Front Suspension Page 3A – 1

Page 3A-1

Section 3A

Front Suspension

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Description ...............................................................................................................................3

2 Wheel Alignment ....................................................................................................................................5

2.1 Steering Geometry................................................................................................................................................. 5

Caster...................................................................................................................................................................... 5

Camber ................................................................................................................................................................... 6

Wheel Toe............................................................................................................................................................... 6

Steering Axis inclination....................................................................................................................................... 7

Scrub Radius.......................................................................................................................................................... 7

Included Angle....................................................................................................................................................... 8

Toe-Out On Turns.................................................................................................................................................. 8

2.2 Wheel Alignment Checking and Adjustment....................................................................................................... 9

Preliminary Inspection .......................................................................................................................................... 9

Caster Adjustment................................................................................................................................................. 9

Camber Adjustment............................................................................................................................................. 10

Toe Adjustment.................................................................................................................................................... 11

2.3 Jacking Precautions............................................................................................................................................ 12

2.4 Front Wheel Hub Assembly – End Float Checking Procedure ........................................................................ 13

3 Service Operations...............................................................................................................................14

3.1 Service Warnings, Cautions and Notes............................................................................................................. 14

3.2 Suspension and Trim Height, Check.................................................................................................................. 15

Preliminary Inspection ........................................................................................................................................ 15

Procedure............................................................................................................................................................. 16

Front and Rear Suspension Height Comparison.............................................................................................. 16

3.3 Front Wheel Hub Assembly, Brake Rotor and/or Brake Shield .......................................................................17

Remove................................................................................................................................................................. 17

Inspect .................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 18

3.4 Front Wheel Hub Studs....................................................................................................................................... 20

Replace................................................................................................................................................................. 20

3.5 Front Strut Assembly .......................................................................................................................................... 22

Remove................................................................................................................................................................. 22

Reinstall................................................................................................................................................................ 23

3.6 Upper Strut Support Bearing and Mount........................................................................................................... 26

Remove................................................................................................................................................................. 26

Reinstall................................................................................................................................................................ 27

3.7 Front Spring ......................................................................................................................................................... 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 29

3.8 Front Strut Unit .................................................................................................................................................... 30

Replace................................................................................................................................................................. 30

3.9 Steering Knuckle.................................................................................................................................................. 31

Remove................................................................................................................................................................. 31

Reinstall................................................................................................................................................................ 32

Techline

Techline

Techline

Techline

Front Suspension Page 3A – 2

Page 3A-2

3.10 Front Control Arm................................................................................................................................................ 34

Remove................................................................................................................................................................. 34

Reinstall................................................................................................................................................................ 34

3.11 Front Control Arm Ball Joint............................................................................................................................... 37

Inspect .................................................................................................................................................................. 37

3.12 Front Control Arm Inner Bushing....................................................................................................................... 38

Replace................................................................................................................................................................. 38

3.13 Front Control Arm Rod Bushing......................................................................................................................... 39

Replace................................................................................................................................................................. 39

3.14 Front Control Arm Rod........................................................................................................................................ 40

Remove................................................................................................................................................................. 40

Reinstall................................................................................................................................................................ 40

3.15 Front Control Arm Rod Insulating Bushing....................................................................................................... 43

Replace................................................................................................................................................................. 43

3.16 Front Suspension Crossmember ....................................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 48

3.17 Stabiliser Bar Link ............................................................................................................................................... 50

Replace................................................................................................................................................................. 50

3.18 Stabiliser Bar........................................................................................................................................................ 52

Remove................................................................................................................................................................. 52

Reinstall................................................................................................................................................................ 53

4 Diagnosis.............................................................................................................................................................. 54

General ................................................................................................................................................................. 54

Strut Diagnosis .................................................................................................................................................... 54

Acceptance Criteria............................................................................................................................................. 54

4.1 Diagnosis Guide................................................................................................................................................... 54

5 Specifications.......................................................................................................................................58

Suspension Travel............................................................................................................................................... 58

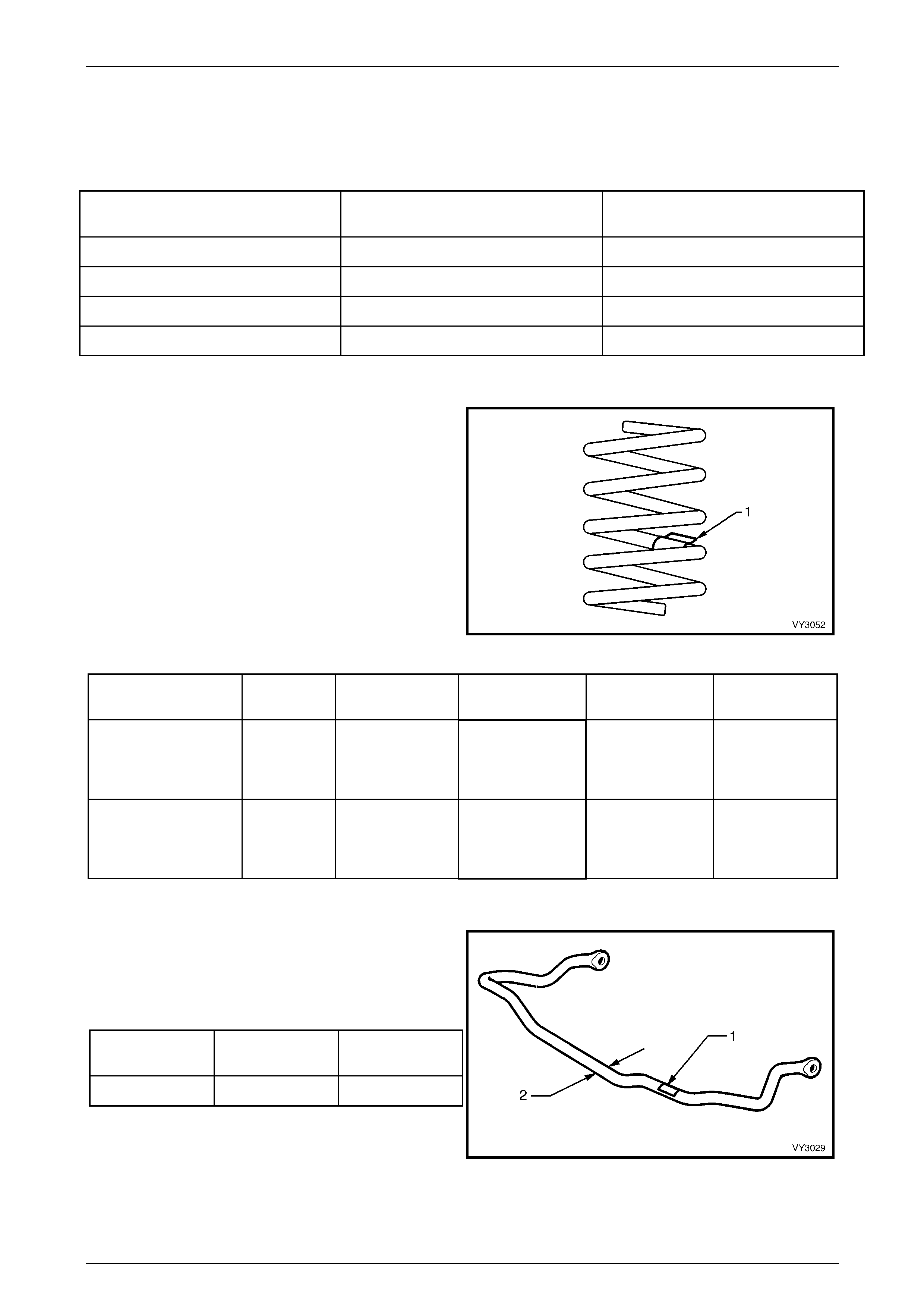

Front Spring Details............................................................................................................................................. 58

Front Stabiliser Bar Details................................................................................................................................. 58

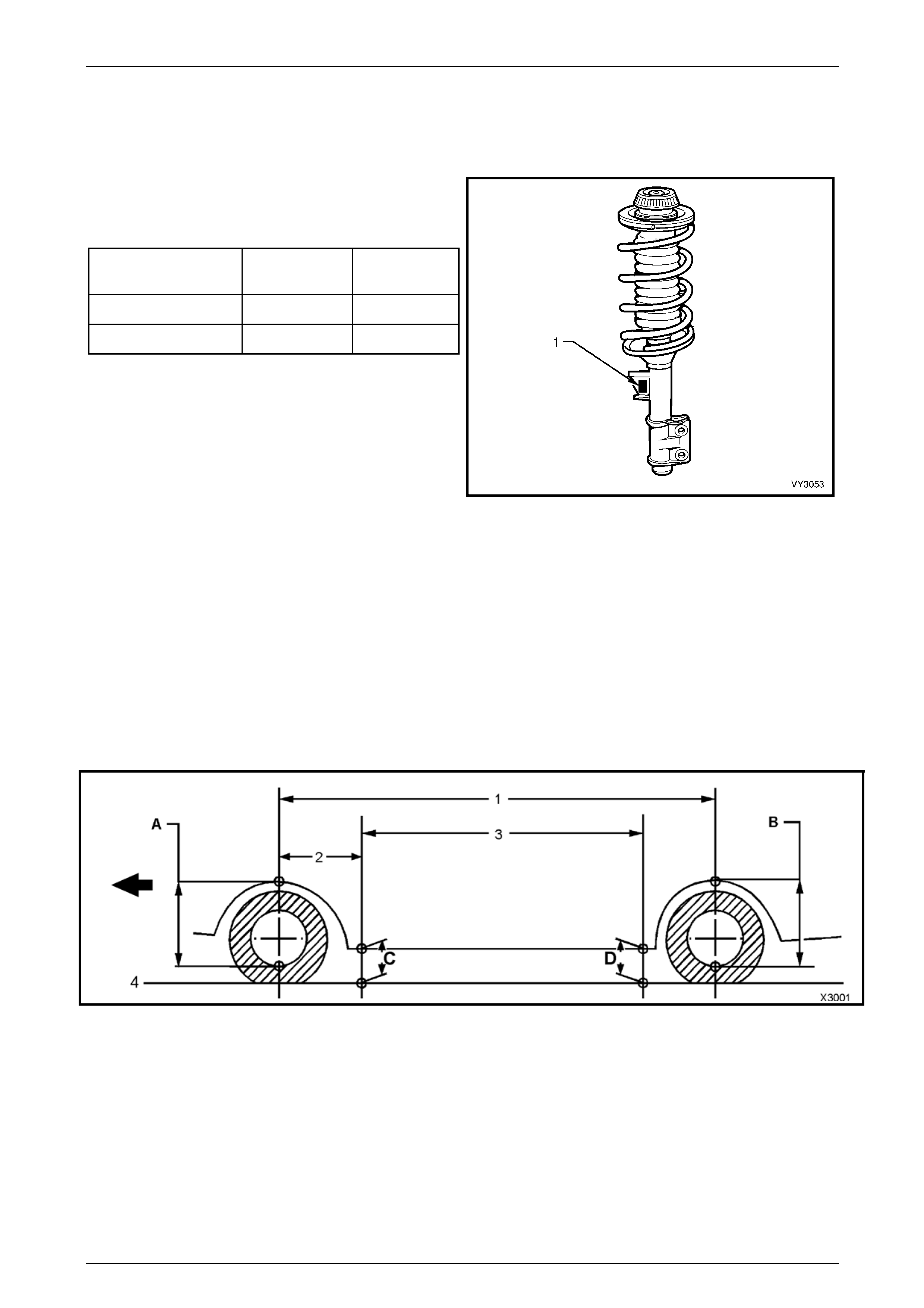

Front Strut Details................................................................................................................................................ 59

Front Control Arm Details................................................................................................................................... 59

Front Wheel Bearings.......................................................................................................................................... 59

Suspension and Trim Height Specifications..................................................................................................... 59

Front Wheel Alignment Specifications .............................................................................................................. 61

6 Torque Specifications..........................................................................................................................62

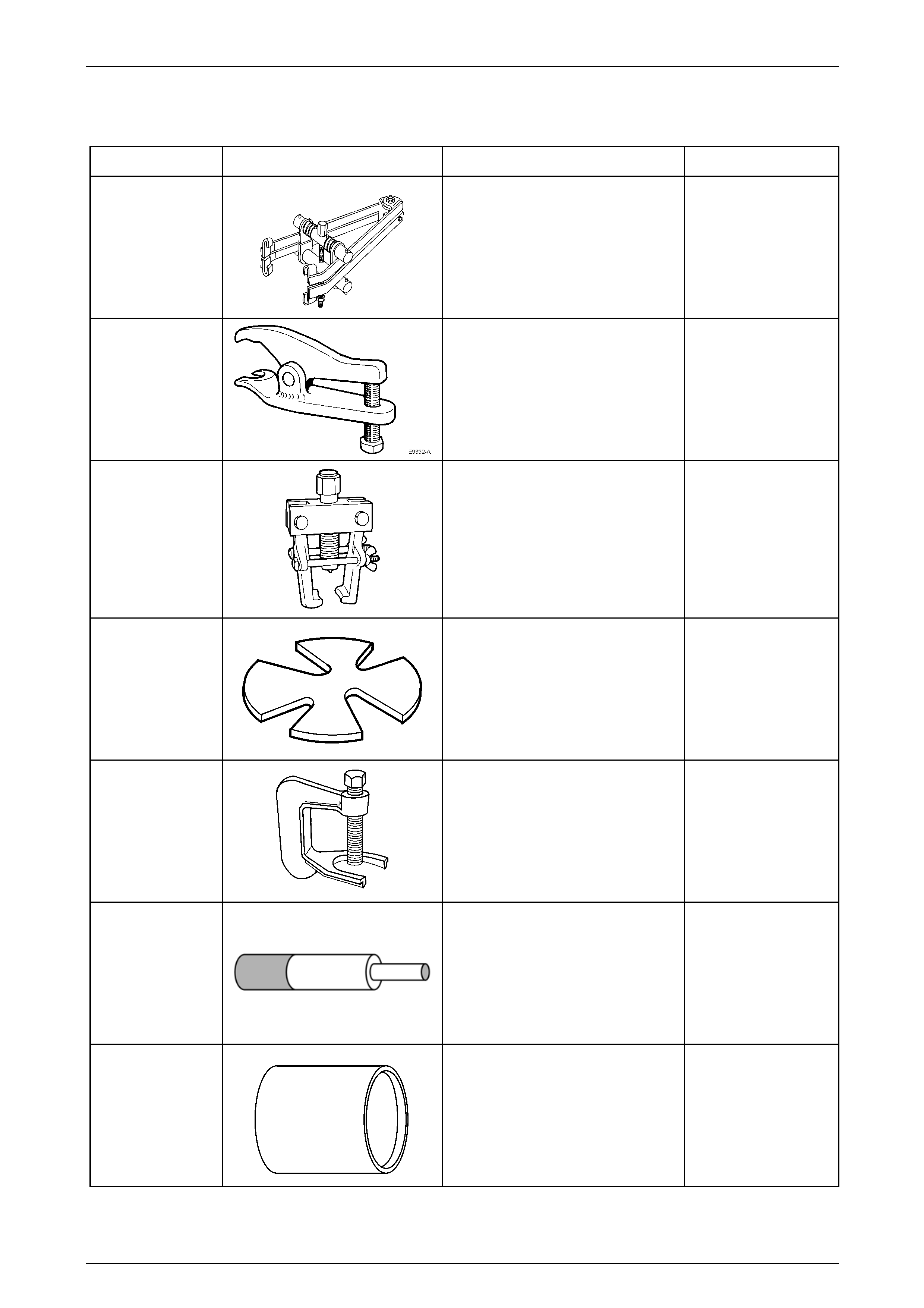

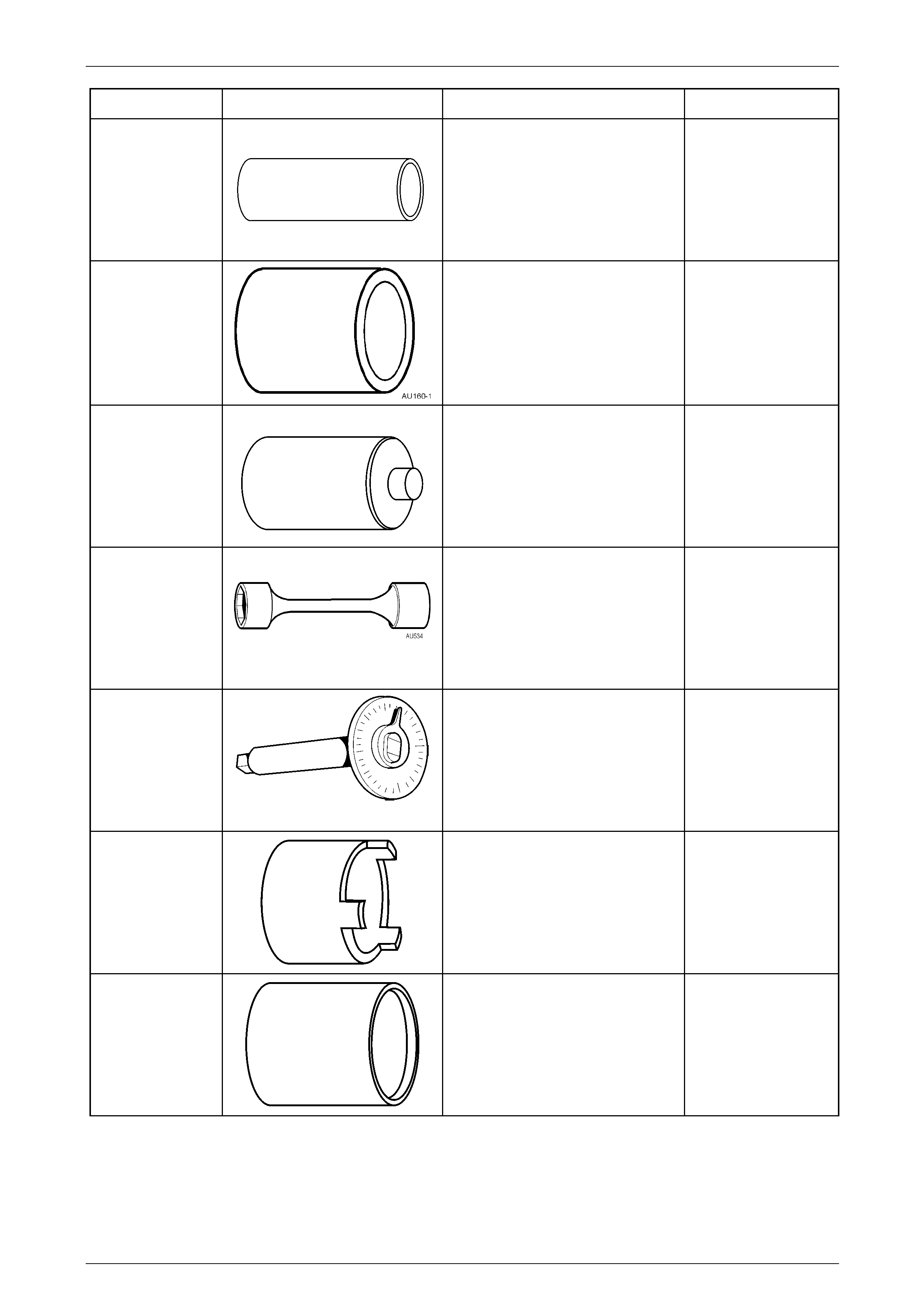

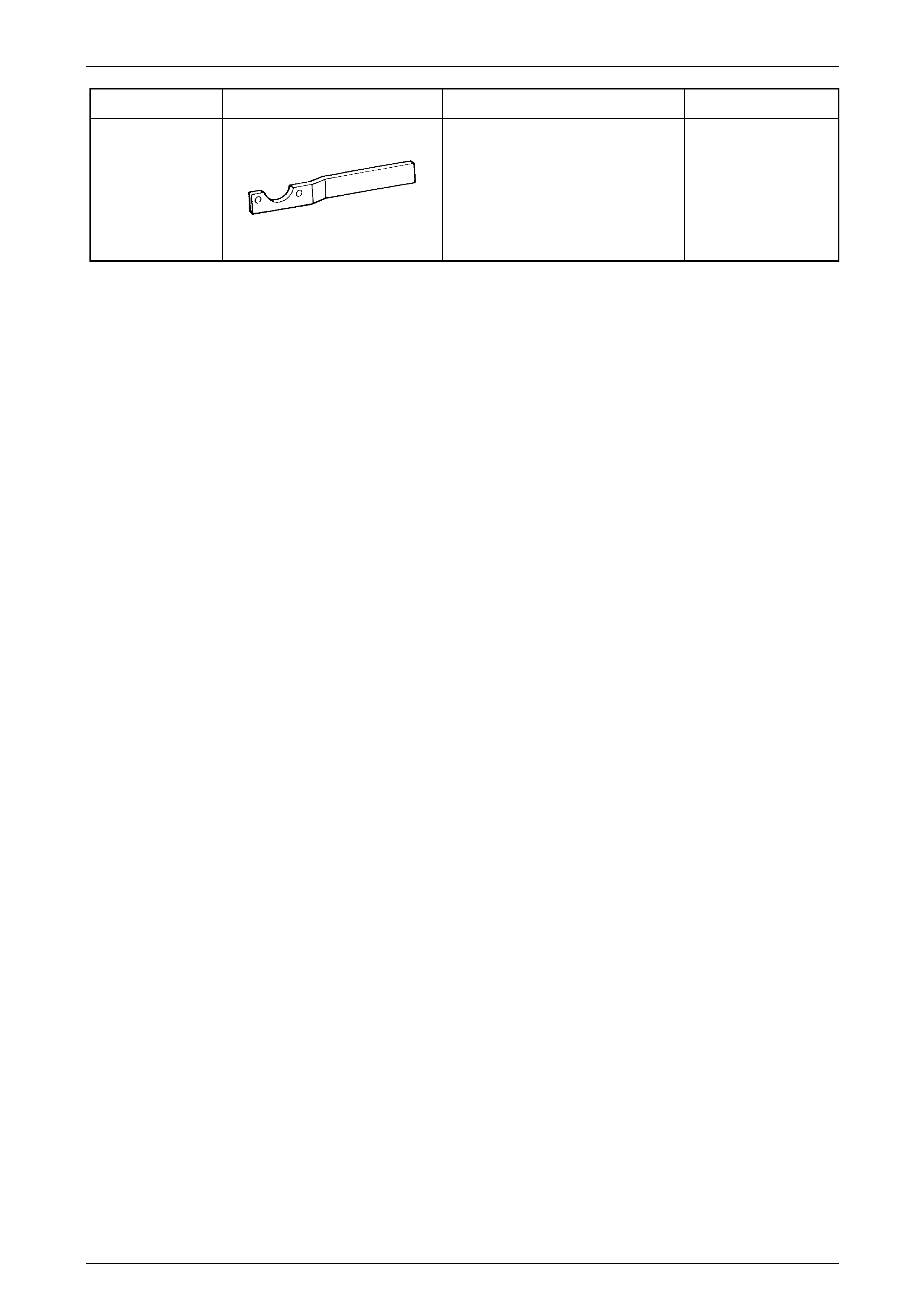

7 Special Tools ........................................................................................................................................63

Front Suspension Page 3A – 3

Page 3A-3

1 General Description

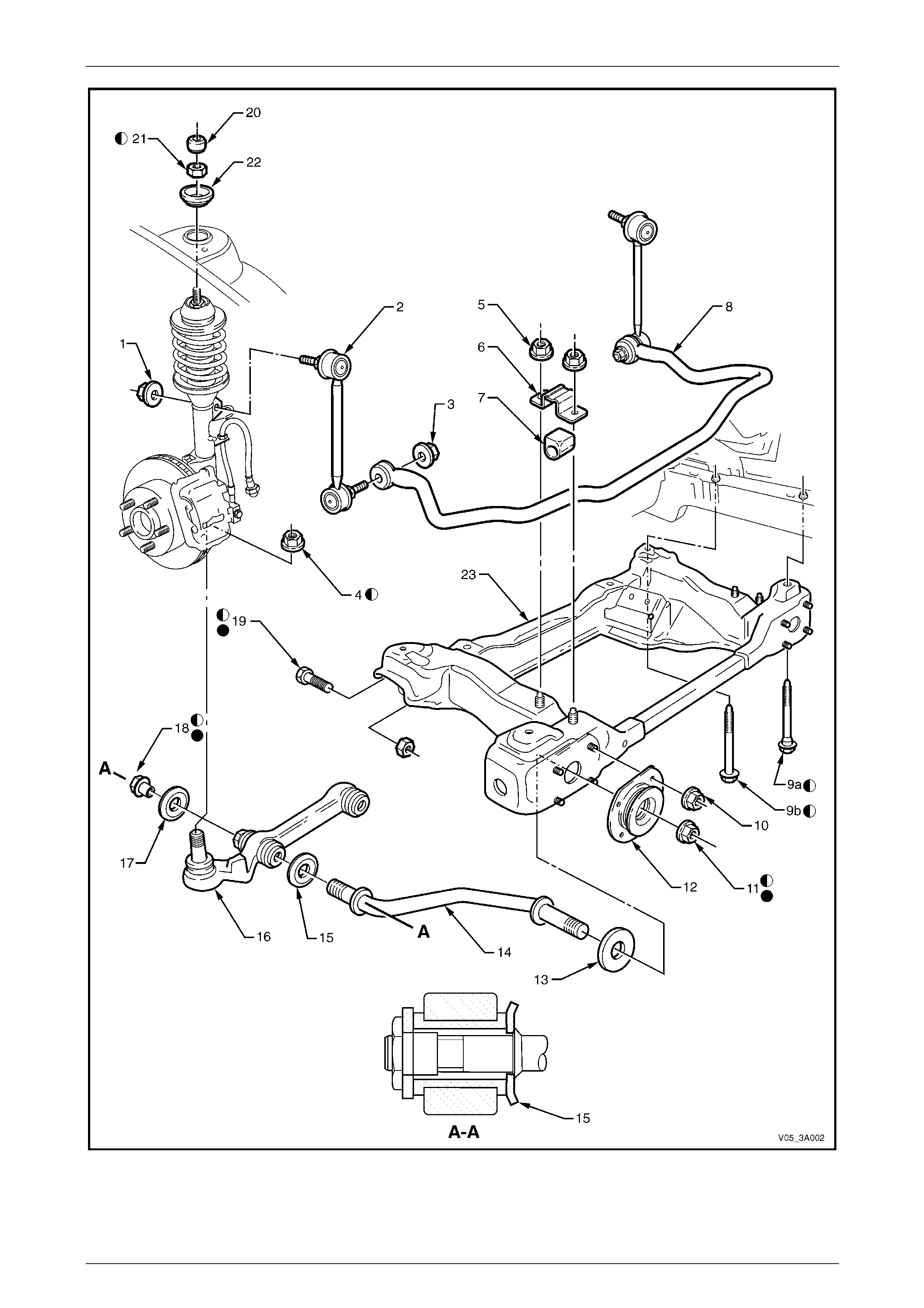

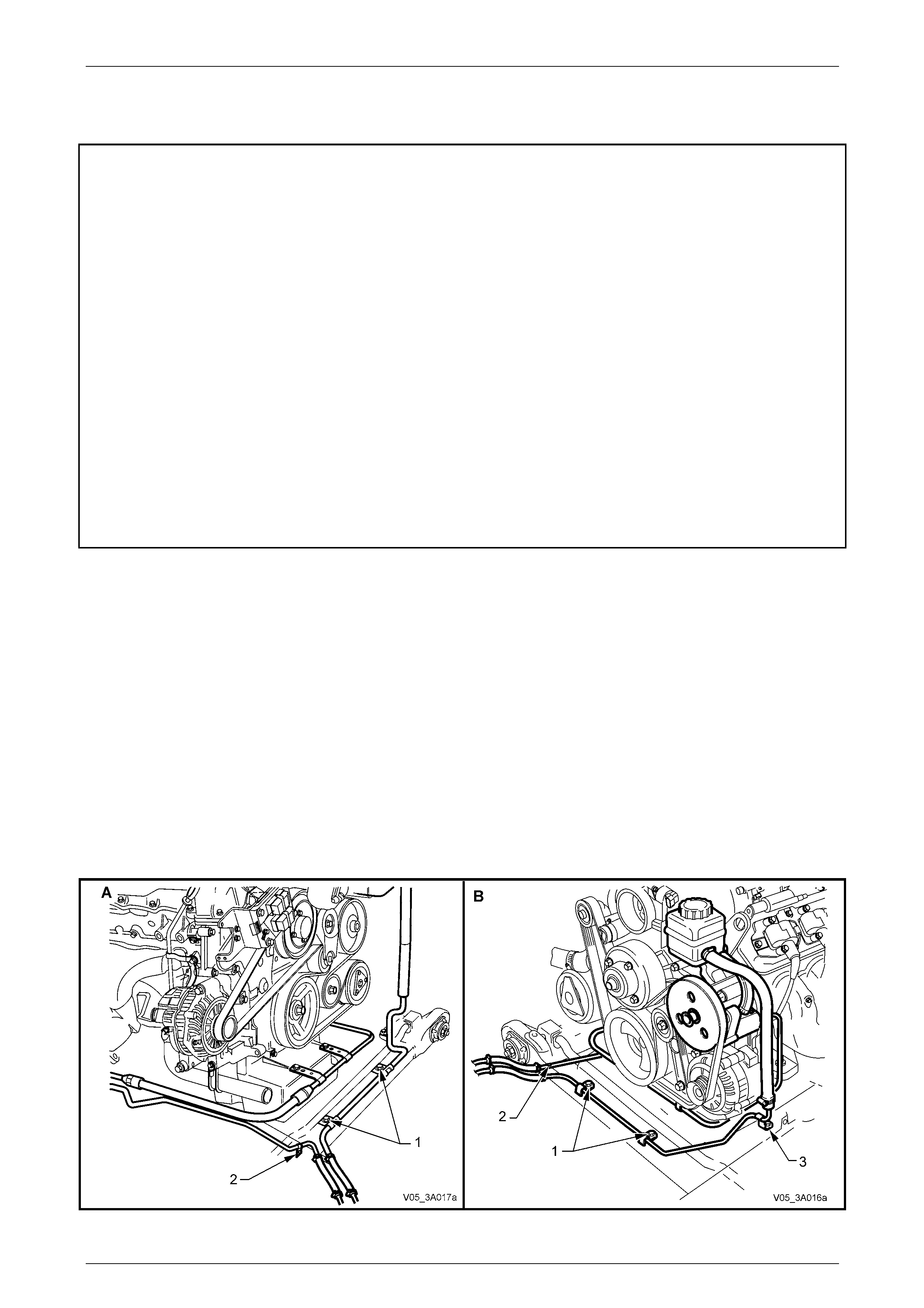

The front suspension fitted to all MY 2005 WL Series vehicl es, operates on the MacPherson strut principle. The

assembly consists of the front crossmember, front control arms, front control arm rods, stabiliser bar an d light weight

strut assemblies (Refer to Figure 3A – 1).

The crossmember is bolted to both longitu din al frame side members. The front crossmember to side member attaching

bolts incorporate a tapere d boss near the head of the bolt to aid in front crossmember to body alig nment during assembly

while the pivots of the front control arms are rubber bushed and are attached to the crossmember by bolt s and nuts. The

outer end of each front control arm is connected to the knuckle on the strut assembly through a front control arm ball joint

assembly.

The strut assembly incorporates a hydraulic wet sleeve type damper inside the strut tube, a rubber front strut dust shield

assembly with air filter and compression rubber, a coil type suspension spring mounte d b etween the strut housing and

upper spring seat collar, a bearing assemb ly and an upper strut support.

The strut assembly is located at the upper end to the body structure by an upper strut support an d secured by a self-

locking nut and locating disc. The lo wer end of the strut tube is fastened to the steering knuckle by two bolts and nuts.

Positioning of the front control arm assembly is control led by a front control arm rod, which connects the front control arm

to the front suspension crossmember. The front control ar m rod is mounted in a rubber bushing at the front control ar m

end and a fluid filled insulator at the other.

A stabiliser bar is mounted to the side memb ers of the crossmember by two brackets and insulating rubbers. The link

connecting the stabiliser bar to each front sus pension strut tube has a ball joint socket stud and nut, at each end.

There are three suspension options available for MY 2005 WL Series veh icles; Standard (Production Op tion F E 1),

Sports (Production Option FE2) and Aut o Levelling (FX3). For information regarding the identification of the suspension

option fitted to a particular vehicle, refer to 9.3 Bod y and Option Plate in Section 0A General Information. For all other

information regarding the suspension application fitted to a particular vehicle, refer to 5 Specifications, in this Section.

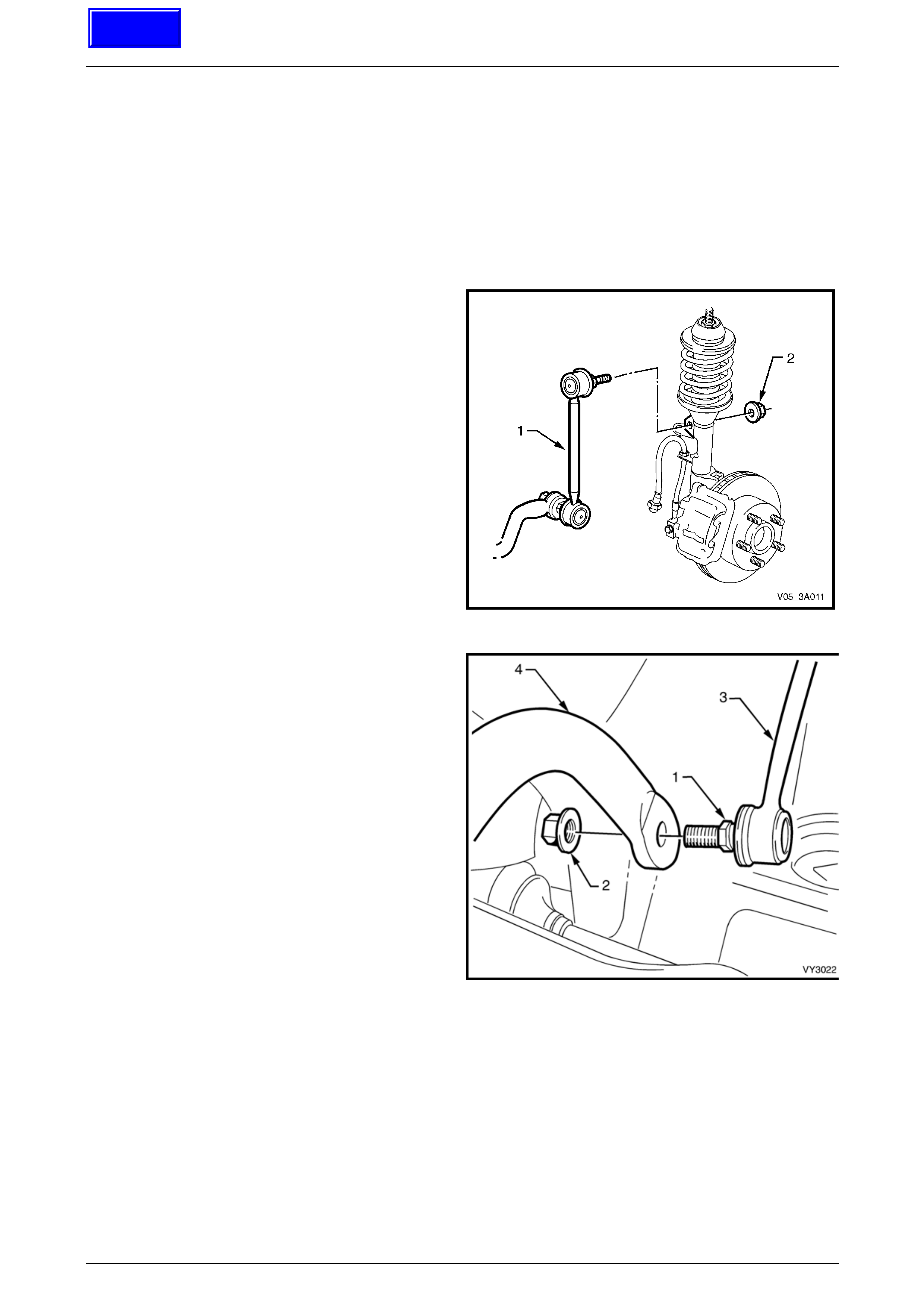

Legend for Figure 3A – 1

1 Nut (2 Places)

2 Link – Stabiliser Bar (2 Places)

3 Nut (2 Places)

4 Nut (2 Places)

5 Nut (4 Places)

6 Bracket (2 Places)

7 Insulator (2 Places)

8 Bar – Stabiliser

9a Bolt – Stepped (2 Places)

9b Bolt – Plain Shanked (2 Places)

10 Nut (8 Places)

11 Nut (2 Places)

12 Insulator Bushing – Front control

13 Washer (1 On Driver’s Side Only)

14 Rod – Front Control Arm (2 Places)

15 Washer – Cupped (2 Places)

16 Control Arm (2 Places)

17 Washer (2 Places)

18 Nut (2 Places)

19 Bolt and Nut (2 Places)

20 Cover – Dust (2 Places)

21 Nut (2 Places)

22 Locating Disc (2 Places)

23 Front Suspension Crossmember

‘A-A’ - Assemble washer ‘15’ as shown.

Fastener must be new and assembled dry.

Fastener must only be fully tightened with the vehicle at curb weight and on all four wheels.

Front Suspension Page 3A – 4

Page 3A-4

Figure 3A – 1

Front Suspension Page 3A – 5

Page 3A-5

2 Wheel Alignment

ATTENTION

All front suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this Section, fasteners MUST be

replaced with parts of the same part num ber or a GM appro ved equivalent. Do n ot use fasteners o f an inferior

quality or substitute design

Torque values must be used as specified during reassembly to ensure proper retention of all front

suspension components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Steering Geometry

To achieve the desired handling characteristics of a vehicle under various operating conditions, modern steering

geometry relates to both front and rear suspension systems. It must also be realised that the various, measurable angles

that can be checked while the vehicle is sta tionary, are no real indication of the changes that occur in a dynamic

situation, when the vehicle is required to have directional stability, during normal manoeuvres, such as straight ahead

driving, cornering or braking.

Even though some of the following descriptions of front wheel alignment angles are not normally measurable and (in

some instances) not adjustable, each is an inherent part of the vehicle's dynamic sus pension tuning that has been

developed over an extended testing program.

Caster

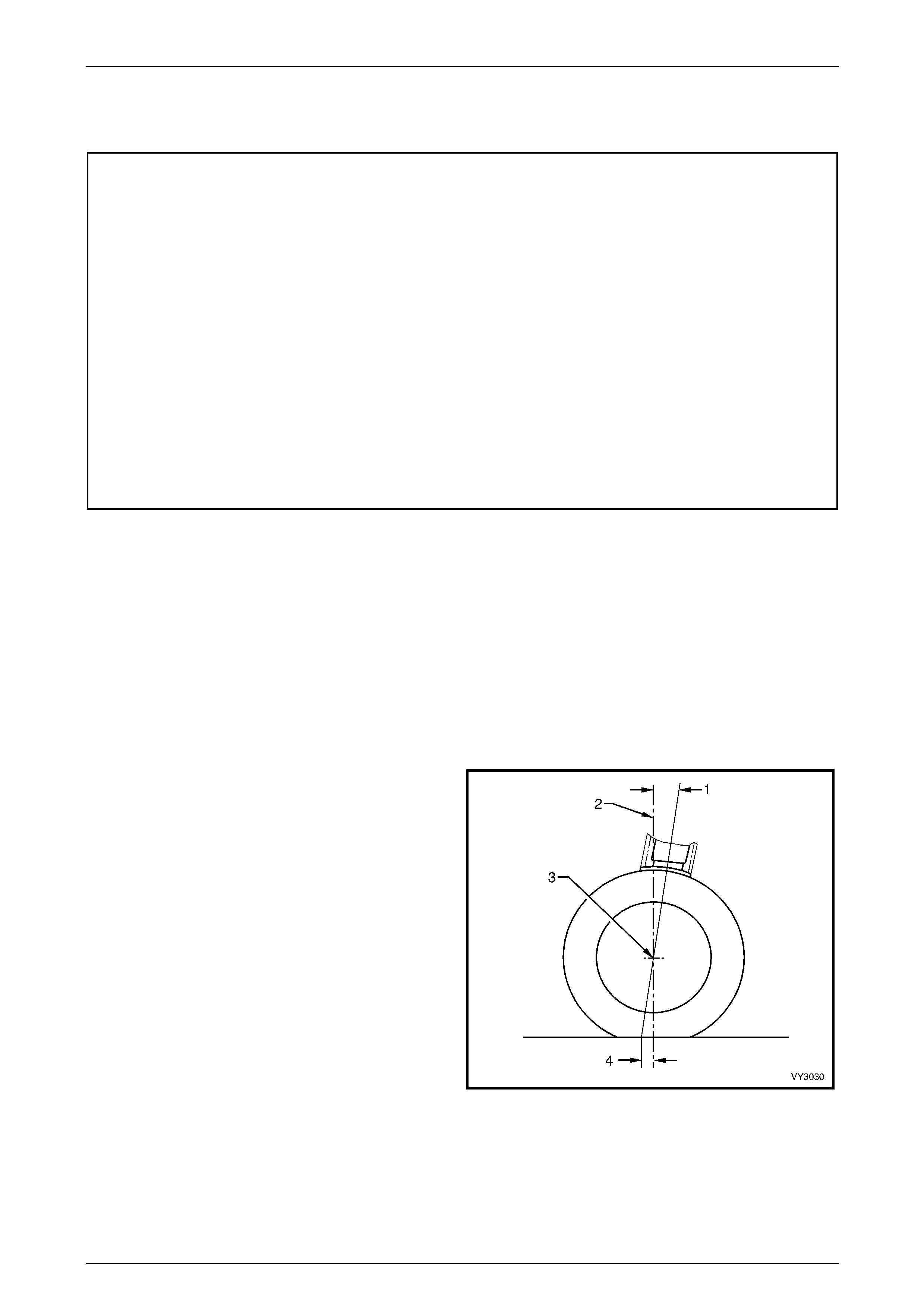

It is usual to describe this front wheel alignment angle as the

tilting of the steering axis either forward or backward (1)

from the vertical (2) when viewed from the side of the

vehicle. A backward tilt at the top steering axis point is said

be positive (+) and a forward tilt is said to be negative (-).

Measurement is usually expressed as an angle in degrees

and minutes. Figure 3A -2 shows the usual practice where

the vertical and steering axis centrelines both pass through

the wheel centre (3).

This results in a caster distance (4), which can be describe d

as being the distance in side view, between the point where

the steering axis contacts the ground and the centre of the

tyre’s footprint contact.

Figure 3A – 2

Front Suspension Page 3A – 6

Page 3A-6

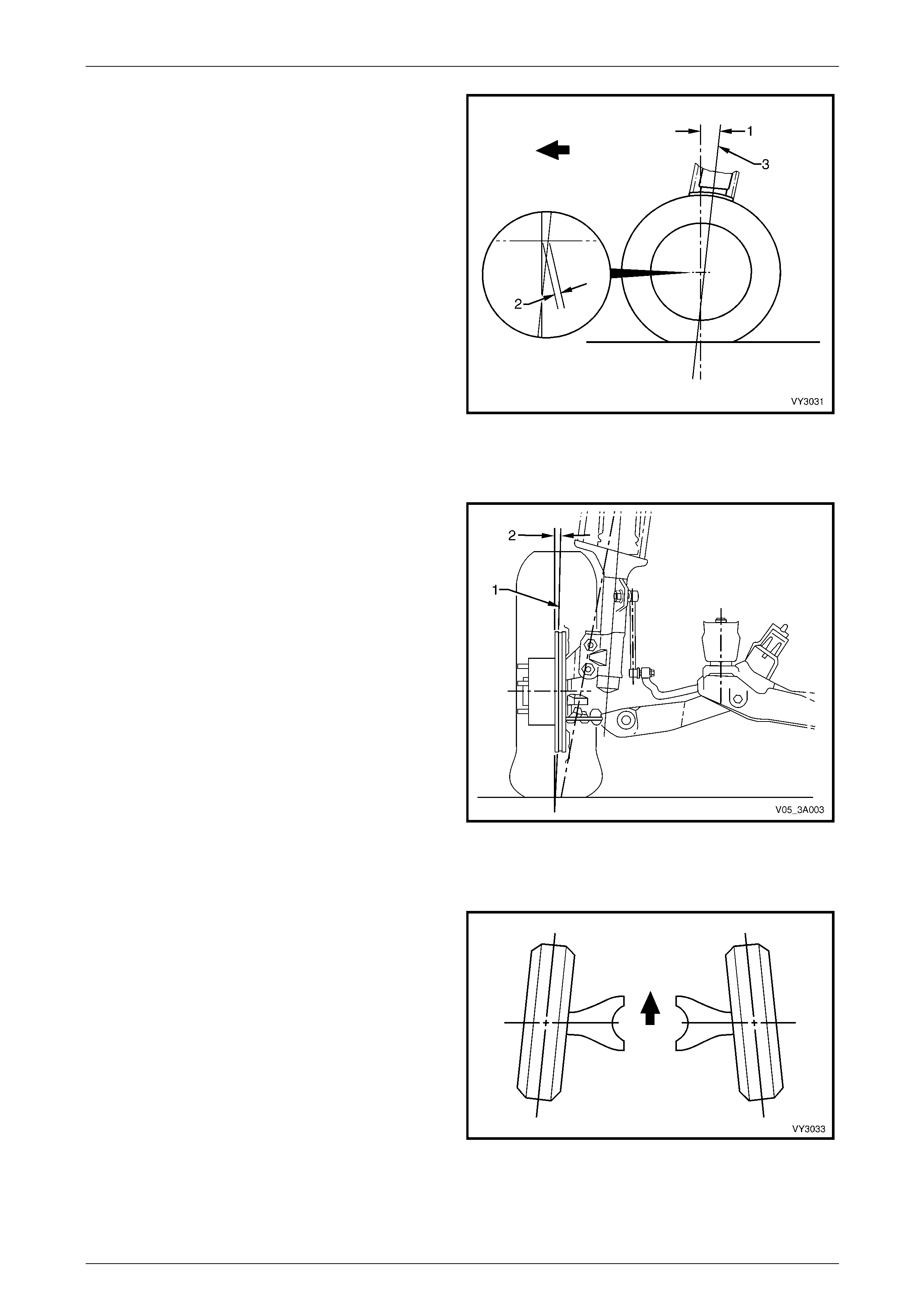

The amount of caster angle (1) will det ermine the ability of

the steering to return to the straight ahead position after a

cornering manoeuvre. Too high an angle though, can result

in an excessive steering effort with associated ‘wheel fight'

and ‘kickback'. To optimise vehicle handling and control

during cornering and to mai ntain the benefits of positive

caster, MY 2005 WL Series vehicles have a 12 mm caster

offset (2) incorporated into the suspension design.

This is achieved by moving the wheel spindl e centreline (3)

forward (in this instance, by 12 mm), which will effectively

reduce the caster distance by that amount (Refer to Figure

3A – 3). This action reduces the undesirable effects of a

high caster angle but maintains the directional stability,

increased front axle lateral gri p and ste ering feel that a high

caster angle normally provi des.

Figure 3A – 3

Camber

This angle is the tilting of the wheels from the vertical (1)

when viewed from the front of the vehicle. When the wheels

tilt outward at the top, the camber (2) is said to be positive

(+). When the wheels tilt inward at the top, camber is said to

be negative (-). The amount of t ilt is measured in degrees

from vertical and this measurement is called the camber

angle.

While unequal camber may re sult in unstable steering or

wander, unequal and/or excessive camber can also cause

rapid tyre wear.

Figure 3A – 4

Wheel Toe

Wheel Toe (Refer to Figure 3A – 5), is the turning in (or out)

of the wheels when viewed from the overhead position. The

actual amount of toe is normally only a few minutes of a

degree. The purpose of a static toe specification is to ensure

parallel rolling of the wheels, once the vehicle is in a

dynamic state.

Excessive toe-in or toe-out may increase tyre wear. With

rear wheel drive vehicles, a slight amount of toe-in,

measured statically with the vehicle at rest, is requir ed to

off-set the small deflections due to rolling resistance and

brake applications which tend to turn the wheels outward.

Figure 3A – 5

Front Suspension Page 3A – 7

Page 3A-7

Steering Axis inclination

When viewed from the vehicle front, Steering Axis

Inclination (1) can be described as being the angle formed

between the steering a xis (2) and the true vertical (3), where

the steering axis is the imaginar y centreline through the

upper strut support bearing an d the front control arm socket

assembly, both components being the pivot points of the

strut assembly.

The Steering Axis Inclination angle is an important factor in

determining steering effort and directional stability of the

vehicle, by assisting caster in keeping th e front wheels in a

central position. Steering Axis Inclin ation also provides a

self-centring effect after cornering.

Figure 3A – 6

Scrub Radius

This term refers to the distance that two imaginary points

are apart, at the road surface (1). These two imaginary

points are;

a The intersection of the steering axis (2) and the

road surface.

b The centreline of the t yre (3) at the road surface.

As road wheel offset will affect scrub radius (4), in the

interests of vehicle handling and safety, non-standard road

wheels are not to be fitted to any MY 2005 WL Series

vehicle.

With rear wheel drive vehicles, it is usual practice to

maintain a positive scrub radius (as shown in Figure 3A – 7)

to make the steering more responsive and d irect, thereby

providing the driver with a more positive sense of the tyre

and road surface interaction.

Figure 3A – 7

Front Suspension Page 3A – 8

Page 3A-8

Included Angle

When both the Steering Axis Inclination an gle (1) and

Camber angle (3) are combined, the resulting angle is

referred to as the Included Angle (2). This information can

be effectively used to determine if a component is damaged

or whether an adjustment is responsible for an out-of-

specification condition occurring.

While Figure 3A – 8 shows a positive camber angle, this has

only been used to clarify the term ‘Included Angle'.

Figure 3A – 8

Toe-Out On Turns

During cornering operations, a vehicle's road wheels all turn

about a common turning point, causing the outer wheels to

try and turn through a greater radius than the inner. To

overcome the tendency for wheel slip under these

conditions, the outer wheel is commonl y caused to toe-out,

to compensate for this increased turning circle.

The amount of toe-out during cornering, is govern ed by the

angle of the steering arms, which are an inh erent part of th e

steering knuckle.

Figure 3A – 9

Front Suspension Page 3A – 9

Page 3A-9

2.2 Wheel Alignment Checking and

Adjustment

ATTENTION

The following fasteners MU ST be replaced when performing these operations:

Steering knuckle to strut attach in g nuts and bolts.

Preliminary Inspection

Before any attempt is made to check camber, caster or toe-in, these preliminary checks should be carried out.

1 Check tyre and tyre mountings. Always check camber and toe-in at the mean run-out position on the tyre or rim.

2 Check and adjust tyre pressures to recommended va lues.

3 Front wheel bearing end float is to be checked to ensure it is within specification, as d etail ed in 2.4 Front W heel

Hub Assembly End Float Che cking Procedure in this Section.

4 The front control arm ball joints should be checked for wear, refer to 3.11 F r ont Control Arm Ball Joint in this

Section.

5 Check steering gear mounting bolts for tightness and steering tie rod ends for wear, refer to 3.6 Left Hand Drive

Power Steering Gear in Section 9 Steering.

6 The vehicle should be at curb weight, fuel tank full, without driver, passengers or luggage etc.

7 Check for improperly operating front struts or rear shock absorbers.

8 Check for loose or missing stabiliser bar or front control ar m rod attachments.

9 Before checking the front wheel alignment, refer to 2.11 Re ar W heel Alignment Checking in

Section 4A1 Rear Suspension for rear wheel alignment details.

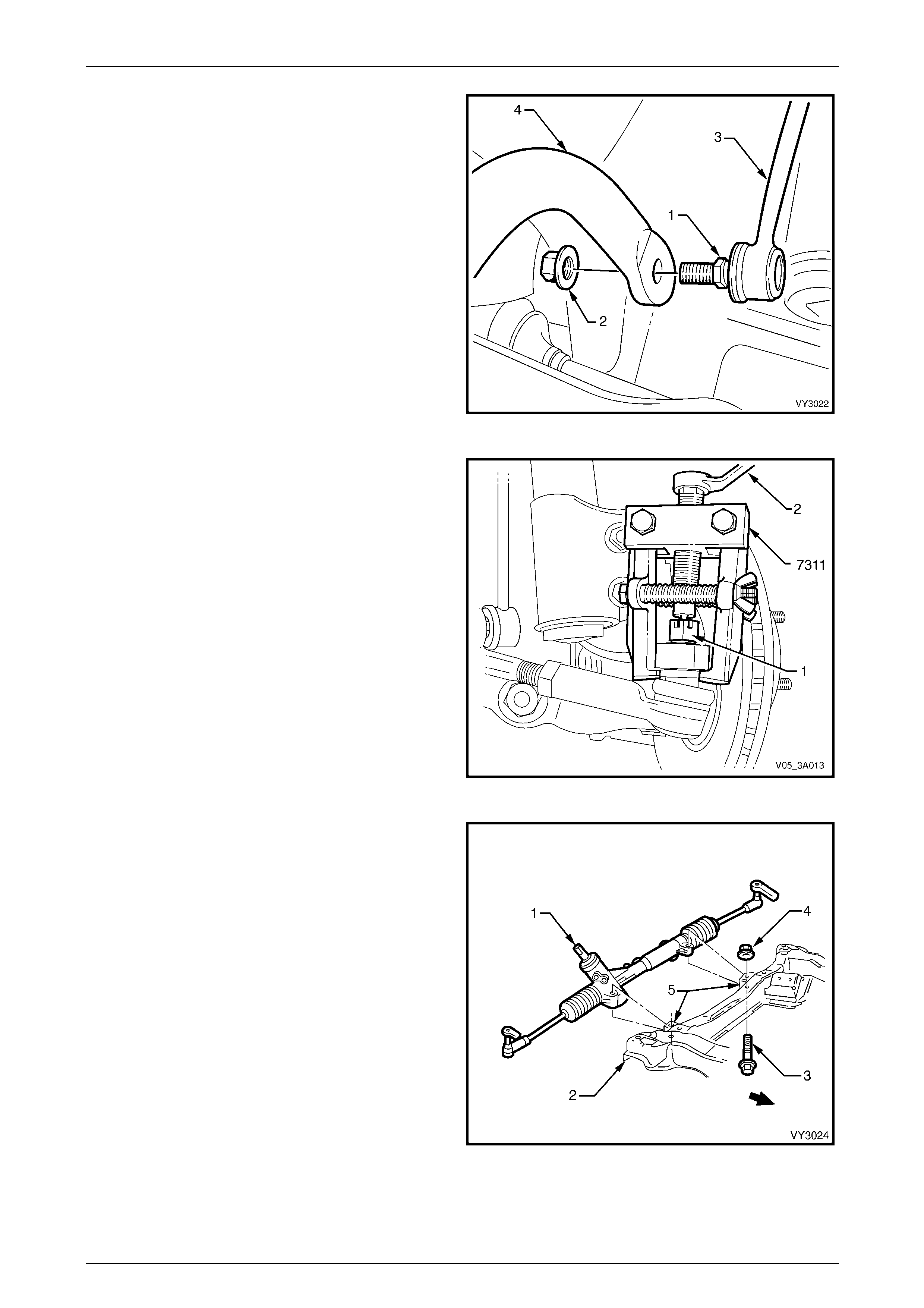

Caster Adjustment

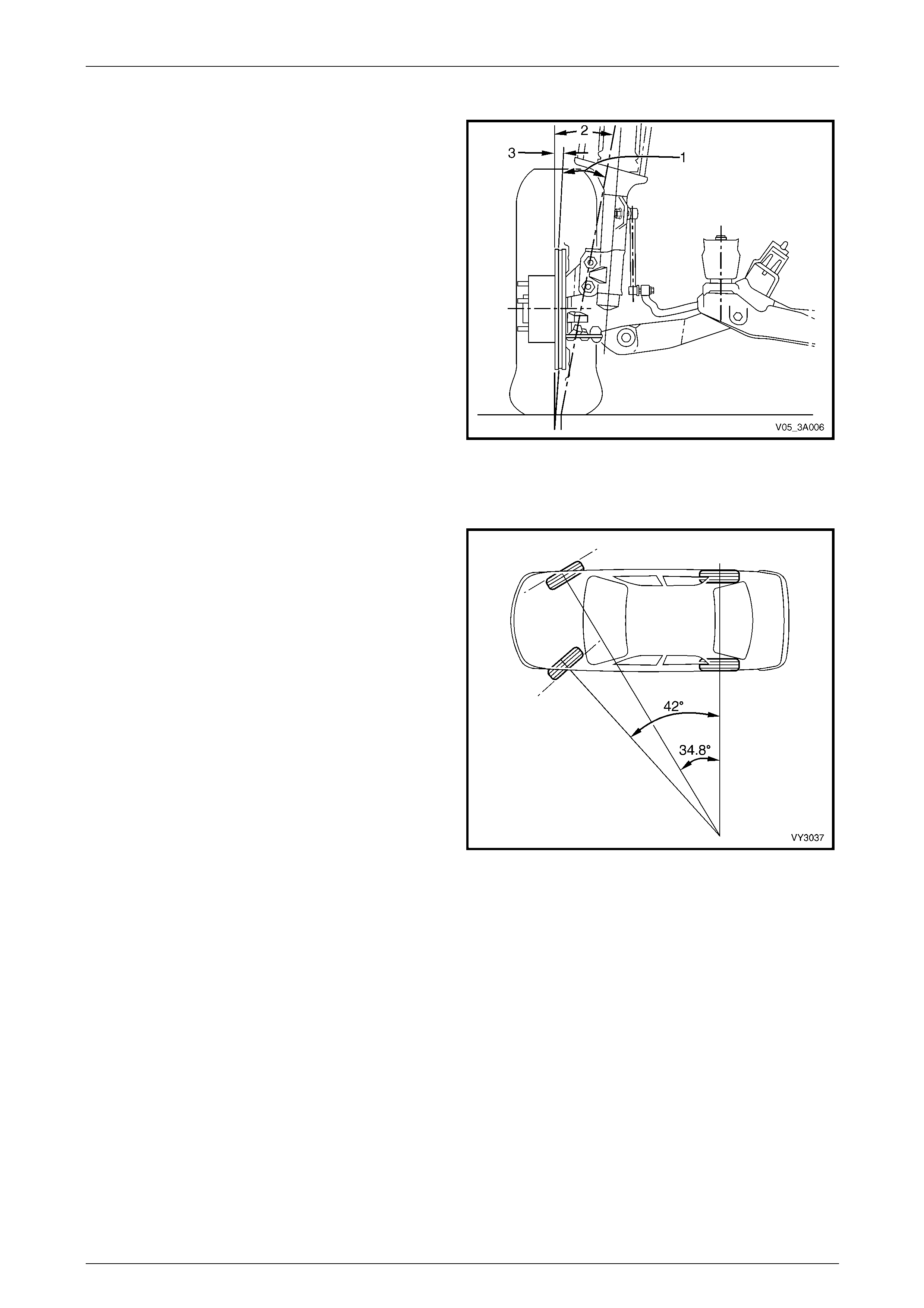

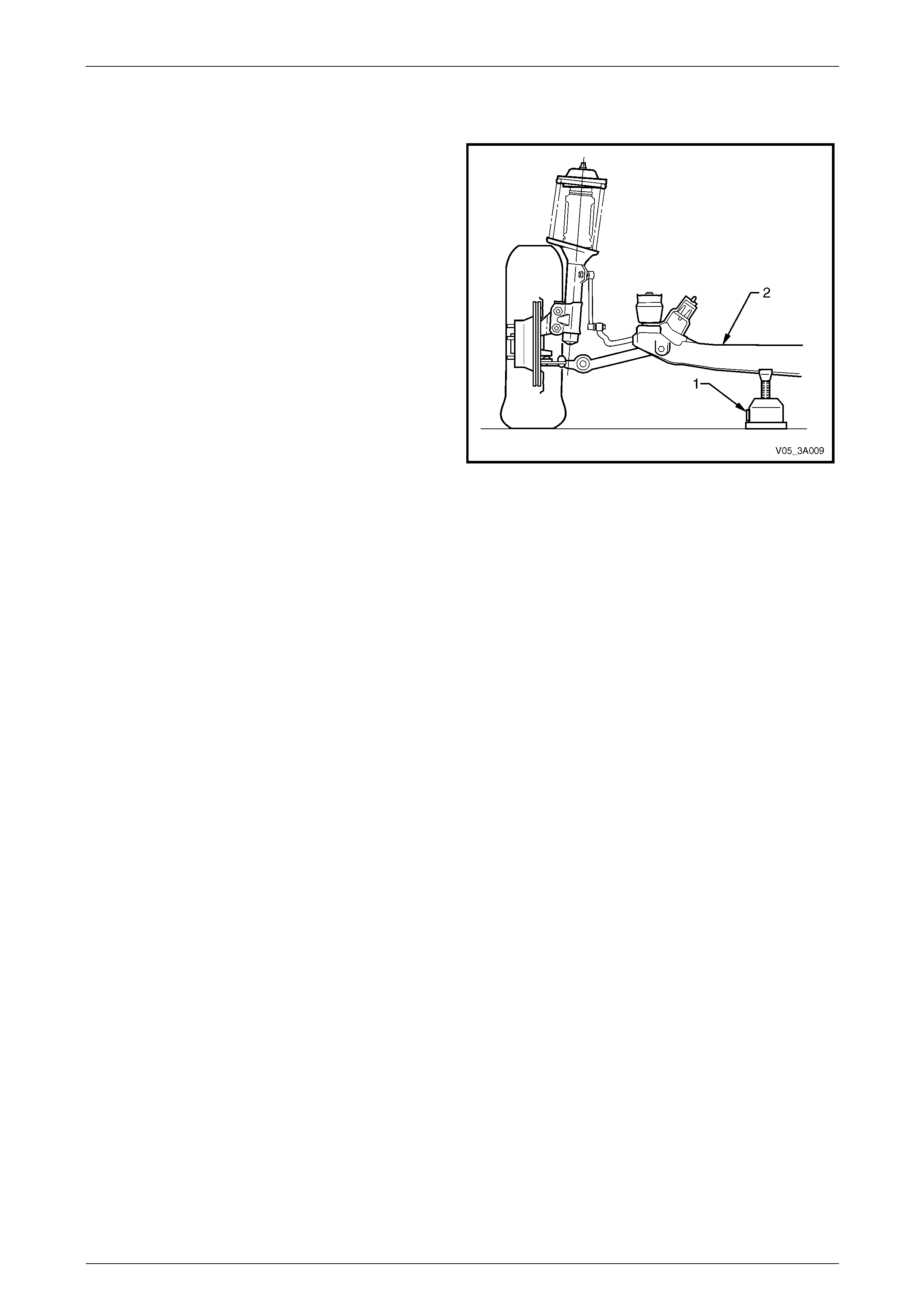

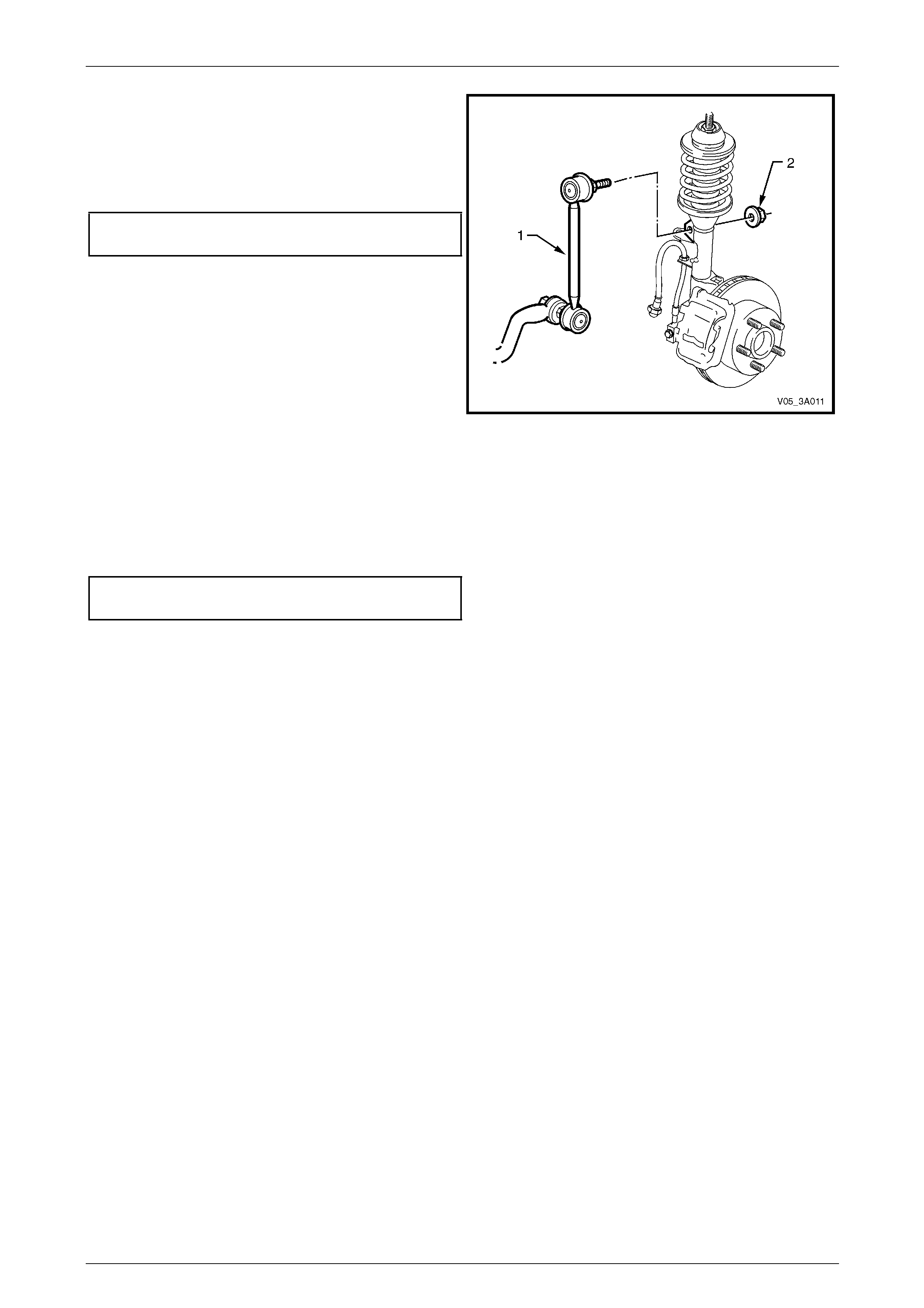

While one bright finished spaced washer (1) will be fitted to

the driver’s side front control arm rod (2), the fitment of an

additional washer is permitted to correct minor caster

adjustments

NOTE

Only one additional spac er washer is to be fitted

and is to be added to the side with the higher

caster reading.

Figure 3A – 10

Front Suspension Page 3A – 10

Page 3A-10

Camber Adjustment

1 Raise the front of the vehicle and support on safety

stands under the front side members. Refer to

2.3 Jacking Precautions in this Section.

2 Remove the centre wheel nut cover and mar k the

relationship of the wheel to the hub stud, using a felt

tipped pen or similar.

3 Remove the wheel attaching nuts and remove the

wheel.

4 Loosen, remove and discard the two lower strut

attaching bolts and nuts (1).

5 Install NEW lower strut attaching bolts and nuts but

do not tighten fully to specificat ion until after the

camber has been adjusted to the recommended

specification.

6 Install the road wheel, alignin g the previously made

marks.

Figure 3A – 11

7 Tighten road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern, refer to

3.1 Service Warnings Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

8 Lower the vehicle to the ground an d bounce several times to settle the suspension.

9 Check the camber angle.

10 If required, adjust the camber by turning the camber adjusting screw (2) in the requir ed direction; clockwise to

reduce negative camber, anti- clockwise to reduce positive camber.

NOTE

The camber adjusting screw has thread sealant

applied in the form of micro-encapsulation and

does not require a lock nut.

11 Raise vehicle once again, support on safety stands and remove the front road wheels.

12 Tighten both steering knuckle bolts and nuts to the correct torque specification.

Steering knuckle to strut bolts

and nuts torque specification ..Stage 1.................85 Nm

Stage 2...............100 Nm

Stage 3 Turn through 90°

13 Install the road wheels, aligning the marks made prior to removal.

14 Remove the jack stands and lower the vehicle.

15 Tighten the road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern. Refer to

3.1 Service Notes and Cautions, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

16 Reinstall the centre wheel nut cover.

17 Check the camber angle again to ensure that it is still within specification.

Front Suspension Page 3A – 11

Page 3A-11

Toe Adjustment

Toe of both front wheels, is checked with the wheels in the straight ahead position.

Adjustment is achieved by windi ng the steering linkage tie rods in or out of the steering linkage tie rod ends, increasing or

decreasing their length, changing the wheel toe setting.

1 Set steering gear and wheels in straight ahead position.

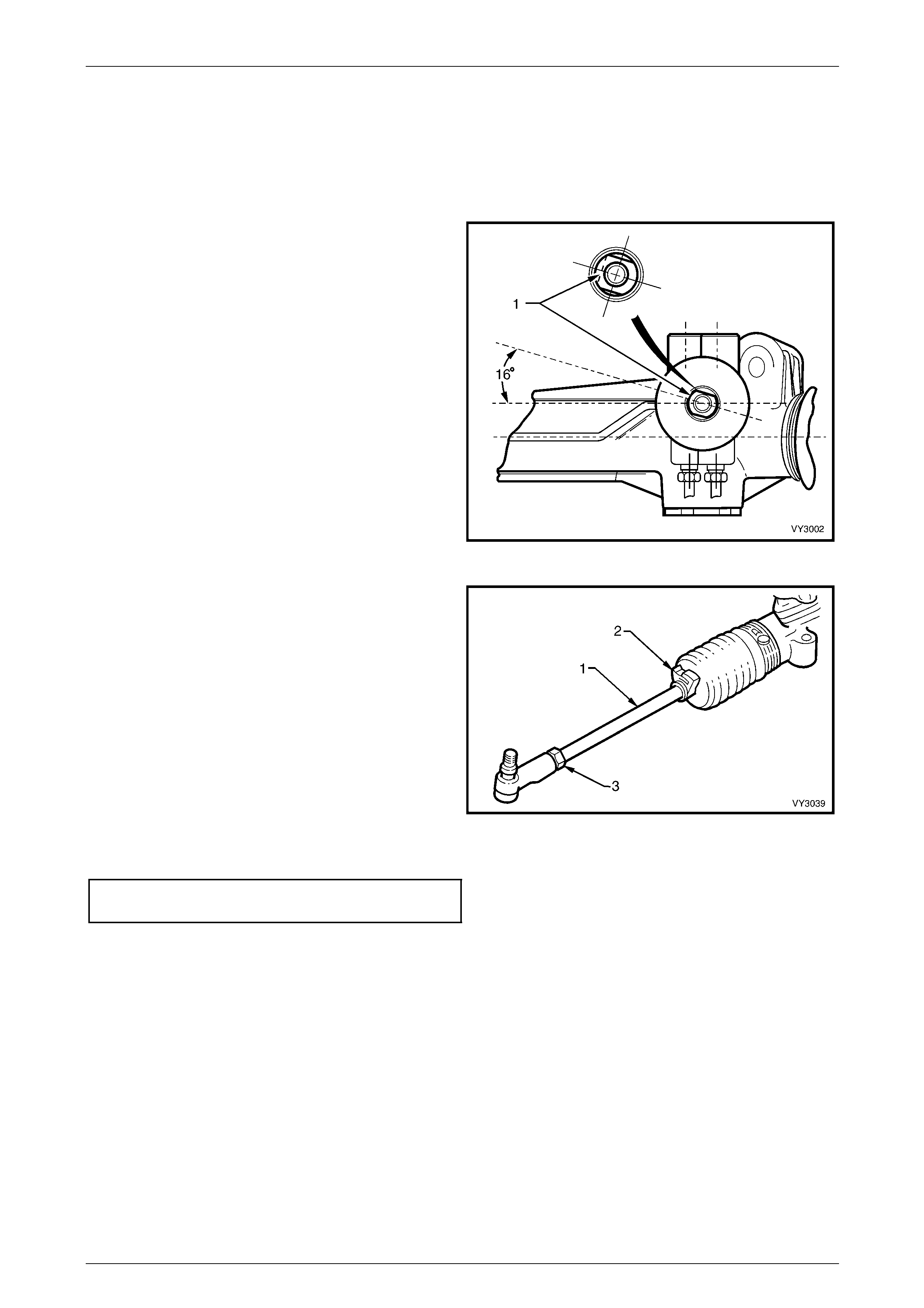

2 To check if steering gear is in straight ahead position

(on-centre), the pinion (input) shaft (1) should be

aligned as shown.

Figure 3A – 12

3 Before adjusting the steering linkage tie rods (1),

disconnect the steering gear outer boot clips (2).

4 Loosen the lock nut (3) at the end of e ach steering

linkage tie rod end.

5 Turn each steering linkage tie rod (1) as required, until

the correct toe is obtained.

NOTE

During the toe adjustment, ensure that the

steering wheel is held in the straight ahead

position.

6 Tighten the lock nuts to the correct torque

specification, checking that the outer tie rod ends are

aligned with their ball studs.

Figure 3A – 13

Steering linkage tie rod to tie rod

end lock nut torque specification...........................50 Nm

7 Tighten the outer boot clips se curely, making sure that the convolutions of the boots are not distorted.

8 With the steering gear in the straight ahead position, ensure that the steering wheel is centralised. If not, remove

and reposition the steering wheel, refer to Section 9A Steering.

Front Suspension Page 3A – 12

Page 3A-12

2.3 Jacking Precautions

When raising the front of the vehicl e with a jack (1), the jack

should be placed under the c entre of the front crossmember

(2). The weight of the vehicle MUST NOT be lifted under the

control arms.

When the vehicle is raised on the jack, it must be firmly

supported on jack stands located under the frame side

members before any work is attempted. If a vehicle is not

correctly supported by jack stands, serious injury can result

if the vehicle should slip off the jack.

For further information relating to the location of jacking and

support points, refer to Section 0A General Information.

Figure 3A – 14

Front Suspension Page 3A – 13

Page 3A-13

2.4 Front Wheel Hub Assembly – End Float

Checking Procedure

1 Raise the front of the vehicle and place on safety stands. Observe the jacking precautions as detailed in

2.3 Jacking Precautions in this Section.

2 Remove the centre wheel nut cover.

3 Mark the relationship of the wheel hub assembly to the brake rotor to preserve on-vehicle wheel balancing.

Remove the wheel attaching nuts and remove road wheel.

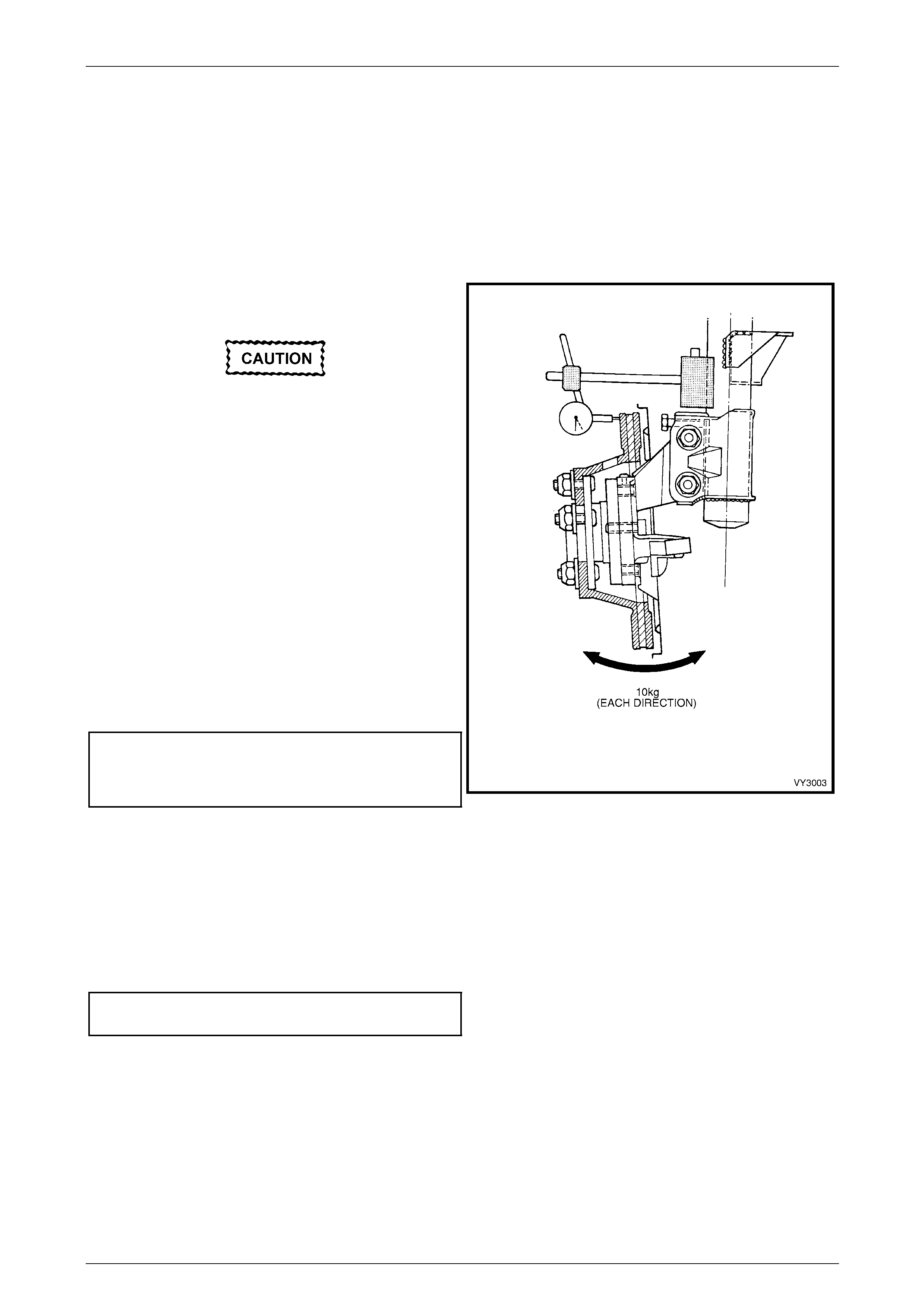

4 Reinstall three, reversed wheel nuts with a flat washer

under each nut, to prevent da mage to the nut thread.

The dial indicator gauge MUST be mounted at

right-angles (90°) to the brake rotor friction

surface.

5 Mount a dial indicator to a suitable magnetic stand and

attach to the front strut tube. Position the dial indicator

pointer at the outer diameter of the rotor, as shown.

6 Apply an outward, 10 kg force to the outer b r ake rotor

diameter, in an opposite pos ition (180°) to the dial

indicator. To maintain consistency, a spring balance

capable of measuring this force, MUST be used. With

the force applied, zero the dial indicator.

7 Apply an inward, 10 kg force to the outer brake rotor

diameter and note the dial in dicator reading.

8 The reading obtained is the an gular movement (NOT

end float) and to determine the bearing’s serviceability,

compare the measured result with the following

specifications.

Wheel Bearing Angular 'Float' Specification

New bearing....................................0.106 mm maximum

Used bearing...................................0.213 mm maximum

Figure 3A – 15

9 Should this inspection show that the wheel bearing assembly is outside the specified, angular ‘float’ dimension,

then the hub must be replaced. Refer to 3.3 F r ont Wheel Hub Assembly Brake Rotor or Shield, in this Section.

10 Remove the dial indicator and stand, and the three wheel nuts and flat washers.

11 Reinstall the road wheel, alig ning the marks made prior to removal and secure with attaching nuts.

12 Lower vehicle to the ground. Tighten road wheel attaching nuts to correct torque specification, working in a ‘star’

pattern. Refer to 3.1 Service Notes and Cautions , in this Section.

Road wheel attaching

nut torque specification ............................. 110 – 140 Nm

13 Reinstall the centre wheel nut cover.

Front Suspension Page 3A – 14

Page 3A-14

3 Service Operations

ATTENTION

All front suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this Section, fasteners MUST be

replaced with parts of the same part num ber or a GM appro ved equivalent. Do n ot use fasteners o f an inferior

quality or substitute design

Torque values must be used as specified during reassembly to ensure proper retention of all front

suspension components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

3.1 Service Warnings, Cautions and Notes

Road Wheels

• Whenever a road w heel is remo ved from or in stalled to an y MY 2005 WL Series vehicle, it MUST be

done in accordance with the procedure provided in Section 10 Wheels and Tyres.

• Whenever a road w heel is removed from the vehicle, the relationshi p of the road wheel to the hub

MUST be marked with a felt tipped pen or similar, to allow those parts to be reinstalled in their

original positions. This is critical to minimise the road wheel runout dimension.

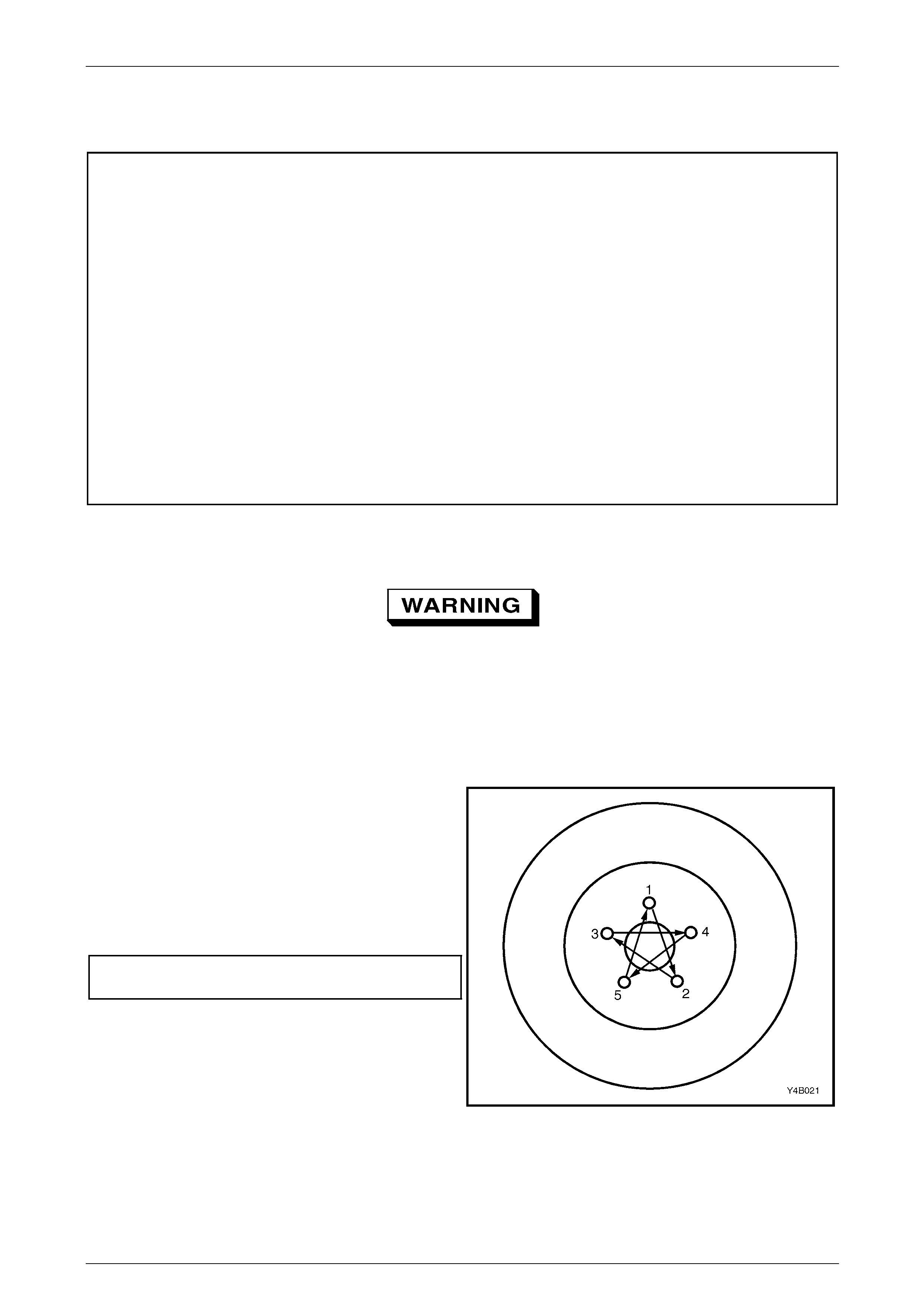

• When reinstalling road wheels, do not use

an impact gun to tighten wheel nuts

unless the impact gun is fitted with a

torque limiter socket (Tool No. AU 534 or

a commercial equivalent). Failure to

correctly tighten w heel nuts to the correct

torque specification and in the correct

order (as shown), may result in a

distorted brake disc, leading to the

development of brake shudder.

Road wheel attaching nut

torque specification...................................110 – 140 Nm

Figure 3A – 16

ABS/TC Components

• Whenever any component that forms part of the ABS (if fitted) is disturbed during Service

Operations, it is vital that the complete ABS system be checked, refer to Section 5 B , AB S, ABS/T C,

Electronic Brake Assist (EBA).

Front Suspension Page 3A – 15

Page 3A-15

3.2 Suspension and Trim Height, Check

• Good judgement must be exercised before

replacing a spring or springs from a

vehicle whose height is within the limits

quoted.

• Even if a vehicle's dimensions should

prove to be slightly outside these

tolerances, the vehicle could well be in a

serviceable condition.

• Spring replacement under conditions of

excessive weight due to non-standard

fittings, undercoating, road dirt, etc; will

assist very little in restoring the vehicle to

its specified height.

The suspension and trim height dimensions for standard vehicles with base equipment only, are provided in

5 Specifications in this Section. The dimensions are for a new vehicle built to standard specification and are on ly

intended as a guide when checking susp ension and trim height dimensions at normal curb weight.

Preliminary Inspection

The following procedure sh ould be followed before checking any suspension or trim height.

1 Vehicle curb weight is defined as:

• Tyre pressures are to specification.

• Fuel tank is full – add additional weight in the rear compartment to compensate if necessary.

• All fluids are at the specified levels.

• Spare tyre is included.

• Tyre and wheel rim sizes are to specification.

• Vehicle contains no passe ngers.

2 Accumulated dirt, distance travelled, etc., must also be taken into consideration when checking vehicle heights.

3 Vehicle must be on a level surface.

4 It must be confirmed that the vehicle has not been subjected to accident d amage.

NOTE

It is normal for the vehicle to sit approximately 4

mm lower at the right hand side front, because of

the vehicle's battery weight.

Front Suspension Page 3A – 16

Page 3A-16

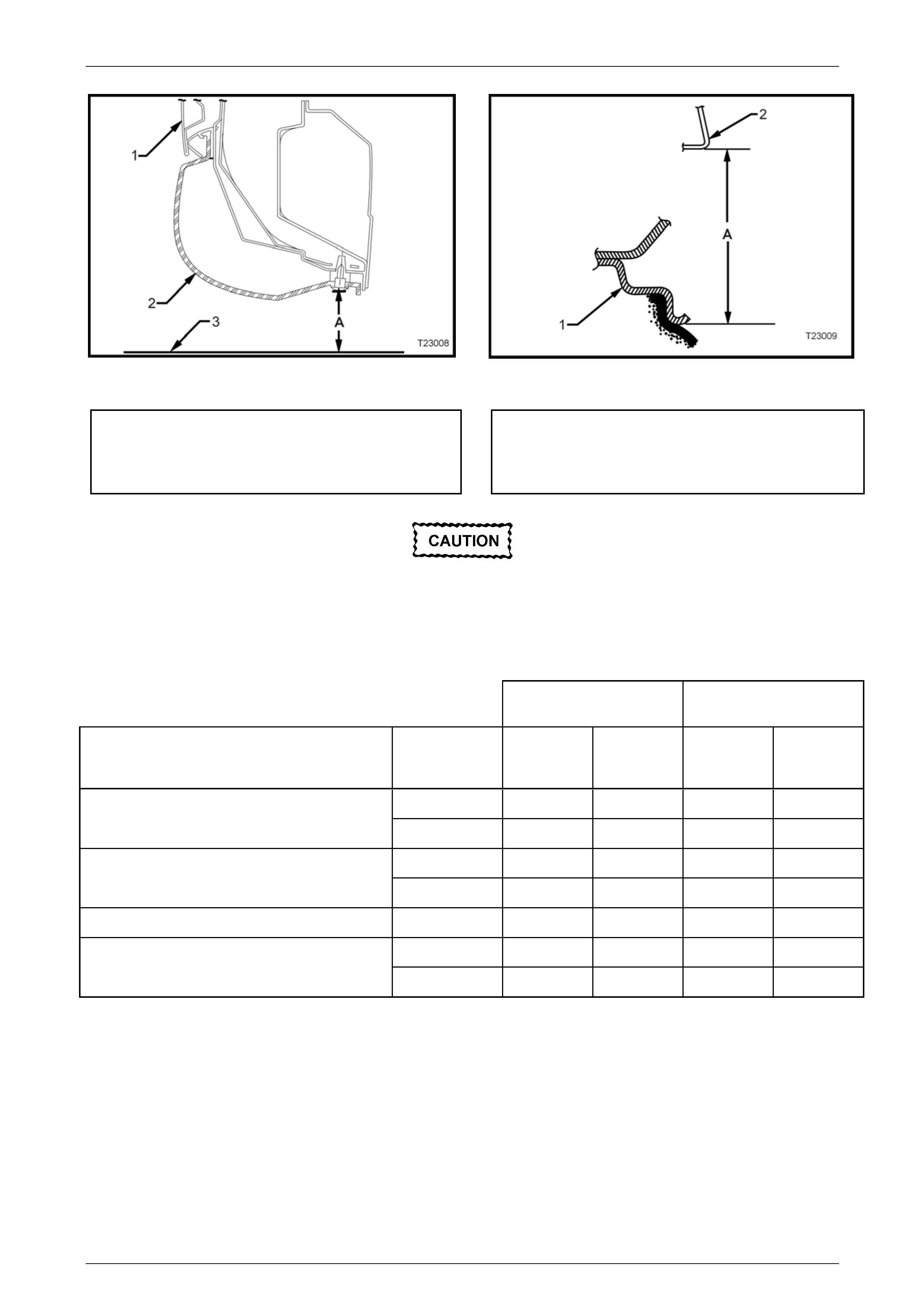

Procedure

1 Push the vehicle up and do wn several times at the front bumper bar with a decreasing force and then gently

remove hands, allowing vehicle to settle on its own.

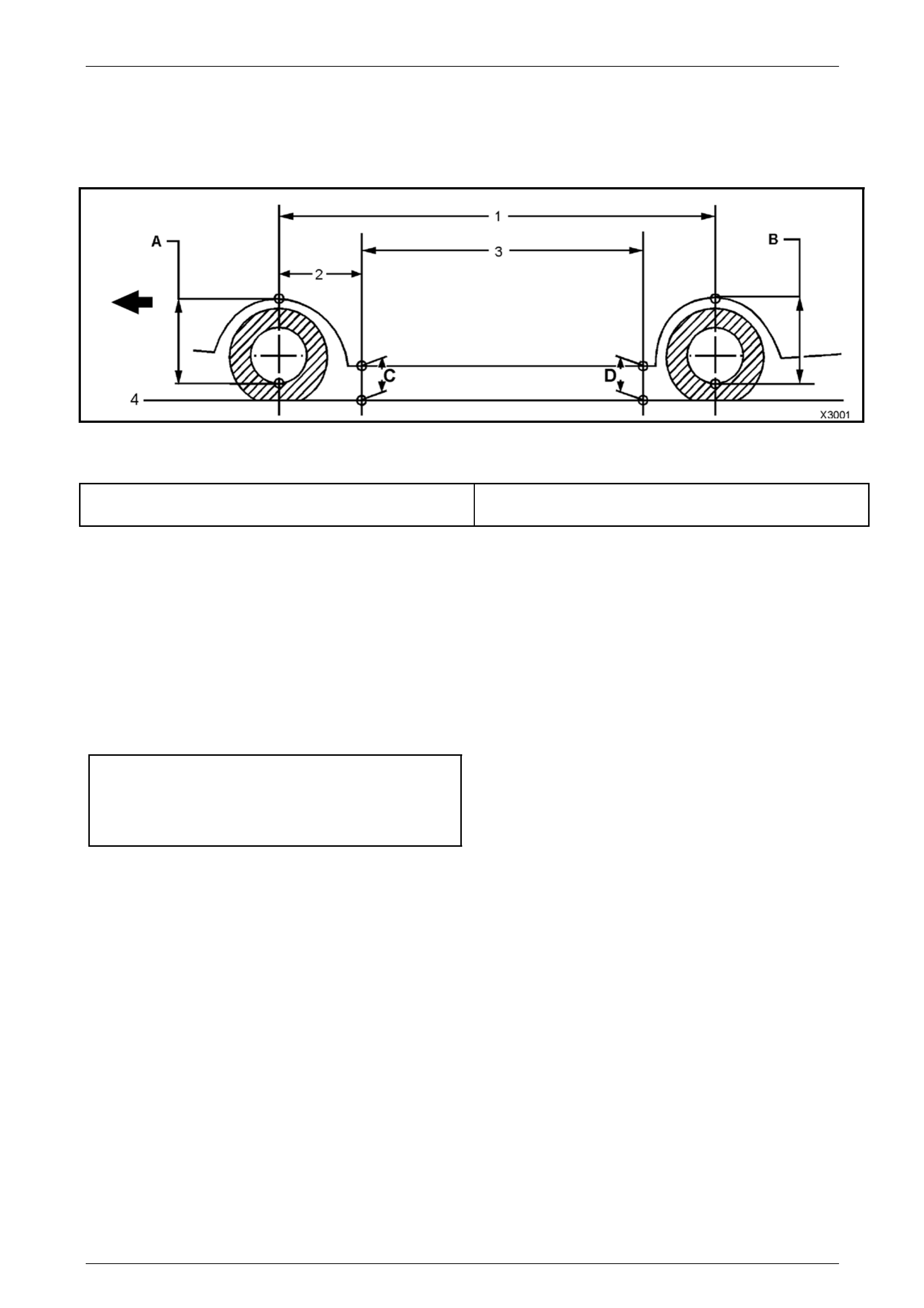

2 Carry out front suspension and trim height check, at ‘A’ and ‘C’ respectively; refer to Figure 3A–17.

Figure 3A – 17

Legend

A Front Suspension Height Location

B Rear Suspension Height Location C Front Trim Height Check Location

D Rear Trim Height Check Location

3 Push the vehicle up and do wn several times at the rear bumper bar with a decreasing force and th en gently

remove hands, allowing vehicle to settle on its own.

4 Carry out vehicle rear suspension and trim height check, at ‘B’ and ‘D’, respectively; refer to 3A–17.

Front and Rear Suspension Height Comparison

1 When checking a vehicle's suspension height, the following tolerances must also be taken into account, before any

spring is replaced. Compare the front and rear suspension height measurements between:

• Front to rear.

• Side to side

Ride Height Variations from Specification

Front to Rear..................................................... ± 20 mm

Side To Side ..................................................... ± 10 mm

Normal Spring Settling........................................± 5 mm

NOTE

Ride height variatio n may also be due to any one

or a combination of the following:

• Spring seat location on the suspens ion/body.

• Incorrect springs. Check spring identification

against the table shown in 5 Specifications in

this Section.

• Non-standard, additional vehicle weight, such

as a tow bar and/or after-market LPG fitment.

• Any combination of the above.

Front Suspension Page 3A – 17

Page 3A-17

3.3 Front Wheel Hub Assembly, Brake Rotor

and/or Brake Shield

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Front strut to steering knuckle attaching nuts and bolts.

Brake caliper to steering knuckle attaching bolts.

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

Front wh eel hub assembly to steering knuckle attaching bolt.

NOTES

• Apart from wheel stud replacement, there are

no serviceable items in the front wheel hub

assembly. As the unit is a 'sealed for life'

assembly, neither bearing adjustment nor

lubrication maintenance is required. Should a

non-standard condition develop, then the hub

assembly must be replaced as a complete

unit.

• While the front wheel hub assembly is

designed to have zero axial free play or ‘end-

float’, some angular movement may be

evident when a rocking force is applied to the

mounted wheel and tyre assembly. Before a

hub is replaced, refer to checking procedure

as detailed in 2.4 Front Wheel Hub Assembly

– End Float Checking Procedure in this

Section.

Remove

1 Observing the jacking precautions as outlin ed in 2.3 Jackin g Precautions in this Section, raise the front of the

vehicle and support on safety stands.

2 Remove the centre wheel nut cover.

3 Mark the relationship of the road wheel to hub or brake rotor. Loosen, then remove the road wheel attaching nuts.

Remove the road wheel.

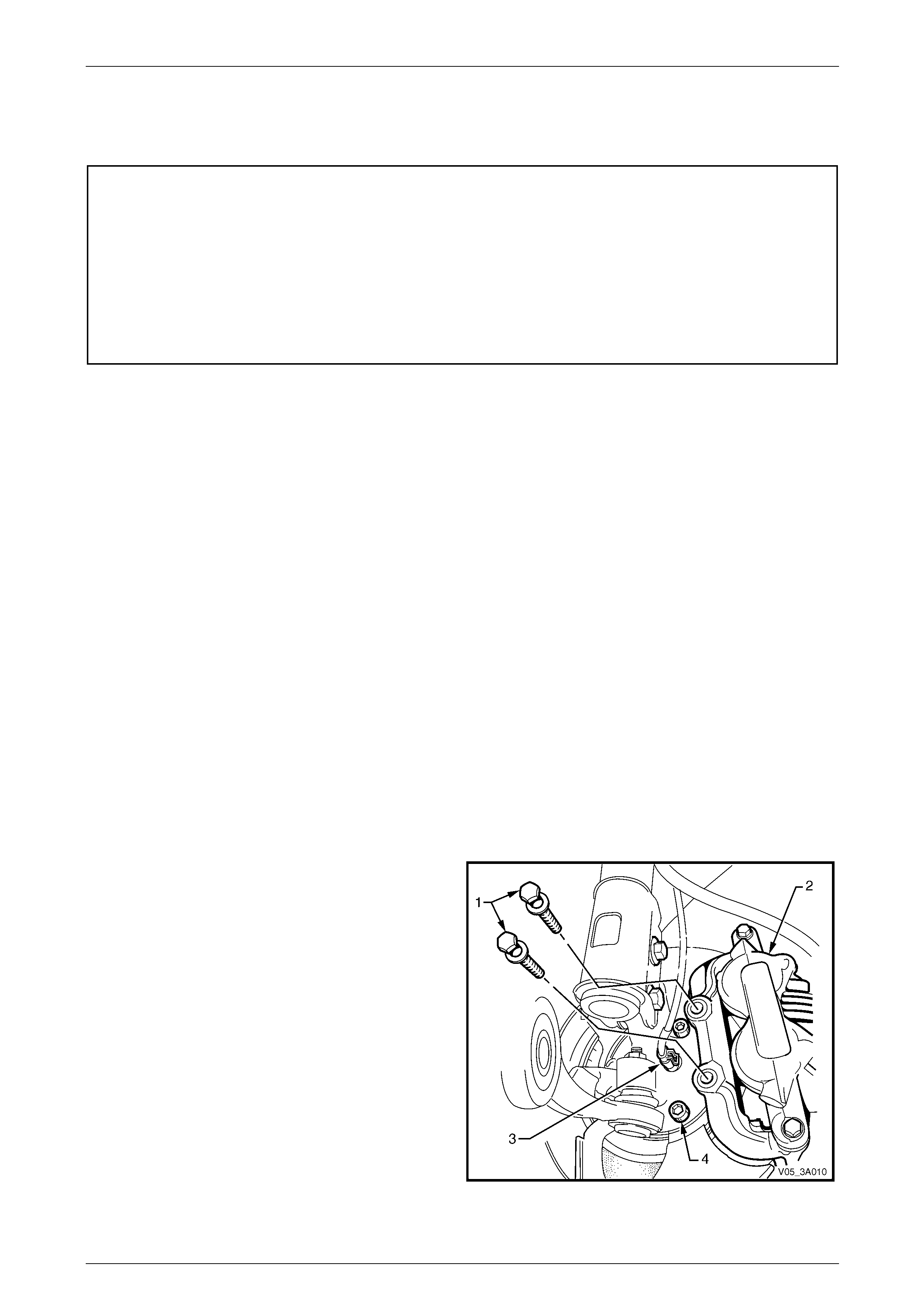

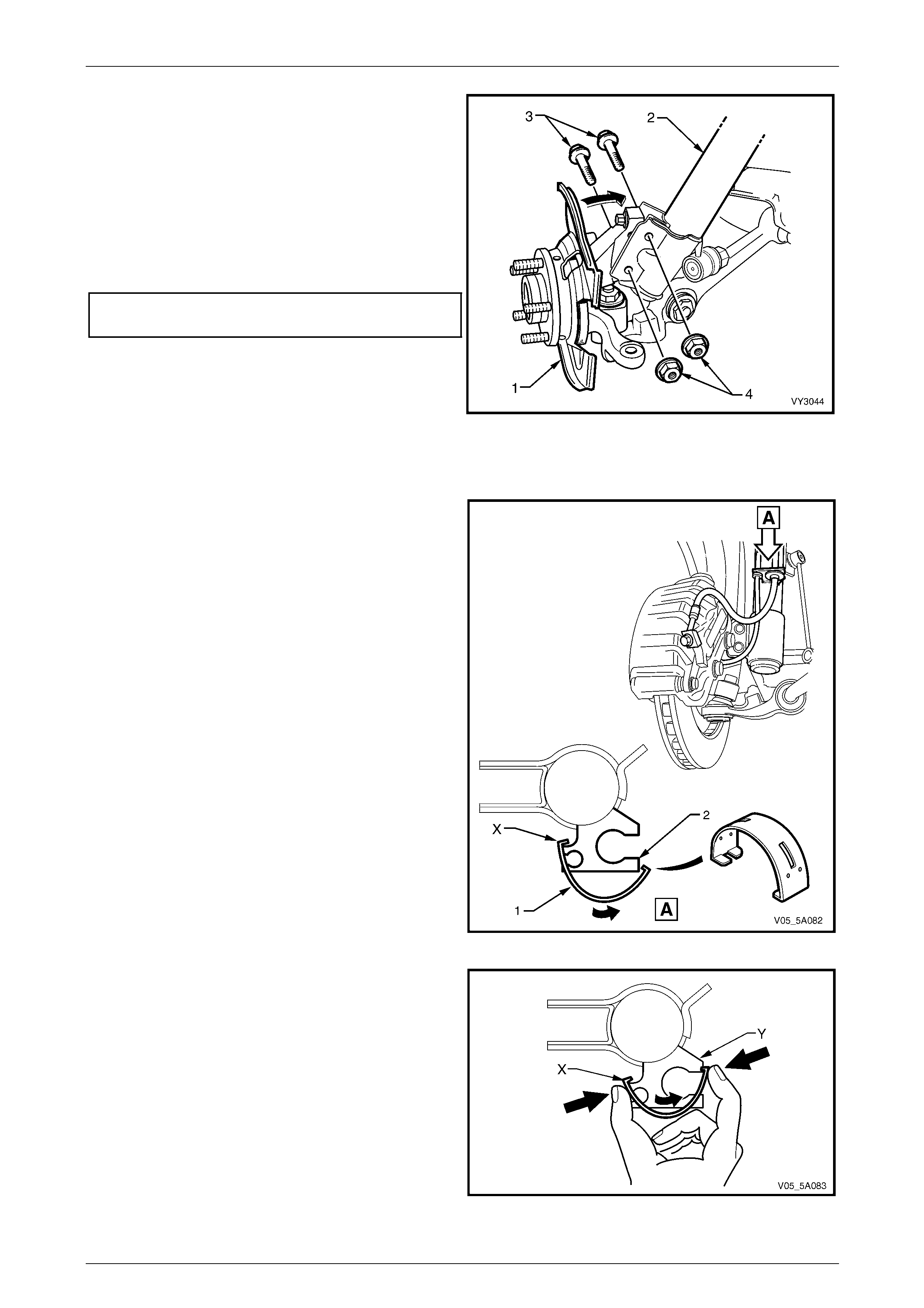

4 Remove the brake caliper retaining bolts and washers

(1) and lift the caliper assembly (2) from the brake

rotor. Position caliper in such a way that no strain is

placed on the brake hose. If necessary, tie caliper to

the suspension spring with a piece of wire. THE

CALIPER IS NOT TO HANG BY THE BRAKE HOSE.

5 The brake rotor to hub location is marked in

production. To maintain this relatio nshi p, ensure that

the rotor to hub position is carefully marked.

NOTE

This is necessary to overcome the possibility of

inducing a brake shudder condition after

reassembly.

6 Remove the brake rotor from the wheel hub a ssembly.

7 Disconnect the ABS wheel speed sensor connector (3)

from the hub sensor connector, by lifting the connector

locking tab and pulling on the connector to disconnect. Figure 3A – 18

Front Suspension Page 3A – 18

Page 3A-18

8 Using a commerciall y available 10 mm Allen key socket and a suitable socket bar, loosen each of the three bolts

(4) holding the hub to the steering knuckle.

NOTE

• If the Allen key socket is too long to fit into the

front, upper hub bolt, then the lower strut to

steering knuckle nut (and bolt ) will need to be

loosened and removed. Discard the removed

bolt and nut, as they must be replaced on

reassembly.

• For the front lower hub bolt, turn wheel

outwards to provide sufficient clearance.

9 If the hub is a tight fit to the knuckle, it may be necessary to loosen the three bolts and tap on the he ads. DO NOT

STRIKE THE HUB.

10 Remove the three bolts and then the hub from steering knuckle.

11 Where removal of the brake shield is nec essary, drill the heads from the three rivets securing the shiel d to the

steering knuckle support.

12 After removal of the shield, carefully dr ill out the remainder of the rivets, using a suitable si zed drill.

Inspect

1 Check wheel studs are pressed firml y into the front wheel hu b assemb ly and ensure threads are not damage d. If

one or more of the wheel studs require replacement, refer to 3.4 Front W heel Hub Studs in this Section for details.

2 Examine the brake rotor for scores or dam age. If either of these conditions exist, the brake rotor shoul d be

machined. Refer to Section 5A Service and Park Braking Systems for details.

3 Check for damage to the shield that may cause fouling of any rotating parts and if suspect, the shield sho uld b e

replaced.

Reinstall

Installation of the front wheel hub assembly, brake rotor a nd br ake shield is the reverse of removal procedures, except

for the following points:

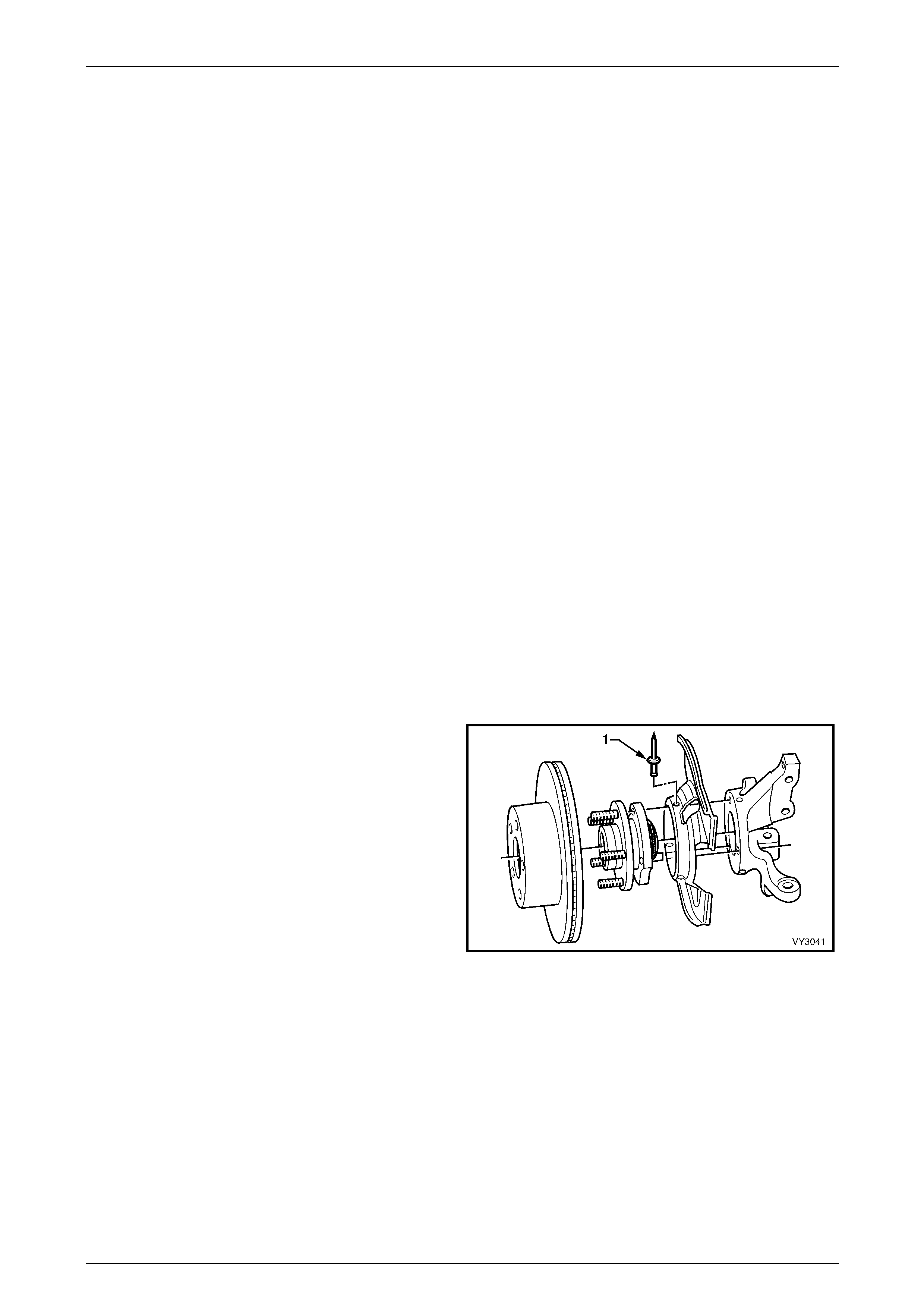

1 If the brake shield has been removed, install three,

common pop rivets (1), using a commerciall y available

pop rivet gun.

NOTE

Install the first rivet in the brake shield hole with

the round hole. This will ensure that the

clearance to brake caliper is c orrect.

2 Before installing the hub, inspect both matin g surfaces

to make sure that they are clean and free from burrs

that could prevent correct alignment of both parts,

once installed.

Figure 3A – 19

Front Suspension Page 3A – 19

Page 3A-19

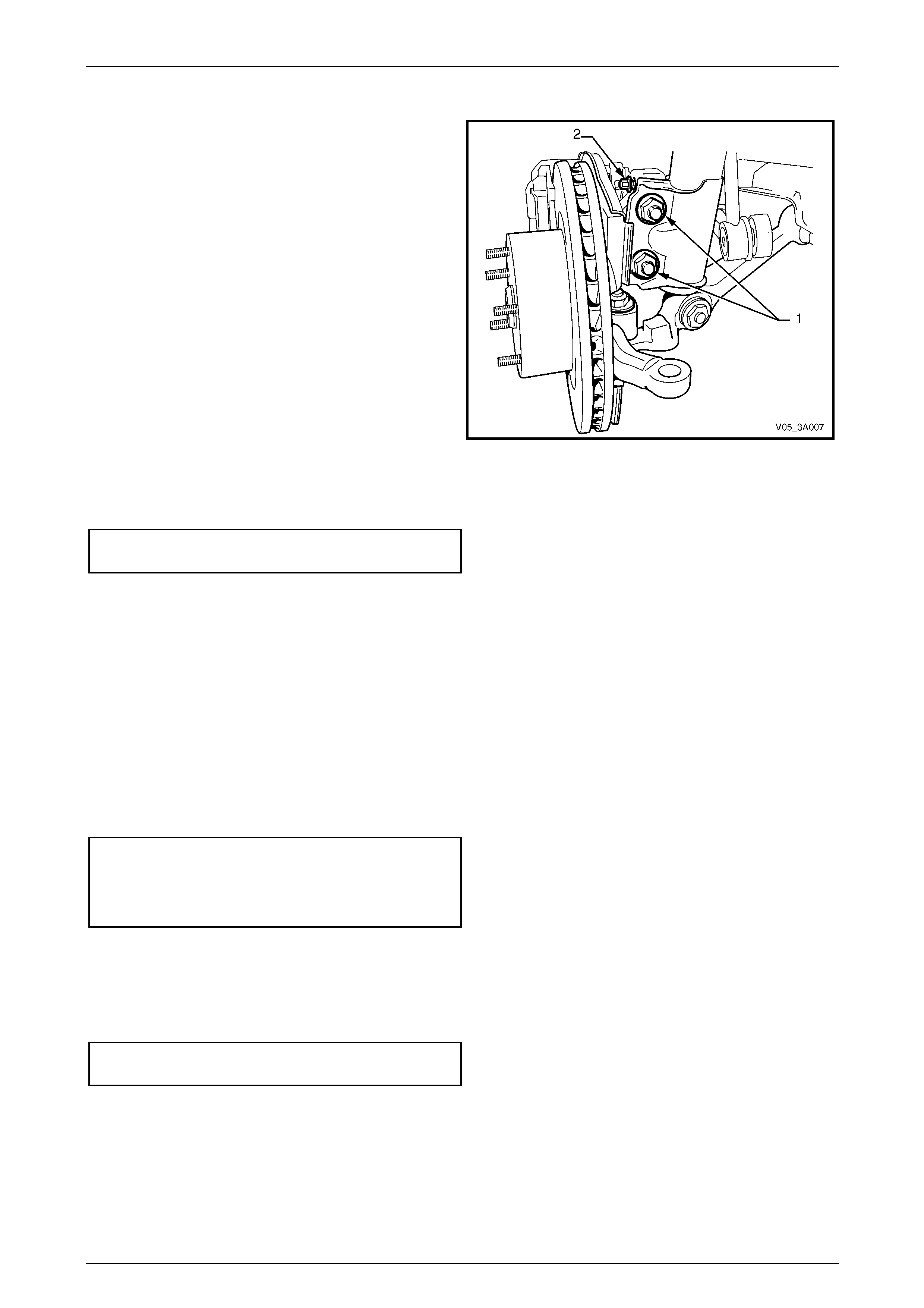

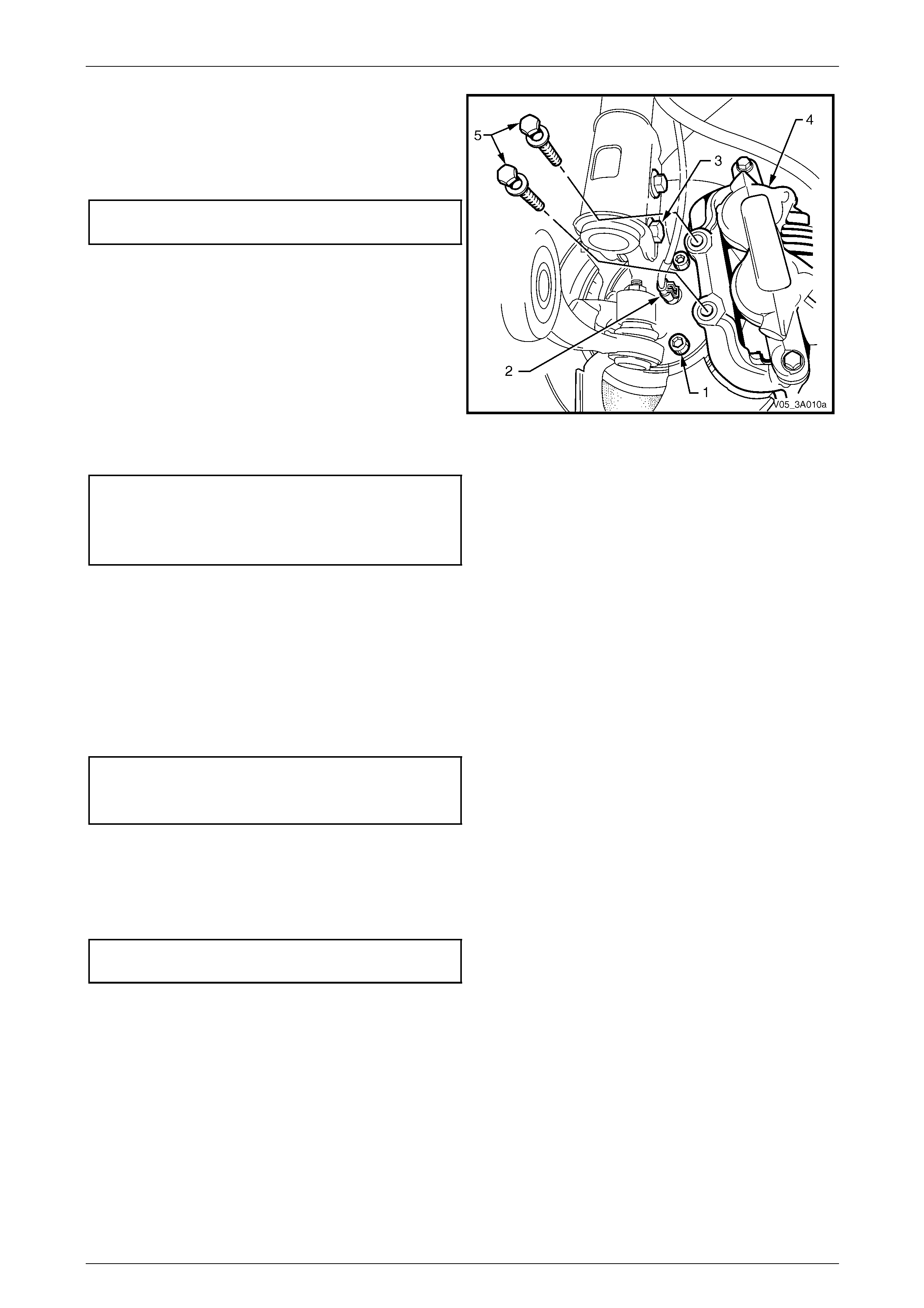

3 Install the hub assembly on to the steering knuckle,

aligning the ABS wheel speed sensor connection on

the hub, with the hole in the steering knuckle.

4 Reinstall the three attaching bolts (1) and tig hten to

the correct torque specification.

Front wheel hub to steering

knuckle bolt torque specification.........................108 Nm

NOTE

The three hub attaching bolts are micro-

encapsulated with thread sealant and are not to

be re-used more than three times. If in doubt, the

bolts should be replaced.

5 Reinstall the ABS wheel speed sensor connector (2),

checking that the locking tang is in place.

6 If removal of the lower strut to steering knuckle bolt

and nut (3) was necessary, the bolt and nut, must be

replaced with new parts. Tighten the bolt and nut to

the correct torque specification. Figure 3A – 20

Steering knuckle to strut bolts

and nuts torque specification Stage 1.................85 Nm

Stage 2...............100 Nm

Stage 3 Turn through 90°

7 Install brake rotor, aligning the marks made before removal.

NOTE

If the hub was replaced, then runout checks must

be carried out on the installed brake rotor. Refer

to Section 5A Service and Park Braking Systems

for important information regarding these checks

8 Install the brake caliper (4) and attaching bo lts (5) and tighten to the correct torque specification.

Brake caliper anchor plate

bolt torque specification...............................85 Nm, then

turn through 45°

9 Reinstall the road wheel, aligning the marks made prior to removal and secure with the attaching nuts.

10 Lower the vehicle to the ground.

11 Tighten the road wheel attaching nuts to correct torque specification, working in a ‘star’ pattern, refer to

3.1 Service Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

12 Reinstall the centre wheel nut cover.

Front Suspension Page 3A – 20

Page 3A-20

3.4 Front Wheel Hub Studs

ATTENTION

The following fasteners MUST be replaced when performing these operations:

Brake caliper to steering knu ckle attaching bolts.

Replace

1 Observing the jacking precautions as outlin ed in 2.3 Jackin g Precautions in this Section, raise the front of the

vehicle and support on safety stands..

2 Remove the centre wheel nut cover.

3 Mark the relationship of the wheel to the hub and rotor. Re move the wheel attaching nuts and remove th e wheel.

NOTE

To avoid the unnecessary removal of the micro-

encapsulated studs retaining the front wheel hub

assembly to the steering knuckle, it is

recommended that wheel stud/s replacement be

carried out with the hub left undisturbed.

4 Remove the brake caliper retaining bolts and washers,

lift the caliper assembly from the brake rotor. Suspend

the caliper on a wire or hook to avoid strain on the

hose. DO NOT ALLOW CALIPER TO HANG BY

BRAKE HOSE.

5 Remove the brake rotor from the hub.

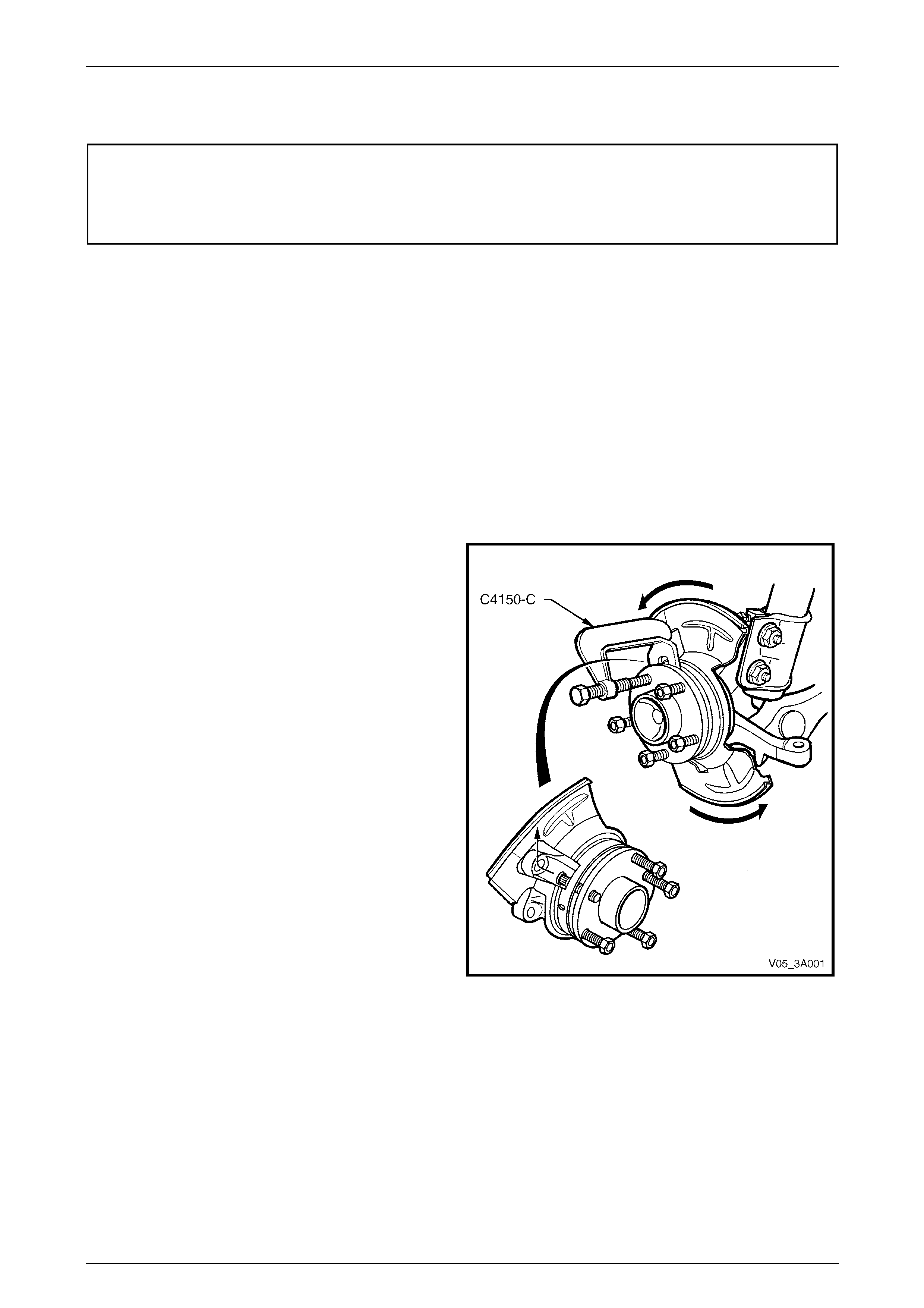

6 Install a wheel nut until the nut is flush with the end of

the stud, then, using Tool No. C4150-C or equival ent,

press the stud/s from the front wheel hub assembl y.

NOTE

To remove the stud/s, first drill out the three

rivets securing the brake shield to the steering

knuckle. Then rotate the shield and remove the

wheel stud by manipulating the head under the

shield and into the one recess in the steering

knuckle, at approximately the 11 o'clock posi tion,

as shown.

Figure 3A – 21

Front Suspension Page 3A – 21

Page 3A-21

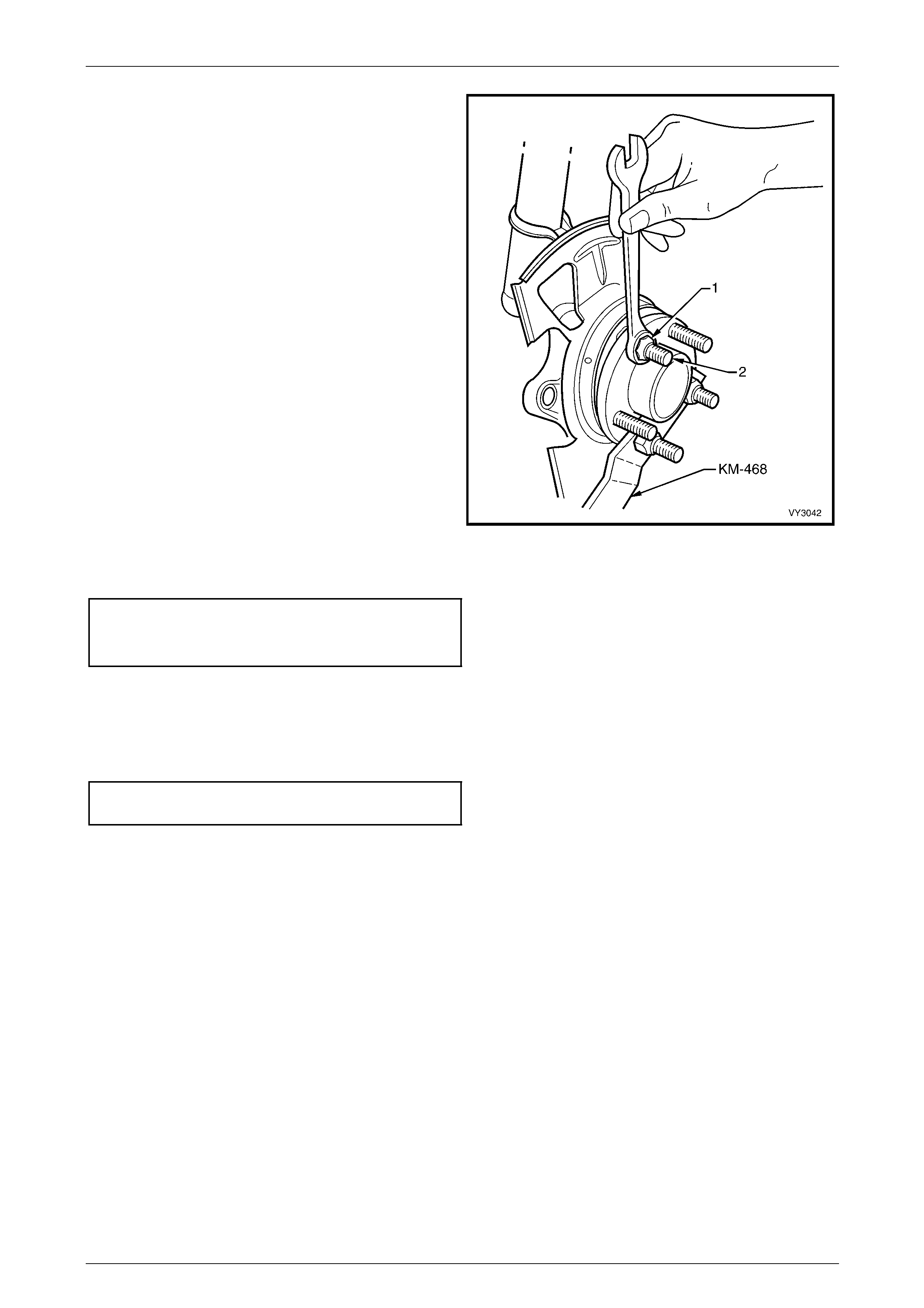

7 New studs can be installed as follows:

a Install Tool No. KM-468, using two reversed

wheel nuts.

b Install the replacement stud by first manipulati ng

the stud under the front brake shield and into the

wheel hub flange.

c Then, after assembling a suitable sized flat

washer and reversed wheel nut (1) onto the

replacement stud (2), hold Tool No. KM-468 and

tighten the wheel nut to draw the stud into place.

d Install any remaining studs in the same manner.

Remove Tool No. KM-468.

8 Using a suitable sized drill, re move the shanks of the

three brake shield retaining rivets. Then use common

pop rivets and a commercially available pop rivet gun

to reinstall the brake shield.

NOTE

Install the first rivet in the brake shield hole with

the round hole. This will ensure that the

clearance to brake caliper is c orrect.

9 Reinstall the brake rotor and caliper. Figure 3A – 22

10 Install NEW caliper anchor plate bolts and tighten to the correct torque spe cification.

Brake caliper anchor plate

bolt torque specification...............................85 Nm, then

Turn through 45°

11 Reinstall the road wheel, alig ning the marks made prior to removal and secure with the attaching nuts.

12 Lower the vehicle to the ground.

13 Tighten the road wheel attaching nuts to correct the torque specification, working in a ‘star’ pattern. Refer to

3.1 Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

14 Reinstall the centre wheel nut cover.

Front Suspension Page 3A – 22

Page 3A-22

3.5 Front Strut Assembly

ATTENTION

The following fasteners MU ST be replaced when performing these operations:

Upper strut locating plate retaining nut

Steering knuckle to strut attach in g nuts and bolts.

Brake caliper to steering knuckle retaining bolts.

Remove

1 Observing the jacking precautions as outlin ed in 2.3 Jackin g Precautions in this Section, raise the front of the

vehicle and support on safety stands.

2 Remove the centre wheel nut cover.

3 Mark the relationship of the road wheel to hub or brake rotor. Loosen, then remove the road wheel attaching nuts.

Remove the road wheel.

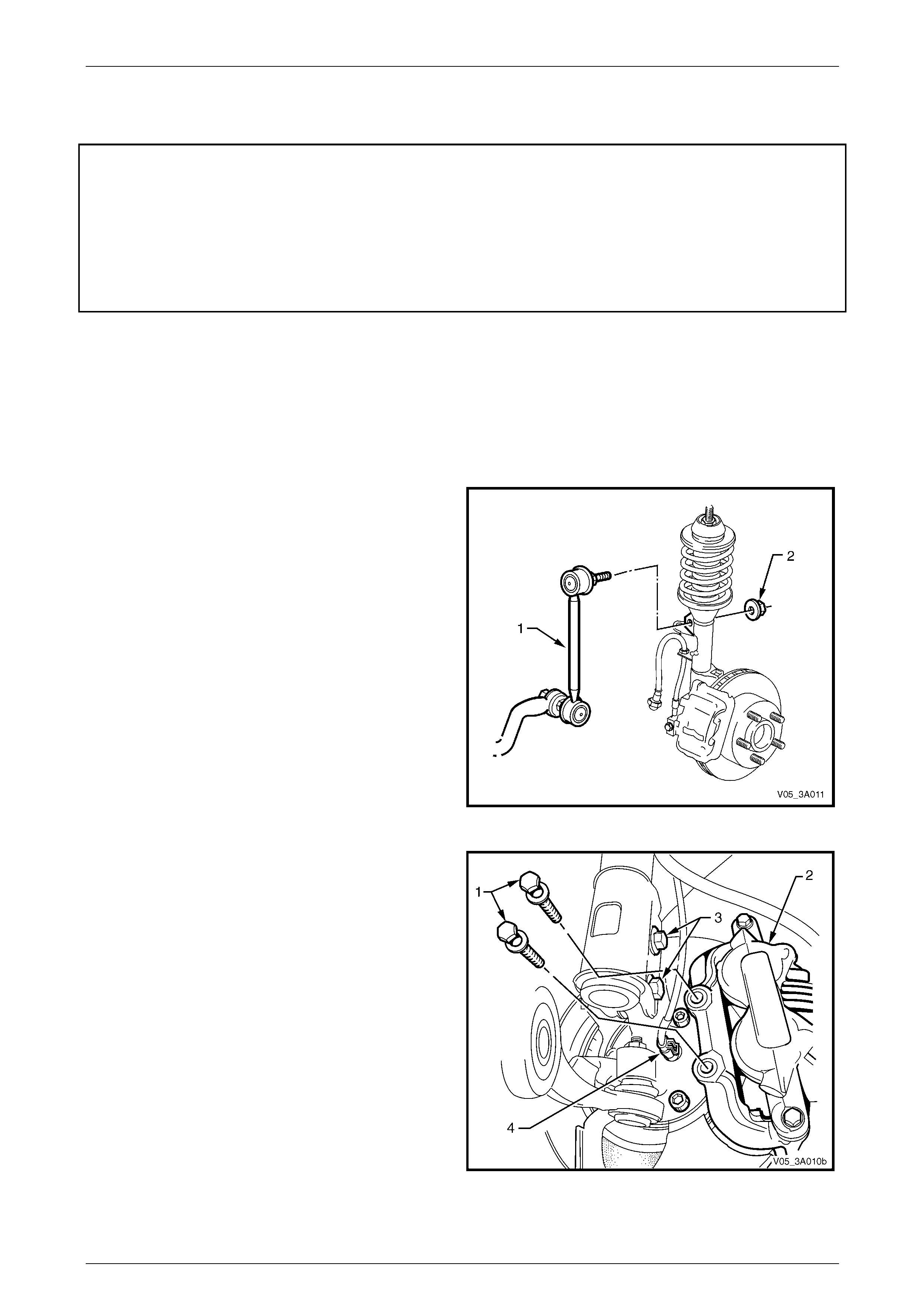

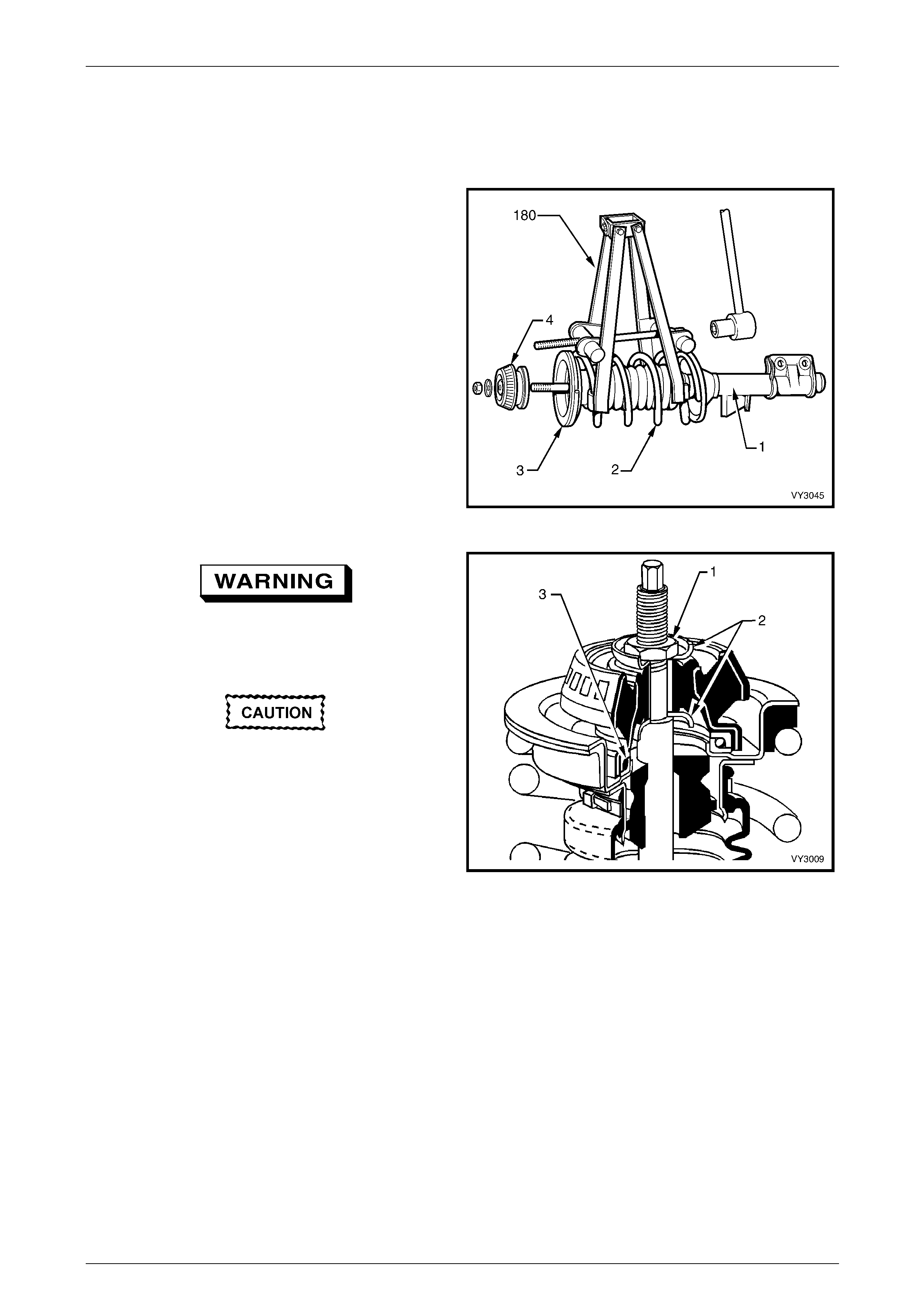

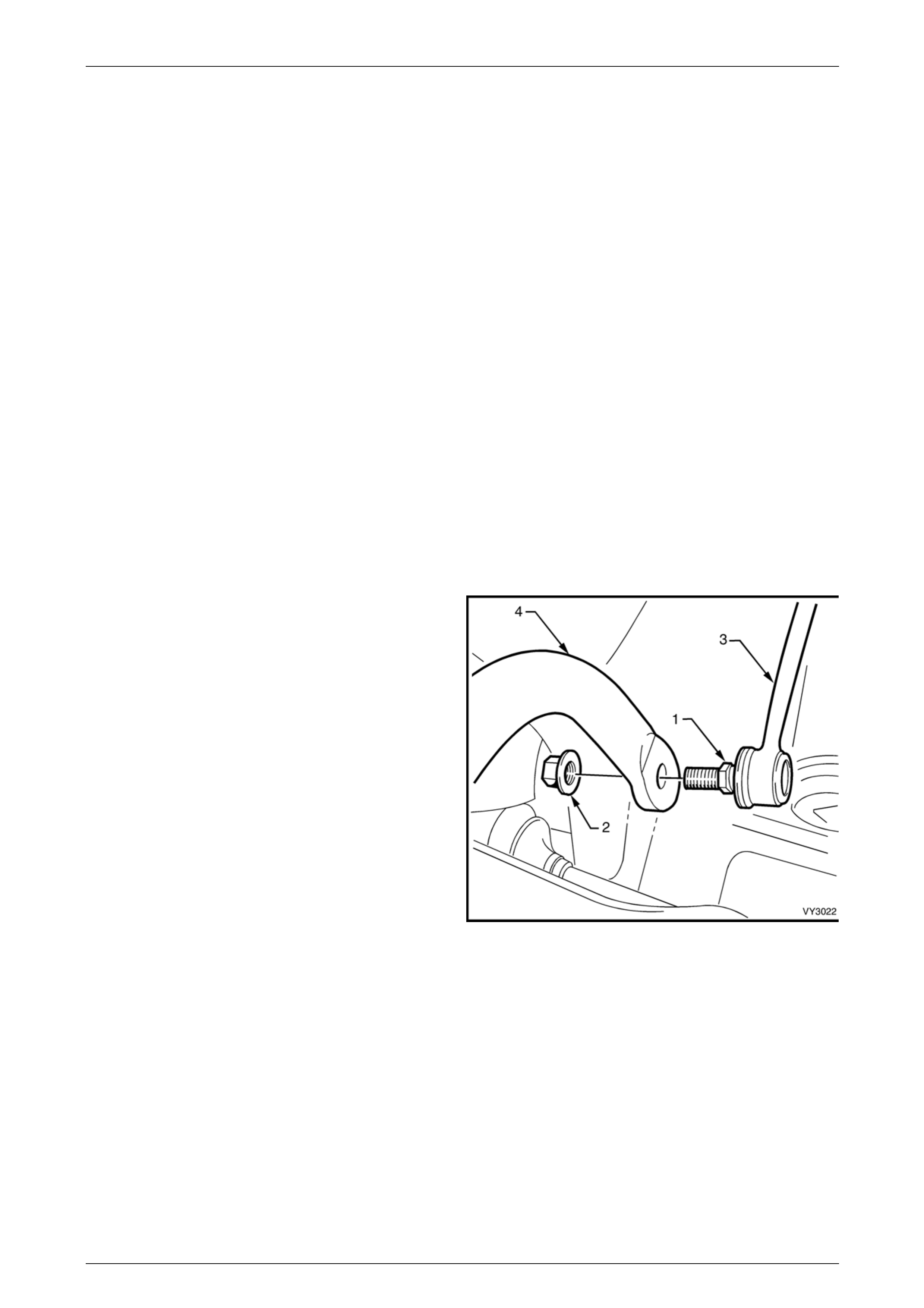

4 Position a suitable size open end spanner to hold the

stabiliser bar link upper ba ll joint stud, then use

another spanner to loosen and remove the u pper nut

(2).

5 Pull the link stud from the strut bracket.

6 Remove the brake hose retaining clip at the

suspension tower bracket by first, prising the end at

the brake hose end free, using a screwdriver or

similar. Remove the clip from the strut bracket, then

discard.

7 Disconnect the ABS wheel speed sensor cable a nd

insulator from the strut bracket.

8 Rotate the brake hose grommet until the flats on the

grommet are aligned with the slot in the strut bracket,

then remove the hose and gro mmet.

Figure 3A – 23

9 Remove the brake caliper retaining bolts and washers

(1), lift the caliper assembly (2) from the brake rotor

and support in such a way that no strain is placed on

the brake hose. THE BRAKE CALIPER IS NOT TO

HANG BY THE BRAKE HOSE.

NOTE

This step is necessary to allow access to the

lower strut mounting bolts and nuts (3).

10 If required, remove the brake rotor from the wheel hu b

assembly. The brake rotor to hub relationship is

marked during production. To ensure this relationship

is maintained, ensure that the rotor to hub position is

carefully marked.

NOTE

This is necessary to overcome the possibility of

inducing a brake shudder condition after

reassembly. Figure 3A – 24

Front Suspension Page 3A – 23

Page 3A-23

11 Remove the brake hose from the strut housi ng bracket by turning the plastic sleeve o n th e hose until the flats on

the sleeve align with the brac ket opening.

12 Position a suitable floor jack fitted with a block of wood on the lift pad under the control arm, and raise it sufficiently

to support the weight.

13 Loosen, remove and discar d the two lower strut to knuckle attaching bolts and nuts.

14 To avoid placing strain on the ABS sensor lead, release the connector locking tang an d pull on the sensor lead

connector (4) to remove from the sensor.

15 Pull the steering knuckle clear of the strut.

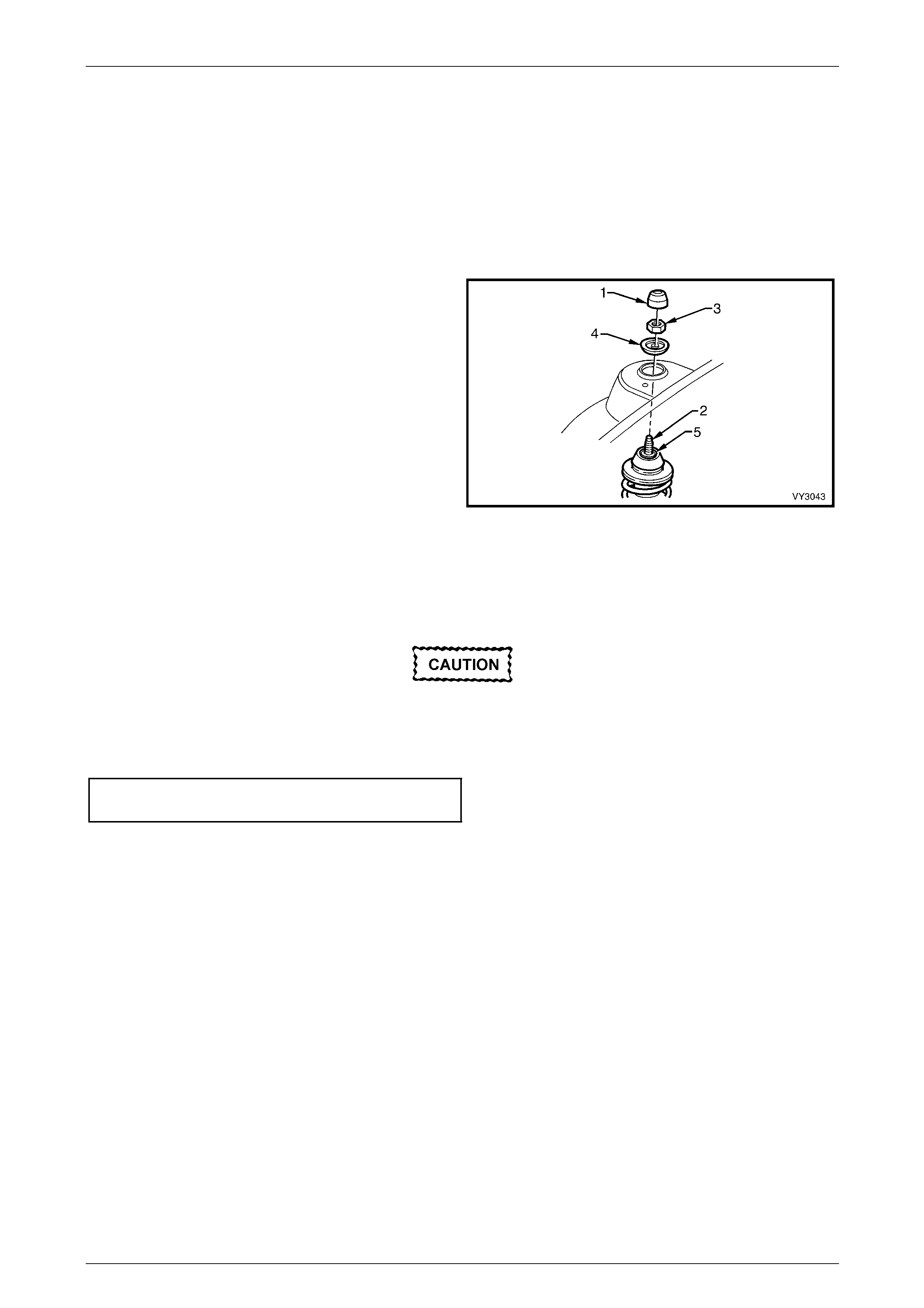

16 Remove the dust cover (1) from the upper strut

support, in the engine compartment.

17 While holding the strut rod shaft (2) with a 10 mm

socket, remove the self-locking nut (3), using a 24 mm

ring spanner, then remove the locating disc (4).

Discard the removed strut rod nut.

18 Carefully lower the strut from the tower, manipulate

the strut to remove the stabiliser stud from the bracket

on the strut and remove the assembly from the

vehicle.

Figure 3A – 25

Reinstall

The torque of the strut bearing retaining nut

(‘5’ in Figure 3A-25) MUST be checked for

correct tightness BEFORE installing the strut

into the vehicle.

Upper strut bearing retaining

nut torque specification.........................................78 Nm

1 Lift the strut assembly into the spring strut tower.

2 Install the locating disc and partially install a NEW upper nut to the strut rod. Do not tighten at this time.

Front Suspension Page 3A – 24

Page 3A-24

3 Pivot the hub and steering knuckle ass embly (1),

sufficiently to line up the bolt holes in the steerin g

knuckle and the lower end of the strut assembly (2).

4 Install NEW retaining bolts (3) and nuts (4), and

tighten to a preliminary torque of 85 Nm.

5 Use a 10 mm socket to hold the strut rod from turning,

then tighten the upper strut rod retaining nut (‘3’ in

Figure 3A – 25) to the correct torque specification,

using a 24 mm ring spanner with a torque wrench

attached.

Upper strut locating plate retaining

nut torque specification.........................................55 Nm

6 Reinstall the wheel speed sensor connector, pushing

firmly onto the sensor until the retaining tang is secure.

7 Reinstall the sensor lead and grommet into the strut

mounting bracket.

8 Reinstall the brake hos e and grommet into the

suspension strut bracket and secure by turning the

grommet through 90°.

Figure 3A – 26

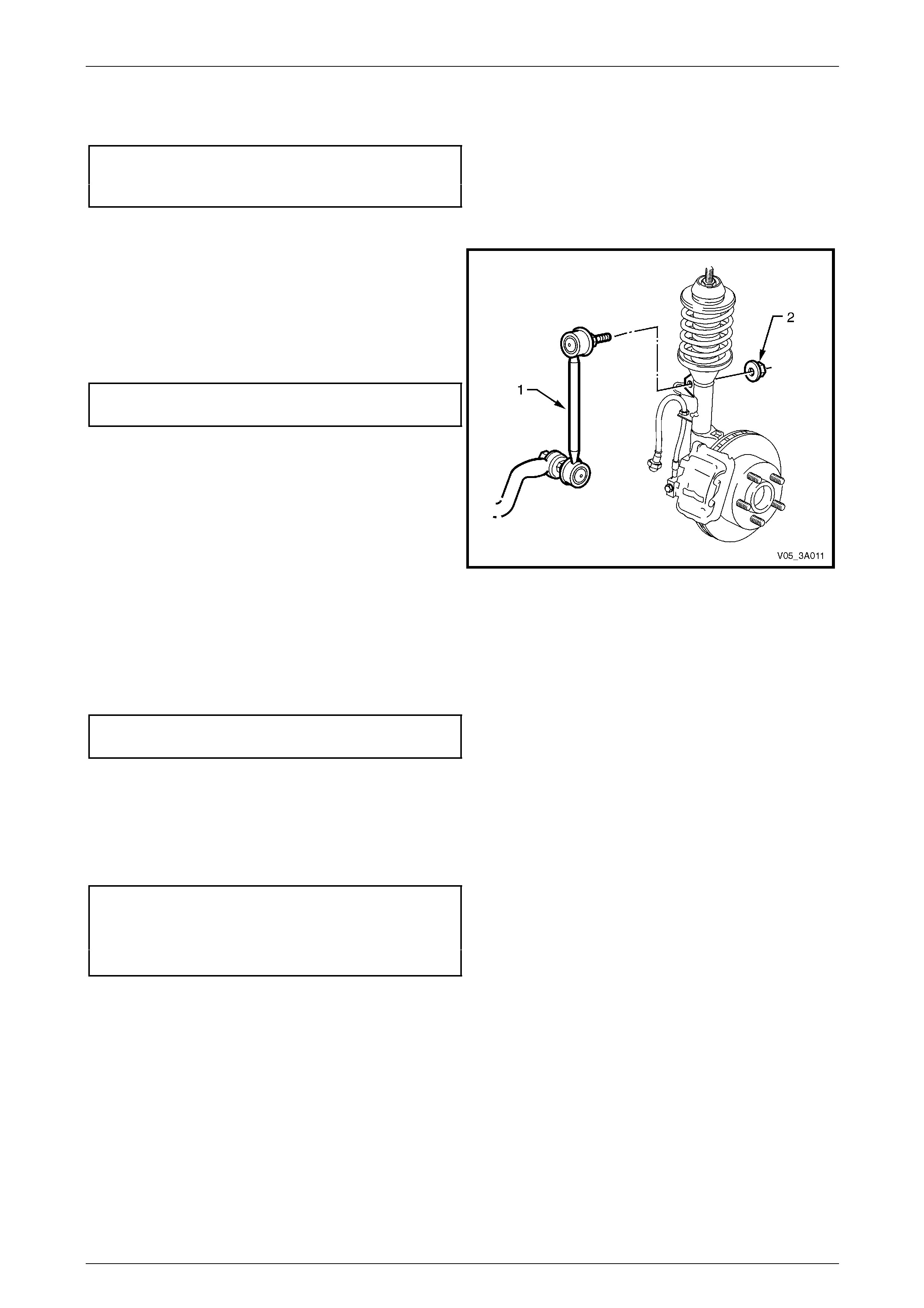

9 Install a NEW brake hose retaining clip, as follows:

a Slide one end of the retaining clip (1) over the

brake hose retaining bracket (2) at point ‘X’,

checking that the strut bracket is aligned with the

slot in the clip.

Figure 5A – 27

b While holding the installed end ‘X’ in place,

rotate the clip around the brak e hose retaining

bracket until the clip ‘clicks’ into position, at

point ‘Y’.

c Squeeze the clip firmly with the thumb and

forefinger of one hand as indic ated, to ensure

that the clip ends are fully engage d.

Figure 5A – 28

Front Suspension Page 3A – 25

Page 3A-25

10 If removed, reinstall the brake rotor, aligning the marks made prior to removal.

11 Reinstall the brake caliper, se cure with NEW attaching bolts and tighten to specification.

Brake caliper anchor plate

bolt torque specification...............................85 Nm, then

turn through 45°

12 Check that the wheel speed sensor lead and the brake hose are routed correctly and the hose is n ot twisted.

13 Reinstall the stabiliser bar link ball joint stud (1) into

the strut bracket.

14 Reinstall the stud retaining nut (2).

15 While holding t he inner stud hexagon with a suitable

set spanner, tighten the nut to the correct torque

specification.

Upper stabiliser bar link stud

nut torque specification.........................................50 Nm

Figure 3A – 29

16 Reinstall the road wheel, alig ning the marks made prior to removal.

17 Lower the vehicle to the ground.

18 Tighten road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern, refer to

3.1 Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

19 Reinstall the centre wheel nut cover.

20 Bounce the vehicle up and down several times to settle the suspension.

21 Check the wheel alignment, a s detailed in 2.2 Wheel Alignment Checking and Adjustment in this Section.

22 Tighten the steering knuckle to strut bolts and nuts to the specified torque values.

Steering knuckle to strut bolts

and nuts torque specification .... Stage 1..............85 Nm

Stage 2 ............100 Nm

Stage 3Turn through 90°

Front Suspension Page 3A – 26

Page 3A-26

3.6 Upper Strut Support Bearing and Mount

Remove

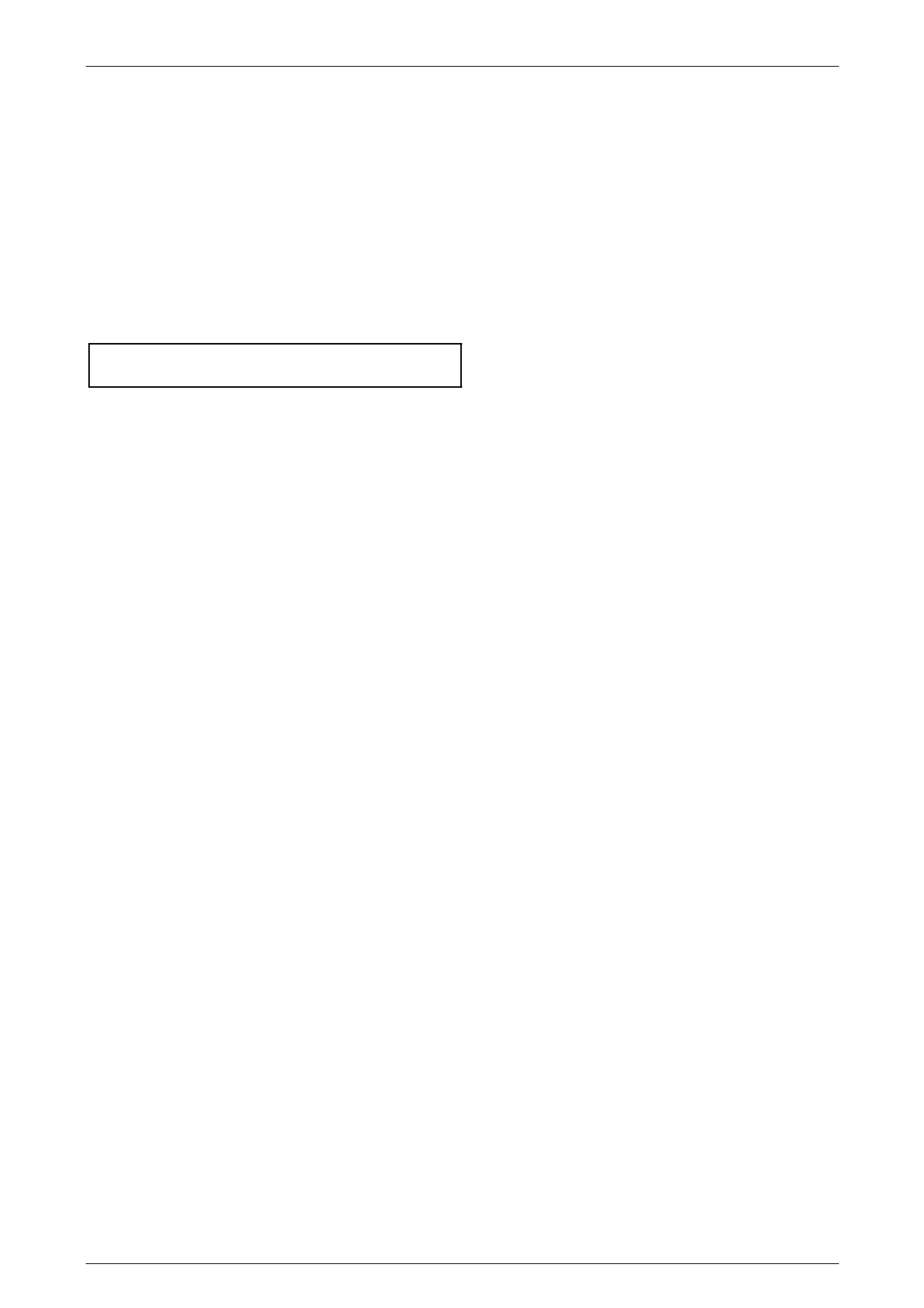

1 Remove the front strut (1) as detailed in 3.5 Front Strut

Assembly in this Section.

2 Fit Tool No. 180 (or a commercially available

equivalent) on to the front spring as shown. Compress

the spring (2) until the upper support bearing (3) has

clearance at the spring seat collar (4).

Figure 3A – 30

Do not attempt to remove the retaining nut

from the strut rod shaft before compressing

the spring.

Under no circumstances is the machined

surface of the piston rod section to be

gripped directly on its outer surface.

3 While holding the strut rod shaft with a 10 mm socket,

remove the upper strut bearing to strut rod retaining

nut (1), using a 24 mm ring spanner.

4 Remove the front suspension strut mount assembly

and the two washers (2) either side.

NOTE

The lower washer may a dhere to the lower edge

of the mount.

Figure 3A – 31

5 Remove the strut bearing (3) from the upper spring seat collar, taking particular note of the bear ing's orientation.

NOTE

The upper support bearing is self-lubricated and

no servicing requirements are necessary. If

considered to be faulty, the bearing is to be

replaced as an assembly.

Front Suspension Page 3A – 27

Page 3A-27

Reinstall

1 Pull the strut rod through the upper spring seat to its maximum length, then remove the strut rod nut.

2 Reinstall the upper bearing with the same orientation as noted on removal. Generally, the coloured or narrow, outer

section, faces towards the upper spring seat collar.

3 While holding the strut rod extended and, after installing the first mount washer with the dished shape facing

downward (refer to '2' in Figure 3A-31), install the upper front suspensi on strut mount assembly over the bearing

and washer.

4 Install the second washer with the dished shape facing upward (refer to '2' in Figure 3A-31 ), then install the

retaining nut.

5 Using a 10 mm socket and a 24 mm ring spanner with a torque wrench attached, tighten the nut to the correct

torque specification.

Upper strut bearing retaining

nut torque specification.........................................78 Nm

6 Release the spring compress or and remove it from the spring.

7 Reinstall the front strut, refer to 3.5 Front Strut Assembly in this Section.

Front Suspension Page 3A – 28

Page 3A-28

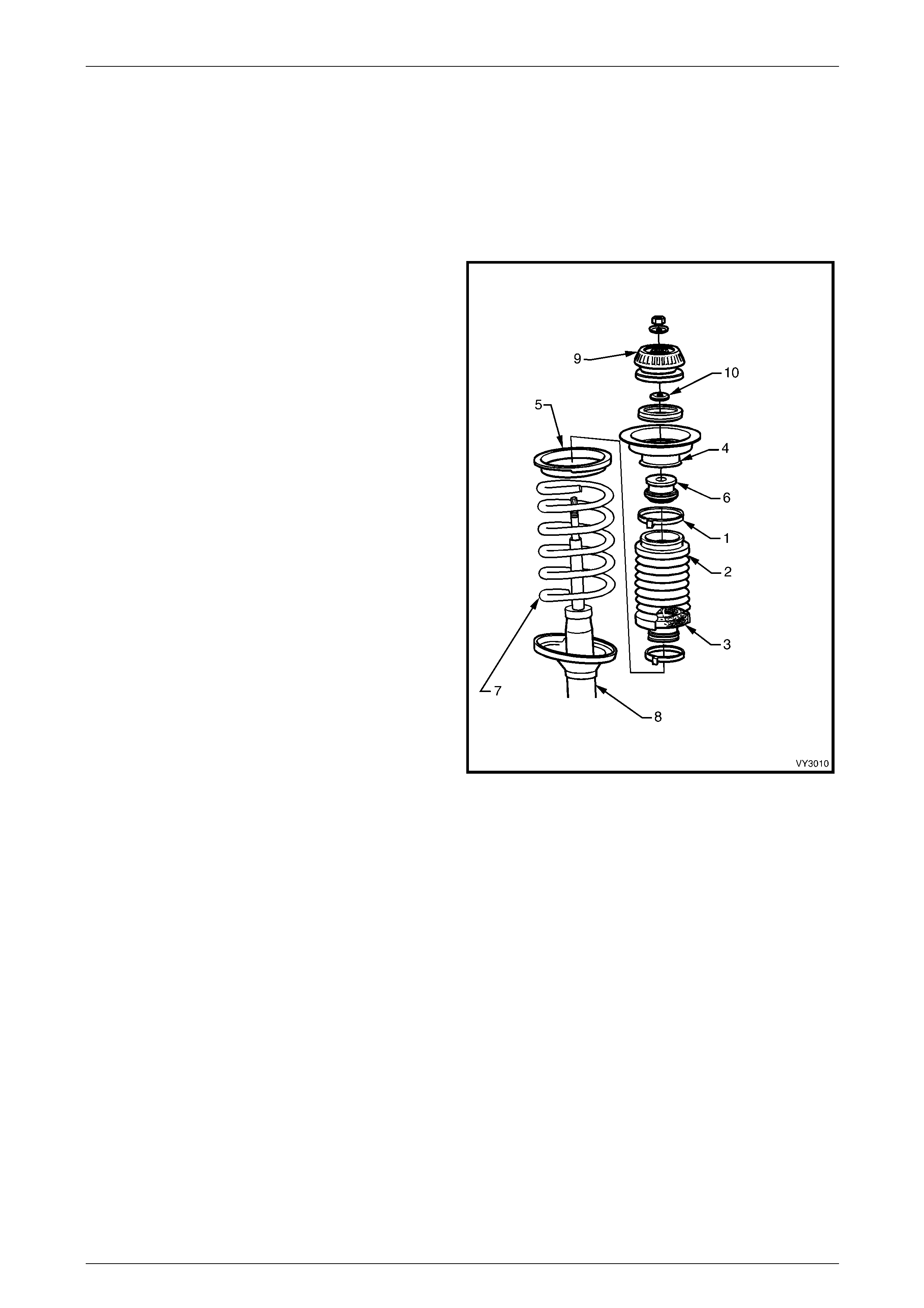

3.7 Front Spring

Remove

1 Remove the front strut, refer to 3.5 Front Strut Assembly in this Section.

2 Remove the front strut dust shield assembly, as detailed in 3.6 Upper Strut Support Bearing and Mount in this

Section.

3 Remove the clamp (1) securing the front strut dust

shield assembly (2) and filter (3) to the upper sprin g

seat collar (4) and discard.

4 Remove the upper spring seat collar, spring insulator

(5) and compression bumper (6) from the top of the

spring (7).

5 Remove the spring from the strut (8) and release the

spring compressor.

Figure 3A – 32

Front Suspension Page 3A – 29

Page 3A-29

Reinstall

If installing a replacement spring, check that

the spring is the correct type for the

suspension system fitted to the vehicle. Refer

to 5 Specifications in this Section for details.

1 Position spring on strut with straight projecting end of spring correctly located in spring seat.

2 Install spring compressor Tool No. 180 (or a commercial equivalent) to the spring (refer to F igure 3A – 30) and

compress it.

3 Install the upper spring insulator, spring seat collar and compression bumper so that the double notch in the upper

flange of the spring seat collar is assembled, facing inward. The spring insulator has a step which locates on to the

straight projecting end of the spring.

4 Install the upper support plate (9), refer to 3.6 Upper Strut Support Bearing and Mount, in this Section.

NOTE

The lower washer (10) may have stuck to the

lower edge of the mount.

5 Fit the upper end of the front strut dust shield assembly over the lower flange of the spring seat collar and secure

with a retaining clamp. Tighten the clamp until the boot rubber is firmly secured.

6 Install front strut, refer to 3.5 Front Strut Assembly in this Section.

Front Suspension Page 3A – 30

Page 3A-30

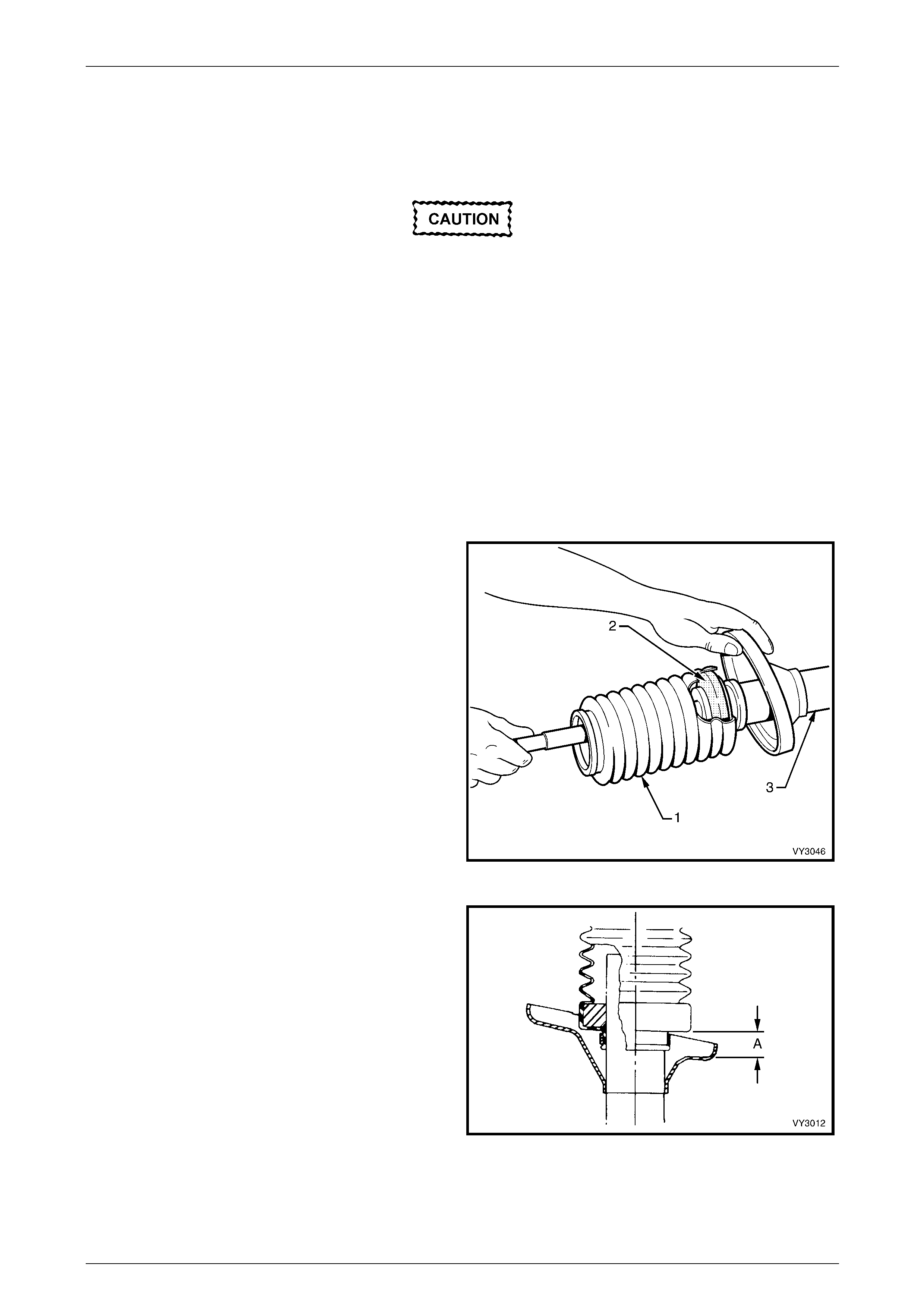

3.8 Front Strut Unit

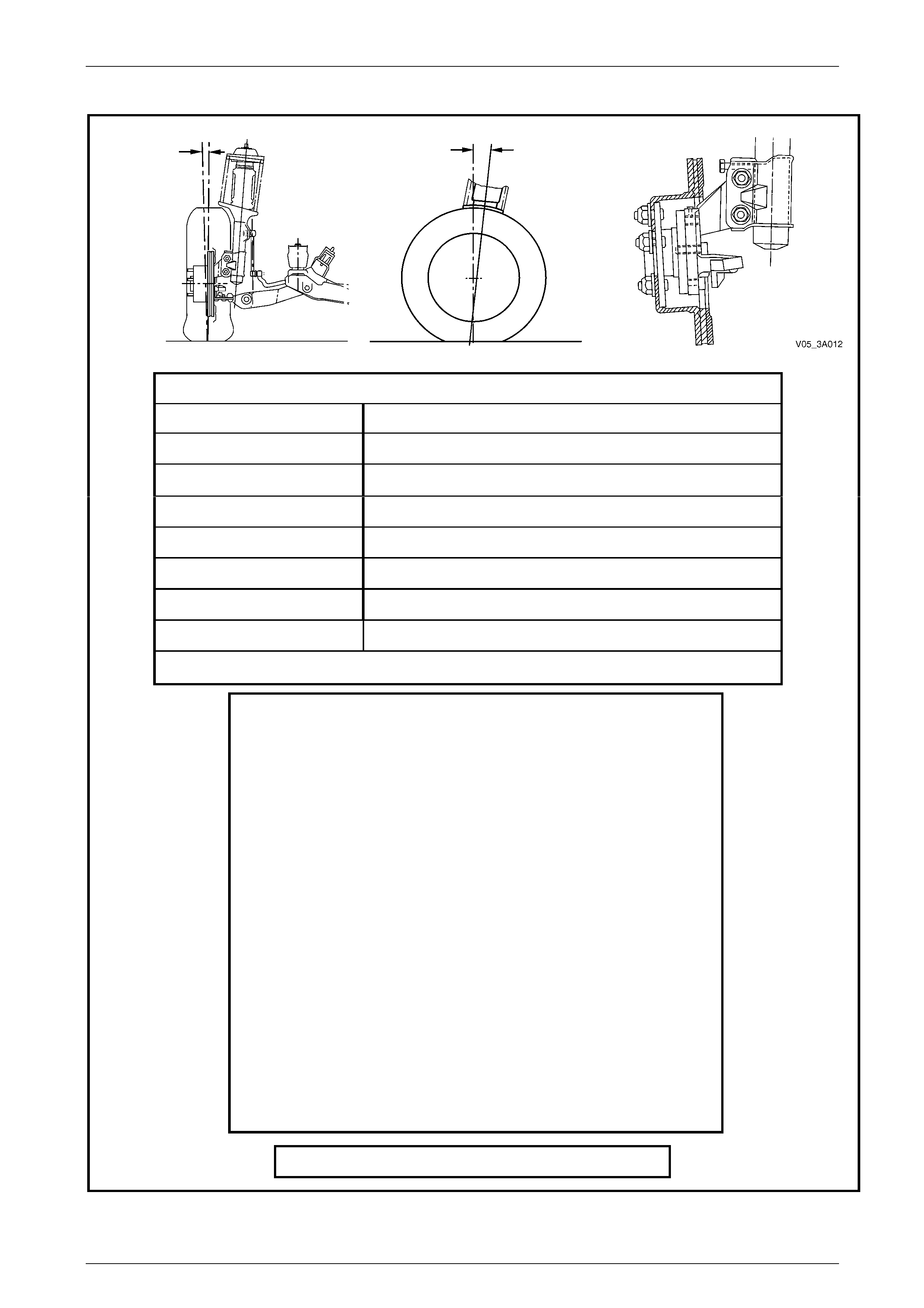

Replace

When replacing the front strut, check that the

replacement is the correct type for the

suspension system fitted to the vehicle. Refer

to 5 Specifications in this Section for details.

NOTE

As the strut assembly is a sealed component, no

overhaul procedures are possible. If any strut

component is found to be unserviceable, the

complete strut must be replaced.

1 Remove the front strut assembly as detailed in 3.5 Front Strut Assembly in this Section.

2 Remove the upper support components as detailed in 3.6 Upper Strut Support Bearing a nd Mount in this Section.

3 Remove the spring as detailed in 3.7 Front Spring in this Section.

4 Remove the lower boot retaining clamp and discard.

Slide the front strut dust shield assembly (1) and filter

(2) from the strut assembly (3).

5 Pull the strut rod fully up and, while supporting the rod

to stop it from slipping back into the strut, install the

front strut dust shield assembly over the strut tube,

ensuring that the filter remains seated insid e the boot

assembly.

Figure 3A – 33

6 Ensure that the bottom of the front strut dust shield

assembly is positioned so that distance ‘A’ is between

30 – 35 mm.

7 Install the retaining clamp and tighten until th e rubber

on the front strut dust shield assembly is firmly

secured.

8 Install the front spring, refer to 3.7 Front Spring in this

Section.

9 Install the upper strut support assembly, refer to

3.6 Upper Strut Support Bearing and Mount in this

Section.

10 Install the front strut assembly, refer to 3.5 Front Strut

Assembly in this Section. Figure 3A – 34

Front Suspension Page 3A – 31

Page 3A-31

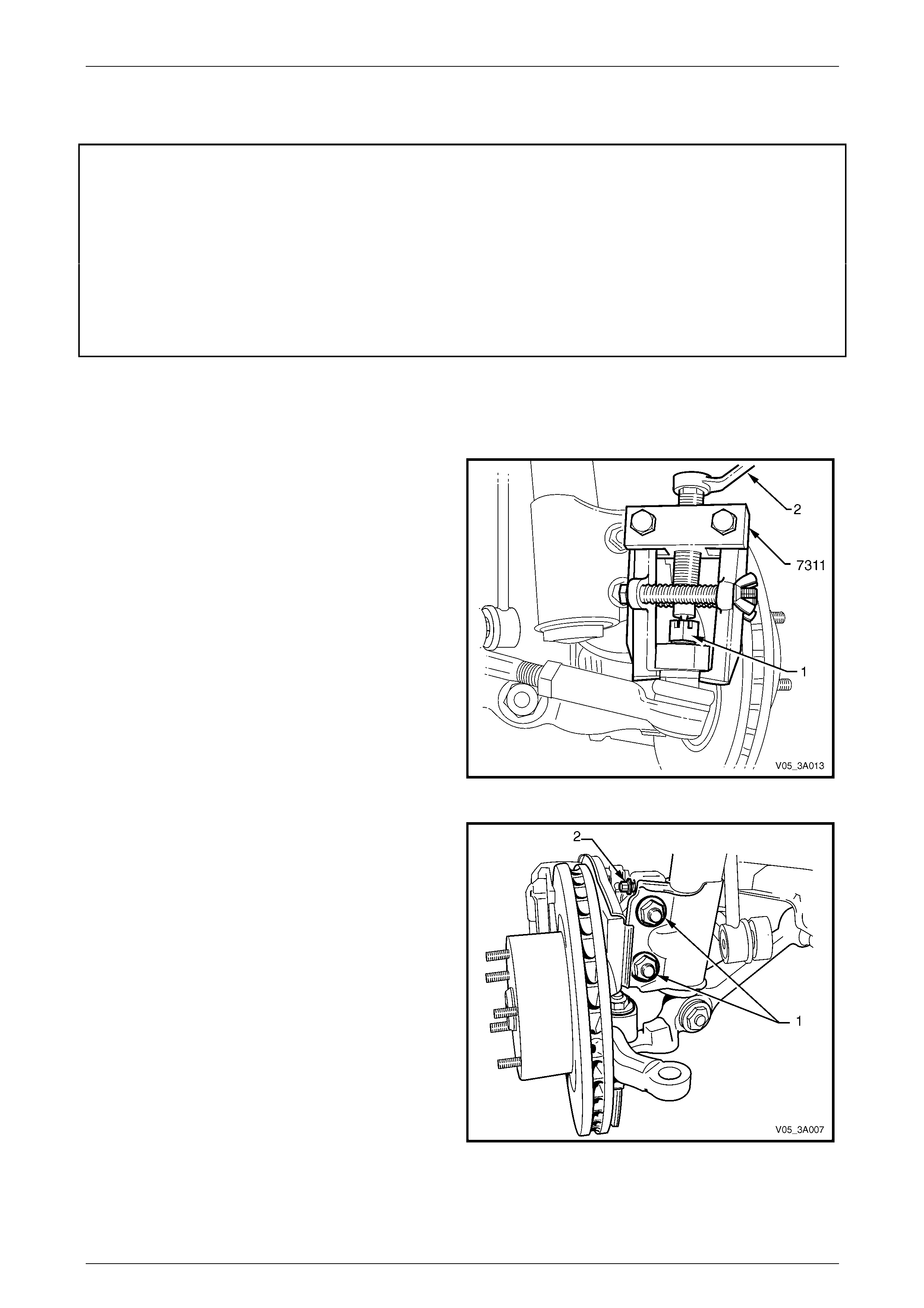

3.9 Steering Knuckle

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical th read lock and should

only be used once. If in doubt, replacement is recommended when performing these operations:

Front control arm ball joint stud nut.

The following fasteners MU ST be replaced when performing these operations:

Steering knuckle to fron t strut attaching nuts and bolts.

Brake caliper to steering knuckle retaining bolts.

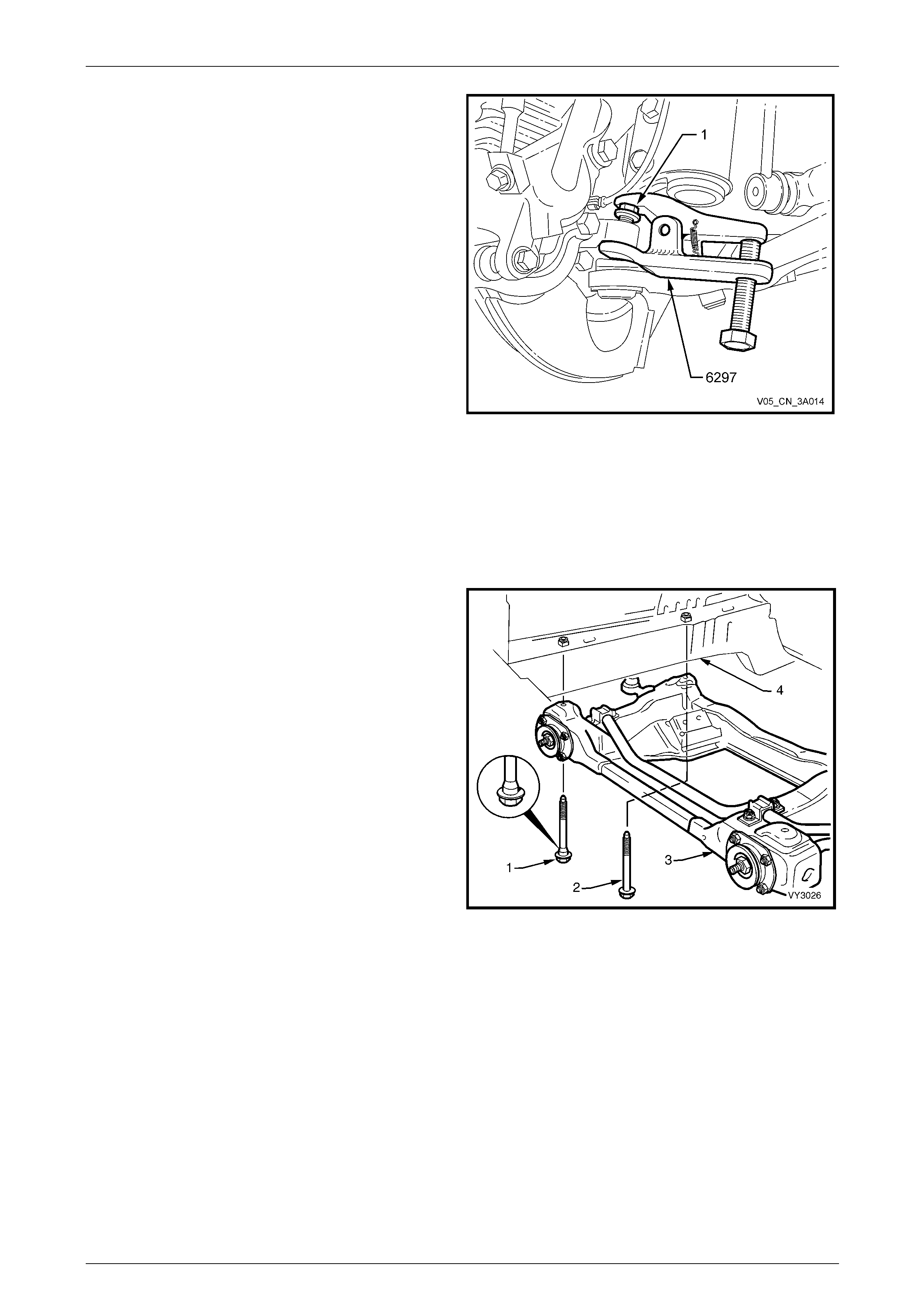

Remove

1 Remove the front brake rotor, wheel hub assembly and brake shield, refer to 3.3 Front Wheel Hub Assembly, Brake

Rotor or Brake Shield in this Section.

2 Remove the split pin and loosen the castellated nut (1)

until the nut is flush with the end of the steering

linkage outer tie rod socket assembly stud.

3 Install Tool No. 7311 as shown and, using a ring

spanner (2), press the stud out from the steering

knuckle.

Figure 3A – 35

4 Loosen, remove and discard the two lower strut

attaching bolts and nuts (1).

5 If the steering knuckle is to be replaced, remove the

camber adjusting bolt (2) from the arm.

Figure 3A – 36

Front Suspension Page 3A – 32

Page 3A-32

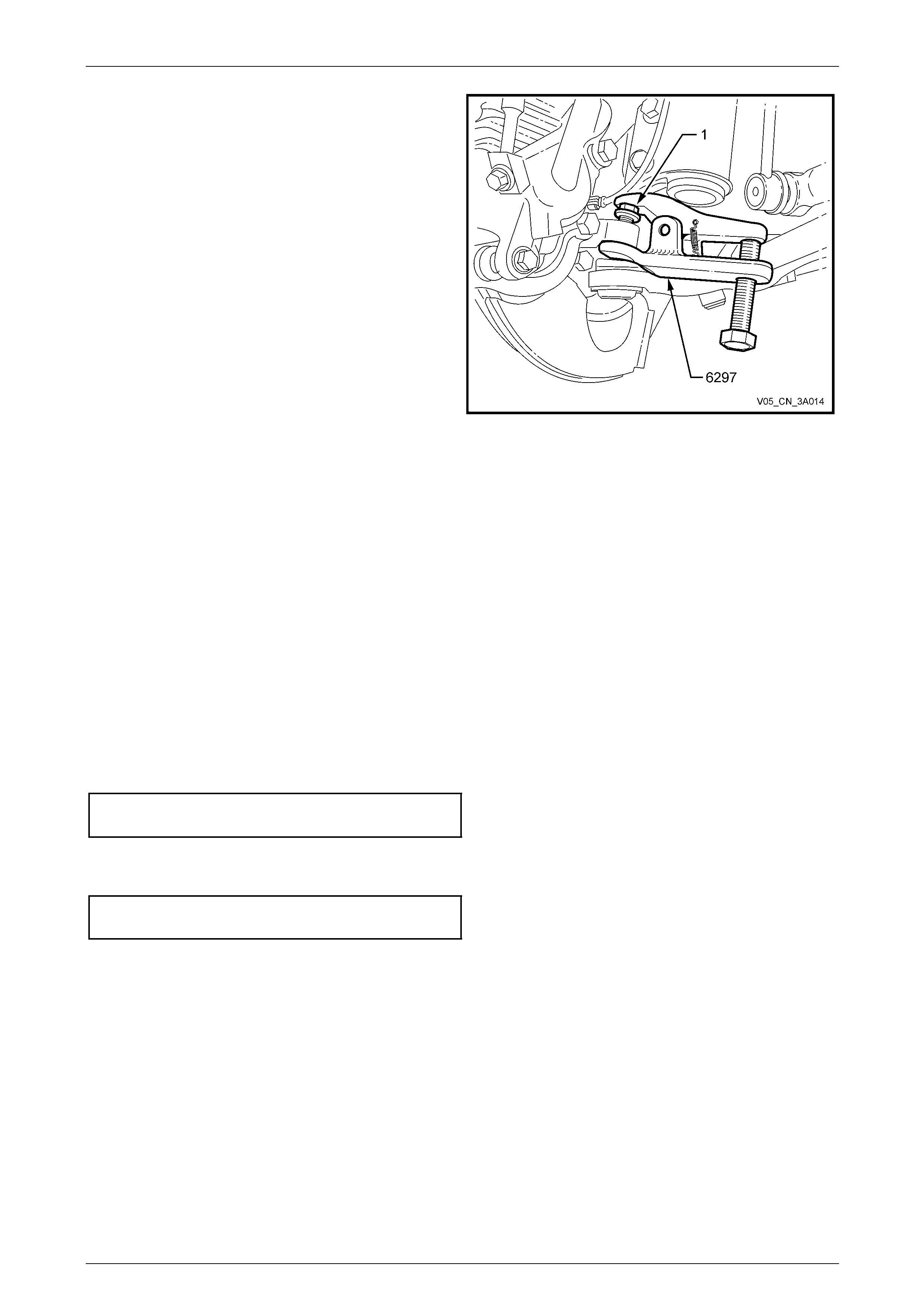

NOTE

While the view shows the brake caliper, rotor,

brake shield and wheel speed sensor lead still

installed, these would all have been removed in

Step 1 of this procedure.

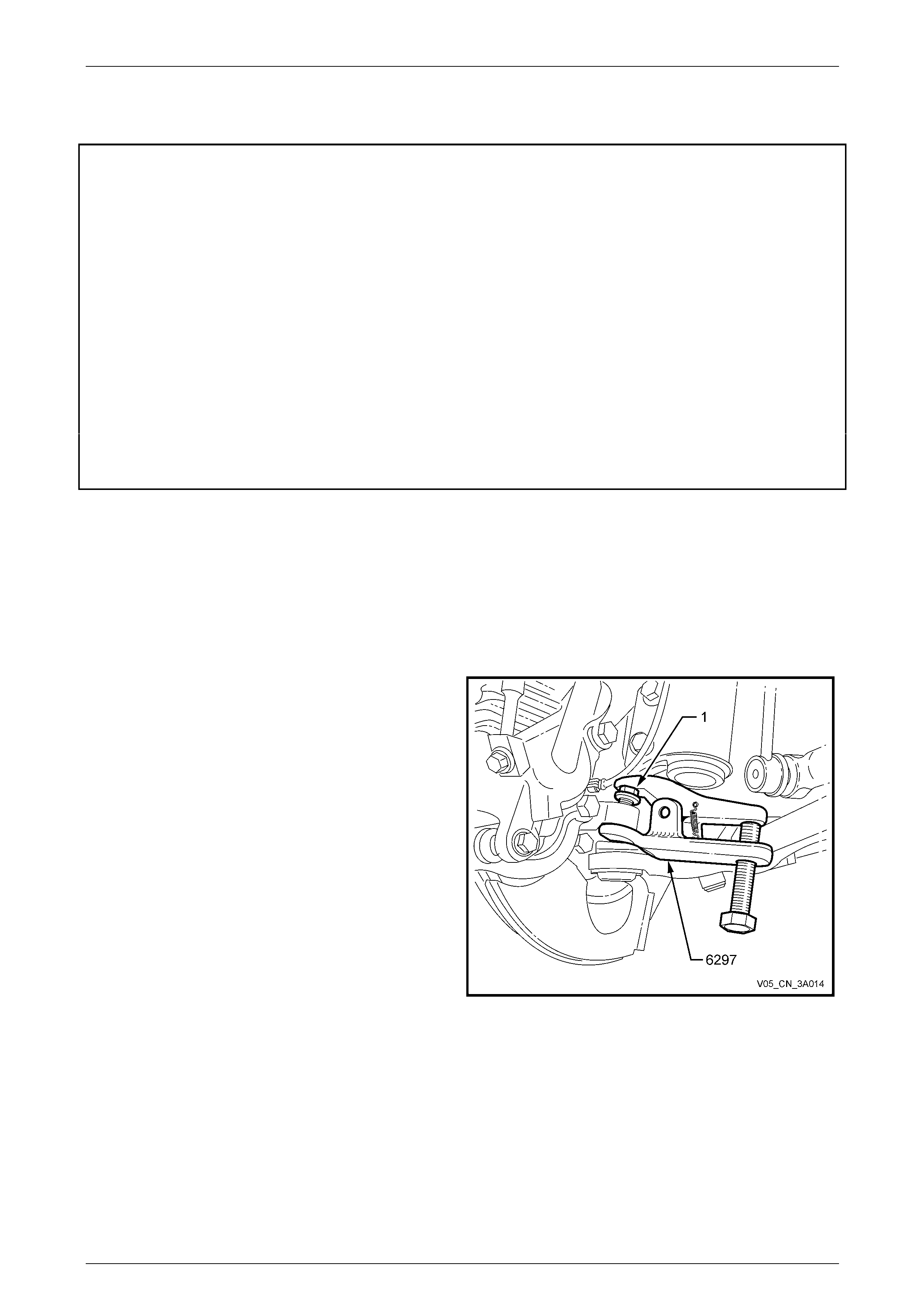

6 Loosen the front control arm socket retainin g nut (1)

until the nut is flush with the end of the front control

arm socket stud thread.

NOTE

As the nut has micro-encapsulated thread

sealant applied, it must be replaced after

removal

7 Install release Tool No. 6297 (or E 9223-A) as shown,

then apply force to the top of the front contro l arm

socket stud by tightening the forcing bolt on the tool,

separating the front control arm socket from the

knuckle.

NOTE

Once a load is applied by the release tool

loading bolt, a sharp tap on the nut end of the

tool will lessen the appl y force required.

Figure 3A – 37

8 Temporarily jam the front control arm socket stud taper into the knuckle to hold the stud, before fully removing the

retaining nut. Discard the removed nut.

9 Separate the knuckle from the front control arm socket stud and remove from the vehicle.

Reinstall

Installation is the reverse of the removal procedures except for the following:

1 Install the steering knuckle over the front con trol arm socket stud, then install NEW lower strut to steering knuckle,

bolts and nuts but do not tighten fully at this stage.

2 Position a suitable floor jack with a block of wood fitted to the lift pad under the front control arm, and raise

sufficiently to support the weight and jam the front control arm socket stud taper into the knuckle.

3 Install a NEW self-locking nut on to the front control arm ball joint stud and tighten the nut to the correct torque

specification.

Front control arm ball joint

nut torque specification.........................................60 Nm

4 Reinstall the steering linkage outer tie rod end into the steering knuckle and tighten the castellated attaching nut to

the correct torque specification. Install new split pin.

Steering linkage outer tie rod end

castellated nut torque specification.......................68 Nm

5 Reinstall the brake shield, wheel hub assembly and front br ake rotor, refer to 3.3 Front Wheel Hub Assembly,

Brake Rotor or Brake Shield in this Section.

NOTE

Check that the brake rotor is installed with the

marks made before removal, aligned.

6 Lower the vehicle to the ground.

7 Bounce the vehicle several times to settle the suspe nsion.

8 Check the wheel alignment, refer to 2.2 Wheel Alignment Checking and Adjustment in this Section.

Front Suspension Page 3A – 33

Page 3A-33

9 Following the wheel alignm ent procedure, it will be necessary to raise the vehicle and tighten the NEW steering

knuckle to strut bolts and nuts to the correct torque specification.

Steering knuckle to strut bolts

and nuts torque specification ..Stage 1.................. 85 Nm

Stage 2................ 100 Nm

Stage 3..Turn through 90°

10 Lower the vehicle to the ground and tighten road wheel attaching nuts to the correct torque specification, working in

a ‘star’ pattern, refer to 3.1 Warnings, Cautions and N otes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

11 Reinstall the centre wheel nut cover.

Front Suspension Page 3A – 34

Page 3A-34

3.10 Front Control Arm

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical th read lock and should

only be used once. If in doubt, replacement is recommended when performing these operations:

Front control arm ball joint stud nut.

The following fasteners MU ST be replaced when performing these operations:

Front control arm inner pivot bolt and nut.

Front control arm rod to front control arm attaching nut.

Front control arm rod to insulating bush attaching nut.

The following fasteners MUST be at curb height before final tightening:

• Front control arm inner pivot bolt and nut.

• Front control arm rod to front control arm attaching nut.

• Front control arm rod to insulating bush attaching nut.

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to 2.3 Jacking Precautions in this Section.

2 Remove the centre wheel nut cover.

3 Mark the relationship of the wheel to hub. Loosen, then remove the roa d wheel attaching nuts and remove the

wheel.

4 Turn the steering out on full lock.

5 Loosen the front control arm socket retainin g nut (1)

until the top of the nut is flush with the top of the front

control arm socket assembly stud thread.

NOTE

As the nut has micro-encapsulated thread

sealant applied, it must be replaced after

removal

6 Install the release Tool No. 6297 (or E 9223-A) as

shown, then apply force to the top of the front control

arm socket assembly stud by tightening the forcing

bolt on the tool, separating the front control arm socket

assembly from the knuckle.

NOTE

Once a load is applied by the release tool

loading bolt, a sharp tap on the nut end of the

tool will lessen the appl y force required.

7 Temporarily jam the front control arm socket assembly

stud taper into the knuckle to hold the stud, before fully

removing the retaining nut. Discard the removed nut.

Figure 3A – 38

8 Separate the front control arm socket assembl y stud from the knuck le.

9 Hold the steering knuckle a way from the front control arm by using a suitable length prop.

Front Suspension Page 3A – 35

Page 3A-35

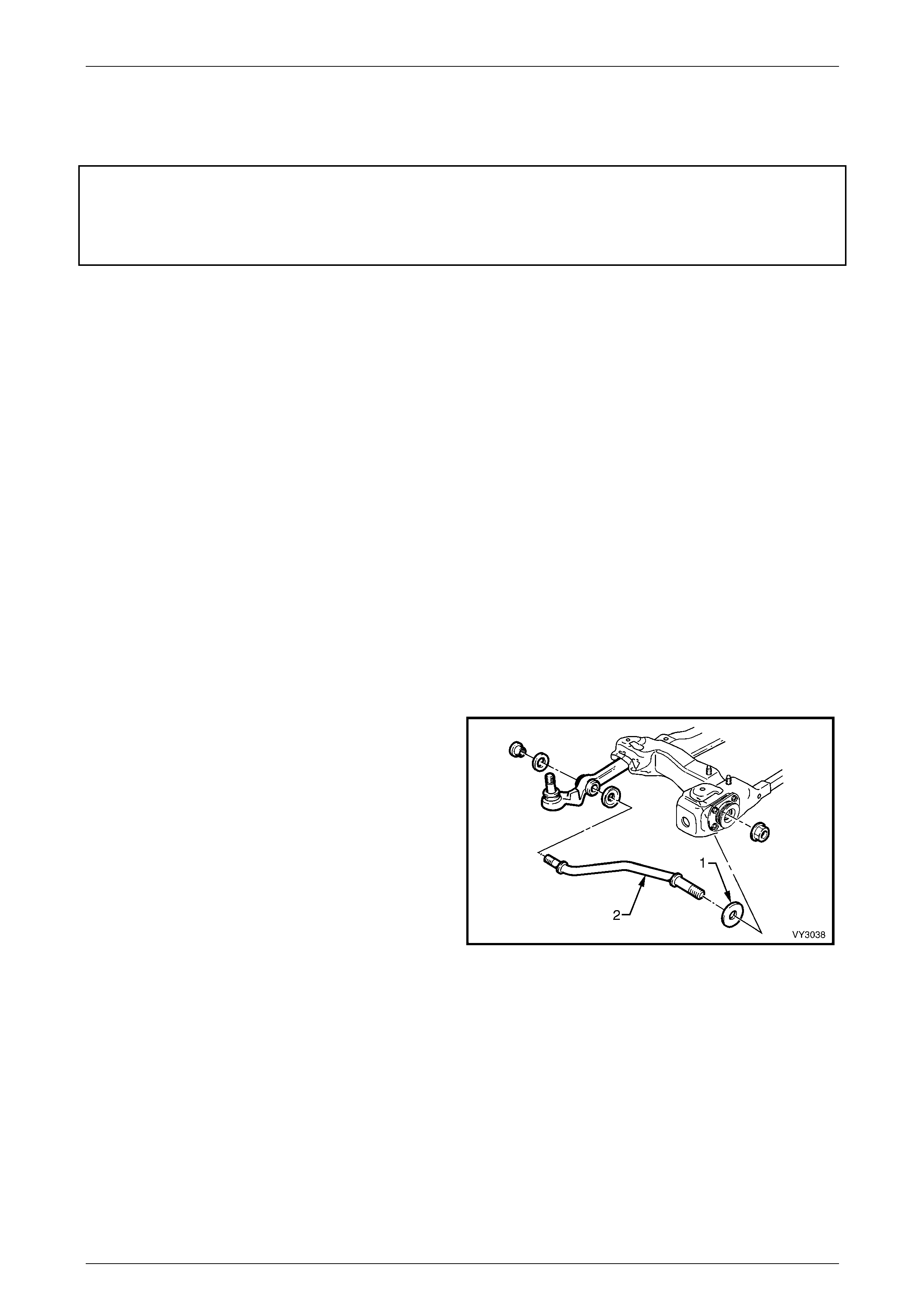

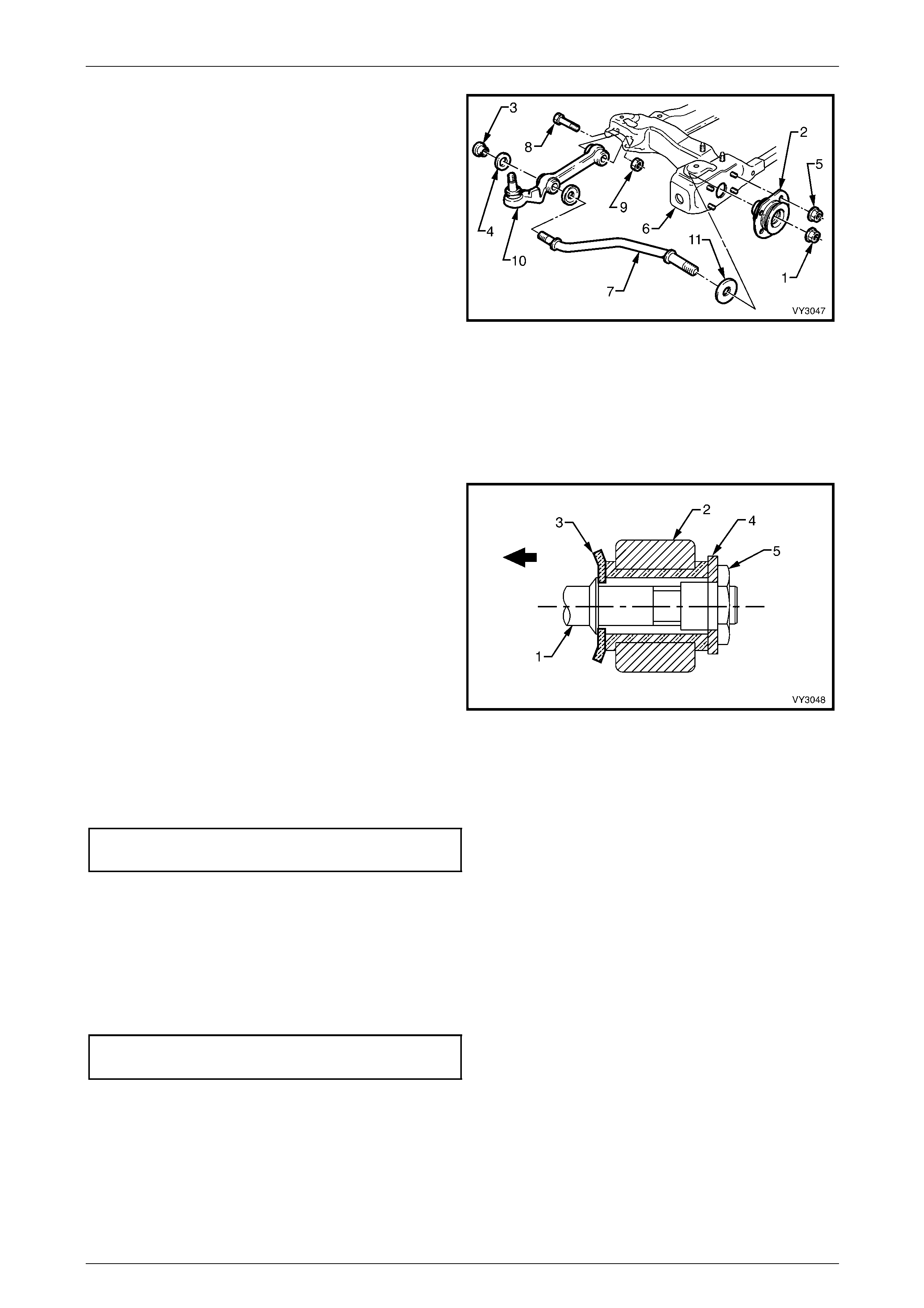

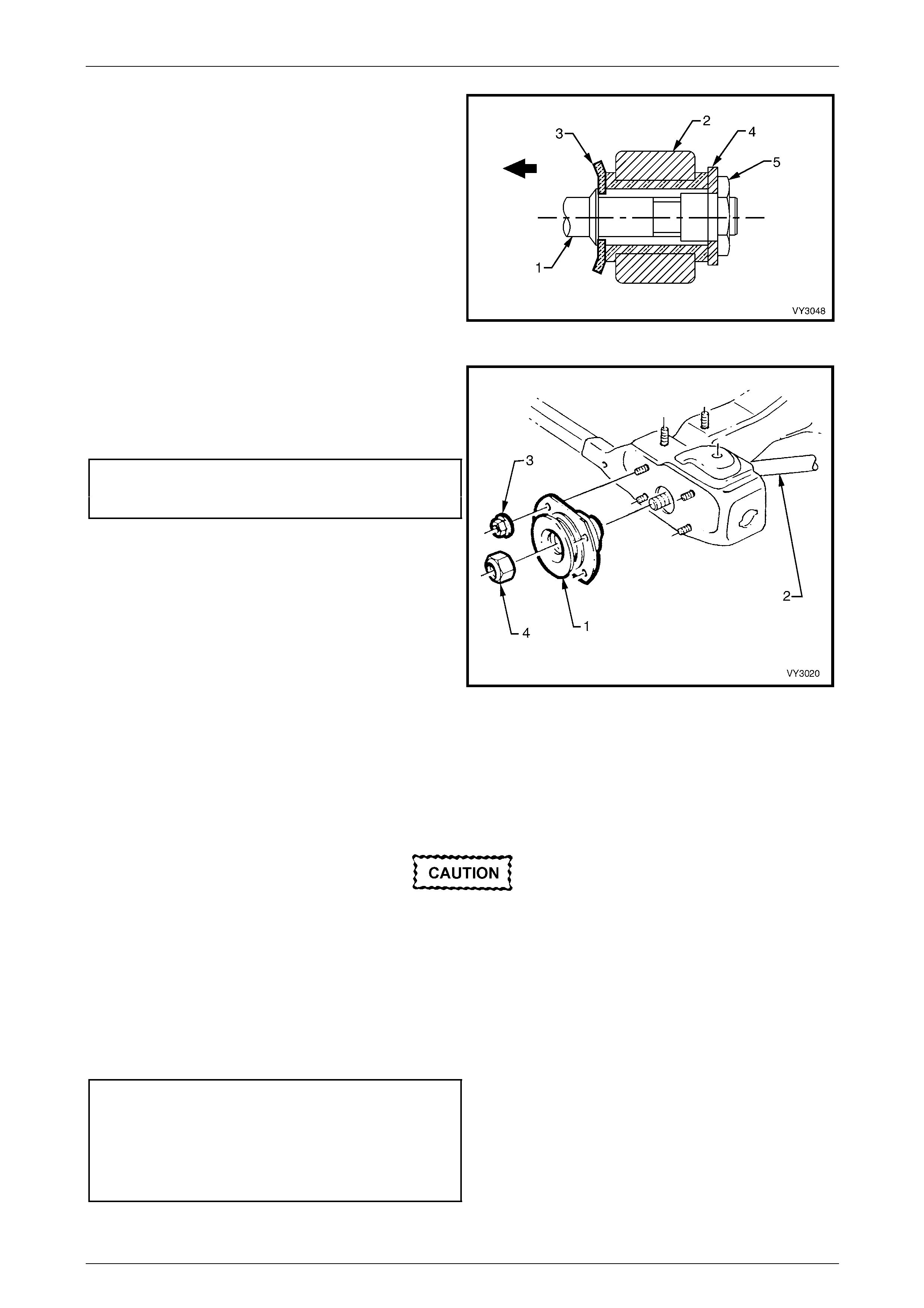

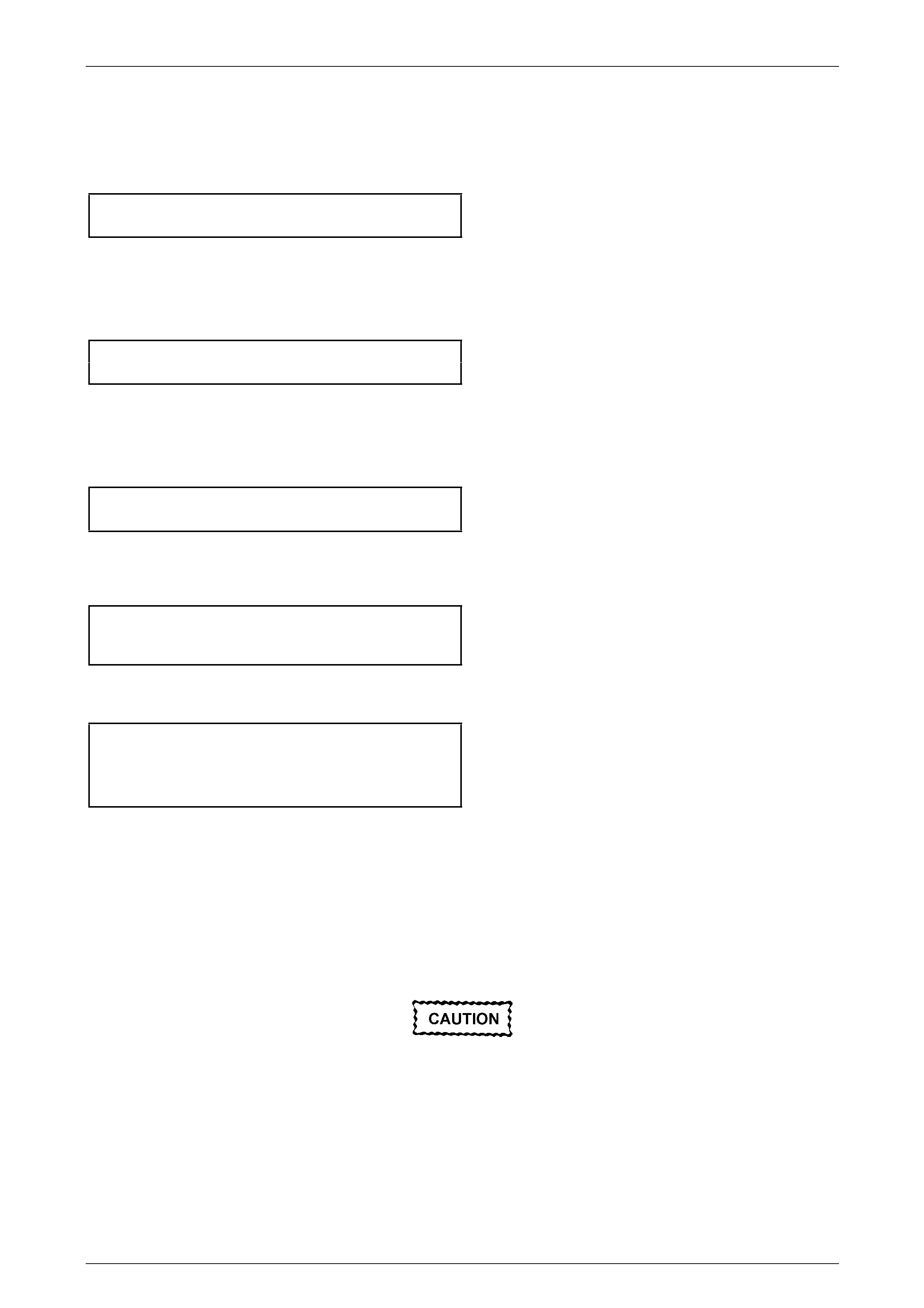

10 Loosen the front control arm rod front nut (1) at the

front control arm rod insulating bushing asse mbly (2).

11 Remove the front control arm rod to front control arm

attaching nut (3) and washer (4). Discard the nut.

12 Remove the four nuts (5) securing the front control

arm rod insulating bushing to the crossmember (6),

then remove the front control arm rod (7) from the front

control arm rod bushing.

13 Remove the front control arm inner pivot bolt (8) and

nut (9). Discard the nut.

14 Remove the front control arm from the vehicle.

Figure 3A – 39

Reinstall

1 Referring to Figure 3A – 39 reinstall the fron t control arm to the crossmember, install the bolt (8), then install a

NEW nut (9), but do not fully tighten at this stage.

2 Reinstall front control arm rod (7) into the crossmember.

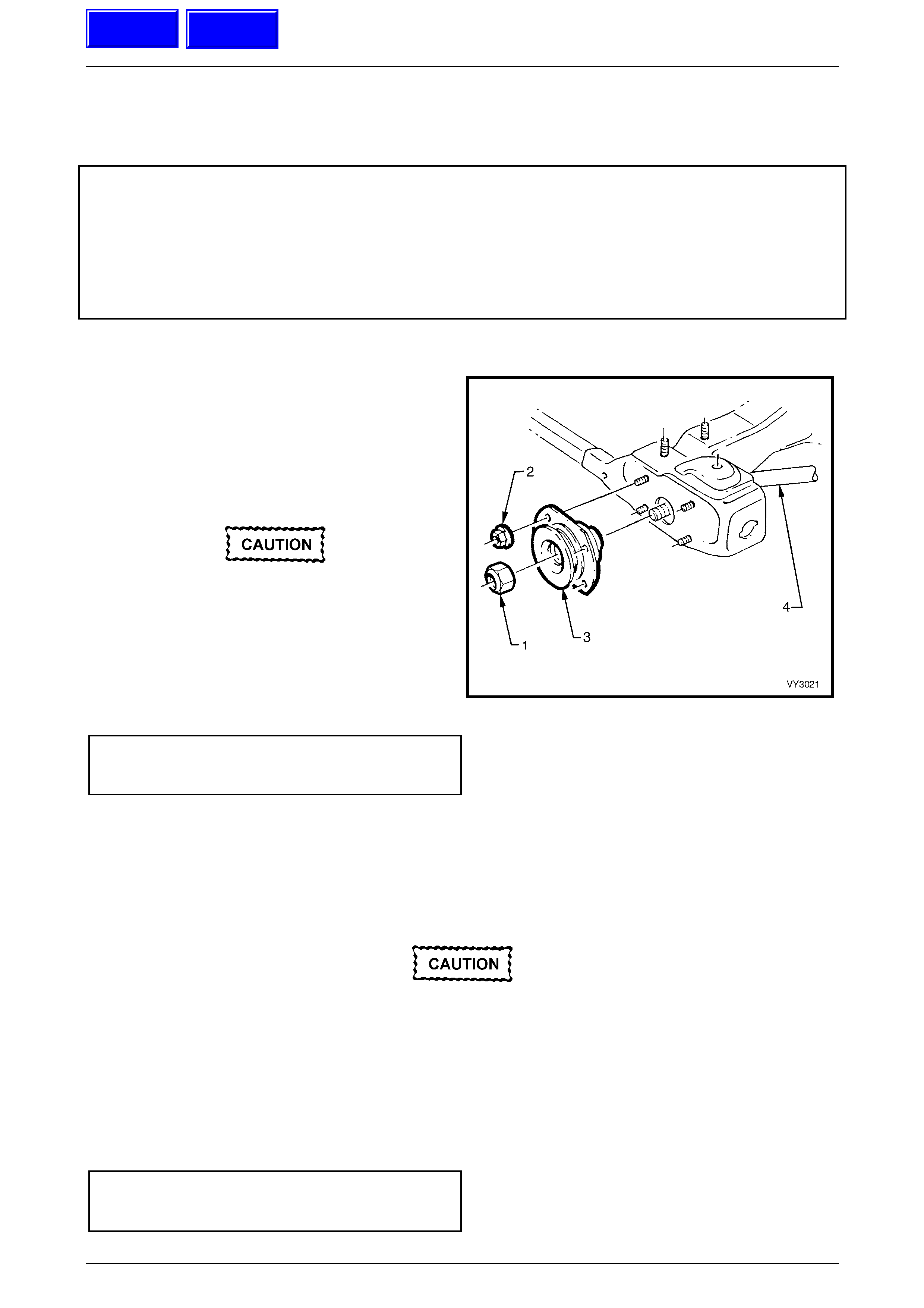

3 Install the front control arm rod (1) to the front control

arm (2) with the convex side of the cupped washer (3)

toward the front control arm bushing, as shown.

4 Reinstall the lower control arm rod to front control arm

washer (4) with a NEW attaching nut (5) but do not

fully tighten at this stage.

Figure 3A – 40

5 If the control arm is being installed on the dri v ers side, reinstall the bright finished flat washer to the front of the

control rod.

6 Reinstall the insulating bushing , install the four retaining nut s and tighten to the correct torque specification.

Front control arm insulating bu s hing

to crossmember nut torque specification ..............23 Nm

7 Install a NEW front control arm rod nut ('1' in Figure 3A – 39) to the front of the front control arm rod but do not

tighten at this stage.

8 Using a suitable floor jack fitted with a block of wood positioned under the front control arm, raise the jack

sufficiently to support the weight of the strut assembly and jam the front control arm socket assembly stud taper

into the knuckle.

9 Install a NEW self-locking nut into the front control arm socket assembly stud and tighten the nut to the correct

torque specification.

Front control arm ball joint

nut torque specification.........................................60 Nm

10 Reinstall the road wheel, alig ning marks made prior to removal.

11 Lower the vehicle to the ground.

12 Bounce the vehicle several times at the front, to settle the suspension.

Front Suspension Page 3A – 36

Page 3A-36

The weight of the vehicle must be on all four

wheels before tightening the front control arm

rod nuts to specification. Failure to adhere to

this requirement will not only result in

reduced insulator bushing life but will

adversely affect the ride and handling

characteristics of the vehicle.

13 With the weight of the vehicle on the four roa d wheels, tighten the front control arm inner pivot bo lt and nut to the

correct torque specifications.

Front control arm inner pivot bolt

and nut torque specification................................103 Nm

14 Tighten both front control arm rod nuts at the front of the front control arm (at the insulating bushin g) and at the

front control arm rod bushing, to the correct torque specific ations.

Front control arm rod to control

arm bushing torque specification ........................103 Nm

Front control arm rod

to front insulating bushing

nut torque specification.......................................148 Nm

15 Tighten road wheel attaching nuts to the correct torque specification, working in a ‘star ’ pattern, refer to

3.1 Warnings, Cautions and Notes, in this Section.

Road wheel attaching

nut torque specification.............................110 – 140 Nm

16 Reinstall the centre wheel nut cover.

17 Check the wheel alignment, refer to 2.2 Wheel Alignment Checking and Adjustment in this Section.

Front Suspension Page 3A – 37

Page 3A-37

3.11 Front Control Arm Ball Joint

NOTE

The front control arm ball joint is not serviced

separately and if found to be faulty, the complete

front control arm assembly must be replaced.

Refer to 3.10 Front Control Arm, in this Section

for the replacement procedur e.

Inspect

The following proced ure should be used when checking the front control arm ball joint for wear:

1 Jack the vehicle up with the jack lift pad located under the centre of the front crossmember. Refer to

2.3 Jacking Precautions, in this Section.

2 Holding the road wheel at the top and bottom, check for play in the front control arm socket assembly by rocking

the wheel.

3 If any up or down movement of stud in front control arm socket assembly housing is dete cted, the front control arm

and ball joint assembly must be replaced.

Front Suspension Page 3A – 38

Page 3A-38

3.12 Front Control Arm Inner Bushing

Replace

1 Remove the front control arm (1), refer to

3.10 Front Control Arm in this Section.

2 Support the front control arm with two pieces of square

scrap (2) and press the bushing from the arm, using

Tool No. AU162.

Figure 3A – 41

3 Using Tool Nos. AU160-1 and KM157-2, install the

new bushing from the front side of the front control

arm (1), until flange (2) on the outer sleeve is flush

with the front control arm.

NOTE

Installation tool KM157-2 should be used in the

orientation shown.

Figure 3A – 42

NOTES

• The front control arm inner bushing (1)

should be lubricated with a soapy water

solution to ease the installation process.

• The bushing MUST be aligne d, as shown.

4 Install the front control arm; refer to 3.10 Front Control

Arm in this Section.

Figure 3A – 43

Front Suspension Page 3A – 39

Page 3A-39

3.13 Front Control Arm Rod Bushing

Replace

1 Remove the front control arm; refer to 3.10 Front

Control Arm in this Section.

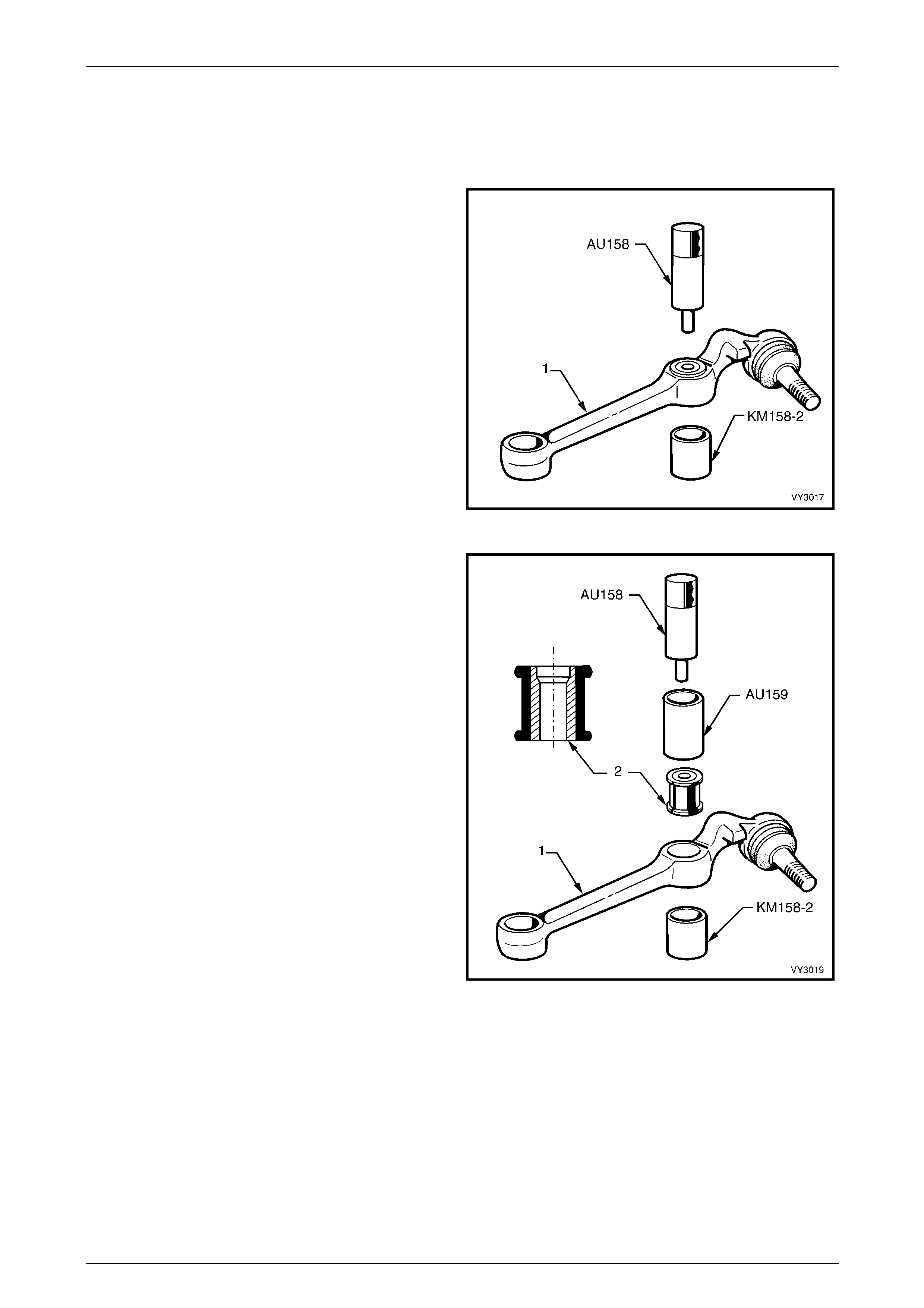

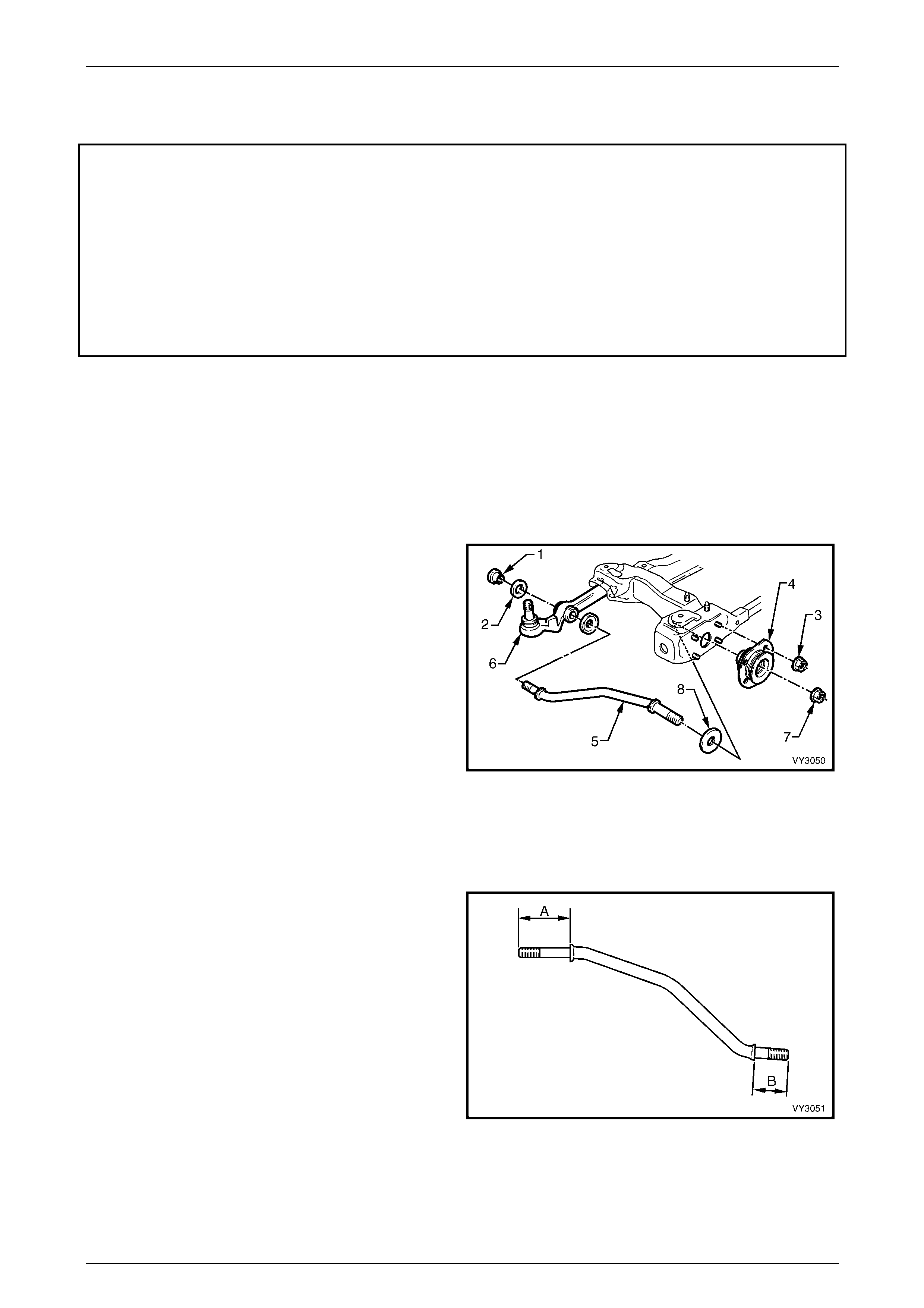

2 Press the front control arm rod bushing from the front