HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–1

20–FEB–2003 Page 2F-1

Section 2F

HVAC Occupant Climate Control (Auto A/C) –

Diagnostics

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

WARNINGS, CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1 General Information............................................................................................................................... 3

2 Diagnostics............................................................................................................................................. 4

2.1 Diagnostic Trouble Codes.....................................................................................................................................4

2.2 Data Display............................................................................................................................................................6

F2: Data Display .....................................................................................................................................................6

F0: Data List............................................................................................................................................................6

F1: Switch Data.......................................................................................................................................................8

2.3 Miscellan eous Tests ............................................................................................................ ................................13

LCD Display Test..................................................................................................................................................13

3 Diagnostic Charts................................................................................................................................ 15

Introduction ..........................................................................................................................................................15

Chart A – Diagnostic Circuit Check....................................................................................................................16

Chart B – OCC System Does Not Power Up.......................................................................................................18

DTC 13 – Ambient Temperature Sensor Voltage Too High...............................................................................21

DTC 14 – Ambient Temperature Sensor Voltage Too Low ...............................................................................24

DTC 15 – In-car Temperature Sensor Voltage Too High...................................................................................27

DTC 16 – In-car Temperature Sensor Voltage Too Low....................................................................................30

DTC 17 – Evaporative Temperature Sensor Voltage Too High (LHD)..............................................................33

DTC 17 – Evaporative Temperature Sensor Voltage Too High (RHD) .............................................................37

DTC 18 – Evaporative Temperature Sensor Voltage Too Low (LHD)...............................................................41

DTC 18 – Evaporative Temperature Sensor Voltage Too Low (RHD) ..............................................................44

DTC 19 – Sun Load Sensor Error........................................................................................................................47

DTC 35 – No Serial Data From PCM....................................................................................................................51

DTC 36 – No Serial Data From BCM....................................................................................................................54

DTC 37 – ROM Checksum Error..........................................................................................................................57

DTC 38 – EEPROM Checksum Error...................................................................................................................59

DTC 39 – RAM Error.............................................................................................................................................61

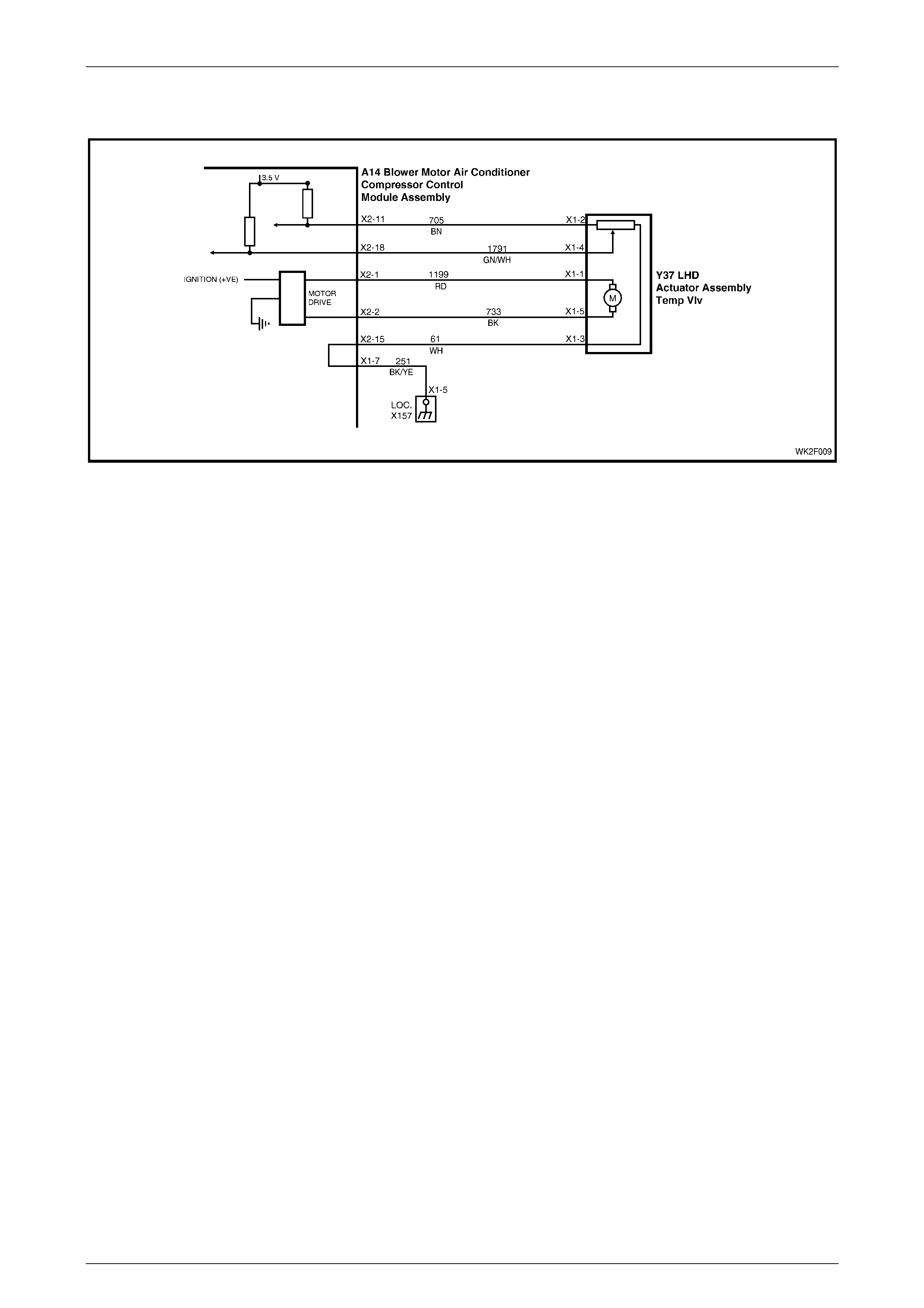

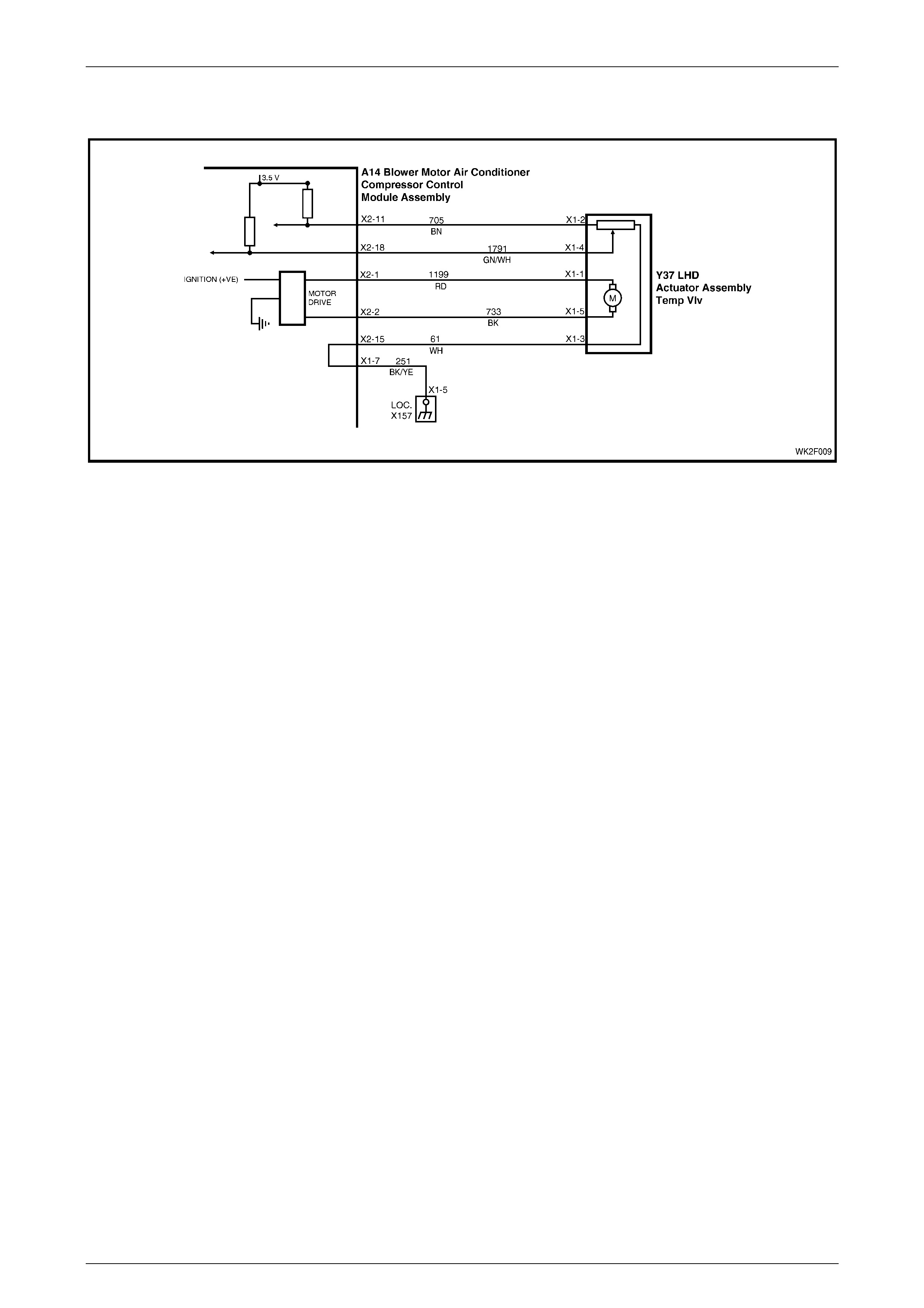

DTC 40 – Air Mix Door Motor Driver Error..........................................................................................................63

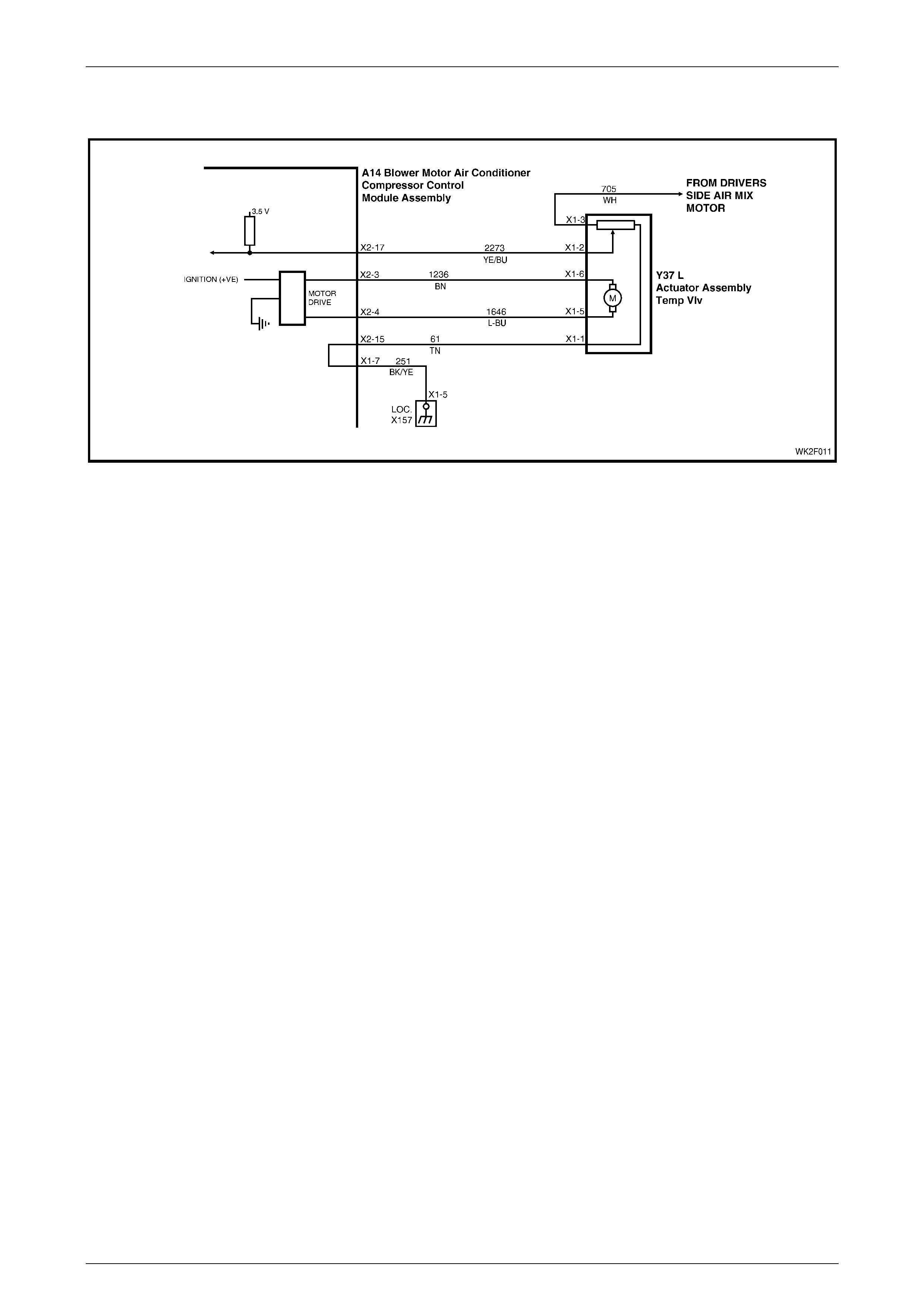

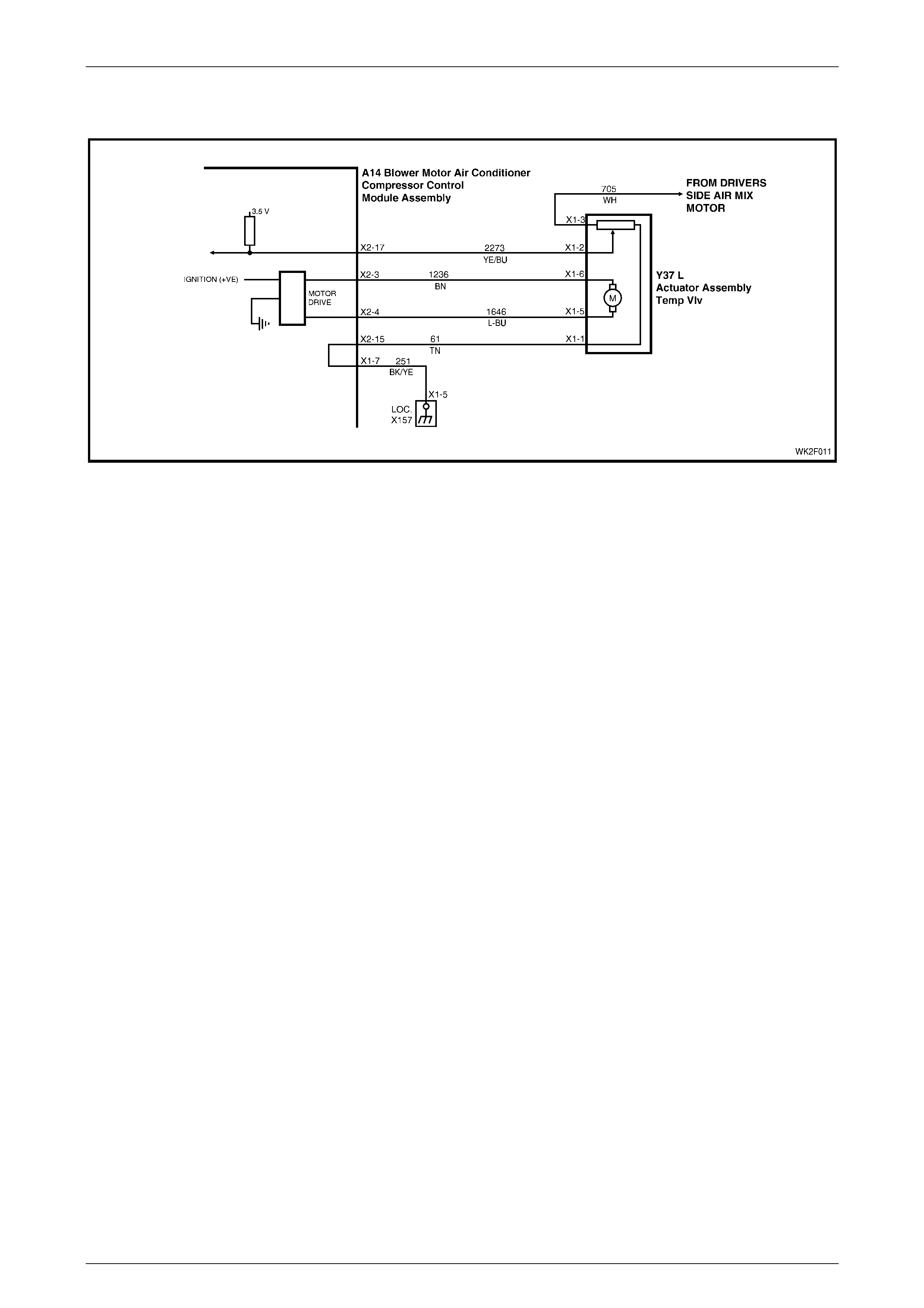

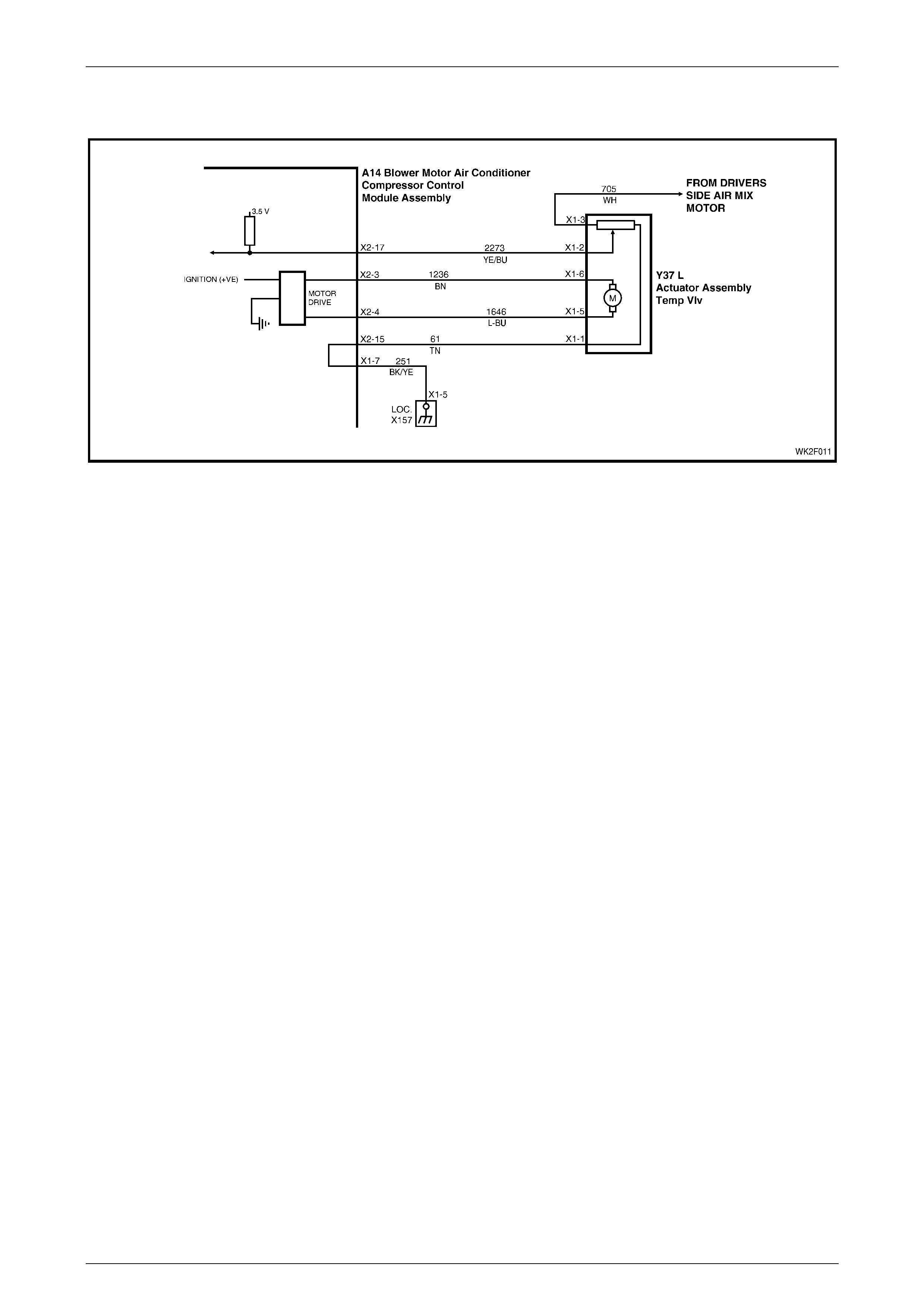

DTC 40 – Air Mix Door Motor Driver Error (Driver’s Side Motor – RHD)..........................................................67

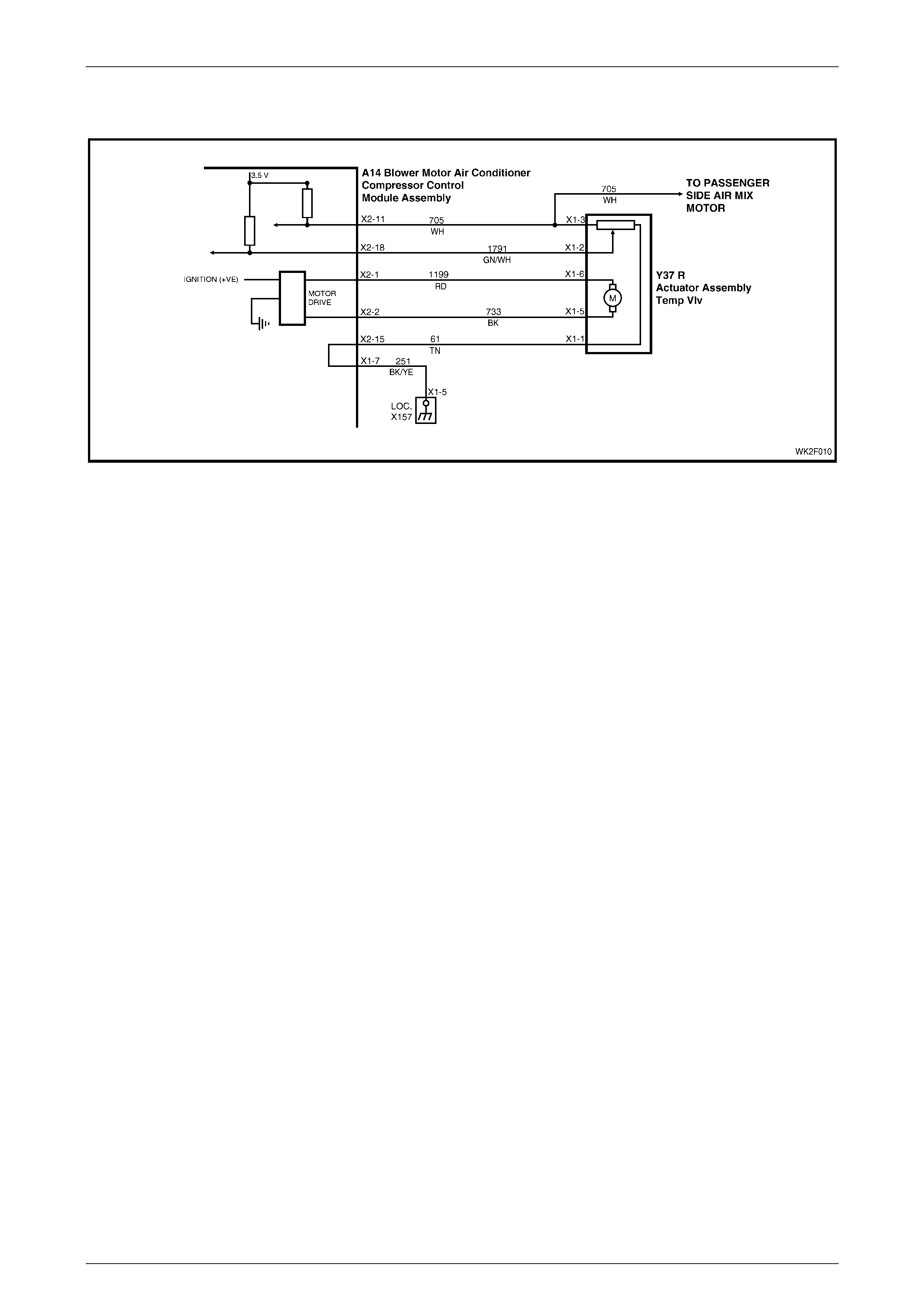

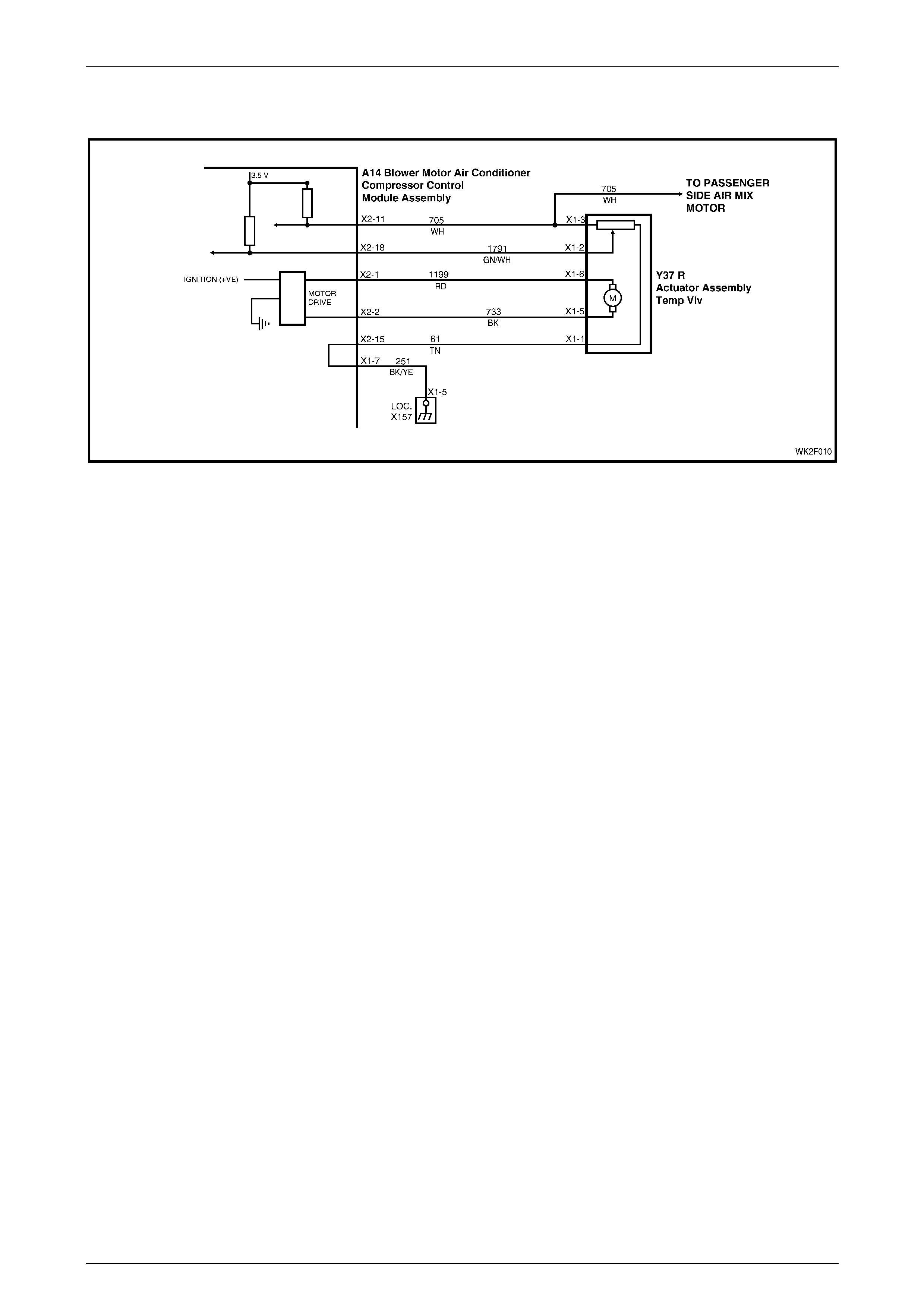

DTC 40 – Air Mix Door Motor Driver Error (Passenger Side Motor – RHD).....................................................71

DTC 41 – Solenoid Driver Error (LHD)................................................................................................................75

DTC 41 – Solenoid Driver Error (RHD)................................................................................................................79

DTC 43 – Driver’s Air Mix Door Motor Feedback Circuit Voltage Too Low (LHD) ..........................................83

DTC 43 – Driver’s Air Mix Door Motor Feedback Circuit Voltage Too Low (RHD)..........................................88

DTC 44 – Driver’s Air Mix Door Motor Feedback Circuit Voltage Too High (LHD)..........................................93

DTC 44 – Driver’s Air Mix Door Motor Feedback Circuit Voltage Too High (RHD).........................................98

DTC 45 – Passengers Air Mix Door Motor Feedback Circuit Voltage Too Low ............................................103

DTC 46 – Passengers Air Mix Door Motor Feedback Circuit Voltage Too High............................................108

DTC 47 – Drivers Air Mix Min. Calibration Error (LHD) ...................................................................................113

DTC 47 – Drivers Air Mix Min. Calibration Error (RHD)...................................................................................117

DTC 48 – Drivers Air Mix Max. Calibration Error (LHD)...................................................................................121

DTC 48 – Drivers Air Mix Max. Calibration Error (RHD)..................................................................................125

Techline

Techline

Techline

Techline

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–2

20–FEB–2003 Page 2F-2

DTC 49 – Pass Air Mix Min. Calibration Error..................................................................................................129

DTC 50 – Pass Air Mix Max. Calibration Error .................................................................................................133

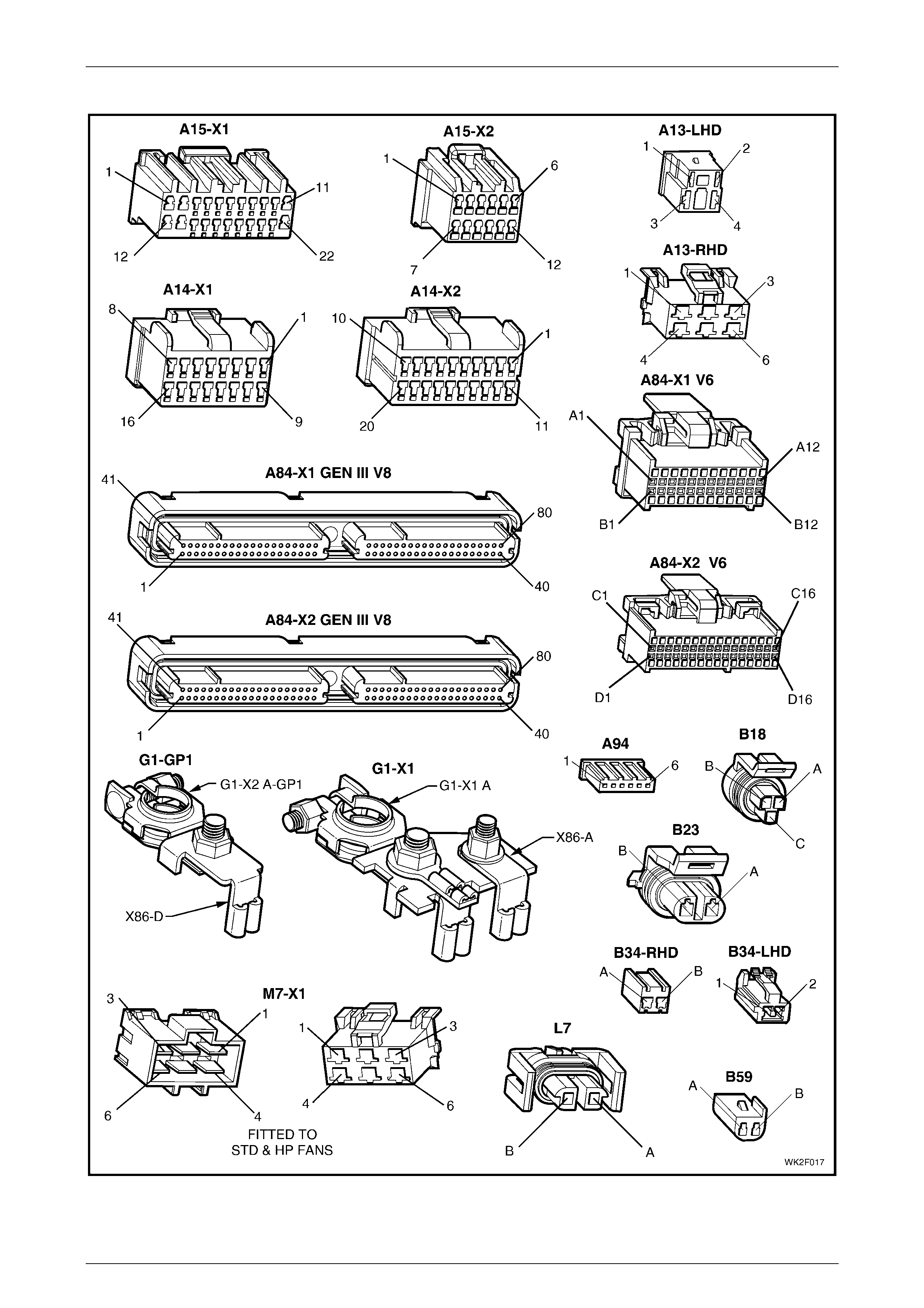

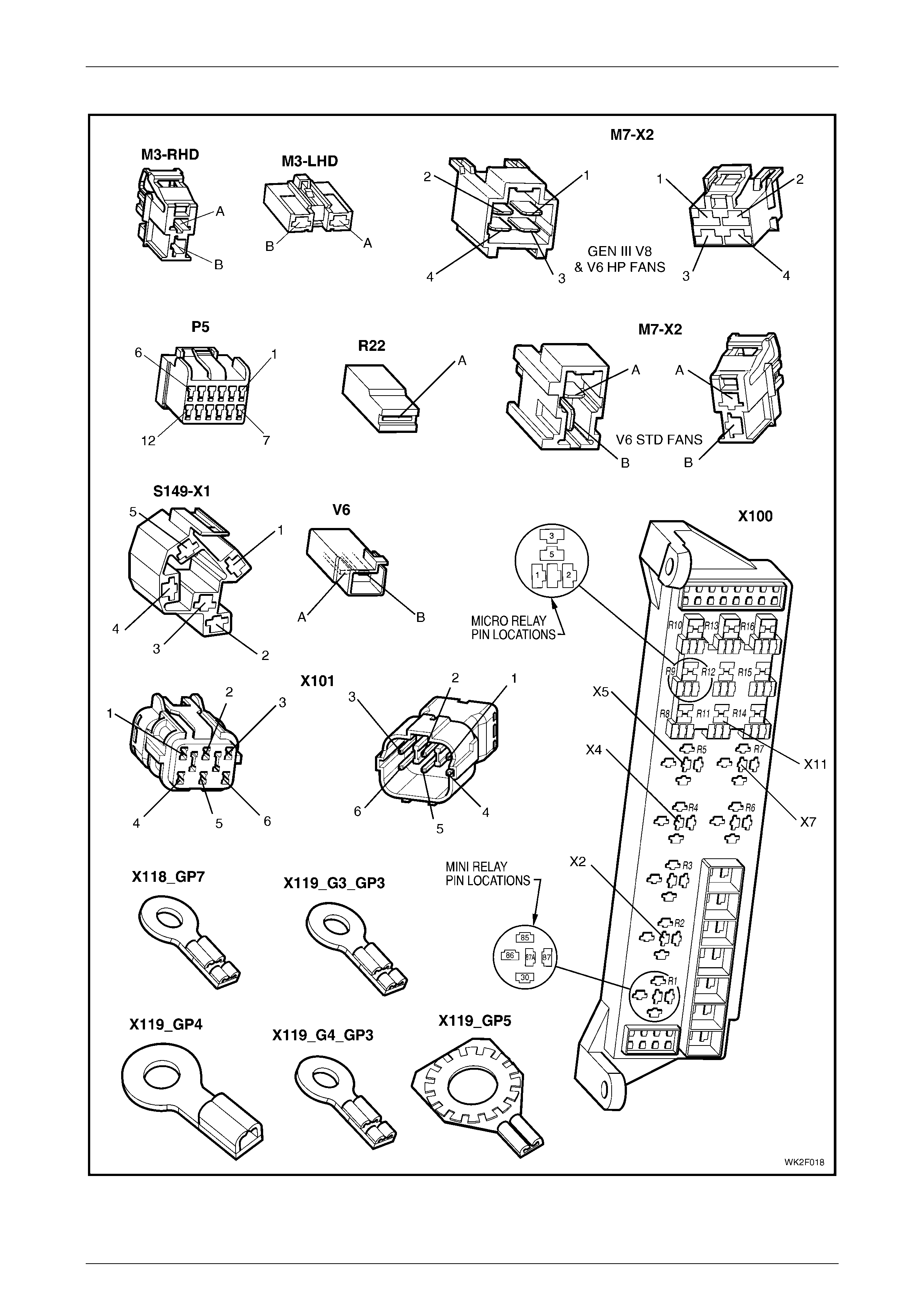

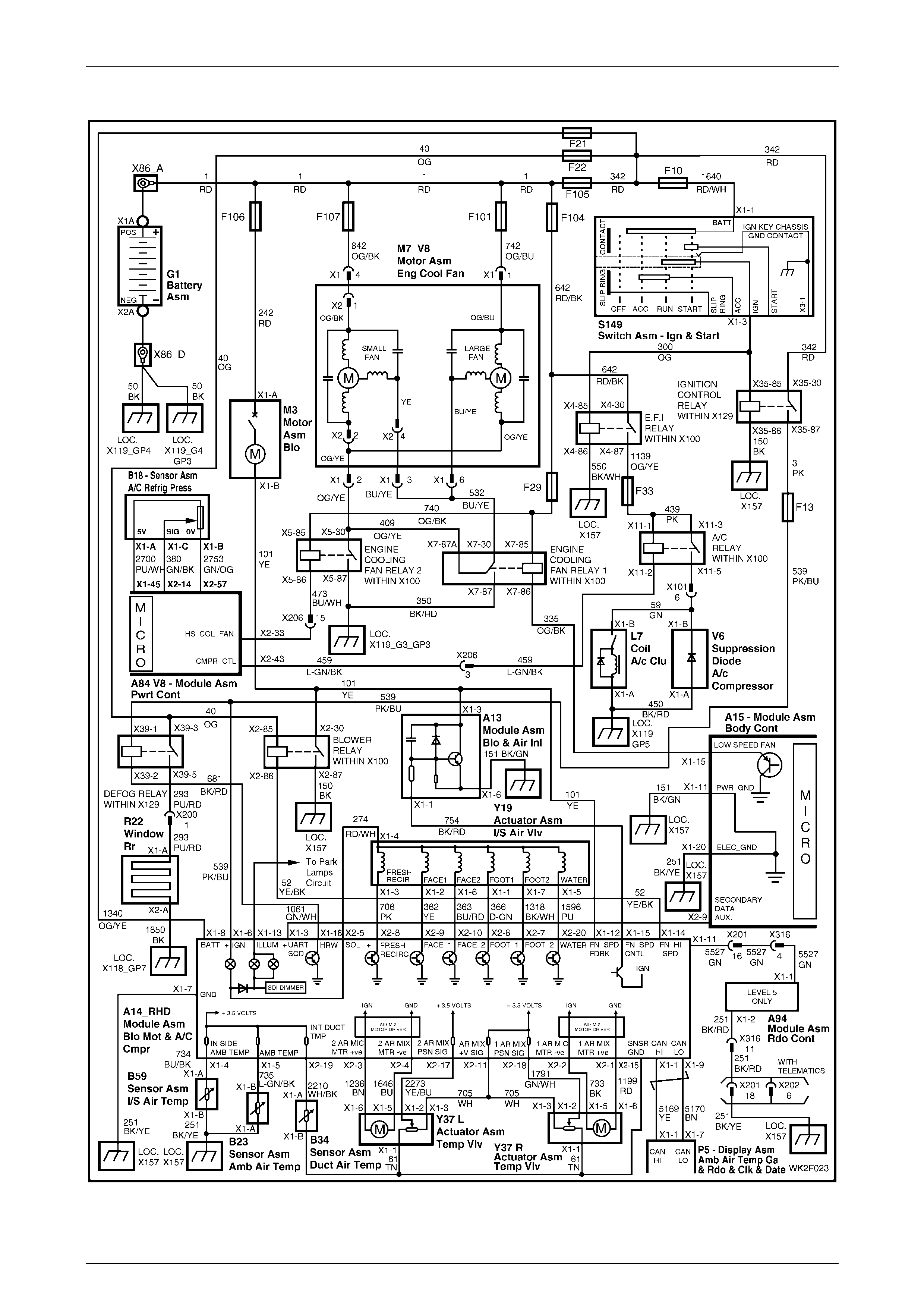

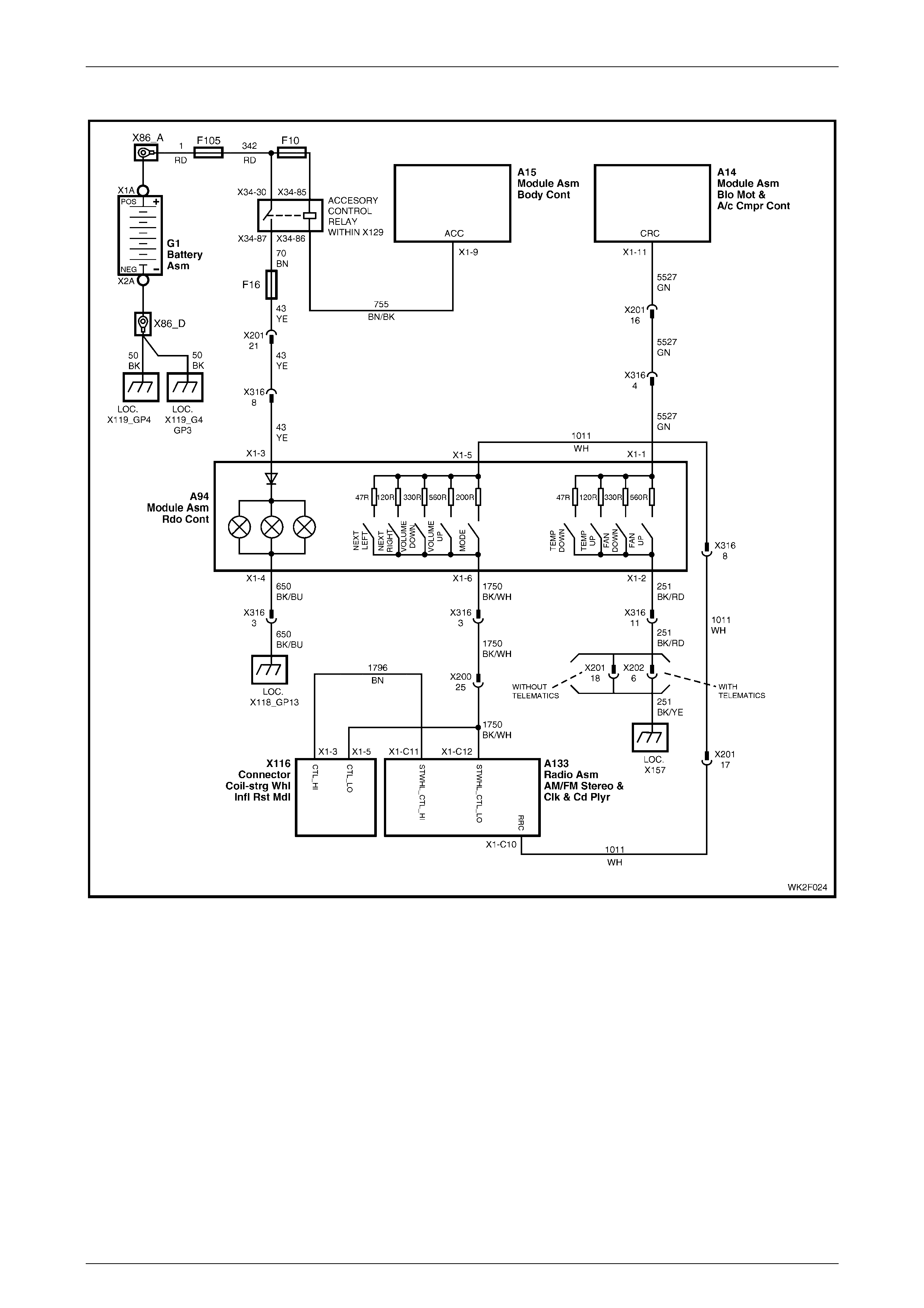

4 Wiring Diagrams ................................................................................................................................ 137

