SECTION 12B - LIGHTING SYSTEM

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or

property damage.

1. GENERAL DESCRI PTI O N

The front lamp assemblies on WH Series models comprise a semi-sealed headlamp and a turn signal lamp and a

parking lamp.

The parking lamp is incorporated in the headlamp assembly and the turn signal assembly is next to the headlamp

assembly.

The headlamp features a dual pocket reflector, quartz halogen bulbs and a parking lamp bulb. The reflector is of

homofocal design, with both inner and outer pockets used for high beam.

The turn signal lamp has a clear appearance lens. The illumination bulb has a orange coloured glass and has offset

locating pins on its base.

Fitted into each front fender, is a turn signal side repeater lamp assembly.

Fog / Cornering lamp assemblies are fitted to the front bumper bar assembly as standard equipment.

The fog lamps are controlled by a switch assembly located in the instrument facia, below the headlamp switch.

The fog lamps operate when the headlamps are switched on and the fog lamp switch button depressed. If the

headlamps are operating on high beam, switching on the fog lamps turns the headlamp low beam off. If the

headlamps are on low beam, they remain on when the fog lamps are switched on.

The cornering lamps operate individually and are operated by the indicator switch and only when either the

headlamps or the park lamps are turned on.

All WH vehicles have a rear quarter lamp housing with stop/tail and turn signal bulbs. The turn signal bulb glass is

coloured orange and has offset locating pins. The orange coloured bulb glass provides the amber light behind the

clear lens of the lamp. Also, different rear quarter lamp harnesses with specific bulb sockets are used for each type

of bulb locating pin style.

The rear compartment lid is provided with separate lamps including; back-up lamp bulb and an additional tail lamp

bulb and rear licence plate lamps. The licence plate lamps are located in the rear compartment lid decor panel,

above the licence plate.

All vehicles are fitted with hazard warning flashers, which are operated by a switch in the instrument facia, located

below the air outlets.

All vehicles are fitted with courtesy lamps in the passenger compartment (dome lamp), ignition lock and glove

compartment. Additional interior lighting is provided by courtesy lamps in door trims, front and rear footwells, rear

compartment, front reading lamp assemblies, rear reading lamps and console bin lamp.

Operation of the parking/tail and headlamps is controlled by a headlamp switch located in the instrument facia, to

the right of the steering wheel. Headlamp high beam or headlamp flash control is by the headlamp and turn signal

control switch stalk to the right of the steering column.

Various relays, located in the engine compartment relay housing and passenger compartment fuse panel, are used

for headlamp, hazard warning, turn signals and fog lamp control.

Turn signal control is by the headlamp and turn signal control switch stalk to the right of the steering column.

Stop lamps operation is controlled by a stop lamp switch fitted into a tubular clip in the brake pedal support.

Back-up lamp operation is controlled by the neutral start/back-up lamp switch which is attached to the side of the

gearshift assembly on the automatic transmission, beneath the console cap.

The WH Series models are fitted with a High Series Body Control Module (BCM). The BCM provides additional

lighting system enhancements. These features are:

1. Automatic Lights Off.

This system deactivates the head and parking/tail lamps when the ignition has been switched from on to off and the

driver’s door is opened. The lamps switch back on when the ignition is switched on, if the headlamps switch is still

turned on. An adjustable time delay can be applied before the headlamps are automatically switched off.

Techline

Techline

2. Dome Lamp Delay.

Additional control of the dome lamp operation by the BCM allows for 30 second delay period to turn the dome lamp

off after all doors are closed. Should the dome lamp be left on by the dome lamp switch, and with ignition off, the

BCM will turn off the dome lamp after a maximum period of two hours to prevent battery drain.

3. Instrument Dimming Control.

Incorporated in the headlamp switch assembly is a control for variable instrument cluster illumination intensity.

4. Rear Lamp Failure Warning.

This system checks for bulb or fuse failure associated with the stop or tail lamps including the high level stop lamp.

For additional information on these systems, including diagnostics, refer Section 12J - BODY CONTROL

MODULES of this Service Information CD.

2. SERVICE OPERATIONS

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

The headlamps and fog lamps must be correctly

aimed in order to obtain the maximum road

illumination and safety that has been built into the

vehicle lighting system. The headlamps and fog

lamp s m us t be chec ked for co rr ec t aim whenever a

bulb or headlamp/fog lamp assembly is replaced,

and after any adjustments or repairs to the front

end sheet metal.

Headlamp aiming machines are in general use.

When using one of these machines, ensure that it

is in good condition and carefully follow the

instructions of the manufacturer.

Regardless of the method used for checking

headlamp and fog lam p aim, the vehic le must be at

kerb weight, that is, with fuel, oil, water and spare

tyre but no passengers. The tyres must be

uniformly inflated to their specified pressure.

NOTE: If the vehic le will regular ly carr y an unus ual

load in the rear com partm ent or tow a trailer, these

loads should be on the vehicle when the

headlamps/fog lamps are checked.

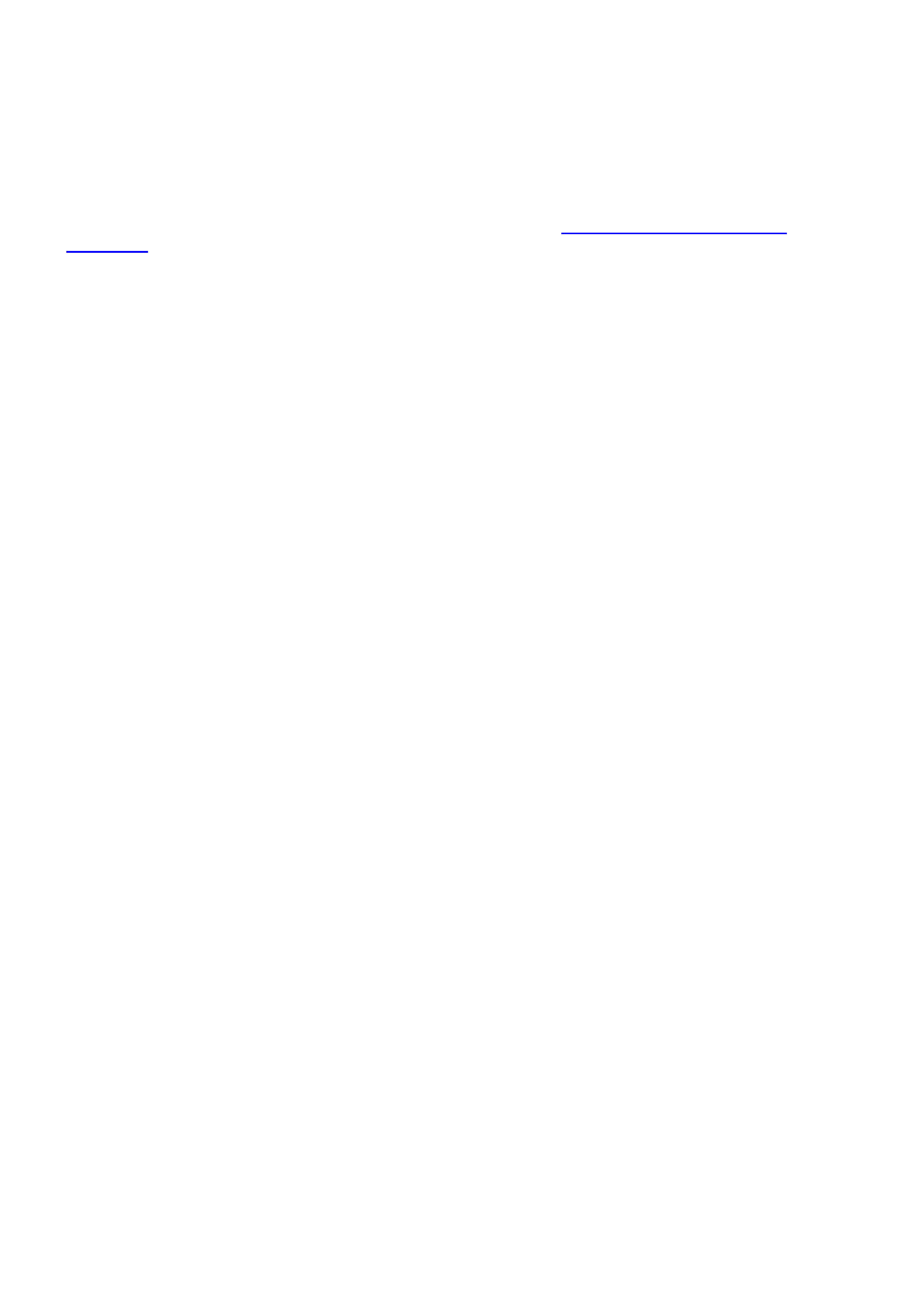

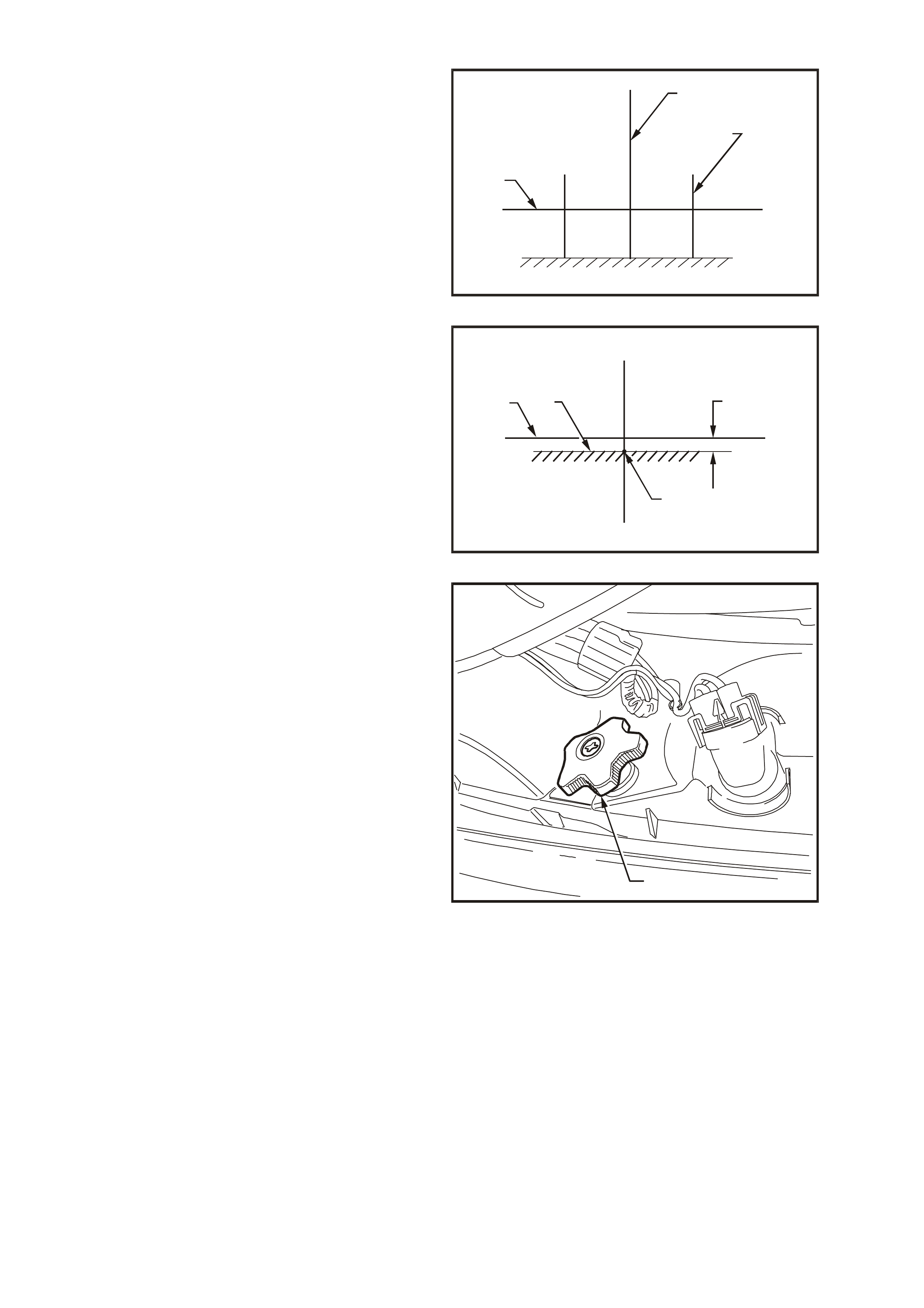

HEADLAMP AIM

1. If suitable test equipment is not available, set

up a screen or use vertical wall, in conjunction

with a flat horizontal floor. Park vehicle

immediately in front of screen and mark

horizontal (1) and ver tical centre lines of left ( 2)

and right (4) headlamps, and vehicle centre line

(3) on the screen or wall.

2. Park vehicle 10 metres in front of screen or

wall ensuring the vehicle is aligned with vehicle

centre line mark on screen.

WH12B001

V

H

H

V2

3

4

1

Figure 12B-1

3. Individually aim each headlamp to a point (1)

on its vertical centre line, 110 mm below the

headlamp horizontal centre line. Item 2 is the

cut-off line.

WH12B002

V

HH

V

110 mm

2

1

Figure 12B-2

Techline

a. Adjust inboard adjuster (1) to achieve

correct vertical beam height.

b. Adjust outboard adjuster (2) to centralise

beam.

Aiming directions (3) for each adjuster are

visible on the headlamp assembly.

WH12B003

3

21

Figure 12B-3

HEADLAMPS AIMING.

ACCEPTABLE VARIATIONS IN

HEADLAMP AIMING POINTS

HL 100 mm

HR 0 mm

V1 100 mm

V2 120 mm

Maximum allowable vertical variation between

any pair of headlamps is not to exceed 20 mm.

4. The allowable variations on headlamp aiming

point settings shown in Fig. 12B-4 are specif ied

as follows:

NOTE: Cut-off line must be within zone (1).

WH12B004

V

H

H

V

1V2

V1

HL

HR

Figure 12B-4

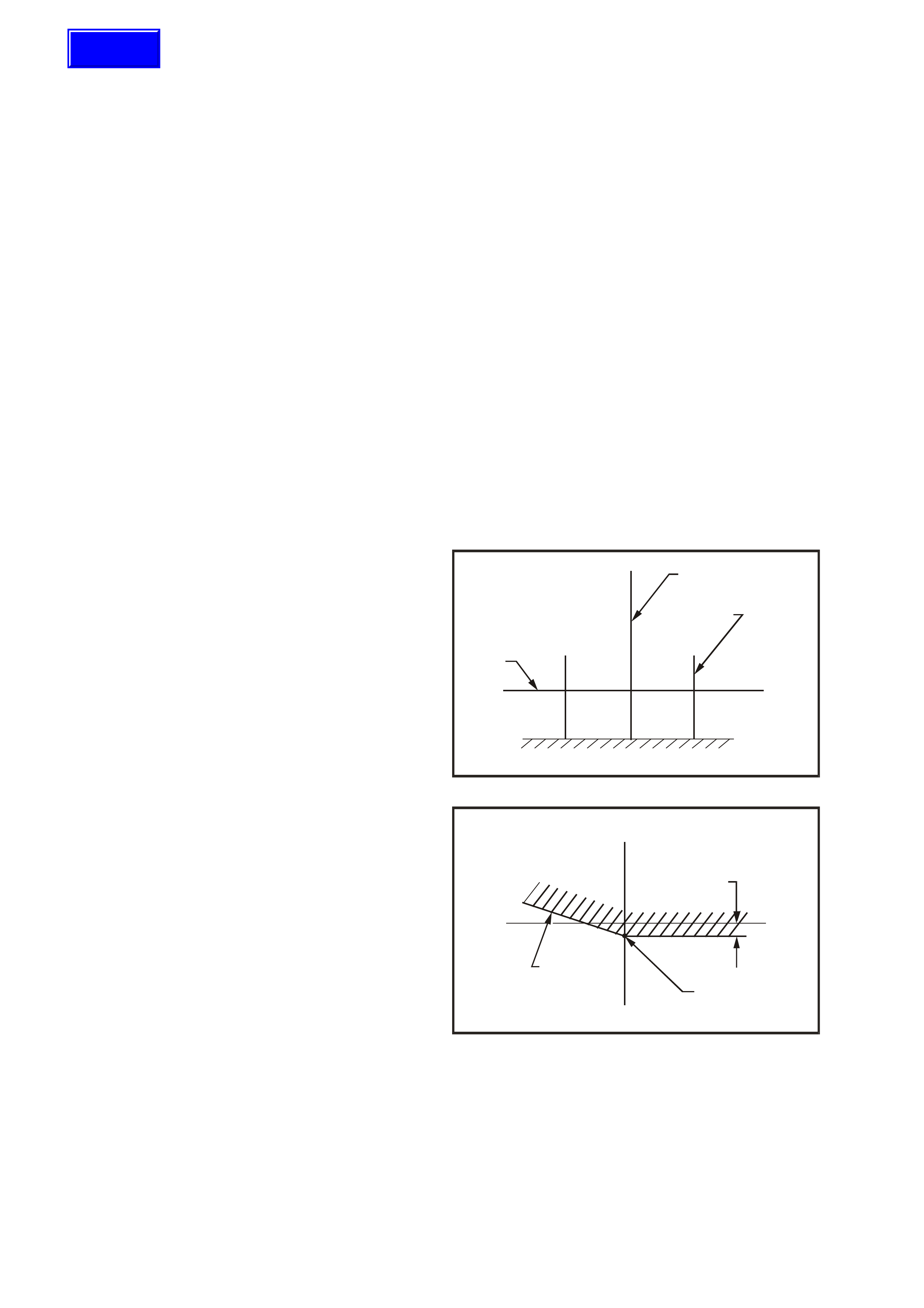

FOG LAMP AIM

1. If suitable headlamp aiming check equipment is

not available, set up a screen or use a vertical

wall, in conjunction with a flat horizontal floor.

Park vehicle im mediately in front of screen and

mark horizontal (1) and vertical centre lines of

left (2) and right (4) headlamps, and vehicle

centre line (3) on the screen.

2. Park vehicle 10 metres in front of screen,

ensuring the vehicle is aligned with centre line

mark on screen.

WH12B001

V

H

H

V2

3

4

1

Figure 12B-5

3. Check headlamp aim and adjust as required,

refer previous instructions.

4. With headlamps turned on low beam, turn fog

lamps on. Individually aim each fog lamp to a

point symmetrical about V axis (2) with cut-off

line (3) 200 mm below headlamp horizontal

centre line (1).

WH12B005

200 mm

2

3

1

V

HH

V

Figure 12B-6

NOTE: There is no provision for horizontal

adjustment. Fog lamps are fixed to vertical

centreline.

Fog lamp aim adjustment is made by rotating

adjuster knob (1) on the back of the lamp

housing. Turning the adjuster anti-clockwise

lowers the beam, turning the adjus ter c loc k wise

raises the beam.

WH12B006

1

Figure 12B-7

2.2 HEADLAMP BULB

REPLACE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Passenger’s side headlamp only

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Driver’s side and passenger’s side

