2

20

00

00

0

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

SERVICE TE CHNICIAN REFERENCE INFORMATION

ALL

(GROUP 0B) February 2000

This Techline is published to provide Dealership Service personnel with a list of commonly

requir ed Holden cont act Fax number s and som e helpful additional information.

HOLDEN SERVICE RELATED FAX No’s

HOLDEN TAS 03 9647 2495

HOLDEN SECURITY INFO. 03 9647 2865

IGM TAS/CAS 03 9644 6622

PIR’s (EDAG FUTURE) 03 9552 8104

REPAC 03 9647 1198

TECHNICI AN’s GUILD 03 9876 5797

CENTRAL SERVICE 03 9647 2525

HOLDEN CAS 03 9647 1237

WARRANT Y ADMIN. 03 9647 2525

Other Information:

PIR forms: request a pad ( 100 forms) by q uot ing “SD 28331” on a Merchandising Material

Order For m and fax to Salmat, on ( 03) 9251 6352.

Security Number Request Form: photocopy form attached to All Dealer Letter DL 63/99.

Tech 1 Repairs: Ref er HSPO Parts Techline Bullet in PT31, dated May 5, 1999.

Update

REAR WINDSCREEN MOULDING DISTORTION "HINT"

VT

(GROUP 1) REISSUE/DELETION February 2000

A Service Techline with t he same title as above was issued in Issue 10, Decem ber , 1999 page 6. That

previous Techline should be destroyed.

The previously issued Techline item recommended removal and refit of distorted mouldings without

glass removal.

The earlier information was released to assist technicians in rectifying vehicles quickly in the pre-

Christmas period, where distortion may have occurred to the mouldings on some vehicles at pre-

delivery and very low kilometres. The procedure quoted was viable only for mouldings not correctly

fitted – and an in-plant rework was carried out using the same information.

It is no longer necessary to use this recommendation. Further replacement of mouldings must be

done as per the released Ser vice information (glass must be removed).

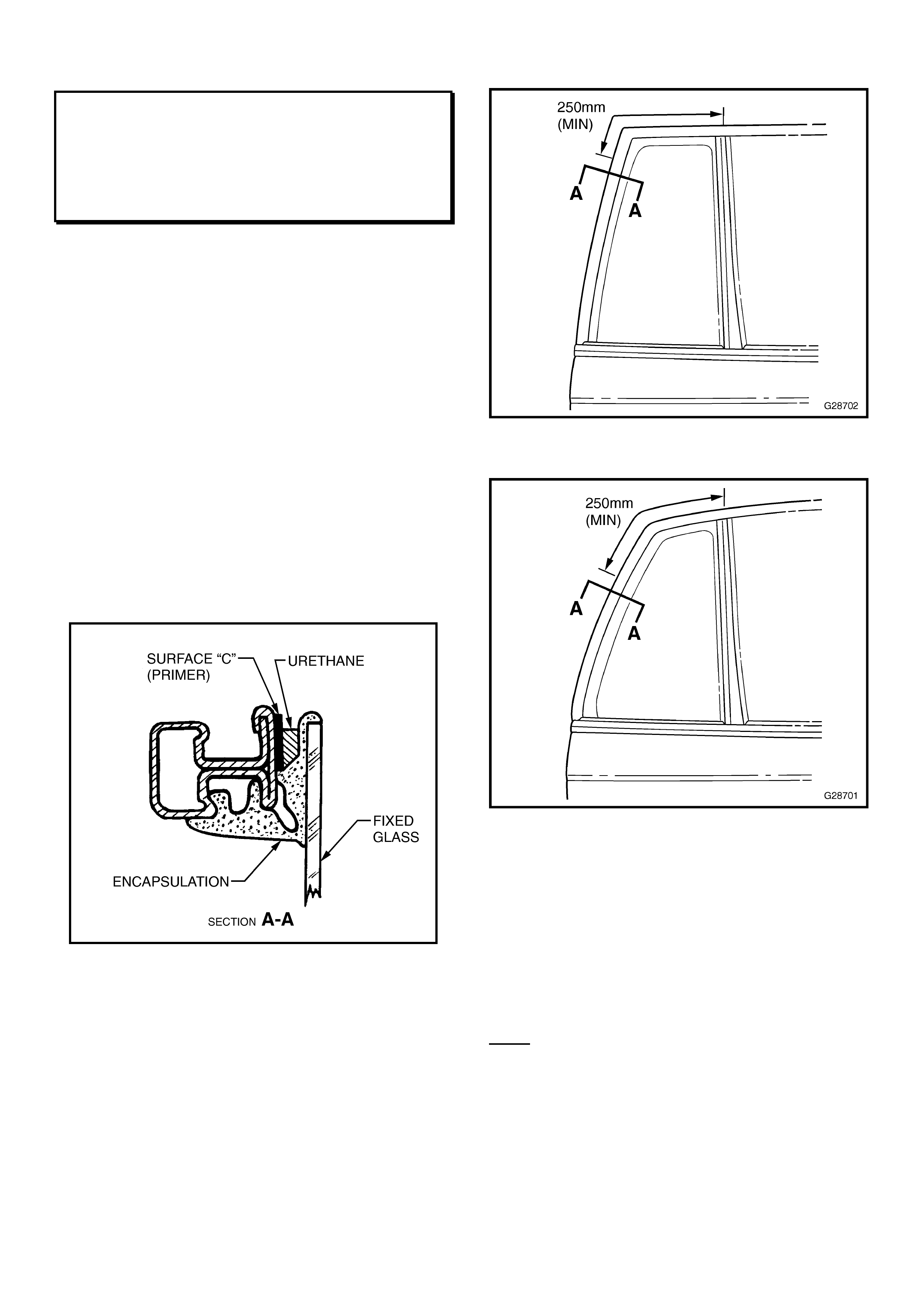

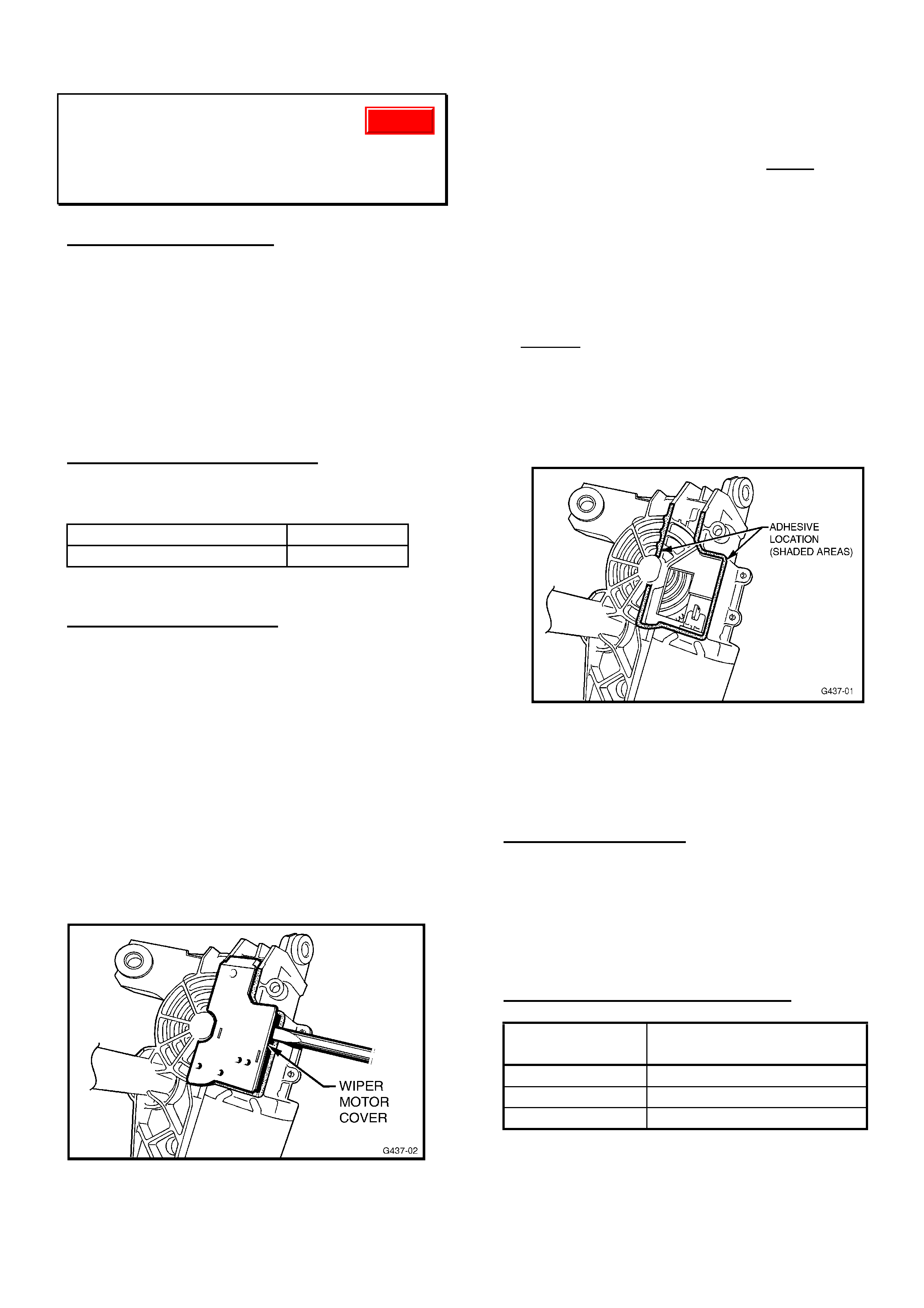

REVISED PROCEDURE FOR FITME NT OF

REAR DOOR FIXED WINDOW GLASS

VT (w agon) & WH

(GROUP 1) February 2000

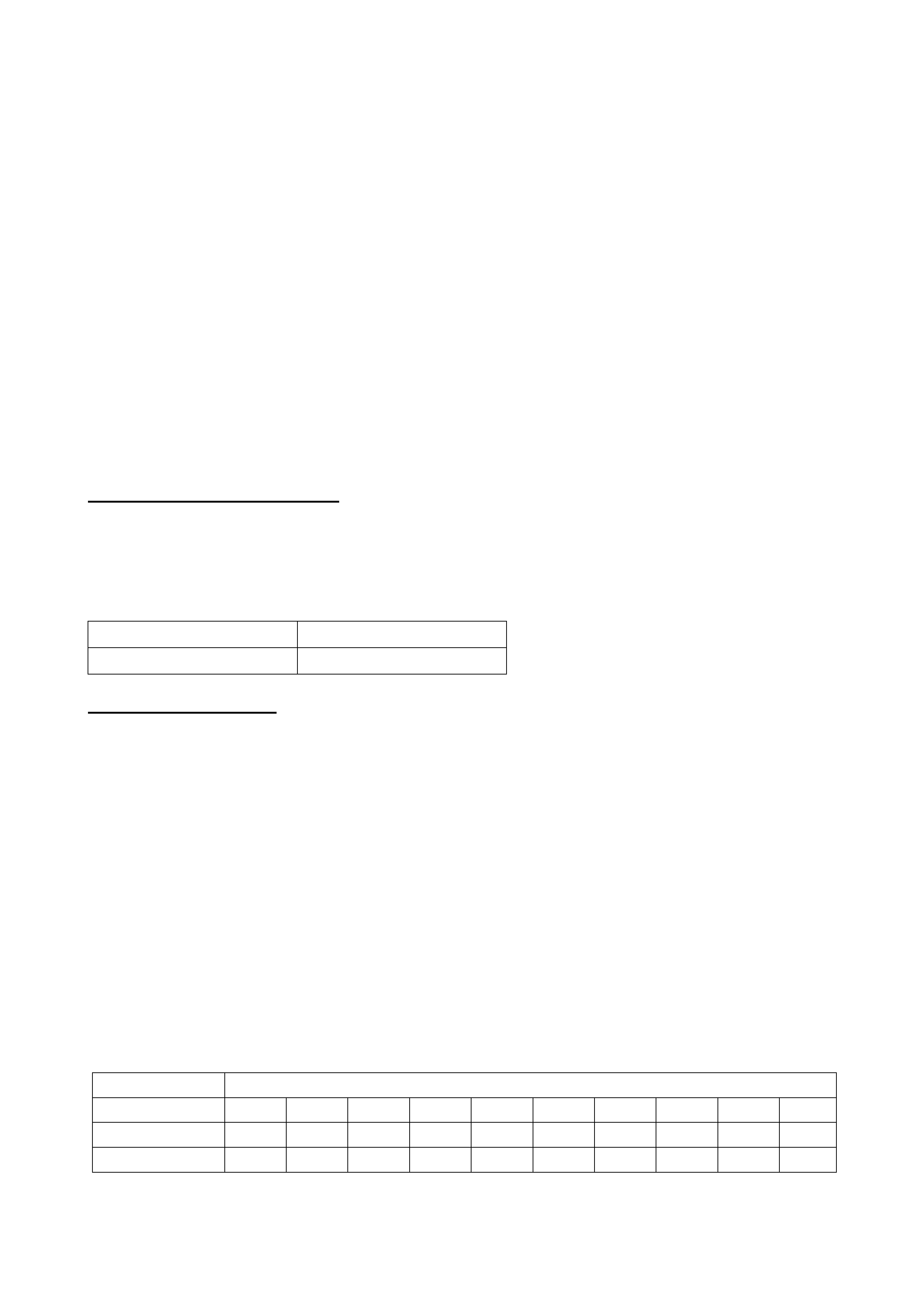

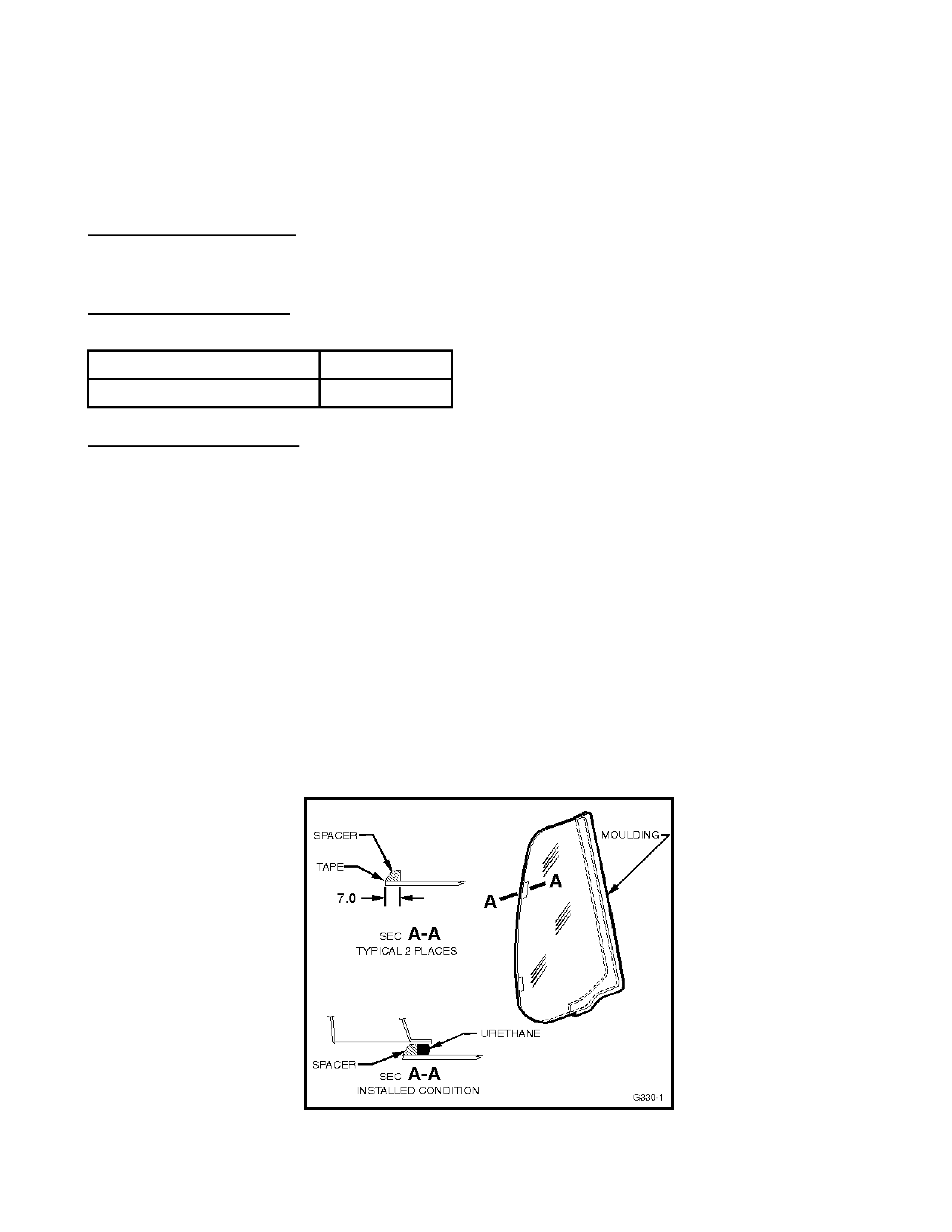

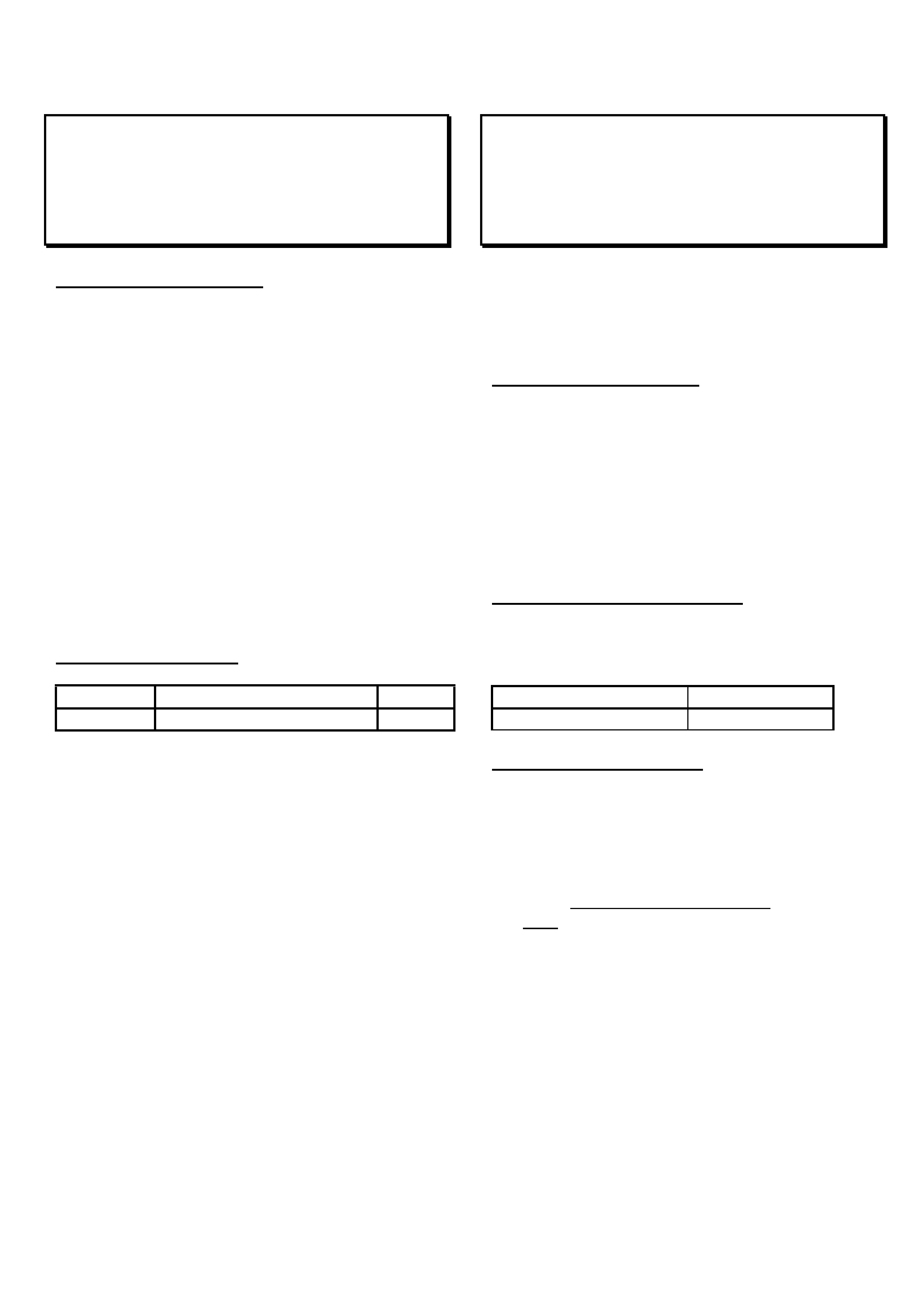

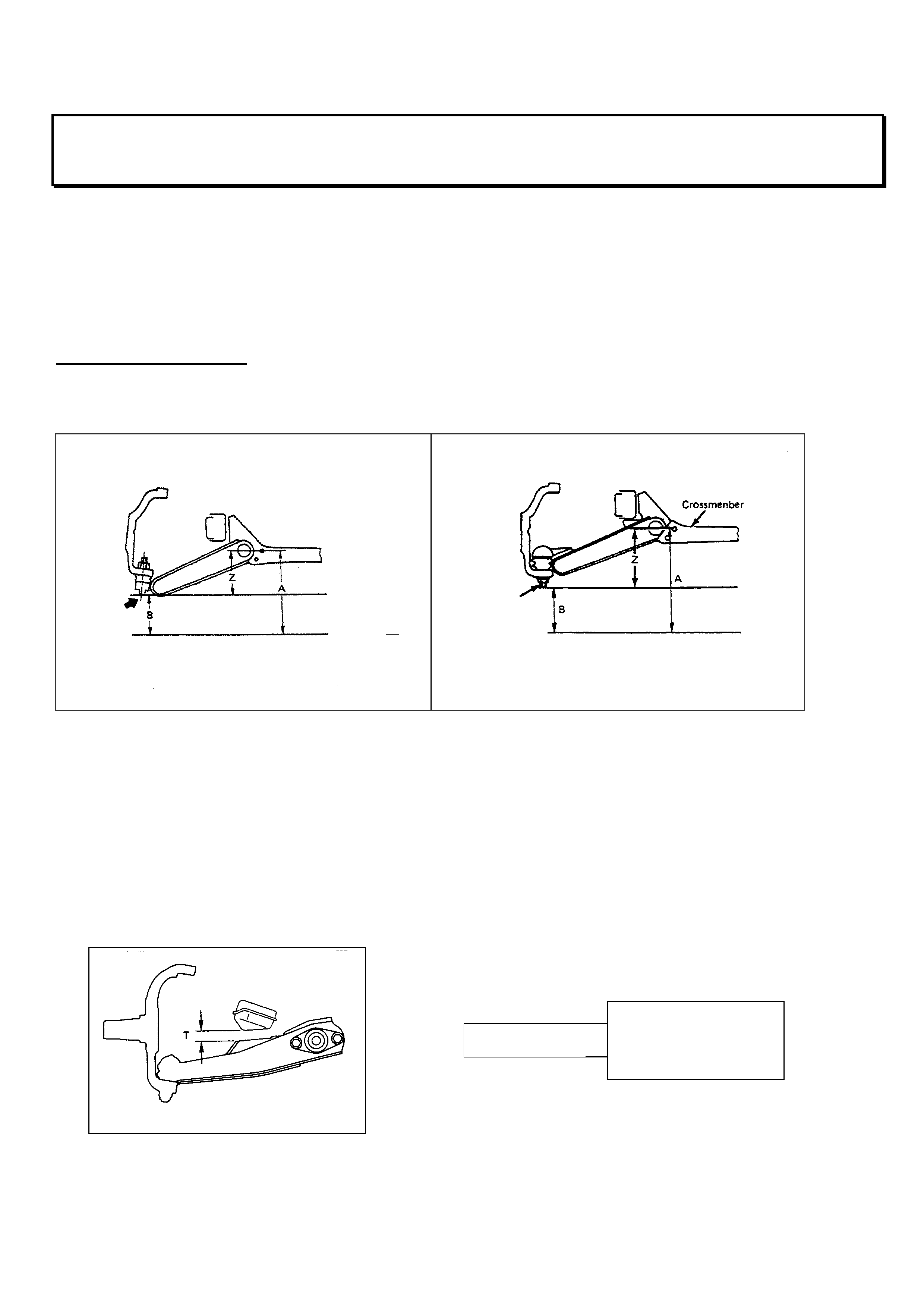

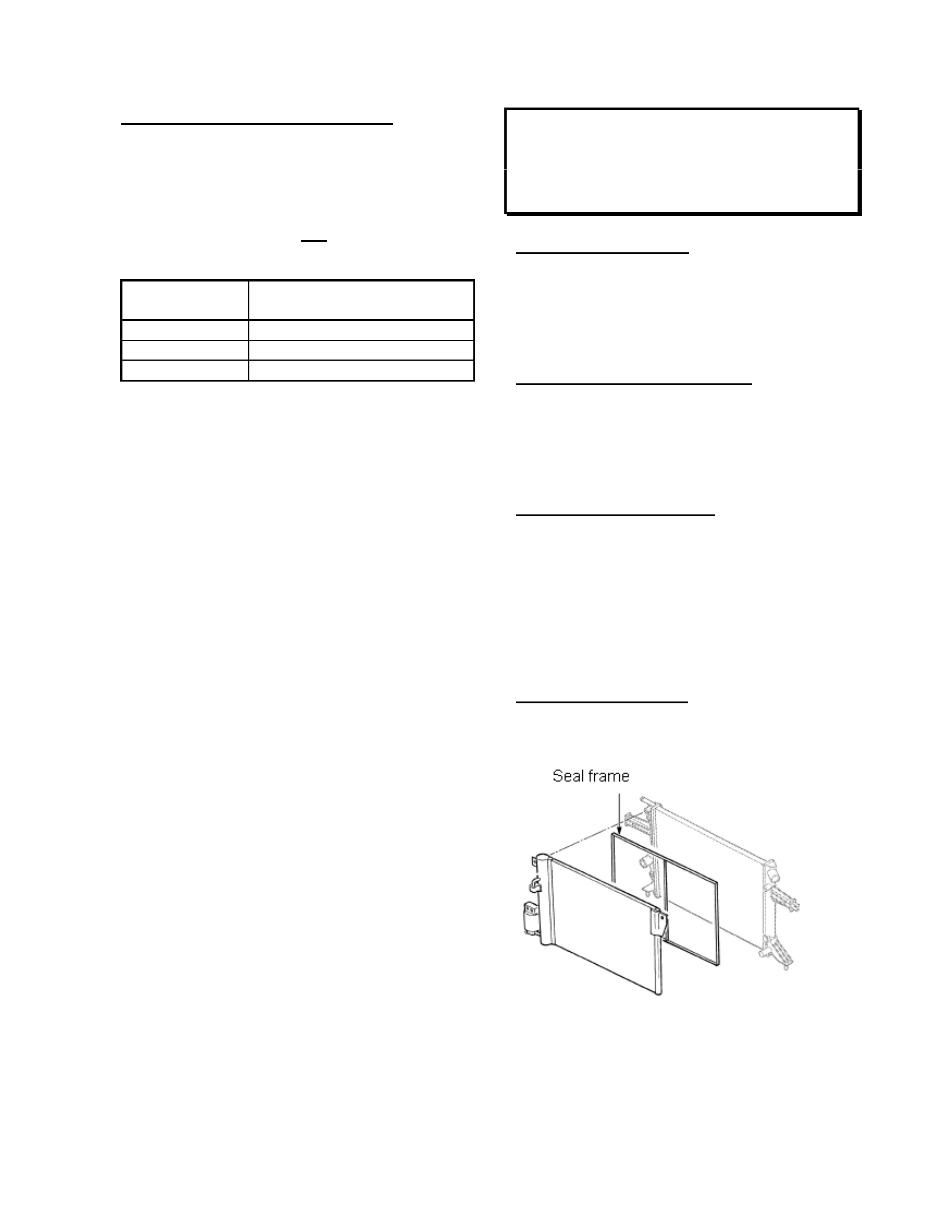

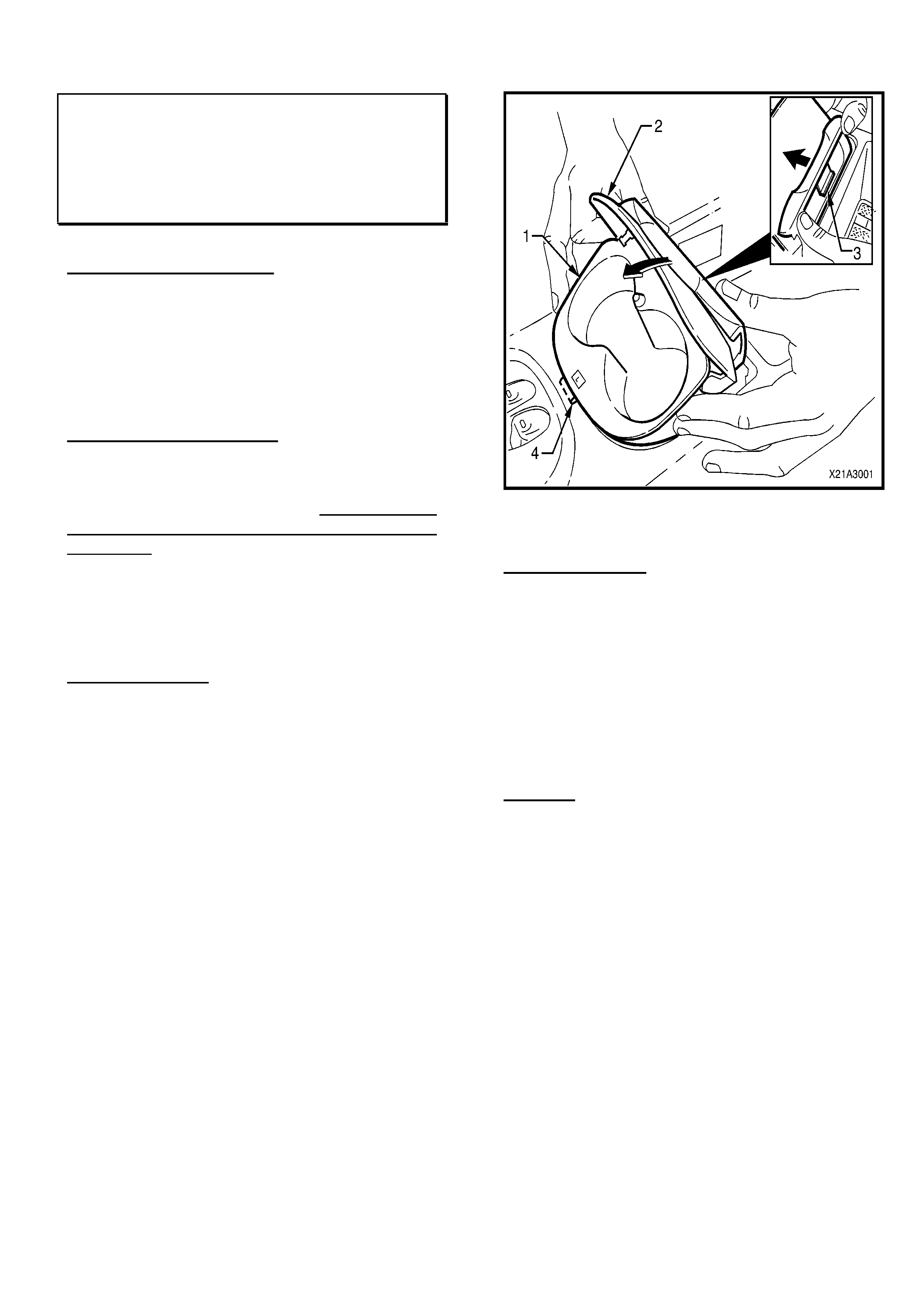

In addition to the rear door fixed window glass

fitment procedure in VT Series Service Manual,

Volume No.1, page 1A5-19, and WH Series

Service Manual Supplement, Volume 1A, page

1A5-24 - when refitting the rear door fixed glass

for any reason, please perform the following

additional procedure.

The removal of the rear door fixed window is the

same as outlined in the service manual. When

reinstalling the window, perform the additional

steps outlined below:

• Using a small br ush, apply primer BETASEAL

43532, or a similar product to the door frame

painted surface "C" as shown in Section A-A

over a minimum length of 250m m as indicat ed

in Figures 1 & 2.

Section A - A

• Ensure the prim er is dr y before proceeding.

• Using a urethane product available from

HSPO P/N VS18319, or alternatively,

BETASEAL 58702, or BETASEAL 15685 -

apply a small, continuous bead in the cavity

between the encapsulated glass and the

primed area of the door frame.

Figure 1. – VT Wagon

Figure 2. - WH

• Reinstall the door frame seal ensuring to

clean up any excess urethane.

Suitable sealants and primers required and

noted in this procedure can be obtained from

windscreen fitment out lets.

Note: for revised procedure for VT sedan rear

door fixed window glass replacement –– Refer to

Techline Bulletin shown on page 93 of 1998

Service Communication Book .

100mm

150mm

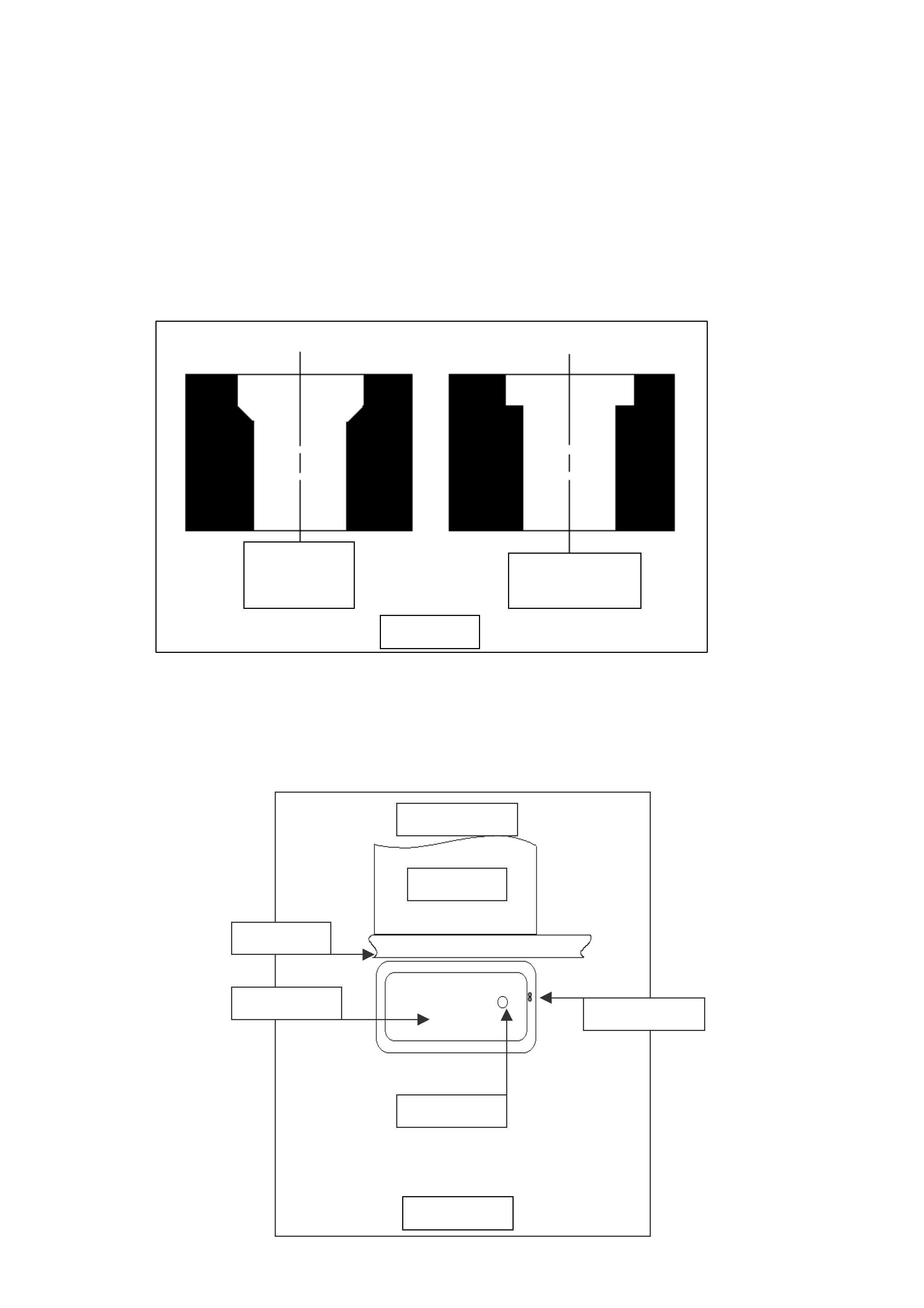

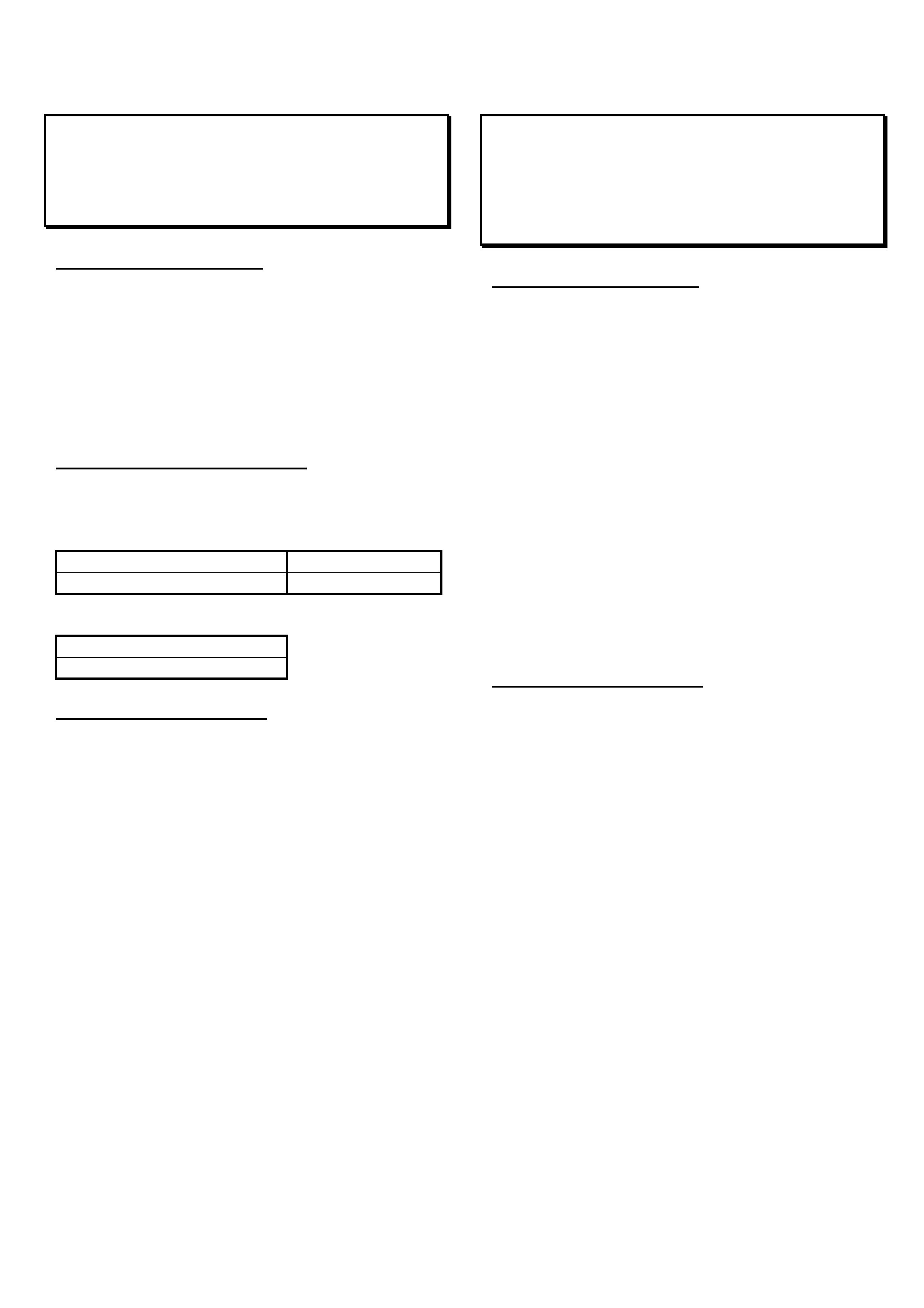

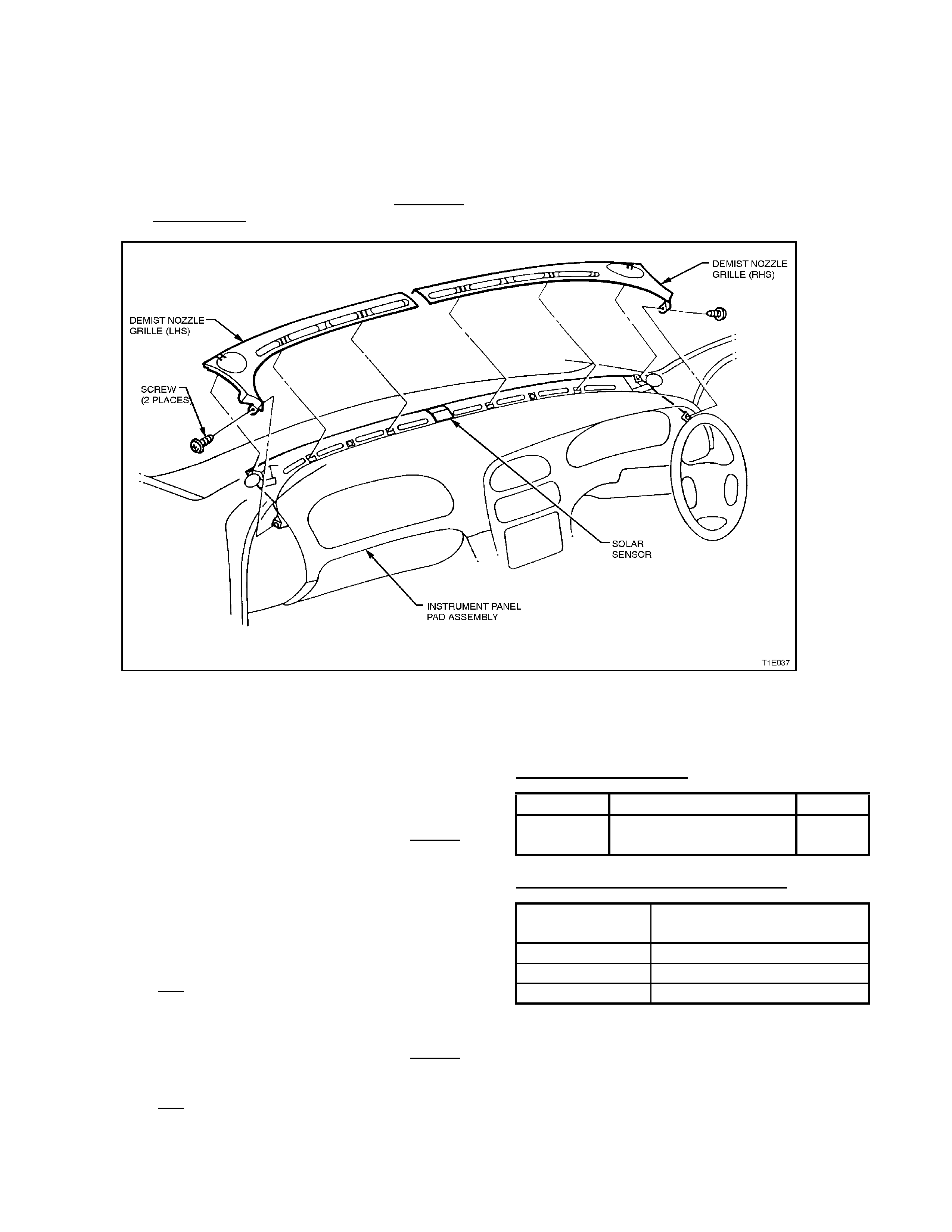

REVISED EVAPORATOR THERMISTOR POSITION

TF RODEO V6

(GROUP 2) February 2000

Information from the field has revealed that V6 Rodeo vehicles may experience evaporator ice –

up on 100km+ distance trips. Evaporator ice up is usually described as poor blower fan output

with large quant it ies of water draining from the evaporat or when the vehicle is stationar y.

Air International has developed a revised thermistor position to prevent the evaporator

temperature dropping below zero degrees which causes the condensation on the evaporator to

freeze.

Refer to the diagram below for the revised thermistor position, and disregard any prior bulletins

referring to this subject.

Note- Evaporator viewed from the air

off side. Thermistor tip location

should be 150 mm from the upper

side and 100 mm (10 fins) from the

left side of the core.

The thermistor clip is approx. 20mm

from the plotted sensor tip point.