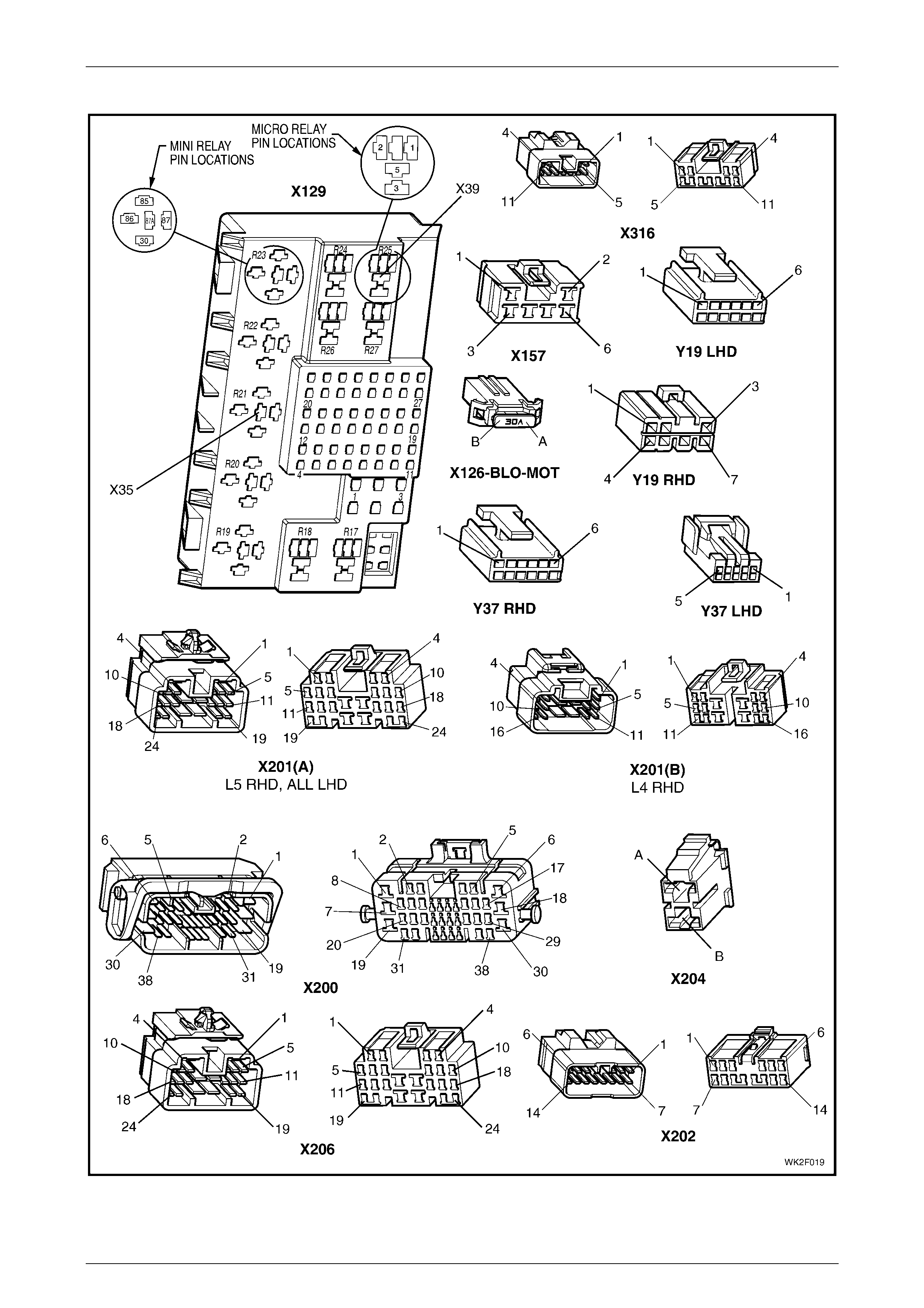

Connectors: HVAC OCC (Auto A/C) System....................................................................................................139

Connectors: HVAC OCC (Auto A/C) System Continued.................................................................................140

Connectors: HVAC OCC (Auto A/C) System Continued.................................................................................141

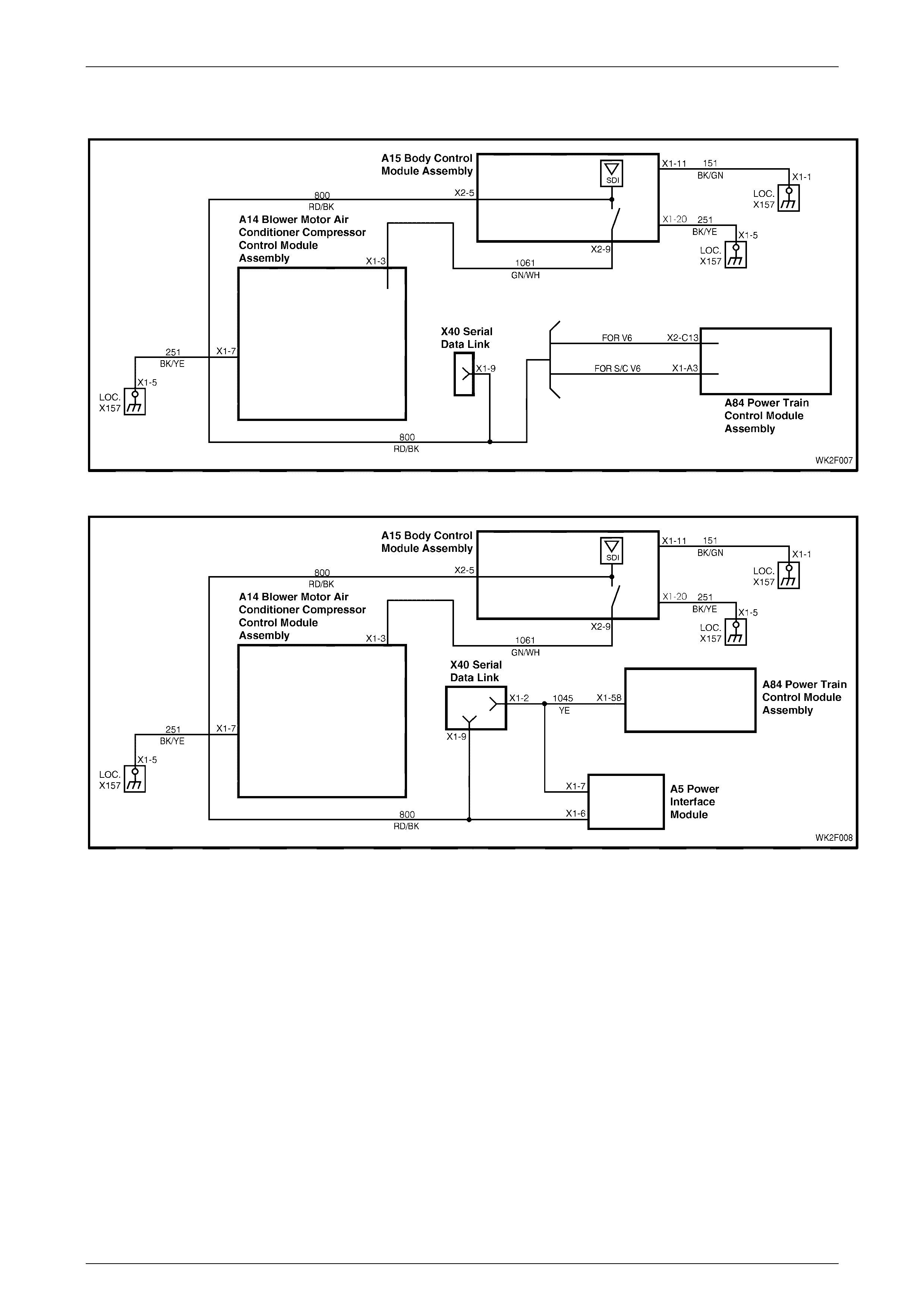

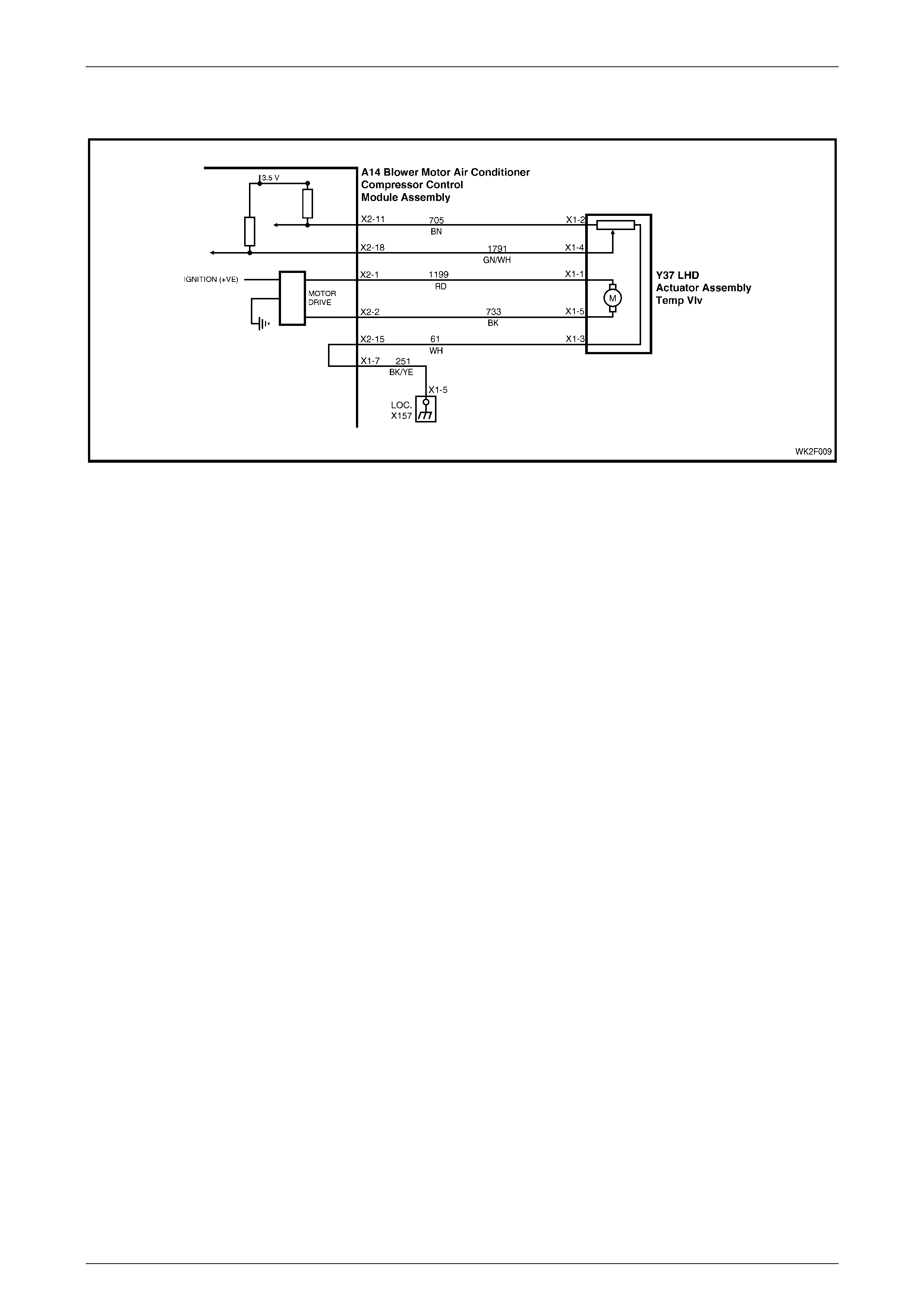

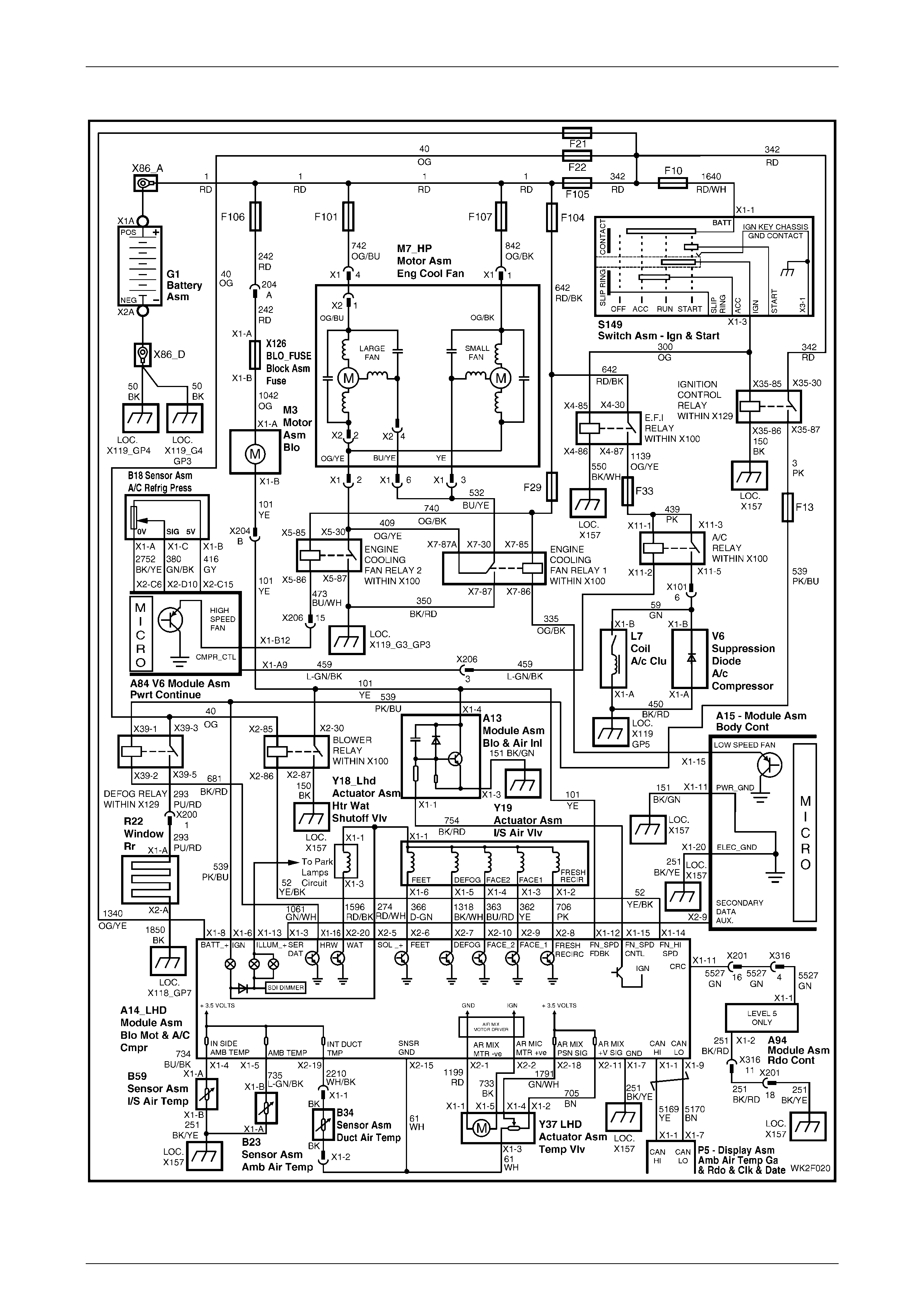

Wiring Diagram: HVAC OCC (Auto A/C) System – V6 (LHD)..........................................................................142

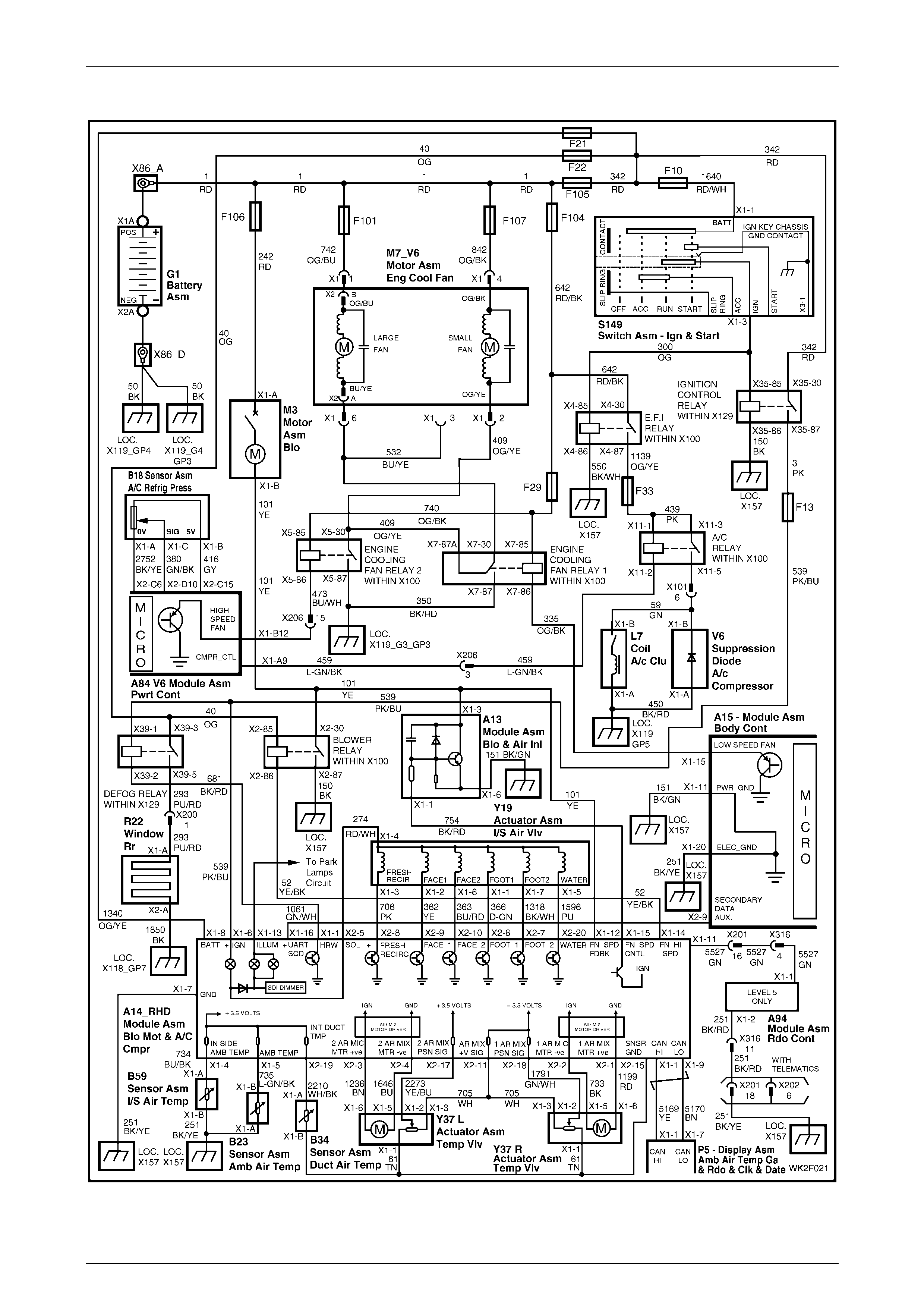

Wiring Diagram: HVAC OCC (Auto A/C) S ystem – V6 (RHD)..........................................................................143

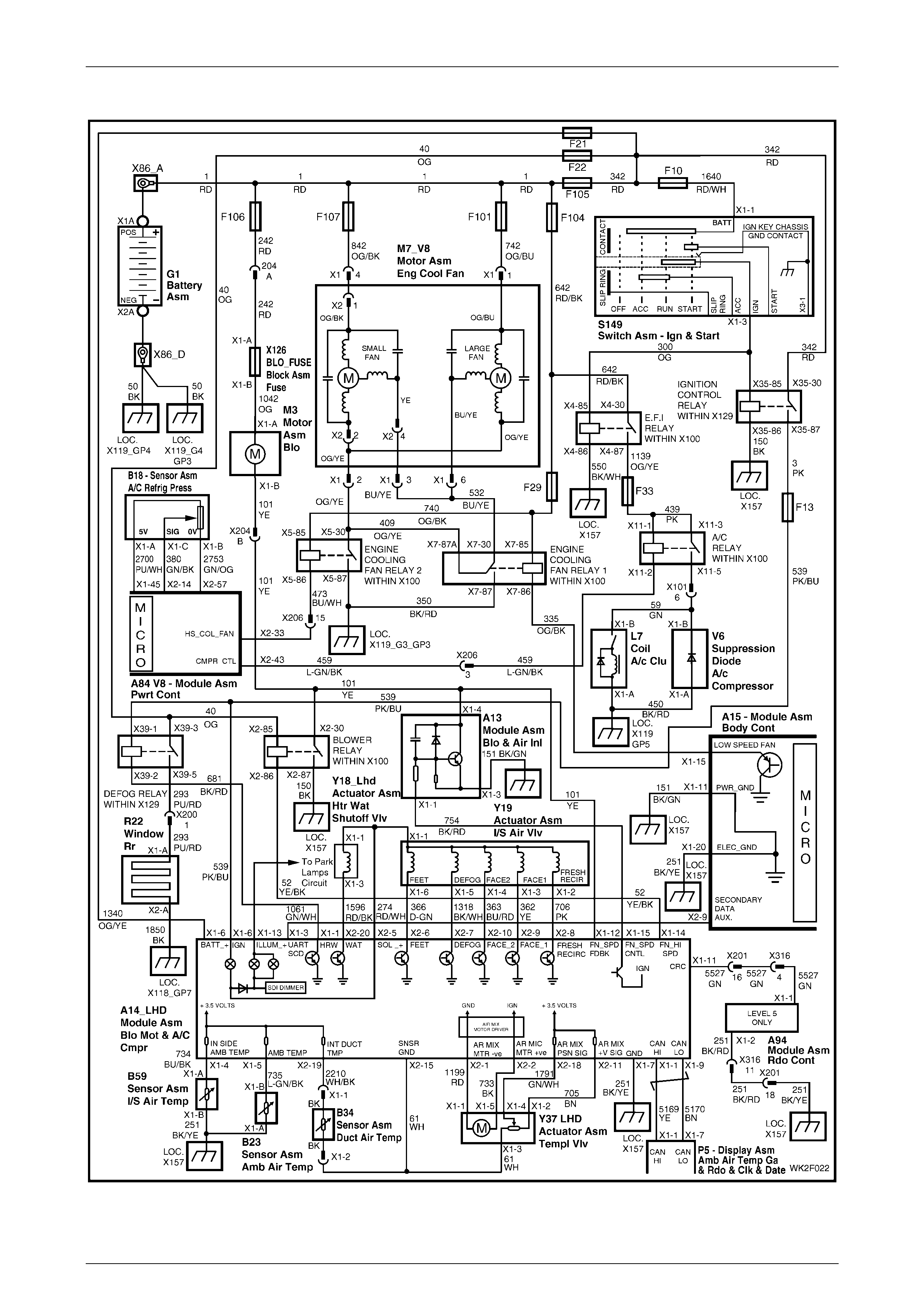

Wiring Diagram: HVAC OCC (Auto A/C) System – GEN III V8 (LHD) .............................................................144

Wiring Diagram: HVAC OCC (Auto A/C) S ystem – GEN III V8 (RHD).............................................................145

Wiring Diagram: Rear Remote Control (Level 5 Models only)........................................................................146

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–3

20–FEB–2003 Page 2F-3

1 General Information

The diagnostic information of the HVAC Occupant Climate Control (Auto A/C) system as fitted to Level 2 to 5 MY2004

WK Series models carries over from the information provided in Section 2F, HVAC Occupant Climate Control (Auto A/C)

– Diagnostics in the MY2003 VY and V2 Series Service Information, noting the following:

• While there are no additional DTCs applicable to MY2004 WK Series models, various wiring terminal assignments

are specific to the W K Series. This necessitates the provision of diagnostic charts applicable only to WK Series

Level 2 to 5 models.

• Level 5 MY2004 WK Series models are fitted with a rear remote control. Additional information is provided in the

Data List, Switch Data Test and Wiring Diagrams applicable to the rear remote control.

• Unlike MY2003 VY and V2 Series models, a diagnostic X symbol is not displayed if the OCC (Auto A/C) develops a

fault.

• All OCC (Auto A/C) control module functions are displayed on the Multi Function Display (MFD) as opposed to a

dedicated HVAC system LCD display as fitted to MY2003 VY and V2 Series models. For further information related

to the MFD, refer to Section 12I MULTI FUNCTION DISPLAY.

For additional diagnosis information on Level 2 to 5 WK MY2004 Series models, i.e. WK Series models equipped with

Occupant Climate Control (Auto A/C), which is not contained within this Section, refer to following Sections as required:

• Section 2C HVAC CLIMATE CONTROL (MANUAL A/C) – SERVICE AND DIAGNOSIS in the MY2003 VY and

V2 Series Service Information, for HVAC components common to Manual A/C and OCC (Auto A/C),

• Section 2F HVAC OCCUPANT CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS in the MY2003 VY and

V2 Series Service Information, for HVAC components applicable only to OCC (Auto A/C).

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–4

20–FEB–2003 Page 2F-4

2 Diagnostics

2.1 Diagnostic Trouble Codes

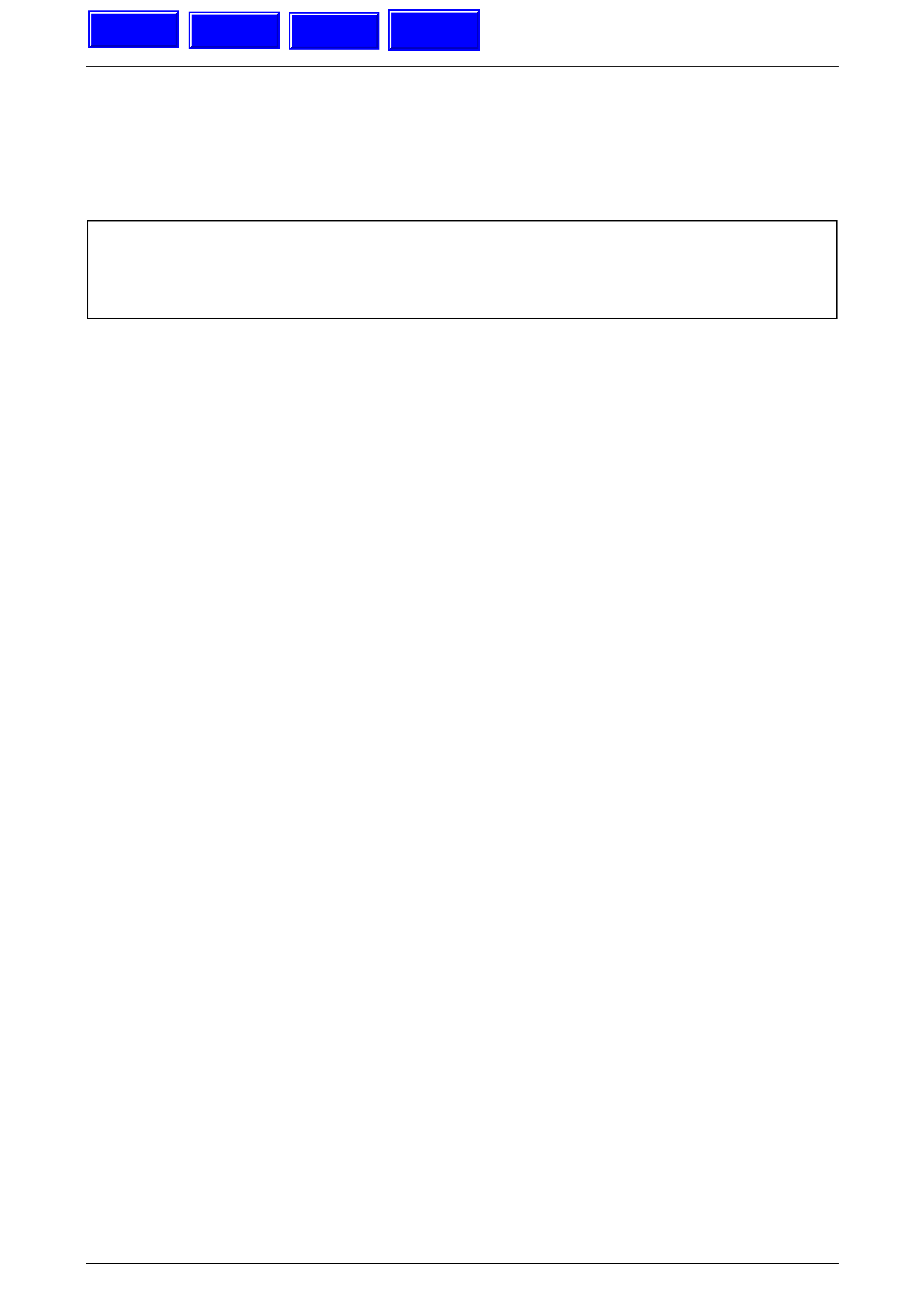

The diagnost ic infor mat ion ac c ess procedures are a

carry over from the MY2003 VY Series except that the

Model Year selection on TECH 2 is now (4) 2004.

Figure 2F – 1

The Vehicle Type selection is WK Series.

