Front Suspension – AWD Page 3B –1

Page 3B – 1

Section 3B

Front Suspension – AWD

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Description ...............................................................................................................................3

2 Wheel Alignment ....................................................................................................................................5

2.1 Steering Geometry................................................................................................................................................. 5

Caster...................................................................................................................................................................... 5

Camber ................................................................................................................................................................... 6

Wheel Toe............................................................................................................................................................... 6

Steering Axis Inclination....................................................................................................................................... 7

Scrub Radius.......................................................................................................................................................... 7

Included Angle....................................................................................................................................................... 8

Toe-Out On Turns.................................................................................................................................................. 8

2.2 Wheel Alignment Checking and Adjustment....................................................................................................... 9

Preliminary Inspection .......................................................................................................................................... 9

Caster Adjustment................................................................................................................................................. 9

Camber Adjustment............................................................................................................................................... 9

Toe Adjustment.................................................................................................................................................... 11

2.3 Jacking Precautions............................................................................................................................................ 12

2.4 Front Wheel Hub Assembly – End Float Checking Procedure ........................................................................ 13

3 Service Operations...............................................................................................................................14

3.1 Service Notes And Cautions............................................................................................................................... 14

3.2 Suspension and Trim Height, Check.................................................................................................................. 15

3.3 Front Wheel Hub Assembly, Brake Rotor and/or Brake Shield .......................................................................16

Remove................................................................................................................................................................. 16

Inspect .................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 18

3.4 Front Wheel Hub Studs....................................................................................................................................... 20

Replace................................................................................................................................................................. 20

3.5 Front Strut Assembly .......................................................................................................................................... 22

Remove................................................................................................................................................................. 22

Reinstall................................................................................................................................................................ 24

3.6 Upper Strut Support Bearing and Mount........................................................................................................... 26

Remove................................................................................................................................................................. 26

Reinstall................................................................................................................................................................ 27

3.7 Front Spring ......................................................................................................................................................... 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 28

3.8 Front Strut Unit .................................................................................................................................................... 29

Replace................................................................................................................................................................. 29

3.9 Steering Knuckle.................................................................................................................................................. 30

Remove................................................................................................................................................................. 30

Reinstall................................................................................................................................................................ 33

3.10 Front Control Arm Ball Joint Assembly............................................................................................................. 35

Inspect .................................................................................................................................................................. 35

Replace................................................................................................................................................................. 35

Techline

Techline

Techline

Front Suspension – AWD Page 3B –2

Page 3B – 2

3.11 Front Control Arm................................................................................................................................................ 36

Remove................................................................................................................................................................. 36

Reinstall................................................................................................................................................................ 38

3.12 Front Control Arm Rear Bushing........................................................................................................................ 40

Replace................................................................................................................................................................. 40

3.13 Front Control Arm Front Isolating Bushing....................................................................................................... 42

Inspect .................................................................................................................................................................. 42

Replace................................................................................................................................................................. 42

3.14 Front Suspension Crossmember Cradle ........................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 48

3.15 Stabiliser Bar Link ............................................................................................................................................... 50

Replace................................................................................................................................................................. 50

3.16 Stabiliser Bar Isolator Bushes............................................................................................................................ 52

Replace................................................................................................................................................................. 52

3.17 Stabiliser Bar........................................................................................................................................................ 53

Remove................................................................................................................................................................. 53

Reinstall................................................................................................................................................................ 54

4 Diagnosis ..............................................................................................................................................55

4.1 General ................................................................................................................................................................. 55

Strut Diagnosis .................................................................................................................................................... 55

Acceptance Criteria............................................................................................................................................. 55

4.2 Diagnosis Guide................................................................................................................................................... 56

Hard or Heavy Steering ....................................................................................................................................... 56

Excessive Play or Looseness in Steering ......................................................................................................... 56

Erratic Steering on Application of Brakes......................................................................................................... 56

Vehicle Pulls to One Side.................................................................................................................................... 57

Front or Rear Wheel Tramp................................................................................................................................. 57

Road Shocks........................................................................................................................................................ 57

Scuffed Tyres....................................................................................................................................................... 58

Cupped Tyres....................................................................................................................................................... 58

Front Wheel Shimmy........................................................................................................................................... 59

Vehicle Wanders.................................................................................................................................................. 59

5 Specifications.......................................................................................................................................60

Suspension Travel............................................................................................................................................... 60

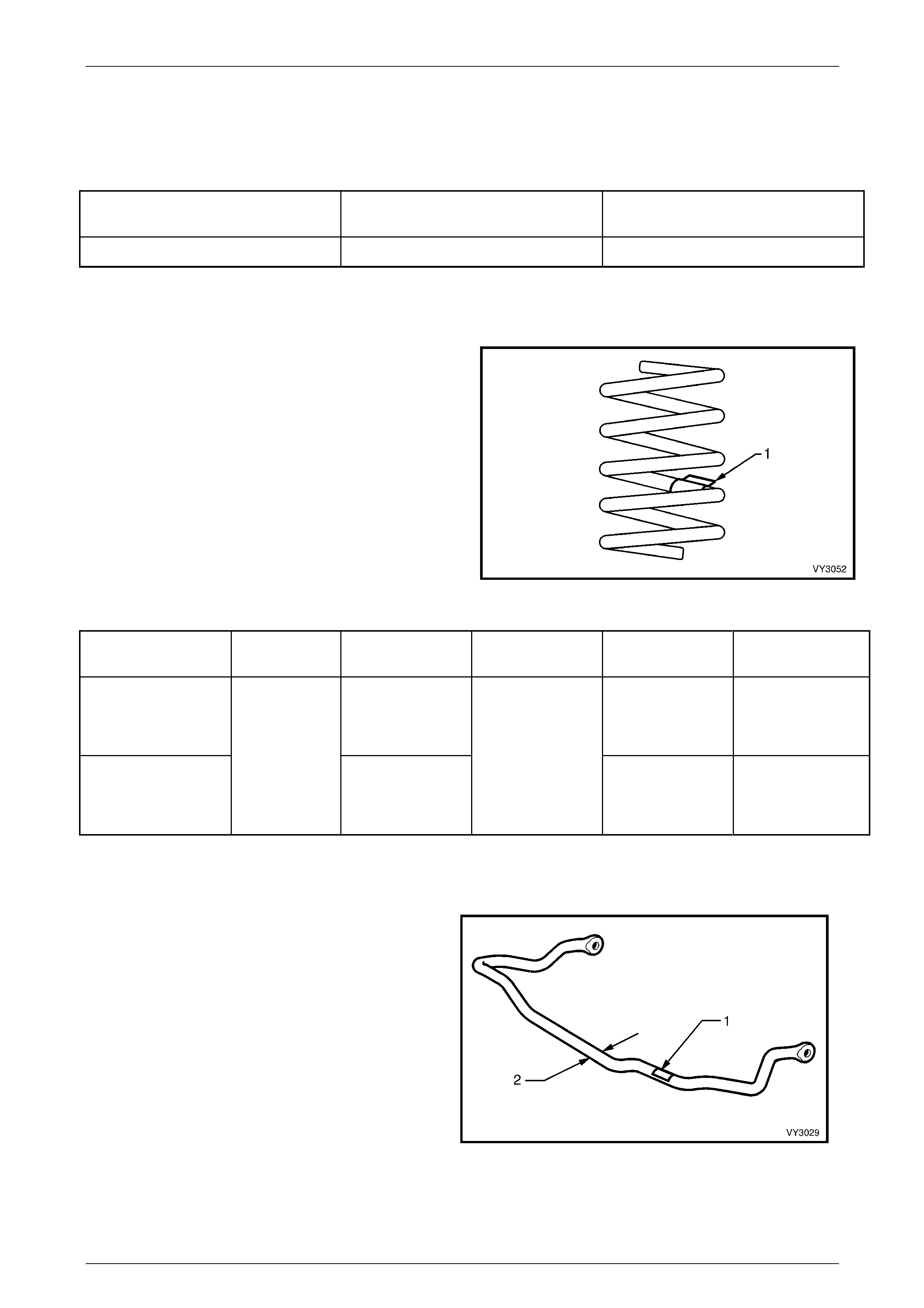

Front Spring Details............................................................................................................................................. 60

Front Stabiliser Bar Details................................................................................................................................. 60

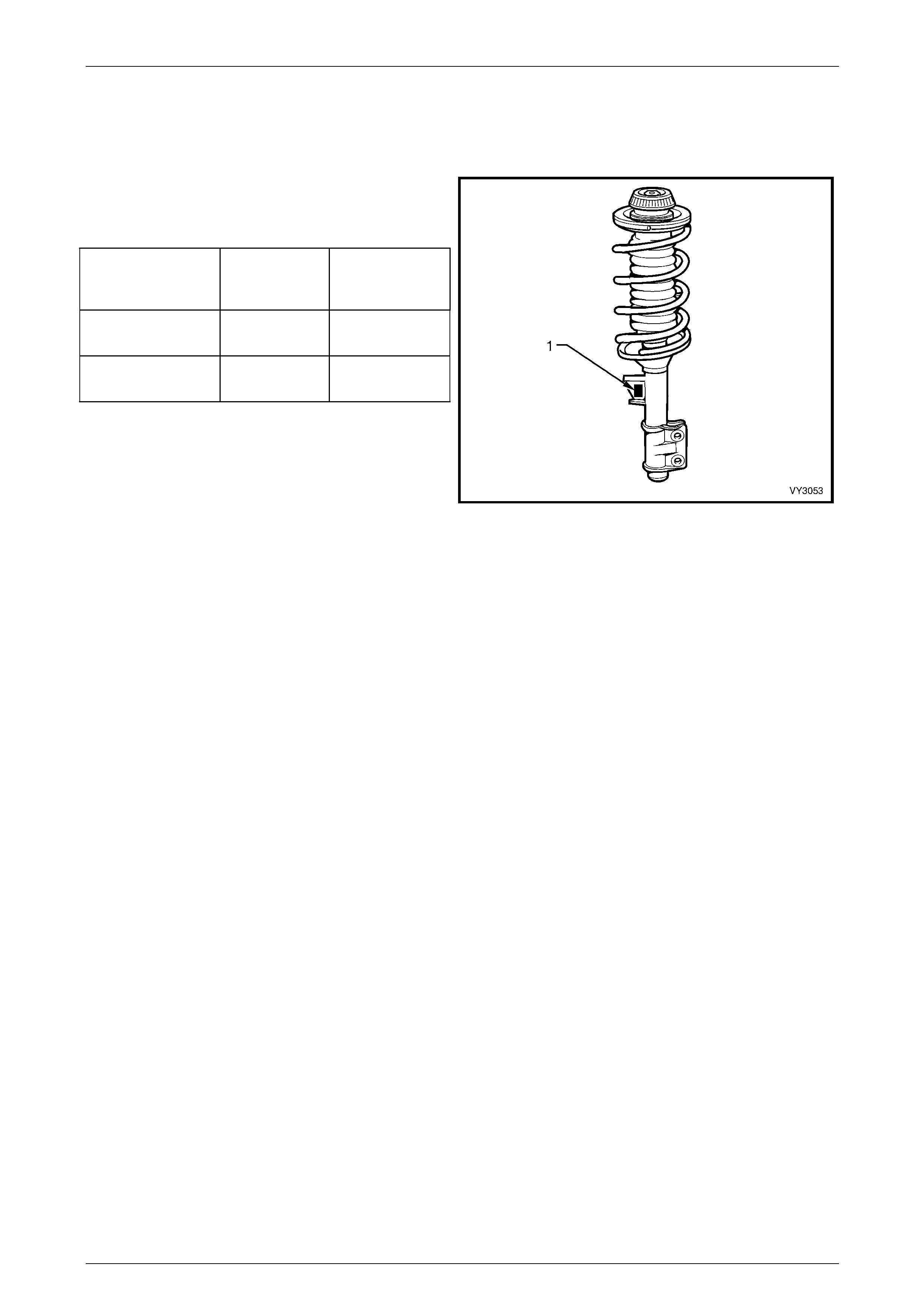

Front Strut Details................................................................................................................................................ 61

Front Control Arm Details................................................................................................................................... 61

Front Control Arm Ball Joint............................................................................................................................... 61

Front Wheel Bearings.......................................................................................................................................... 61

Wheel Bearing Angular 'Float' ............................................................................................................................ 61

Suspension Trim Height Specifications ............................................................................................................ 62

Front Wheel Alignment Specifications .............................................................................................................. 63

6 Torque Specifications..........................................................................................................................64

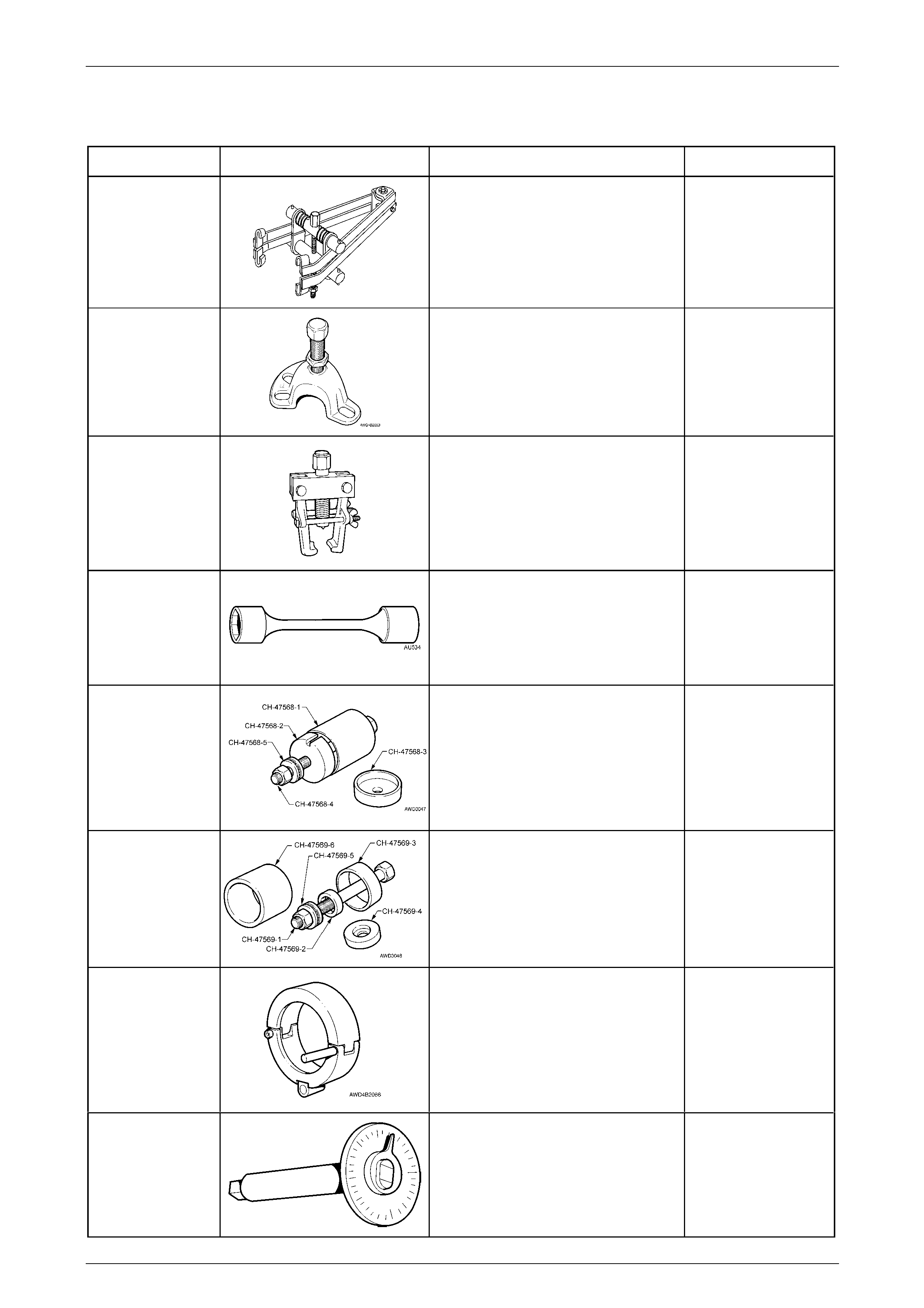

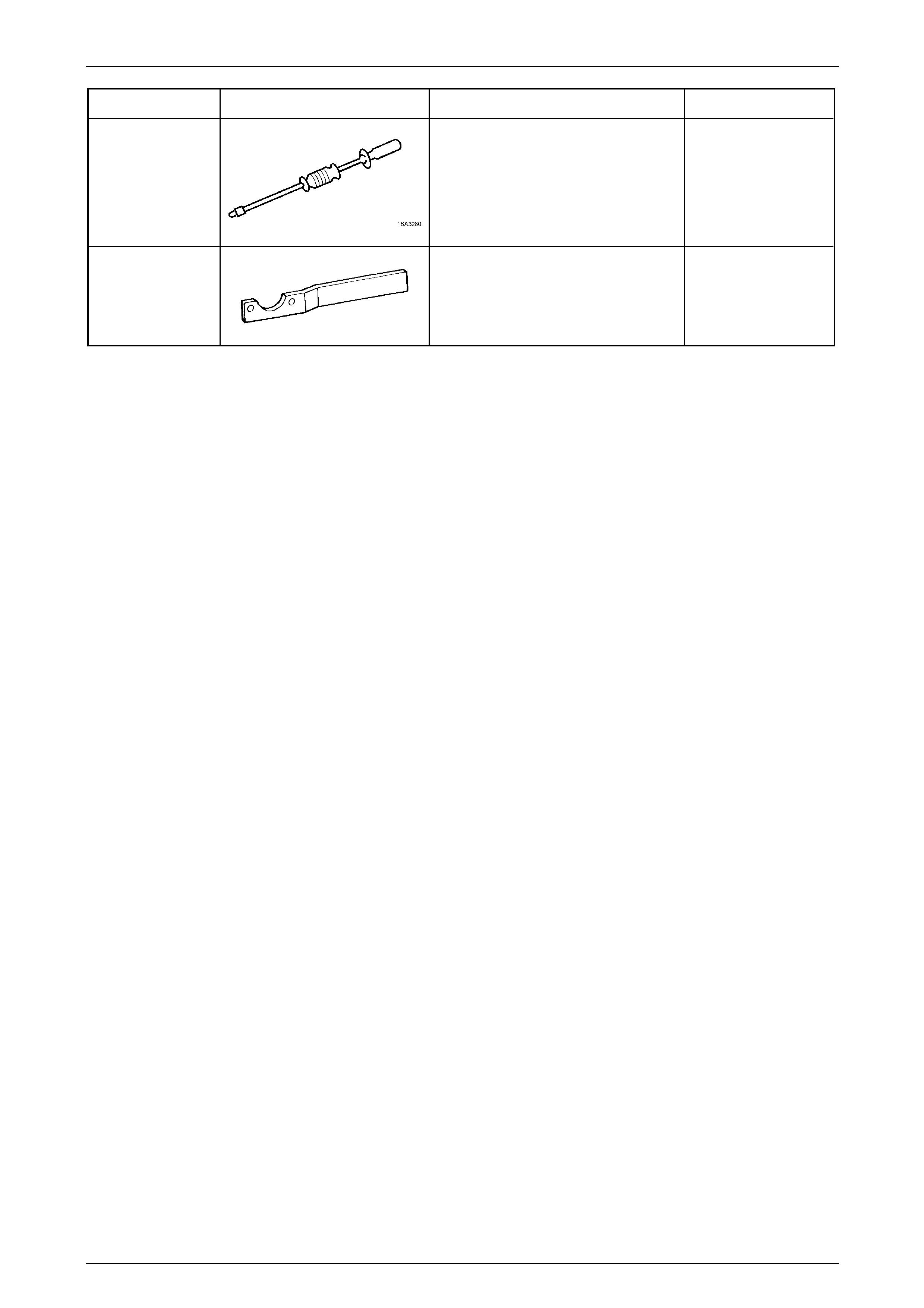

7 Special Tools ........................................................................................................................................65

Front Suspension – AWD Page 3B –3

Page 3B – 3

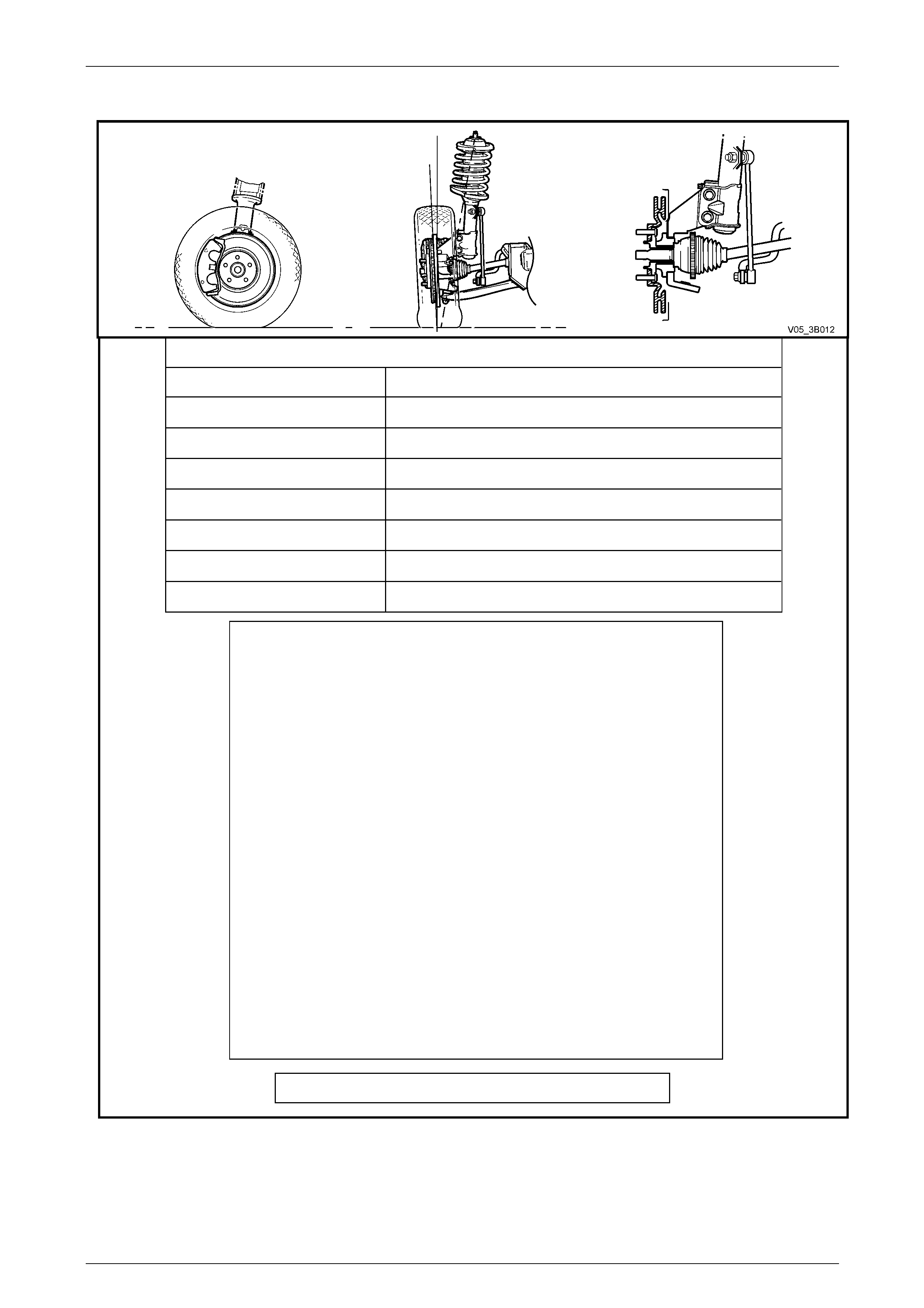

1 General Description

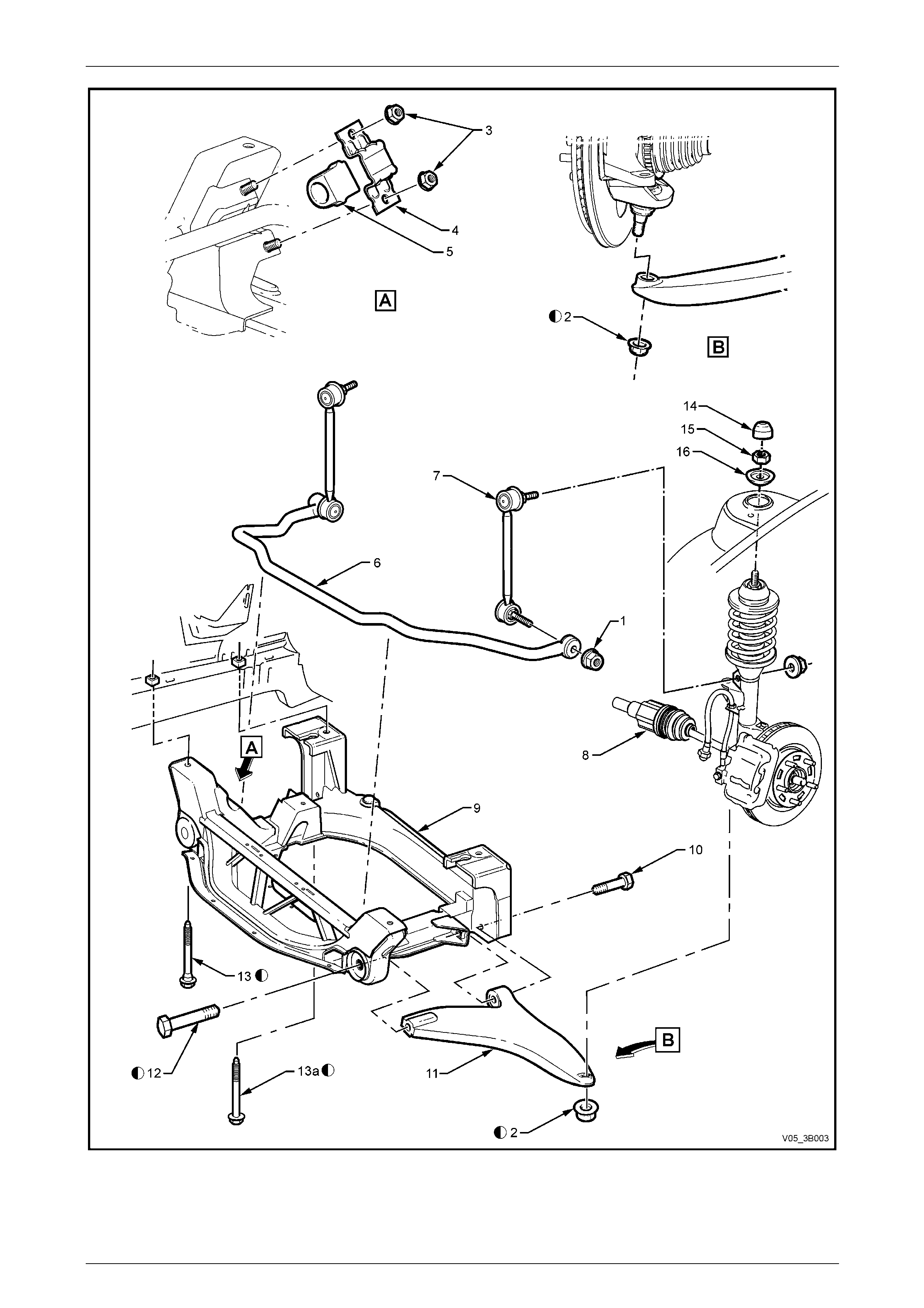

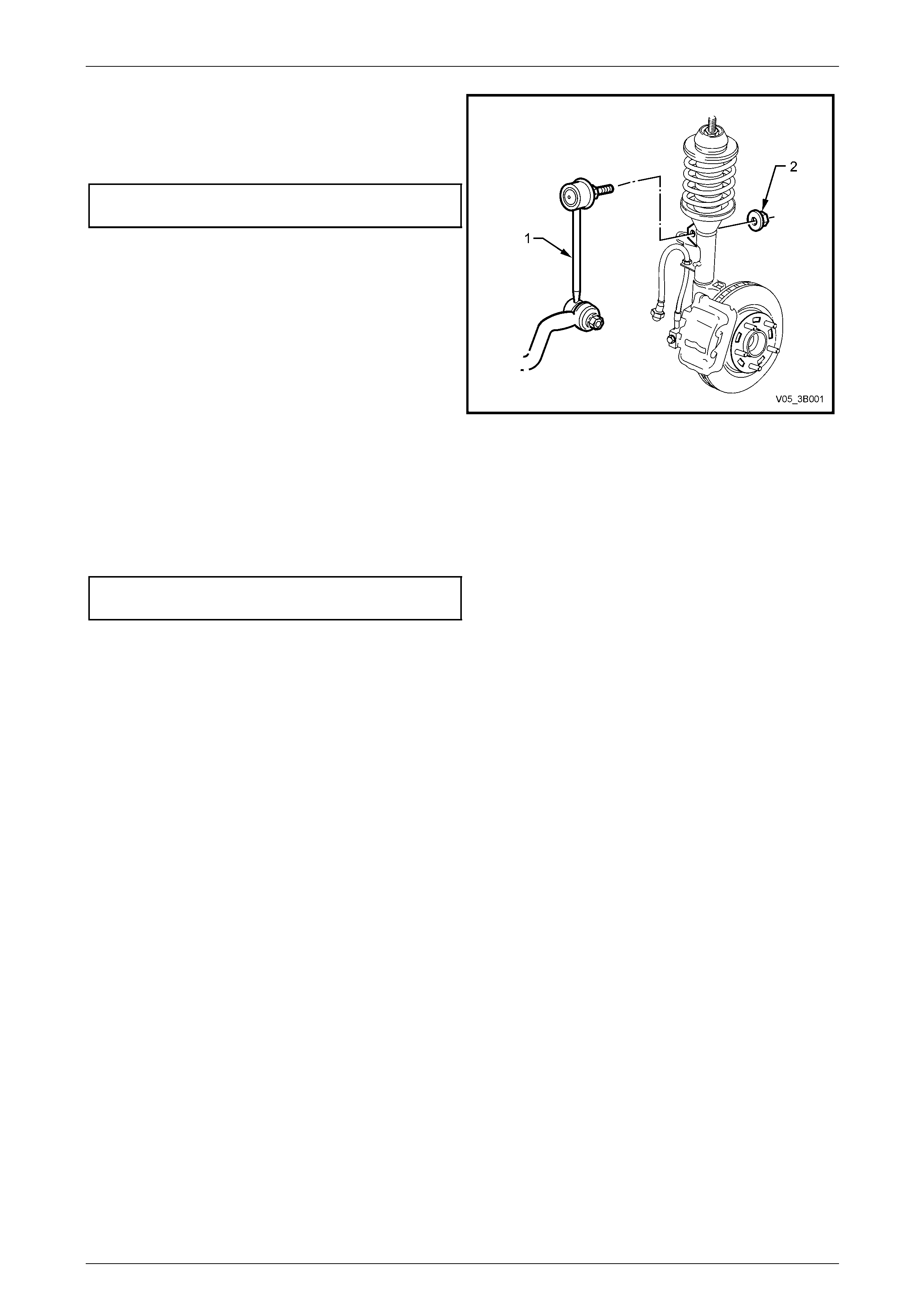

The front suspension fitted to all MY2005 A WD Models operates on the McPherson strut principle. The assembly

consists of the front suspension crossmember cradle, lower control arms, stabiliser bar and heavy duty strut assemblies

(Refer to Figure 3-1).

