SECTION 3 - FRONT SUSPENSION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

1. GENERAL DESCRIPTI ON

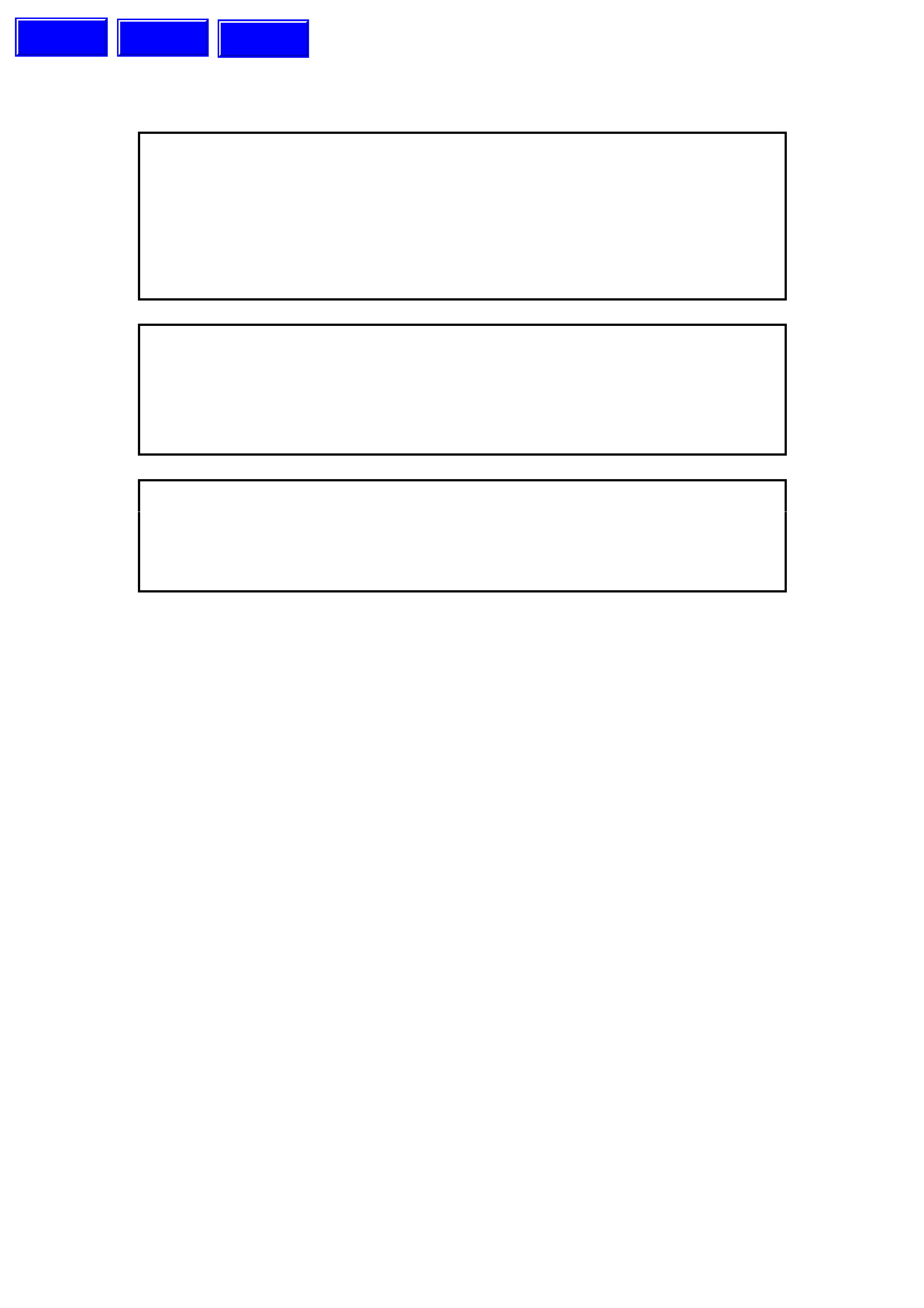

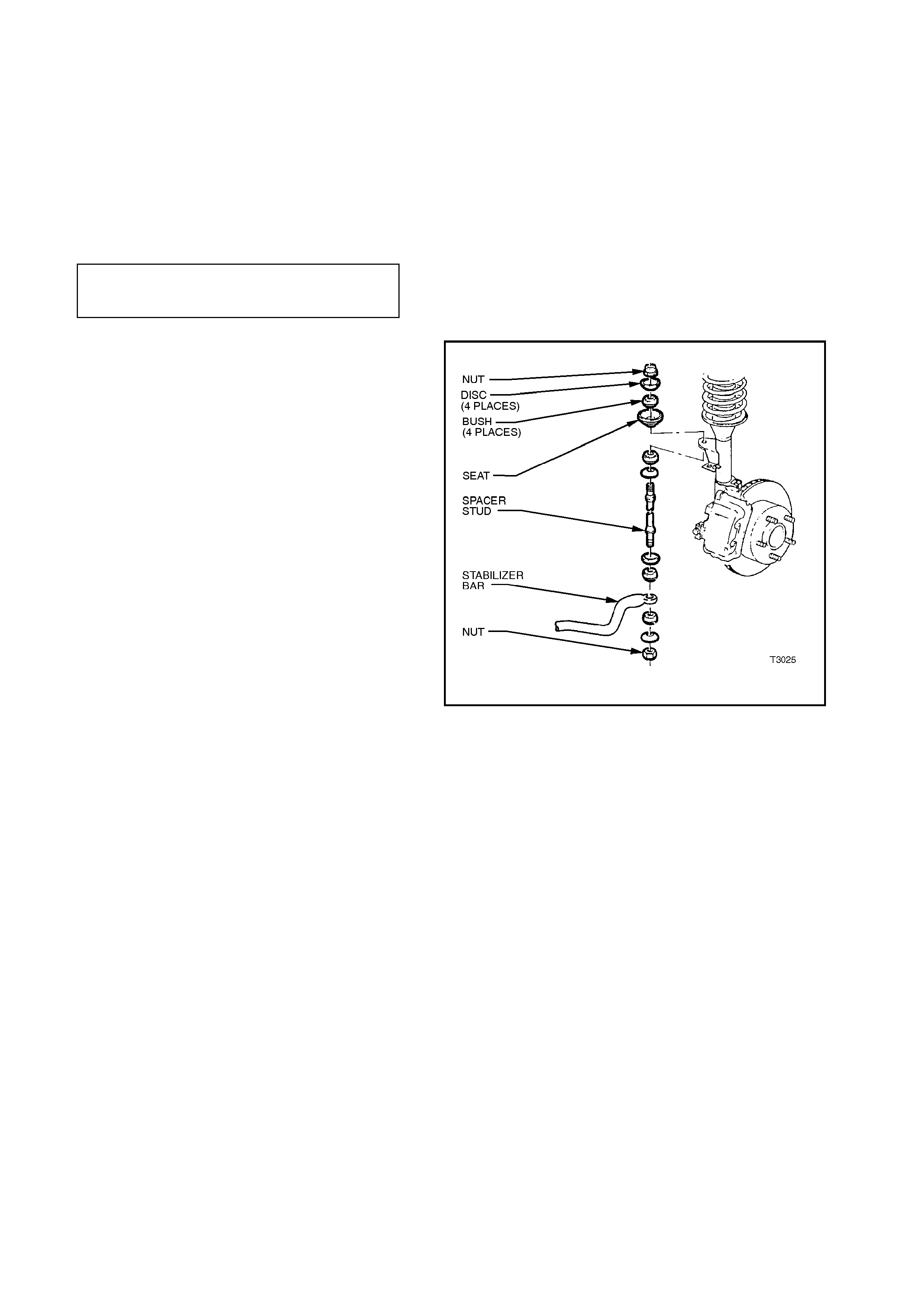

The front suspension fitted to all VT Series models operates on the MacPherson strut principle. The assembly

consists of the front crossmember, lower control arms, tension rods, stabiliser bar and strut assemblies (Refer to

Figure 3-2).

The crossmember is bolted to both longitudinal frame side members, while the inner pivots of the lower control

arms are rubber bushed and are attached to the crossmember by bolts and nuts. The outer end of each lower

control arm is connected to the knuckle on the strut assembly through a ball joint.

The strut assembly incorporates a hydraulic wet sleeve type damper inside the strut tube, a rubber dust boot with air

filter and compression rubber, a coil type suspension spring mounted between the strut housing and upper spring

seat collar, a bearing assembly and an upper strut support.

The strut assembly is located at the upper end to the body structure by an upper strut support and secured by a

self-locking nut and locating disc, while the lower end of the strut tube is fastened to the steering knuckle by two

bolts and nuts.

Positioning of the lower control arm assemblies is controlled by tension rods connecting the lower control arms to

the front suspension crossmember. The tension rods are mounted in a rubber bush at the lower control arm end

and a fluid filled damper at the other.

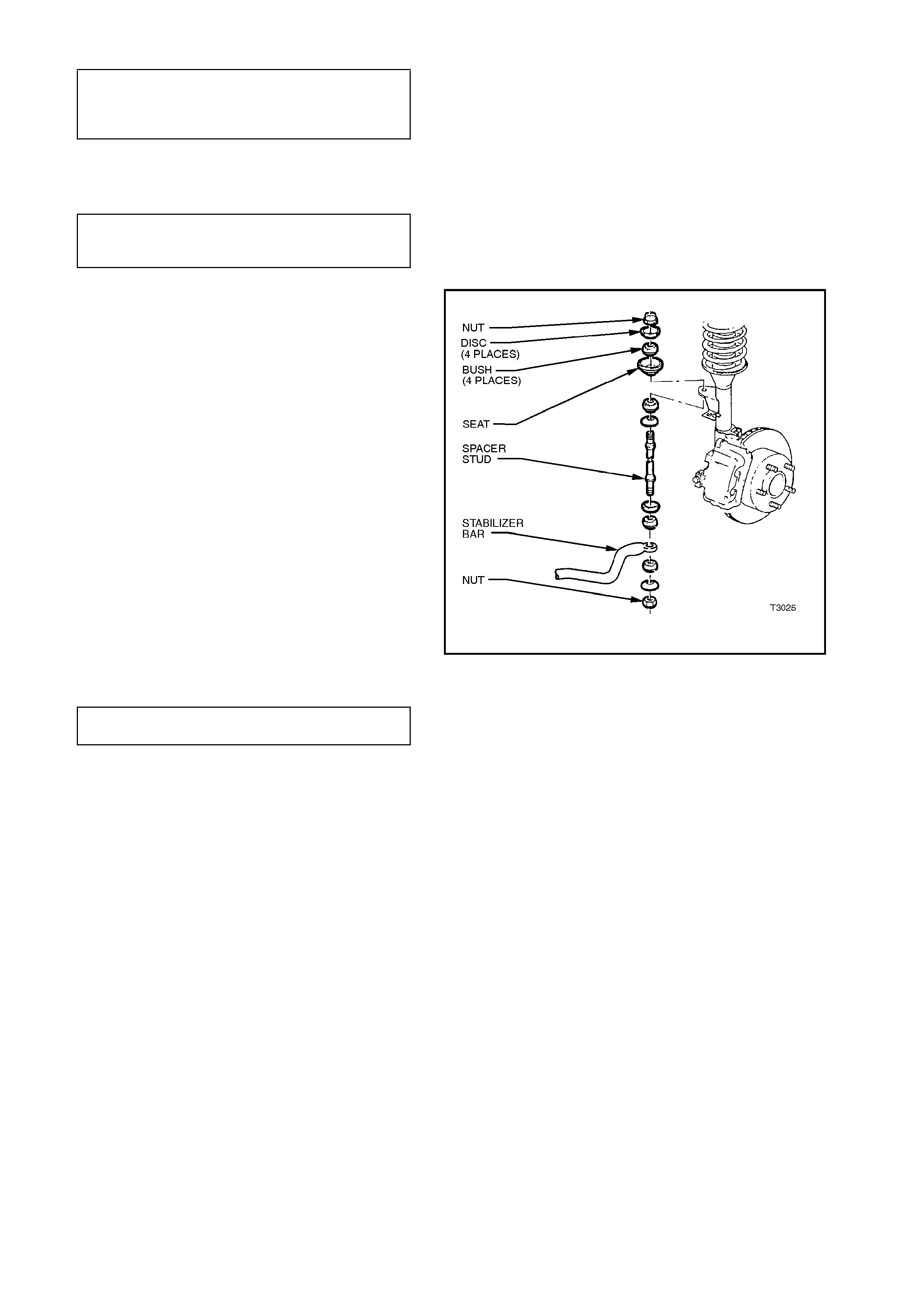

A stabiliser bar is mounted to the side members of the crossmember by two brackets and insulating rubbers, and

attached to each strut tube by a spacer stud, insulating bushes, retainers and attaching nuts.

Production option FE2, SPORTS SUSPENSION PACK, is available as an option on all VT Series sedan models.

For identification information and specification details for the STANDARD or FE2 suspension types, refer to

6. SPECIFICATIONS in this Section.

Techline

Techline

Techline

Figure 3-2

2. WHEEL ALIGNMENT

2.1 STEERING GEOMETRY

To achieve the desired handling characteristics of

a vehicle under various operating conditions,

modern steering geometry relates to both front and

rear suspension systems. It must also be realised

that the various, measurable angles that can be

checked while the vehicle is stationary, is no real

indication of the changes that occur in a dynamic

situation when the vehicle is required to have

directional stability during normal manoeuvres such

as straight ahead driving, cornering and braking.

Even though some of the following descriptions of

front wheel alignment angles are not normally

measurable and (in some instances) not

adjustable, each is an inherent part of the vehicle's

dynamic suspension tuning that has been

developed over an extended testing program.

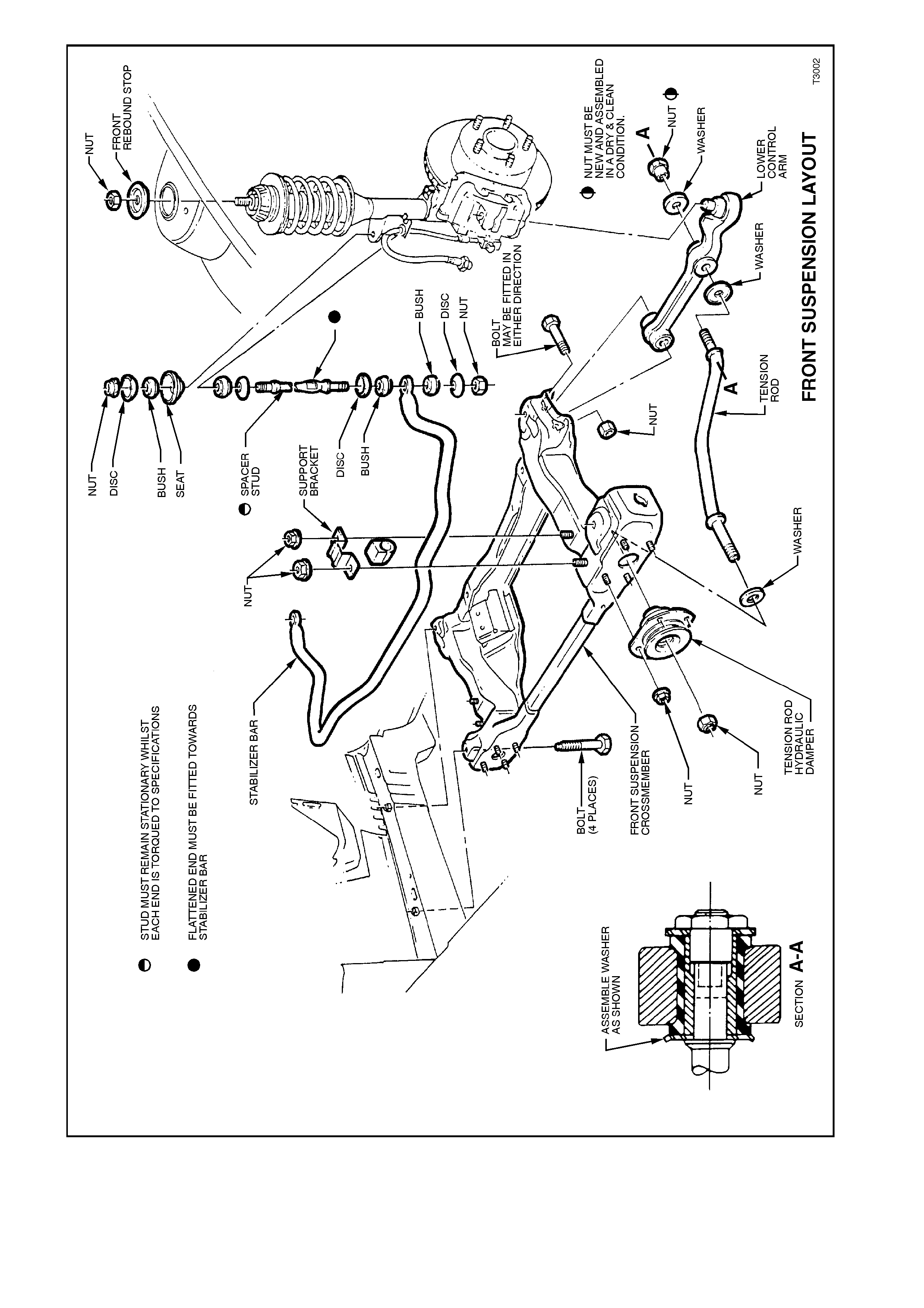

CASTER

It is usual to describe this front wheel alignment

angle as the tilting of the steering axis either

forward or backward from the vertical (when viewed

from the side of the vehicle). A backward tilt at the

top steering axis point is said be positive (+) and a

forward tilt is said to be negative (-). Measurement

is usually expressed as an angle in degrees and

minutes. Figure 3-3 shows the usual practice where

the vertical and steering axis centrelines both pass

through the wheel centre.

This results in a caster distance, which can be

described as being the distance in side view,

between the point where the steering axis contacts

the ground and the centre of the tyre’s footprint

contact.

Figure 3-3

The amount of caster angle will determine the

ability of the s teering to return to the straight ahead

position after a cornering manoeuvre. Too high an

angle though, can result in an excessive steering

effort with associated ‘wheel fight' and ‘kickback'.

To optimise vehicle handling and control during

cornering and to maintain the benefits of positive

caster, VT Series vehicles have a 12 mm caster

offset incorporated into the suspension design.

This is achieved by moving the wheel spindle

centreline forward (in this instance, by 12 mm),

which will effectively reduce the caster distance by

that amount (see Figure 3-4). This action reduces

the undesirable effects of a high caster angle but

maintains the directional stability, increased front

axle lateral grip and steering feel that a high caster

angle normally provides.

Figure 3-4

Techline

Techline

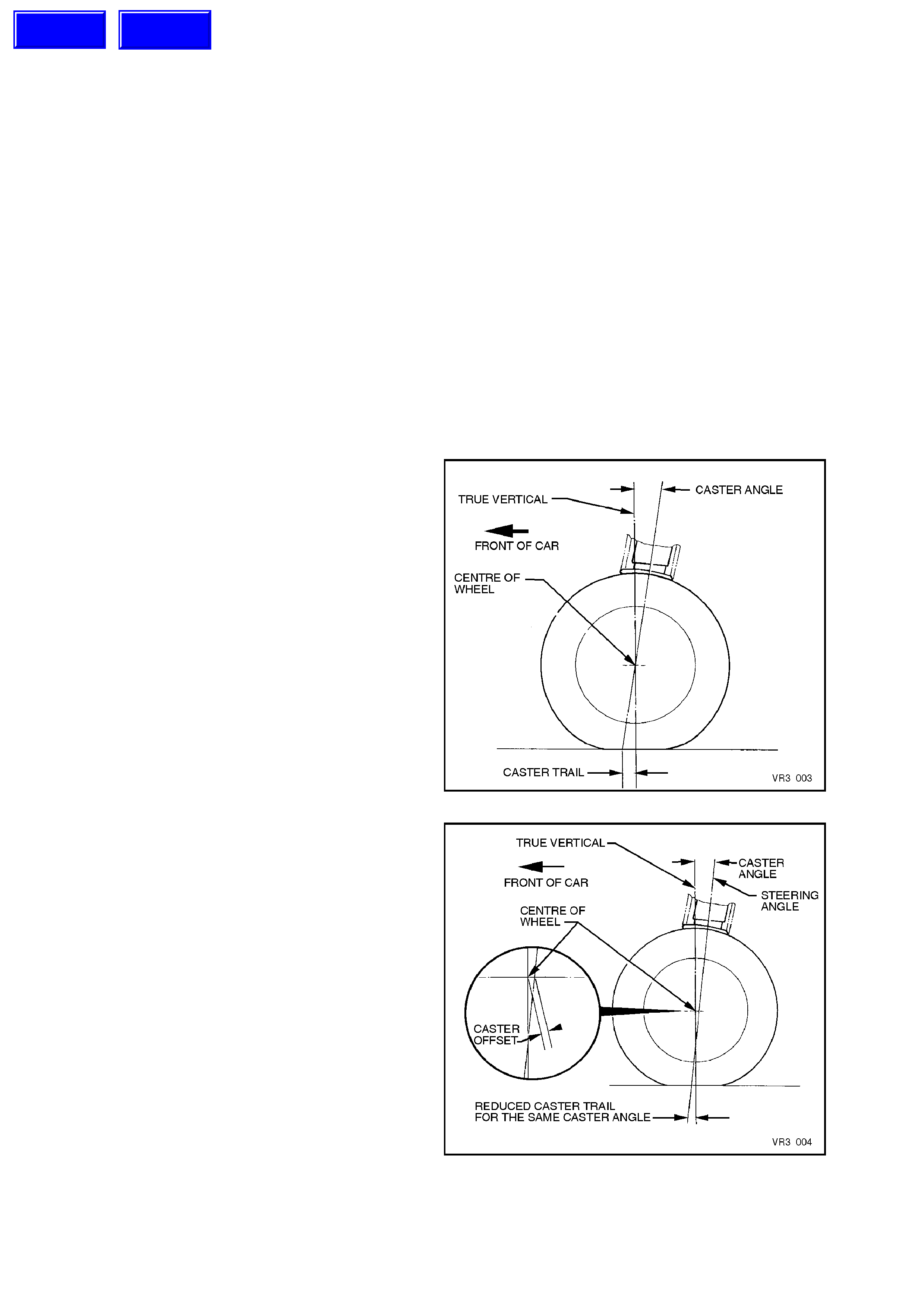

CAMBER

This angle is the tilting of the wheels from the

vertical when viewed from the front of the vehicle.

When the wheels tilt outward at the top, the camber

is said to be positive (+). When the wheels tilt

inward at the top, cam ber is said to be negative (-).

The amount of tilt is measured in degrees from

vertical and this m easurement is called the cam ber

angle.

While unequal camber may result in unstable

steering or wander, unequal and/or excessive

camber can also cause rapid tyre wear.

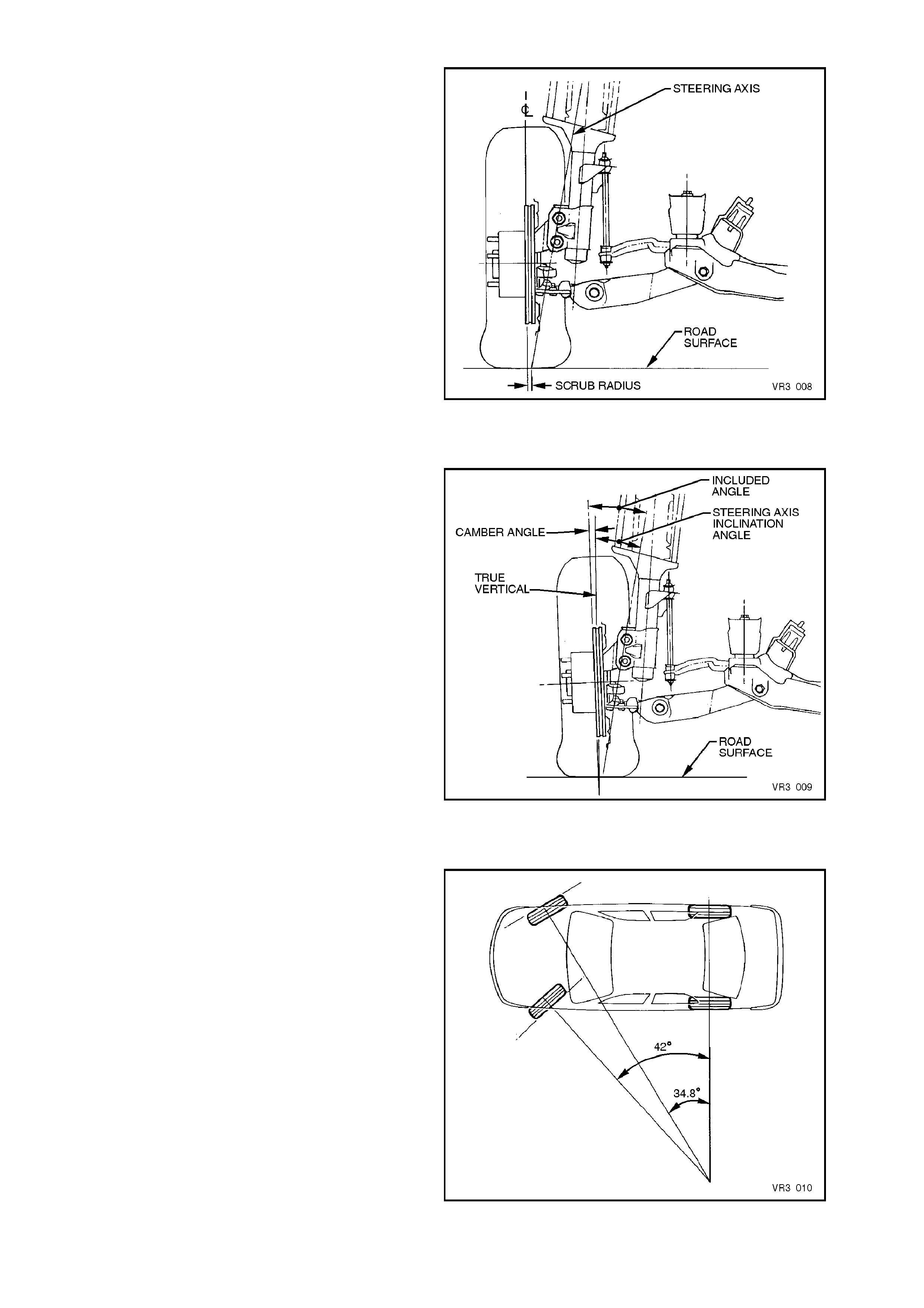

Figure 3-5

WHEEL TOE

Wheel Toe (see Figure 3-6), is the turning in (or

out) of the wheels when viewed from the overhead

position. The actual amount of toe is normally only

a few minutes of a degree. The purpose of a static

toe specification is to ensure parallel rolling of the

wheels, once the vehicle is in a dynamic state.

Excessive toe-in or toe-out may increase tyre wear.

With rear wheel drive vehicles, a slight amount of

toe-in, measured statically with the vehicle at rest,

is required to off-set the small deflections due to

rolling resistance and brake applications which tend

to turn the wheels outward.

Figure 3-6

STEERING AXIS INCLINATION

When viewed from the vehicle front, Steering Axis

Inclination can be described as being the angle

formed between the steering axis and the true

vertical (see Figure 3-7), where the steering axis is

the imaginary centreline through the upper strut

support bearing and the lower ball joint, both

components being the pivot points of the strut

assembly.

The Steering Axis Inclination angle is an important

factor in determining steering effort and directional

stability of the vehicle, by assisting caster in

keeping the front wheels in a central position.

Steering Axis Inclination also provides a self-

centring effect after cornering.

