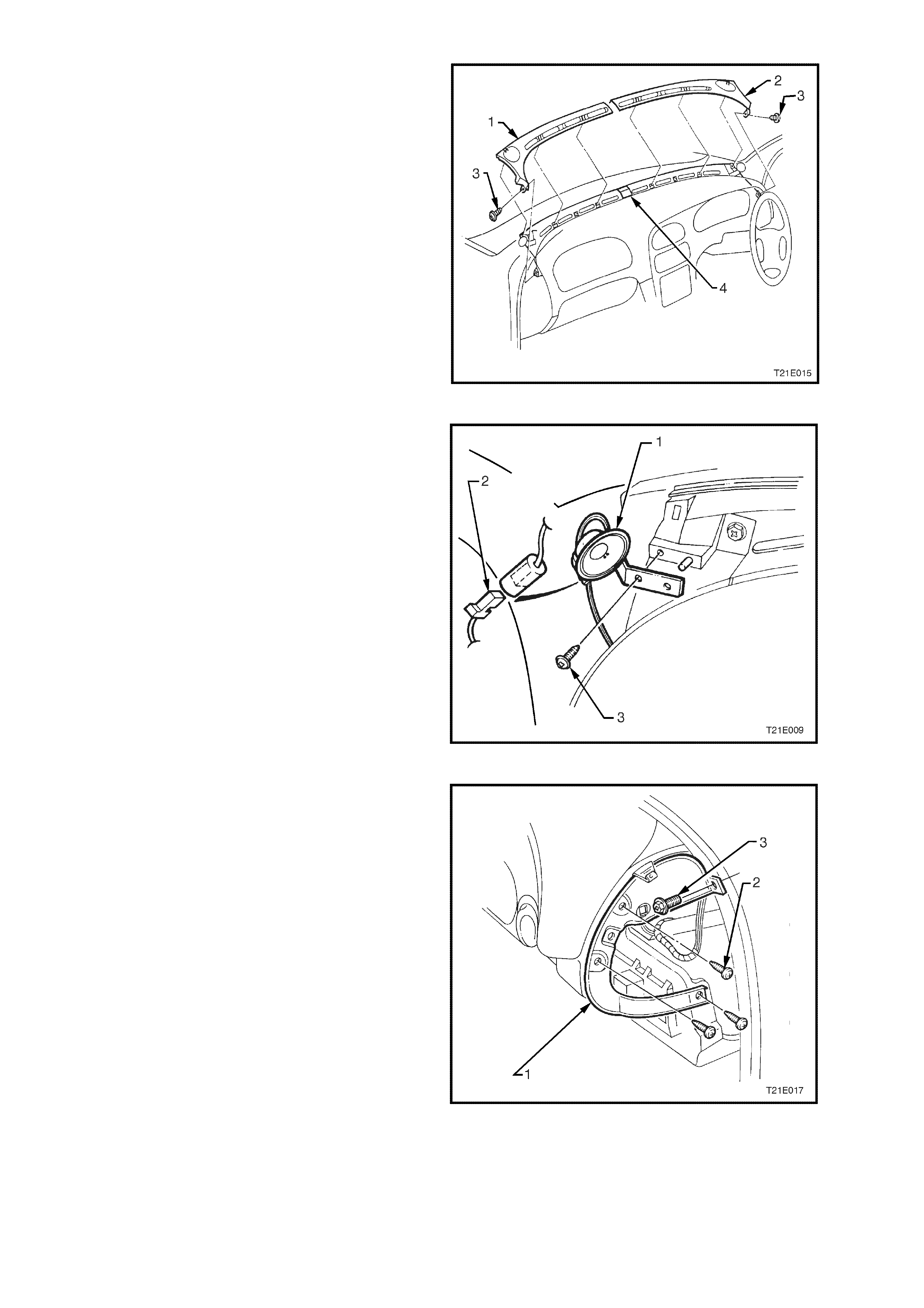

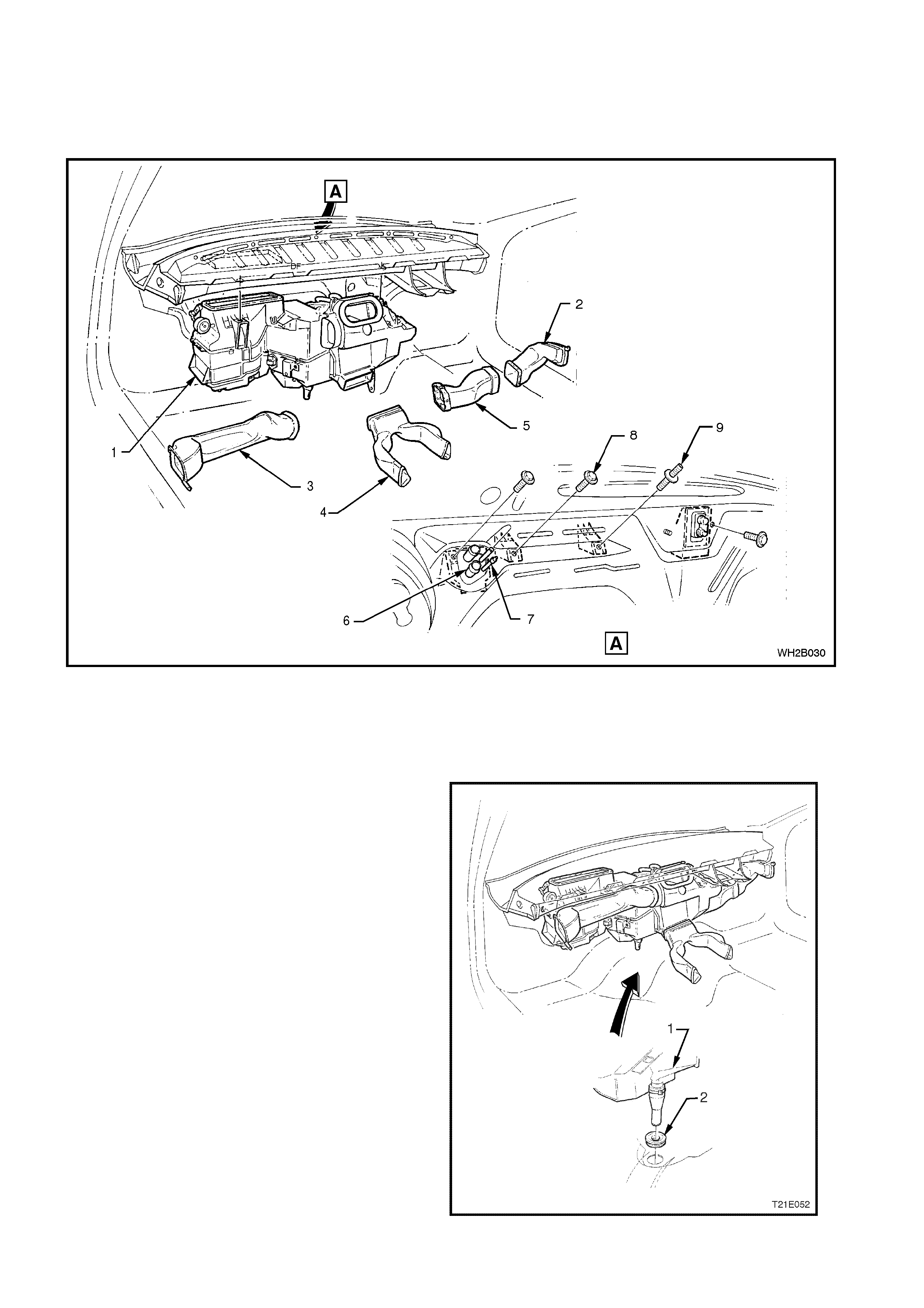

Figure 2B-11

7. Adjust steering wheel to upper most position.

Grasp the right hand side of the instrument

panel lower cover panel (1) firmly and pull

towards rear of vehicle. Repeat the procedure

for the left hand side of the cover.

Using a flat bladed screwdriver, prise the left

hand instrument panel lower cover panel hinge

pin (2) out.

Tilt the instrument panel lower cover down on

the left side and dis engage the right hand hinge

pin. Remove panel.

Figure 2B-12

8. Release the steering column height adjuster,

com pletely lower steering colum n and leave lever

in the released position.

9. Insert finger between the steering wheel and the

lower cover as shown in Fig. 2B-13 and apply a

small amount of pressure (pushing towards the

instrument cluster) while lifting the upper cover

upwards.

Figure 2B-13

10. Remove screw (2) securing the lower cover (1)

to the steering column.

11. Slide lower cover toward the steering wheel to

release cover fr om the two retaining tangs ( 3) on

the steering column.

12. While feeding the key reader outer surround

from lower cover, remove cover.

Figure 2B-14

13. Rem ove the two scrivets (2 ) securing the f ootwell

upper closing panel (1).

Prise off the retaining button (3) and detach the

footwell upper closing panel.

Disconnect front footwell lamp from footwell

upper closing panel.

Figure 2B-15

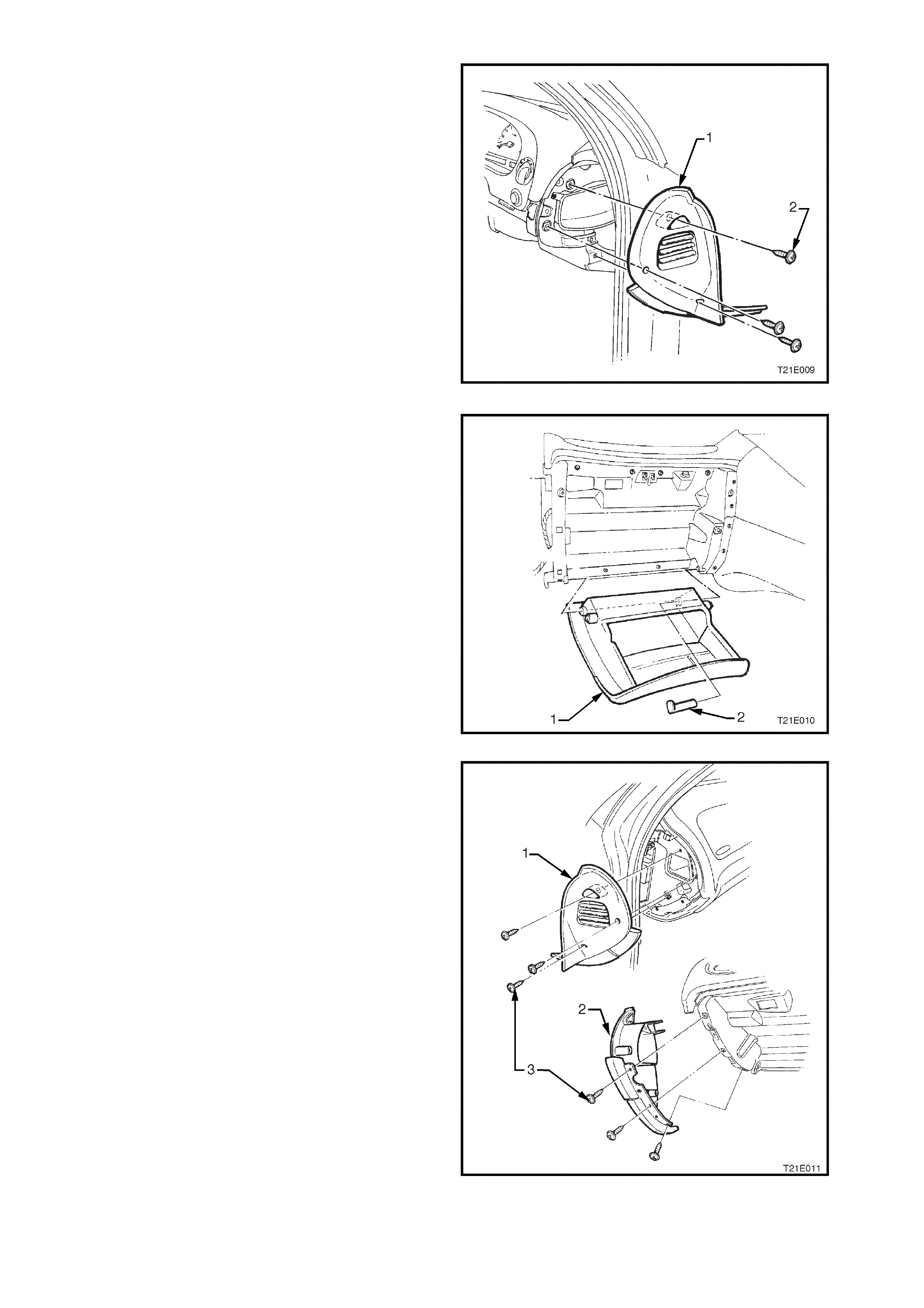

14. Remove two screws (2) securing the diagnostic

link connector (1) to the instrument panel lower

trim right side assembly .

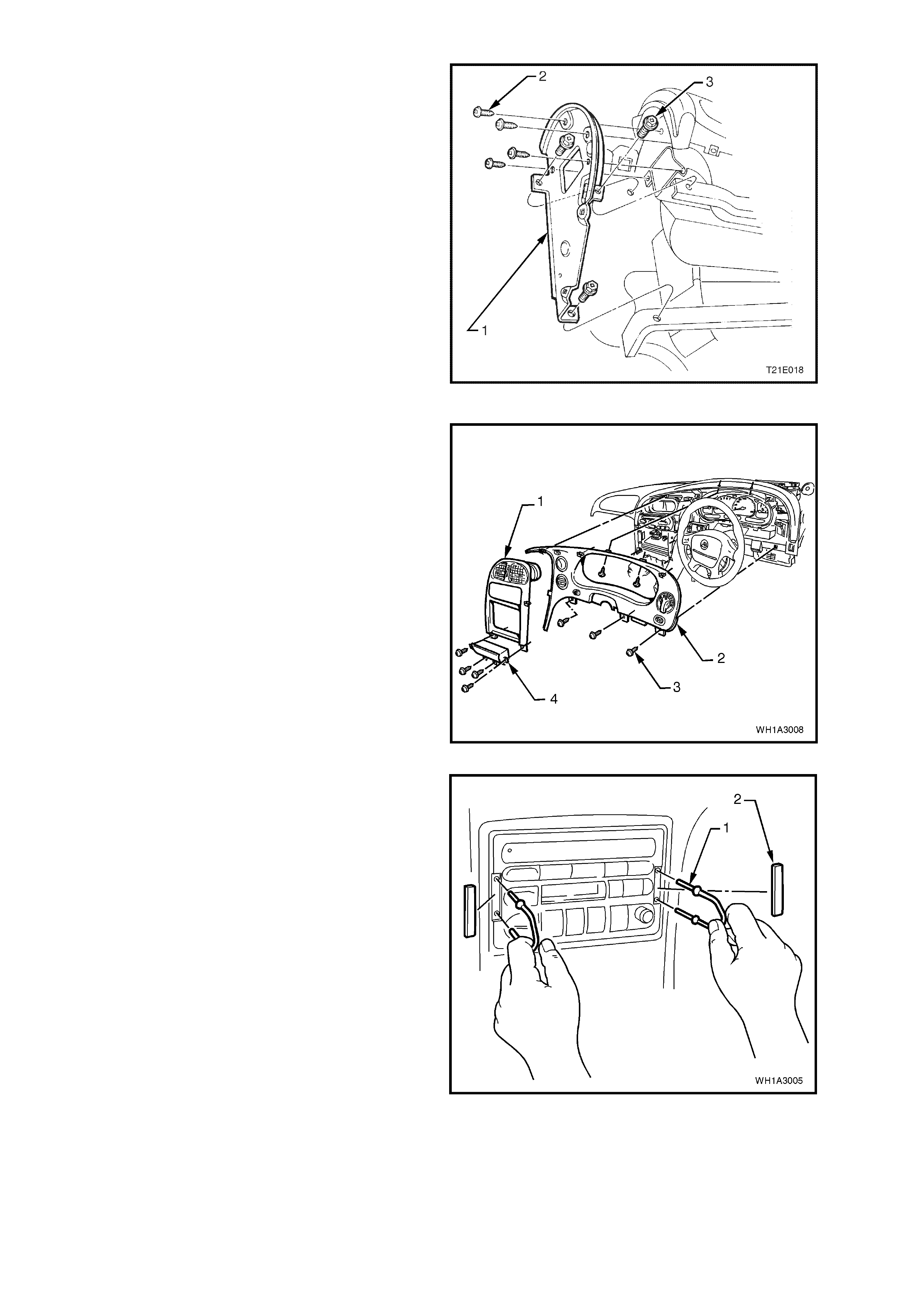

Figure 2B-16

15. Remove the five screws attaching the instrument

panel lower trim right side rail assembly,

disengage BCM from panel and remove panel.

Figure 2B-17

16. Remove the three screws (2) securing the right

hand instrument panel end cap (1) to the

instrument panel and remove end cap.

Figure 2B-18

17. Open the instrument panel compartm ent (1), and

lever the hinge pin (2) from the right side of the

compartment. Lower compartment and withdraw

the pin. Disengage right hand travel limiting peg

from slot in instrument panel roof by deforming

plastic tang.

Figure 2B-19

18. Rem ove the six screws (3) securing the left hand

instrument panel end cap cover (1) and end cap

(2) to the instrument panel and remove end cap

cover and end cap.

Figure 2B-20

19. Remove the 11 retaining screws (2) from

instrument panel compartment roof (1).

Disconnect the instrument panel compartment

lamp (3) and switch (4) connectors, disconnect

the luggage compartment lock switch connector

(5) and unclip instrument panel compartment

wiring harness (6).