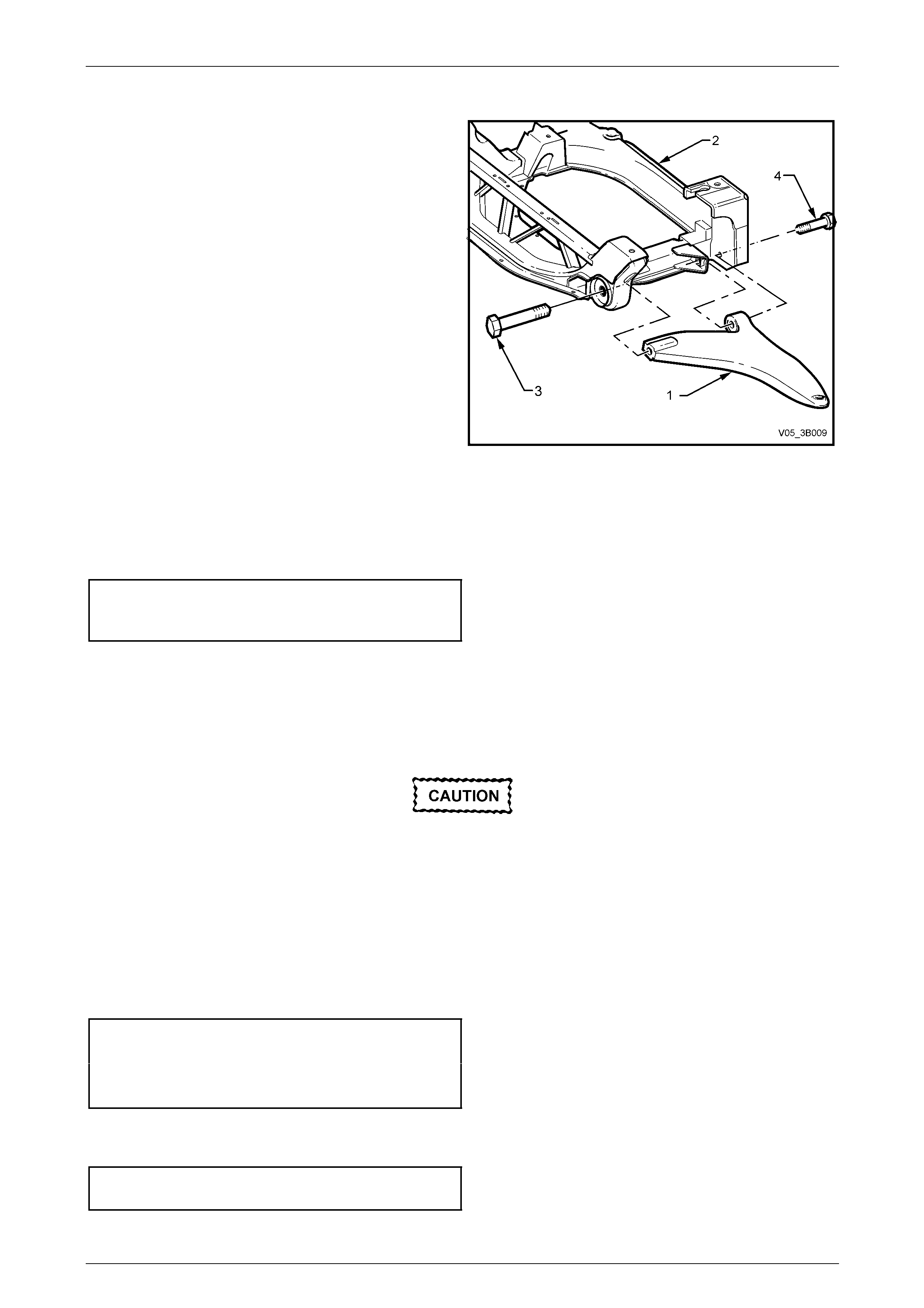

The front suspension crossmember cra dle i s bolted to both longitudinal frame side members. The front suspension

crossmember cradle to side member attaching bolts incorporate a tapered boss near the head of the front two bolts to

assist in crossmember to body alignment during assembly. The lower control arm pivots are rubber bushed at the inner

ends and are attached to the crossmember by a micro-encapsulated bolt at the front and a bolt at the rear. The outer end

of each front control arm is connected to the steering knuckle throu gh a front control arm ball joint assembly.

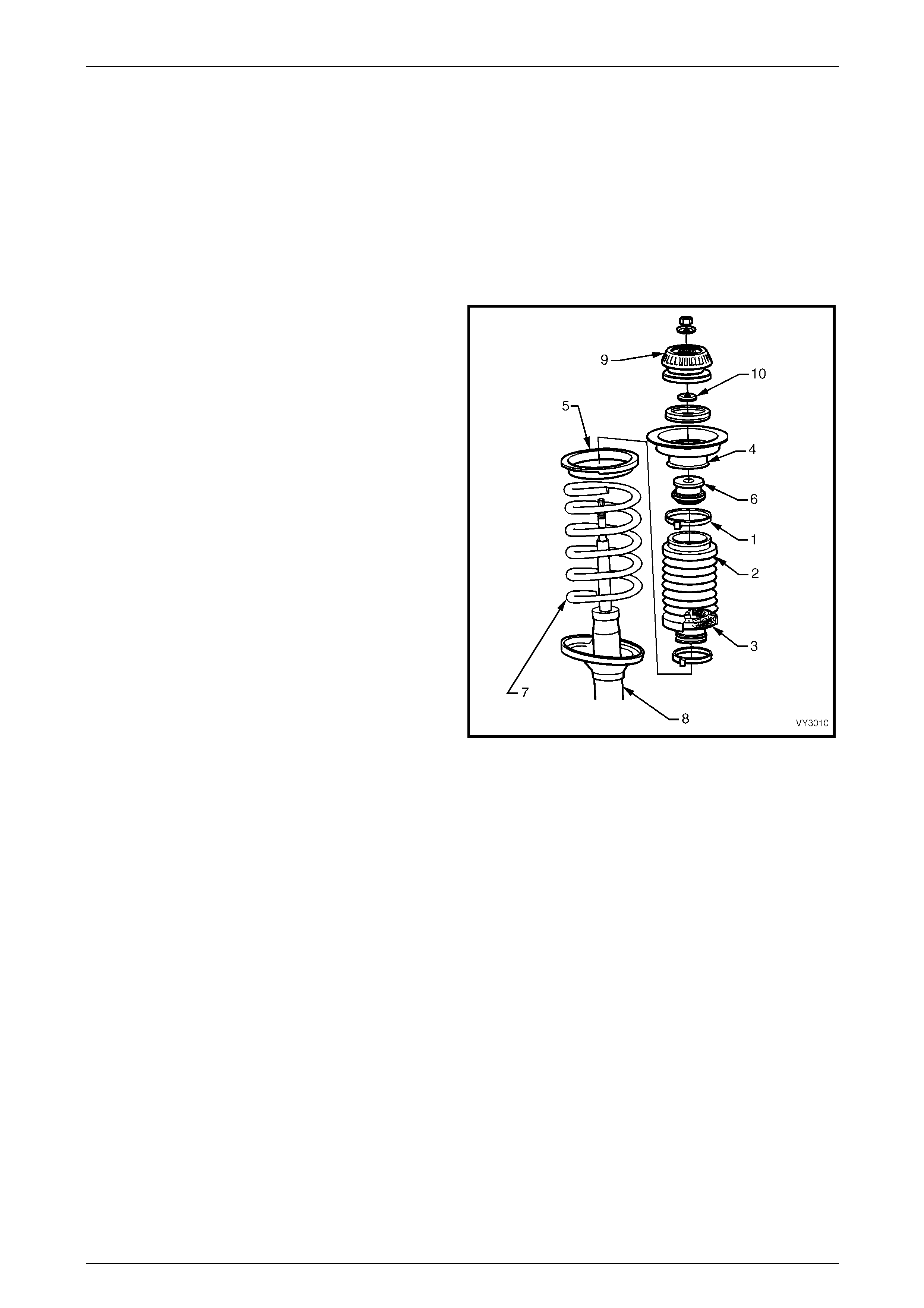

The strut assembly incorporates a hydraulic wet sleeve type damper inside the strut tube, a rubber front strut dust shield

assembly with air filter and compression rubber, a coil type suspension spring mounte d b etween the strut housing and

upper spring seat collar, a bearing assemb ly and an upper strut support.

The strut assembly is located at the upper end to the body structure by an upper strut support an d secured by a self-

locking nut and locating disc. The lo wer end of the strut tube is fastened to the steering knuckle by two bolts and nuts.

A stabiliser bar is mounted to the side memb ers of the crossmember by two brackets and insulating rubbers. The link

connecting the stabiliser bar to each front sus pension strut tube has a ball joint socket stud and nut, at each end.

To increase body rigidity, a strut brace is attached to each strut tower by two nuts on each side. For service procedures

relating to this strut brace, refer to Section 1A1 Body.

Legend for Figure 3B – 1

1 Flanged Nut (4 Places)

2 Flanged Nut (2 Places

3 Flanged Nut (4 Places)

4 Bracket (2 Places)

5 Insulator (2 Places)

6 Bar – Stabiliser

7 Stabiliser Bar Link (2 Places)

8 Driveshaft (2 Places)

9 Cradle Front Suspension

10 Bolt – Rear, Control Arm Mounting (2 Places)

11 Front Control Arm (2 Places)

12 Bolt – Front Control Arm Mounting (2 Places)

13 Front, Flanged (2 Places)

13a Bolt – Rear, Plain (2 Places)

14 Cover – Dust (2 Places)

15 Nut – Front Strut Upper

16 Locating Disc (2 Places)

Fasteners must be new and assembled dry.

Front Suspension – AWD Page 3B –4

Page 3B – 4

Figure 3B – 1

Front Suspension – AWD Page 3B –5

Page 3B – 5

2 Wheel Alignment

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W here specified in this Section, fasteners MUST be replaced w ith parts of the

same part number or an approved equivalent. Do not use fasten ers of an inferior quality or substitute desig n.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one or more of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Steering Geometry

To achieve the desired handling characteristics of a vehicle under various operating conditions, modern steering

geometry relates to both front and rear suspension systems. It must also be realised that the various, measurable angles

that can be checked while the vehicle is sta tionary, are no real indication of the changes that occur in a dynamic

situation, when the vehicle is required to have directional stability, during normal manoeuvres, such as straight ahead

driving, cornering or braking.

Even though some of the following descriptions of front wheel alignment angles are not normally measurable and (in

some instances) not adjustable, each is an inherent part of the vehicle's dynamic sus pension tuning that has been

developed over an extended testing program.

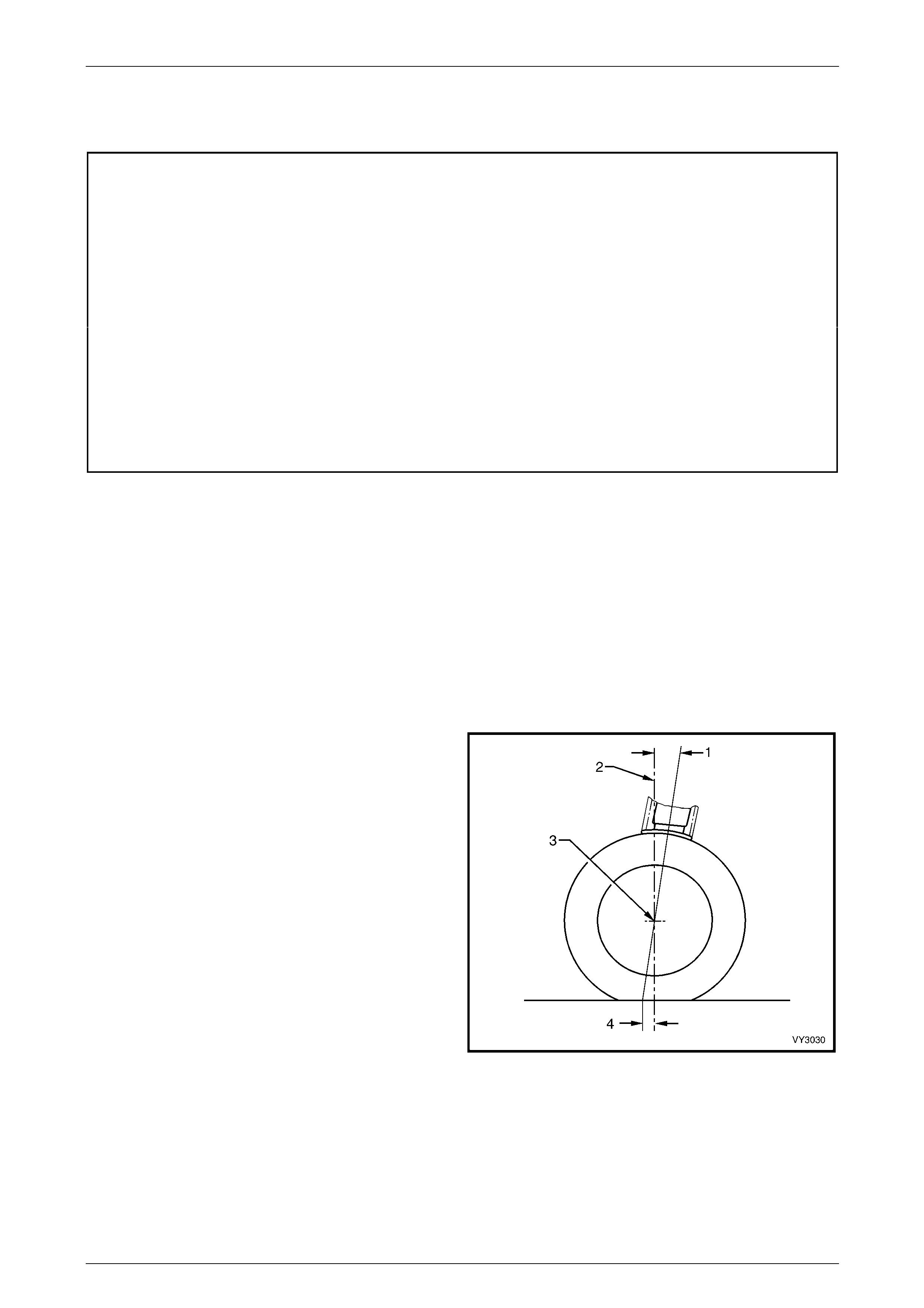

Caster

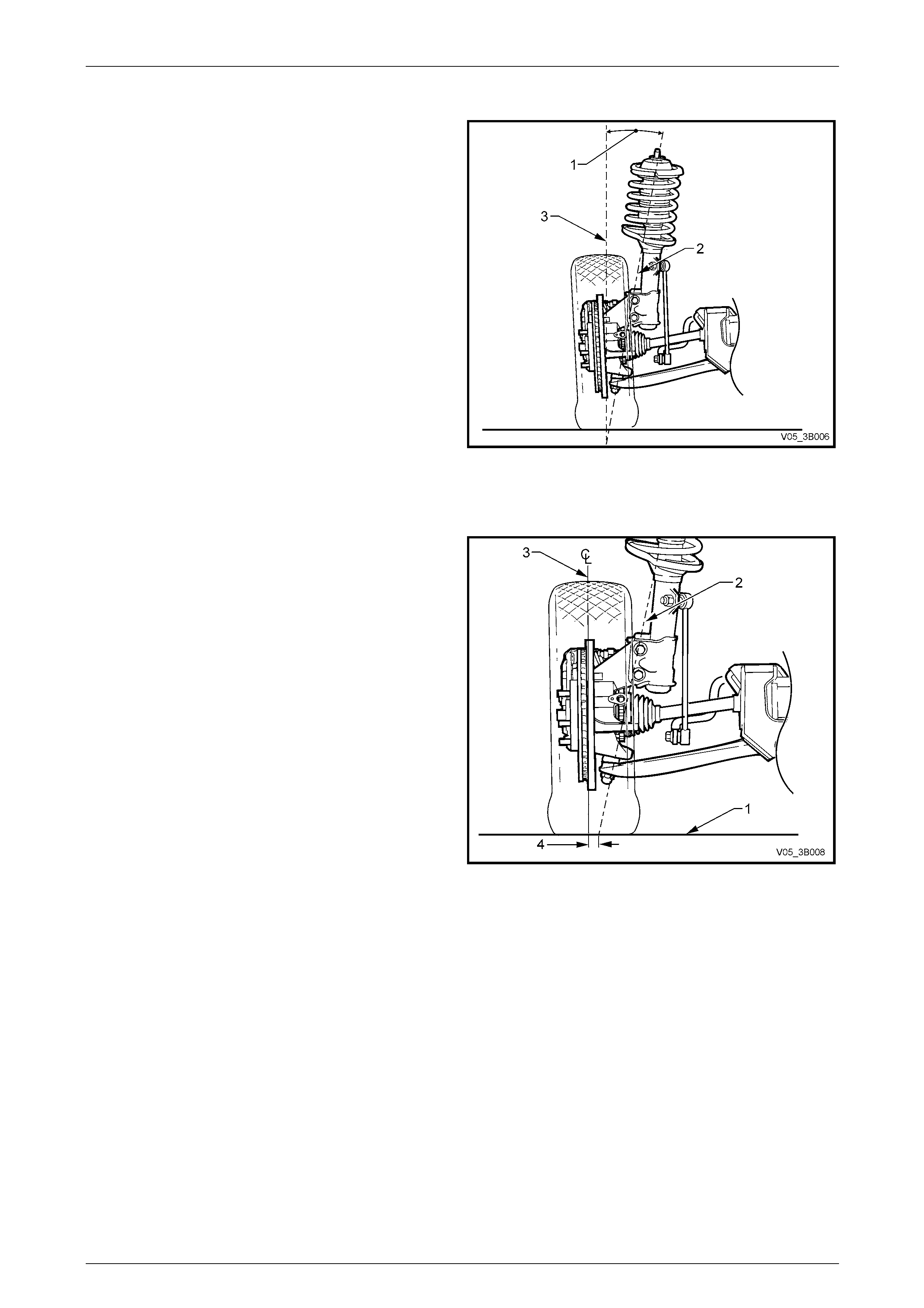

It is usual to describe this front wheel alignment angle as the

tilting of the steering axis either forward or backward (1)

from the vertical (2) when viewed from the side of the

vehicle. A backward tilt at the top steering axis point is said

be positive (+) and a forward tilt is said to be negative (–).

Measurement is usually expressed as an angle in degrees

and minutes. Figure 3B-2 shows the usual practice where

the vertical and steering axis centrelines both pass through

the wheel centre (3).

This results in a caster distance (4), which can be describe d

as being the distance in side view, between the point where

the steering axis contacts the ground and the centre of the

tyre’s footprint contact.

Figure 3B – 2

Front Suspension – AWD Page 3B –6

Page 3B – 6

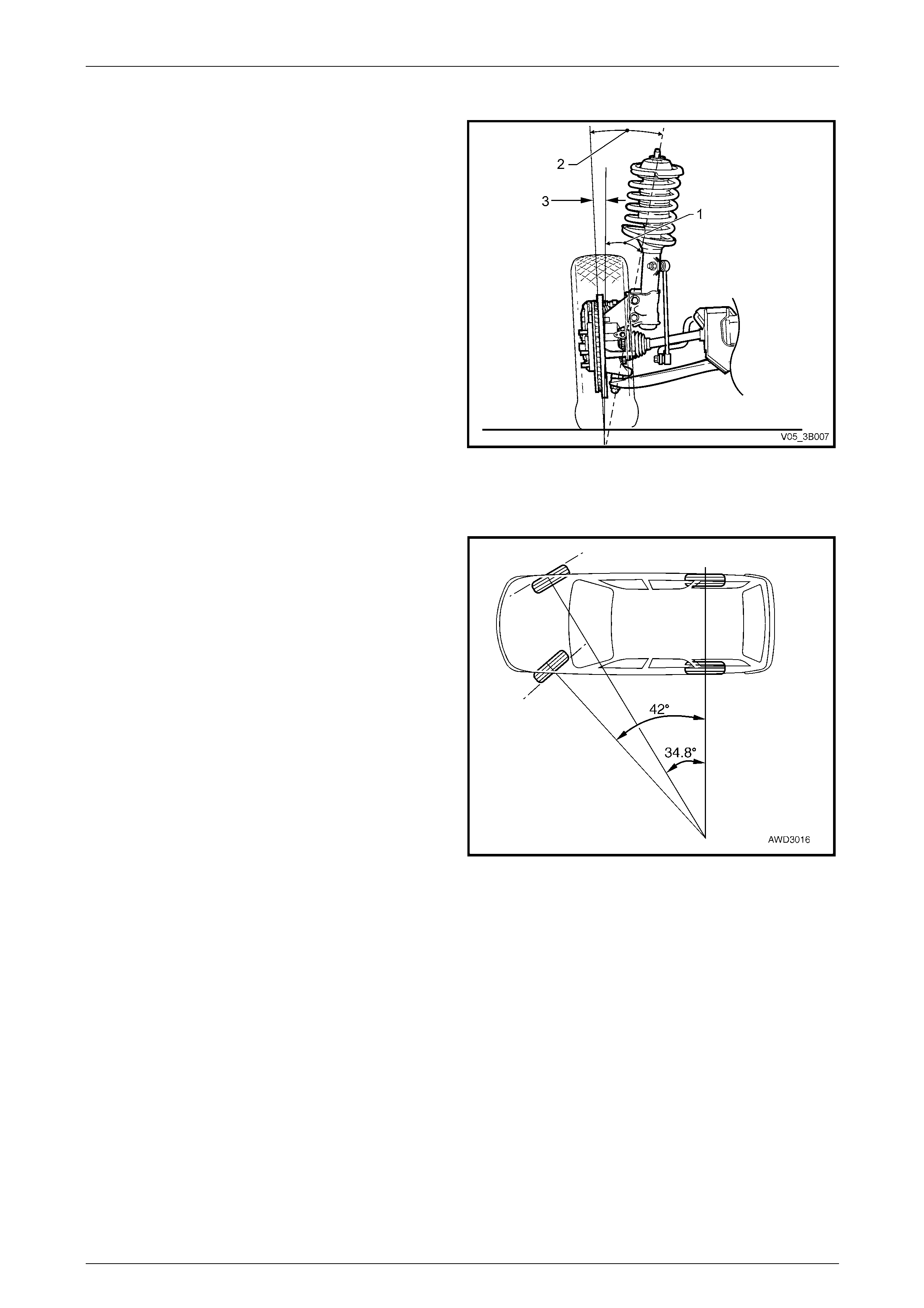

The amount of caster angle (1) will det ermine the ability of

the steering to return to the straight ahead position after a

cornering manoeuvre. Too high an angle though, can result

in an excessive steering effort with associated ‘wheel fight'

and ‘kickback'. To optimise vehicle handling and control

during cornering and to mai ntain the benefits of positive

caster, MY2005 AWD models have a 32.1 mm caster trail

(2) incorporated into the suspension design.

This is achieved by moving the wheel spindl e centreline (3)

forward (in this instance, by 32.1 mm), which will effectively

reduce the caster distance by that amount (Refer to Figure

3B-3). This action reduces the undesirab le effects of a high

caster angle but maintains the directional stabil ity, increased

front axle lateral grip and steering feel that a high caster

angle normally provi des.

Figure 3B – 3

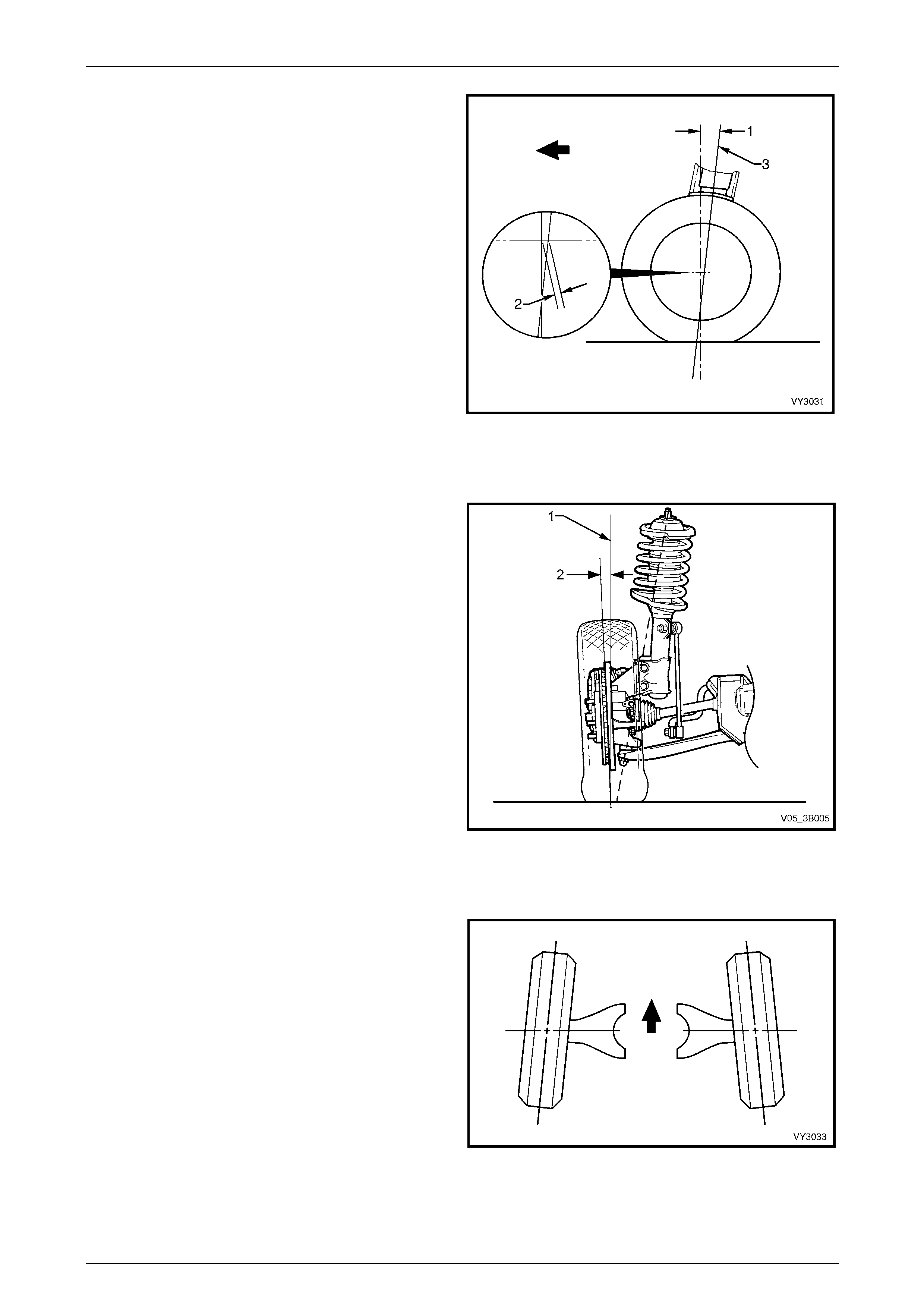

Camber

This angle is the tilting of the wheels from the vertical (1)

when viewed from the front of the vehicle. When the wheels

tilt outward at the top, the camber (2) is said to be positive

(+). When the wheels tilt inward at the top, camber is said to

be negative (–). The amount of tilt is measured in degrees

from the vertical and this measurement is called the camber

angle.