Figure 3-7

SCRUB RADIUS

This term refers to the distance that two imaginary

points are apart, at the road surface. These two

imaginary points are;

a. The intersection of the steering axis and

the road surface.

b. The centre of the tyre footprint on the road

surface.

As road wheel offset will affect scrub radius, in the

interests of vehicle handling and safety, non-

standard road wheels are not to be fitted to any

Holden vehicle.

With rear wheel drive vehicles, it is usual practice

to maintain a positive scrub radius (as shown in

Figure 3-8) to make the steering more responsive

and direct, thereby providing the driver with a more

positive sense of the tyre and road surface

interaction.

Figure 3-8

INCLUDED ANGLE

When both the Steering Axis Inclination angle and

Camber are combined, the resulting angle is

referred to as the Included Angle. This information

can be effectively used to determine if a component

is damaged or whether an adjustment is

responsible for an out-of-specification condition

occurring.

While Figure 3-9 shows a positive camber angle,

this has only been used to clarif y the term ‘Included

Angle'.

Figure 3-9

TOE-OUT ON TURNS

During cornering operations, a vehicle's road

wheels all turn about a common turning point,

causing the outer wheels to try and turn through a

greater radius than the inner. To overcome the

tendency for wheel slip under these conditions, the

outer wheel is commonly caused to toe-out, to

compensate for this increased turning circle.

The amount of toe-out during cornering, is

governed by the angle of the steering arms, which

are an inherent part of the steering knuckle.

Figure 3-10

2.2 WHE EL ALIGNMENT CHECKING AND ADJUSTMENT

PRELIMINARY INSPECTION

Before any attempt is made to check camber,

caster or toe-in, these preliminary checks should

be carried out.

1. Check tyre and tyre mountings. Always check

camber and toe-in at the mean run-out

position on the tyre or rim.

2. Check and adjust tyre pressures to

recommended values.

3. Front wheel bearing end float is to be chec k ed

to ensure it is within specification, as detailed

in 2.4 FRONT WHEEL BEARING HUB -

END FLOAT CHECKING PROCEDURE, in

this Section.

4. Lower control arm ball joints and inner bushes

should be checked for wear.

5. Check steering gear mounting bolts for

tightness and tie rod ball joints for wear.

6. The vehic le should be at c urb weight, f uel tank

full, without driver, passengers or luggage etc.

7. Check for improperly operating front struts or

rear shock absorbers.

8. Check for loose or missing stabiliser bar or

tension rod attachments.

9. Before checking the front wheel alignment,

refer to 4A REAR SUSPENSION for rear

wheel alignment details.

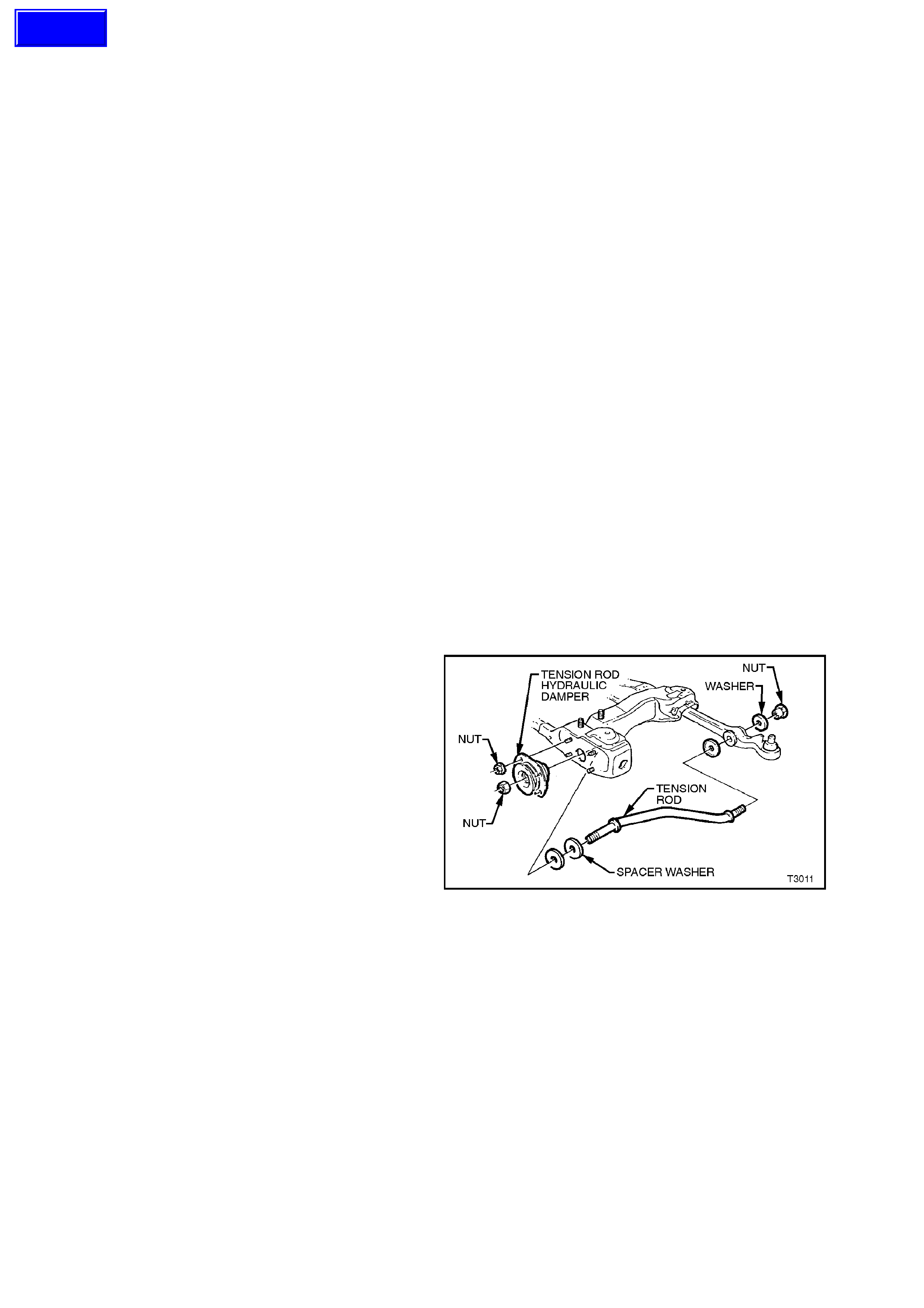

CASTER ADJUSTMENT

Only a nominal change in caster angle is

achievable and is limited to the addition (or

deletion) of a spacer washer to one of the tension

rods. The sole purpose of fitting this spacer is to

equalise caster angle from side to side, to within 0°

30'. Only one spacer washer is to be f itted and is to

be added to the side with the higher caster reading.

Figure 3-11

Techline

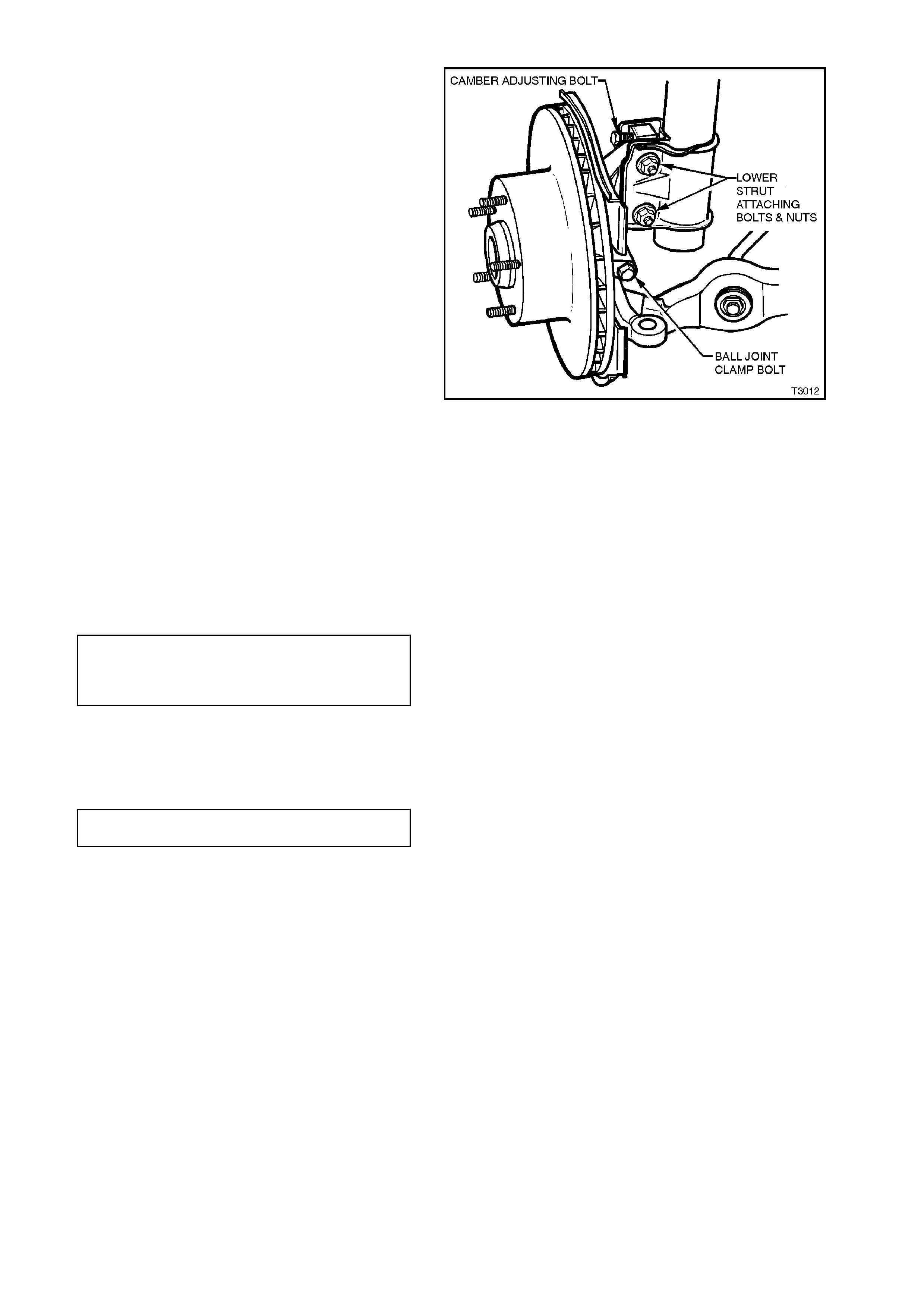

CAMBER ADJUSTMENT

1. Raise front of vehicle using a lifting jack under

front crossmember and support on safety

stands under front side members. Refer to

2.3 JACKING PRECAUTIONS in this Section

for details.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels) and mark relationship of

wheel to hub or brake disc.

3. Remove wheel attaching nuts and remove

wheel.

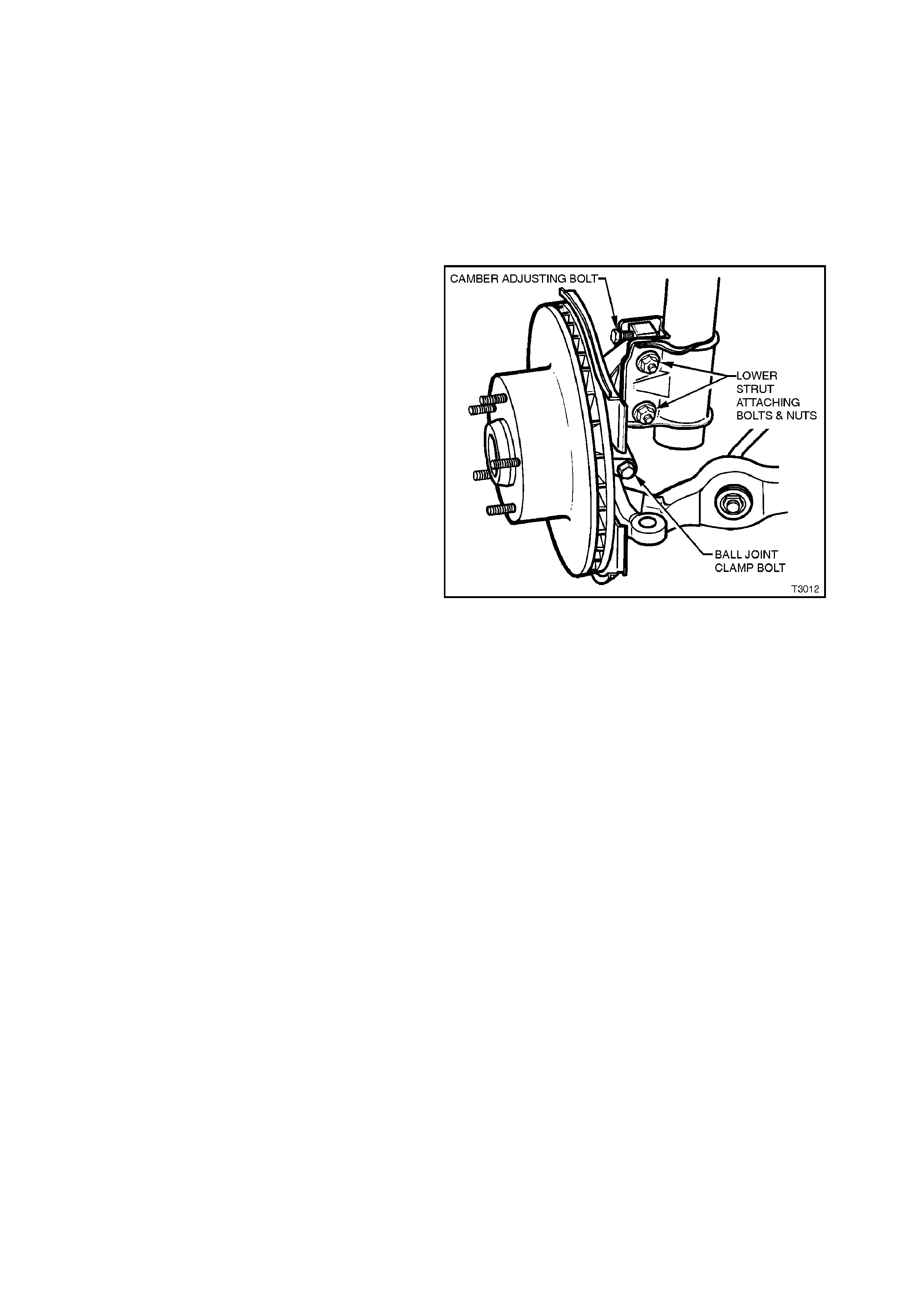

4. Loosen, remove and discard the two lower

strut attaching bolts and nuts (refer Figure 3-

12).

Reinstall NEW lower strut attaching bolts and

nuts but do not tighten until after the camber

has been adjusted to the recommended

specification.

5. Adjust camber by turning the camber adjusting

screw in the required direction. Clockwise to

reduce negative camber, anti-clockwise to

reduce positive camber.

NOTE:

The camber adjusting screw has thread sealant

applied in the form of micro-encapsulation and

does not require a lock nut.

Figure 3-12

6. Tighten both steering knuckle bolts and nuts

to the correct torque specification.

NOTE:

New bolts and nuts MUST be used!

STEERING KNUCKLE TO

STRUT ATTACHING

BOLTS & NUTS

TORQUE SPECIFICATION

Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn

through 90°

7. Install road wheels, aligning the marks made

prior to removal.

8. Remove jack stands and lower vehicle.

9. Tighten road wheel attaching nuts to correct

torque specifications.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

10. Refit wheel cover/centre cap.

11. Check the camber angle again to ensure that

it is within specification (refer to Figure 3-15).

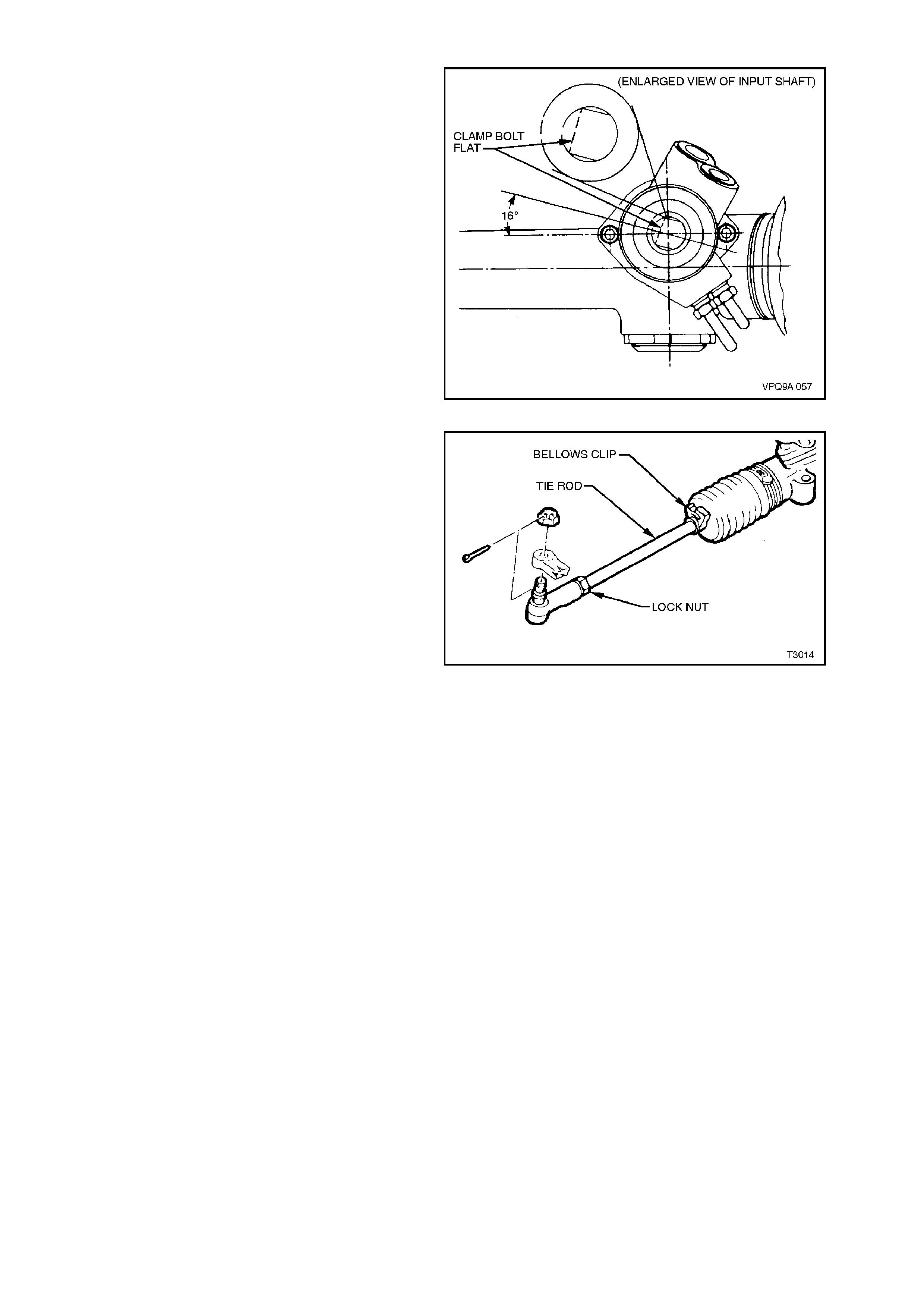

TOE ADJUSTMENT

Toe of both front wheels, is checked with the

wheels in the straight ahead position.

Adjustm ent is achieved by winding the tie rods in or

out of the tie rod ends, thus increasing or

decreasing their length and thereby altering the toe-

in setting.

1. Set steering gear and wheels in straight ahead

position.

To check if steering gear is in straight ahead

position (on centre), refer to Figure 3-13.

Figure 3-13

2. Before adjusting tie rods, disconnect steering

gear outer bellows clips.

3. Loosen lock nut at end of each tie rod.

4. Turn each tie rod as required, until the correct

toe is obtained.

NOTE:

During toe adjustment, ensure that steering wheel

is held in the straight ahead position.

5. Tighten lock nuts, ensuring that tie rod ends

are in alignment with their ball studs, then

tighten outer bellows clips securely, making

sure that convolutions of the boots are not

distorted.

6. With steering gear in straight ahead position,

ensure that steering wheel is centralised. If

not, remove steering wheel (refer to

Section 9 STEERING and reposition.

Figure 3-14

WHEEL ALIGNMENT SPECIFICATIONS

Figure 3-15

FRONT WHEEL ALIGNMENT AT KERB WEIGHT

Wheel Alignment

Angle Specification

Camber (± 0° 12') – 0° 12'

Caster 7° 45' ± 1° 15'

Toe-in Degrees Total 0° 10’ ± 0° 10’

Degrees per Wheel 0° 5’ ± 0° 5’

Toe-out on Turns 1° 42’ @ 20° turn angle ± 1° 30’

Steering Axis Inclination Angle 12° 52’ ± 1° 30

Included Angle 12° 40’ ± 1° 30’

SERVICE INFORMATION

•The adjusting values for camber, caster and toe-in must remain

within the tolerances specified. The difference between left and

right must not exceed the following:

CASTER............. 0° 36’

CAMBER............ 0° 48’

TOE-IN............... 0° 10’

•The specifications listed are the nominal value, with acceptable

variance from this central point. Where possible, an attempt should

always be made to achieve the nominal settings when changing.

•Front wheel camber alters as a function of front suspension height.

•Camber adjusting bolt: After loosening both lower strut to steering

knuc kle bolts and nuts, adjust c amber by turning the adjusting bolt

clockwise to decrease negative camber and anti-clockwise to

increase negative camber. After adjustment, both bolts and nuts

MUST be replaced with new parts and tightened to the

recommended torque setting.

•The rear wheel alignment should be checked and corrected if

necessary (refer to Section 4 REAR SUSPENSION) before

checking front wheel alignment.

Fuel Mass (kg) with Full Tank

Vehicle Model All Models

All Models 56

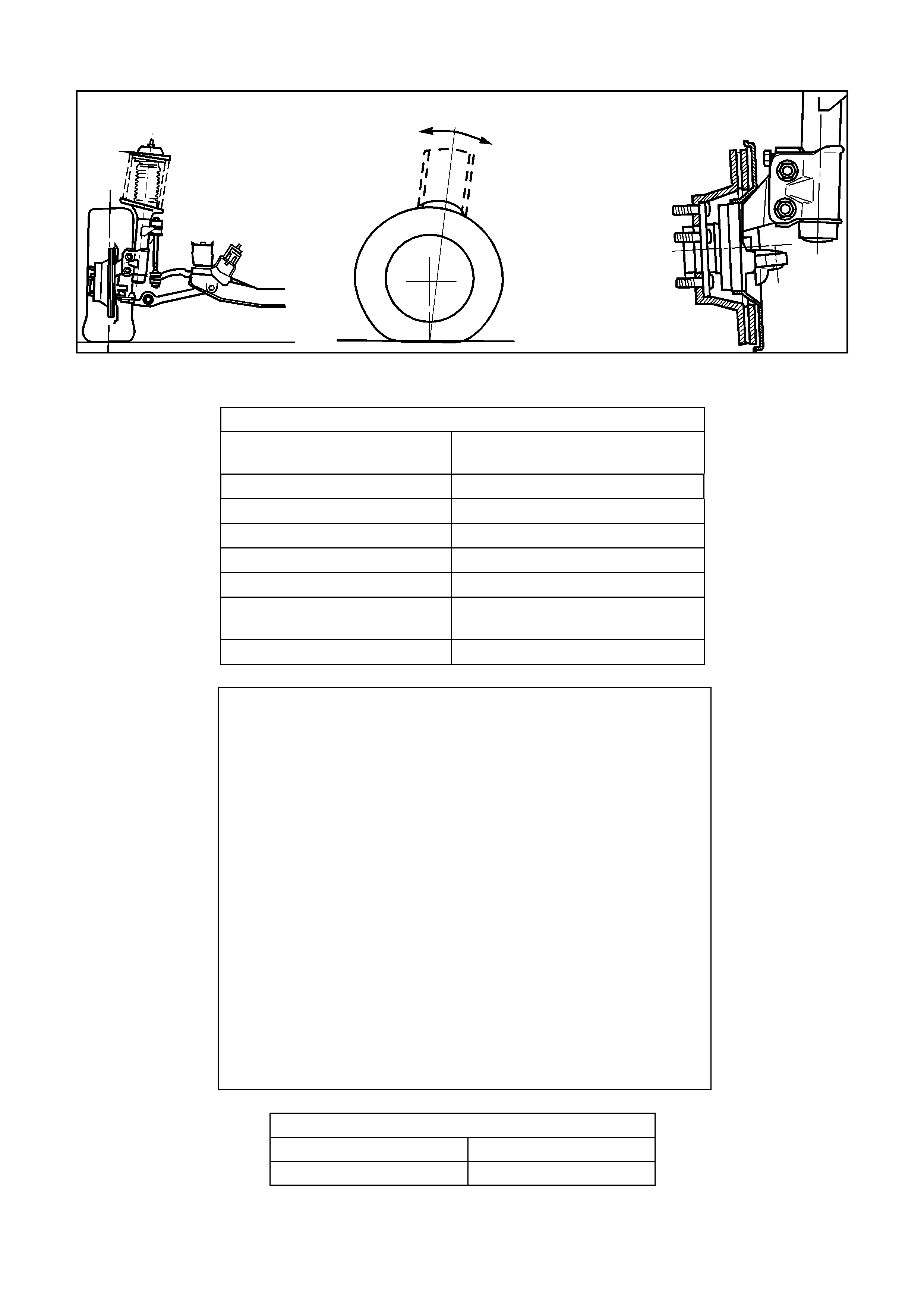

2.3 JACKING PRECAUTIONS

When raising the front of the vehicle with a jack,

the jack should be placed under the front

crossmember. THE WEIGHT OF THE VEHICLE

MUST NOT BE LIFTED UNDER THE LOWER

CONTROL ARMS.

When the vehicle is raised on the jack, it must be

firm ly supported on safety stands located under the

fram e side m em bers befor e any work is attem pted.

If a vehicle is not correctly supported by safety

stands, serious injury can result if the vehicle

should slip off the jack.