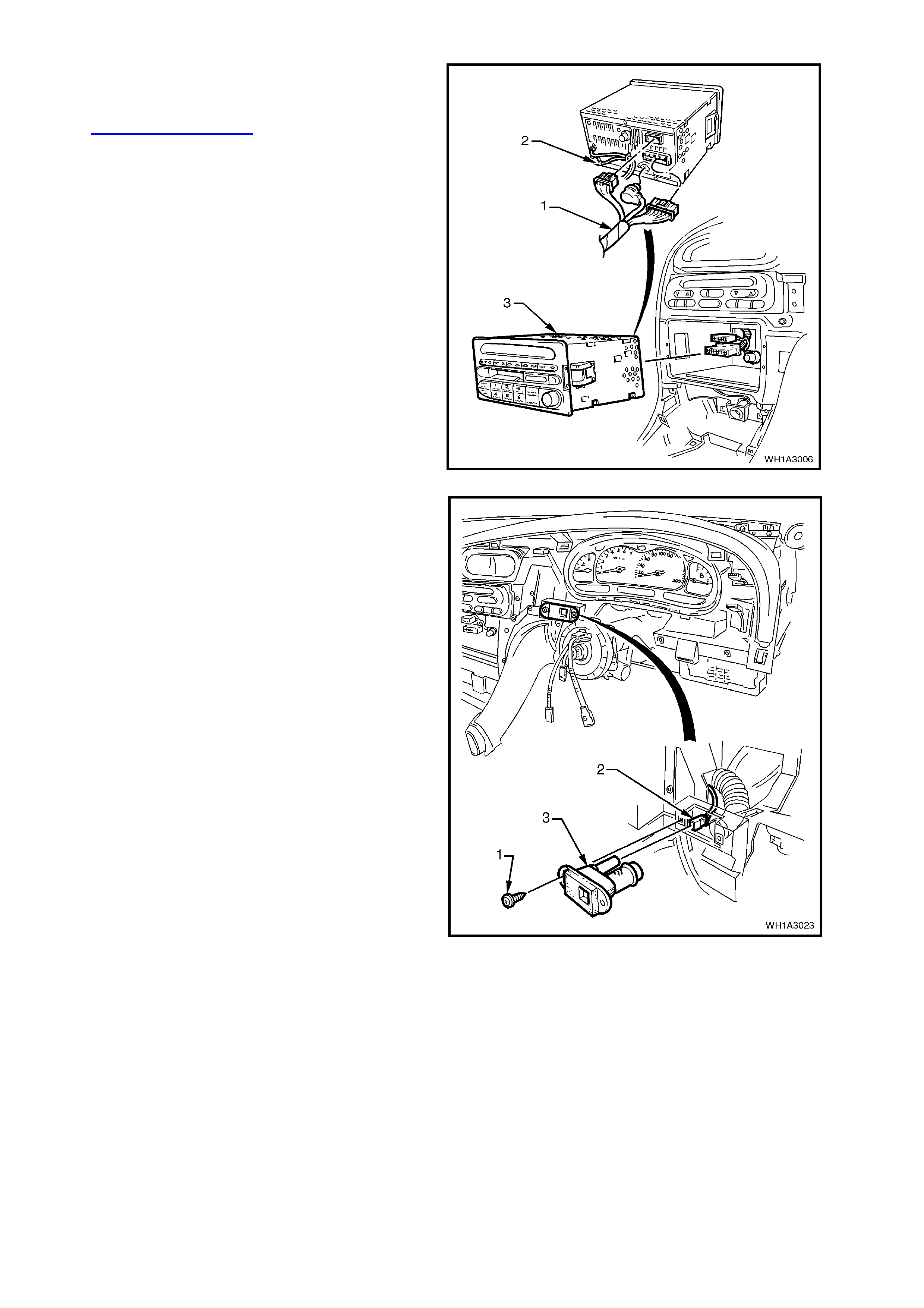

Figure 2B-21

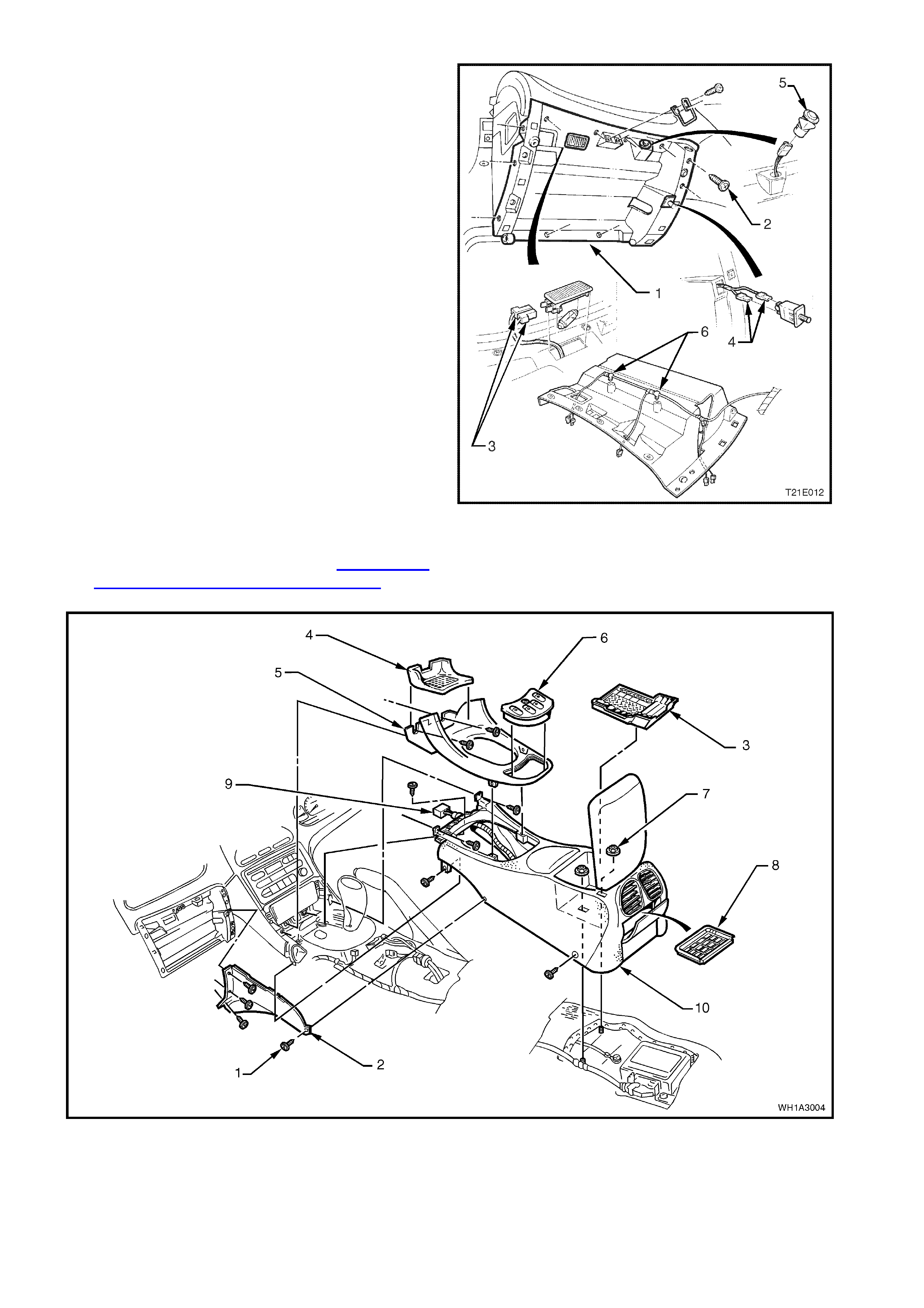

20. Remove the transmission console and detach

console wiring harness, refer to Section 1A3

INSTRUMENT PANEL & CONSOLE of this

Service Information CD.

Figure 2B-22

Legend

1. Screw (11 places)

2. Centre facia side extension left side shown

3. Insert

4. Rubber cap

5. Transmission console cap

6. Power window switch assembly

7. Nut (2 places)

8. Insert

9. Console harness

10. Centre console

21. Remove the two retaining screws (3) from the

left (1) and right (2) hand demist nozzles and,

taking care not to damage the SUN

SENSOR/REMOTE RECEIVER MODULE /

remote receiver module, remove both demist

nozzles.

Figure 2B-23

21. Disconnect the left and right front instrument

panel speaker wiring harness connectors (2).

Using a Phillip’s head screwdriver, remove the

two screws (3) (one each side) attaching front

instrum ent panel speakers (1) and rem ove both

speakers.

Figure 2B-24

22. Remove the four retaining screws (2 & 3) from

the instrument panel carrier end panel (1) right

side and remove panel.

Figure 2B-25

23. Remove the four attaching screws (2) securing

instrument panel carrier end panel (1) left side

and three bolts (3) attaching the passenger air

bag support rail, lower lef t side r ail, and rem ove

panel.

Figure 2B-26

24. Remove screws (3) retaining the instrument

facia (2) and instrument facia storage

compartment assembly (4).

25. Remove instrument facia storage compartment

and pull instrument facia escutcheon (1) from

retaining clips.

26. Remove instrument facia by pulling facia from

retaining clips.

NOTE: Care must be taken to disconnect the

headlamp switch connector, fog lamp switch

connector, trip computer switch connector, clock

connector and hazard switch connector from main

wiring harness.

Figure 2B-27

27. Remove left hand centre facia side extension,

unclip antenna leads from inboard end of

glovebox lower rail.

NOTE: This is necessary to provide enough

antenna cable to pull radio forward.

28. Remove service tool hole snap on covers (2)

and remove radio/cassette/CD from instrument

panel using service tool 179 1308 0000 (1).

Figure 2B-28

29. Disconnect radio/cassette harness and CD

connector. Disconnect antenna and diversity

antenna. For further information, refer to

Section 12D RADIO of the WH Service

Supplement.

Figure 2B-29

30. Rem ove the two screws (1) securing the in-car

temperature sensor to the instrument panel

and remove the in-car sensor. Disconnect the

wiring harness connector (2) and as pirator tube

from the in-car temperature sensor (3).

Figure 2B-30

31. Remove the 13 screws securing the c entre f ac ia

assembly to the instrument panel and remove

centre facia assembly.

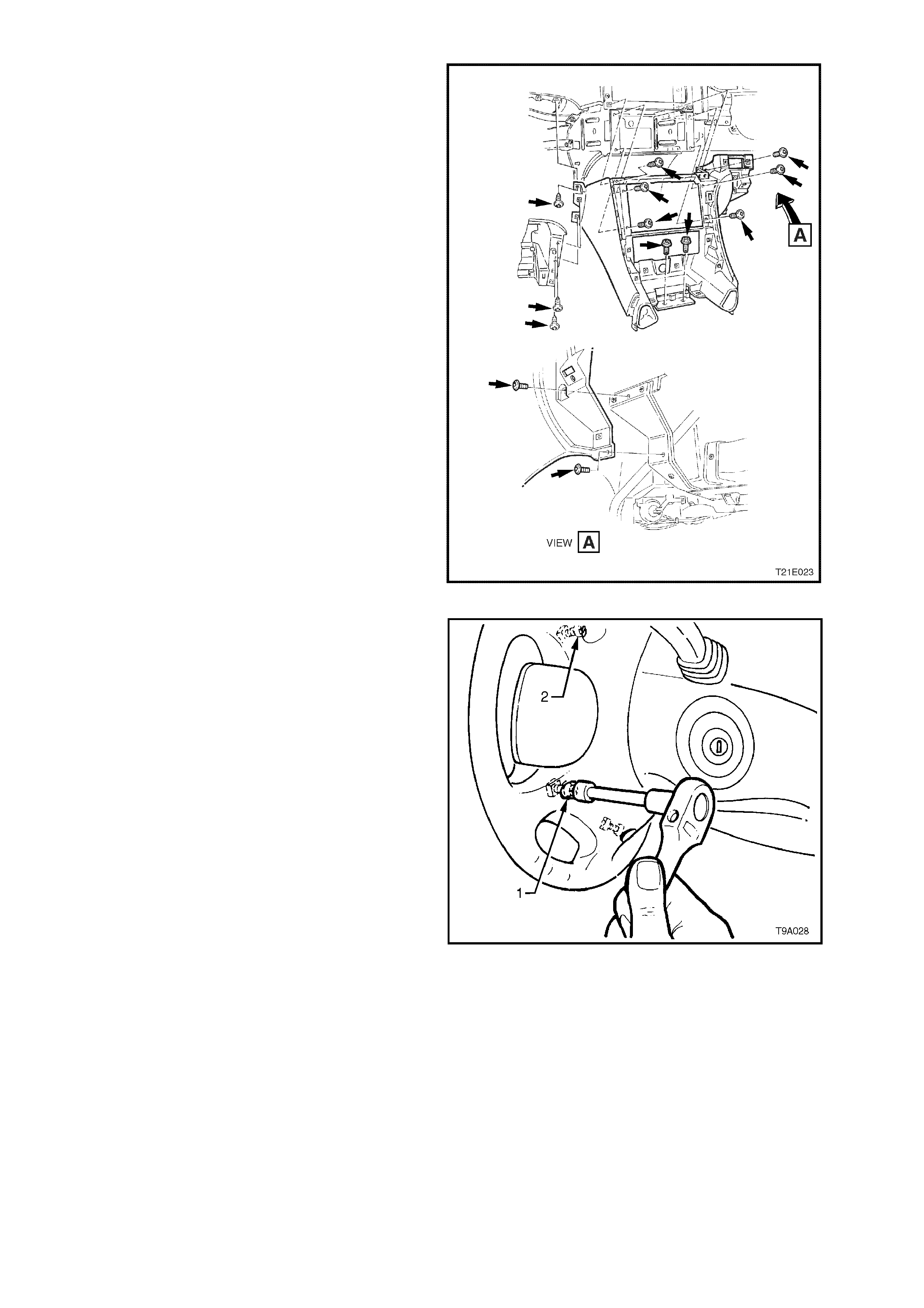

Figure 2B-31

32. Using a number T30H Torx bit (1),

commercially available or Tool No. ETX30H

and a suitable holder suc h as T ool No. J 25359-

8, loosen and remove four screws (2) from the

rear of steering wheel securing the horn bar

and air bag inflator module assembly to the

steering wheel.

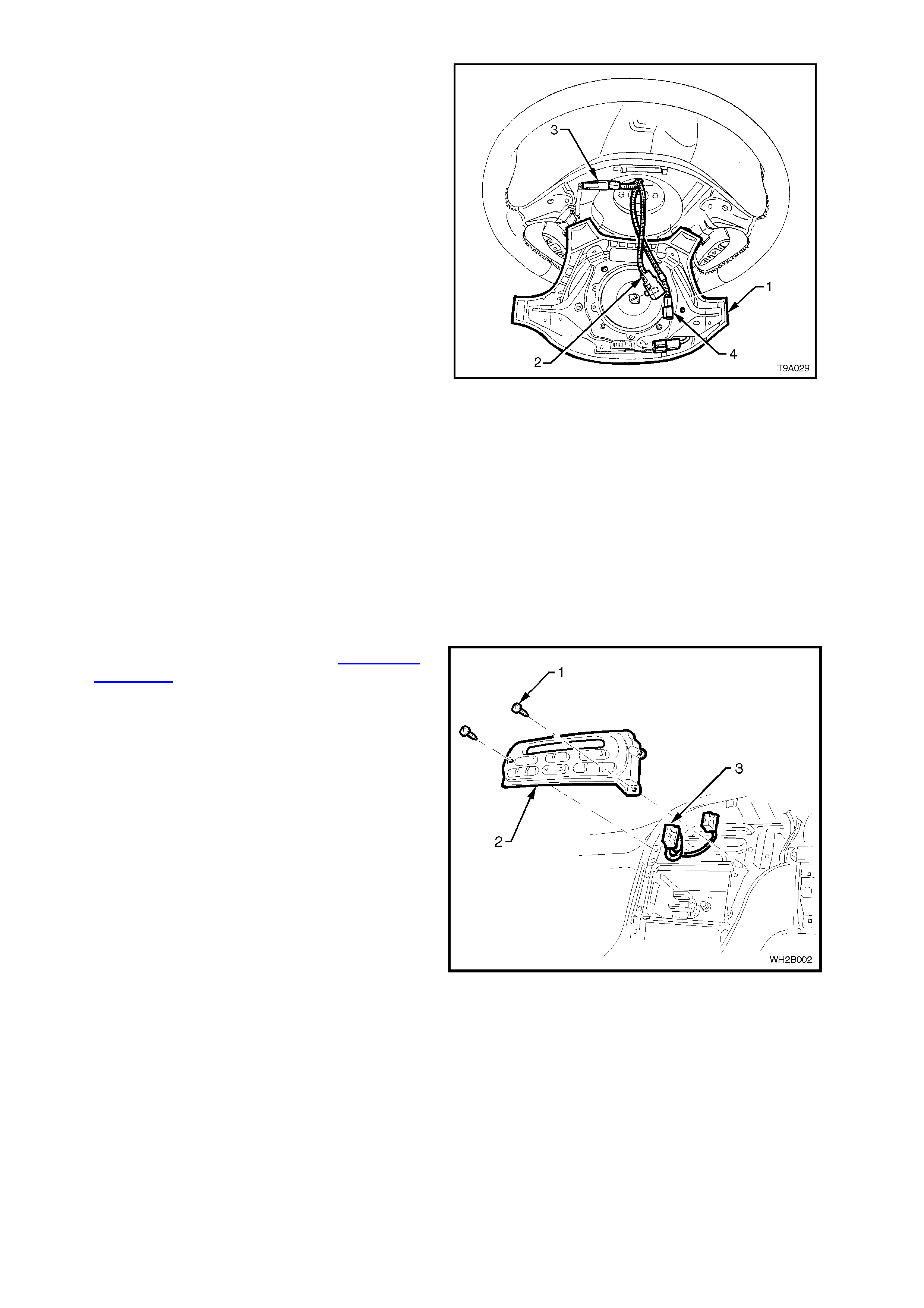

Figure 2B-32

33. Lift up horn bar and air bag inflator module

assembly (1) from the steering wheel, remove

the yellow clock spring to inflator assembly

connection (2) and disconnect wiring harness

connectors (3 and 4) from rear of assembly,

refer to Fig 2B-33.

NOTE: Take extrem e care when disconnecting the

left hand horn pad connector (3) from the stereo

control wiring connector otherwise, damage to the

stereo control wiring could result.

34. Remove horn bar and air bag inflator module

assembly.

CAUTION: When carrying a live (undeployed)

horn bar and air bag inflator module assembly,

make sure the bag opening in the horn bar is

pointed away from you. Never carry the horn

bar and air bag inflator module assembly by the

horn bar wires or connectors on the underside

of the assembly. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

When placing a live horn bar and air bag

inflator module assembly on a bench or other

surface, always face the bag and horn bar up,

away from the surface. Never rest the horn bar

and air bag inflator module assembly with the

horn bar f ace down . This is necessary so th at a

free space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment. Otherwise, personal injury may

result.

Figure 2B-33

35. Remove the steering wheel, refer Section 9A

STEERING of the VT Series I Service

Information.

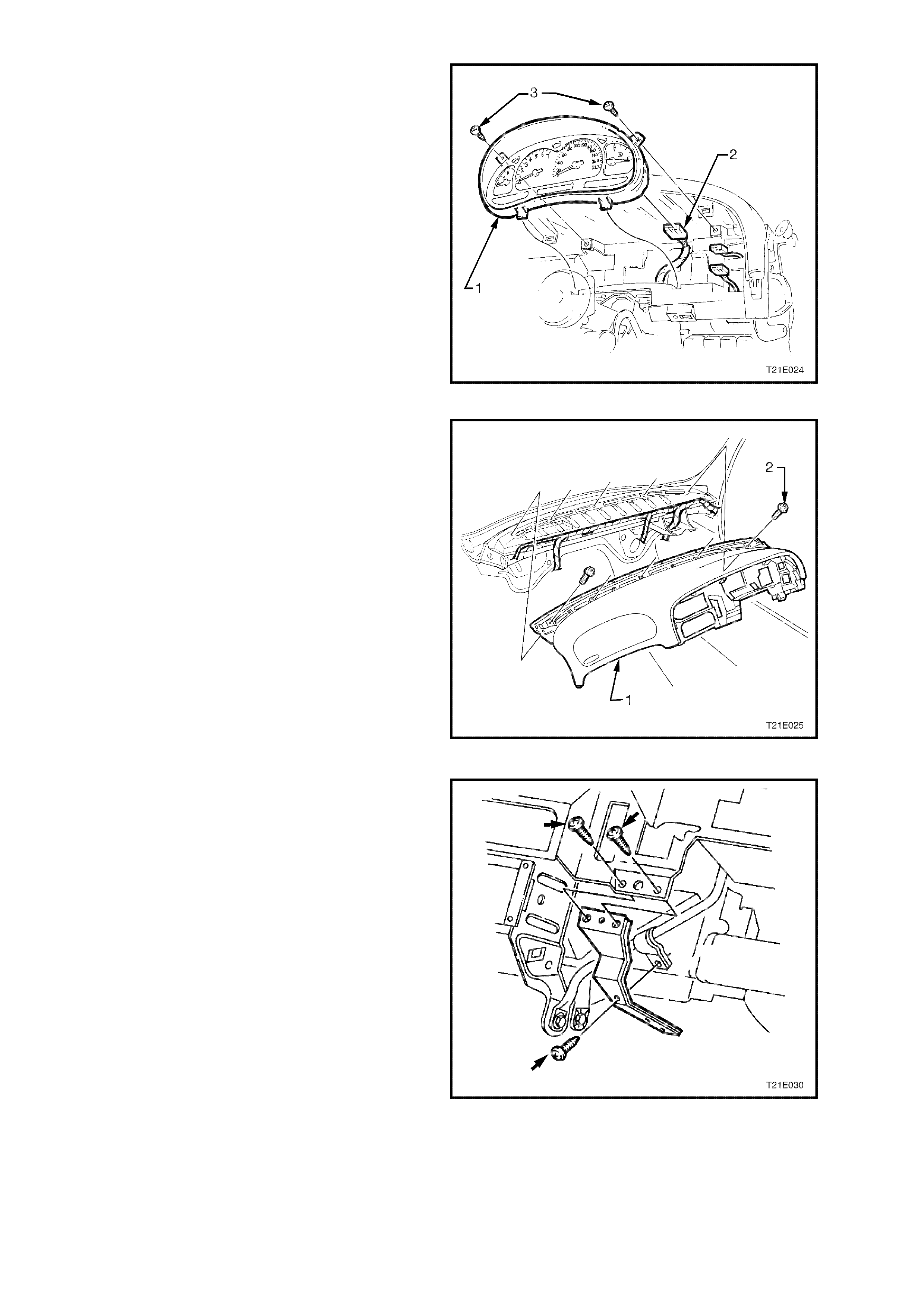

36. Remove the screws (1) securing the ECC

module (2) to the instrument panel.

37. Disconnect the wiring harness connections (3).

Remove the ECC module.

Figure 2B-34

38. Remove the two screws (3) securing the

instrument cluster assembly (1) and disconnect

instrument connector (2).