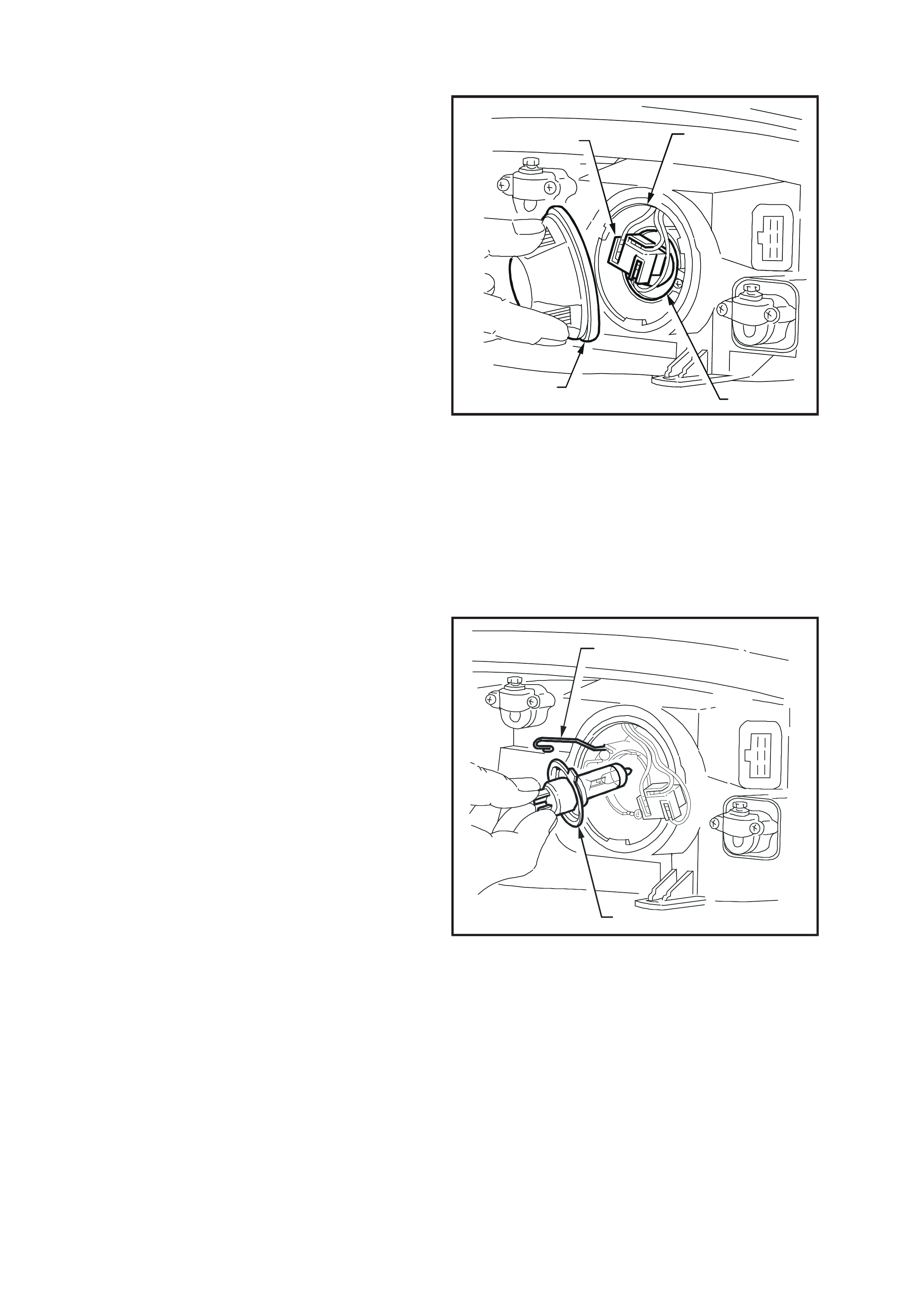

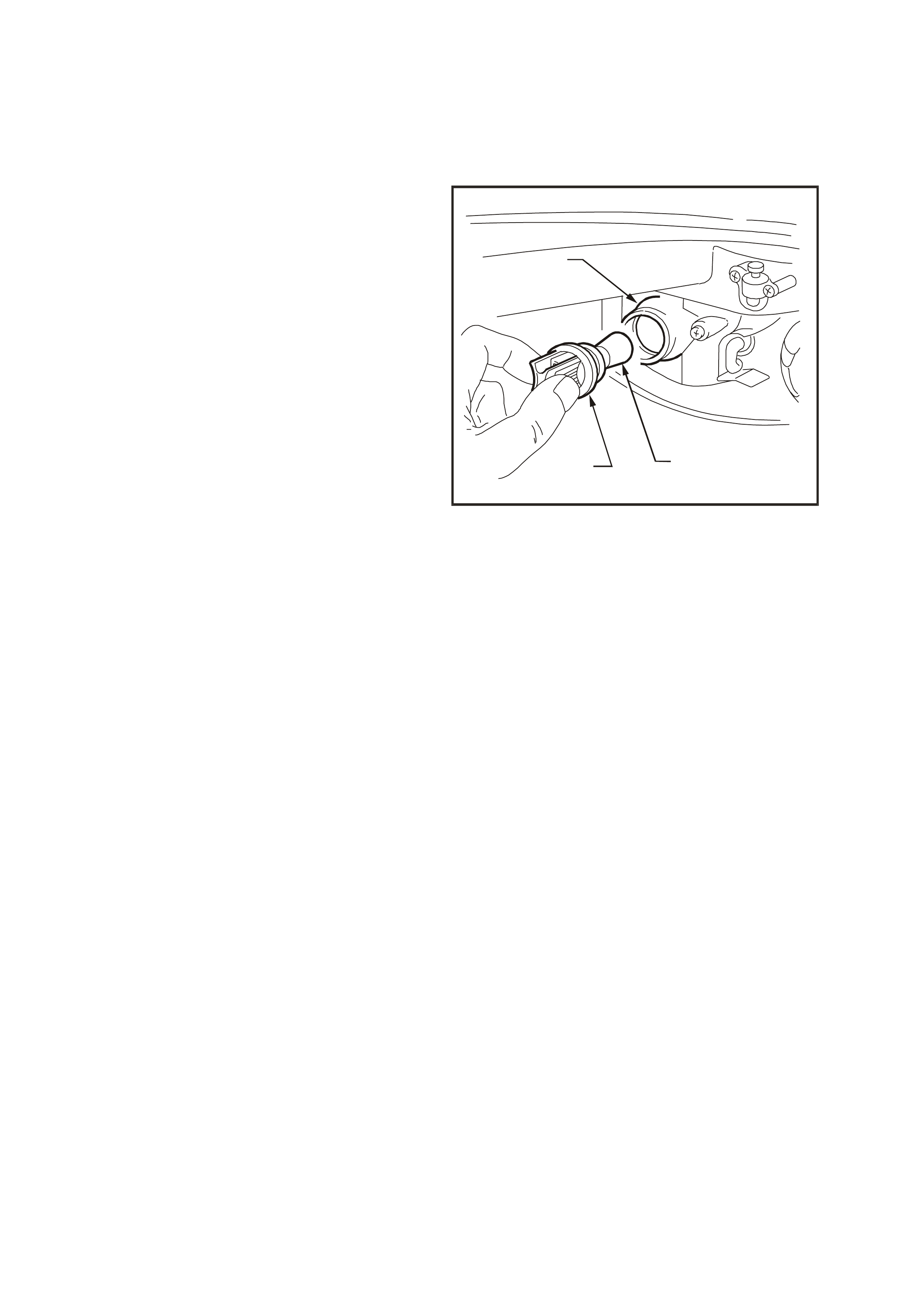

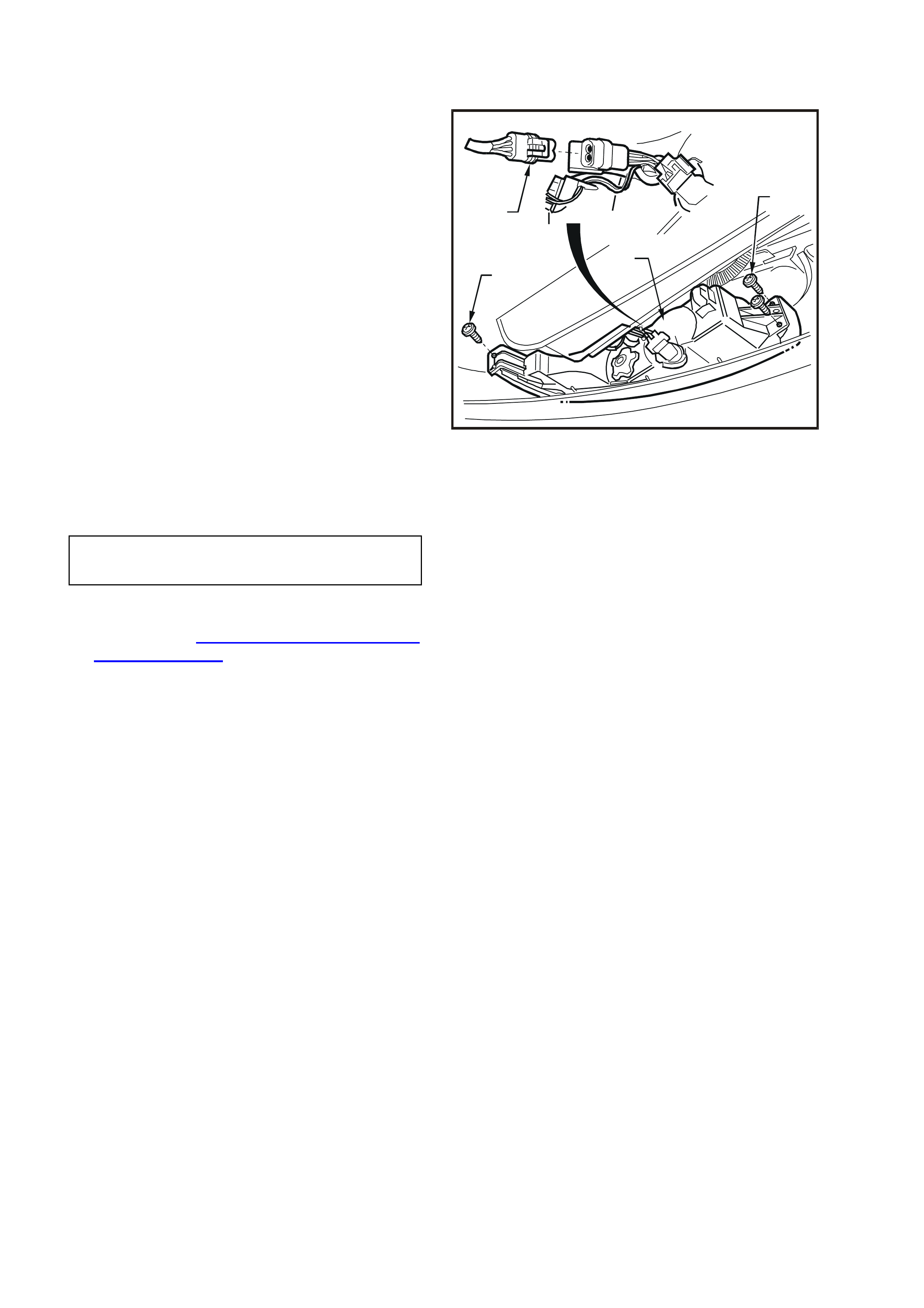

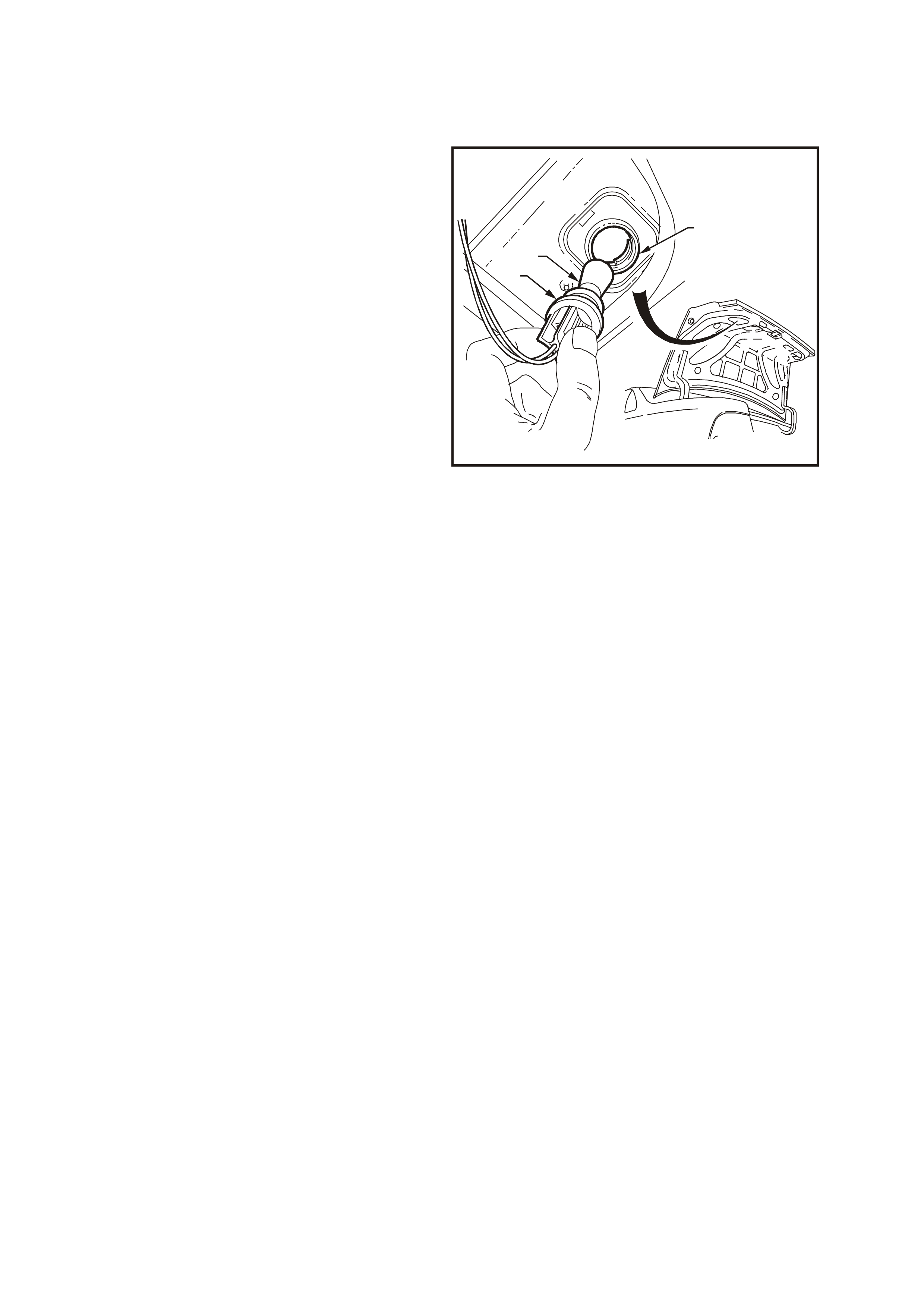

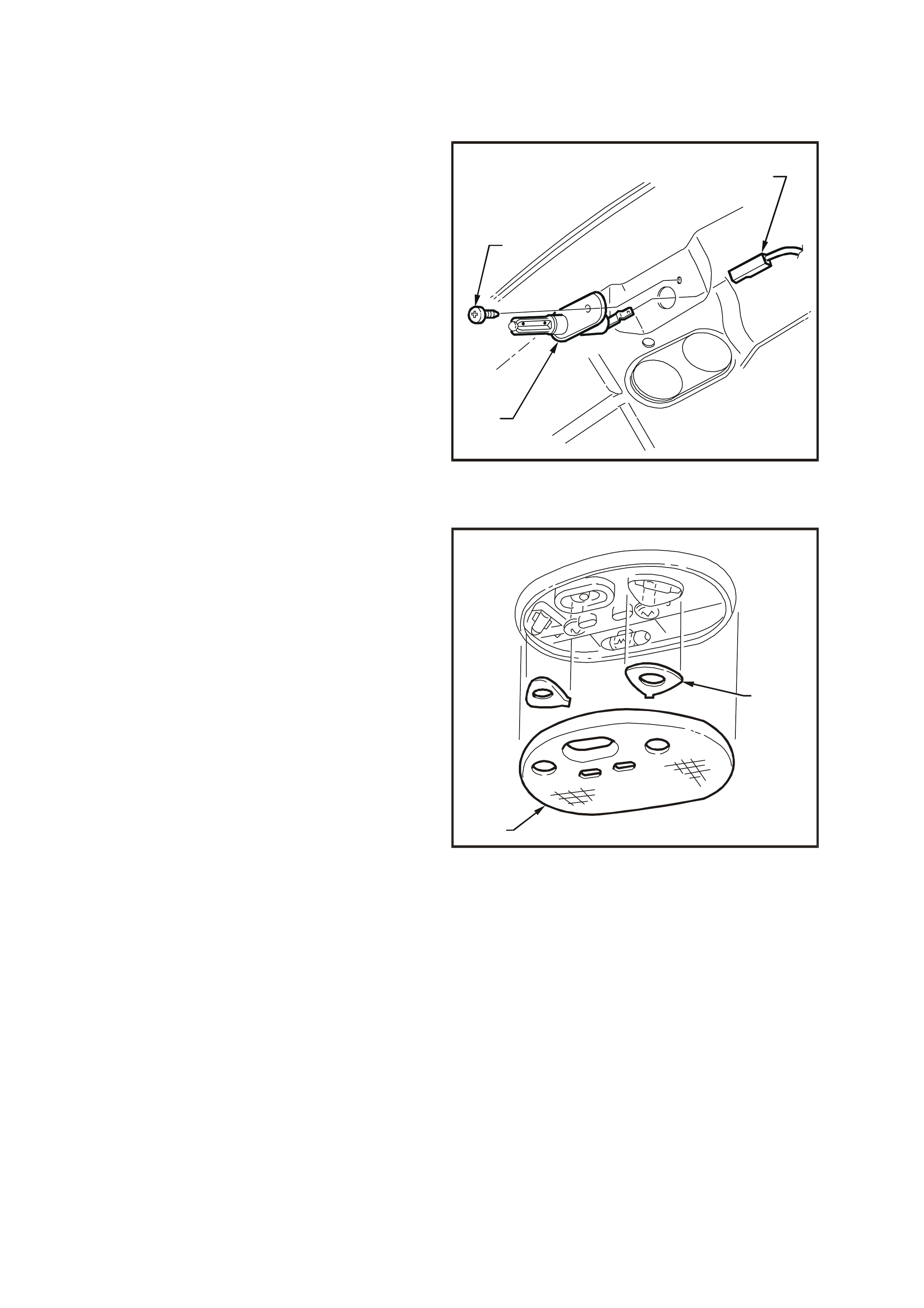

2. From inside engine compartm ent, remove dust

cap (1) from rear of headlam p assembly (2) by

turning dust cap anti-clockwise and pulling

away from headlamp assembly. If dust cap seal

stays on headlamp ass embly, rem ove seal and

install onto cap.

3. Carefully pull wiring harness connec tor (3) f rom

rear of bulb (4).

32

14

WH12B007

Figure 12B-8

4. Depress and unclip bulb s pring retainer (1) and

pivot clear of bulb. Remove bulb (2) from

reflector.

NOTE: Do not handle quartz envelope of headlamp

bulb. If touched accidentally, wipe im mediately with

methylated spirits or bulb performance will

deteriorate.

5. Install new bulb (2) into reflector, ensuring

correct mating of bulb base locating tangs with

reflector cut-outs. Install s pring retainer (1) and

wiring harness connector.

NOTE: The different sized locating tangs on the

bulb base and mating cut-outs in the reflector will

allow the bulb to seat correctly into the reflector in

one location only. This ensures correct relationship

of the bulb to the reflector.

6. Inspect rubber seal in dust cap to ensur e that it

is not damaged and that it is seated cor rect ly in

cap. Replace seal if damaged.

7. Install cap to rear of headlamp housing with

cap tang located facing down. Lock cap into

place by turning clockwise.

WH12B008

1

2

Figure 12B-9

Driver’s side only

Install battery if removed, secure battery retaining

clamp and reconnect battery terminals.

Driver’s side and passenger’s side

8. Check headlamp operation and aim headlamps

(headlamp aim varies from bulb to bulb), refer to

2.1 AIMING OF HEADLAMPS AND FOG LAM PS

in this Section.

Passenger’s side (with GEN III V8 engine) only

Install air inlet snorkel into air cleaner housing by

aligning snorkel with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and install

four scrivets to secure cover.

2.3 PARKING LAMP BULB

REPLACE

1. Open engine compartment hood.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Passenger’s side headlamp only

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Driver’s side and passenger’s side

2. From inside engine compartm ent, remove dust

cap (1) from rear of headlam p assembly (2) by

turning dust cap anti-clockwise and pulling

away from headlamp assembly. If dust cap seal

stays on headlamp ass embly, rem ove seal and

install onto cap.

32

14

WH12B007

Figure 12B-10

3. Remove parking lamp socket (1) from

reflector (2). Alternatively, use pointed nose

pliers to pull out parking lamp socket if access

is difficult. Pull bulb (3) from socket.

4. Insert new bulb into socket and install socket

into reflector.

5. Inspect rubber seal in dust cap to ensur e that it

is not damaged and that it is seated cor rect ly in

cap.

Install cap to rear of headlamp housing and

lock cap into place by turning clockwise.

Driver’s side only

Install battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s side and passenger’s side

6. Check parking lamp operation.

Passenger’s side (with GEN III V8 engine) only

Install air inlet snorkel into air cleaner housing

by aligning snork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

WH12B009

1

2

Figure 12B-11

2.4 INBOARD HIGH BEAM BULB

REPLACE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Passenger’s side headlamp only

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Driver’s side and passenger’s side

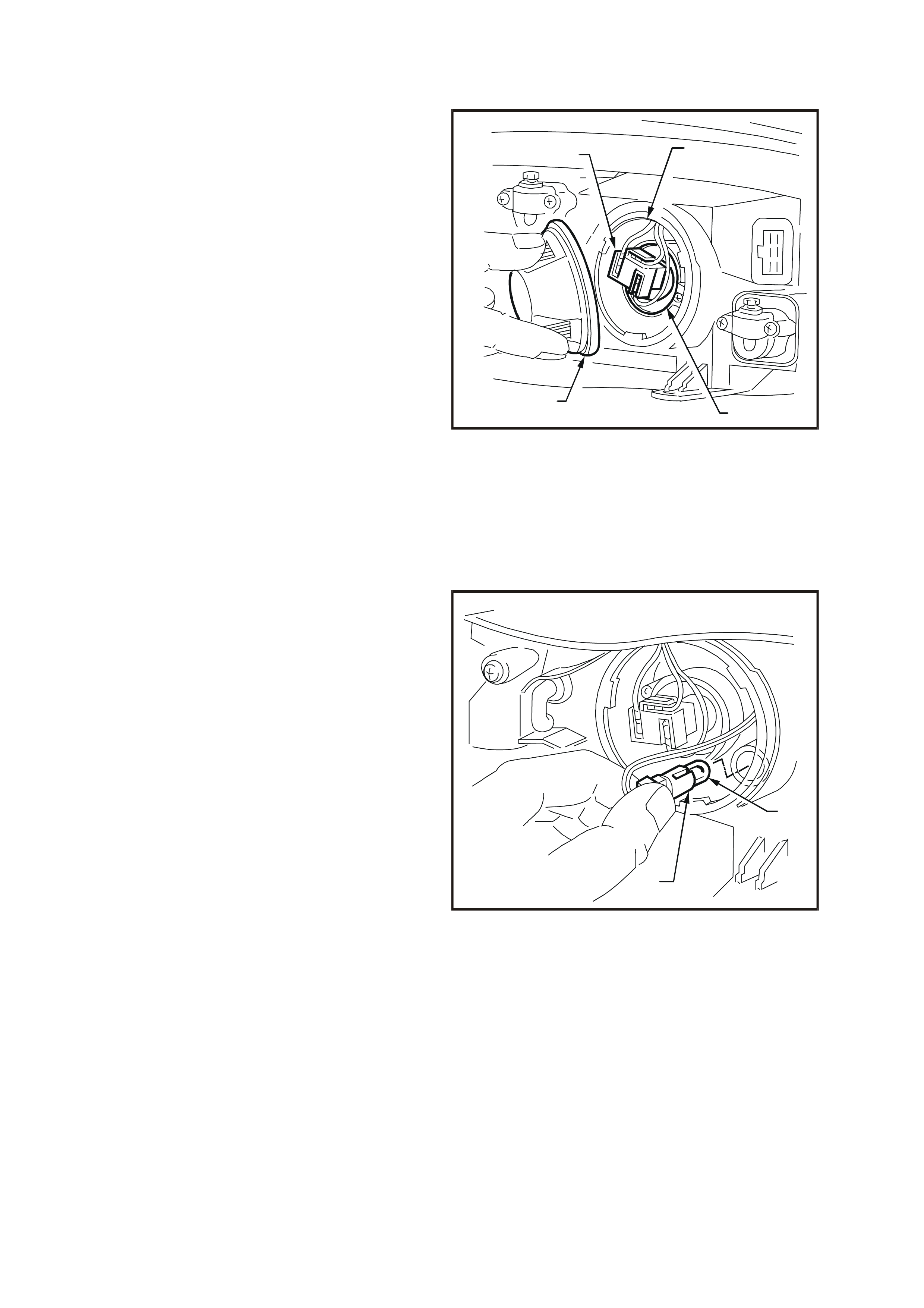

2. From inside engine compartment, remove

inboard high beam dust cap (1) from rear of

headlamp assembly (2) by turning dust cap

anti-clock wise and pulling away f rom headlam p

assembly. If dust cap seal stays on headlamp

assembly, remove seal and install onto cap.

WH12B010

2

1

Figure 12B-12

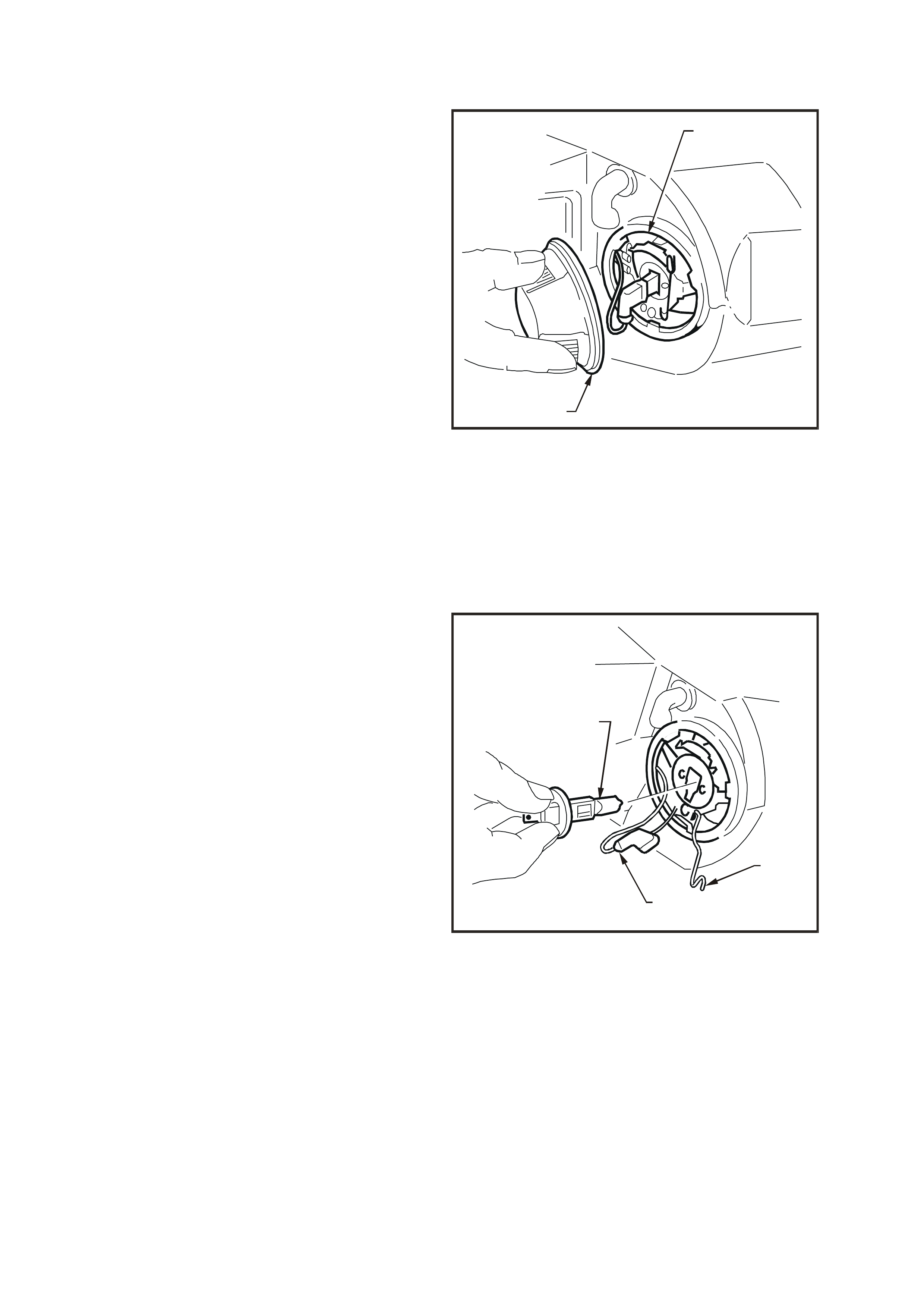

3. Disconnect harness connector (1) from

bulb (2). Depress and unclip bulb retaining

clip (3) to release, and allow to fall clear of

bulb. Pull out bulb.

4. Install new bulb into reflector, ensuring that

locating lug on bulb housing aligns with square

edge on bulb and locating lugs on bulb mate

with holes on bulb housing. Reconnect bulb

retaining clip. Connect bulb harness connector.

NOTE: Do not handle quartz envelope of inboard

high beam bulb. If touched accidentally, wipe

immediately with methylated spirits or bulb

performance will deteriorate.

5. Inspect rubber seal in dust cap to ensur e that it

is not damaged and that it is seated correctly.

Install dust cap onto rear of headlamp housing

and lock into place by turning clockwise.

Driver’s side only

Install battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s side and passenger’s side

6. Test operation of inboard high beam lamp bulb.

Passenger’s side (with GEN III V8 engine) only

Install air inlet snorkel into air cleaner housing

by aligning snork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

WH12B011

2

1

3

Figure 12B-13

2.5 FRONT TURN SIGNAL LAMP BULB

REPLACE

NOTE: If replacing a front turn signal lamp bulb,

ensure the cor rect type is fitted. For all m odels, the

bulb glass is coloured orange and has offset

locating pins.