Figure 3-16

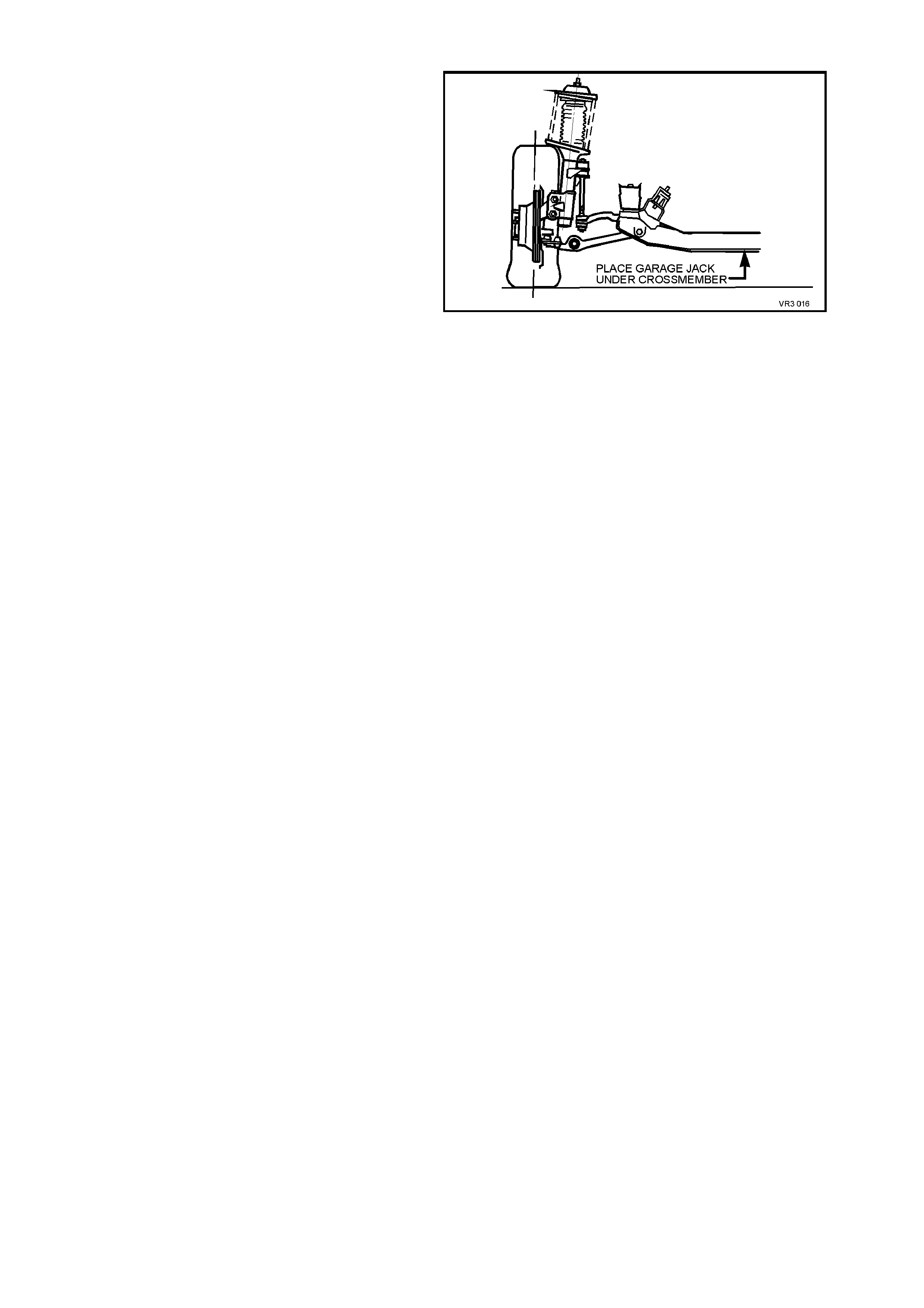

2.4 FRONT WHEEL BEARING HUB - END FLOAT CHECKING PROCEDURE

1. Raise front of vehicle and place on safety

stands. Observe jacking precautions as

detailed above.

2. Remove wheel covers (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel hub to brake disc to

preserve on-vehicle wheel balancing. Remove

wheel attaching nuts and remove road wheel.

4. Temporarily reinstall three, reversed wheel

nuts with a flat washer under each nut, to

prevent damage to the nut thread.

5. Mount a dial indicator to a suitable magnetic

stand and attach to the front strut tube.

Position the dial indicator pointer at the outer

diameter of the disc, as shown.

6. Apply an outward, 10 kg (22 lbf) force to the

outer brake disc diameter, in an opposite

position (180°) to the dial indicator. To

maintain consistency, a spring balance

capable of measuring this force, MUST be

used. With the force applied, zero the dial

indicator.

7. Apply an inward, 10 kg (22 lbf) force to the

outer brake disc diameter and note the dial

indicator reading.

8. The reading obtained is the angular movement

(NOT end float) and to determine the bearing’s

serviceability, compare the measured result

with the following specifications.

WHEEL BEARING ANGULAR ‘FLOAT’ SPECIFICATION

NEW BEARING 0.106 mm (0.0042”) Maximum

USED BEARING 0.213 mm (0.0085”) Maximum

9. Should this inspection show that the wheel

bearing assembly is outside the specified,

angular ‘float’ dimension, then the hub must be

replaced. Refer to operation

3.2 FRONT WHEEL HUB BRAKE DISC OR

BRAKE SHIELD, in this Section.

10. Remove the dial indicator and stand, and the

three wheel nuts and flat washers.

11. Reinstall road wheel, aligning marks made

prior to removal and secure with attaching

nuts.

12. Raise vehicle, remove safety stands and lower

vehicle to the ground. Tighten road wheel nuts

to the correct torque specification.

Figure 3-17

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

13. Reinstall wheel cover/centre cap.

3. MI NOR SERVICE OPERATIONS

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

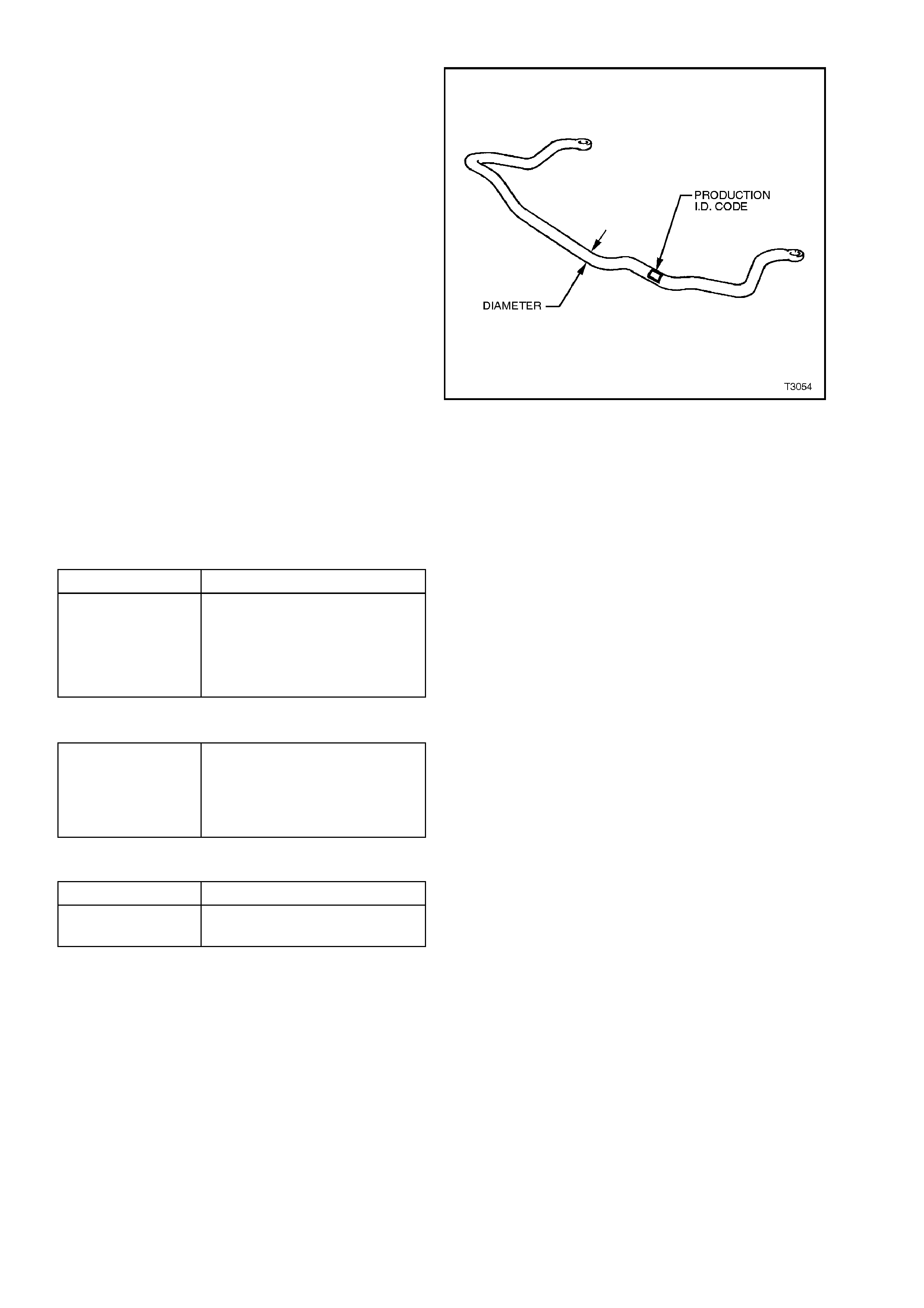

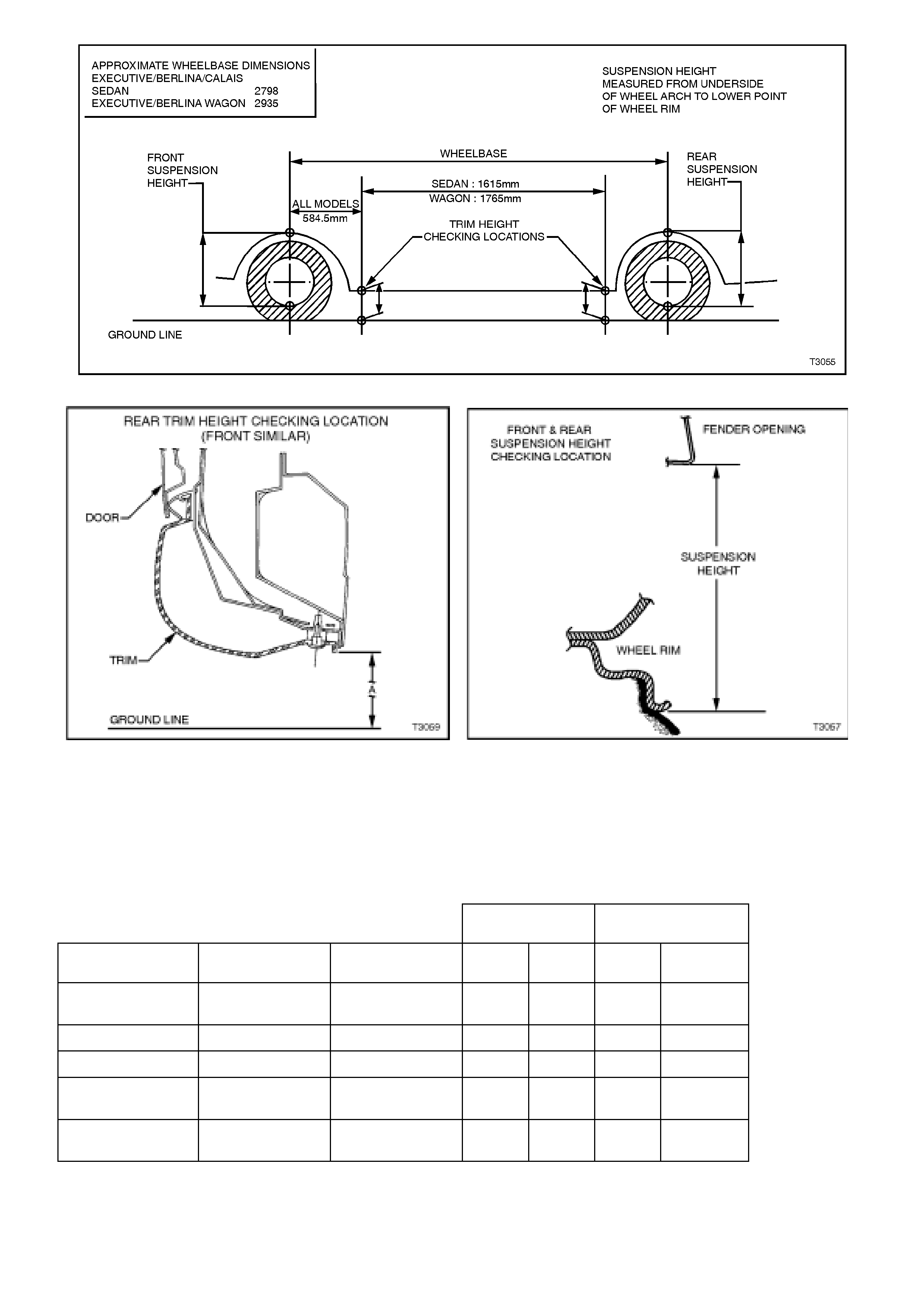

3.1 SUSPENSION AND TRIM HEIGHT, CHECK

The suspension and trim height dimensions are

provided in 6 SPECIFICATIONS in this Section.

The dimensions are for a new vehicle built to

standard specification and only intended as a

guide when checking suspension and trim height

dimensions at normal curb weight. Normal curb

weight is defined as a vehicle with a full tank of

fuel, all fluids at the specified levels, spare tyre

included, tyre pressures as specified and no

passengers. Accumulated dirt, mileage, etc., must

also be taken into consideration when checking

vehicle heights.

The following procedure should be followed before

checking any suspension or trim height.

1. All checks must be carried out on a LEVEL

surface, after the vehicle's tyre pressures have

been checked and it has been confirmed that

the vehicle has not suffered accident damage.

2. On average, all VT Series vehicles will sit

approximately 4 mm lower at the right hand

side front, because of the vehicle's battery

weight.

3. Push vehicle up and down several times at the

front bumper bar with a decreasing force and

then gently remove hands, allowing vehicle to

settle on its own. Carry out vehicle front trim

and suspension height check.

4. Push vehicle up and down several times at the

rear bumper bar with a decreasing force and

then gently remove hands, allowing vehicle to

settle on its own. Carry out vehicle rear trim

and suspension height check.

As shown in the specification listing (refer to

6 SPECIFICATIO NS in this Section), there are two

diff erent dimensions that m ust be c hecked and the

location for the measurements to be taken is

critical to correctly establishing a standard vehicle

condition. When checking a vehicle's ride height,

the following tolerances must also be taken into

account, before any spring is replaced.

RIDE HEIGHT VARIATIONS FROM SPECIFICATION

FRONT TO REAR................................ ± 20 mm

SIDE TO SIDE..................................... ± 10 mm

NORMAL SPRING SETTLING ............ ± 5 mm

NOTE:

Ride height variation may also be due to any one or

a combination of the following:

-Spring seat location on the suspension/body.

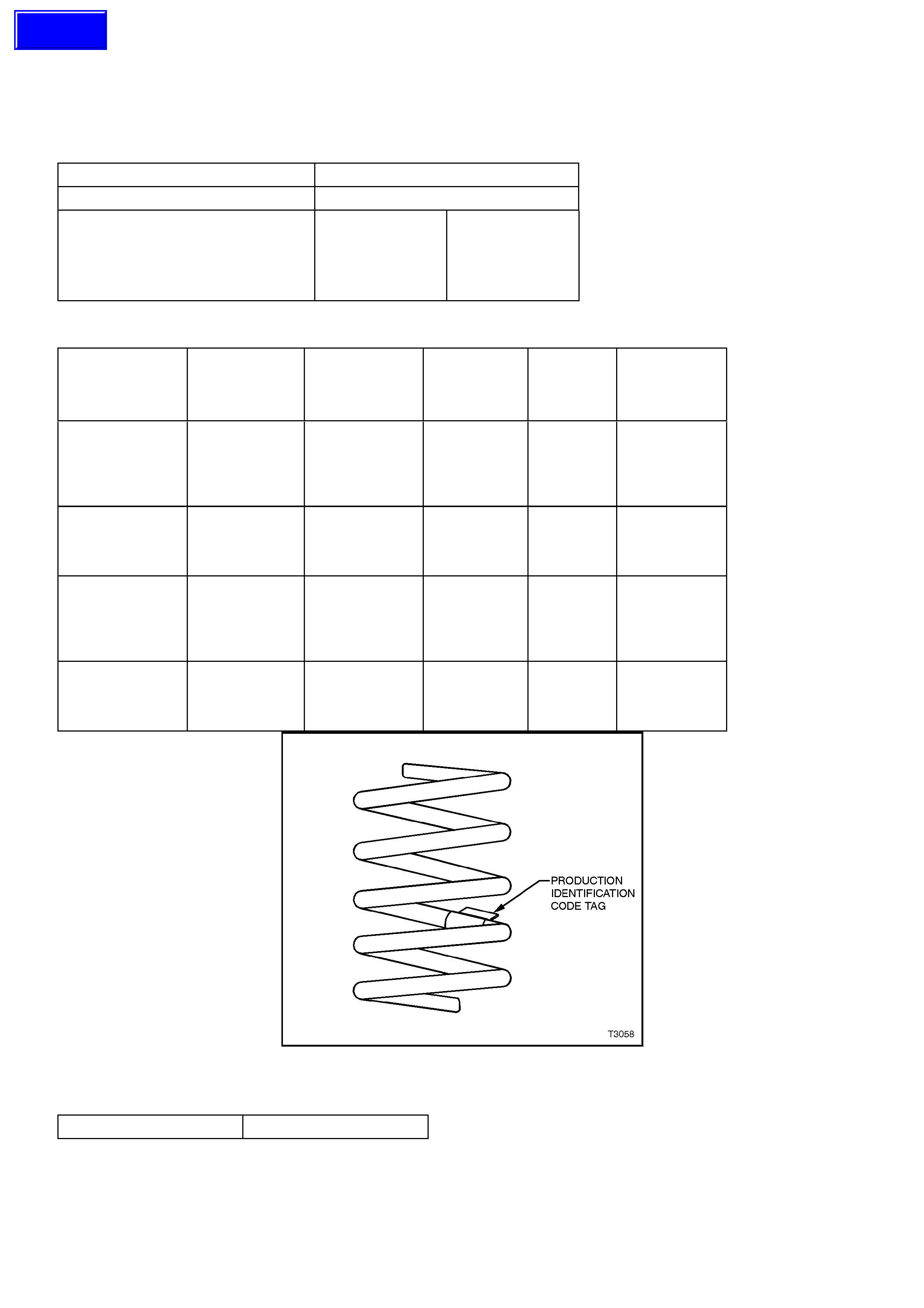

-Incorrect springs; Check spring identification

against the table shown in

6 SPECIFICATIONS in this Section.

-Non-standard, additional vehicle weight, such

as a tow bar and/or LPG fitment.

-Any combination of the above.

CAUTION:

Good judgement must be exercised before

replacing a spring or springs from a vehicle

whose height is within the limits quoted. Even

should a vehicle's dimensions prove to be

slightly outside these tolerances, the vehicle

could well be in a serviceable condition.

Spring replacement under conditions of

excessive weight due to non standard fittings,

undercoating, road dirt, etc; will assist very

little in restoring the vehicle to its specified

height.

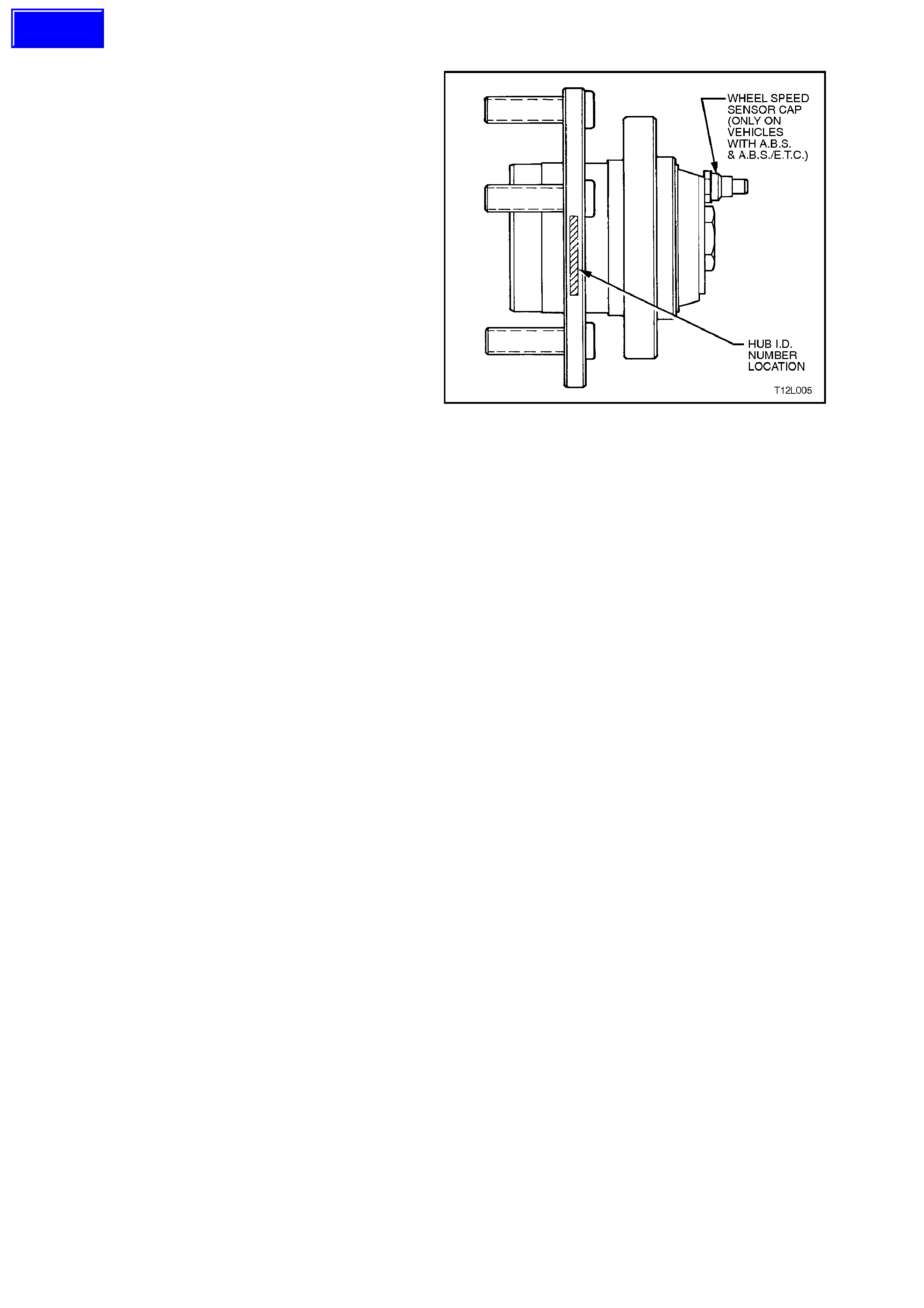

3.2 FRONT WHEE L HUB, BRAKE DISC OR BRAKE SHIELD

NOTE 1:

Apart from wheel stud replacement, there are no

serviceable item s in the front wheel hub assembly.

As the unit is a 'sealed for life' assembly, neither

bearing adjustment nor lubrication maintenance is

required. Should a non-standar d condition develop,

then the hub assembly must be replaced as a

complete unit.

NOTE 2:

If an ABS hub requires replacement, the correct

assembly must be fitted. If not, the ABS will

malfunction. Either the hub will have an ABS lead

connection or it will not.

NOTE 3:

While the f r ont wheel hub is des igned to have zero

axial free play or ‘end-float’, some angular

movement m ay be evident when a rocking force is

applied to the mounted wheel and tyre assembly.

Before a hub is replaced, refer to checking

procedure, detailed in Operation 2.4 in this Section

of the Service Manual.

.