Figure 2B-35

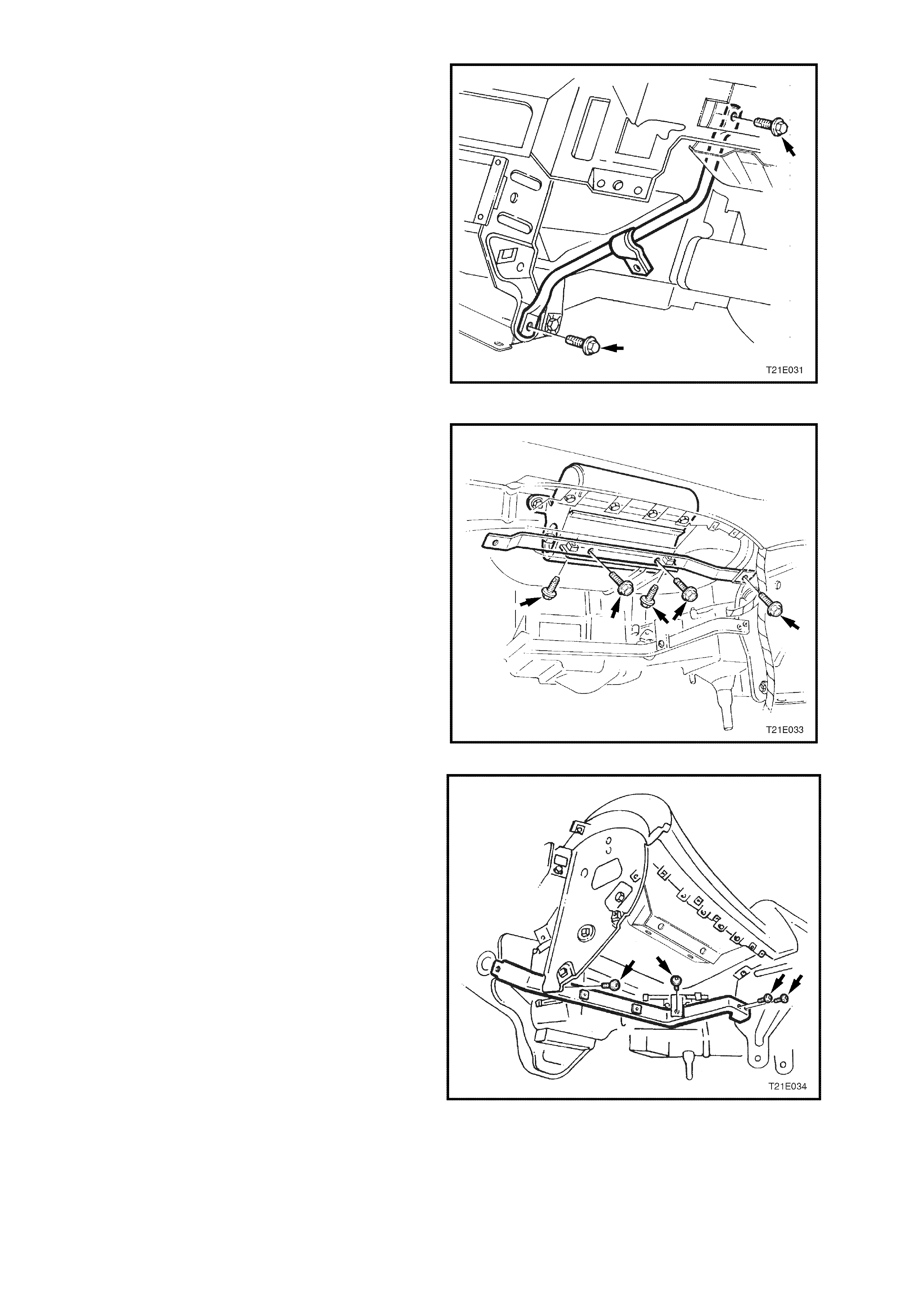

39. Remove the five retaining screws (2) along top

edge of instrument panel pad (1) and remove

pad.

Figure 2B-36

40. Remove the three screws securing the centre

facia support rail to the instrument panel, and

remove support rail.

Figure 2B-37

41. Remove the lower steering column inner

bracket screws (2) and remove bracket.

Figure 2B-38

42. Remove the f ive sc r ews sec ur ing the pas s enger

air bag support rail assembly and remove rail.

Figure 2B-39

43. Remove two screws connecting lower left side

rail to instrument panel carrier assembly.

Remove single screw connecting lower left side

rail to instrument panel carrier end panel left

side. Rem ove single sc rew connecting lower lef t

side rail to body mount.

Figure 2B-40

44. Remove the six instrument panel carrier rail

assembly retaining screws and remove carrier

rail.

Figure 2B-41

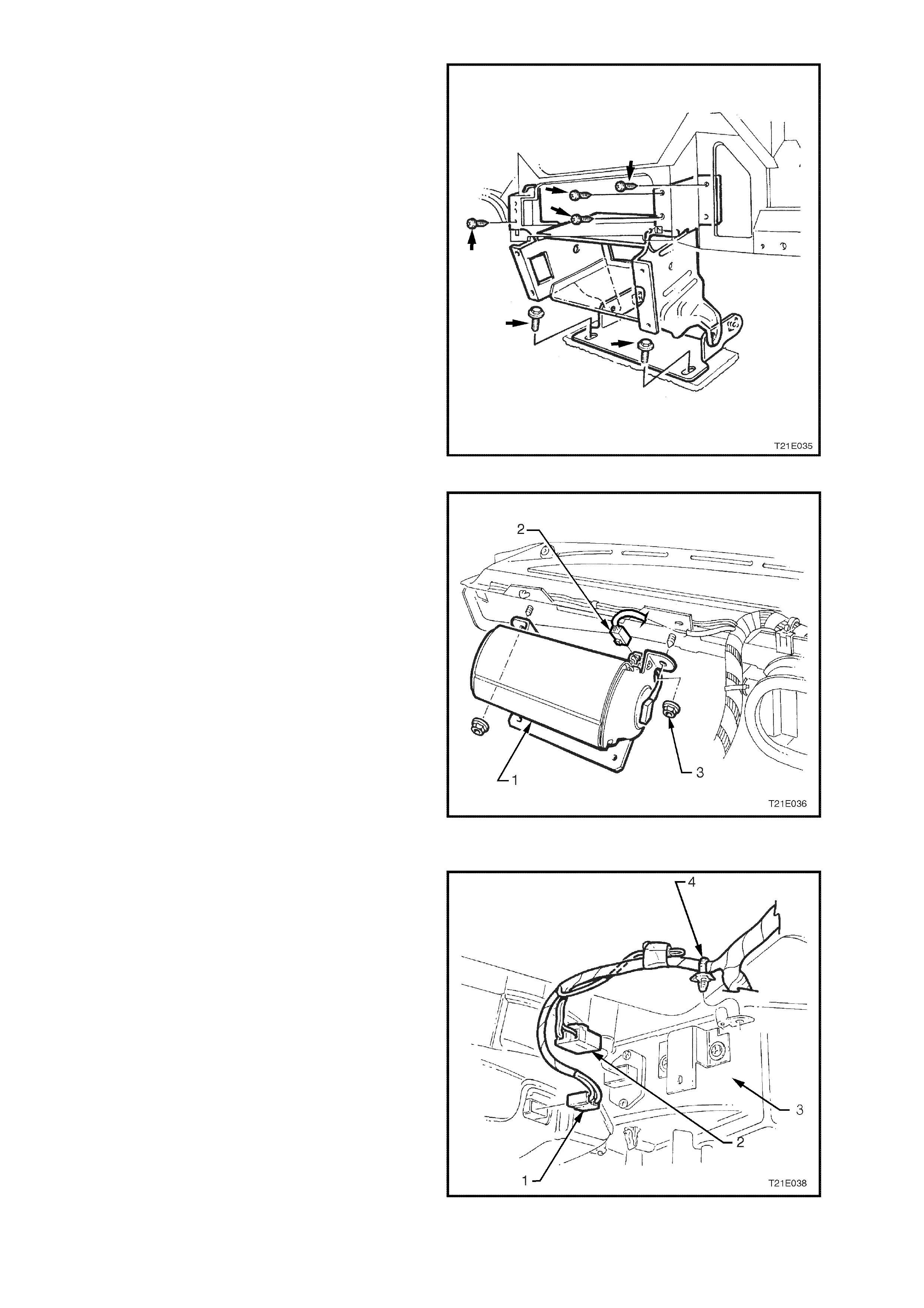

45. Disconnect the passenger air bag connector (2)

located on the right hand side of air bag (1).

Remove the two nuts (3) attac hing the air bag to

instrument panel assembly.

CAUTION: When carrying a live (undeployed)

front passenger's air bag inflator module

assembly, make sure the b ag openin g is poin ted

away from you. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury. When placing a live

front passenger's air bag inflator module

assembly on a bench or other surface, always

face with the air bag up, away from the surface.

Never rest the air bag inflator module assembly

wit h the air bag f ace down . This is necessary so

that a free space is provided t o allow t he air bag

to expand in the unlikely event of accidental

deployment. Otherwise, personal injury may

result. Figure 2B-42

46. Disconnect the blower motor wiring harness

connector (1) and fan speed control wiring

harness connector (2) from the HVAC unit (3).

Detach wiring harness retaining clip (4) from

HVAC unit.

Figure 2B-43

47. Tag and disconnect the heater hoses and

vacuum lines at the cockpit module, refer Fig.

2B-44 (V6 application) or Fig. 2B-45 (GEN III V8

application).

Figure 2B-44

Figure 2B-45

48. Rem ove the washer f aced bolt (3) retaining the

tube plate to the TXV (1).

49. Discard O – rings (4).

50. Unscrew two capscrews (2) and remove TXV

(1).

51. Plug all fittings

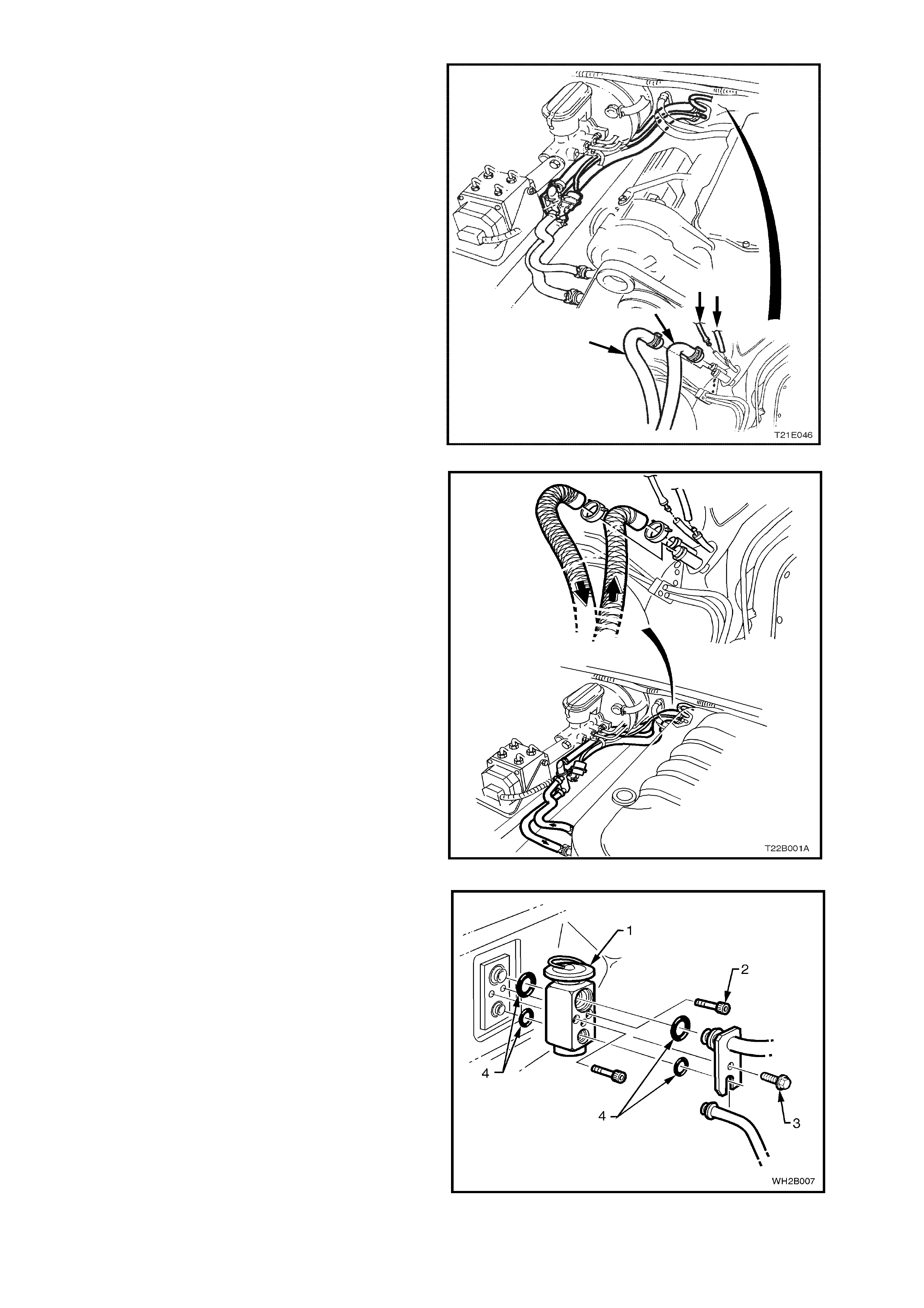

Figure 2B-46

52. From within the engine compartment, remove

the three screws and one stud securing the

heater case assembly to the cockpit module.

53. Disconnect right and left side air ducting and

rear compartment ducting from HVAC case.

Figure 2B-47

Legend

1. HVAC unit

2. Outer RHS duct

3. Outer LHS duct

4. Rear duct

5. Inner RHS duct

6. Heater hose connections

7. HVAC vacuum hose connections

8. Screw (3 places)

9. Stud (1 place)

54. Remove the HVAC unit (1) from the vehicle by

disengaging the drain grommet (2) and easing

the assem bly from the vehicle tak ing c are not to

strain the heater core tubes.

Figure 2B-48

REINSTALL

Reinstallation is the reverse of removal pr ocedures

ensuring that all fastners are tightened to the

correct torque specification, refer 4. TORQUE

WRENCH SPECIFICATIONS in this Section.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M SRS of the

VT Series I Serv ice Information or in Section 00

CAUTIONS AND NOTES the the WH Service

Information.

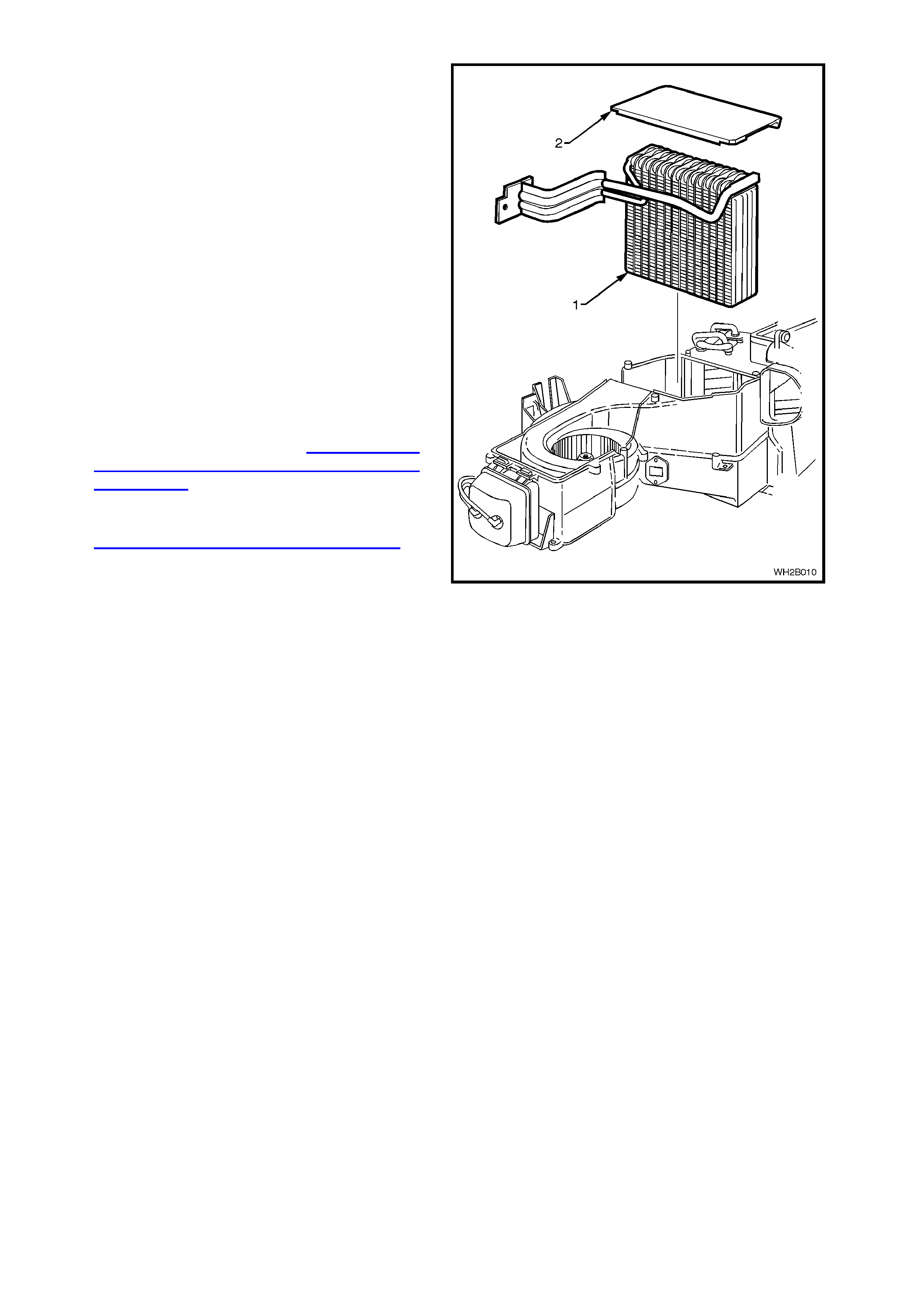

2.9 EV APORATOR CORE

REMOVE

1. Recover refrigerant, refer to Section 2C AIR

CONDITIONING ECC - SERVICING AND

DIAGNOSIS of the WH Service Information.

2. Drain cooling system, refer to Section 0B

LUBRICATION AND SERVICE of the WH

Service Information.

3. Remove the instrument panel carrier, refer to

2.8 HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

4. Remove the heating, ventilation and air

conditioning (HVAC) unit, refer to 2.8

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT.

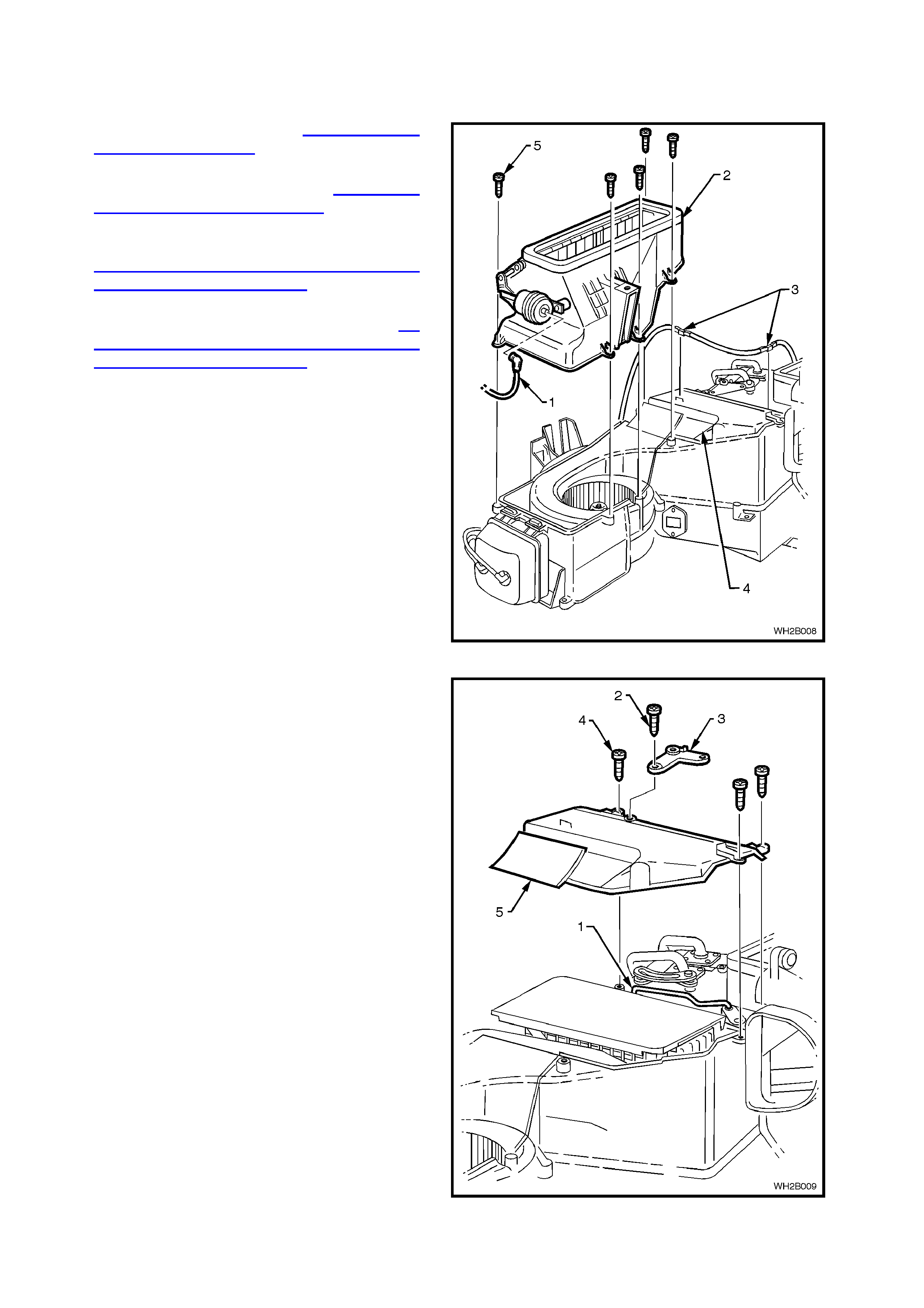

5. Disconnect the vacuum hose (1) from the

fresh/ recirculation actuator and vacuum tube

harness clips (3).