Figure 2F – 2

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–5

20–FEB–2003 Page 2F-5

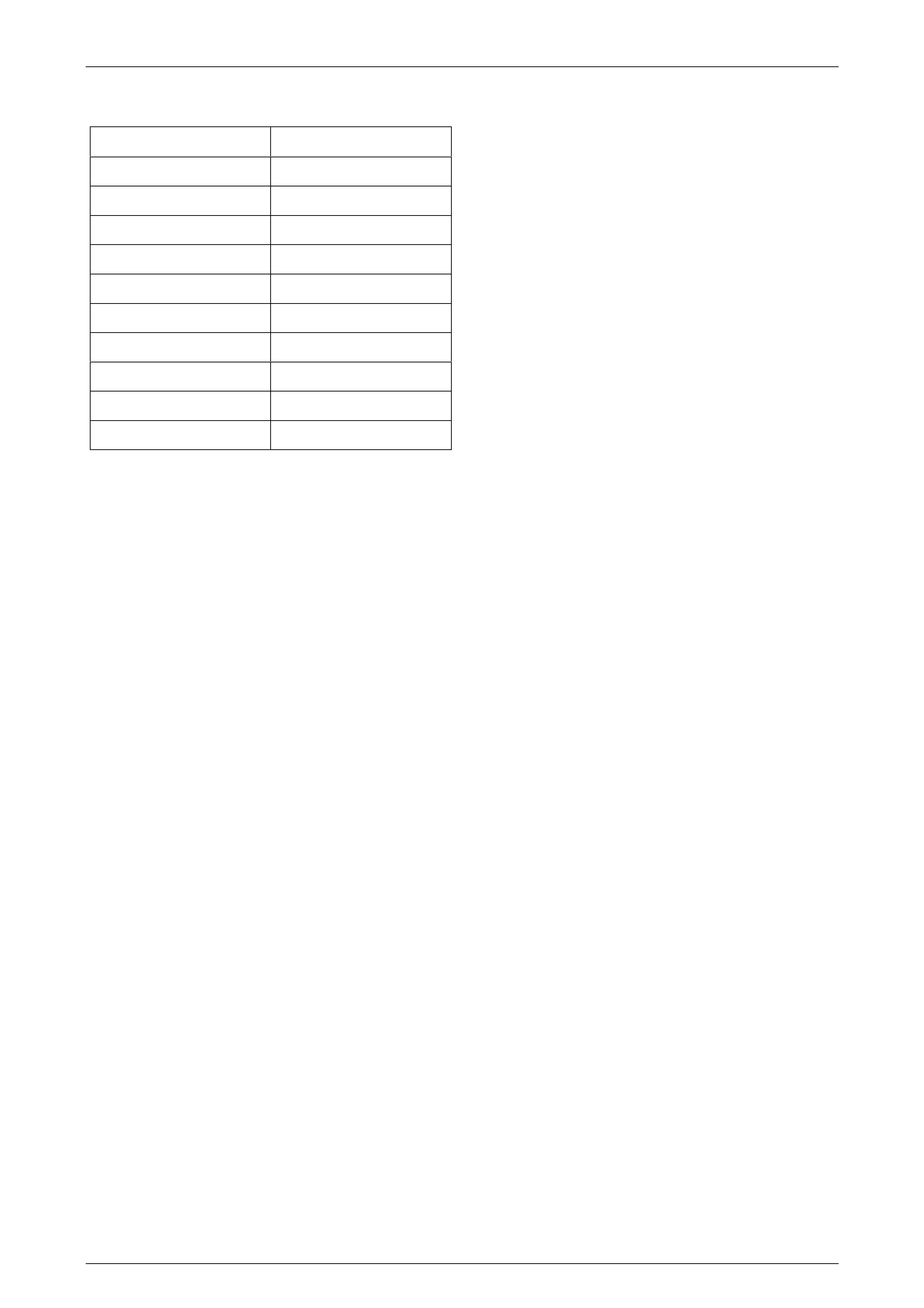

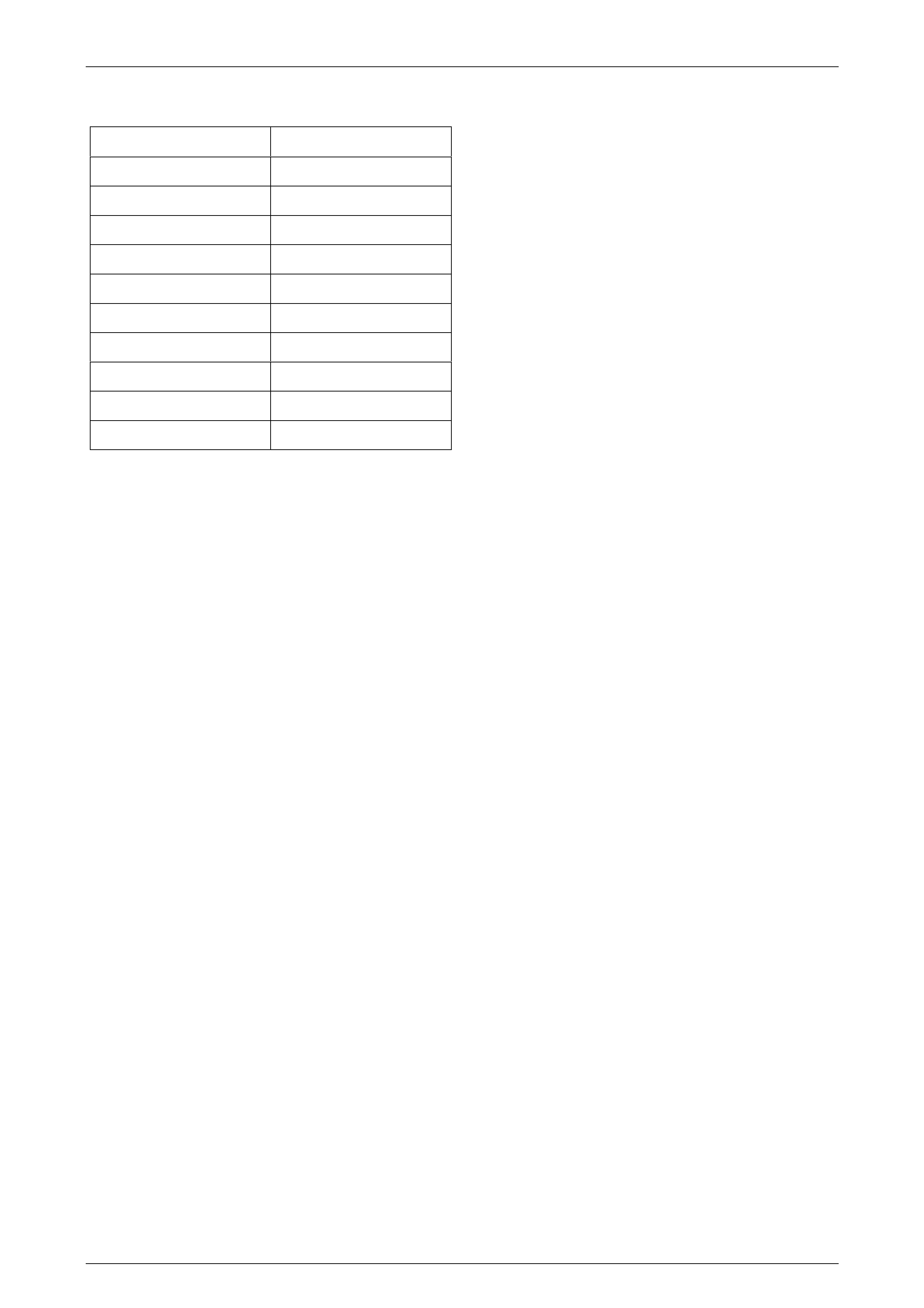

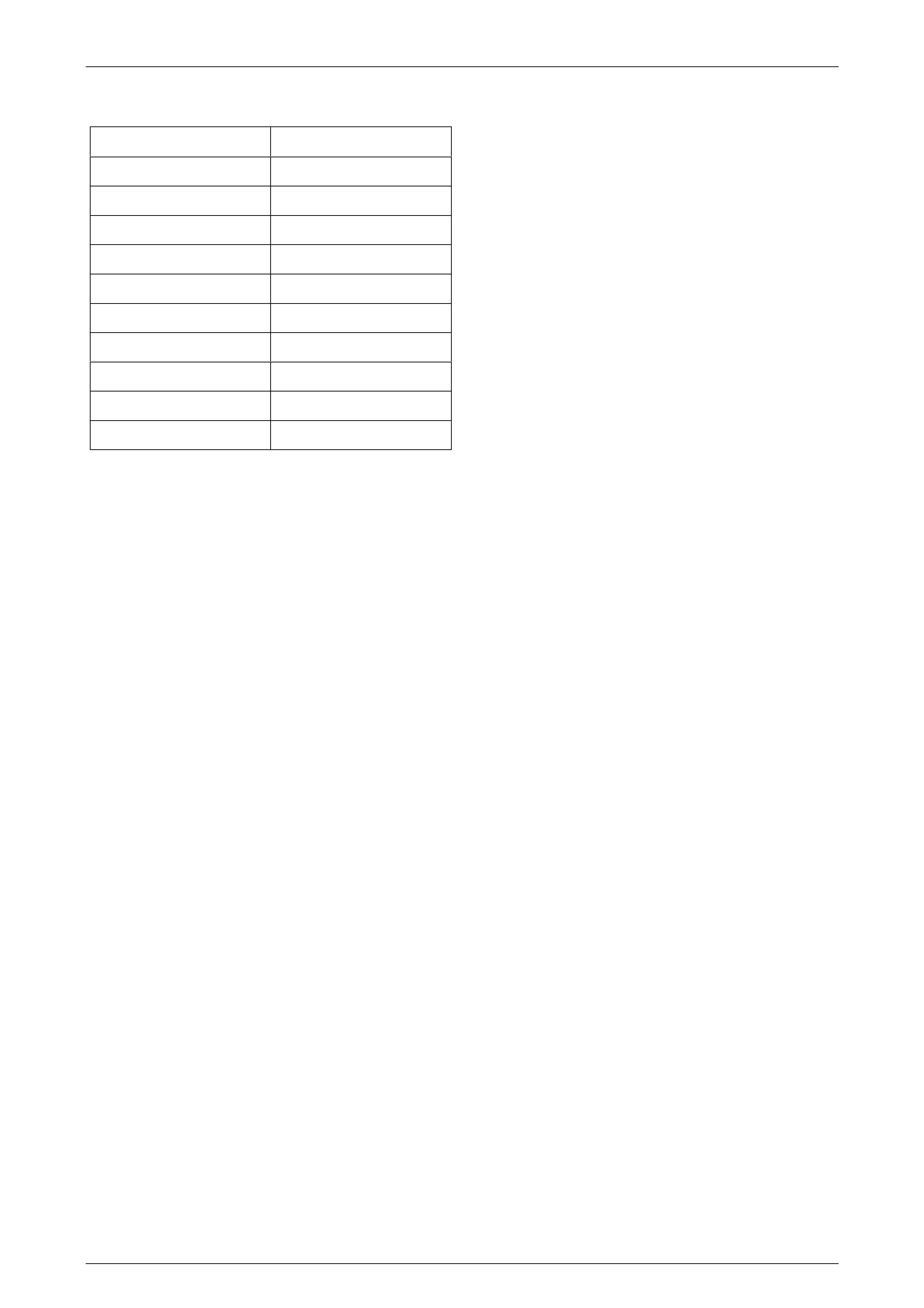

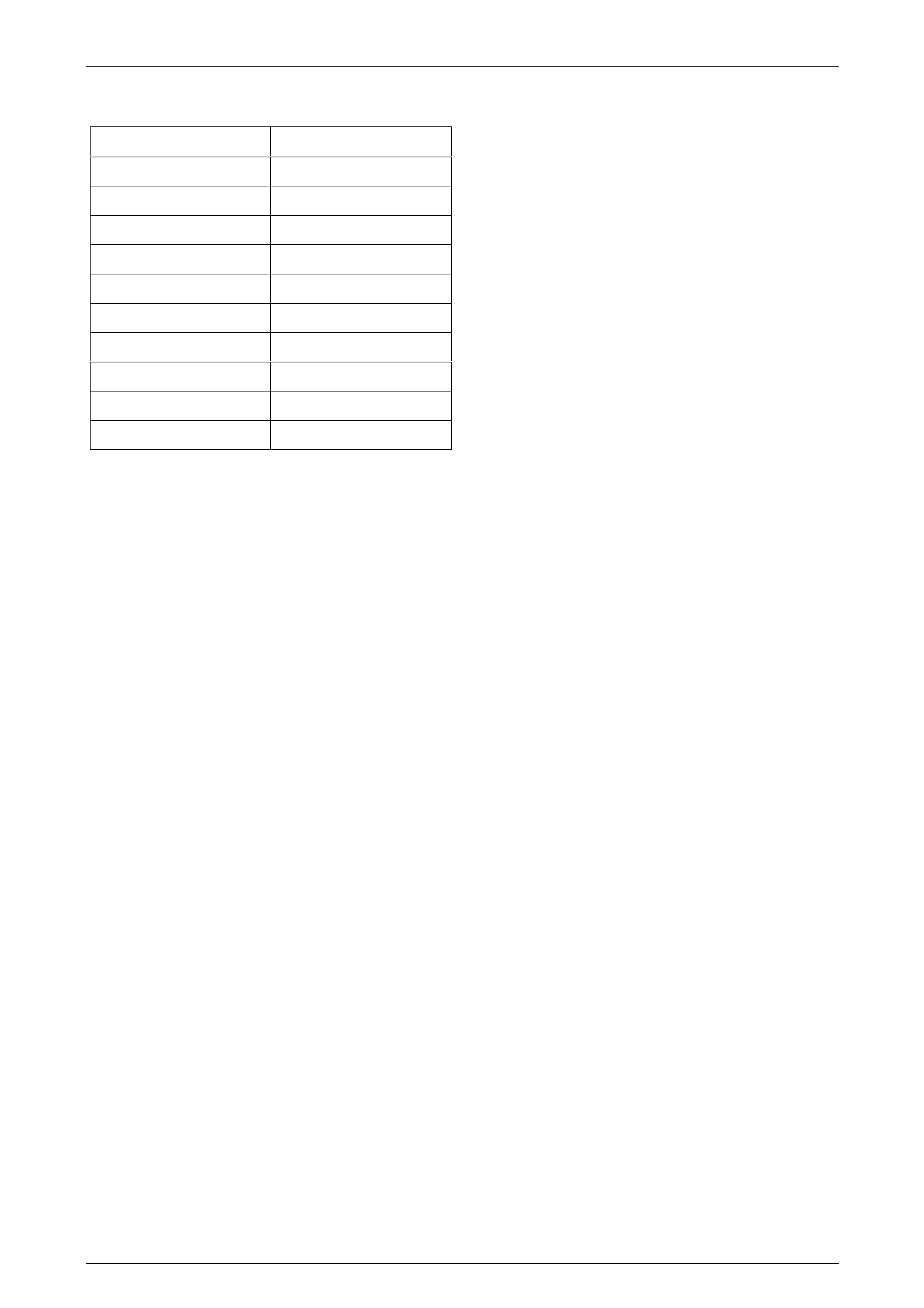

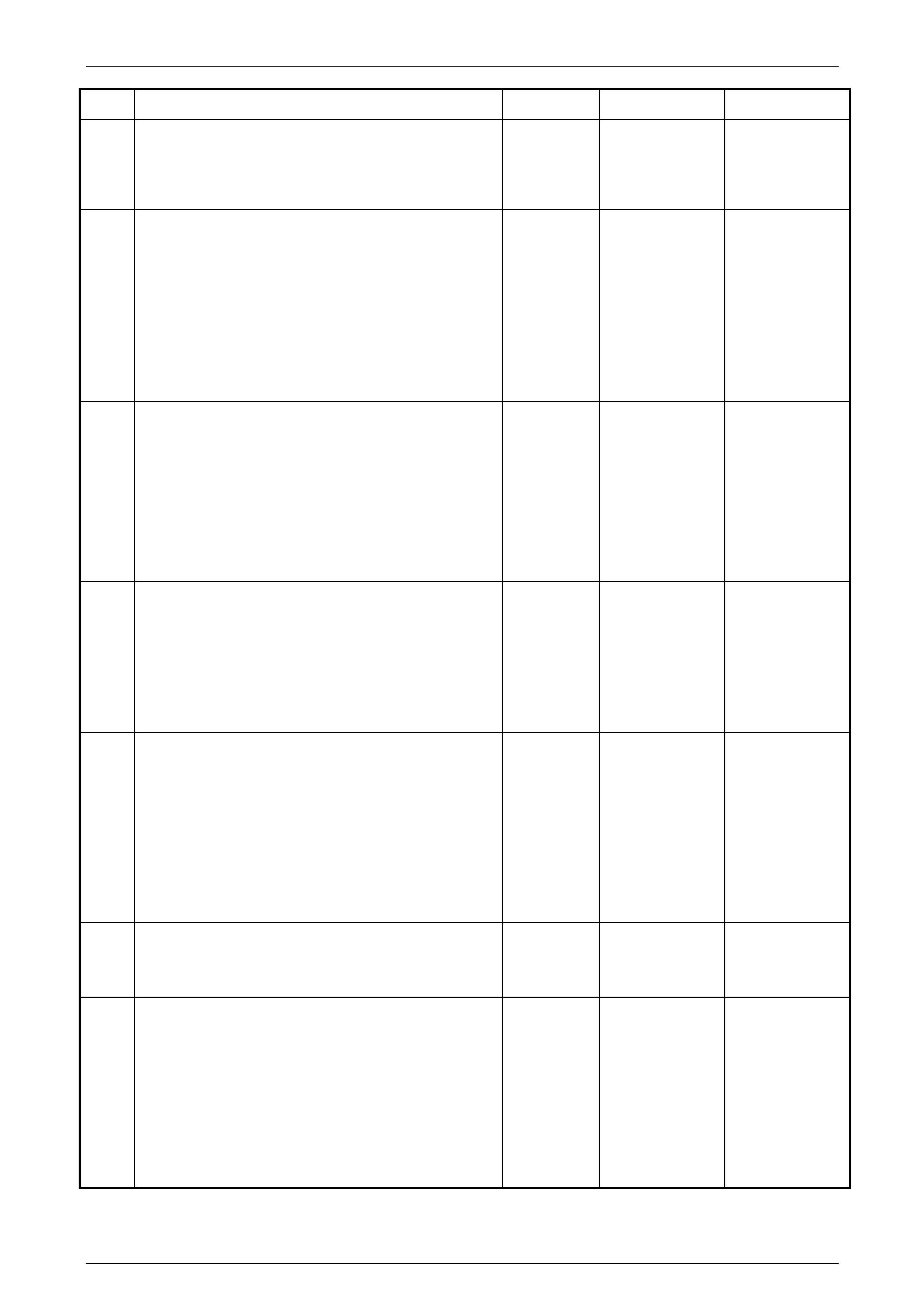

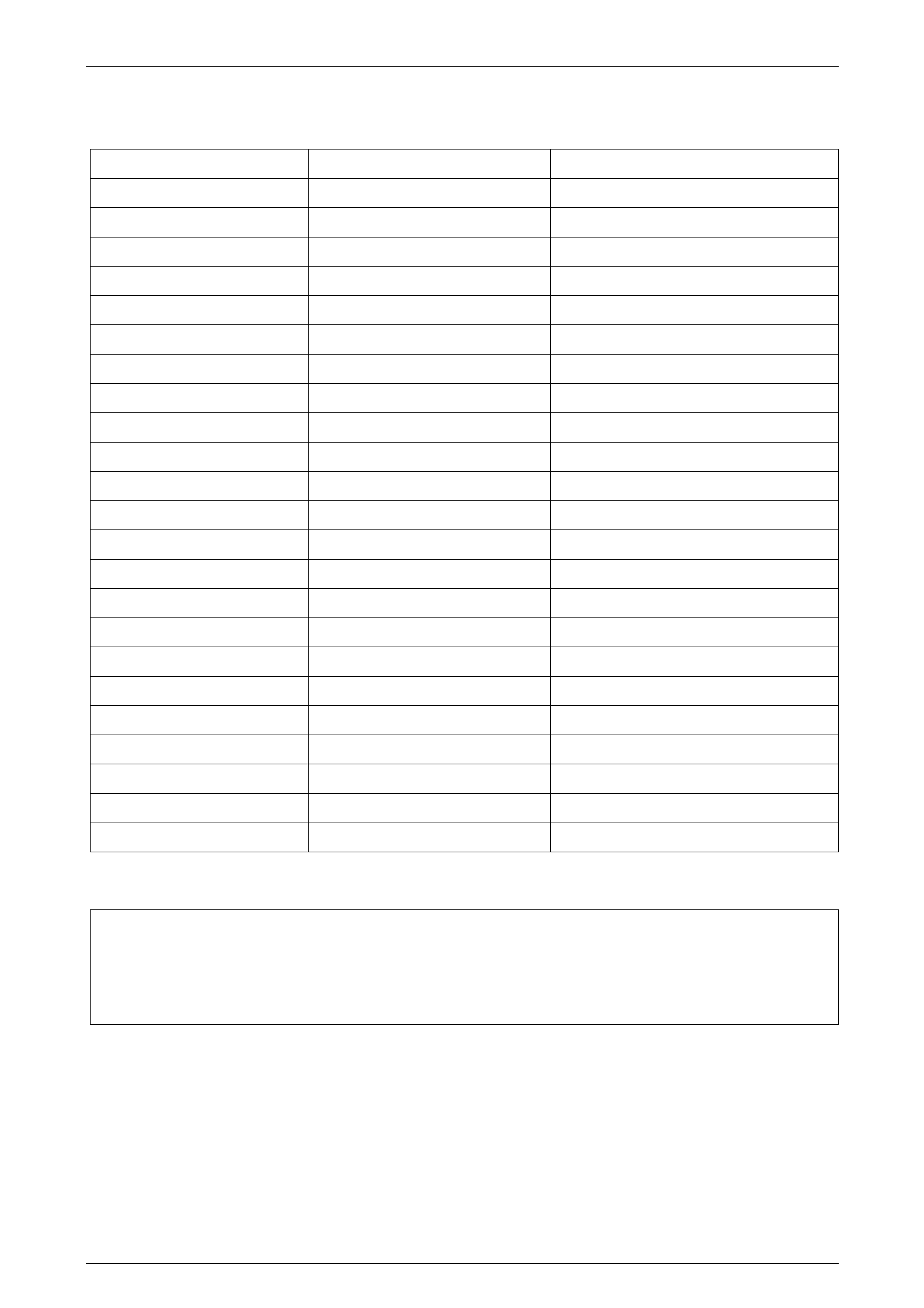

The following table lists all OCC system DTCs applicable to Level to 2 to 5 MY2004 WK Series vehicles.

DTC Code Description

13 Ambient temperature sensor voltage too high

14 Ambient temperature sensor voltage too low

15 In car temperature sensor voltage too high

16 In car temperature sensor voltage too low

17 Evaporative temperature sensor voltage too high

18 Evaporative temperature sensor voltage too low

19 Sun load sensor error

35 No serial data from PCM

36 No serial data from BCM

37 ROM checksum error

38 EEPROM checksum error

39 RAM error

40 Air mix door motor driver error

41 Solenoid driver error

43 Driver’s air mix door motor feedback circuit voltage too low

44 Driver’s air mix door motor feedback circuit voltage too high

45 Passenger’s air mix door motor feedback circuit voltage too low

46 Passenger’s air mix door motor feedback circuit voltage too high

47 Driver Airmix Min. Calibration Error

48 Driver Airmix Max. Calibration Error

49 Pass Airmix Min. Calibration Error

50 Pass Airmix Max. Calibration Error

NOTE: for diagnosis of the pressure transducer, refer to the following Sections in the MY2003 VY and V2 Series Service

Information:

• Section 6C1 POWERTRAIN CONTROL MODULE – V6 ENGINE.

• Section 6C2 POWERTRAIN CONTROL MODULE – V6 SUPERCHARGED ENGINE.

• Section 6C3 POWERTRAIN CONTROL MODULE – GEN III V8.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–6

20–FEB–2003 Page 2F-6

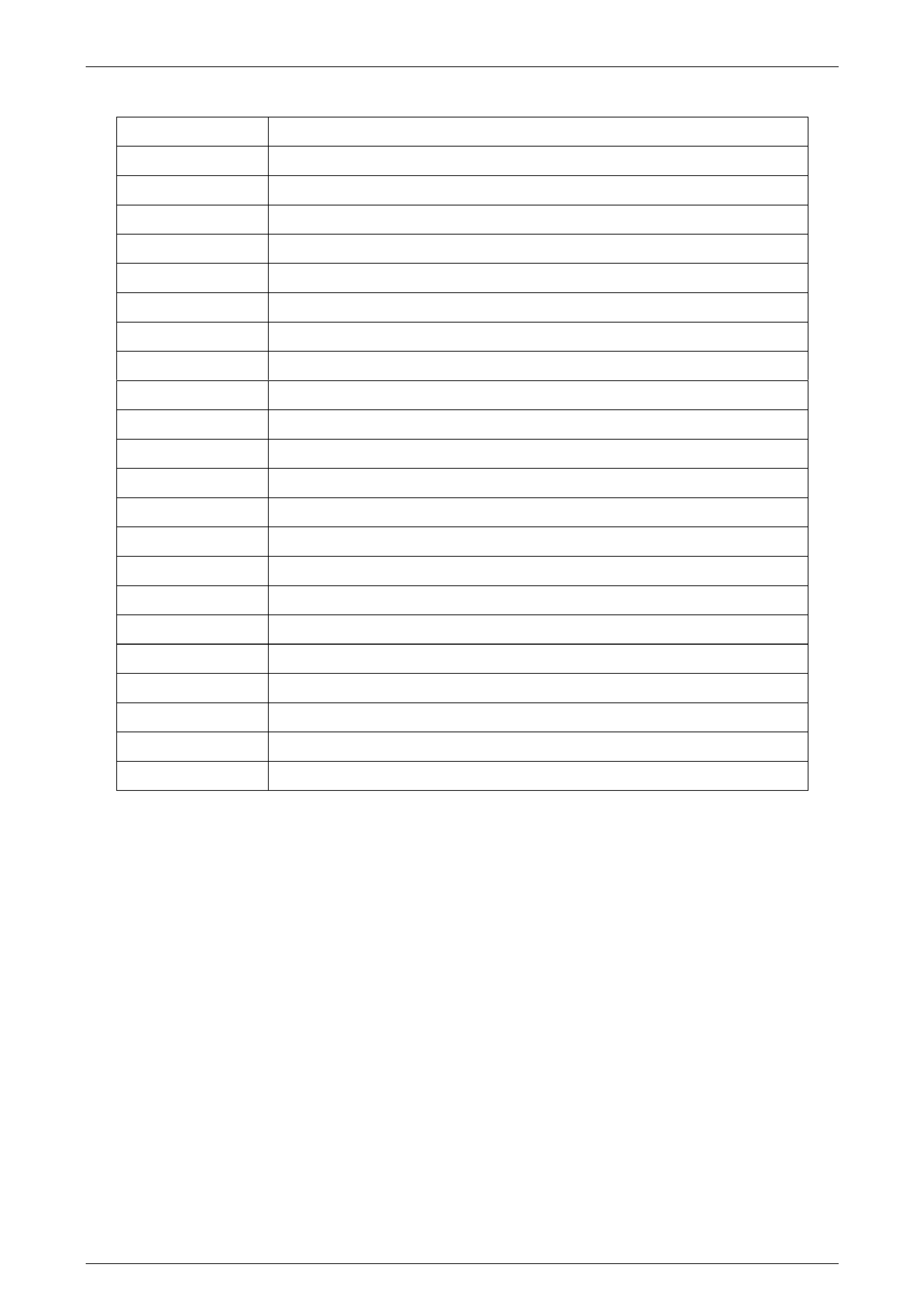

2.2 Data Displa y

F2: Data Display

If the F2: Data Display mode is selected from the Body

menu, an additional menu will appear giving the operator

the option of selecting:

F1: OCC Data List,

F2: OCC Switch Data,

F3: System Identification or,

Air Mix Door Calibration Positions.

Figure 2F – 3

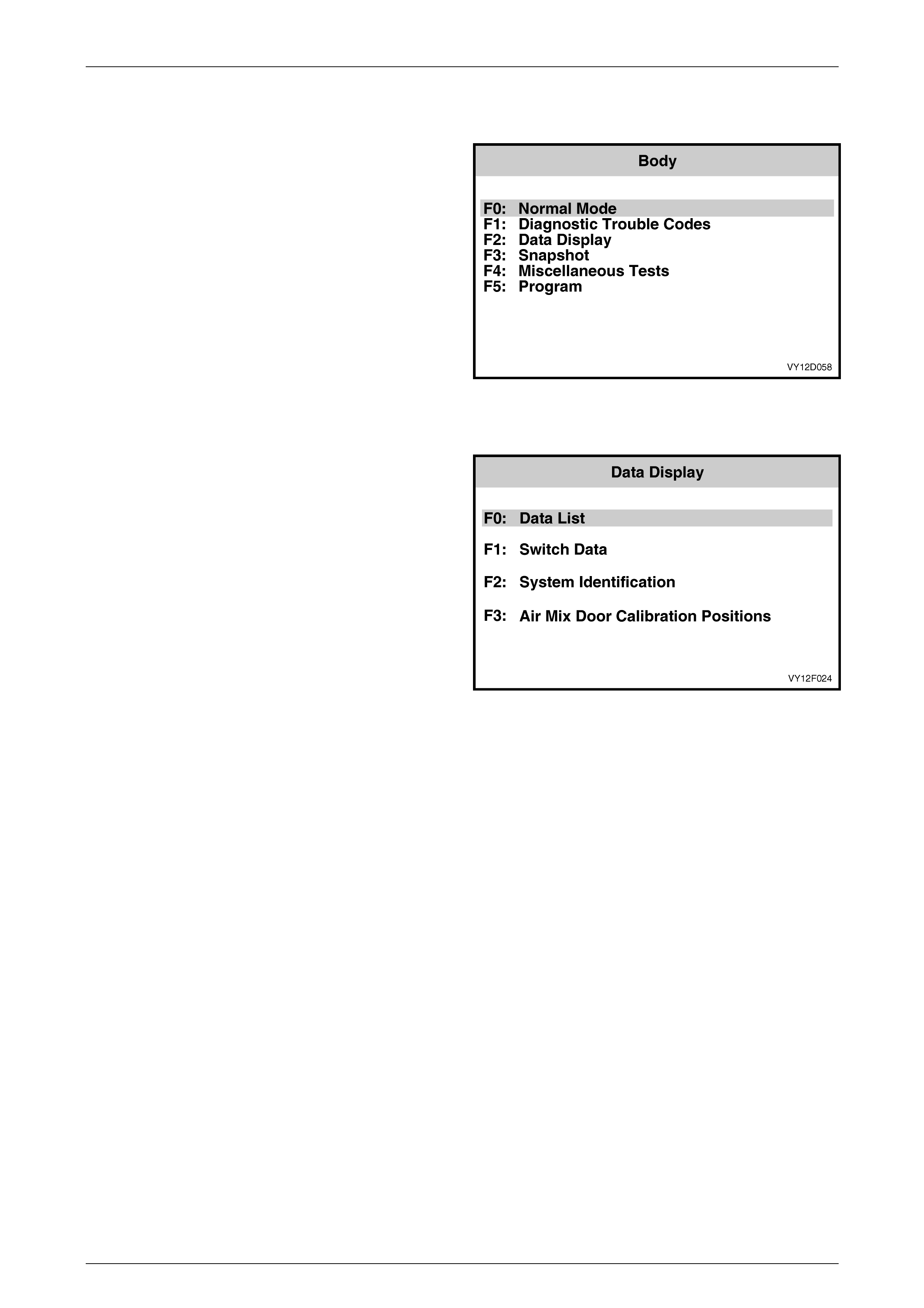

F0: Data List

When F2: DATA DISPLAY is selected followed by

F0: DATA LIST, the Switch Data Table will be displayed.

The data list displays inputs and outputs of the OCC

system.

Figure 2F – 4

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–7

20–FEB–2003 Page 2F-7

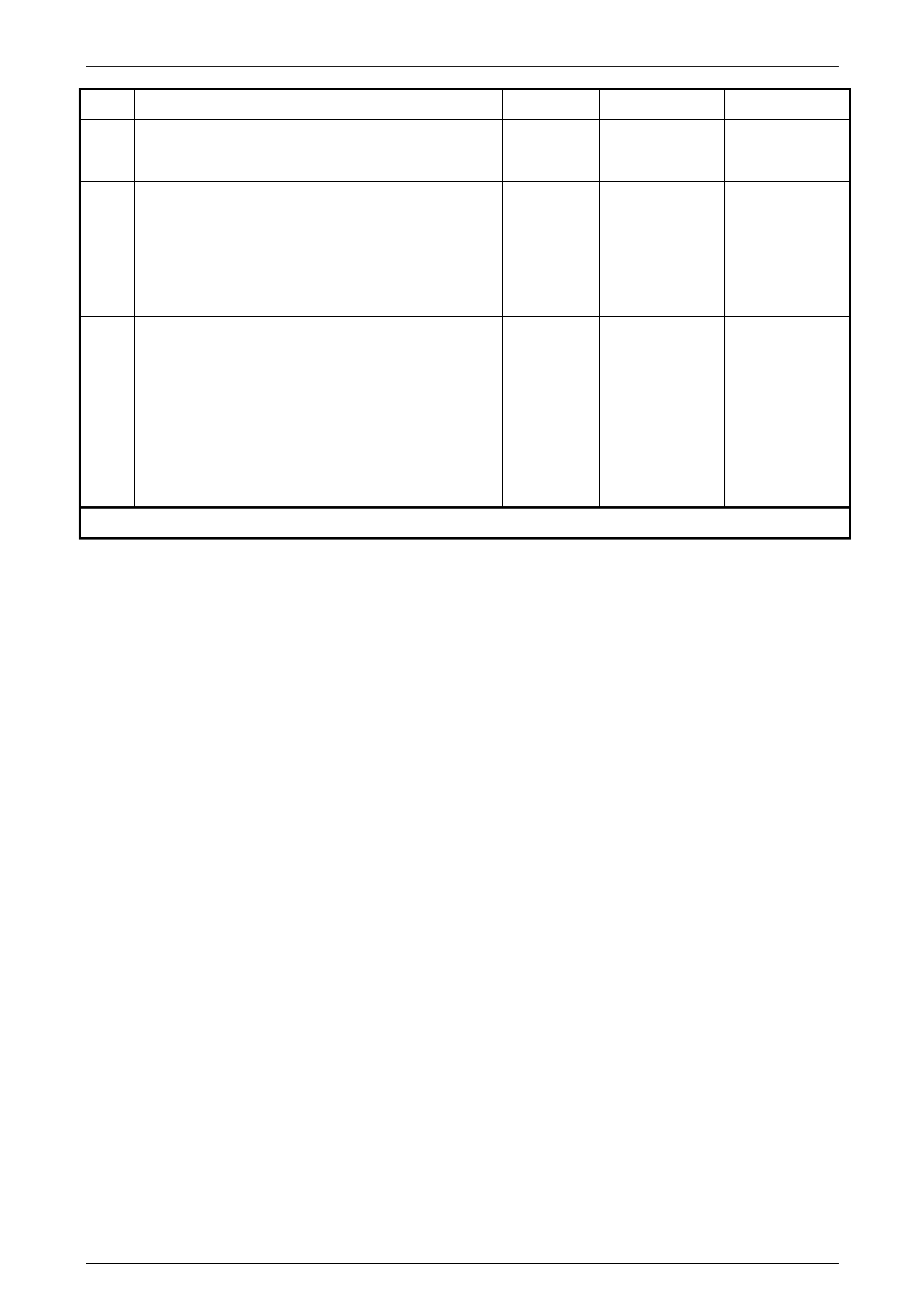

The following table shows all items in the DATA LIST, together with their expected readings:

OCC Type

Data List Reading Single

Zone Dual

Zone

System Status On/Off X X

Battery Voltage Approx 13.5 V X X

Ignition Status OFF/ON X X

Air Conditioning Request NO/YES X X

Evaporative Temperature Sensor 0 to 3.5 ± 0.2 V X X

Evaporative Temperature °C X X

Ambient Temperature Sensor 0 to 3.5 ± 0.2 V X X

Ambient Temperature Degrees °C X X

Dampened Ambient Temperature Degrees °C X X

In Car Temperature Sensor 0 to 3.5 ± 0.2 V X X

In Car Temperature Degrees °C X X

Blower Fan Speed Manual: 1234 and HIGH, Auto: Low, Mid and High X X

Desired Blower Fan Speed % X X

Blower Fan Speed Control % X X

Blower Fan Speed Feedback Voltage V X X

Drivers Air Mix Motor Position Desired % X X

Drivers Air Mix Motor Position Feedback % X X

Drivers Air Mix Motor Position Feedback Voltage 0 to 3.5 ± 0.2 V X X

Passengers Air Mix Motor Position Desired % X

Passengers Air Mix Motor Position Feedback % X

Passengers Air Mix Motor Position Feedback Voltage 0 to 3.5 ± 0.2 V X

*Rear Remote Control Input Voltage 5.0 V X X

Engine Coolant Temperature Degrees °C X X

Sun Load Steps: 0 – 255 X X

Driver Set Temperature Degrees °C X X

Passengers Set Temperature Degrees °C X

Operating Mode Manual/auto X X

Outlet Mode Face / floor / blend / foot X X

Inlet Mode Fresh / Recirc X X

Startup Strategy None, Recirc / Delay, Demist / Delay, Purge,

A/C Purge, Fresh / Delay X X

Fresh / Recirculation Solenoid Off/On X X

Water Valve Solenoid Off/On X X

Water Valve Closed/Open X X

Face 2 Solenoid Off/On X X

Face 1 Solenoid Off/On X X

Foot 2 Solenoid Off/On X X

Foot 1 Solenoid Off/On X X

High Fan Relay Inactive: 12 V Active: 0 V X X

Rear Demist Relay Off/On X X

Park Lamp Input Off/On X X

Front Demist LED Off/On X X

Rear Demist LED Off/On X X

• Applicable only to models fitted with rear remote control i.e. Level 5.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–8

20–FEB–2003 Page 2F-8

F1: Switch Data

In this mode, the operator is able to test the function of

each switch on the OCC control module and on level 5

models, the rear remote control. When F2: DATA

DISPLAY is selected followed by F1: SWITCH DATA,

the Switch Data Table will be displayed.

NOTE

The OCC control module buttons will need to

be held on when carrying out this test due to

a normal delay in information transfer.

To test the OCC control module switches in this mode,

turn on the ignition and the OCC system. Activate each

switch on the OCC control module and observe the

TECH 2 screen to see if the TECH 2 display changes the

switch status from Off to On.

Figure 2F – 5

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–9

20–FEB–2003 Page 2F-9

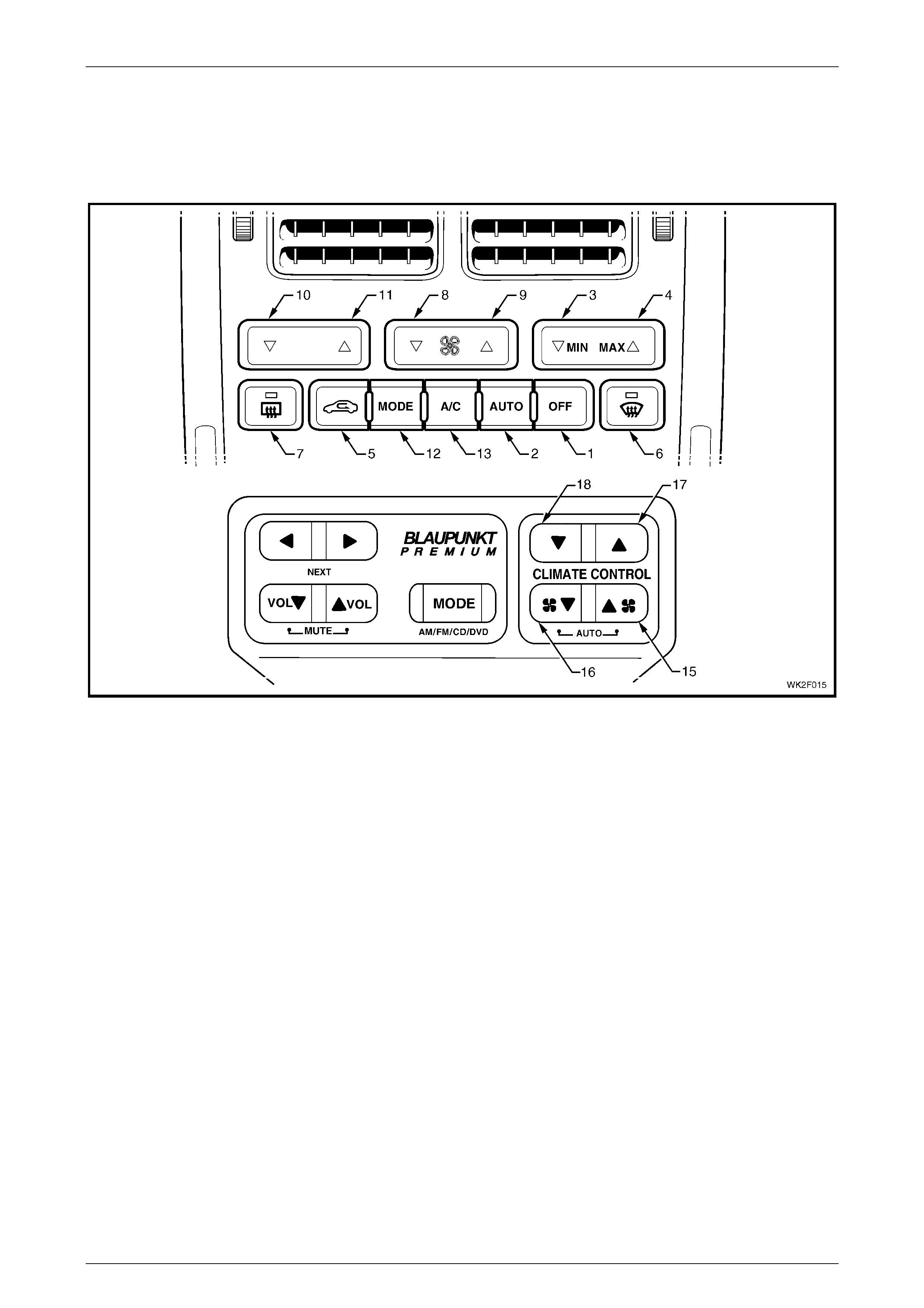

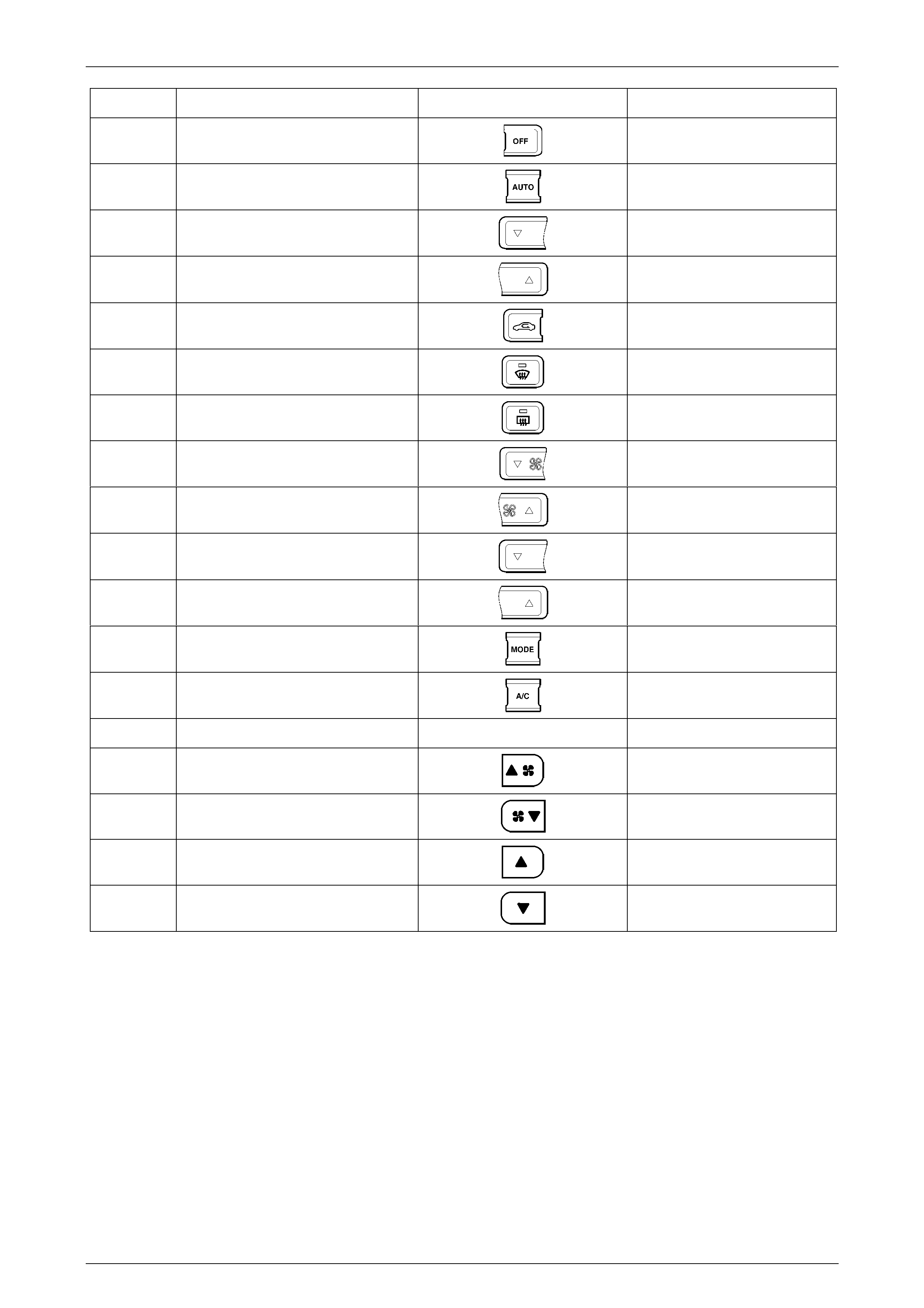

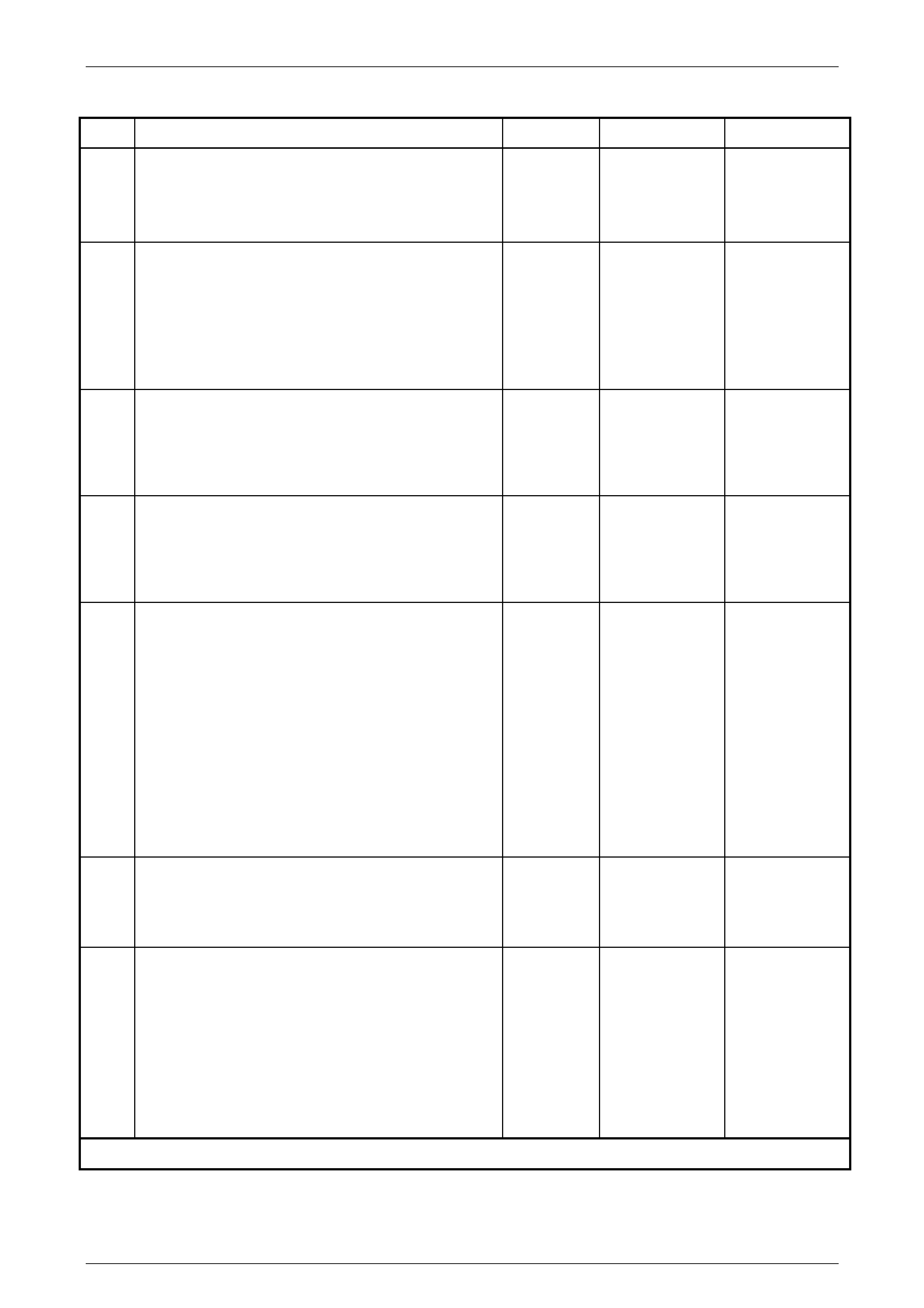

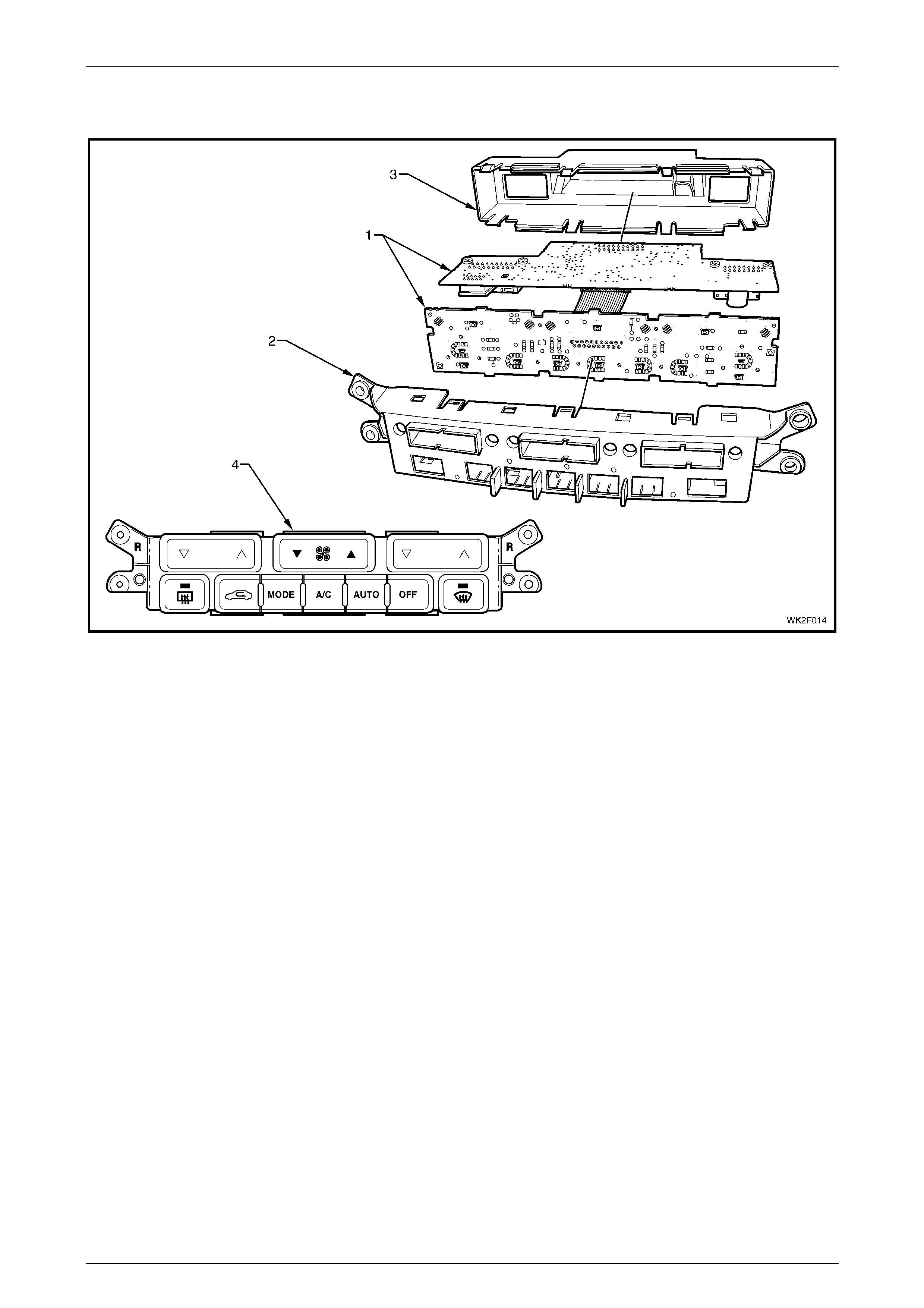

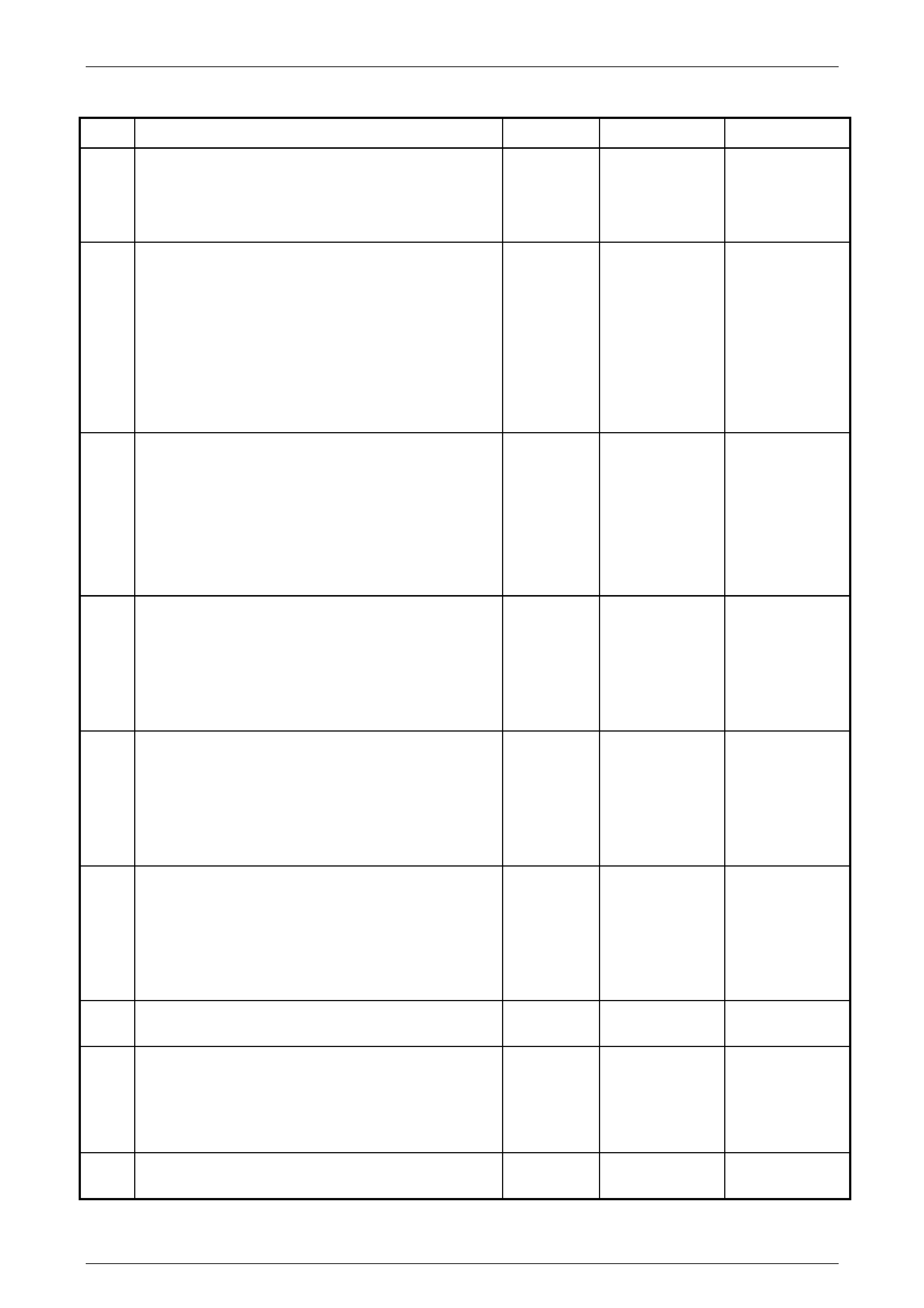

Figure 2F – 6 shows the OCC control module switch configuration applicable to LHD models in the upper section and the

rear remote switch configuration in the lower section. The switches are numbered in accordance test sequence in

Tech 2.The table following shows all items in the SWITCH DATA, the switch graphics and their expected test readings.