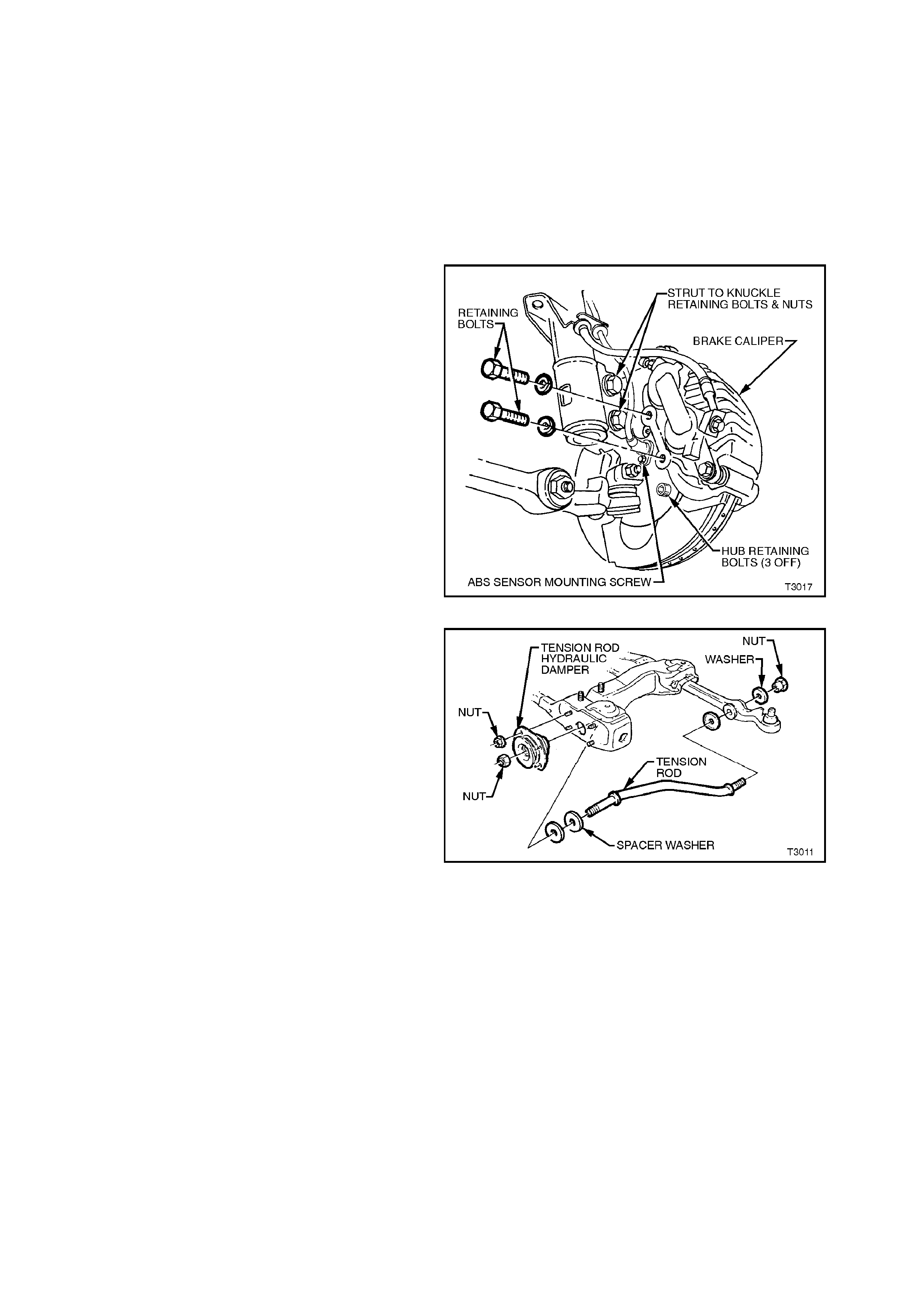

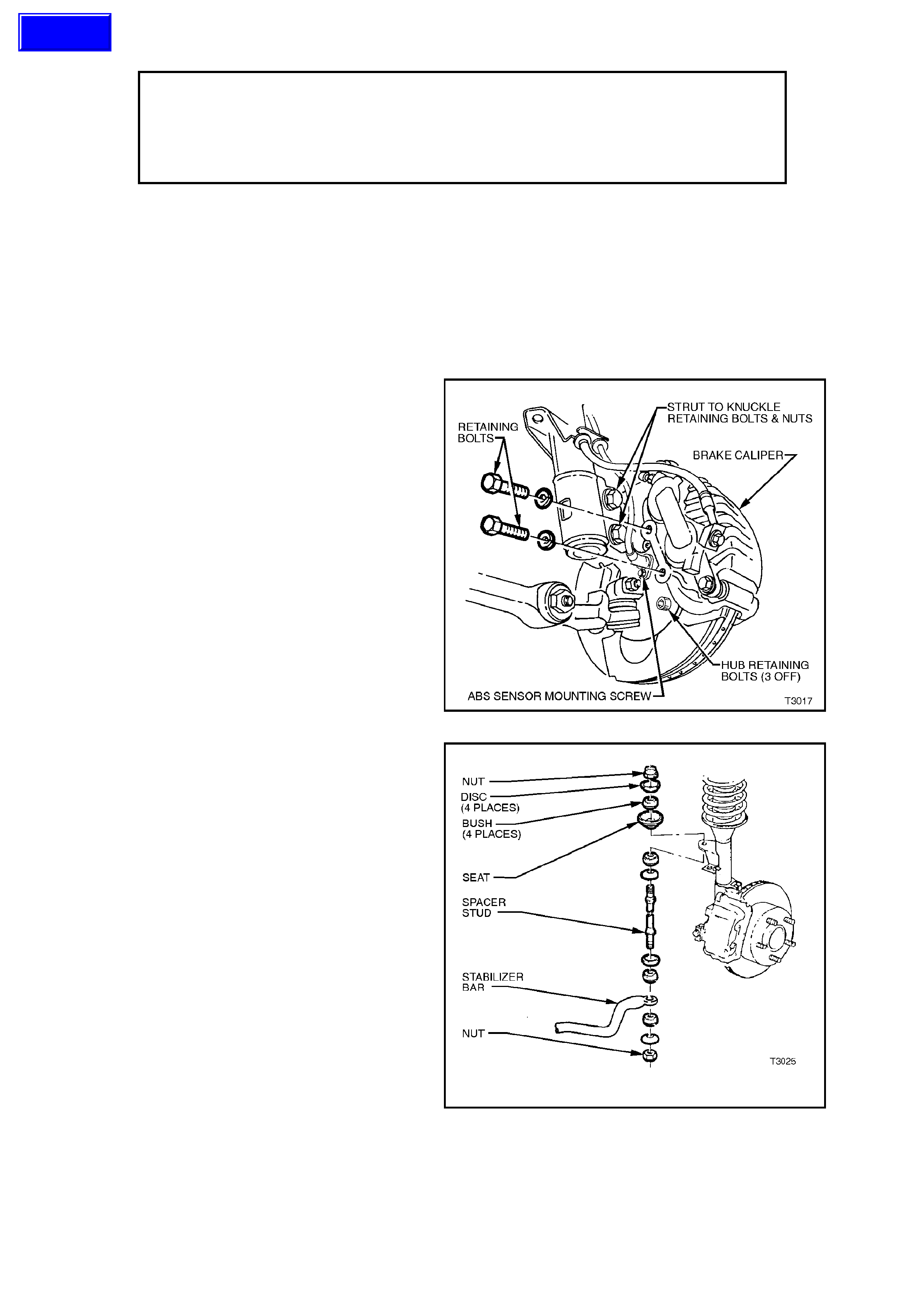

Figure 3-18

Techline

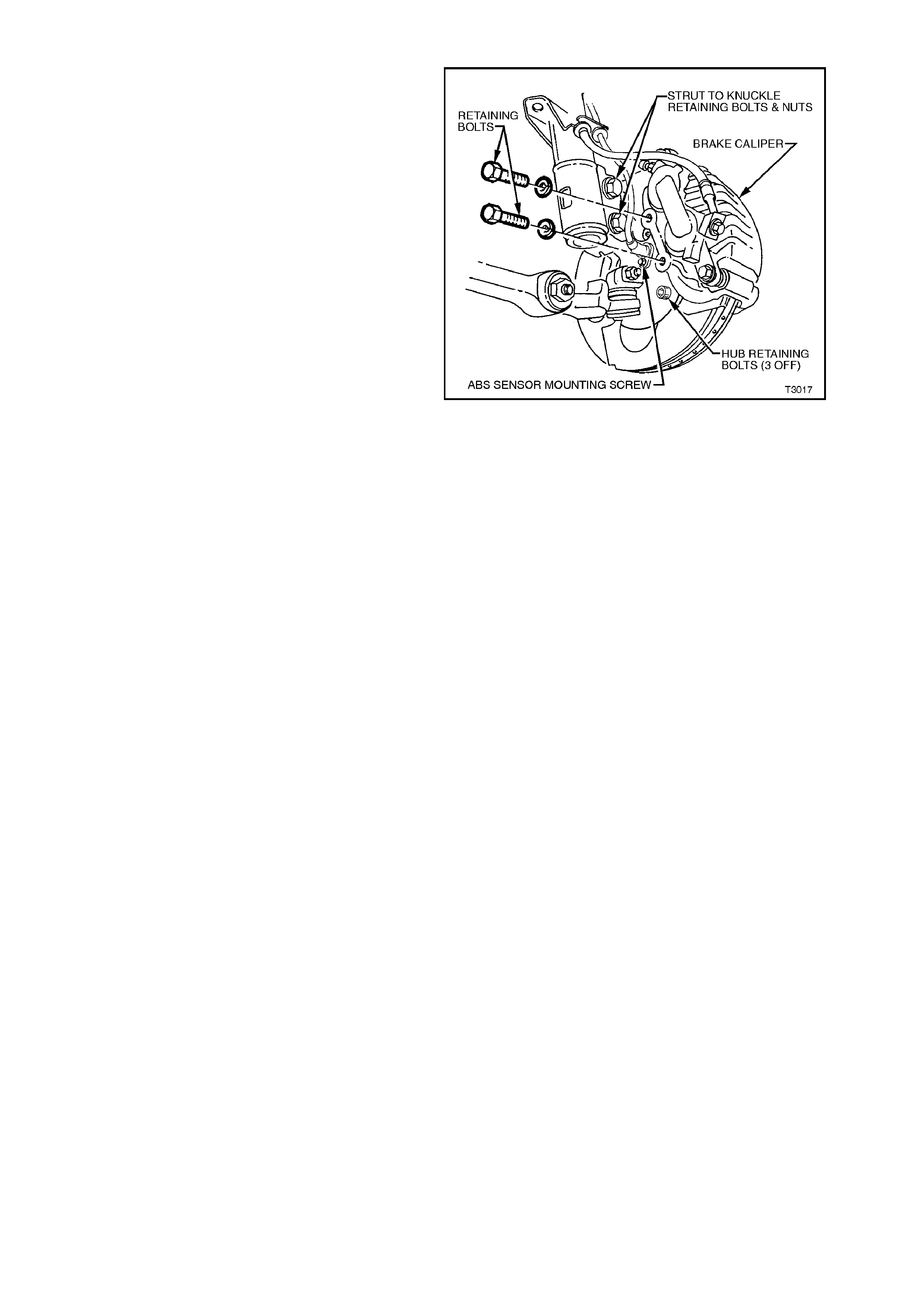

REMOVE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as

outlined in 2.3 JACKING PRECAUTIONS in

this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub or brake

disc. Remove wheel attaching nuts and

remove wheel.

4. Remove brake caliper anchor plate retaining

bolts and washers, lift caliper assembly from

brake disc. Position caliper in such a way that

no strain is placed on the brake hose. If

necessar y, tie caliper to the suspens ion spring

with a piece of wire. THE CALIPER IS NOT

TO HANG BY BRAKE HOSE.

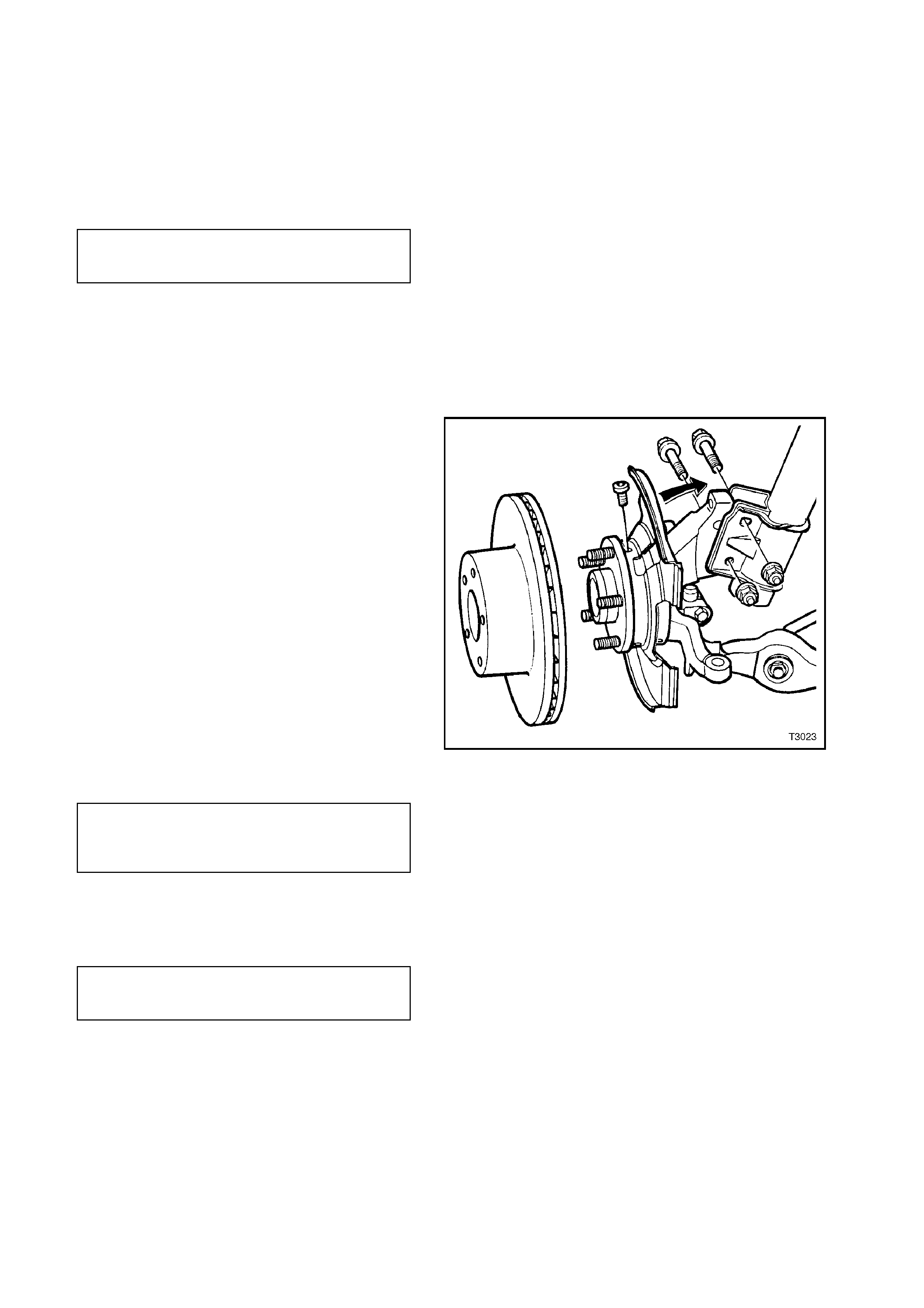

5. Remove brake disc from the wheel bearing

hub.

NOTE:

For vehicles equipped with ABS, disconnect the

wheel speed sensor connector from the steering

knuckle. To do this, use a 5 mm Allen key (or

socket), remove the set screw and then, holding

the cable retaining bracket, twist and gently pull on

the sensor c onnec tor end. Don't los e the s ealing O-

ring.

6. Using a commercially available 10 mm Allen

key socket and a suitable socket bar, loosen

each of the three bolts holding the hub to the

steering knuckle.

NOTE 1:

For the fr ont lower hub bolt, turn wheel outwards to

provide clearance between the ball joint rivet and

the hub bolt.

NOTE 2:

If the Allen key socket is too long to fit into the front,

upper hub bolt, then the lower strut to steering

knuckle nut will need to be removed and the bolt

withdrawn.

7. If the hub is a tight f it to the knuck le, it m ay be

necessary to loosen the three loosened bolts

and tap on the heads. DO NOT STRIKE THE

HUB.

Figure 3-19

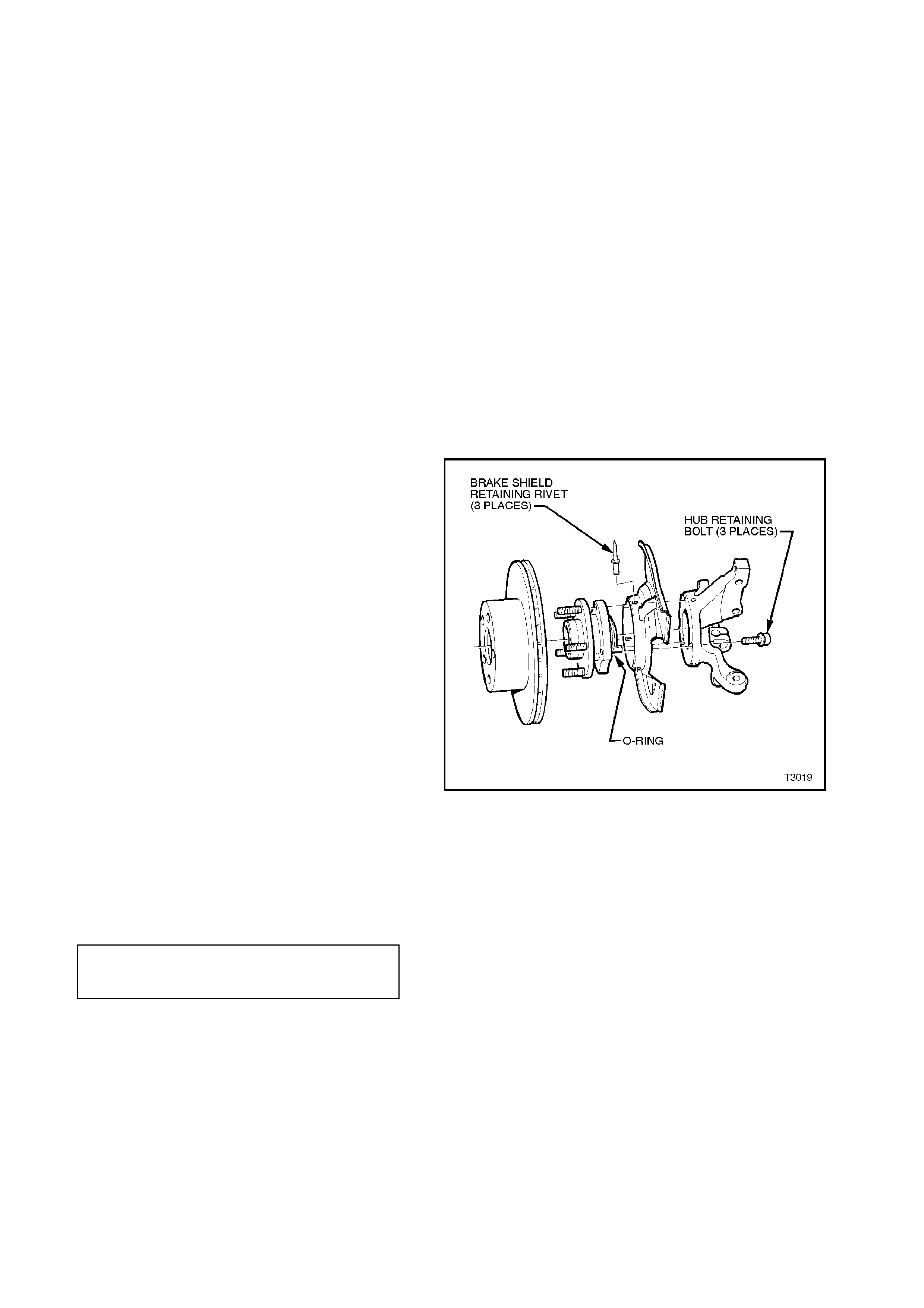

8. Remove the thr ee bolts and then the hub from

steering knuckle.

9. If removal of the brake shield is necessary,

drill the heads from the three rivets securing

the shield to the steering knuckle support.

10. After removal of the shield, carefully drill out

the remainder of the rivets, using a suitable

sized, sharp drill.

INSPECT

1. Check wheel studs to ensure threads are not

damaged, and that studs are pressed firmly

into the front wheel hub.

If one or more wheel studs require

replacement, refer to operation

3.3 FRONT HUB WHEEL STUD in this

Section, for details.

2. Examine brake disc for scores or damage.

If either of these conditions exist, the brake

disc should be machined. Refer to

Section 5A BRAKES for details.

3. Check for damage to the shield that may

cause fouling of any rotating parts and if

suspect, the shield should be replaced.

REINSTALL

Installation of the f ront wheel hub and brak e disc is

the reverse of removal procedures, except for the

following points:

All Models:

1. If the brake shield has been removed, install

three, common pop rivets, using a

commercially available pop rivet gun.

NOTE:

Install the fir st rivet in the brak e shield hole with the

round hole. This will ensure that the clearance to

brake caliper is correct.

2. Before installing the hub, inspect both mating

surf aces to mak e sure that they are clean and

free from burrs that could prevent correct

alignment of both parts, once installed.

3. Prior to installation, it is also vital that the

sealing O-ring located around the mounting

flange, is checked to ensure its serviceability.

Failing to adequately seal the hub to steering

knuc kle interf ace, will caus e water to be dr awn

into the cavity in the steering knuckle, during

the normal heating and cooling cycle of vehicle

operation.

Without ABS:

4a. Install the hub assembly to the steering

knuckle.

5a. Install the three attaching bolts and tighten to

the correct torque specification.

Figure 3-20

FRONT HUB TO STEERING

KNUCKLE ATTACHING BOLT

TORQUE SPECIFICATION 100 - 115 Nm

NOTE:

The three hub attaching bolts are micro-

encapsulated with thread sealant and are not to be

re-used m ore than thr ee times. If in doubt, the bolts

should be replaced.

With ABS:

4b. Carefully align the sensor connection on the

hub, with the hole in the steering knuckle, then

install the three hub attaching bolts and tighten

to the correct torque specification.

FRONT HUB TO STEERING

KNUCKLE ATTACHING

BOLT TORQUE SPECIFICATION 100 - 115 Nm

5b. Fit the wheel speed sensor connector, then

install the cable retaining bracket set screw

and tighten to specification.

SENSOR CABLE

RETAINING SCREW

TORQUE SPECIFICATION 6 - 14 Nm

All Models:

6. If removal of the lower strut to steering

knuckle bolt was necessary, the bolt and nut,

must be replaced with new parts and tightened

to the correct torque specification.

STEERING KNUCKLE

TO STRUT ATTACHING

BOLTS & NUTS

TORQUE SPECIFICATION

Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn

through 90°

7. Reinstall brake disc and brake caliper,

tightening attaching bolts to specification.

BRAKE CALIPER ANCHOR

PLATE RETAINING BOLTS

TORQUE SPECIFICATION

80 - 90 Nm

then turn through

40° - 50°

8. Reinstall road wheel, aligning the marks made

prior to removal and secure with the attaching

nuts.

9. Remove jack stands and lower vehicle.

10. Tighten road wheel attaching nuts to correct

torque specification.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

11. Refit wheel cover/centre cap.

3.3 FRONT WHE EL HUB STUDS

REPLACE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as

outlined in 2.3 JACKING PRECAUTIONS in

this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub and disc.

Remove wheel attaching nuts and remove

wheel.

4. Remove brake caliper anchor plate retaining

bolts and washers, lift caliper assembly from

brak e disc. Sus pend caliper on wire or hook to

avoid strain on the hose. DO NOT ALLOW

CALIPER TO HANG BY BRAKE HOSE.

5. Remove brake disc from hub.

6. Using Tool No. AJ24292-C or equivalent,

press stud/s from the front hub after first

installing a wheel nut until the nut is flush with

the end of the stud.

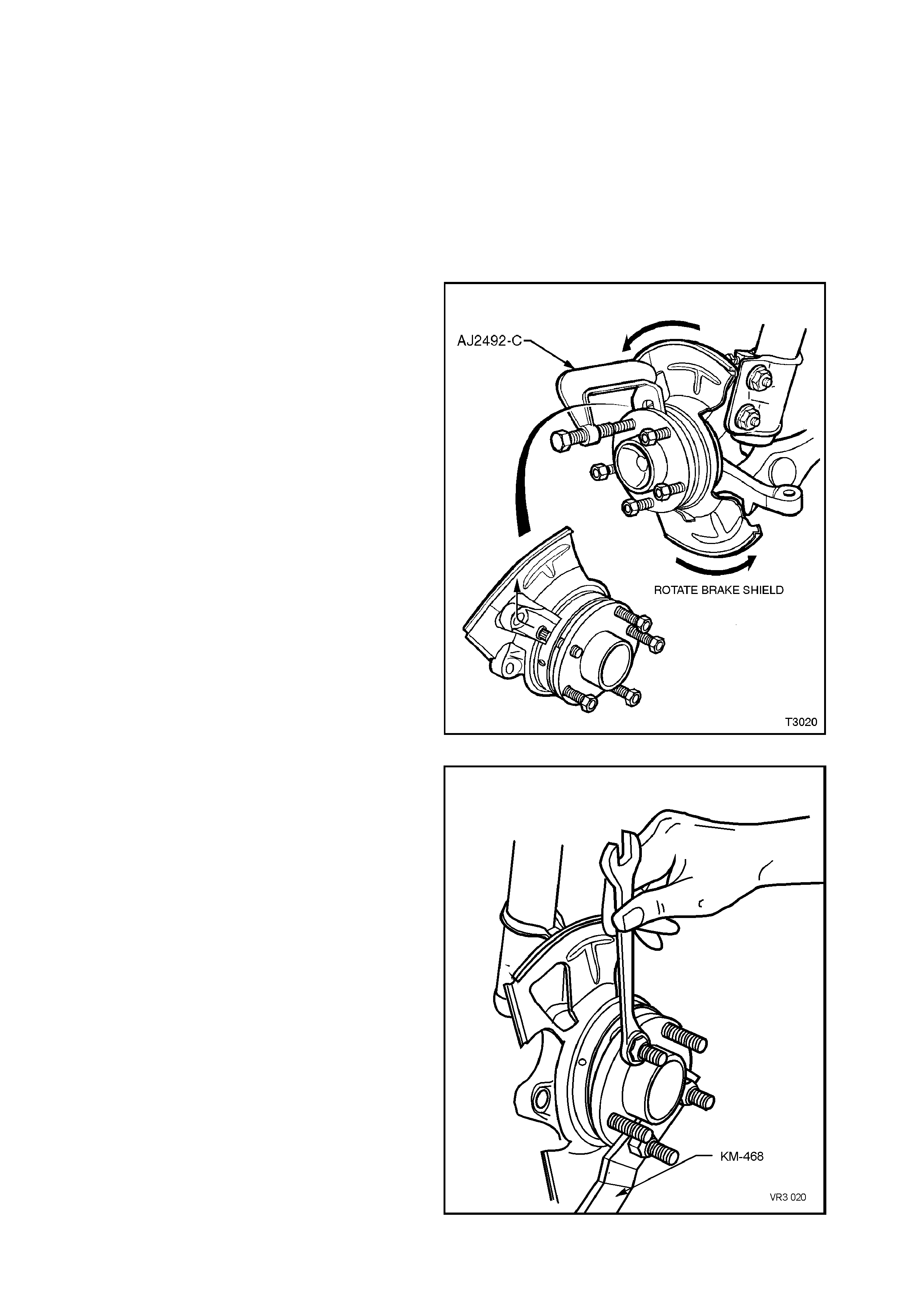

NOTE 1:

To avoid the unnecessary removal of the micro-

encapsulated studs retaining the front hub to the

steering knuckle, it is recommended that wheel

stud/s replacement be carried out with the hub left

undisturbed.

NOTE 2:

To remove the stud/s, first drill out the three rivets

securing the brake shield to the steering knuckle.

Then rotate the shield and remove the wheel hub

stud by manipulating the head under the shield and

into the one recess in the steering knuckle, at

approximately the 11 o’clock position, as shown.

Figure 3-21

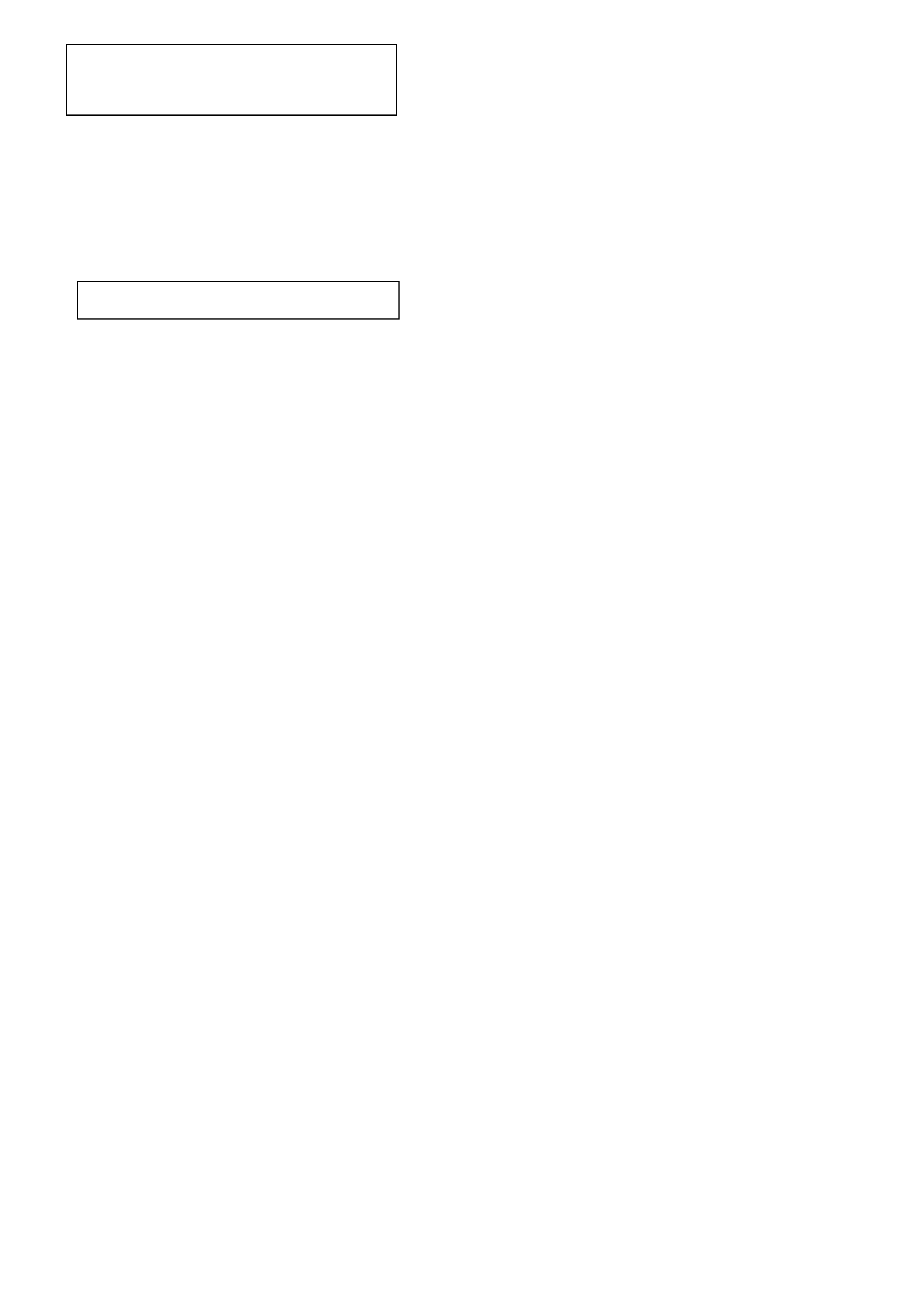

7. New studs can be installed as follows;

a. Install Tool No. KM468, using two revers ed

wheel nuts.

b. Install replacement stud by first

manipulating the stud under the disc brake

shield and into the wheel hub f lange. T hen,

after assembling a suitable sized flat

washer and reversed wheel nut onto the

replacement stud, hold Tool No. KM468

and tighten the wheel nut to draw the stud

into place.

c. Install any remaining studs in the same

manner. Remove Tool No. KM-468.

8. Using a suitable sized, sharp drill remove the

shanks of the three brake shield retaining

rivets. Then use common pop rivets and a

commercially available pop rivet gun to

reinstall the brake shield.

NOTE:

Install the fir st rivet in the brak e shield hole with the

round hole. This will ensure that the clearance to

brake caliper is correct.