6. Remove the fres h/r ecir culation hous ing f ive s elf

tapping screws (5). Remove fresh/recirculation

housing.

Figure 2B-49

7. Disconnect the vacuum tube harness retaining

clips above the evaporator core cover (5).

8. Remove the aspirator tube and evaporator air

sensor electrical connector.

9. Remove the four evaporator core cover self

tapping screws (3), remove the core cover.

Figure 2B-50

10. Lift of f the upper insulator (2) and gently lift out

the evaporator core (1) ensuring no damage

occurs to the foam liners.

REINSTALL

1. Reinstall the evaporator core in the reverse

order of removal.

2. Reinstall the HVAC unit and instrument panel

carrier as described in 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT.

3. Evacuate and charge the system with

775 - 825 g of R134a refrigerant, refer to

Section 2C AIR CONDITIONING ECC -

SERVICING AND DIAGNOSIS of the WH

Service Information. Figure 2B-51

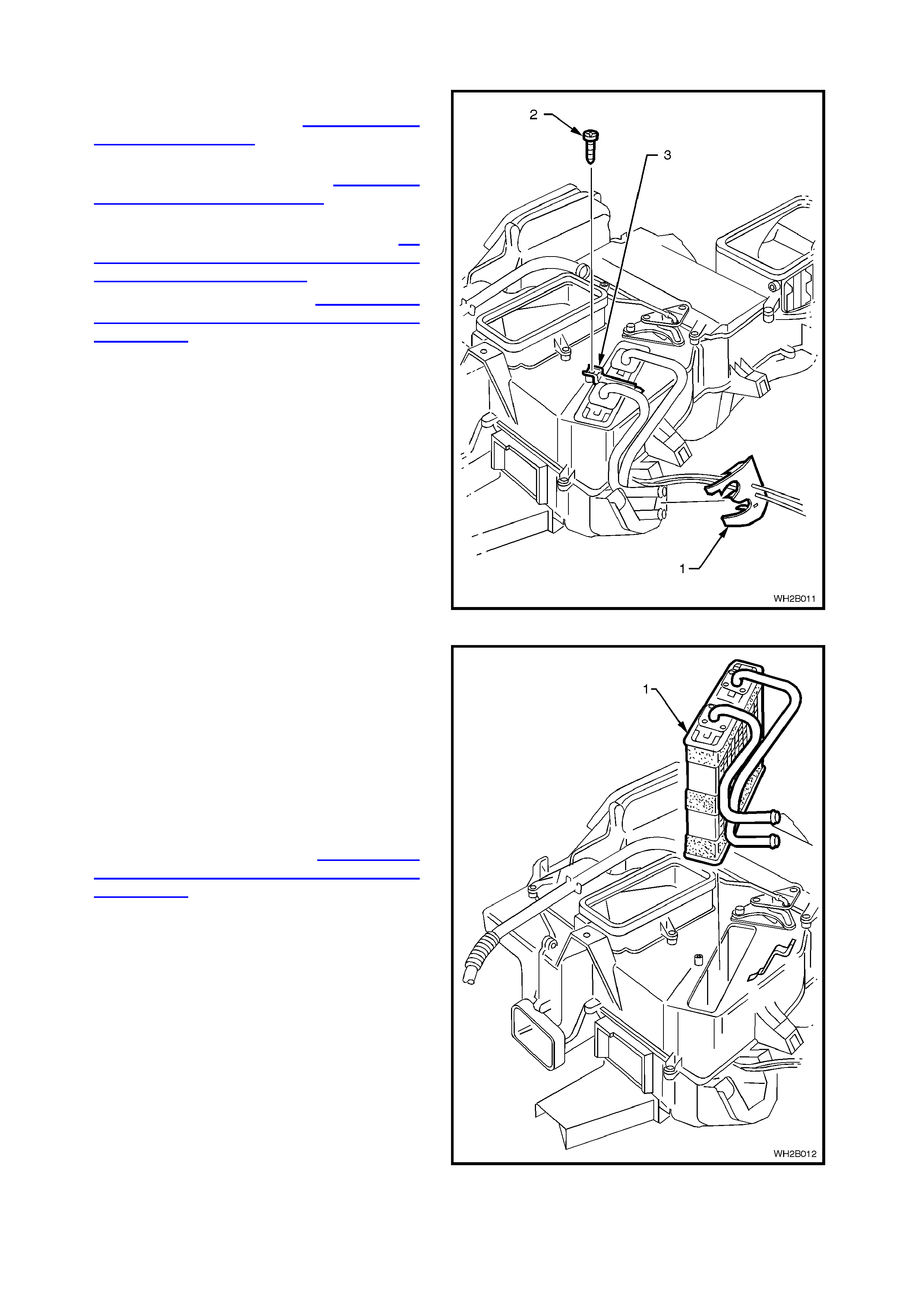

2.10 HE ATER CORE

REMOVE

1. Recover refrigerant, refer to Section 2C AIR

CONDITIONING ECC - SERVICING AND

DIAGNOSIS of the WH Service Information.

2. Drain cooling system, refer to Section 0B

LUBRICATION AND SERVICE of the WH

Service Information.

3. Remove instrument panel carrier, refer to 2.8

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

4. Remove HVAC unit, refer to 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT.

5. Unclip and remove plastic heater pipe retainer

(1) from rear of the HVAC unit.

6. Unscrew the self tapping screw (2) from the

plastic heater core retaining (3) strap and

remove strap.

7. Gently lift out the heater core assembly.

Figure 2B-52

REINSTALL

1. Slide the heater core (1) into the aperture

provided in the HVAC unit.

NOTE: Ensure the foam seals are not damaged

when inserting heater core.

2. Install the heater core plastic retaining strap.

Slide one side under the HVAC unit case and

secure with one self tapping screw.

3. Install the heater core pipe plastic retainer

located at the rear of the case.

4. Install the HVAC unit, refer to 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT in this Section.

5. Install the instrument panel carrier.

6. Refill the cooling system and bleed.

7. Evacuate and charge the system with

775 - 825g of R134a refrigerant.

Figure 2B-53

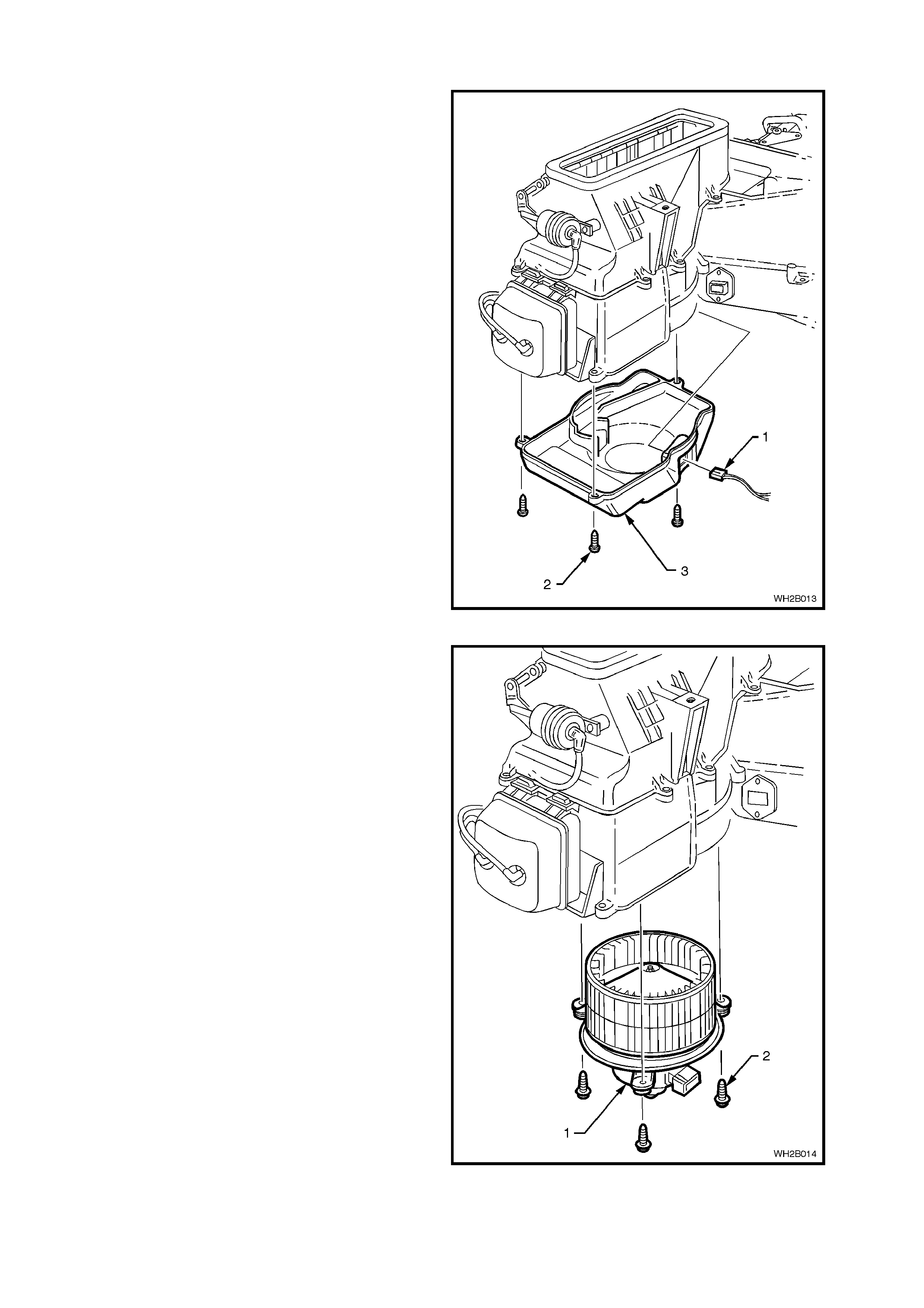

2.11 BLOWER MOTOR

REMOVE

1. Remove the footwell upper closing panel left

side (unclip).

2. Disconnect the blower motor electrical

connector (1).

3. Unscrew the blower motor access cover (3)

three self tapping screws (2).

Figure 2B-54

4. Locate the three blower motor retaining screws

and remove.

5. Gently remove the blower motor assembly.

NOTE: Ensure the blower motor wheel balancing

clips are not dislodged during removal.

REINSTALL

1. Install the blower motor (1) using three self

tapping screws ( 2). Ensur e the flat washers are

on the self tapping screws.

NOTE: When installing the blower motor ensure

that the balance clips have not been dislodged from

the blower motor wheel.

2. Install the blower motor access cover using the

three self tapping screws.

3. Connect the blower motor electrical plug to the

blower motor.

4. Install the footwell upper closing panel left side.

Figure 2B-55

2.12 BLOWER MOTOR RESISTOR

REMOVE

1. Remove the instrument panel lower

compartment, the instrument panel end cap

cover left-hand side and the instrument

compartment roof refer to 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT in this Section.

2. Detach the electrical connector (3) and two self

tapping screws (2) retaining the blower motor

resistor (1).

4. Remove the resistor assembly.

REINSTALL

1. Install the blower motor resistor using the

original two self tapping screws.

2. Reconnect the electrical connector.

3. Replace the instrument compartment roof

using original screws.

4. Install the instrument panel end cap cover left

side using original screws.

5. Reinstall the instrument panel lower

compartment using original pins.

Figure 2B-56

2.13 VACUUM TANK

REMOVE

1. Remove instrument facia assembly, refer to 2.8

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

2. Disconnect the two vacuum connections (2) at

the vacuum tank (1).

3. Unscrew the one self tapping screw from the

lower section of the tank.

5. Move vacuum tank outwards and down to

dislodge the retaining tangs.

REINSTALL

Reinstall the vacuum tank in the reverse order of

removal. Figure 2B-57

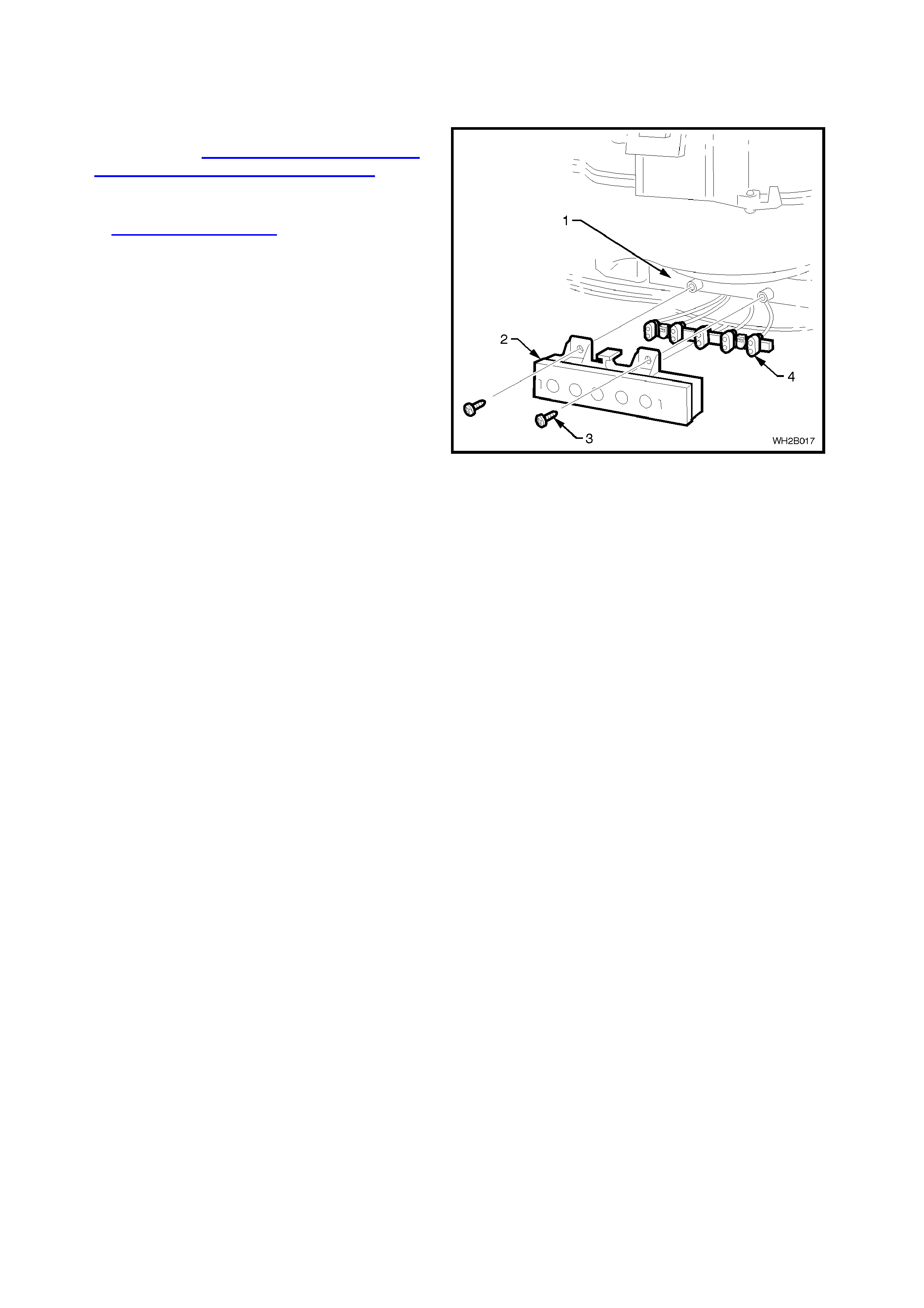

2.14 VACUUM SOLENOID PACK

REMOVE

1. Remove the footwell upper closing panel left

side, refer to 2.8 HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this

Section.

2. Remove the blower motor access cover, refer

to 2.11 BLOWER MOTOR in this Section.

3. Disconnect the vacuum solenoid pack vacuum

manifold (4).

5. Remove the two self tapping screws (3) and

detach the vacuum solenoid pack (2) from the

blower motor access cover (1).

REINSTALL

Reinstall is the reverse order of removal. Figure 2B-58

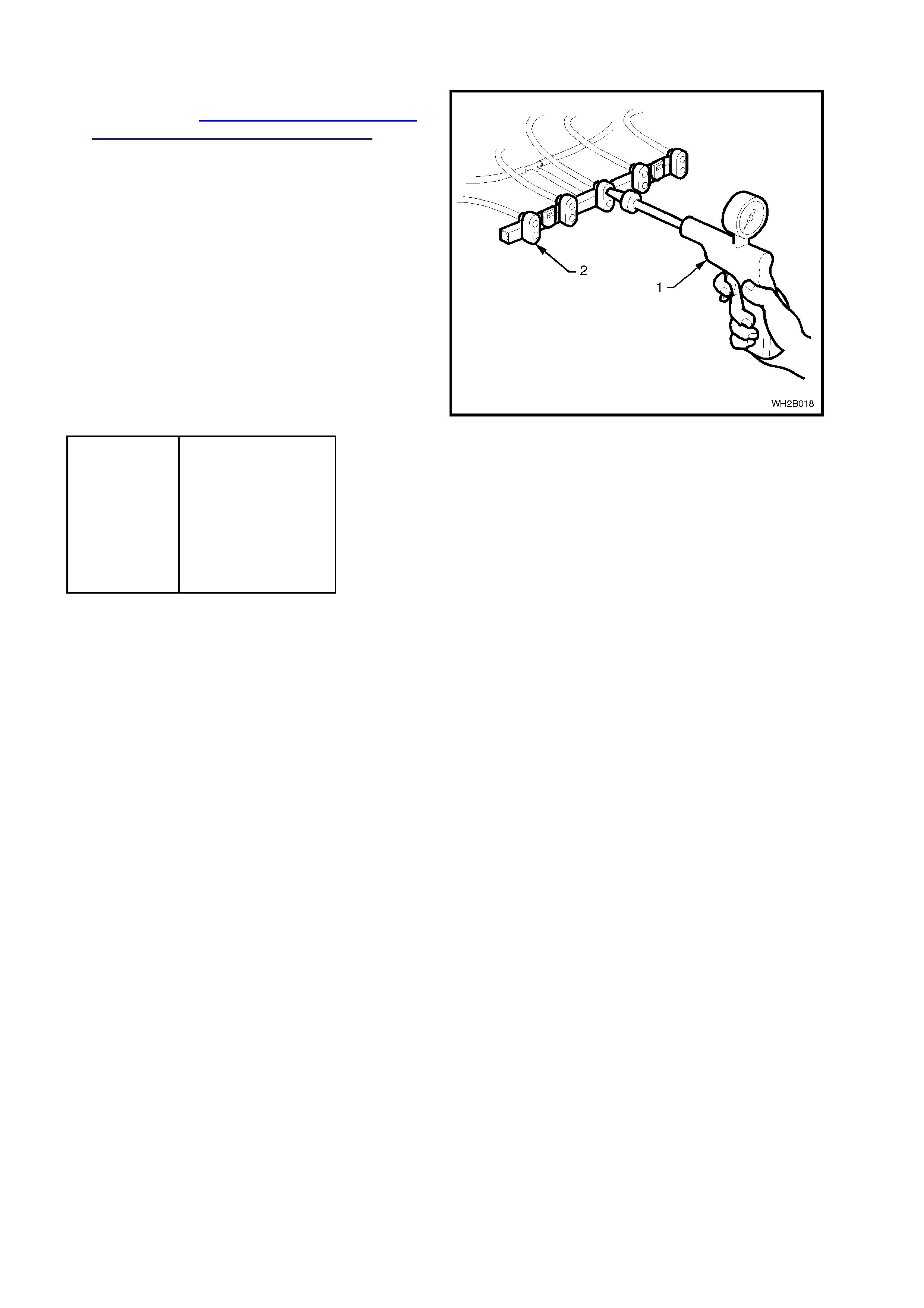

2.15 VACUUM LINE CHECK

1. Remove the footwell upper closing panel left

side, refer to 2.8 HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this

Section.