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Passenger’s side headlamp only

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Driver’s side and passenger’s side

2. From inside engine compartment, twist to

release bulb socket (1) from behind headlamp

assembly (2).

3. Depress bulb (3) into socket (1) and rotate to

remove.

4. Inspect O-ring on bulb socket for damage and

correct seating. Replace O-ring if necessary.

5. Install new bulb into socket, install socket into

housing and twist to lock into position.

Driver’s side only

Install battery if removed, secure battery

retaining clamp and reconnect battery

terminals.

Driver’s side and passenger’s side

6. Check turn signal lamp operation.

Passenger’s side (with GEN III V8 engine) only

Install air inlet snorkel into air cleaner housing

by aligning snork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

WH12B012

1

2

3

Figure 12B-14

2.6 HEADLAMP AND TURN SIGNAL/PARKING LAMP ASSEMBLY

REMOVE

1. Open engine compartment.

Driver’s side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Disconnect battery terminals, remove battery

retaining clamp and remove battery from

engine compartment.

Passenger’s side headlamp only

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Driver’s side and passenger’s side

2. From inside engine compartment, disconnect

wiring harness connector from headlamp

assembly. Remove turn signal lamp bulb

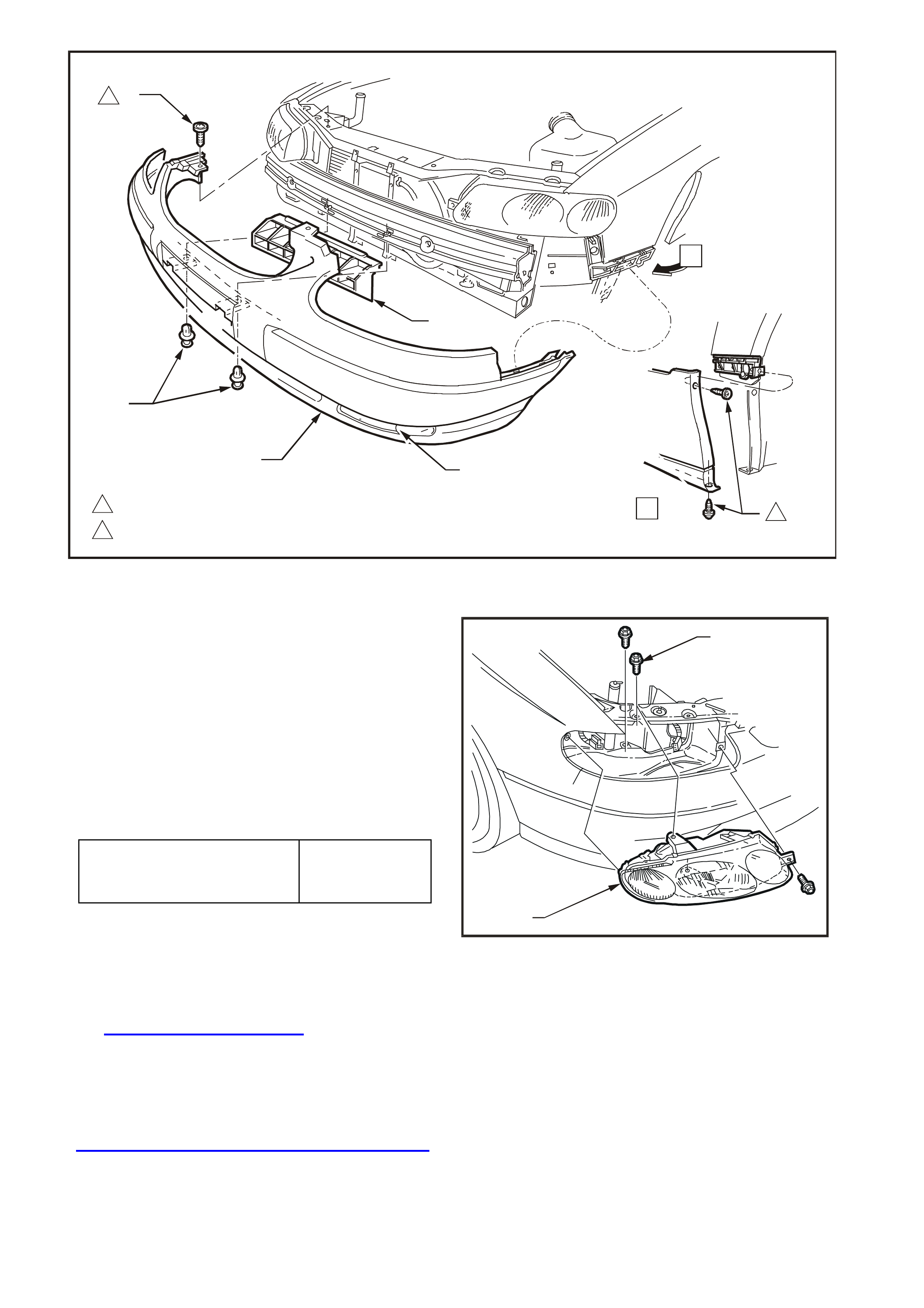

socket from headlamp assembly.

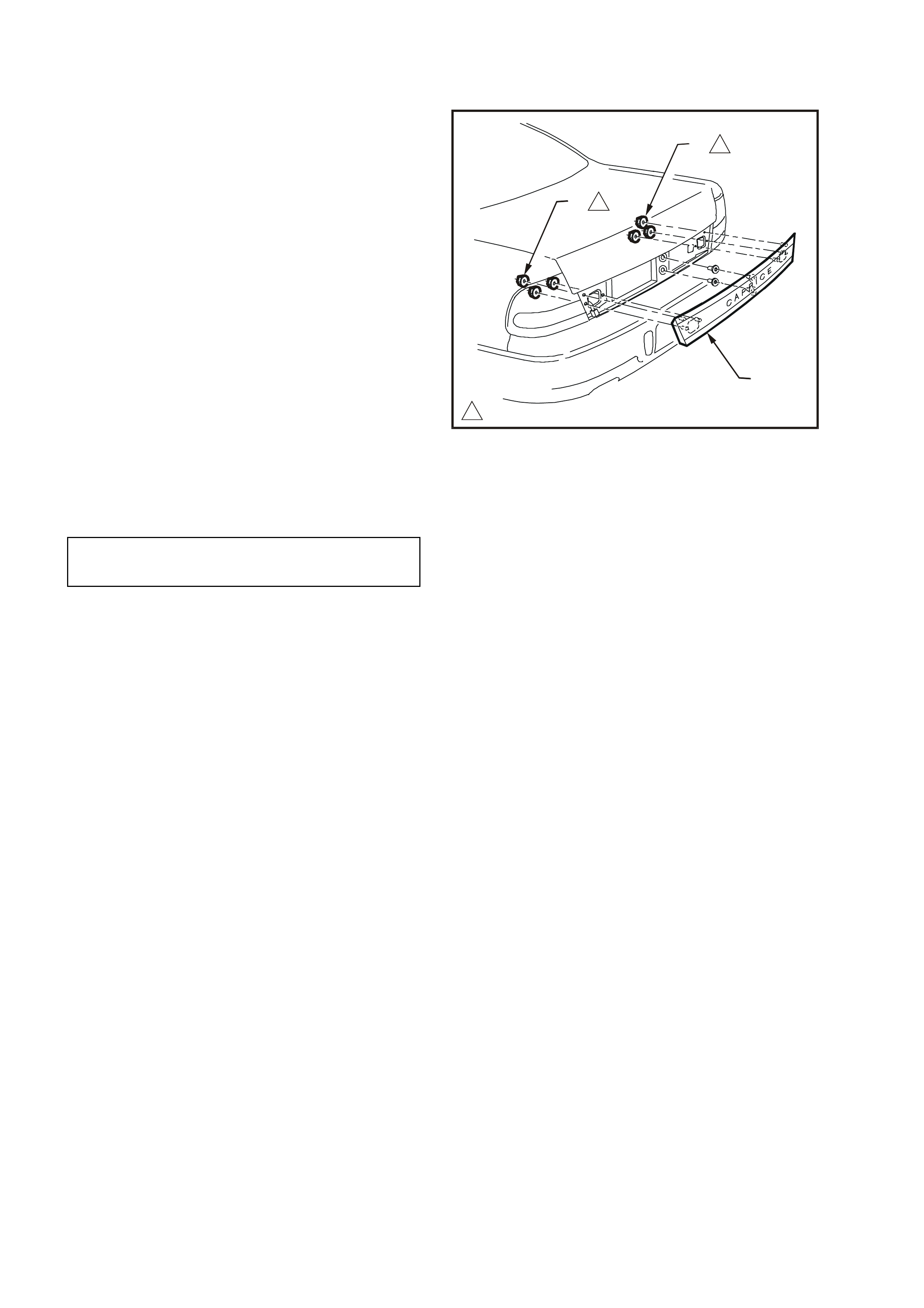

3. Remove two bumper f a cia r etaining sc r ivets ( 1)

from behind number plate.

4. Remove screws (2) securing bumper facia

sides to front fender inner liner at wheel arch

opening.

5. Remove two screws (3) securing bumper facia

to radiator support upper panel.

6. From behind front spoiler, disconnect main

wiring harness from harness connectors on

fog / cornering lamp assemblies (4).

7. With the facia supported, pull the facia side

members out, disconnect the facia side

supports, then slide the facia (5) forward

rem oving the facia assem bly, refer to Fig. 12B-

15

NOTE: When removing facia (5), support the upper

centre support facia (6), which is held in place by

bumper facia and will otherwise fall.

WH12B013

3

1

54

6

A

1

2.5 - 4.0 Nm

2

2

1.0 - 3.0 Nm

2

A

1

Figure 12B-15

HEADLAMP AND TURN

SIGNAL /PARKING LAMP

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 2 – 5 Nm

8. Remove three headlamp retaining screws (1)

and remove headlamp & turn signal / parking

lamp assembly (2).

REINSTALL

Installation of the headlamp & turn signal / parking

lamp assembly is the reverse of removal

procedure, noting the following points:

1. Install headlamp and turn signal / park ing lamp

assembly (2) and tighten retaining screws (1) to

the correct torque specification.

2. Install front bumper facia assembly by

snapping the facia onto the retainers at guide

rails, one side at a time.

3. Ensure correct fender, hood and headlamp

clearance, adjust facia if necessary, refer

Section 1D BUMPER BARS of the VT Ser ies I

Service Information.

4. Reconnect all wiring harness connectors and

check operation of headlamp and turn

signal/parking lamps and fog / cornering lamps.

Check headlamp (and fog lamps) aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

in this Section.

WH12B014

2

1

Figure 12B-16

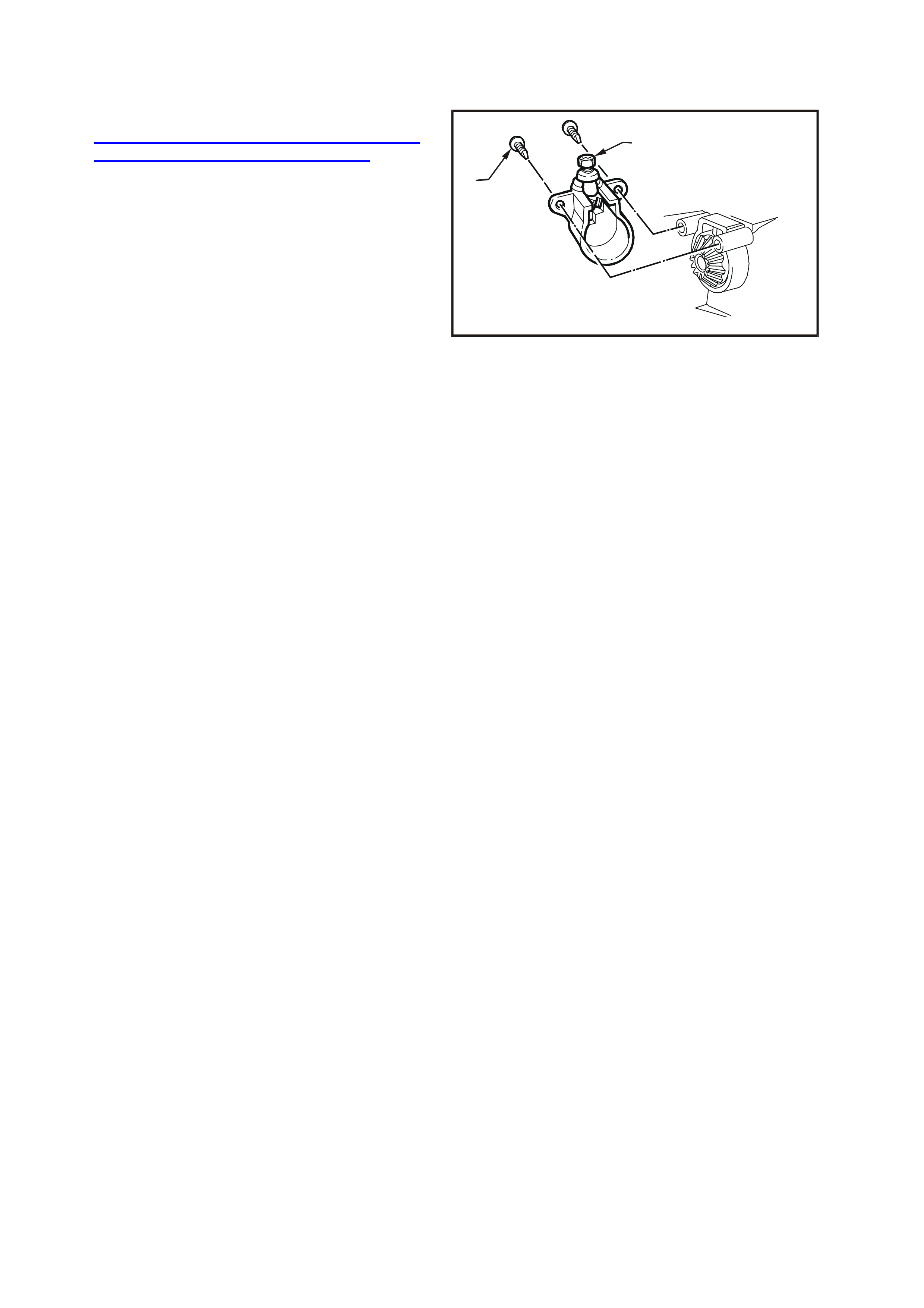

2.7 HEADLAMP ADJUSTER

REMOVE

1. Remove headlamp assembly refer to

2.6 HEADLAMP AND TURN

SIGNAL/PARKING LAMP ASSEMBLY in this

Section.

2. Remove two screws securing headlamp

adjuster to headlamp assembly and remove

adjuster.

3. Inspect adjuster and replace if worn or

damaged.

REINSTALL

Installation of the headlam p adjuster is the reverse

of removal procedure, noting the following point:

1. Align bevel gear to avoid tooth abutment with

mating gear prior to tightening securing screws.

WH12B015

1

2

Figure 12B-17

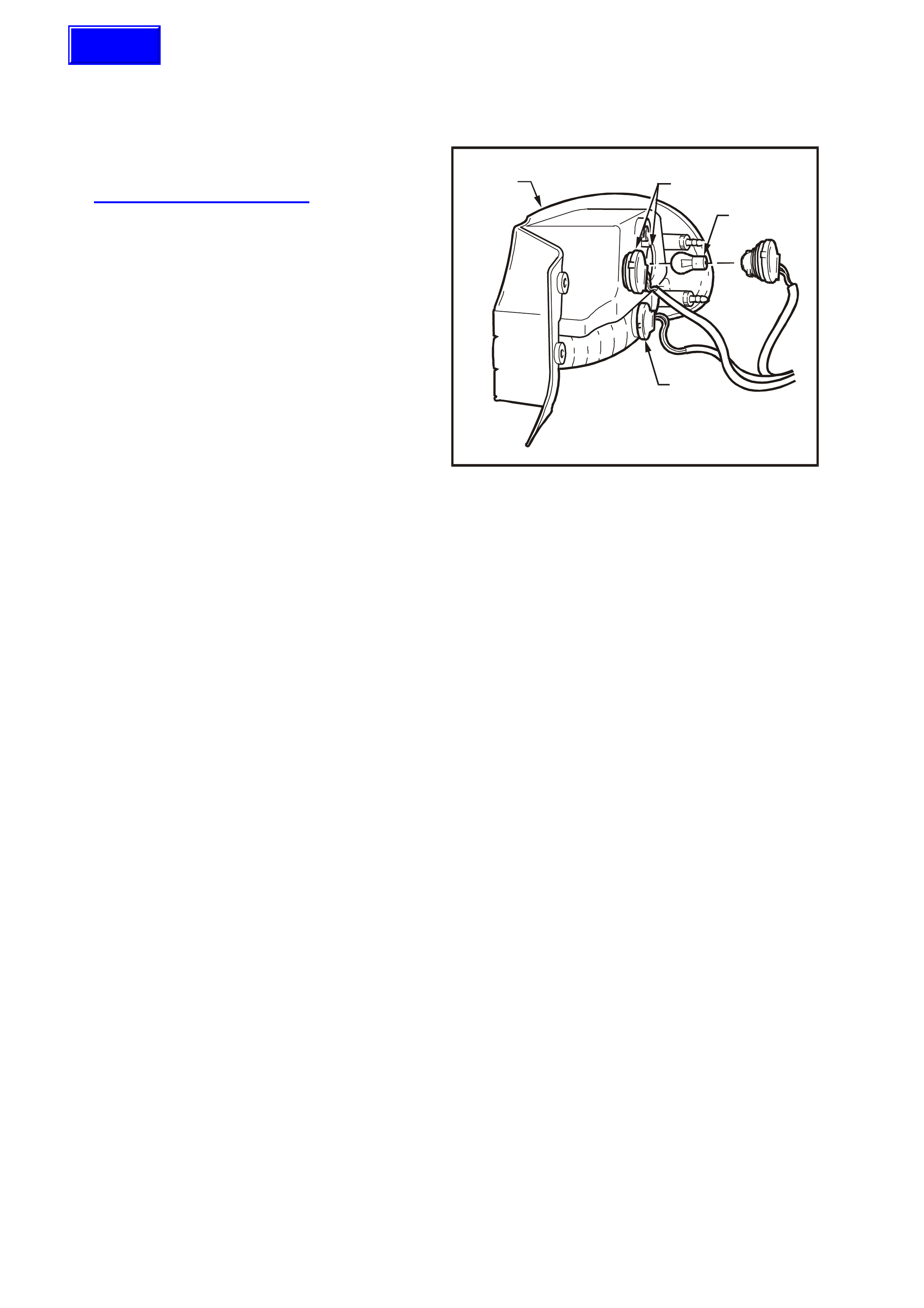

2.8 FOG LAMP BULB

REPLACE

1. From behind the front spoiler, twist to release

bulb socket (2) from fog / cornering lamp

assembly and remove bulb socket from lamp

assembly.

2. Pull bulb (1) from socket and inspect condition

of soc ket O- ring seal. Replace seal if dam aged

or deformed.

3. Insert new bulb into socket, then install bulb

socket into lamp assembly and twist to lock.

NOTE: Do not handle quartz envelope of fog lamp

bulb. If touched accidentally, wipe im mediately with

methylated spirits or bulb performance will

deteriorate.

WH12B016

21

Figure 12B-18

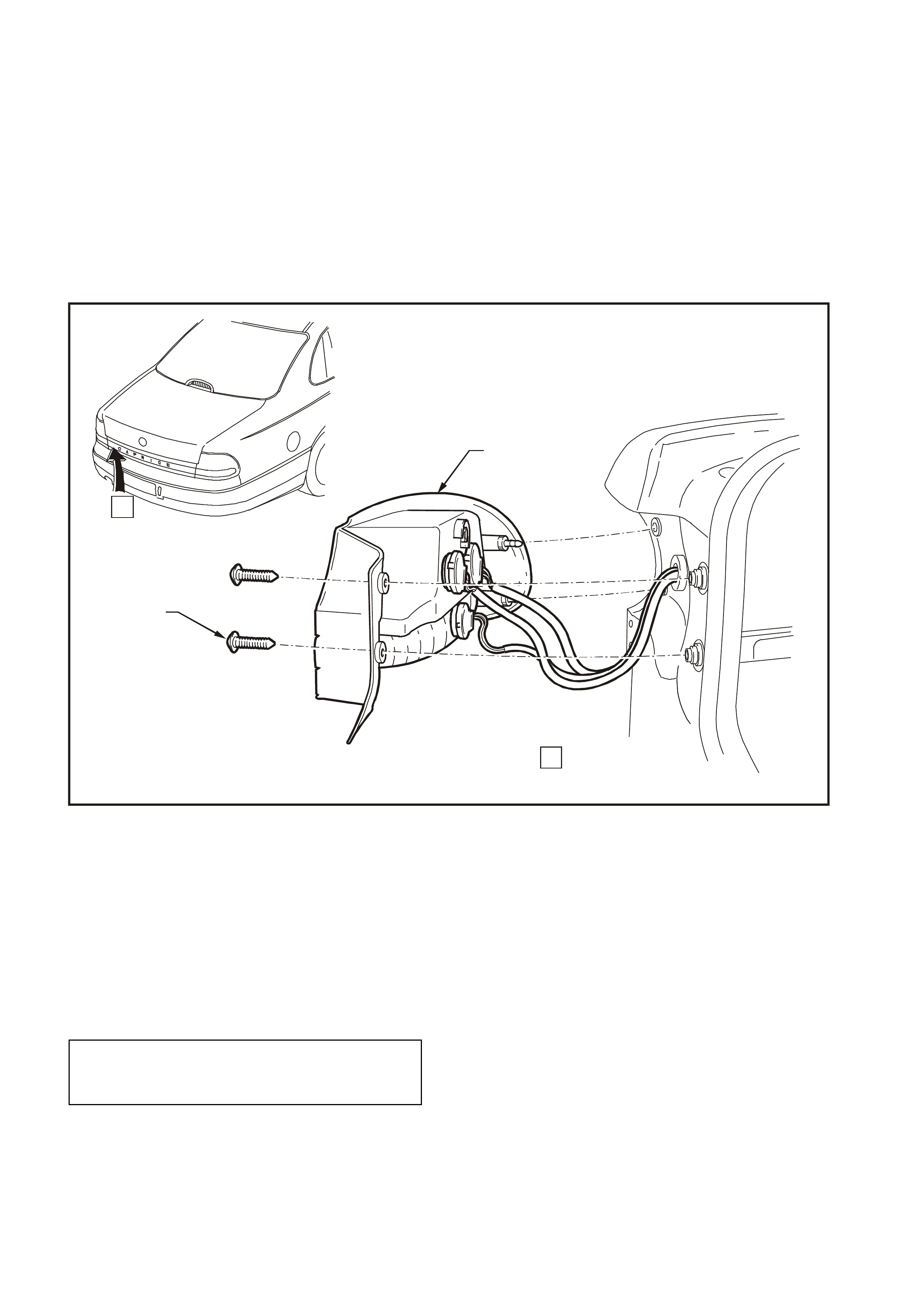

2.9 FOG / CORNERING LAMP ASSEMBLY

REMOVE

1. From behind front spoiler, disconnect main

wiring harness (1) from fog / cornering lamp

assembly harness connector.

2. Remove three Philips head s cr ews ( 2) s ec uring

the fog / cornering lamp assembly (3).

3. Pull cornering lamp end of as sembly away from

bumper bar, then slide fog lamp end of

assem bly out from behind lug in fog / cor nering

lamp aperture.

REINSTALL

Installation of the f og lamp as sembly is the r everse

of removal procedures, noting the following points:

1. Ins tall fog lam p assem bly to bum per bar beam ,

ensuring that locating screw in lamp mounting

frame is located in the mating hole in the

bumper bar beam.

2. Tighten lamp mounting frame to bumper bar

beam and facia screws to the correct torque

specification.

WH1D008

3

1

2

2

Figure 12B-19

FOG LAMP TO BUMPER BAR

FACIA RETAINING SCREW

TORQUE SPECIFICATION 2 – 5 Nm

3. Check fog lamp operation. Recheck fog lamp

aim, refer to 2.1 AIMING OF HEADLAMPS

AND FOG LAMPS in this Section.

2.10 FOG LAMP SWITCH

REMOVE

1. Disconnect battery earth lead.

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the

VT Series I Service Information.

2. Release steering c olumn height adj usting lever

and completely lower steering column, lock

lever in this position.

Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

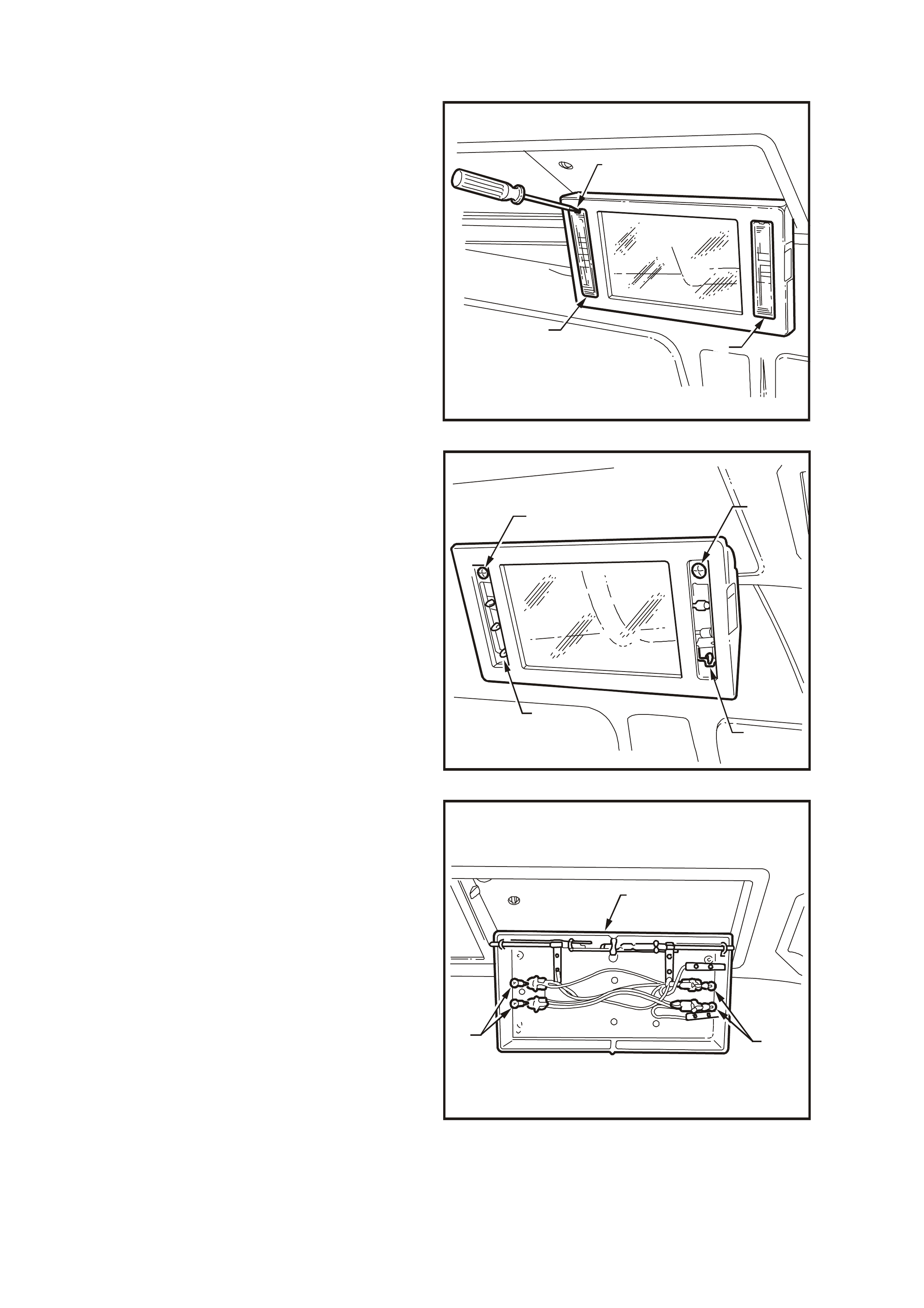

3. Remove instrument facia panel (1) in order to

gain access to rear of fog lamp switch (3). For

further information refer to Section 1A3

INSTRUMENT PANEL AND CONSOLE of the

VT Series I Service Information.

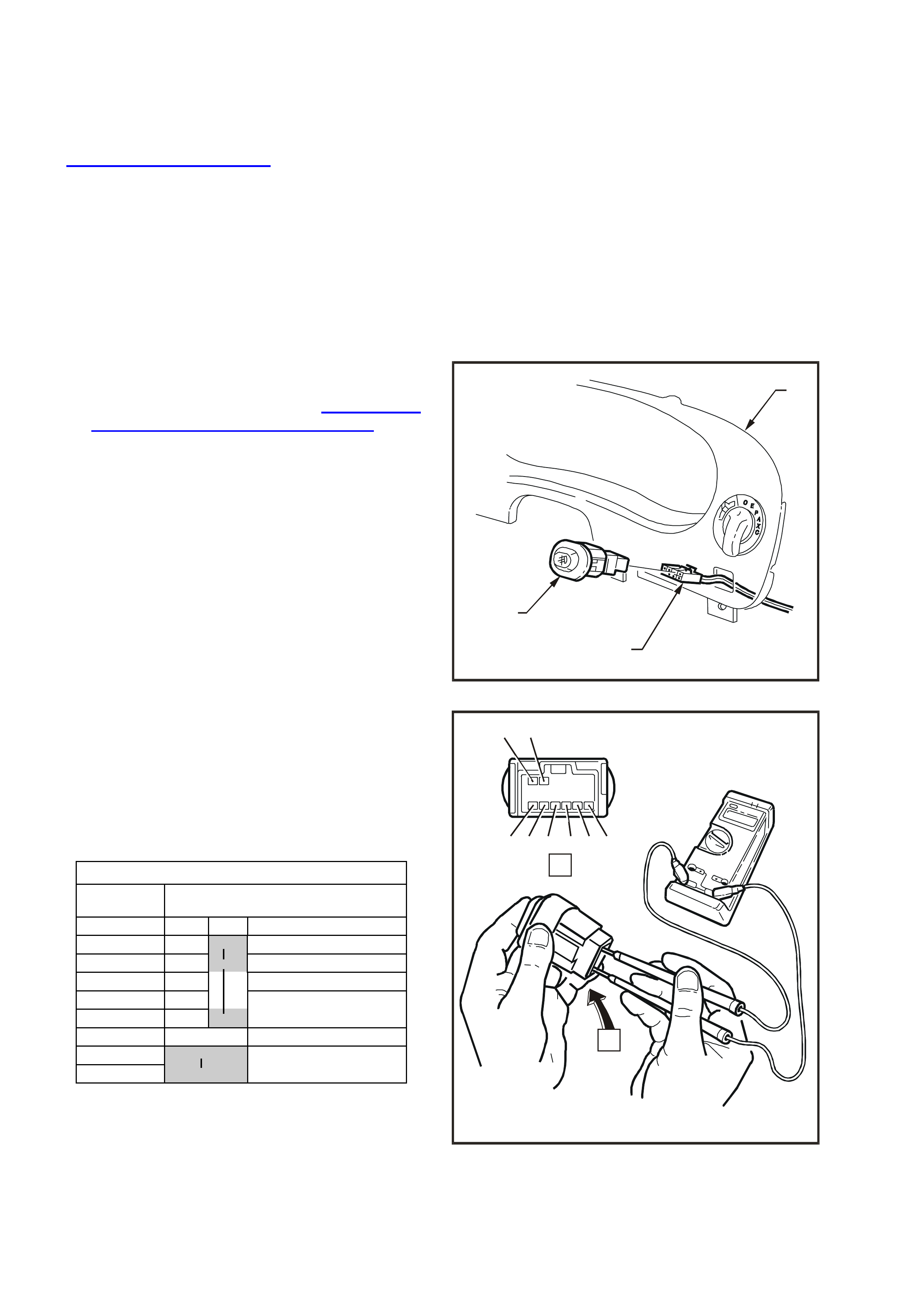

4. Depress retaining tang on instrument harness

to fog lam p switch connector ( 2), pull connector

from switch.

5. Squeeze together retaining tangs at side of

switch and push switch out from facia.

WH12B018

3

2

1

Figure 12B-20

FOG LAMP SWITCH CONTACTS

TERMINAL

NO. SWITCH

STATUS

OFF ON

1 O

2 O

3

4 Switch On Indi cator

5 O

6

7 OIlluminat i on B ul b

8 O

TEST

With the aid of an ohmmeter, check continuity of fog

lamp switch contacts using the following chart.

If continuity is not as specified at any switch

position, replace switch assembly.

WH12B019

A

A

654 3 12

87

Figure 12B-21

REINSTALL

Installation of the fog lamp switch is the reverse of

removal procedures, noting the following points:

1. If, when instrum ent fac ia was pulled away fr om

instrument panel pad, the pad retaining clips

came away with the facia lugs, pull clips from

lugs and install into pad holes.

If fitted, ensure that steering column to

instrument facia screen lip is fitted correctly to

edge on instrument panel pad. Install

instrument facia and ensure that it is held to the

instrument panel pad securely.

2. Check fog lamp operation and ensure that

switch illumination bulb illuminates when the

headlamps are turned on.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M

SUPPLEMENTAL REST RAINT SYSTEM of the VT

Series I Service Information.

2.11 CORNERING LAMP BULB

REPLACE

1. From behind the front spoiler, twist to release

bulb socket (2) from fog / cornering lamp

assembly (3) and remove bulb socket from

lamp assembly.

2. Pull bulb (1) from socket and inspect condition

of sock et O-ring seal. Replace seal if dam aged

or deformed.

3. Insert new bulb into socket, then install bulb

socket into lamp assembly and twist to lock.

2

3

1

WH12B062

Figure 12B-22

2.12 SIDE REPEATER LAMP

REMOVE

1. Grip rear edge of lamp housing (2) with finger

tips and pull housing forward and outwards

from fender panel. Once housing has released

from fender panel, remove housing and twist

bulb socket to release from housing.

2. If required, pull bulb from socket to replace.

3. Inspect lam p housing and bulb sock et seals f or

damage, replace if necessary.

REINSTALL

1. If necessary, install new bulb to socket.

2. Assem ble repeater lam p housing to s ock et and

twist socket to lock into housing.

3. Install lamp housing into fender opening with

housing locking nib facing forward and

engaging into opening.

4. Push rear of lamp hous ing into fender opening,

ensuring lamp housing is securely locked to

fender.

5. Check repeater lamp operation.

WH12B020

1

2

Figure 12B-23

2.13 HIGH LEVEL STOP LAMP

BULB REPLACEMENT

Access to the bulb is thr ough the rear c ompartment

and up through the upper rear panel opening

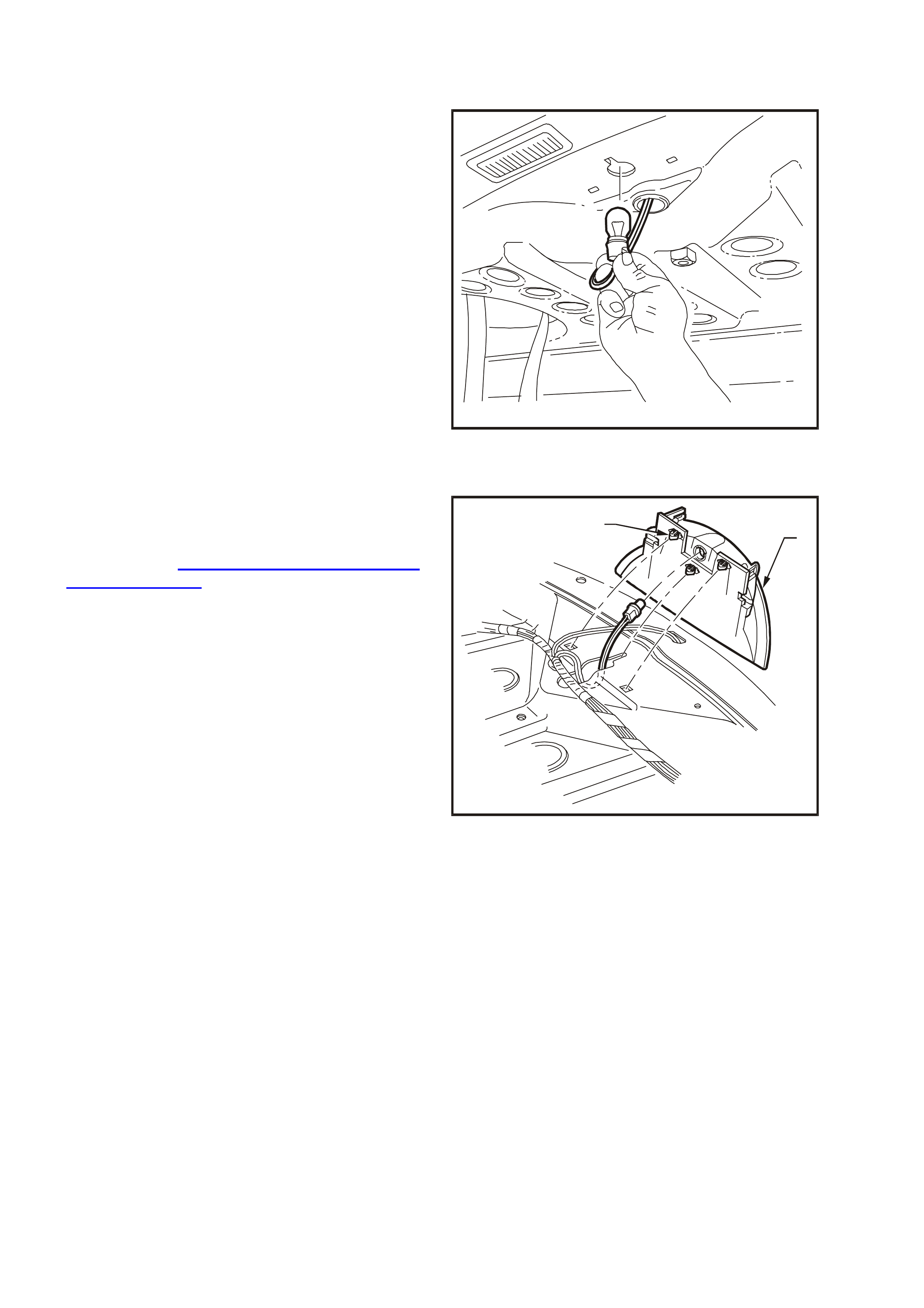

beneath the stop lamp mounting.

1. Twist bulb socket to release from lamp. Pull

socket down into rear compartment and pull

bulb from socket.

NOTE: It may be necessary to use a pair of pointed

nose pliers to hold and release bulb socket.

2. Install new bulb into socket and install bulb

socket into housing.

WH12B021

Figure 12B-24

LAMP REPLACEMENT

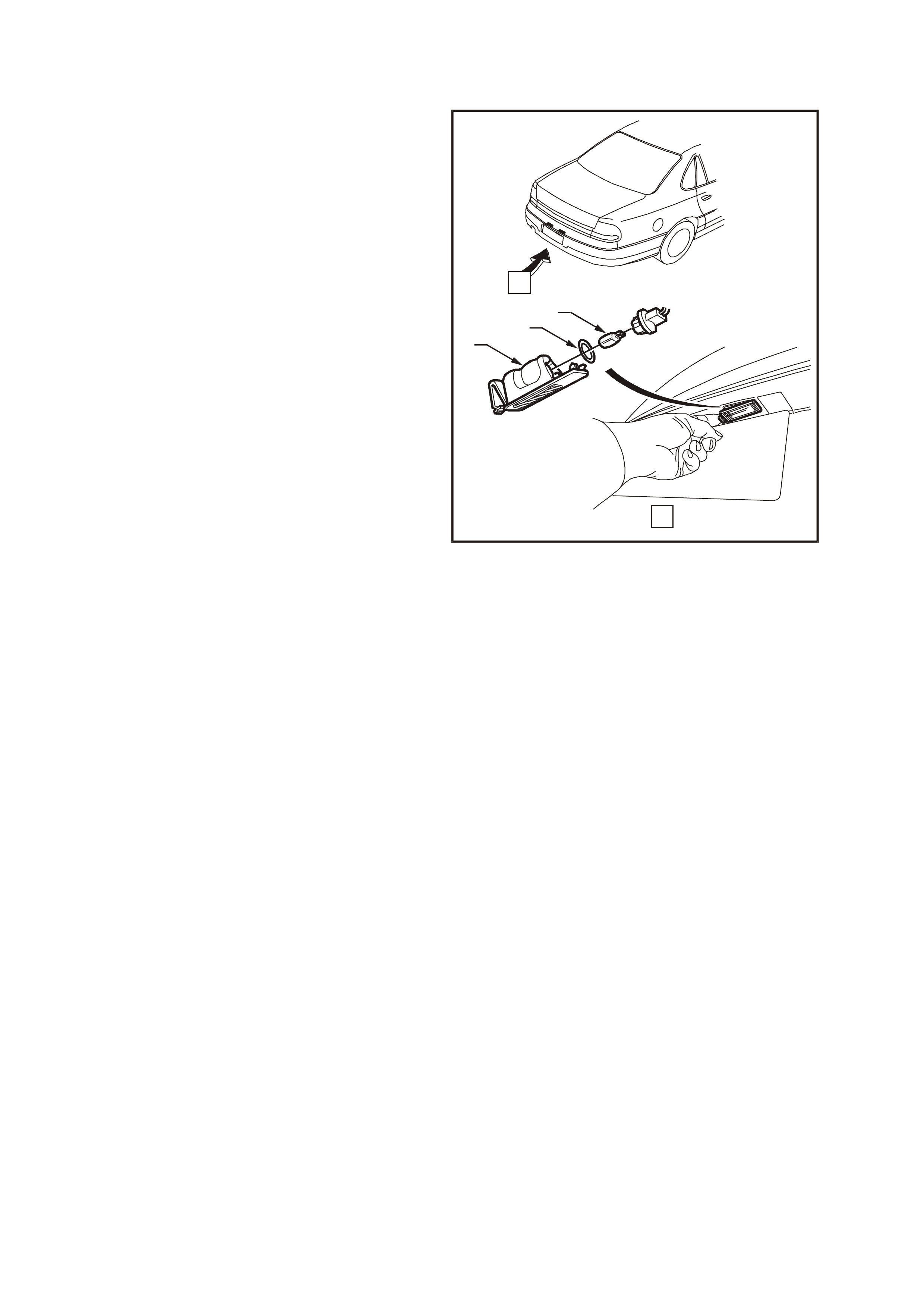

Fig. 12B-25 illustrates the installation of the high

level stop lamp.

To remove lamp assembly (2), remove rear parcel

shelf, refer to Section 1A8 HEADLINING AND

REAR END TRIM of the VT Series I Service

Inform ation. Remove bulb and s ocket as described

previously. Disengage retaining clips (1) securing

high level stop lamp to upper back panel and

remove lamp assembly.

On installation of high mount stop lamp, ensure that

stop lamp housing is pushed fully rearward before

engaging retaining clips.

WH12B022

12

Figure 12B-25

2.14 LICE NCE PLATE LAMP/BULB

REMOVE

1. Push locking tang located at end of lamp

assembly (1) towards lamp and pivot lamp

assembly down to remove from aperture.

2. Withdraw socket and bulb assembly from lamp.

3. Pull bulb (3) from socket.

4. Inspect bulb socket sealing ring (2), lamp lens,

lamp locking tang and lamp locating lugs for

damage, replace lamp if required.

REINSTALL

1. Push new bulb into bulb socket.

2. Check lamp operation.

3. Install lamp assembly, ensuring that locking

tang secures lamp assembly.

WH12B024

A

A

123

Figure 12B-26

2.15 REAR LAMP BULBS

STOP/TAIL AND TURN SIGNAL LAMP BULBS

REPLACE

1. Open rear compartment.

2. Remove rear lamp assembly (1) refer to

2.16 REAR LAMP ASSEMBLY in this Section.

3. Remove appropriate bulb socket (2) or (3) by

turning and removing socket.

4. Remove bulb (4) from socket by depressing

bulb into its socket and then rotate to remove.

Inspect bulb socket to lamp housing seals for

damage, replace if necessary.

5. Insert new bulb into socket and install socket

into lamp housing, ensuring socket locks

securely into place.

6. Check rear lamp operation.

WH12B025

2

1

4

3

Figure 12B-27

Techline

2.16 REAR LAMP ASSEMBLY

REAR QUARTER LAMP ASSEMBLY

REMOVE

1. Open rear compartment.

Remove rear quarter lamp assembly (1) to

body attaching screws (2).

2. Pull rear quarter lamp assembly (1) rearward

out from panel so that locating pegs on side of

lamp assembly snap free from retainers. W hile

supporting lamp housing, remove bulb sockets

by turning and removing socket.

1

2

WH12B023

A

A

Figure 12B-28

REINSTALL

1. Insert bulb sockets into rear quarter lamp

housing, ensuring sockets lock securely into

place.

2. Ensure that rear quarter lamp harness

grommet is seated correctly. Assemble lamp

housing to body, ensuring locating pegs snap

into retainers and install and tighten attaching

screws to the correct torque specification.

REAR QUARTER LAMP

HOUSING TO BODY

ATTACHING SCREW

TORQUE SPECIFICATION

3 – 4 Nm

3. Check rear lamp operation.

2.17 REAR COMPARTMENT LID LAMP ASSEMBLY

REMOVE

3. Reconnect wiring harness connec tor and install

reverse lamp bulb and socket assemblies.

4. Check rear lamp operation.

1. Open rear compartment lid.

2. From inside rear compartment lid, remove

cover trim and remove reverse lamp socket

and bulb assemblies by turning and pulling

sockets from compartment lid lamp assembly

(2).

3. Remove lamp assembly to rear compartment

lid attaching nuts (1).

NOTE: Carefully pull lamp assembly away from

compartment lid ensuring that studs, positioned

centrally in lamp assembly, do not bind in nutserts

which could damage the lamp assembly.

REINSTALL

1. Check condition of lamp housing to rear

compartment lid rubber sealing gasket and

replace if damaged.

2. Position lamp assembly (2) on rear

compartment lid, engaging lamp assembly

tongue in and around moulding mounting boss

grommet. Install and tighten attaching nuts (1)

to the correct torque specification.

2

1

1

1

1

1

2.0 - 5.0 Nm WH12B026

Figure 12B-29

REAR COMPARTMENT LID LAMP

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2 – 5 Nm

2.18 RE AR COMPARTMENT LID LAMP BULB

REVERSE LAMP BULB

REPLACE

1. Open rear compartment lid.

2. From inside rear compartment lid, remove

cover trim and remove reverse lamp socket

and bulb assembly (3) by turning and pulling

sockets from compartment lid lamp

assembly (1).

3. Remove bulb (2) from socket by depressing

bulb into its socket and then rotate to remove.

Inspect bulb socket to lamp housing seals for

damage, replace if necessary.

4. Insert new bulb into socket and install socket

into lamp housing, ensuring socket locks

securely into place, then install cover trim.

5. Check rear lamp operation.

WH12B063

1

2

3

Figure 12B-30

2.19 INTERIOR LAMPS

NOTE: The interior lighting configuration is

dependant on the vehicle model and trim level.

DOOR COURTESY LAMPS

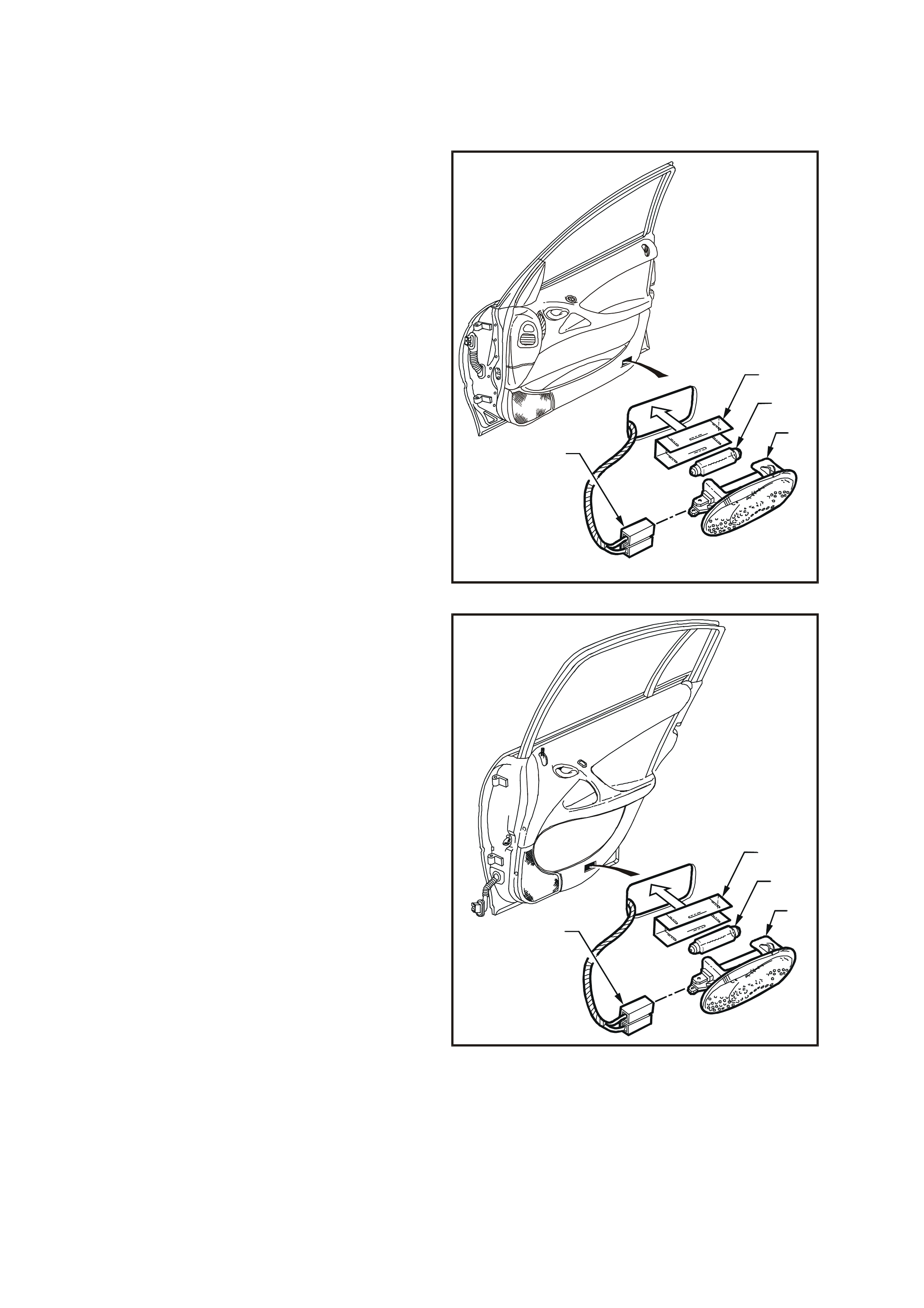

Figs. 12B-31 and 12B-32 illustrate the installation of

the front and rear door courtesy lamps.

