SECTION 6A1 - ENGINE MECHANICAL (M15 ENGINE)

1. GENERAL DESCRIPTION

1.1 ENGINE

1.2 ENGINE LUBRI CATION

2. DIAGNOSIS

2.1 DIAGNOSIS TABLE

2.2 COMPRESSION CHECK

2.3 ENGINE VACUUM CHECK

2.4 OIL PRESSURE CHECK

2.5 VALVE LASH (CLEARANCE)

Inspection

Replacement of Shim

3. ON-VEHICLE SERVICE

3.1 AIR CLEANER ELEMENT

Removal

Inspection and Cleaning

Installation

3.2 AIR CLEANER ASSEMBLY AND

RESONATOR

Removal

Installation

3.3 KNOCK SENSOR

3.4 CYLINDER HEAD COVER

Removal

Installation

3.5 THROTTLE BODY AND INTAKE

MANIFOLD

Removal

Installation

3.6 EXHAUST MANIFOLD

Removal

Installation

3.7 OIL PAN AND OIL PUMP STRAINER

Removal

Clean

Installation

3.8 ENGINE MOUNTINGS

4. UNIT REPAIR AND OVERHAUL

4.1 ENGINE ASSEMBLY

Removal

Installation

4.2 TIMING CHAIN COVER

Removal

Clean

Inspection

Installation

4.3 OIL PUMP

Removal

Disassembly

Inspection

Measurement

Assembly

Installation

4.4 TIMING CHAIN AND CHAIN TENSIONER

Removal

Inspection

Installation

WARNING:

For vehicles equipped with Supplemental Restraint (Airbag) System:

• Service on and around the airbag system components or wiring must be performed only by

an authorised HO LDEN retailer. Please observe all WARNINGS and SERVICE PRECAUTIONS

refer to Se ction 10B AIRBA G SYSTEM, ON-V EHICLE SERVICE be fore performing s ervice on

or around the airbag system components or wiring. Failure to follow WARNINGS could result

in unintentional activation of the system or could render the system inoperative. Either of

these two conditions may r esult in severe injury.

• The procedures in this section must be followed in the order listed to temporarily disable the

airbag system and prevent false diagnostic codes from setting. Failure to follow procedures

could result in possible airbag system activation, personal injury or otherwise unneeded air-

bag system repairs.

• Technical service work must be started at least 90 seconds after the ignition switch is turned

to the “LOCK” position and the negative cable is disconnected from the battery. Otherwise,

the syst em may be act ivat ed by res er ve ene rgy i n the Sen sing and Diag nost i c Modu le (SDM) .

4.5 CAMSHAFT, TAPPET AND SHIM

Removal

Inspection

Installation

4.6 VALVES AND CYLINDER HEAD

Removal

Disassembly

Inspection

Assembly

Installation

4.7 PISTONS, PISTON RINGS,

CONNECTING RODS AND CYLINDERS

Removal

Disassembly

Cleaning

Inspection

Assembly

Installation

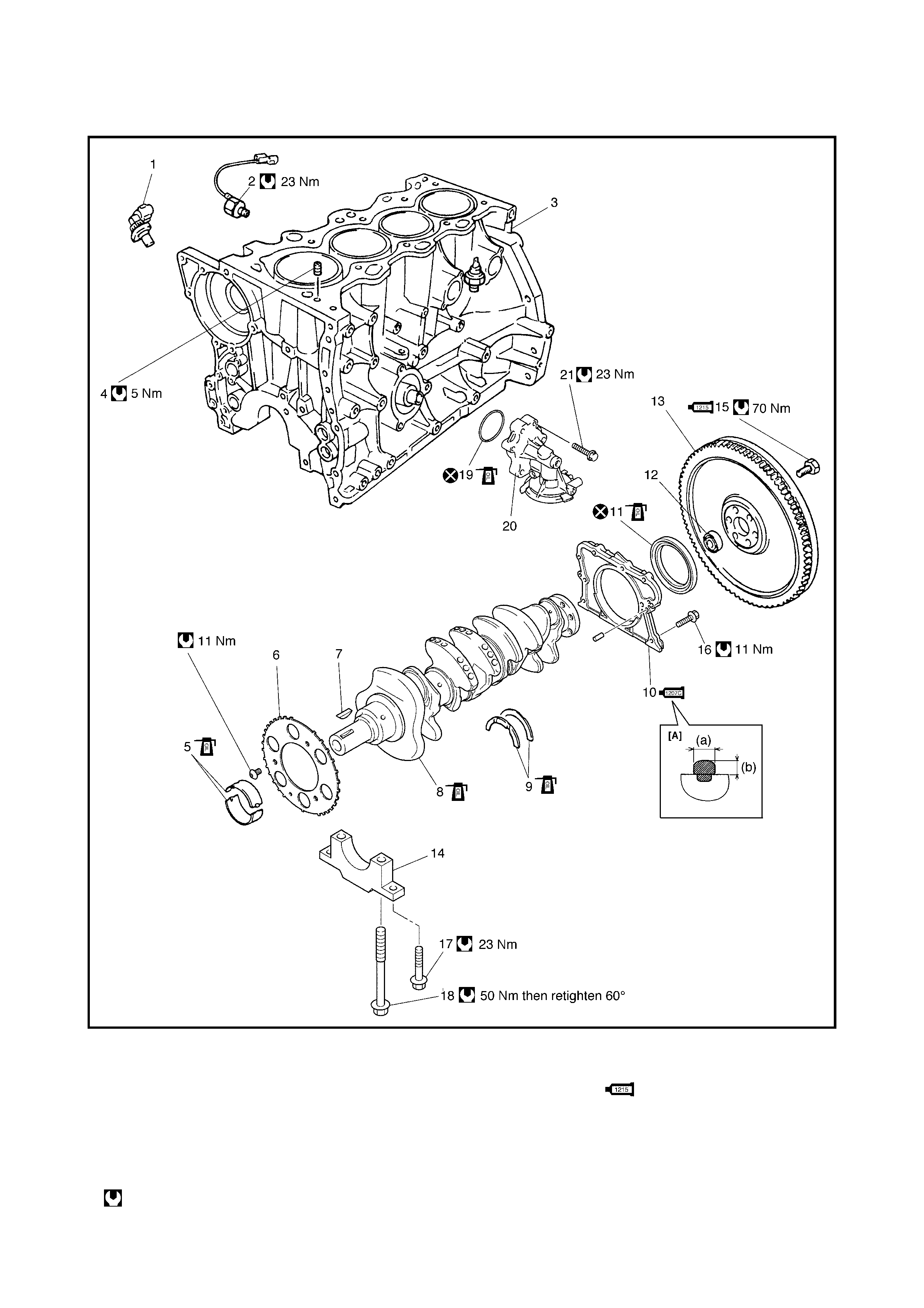

4.8 MAIN BEARINGS, CRANKSHAFT

AND CYLINDER BLOCK

Removal

Inspection

Main Bearings

Selection of Main Bearings

Cylinder Block

Installation

5. REQUIRED SERVICE MATERIAL

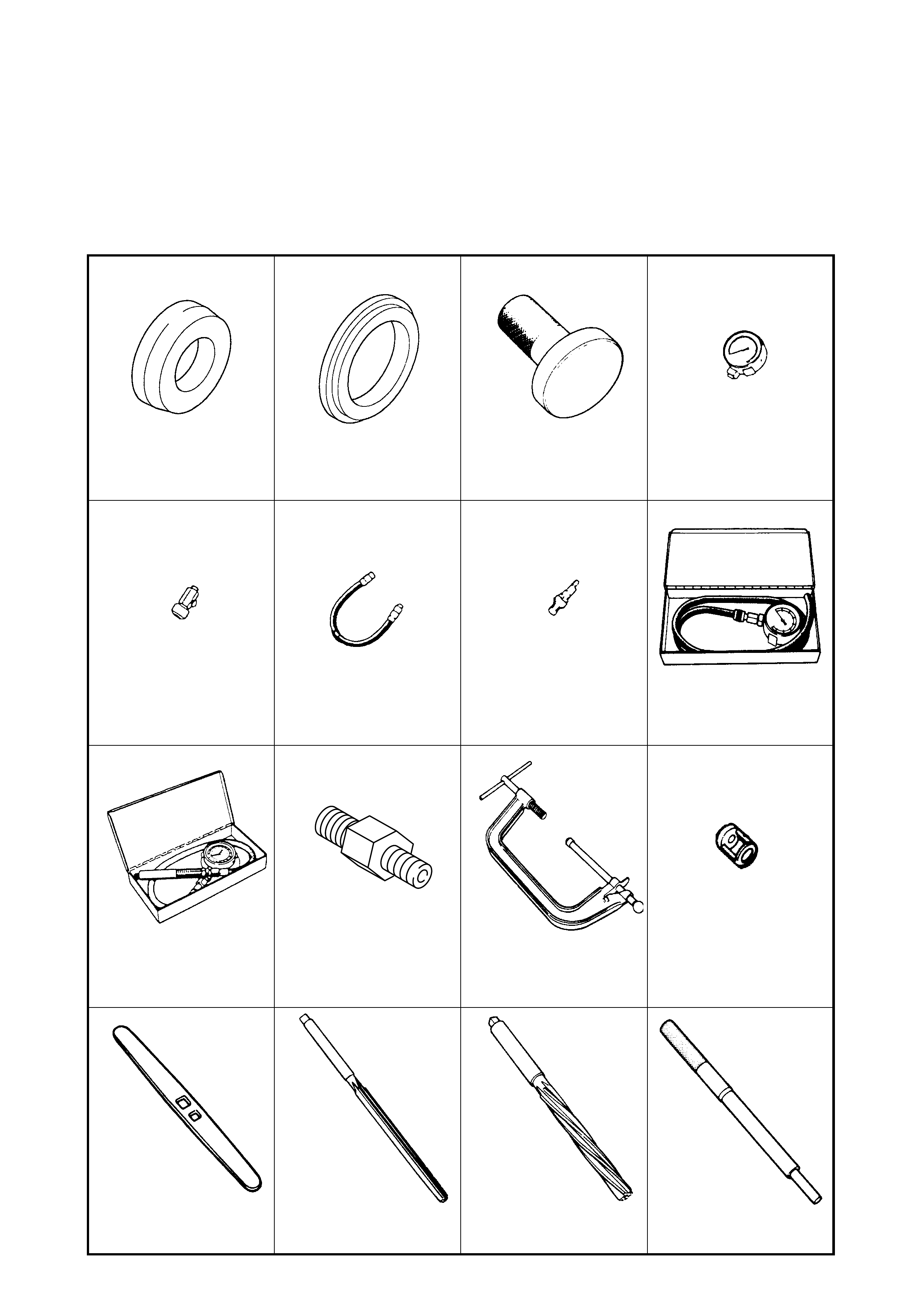

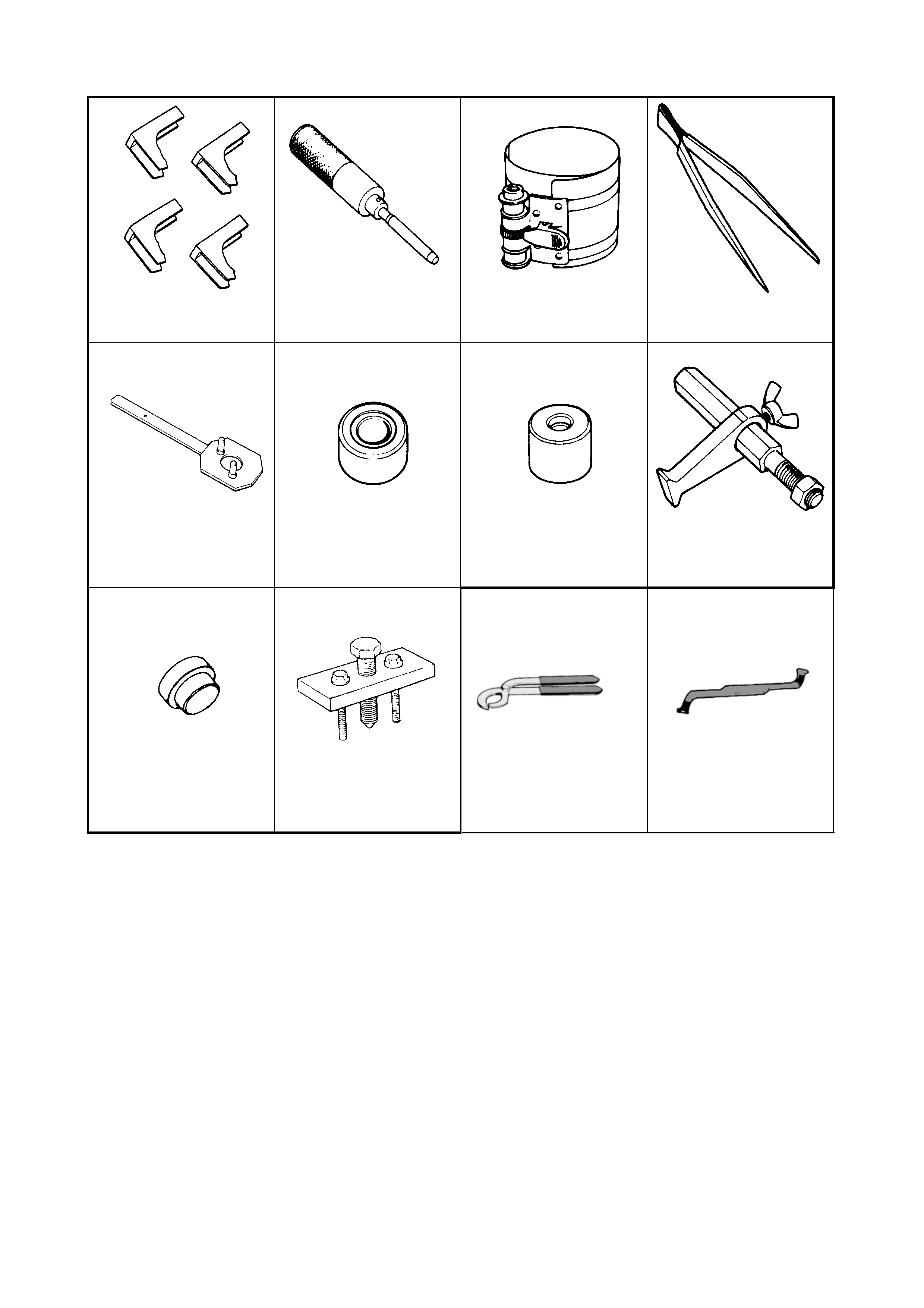

6. SPECIAL TOOLS

1. GENERAL DESCRIPTION

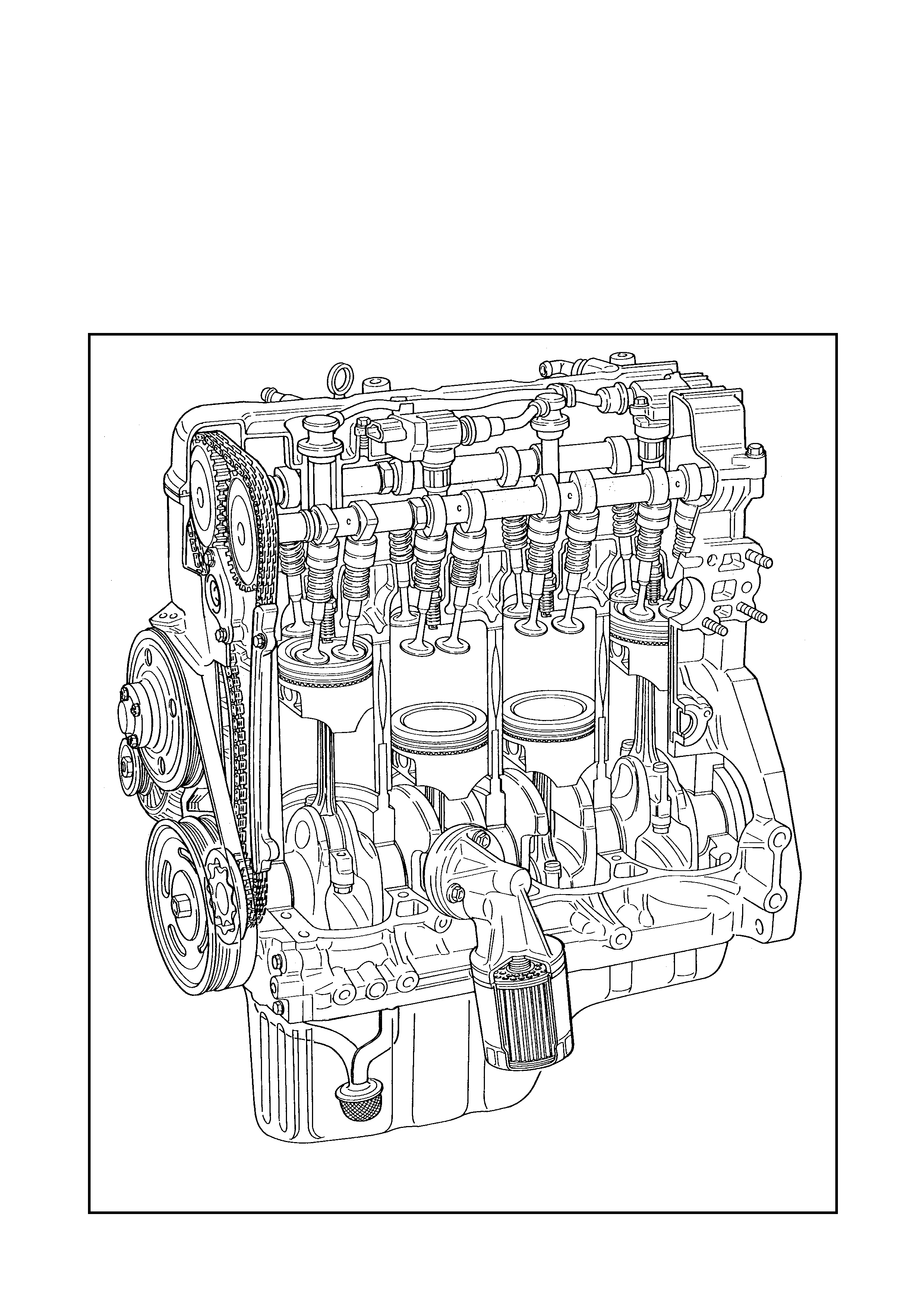

1.1 ENGINE

The engine is a water-cooled, in line 4 cylinder, 4 stroke petrol unit with Double Overhead Camshaft

(DOHC) valve mechanism arranged in a “V” type valve configuration with 16 valves (4 valves per

cylinder. The double overhead camshafts are mounted over the cylinder head and are driven from the

crankshaf t throu gh a timing chain. There are no push ro ds in the valve train system.

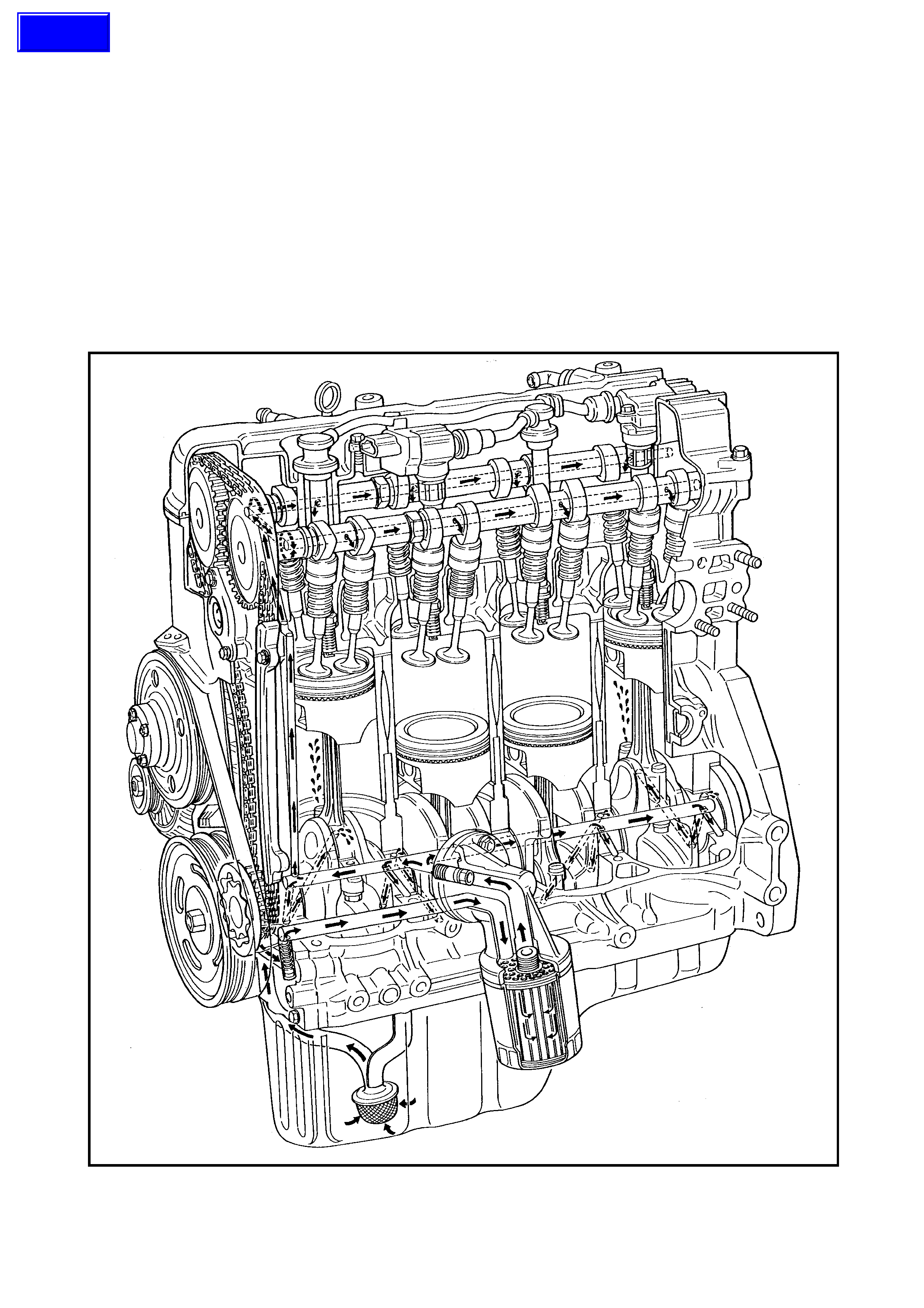

1.2 ENGINE LUBRICATION

The oil pump is a troc hoi d typ e, and mount ed on the crank sh aft. Oil is drawn up throug h t he oil pum p str ainer

and passed through the pum p to the oil filte r.

The filtered oil flows into two paths in the cylinder block.

Along one path, oil reaches the crankshaft journal bearings. Oil from the crankshaft journal bearings is sup-

plied to the conn ecting rod be arings via intersecting passag es drilled in the crank shaft, then is injected from

the big end of the connecting rod to lubricate the piston, rings, and cylinder wall.

In the second path, oil travels up to the cylinder head and lubricates the valves and camshafts, etc., after

passing through the internal oilway of the camshafts.

An oil relief valve is provided on the oil pump. This valve relieves oil pressure when the pressure exceeds

approximately 400 kPa.

Techline

2. DIAGNOSIS

2.1 DIAGNOSIS TABLE

Refer to Section 6, 2.4 ENGINE DIAGNOSTIC TABLE.

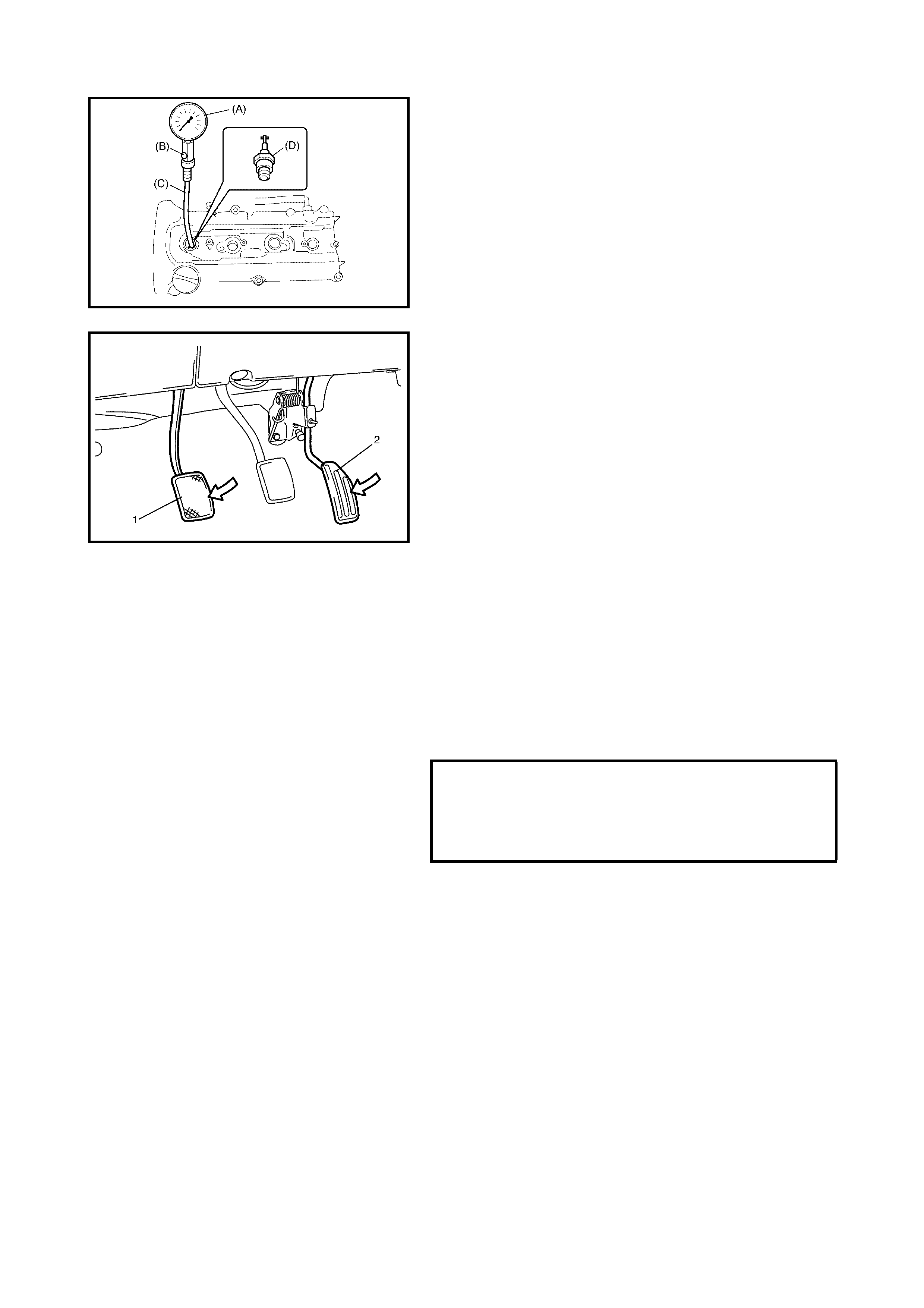

2.2 COMPRESSION CHECK

Check compression on all 4 cylinders as follows:

1. Warm up engine to normal operating temperature.

2. Stop engine after warming up.

NOTE: After warming up engine, place transmission gear

shift lever in Neutral (shift selector lever to “P” for A/T

vehicles), and set parking brake and block drive wheels

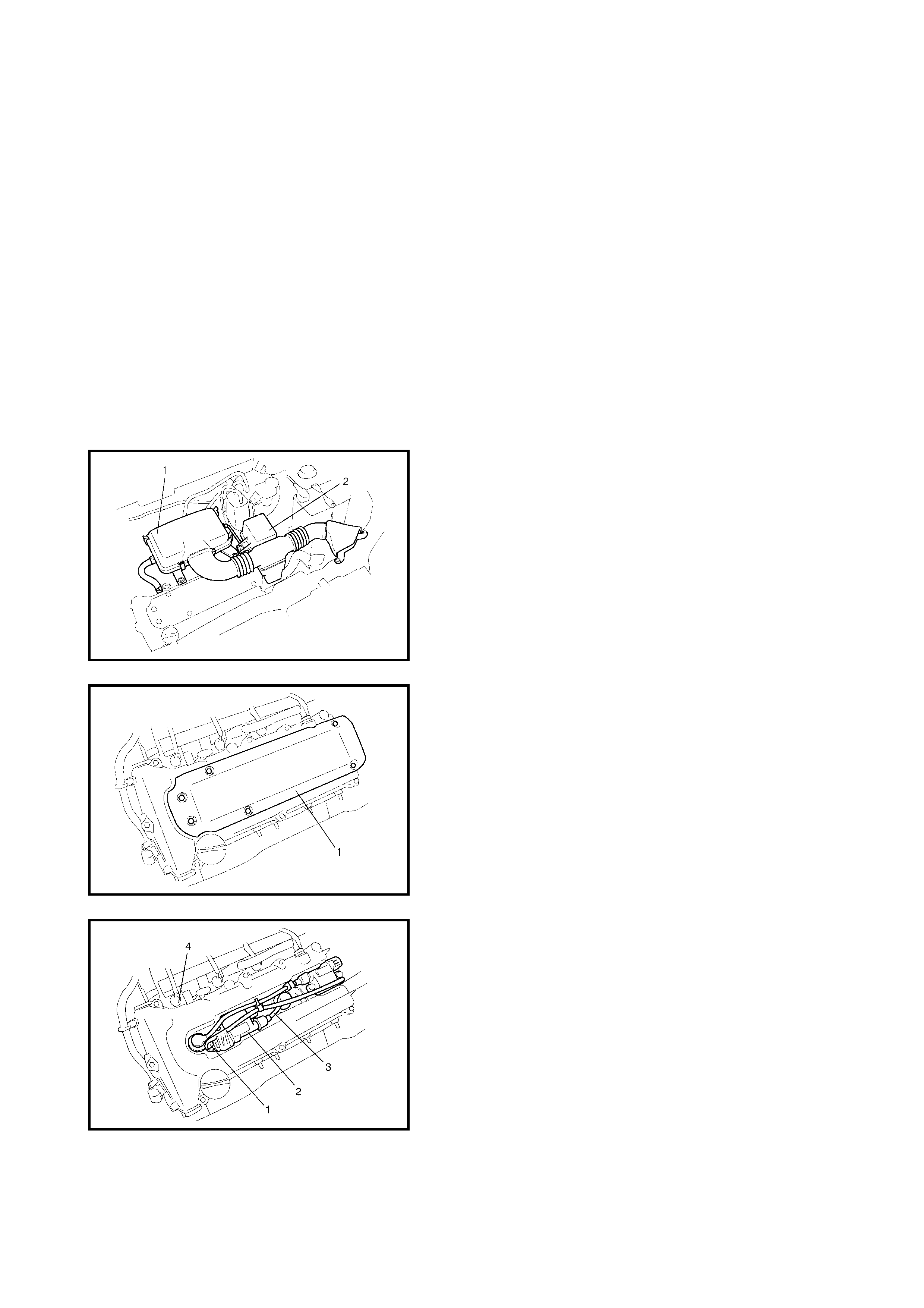

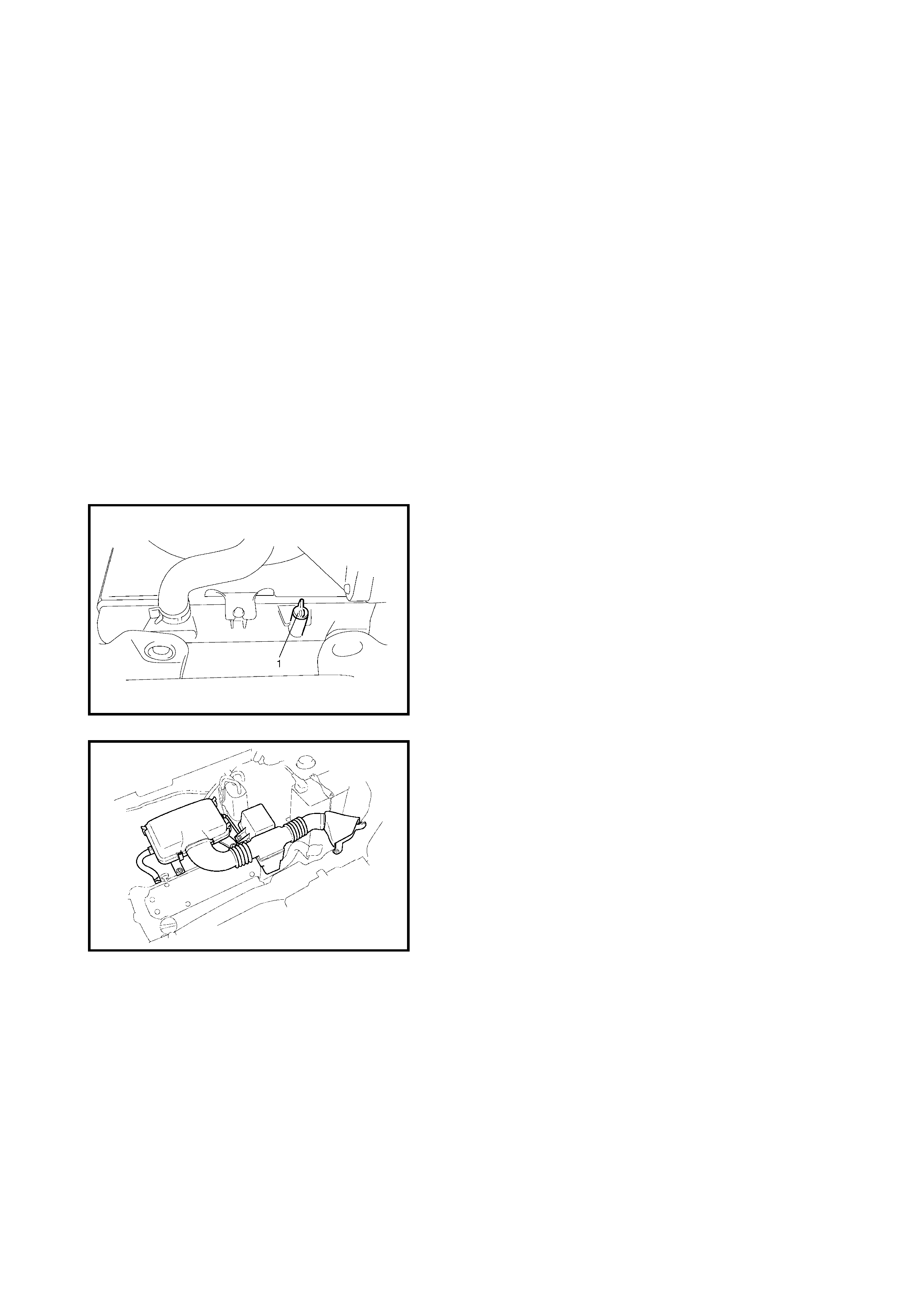

3. Remove air cleaner assembly (1), resonator (2) and

hoses. Refer to 3.2 AIR CLEANER ASSEMBLY AND

RESONATOR in this Section.

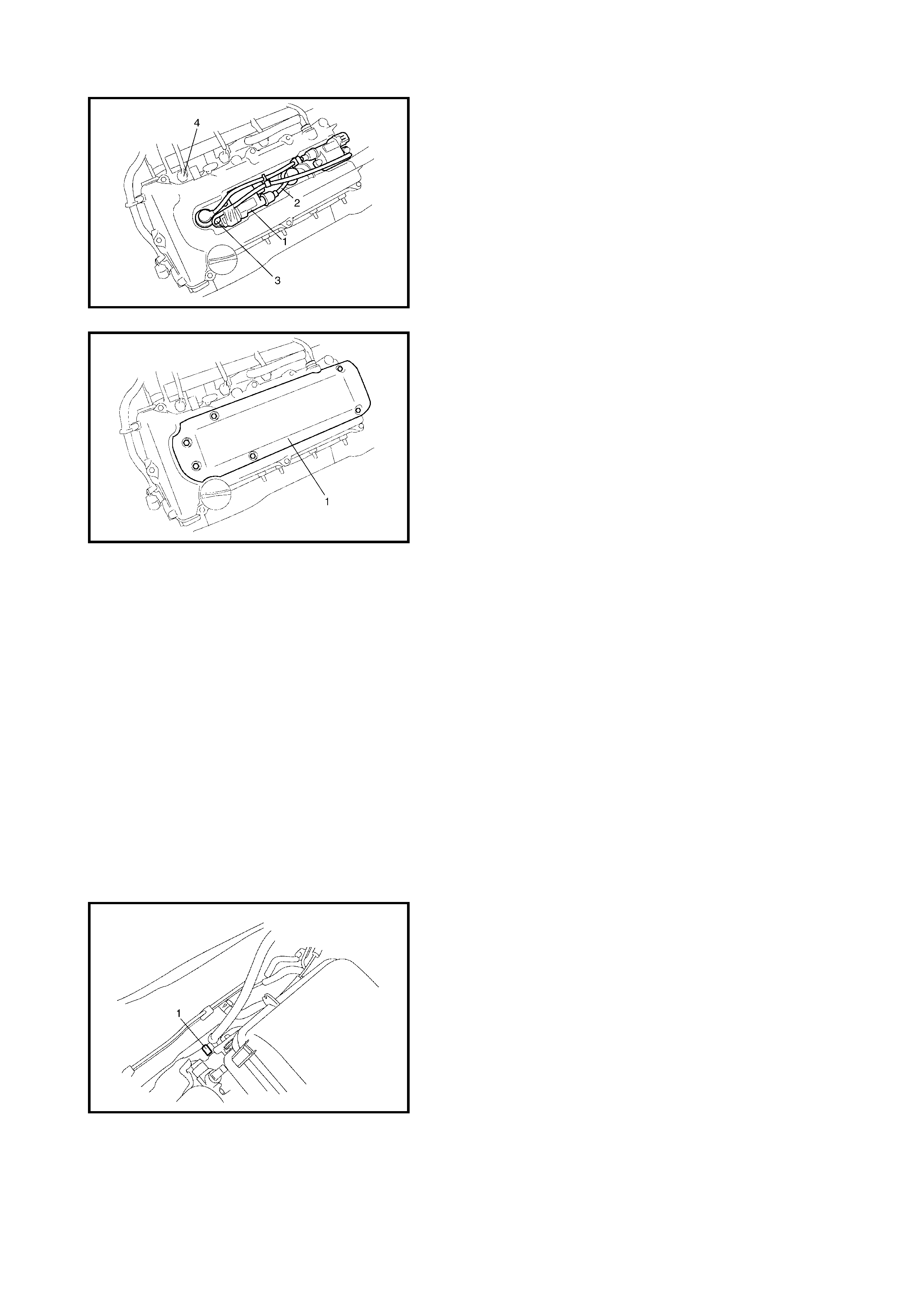

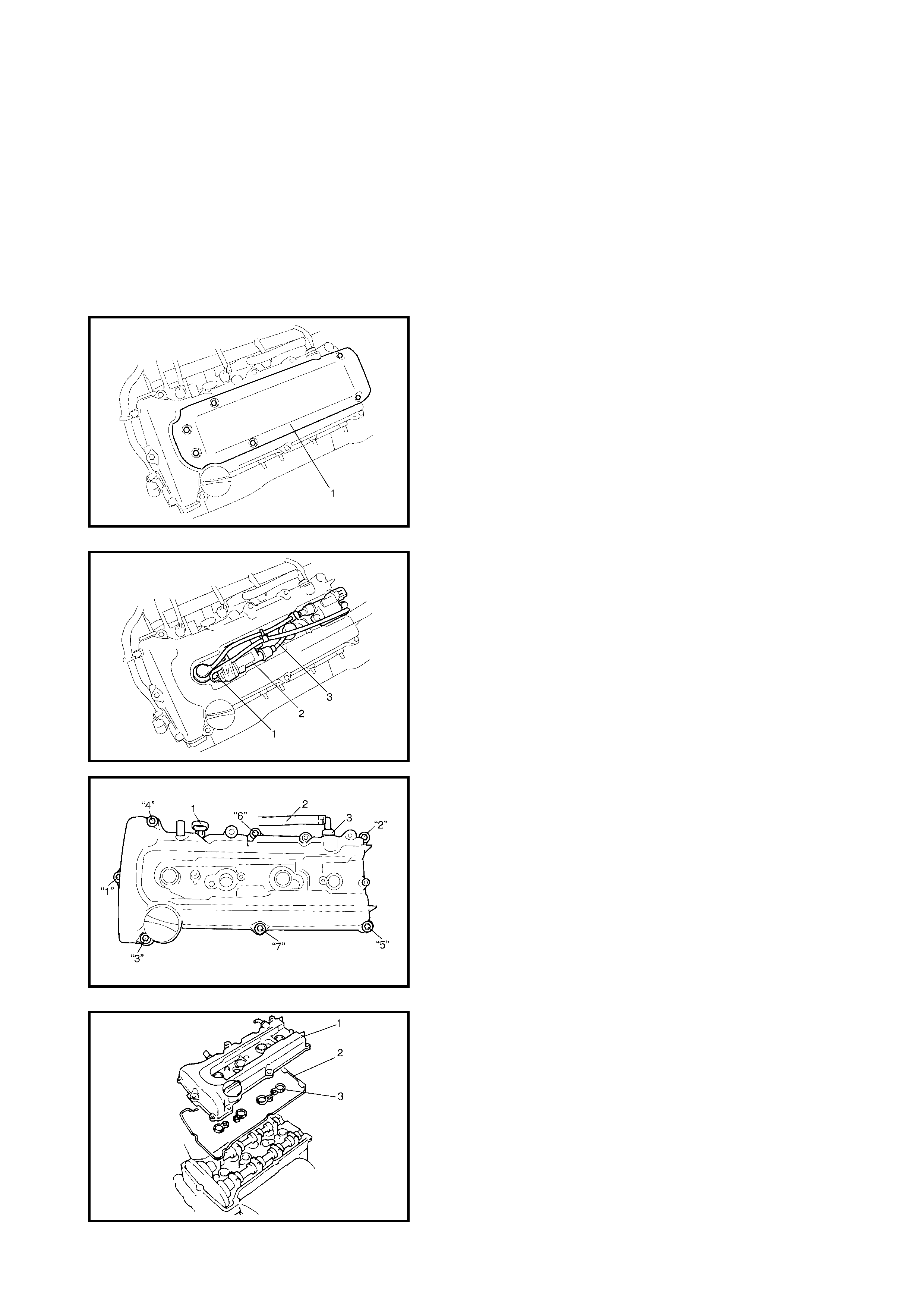

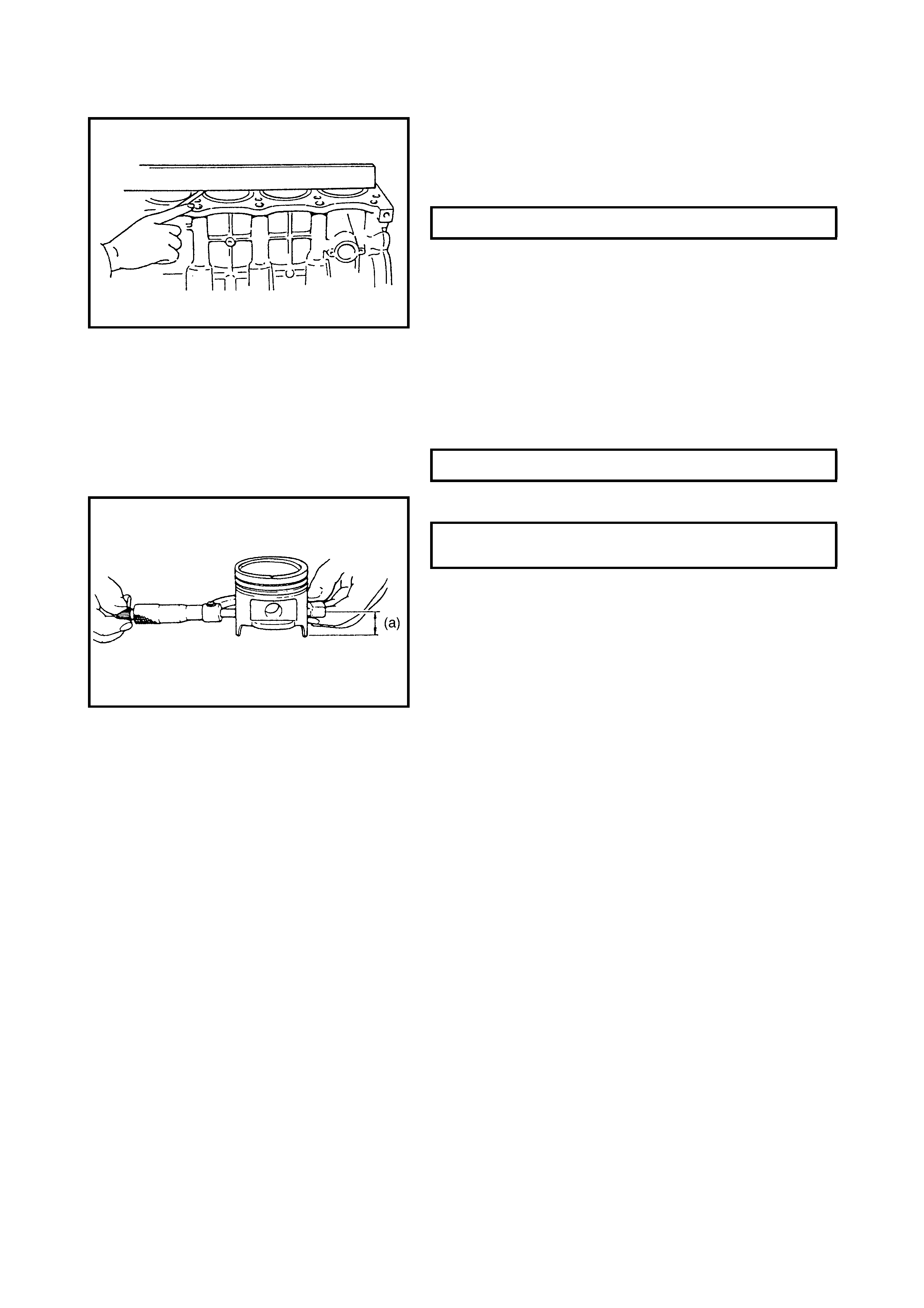

4. Remove the cylinder head upper cover (1).

5. Disconnect the ignition coil connectors (1).

6. Remove the ignition coil assemblies (2) with high-

tension leads (3).