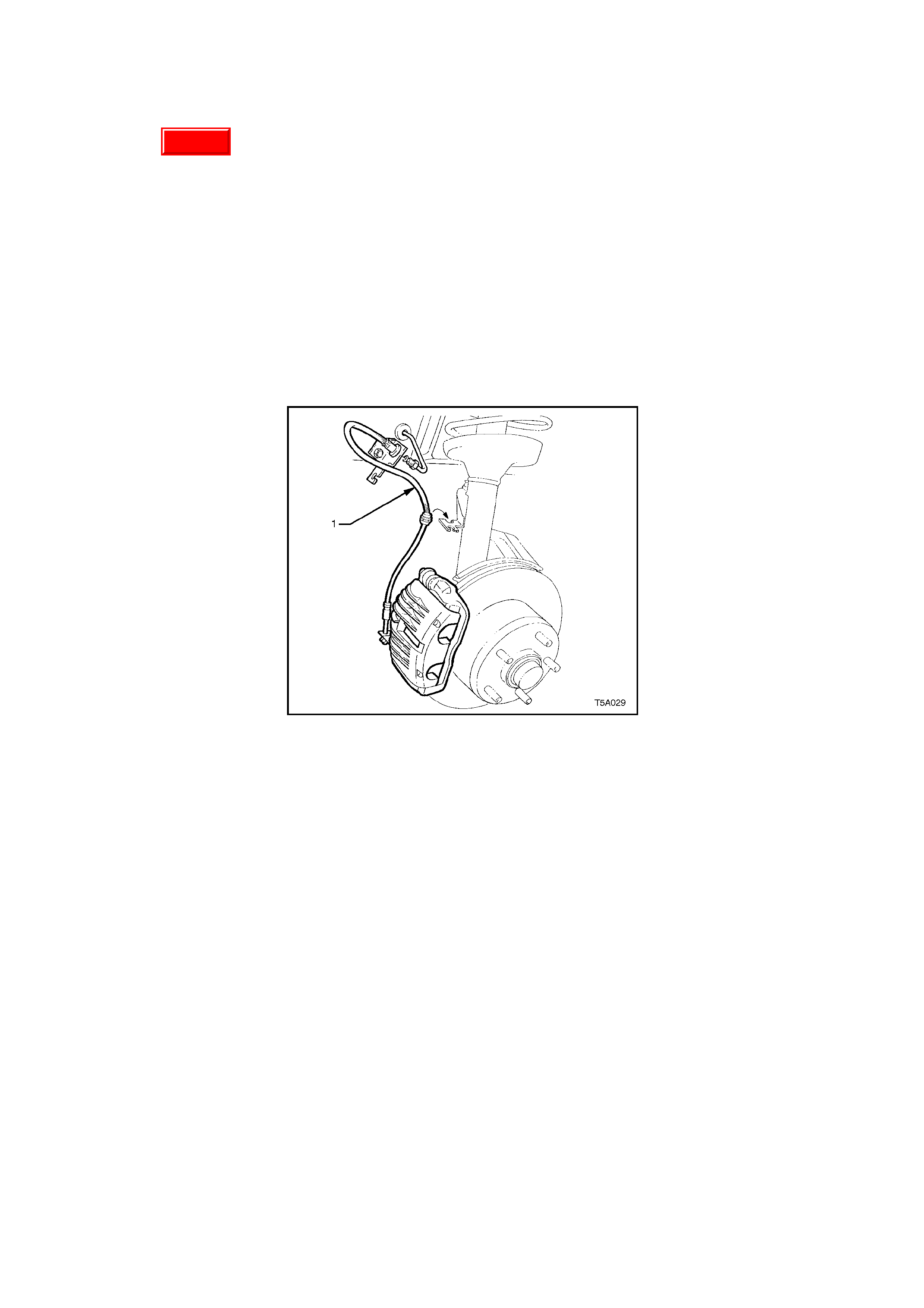

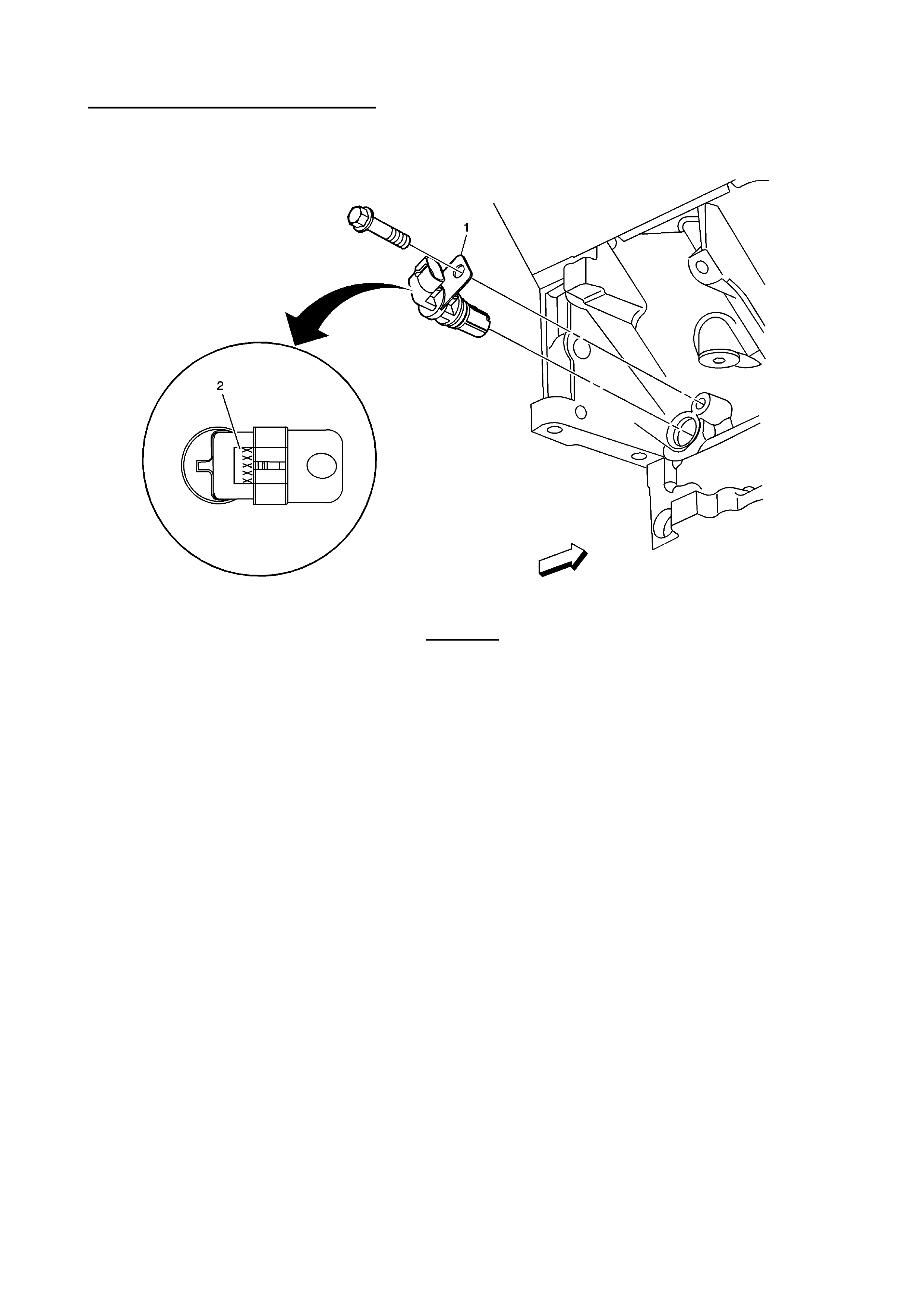

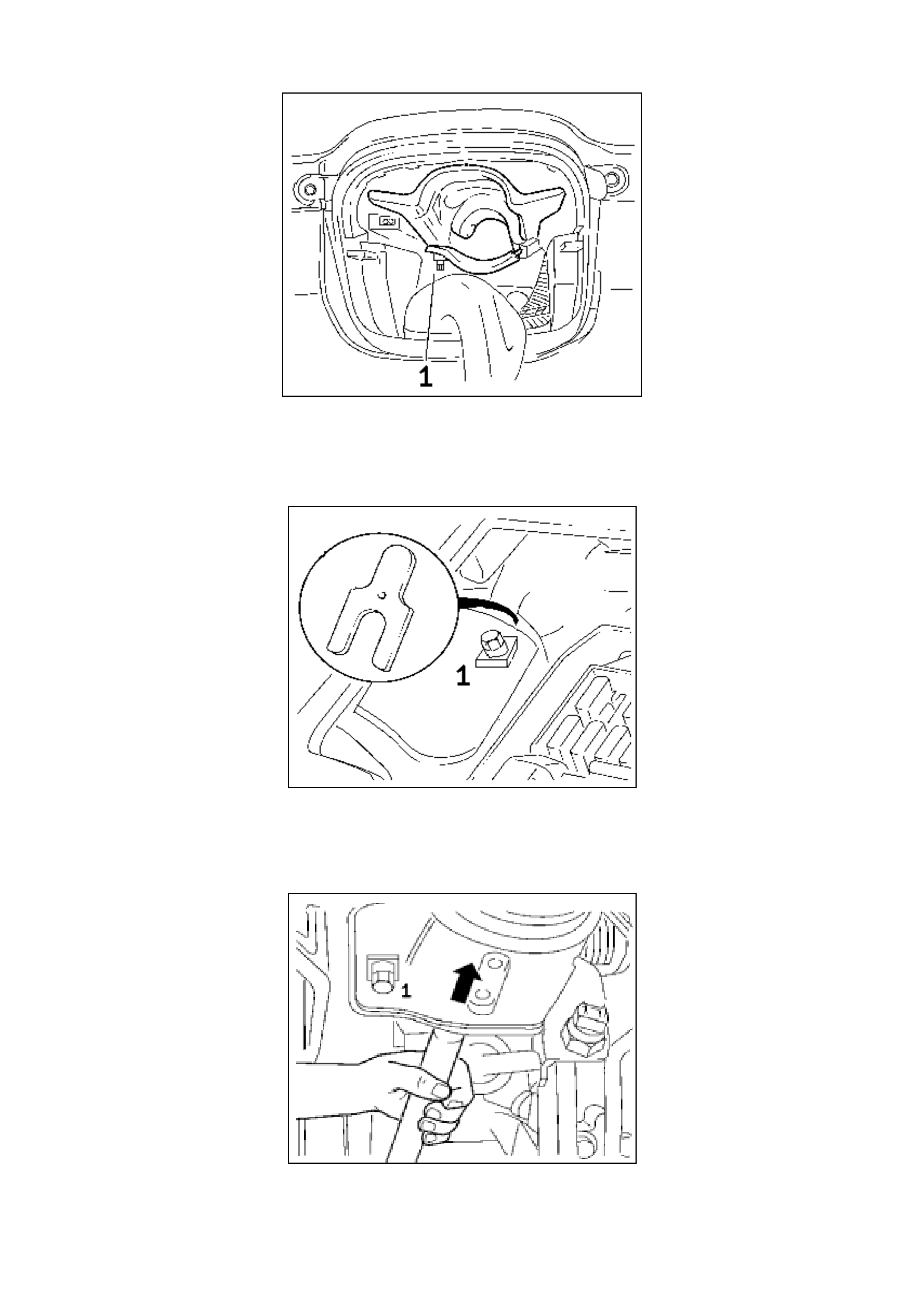

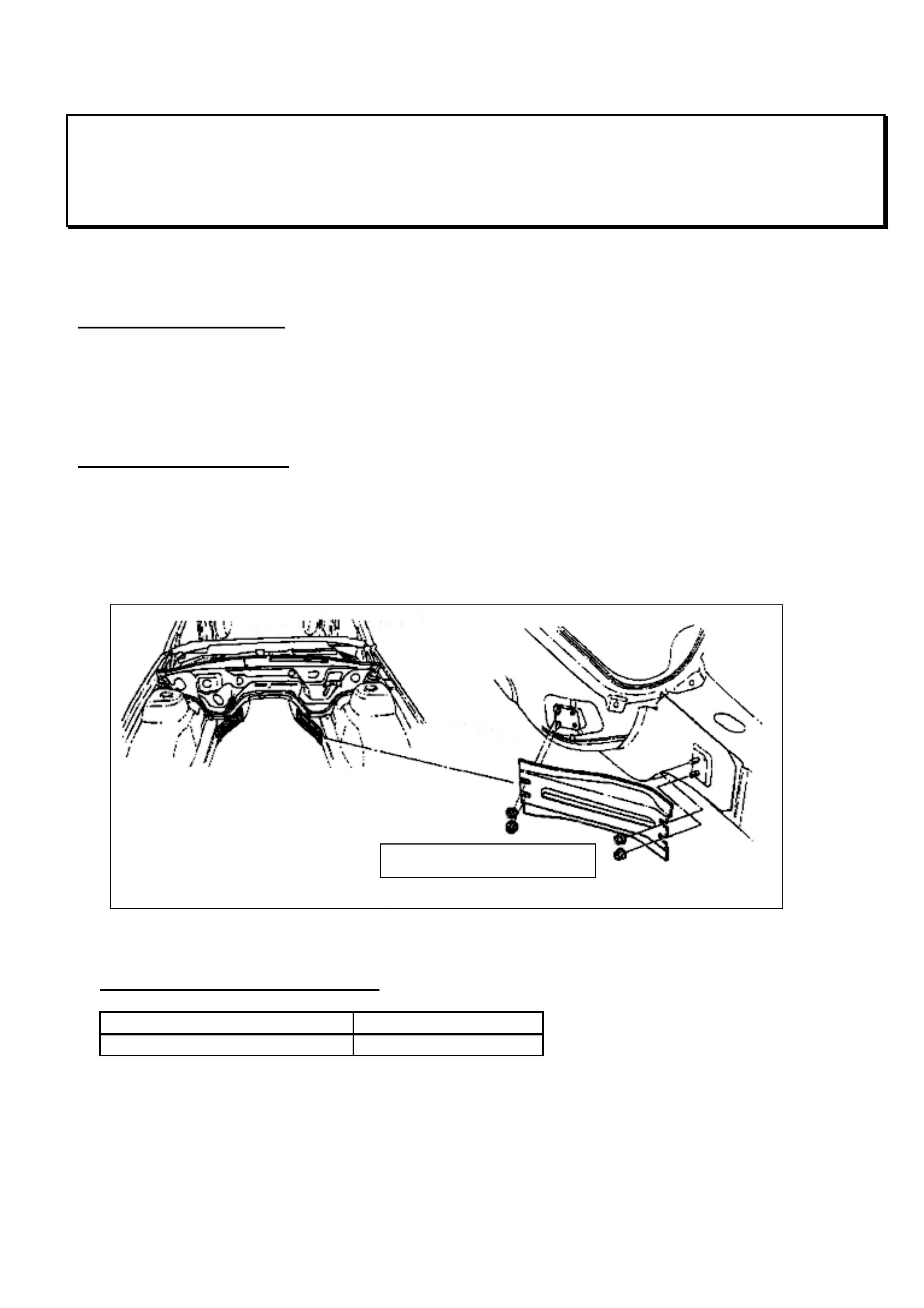

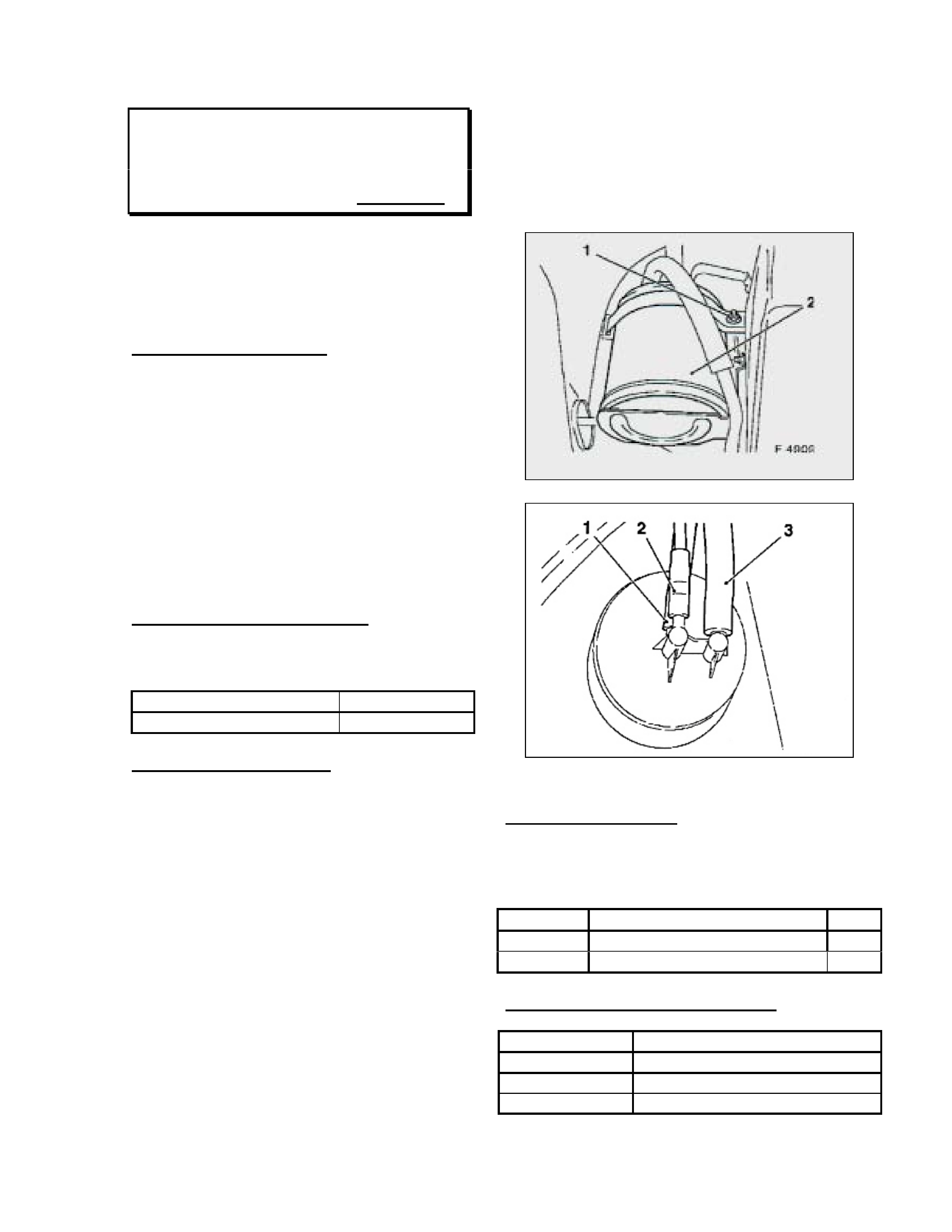

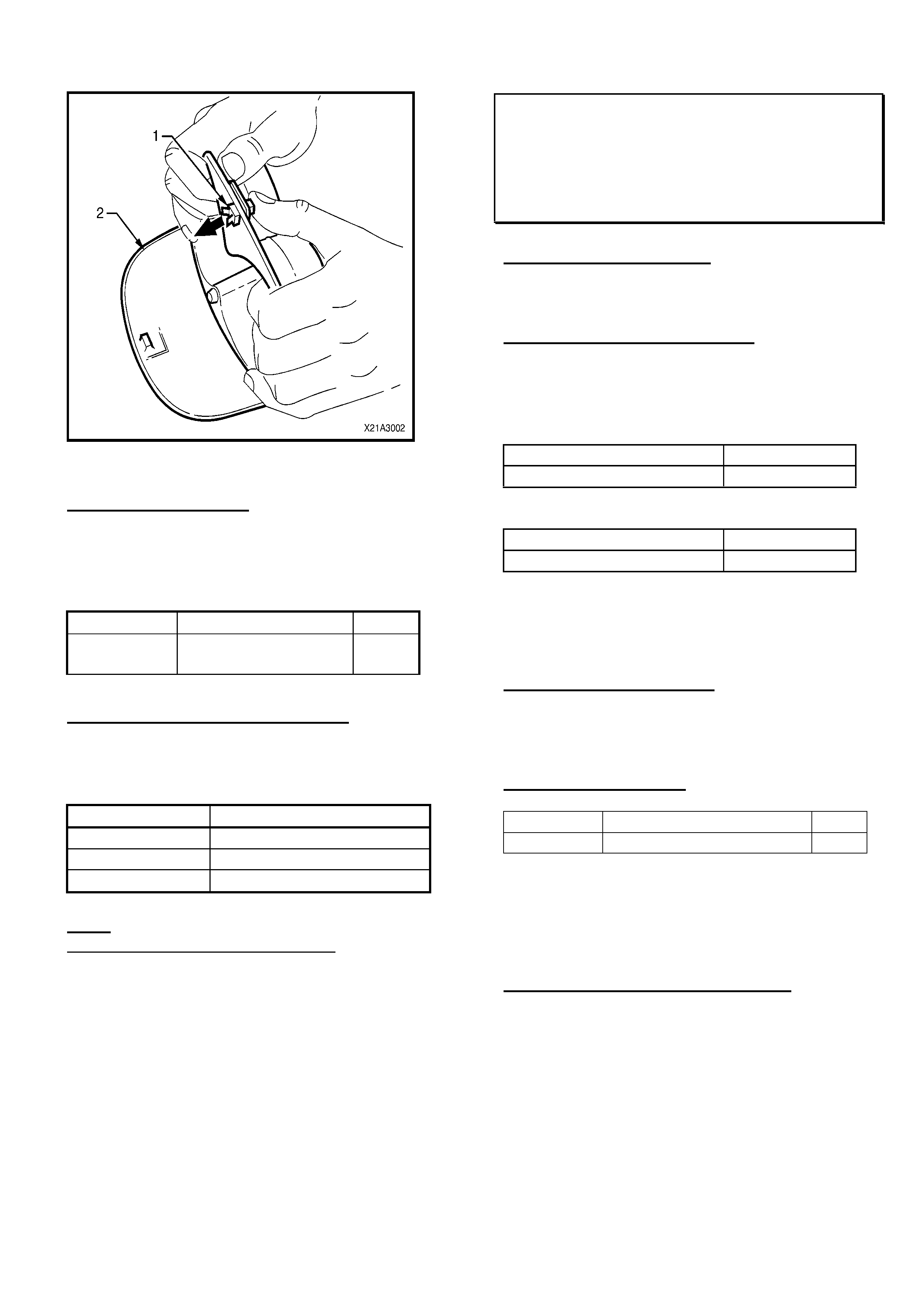

FRONT BRAKE HOSE RETENTION PRECAUTION

VT, WH

(GROUP 5) February 2000

This Techline item is a precautionary note to ensure correct reinstallation procedures are carried

out whenever front suspension, steering, or front br ake work is carried out on a vehicle.

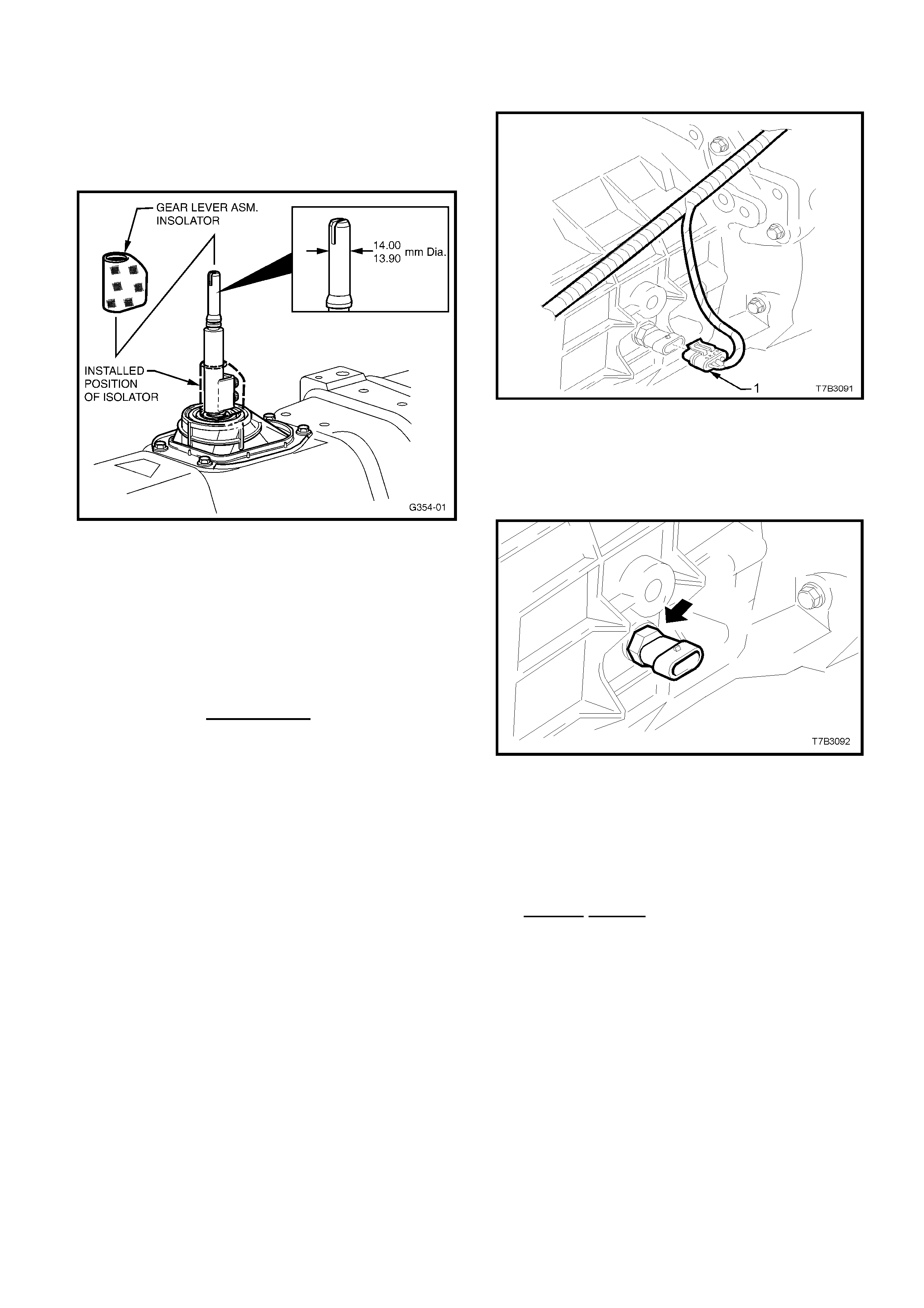

Whenever front brake hose/s are removed from their retaining clip/s (on front suspension strut

body) during any service work, the br ake hose/s must be refitt ed int o t heir retaining clip/ s .

Refer to the sketch below for brake hose (1) location, showing its method of location in the strut

mounted clip.

Update

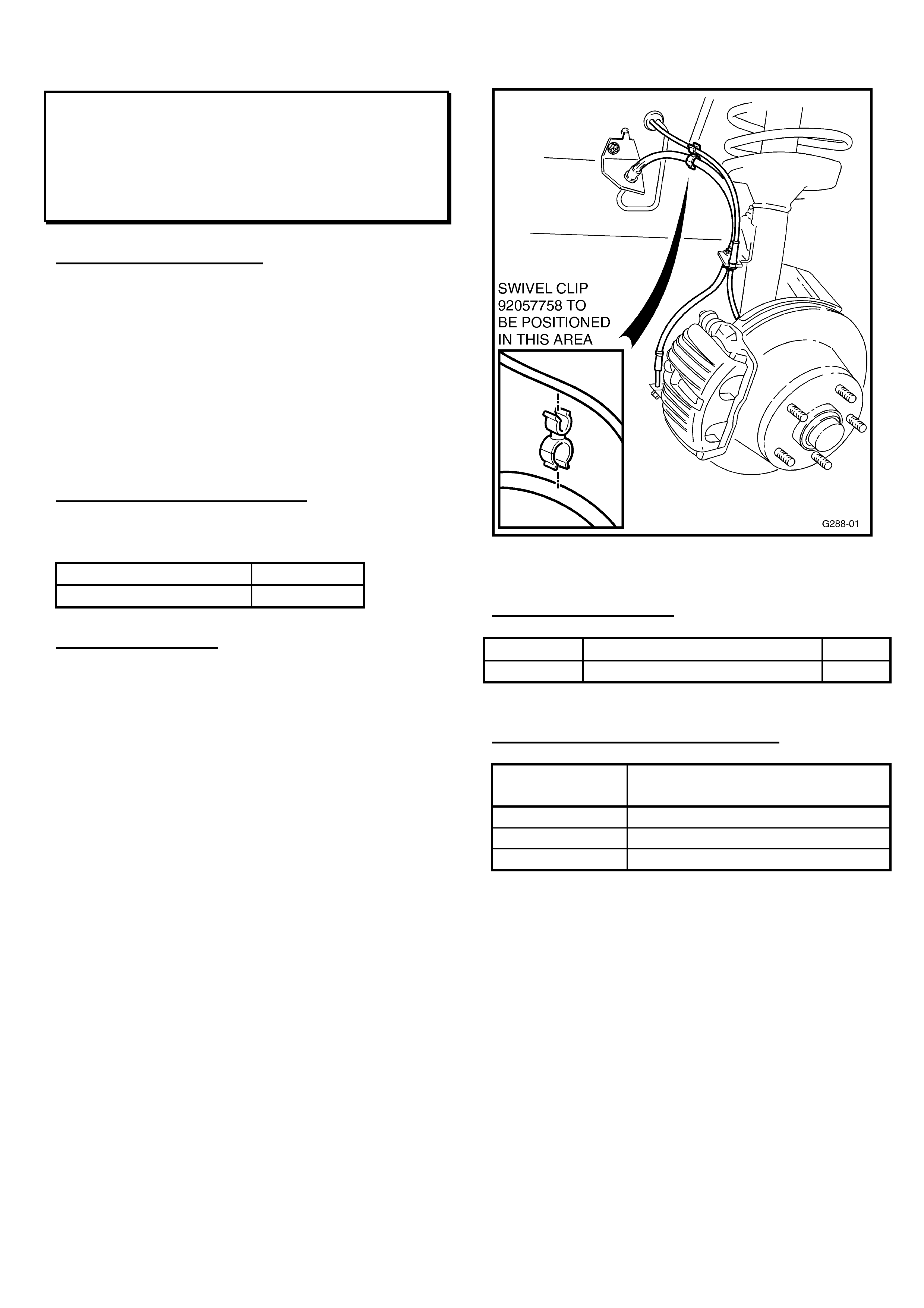

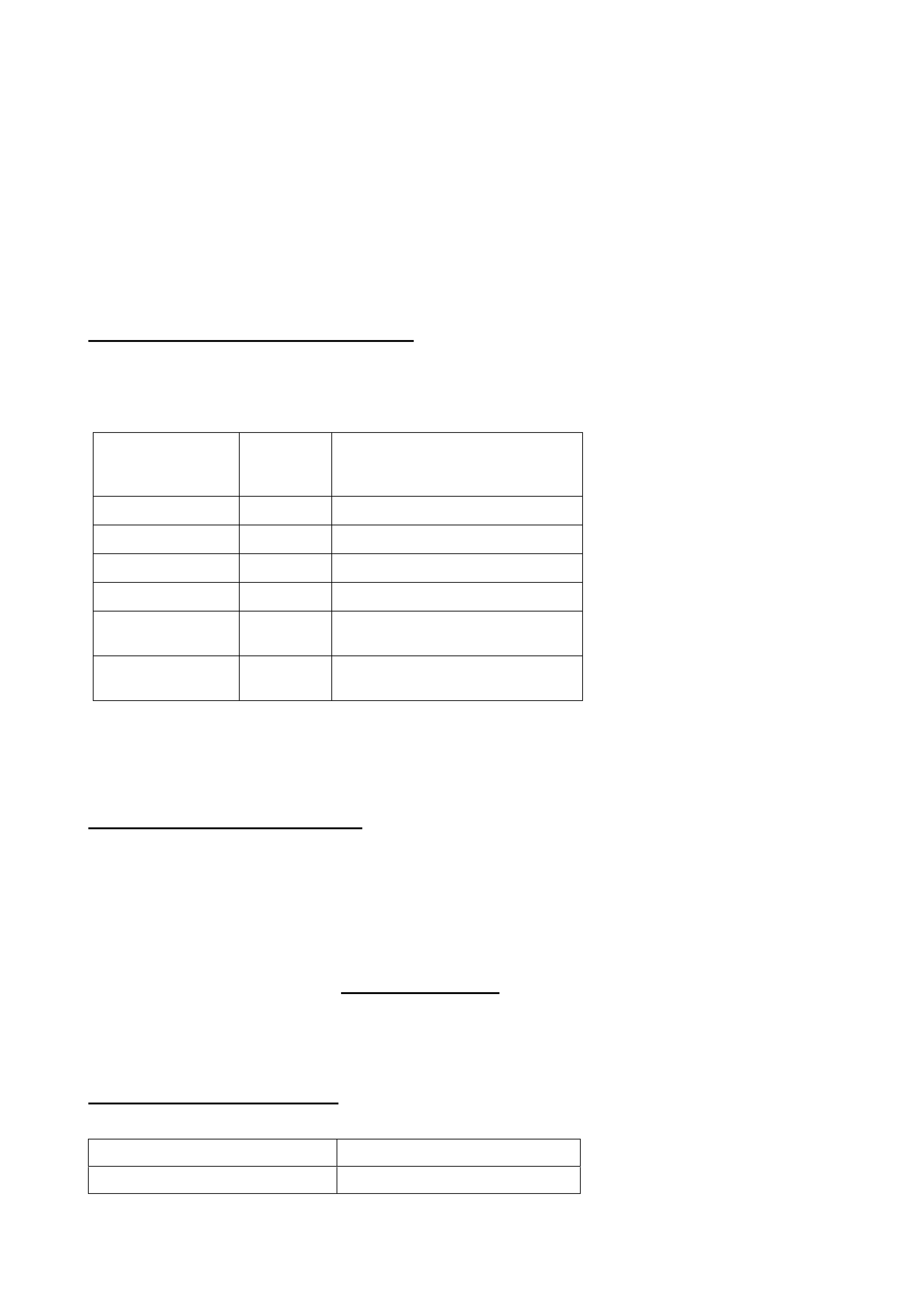

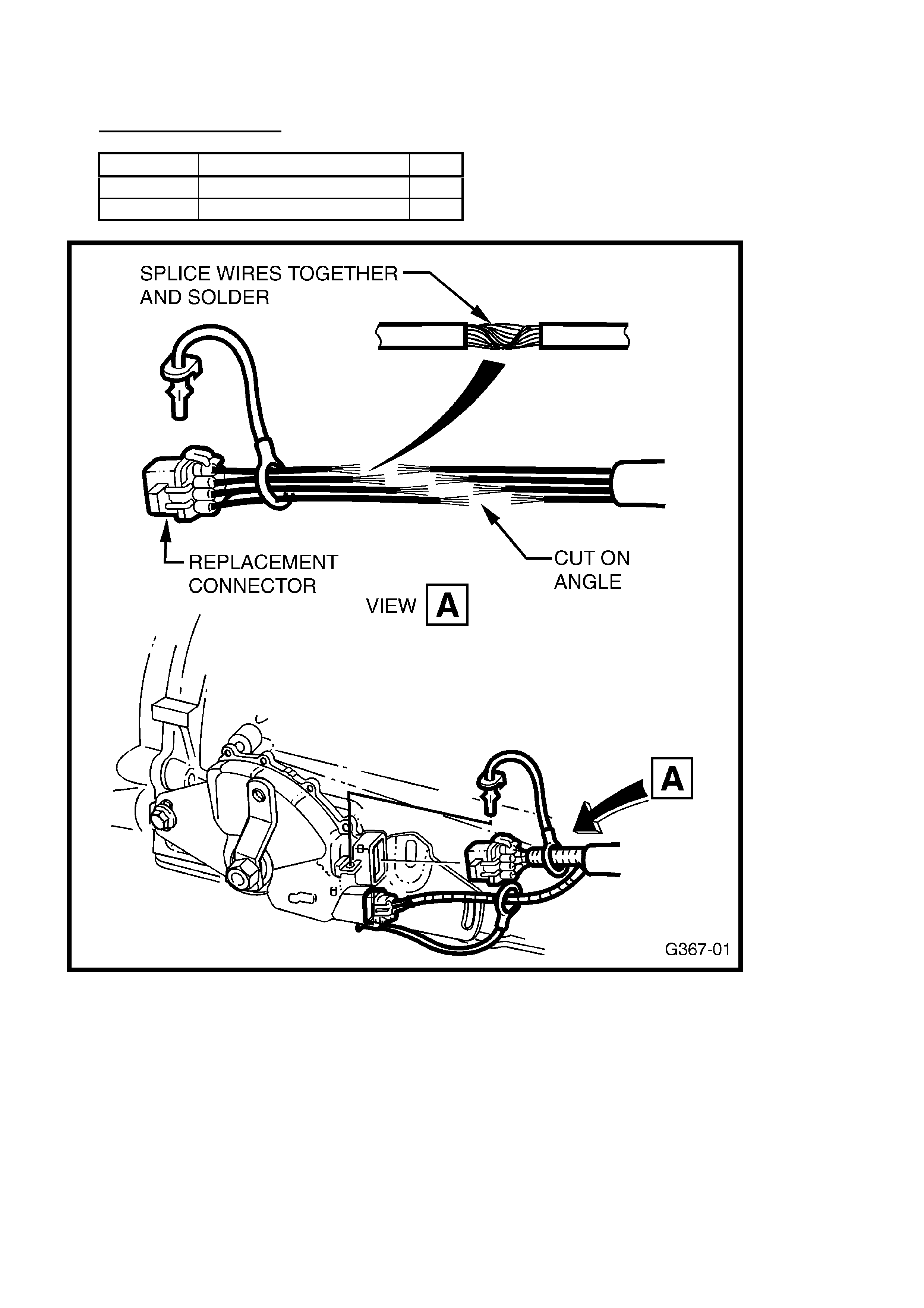

ABS WARNING LAMP ILLUMINATES - LHF

ABS SENSOR LEAD RETENTION

VT with ABS, & WH

(GROUP 5) February 2000

PROBLEM DESCRI PTION

On extreme suspension movement during turns,

excess length of the LHF ABS wheel sensor lead

may come into contact with the stabiliser bar

vertical link. The result of this may be an ABS

DTC 25 or 27, because the lead becomes

disconnected or stressed (causing poor terminal

contact) during suspension movement, resulting

in the ABS warning lamp on the instrument panel

illuminating, and ABS function being eff ect ed.

PRODUCTION RECTIFICATION

A retaining clip has been fitted to vehicles from:

PSN No.: Build Date:

L536320 01/12/99

SERVICE ACTIONS:

Where a VT(with ABS) or a WH is presented for

service with an ABS warning lamp illuminated, or

DTCs 25 or 27 stored in the ABS module, the

following procedur e should be car r ied out :

1. Turn vehicle steering to the furthest left

position.

2. Locate the left -hand front ABS sensor lead.

3. Inspect the sensor lead for damage, poor

routing, connector engagement or

disconnection, correct as necessar y.

4. Fit sensor lead retaining clip to brake hose

and sensor lead to ensure routing of lead as

per Figur e 1.

5. Connect Tech 2 and clear any existing ABS

DTCs.

6. Roadtest vehicle to ensure fault has been

rectified. Should any fault reoccur further

diagnosis should be carried out to determine

cause.

NOTE: This condition only affects VT/WH (with

ABS), from: L384387 to L536319, (built 29/09/98

to 01/12/99). An ABS retention clip should NOT

be fitted to vehicles built prior to L384387, as the

ABS lead length on those vehicles is shorter and

does not req uir e r etention.

Figure 1.

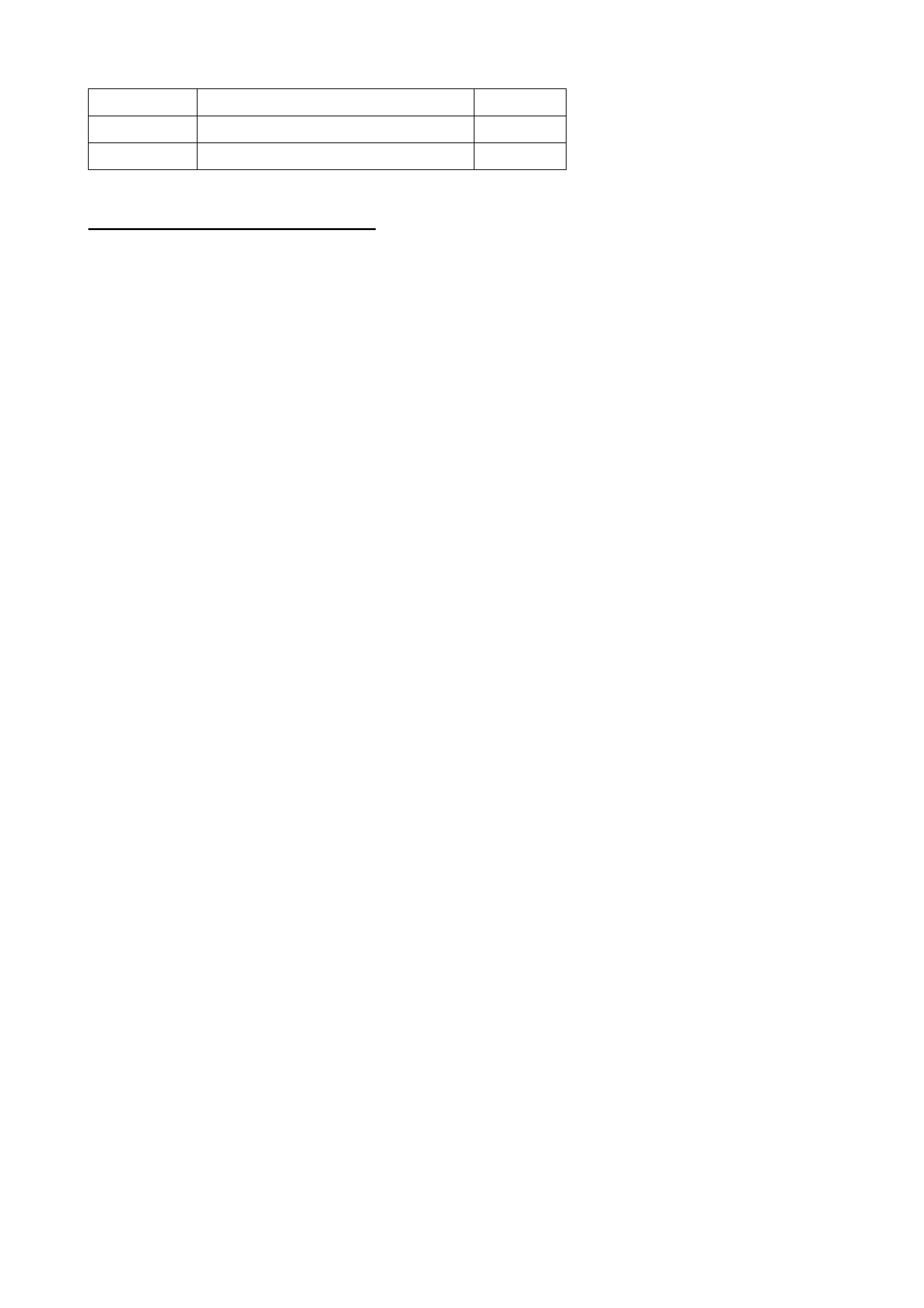

PARTS INFORMATION

Part No.: Description: Qty

92057758 Clip – Sensor Lead Retaining 1

WARRANTY CLAIM I NFORMATION:

Description Install re t aining clip to LHF ABS

sensor lead

Labour Op. No. H000216

Time 0.3 hr

Failure Code 51

CRANKSHAFT PULLEY BOLT

RODEO with 4JB1 –T

(GROUP 6A) February 2000

From engine number: 586429 (build - December 99), the crankshaft front pulley bolt tension for

the 4JB1- T engine has been increased to 24+/- .5kg.m (174+/- 4lb.ft, 235+/-5N.m) from 21+/- 2

kg . m (152+/- 14lb.ft, 206+/- 20 N. m).

All relevant workshop manuals should be chang ed accor dingly.

Dealers aware of any failed or loose bolts in engines manufactured after the above breakpoint

should notif y I-GM TAS immediately. (PH: 1800 032 608 )

Modified

insertion

p

oin

t

Early insertion

point

TURBOCHARGER FAILURE

JACKAROO with 4JX1 –TC

(GROUP 6A) February 2000

Jackaroo’s fitted with the 4JX1 –TC diesel engine may experience turbocharger failure due to air

leaking int o the suction side of t he primary oil pump at the oil st r ainer o ring.

Isuzu have modified the insertion point of the strainer for improved installation and sealing from

VIN no. JACUBS73GW7101646. Please refer to Diag ram A

All 4JX1 engines with turbocharger f ailure t hat are before the br eak point (JACUBS73G W7101646)

must have the following proceedure carried out t o pr event r epeat failure.

1) Check for two punch marks on the lip of the lower sump, adjacent to the drain plug. (refer

diagram B). If present the seal has already been replaced,do not proceed further,

contact IGM TAS.

Diagram A

Main sump

Lower sump

Front axle

Drain plug

Punch marks

Front of engine

N

ote – As viewed from underneath of vehicle.

Diagram B

2) Drain engine oil.

3) Remove lower sump

4) Remove primary oil pump str ainer and discar d

Note - There are two strainers visable when the lower sump is removed. The primary oil pump

strainer is fitted into the cylinder block and has a mounting bolt that attaches to main

bearing cap. T he secondar y oil pump st r ainer is fitted t o t he alum inium main sump.

5) Clean strainer inser t ion point

6) Fit new oil strainer ( Par t #. 8971370363) and seal ( Part #. 8971377980)

Note - W hen fitting new strainer and seal apply three bond 1207b ( HSPO part #.0882600080A )

sealant, to the seal.

7) Tension str ainer m ount bolt (20Nm)

8) Refit lower sump ( Use t hr ee bond 1207b on sealing surfaces)

9) Fill engine with oil

10) Test engine oil pressure with master gauge (refer 4JX1 workshop manual, section 6G,

page 3)

11) Center punch two marks into the lip of the lower sump adjacent to the drain plug as depicted

in diagram B.

ENGINE FRONT & REAR SEAL INSTALLATION TOOL CAUTION

VT, WH (GEN III V8)

(GROUP 6A) REISSUED February 2000

This Service Techline supersedes the previous Techline on this topic (Issue 10, December, 1999

page 9). This previous Techline should be dest r oyed.

This Techline item provides a revised service procedure regar ding engine f r ont seal replacement.

REVISED PROCEDURE:

W hen inst alling a f ront seal, or fr ont engine cover - Cent ralising t ool J41476 m ust not be at tached

with bolt/s.

The tool must be installed on the shaft and held in position by hand - using bolt/s to retain the

tool and over-tightening the bolt/s will result in tool breakage.

Please check the updated information in the current VT Service Manual CD. A revised page

6A3-92 copy is included (following this page) to attach over VT Series II Service Manual, Volume

14A, Page 6A3- 92 t o show this revision.