2. Locate the vacuum solenoid pack and

disconnect the plastic vacuum manifold (2).

3. Using a Mityvac (1) or similar, connect to the

appropriate port of the plastic vacuum m anifold

(see table below).

4. Create a vacuum, view Mityvac gauge to see if

the needle rises to positive pressure indicating

a vacuum leak.

5. If a vacuum leak is indicated it could be either

the vacuum tubing or the vacuum actuator

(check to see if the vacuum tubing is dislodged

from the vacuum actuator). Each of these

components will have to be vacuum leak

checked individually.

COLOUR FUNCTION

Green Bi-level

Red Floor

White Centre Vent

Orange Foot / Demist

Blue Recirc / Fresh

Black Vacuum Source

6. Once check is completed, reinstall all removed

com ponents ens uring that the vac uum tubing is

secure and correctly connected.

Figure 2B-59

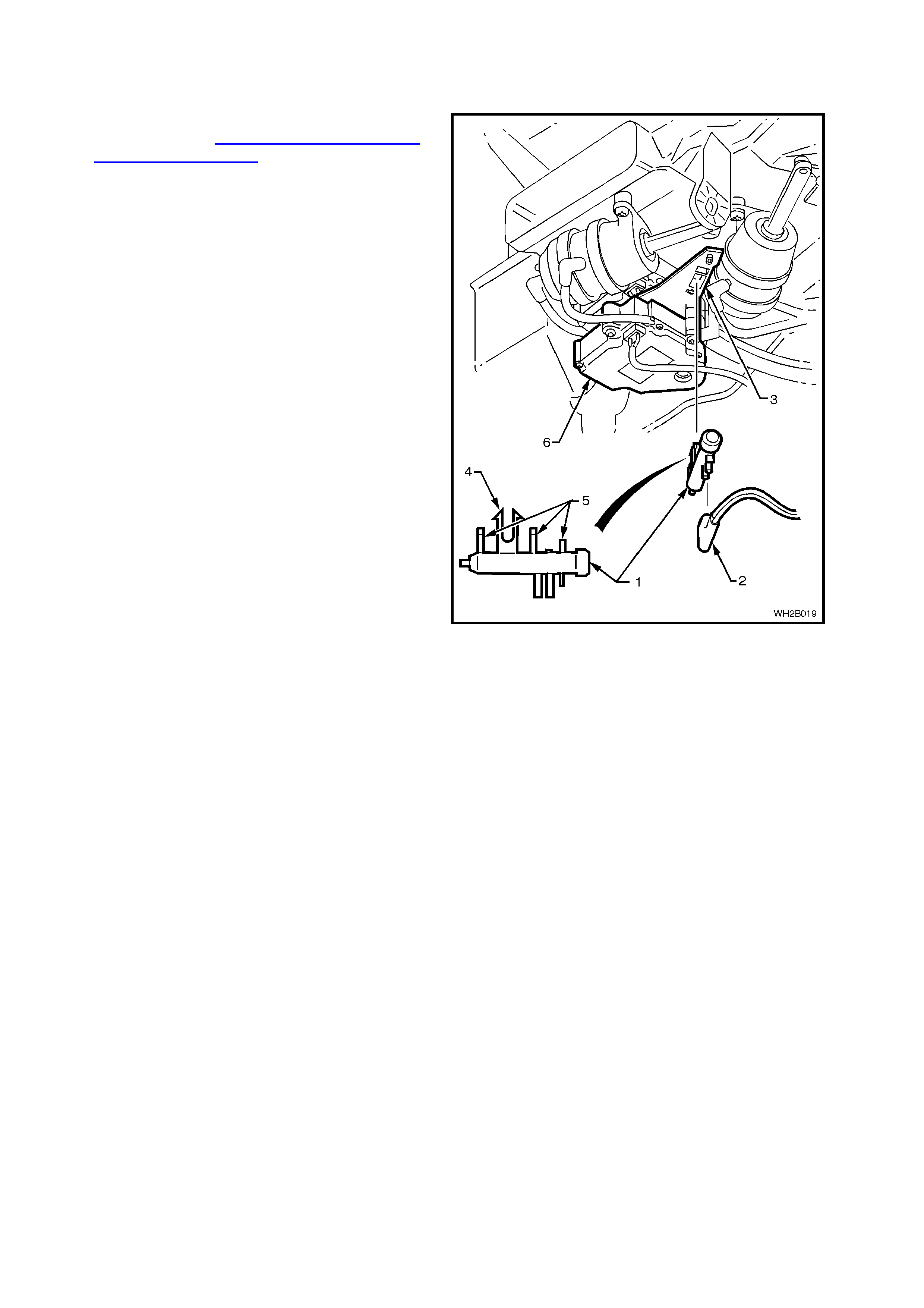

2.16 HE ATER VALVE VACUUM SWITCH

REMOVE

1. Remove the right hand side centre facia

extension, refer Section 1A3 INSTRUMENT

PANEL & CONSOLE of the WH Service

Information.

2. Locate the vacuum switch (1) adjacent to the

air mix motor (6) and remove the vacuum port

manifold (2).

3. From the upper section of the vacuum switch

bracket (3) push the two locking legs (4)

together and remove the vacuum switch.

REINSTALL

1. Firmly insert the vacuum switch into the

mounting bracket ensuring the three locating

pins (5) slide into their positions.

2. Re-connect the vacuum port manifold (one

directional fit).

3. Re-attach right hand side centre facia

extension. Figure 2B-60

2.17 FRESH/RE CIRCULATION ACTUATOR

REMOVE

1. Remove the instrument panel lower

compartment, the instrument panel end cap

cover left side and the footwell upper closing

panel left side refer to 2.8 HEATING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT in this Section.

2. Disconnect the vacuum tube (3) and vacuum

actuator rod (1) from the fresh/recirculation

lever.

3. Using a stubby Phillip’s head screwdriver

remove the vacuum actuator two self tapping

screws (2).

REINSTALL

Reinstallation takes place in the reverse order of

removal.

Figure 2B-61

2.18 BI-LEVEL/CENTRE VENT AND DEMIST/FOOT ACTUATOR

REMOVE

1. Remove instrument panel carrier, refer to 2.8

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

2. Remove the HVAC unit (ref er to 2.8 HEAT ING,

VENTILATION AND AIR CONDITIONING

(HVAC) UNIT.

3. From the underside of the HVAC unit, locate

the vacuum actuator for removal.

4. Gently unclip the white Bi level/centre vent

vacuum actuator rod (1) from the door lever.

Remove the coloured vacuum tubing (2 and 3)

from the ports.

NOTE: Take note of the vacuum tubing positions.

Orange vacuum line (2)

Red vacuum line (3)

4. Detach the vacuum actuator two self tapping

screws (4).

REINSTALL

Reinstall the vacuum actuator in the reverse order

of removal.

NOTE: If in doubt about the correct colour coding

of the vacuum tubes to the vacuum actuator’s ports

refer to Section 2A AIR CONDITIONING - ECC -

PRINCIPLES AND OPERATION, Fig. 2A-19.

NOTE: Vacuum actuator with WHITE rod - connect

to WHITE coloured levers.

Vacuum actuator with BLACK rod - connect to

BLACK coloured gears.

Figure 2B-62

Legend

1. Demist/floor actuator rod (black).

2. Vacuum line (orange).

3. Vacuum line (red).

4. Screws (2).

Figure 2B-63

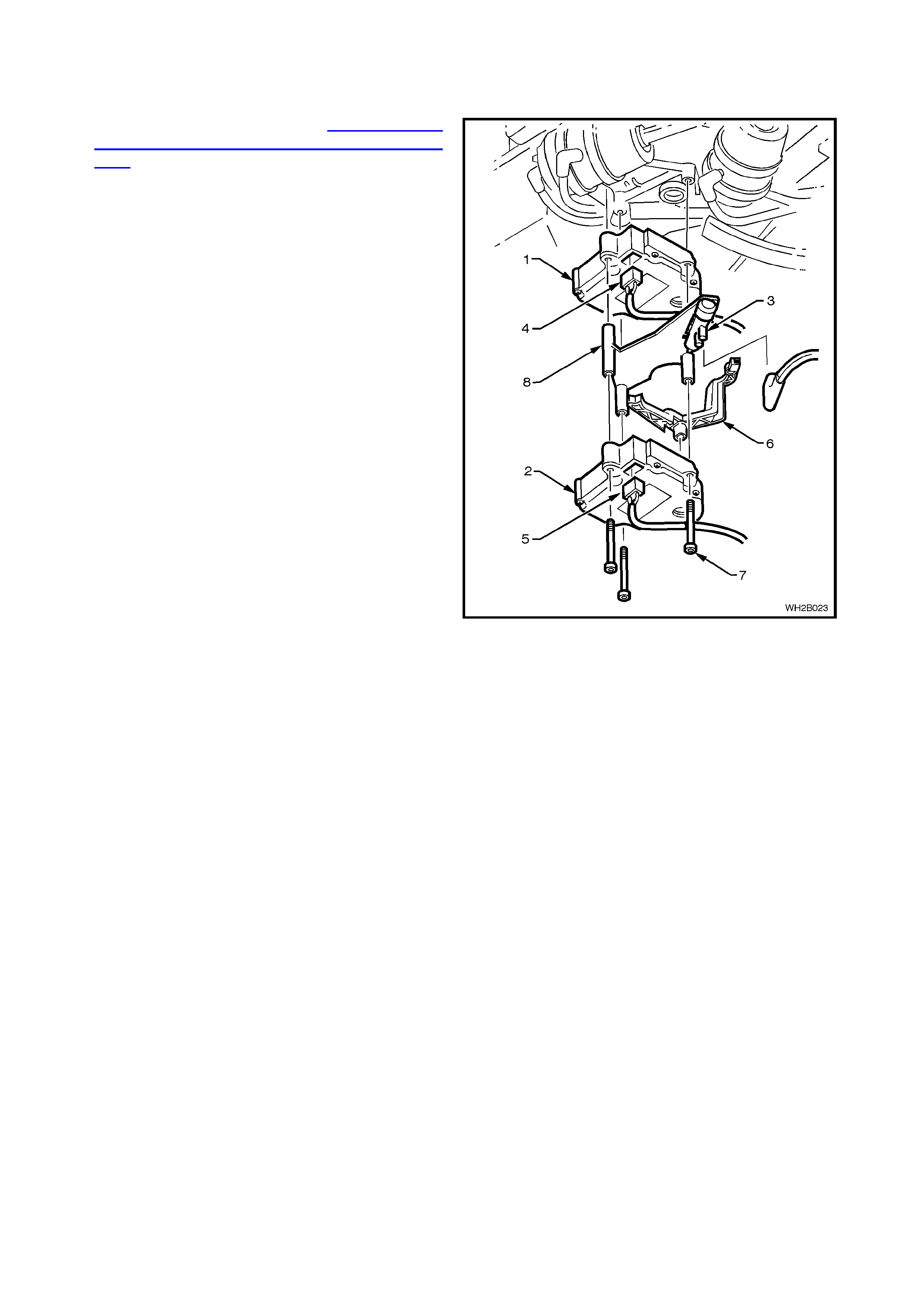

2.19 AIR MIX MOTORS

REMOVE

1. Remove HVAC, refer to 2.8 HEATING,

VENTILATION AND AIR CONDIT IONING (HVAC)

UNIT in this Section.

2. From the underside of the HVAC unit, locate the

air mix motors (1,2).

3. Disconnect the vac uum m anifold from the vacuum

switch (3), two electrical connections (4,5) and the

upper mixing door lever (6).

5. Unscrew the three self tapping screws (7) used to

retain the air mix motor pack and remove.

REINSTALL

1. Align the HVAC shaft end with the upper air mix

motor drive (1) (left hand side) and hold in position.

2. Install the intermediate mounting plate (8) under

the upper air mix motor (1).

3. Install the lower air m ix motor (2) (right hand side)

and secure the air m ix m otor pac k with the or iginal

three self tapping screws (7).

4. Re-connect the electrical connections (4,5),

vacuum switch (3) and upper mixing door lever (6).

5. Refit the HVAC unit. Figure 2B-64

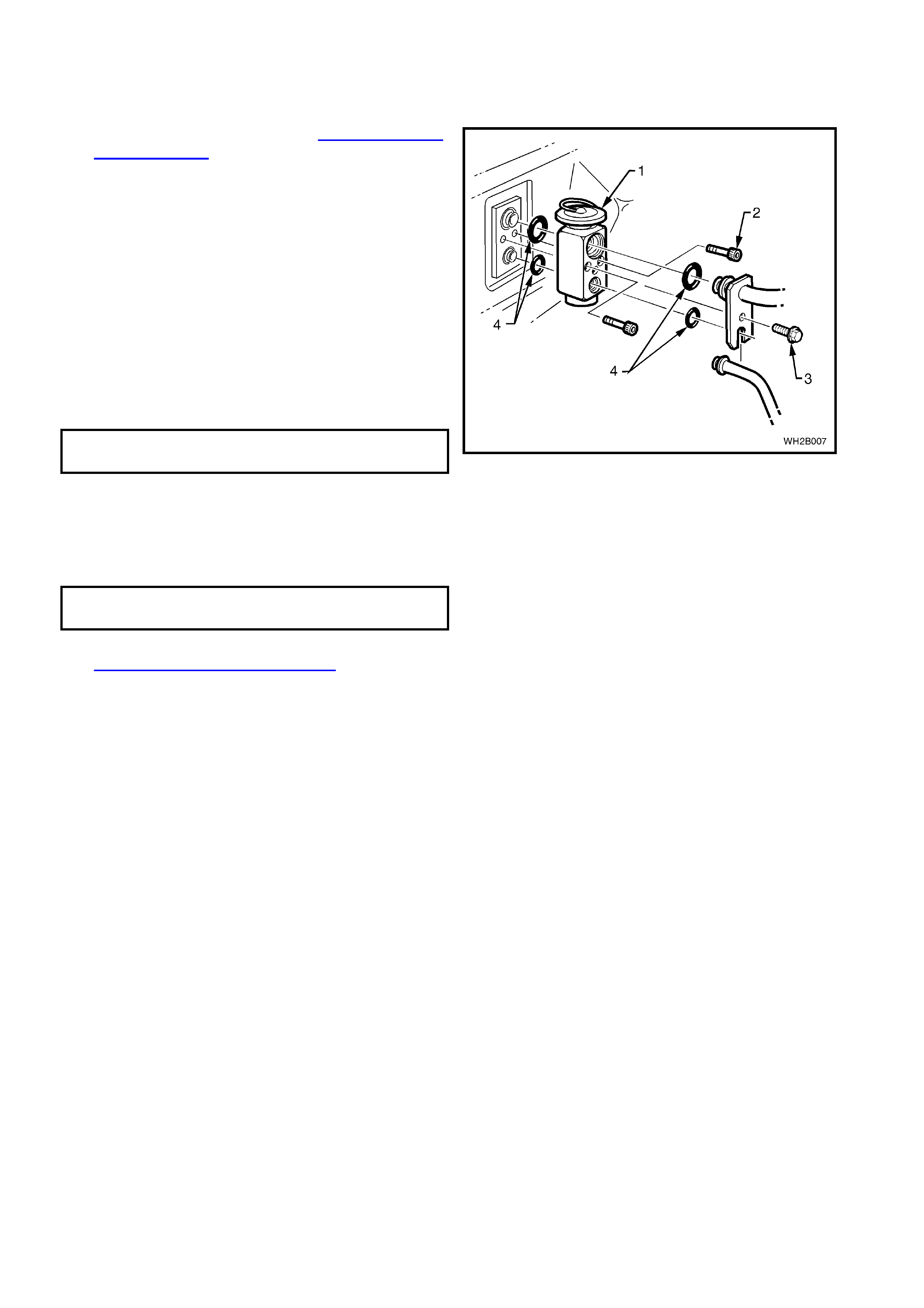

2.20 THERMAL EXPANSION VALVE (TXV)

REMOVE

1. Recover refrigerant, refer to Section 2C AIR

CONDITIONING - SERVICING AND DIAGNOSIS

of the WH Service Information.

2. Remove the washer faced bolt (3) retaining the

tube plate to the TXV (1).

3. Discard O - rings (4).

4. Unscrew two capscrews (2) and remove TXV (1).

REINSTALL

1. Lubricate and fit two new O - rings to the

evaporator tubes.

2. Insert the TXV (diaphragm facing upwards) onto

the evaporator tubes.

3. Secur e the TX V to the evaporator tube plate using

the two cap screws.

EVAPORATOR TUBE PLATE

SECURING SCREWS 4.0 - 4.5 Nm

TORQUE SPECIFICATION

4. Fit two new lubricated O - rings to the liquid and

suction tubes.

5. Insert the liquid and suction tubes and retaining

plate onto the TXV.

6. Secure using original bolt.

WASHER FACED TUBE PLATE

RETAINING BOLT 7.5 - 12.5 Nm

TORQUE SPECIFICATION

7. Evacuate and charge the A/C system refer to

Section 2C AIR CONDITIONING - SERVICING

AND DIAGNOSIS of the WH Service Information.

Figure 2B-65

2.21 CONDE NSER - V6 & V8

REMOVE

1. Recover refrigerant from the A/C system, refer

to Section 2C AIR CONDITIONING -

SERVICING AND DIAGNOSIS of the WH

Service Information.

2. Remove the radiator assembly, refer to

Section 6B1 ENGINE COOL ING - V6 ENG INE

of the VT Series I Service Information or

Section 6B3 ENGINE COOLING - GEN III V8

ENGINE of the VT Series II Service

Information.

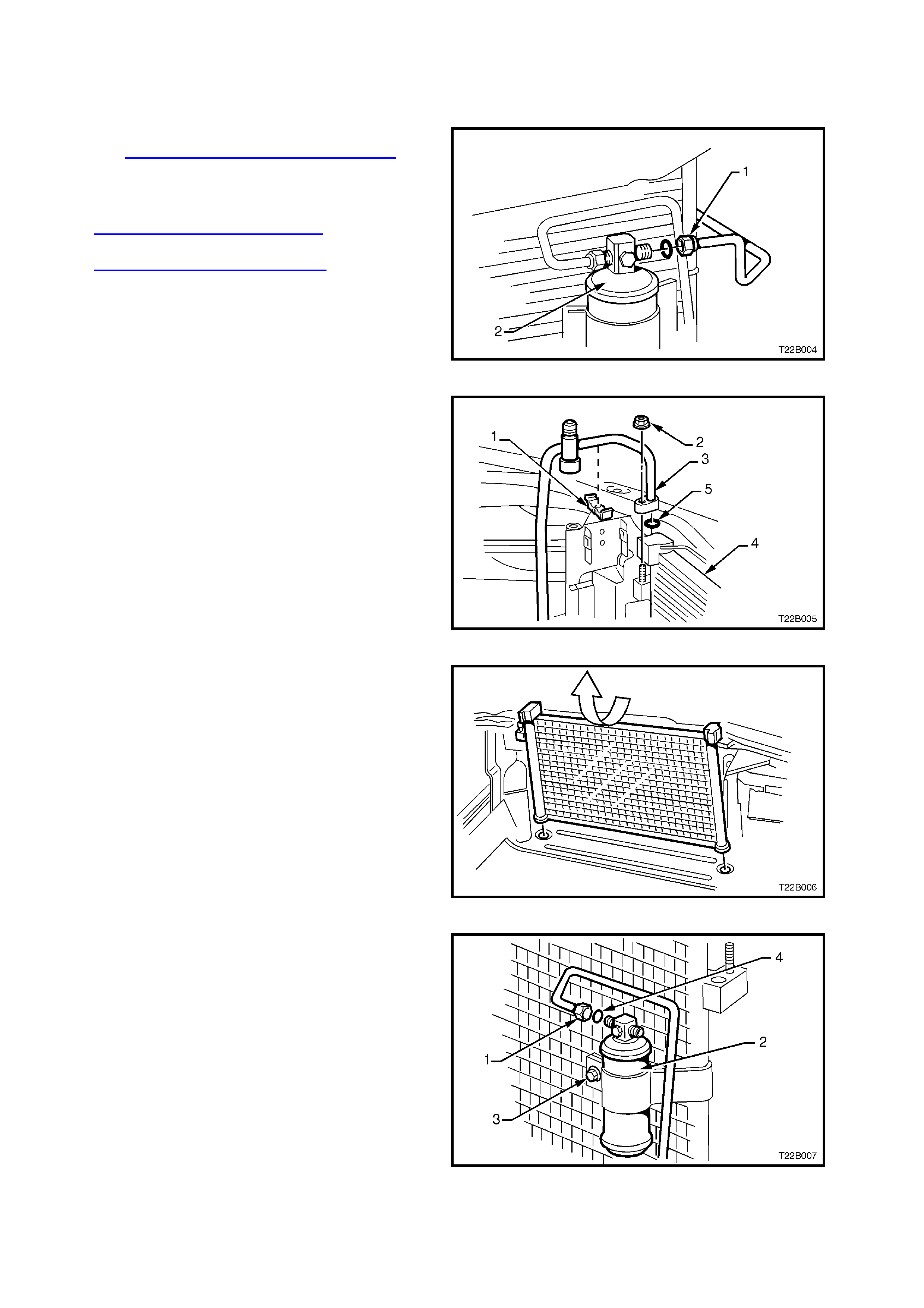

3. Through the front bumper bar opening,

unscrew the liquid tube f itting (1) f rom the Filter

Drier Receiver (FDR) (2) outlet. Figure 2B-66

4. Gently prise open discharge tube retaining clip

(1).