The progression of the table follows the switch test sequence in Tech 2. Turn each switch on and off beginning at the

OFF switch (1) and progress through the switch clusters of the OCC control module and on Level 5 models, the rear

remote control as shown in Figure 2F – 6.

Figure 2F – 6

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–10

20–FEB–2003 Page 2F-10

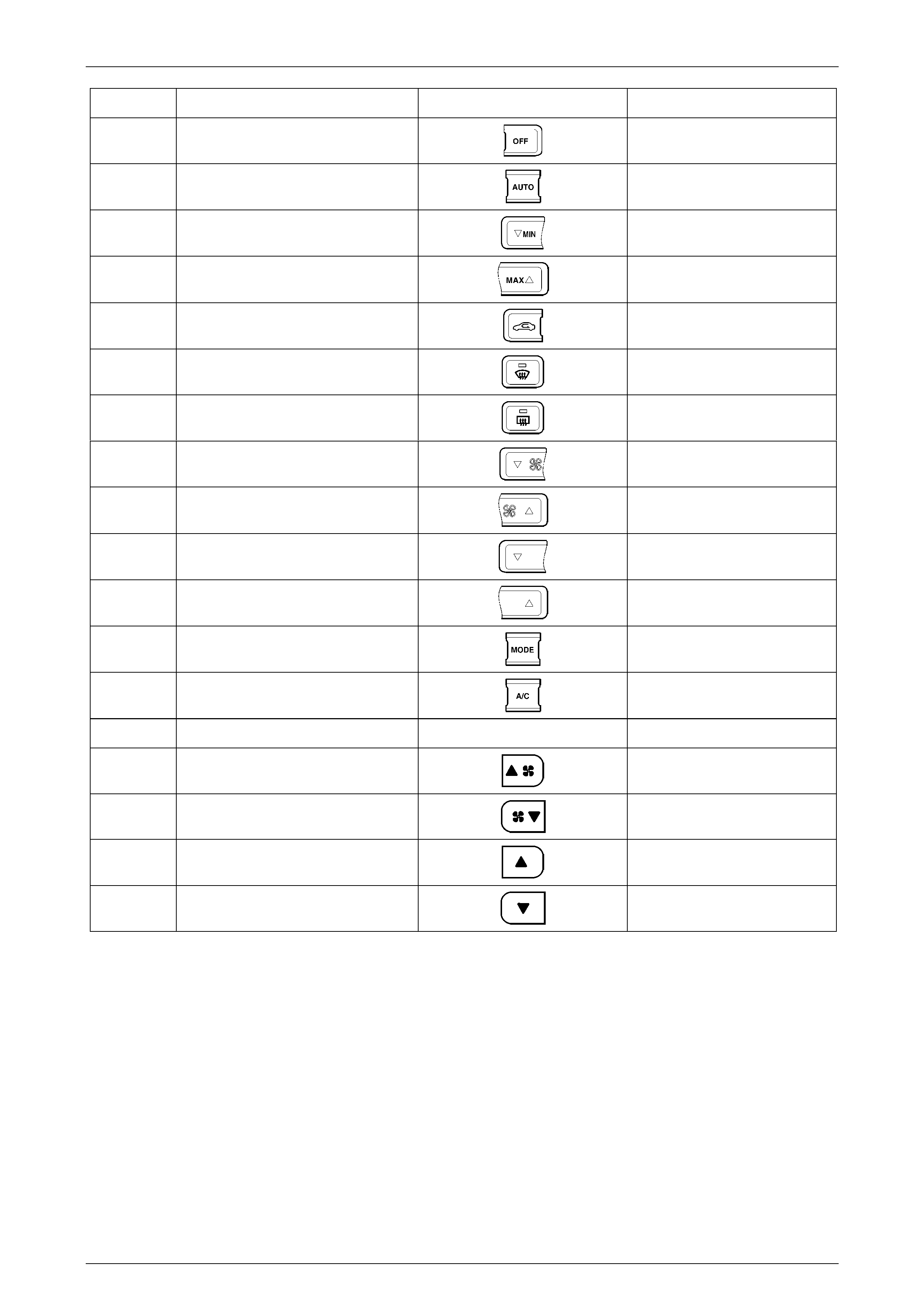

Sequence Switch Data Switch Reading

1 Off Switch Off/On

2 Auto Switch Off/On

3 Minimum Temperature Switch Off/On

4 Maximum Temperature Switch Off/On

5 Recirculation Switch Off/On

6 Front Demist Switch Off/On

7 Rear Demist Switch Off/On

8 Fan Down Switch Off/On

9 Fan Up Switch Off/On

10 Temperature Down Switch Off/On

11 Temperature Up Switch Off/On

12 Mode Switch Off/On

13 Air Conditioning Switch Off/On

14 *Rear Remote Input

15 *Rear Remote Fan Up Off/On

16 *Rear Remote Fan Down Off/On

17 *Rear Remote Temperature Up Off/On

18 *Rear Remote Temperature Down Off/On

• Applicable to only to models fitted with rear remote control i.e. Level 5.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–11

20–FEB–2003 Page 2F-11

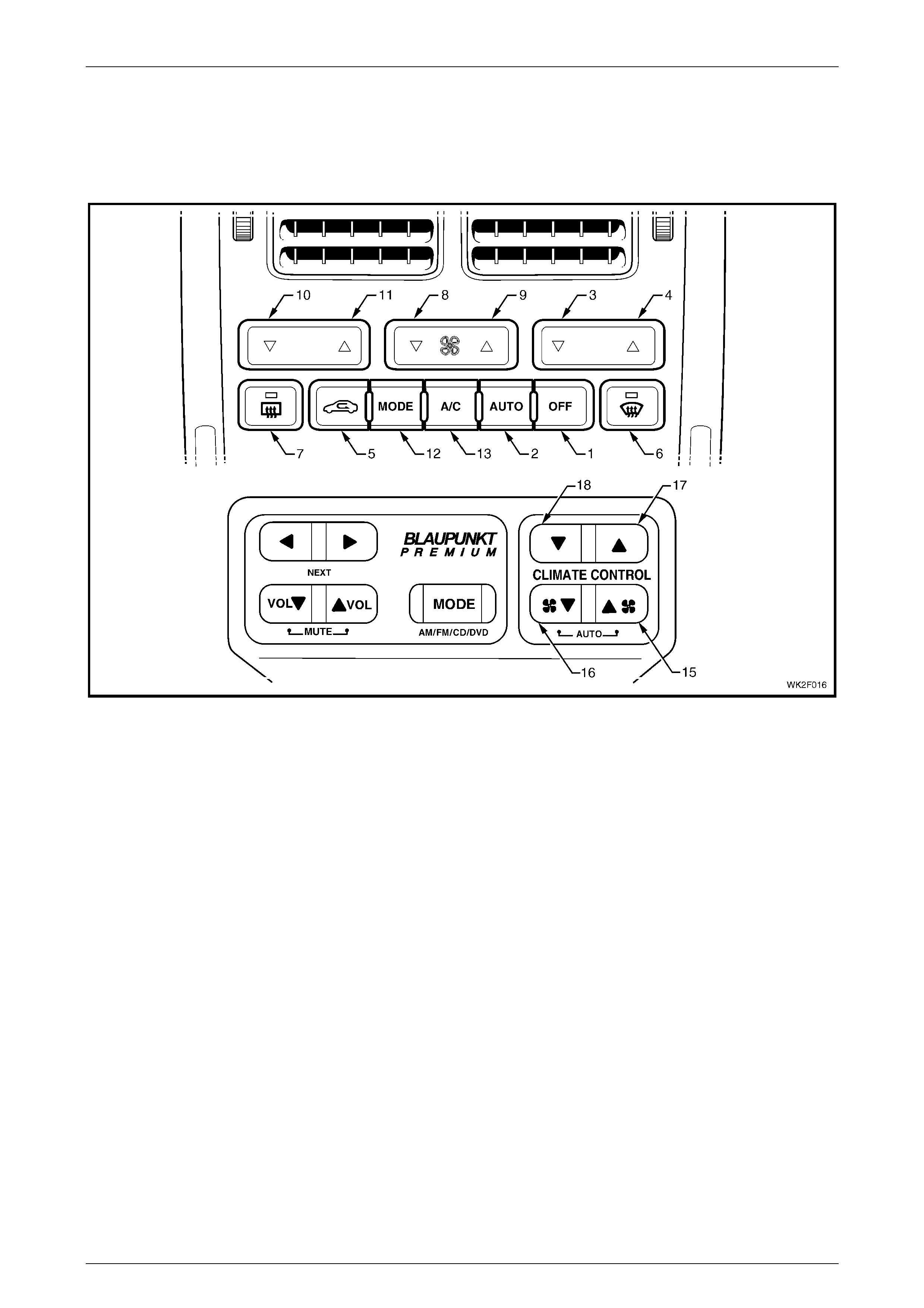

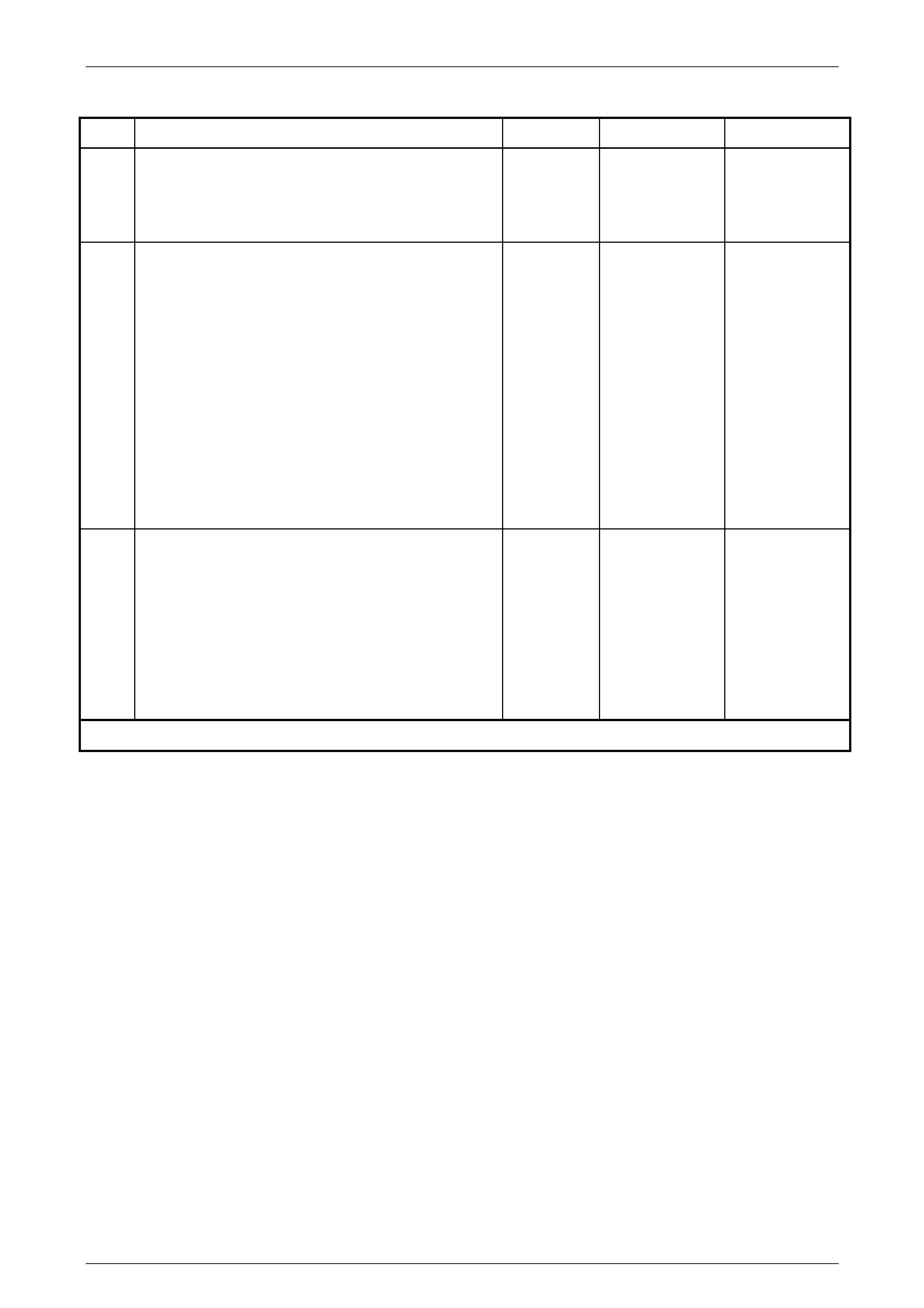

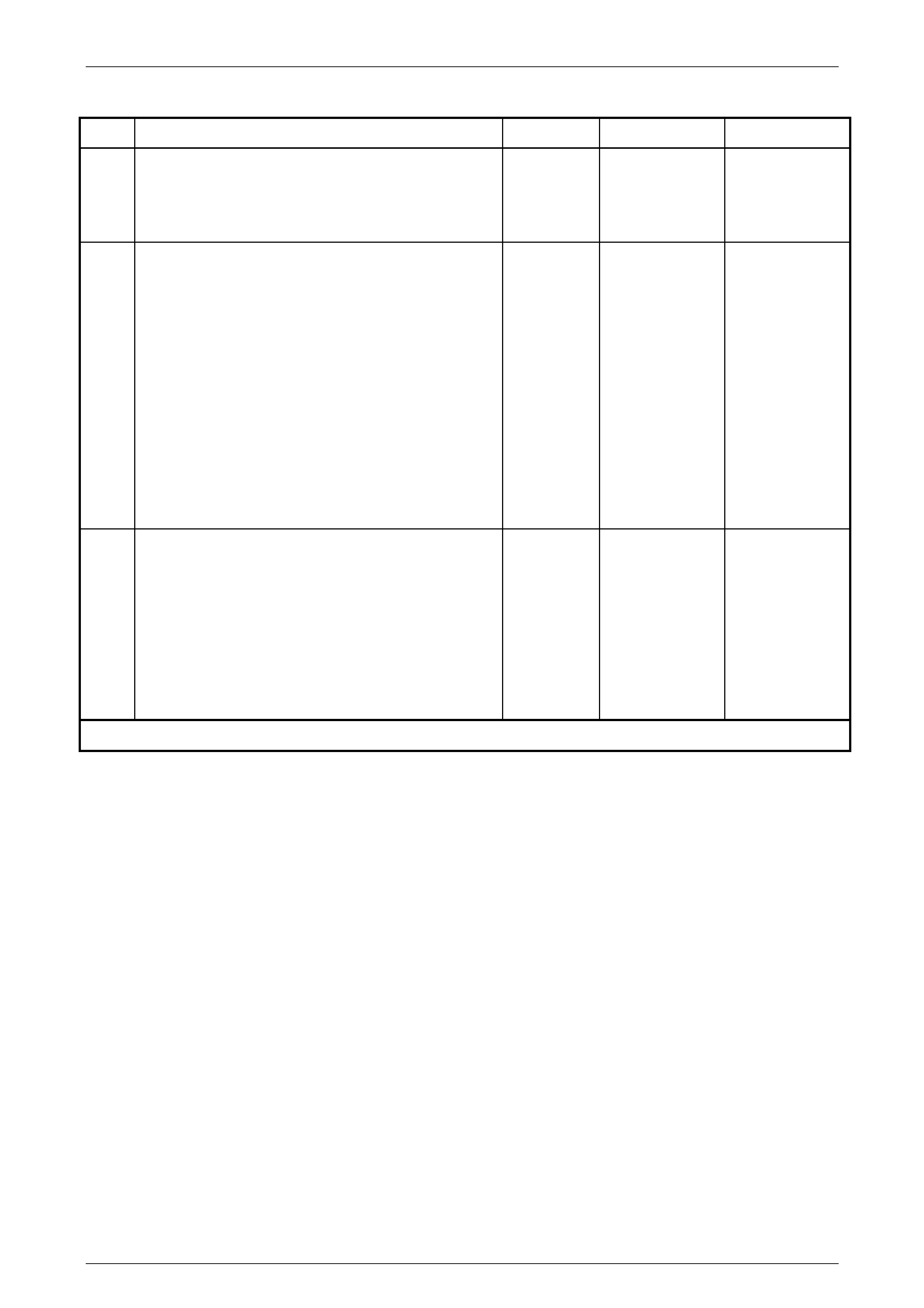

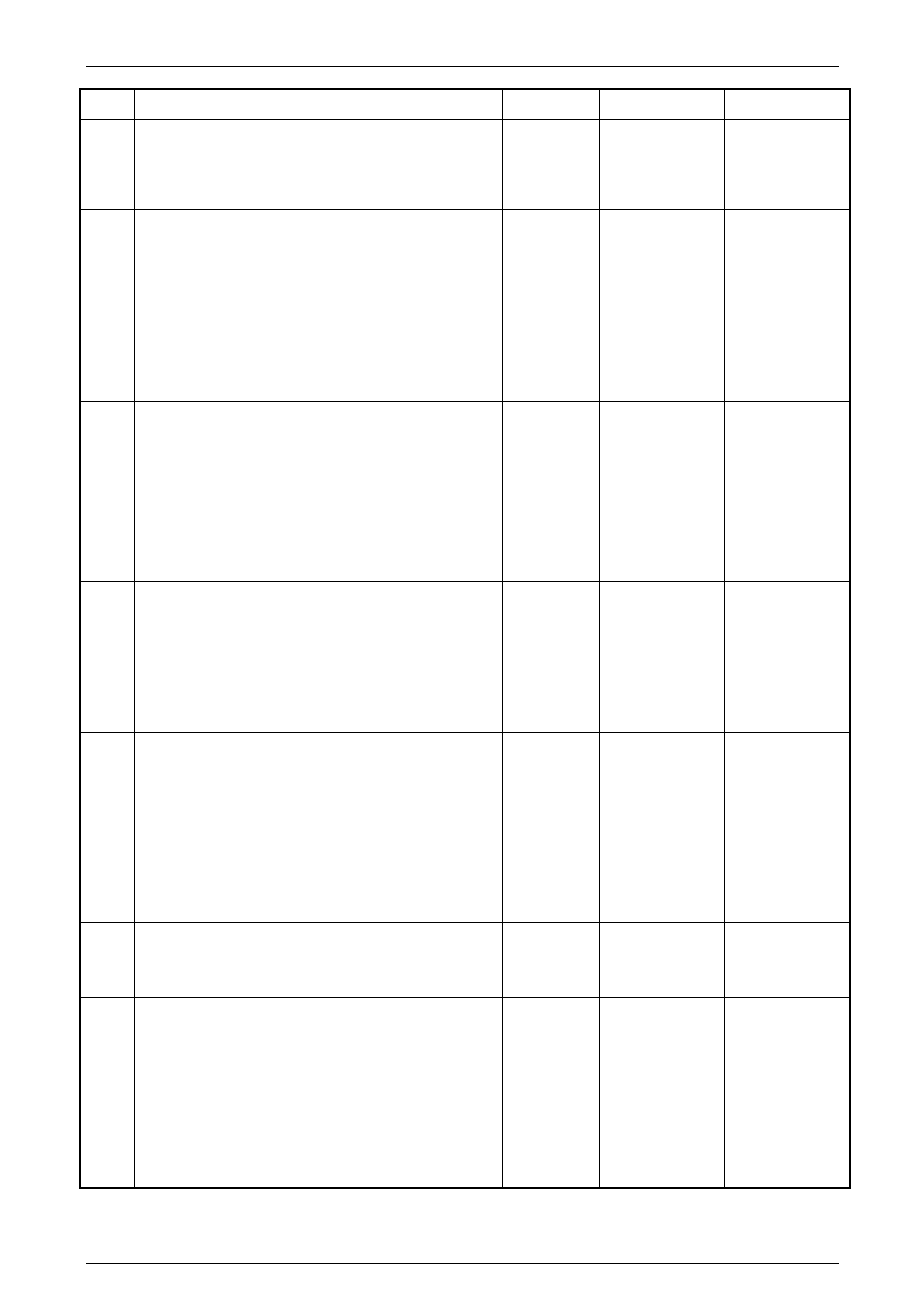

Figure 2F – 7 shows the OCC control module switch configuration applicable to RHD models in the upper section and

the rear remote switch configuration in the lower section. The switches are numbered in accordance test sequence in

Tech 2.The table following shows all items in the SWITCH DATA, the switch graphics and their expected test readings.

The progression of the table follows the switch test sequence in Tech 2. Turn each switch on and off beginning at the

OFF switch (1) and progress through the switch clusters of the OCC control module and on Level 5 models, the rear

remote control as shown in Figure 2F – 7.

Figure 2F – 7

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–12

20–FEB–2003 Page 2F-12

Sequence Switch Data Switch Reading

1 Off Switch Off/On

2 Auto Switch Off/On

3 Driver’s Temp. Down Switch Off/On

4 Driver’s Temp. Up Switch Off/On

5 Recirculation Switch Off/On

6 Front Demist Switch Off/On

7 Rear Demist Switch Off/On

8 Fan Down Switch Off/On

9 Fan Up Switch Off/On

10 Passenger Temp. Down Switch Off/On

11 Passenger Temp. Up Switch Off/On

12 Mode Switch Off/On

13 Air Conditioning Switch Off/On

14* Rear Remote Input

15* Rear Remote Fan Up Off/On

16* Rear Remote Fan Down Off/On

17* Rear Remote Temperature Up Off/On

18* Rear Remote Temperature Down Off/On

* Applicable to only to models fitted with rear remote control i.e. Level 5.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–13

20–FEB–2003 Page 2F-13

2.3 Miscellaneous Tests

The majority of Miscellaneous Test procedures and expected results are the same or similar as those applying to

MY2003 VY and V2 Series vehicles. Accordingly, for the following Miscellaneous Test procedures, refer to Section 2F,

1.2 TECH 2 TEST MODES AND DISPLAYS FOR OCC DIAGNOSIS in the MY2003 VY and V2 Series Service

Information.

• Driver’s Air Mix Door

• Passenger’s Air Mix Door

• Blower Speed

• Maximum Fan Relay

• Outlet Mode

• Illumination

• Front Demist LED

• Rear Demist LED

• Rear Demist Relay

• A/C Request

• Solenoids

NOTE 1

During the Outlet Mode test on MY2003 VY and

V2 Series vehicles, the mode graphics are

displayed on the OCC control module LCD as

each mode is selected. The mode graphics are

not displayed on the Multi Function Display as

each mode is selected when this test is

conducted on WK Series models

NOTE 2

During the Illumination test, only the illumination

level of the graphics on the WK Series OCC

control module is altered. The illumination level of

the Multi Function Display remains unchanged.

LCD Display Test

PURPOSE OF TEST:

To ensure that all segments are functioning and can be

displayed on the MFD screen.

PRE-CONDITION:

Engine not running.

PROCEDURE:

With TECH 2 connected to the DLC select:

Body /

Occupant Climate Control /

Miscellaneous Tests /

LCD Display Tes t.

Figure 2F – 8

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–14

20–FEB–2003 Page 2F-14

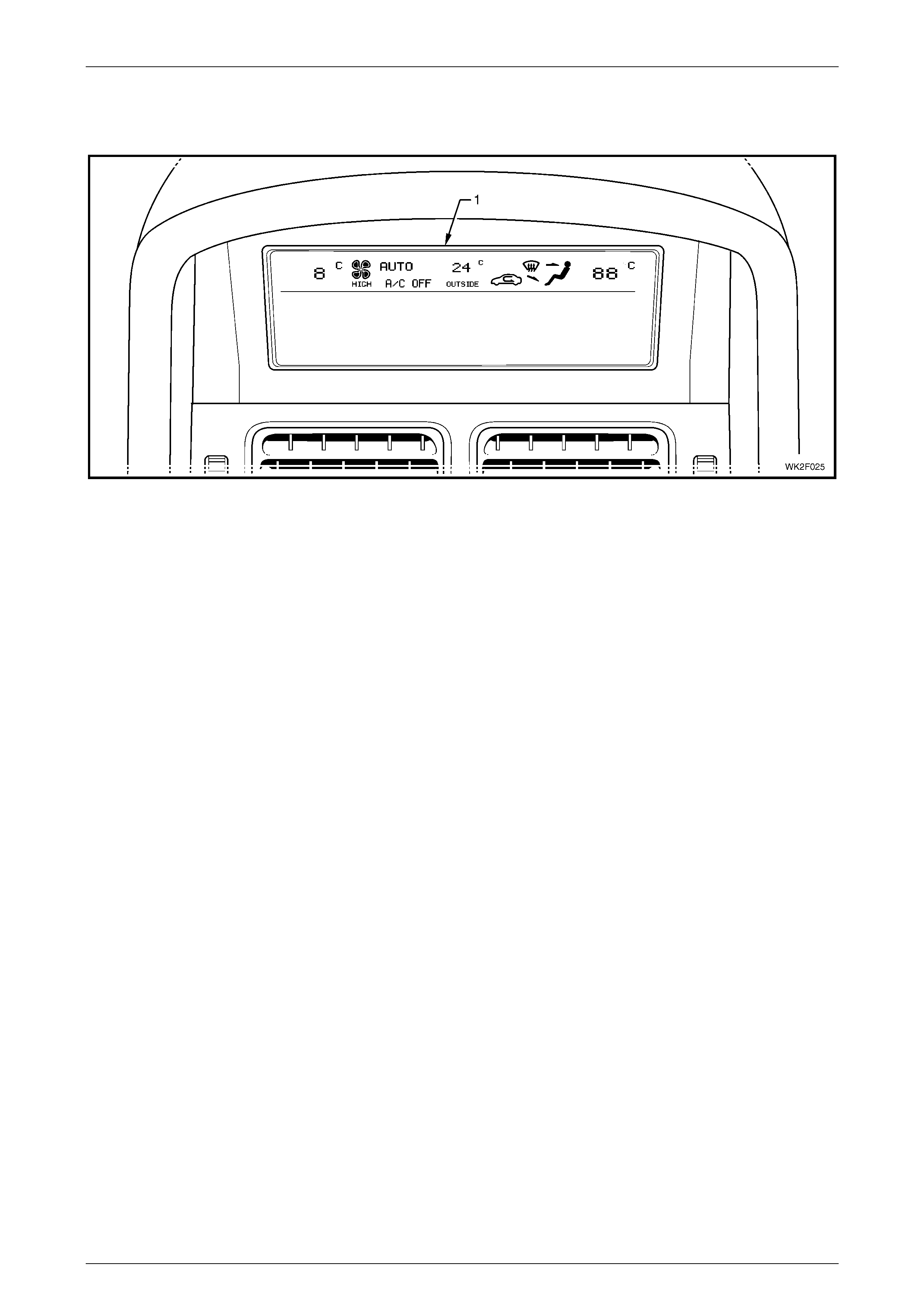

Using the On/Off soft keys on TECH 2, activate and deactivate the upper section of the Multi Function Display. The MFD

should display upper screen detail identical to that shown in Figure 2F – 9. All segments should appear for approximately

5 seconds after the On soft key is activated.

Figure 2F – 9

For additional tests relating to the MFD display, refer to Section 12I, 3.6 MISCELLANEOUS TESTS.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–15

20–FEB–2003 Page 2F-15

3 Diagnostic Charts

Introduction

A number of wiring terminal assignments are specific to the MY2004 WK Series models necessitating the provision of the

following diagnostics charts applicable only to WK Series Level 2 to 5 models.

These charts are designed to provide fast and efficient fault location of the OCC (Auto A/C) system. Each diagnostic

chart consists of a diagnostic chart and pertinent information including Diagnostic Trouble Code (DTC) setting

parameters and, in most charts, a circuit diagram.

At the end of this Section electrical connector diagrams and wiring diagrams applicable to OCC (Auto A/C) systems as

fitted to Level 2 to 5 MY2004 WK Series vehicles are provided and can be used in conjunction with the diagnostic chart

circuit diagrams when diagnosing circuit faults. Refer to 4 Wiring Diagrams in this Section. For electrical connector

locations and additional wiring diagram information, refer to Section 12P WIRING DIAGRAMS.

When carrying out wiring checks as directed to by the diagnostic charts, rather than probe terminals and connectors with

incorrect sized multimeter connections, use the adaptors contained in connector test adaptor kit KM-609. This will

prevent any possibility of spreading or damaging wiring harness terminals.

Ensure that at the completion of any diagnostic procedure, all diagnostic tools are removed and all OCC (Auto A/C)

components are correctly con nect ed.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–16

20–FEB–2003 Page 2F-16

Chart A – Diagnostic Circuit Check

Circuit Description

When investigating any complaint of an OCC system problem or malfunction, always begin diagnosis with the following

diagnostic circuit check. This check is a preliminary procedure that checks to ensure the OCC system is communicating

on the serial data line as well as helping to identify a problem or malfunction and directing the reader to the appropriate

diagnostic chart in this Section.

With TECH 2 connected to the DLC and the ignition switched on, TECH 2 should display serial data communication. If

TECH 2 does not display serial data, the serial data circuit may be open or shorted.

In addition to the OCC control module there are several other control modules that are connected to the serial data line

(PCM, BCM, ABS/TCS, instruments and SDM). Any one of these control modules could cause a fault on the serial data

line. This fault could result in TECH 2 not being able to display serial data.

Test Description:

The numbers below refer to Step numbers in diagnostic

chart A.

1. This test checks if the OCC control module is being

powered up.

2. This test determines if TECH 2 is being powered up.

3. This test checks if TECH 2 can communicate with

the OCC control module. If TECH 2 cannot

communicate with the OCC control module, you will

not be able to determine which DTC has been

stored in the OCC control modules memory.

4. Determines which DTC has been stored in the OCC

control modules memory. This test determines if a

DTC was current and has been rectified. An

intermittent problem will cause a DTC to be stored.

5. During this test the OCC control module recalibrates

the air mix doors. An incorrectly calibrated air mix

door will cause incorrect operation of the OCC

system.

6. Che cks accur acy of OCC sensors.

7. During this test, the operation of the air conditioning

section of the OCC system is checked.

Notes On Diagnostic Chart:

1. Refer to Section 0C TECH 2 for connecting and using

TECH 2.

2. Refer to 1.2 TECH 2 TEST MODES AND DISPLAYS

FOR OCC DIAGNOSIS in the MY2003 VY and V2 Series

Service Information for further information on

programming of the OCC control module.

3. OCC sensors can be checked using the following

procedure and should also be checked in the order as

listed:

• In-car Temperature Sensor – connect TECH 2 to the

DLC, select Body / Occupant Climate Control / Data

Display / Data List / In Car Temperature Sensor.

• Ambient Temperature Sensor – connect TECH 2 to the

DLC, select Body / Occupant Climate Control / Data

Display / Data List / Ambient Temperature Sensor.

• Sun Load Sensor (Sun Sensor/Remote Receiver) –

refer to DTC 19 diagnostic chart in this Section for a

procedure on checking this sensor.

• Evaporative Sensor – connect TECH 2 to the DLC,

select Body / Occupant Climate Control / Data Display /

Data List / Evap Temperature Sensor.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–17