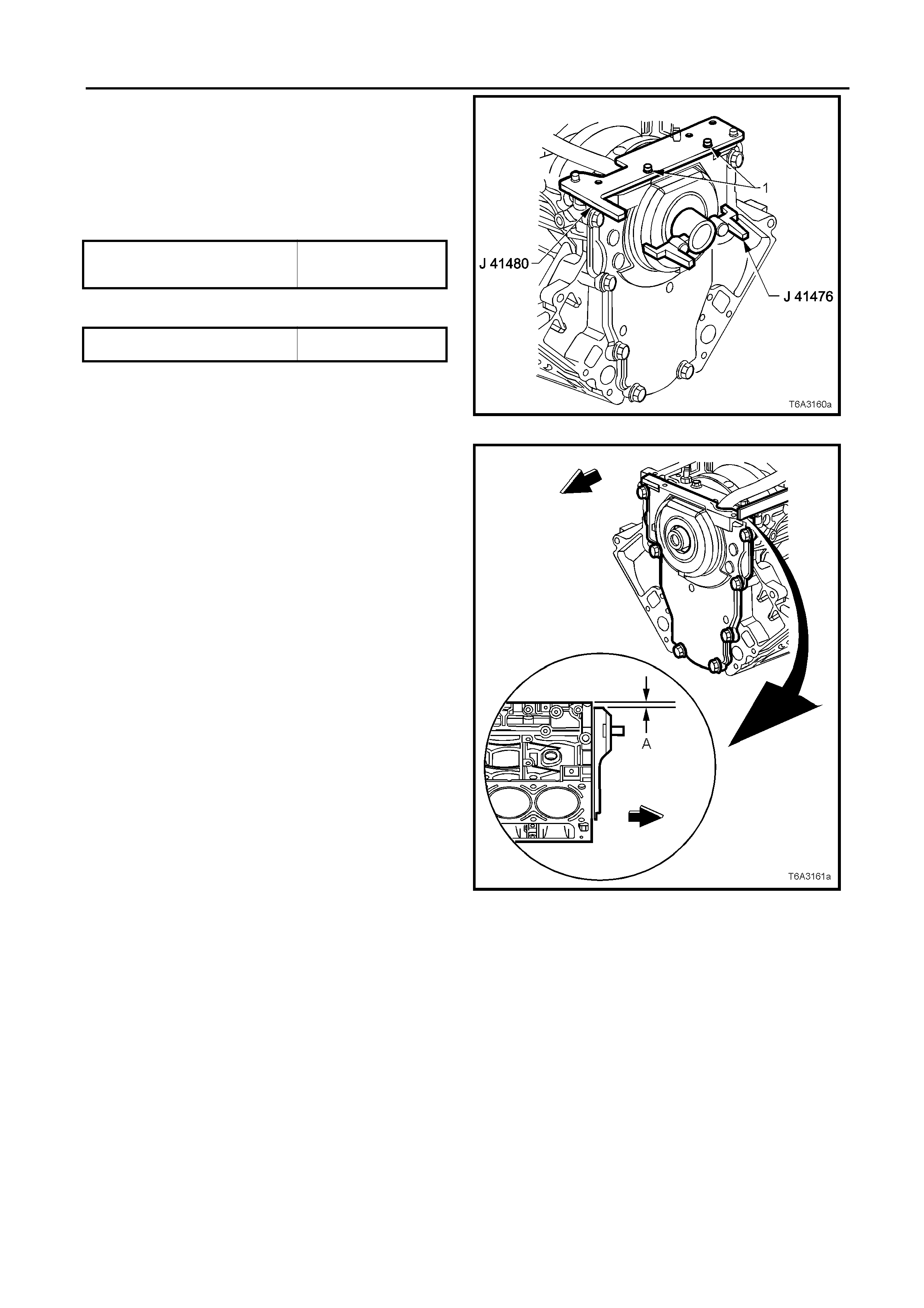

6A3-92 ENGINE MECHANICAL – GEN III V8 ENGINE

5. Install centralising Tool J 41476 as shown and hold

in position by hand.

NOTE: DO NOT install the crankshaft balancer bolt to

retain. If the bolt is installed and over-ti

g

htened the

alignment tool will be destroyed.

Important: Ali

g

n the tapered le

g

s of the tool with the

machined alignment surfaces on the front cover.

6. Ti

g

hten the two bolts

(

1

)

securin

g

Tool J 41480 to

the front cover, to the specified torque.

ALIGNMENT TOOL TO FRONT

COVER BOLT 25 Nm

TORQUE SPECIFICATION

7. Ti

g

hten the en

g

ine front cover bolts to the correct

torque specif ic atio n.

ENGINE FRONT COVER BOLT

TORQUE SPECIFICATION 25 Nm

8. Remove the alignment tools.

Figure 6A3-1

9. Measure the oil pan surface to front cover fo

r

flatness, as follows:

a. Place a strai

g

ht ed

g

e across the en

g

ine bloc

k

and front cover oil pan sealin

g

surfaces. Avoid

contact with the portion of the

g

asket tha

t

protrudes into the oil pan surface.

b. Insert a feeler

g

au

g

e between the front cove

r

and the strai

g

ht ed

g

e tool. The cover must be

flush with the oil pan surface or no more than

0.25 mm below flush (dimension ‘A’).

c. If the front cover-to-engine block oil pan surface

alignment is not within specifications, repeat the

cover alignment procedure.

10. If the correct front cover to en

g

ine block ali

g

nment

cannot be obtained, replace the front cover.

Figure 6A3-2

ENGINE VIBRATION ON ACCELERATION

JS VECTRA with C22SEL (A/T only)

(GROUP 6A) February 2000

PROBLEM DESCRIPTION

Some vehicles fitted with C22SEL engines and automatic transmission, may exhibit an engine

vibration or “boom”, upon medium to heavy acceleration from a stationary position at 1300 –

1700 rpm.

SERVICE RECTIFICATION

When presented with a customer complaint vehicle having the symptoms described above,

technicians should apply the following t hr ee- step procedure.

A. - Replace rear engine mount

Replace the rear eng ine mounting with the revised part detailed below. Follow instr uctions set out

in TIS 2000, Service Information section, Engine and Engine aggregates, Repair (remove, install,

adjust).

B. - De - stress engine and exhaust system

De-stress procedur e m ust be carried out on a 4 post hoist.

1. Drive vehicle onto vehicle hoist and disconnect battery. Select PARK and apply the

HANDBRAKE

2. Loosen the bolts securing the engine tor que rod, located at the RHF strut tower.

3. Raise vehicle on hoist to gain access to the RHF eng ine mount undercover, to g ain access to

engine mount at t achm ents.

4. Remove RHF engine mount under cover.

5. Loosen all engine mount t o sub- frame at t achm ents.

6. Loosen exhaust bolts at the joining interfaces

-Manifold to front pipe

-Front pipe to int ermediate pipe

-Interm ediate pipe to rear muffler

7. Lower vehicle on hoist, re-connect t he vehicle batt er y and star t the engine.

8. With the foot brake depressed, and engine idling repeatedly shift transmission between

reverse and drive a minimum of 10 times.

9. Select PARK, tur n engine off, disconnect t he vehicle batt er y.

10. Re-t or que the engine torque reaction rod bolts to specified torque.

11. Re-t or que the vehicle engine mounts t o the specified tor que.

12. Re-torque the vehicle exhaust system bolts to specified torque. Starting from the front of the

exhaust system through t o t he r ear .

NOTE: Refer TIS 2000, Service Information / Standard Information / ‘Other Information’

section for torque specs.

13. Re-fit RHF engine m ount undercover.

14. Lower hoist, re-connect the vehicle battery and adjust the engine idle speed as defined below.

C. - Adjust engine idle speed

1. With engine at normal operat ing temperat ur e, Connect Tech 2 to t he vehicle.

2. Select – Diagnostics / Model Year / Model type / Engine / Additional Functions / Adjust Idle

Speed.

3. Adjust eng ine idle speed to achieve 896 RPM, press the “confirm” soft key at the base of the

Tech 2 screen to com plet e.

4. With Tech 2 still connected, return to the additional functions menu and select Adjust Idle

Drive.

5. Adjust idle drive setting to achieve 896 RPM press the “confirm” soft key at the base of the

Tech 2 screen to com plet e.

6. Remove Tech 2 fr om the vehicle and road test to confirm success of pr ocedur e.

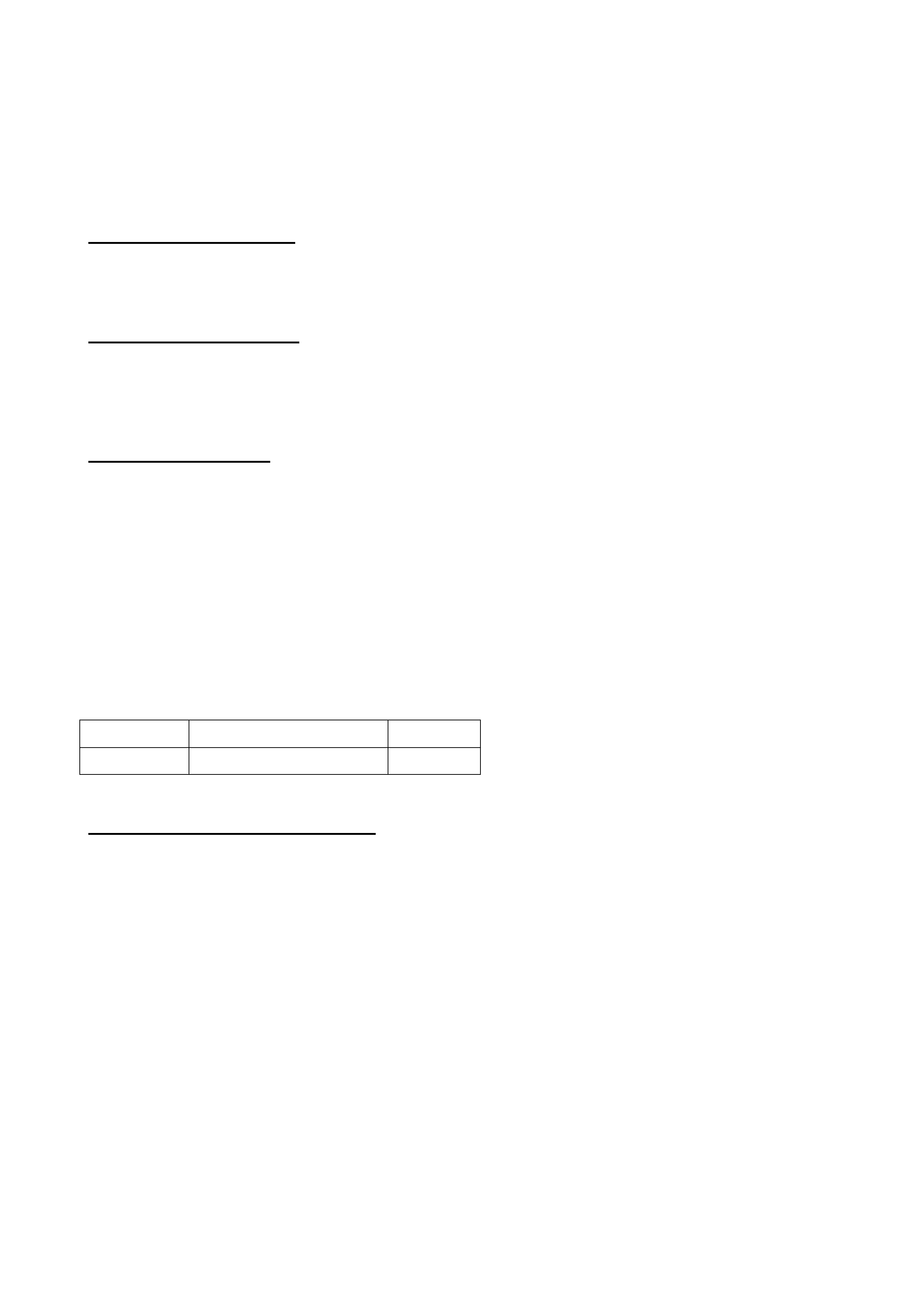

PARTS INFORMATION

Part No.: Description: Qty

90538303 Damper Block – Rear Mount 1

WARRANTY CLAIM I NFORMATION:

Description Tak e- off Vibr at ion Cor rection

Labour Op. No. J000636

Time 1.5 hr

Failure Code 28

HOLDEN ENGINE OIL AVAILABILITY

VS, VT, WH

(GROUP 6A) February 2000

This Techline bulletin is released to ensure technicians are aware of the following oils that are

available from HSPO:

Part No.: Description: Size

92142396 GF2 10W- 30 OIL 5 Litre

Preferred oil for use in all V6 (normally aspirated) and V6 Supercharged engines and Gen III V8.

Its use provides fuel economy benefits over the originally recommended 20W-50 SG/SH/SJ oil.

Not recommended for use in 5.0 l i t re V8 engine.

Holden recommends the use of 10W/30 GF2 engine oil for all VS & VT V6 engines with the

exception of LPG fuelled engines.

Part No.: Description: Size

92140105 20W-50 SJ/ CF O IL 5 Litre

For use in all V6 (normally aspirated) and V6 Supercharged engines and 5 litre V8 – normal

operating conditions – this oil is still a recommended oil f or V6 engines, but does not allow the f uel

economy benefits of GF2 10W-30 oil (as noted above).

Part No.: Description: Size

92142397 15W-40 SJ/ CF O IL 5 Litre

For use in all V6 (normally aspirated) and V6 Superchar ged engines and 5 lit re V8 – f or prolonged

use in snow areas - is still a recom mended oil f or V6 engines, but does not allow the fuel econom y

benefit s of GF2 10W-30 oil (noted above).

Part No.: Description: Size

92142398 LPG 15W-40 OIL 5 Litre

For use specifical ly in LPG equipped V6 vehicles.

Full HSPO information regarding these oils was published in Parts Bulletin M434, dated

26 October, 1999. Refer to your Parts Department to view HSPO Parts Bulletin M434, which

includes a Product News Brochure regarding these oils.

INTERMITTENT COLD STALL

SB with C14NZ

(GROUP 6A) February 2000

PROBLEM DESCRIPTION

Some vehicles fitted with C14NZ engines may experience an intermittent stall condition on

deceleration, shor tly after cold start. Some reports also suggest that intermitt ent stall may occur if

the engine is left idling for long per iods during engine warm up. Af ter t he stall condition occurs the

engine may appear to cr ank fast, have a lack of compression or be hard to restart. This condition

will be more pronounced in colder climates or during the winter months where ambient

temperat ur es below 10 degr ees exist.

SERVICE RECTIFICATION

1. Service personnel should thoroughly question the customer to ensure that the symptoms of

the stall complaint meet with the symptoms described above.

2. Connect Tech 1 and inspect vehicle for any DTC’s that may exist. Rectify the cause of these

DTC’s prior t o any further diagnosis.

3. Connect Tech 1 and compare engine data list parameters against QUICK CHECK F0: DATA

LIST SB Series, Service Manual, Volume 3, page J226. Any data errors can be further

diagnosed in section 5. 1. 6 of SB Series, Ser vice Manual, Volume 3, pag e J234

4. Install T ech 1, road test vehicle and attempt t o reproduce com plaint. SNAPSHOT engine data

list when stall occurs. Compar e captured data with :

- Q UICK CHECK F0: DATA LIST, SB Series, Ser vice Manual, Volume 3, page J226

- Section 5. 1.6 SB Series, Service Manual, Volume 3, page J234.

5. Install a fuel pressure gauge to the vehicle. Ensure that fuel pressure is within specification

and that no fuel system flow restrict ions exist. Fuel pressure gaug e may be left on the vehicle

while road testing to monitor any immediate loss of pressure when stalling occurs. (When

these actions are carried out – ensure that appropriate safeguards are made so no damage

occurs to any f uel line, and no fuel leak exists before, during or af t er the procedure.)

6. Check for loose connections. Apply a general “wiggle t est” to engine and m ain wiring har ness

connections as a means of fault location.

7. Check base ig nit ion t im ing setting as per SB Series, Service manual, Volume 3, page J-203.

Aft er com pleting the above inspections if no fault can be identified carry out the following:

8. Replace engine hydraulic lifters with revised part number detailed below. Refer SB Series

Service Manual, Volume 3, Page J 117.

9. After fitting revised hydraulic lifters ensure that engine oil fill meets Holden specification

15W-40 or 15W-50 meeting ACEA A2 or A3. Refer 1998 service communication book.

Page 103.

10. Roadtest vehicle and ensure no further st all exists.

11. Should any stall be evident after fitting of revised parts, refer to Service Techline, Issue 1,

February 1999, page 17 for f urther rectification and specific inspections.

PARTS INFORMATION

Part No.: Description: Qty

92065681 Hydraulic Lifter 8

A “H” etched on t he m achined land of the hydraulic lif ter plunger ident ifies the revised type lift er.

WARRANTY CLAIM I NFORMATION:

Where r eplacement of hydraulic lifters is r equired, use Warranty Claim information detailed below.

Description Cold Stall - Lifter Replace

Labour Op. No. J000639

Time 1.3 hr

Failure Code 83

W here a preliminary inspection identifies a fault and requirement for part replacement, other than

hydraulic lifter replacement, claim the relevant part labour operation as per the Labour Time

Manual. Where additional time is required, additional to published time, seek authorisation from

zone service representative.

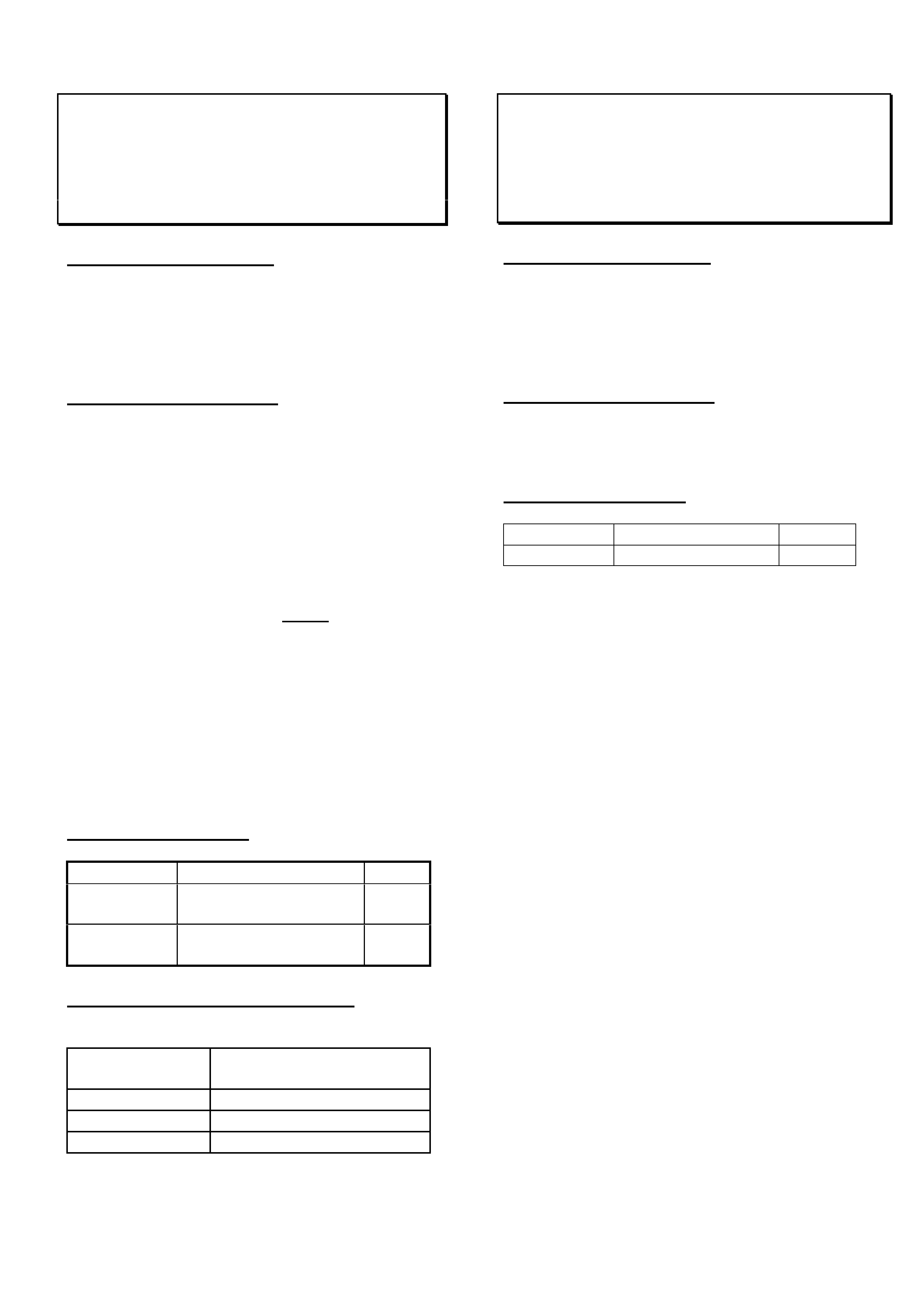

DTC P0341/ P0342/ P0343 SET - CAM POSITION SENSOR FAULT

VT, WH with GEN III V8

(GROUP 6C) February 2000

PROBLEM DESCRIPTION

Investigation into reports of DTCs P0341, P0342, P0343 have identified a potentially faulty

camshaft position sensor. Separation of the camshaft position sensor internal circuit board can

cause the fault to occur. Customers may report that the check engine lamp is illuminated or that

extended cranking times exist.

SERVICE RECTIFICATION

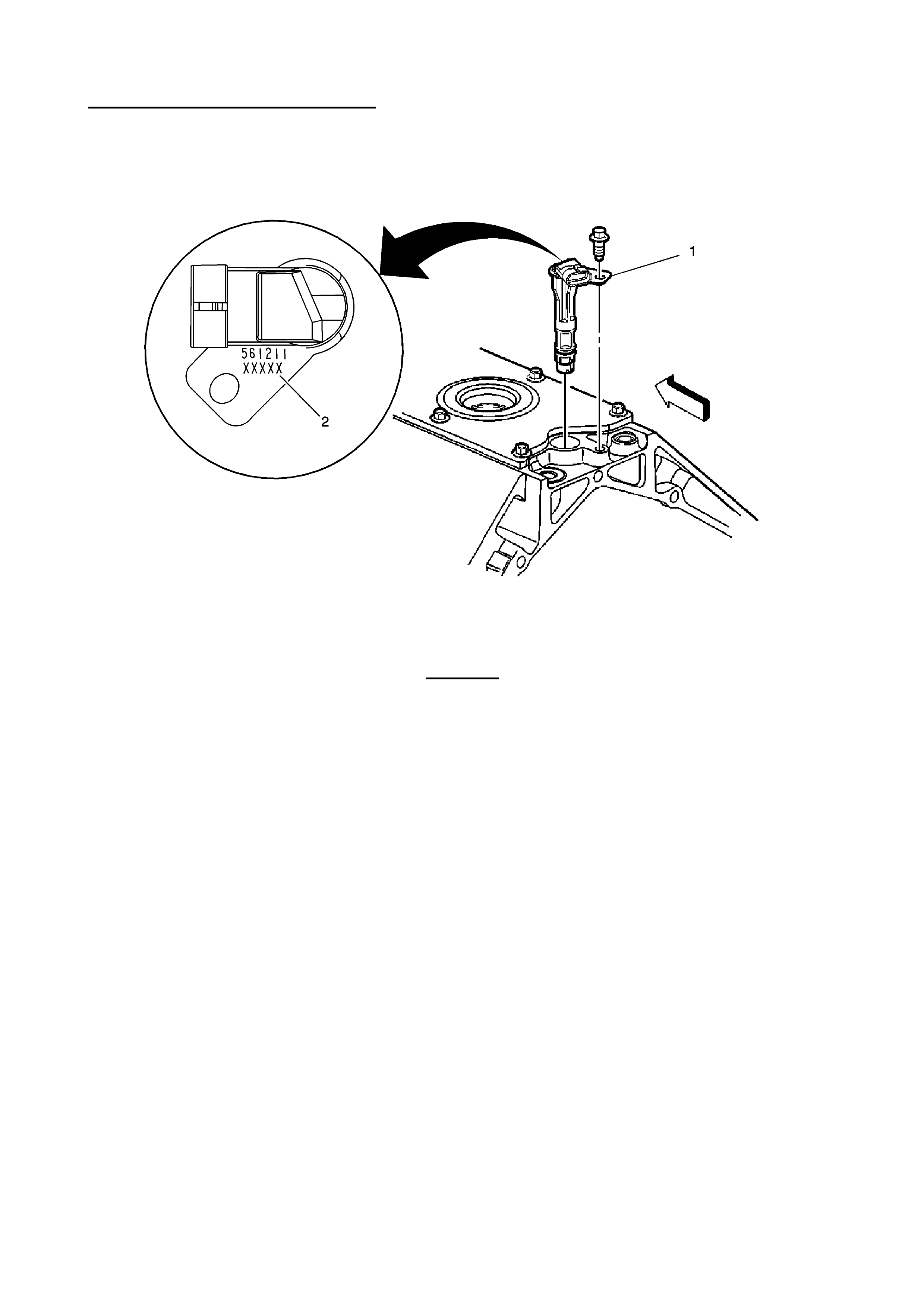

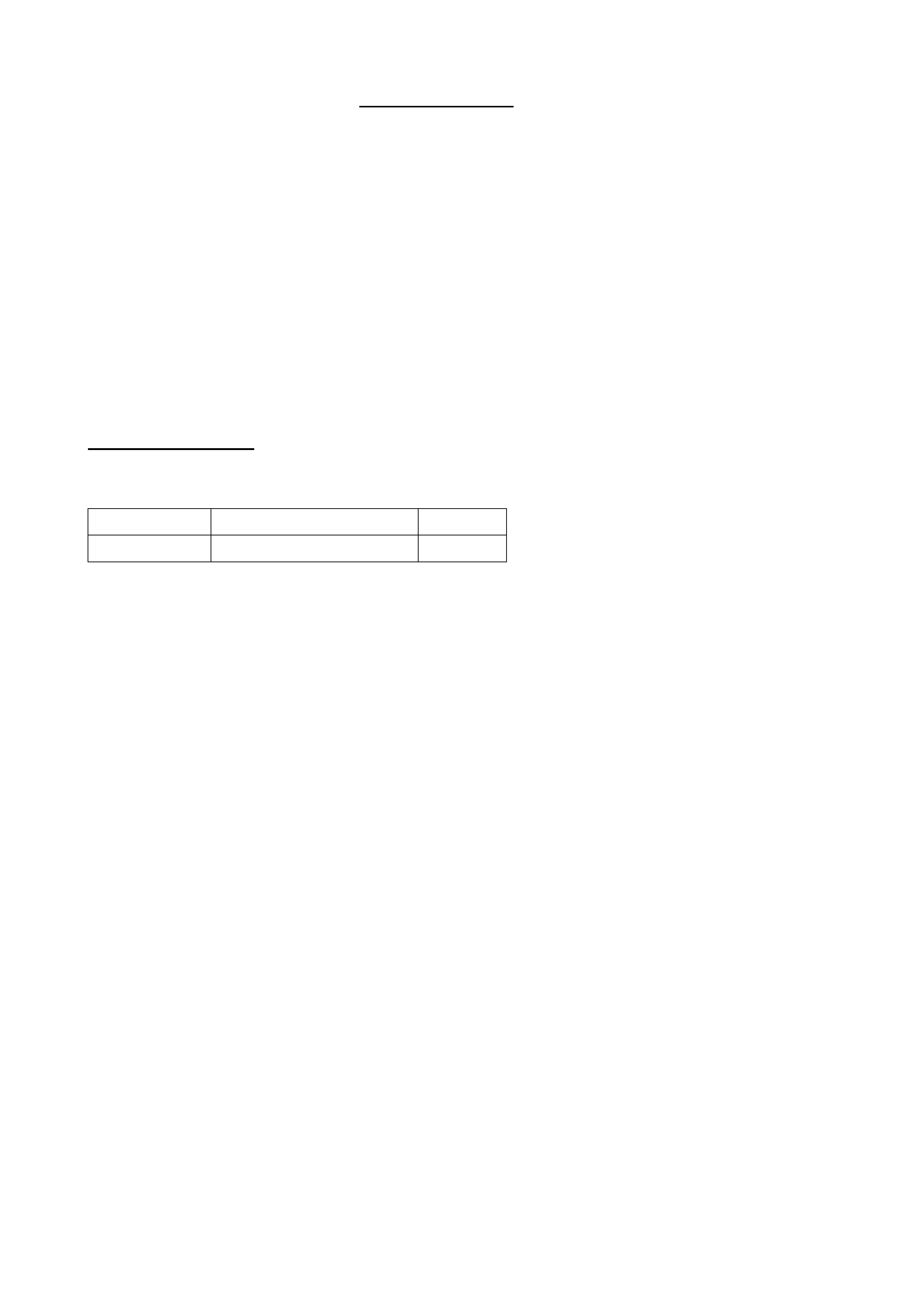

Should the fault occur, inspect the date code stamped on the camshaft position sensor - Refer

Figure 1.

Replace fault y camshaft position sensor s with date codes numerically lower than t he following:

Camshaf t Position Sensor Date Code - 99246 ( r epr esent s day 246 of 1999)

Clear any existing DTC’s and roadt est the vehicle.

Where the DTC re- occurs af t er r eplacement of a fault y camshaf t sensor , or the sensor fitted t o the

vehicle is post breakpoint of the dates advised above, carry out existing diagnostic procedures in

current ser vice inf ormation relevant to the code/ s st or ed.

PRODUCTION RECTIFICATION

A vehicle ISOVIN or PSN No. is not available. The appr oximate eng ine number, f or int roduction of

post breakpoint camshaft position sensors into engine production is:

Engine No.: Build Date:

VF99263XXXX 20/09/99 (=day 263)

NOTE: this Engine No. defines that any engines built on day 263 of 1999 are “OK”.

W here “99” = 1999, “263” = day 263, and “XXXX” represents the serial number of the engine built

that day.

PARTS INFORMATION

All camshaft position sensors in HSPO stock have been inspected and are post breakpoint of the

dates advised.

Any camshaft position sensors found in dealer parts st ock with date codes earlier than t hat shown

above must not be used, but r eturned to HSPO for credit.

Sensor part num ber ( for reference) is:

Part No.: Description: Qty

12561211 Sensor, Camshaft Position 1

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual.

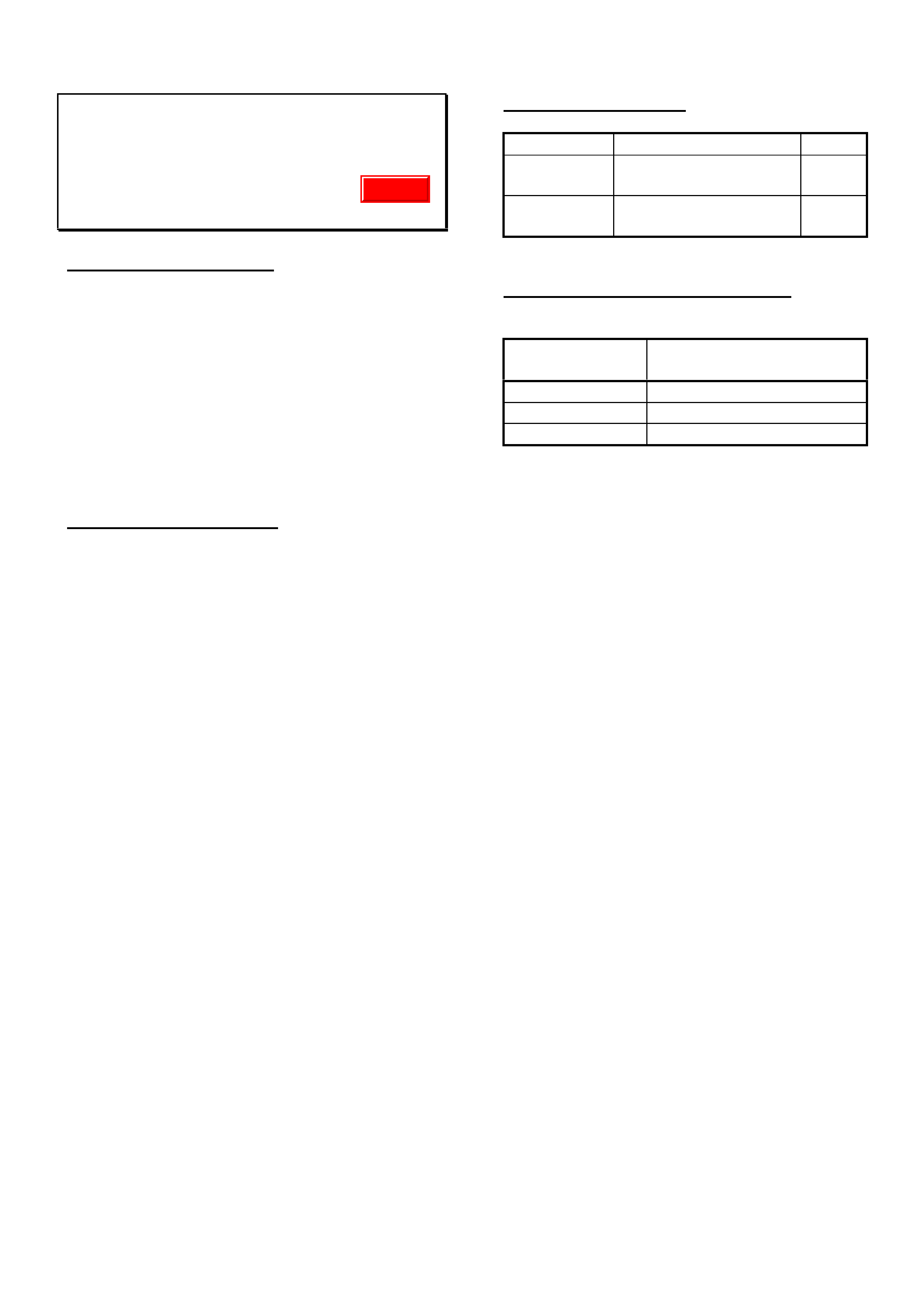

Figure 1

1. Camshaft Position Sensor

2. Date Code (Replace if Date Code “XXXXX” is lowe r than 99246)

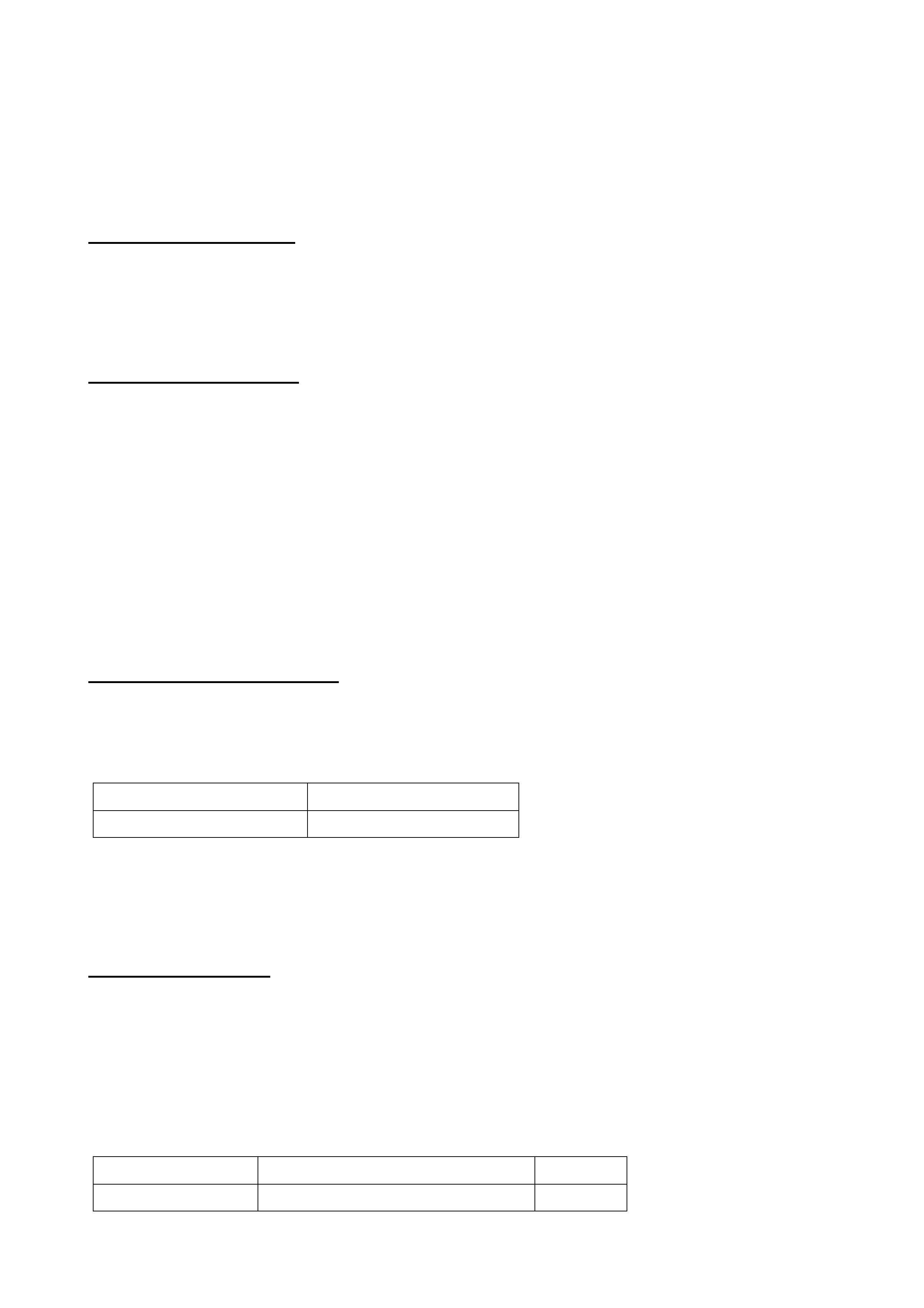

DTC P0335/ P0336 SET - CRANK POSITION SENSOR FAULT

VT, WH with GEN III V8

(GROUP 6C) February 2000

PROBLEM DESCRIPTION

Investigat ions into reports of DTCs P0335 and P0336 have identif ied a pot entially f aulty crank shaf t

position sensor. Separation of the crankshaft position sensor internal circuit board can cause the

fault to occur. Customers may report that the engine is unable to be started, an engine stall

condition has occurred or that the check engine lamp is illuminated.

SERVICE RECTIFICATION

Should the fault occur, inspect the date code stamped on the, crankshaft position sensor - Refer

Figure 1.

Replace crankshaft position sensor s with date codes numerically lower than t he following:

Crankshaft Position Sensor Dat e Code – 99237

(Represents day 237 of 1999)

Clear any existing DTC’s and roadt est the vehicle.

Where the DTC re-occurs after replacement of a faulty crankshaft position sensor or the sensor

fitted to the vehicle is post breakpoint of the dates advised above. Carry out existing diagnostic

procedures in curr ent Ser vice information relevant t o the code/s stored.

PRODUCTION RECTIFICATION

A vehicle ISOVIN or PSN No. is not available. The appr oximate eng ine number, f or int roduction of

post break point crankshaft position sensors int o engine production is:

Engine No.: Build Date:

VF99263XXXX 20/09/99 (=day 263)

NOTE: this Engine No. defines t hat any eng ines built on day 263 of 1999 are “OK”.

W here “99” = 1999, “263” = day 263, and “XXXX” represents the serial number of the engine built

that day.

PARTS INFORMATION

All crankshaf t position sensor s in HSPO st ock have been inspected and ar e post break point of the

dates advised.

Any crankshaft position sensors found in dealer parts stock with date codes earlier than that

shown above must not be used, but returned to HSPO for cr edit .

Sensor part num ber ( for reference) is:

Part No.: Description: Qty

12560228 Sensor, Crankshaft Posit ion 1

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual.