While unequal camber may re sult in unstable steering or

wander, unequal and/or excessive camber can also cause

rapid tyre wear.

Figure 3B – 4

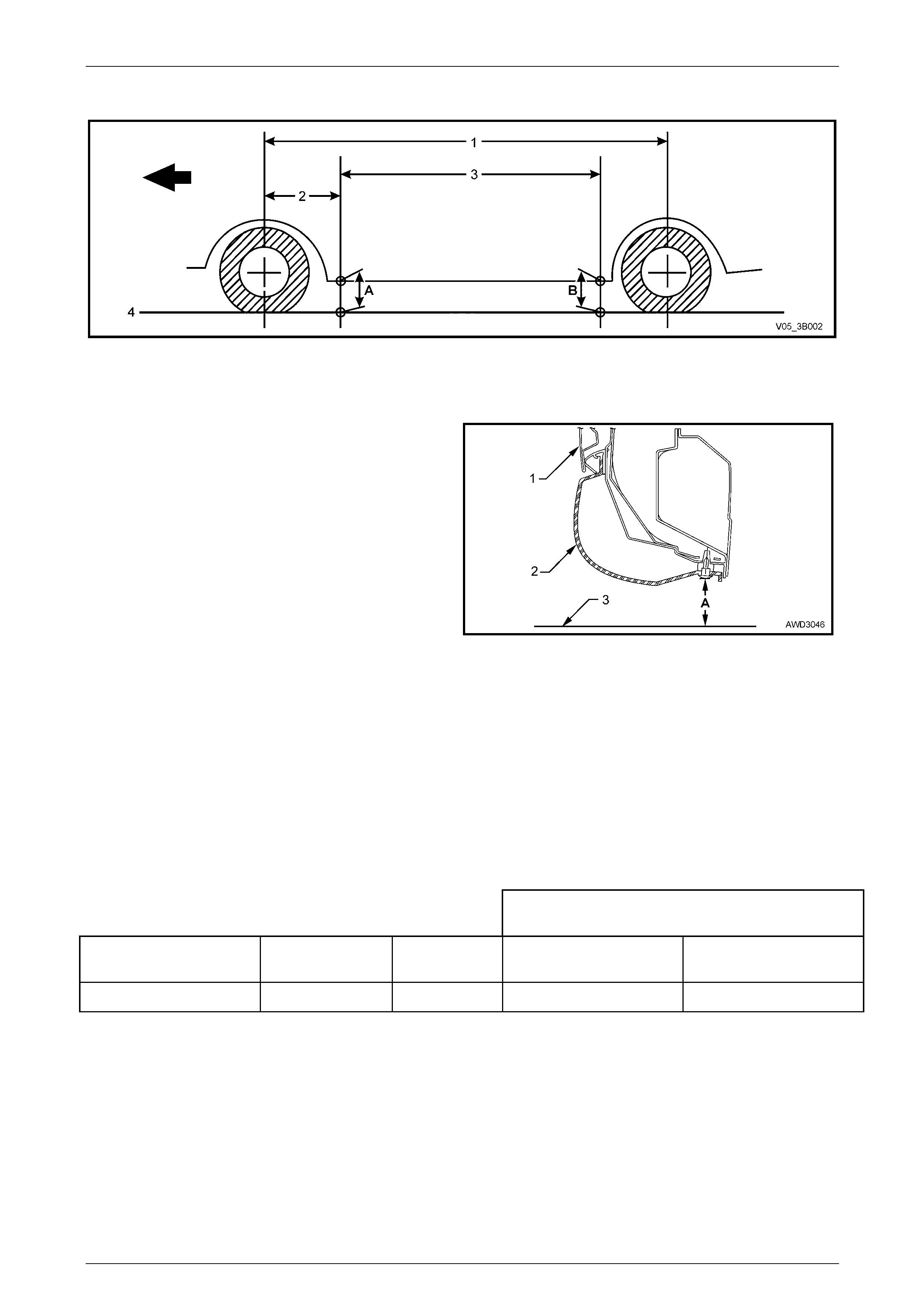

Wheel Toe

Wheel Toe (Refer to Figure 3 B -5), is the turning in (or out)

of the wheels when viewed from the overhead position. The

actual amount of toe is normally only a few minutes of one

degree. The purpose of a static toe specification is to ensure

parallel rolling of the wheels, once the vehicle is in a

dynamic state.

Excessive toe-in or toe-out may increase tyre wear. With

rear wheel drive vehicles, a slight amount of toe-in,

measured statically with the vehicle at rest, is requir ed to

off-set the small deflections due to rolling resistance and

brake applications which tend to turn the wheels outward,

when the vehicle is in motion.

Figure 3B – 5

Front Suspension – AWD Page 3B –7

Page 3B – 7

Steering Axis Inclination

When viewed from the vehicle front, Steering Axis

Inclination (1) can be described as being the angle formed

between the steering a xis (2) and the true vertical (3), where

the steering axis is the imaginar y centreline through the

upper strut support bearing an d the lower control arm ball

joint assembly, both components being the pi vot points of

the strut assembly.

The Steering Axis Inclination angle is an important factor in

determining steering effort and directional stability of the

vehicle, by assisting caster in keeping th e front wheels in a

central position. Steering Axis Inclin ation also provides a

self-centring effect after cornering.

While not an adjustable angle , the steering axis inclination

(1) on MY 2005 AWD Models, is 13.3 degr ees.

Figure 3B – 6

Scrub Radius

This term refers to the distance (4) that t wo imaginary points

are apart, at the road surface (1). These two imaginary

points are;

a. The intersection of the steering axis (2) and the road

surface (1).

b. The centreline of the tyre (3) at the road surface (1).

As road wheel offset will affect scrub radius (4), in the

interests of vehicle handling and safety, non-standard road

wheels are not to be fitted to any MY 2005 AWD vehicle.

With rear wheel drive vehicles, it is usual practice to

maintain a positive scrub radius (as shown) to make the

steering more responsive and direct, thereby providing the

driver with a more positive sense of the t yre and road

surface interaction.

Figure 3B – 7

Front Suspension – AWD Page 3B –8

Page 3B – 8

Included Angle

When both the Steering Axis Inclination an gle (1) and

Camber angle (3) are combined, the resulting angle is

referred to as the Included Angle (2). This information can

be effectively used to determine if a component is damaged

or whether an adjustment is responsible for an out-of-

specification condition occurring.

While Figure 3B-8 shows a positive camber angle, this has

only been used to clarify the term ‘Included Angle'.

Figure 3B – 8

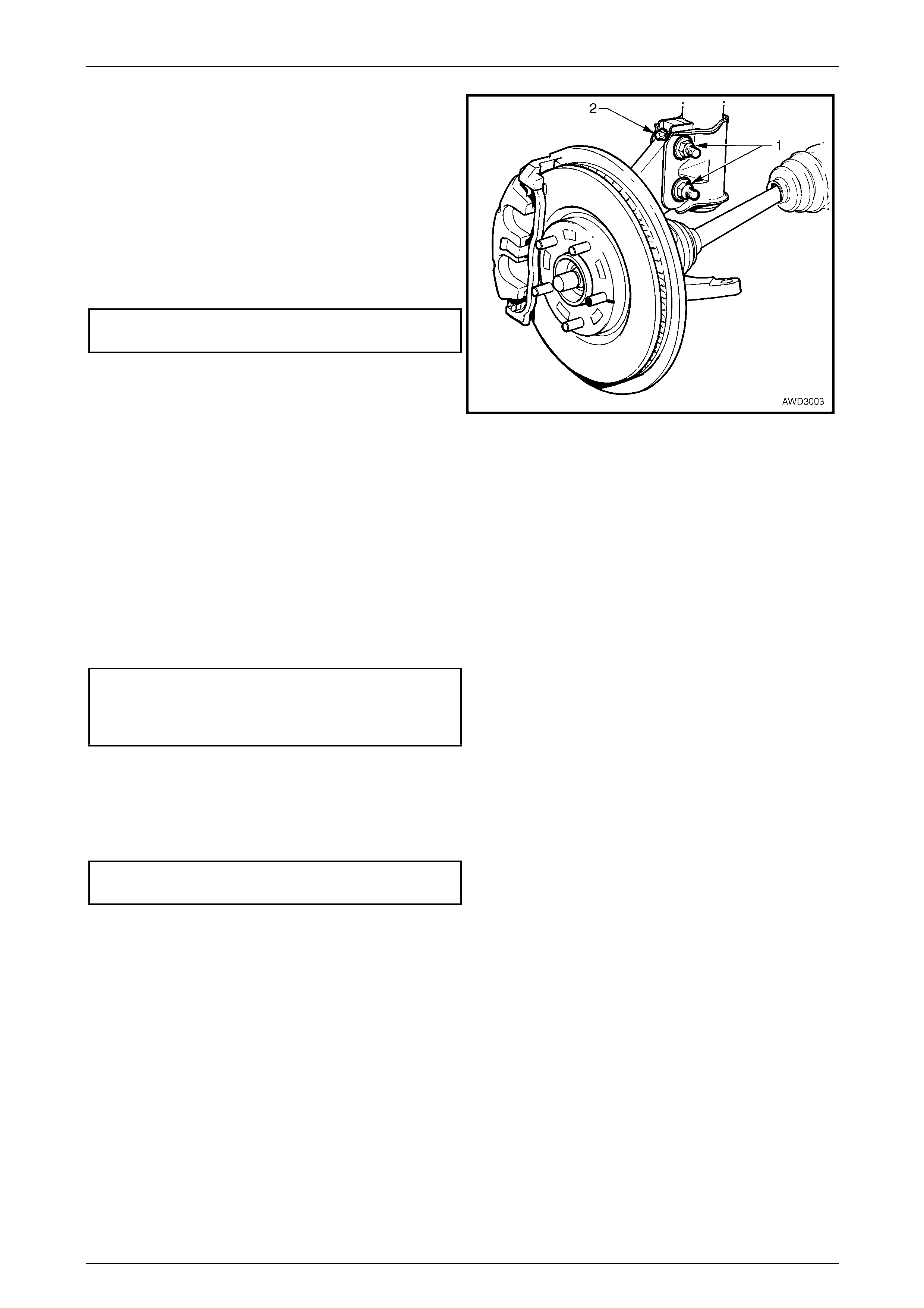

Toe-Out On Turns

During cornering operations, a vehicle's road wheels all turn

about a common turning point, causing the outer wheels to

try and turn through a greater radius than the inner. To

overcome the tendency for wheel slip when cornering, the

outer wheel is commonly cau sed to toe-out, to compensate

for this increased turning circle.

The amount of toe-out during cornering, is govern ed by the

angle of the steering arms, which are an inh erent part of th e

steering knuckle.

Figure 3B – 9

Front Suspension – AWD Page 3B –9

Page 3B – 9

2.2 Wheel Alignment Checking and

Adjustment

LT Section No. – 06-212

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Steering knuckle to strut attach in g bolts and nuts.

Preliminary Inspection

Before any attempt is made to check camber, caster or toe-in, these preliminary checks should be carried out.

1 Check tyre and tyre mountings. Always check camber and toe-in at the mean run-out position on the tyre or rim.

2 Check and adjust tyre pressures to recommended va lues.

3 Front wheel bearing end float is to be checked to ensure it is within specification, refer to 2.4 Front Wheel Hub

Assembly – End Float Checking Proce dure, in this Section.

4 Front lower control arm socket assembly and pivot bushing should be checked for wear, refer to 3.10 Front Contro l

Arm Ball Joint Assembly, in this Section.

5 Check steering gear mounting bolts for tightness and steering linkage outer tie rod sockets for wear, refer to

Section 9 Steering, for the procedures.

6 The vehicle should be at curb weight, fuel tank full, without driver, passengers or luggage etc.

7 Check for improperly operating front struts or rear shock absorbers.

8 Check for loose or missing stabiliser bar or spacer stud to strut tube attachments.

9 Before checking the front wheel alignment, refer to Section 4A1 Independent Coil Spring Rear Sus pe nsion, for

wheel alignment details.

Caster Adjustment

No provision for caster adjustment is provi de d with the front suspension design utilised for MY2005 AWD Models.

Camber Adjustment

1 Raise the front of the vehicle and support on safety stands under the front side members. Refer to 2.3 Jacking

Precautions in this Section.

2 Remove the centre wheel cap and mark the relati onship of the wheel to the hub stud, using a felt tipped pen or

similar.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain

component relationships and to avoid brake rotor

distortion and the creation of brake shudder, after

the vehicle is placed back in service.

Front Suspension – AWD Page 3B –10

Page 3B – 10

4 Loosen, remove and discard the two lower strut

attaching bolts and nuts (1).

Install NEW lower strut attaching bolts and nuts but do

not tighten fully to specification until after the camber

has been adjusted to the recommended specification.

5 Reinstall the road wheel, aligning the previously made

marks. Tighten the road wheel attaching nuts to

correct torque specification, working in a ‘star ’ pattern.

Refer to Section 10 Wheels and Tyres, for detailed

information regarding installati on procedure for the

road wheels.

Road wheel attaching nut

torque specification..................................110 – 140 N.m

6 Lower the vehicle to the grou nd and bounce several

times to settle the suspension, then check the camber

angle.

Figure 3B – 10

7 If required, adjust the camber by turning the camber adjusting screw ('2' in Figure 3B-10) in the required directi on;

clockwise to reduce negative camber, anti-clockwise to reduce positive camber.

NOTE

The camber adjusting screw has thread sealant

applied in the form of micro-encapsulation and

does not require a lock nut.

8 Raise vehicle once again, support on safety stands and remove the front road wheels.

9 Tighten both steering knuckle attaching nuts to the correct torque specificati on.

( ) Steering knuckle to strut

attaching nut torque specification............ Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn throu gh 90°

10 Install the road wheels, aligning the marks made prior to removal.

11 Remove the jack stands and lower the vehicle.

12 Tighten the road wheel attaching nuts to the correct tor que specification, working in a ‘star’ pattern. Refer to

Section 10 Wheels and Tyres, for detailed information regarding installation procedure for the road wheels.

Road wheel attaching nut

torque specification..................................110 – 140 N.m

13 Install the centre wheel cap.

14 Check the camber angle again to ensure that it is still within specification.

Front Suspension – AWD Page 3B –11

Page 3B – 11

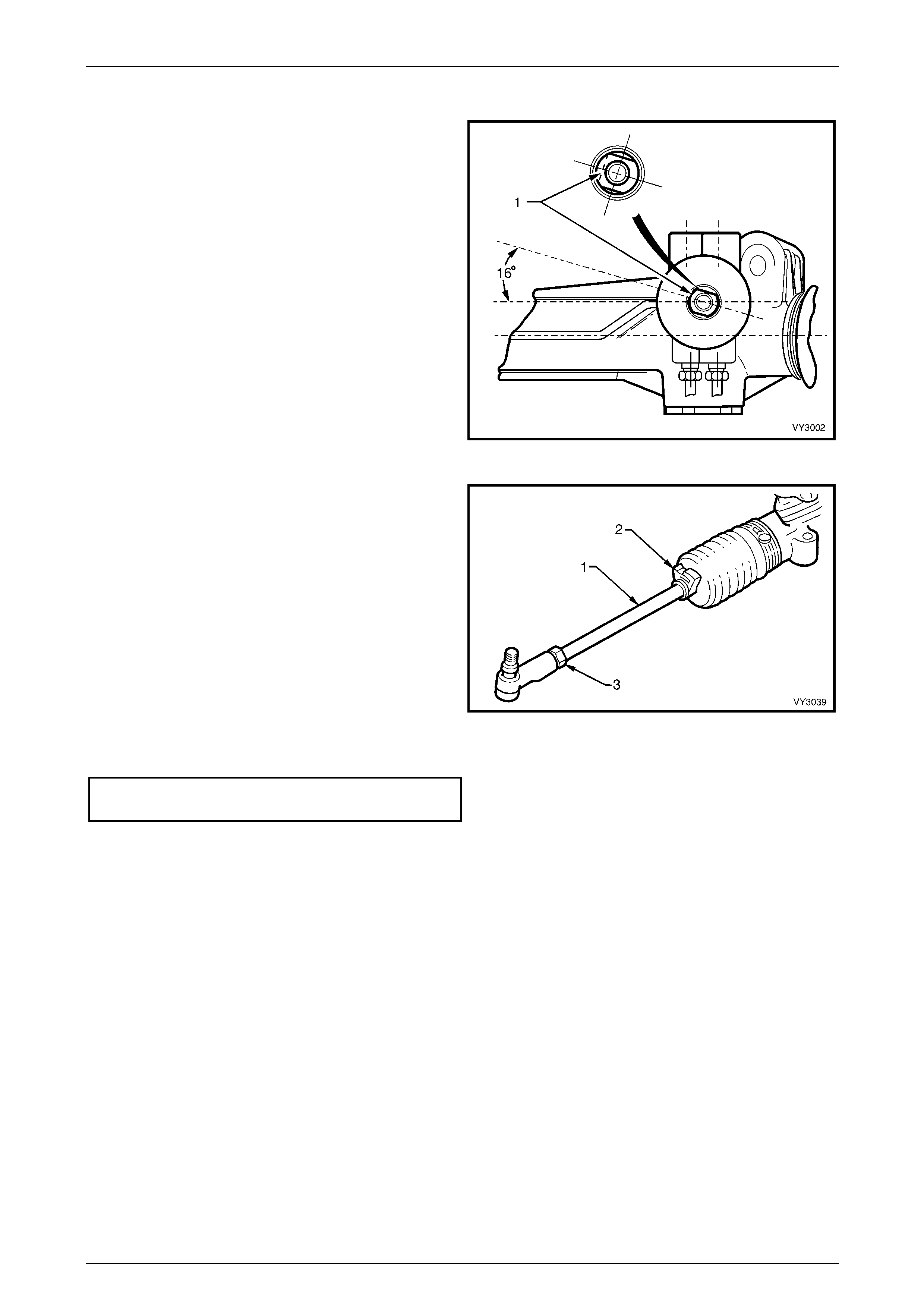

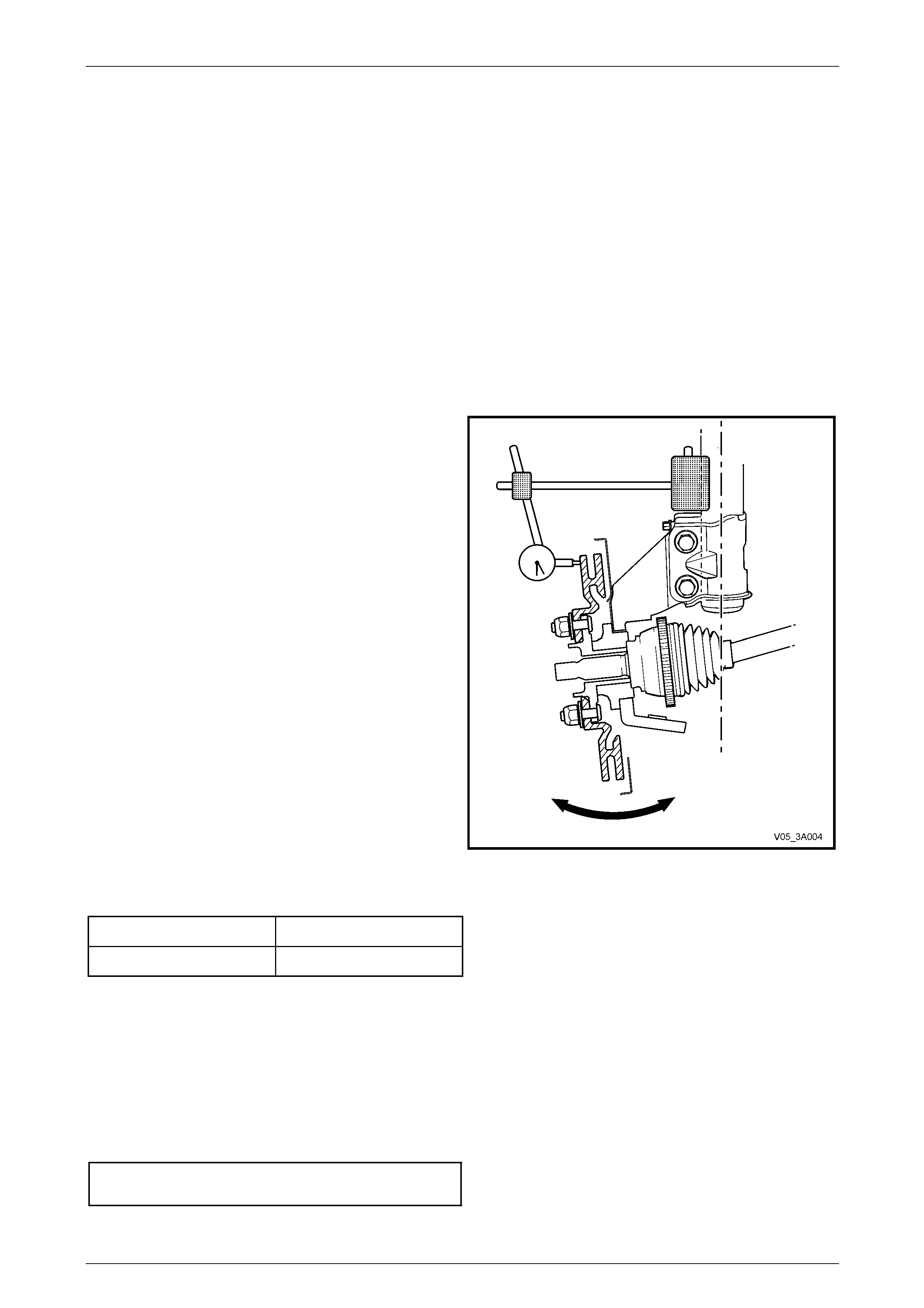

Toe Adjustment

Toe of both front wheels, is checked with the wheels in the

straight ahead position.

Adjustment is achieved by winding the steering linkage inner

tie rod into or out from the outer tie end, thus increas ing or

decreasing the linkage length and thereby a ltering the toe-in

setting.

1 Set steering gear and wheels in straight ah ead

position.

2 To check if steering gear is in straight ahead position

(on-centre), the pinion (input) shaft (1) should be

aligned as shown.

Figure 3B – 11

3 Before adjusting the steering linkage inner tie rods (1),

disconnect the steering gear outer boot clips (2).

4 Loosen the lock nut (3) at the end of e ach steering

linkage outer tie rod end.

5 Turn each steering linkage inner tie rod as required,

until the correct toe is obtained.

NOTE

During the toe adjustment, ensure that the

steering wheel is held in the straight ahead

position.

6 Tighten the lock nuts to the correct torque

specification, ensuring that the steering linkage outer

tie rod ends are in alignment with their ball studs.

Figure 3B – 12

Steering linkage tie rod to outer

tie rod end lock nut torque specification................65 Nm

7 Tighten the outer boot clips se curely, making sure that the convolutions of the boots are not distorted.

8 With the steering gear in the straight ahead position, ensure that the steering wheel is centralised. If not, remove

and reposition the steering wheel, refer to Section 9 Steering.

Front Suspension – AWD Page 3B –12

Page 3B – 12

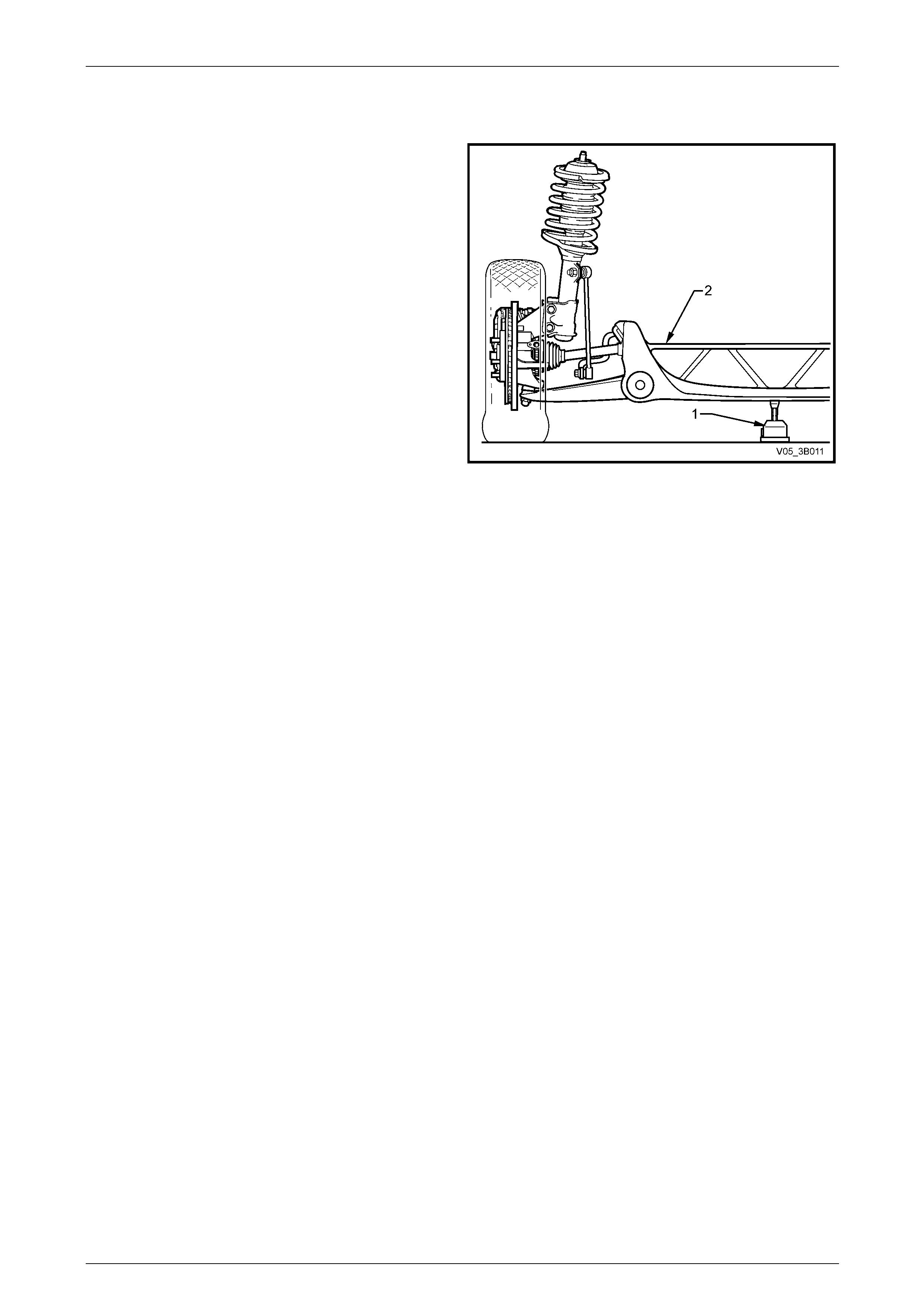

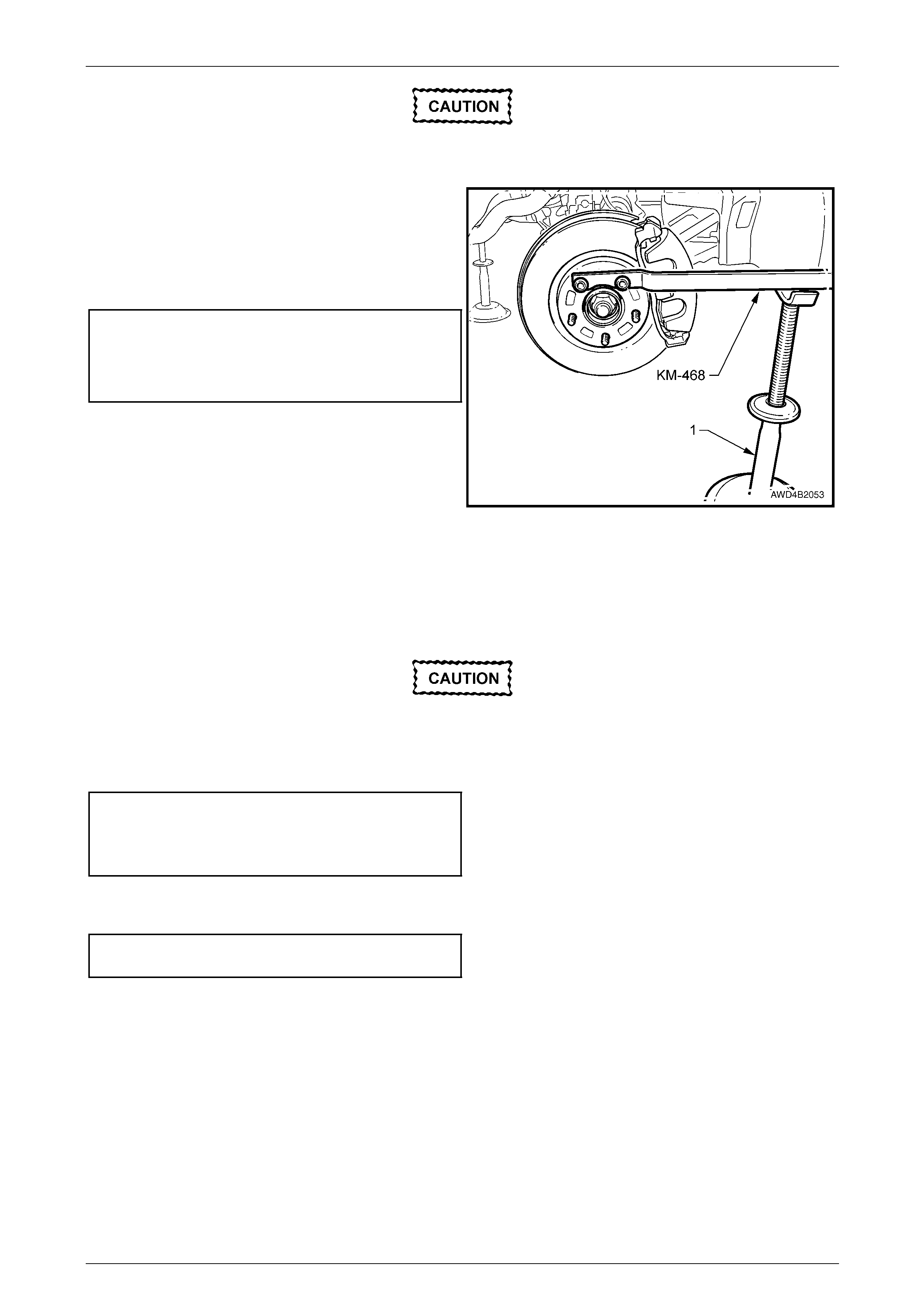

2.3 Jacking Precautions

When raising the front of the vehicl e with a jack (1), the jack

should be placed under the c entre of the front suspension

crossmember cradle (2). THE WEIGHT OF THE VEHICLE

MUST NOT BE LIFTED UNDER THE CONTROL ARMS.