5. Remove nut (2) retaining the discharge hose

pad fitting (3) to the condenser (4).

6. Cap all open tubes/hoses to avoid moisture

from entering the system.

7. Discard O - rings (5).

Figure 2B-67

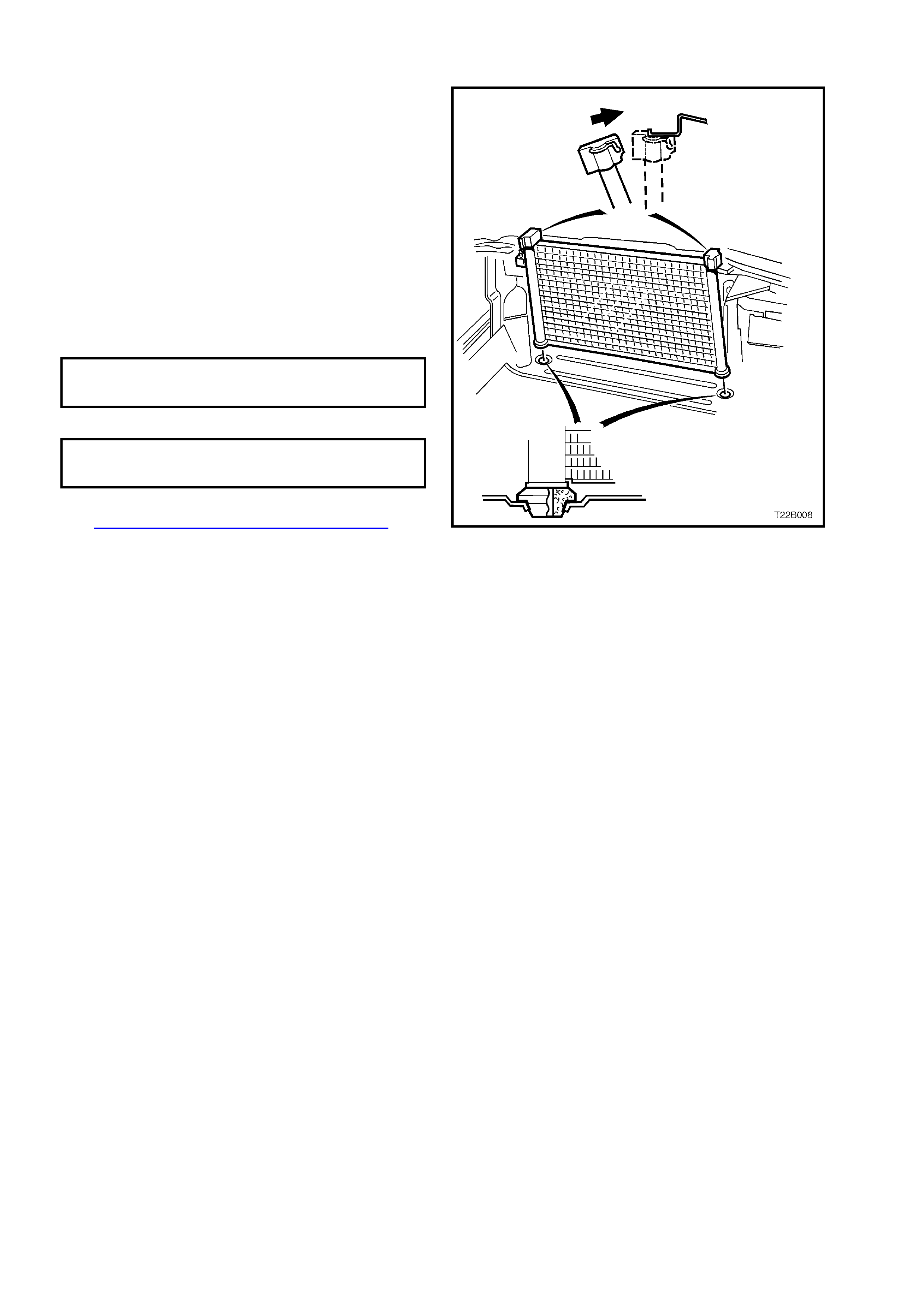

8. Disconnect the ambient temperature sensor

electrical connector from the front right hand

side of the condenser.

9. Tilt the condenser towards engine and lift

upwards.

Figure 2B-68

10. Mark mounting position of FDR for correct

reinstallation.

11. Unscrew the FDR inlet fitting (1) loosen the

FDR mounting brack et bolt (3) and remove the

FDR (2).

12. Discard O - ring (4).

NOTE: Mark mounting position of FDR for correct

repositioning.

Figure 2B-69

REINSTALL

Reinstallation of the condenser is the reverse of

removal procedure, noting the following.

1. Always use new O - rings and lubricate with

PAG refrigerant oil (part number 12345923)

before fitting.

CAUTION: Do not allow PAG refrigerant oil to

contact bare skin or vehicle paintwork. If contact

occurs to either, wash PAG refrigerant oil off

immediately.

2. When reinstalling the FDR, ensure the FDR

inlet tube is connected to the f itting on the FDR

with the word 'IN' refer to markings on FDR

before removal.

DISCHARGE TUBE PAD

RETAINI NG NUT 7.5 - 12.5 Nm

TORQUE SPECIFICATIO N

AIR CONDIT IONING TUB E

FITTING TO FDR TORQUE 7.5 - 12.5 Nm

SPECIFICATION

5. Recharge air conditioning system, refer to

Section 2C AIR CONDITIONING -

SERVICING AND DIAGNOSIS of the WH

Service Information. Figure 2B-70

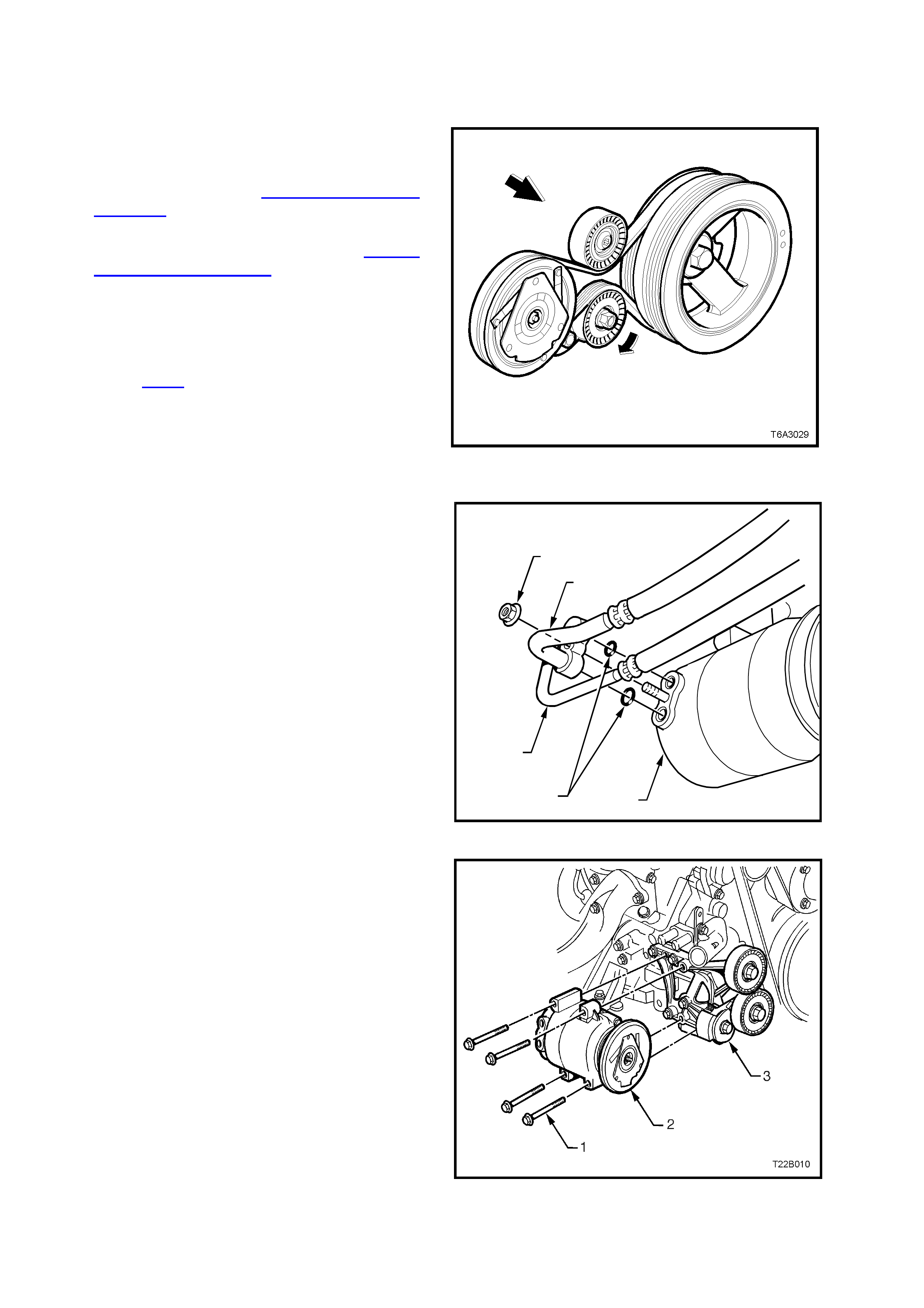

2.22 A/C DRIVE BELT - V6 ENGINE

REMOVE

1. Using a 17mm ring spanner on the drive belt

tensioner pulley retaining bolt, release the belt

tension.

2. Starting at the water pump pulley remove the

drive belt.

REINSTALL

1. Using the diagram in Fig. 2B-71 fit the drive

belt starting at the water pump pulley.

2. Ensure the vee grooves of the drive belt align

with the grooves in the pulley s.

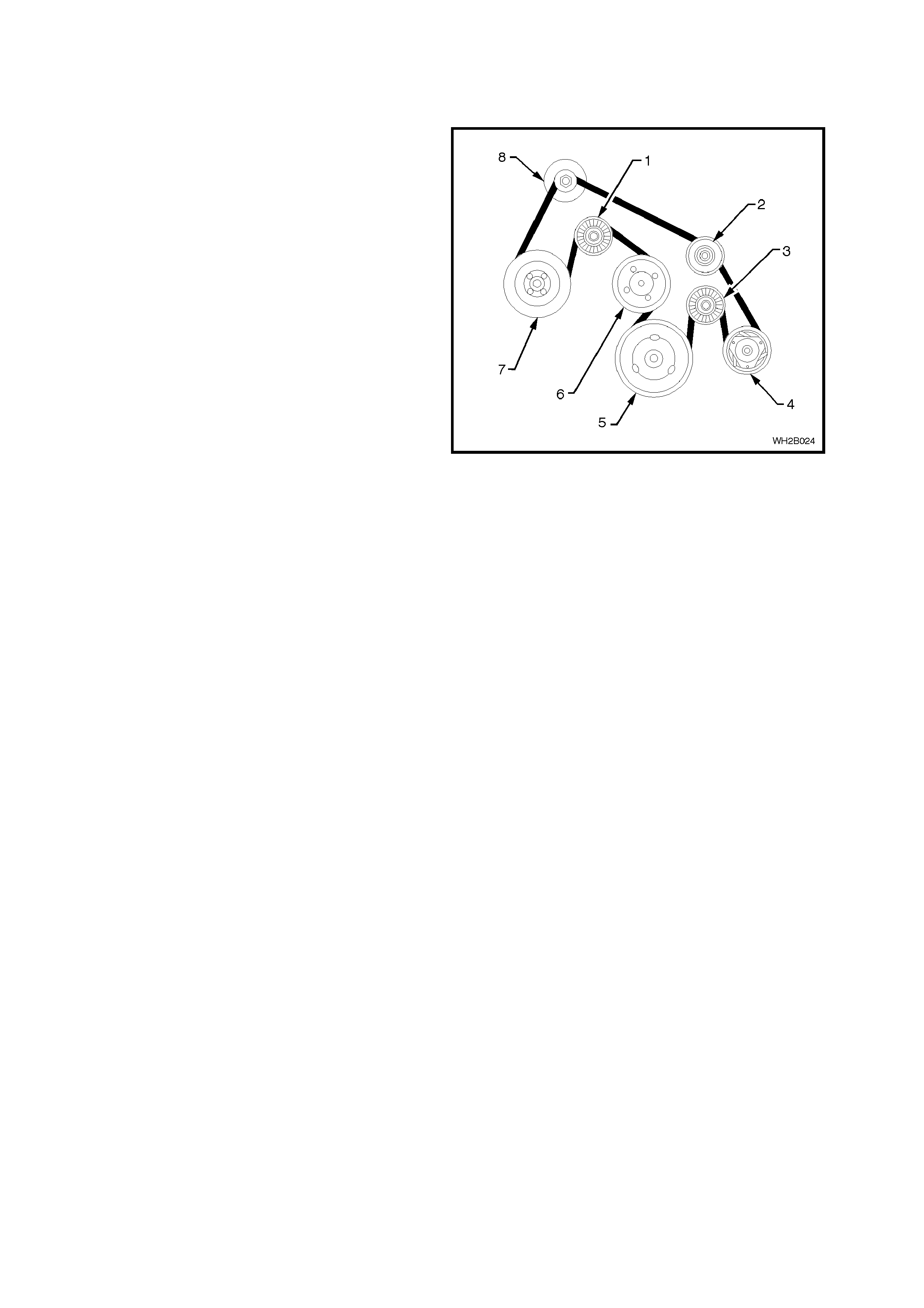

Legend

1. Drive belt tensioner

2. Idler pulley

3. A/C idler pulley

4. Compressor

5. Crankshaft pulley

6. Water pump pulley

7. Power steering pump pulley

8. Generator pulley

Figure 2B-71

2.23 A/C DRIVE BELT - V6 SUPERCHARGED ENGINE

REMOVE

1. Using a 17mm ring spanner on the

supercharger drive belt tensioner (1), release

the supercharger drive belt tension.

2. Remove the supercharger drive belt starting at

the double idler pulley (5).

3. Using a 17mm ring spanner on the main drive

belt tensioner pulley retaining bolt (10), release

the belt tension.

4. Starting at the water pump pulley (7) remove

the drive belt.

REINSTALL

1. Using the diagram in Fig. 2B-72 fit the drive

belt and then the supercharger belt starting at

the water pump pulley (drive belt) and double

idler pulley (supercharger drive belt).

2. Ensure that the vee grooves of both dr ive belts

align with the pulley grooves.