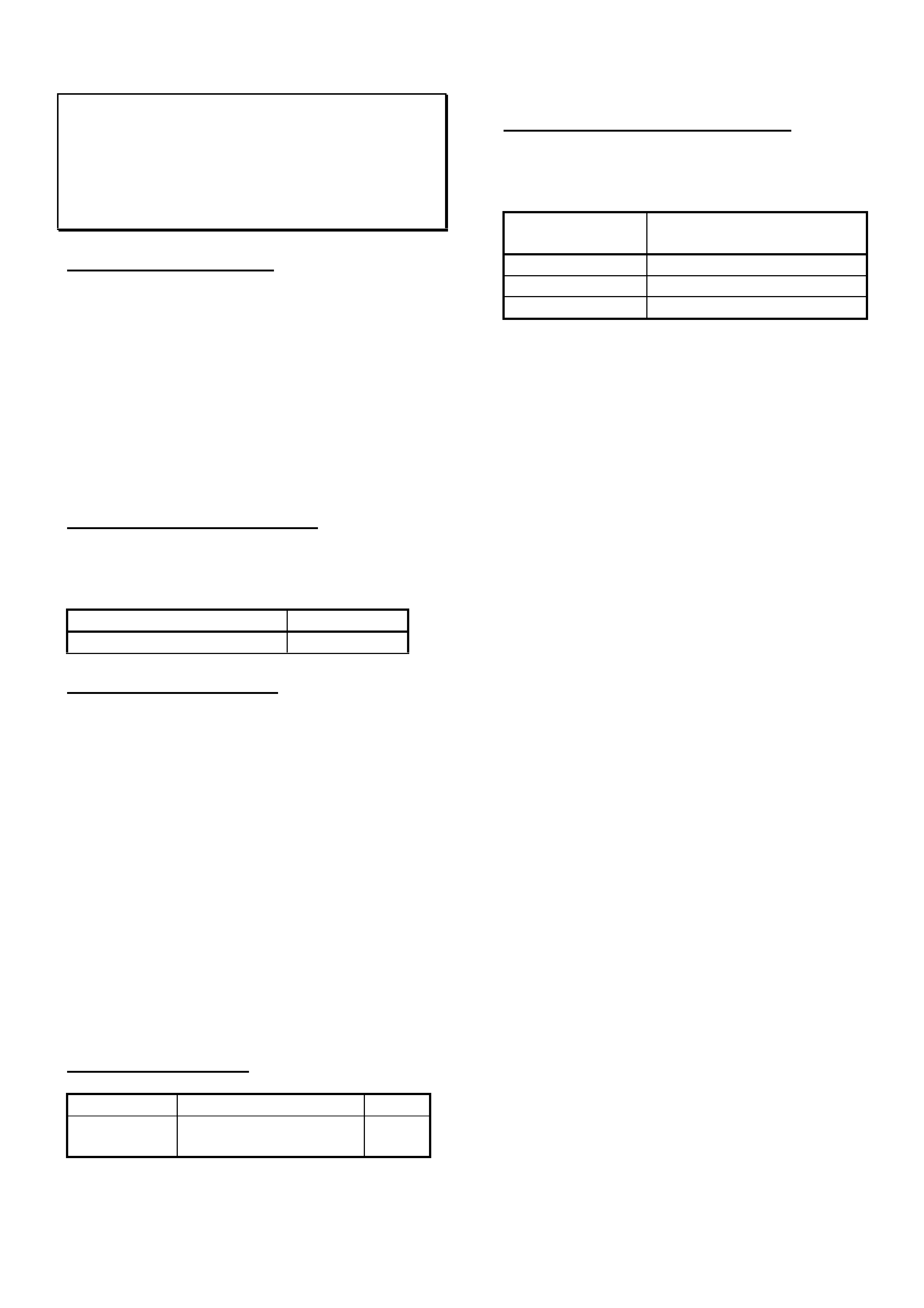

Figure 1

1. Crankshaft Position Sensor

2. Date Code (Replace if Date Code “XXXXX” is lowe r than 99237)

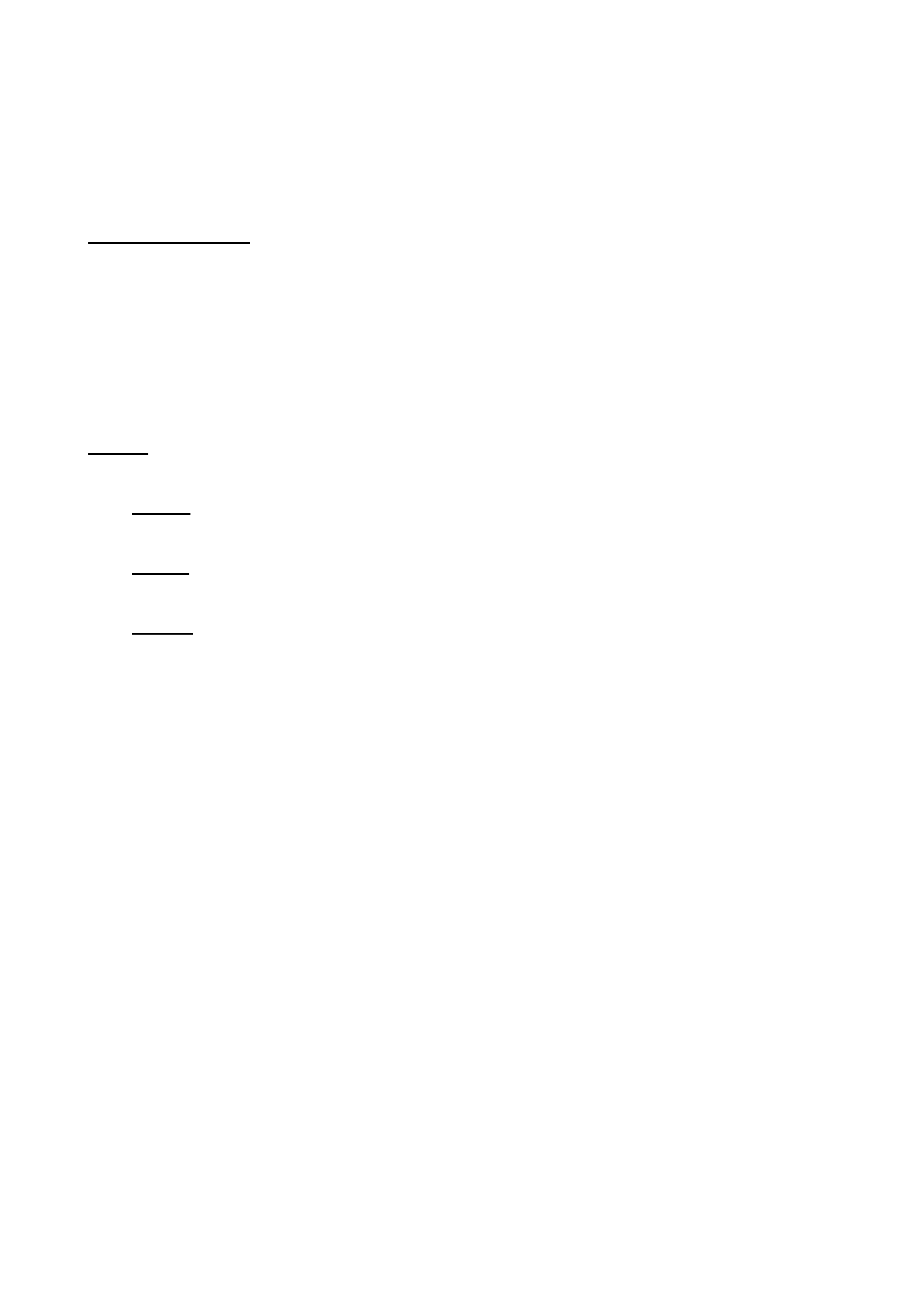

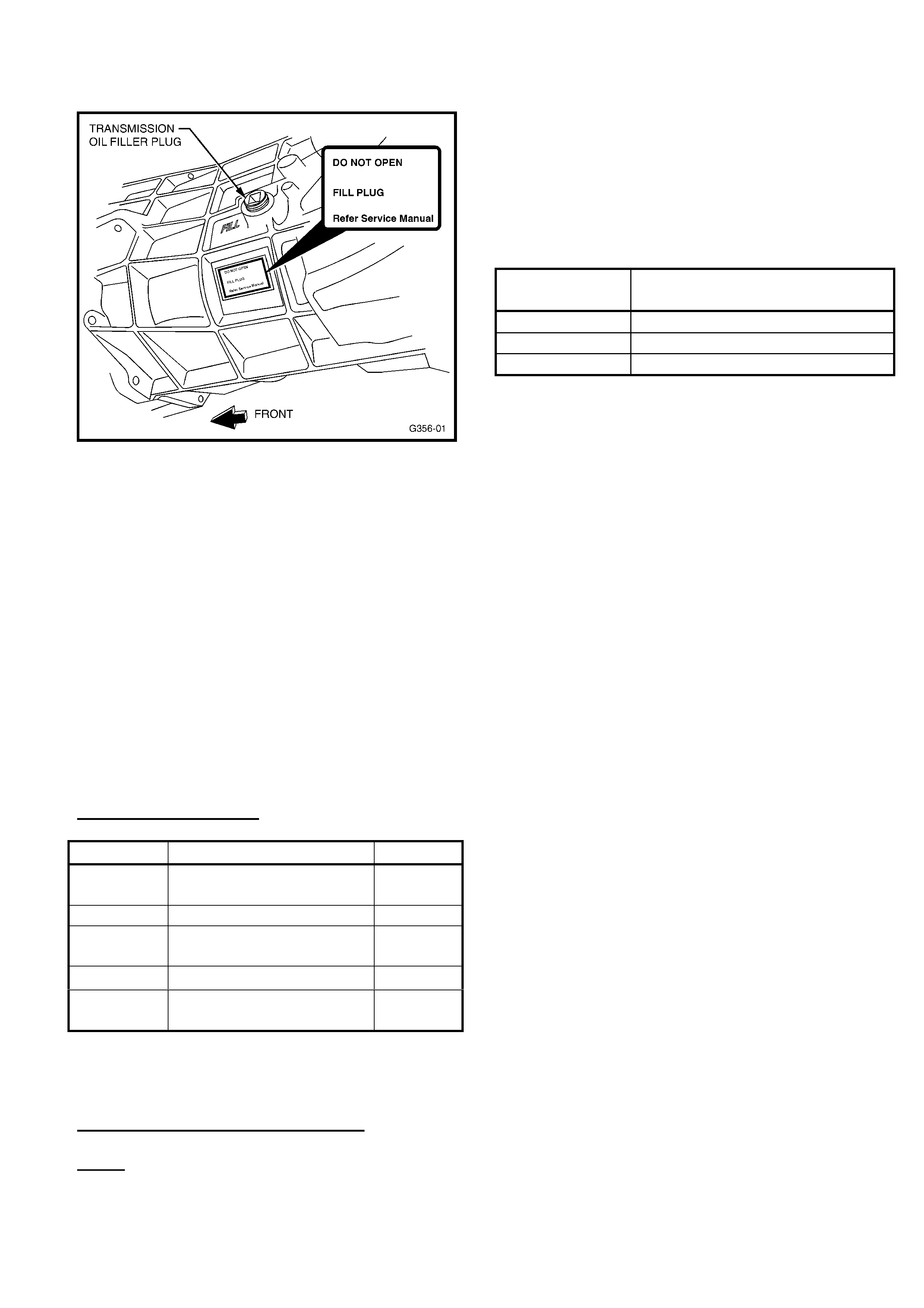

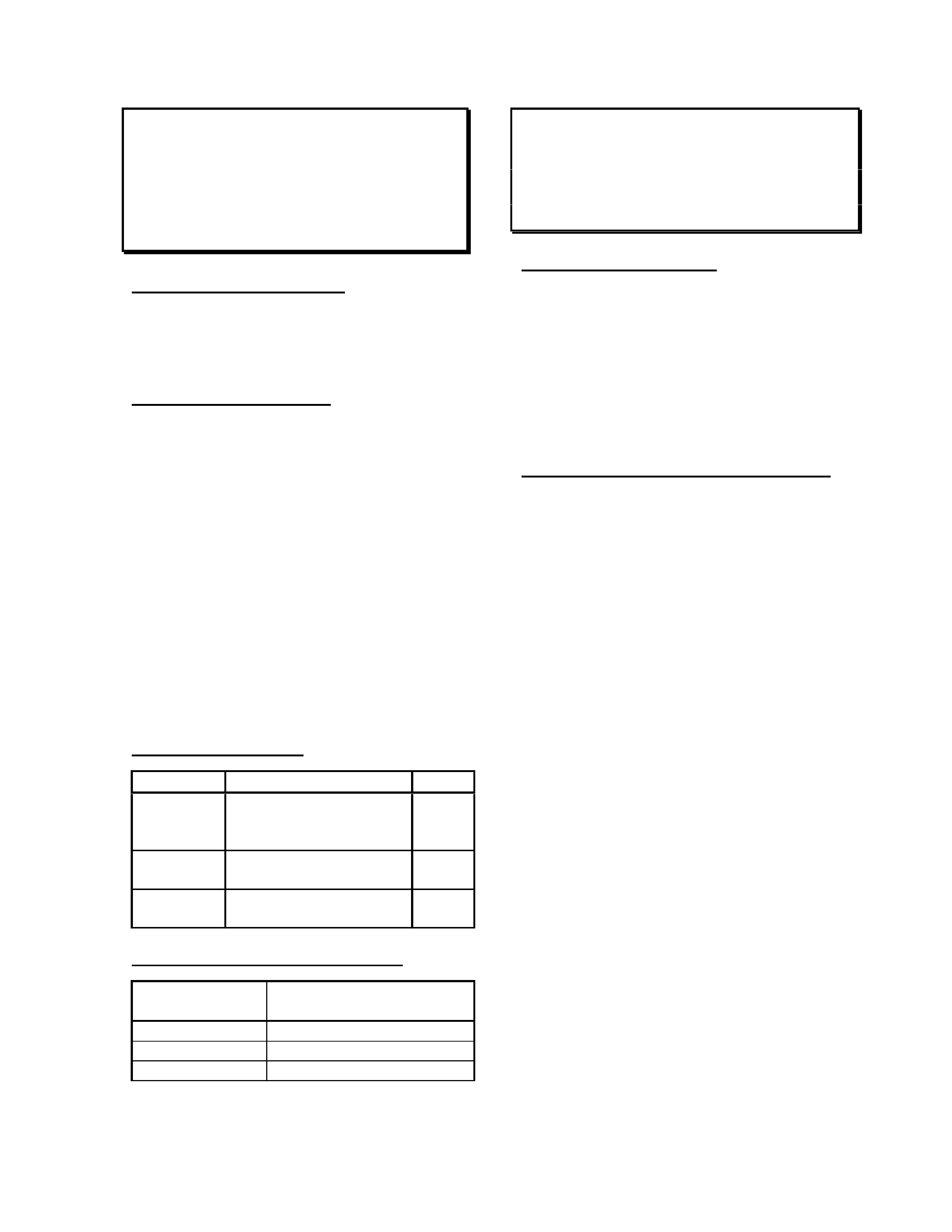

M/T OIL SPEC. REVISION

JS, JR, TR, TS, SB

(GROUP 7A) REISSUED February 2000

This Service Techline supersedes the previous Techline on this topic (Issue 10, December, 1999

page 12). This previous Techline should be dest r oyed.

This Techline is to advise technicians of a new manual transmission oil specification for use in

JS Series II, with F23 M/T.

Oil specified for these transmissions is:

CASTROL SMX-O

This oil is also recom m ended for the following models - by transmission type:

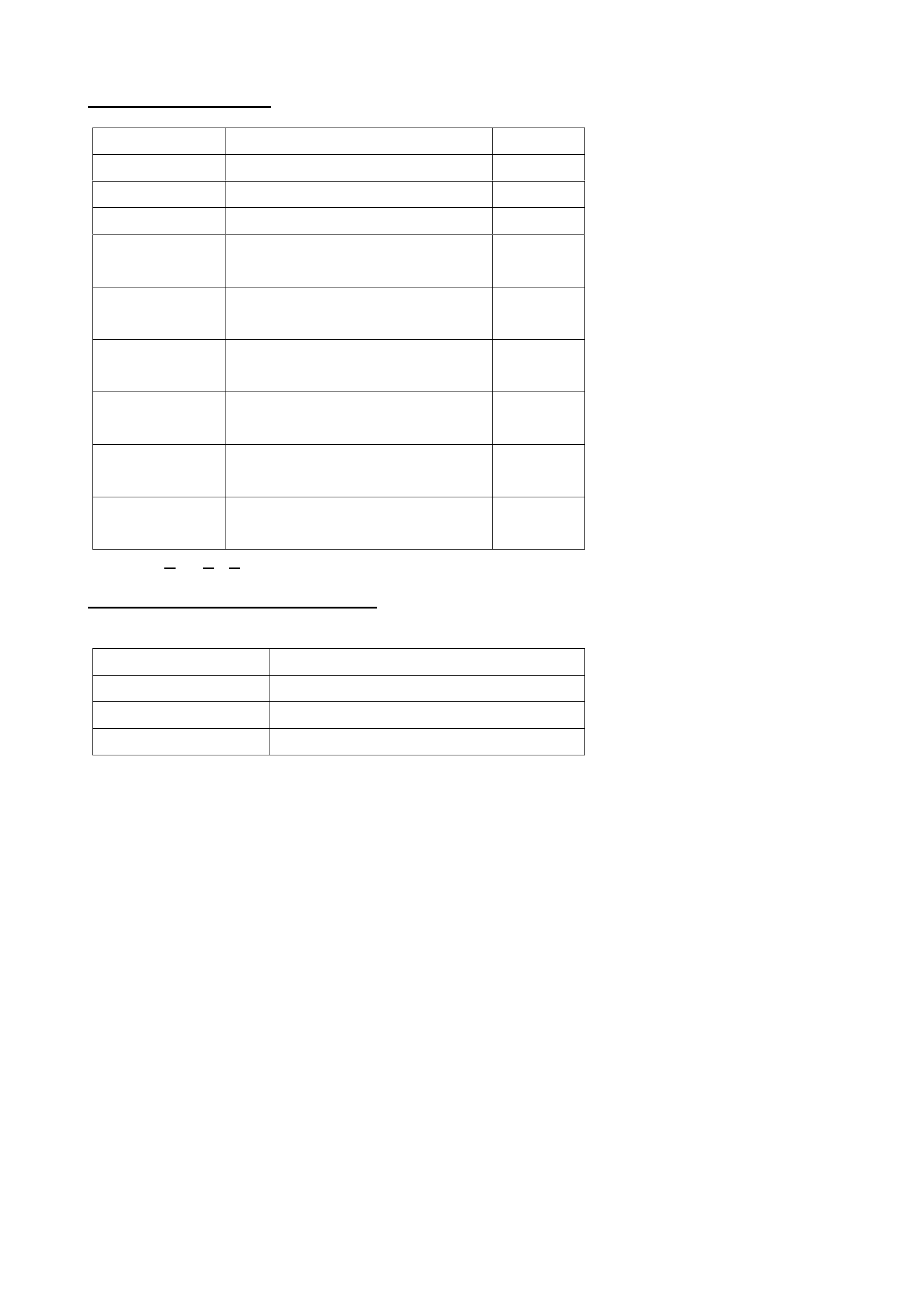

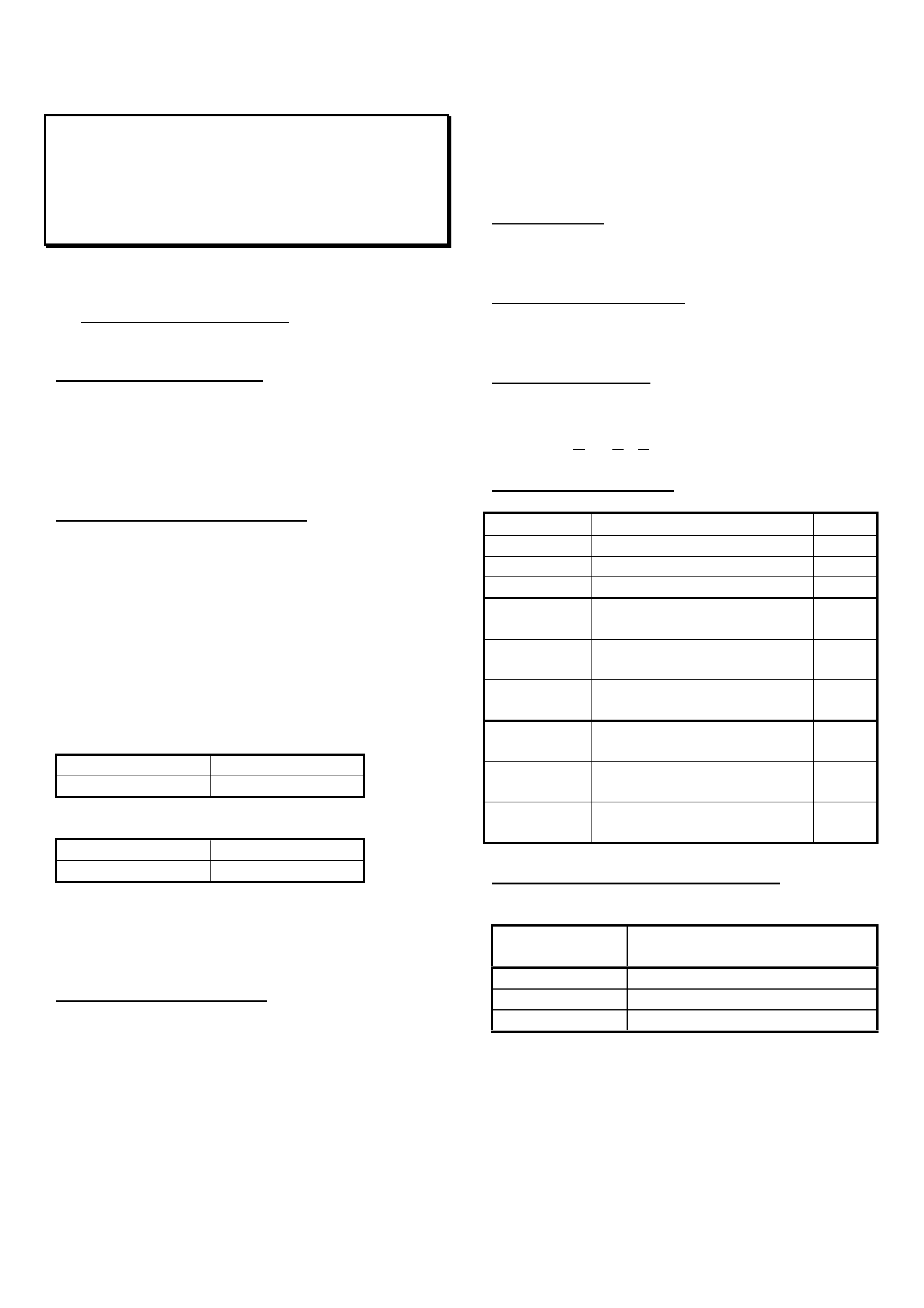

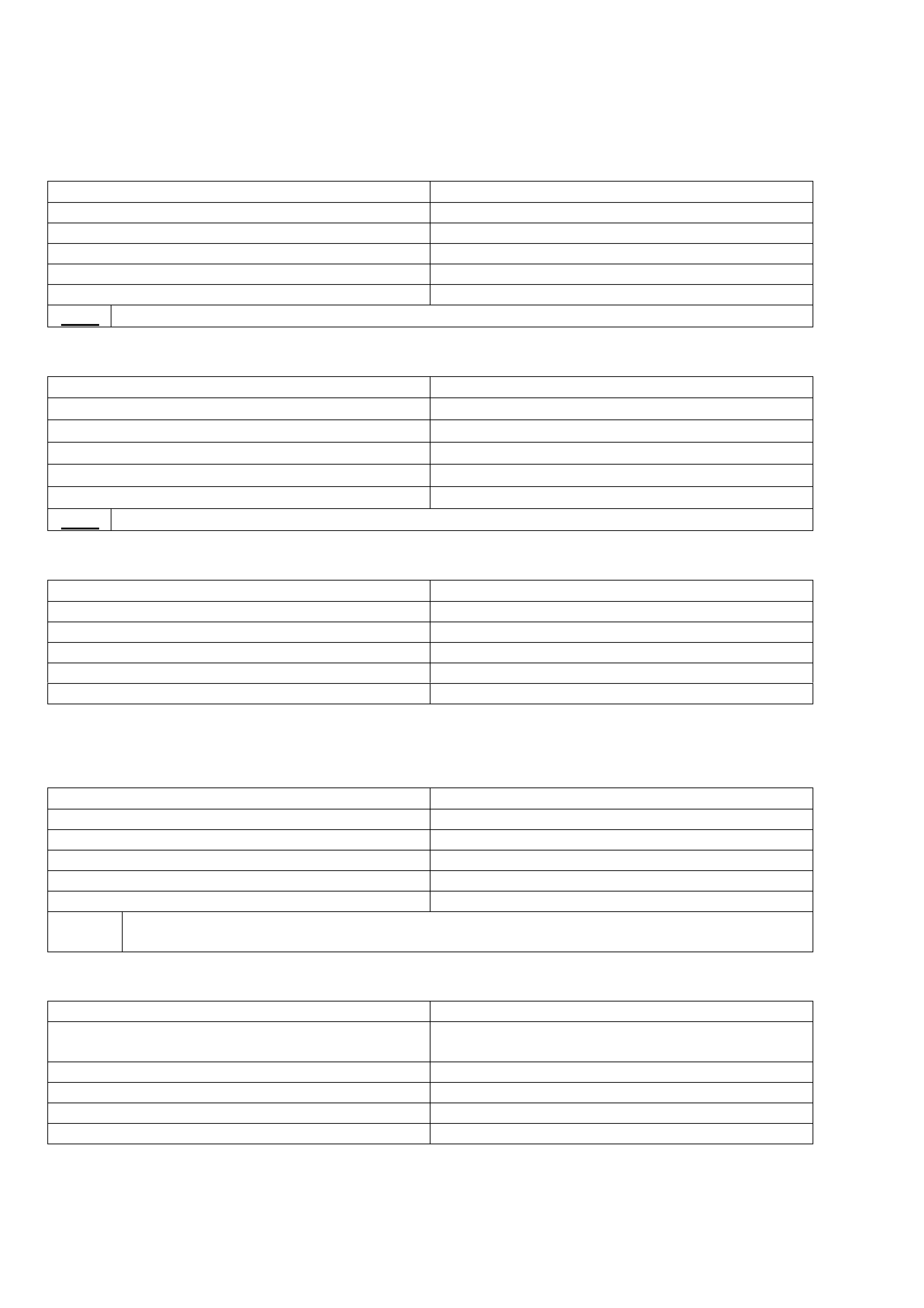

Model

&

Trans. Type

Castrol

SMX-O Current Holden 92140007

and Previously available oils

MTF1067, MTF1067 & MTF0063

SB – All M/T ✔

✔✔

✔✓

TR – All M/T ✔

✔✔

✔✓

TS – All M/T ✔

✔✔

✔✓

JR – All M/T ✔

✔✔

✔✓

JS Series I,

F18 Trans. ✔

✔✔

✔✓

JS Series II,

F23 Trans. ✔

✔✔

✔✖

✔

✔✔

✔ = RECOMMENDED

✓ = MAY BE USED

✖ = DO NO T USE

SERVICE USAGE & PRECAUTION

Castrol SMX-O oil MUST be used at all times in JS Vectra Series II with F23 M/T, and may be

used for ser vice replacem ent or ‘top-up’ of oil in t he above manual t r ansm issions.

Holden oil Part No. 92140007 remains available from HSPO, and can be used as per

recommendat ions in t he chart above.

Castrol SMX-O r eplaces pr eviously released Castrol oils MTF1067, MTF1067 & MTF0063

These previously released oils MUST NOT be used in JS Series II, F23 M/T, for durability

reasons.

At the time of release of this bulletin, there are no commercially available equivalents to Castrol

SMX-O for this JS Series II usage.

PRODUCTION INTRODUCTION

Oil to this specification was introduced at st ar t of JS Vectr a Ser ies I I vehicle production as follows:

ISOVIN: Build Date:

W0L0JBF19YL482379 30/07/99

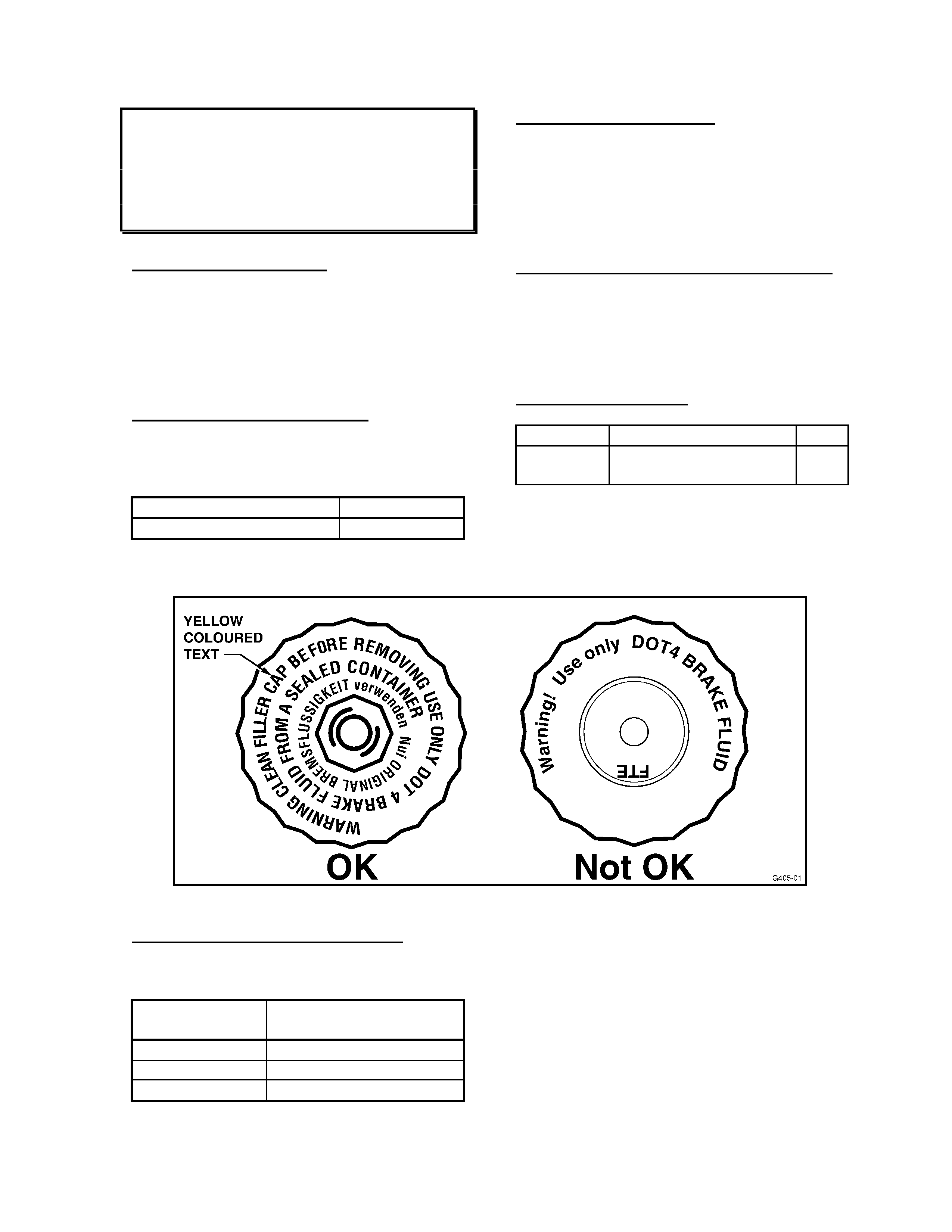

FUEL TANK/CAP REPLACEMENT REQUIREMENT

JR (All), JS (Hatch)

(GROUP 8) February 2000

SERVICE REQUI REMENT

Whenever a fuel tank is replaced on:

JR - all models

JS - Hatch models only with compliance Plate dated up to and including 31/12/98.

the f uel t ank filler cap should also be r eplaced with a later filler cap.

PRODUCTION RECTIFICATION

The later filler cap (vented type) has been fitted to all JS Sedan and Wagons from start of JS

production, and t o JS Hat c h m odels with Compliance Plat es dat ed after 01/ 01/ 99.

Compliance Plates are locat ed on RHF strut tower.

PARTS INFORMATION

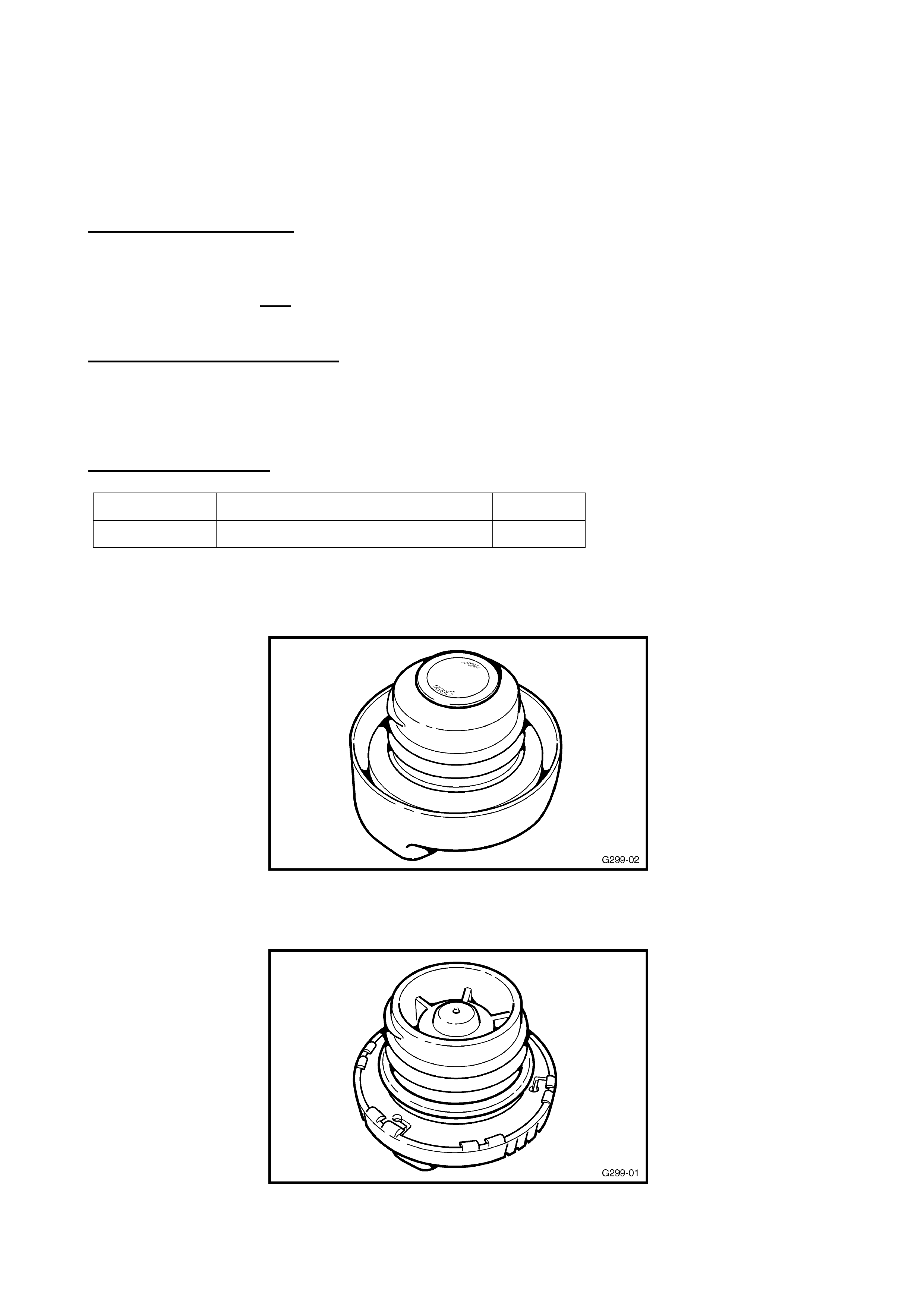

Part No.: Description: Qty

92078849 Cap, Fuel Filler 1

To identify early (non-vented) and later (vented) filler caps fitted to vehicles – the following

sketches ar e pr ovided. Ear lier design f iller caps ar e no longer available from HSPO .

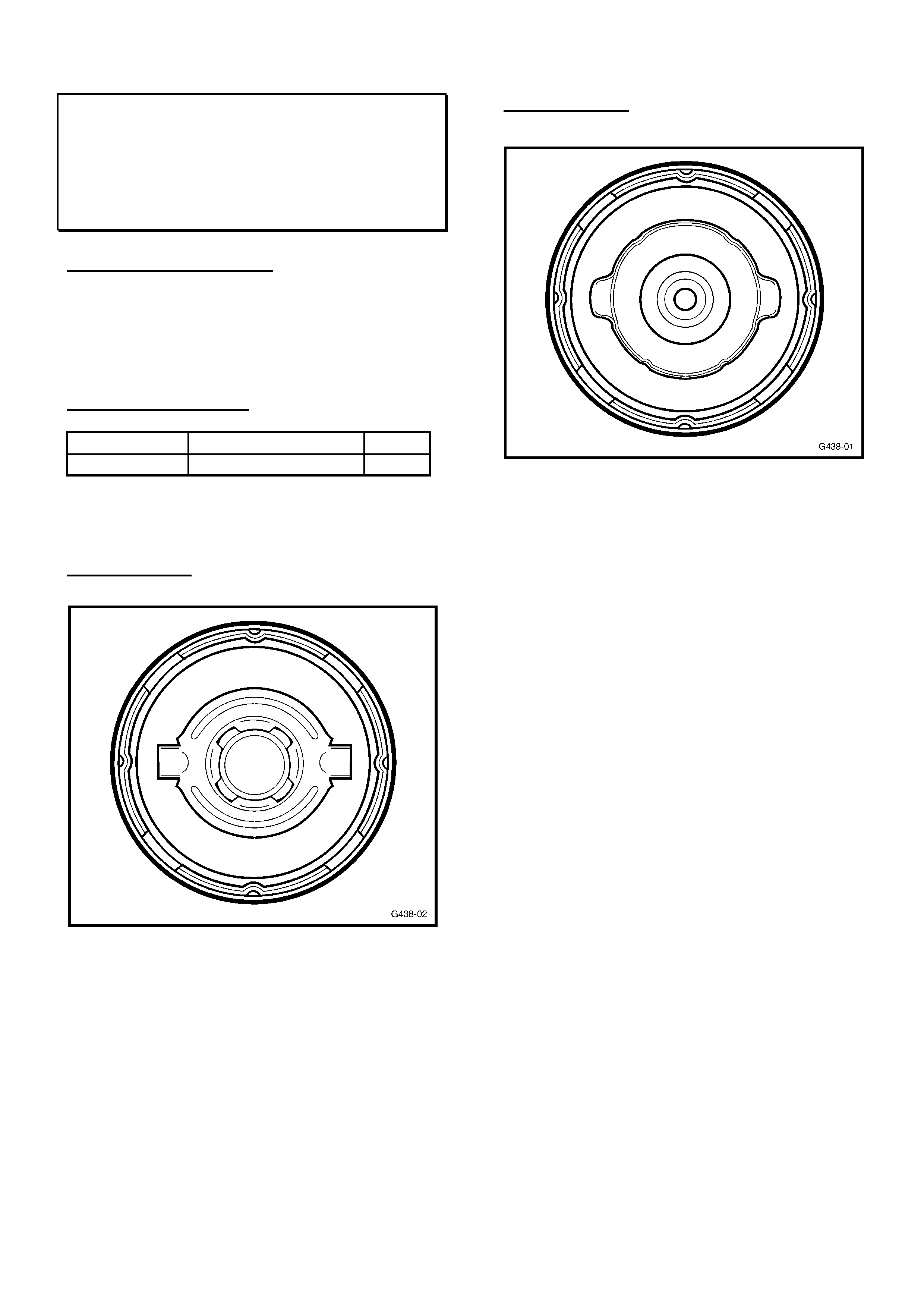

Early Filler Cap

Do NOT re-fit when replacing a fuel tank

Later Filler Cap

Fit when replacing fuel tank (as noted).

POOR AM RADIO RECEPTION

JS

(GROUP 12) February 2000

PROBLEM DESCRIPTION

Some vehicles are reported to have poor radio reception and excessive levels of vehicle induced

interference while listening to “AM” band stations. Investigations have identified ignition noise and

poor antenna connections as the pr im ar y causes.

Various root causes have been identified and f ixes introduced to overcome recept ion problems on

the “AM” band.

PRODUCTION RECTIFICATION

•Ignit ion system ear t h st rap installation for JS:

Introduced Start of Production

•Antenna lead routing on the right hand side of the vehicle:

Introduced 12/11/98, Tag L396309.

•Installation of turn sig nal relay to overcome popping noise:

Introduced 11/ 01/ 99, W1361702.

•Assembly plant test t he r eception signal:

Introduced May 99.

SERVICE RECTIFICATION

•For vehicles built prior to 12/11/98, L396309 refer to the September 98’ Techline (Page 80 of

1998 Service Communicat ion Book) on the same subject and f ollow the procedures to rer oute

the antenna cable. Then continue with the checks out lined below.

•Vehicles built af ter 12/11/98, L396309 will have the antenna cable re r outed. Technicians are

advised to commence with antenna circuit connection and earthing checks.

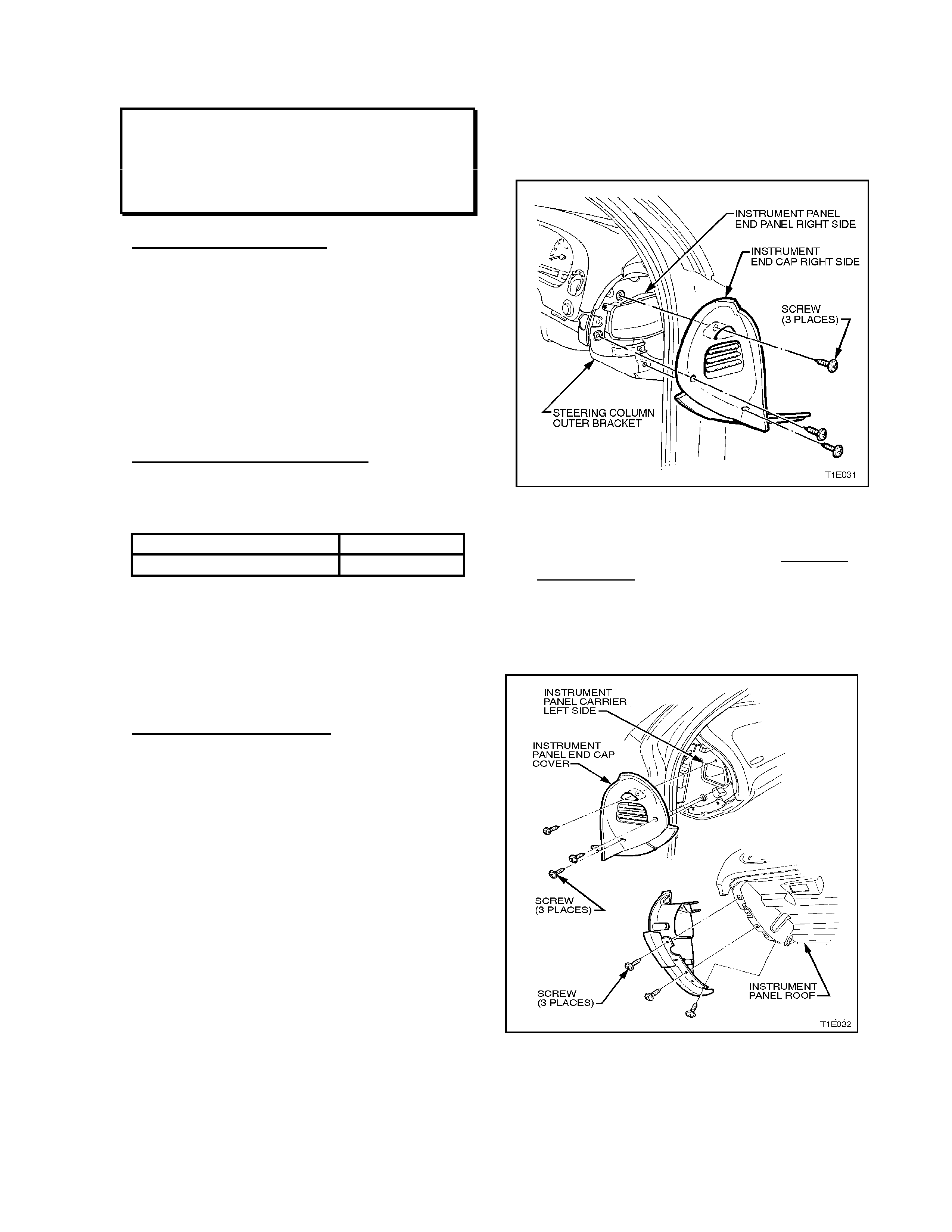

1. Use the Vectra radio rem oval k eys, to detach the radio from the cr adle.

2. Remove the radio cradle and ensure the antenna connector at the back is inserted correctly

and the centre m etal pin of the ant enna is not broken or bent .

Note: The antenna connection may become dislodged whilst reinstalling the radio. Apply

some tape to the connection preventing the antenna from dislodging during the radio

installation.

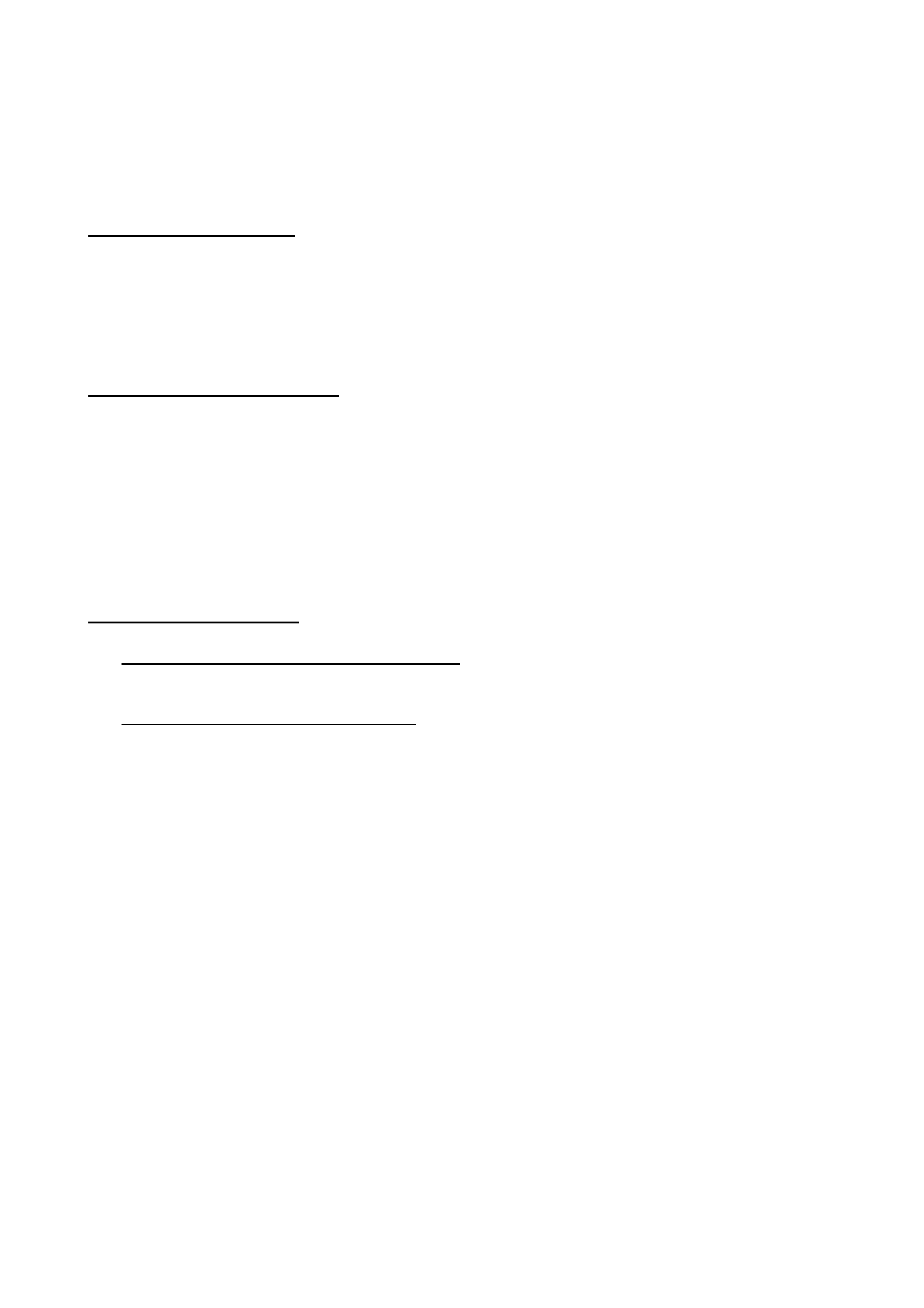

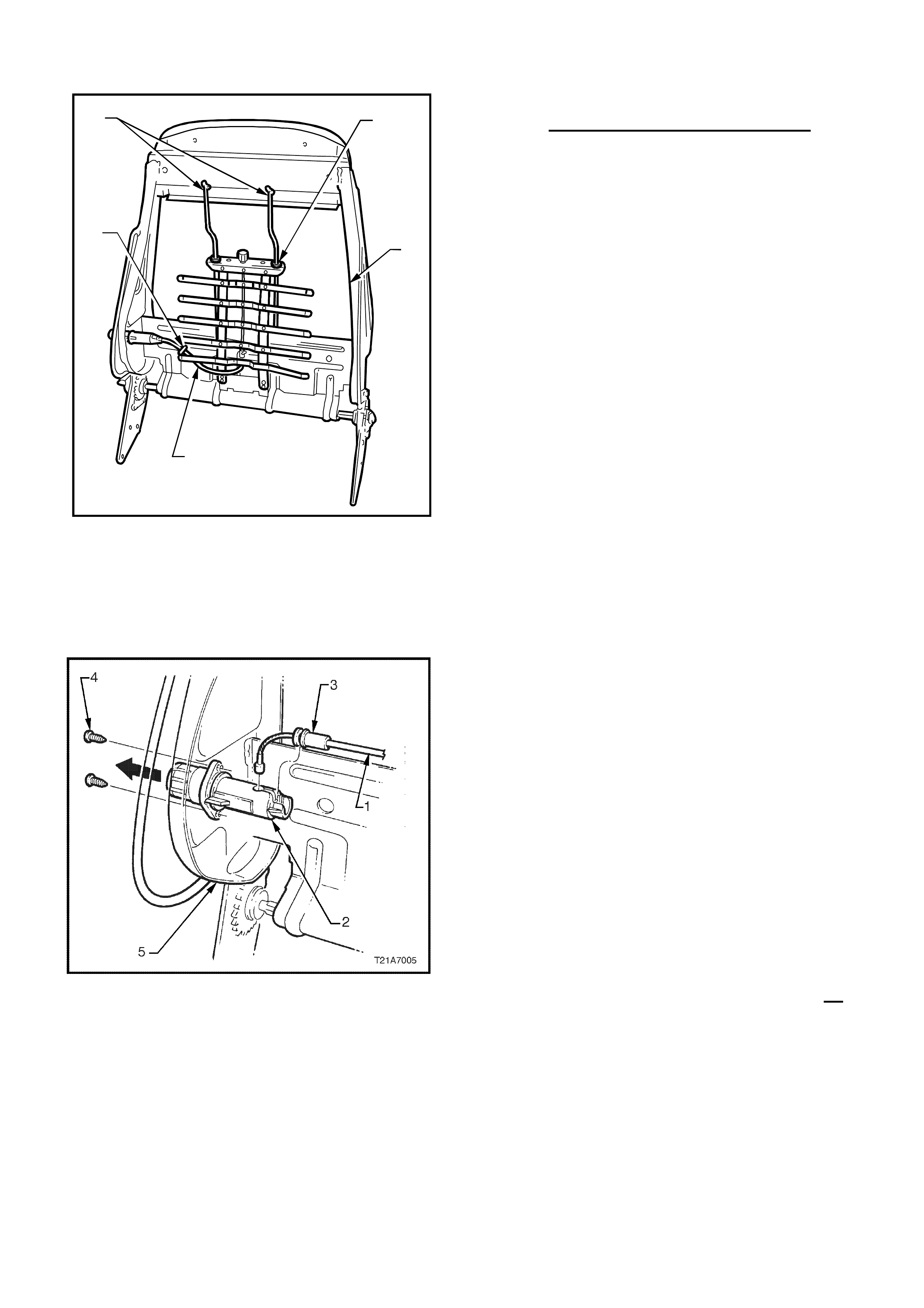

3. On sedan models, remove the parcel shelf and ensure that the two antenna amplifier box

attaching nuts are tight (1). Also check that the 2 pin power connector to the amplifier is f ully

home (2). (Refer to Figure “A” following).