REMOVE

1. To remove lamp assembly use a fine bladed

screwdriver inserted between notch in lens

surround and door trim. Pus h sc r ewdriver down

to depress locking tang and prise edge of

courtesy lamp (3) away from door trim.

2. Insert screwdriver in notch at bottom edge of

lamp, depress locking tang, prise bottom edge

of lam p away from door and rem ove lam p from

door aperture. Disconnect wiring harness

connector (4).

3. To remove bulb from lamp, pull protective

metal cover (1) from back of lamp to gain

access to bulb (2), then bend back lever

contact retaining the bulb and remove bulb.

WH12B027

4

1

3

2

Figure 12B-31

REINSTALL

1. Insert new bulb (2), ensuring that lever contact

retains bulb securely.

2. Slide protective m etal cover (1) into position on

back of lamp (3).

3. Connect wiring harness connector (4) to

terminals on lamp.

4. Install lamp (3) into aperture in door, ensuring

that wiring harness and connectors are

positioned behind door trim, then push lamp

assembly firmly into position.

WH12B028

4

1

3

2

Figure 12B-32

GLOVE COMPARTMENT LAMP

Fig. 12B-33 illustrates the installation of the glove

com partm ent lamp. To gain ac cess to bulb ( 2), use

a fine bladed screwdriver to carefully lever out lens

(1) from instrument panel.

To rem ove bulb f rom lens, bend bac k lever contact

retaining the bulb and remove bulb. If necessary,

remove harness connector (3) to provide better

access to bulb.

When installing bulb, ensure that lever contact

retains bulb securely.

WH12B029

1

3

2

Figure 12B-33

REAR COMPARTMENT LAMP

Fig. 12B-34 illustrates the installation of the rear

compartment lamp. To gain access to bulb, use a

fine bladed screwdriver to carefully lever out lens

(3).

To remove bulb (2) from lens, bend back lever

contact retaining bulb and remove bulb. If

necessary, remove harness connector (1) to

provide better access to bulb.

When installing bulb, ensure that lever contact

retains bulb securely.

WH12B030

2

3

1

Figure 12B-34

REAR COMPARTMENT LAMP SWITCH

The rear compartment lamp is operated by a

switch attached to the rear compartment lid.

REMOVE

1. Remo ve attaching screw (1) and pull s witch (3)

out far enough to gain ac ces s to wiring har ness

connector (2).

2. Disconnect wiring harness connector and

remove switch.

REINSTALL

Installation is the reverse of the removal procedure.

1

2

3

WH12B031

Figure 12B-35

DOME AND FRONT READING LAMPS

Fig. 12B-36 illustrates the installation of the dome

and front reading lamp assembly. To gain access

to bulb, use a fine bladed screwdriver inserted

between notch in lens surround and edge of lens.

Carefully lever out lens (2) from housing, gently

prising from all four notches, ensuring no damage

is made to housing surround or headlining.

The dome lamp bulb is a festoon bulb and can be

removed by bending contacts out from bulb. Once

installed, ensure that they are lock ed fir mly in place

in their sockets.

To gain access to the reading lamp bulbs, remove

bulb cover plates (1) by gently levering thin tab

away fr om housing using a f ine bladed s crewdriver .

Reading lamp bulbs are festoon bulbs and can be

removed by bending contacts out from bulb. Once

installed, ensure that they are lock ed fir mly in place

in their sockets. Install bulb cover plates and click

firmly into place.

Install lens.

WH12B032

2

1

Figure 12B-36

REAR VANITY MIRROR LAMP BULBS

REPLACE

1. Depress vanity mirror button and allow vanity

mirror to swing down.

2. Using a fine blade screwdriver, carefully lever

notched ends of mirror lamp lens from mirror

housing.

WH12B058

1

2

3

Figure 12B-37

3. Remove two screws from mirror housing.

4. Using a fine blade screwdriver, lever up

housing body retainers and pull mirror housing

lower half bottom edge from top half.

NOTE: Take care not to lose lamp switch slider as

mirror housing is separated.

WH12B059

1

32

1

Figure 12B-38

5. Pull Bulb/s from socket.

6. Install new bulb/s.

WH12B060

2

11

Figure 12B-39

7. Install lamp switch slider into housing lower

half, ensur e that it is located cor rectly in slot on

side of housing.

8. Engage housing lower half onto top edge

retainer of housing upper half. Squeeze

together lower corners of housing halves to

engage retainers in each bottom corner.

9. Install and tighten mirror housing screws.

10. Install m irror lamp lens into m irror housing with

notched ends facing upward.

11. Switch mirror lamp on and ensure that bulbs

illuminate.

WH12B061

1

2

3

Figure 12B-40

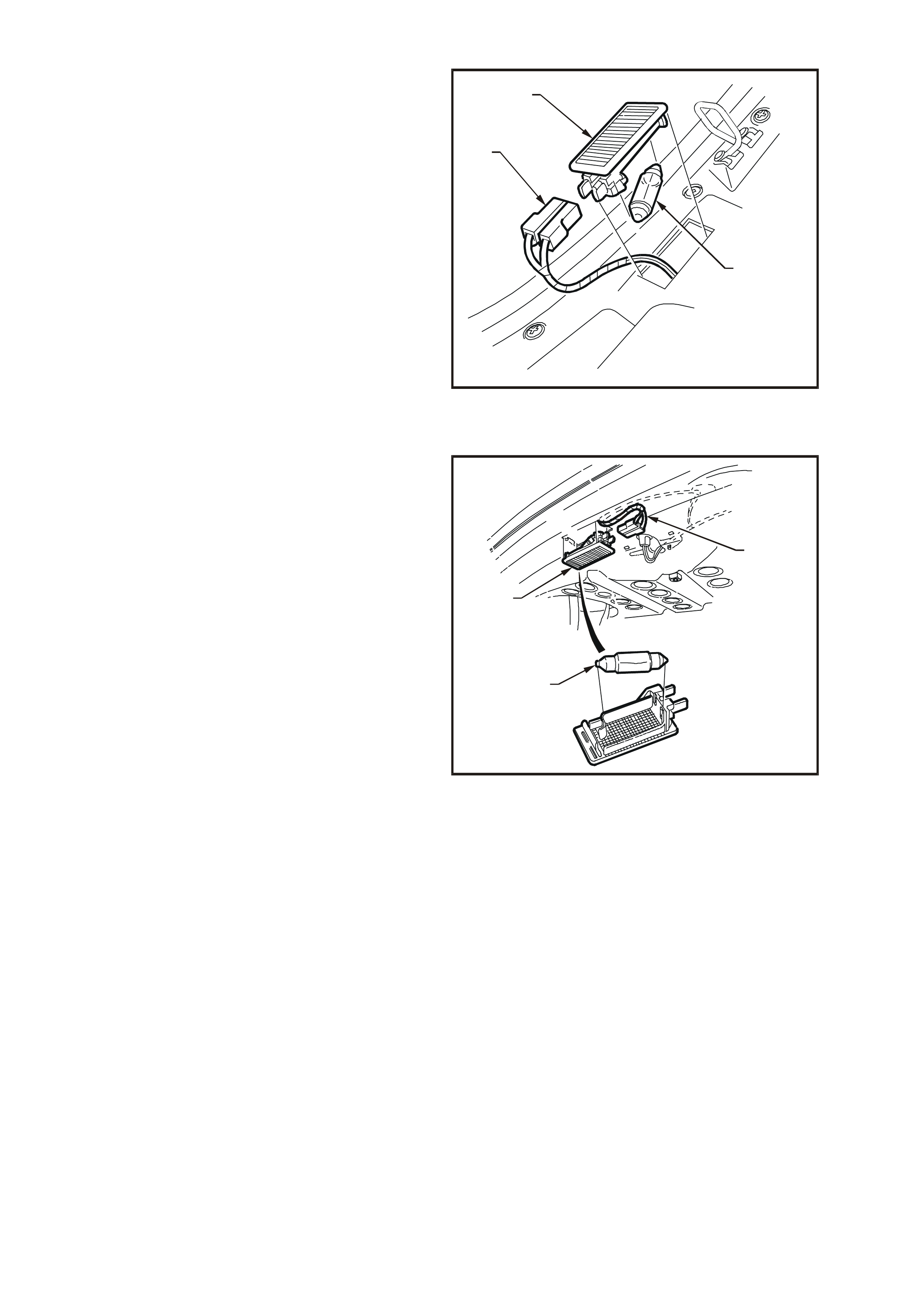

FOOTWELL LAMPS

Front footwell lamp bulbs are located in sockets

which are a twist fit into right and left hand

instrument panel side trims (1).

Bulbs (2) are a push fit into socket. Bulbs are fitted

with a green cover. When installing new bulb,

ensure that new cover is installed onto bulb.

The sockets are part of the main wiring harness.

WH12B033

2

1

Figure 12B-41

DOOR JAMB SWITCHES

The door j amb s witches are installed in eac h of the

door hinge pillars. When the door of the vehicle is

closed, a plunger in the switch is depressed,

creating an open circuit in the earth circuit. When

the door is opened, the plunger is released and

completes the circuit to earth.

Remove Philips head screw (1) securing switch to

door pillar, withdraw switch (3) from pillar and

disconnect wiring harness connectors (2).

Installation of the switch is reverse of the removal

procedure.

WH12B034

1

2

3

Figure 12B-42

CONSOLE BIN LAMP

From inside of console, use a fine bladed

screwdriver to carefully lever lamp (1) from side of

console. To provide better access to lamp,

disconnect wiring harness connectors from lamp

and remove lamp from console bin.

Bulb (2) can be replaced by bending back contact

retaining bulb and removing bulb.

When installing bulb, ensure that lever contact

retains bulb securely.

Connect wiring harness connectors to lamp, then

insert wiring harness and lamp into aperture in

console bin.

WH12B035

1

2

Figure 12B-43

CONSOLE BIN LAMP SWITCH

REMOVE

1. Open console bin and pull switch (1) from

console bin assembly.

2. Disconnect wiring connector from switch and

remove switch from console bin.

WH12B036

1

Figure 12B-44

REAR READING LAMP

Fig. 12B-45 illustrates the installation of the rear

reading lamp assembly. To gain access to bulb,

use fine bladed screwdriver and gently lever

lamp (2) from aperture in headlining, ensuring no

damage is made to lens or headlining.

Bulb (3) can be replaced by bending back contact

retaining bulb and removing bulb. If necessary,

disconnect wiring harness connectors (1) from

lamp.

When installing bulb, ensure that lever contact

retains bulb securely.

Connect wiring harness connectors to lamp, then

insert wiring harness and lamp into aperture in

headlining. Push lamp firmly into aperture.

WH12B037

1

2

3

Figure 12B-45

FRONT VANITY MIRROR LAMP

Fig. 12B-46 illustrates the installation of the front

vanity mirror lamp. Lower visor and lift flap to

expose vanity mirror and lamp assembly. To gain

access to bulb, use fine bladed screwdriver and

gently lever front vanity mirror lamp cover

assembly (1) from visor and pivot assembly.

NOTE: Damage to vanity mirror lamp surround will

occur if car e is not taken when levering lamp c over

assembly.

Bulb (2) can be replaced by bending back contact

retaining bulb and removing bulb.

When installing bulb, ensure that lever contact

retains bulb securely.

If replacing lamp housing, pull wiring harness

connectors from lamp housing terminals.

WH12B038

2

1

Figure 12B-46

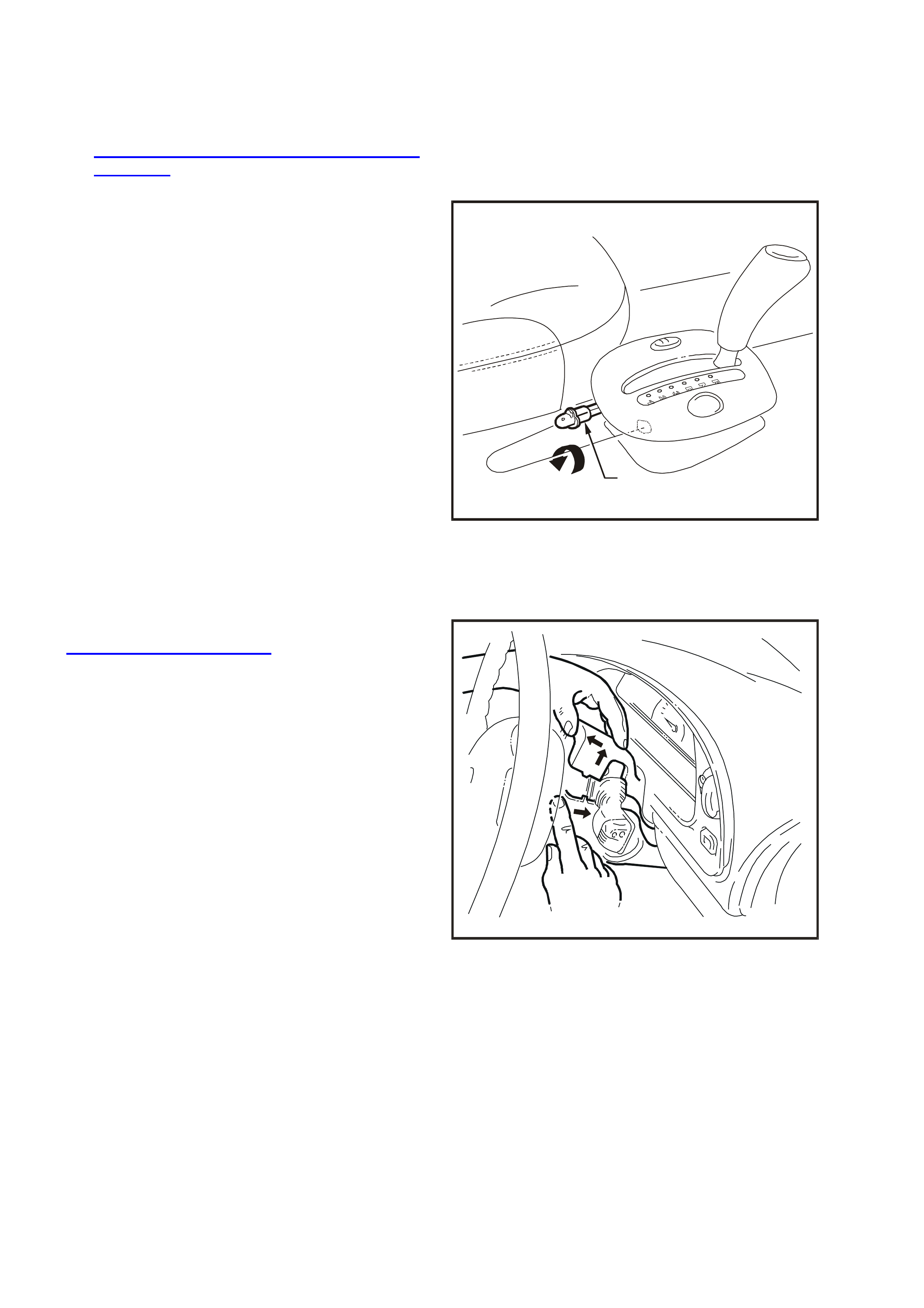

GEARSHIFT INDICATOR LAMP BULB

REPLACE

1. Disconnect battery earth lead.

2. Remove transmission console as described in

Section 1A3 INSTRUMENT PANEL &

CONSOLE of the VT Series I Service

Information.

3. From beneath cons ole cap, disconnec t cons ole

wiring harness to illumination connectors.

4. Disconnect illumination bulb socket and pull

bulb (1) from socket.

5. Install new bulb into socket. Install socket into

holder and twist clockwise to retain.

6. Install transmission console cap assembly,

reverse to removal procedures, ensuring all

connectors are reconnected.

7. Connect battery earth lead.

8. Turn headlamps on and ensure bulb

illuminates.

WH12B039

1

Figure 12B-47

IGNITION LOCK LAMP

REPLACE

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the

VT Series I Service Information.

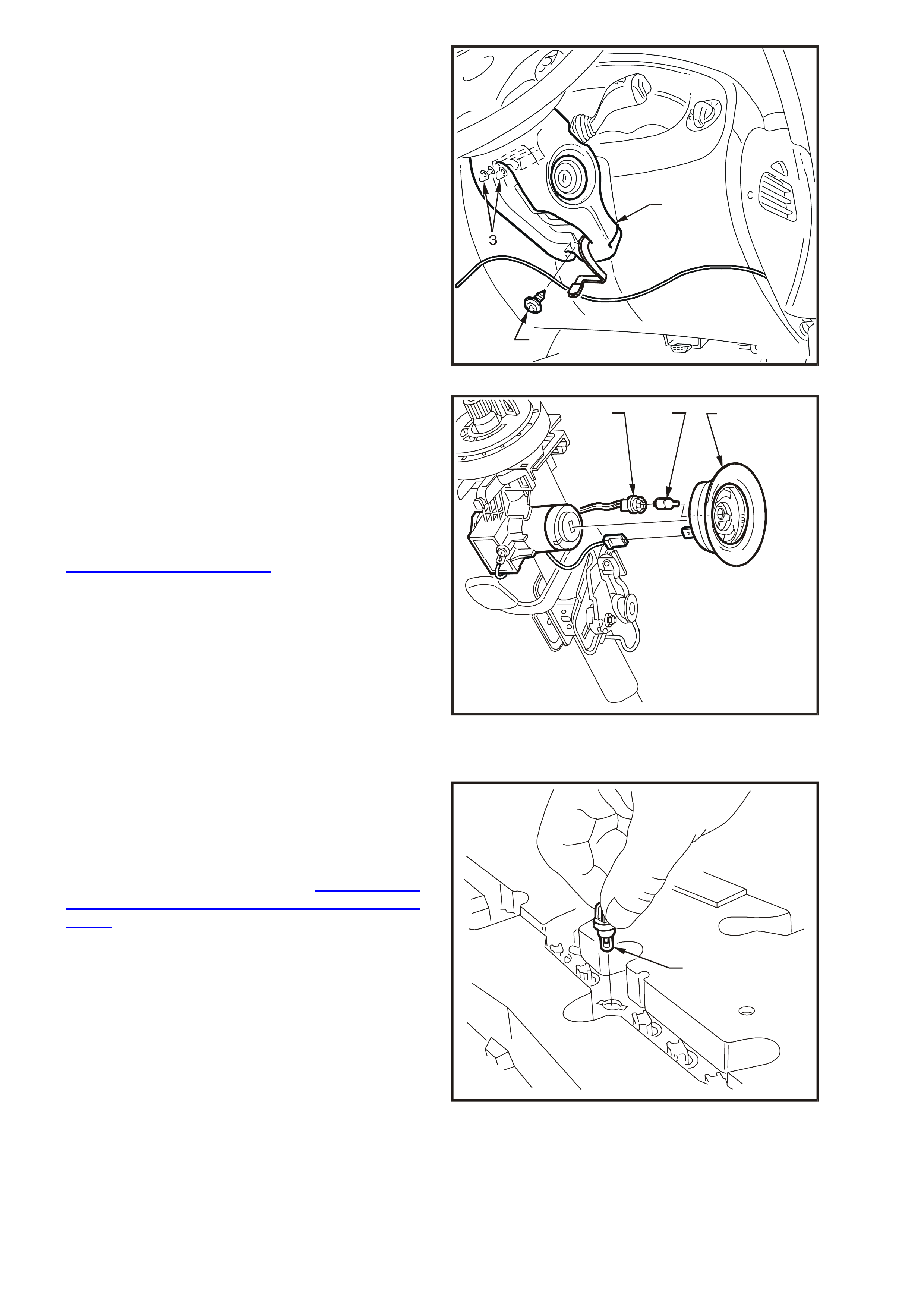

1. Release steering column height adjuster,

com pletely lower s teering c olumn and leave the

lever in the released position.

2. Insert finger between the steering wheel and

the lower cover as shown in Fig. 12B-48 and

apply a small amount of pressure (pushing

towards the instrument cluster) while lifting the

upper cover upwards.

WH12B041

Figure 12B-48

3. Remove screw (2) securing the lower cover (1)

to the steering column.

4. Slide the lower cover towards the steering

wheel to release the cover from the two

retaining tangs (3) on the steering column.

5. Remove the lower cover, while feeding the key

reader outer surround from the lower cover.

2

1

WH12B040

Figure 12B-49

6. Pull ignition lock lamp socket (1) from lamp

housing on key reader assembly (3).

7. Pull bulb (2) from socket.

8. Replace bulb and install lamp housing to key

reader assembly.

9. Install steering column covers in reverse order

of removal procedure.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M

SUPPLEMENTAL REST RAINT SYSTEM of the VT

Series I Service Information.

WH12B042

321

Figure 12B-50

INSTRUMENT CLUSTER ASSEMBLY LAMP BULBS

The instrument assembly and warning lamp

illumination bulbs ar e a push fit into a so cket, which

in turn are a twist fit into the rear of the instrument

case and flexible printed circuit board.

To remove the lamp socket (1), remove the

instrument cluster, refer to Section 12C

INSTRUMENTS, WIPERS/ WASHERS AND

HORN of this Ser vice Inform ation CD. Rem ove the

lamp socket (1) from the printed circuit board and

pull bulb from its socket.

Installation of the ins trum ent c luster assembly lam p

bulbs is the reverse of removal procedure.

WH12B043

1

Figure 12B-51

TRIP COMPUTER SWITCH ASSEMBLY ILLUMINATION BULB

The trip computer assembly illumination bulb is a

push fit into a socket, which in turn is a twist f it into

the rear of the trip computer flexible printed circuit

board.

To remove the lamp socket (1), remove the trip

computer switch assembly (2), refer to Section

12C INSTRUMENTS, WIPERS/WASHERS AND

HORN of this Ser vice Inform ation CD. Rem ove the

lamp socket (1) from the printed circuit board and

pull bulb from its socket.

NOTE: Procedures for replacing the trip computer

assembly illumination lamps are covered in

Section 12C INSTRUMENTS,

WIPERS/WASHERS AND HORN of this Service

Information CD.

WH12B044

2

1

Figure 12B-52

INSTRUMENT FACIA AND CENTRE FACIA ESCUTCHEON SWITCH ILLUMINATION BULBS

The instrument facia and centre facia escutcheon

switch assemblies are illuminated by a bulb and

socket assembly which is a twist fit into the

underside of the switch assembly.

To remove switch assembly (1), refer to Section

12C INSTRUMENTS, WIPERS/WASHERS AND

HORN of this Service Inform ation CD. Then, using

a fine bladed screwdriver, inserted into cross on

bulb socket, twist socket anti-clockwise, remove

bulb and socket assembly (2).

Installation of the bulb and socket assembly is the

reverse of the removal procedure.