20–FEB–2003 Page 2F-17

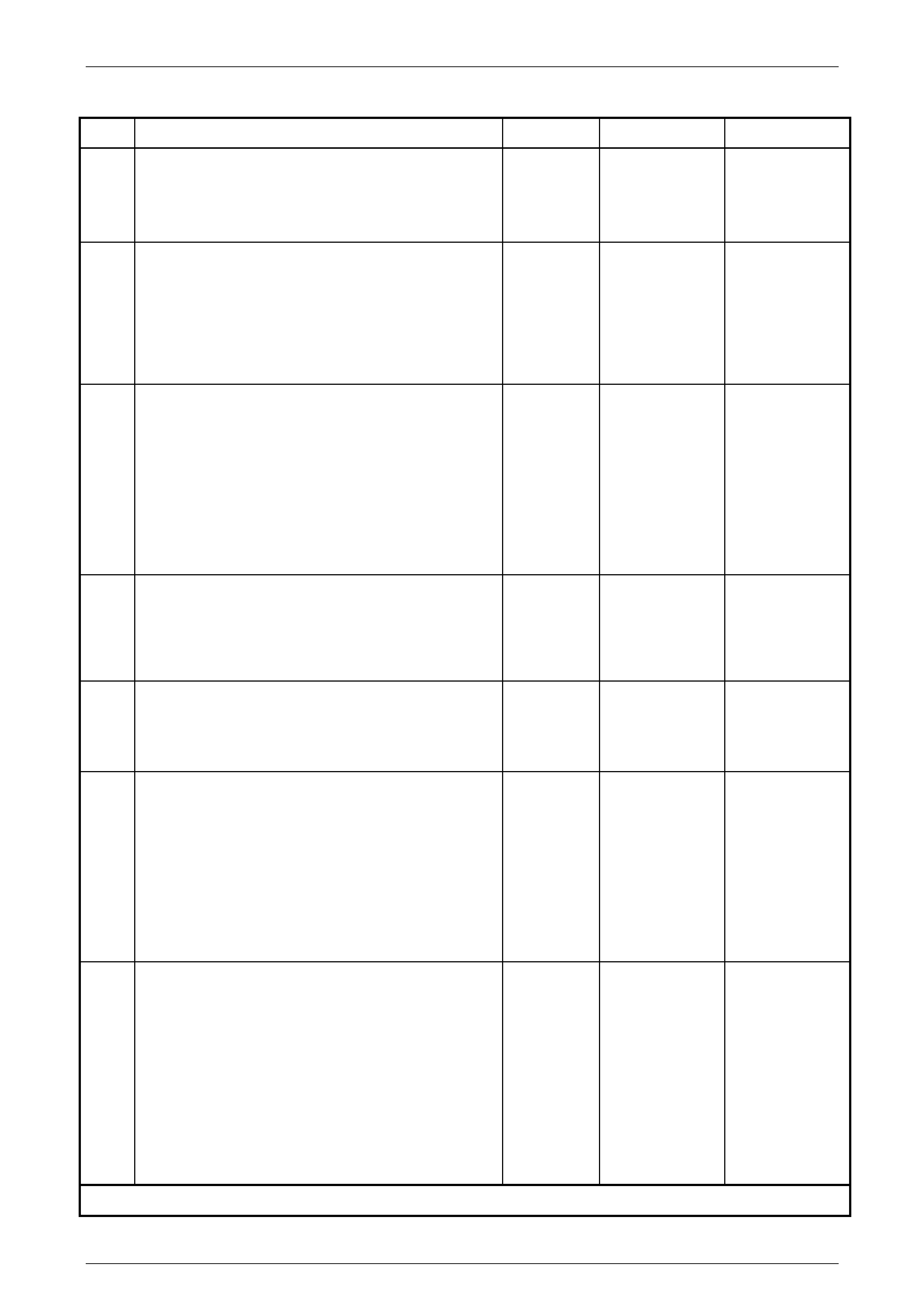

Chart A – Diagnostic Circuit Check

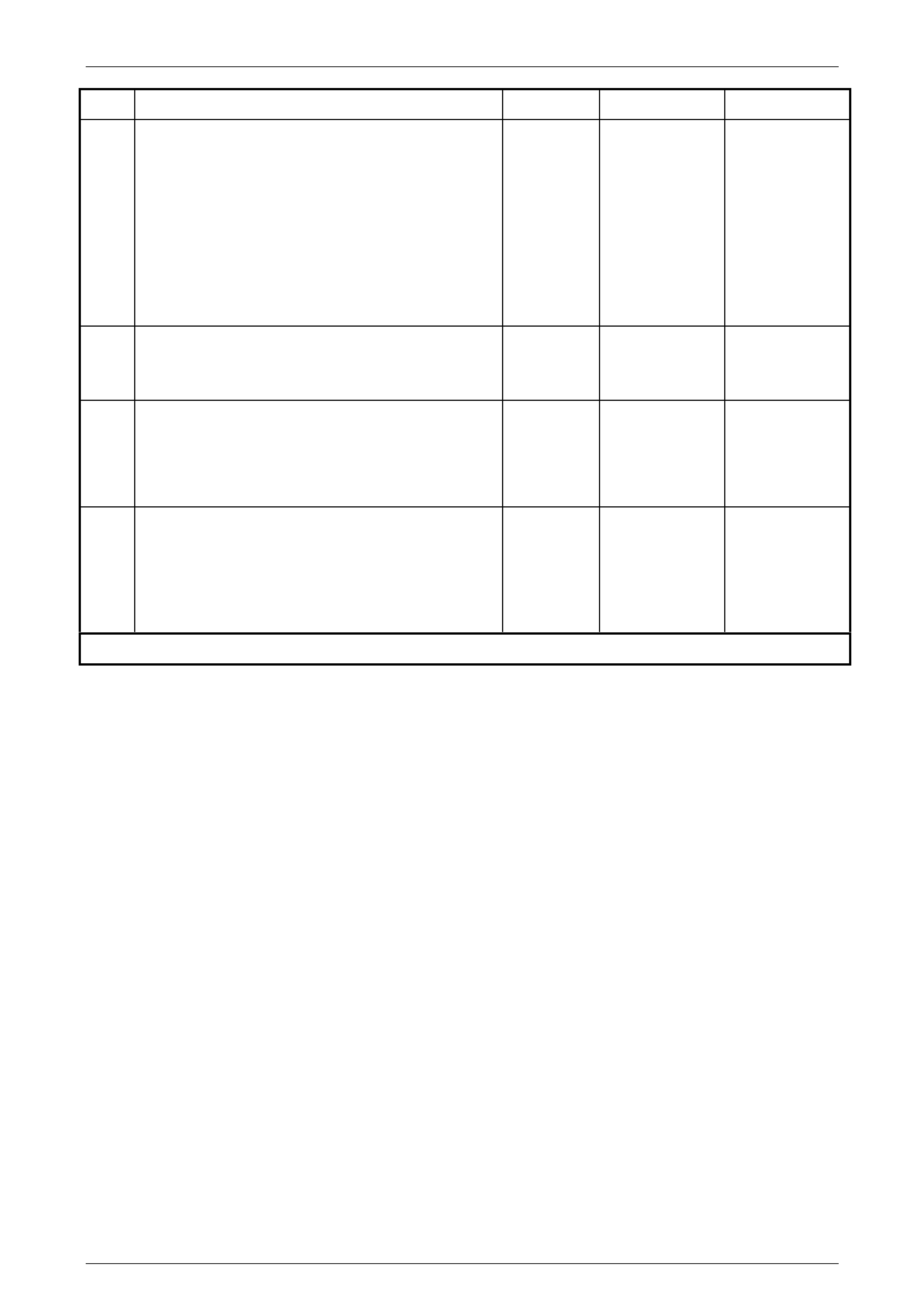

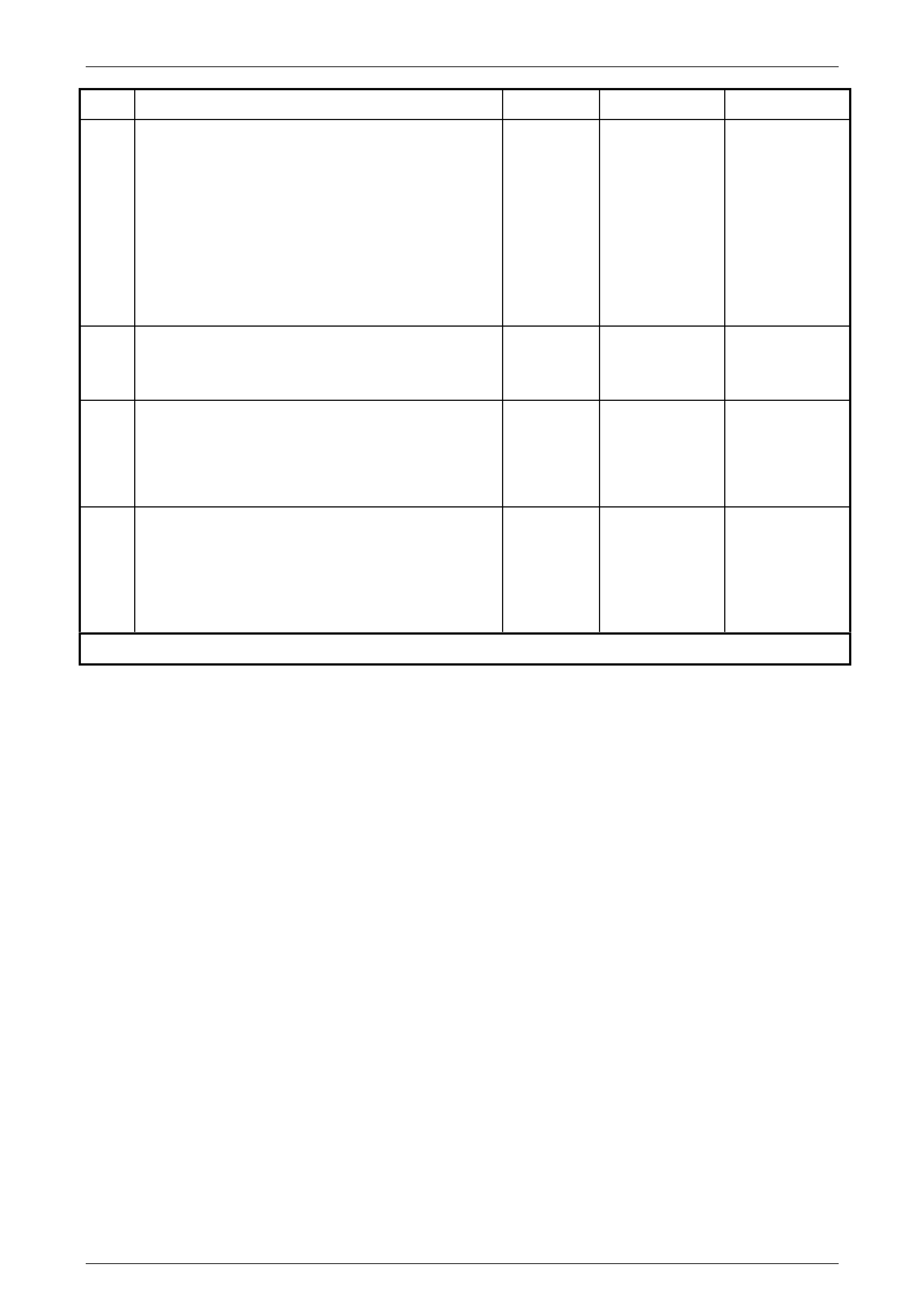

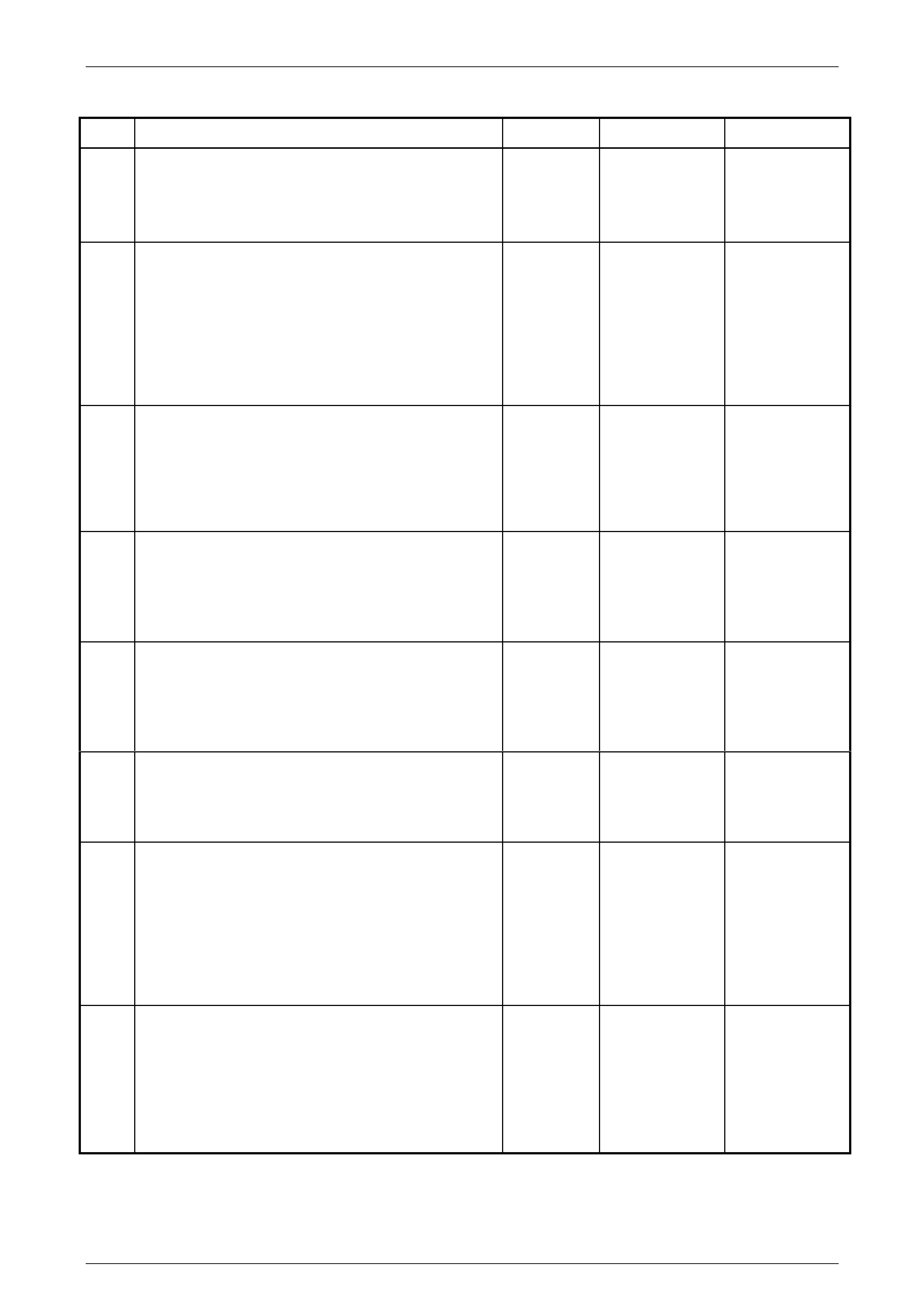

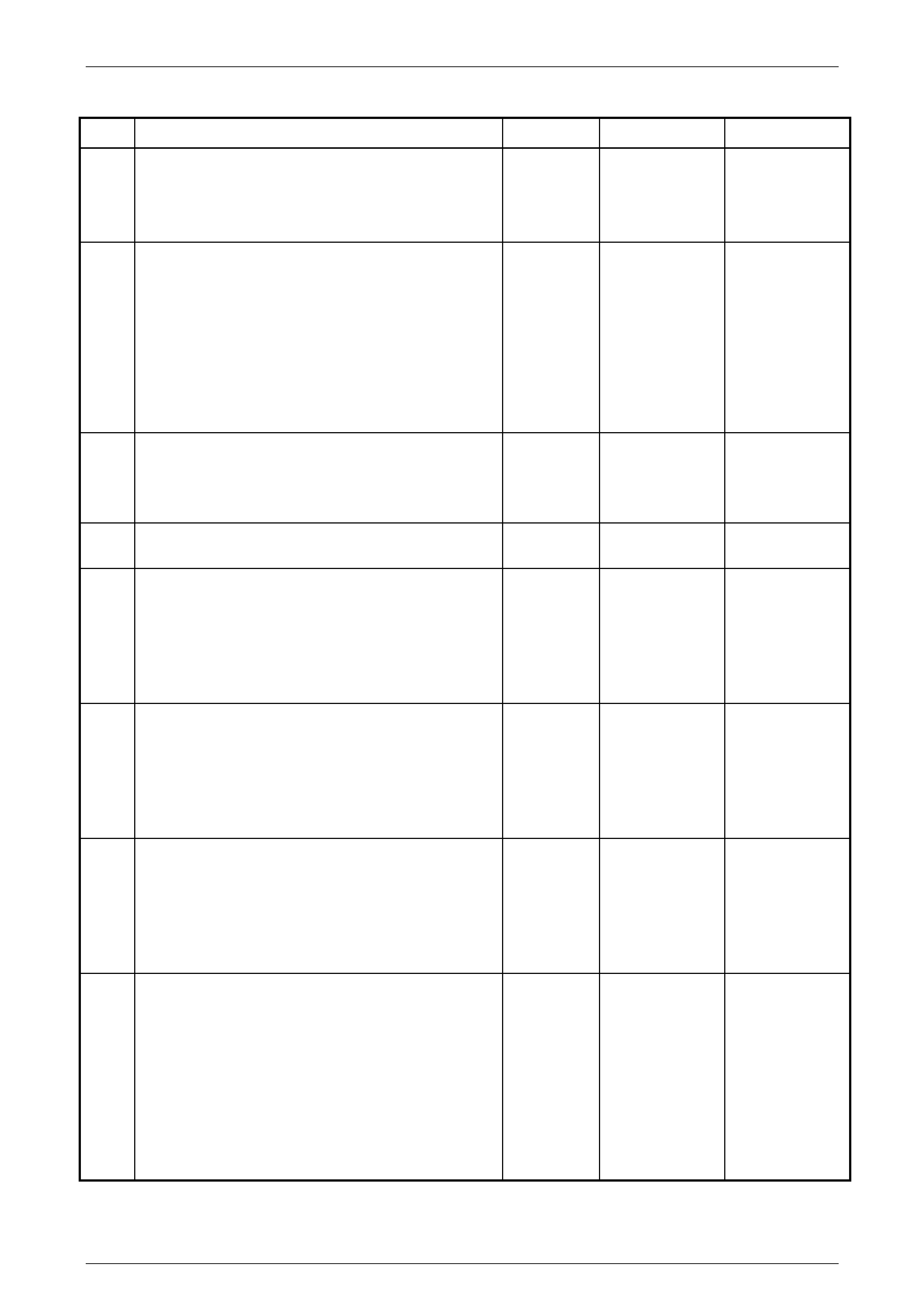

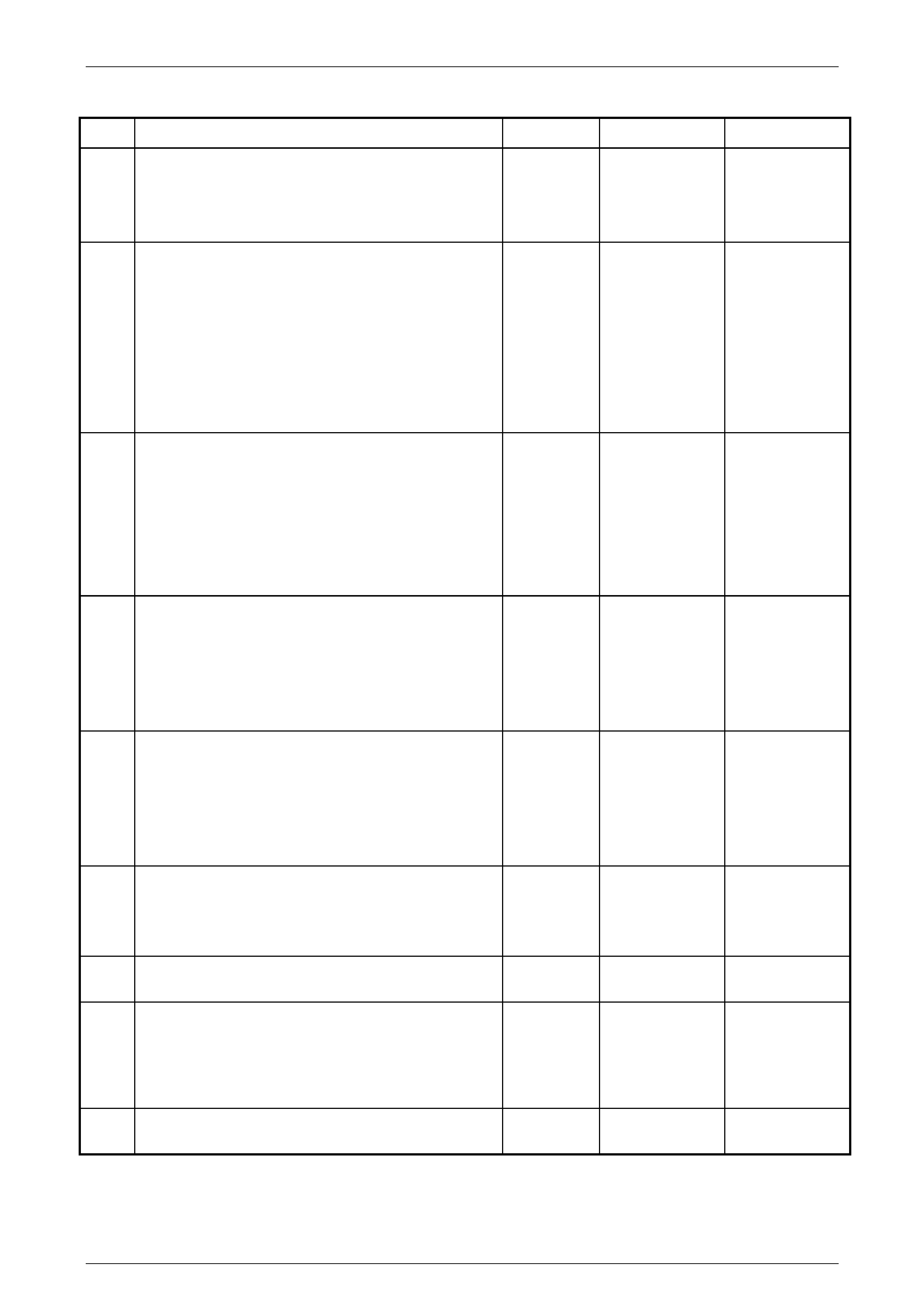

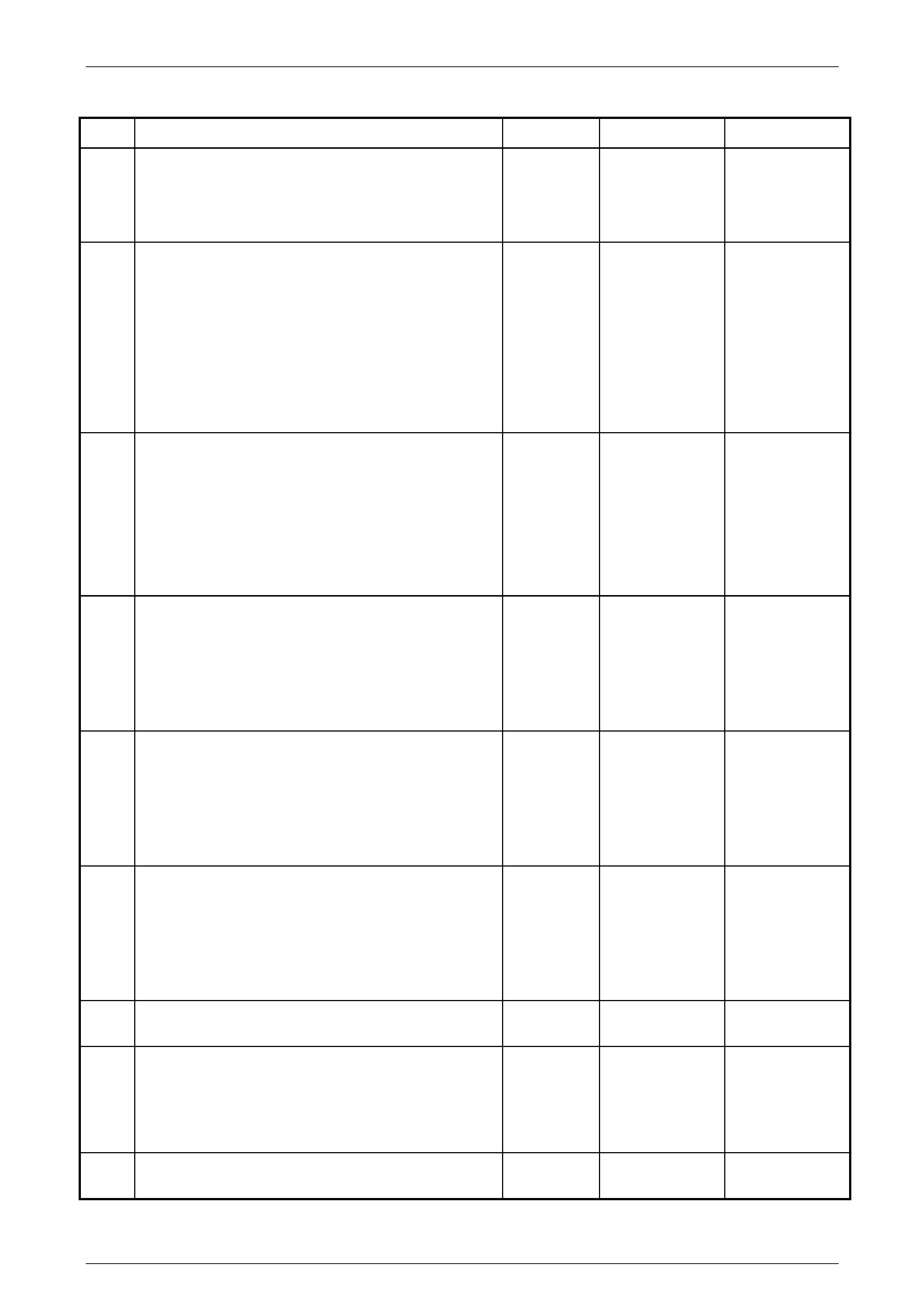

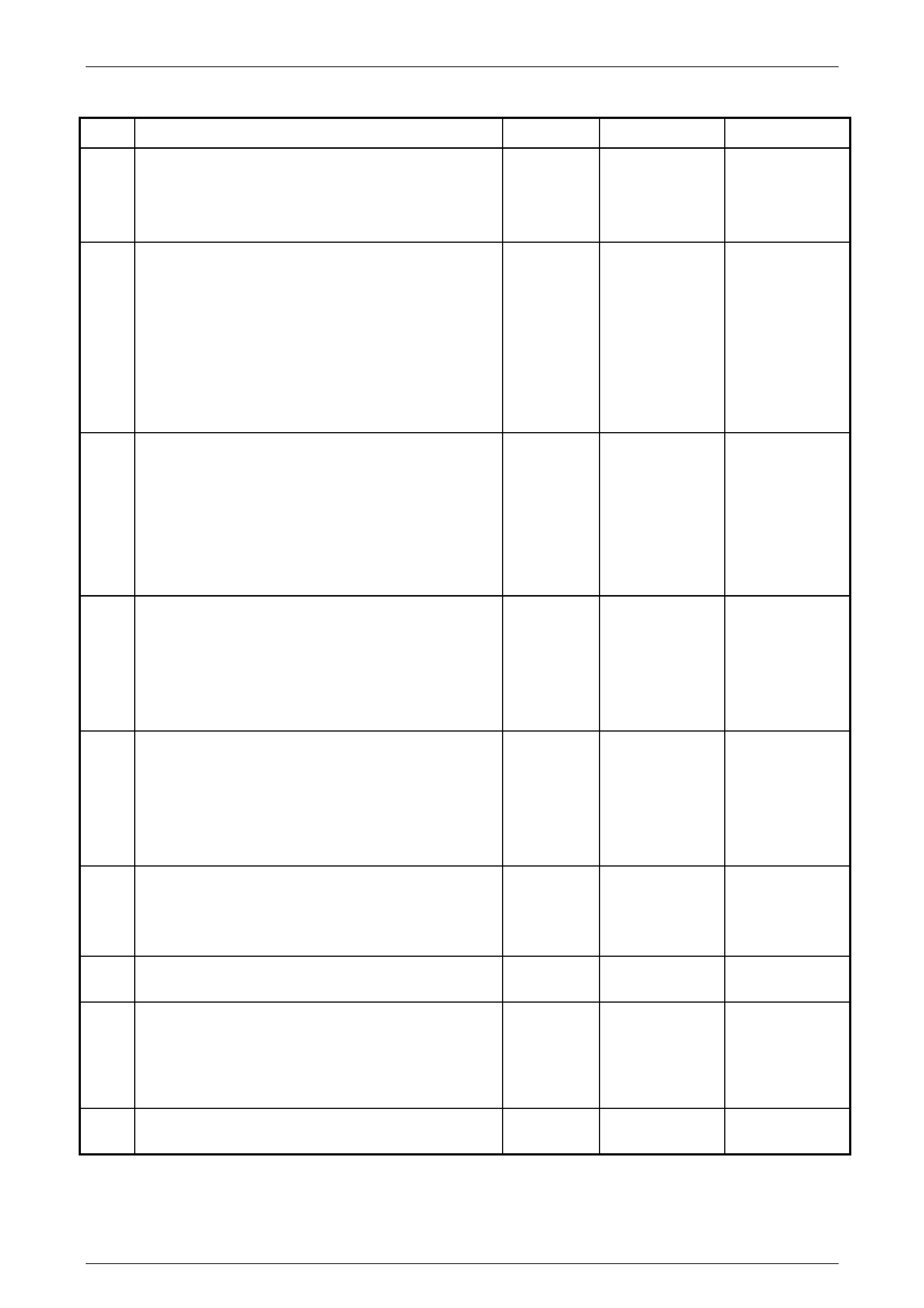

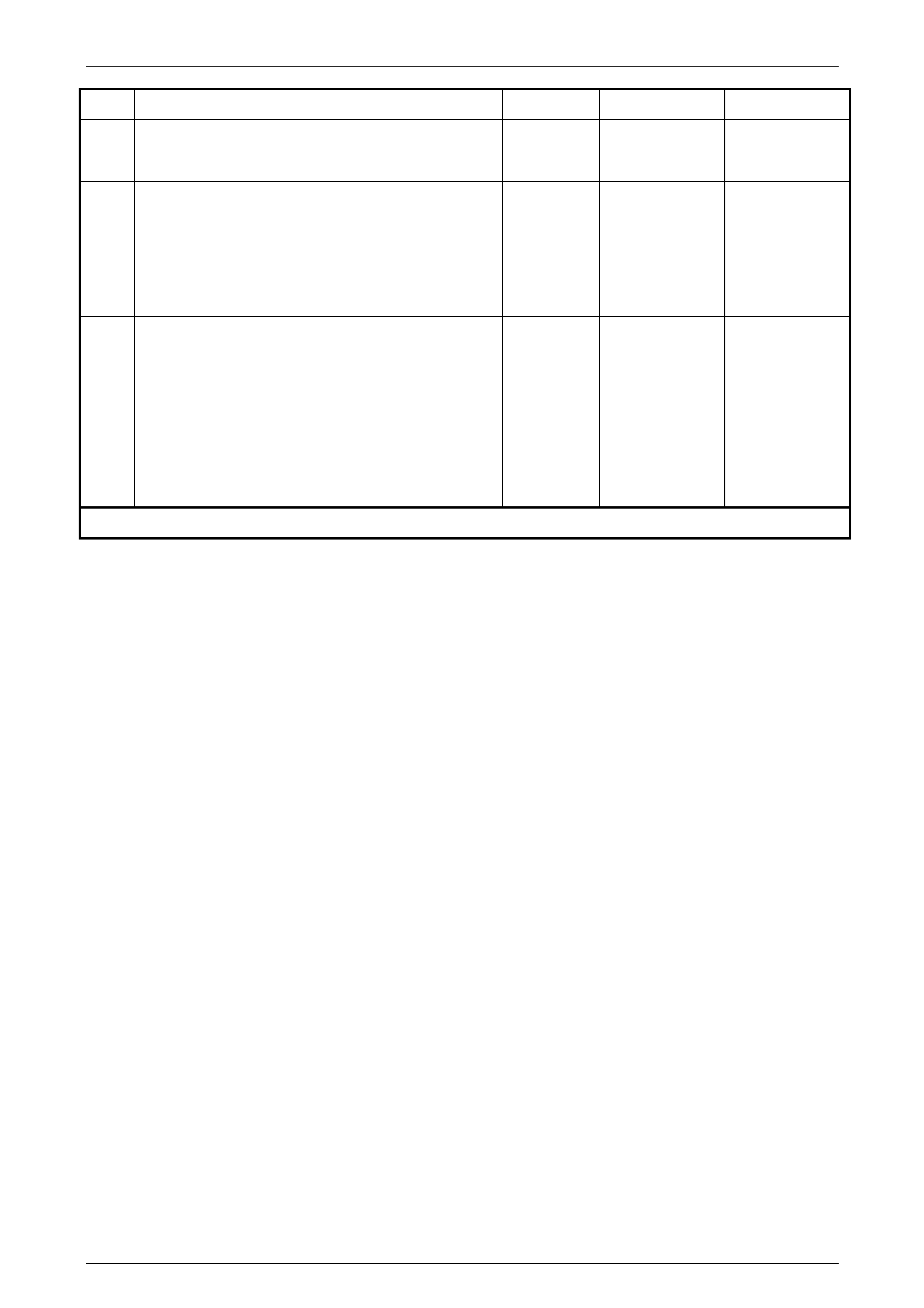

STEP ACTION VALUE YES NO

1 Turn the ignition on.

Turn on OCC system.

Does MFD screen activate to display HVAC settings?

Go to Step 2. Go to Chart B –

OCC SYSTEM

DOES NOT

POWER UP in

this Section.

2 Connect TECH 2 to the DLC. (Refer to Notes on

Diagnostic Chart for this chart, Note 1.)

Turn the ignition on.

Push power button on TECH 2.

Does TECH 2 power up?

Go to Step 3. Go to TECH 2

diagnosis. Refer

to Section 0C,

TECH 2.

3 With TECH 2 connected, select Diagnostics / Model

Year / Vehicle Model / Body / Occupant Climate Control.

Does TECH 2 display OCC System Identification Screen

information (i.e. part number etc.)?

Go to Step 4. Go to BCM Serial

Data

Communication

diagnostics. Refer

to Section 12J,

4.2 SERIAL DATA

COMM UNICN

(BU S MAST ER)

in the MY2003

VY and V2

Series Service

Information.

4 With TECH 2 connected and the ignition on, select

Diagnostic Trouble Codes / Read DTC Information.

Does TECH 2 display any DTCs?

Go to applicable

DTC Chart in this

Section.

Go to Step 6.

5 With TECH 2 connected, the ignition on and OCC

system selected, select Program / Calibrate Air Mix Door

/ Calibrate.

Does TECH 2 display a value greater than 5%?

OCC air mix

doors have been

recalibrated.

Refer to DTC 48

to DTC 50 as

applicable, in this

Section.

6 Check the accuracy of the OCC sensors. (Refer to

3. ELECTRICAL COMPONEN T TESTS in this Section.)

Are the OCC sensors OK?

Go to Step 7. Replace the

faulty OCC

sensor, refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

7 Perform the DELPHI V5 and V7 compressor and TXV

system diagnosis. Refer to Section 2C, 4. DELPHI V5

AND V7 COMPRESSOR AND TXV SYSTEM

DIAGNOSTICS.

Does the system pass the diagnosis test?

No fault found

with OCC

system. System

Code Index may

need to be

Programmed.

Refer to

F1:PROGRAM

CODE INDEX in

this Section 2F,

1.2 TECH 2

TEST MODES

AND DISPLAYS

FOR OCC

DIAGNOSIS in

the MY2003 VY

and V2 Series

Service

Information.