Figure “A”

4. On hatch and wagon models, ensure the attaching nut that holds the antenna amplifier to the

roof panel is not loose. This nut and stud is the earth path for the ant enna amplifier so a good

earth is crit ical.

5. Also on hatch and wagon models, check the coaxial cable where it enters the amplifier for

damage such as a f rayed coaxial cable shield or exposed bare copper. To check coaxial cable

integrity at this location, tune the radio to a weak “AM” band station and increase the volume.

Then wrigg le t he ant enna lead and listen for changes in the level of inter ference.

TURN SIGNAL LAMPS INOPERATIVE AT LOW AMBIENT TEMPS.

VT

(GROUP 12) February 2000

PROBLEM DESCRIPTION

Investigation into reports of turn signal lamps inoperative at low ambient temperatures, have

identified the cause as being the hazard warning switch being partially dislodged in the instrument

panel fascia. This is caused by the lower locking tang of the switch distorting the switch case,

which in turn causes an interruption in the turn signal circuitry through the hazard switch.

PRODUCTION RECTIFICATION

Hazard warning switches with revised locking tangs have been fitted to vehicles from:

ISOVIN: Build Date:

6H8VTK69HYL543303 16/12/99

SERVICE RECTIFICATION

If presented with a vehicle that exhibits the symptoms described above, technicians should replace

the switch assembly with a post breakpoint part.

PARTS INFORMATION

Order the new part from HSPO PartFinderTM - all parts at HSPO are of the latest specification.

Revised hazard switches can be identif ied by date code. T he date code is hot st amped, par allel to

the lower edge of the switch body, on the left side of the switch body, when viewing t he switch as it

would be mounted in the instrum ent panel fascia.

OK parts ar e dat e coded: 06M9 and higher.

Where: 06 = Day; M = December; 9 = 1999

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual.

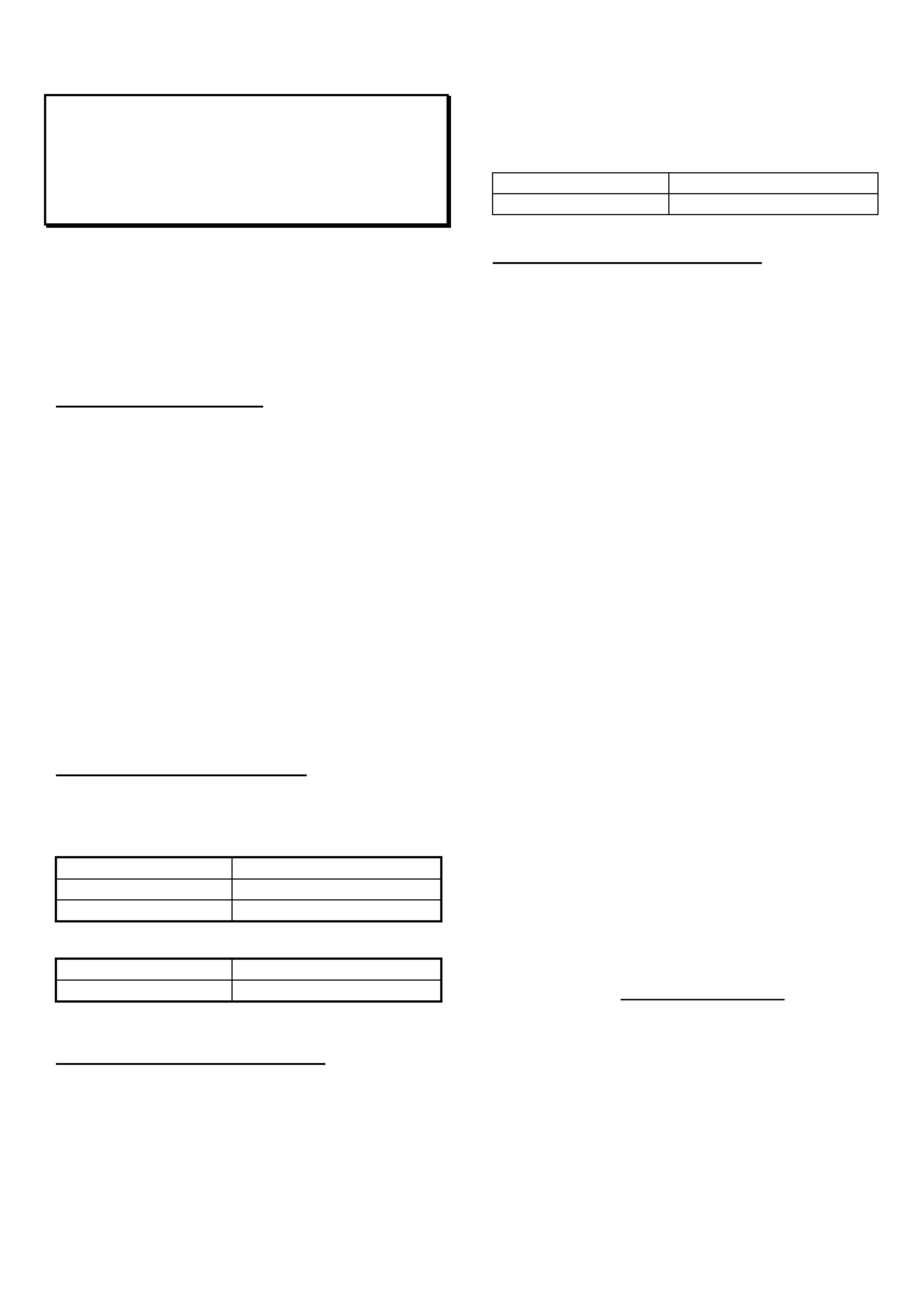

SPEED SIGNAL CONVERTER MODULE

JS (non-ABS)

(GROUP 12) February 2000

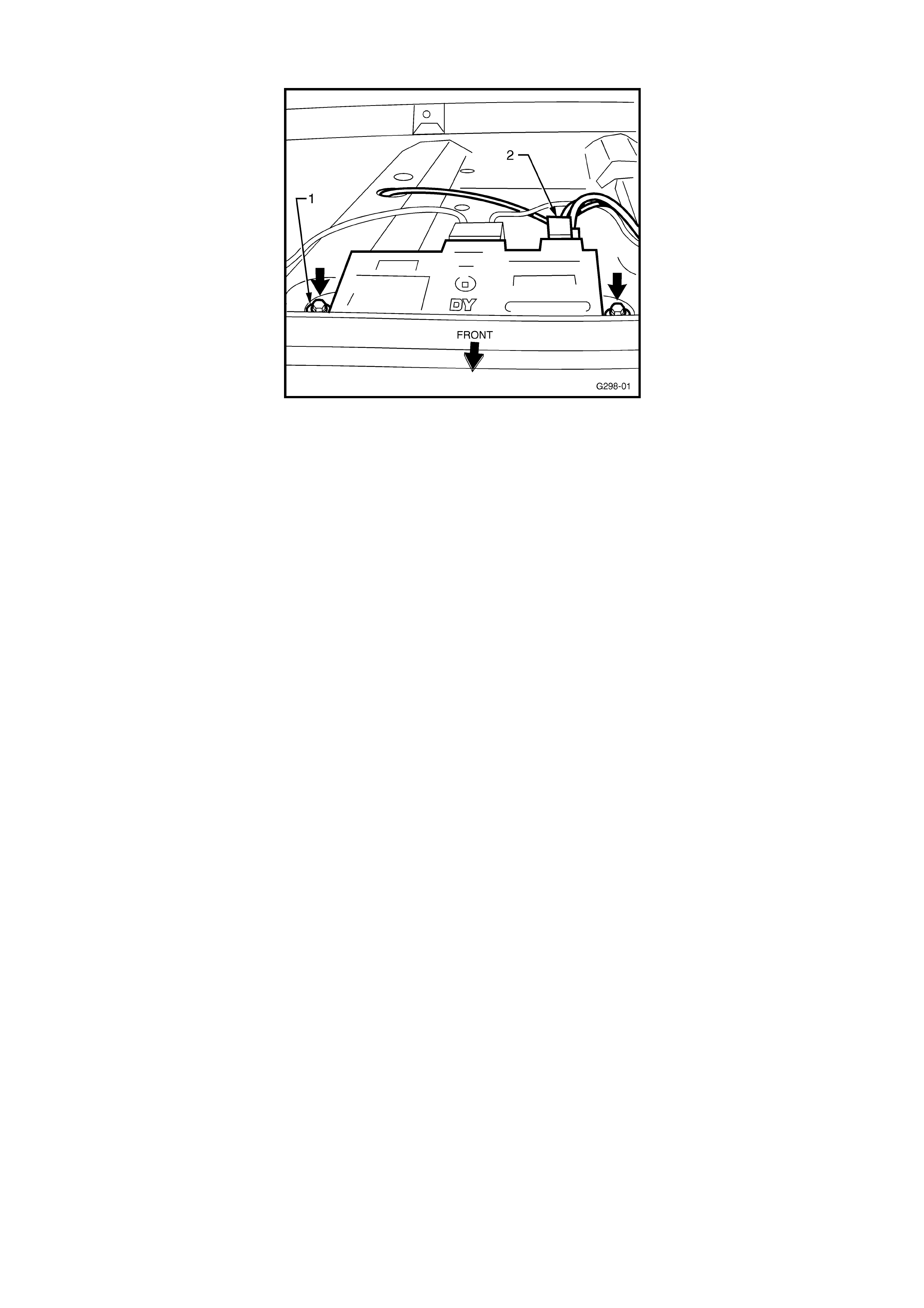

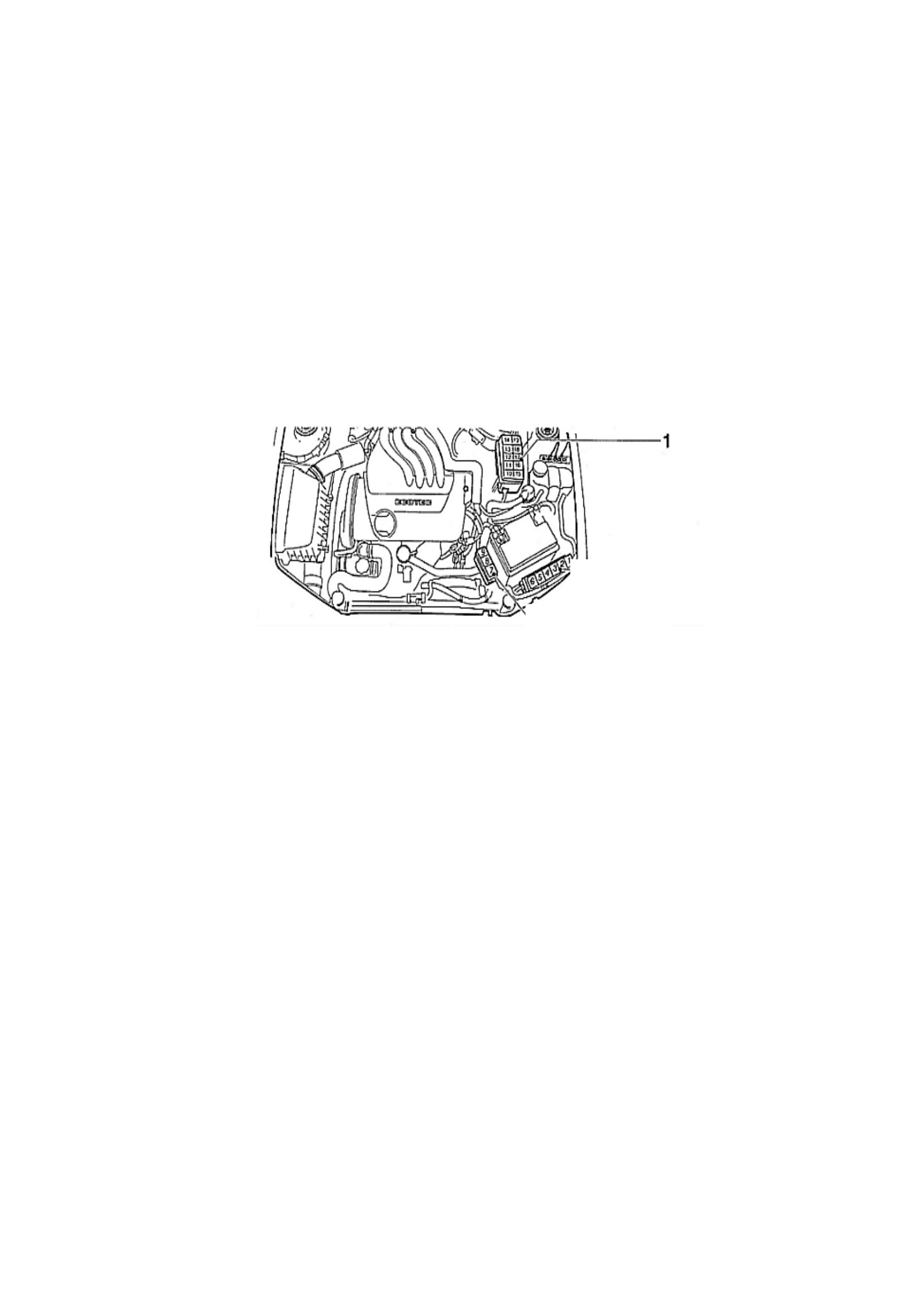

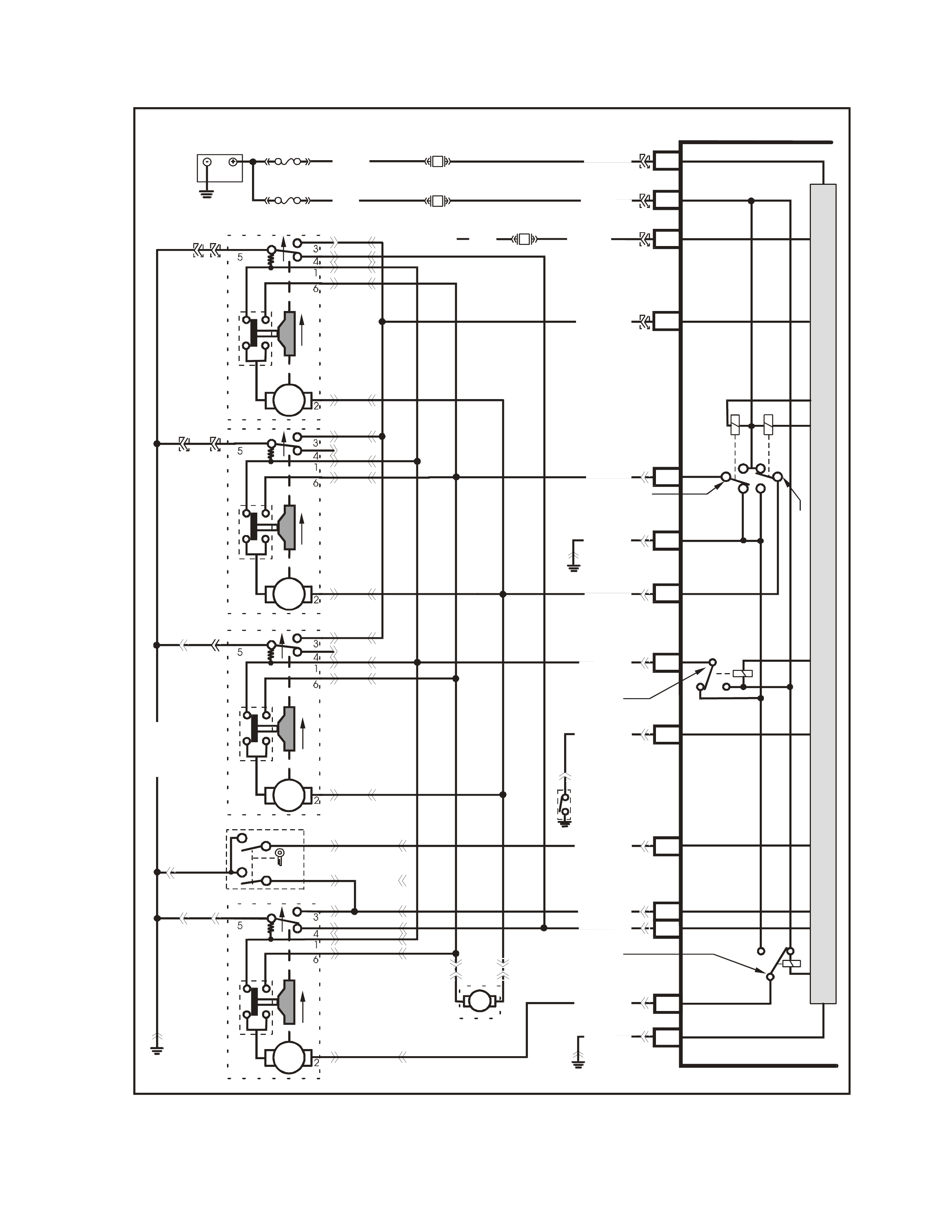

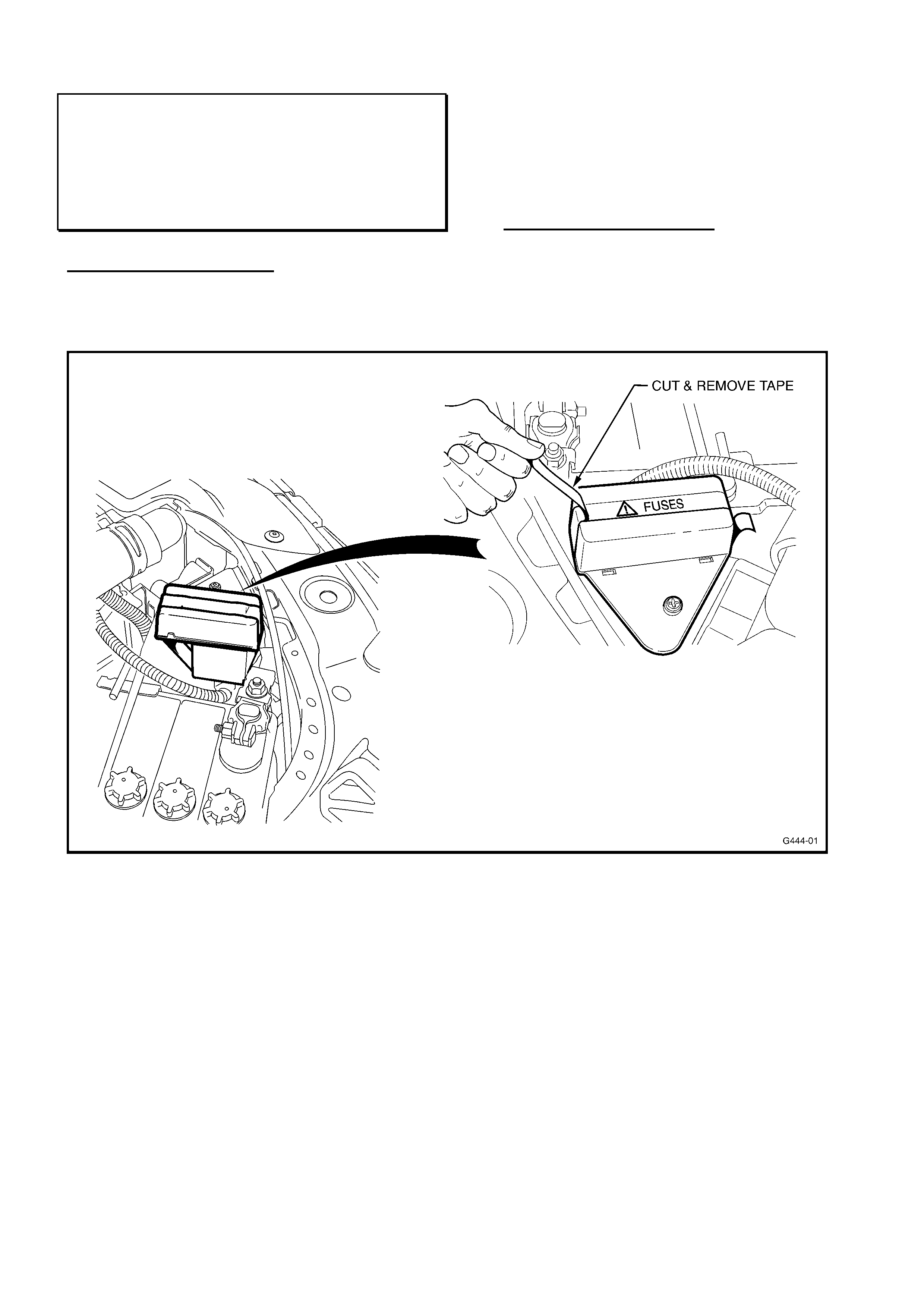

Some technicians have experienced difficulty in locating the speed signal converter module fitted

to JS Vectra vehicles without ABS. The JS series circuit diagrams indicate that the module is

located in the passenger compartment in the vicinity of the instrument panel, this information is

incorrect.

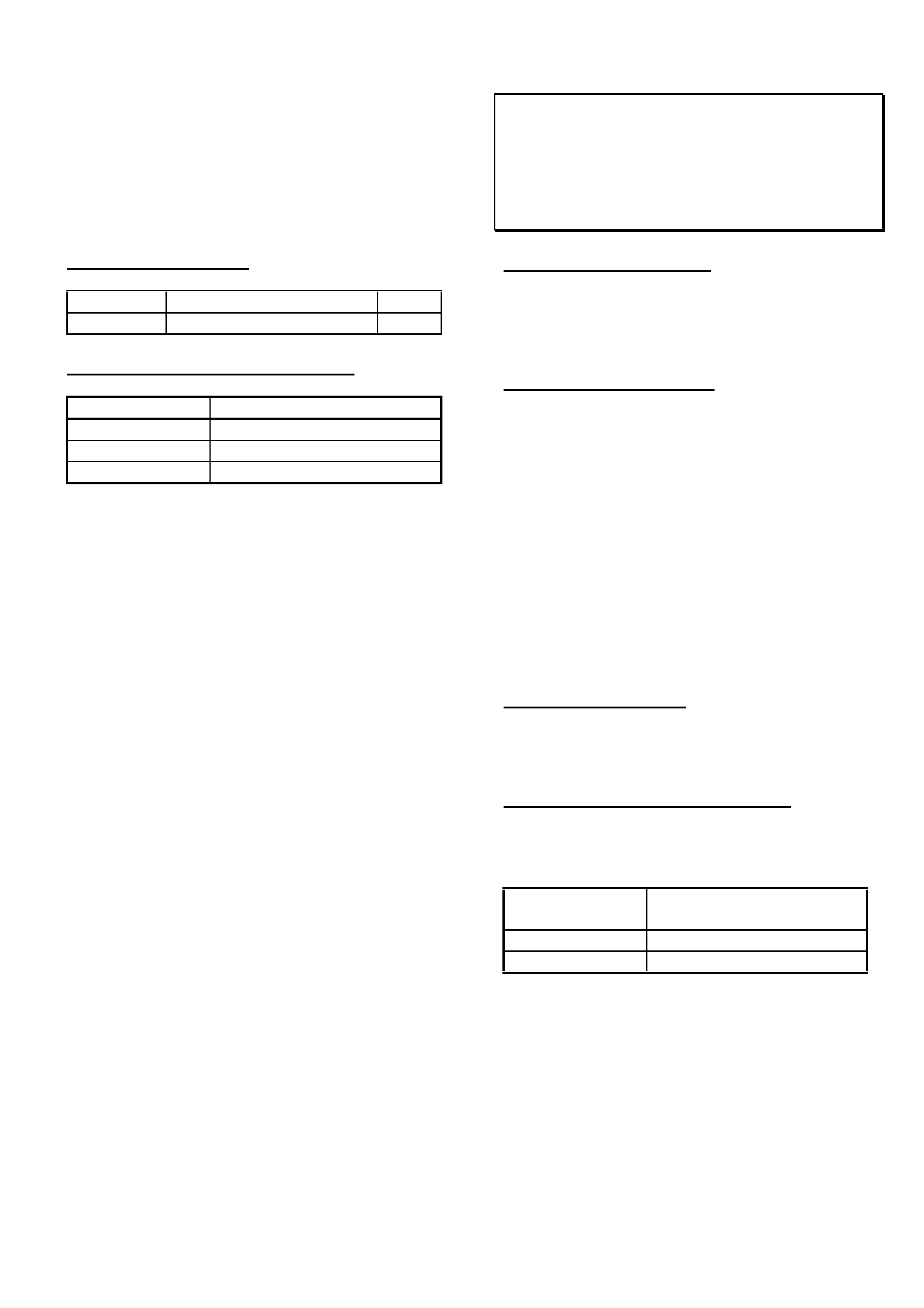

The speed signal converter module is in fact fitted in the relay box mounted in the engine

compartm ent (ref er k ey 1 figur e 1). The speed convert er module can be identif ied by its dist inctive

orange colour. Dealerships should update their copies of the JS Circuit Diagram Manual - Vehicle

Electrical System, “Views of relays and fuses” section, page 31 to reflect the correction in this

Techline issue.

Figure 1

POOR AM RADIO RECEPTION – TURN SIGNAL RELAY INTERFERENCE

JS

(GROUP 12) February 2000

PROBLEM DESCRIPTION

Some customers have complained that when using the turn sig nals with the radio t uned to an AM

radio station, they can hear indicator “popping” noise through t he r adio.

PRODUCTION RECTIFICATION

A revised relay was introduced into production in the impor ted model only.

ISOVIN: Build Date:

W0L0JBF68W1361702 11/01/99

This relay was not introduced into local pr oduction.

SERVICE RECTIFICATION

A revised turn signal relay with a noise filter installed, has been released to suppress the

interference.

Dealers are advised to fit this relay to rectify complaints of turn signal interf erence. The relay can

be distinguished by its yellow colour.

Note: The revised relay combines both left and right side turn signal relays. Technicians only

need to f it one r eplacem ent relay when fitting the r evised type.

PARTS INFORMATION

Part No.: Description: Qty

09134880 Flasher, T ur n Signal 1

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual.

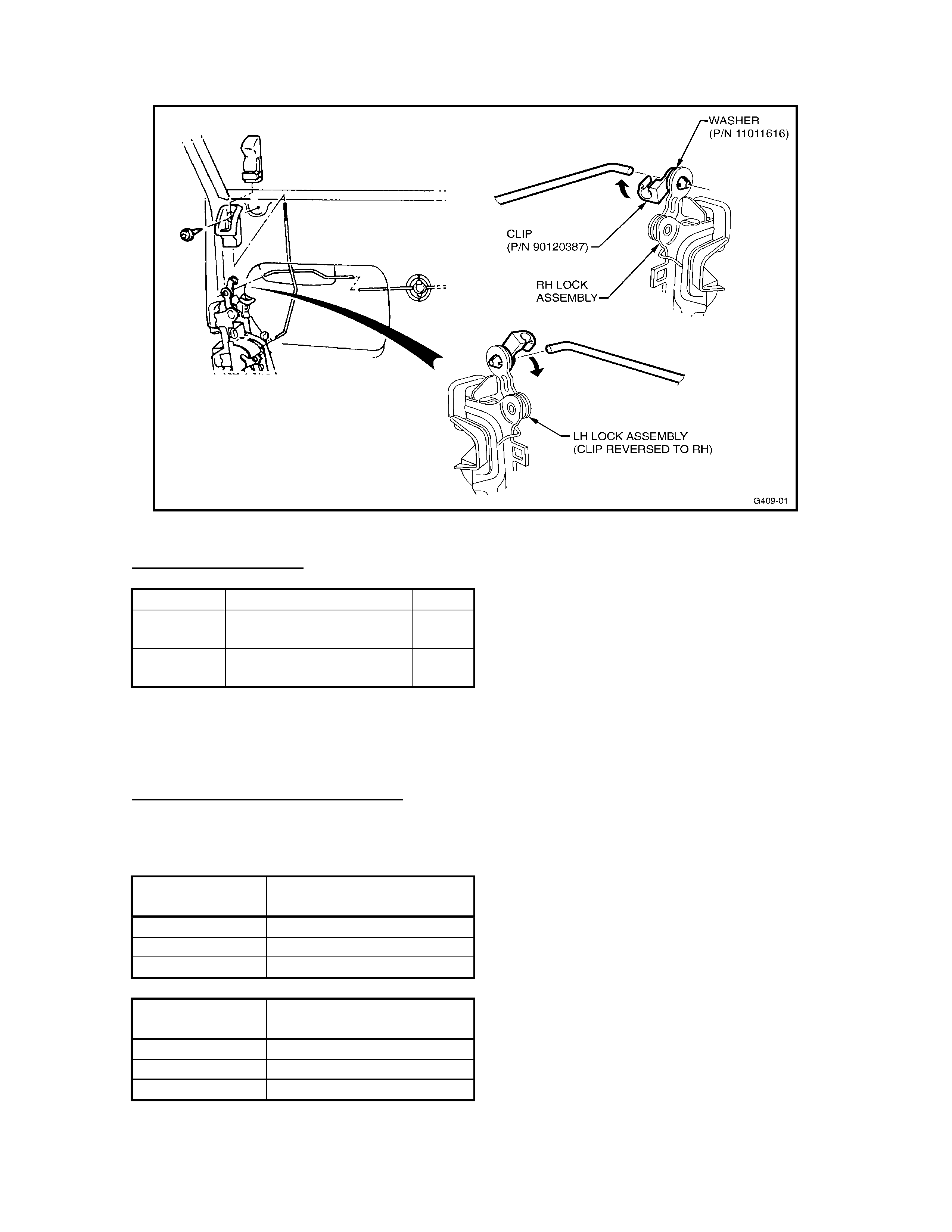

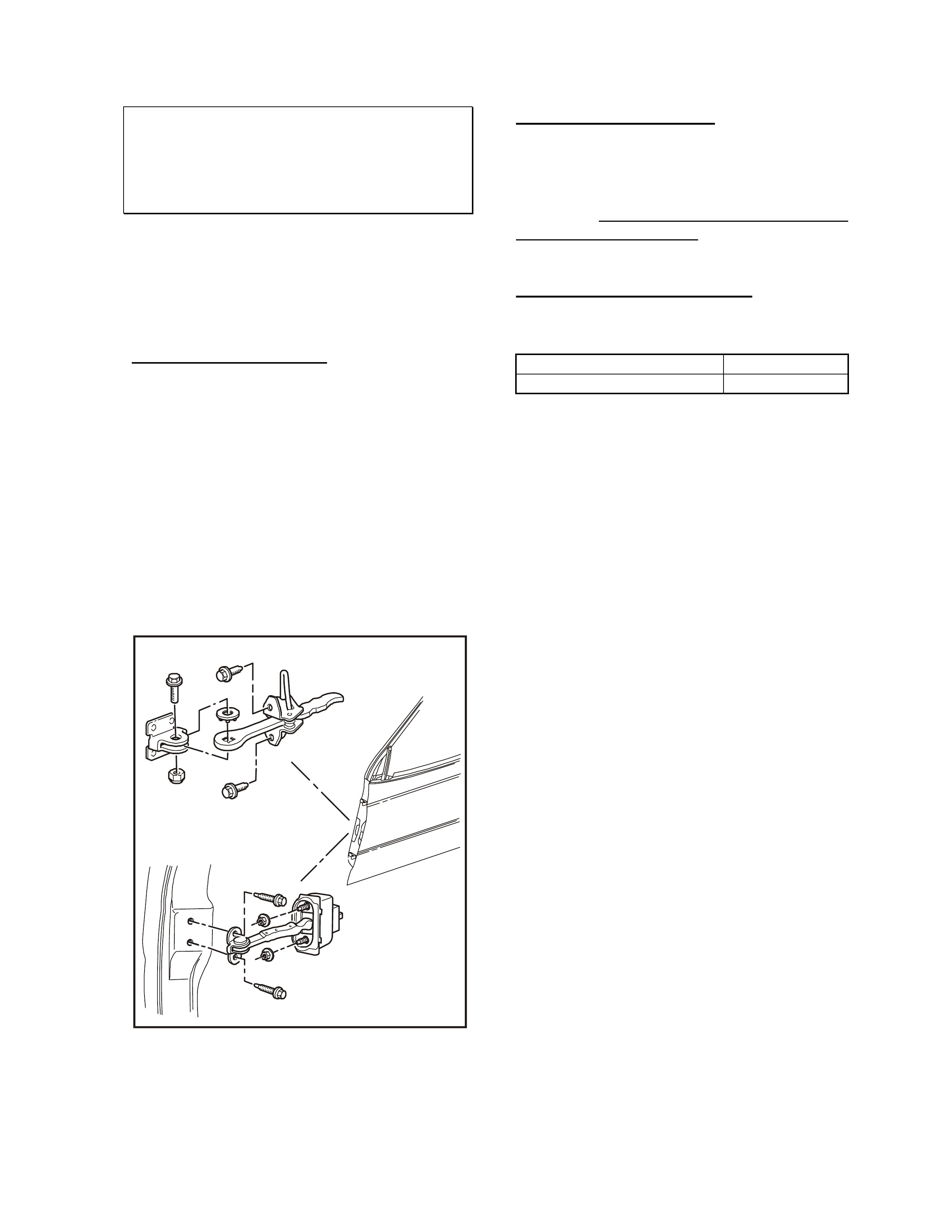

DOOR SNIB (LOCK) BUTTON BINDING

VT, WH

(GROUP 1) HINT March 2000

PROBLEM DESCRI PTION

On some vehicles, the door snib (lock) button may appear to bind up in its mechanism when it is

operated by remote button or manually. The snib button may also feel ‘notchy’ during manual

operation.

This condition may be caused by excessive friction within the door lock, or incorrect adjustment

(too long) of the exterior door handle rod.

SERVICE RECTIFIC ATION

Before attempting any other rectification, ensure locks have been:

1. Lubricated as per Techline Bulletin June, 1999, Issue 4, page 8, then check for OK snib button

operation,

2. Checking lock rod adjustment as per Techline Bulletin June, 1999, Issue 4, page 8.

NOTE: incor r e ct lock rod adjustment (too long) can result in the lock mechanism binding.

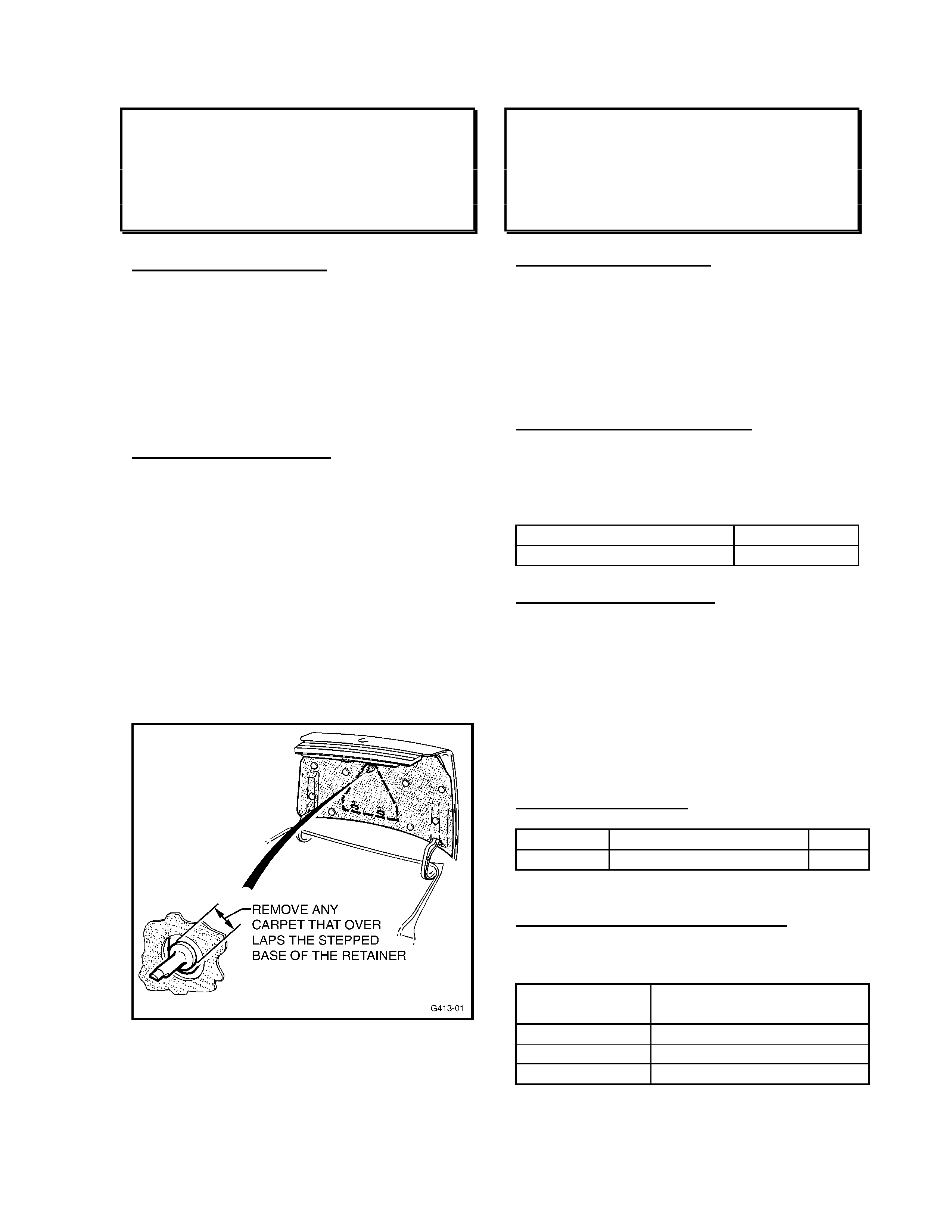

REGISTRATION PLATE RATTLE

WH

(GROUP 1) REISSUED March 2000

This Techline item was previously published in Service Techline Issue 6/99 to advise technicians

and pre-delivery departments of the need to correctly mount registration plates to WH Series

vehicles. Field reports indicate that correct registration mount fixing procedures are not being

adhered to and customers continue to complain about rattles f rom incorrectly mounted registr ation

plates. Please ensure this Techline item is distributed to the correct dealership personnel to

prevent further occurrence of registration plate rattle.

PROBLEM DESCRI PTION

Front and rear registration plates may rattle due to incorrect mounting.

Four screws are required to mount each registration plate securely.

The front r egistration plate must have four fasteners located along the top of the plate, two on the

ends and two slightly inboard (same as VT Series vehicles).

The rear plate also utilises four fasteners. The two top fasteners screw into a boss, while the two

bottom fasteners ‘self -tap’ into the bumper facia. There are no bosses in the facia at the bottom of

the plate, but the screws will hold.

To prevent plate rattles, please use four fasteners to attach each registration plat e.

FRONT SEAT BELT WEBBING CATCHES ON RECLINER/ LUMBAR KNOB/S

VT, WH

(GROUP 1) March 2000

PROBLEM DESCRI PTION

Customer survey results indicate that some customers have experienced a condition where the

front seat belt webbing did not freely slide over t he front seat recliner knob or lumbar knob.

PRODUCTION RECTIFICATION

As a continuous product improvement, the surface finish to both knobs has been revised and

introduced into production. The revised knobs feature a hard surface finish compared to the earlier

“soft feel” knobs. This enables the seat belt webbing to slide more easily over the knob.

Revised knob/s were introduced into VT/WH production as follows:

For Pewter Colour Knobs:

PSN: Build Date:

L521331 25/10/99

For Shale Colour Knobs:

PSN: Build Date:

L527046 07/11/99

Note: Taupe colour trim (and knobs) was not carried into VT Series II (introduction L464495,

31/05/99).

SERVICE RECTIFIC ATION

Where a customer complains of seat belt webbing “catching” on recliner or lumbar knobs, on

vehicles built prior to the above breakpoints, the revised knobs should be installed to both front

seats.

Parts requir ed are detailed in Parts Information below.

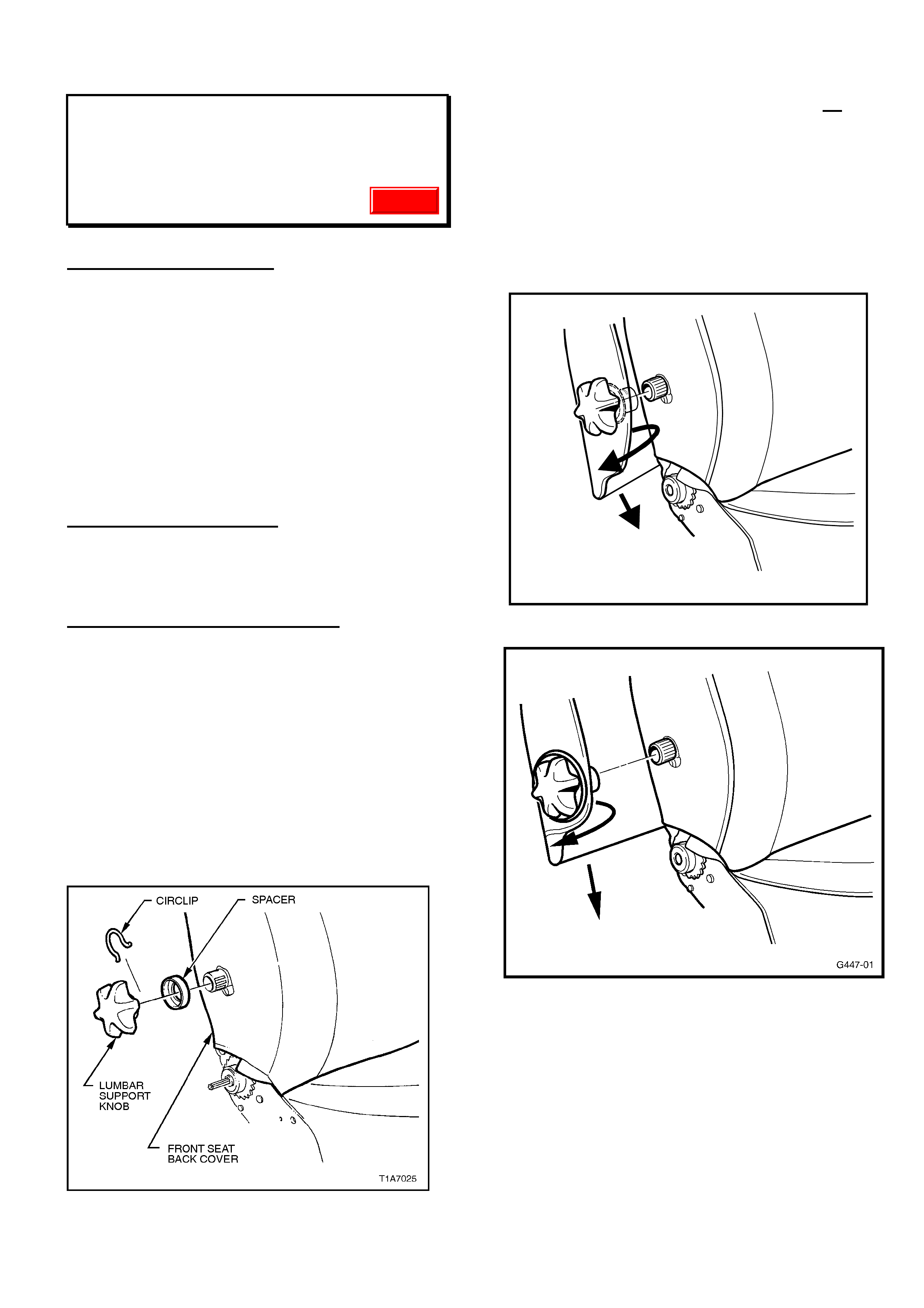

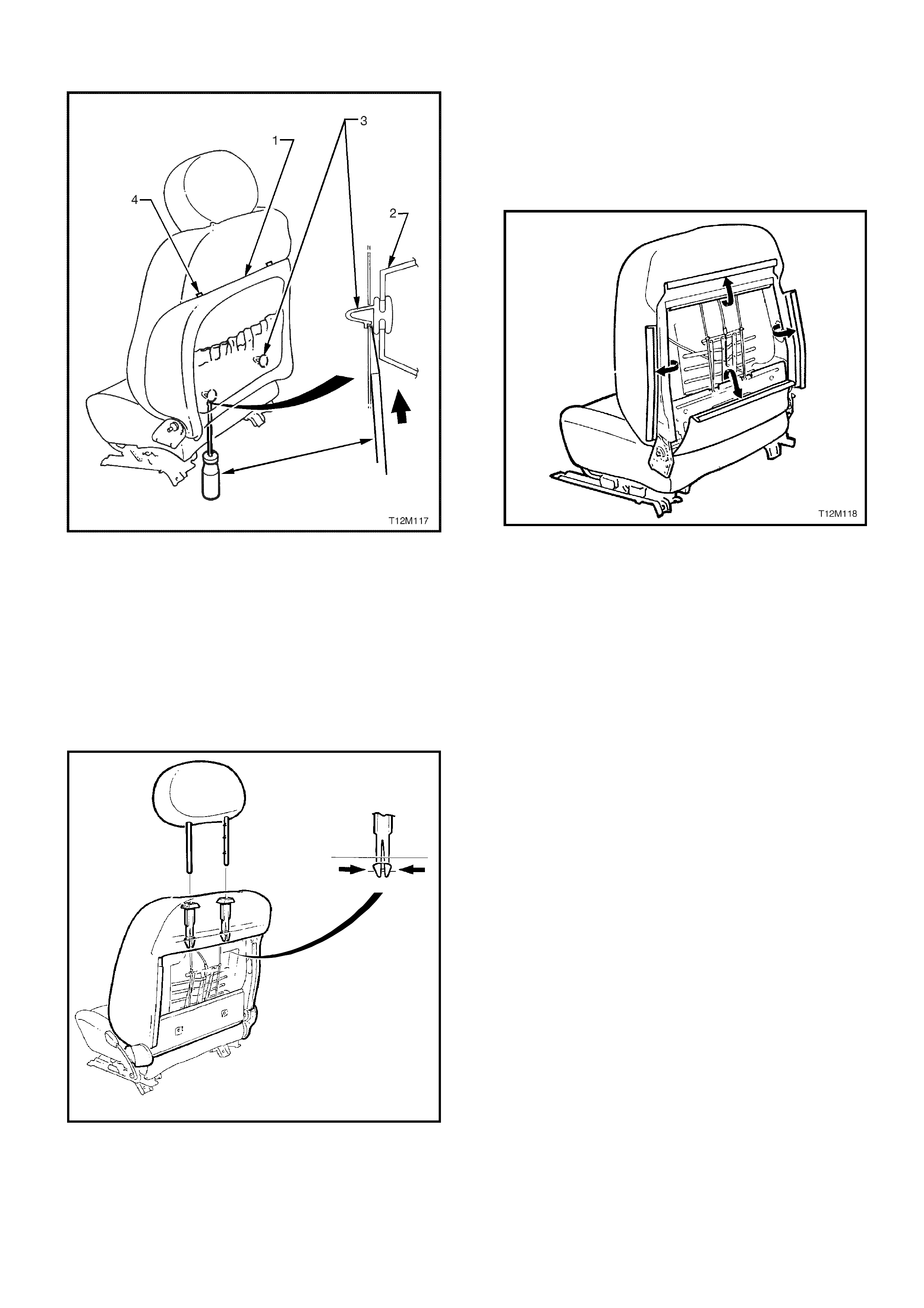

Whe n replacing the knobs, refer to the following service information:

Recliner Knob:

VT Service Manual, Volume 12, Page 12M-21,

Ref. 2.3

Lumbar Knob (non- Side Air Bag):

VT Service Manual, Volume 14A, Page 1A7-5,

Ref. 2.2

Lumbar Knob (Side Air Bag):

VT Service Manual, Volume 14A, Page 1A7-6,

Ref. 2.4

Update

PARTS INFORMATION

Part No.: Description: Qty:

92143234 Recliner Knob - Shale 1

92143235 Recliner Knob - Pewter 1

92143238 Recliner Knob - Taupe 1

92143230 Lumbar Knob, (non-SAB)

- Shale 1

92143231 Lumbar Knob, (non-SAB)

- Pewter 1

92143236 Lumbar Knob, (non-SAB)

- Taupe 1

92143232 Lumbar Knob, (SAB)

- Shale 1

92143233 Lumbar Knob, (SAB)

- Pewter 1

92143237 Lumbar Knob, (SAB)

- Taupe 1

* “SAB” – Side Air Bag

WARRANTY CLAIM INFORMATION:

Use the following information:

Description Rod, Selector Control - Replace

Labour Op. No. C000397

Time 0.3 hr

Failure Code 39

FRONT BRAKE SQUEAL NOISE

TS

(GROUP 5) March 2000

PROBLEM DESCRI PTION

Front brakes may exhibit a “squeal” noise during light brake application.