WH12B045

1

2

Figure 12B-53

2.20 STOP LAMP SWITCH

REMOVE

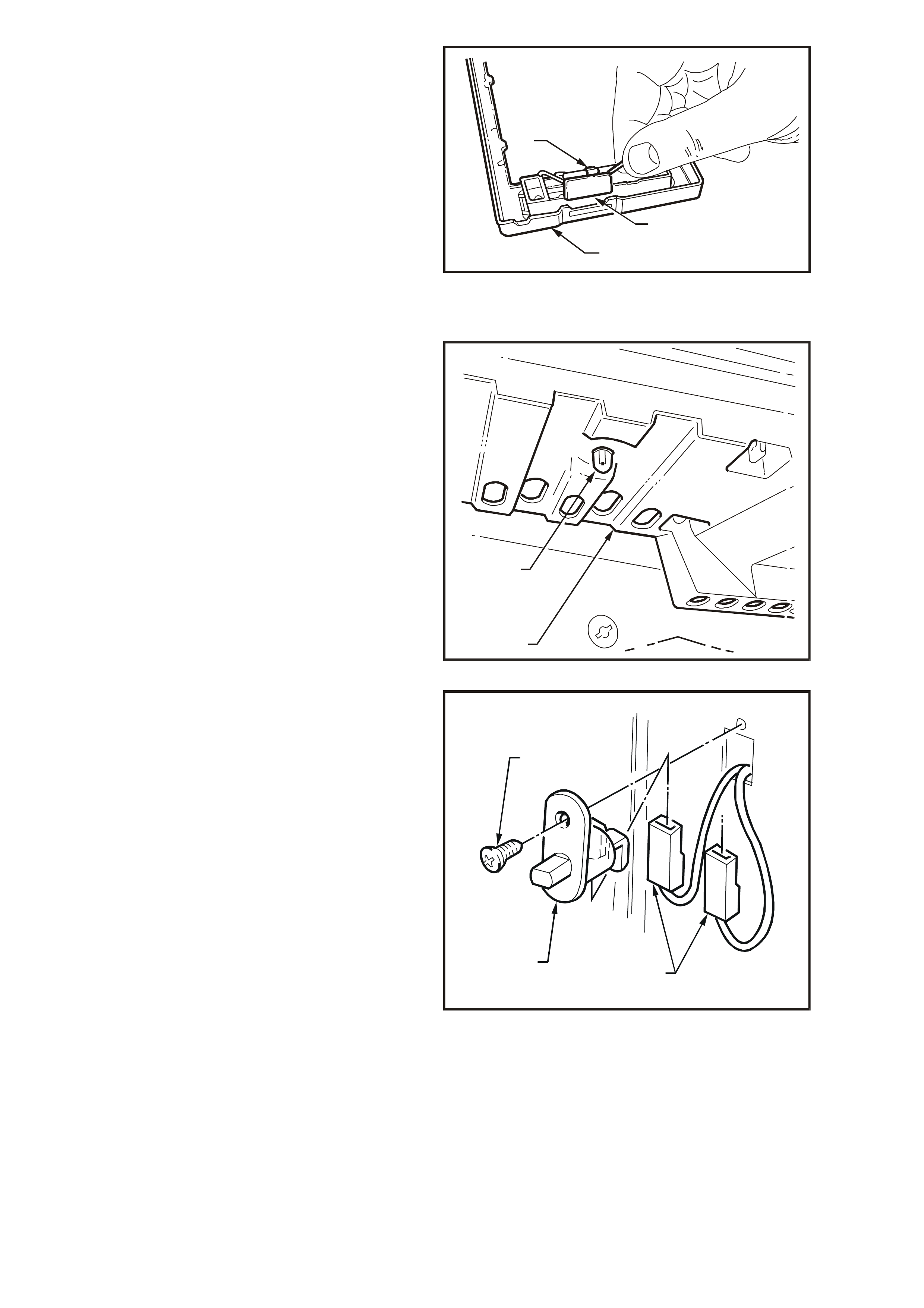

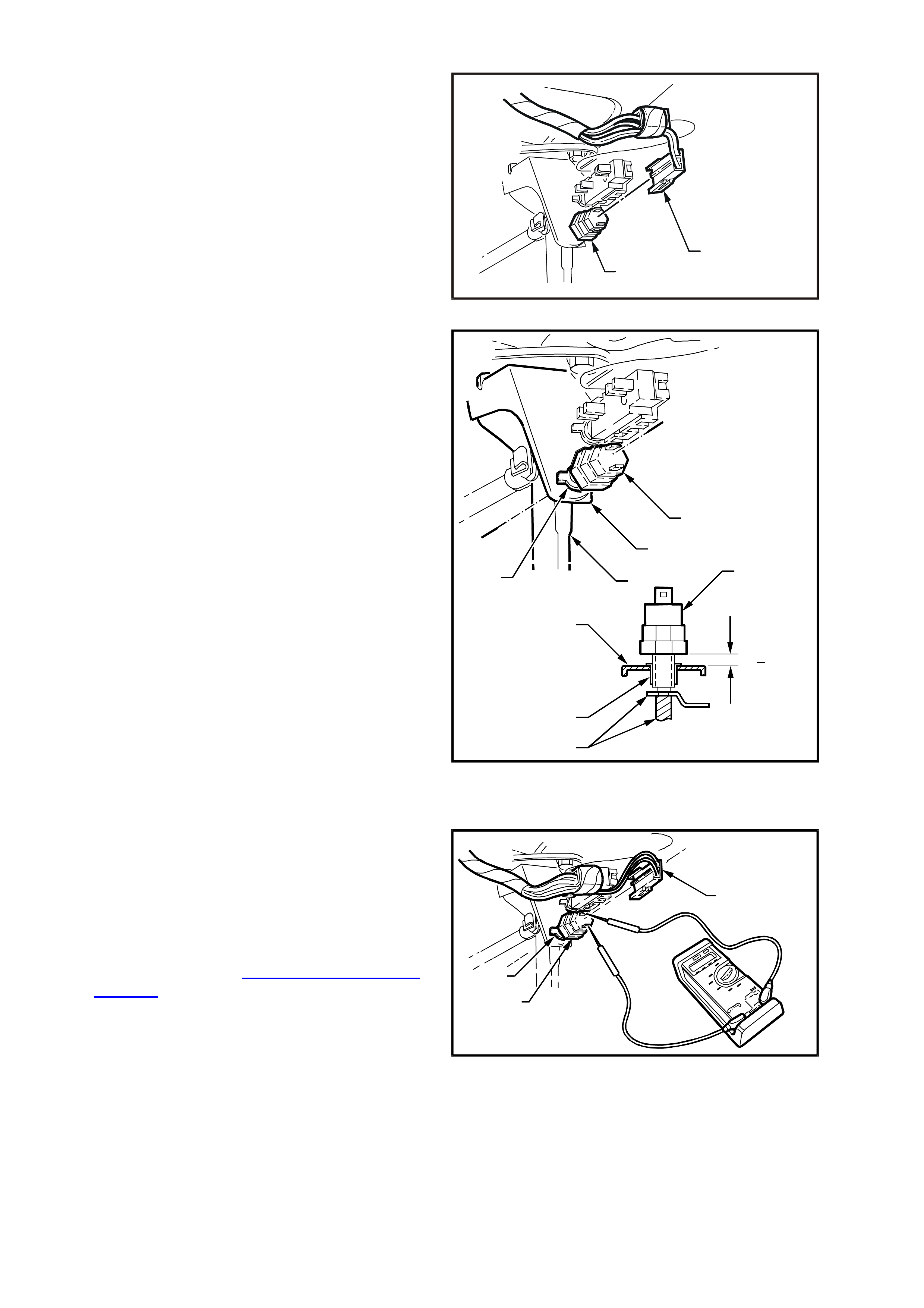

1. Disconnect wiring harness connector (1) from

the stop lamp switch (2).

2. Rotate switch anticlockwise and remove from

the mounting nut.

WH12B046

21

Figure 12B-54

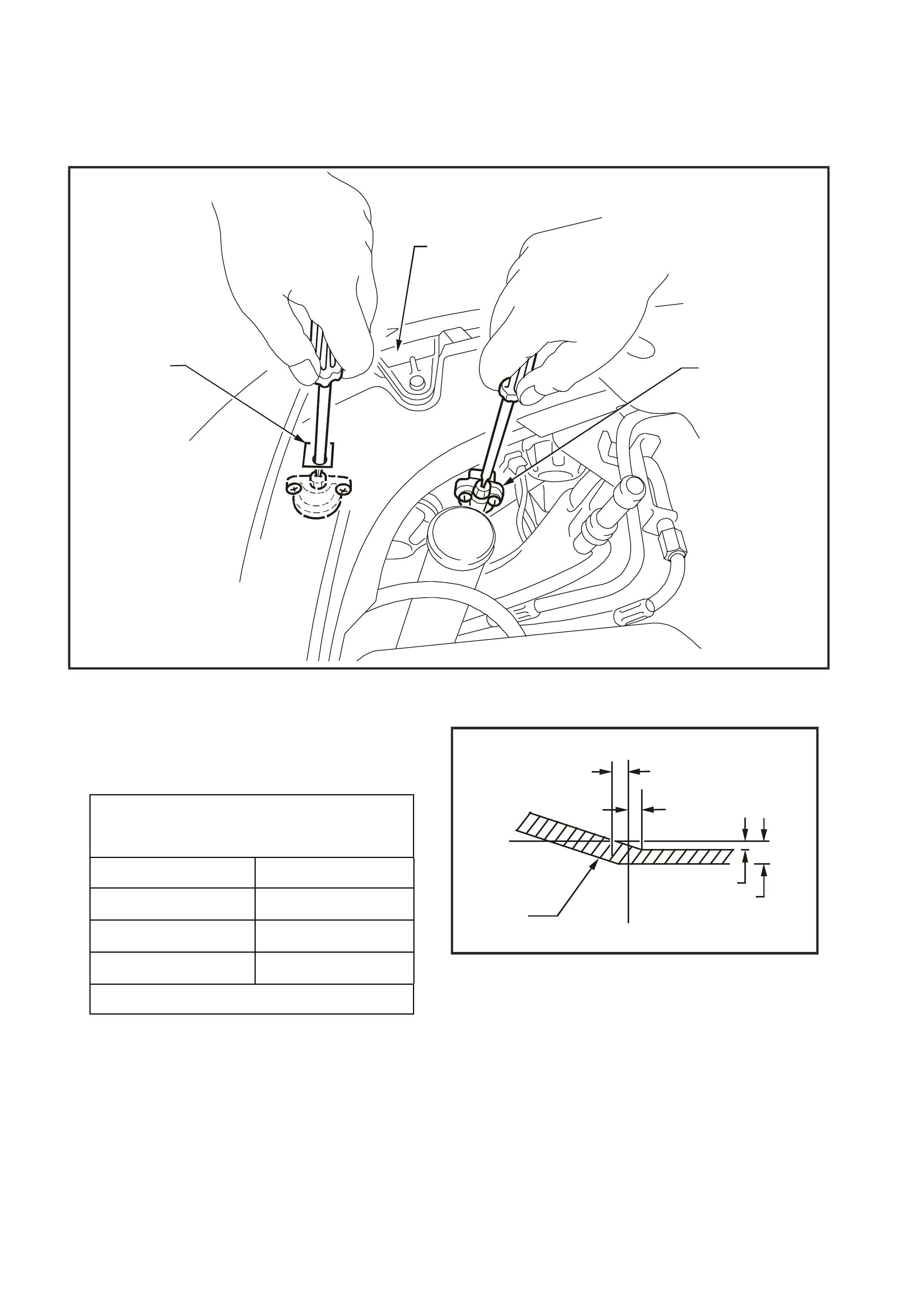

REINSTALL AND ADJUST

1. Install the stop lamp switch (1) into the

mounting nut (2) on the brake pedal support

(3).

2. With the brake pedal (4) in its rest position,

install switch into mounting nut (2). Adjust the

switch to the clearanc e dim ension shown in F ig

12B-55.

3. Connect wiring harness connector to switch.

T212E046

1

3

2

4

6 0.5mm

A

A

1

3

4

2

A

-A

+

Figure 12B-55

TESTING SWITCH CONTACTS

1. Check adjustment of the stop lamp switch (1),

refer to the following switch installation and

adjustment procedure and adjust the switch as

required.

Ensure that the brake lights ar e operating when

the brake pedal is depressed.

If brake lights are not operating, repair as

necessary, refer to Section 12B LIGHTING

SYSTEM of the VT Series I Service

Information.

2. Remove wiring harness connector (2) from the

terminals of the stop lamp switch (1).

3. Connect an ohmmeter across the switch

terminals and the ohmmeter should indicate

open circuit with the brake pedal at rest.

4. Depress the brake pedal and the ohmmeter

should indicate continuity.

T212E045

2

3

1

Figure 12B-56

5. Replace the switch if the tests pr ove the switch

to be faulty.

6. If the test proves the switch to be OK, connect

the wiring harness connector to the switch.

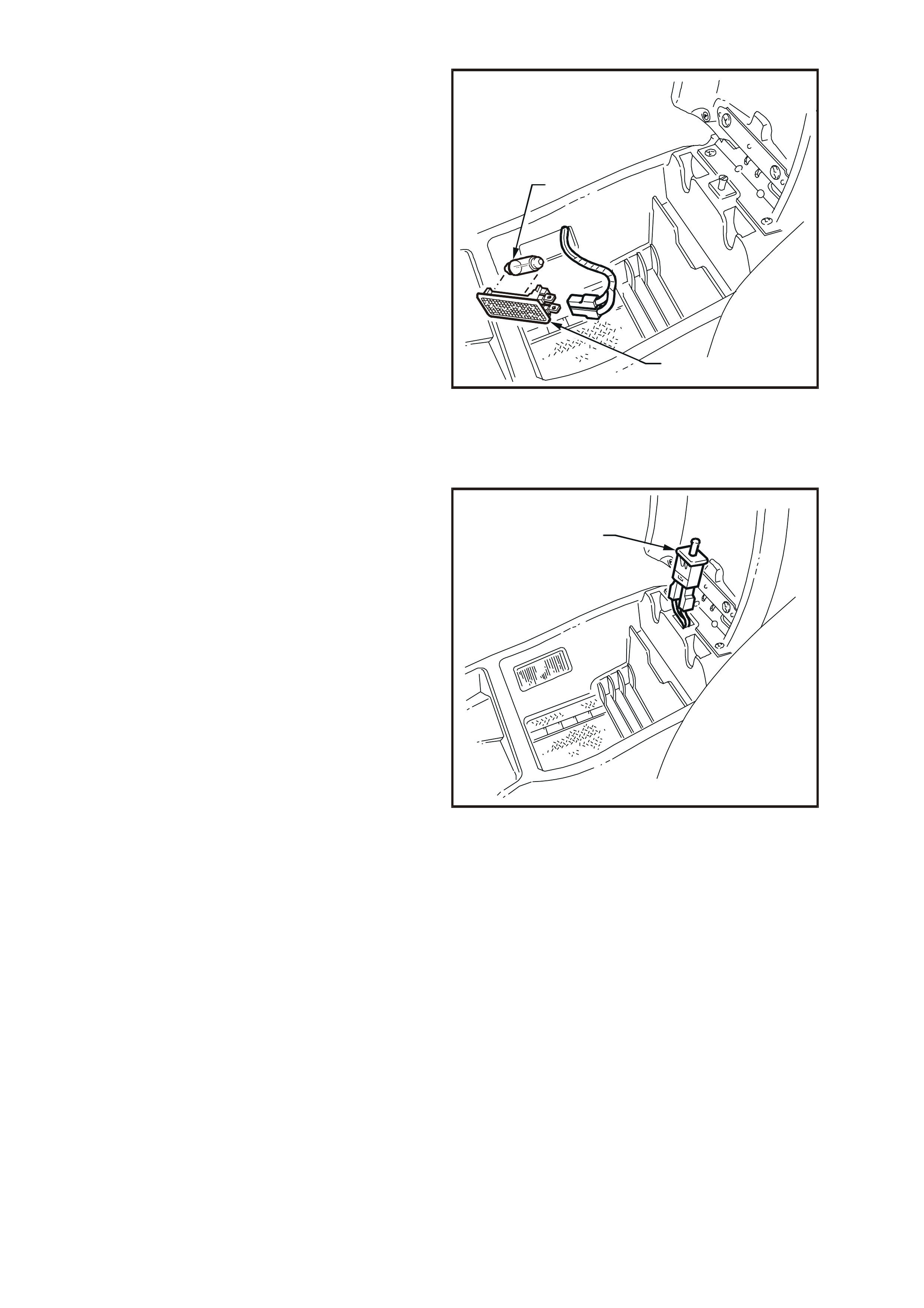

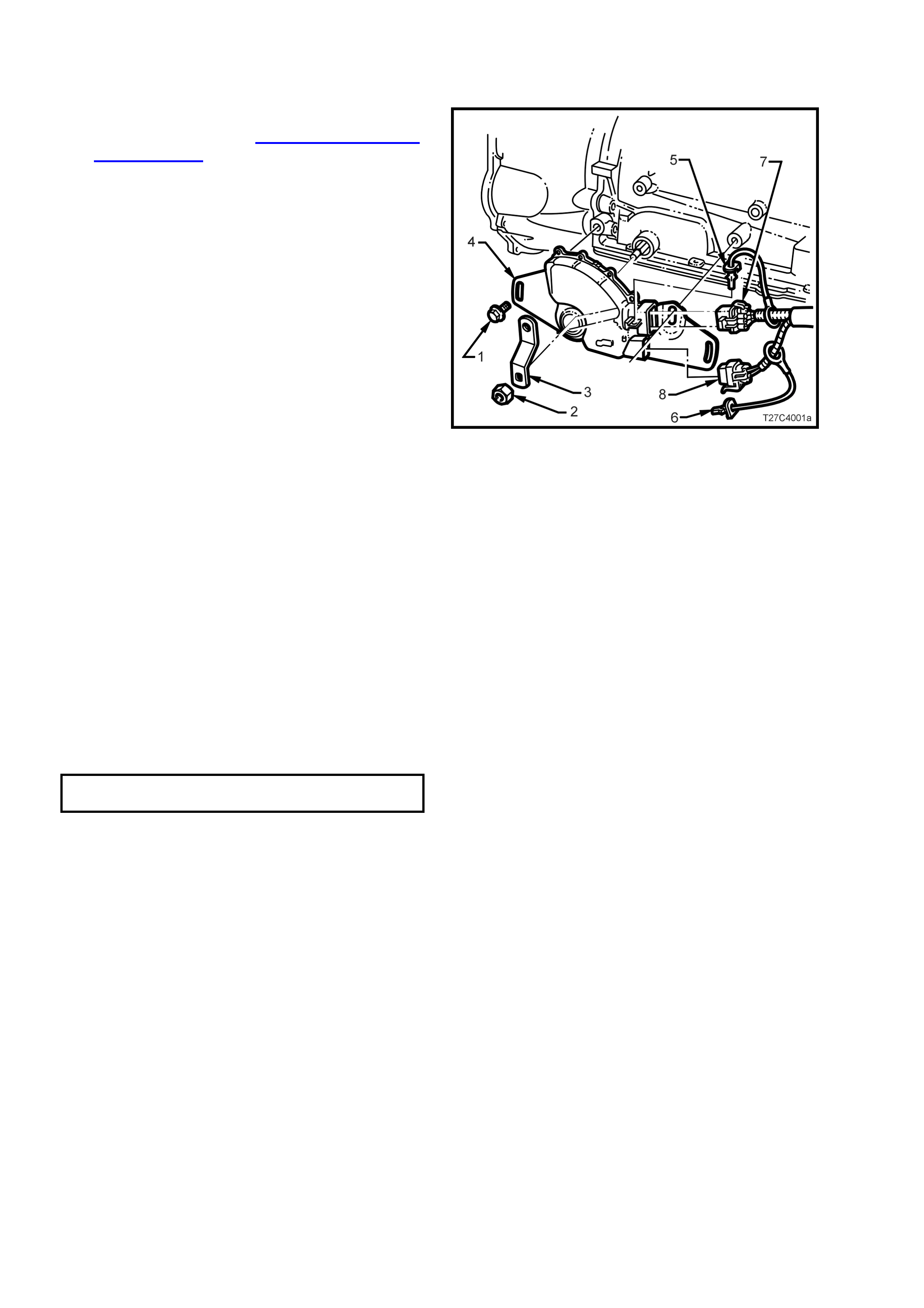

2.21 NEUTRAL START/BACK-UP LAMP SWITCH

REMOVE

1. Raise the front of the vehicle and place on

safety stands. Refer to Sect ion 0A, GENERAL

INFORMATION of the VT Series I Service

Information for the location of recommended

jacking points.

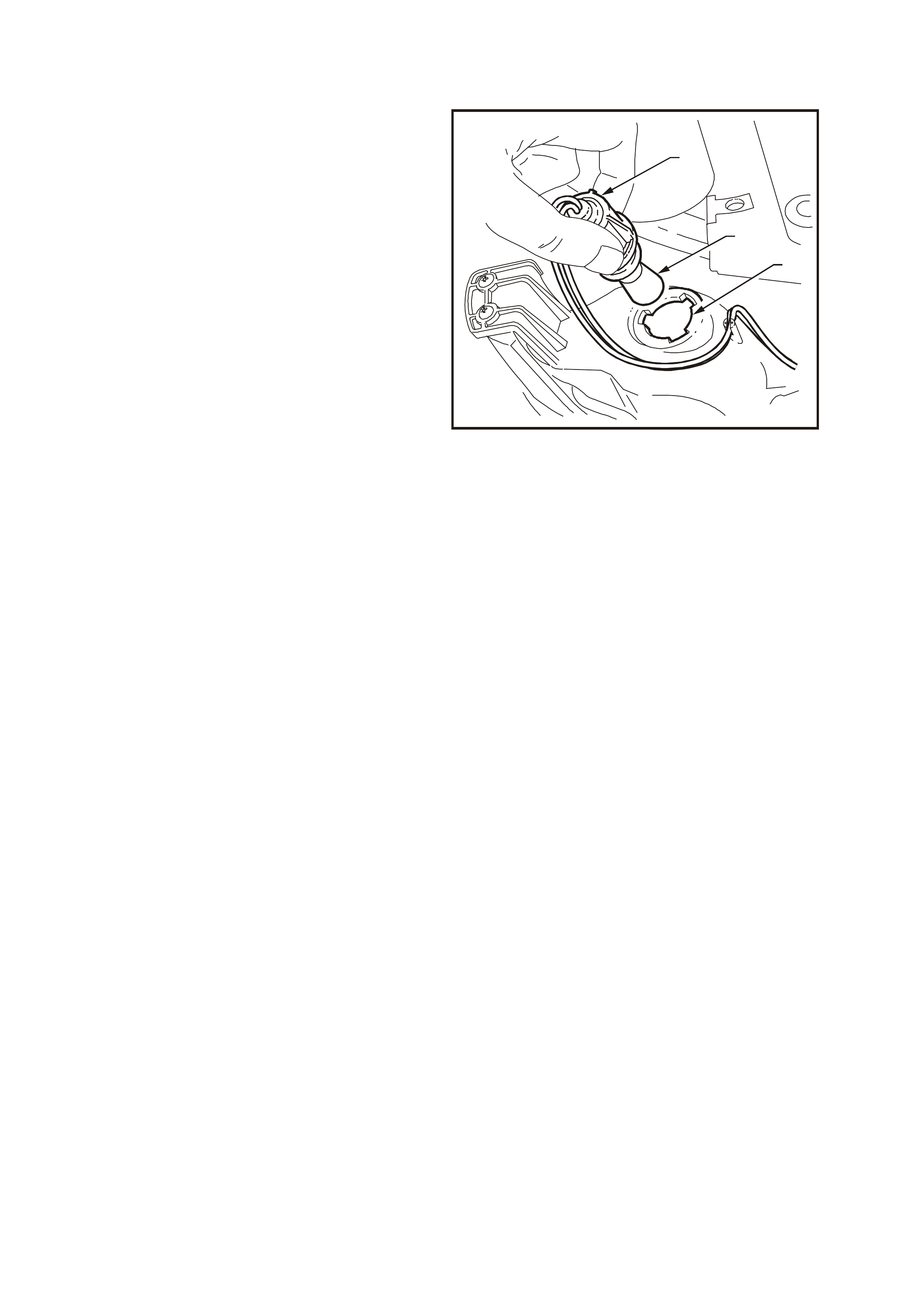

2. While holding the lower selector lever (3) with

an adjustable wrench, r emove the retaining nut

(2).

3. Carefully remove the lever (3) from the

transmission manual shaft.

4. Prise the wiring harness connector CPA

(Connector Position Assurance) securing pins

(5 and 6) from the neutral start and back-up

lamp switch (4), taking care not to break the

pins in the process. Disconnect the two wiring

harness connectors (7) from the switch

assembly (8).

5. Remove the two switch retaining screws (1),

then slide the switch assembly (4) over the

manual shaft and remove from the vehicle.

NOTE: Connector ‘8’ and the CPA ‘6’, are used f or

the PRNDL indicator in the instrument panel.

Figure 12B-57

REINSTALL

Reinstallation of the neutr al start and bac k -up lamp

switch is the reverse of the removal procedure

except for the following:

1. When installing the two switch sec uring s crews

(‘1’ in Fig. 12B-57), leave them f inger tight, until

the switch adjustment process has been

completed.

2. After installing the selector lever and retaining

nut, hold the lever with an adjustable wrench

and tighten the nut to the correct torque

specification.

SELECTOR LEVER RETAINING

NUT TORQUE SPECIFICATION 15 – 35 Nm

3. On completion of the neutral start and back -up

lamp switch adj ustment proc edure that follows,

check that the engine c an only be s tarted when

the gearshift lever is either in the ‘P’ (Park) or

‘N’ (Neutral) positions.