7. Remove all spark plugs.

8. Disconnect fuel injector leads (4) at the connectors.

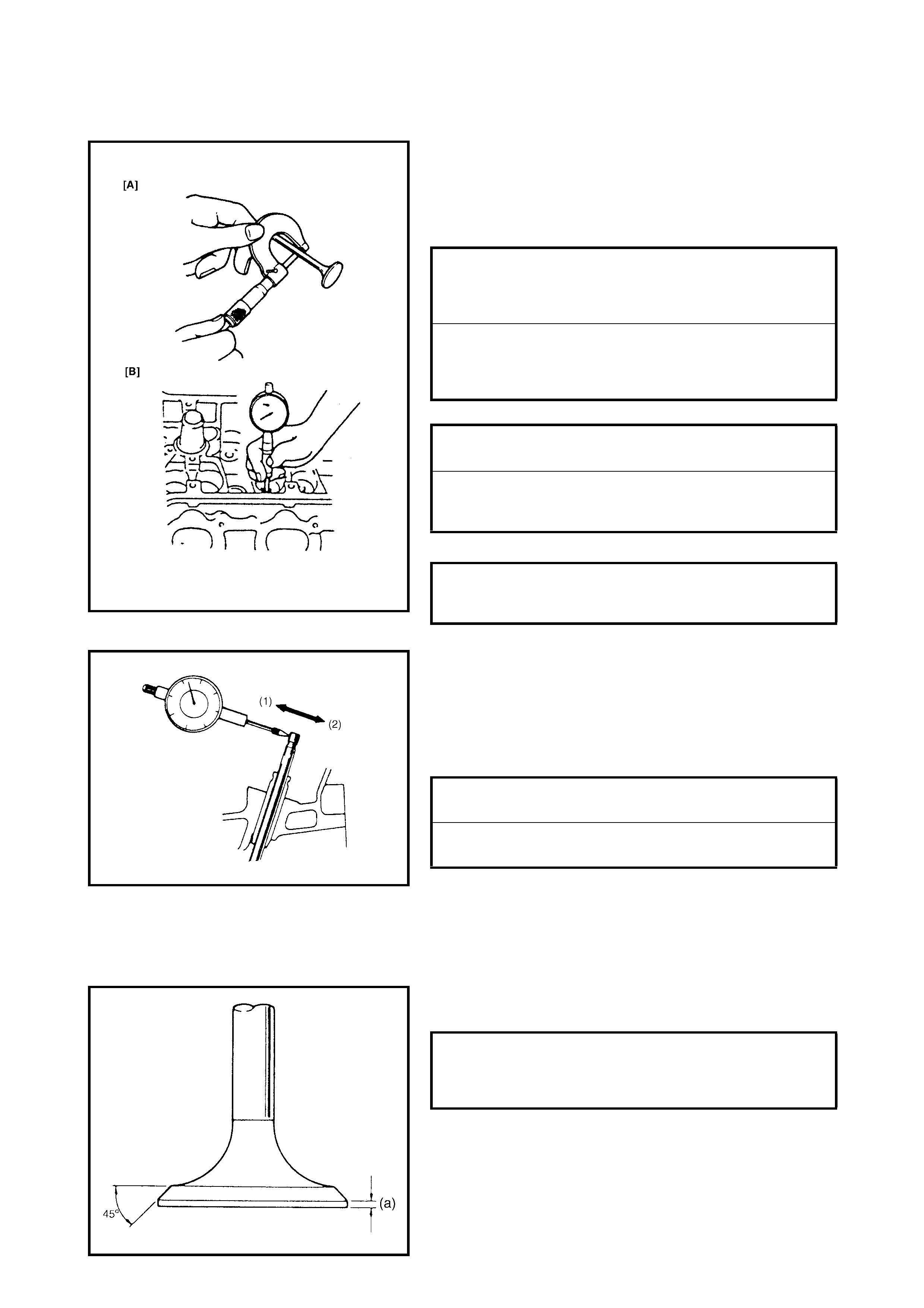

9. Install special tools (compression gauge) 09915-

64510-001 (A), 09915-64510-002 (B), 09915-64530

(C) and 09915-67010 (D) into spark plug hole.

10. Disengage clutch (1) (to lighten starting load on

engine) fo r M/T v ehi cle, a nd depress a cc eler ato r p eda l

(2) all the way to make throttle fully open.

11. Crank engine with fully charged battery and read the

highest pressure on the compression gauge.

NOTE:

• To measu re th e engi ne com press ion, cra nk the en gin e

to at least 250 rpm using a fully charged battery.

• If the measured compression pressure is lower than

the limit value, ensure that the special tools are fitted

correctl y. If they are co rrectly i nstalled, the lik ely caus e

of compression pressure leakage will be from where

the piston rings contact the cylinder wall.

12. Carry out Steps 9 through 11 on each cylinder to obtain

four readings.

COMPRESSION PRESSURE

STANDARD

LIMIT

MAXIMUM DIFFERENCE BETWEEN

ANY TWO CYLINDERS

1400 kPa

1100 kPa

100 kPa

13. After checking, install the spark plugs and ignition coil

assemblies (1) with the high-tension leads (2).

14. Connect the ignition coil connectors (3).

15. Connect the fuel injector lead (4) connectors.

16. Check the c ylinde r head upper co ver g asket for deter i-

oration. Rep lace i f d ama ged. In stall th e gaske t i nto th e

groove in the cylinder head upper cover (1) securely.

17. Install the cylinder head upper cover with gasket onto

the cylinde r hea d cover.

18. Install the air cleaner assembly, resonator and hoses,

refer to 3.2 AIR CLEANER ASSEMBLY AND

RESONATOR INSTA LLATION in this Section.

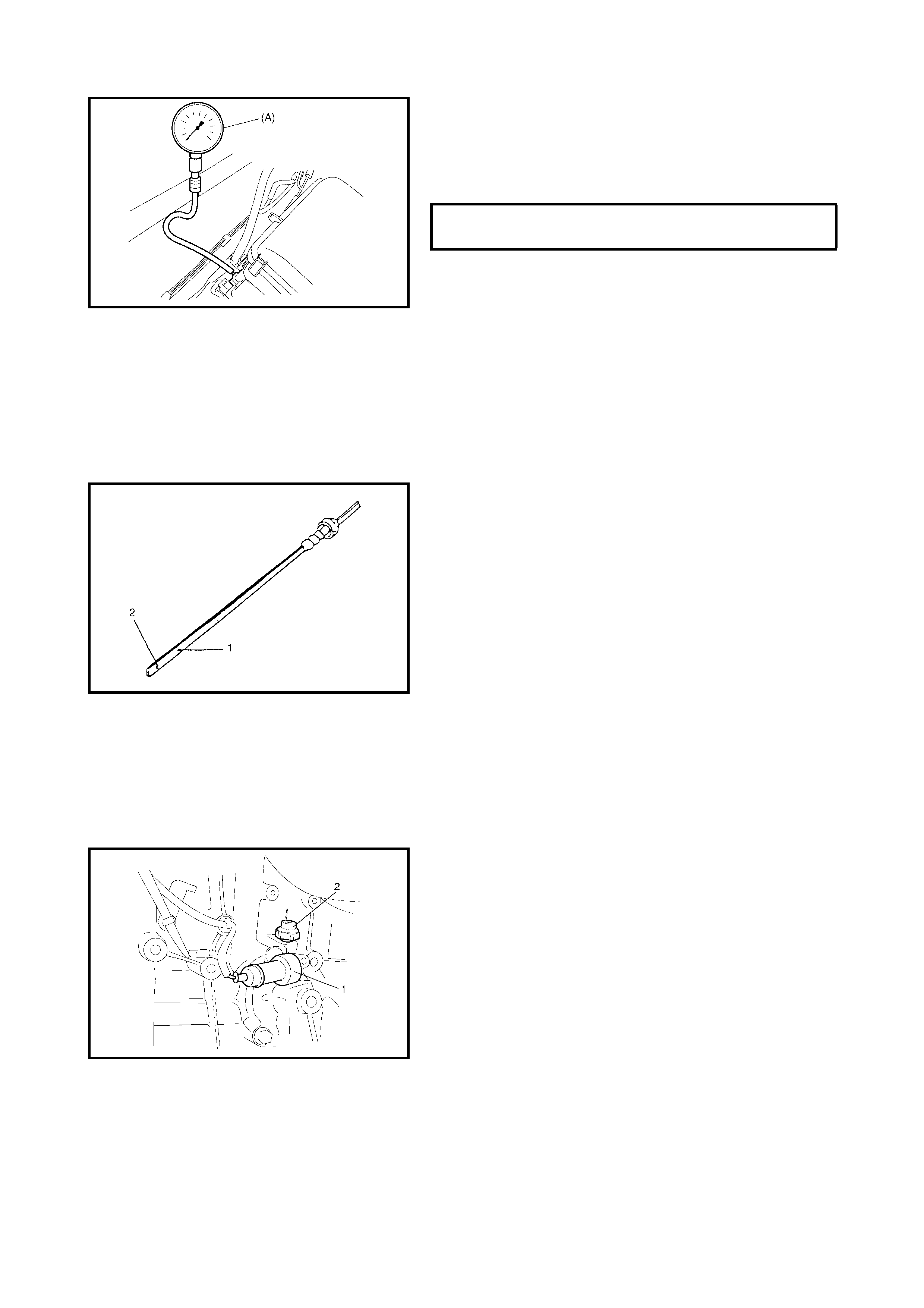

2.3 ENGINE VACUUM CHECK

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The vacuum

checking procedure is as follows :

1. Warm up the engine to normal operating temperature.

NOTE: After warming up the engine, be sure to place the

transm ission gear shift lever in Neutral (shift selector lever

to P range for A/T vehicles), and set parking brake and

block dr ive wheel s.

2. Stop engine and turn off the all electric switches.

3. Remove cap (1) from the intake manifold.

4. Connect special tool (Vacuum gauge) 09915-67310 (A)

to intake manifold.

5. Run the engine at specified idle speed and read the

vacuum gauge. The vacuum should be within specifi-

cation.

6. After checking, disconnect the special tool (Vacuum

gauge) from the intake manifold.

7. Refit the cap to the intake manifold.

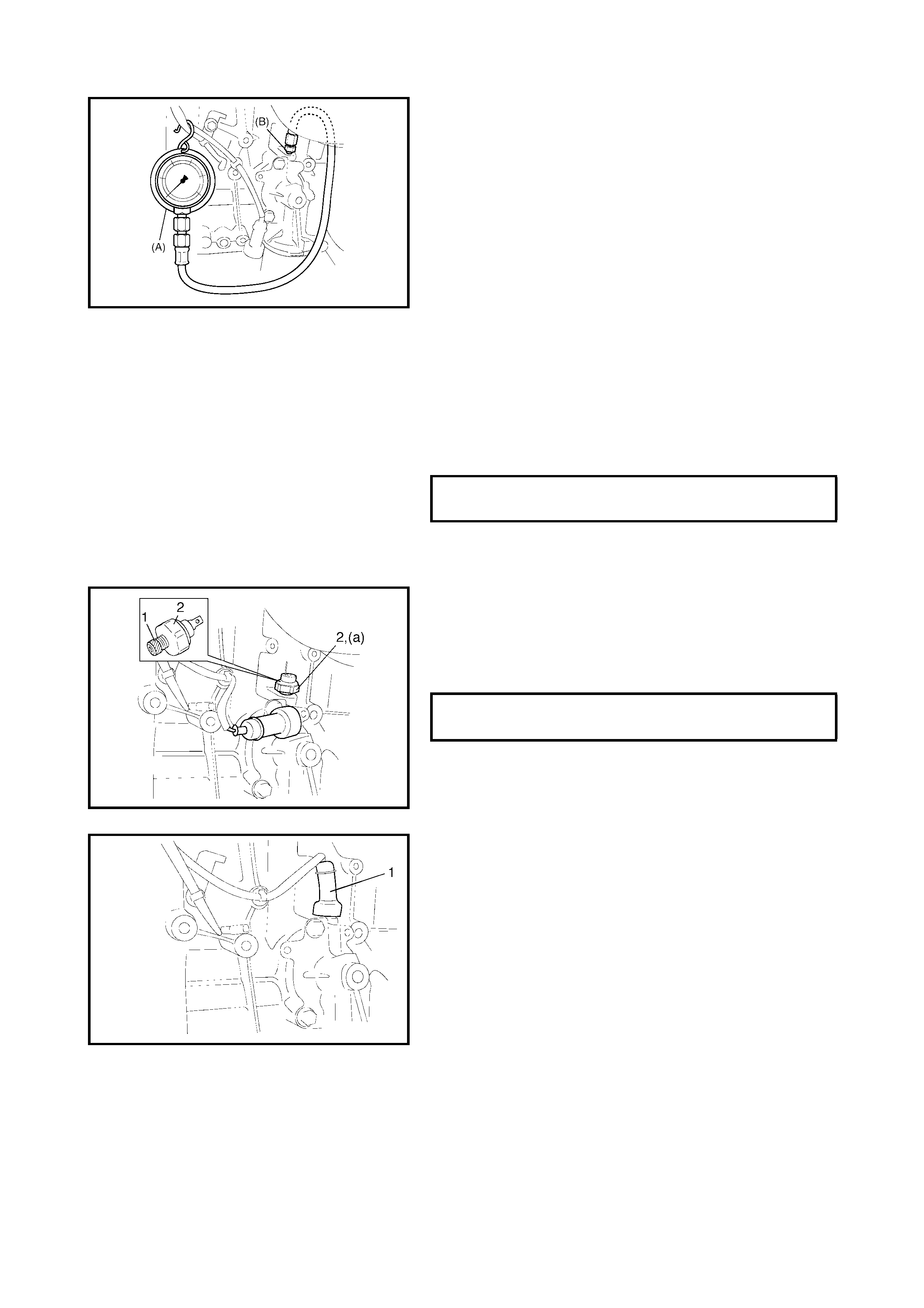

2.4 OIL PRESSURE CHECK

NOTE: Prior to chec king the oil pressu re, che ck the follow-

ing items.

• Oil level in sump.

If oil le vel is low (2 ), add oil u p to the FULL le vel mark

(hole) (1) on the oil level gauge.

• Oil qualit y

If oil is discoloured, or has deteriorated, change it.

For particular oil to be used, refer to Section 0B,

4. RECOMMENDED FLUIDS AND LUBRICANTS.

•Oil leaks

If a leak is found, repair it.

1. Disconnect the oil pressure switch connector (1) and

remove the oil pressure switch (2) from the cylinder

block.

VACUUM SPECIFICATION (@ SEA

LEVEL) AT SPECIFIED IDLE SPEED 59 - 73 kPa

2. Install spec ial tool s 0991 5-77310 (A) and 0991 5-782 11

(B) (Oil pressure gauge) to the oil pressure switch

threaded hole.

3. Start the engine and warm it up to normal operating

temperature.

NOTE: Be sure to place the transmission gear shift lever in

NEUTRAL (shift control lever to P range for A/T vehicles),

and set the parking brake and block drive wheels.

4. After warming up, rai se the engine sp eed to 4,000 rp m

and measure the oil pressure .

5. Stop the engine and remove the oil pressure gauge

and attachment.

6. Before reinstalling the oil pressure switch (2), be sure

to wrap its thread with sealing tape (1) and tighten

switch to specified torque.

NOTE: If the sealing tape edge has bulged out from the

thread of the switch, trim it off.

7. Start the engine and check the oil pressure switch for

oil leakage.

If oil leakage occurs, rectify it.

8. Connect the oil pressure switch connector (1).

OIL PRESSURE SPECIFICATION @

4000 RPM MORE THAN

270 kPa

OIL PRESSURE SWITCH (a)

TORQUE SPECIFICATION 14 Nm

2.5 VALVE LASH (CLEARANCE)

INSPECTION

1. Remove the negative cable at battery.

2. Remove the cylinder head cover, refer to

3.4 CYLINDER HEAD COVER, REMOVAL in this

Section.

3. Remove the right side engine cover if necessary.

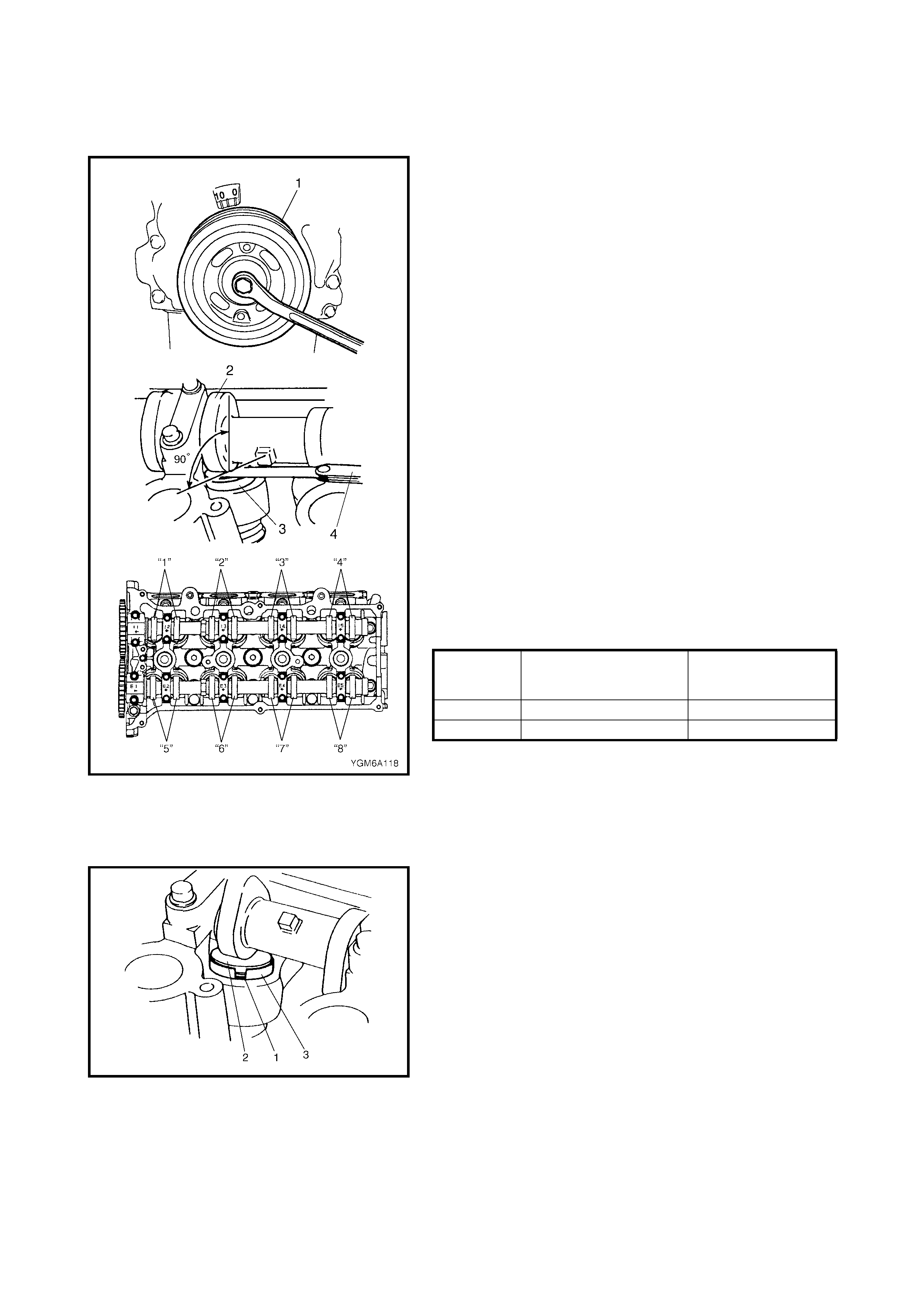

4. Using a 17 mm wrench, turn the crankshaft pulley (1)

clockwise until the cam lobes (2) become perpendicu-

lar to the shim faces (3) at valves “1” and “7” as shown

in the figure.

5. Check the valve lashes with a thickness gauge (4) as

indicated in the following steps.

a. Check and note the valve lashes at valves “1” and

“7”.

b. Turn the camshafts 90° (by turning the crankshaft

with a 17 mm wrench).

c. Make sur e that the c am lobes are perpendicu lar to

the shim faces at valves to be checked (in this

case, “3” and “8”), if not, adjust by turning crank-

shaft. Check and note the valve lashes.

d. As in Steps b and c, check and note the valve

lashes at valves “4” and “6”.

e. As in Steps b and c, check and note the valve

lashes at valves “2” and “5”.

Valve clearance specification

If the valv e lash i s not with in spe cificati on, recor d the va lve

lash and adjust it to specification by replacing shim.

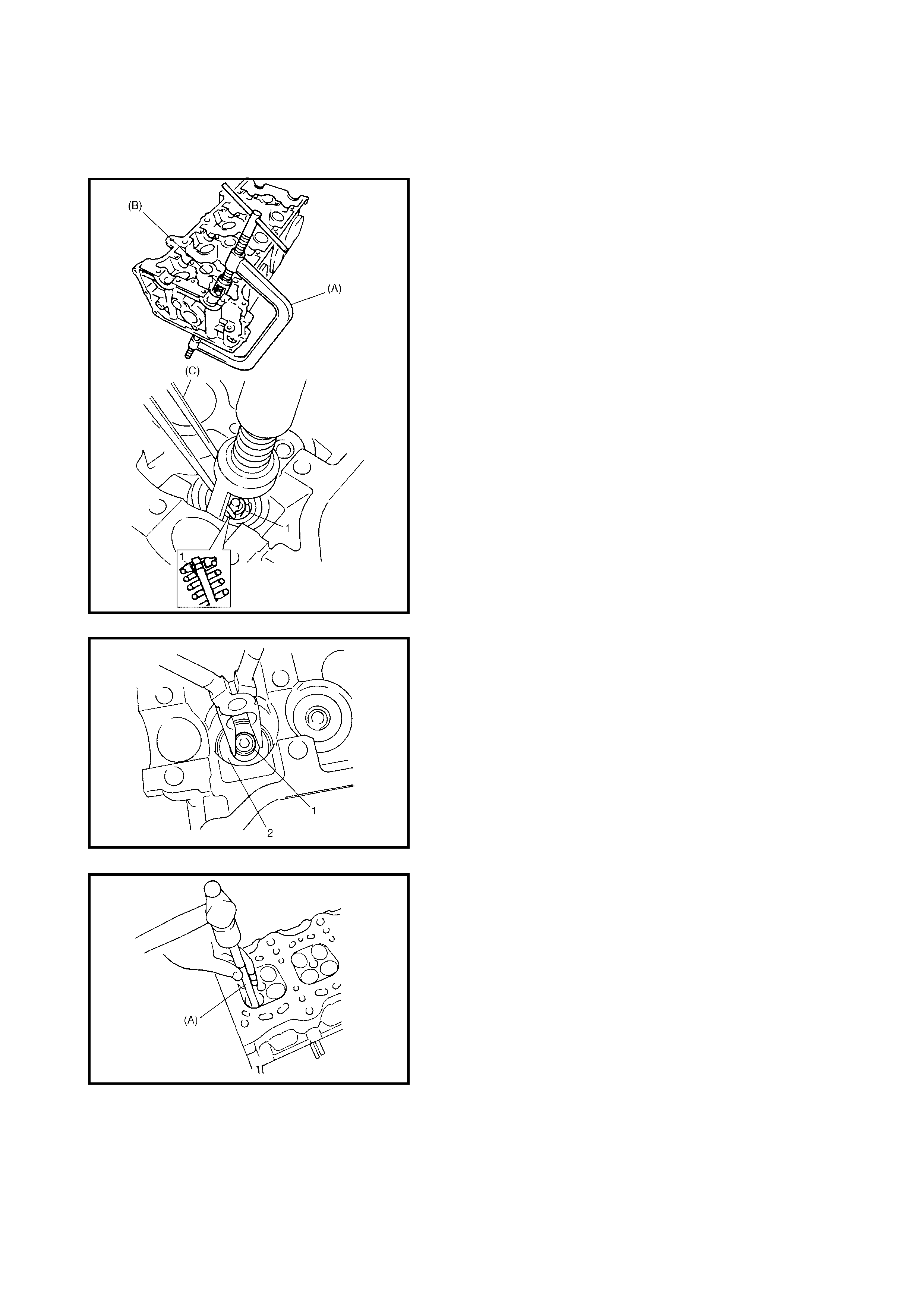

REPLACEMENT OF SHIM

1. Close the valve whose shim (2) is to be replaced by

turning the crankshaft using a 17 mm wrench, then turn

tappet (3) until its cut section (1) faces inwards as

shown in the figure.

WHEN COLD

(COOLANT TEMP. IS

15 – 25°C)

WHEN HOT

(COOLANT TEMP.

IS 60 – 68°C)

INTAKE 0.18 – 0.22 mm 0.21 – 0.27 mm

EXHAUST 0.28 – 0.32 mm 0.30 – 0.36 mm

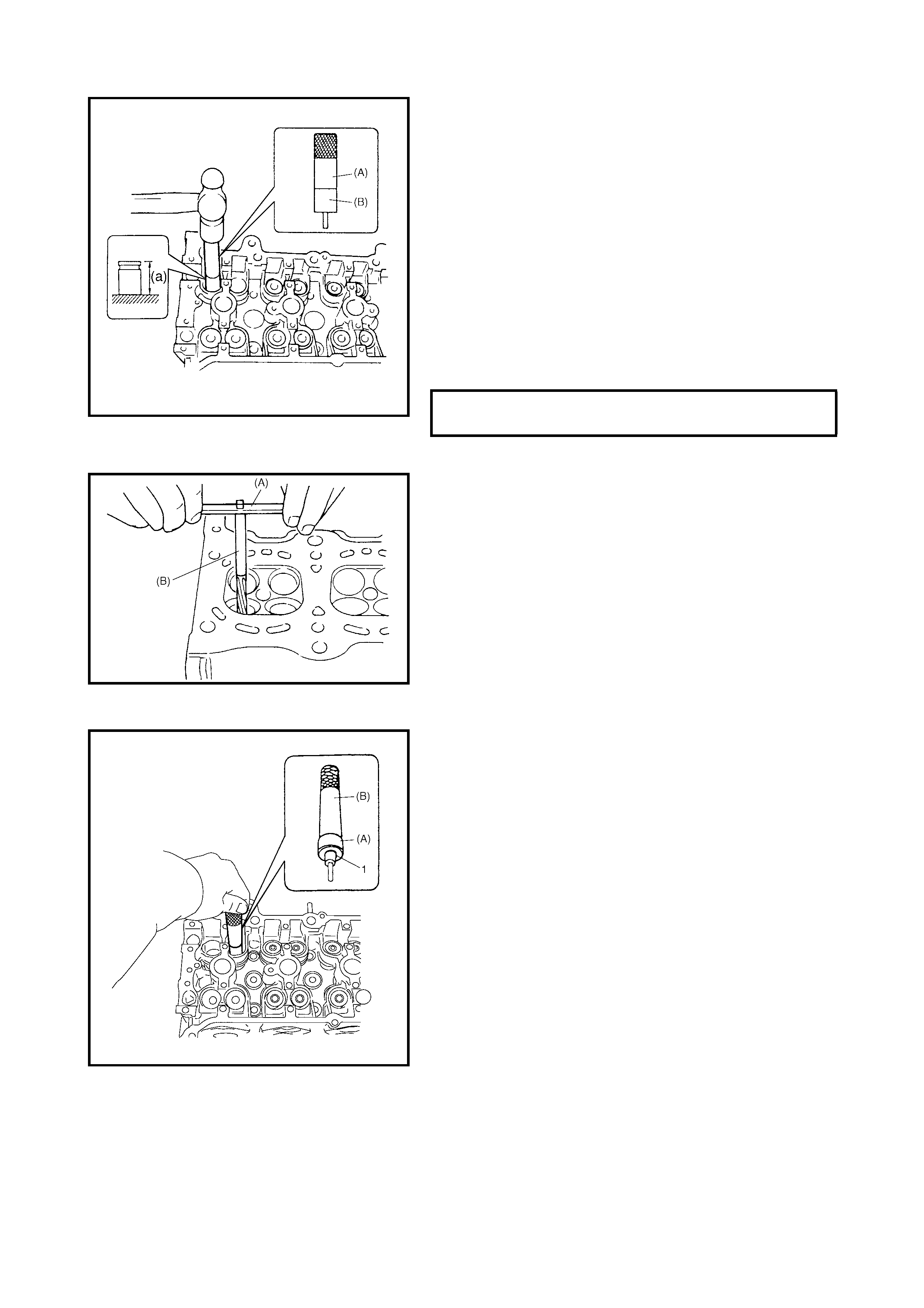

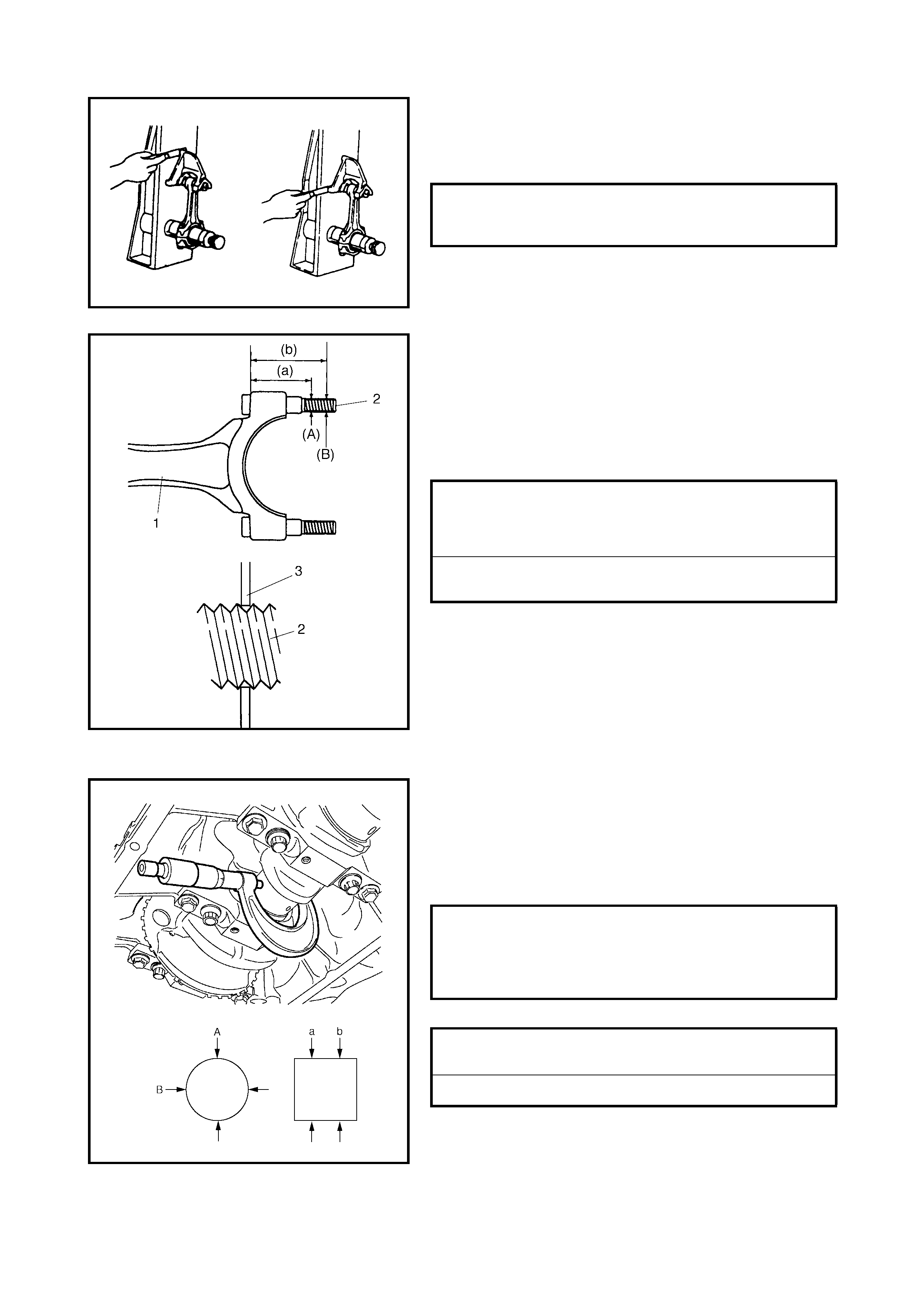

2. Place the J42689-AUS Pliers around the camshaft as

shown in the figure, and rotate the pliers to depress the

tappet.

3. Locate the 09222-2D000/2 Valve Shim Bucket Spacer

between the camshaft and the tappet edge as shown.

This will keep the tappet depressed while the shim is

replaced.

4. Remove the J42689-AUS Pliers

5. Remove the shim (1) using a magnet (2) as shown in

the figure.

WARNING: Never place hands between the camshaft

and the tappets.

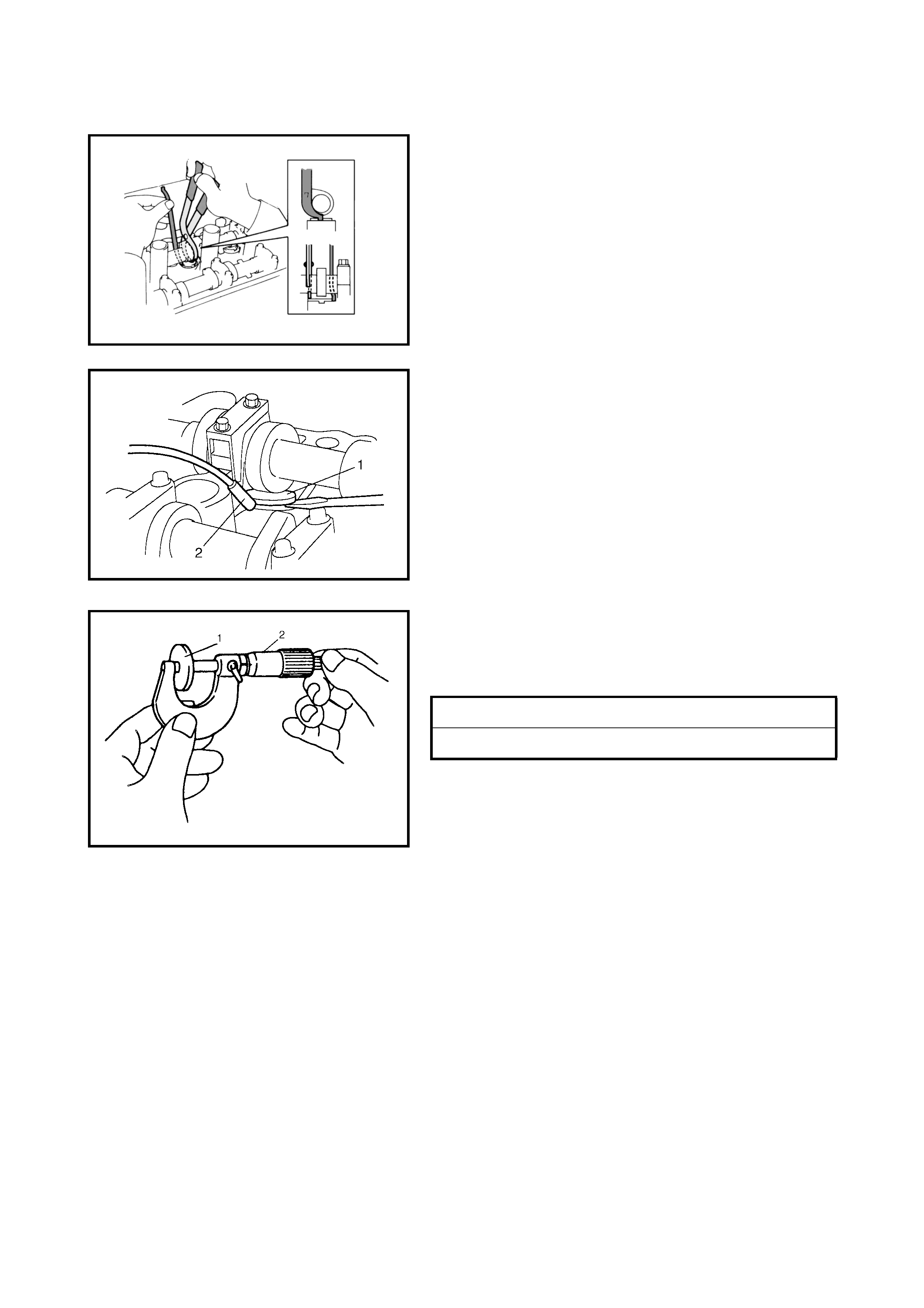

6. Using a micrometer (2), measure the thickness of the

removed shim (1), then determine the required

thickness of the new replacement shim using the

following formula and table.

A : Thickness of new shim

B : Thickness of removed shim

C: Measured valve lash clearance

Intake side shim example:

When th e thickness of the removed shim is 2.40 mm, and

the measured valve clearance is 0.45 mm.

A = 2.40 mm + (0.45 mm – 0.20 mm) = 2.65 mm.

Calculated thickness of new shim = 2.65 mm.

SHIM THICKNESS - INTAKE SIDE A = B + (C – 0.20mm)

SHIM THICKNESS - EXHAUST SIDE A = B + (C – 0.30mm)

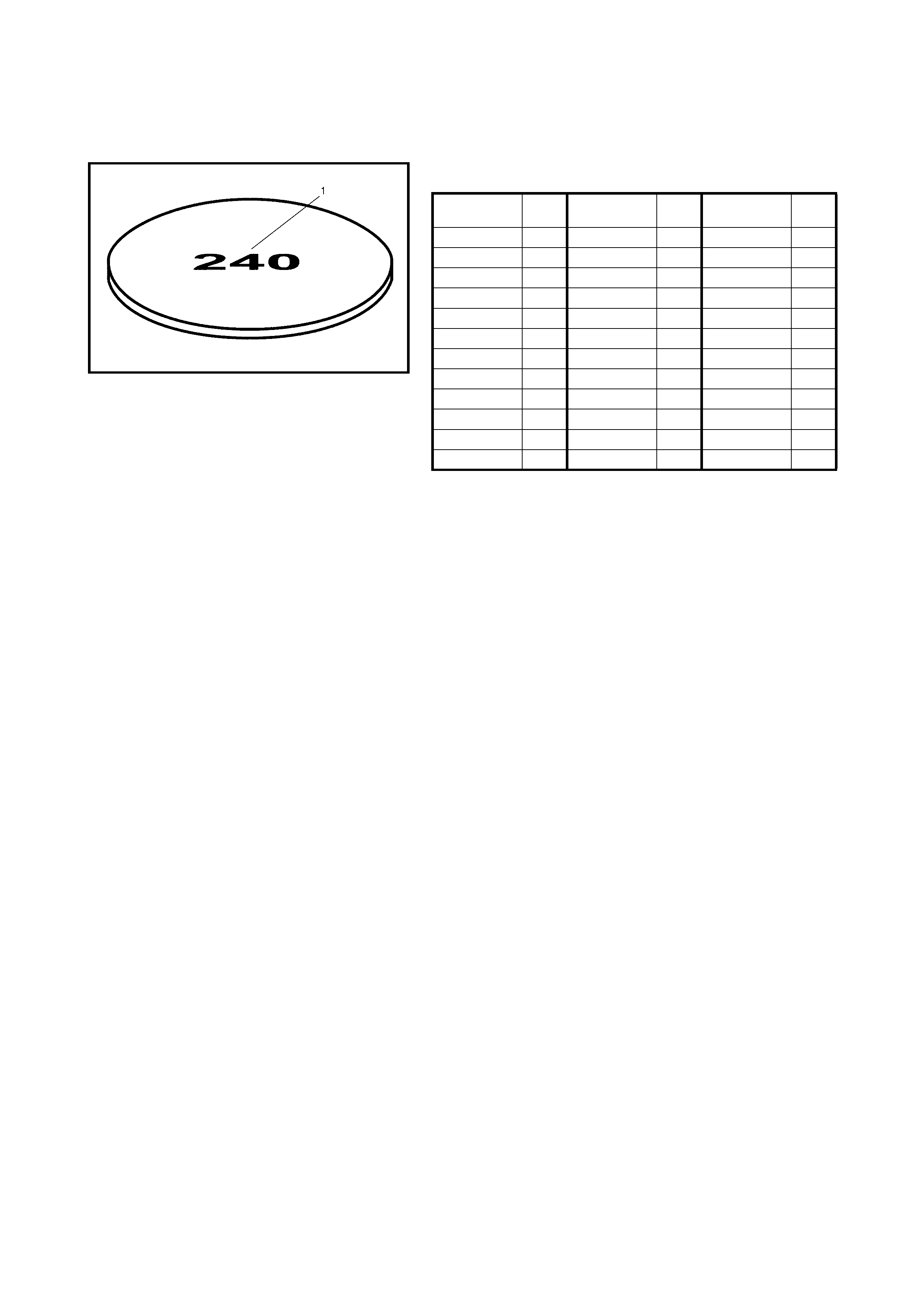

7. Select a n ew sh im No. (1 ) with a thi c kn es s as c lo se as

possible to the calculated valve.

Available new shims thickness and number.

8. Install the new shim with the shim number facing the

tappet.

9. Place the J42689-AUS Pliers around the camshaft,

then rotate the pliers to depress the tappet and remove

the 09222-2D000/2 Valve Shim Bucket Spacer.

10. Remove the J42689-AUS Pliers.

11. Recheck the valve lash clearance after replacing

shims.

12. After checking and adjusting all valves, install cylinder

head cover, refer to 3.4 CYLINDER HEAD COVER,

INSTALLATION in this Section.

THICKNESS

mm SHIM

No. THICKNESS

mm SHIM

No. THICKNESS

mm SHIM

No.

2.18 218 2.48 248 2.78 278

2.20 220 2.50 250 2.80 280

2.23 223 2.53 253 2.83 283

2.25 225 2.55 255 2.85 285

2.28 228 2.58 258 2.88 288

2.30 230 2.60 260 2.90 290

2.33 233 2.63 263 2.93 293

2.35 235 2.65 265 2.95 295

2.38 238 2.68 268 2.98 298

2.40 240 2.70 270 3.00 300

2.43 243 2.73 273

2.45 245 2.75 275

3. ON-VEHICLE SERVICE

3.1 AIR CLE A NER ELEMEN T

REMOVAL

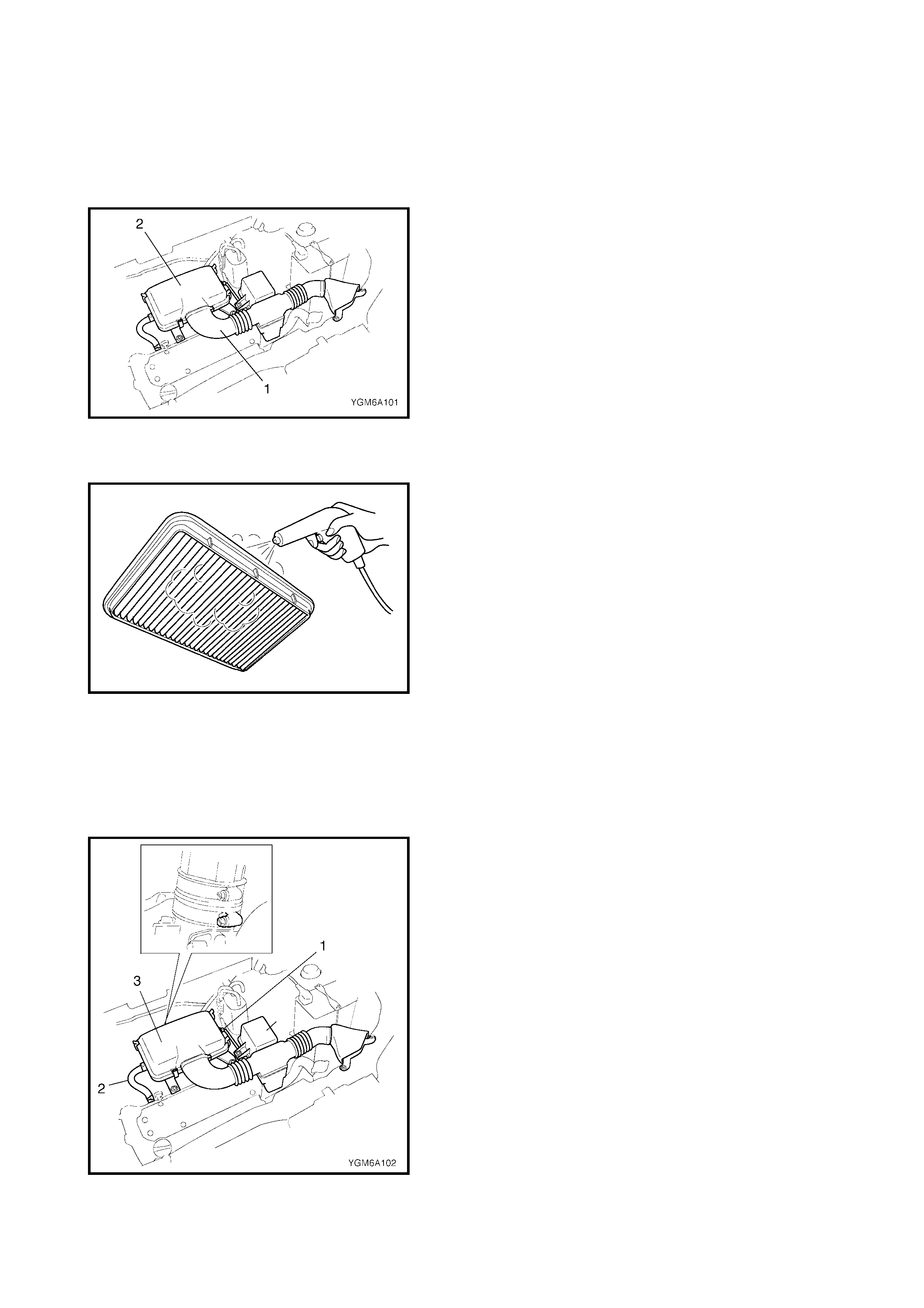

1. Disconnect the air cleaner inlet hose (1) from the air

cleaner case (2).