Carry out repair

procedure as

detailed in Delph i

V5 and V7

Compressor TXV

System

Diagnosis. Refer

to Section 2C,

HVAC CLIMATE

CONTROL

(MANUAL A/C) –

SERVICING &

DIAGNOSIS in

the MY2003 VY

and V2 Series

Service

Information.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–18

20–FEB–2003 Page 2F-18

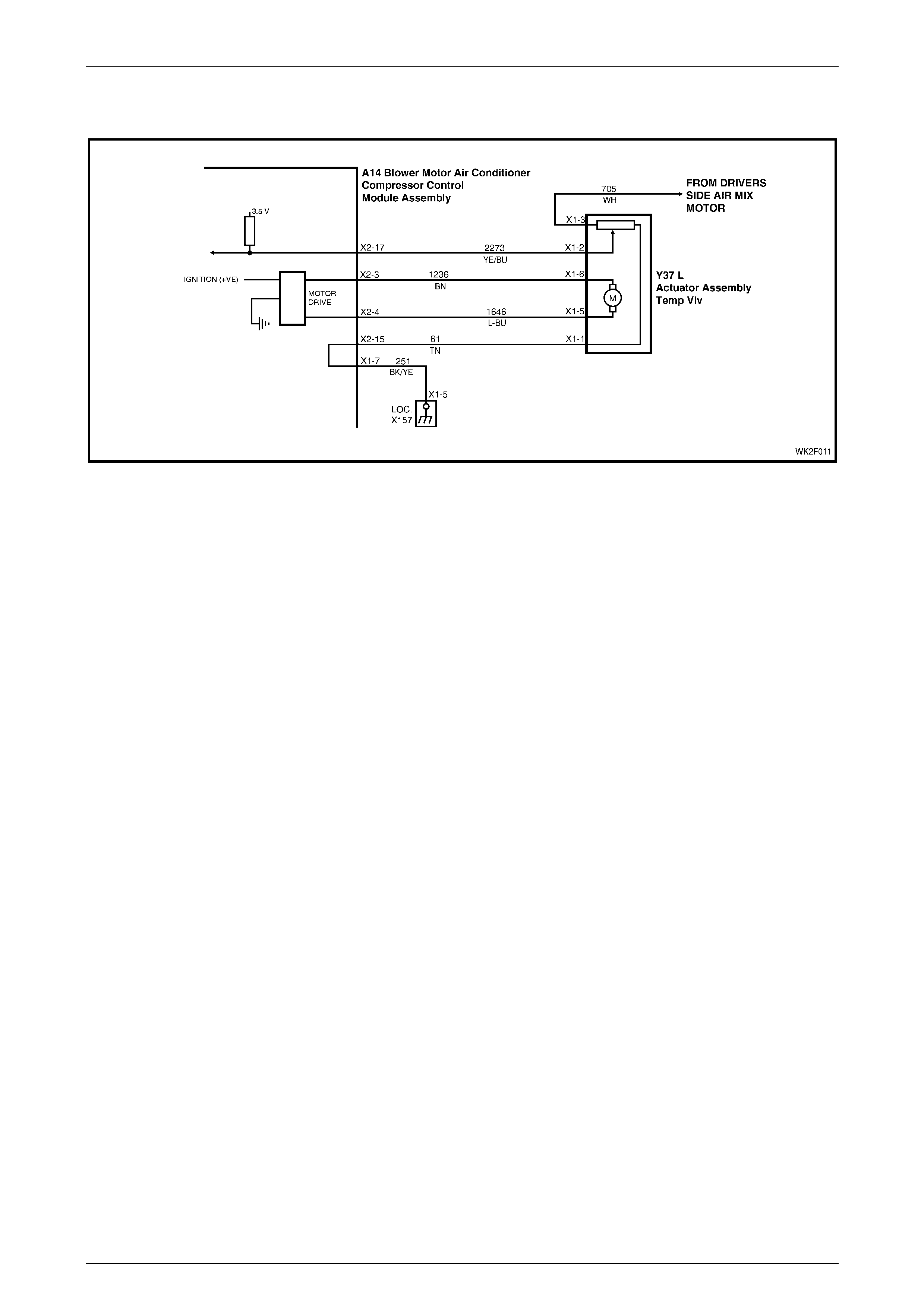

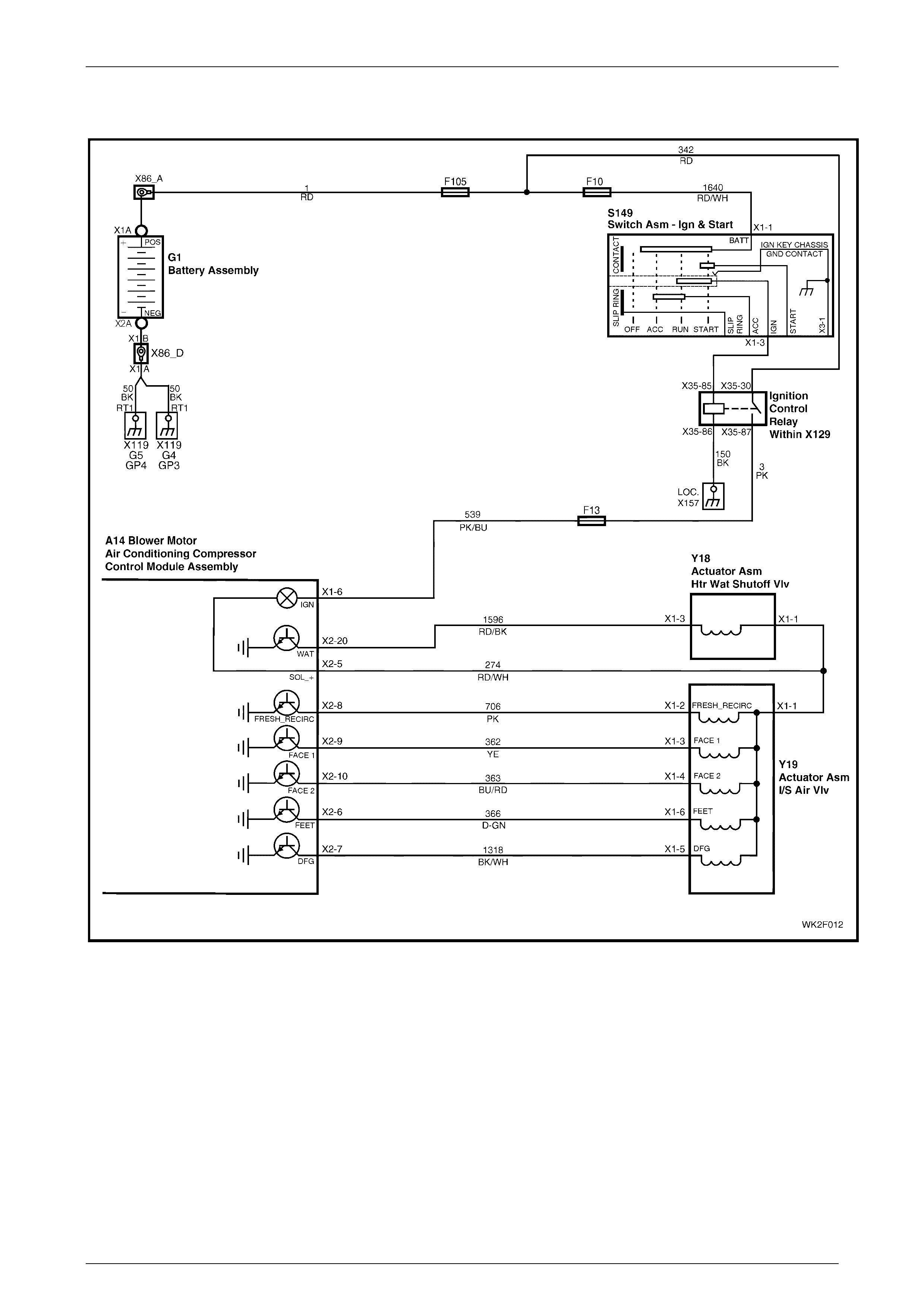

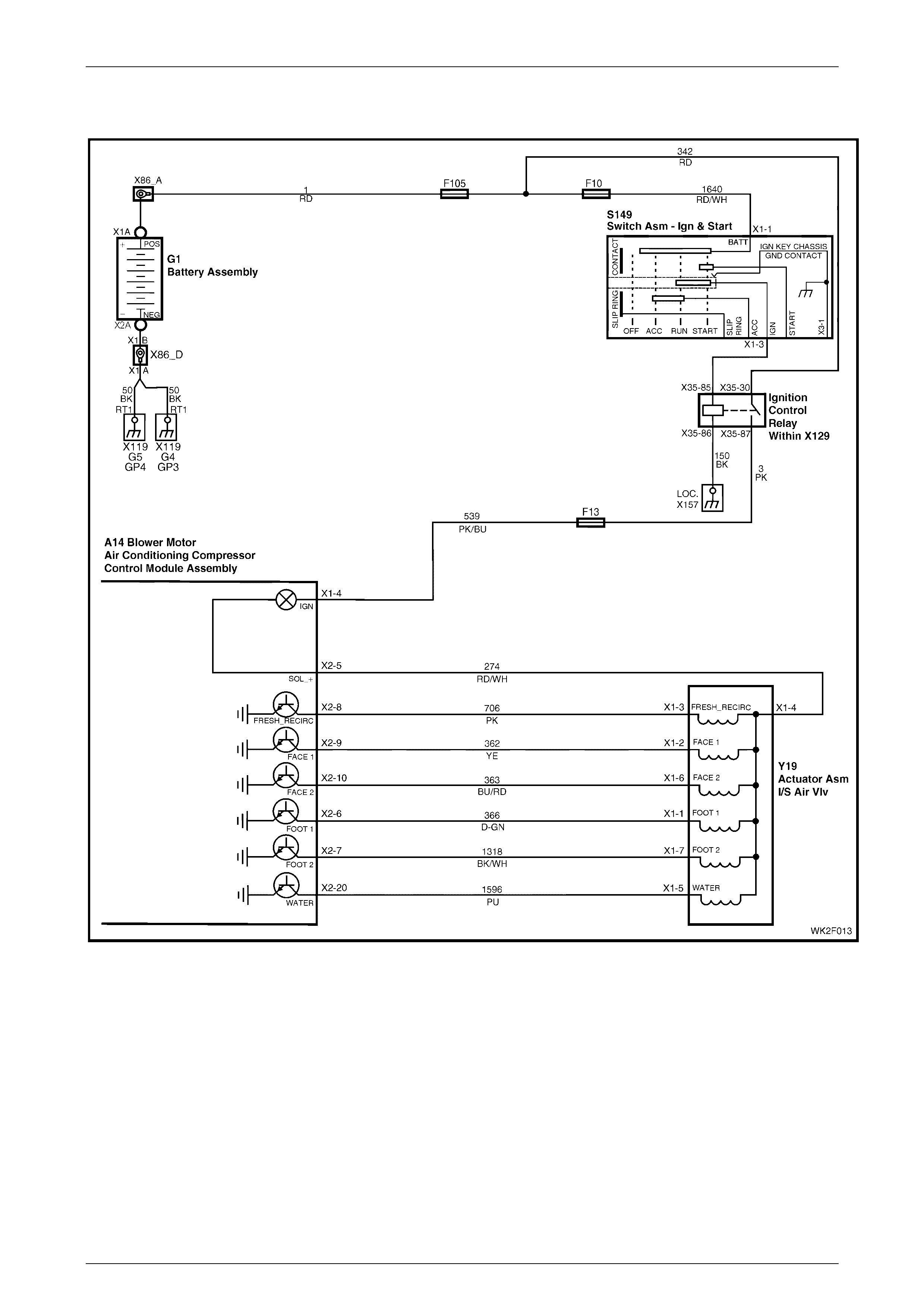

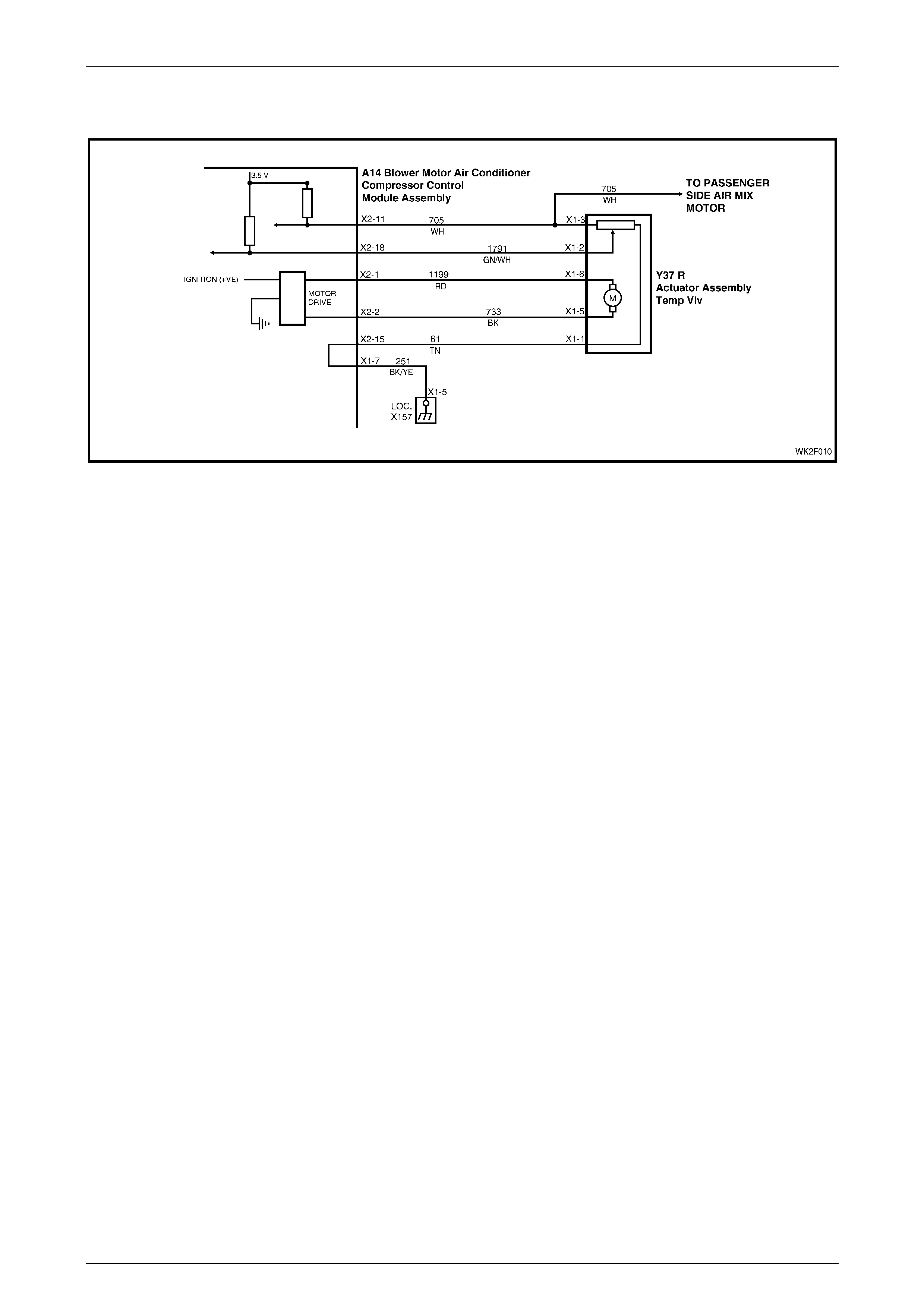

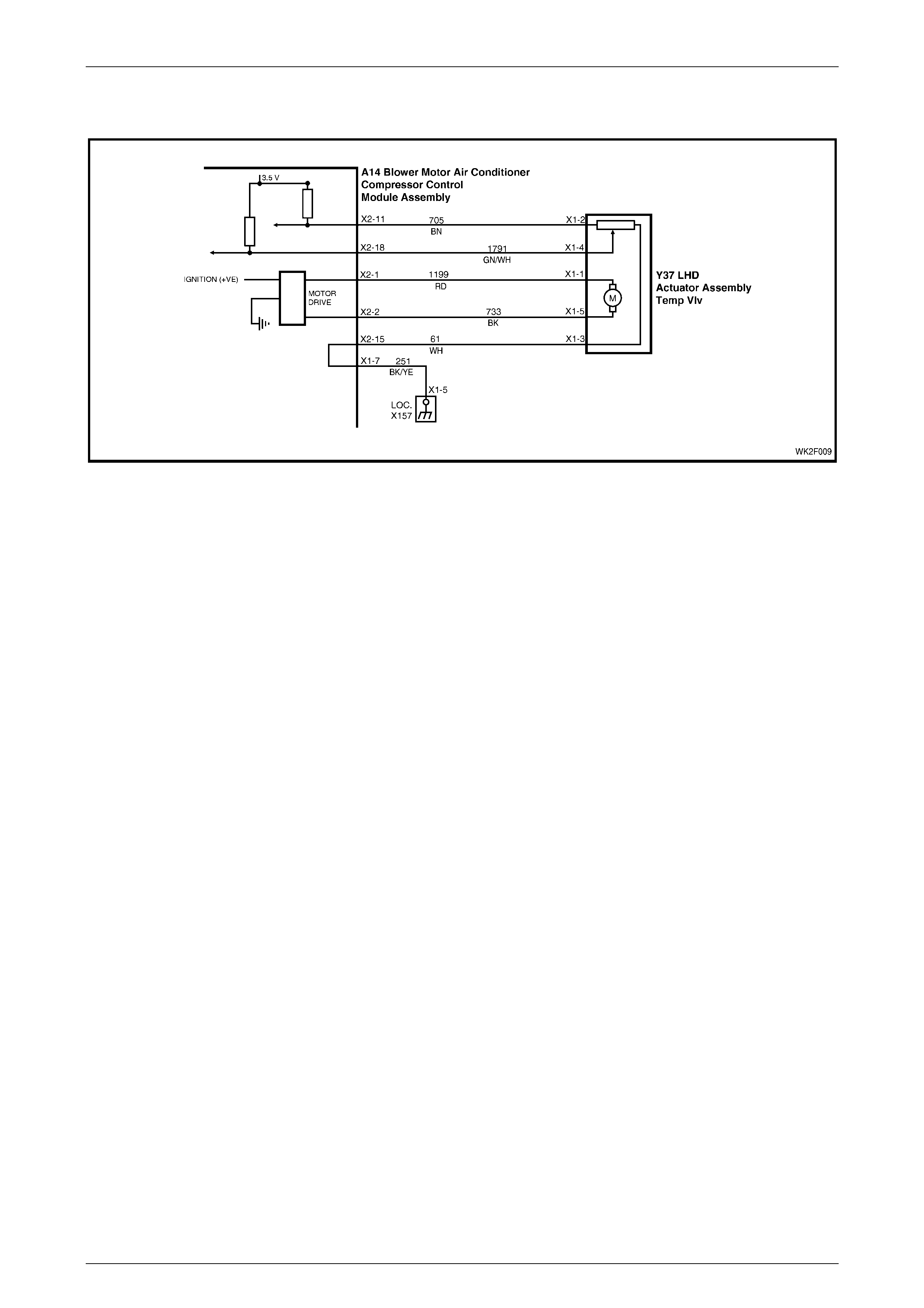

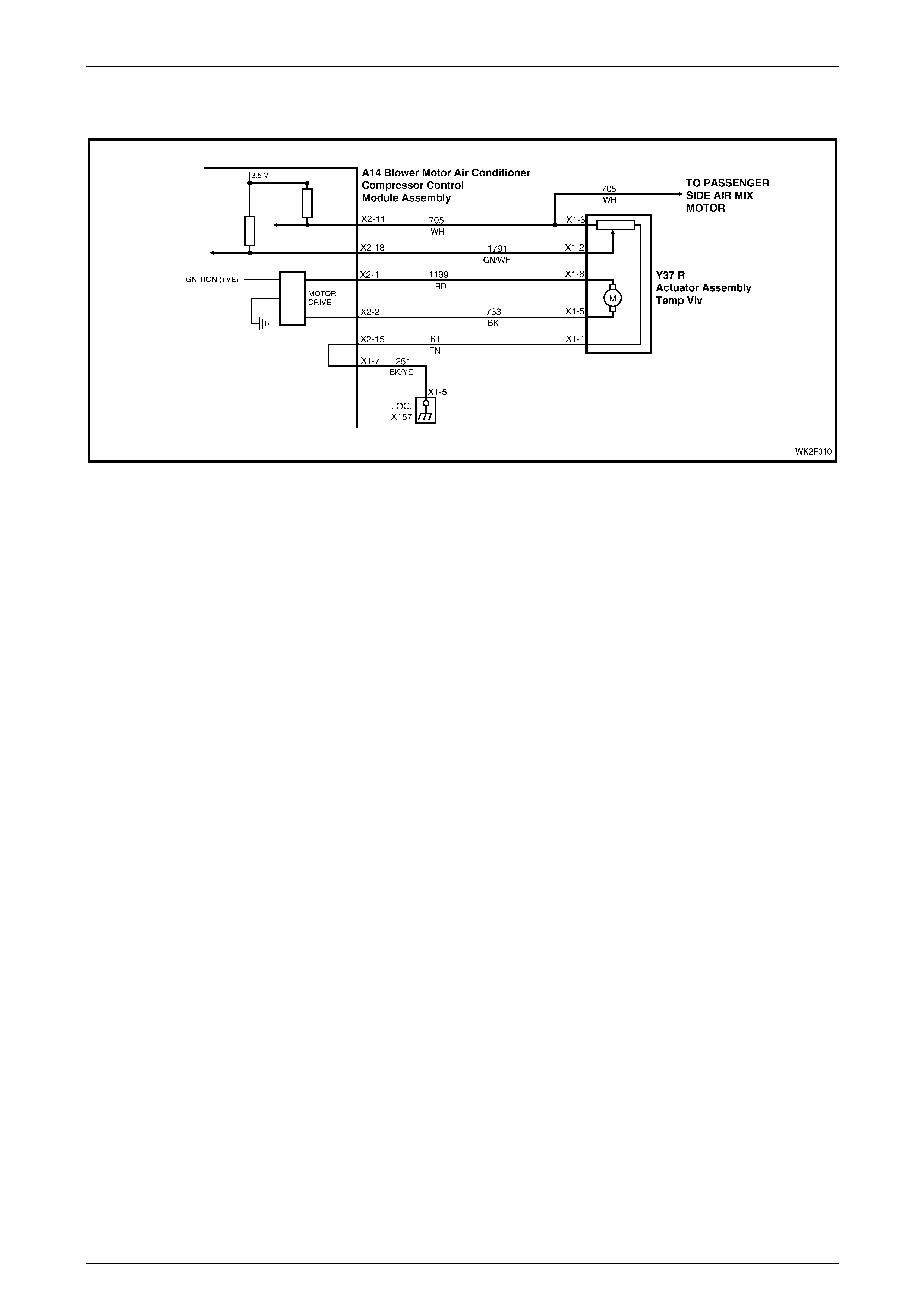

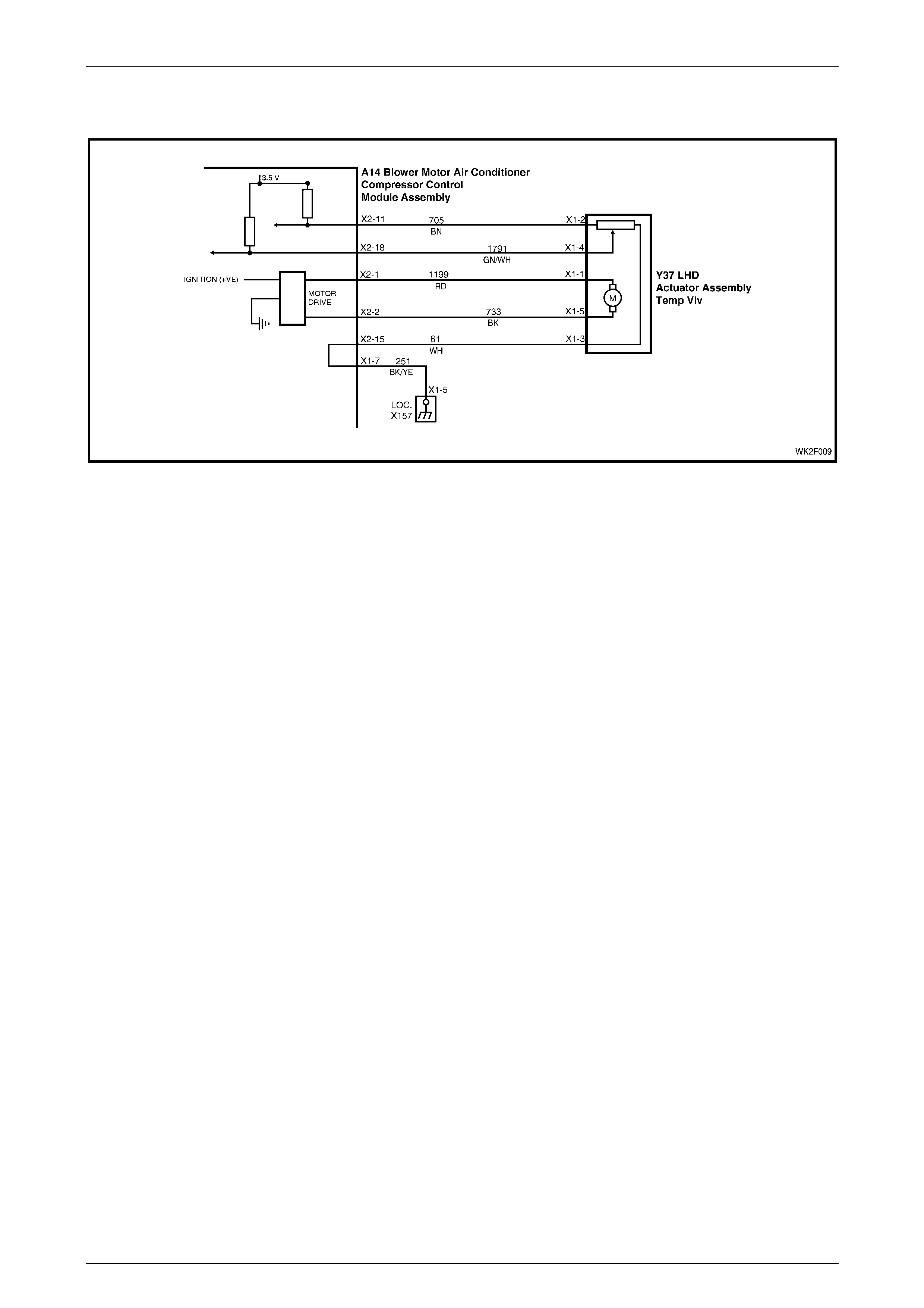

Chart B – OCC System Does Not Power Up

Figure 2F – 10

Circuit Description

Battery power is supplied to the OCC control module, terminal X1-6, with the ignition switch in the ignition or start

positions through fuse F13 (located in the passenger compartment fuse panel).

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–19

20–FEB–2003 Page 2F-19

Test Description:

The numbers below refer to Step numbers in diagnostic

chart B:

1. The diagnostic circuit test is the beginning of all

diagnostics and should be performed whenever

diagnosing an OCC system complaint.

2. This test checks if the fuse F13 is OK.

3. This test determines if power is being supplied to

fuse F13.

4. This test determines if the OCC control module has

a power supply and a ground. If the OCC control

module has pow er and ground and the module is not

being activated when the ignition and the OCC

system is turned on.

5. If battery voltage was not available during Step 4,

this test determines if the power supply circuit 539 to

the OCC control module has continuity.

6. If battery voltage was not available during Step 4,

this test determines if the ground circuit 251 to the

OCC control module has continuity.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–20

20–FEB–2003 Page 2F-20

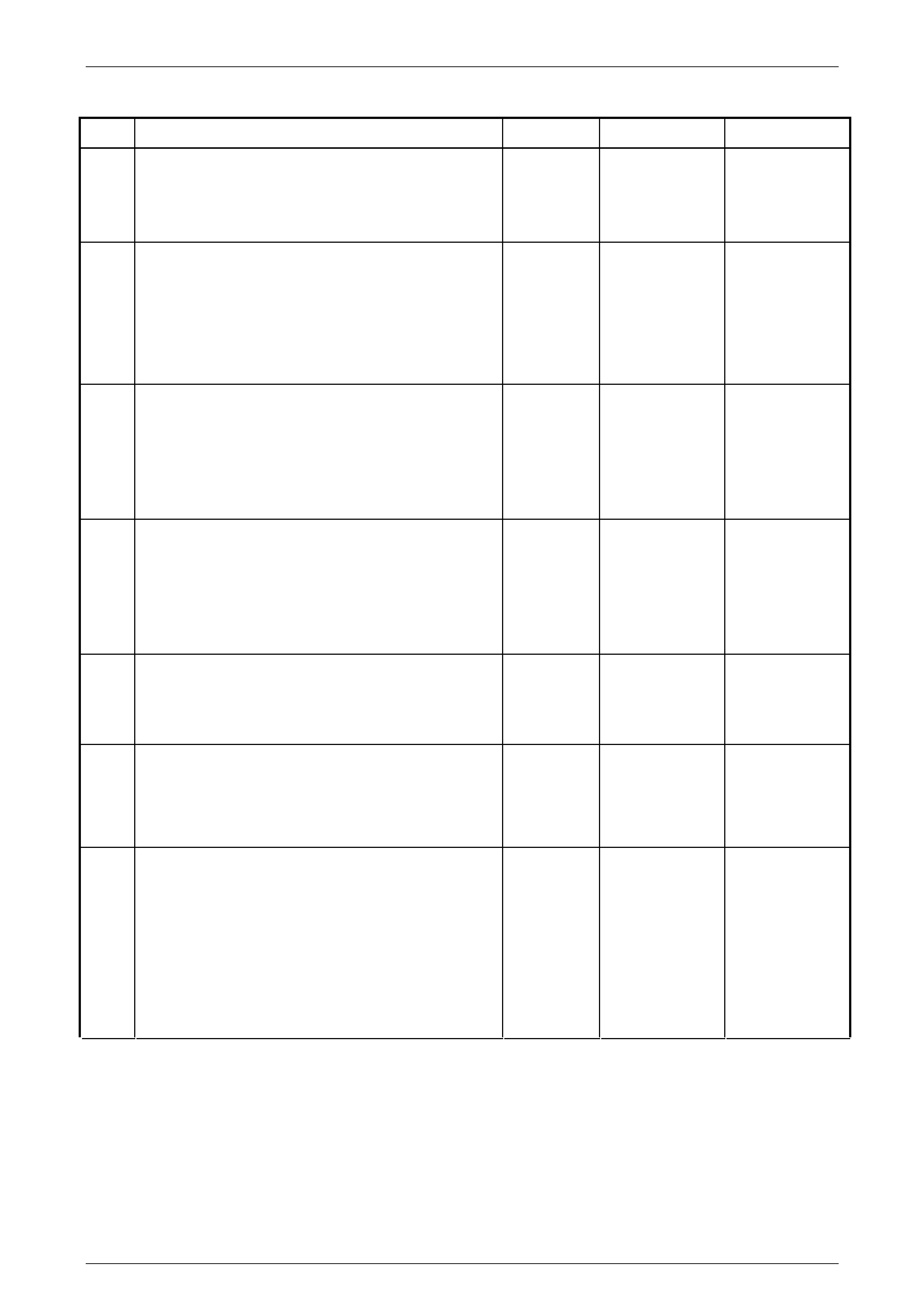

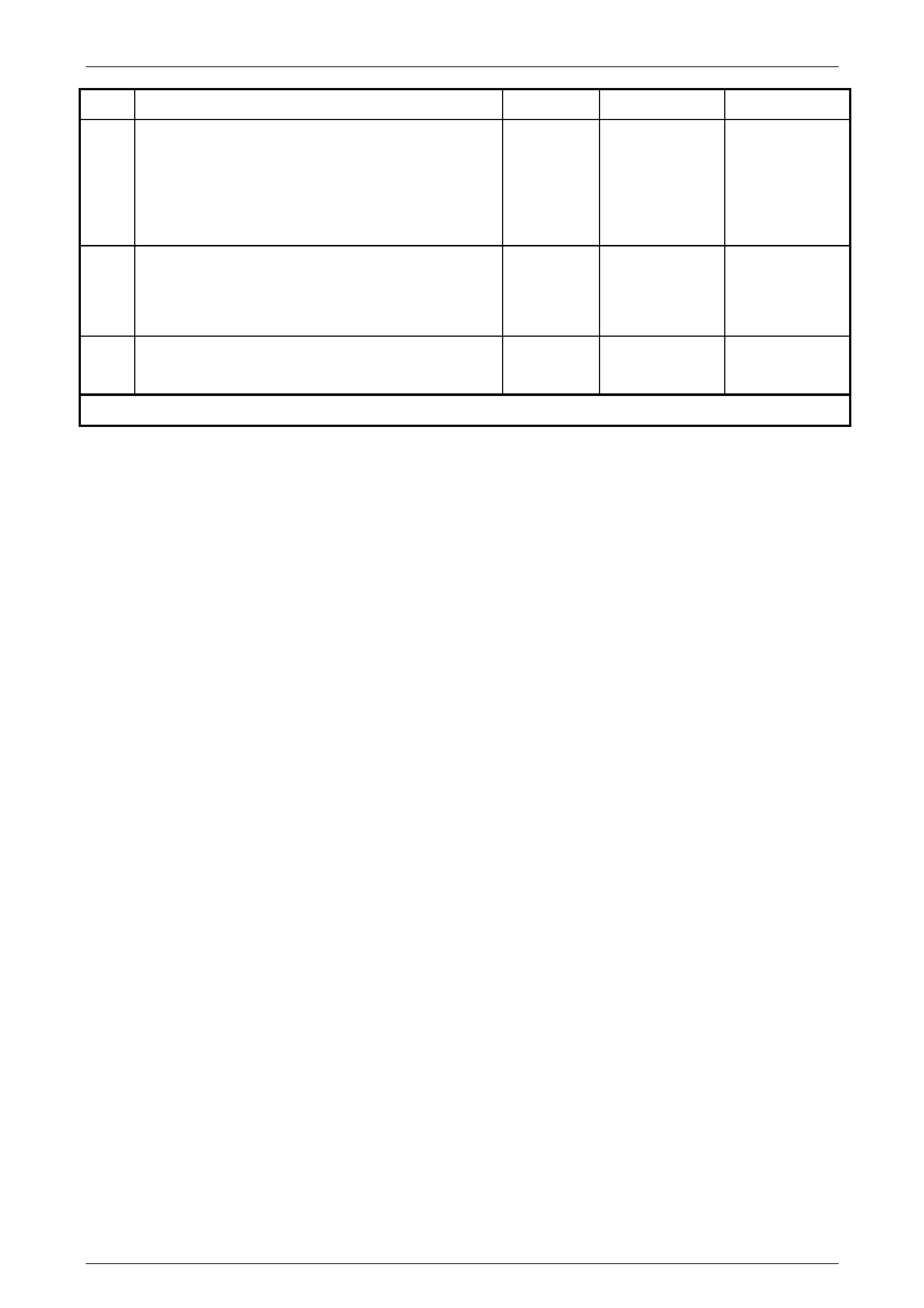

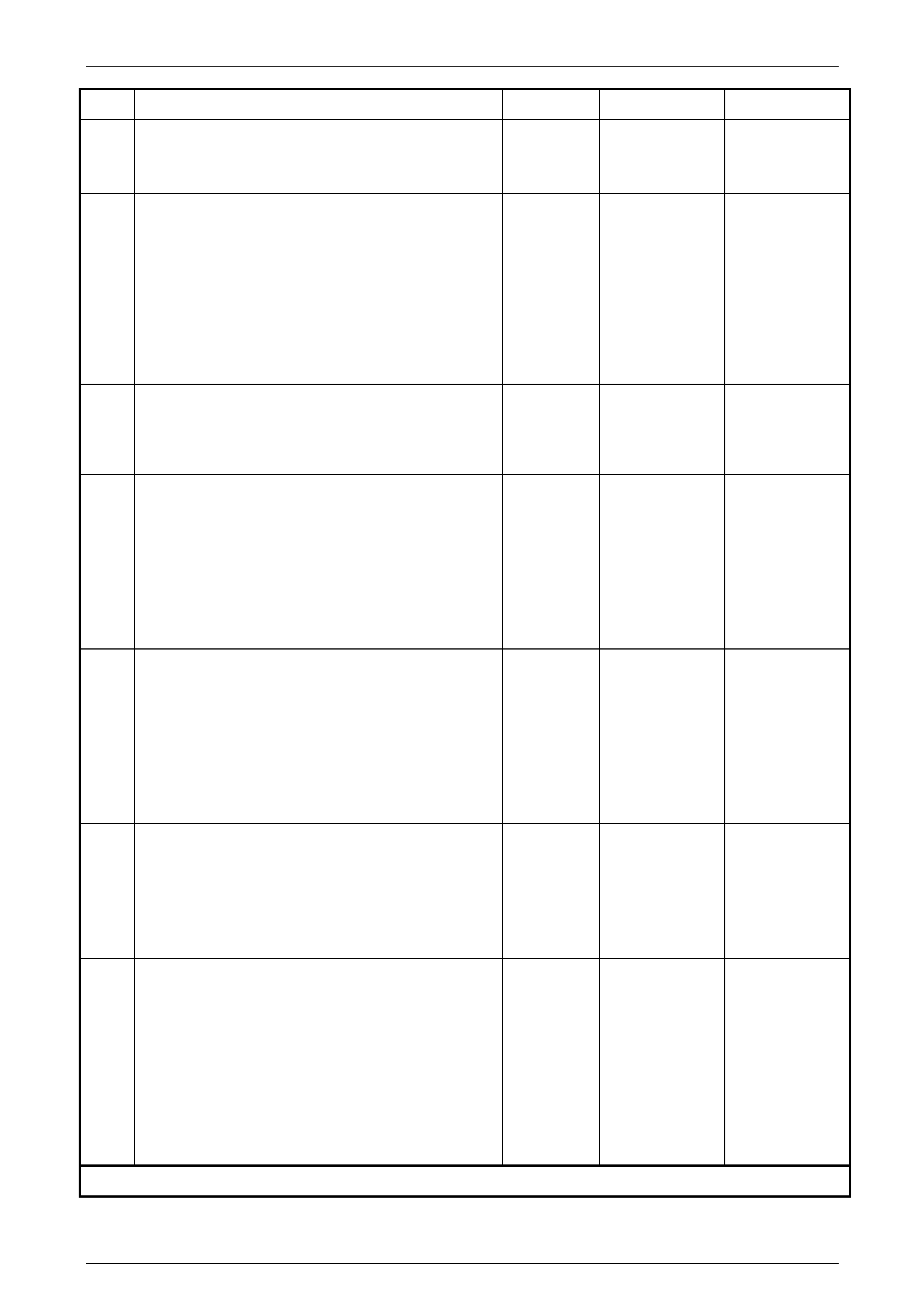

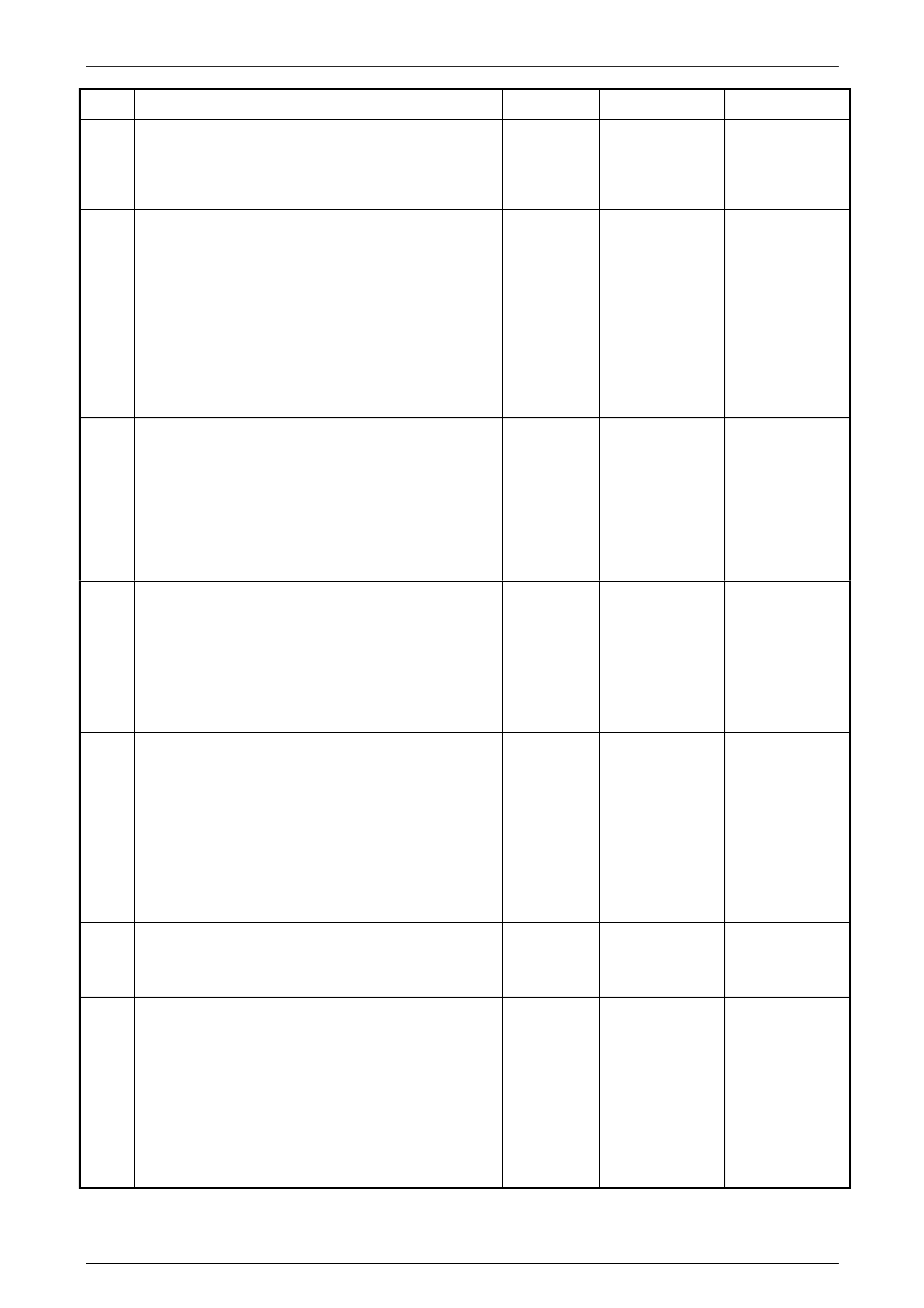

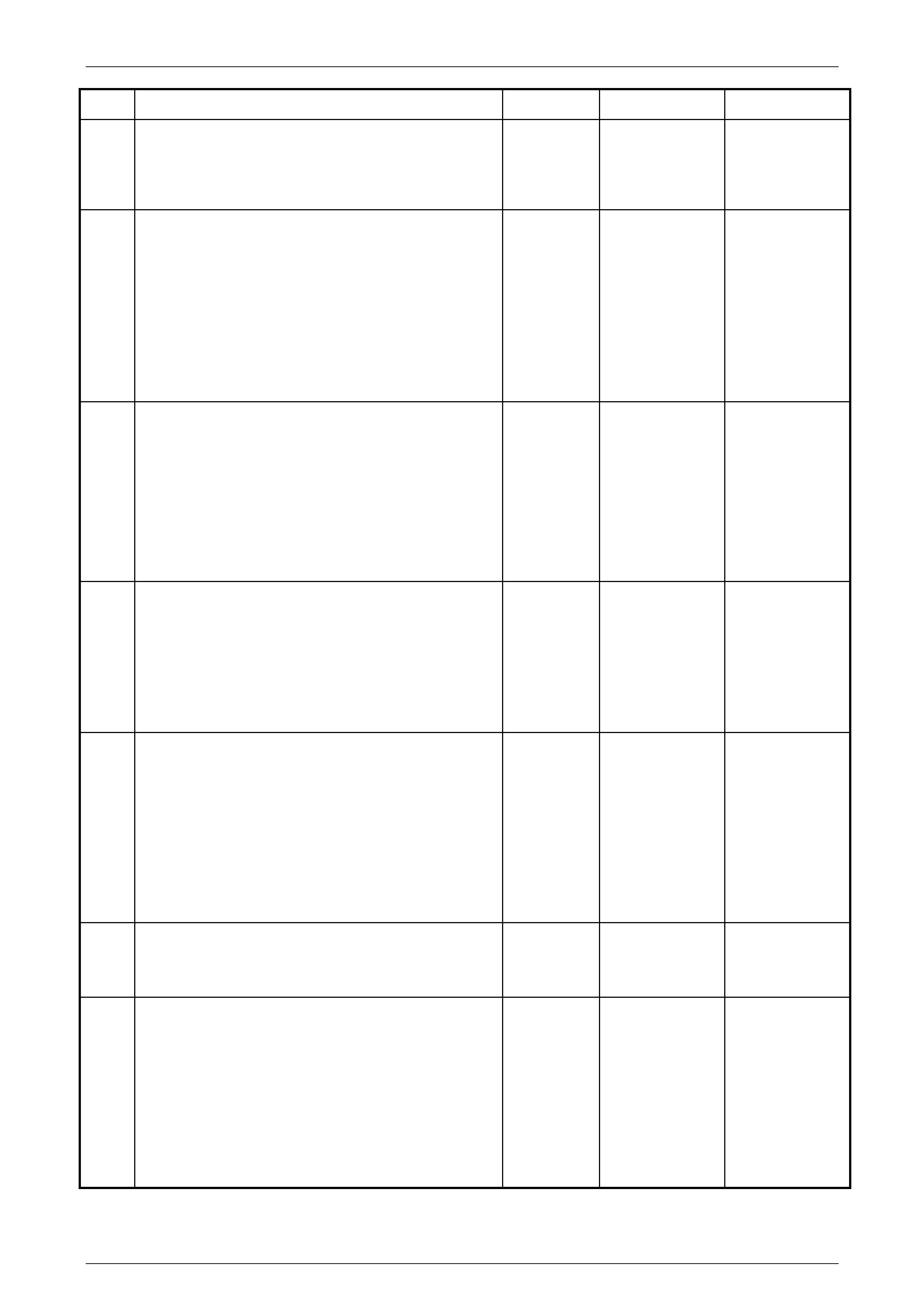

Chart B – OCC System Does Not Power Up Diagnostic Chart

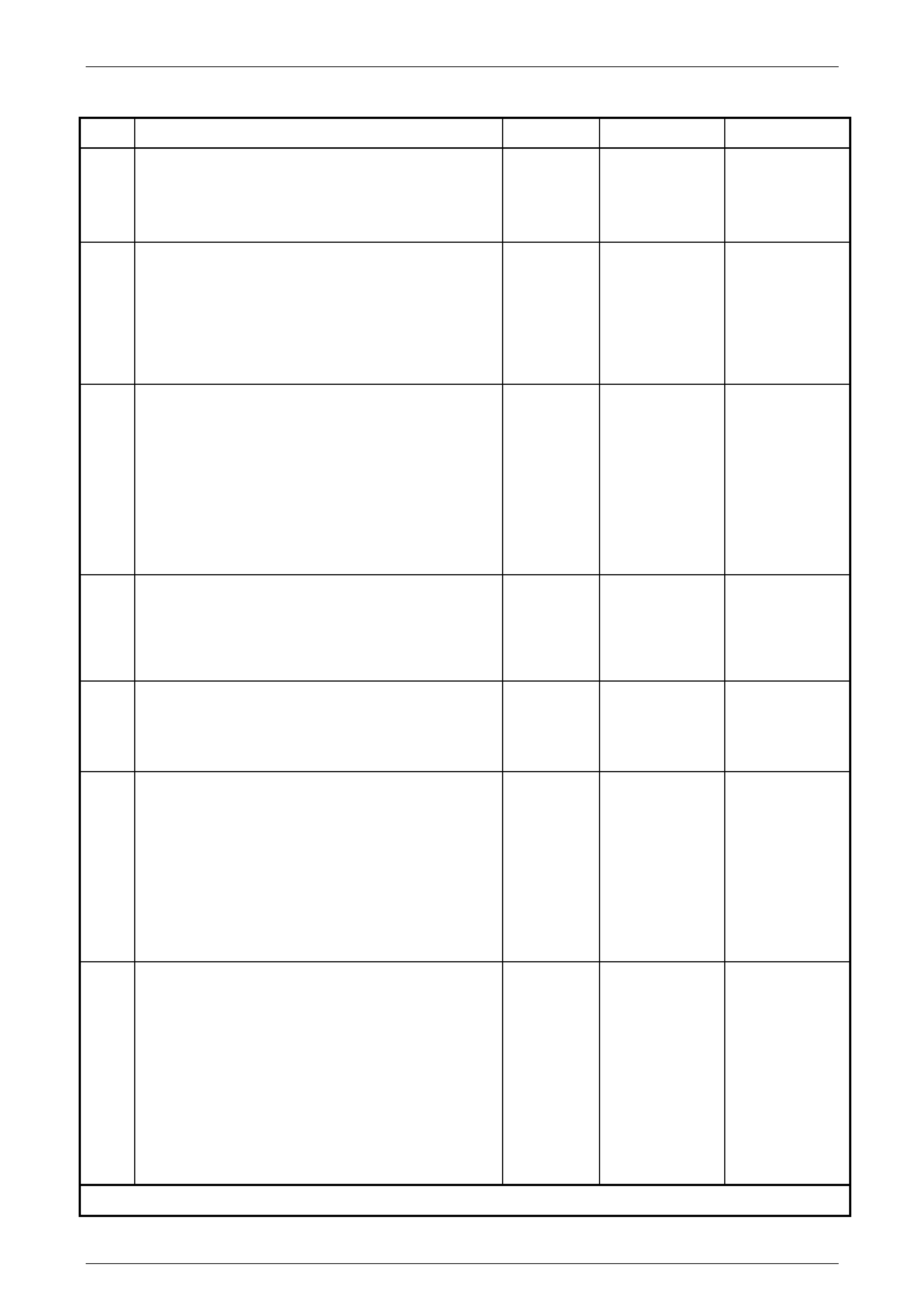

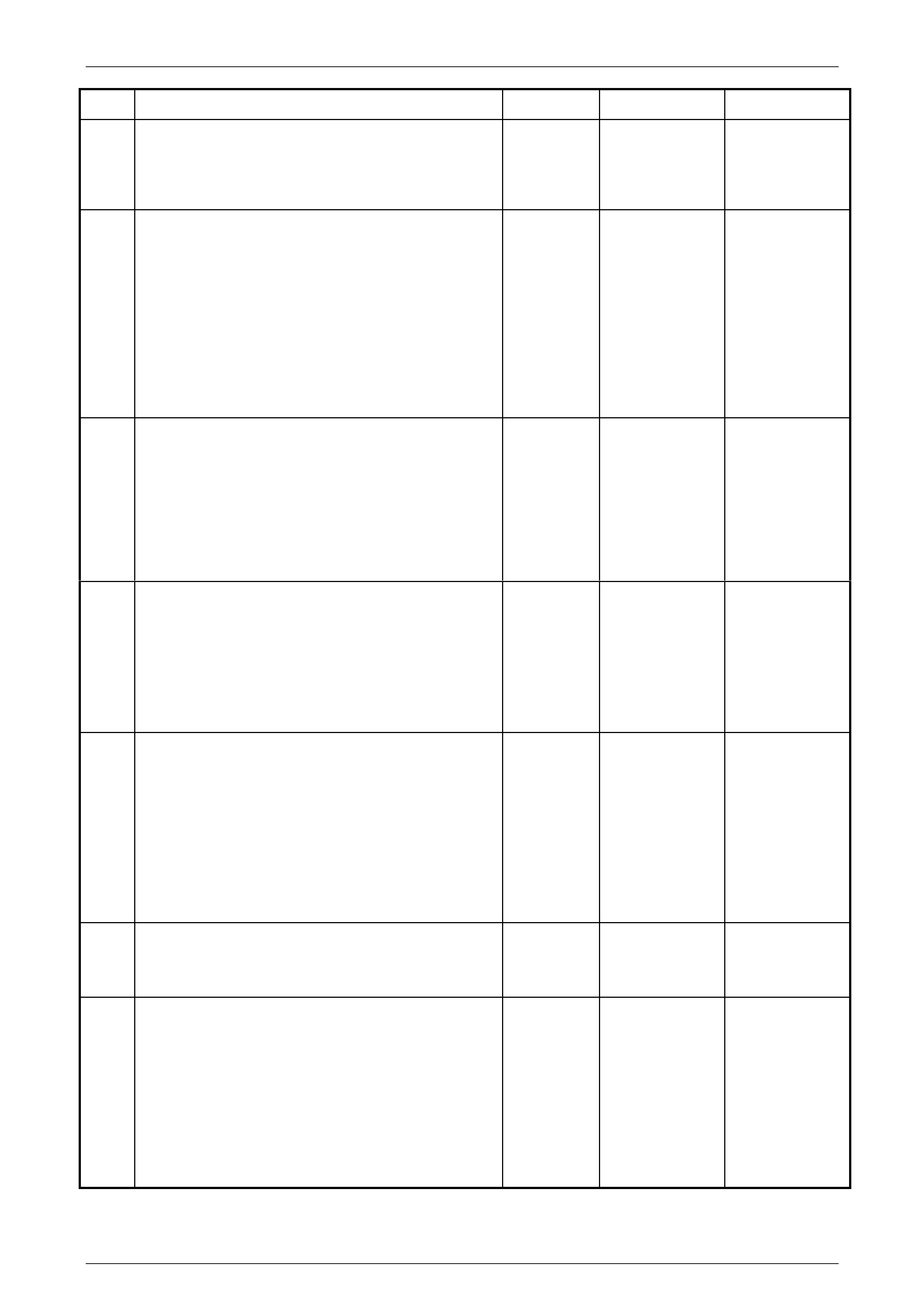

STEP ACTION VALUE YES NO

1 Has the Diagnostic Circuit Check been performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Check fuse F13.

Is the fuse OK?

Go to Step 3. Check for cause

of blown fuse

and replace the

fuse.

3 Turn the ignition on.

Back-probe fuse F13, circuit 3 with a voltmeter to

ground. (Refer to Notes on Diagnostic Chart for this

chart, Note 1.)

Is the value as specified?

Battery

voltage Go to Step 4. Repair faulty

circuit 3.

4 Remove the OCC control module. (Refer to Section 2E,

OCCUPANT CLIMATE CON T ROL (AUTO A/C)

REMOVAL AND INSTALLATION.)

Turn the ignition on.

Probe between OCC control module (A14) connector

terminal X1-6, circuit 539 and terminal X1-7, circuit 251

with a voltmeter to ground.

Is the value as specified?

Battery

voltage Replace the

OCC contro l

module, refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Install the OCC

control modu le

(Refer to

Section 2E,

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C)

REMOVAL AND

INSTALLATION.)

and go to Step 5.

5 Turn the ignition off.

Back-probe between OCC control module terminal X1-6,

circuit 539 and fuse F13 with an ohmmeter to ground.

Is the value as specified?

Less than

1 ohm Go to Step 6. Repair faulty

circuit 539.

6 Turn the ignition off.

Back-probe OCC control module terminal X1-7,

circuit 251 with an ohmmeter to a known good ground.

Is the value as specified?

Less than

1 ohm Check for

intermittent

connect ion at

OCC contro l

module

connector

A14 X1. Check

sizing of

connector

A14 X1

terminals.

Repair faulty

circuit 251.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–21

20–FEB–2003 Page 2F-21

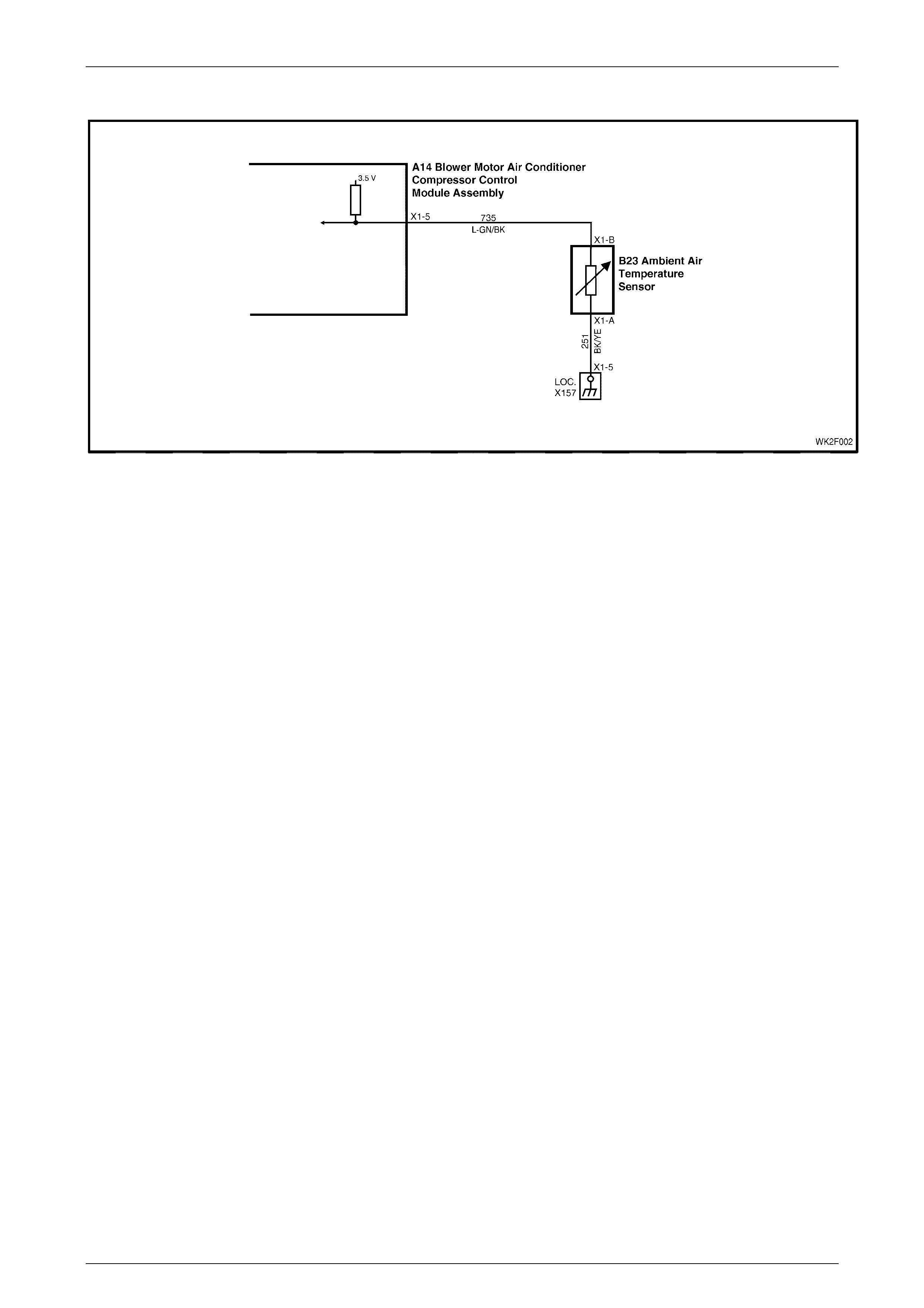

DTC 13 – Ambient Temperature Sensor Voltage Too High

Figure 2F – 11

Circuit Description:

The Ambient Temperature Sensor (ATS) uses a thermistor to control the signal voltage to the OCC control module. The

OCC control module applies a voltage of 3.2 ± 0.2 volts to the sensor. When the air is cold, the ATS resistance is high,

therefore the OCC control module will sense a high signal voltage. If the ambient air is warm, the ATS resistance is low

therefore the OCC control module will sense a low signal voltage.

DTC 13 will set if: the ATS sensor signal voltage is more than 3.5 ± 0.2 volts or if the ATS sensor wiring harness

(circuit 735) or connectors are open circuited for a period of 10 seconds.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. Checks that the conditions for setting the DTC are

present or if fault is intermitten t.

3. Checks integrity of circuit 735.

4. Checks if sensor is serviceable by testing resistance

across ATS.

5. Checks for an intermittent connection at ATS.

6. Checks for an open in circuit 251.

7. Checks for an open in circuit 735.

8. Checks for short to voltage in circuit 735.

Diagnostic Aids:

The default temperature for an open circuit is 22.5°C.

If the vehicle is left idling for an extended period, the ambient

temperature readings will rise owing to heat radiated by the

A/C condenser and lack of airflow.

When using the temperature/resistance chart less than, place

a thermometer as cl ose as po ssi ble to the sens or being

tested, compare this temperature figure taken to the

resistance value.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and using

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–22

20–FEB–2003 Page 2F-22

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

0 15920 – 16750

10 9715 – 10193

20 6107 – 6389

30 3943 – 4115

40 2610 – 2717

50 1767 – 1836

60 1201 – 1291

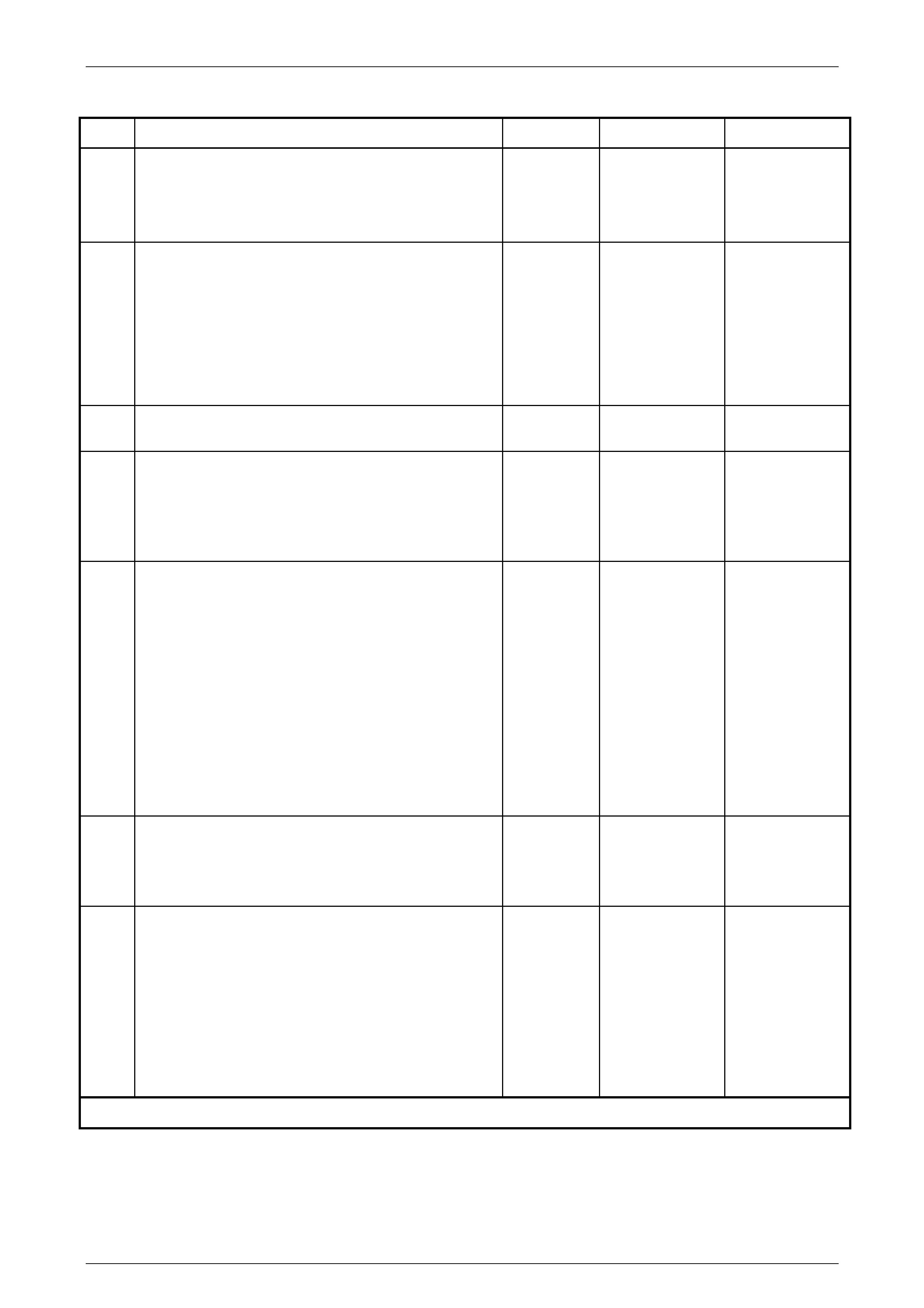

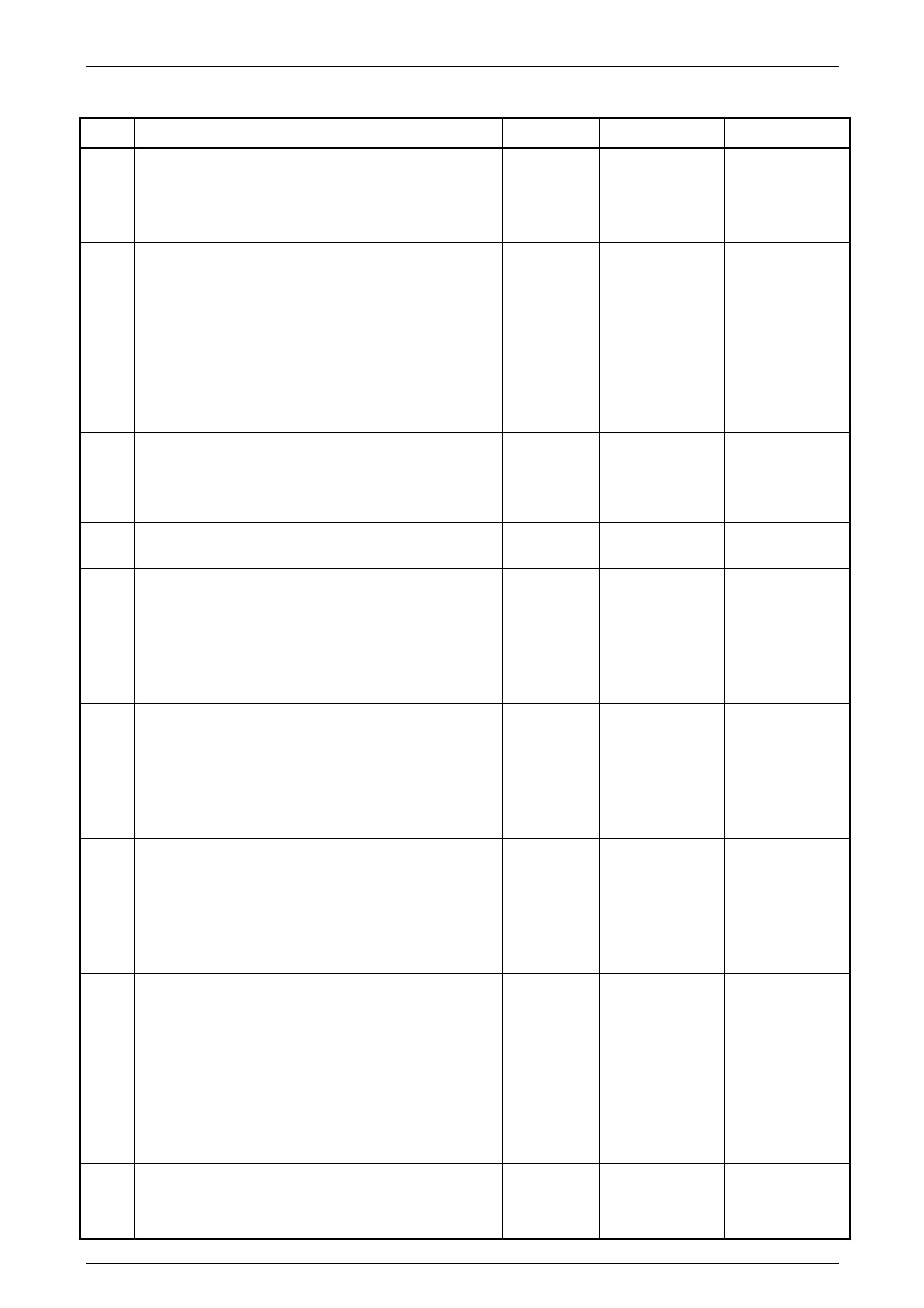

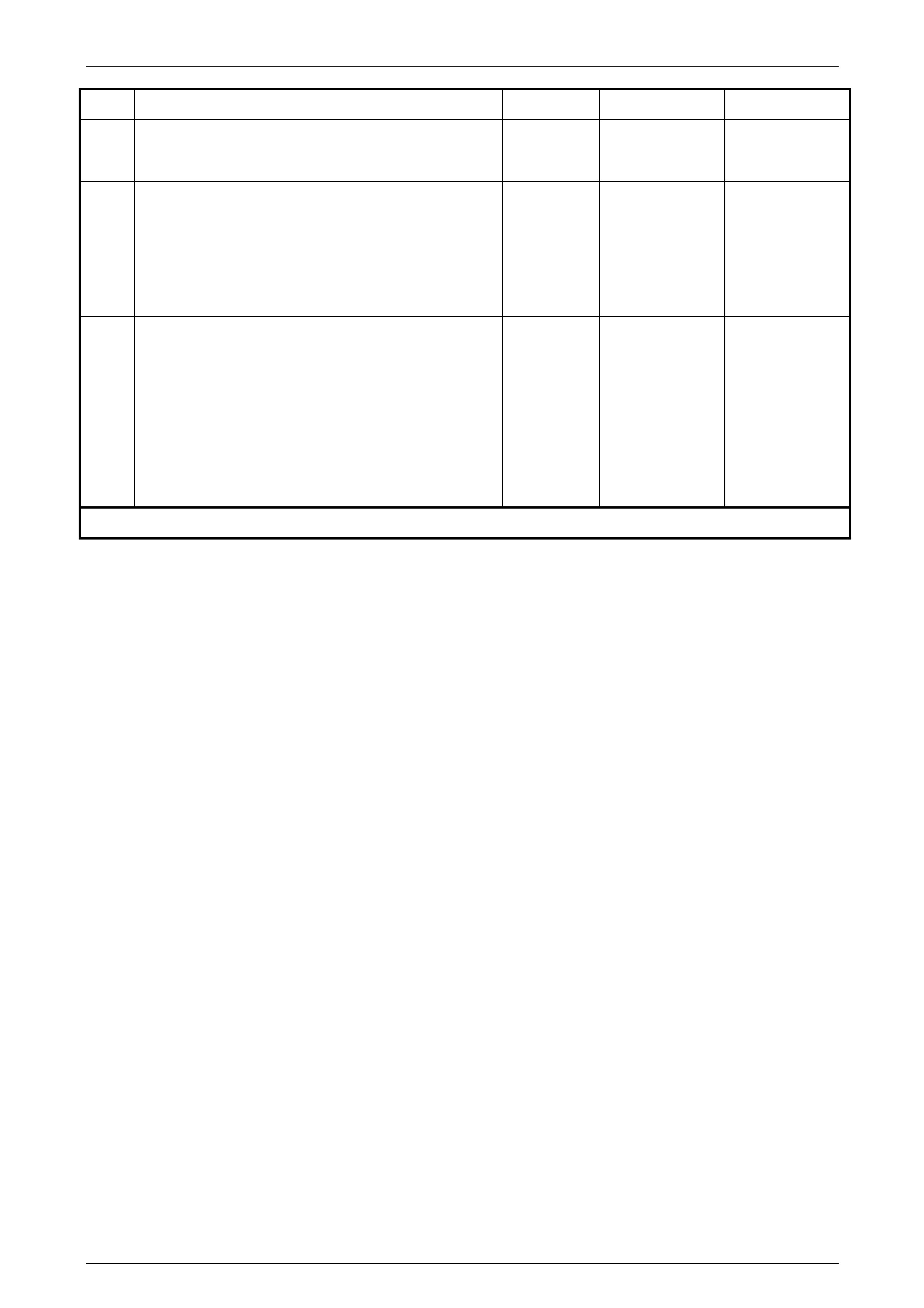

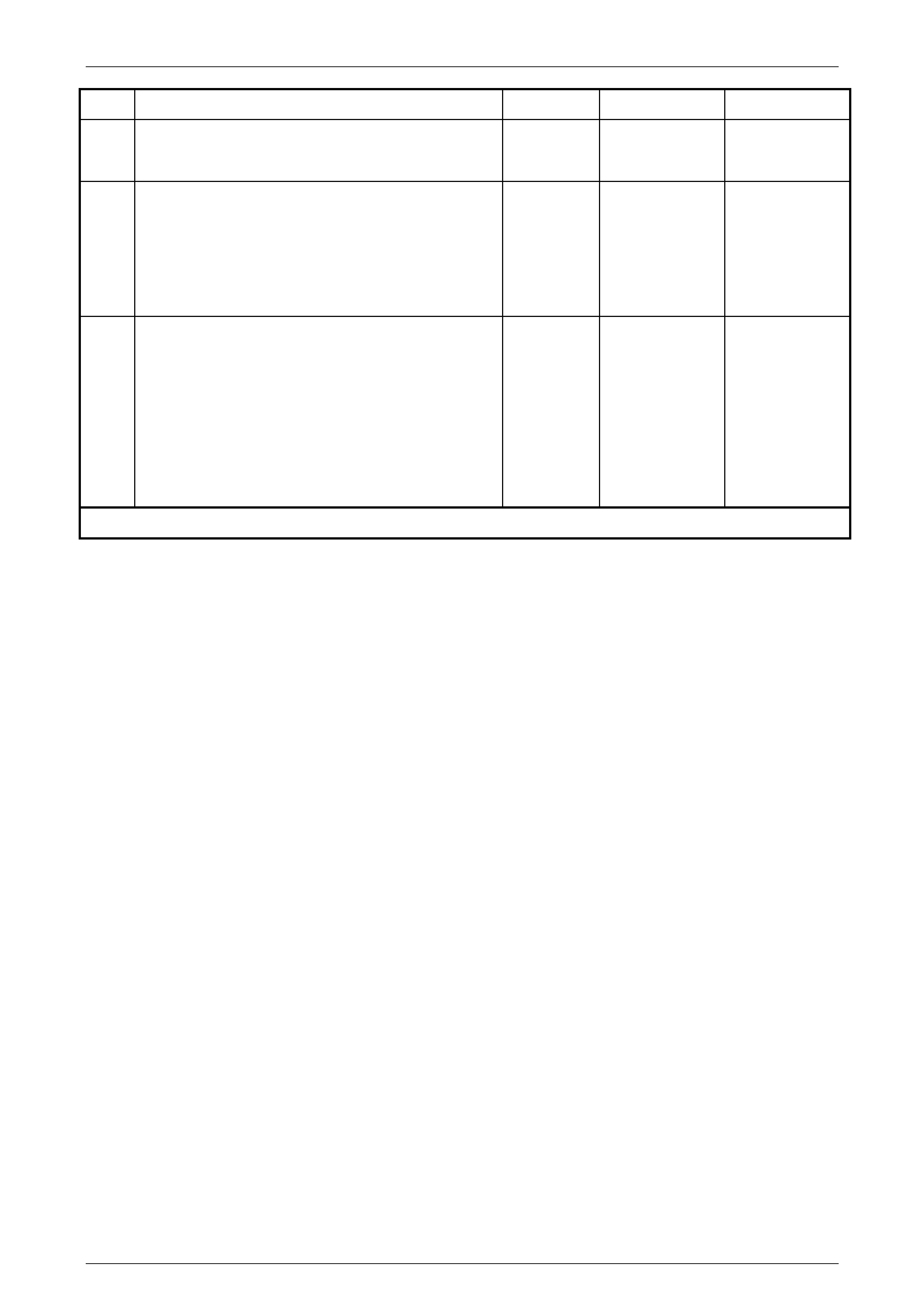

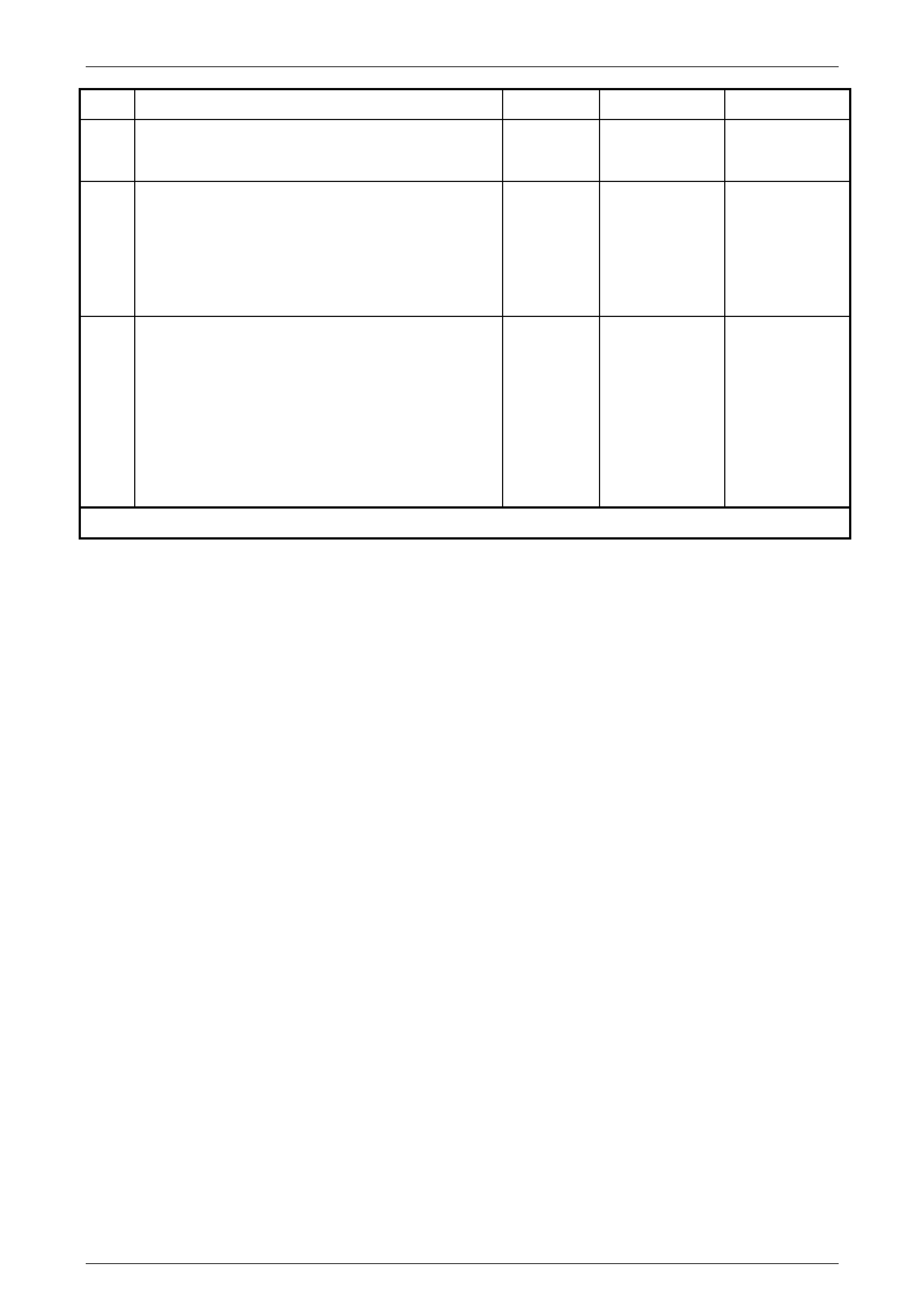

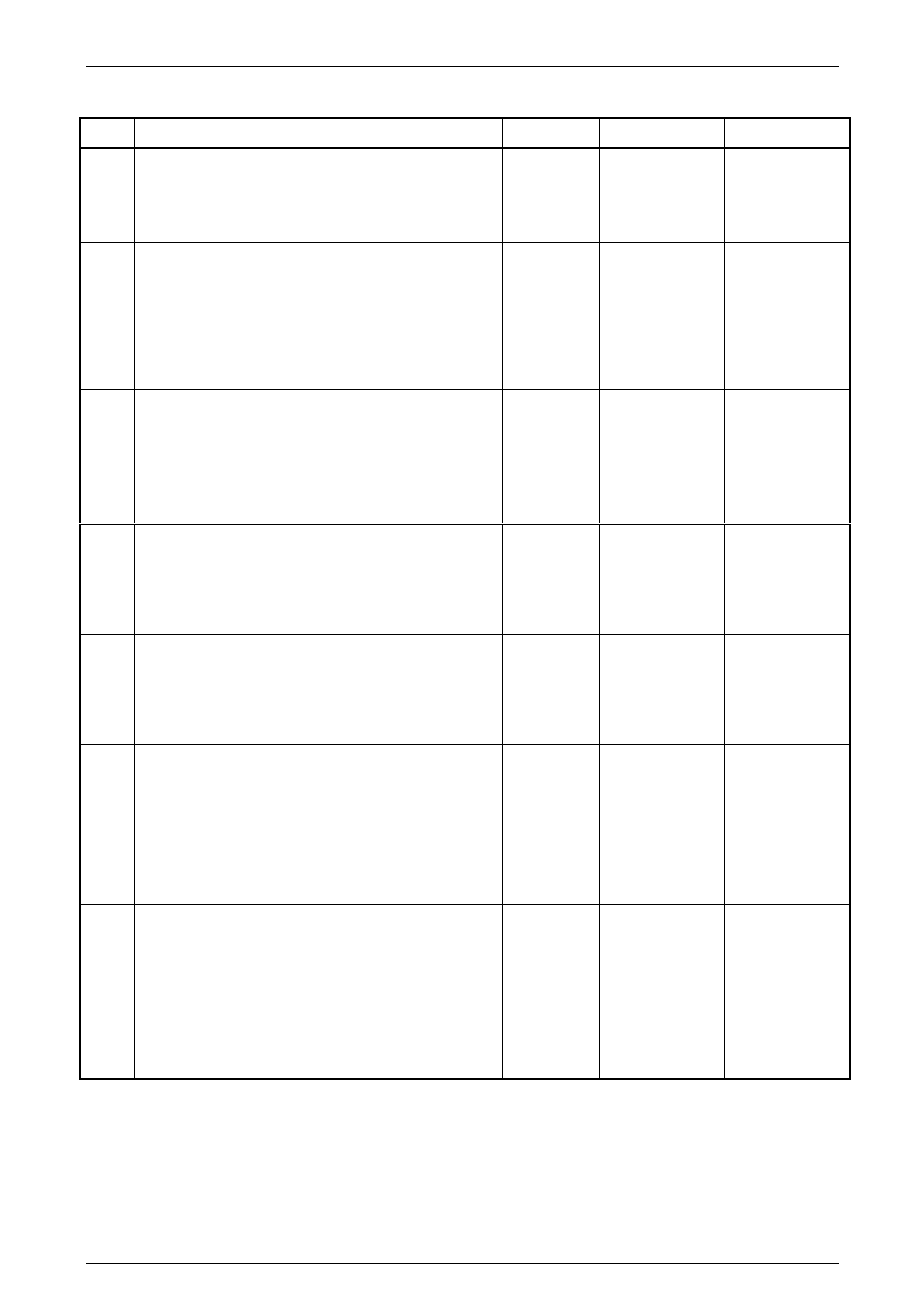

DTC 13 – Ambient Temperature Sensor Voltage Too High Diagnostic Chart

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Ambient Air Temperature Sensor.

Does TECH 2 display a value above 3.4 volts?

Go to Step 3. DTC 13

intermittent. If no

additional DTCs

were stored.

Refer to

3 DIAGNOSTIC

CHARTS in this

Section.

3 With TECH 2 connected and Ambient Air Temperature

Sensor displayed, disconnect the ambient air

temperature sensor wiring harness connector B23 X1.

Place a jumper wire between the two terminals of

connector B23 X1.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 4. Go to Step 6

4 With the ambient air temperature sensor wiring harness

connector disconnected, probe between the ambient air

sensor terminals with an ohmmeter to ground.

Is the value as specified?

Refer to

DTC 13

Temp.

Resistance

Chart

outlined

previously.

Go to Step 5. Replace faulty

ambient air

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C)–

REMOVAL &

INSTALLATION.

5 Inspect the ambient air temperature sensor wiring

harness connector for an intermittent or loose terminal.

Is connector OK?

Go to Step 8 Repair faulty

connector.

6 With TECH 2 connected and Ambient Air Temperature

Sensor displayed, back-probe between OCC control

module connector terminal X1-5, circuit 735 and chassis

ground with a jumper lead.

Does TECH 2 display a value less than 0.4 volt?

Repair faulty

circuit 251. Go to Step 7

7 Check the integrity of circuit 735 between ambient air

temperature sensor connector terminal X1-B and OCC

control modu le con nect or term inal X 1-5.

Is the circuit OK?

Go to Step 8 Repair faulty

circuit 735.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–23

20–FEB–2003 Page 2F-23

STEP ACTION VALUE YES NO

8 Turn the ignition off.

Disconnect OCC wiring harness connectors A14 X1 and

A14 X2.

Remove the jumper lead from the ambient air

temperature sensor connector.

Turn the ignition on.

Back-probe ambient air temperature sensor wiring

harness connector terminal X1-B circuit 735 with a

voltmeter to chass is grou nd.

Is the value as specified?

0.4 volt Replace the

faulty OCC

control modu le.

Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuit 735.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–24

20–FEB–2003 Page 2F-24

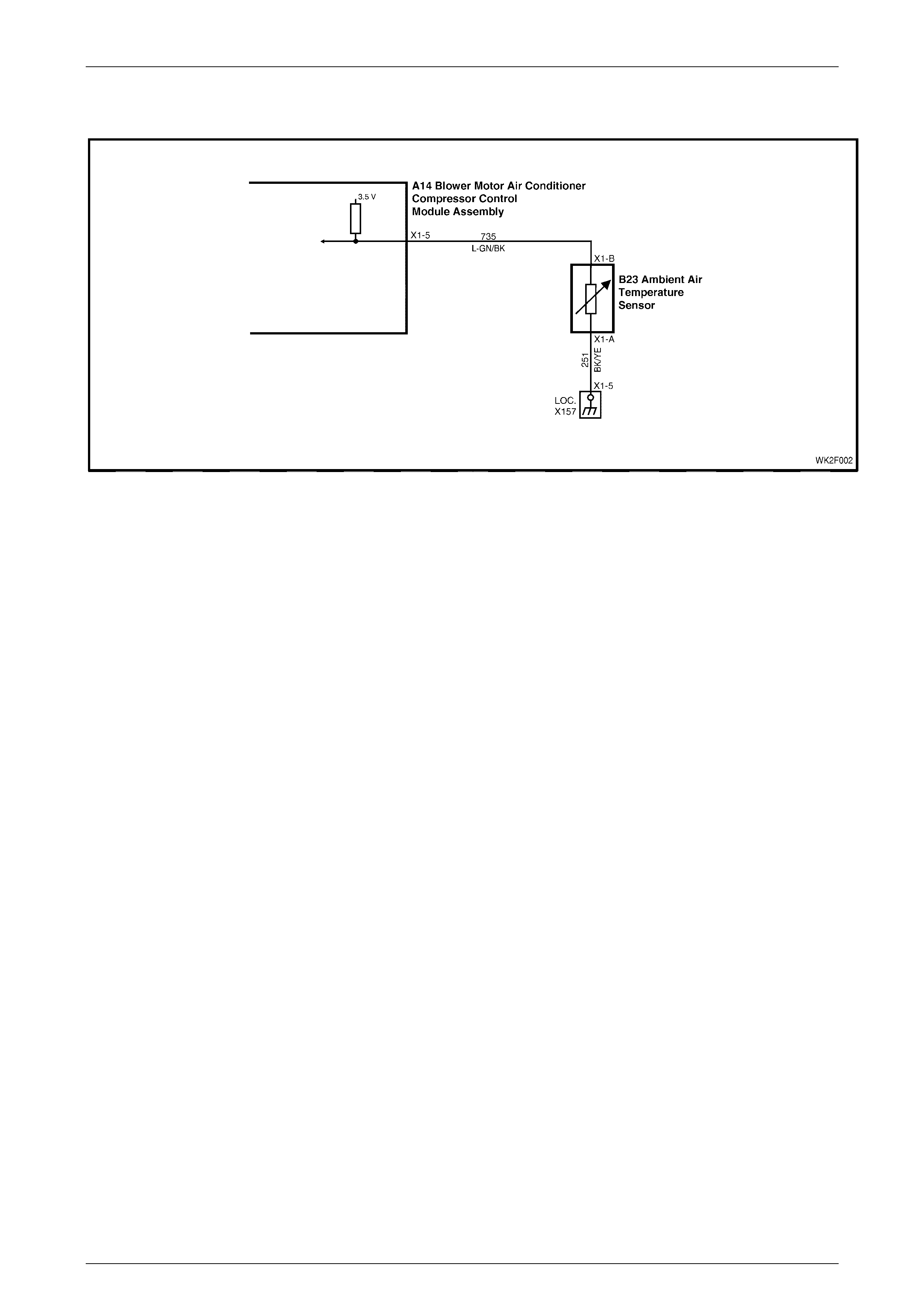

DTC 14 – Ambient Temperature Sensor Voltage Too Low

Figure 2F – 12

Circuit Description:

The Ambient Temperature Sensor (ATS) uses a thermistor to control the signal voltage to the OCC control module. The

OCC control module applies a voltage of 3.2 ± 0.2 volts to the sensor. When the air is cold, the ATS resistance is high,

therefore the OCC control module will sense a high signal voltage. If the ambient air is warm, the ATS resistance is low

therefore the OCC control module will sense a low signal voltage.

DTC 14 will set if: the ATS sensor signal voltage is more than 0.3 volts or if the ATS sensor wiring harness (circuit 735)

or connectors are open circuited for a period of 10 seconds.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the sensor is causing the short

circuit.

4. This test checks if sensor is functioning correctly.

5. Checks for intermittent connection at sensor.

6. Checks for a short circuit of sensor signal wire to

ground.

Diagnostic Aids:

The default temperature for an open circuit is 22.5°C.

If the vehicle is left idling for an extended period, the ambient

temperature readings will rise owing to heat radiated by the

A/C condenser and lack of airflow.

When using the temperature/resistance chart less than, place

a thermometer as cl ose as po ssi ble to the sens or being

tested, compare this temperature figure taken to the

resistance value.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and using

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–25

20–FEB–2003 Page 2F-25

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

0 15920 – 16750

10 9715 – 10193

20 6107 – 6389

30 3943 – 4115

40 2610 – 2717

50 1767 – 1836

60 1201 – 1291

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–26

20–FEB–2003 Page 2F-26

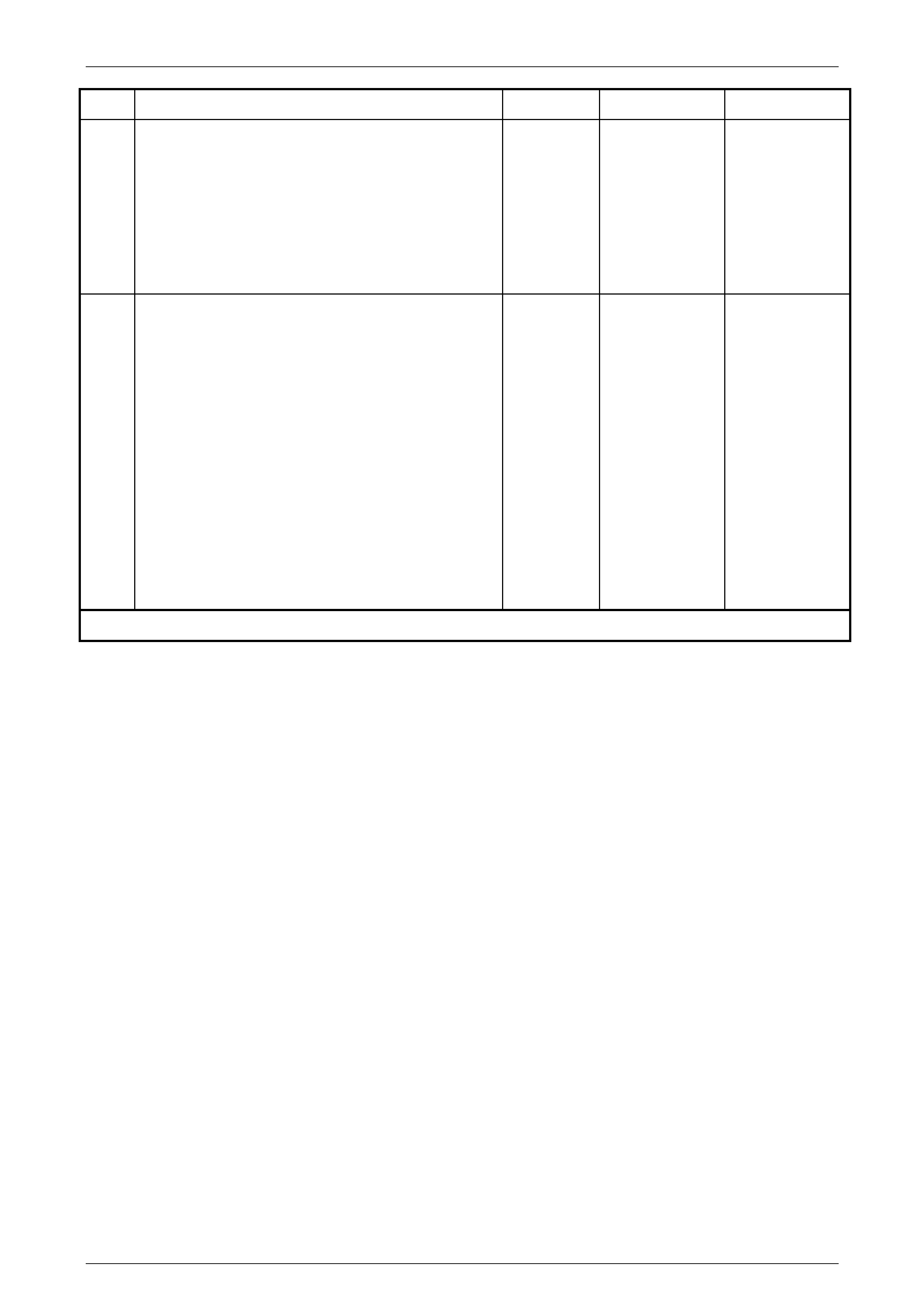

DTC 14 – Ambient Temperature Sensor Voltage Too Low Diagnostic Chart

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Ambient Air Temperature Sensor.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 3. DTC 14

intermittent. If no

additional DTCs

were stored,

refer to

3 DIAGNOSTIC

CHARTS in this

Section.

3 With TECH 2 connected and Ambient Air Temperature

Sensor displayed, disconnect ambient air temperature

sensor wiring harness connector B23 X1.

Does TECH 2 display a value more than 3.4 volts?

Go to Step 4. Go to Step 6.

4 With the ambient air temperature sensor wiring harness

connector disconnected, back-probe between the

ambient air sensor termi nal s.

Is the value as specified?

Refer to

DTC 14

Temp.

Resistance

Chart.

Go to Step 5. Replace the faulty

ambient air

temperature

sensor. Refer to

S e c t io n 2E, HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

5 Check for an intermittent short to ground in circ uit 735

between OCC control module connector terminal X1-5

and ambient air sensor con ne ctor terminal X 1-B.

Is the circuit OK?

Repair faulty

connector. Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

6 Check circuit 735 for a short circuit to ground.

Is the circuit OK?

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuit 735.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–27

20–FEB–2003 Page 2F-27

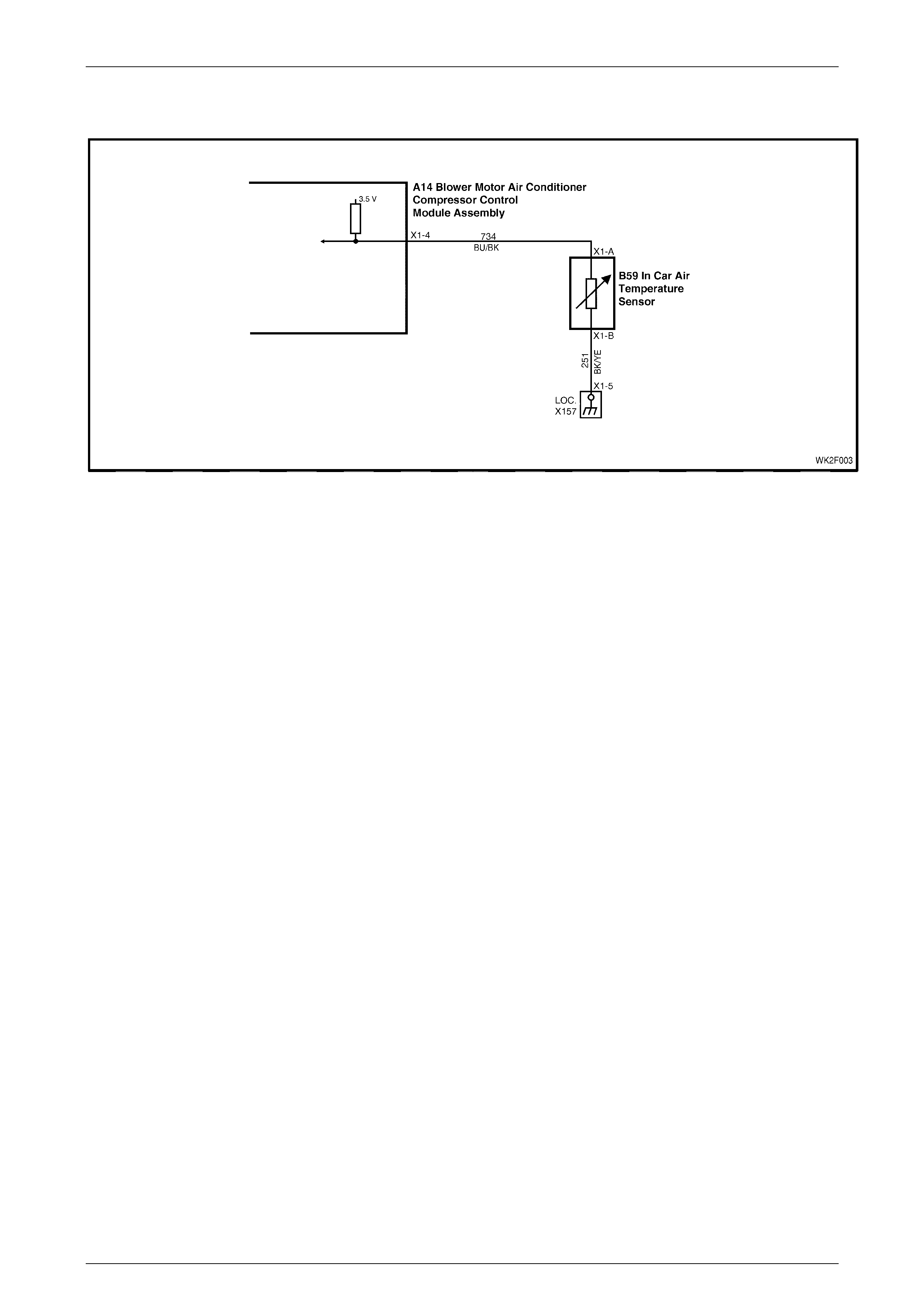

DTC 15 – In-car Temperature Sensor Voltage Too High

Figure 2F – 13

Circuit Description:

The In-car Temperature Sensor (ITS) is a thermistor used to vary voltage signals to control the signal voltage to the OCC

control module. The OCC control module applies a voltage of 3.5 ±0.2 volts to the sensor, via circuit 734. When the

vehicle interior air is cold, the ITS resistance is high therefore the OCC control module will sense a high signal voltage. If

the air is warm, the ITS resistance is low, therefore the OCC control module will sense a low signal voltage.

DTC 15 will set: if the ITS signal voltage is more than 3.5 ± 0.2 volts or if the ITS sensor wiring harness (circuit 734) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. Checks that the conditions for setting the DTC are

present or if fault is intermitten t.

3. Checks integrity of circuit 734.

4. Checks if sensor is serviceable by testing resistance

across ITS.

5. Checks for an intermittent connection at ITS.

6. Checks for an open in circuit 251.

7. Checks for an open in circuit 734.

8. Checks for short to voltage in circuit 734.

Diagnostic Aid s:

The default temperature for an open circuit is 22.5°C.

When using the temperature/resistance chart less than, place

a thermometer as cl ose as po ssi ble to the sens or being

tested, compare this temperature figure taken to the

resistance value.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–28

20–FEB–2003 Page 2F-28

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 7009 – 7536

10 5477 – 5856

15 4310 – 4583

20 3416 – 3612

25 2725 – 2865

30 2175 –2299

35 1746 – 1857

40 1410 – 1508

45 1145 – 1231

50 935 – 1010

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–29

20–FEB–2003 Page 2F-29

DTC 15 – In-car Temperature Sensor Voltage Too High Diagnostic Chart

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List / In-

car Temperature Sensor.

Does TECH 2 display a value above 3.4 volts?

Go to Step 3. DTC 15

intermittent. If no

additional DTCs

were stored,

refer to

3 DAGNOSTIC

CHARTS in this

Section.

3 With TECH 2 connected and In-car Temperature Sensor

displayed, disconnect the in-car temperature sensor

wiring harness connector B59 X1.

Probe between the two terminals of the connector with a

jumper wire.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 4. Go to Step 6.

4 With the in-car temperature sensor wiring harness

connector disconnected, probe between the two

terminals of the connector with an ohmmeter. (Refer to

Notes on Diagnostic Chart for this chart, Note 1).

Is the value as specified?

Refer to

DTC 15

Temp.

Resistance

Chart.

Go to Step 5. Replace faulty

in-car

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

5 Inspect the in-car temperature sensor wiring harness

connector for an intermittent or loose terminal.

Is the connector OK?

Go to Step 8. Repair faulty

connector.

6 With TECH 2 connected and In-car Temperature Sensor

displayed, back-probe OCC connector terminal X1-4,

circuit 734 with a jumper lead to chassis ground.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 7. Repair faulty

circuit 251.

7 Check the integrity of circuit 734 between the OCC

control module connector and in car temperature sensor

connector. (Refer to Notes on Diagnostic Chart for this

chart, Note 1.)

Is the circuit OK?

Go to Step 8. Repair faulty

circuit 734.

8 Turn the ignition OFF.

Disconnect the OCC control module wiring harness

connectors A14 X1 and A14 X2.

Remove jumper lead from the in-car temperature sensor

connector.

Turn the ignition on.

Back-probe in-car temperature sensor wiring harness

connector term inal X1-A, circuit 734 with a voltmeter to

chassis ground.

Is the value as specified?

Less than

0.4 volt Replace the

faulty OCC

control modu le.

Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuit 734.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–30

20–FEB–2003 Page 2F-30

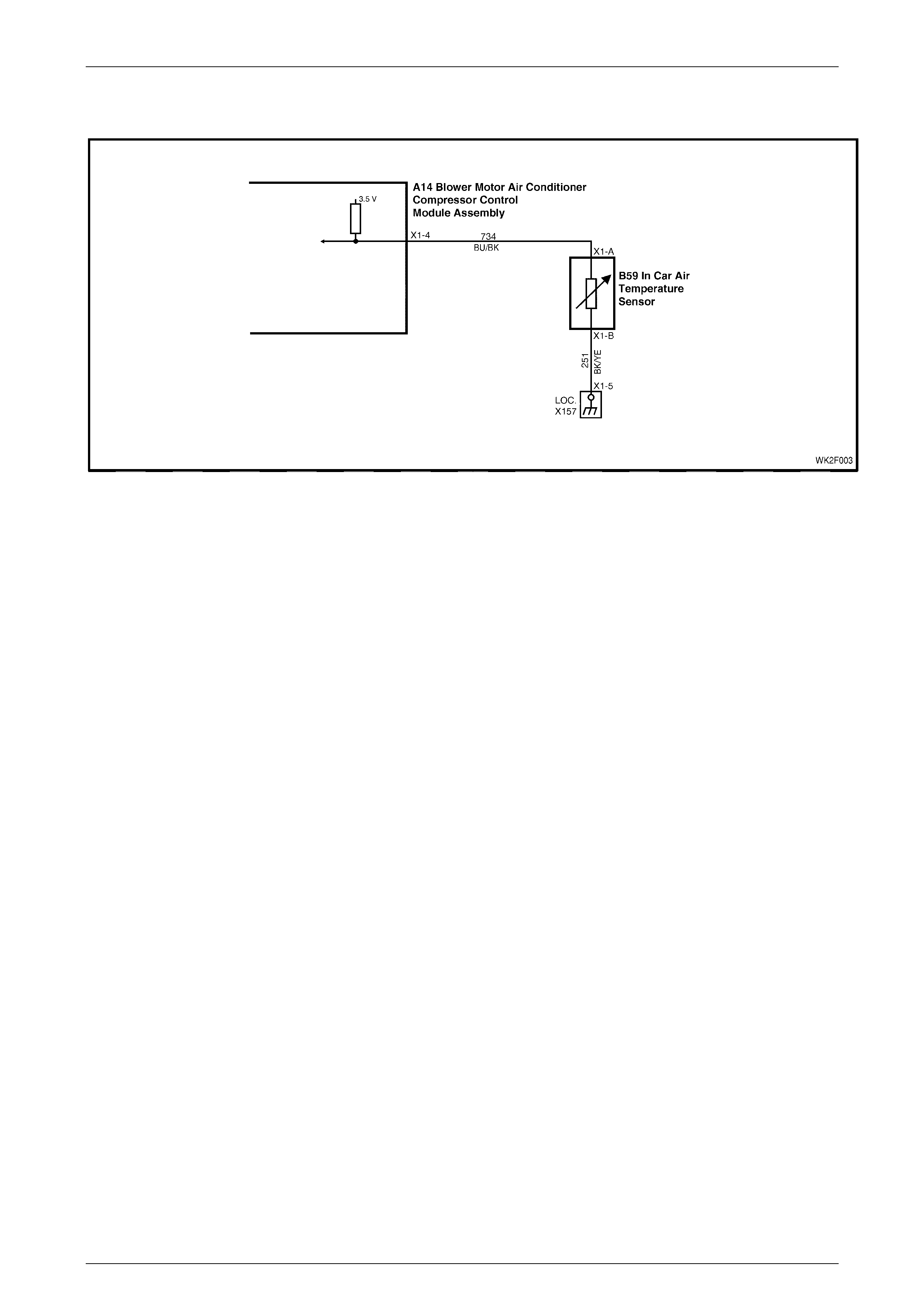

DTC 16 – In-car Temperature Sensor Voltage Too Low

Figure 2F – 14

Circuit Description:

The in-car temperature sensor (ITS) is a thermistor used to vary voltage signals to the OCC control module. The OCC

control module applies a voltage of 3.5 ±0.2 volts to the sensor. When the vehicle interior air is cold, the ITS resistance is

high, therefore the OCC control module will sense a high signal voltage. If the air is warm, the ITS resistance is low,

therefore the OCC control module will sense a low signal voltage.

DTC 16 will set: if the ITS signal voltage is less than 0.3 volt or if the ITS sensor wiring harness (circuit 734) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the sensor is causing the short

circuit.

4. This test checks if sensor is functioning correctly.

5. Checks for intermittent connection at sensor.

6. Checks for a short circuit of sensor signal wire to

ground.

Diagnostic Aid s:

The default temperature for an open circuit is 22.5°C.

When using the temperature/resistance chart less than, place

a thermometer as cl ose as po ssi ble to the sens or being

tested, compare this temperature figure taken to the

resistance value.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–31

20–FEB–2003 Page 2F-31

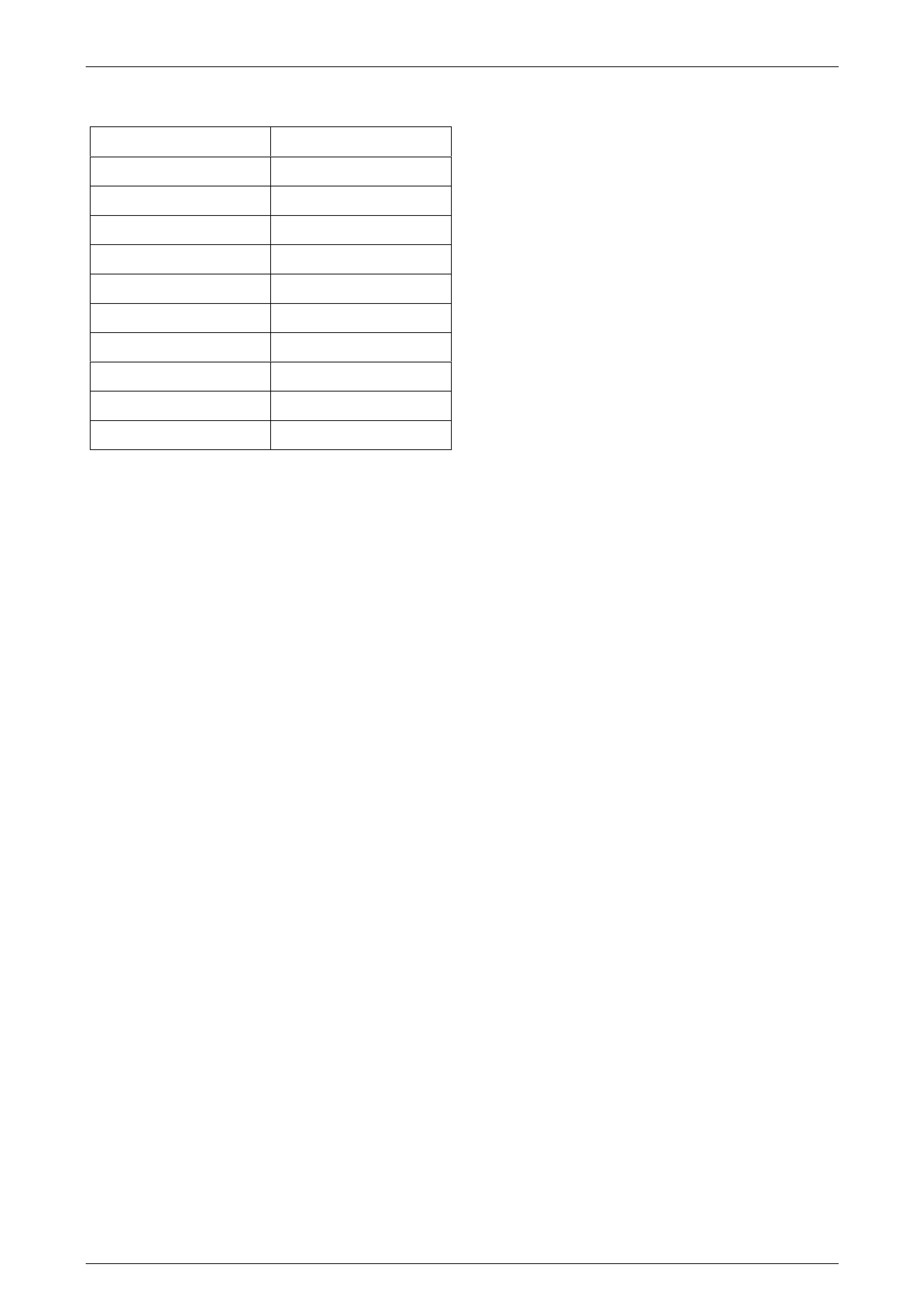

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 7009 – 7536

10 5477 – 5856

15 4310 – 4583

20 3416 – 3612

25 2725 – 2865

30 2175 –2299

35 1746 – 1857

40 1410 – 1508

45 1145 – 1231

50 935 – 1010

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–32

20–FEB–2003 Page 2F-32

DTC 16 – In-car Temperature Sensor Voltage Too Low Diagnostic Chart

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

In-car Temperature Sensor.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 3. DTC 16

intermittent. If no

additional DTCs

were stored,

refer to

3 DIAGNOSTIC

CHARTS in this

Section.

3 With TECH 2 connected and In-car Temperature Sensor

displayed, disconnect the in-car temperature sensor

wiring harness connector B59 X1.

Does TECH 2 display a value above 3.4 volts?

Go to Step 4. Go to Step 6.

4 With the in-car temperature sensor wiring harness

connector disconnected, probe between the in-car

sensor terminals with an ohmmeter. (Refer to Notes on

Diagnostic Chart for this chart, Note 1.)

Is the value as specified?

Refer to

DTC 16

Temp.

Resistance

Chart.

Go to Step 5. Replace the

faulty in-car

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

5 Check the in-car temperature sensor connectors B59 X1

and A14 X1, circuit 734 for an intermittent short to

ground. (Refer to Notes on Diagnostic Chart for this

chart, Note 1.)

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

connector.

6 Check the integrity of circuit 734. (Refer to Notes on

Diagnostic Chart for this chart, Note 1.).

Is the circuit OK?

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuit 734.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–33

20–FEB–2003 Page 2F-33

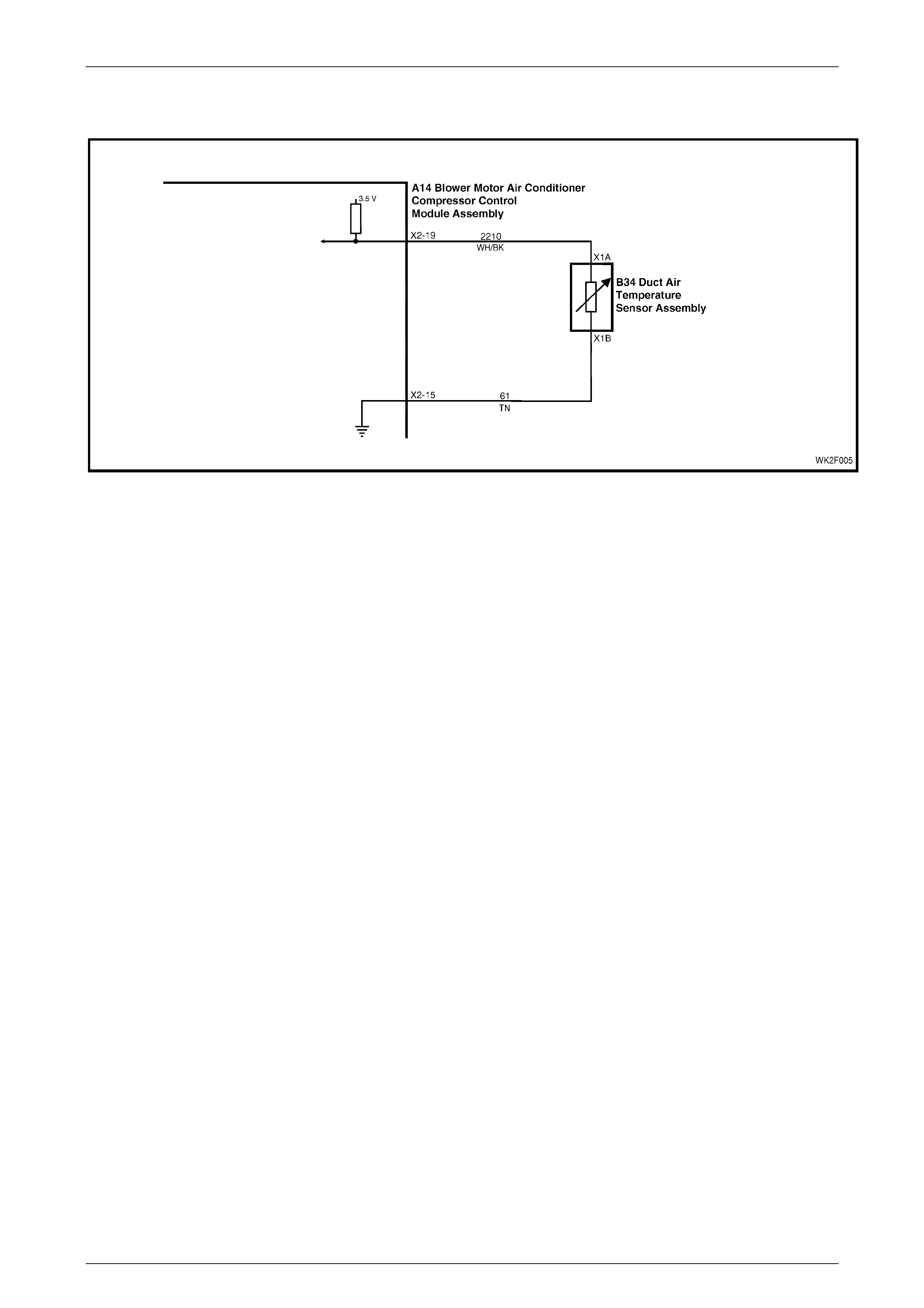

DTC 17 – Evaporative Temperature Sensor Voltage Too High (LHD)

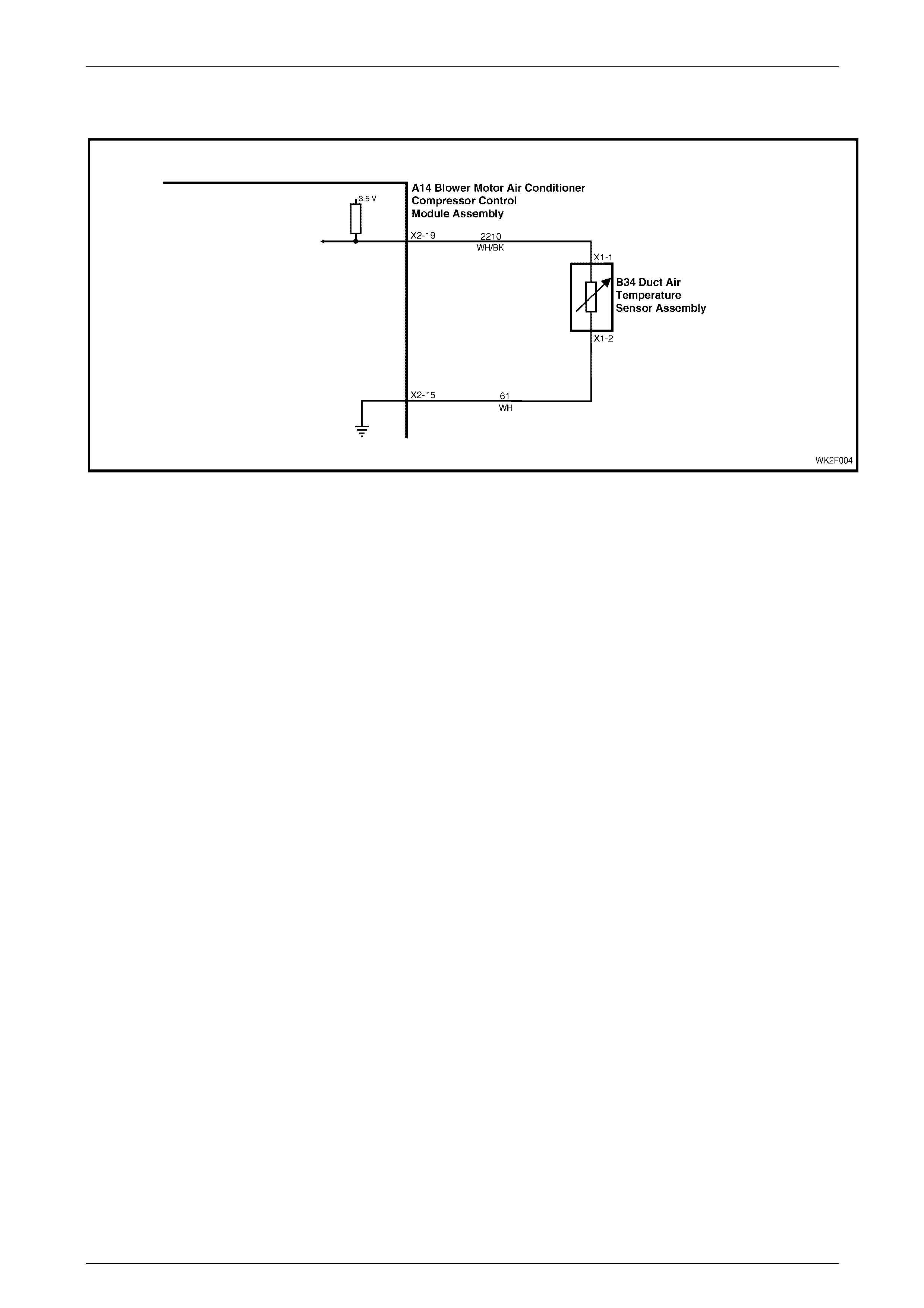

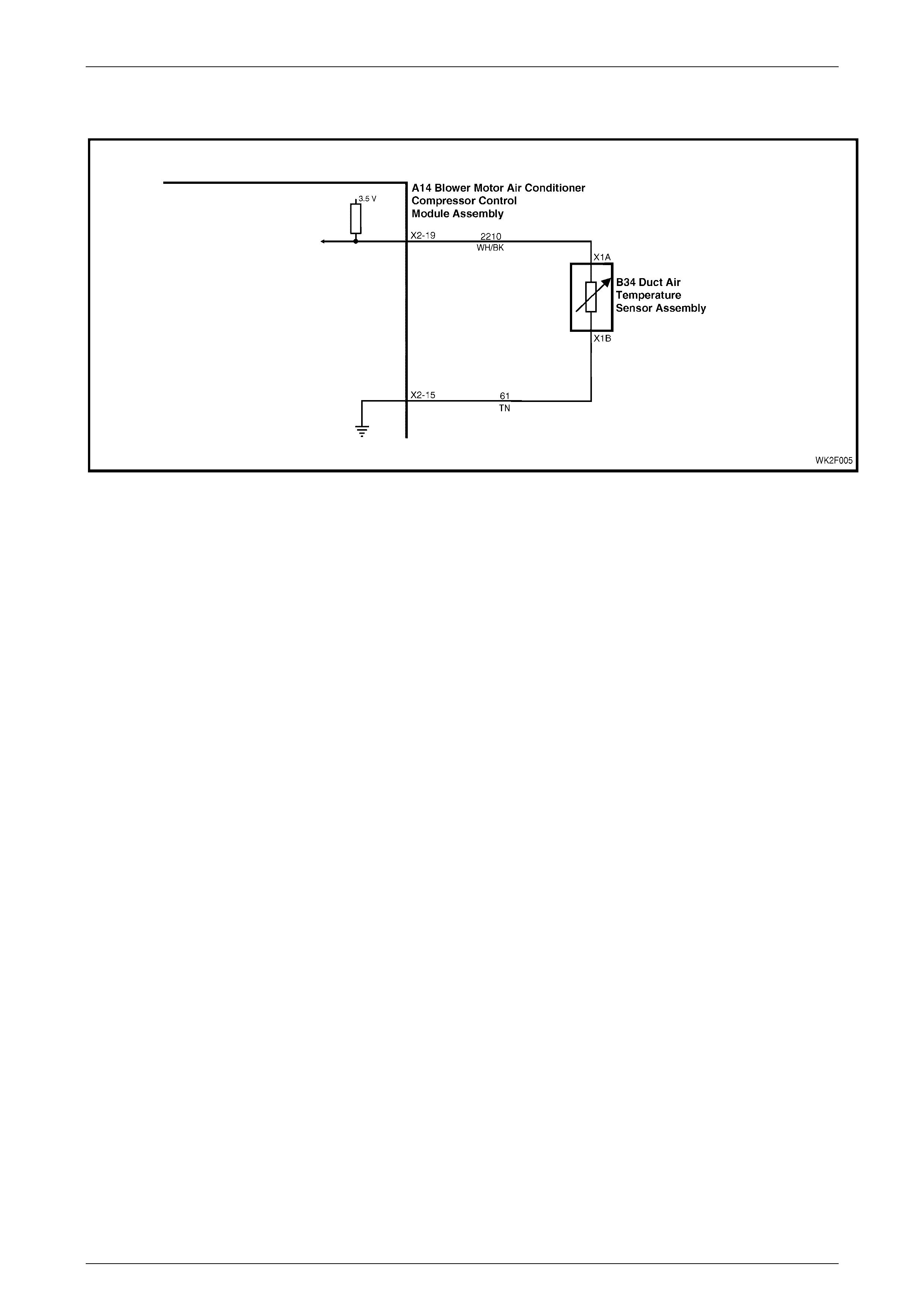

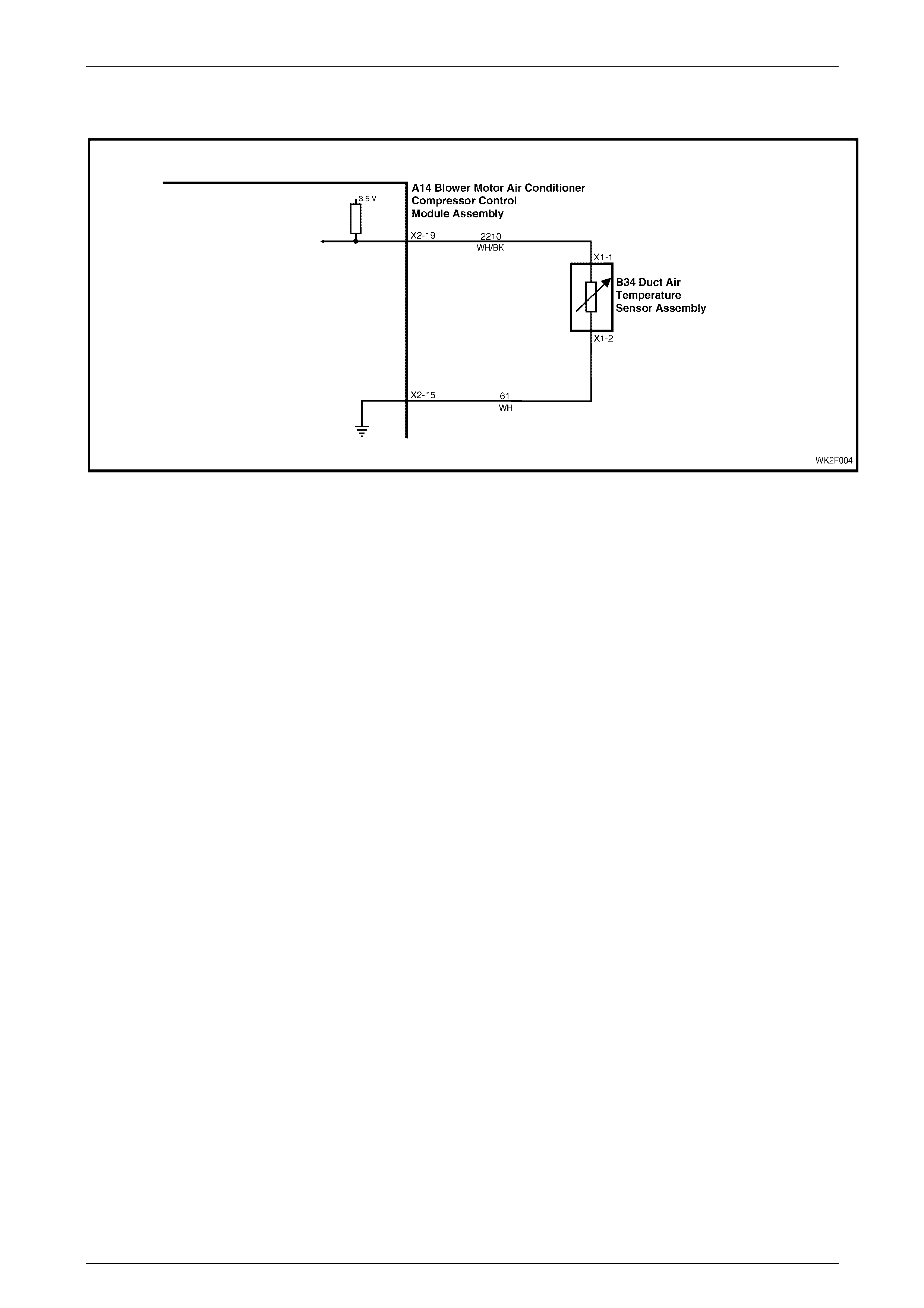

Figure 2F – 15

Circuit Description:

The evaporative temperature sensor (ETS) uses a thermistor to vary voltage signals to the OCC control module. The

OCC control module applies a voltage of 3.6 ±0.18 volts to the sensor. When the air is cold, the ETS resistance is high;

therefore the OCC control module will sense a high signal voltage. If the air is warm the resistance is low, therefore the

OCC control module will sense a low signal voltage.

DTC 17 will set: if the ETS signal voltage is more than 3.4 volts or if the ETS sensor wiring harness (circuit 2210) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the wiring or sensor is open

circuit.

4. This test checks if wiring is shorted to the ignition

feed in the OCC harness.

5. This test checks if wiring is shorted to the 3.5 V feed

in the OCC harness.

6. This test checks if wiring is shorted to a voltage in

the main wiring harness.

7. Check for intermittent connection at OCC.

8. This test checks if sensor is functioning correctly.

9. Check for intermittent con nection at sensor.

10. This test checks for an open circuit sensor ground

wire.

11. This test checks for an open circuit sensor signal

wire.

Diagnostic Aid s:

The default temperature for an open circuit is 5°C.

When using the temperature/resistance chart less than, place

a thermometer in the centre vent, set temperature to full cold

and manual fan speed to 2. This will give an approximate

evaporative air temperature. Compare this figure taken to the

chart less than.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–34

20–FEB–2003 Page 2F-34

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 4300 – 4850

10 3600 – 4050

15 2950 – 3250

20 2320 – 2625

25 1990 – 2200

30 1675 –1850

35 1330 – 1470

40 1140 – 1260

45 950 – 1050

50 850 – 950

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–35

20–FEB–2003 Page 2F-35

DTC 17 – Evaporative Temperature Sensor Voltage Too High Diagnostic Chart (LHD)

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Evap Temperature Sensor.

Does TECH 2 display a value above 3.4 volts?

Go to Step 3. DTC 17

intermittent. If no

additional DTCs

were stored,

refer to

3 DIAGNOSTIC

CHARTS in this

Section.

3 Disconnect OCC connector A14 X2.

Probe between OCC evaporative air temperature sensor

(ETS) terminals X2-19 and X2-15 with an ohmmeter.

(Refer to Notes on Diagnosti c Chart for this chart,

Note 1).

Is the value as specified?

Refer to

DTC 17

Temp.

Resistance

Chart.

Go to Step 4. Go to Step 8.

4 With the OCC connector A14 X2 disconnected, probe

between OCC harness connector terminals X2-5,

circuit 274 and X2-19, circuit 2210 with an ohmmeter.

Does a short exist?

NOTE: Any resistance measured here qualifies as a

short

Ohms Repair faulty

circuits 274 and /

or 2210.

Go to Step 5.

5 With the OCC connector A14 X2 disconnected, probe

between OCC harness connector terminal X2-11,

circuit 705 and connector terminal X2-19, circuit 2210.

Is the value as specified?

Less than

4 kilohms Repair faulty

circuits 705 and

2210.

Go to Step 6.

6 Turn the ignition on.

Back-probe OCC harness connector terminal X2-19,

circuit 2210 with a voltmeter to chassis ground.

Is the value as specified?

Less than

0.4 volt Go to Step 7. Repair faulty

circuit 2210.

7 Inspect the OCC harness connector A14 X2 for an

intermittent or loose terminal.

Is the connector OK?

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

connector

A14 X2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–36

20–FEB–2003 Page 2F-36

STEP ACTION VALUE YES NO

8 Disconnect ETS connector B34 X1.

Probe between the evaporative air temperature sensor

terminals with an ohmmeter. (Refer to Notes on

Diagnostic Chart for this chart, Note 1.)

Is the value as specified?

Refer to

DTC 17

Temp.

Resistance

Chart.

Go to Step 9. Replace the faulty

evaporative

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

9 Inspect the evaporative air temperat ure sen sor harn ess

connector B34 X1 for an intermittent or loose terminal.

Is the connector OK?

Go to Step 10. Repair faulty

connector

B34 X1.

10 Check the integrity of circuit 61 between (B34) connector

terminal X1-2 and (A14) connector terminal X2-15.

(Refer to Notes on Diagnosti c Chart for this chart,

Note 1.)

Is the circuit OK?

Go to Step 11. Repair faulty

circuit 61.

11 Check the integrity of circuit 2210 between (B34)

connector terminal X1-1 and (A14) connector

terminal X2-19.

Is the circuit OK?

Reconnect

evaporative air

temp sensor

harness

connector

B34 X1 and go to

Step 4.

Repair faulty

circuit 2210.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–37

20–FEB–2003 Page 2F-37

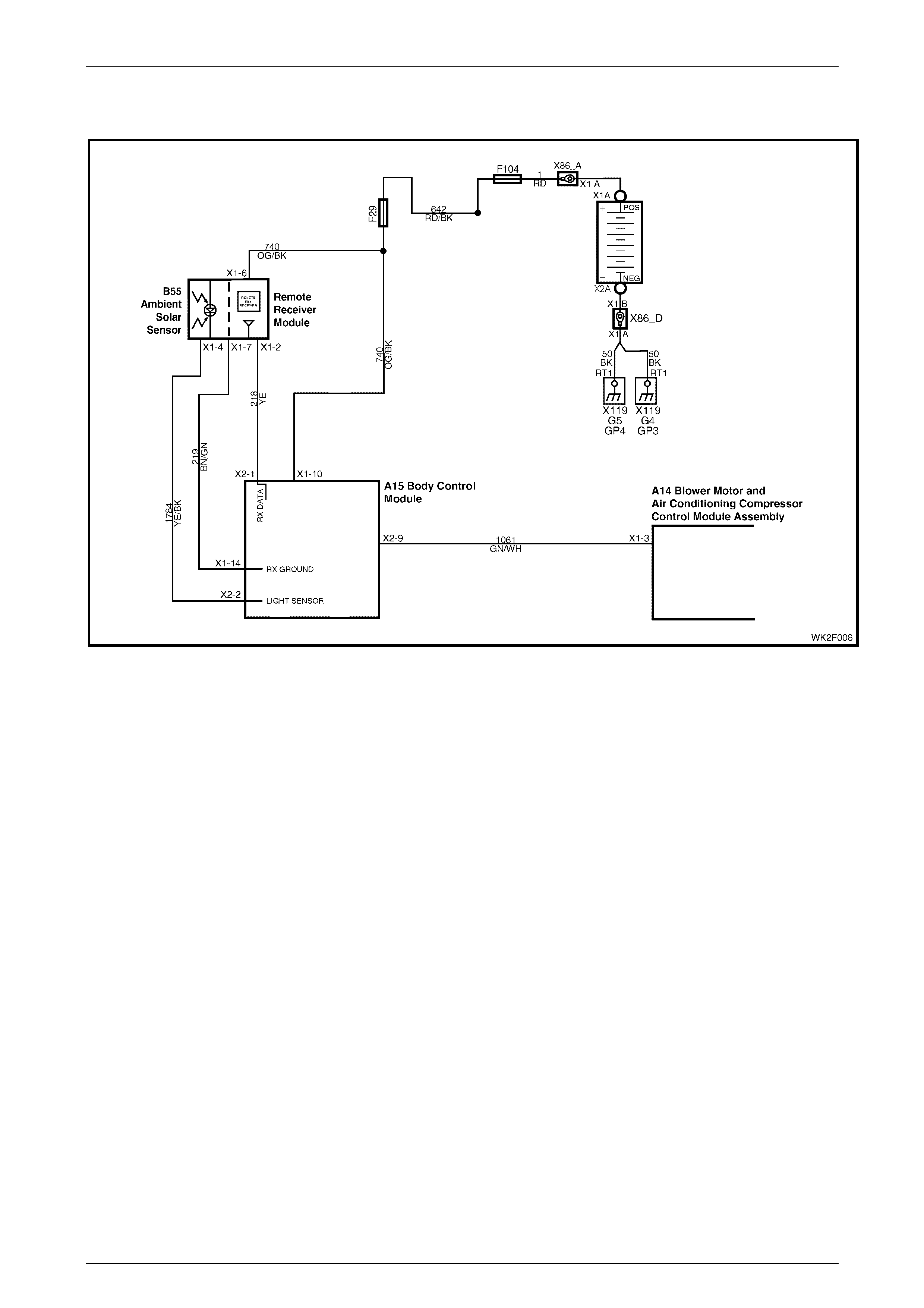

DTC 17 – Evaporative Temperature Sensor Voltage Too High (RHD)

Figure 2F – 16

Circuit Description:

The evaporative temperature sensor (ETS) uses a thermistor to vary voltage signals to the OCC control module. The

OCC control module applies a voltage of 3.6 ±0.18 volts to the sensor. When the air is cold, the ETS resistance is high;

therefore the OCC control module will sense a high signal voltage. If the air is warm the resistance is low, therefore the

OCC control module will sense a low signal voltage.

DTC 17 will set: if the ETS signal voltage is more than 3.4 volts or if the ETS sensor wiring harness (circuit 2210) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the wiring or sensor is open

circuit.

4. This test checks if wiring is shorted to the ignition

feed in the OCC harness.

5. This test checks if wiring is shorted to the 3.5 V feed

in the OCC harness.

6. This test checks if wiring is shorted to a voltage in

the main wiring harness.

7. Check for intermittent connection at OCC.

8. This test checks if sensor is functioning correctly.

9. Check for intermittent con nection at sensor.

10. This test checks for an open circuit sensor ground

wire.

11. This test checks for an open circuit sensor signal

wire.

Diagnostic Aid s:

The default temperature for an open circuit is 5°C.

When using the temperature/resistance chart less than, place

a thermometer in the centre vent, set temperature to full cold

and manual fan speed to 2. This will give an approximate

evaporative air temperature. Compare this figure taken to the

chart less than.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–38

20–FEB–2003 Page 2F-38

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 4300 – 4850

10 3600 – 4050

15 2950 – 3250

20 2320 – 2625

25 1990 – 2200

30 1675 –1850

35 1330 – 1470

40 1140 – 1260

45 950 – 1050

50 850 – 950

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–39

20–FEB–2003 Page 2F-39

DTC 17 – Evaporative Temperature Sensor Voltage Too High Diagnostic Chart (RHD)

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Evap Temperature Sensor.

Does TECH 2 display a value above 3.4 volts?

Go to Step 3. DTC 17

intermittent. If no

additional DTCs

were stored,

refer to

3 DIAGNOSTIC

CHARTS in this

Section.

3 Disconnect OCC connector A14 X2.

Probe between OCC evaporative air temperature sensor

(ETS) terminals X2-19 and X2-15 with an ohmmeter.

(Refer to Notes on Diagnosti c Chart for this chart,

Note 1.)

Is the value as specified?

Refer to

DTC 17

Temp.

Resistance

Chart.

Go to Step 4. Go to Step 8.

4 With the OCC connector A14 X2 disconnected, probe

between OCC harness connector terminals X2-5,

circuit 274 and X2-19, circuit 2210 with an ohmmeter.

Does a short exist?

NOTE: Any resistance measured here qualifies as a

short

Ohms Repair faulty

circuits 274 and /

or 2210.

Go to Step 5.

5 With the OCC connector A14 X2 disconnected, probe

between OCC harness connector terminal X2-11,

circuit 705 and connector terminal X2-19, circuit 2210.

Is the value as specified?

Less than

4 kilohms Repair faulty

circuits 705 and

2210.

Go to Step 6.

6 Turn the ignition on.

Back-probe OCC harness connector terminal X2-19,

circuit 2210 with a voltmeter to chassis ground.

Is the value as specified?

Less than

0.4 volt Go to Step 7. Repair faulty

circuit 2210.

7 Inspect the OCC harness connector A14 X2 for an

intermittent or loose terminal.

Is the connector OK?

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

connector

A14 X2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–40

20–FEB–2003 Page 2F-40

STEP ACTION VALUE YES NO

8 Disconnect ETS connector B34 X1.

Probe between the evaporative air temperature sensor

terminals with an ohmmeter. (Refer to Notes on

Diagnostic Chart for this chart, Note 1).

Is the value as specified?

Refer to

DTC 17

Temp.

Resistance

Chart.

Go to Step 9. Replace the faulty

evaporative

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

9 Inspect the evaporative air temperat ure sen sor harn ess

connector B34 X1 for an intermittent or loose terminal.

Is the connector OK?

Go to Step 10. Repair faulty

connector

B34 X1.

10 Check the integrity of circuit 61 between (B34) connector

terminal X1-B and (A14) connector terminal X2-15.

(Refer to Notes on Diagnosti c Chart for this chart, Note

1.)

Is the circuit OK?

Go to Step 11. Repair faulty

circuit 61.

11 Check the integrity of circuit 2210 between (B34)

connector term inal X1-A and (A14) connector

terminal X2-19.

Is the circuit OK?

Reconnect

evaporative air

temp sensor

harness

connector

B34 X1 and go to

Step 4.

Repair faulty

circuit 2210.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–41

20–FEB–2003 Page 2F-41

DTC 18 – Evaporative Temperature Sensor Voltage Too Low (LHD)

Figure 2F – 17

Circuit Description:

The evaporative temperature sensor (ETS) uses a thermistor to control the signal voltage to the OCC control module.

The OCC control module applies a voltage of 3.6 ±0.18 volts to the sensor. When the air off the evaporator core is cold,

the ETS resistan ce is high, therefore the OCC control module will sense a high signal voltage. If the air is warm, the ETS

resistance is low, therefore the OCC control module will sense a low signal voltage.

DTC 18 will set: if the ETS signal voltage is less than 0.3 volt or if the ETS sensor wiring harness (circuit 2210) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the sensor or wiring is causing the

short circuit.

4. This test checks if sensor and wiring is functioning

correctly.

5. Check for intermittent con nec ti on at sensor

6. This test checks for a short circuit of the sensor

signal wire to ground.

7. This test determines if the sensor is shorted or the

wire is shorted.

Diagnostic Aid s:

The default temperature for an open circuit is 5°C.

When using the temperature/resistance chart less than, place

a thermometer in the centre vent, set temperature to full cold

and manual fan speed to 2. This will give an approximate

evaporative air temperature. Compare this figure taken to the

chart less than.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–42

20–FEB–2003 Page 2F-42

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 4300 – 4850

10 3600 – 4050

15 2950 – 3250

20 2320 – 2625

25 1990 – 2200

30 1675 –1850

35 1330 – 1470

40 1140 – 1260

45 950 – 1050

50 850 – 950

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–43

20–FEB–2003 Page 2F-43

DTC 18 – Evaporative Temperature Sensor Voltage Too Low Diagnostic Chart (LHD)

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC (Refer to Notes on

Diagnostic Chart for this chart, Note 2.)

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Evap Temperature Sensor.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 3. DTC 18

intermittent. If no

additional DTCs

were stored,

refer to 3

DIAGNOSTIC

CHARTS in this

Section

3 With TECH 2 connected and Evap Temperature Sensor

displayed, disconnect the OCC wiring harness A14 X2.

Does TECH 2 display a value above 3.4 volts?

Go to Step 4. Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

4 With the OCC connector A14 X2 disconnected, probe

between the OCC connector terminals X2-19 and X2-15

with an ohmmeter. (Refer to Notes on Diagnostic Chart

for this chart, Note 1.)

Is the value as specified?

Refer to

DTC 18

Temp.

Resistance

Chart.

Go to Step 5. Go to Step 7

5 With the OCC connector A14 X2 disconnected, probe

OCC harness connector terminal X2-19, circuit 2210

with an ohmmeter to ground.

Is the value as specified?

More than

0 ohm Repair faulty

circuit 2210. Go to Step 6

6 Inspect the OCC and evaporative air temperature sensor

wiring harness and connectors B34 X1 and A14 X2 for

an intermittent short.

Are the circuits OK?

Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuits /

connect ors as

necessary.

7 Disconnect the evaporative temperature sens or

connector B24 X1.

Install OCC connectors A14 X1 and A14 X2.

With TECH 2 connected, select Body / Occupant

Climate Control / Data Display / Data List / Evap

Temperature Sensor.

Does TECH 2 display a value above 3.4 volts?

Replace the

faulty

evaporative

temperature

sensor. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

Repair faulty

circuit 2210.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COMPLETED, VERIFY CORRECT OPERATION

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–44

20–FEB–2003 Page 2F-44

DTC 18 – Evaporative Temperature Sensor Voltage Too Low (RHD)

Figure 2F – 18

Circuit Description:

The evaporative temperature sensor (ETS) uses a thermistor to control the signal voltage to the OCC control module.

The OCC control module applies a voltage of 3.6 ±0.18 volts to the sensor. When the air off the evaporator core is cold,

the ETS resistan ce is high, therefore the OCC control module will sense a high signal voltage. If the air is warm, the ETS

resistance is low, therefore the OCC control module will sense a low signal voltage.

DTC 18 will set: if the ETS signal voltage is less than 0.3 volt or if the ETS sensor wiring harness (circuit 2210) or

connect ors are open cir cuit ed for 10 second s.

Test Description:

Number(s) below refer to Step numbers in the following

Diagnostic Chart:

1. Ensures the Diagnostic Circuit Check has been

performed.

2. This test checks that the conditions that would set

the DTC, are present.

3. This test checks if the sensor or wiring is causing the

short circuit.

4. This test checks if sensor and wiring is functioning

correctly.

5. Check for intermittent con nec ti on at sensor

6. This test checks for a short circuit of the sensor

signal wire to ground.

7. This test determines if the sensor is shorted or the

wire is shorted.

Diagnostic Aid s:

The default temperature for an open circuit is 5°C.

When using the temperature/resistance chart less than, place

a thermometer in the centre vent, set temperature to full cold

and manual fan speed to 2. This will give an approximate

evaporative air temperature. Compare this figure taken to the

chart less than.

Notes On Diagnostic Chart:

1. Refer to 4 Wir ing Diagrams in this Section for views of

OCC system related electrical connectors and complete

OCC system wiring diagrams.

2. For electrical connector locations and additional wiring

diagram informat ion, refer to Section 12P WIRING

DIAGRAMS.

3. Refer to Section 0C TECH 2 for connecting and us ing

TECH 2.

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–45

20–FEB–2003 Page 2F-45

Temperature Resistance Chart

AMBIENT°

°°

°C RESISTANCE Ω

ΩΩ

Ω

5 4300 – 4850

10 3600 – 4050

15 2950 – 3250

20 2320 – 2625

25 1990 – 2200

30 1675 –1850

35 1330 – 1470

40 1140 – 1260

45 950 – 1050

50 850 – 950

HVAC Occupant Climat e Control (Auto A/ C) – Diagnostic s Page 2F–46

20–FEB–2003 Page 2F-46

DTC 18 – Evaporative Temperature Sensor Voltage Too Low Diagnostic Chart (RHD)

STEP ACTION VALUE YES NO

1 Was the Diagnostic Circuit Check performed? Go to Step 2. Go to Chart A –

DIAGNOSTIC

CIRCUIT

CHECK in this

Section.

2 Connect TECH 2 to the DLC (Refer to Notes on

Diagnostic Chart for this chart, Note 2.)

Select Diagnostics / Model Year / Vehicle Model / Body /

Occupant Climate Control / Data Display / Data List /

Evap Temperature Sensor.

Does TECH 2 display a value less than 0.4 volt?

Go to Step 3. DTC 18

intermittent. If no

additional DTCs

were stored,

refer to 3

DIAGNOSTIC

CHARTS in this

Section

3 With TECH 2 connected and Evap Temperature Sensor

displayed, disconnect the OCC wiring harness A14 X2.

Does TECH 2 display a value above 3.4 volts?

Go to Step 4. Replace the faulty

OCC control

module. Refer to

Section 2E,

HVAC

OCCUPANT

CLIMATE

CONTROL

(AUTO A/C) –

REMOVAL &

INSTALLATION.

4 With the OCC connector A14 X2 disconnected, probe

between the OCC connector terminals X2-19 and X2-15

with an ohmmeter. (Refer to Notes on Diagnostic Chart

for this chart, Note 1.)

Is the value as specified?

Refer to

DTC 18

Temp.

Resistance

Chart.

Go to Step 5. Go to Step 7

5 With the OCC connector A14 X2 disconnected, probe

OCC harness connector terminal X2-19, circuit 2210