PRODUCTION RECTIFICATION

Revised brake pads installed:

VIN: Build Date:

Y5000001 13/08/99

SERVICE RECTIFIC ATION

1. Test drive vehicle and determine that the squeal is orig inat ing from the front brakes.

2. Replace front brake pads (as per TIS instructions).

IMPORT ANT NOTE: Ensure to clean the brake pad guides in the caliper and the caliper itself with

a soft wire brush. Apply anti-sq ueak paste to the guides as shown in TIS.

PARTS INFORMATION

Part No.: Description: Qty

09195607 Brake Pads, Front Brake

without ABS 1

09192157 Brake Pads, Front Brake

with ABS 1

90166282 Anti-squeak paste 1

WARRANTY CLAIM INFORMATION:

Use existing Labour Time Manual info. as follows:

Description Fr ont disc brake pads - Replace

Labour Op. No. H105000

Time 0.9 hr

Failure Code 90

Update

P0335 - CRANKSHAFT REVOLUTION SENSOR REVISION

TR, JR (4Cyl); JS (4Cyl)

(GROUP 6C) March 2000

PROBLEM DESCRI PTION

Investigation into reports of DTC P0335 (incorrect RPM signal) stored in the Engine Control Unit

(ECU), have been identified as failure of the Crankshaft Revolution Sensor (CRS). In some

instances DTC P0340 may also be stored.

PRODUCTION RECTIFICATION

A revised CRS was introduced into JS production at:

ENGINE No.: Build Date:

C22SEL25014889 Jan. , 2000.

SERVICE RECTIFIC ATION

When presented with a vehicle storing DTC P0335, technicians should follow the relevant

diagnosis for this code - Refer TIS 2000, Checking Procedures. Care should be taken to ensure no

fault exists with the CRS circuit or mounting. Full, correct diagnosis must be carried out to ensure

there is no unnecessary replacement of either the CRS, or an ECU. If no fault is identified on

inspection, the CRS should be replaced with t he revised part detailed below.

PARTS INFORMATION

This revised Crankshaft Revolution Sensor should be used in all cases requiring replacement, on

TR, & JR/JS 4 Cyl. Engine vehicles.

Part No.: Description: Qty

09174621 Crankshaft Rev’n Sensor 1

New Part Identification:

The part number is moulded into the plastic body of the sensor.

Any Crankshaft Revolution Sensors found in dealer parts stock with previous part number

90506103, must not be used, but ret urned to HSPO for credit.

WARRANTY CLAIM INFORMATION:

Use existing information in Labour Time Manual

Update

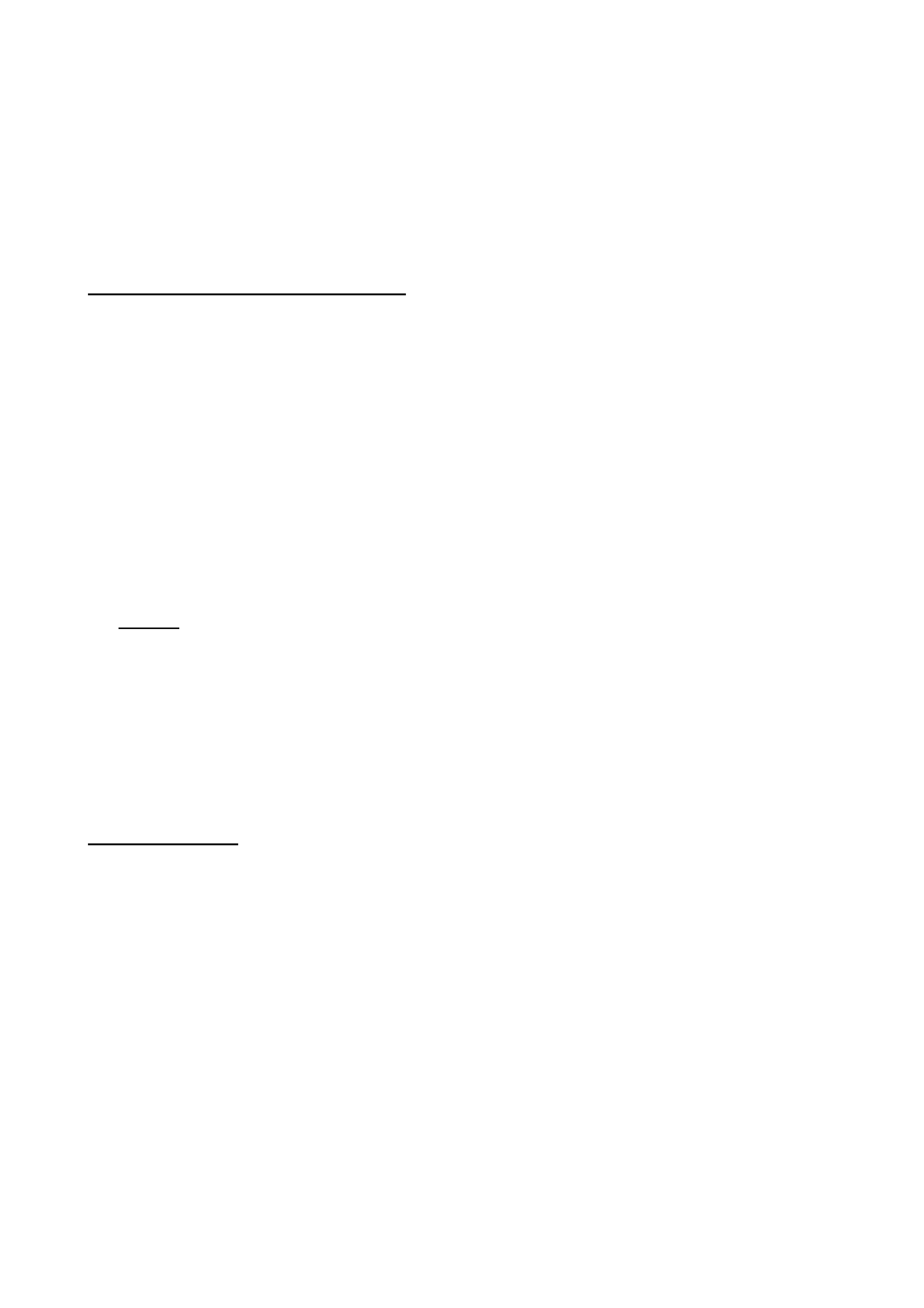

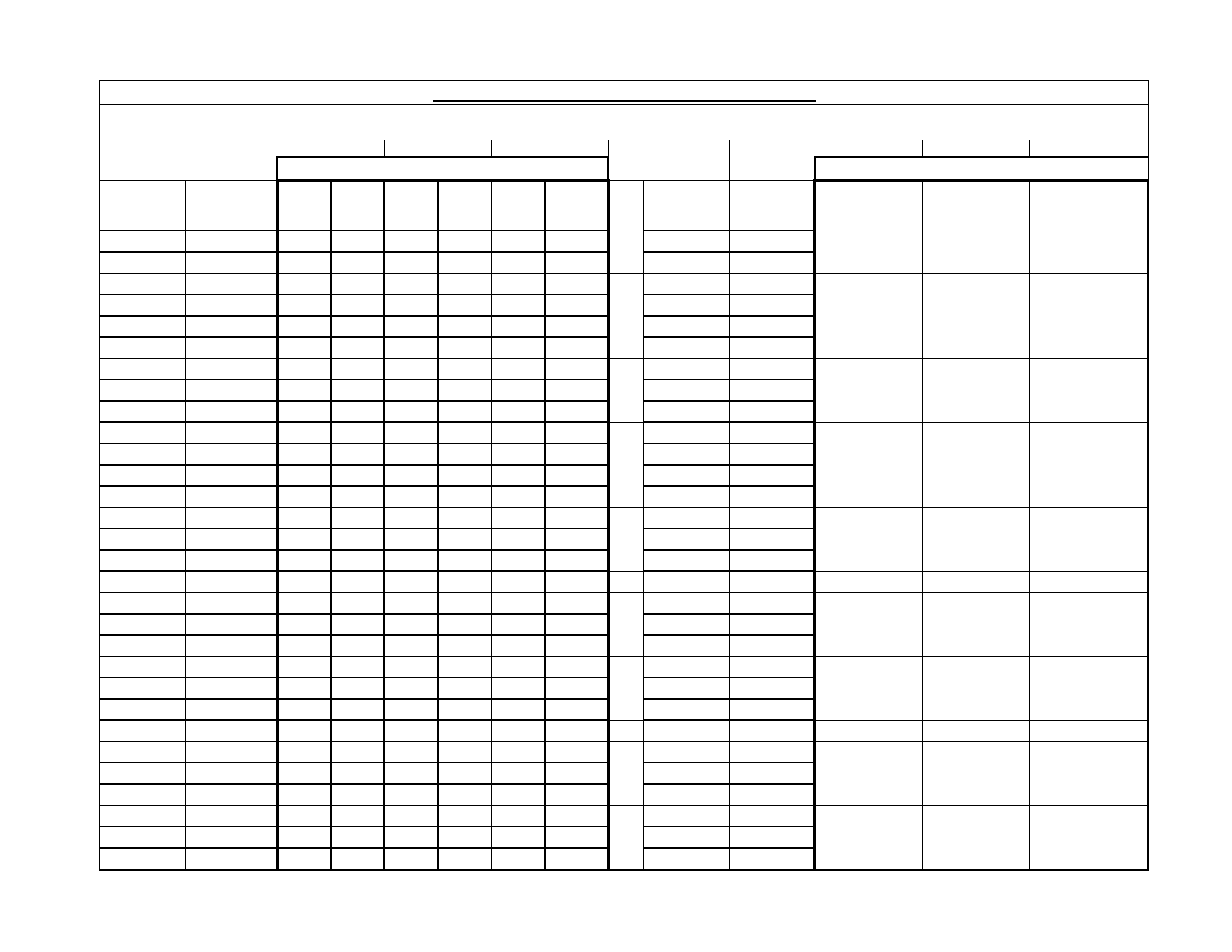

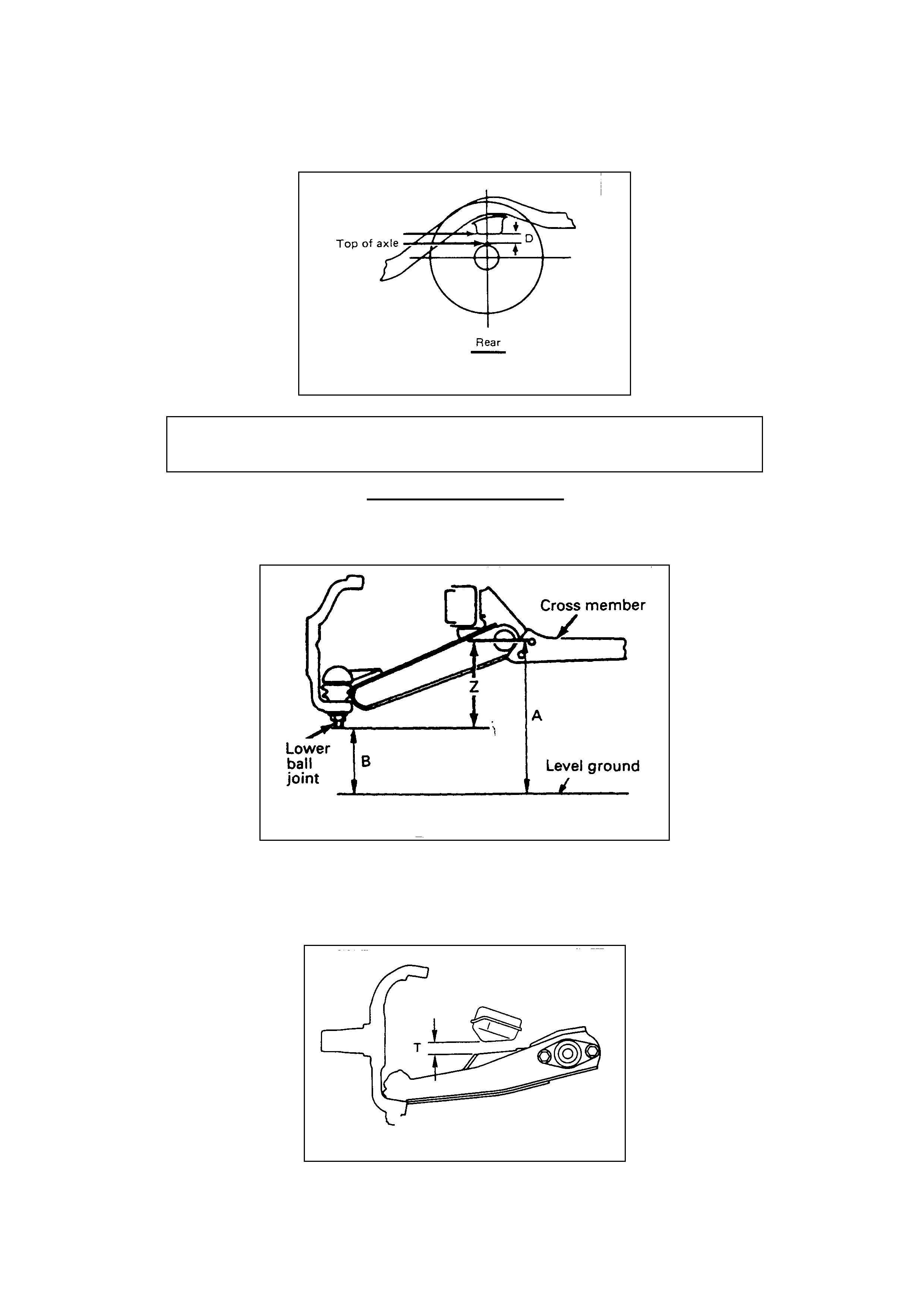

STEERING COLUMN INSTALLATION PROCEDURE

TS

(GROUP 9) REISSUED March 2000

This Techline is re-published because:

•a number of steering shaft and related parts have been replaced unnecessarily,

•a number of steering shaft lower bearings have been damaged as a result of

technicians NOT following this procedure.

The following information was previously released in Techline Issue 8, October, 1999, page 8.

Whenever reinstalling or replacing the steering column assembly in TS series Astra built prior to

the production breakpoint shown below. It is critical the correct lower steering column mounting

clamp load is achieved. Failure to correctly set this clamp load may result in two separate

conditions. If too loose, a rattle condition at the base of the steering column may be experienced. If

too tight, failure of the lower steering column bearing may result.

PRODUCTION RECTIFICATION

Tighter production tolerances to the lower steering column mounting bracket have eliminated the

requirem ent for this critical clamp load adjustment.

Vehicle breakpoint is as specified below:

ISOVIN: Build Date:

W0L0TGF48X5033674 21/09/98

SERVICE PROCEDURE

Technicians need to ensure that the procedures outlined below are applied at all times when the

steering column is reinstalled or replaced in TS series vehicles built prior to the above mentioned

breakpoint. .

1. Reinstall the steering column assembly as per removal and reinstallation procedures set out

on the TIS CD ROM, Group M – Steering “Remove and reinstall steering column assembly”

(Steering column assembly adjust able).

2. Centralise the steering wheel and engage the steering lock.

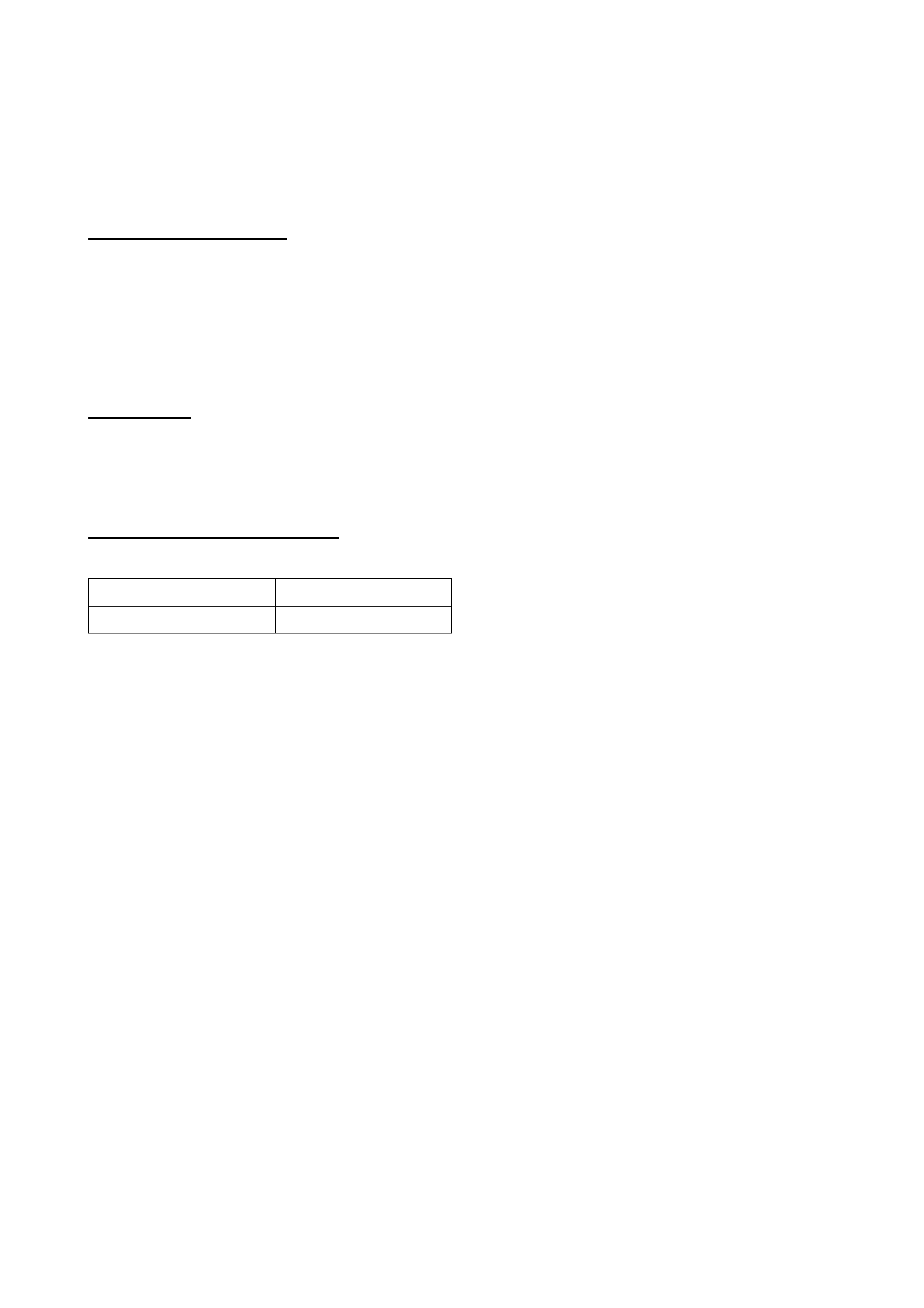

3. Move the adjustable steering lever out of the lock position so the steering column can be

moved up or down, in or out.

4. Locate the clamp bolt (1) that houses the lower steering column bearing and loosen to allow

the installation of the first shim package of 4.0mm (bolt (1) threaded end visible with a 7mm

hex on end of bolt) as indicated in Figure A (showing the steering column removed for clarity).

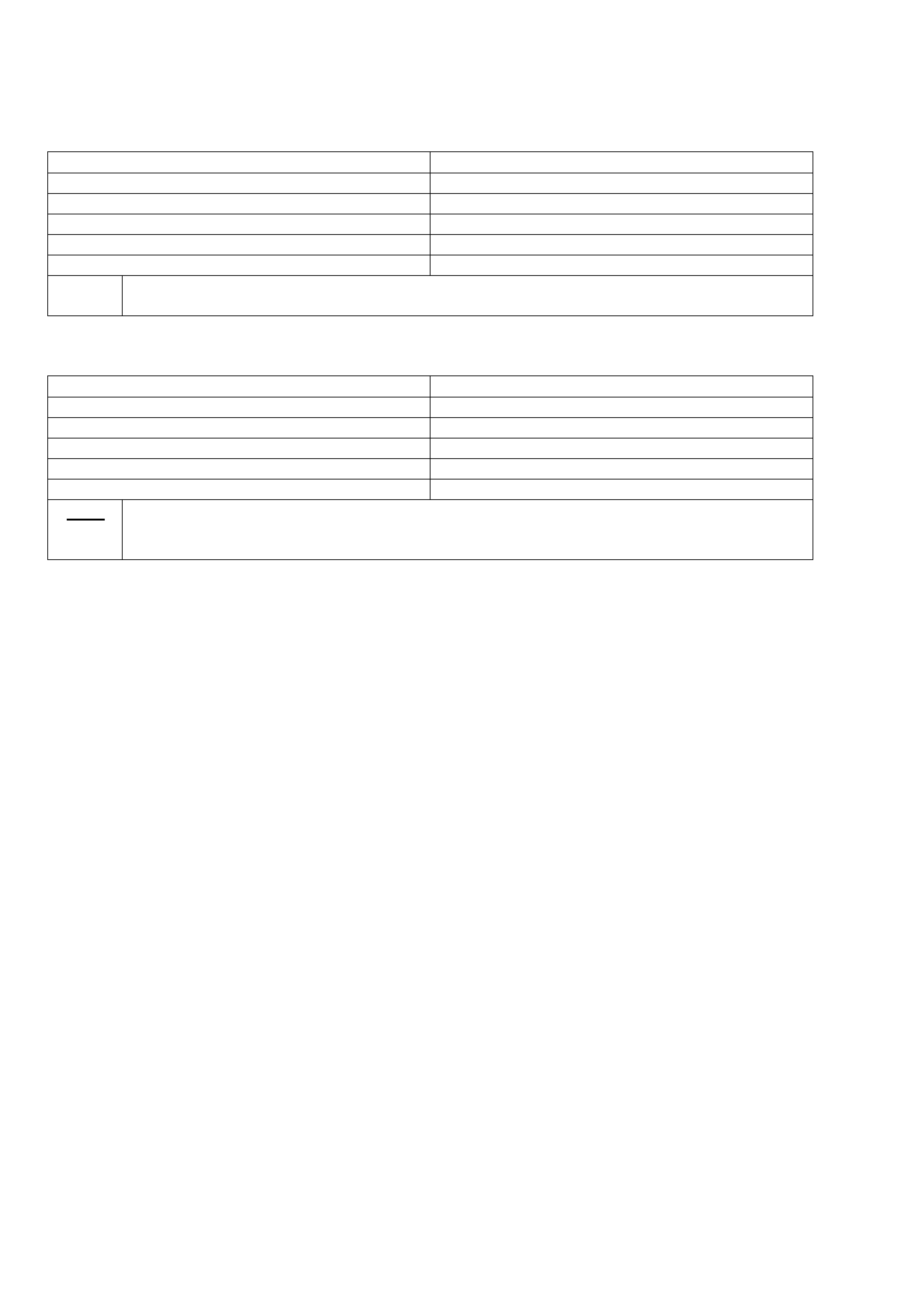

Shim in mm Number of shims

0.4 21-321-321

1.6 2221111- --

Total 4.0 3.6 3.2 2.8 2.4 2.0 1.6 1.2 0.8 0.4

FIGURE A

5. Beginning with an overall thickness of 4.0 mm insert the package of 4 shims, as indicated in

Figure B, between the steering column bracket and the crossmember and tighten the clamp

bolt to 22 Nm/16 ft.lb.

FIGURE B

6. To check if the clamping f orce is correct, grasp the steering shaft at the intermediate shaft end

and push the steering shaft axially with moderate effort (in the direction of the arrow) as

indicated in Figure C.

FIGURE C

7. If the visible grey guide sleeve located in t he clamp on the steering column is moved, release

the clamp bolt and remove one 0.4mm shim.

8. With the reduced shim package of 3.6 mm, tighten the clamp bolt again to 22 Nm/16 ft.lb.

Repeat the checking procedure, observing whether the grey guide sleeve continues to move.

Repeat the procedure of continually reducing the overall thickness of the shims by 0.4 mm

until the guide sleeve ceases to move while applying moderate effort as indicated.

9. Once the correct number of shims has been determined, push the st eering column inwards as

far as it will go and check that the grey sleeve located within the clamp is positioned towards

the front of the vehicle as far as possible. It may be necessary to loosen the clamp bolt and

apply an axial force to the steering shaft towards the front of the vehicle until the grey sleeve

seats on the clamp in it’s forward most position. Ensure to tighten the clamp bolt to

22N m/1 6 ft.lb.

10. Re-inst all all com ponents. Move the steering column adjustment lever into the lock position.

PARTS INFORMATION

Shim kits to adjust clamping load are available via HSPO under the part number supplied below.

Part No.: Description: Qty

09192728 Shim kit 1

SERVICE TE CHNICIAN REFERE NCE INFORMATION

ALL

(GROUP 0B) UPDATED March 2000

This Techline is published to provide Dealership Service personnel with a list of commonly required

Holden contact Fax numbers and some helpful additional information.

HOLDEN SERVICE RELATED FAX No’s

HOLDEN TAS 03 9647 2495

HOLDEN SECURITY INFO. 03 9647 2865

IGM TAS/CAS 03 9644 6622

PIR’s (EDAG FUTURE) 03 9552 8104

REPAC 03 9647 1198

TECHNICIAN’s GUILD QUESTIONNAIRES,

Tech. Guild Issue content,

and Questionnaire queries ONLY: 03 9876 5797

TECHNICIAN’s GUILD ADMINISTRATION

For all other Tech. Guild queries (enrolments,

prizes, dates, exam venues, etc): 03 9647 2525

CENTRAL SERVICE 03 9647 2525

SERVICE ENGI NEERING 03 9647 2525

HOLDEN CAS 03 9647 1237

WARRANTY ADMIN. 03 9647 2525

Othe r In fo rmation :

PIR forms: request a pad (100 forms) by quoting “SD 28331” on a Merchandising Material Order

Form and fax to Salmat, on (03) 9251 6352.

Security Number Request Form: photocopy form attached to All Dealer Letter DL 63/99.

Vehicle Security Info. Change Advice Form: photocopy form attached to All Dealer Letter

DL 63/99.

Tech 1 Repairs: Refer HSPO Parts Techline Bulletin PT31, dated May 5, 1999.

Tech 2 Repairs: Refer All Dealer Letter DL 43/97

Tech 2 Cable Repairs: Refer All Dealer Letter DL 06/00

JS Vectra Circuit Diagram Manual Update Pages: Refer All Dealer Letter DL 58/99

TS Astra Circ uit Di agram Update Pages: Refer All Dealer Letter DL 01/99

INSTRUMENT CLUSTER - TRIPME TER FUNCTION

JR, JS

(GROUP 12) March 2000

Some customers may report that their tripmeter is intermittently resetting to zero without command

- mainly on long distance trips. To reduce the possibility of unnecessary instrument cluster

replacement, this Techline has been issued to define the counting/reset parameters of the

tripmeter fun c tion.

JR & JS SERIES 1

All JR, and JS Series 1 instrument cluster tripmeters are designed to count to 1999 kilometr es and

reset to zero at the 2000 kilometre mark.

JS SERIES 2

JS Series 2 instrument cluster tripmeters are designed to count to 999 kilometres and reset t o zero

at 1000 kilometre mark.

INSTRUMENT PROGRAMMING - TRIPLE WINDOW TYPE

VT

(GROUP 12) March 2000

Included in Tech 2 software version 8.100, TIS 2000 CD 7.0B, is a new function that allows

instrume nt clusters to be configured for vehicles with and without Elect r onic Climate Control (ECC).

This function should be used when fitting or replacing instrument clusters. Failure to correctly

program the instrument configuration may result in an “X” being displayed in the instrument right

side display window, along with instrument DTC 10.

In Particular, this is relevant where triple window display type instruments are fitted to vehicles

without electr onic clim ate control ie. HSV or HBD upgrade.

To correctly configure the instrument clusters ECC option follow the steps detailed below.

1. Select Diagnostics / Model Year / VT Commodore / F3: Body / Instrument / F5: Program / F0:

Instrument Config uration.

2. Press the NEXT soft key at the base of the Tech 2 screen to scroll to the ECC option

configuration.

3. Press the MODIFY soft key at the base of the Tech 2 screen.

4. Select the DISABLE soft key at the base of the Tech 2 screen (for vehicles without ECC).

Select the ENABLE soft key at the base of the Tech 2 screen (for vehicles with ECC).

5. After the configuration has been modified the Tech 2 will display the current configuration.

Select the PROGRAM soft key at the base of the Tech 2 screen to accept the configuration

settings.

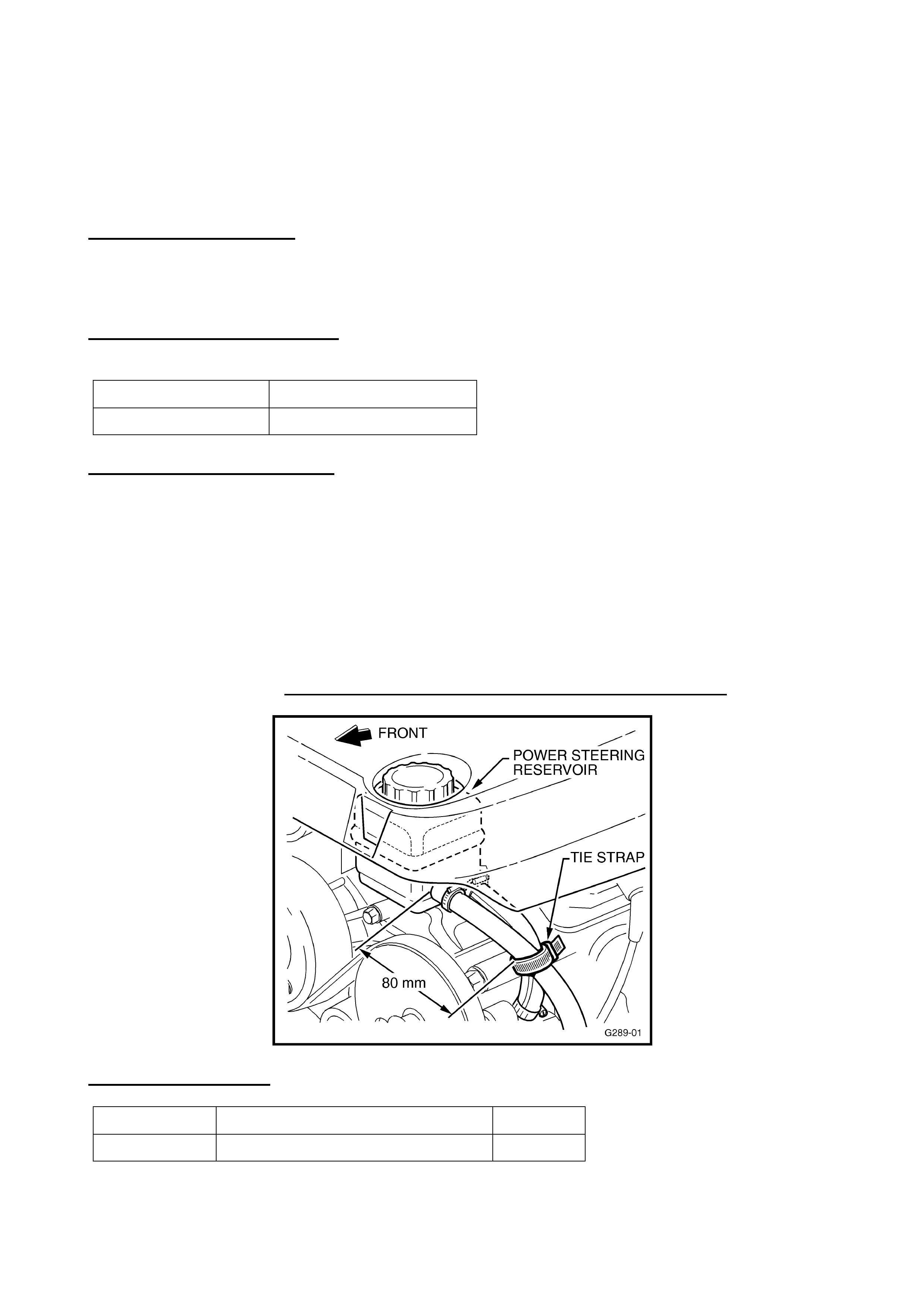

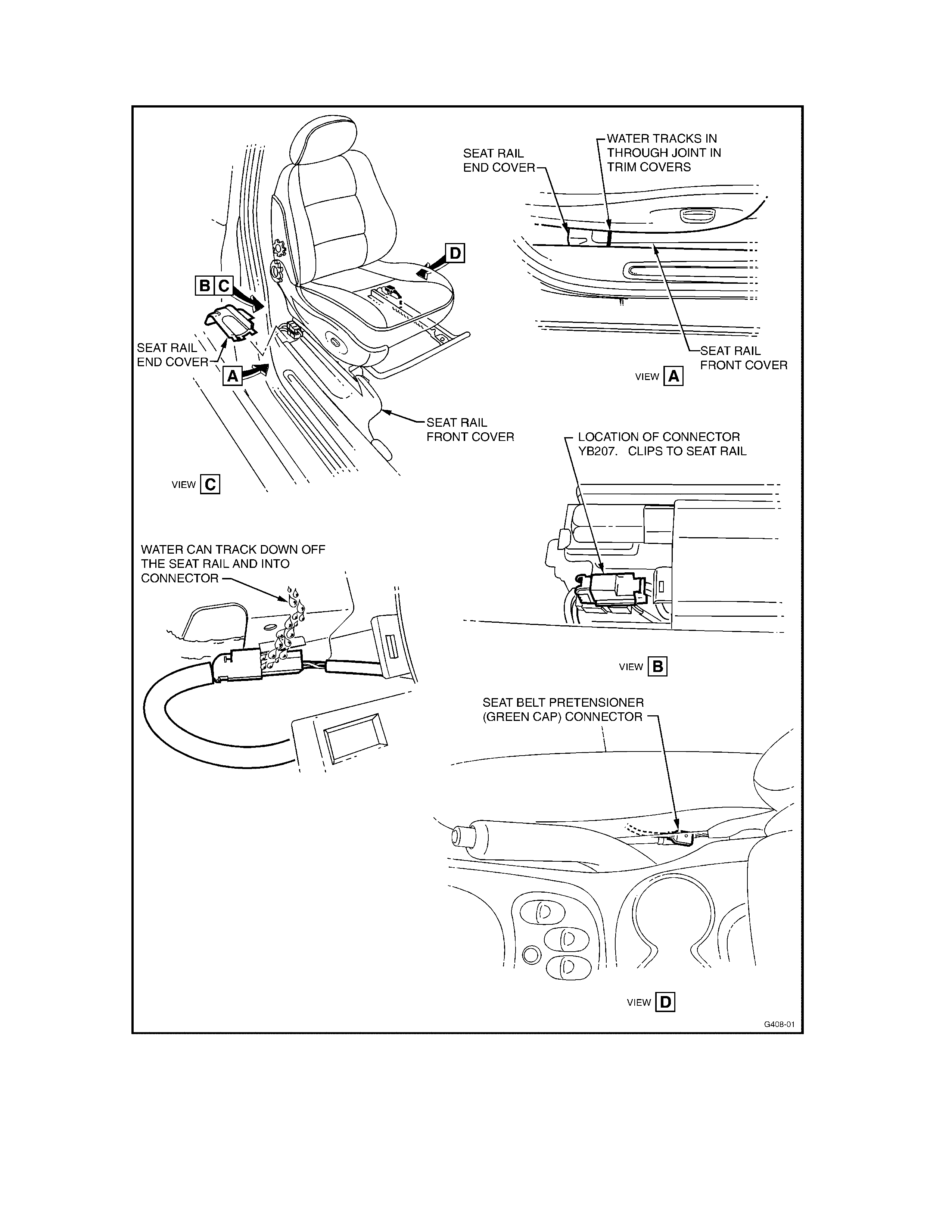

POWER STEERING HOSE RETENTION

VT, WH with GEN III V8

(GROUP 9) February 2000

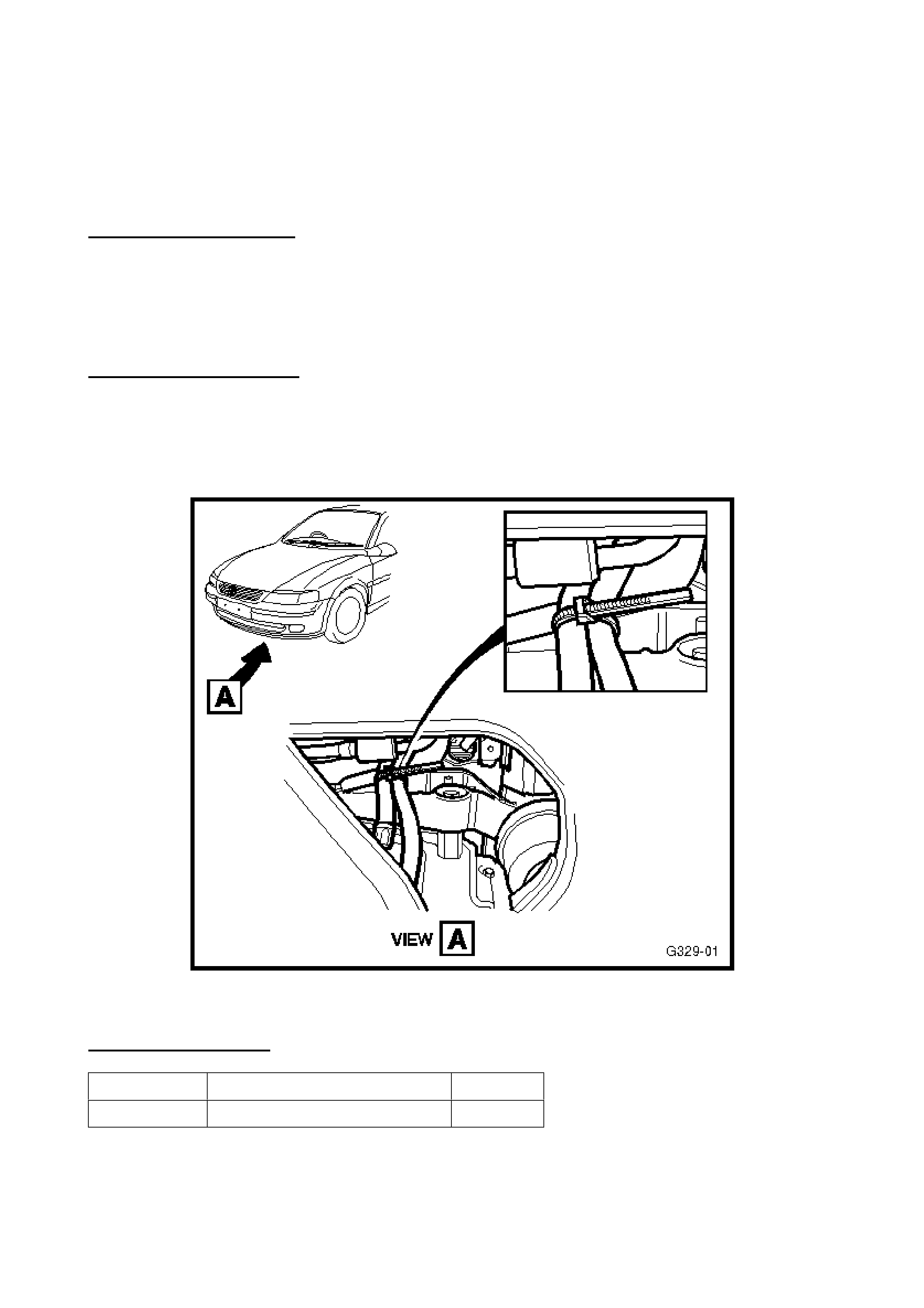

PROBLEM DESCRIPTION

PIR’s have been received, which advise of a power steering (P/S) fluid leak, caused by the P/S

return hose cont acting with the power steering pump pulley.

PRODUCTION RECTIFICATION

A tie strap has been added in pr oduct ion from:

PSN No. : Build Date:

L493683 14/08/99

SERVICE RECOM MENDATION

When fitting or re-fitting a P/S return hose for any reason, carry out the following hose

replacement pr ocedur e:

•On fitting the new P/S return hose, turn the upper (reservoir) end away from the P/S pump

pulley, before tightening the hose clamp.

•Re-f it the existing tie st rap (p/ n 92138212) t o the power steering hoses, 80m m f r om t he power

steering reservoir - as shown in the accompanying sketch. If the vehicle is built before

L493683 – fit a tie strap during this hose replacement. (Refer ‘Warranty Claim Information’).

Addition of this tie strap ensures t hat the hose cannot contact t he P/ S pum p pulley.

When fitting the t ie st r ap, ensur e t he P/S hoses are not compressed by the tie str ap.

PARTS INFORMATION

Part No.: Description: Qty

92138212 Strap –Tie, P/S Retention 1

WARRANTY CLAIM INFORMATION:

The following labour operation number m ay be used ONLY for addition of a tie strap, to vehicles built prior to

L493683, when replacing a damaged P/S return hose, or re-fitting a P/S return hose.