Legend

1. Supercharger drive tensioner.

2. Idler.

3. Accessory drive idler.

4. Compressor.

5. Double idler pulley.

6. Crankshaft.

7. Water pump.

8. Power steering pump.

9. Alternator.

10. Drive belt tensioner.

11. Supercharger.

Figure 2B-72

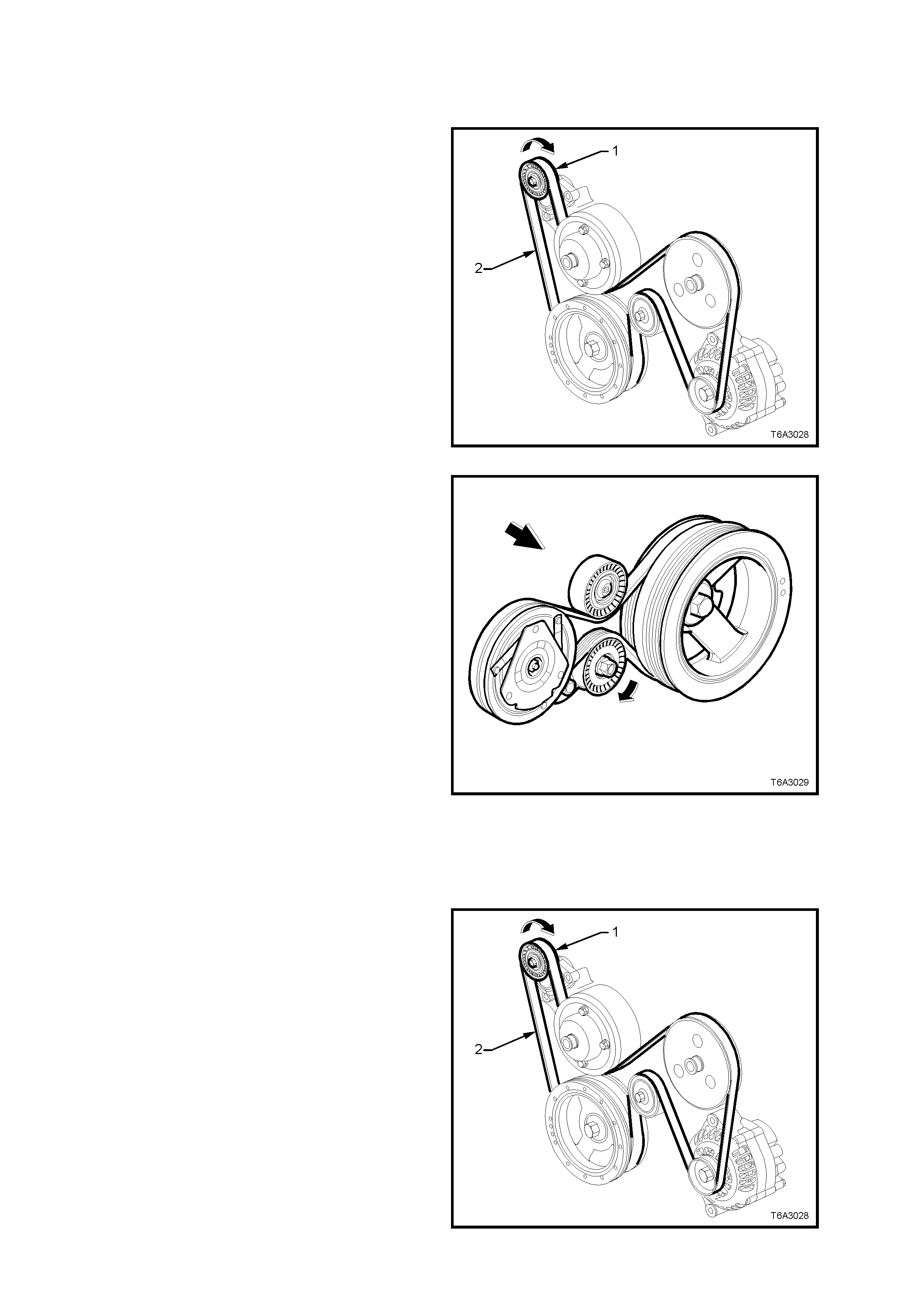

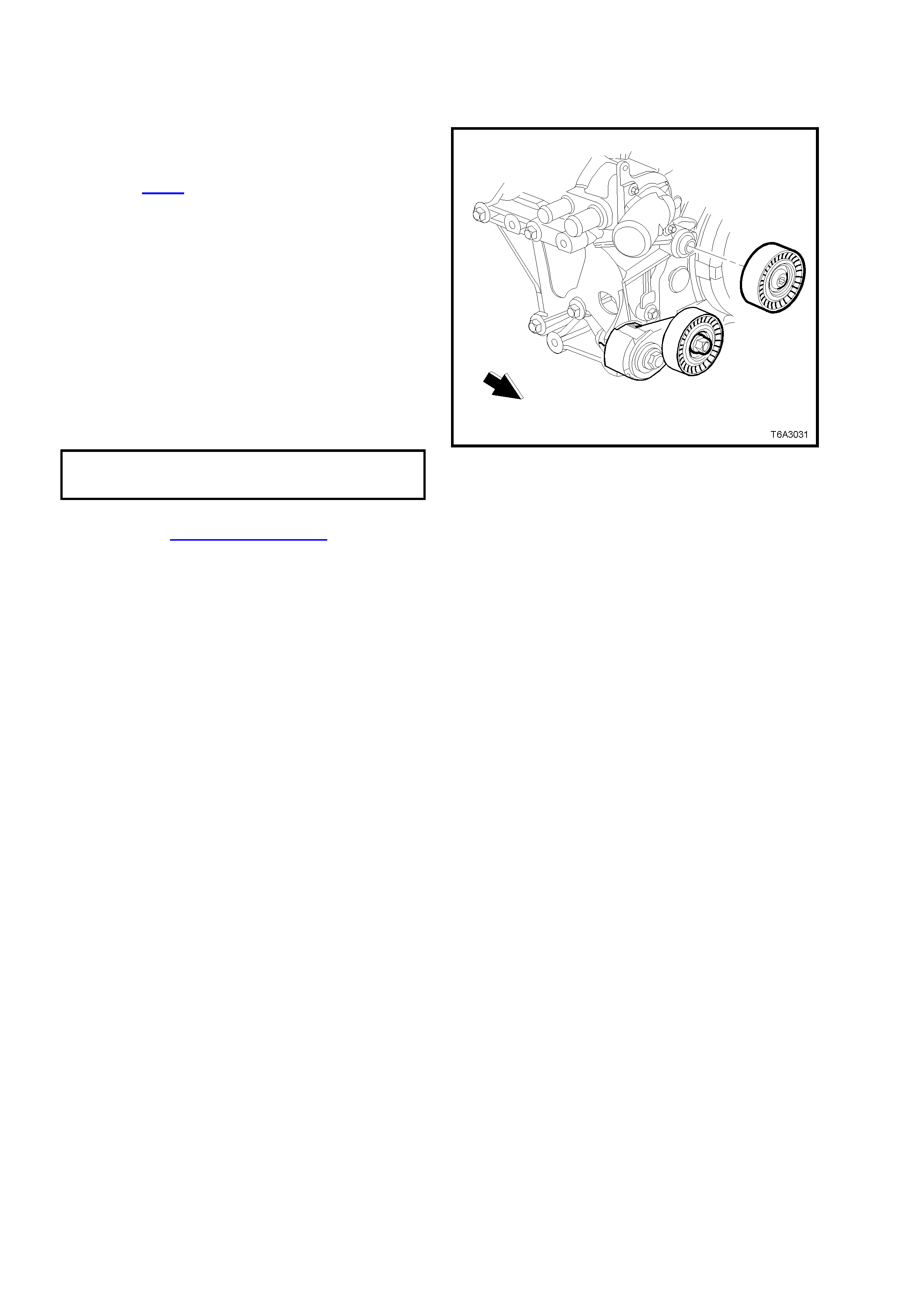

2.24 A/C DRIVE BELT - GEN III V8 ENGINE

REMOVE

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the engine

accessory drive belt tensioner (1), in the

direction indicated, to reduce belt tension.

2. Remove the engine drive belt (2), taking note of

the belt routing.

Figure 2B-73

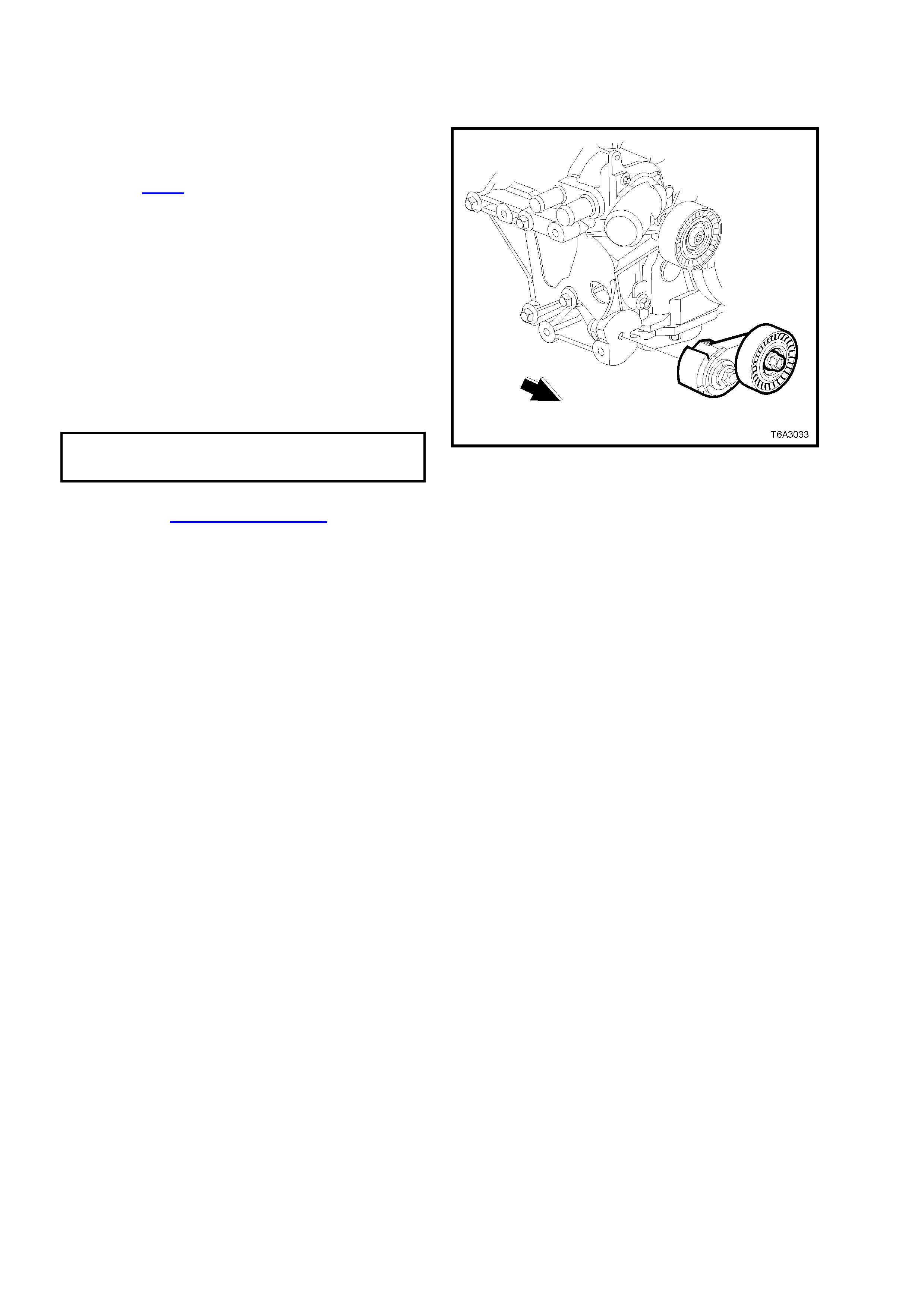

3. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown, to

relieve belt tension.

4. Rem ove the air conditioning drive belt f rom the

pulleys.

4. Inspect belts for damage and replace if

necessary.

REINSTALL

1. Clean the engine accessory and air

conditioning drive belt running surfaces

2. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown,

install the drive belt over the pulleys, routing the

belt correctly as shown.

3. Inspec t the ins tallation to ensure that the belt is

correctly aligned on all pulleys.

Figure 2B-74

4. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the engine

accessory drive belt tensioner (1), in the

direction indicated, inst all the engine accessory

drive belt (2) over the pulleys, routing the belt

correctly, as shown.

5. Inspec t the ins tallation to ensure that the belt is

correctly aligned on all pulleys.

6. Start the engine to ensure correct operation.

Figure 2B-75

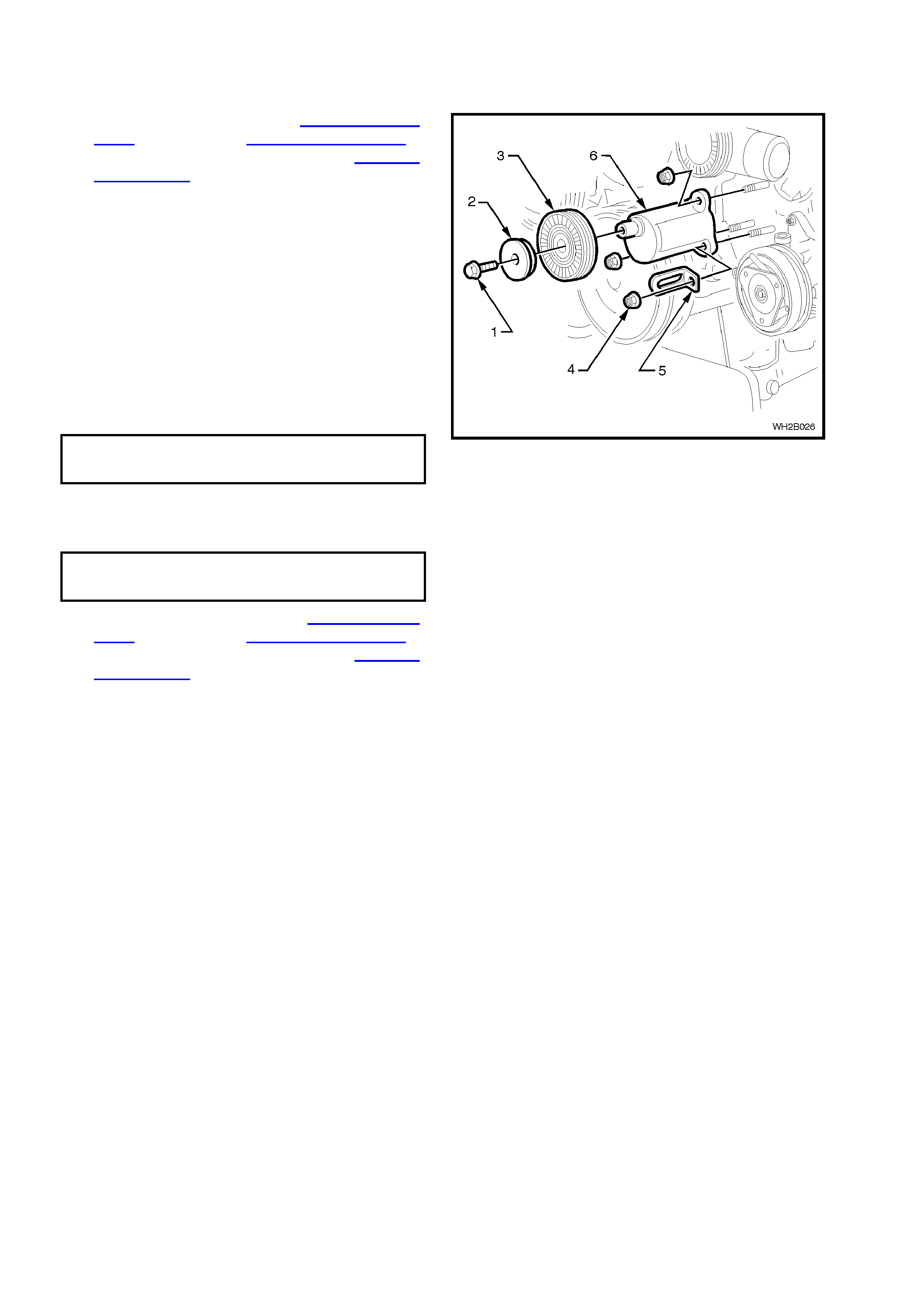

2.25 A/C DRIVE BELT IDLER PULLEY - V 6 ENGINE

REMOVE

1. Remove drive belt, refer to 2.22 A/C DRIVE

BELT – V6 ENGINE, 2.23 A/C DRIVE BELT –

V6 SUPERCHARGED ENGINE or 2.24 A/C

DRIVE BELT – GEN III V8 ENGINE in this

Section.

2. Unscrew the idler pulley retaining bolt (1).

3. Remove bolt, washer (2) and pulley (3).

4. Unscrew and remove the three mounting

bracket nuts (4).

5. Detach the idler mounting bracket from engine

(6).

REINSTALL

1. Fit the idler mounting bracket to engine.

2. Install the harness clip (5) as shown.

3. Install the three nuts.

MOUNTING BRACKET

RETAINING NUTS 20 - 30 Nm

TORQUE SPECIFICATION

4. Replace the pulley, washer and bolt onto the

idler pulley bracket.

5. Tighten the idler pulley retaining bolt.

IDLER PULLE Y

RETAINI NG B OLT 45 - 50 Nm

TORQUE SP ECIFI CA T ION

6. Replace the drive belt, refer to 2.22 A/C DRIVE

BELT – V6 ENGINE, 2.23 A/C DRIVE BELT –

V6 SUPERCHARGED ENGINE or 2.24 A/C

DRIVE BELT – GEN III V8 ENGINE in this

Section

Figure 2B-76

2.26 A/ C DRIVE BELT IDLER PULLEY - GEN III V8 ENGINE

REMOVE

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown in

Figure 2B-74, to relieve belt tension.

2. Rem ove the air conditioning drive belt f rom the

pulleys but leave hanging on the crankshaft

pulley.

3. Using a commercially available, Torx bit T50,

remove the bolt securing the air conditioning

compressor drive belt idler pulley to its

mounting boss on the water pump housing,

then remove the pulley assembly.

REINSTALL

1. Install the idler pulley to its mounting boss.

2. Install the idler pulley retaining bolt and tighten

to the correct torque specification.

AIR CONDIT IONING COMPRESSOR

DRIVE B ELT IDLER P ULLE Y BOLT 40.0 - 60.0 Nm

TORQUE SPECIFICATION

3. Reinstall the air conditioning compressor drive

belt. Refer 2.24 A/C DRIVE BELT – GEN III V8

ENGINE - REINSTALL in this Section for the

necessary procedure.

Figure 2B-77

2.27 A/CONDITIONING DRIVE BELT TENSIONER - GEN III V8 ENGINE

REMOVE

1. Using a 15mm socket attached to the centre

bolt of the tensioner, rotate the air conditioning

drive belt tensioner in the direction shown in

Figure 2B-74, to relieve belt tension.

2. Rem ove the air conditioning drive belt f rom the

pulleys but leave hanging on the crankshaft

pulley.

3. Remove the bolt securing the air conditioning

compressor drive belt tensioner, then remove

the assembly.

REINSTALL

1. Install the tensioner assembly and the

mounting bolt.

2. Tighten the tensioner mounting bolt to the

correct torque specification.

AIR CONDI T I O NING DRIVE BELT

TENSIONER BOLT 21.0 - 29.0 Nm

TORQUE SP ECIFI CA T ION

3. Reinstall the air conditioning compressor drive

belt. Refer 2.24 A/C DRIVE BELT – GEN III V8

ENGINE - REINSTALL in this Section for the

necessary procedure.

Figure 2B-78

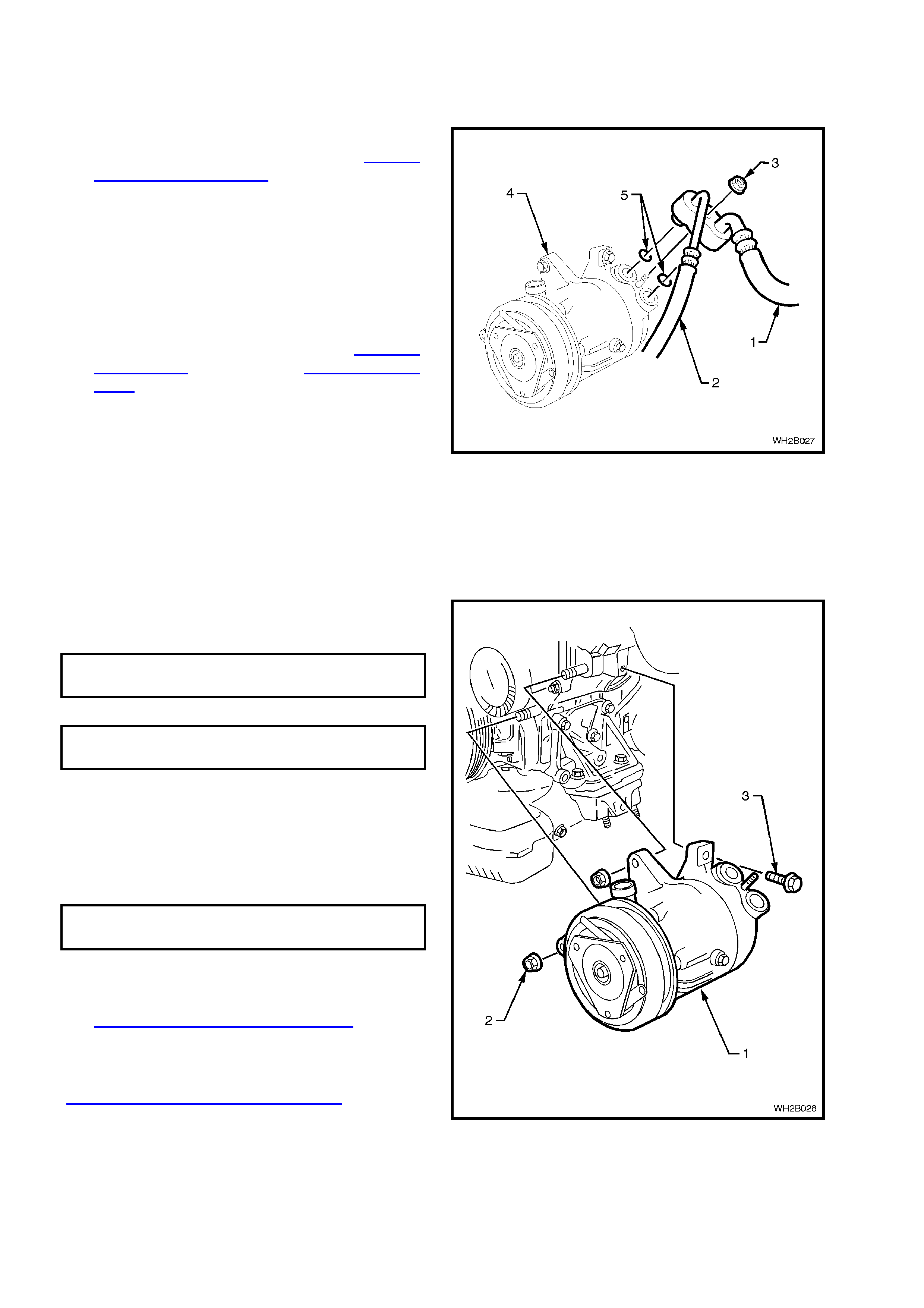

2.28 COMPRESSOR - V6 ENGINE

REMOVE

1. Disconnect the battery ground cable.

2. Recover refrigerant charge, refer Section

2C AIR CONDITIONING - ECC SERVICING

AND DIAGNOSIS of the WH Service

Information.

3. Remove the suction/discharge hose pad fitting

nut (3) from the compressor (4 ).

4. Cap or plug disconnected suction (1) and

discharge (2) hoses and ports immediately to

prevent absorption of moisture from the

atmosphere.

5. Remove the A/C drive belt, refer 2.22 A/C

DRIVE BELT – V6 ENGINE, 2.23 A/C DRIVE

BELT – V6 SUPERCHARGED ENGINE in this

Section.

6. Jack up the vehicle and place the vehicle on

jack stands.

7. Disconnect the compressor clutch electrical

connector.

8. Rem ove the two nuts and one bolt retaining the

compressor to the engine block.

Figure 2B-79

REINSTALL

1. Fit the compressor to the engine using the

original two nuts and bolt. Torque to

specifications.

