SECTION 1A1 - BODY

CAUTION:

This vehicle is equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tension ers and a driver’s side air bag, or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS d eployment, result ing in po ssible person al injury or unnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning 'OFF' the manual service

valve an d then draining the LPG service lines, bef ore any service work is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

1. GENERAL DESCRIPTI ON

The VT Series is a completely new vehicle design. All sheetmetal, interior trim, air conditioning, and lighting systems

have been redesigned. Bumper facias complement the new styling and accommodate below bumper engine cooling

entry. Head, turn signal and rear lamps are modified to suit design changes.

Techline

2. SERVICE OPERATIONS

2.1 PLASTIC COMPONENT LOCATIONS

Plastic components are used throughout the vehicle. To assist with the identification and composition of those

components refer to the following chart.

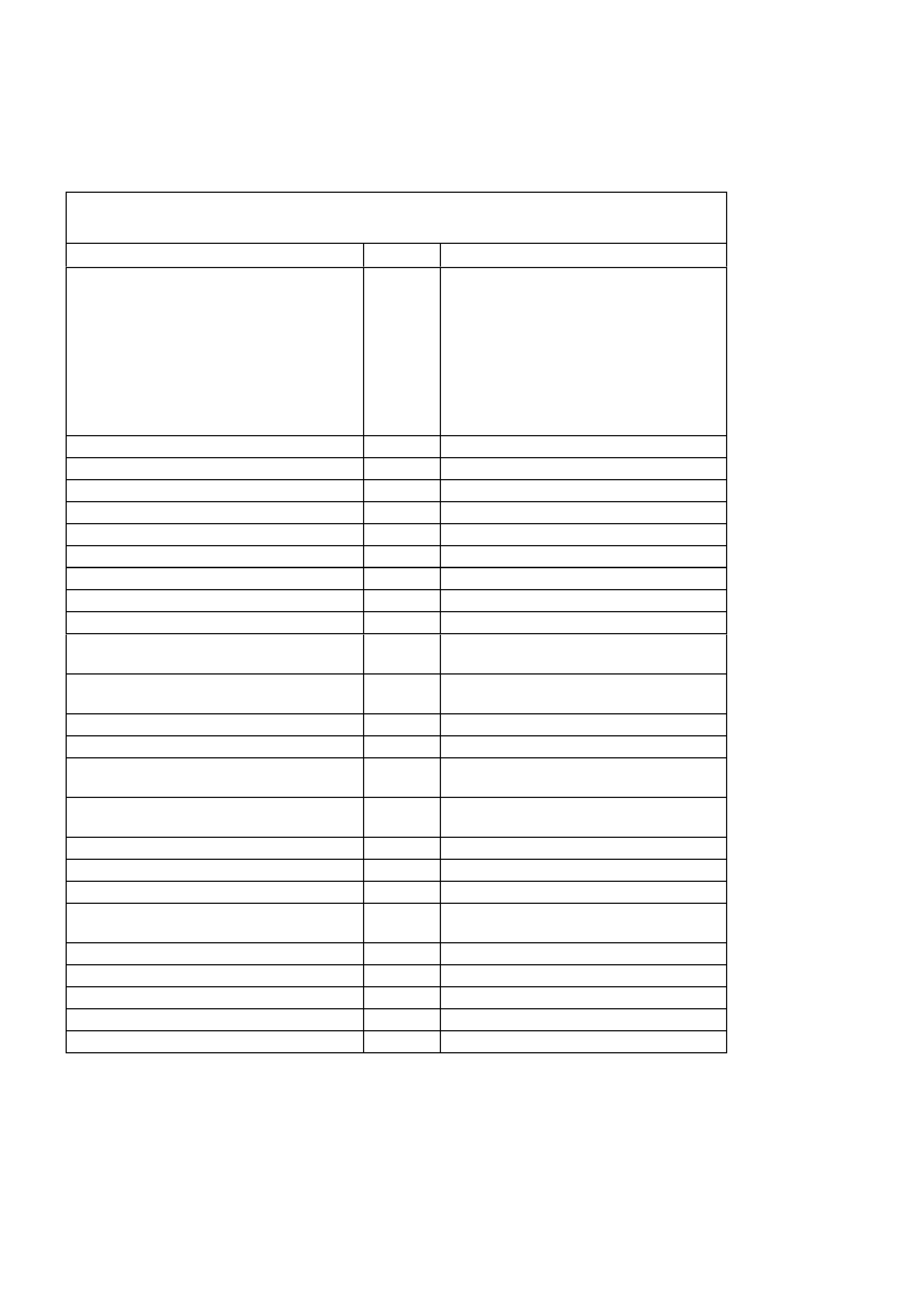

PLASTIC COMPONENT LOCATIONS

COMPONENT CODE PLASTIC TYPE

Radiator grille ABS Acrylonitrile Butadiene Styrene

Front Bumper Bar TPO Thermoplastic Olefin

Rear Bumper Bar TPO Thermoplastic Olefin

Air Baffle PP Polypropylene

Fender Liner TPO Thermoplastic Olefin

Front Turn Signal Lamp PMMA Polymethyl Methacrylate

Plenum Chamber Cover ASA Acrylate Styrene Acrylonitrile

Door Airbox PPE Polypropylene Ether

Coolant Reservoir V6 PP Polypropylene

Coolant Reservoir V8 PE Polyethylene

Cooling Fan Shroud PP Polypropylene

Instrument Panel Pad PU PVC/ASA Skin, Polyurethane Foam

Console ABS Acrylonitrile Butadiene Styrene

Shroud Lower Trim Assembly PP Polypropylene

Front Pillar Garnish PPE Polypropylene Ether

Centre Pillar - Upper Trim Assembly ABS Acrylonitrile Butadiene Styrene

Centre Pillar - Lower Trim Assembly ABS Acrylonitrile Butadiene Styrene

Quarter Window Inner Trim Assembly -

Sedan ABS Acrylonitrile Butadiene Styrene

Quarter Window Inner Trim Assembly -

Station Wagon ABS Acrylonitrile Butadiene Styrene

Rocker Panel Cover PP Polypropylene

Heater Case PP Polypropylene

Tailgate Upper Trim - Station Wagon ABS/PC Acrylonitrile Butadiene

Styrene/Poycarbonate

Tailgate Lower Trim - Station Wagon ABS/PC Acrylonitrile Butadiene Styrene/

Poycarbonate

Rear Tail lamp PMMA Polymethyl Methacrylate

Rear Compartment Lid Lamp Assembly ABS Acrylonitrile Butadiene Styrene

Licence Plate Lamp Assembly PC Poy carbonate

Wheel Covers ABS/PC Acrylonitrile Butadiene Styrene/

Poycarbonate

Body Side Mouldings PVC Polyvinylchloride (Vinyl)

Fuel Filler Door PPE/PA Polyphenylene/Polyamide

Glove Box ABS Acrylonitrile Butadiene Styrene

Centre Facia ABS Acrylonitrile Butadiene Styrene

Rocker Panel Skirts TPO Thermoplastic Olefin

2.2 BODY SHELL PARTS REPLACEMENT

When replacing or repairing a part or sub-assembly, care must be taken to ensure that correct alignment and

strength of unit as a whole is maintained. In some instances, major damage to the body or frame can be more

effectively and economically repaired by replacing a part or sub-assembly with a new one, rather than repairing the

damaged part.

Spot welding is used extensively for joining panels together, particularly around the flanged edges of dash panel,

windshield and back window openings, along edges of rocker panels and lower edge of the rear body.

When replacing a section that is normally attached by this method and spot-welding equipment is not available, or

the location of the parts restricts access, the part or assembly should be attached by the welding method known as

‘Plug Welding’, which is as follows:

1. Remove the damaged part by cutting through the spot welds between the panels with a thin-edged chisel or by

drilling the spot welds.

2. Drill 5 mm diameter holes in either the new or mating part to correspond with the spacing and location of the

original spot welds. Parts to be drilled are determined by accessibility for the following operations.

3. Clamp the new part in position and gas or arc weld the two parts together through each hole, finally dressing

off any high spots on exposed surfaces.

When replacing parts such as roof panels, rear quarter or rocker panels; where a butt or overlap weld is required,

the joint of the panels must be formed below the normal contour. This allows for filling over the join and eliminates

the possible reduction of sheet metal thickness following the necessary buffing or grinding of a normal welding

operation.

IMPORTANT:

Following replacement or repair of body components, it is essential that effective rust proofing techniques, as

outlined in the following paragraphs, be observed.

2.3 ANTI-CORROSIVE TREATMENT

Precoated and galvanised s teel is us ed extens ively for various body panels for inc reas ed c orr os ion protec tion of the

body. Body panels such as the door, tail gate and rear compartment lid outer panels are precoated on the inner

surface of the metal to improve corrosion protection. Other body structure members have complete double sided

galvanised protection.

In addition, a rust preventative mater ial is s pr ayed after paint application to areas s uc h as inter ior s ur f ac es of door s ,

etc.

Any repair or replacement of panels, assemblies, etc., that disturb this anti-corrosive treatment must be resealed

and should be included as part of the repair or replacement operation.

Anti-corrosive compounds used for repairs should be light bodied materials designed to penetrate between metal-

to-metal surfaces such as pinch weld flanges and integral panel attaching points.

All bare m etal s urfaces must be tr eated with m etal c onditioner and primed. These oper ations need to be c ar ried out

prior to the application of sealer s, waxes and s ound deadeners. Attac hing points of new replacem ent panels s hould

be resealed. The hemming flanges of replacement doors, tailgates and rear compartment lids will require resealing.

Open joins which require bridging of the sealer to close a gap should be sealed with a heavy bodied caulking

material. When colour application is required to restore repaired areas to original appearance, conventional

refinishing preparation, undercoat build-up and colour application techniques should be employed.

When deadeners are disturbed during damage repair, or a panel has been replaced, the deadener material must be

replaced with an equivalent material. The location and pattern for replacement material can be determined by

observing the original deadener application outlines.

IMPORTANT:

Follow label directions for materials selected.

2.4 WATER AND DUST LEAK DIAGNOSIS

Diagnosis of body leaks are complicated by the fact that the appearance of water at one point can be caused by

seepage through any one or more of m any possible locations . As an ex ample of this indirec t entr y, the caus e of wet

front floor coverings may be due to water entering past the door weatherstrip, through the door inner panel, between

the windshield and its adhesive compound or through any one of the joins in the floor panel, ventilator or dash

panels, therefore, point or points of water or dust entry must be established before effective resealing can be carried

out.

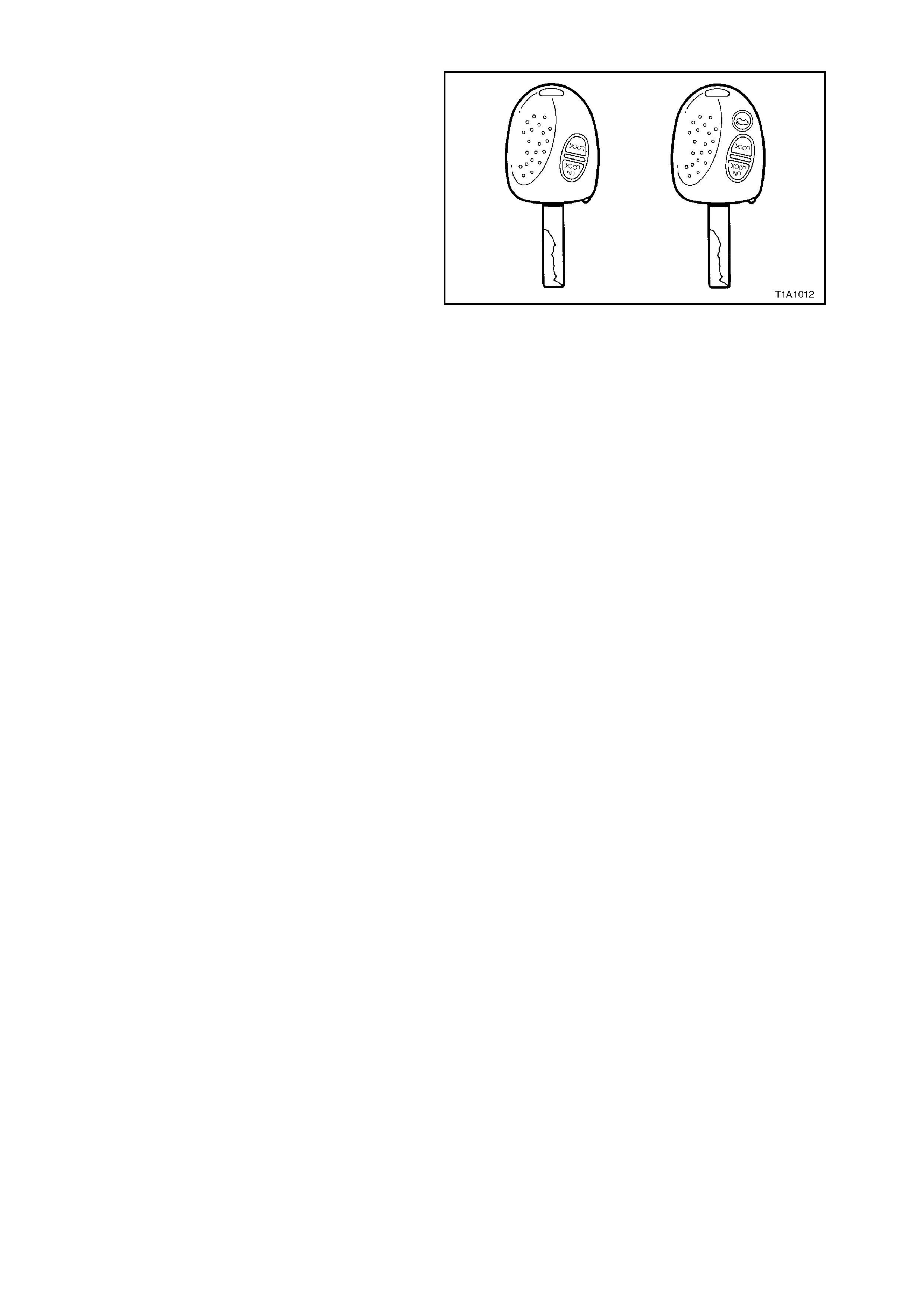

2.5 LOCK CYLINDE RS AND KEYS

A single key locking system is used on all VT

Series models. This key operates all locks on the

vehicle.

Two types of k eys are used which is dependant on

body style. The three button key is used on the

sedan while the two button is used on the wagon

body style.

The two button key features a lock and an unlock

button, while the three button key includes a boot

release button.

The key identification number is located on the

vehicle se curity card.

It is essential that this key number be available

should a replacement key be required. Figure 1A1-1

2.6 METAL REPLACEMENT PARTS REFINISHING

Metal service replacement parts (or assemblies) are painted with a black, ‘high-bake’ factory primer. For proper

adhesion of colour coats in service, the following refinish steps are necessary.

1. Clean part with a wax and grease removing solvent such as Prepsol.

2. Scuff-sand panel lightly with wet or dry number 400 paper and water. Avoid cut-throughs. Reclean part, then

apply sealer to entire part.

3. If factory primer coat has been cut through, apply metal conditioner to the exposed bare metal. Follow

directions on container label.

4. Apply primer-surfacer to entire part; allow to dry thoroughly before sanding.

5. Sand primer-surfacer using wet or dry number 400 paper and water. Do not sand sealer.

6. Re-clean part.

7. Apply colour coats to parts.

8. Follow direction on container label for drying time before compounding.

9. Compound part by hand or with power equipment.

10. Non-sealing polish may be applied after rub-out if desired. Waxes however, should NOT be applied until the

paint finish has aged for at least two months.

2.7 BODY LUBRICATION

The moving mechanical parts of the body which have metal to metal contact are lubricated at assembly.

Operating conditions, whether normal or otherwise, determ ine the effective lif e of the lubricant and for this reason,

lubrication in service is important. Equally important is the type of lubricant to be used and, for your guidance, we list

locations and recommended lubricants.

WARNING:

CARELESS OR EXCESSIVE APPLICATION OF BODY LUBRICANTS CAN RESULT IN STAINING OF PAINT

FINISH, INTERIOR TRIM OR DAMAGE TO CLOTHING. USE LUBRICANTS SPARINGLY AND REMOVE

ACCIDENTAL APPLICATION FROM PAINT FINISH IMMEDIATELY.

PARTS READILY ACCESSIBLE

Where practical, use lithium grease; otherwise use light oil.

Engine Hood Catch

Engine Hood Lock

Engine Hood Hinge

Door Hinge Sleeves and Check Links

Rear Compartment Lid Hinge

Rear Compartment Lid Lock Mechanism

Lock Cylinders

Apply Powdered Graphite through Key aperture (do not oil).

Ignition Lock Cylinder

Rear Compartment Lid Lock Cylinder

Door Lock Cylinder

Instrument Panel Compartment Lock Cylinder

Door Lock Striker Bolt/Fork Bolt

Use Solidoil or equivalent.

Door Lock Striker Bolt

Door Lock Fork Bolt

PARTS CONCEALED NECESSITATING DISASSEMBLY

Where practicable, use lithium grease, otherwise use light oil.

Door Window Regulator

Door Window Cams

Door Lock Mechanism

Door Lock Remote Control

Front Seat Adjuster

Driver’s Seat Height Adjuster

2.8 SHROUD LOWER TRIM ASSEMBLY

REMOVE

1. Remove the dash panel lower trim assembly and release the forward section of rocker panel cover.

2. Remove the upper retainer screw and the screw beneath the rocker panel cover securing the shroud lower trim

assembly to the rocker panel.

3. Pull the shroud lower trim assembly rearward from the retainer removing the assembly.

Figure 1A1-2

REINSTALL

Reverse removal operations.

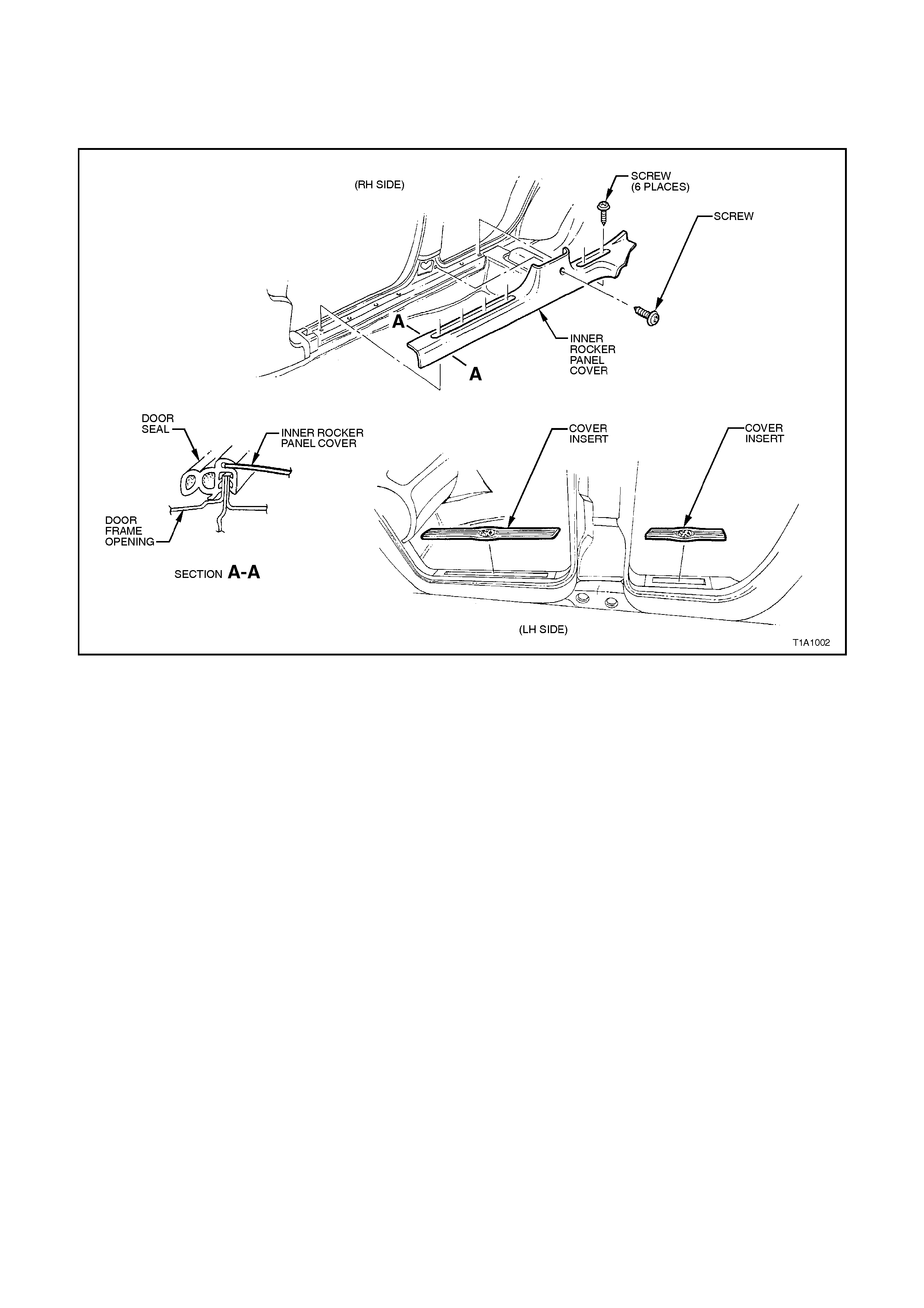

2.9 ROCKER P ANEL COVER

REMOVE

Remove rocker panel cover inserts and rocker panel cover retainer screws from rocker panel removing cover

assembly.

Figure 1A1-3

REINSTALL

Reverse removal operations.

2.10 FLOOR CARPET AND INSULATOR ASSEMBLY

REMOVE

CAUTION: It will be necessary to disable the

SRS (Air Bag) prior to this operation. Refer to

DISABLING THE SRS, Section 12M

SUPPLEMENTAL RE STRA I NT SYSTEM.

NOTE: Clean hands are esse ntia l when work ing on

the body interior trim.

1. Remove the rear seat cushion, refer to

2.18 REAR SEAT CUSHION AND BACK

ASSEMBLY – SEDAN or 2.23 REAR SEAT

CUSHION – WAGON in Section 1A7 – SEAT

AND SEAT BELT ASSEMBLIES.

2. Remove both front seats; refer to

2.1 FRONT BUCKET SEAT ASSEMBLIES in

Section 1A7 – SEAT AND SEAT BELT

ASSEMBLIES.

3. Remove the park brake lever cover by

grasping the cover firmly by hand and sliding

over the park brake lever, refer to

2.7 PARK BRAKE LEVER in Section 5A –

STANDARD BRAKES.

4. Remove front seat belt lower bolts, refer to

2.32 FRONT SEAT BELT RETRACTOR AND

HEIGHT ADJUSTER ASSEMBLY in Section

1A7 – SEAT AND SEAT BELT ASSEMBLIES.

5. Remove the instrument panel compartment;

refer to 1.2 INSTRUMENT PANEL

COMPARTMENT in Section 1A3 –

INSTRUMENT PANEL AND CONSO LE.

6. Remove the instrument panel cover RH lower

cover, refer to 1.1 INSTRUMENT PANEL

LOWER COVER – RIGHT SIDE in Section

1A3 – INSTRUMENT PANEL AND CONSOLE.

7. Remove the LH footwell closing panel, refer to

1.6 INSTRUMENT PANEL PAD ASSEMBLY

in Section 1A3 – INSTRUMENT PANEL AND

CONSOLE.

8. Remove the RH footwell upper closing panel,

refer to 1.6 INSTRUMENT PANEL PAD

ASSEMBLY in Section 1A3 – INSTRUMENT

PANEL AND CONSOLE.

9. Remove centre console and console side

extens ions, r ef er to 1.3 CENTRE CONSOLE in

Section 1A3 – INSTRUMENT PANEL AND

CONSOLE.

10. Remove both rocker panel trims; refer to

2.9 ROCKER PANEL TRIM in Section 1A1 –

BODY.

11. Remove both shroud lower trims; refer to

2.8 SHROUD LOWER TRIM ASSEMBLIES in

Section 1A1 – BODY.

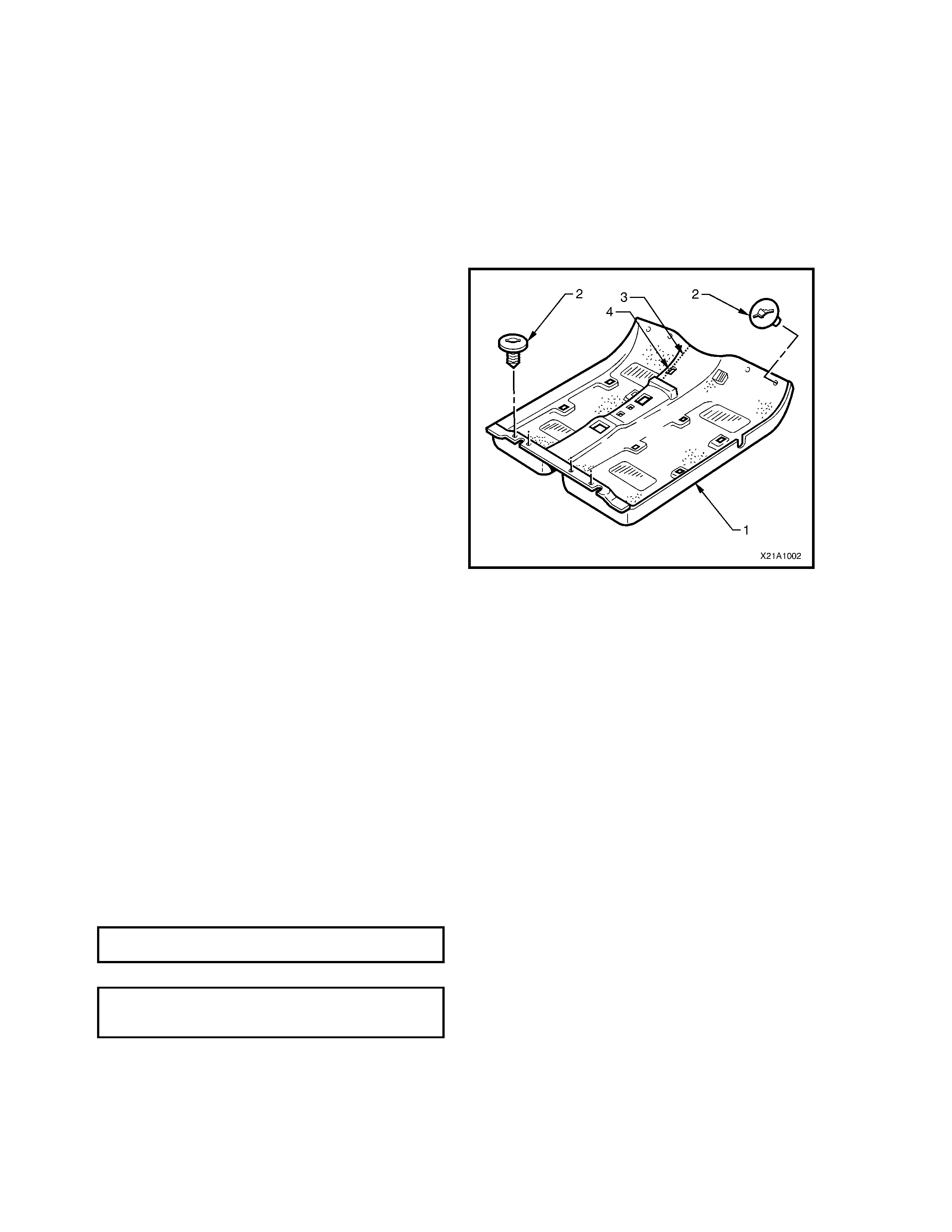

12. Remove the two screws (1) securing the

footrest pad (2) to the footrest mounting

bracket (3).

13. Remove footrest pad.

Figure 1A1-4

14. Disconnect the SRS sensing and diagnostic module wiring harness from the module, refer to

2.7 SENSING AND DIAGNOSTIC MODULE (SDM) in Section 12M SUPPLEMENTAL RESTRAINT SYSTEM

(Version 6.2) or 2.4 SENSING AND DIAGNOSTIC MODULE (SDM) in Section 12M SUPPLEMENTAL

RESTRAINT SYSTEM (Vers ion 8.0 or 8.1)

15. For vehicles fitted with an automatic transmission, remove the selector control lever assembly; refer to

3.3 SELECTOR CONTROL LEVER ASSEMBLY in Section 7C4 – HYDRA-MATIC 4L60E AUTOMATIC

TRANSMISSION – ON VEHICLE SERVICING.

16. For vehicles fitted with manual transmission, remove the gearshift lever. For vehicles fitted with a V6 engine;

refer to 3.4 GEARSHIFT LEVER in Section 7 B1 MAN UAL TRANSMISSION – V6 ENGINE. For Vehicles f itted

with a V8 engine; refer to 3.4 GEARSHIFT LEVER in Section 7B2 MANUAL TRANSMISSION – V8 ENGINE.

17. Remove the instrument panel carrier to floor mounting bracket bolts; refer to 2.1 COCKPIT MODULE in Section

1E – COCKPIT MODULE.

18. Remove t he eight car pet and insula tor ret aining

clips (2) from the carpet and insulator assembly

(1) by rotating the clips counter clockwise and

lifting clear of studs.

19. From inside the LH footwell, grasp the edge of

the hole in the floor carpet and insulator

asse mbly (4) around the evaporator dra in hose

and tear open the perforated line (3) by pulling

the carpet away from the transmission tunnel.

NOTE: To assist in the removal and reinstallation

of t he floor car pet assemb ly, it has been perfo rated

from the front edge, through the centre of the

evaporator drain cut out to the forward edge of the

radio support bracket cut out

20. Slide the remaining flap of carpet out from

under the heating, ventilation and air

conditioning (HVAC) unit and into the RH

footwell.

21. Carefully manoeuvre the floor carpet and

insulator assembly from vehicle.

Figure 1A1-5

REINSTALL

The reinstallation pr oced ur e for the floor c ar pet and

insulator assembly is the reverse of the removal

proce dure, noting the follo wing:

1. Cut alon g the perf orate d line in the floor car pet

that runs from the forward edge of the carpet,

through the evaporator drain cut-out to the

forward edge of the radio support bracket cut-

out prior to re installing.

2. Ensure that all cut-outs in the carpet are

correctly aligned and install the eight retainers

and front seat belt lower attaching bolts to

secure the carpet prior to reinstalling the seats

and cons ole.

3. Ensure all fasteners are tightened to the

correct torque specifications.

FOOTREST PAD ATTACHING SCREWS 2 – 5

TORQUE SPECIFICATION Nm

FRONT SEAT BELT LOWER

ATT ACHI NG BOLT 40 – 54 Nm

TORQUE SPECIFICATION

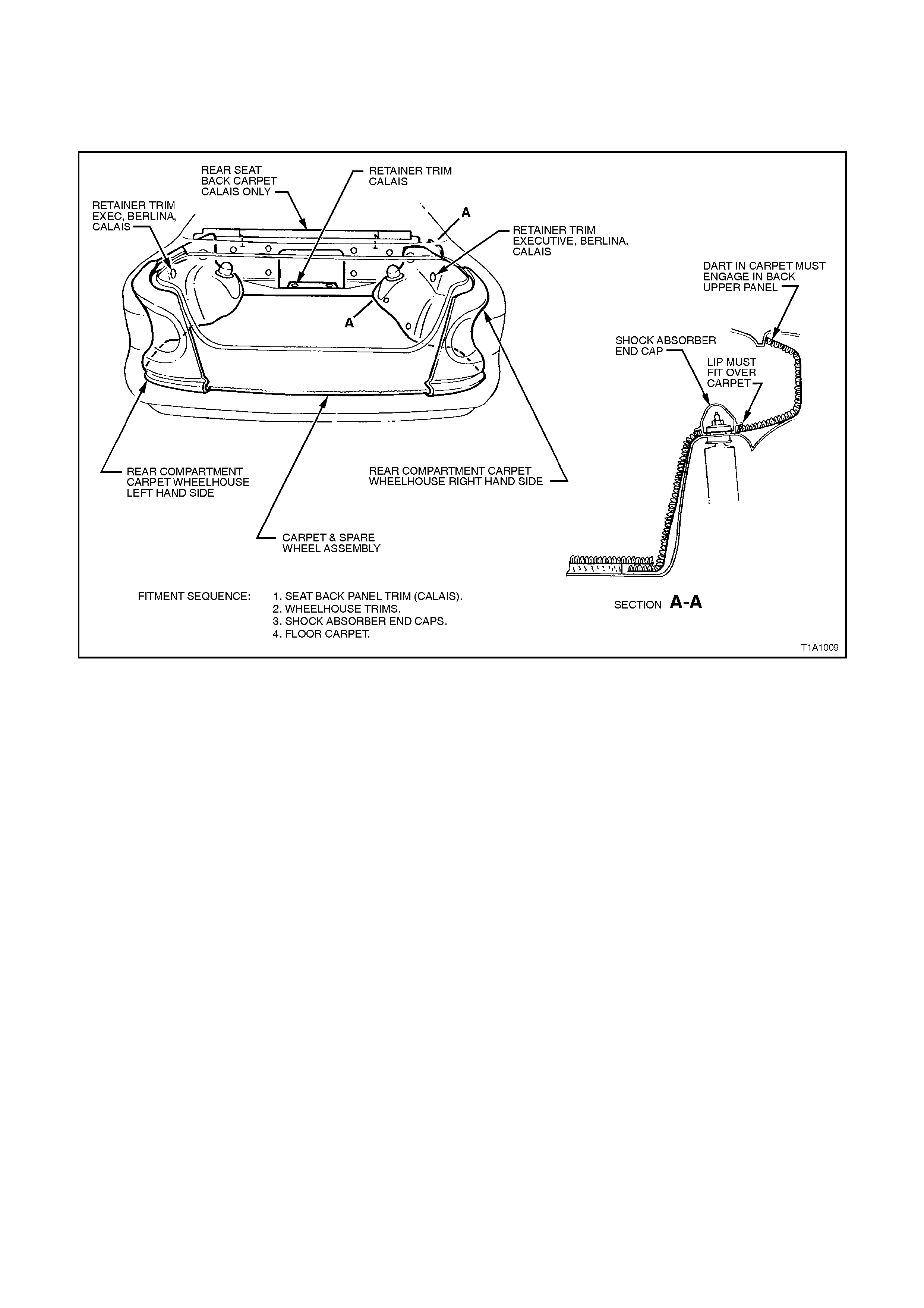

2.11 FLOOR COVERING ASSEMBLY- REAR COMPARTMENT- SEDAN

Removal and installation of the rear compartment carpet involves removal of the spare wheel cover and carpet

assembly. During installation locate the carpet edges and install the spare wheel cover.

The wheelhouse trim is held in place by retainers at the wheelhouse and at the rear compartment lid opening by the

rear crossmember trim.

Figure 1A1-5

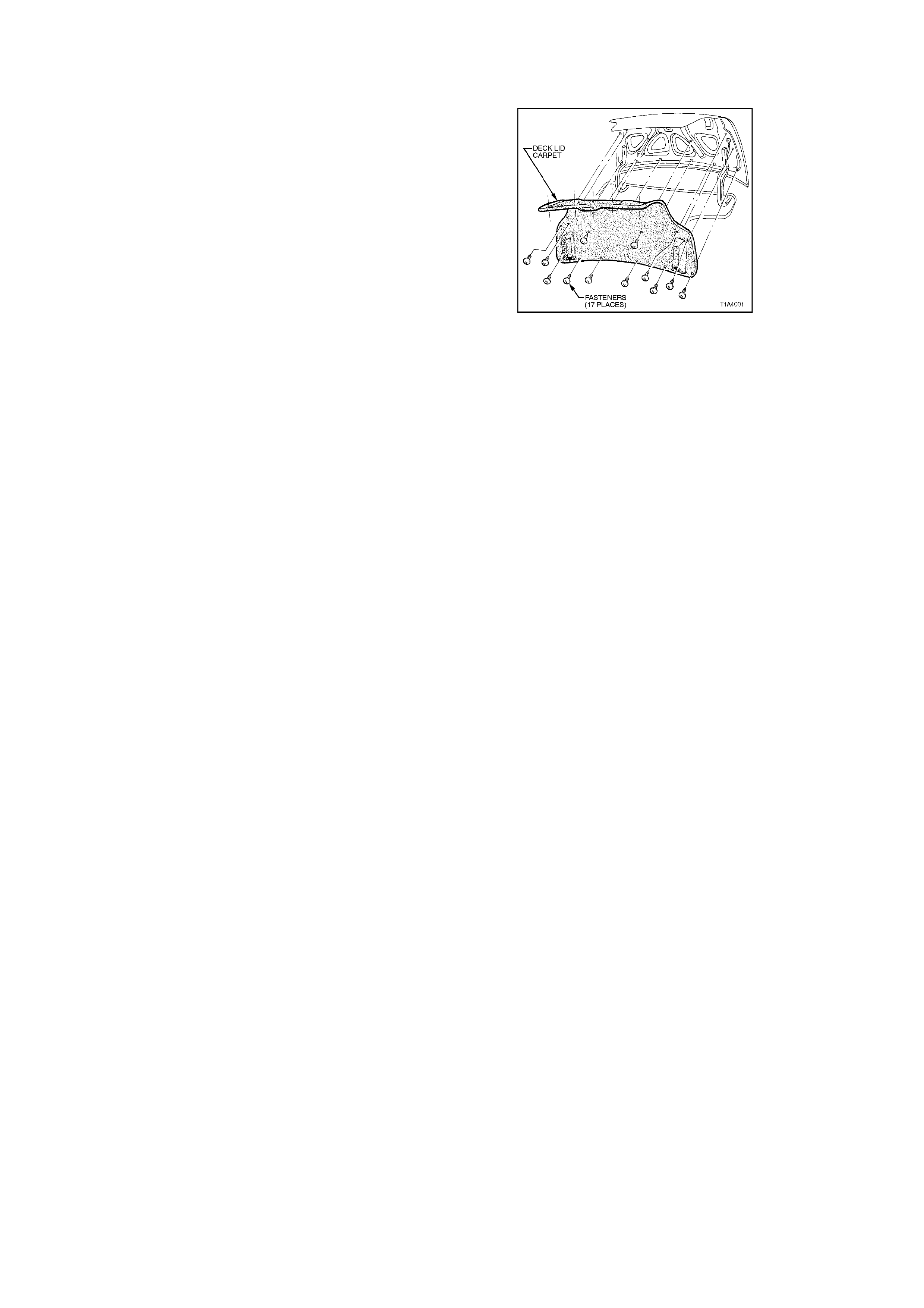

2.12 CARPET ASSEMBLY - REAR COMPARTMENT LID LINER

REMOVE

1. Remove the retainers securing the carpet

assembly to the rear compartment lid.

2. Move the carpet assembly from its position on

the rear compartment lid, open the hinge slots

at the base of the carpet assembly and

remove the carpet.

Figure 1A-6

REINSTALL

Reverse removal operations.

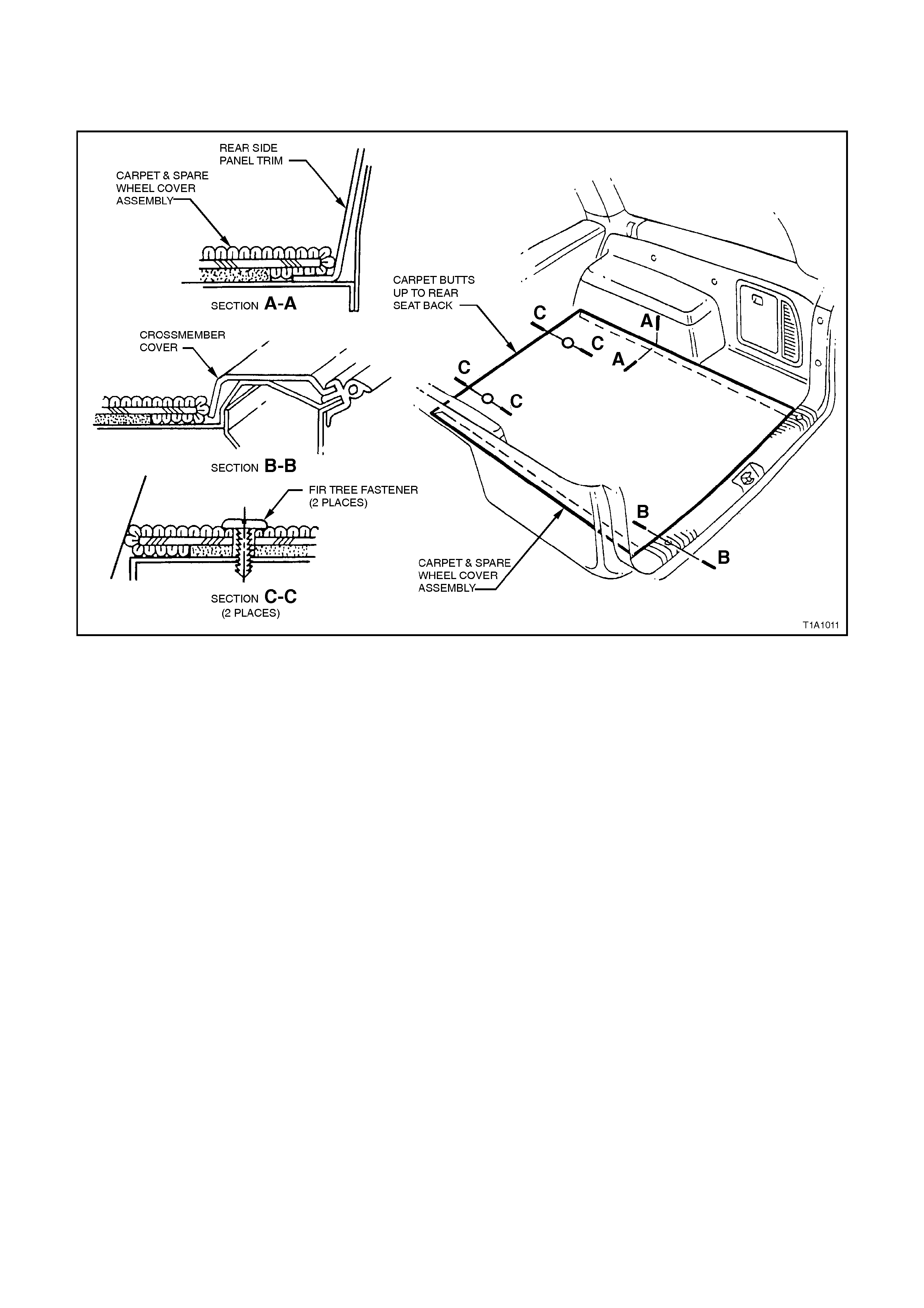

2.13 CARPET ASSEMBLY - LOAD COMPARTMENT - STATION WAGON

REMOVE

1. Remove the two Fir tree fasteners from load compartment area and lift the carpet from the vehicle.

Figure 1A1-7

REINSTALL

Reverse removal operations.

Figure 1A1-8

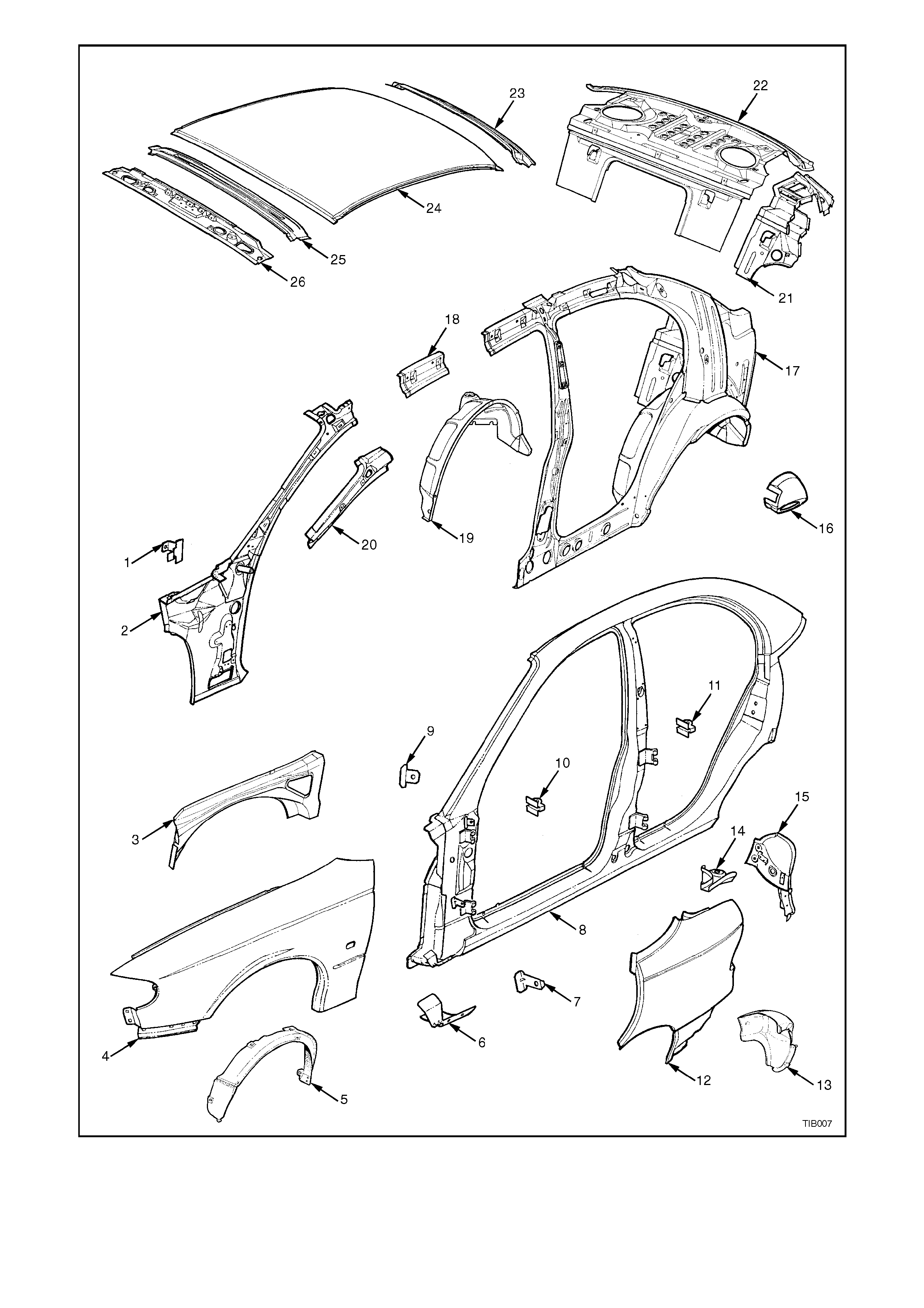

BODY SIDE - SEDAN

Listed below are assemblies and individual panels that are available for replacement.

The purpose of these illustrations is to provide the repairer with a better understanding of available replacement

panels.

1. Bracket - trim attachment.

2. Pillar - front body inner.

3. Brace - wheelhouse (front).

4. Fender panel (front).

5. Front fender liner.

6. Support - fender.

7. Angle - fender lower.

8. Frame assembly - door opening.

9. Angle - fender upper.

10. Support - front door check.

11. Support - rear door check.

12. Panel - rear quarter (side panel outer).

13. Liner - rear wheelhouse.

14. Gusset - side panel.

15. Insert assembly - tail lamp.

16. Cap - fuel filler.

17. Side panel assembly - inner.

18. Frame - side front roof.

19. Wheelhouse inner assembly.

20. Reinforcement - ‘A’ pillar upper.

21. Brace - upper wheelhouse.

22. Panel assembly - back upper.

23. Frame - roof rear.

24. Panel - roof.

25. Support - roof.

26. Rail - windshield header.

Figure 1A1-9

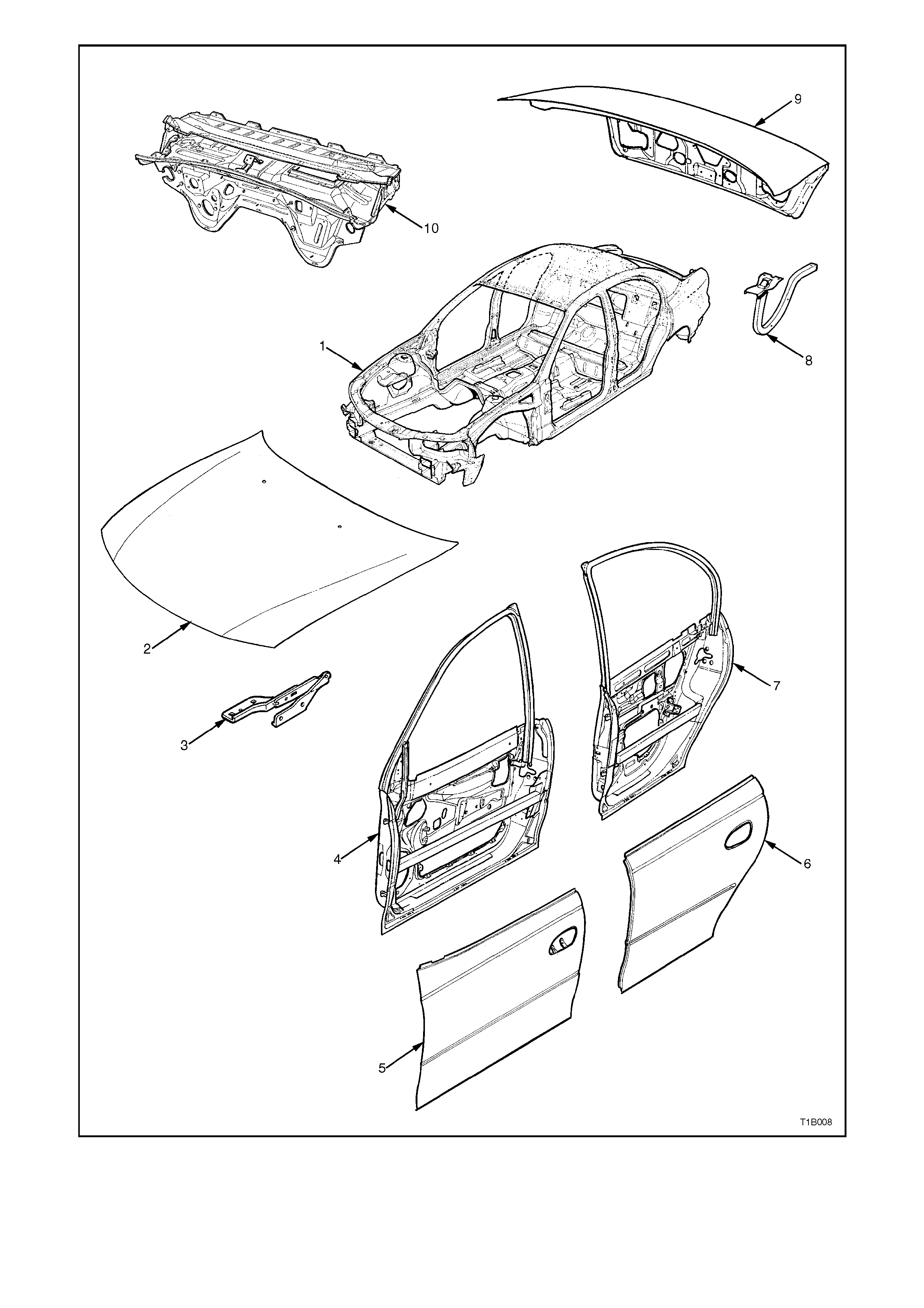

BODY SHELL - SEDAN

Listed below are assemblies and individual panels that are available for replacement.

The purpose of these illustrations is to provide the repairer with a better understanding of available replacement

panels.

1. Body shell.

2. Engine hood.

3. Hinge assembly - engine hood.

4. Door assembly - front (inner).

5. Panel assembly - front door outer.

6. 6. Panel assembly - rear door outer.

7. Door assembly - rear (inner).

8. Arm and bracket assembly - decklid hinge.

9. Decklid assembly - rear.

10. Dash panel assembly.

Figure 1A1-10

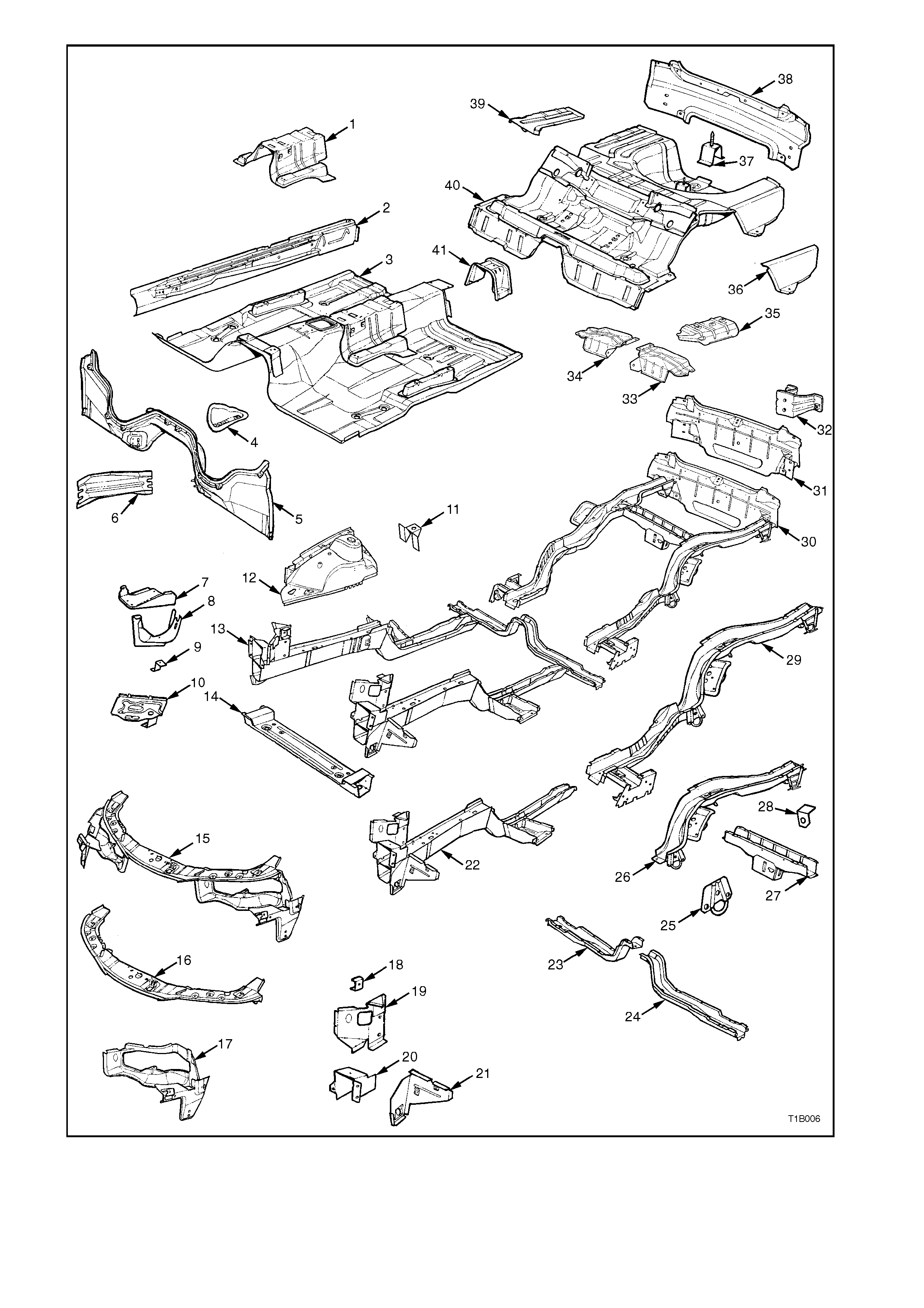

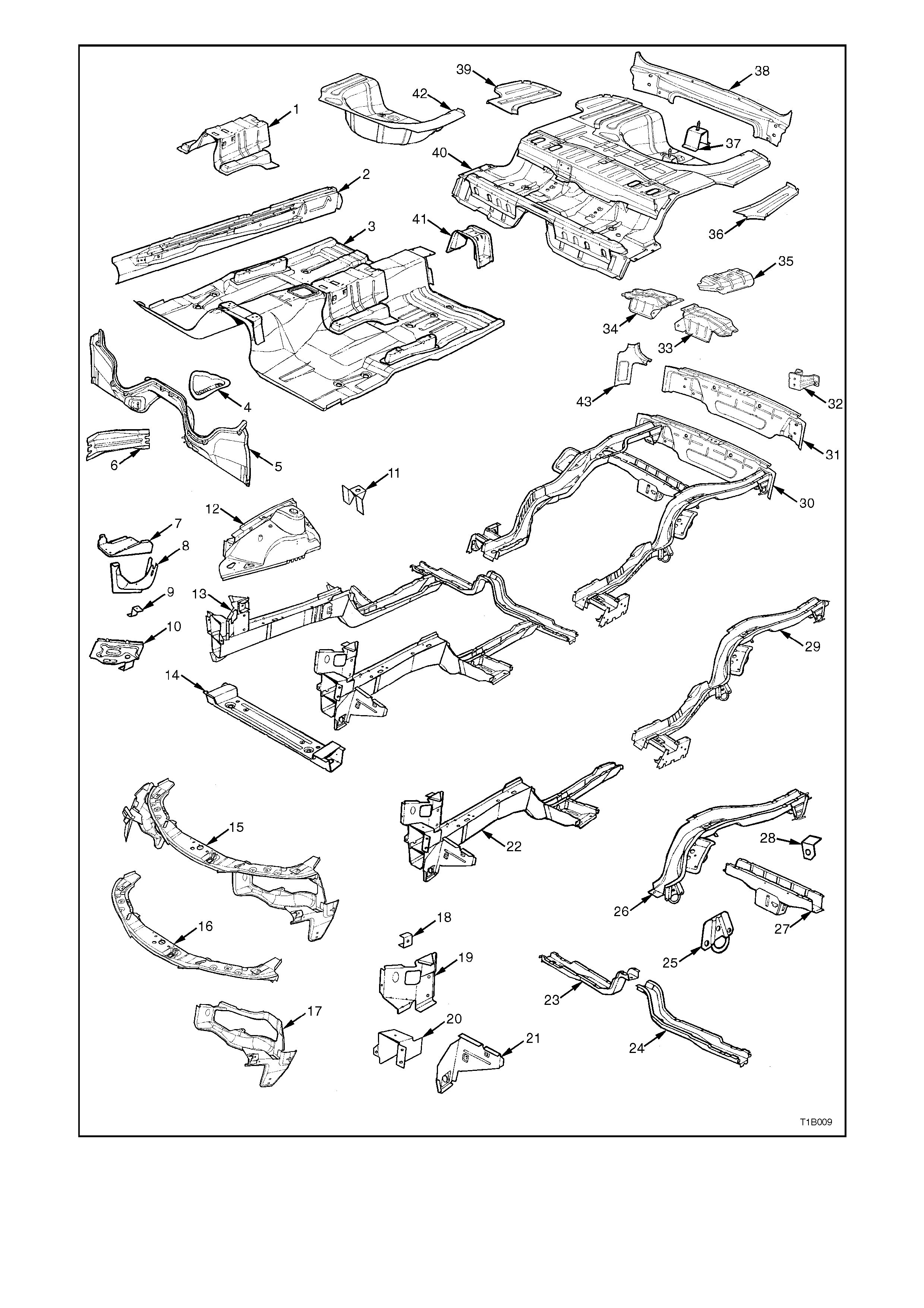

UNDER BODY - STATION WAGON

Listed below are assemblies and individual panels that are available for replacement.

The purpose of these illustrations is to provide the repairer with a better understanding of available replacement

panels.

1. Reinforcing assembly - inner seat attachment.

2. Reinforcing - floor panel side.

3. Floor assembly - front.

4. Mount assembly - power unit.

5. Extension assembly - floor panel front.

6. Brace - longitudinal to front floor.

7. Bracket - ABS modulator upper.

8. Bracket - ABS modulator lower.

9. Bracket - support modulator lower.

10. Tray assembly - battery.

11. Bracket assembly - anti-theft horn mounting.

12. Panel assembly - front fender skirt.

13. Frame work - under body front.

14. Cross member assembly - front (member

assembly - front lower).

15. Panel assembly - front.

16. Panel assembly - front.

17. Front panel - side.

18. Bracket - radiator support side.

19. Support - front panel side.

20. Bracket - bumper beam mounting

21. Console - front panel.

22. Longitudinal assembly (front)

23. Crossmember assembly (RH) center

24. Crossmember assembly (LH) center

25. Hook tie down rear

26. Extension assembly - longitudinal (rear)

27. Crossmember assembly - rear

28. Bracket assembly - brake hose

29. Longitudinal - complete

30. Frame work assembly - rear

31. Reinforcement assembly - back panel lower

32. Bumper beam mounting bracket assembly (rear)

33. Heat shield assembly - intermediate muffler (V6)

34. Heat shield assembly - intermediate muffler (V8)

35. Head shield - rear muffler

36. Web plate - rear

37. Stand assembly - spare wheel

38. Back panel assembly - lower

39. Web plate - rear

40. Floor assembly - rear

41. Reinforcement assembly - center bearing

42. Panel - rear floor rear (spare wheel cover)

43. Extension - back panel lower reinforcement

Figure 1A1-11

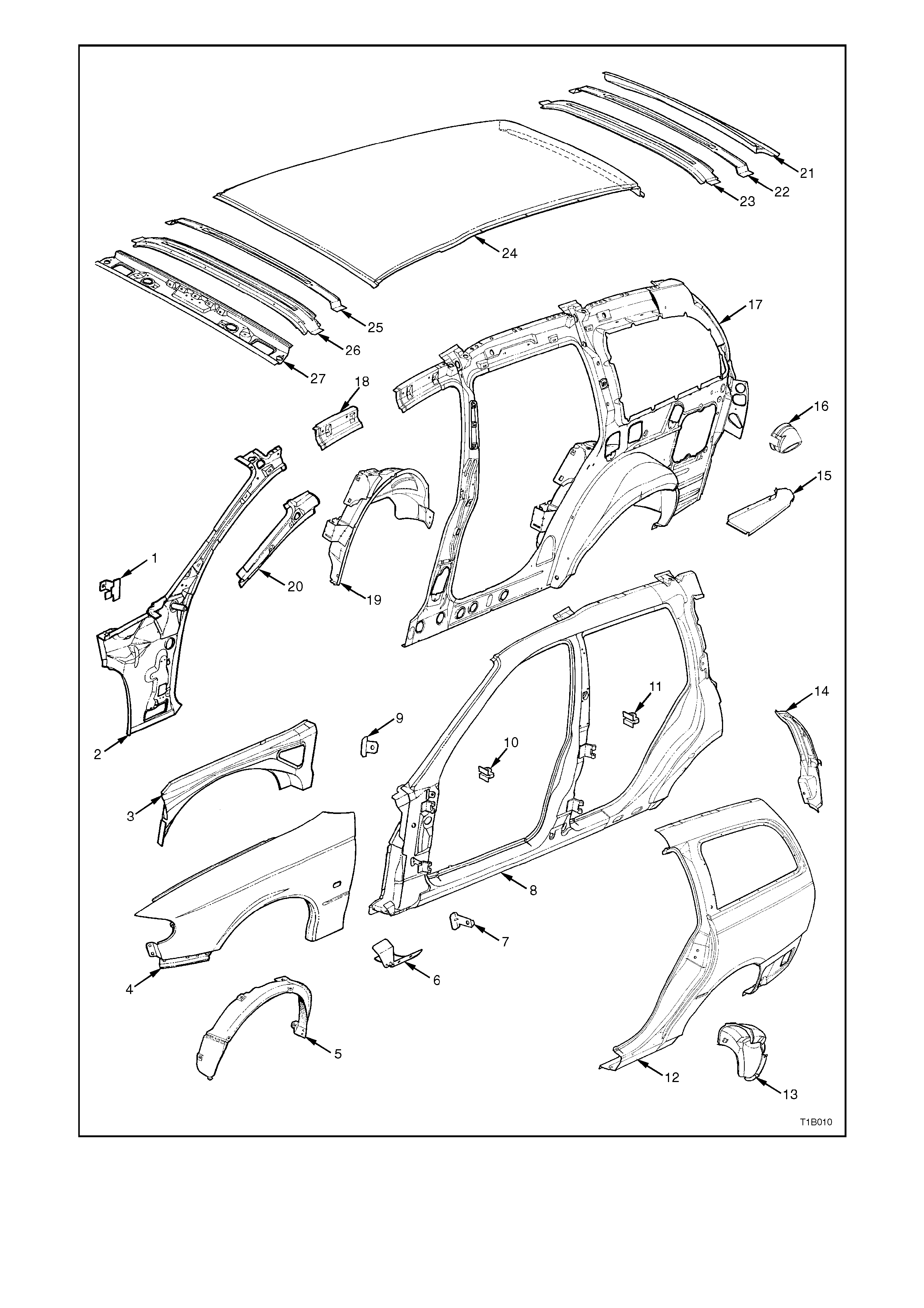

BODY SIDE - STATION WAGON

Listed below are assemblies and individual panels that are available for replacement.

The purpose of these illustrations is to provide the repairer with a better understanding of available replacement

panels.

1. Bracket - trim attachment.

2. Pillar - front body inner.

3. Brace - wheelhouse (front).

4. Fender panel (front).

5. Front fender liner.

6. Support - fender.

7. Angle - fender lower.

8. Frame assembly - door opening.

9. Angle - fender upper.

10. Support - front door check.

11. Support - rear door check.

12. Panel - rear quarter (side panel outer).

13. Liner - rear wheelhouse.

14. Gusset assembly - tail lamp.

15. Plate - closing, side outer.

16. Fuel filler cap.

17. Side panel assembly - inner.

18. Frame - side front roof.

19. Wheelhouse inner assembly.

20. Reinforcement - ‘A’ pillar upper.

21. Frame - roof rear.

22. Support - roof no. 4.

23. Support - roof no. 3.

24. Panel - roof.

25. Support - roof no. 2.

26. Support - roof no. 1.

27. Rail - windshield header.

Figure 1A1-12

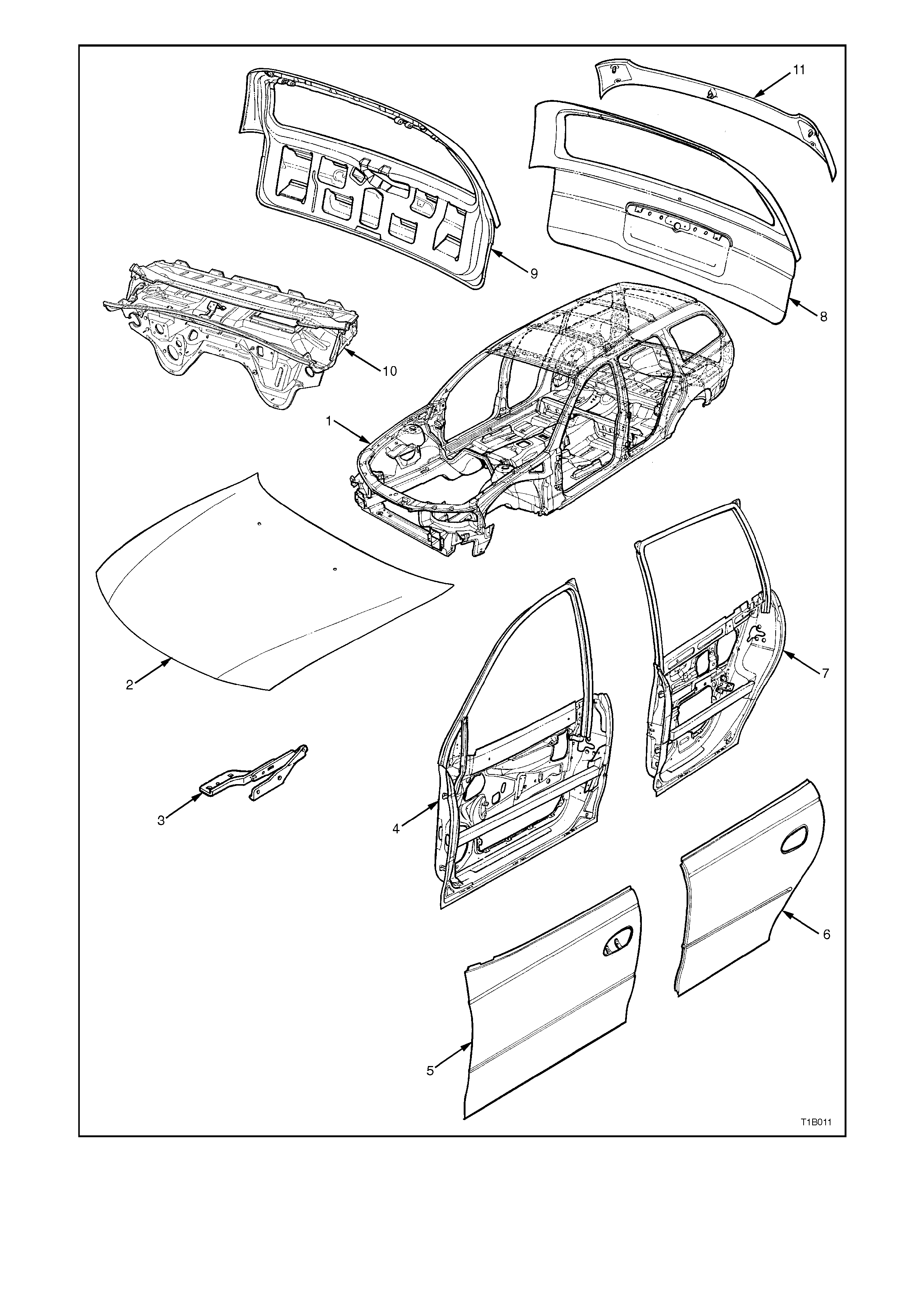

BODY SHELL - STATION WAGON

Listed below are assemblies and individual panels that are available for replacement.

The purpose of these illustrations is to provide the repairer with a better understanding of available replacement

panels.

1. Body shell.

2. Engine hood.

3. Hinge assembly - engine hood.

4. Door assembly - front (inner).

5. Panel assembly - front door outer.

6. Panel assembly - rear door outer.

7. Door assembly - rear (inner).

8. Panel - tailgate outer.

9. Panel assembly - rear end gate.

10. Dash panel assembly.

11. Deflector assembly - tailgate.

Figure 1A1-13