9. Reinstall brak e disc and caliper, tightening the

caliper retaining bolts to the correct torque

specification. Figure 3-22

BRAKE CALIPER

ANCHOR PLATE

RETAINING BOLTS

TORQUE SPECIFICATION

80 - 90 Nm,

then turn

through

40° - 50°

10. Install the road wheel, aligning the marks

made prior to removal and secure with the

attaching nuts.

11. Remove jack stands and lower vehicle.

12. Tighten road wheel attaching nuts to correct

torque specification.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

13. Refit wheel cover/centre cap.

4. MAJOR SERVICE OPERATIONS

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

4.1 FRONT STRUT ASSEMBLY

REMOVE

1. Raise front of vehicle and support on safety

stands. Observe jacking precautions as

outlined in 2.3 JACKING PRECAUTIONS in

this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub or brake

disc. Remove road wheel attaching nuts and

remove wheel.

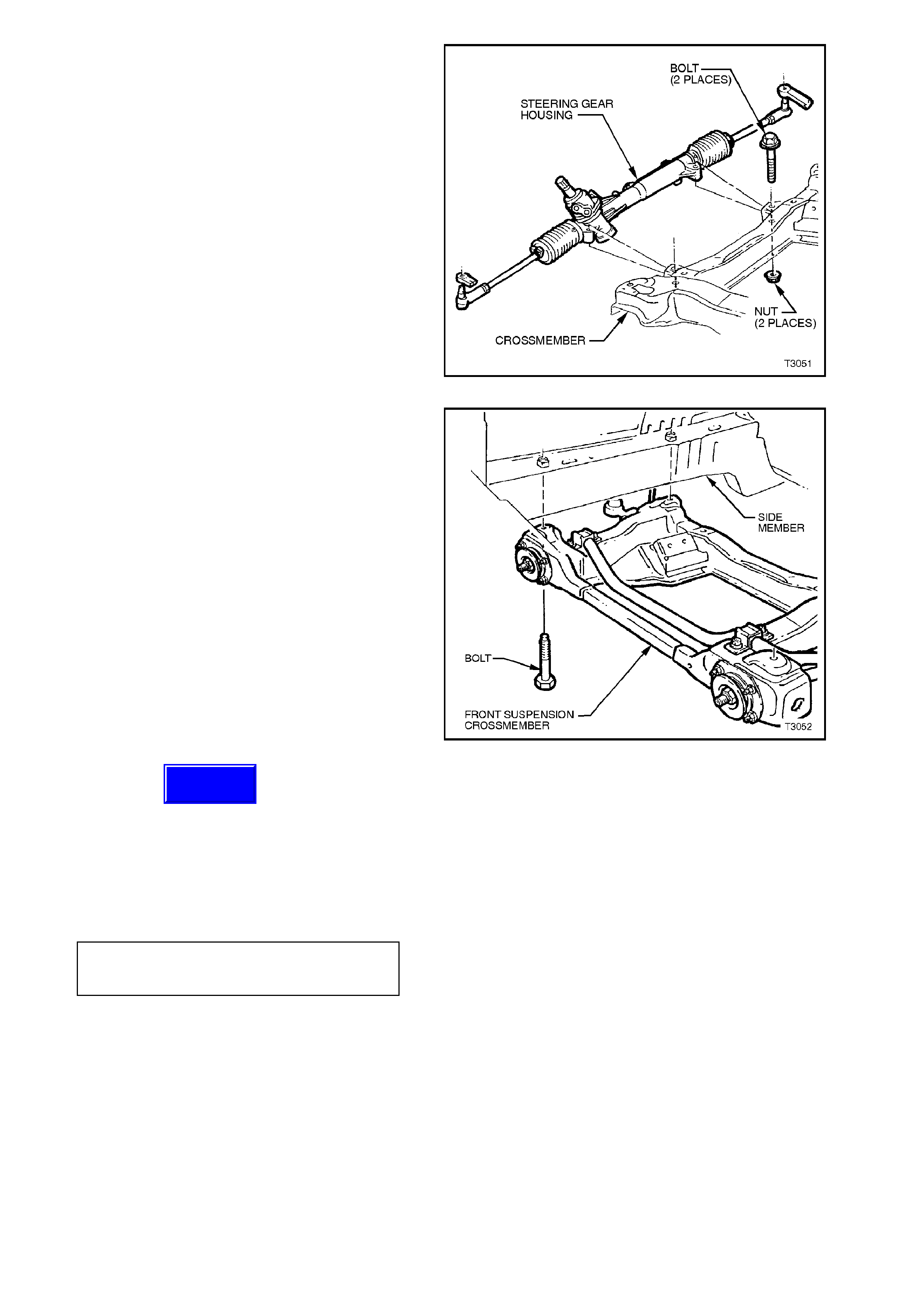

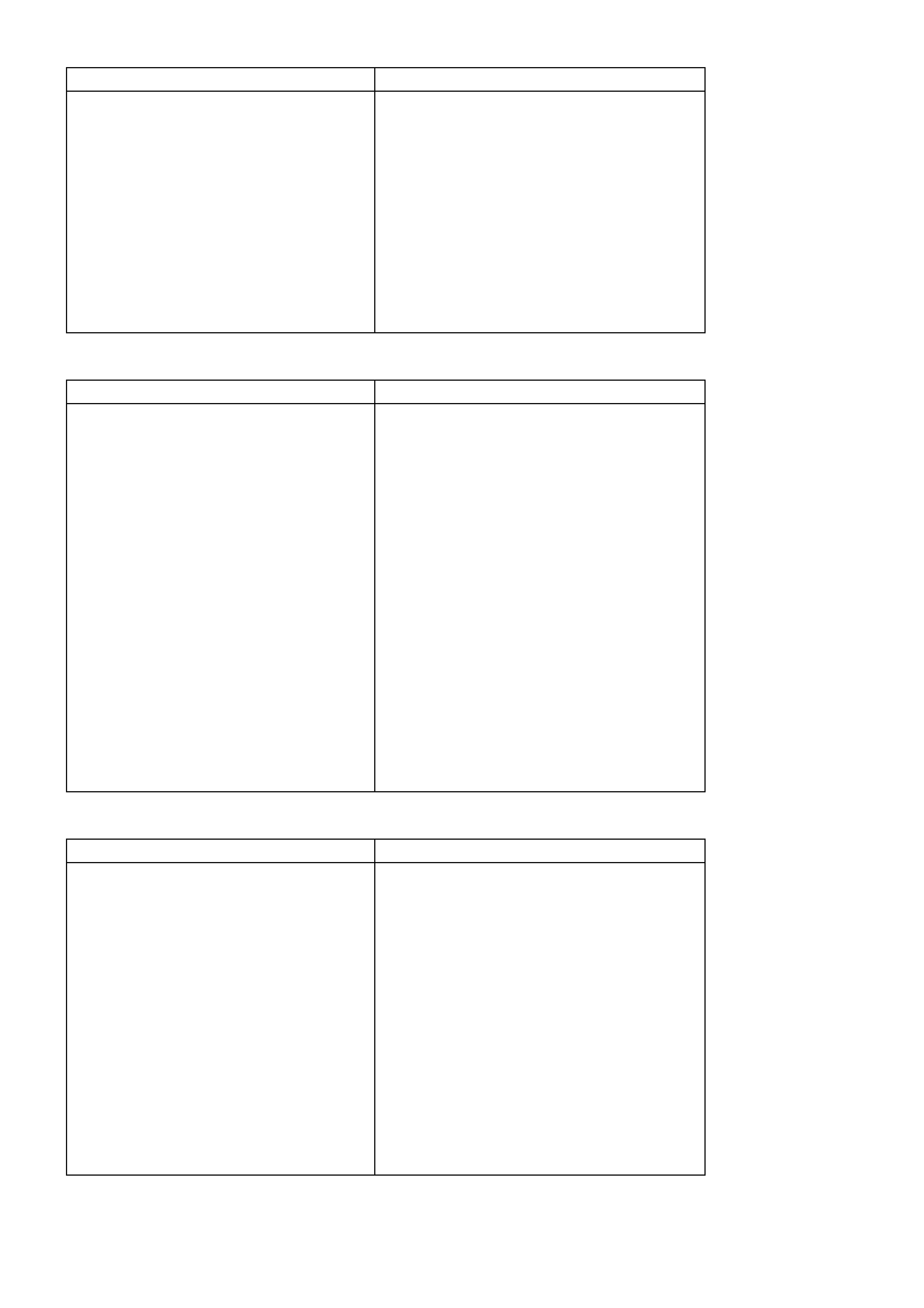

4. Position a suitable size open end spanner

over flat in stabiliser bar spacer stud, remove

upper nut, disc, bush and seat.

5. If the vehicle is fitted with ABS, disconnect the

wheel speed sensor cable by pulling the

insulator from the strut bracket.

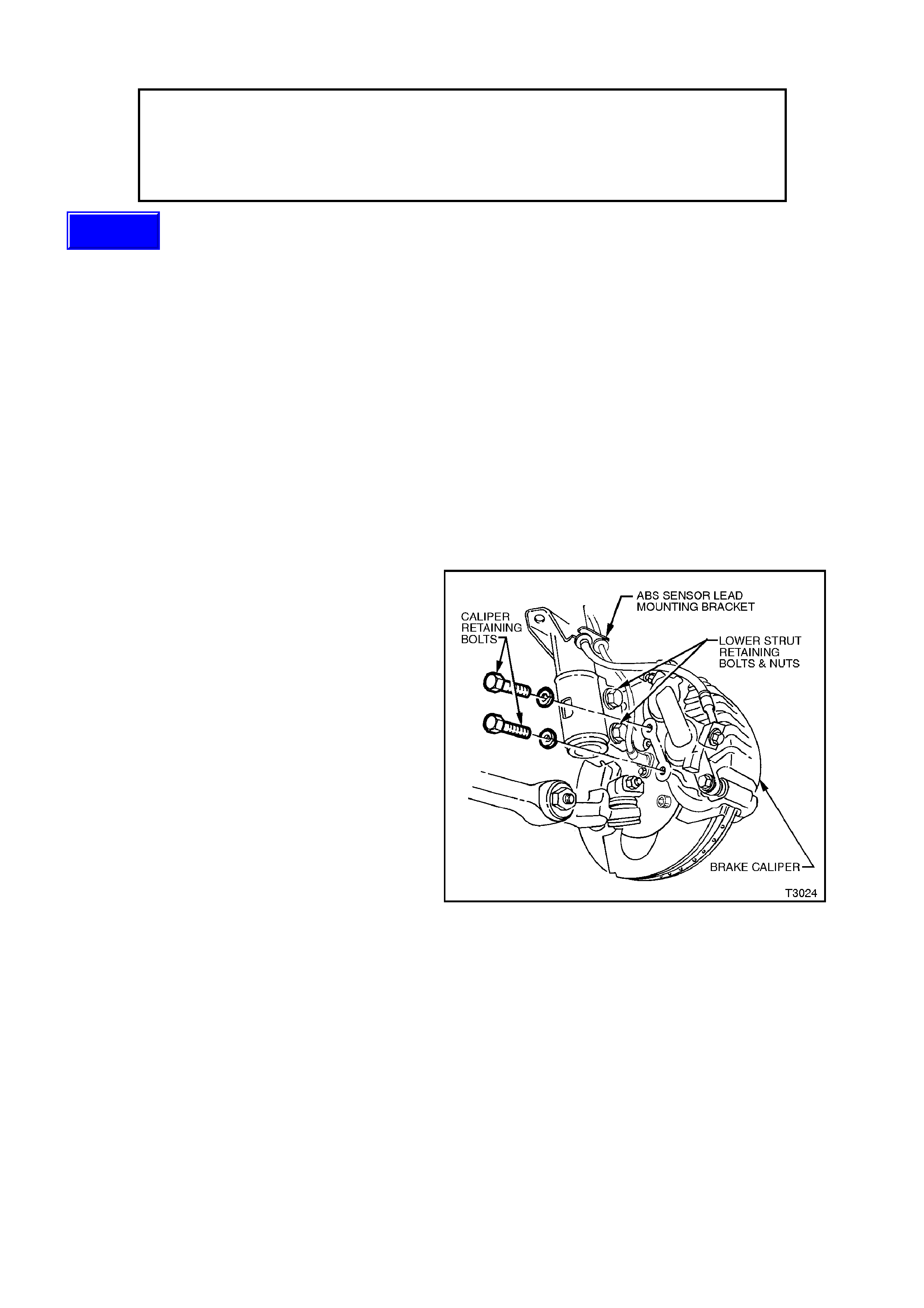

6. Remove the brake caliper anchor plate

retaining bolts and washers, lift the caliper

assembly from the brake disc and support in

such a way that no strain is placed on the

brake hose. THE BRAKE CALIPER IS NOT

TO HANG BY THE BRAKE HOSE.

NOTE:

This step is necessary to provide access to the

lower strut mounting bolt and nut.

7. Remove brake hose from the strut housing

bracket by turning plastic sleeve on the hose

until flats on sleeve align with bracket opening.

8. Using a suitable f loor jac k f itted with a bloc k of

wood, position under the lower control arm,

just sufficient to support the weight.

9. W hile holding the strut rod shaft with a 10 mm

socket, remove the self-lock ing nut, using a 24

mm (15/16") ring spanner, then remove the

locating disc. DISCARD THE STRUT ROD

NUT.

10. Loosen, remove and DISCARD the two lower

strut to knuckle attaching bolts and nuts.

11. Pull the steering knuckle clear of the strut,

taking care not to place any strain on the ABS

Sensor cable (if fitted).

12. Carefully lower the strut from the tower,

manipulate the strut to remove the stabiliser

stud fr om the brack et on the str ut and rem ove

the assembly from the vehicle.

Figure 3-23

Techline

REINSTALL

NOTE:

In the interests of vehicle saf ety, it is important that

fastener s are r eplaced with new parts where stated

during the reinstallation process described here.

IMPORTANT:

The torque of the strut bearing retaining nut MUST

be checked for correct tightness BEFORE installing

the strut into the vehicle!

UPPER STRUT BEARING

RETAINING NUT

TORQUE SPECIFICATION 70 - 85 Nm

1. Manipulate the strut assembly so that the

stabiliser bar stud is located in the strut

bracket, then locate strut assembly into the

spring strut tower.

2. Af ter ins talling the locating disc , partially install

a NEW nut to the strut rod. Do not tighten at

this time.

3. Pivot the hub and steering knuckle

assemblies, sufficient to line up the bolt holes

in the steering knuckle and the lower end of

the strut assembly.

4. Install NEW retaining bolts and nuts, and

tighten in stages to the specified torque

values.

Figure 3-24

STEERING KNUCKLE TO

STRUT ATTACHING

BOLTS & NUTS

TORQUE SPECIFICATION

Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn

through 90°

5. While holding the strut rod f rom tur ning, with a

10 mm socket, tighten the upper strut rod

retaining nut to the correct torque

specification, using a 24 mm (15/16”) ring

spanner with a torque wrench attached.

UPPER STRUT LOCATING

PLATE RETAINING NUT

TORQUE SPECIFICATION 50 - 60 Nm

6. Install the brake hose to the strut bracket by

turning plastic sleeve on the hose until the flats

on the sleeve align with the bracket opening.

7. If removed, install the brake disc, then install

the brak e caliper , tightening the attac hing bolts

to specification.

BRAKE CALIPER

ANCHORPLATE

RETAINING BOLTS

TORQUE SPECIFICATION

80 - 90 Nm,

then turn through

40° - 50°

8. If the vehicle is fitted with ABS, fit the wheel

speed sensor connector, then install the cable

retaining bracket set screw and tighten to

specification.

SENSOR CABLE

RETAINING SCREW

TORQUE SPECIFICATION 6 - 14 Nm

9. Install stabiliser bar spacer stud nut after

ensuring that all components are assembled

as shown. While holding the spacer stud with

a suitable open end spanner, tighten the upper

retaining nut until the thread end.

NOTE:

Do not use power tools for this tightening operation,

otherwise thread damage will result.

10. Install road wheel, aligning the marks made

prior to removal.

11. Remove safety stands and lower vehicle.

12. Tighten road wheel attaching nuts to the

correct torque specification.

Figure 3-25

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

13. Refit wheel cover/centre cap.

14. Bounce vehicle up and down several times to

settle suspension.

15. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.2 UPPER STRUT SUPPORT BEARING AND MOUNT

REMOVE

1. Remove front strut as detailed in Operation

4.1 FRONT STRUT ASSEMBLY - REMOVE

in this Section.

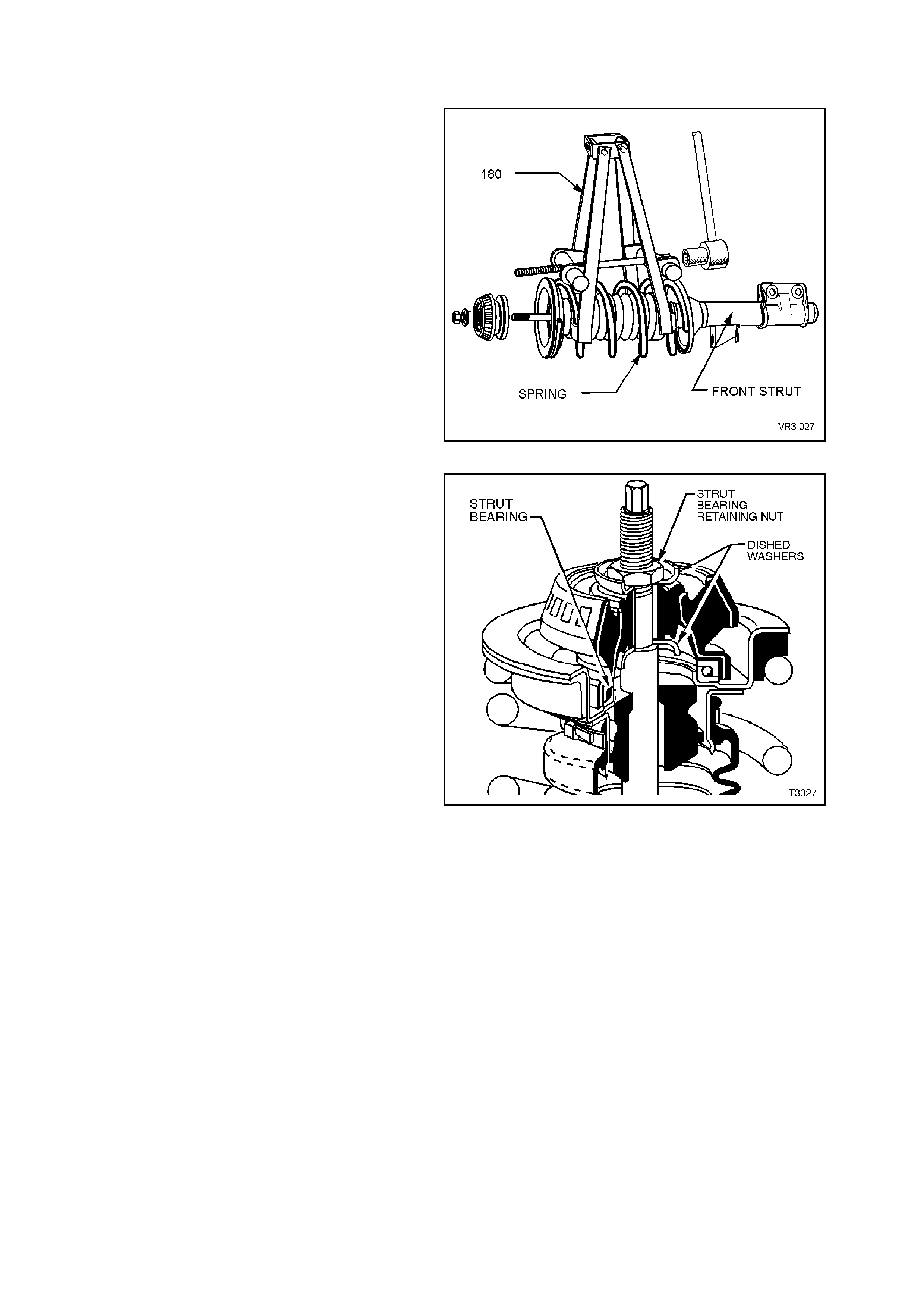

2. Fit Tool No. 180 as shown and compress the

spring until the upper support bearing has

clearance at the spring seat collar.

Figure 3-26

3. W hile holding the strut rod shaft with a 10 mm

sock et, remove the upper s trut bearing to str ut

rod retaining nut, using a 24 mm (15/16") ring

spanner.

4. Remove the strut mount and the two washers

(one each side of the mount).

NOTE:

The lower washer may be stuck to the lower edge

of the mount.

5. Remove the strut bearing from the upper

spring seat collar, taking particular note of

the bearing's orientation.

CAUTION:

Do not attempt to remove the retaining nut from

the strut rod shaft before compressing the

spring.

NOTE 1:

The upper suppor t bearing is self -lubricated and no

servicing requirements are necessary. If

considered to be faulty, the bearing is to be

replaced as an assembly.

NOTE 2:

Under no circums tanc es is the m ac hined s urface of

the piston rod section to be gripped directly on the

outer surface.

Figure 3-27

REINSTALL

1. Pull strut rod through upper spring seat to its

maximum length, then remove the strut rod

nut.

2. Install the upper bearing with the same

orientation as noted on rem oval. Norm ally, the

coloured or narrow, outer section, faces

towards the upper spring seat collar.

3. While holding the strut rod ex tended and, af ter

installing the first mount washer with the

dished shape facing downward (refer to Figure

3-27), install the upper strut mount over the

bearing and washer.

4. Install the second washer with the dished

shape facing upward (refer to Figure 3-27)

and install the retaining nut.

5. Using a 10 mm socket and a 24 mm (15/16")

ring spanner with a torque wrench attached,

tighten the nut to the correct torque

specification.

UPPER STRUT BEARING

RETAINING NUT

TORQUE SPECIFICATION 70 - 85 Nm

6. Release spring and remove compressor.

7. Reinstall front strut as detailed in

4.1 FRONT STRUT ASSEMBLY in this

Section.

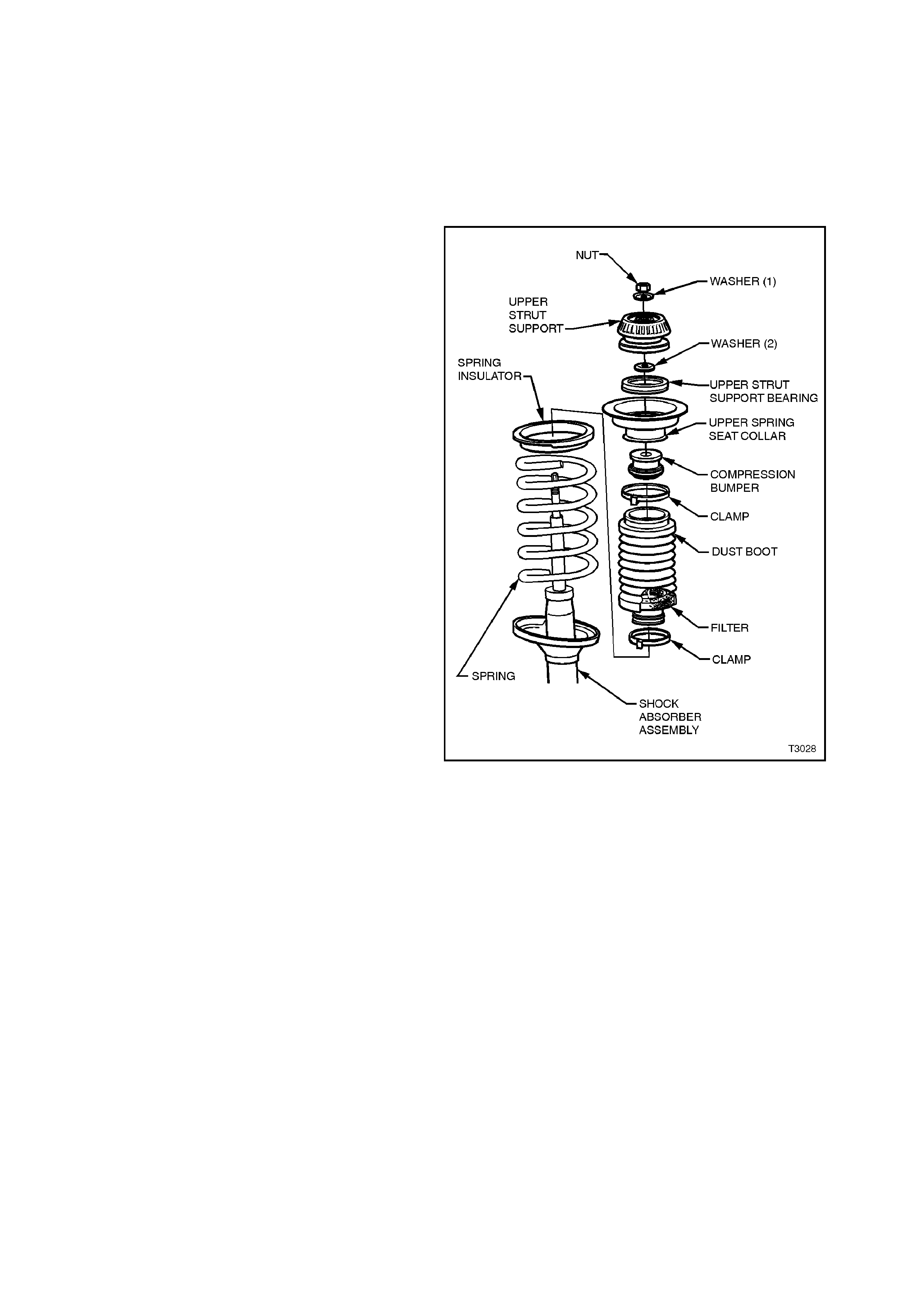

4.3 FRONT SPRING

REMOVE

1. Remove front strut as per

4.1 FRONT STRUT ASSEMBLY in this

Section.

2. Remove upper strut mount, as detailed in

4.2 UPPER STRUT SUPPORT BEARING

AND MOUNT in this Section.

3. Remove the clamp securing the dust boot to

the upper spring seat collar and discard.

4. Remove upper spring seat collar, spring

insulator and compression bumper from the

top of the spring.

5. Remove spring from the strut and release the

spring compressor.

REINSTALL

NOTE:

If installing a replacement spring, ensure that the

spring is the corr ect type for the sus pens ion s ystem

fitted to the vehicle. Refer to 6 SPECIFICATIONS

in this Section for details.

1. Position spring on strut with straight projecting

end of spring correctly located in spring seat.

2. Install spring compressor Tool No. 180 and

compress spring.

3. Install upper spring ins ulator, s pring seat c ollar

and compression bumper so that the double

notch in upper flange of the spring seat collar

is assembled, facing inward. The spring

insulator has a step which locates in the

straight projecting end of spring.

4. Reinstall upper support plate as per

4.2 UPPER STRUT SUPPORT BEARING

AND MOUNT in this Section.

NOTE:

The lower washer (2) may be stuck to the lower

edge of the mount.

5. Fit the upper end of the dust boot over the

lower flange of the spring seat collar and

secure with a retaining clamp that has been

tightened until the boot rubber is firmly

secured.

6. Reinstall front strut as per

4.1 FRONT STRUT ASSEMBLY in this

Section.

Figure 3-28

4.4 FRONT STRUT UNIT

REPLACE

NOTE 1:

When replacing the front strut, ensure that the

replacement unit is the correct type for the

suspension system fitted to the vehicle. Refer to

6 SPECIFICATIONS in this Section for details.

NOTE 2:

As the strut assembly is a sealed component, no

overhaul procedures are possible and if found to be

unserviceable, then the complete strut must be

replaced.

1. Remove front strut assembly as detailed in

4.1 FRONT STRUT ASSEMBLY in this

Section.

2. Remove upper support plate as detailed in

4.2 UPPER STRUT SUPPORT BEARING

AND MOUNT in this Section.

3. Remove spring as detailed in

4.3 FRONT SPRING in this Section.

4. Remove lower boot retaining clamp and

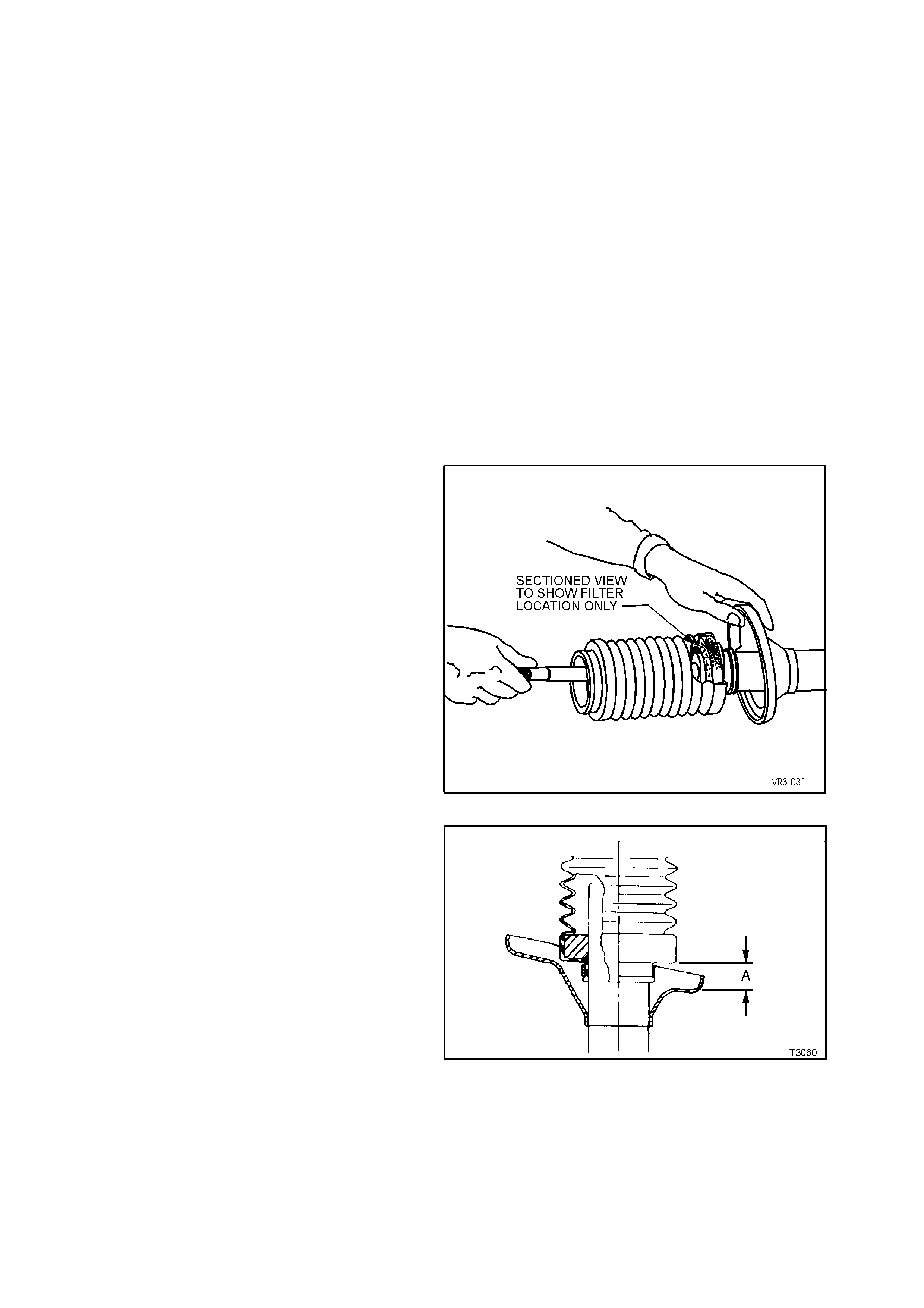

discard. Slide dust boot and filter from the strut

assembly.

5. Pull strut rod fully up and, while supporting the

rod to stop it from slipping back into the strut,

install dust boot assembly over the strut tube,

ensuring that the filter remains seated in boot

assembly.

Figure 3-29

6. Ensure that bottom of dust boot is positioned

so that distance ‘A’ is from 30 - 35 mm.

7. Install retaining clamp and tighten until rubber

on dust boot is firmly secured.

8. Reinstall front spring as detailed in

4.3 FRONT SPRING in this Section.

9. Reinstall upper strut support assembly as

detailed in 4.2 UPPER STRUT SUPPORT

BEARING AND MOUNT in this Section.

10. Reinstall front strut assembly as detailed in

4.1 FRONT STRUT ASSEMBLY in this Section.

Figure 3-30

4.5 STEE RING KNUCKLE

REMOVE

1. Rem ove front br ak e disc, wheel hub assem bly

and brake shield, as detailed in

3.2 FRONT WHEEL HUB, BRAKE DISC OR

BRAKE SHIELD in this section.

2. Remove the split pin and nut from steering tie

rod ball joint stud and press stud out from

steering knuckle, using Tool No. 9A10.

3. Remove the ball joint clamp bolt and nut from

the steering knuckle and discard nut.

NOTE:

Because the nut is of a self-locking design, it m ust

be replaced, after removal.

4. Loosen, remove and discard the two lower

strut attaching bolts and nuts as shown.

5. If the steering knuckle is to be replaced,

remove the camber adjusting bolt from the

arm.

Figure 3-31

REINSTALL

Installation is the reverse of removal procedures

except for the following:

1. Install NEW lower strut to steering knuckle,

bolts and nuts but do not tighten fully at this

stage.

2. Install ball joint stud in steering knuckle and

install the clamp bolt and a NEW self-locking

nut, tightening to the correct torque

specification.

BALL JOINT CLAMP BOLT

TORQUE SPECIFICATION 70 Nm, then turn

through 30° - 40°

3. Install steering tie rod end ball joint stud to the

steering knuckle and tighten the castellated

attaching nut to the correct torque

specification. Install new split pin.

TIE ROD BALL JOINT STUD

CASTELLATED NUT

TORQUE SPECIFICATION 58 - 71 Nm

4. Install front brake disc, wheel hub assembly

and brake shield, as detailed in 3.2 FRONT

WHEEL HUB, BRAKE DISC OR BRAKE

SHIELD in this Section.

5. Temporarily install road wheel/s and lower

vehicle to the ground.

6. Bounce vehicle up and down several times to

settle suspension.

7. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

8. Following wheel alignment operations, it will

be necessary to raise the vehicle and tighten

the NEW steering knuckle to strut bolts and

nuts to the correct torque specification.

STEERING KNUCKLE TO

STRUTATTACHING

BOLTS & NUTS

TORQUE SPECIFICATION

Stage 1 85 Nm

Stage 2 100 Nm

Stage 3 Turn

through 90°

9. After reinstalling the road wheel and aligning

the marks made prior to removal, install the

nuts, lower the vehicle to the ground and

tighten road wheel attaching nuts to the

correct torque specification.

ROAD WHEEL

ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

10. Refit wheel cover/centre cap.

4.6 LOWE R CONTROL ARM

REMOVE

1. Raise front of vehicle and place safety stands

under side frame members. Observe jacking

precautions as outlined in

2.3 JACKING PRECAUTIONS in this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub. Remove

road wheel attaching nuts and remove wheel.

4. Remove brake caliper anchor plate retaining

bolts and washers, lift caliper assembly from

brak e disc . Sus pend caliper on wire or hook to

avoid strain on the hose. THE CALIPER

MUST NOT HANG BY BRAKE HOSE.

5. Remove brake disc from hub.

6. Using a sharp drill, remove the rivet heads

retaining the disc brake shield and pull shield

toward hub to provide clearance for the ball

joint to be removed from the steering knuckle.

7. Remove the ball joint clamp bolt and nut from

the steering knuckle. Discard the nut.

NOTE:

Because the nut is of a self-locking design, it m ust

be replaced, after removal.

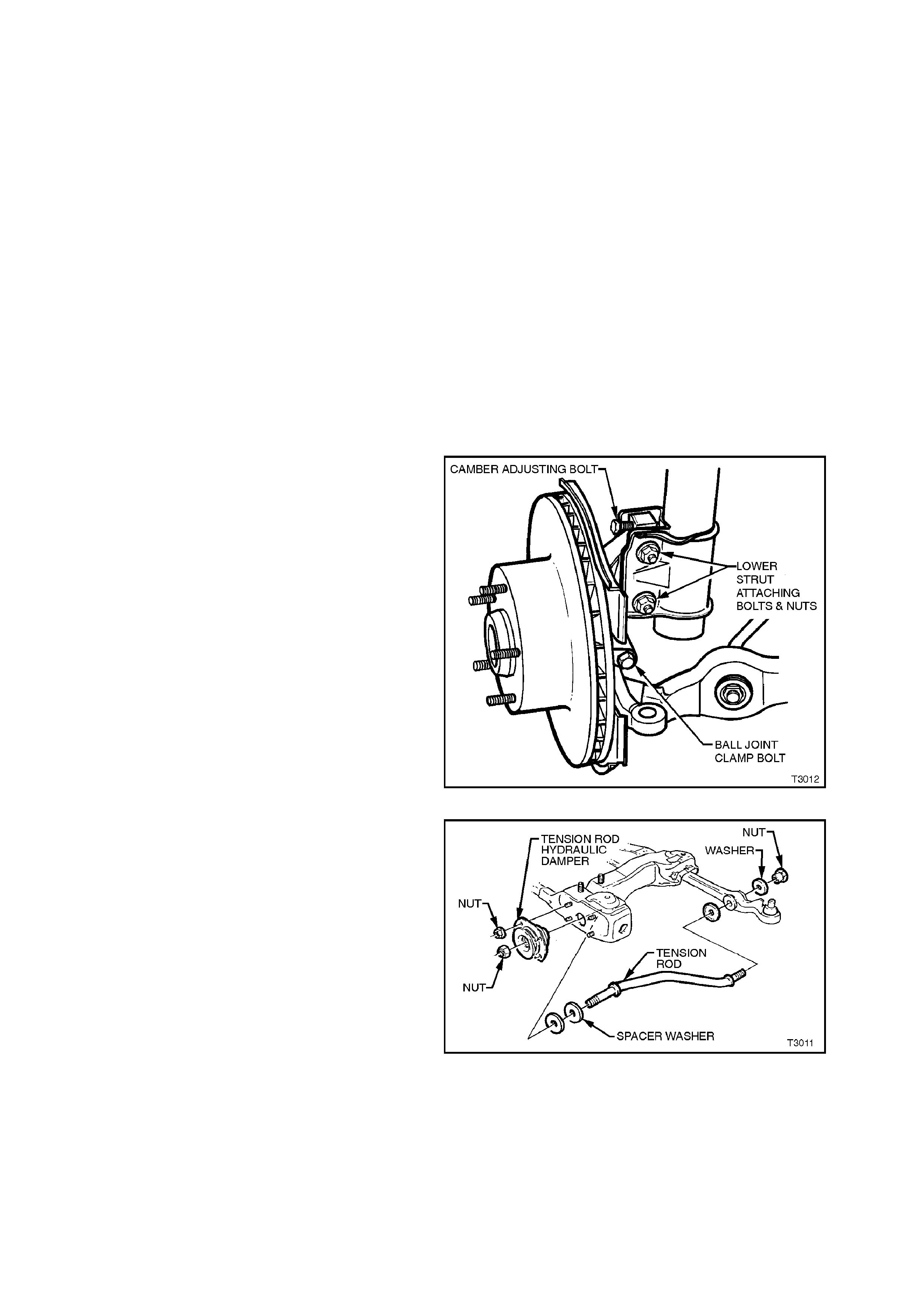

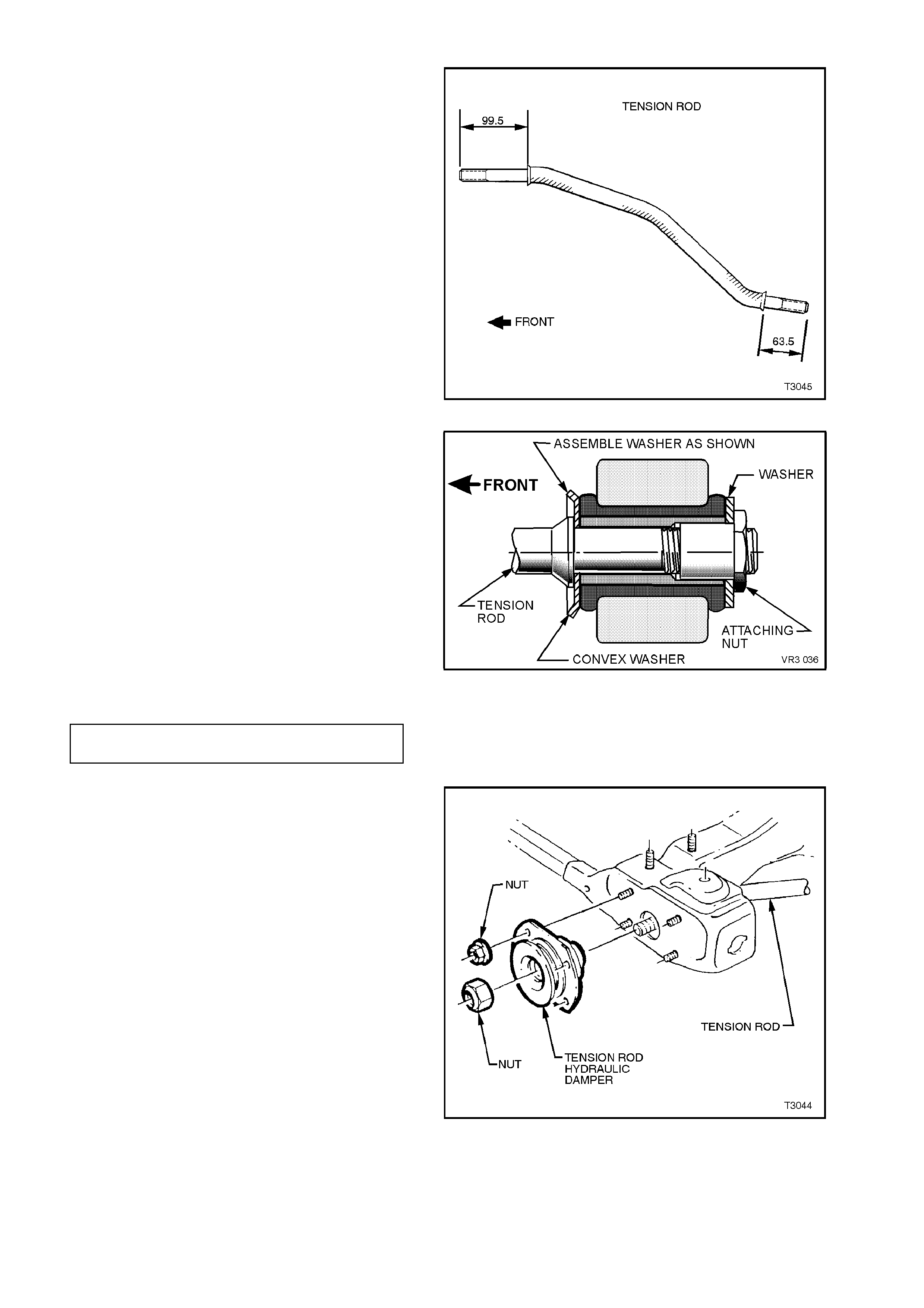

Figure 3-32

8. Remove tension rod to control arm attaching

nut and washer. Discard nut.

9. Loosen the tension rod front nut at the tension

rod bush assembly.

10. Remove the four nuts securing the tension

rod, front bus h assem bly to the cross mem ber,

then remove the tension rod from the lower

control arm, outer bush.

11. Remove control arm inner pivot bolt and nut.

Discard nut.

12. Remove control arm from the vehicle.

Figure 3-33

REINSTALL

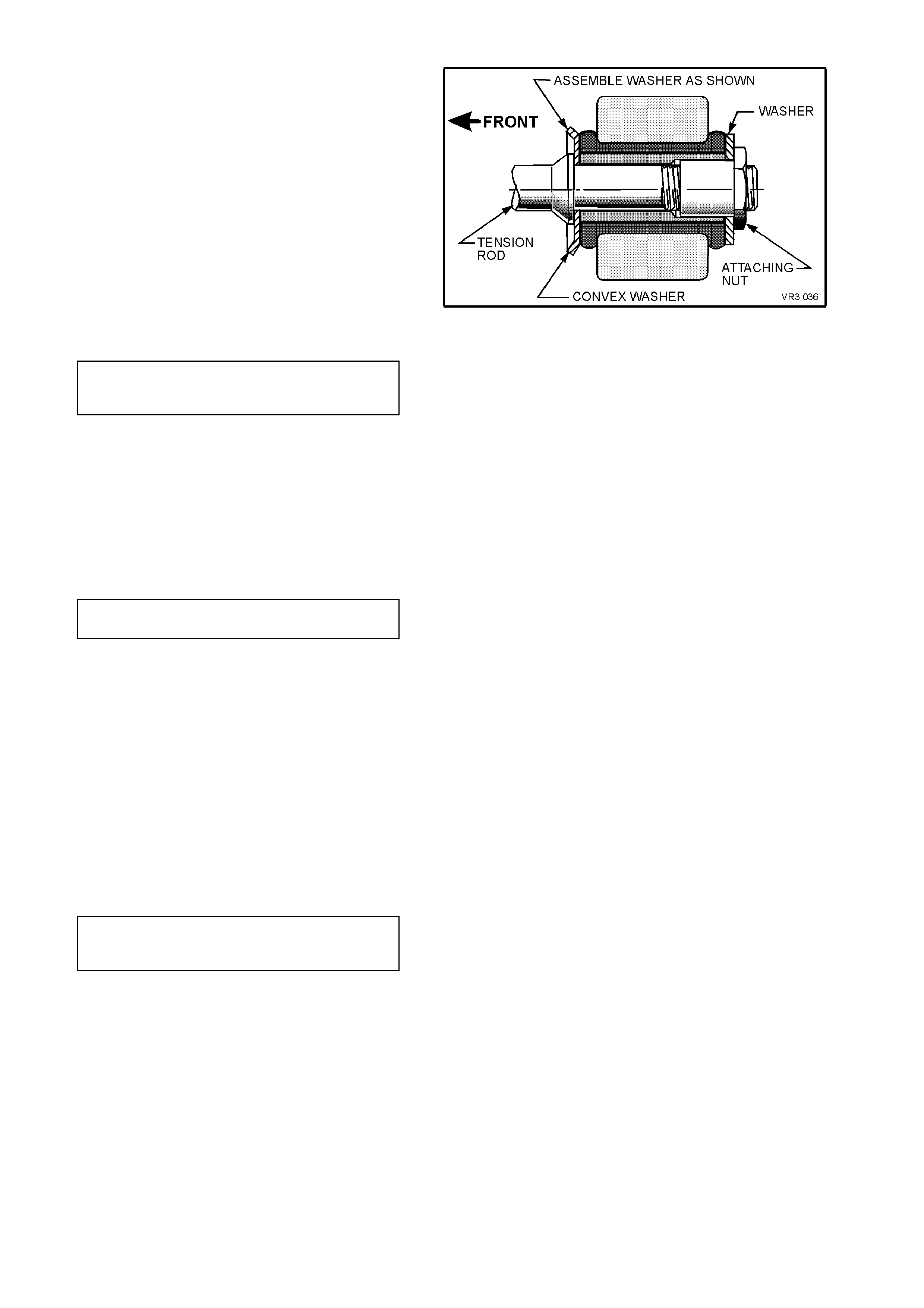

1. Install tension rod to control arm with convex

side of washer toward control arm bush, as

shown. Install tension rod to control arm

washer with a NEW attaching nut but do not

fully tighten at this stage.

2. Install tension rod, front bush assembly to the

crossmember, install the four retaining nuts

and tighten to the correct torque specification.

Figure 3-34

TENSION ROD BUSH TO

CROSSMEMBER OUTRIGGER

NUT TORQUE SPECIFICATION 20 - 26

Nm

NOTE:

Install a NEW tension rod nut but do not tighten at

this stage.

3. Install ball joint stud in steering knuckle and

install the clamp bolt and a NEW self-locking

nut, tightening to the correct torque

specification.

BALL JOINT CLAMP BOLT

TORQUE SPECIFICATION 70 Nm, then turn

through 30° - 40°

4. Using a suitable size drill, remove the brake

shield rivet shanks from the steering knuckle

support. Then reinstall the brake shield, using

common pop rivets and a commercially

available pop rivet gun.

NOTE:

Install the fir st rivet in the brak e shield hole with the

round hole. This will ensure that the clearance to

brake caliper is correct.

5. Reinstall brak e disc and caliper, tightening the

caliper retaining bolts to the correct torque

specification.

BRAKE CALIPER ANCHOR

PLATE RETAINING BOLTS

TORQUE SPECIFICATION

80 - 90 Nm,

then turn

through 40°-50°

6. Install road wheel, aligning marks made prior

to removal.

7. Remove safety stands and lower vehicle.

8. Bounce vehicle up and down several times to

settle suspension.

9. Tighten control arm inner pivot bolt to the

correct torque specifications.

LOWER CONTROL ARM

INNER PIVOT BOLT

TORQUE SPECIFICATION 95 - 110 Nm

10. Tighten the tension rod nuts, both at the lower

control arm and the tension rod hydraulic

damper, to the correct torque specifications.

TENSION ROD TO CONTROL

ARM ATTACHING NUT

TORQUE SPECIFICATION 95 - 110 Nm

TENSION ROD TO TENSION

ROD HYDRAULIC DAMPER

TORQUE SPECIFICATION 140 - 155 Nm

IMPORTANT:

The weight of the vehicle must be on all four

wheels before tightening the tension rod to

specification. Otherwise the tension rod hydraulic

damper be incorrectly preloaded, reducing the life

of the damper and affect ride and handling.

11. Tighten road wheel attaching nuts to the

correct torque specification.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

12. Refit wheel cover/ centre cap.

13. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

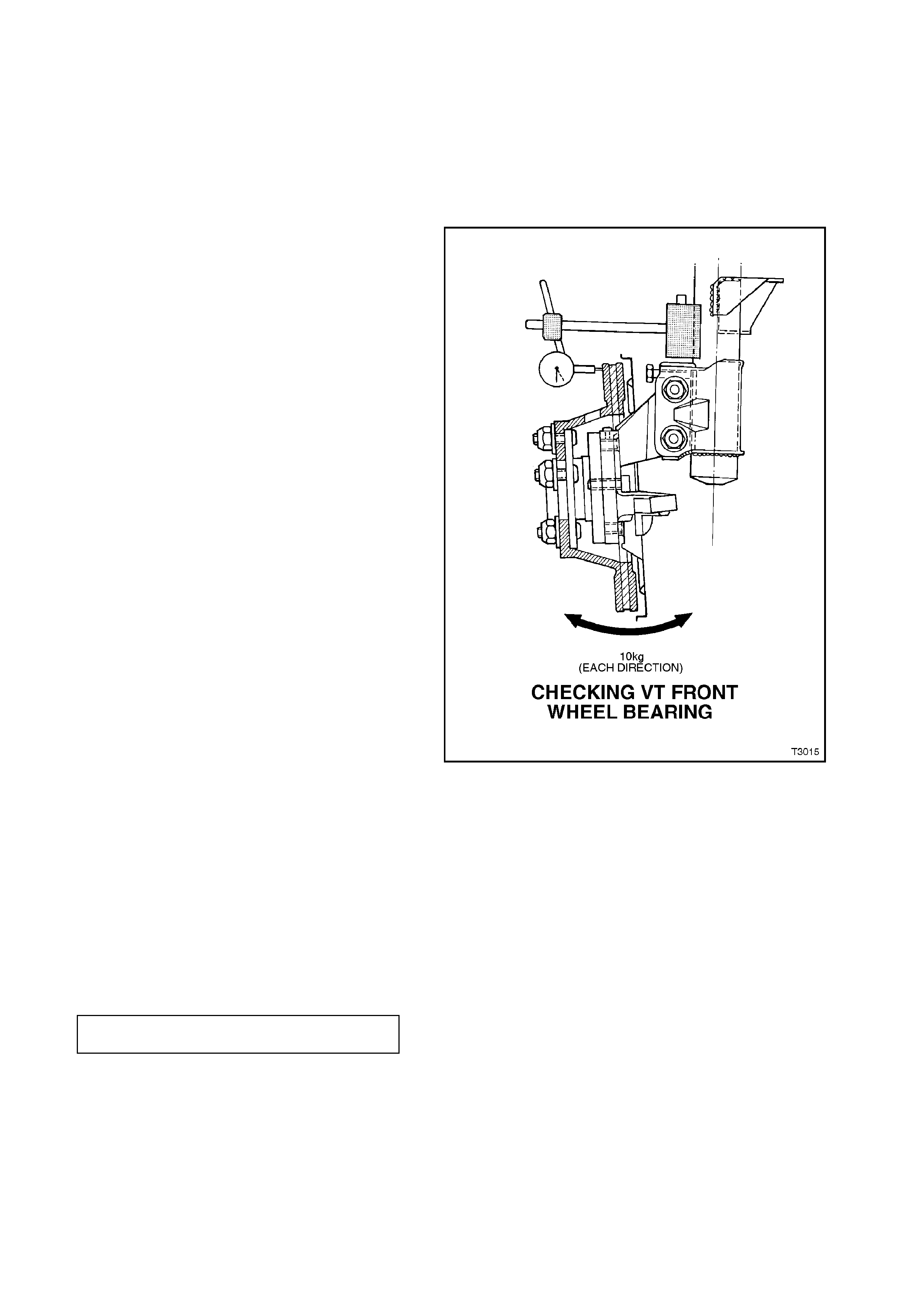

4.7 LOWE R CONTROL ARM BALL JOINT

INSPECT

The following procedure should be used when

checking the ball joint for wear.

1. Jack up vehicle under crossmember.

2. Holding the road wheel at top and bottom,

check for play in the ball joint by rocking

wheel.

If any up or down movement of stud in ball

joint housing is detected, the control arm and

ball joint assembly must be replaced, as the

ball joint is not serviced separately.

4.8 LOWER CONTROL ARM INNER PIVOT BUS H

REPLACE

1. Remove control arm as per

4.6 LOWER CONTROL ARM in this Section.

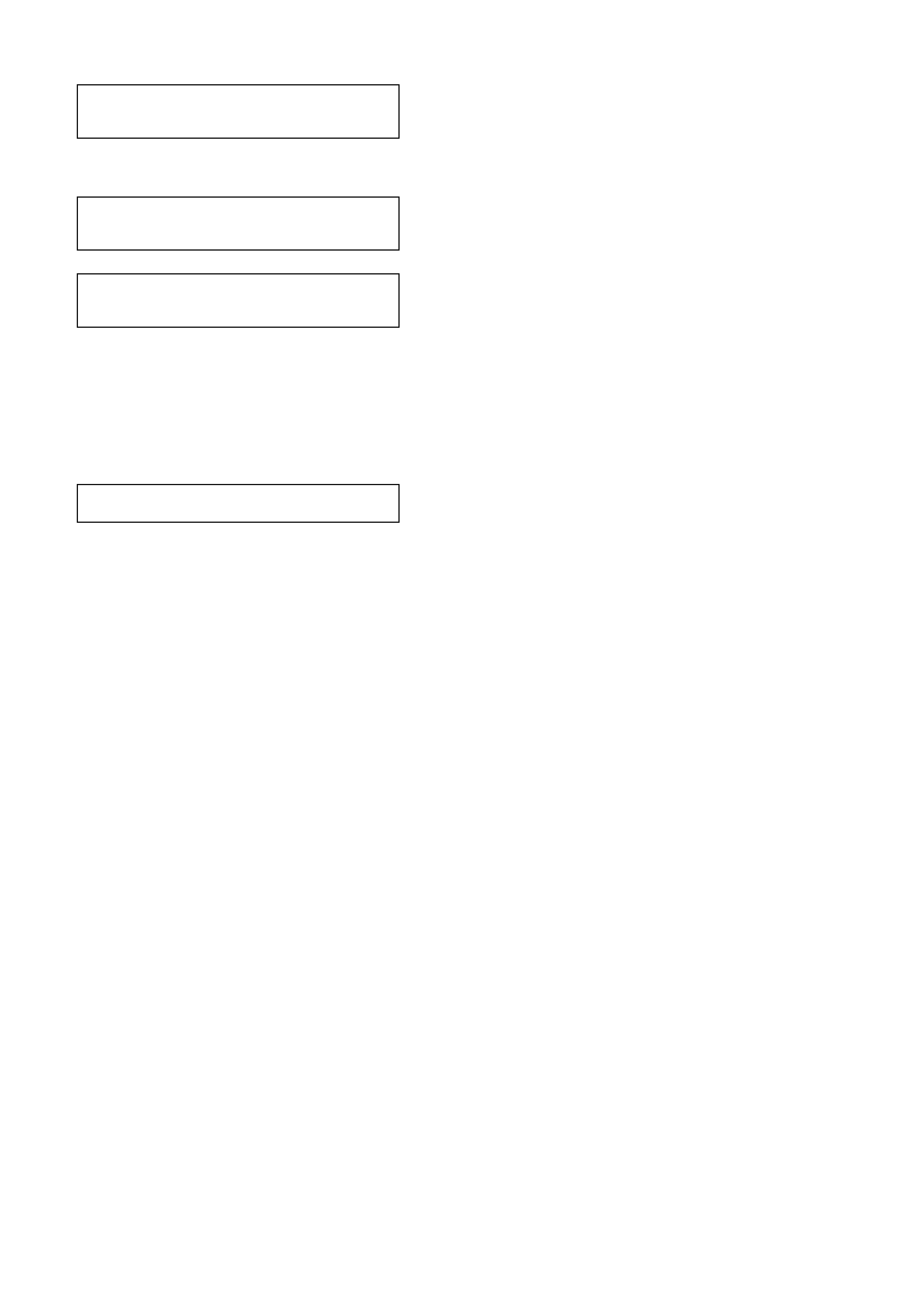

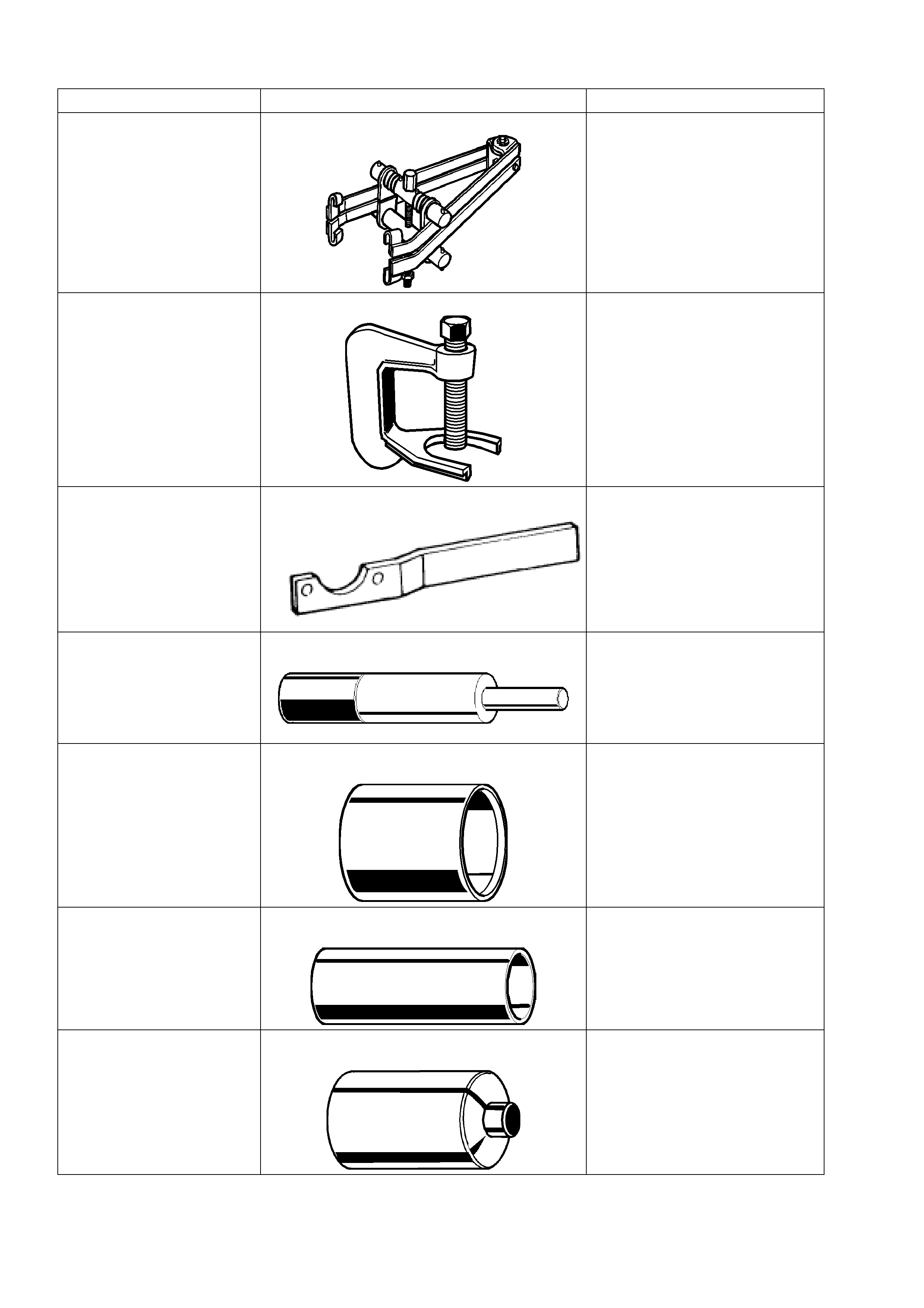

2. Support the lower control arm with two pieces

of square scrap and press the bush from the

arm, using Tool No. AU162.

Figure 3-35

3. Using Tool Nos. AU160-1 and KM157-2, install

new bush from front side of control arm, until

flange on outer sleeve is flush with control

arm.

NOTE 1:

The bush MUST be aligned correctly, as shown.

NOTE 2:

The bush may be lubricated with a soapy water

solution to ease the installation process.

NOTE 3:

Tool No KM157-2 is us ed in the rever s e direc tion to

some previous ‘V’ car models.

4. Reinstall control arm as detailed in

4.6 LOWER CONTROL ARM in this Section. Figure 3-36

4.9 LOWER CONTROL ARM TENSION ROD BUSH

REPLACE

1. Remove control arm as per

4.6 LOWER CONTROL ARM in this Section.

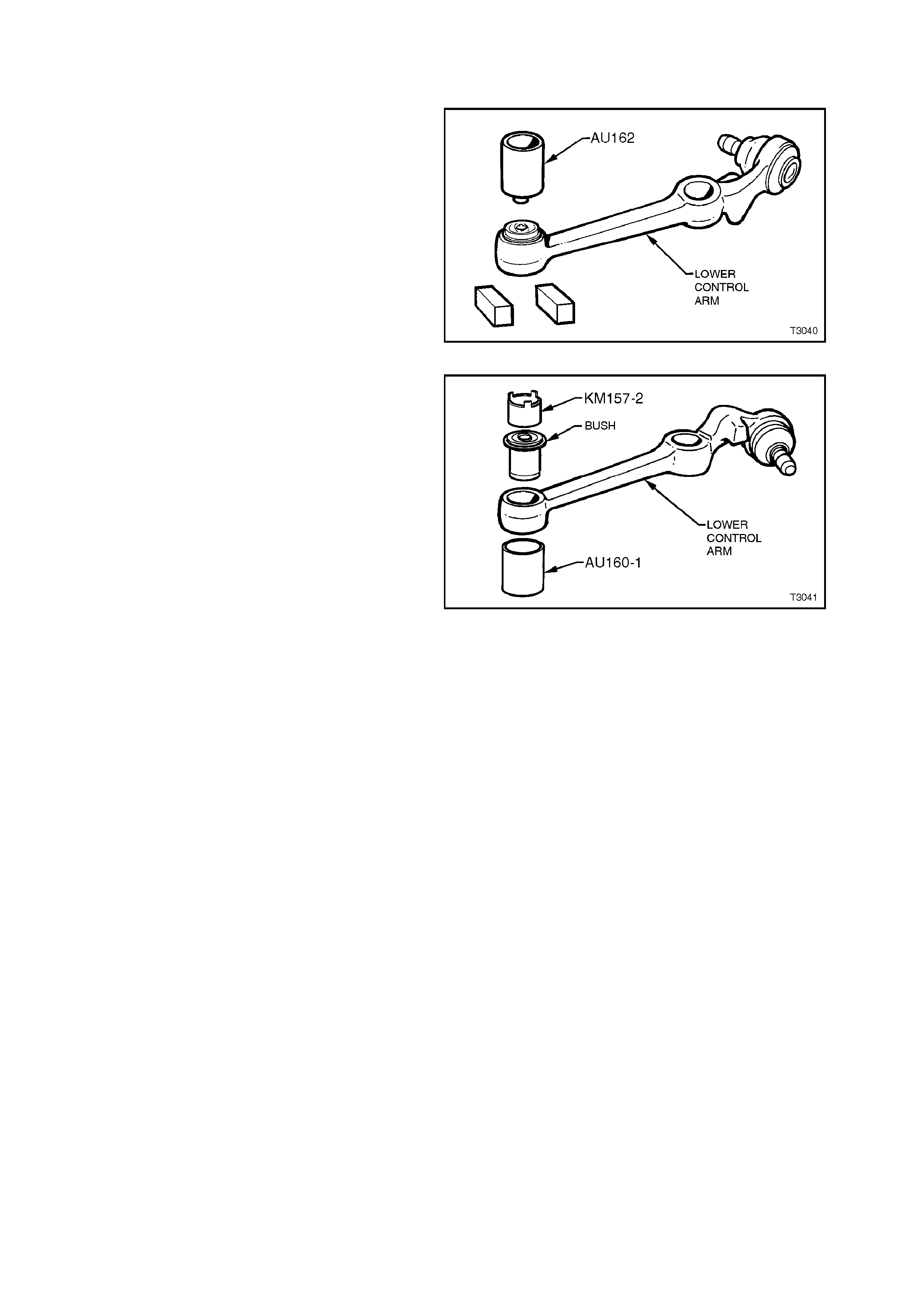

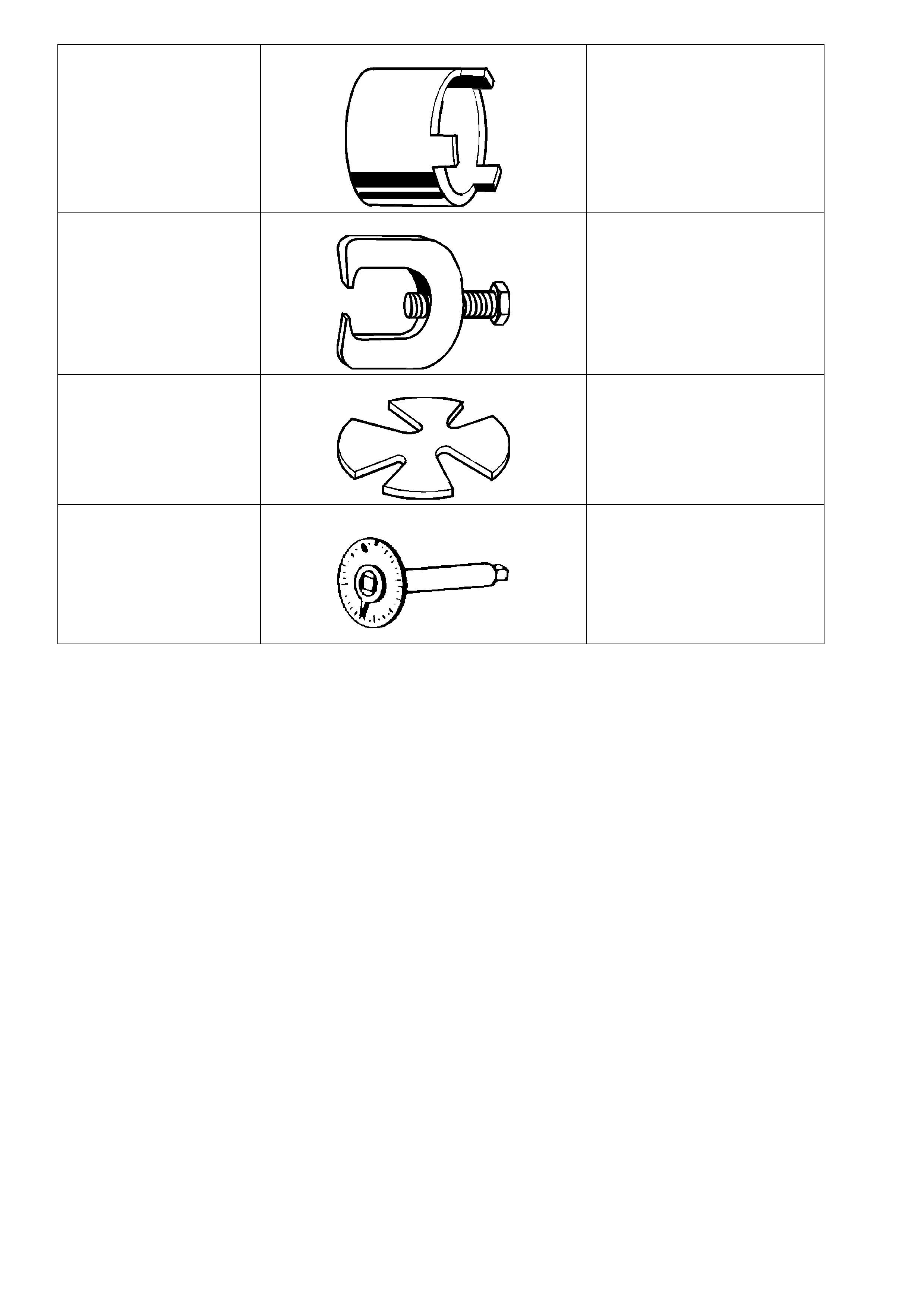

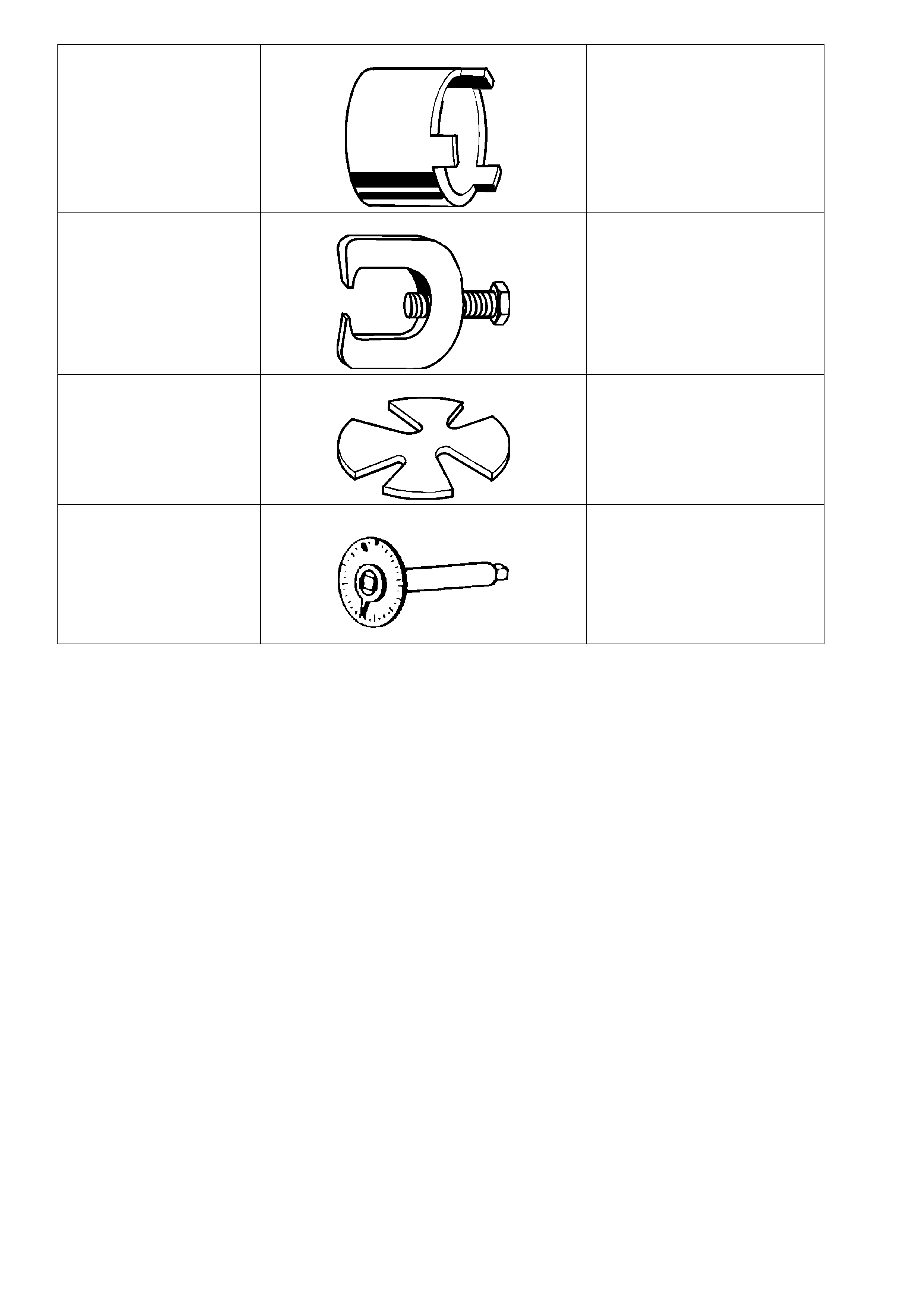

2. Press out tension rod bush from control arm

using Tool No AU158 and KM158-2 as shown.

Figure 3-37

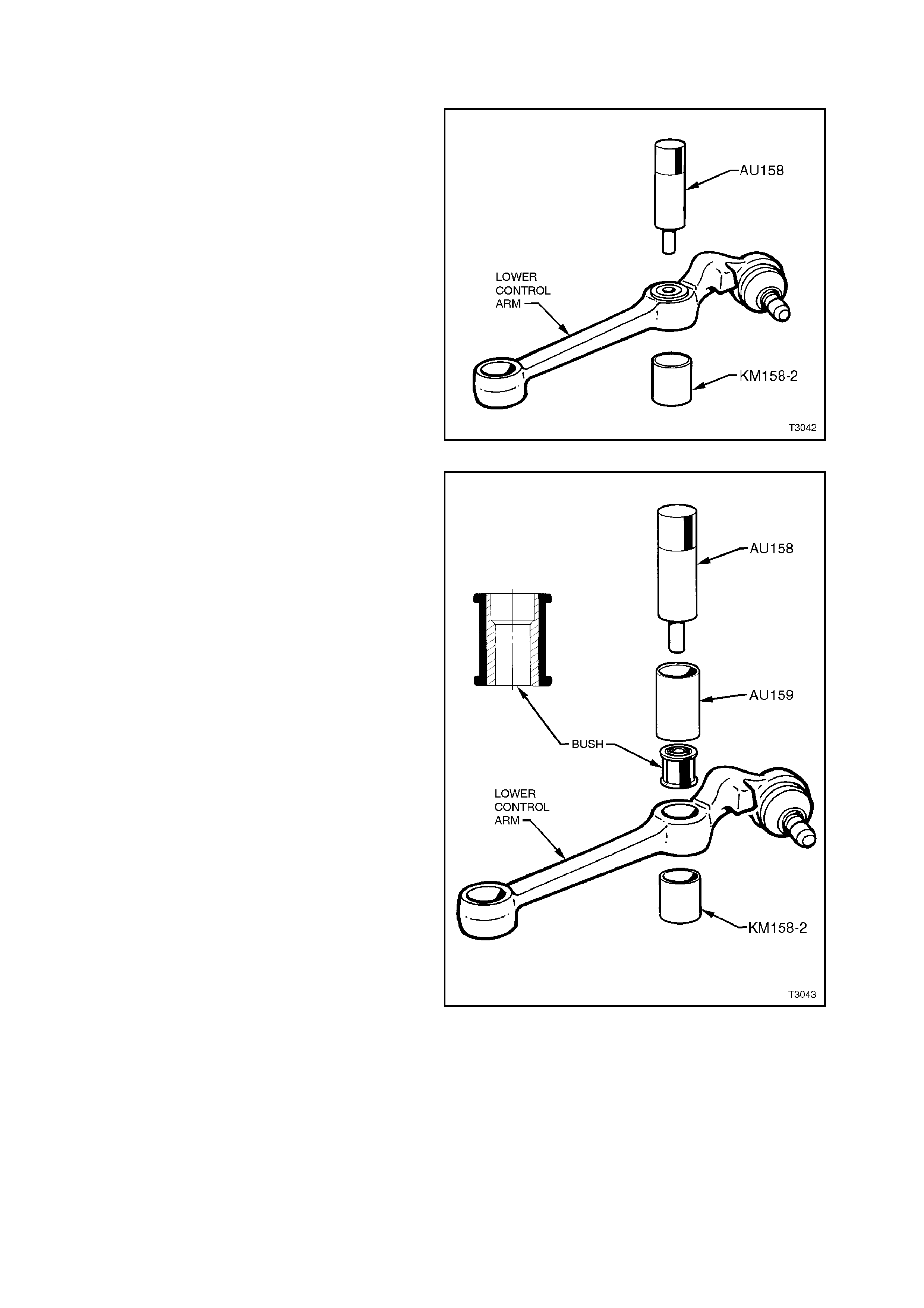

3. Press in a new tension rod bush using Tool

No’s AU158, AU159 and KM158-2 as shown.

To assist in installation, dip bush in a soapy

water solution. Install bush with larger

diameter of s tepped tens ion rod mounting hole

toward rear of control arm.

NOTE:

Press the bush in until it is centrally located in the

control arm.

4. Reinstall control arm as per

4.6 LOWER CONTROL ARM in this Section.

Figure 3-38

4.10 LOW ER CONTROL ARM TENSION ROD

REMOVE

1. Jack up front of vehicle and place safety

stands under side frame members. Observe

jacking precautions as outlined in

2.3 JACKING PRECAUTIONS in this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub. Remove

road wheel attaching nuts and remove wheel.

4. Remove brake caliper anchor plate retaining

bolts and washers, lift caliper assembly from

brak e disc. Sus pend caliper on wire or hook to

avoid strain on the hose. DO NOT ALLOW

CALIPER TO HANG BY BRAKE HOSE.

5. Remove brake disc from hub.

6. Drill out the three rivets securing the brake

disc shield and pull shield toward hub to

provide clearance for the ball joint to be

removed from the steering knuckle.

7. Remove the ball joint clamp bolt and nut from

the steering knuckle. Discard the self-locking

nut.

Figure 3-39

8. Remove tension rod to control arm attaching

nut and washer. Discard the nut.

9. Remove four nuts attaching the tension rod

hydraulic damper assembly to the

crossmember outrigger.

10. Remove tension rod and tension rod damper

assembly from lower control arm and through

the crossmember outrigger.

11. Secure the tension rod in protected vice jaws,

then remove the tension rod to tension rod

damper assembly retaining nut. Discard the

nut.

12. Remove spacer washer (if fitted) from tension

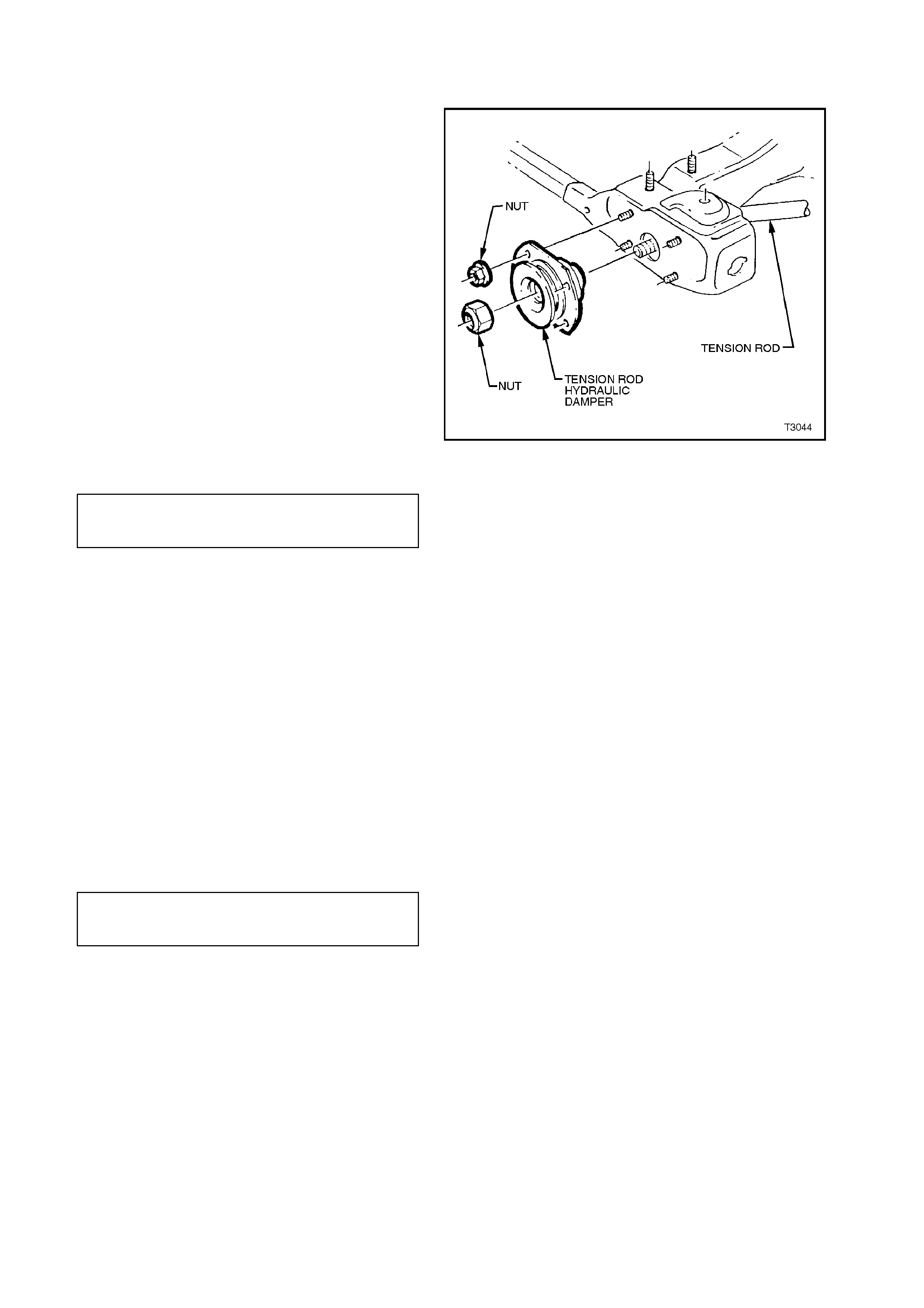

rod. Figure 3-40

REINSTALL

1. Install flat inner washer to front end of tension

rod.

NOTE 1:

There may be m or e than one f lat spac er washer at

the inner side of the bush (See Figure 3-42). If

fitted, this second washer is only used to equalise

the caster angle from side to side and should be

reinstalled until Step 12 that follows.

NOTE 2:

The front end of the tension rod is identified by the

longer length of the shouldered ends, as shown.

Figure 3-41

2. Install tension rod into the hole in the

crossmember outrigger and then into the

control arm, with the washer installed as

shown. Loosely install tension rod to control

arm washer with a NEW attaching nut but do

not fully tighten at this stage.

3. Install ball joint stud in steering knuckle and

install the clamp bolt and a NEW nut,

tightening to the correct torque specification.

Figure 3-42

BALL JOINT CLAMP BOLT

TORQUE SPECIFICATION 70 Nm, then turn

through 30° - 40°

4. Install tension rod, hydraulic damper

assem bly, over the tension r od and install four

retaining nuts to the crossmember outrigger

studs. Tighten to the correct torque

specification.

Figure 3-43

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY

ATTACHING

NUTS TORQUE SPECIFICATION 20 - 26 Nm

5. Install a NEW tension rod retaining nut but do

not fully tighten at this stage.

NOTE:

If fitted, ensure that the spacer washer is installed

over the tension rod before fitting the tension rod

damper.

6. Reinstall disc brake shield pop rivets. Refer

Operation 3.2 FRONT WHEEL HUB, BRAKE

DISC OR BRAKE SHIELD in this Section for

details.

7. Reinstall brake disc and brake caliper,

tightening attaching bolts to specification.

BRAKE CALIPER

ATTACHING BOLT

TORQUE SPECIFICATION

80 - 90 Nm,

then through

40° - 50°

8. Reinstall road wheel, aligning the marks made

prior to removal and secure with the attaching

nuts.

9. Remove safety stands and lower vehicle.

10. Bounce vehicle up and down several times to

settle suspension.

11. With the vehicle at curb position, tighten both

the tension rod to HYDRAULIC damper and

the tension rod to control arm attaching nuts to

the correct torque specifications.

TENSION ROD TO HYDRAULIC

DAMPER ATTACHING NUT

TORQUE SPECIFICATION 140 - 155

Nm

TENSION ROD TO CONTROL

ARM ATTACHING NUT

TORQUE SPECIFICATION 95 - 100 Nm

IMPORTANT:

The weight of the vehicle must be on all four

wheels before tightening the tension rod to

specification. Otherwise the fluid filled tension rod

bush will be incorrectly preloaded, reducing the life

of the bush and effect ride and handling.

12. Tighten road wheel attaching nuts to the

correct torque specification.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

13. Refit wheel cover/centre cap.

14. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.11 FRONT SUSPENSION TENSION ROD, HYDRAULIC DAMPER

REPLACE

1. Remove lower control arm tension rod, front

retaining nut and discard. Refer to

4.10 CONTROL ARM TENSION ROD in this

Section for more detail.

2. Remove the four nuts securing the tension

rod, hydraulic damper assembly to the

crossmember outrigger studs. Remove

damper from the vehicle.

3. Install tension rod, hydraulic damper

assembly, over the tension rod and reinstall

four retaining nuts to the crossmember

outrigger studs. Tighten to the correct torque

specification.

Figure 3-44

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY ATTACHING

NUTS TORQUE SPECIFICATION 20 - 26 Nm

4. Install a NEW tension rod retaining nut but do

not fully tighten at this stage.

NOTE:

If fitted, ensure that the spacer washer is installed

over the tension rod before fitting the tension rod

damper.

5. Reinstall road wheel, aligning the mar ks m ade

prior to removal and secure with the attaching

nuts.

6. Remove safety stands and lower vehicle.

7. Bounce vehicle up and down several times to

settle suspension.

8. With the vehicle at curb position, tighten the

tension rod to hydraulic attaching nut to the

correct torque specification.

TENSION ROD TO HYDRAULIC

DAMPER ATTACHING NUT

NUTS TORQUE SPECIFICATION 140 - 155 Nm

IMPORTANT:

The weight of the vehicle must be on all four

wheels before tightening the tension rod to

specification. Otherwise the fluid filled tension rod

bush will be incorrectly preloaded, reducing the life

of the bush and effect ride and handling.

10. Tighten road wheel attaching nuts to the

correct torque specification.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140

Nm

11. Refit wheel cover/centre cap.

12. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.12 FRONT SUSPENSION CROSSMEMBER

CAUTION:

Before disturbing the front suspension crossmember mounting bolts, an alignment

procedure is required on installation and a special tool is required for this purpose. If

this tool is not available, then the crossmember cannot be correctly aligned and

steering abnormalities will result.

REMOVE

1. Jack up front of vehicle and place safety

stands under side frame members. Observe

jacking precautions as outlined in 2.3

JACKING PRECAUTIONS in this Section.

2. Remove wheel cover (steel wheels) or centre

cap (alloy wheels).

3. Mark relationship of wheel to hub. Remove

road wheel attaching nuts and remove wheel.

4. Remove brake caliper anchor plate retaining

bolts and washers, lift caliper assembly from

brak e disc. Sus pend caliper on wire or hook to

avoid strain on the hose. DO NOT ALLOW

CALIPER TO HANG BY BRAKE HOSE.

5. Remove brake disc from hub.

6. Drill out the three rivets securing the brake

disc shield and pull shield toward hub to

provide clearance for the ball joint to be

removed from the steering knuckle.

7. Remove the ball joint clamp bolt and nut from

the steering knuckle. Discard the self-locking

nut.

Figure 3-45

8. Using a suitable size open end spanner, hold

the stabiliser bar spacer stud and remove the

lower nut, washer and bush from both sides.

NOTE:

The illustration shows an exploded view of the

assembly, for convenience only.

Figure 3-46

Techline

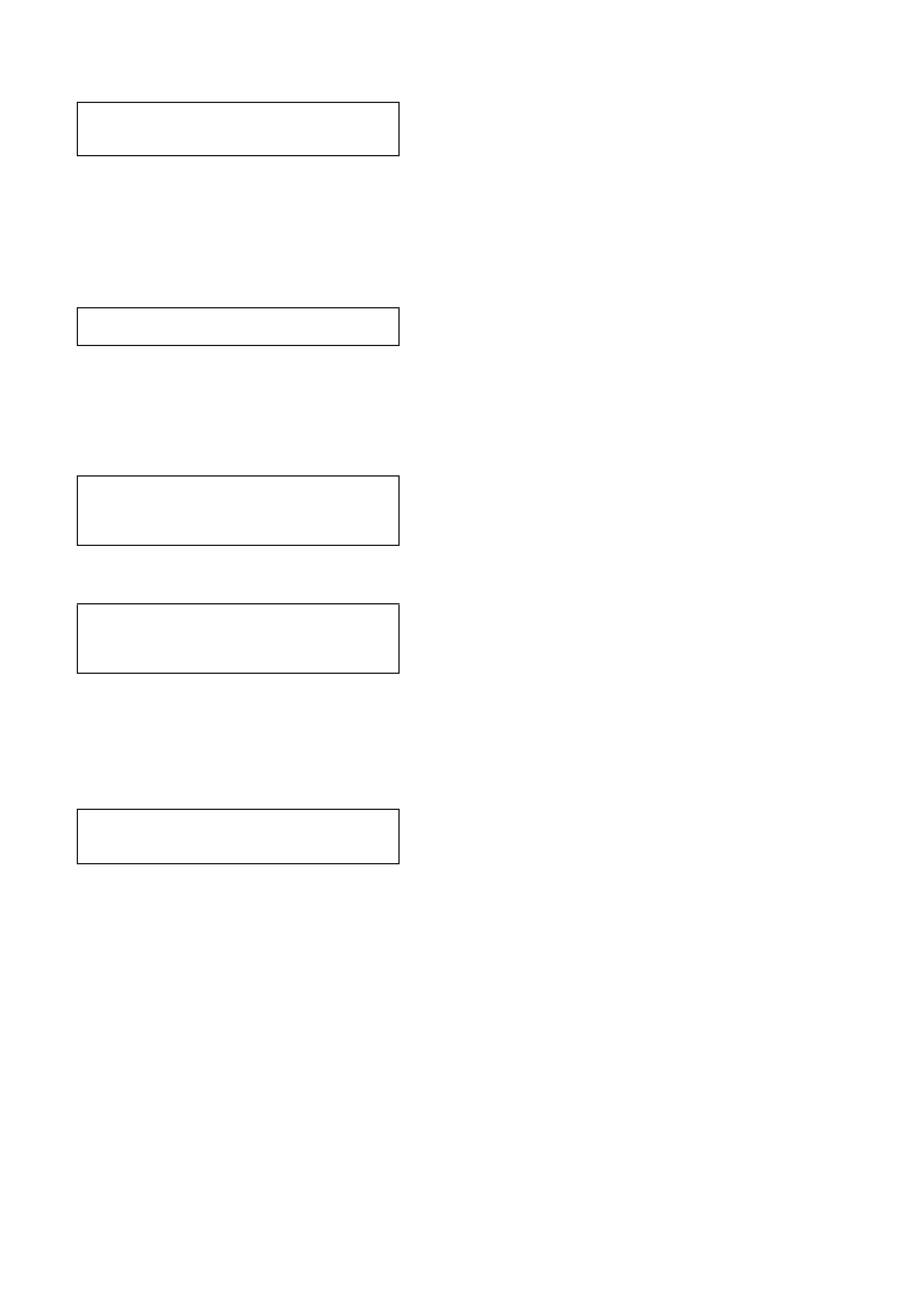

9. Remove steering gear housing to

crossmember mounting bolts, washers and

nuts. Remove steering gear housing from

crossmember mountings.

10. Mark hood hinge positions with felt tipped pen

and remove engine hood.

11. Support engine on a suitable lifting hook and

remove engine mounts to crossmember bolts

or nuts, refer to Section 6A1 ENGINE

MECHANICAL (V6) or Section 6A2 ENGINE

MECHANICAL (V8) for details.

NOTE:

On vehicles with V6 engine, it will be necessary to

loosen engine mounting to cylinder block attaching

bolts.

Figure 3-47

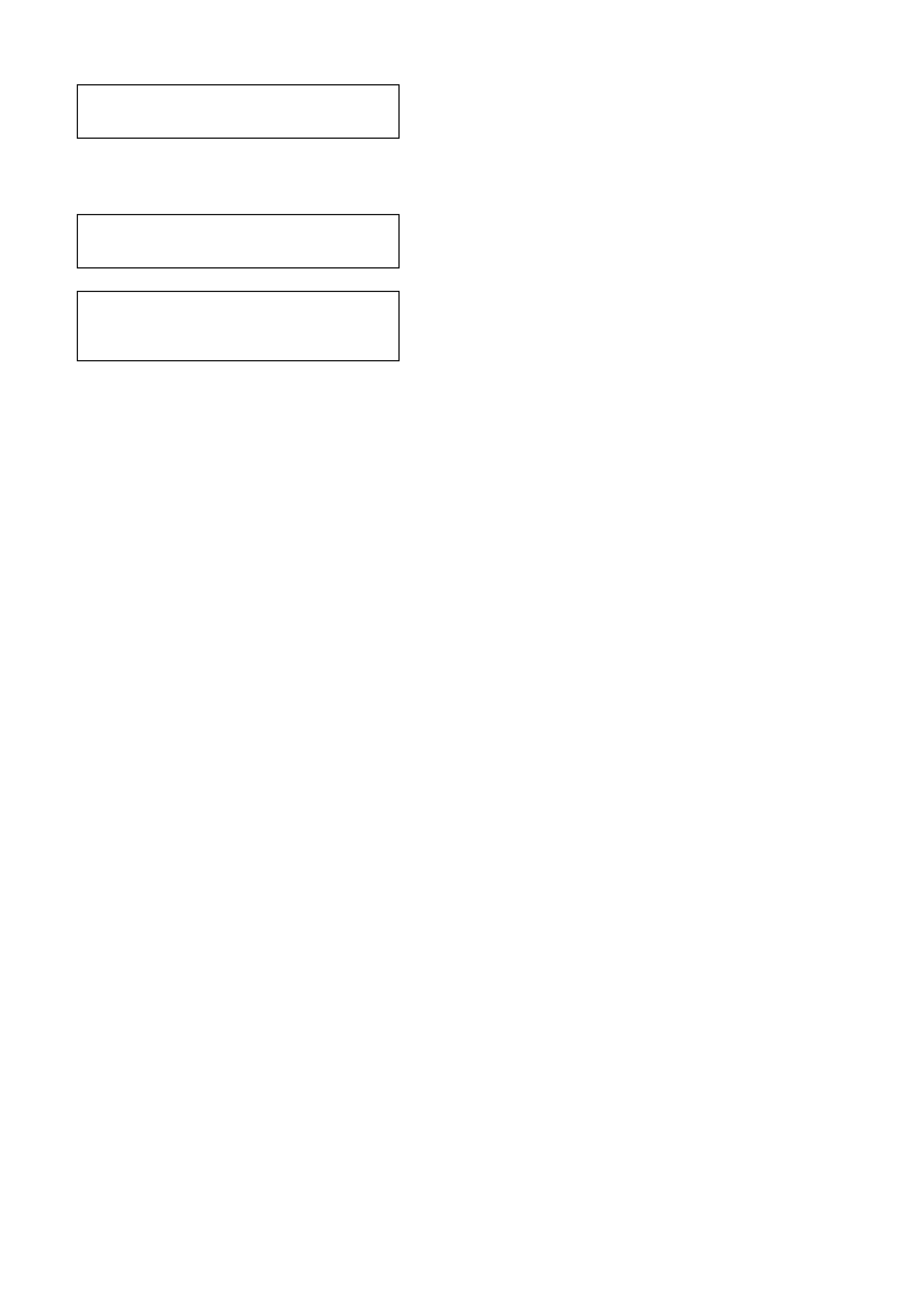

12. Support crossmember on a jack and remove

four bolts securing the crossmember to side

frame members.

NOTE:

If it is known that the same crossmember will be

reinstalled, then scribing alignment marks on the

side frame members before loosening the four

mounting bolts will greatly facilitate alignment

during reassembly.

13. Lower, then remove crossmember from

vehicle.

14. As required, remove the lower control arms,

tension rod hydraulic dampers, tension rods

and stabiliser bar from the crossmember.

Figure 3-48

REINSTALL

W hile the majority of the installation process is the

reverse of removal procedures, note the following

points:

1. Install the stabiliser bar insulating rubbers and

brackets to the crossmember, tightening

retaining nuts to the correct torque

specification.

STABILISER BAR SUPPORT

BRACKET RETAINING NUT

TORQUE SPECIFICATION 24 - 30 Nm

2. When installing the cr ossm ember , it MUST be

aligned correctly, by using the Special Tool

developed for that purpose. Refer to

Section 1A2 BODY DIMENSIONS for details

of the procedure and use of this tool.

CAUTION:

Failure to correctly align the crossmember to

the centreline of the vehicle will result in

steering abnormalities!

Techline

3. Tighten crossmember to side member

attaching bolts to the correct torque

specification.

CROSSMEMBER TO SIDE

MEMBER BOLT

TORQUE SPECIFICATION 120 - 125 Nm

4. Reinstall the two control arms to the

crossmember, installing the pivot bolts from

the rear to the front. Install NEW nuts but do

not fully tighten at this stage.

5. If the lower control arms were removed with

the crossmember, install the ball joint stud to

the steering knuckle and tighten a NEW bolt to

the correct torque specification.

BALL JOINT CLAMP BOLT

TORQUE SPECIFICATION 70 Nm, then turn

through 30° - 40°

6. Reinstall both tension rods, loosely installing

washers and NEW retaining nuts, as detailed

in 4.10 CONTROL ARM TENSION ROD in

this Section. Do not tighten at this time. The

tension rod hydraulic damper mounting nuts

however, can be tightened to the correct

torque specification.

TENSION ROD HYDRAULIC

DAMPER ASSEMBLY

ATTACHING NUTS

TORQUE SPECIFICATION 20 - 26 Nm

7. Refit steering gear housing to crossmember,

tighten mounting nuts to the correct torque

specification.

STEERING GEAR HOUSING

TO CROSSMEMBER

MOUNTING NUT

TORQUE SPECIFICATION

70 - 85 Nm

8. Reconnect engine mounts to crossmember,

refer to Section 6A1 ENGINE MECHANICAL

(V6) or Section 6A2 ENGINE MECHANICAL

(V8) for details.

9. Reinstall brak e disc and caliper, tightening the

caliper retaining bolts to the correct torque

specification.

BRAKE CALIPER ANCHOR

PLATE RETAINING BOLTS

TORQUE SPECIFICATION

80 - 90 Nm,

then turn through

40°-50°

10. Install road wheel, aligning marks made prior to

removal.

11. Refit engine hood.

12. Remove safety stands and lower vehicle.

13. Bounce vehicle up and down several times to

settle suspension.

14. Tighten lower control arm, inner pivot bolt nuts

to the correct torque specifications.

LOWER CONTROL ARM

INNER PIVOT BOLT NUTS

TORQUE SPECIFICATION 95 - 100 Nm

15. With the vehicle at curb position, tighten the

tension rod attaching nuts at the lower control

arm and the hydraulic damper, to the correct

torque specifications.

TENSION ROD TO CONTROL

ARM ATTACHING NUT

TORQUE SPECIFICATION 95 - 110 Nm

TENSION ROD

TO HYDRAULIC

DAMPER ATTACHING NUT

TORQUE SPECIFICATION

140 - 155

Nm

IMPORTANT:

The weight of the vehicle must be on all four

wheels before tightening the tension rod to

specification. If not, the fluid filled tension rod bush

will be ruptured, once the vehicle is put back into

service.

16. Check wheel alignment, as detailed in

2.2 WHEEL ALIGNMENT CHECKING AND

ADJUSTMENT in this Section.

4.13 STABILISER BAR

NOTE:

To remove the stabiliser bar completely from the vehicle, it will first be necessary to remove the crossmember.

Refer to Operation 4.12 FRONT SUSPENSION CROSSMEMBER in this Section.

Alternatively, the stabiliser bar insulators and mounting brackets, and/or the spacer stud, nuts, discs or bushes, can

all be replaced without removing the stabiliser bar from the vehicle.

REMOVE

1. Raise front of vehicle and support on safety stands. Observe jacking precautions as outlined in 2.3 JACKING

PRECAUTIONS in this Section.

2. After scribing crossmember alignment marks on the side frame members, remove the front suspension

crossmember mounting bolts, then lower enough to enable removal of the stabiliser bar from the vehicle.

3. Remove nuts securing support bracket to each side of the crossmember, then remove the stabiliser bar,

support brackets and insulators from the crossmember.

4. Remove the insulators from the stabiliser bar.

REINSTALL

1. Assem ble two insulators and s upport brackets

to stabiliser bar and bolt brackets to

crossmember outrigger.

NOTE:

The s lot in each insulator should face f orward, and

the rounded sections on the insulators should seat

in the mating recesses in the crossmember side

frame.

2. Tighten stabiliser bar support bracket bolts to

the correct torque specification.

STABILISER BAR SUPPORT

BRACKET RETAINING NUTS

TORQUE SPECIFICATION 24 - 30 Nm

3. Install stabiliser bar spacer stud nut after

ensuring that all components are assembled

as shown. While holding the spacer bar

spacer stud with a suitable sized spanner,

install the lower nut and tighten until the nut is

fully installed onto the threaded section of the

stud.

NOTE 1:

Do not use power operated tools for this operation

as thread damage will result

NOTE 2:

The illustration shows an exploded view of the

assembly, for convenience only.

4. Install front suspension crossmember, as

detailed in Operation

4.12 FRONT SUSPENSION

CROSSMEMBER in this Section.

5. Remove safety stands and lower vehicle.

Figure 3-49

5. DIAGNOSIS

GENERAL

When diagnosing suspected front suspension

problems, it should be remembered that steering,

wheels and tyres all have an effect on front end

performance (Refer to Section 9A STEERING or

Section 9B SPEED SENSITIVE POWER

STEERING and Section 10 WHEELS AND

TYRES for details).

STRUT DIAGNOSIS

1. Test by quickly pushing up and down on the

bumper bar at the front corner of the vehicle.

Compare the resistance to movement with a

similar vehicle having acceptable ride quality.

2. Inspect the struts for excessive fluid leakage.

ACCEPTANCE CRITERIA

A strut DOES NO T require r eplacem ent, if any or a

combination of the following are present:

• An oily build-up at the end of the piston rod, up

to 1 cm wide.

• Oily ‘sludge’ accum ulated f r om normal oper ating

conditions to 4 cm from the top of the strut body.

• Road grease, oil, sand and dust discolouration

on the body, does not constitute a leak ing strut.

If this condition is evident, the strut should be

wiped clean and checked at a later service.

NOTE:

Should one strut prove to be leaking and require

replacement, provided the remaining strut is

serviceable, it does not also need to be replaced.

5.1 DIAGNOSIS GUIDE

HARD OR HEAVY STEERING

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Low or uneven tyre pressures 1. Inflate tyres to specified pressure for

specific load conditions. See tyre

placard attached to the vehicle

2. Steering gear or connections too tight

or misaligned 2. Adjust steering gear or replace

components as necessary.

See Section 9A.

3. Insufficient fluid in steering gear. 3. Check steering gear fluid level. Top up,

using only DEXRON III® fluid. Check

system for leaks. See Section 9A.

4. Excessive caster 4. Check front wheel alignment. Adjust as

necessary. See Operation 2.2, in this

Section.

5. Lower control arm/s and/or tension

rod/s bent. 5. Check alignment of control arms and

tension rods. Replace components as

necessary. See Operation 2.2, in this

Section.

6. Steering knuckle bent. 6. Replace steering knuckle. See Operation

4.5 in this Section.

7. Excessive toe-in. 7. Check and adjust wheel toe. See

Operation 2.2, in this Section.

Techline

Techline

EXCESSIVE PLAY OR LOOSENESS IN TEERING

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Steering gear or connections loose or

worn. 1. Adjust steering gear or install new

components as required. See Section 9A.

2. Control arm ball joint loose or worn. 2. Replace ball joint assembly. See

Operation 4.7, in this Section.

3. Front wheel bearings worn. 3. Replace front hub assembly. See

Operation 3.2, in this Section.

4. Loose attachment of crossmember to

frame. 4. Check, align and tighten crossmember

attaching nuts. See Operation 4.12, in this

Section and Section for alignment

procedures.

ERRATIC STEERING ON APPLICATION OF BRAKES

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Low or uneven tyre pressures. 1. Inflate tyres to specified pressure for

specific load conditions. See ty re placard

attached to the vehicle.

2. Excessive front brake disc runout. 2. Machine front discs. Refer to Section 5A.

3. Front brake pads contaminated with

lubricant. 3. Replace brake pads. Correct cause of

lubricant lleakage.

4. Insufficient or uneven caster. 4. Check front wheel alignment. See

Operation 2.2, in this Section.

5. Steering knuckle bent. 5. Replace steering knuckle. See Operation

4.5, in this Section.

6. Excessive play in steering gear. 6. Adjust steering gear or replace worn

components, See Section 9A.

VEHICLE PULLS TO ONE SIDE

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Low or uneven tyre pressures. 1. Inflate tyres to specified pressure for

specific load conditions. See ty re placard

attached to the vehicle.

2. Rear wheels not tracking with front

wheels 2. Check alignment of rear wheels with front

wheels and correct as necessary. See

Section 4A, for details of rear wheel

alignment.

3. Front brake pads contaminated with

lubricant. 3. Replace brake pads. Correct cause of

lubricant leakage.

4. Toe-in incorrect. 4. Adjust toe-in to specification. See

Operation 2.2 in this Section.

5. Incorrect or uneven caster or camber. 5. Check wheel alignment. Adjust as

necessary. See Operation 2.2, in this

Section.

6. Rear axle assembly shifted. 6. Check attaching bolts for looseness and

control arm bushes for wear.

See Section 4A.

7. Steering knuckle bent.7. Replace steering knuckle. See Operation

4.5 in this Section.

FRONT OR REAR WHEEL TRAMP

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Wheels and tyres out of balance. 1. Balance wheels and tyres. Also check for

eccentric or bulged tyres. Replace as

necessary. See Section 10.

2. Front struts or rear shock absorbers

operating incorrectly, leaking fluid or

inoperative.

2. Check operation and replace components

as necessary. See Operation 4.1 in this

Section or Section 4A.

ROAD SHOCKS

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Incorrect tyre pressures. 1. Inflate tyres to specified pressure for

specific loadconditions. See ty re placard

attached to the vehicle.

2. Steering gear incorrectly adjusted. 2. Adjust steering gear. See Section 9A.

3. Front struts or rear shock absorbers

operating incorrectly or unevenly,

leaking fluid or inoperative.

3. Check operation and replace components

as necessary. See Operation 4.1 in this

section or Section 4A.

4. Compression or rebound rubbers

damaged or missing. 4. Replace missing or damaged parts. See

Operation 4.4 in this Section.

5. Unbalanced wheels. 5. Balance wheels as detailed in Section 10.

6. Incorrect wheel alignment.6. Check and adjust. See Operation 2.2 in

this Section.

SCUFFED TYRES

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Toe-in incorrect. 1. Adjust toe-in. See Operation 2.2 in this

Section.

2. Tyres improperly inflated. 2. Inflate tyres to specified pressure for

specific load conditions. See ty re placard

attached to the vehicle.

3. Wheels or tyres out-of-true. 3. Check for wheel and tyre wobble. Check

that the wheels and tyres are correctly

mounted. Balance wheels and tyres.

See Section 10.

4. Control arm ball joint/s worn. 4. Replace worn components. See Operation

4.8 in this Section.

5. Uneven caster and camber. 5. Check wheel alignment. Adjust as

necessary. See Operation 2.2, in this

Section.

6. Lower control arm/s or tension rod/s. 6. Check alignment of control arm/s and

tension rod/s.Replace components as

necessary . See Operations 4.6 and 4.10

in this Section.

7. Steering knuckle bent.7. Replace steering knuckle. See Operation

4.5, in this Section.

CUPPED TYRES

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Tyres improperly inflated. 1. Inflate tyres to specified pressure for

specific load conditions. See ty re placard

attached to the vehicle.

2. Wheels and tyres out-of-balance. 2. Balance wheels and tyres. Also check for

eccentric or bulged tyres. Replace as

necessary. See Section.

3. Dragging brakes. 3. Check for seizing of the brake calipers

and/or park brake mechanism. See

Section 5A.

4. Control arm ball joint/s and/or wheel

bearings worn. 4. Replace worn components. See Operation

4.7 or 3.2 in this Section.

5. Uneven caster. 5. Check wheel alignment. Adjust as

necessary. See Operation 2.2, in this

Section.

6. Steering knuckle bent 6. Replace steering knuckle. See Operation

4.5, in this Section.

FRONT WHEEL SHIMMY

SYMPTOM AND PROBABLE CAUSE REMEDY

1. Low or uneven tyre pressures. 1. Inflate tyres to specified pressure for

specific load conditions. See ty re placard

attached to the vehicle.

2. Steering connections incorrectly

adjusted or worn. 2. Adjust steering gear or install new

components as needed. See Section 9A.

3. Control arm ball joint/s and/or wheel

bearings worn. 3. Replace worn components. See Operation

4.7 or 3.2 in this Section.

4. Wheels and tyres out-of-balance. 4. Balance wheels and tyres. Also check for

eccentric or bulged tyres. Replace as

necessary. See Section 10.

5. Wheels or tyres out-of-true. 5. Check for wheel and tyre wobble. Check

that the wheels and tyres are correctly

mounted. Balance wheels and tyres.

See Section 10.

6. Incorrect or uneven caster or incorrect