SECTION 1B - AIR CONDITIONING

1. GENERAL DESCRIPTION

1.1 REFRIGERANT CIRCULATION

1.2 REFRIGERANT TYPE

1.3 MAJOR COMPONENT S AND

LOCATION

2. DIAGNOSIS

2.1 GENERAL DIAGNOSIS TABLE

2.2 ABNORMAL NOISE DIAGNOSIS

Abnormal Noise From Compressor

Ab normal Noise Fr om

Magnetic Clutch

Ab normal Noise Fr om Tubing

Ab normal Noise Fr om

Condenser Assembly

Ab normal Noise Fr om

Crankshaft Pulley

Ab normal Noise Fr om

Tension Pulley

Ab normal Noise Fr om

A/C Evaporator

Ab normal Noise Fr om B lo we r

Fan Motor

2.3 QUICK CHECK OF

REFRIGERANT CHARGE

Checking Refrige rant Charge

2.4 PERFORMANCE DIAGNOSIS

Performance Di agnosis

Table

High Pressure Gauge

Low Pressure Gauge

Thermometer At Centre Duct

Detail Diagnosis Table

(Ambient Temperature at 30°c)

2.5 COMPRESSOR DRIVE BELT

Inspection

Adjustment

Replacement

3. ELECTRICAL DIAGNOSIS

3.1 WIRING DIAGRAM

3.2 A/C SYSTEM INSPECTION OF

ECM AND ITS CIRCUITS

Vol tage Check

ECM Vol tage Va lu es Ta ble fo r

A/C Control

4. REFRIGERANT RECOVERY,

EVACUATING AND CHARGING

4.1 OPERATING PROCEDURE FOR

REFRIGERANT CHARGING

4.2 RECOVERY

Refrigerant Recovery

4.3 REPLENISHING

COMPRESSOR OIL

WARNING:

For vehicles equipped with Supplem en tary Restra int (Airbag) System:

• Service on and around the airbag system components or wiring must be performed only by an

authorised HOLDEN retailer. Refer to AIRBAG SYSTEM-COMPONENTS and WIRING LOCATION

VIEW under GENERAL DESCRIPTION in Section 10B AIRBAG SYSTEM in order to confirm

whether you are performing service on or near the airbag system co mponents or wiring. Please

observe all WARNINGS and SER VICE PRECA UTIONS u nder ON- VEHICLE SER VI CE i n Sectio n 10B

AIRBAG SYSTEM before performing service on or around the air bag syste m co m po nen ts o r wir-

ing. Failure to follow WARNINGS could result in unintentional activation of the system or could

render the system inoper ative. Either of these two conditions may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is turne d to

the “LOCK” position and the negative cable is disconn ected from the battery. Otherwise , the sys-

tem may be activated by reserve energ y in the Sensing and Diagnostic Module (SDM).

CAUTION:

The ai r conditioning system of this vehi c l e uses refri gerant HFC-134a (R-134a).

Neither the refrige rant, compr essor o il or com ponent p arts ar e interchang eable betw een the differ-

ent types of A/C refrigerant.

For identification of which refrigerant is used, refer to 1.1 REFRIGERANT TYPE in this Section.

When replenish ing or changi ng refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C refrigerant installed in the vehicle

being ser viced. Use of inco rrect par ts will resul t in leakage o f refriger ant, damage to par ts or other

faulty conditions.

Techline

Wh en C harging with

Refrigerant Only

When Rep lacing Comp resso r

When Rep lacing Other Parts

4.4 EVACUATING

Evacu ating Proce dure

4.5 CHECKING SYSTEM FOR

PRESSURE LEAKS

4.6 CHARGING

Charging Procedure

4.7 REMOVING MANIFOLD

GAUGE SET

4.8 LEAK TEST

Liquid Leak Detectors

5. ON-VEHICLE SERVICE

5.1 SERVICE PRECAUTION

Refrigerant Line

Handling Refrigerant

HFC-134a (R-134a)

Refrigerant Reco very

Refrigerant Charge

5.2 CONDENSER ASSEMBLY

Inspection

Removal

Installation

5.3 RECEIVER/DRIER

Removal

Installation

5.4 CONDENSER COOLING FAN

Removal

Installation

Inspection

5.5 COOLING UNIT (EVAPORATOR)

Removal

Inspection

Installation

5.6 A/C EVAPORATOR

TEMPERATURE SENSOR

5.7 EXPANSION VALVE

Removal

Installation

Inspection

5.8 A/C REFRIGERANT PRESSURE

SWITCH

Inspection

5.9 A/C SWITCH

Removal and Installation

Inspection

5.10 COMPRESSOR RELAY AND

CONDENSER COOLI NG

FAN RELAY

Inspection

5.11 COMPRESSOR

Removal

Installation

5.12 MAGNETIC CLUTCH

Inspection

Removal

Installation

5.13 LIP TYPE SEAL

Removal

Installation

6. REQUIRED SERVICE MATERIAL

7. SPECIAL TOOLS

1. GENERAL DESCRIPTIO N

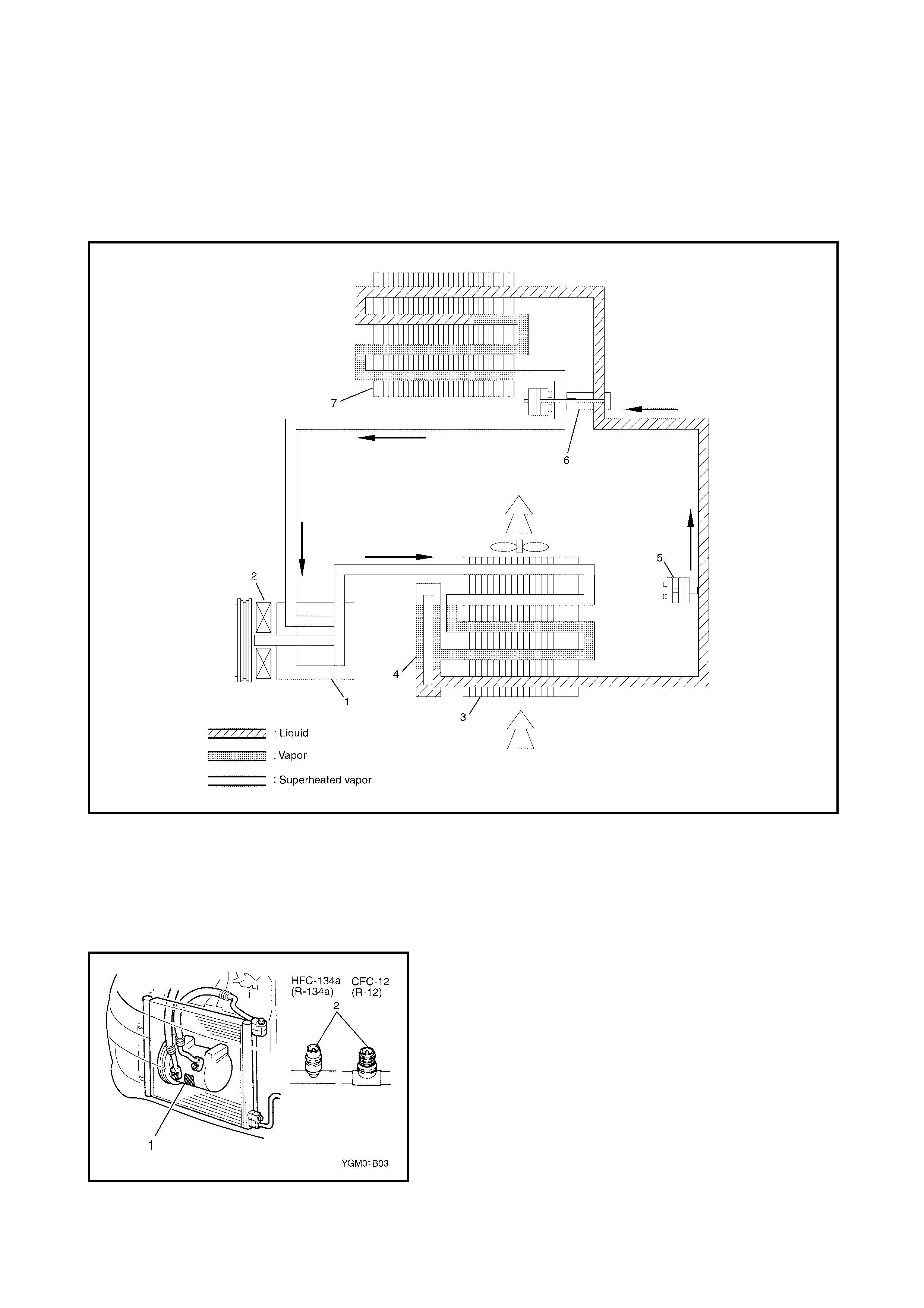

1.1 REF RIGERANT CIRCULATION

Legend

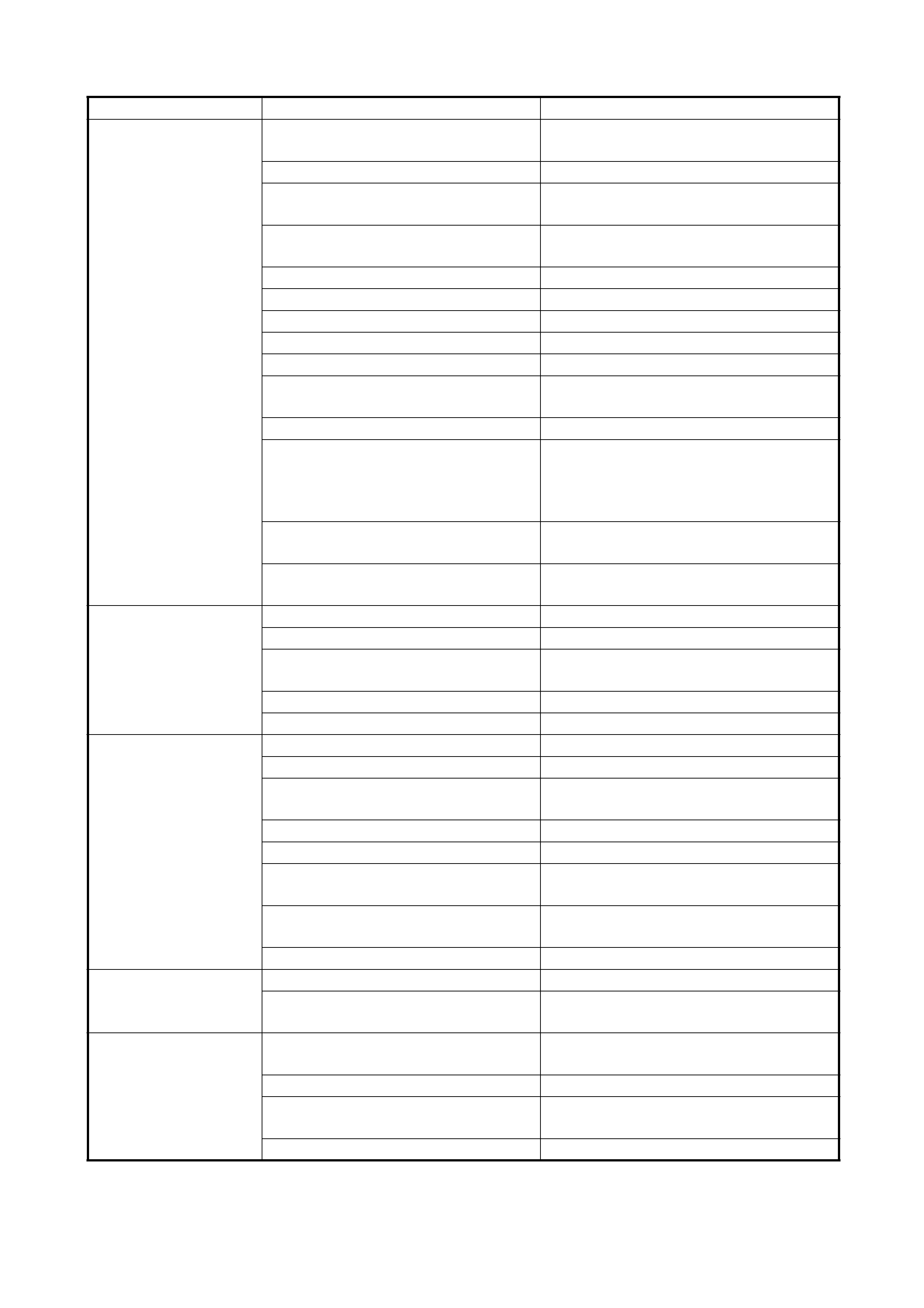

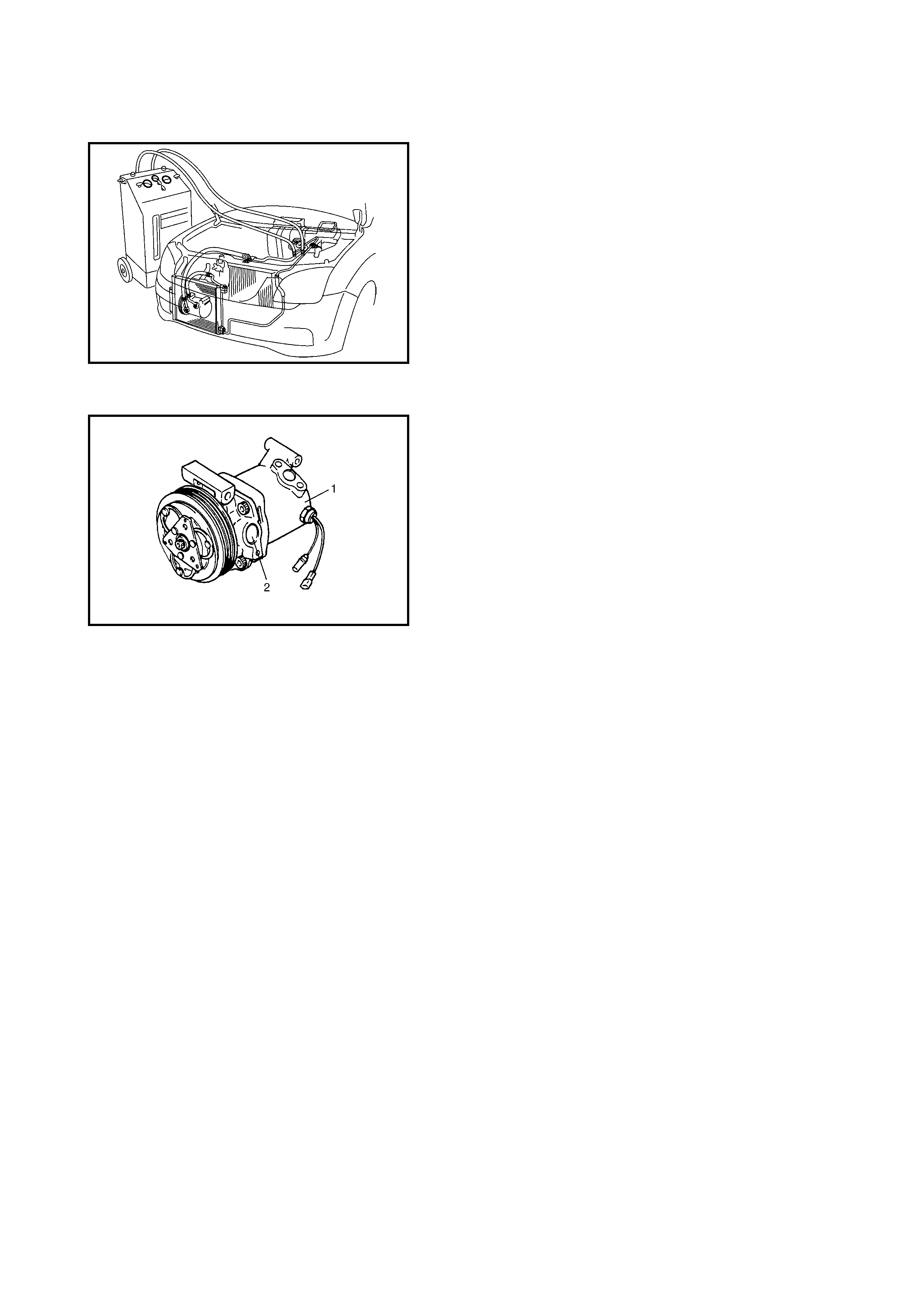

1.2 REFRIGERANT TYPE

The refrigerant used in this vehicle is HFC-134a (R134a).

This can be confirmed on the compressor label (1) or by

the shape of the service (charge) valve (2).