ADJUST

1. With the vehicle raised, rotate the neutral start

and back-up lamp switch back and forth until

the best ‘neutral’ position is attained, then

lightly tighten the front bolt to retain.

2. With the ignition switched to the ON position,

check that the engine can only be started in

either the Park or Neutral selector positions. A

further light adjustment may be required to

achieve this state.

Also check that the engine will not crank in any

of the rem aining selec tor positions and that the

Reverse lam ps illuminate when Reverse range

is selected.

3. After switch adjustment, tighten the switch

retaining bolts to the correct torque

specification.

NOTE: To gain access to the rear bolt, it will be

necessary to rem ove the wiring harness connector

(‘7’ in Fig. 12B-57). Following the bolt tightening

procedure, reinstall the connector/s and the CPA

securing pin/s.

NEUTRAL START & BACK-UP

LAMP SW ITCH RETAINING BOLT 15 - 35 Nm

TORQUE SPECIFICATION

4. Lower the vehicle to the ground and check the

operation of the neutral start and bac k-up lam p

switch. The vehicle should only start in either

‘P’ (Park) or ‘N’ (Neutral) ranges and the

reverse lamps should only illuminate when the

‘R’ (Reverse) range is selected.

5. Check the selector linkage adjustment.

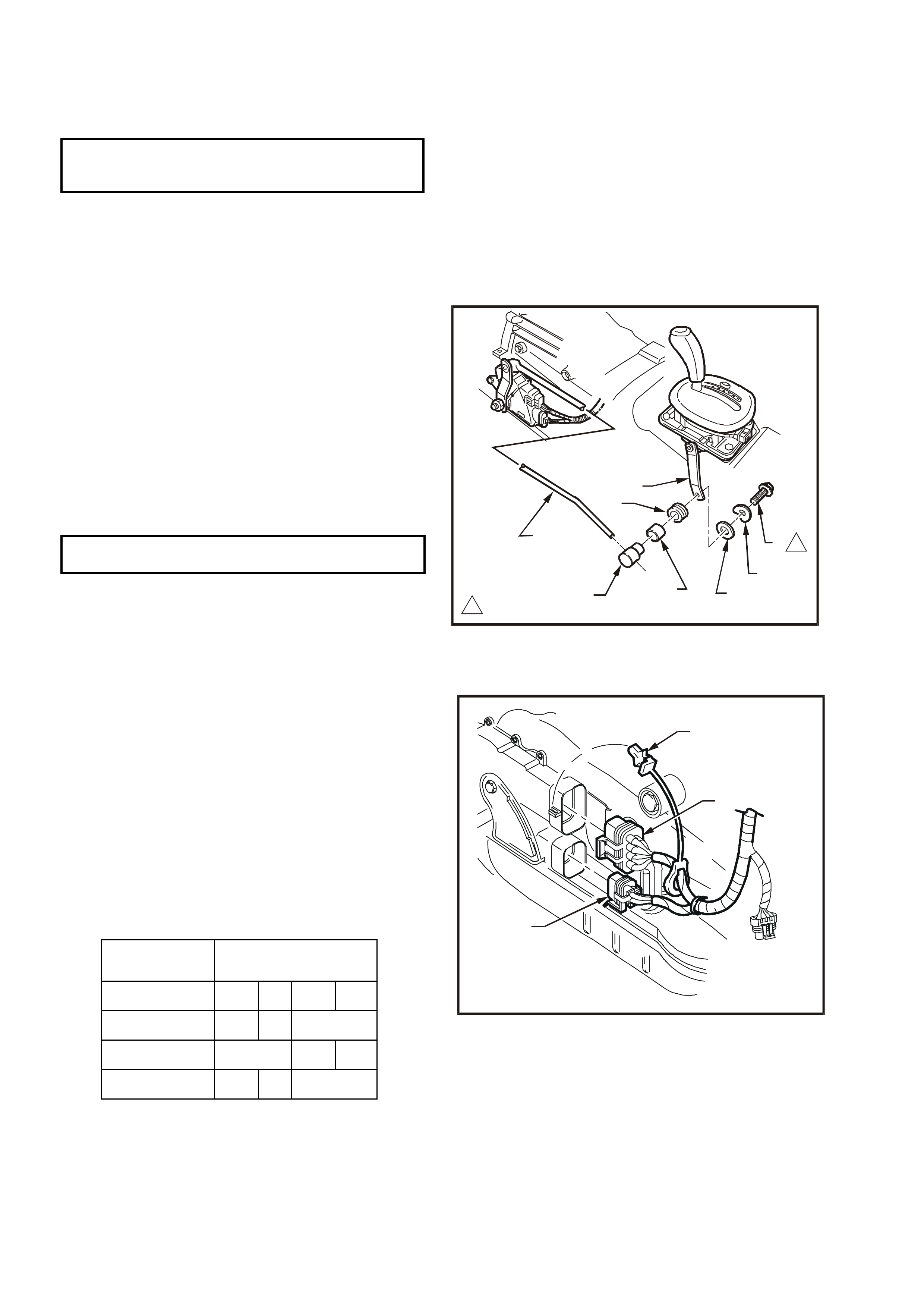

Proceed as follows:

1. Loosen locking screw (1) at selector

control lever (7) to allow selector rod (8) to

slide through trunnion (4).

2. At neutral/start and back-up switch end of

selector rod (8), move transmission

selector lever into P (Park) position.

3. Move selector control (gearshift) lever into

P (Park) position, then tighten locking

screw (1) at selector control lever (7) to

specified torque.

SELECTOR LEVER LOCKING

BOLT TORQUE SPECIFICATION 15 – 35 Nm

WH12B064

1

1

2

3

4

6

5

7

8

1

15.0 - 35.0 Nm

Figure 12B-58

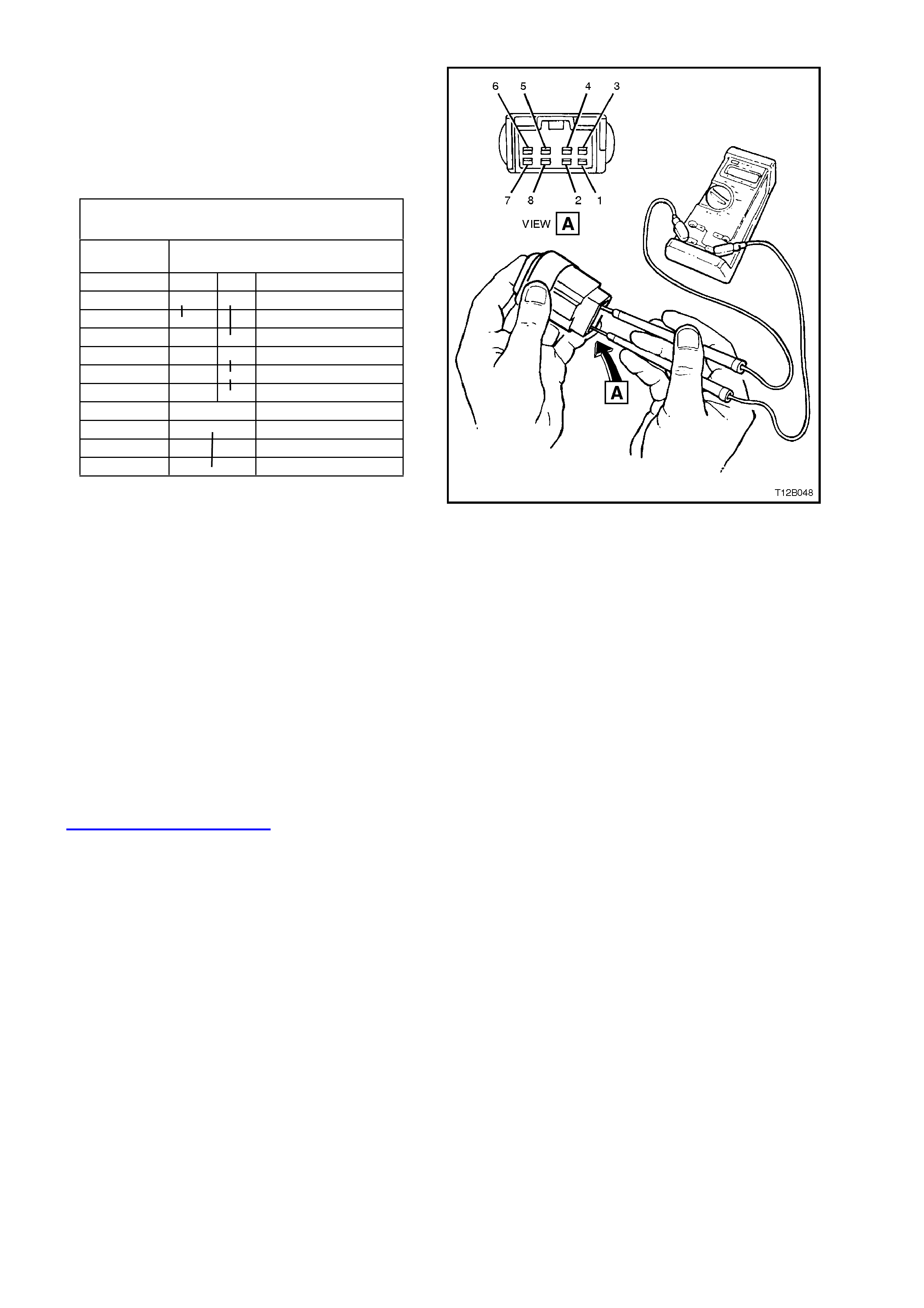

TEST

Before c onducting the following test, ensure that the

gearshift linkage is correctly adjusted, refer to

previous instructions on gearshift adjustment.

1. Disconnect battery earth lead.

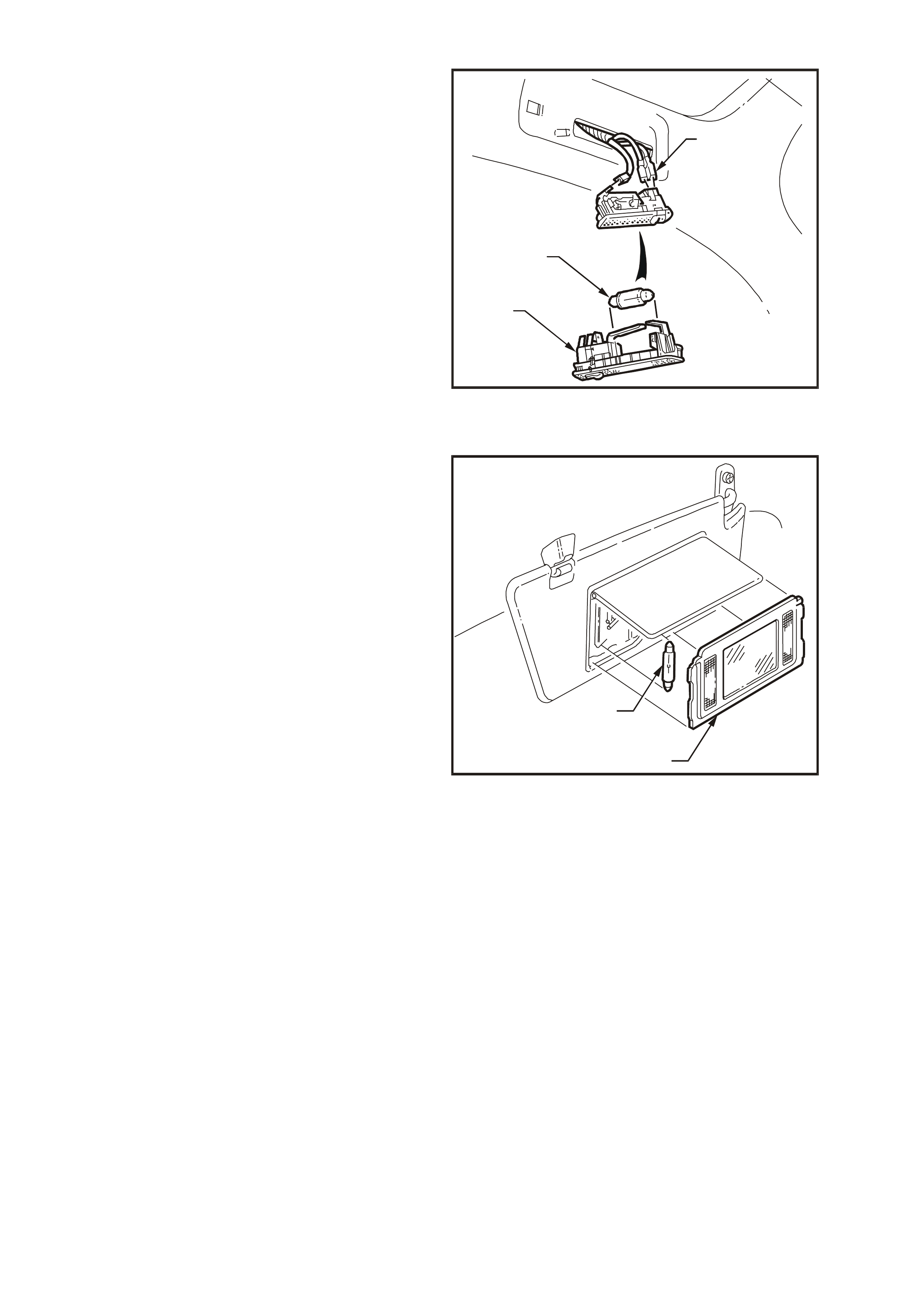

2. Pull back harness connector retainer (1) and

disconnect main wiring harness connector (2)

from neutral start/back -up switch wiring harness

connector.

3. Using an ohmmeter connected to switch wiring

harness connector terminals, select each gear

and check for continuity between switch

terminals as per the following chart.

If continuity between terminals is not as

specified, replace switch as detailed in Remove

and Reinstall, detailed in this Section.

WH12B049

1

2

3

Figure 12B-59

SWITCH

POSITION TERMINAL No

339 24 434 150

PO

OO

O––––

––––––––

––––O

OO

O

RO

OO

O––––

––––––––

––––O

OO

O

NO

OO

O––––

––––––––

––––O

OO

O

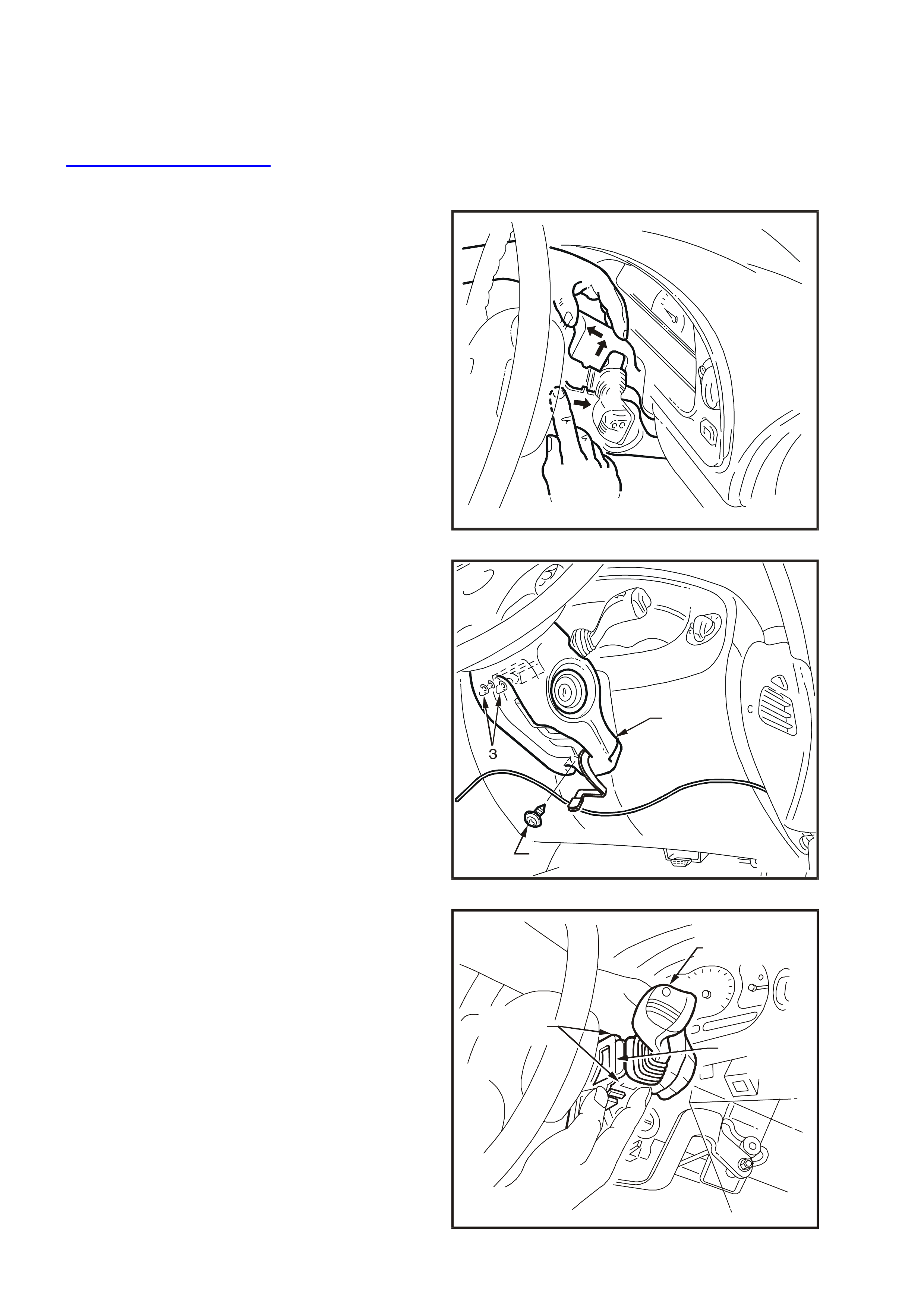

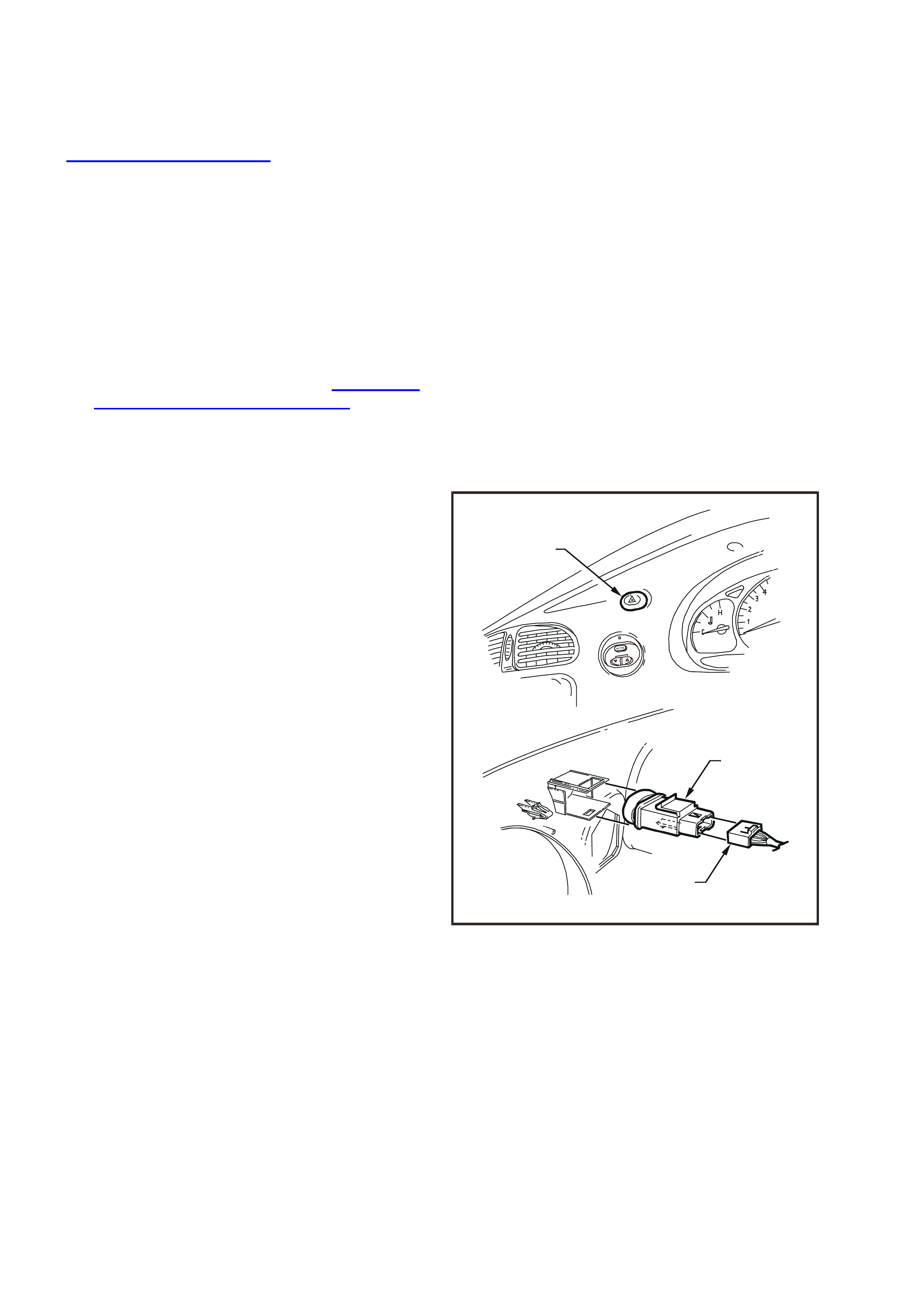

2.22 HEADLAMP AND TURN SIGNAL CONTROL SWITCH ASSEMBLY

REMOVE

1. Disconnect battery earth lead.

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the

VT Series I Service Information.

2. Release steering column height adjuster,

com pletely lower s teering c olumn and leave the

lever in the released position.

3. Insert finger between the steering wheel and

the lower cover as shown in Fig. 12B-59 and

apply a small amount of pressure (pushing

towards the instrument cluster) while lifting the

upper cover upwards.

WH12B041

Figure 12B-60

4. Remove screw (2) securing the lower cover (1)

to the steering column.

5. Slide the lower cover towards the steering

wheel to release the cover from the two

retaining tangs (3) on the steering column and

remove the lower cover.

2

1

WH12B040

Figure 12B-61

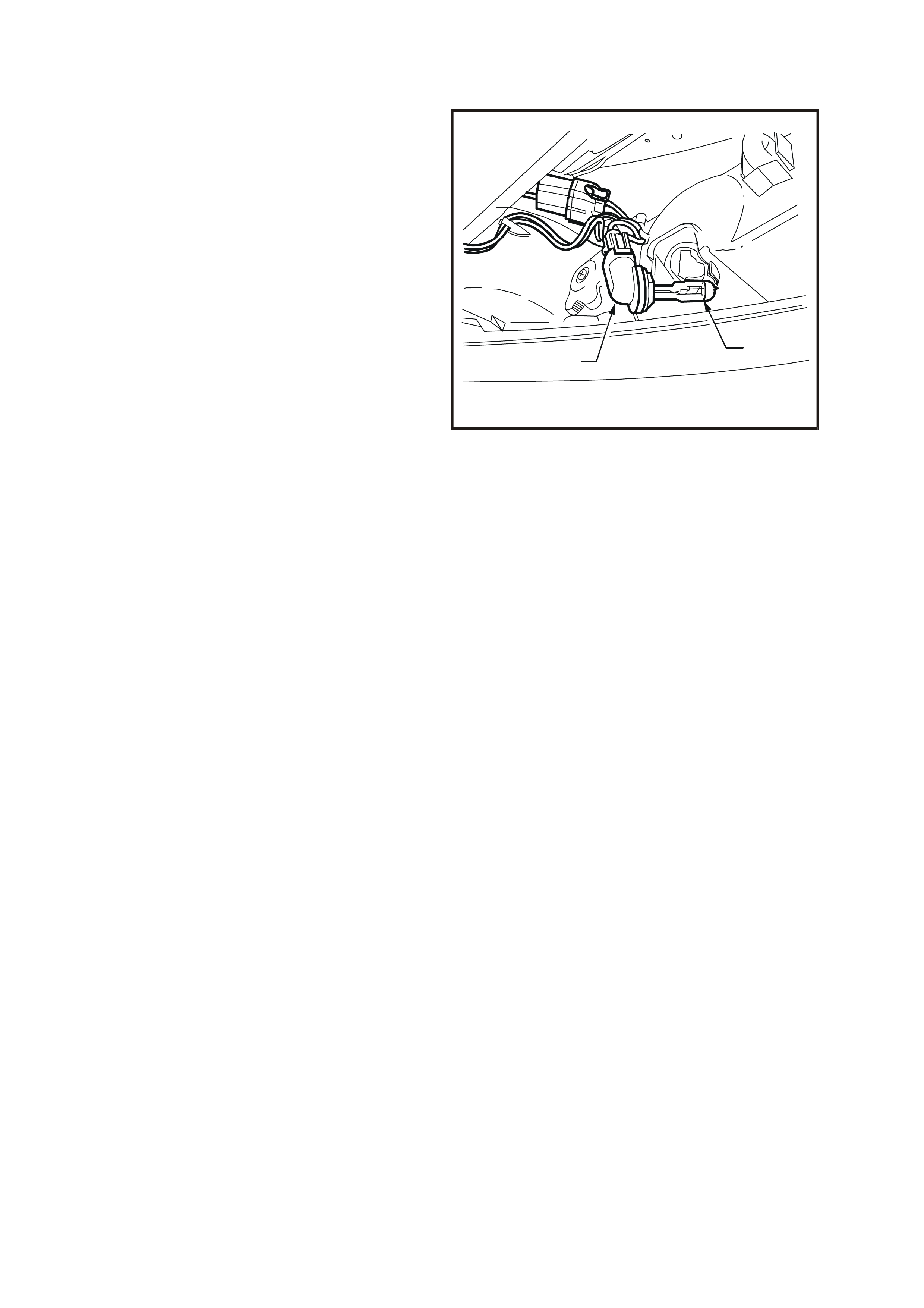

6. On headlamp and turn signal control switch (1)

with integrated cruise control switch contacts,

disconnect wiring harness connector to cruise

control switch harness connector.