2. Open the air cleaner case by unhooking its clamps.

3. Remove the air cleaner element from case.

INSPECTION AND CLEANING

• Check air cleaner element for dirt.

• Blow off any dust using compressed air from the air

outlet side of the element.

• Replace excessively dirty element.

INSTALLATION

Reverse removal procedure for installation.

3.2 AIR CLE ANER ASSEMBLY AND RE SO N AT O R

REMOVAL

1. Disconnect negative cable at battery.

2. Disconnect intake air temperature (IAT) sensor

connector (1).

3. Disconnect the breather hose (2) from the cylinder

head cover.

4. Remove the air cleaner assembly (3), resonator (4)

and their hoses.

INSTALLATION

Reverse removal procedure for installation.

3.3 KNOCK SENSOR

Refer to Section 6E1, 2.3 ELECTRONIC CONTROL

SYSTEM, KNOCK SENSOR.

3.4 CYLINDE R HEAD COVER

REMOVAL

1. Disconnect negative cable at battery.

2. Remove the air cleaner assembly, resonator and

hoses, refer to 3.2 AIR CLEANER ASSEMBLY AND

RESONATOR REMOVAL.

3. Remove cylinder head upper cover (1).

4. Disconnect ignition coil connectors (1).

5. Remove ignition coil assemblies (2) with high-tension

leads (3).

6. Remove the oil level gauge (1).

7. Disconnect the PCV hose (2) from the PCV valve (3)

and release the harness clamp.

8. Remove the cylinder head co ver mounting bolts in the

order shown in the figure.

9. Remove the cylinder head cover (1) with the cylinder

head cover gasket (2) and spark plug hole gaskets (3).

INSTALLATION

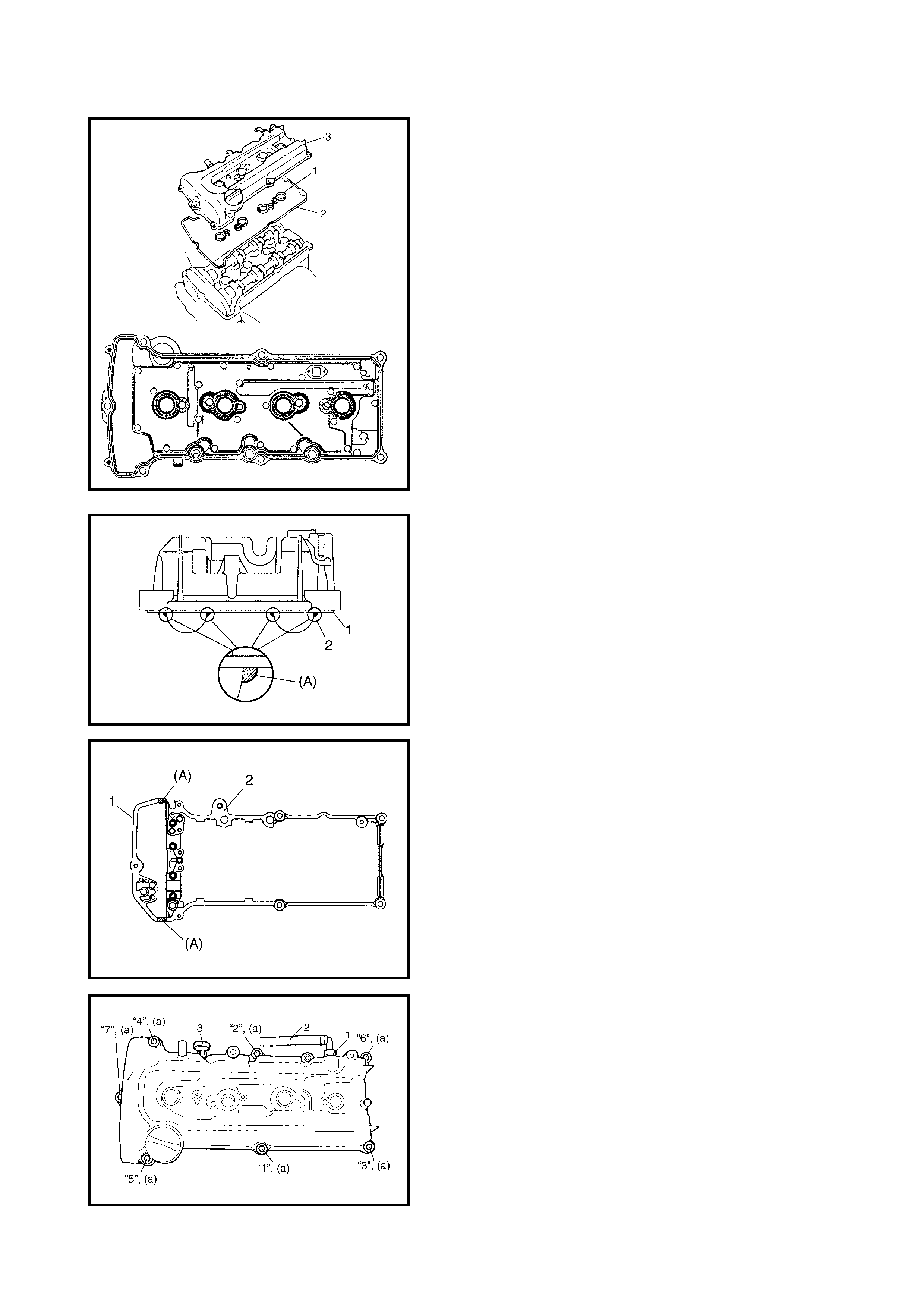

1. Install new spark plug hole gaskets (1) and a new

cylinder head cover gasket (2) to the cylinder head

cover (3) as shown in the figure.

2. Remove oil, old sealant, and dust from the sealing

surface on the cy l ind er h ead an d co ve r. After cl ea nin g ,

apply sealant “A” to the following points.

• Cylinder head cover gasket (1) sealing surface area (2)

as shown.

(A): Sealant - Three Bond No. 1207C

• Timing ch ain cove r (1) and cy linder head ( 2) matchin g

surface as shown.

(A): Sealant - Three Bond No. 1207C

3. Install cylinder head cover to cylinder head.

NOTE: When installing the cylinder head cover, ensure that

the cylinder head cover gasket and the spark plug hole

gaskets do not fall off or become misplaced.

4. Gradual ly tighten the bolts in the orde r indicated in the

figure until they reach the specified torque.

5. Connect the PCV hose (2) to the PCV valve (1).

6. Install the oil level gauge (3).

7. Install the ignition coil assemblies with the high-tension

leads.

8. Connect the ignition coil connectors and clamp

harness securely.

9. Install the cylinder head upper cover.

10. Install the air cleaner assembly, resonator and hoses,

refer to 3.2 AIR CLE ANER ASSEMBLY AND

RESONATOR, INSTALLATION in this Section.

11. Connect the negative cable at the battery.

CYLINDER HEAD COVER BOLTS (a)

TORQUE SPECIFICATION 8 Nm

3.5 THROTTLE BODY AND INTAKE MANIFOLD

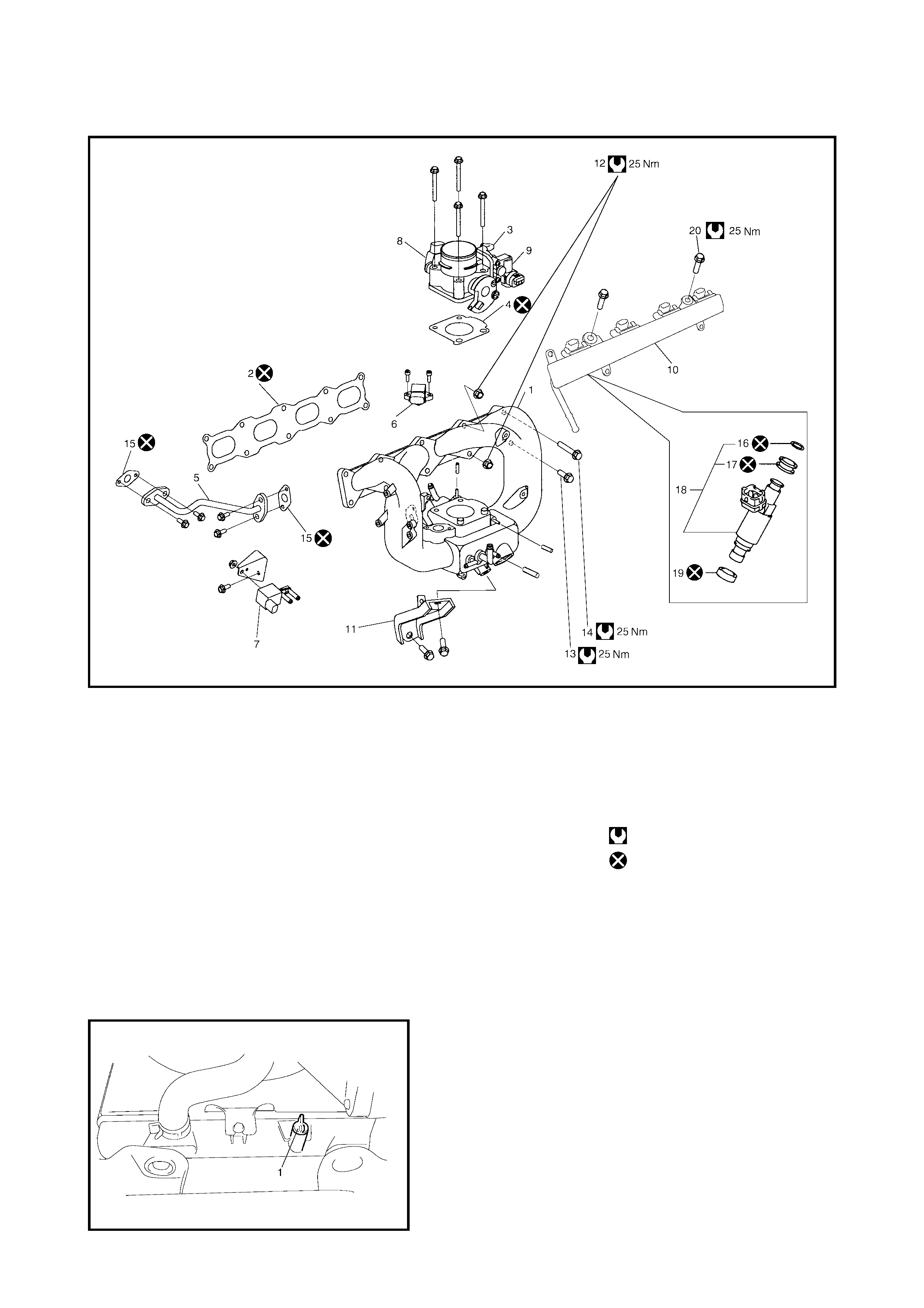

Legend

REMOVAL

1. Relieve the fuel p ressur e, refer to Sec tion 6 , 1.4 FUE L

PRESSURE RELIEF PROCEDURE.

2. Disconnect the negative cable at the battery.

3. Drain the coolant by loosening the drain plug (1).

WARNING: To avoid the dange r of being burned, do n ot

remove the drain plug (1) and radiator cap while the

engine and radiator are still hot. Scalding fluid and

steam can be blown out under pressure if the plug and

cap are taken off before the system has cooled suffi-

ciently.

1. Intake manifold 10. Fuel delivery pipe 17. Grommet

2. Intake manifold gasket 11. Intake manifold stiffener 18. Injector assembly

3. Throttle body 12. Intake manifold mounting nut 19. Cushion

4. Gasket 13. Intake manifold mounting bolt 20. Fuel delivery pipe mounting

5. EGR pipe (short) bolt

6. MAP sensor 14. Intake manifold mounting bolt Tightening torque

7. EVAP canister purge valve (long) Do not reuse.

8. TP sensor 15. EGR pipe gasket

9. IAC valve 16. O-Ring

4. Remove the air cleaner assembly, resonator and

hoses, refer to 3.2 AIR CLEANER ASSEMBLY AND

RESONATOR, REMOVAL in this Section.

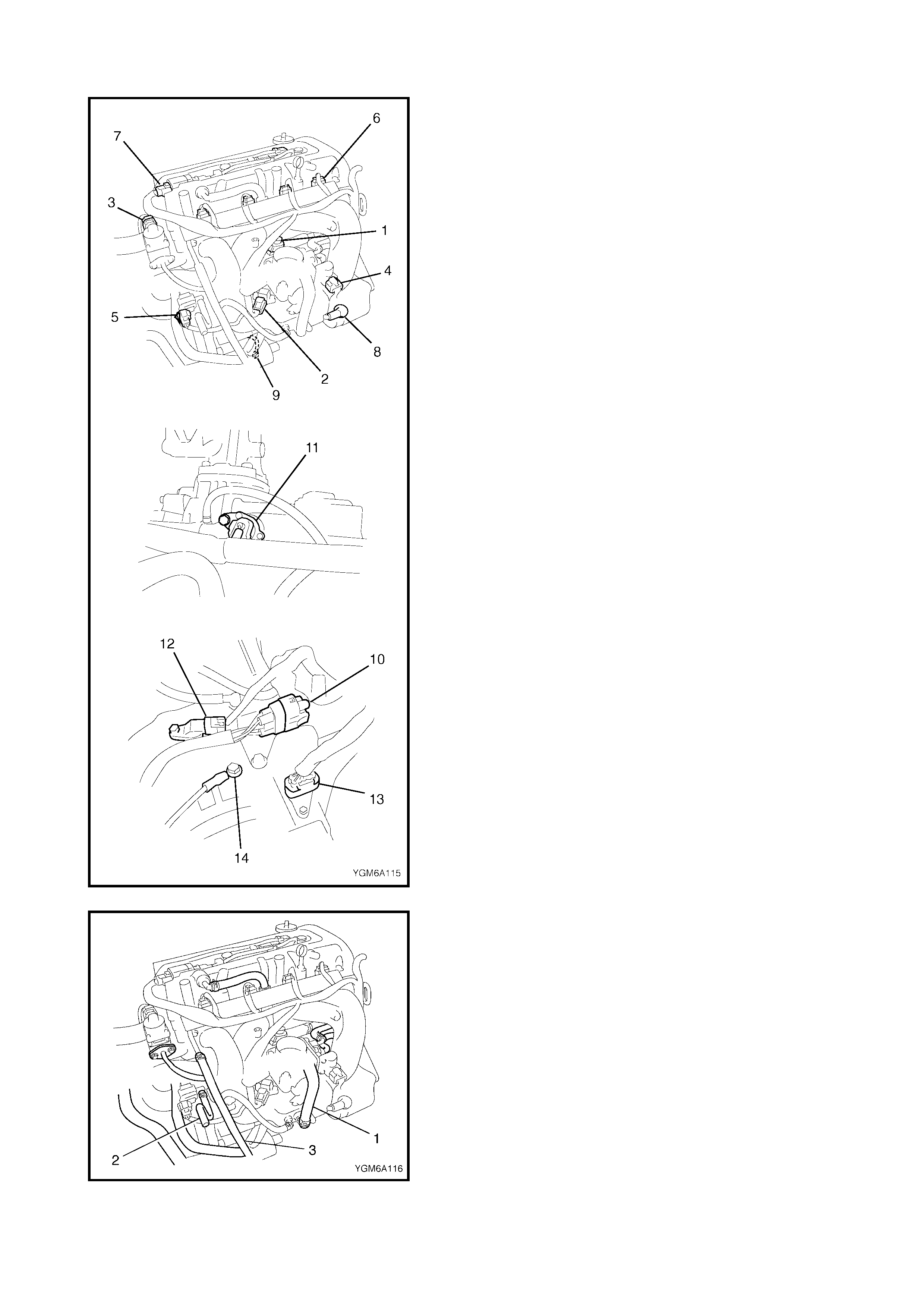

5. Disconnect the following electric leads:

•IAC valve (1)

• TP sensor (2)

• EVAP canister purge valve (3)

• MAP sensor (4)

• Fuel injector wire harness at connectors (5)

• Wire harness clamps

6. Disconnect accelerator cable from throttle body.

7. Disconnect the following hoses :

• Brake booster hose (1) from the intake manifold

• PCV hose (2) from the PCV valve

• Canist er purge h ose (3) from the EVAP canist er purge

valve

• Water hoses (4) from the throttle body and thermostat

case

• Fuel feed hose (5) from the fuel delivery pipe

8. Remove fuel delivery pipe with fuel injectors from the

cylinder head.

9. Disconnect the EGR pipe (6) from the EGR valve.

10. Remove the intake manifold stiffener (1).

11. Remove the intake manifold (1) with the throttle body

(2) and the EGR pipe (3) from the cylinder head.

12. Remove the gasket from the intake manifold.

INSTALLATION

Reverse the removal procedure for installation noting the

following:

• Always use a new intake manifold gasket and EGR

pipe gasket.

• Tighten bolts (1) and nuts (2) to specified torque.

• Check to ensure that all removed parts have been

refitted.

• Adjust th e accel erator cab le pla y, refer to Se ction 6E 1,

2. ON VEHICLE SERVICE, ACCELERATOR CABLE

ADJUSTMENT.

• Refill cooling system, refer to Section 6B,

3.3 COOLING SYSTEM FLUSH AND REFILL.

• Once installation is complete turn the ignition switch

ON, but with the engine OFF, and check for fuel leaks.

• Finally, start the engine and check for engine coolant

leaks.

INTAKE MANIFOLD BOLTS & NUTS (a)

TORQUE SPECIFICATION 25 Nm

3.6 EXHAUST MANIFOLD

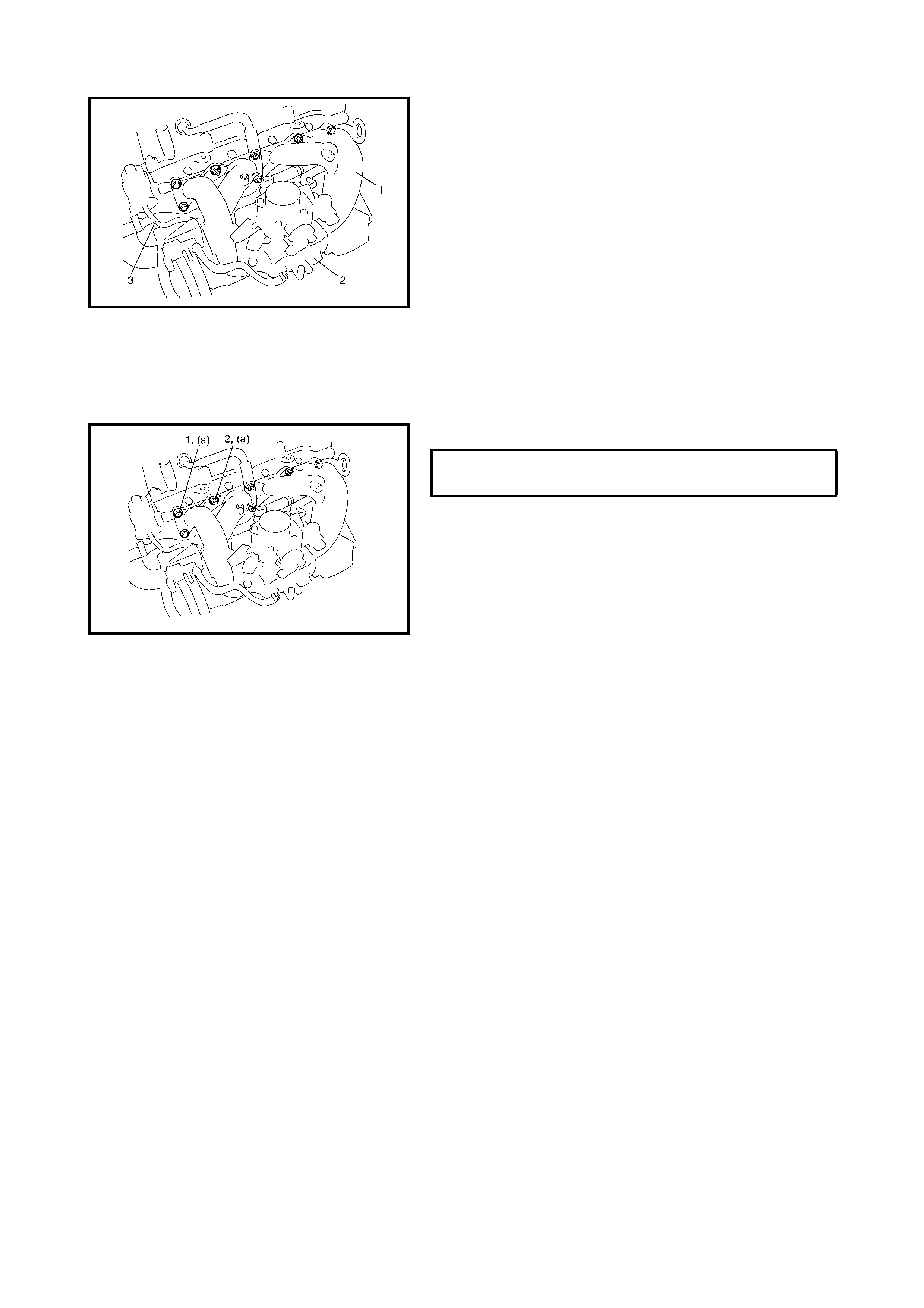

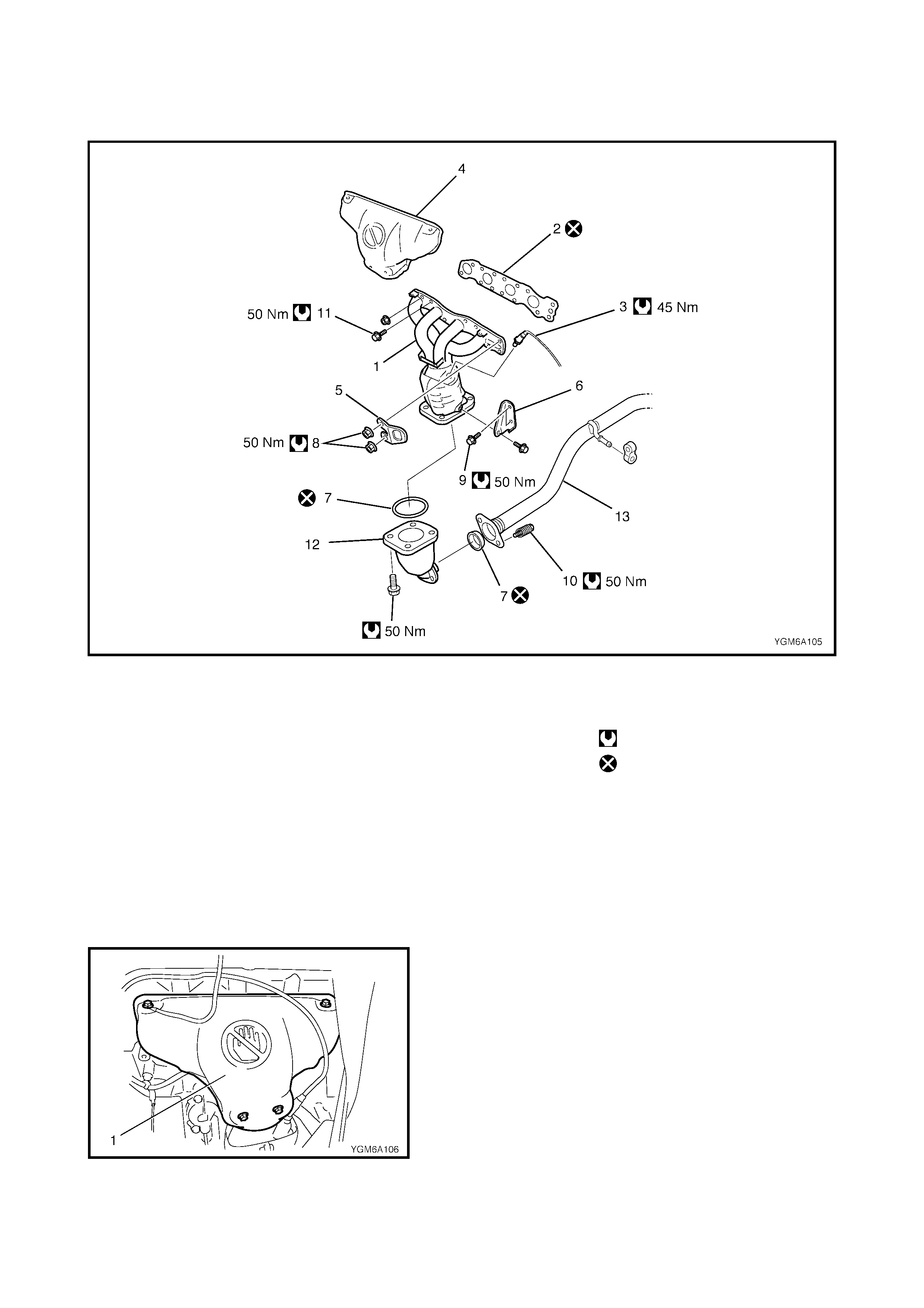

Legend

WARNING: To avoid being burned, do not service the exhaust system while it is still hot. Service

should be performed after the system cools down.

REMOVAL

1. Disconnect the negative cable at the battery.

2. Disconnect the heated oxygen sensor connector and

detach it from its stay.

3. Remove the front bumper with front grille, refer to

Section 9, 2.12 FRONT BUMPER, REMOVAL.

4. Remove radiator, refer to Section 6B, 4.6 RADIATOR,

REMOVAL.

5. With hose connected, detach the A/C condenser from

the vehicle body, refer to Secti on 1B,

5.2 CONDENSER ASSEMBLY, REMOVAL.

6. Remove exhaust manifold cover (1).

1. Exhaust manifold 8. Exhaust manifold mounting 12. Exhaust No.1 pipe

2. Exhaust manifold gasket nut 13. Exhaust No.2 pipe

3. Heated oxyge n sensor 9. Exhau st manifo ld sti ffener Tightening torque

4. Exhaust manifold cover bolt Do not reuse.

5. Engine hook 10. Exhaust No.2 pipe bolt

6. Exhaust manifold stiffener 11. Exhaust manifold mounting

7. Seal ring bolt

7. Remove the exhaust manifold stiffener (1).

8. Disconnect the exhaust No.2 pipe (2) from the exhaust

manifold.

9. Remove the exhaust manifold (1) and its gasket from

the cylinde r hea d.

INSTALLATION

1. Install a new exhaust manifold gasket on the cylinder

head.

Install the exhaust manifold.

Tighten the exhaust manifold bolts and nuts to

specified torque.

2. Check the seal ring for deterioration or damage and

replace as necessary.

Install the seal r ing and connect exhaust No.2 pip e (1)

to the exhaust manifold.

Tighten pipe fasteners to specified torque.

3. Install the exhaust manifold stiffener (2).

Tighten the exhaust manifold stiffener bolts to specified

torque.

EXHAUST MANIFOLD BOLTS & NUTS (a)

TORQUE SPECIFICATION 50 Nm

EXHAUST No.2 PIPE BOLTS (a)

TORQUE SPECIFICATION 50 Nm

EXHAUST MANIFOLD STIFFENER

BOLTS (b) 50 Nm

4. Install the exhaust manifold cover (1).

5. Install the A/C condenser to the vehicle, refer to

Section 1B, 5.2 CONDEN SER ASSEM BLY

INSTALLATION.

6. Install the radiator, refer to S ectio n 6B, 4. 6 RADIATOR

INSTALLATION.

7. Connect the heated oxygen sensor connector and fit

connector to bracket securely.

8. Install the front bumper with front grille, refer to

Section 9, 2.12 FRONT BUMPER INSTALLATION.

9. Connect the negative cable at the battery.

10. Check the exhaust system for exhaust gas leakage.

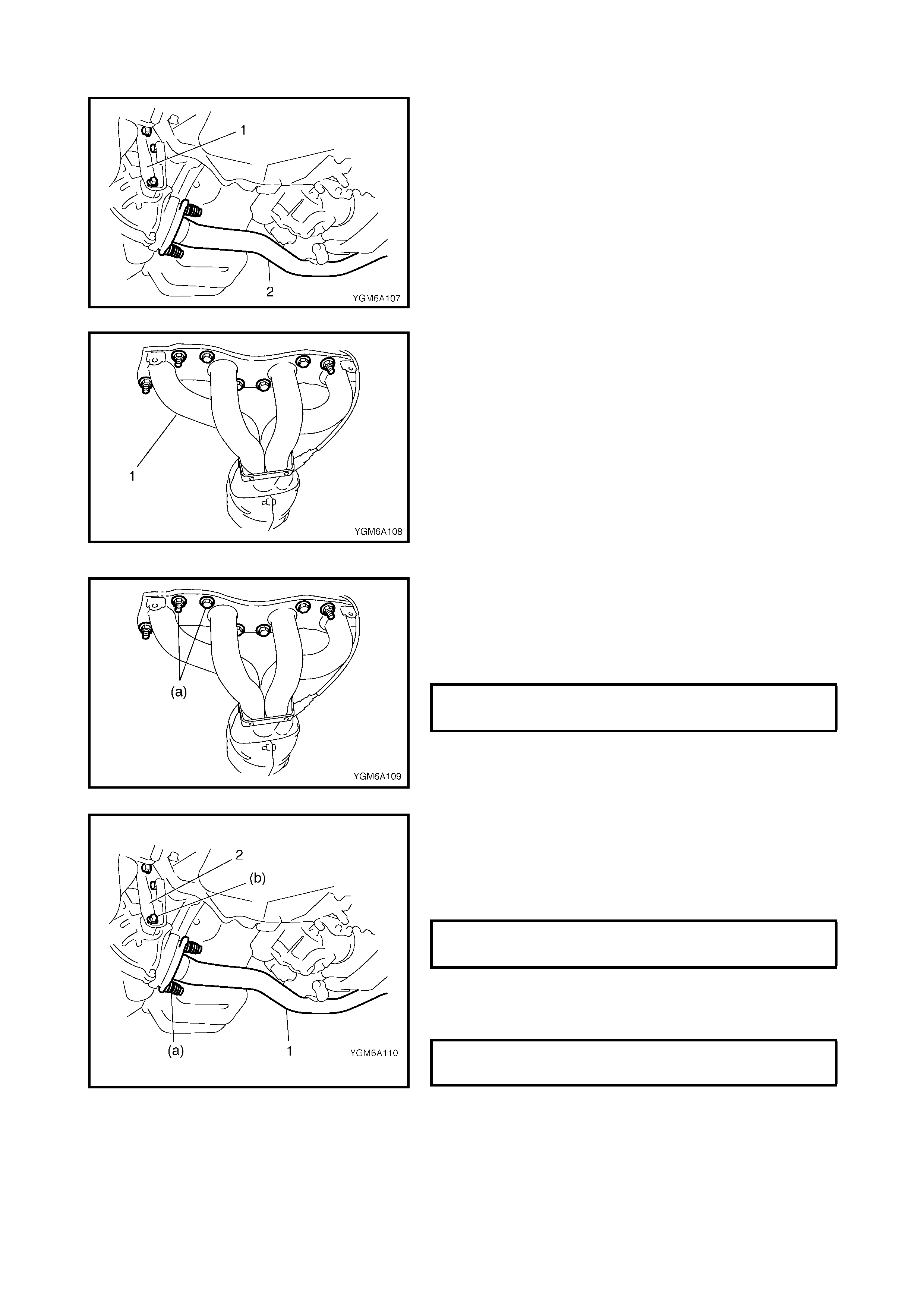

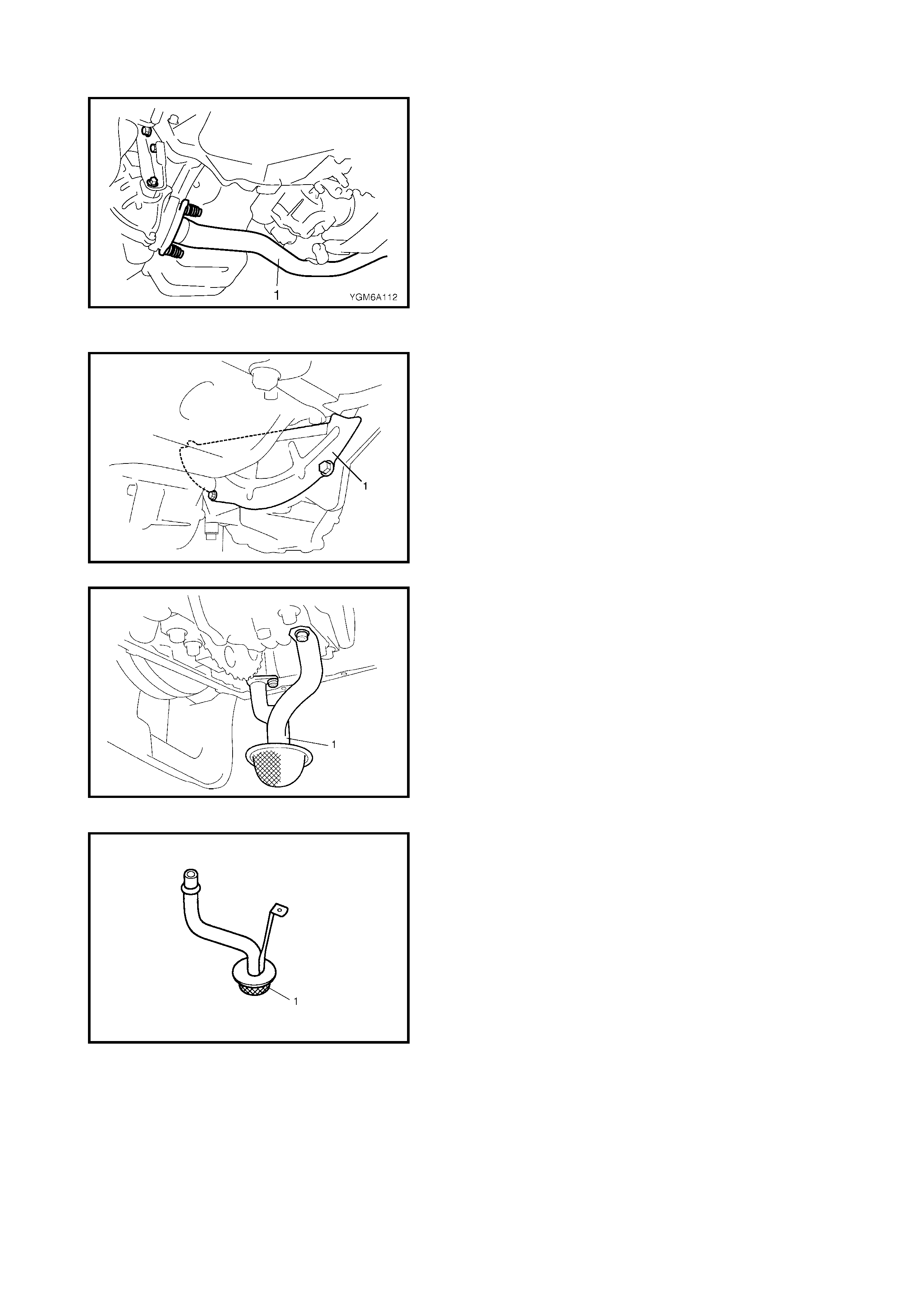

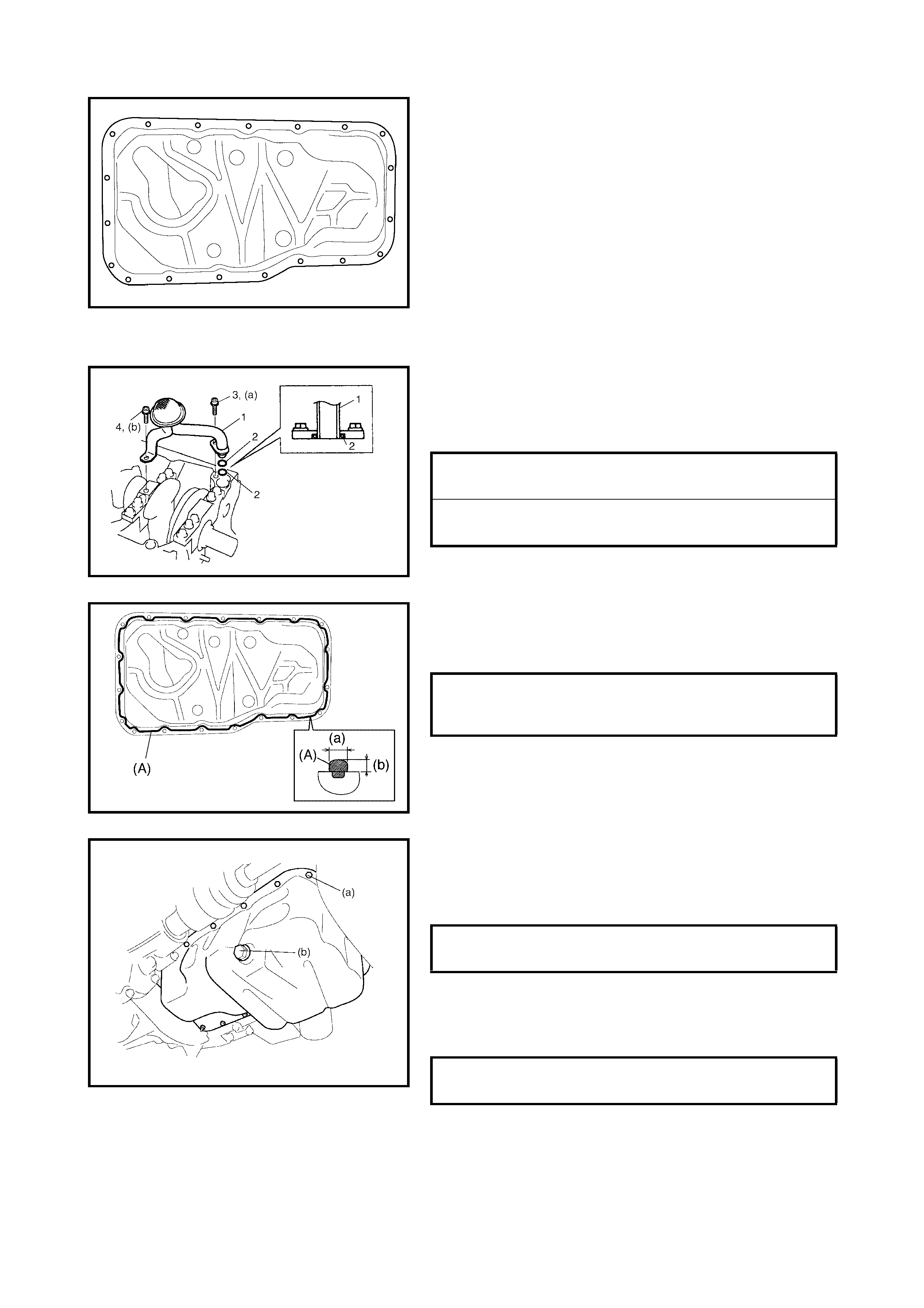

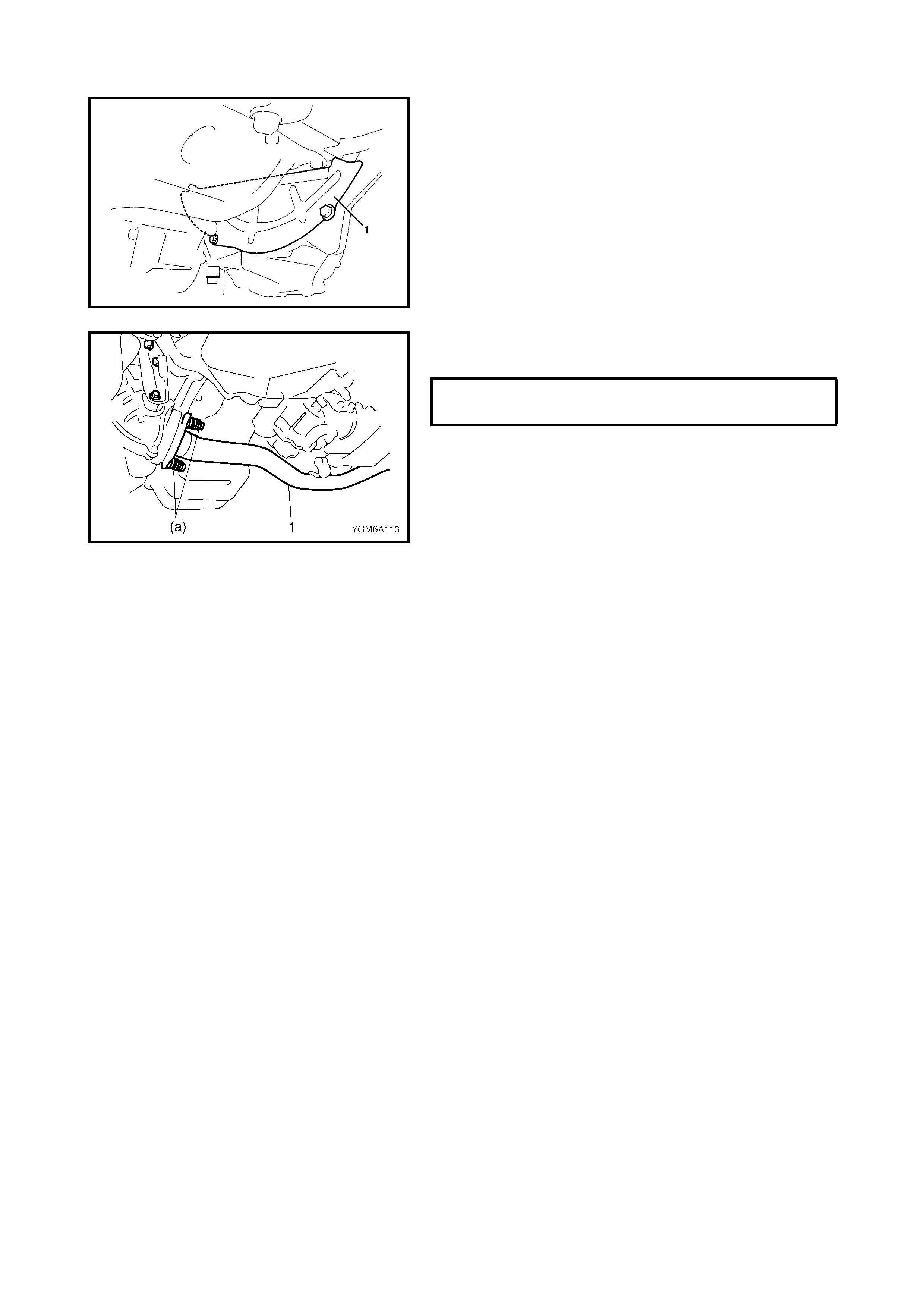

3.7 OIL PAN AND OIL PUMP STRAINER

Legend

REMOVAL

1. Disconnect the negative cable at the battery.

2. Remove the oil level gauge.

3. Support the engine with a support device (1).

[A] : Sealant application amount 2. Strainer 8. Oil pan nut

“a” : 3 mm (0.12 in.) 3. O-ring 9. Oil pan bolt

“b” : 2 mm (0.08 in.) 4. Gasket Tightening torque

1. Oi l pan

: Apply sealant - Three

Bond No. 1207C to mating

surface.

5. Drain plug Do not reuse.

6. Strainer bolt

7. Bracket bolt

4. Remove exhaust No.2 pipe (1).

5. Drain the engine oil by removing drain plug.

6. Remove the clutch housing (torque converter housing

for A/T vehicle) lower plate (1).

7. Remove the transfer unit, refer to Section 7D,

4.1 TRANSFER UNIT, REMOVAL.

8. Remove the oil pan then the oil pum p straine r (1) from

the cylinde r blo ck.

CLEAN

• Clean the oil pump strainer screen (1).

• Clean th e sealing sur face on the oi l pan and the cylin-

der block.

Remove oi l, old s ealant and dust fro m the sea ling sur-

face.

INSTALLATION

1. Install new O -r ing s (2) to the oi l str ai ner p ipe as s ho wn

in the figure and install the oil pump strainer (1).

Tighten the strainer bolt (3) first and then the bracket

bolt (4) to specified torque.

2. Apply sealant continuously to the oil pan mating

surface as shown in the figure.

(A): Sealant - Three Bond No. 1207C

3. After fitting the oil pan to the cylinder block, loosely fit

the securing bolts. Start tightening the bolts at the

centre, moving outward, tightening one bolt at a time to

specified torque.

4. Install a new ga sket on th e drain plug then fit to the oil

pan.

Tighten drain plug to specified torque.

OIL SUMP STRAINER BOLT (a)

TORQUE SPECIFICATION 11 Nm

OIL PUMP STRAINER BRACKET BOLT (b)

TORQUE SPECIFICATION 11 Nm

SEALANT AMOUNT FOR OIL PAN

WIDTH (a)

HEIGHT (b) 3.0 mm

2.0 mm

OIL PAN BOLTS & NUTS (a)

TORQUE SPECIFICATION 11 Nm

OIL PAN DRAIN PLUG BOLT (b)

TORQUE SPECIFICATION 50 Nm

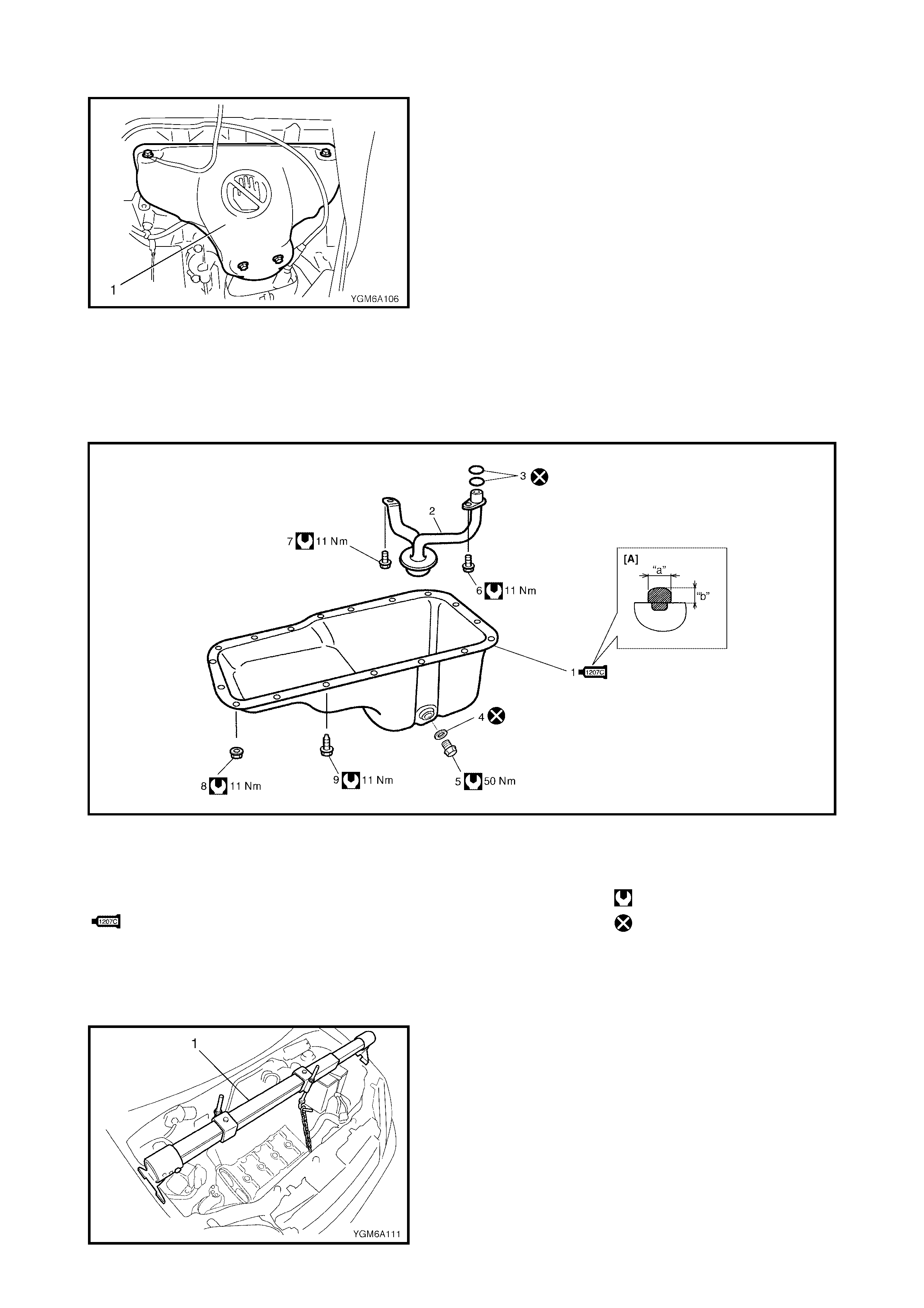

5. Install the clutc h housing (tor que converte r housing for

A/T vehicle) lower plate (1).

6. Install transfer unit, refer to Section 7D,

4.6 TRANSFER UNIT, INSTALLATION.

7. Install exhaust No.2 pipe (1).

Tighten bolts to specified torque.

8) Install th e oi l lev e l ga ug e .

9) Refill the engine with engine oil, refer to ENGINE

OIL AND FILTER in Section 0B , 2.1 ENG I N E.

10) Ensure there is no engine oil leakage from oil pan

or exhaust gas leakage at pipe conne ction.

EXHAUST No.2 PIPE BOLTS (a)

TORQUE SPECIFICATION 50 Nm

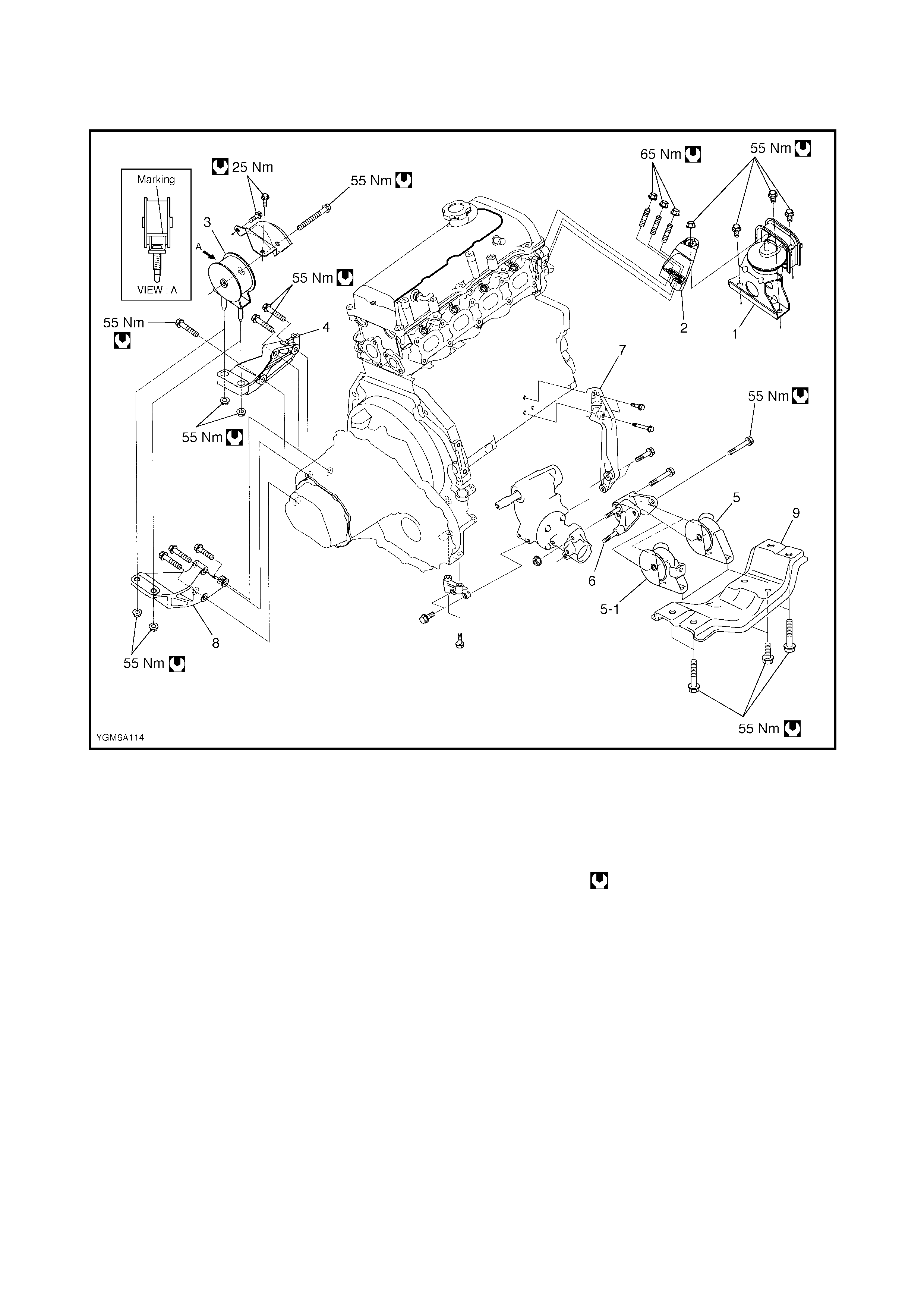

3.8 ENGINE MOUNTINGS

Legend

1. Engine right mounting 5. Engine rear mounting 7. Engine stiffener

2. Engine right mounting

bracket (M/T Vehicle ) 8. E ngi ne left mounti ng brack et

5-1. Engine rear mounting (for M/T vehicle)

3. Engine left mounting (A/T Vehicle) 9. Engine rear mounting member

4. Engine left mounting

bracket (for A/T vehicle) 6. Engine rear mounting Tightening torque

bracket

4. UNIT REPAIR AND OVERHAUL

4.1 ENGINE ASSEMBLY

REMOVAL

1. Relieve fuel pressure, refer to Section 6,

1.4 FUEL PRESSURE RELIEF PROCEDURE .

2. Disconnect the negative cable at the battery.

3. Remove the engine hood after disconnecting wind-

shield washer hose, refer to Section 9,

2.4 HOOD, REMO VA L .

4. Remove the right and left side engine under covers.

5. Remove th e A/C compresso r belt, refer to Section 1B,

2.5 COMPRESSOR DRIVE BELT, REPLACEMENT.

6. Remove water pump belt.

7. Drain engine oil, transmission oil or A/T fluid (for A/T

vehicle) and transfer oil.

8. Drain coolant.

WARNING: To avoid being burned, do not r emove drai n

plug (1) and radiator cap while engine and radiator are

still hot. Scalding fluid and steam can be blown out

under pressure if plug and cap are taken off before

system has cooled sufficiently.

9. Remove the air cleaner assembly, resonator and

hoses, refer to 3.2 AIR CLEANER ASSEMBLY AND

RESONATOR in this Section.

10. Remove the A/C condenser, refer to Section 1B,

5.2 CONDENSER ASSEMBLY, REMOVAL.

11. Remove the A/C compressor, refer to Section 1B,

5.11 COMPRESSOR, REMOVAL.

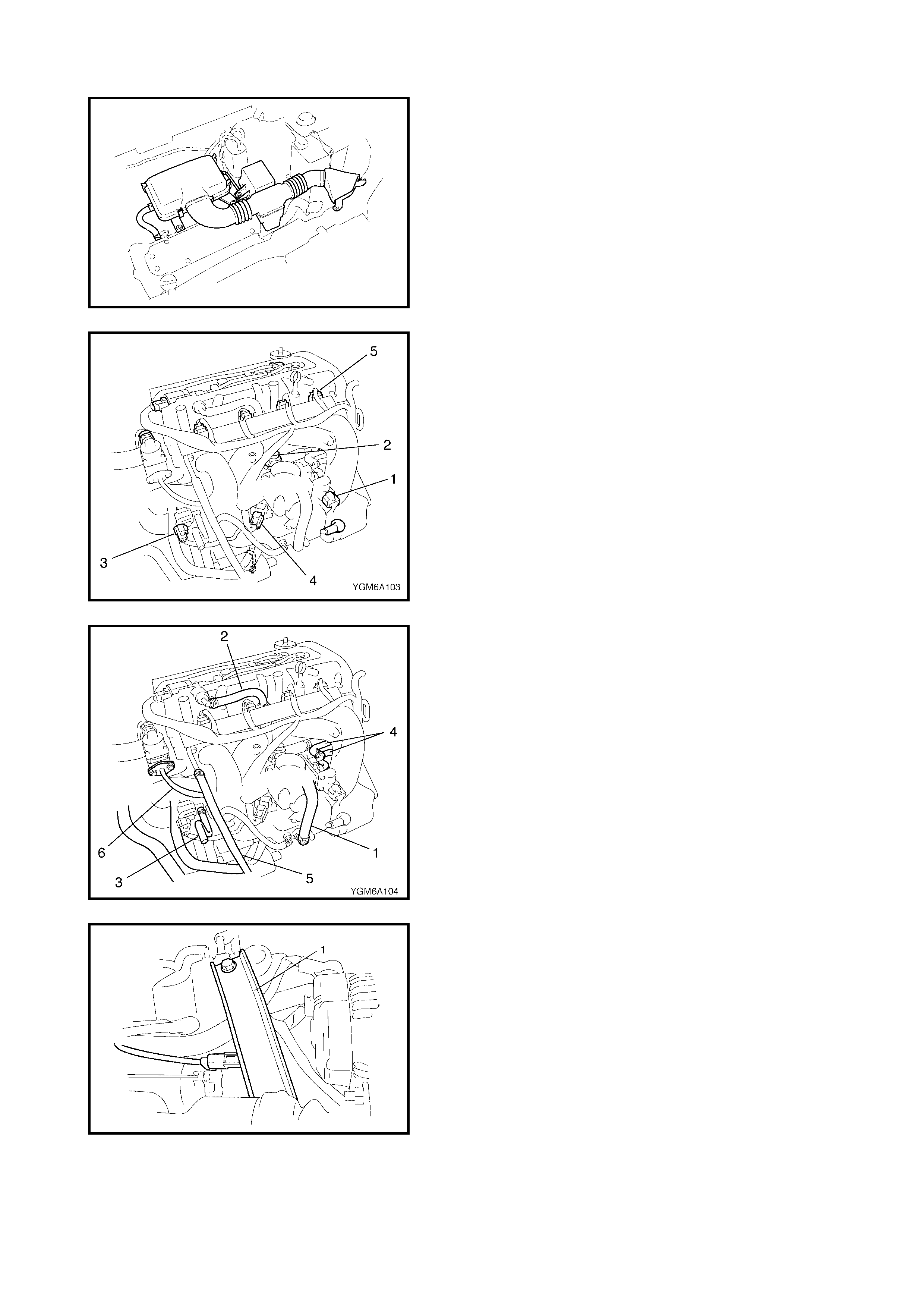

12. Disconnect the following electric leads:

• TP sensor (1)

• MAP sensor (2)

• ECT sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Heated oxygen sensor

•EGR valve (3)

•IAC valve (4)

• EVAP canister purge valve (5)

• Injectors (6)

• Ignition coil assembly (7)

• Engine oil pressure switch

• Generator (8)

• Starting moto r

• Ground terminal (9) from exhaust manifold and cylin-

der block

•VSS

• Back up light switch (For M/T vehicle)

• Transmission range sensor (10) (For A/T vehicle)

• A/T VSS (11) (For A/T vehicle)

• Input shaft speed sensor (12) (For A/T vehicle)

• A/T shift solenoid and A/T temp. sensor (13) (For A/T

vehicle)

• Battery ground cable (14) from transmission

• Each wire harness clamps

13. Remove fuse box from its bracket.

14. Disconnect the following cables:

• Accel erator cable

• G ear select control cable (For M/T vehicle)

• Gear shift control cable (For M/T vehicle)

• Clutch cable (For M/T vehicle)

• Gear select cable (For A/T vehicle)

15. Disconnect the following hoses:

• Brake booster hose (1) from intake manifold

• Canister purge hose (2) from EVAP canister purge

valve

• Fuel feed hose (3) from fuel delivery pipe

• Heater inlet and outlet hoses from each pipe

• Radiator inlet and outlet hoses from each pipe

16. Remove the exhaust No.2 pipe (1).

17. Remove the right and left drive shafts, refer to

Section 4A, 3.1 DRIVE SHAFT ASSEMBLY,

REMOVAL.

18. Remove the propeller shaft., refer to Section 4B,

3 ON VEHICLE SERVICE, REMOVAL.

19. Remove the generator, refer to Section 6H,

3.3 GENERATOR, REMOVAL.

20. Install lifting device.

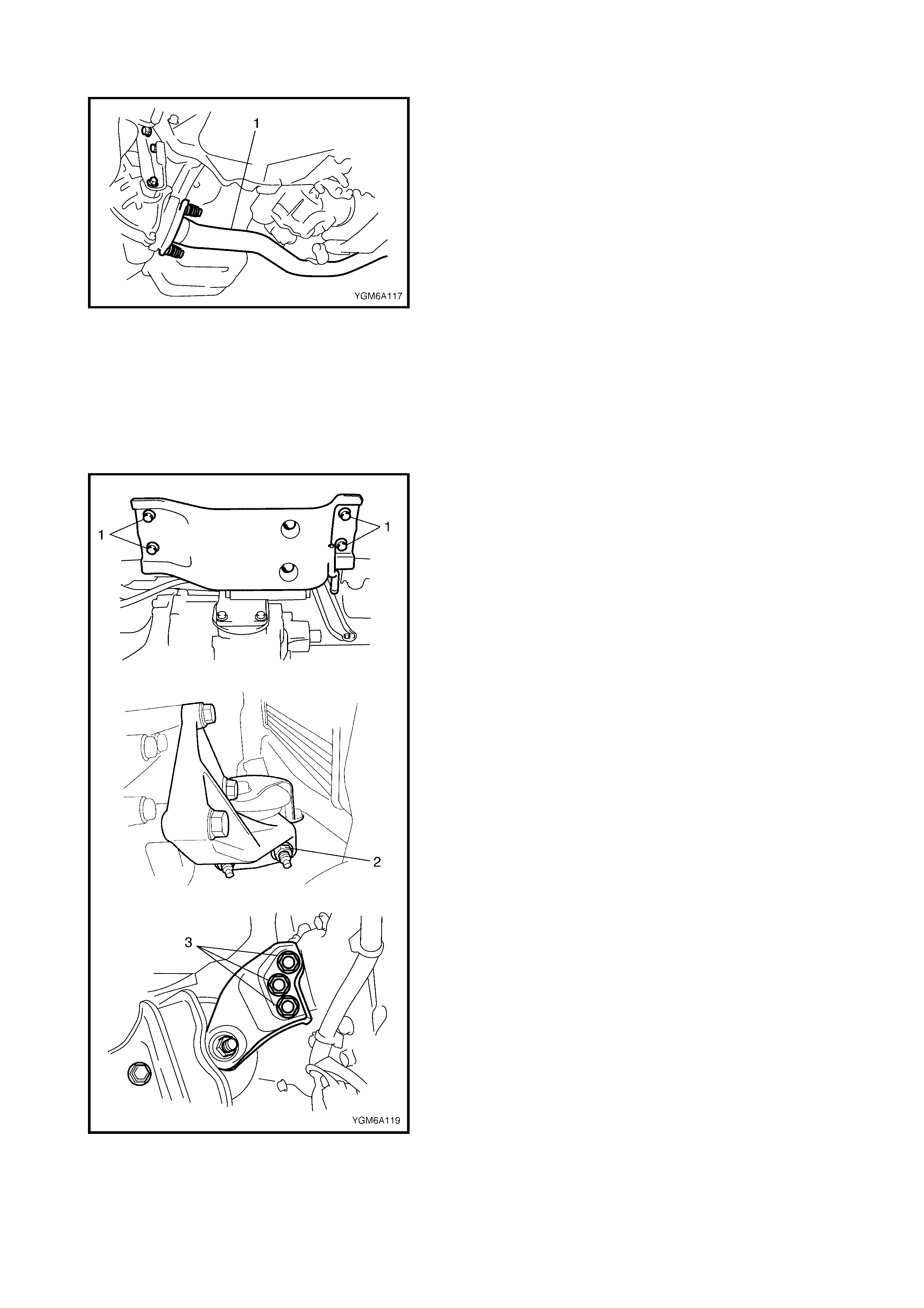

21. Remove the engine rear mounting member bolts (1),

engine left mounting bracket nuts (2) and engine right

mounting nuts (3).

22. Before rem oving the en gine a nd trans missi on from th e

vehicle, recheck to make sure all hoses, electric wires

and cables are disconnected from the engine and

transmission.

23. Lower the engine and the transmission from the

vehicle.

24. Remove the transfer unit from the transmission, refer

to Section 7D, 4.1 TRANSFER UNIT, REMOVAL.

25. Remove the transmission from the engine, refer to

Sections 7A MANUAL TRANSAXLE or

7B AUTOM AT IC TR AN S AXLE .

26. Remove the clutch cover and clutch disk, refer to

Section 7C (M/T), 4.1 CLUTCH COVER, CLUTCH

DISC AND FLYWHEEL, REMOVAL.

INSTALLATION

1. Install the clutch co ve r and c lut ch di sk, re fer t o S ec tio n

7C (M/T), 4.1 CLUTCH COVER, CLUTCH DISC AND

FLYWHEEL, INSTALLATION.

2. Fit the transmission to the engine, refer to

Sections 7A MANUAL TRANSAXLE or

7B, AUTOMATIC TRANSAXLE.

3. Install the transfer unit to the transmission, refer to

Section 7D, 4.6 TRANSFER UNIT, INSTALLATION.

4. Lift the engine with the transmission into the engine

compartment, but do not remove lifting device.

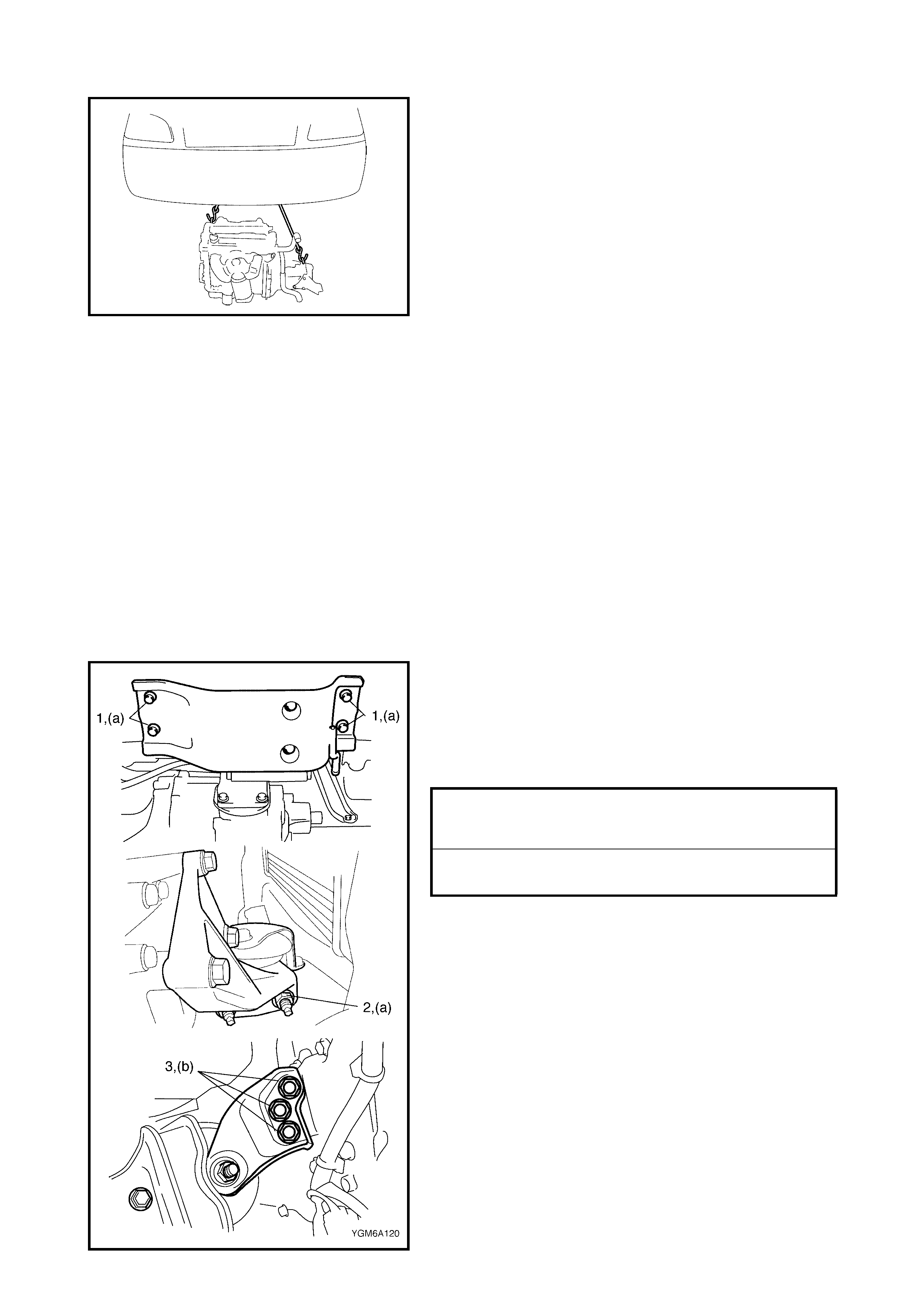

5. Install the engine rear mounting member bolts (1),

engine left mounting bracket nuts (2) and engine right

mounting nuts (3).

Tighten these bolts and nuts to specified torque.

6. Remove lifting device.

ENGINE MOUNTING BOLTS & NUTS -

M10 (a)

TORQUE SPECIFICATION 55 Nm

ENGINE RIGHT MOUNTING NUTS (b)

TORQUE SPECIFICATION 65 Nm

7. Install the generator, refer to Section 6H,

3.3 GENERATOR, INSTALLATIO N .

8. Install the propeller shaft, refer to Section 4B,

3 ON-VEHICLE SERVICE, INSTALLATION.

9. Install the drive shafts, refer to Section 4A,

3.1 DRIVE SHAFT ASSEMBLY, INSTALLATION.

10. Install the exhaust No.2 pipe and tighten pipe fasteners

to specified torque.

11. Refit disconnected hoses, cables and electric wires

previou sly remov ed .

12. Install air cleaner assembly, resonator and hoses, refer

to 3.2 AIR C LEANER ASSEM BLY A ND RESONATOR

in this Sectio n.

13. Install the A/C compressor, refer to Section 1B,

5.11 COMPRESSOR, INSTALLATION.

14. Install the A/C condenser, refer to Section 1B,

5.2 CONDENSER ASSEMBLY, INSTALLATION.

15. Adjust the water pump belt tension, refer to Section 6B,

4.9 WATER PUMP/GENERATOR DRIVE BELT

INSTALLATION.

16. Adjust the A/C compressor belt tension, refer to

Section 1B, 2.5 COMPRESSOR DRIVE BELT

ADJUSTMENT.

17. Adjust th e accel erator cab le pla y, refer to Se ction 6E 1,

2. ON-VEHICLE SERVICE ACCELERATOR CABLE

ADJUSTMENT.

18. Check to ensure that all removed parts are back in

place. Reinstall any necessary parts which have not

been reinstalled.

19. Refill cooling system with coolant, engine with engine

oil and A/T with specified A/T fluid (vehicle with A/T),

refer to Section 0B MAINTENANCE AND

LUBRICATION - 4. RECOMMENDED FLUIDS AND

LUBRICANTS.

20. Connect the negative cable at the battery.

21. Ensure ther e are no fuel leaks , co ol ant leak s , oil lea ks ,

A/T fluid leaks (vehicle with A/T) and exhaust gas

leaks.

EXHAUST No.2 PIPE BOLTS (a)

TORQUE SPECIFICATION 50 Nm

4.2 TIMING CHAIN COVER

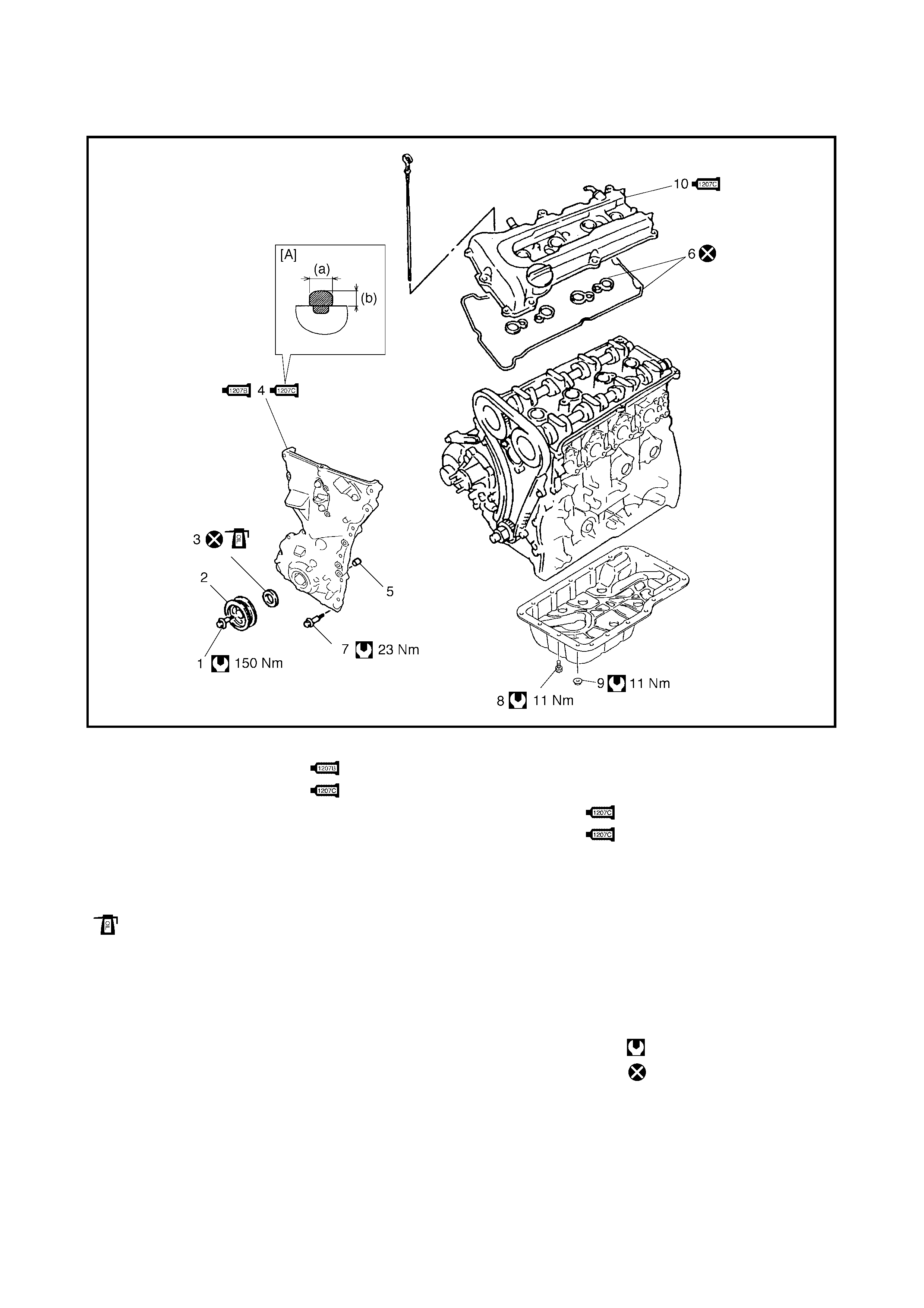

Legend

[A] : Sealant application

amount 4. Timing chain cover 8. Oil pan mounting bolt

Apply sealant Three Bond

No. 1207B

to the mating surface of

cylinder and cylinder head.

: Apply sealant Three Bond

No. 1207C to the mating

surface of timing chain cover

referring to the figure of Step

1) in INSTALLATION.

9. Oil pan mounting nut

(a): 3 mm 10. Cylinder head cover

: apply sealant

Three Bond No.1207C to

the sealing point for

timing chain over mating

surface and cylinder head

gasket se ali ng poi nt.

Refer to 3.4 CYLINDER

HEAD COVER,

INSTALLATION

(b): 2 mm

1. Cr ank shaft pulle y

bolt

2. Cr ank shaft pulle y

3. Oil seal

: Apply engine oil to

oil seal lip. 5. Locating pin

6. Cylinder head cover gasket

7. Timing chain cover mounting Tightening torque

bolts Do not reuse.

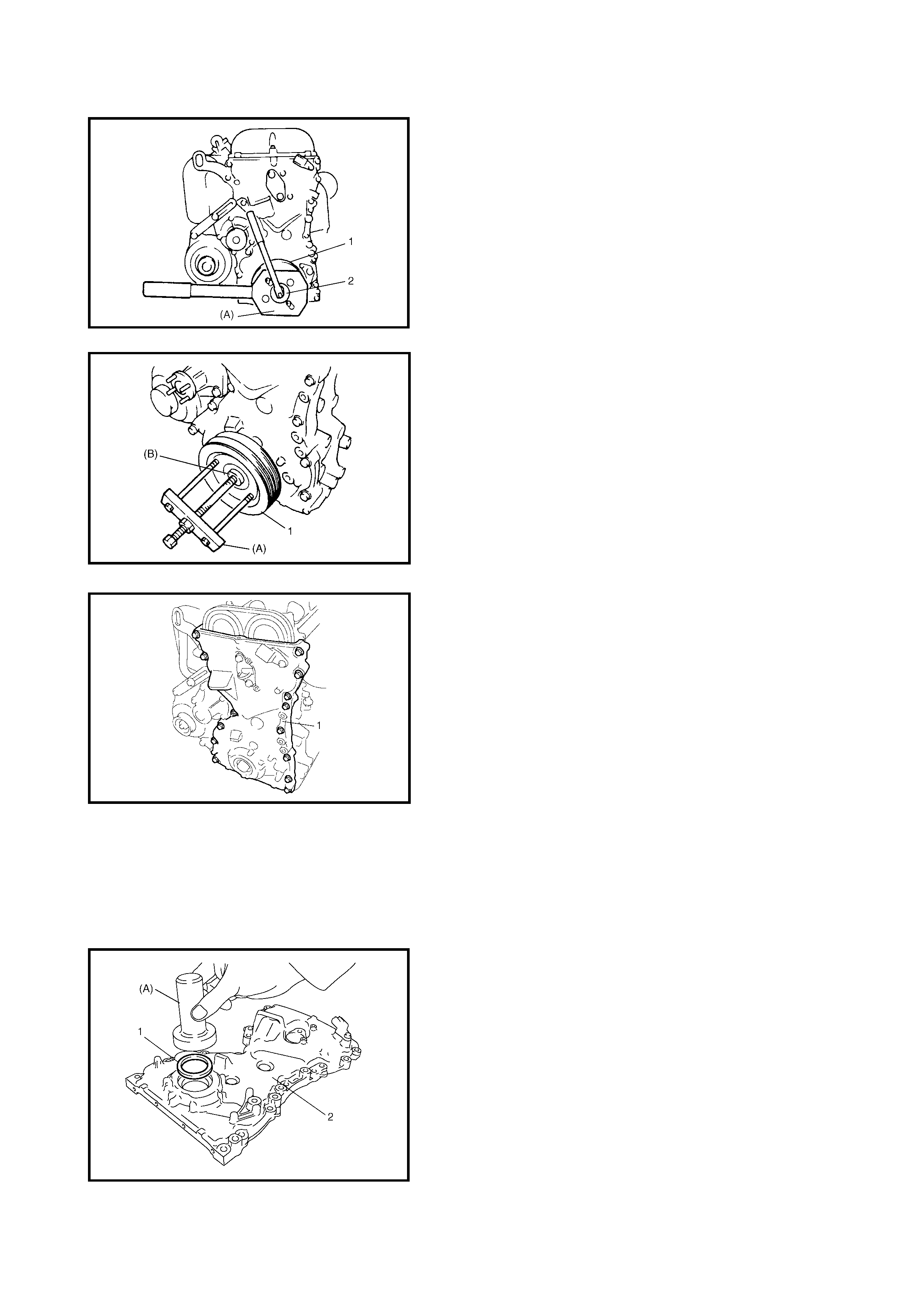

REMOVAL

1. Remove the engine assembly from the vehicle, refer

to 4 .1 ENG INE AS SE MB LY REM O VAL in this Section.

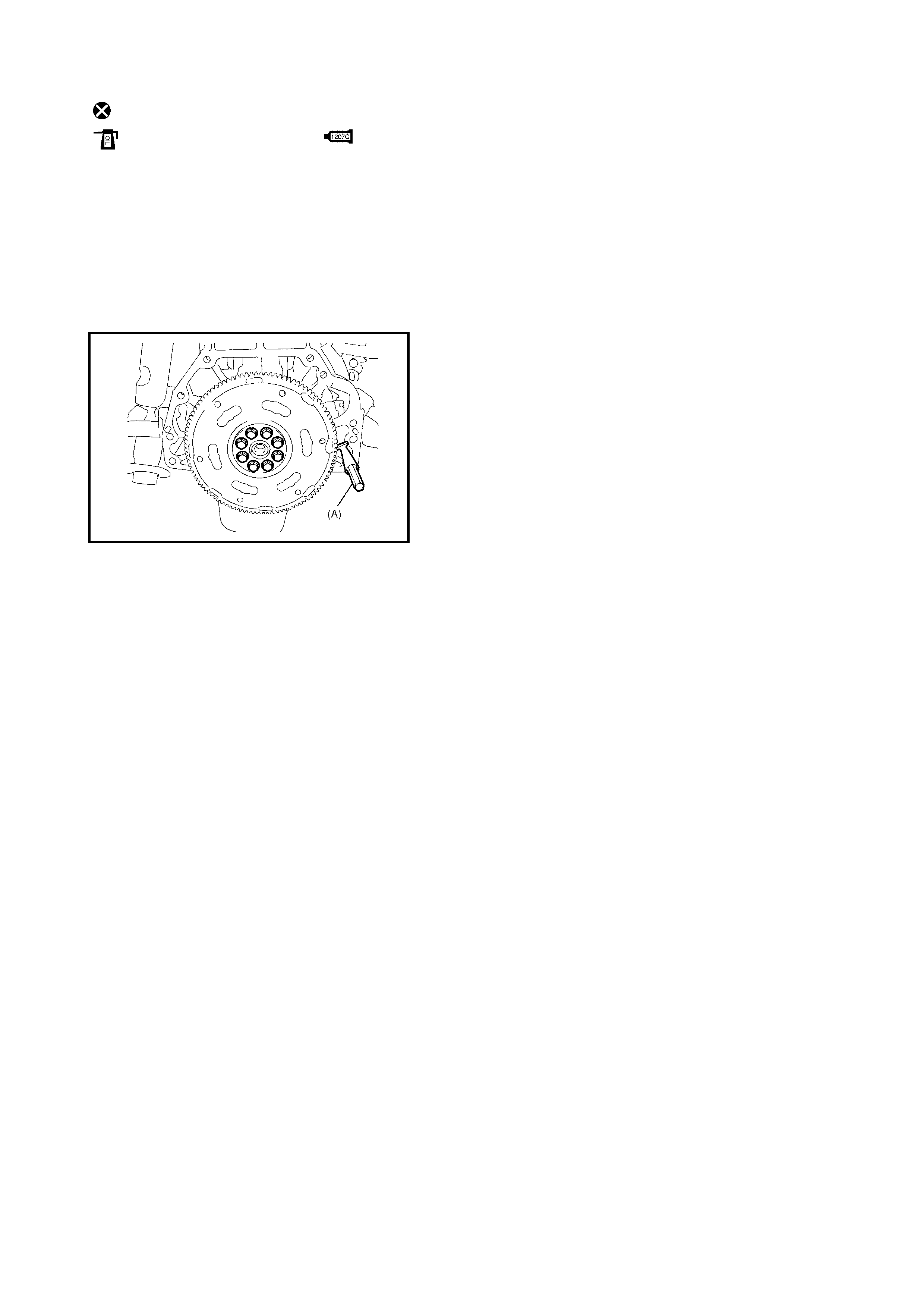

2. Remove the crankshaft pulley bolt (2).

To lock the crankshaft pulley (1), use special tool

09917-68221 (A) as shown in the figure.

3. Remove the crankshaft pulley (1).

If it is hard to remove, use special tools 09944-36011

(A) and 09926-58010 (B) as shown in the figure.

4. Remove the cylinder head cover, refer to

3.4 CYLINDER HEAD COVER in this Section.

5. Remove the oil pan, refer to 3.7 OIL PAN AND OIL

PUMP STRAINER in this Section.

6. Remove the water pump pulley.

7. Remove the timing chain cover (1).

CLEAN

• Clean the sealing surface on the timing chain cover,

cylinder block and cylinder head.

Remove oil, old sealant and dust fr om the sealing

surface.

INSPECTION

• Check the oil seal (1) lip for wear or other damage.

Replace as necessary.

NOTE: When i nstalling a ne w oil seal , tap it in un til its su r-

face is flush with the edge of the timing chain cover (2).

To install oil seal, use special tool

(Bear ing insta ller ) 099 13-75 520 (A ).

INSTALLATION

Reverse the removal procedure to install the timing chain

cover, noting the following points.

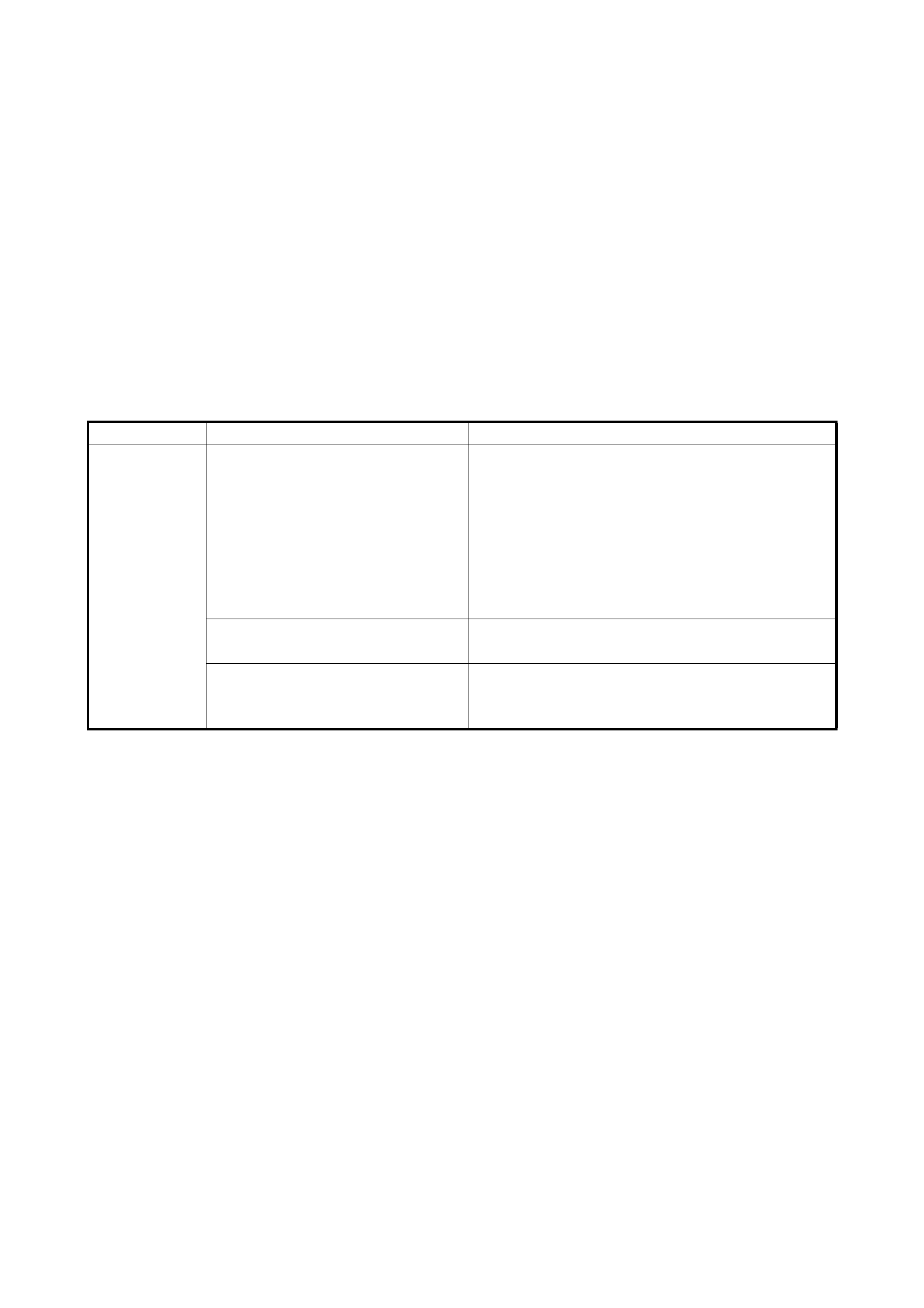

1. Apply sealant (A) to the mating surface of the cylinder

and cylinder head and sealant (B) to the mating

surface of the timing chain cover as shown in the

figure.

(A): Sealant - Three Bond No. 1207B

(B): Sealant - Three Bond No. 1207C

2. Apply engine oil to the oil seal lip, then install the timing

chain cover (1).

Tighten bolts and nut to specified torque.

NOTE: Before installing the timing chain cover, check that

the locating pin is securely fitted.

3. Install the water pump pulley.

4. Install the cylinder head cover.

5. Install the oil pan.

6. Install the crankshaft pulley (1). Tighten bolt (2) to

specified torque. To lock the crankshaft pulley, use

special tool 09917-68221 (A) as shown in the figure.

7. Install the engine assembly to vehicle, refer to

4.1, ENGINE ASSEMBLY INSTALLATION in this

Section.

SEALANT AMOUNT FOR TIMING

CHAIN COVER WIDTH (a)

HEIGHT (b) 3.0 mm

2.0 mm

TIMING CHAIN COVER BOLTS (a)

TORQUE SPECIFICATION 23 Nm

CRANKSHAFT PULLEY BOLT (a)

TORQUE SPECIFICATION 150 Nm

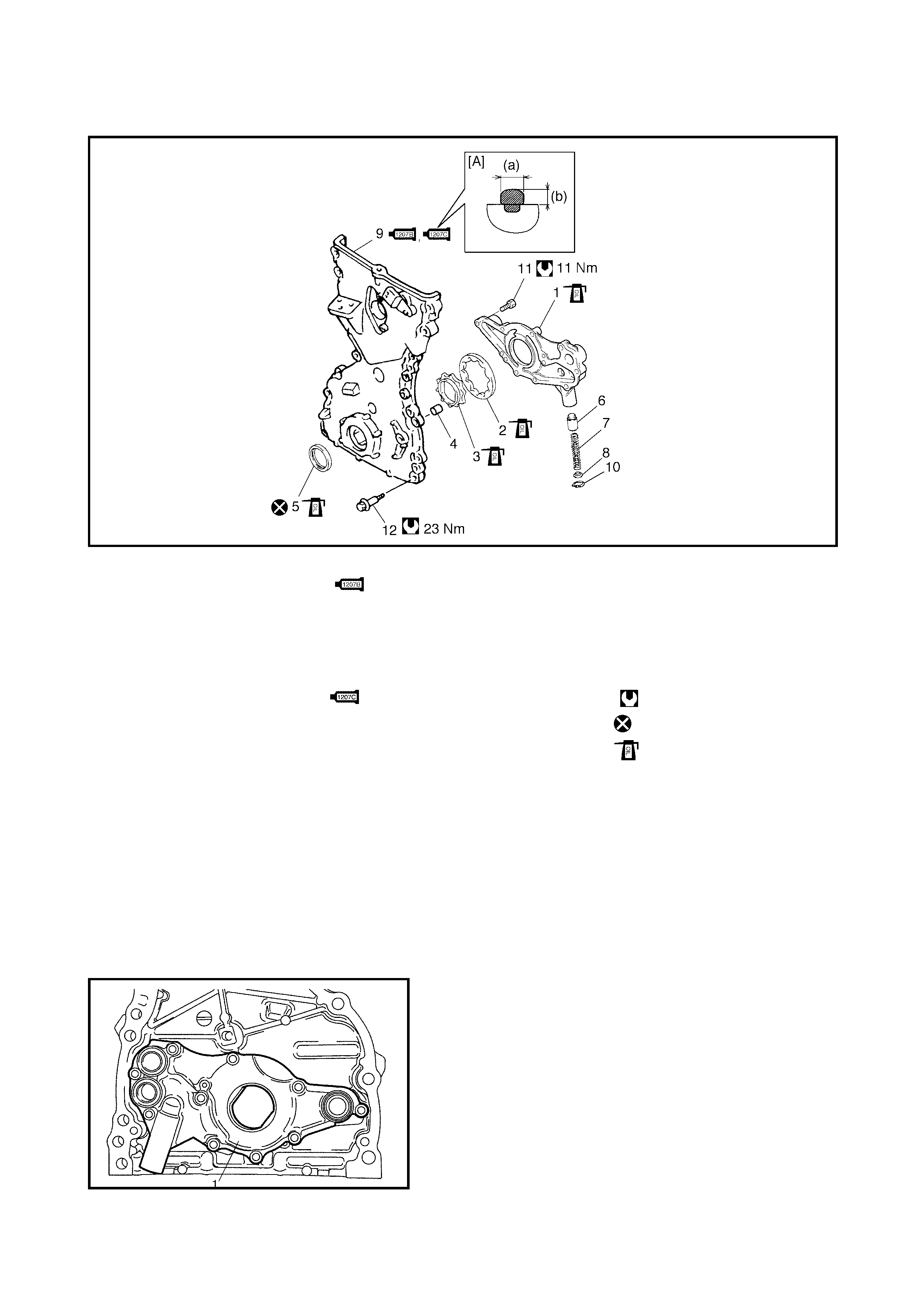

4.3 OIL PUMP

Legend

REMOVAL

1. Remove timing chain cover, refer to 4.2 TIMING

CHAIN COVER, REMOVAL in this Section.

DISASSEMBLY

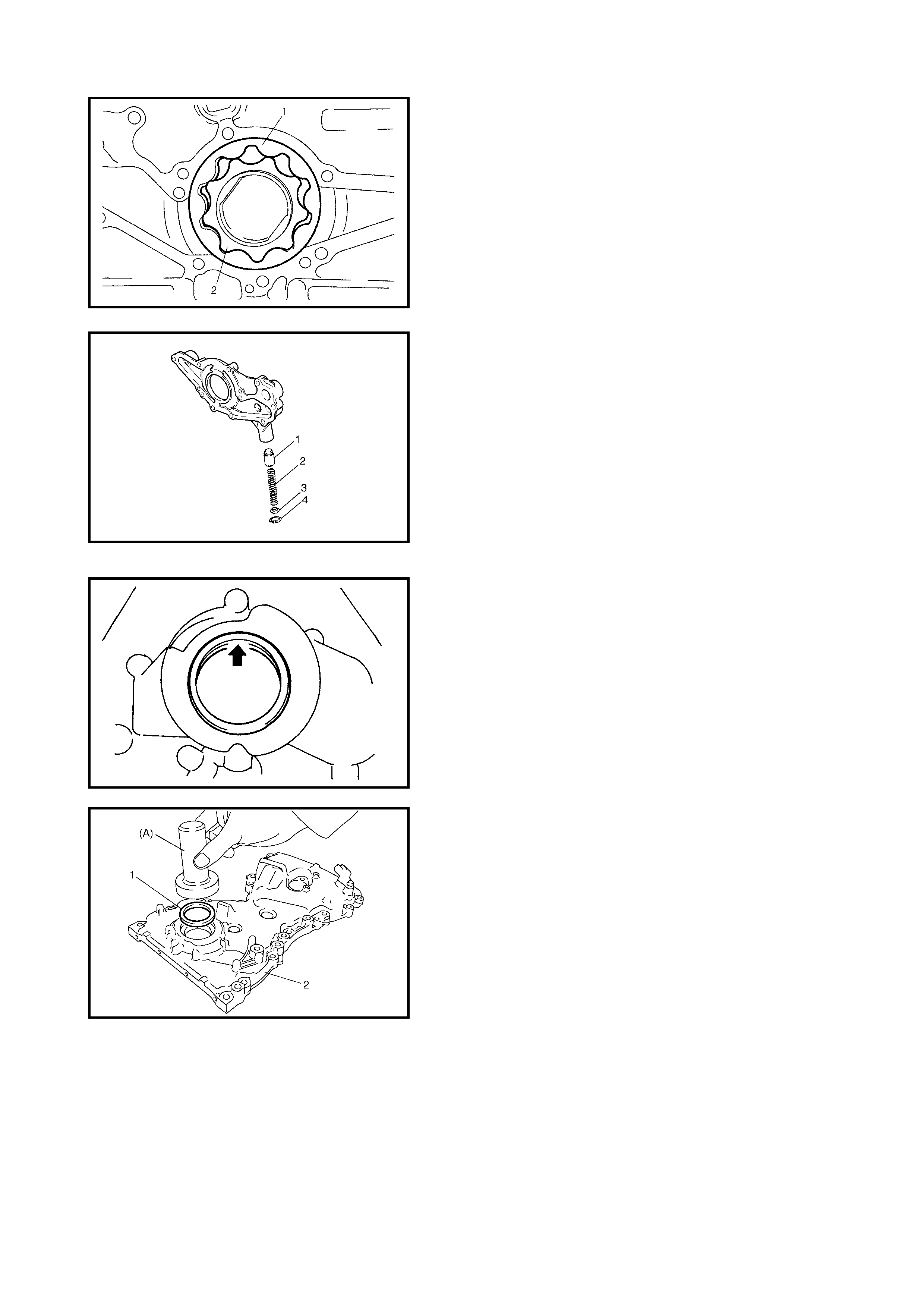

1. Remove rotor plate (1) by removing its mounting bolts.

[A] : Sealant application amount 9. Timing chain cover 10. Circlip

(a): 3 mm (0.12 in.) :Apply sealant Three Bond

No. 11. Oil pump mounting bolt

(b): 2 mm (0.08 in.) 1207B to the mating surface of 12. Timing chain cover

1. Rotor plate cylinder and cylinder head. mounting bolts

2. Outer rotor : Apply sealant Three Bond

No. 1207C to mating surface

of timing chain cover, refer to

the figure in Step 1 in

4.2 TIMING CHAIN COVER,

INSTALLATION

Tightening torque

3. Inner rotor Do not reuse.

4. Pin Apply thin coat of engine oil

5. Oil seal to sliding surface of each

6. Relief valve parts.

7. Spring

8. Retainer

2. Remove outer rotor (1) and inner rotor (2).

3. Remove relief valve (1), spring (2) and retainer (3) by

removing circlip (4).

INSPECTION

• Check the oil seal lip for wear or other damage.

Replace as necessary.

NOTE: When installing a new oil seal (1), press-fit using

specia l tool 09 913-7552 0 (A) until i ts end face i s flush wi th

oil pump case (2) end face.

• Check outer (1) and inner rotors (2), rotor plate, and oil

pump case for excessive wear or damage.

• Check relief valve (1) for excessive wear or damage

and ensure it operates smoothly.

MEASUREMENT

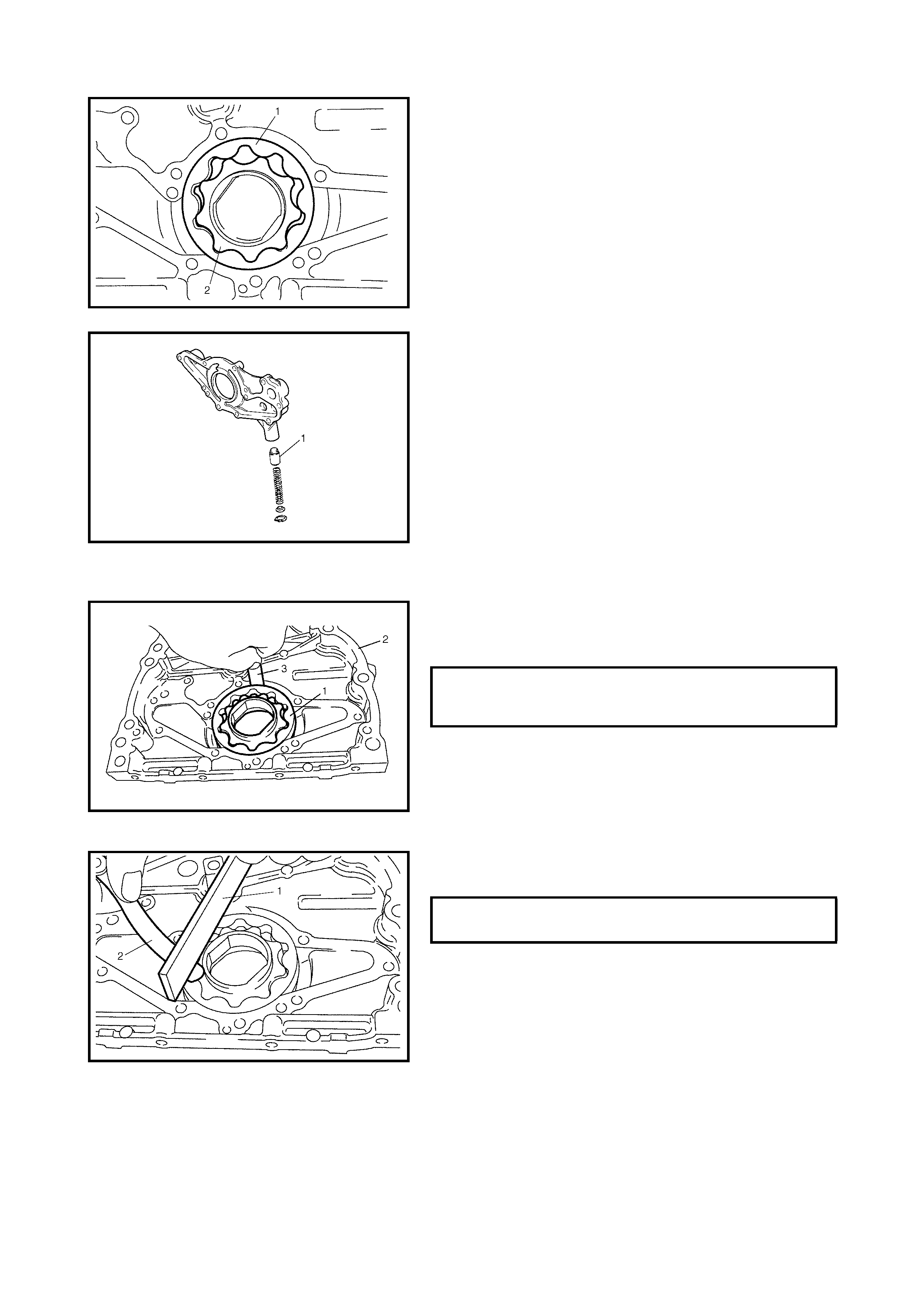

Radial Clearance

Check radial clearance between outer rotor (1) and case

(2), using thickness gauge (3).

If clearance exceeds its limit, replace outer rotor or case.

Side Clearance

Using a straight edge (1) and thickness gauge (2), mea-

sure the side clearance.

LIMIT ON RADIAL CLEARANCE

BETWEEN OUTER ROTOR AND CASE

FOR OIL PUMP 0.310 mm

LIMIT ON SIDE CLEARANCE FOR OIL

PUMP INNER ROTOR 0.15 mm

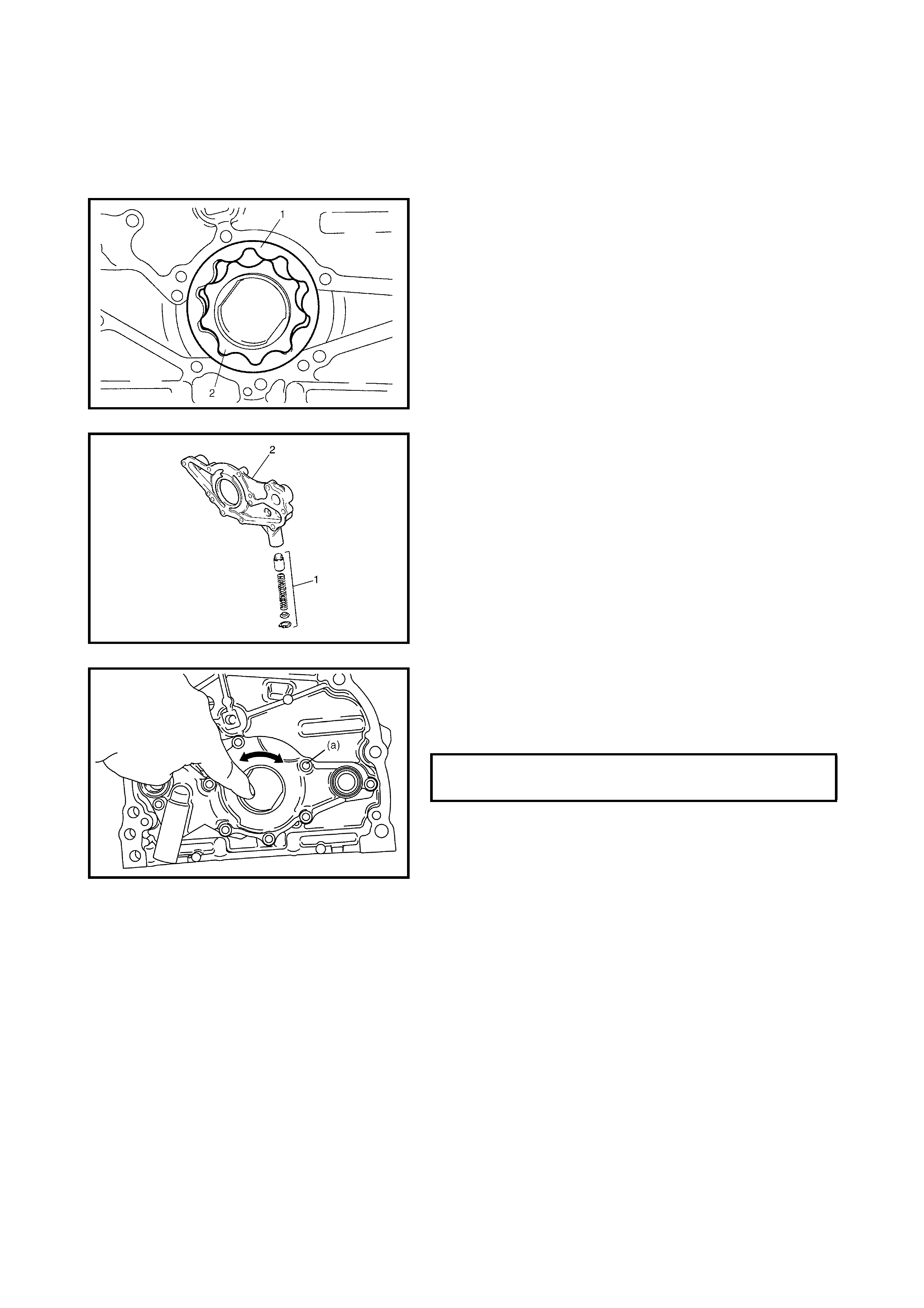

ASSEMBLY

1. Wash, clean and dry all disassembled parts.

2. Apply a thin coat of engine oil to the inner and outer

rotors, oil seal lip portion, and inside surfaces of oil

pump case and plate.

3. Install outer (1) and inner rotors (2) to oil pump case.

4. Install relief valve components (1) to the rotor plate (2).

5. Install the rotor plate and tighten all bolts to specified

torque.

After installing the plate, ensure that rotors turn

smoothly by hand (0.3 Nm torque or below).

INSTALLATION

For installation, refer to 4.2 TIMING CHAIN COVER

INSTALLATION in this Section.

OIL PUMP ROTOR PLATE BOLTS (a)

TORQUE SPECIFICATION 11 Nm

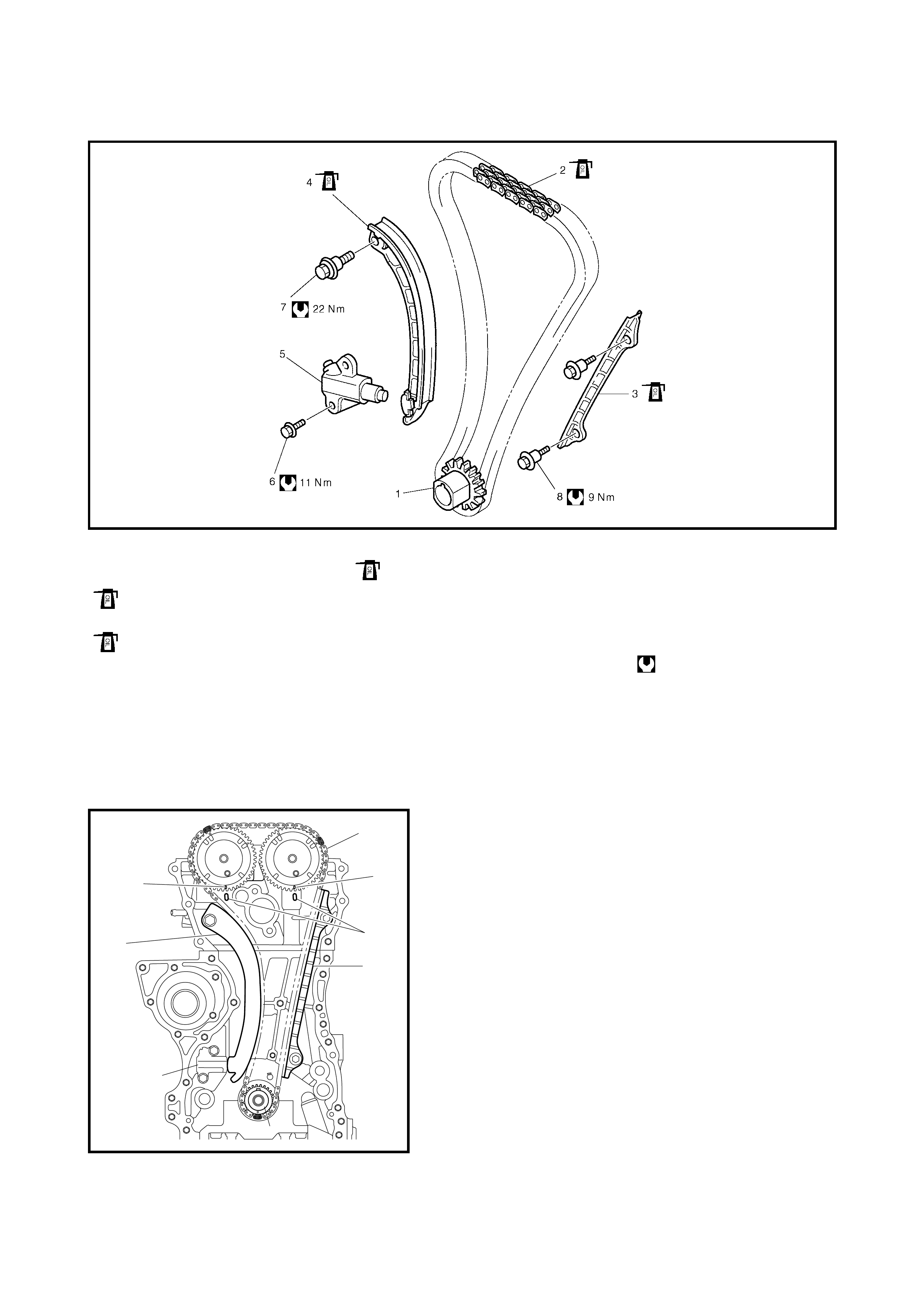

4.4 TIMING CHAIN AND CHAIN TENSIONER

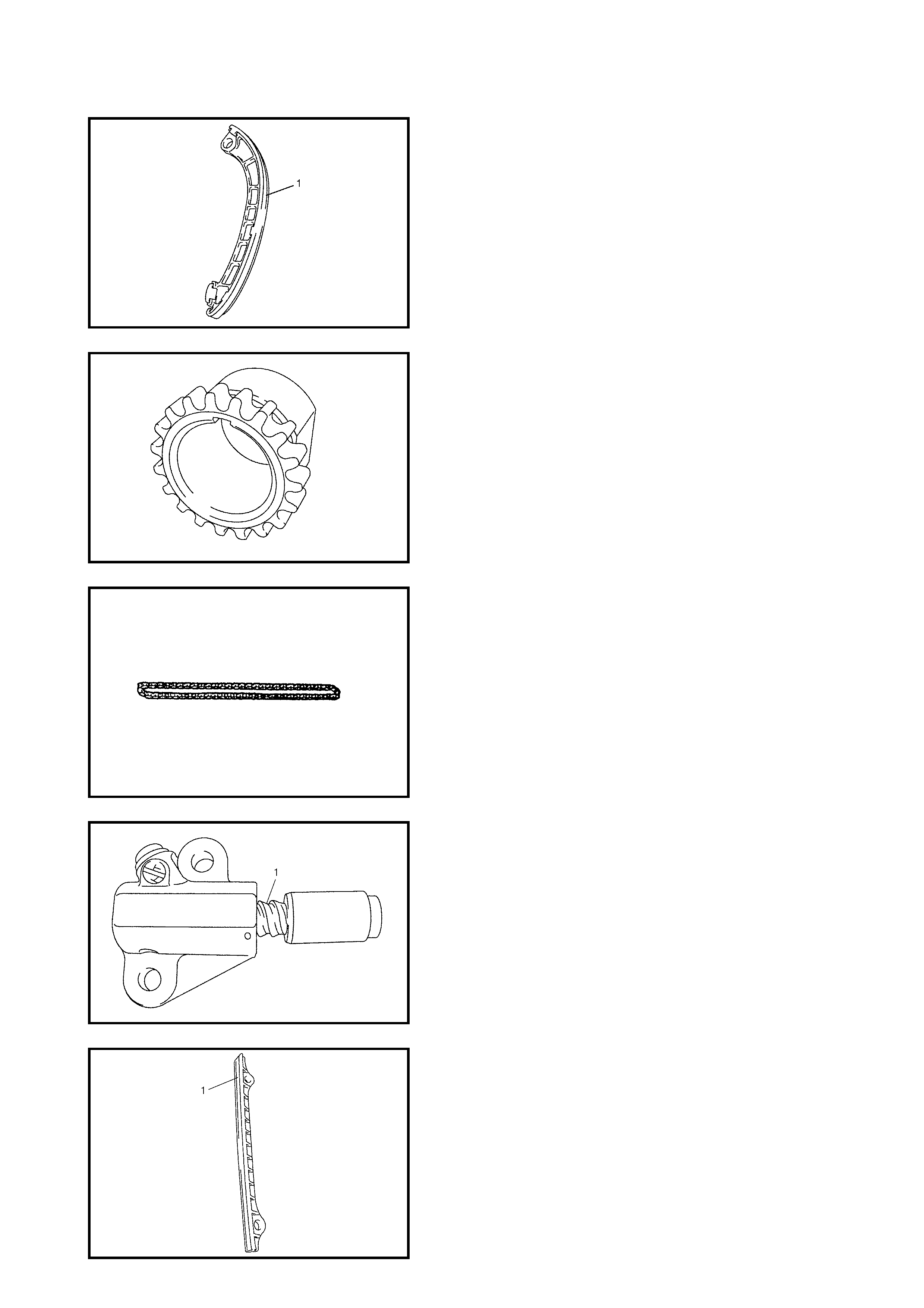

Legend

REMOVAL

1. Remove the timing chain cover, refer to 4.2 TIMING

CHAIN COVER, REMOVAL in this Section.

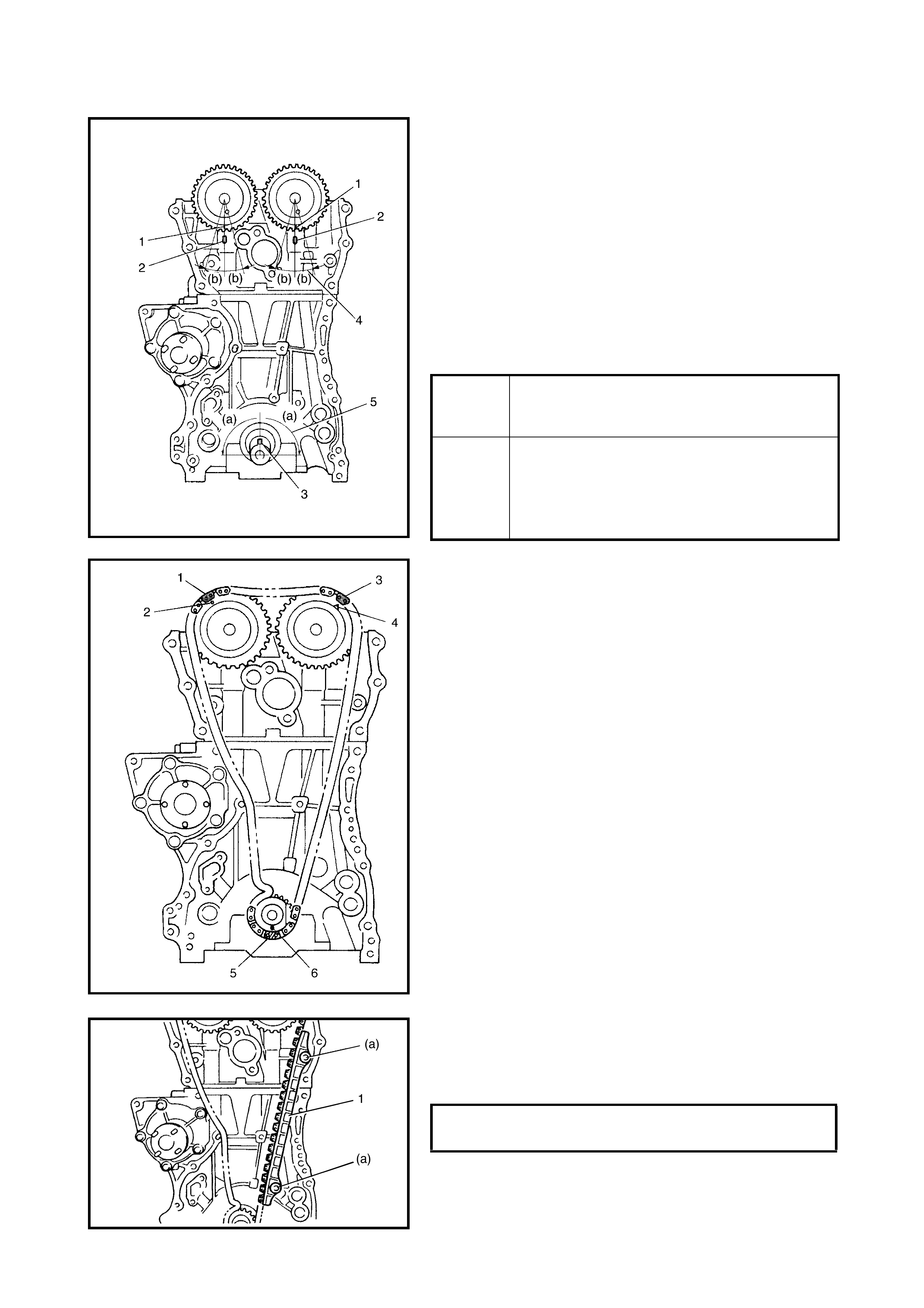

2. Align both the intake and exhaust camshaft timing

sprocket marks (1) with the notches (2) on the cylinder

head respectively by turning the crankshaft.

3. Remove the timing chain tensioner adjuster assembly

(3).

4. Remove the timing chain tensioner (4).

5. Remove the timing chain No.1 guide (5).

6. Remove the timin g chai n (6 ) with the cran ksha ft timing

sprocket (7).

CAUTION: After the timing chain is removed, DO NOT

turn crankshaft and camshafts independently more

than the allowable turning range, refer to 4.4 TIMING

CHAIN AND TENSIONER, INSTALLATION in this

Section.

If turned, interference may occur between the piston

and valves, and valves themselves, and parts relating

to the piston and valves may be damaged.

1. Crankshaft timing sprocket 4. Timing chain tensioner

: Apply engine oil to sliding

surface.

7. Chain tensioner

mounting bolt

2. Timing cha in

: Apply engine oil. 8. Chain guide mounting

bolt

3. Timing chain No.1 guide

: Apply engine oil to sliding

surface.

5. Timing chain tensioner

adjuster assembly Tightening torque

6. Chain tensioner adjuster

mounting bolt

4

5

6

2

1

1

3

7

INSPECTION

Timing chain tensioner

• Check shoe (1) for wear or damage.

Crankshaft timing sprocket

• Check the teeth of the sprocket for wear or damage.

Timing chain

• Check the timing chain for wear or damage.

Timing chain tensioner adjuster

• Check that the tooth surfaces (1) are not damaged.

Timing chai n No .1 guide

• Check shoe (1) for wear or damage.

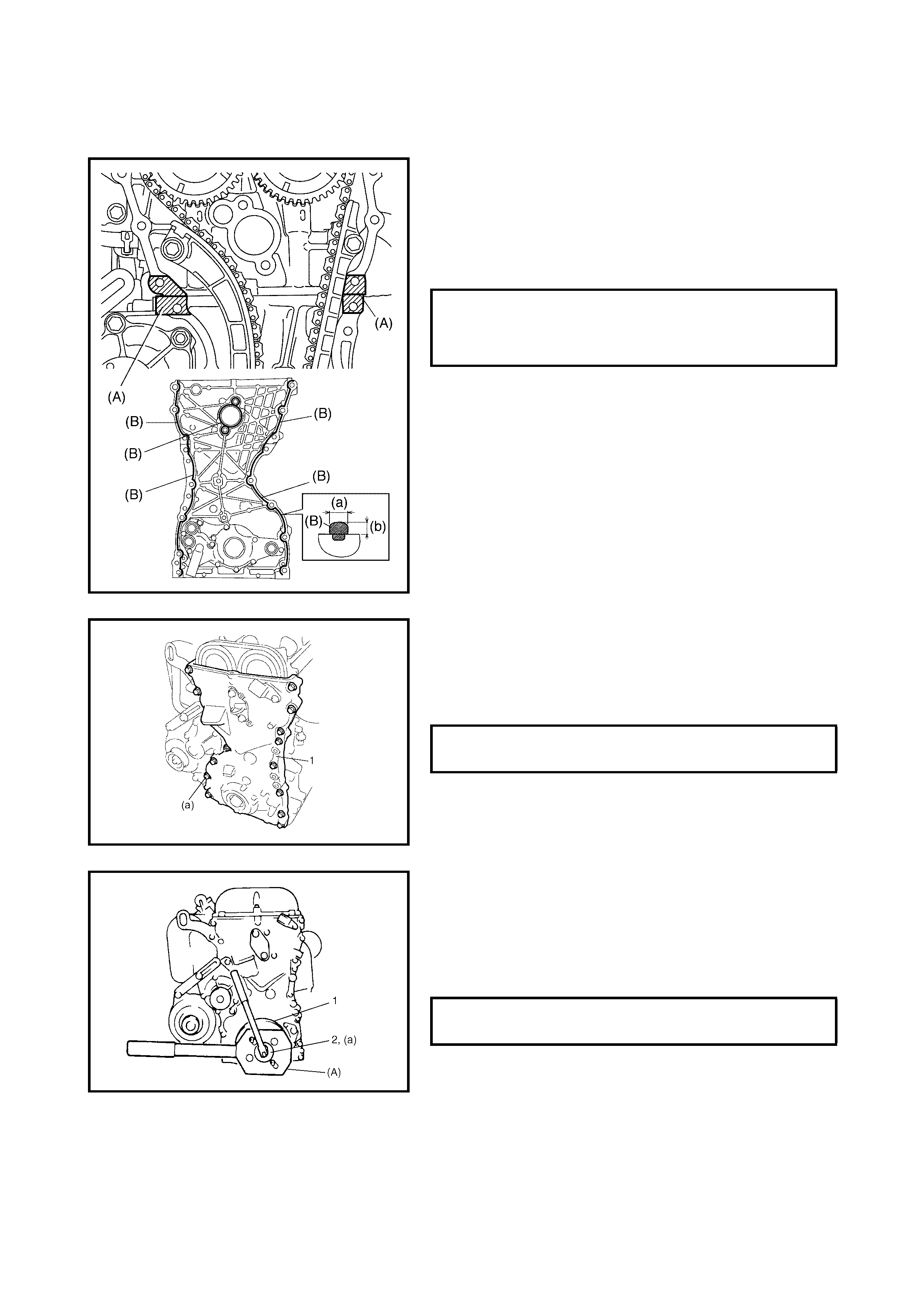

INSTALLATION

CAUTION: After the timing chain is removed, never

turn th e cra nksh a ft and camshafts independ ent ly more

than the limit (a) and (b) as shown in the figure.

If turned, interference may occur between the piston

and valves and the valves themselves, and parts

related to the piston and valves may be damaged.

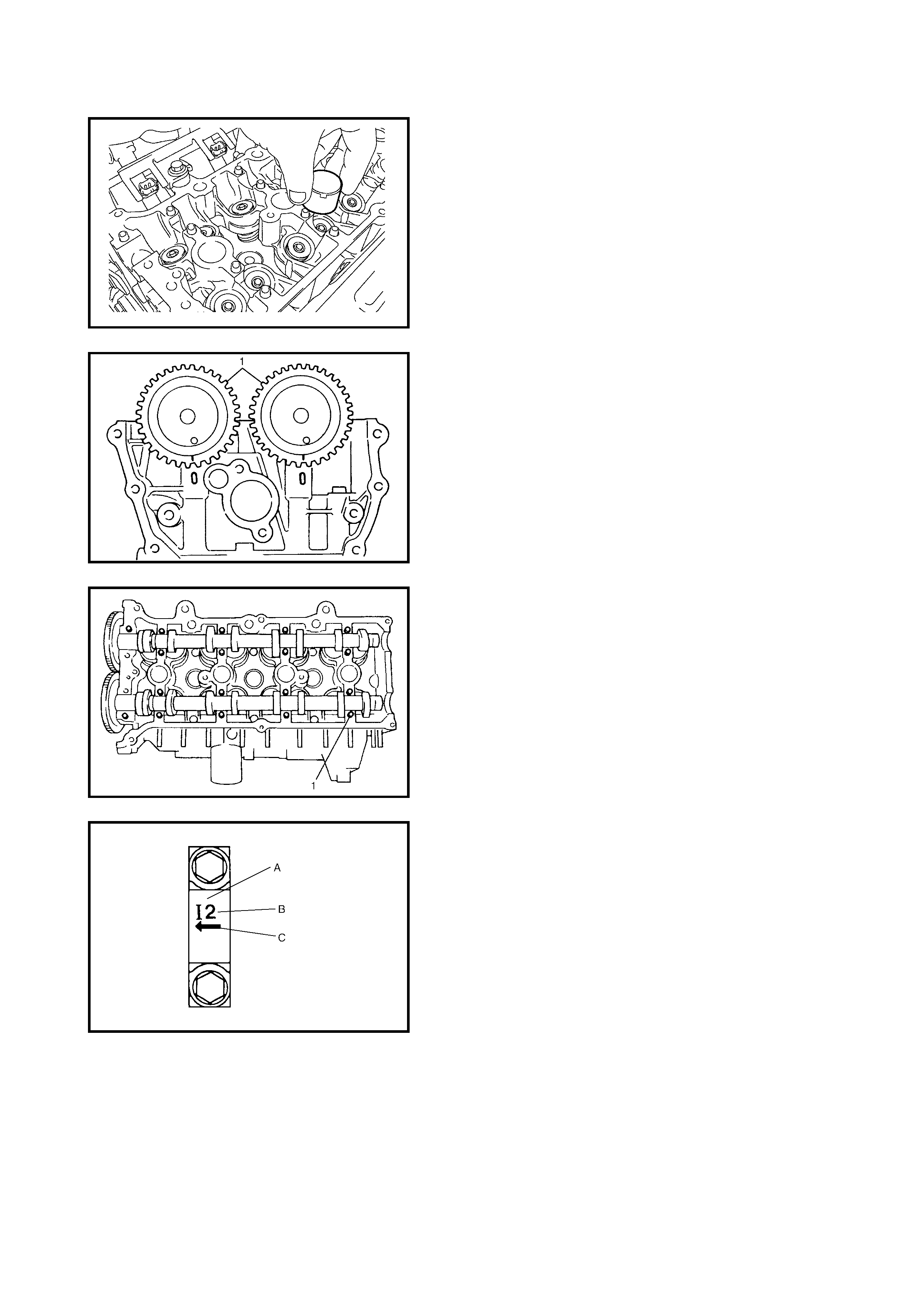

1. Check that the matching marks (1) on the intake and

exhaust ca mshaft timing sp rockets matc h with notc hes

(2) on the cylinder head as shown in the figure.

2. Set key (3) and turn crankshaft to position key on the

upside of the crankshaft.

3. Install the timing chain by aligning the dark blue plate

(1) of the timing chain with the mark (2) on the

camshaft timing sprocket, then by aligning dark blue

plate (3) with the triangle mark (4) as shown in the

figure.

4. Fit the crankshaft timing sprocket to the timing chain by

aligning the gold plate (5) on the timing chain with mark

(6) on the crankshaft timing sprocket.

Install the crankshaft timing sprocket, with the chain

fitted in position, onto the crankshaft.

5. Apply engine oil to the sliding surface of the timing

chain No.1 guide (1) and install it as shown in the

figure.

Tighten the guide bolts to specified torque.

(a) 90° (5) Crankshaft allowable turning range.

By key on crankshaft, within 90° from top

on both right and left.

(b) 15° (4) Camshaft (INTAKE and EXHAUST)

allowable turning range.

By marks on camshaft timing sprocket

within 15° from notches on cylinder head

on both right and left.

TIMING CHAIN No.1 GUIDE BOLT (a)

TORQUE SPECIFICATION 9 Nm

6. Apply engine oil to the sliding surface of the chain

tensioner (1) and install the chain tensioner and

spacer.

Tighten tensioner bolt to specified torque.

7. Ensure that the matching marks (1) on the intake and

exhaust camshaft timing sprockets are correctly

aligned with the dark blue plates (2) on the timing chain

and matching mark (3) on the crankshaft timing

sprocket is correctly aligned with the gold plate (4) on

the timing chai n.

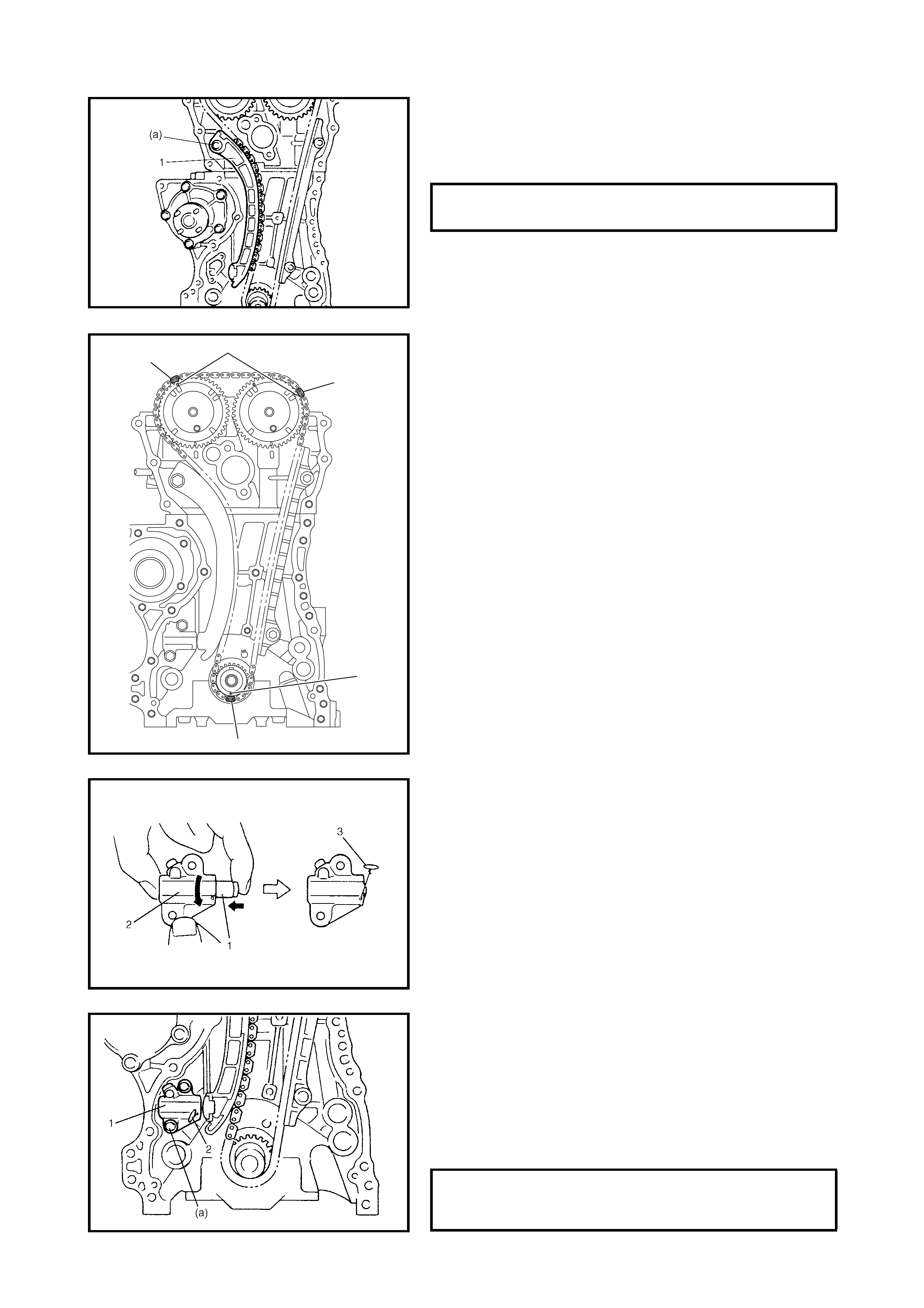

8. Screw in the timing chain tensioner adjuster plunger (1)

by turning the body (2) in the direction of the arrow.

Install a retainer (3) (wire) to hold the plunger in place.

9. Install the timing chain te nsion er adjus ter asse mbly (1)

with the retainer (2) still in place.

Tighten the adjuster bolts to the specified torque then

remove the retainer (wire) from the chain tensioner

adjuster assembly.

CAUTION: Ensure the plunger ret a iner is removed aft er

the timing chain adjuster is fitted.

TIMING CHAIN TENSIONER BOLT (a)

TORQUE SPECIFICATION 22 Nm

2

2

1

3

4

TIMING CHAIN TENSIONER

ADJUSTER BOLTS (a)

TORQUE SPECIFICATIONS 11 Nm

10. Apply engine oil to the timing chain then turn the crank-

shaft clockwise two revolutions. Check that the

matching marks (1) on the intake and exhaust

camshaft timing sprockets align with the notches (2) on

the cylinder hea d and that the key (3) is on the upside

of the crankshaft as shown in the figure.

If any of the alignment marks do not match, adjust

chain and/or sprockets, refer back to Step 7.

11. Install timing chain cover, refer to 4.2 TIMING CHAIN

COVER, INSTALLATION in this Section

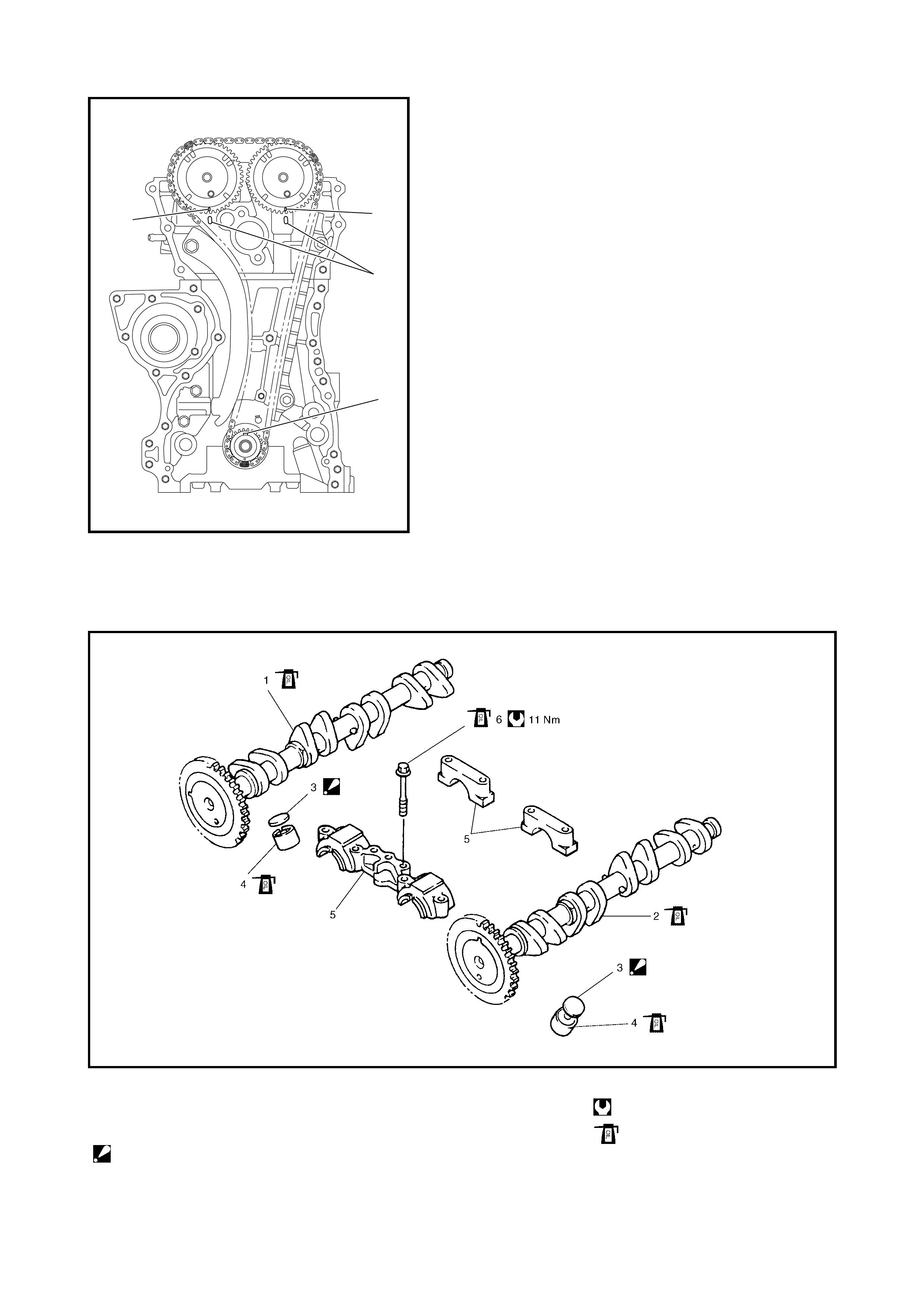

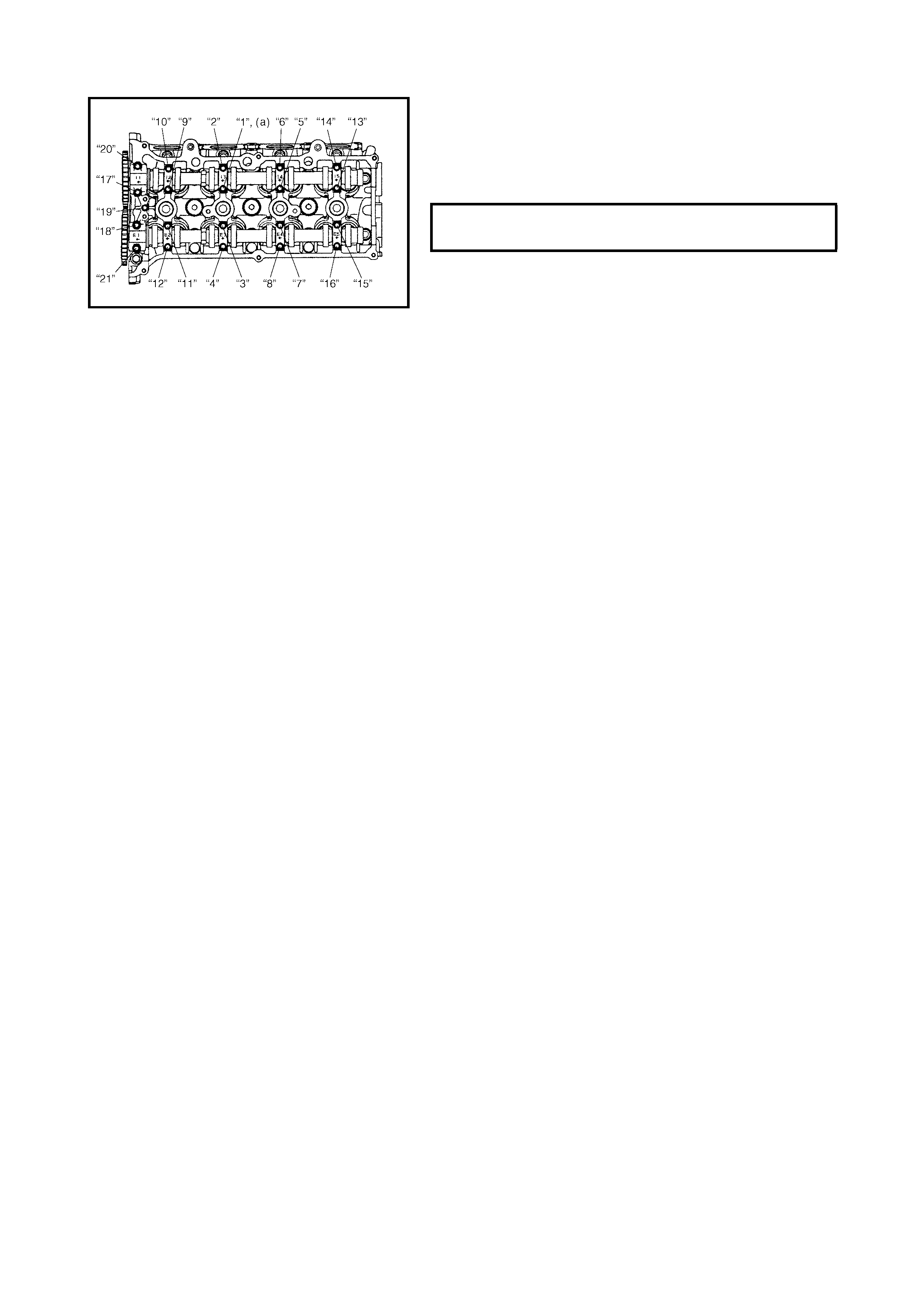

4.5 CAMSHAFT, TAPPET AND SHIM

Legend

2

1

1

3

1. Intake camshaft 4. Tappet Tightening torque

2. Exhaust camshaft 5. Camshaft housing Apply engine oil to sliding

surface of each part.

3. Shim

: Shim Number on it faces

the tappet side.

6. Camshaft housing bolt

REMOVAL

1. Remove the timing chain cover, refer to 4.2 TIMING

CHAIN COVER REMOVAL in this Section.

2. Remove the timing chain, refer to 4.4 TIMING CHAIN

AND CHAIN TENSIONER, REMOVAL in this Section.

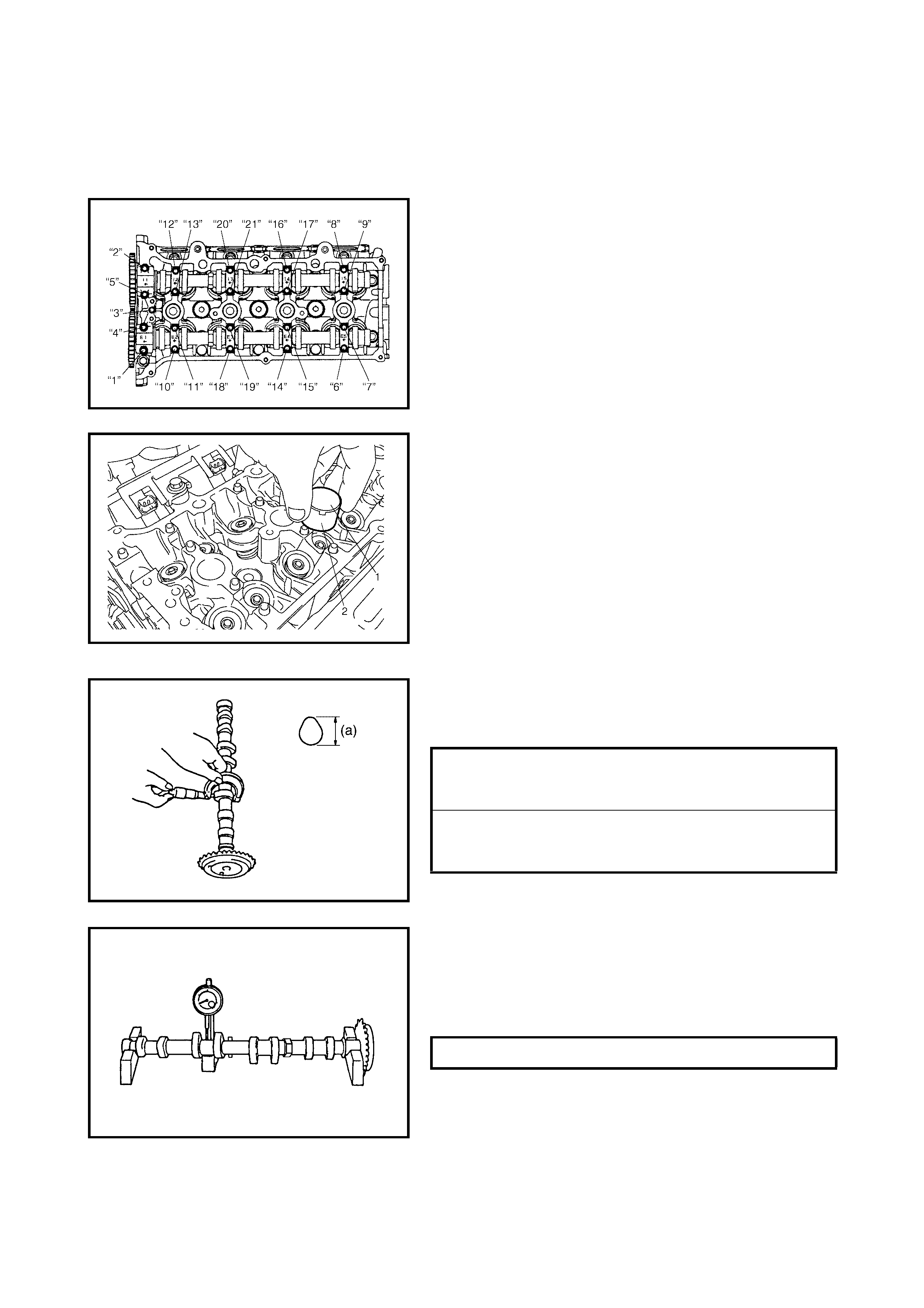

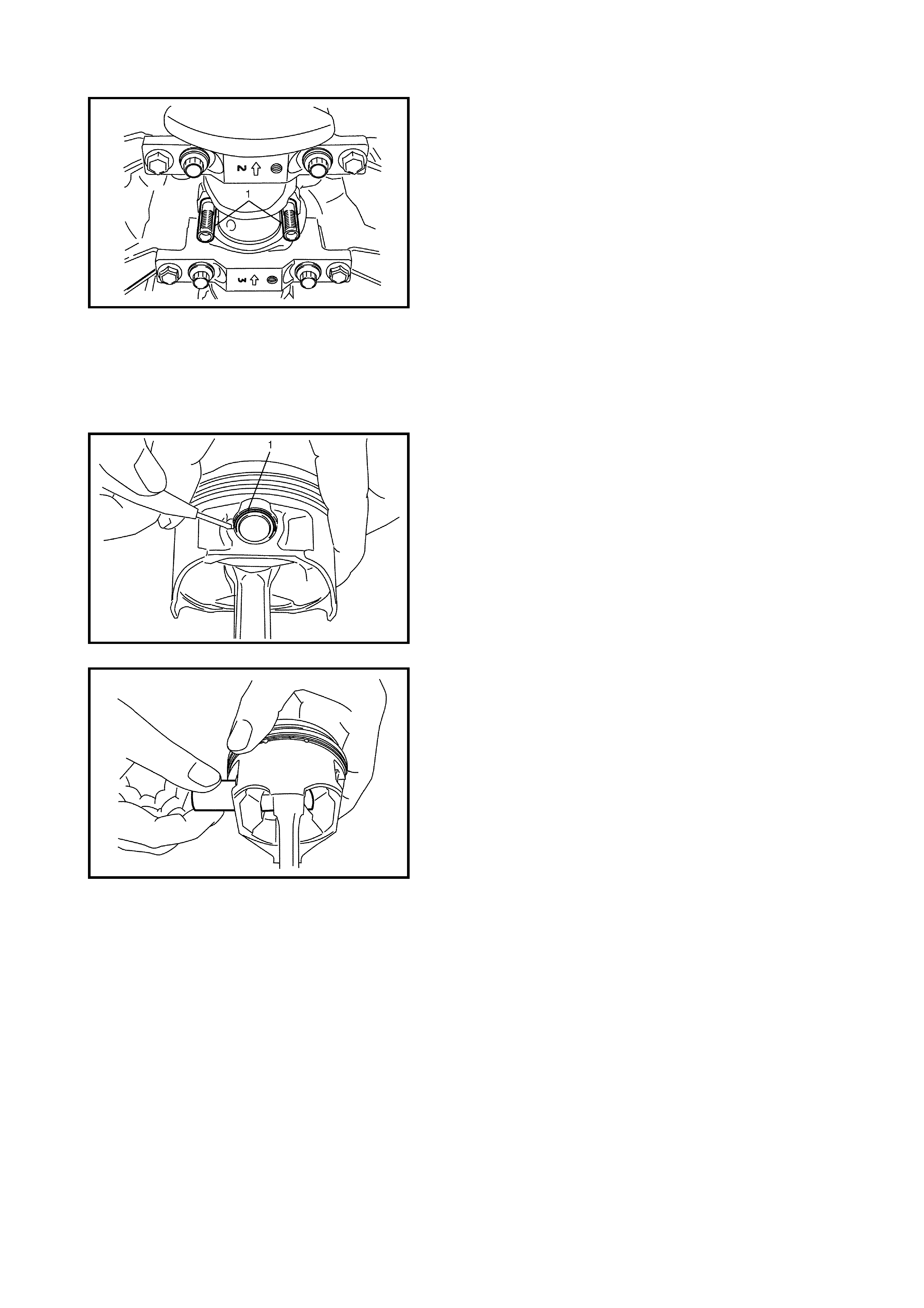

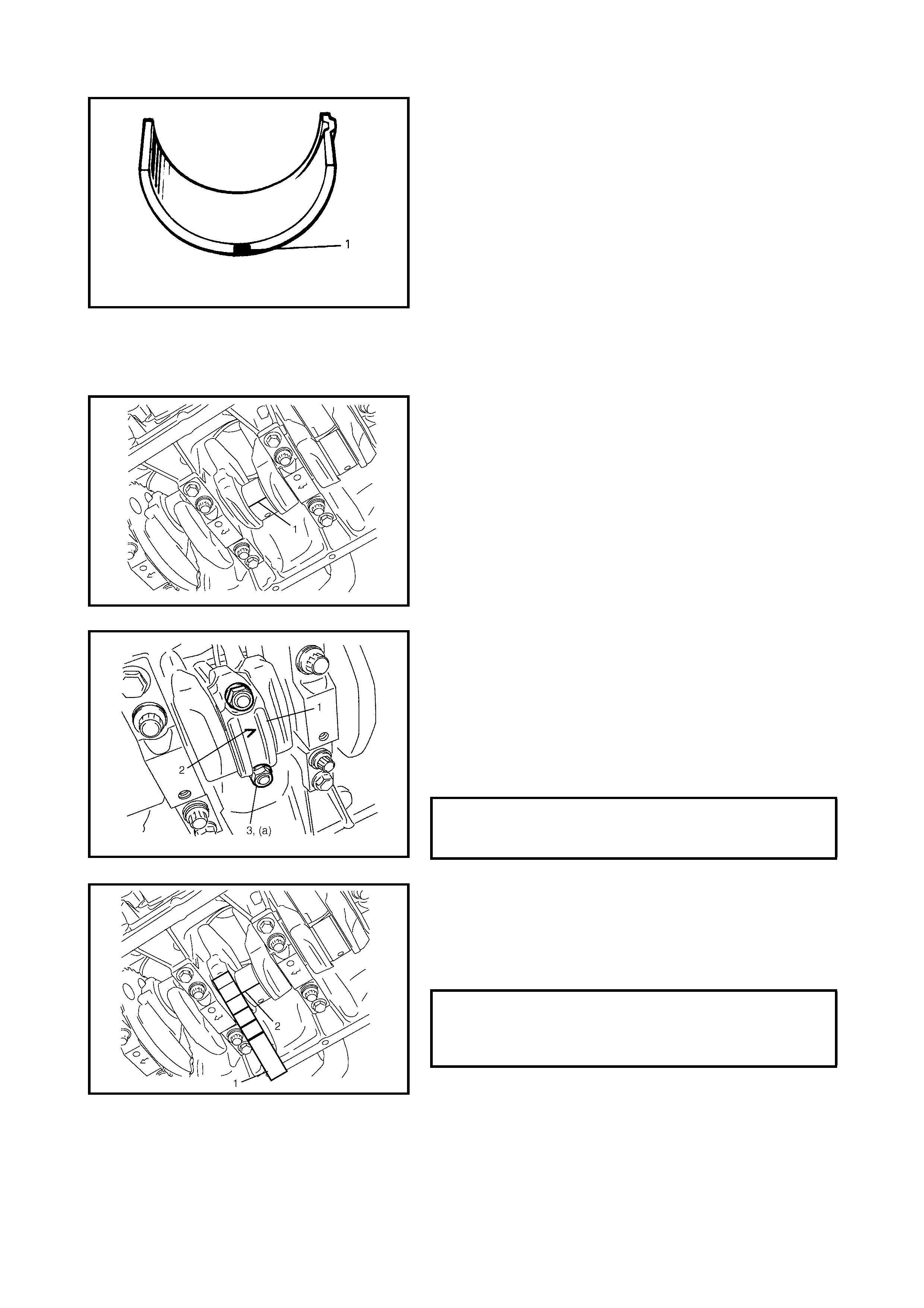

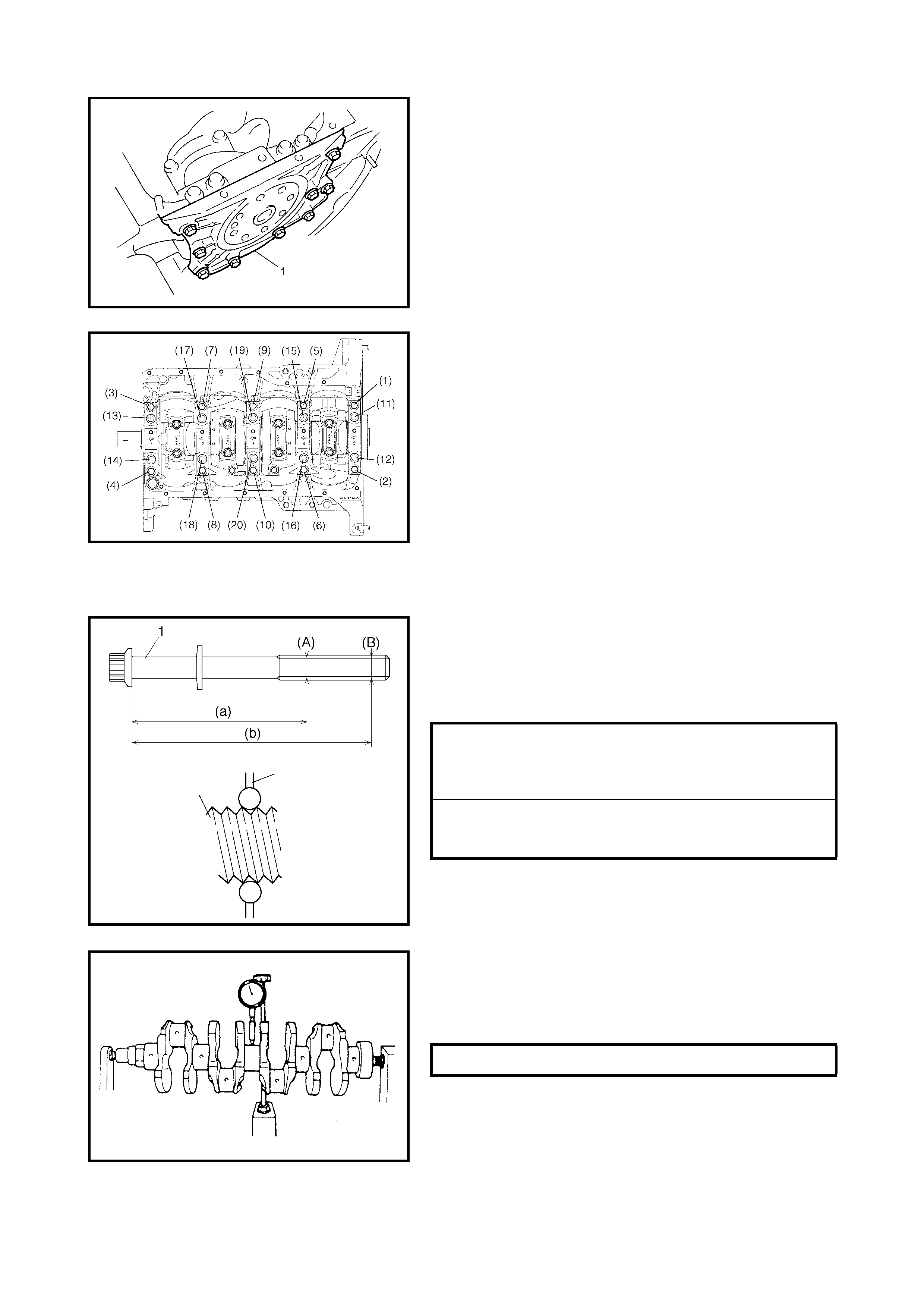

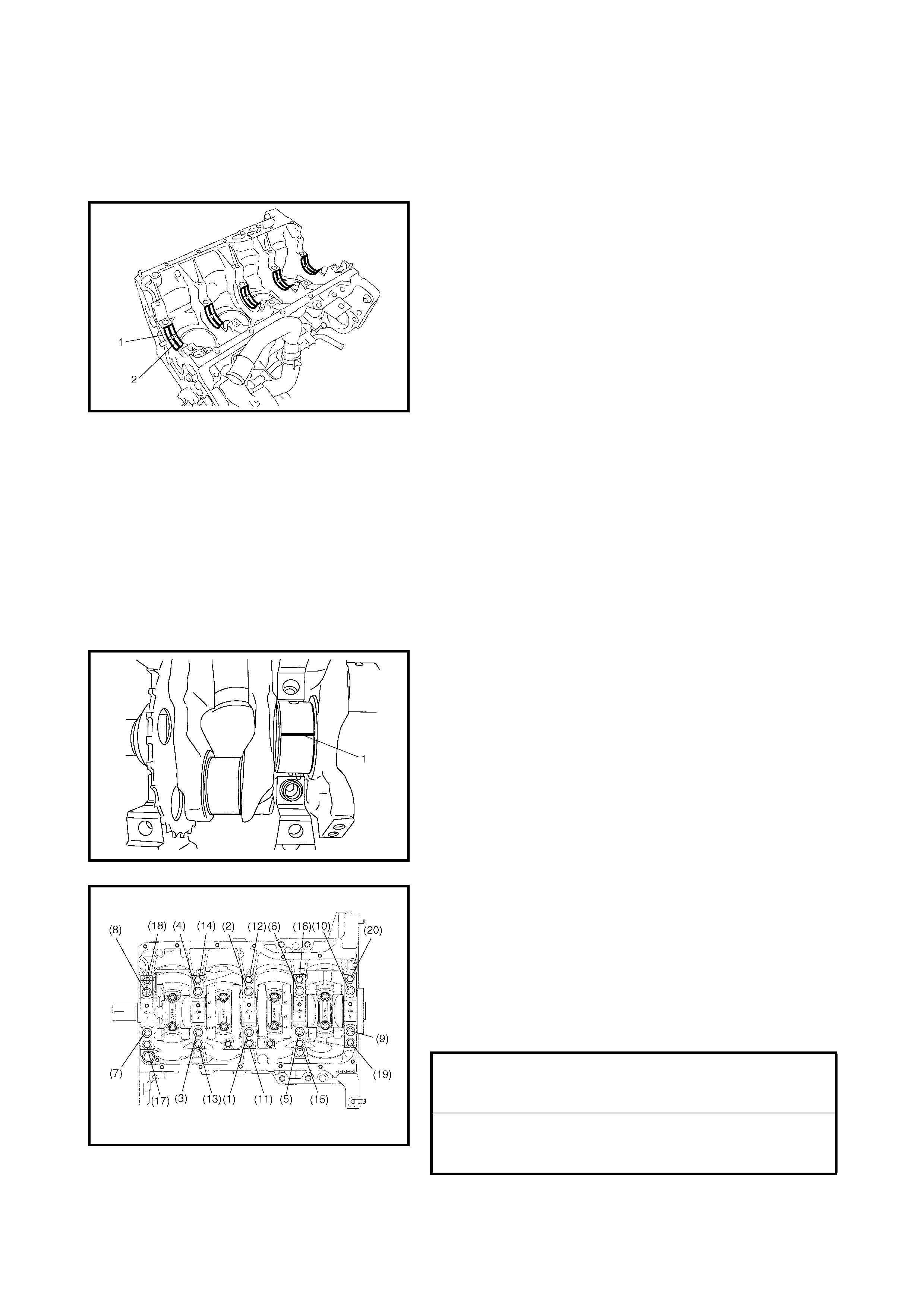

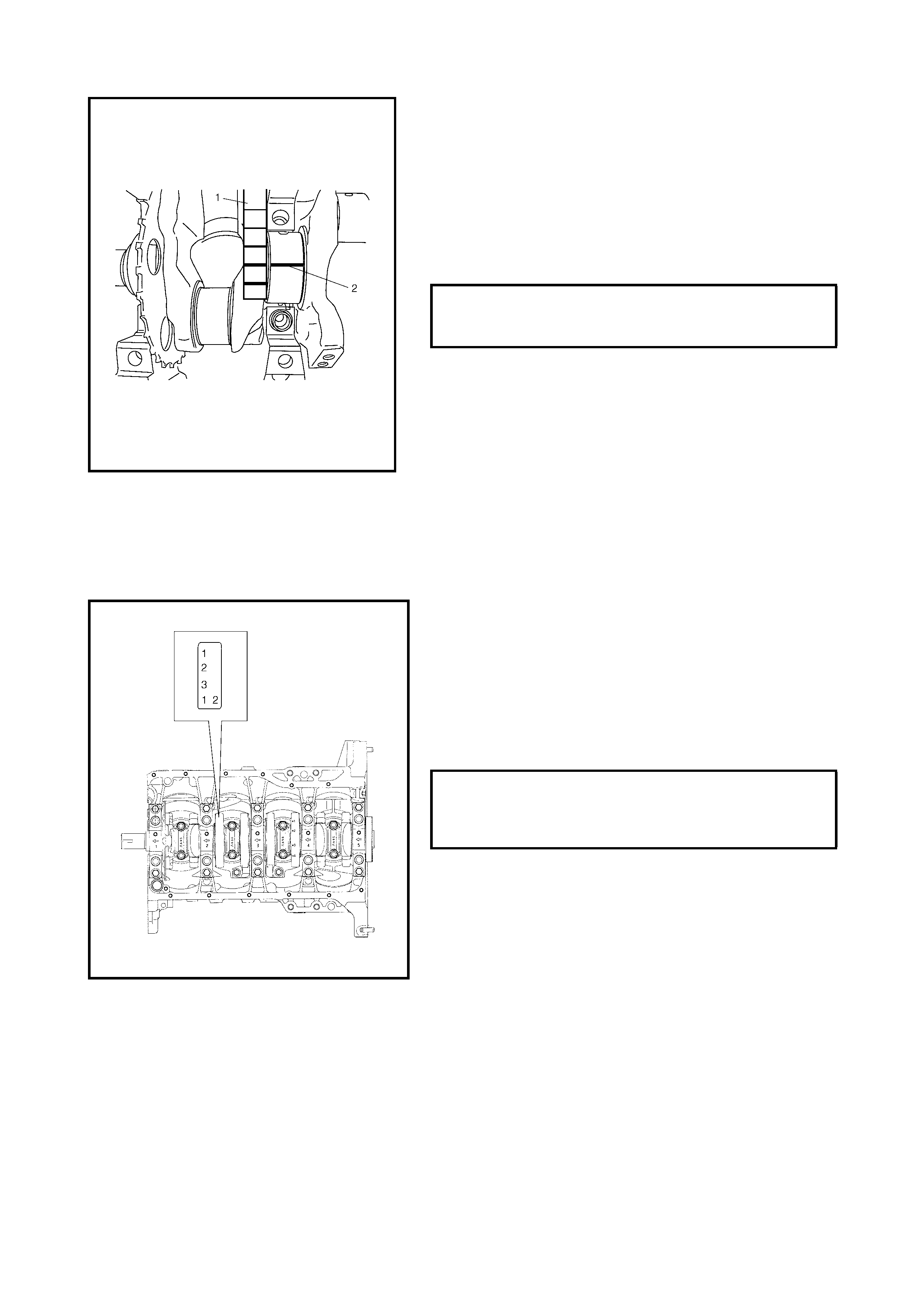

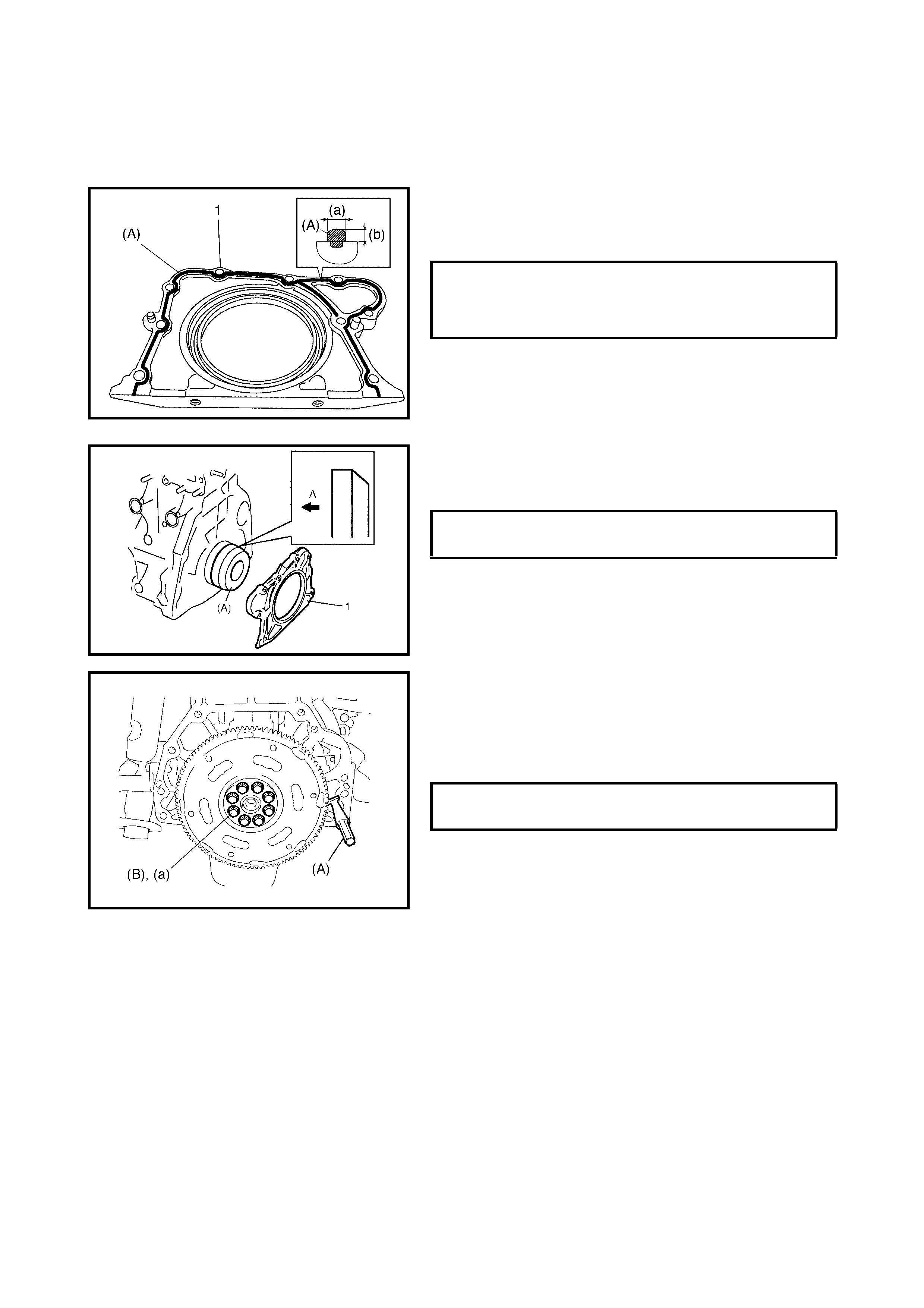

3. Loosen the camshaft housing bolts in the order

indicated in the figure then remove them.

4. Remove the camshaft housings.

5. Remove the intake and exhaust camshafts.

6. Remove the tappets (2) with the shims (1).

INSPECTION

Cam Wear

Using a micrometer, measure the cam height (a). If the

measured height is below the limit, replace the camshaft.

Camshaft Runout

Set the c amshaft betw een two “V” b locks a nd meas ure the

runout using a dial gauge.

If the meas ured runout e xceeds the lim it, replace the c am-

shaft.

INTAKE CAM HEIGHT (a) STANDARD

LIMIT 44.9 19 - 45.089 mm

44.81

EXHAUST CAM HEIGHT (a)

STANDARD

LIMIT 44.3 99 - 44.559 mm

44.28 mm

CAMSHAFT RUNOUT LIMIT 0.10 mm

Camshaft Journal Wear

Check the camshaft journals and camshaft housings for pit-

ting, scratches, wear or damage.

If any damage is found, replace the camshaft or cylinder

head with the housings. Never replace the cylinder head

without replacing the housings.

Check the camshaft journal clearance using gauging plas-

tic. Checking procedure is as follows.

1. Clean housings and camshaft journals.

2. Remove all tappets with shims.

3. Install the camshafts onto the cylinder head.

4. Place a piece of gauging plastic the full width of the

journal of the camshaft (parallel to camshaft).

5. Install the camshaft housings.

6. Gradually tighten the camshaft housing bolts in the

order indicated in the figure until they reach the

specified torque.

NOTE: Do not rotate the camshaft while the gauging plastic

is installed.

7. Remove the housings, and using the scale (2) on the

gauging plastic (1) envelope, measure the gauging

plastic width at its widest point.

CAMSHAFT HOUSING BOLTS (a)

TIGHTENING TORQUE 11 Nm

CAMSHAFT JOURNAL CLEARANCE -

INTAKE No.1 STANDARD

LIMIT 0.020 - 0.072 mm

0.12 mm

CAMSHAFT JOURNAL CLEARANCE -

OTHERS STANDARD

LIMIT 0.045 - 0.087 mm

0.12 mm

If the measured camshaft journal clearance exceeds the

limit, measure the journal (housing) bore and the outside

diameter of the camshaft journal. Replace the camshaft or

the cylinde r head assembly, which ever differs greater from

its specification.

Tappet and Shim Wear

Check tappet and shim for pitting, scratches or damage.

If any damage is found, replace.

Measur e the cylinder head tappet b ore and the tappet out-

side diameter to determine the cylinder head-to-tappet

clearance. If the clearance exceeds the limit, replace the

tappet or the cylinder head.

CAMSHAFT JOURNAL DIAMETER [A]

- INTAKE No.1 26.940 - 26.955 mm

CAMSHAFT JOURNAL DIAMETER [A]

- EX HAUST No.1 29.934 - 26.95 5 mm

CAMSHAFT JOURNAL DIAMETER [A]

- OTHER 22.934 - 22.955 mm

CAMSHAFT JOURNAL BEARING

BORE [B] - EXHAUST No.1 27.000 - 27.021 mm

CAMSHAFT JOURNAL BEARING

BORE [B] - OTHER 23.00 - 23.021 mm

CYLINDER HEAD TO TAPPET

CLEARANCE STANDARD

LIMIT 0.025 - 0.066 mm

0.15 mm

TAPPET OUTSIDE DIAMETER [A]

STANDARD 30.959 - 30.975 mm

CYLINDER HEAD TAPPET BORE [B]

STANDARD 31.000 - 31.025 mm

INSTALLATION

1. Apply engine oil around the tappets then install the

tappets and shims onto the cylinder head.

NOTE: When install ing th e shim, ma ke sur e the s him num-

ber faces the tappet.

2. Install the camshafts (1).

NOTE: Before install ing the camshafts, turn the cra nkshaft

until the key position faces upward. Refer to 4.4 TIMING

CHAIN AND CHAIN TENSIONER in this Section.

Apply engine oil to the sliding surface of each camshaft and

camshaft journal then install them as shown in the figure.

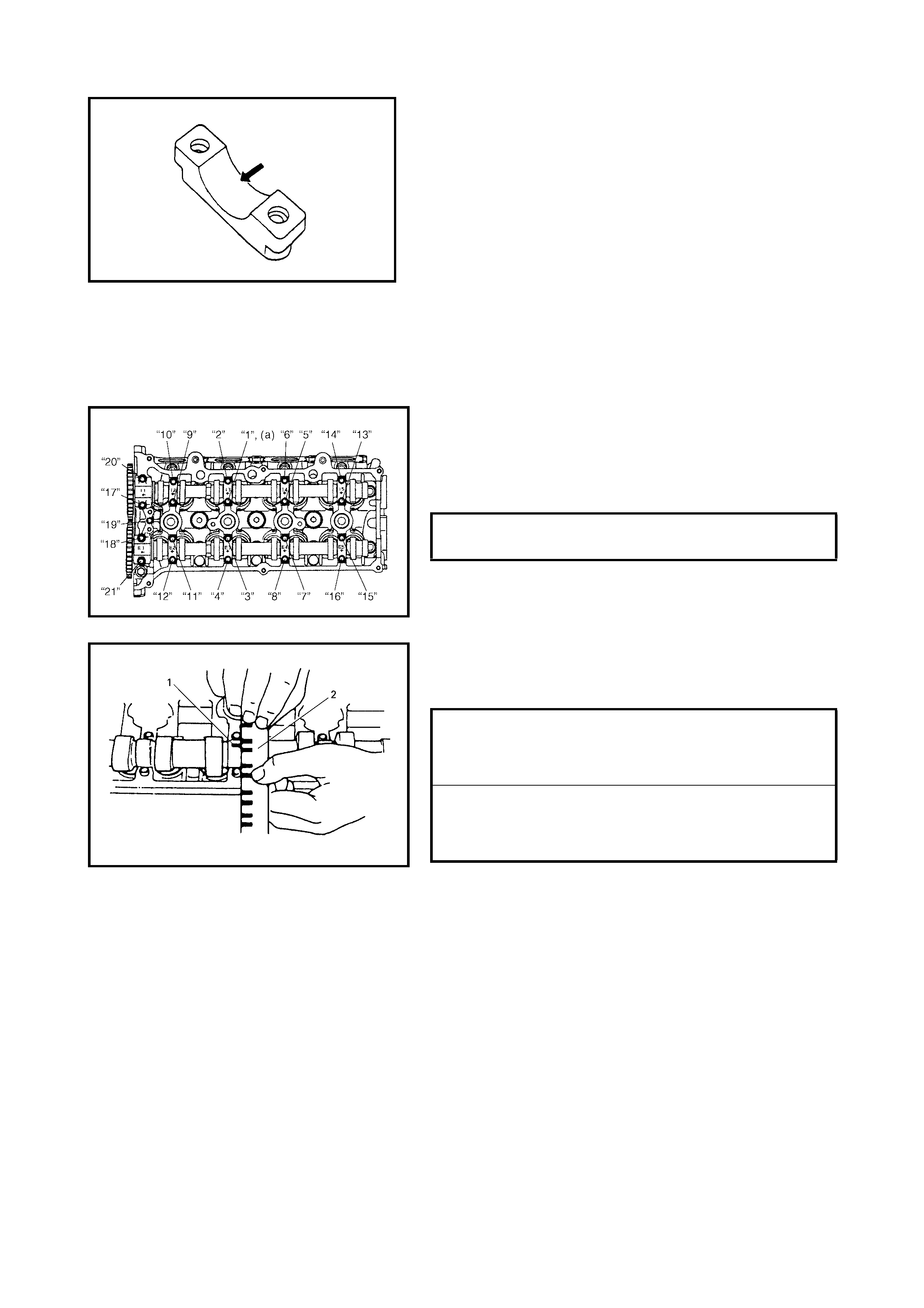

3. Install the camshaft housing pins (1), if removed, as

shown in the figure.

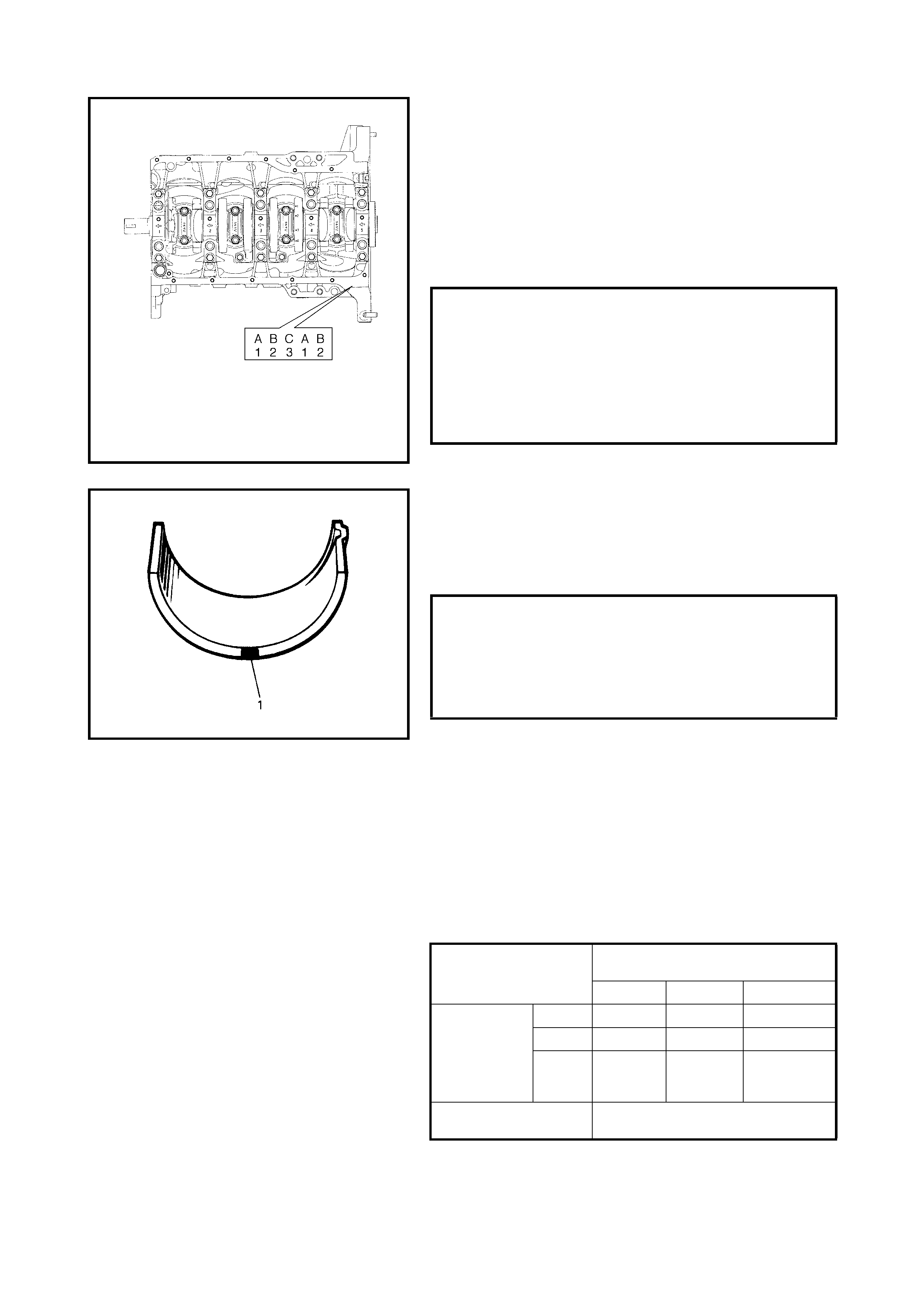

4. Check the position of the camshaft housings.

Embossed marks are provided on each camshaft

housing, indicating position and direction for installa-

tion. Install housings as indicated by these marks.

A: I = Intake side and E = Exhaust side.

B: Position from timing chain side.

C: Pointing to timing chain side.

5. Apply engine oil to the housing bolts, then fit loosely.

Gradually tighten the housing bolts by the following

numeric al order i n the fig ure. Tighten them evenly an d

repeat the tighten ing se quence two o r thr ee times u ntil

they reach the speci fi ed tor que .

6. Install the timing chain with the crankshaft sprocket,

refer to 4.4 TIMING CHAIN AND CHAIN TENSIONER

INSTALLATION in this Section.

7. Install the timing chain cover, refer to 4.2 TIMING

CHAIN COVER INSTALLATION in this Section.

8. Check valve lash clearance, refer to 2.5 VALVE LASH

(CLEARANCE) in this Section.

9. Refer to 4.2 TIMING CHAIN COVER, INSTALLATION

in this Section and perform Steps 1 to 3.

CAMSHAFT HOUSING BOLTS (a)

TORQUE SPECIFICATION 11 Nm

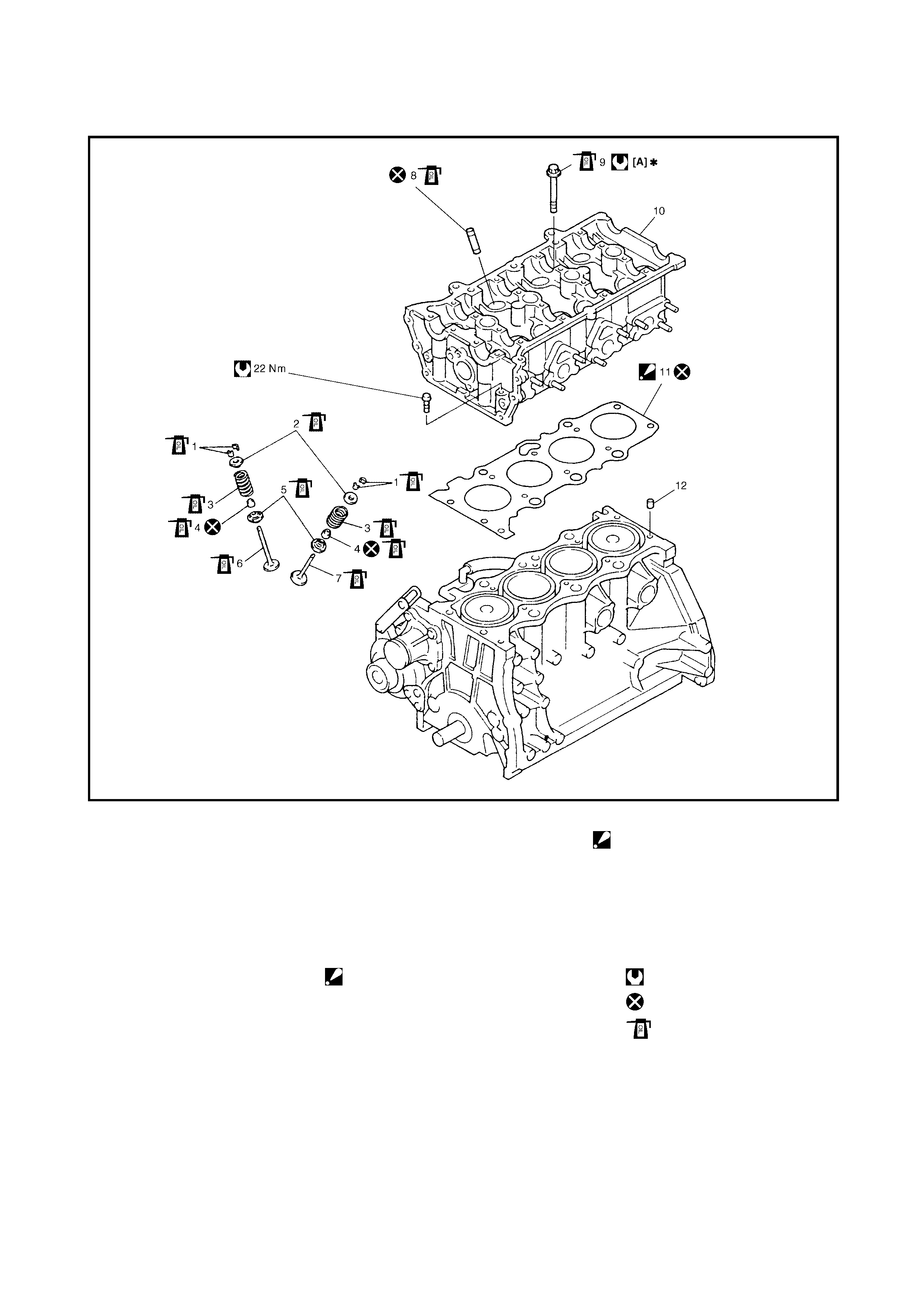

4.6 VALVES AND CYLINDER HEAD

Legend

[A] 1) T ighten all bolts at 40 Nm

2) Turn all bolts at 60°

3) Then, Turn all bolt at 60°

once again

4. Valve stem seal 11. Cylinder head gasket

: “TOP” mark stamped on

the gasket is positioned

on the crankshaft pulley

side, facing up.

✱5. Valve spring seat

6. Intake valv e

7. Exhaust valve

1. Valve cotters 8. Valve guide 12. Knock pin

2. Valve spring retainer 9. Cylinder head bolt Tightening torque

3. Valve spring 10. Cylinder head Do not reuse.

Apply engine oil to sliding

surface of each part.

REMOVAL

1. Remove engine assembly from vehicle, refer to

4.1, ENGINE ASSEMBLY, REMOVAL in this Section.

2. Remove intake manifold stiffener (1).

3. Remove the oil pan, refer to 3.7 OIL PAN AND OIL

PUMP STRAINER in this Section.

4. Remove the cylinder head cover, referring to

3.4 CYLINDER HEAD COVER, REMOVAL in this

Section.

5. Remove the timing chain cover, refer to Steps 2 to 6,

4.2 TIMING CHAIN COVER, REMOVAL in this

Section.

6. Remove the timing chain, refer to Steps 2 to 6,

4.4 TIMING CHAIN AND CHAIN TENSIONER,

REMOVAL in this Section.

7. Remove the intake and exhaust camshafts, refer to

Steps 3 to 6, 4.5 CAMSHAFT, TAPPET AND SHIM,

REMOVAL in this Section.

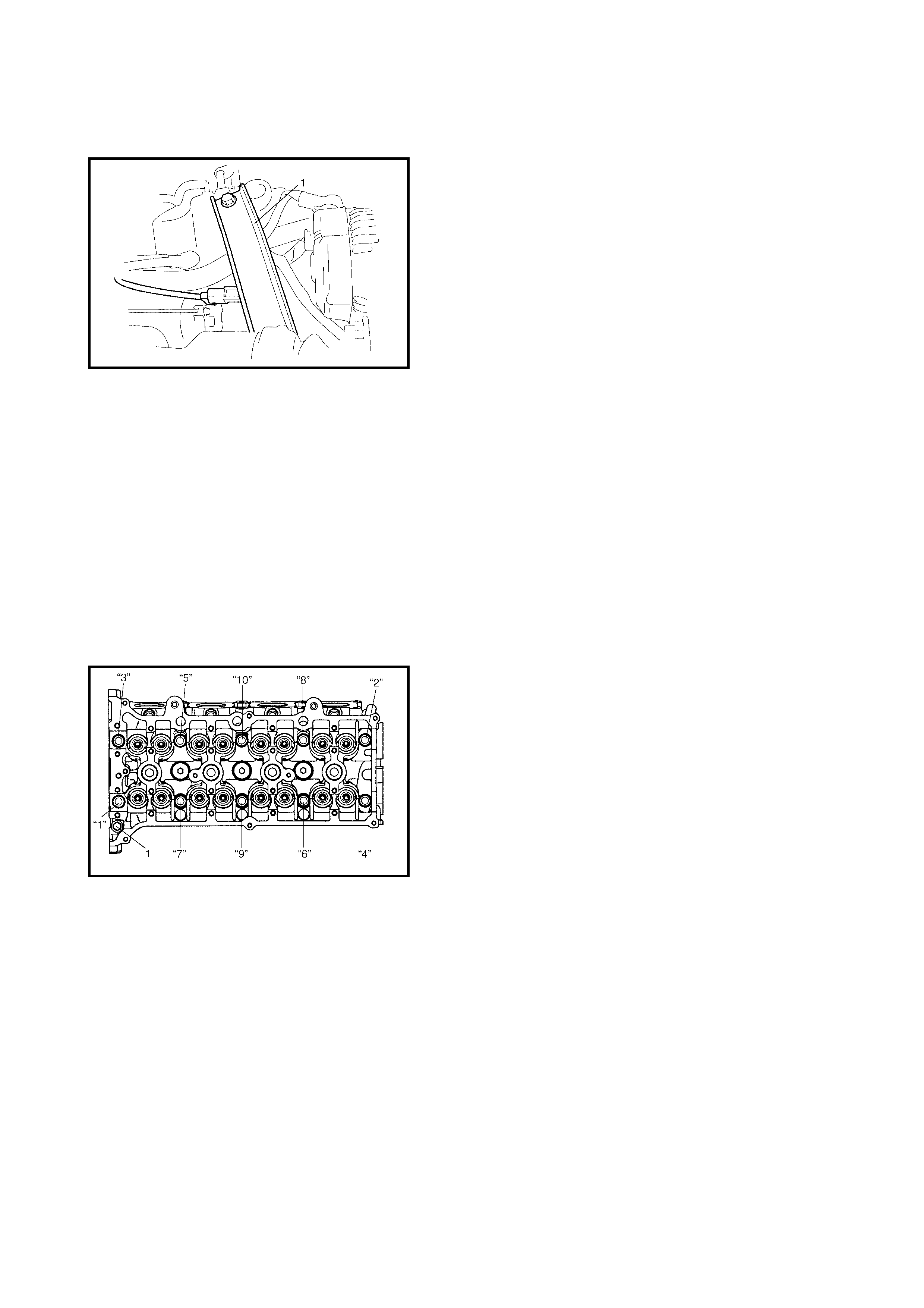

8. Loosen the cylinder head bolts in the order indicated in

the figure using a 12 corner socket wrench then

remove them.

NOTE:

• Remember to remove the (M8) bolt (1) as shown in the

figure.

9. Check the cylinder head and remove or disconnect any

further parts as necessary.

10. Remove the exhaust manifold, if necessary, refer to

3.6 EXHAUST MANIFOLD in this Se ct io n.

11. Remove the cylinder head with the intake manifold and

exhaust manifold (if still fitted). Use lifting device, if

necessary.

DISASSEMBLY

1. For ease in servicing the cylinder head, remove the

intake manifold, injectors and exhaust manifold from

the cylinde r hea d.

2. Using special tools (Valve lifter) 09916-14510 (A) and

09916-14910 (B), compress the valve springs and

remove the valve cotters (1) using special tool

(Forceps) 09916-84511 (C).

3. Release the special tool and remove the spring

retainer and valve spring.

4. Remove the valve from the combustion chamber side.

5. Remove the valve stem seal (1) from the valve guide,

then the valve spring seat (2 ).

NOTE: Do not reuse the seal once it has been disassem-

bled. Always use new oil seals when assembling.

6. Using sp ecial tool (valve guide remover) 0 9916-44910

(A), drive the valve guide out from the combustion

chamber side to the valve spring side.

NOTE: Do not reuse the valve guide once disassembled.

Be sure to use a new v alve gui de (Ov ersize) when ass em-

bling.

7. Place disassembled parts, except valve stem seals

and va lve gui des , i n o rd er so that they c an be in stalle d

in their original position.

INSPECTION

Valve Guides

Using a m ic rome ter and a bo re gau ge, take dia met er read-

ings of the valve stems and the valve guides to check

stem-to -guide clearan ce. Be sure to take readings at more

than one place along the length of each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

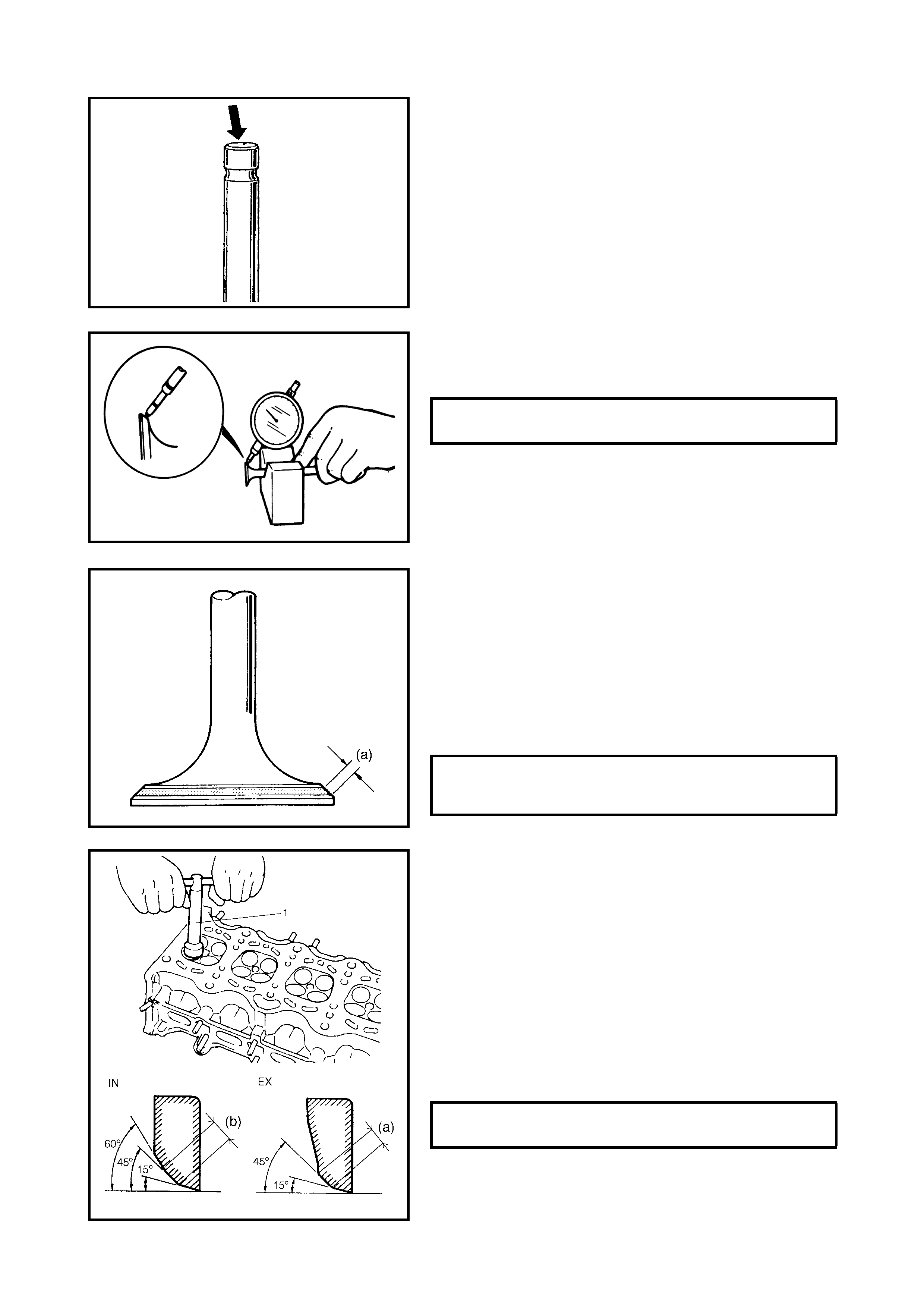

If a bore gauge is not avail abl e, ch eck the end def lecti on of

the valve stem with a dial gauge.

Move t he stem e nd in directi ons (1 ) an d (2) to mea su re the

end deflection.

If the deflection exceeds the limit, replace the valve stem

and valve guide.

Valves

• Remove all carbon from valves.

• Inspect each valve for wear, burn or distortion on its

face and stem end, replace if necessary.

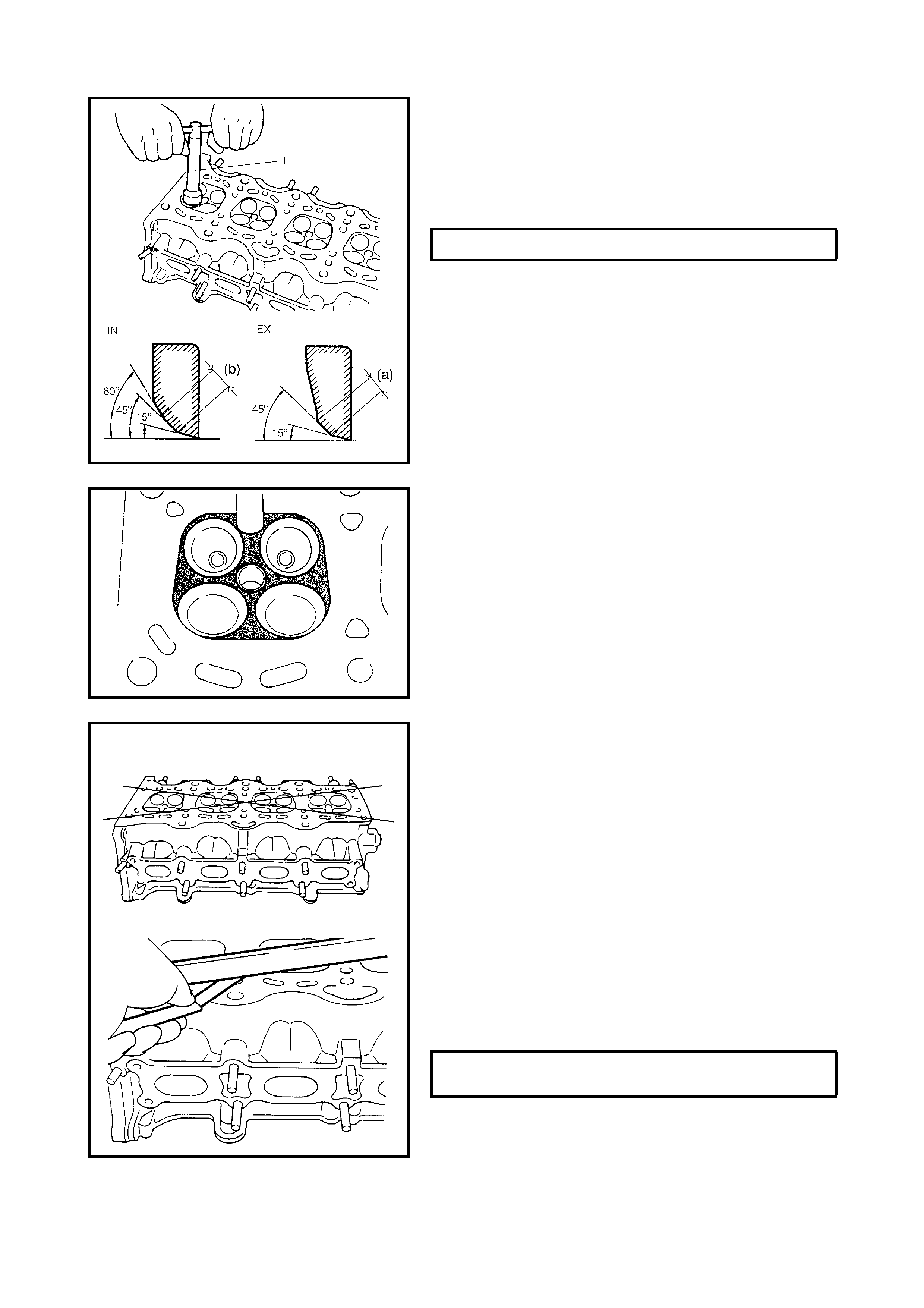

• Measure the thickness (a) of the valve head. If the

measured thickness exceeds the limit, replace valve.

INTAKE VALVE STEM-TO-GUIDE

CLEARANCE STANDARD

LIMIT 0.020 - 0.047 mm

0.07 mm

EXHAUST VALVE STEM-TO-GUIDE

CLEARANCE STANDARD

LIMIT 0.045 - 0.072 mm

0.09 mm

INTAKE VALVE STEM DIAMETER [A]

STANDARD 5.465 - 5.480 mm

EXHAUST VALVE STEM DIAMETER

[A] STANDARD 5.440 - 5.455 mm

INTAKE AND EXHAUST VALVE GUIDE

BORE [B] STANDARD 5.500 - 5.512 mm

INTAKE VALVE STEM END

DEFLECTION LIMIT 0.14 mm

EXHAUST VALVE STEM END

DEFLECTION LIMIT 0.18 mm

INTAKE & EXHAUST VALVE HEAD

THICKNESS STANDARD

LIMIT 1.22 - 1.55 mm

0.9 mm

• Inspect th e valve stem end face fo r pitting and wear. If

pitting or wear is evident, the valve stem end may be

resurfaced. If resurfacing the valve stem end removes

the chamfer, the valve must be replaced.

• Check each valve for radial runout with a dial gauge

and “V” block. To check runout, rotate valve slowly. If

runout exceeds its limit, replace valve.

• Seating contact width:

Create a contact pattern on each valve by applying a

uniform coat of marking compound to the valve seat

and tapping the seat with the valve head in a circular

motion. A valve lapper (tool used in valve lapping)

must be used.

The pattern produced on the seating face of the valve

must be a con tinuou s ring withou t any breaks , and the

width of the pattern must be within the specified range.

• Valve seat repair:

If the valve seat does not produce a uniform contact

pattern on the valve or the contact width of the seat is

out of the specified range it must be repaired.

Repair the valve seat by regrinding or by cutting and

regrinding then finish by lapping.

a. EXHAUST VALVE SEAT: Use valve seat cutters (1)

to make two cuts as illustrated in the figure. Two

cutters must be used: the first for making a 15°

angle, and the s econd for mak ing a 45° angle . The

second cut must be made to produce the desired

seat width.

LIMIT ON VALVE HEAD RADIAL

RUNOUT 0.08 mm

STANDARD SEATING WIDTH (a)

REVEALED BY CONTACT PATTERN

ON VALVE FACE - INTAKE & EXHAUST 1.1 - 1.3 mm

SEAT WIDTH FOR EXHAUST VALVE

SEAT (a) 1.1 - 1.3 mm

b. INTAKE VALVE SEAT: Use valve seat cutters to

make three cuts as illustrated in the figure. Three

cutters must be used: the 1st for making the 15°

angle, the 2nd for making the 60° angle, and 3rd for

making the 45° angle. The 3rd cut (45°) must be

made to produce the desired seat width.

c. VALVE LAPPING: Lap the valve seat in two steps,

first with a coars e lapping com pound a pplied to th e

face and second, with a fine compound, using a

valve lapper according to normal lapping proce-

dures.

Cylinder Head

• Remove all carbon deposits from the combustion

chambers.

NOTE: Do not use a sharp-edged tool to scrape off the car-

bon deposits. Take care not to scuff or nick the metal sur-

faces when decarbonizing. This also applies to the valves

and the valve seats.

• Check the cylinder head for cracks around the intake

and exhaust ports, combustion chambers and head

surface.

Using a straightedge and a thickness gauge, check the

flatness of the gas keted surf ace at two loc ation s. If the

distortion limit, given below, is exceeded, repair the

gasketed surface with a surface plate and abrasive

paper of about No.400 (Waterproof silicon carbide

abrasive paper ): place abras ive paper on and over the

surface pl ate an d ru b th e g as ke ted su rf ace a gai ns t th e

paper to grind off any high spots. Should this fail to

reduce the thickness gauge readings to be within the

limit, replace the cylinder head.

Combustion gas leaks from the head gasket joint is

often due to a warped ga sketed su rface: su ch leakag e

results in reduced power output.

SEAT WIDTH FOR INTAKE VALVE SEAT (b) 1.1 - 1.3 mm

LIMIT OF DISTORTION FOR CYLINDER

HEAD SURFACE ON PISTON SIDE 0.03 mm

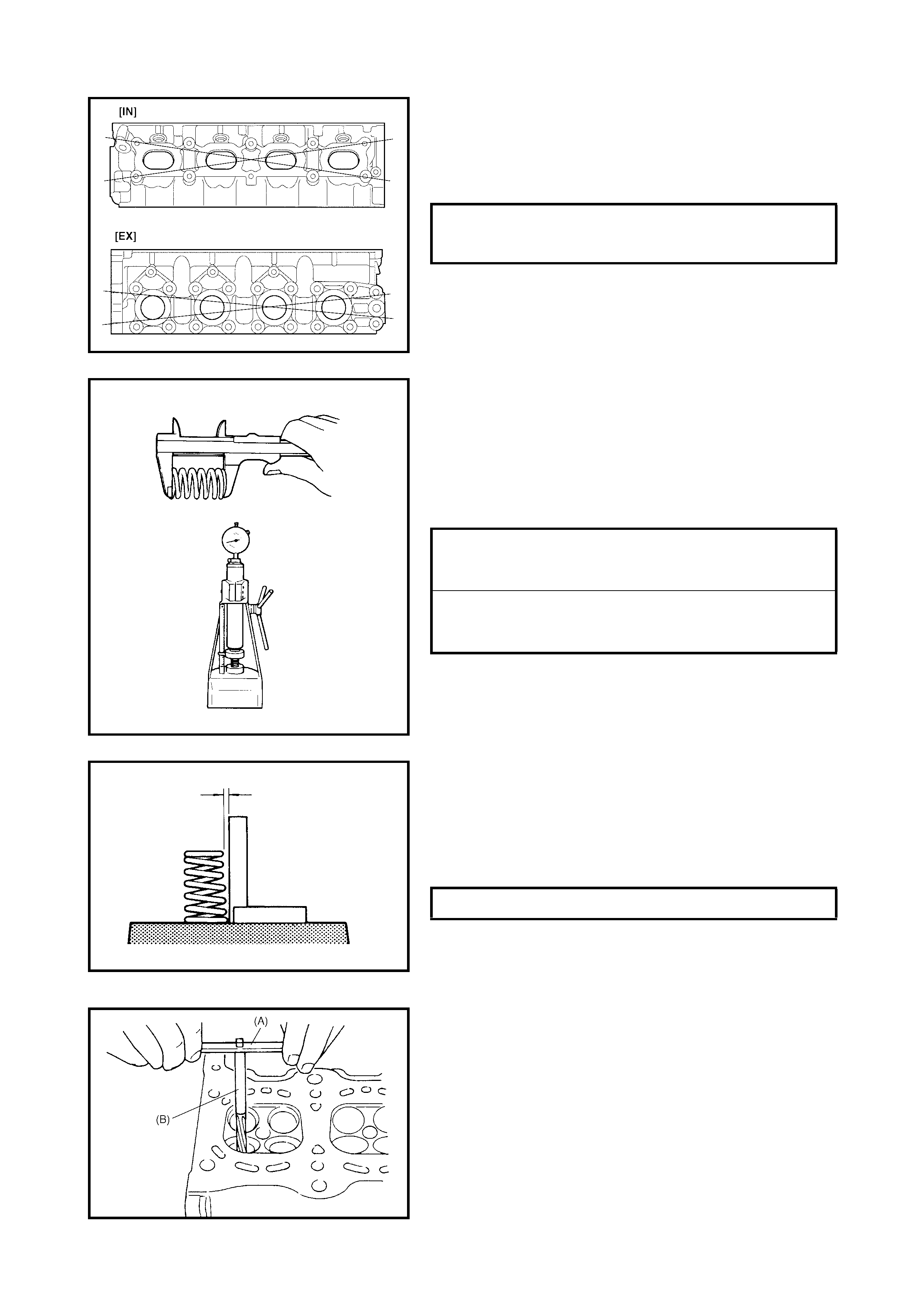

• Distortion of the manifold seating faces:

Check the manifold seating faces on the cylinder head,

using a straightedge and thickness gauge, to deter-

mine if these faces need to be corrected or the cylinder

head needs to be replaced.

Valve Springs

• Referring to the data given below, check that each

spring is in sound condition, free of any evidence of

breakage or weakening. Weakened valve springs can

cause chatter and a possibility of reduced power output

due to gas leakage caused by decreased seating pres-

sure.

• Spring squareness:

Use a squar e and a surfa ce plate to ch eck each va lve

spring for squareness, (i.e, the clearance between the

end of the v alve spring an d the square). Valve springs

that do not meet the specified limit given below must

be replaced.

ASSEMBLY

1. Before installing the valve guides into the cylinder

head, ream the guide hole with special tool (10.5 mm

reamer) 09916-34542 (A) and 09916-37320 (B) to

remove burrs and make it truly round.

LIMIT OF DISTORTION FOR CYLINDER

HEAD SURFACE ON INTAKE &

EXHAUST MANIFOLD 0.05 mm

VALVE SPRING FREE LENGTH

STANDARD

LIMIT 36.83

35.83

VALVE SPRING PRELOAD STANDARD

LIMIT 107 - 125 N

102 N

VALVE SPRING SQUARENESS LIMIT 1.6 mm

2. Install the valve guide to the cylinder head.

Heat the cylinder head uniformly to a temperature of 80

to 100 °C (176 to 212 °F) so that the head will not be

distorted, then drive the new valve guides into the

valve hole with special tools. Drive in the new valve

guide until special tool (Valve guide installer) 09916-

58210 (A) and 09916-56011 (B) contacts the cylinder

head.

After installation, make sure that the valve guide

protrudes by the specified dimension (a) from the

cylinder head.

NOTE:

• Always use new valve guides.

• Intake and exhaust valve guides are identical.

3. Ream the valve guide bore with special tool (5.5 mm

reamer) 09916-34542 (A) and 09916-34550 (B). After

reaming, clean bore.

4. Install the valve spring seat to the cylinder head.

5. Install a new valve stem seal (1) to the valve guide.

After applying engine oil to the seal and spindle of the

special tool (Valv e guide ins taller handle) , fit oil se al to

spindle, then install the seal to the valve guide by

pushing special tool 09917-98221 (A) and 09916-

58210 (B) by hand.

After installation, check that the seal is correctly fixed

to the valve guide.

NOTE:

• Do not reuse valve stem seals. Always install new

seals.

• When insta lling, nev er tap or hit the special too l with a

hammer. Only install the seal to the guide by pushing

the special tool by hand. Tapping o r hitting the special

tool may cause damage to the seal.

SPECIFICATION FOR INTAKE VALVE

GUIDE PROTRUSION (a) 11.1 - 11.5 mm

6. Install the valves to the valve guides.

Before installing the valve to the valve guide, apply

engine o il to th e st em seal, v al v e g uide bore an d valv e

stem.

7. Install the valve springs and spring retainers.

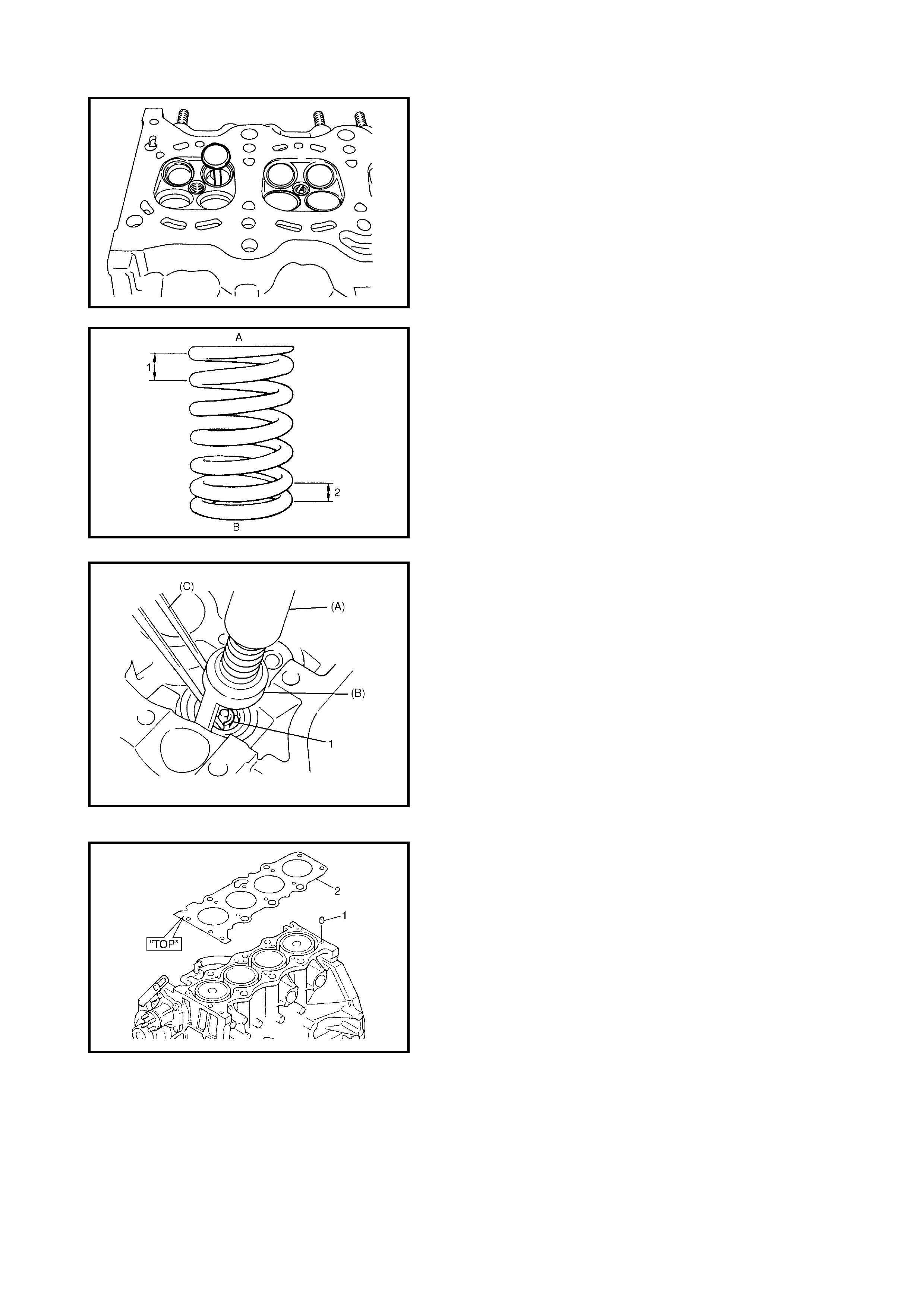

Each valve spring has a top end [large-pitch end (1)]

and a bottom end [small-pitch end (2)]. Be sure to

position the spring in place correctly with its bottom end

(small-pitch end) facing the bottom (valve spring seat

side) (B).

8. Using special tools (Valve lifter) 09916-14510 (A),

09916-14910 (B) and 09916-84511 (C), compress the

valve spring and fit the two valve cotters (1) into the

groove in the valve stem.

NOTE:

When compressing the valve spring, take care

not to damage the inside face of the tappet installation

hole.

9. Install the intake manifold, injectors and exhaust

manifold to the cylinder head.

INSTALLATION

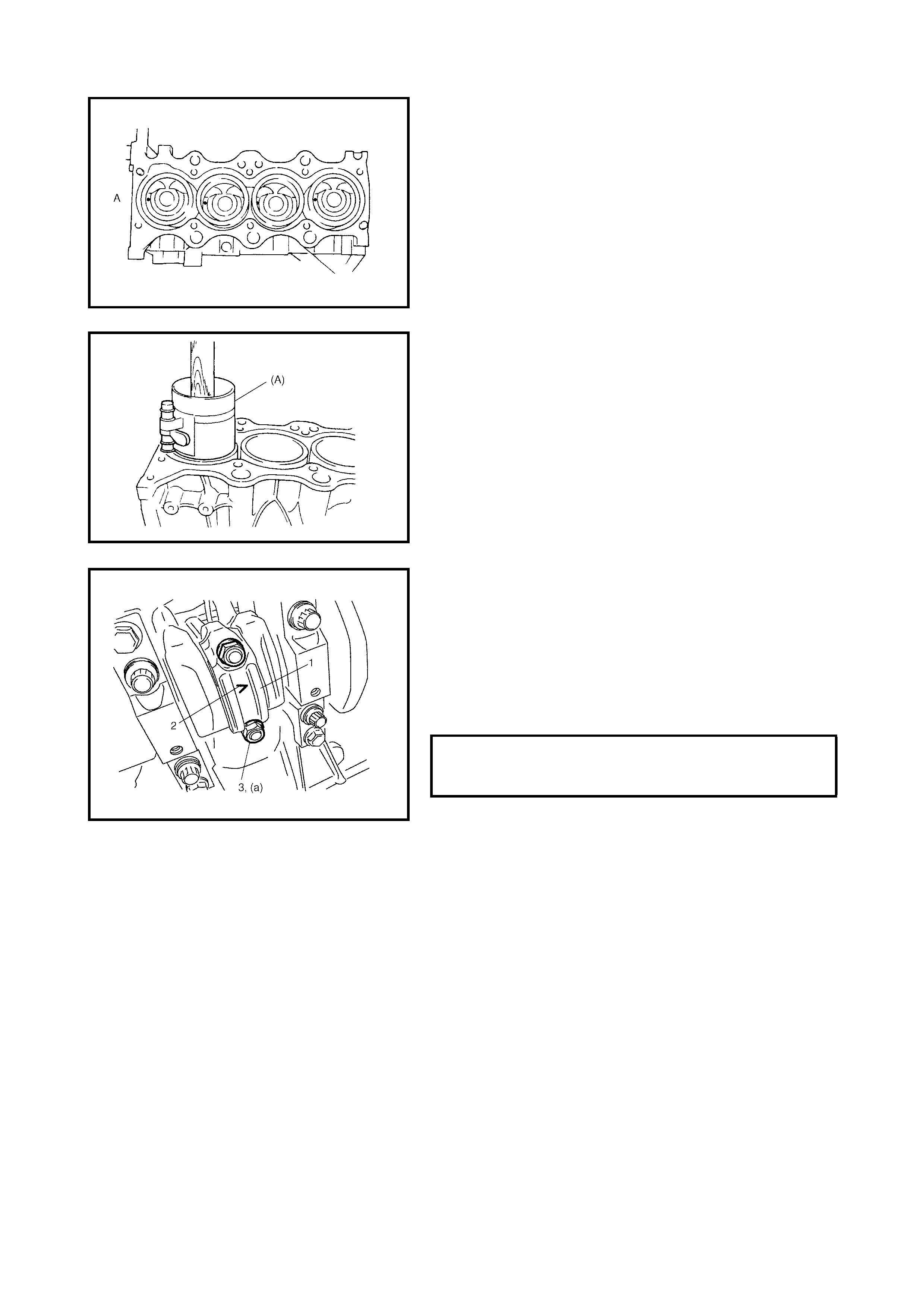

1. Clean the mating surface of the cylinder head and

cylinder block.

Remove oil, old gasket and dust from the mating

surface.

2. Install the knock pins (1) to the cylinder block.

3. Install a new cylinder head gasket (2) to the cylinder

block.

The TOP mark stamped on the gasket must be at the

crankshaft pulley end and facing up (toward the

cylinder head).

4. Make sure that the oil jet (venturi plug) (1) is installed

and that it is not clogged.

When installing the oil jet, be sure to tighten to

specified torque.

5. Install the cylinder head onto the cylinder block.

NOTE: If possible u se new cylinder head bolts. If they are

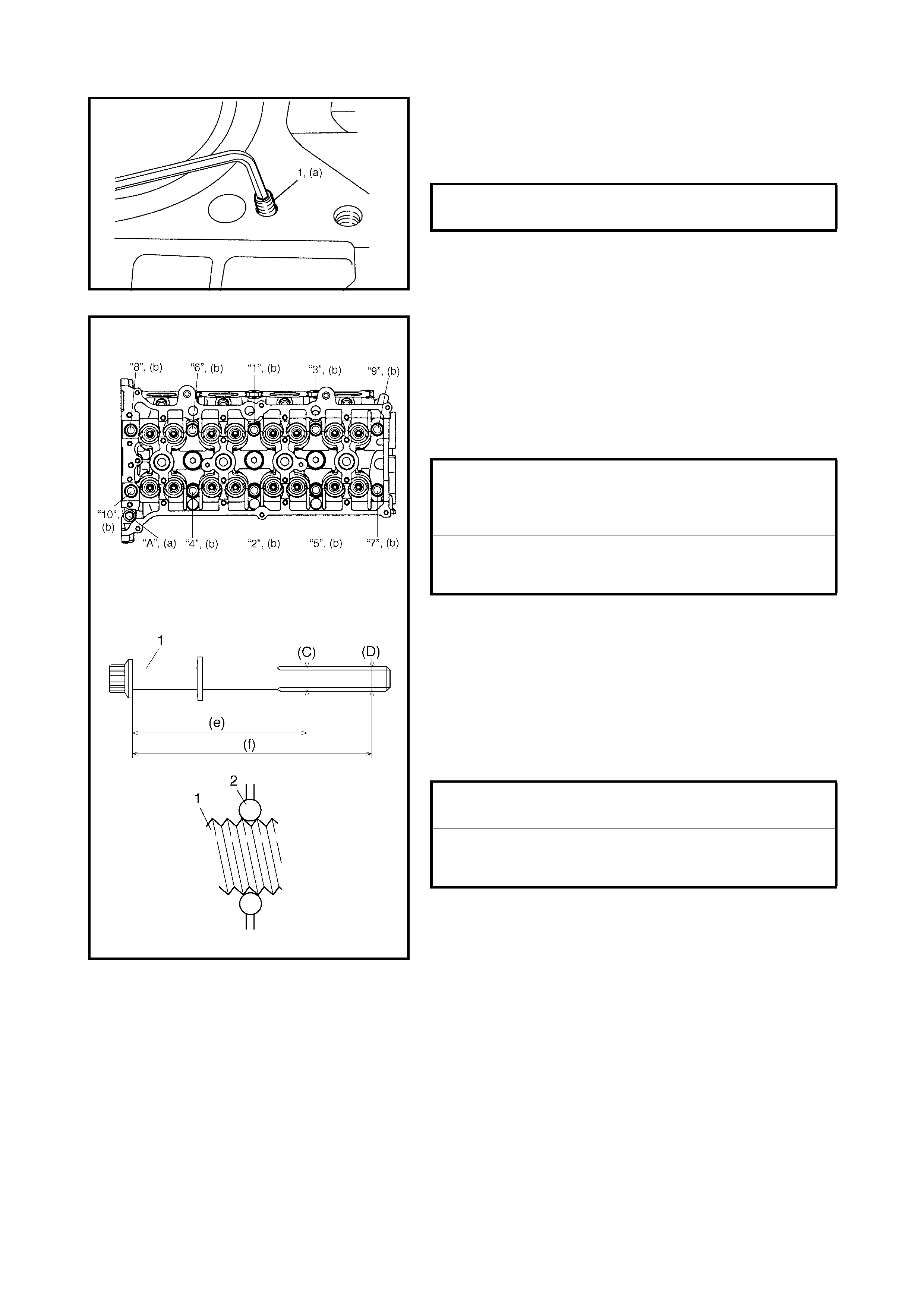

to be reused, check each bolt for thread deformation.

Measure the thread diameter of the cylinder head bolt (1) at

(C) and (D ) poin ts indicated i n the figure using a m icrome-

ter (2), an d calc ulate t he difference i n diame ters, (C) – ( D).

If it exceeds the limit, replace with new ones.

Apply engine oil to the cylinder head bolts and tighten them

gradually as follows.

a. Tighten the cylinder head bolts (“1” – “10”) to 20 Nm

following the numerical or der as shown, us ing a 12

corner socket wrench.

b. Repeat Step a, but tighten bolts to 40 Nm.

c. Turn all bolts 60° following the previous sequence.

d. Repeat Step c.

e. Tighten bolt “A” to specified torque.

6. Install the exhaust manifold stiffener, refer to 3.6

EXHAUST MANIFOLD INST ALLATION in this Section.

7. Install the camshafts, refer to 4.5 CAMSHAFT,

TAPPET AND SH IM INSTALL AT IO N in this Section.

8. Install the timing chain, refer to 4.4 TIMING CHAIN

AND CHAIN TENSIONER INSTALLATION in this

Section.

9. Install the timing chain cover, refer to 4.2 TIMING

CHAIN COVER in this Section.

10. Install the cylinder head cover, refer to 3.4 CYLINDER

HEAD COVER INSTALLATION in this Section.

11. Install the oil pan, refer to 3.7 OIL PAN AND OIL PUMP

STRAINER INSTALLATION in this Section.

12. Install the intake manifold stiffener and connect all

hoses, refer to 3.5 THROTTLE BODY AND INTAKE

MANIFOLD INSTALLATION in this Section.

13. Refer to 4.2, TIMING CHAIN COVER INSTALLATION

in this Section and perform Steps 3 to 7.

VENTURI PLUG (a)

TORQUE SPECIFICATION 5 Nm

CYLINDER HEAD BOLT DIAMETER

MEASUREMENTS POINTS (e)

(f) 83.5 mm

115 mm

CYLINDER HEAD BOLT DIAMETER

DIFFERENCE (DEFORMATION) LIMIT

(C) – (D) 0.1 mm

CYLINDER HEAD BOLT - M8 (a)

TORQUE SPECIFICATION 22 Nm

CYLINDER HEAD BOLTS - M10 (b)

TORQUE SPECIFICATION

20 Nm THEN

40 Nm THEN

TURN 60° TWICE

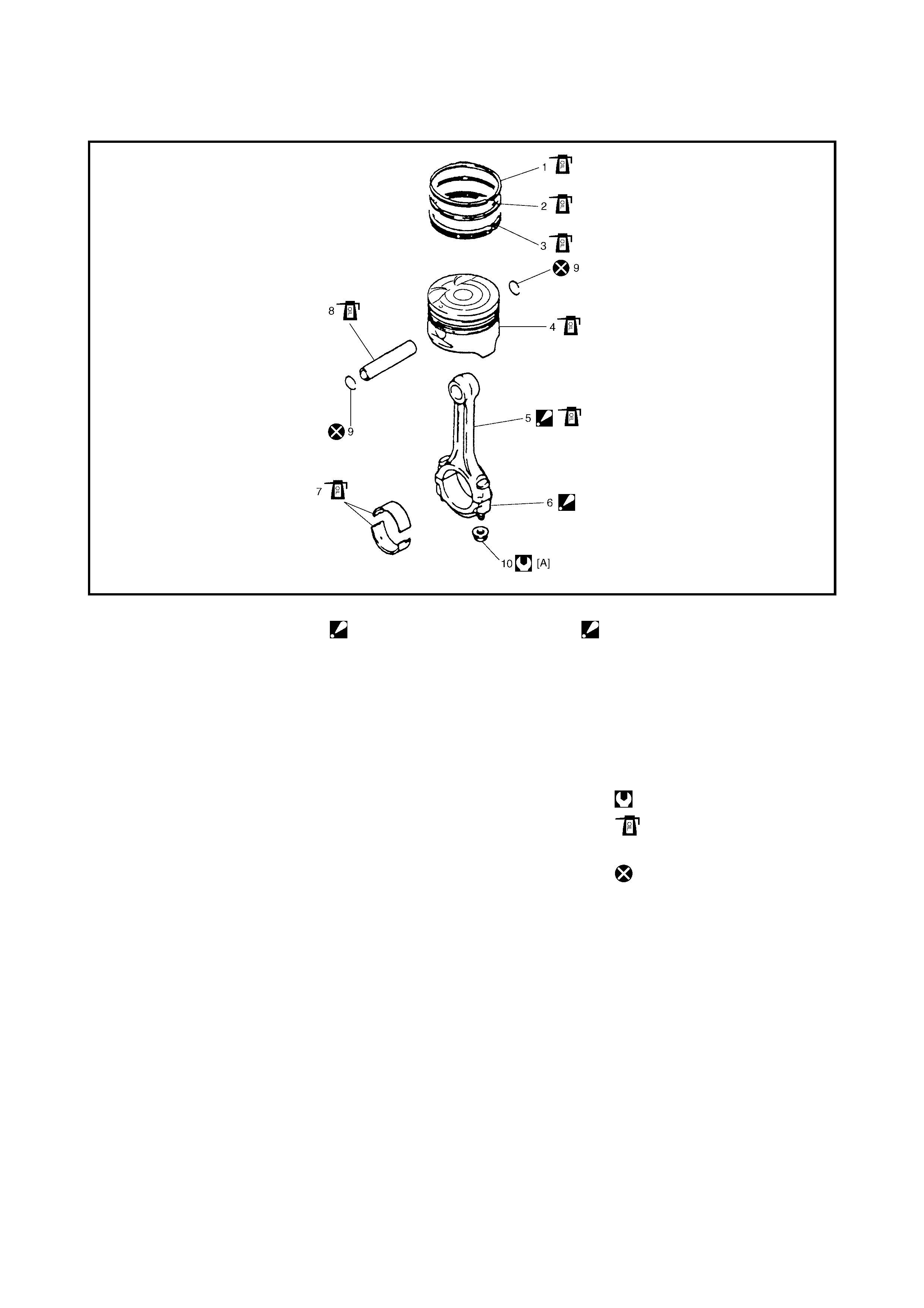

4.7 PISTONS, PISTON RINGS, CONNECTING RODS AND CYLINDERS

Legend

REMOVAL

1. Remove engine assembly from vehicle, refer to

4.1 ENGINE ASSEMBLY, REMOVAL in this Section

2. Remove cylinder head, refer to 4.6 VALVES AND

CYLINDER HEAD REMOVAL in this Section.

3. Mark cylinder number on all pistons, connecting rods

and connecting rod caps using silver pencil or quick

drying paint.

4. Remove connecting rod bearing caps.

[A] : 1) Tighten all nuts to

15 Nm

2) Turn all nuts to 45°

3) Then, turn all nuts 45°

5. Connecting rod

: Apply engine oil to sliding

surface ex cep t inne r

surface of big end, and

rod bolts. Make sure rod

bolt diameter when reuse

it due to plastic

deformation tightening.

Refer to 4.7 PISTONS,

PISTON RINGS,

CONNECTION RODS

AND CYLINDERS.

6. Connecting rod bearing

cap : Point arrow mark on

cap to crankshaft pulley

side.

once again 7. Connecting rod bearing

1. Top ri ng 8. Pisto n pin

2. 2nd ring 9. Piston pin circlip

3. Oil ring 10. Bearing cap nut

4. Pis ton Tightening torque

Apply engine oil to sliding

surface of each parts.

Do not reuse.

5. Install guide hose (1) over the threads of the rod bolts.

This prevents damage to the bearing journal and rod

bolt threads when removing the connecting rod.

6. Decarbonise the top of the cylinder bore before

removing the piston from the cylinder.

7. Push the piston and the connecting rod assembly out

through the top of the cylinder bore.

DISASSEMBLY

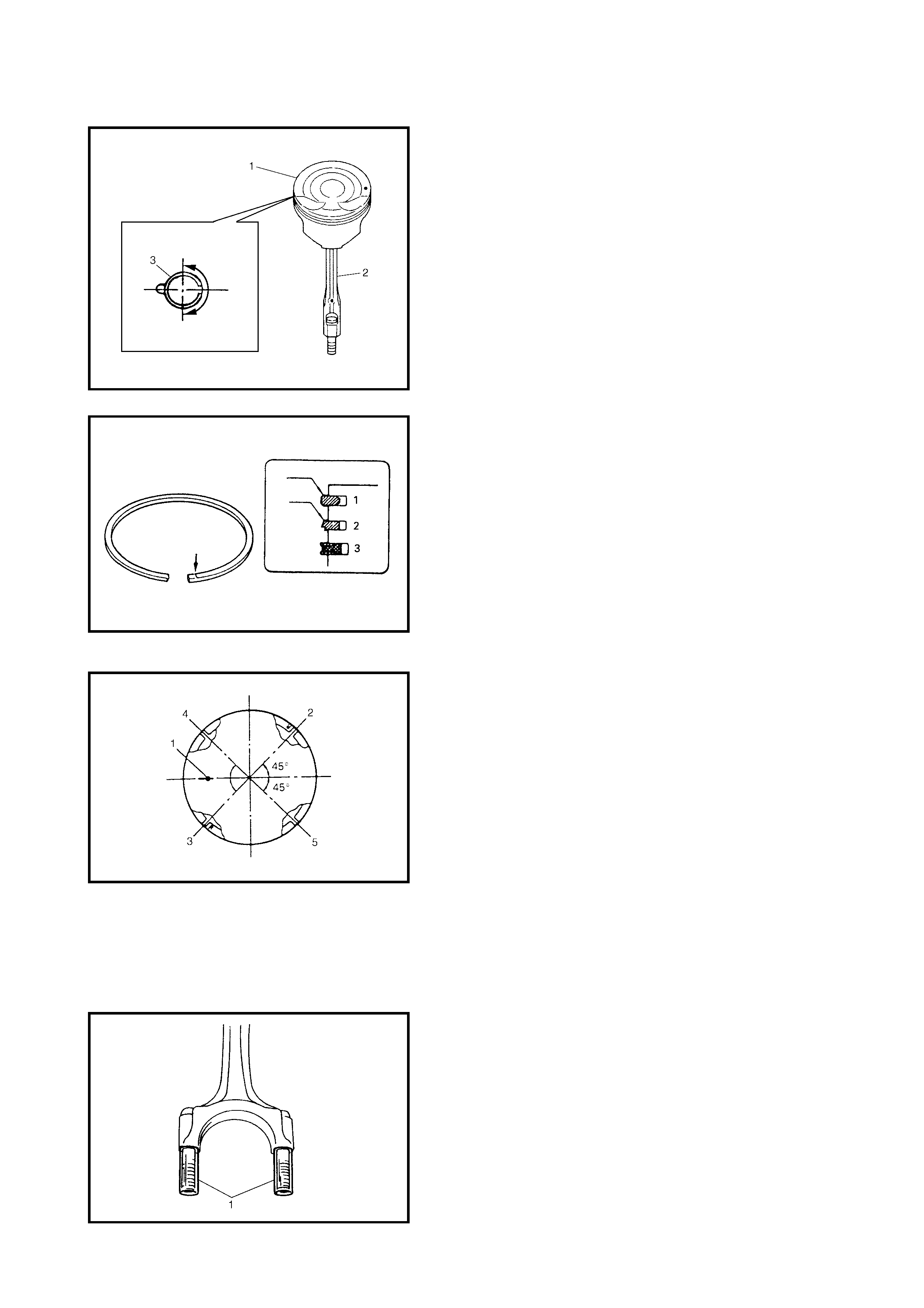

8. Using a piston ring expander, remove the two com-

pression rings (top and 2nd) and the oil ring from the

piston.

9. Remove the piston pin from the connecting rod.

• Ease out piston pin circlips (1), as shown.

• Force piston pin out.

CLEANING

Decarbonise the piston head and ring grooves, using a

suitable tool.

INSPECTION

Cylinder

• Inspect cylinder walls for scratches, roughness or

ridges which indicate excessive wear. If the cylinder

bore is very rough or deeply scratched or ridged,

rebore the cylinder and use an oversize piston.

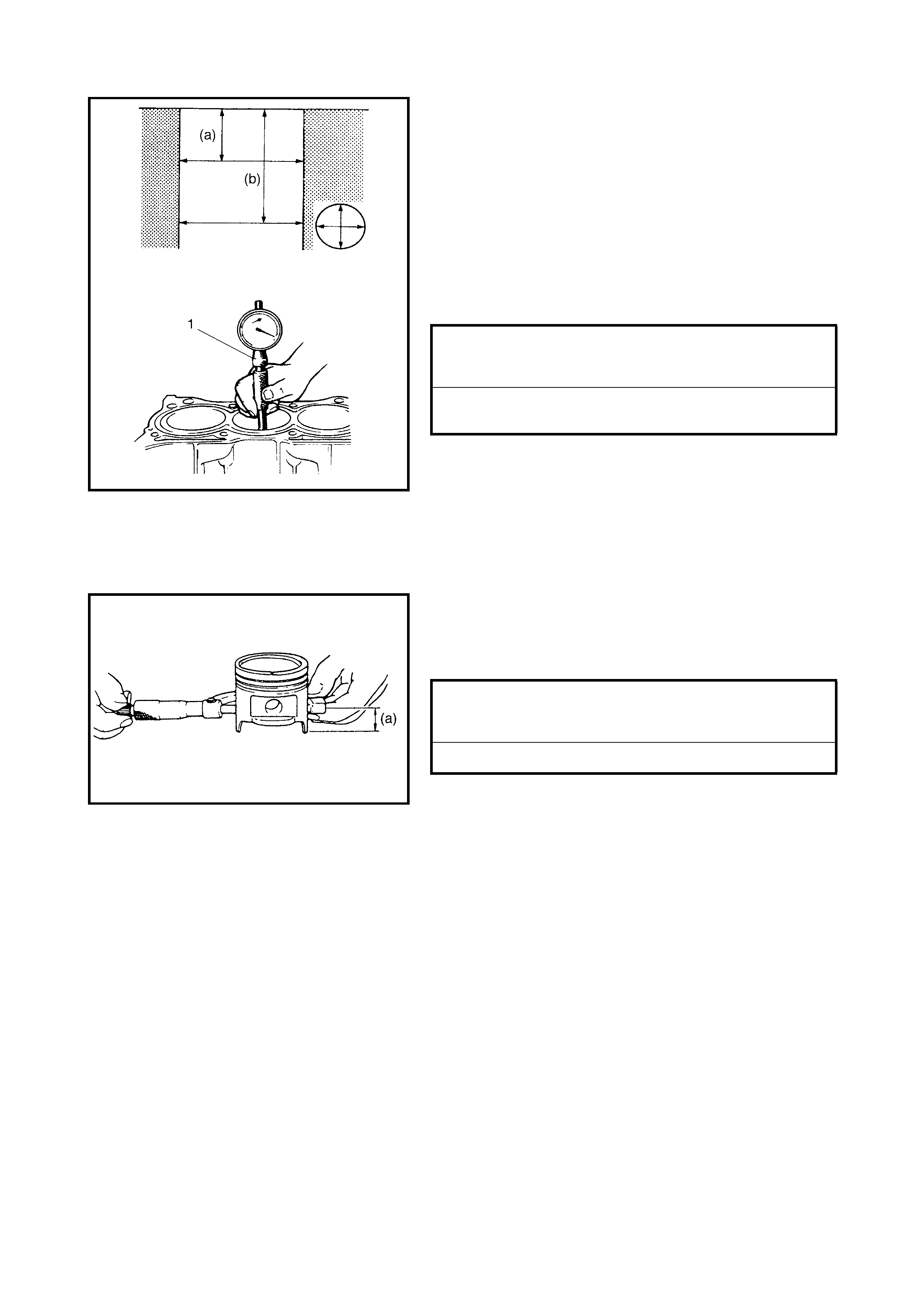

• Using a cylinder gauge (1), measure the cylinder bore

in the thrust and axial directions at two positions, (a) -

50 mm and (b) - 100 mm from the top of the cylinder

wall, as shown in the figure.

If any of the following conditions are noted, rebore the

cylinder.

1. The cylinder bore diameter exceeds the limit.

2. The difference in measurements at the two positions

exceeds the taper limit.

3. The difference between the thrust and axial measure-

ments exceeds the out-of-round limit.

NOTE: If any one of the four cylinders has to be rebored,

rebore all four to the same next oversize. This is necessary

to maintain uniformity and balance

.

Pistons

• Inspect pistons for faults, cracks or other damage.

Damaged or faulty pistons should be replaced.

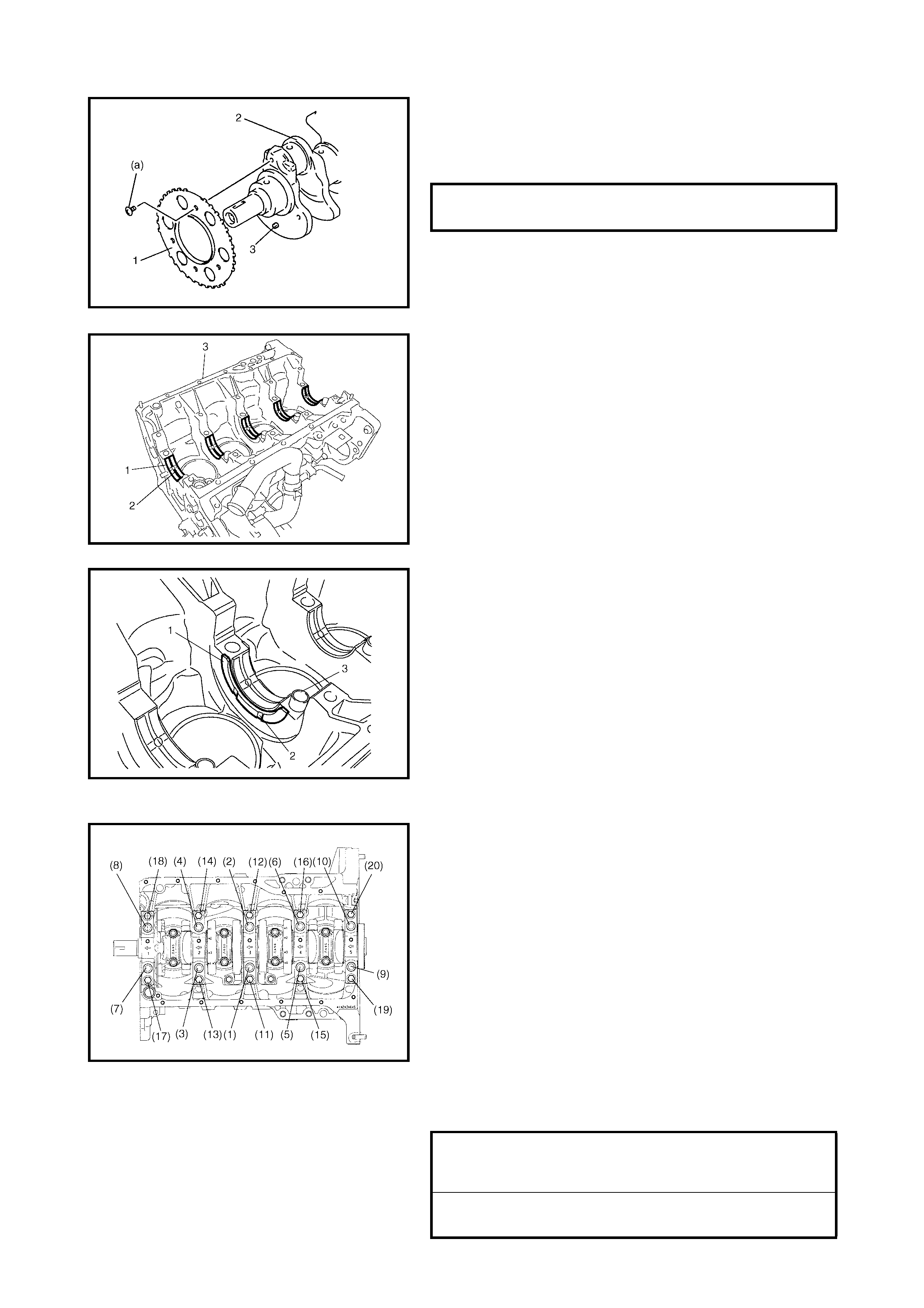

• Piston diameter:

As indicated in the figure (a), the piston diameter

should be measured 19.5 mm from the piston skirt, in

the opposite direction to the piston pin.

CYLINDER BORE DIAMETER

STANDARD

LIMIT 78.00 - 78.014 mm

78.114 mm

CYLINDER TAPER & OUT-OF-ROUND

LIMIT 0.10 mm

PISTON DIAMETER SPECIFICATION

STANDARD SIZE

SIZE WITH COATING 77.9 53 - 77.968 mm

77.969 - 77.98 4 mm

0.5 mm OVERSIZE 78.453 - 78.468 mm

• Piston clearance:

Measure the piston diameter (1) at position (a), 19.5

mm from the piston skirt and the cylinder bore diameter

(2). Piston clearance is the difference in the two mea-

surements. Piston clearance should be within specifi-

cation as given below. If it is out of specification, rebore

the cylinde r and fit oversi ze pisto ns .

NOTE: Cylinder bore diameters used here are measured in

thrust direction at two positions.

• Ring groove clearance:

Before checking, the piston grooves must be clean, dry

and free from carbon deposits.

Fit the new piston ring (1) into the piston groove, and

measure the clearance between the ring and the ring

land using a thickness gauge (2). If the clearance is

outside the limit, replace the piston.

Piston Pin

• Check the piston pin, connecting rod small end bore

and piston bore for wear or damage, paying particular

attention to the c ond ition of the sm all end bo r e b ush. If

the pin, connecting rod small end bore or piston bore is

badly worn or damaged, replace the pin, connecting

rod and/or piston.

PISTON CLEARANCE

PISTON CLEARANCE WITH COATING 0.032 - 0.061 mm

0.016 -0.045 mm

TOP RING GROOVE CLEARANCE

STANDARD

LIMIT 0.03 - 0.07 mm

0.12 mm

2ND RING GROOVE CLEARANCE

STANDARD

LIMIT 0.02 - 0.06 mm

0.10 mm

OIL RING GROOVE CLEARANCE

STANDARD 0.03 - 0.17 mm

• Piston pin clearance:

Check the piston pin clearance in the small end and

piston. Repl ace the connecti ng rod and/or pist on if the

small end is badly worn or damaged or the measured

clearance exceeds the limit.

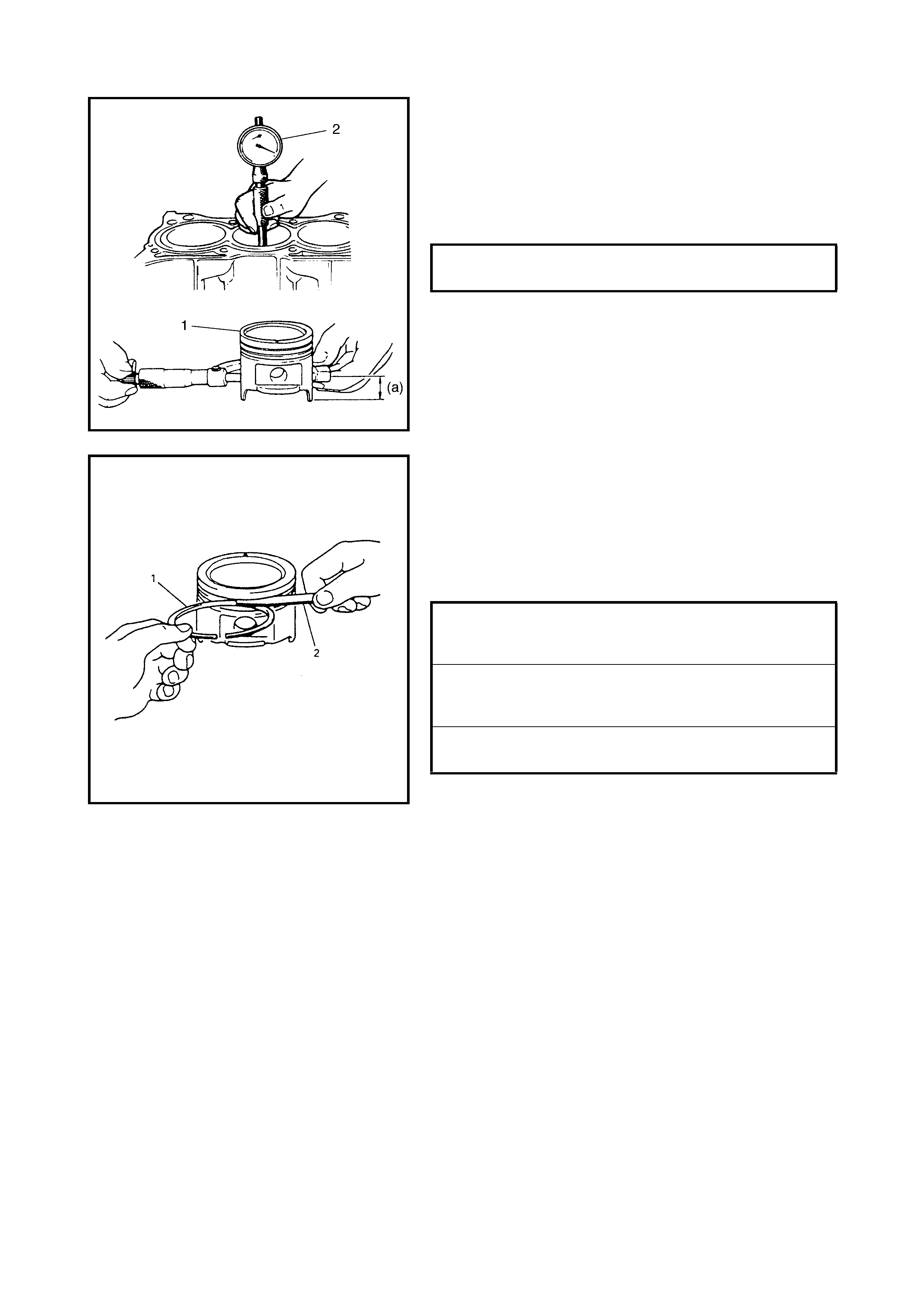

Piston Rings

To measure the end gap, insert the piston ring (1) into the

cylinder bore and measure the gap using a thickness

gauge (2).

If the measured gap is out of specification, replace ring.

NOTE: Decarbonise and clean top of cylinder bore before

inserting piston ring.

Connecting Rod

• Big-end side c learance:

Check the big-end of the connecting rod for side

clearance, with the connecting rod fitted and con-

nected to the crank pin in the normal manner. If the

measured clearance is found to exceed the limit,

replace the connecting ro d.

PISTON PIN CLEARANCE IN

CONNECTING ROD SMALL. END 0.003 - 0.014 mm

PISTON PIN CLEARANCE IN

PISTO N 0.006 - 0.017 mm

SMALL END BORE 20.003 - 20.011 mm

PISTON PIN DIAMETER 19.997 - 20.000 mm

PISTON BORE 20.006 - 20.014 mm

TOP PISTON RING END GAP

STANDARD

LIMIT 0.20 - 0.35 mm

0.7 mm

2ND PISTON RING END GAP

STANDARD

LIMIT 0.30 - 0.45 mm

1.0 mm

OIL PISTON RING END GAP

STANDARD

LIMIT 0.20 - 0.70

1.5 mm

BIG-END SIDE CLEARANCE

STANDARD

LIMIT 0.25 - 0.40 mm

0.55 mm

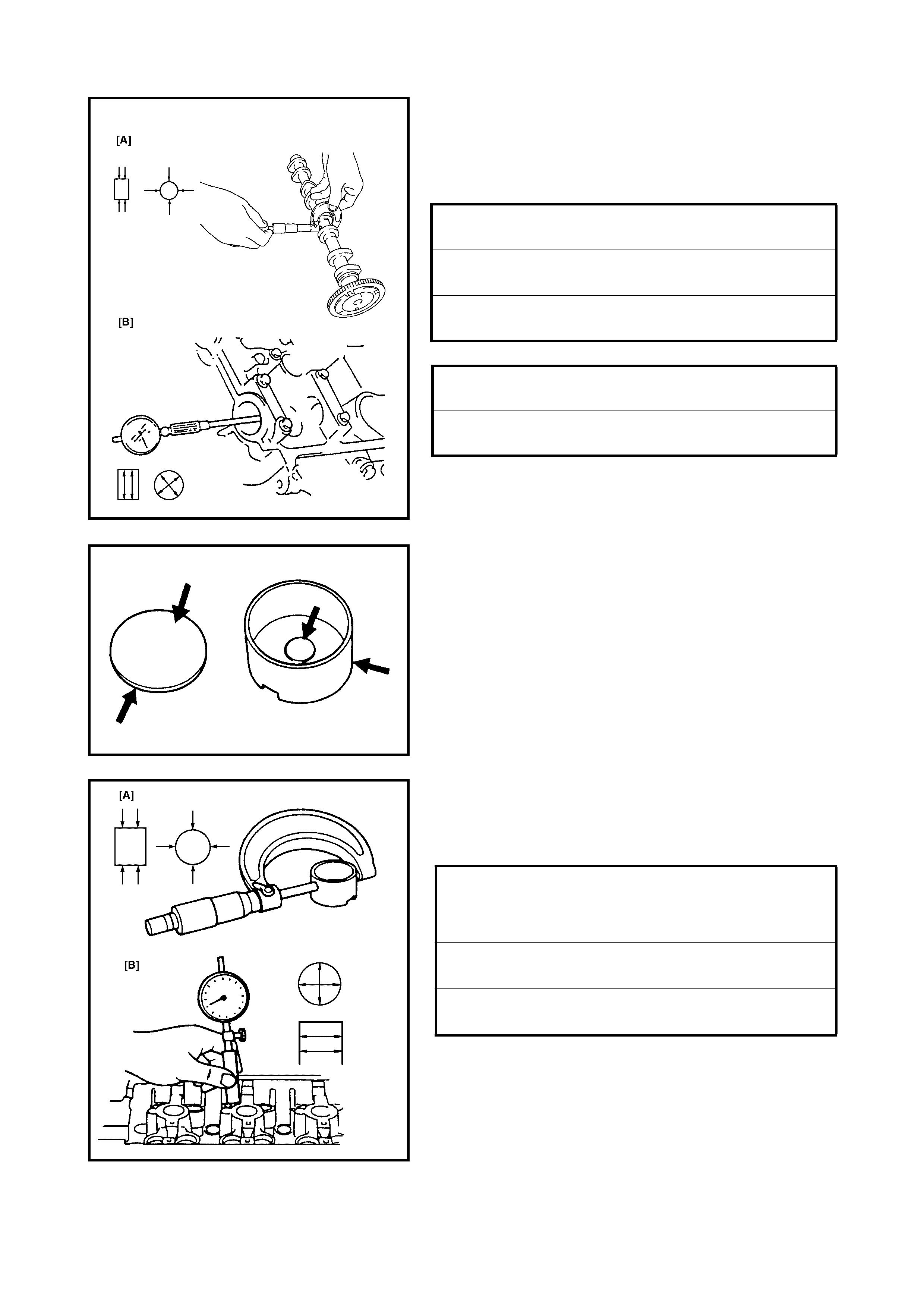

• Connecting rod alignment:

Mount the connecting rod on an aligner to check for

bow and twist. If the limit is exceeded, replace the con-

necting rod.

• Connecting rod (1) bolt deformation (Plastic deforma-

tion tightening bolt).

Measure the connecting rod bolt (2) thread diameter

with a micr om eter ( 3) at poi nts (A) and (B) as sh own in

the figure.

Calculate the difference in diameters (A) - (B). If it

exceeds the limit, replace the connecting rod.

Crank Pin and Connecting Rod Bearings

• Inspect the crank pin for uneven wear or damage.

Measure th e crank pin for out-of-round or taper with a

micrometer. If the crank pin is damaged, out-of round

or taper is outside the limit, replace the crankshaft or

regrind the crank pin to undersize and use an under-

size bearing.

CONNECTING ROD ALIGNMENT

LIMIT ON BOW

LIMIT ON TWIST 0.05 mm

0.10 mm

CONNECTING ROD BOLT

MEASUREMENT POINTS (a)

(b) 32 mm

40 mm

CONNECTING ROD BOLT DIAMETER

DIFFERENCE LIMIT (A) – (B) 0.1 mm

CRANK PIN DIAMETER

STANDARD CONNECTING ROD

BEARING SIZE

UNDERSIZE CONNECTING ROD

BEARING - 0.25 mm

41.982 - 42.00 0 mm

41.732 - 41.75 0 mm

CRANK PIN OUT-OF-ROUND

LIMIT (A – B) 0.01 mm

CRANK PIN TAPER LIMIT (a – b) 0.01 mm

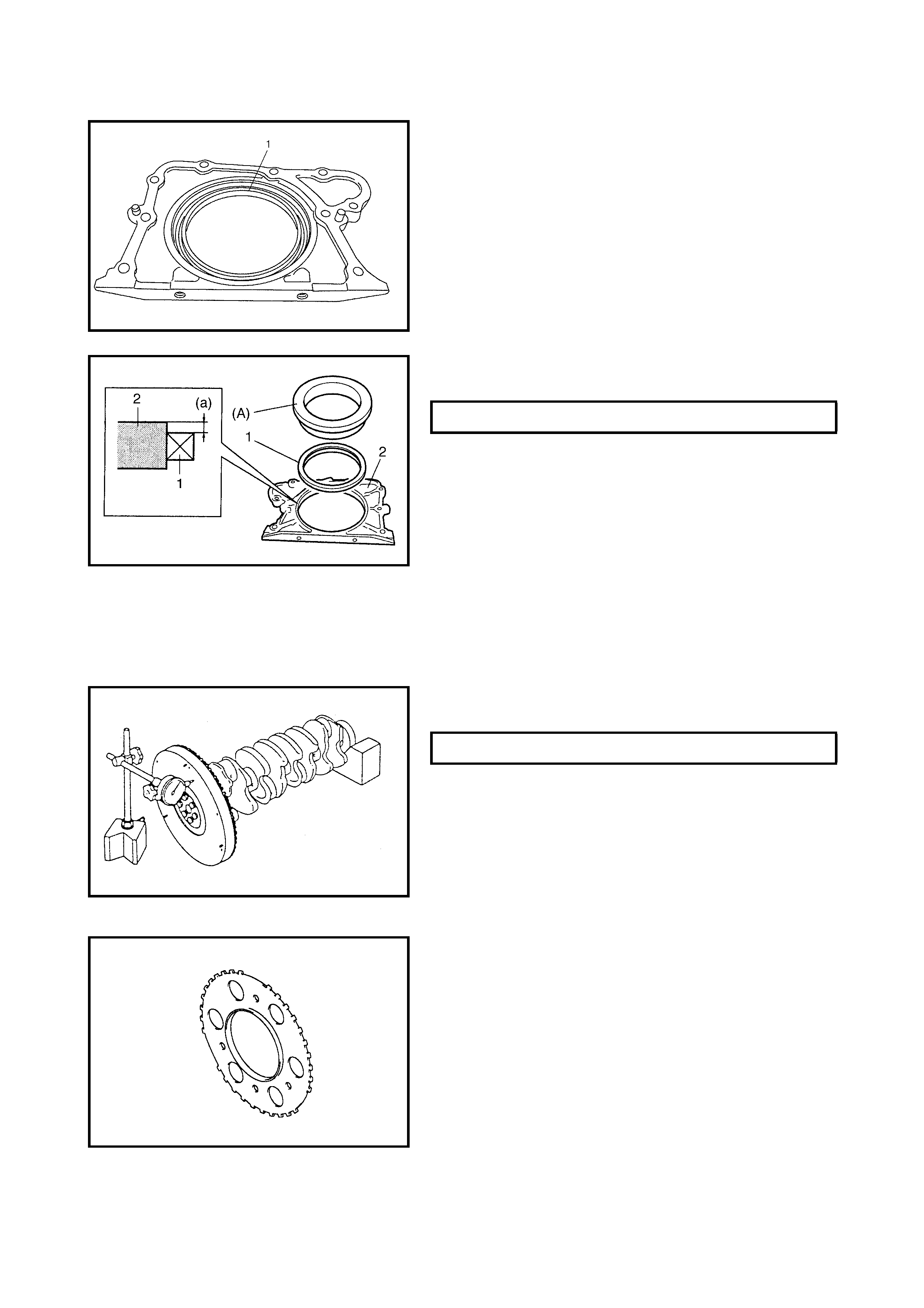

• Rod bearing:

Inspect the bearing shells for signs of fusion, pitting,

burn or flaking and observe contact pattern. Bearing

shells found to be defective must be replaced.

Two kinds of rod bearings are available; standard size

bearings and 0.25 mm undersize bearings. Undersize

bearings can be identified by red paint (1) at the posi-

tion indicated in the figure, undersize bearing thickness

is 1.605 – 1.615 mm at the centre point.

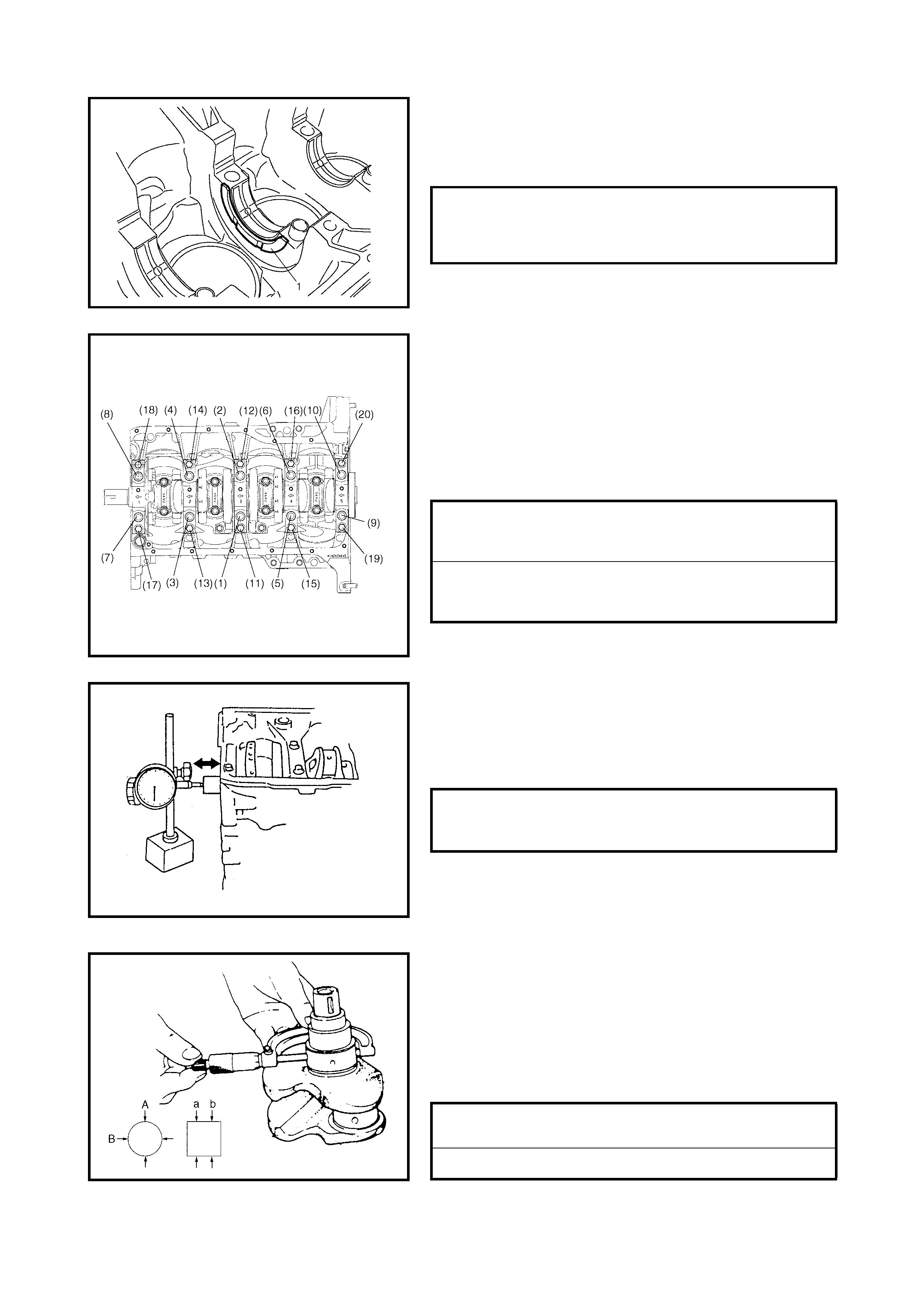

• Rod bearing clearance:

1. Before checking bearing clearance, clean bearing and

crank pin.

2. Install bearing in connecting rod and bearing cap.

3. Place a piec e of gau gi ng pl astic (1) the ful l width of the

crank pin where contacted by the bearing (parallel to

the crankshaft), avoiding the oil hole.

4. Install the rod bearing cap (1) to the connecting rod.

When installing cap, be sure to point arrow mark (2) on

cap towards the crankshaft pulley side, as shown in

the figure. After applying engine oil to the connecting

rod bolts, tighten cap nuts (3) gradually as follows.

a. Tighten all cap nuts to 15 Nm

b. Retighten them 45°.

c. Repeat Step b.

4. Remove the cap and using the scale (1) on the

gauging plastic (2) envelope, measure the gauging

plastic width at the widest point (clearance).

If the clear ance exce eds the limit, use a n ew standard

size bearing and remeasure clearance.

5. If the clearance cannot be brought within the limit, even

using a new standard size bearing, regrind the

crankpin to undersize and use a 0.25 mm undersize

bearing.

NOTE: After checking the rod bearing clearance, be sure to

check for Connecting rod bolt deformation.

Refer to 4.6 PISTONS, PISTON RINGS, CONNECTING

RODS AND CYLINDERS, INSPECTION in this Section.

CONNECTING ROD BEARING CAP

NUTS (a)

TORQUE SPECIFICATION 15 Nm THEN

TURN 45° TWICE

CONNECTING ROD BEARING

CLEARANCE STANDARD

LIMIT 0.029 - 0.047 mm

0.065 mm

ASSEMBLY

1. Install the pi ston pin to the piston (1) and the connect-

ing rod (2):

a. App ly en gin e oi l to th e pis ton p in and the pis to n pi n

holes in the piston and connecting rod.

b. Fit the connecting rod as shown in figure.

c. Insert the piston pin to the piston and connecting

rod.

d. Install the piston pin circlips (3).

NOTE: The c ircli p sh ould b e inst a lle d wit h it s cut pa rt fa cing

as shown in the figure. Install it so that the circlip end gap

comes within the range indicated by the arrow.

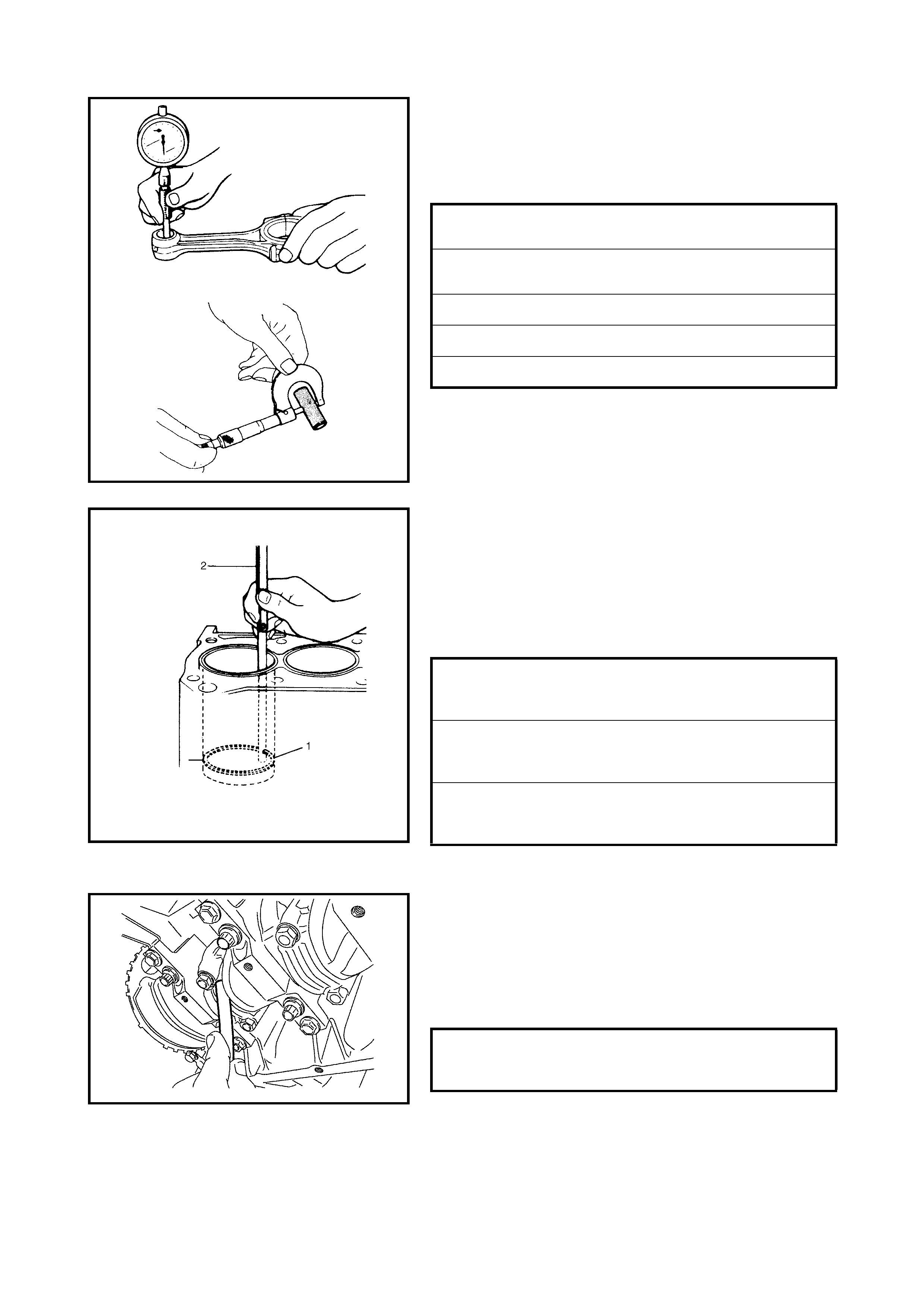

5. Install the piston rings to the piston:

a. As indicated in the figure, the 1st and 2nd rings

both have a “T” mar k. When ins talling these piston

rings onto the piston, ensure the marked side of

each ring faces the top of the piston.

b. The 1st ring (1) differs from the 2nd ring (2) in thick-

ness, shape and the colour of the surface contact-

in g the cylinder wall.

Refer to the figure to distinguish the 1st ring from

the 2nd ring.

c. When installing the oil ring (3), install the spacer

first then the two rails.

4. After installing the three rings (1st, 2nd and oil rings),

distribute their end gaps as shown in the figure.

1 – Front mark

2 – 1st ring end gap

3 – 2nd ring end gap and oil ring spacer gap

4 – Oil ring upper rail gap

5 – Oil ring lower rail gap

INSTALLATION

1. Apply engine oil to pistons, rings, cylinder walls, con-

necting rod bearings and crankpins.

NOTE: Do not apply oil between the connecting rod and

the bearing or between the cap and the bearing.

2. Install guide hoses (1) over the connecting rod bolts.

These guide hoses protect the crank pin and threads of

the conne cting r od bolt from damage d uring th e instal-

lation of the connecting rod and piston assembly.

3. When installing the piston and the connecting rod

assembly into the cylinder bore, point the front mark on

the piston head towards the crankshaft pulley side (A).

4. Install the pi ston a nd con necting r od ass embly into th e

cylinder bore. Use special tool (Piston ring compres-

sor) 09916-77310 (A) to compress rings. Guide the

connecting rod into place on the crankshaft.

Using a hammer handle, tap the piston head to install

the piston into the bore. Hold the ring compressor

firmly against the cylinder block until all piston rings