1. Compressor 4. Receiver/drier 7. Evaporator

2. Magnet cl utch 5. A/C refrigerant pressure swi t ch

3. Condense r assembly 6. Expansion valve

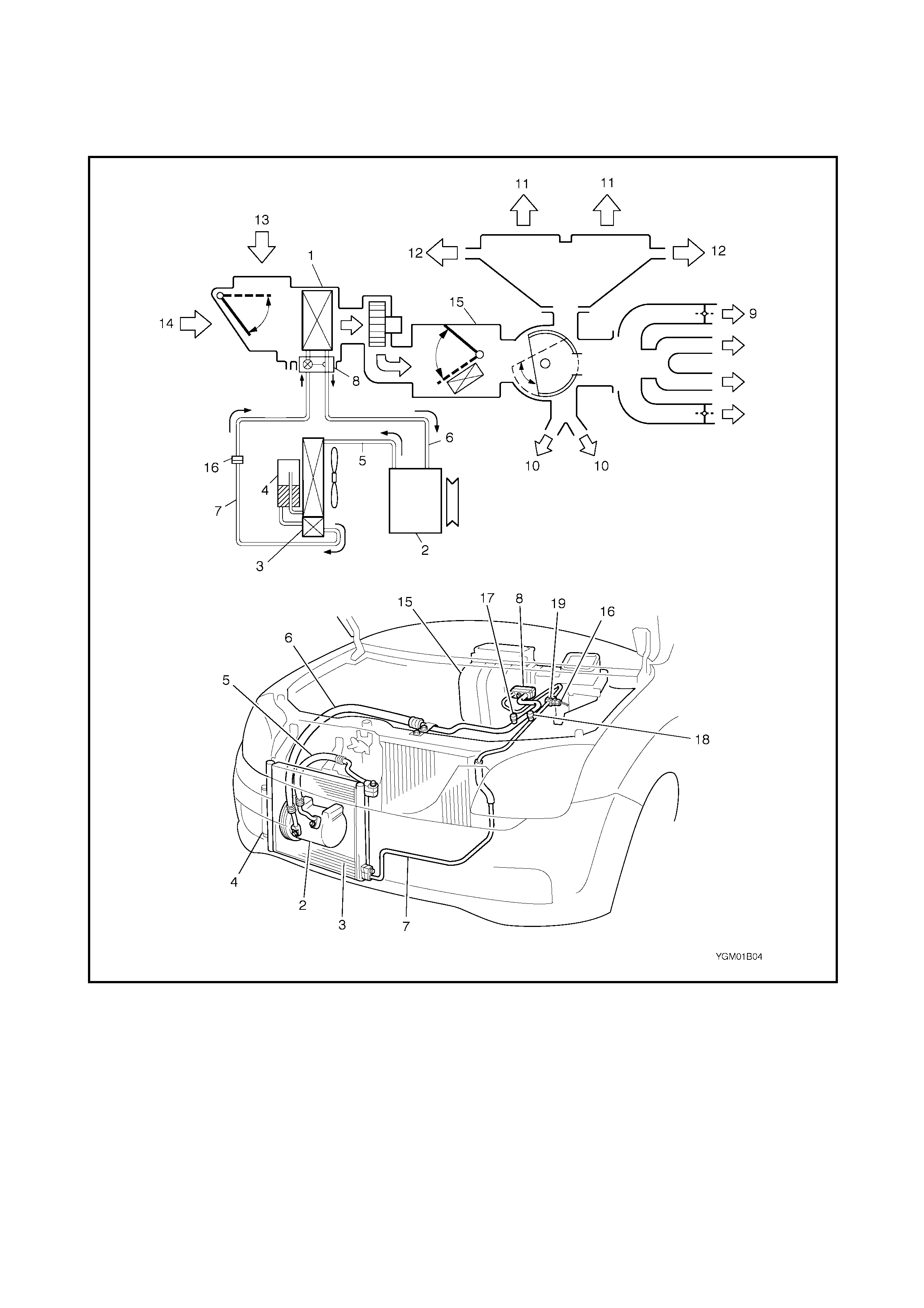

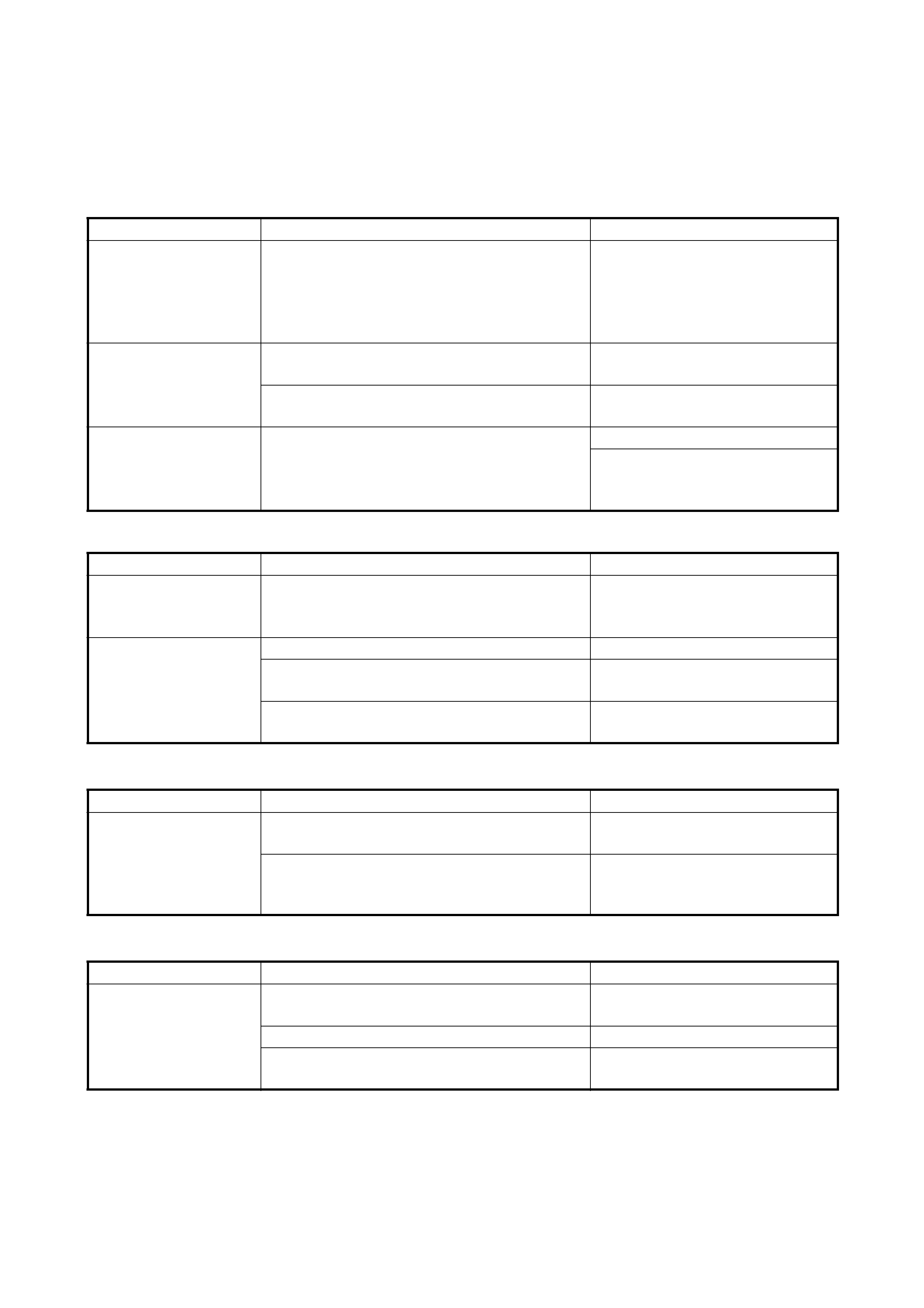

1.3 MAJOR COMPONENTS AND

LOCATION

Legend

1. Cooling unit 8. Expansion valve 15. Heater unit

2. Compress or 9. Ventilation air 16. A / C refrigerant pressure switch

3. Condenser assembly 10. F oot air 17. Low pressure charge valve

4. Receiver drier 11. Defroster air 18. Hi gh pr essure charge valve

5. Discharge hose 12. Demister air 19. S igh t glass

6. Suction pipe 13. Fresh air

7. Condenser outlet (liquid)

tube 14. Recirculation air

2. DIAGNOSIS

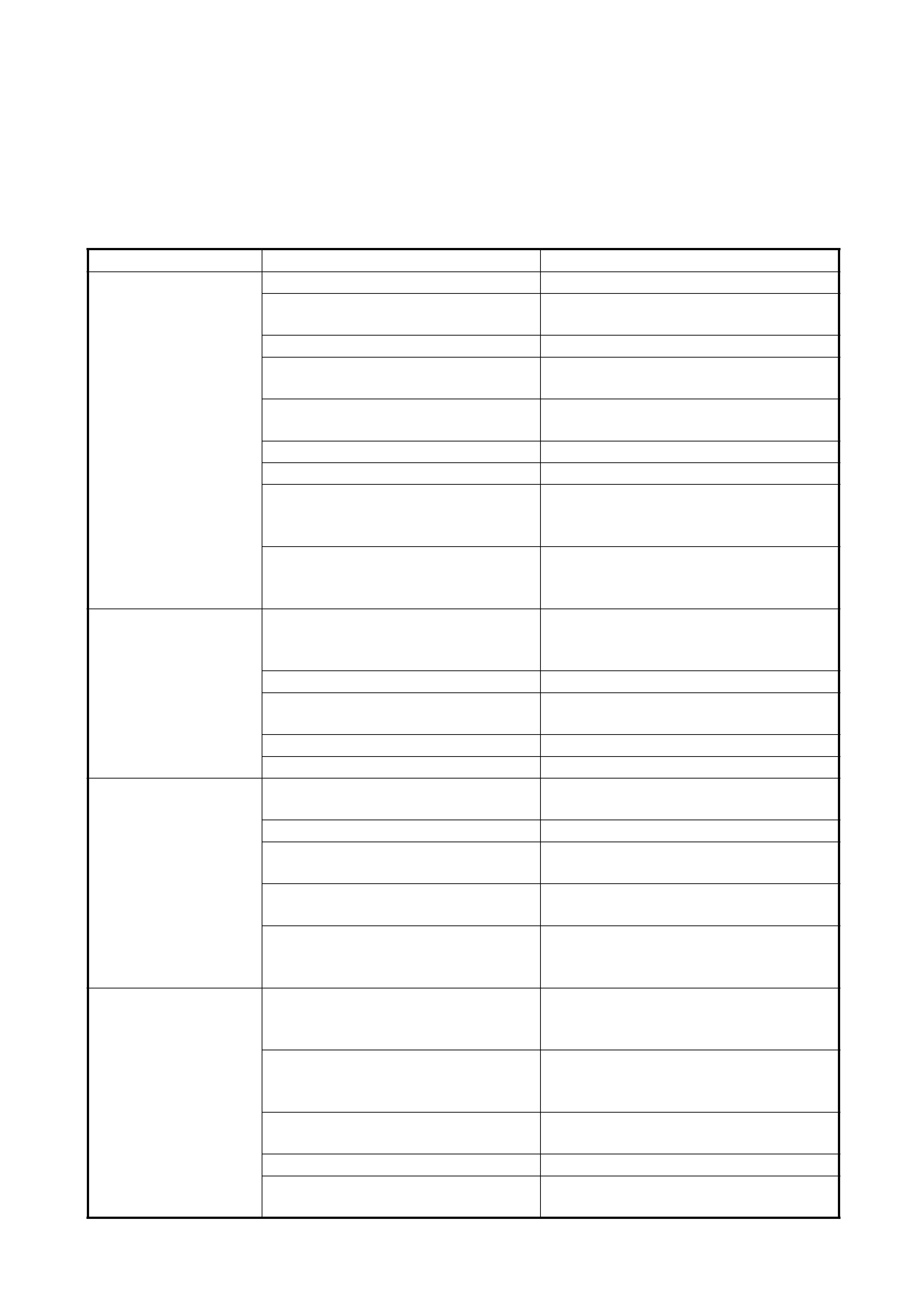

2.1 GENERAL DIAGNOSIS TABLE

Condition Possible Cause Correction

N o cool air flow

(A/C system won’t

operative)

No refrigerant Perform recover, e vacuation and charging.

Fuse blown Check fuses in circuit fuse and main f use

boxes, and check short circuit to ground.

A/C switch faul ty Check A/C switch.

Blower f an switch faul ty Check blower f an switch, refer to Sec tion

1A - HEATER AND VENTILATION.

A/C evaporator temperature sensor

faulty Chec k A/C evaporator temperature sen-

sor.

A/C refrigerant pressure switch faulty Check A/C refrigerant pressure switch.

Wi ring or grounding faul ty Repair as necessary.

ECT sensor faulty Check ECT sensor, refer to Section 6E1 -

ENGINE AND EMI SSION CONTROL

SYSTEM

ECM and its circuit f aulty Check ECM and its circuit, refe r to Section

6E1 - ENGINE AND EMISSION

CONTROL SYSTEM.

N o cool air flow

(A/C comp resso r

won’t operati ve)

ECM f aul ty Check ECM and its ci rcuit refer to Section

6E1 - ENGINE AND EMISSION

CONTROL SYSTEM.

Magnet clutch faulty Check magnet i c clutch.

Compressor dri ve belt loosen or bro-

ken Adjust or replace drive belt.

Compressor faulty Check compressor.

Compressor thermal swi tch faulty Check compressor th e rmal s wit ch

N o cool air flow

(A/C conden ser

cooling fan motor

won’t operati ve)

Fuse blown Check fuses in circuit fuse and main f use

boxes, and check short circuit to ground.

Wi ring or grounding faul ty Repair as necessary.

Radiator/cond ens er cooling fan motor

relay faulty Check radiator/condenser c ooling f an

moto r relay No. 1 , No.2 and No.3.

Radiator/cond ens er cooling fan motor

faulty Chec k radiator/condenser c ooling f an

motor.

ECM f aul ty Check ECM and its ci rcuit refer to Section

6E1 - ENGINE AND EMISSION

CONTROL SYSTEM

N o cool air flow

(Blower fan moto r

won’t operati ve)

Fuse blown Check “HTR” fuse in circuit fus e box and

main fuses, and check short circuit to

ground.

Blower fan motor resistor faul ty Check blower f an motor resi st or, refer to

Section 1A - HEATER AND

VENTILATION.

Blower f an switch faul ty Check blower f an switch, refer to Sec tion

1A - HEATER AND VENTILATION.

Wi ring or grounding faul ty Repair as necessary.

Blower f an motor faulty Check blower f an motor, ref er to Section

1A - HEATER AND VENTILATION.

N o cool air flow or

coolin g is inadequ a t e

(A/C system op erates

normally)

Insufficient or excessive charge of

refrigerant Check refri gerant charge and system for

leaks.

Condens er clogged Check condens er.

A/C e vaporator cl ogged or frost ed Check A/C ev aporator and A/C e vaporator

temperature sensor.

A/C evaporator temperature sensor

faulty Chec k A/C evaporator temperature

sensor.

Expansion val ve f aulty Check e xpansion valve.

Receiver/drier clogged Check receiver/dr ier.

Compressor dri ve belt loose or broken Adjust or replace drive belt.

Magneti c clutch faulty Chec k magnet i c clutch.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/drier, and perform

evacuation and charging.

Air leaking from cooling unit or air duct Repair as necessary.

Heater and ventilation system faulty Check air inlet box (cooling unit), heater

control assembly and heater unit referring

to Section 1A - HEATER AND

VENTILATION.

Blower f an motor faulty Check blower f an motor, ref er to Section

1A - HEATER AND VENTILATION.

Excessive compre ssor oil exis ti n g in

A/C syste m Dr ain exce ss co mpresso r oil from A/C

syste m circuit a nd check compress or.

N o cool air flow or

intermittent cool air

flow only

Wi ring connect ion faul ty Repai r as nec essary.

Expansion val ve f aulty Check e xpansion valve.

Excessive moisture in A/C system Replace receiver/drie r and perform

evacuation and charging.

Magneti c clutch faulty Chec k magnet i c clutch.

Excessive charge of refrigerant Check charge of refrigerant.

C ool a ir flows only at

hi gh vehicle speed Condens er clogged Check condens er.

Condenser cooling fan motor f aul ty Check condenser cooling fan motor.

Condens er cooling fan motor relay

faulty Check condenser cooling fan motor relay

Condensder cooling fan blade faulty Check condenser cooling fan blade

Insufficient charge of refrig erant Check refrigerant charge.

Air in A/C system Replace receiver/drier, and perform evac-

uation and charging.

Compressor dri ve belt loose or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Co ol air flow only at

hi gh vehicle speed Excessive charge of refrigerant Check charge of refrigerant.

A/C e vaporator frost ed Check A/C e v aporator and A/C e vaporator

temperature sensor.

Insu ffi cient strength

of cool air flow A/C e vaporator clogged or froste d Check A/C e v aporator and A/C e vaporator

temperature sensor.

Air leaking from cooling unit or air duct Repair as necessary.

Blower f an motor faulty Check blower f an motor, ref er to Section

1A - HEATER AND VENTILATION.

Wi ring or grounding faul ty Repair as necessary.

Condition Possible Cause Correction

2.2 ABNOR MAL NOISE DIAGNOSIS

There are variou s types of n oise, ranging from t hose produced in the en gine compartment to thos e from t he

passeng er compartment , from rumbling to whistling noises.

ABNORMAL NOISE FROM COMPRESSOR

ABNORMAL NOISE FROM MAG NETIC CLUTCH

ABNORMAL NOISE FROM TUBING

ABNORMAL NOISE FROM CONDENSER ASSEMBLY

Condition Possible Cause Correction

During compressor

operation, a rumbling

noi se i s he ard pr opor-

tional to engine

revolutions.

Inadequate clearance in piston area (pi ston or

swash-plate) Repair or replace compressor as

necessary.

A loud noise is heard

at a certain rpm, dis-

proportionately to

engine re volution.

Loose or faulty compressor drive belt Adju st drive belt tension, or

replace drive belt.

Loose com pressor mount ing bolts Retighten mounting bolts.

A loud rattle is heard

at l ow en g ine rpm . Loose compressor clutch plate bolt Ret i ghten clutch plate bolt.

Replace compress or if it has oper-

ated in this condition for a long

time.

Condition Possible Cause Correction

A rumbling noise is

heard whe n comp res-

s or is not operating.

Worn or damaged bearings Replace magnetic cl utch

assembly.

A chattering noise is

heard whe n comp res-

s or is enga g e d.

Faulty clutch clearance (excessive) A dju st clutch clearance.

Worn clutch friction surface Re place magnet ic clutch

assembly.

Compress or oil leaked from lip type seal, con-

taminating the friction surface Replace compress or body

assembly.

Condition Possible Cause Correction

A droning noise is

heard inside vehi cle,

but no t partic ul a rly

noticeable in engine

compartment.

Faulty tubing clamps Repos ition clamps or increase the

number of clamps.

Resonance caus ed by pulsation from

variati ons in refrigerant pressure Attach a silencer to tubing, or

modi fy its position and length.

Condition Possible Cause Correction

Considerable

vibration in

condenser.

Resonance from condenser assembly bracket

and body Firmly insert a silencer between

condenser brac k et and body.

Loose condenser c ooling fan mounting bolts Re tighten mounting bolts

Faulty condenser cooling fan blade Replace condenser cooling fan

blade.

ABNORMAL NOISE FROM CRANKSHAFT PULLEY

ABNORMAL NOISE FROM TENSION PULLEY

ABNORMAL NOISE FROM A/C EVAPORATOR

ABNORMAL NOISE FROM BLOWER FAN MOTO R

Condition Possible Cause Correction

A loud ra tt ling no i se

is he ard at idle or on

sudd en accelerati on .

Loose crankshaft pulley bolt Re tighten bolt.

Condition Possible Cause Correction

Cl attering noise is

he ard from pu ll ey. Worn or damaged bearing Repl ace tension pulley.

Pul le y cranks upon

contact. Crack ed or l oose brack et Repl ace or retighten bracket .

Condition Possible Cause Correction

Whistlin g sound is

heard from A/C evap-

orator.

Depending on the combina tion of the interior/

ext erior temperatures, engine rpm and refrig-

erant pressure, the refrigerant flowing out of

the expansion valv e may, under c ertain condi-

tions, make a whistling sound

At times , slightly decreasi ng refrig-

erant volume ma y stop this noise.

Inspect expansion valve and

replace if faulty.

Condition Possible Cause Correction

Blower fan moto r

e m its a chir ping

sound in proportion

to its speed of

rotation.

Worn or damaged motor brushes or

commutator Repair or replace blower fan

motor.

Flu tt e ri ng noise or

la rge dr on in g noi se is

heard from blower fan

motor.

Leaves or other debr is introduced from fresh

air inlet to blower fan motor Re move debris and ensure the

fresh air inlet screen is intact.

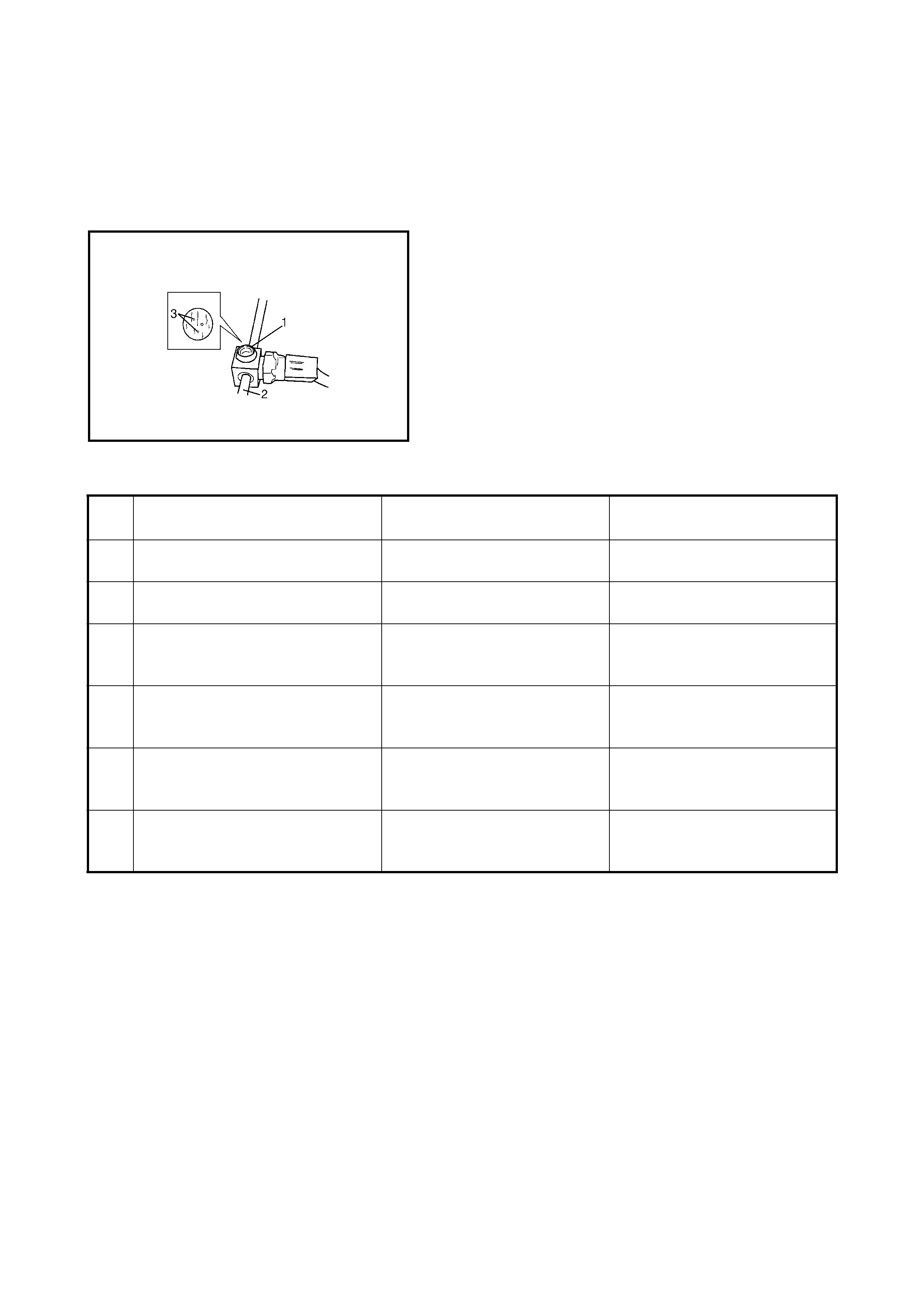

2.3 QUICK CHECK OF REFRIGERANT CHARGE

The following procedure can be us ed for quickly checking if

the A/C system has a proper charge of refrigerant.

Run the engine at fast idle, and operate the A /C at its maxi-

mum cooling capacity for a few minutes.

Then look at the sight glass (1) on the condenser outlet

pipe (2) and compa re what is obser ved with the symptoms

listed i n the tabl e below.

CHECKING REFRIGERANT CHARGE

NOTE: For specified amount of refrigerant, refer to 4.1 OPERATION PROCEDURE FOR REFRIGERANT

CHARGING in this Section.

Item

No. Symptom Charge of refrigerant

condition Correction

1. Bu bbles (3) obser ved in sight

glass Insufficient charge of refriger ant

in system Check syst e m f o r leaks wit h a

leak tester.

2. No bubbles (3) observed in sight

glass No or insufficient charge of

ref rigera nt in system Refer to the items 3 and 4.

3. No temperature diff erence

between compressor inlet and out-

let

Empty or nearly emp ty system Evacuate and charge system

and then check it for leaks with

a leak tester.

4. Noticeable temperature difference

between compressor inlet and out-

let

Proper or too much charge of

ref rigera nt in system Refer to the items 5 and 6.