7. Depress r etaining tangs (3) on s witch ass embly

and withdraw switch from switch hous ing (2) on

steering column.

8. Depress wiring harness connector retaining

tangs and pull connectors from rear of switch.

WH12B050

1

2

3

Figure 12B-62

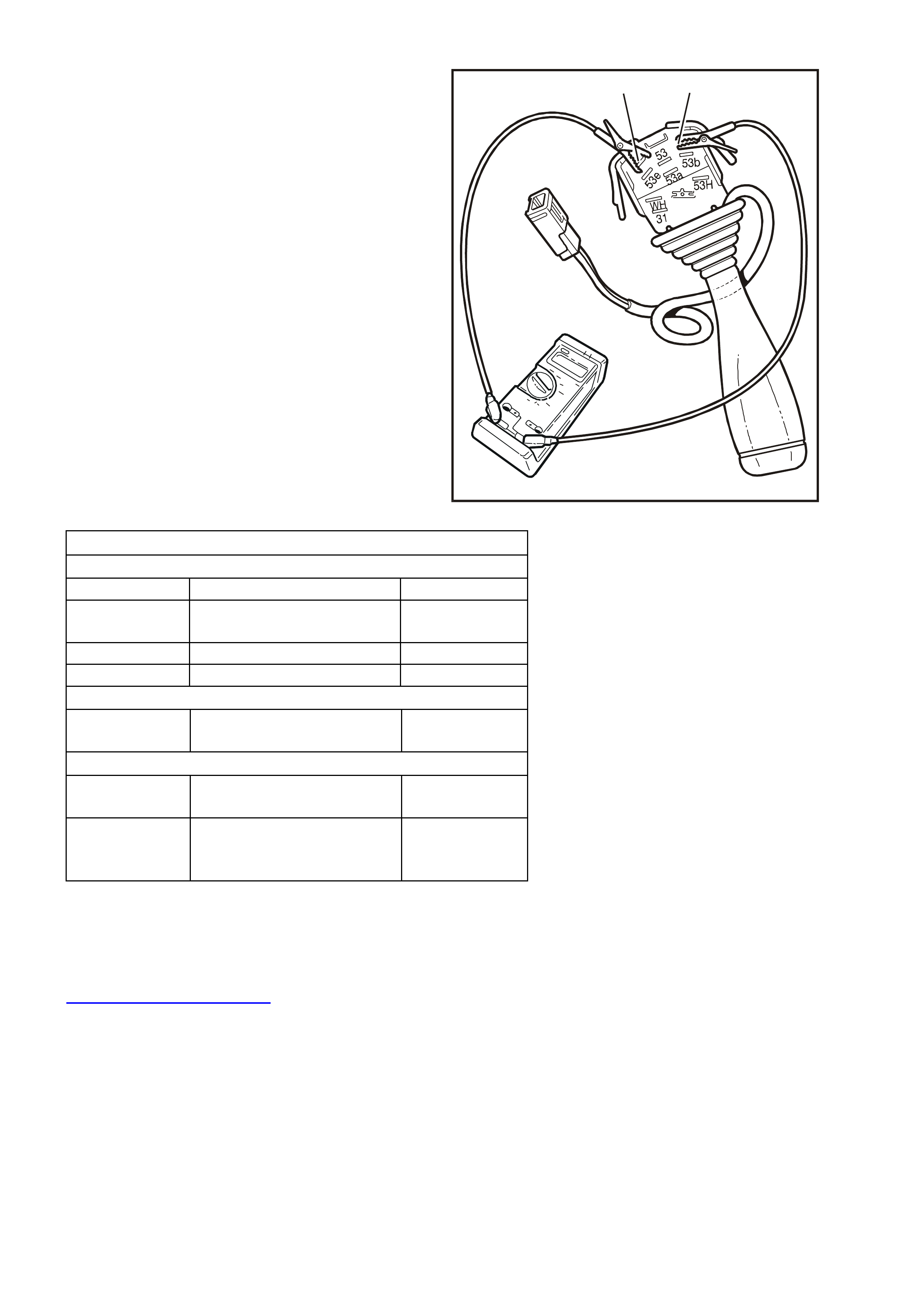

TESTING SWITCH

Using an ohmmeter, check switch contacts for

continuity at each switch position as indic ated in the

following chart.

If continuity between switch terminals is not as

specified, replace switch assembly.

NOTE: Switch terminal numbering is indicated on

the switch body, adjacent to each terminal.

WH12B051

49a49aR

Figure 12B-63

HEADLAMP AND TURN SIGNAL CONTROL SWITCH ASSEMBLY

TURN SIGNAL SWITCH CONTACTS

Switch Terminals Switch Pos i tion Indicat i on If OK

49a and 49aR

49a and 49aL Switch in cent ral position Open circuit

49a and 49aR Switch in right-hand turn position Continuity

49a and 49aL Switch in left-hand turn posit i on Continuity

HEADLAMP F L A SH CONTACTS

30 and 56a Flash positi on

High beam or central posi tion Continuity

Open circui t

HEADLAMP HIGH BEAM CONTACTS

56 and 56a Flash or central position

High beam position Open circui t

Continuity

56 and 56b Central posit i on

High beam position

Flash position

Continuity

Open circui t

Continuity

REINSTALL

Installation of the s witch assem bly is the reverse of

the removal procedure, noting the following points:

1. Check switch operation once it is installed.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the VT

Series I Service Information.

2.23 HEADLAMP SWITCH

REMOVE

1. Disconnect battery earth lead.

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM

2. Release steering colum n height adjusting lever

and completely lower steering column. Lock

lever in this position.

3. Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

4. Remove fasteners securing instrument facia to

instrument panel, refer to Section 1A3

INSTRUM ENT PANEL & CONSOLE of the VT

Series I Service Information

5. Pull instrument facia out only far enough to

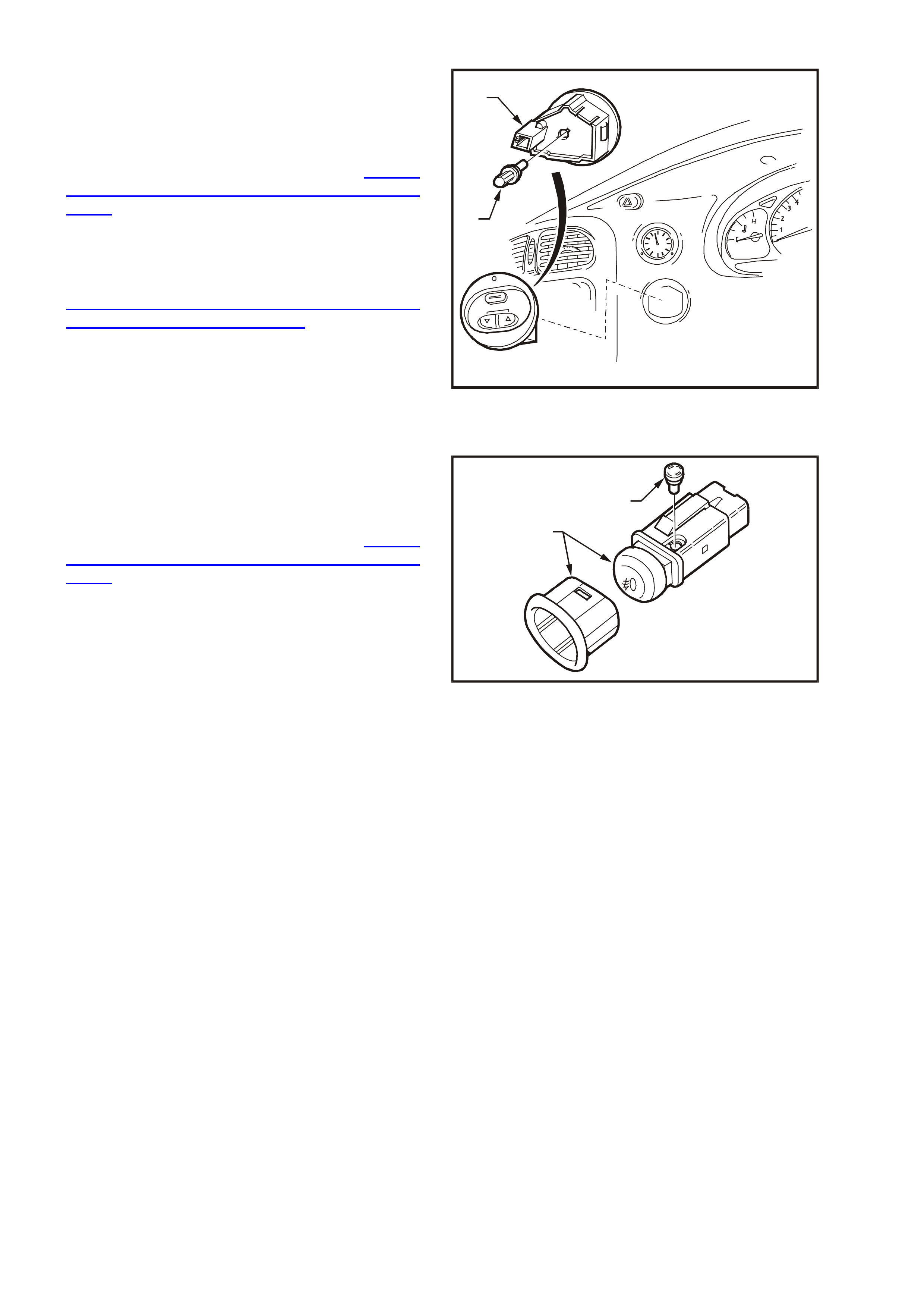

gain access to rear of headlamp switch.

6. Pull connector (1) from headlamp switch (2).

7. Depress retaining tang on headlamp switch

connector and remove switch from facia.

WH12B047

1

2

Figure 12B-64

TESTING SWITCH

HEADLAMP SWITCH

Switch Position Terminal No.

1234567

Off

Park Lamps O O

Headlamps O O O

Low Intensity O O

High Intensity O O

Dome Lamp O O

With the aid of an ohmmeter, check continuity of

headlamp switch contacts, using the following

chart.

If continuity is not as specified at any switch

position, replace switch cluster assembly.

At low intensity setting, reading should be approx.

2.65 kΩ and at high intensity setting, approx. 5.3

kΩ.

WH12B048

75

4

1

Figure 12B-65

REINSTALL

Installation of the headlamp switch is the reverse of

the removal procedure, noting the following points:

1. If, when instrum ent fac ia was pulled away fr om

instrument panel pad, the pad retaining clips

came away with the facia lugs, pull clips from

lugs and install into pad holes. Fit instrument

facia and ensure that it is held to the

instrument panel pad securely.

2. Check for correct operation of headlamps and

switch.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the VT

Series I Service Information.

2.24 HAZARD WARNING FLASHER S WITCH

REMOVE

1. Disconnect battery earth lead.

CAUTION: Disable the SRS (Air Bag). Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the

VT Series I Service Information.

2. Release steering colum n height adjusting lever

and completely lower steering column, lock

lever in this position.

3. Place a clean shop rag over and around

steering column upper cover. This step is

important so as to prevent any possibility of

damage to cover when removing the

instrument facia.

4. Remove fasteners securing instrument facia to

instrument panel, refer to Section 1A3

INSTRUM ENT PANEL & CONSOLE of the VT

Series I Service Information.

Pull instrument facia out only far enough to

gain access to rear of all instrument facia

switches.

5. Depress retaining tangs on instrum ent harness

to facia s witch connector (2) and pull connec tor

from switches.

6. Remove instrument facia.

7. Squeeze together retaining tangs at side of

hazard warning flasher switch (1) and push

switch out from facia.

WH12B054

1

1

2

Figure 12B-66

TEST

REINSTALL

Installation of the hazard warning flasher switch is

the reverse of removal procedures, noting the

following points:

1. If, when instrum ent fac ia was pulled away fr om

instrument panel pad, the pad retaining clips

came away with the facia lugs, pull clips from

lugs and install into pad holes. Install

instrument facia and ensure that it is held to

the instrument panel pad securely.

2. Check hazard warning flasher switch operation

and ensure that switch illumination bulb

illuminates when the headlamps are turned on.

IMPORTANT: Enable the SRS (Air Bag). Refer to

ENABLING THE SRS, Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of the VT

Series I Service Information.

With the aid of an ohmmeter, check continuity of

hazard warning flasher switch contacts, using the

following chart.

If continuity is not as specified at any switch

position, replace switch assembly.

Figure 12B-67

HAZARD WARNING FLASHER SWITCH

CONTACTS

Terminal

No. Switch

Status

OFF ON

1 O O Flasher unit

2 O Ignition

3 O Battery

4 O Flasher unit

5 O Lamp

6 O Lamp

7 O Illum i nat i on +

Approx. 35 ohms

8 O Illum i nat i on –

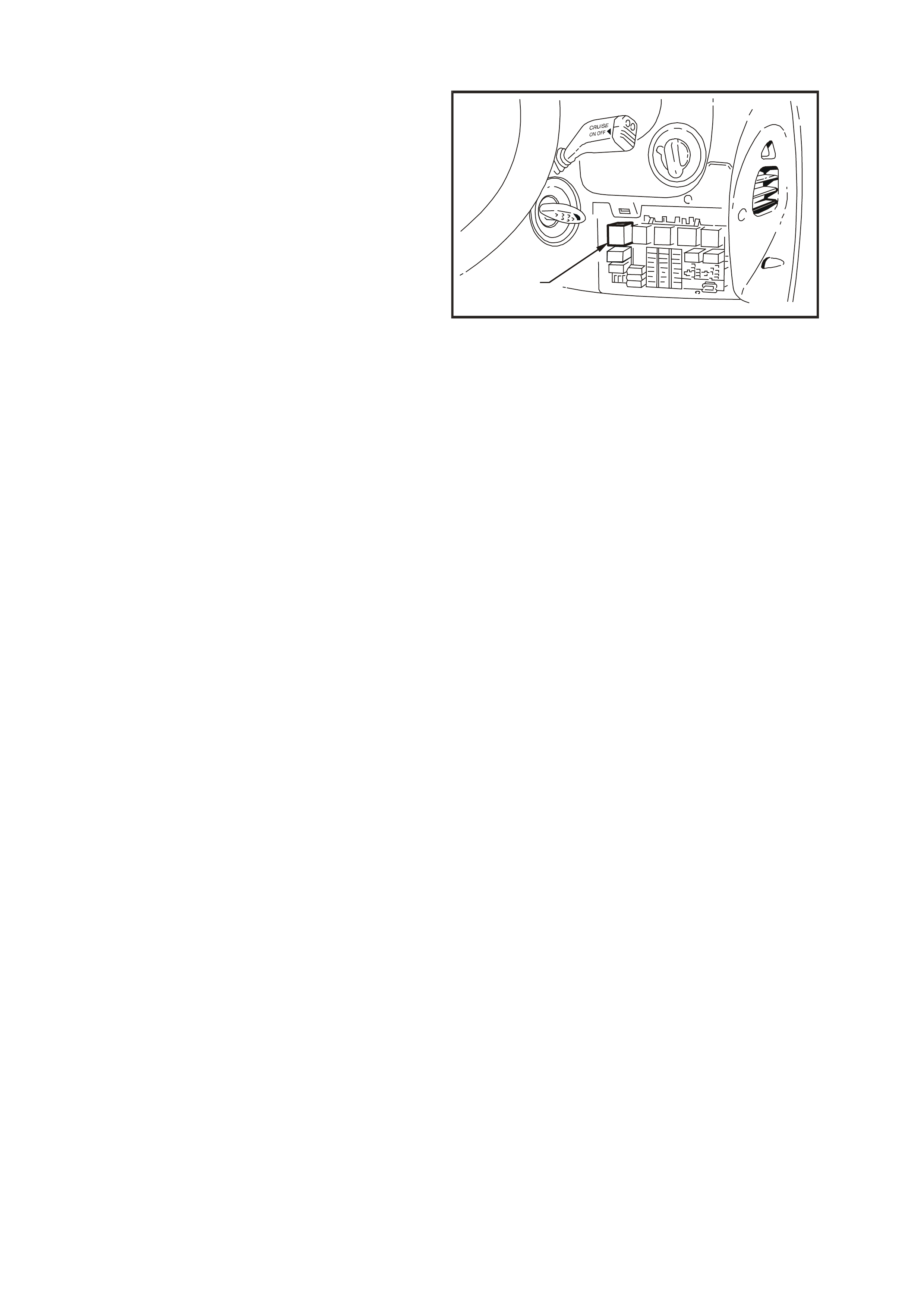

2.25 TURN S IGNAL AND HAZARD FLASHER UNIT

REPLACE

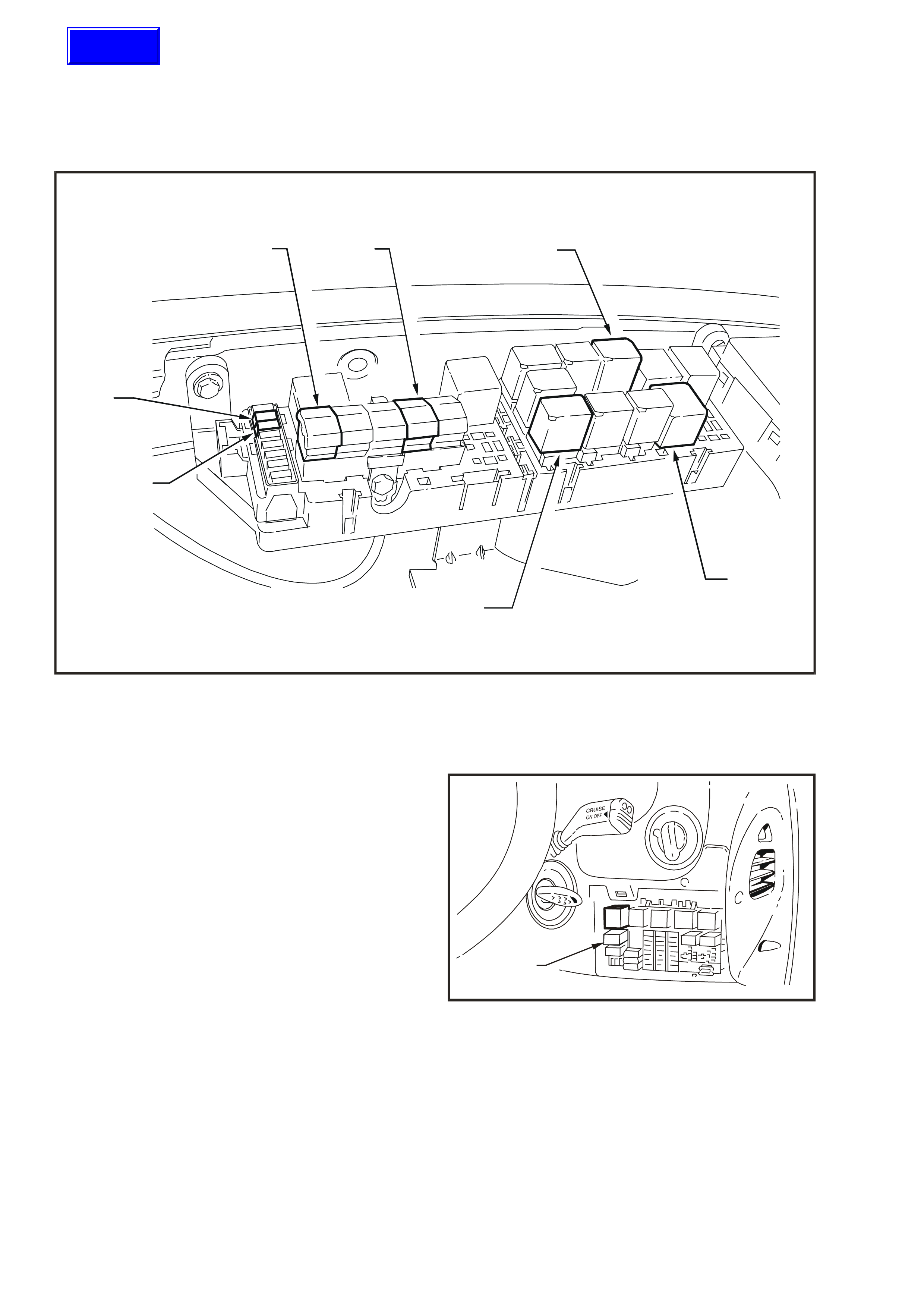

Fig. 12B-67 illustrates the location on the interior

fuse panel and installation of the turn signal and

hazard flasher unit (located inside the vehicle,

attached to the fuse panel).

Access to the turn signal and hazard flasher unit is

by gripping the upper portion of the instrument

panel right-hand cover assembly and pulling down,

disengaging the retaining clips.

WH12B055

1

Figure 12B-68

2.26 HEADLAMPS AND PARKING LAMPS RELAYS

REPLACE

Fig. 12B-68 illustrates the location in the engine

compartment relay housing of the relays used for

the headlamp operation, fog lamp relay and the

fusible link FJ.

WH12B056

123

4

5

6

7

Figure 12B-69

1. Headlamp fusible links 4. Headlamp high beam relay 6. Left-hand headlamp fuse

2. Main fusible link 5. Headlamp low beam relay 7. Right-hand headlamp fuse

3. Fog lamp relay

The parking lamps relay is located inside the

vehicle, attached to the fuse panel. Access to the

parking lamps relay is by opening the instrument

panel right-hand cover.

WH12B057

1

Figure 12B-70

Techline

3. SPECIFICATIONS

BULB POWER RATING

(WATTS) BASE TYPE

Headlamps:

Hi/Lo Beam (Outboard)

Inboard High Beam 60/55

55 H4

H1

Fog Lamps 27 H27W/2

Parking Lamps (Front) 5 Wedge

Turn Signal Lamps (Front) 21 Offset Pin (Orange glass)

Side Repeater Lamp 5 Wedge

Turn Signal (Rear) 21 Offset Pin (Orange glass)

Back-Up Lamp 21 Std. Parallel Pin

Stop And Tail Lamp 21/5 Std. Parallel Pin

Licence Plate Lamp 5 Wedge

Instrument Cluster Illumination

Lamp 5 Wedge

Instrument Cluster Warning

Cluster Lamp 1.2 Wedge

Trip Computer Illumination Lamp 1.2 Wedge

Rear Compartment 10 Festoon

Dome (Courtesy) Lamp 10 Festoon

Front Seat Reading Lamp 5 Std. Parallel Pin

Rear Seat Reading Lamp 5 Wedge

Glove Compartment Lamp 10 Festoon

Front Footwell Lamps 2.7 Wedge

Front Vanity Mirror Lamp 1.4 Wedge

Door Courtesy Lamp 5 Festoon

Console Bin Lamp 5 Festoon

High Mounted Stop Lamp 18 Wedge

Front And Rear Cigar Lighter

Lamp 1.2 Wedge

Ignition Lock Lamp 1.2 Wedge

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Headlamp and turn signal/parking lamp

assembly securing screws.................................................... 2 – 5

Fog lamp to bumper bar facia retaining screws.................... 2 – 5

Dome lamp attaching screws................................................ 3 – 5

Door jamb switch attaching screws ...................................... 3 – 5

Headlamp adjuster attaching screws.................................... 3 – 5

Rear compartment lid lamp assembly attaching nuts........... 2 – 5

Rear compartment lamp switch attaching screw.................. 1 – 3

Rear lamp housing retaining screw....................................... 1 – 3

Transmission selector lever locking bolt............................... 15 – 35

Rear quarter lamp housing attaching screws ....................... 3 – 4

Selector lever retaining nut................................................... 15 – 35

Neutral/Start and Back-up switch retaining screw ................ 15 – 35