COMPRESSOR ASSEMBLY

RETAINING NUT 40 - 55 Nm

TORQUE SPECIFICATION

COMPRESSOR ASSEMBLY

RETAINING BOLT 20 - 30 Nm

TORQUE SPECIFICATION

2. Fit the A/C drive belt.

3. Remove the compressor port protection caps.

4. Fit two new port sealing washers (5).

5. Secur e the suction/dis charge hos e ass em bly to

the compressor with original nut.

SUCTION/DISCHA RGE HOSE

ASSEMBLY SECURING NUT 28 - 42 Nm

TORQUE SPECIFICATION

6. Evacuate and charge the A/C system with

775 - 825 g of R134a refrigerant, refer to

Section 2C AIR CONDITIONING - ECC

SERVICING AND DIAGNOSIS of the WH

Service Information.

NOTE: If r eplacing with a new compr essor, refer to

Section 2C AIR CONDITIONING - ECC

SERVICING AND DIAGNOSIS for lubrication

requirements. Figure 2B-80

2.29 COMPRESSOR - GEN III V8 ENGINE

REMOVE

1. Disconnect the battery ground cable.

2. Drain coolant and remove the heater hoses

and lower radiator coolant hose from the

cylinder block, refer to Section 6B3 ENGINE

COOLING - GEN III V8 ENGINE of the VT

Series II Service Information.

3. Recover refrigerant charge, refer to Section

2C AIR CONDITIONING - ECC SERVICING

AND DIAGNOSIS of the WH Service

Information.

4. Using a 15mm socket attached to the centre

bolt of the air conditioning drive belt tensioner,

rotate the tensioner in the direction shown in

Figure 2B-74, to relieve belt tension.

5. Rem ove the air conditioning drive belt f rom the

pulleys but leave hanging on the crankshaft

pulley.

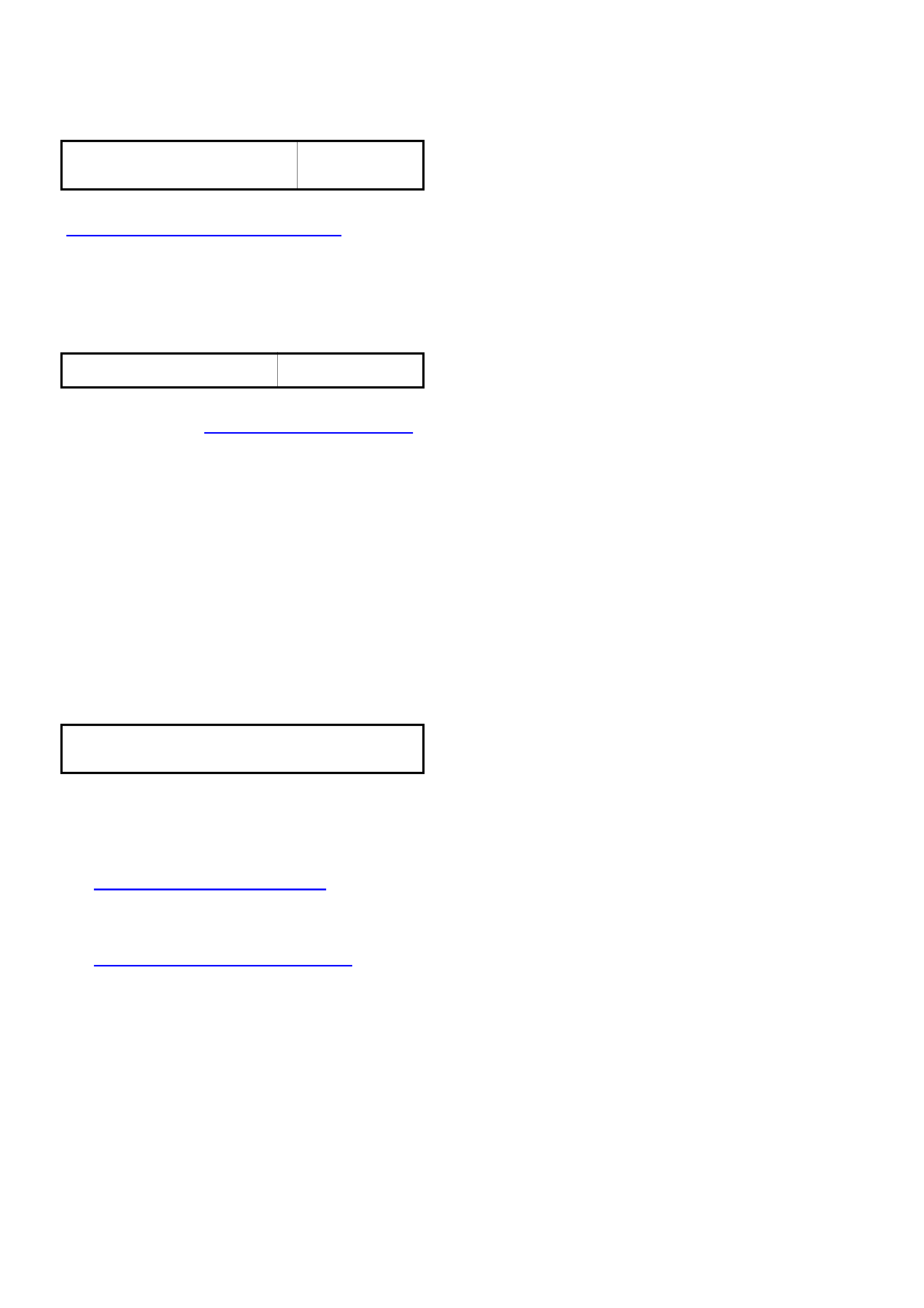

Figure 2B-81

6. Loosen and remove the nut (1) retaining the

suction (2) and discharge (3) hoses to the

compressor (4). Remove the hoses (2 & 3)

from the compressor.

7. Discard O-ri ngs (5).

8. Cap or plug the ports immediately to prevent

entry of moisture from the atmosphere.

9. Disconnect the compressor clutch electrical

connector.

T22B009

1

2

3

54

Figure 2B-82

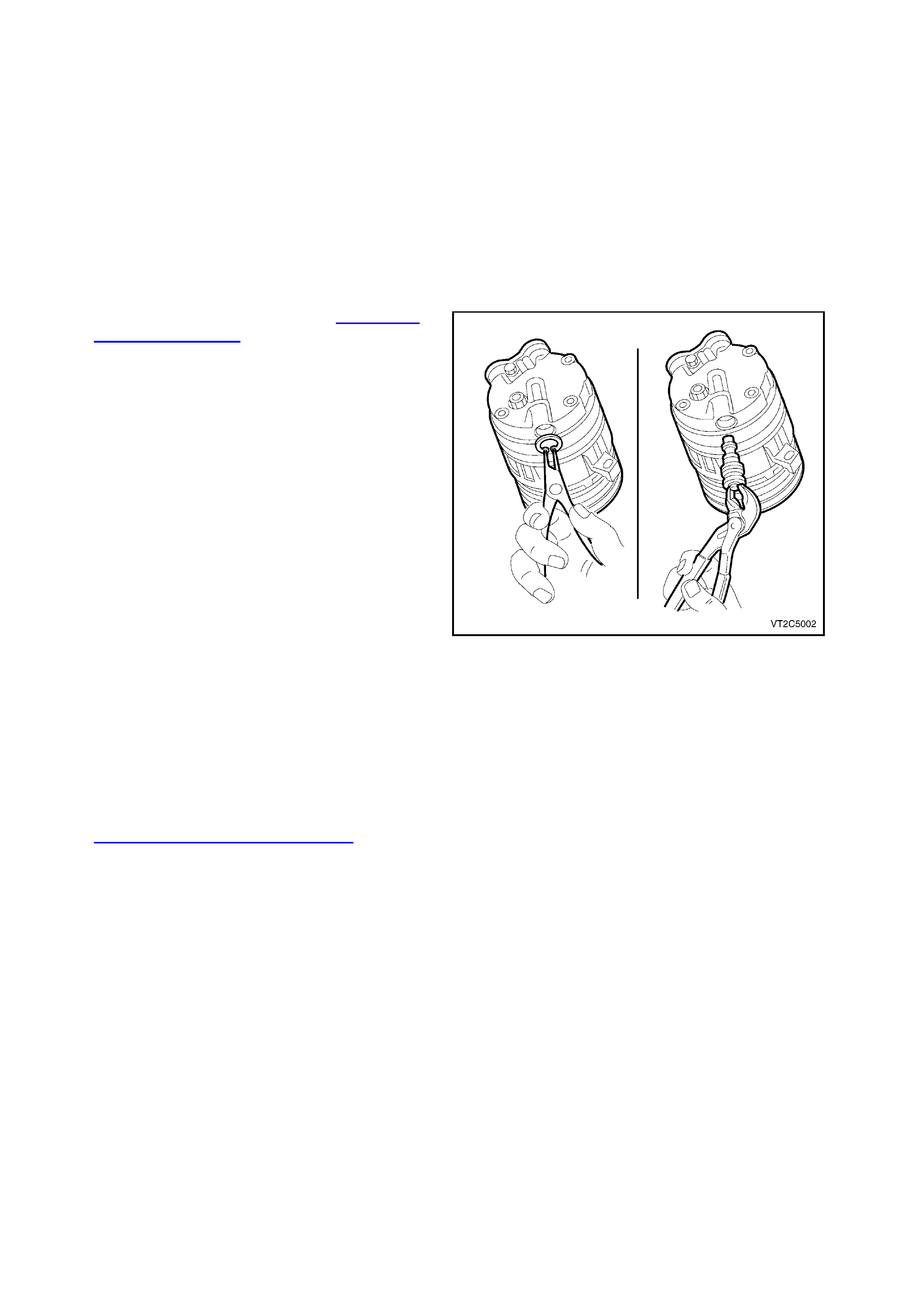

10. Remove the four bolts (1) retaining the

compressor (2) to the mounting bracket (3).

NOTE: Figure 2B-83 shows several components

removed for clarity only (ie. heater and coolant

hoses). To remove the compressor, it is not

necessary to remove these components.

11. Remove compressor.

12. If necessary, remove the four bolts retaining

the compressor mounting bracket to the

cylinder block and remove the mounting

bracket.

Figure 2B-83

REINSTALL

1. If removed, reinstall the compressor mounting

bracket and tighten the four retaining bolts to

the correct torque specification.

COMPRESS OR MOUNT I NG BRACKE T

RETAINI NG B OLT 40.0 - 60.0 Nm

TORQUE SPECIFICATIO N

NOTE: If replacing with a new compressor refer to

Section 2C AIR CONDITIONING - ECC

SERVICING AND DIAGNOSIS of the WH Service

Information for lubrication

requirements/specifications.

2. Fit the compressor to the compressor

mounting bracket, install the four retaining bolts

and tighten to the correct torque specification.

COMPRESSOR RE TA INING BOLT 40.0 - 60.0

TORQUE SPECIFICATIO N Nm

3. Reinstall the air conditioning compressor drive

belt. Refer 2.24 A/C DRIVE BELT-

REINSTALL in this Section for the necessary

procedure.

4. Remove caps from compressor ports and

install new sealing washers.

5. Using new O-rings lubricated with PAG

refrigerant oil (part number 12345923) install

the air conditioning suc tion and dis charge hose

pad fitting onto the compressor.

CAUTION: Do not allow PAG refrigerant oil to

contact bare skin or vehicle paint work. If contact

occurs to either, wash PAG refrigerant oil off

immediately.

6. Install the suction and discharge hose pad

retaining nut and tighten to the correct torque

specification.

SUCTION AND DISCHA RGE HOSE

PAD RETA INING NUT 28.0 - 42.0 Nm

TORQUE SPECIFICATIO N

7. Connect the compressor clutch electrical

connector.

8. Connect heater and lower radiator coolant

hoses, refill coolant s ystem with c or re ct coolant

and pressure test coolant system, refer to

Section 6B3 ENGINE COOLING - GEN III V8

ENGINE of the VT Series II Service

Information.

9. Recharge air conditioner system, refer to

Section 2C AIR CONDITIONING - ECC

SERVICING & DIAGNOSIS of the W H Service

Information.

3. M INOR COM PRESSOR REPAIR PROCEDURES

The illustration used in the following procedure show the compressor removed from the vehicle for easier viewing.

When servicing the compressor, remove only the parts that preliminary diagnosis shows are in need of service.

Removal and installation of external compressor parts and disassembly/assembly of internal parts must be

performed on a clean workbench. The work area, tools and parts must be clean at all times.

NOTE: The only components that can be serviced are:-

Control Valve

Port Sealing Washers

3.1 COMPRESSOR CONTROL VALVE

REMOVE

1. Recover the refrigerant, refer to Section 2C

AIR CONDITIONING - ECC SERVICING AND

DIAGNOSIS of the WH Service Information.

2. Jack vehicle up and place on jack stands.

3. From beneath the vehicle remove the circlip

securing the control valve to the compressor.

4. Using a pair of s uitable c irc lip plier s r emove the

control valve from the compressor by pulling

downwards. Quickly insert replacement control

valve (this will avoid any minor oil loss).

REINSTALL

1 Lubricate the control valve O - rings and

carefully push control valve into the

compressor.

NOTE: V6 and V8 control valves have different

control settings. Ensure that the correct valve is

installed.

2. Inspect original control valve retaining circlip, if

undamaged use to secure valve, if not replace

with new circlip. Ensure circlip is FULLY

seated.

3. Add to the compress or through the suc tion port

any new lubricating oil required, if oil had been

lost during control valve removal.

4. Evacuate and charge the A/C system with

775 - 825 g of R134a refrigerant, refer to

Section 2C AIR CONDITIONING - ECC

SERVICING AND DIAGNOSIS.

Figure 2B-84

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Lower steering column shroud screw ................................... 0.5 - 2

Instrument panel end cap cover attaching screws................ 1 - 3

Instrument panel compartment attaching screws................. 1 - 3

Instrument panel compartment lock striker attaching screws 1 - 3

Centre console securing screws........................................... 1 - 3

Centre console bin retaining nuts ......................................... 1 - 3

Transmission console retaining screws................................ 1 - 3

Centre console storage compartment securing screws........ 1 - 3

Demist nozzle retaining screws ............................................ 1 - 3

Front dash speaker retaining screws.................................... 1 - 2

Instrument panel carrier end panel attachment screws........ 1 - 3

Instrument facia assembly retaining screws......................... 1 - 3

Centre facia assembly securing screws ............................... 1 - 3

ECC securing screws............................................................ 1 - 3

Combined instruments assembly securing screws............... 1 - 3

Instrument panel carrier retaining screws............................. 7 - 12

Instrument panel lower trim right side rail assembly

retaining screws.................................................................... 1 - 3

Centre facia side extension support rail attaching screws.... 1 - 3

Support steering column bracket inner securing screws...... 3 - 5

Passenger air bag support rail securing screws................... 2.5 - 5

Lower left side rail connecting screws .................................. 1 - 3

Instrument panel carrier rail assembly securing screws....... 1 - 3

Passenger side air bag securing nuts................................... 15 - 25

TXV attaching screws........................................................... 3 - 8

Heating, ventilation and air conditioning unit attachment

screws to the passenger compartment................................. 6 - 14

Heating, ventilation and air conditioning unit attachment

screws to the engine bay...................................................... 2 - 5

Evaporator tube plate securing screws................................. 4.0 - 4.5

Washer faced tube plate retaining bolt................................. 7.5 - 12.5

TXV Pipe bracket retaining bolt ............................................ 7.5 - 12.5

FDR pipe flange nut.............................................................. 7.5 - 12.5

Condenser discharge pad retaining nut................................ 7.5 - 12.5

Condenser inlet pad fitting nut.............................................. 7.5 - 12.5

Air conditioning tube fittings to FDR...................................... 7.5 - 12.5

GEN III V8 ENGINE

Air conditioning compressor drive belt idler pulley bolt......... 40. - 60

Air conditioning compressor drive belt tensioner bolt ........... 21 - 29

Compressor mounting bracket retaining bolt........................ 40 - 60

Compressor retaining bolt..................................................... 40 - 60

Compressor suction and discharge hose pad retaining nut.. 28 - 42

V6 ENGINE

Compressor retaining bolt..................................................... 20 - 30

Compressor retaining nut ..................................................... 40 - 55

Idler pulley mounting bracket retaining nut .......................... 20 - 30

Idler pulley retaining bolt....................................................... 40 - 50

Compressor suction and discharge hose retaining nut......... 28 - 42

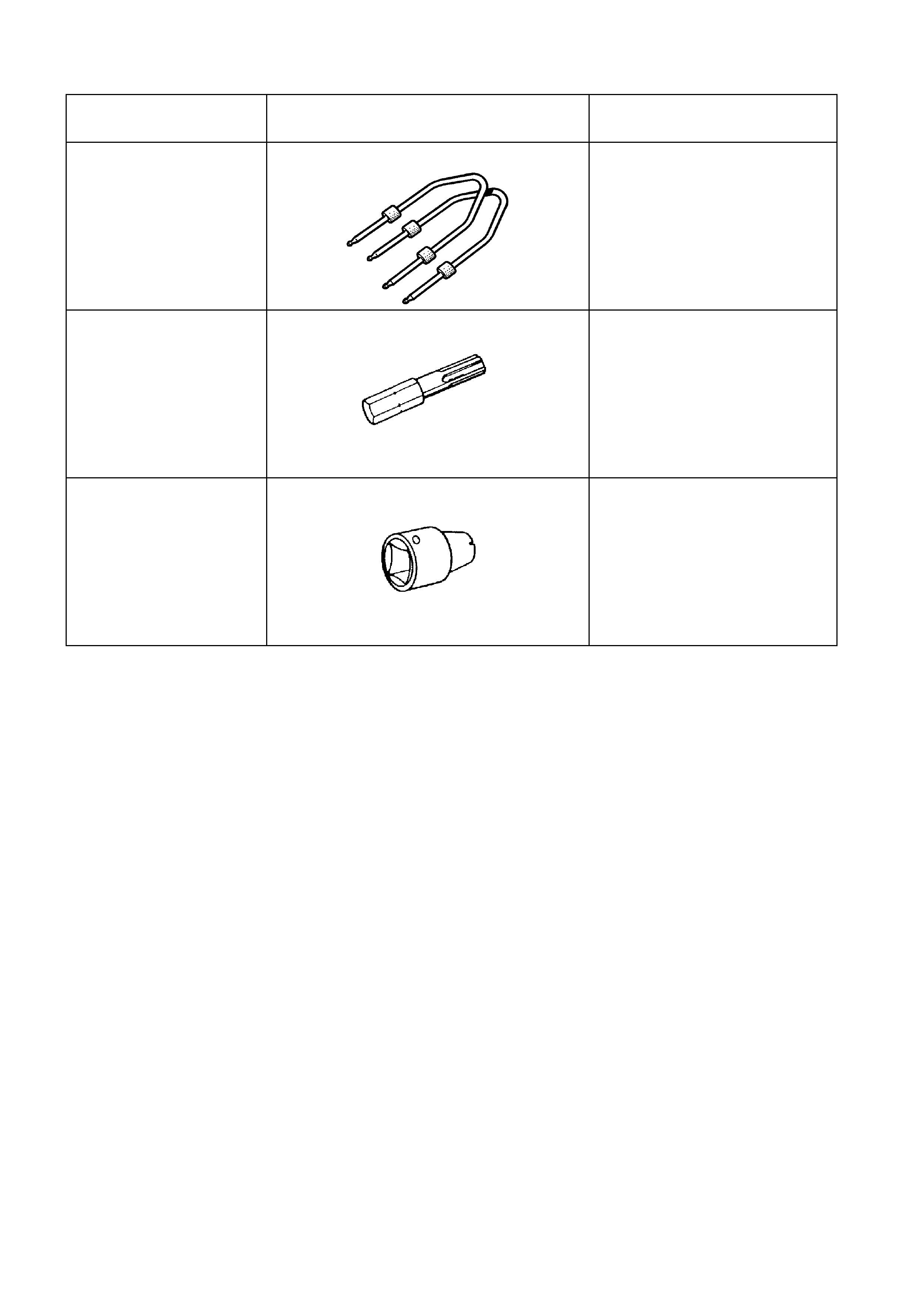

5. SPECIAL TOOLS

TOOL NO. REF

IN TEXT TOOL DESCRIPTION COMMENTS

179 1308 0000 RADIO REMOVAL TOOL

ETX30H T30H TORX BIT Used to remove screws securing

horn bar and air bag inflator

module assembly to steering

wheel and SRS SDM to floor

mounting bracket

Previously released.

J25359-8 TORX BIT HOLDER Used with ETX30H Torx bit

Previously released.