When the vehicle is raised on the jack, it must be firmly

supported on safety stands located under the frame side

members before any work is attempted. If a vehicle is not

correctly supported by safety stands, serious injury can

result if the vehicle should slip off the jack.

For further information relating to the location of jacking and

support points, refer to Section 0A General Information.

Figure 3B – 13

Front Suspension – AWD Page 3B –13

Page 3B – 13

2.4 Front Wheel Hub Assembly – End Float

Checking Procedure

LT Section No. – 06-212

1 Raise the front of the vehicle and place on safety stands. Refer to 2.3 Jacking Precautions in this Section.

2 Remove the wheel nut caps.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres, for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain

component relationships and to avoid brake rotor

distortion and the creation of brake shudder, after

the vehicle is placed back in service.

4 Temporarily install three, reversed wheel nuts with a

flat washer under each nut, to prevent damage to the

nut thread.

5 Mount a dial indicator on to a suitable magnetic stand

and attach to the front strut tube. Position the dial

indicator pointer at the outer diameter of the rotor, as

shown.

NOTE

The dial indicator gauge must be mounted at

right-angles (90°) to the brake rotor friction

surface.

6 Apply an outward, 10 kg force to the outer b r ake rotor

diameter, in an opposite pos ition (180°) to the dial

indicator. To maintain consistency, a spring balance

capable of measuring this force, MUST be used. With

the force applied, zero the dial indicator.

7 Apply an inward, 10 kg force to the outer brake rotor

diameter and note the dial in dicator reading.

8 The reading obtained is the angular movement (not to

be confused as end float). To determine the bearing

serviceability, compare the measured result with the

following specifications.

Figure 3B – 14

Wheel Bearing Angular ‘Float’ Specification

New Bearing 0.106 mm Maximum

Used Bearing 0.213 mm Maximum

9 Should this inspection show that the wheel bearing assembly is outside the specified, angular ‘float’ dimension,

then the hub must be replaced. Refer to 3.3 F r ont Wheel Hub Assembly Brake Rotor and/or Brake Shie ld in this

Section.

10 Remove the dial indicator and stand, and the three wheel nuts and flat washers.

11 Install the road wheel, alignin g the marks made prior to removal and secure with attaching nuts.

12 Raise the vehicle, remove the safety stands and lower vehicle to the ground. Tighten road wheel attaching nuts to

correct torque specification, working in a ‘star’ pattern. Refer to Section 10 Wheels and T yres, for detaile d

information regarding the installation procedure for the road wheels.

Road wheel attaching nut

torque specification..................................110 – 140 N.m

13 Reinstall the centre wheel nut cap.

Front Suspension – AWD Page 3B –14

Page 3B – 14

3 Service Operations

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W here specified in this Section, fasteners MUST be replaced w ith parts of the

same part number or an approved equivalent. Do not use fasten ers of an inferior quality or substitute desig n.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one or more of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

3.1 Service Notes And Cautions

CAUTION

Whenever any component that forms part of

the ABS (if fitted) is disturbed during Service

Operations, it is vital that the complete ABS

system be checked. Refer to Section 5B ABS /

TCS / ESP.

NOTE

• Whenever a road wheel and/or brake disc is

removed from or installed to a MY2005 AWD

vehicle, it MUST be done in accord with the

procedure provide d in Section 10 Wheels and

Tyres.

• To ensure proper retention of the control arm,

the ball joint stud and the corresponding

tapered hole in the control arm must be

cleaned of dirt and foreign matter prior to

reinstallation.

Front Suspension – AWD Page 3B –15

Page 3B – 15

3.2 Suspension and Trim Height, Check

Good judgement must be exercised before

replacing a spring or springs from a vehicle

whose height is within the limits quoted. Even

if a vehicle's dimensions should prove to be

slightly outside these tolerances, the vehicle

could well be in a serviceable condition.

Spring replacement under conditions of

excessive w eight du e to non-stand ard fittin gs,

undercoating, road dirt, etc; will assist very

little in restoring the vehicle to its specified

height.

The vehicle trim height dimensions for standard vehicles with base equi pment only, are provided in 5 Specifications in

this Section. The dimensions are for a new vehicle built to standard specification and only intended as a guide when

checking trim height dimensions at normal curb weight.

Normal curb weight is defined as a vehicl e with a full tank of fuel, all fluids at the specified levels, spare tyre included,

tyre pressures as specified an d no passengers. Accumulated dirt, distance travelled, etc., must also be taken into

consideration when checking vehicle heights.

The following procedure sh ould be followed before checking any suspension or trim height.

1 All checks must be carried out on a LEVEL surface, after the vehicle's tyre pressures have been checked and it has

been confirmed that the vehicle has not been subjected to accident damage.

2 On average, all MY 2005 AWD models will sit approximately 4 mm lower at the right hand side front, because of

the vehicle battery weight.

3 Push the vehicle up and do wn several times at the front bumper bar with a decreasing force and then gently

remove hands, allowing vehicle to settle on its own. Carry out vehicle suspension front trim height check.

4 Push the vehicle up and do wn several times at the rear bumper bar with a decreasing force and th en gently

remove hands, allowing vehicle to settle on its own. Carry out vehicle rear trim and suspension height ch eck.

As shown in the specification listing (refer to 5 Specifications in this Section), there is only the one set of dimensions that

must be checked and the location for the measurements to be taken is critical, to correctly establ ish a standard vehicle

condition.

NOTE

Excessive trim height variation may also be due

to any one or a combination of the following:

• Spring seat location on the suspens ion/body.

• Incorrect springs; Check spring identification

against the table shown in 5 Specifications in

this Section.

• Non-standard, additional vehicle weight, such

as after-market equipment.

• Any combination of the above.

Front Suspension – AWD Page 3B –16

Page 3B – 16

3.3 Front Wheel Hub Assembly, Brake Rotor

and/or Brake Shield

LT Section No. – 06-212

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Brake caliper ancho r p late to steering knuckle retainin g bolts.

NOTE

• Apart from wheel stud replacement, there are

no serviceable items in the front wheel hub

assembly. As the unit is a 'sealed for life'

assembly, neither bearing adjustment nor

lubrication maintenance is required. Should a

non-standard condition develop, then the hub

assembly must be replaced as a complete

unit.

• While the front wheel hub assembly is

designed to have zero axial free play or ‘end-

float’, some angular movement may be

evident when a rocking force is applied to the

mounted wheel and tyre assembly. Before a

hub is replaced, refer to 2.4 Front Wheel Hub

Assembly – End Float Checking Procedure, in

this Section.

Remove

1 Observing the jacking precautions – refer to 2.3 Jacking Precautions in this Section, raise the front of the vehicle

and support on safety stands.

2 Remove the centre wheel nut caps, then mark the relationship of the road wheel to hub or brake rotor.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres, for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain

component relationships and to avoid brake rotor

distortion and the creation of brake shudder, after

the vehicle is placed back in service.

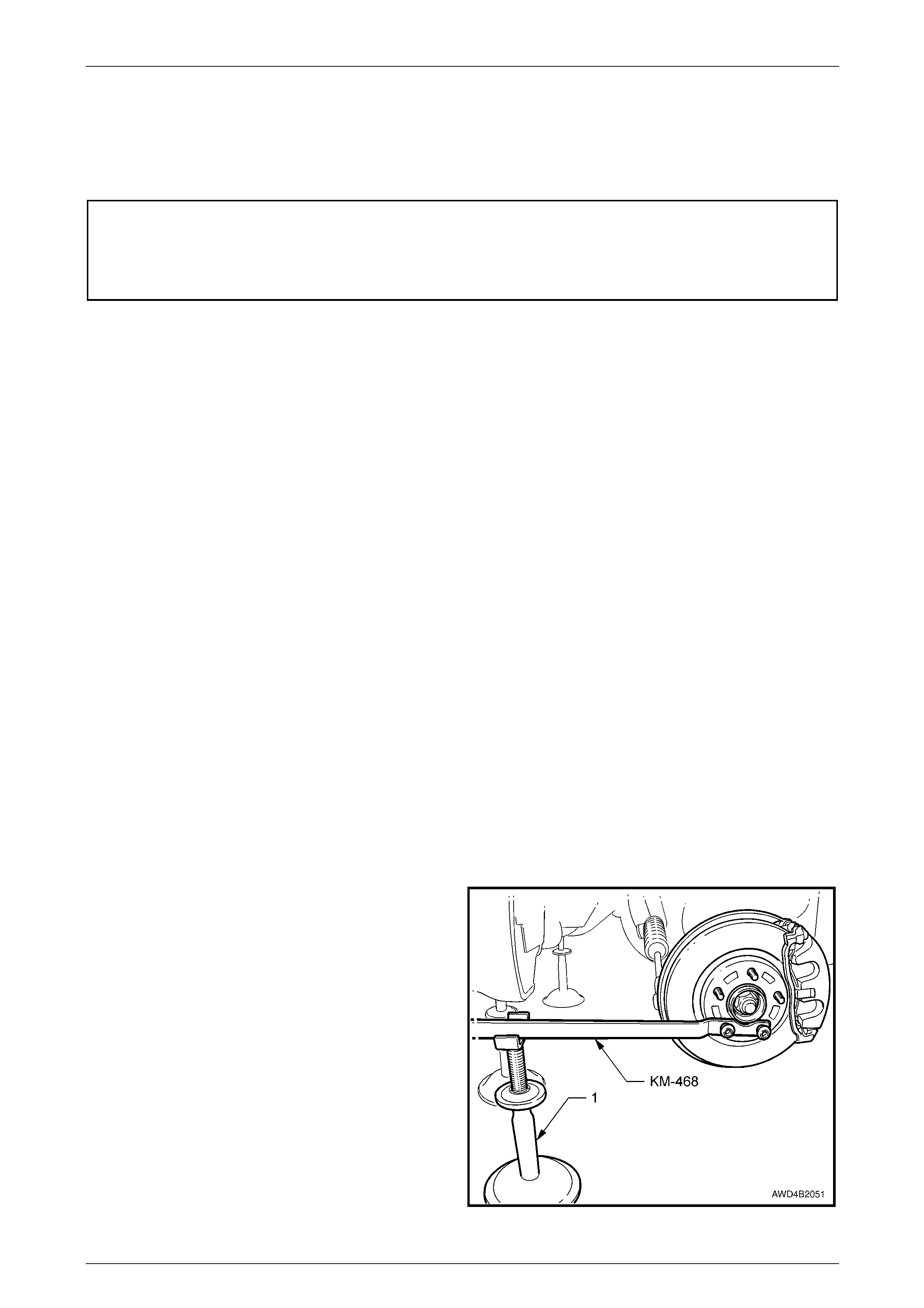

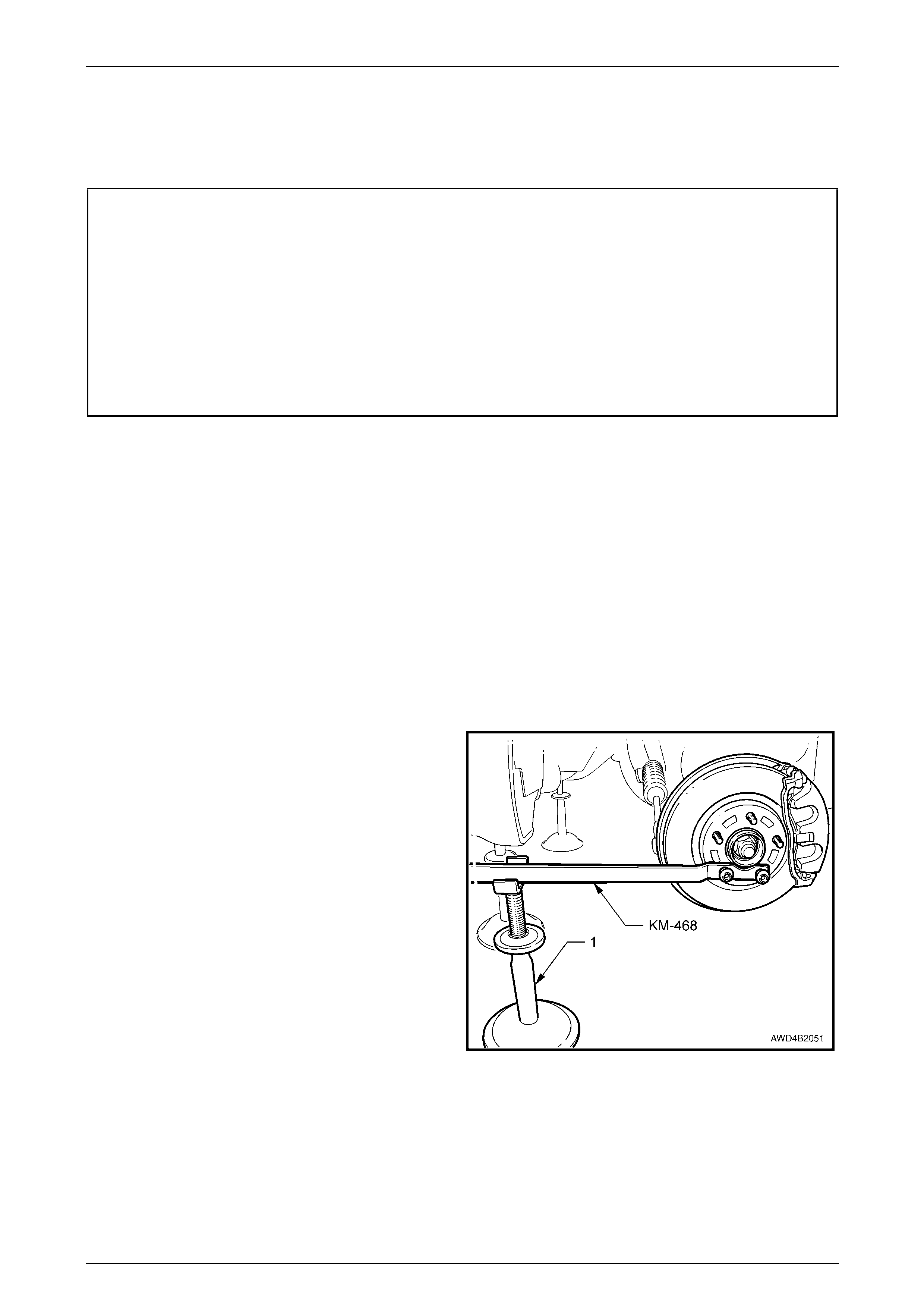

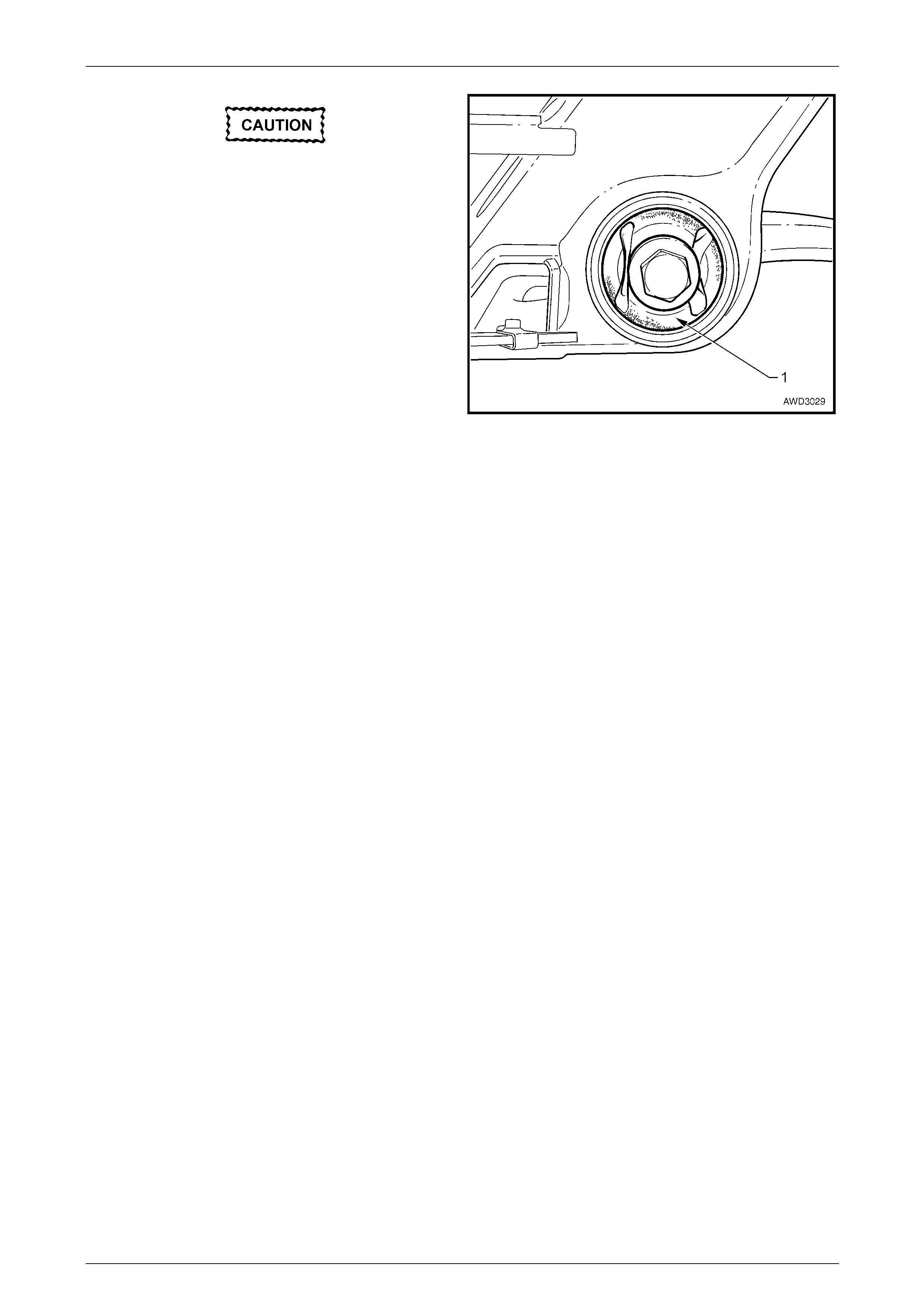

4 Attach holding tool KM-468 to the wheel hub with t wo

inverted wheel nuts. Support the tool outer end on a

safety stand (1).

5 Using a 36 mm socket and suitable socket equipment,

loosen then remove the drive s haft retaining nut and

flat washer. Discard the removed nut.

Figure 3B – 15

Front Suspension – AWD Page 3B –17

Page 3B – 17

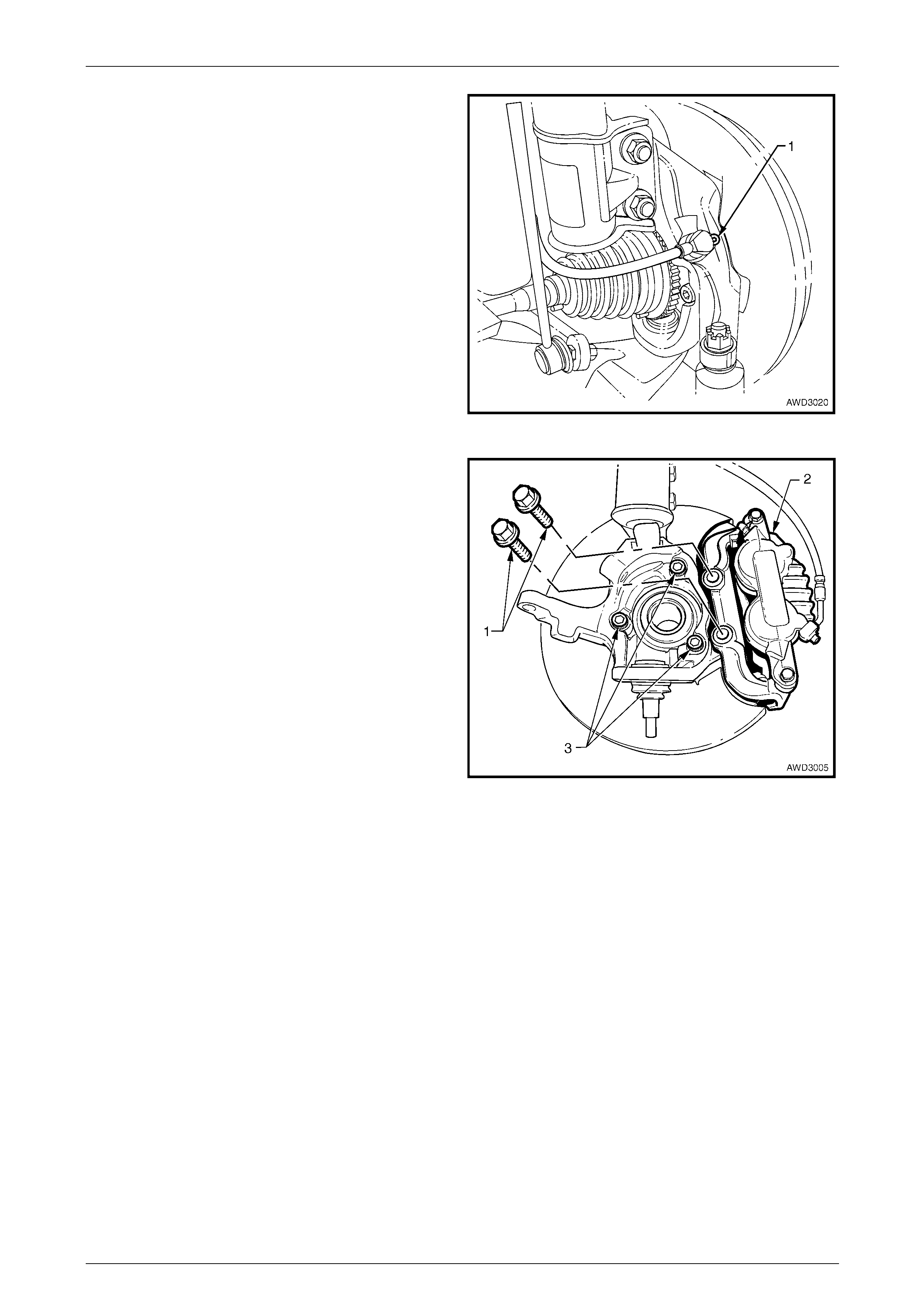

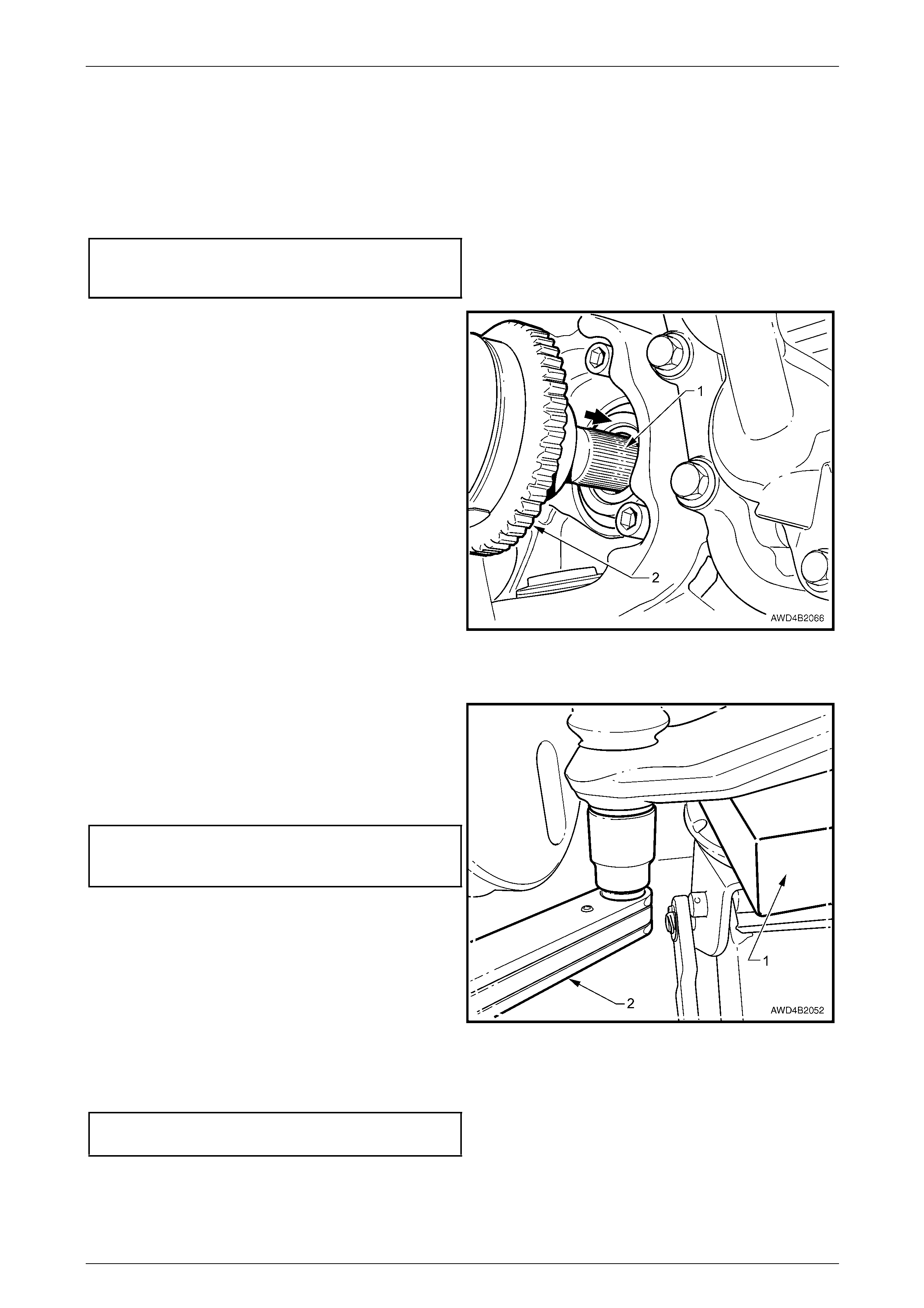

6 Remove the Allen key head ed screw (1) securing the

wheel speed sensor to the steering knuckle, grasp the

sensor and twist back and forth while pulling, to

remove. Secure sensor with tie wire or similar to

prevent sensor damage during the service procedure.

7 Remove the front driveshaft. Refer to Section 4B3

Front Final Drive, Bearing Housing & Driveshafts.

Figure 3B – 16

8 Remove the brake caliper retaining bolts and captive

washers (1), then lift the caliper assembly (2) from the

brake rotor. Position caliper in such a way that no

strain is placed on the brake hose. If necessary, tie

caliper to the suspension spring with a piece of wire.

THE CALIPER IS NOT TO HANG BY THE BRAKE

HOSE. Discard the removed caliper bolts as they must

be replaced on reassembly.

9 Even though the brake rotor to hub location is marked

in production, ensure that the rotor to hub position is

carefully marked, to ensure the correct relationship on

reassembly.

NOTE

This is necessary to overcome the possibility of

inducing a brake shudder condition after

reassembly.

10 Remove the brake rotor from the wheel hub a ssembly

and carefully set to one side.

11 Using a commerciall y ava ilable 10 mm Allen key

socket and suitable socket eq uipment, loosen each of

the three bolts (3) holding the wheel be aring hub to the

steering knuckle.

Figure 3B – 17

12 If the hub is a tight fit to the knuckle, it may be necessary to loosen the three bolts and tap on the he ads. DO NOT

STRIKE THE HUB, NOR THE WHEEL BEARING.

13 Remove the three bolts and then the hub from steering knuckle.

Front Suspension – AWD Page 3B –18

Page 3B – 18

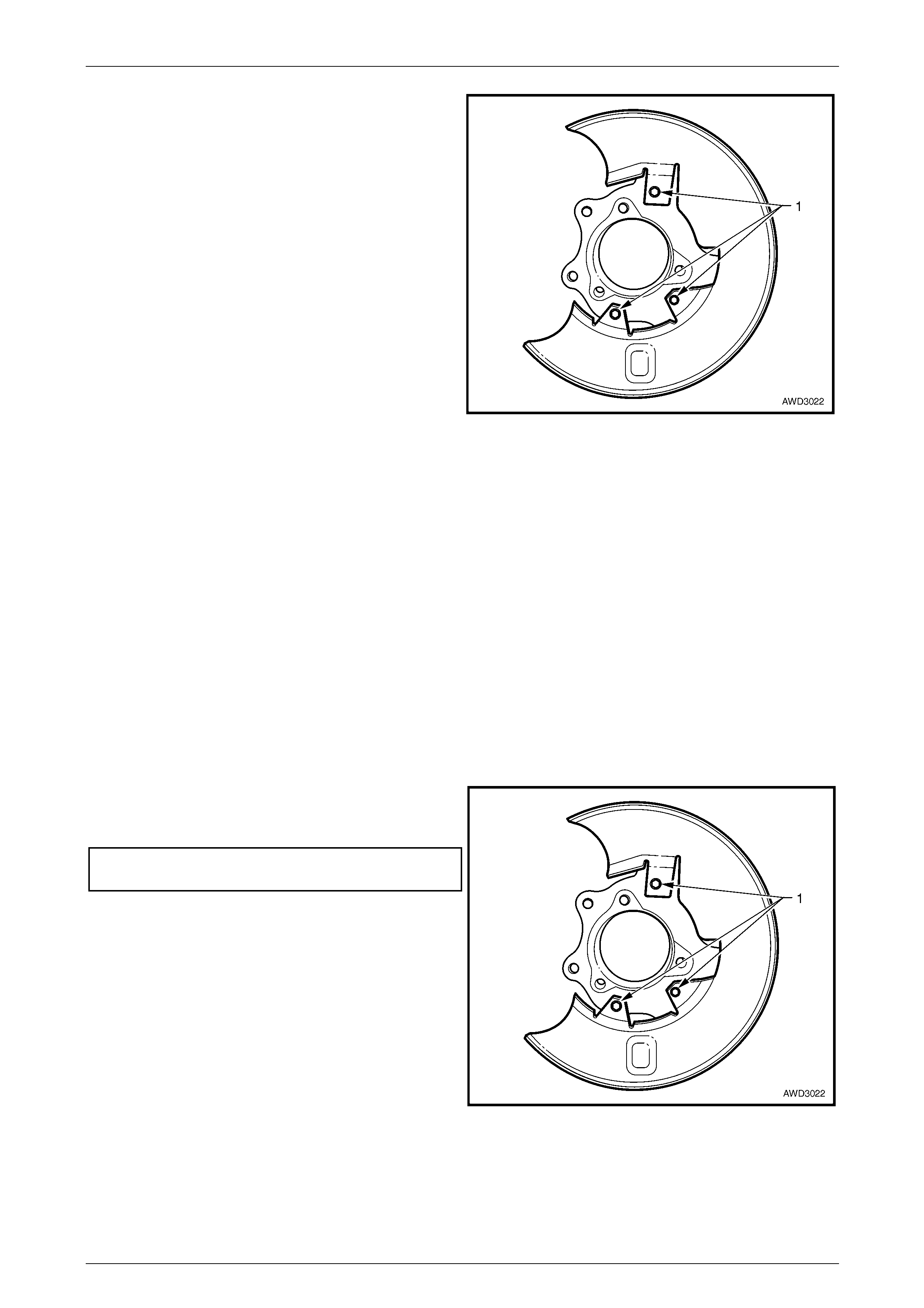

14 Where removal of the brake shield is nec essary,

Remove the three screws (1) securing the shield to the

steering knuckle support, then remove the br ake

shield from the steering knuckle.

Figure 3B – 18

Inspect

1 Check wheel studs are pressed firml y into the front wheel hu b assemb ly and ensure threads are not damage d. If

one or more of the wheel studs require replacement, refer to 3.4 Front W heel Hub Studs in this Section for details.

2 If a check before hub removal showed that the wheel bearing angular 'float' exceeded specification, if rotation of the

hub feels 'gritty' or rough, or if a greas e leak is evident, then the hub and bearing assembly must be replaced as a

unit.

3 Examine the brake rotor for scores or dam age. If either of these conditions exist, the brake rotor shoul d be

machined or replaced. Refer to Section 5A Service and Park Braking System, for details.

4 Check for damage to the shield that may cause fouling of any rotating parts and if suspect, the shield sho uld b e

replaced.

Reinstall

Installation of the front wheel hub assembly, brake rotor a nd br ake shield is the reverse of removal procedures, except

for the following points:

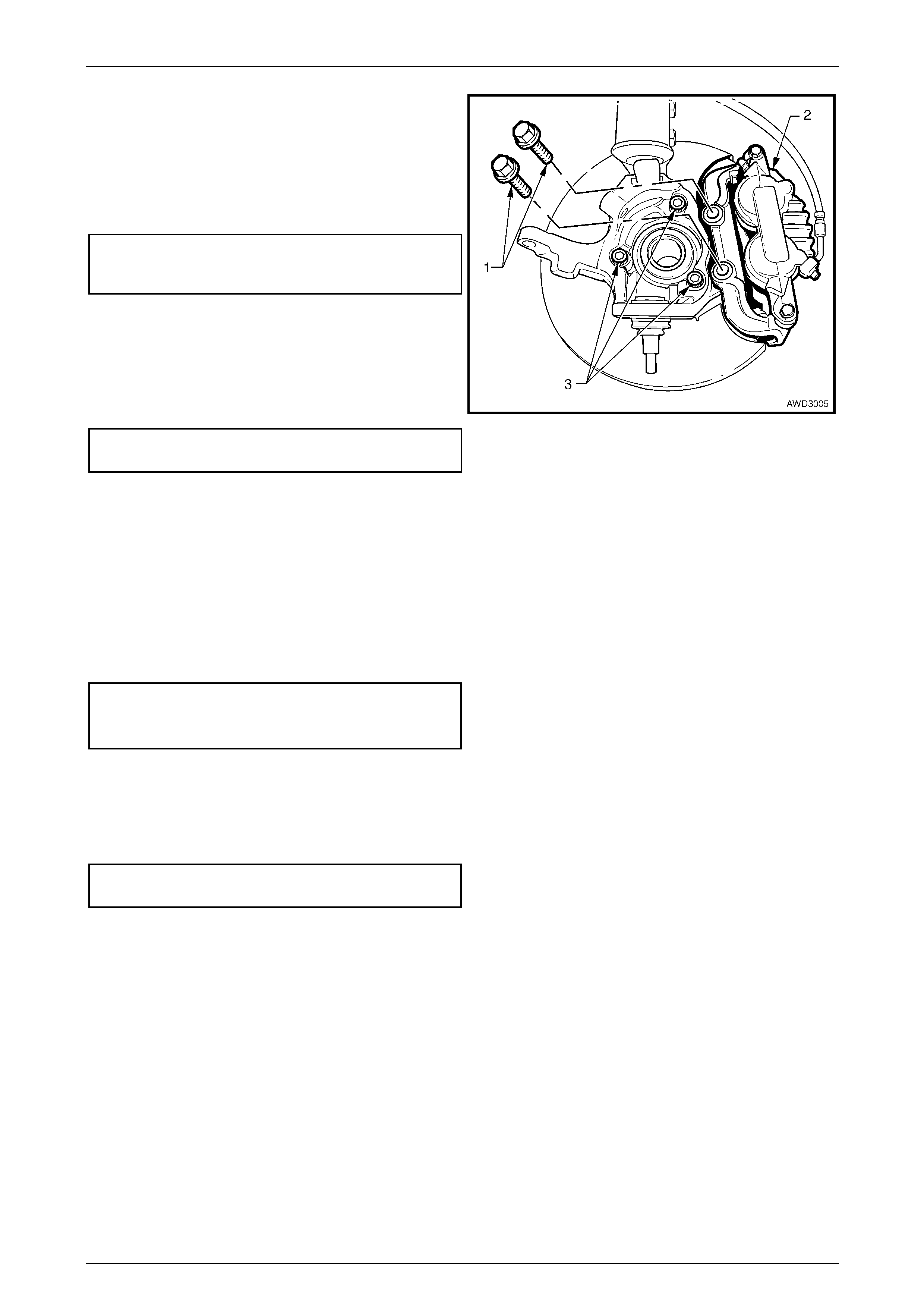

1 If the brake shield has been removed, install the three

retaining screws and tighten to the correct torque

specification.

Brake shield retaining screw

torque specification.................................................9 Nm

2 Before reinstalling the hub, inspect both mati ng

surfaces to make sure that they are clean and free

from burrs that could prevent correct alignment of both

parts, once installed.

Figure 3B – 19

Front Suspension – AWD Page 3B –19

Page 3B – 19

3 Install the hub assembly onto the steering knuckle.

NOTE

The holes will only a lign in one position.

4 Install the three attaching bolts (3) and tighten to the

correct torque specification.

Front wheel hub assembly to

steering knuckle attaching bolt

torque specification.............................................108 Nm

5 Reinstall the front driveshaft. Refer to Section 4B3

Front Final Drive, Bearing Housing & Driveshafts, for

the procedure.

6 Reinstall the wheel speed sensor to the steering

knuckle, reinstall the securing screw and tighten to the

correct torque specification.

Front wheel speed sensor ret aining

screw torque specification.....................................10 Nm

7 Install brake rotor, aligning the marks made before

removal.

Figure 3B – 20

NOTE

If the hub was replaced, then runout checks must

be carried out on the installed brake rotor. Refer

to Section 5A Service and Park Braking System,

for important information regarding these checks.

8 Install the brake caliper (2) and NEW attachi ng bolts (1) and tighten to the correct torque specification.

( ) Brake caliper anchor plate

retaining bolts torque specification........................85 Nm

then turn through 45°

9 Install the road wheel, alignin g the marks made prior to removal and secure with the attaching nuts.

10 Remove the jack stands and lower the vehicle.

11 Tighten the road wheel attaching nuts to correct torque specification, working in a ‘star’ pa ttern, refer to

Section 10 Wheels and Tyres.

Road wheel attaching nut

torque specification..................................110 – 140 N.m

12 Install the centre wheel nut caps.

Front Suspension – AWD Page 3B –20

Page 3B – 20

3.4 Front Wheel Hub Studs

LT Section No. – 06-212

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Brake caliper ancho r p l ate to steering knuckle retaining bolt.

Replace

1 Remove the front wheel hub assembly. Refer to 3.3 Front Wheel H ub Assembly, Brake Rotor and/or Brake Shield,

Remove, in this Section.

NOTE

Hub removal is necessary, because there is

insufficient space behind the hub flange to

remove the stud with the hub assembly installed

to the steering knuckle.

Under no circumstances is a hammer to be

used in either stud removal or installation

operations. If a hammer is used, distortion of

the wheel hub flange will most probably

result.

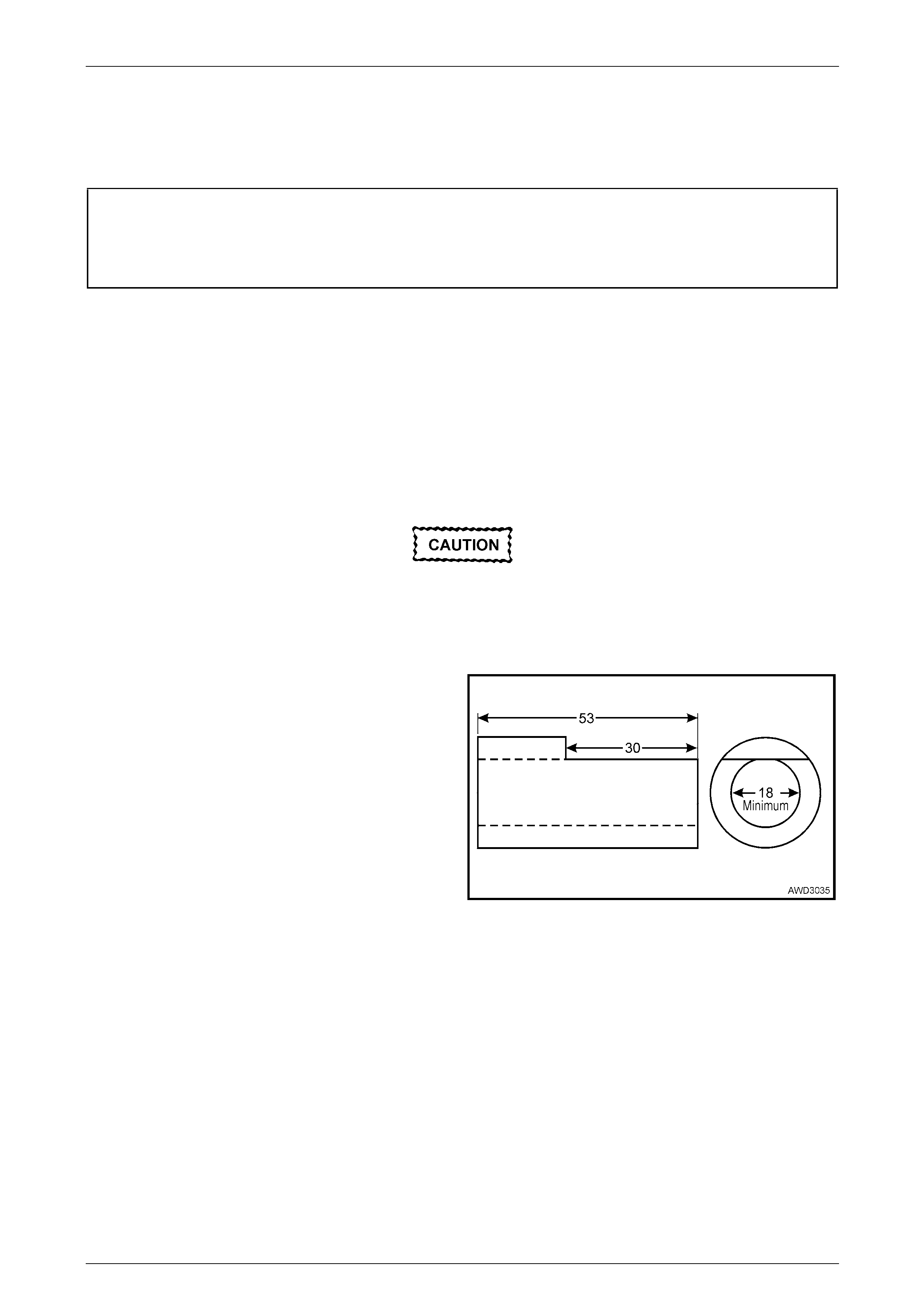

2 Fabricate a piece of thick walled pipe (i.e. 25 mm

water pipe), removing a section, as indicated. As this

single piece is used to both re move and install a new

stud, squaring the ends in a lathe is recommend ed.

Figure 3B – 21

Front Suspension – AWD Page 3B –21

Page 3B – 21

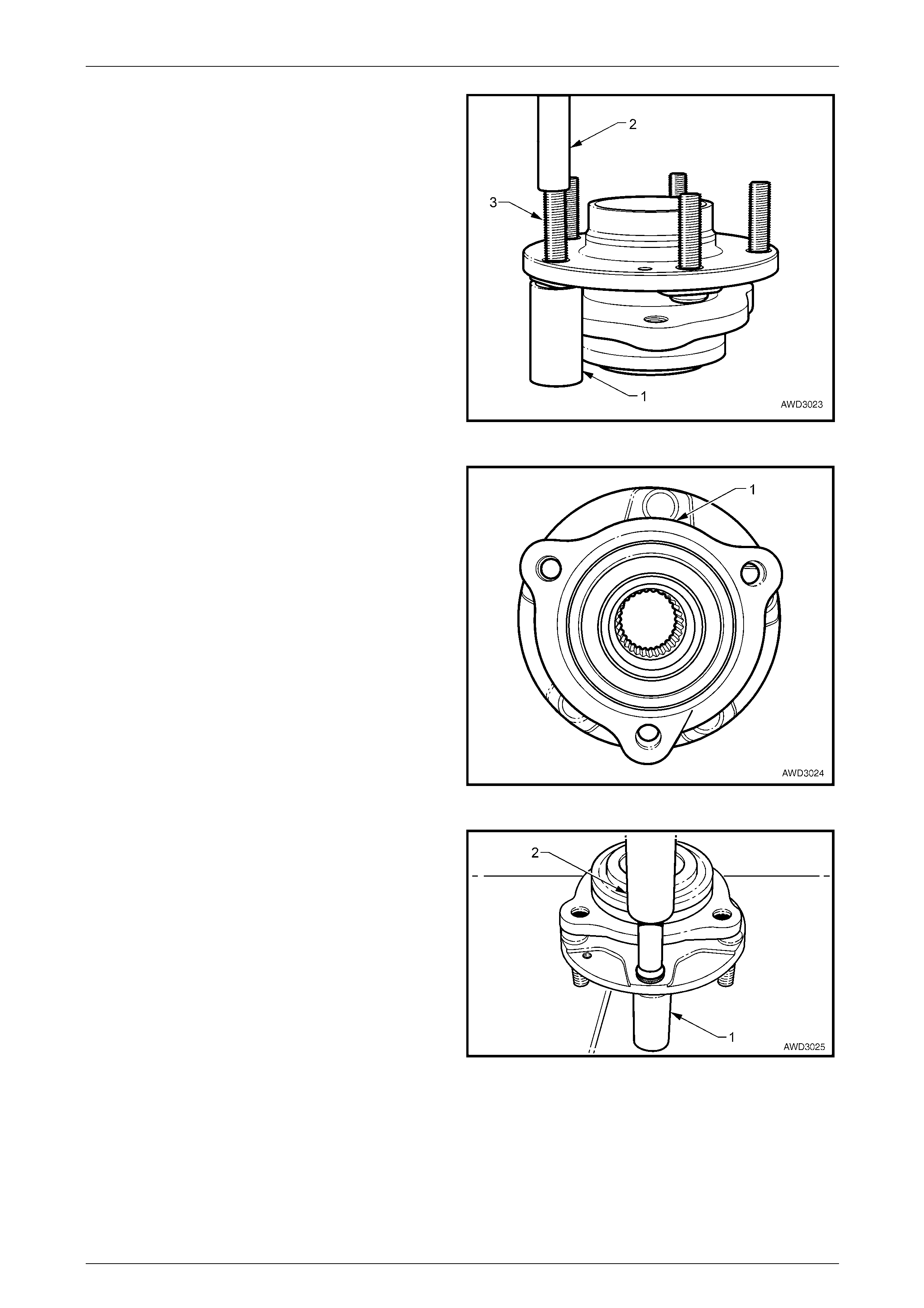

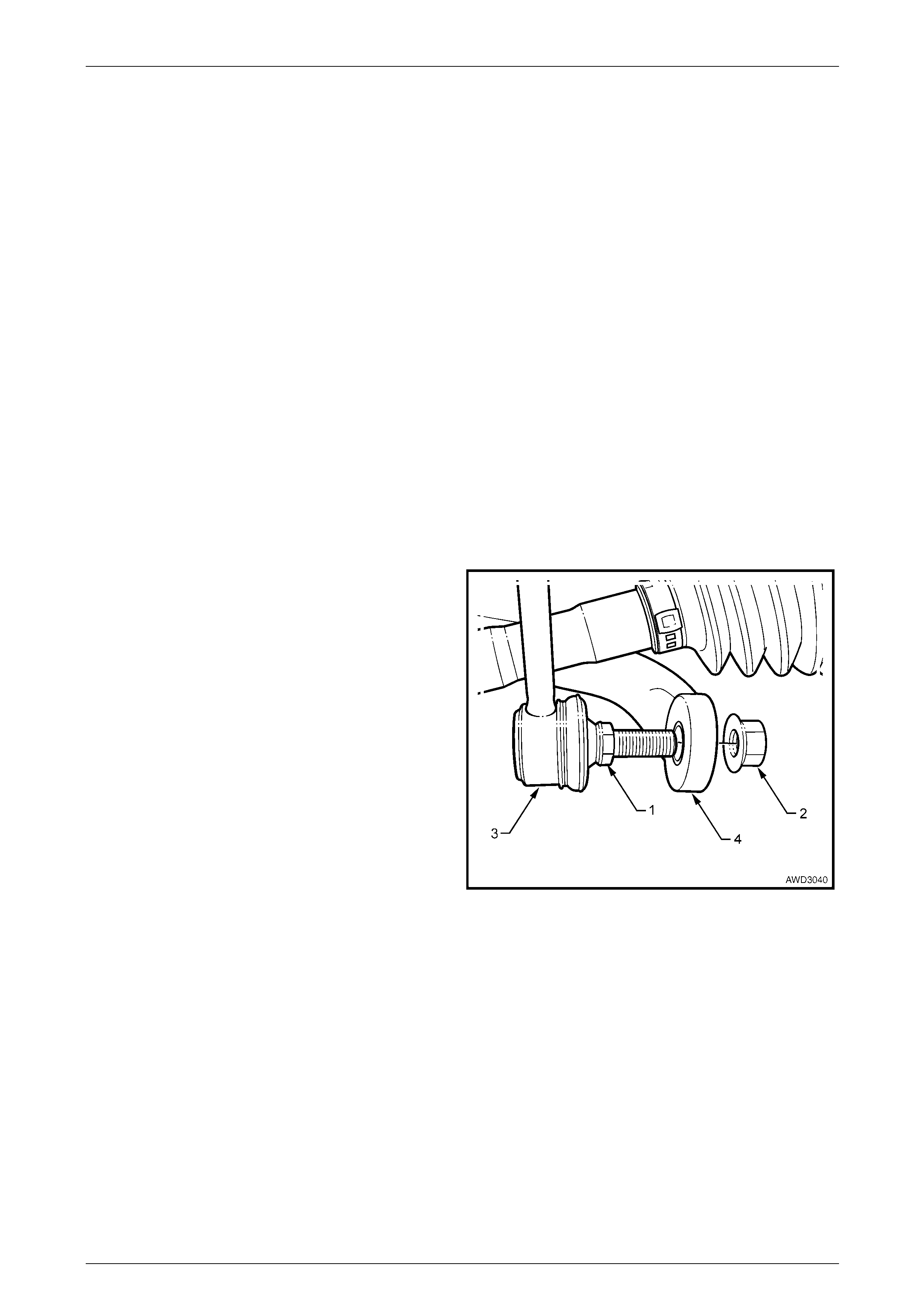

3 Arrange the fabricated pipe (1) over the head of the

stud to be removed, with the flat of the cut-out section,

against the hub flange, then use a suitable drift (2) to

press the stud (3) from the wheel hub flange.

Figure 3B – 22

NOTE

Of the three wheel hub fl anges, there is onl y one

(1) that provides sufficient clearance to allow

removal of the wheel stud.

Figure 3B – 23

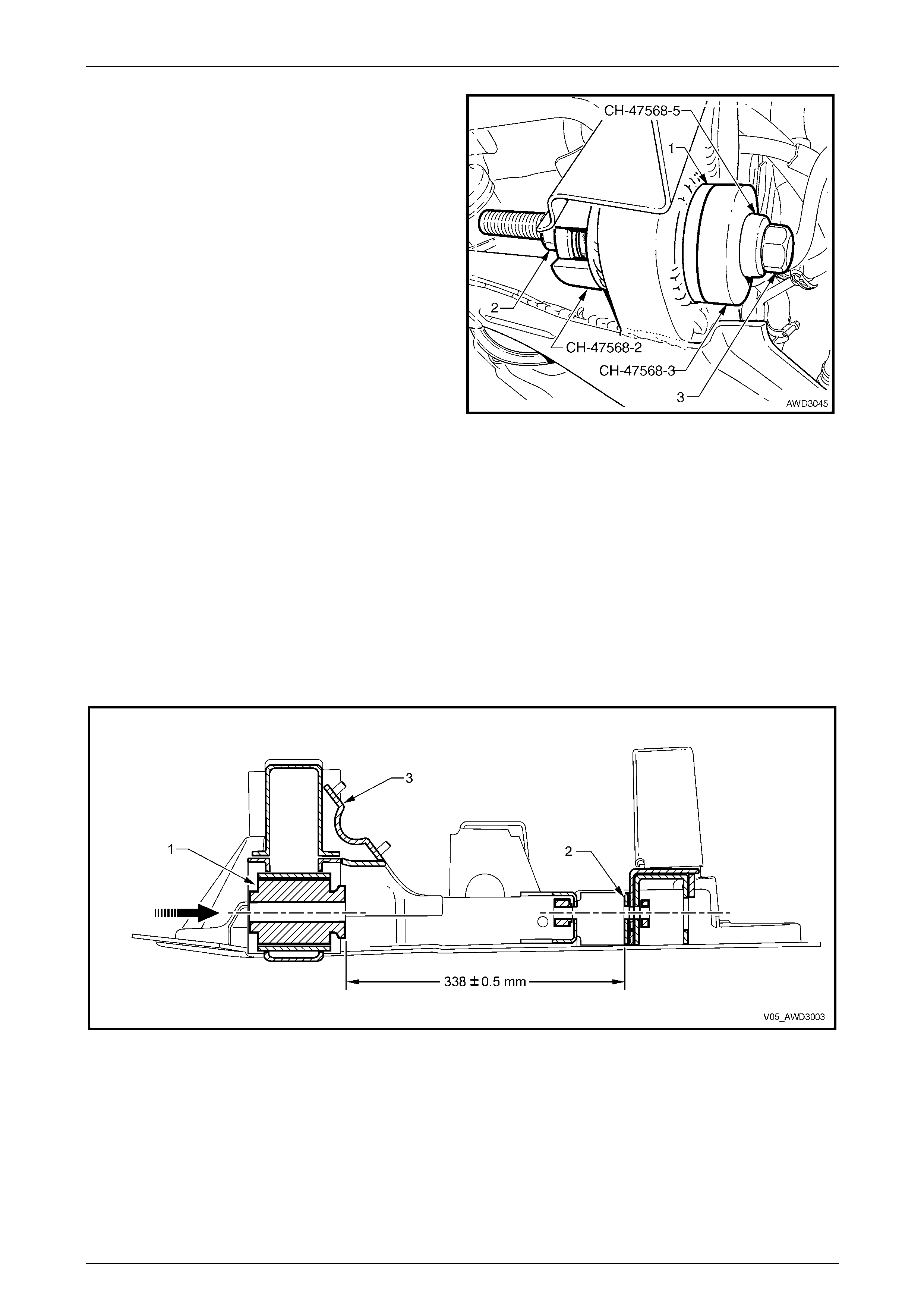

4 Setup the wheel bearing hu b wit h the pipe (1) under

the flange hole where the new stud is to be installed.

5 Use the same drift (2), press the stud into the wheel

hub flange, until fully installed.

NOTE

If the press effort was minimal during installation

or the stud is loose in the flange when installed,

then replace the front wheel bearing hub and

flange assembly.

6 Reinstall the front wheel hub assembly. Refer to

3.3 Front Wheel Hub Assembly, Brake Rotor and/or

Brake Shield, Reinstall, in this Section.

7 Reinstall the front driveshaft. Refer to Section 4B3

Front Final Drive, Bearing Housing & Driveshafts.

Figure 3B – 24

Front Suspension – AWD Page 3B –22

Page 3B – 22

3.5 Front Strut Assembly

LT Section No. – 06-212

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Upper strut locating plate retaining nut.

Brake caliper ancho r p late to steering knuckle retainin g bolts.

Steering knuckle to strut attach in g nuts and bolts.

Remove

1 Observing the jacking precautions as outlin ed in 2.3 Jackin g Precautions in this Section, raise the front of the

vehicle and support on safety stands.

2 Remove the centre wheel nut caps.

3 Mark the relationship of the road wheel to hub or brake rotor. Loosen, then remove the road wheel attaching nuts,

working in a 'star' pattern. Refer to Section 10 Wheels and Tyres, for detailed information. Remove the road wheel.

NOTE

Step 3 is necessary to maint ain part relationships

and to avoid brake rotor distortion and the

creation of brake shudder, after the vehicle is

placed back in service.

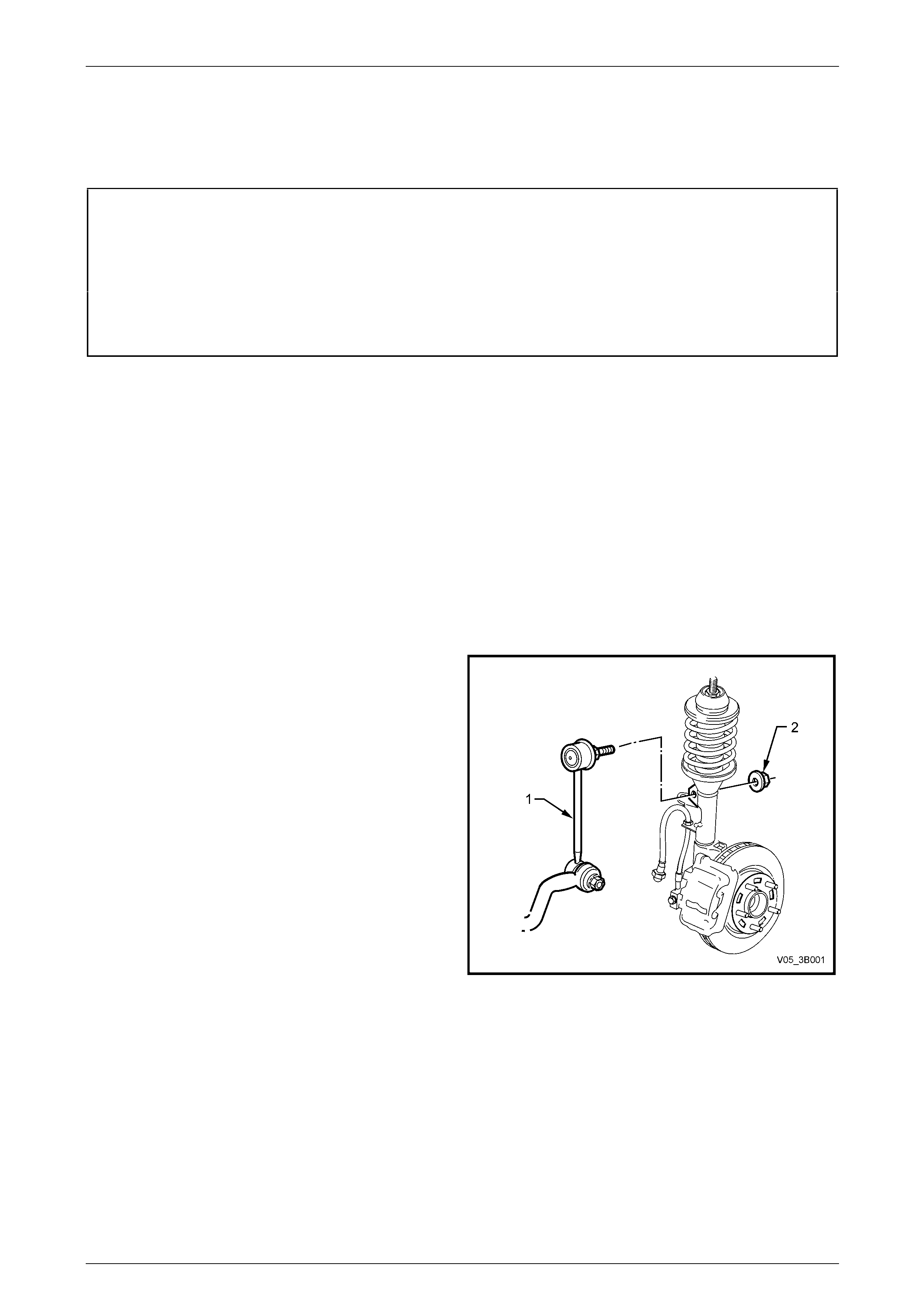

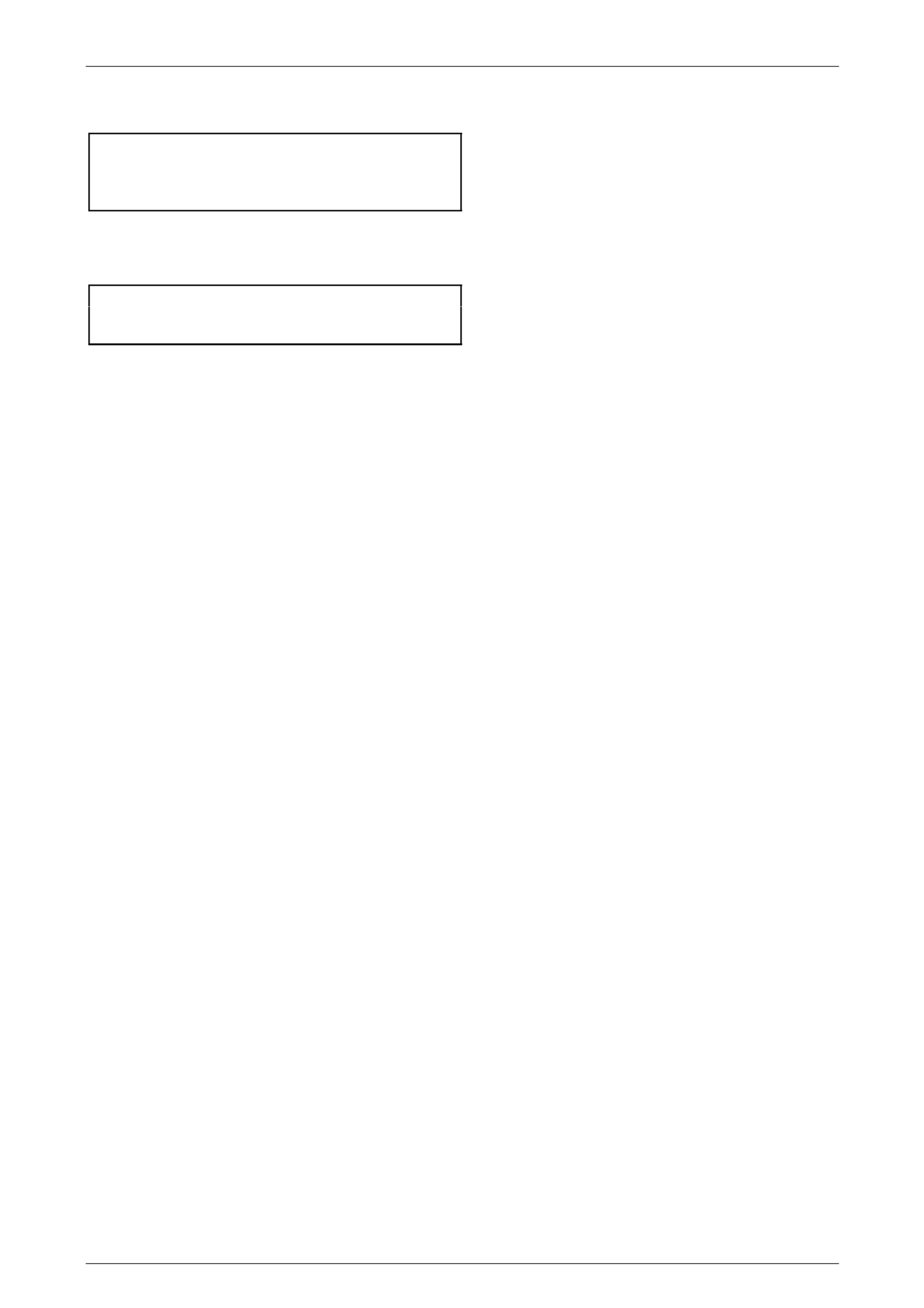

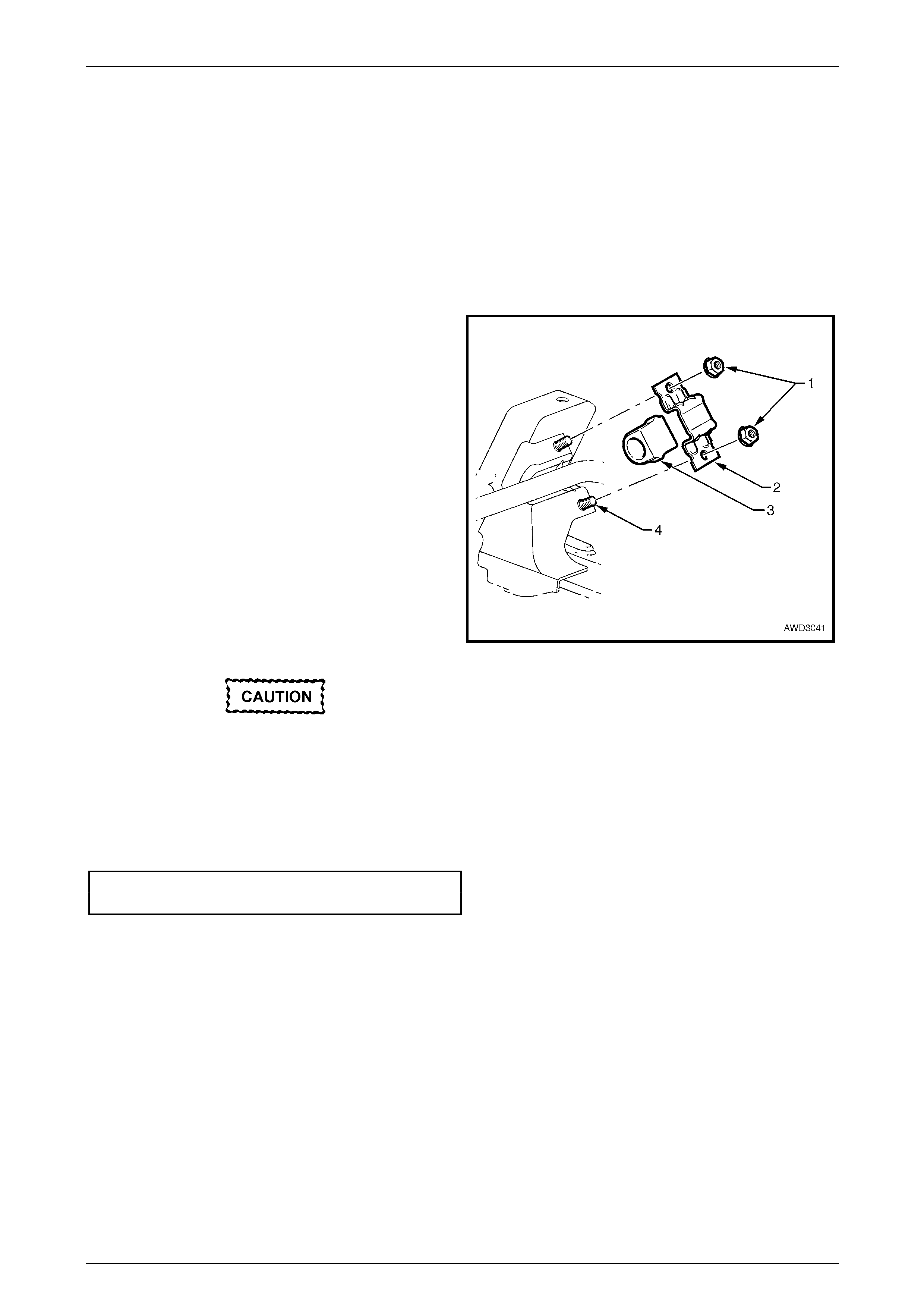

4 Using a suitable size spanner, hold the upper, inner

stabiliser bar spacer stud, then use a second spanner

to loosen and remove the stabiliser bar spacer stud

nut (2).

5 Disconnect the wheel speed sensor cable and

insulator from the strut bracket.

Figure 3B – 25

Front Suspension – AWD Page 3B –23

Page 3B – 23

6 To avoid placing strain on the whe el speed sensor

cable, remove the Allen key head ed screw (1)

securing the front wheel speed sensor to the steering

knuckle.

7 Grasp the sensor and twist back and forth while

pulling, to remove. Secure sensor with tie wire or

similar to prevent sensor damage during the service

procedure.

Figure 3B – 26

8 Remove the brake hose (1) from the strut housing

bracket (2) by turning the plastic sleeve (3) on the

hose until the flats on the sleeve align with the bracket

opening.

Figure 3B – 27

9 Remove the brake caliper retaining bolts and washers

(1), lift the caliper assembly (2) from the brake rotor

and support in such a way that no strain is placed on

the brake hose. THE BRAKE CALIPER IS NOT TO

HANG BY THE BRAKE HOSE. Discard removed bolts

as they must be replaced on reassem bl y.

10 Remove the brake rotor from the wheel hub assembly.

The brake rotor to hub relationship is marke d duri ng

production. To ensure this relationship is maintained,

ensure that the rotor to hub position is carefully

marked.

NOTE

• This is necessary to overcome the possibility

of inducing a brake shudder condition after

reassembly

• These two steps are primarily aimed at

reducing the weight of components that will

need to be supported after the strut to

knuckle bolts are removed. Figure 3B – 28

11 Position a suitable floor jack fitted with a block of wood on the lift pad under the front control arm and raise it

enough to support the weight.

Front Suspension – AWD Page 3B –24

Page 3B – 24

Unless the front wheel hub, knuckle and dust

shield are supported when the two strut to

knuckle bolts and nuts are removed, these

components will fall outward. Apart from the

risk of personal injury, the driveshaft inner

tripot joint will be separated, resulting in the

need to replace the joint and dust boot.

12 While supporting the front wheel hub, steering knuckle and dust shield, loosen, remove then d iscard the two lower

strut to knuckle attaching bolts and nuts.

13 While continuing to support the steering knuckle pull it clear from the strut.

14 Ensure that the steering knuckle is maintained in a 'normal' attitude, by securing with wire to the brake pipe bracket.

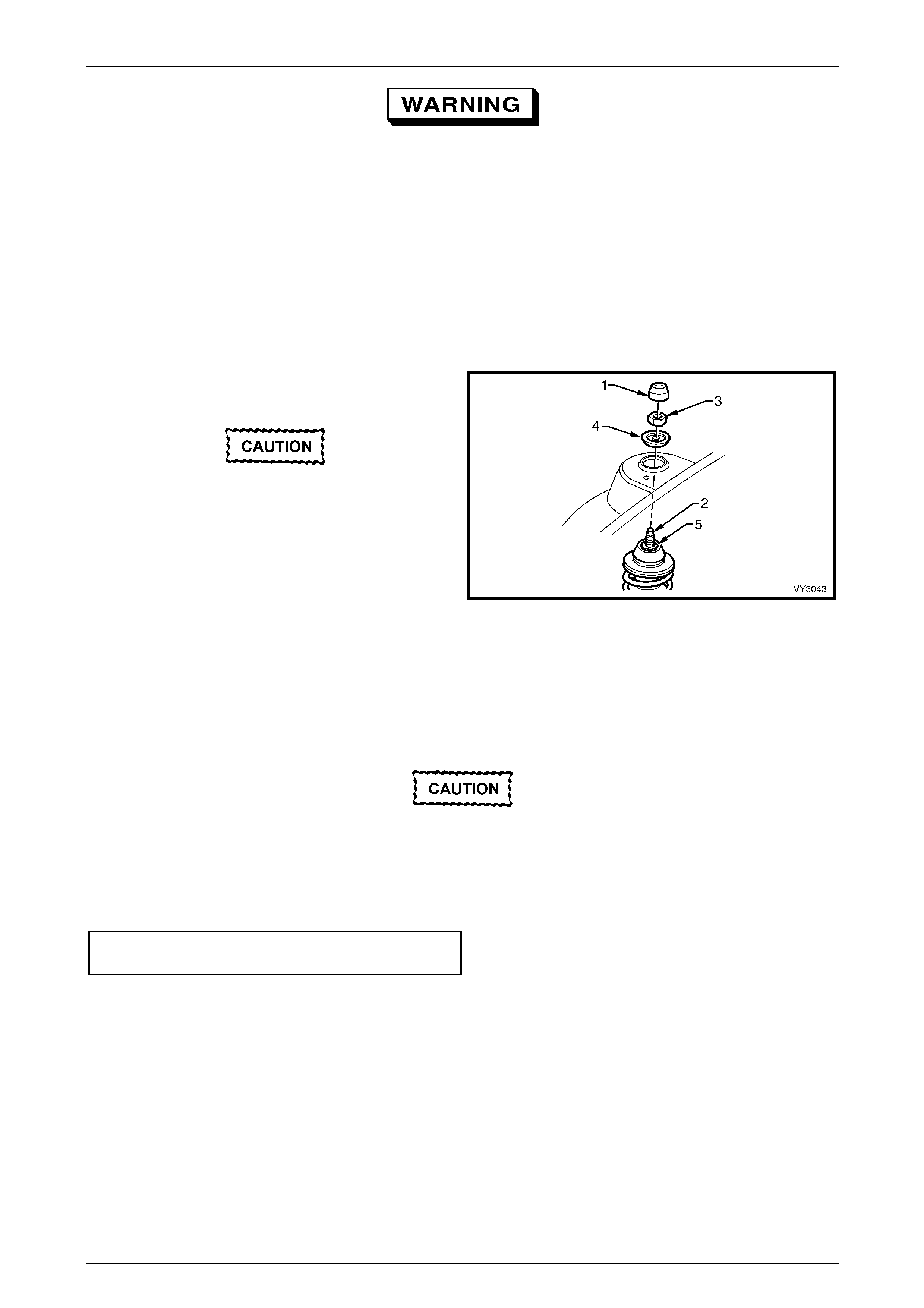

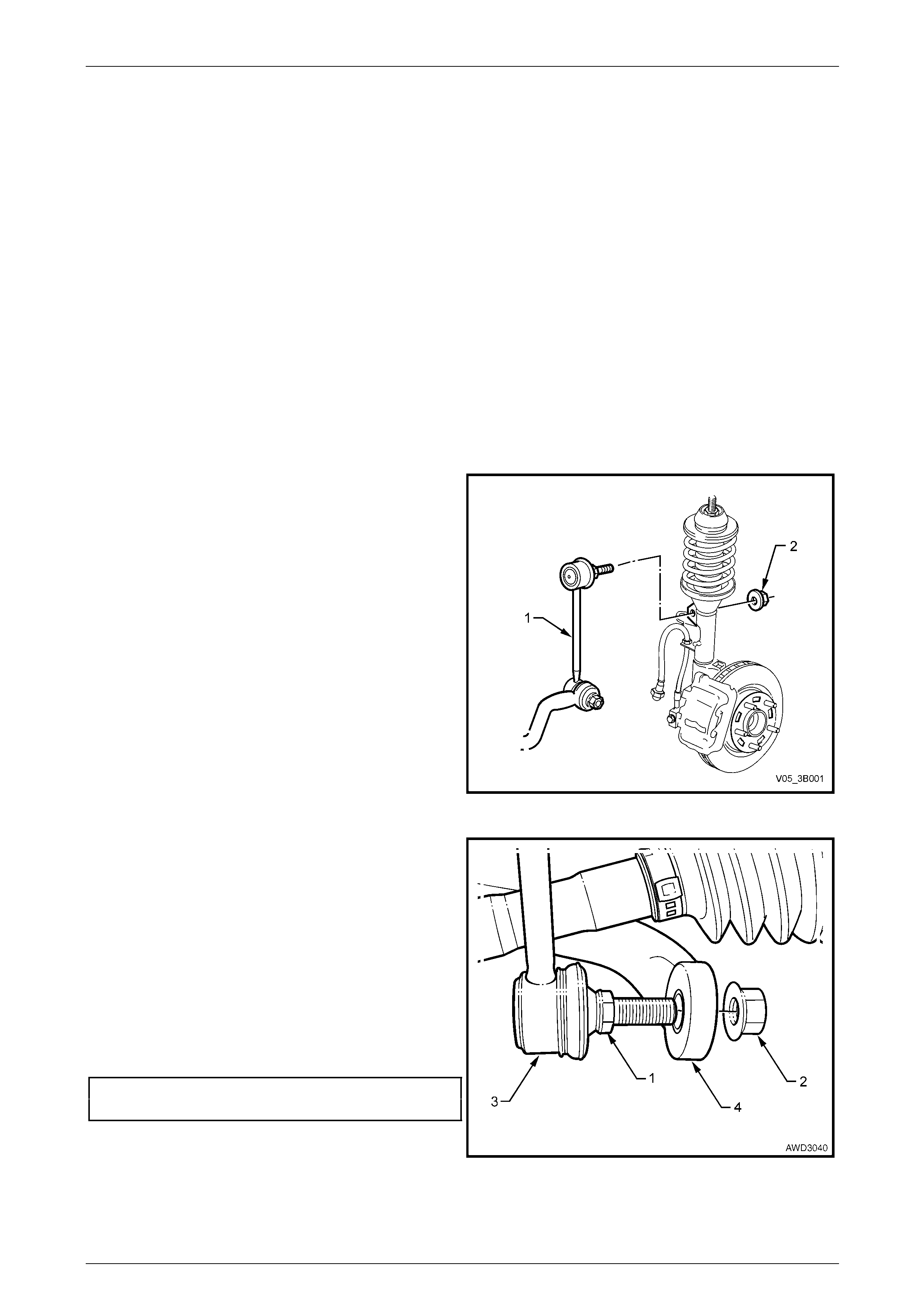

15 Remove the dust cover (1) from the upper strut

support, in the engine compartment.

Support the strut assembly, while performing

the next step, to stop the strut falling free,

causing possible damage.

16 While holding the strut rod shaft (2) with a 10 mm

socket, remove the self-locking nut (3), using a 24 mm

ring spanner, then remove the locating disc (4).

Discard the strut rod nut.

17 Carefully lower the strut (5) from the tower, manipulate

the strut to remove the stabiliser stud from the bracket

on the strut and remove the assembly from the

vehicle.

Figure 3B – 29

Reinstall

The torque of the strut bearing retaining nut

MUST be checked for correct tightness

BEFORE installing the strut into the vehicle.

1 Use a 10 mm socket to hold the strut rod from turning, then tighten the strut bearing retaining nut (‘5’ in Figure 3B-29)

to the correct torque specification, using a 24 mm ring spanner with a torque wrench attached.

Upper strut bearing retaining

nut torque specification.........................................78 Nm

2 Manipulate the strut assembly so that the stabiliser bar stud is located in the strut bracket, then locate the strut

assembly into the spring strut tower.

3 After installing the locating disc, partially install a NEW upper nut to the strut rod. Do not tighten at this time.

Front Suspension – AWD Page 3B –25

Page 3B – 25

4 While supporting the steering knuckle, hub and dust

shield assembly (1), remove the secur ing wire and

align the knuckle holes suffici ently to line up the bolt

holes in the steering knuckle and the lower end of the

strut assembly (2).

5 Install NEW retaining bolts (3) (from front to rear) and

nuts (4), and tighten to a preliminary torque of 85 Nm.

6 Use a 10 mm socket to hold the strut rod from turning,

then tighten the upper strut rod retaining nut (‘3’ in

Figure 3B-29) to the correct torque specification, using

a 24 mm ring spanner with a torque wrench attached.

( ) Upper strut locating plate

retaining nut torque specification ..........................55 Nm

7 Install the brake hose to the strut bracket by turning

the plastic sleeve on the hose until the flats on the

sleeve align with the bracket opening.

Figure 3B – 30

8 Reinstall the brake rotor, align ing the marks made prior to removal.

9 Reinstall the brake caliper, tig htening the NEW attaching bo lts to specificati on.

( ) Brake caliper anchor plat e

retaining bolts torque specification........................85 Nm

then turn through 45°

10 Reinstall the wheel speed sensor to the steering knuckle, securing with the Allen ke y headed screw and tightening

to the correct torque specification.

Front wheel speed sensor att aching

screw torque specification.....................................10 Nm

11 Reinstall the sensor lead and insulator into the strut mounting bracket.

12 Reinstall the stabiliser bar link ball joint stud into the

strut bracket.

13 Reinstall the stud retaining nut (2).

14 While holding the inner stud hexagon with a suitab le

set spanner, tighten the nut to the correct torque

specification.

Upper stabiliser bar link stud

nut torque specification.........................................50 Nm

15 Reinstall the road wheel, aligning the marks made

prior to removal.

16 Remove the safety stands and lower vehicle.

17 Tighten road wheel attaching nuts to the correct torque

specification, working in a ‘star’ pattern, refer to

Section 10 Wheels and Tyres.

Road wheel attaching nut

torque specification..................................110 – 140 N.m Figu re 3B – 31

18 Reinstall the centre wheel nut caps.

19 Bounce the vehicle up and down several times to settle the suspension.

20 Check and correct the wheel alignment, as required. Refer to 2.2 Wheel Alignment Checking and Adjustment, in

this Section.

Front Suspension – AWD Page 3B –26

Page 3B – 26

3.6 Upper Strut Support Bearing and Mount

LT Section No. – 06-210

Remove

1 Remove the front strut (1), refer to 3.5 Front Strut

Assembly, in this Section.

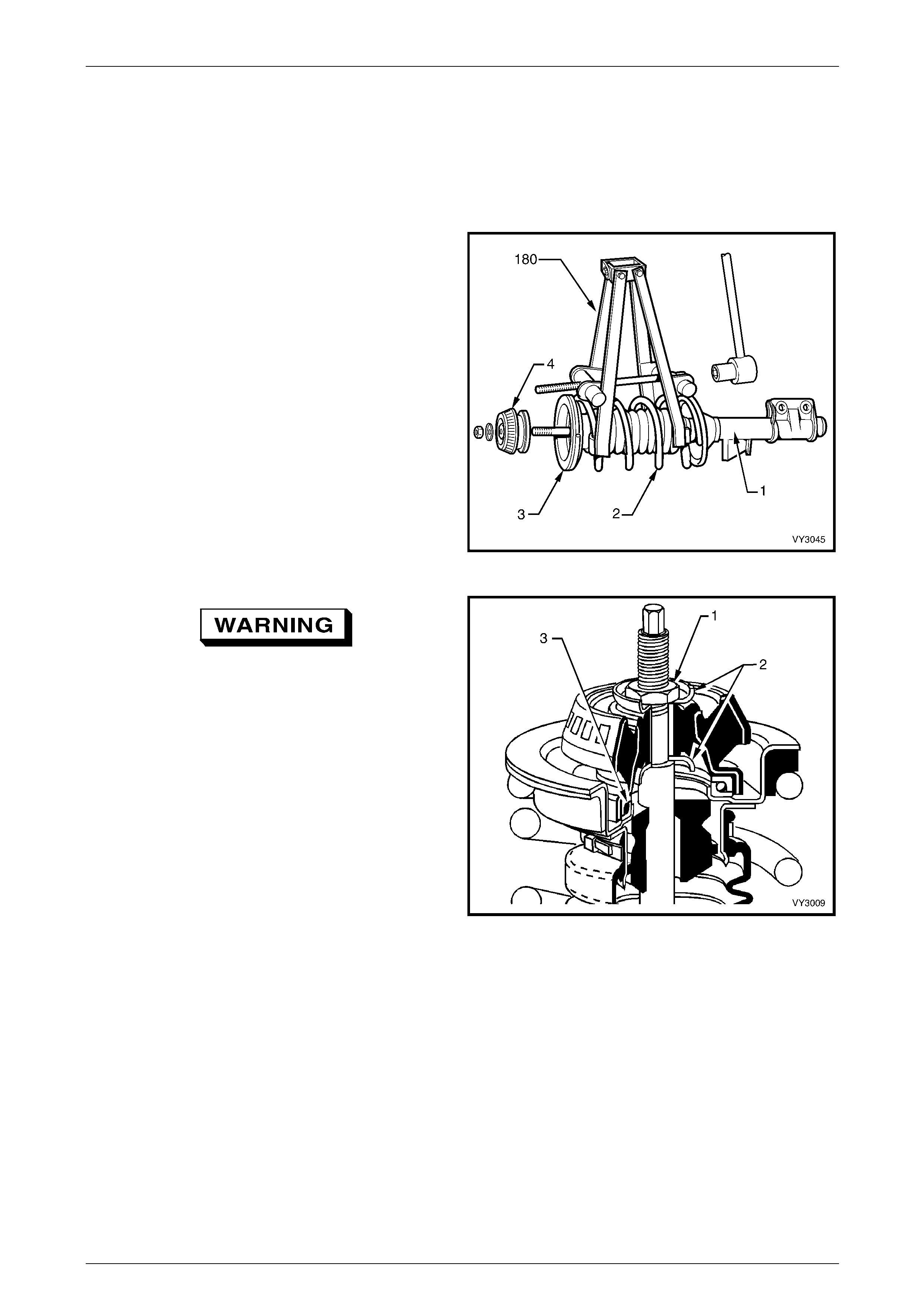

2 Fit Tool No. 180 (or a commercially available

equivalent) to the front spring as shown. Compress the

spring (2) until the upper support beari ng (4) has

clearance at the spring seat collar 3).

Figure 3B – 32

Do not attempt to remove the retaining nut (1)

from the strut rod shaft before compressing

the spring.

3 While holding the strut rod shaft with a 10 mm socket,

remove the upper strut bearing to strut rod retaining

nut (1), using a 24 mm ring spanner.

4 Remove the front suspension strut mount assembly

and the two washers (2) fitted to each side.

NOTE

The lower washer may be stuck to the lower

surface of the mount.

5 Remove the strut bearing (3) from the upper spring

seat collar, taking particular note of the beari ng

orientation.

NOTE

• The upper support bearing is self-lubricated

and no servicing requirements are

necessary. If considered to be faulty, the

bearing is to be replaced as an assembly.

• Under no circumstances is the machined

surface of the piston rod section to be

gripped directly on its outer surface.

Figure 3B – 33

Front Suspension – AWD Page 3B –27

Page 3B – 27

Reinstall

1 Loosely reinstall the strut rod nut, then pull the piston rod through the u pper spring seat to its maximum length, then

remove the strut rod nut.

2 Install the upper bearing with the same orientation as noted on removal. Usually, the coloured or narr ow, outer

section, faces down to the upper spring seat collar.

3 While holding the strut rod extended and, after installing the first mount washer with the dished shape facing

downward (refer to item 2 in Figure 3B-33), install the upper front suspension strut mount assembly over the

bearing and washer.

4 Install the second washer with the dished shape facing upward (refer to item 2 in Figure 3B-33) and insta ll the

retaining nut.

5 Using a 10 mm socket and a 24 mm ring spanner with a torque wrench attached, tighten the nut to the correct

torque specification.

Upper strut bearing retaining

nut torque specification.........................................78 Nm

6 Release the spring compress or and remove it from the spring.

7 Install the front strut, refer to 3.5 Front Strut Assembly in this Section.

Front Suspension – AWD Page 3B –28

Page 3B – 28

3.7 Front Spring

LT Section No. – 06-210

Remove

1 Remove the front strut, refer to 3.5 Front Strut Assembly in this Section.

2 Remove the front strut upper mount and bea ring assembly, refer to 3.6 Upper Strut Support Bearing and Mount in

this Section.

NOTE

The spring compressor is not shown in this

exploded view, as it is assumed that Steps 1 and

2 have already been carried out.

3 Remove the retaining clamp (1) securi ng the front strut

dust shield assembly (2) and filter (3) to the upper

spring seat collar (4).

4 Remove the upper spring seat collar (4), spring

insulator (5) and compression bump er (6) from the top

of the spring (7).

5 Remove the spring (7) from the strut (8) and release

the spring compressor.

Figure 3B – 34

Reinstall

NOTE

If installing a replacement spring, ensure that the

spring is the correct type for this vehicle. Refer to

5 Specifications in this Section for details.

1 Position spring on strut with straight projectin g end of spring correctly located in the lower spring seat.

2 Install spring compressor Tool No. 180 or a commercially available equivalent, to the spring (refer to Figure 3B-32)

and compress it.

3 Reinstall the upper spring i nsulator, spring seat collar and compression bumper so that the double notch in the

upper flange of the spring seat collar is assembled, facing inward. The spring insulator has a step which locates on

to the straight projecting end of the spring.

4 Install the front strut upper bearing and s upport (9), refer to 3.6 Upper Strut Support Bearing and Mount in this

Section.

NOTE

Check that the lower washer (10) is not binding

with the lower edge of the mount.

5 Fit the upper end of the front strut dust shield assembly over the lower flange of the spring seat collar and secure

with a retaining clamp. Tighten the clamp un til the boot rubber is firmly secured to the spring seat collar flange.

6 Reinstall front strut, refer to 3.5 Front Strut Assembly in this Section.

Front Suspension – AWD Page 3B –29

Page 3B – 29

3.8 Front Strut Unit

LT Section No. – 06-212

Replace

NOTE

• When replacin g the front strut , ensure th at the

replacement unit is the correct type for this

vehicle. Refer to 5 Specifications in this

Section for details.

• As the strut assembly is a seale d component,

no overhaul procedures are possible. If any

strut component is found to be unserviceable,

the complete strut must be replaced.

1 Remove the front strut assembly, refer to 3.5 Front Strut Assembly in this Section.

2 Remove the upper support components, refer to 3.6 Upper Strut Support Bearing and Mount in this Section.

3 Remove the spring, refer to 3.7 Front Spring in this Section.

4 Remove the lower boot, worm drive retaining clamp.

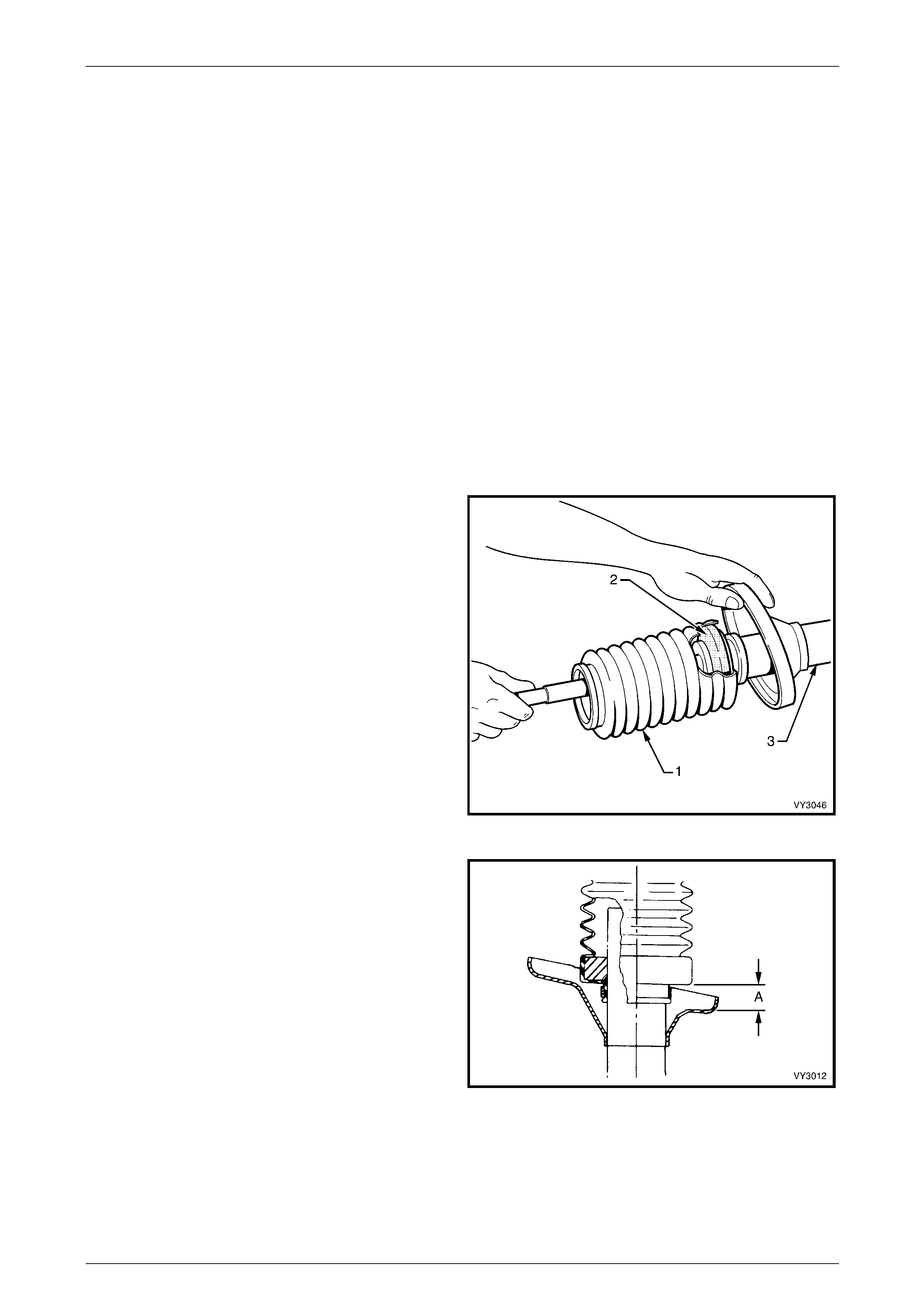

Slide the front strut dust shield assembly (1) and filter

(2) from the strut assembly (3).

5 Pull the strut rod fully up and, while supporting the rod

to stop it from slipping back into the strut, reinstall the

front strut dust shield assembly over the strut tube,

ensuring that the filter (2) remains seated inside the

boot assembly (1).

Figure 3B – 35

6 Ensure that the bottom of the front strut dust shield

assembly is positioned so that distance ‘A’ is between

30 – 35 mm.

7 Install a new worm drive retaining clamp and tighten

until the rubber on the front strut dust shield assembly

is firmly secured.

8 Reinstall the front spring refer to 3.7 Front Spring in

this Section.

9 Reinstall the upper strut support assembl y r efer to

3.6 Upper Strut Support Bearing and Mount in this

Section.

10 Reinstall the front strut assembly refer to

3.5 Front Strut Assembly in this Section. Figure 3B – 36

Front Suspension – AWD Page 3B –30

Page 3B – 30

3.9 Steering Knuckle

LT Section No. – 06-212

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt , rep lacement is recommended when performing these operations:

Front control arm ball joint stud nut.

The following fasteners MUST be replaced when performing these operations:

Front driveshaft outer retaining nut.

Steering knuckle to strut attach in g nuts and bolts.

Brake caliper ancho r p late to steering knuckle retainin g bolts.

Remove

1 Observing the jacking precautions as outlin ed in 2.3 Jackin g Precautions in this Section, raise the front of the

vehicle and support on safety stands.

2 Remove the centre wheel caps and mark the relationship of the wheel to the hub stud, using a felt tipped pen or

similar.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres, for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain part

relationships and to avoid brake rotor distortion

and the creation of brake shudder, after the

vehicle is placed back in service.

4 Attach holding tool KM-468 to the wheel hub with t wo

inverted wheel nuts. Support the tool outer end on a

safety stand (1).

5 Using a 36 mm socket and suitable socket equipment,

loosen then remove the drive s haft retaining nut and

flat washer. Discard the removed nut.

Figure 3B – 37

Front Suspension – AWD Page 3B –31

Page 3B – 31

Under no circumstances is the end of the

driveshaft to be struck with a hammer to

dislodge the splines. To do so, will not only

damage the front hub bearing but the

driveshaft to outer CV joint snap ring can be

also be dislodged.

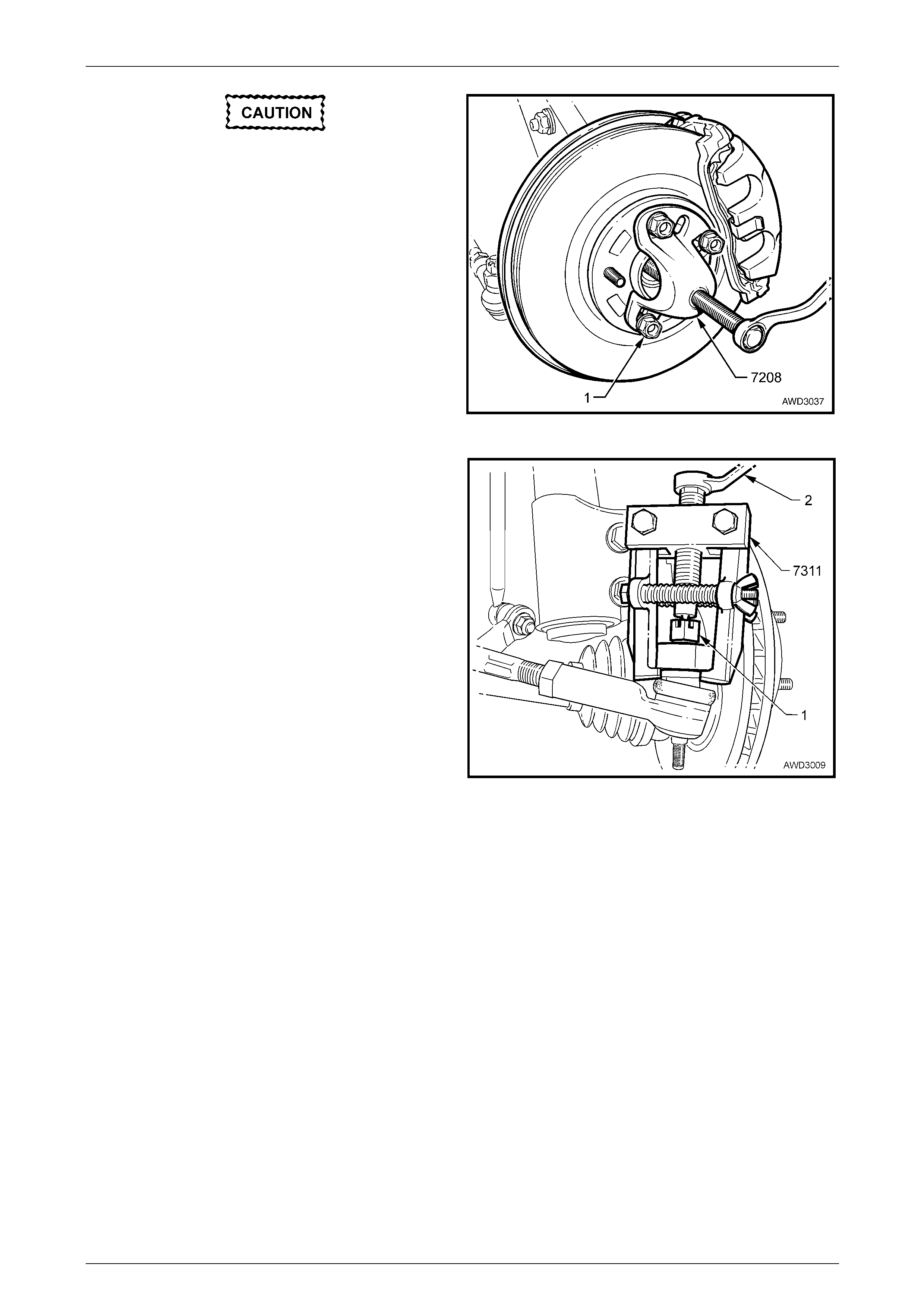

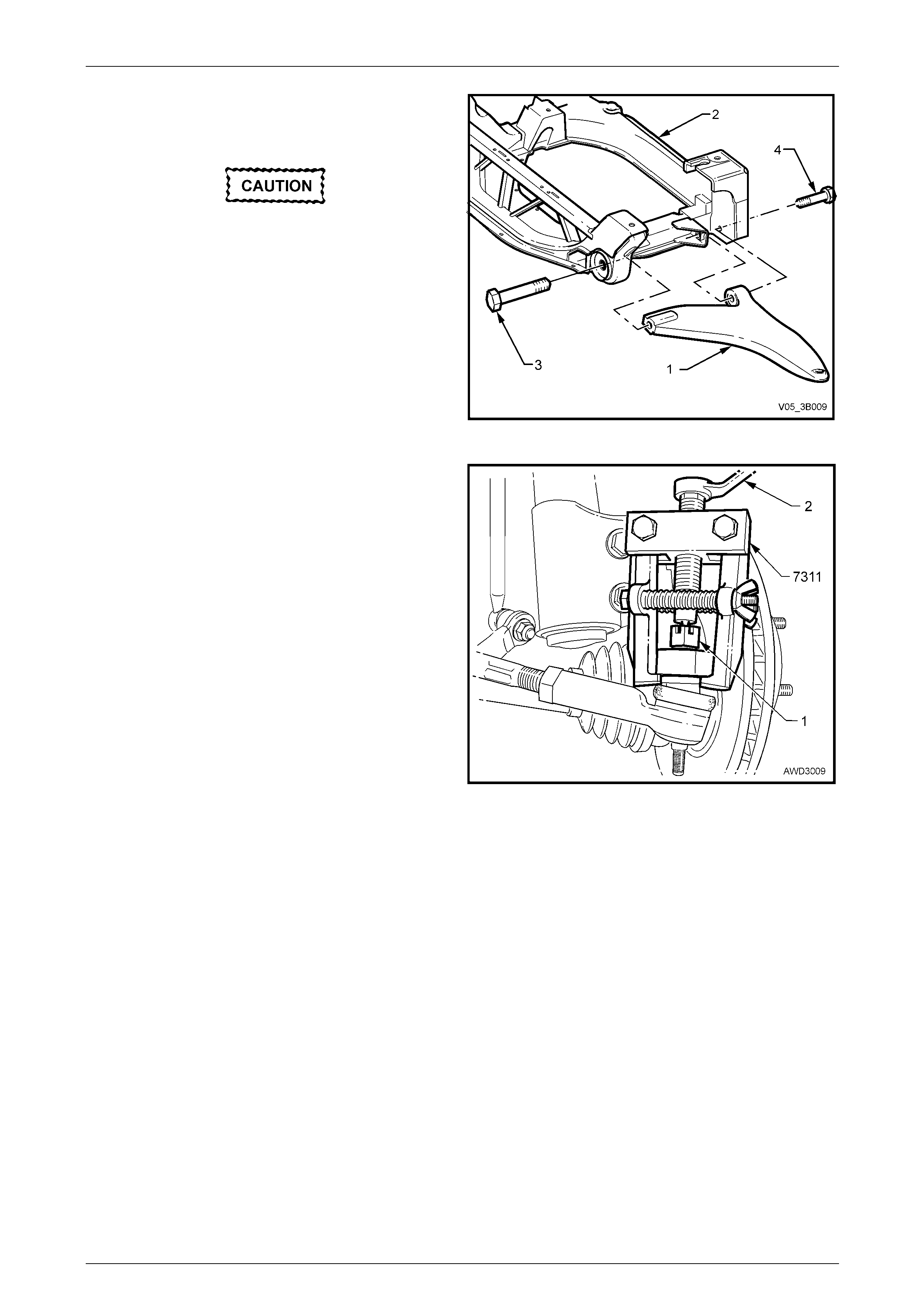

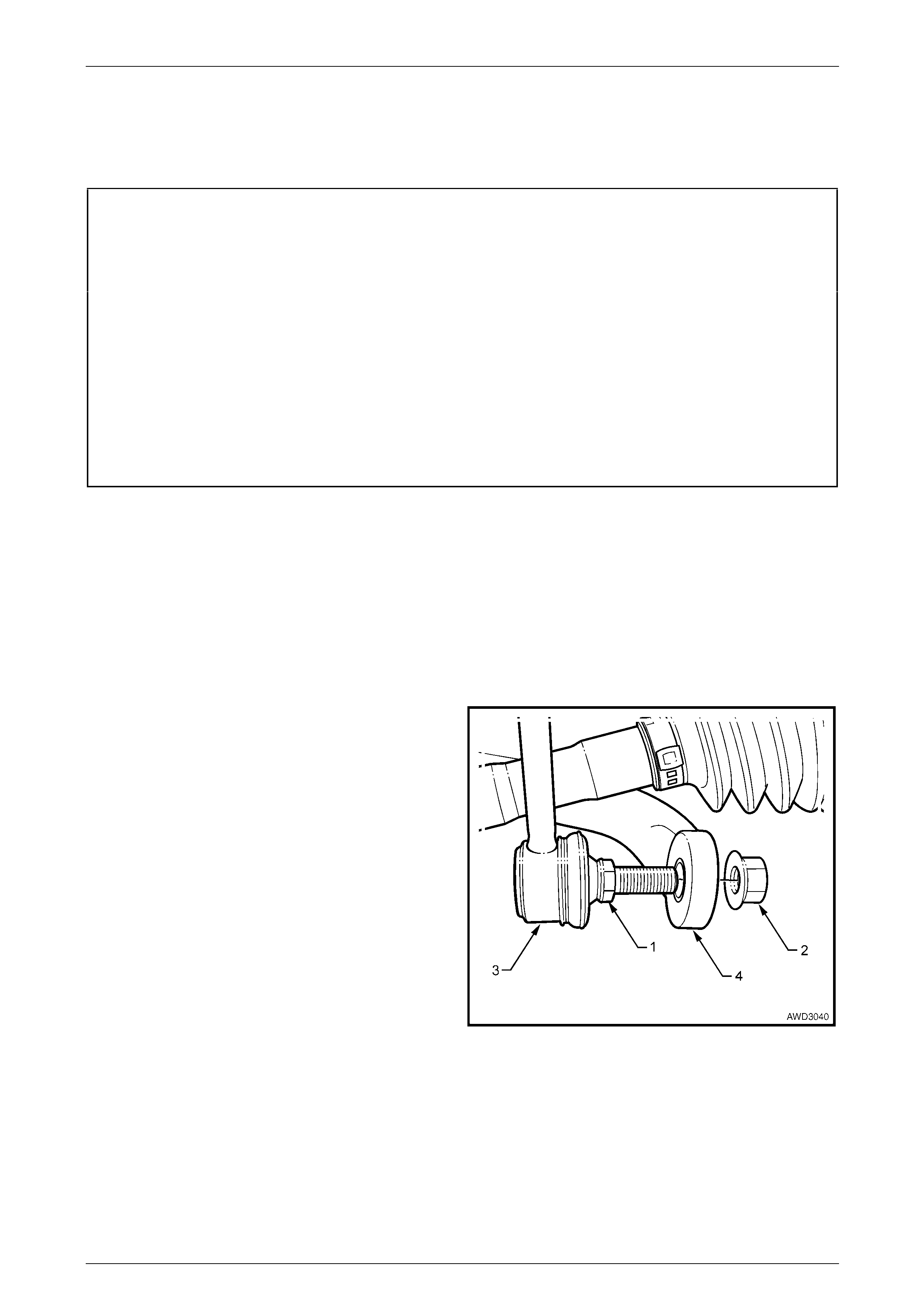

6 Install Tool No. 7208 to the front hub studs and secure

with three of the wheel nuts (1).

NOTE

If not previously modified, it will be necessary to

use a round file to lengthen the slots i n Tool No.

7208, to fit over the wheel studs.

7 Tighten the forcing screw to separate the fro nt hub

and outer driveshaft splines. Remove Tool No. 7208. Figure 3B –38

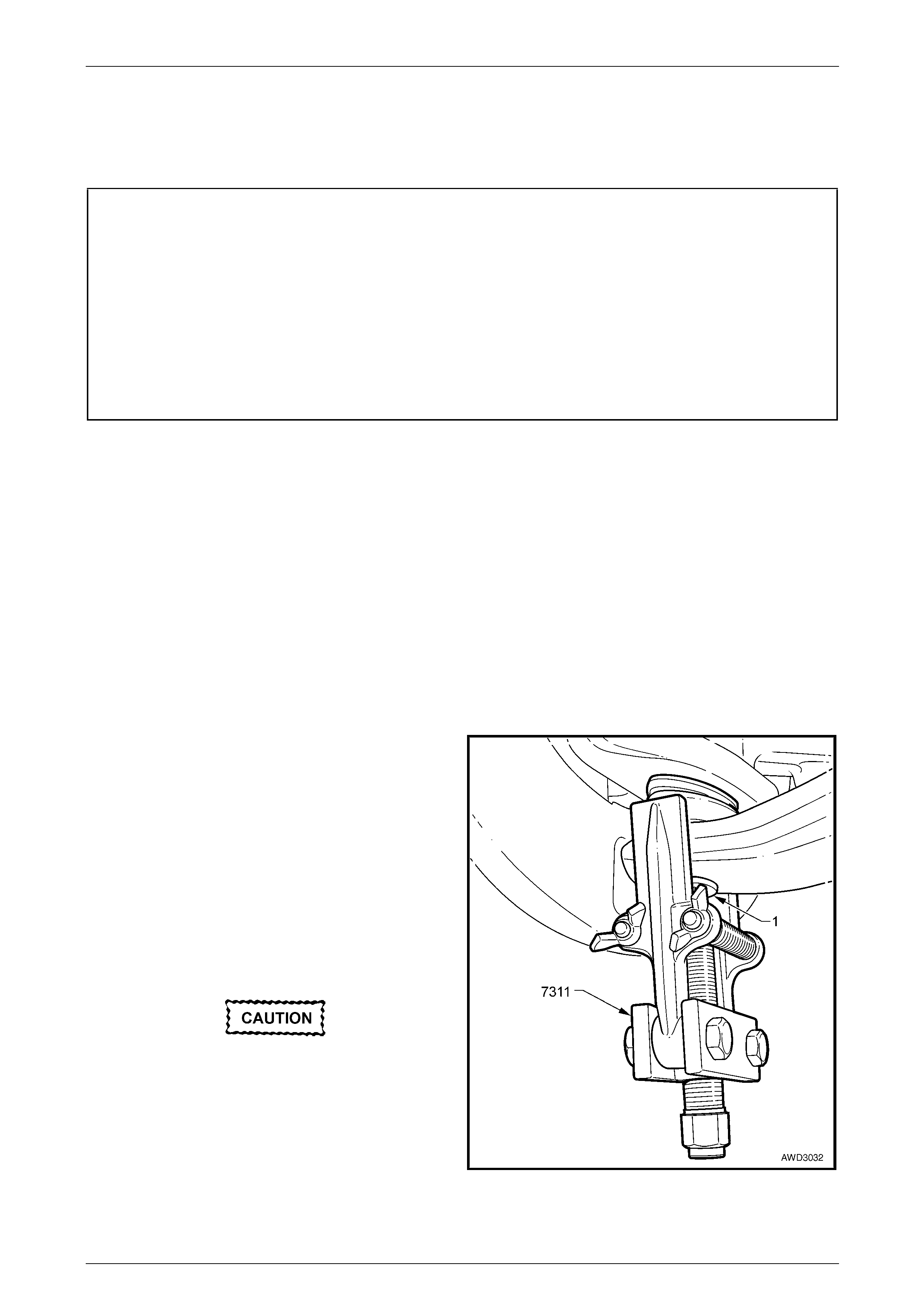

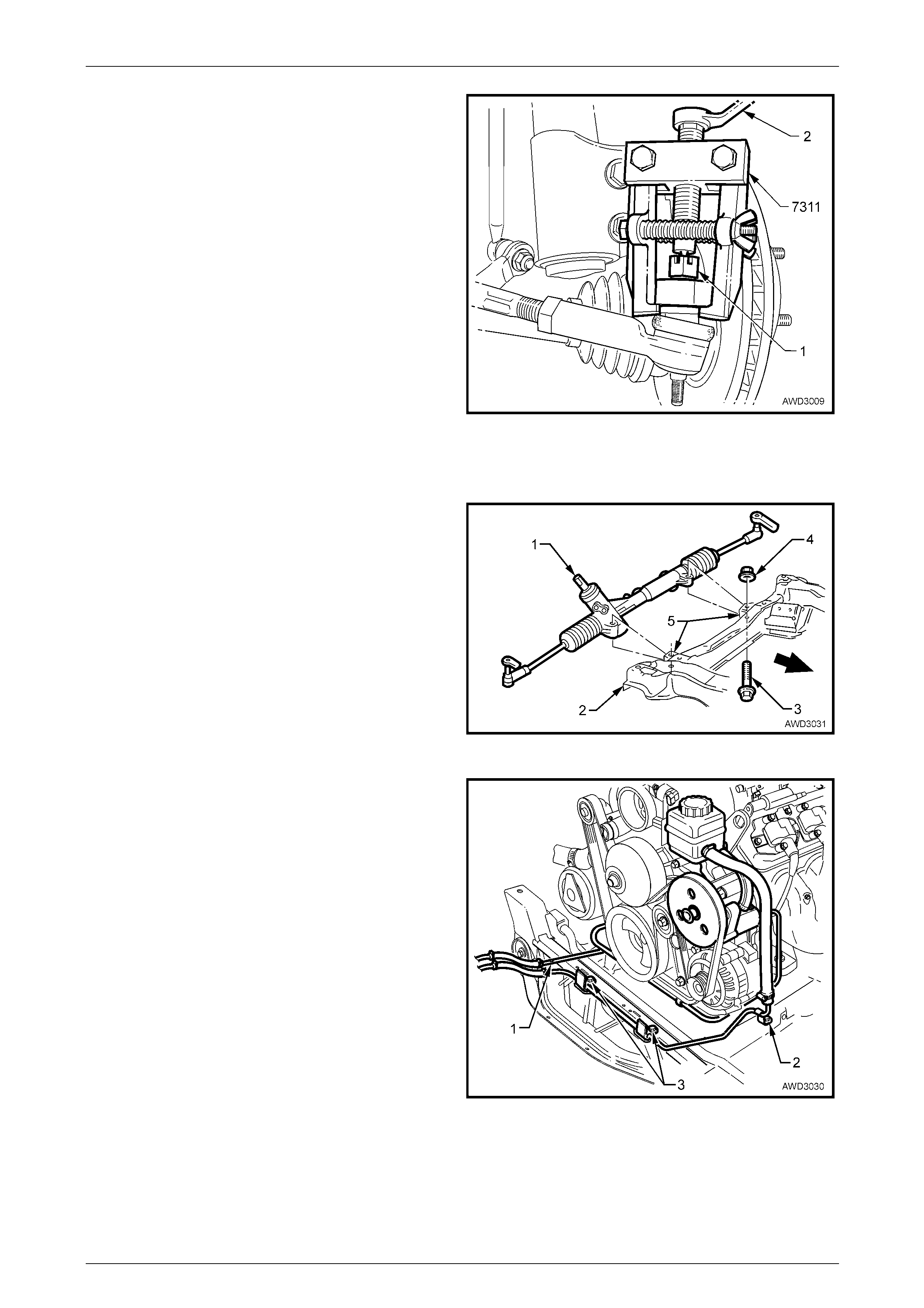

8 Remove the split pin and loosen the castellated nut (1)

until the nut is flush with the end of the tie rod end

stud.

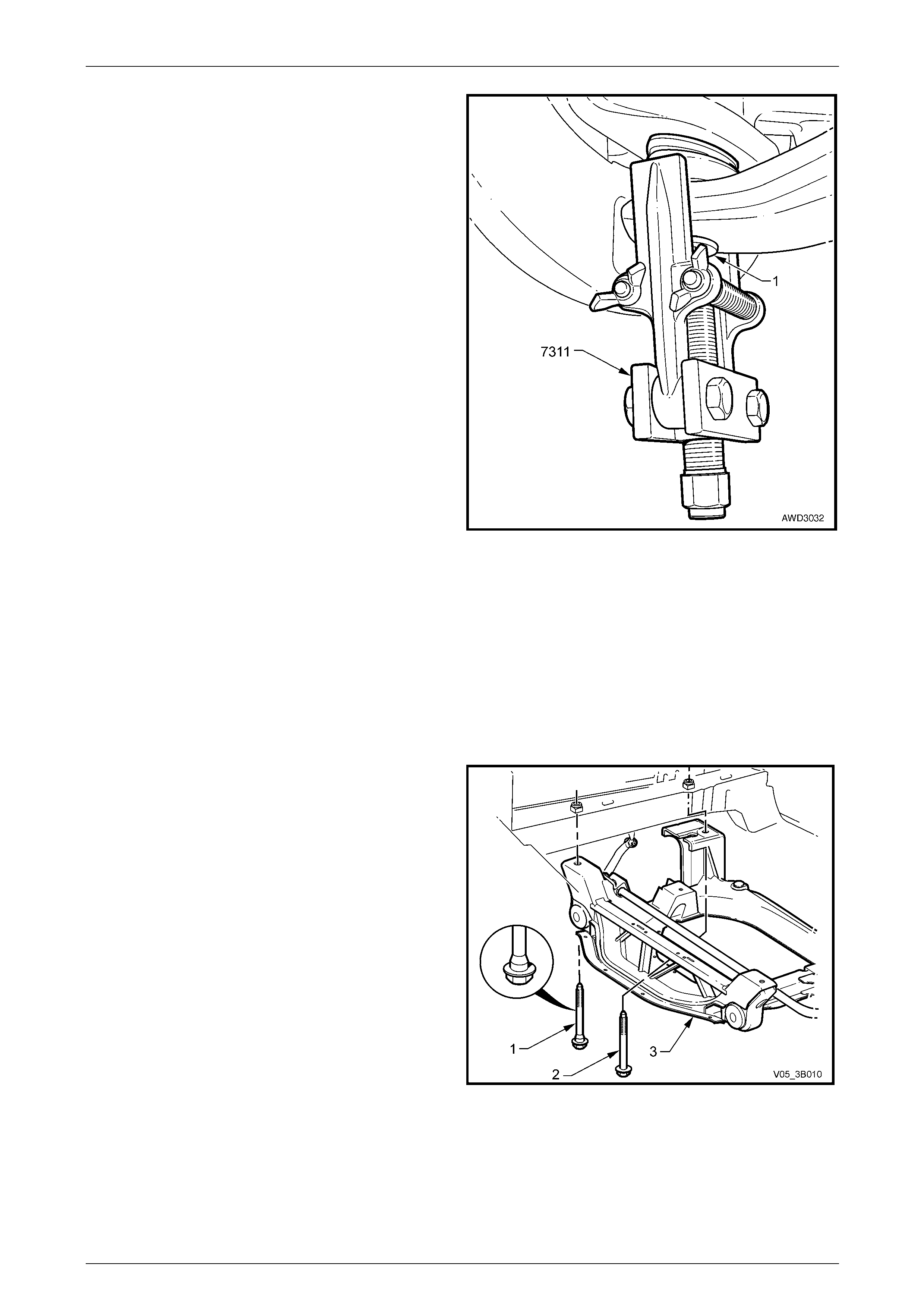

9 Install Tool No. 7311 as shown and, using a ring

spanner (2), press the stud out from the steering

knuckle.

Figure 3B – 39

10 After marking the relationship of the brake rot or to the front hub with a felt tipped pen or similar, remove the front

brake caliper and rotor. Discard the caliper attaching bolts as they must be replaced on reassembly.

11 Remove the three screws securing the brake shield to the steering knuckle, then remove t he shield and set to one

side.

Front Suspension – AWD Page 3B –32

Page 3B – 32

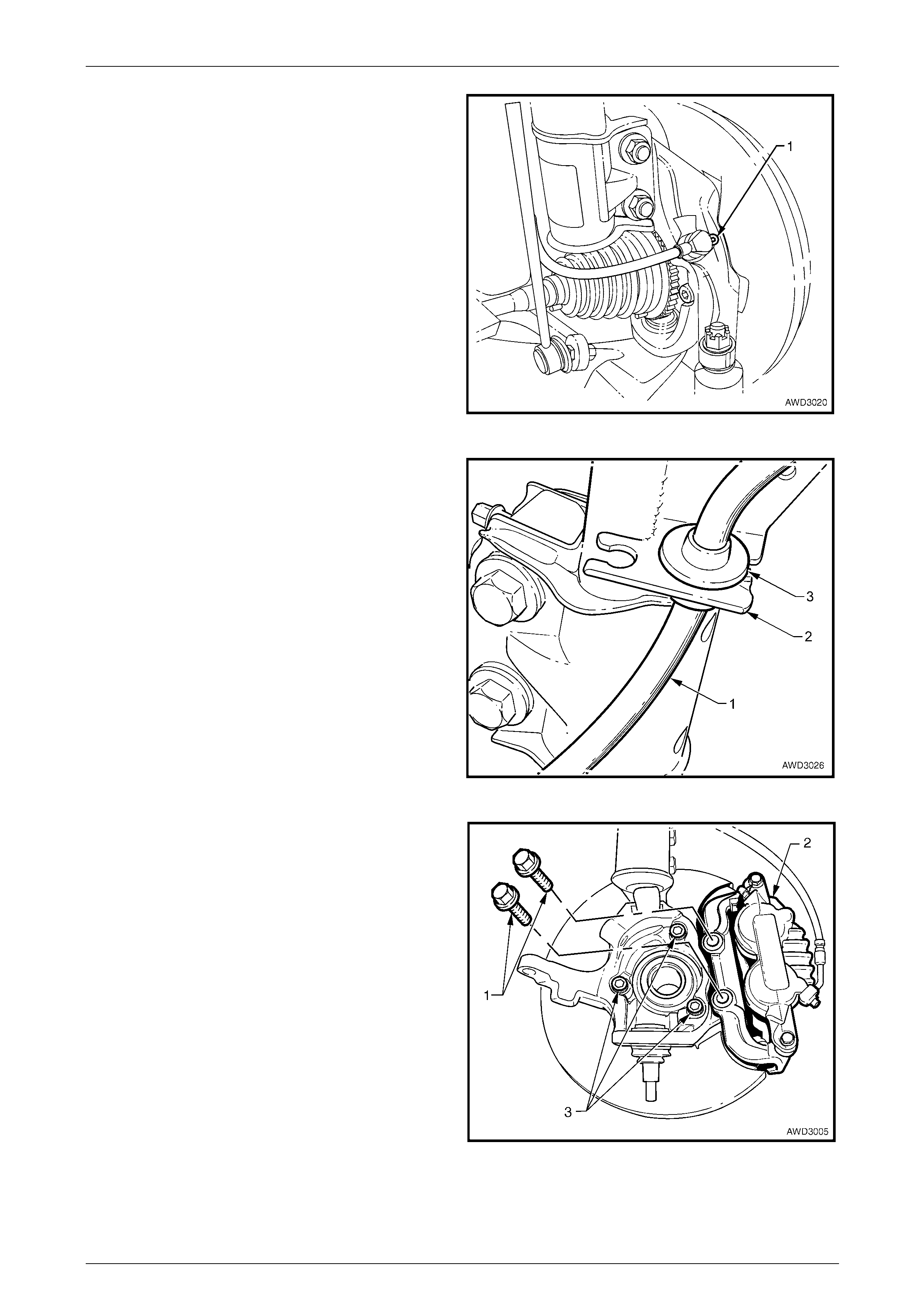

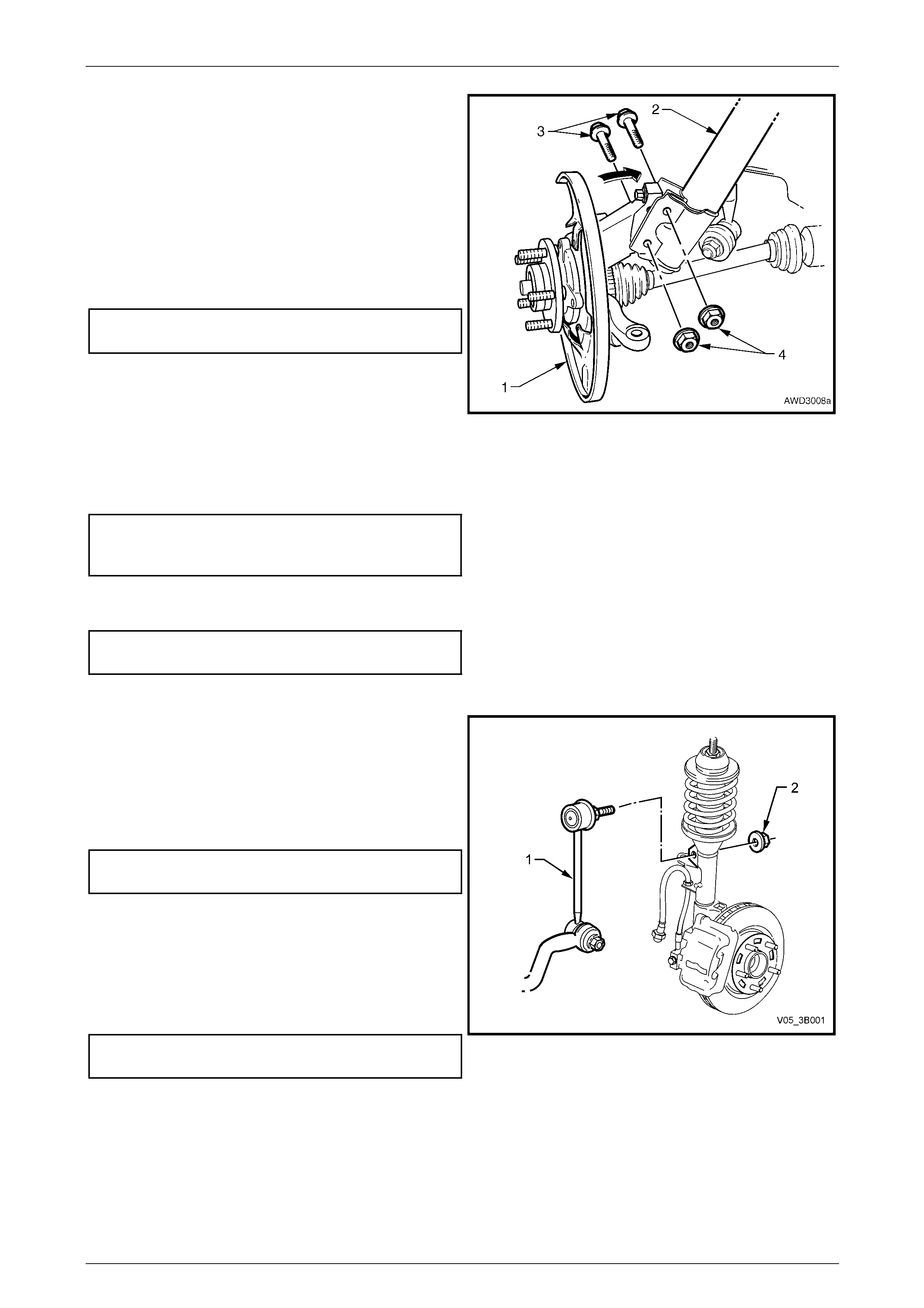

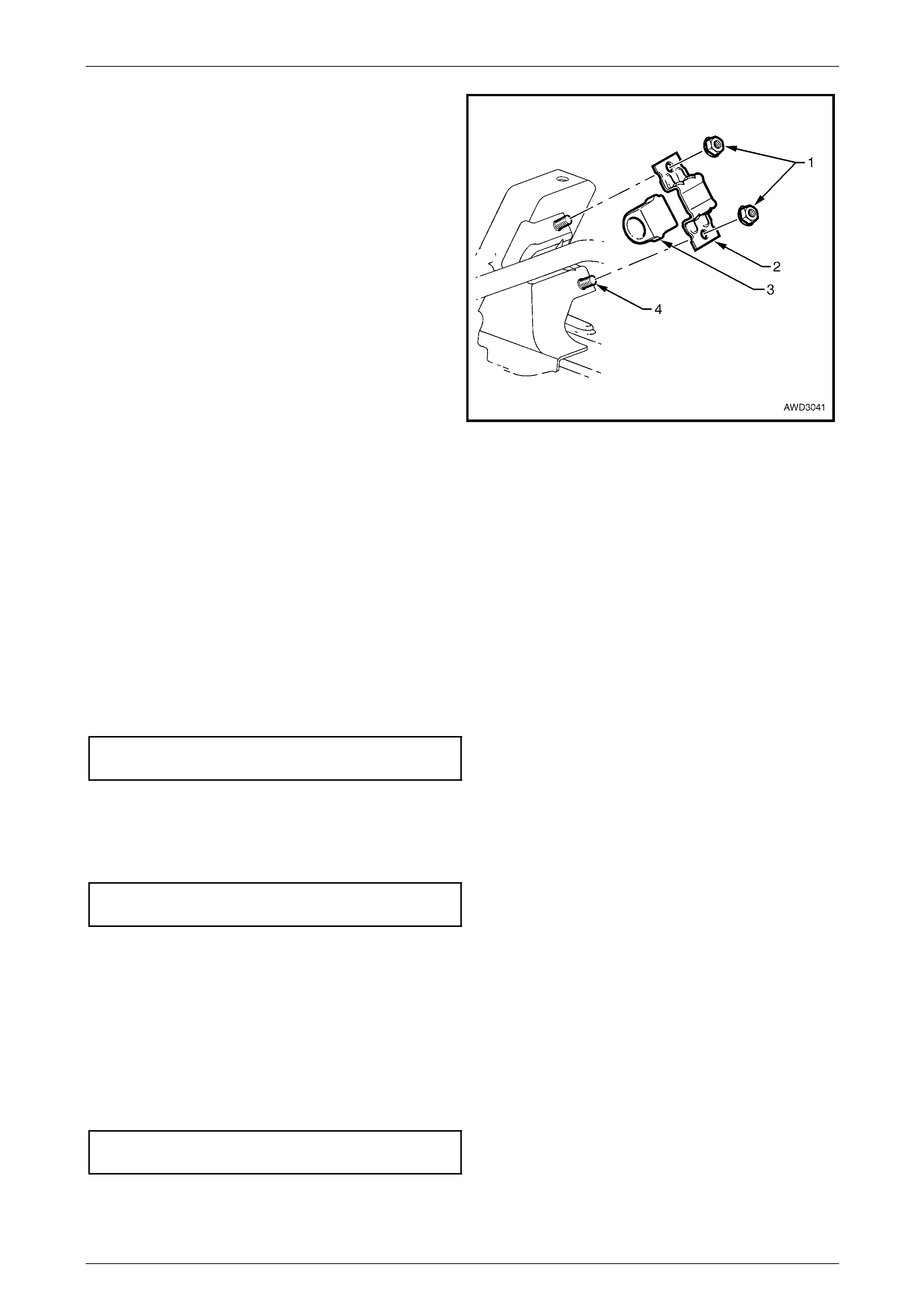

12 Loosen the front control arm ball joi nt retain ing nut (1)

until the nut is flush with the end of the front lower

control arm socket stud thread.

13 Install Tool No. 7311 as shown, then apply force to the

end the lower control arm ball joint stud by tig htening

the forcing bolt on the tool, separati ng the lower

control arm from the ball joint stud.

Figure 3B – 40

14 Loosen, remove and discard the two lower strut

attaching bolts and nuts (1).

15 If the steering knuckle is to be replaced, remove the

camber adjusting bolt (2) from the arm.

Figure 3B – 41

16 After placing a piece of wood on the lifting pad of a floor jack, place under t he front control arm and raise to

temporarily jam the front control arm ball joint stud taper into the knuckle. Fully remove and disc ard the ball joint

nut, as it has micro-encapsulation sealant applied and shou ld be replaced on reassembly.

17 Before removing the steering knuckle, support the driveshaft with wire tied to the brake pipe bracket. Do not apply

the wire around the outer CV joint boot. Driveshaft support is needed to avoid damage to the inner tripot joint b oot

and to prevent joint separation , when the steering knuckle is removed from the vehicle.

18 Separate the front hub, steering knuckle and ball joint stud from the lower control arm and remove the assembly

from the vehicle. Leave the floor jack supporting the front control arm.

Front Suspension – AWD Page 3B –33

Page 3B – 33

Reinstall

Reinstallation is the reverse of the removal procedures except for the following:

1 If removed, reinstall the brake shield to the steering knuckle, refer to 3.3 Front Wheel Hub Assembly, Brake Rotor

and/or Brake Shield, Reinstall, in this Section.

2 Reinstall the front hub to the steering knuckle, reinstall the three retaining bolts and tighten to the correct torque

specification.

Front wheel hub assembly to

steering knuckle attaching bolt

torque specification.............................................108 Nm

3 Lightly lubricate the outer driveshaft splines (1) with

the recommended final drive l ubricant.

4 Reinstall the steering knuckle and ball joint assembl y

over the lower control and engag e the splines of the

driveshaft with those in the hub.

5 Pull on the wheel speed sensor pulse ring (2) fitted to

the outer CV joint to install the splines into the front

hub. Take care not to damage the wheel speed sensor

ring in the process.

NOTE

As the splined shaft is designed to be an

interference fit to the hub, use the old retaining

nut and washer to fully install the shaft through

the front wheel hub.

Figure 3B – 42

6 Install NEW lower strut to steering knuckle, bolts and nuts but do not tighten fully at this stage.

7 With the floor jack and block of wood (1) still

supporting the front control arm, jam the front control

arm ball joint stud taper into the front control arm.

8 Install a new self-locking nut on to the ball joint stud,

then use an accurate torque wrench (2) to tighten the

nut to the correct torque specification.

( ) Front control arm ball joint

stud nut torque specification ........................70 Nm, then

turn through 35°

Figure 3B – 43

9 Reinstall the steering linkage outer tie rod socket stud into the steering knuckle and tighten the castellated

attaching nut to the correct torque specification. Install new split pin.

Outer tie rod end stud, castellated nut

torque specification...............................................65 Nm

10 Reinstall the front brake rot or and ca liper assembly, refer to 3.3 Front Wheel Hub Assembly, Brake Rotor and/or

Brake Shield in this Section.

Front Suspension – AWD Page 3B –34

Page 3B – 34

The brake rotor must be installed , aligning the

marks made prior to removal.

11 Install holding tool KM-468 to two of the wheel studs

and secure with two wheel nut s. Support the outer end

of the holding tool on a safety stand (1).

12 Remove the old driveshaft nut and washer used during

the reassembly process. Reinstall the washer with a

new nut and tighten to the correct torque specification.

( ) Front driveshaft outer

retaining nut torque

specification................ Stage 1 ..........................130 Nm

Stage 2 ... Loosen nut until loose

Stage 3 ..........................200 Nm

13 If it was the left driveshaft that was removed, check

the final drive lubricant level, topp ing up as required.

Refer to 2.1 Checking Final Drive Lubrica nt L evel, in

Section 4B3 Front Final Drive, Bearing Housing &

Driveshafts.

14 Reinstall the road wheel, aligning the marks made

prior to removal. Figure 3B – 44

15 Temporarily install the road wheel/s and lower the vehicle to the ground.

16 Bounce the vehicle up and down several times to settle the suspension.

17 Check the wheel alignment, refer to 2.2 Wheel Alignment Checking and Adjustment in this Section.

Following the wheel alignment, it will be

necessary to raise the vehicle and tighten the

NEW steering knuckle to strut bolts and nuts

to the correct torque specification.

( ) Steering knuckle to strut nut

torque specification Stage 1.......................85 Nm

Stage 2.....................100 Nm

Stage 3...... Turn through 90°

18 Lower the vehicle to the ground an d tighten the road wheel attaching nuts to the correct torque specification,

working in a ‘star’ pattern, refer to 2.3 Wheel and Tyre Removal and Installation, in Section 10 Wheels and Tyres.

Road wheel attaching nut

torque specification..................................110 – 140 N.m

19 Install the centre wheel caps.

Front Suspension – AWD Page 3B –35

Page 3B – 35

3.10 Front Control Arm Ball Joint Assembly

LT Section No. – 06-200

Inspect

The following procedure should be used when checking the lower control arm ball joint assembly for wear.

1 Raise the vehicle with the jack lift pad located under the centre of the front suspension crossmember cradle.

2 Holding the road wheel at the top and bottom, check for play in the lower control arm ball joint assembly by rocking

the wheel.

3 If any up or down movement of stud in lower control arm ball joint assembly housing is detected, the steering

knuckle and lower control arm ball joint assembly must be replaced.

Replace

As the ball joint is not serviced separately from the steering knuckle, should insp ection sh ow that the ball joint is faulty,

then the steering knuckle and ball joint assembly must be replaced as an assembly. Refer to 3.9 Steering Knuckle, in this

Section.

Front Suspension – AWD Page 3B –36

Page 3B – 36

3.11 Front Control Arm

LT Section No. – 06-200

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt , rep lacement is recommended when performing these operations:

Front control arm ball joint stud nut.

The following fasteners MUST be replaced when performing these operations:

Front control arm front isolator and rear bushing retaining bolts.

Before the following fasten ers are fully tightened, the vehicle MUST be at curb height:

• Front control arm front isolator and rear bushing retaining bolts.

Remove

1 Observing the jacking precautions, refer to 2.3 Jacking Prec autions in this Section, raise the front of the vehicle and

support on safety stands.

2 Remove the centre wheel caps and mark the relationship of the wheel to the hub stud, using a felt tipped pen or

similar.

3 Loosen, then remove the road wheel attaching nuts, working in a 'star' pattern. Refer to Section 10 Wheels and

Tyres, for detailed information. Remove the road wheel.

NOTE

Steps 2 and 3 are necessary to maintain part

relationships and to avoid brake rotor distortion

and the creation of brake shudder, after the

vehicle is placed back in service.

4 Turn the steering out on full lock.

5 Loosen the front control arm ball joi nt retain ing nut (1)

until the top of the nut is flush with the end of the front

control arm ball joint stud thread.

6 Install the release Tool No. 7311, then tighte n the

forcing bolt on the tool to separate the front control

arm ball joint stud from the front control arm.

7 Temporarily jam the front control arm ball joint stud

taper into the knuckle to hold the stud, before fully

removing the retaining nut. As the ball joi nt stud nut

has micro-encapsulation sealant applied to the

threads, it should be replaced on reassembly.

Do not allow the front driveshaft to extend to

the stage wh ere the inner tripot en d becomes

separated. After release of the ball joint,

ensure that the outer en d is released from the

wheel hub and supported by tie wire.

8 Separate the front control arm ball joint stud from the

control arm. Figure 3B – 45

Front Suspension – AWD Page 3B –37

Page 3B – 37

9 Remove the screws and scrivets securing the front

plastic under tray from the front bumper, then remove

the under tray from the vehicle.

Thread sealant on this front bolt may make

the removal effort high. However, under no

circumstances is heat to be applied to the

control arm, in an attempt to soften the

sealant.

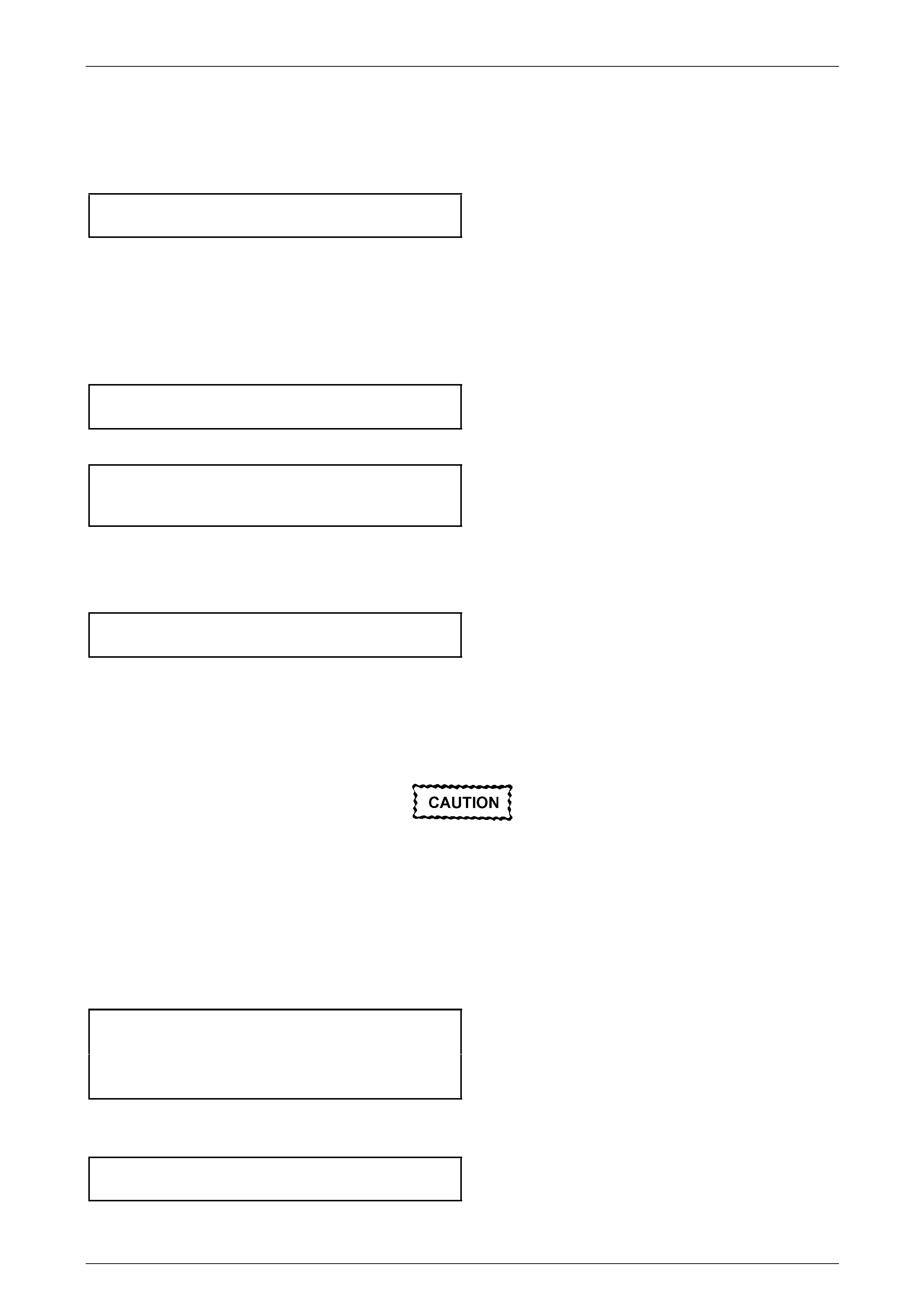

10 Using a 24 mm socket and suitable equipment, loosen

then remove the front control arm front isolator bolt (3),

until several threads remain.

Figure 3B – 46

12 Remove the split pin and loosen the castellated nut (1)

until the nut is flush with the end of the tie rod end

stud.

13 Install Tool No. 7311 as shown and, using a ring

spanner (2), press the stud out from the steering

knuckle.

14 To gain access to the rear bushin g retain ing bolt (4),

turn the steering out on full lock and hold in this