Description Add Strap to P/S Hoses

Labour Op. No. M000172

Time 0.3 hr

Failure Code 25

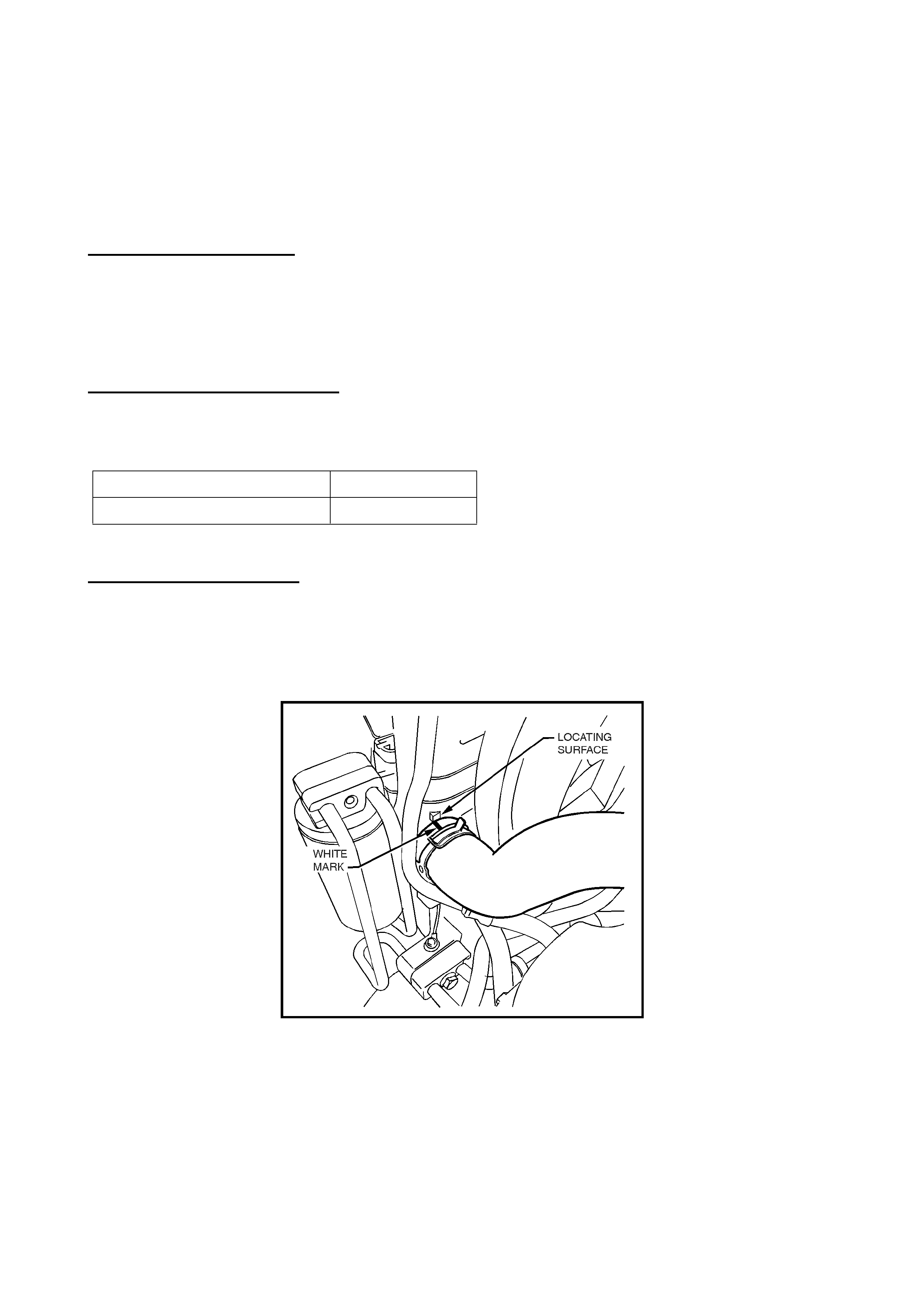

LOWER RADIATOR HOSE INSTALLATION PRECAUTIONS

JR, JS (4 Cyl. Engines)

(GROUP 6K) March 2000

PROBLEM DESCRI PTION

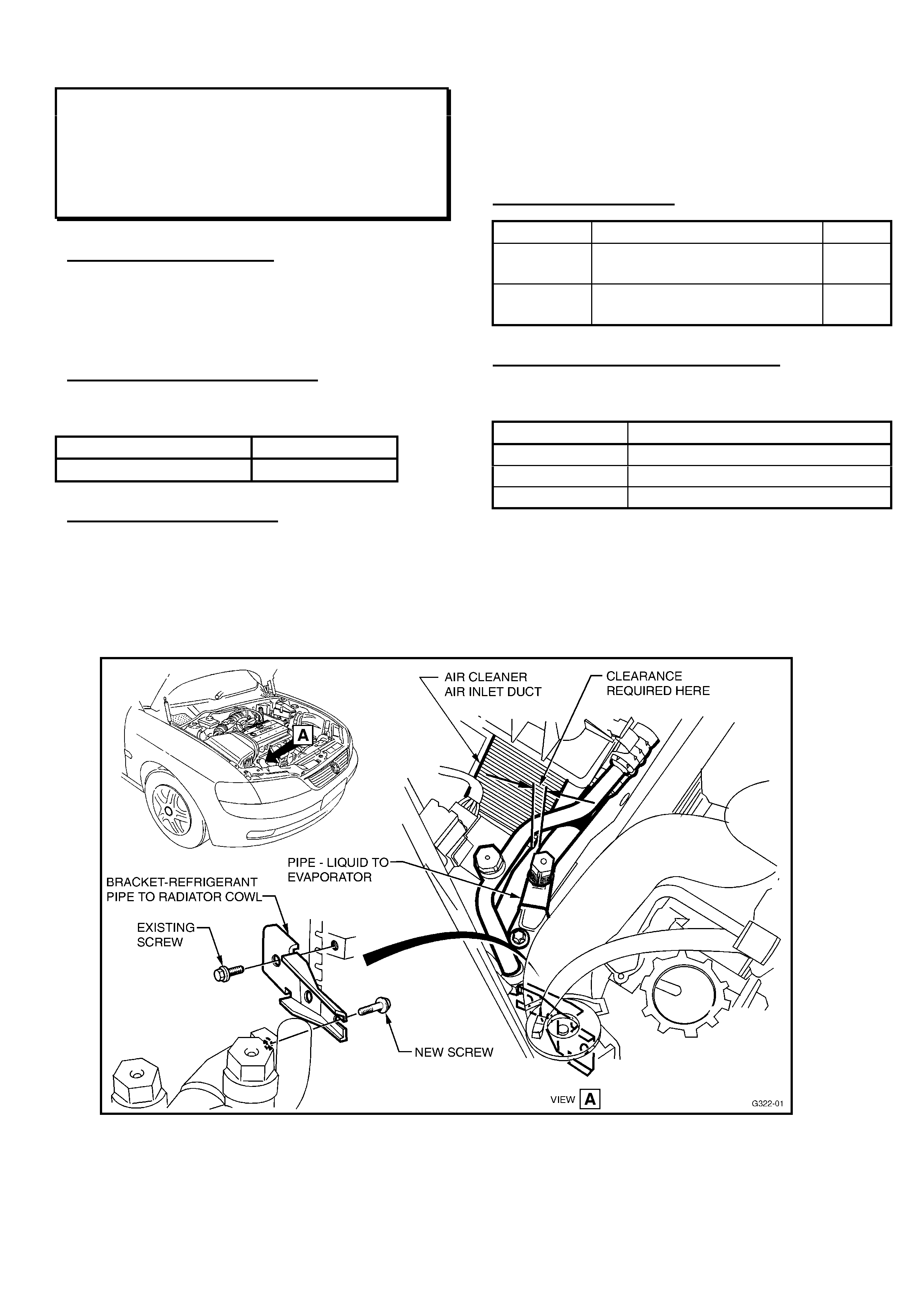

The following precautions must be observed during lower radiator hose installation, to ensure no

abrasion occurs, that may result in a coolant leak. In addition, a protective cap has been added to

A/T filler tube retaining studs to ensure no abrasion can occur.

PRODUCTION RECTIFICATION

The installation precautions noted below are existing procedures in the vehicle assembly plant.

The protective cap (as mentioned in Figure 3 below) was introduced into production at:

ISOVIN: Build Date:

W0L0JBF19XL430814 01/03/99

SERVICE RECTIFIC ATION

W hen installing a lower radiator hose, ensure correct positioning of the lower radiator hose by:

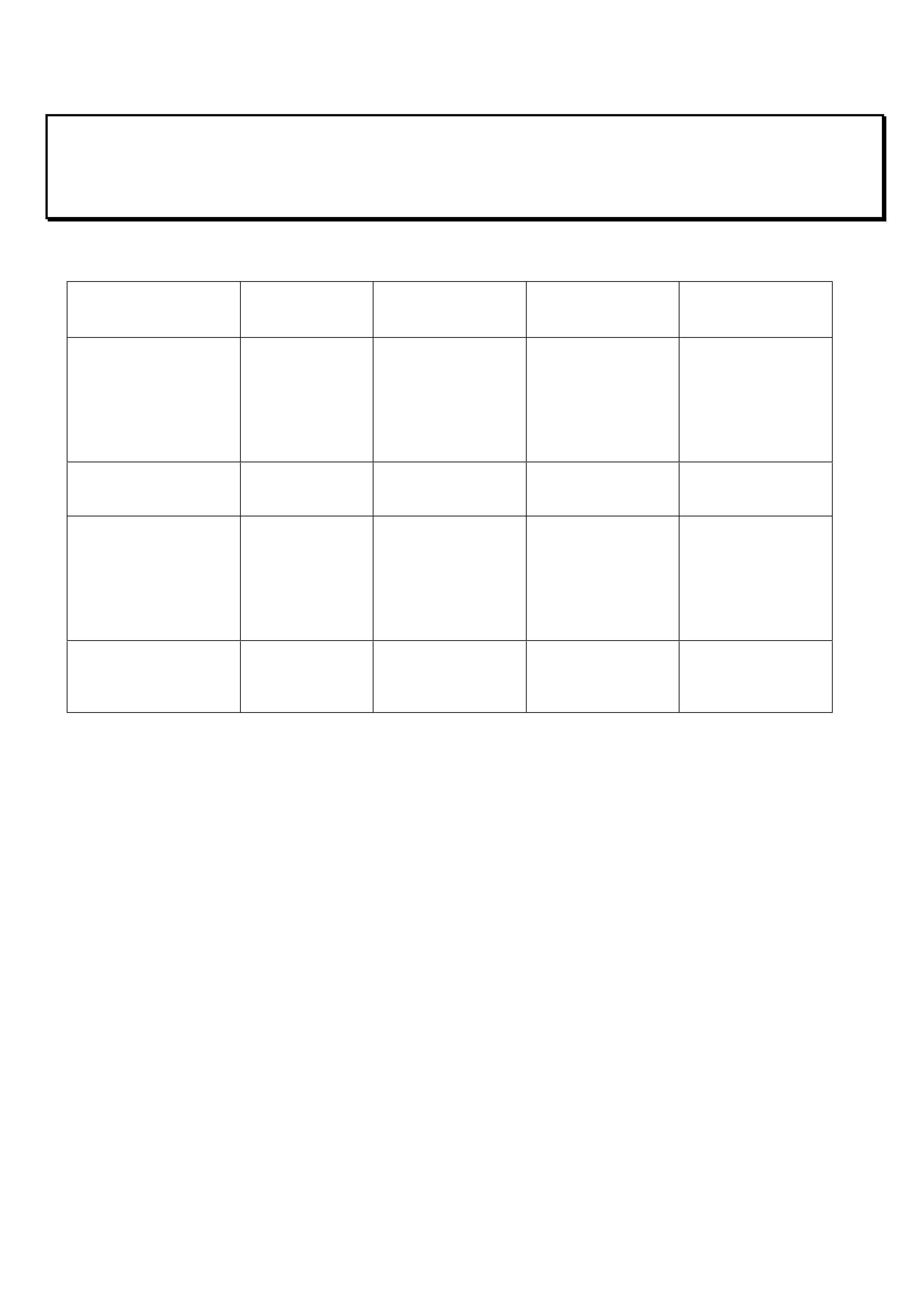

1. Aligning the white paint mark on the lower end of the hose, with the moulded boss on the

radiator end tank – Refer Figure 1 which shows the correct hose positioning .

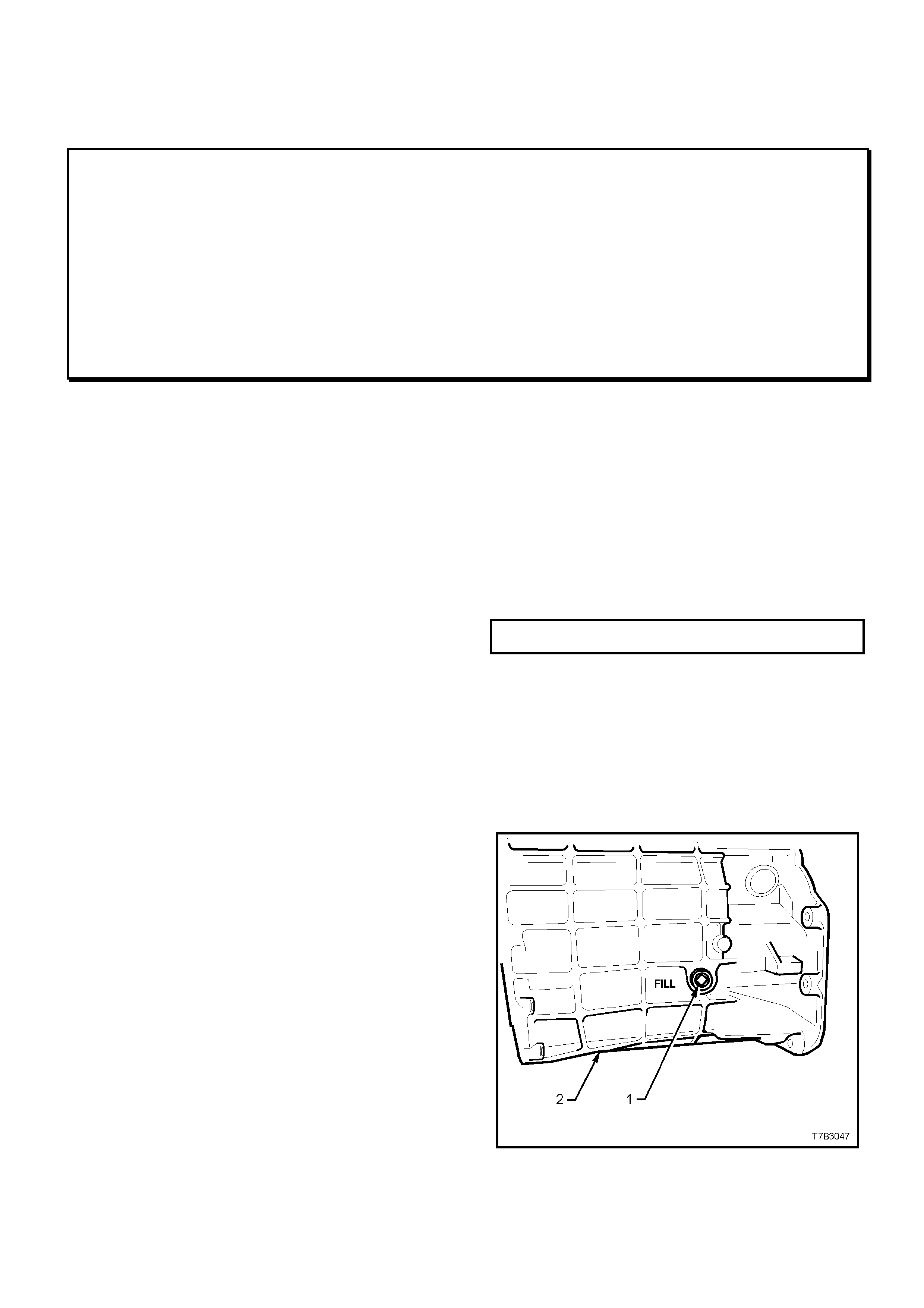

Figure 1.

2. Adjusting the position of the hose (by loosening connections and twisting the connections) so

that adequate clearance exists between the electrical harness connector – Refer Figure 2 for

details of clearance and hose positioning.

Figure 2.

3. On A/T equipped vehicles: where the branch of the lower hose runs past the A/T filler tube

retaining bracket nut, add a protective cap – P/N 90539656 – Refer Figure 3.

Figure 3.

View from front of engine compartment towards A/T."

INTERIOR RATTLE NOISE DIAGNOSIS

ALL MODELS (MELBOURNE BASED VEHICLES)

(GROUP 1) April 2000

PROBLEM DESCRIPTION

When investigating instrument panel “rattle” complaints, where a vehicle is fitted with an “e-TAG”

unit ( electronic sig nal transm itter f or use on t he Melbourne CityLink electr onic tollway system), f irst

remove the e-T AG unit.

Any rattle that may emanate from the “e-TAG” unit could lead to misdiagnosis of the noise, in the

belief t hat interior trim or com ponents in the instrument panel may be the cause.

NOTE: “ e-TAG’s” ar e normally attached to the inside of the front windscreen behind the rear view

mirror, via a mounting bracket, and are detachable. The “e-TAG” can be detached from the

bracket by g r ipping the “e-T AG” and rotating the top rearwards and downward.

Should an “e- TAG” be def ined as the cause of a rat t le noise – t he customer should be advised that

the ratt le is em anat ing fr om t he “e-TAG” , not the vehicle.

Update

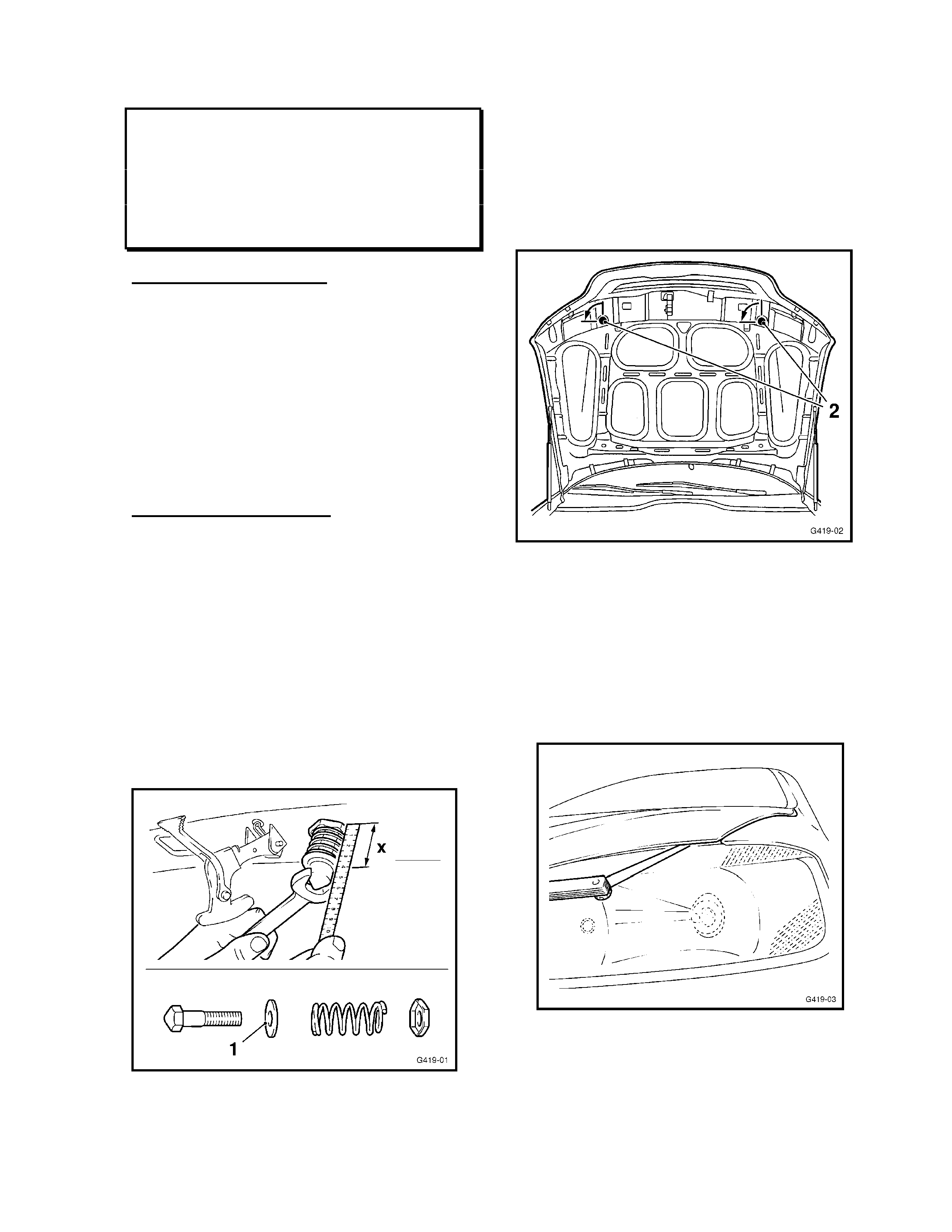

QUARTER WINDOW GLASS – IMPROVING GLASS FIT

VS Utility

(GROUP 1) April 2000

PROBLEM DESCRI PTION

Poor appearance of utility quarter window fixed glass - a gap at the top of the glass between glass and

rear side window cover - is caused by the locat ion of the glass in the body opening.

PRODUCTION REVI SION

Revised glass and mouldings were fit ted to vehicles in production fr om :

ISOVIN: Build Date:

6H8VSK80HXL454372 30/04/99

SERVICE RECTIFICATION

To improve the fit of the quarter window glass on complaint vehicles, the following procedure should

be carried out.

On vehicles built before L454373 - discard old glass and moulding and use NEW glass and NEW moulding,

fitted as per these instructions:

On v ehicles built after L454373 – glass and moulding (with moulding shape as per Figure 2) m ay be re-used,

and fitted as per these instructions:

IMPO RTANT NOTE: If the procedure below is to be carried out as a sub-let repair, provide a copy of

this Techline t o t he sub-let repairer.

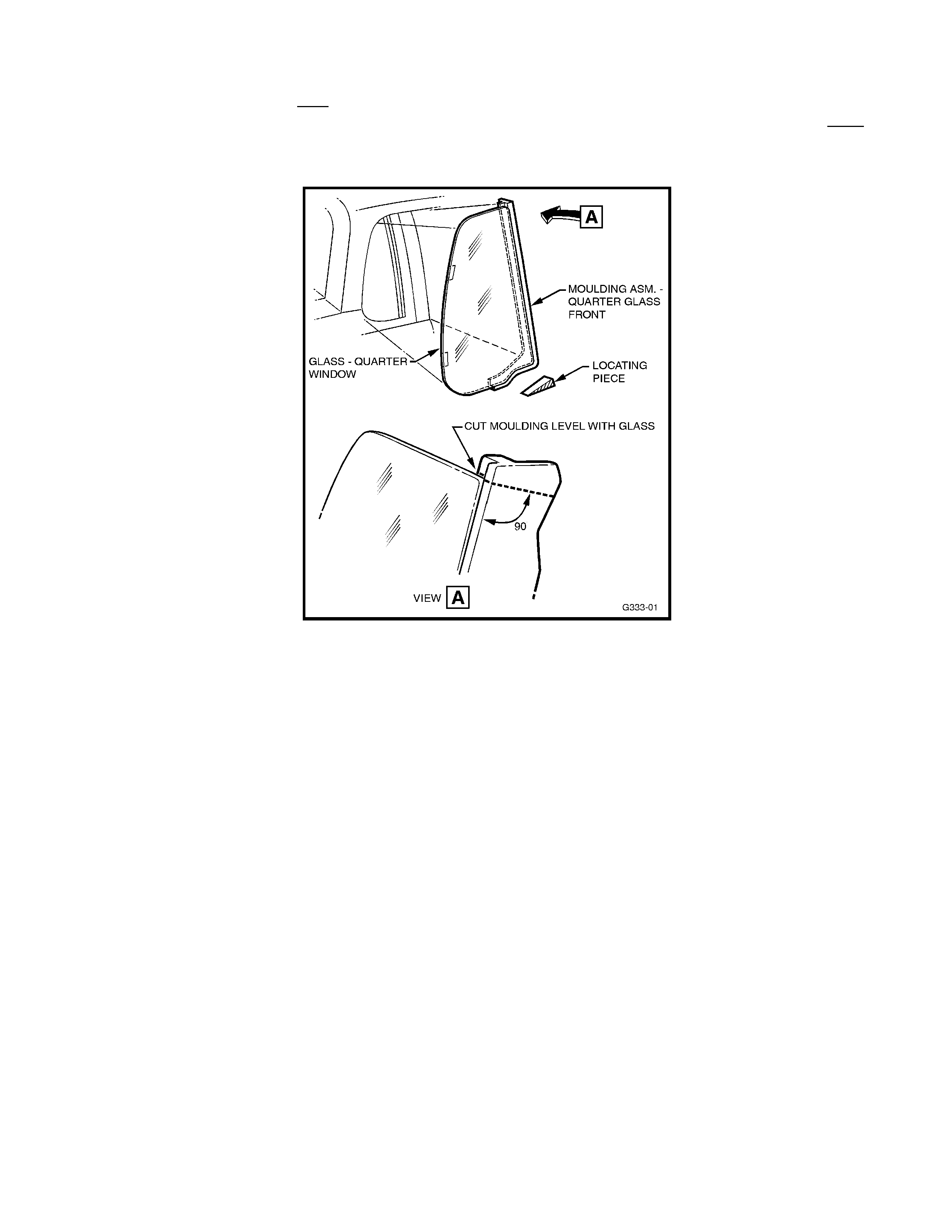

1. Remove quarter window glass, using existing removal procedures in the VR Service Manual,

Volume 1, Pag e 1A7- 11.

2. Remove remnants of old urethane from glass and body aperture flange, then clean the quarter

window glass and body opening with a lint free rag wetted with Prepsol.

3. Apply spacers - p/ n 92039967 – as shown in Section A-A in Figure 1.

NOTE: spacers MUST be applied or poor glass fit t o body and outer cover will result.

Figure 1 –Spacer locati on and uret hane i n ‘fitted’ l ocat i on.

4. Fit moulding to glass, if new glass and moulding are being f itted.

5. Using a hack saw, cut of f any excess moulding protruding above the top of the glass until it is f lush

with the top of the glass, and follow a ‘cut’ line perpendicular (90°) to t he glass. Refer to Figure 2.

NOTE: Take care with these operations, or glass breakag e m ay result .

Figure 2

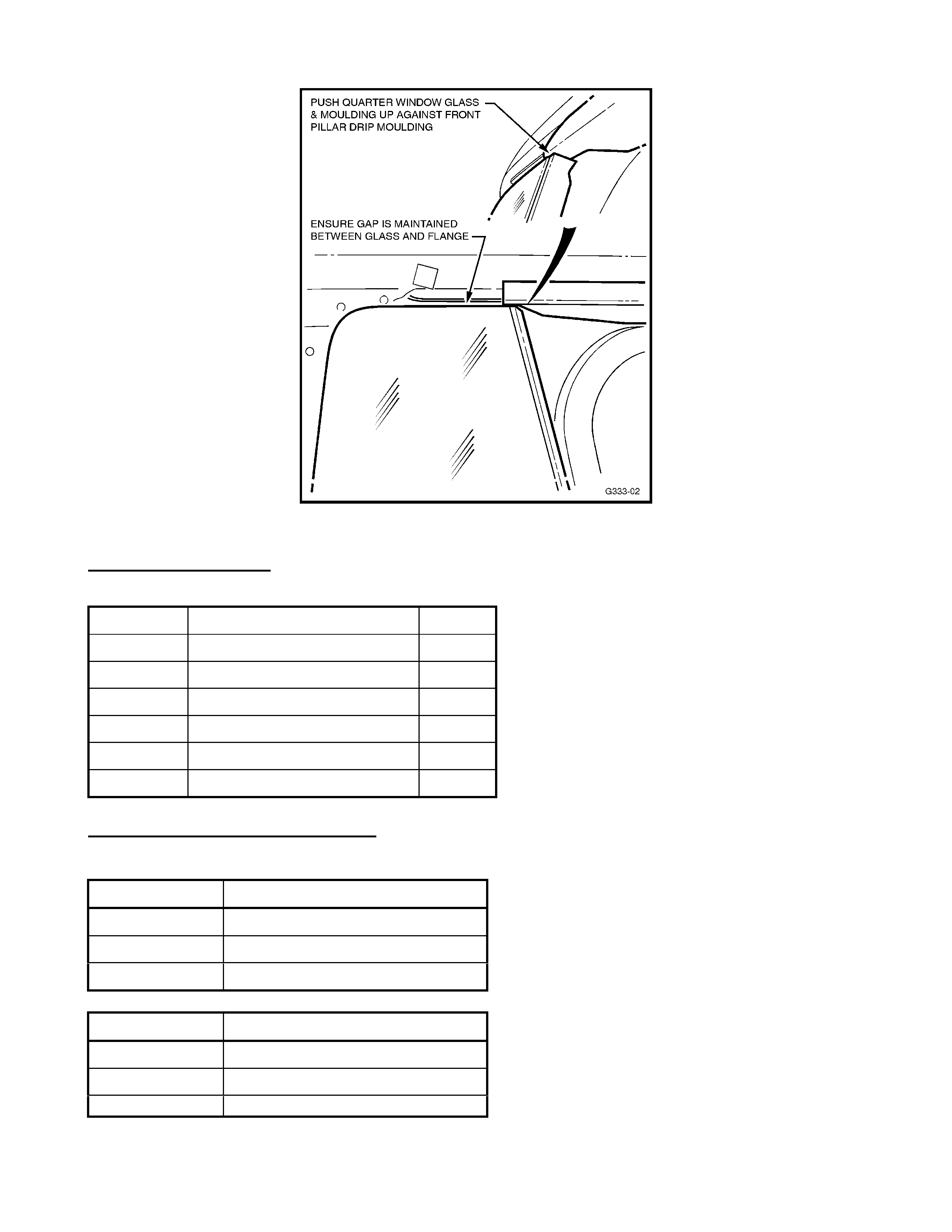

6. Perform a trial fitment of the glass assembly. Ensure there is no interference between the

moulding and t he dr ip gutter. Refer to figure 3.

NOTE: There must be a small gap between the glass and the drip gutter sheet metal. Refer to

Figure 3.

7. Apply urethane to the body aperture flange. Urethane should be inboard of spacers – Refer to

Figure 1.

8. Install the quarter window glass to the body aperture flange, ensure the top, forward corner

locates as per the trial f it, then press glass firmly into position. Do not f orce the glass to sit flush

with the drip gutter. Refer Figure 3.

9. Insert a locating piece – p/n 92075426 – under the lowest portion of the glass to hold the glass

during t he ur et hane curing process. Refer to figure 2 f or location.

10. Check ef fect iveness of sealing from inside the vehicle. Should any gaps in the sealing exist, apply

additional urethane on t he out side to fill these gaps. Using a flat bladed tool, sm oot h the surface of

the urethane ar ound the edge of the outside of t he glass to ensure ef fective sealing.

11. Reinstall quarter window inner trim moulding (Refer 1A9 HEADLINING AND REAR END TRIM

Section in VR Series Service Manual, Volume 1).

12. Tighten q uar ter window drip moulding attaching screws and refit the rear side window cover (Refer

1A5 LOAD COMPARTMENT AND ENDGATE Section in VR Series Service Manual, Volume 1).

Figure 3

PARTS INFORMATION

The quantities quoted below are for one side only:

Part No.: Description: Qty:

92056371 Glass - Qtr Window (RH) 1

92056372 Glass - Qtr Window (LH) 1

92056373 Moulding - Q t r Window (RH) 1

92056374 Moulding - Q t r Window (LH) 1

92039967 Spacer - Qtr Window 2

92075426 Locating Piece - Qtr Window 1

WARRANTY CLAIM I NFORMATION:

Use existing information in Labour Time Manual as shown:

Description Glass Asm. Side Panel RH – Repl.

Labour Op. No. C004100

Time 1.1 hr

Failure Code 25

Description Glass Asm. Side Panel LH – Repl.

Labour Op. No. C004200

Time 1.1 hr

Failure Code 25

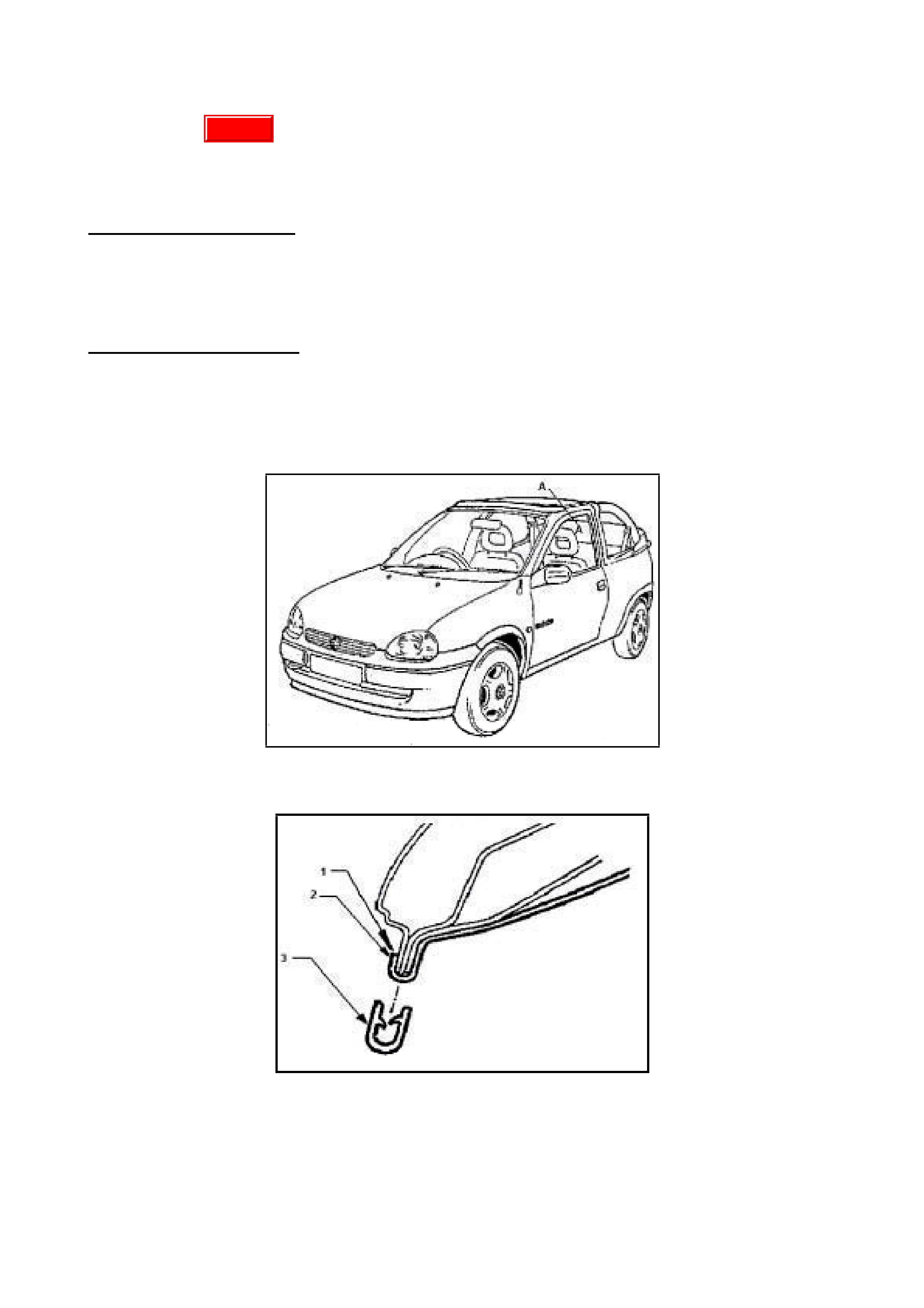

WATER LEAK INTO HEADLINING

SB CABRIO

(GROUP 1) April 2000

PROBLEM DESCRIPTION

Damp patches in the headlining material around the top of the A pillar may be evident after a

vehicle roof has been soaked for extended periods of time. The water entry that causes this

condition has been found to be via the headlining m aterial extending too far into a wet area along

the roof and door weatherstrip flanges.

SERVICE RECTIFICATION

To rectify this water entry condition, it is necessary to trim excess headlining material from the

upper door weatherstrip flange, and the roof weatherstrip flange, as follows:

Refer to Figure 1 for location of the typical section through both flanges, as noted in the following

Figures and t ext.

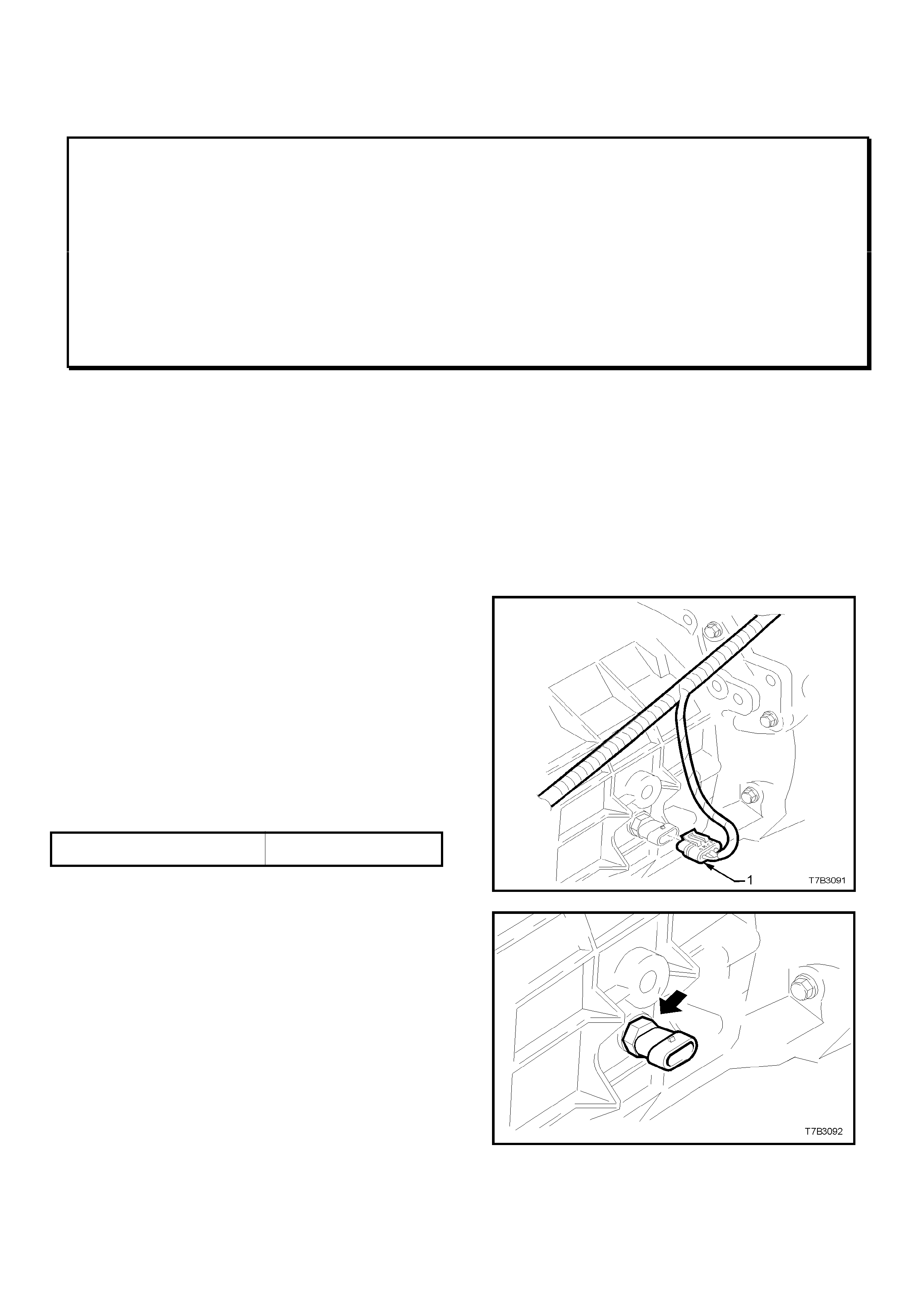

Figure 1.

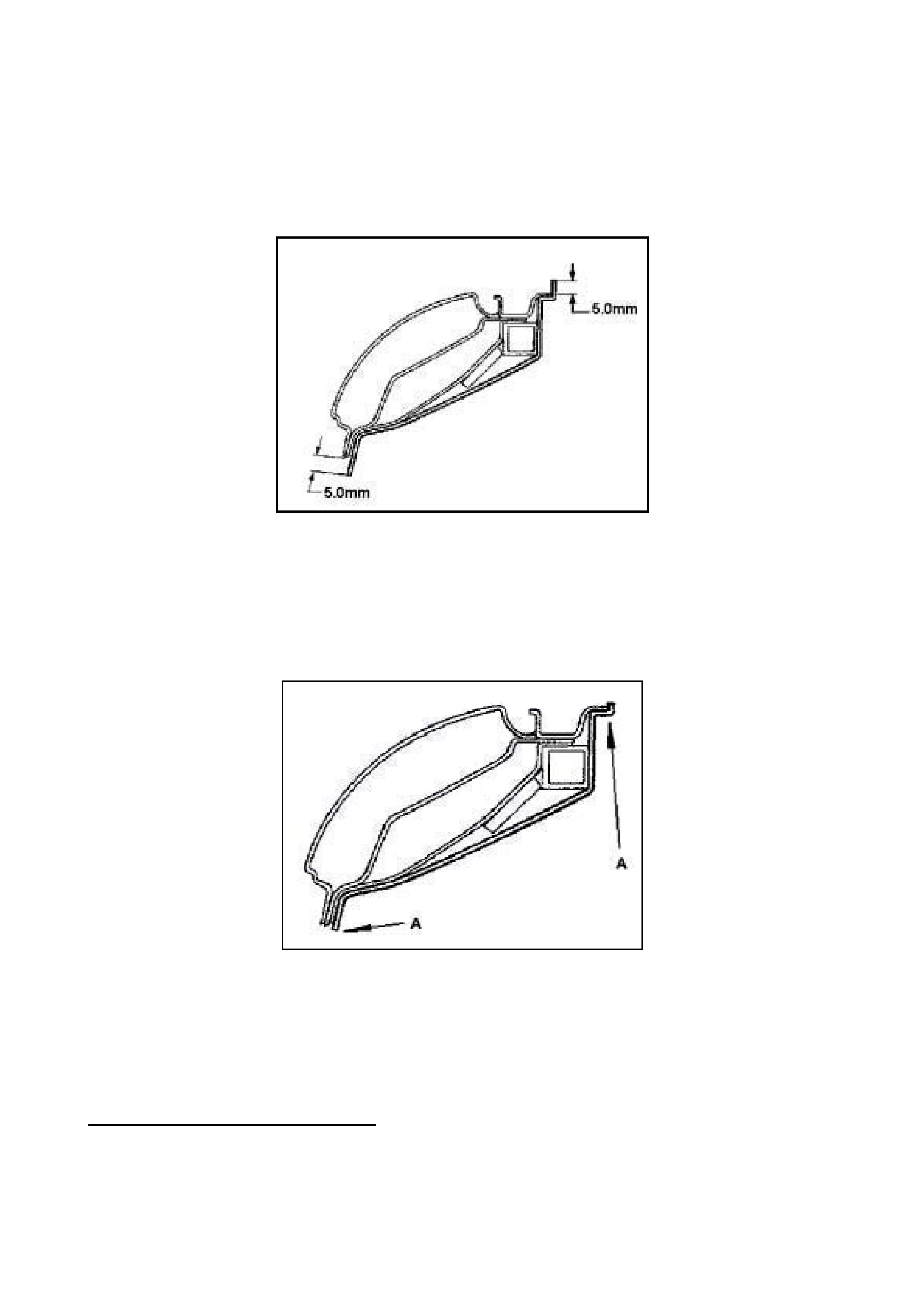

Refer Figure 2 for Secti on A-A.

Figure 2 – Typical sect i on

(door opening shown, roof secti on same)

1 = Edge of headlining exposed to water from outside vehicle.

2 = Excess headlining material extending into wet area.

3 = Weatherstrip.

Update

1. Open doors and roof.

2. Remove roof weatherst r ip and t op por t ion of door weatherstrip.

3. Caref ully remove the portion of the headlining material that is folded over and glued to the r oof

and door weatherstrip flanges (Only remove the material that is glued to the flange ends and

extends into the outside “wet” area). Take care not to tear or stretch the material during this

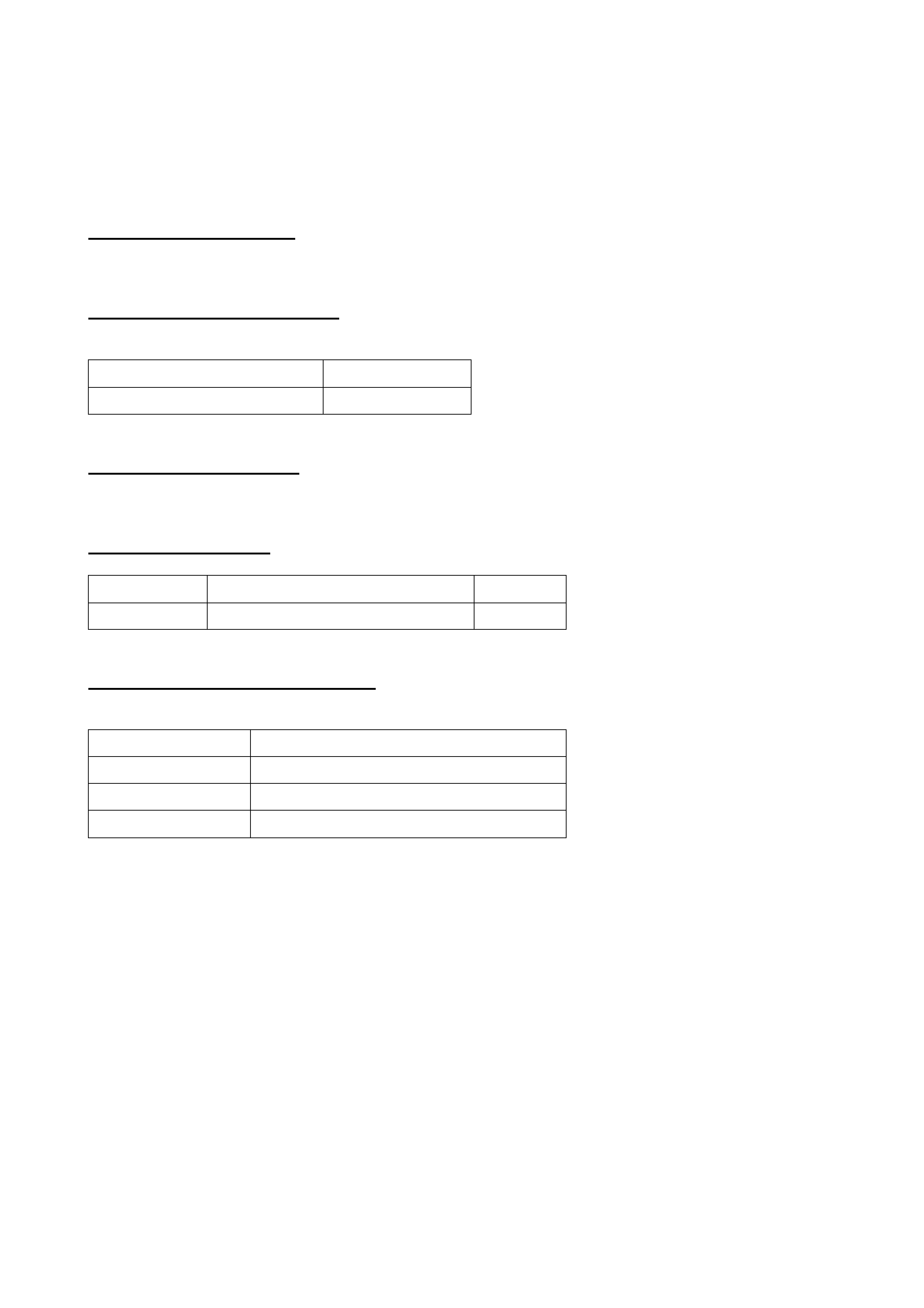

removal process. Figure 3 shows the headlining material removed from the flanges, and the

areas of excess (5m m appr ox.) m at er ial.