5. When A /C is turne d OFF, refriger-

ant in sight glass clears immedi-

ately and remains clear

Too much charge of refrigerant

in system Recharge with specified

amount of refrigerant.

6. When A /C is turne d OFF, refriger-

ant in sight glass initially produces

bubbles and then clears

Proper refrigerant charge in

system No correction needed bec ause

refrigerant charge is norm al .

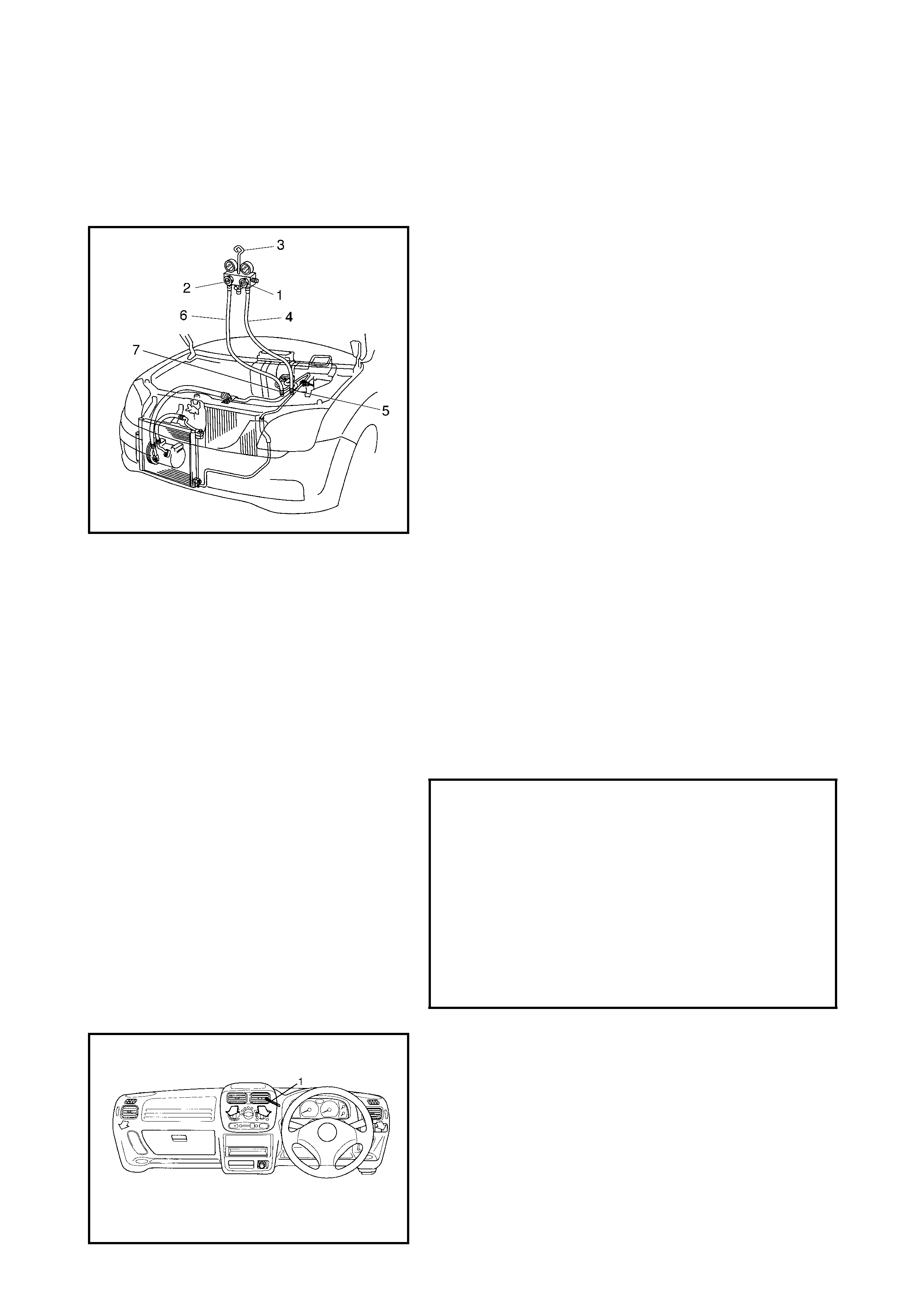

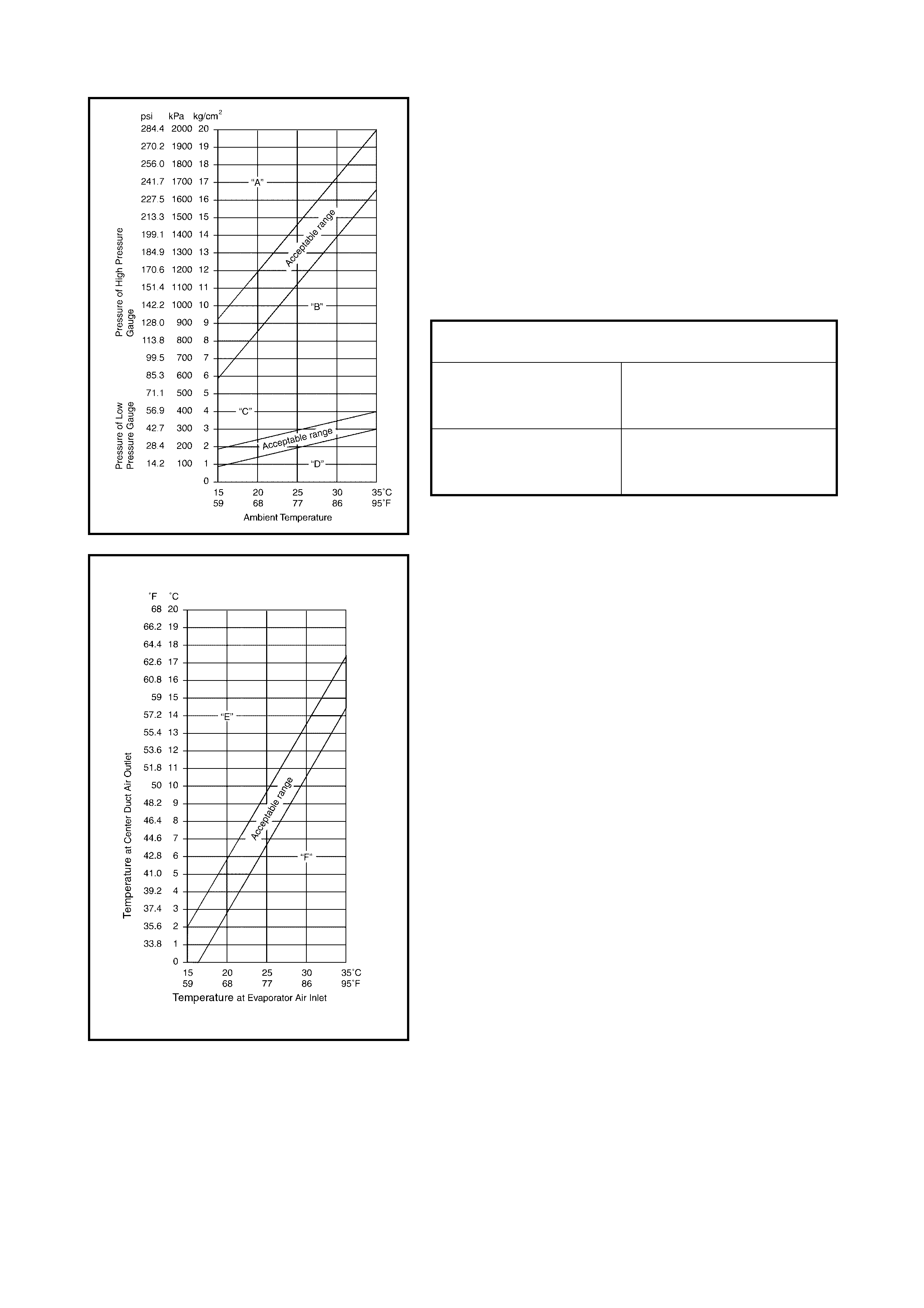

2.4 PERFORMANCE DIAGNOSIS

1. Confirm that vehicle and environmental conditions are

as follows.

•Vehicle is not exposed to direct sun.

•Ambient temperatu re is within 15 – 35°C.

2. Make sure that high pressure valve (1) and low

pressure valve (2) of manifo ld gauge set (3) are firmly

closed.

3. Connect high pressure charging hose (4) to high

pressure service valve (5) and connect low pressure

charging hose (6) to low press ure service valve (7).

4. Bleed the air in charging hoses (4), (6) by loosening

their respective n uts on manifold gauge set (3), utiliz ing

the refrigerant pressure. When a hissing sound is

heard, imme diately tighten nut.

CAUTION: Do not interchange high and low pressure

charging hoses by mistake.

5. Warm up engine to normal operating temperature

(engine coolant temperature at 80 – 90°C) and keep it

at specified idle speed.

6. Turn A/C switch to ON position, and set blower fan

switch at “H” (4th position), temperature dial at

“COOL”, air outlet control dial at “FACE” and fresh/

recirculation control dial at “RECIRCULATION”.

(Confirm that A/C compressor and condenser cooling

fan are working. )

Keep all windows, doors and engine hood open.

Perf ormance diagnosis condition

7. With dry bulb thermometer (1) inserted into centre duct

air out let an d another one set near evaporator air inlet,

read temperature indica ted on each thermometer.

Ambient temperature 15 – 35°C

Engine rpm Keep to 1,500 rpm.

Blower f an switch “H” (4th position)

Temperature control “Cool”

Air outlet control “Face”

Vehicle Doors All open

Air inlet door position Recircula tion

8. Check that the pressure of the low side and high side is

within the shaded range on the graph.

If each gauge reading is not within specified pressures,

correct defective part, refer to PERFORMANCE

DIAGNOSIS TABLE in 2.4 PERFORMANCE

DIAGNOSIS in this Section.

NOTE: Pressure registered on gauge varies with ambient

temperature. Therefore, use the graphs when determining

if pressures are normal or not.

Low side and high side pressure example:

9. Check inlet port temperature-to-outlet port temperature

relationship using graph.

For example, if evaporator inlet port temperature is

25°C and centre duct air outlet temperature is 8°C,

their crossing point is within acceptable range as

shown in graph.

If crossing point is out of acceptable range, diagnose

trouble, refer to PERFORMANCE DIAGNOSIS TABLE

in 2.4 PERFORMANCE DIAGNOSIS in this Section.

Gaug es sho uld read as follows when ambien t

tem pera ture is 30 °C.

Pressu re

on high pres sure gauge 1400 – 1750 kPa

14.0 – 17. 5 kg/cm2

199.1 – 248. 9 psi

Pressu re

on low pressure gauge 230 – 350 kPa

2.3 – 3.5 kg /cm2

32.7 – 49. 8 psi

PERFORMANCE DIAGNOSIS TABLE

NOTE: If ambient temperature is approximately 30°C, it is possible to diagnose A/C system in detail, refer to

DETAIL DIAGNOSIS TABLE (AMBIENT TEMPERATURE AT 30 °C) under 2.4 PERFORMANCE DIAGNOSIS

in th is Sec t io n. HIGH PRESSURE GAUGE

LOW PRESSURE GAUGE

THERMOMETER AT CENTRE DUCT

Cond ition Possible Cause Correction

Pr es sure high

(“A” area of hi gh side

graph)

Refrigerant overc harged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage on high side Clean or replace.

Condenser cooling fan malfunction (Insufficient

cooling of condenser) Check condenser cooli ng f an.

Dirt y or bent condenser fins (Insufficient cool-

ing of condenser) Clean or repair.

Compressor malfunction (Insuff i ci ent oil etc.) Check compressor.

Engine overheating Check engine cooling system,

refer to Section 6B - ENGINE

COOLING.

Pressure low

(“B” area of hi gh side

graph)

Insufficient refriger ant (Insufficient charge or

leakage) Check for leakage, repa ir if

nec essary and recharge.

Expansion valve malfunction (valv e opens too

wide) Check expansion valve.

Compressor malfunction (Insufficient compres-

sion) Check compresso r.

Condition P ossible Cause Correction

Pr es sure high

(“C” area of low side

graph)

Expansion valve malfunction

(valve opening too wide) Check expansion valve.

Compressor malfunction

(Insufficient compression) Check compressor.

Pressure low

(“D” area of low side

graph)

Insufficient refrigerant

(Insufficient charge or leakage) Check for leakage, repair if

nece ssary and recharge.

Expansion valve malfunction

(valve opening too narro w) Check expansion valve.

Clogged refrigerant passage (crushed pipe) Repair or replace.

Condition P ossible Cause Correction

Outlet ai r tempera-

ture at centre duct is

high

(Cros sing poi nt i s in

area “E”)

Insufficient or excessive charge of refrigerant Ch eck refrigerant pressure.

Dirty or bent A/C evaporator fins Cl ean or repair.

Air leakage from cooling (heater) unit or air

duct Re pair or replace.

Malfunctioning switchover function of door in

cooling (heat er) unit Repair or replace.

Compressor malfun cti o n Check compressor.

Outlet ai r tempera-

ture at centre duct is

low

(Cros sing poi nt i s in

area “F”)

Insufficient air volume from centre duc t

(Heater blo wer malfunction) Chec k blower motor and fan.

Compressor malfun cti o n Check compressor.

DETAIL DIAGNO SI S TABLE (AMBIENT TEMPE RATURE AT 30 °C)

Condition

Possible Cause Correction

MANIFOLD

GAUGE MPa

(kg/cm2)

(psi)

Detail

Lo Hi

0.23 – 0.3 5

(2.3 – 3.5)

(33 – 50)

1.4 – 1.75

(14 – 17.5)

(200 – 249)

Normal condition ––

Negative

pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3)

The low pressure sid e

reads a neg ative pres-

sure, and the high

pressu re side reads an

extremely low pres-

sure.

Prese nce of frost

around tubing to and

fr om receiver/drier and

expansion valve.

Dust particles or water

droplets are eit her stuck

or frozen inside expan-

sion valve , prev enting the

refrigerant from flo wing

Clean expansion valve.

Replace it if it c annot be

cleaned.

Replace receiver/drier .

Evacuate the A/C system

and recharge with fresh

refrigerant.

Normal :

0.23 – 0.3 5

(2.3 – 3.5)

(33 – 50)

¦ Ø

Abnormal :

Negative

pressure

Normal :

1.4 – 1.75

(14 – 17.5)

(200 – 249)

¦ Ø

Abnormal :

0.7 – 1.0

(7 – 10)

(100 – 142)

During A/C operation,

the low pressure side

sometimes indicates

negative pre ssure , and

sometimes normal

pressure. Also high

pressu re side reading

fluctuates between

abnormal and normal

pressure.

Expansion valve is frozen

due to moisture in the

system, and temporar ily

shuts off the refrigera-

tion cycle

Replace expans ion

valve.

Replace receiver/drier .

Eva cu a te A/C system

and recharge with fresh

refrigerant.

0.05 – 0.1 5

(0.5 – 1.5)

(4.2 – 21.3)

0.7 – 1.0

(7 – 10)

(100 – 142)

Bo t h low an d hi gh

pressu re sides in di-

cate low readings.

Co nt i nuous air bub-

bles are visible through

sight gl ass.

O u t p ut ai r is s l ight ly

cold.

Insufficient refriger ant in

system

(Refrigerant leaking)

Using leak detector,

check for leaks and

repair as necessary.

Recharge refrigerant to

the specified amou nt.

If the pressure readi ng is

almost 0 when the

manifold gauges are

attached, check for any

leaks, repair them, and

evacuate the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85. 3)

Press ure on low pres-

sure side is high .

Pres sure on hi gh pres-

sure side is low.

Both pressure becom-

ing equal right after A/C

is turned OFF.

Internal leak in

compressor Inspect compresso r and

repair or replace as

necessary.

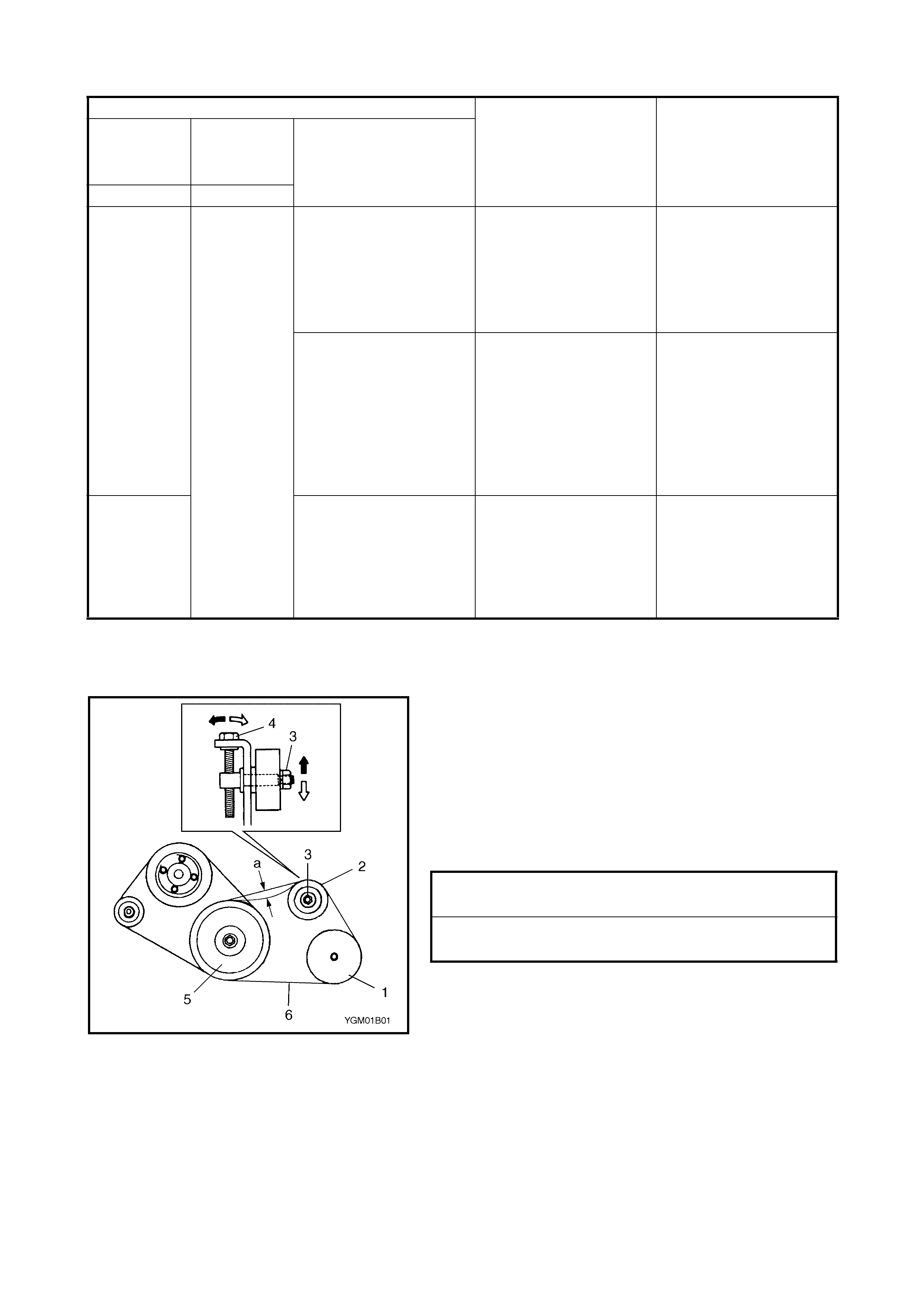

2.5 COMPRESSOR DRIVE BELT

INSPECTION

•Check compressor drive belt (6) for wear and cracks,

and replace as required.

•Check compressor drive belt (6) tension by measuring

how much it deflects when pushed at the midpoint

between the crankshaft pulley (5) and the tension pul-

ley (2) with about 100 N (10 kg) force after the crank-

shaft pulley is rotated 1 rev ol ution.

Adjust the belt tension if it is not within specifications,

refer to the follo wing procedures.

ADJUSTMENT

1. Loosen tension pulley nut (3).

2. Adju st the belt tension with the tension pulley adjusting

bolt (4).

3. Tighten tension pulley nut (3).

4. Turn the crank pulley (5) 1 revolution, then check belt

tension.

REPLACEMENT

1. Loosen tension pulley nut (3).

2. Loose n belt tension by loosening pulley adjusting

bolt (4).

3. Remove compressor driv e belt (6).

4. Install new compressor drive belt.

5. Adjust belt tension, refer to above proced ures.

0.35 – 0.4 5

(3.5 – 4.5)

(50 – 64)

2.0 – 2.5

(20 – 25)

(285 – 355)

High pressure reading

on both low and high

pressu re sides.

Air bubbles are not vis-

ible even when engine

rpm is l o wered.

Overcharged A/C system Adjust refr igerant to

specified amount .

Faul ty condens er

cooling oper ation Clean condenser.

Faul ty condens er

cooling fan operation I nspec t and repair

condenser cooling fan.

High pressure reading

on both low and high

pressu re sides.

Low pressure side tub-

ing is not cold when

touched.

Air bubbles are visible

throug h sight gla ss.

Presence of air in A/C

system

(Improperl y ev acuated)

Replace receiver/drier .

Inspect quan tity of com-

pressor oil and presence

of contam inants in o il.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.5 5

(4.5 – 5.5)

(64 – 78)

High pressure reading

on both low and high

pressu re sides.

La rge a m o unt of fros t

or dew on th e l ow pre s-

su re sid e tubi ng.

Faul ty expans ion valve

Refrigerant flow is not

regulated proper ly

Replace expans ion

valve.

Condition

Possible Cause Correction

MANIFOLD

GAUGE MPa

(kg/cm2)

(psi)

Detail

Lo Hi

COMPRESSOR DRIVE BELT

TENSION (a) 3 - 5 mm

NEW COMPRESS OR DRIVE BELT

TENSION (a) 2 - 4 mm

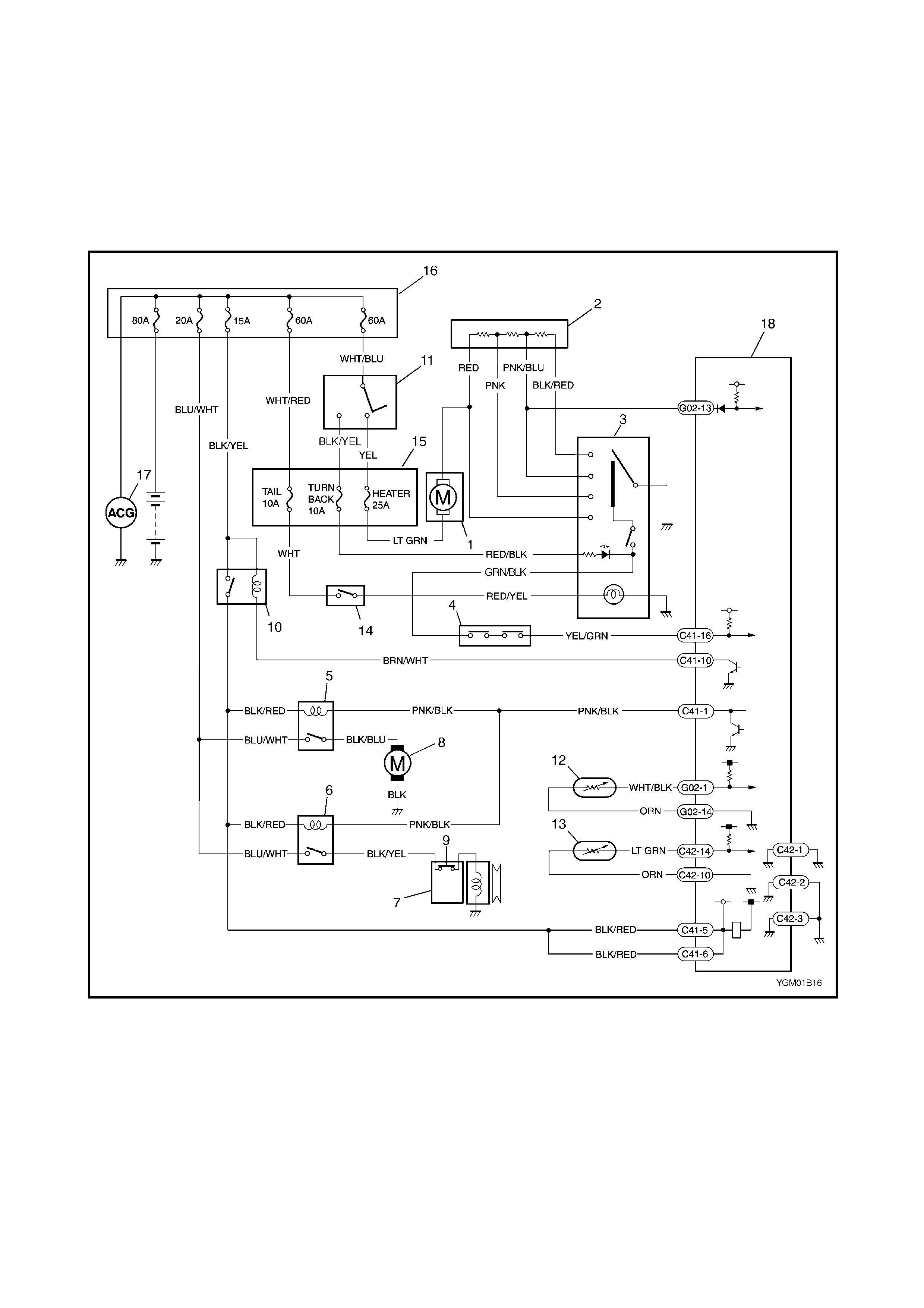

3. ELECTRICAL DIAGNOSIS

3.1 WIRING DIAGRAM

Legend

1. Blower fan m otor 6. Compres sor relay 13. ECT sensor

2. Blower fan m otor resistor 7. Com pres sor 14. Lighting switch

3. Blower fan sw itch and A/C

switch 8. Condenser cooling fan

motor 15. Circuit fuse box

16. Main fuse box

4. A/C refrigerant pressure

switch 9. Com pres sor ther m al switch 17. Generator

10. Main relay 18. ECM

5. Condenser cooling

fan motor relay 11. Ignition switch

12. A/C e vaporator temperature sensor

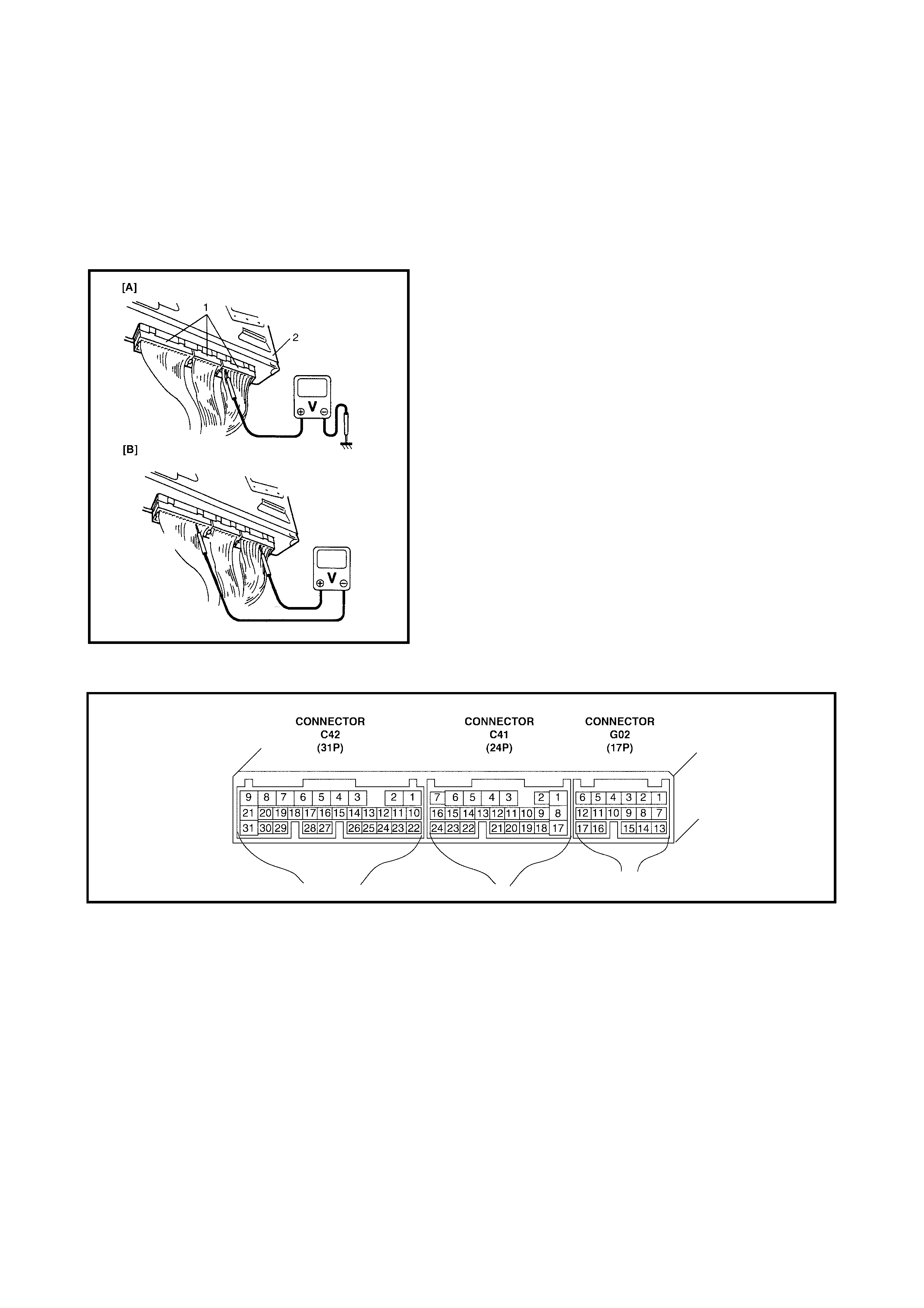

3.2 A/C SYSTEM INSP ECTION OF ECM AND ITS CIRCUITS

ECM and its circuits can be checked at ECM wiring con-

nectors by measuring voltage.

CAUTION:

ECM cannot be checked by itself. It is

strictly prohibited to connect voltmet er or ohmmeter to

ECM with connectors disconnected from it.

VOLTAGE CHECK

1. Remove ECM from vehicle, refer to Section 6E1,

2.3 ELECTRONIC CONTROL SYSTEM -

ECM REMOVAL AND INSTALLATION.

2. Connect ECM connectors (1) to ECM (2).

3. Check voltage at each terminal of connectors.

NOTE: As each terminal voltage is affected by the battery

voltage, confirm that the battery voltage is 11 V or more

when ignition switch is ON position

.

Terminal arrangement of ECM coupler (Viewed from harness side).

ECM VOLTAGE VALUES TABLE FOR A/C CONTROL

Terminal Wire Circuit Me asureme nt

ground Normal value Condition

C41-1 PNK/

BLK A /C co m pre ss or

clutch and

condenser f an

switch

Ground to

engine (Fig B) 0 – 1 V Fulfill all the following conditions:-

• Bl ower speed selector ON

• A/C switch ON

• Engi ne running

• A/C pre ssu r e sens o r ON

12 – 15 V Except the above mentioned condition

wit h engine runni ng

C41-5 BLK/

RED Main power

supply for ECM Ground to

engine (Fig B) 10 – 14 V Ignition switc h ON with engine not

running

C41-6 BLK/

RED Main power

supply for ECM Ground to

engine (Fig B) 10 – 14 V Ignition switc h ON with engine not

running

C41-10 BRN/

WHT Main relay drive Ground to

engine (Fig B) 0.5 – 1.2 V Ignition switch ON wit h engine not

running

10 – 14 V Igniti on switch OFF

C41-16 YEL/

GRN A/C switch input Ground to

engine (Fig B) 10 – 14 V Except the above mentioned condition

wit h engine runni ng

0 – 1 V Fulfill all the following con ditions:-

• Bl ower speed selector ON

• A/C switch ON

• Engi ne running

• A/C pre ssu r e sens o r ON

C42-1 BLK/

ORN Main ground for

ECM Ground to

body (F ig A) -0.5 – 1 V Engine running

C42-2 BLK ECM gr ound for

power c ircuit Ground to

body (F ig A) –0.5 – 1 V E ngine running

C42-3 BLK/

ORN ECM ground for

power c ircuit Ground to

body (F ig A) –0.5 – 1 V E ngine running

C42-10 ORN Sensor g r ound

for ECT sensor Ground to

body (F ig A) –0.5 – 1 V E ngine running

C42-14 LT

GRN ECT sensor

input Ground to

engine

(Fig B)

0.71 – 0.75 V

(298 – 320 9)Engine coolant temperature at

approximately 80°C with eng ine

running

0.35 – 0.37 V

(135 – 144 9)En gi ne coo lant tempe ra ture at Appro x i-

mately 110°C with engine running

If the te m pe ra tu r e i s mo r e than

112.5°C, compr essor and c ondenser

cooling fan shoul d stop (restart at less

than 110°C)

G02-1 WHT./

BLK A/C evaporator

temperature

sensor input

Ground to

engine (Fig B) 2.09 – 2.17 V

(1940 - 2060

9)

Evapor ator thermistor tempera ture at

approximately 25°C with eng ine

running

3.52 - 3.59 V

(6450 - 6859

9

A/C evaporator thermistor at

approximately 0°C wit h engine runnin g

If the temperature is less than approxi-

mately 2.5°C, compressor and con-

denser cooling fan should stop (restart

at more than approximately 4°C

G02-10 ORN Sensor ground

for A /C evapora-

tor temperature

sensor

Ground to

body (F ig A) -0.5 – 1 V Engine running

G02-13 PNK/

BLU Blower fan

speed input Ground to

engine (Fig B) 0 – 1 V Bl ower fan motor switch “ML”, “MH”, or

“H” with engine runni ng

4 – 7 V Blower fan mot or switch “L” position

wit h engine runni ng

10 – 14 V Blower fan motor switch OFF with

engine runnin g

4. REFRIGERANT RECOVERY, EVAC UATING AND CHARGING

WARNING

•Your eyes shou ld not be exposed to refrigeran t (liquid).

Any liquid HFC-134a (R-134a) escap in g by accident has a tempera ture as low as approxima tely

–6°C below freezing point. Should liquid HFC-134a (R-134a) get into your eyes, it may cause a seri-

ous injury. Always wear goggles to protect your eyes against accidental injury. Should HFC-134a

(R-134a) contact your eyes, consult a doctor immed iately.

•Do not rub the affected eye(s). Instead, use large quantities of fresh cold water to sp lash over the

affected area to gradually raise the temperature above freezing point.

•Obtain proper treatment as soon as possible from a doctor or eye speci alist.

•Should t he HFC-134a (R-134a) liquid come into contact with your skin, the affected area should be

treated in the same as when skin is frostbitten or frozen.

•Refrigerant must not be handled near where welding or steam cleaning is being performed.

•Refrig eran t sho uld b e ke pt i n a cold and dark place. It shoul d never b e stor ed whe re h igh temper-

atures are anticipated, e.g. exposure to direct sun light, close to fire or inside vehicle (including

boot).

Avoid breathing fumes produced when HFC-134a (R-134a) is burned. Such fumes may be hazardous

to health.

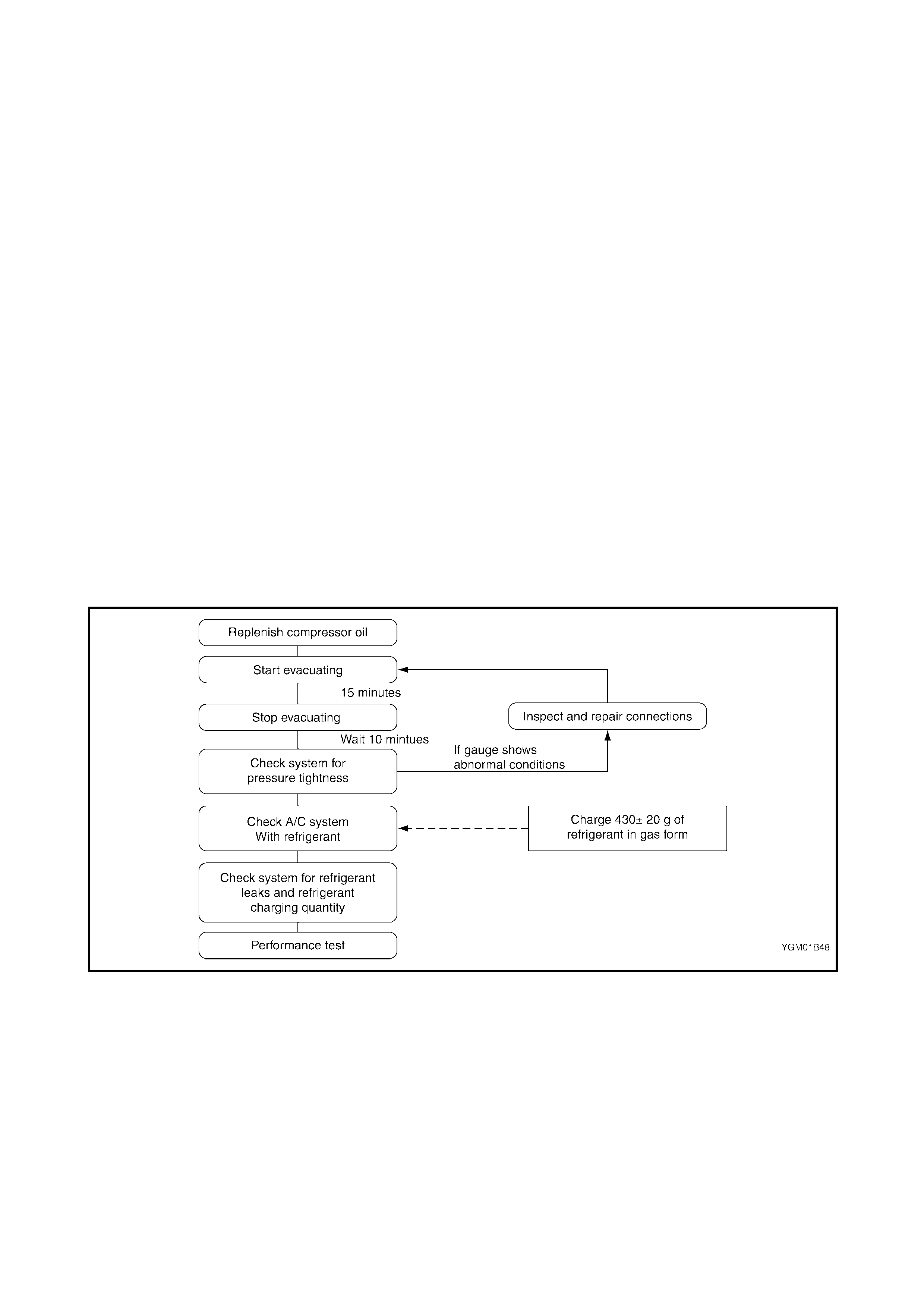

4.1 OPERATING PROCEDURE FOR RE FRIGERANT CHARGING

4.2 RECOVERY

REFRIGERANT RECOVERY

When discharging refrigerant from the A/C system, always

recover it using refrigerant recovery and recycling equip-

ment. Discharging refrigerant HFC-134a (R-134a) into the

atmosphere could cause an adverse effect to the environ-

ment.

NOTE:

•After recovering refrigerant from the system, the

amount of removed compressor oil must be measured

to all o w f or accurat e replenishment.

•When using recov ery and recycling equipment, be sure

to foll ow the manufactures instruct i ons.

4.3 REPLENISHING COMPRESSOR OIL

Repleni sh the compressor (1) w ith the sp ecified am ount of

compressor oil via the compressor suction port (2) before

evacuating and charging the system with refrigerant.

WHEN CHARGING WITH REFRIGERANT ONLY

When charging the system with refrigerant without replac-

ing any components, replenish the same amount of com-

pressor oil that was measured when the refrigerant was

recovered (if no measurement w as tak en, replenish with 30

cc of compressor oil).

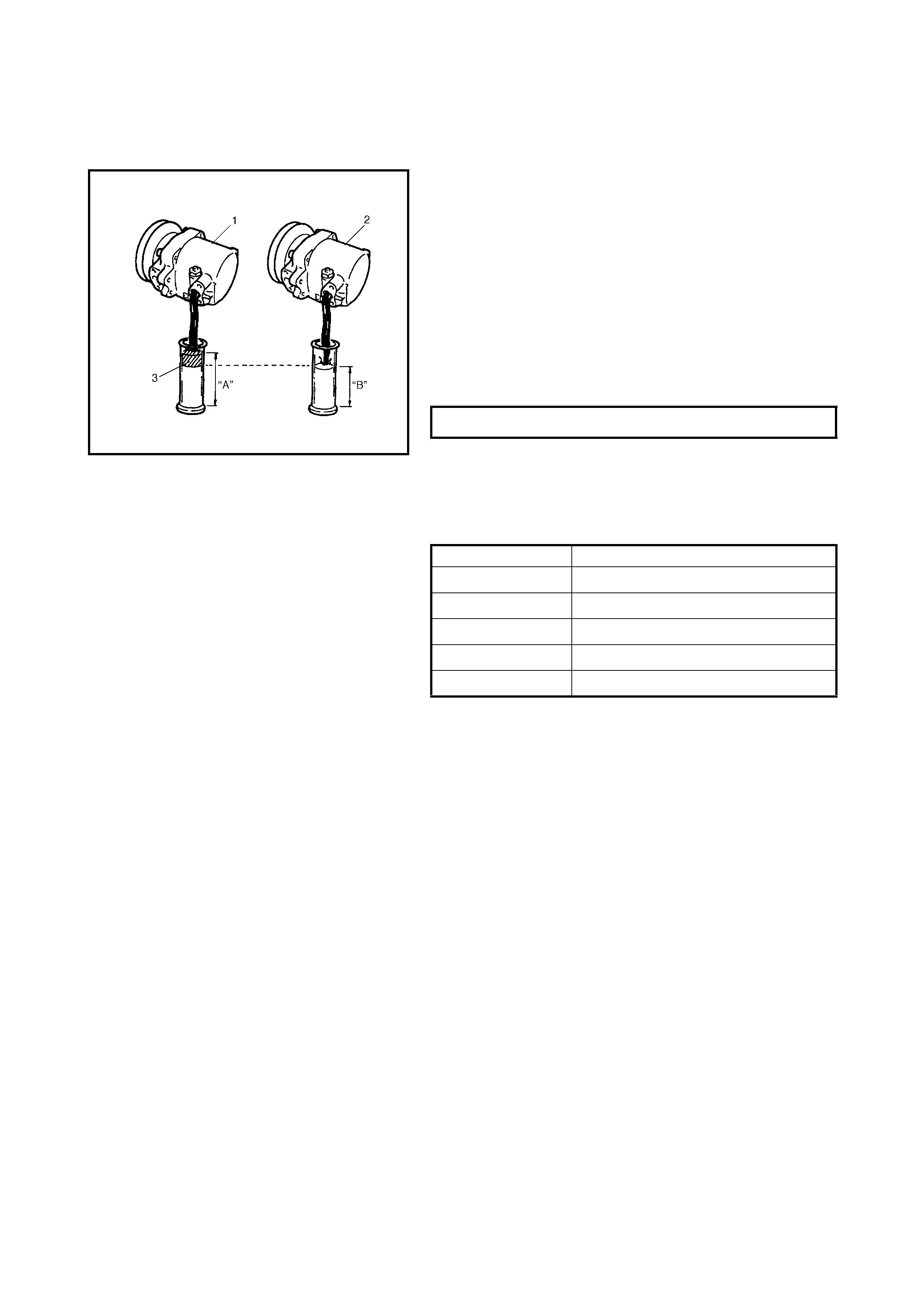

WHEN R EPLACIN G COM PRES SOR

CAUTION: Be sure to use HFC-134a (R-134a) com-

pr essor oil.

The correct amount of compressor oil for the A/C system is

sealed in each new compressor. When using a new com-

pressor as a replacement, compressor oil will need to be

drained from it to allo w f or oil already present i n the system.

Calculate the correct amount as follows.

“C” = “A” – “B”

“C”: Amount of oil to be drained (3).

“A”: Amount of oil sealed in a new compressor (1).

“B”: Amount of oil remaining in removed compressor (2).

NOTE: Factory supplied compressor assembly contains

the following amount of oil.

WHEN REPLACING OTHE R PARTS

When the parts listed below are replaced, replenish the

compressor with the quantity of compressor oil indicated.

OIL AMOUNT IN COMPRESSOR 120 cc

Replaced part Amou nt of compresso r oi l

Evaporator 25 cm3 (25 cc)

Condenser 15 cm3 (15 cc)

drier 20 cm3 (20 cc)

Hoses 10 cm3 (10 cc) each

Pipes 10 cm3 (10 cc) each

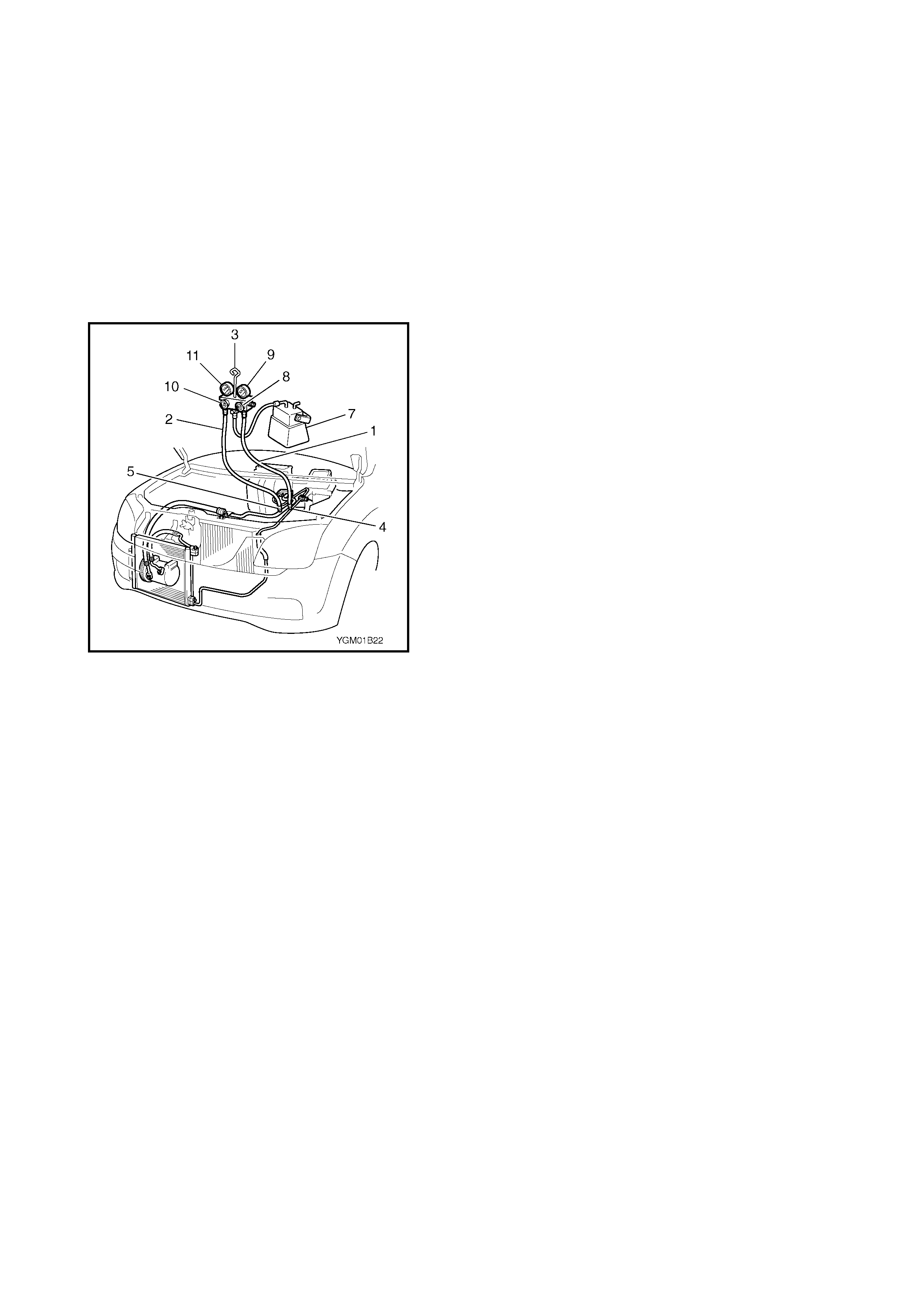

4.4 EVACUATING

EVACUATING PROCEDURE

CAUTION: Do not evacuate before recovering refriger-

ant in syst em.

NOTE: Whenever opened (exposed to atmospheric air),

the air conditioning sy stem must be e vac uated using a vac-

uum pump. A manifold gauge set should be connected to

the A/C system which should be evacuated for approxi-

mately 15 minutes.

1. Connect high pressure (HI) charging hose (1) and low

pressure (LO) c hargi ng hose (2) of the manifold gau ge

set (3) as follows:

High pressure charging hose (1) ® High pressure

charge port (4) on con denser outlet (liquid) tube.

Low pressure charging hose (2) ® Low pressure

charge port (5) on suction tube.

2. Attach centre charging hose (6) of manifold gauge set

(3) to vacuum pump (7).

3. Operate vacuum pump (7), and open the discharge

side valve (HI) (8) of the manifold gauge set (3).

If there is no blockage in the system, there will be an

indication on the high pressure gauge (9).

In this cas e, open the other side valve (LO) (10) of t he

set and evacu ate th e syste m.

4. After appro ximately 10 minutes the low pressure gauge

(11) should show a vacuum lower than –760 mmHg

providing no leakage exists.

NOTE:

•If the system does not show a vacuum below –760

mmHg, close both valves, stop the vacuum pump and

watch the movemen t of the low pressure gauge.

•Increas e in the gauge readi ng sugges ts existence of a

leak. In this case, repair the system before continuing

with the evacuation.

•If the gauge shows a stable reading (suggesting no

leakage), continue evacuation.

5. Evacuation should be carried out for a total of at least

15 minutes.

6. Continue evacuation until low pressure gauge (9)

indicates a vacuum less than –760 mmHg, and then

close both valves (8), (10).

7. Stop vacuum pump (7). Disconnect centre charging

hose (6) from pump inlet. Now, the system is ready for

charging refrigerant.

4.5 CHECKING SYSTEM FOR PRESSURE LEAKS

After completing the evacuation, close the manifold gauge

high pressure valve and low pressure valve and wait 10

minutes. Verify that low pressure gauge reading has not

changed.

CAUTION: If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing connec-

tions, make necessary repairs, evacuate the system

once again, ensuri ng there are no leaks.

4.6 CHARGING

CAUTION:

•Always charge through the low pressure side of the A/C system once the initial charging proce-

dure is perfor m ed f rom the high pressure side wi t h the engine not runnin g.

•Never charge to the high pressure side of the A/C system with the engine running.

•Do not charge wh ile comp resso r is hot.

•When installin g a tap valve to a refrigera nt contain er, carefully follow directions given by the man-

ufacturer.

•A pressure gaug e shoul d always be used before and during charging.

•The refrigerant container should be com pletely emptied of refrigerant before being discarded.

•The refrigerant container should not be subjected to a heat of 40°C or ov er.

The refrigerant container should not be upended during charging. Upending the container could

cause liquid refrigerant to enter the compressor, creating problems such as compression of liquid

refrigerant.

NOTE: The air conditioning system contains HFC-134 a (R-134a).

The following method for charging the refrigerant system uses refrigerant from a ref rigerant service container.

When cha rging with refrigerant recovered using refrigerant and recycling equipment (when recycling refriger-

ant), follow the equipment manufacturer’s instructions.

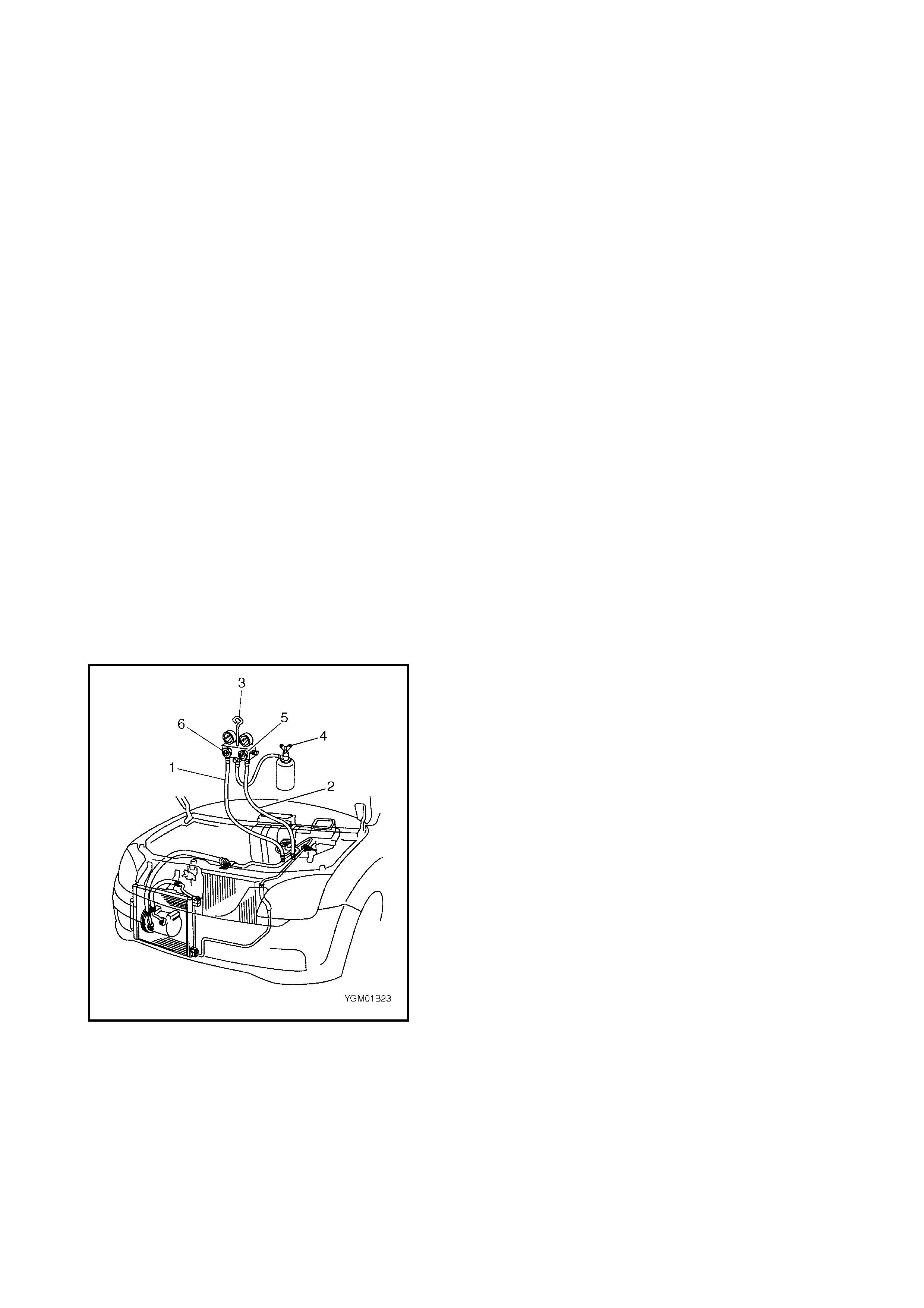

CHARGING PR OCEDURE

Initial charging of the A/C system is performed from the

high pressure side with the engine not running.

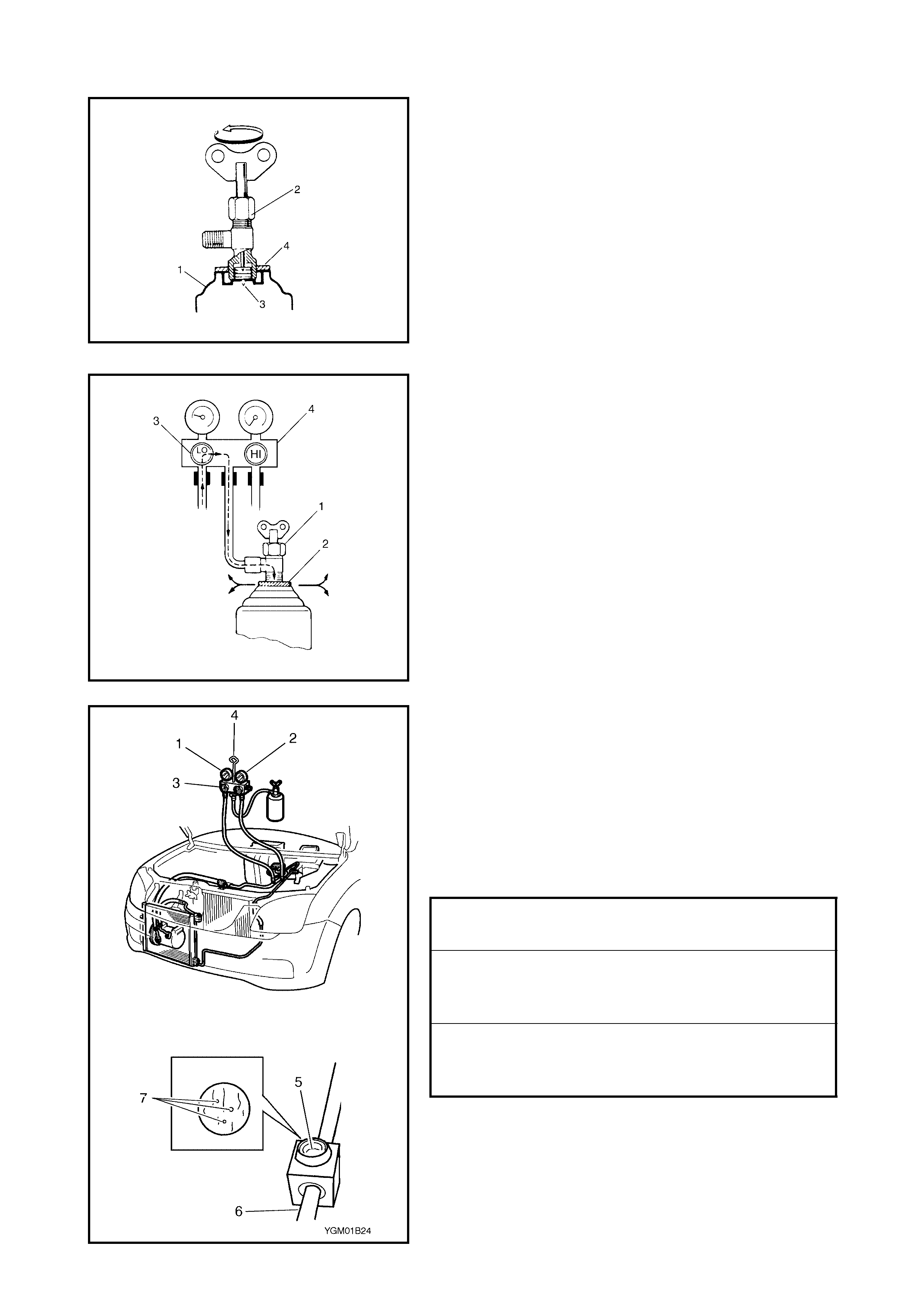

This must be followed by charging from the low pressure

side with the engine running.

1. Check to mak e sure that the hos es are routed correctly

after e va cua ti ng the syst em.

2. Connect the Low pressure charging hose (1) and the

High press ure chargin g hose (2) of t he m anifold gauge

set (3) in the correct manner as shown. Open the

refrigerant container valve (4) to purge the charging

line.

3. Open the high pressure side valve (5) and charge

refrigerant to system.

4. After a short period, open the low pressure side valve

(6) and close the high pressure side valve (5).

WARNING: Make sure that the high pressure side

valve is closed securely.

5. Star t t he engine a nd maintain engin e speed at 1500 r/

min. Operate the air conditioning.

6. Charge the A/C system with refrigerant in a vapor state

(at this stage, the refrigerant container (4) should

remain upr ight).

7. When the refrigerant container (1) is empty and

charging is not complete, use the following procedure

to replace it.

a. Close the low pressure valve.

b. Replace the empty container (1) with a refrigerant

container which has been charged with refrigerant.

If using a refrigerant container tap v al ve (2), use the

following procedure for replacem ent .

i. Retract needle (3) and remove refrigerant con-

tainer tap valve (2) by loosening its plate nut (4).

ii. Install the previously removed refrigerant con-

tainer tap valve (2) to a new refrigerant con-

tainer (1).

c. Purge any air existing in the centre charging hose

When using a refrigerant container tap valve, use

the following procedure to purge air.

i. Fully tighten the refrigerant container tap valve

(1), t hen loosen (open) plate nut (2) slight l y.

ii. Open the low pressure side valve (3) of the

manifold gauge set (4) a littl e.

iii. As soon as the refrigerant comes out with a

“hiss” through a cle arance between the refr iger-

ant contai ner and the tap valve, tighten plate nut

(2) as well as low pressure side val ve (3).

iv. Turn handle of tap valv e (1) clockwise so that its

needle is screwed into the new container to

allow for refrigerant flow.

5. After the system has been charged with the specified

amount (410 – 450 g) of refrigerant or when the low

pressure gauge (1) an d high pressure gauge (2) have

indicated t he following specified amount, clo se th e low

pressure side valve (3) on manifold gauge set (4). Look

into the sight gl ass (5) on the condenser o utlet (liquid)

tube (6) and check that there are no bubbles (7),

meani ng the system is fully charged.

Low side and high side pres sure example

Gauges should read as follows when ambi ent

temperature is 30°C.

Pressure

on high pressure gauge 1400 – 1750 kPa

14.0 – 17. 5 kg/cm2

199.1 – 248.9 psi

Pressure

on low pressure gaug e 230 – 350 kPa

2.3 – 3.5 kg/cm2

32.7 – 49.8 psi

4.7 REMOVING MANIFOLD GAUGE SET

CAUTION: High pressure side is normally under high pressure . Care must be taken to protect your

eyes and skin.

When th e A/C system has been charged with t he specified amount of refr igerant, remove the manifold gauge

set as foll ows:

1. Close the lo w pressure side valve on the manifold gauge set. (The high pressure side valve should remain

closed dur ing the process of charging.)

2. Close th e refrigerant container valve.

3. St op engine.

4. Us ing rag, remove charging hoses from charge ports. This operation must be performed rapidly.

5. Repla ce caps on charge por t s.

4.8 LEAK TEST

Whenever a refrigerant leak is suspected in the system or any service operation has been performed which

may result in disturbing lines or connections, it is advisable to test f or leaks.

Comm on sense should be used in performin g any refrigerant leak test, since the need and extent of any such

test wil l, in general, depend upon the nature of a complaint and t he type of a servic e performed on the system .

LIQUID LEAK DETECTORS

WARNING:

•To prevent explosions or fires, make sure that

there are no flammable materi als in the vicinity.

•When exposed to fire, the refrigerant turns into a

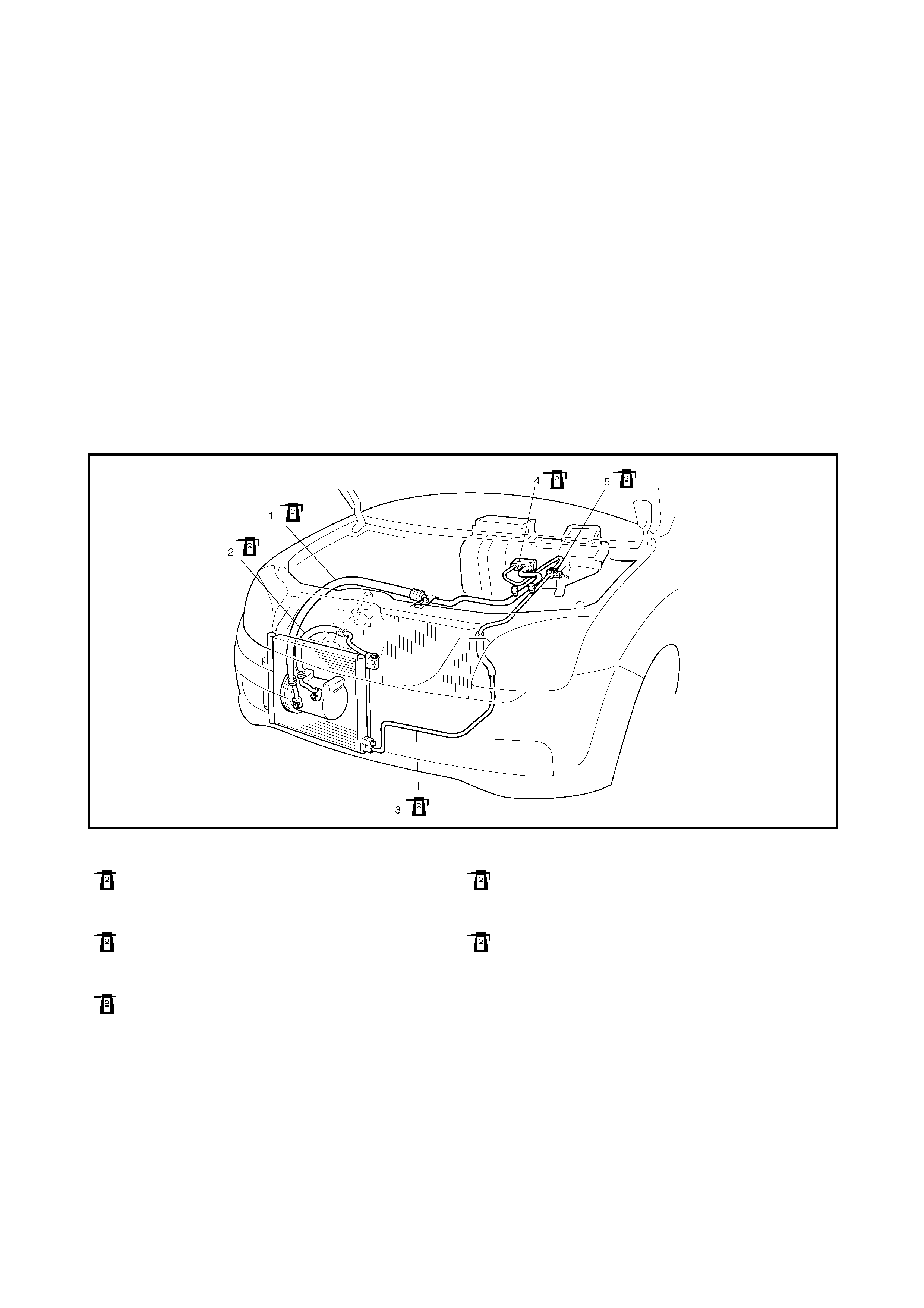

poison ous gas (phosg ene ). Do not inhale this gas.

There are numerous fittings and locations throughout the

air conditioning system where liquid leak detector solution

may be used to pinpoint refri gerant leaks.

By applying the solution to the area in question with a

swab, bubbles w ill qu ickly form if the re is a leak .

For confined are as, such as s ections of th e evaporator and

condenser, an electronic (refrigerant) leak detector (A) is

more practical for deter m ining leaks.

5 . ON-VEHICLE SERVICE

CAUTION: Should refrigerant HFC-134a (R-134a) make contact with your eye(s), consult a doctor

immediately.

•Do not use y our hand to rub affected eye(s). Use lar ge quantities of fresh cold water to spl ash over

the affected area to gradually raise the temperature above freezing point.

•Obtain medic al treatment as soon as possible from a doctor or eye specialist. Should liquid refrig-

erant HFC-134a (R-134a) contact your skin, the affected part should be treated in the same as

frostbitten or frozen skin.

5.1 SERVICE PRECAUTION

When servicing the air conditioning system , note the following instruc tions.

REFRIGERANT LINE

Legend

•Never use heat for bending pi pes. When bending a pipe, try to make the bend radius as sli ght as possible .

•Keep inter nal parts of air conditioni ng free from moisture a nd dir t. When disconn ecting any li ne from t he

system, install a blind plug or cap to the fitting immediately.

•When connecting hoses and pipes, apply a few drops of compressor oi l (refrigerant oil) to seats of cou-

pling nuts and O-rings .

•When tighteni ng or loosening a fitting, use two spanne rs, one for tu rn ing and the other for support.

1. S uc tion hose:

Appl y compresso r oil (refrig erant oil) to

O-ring.

4. E x pansion valve:

Apply comp ressor oil (refrigerant oil) to

O-ring.

2. Dis charge hos e:

Appl y compresso r oil (refrig erant oil) to

O-ring.

5. A /C refrig erant pressure switch:

Apply comp ressor oil (refrigerant oil) to

O-ring.

3. Condenser out let pipe:

Appl y compresso r oil (refrig erant oil) to

O-ring.

• Tighten flared nuts by the following the specified torque.

• Route the drain hose so that drained water does not make contact with vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compressor suction side,

refer to 4.3 REPLENISHING COMPRESSOR OIL in this Section.

HANDLING REFRIGERANT HFC-134A (R-134A)

• Always wear goggles to protect your eyes.

• Avoid direct contact with liquid refrigerant.

• Do not heat refrigerant container higher than 40°C.

• Do not discharge refrigerant into the atmosphere.

• Do not allow liquid refrigerant to touch vehicle surfaces. Refrigerant combined with moisture is corrosive

and will tarnish surfaces of bright metals including chrome.

REFRIGERANT RECOVERY

When discharging refrigerant out of the A/C system, always recover it using refrigerant recovery and recycling

equipment. Discharging refrigerant HFC-134a (R-134a) into the atmosphere could cause adverse effects to

the environment.

REFRIGERANT CHARGE

After replenishing compressor oil and evacuating, recharge the system with the correct amount of refrigerant,

refer to 4.6 CHARGING in this Section.

CAUTION: Do not perform an additional refrigerant charge to the A/C system. This could cause it to

overcharge.

5.2 CONDENSER ASSEMBLY

CAUTION: Be careful not to damage condenser fins. If condenser fins are bent, straighten them

using a flat head screwdriver or pair of pliers.

INSPECTION

Check the following.

• Clogged condenser fins.

If, clogging is found, condenser fins should be washed with water, and dried with compressed air.

• Condenser fins for leakage and breakage.

If any defects are found, repair or replace condenser.

• Condenser fittings for leakage.

If any defects are found, repair or replace condenser.

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Recover refrigerant from A/C system, refer to

4.2 RECOVERY in this Section.

NOTE: The amount of removed compressor oil must be

measured for correct replenishment of compressor oil.

3. Remove front bumper, refer to Section 9,

FRONT BUMPER and REAR BUMPER.

4. Disconn ect the co ndenser c ool ing fan motor connector

(1).

8mm PIPE

TORQUE SPECIFICATION 13 Nm

12mm PIPE

TORQUE SPECIFICATION 23 Nm

14.5mm PIPE

TORQUE SPECIFICATION 33 Nm

5. Disconnect discharge hose (1) and condenser outlet

(liquid) tube (2) from condenser (3).

NOTE: Cap open fittings immediately to keep moisture out

of system.

6. Remove condenser mounting bolts (4).

7. Remove condenser (3).

INSTALLATION

Reverse removal procedure to install condenser assembly

noting the following instructions.

• Replenish specified amount of compressor oil to com-

pressor suction side, refer to 4.3 REPLENISHING

COMPRESSOR OIL in this Section.

• Evacuate and charge system refrigerant, refer to

4.4 EVACUATING and 4.6 CHARGING in this Section.

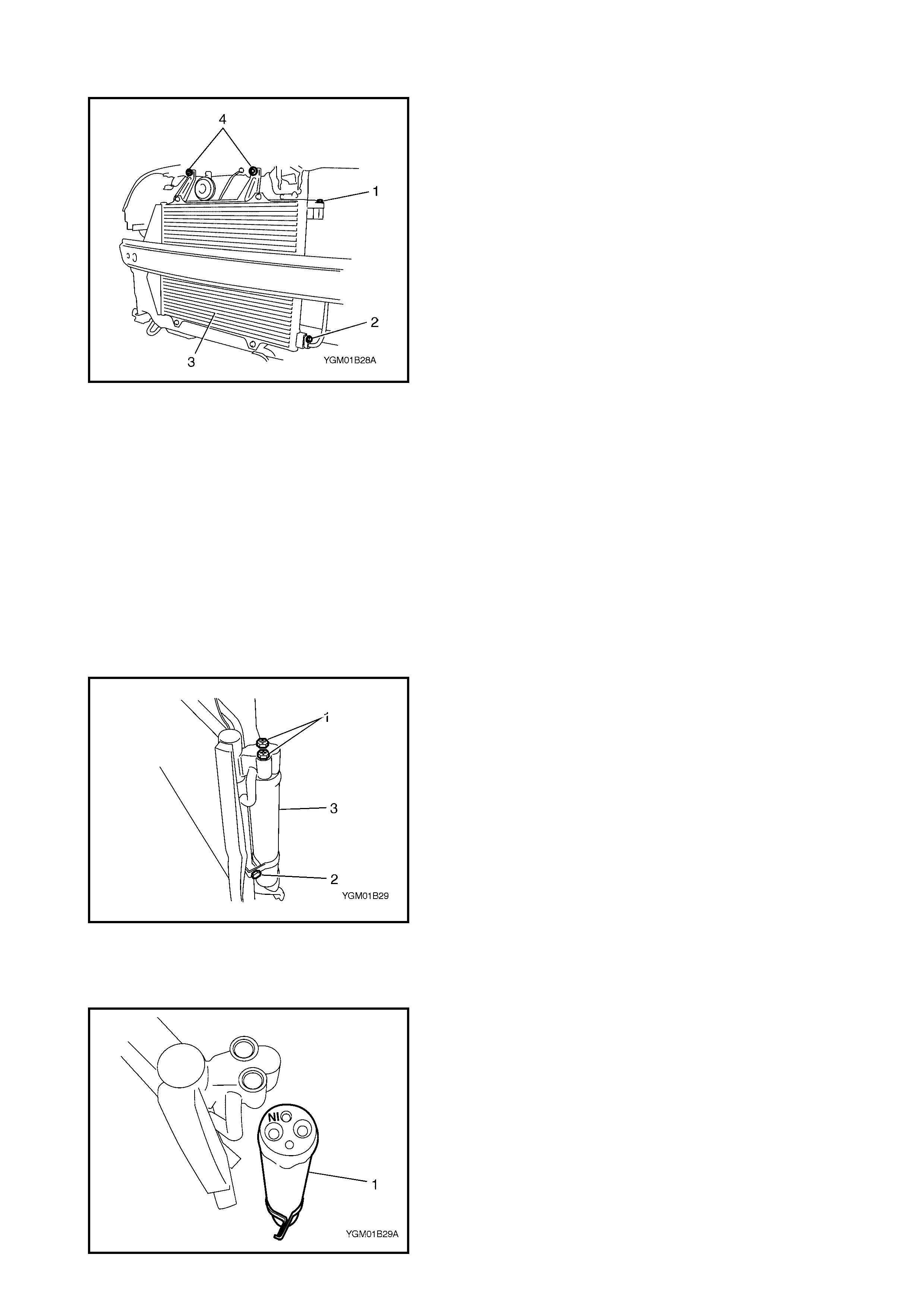

5.3 RECEIVER/DRIER

REMOVAL

1. Remove condenser assembly, refer to

5.2 CONDENSER ASSEMBLY in this Section.

2. Loosen receiver/drier attaching bolts (1), (2).

3. Remove receiver/drier (3).

INSTALLATION

Reverse removal procedure to install receiver/drier noting

the following instructions.

• Replenish specified amount of compressor oil to com-

pressor suction side, refer to 4.3 REPLENISHING

COMPRESSOR OIL in this Section.

• Evacuate and charge system refrigerant, refer to

4.4 EVACUATING and 4.6 CHARGING in this Section.

•Be sure to i nstall receiver/drier (1) in the correct orien-

tation as shown.

5.4 CONDENSER COOLING FAN

REMOVAL

1. Remove condenser assembly, refer to

5.2 CONDENSER ASSEMBLY in this Section.

2. Remove condenser cooling fan motor mounting bolts

(1).

3. Remove conde nser cooling fan from condenser.

INSTALLATION

Reverse removal procedure to install condenser cooling fan

motor noting the following inst ructions.

•Replenish specified amoun t of compressor oil to com-

pressor suction side, refer to 4.3 REPLENISHING

COMPRESSOR OIL in this Section.

• Evacuate and charge refrigerant, refer to

4.4 EVACUATING and 4.6 CHARGING in this Section.

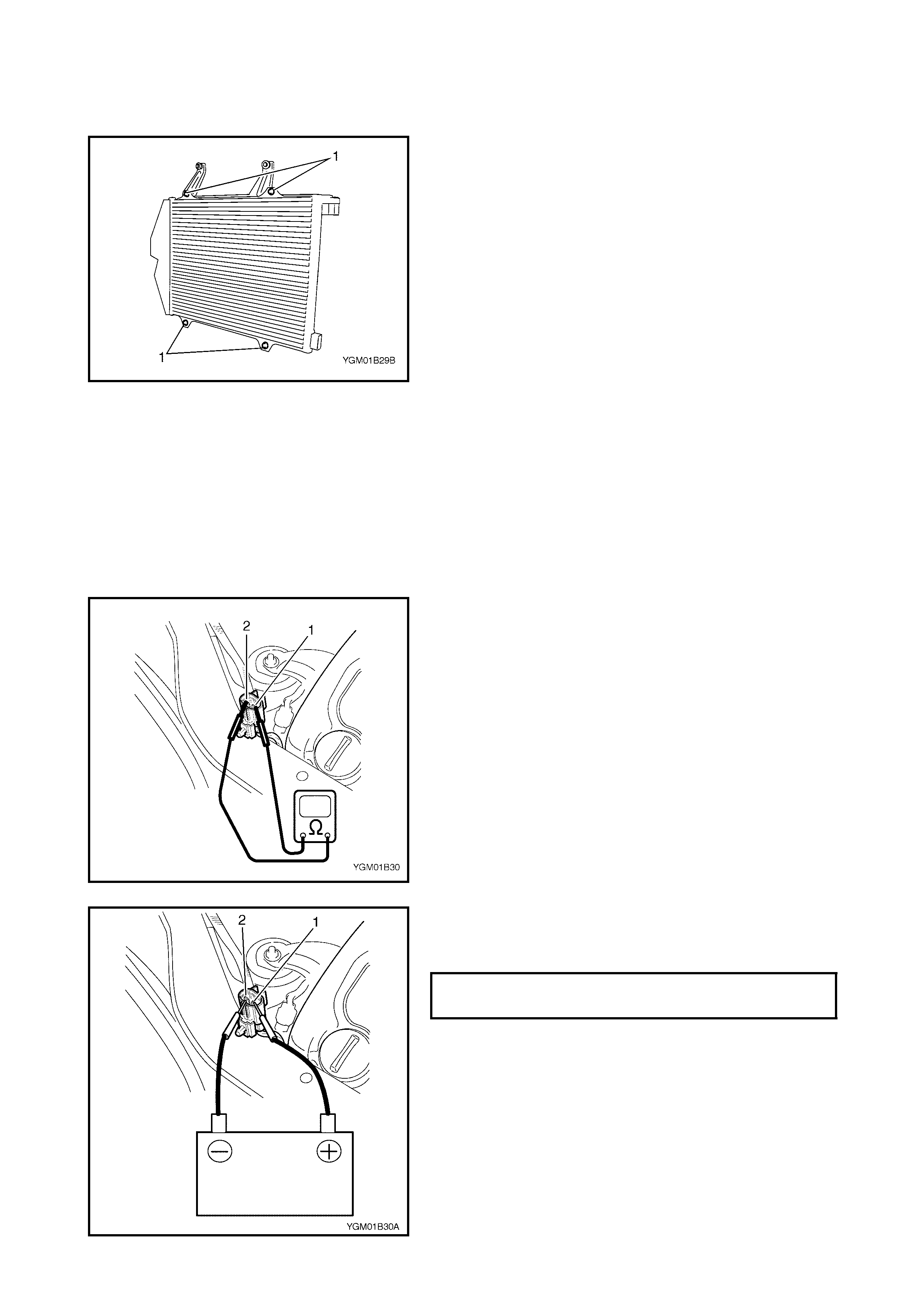

INSPECTION

1. Check condenser cooling fan motor for continuity

between term ina l (1) and (2) as shown.

If there is no continuity, repla ce condenser cooling fan

motor.

2. Connect battery to condenser cooling fan motor

ter m inal (1) and (2) as shown in figure, then ch eck that

the c ondenser c ooling f an motor operates smoothly.

3. Check condenser cooling fan blades f or damage. If any

damage is found, replace conde nser cooling fan blade.

CONDENSER COOLING FAN SPECI-

FIED CURRENT @ 12 VOLT 8 A MAX.

5.5 COOLING UNIT (EVAPORATOR)

Legend

CAUTION: Be careful not to damage A/C evaporator

fins. If A/C evaporator fins are bent, straighten them

using a flat head screwdriver or pair of pliers.

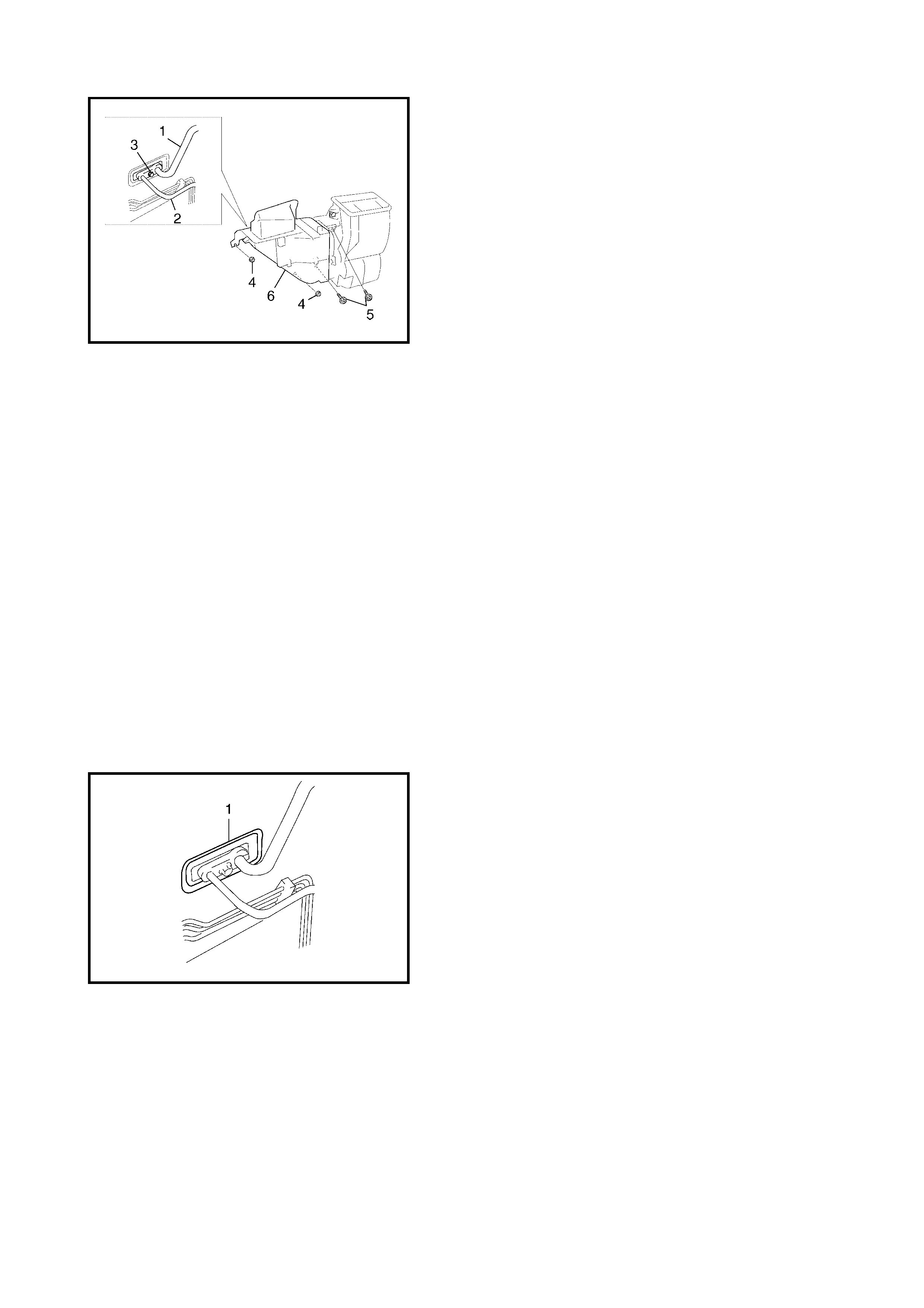

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Recover refrigerant from A/C system, refer to

4.2 RECOVERY in this Section.

NOTE: The amount of removed compressor oil must be

measured for correct replenishment of compressor oil.

3. Remove glove box, refer to Section 9,

3.1 INSTRUMENT PANEL.

4. Remove f resh air control cable (1) and A/C evaporator

tempera ture sensor connector.

1. A/C evaporator 5. Cooling unit packing 11. O-ring

2. A/C evaporator tempe rature sensor 6. Dash seal 12. Door link

3. Expansion valve 7. Seal 13. Lower packing

4. Evaporator case

: Apply sealant, Three Bond 1216B to

hatched

part “A”.

8. Fres h air duct case Do not reuse.

9. Clamp

10. Air inlet door

5. Disconnect suction hose (1) and condenser outlet hose

(2) by removing attaching bolt (3).

NOTE: Cap open fittings immediat ely to keep mois ture out

of system.

6. Remove cooling unit mounting nuts (4) and screws (5).

7. Remove cooling unit (6).

INSPECTION

Check the following.

• Clogging of A/C evaporator fins.

If any clog ging is fou nd, A/C evapo rator fins sho uld be

washed with water and dried with compressed air.

• A/C evaporator fins for leakage and breakage.

If any defects are found, repair or replace A/C evapora-

tor.

• A/C evaporator fittings for leakage.

If any defects are found, repair or replace A/C evapora-

tor.

INSTALLATION

Reverse removal procedure to inst all cooling unit noting the

following instructions.

• If the A/C evaporator temperature sensor was

removed, it must be reinstalled in the original position.

• Replenish specified amount of compressor oil to com-

pressor suction side, refer to 4.3 REPLENISHING

COMPRESSOR OIL in this Section.

• Ensure the seal (1) is fitted uniformly around the fire-

wall installation hole.

• Evacuate and charge refrigerant, refer to

4.4 EVACUATING and 4.6 CHARGING in this Section.

• Adjust fresh air control cable, refer to

Section 1A, 3.4 HEATER CONTROL ASSEMB LY.

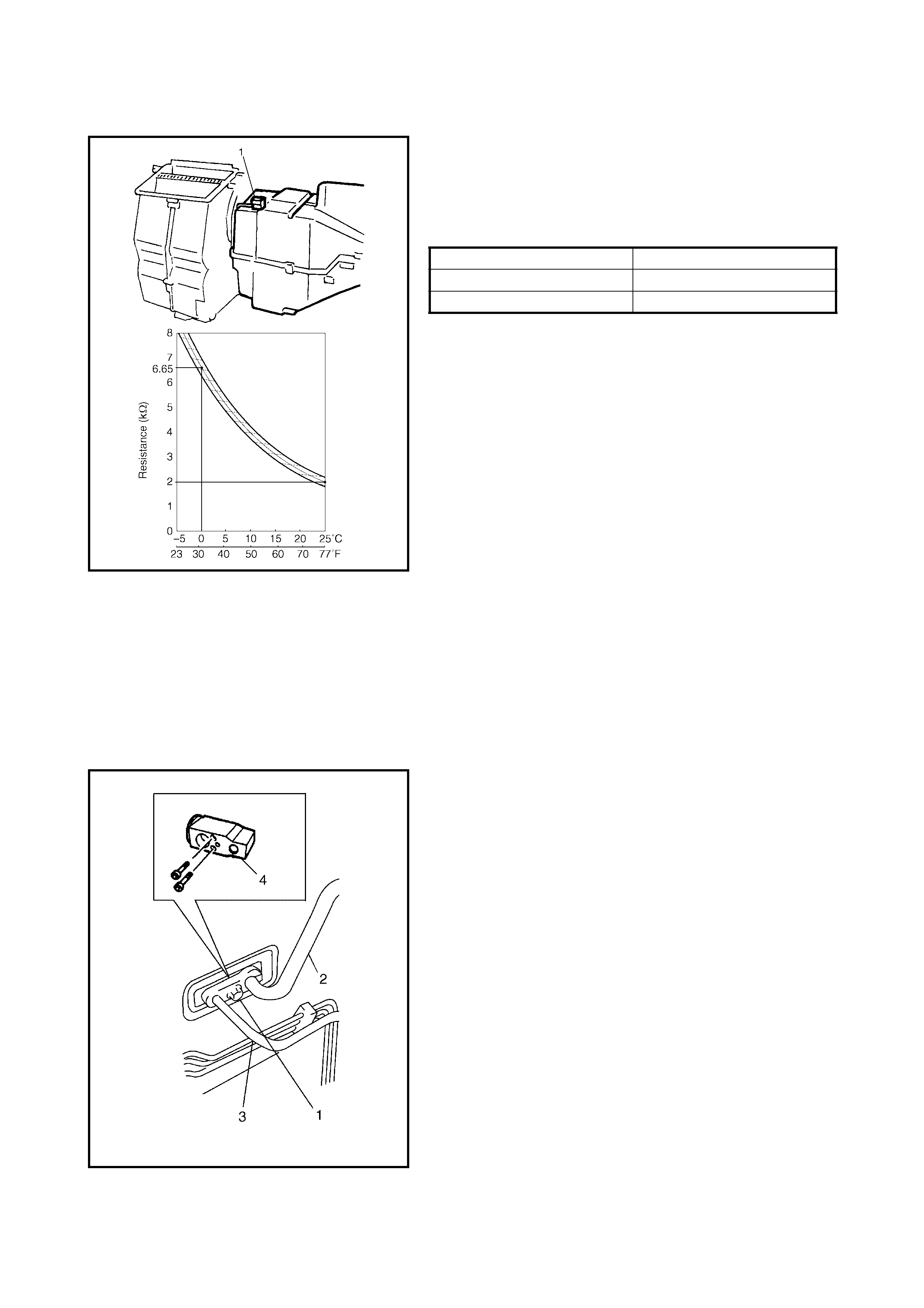

5.6 A/C EVAPORATOR TEMPERATURE SENSOR

Check the resistance between the terminals for the A/C

evaporator temperature sensor (1).

If results are not as specified, replace the A/C evaporator

temperature sensor.

A/C evaporator temperature sensor resistance

NOTE: When A/C evaporator temperature sensor is

removed, it must be reinstalled in original position.

5.7 EXPANSION VALVE

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Recover refrigerant from the A/C system, refer to

4.2 RECOVERY in this Section.

NOTE: The amount of removed compressor oil must be

measured for correct replenishment.

3. Remove attaching bolt (1).

4. Remove suction hose (2) and receiver/drier outlet

(liquid) tube (3) from expansion valve (4).

NOTE: Cap open fittings immediately to keep moisture out

of system.

5. Remove expansion valve (4).

INSTALLATION

Reverse removal procedure to install expansion valve not-

ing the following instructions.

• Replenish the specified amount of compressor oil to

the compressor suction side, refer to 4.3 REPLENISHING

COMPRESSOR OIL in this Section.

• Evacuate and charge system refrigerant, refer to

4.4 EVACUATING and 4.6 CHARGING in this Section.

INSPECTION

Refer to 2.4 PERFORMANCE DIAGNOSIS in this Section.

Sensor Temperature Resi stance

0°C 6.4 – 6.9 k W

25°C1.8 – 2.2 kW

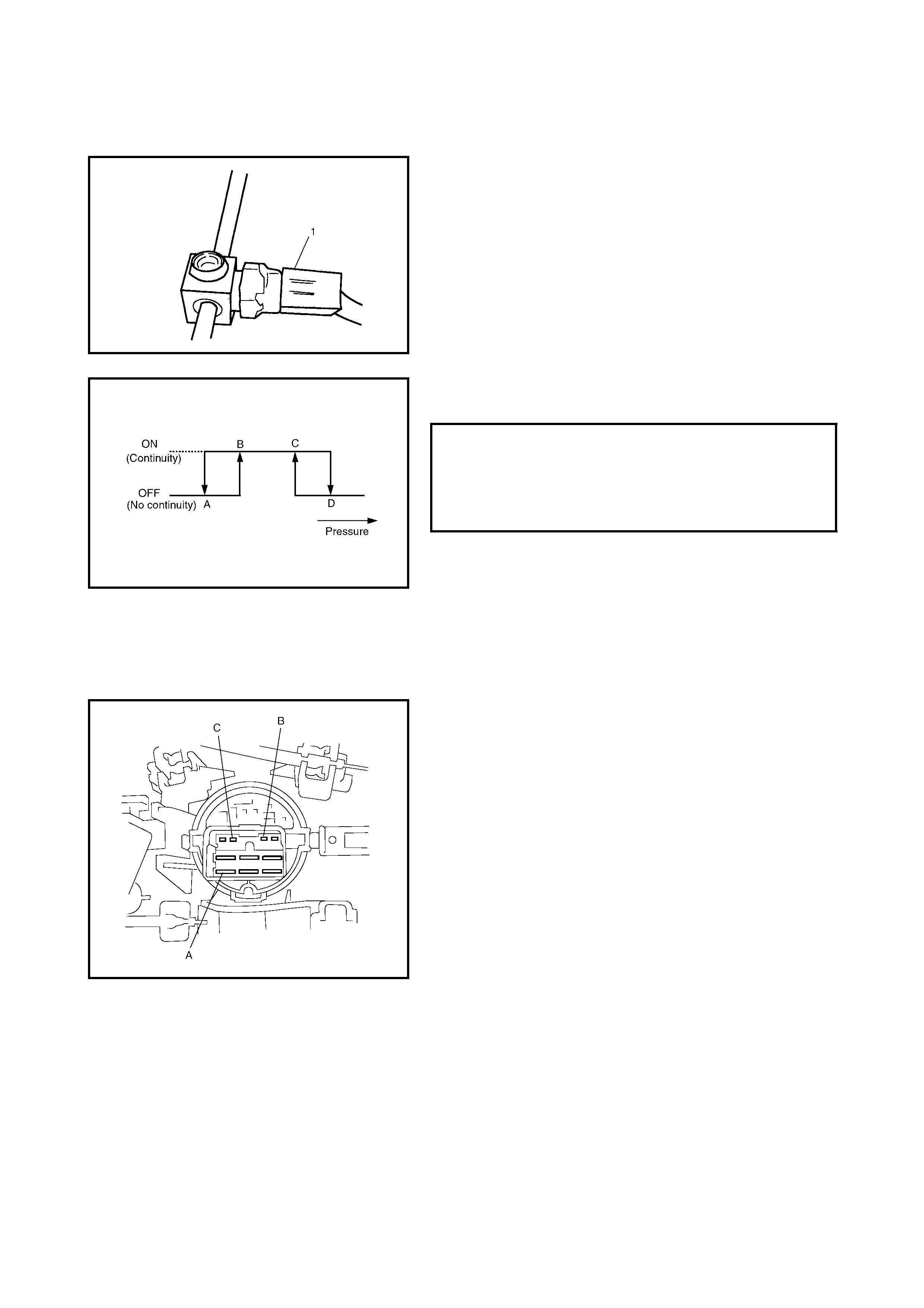

5.8 A/C REFRIGERANT PRESSURE SWITCH

INSPECTION

1. Check the A/C refrigerant pressure switch (1) for conti-

nuity at normal temperature (approximately 25°C)

when the A/C system has the correct charge of refrig-

erant and the A/C system (compressor) is operating.

The refrigerant pressure switch should show correct

continuity.

2. Check continuity between high and low pressure [A]

switch terminals (1) at specified pressure as shown.

5.9 A/C SWITCH

REMOVAL AND INSTALLATION

Refer to Section 1A, 3.4 HEATER CONTROL ASSEMBLY.

INSPECTION

•Press A/C switch button and check if there is continuity

between t erminal s (A) and (B).

•Connect battery voltage (+) to terminal (C) and (–) to

terminal (A), and then press A/C Switch button and

che ck if ind ic a tor lamp lights.

HIGH AND LOW PRESSURE SWITCH

SPECIFICATION (APPROX.) A

B

C

D

200 kPa

230 kPa

2600 kPa

3200 kPa

5.10 COMPRESSOR RELAY AND CONDENSER COOLING FAN RELAY

INSPECTION

1. Disconnect negative (-) cable at battery.

2. Remove condenser cooling fan relay (1) and compres-

sor relay (2) from main fuse box.

3. Check that there is no continuity between terminal (c)

and (d). If there is continuity, replace relay.

4. Connect battery positive (+) terminal to terminal (b) of

relay.

Connect battery negative (-) terminal to terminal (a) of

relay.

Check continuity between terminal (c) and (d).

If there is no continuity when relay is connected to the

battery, replace relay.

5.11 COMPRESSOR

REMOVAL

1. Run engine at idle speed with air conditioning ON for

10 minutes then stop the engine.

2. Disconnect negative (–) cable at battery.

3. Remove front bumper, refer to Section 9,

FRONT BUMPER and REAR BUMPER.

4. Remove condenser assembly, refer to

5.2 CONDENSER ASSEMBLY in this Section.

5. Remove compressor drive belt (1) by loosening tension

pulley nut (2) and adjusting bolt (3).

6. Disconnect magnetic clutch lead wire connector.

7. Disconnect suction pipe (4) and discharge hose (5)

from compressor (6).

NOTE: Cap open fittings immediately to keep moisture out

of system.

8. Remove compressor mounting bolts (7), and remove

compressor (6) from the compresso r mounting bracket.

INSTALLATION

Reverse removal procedure to install compressor noting

the following instructions.

• If the compressor is replaced, add new compressor oil,

refer to 4.3 REPLENISHING COMPRESSOR OIL in

this Section.

• Evacuate and charge system, refer to 4.2 RECOVERY

in this Section.

• Adjust drive belt tension, refer to 2.5 COMPRESSOR

DRIVE BELT in this Section.

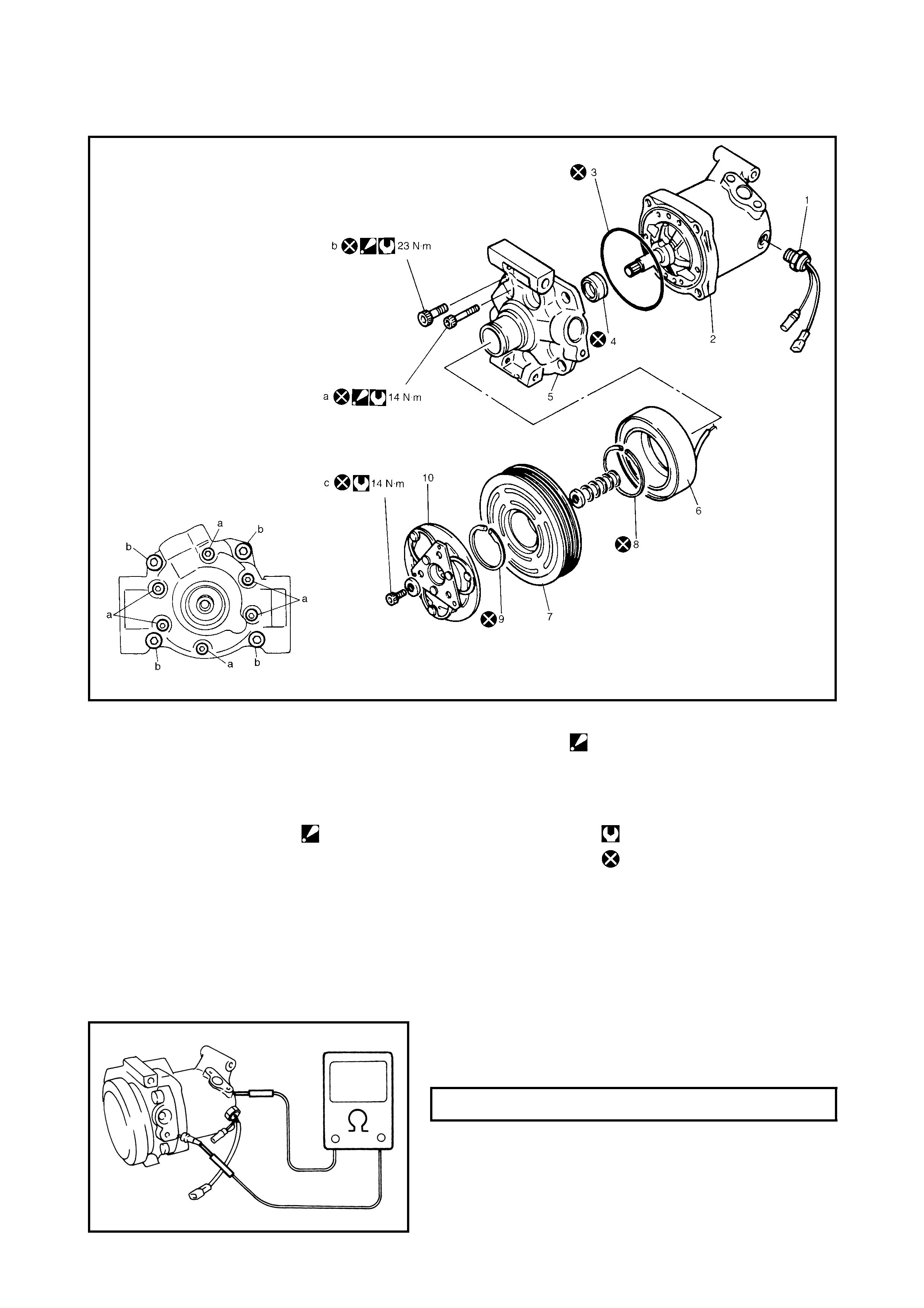

5.12 MAGNETIC CLUTCH

Legend

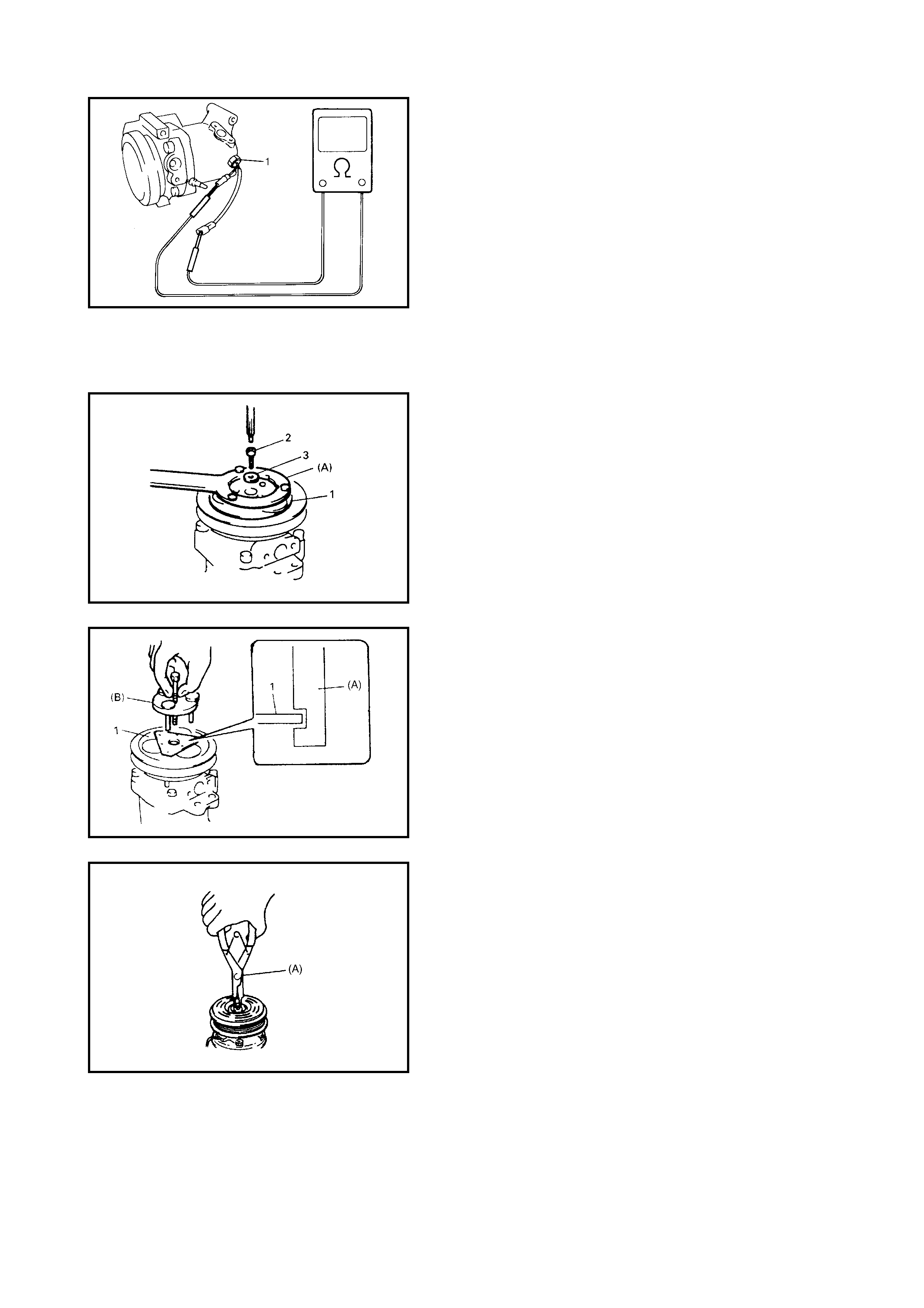

INSPECTION

•Check clutch plate and clutch pulley for wear and signs

of oil leakage.

•Check clutch pulley bearing for noise, wear and grease

leakage.

•Measure clutch coil for resistance at 20°C.

If the measured resistance does not remain within tol-

erance, replace ma gnet ic clutch assembly.

1. Compressor thermal

protection switch 7. Clutc h pulley b. Front head bolt

: Tighten bolt (a) first, and

next (b)

8. Circlip

2. Compressor body 9. Circlip

3. O-r ing 10. Clut ch plate c. C lutch plate bolt

4. Lip type seal a. Front head bolt

: Tighten bolt (a) first, and

next (b)

Tightening torque

5. Front head D o not reuse.

6. Clutch coil

CLUTCH COIL RESISTANCE 3.4 - 4. 1 W

• Use an ohmmeter to check thermal protection switch

(1) for continuity.

If there is no continuity, replace switch.

REMOVAL

1. Remove compressor from vehicle. Refer to

5.11 COMPRESSOR in this Section.

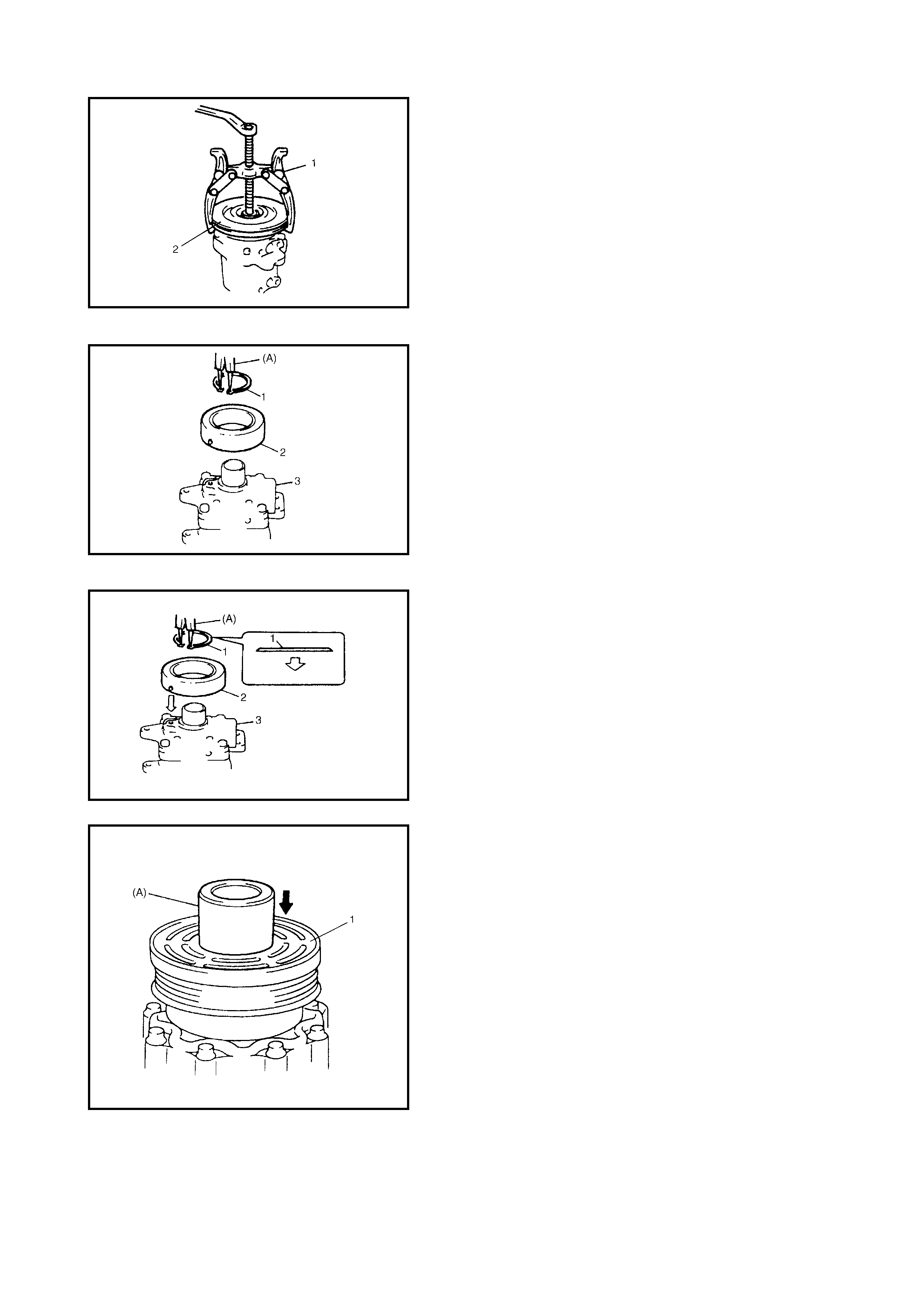

2. Fit spec ial to ol 0 9991-060 20 (A ) t o clu tch p late (1) a nd

remov e clutch plat e bolt (2) and washer ( 3).

3. Using special tool 09991-06030 (A), remove clutch

plate (1).

4. Remove shims from shaft.

5. Using special tool 09900-06107 (A), remove circlip.

6. Remove clutch coil lead wire clamp by loosening its

screw and disconnect clutch coil lead wire from thermal

switch lead wire .

7. Remove the clutch pulley (2) with a suitable, commer-

cially av ailabl e puller (1).

NOTE:

•Take care not to damage pulley when removing.

•Be careful not to scratch beari ng.

8. Remove cl u tch co il.

9. Remove circlip (1) by using special tool 09900-06107

(A).

10. Remove clutch coil (2) from compressor (3).

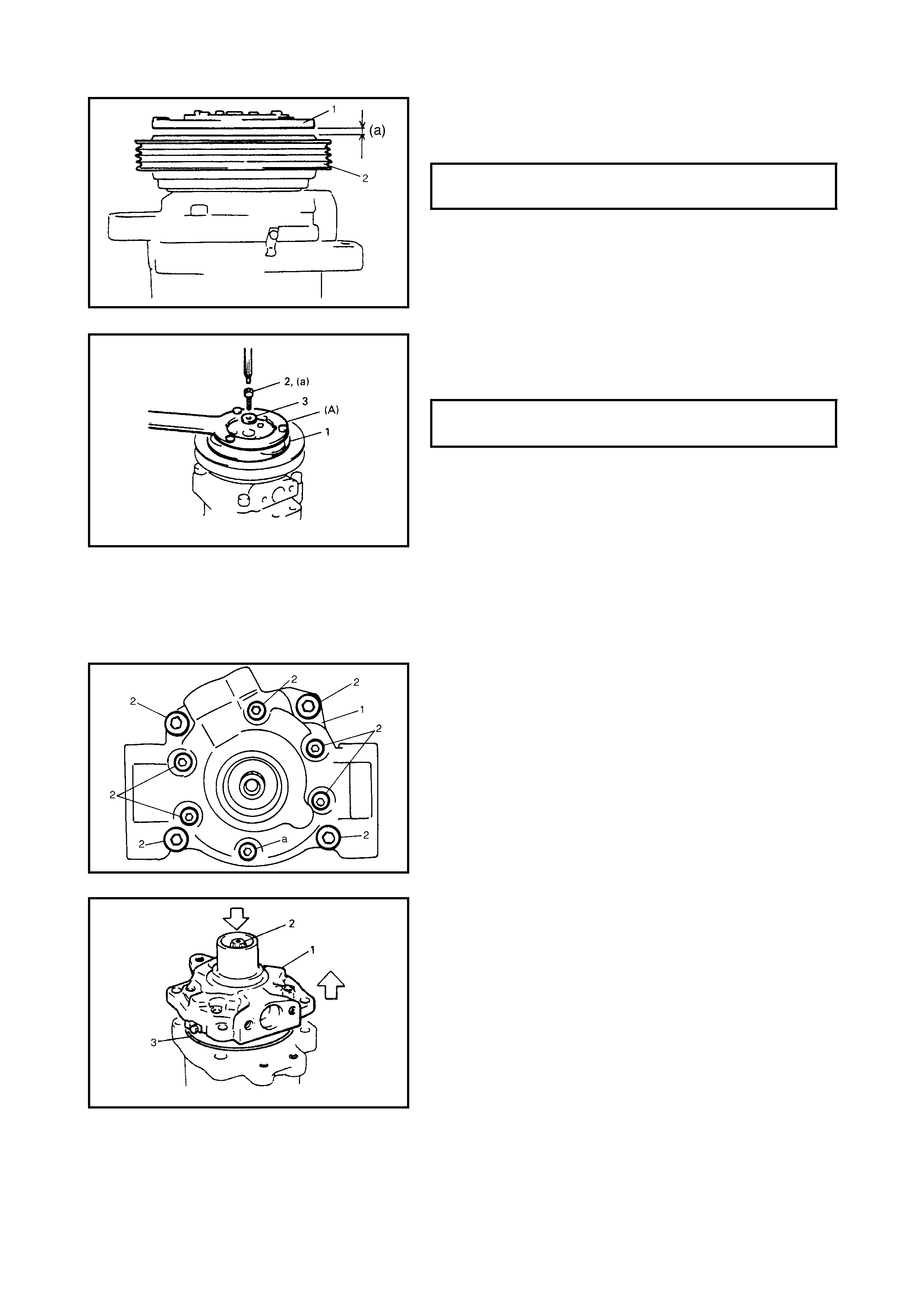

INSTALLATION

1. Install clutch coil (2).

Protrus ion on underside of clutch coil must match ho le

in compressor (3) to prevent movement and to allow

correct location of lead wire.

2. Using special tool 09900-06107, install new circlip (1)

as shown.

3. Install clutch pulley (1).

a. Set clutch pulley (1) squarely over clutch pulley

installation boss.

b. Place special tool 099961-06010 (A) onto clutch

coil bearing.

Ensure that edge rests only on inner race of bear-

ing.

c. Inst a ll circl ip.

CAUTION: Be careful not to scratch bearing seat.

4. Adjust the clearance, between the clutch plate (1) and

the clutch pulley (2) by fitting shims on the compressor

shaft.

5. Secure the new clutch plate (1) with the clutch plate

bolt (2) and washer (3) to specified torque as shown

using special tool 09991-06020 (A).

5.13 LIP TYPE SEAL

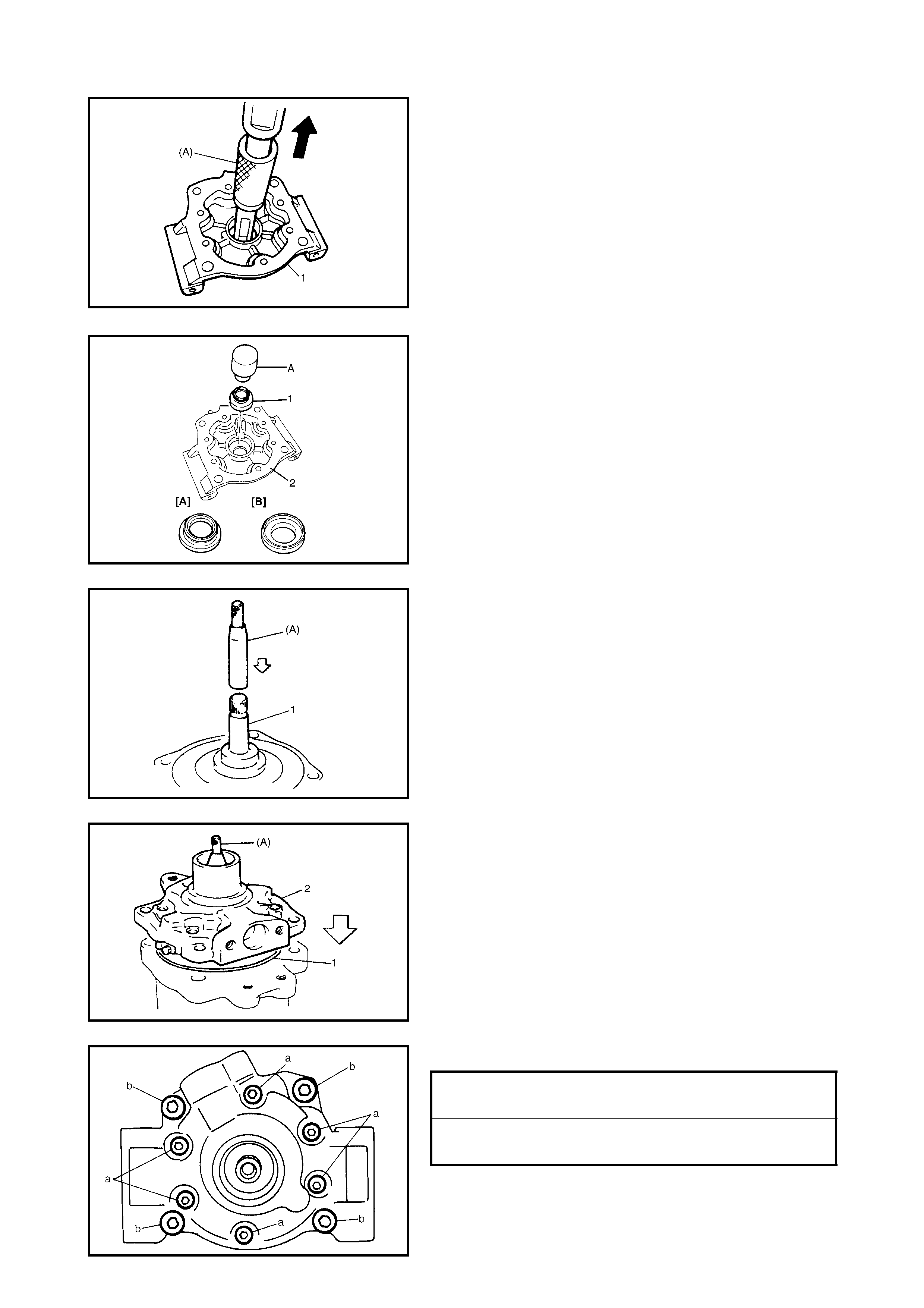

REMOVAL

1. Remove the magnetic clutch, refer to 5.12 MAGNETIC

CLUTCH in this Section.

2. Remove front head (1) mounting bolts (2).

3. Remove front head (1) by pus hing cylinder shaft (2).

NOTE: Be careful not to remove cylinder f rom front head.

4. Remov e O-ring (3).

CLEARANCE BETWEEN CLUTCH

PLATE AND CLUTCH PULL EY (a) 0.3 - 0.6 mm

CLUTCH PLATE BOLT (a)

TORQUE SPECIFICATION 14 Nm

5. Remove lip type seal from f ront head (1) u sing speci al

tool 09923-73210 (A ).

INSTALLATION

1. Press-fit new lip type seal (1) into front head (2) u sing

specia l tool 09991-06 050. Ensure l ip type sea l is fitted

correctly, top side [A] up and back side [B] down.

CAUTION: Do not reuse lip type seal (1) once removed

from compressor.

2. Coat special too l 09991-06040 (A) surface with oil and

place it on cylinder shaft (1).

3. Install new O-ring (1) to case.

4. Appl y compresso r oil to lip type seal and O-ring (1).

5. Install front head (2).

6. Tighten new front head mounting bolts (a), (b).

NOTE:

•Be sure to use new front head mounting bolts .

•Tighten bolt (a) first, and next (b).

FRONT HEAD BOLT (a)

TORQUE SPECIFICATION 9 Nm

FRONT HEAD BOLT (b)

TORQUE SPECIFICATION 22 Nm

6. REQUIRED SERVICE MATERIAL

7. SPECIAL TOOLS

NOTE: Refer to Section 0A GENERAL INFORMATION - 7. CONSOLIDATED TOOLS for a detailed list of

special tools and the local equivalent if one is available.

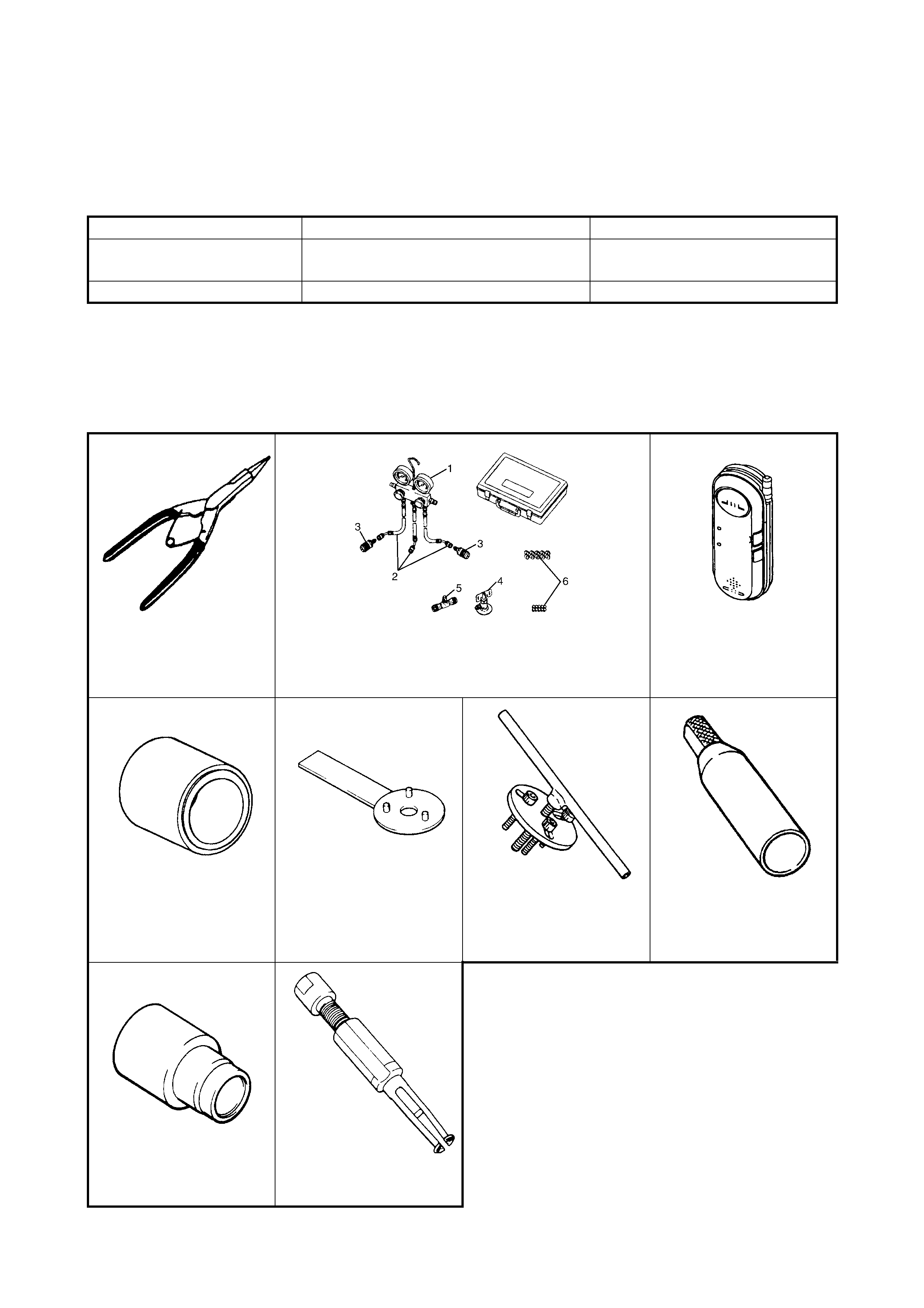

NOTE: This kit includes the following items: 1. Manifold gauge, 2. Changing hose, 3. Quick connector, 4.

Refrigerant container tap valve, 5. Refrigerant container T joint, 6. Packing set

Material

Recommended product

Use

Compressor oil

(Refrigerant oil) COMPRESSOR OIL RS20 (150 cc) • O-ring

• Each component

Sealant Three BOND No.1216B • Cooling unit

09900-0 610 7 0 999 0-060 10 09990 -86011

Snap ring pliers

(Opening type) Manifold gauge set

See NOTE below. Gas leak detector

09991-06010 09991-06020 09991-06030 09991-06040

Magnet clutch pulley

installer Armature plate spanner Armature plate remover Lip type seal protector

09991-06050 09923-73210

Lip type seal installer Bearing remover