]

Figure 3

Shows excess headlining material on both the door

weatherstrip fl ange ( l ower) and t he roof weatherstr i p f l ange ( upper)

4. Clean any remnants of headlining material or glue from the flanges, so no air or water entry

gaps exist.

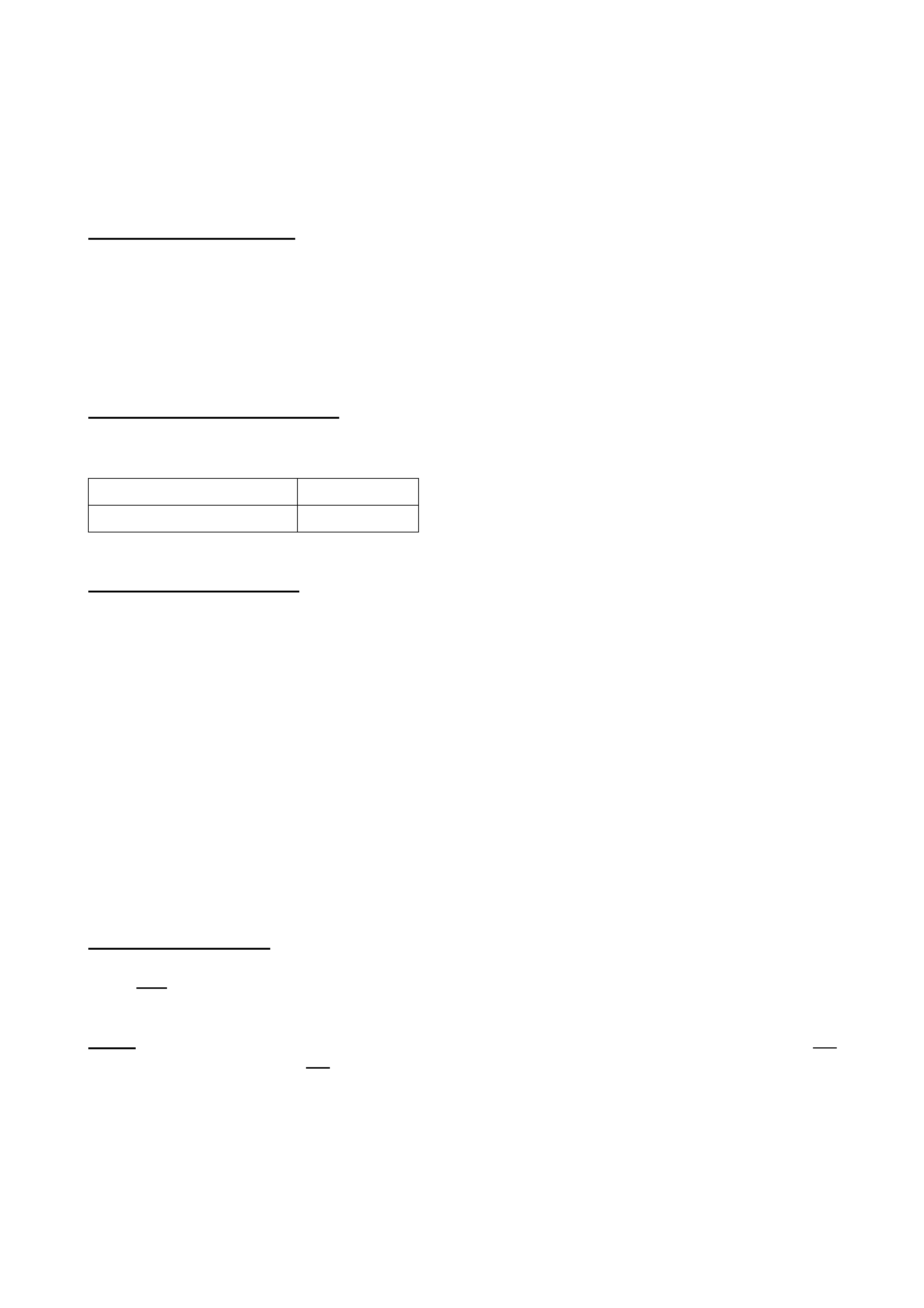

5. W ith a sharp k nif e, neatly trim t he excess headlining mater ial flush with the f langes, as shown

in Figure 4, t aking care not to damage paint finish.

Figure 4

“A” Shows tr i mmed headl i ni ng areas

6. If the headlining material separates from the inboard side of the flange during this process,

add glue behind the material to retain it, or use waterproof tape to retain the material to the

flang e edge. Make sure any tape used is not visible when the weatherstrip is ref it t ed.

7. Caref ully refit the weatherstrips t o the roof and door flanges.

WARRANTY CLAIM I NFORMATION:

Description Correct headlining water leaks

Labour Op. No. B000400

Time 0.6 hr

Failure Code 87

ACCESSORY POWER SOCKET LOOSE

VT, WH

(GROUP 12) April 2000

PROBLEM DESCRIPTION

The accessory power socket loosens in console mounting hole, due to insufficient

retention t orque capability of the existing nut and shell.

PRODUCTION RECTIFICATION

A revised (shorter) power accessory sock et shell has been fitted t o vehicles f r om:

ISOVIN: Build Date:

6H8VTK69HYL551551 01/02/00

SERVICE RECTIFICATION

Vehicles presented with a loose power accessory socket should have a new power

accessory socket shell – P/ N 92094030 - fitted.

PARTS INFORMATION

Part No.: Descri pt i on: Qty

92094030 Shell – Accessory Access. 1

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual as shown:

Description Accessory Power Socket – Repl.

Labour Op. No. N311700

Time 0.5 hr

Failure Code 27

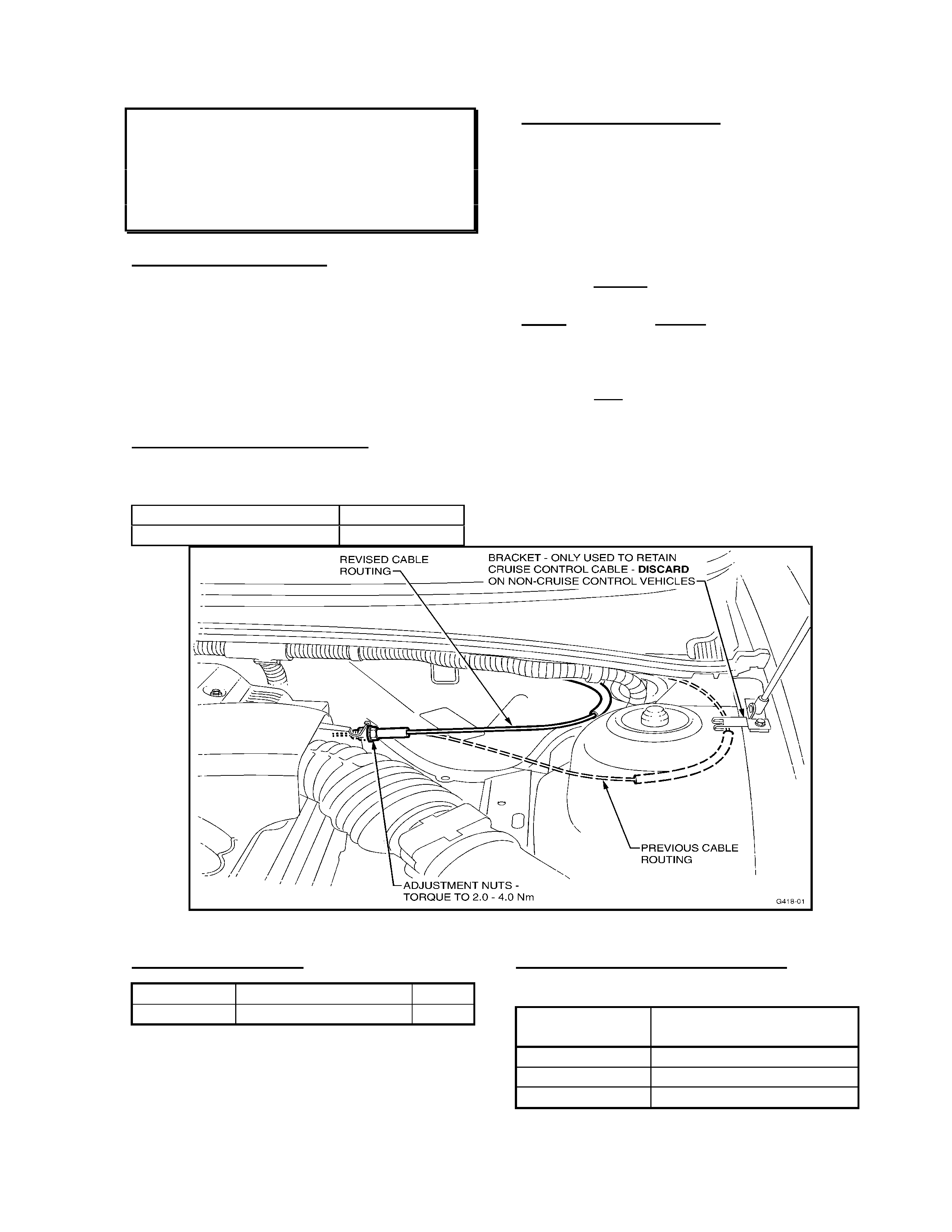

CRUISE CONTROL “DROP-OUT”

VS UTILITY

(GROUP 12) April 2000

PROBLEM DESCRIPTION

Some customers may experience an intermittent disengagement of the cruise control, particularly

when driving for long periods. A change to the speedometer operating mechanism on later built

VS Utility vehicles has raised this concern.

Electrical “noise” generated on the speedometer voltage supply has been identified as the cause.

This inter ference af fects t he vehicle speed signal being supplied to the cruise control module. The

module is sensitive to this int er ference, causing a cruise control dropout condition.

PRODUCTION RECTIFICATION

Revised speedometer assemblies, with increased capacitance to rectify this condition, have been

introduced into pr oduction from:

ISOVIN: Build Date:

6H8VSK80HYL560257 24/02/00

SERVICE RECTIFICATION

The following replacement recomm endation affects vehicles built in the f ollowing ranges:

V6 Utility

From :6H8VSK80HWL345970, 12/6/98

To :6H8VSK80HYL560257, 24/02/00

V8 Utility

From :6H8VSK80UWL346473, 15/6/98

To :6H8VSK80HYL560257, 24/02/00

(This is a V6 Isovin, and is supplied for “limiting” the affected range only)

When presented with a VS Utility from the breakpoint specified above that exhibits intermittent

cruise control dropout, technicians should perf orm a basic inspection of t he cruise control system.

These inspections should include all circuit connections and adjustments of both of the cruise

control stop lamp switches. If no faults are identified replace the speedometer assembly with the

revised part specif ied.

PARTS INFORMATION

Revised speedometer assemblies can be identif ied by locating the VDO date code label, adhered

to the rear f ace of the assem bly. This label shows the date of manuf acture and should have a date

code “210200” or lat er .

NOTE: T here are t wo labels located on the rear of the speedom eter assem bly. The one on t he top

face of the assembly should not be used t o ident ify breakpoint parts.

All parts in stock in HSPO warehouse, at time of publication, are of the latest specification.

Distributor or Dealership parts stock , found t o be date coded prior to the date code shown above,

should be returned t o HSPO for cr edit .

Part No.: Description: Qty

92142867 Speedometer Asm. 1

92142866 Speedomet er Asm . (Police) 1

WARRANTY CLAIM I NFORMATION:

Use existing information in Labour Time Manual f or removal and replacement of the speedometer

assembly.

CRUISE CONTROL INOPERATIVE - HINT

VR, VS, VT

(GROUP 12) April 2000

When presented with a “cruise control inoperative” condition in any of the above model vehicles,

technicians should inspect the stop lamp circuit for correct oper at ion.

In some instances failed stop lamp globes have been the cause of the cruise control system

becoming inoperative, resulting in unnecessary replacement of parts and unnecessary or

excessive diagnosis times.

A pull up type resistor cir cuit is at tached to t erm inal “G” of the cr uise contr ol module. This monitor s

the stop lamp cir c uit via the stop lamp globes to eart h.

In the event that this circuit becomes int errupted, IE: Poor connections (open circuit) or failed stop

lamp globes, this disables the operation of the cruise contr ol system .

Every eff ort should be made to def ine the cause of t he stop lamp circuit failure, to ensure that this

fault does not r eoccur .

FINAL DRIVE/REAR AXLE OIL - NAME CHANGE

VP, VQ, VR, VS, VT, WH

(GROUP 4) April 2000

OIL NAME CHANGE

Spicer Axle Australia, Holdens final drive unit/rear axle supplier, and Mobil Oil Australia Ltd.,

advise that Mobilube SHC 80W/140 ID oil is now known as:

Mobilube SHC ID

This nam e change was effect ive fr om December 1, 1999, and has tak en place to avoid confusion

with another Mobil product bearing a sim ilar nam e.

USAGE

This oil is recom m ended for use in:

VP/VQ:

All V8

All Utilities

VR/VS:

V6 with LSD

All V8

VT/WH:

All S/C V6 & V8

Wagons with V6 & M/T

The oil is Synthetic Hypoid Gear Oil to Holden’s Specificat ion HN2040. Refer to individual Service

Manuals for equivalents, where available.

Please ensure all Service and Parts personnel are aware of this name change, to ensure the use

of t he cor r ect oil in the above vehicles.

LEAK DETECTION DYE ADDED TO ENGINE OIL

JS, V6

(GROUP 6A) April 2000

PRODUCTION CHANGE:

This T echline bullet in is an inf ormat ion item t o advise that f r om eng ine number 08 480 202 built on

09/03/00, a sm all amount of fluorescent dye has been added to the first fill engine oil.

This dye confor m s t o GM Mat erial Specifications.

It is possible that a small number of engines, built for validation, prior to the breakpoint will also

have dye.

The chang e has been made as a q uality improvement to enable bet ter leak detection capability, in

the engine assem bly plant.

IN SERVICE:

It should be noted that under normal lighting the engine oil with have a red/brown appearance,

somewhat different t o nor mal engine oil.

Please advise all pre-delivery and service technicians of this change, so there is no concern that

oil in these engines is “ contaminated”.

PRODUCTION INTRODUCTION

A small amount of fluor escent dye has been added to t he first fill engine oil from:

Engine No.: Build Date:

08 480 202 09/03/00

DTC P0340 - CAM SENSOR INCORRECT SIGNAL

TR, JR (4 Cyl), JS (4 Cyl)

(GROUP 6C) April 2000

PROBLEM DESCRIPTION

Investigations into unnecessary ECU replacement, where DTC P0340 (camshaft sensor incorrect

signal) is stored, have identified the camshaft posit ion sensor as the cause of the f ailure. In some

instances DTC P0335 m ay also be stor ed.

SERVICE RECTIFICATION

When presented with a vehicle storing DTC P0340, technicians should follow the relevant

diagnosis for this code - Refer TIS 2000, Checking Procedures. Care should be taken to ensure

no fault exists with the Camshaft sensor circuit or mounting. If no fault is identified on inspection,

the Camshaft sensor should be replaced with the revised part detailed below.

PARTS INFORMATION

Revised Camshaft posit ion sensors can be identified by a manufactur ing date code located on the

rear face of the sensor (sensor in position on engine). The date code is stamped in white ink and

should be “2098b” or higher.

Date Code Int er pr e t ation:

“20” = week 20; “98” = 1998; “ b” = disr egard

All part s in stock in the HSPO warehouse at time of publication ar e of the lat est specification. Any

old stock found in Distributor or Dealership parts stock date coded prior to the date code above

should be returned t o HSPO for cr edit .

Any Camshaft Revolution Sensors in Distributor or Dealership parts stock – under previous part

number 90506103, m ust not be used, but ret ur ned t o HSPO for cr edit .

Part No.: Descripti on: Qty

90458252 Camshaft sensor 1

WARRANTY CLAIM I NFORMATION:

Use existing inf or m ation in Labour Time Manual

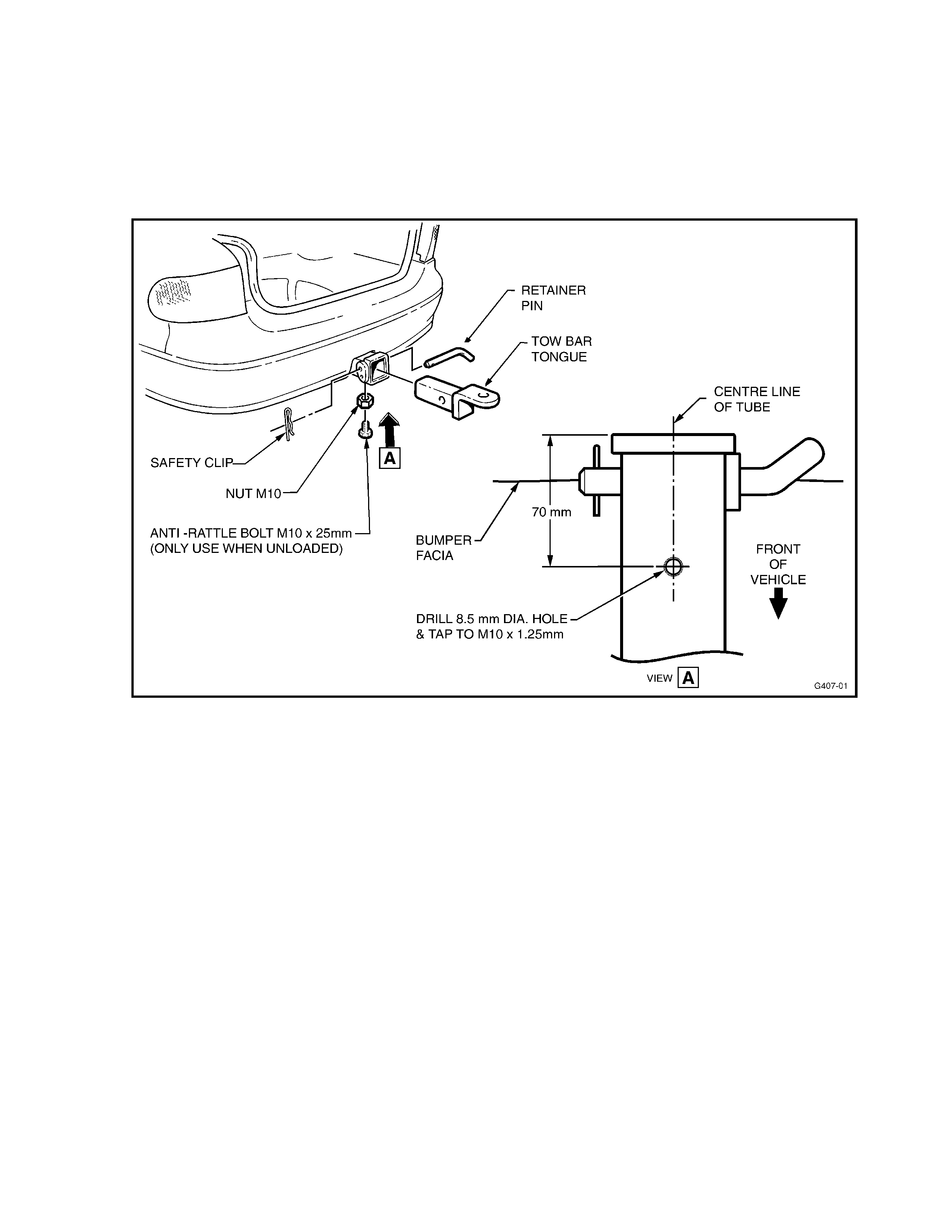

A/ T COOLER HOSE RETENTION

JS w ith A/T

(GROUP 7B) April 2000

PROBLEM DESCRIPTION

All A/T oil cooler hoses are r etained by a tie str ap (fitt ed in production), located ar ound the hoses,

between the A/T body and the radiator, visible from under the vehicle

If the hose retaining strap is not replaced - after removal for any reason, the A/T oil cooler hoses

may rub on the front engine/ trans. mount, causing hose damage, and pot entially, a leak.

SERVICE RECTIFICATION

The A/T oil cooler hose retaining tie strap must be replaced after removal for any reason. If any

vehicle is found, during servicing, to have the t ie st r ap m issing, a new tie strap should be f it t ed.

The sketch below shows the location of t he tie strap.

Figure 1 – Showing tie st rap location

PARTS INFORMATION

Part No.: Description: Qty

9275610 Strap – Hose Retaining 1

A/T REPLACEMENT REQUIREMENT - COOLER FLUSH & FLOW RATE CHECK

VR, VS, VT, WH

(GROUP 7B) April 2000

Analysis of SRTA returned automatic transmissions, and the incidence of repeat transmission

failure/replacement, highlights the need for technicians to ensure an A/T cooler flush and flow

check is done.

It is recommended that Service Managers, Workshop Controllers or Service Advisors

advise technicians to carry out the procedure – by adding the wording “Cooler Flush &

Flow Rate Check Required” to Repair Orders - w henever:

• a changeover or replacement tr ansmi ssion is installed.

• fluid contaminat i on i s suspected.

The procedure appears in the VT Service Manual, Volume 14C, Page 7C4-5 (last printed version) or in the

latest version of Holden SIP CD, Section 7C4 - 2.3 TRANSMISSION COOLER REVERSE FLUSH AND

FLOW RATE CHECK

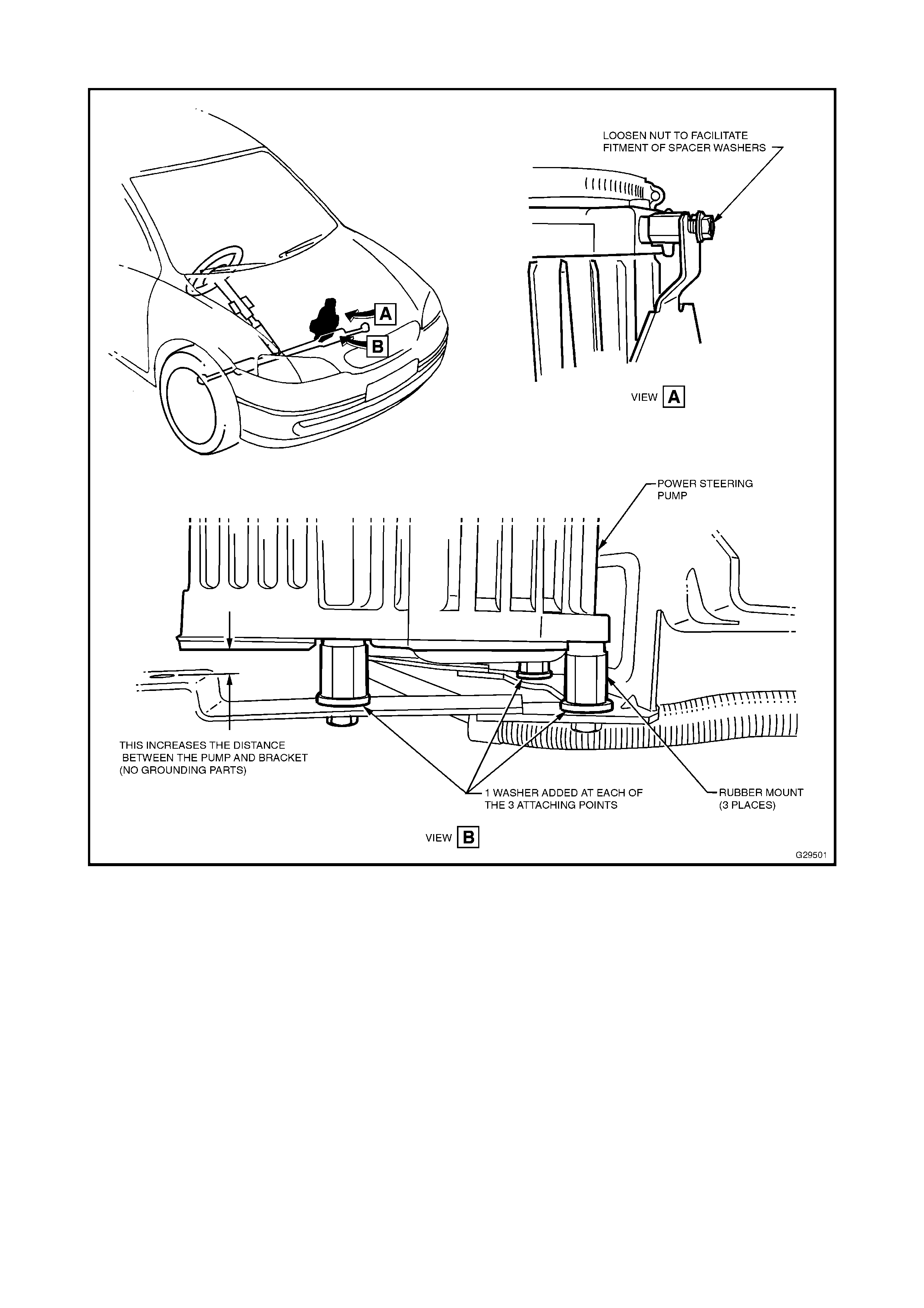

STEERING WHINE NOISE

TS (TRW Steering Gear)

(GROUP 9) April 2000

PROBLEM DESCRIPTION

Some cust omers may complain of a light “whine” noise f rom steering , when steering is turned j ust

off-centre, at low speed.

Investigations have revealed that noise can be transferred into the vehicle body, if the P/S pump

body contacts the pump m ount ing bracket (beneath the pump).

PRODUCTION RECTIFICATION

To correct noise complaints as described above, as an interim action, washers were added at

three locations bet ween the P/S pum p and it s mounting bracket f r om :

ISOVIN: Build Date:

Not Available 12/08/99

As a final corr ective action, a r evised power steering pump m ounting brack et, with upward swaged

lower mounting holes, has been int r oduced into vehicle production at:

ISOVIN: Build Date:

Not Available 01/03/00

As the revised bracket is not yet available from HSPO, the following Service Rectification will be

required on complaint vehicles where interference between P/S pump and mounting bracket is

defined.

When parts are available from HSPO, a Techline Bulletin will be released, advising to fit the

revised bracket in lieu of this procedur e.

SERVICE RECTIFICATION

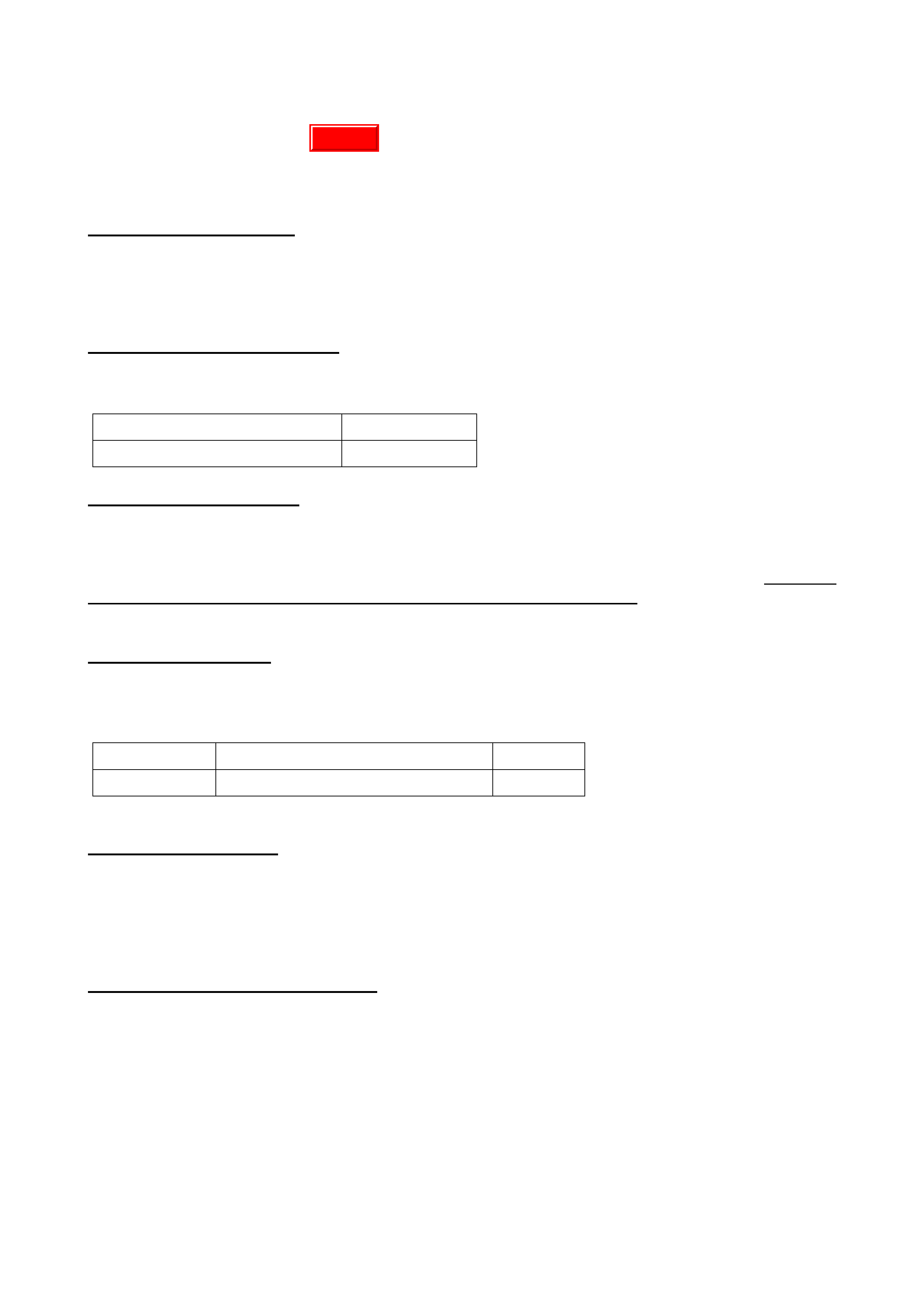

If an abnormal P/S “whine” noise is reported on a vehicle with TRW steering system; where the

noise occurs when steering wheel is turned “just off-centre” at low speed – the following check

must be carried out :

Raise vehicle on a hoist and check that clearance exists between the P/S pump and the pump

mounting bracket, at the inboard (RH) side of the pump. This can be done by raising the vehicle

on a hoist and passing a feeler strip or piece of thin card between the pump and bracket, to

ensure clearance exists. NO CO NTACT SHO ULD BE EVIDENT AT THE INBOARD SIDE OF THE

PUMP/BRACKET.

If clearance exi st s - furt her diagnosis is required to define the cause of the noise.

If no clearance exi st s - carry out the following procedure:

1. Loosen the single upper mounting nut, accessible from engine compartment and located

horizontally on the outboard (LH) side of the pump body. Loosening this mounting nut allows

pump movement lat er .

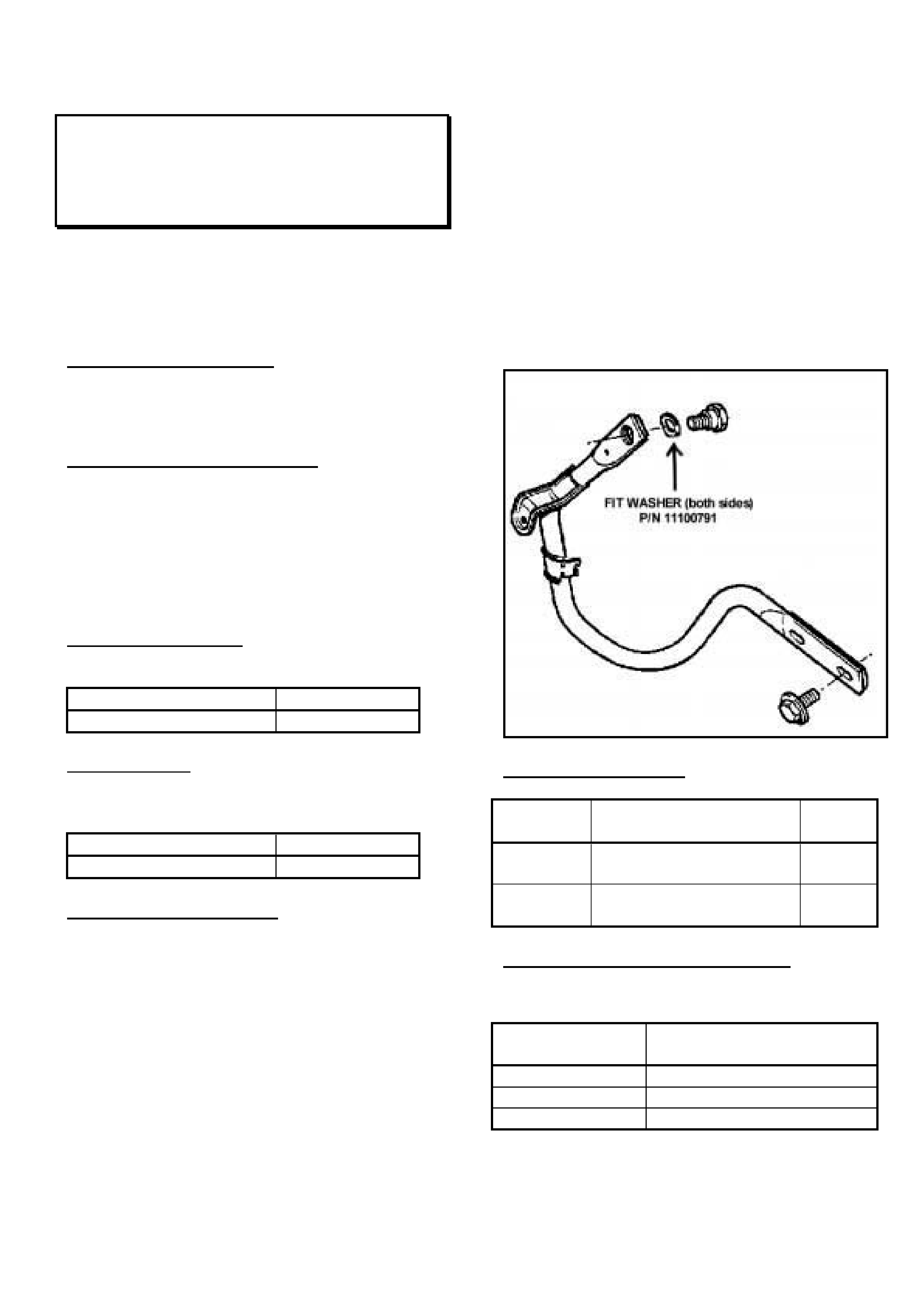

Refer View A in Figure 1 below.

2. Raise vehicle on a hoist.

3. From under vehicle, loosen and remove the three pump t o mounting bracket mounting nuts –

the third mount is accessible from behind LHF wheel. (rubber mounts above nuts should be

held during loosening, with a 14mm spanner).

4. Have an assistant lif t t he power st eering pump up of f the mount ing bracket , providing enough

clearance to fit a washer – P/N 11035613 – on the mounting bracket at all three lower

mounting holes between the pump and its mounting bracket (glue washers to bracket if

required, to assist assembly).

NOTE: the washers requir ed ar e a specific size – do not use any other washers.

Refer View B in Figure 1 below.

5. Lower the pump onto the washers/mount ing bracket .

6. Reinstall the three lower mounting nut s to the mounting studs, torque to 7Nm (rubber mounts

should be held during t or quing, with a 14mm spanner ) .

7. Torque the upper mounting stud (in engine compartment) to 7Nm (rubber mount should be

held during t or quing, with a 14mm spanner ) .

PARTS INFORMATION

Part No.: Descript i on: Qty:

11035613 Washer – P/ S Spacer 3

WARRANTY CLAIM I NFORMATION:

Description Fit P/S Spacer Washers

Labour Op. No. M000178

Time 0.4 hr

Failure Code 40

Figure 1

1

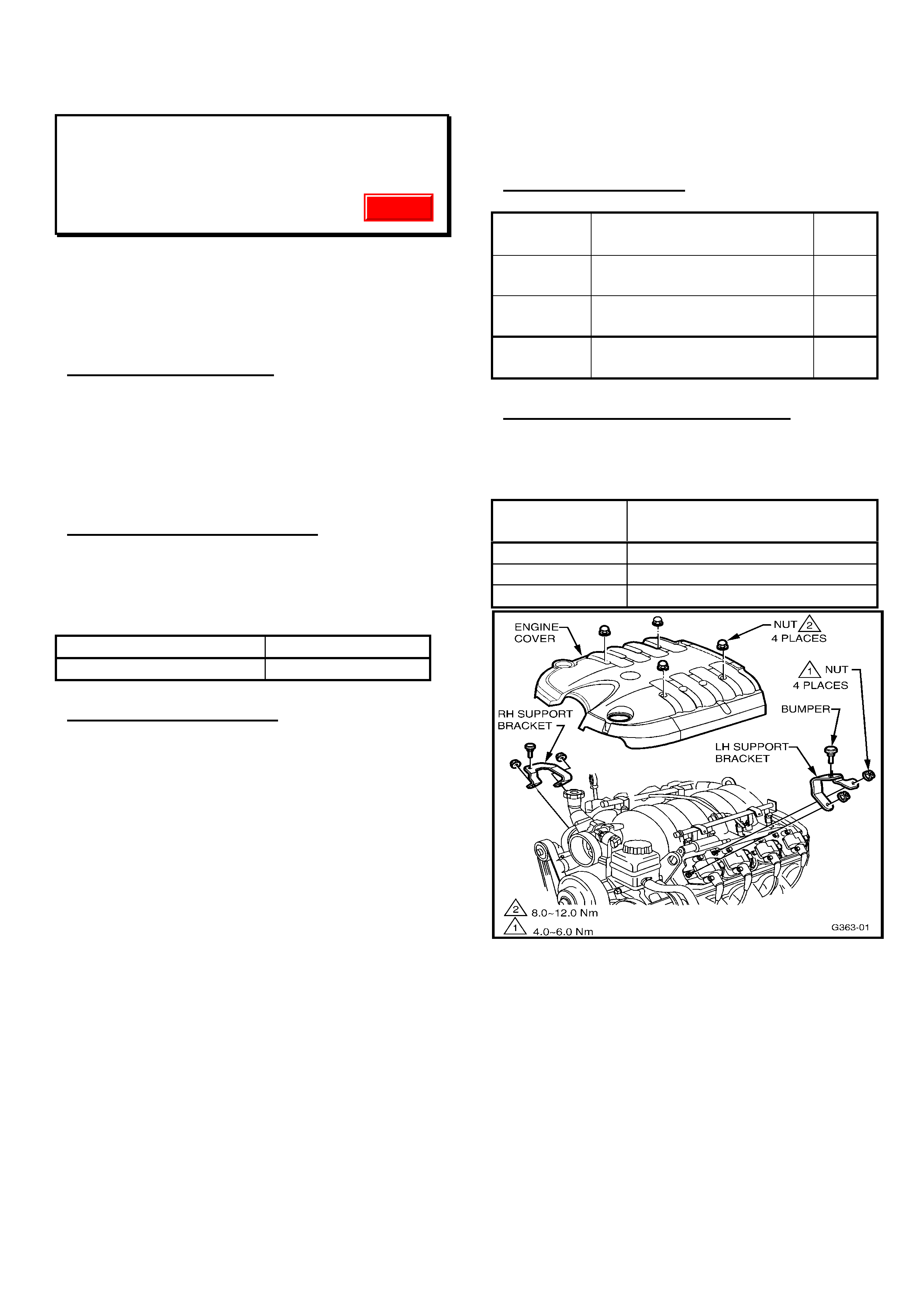

INLET MANIFOLD – ALTERNATIVE PART

USAGE

VT & WH with Gen III V8

(GROUP 6A) May 2000

PROBLEM DESCRIPTION

TAS has received calls regarding replacement

engine assemblies ex-HSPO, being fitted with an

alternative inlet manifold that appears different to

the manifold on the original engine.

An alternative inlet manifold (that has a plugged

hole at the top, front of the manifold) has been

fitted to engines in vehicle production, and for

HSPO supply (this plugged hole is used for a

derivative of the Gen III engine used in other

market areas).

This manifold is different only by the addition of a

“plugged hole”, and is totally interchangeable with

the “non-plugged’ manifold.

PRODUCTION RECTIFICATION

No breakpoint information is required for this

alternative manifold, as it is used intermittently.

SERVICE RECTIFICATION

Do not replace the manifold, as both manifolds

are fully interchangeable.

Technicians should not be concerned that there is

any additional component to be fitted at the

plugged hole location.

PARTS INFORMATION

No specific parts information is required – existing

parts and part numbers are unchanged, and

interchangeability is not affected.

ENGINE STALL ON DECELERATION/HIGH

ENGINE IDLE SPEED

JR, JS with C20SEL or C22SEL Engine

(GROUP 6M) May 2000

This Service Techline updates the previous

Techline on this topic (Issue 10, December, 1999

page 15) – by providing new part number

information.

PARTS INFORMATION

Since release of the original Techline item on this

condition, a kit comprising necessary components

has been made available.

For initial fitment of PCV oil separator as per the

previously issued Techline, order:

Part No.: Description: Qty

92065659 Kit, PCV Oil Separator 1

90411546 Valve – Idle Air Control (IAC). 1

09240103 Gasket - IACV 1

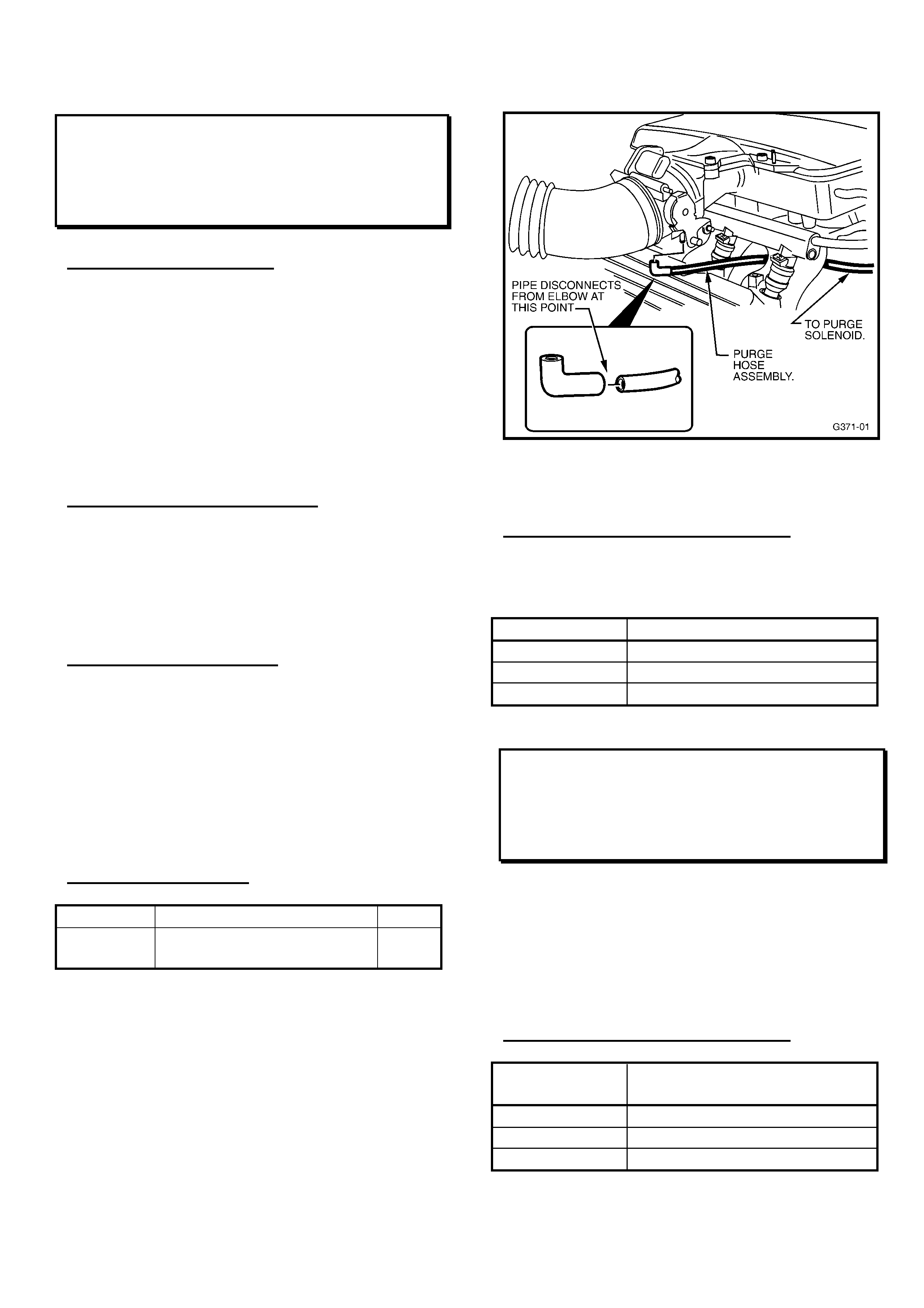

For reference, kit 92065659 contains: