SECTION 12J-2 - HIGH SERIES BODY CONTROL

MODULE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bag s or seat belt pre- tensio ners, d riv er’s and fron t p asseng er’s air bag and lef t and rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System of the

VT Series I Service Information before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Section of this Service Information CDfor more

specific servicing information.

1. GENERAL DESCRIPTI ON

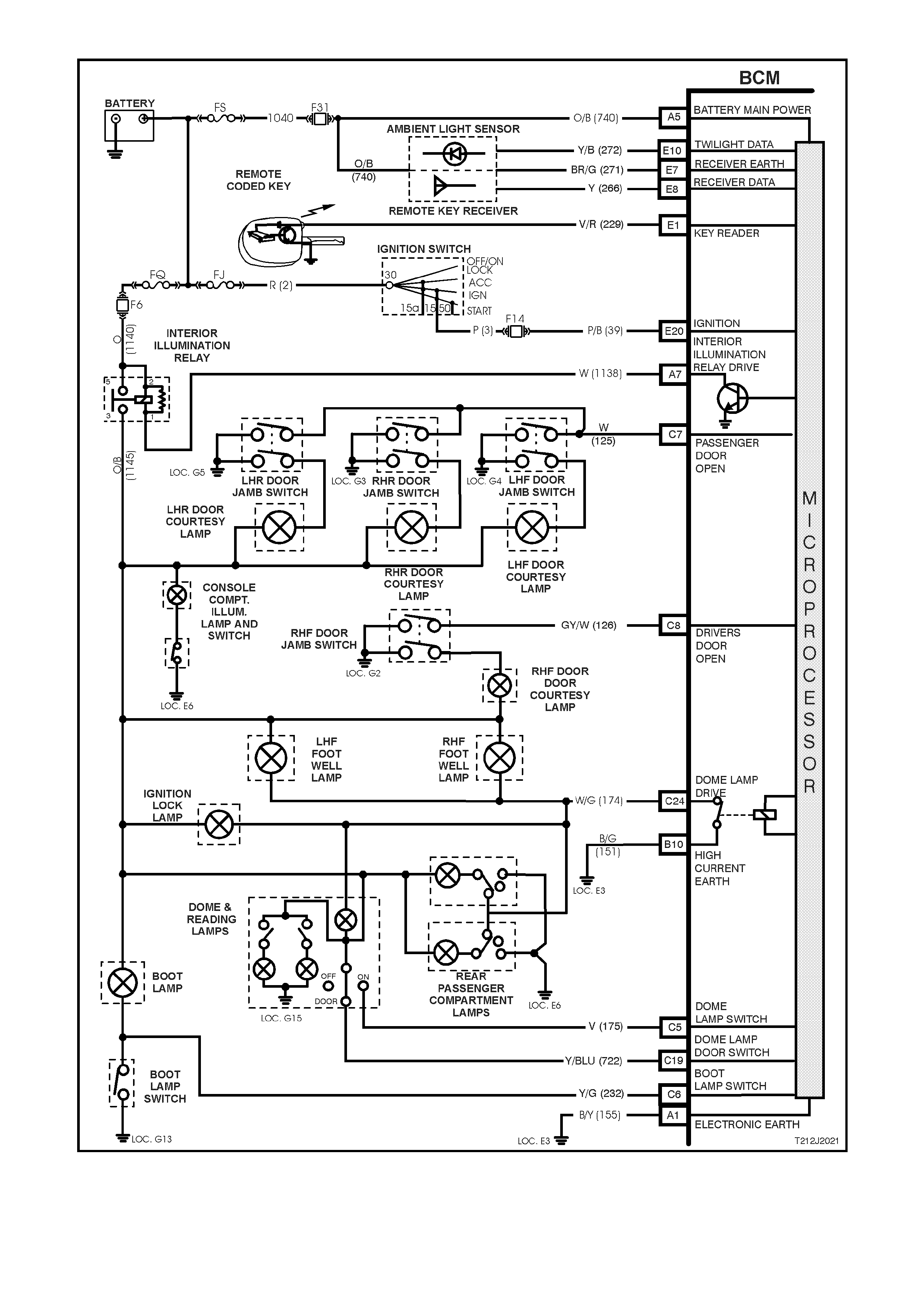

A Body Control Module (BCM), both High and Low Series, com bine into one centr al m odule, the control or assist of

various vehicle electrical systems or features, rather than having individual modules for each system or feature.

High Series BCMs are fitted as standard equipment on all VT Series Berlina and Calais Models.

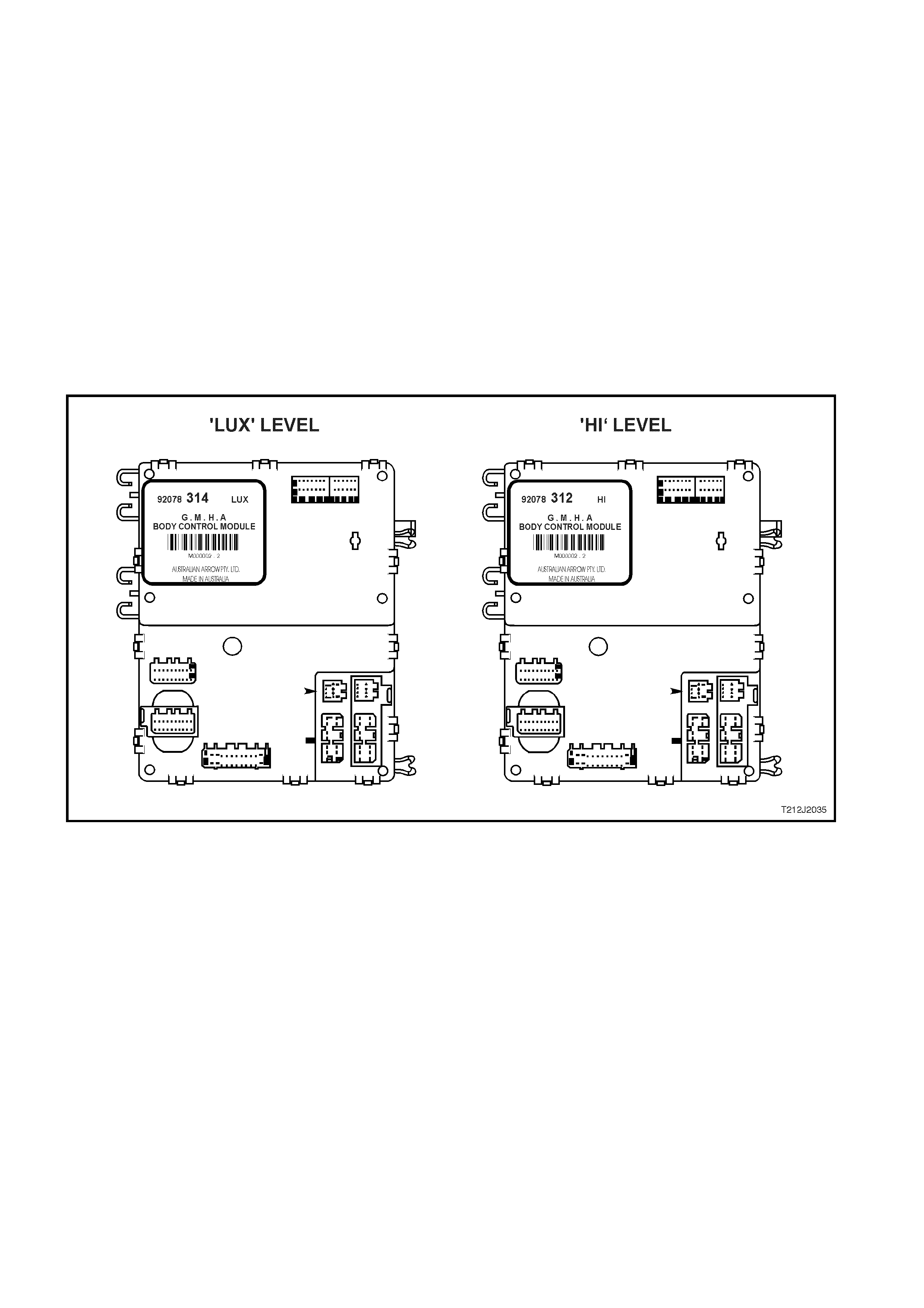

Two levels of High Series BCM’s have been released, a LUX level for Berlina Models and the HI level for Calais. If a

service operation or diagnostic procedure requires that a High Series BCM must be replaced, ensure that the

correct BCM level is reinstalled for the particular level of vehicle.

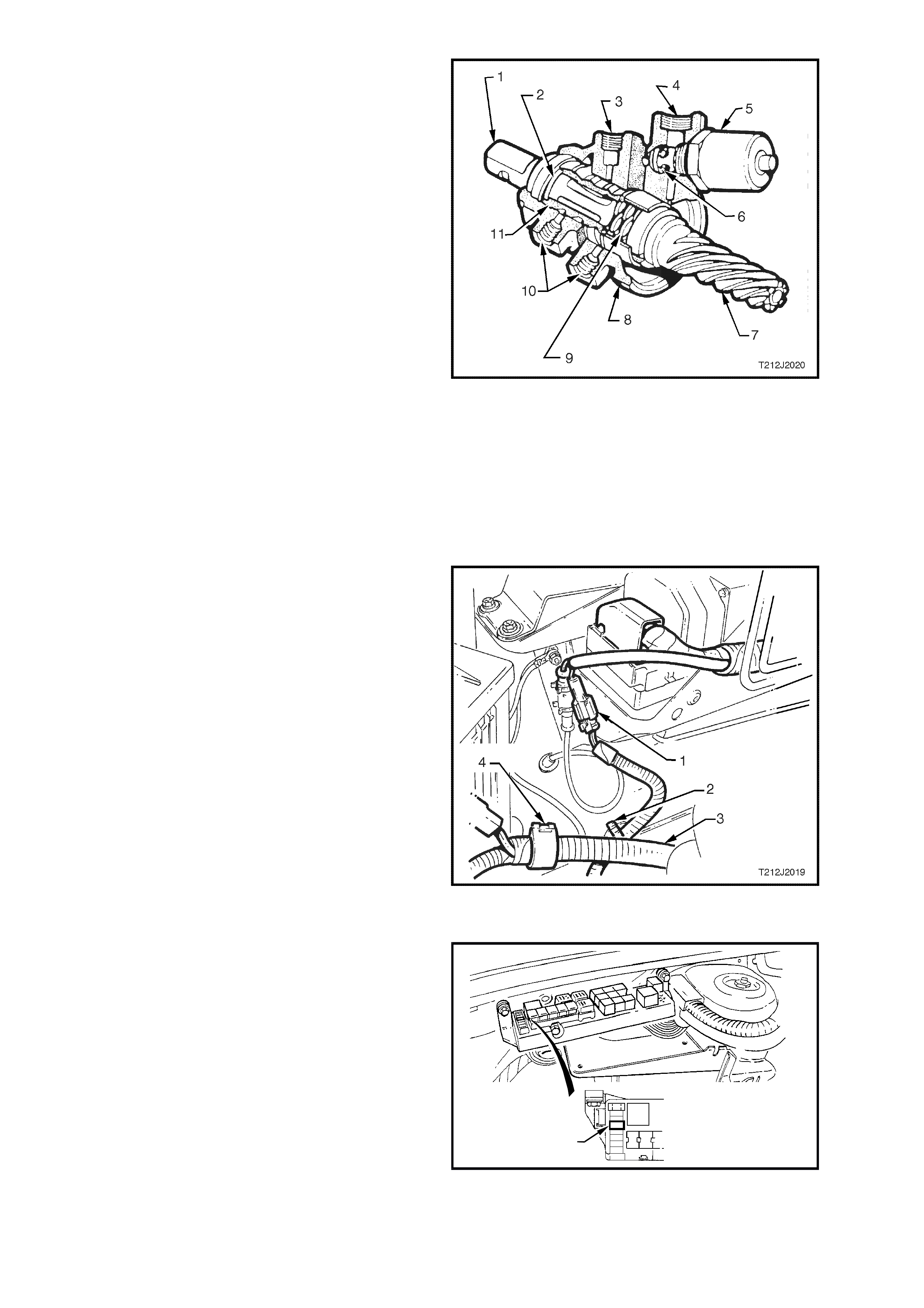

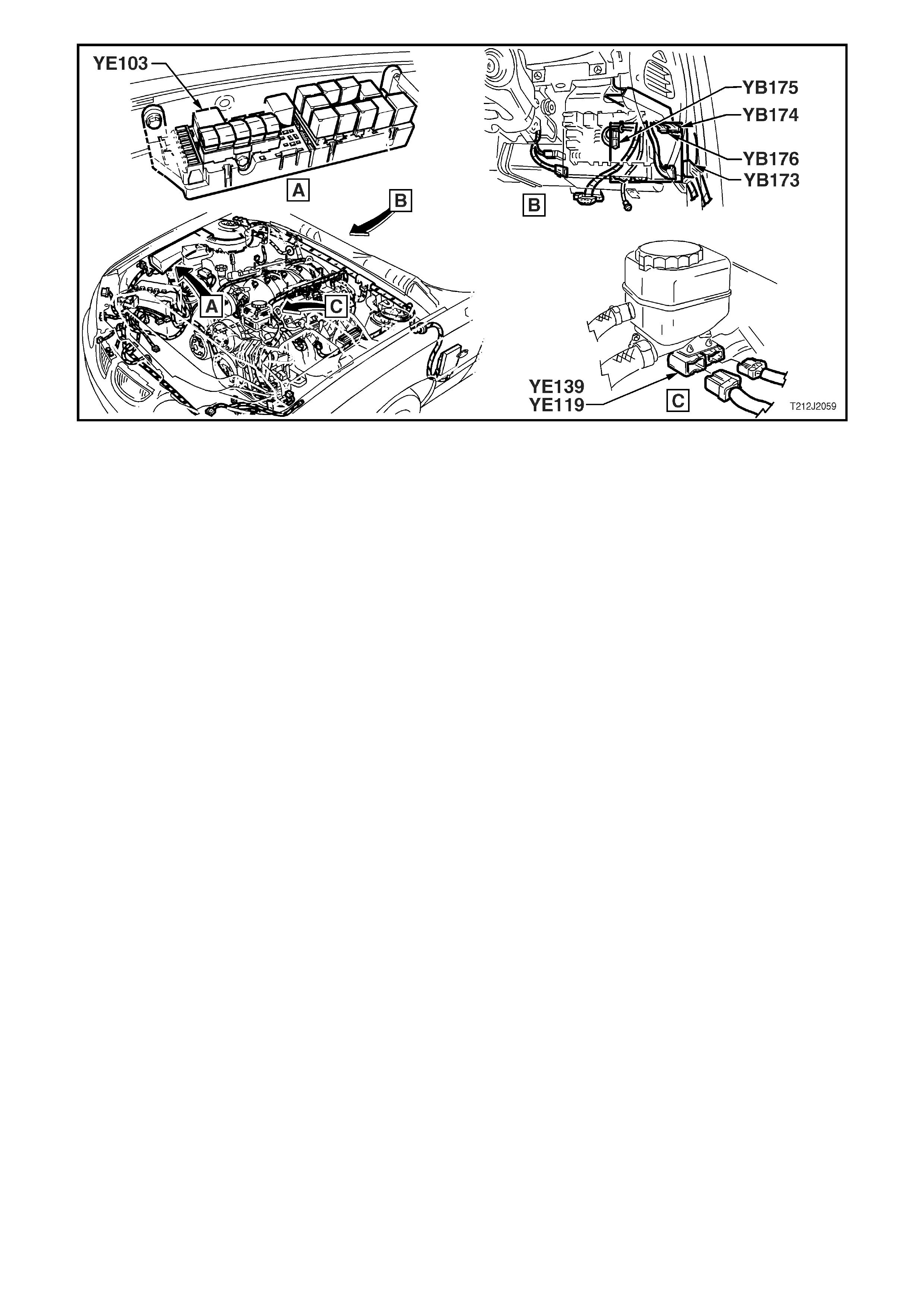

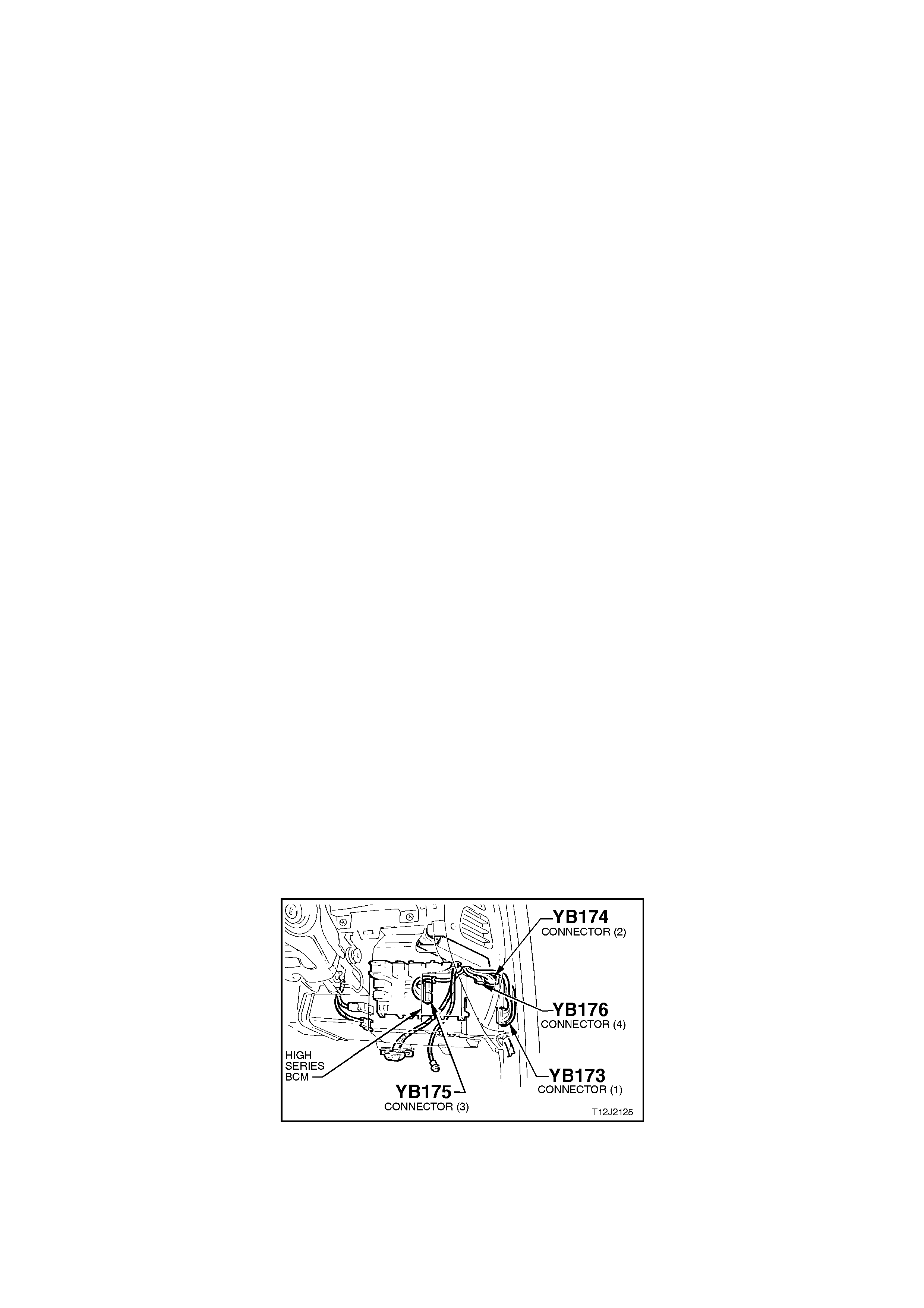

The High Series BCM is located beneath the instrument cluster, to the right of the steering column, refer to Fig.

12J-2-2. Fig. 12J-2-1 illustrates the identification details for the High Series BCM. External identification can be

made by referring to the last three digits of the BCM part number.

Information regarding Low Series BCMs, fitted to VT Series Executive and Acclaim Models, can be found in

Section 12J-1 LOW SERIES BODY CONTROL MODULE of the VT Series II Service Information.

With the introduction of VT Series II Models, comes various upgrade features (and changes) for the BCM. The

following list provides a summary of these new features, additional and more detailed information of an individual

features can be found within this Section.

• Remote deadlocking via remote key (two lock button presses within ten seconds).

• Battery saver feature; turns off all internal lam ps after one hour (default setting) of the ignition being switched

off.

NOTE: This f eatur e inc ludes a pr e-deliver y mode which sets the timer to a shor ter period of thr ee minutes until

the vehicle has travelled above 20km/h for a cumulative period of 30 minutes. After this period, the battery

saver timer sets to one hour.

• The standing current in the BCM has also been lowered from 18mA to 4mA.

• Key off courtesy lamp; courtesy lamp comes on for 30 seconds when the ignition is switched off.

• Disablement of the in-vehicle boot release button when security system armed.

• Approach illumination entry (high series BCM only); headlamps and/or park lamps are turned on for 30

seconds (dependant on headlamp switch position) when the vehicle is unlocked via the remote key.

• Deletion of 2 hour override. For the override feature to be deleted, both the BCM and the PCM had to be

changed. These changes were staggered in introduction;

BCMs were changed in July 1998.

V6 PCMs were changed in October 1998.

V8 PCMs were changed in December 1998.

• Serviceability of door lock microswitch (at VT start of production, microswitches were serviced as part of the

door handle assembly only).

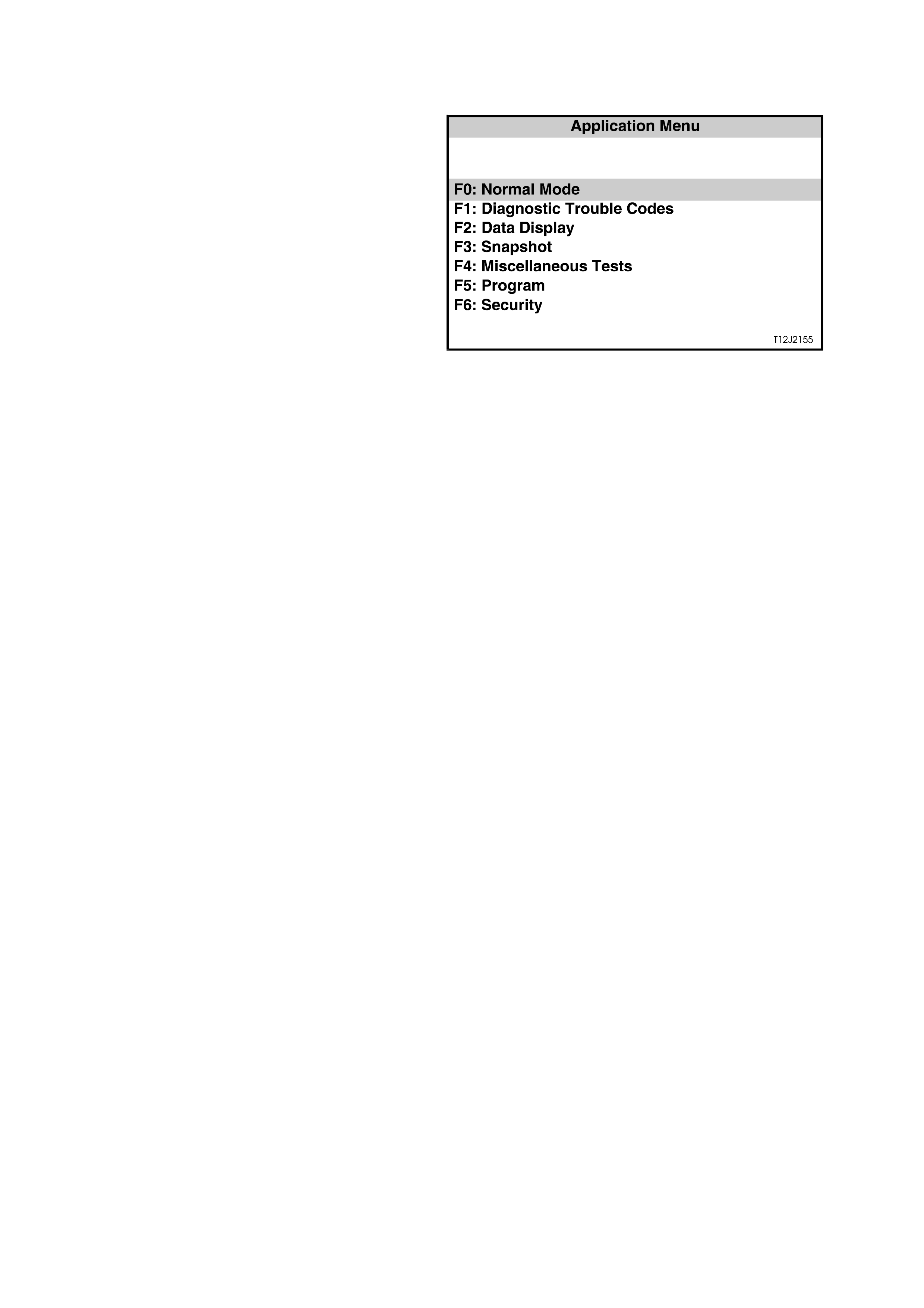

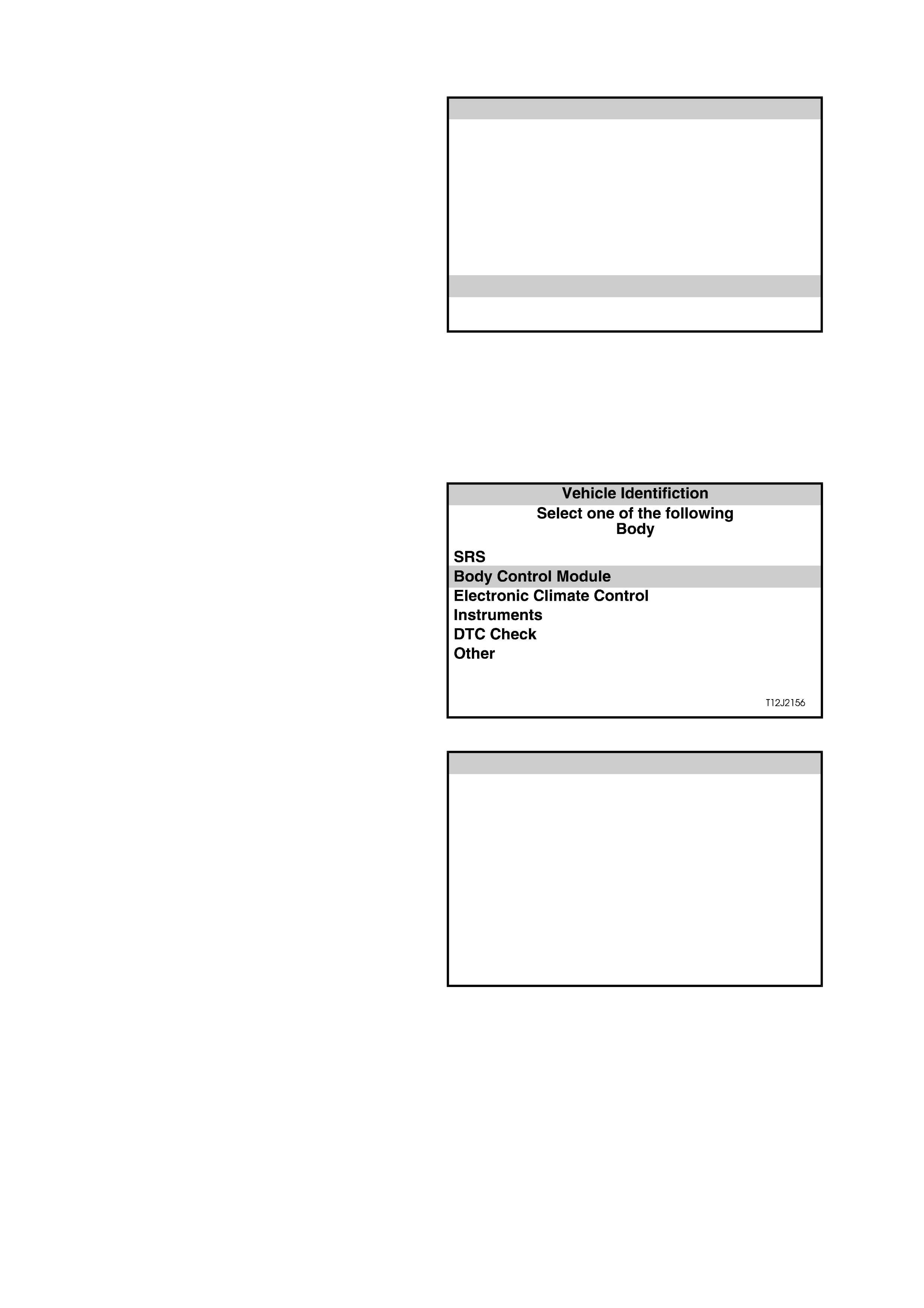

Techline

Techline

Techline

Techline

Techline

Techline

Techline

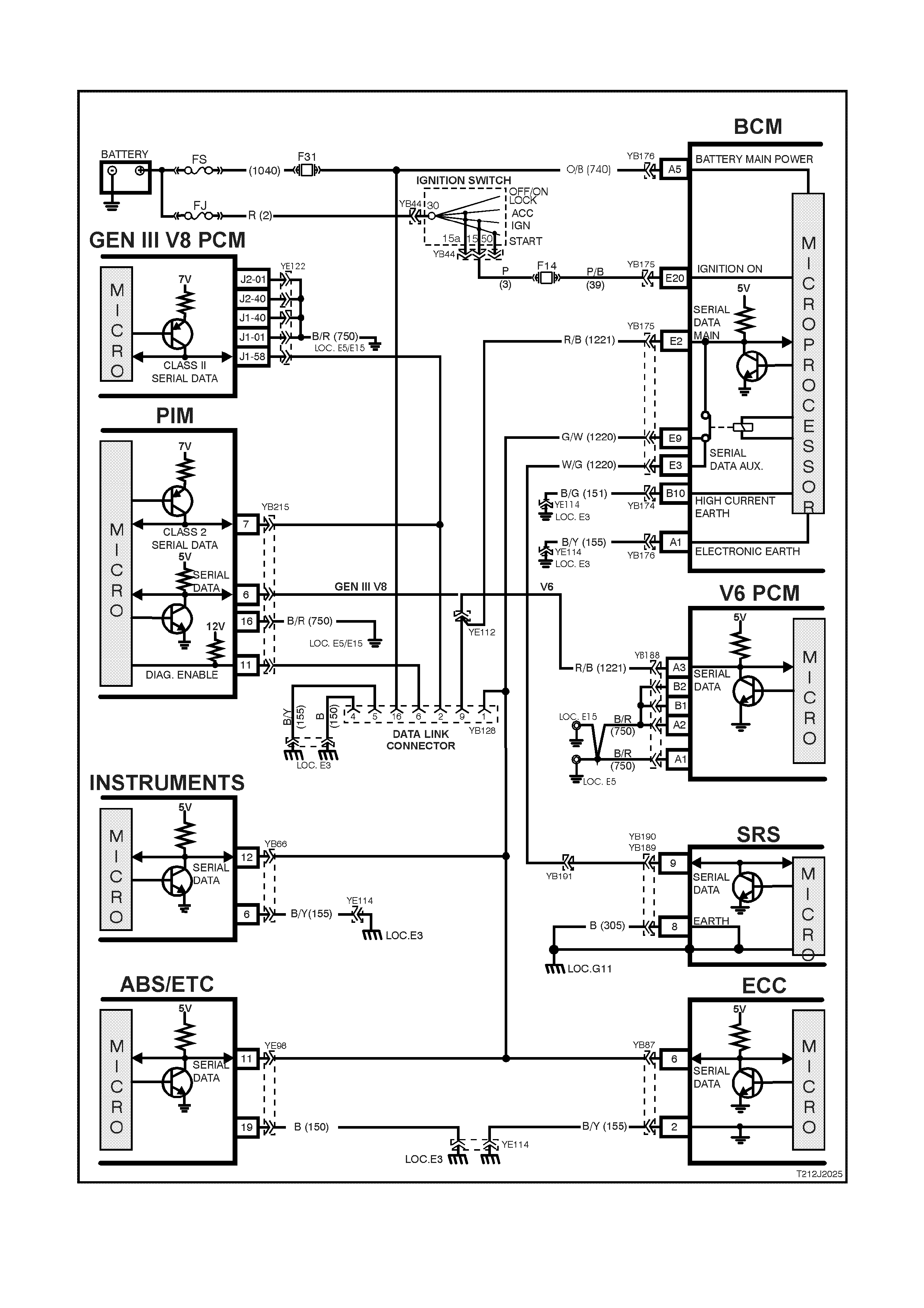

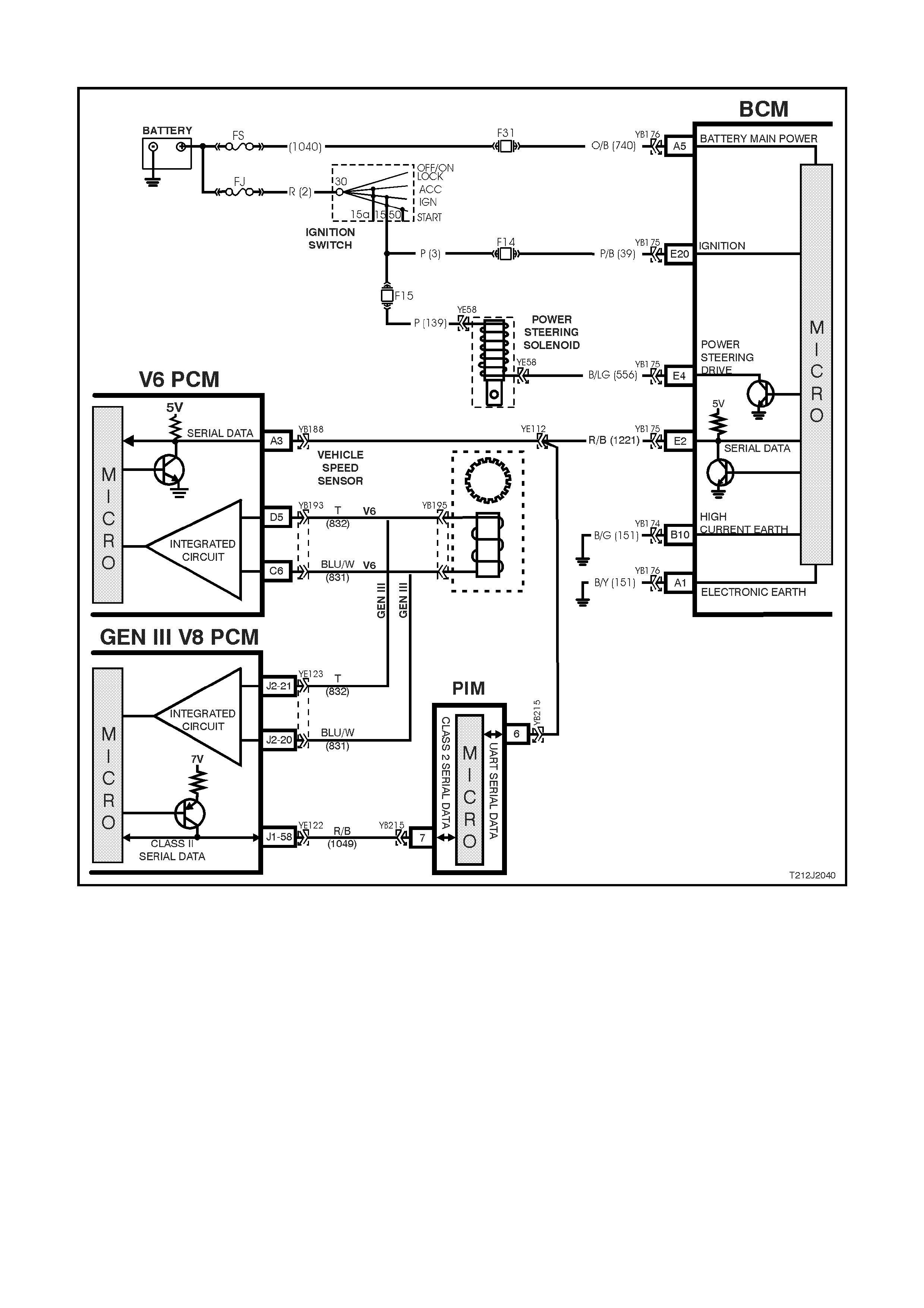

Also released f or VT Series II Models is the new GEN III V8 engine. T he Powertrain Control Module (PCM) f or this

engine uses what is referred to as ‘Class 2’ serial communication. All other control modules, including the BCM,

communicate serial data, in what is referred to as UART (Universal Asynchronous Receive and Transmit). The

‘Class 2’ communication is more sophisticated than UART, and as such, requires a Powertrain Interface Module

(PIM) to convert Class 2 communication into UART.

In sim ple terms, the G EN III V8 engine PCM comm unicates in a dif ferent language than the other c ontrol modules

and therefore requires the PIM to translate the PCM information into the same language as the other control

modules communicate in. Refer to 1.2 SERIAL DATA COMMUNICATION (BUS MASTER) for more information .

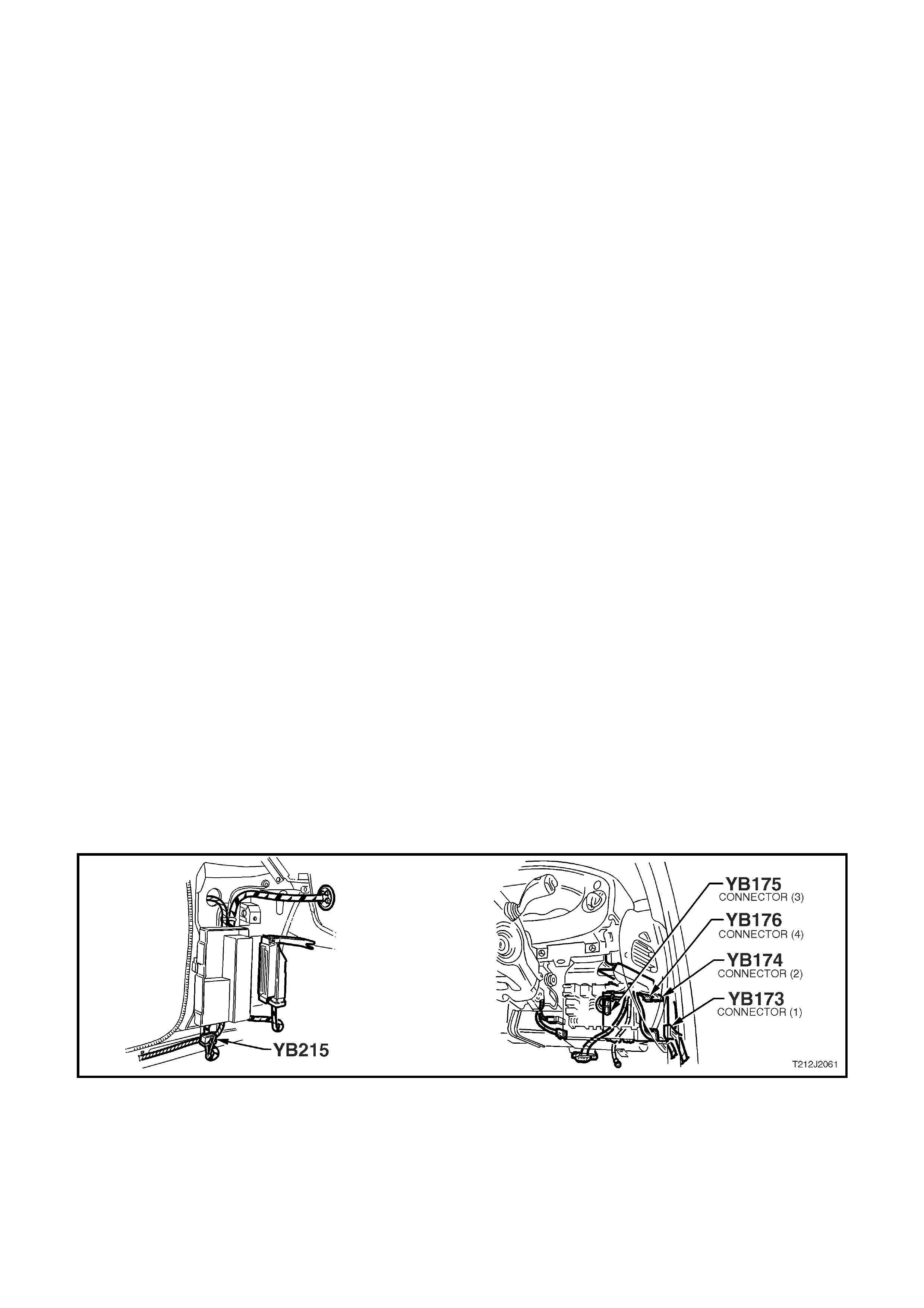

The PIM is located in the same location as a V6 PCM; behind the passenger side shroud lower trim assembly.

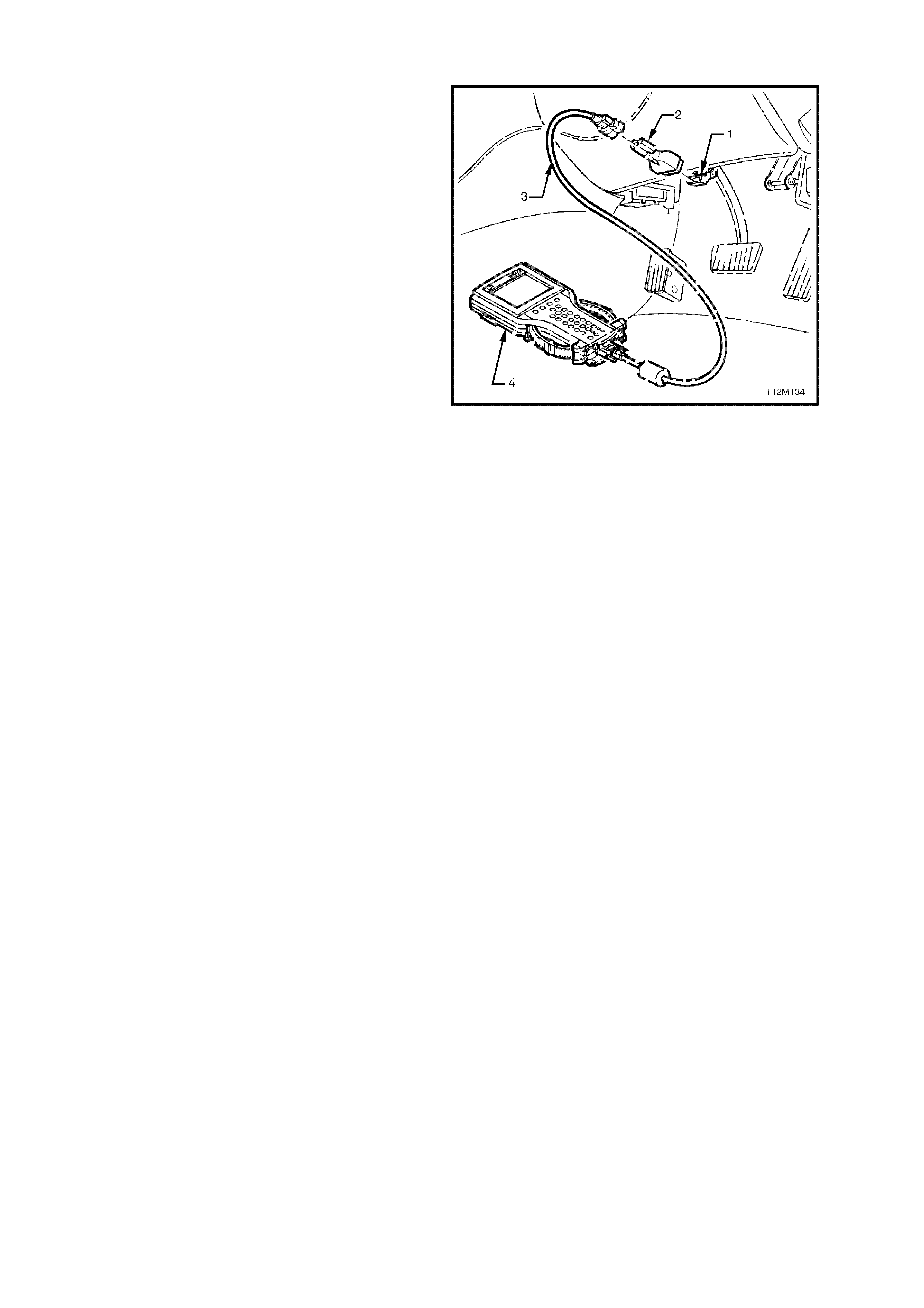

Specific software has been developed for use with the TECH 2 diagnostic scan tool to assist with various vehicle

electrical system fault finding, including the various BCM functions and controls.

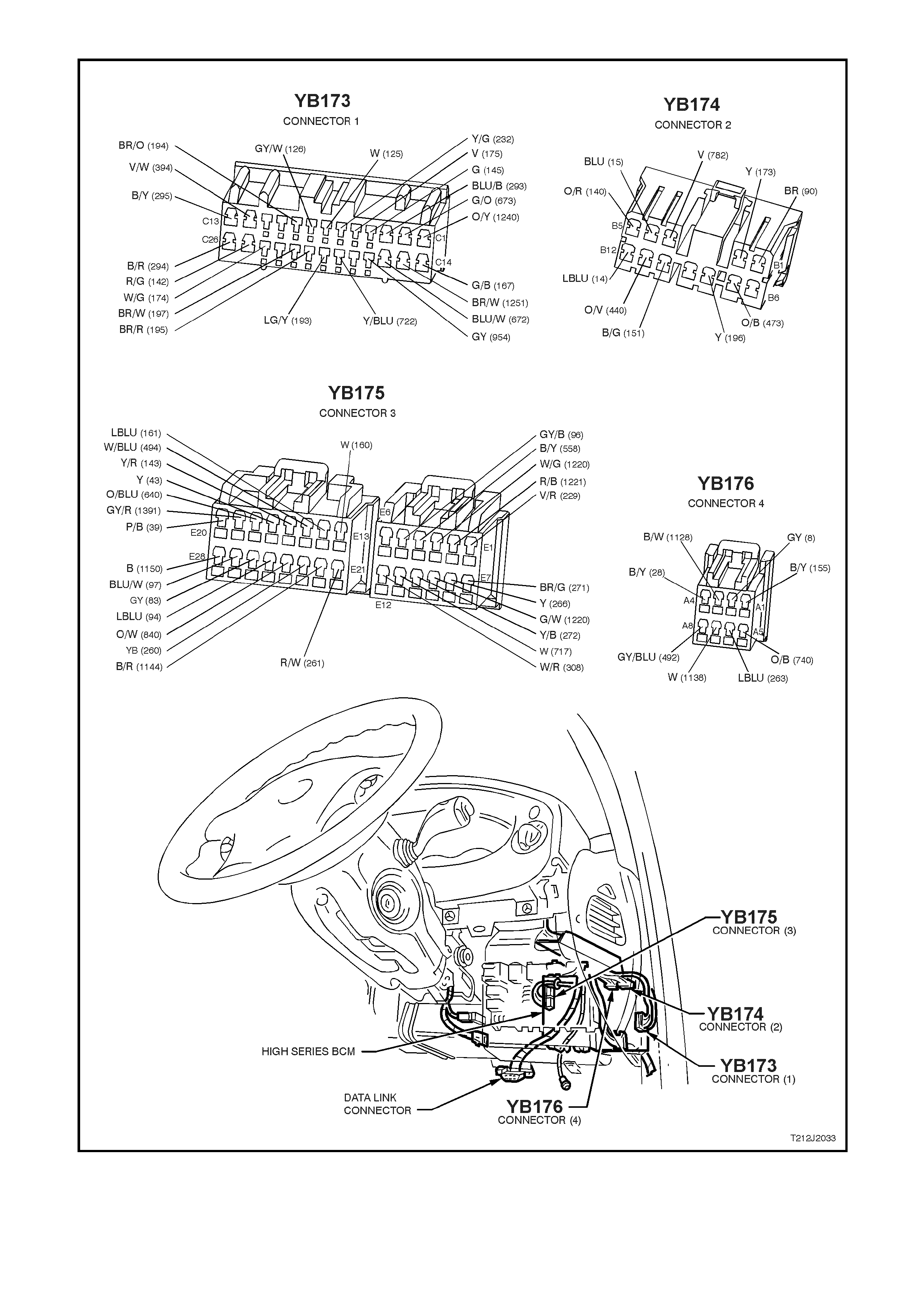

The T ECH 2 connection f or the High Series BCM serial data com munic ation is via the Data Link Connec tor (DLC),

attached to the instrument panel lower right hand trim, to the left of the steering column, refer to Fig 12J-2-2.

This Section has been compiled to address these new features and changes only. For information that is not

covered in this Section, including General Description, Service Operations, Diagnosis and Special Service Tools,

refer to Section 12J-2 HIGH SERIES BODY CONTROL MODULE of the VT Series I Service Information.

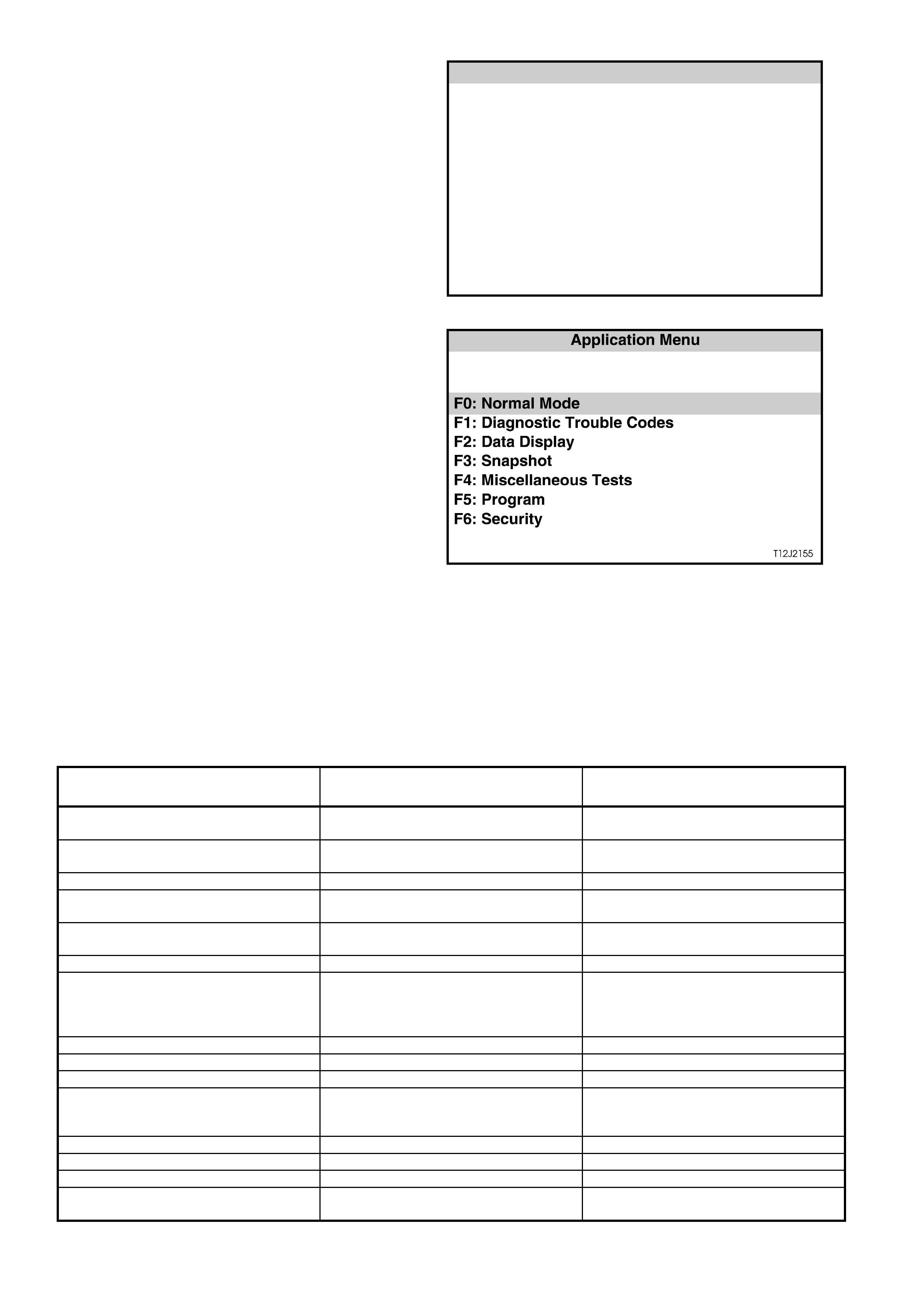

Figure 12J-2-1 High Series BCM Identification

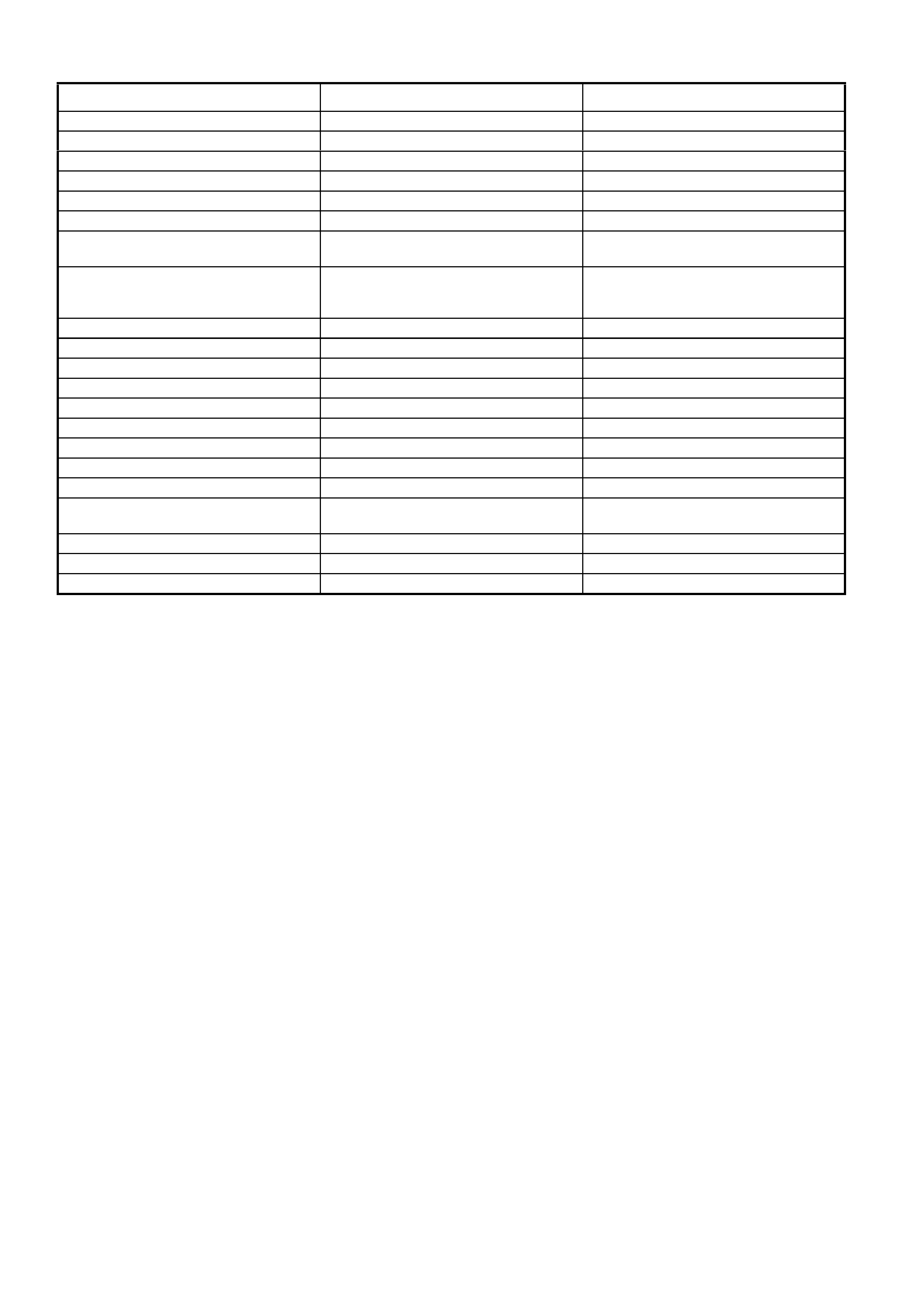

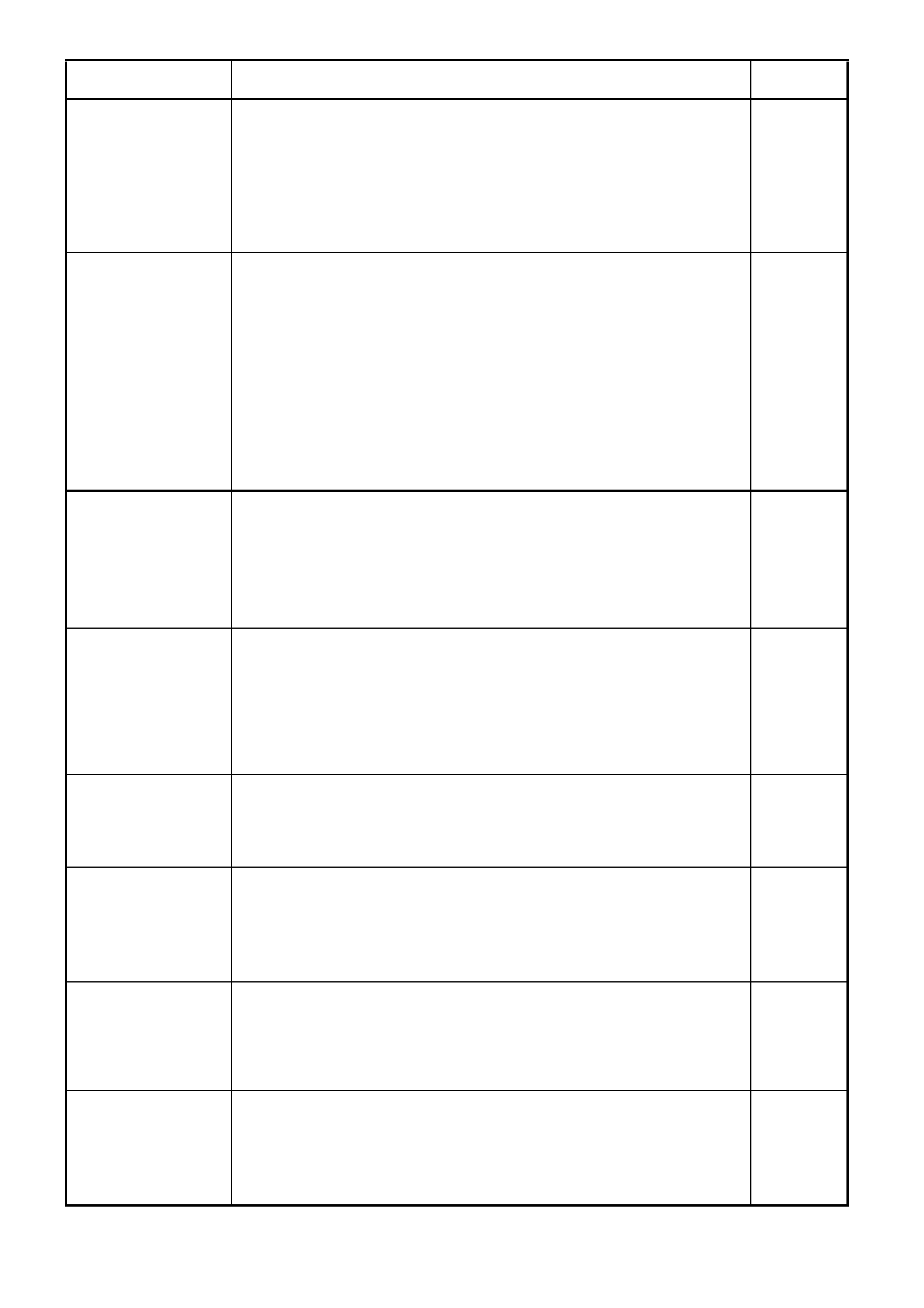

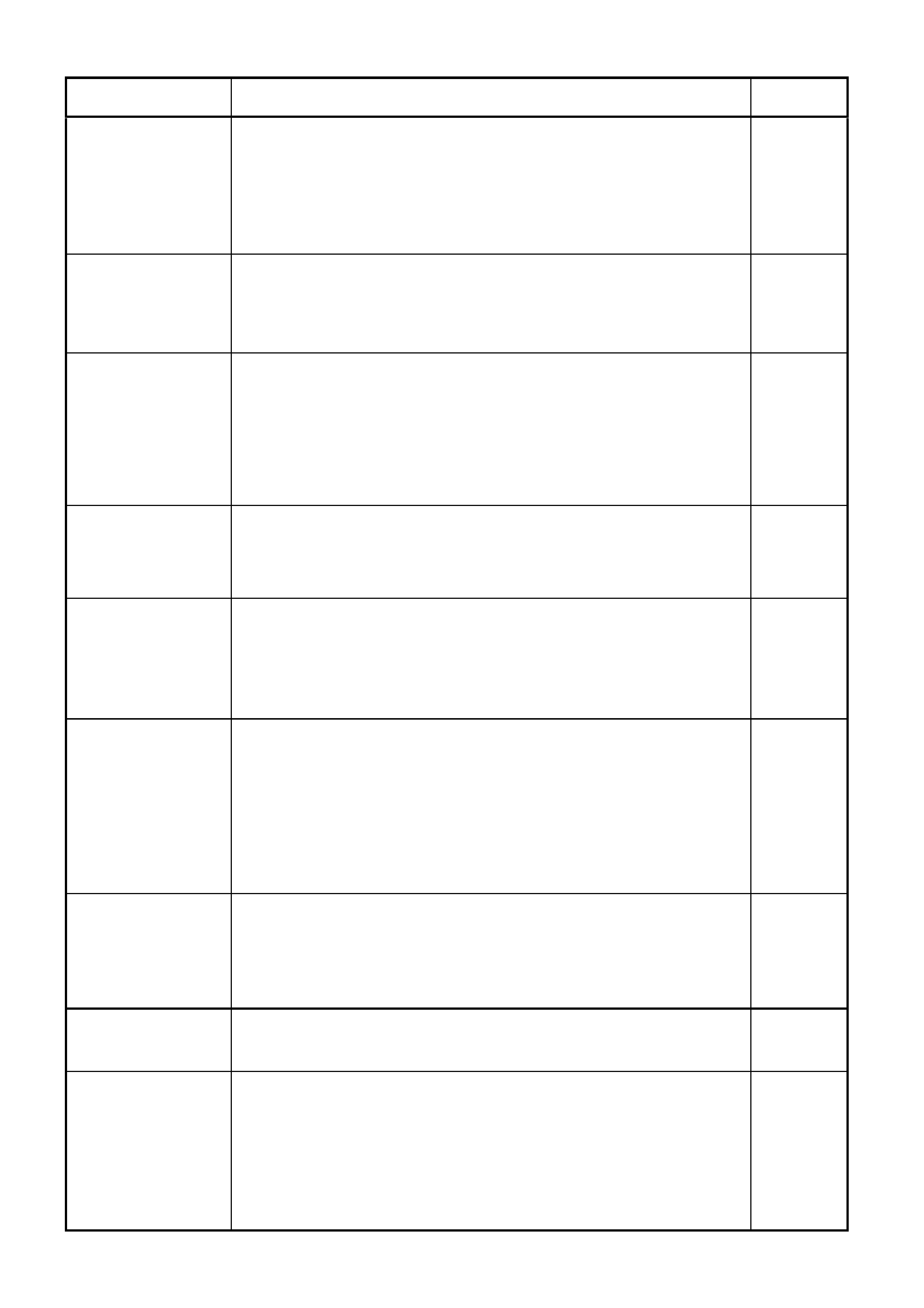

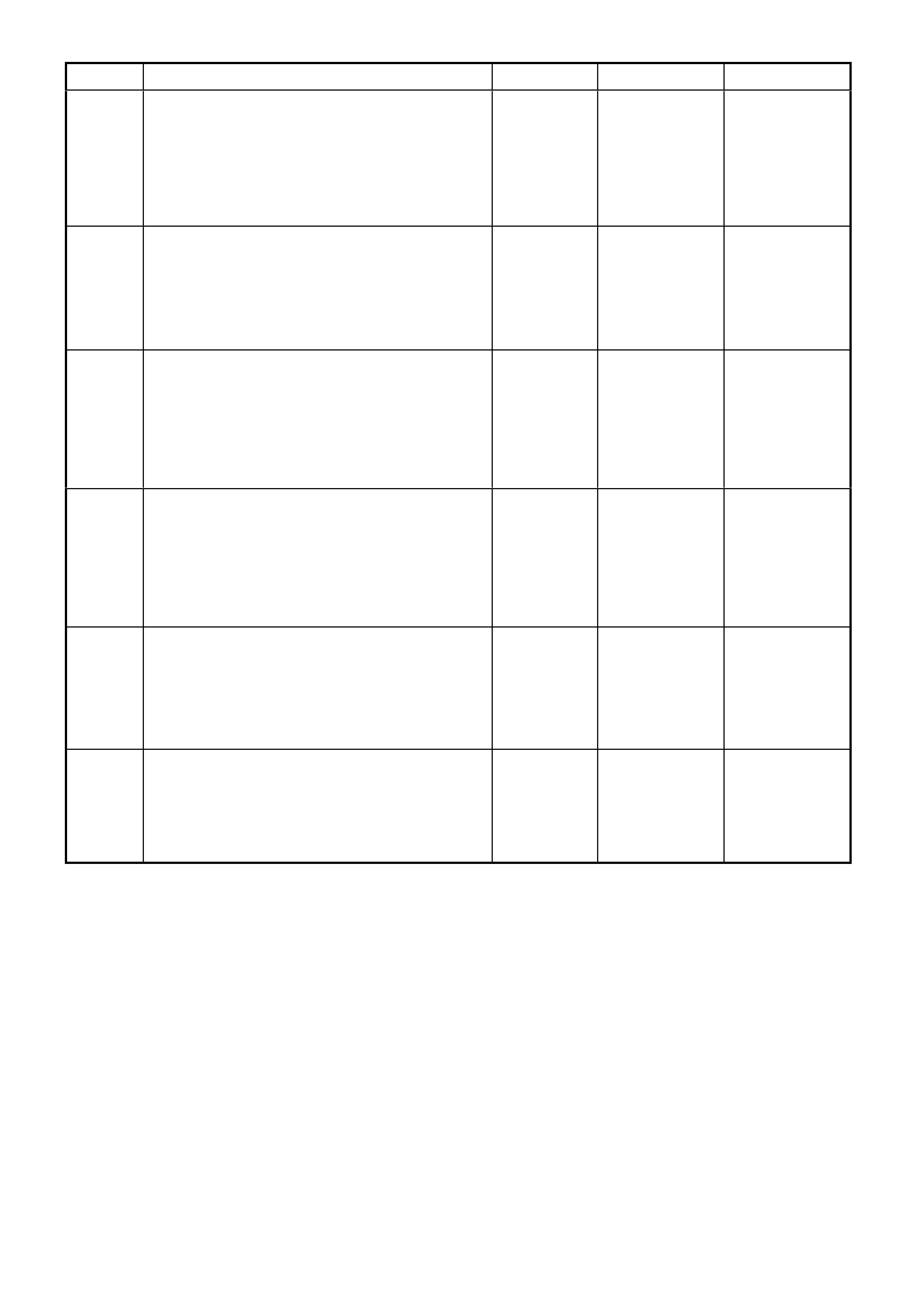

BODY CONTROL MODULE FEATURES

BCM FEATURE LEVEL 7 (BERLINA) LUX – 314 LEVEL 0 (CALAIS) HI - 312

Central door locking A A

Boot release with speed interlock A A

Power window system A A

Power antenna control A A

Dome lamp delay control A A

Rear lamp failure warning lamp control N/A A

Road speed dependent and variable

dwell wiper control - front AA

Intermittent and synchronised to front

rear wiper control with full wipe in

reverse gear (wagon only)

AN/A

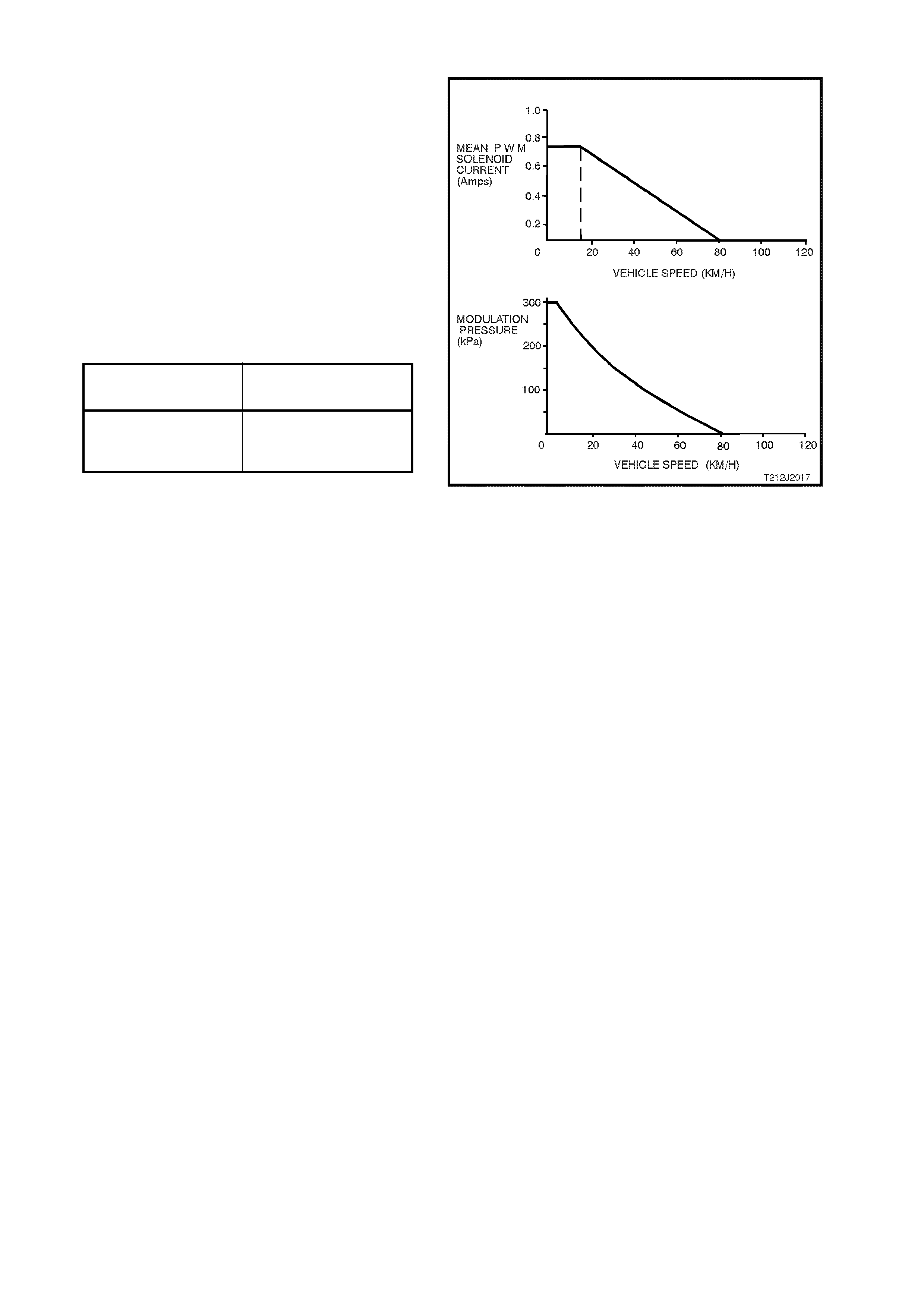

Speed sensitive power steering N/A A

Instrument dimming control A A

Automatic lights OFF (variable) A A

Automatic lights ON - twilight sentinel N/A A

Engine disable A A

Alarm A A

Engine cooling low speed fan control A A

Priority key system N/A A

Cruise control interface A A

SRS (air bag) deployment vehicle

shutdown AA

Serial data interface A A

Battery saver mode A A

Approach illumination A A

N/A = NOT AVAILABLE A = AVAILABLE

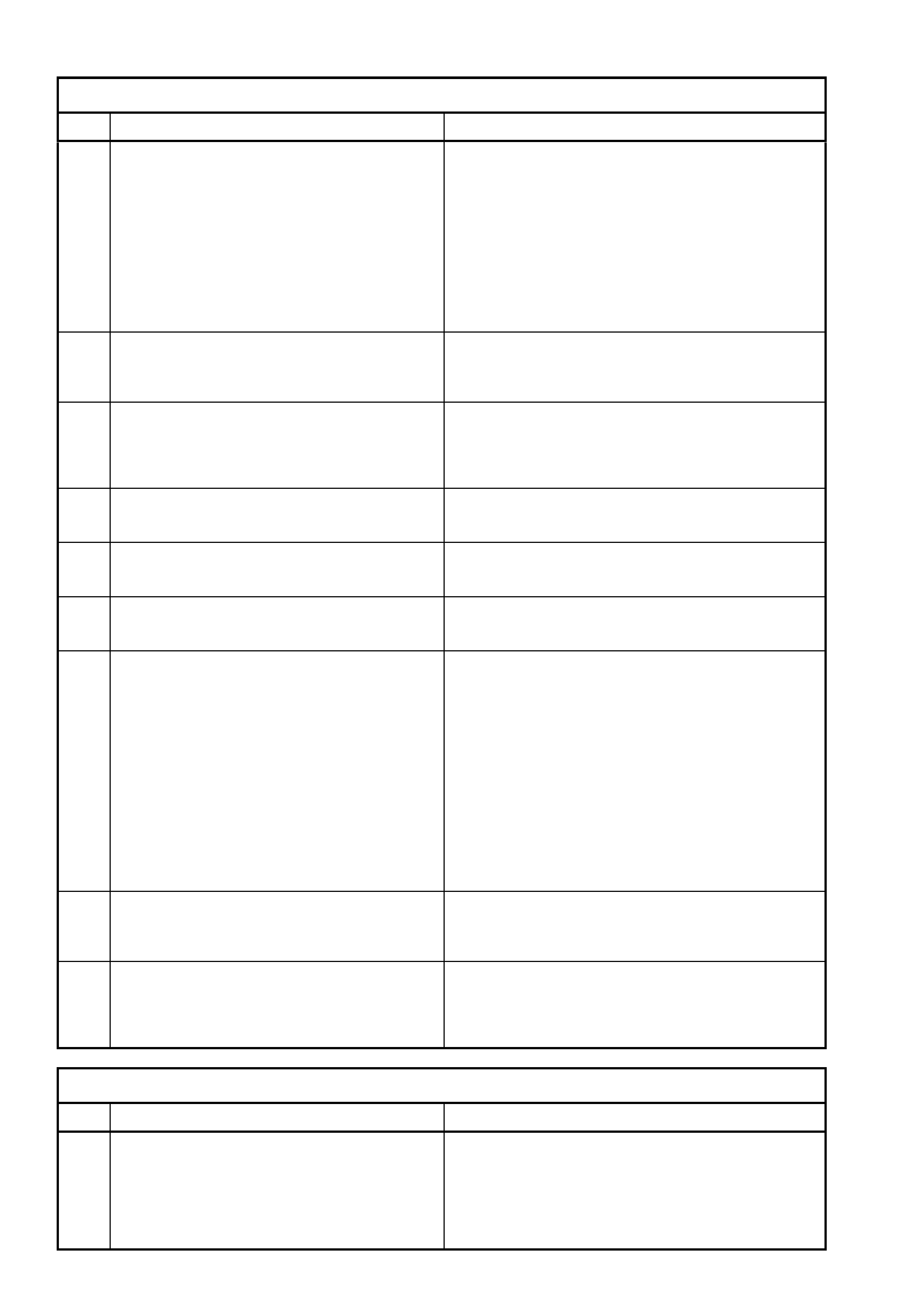

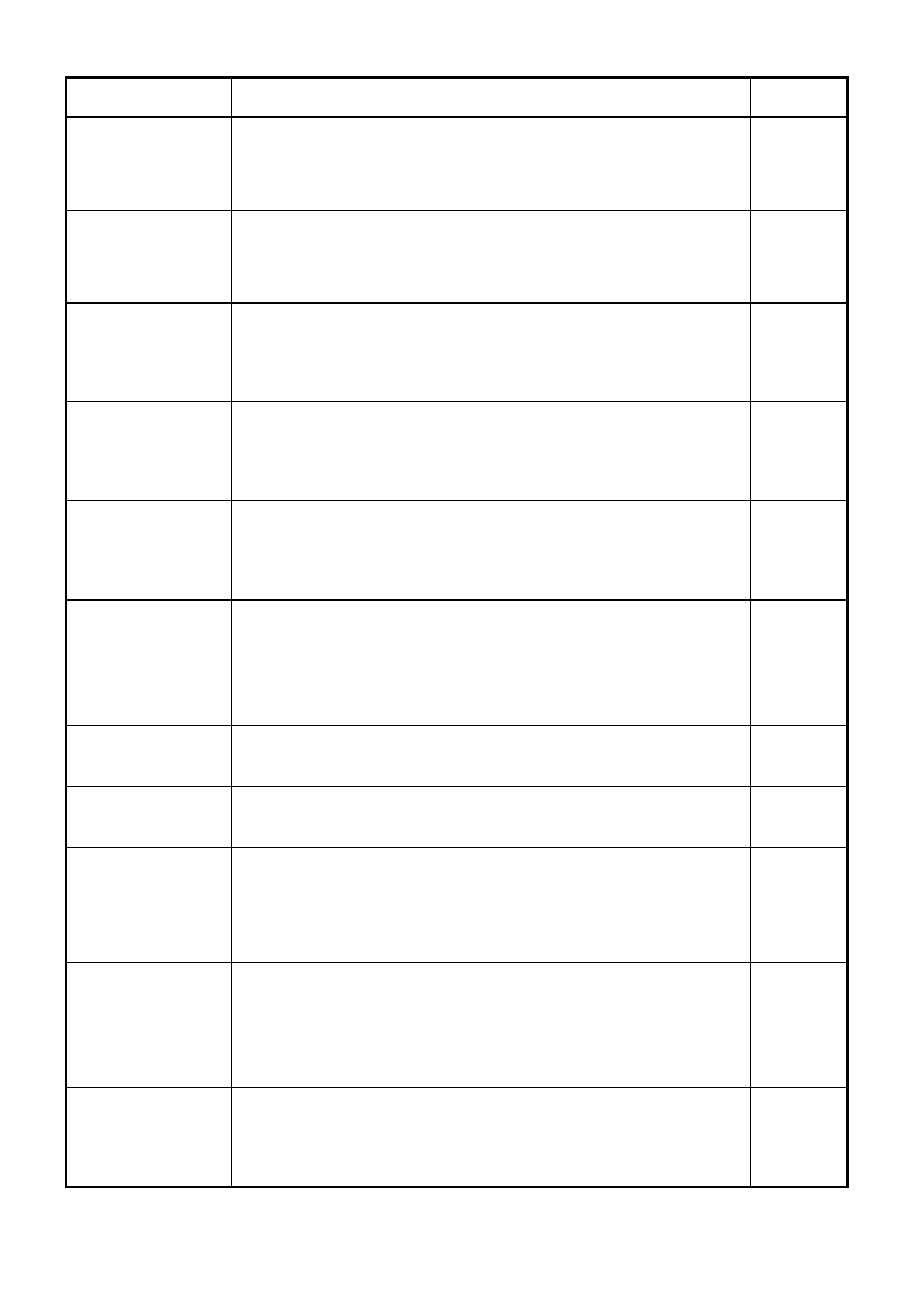

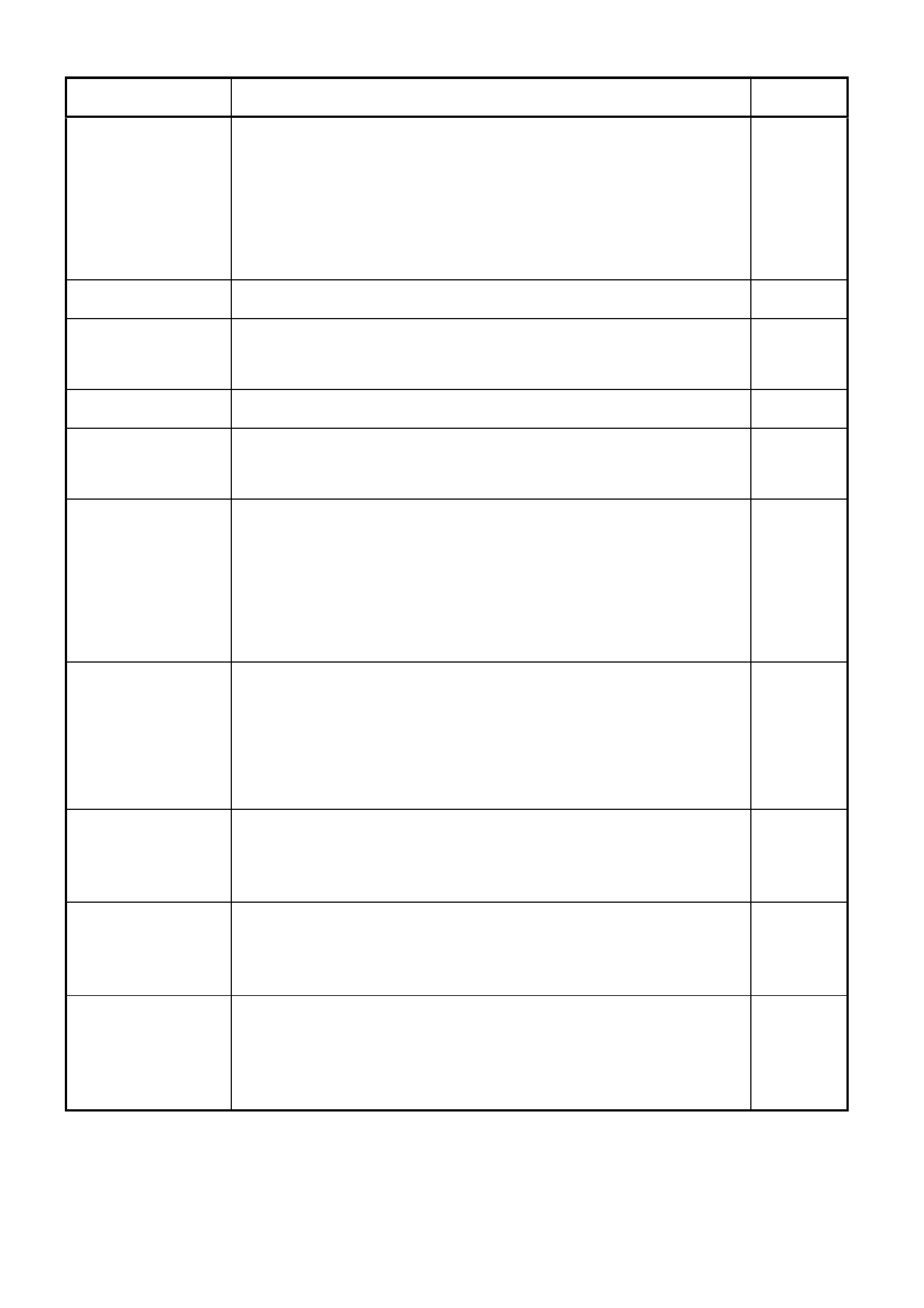

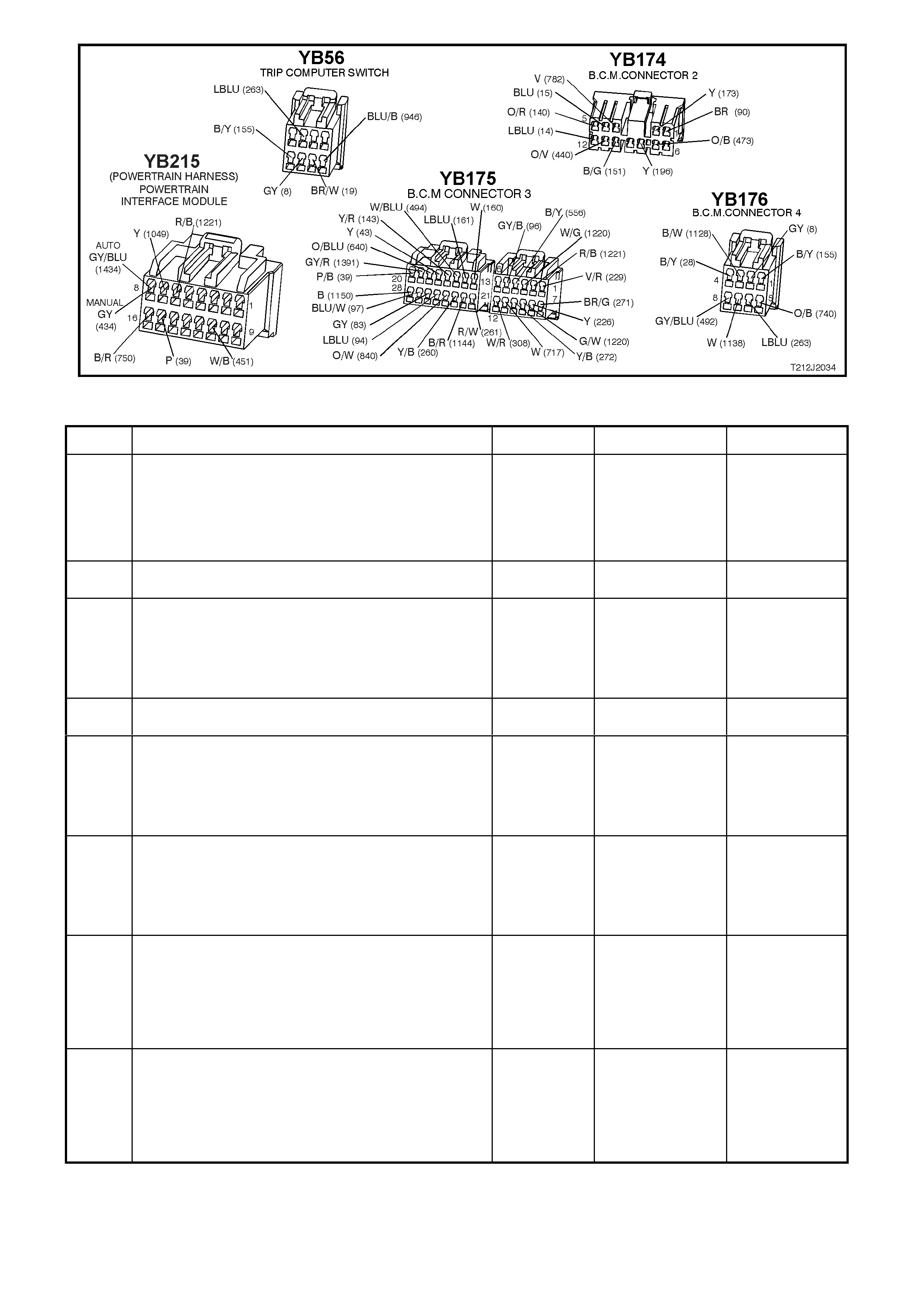

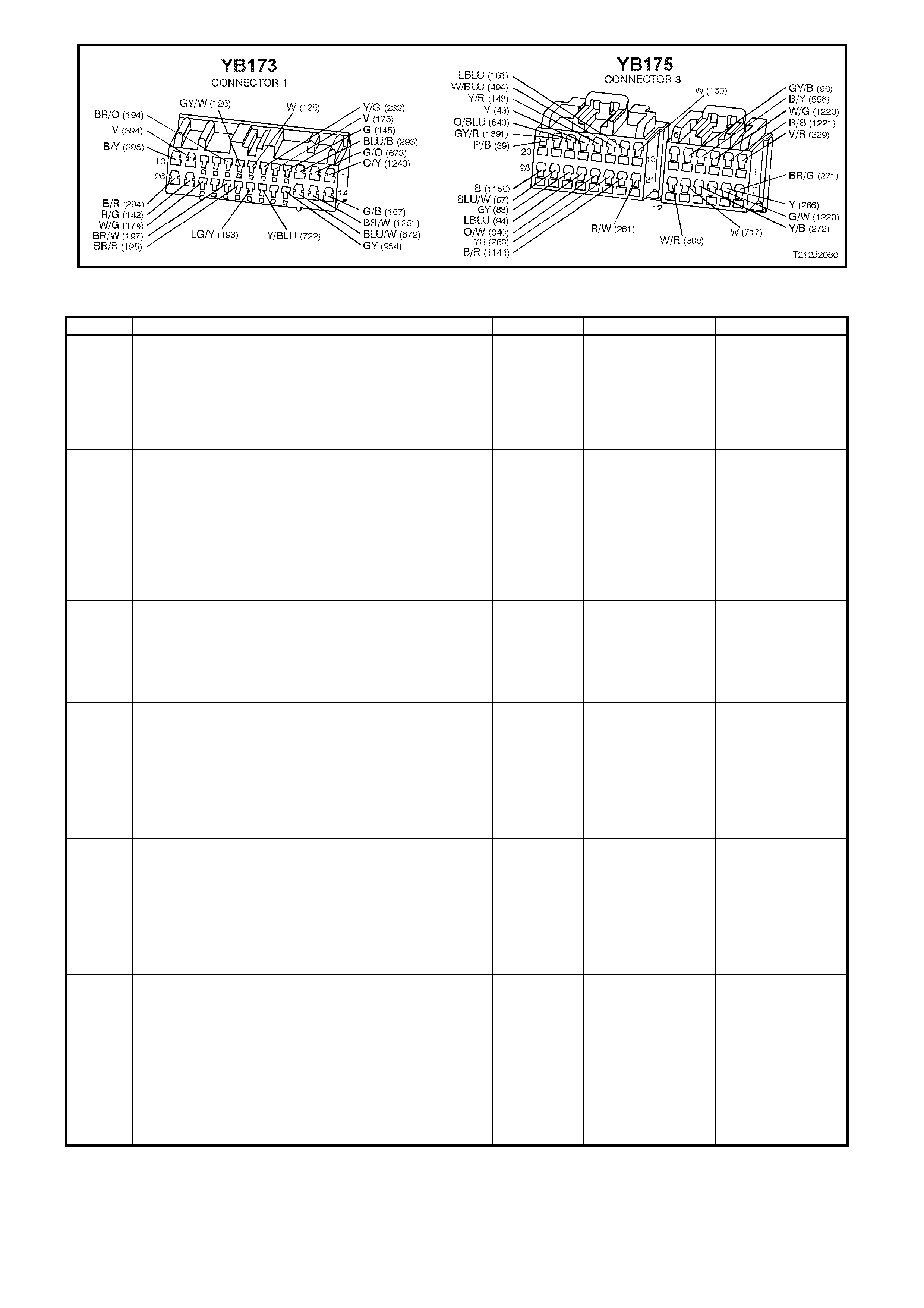

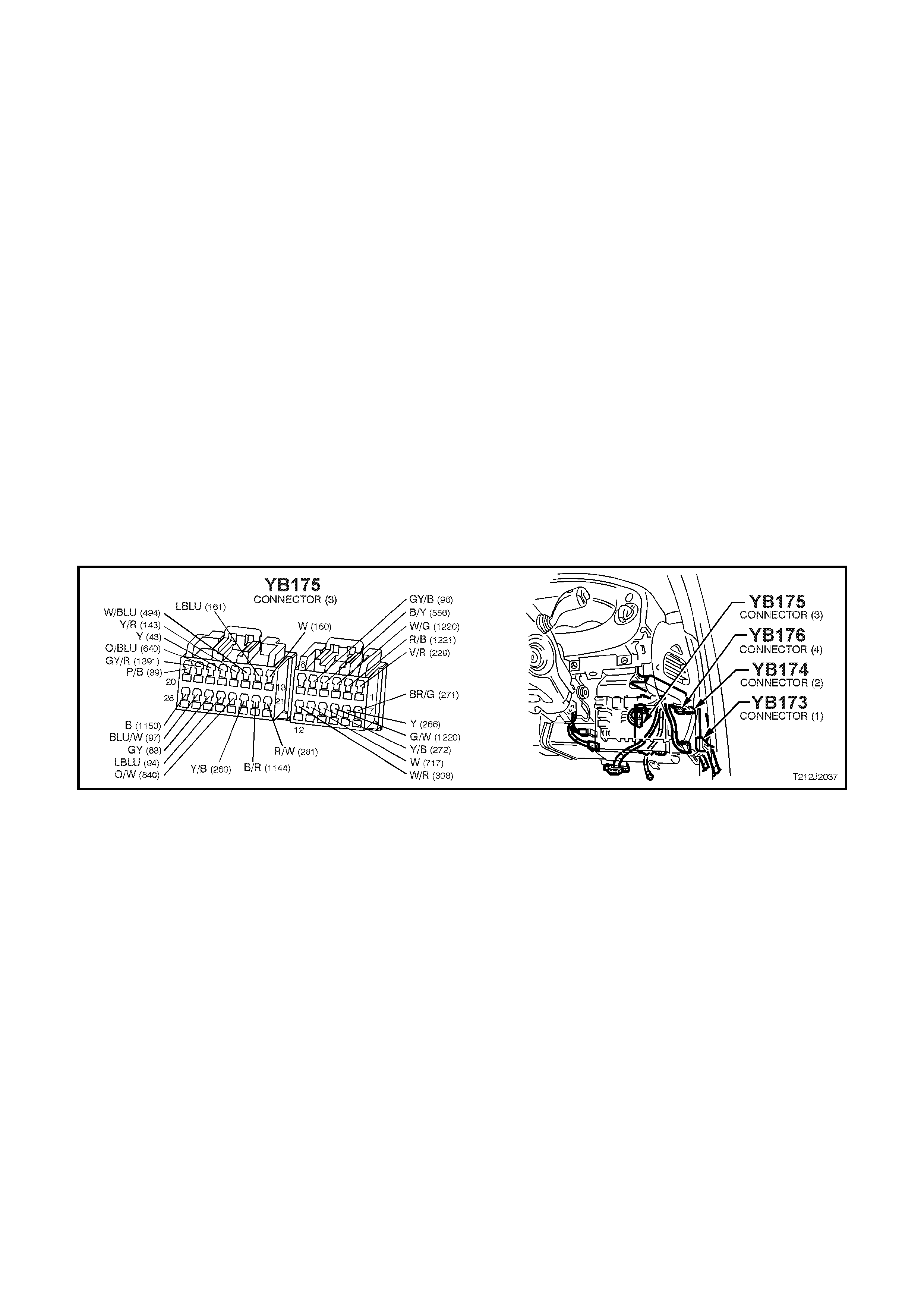

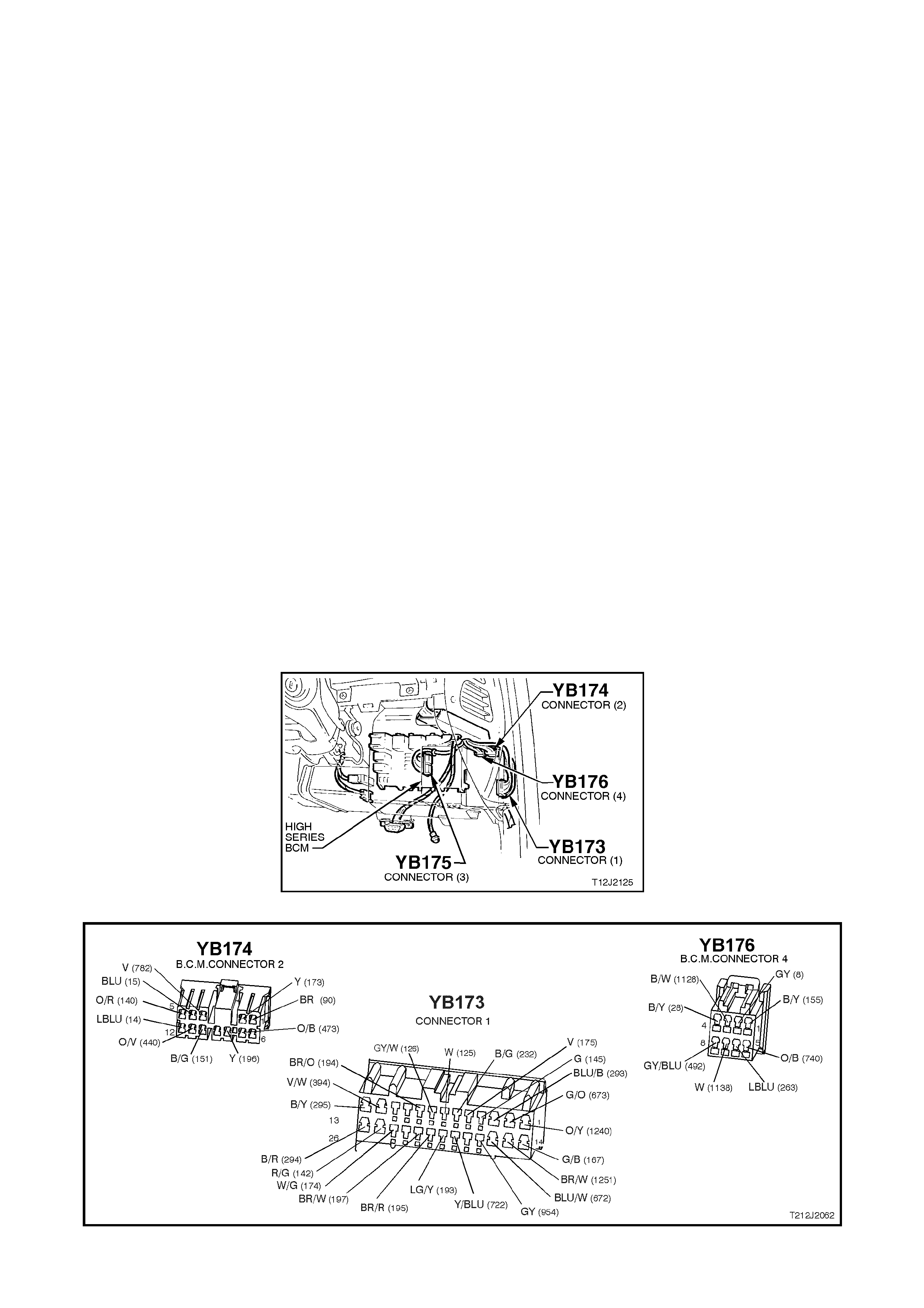

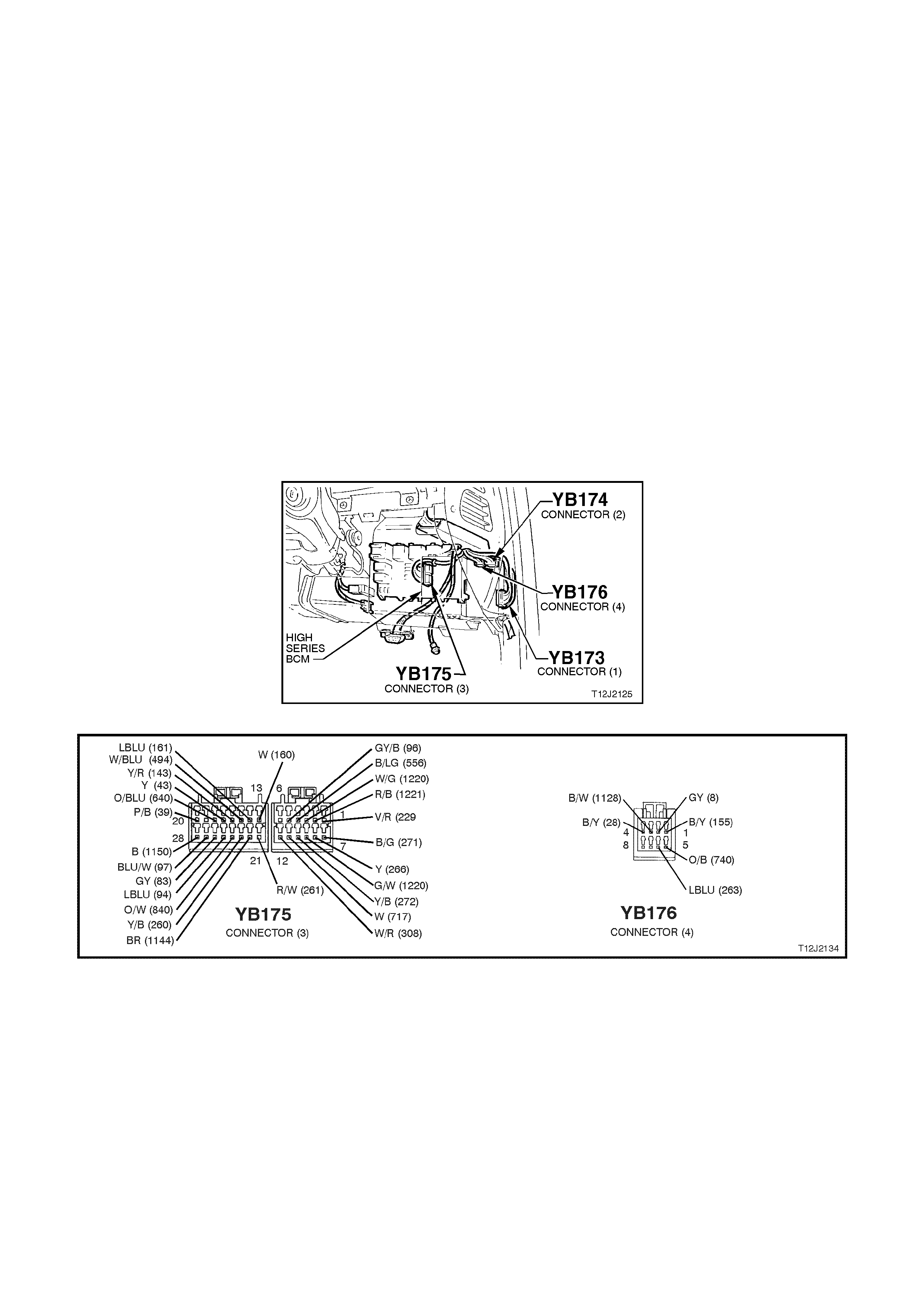

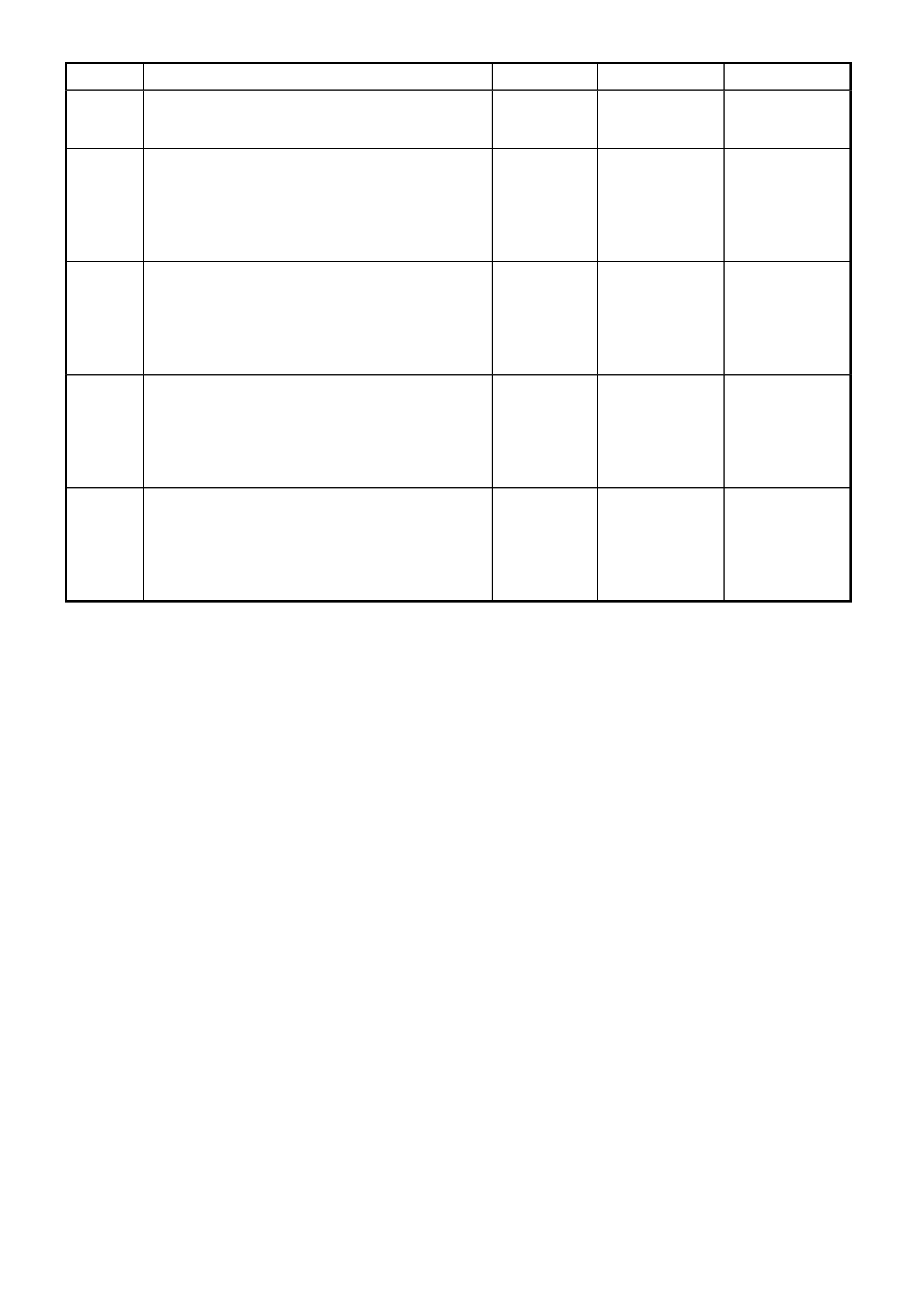

Figure 12J-2-2 BCM location and connector/terminal assignment

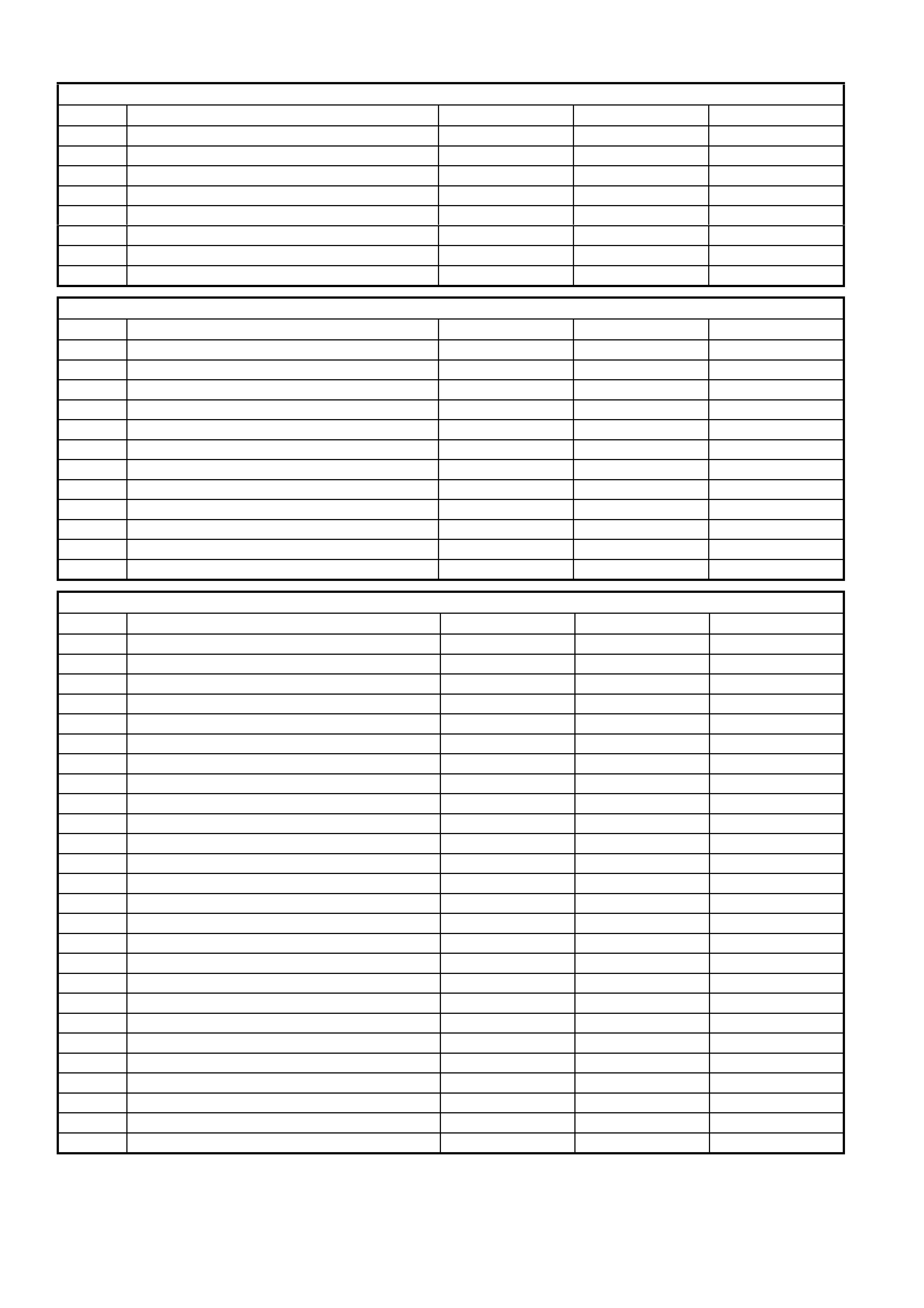

HIGH SERIES BCM TERMINAL IDENTIFICATION

YB176 CONNECTOR 4

PIN NO. DESCRIPTION CIRCUIT WIRE COLOUR CIRCUIT TYPE

A1 EARTH (ELECTRONIC) 155 B/Y E

A2 INSTRUMENT ILLUMINATION OUTPUT 8 GY O

A3 THEFT DETERRENT HORN OUTPUT 1128 B/W O

A4 HORN OUTPUT 28 B/Y 0

A5 BATTERY POSITIVE 740 O/B P

A6 THEFT DETERRENT LED OUTPUT 263 LBLU O

A7 INTERIOR ILLUMINATION OUTPUT 1138 W O

A8 REAR WI PER OUTPUT 492 GY/BLU O

YB174 CONNECTOR 2

PIN NO. DESCRIPTION CIRCUIT WIRE COLOUR CIRCUIT TYPE

B1 WI PER OUTPUT 90 BR O

B2 POWER WINDOW OUTPUT 173 Y O

B3 PRIORITY KEY ONE OUTPUT 782 V O

B4 RIGHT INDICATOR OUTPUT 15 BLU O

B5 INDICATOR POWER 140 O/R P

B6 NC

B7 LOW FAN SPEED OUTPUT 473 O/B O

B8 WIPER PARK INPUT 196 Y PD/O

B9 NC

B10 POWER EARTH 151 B/G E

B11 DOOR LOCK POWER 440 O/V P

B12 LEFT INDICATOR OUTPUT 14 LBLU O

YB173 CONNECTOR 1

PIN NO. DESCRIPTION CIRCUIT WIRE COLOUR CIRCUIT TYPE

C1 WINDOW POWER INPUT 1240 O/Y P

C2 WINDOW MOTOR OUTPUT 673 G/O O

C3 DRIVERS DOOR UNLOCK OUTPUT 293 BLU/B O

C4 ANTENNA DRIVE OUTPUT 145 G O

C5 DOME ON INPUT 175 V PD

C6 BOOT LAMP INPUT 162 Y/G PPU

C7 PASSENGER DOOR AJAR INPUT 125 W PPU

C8 DRIVERS DOOR AJAR INPUT 126 GY/W PPU

C9 PASSENGERS DOOR UNLOCK INPUT 194 BR/O PU

C10 NC

C11 NC

C12 DEADLOCK OUTPUT 394 V/W O

C13 ALL DOORS, LOCK OUTPUT 295 B/Y O

C14 WINDOW DOWN INPUT 167 G/B PD

C15 STOP/TAIL SENSE INPUT 1251 BR/W I

C16 WINDOW UP INPUT 672 BLU/W PD

C17 ANTENNA DIRECTION OUTPUT 954 GY O

C18 NC

C19 DOME - DOOR INPUT 722 Y/BLU PD

C20 UNLOCK INPUT 193 LG/Y PPU

C21 LOCK INPUT 195 BR/R PPU

C22 DEADLOCK REQUEST INPUT 197 BR/W PPU

C23 NC

C24 DOME LAMP OUTPUT 174 W/G O

C25 BOOT OUTPUT 142 R/G O

C26 PASSENGER DOOR UNLOCK OUTPUT 294 B/R O

YB175 CONNECTOR 3

PIN NO. DESCRIPTION CIRCUIT WIRE COLOUR CIRCUIT TYPE

E1 SLIP RING 229 V/R I/O

E2 SERIAL DATA INTERFACE MAIN BUS 1221 R/B I/O

E3 AIRBAG SERIAL DATA INTERFACE BUS 1220 W/G I/O

E4 POWER STEERING SOLENOID OUTPUT 558 B/Y O

E5 WIPER DWELL INPUT 96 GY/B PU

E6 NC

E7 RECEIVER EARTH 271 BR/G E

E8 RECEIVER DATA 266 Y I

E9 SERIAL DATA INTERFACE AUXILIARY BUS 1220 G/W I/O

E10 TWILIGHT INPUT (AMBIENT LIGHT SENSOR) 272 Y/B I

E11 INSTRUMENT DIMMER INPUT 717 W PU

E12 AUTO LIGHTS EARTH OUTPUT 308 W/R O

E13 ANTENNA DOWN INPUT 160 W PPU

E14 ANTENNA UP INPUT 161 LBLU PPU

E15 REAR WASHER INPUT 494 W/BLU PD

E16 RADIO ON INPUT 143 Y/R PD

E17 ACCESSORIES INPUT 43 Y PD, P

E18 STOP LAMP FUSE INPUT 640 O/BLU PD

E19 REAR WIPER INPUT 1391 GY/R PD

E20 IGNITION INPUT 39 P/B PD, P

E21 BONNET SWITCH INPUT 261 R/W PPU

E22 BOOT RELEASE INPUT 1144 B/R PPU

E23 BONNET SWITCH INPUT 260 Y/B PD

E24 PARK LAMP FUSE INPUT 840 O/W PD

E25 FRONT SCREEN WASH/WIPE INPUT 94 LBLU PU

E26 CRUISE CONTROL ON INPUT 83 GY PD

E27 FRONT INTERMITTENT AUTO WIPE INPUT 97 BLU/W PD

E28 LIGHTS OFF EARTH OUTPUT 1150 B O

GLOSSARY

E - Earth I/O - Input / Output O - Output PD - Pull down PU - Pull up

I - Input NC - No circuit P - Power PPU - Pulsed pull up

B - Black DKBLU - Dark blue LBLU - Light blue P - Pink V - Violet

BLU - Blue G - Green LG - Light green R - Red W - Wh ite

BR - Brown GY - Grey O - Orange T - Tan Y - Yellow

1.1 BATTERY SAVER MODE

The BCM Battery Saver Mode provides vehicle battery protection (through reduced current consumption). After a

programmed delay period (shut down timer) the BCM -:

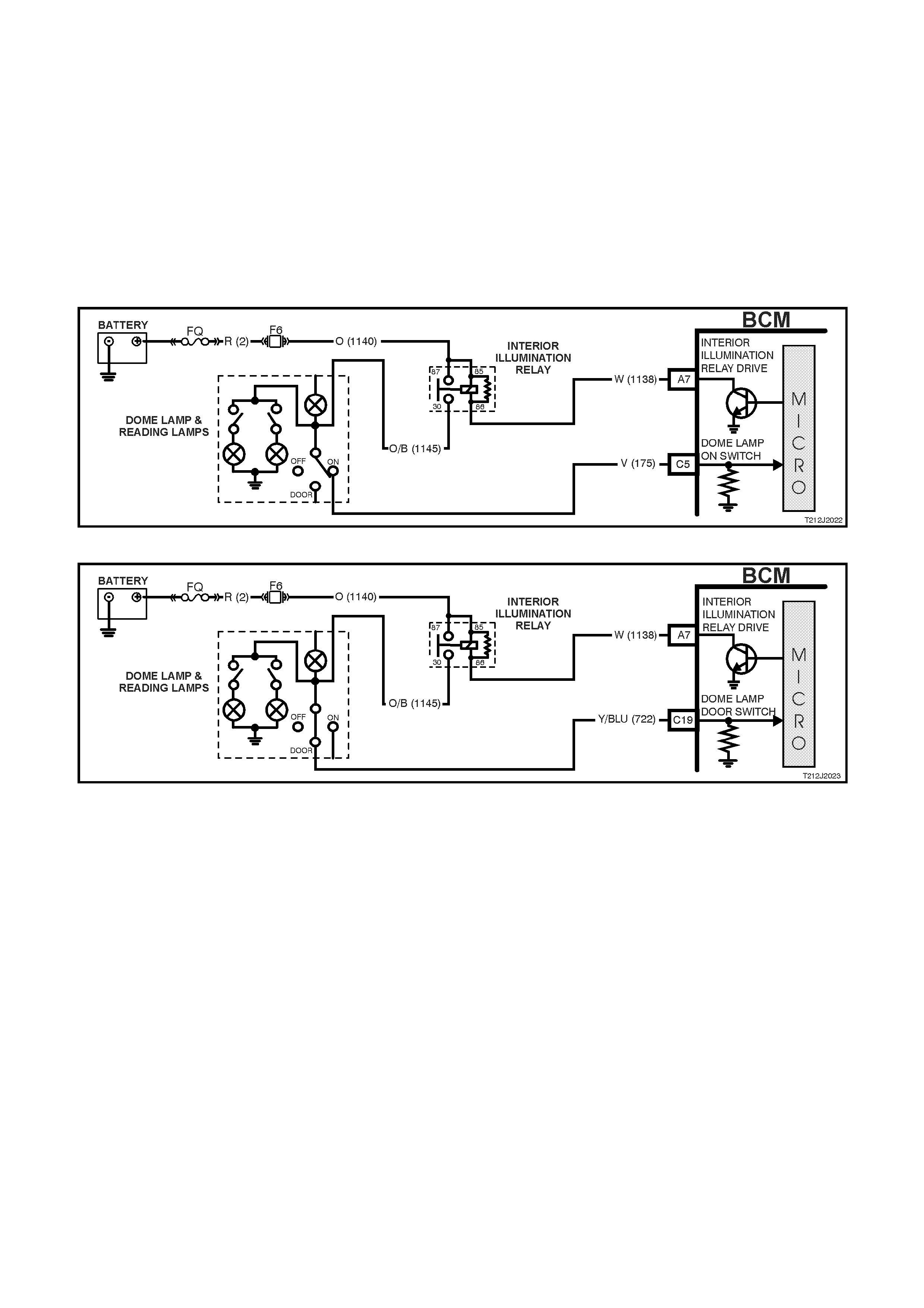

1. De-activates the interior illumination relay which supplies battery voltage to all interior dome, ignition loc k, glove

and boot lamps, protecting the battery in the event of-:

A lamp mistakenly left on (ie. door open) or a faulty illumination circuit or component causing excess current

consumption.

2. De-activates the power window relay (separate from the normal power window off delay function).

3. Disables BCM inputs normally not required with the ignition in the ‘OFF’ position, to reduce its own current

consumption.

The battery saver delay period has a default value of one (1) hour, however can be set from 2 to 255 minutes via

TECH 2. The delay period (shut down timer) is initiated when the ignition is switched to the ‘OFF’ position.

Whilst in Battery Saver Mode, the BCM is ‘woken’ up when:

1. The bonnet, boot or any door is opened.

2. The BCM receives a valid RF key ‘LOCK’, ‘UNLOCK’ or ‘BOOT’ signal.

3. The Ignition is switched to the ‘ACC’ or ‘ON’ position.

4. The doors unlocked via the driver’s door microswitch.

5. The deadlock switch is activated.

6. TECH 2 is communicating with the BCM.

7. The headlamp switch is cycled from ‘OFF’ – ‘ON’ or ‘ON’ – ‘OFF’.

8. The rear compartment lock switch, located in the glove box, is activated.

9. When the alarm is activated.

PRE-DELIVERY MODE.

The BCM provides additional battery protection (pre-deliver y mode), where the battery saver delay period is set to a

shorter value, three (3) minutes. This value is estimated to be the equivalent period prior to customer delivery.

Pre-delivery mode is disabled once the vehicle has travelled for a total of thirty (30) minutes at speeds above 20

km/h.

Pre-delivery mode can be enabled and disabled via TECH 2.

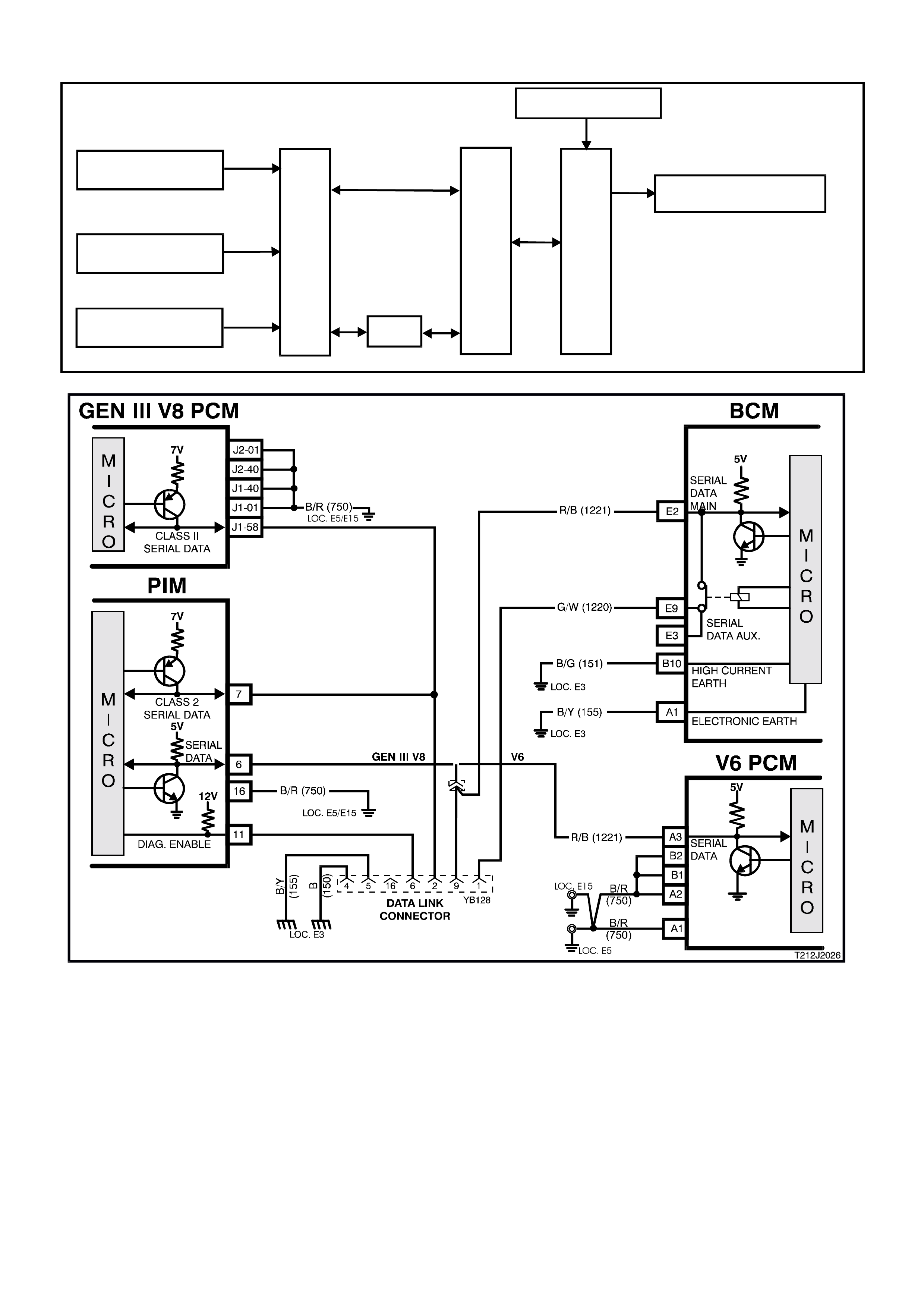

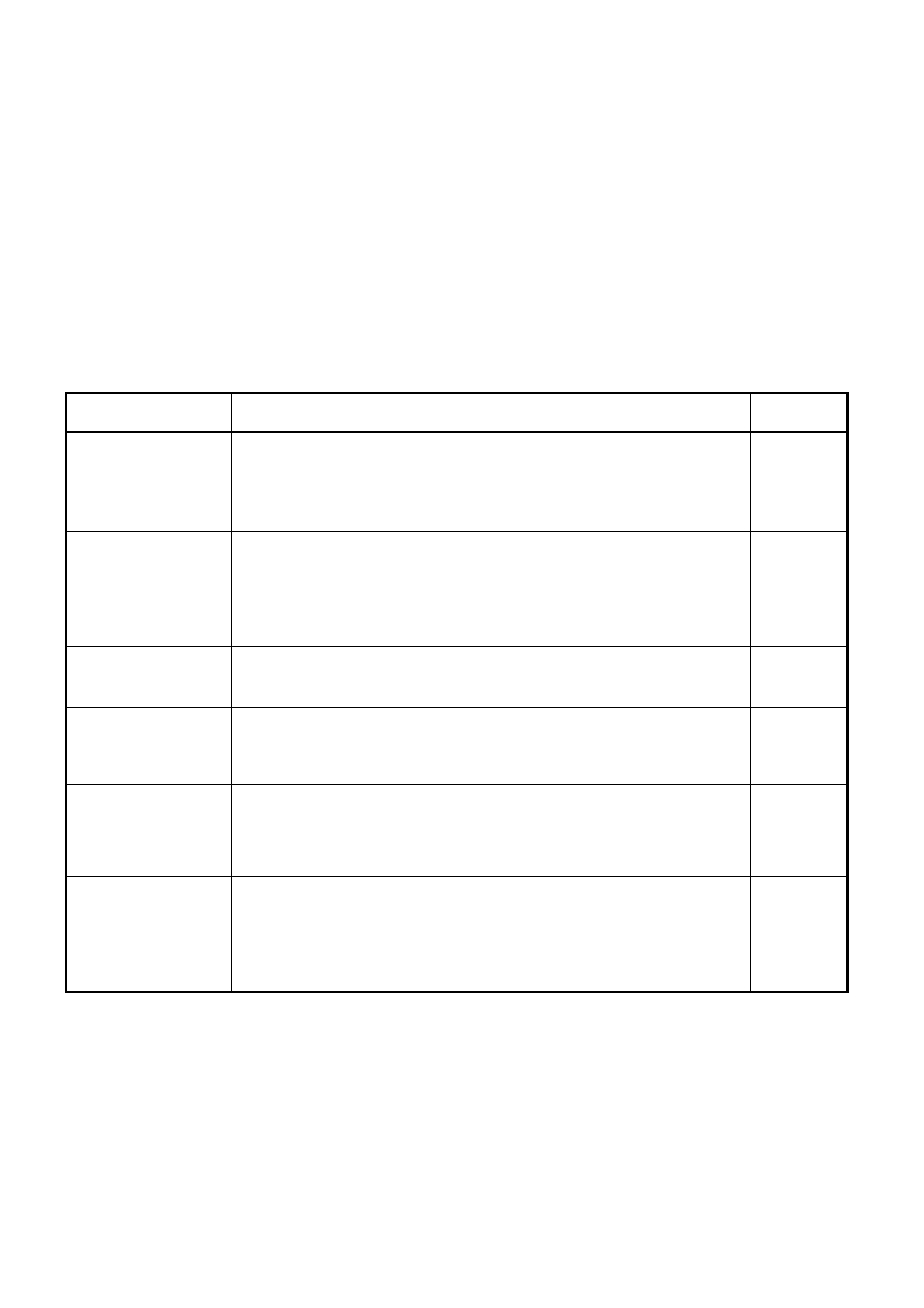

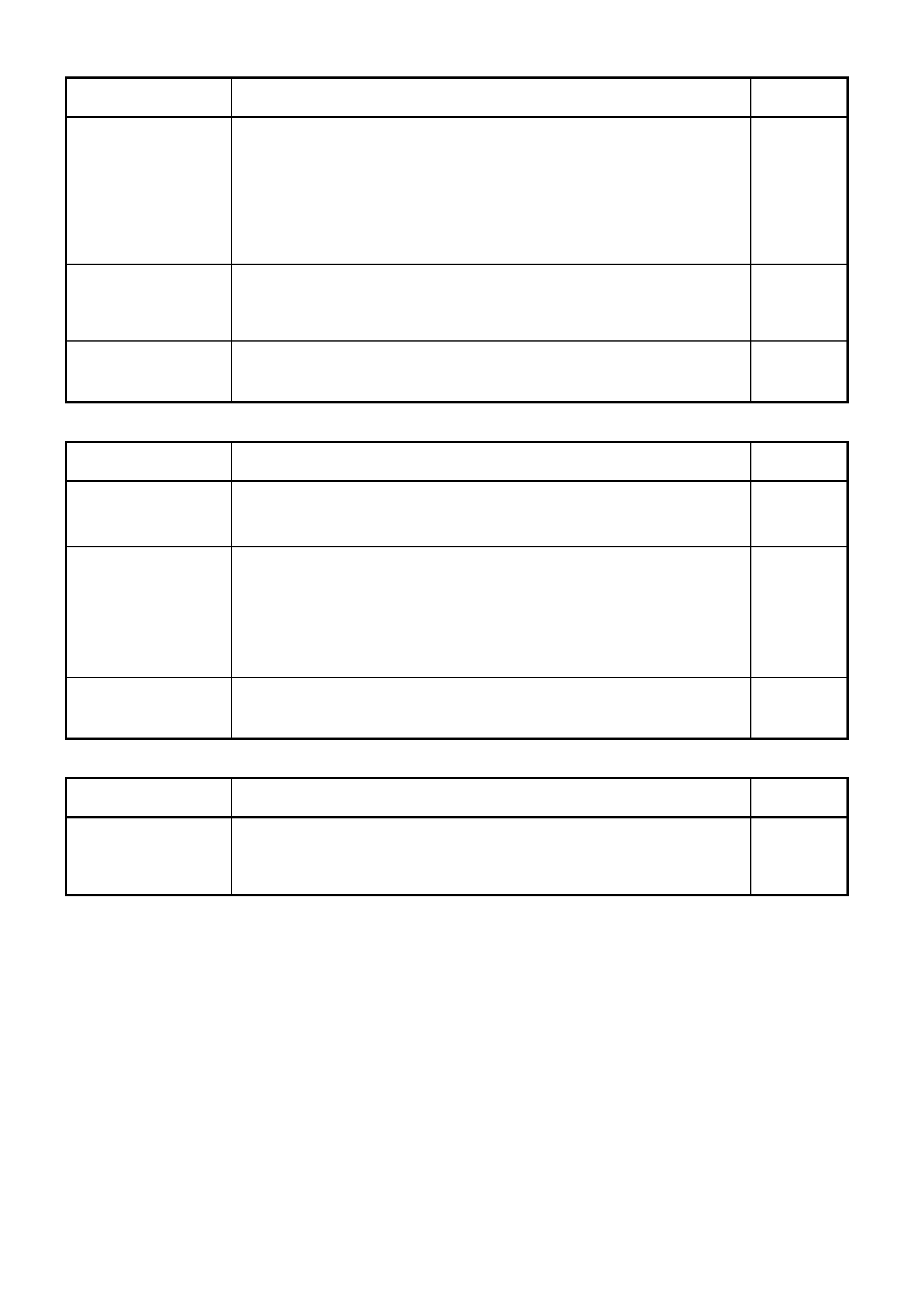

1.2 SE RIAL DATA COMMUNICATION(BUS MASTER)

GENERAL INFORMATION

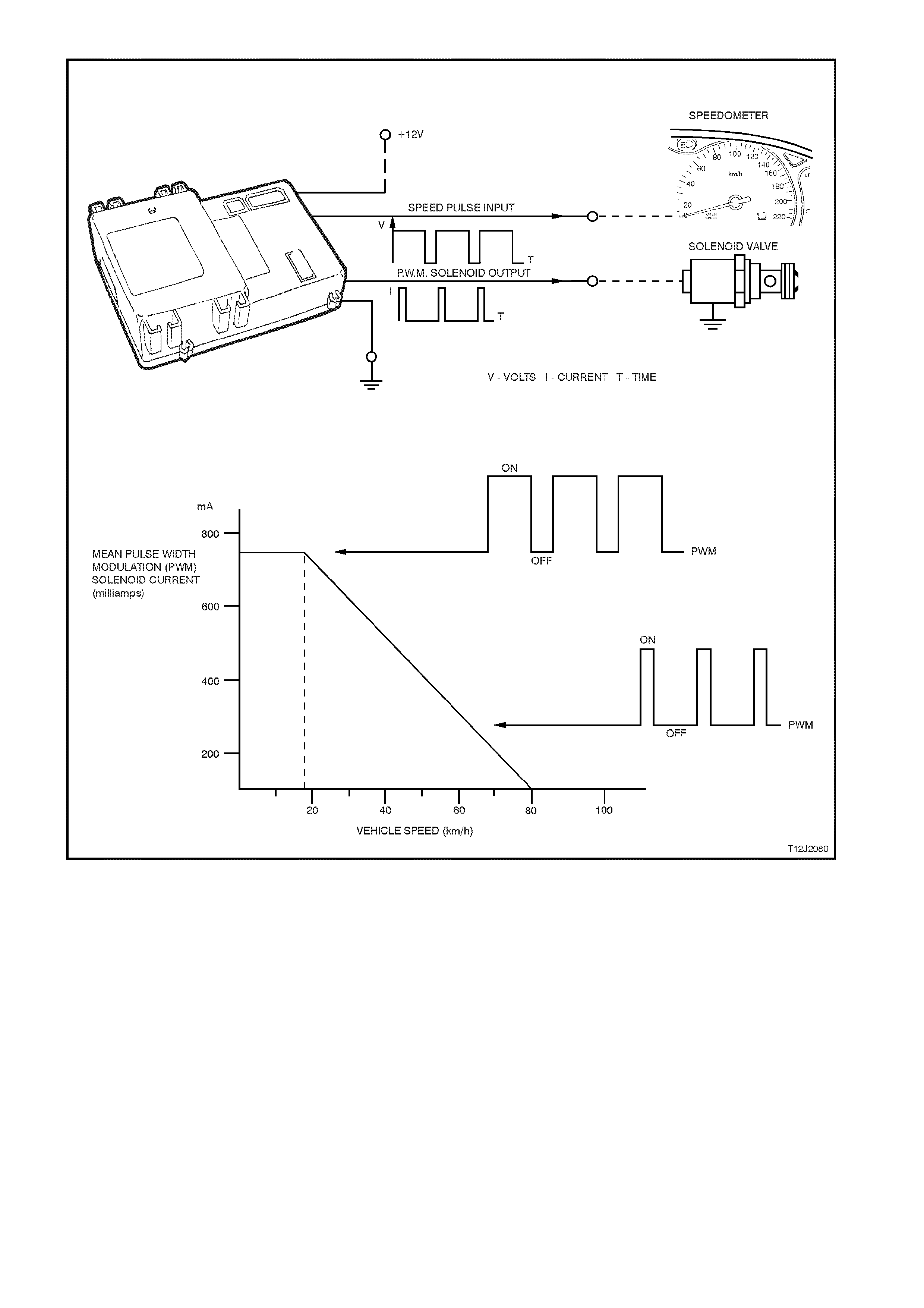

Various devices; system control modules of the vehicle, as well as TECH 2 communicate with each other. The

communication between control modules and com munication with the TECH 2 diagnostic scan tool is achieved on

the serial com munic ation lines using serial data. Serial data tr ansfers inf ormation in a linear f ashion - over a single

line, one bit at a time. The serial data line is referred to as the ‘data bus’.

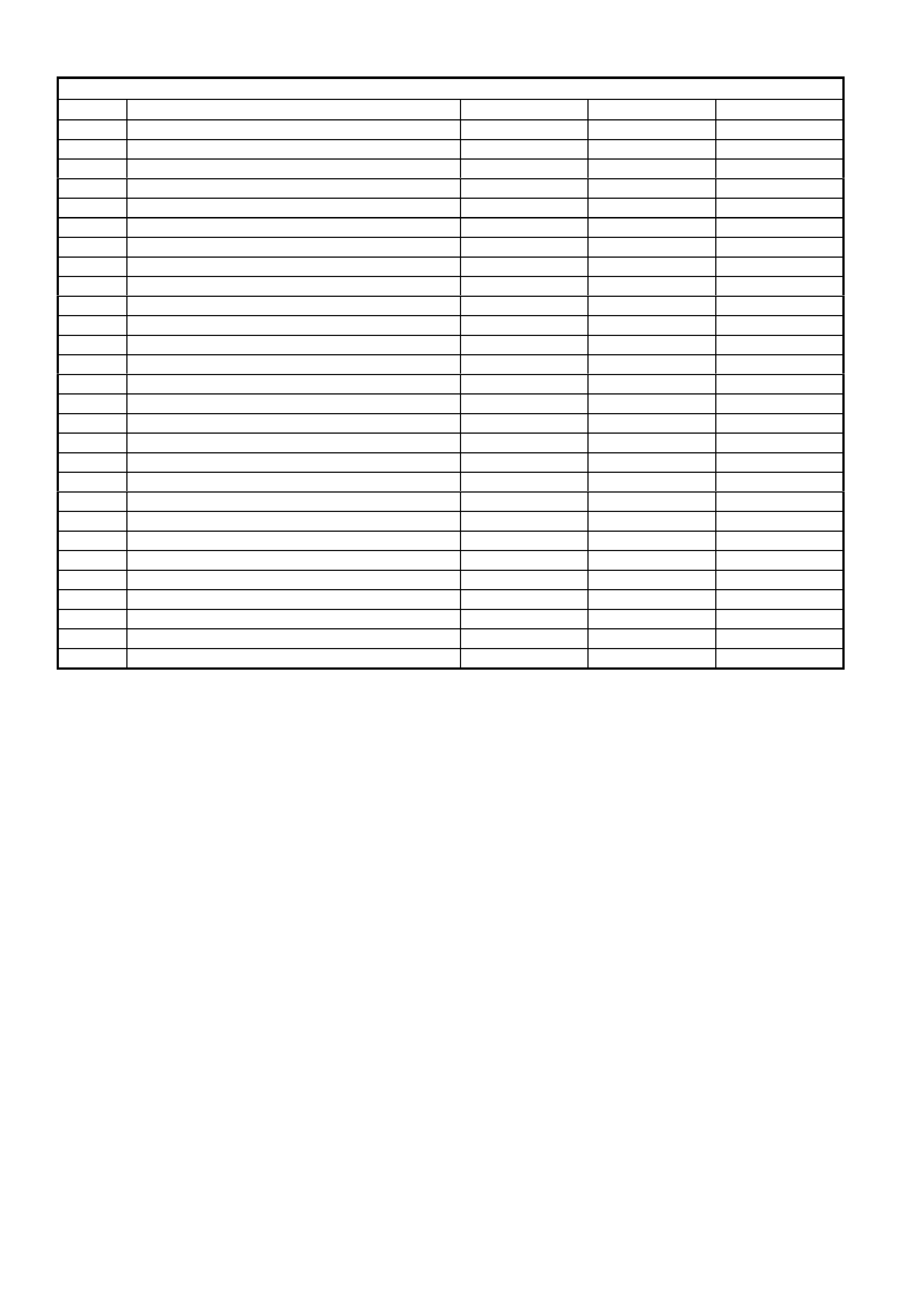

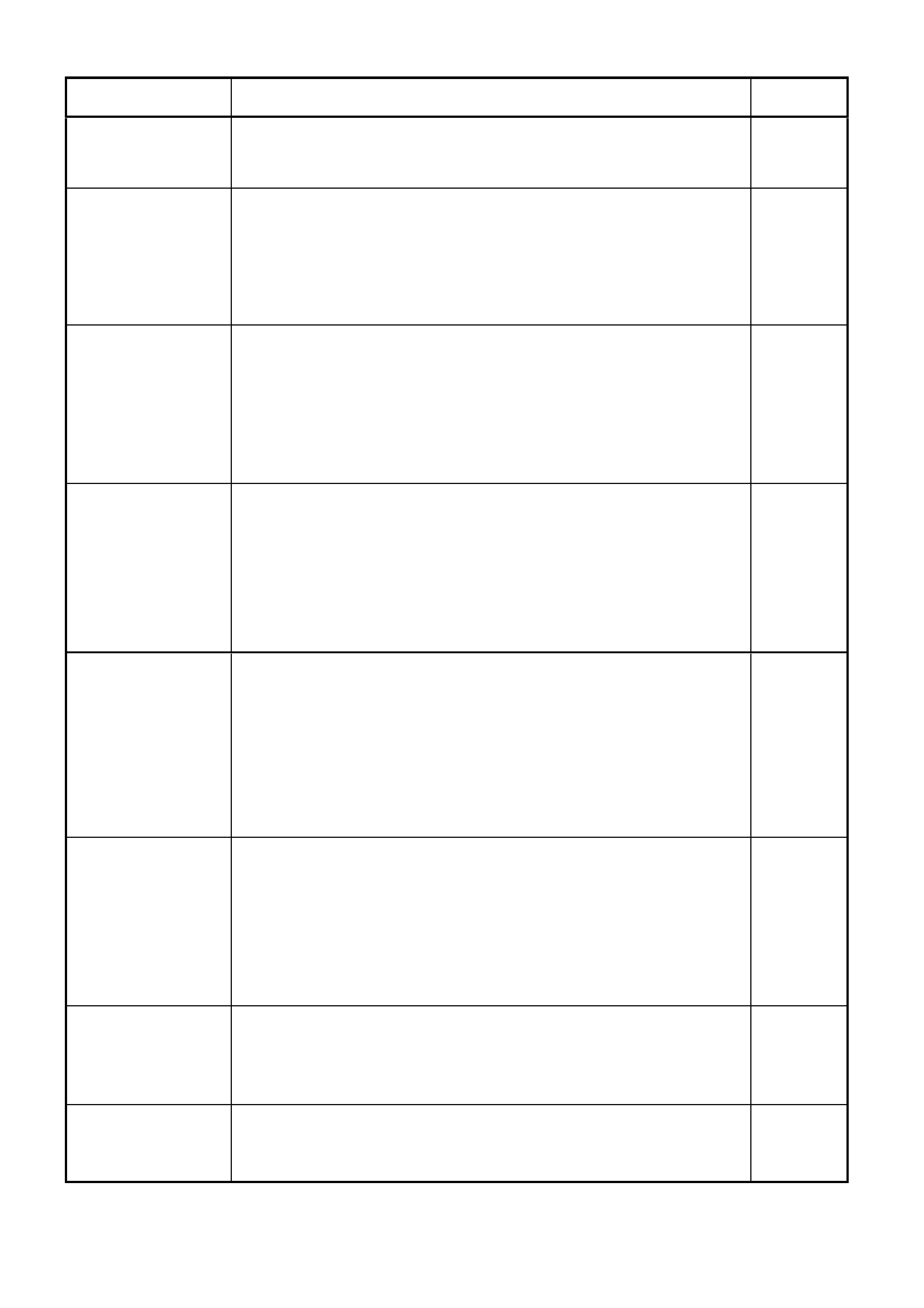

Excluding the GEN III V8 PCM, all control modules communicating on the data bus communicate using UART

communication.

UART is a 5 volt data line that toggles the voltage to earth (0 volts ) at a fixed bit puls e width dur ing c om m unication.

UART trans m its data at the rate of 8.2 k ilobits per s econd ( 8192 bits /sec). In UART com m unications , when ther e is

no communication on the data line, the system voltage will be 5 volts.

The GEN III V8 PCM uses Class 2 com m unication. T his type of com m unication toggles the data line from 0 volts to

7 volts at a either a short or long pulse width at rate of 10.4 kilobits per second (average). In Class 2

communications, when there is no communication on the data line, the system voltage will be 0 volts.

As the ‘Class 2’ c omm unication is diff erent to UART (dif ferent languages), c omm unication between the modules is

incompatible, and as such, requires a Powertrain Interface Module (PIM) to convert Class 2 communication into

UART, and UART into Clas s 2 (a tr anslator ). Refer to ‘POWERT RAIN INTERFACE MO DULE (PIM)’ in this Sec tion

for additional information on this module.

TECH 2 is able to communicate with both UART and Class 2 control modules.

T212J1012

11

0

1

00

1

0

1

0

5V

0V

UART

CLASS 2

11 1

111

000 0

000

7V

0V

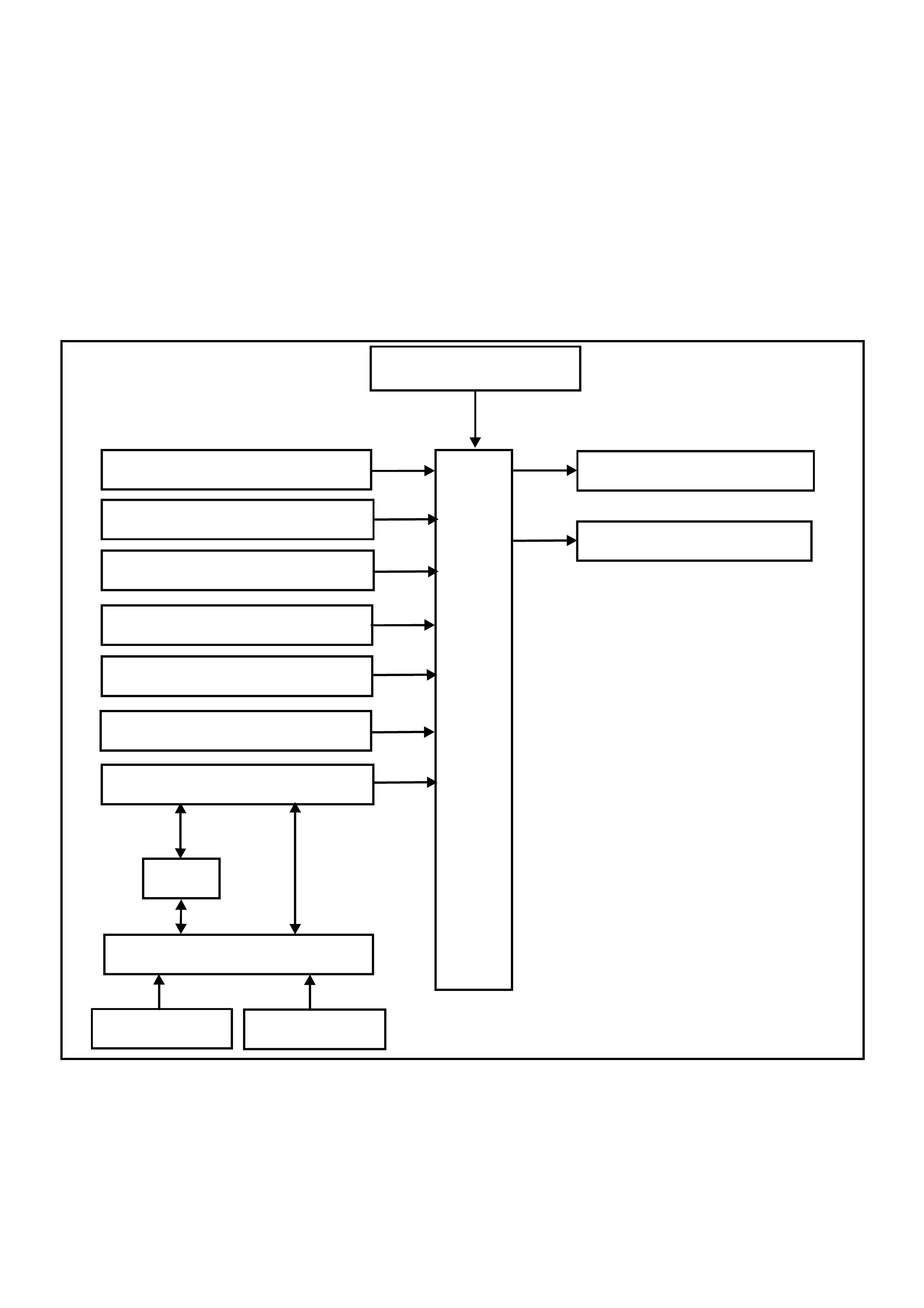

Figure 12J-2-3 Serial Data Digital Wave Form

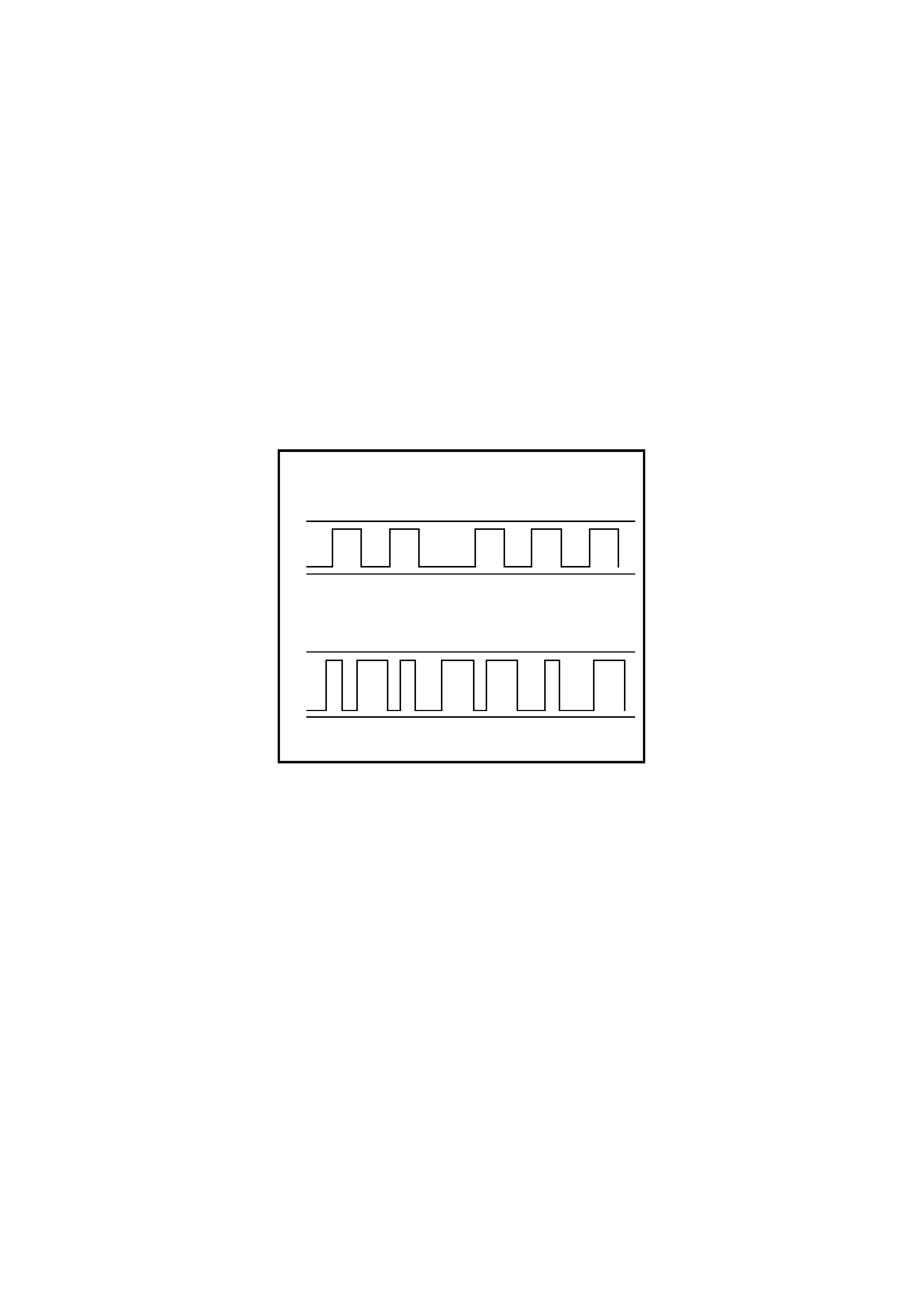

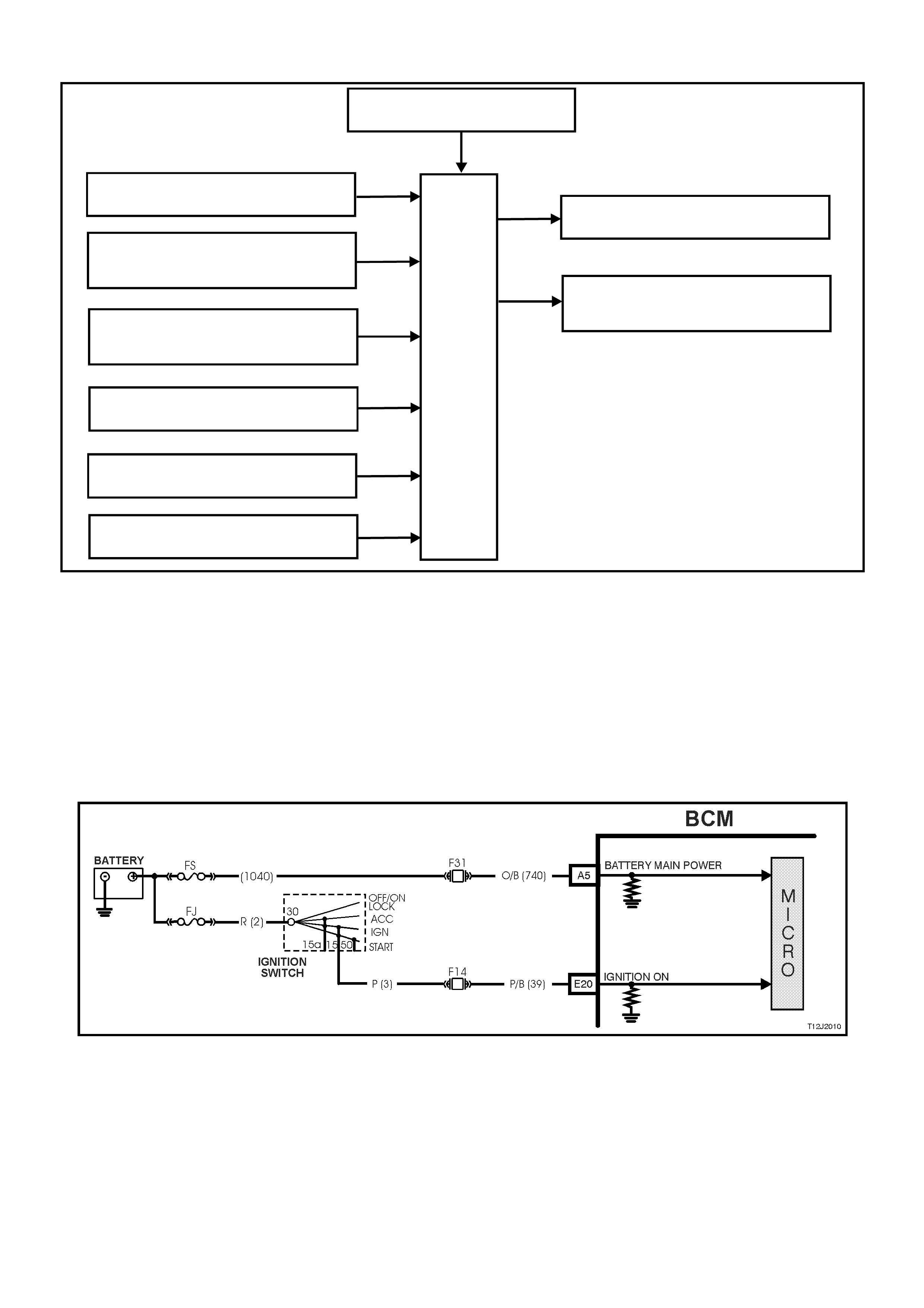

On all VT Series Models, the BCM is the Bus Master of the serial data communication system. The BCM

periodically polls (surveys) each device on the data bus and requests status data.

The devices (control modules) the BCM polls are:

• Body Control Module (BCM).

• V6 and V6 supercharged engine Powertrain Control Module (PCM).

• Powertrain Interface Module (PIM), GEN III V8 engines only.

• Instrument cluster (INS).

• Antilock Brake/Electronic Traction Control System (ABS/ETC) module.

• Supplemental Restraint System (SRS) Sensing and Diagnostic Module (SDM).

• Electronic Climate Control (ECC) module.

• TECH 2 diagnostic scan tool.

The data provided by each device may be utilised by any device connected to the bus.

Each device has a unique response Message Identifier Word (MIW) for ease of identification.

The bus m aster (BCM) polls eac h device with a serial data mes sage which includes that devices MIW. The device

responds by putting a serial data m essage onto the bus which inc ludes its MIW and data, of which is r etrieved and

utilised by any device requiring it.

The BCM polls each device for a status update, once ever y 300 millis econds. T he ex ception to this being the PCM

(V6) and PIM (GEN III V8) which are polled twice every 300 milliseconds.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the

PCM (via the PIM on vehicles with GEN III V8 engines) f or thef t deter rent pur poses . If the BCM does not r ec eive an

OK TO START message from the PCM within 0.5 seconds of ignition on, the auxiliary data bus is isolated via

switching from the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the

BCM, PCM or PIM (GEN III V8 only), causing a problem on the bus and inhibiting theft deterrent communications.

This period (short loop time) continues until the PCM responds with an acknowledgment or a maximum of five

seconds after which the BCM will switch to the standard polling sequence.

Following successful theft dterrent communications, the BCM begins sequential polling of devices on the bus and

normal system operation is established.

When the ignition switch is in the OFF position, the BCM continues to poll, allowing for TECH 2 communications

and external control of the bus prior to the ignition being switched on.

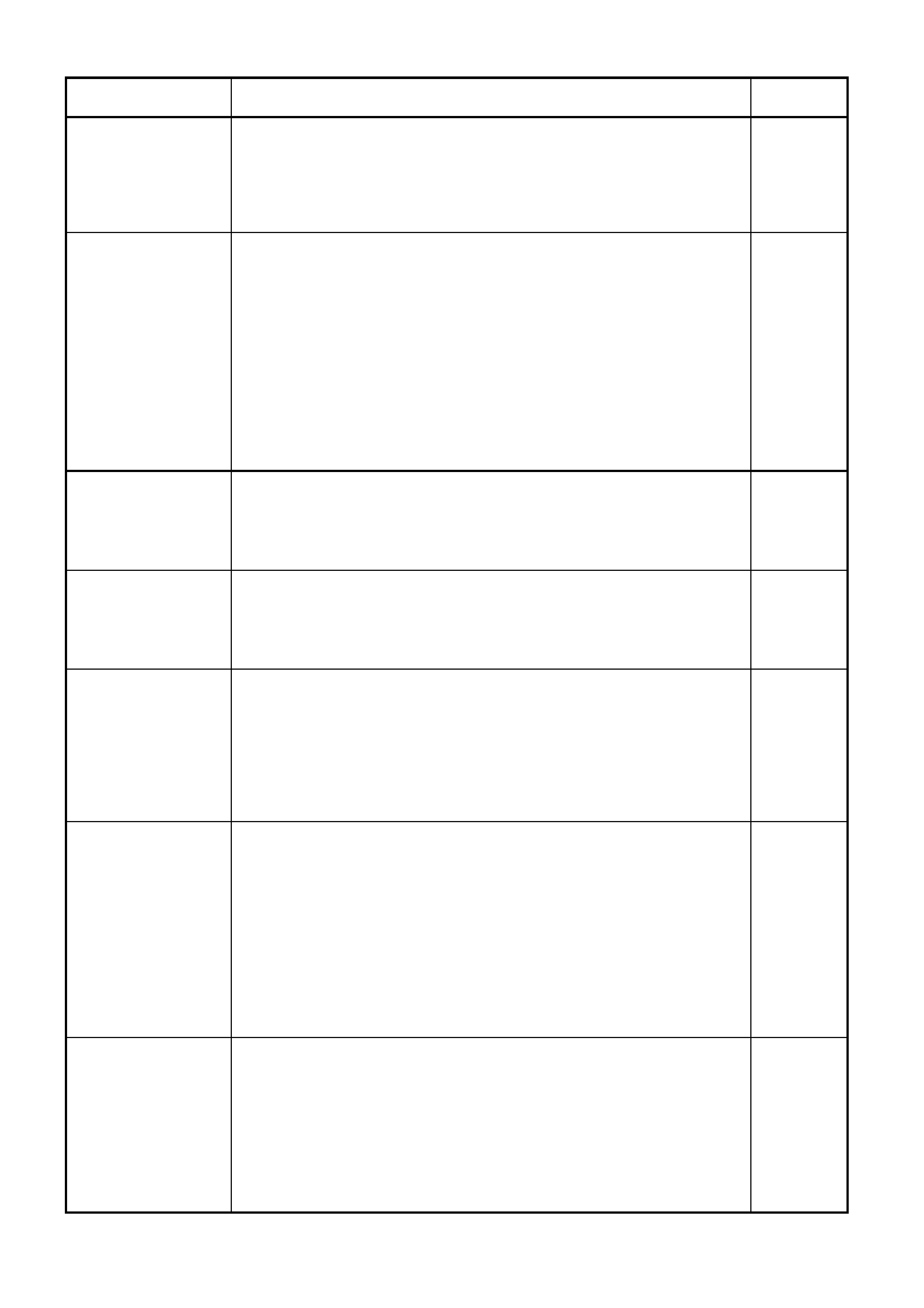

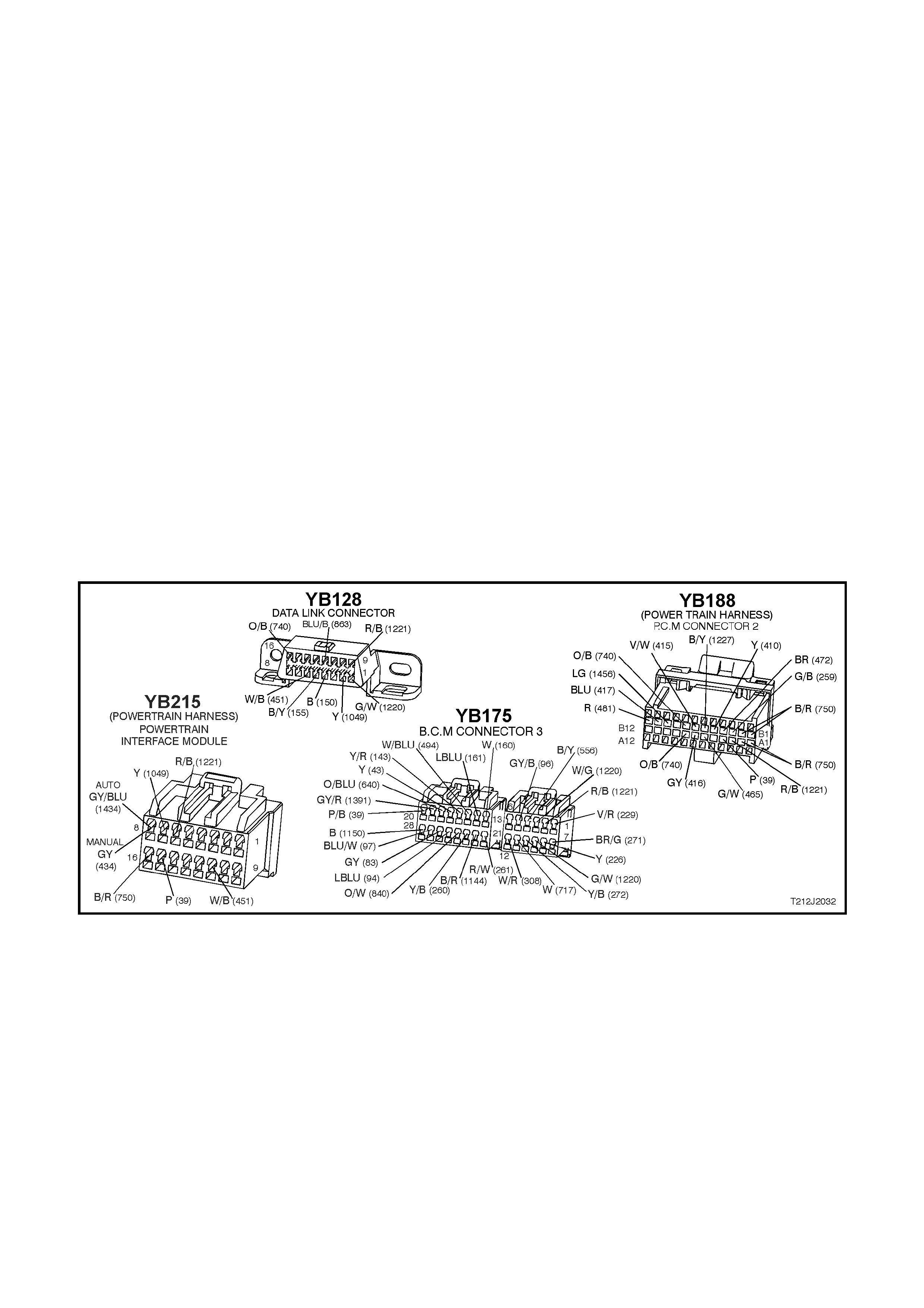

Powertrain Interface Module (PIM)

The PIM is a hardware and serial communications interface between the GEN III V8 PCM and the vehicles

electrical s ystem . The prim ary purpose of this module is to allow the GEN III PCM to interf ace (talk ) to the existing

communications bus (UART) operating in the vehicle. The PIM acts as a transparent bi-directional translation

device, which allows data to flow between the modules with varying communication protocols; Class 2 and UART.

When the ignition switch is turned from the OFF position to the ON position, and the PIM receives a poll from the

BCM, the PIM requests data from the GEN III PCM via its Class 2 interface and transfers this information to the

other control modules via the UART bus (Serial communications bus). The PIM also monitors responses from other

control modules on the UART bus and, using its Class 2 connection, transfers any information relevant to the GEN

III PCM as required.

T212J2031

Figure 12J-2-4 PIM location

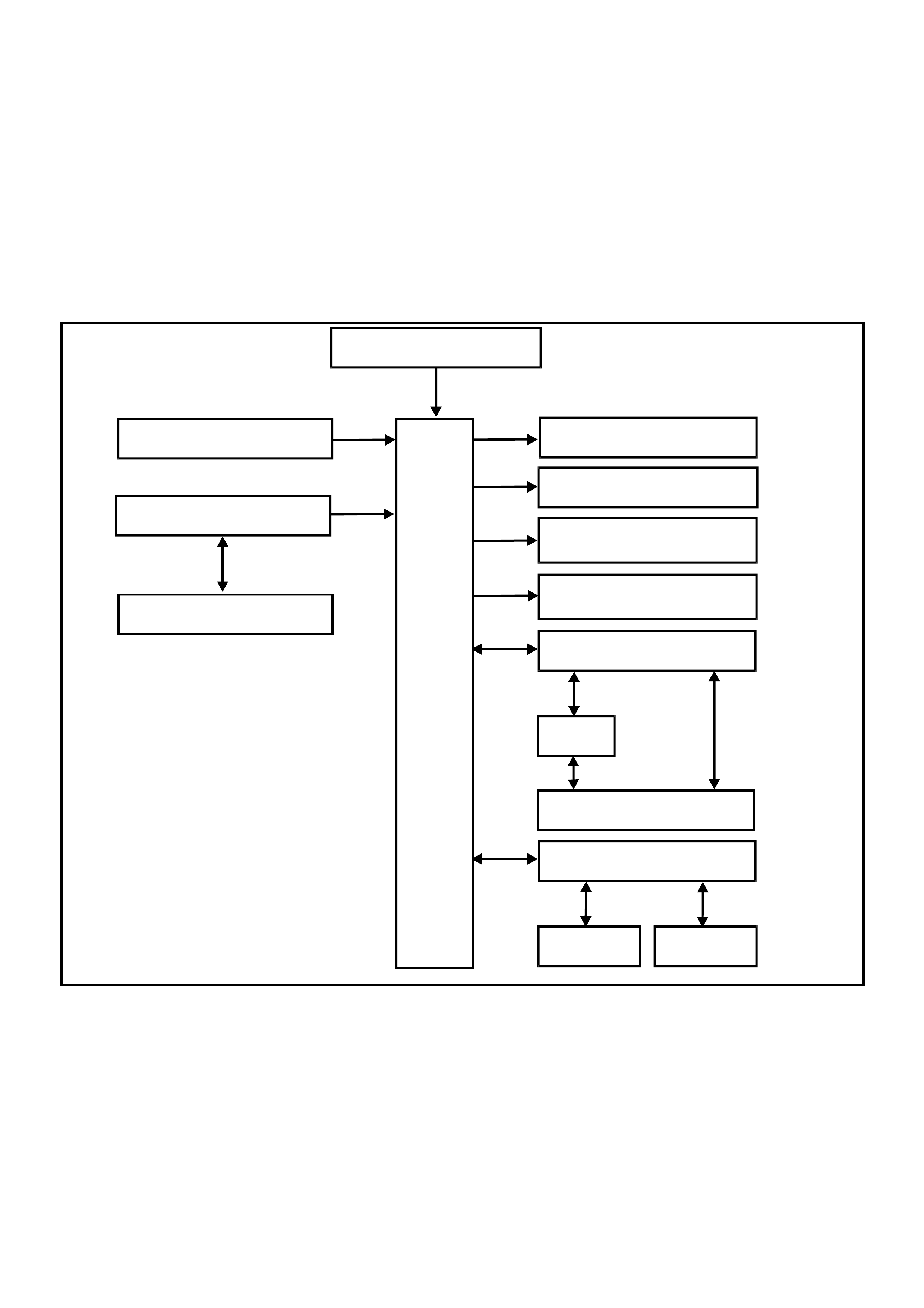

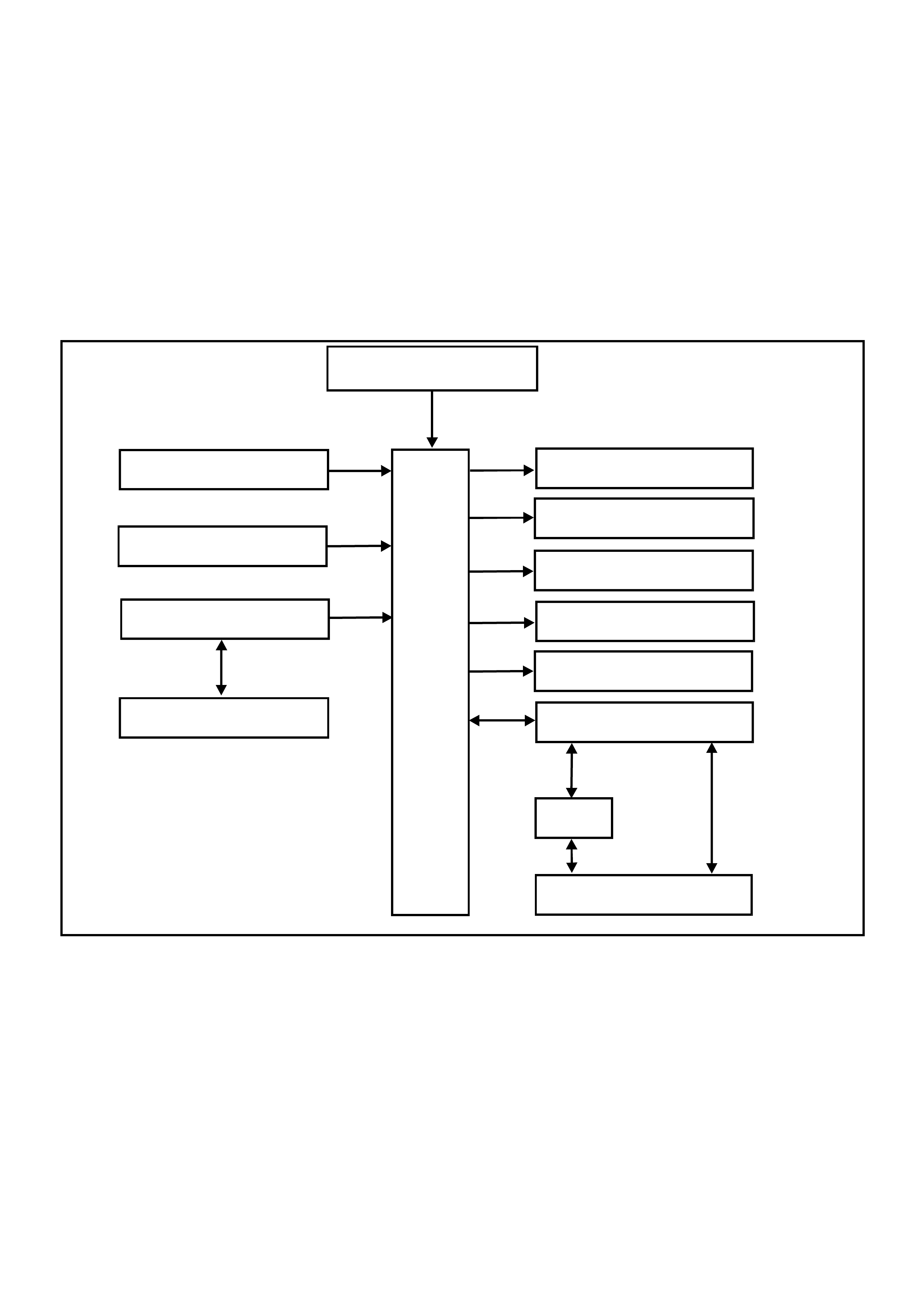

SYSTEM OVERVIEW - SERIAL COMMUNICATION

BATTERY POWER

BCM

SERIAL DATA MAIN

DLC

SERIAL DATA AUX

ABS/ETC ECC

INSTRUMENTS

SRS SERIAL DATA AUX

SRS

PCMPIM

GEN III V8

ENGINE V6 & V6 S/C

ENGINE

T212J2011

INPUTS / OUTPUTS

Serial Data Signal - Main

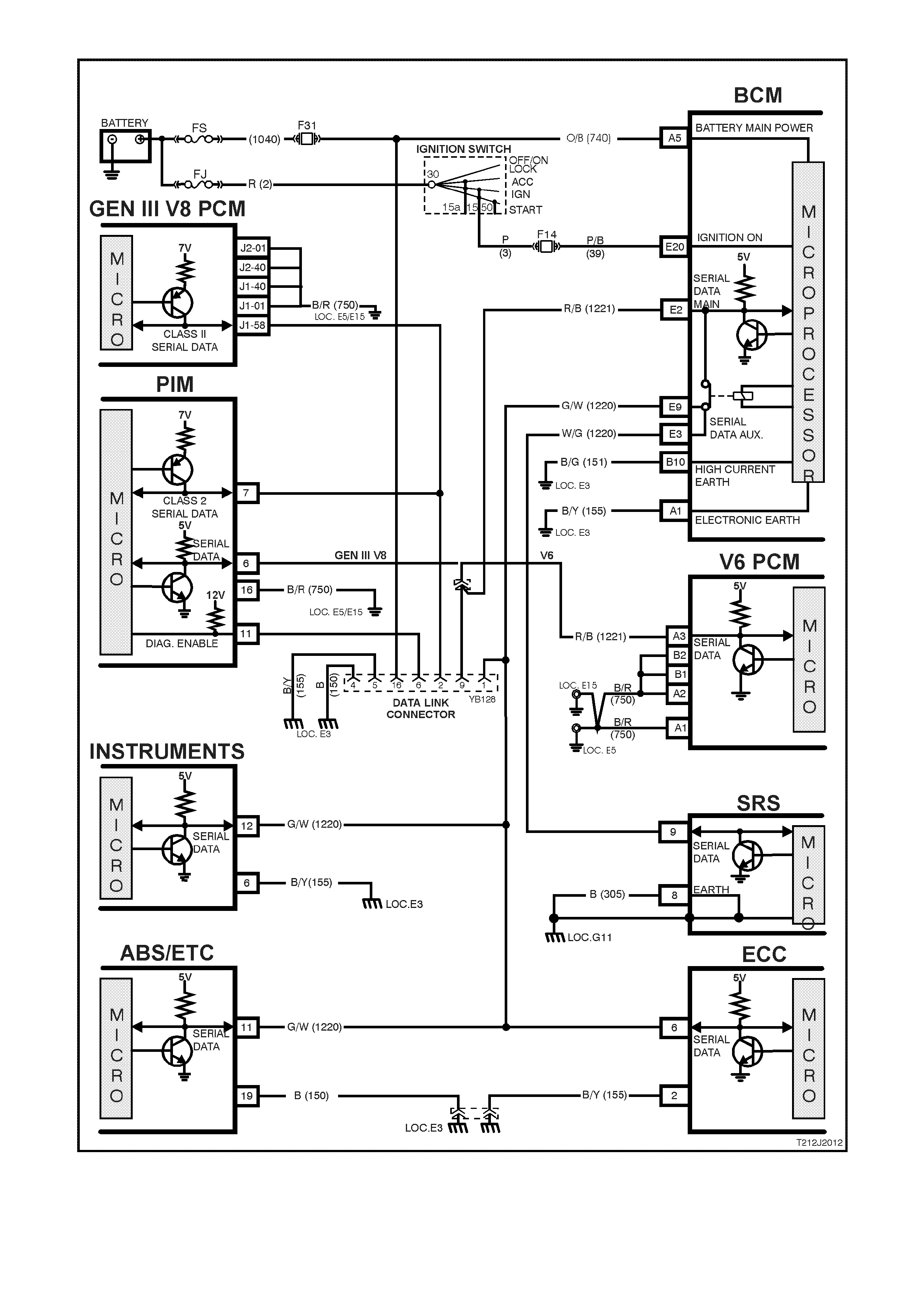

BCM terminal E2, serial data signal - main, refer Fig. 12J-2-6, is connected to the PCM (via PIM on vehicles with

GEN III V8 engines) and DLC via circuit 1221 (Red/Black wire). It is via this line that the BCM com municates with

the PCM and external devices connected to the DLC, at all times.

Serial Data Signal - Auxiliary

BCM term inal E9 and E3, serial data signal - auxiliary, refer to Fig. 12J -2-6, is connected to the instr ument c luster,

ABS/ETC and ECC modules via circuit 1220 (Green/White wire) and to the SRS module via circuit 1220

(White/Green wire). It is via this line (circ uit 1220) that the BCM com munic ates with these devices, af ter succes sful

theft deterrent c omm unications between the PCM and BCM (via the serial data - m ain line when the ignition switch

is turned from the OFF to ON position).

During theft deterrent communications, If the BCM does not receive an OK TO START message from the PCM

within 0.5 seconds of ignition on, the serial data - auxiliary line is isolated from the serial data - main line via

switching within the BCM. (This will continue for a five second period if there is still no acknowledgment from the

PCM, before it starts polling)

INPUTS

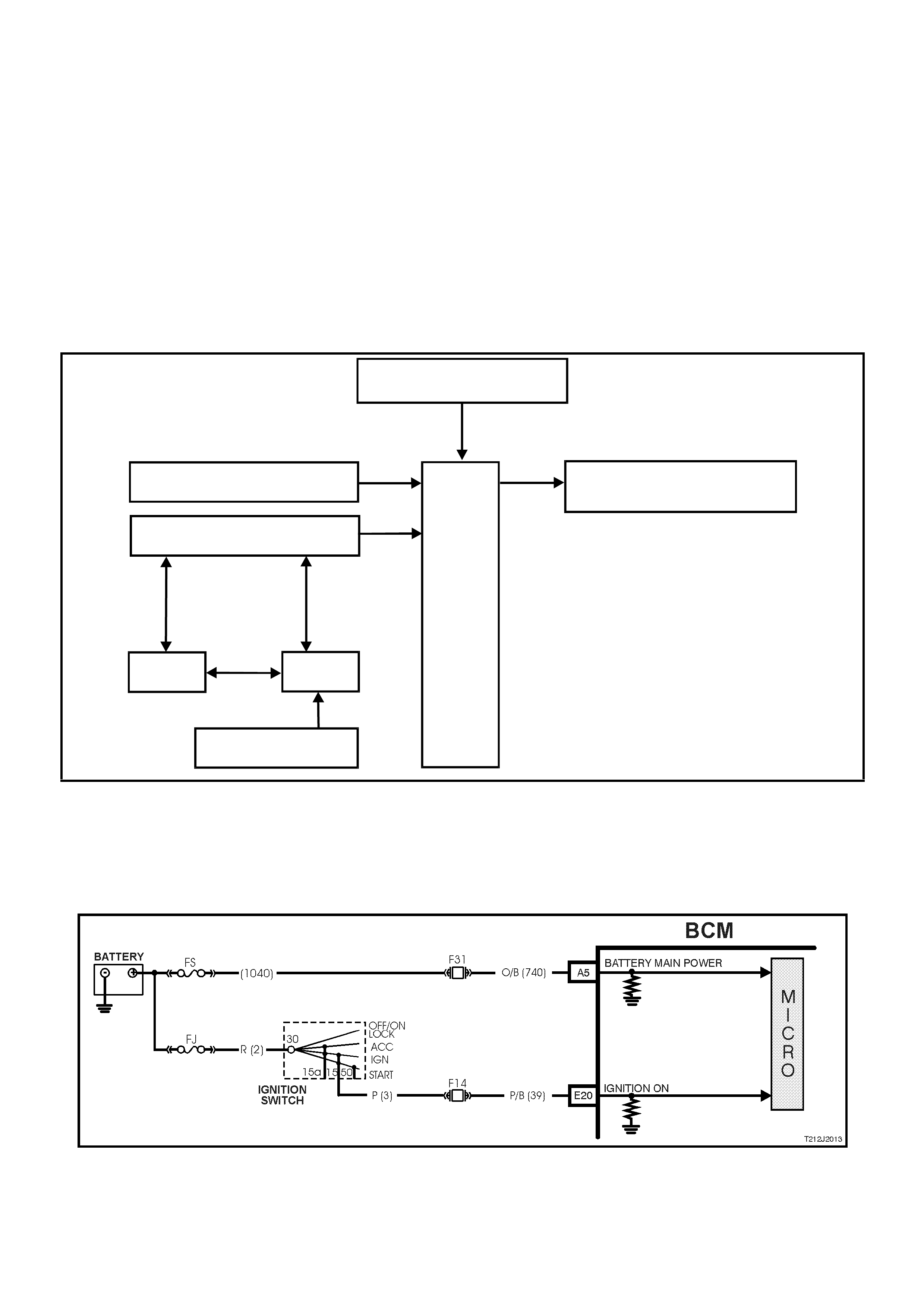

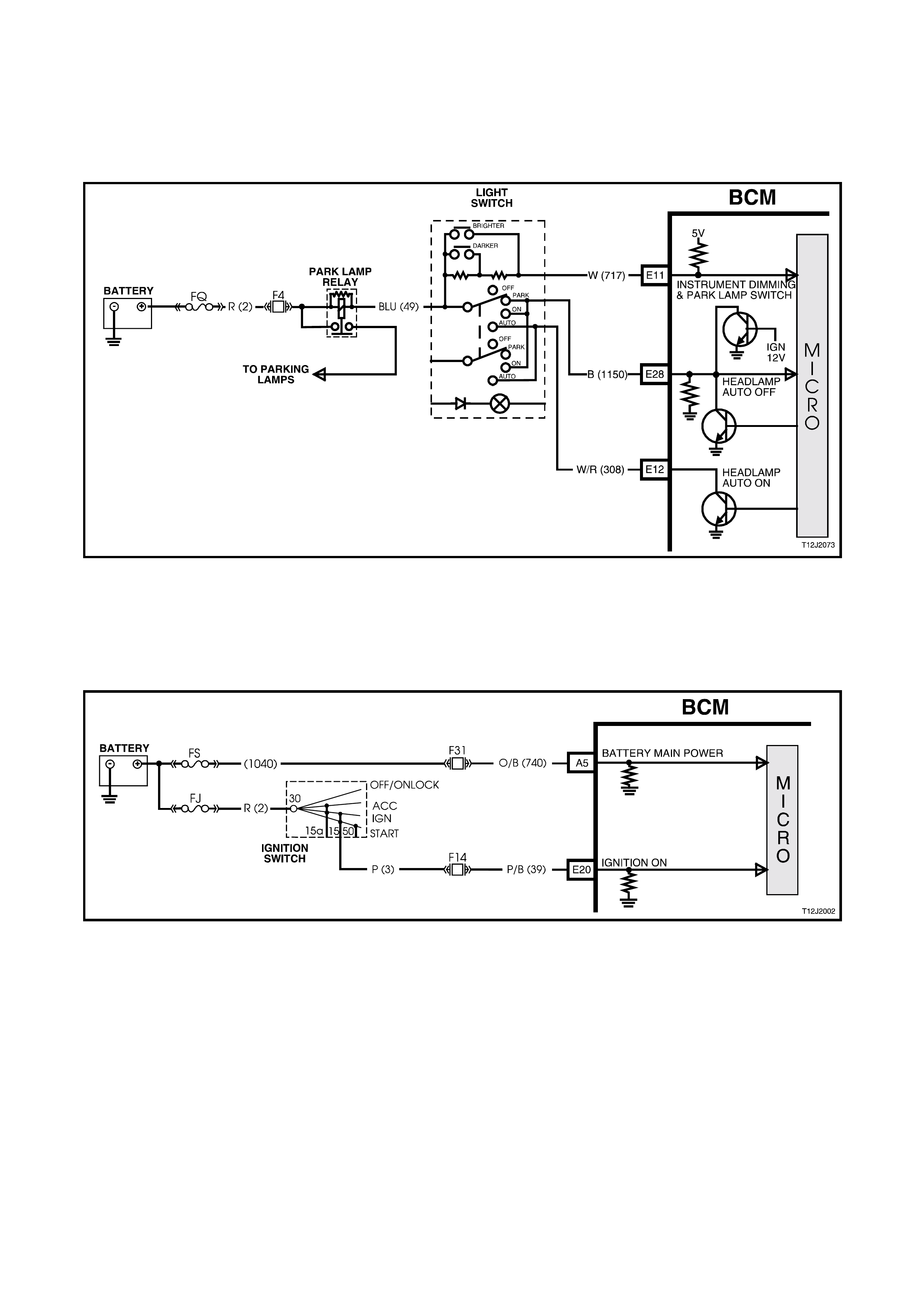

Ignition Switch ON Input Signal

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or ST ART pos ition, battery voltage is applied to the BCM term inal E20 f rom the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire), refer to Fig. 12J-2-5.

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and theref ore, only the m ain connectors and wiring colours ar e shown. For com plete circuits details, refer to

either the relevant diagnostic Section or Section 12P WIRING DIAGRAMS of the VT Series II Service Information.

M

I

C

R

O

BCM

T212J2013

BATTERY

FS

F31

A5

O/B (740 )

(1040)

BAT T ERY MAIN POWER

FJ

R ( 2)

F14

E20

P/ B (39)

IGNITION ON

15a 1550

30 ACC

IGN

START

IGNITION

SWITCH

P (3)

Figure 12J-2-5 Ignition switch ON input signal

Figure 12J-2-6 Serial data communication circuit

1.3 CENTRAL DOOR LOCKING SYSTEM

GENERAL INFORMATION

On VT Series II Models, the centr al door lock ing system ess entially carries over f rom VT Series Models, noting the

following:

On VT Series II Models, it is possible to deadlock the doors via the remote coded key.

NOTE: Although the VT Series II central door locking system essentially carries over, if diagnosing a central door

locking circuit fault, reference to the wiring diagrams in Section 12P WIRING DIAGRAMS of the VT Series II

Service Information should be made.

For information details , including Gener al Information, Ser vice Oper ations and Diagnosis of the centr al door lock ing

systems that is not covered in this Section, refer to Section 12J-2 HIGH SERIES BODY CONTROL MODULE of

the VT Series I Service Information.

SYSTEM CHECK

The operation of the central door locking system is independent of the ignition being switched ON or OFF.

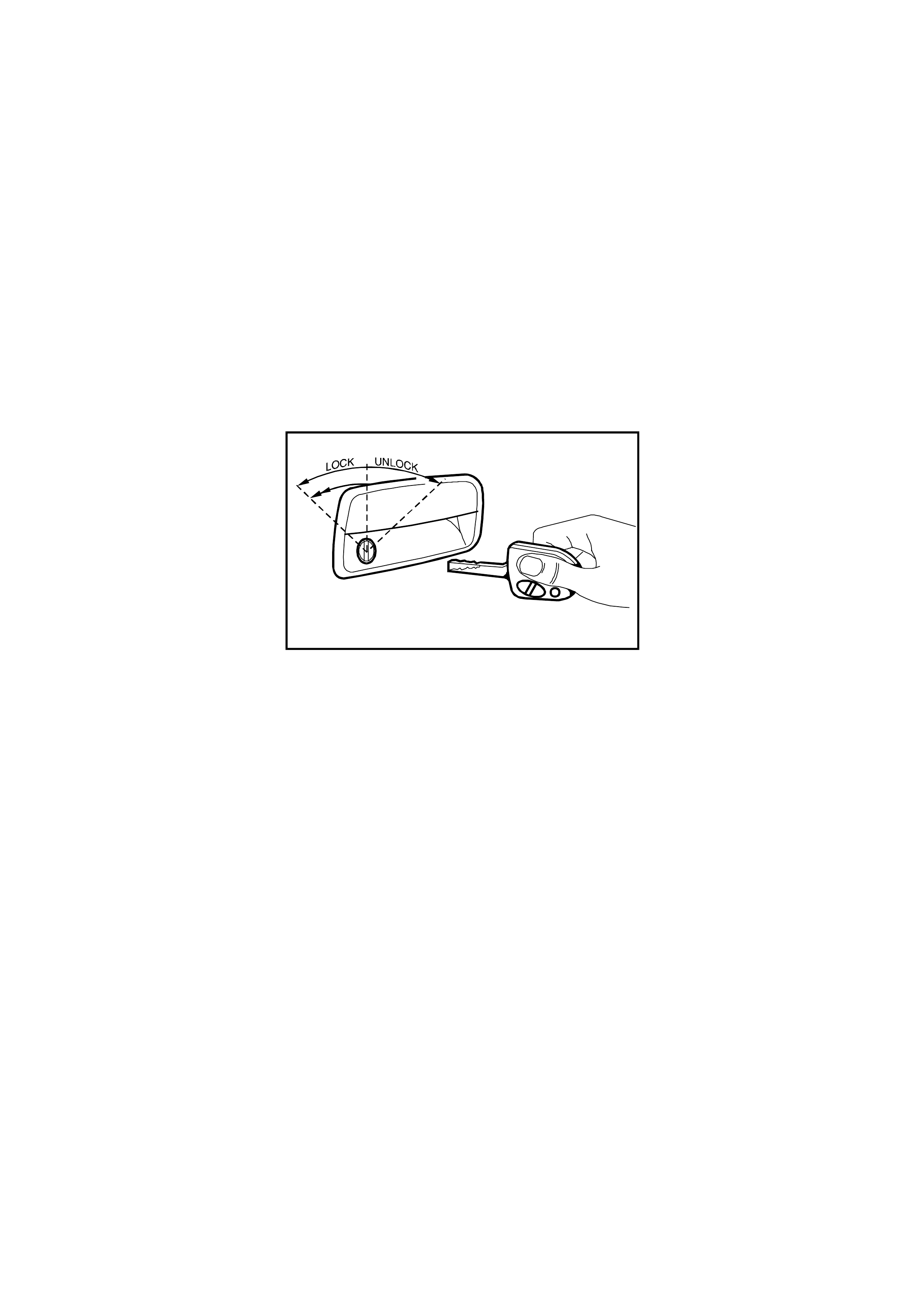

The figure below shows the key positions on the driver’s door for the various key locking functions.

Deadlock refers to the electrical means that can be activated to ensure vehicle security by inhibiting door lock

operation.

T212J1034

Figure 12J-2-7 Deadlocking with two sequential lock activation’s

Deadlock

The deadlocking feature applies to all four doors, but not to the luggage compartment lid or tailgate.

The deadlocking feature is engaged as follows:

• Two sequential lock activation’s of the door lock microswitch or

• Operating the ‘lock’ button on the remote coded key twice within 10 seconds.

The turn signal lamps turning on for three seconds indicate successful deadlocking via the remote coded key.

If the vehicle is already deadlocked, pressing the lock button on the remote coded key will cause the turn signal

lamps to turn on for three seconds, indicating that the vehicle is already deadlocked.

If the vehicle is locked (not deadlocked) pressing the lock button on the remote coded key 10 seconds after the

previous press, the doors will not deadlock and the turn signal lamps will flash briefly, indicating that the doors are

only lock ed. Pressing the loc k button again, within in a ten second period will caus e the doors to deadloc k and turn

the signal lamps will turn on for three seconds.

After the deadlocking feature device has been engaged, unlocking is possible at the driver’s door from outside, by:

• Inserting the key into the driver’s door lock cylinder and turning the key to the unlock position or

• Activating the un-lock button on the remote key unlocks the deadlocks on all doors, but only unlocks the

driver’s door (providing two stage unlocking is enabled).

To ensure access to the vehicle if the electrical system should fail (discharged battery), after the system has been

engaged, the driver’s door lock cylinder can be moved independently of the actuator and therefore allowing

unlocking of the driver’s door latch.

The rear com partment lid or tailgate can be lock ed/unlocked when the m echanical deadloc king featur e is actuated,

while leaving the doors secured.

NOTE: Deadlocking is not possible with the ignition in the ON position.

Remote Coded Key Check

Check that the remote coded key locks all doors when the rem ote coded key lock button is pressed, at a distance

within 4 metres from the driver’s side B pillar.

When the rem ote coded k ey unlock button is pr essed the driver 's side should unlock ( vehicles pr ogram m ed for two

stage unlock). Pressing the un-lock button again and all passenger doors (and tailgate on station wagon models)

should unlock.

On vehicles programmed for single stage unlock, the single press of the unlock button will unlock all doors and

tailgate on station wagon models.

If this test does not prove satisfactory, refer to 2.3 REMOTE CODED KEY in Section 12J-2 HIGH SERIES BODY

CONTROL MODULE of the VT Series I Service Information for a more detailed diagnosis before continuing with the

central locking system check.

Figure 12J-2-8 Remote coded key

Checking the Deadlock Feature

Open all windows.

Close all doors.

Actuate the deadlock feature from the driver’s door with the key.

Check that all door lock buttons cannot be pulled up. They are electrically blocked.

NOTE: The door lock (snib) buttons can be pulled up slightly, but they will be under tension.

Overheating Prevention

In the event of m ultiple activation’s within a defined tim e period, the central door lock ing system will be deactivated

and remain inoperative for a def ined time period to prevent the door actuators from overheating. After a fixed tim e

delay, the system will re-activate and operate as normal.

1.4 THEFT DETERRENT SYSTEM

GENERAL INFORMATION

The theft deterrent system on VT Series Models uses a remote coded key to arm and disarm the system, and

where fitted, electric ally lock or unlock all doors and tailgate ( s tation wagon), or oper ate the boot unloc k m ec hanis m

(sedan models).

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to

either the relevant diagnostic procedures in this Section or Section 12P WIRING DIAGRAMS of the VT Series II

Service Information.

SYSTEM OPERATION

When enabled, there are two modes of theft deterrent operation, armed and disarmed.

Armed

Once the theft deterrent system is enabled, it can be manually armed in one of two ways:

Actively, by pressing the lock button on the remote coded key or,

Passively, as the BCM will automatically arm 30 seconds after the ignition is turned off.

When the system is armed, the start relay (located in the engine compartment relay housing) and the engine

management system Powertrain Control Module (PCM) and on vehicles with GEN III V8 engines, Powertrain

Interface Module (PIM) are disabled, preventing the engine from being started.

Disarmed

With the system disarmed and the PCM/PIM enabled, the engine will be allowed to be started when the ignition

switch is turned to the run position.

The theft deterrent system can be disarmed in two ways:

1. Pressing the unlock button on the remote coded k ey. This unlocks the doors, turns the interior dom e lamp on

and fully disarms the system for 30 seconds or,

2. By insert ing the remote c oded key into the ignition switch key barrel and tur ning the ignition to the O N or RUN

position. This causes the BCM to read a security code serial data output from the remote coded key contact

pin via the remote coded key reader assembly.

NOTE 1: Both the V6 and V8 systems will allow upto one second crank if the code is invalid. In most cases this

results in the engine starting for a short period but dies after two – three seconds. (Under normal conditions, this

allows for f uel pr iming and reduc es s tart delays while the security mess age is being validated). Engine c r ank is then

disabled until the next ignition cycle (key off – on).

NOTE 2: Should the engine crank briefly when the ignition switch is turned to the START position (ie. due to mis-

aligned or a faulty remote coded key reader) then pressing the unlock button on the remote coded key will also

disarm the theft deterrent system.

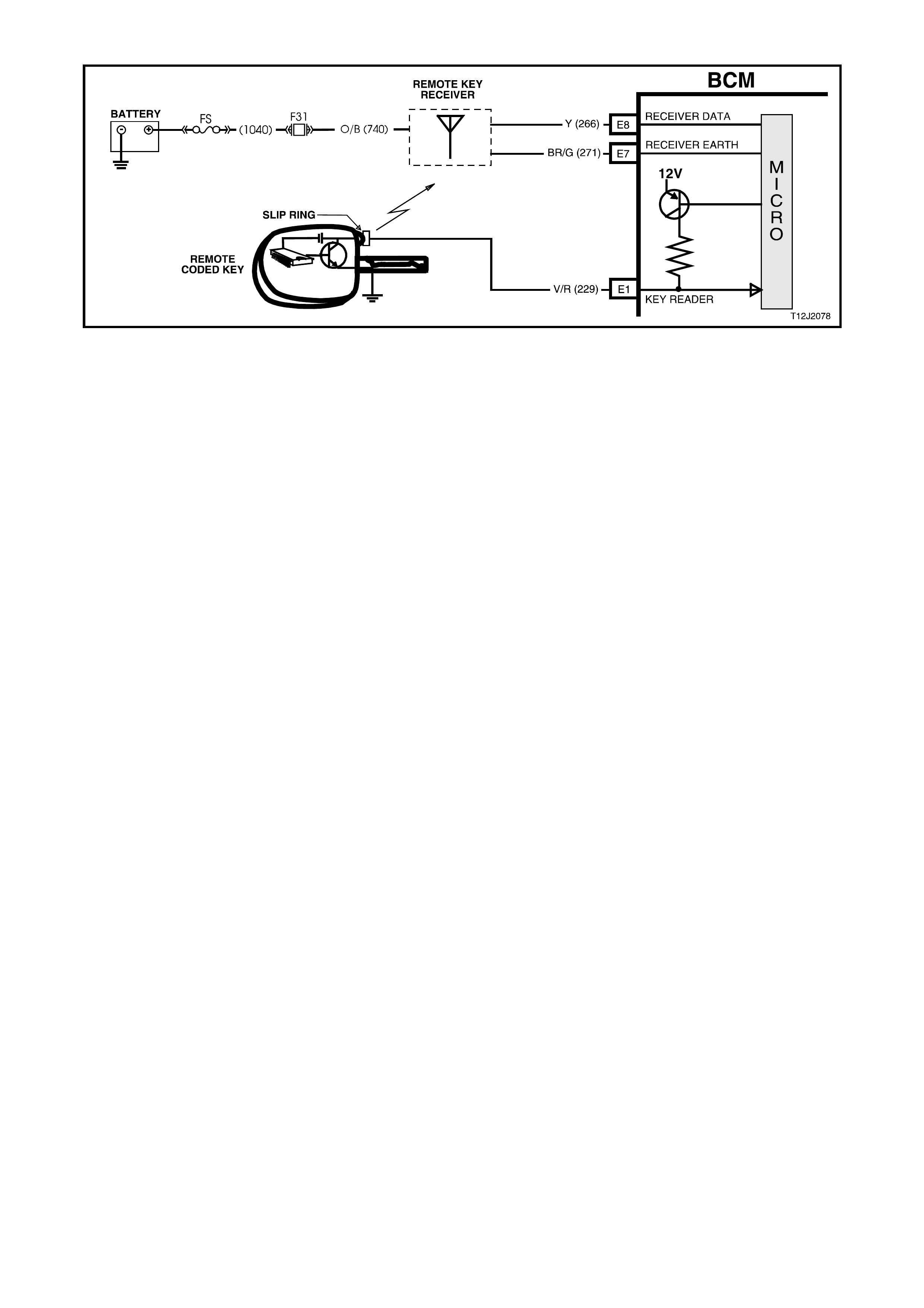

Remote Coded Key (Refer to Fig. 12J-2-9)

The theft deterrent system uses a remote coded key to arm and disarm the system, and electrically lock or unlock

all doors and tailgate (station wagon), or operate the boot unlock mechanism (sedan models).

Its own internal battery powers the remote coded key. If its internal battery fails, the remote coded key reader can

power the remote coded key once the key is inserted into the ignition switch key barrel and turned to the IGN or

START position.

The radio frequency transmitted by the remote key is received by the BCM remote receiver, located in the

instrument panel, between the demist ducts.

When the theft deterrent system is armed by pressing the remote coded key lock button, the indicators will flash

once and the theft deterrent alert indicator LED will begin to flash. Disarming the system by pressing the unlock

button will cause the indicators to flash twice and the theft deterrent alert indicator LED will stop flashing.

NOTE: Passive arming of the system does not automatically operate the door locks or flash the indicators.

Figure 12J-2-9 Remote coded key circuit

Theft Deterrent Alert Indicator LED

The theft deterrent alert indicator LED is used to indicate the state of the system . A flashing LED indicates that the

system is arm ed and consequently the vehicle cannot be started. When the LED is turned of f, the BCM is disarm ed

and the engine can be started.

The theft deterrent LED is incorporated into the trip computer switch assembly in the instrument panel facia.

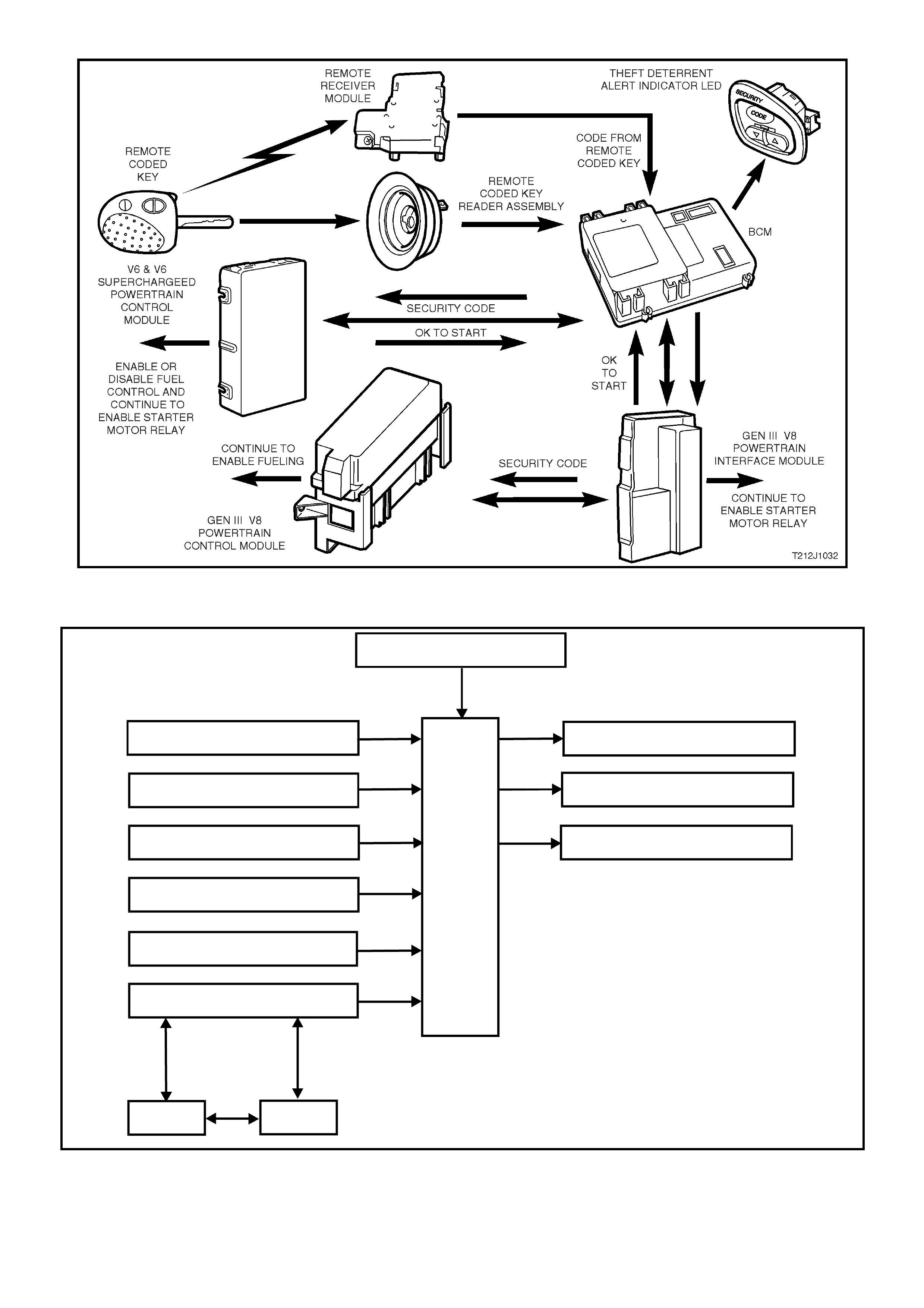

Operation (Refer to Fig. 12J-2-10)

V6 and V6 Supercharge d Engine

When the ignition switch is turned to the ON position, the BCM polls the PCM and sends an encrypted BCM/Key

security code (The security code is received via the BCM slip ring or remote receiver in the event of no slip ring

communication). The PCM compares the received security code with it’s stored security code and if the codes

match, the PCM will enable injector f uelling and continue engine crank ing. The PCM will return an OK TO ST ART

message, which tells the BCM to jump from SHORT LOOP mode to the LONG LOOP mode.

GEN III V8 Engine

When the ignition switch is turned to the ON position, the BCM polls the PIM and sends an encrypted BCM/Key

security code (The security code is received via the BCM slip ring or remote receiver in the event of no slip ring

communication). The PIM compares the received security code with it’s stored security code and if the codes

match, the PIM will continue enabling engine cranking and send a separate encrypted security code to the PCM.

The PCM compares this code with its stored security code and if the codes match, the PCM will enable injector

fuelling to continue. The PIM will return an OK TO START message, which tells the BCM to jump from SHORT

LOOP mode to the LONG LOOP mode.

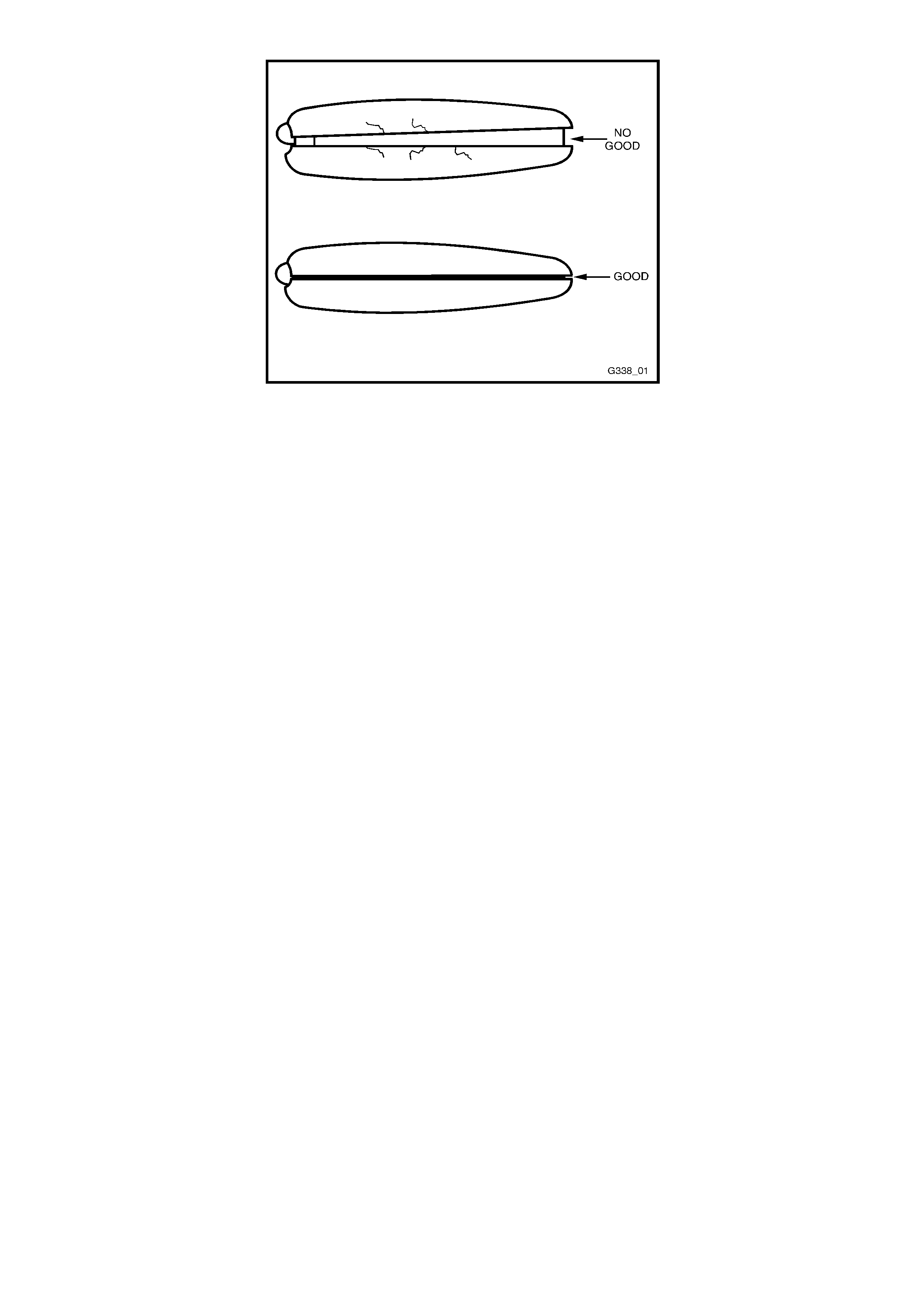

NOTE: Regardless of the engine configuration, it is very important that the remote coded key reader is aligned

correc tly with the ignition lock assembly, or m isalignment with the rem ote coded key contact may occur r esulting in

intermittent or no engine cranking or starting.

Figure 12J-2-10 Theft deterrent system

SYSTEM OVERVIEW - THEFT DETERRENT

BATTERY POW ER

LH TU RN SI GNAL

RH TURN SIGNAL

THEFT DETERRENT LED

BCM

TURN SIGNAL POWER

DRIVER’S DOOR OPEN

REMOTE RECEIVER

KEY RE AD ER

IGNITION SWITCH ON

T212J1024

SERIAL DATA

PCM

PIM

GEN III V8

ENGINE V6 & V6 S/C

ENGINE

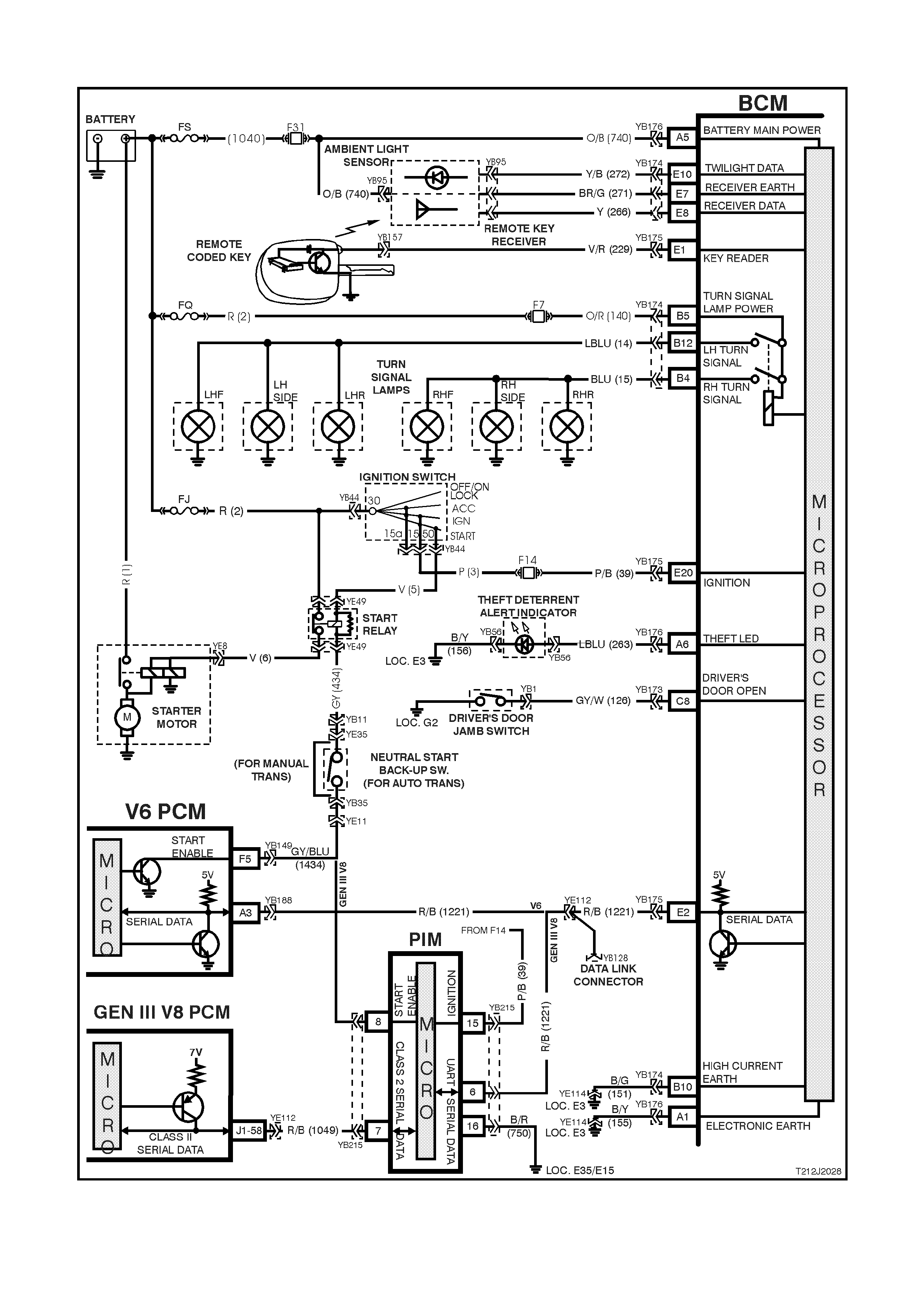

CIRCUIT OPERATION (Refer to Fig. 12J-2-15)

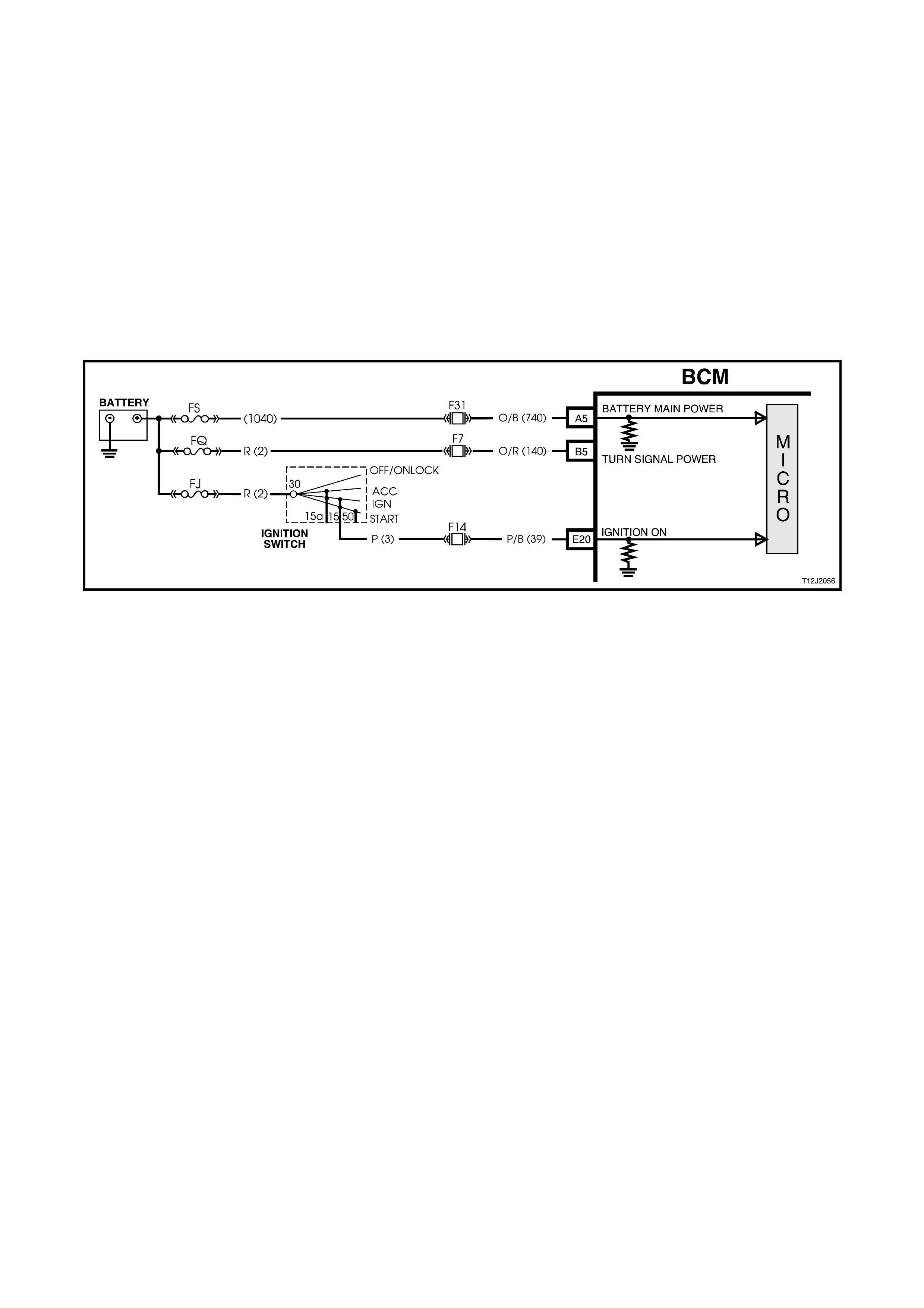

Battery Power (Refer to Fig. 12J-2-11)

Battery voltage is applied to the BCM microprocessor from terminal A5 at all times from fusible link FS and fuse F31

via circuit 740 (Orange/Black wire).

Indicators Power (Refer to Fig. 12J-2-11)

Battery voltage is applied to BCM terminal B5 at all times from fusible link FQ and fuse F7 via circuit 140

(Orange/Red wire).

Inputs

Ignition Switch ON Input Signal (Refer to Fig. 12J-2-11)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or ST ART pos ition, battery voltage is applied to the BCM term inal E20 f rom the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

Figure 12J-2-11 Battery power, turn signal indicator power and ignition switch on input circuit

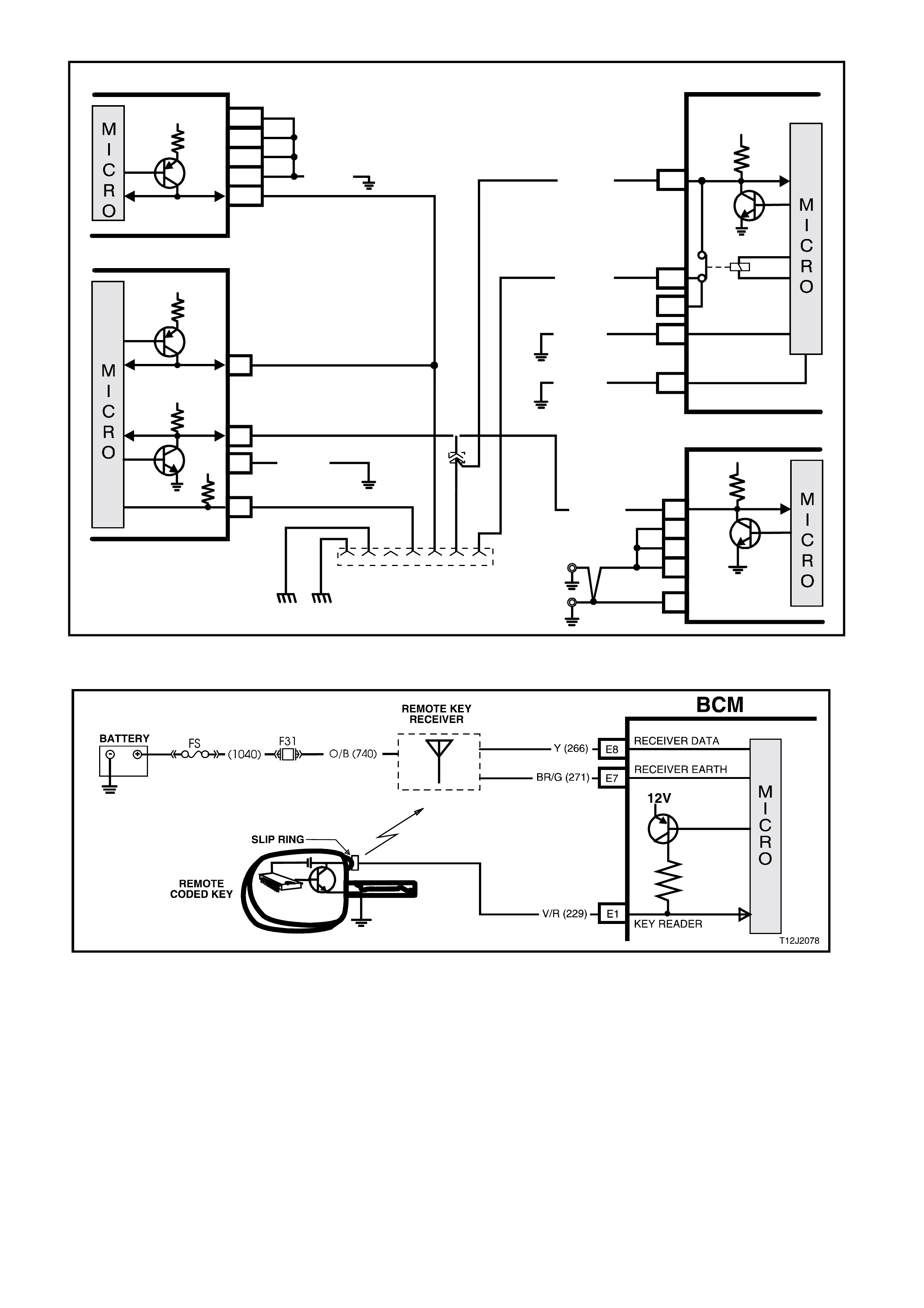

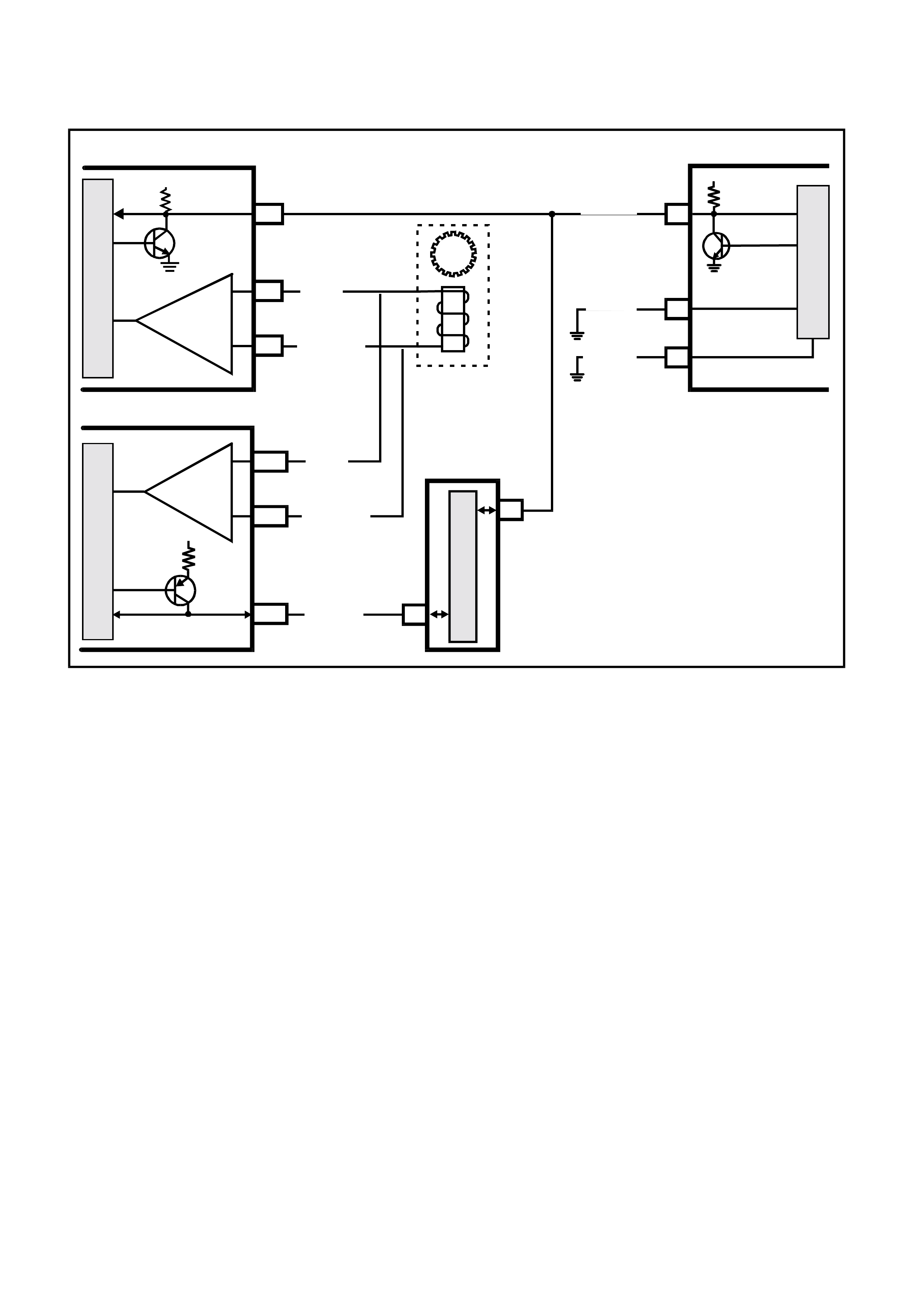

BCM and Powertrain Control Module Communication (Serial Data)

(Refer to Figs. 12J-2-12 and 12J-2-13)

V6 and V6 Supercharged Engine

When the ignition switch is turned to the ON pos ition, the BCM polls the PCM and sends a secur ity code. T he PCM

compares this code with it’s stored code and if they match, the PCM will enable fuel system control and continue

engine cranking.

The serial data from the remote coded key is applied to BCM terminal E1, circuit 229 (Violet/Red wire).

GEN III V8 Engine

W hen the ignition switch is turned to the ON position, the BCM polls the PIM and sends a security code. The PIM

compares this code with its stored code and if they match, the PIM continues engine enabling cranking and sends

the GEN III V8 PCM a security code. The GEN III V8 PCM compares this code with its stored code and, if they

match, the PCM will continue engine fuelling.

The serial data from the remote coded key is applied to BCM terminal E1, circuit 229 (Violet/Red wire).

Figure 12J-2-12 Serial data circuit

Figure 12J-2-13 Remote coded key circuit

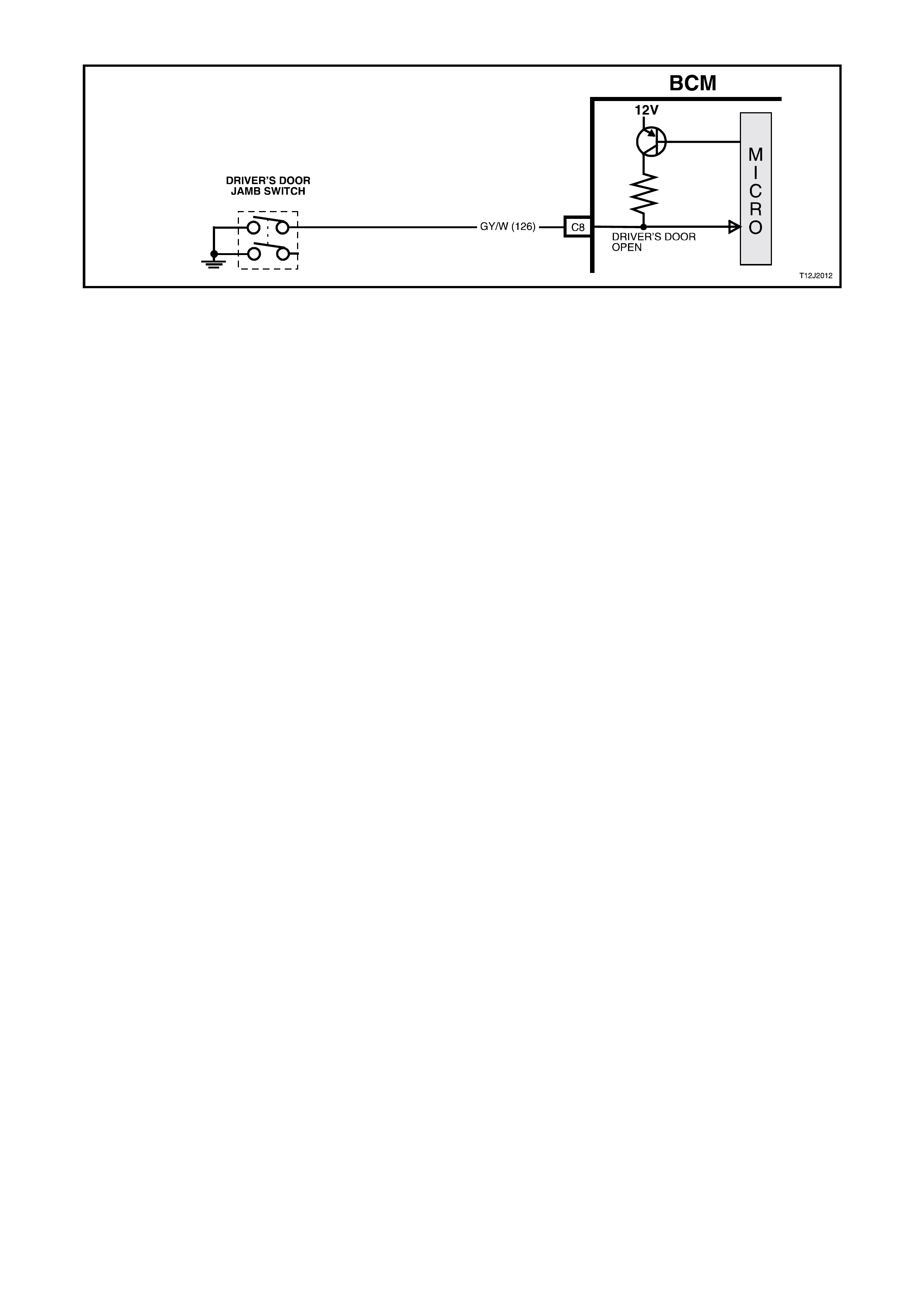

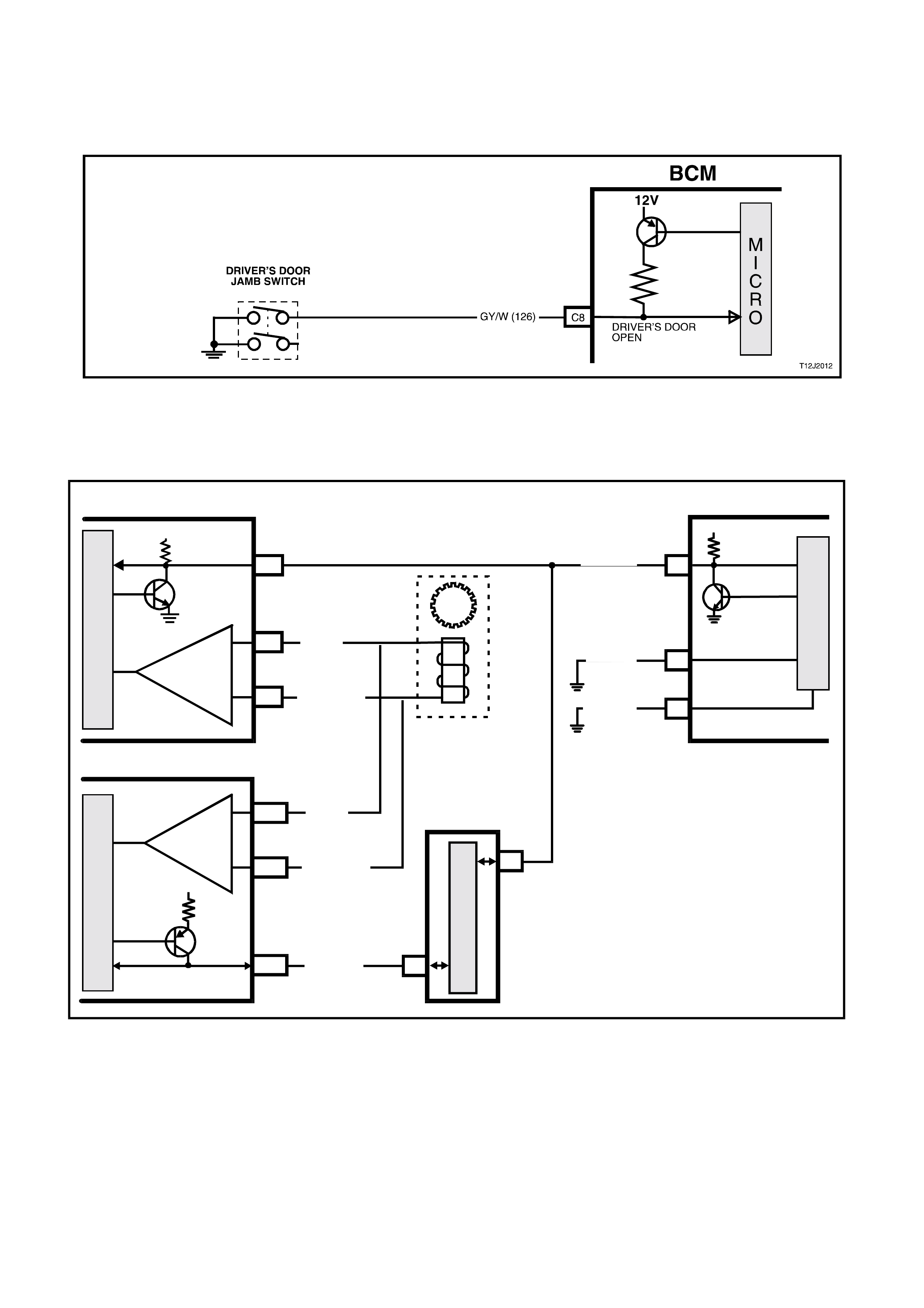

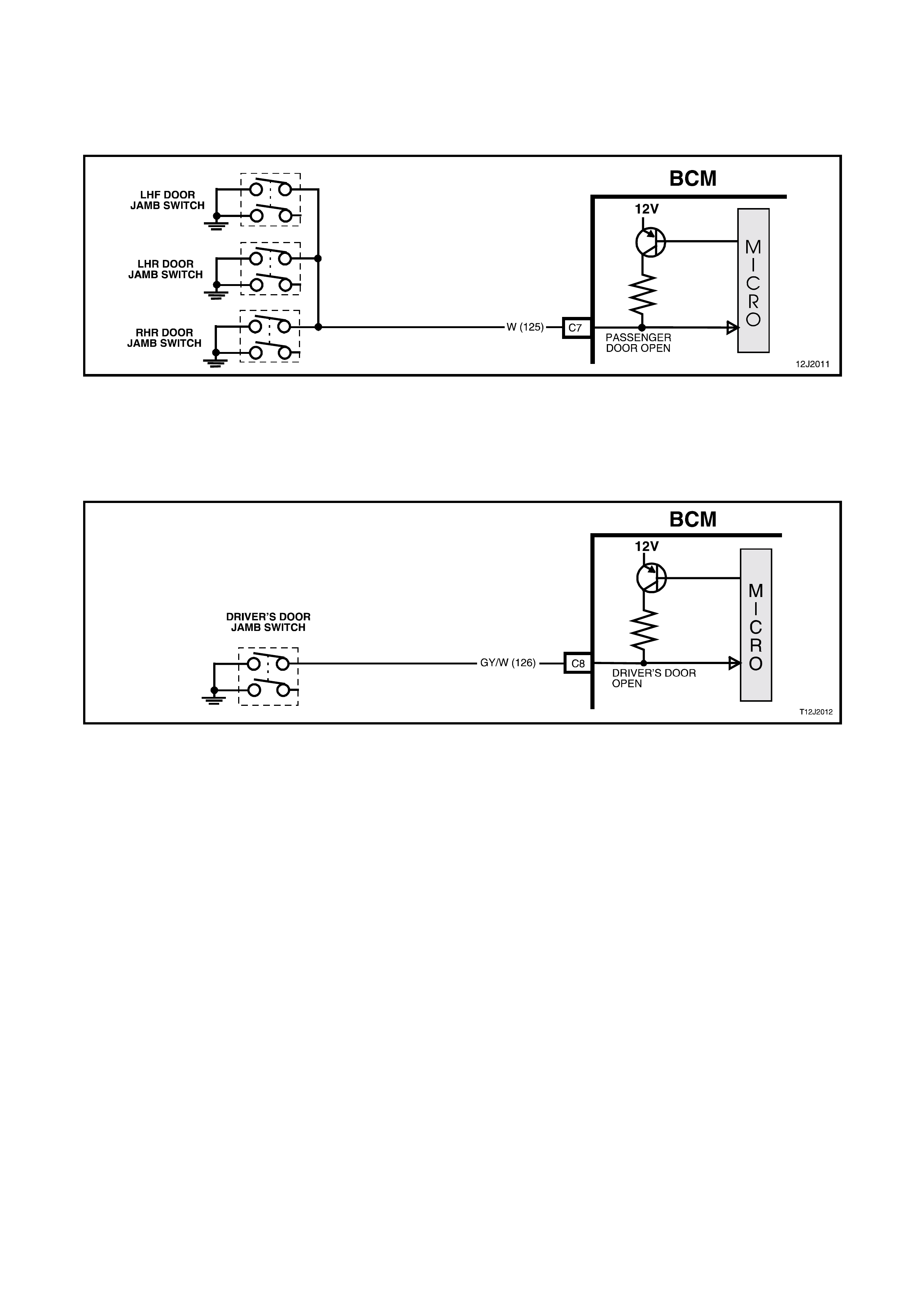

Driver's Door Jamb Switch (Refer to Fig. 12J-2-14)

The BCM uses this input signal to determine if the driver's front door is opened or closed. The BCM must sense that

the driver's door is closed before the theft deterrent system can be actively armed.

When the door is opened, the jamb switch earths terminal C8 via circuit 126 (Grey/White wire). This causes the

voltage at terminal C8 to be pulled low, less than 0.2 volt (driver's door open). This low voltage at terminal C8 is

seen by the BCM as the driver's door open input signal.

B/Y

(155)

B

(150)

LOC. E3

GEN III V8

YB128

642516 9 1

D ATA LINK

CONNECTOR

16

B/Y (155)

B/G (151)

LOC. E3

LOC. E3

R/B (1221)

G/W (1220)

B/R (750)

PIM

SERIAL

DATA

5V

7V

7V

12V

ELECTRONIC EARTH

HIGH CURRENT

EARTH

A1

B10

E2

E9

E3

SERIAL

DATA

MAIN

SERIAL

DATA AUX.

5V

6

11

7

DIAG. ENABLE

CLASS 2

SERIAL DATA

LOC. E5/E1 5

LOC. E5/E15

GEN III V8 PCM BCM

J1-58

J2-01

J2-40

J1-40

J1-01

CLASS II

SERIAL DATA

B/R (750)

T212J2026

R/B (1221)

LOC. E15

LOC. E5

V6 PCM

A3

B2

B1

A2

A1

SERIAL

DATA

5V

B/R

(750)

B/R

(750)

V

6

Figure 12J-2-14 Driver’s door jamb switch circuit

Outputs Refer to Fig. 12J-2-26

Left Hand Indicators

The BCM controls the operation of the left hand indicators by pulsing its internal indicator relay. This causes the

indicator relay contacts to close and open a number of times. This allows battery voltage from terminal B5 to be

applied internally to terminal B12, to the left hand indicator lamps via circuit 14 (Light Blue wire).

Right Hand Indicators

The BCM c ontrols the operation of the right hand indic ators in the s am e m anner as the lef t hand indicator s. Pulsing

of its internal indicator relay causes the indicator relay contacts to close and open a number of times. This allows

battery voltage from terminal B5 to be applied internally to terminal B4, to the right hand indicator lam ps via circuit

15 (Blue wire).

Theft Deterrent Alert Indicator LED

The theft deterrent alert indicator LED will continuously flash on and off whenever the system is armed. The BCM

controls the oper ation of the thef t deter rent aler t indicator LED by pulsing an internal switch on and off , which in tur n

switches the voltage applied to the theft deterrent alert indicator LED via terminal A6, circuit 263 (Light Blue wire).

Figure 12J-2-15 Theft deterrent system circuit

1.5 ENTRY DETERRENT SYSTEM

GENERAL INFORMATION

On VT Series II Models, the entry deterrent system carries over from earlier VT Series Models, noting the following:

Comm unic ation between the PCM and the BCM on vehicles with GEN III V8 engines is via the Powertrain Interf ace

Module (PIM).

The rear compartment lock switch (boot release button) is disabled when the theft deterrent system is armed via the

remote code key, driver’s door microswitch, when deadlocked or when the vehicle is in battery saver mode.

The rear compartment lock switch is only enabled when the theft deterrent system is disarmed via the remote

coded key or remote key reader (valid security code).

If diagnosing a circuit fault with the entry deterrent system, reference to the wiring diagrams in

Section 12P WIRING DIAGRAMS of the VT Series II Service Information should be made.

For additional details, including General Description, Service Operations and Diagnosis of the entry deterrent

system that is not covered in this Section, refer to Sectio n 12J- 2 HIGH SERIES BODY CONTROL MO DULE of the

VT Series I Service Information.

SYSTEM OVERVIEW - ENTRY DETERRENT

BATTERY POWER

BCM

TURN SIGNAL POWER

IGNITION SWITCH ON

BONNET OPEN SWITCH HORN RELAY

LH TURN SIG NAL

RH TURN SIGNAL

BOOT SO LENOID D RIVE

THEFT DETERRENT LED

DOME LAMP

THEFT DETERRENT

HORN REL AY

BOOT LAMP SWITCH

KEY READ ER

DRIVER’S DOOR OPEN

PASSENGER’S DOOR OPEN

T212J2051

S ERIA L DATA

BOOT RELEASE

REMOTE RECEIVER

V EHI CLE SP EED

PCM

PIM

GEN III V8

ENGINE V6 & V6 S/C

ENGINE

1.6 POWER WINDOW SYSTEM

GENERAL INFORMATION

The BCM controls the following functions of the power window system:

1. Control of positive supply to all door window motors.

2. Automatic down of driver's door window (activated when the driver's power window switch DOWN button is

depressed for more than 0.4 seconds).

Once activated, the automatic down feature is cancelled within 100 ms (0.01 second) after:

a. The driver's power window switch UP button is depressed f ollowing which the window will move upward (if up

button is held) or:

b. The driver's power window switch DOW N button is depressed (the window will stop when the down button is

released).

3. With ignition on, power is supplied continuously to the window system.

4. W hen the ignition is switched off and no door has been opened, power is s upplied to the window system f or a

maximum of 60 minutes, provided the BCM has not entered battery saver mode. If battery saver mode is

active, power will be removed from the window system when the ignition is switched off.

5. In the event of any door being opened, power is supplied to the system for 45 s econds m aximum , tim ed from

when any door was opened. If during this period the power window switch is activated again, the 45 second

period will recommence from 0 seconds.

W hen the doors ar e remotely unlocked (by using the rem ote coded key), provided the vehicle is not in battery

saver m ode, power is s upplied to the system f or a 60 m inutes (If the vehicle is in battery saver m ode, power is

removed from the system). The delay is cancelled when the doors are locked by the remote coded key.

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to

either the relevant diagnostic section or Section 12P WIRING DIAGRAMS of the VT Series II Service Information.

SYSTEM CHECK

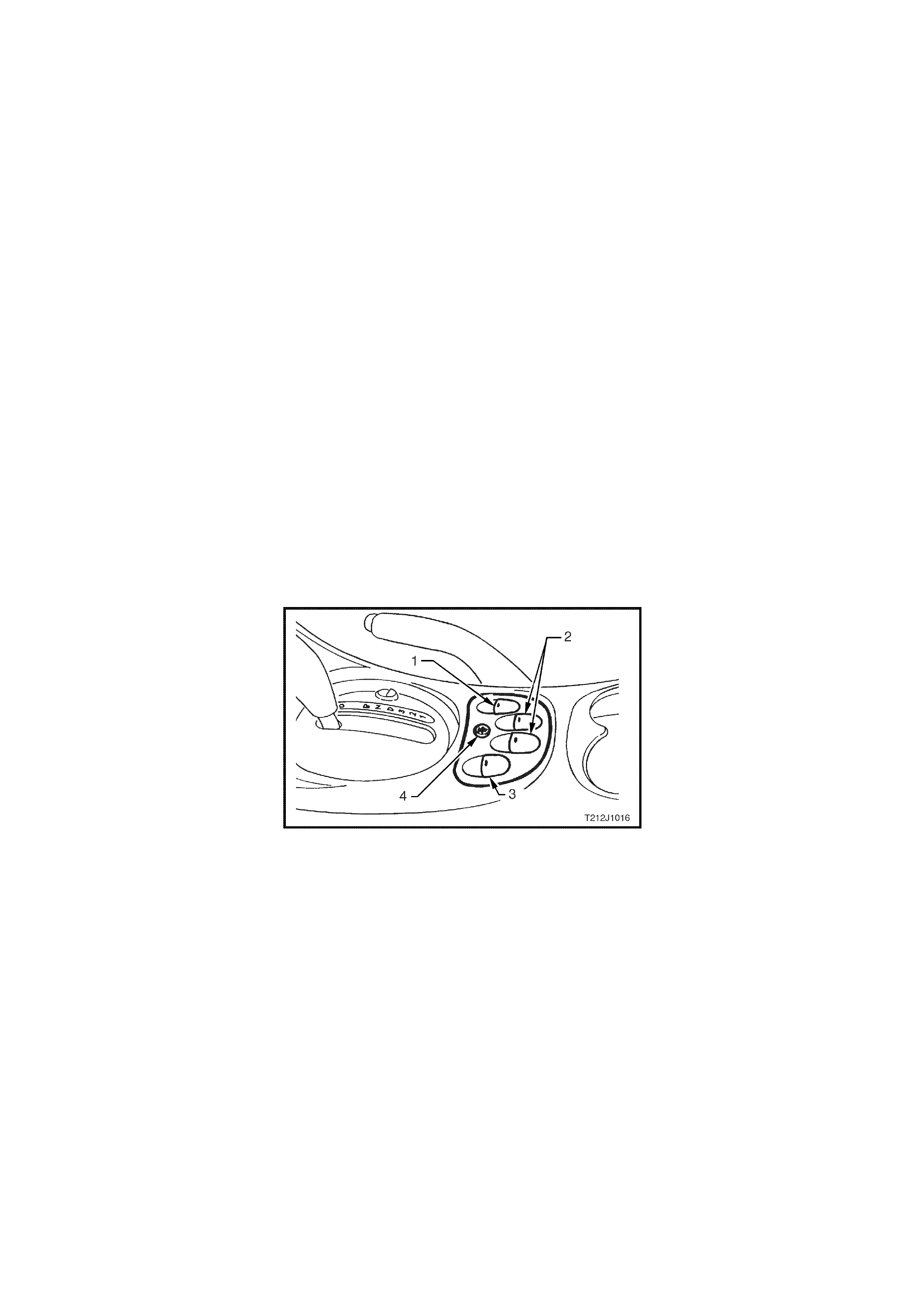

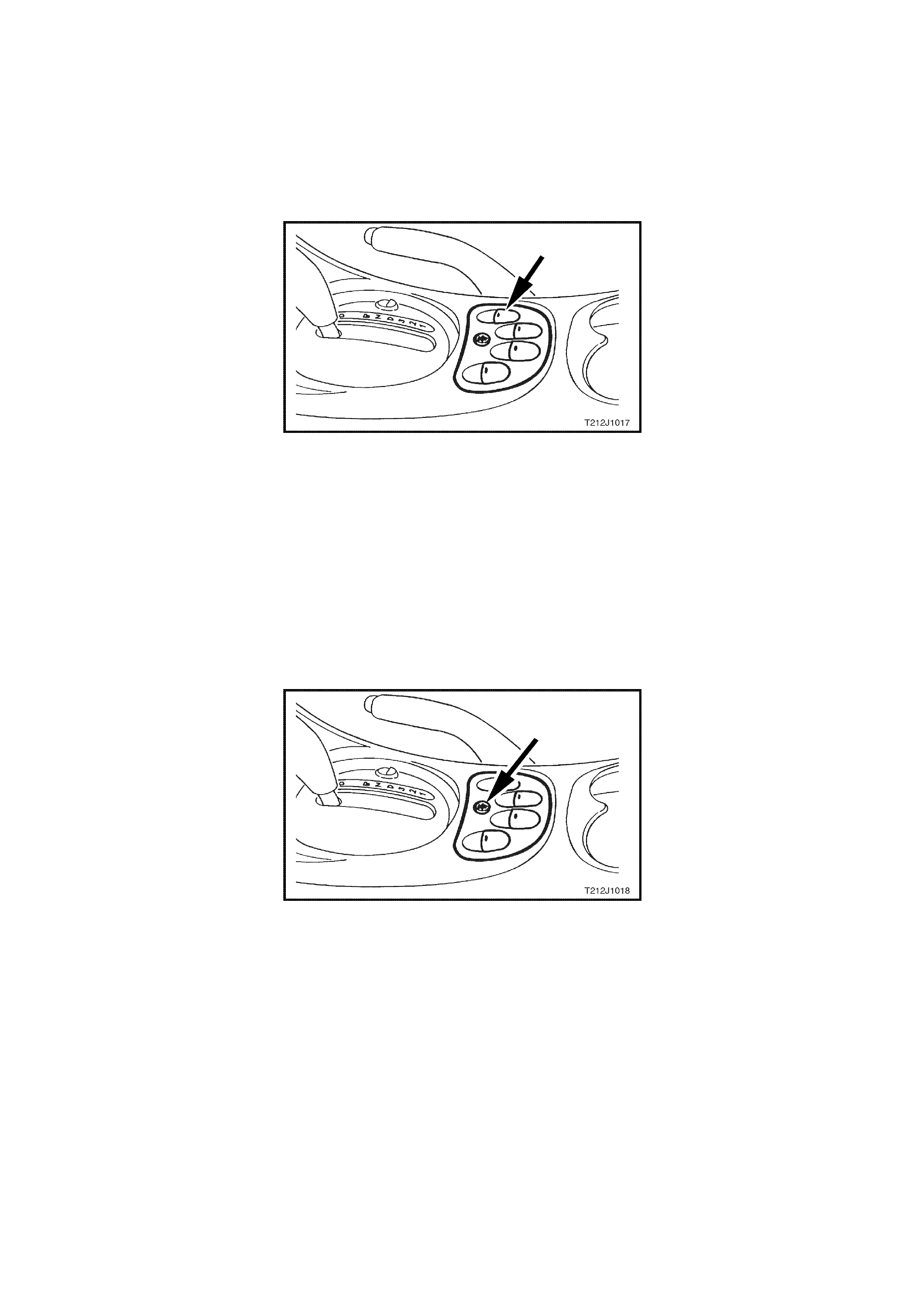

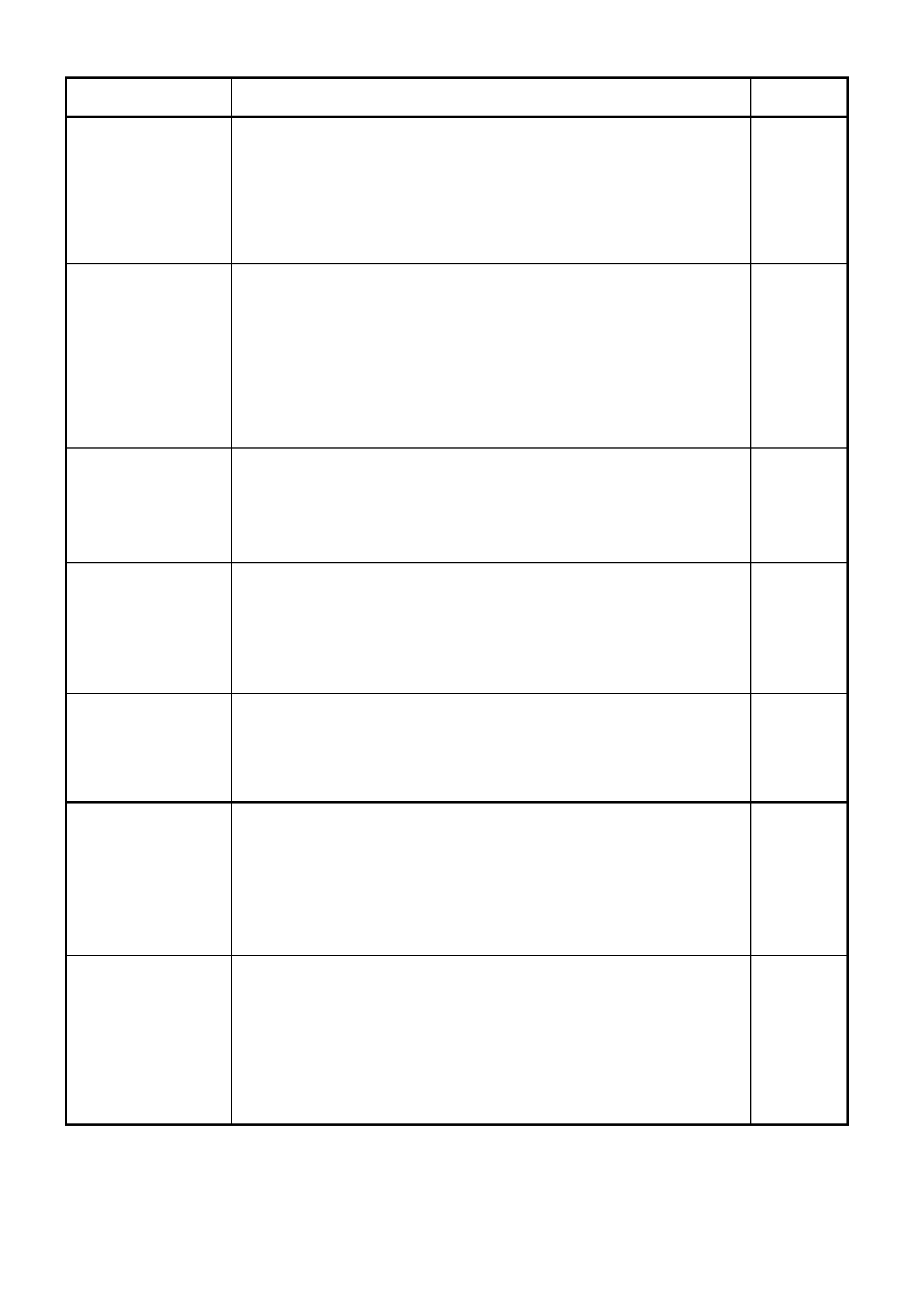

Figure 12J-2-16 Power w indow switch assembly

1. Drivers window switch.

2. Rear passenger window switches (left and

right hand).

3. Front passenger window switch.

4. Child safety switch.

Prerequisite Condition

The child safety switch must be switched OFF. This will be indicated by the green lights emitting diodes (LED) in

each of the rear door rocker switches being illuminated.

System Active

System active is indicated by the illumination of the lights in each of the rocker switches.

When the ignition switch is turned ON, all switches are active.

With the ignition switch turned OFF, all switches will remain active for 45 seconds after any door is opened.

With the ignition switch turned OFF, all switches will remain active for approximately 60 minutes, PROVIDED

THERE ARE NO OPEN DOORS.

System Inactive

Lights are not illuminated.

Automatic DOWN Operation of Driver’s Window

With the driver’s window in the fully UP position and the ignition switch turned to O N, pr ess the dr iver window switch

to the window DOWN position for more than 0.5 seconds and release.

The window will continue to lower automatically until the fully DOWN position is reached.

To interrupt this function, press the UP button momentarily.

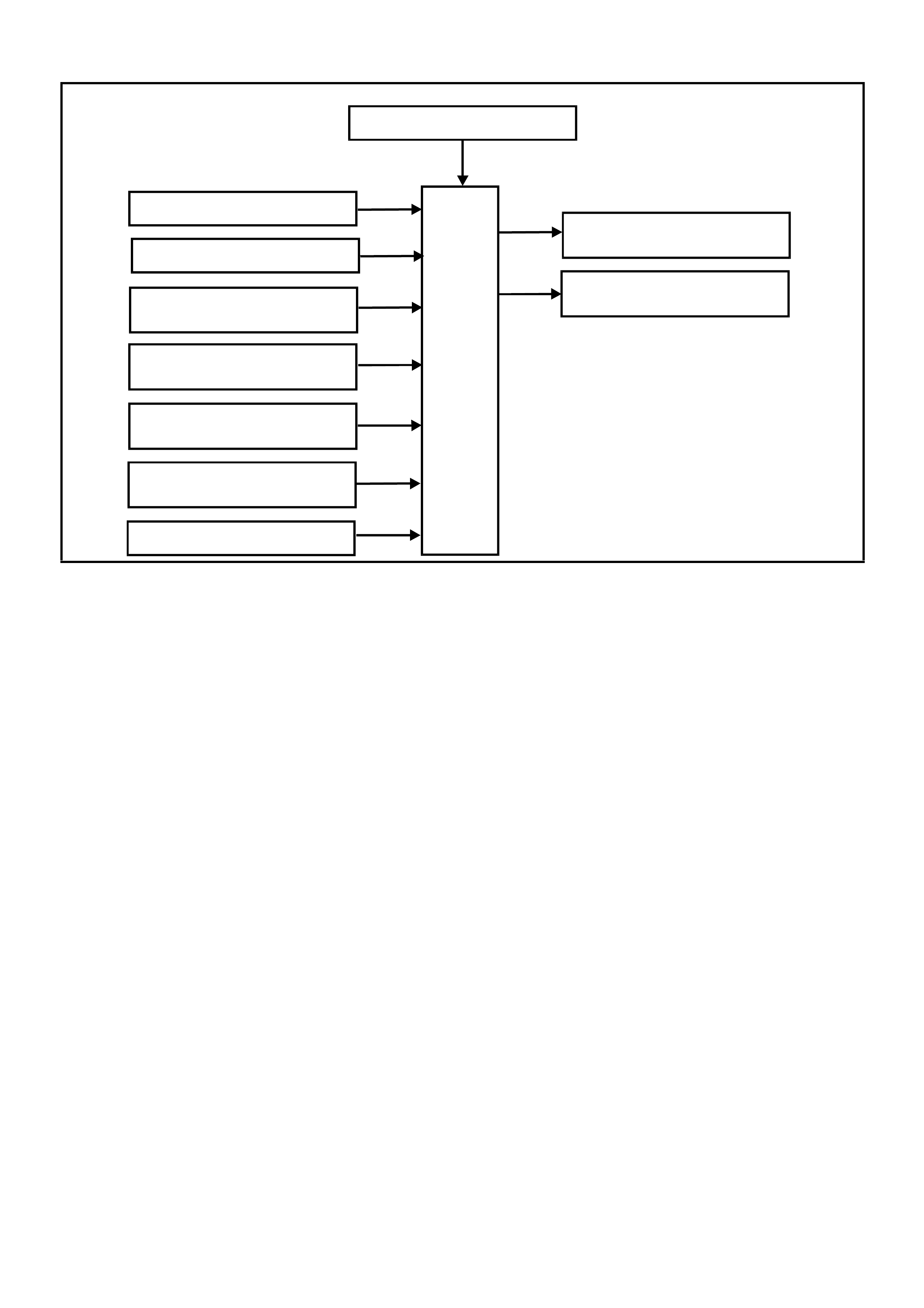

Figure 12J-2-17 Driver’s power window switch

Child Safety Switch

W hen the child safety switch (override switch) is OFF, the rear windows can be opened or closed from the centre

console switch assembly or the rocker switches in each of the rear doors.

Check the operation of this feature, as per the following:

1. Switch ignition ON.

2. Check that the green LED in each of the rear door rocker switches is illuminated.

3. Open and close the rear door windows using the rocker switches in the rear doors.

4. Press the child saf ety switch button in the centre of the switch as sem bly in the console as shown in Fig. 12J- 2-

18.

5. Check that the green LED in each of the rear door rock er s witches extinguis hes and that the rear windows can

only be raised or lowered from the switch in the centre console.

Figure 12J-2-18 Child safety switch

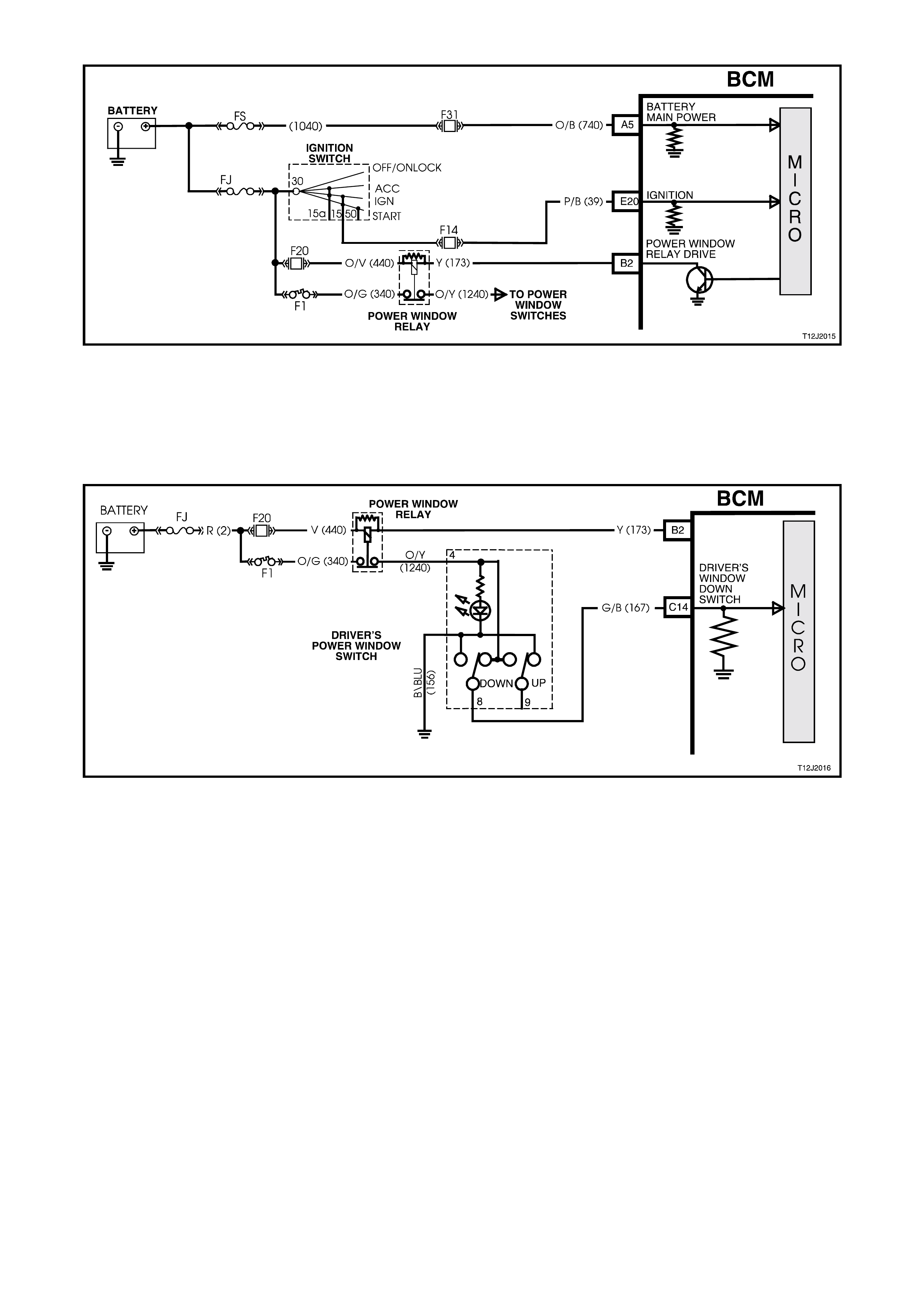

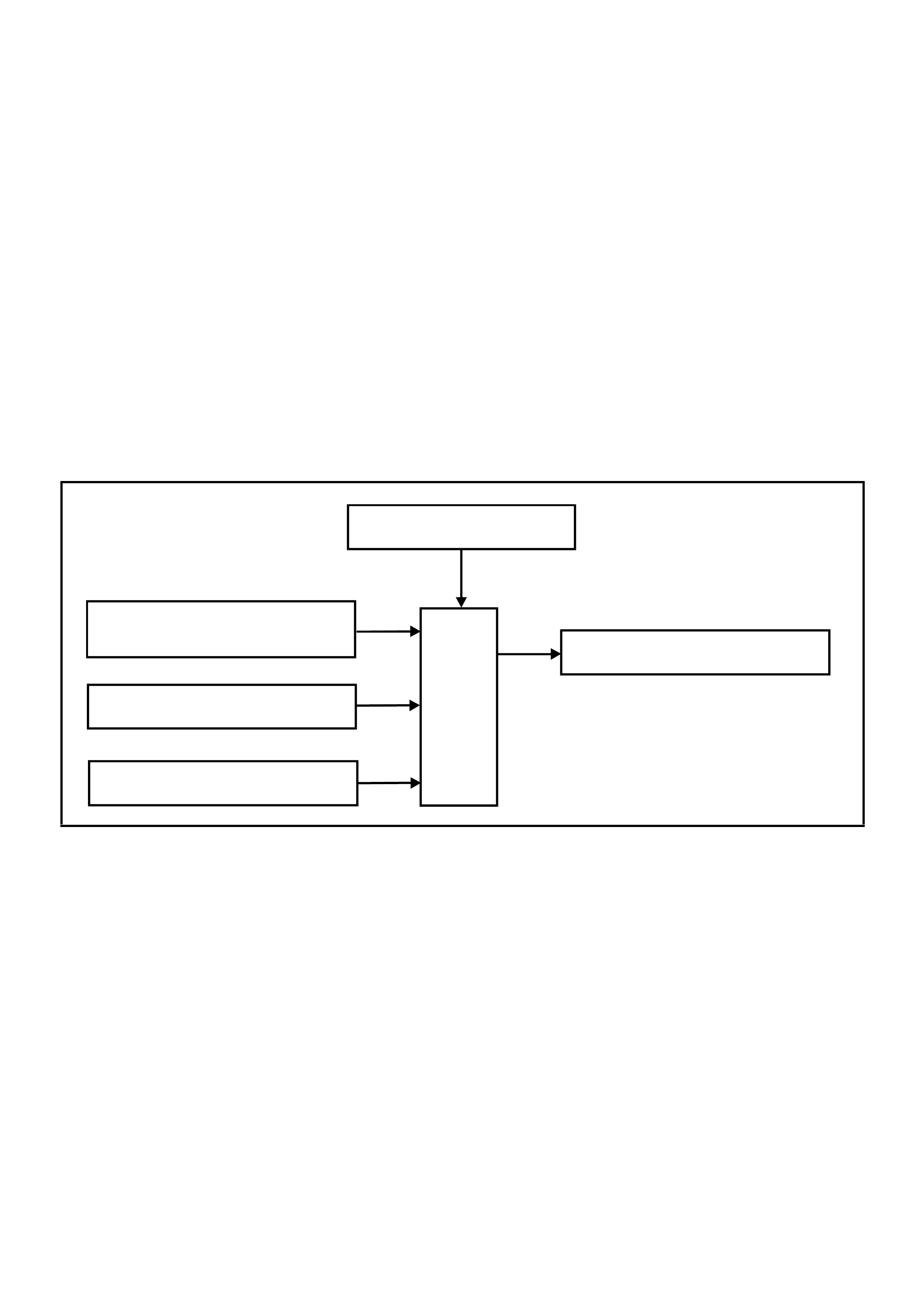

SYSTEM OVERVIEW - POWER WINDOWS

BATTERY POWER

BCM

DRIVER’S WINDOW

DOWN SWITCH

IGNITION SWITCH ON

DRIVER’S WINDOW

MOTOR

T212J2001

POWER WINDOW

RELAY

DRIVER’S WINDOW

UP SWITCH

DRIVER’S DOOR

JAMB SWITCHES

PASSENGER DOO R

JAMB SWITCHES

REMOTE RECEIVER

WINDOW POWER

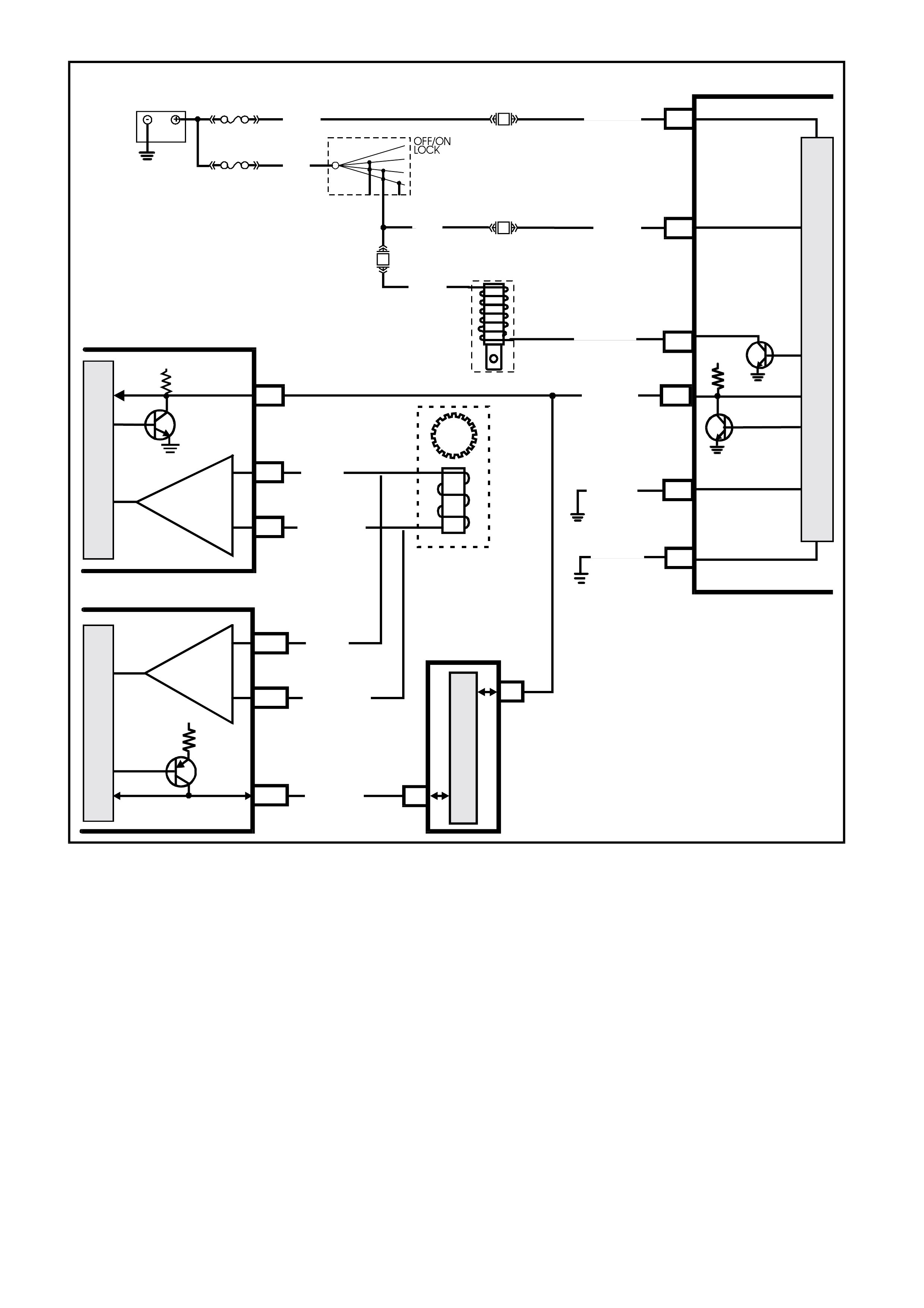

CIRCUIT OPERATION

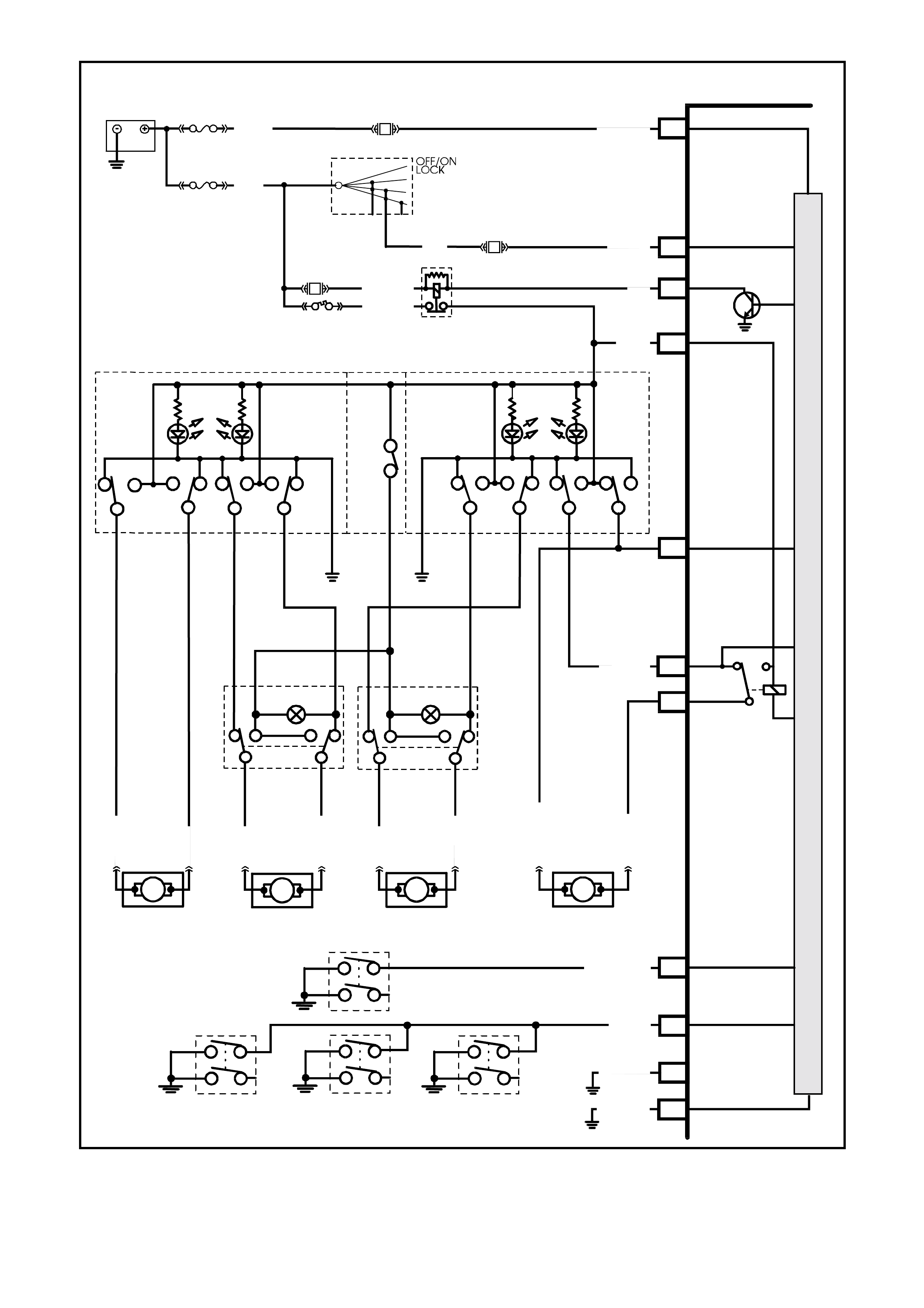

A permanent magnet motor operates each of the power window mechanisms to raise or lower the window glass.

The direction in which the motor turns depends on the polarity of a voltage supplied to its terminals. The power

window switches, located in the centre console, or in the rear doors, control the polarity of the supply voltages.

The BCM has two main control functions in the power window system.

1. To control the operation of the power window relay and hence, power supply to the whole system.

2. To control the operation of the driver's side front window motor.

OPENING WINDOW - DRIVER'S DOOR (Refer to Figs. 12J-2-21 and 12J-2-22)

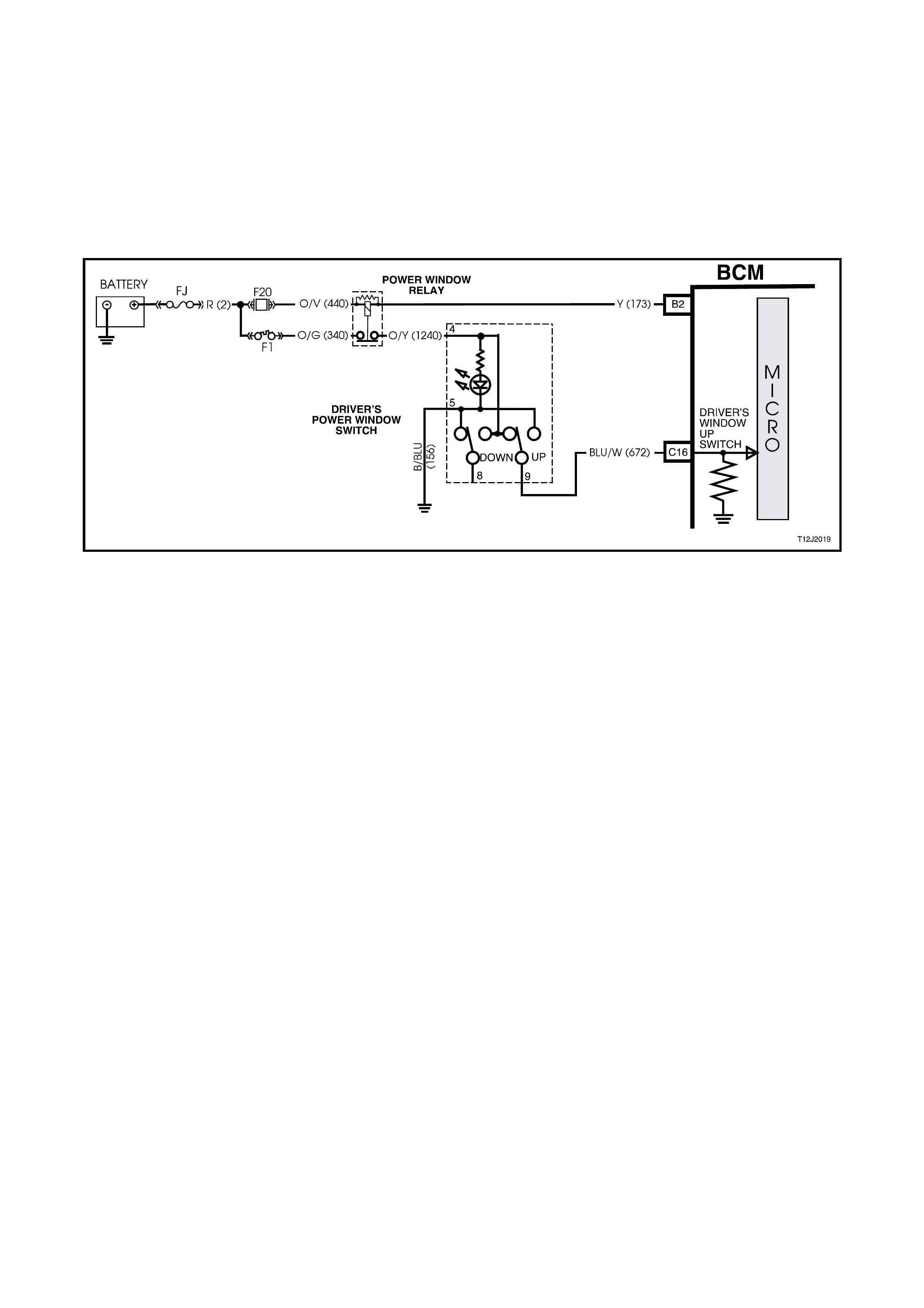

Ignition Switch ON Input Signal (Refer to Fig. 12J-2-19)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. When the

ignition switch is in the IGN or ST ART pos ition, battery voltage is applied to the BCM term inal E20 f rom the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

W hen the BCM receives an ignition ON input it energises the power windows relay (voltage supplied by fuse F20

circuit 440 Orange/Violet wire) by earthing the relay’s pull-in coil via circuit 173 (Yellow w ire) and BCM terminal B2.

With the relay coil energised, the relay contacts close and power via f usible link FJ and circuit br eak er F1 is applied

to the power window switches and each of the lights of the window switches (for rear door window switches, the

power window override switch in the front power window switch must be off). The opposite side of each light is

connected to earth, therefore the lights are illuminated (system active).

By depressing and releasing the driver's front window switch down button within 0.4 of a second (so as not to

engage the automatic down feature), this allows battery voltage from the power windows relay, circuit 1240

(Orange/Yellow wire), and the power window switch terminal 4, through to terminal 8 and then BCM terminal C14

(window down signal input), through the relay contacts and BCM term inal C2 to one side of the driver's s ide power

window motor on circuit 673 (Green/Orange wire).

The opposite side of the motor is connected to earth on circuit 672 Blue/White wire via power window switch

terminals 9 and 5 to circuit 156 (Black/Blue wire). This causes the motor armature to rotate, operating the window

regulator to lower the window.

As described under power windows general info rmation, the dr iver's window will automatically travel fully downward

provided the power window switch down button is depressed for more than 0.4 s econds. T he BCM micr oprocessor

senses the tim e the down button is depressed via term inal C14 and energises the internal relay so as to allow the

window to lower fully.

Figure 12J-2-19 Ignition switch on input signal

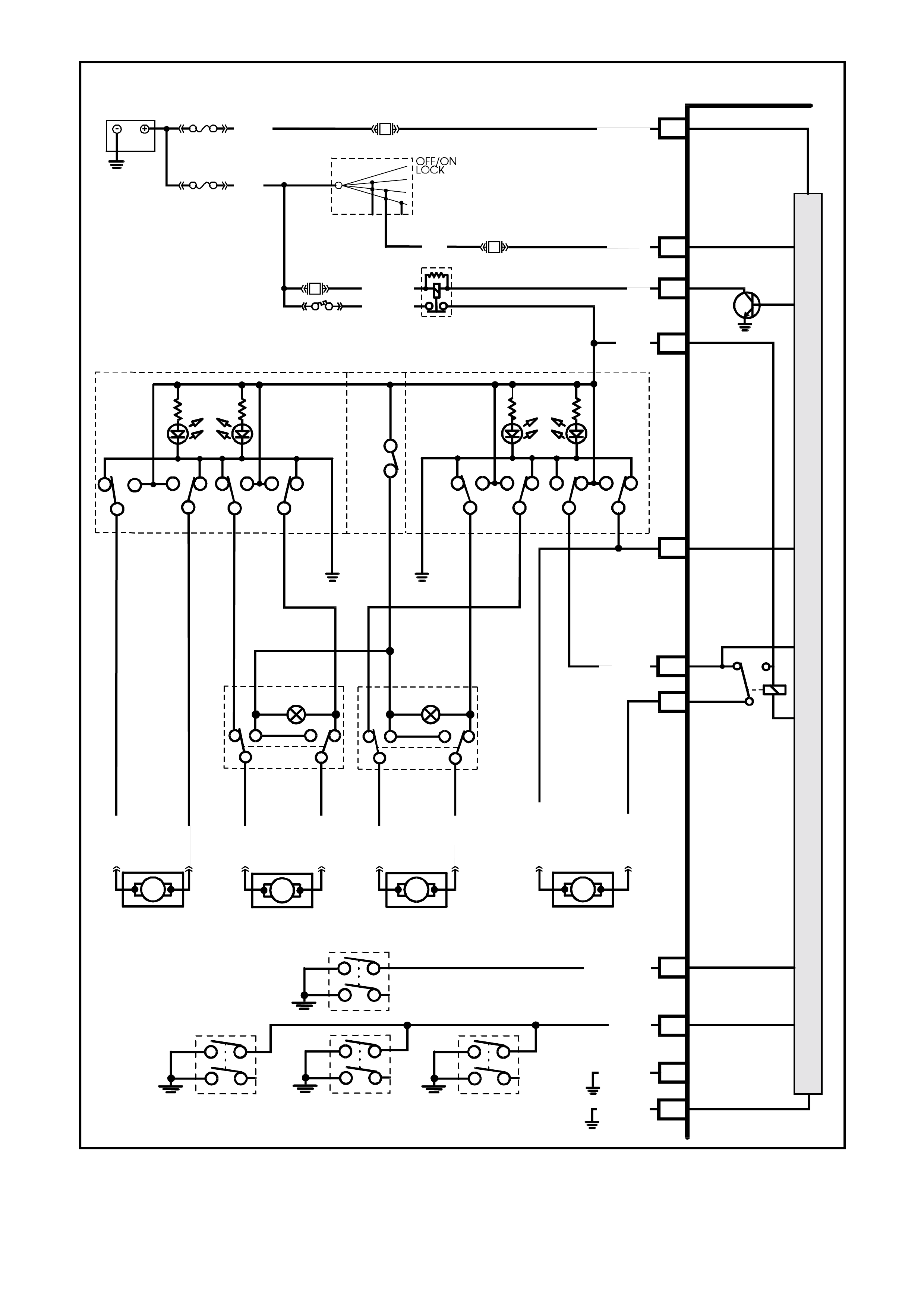

Driver's Front Window Down Switch Input Signal (REFER TO FIG. 12J-2-20)

W ith the driver's front window switch down button depressed, battery voltage from the power windows relay, circ uit

1240 Orange/Yellow wire, and the power window switch terminal 4, through to terminal 8 is applied to BCM ter minal

C14 (window down signal input).

Figure 12J-2-20 Driver’s front window down switch input circuit

W hen the BCM receives a driver's fr ont window down switch input signal it energis es an internal relay. This caus es

the relay contacts to changeover, allowing battery voltage from the power windows relay contacts, BCM terminal

C1, through the BCM internal relay contacts and BCM terminal C2 to one side of the driver's side power window

motor on circuit 673 (Green/Orange wire).

If the window is travelling downward and the down button is again depress ed, the BCM mic roprocess or senses this

(voltage again sensed at BCM term inal C14) and de-energises the internal relay, the contacts open and the m otor

stops.

Should the up button be mo mentarily depressed whilst the window is travelling downward, positive battery voltage is

applied to both sides of the motor armature and the motor stops. If the up button is continuously depressed whilst

the window is travelling downward, the window down function is cancelled. The window will then move upward as

described in the following text.

BATTERY

IGNITION SWITCH

FS

FJ

F31

A5

O/B (74 0)

(1040)

R (2)

F14

E20

B2

P/ B (39)

15a 15 50

30 ACC

IGN

START

F1

F20

O/V (440 )

O/G (340)

Y

(173)

P (3)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

DRIVER'S

WINDOW

MOTOR

RHR WINDOW

MOTOR

LHR WINDOW

MOTOR

LHF W I NDOW

MOTOR

BATTERY MAIN POWER

LHF POWER

WIND OW SWIT CH DRIVER'S POWE R

WINDOW SWITCH

OVERRIDE

SWITCH

BCM

C14 WINDOW

EARTH

WINDOW

DOWN

C2

B/ G (151)

B10 HIGH CURRENT

EARTH

T212J2002

C1

IGNITION

POWER WINDOW

RELAY DRIVE

WINDOW

POWER

G/B (16 7 )

DRIVERS

WINDOW

UP SWITCH

113 325

UP DOWNDOWNUP

3

1

4

2

3

1

4

2

LHR

POWER

WINDOW

SWI T C H

RHR

POWER

WINDOW

SWITCH

BLU (671)

G (6 7 0 )

G (6 7 0 )

G (6 6 7 )

BLU (671)

BLU (666)

BLU/ W (672)

B/ BLU

(156)

B/ BLU

(156)

G/O (67 3 )

9

4

8

7

6

5

12 UPDOWN DOWN UP

C16

DRIVERS

WINDOW

DOWN

SWITCH

B/ Y (155)

ELECTRON IC EARTH

A1

W (125) C7

RHR DOOR

JAMB SWITCH LHF DO O R

JAMB SWITCH

LHR DOOR

JAMB SWITCH

PASS.

DOOR

SWITCH

DRIVER 'S DOOR

JAMB SWITCH

GY/W (126) C8 DRIVER'S

DOOR

OPEN

O/Y

(1240)

Figure 12J-2-21 Driver’s window manual down operation circuit

BATTERY

IGNITION SWITCH

FS

FJ

F31

A5

O/B (74 0)

(1040)

R (2)

F14

E20

B2

P/ B (39)

15a 15 50

30 ACC

IGN

START

F1

F20

O/V (440 )

O/G (340)

Y

(173)

P (3)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

DRIVER'S

WINDOW

MOTOR

RHR WINDOW

MOTOR

LHR WINDOW

MOTOR

LHF W I NDOW

MOTOR

BATTERY MAIN POWER

LHF POWER

WIND OW SWIT CH DRIVER'S POWE R

WINDOW SWITCH

OVERRIDE

SWITCH

BCM

C14 WINDOW

EARTH

WINDOW

DOWN

C2

B/ G (151)

B10 HIGH CURRENT

EARTH

T212J2003

C1

IGNITION FUSE F10

POWER WINDOW

RELAY DRIVE

WINDOW

POWER

G/B (16 7 )

DRIVERS

WINDOW

UP SWITCH

113 325

UP DOWNDOWNUP

3

1

4

2

3

1

4

2

LHR

POWER

WINDOW

SWI T C H

RHR

POWER

WINDOW

SWITCH

BLU (671)

G (6 7 0 )

G (6 7 0 )

G (6 6 7 )

BLU (671)

BLU (666)

BLU/ W (672)

B/ BLU

(156)

B/ BLU

(156)

G/O (67 3 )

9

4

8

7

6

5

12 UPDOWN DOWN UP

C16

DRIVERS

WINDOW

DOWN

SWITCH

B/ Y (155)

ELECTRON IC EARTH

A1

W (125) C7

RHR DOOR

JAMB SWITCH LHF DO O R

JAMB SWITCH

LHR DOOR

JAMB SWITCH

PASS.

DOOR

SWITCH

DRIVER 'S DOOR

JAMB SWITCH

GY/W (126) C8 DRIVER'S

DOOR

OPEN

O/Y

(1240)

Figure 12J-2-22 Driver’s window automatic down operation circuit

CLOSING WINDOW (Refer to Fig. 12J-2-24)

Driver's Front Window Up Switch Input Signal (REFER TO FIG. 12J-2-23)

By depressing and holding down driver's front window up button, battery voltage from the power windows relay

circuit 1240 (Orange/Yellow wire) is applied, via power window switch terminals 4 and 9, to the driver's side power

window motor circuit 672 (Blue/White wire).

The oppos ite side to the m otor cir cuit 673 (Gr een/Orange wire) is connected to ear th via BCM term inal C2, thr ough

the BCM internal relay contacts, BCM terminal C14 to switch terminals 8 and 5 to earth circuit 156 (Black/Blue wire).

This causes the m otor arm ature to rotate, operating the window regulator to raise the window as long as the power

window switch up button is depressed.

Figure 12J-2-23 Driver’s front window up switch input signal circuit

Window Operation - Passenger Doors

Power is supplied to all the power window switches fr om the power window relay (to the rear door switches pr ovided

the power window override switch is off). If the power window override switch is on, (contacts between terminals 4

and 12 are open) the power supply to the rear door power window switches is interrupted.

With the switch buttons at rest, all switch contacts are connected to earth circuit 156 (Black/Blue wire). By

depressing the appropr iate passenger's window switch down or up button, battery voltage from the power windows

relay, is applied to one side of the window m otor, via the depres sed switch c ontact. With the other s ide of the m otor

connected to earth, the motor armature will rotate, operating the window regulator to raise or lower the window as

long as the window switch button is depressed.

BATTERY

IGNITION SWITCH

FS

FJ

F31

A5

O/B (74 0)

(1040)

R (2)

F14

E20

B2

P/ B (39)

15a 15 50

30 ACC

IGN

START

F1

F20

O/V (440 )

O/G (340)

Y

(173)

P (3)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

DRIVER'S

WINDOW

MOTOR

RHR WINDOW

MOTOR

LHR WINDOW

MOTOR

LHF W I NDOW

MOTOR

BATTERY MAIN POWER

LHF POWER

WIND OW SWIT CH DRIVER'S POWE R

WINDOW SWITCH

OVERRIDE

SWITCH

BCM

C14 WINDOW

EARTH

WINDOW

DOWN

C2

B/ G (151)

B10 HIGH CURRENT

EARTH

T212J2004

C1

IGNITION

POWER WINDOW

RELAY DRIVE

WINDOW

POWER

G/B (16 7 )

DRIVERS

WINDOW

UP SWITCH

113 325

UP DOWNDOWNUP

3

1

4

2

3

1

4

2

LHR

POWER

WINDOW

SWI T C H

RHR

POWER

WINDOW

SWITCH

BLU (671)

G (6 7 0 )

G (6 7 0 )

G (6 6 7 )

BLU (671)

BLU (666)

BLU/ W (672)

B/ BLU

(156)

B/ BLU

(156)

G/O (67 3 )

9

4

8

7

6

5

12 UPDOWN DOWN UP

C16

DRIVERS

WINDOW

DOWN

SWITCH

B/ Y (155)

ELECTRON IC EARTH

A1

W (125) C7

RHR DOOR

JAMB SWITCH LHF DO O R

JAMB SWITCH

LHR DOOR

JAMB SWITCH

PASS.

DOOR

SWITCH

DRIVER 'S DOOR

JAMB SWITCH

GY/W (126) C8 DRIVER'S

DOOR

OPEN

O/Y

(1240)

Figure 12J-2-24 Driver’s window manual up operation circuit

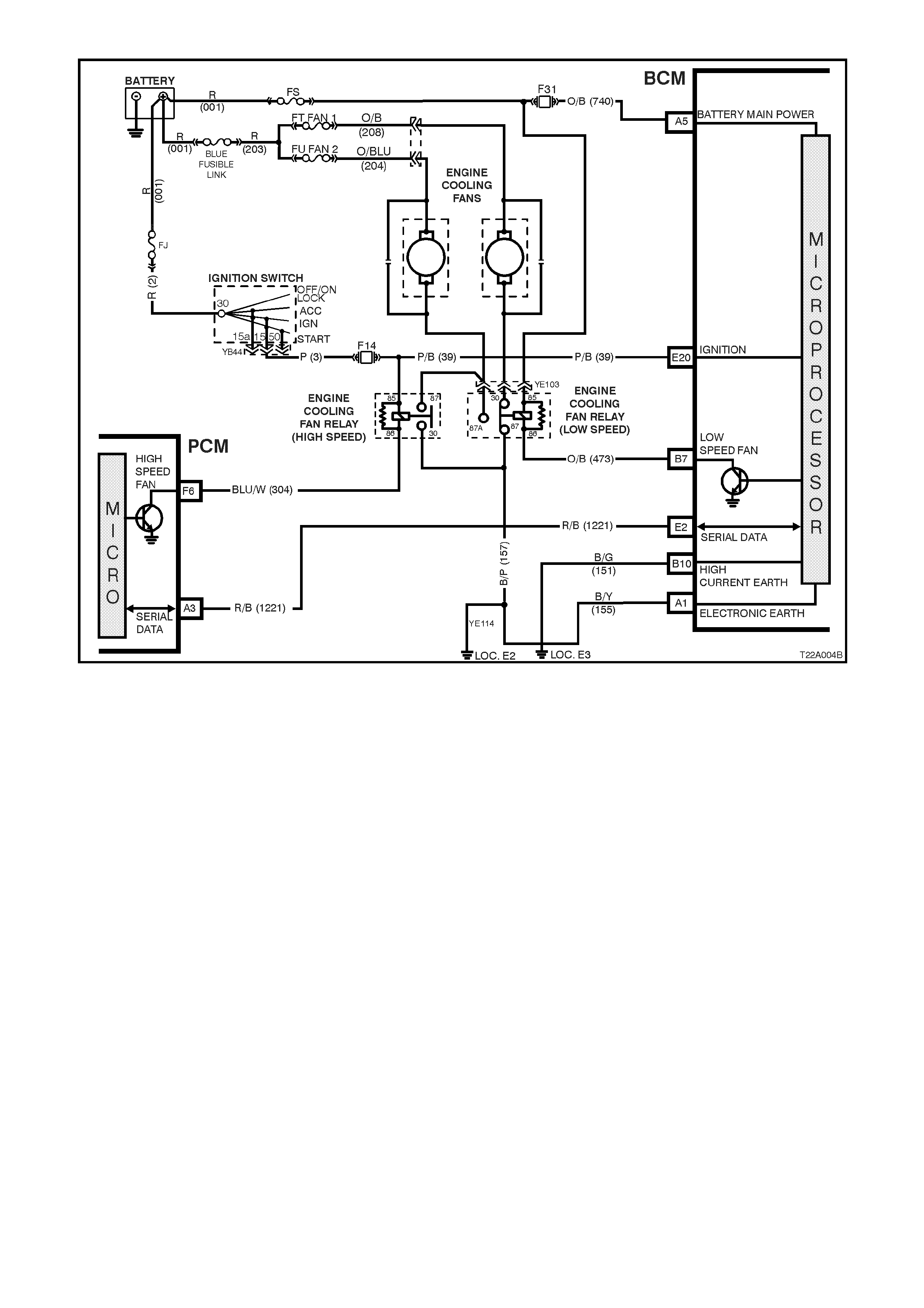

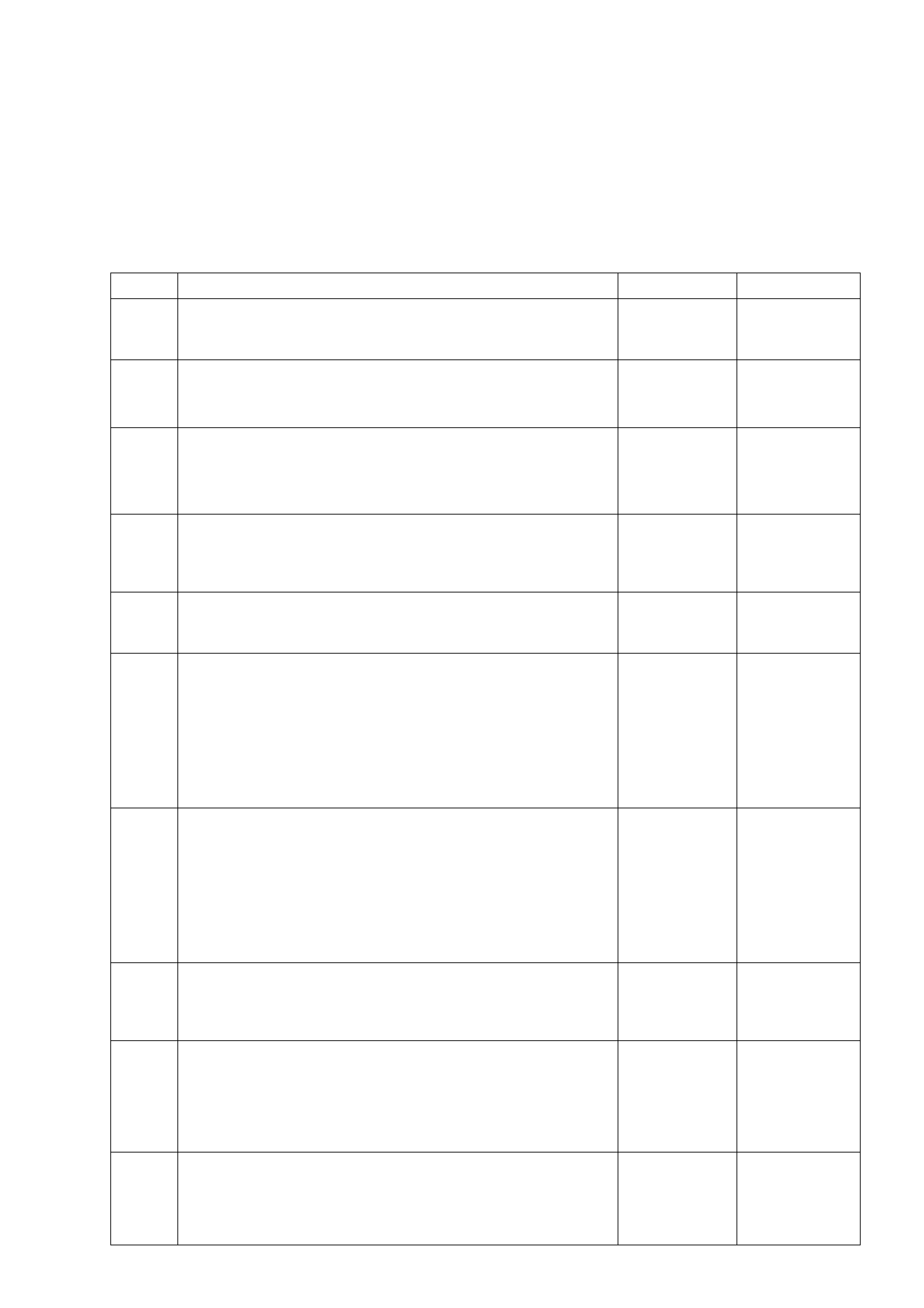

1.7 ENGINE COOLING FAN LOW SPEED CONTROL

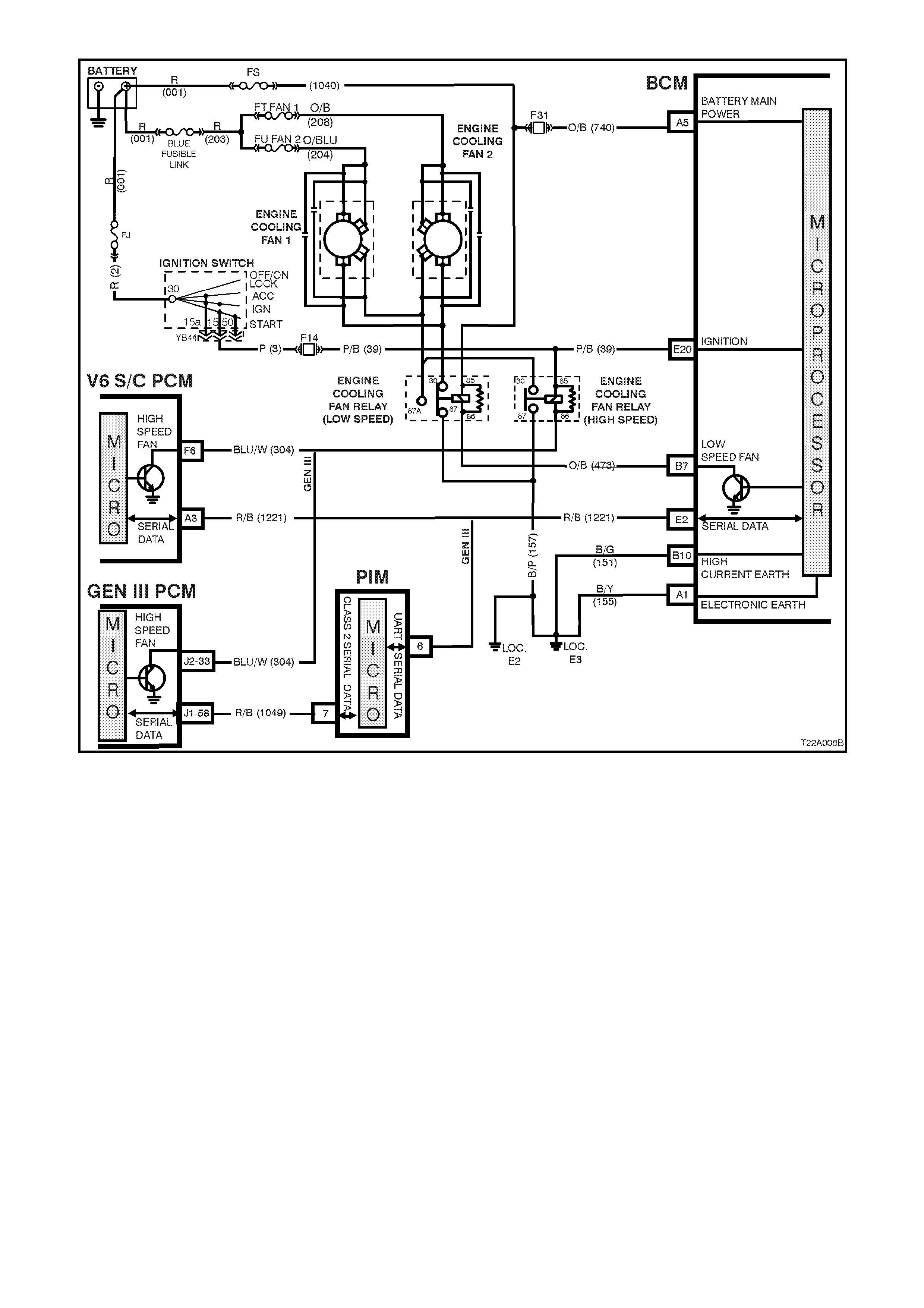

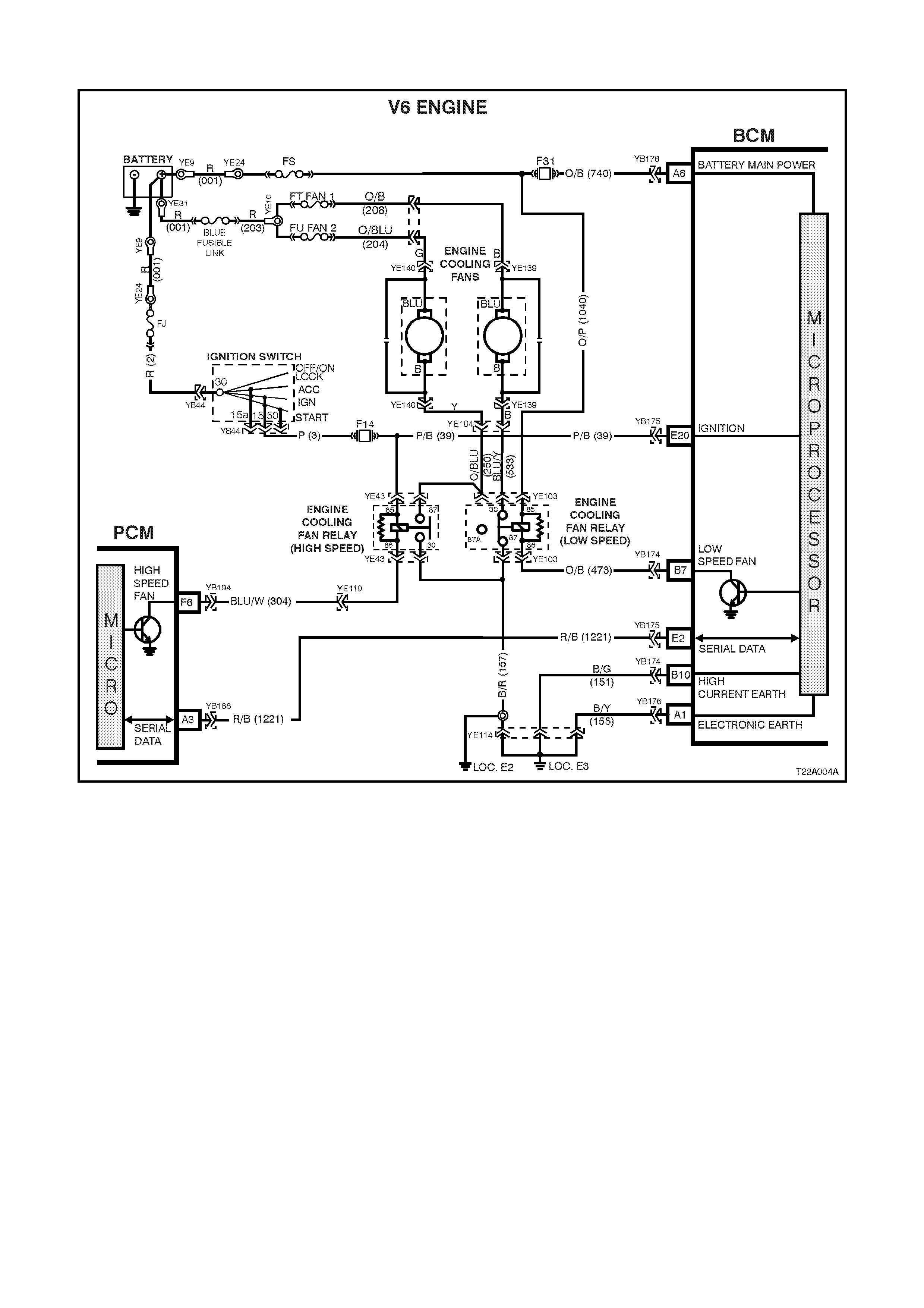

GENERAL INFORMATION (Refer to Figs. 12J-2-25, 12J-2-26 and 12J-2-27)

VT Series II Models with V6 engines have two single speed electr ic engine cooling fans; a low speed f an and a high

speed fan. All other VT Series Models, r egardless of the engine c onfiguration (including G EN III V8), are equipped

with two, two speed electric cooling fans.

The engine cooling fan assemblies provide the primary means of moving air through the engine radiator. These

fans are placed between the radiator and the engine and have their own shroud. These fans configurations are

used on all vehicles even if not equipped with air conditioning. There is no fan in front of the A/C condenser.

The electric engine cooling fans are used to cool engine coolant flowing through the radiator, and if fitted, refrigerant

flowing through the A/C condenser.

On vehicles with V6 engines, the engine cooling fan m otors have two term inals ; one positive and one negative. T he

positive terminals are permanently connected to battery voltage. When the negative terminal is connected to

earthed through the low speed cooling fan relay, the low speed cooling fan will operate. When the negative term inal

is connected to earth via the high speed cooling fan relay, both cooling fans will operate.

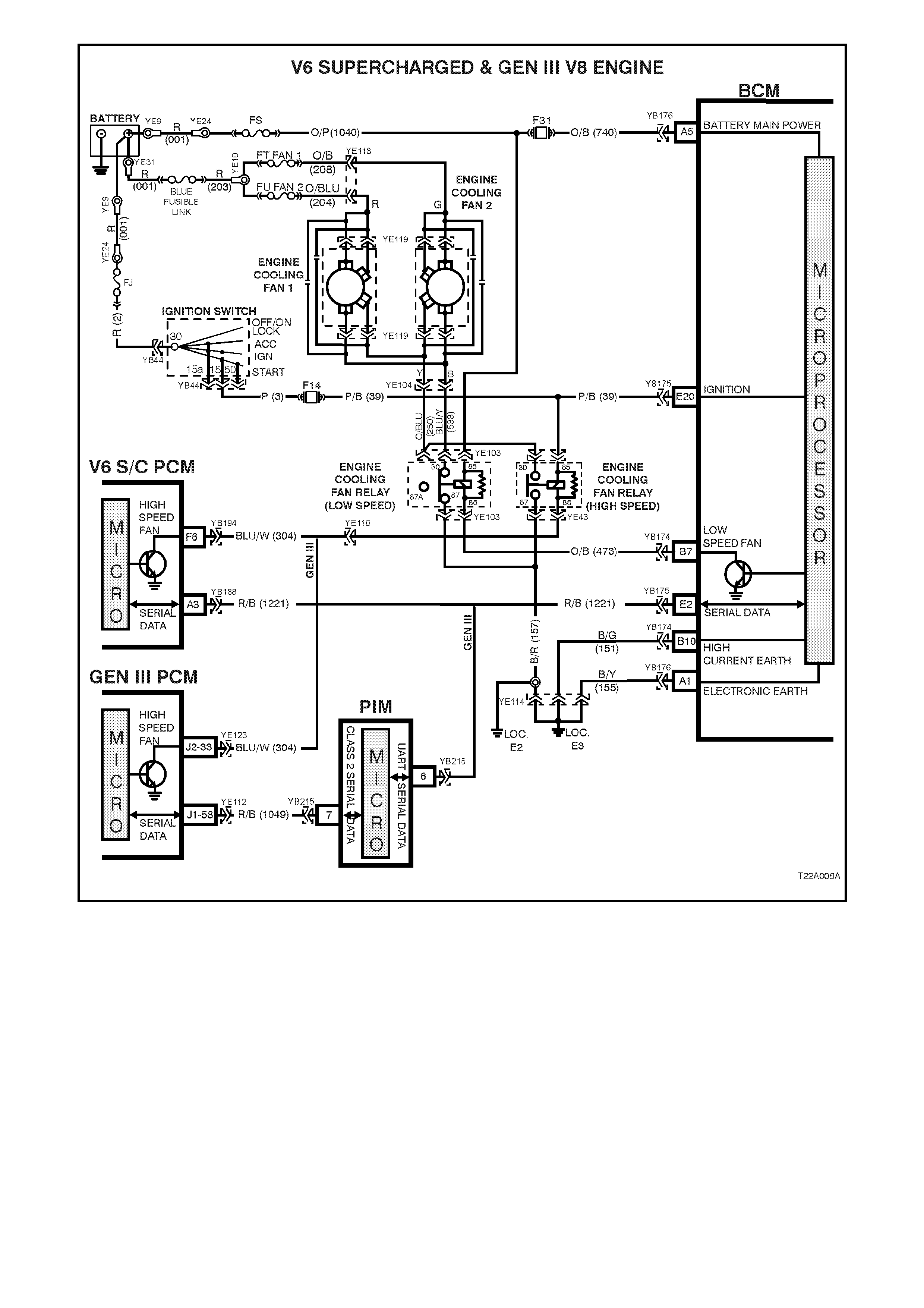

On vehicles with either V6 supercharged or GEN III V8 engines , the engine cooling fan m otors have f our term inals,

two negative and two positive terminals. The two positive terminals are permanently connected to battery voltage.

When one of the negative terminals is earthed, both cooling fan motors will operate at low speed. When both

negative terminals are earthed, both cooling fans will operate at high speed.

Regardless of the engine configuration, the low speed cooling f an operation is enabled when the low speed engine

cooling fan micr o r elay (located in the engine com par tment relay housing, labelled Lo Fan) is ener gis ed by the Body

Control Module (BCM) via a request from the Powertrain Control Module (PCM). The PCM will request low speed

fan enable and disable via serial data communication to the BCM on circuit 1221 (Red/Black wire). After the PCM

requests a change in the state of the low speed relay (i.e. OFF to ON or ON to OFF), the BCM will send a serial

data response message back to the PCM confirming it received the message.

NOTE: On vehicles with GEN III V8 engines, serial data communication between the PCM and BCM is via the

Powertrain Interface Module (PIM).

The PCM determ ines when to enable the low speed fan relay based on inputs from the A/C reques t signal, Cooling

Temperature Sensor (CTS) and the Vehicle Speed Sensor (VSS).

For information regarding the engine cooling fan high speed control, refer to either Section 2A HEATING & AIR

CONDITIONING - DESCRIPTION & OPERATION, or, depending on the engine variation,

Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE of the VT Series I Service Information

Section 6C3 POWERTRAIN MANAGEMENT - GEN III V8 ENGINE of the VT Series II Service Information.

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and therefore, only the main connectors and wiring colours are shown. For complete circuit details, refer to

either the relevant diagnostic section or Section 12P WIRING DIAGRAMS of the VT Series II Service Information.

SYSTEM OVERVIEW - ENGINE COOLING FAN, LOW SPEED CONTROL

BATTERY POWER

BCM

PCM

ENGINE COOLING FAN

LOW SPEED RELAY

T212J2052

VEHICLE SPEED

ENGINE COOLANT

TEMPERATURE

A/C REQUEST

PIM

GEN III V8

EN G INE

V6 & V6 S/C

ENG INE

S

E

R

I

A

L

D

A

T

A

Figure 12J-2-25 Main serial data communication circuit

CIRCUIT OPERATION

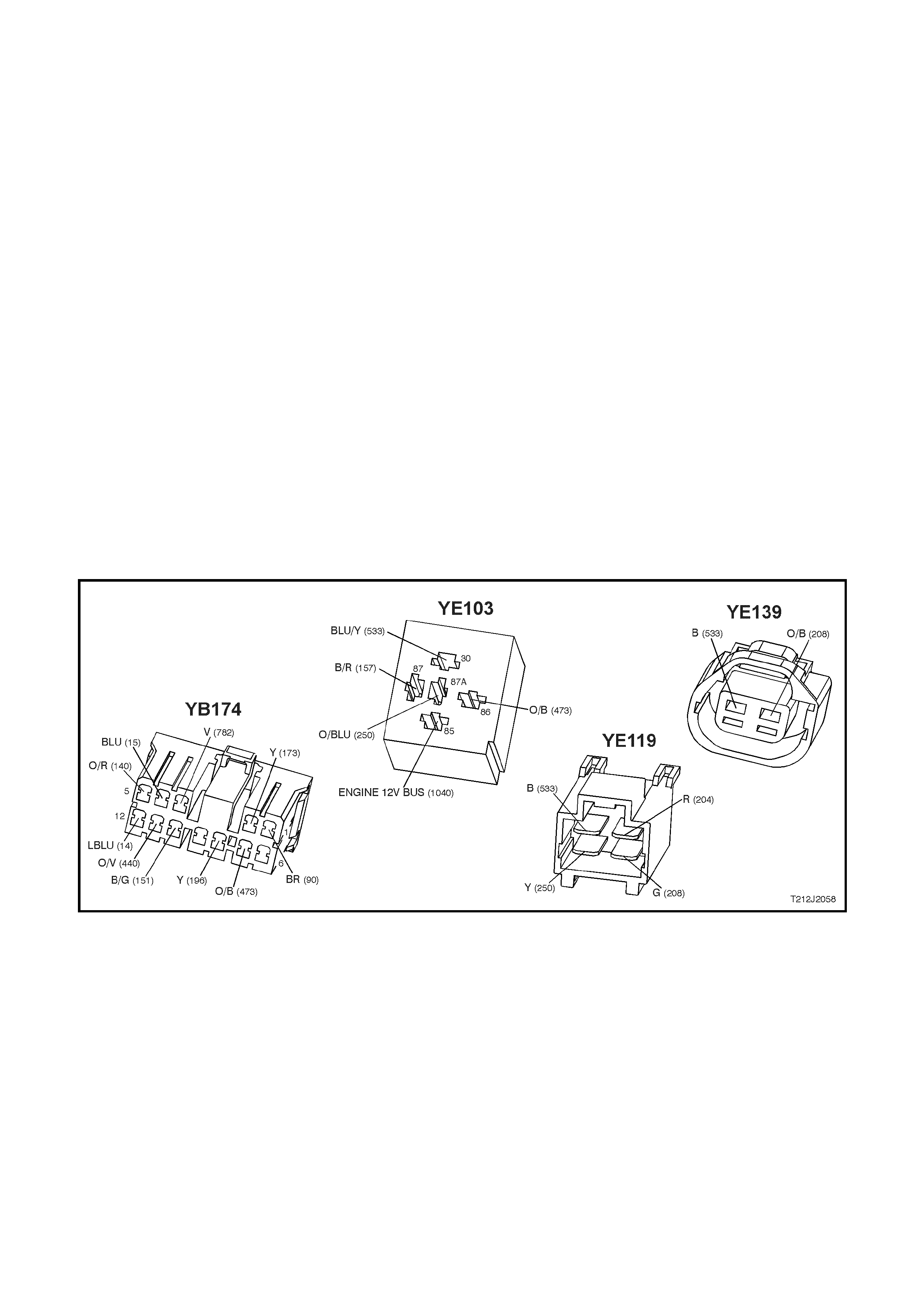

V6 ENGINE (refer Fig. 12J-2-26)

The engine cooling low speed fan relay is energised by the BCM earthing terminal B7, circuit 473 (Orange/Brown

wire). This causes the relay contacts to switch over from 30-87A to 30-87 and circuit 157 (Black/Pink wire) is

earthed through the relay and to the low speed fan terminal on circuit 533 (Blue/Yellow wire). Battery voltage is

supplied to the other low speed fan terminal via circuit 208 (Yellow wire).

V6 SUPERCHARGED & GEN III V8 ENGINES (refer Fig. 12J-2-27)

The engine cooling low speed fan relay is energised by the BCM earthing terminal B7, circuit 473 (Orange/Brown

wire). This causes the relay contacts to switch over from 30-87A to 30-87 and circuit 157 (Black/Pink wire) is

earthed through the relay and to the low speed fan term inal on circuit 533 (Blue/Yellow wire). T he other low speed

fan terminal is connected to battery voltage via circuit 204 (Orange wire).

LOW SPEED FAN OPERATION

The low speed cooling fan relay will be turned ON when:

•Air conditioning request indicated (YES) and the vehicle speed is less than 30 km/h or

•Air conditioning pressure is greater than 1500 kPa or

•Coolant temperature is greater than 104°C (V6 and V6 supercharged) / 98°C (GEN III V8) or

•Vehicles with V6 and V6 supercharged engines; an engine coolant temperature sensor failure is detected by

the PCM, refer to Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE for additional information.

Vehicles with GEN III V8 engines; when a coolant tem perature sens or failure in conjunction with an Intake Air

Temperature (IAT) sensor failure is detected by the PCM, refer to Section 6C3 POWERTRAIN

MANAGEMENT - GEN III V8 ENGINE for additional information.

•When the ignition switch is turned from ON to OFF and the engine coolant temperature is above 117°C (V6

and V6 superchar ged) / 113°C (GEN III V8). T he BCM will continue to energise the low speed engine cooling

fan micro relay for four minutes.

The PCM will request the BCM to switch off the low speed cooling fan relay when the following conditions have

been met:

•Air conditioning request not indicated (NO) and the coolant temperature is less than 99°C (V6 and V6

supercharged) / 95°C (GEN III V8) or

•Air conditioning reques t indic ated (YES) with press ure les s than 1170 kPa, vehic le speed gr eater than 50 km /h

and coolant temperature less than 99°C (V6 and V6 supercharged) / 98°C (GEN III V8).

NOTE: On vehicles with GEN III V8 engines, the low speed cooling fan run on time has a minimum default

value of 30 seconds.

Figure 12J-2-26 V6 engine - cooling fan low speed control

Figure 12J-2-27 V6 supercharged and GEN III engine - cooling fan low speed control

1.8 AUTOMATIC LIGHTS OFF (WITHOUT TWILIGHT SENTINEL)

GENERAL INFORMATION

The autom atic light control (lights off ) feature is designed to automatic ally switch the headlam ps and park ing lam ps

off when the driver leaves the vehicle.

NOTE: Sinc e this system is safety related, it is m andatory that in the event of a s ystem failure, the def ault status of

the BCM light control outputs ar e in the ON s tate when the ignition switch is in the IGN pos ition. T his will give dir ect

control of the lights to the headlamp switch.

The sequence of events required to switch the lights off automatically are as follows:

1. The vehicle road speed input to the BCM indicates speed is les s than 10 k ilometr es per hour and there has not

been a sudden loss of speed (ignition being switched off with the vehicle travelling above 10 km/h).

2. The BCM senses that the ignition switch is turned from ON to OFF and remains in the off position.

3. The headlamp switch has not been turned on after the ignition switch was turned off.

4. The BCM senses the driver's door has been opened or that it is already open.

W hen the ignition switch is turned back to IGN position, the lights will turn back on to the position selected by the

headlamp switch and the mode of headlamps operation (ie. high or low beam or fog lam ps [if fitted]) determ ined by

the position of the relevant switches.

Turning the headlamp switch off deactivates the automatic lights system.

There is a delay period before the automatic lights off featur e deactivates the vehic le lights. T his tim e period c an be

set by the driver using the following procedure.

1. Turn ignition switch to the IGN position, switch parking lamps on and close the driver's door.

2. Hold the headlamp switch instrument cluster illumination switch control lever in the down position continuously.

3. Turn the ignition switch to the ACC position.

4. Open the driver's door.

This initiates the start of the time delay period.

5. Wait the required delay time period and release the illumination switch control lever.

6. Turn the ignition switch to the OFF position

This sets the time delay period and switches off the parking lamps.

The delay period adjustment is only possible whilst road speed input to the BCM is zero. A maximum of 180

seconds applies to the time delay period and the default setting is 0 seconds. The time delay period resets to

default value whenever the battery or fuse F31 is disconnected from the vehicle.

This time delay is also dependent on the priority key system . The tim e delay period can be set f or the priority 1

and priority 2 keys. The time delay is recalled when the unlock button on the remote is pressed and is

dependent on whether priority 1 or priority 2 key is used.

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and theref ore, only the m ain connectors and wiring colours ar e shown. For com plete circuits details, refer to

either the relevant diagnostic section or Section 12P WIRING DIAGRAMS of the VT Series II Service Information.

SYSTEM OVERVIEW - AUTOMATIC LIGHTS OFF

BCM

BATTERY POWER

IGNITION SWITCH ON

INST RUM ENT D I MMI NG /

PARK LAMP SWITCH

DRIVER’S DOOR JAMB SW ITCH

T212J2053

HEADLAMP RELAY

PARKING LAMP RELAY

SERIAL DATA

VEHICLE SPEED

PCM

PIM

GEN III V8

ENGINE V6 & V6 S/C

ENGINE

CIRCUIT OPERATION

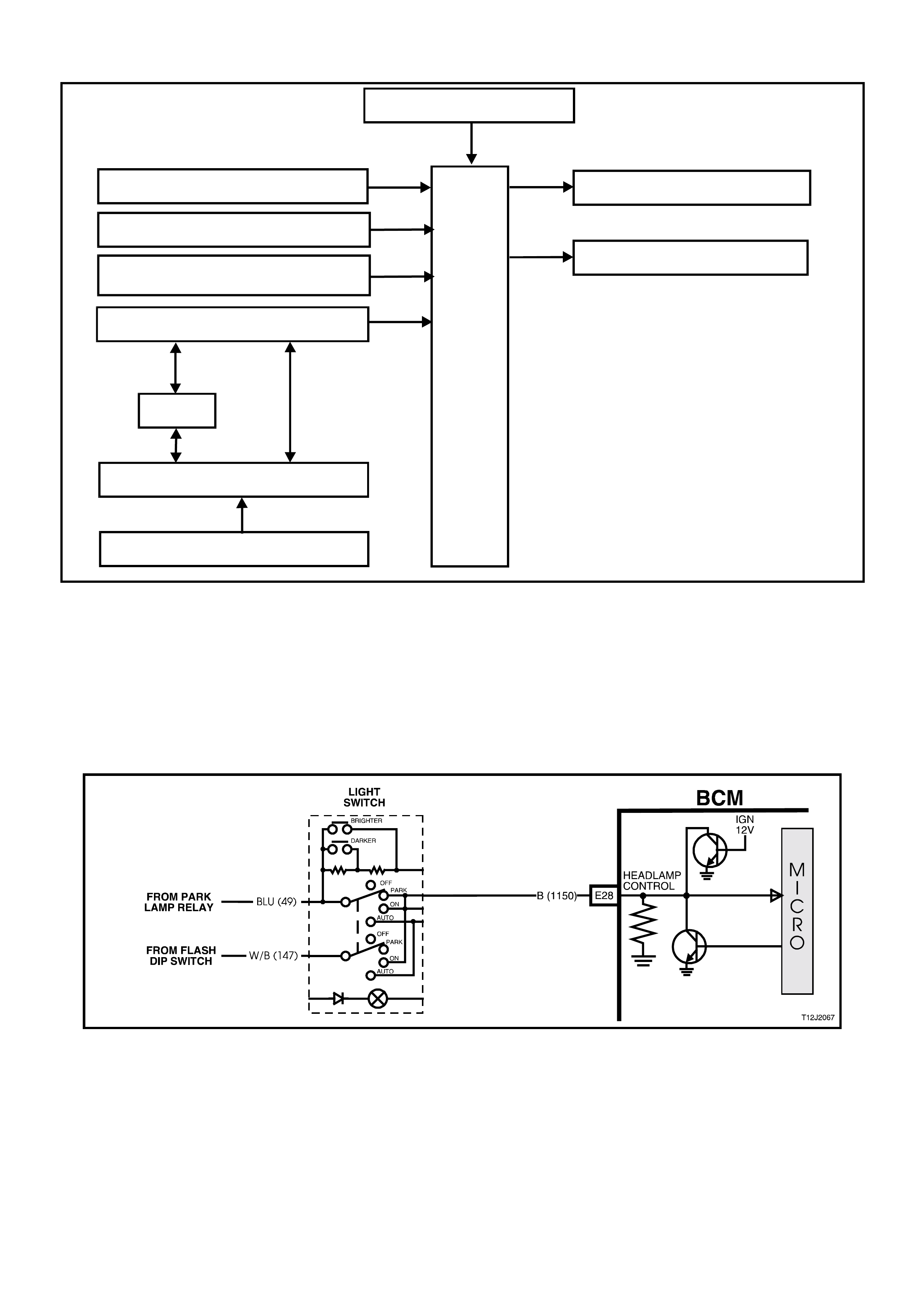

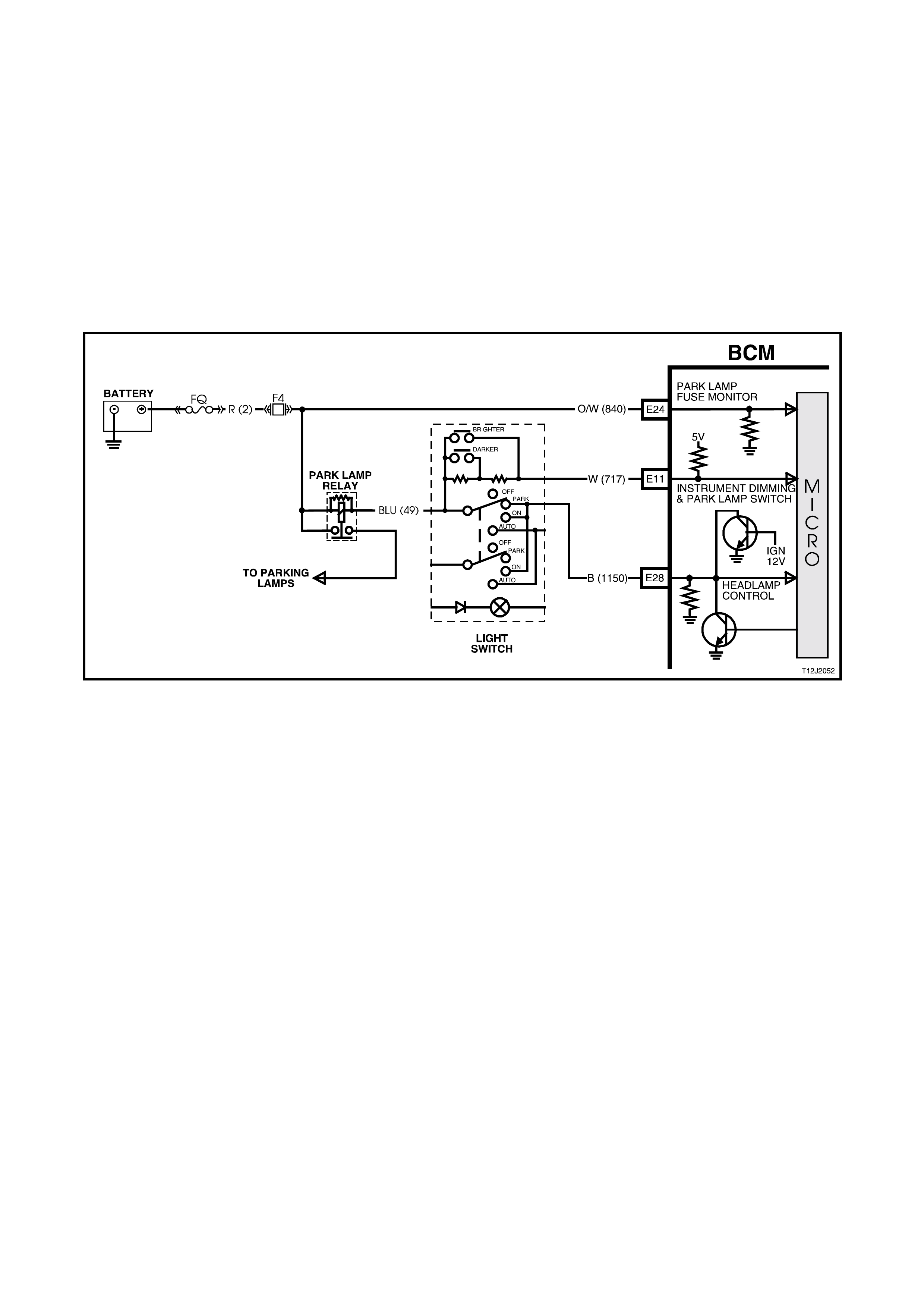

Headlamp Control Input Signal (Refer to Fig. 12J-2-28)

The BCM m onitor s the voltage on term inal E28 to determine the pos ition of the headlam p and park ing lam p switch.

W hen the headlam ps or parking lam p are on, the voltage at BCM term inal E28 will be less than 0.2 volt. W hen the

automatic headlamps OFF system has turned the lights off, the voltage at terminal E28 will be 12 volts. If the

headlamp s witch is turned of f, the voltage at term inal E28 will be less than 0.2 volt. T he BCM s ees this low voltage

at terminal E28 as a change in status of the headlamp switch and will turn the automatic lights system off. The lights

will then turn back on when a change in position of the switch occurs.

Figure 12J-2-28 Headlamp control input signal

Driver’s Door Open Input Signal (Refer to Fig. 12J-2-29)

W hen the dr iver’s door is opened, BCM ter minal C8 is connected to earth via circuit 126 (G rey/White wire) and the

driver's door jamb switch. This causes the voltage at terminal C8 to pulled low, less than 0.2 volt (driver's door

open). This low voltage at terminal C8 is seen by the BCM as the driver's door open input signal.

Figure 12J-2-29 Driver’s door open input signal

Vehicle Speed Signal (Refer to Fig. 12J-2-30)

The BCM, terminal E2, receives vehicle speed information from the PCM/PIM via the serial communications bus,

circuit 1221 (Red/Black wire).

Figure 12J-2-30 Vehicle speed signal

BCM

R/B (1221) E2 SERIAL DATA

5V

B/G (151)

B10

B/Y (151)

A1

HIGH

CURRENT EARTH

T212J2038

ELECTRONIC EARTH

M

I

C

R

O

BLU/W (831)

BLU/W (831)

T (832)

V6

GEN III

GEN III

V6

T (832)

INTEGRATED

CIRCUIT

INTEGRATED

CIRCUIT

M

I

C

R

O

M

I

C

R

O

V6 PCM

GEN III V8 PCM

SERIAL DATA

5V

A3

C6

D5

VEHICLE

SPEED

SENSOR

R/B (1049)J1-58

J2-21

J2-20

CLASS II

SERIAL DATA

7V

PIM

6

7

M

I

C

R

O

CLASS 2 SERIAL DATA

UART SERIAL DATA

Ignition Switch ON Input Signal (Refer to Fig. 12J-2-31)

The BCM uses this input signal to determine when the ignition switch is in the IGN or START position. W hen the

ignition switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 f rom the ignition

switch and fuse F14 via circuit 39 (Pink/Black wire).

M

I

C

R

O

BCM

T212J2013

BATTERY

FS

F31

A5

O/B (740 )

(1040)

BAT T ERY MAIN POWER

FJ

R ( 2)

F14

E20

P/ B (39)

IGNITION ON

15a 1550

30 ACC

IGN

START

IGNITION

SWITCH

P (3)

Figure 12J-2-31 Ignition switch on input signal

Instrument Illumination Dimmer Switch Input (Refer To Fig. 12J-2-32)

W hen the illumination switch lever is in the down position (DIM-), BCM terminal E11 is connected to earth via the

headlamp s witch and the 2.7 kilohm resistor in the switch as sembly. This causes the voltage at BCM terminal E11

to go from above 5 volts to approximately 1.3 volts. This voltage at BCM terminal E11 is seen by the BCM as the

input signal that determines the delay period for the automatic lights off feature for the period that the voltage is

present.

NOTE: This circuit will only work while the headlamp switch is in the PARK or ON positions and the ignition switch is

in the ACC or IGN positions.

Figure 12J-2-32 Instrument illumination dimming switch input

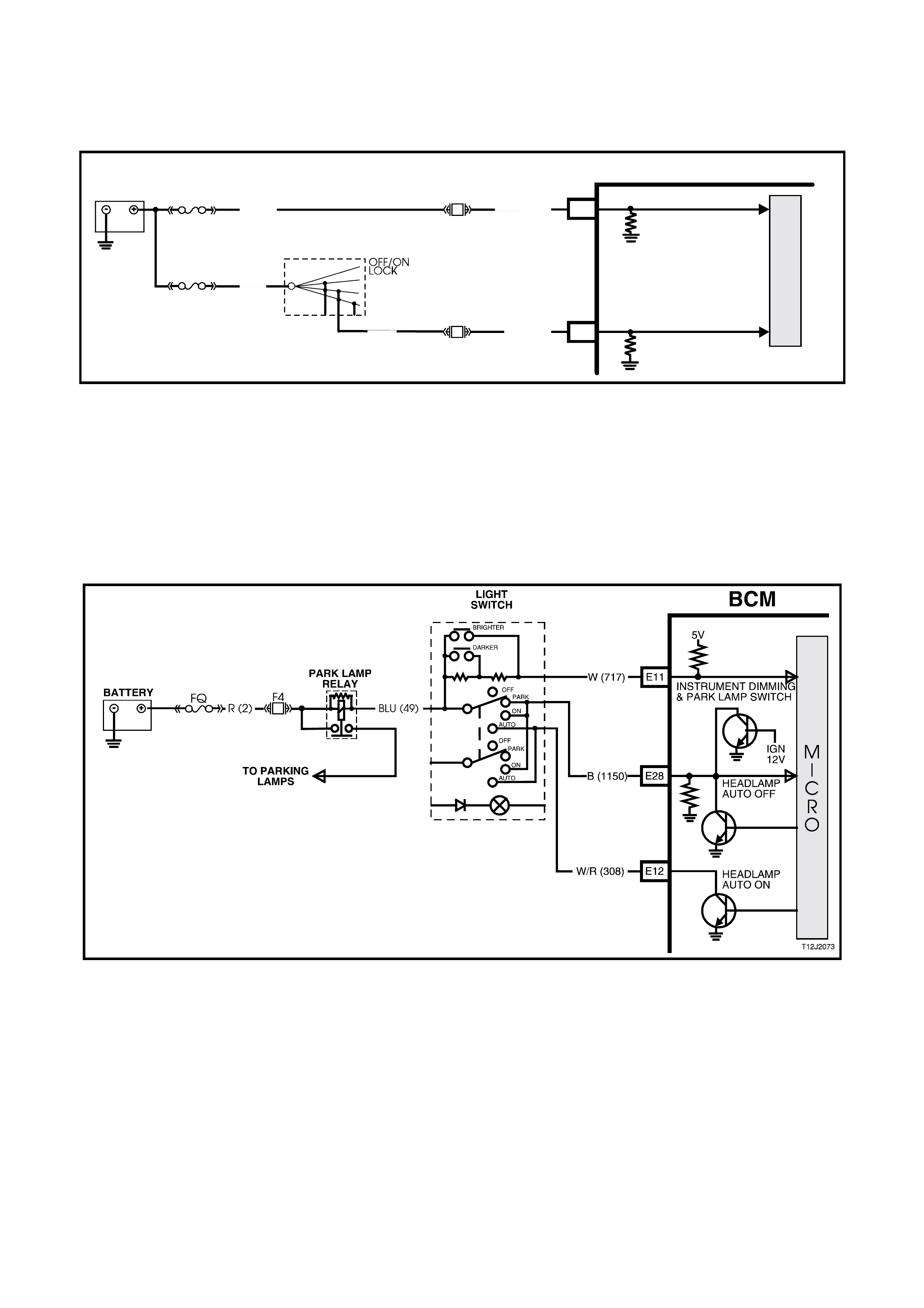

Power Supplies (Refer to Fig. 12J-2-33)

Battery voltage is applied to the low, high beam and fog lamps (if fitted) relays from fusible link FQ, circuit 2 (Red

wire) and fuses F30 and F29.

Battery voltage is applied to the parking lamps re lay from f us ible link FQ c irc uit 2 ( Red wire) and f us e F 4, cir cuit 840

(Orange/White wire).

The BCM controls the operation of the exterior light circuits by enabling its internal control circuit, which provides the

earth circuit for the relays.

High Beam Relay Earth Circuit (Refer to Fig. 12J-2-33)

The earth circuit for the high beam headlamp relay is via circuit 10, (Blue/Yellow wire), through the headlamp and

turn signal control (flash/dip) switch assembly, circuit 147 (White/Black wire), headlamp switch contacts to BCM

terminal E28, circuit 1150 (Black wire) and then to earth through internal switching.

Low Beam Relay Earth Circuit (Refer to Fig. 12J-2-33)

The earth circuit for the low beam headlamp relay is via 103 (White wire), through the headlamp and turn signal

control (f lash/dip) switch ass em bly, circuit 147 (White/Black wire), headlam p switch contrac ts to BCM term inal E28,

circuit 1150 (Black wire) and then to earth through internal switching.

Parking Lamps Relay Earth Circuit (Refer to Fig. 12J-2-33)

The earth circuit for the parking lamps relay is via the closed parking lamps contacts in the headlamp switch,

through BCM terminal E28, circuit 1150 (Black wire) and then to earth through internal switching.

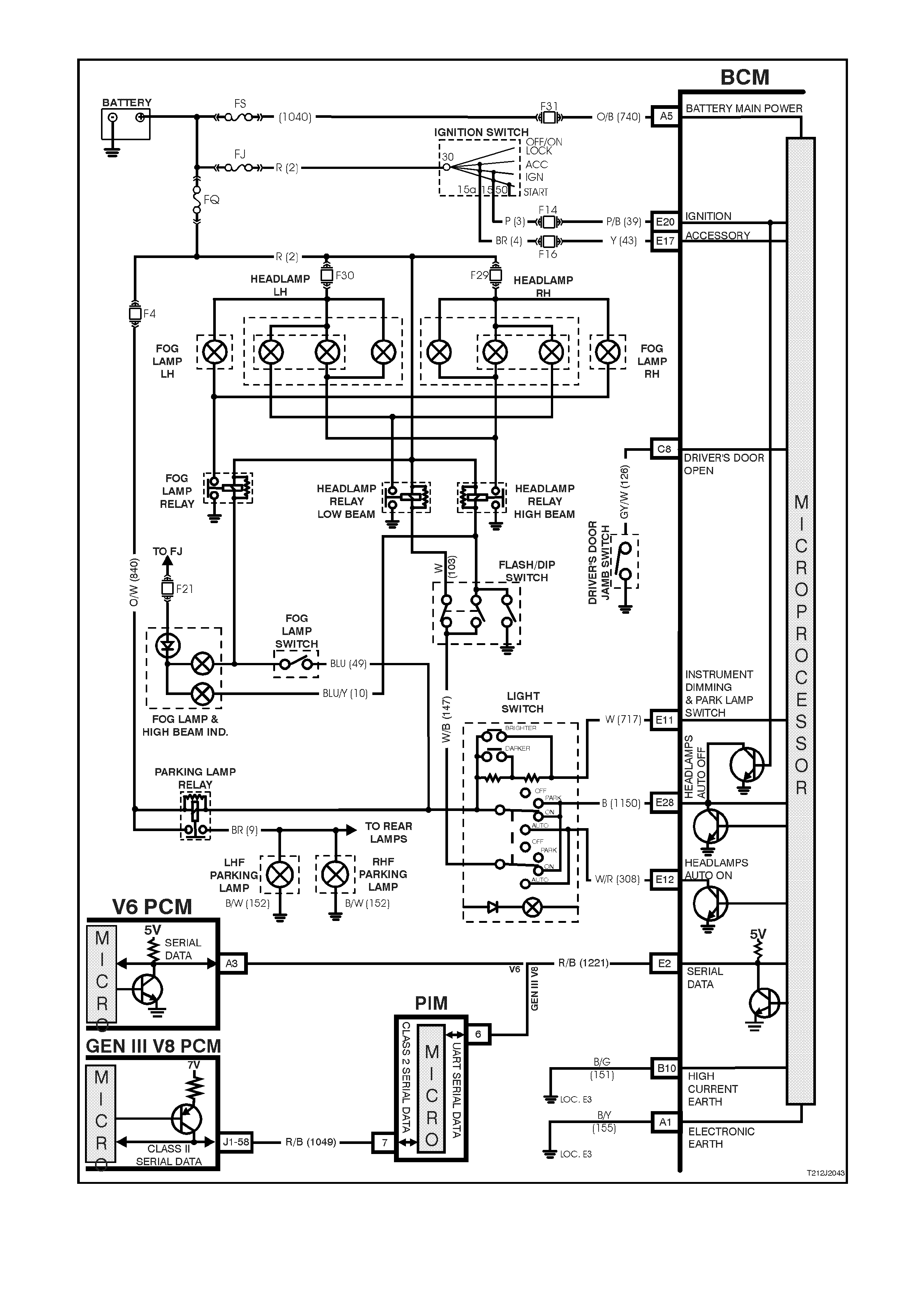

Figure 12J-2-33 Automatic lights off control circuit

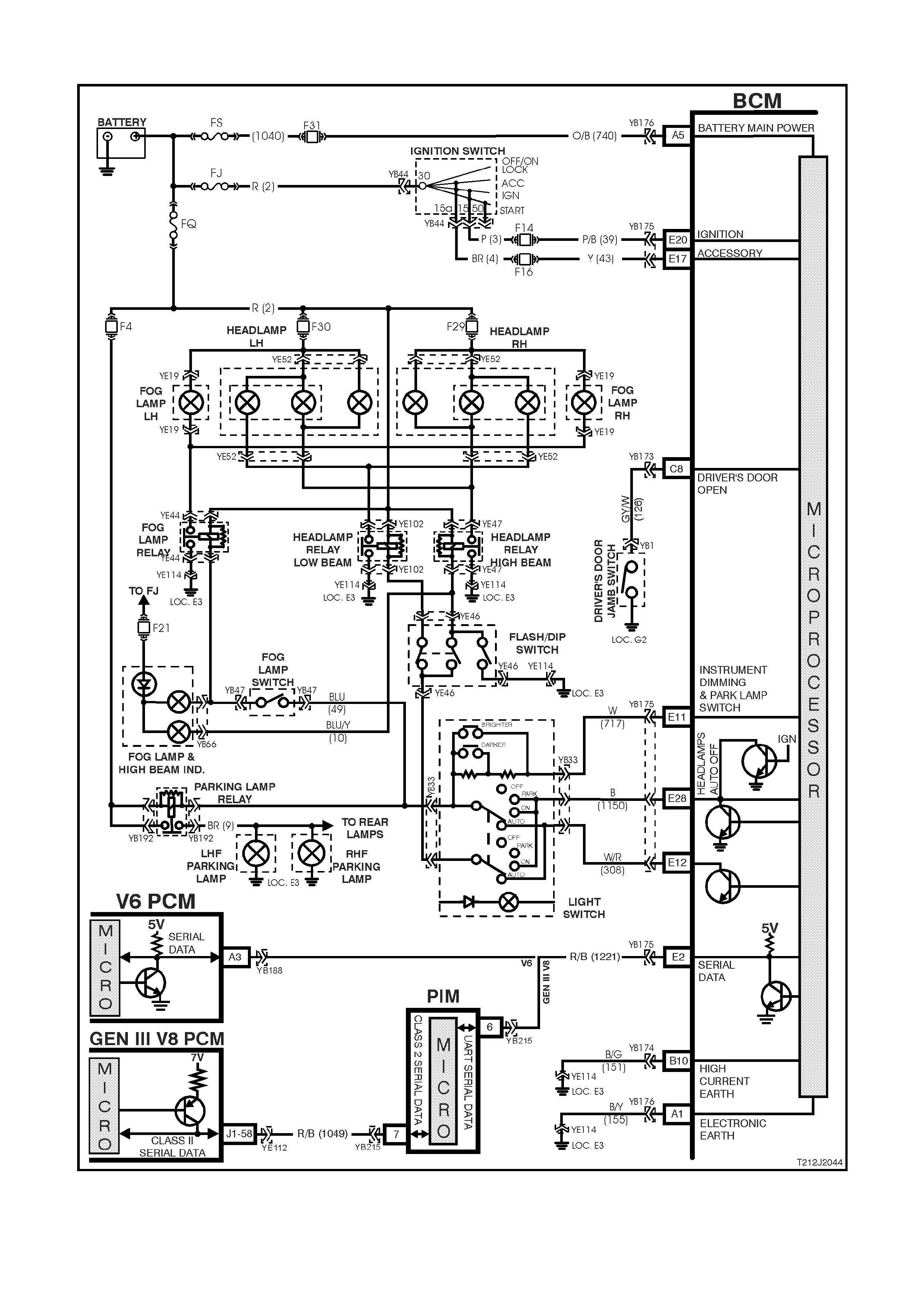

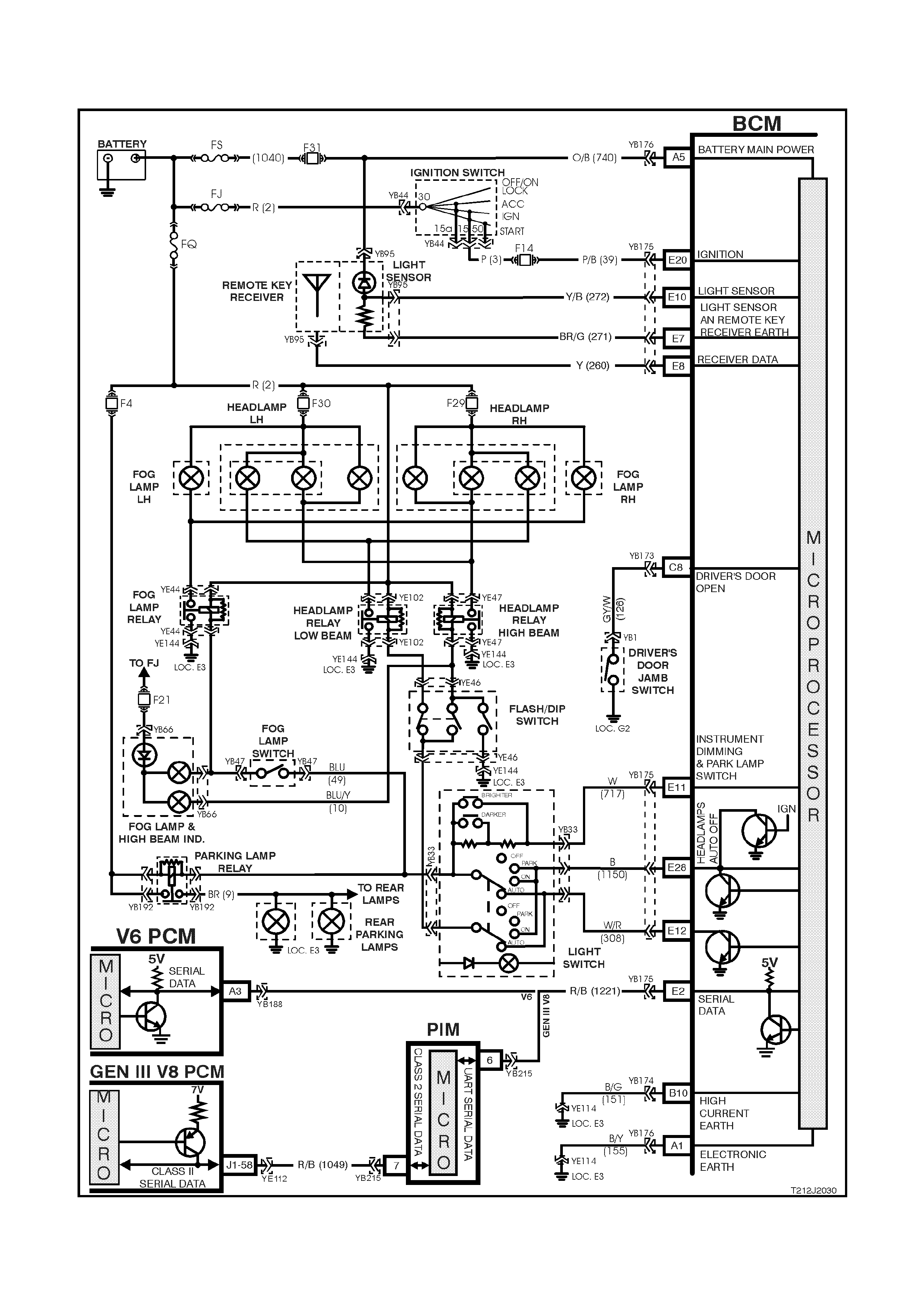

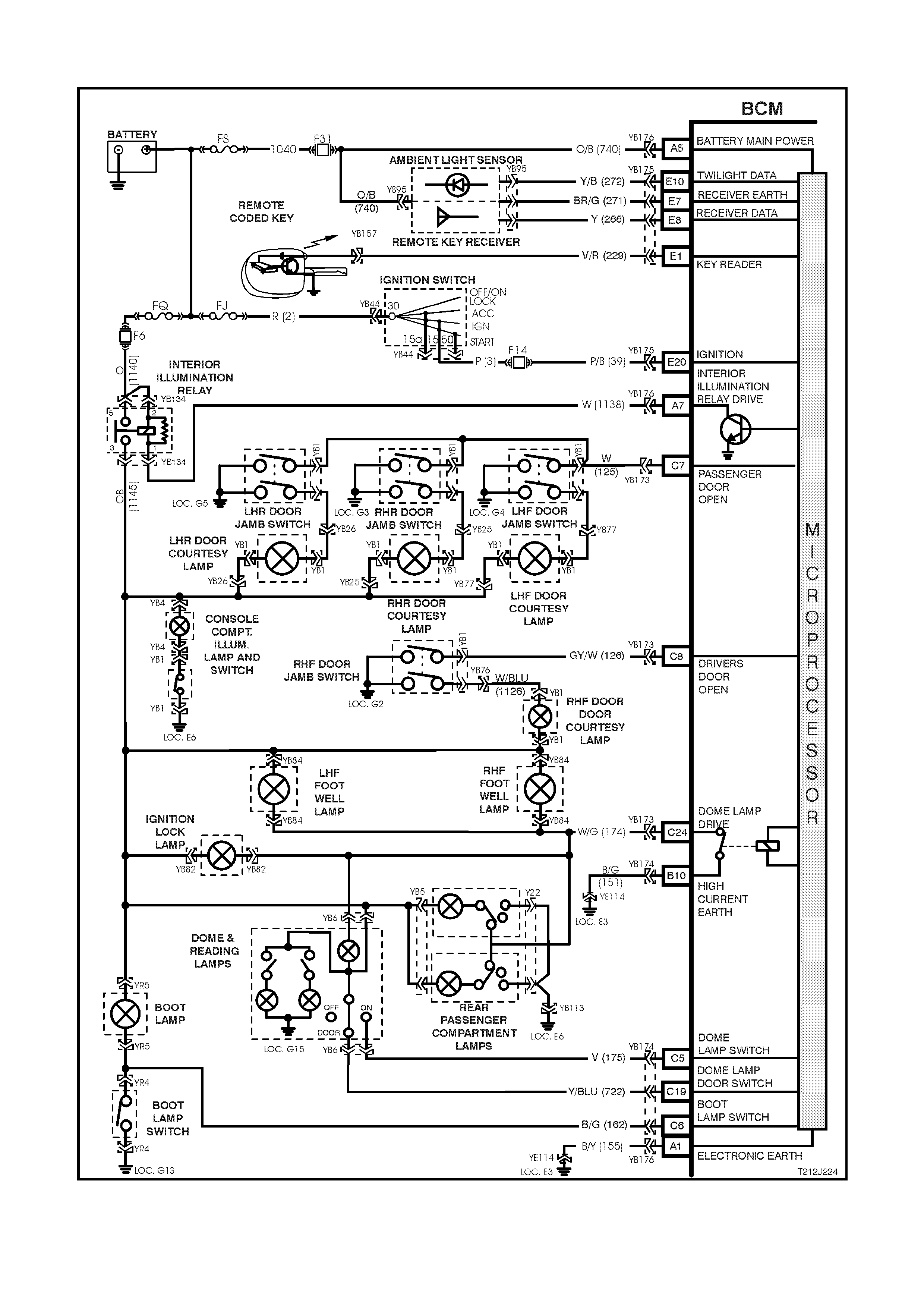

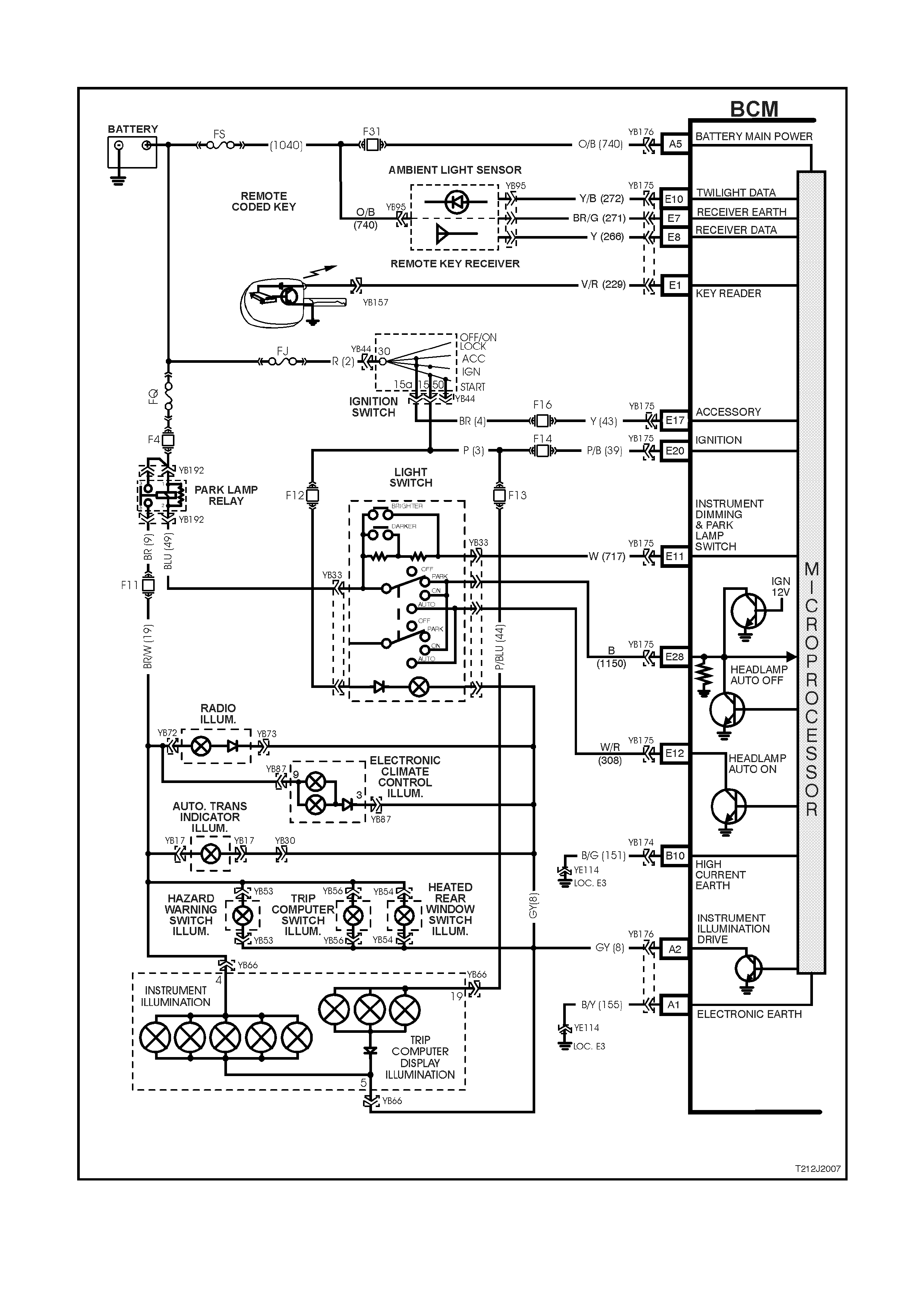

1.9 AUTOMATIC LIGHT CONTROL -LIGHTS ON AND

OFF / APPROACH ILLUMINATION (WITH TWILIGHT SENTINEL)

GENERAL INFORMATION

NOTE: The circuit diagr am s shown in this G eneral Desc ription Section ar e to aid in interpreting the oper ation of the

circuit and theref ore, only the m ain connectors and wiring colours ar e shown. For com plete circuits details, refer to

either the relevant diagnostic section or Section 12P WIRING DIAGRAMS of the VT Series II Service Information.

Automatic lights ON and OFF (High Series BCM only)

The autom atic light control (lights on and of f) f eature (with twilight sentinel) turns the vehicle headlamps on and off,

depending on the outside light level. This feature will work only while the headlamp switch is in the Auto position and

the ignition on. The lights will operate as normal in other switch positions.

The operation of the headlamps when the ignition is switched off and the headlam p switch in the Auto position will

be the same as the Auto lights off operation.

A sensor is m ounted in the instr um ent panel pad of the vehic le to monitor the am ount of light in f ront of the vehicle.

The BCM monitors the output of this sensor and determ ines when the light levels are low enough to turn them on.

TECH 2 can be used to select several different ON/OFF light levels to suit the customer preferences.

Approach illumination (High Series BCM)

The approach illumination feature turns the vehicle head and/or park lamps (dependant on headlamp switch

position) on for 30 seconds when the doors are unlocked with the remote coded key.

This provides additional c ustom er secur ity when approaching the vehic le at night. T he lights will tur n of f again if the

vehicle is locked with the remote coded key within 30 seconds of the approach illumination being activated.

When the approach feature is activated, subs equent operation of the remote coded key unlock button will reactivate

the lights to remain on for a further 30 seconds.

The approach illumination feature only operates during dark conditions. The BCM monitors the output of the sun

sensor and determines when the light levels are low enough to enable the approach illumination feature.

The lights resume to normal operation when the ignition is switched to the on position.

TECH 2 has the capability to enable and disable the approach illumination feature.

SYSTEM OVERVIEW - AUTOMATIC LIGHTS ON / APPROACH ILLUMINATION

BATTERY POWER

BCM

HEADLAMP RELAY

PARK LAMP RELAY

REMOTE RECEIVER

LIGHT SENSOR

(SUN SENSOR)

T212J2009

IGNITION SWITCH ON

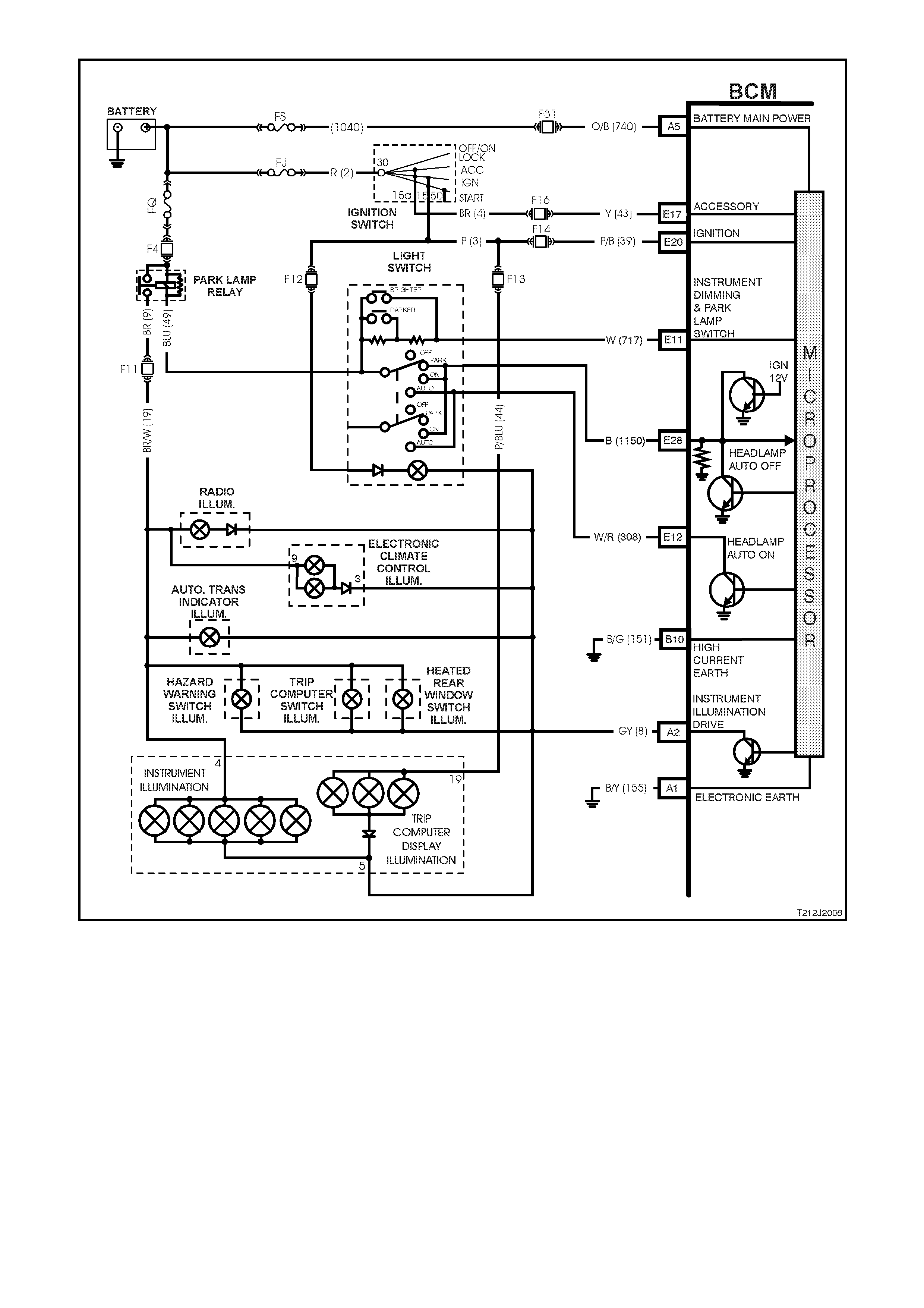

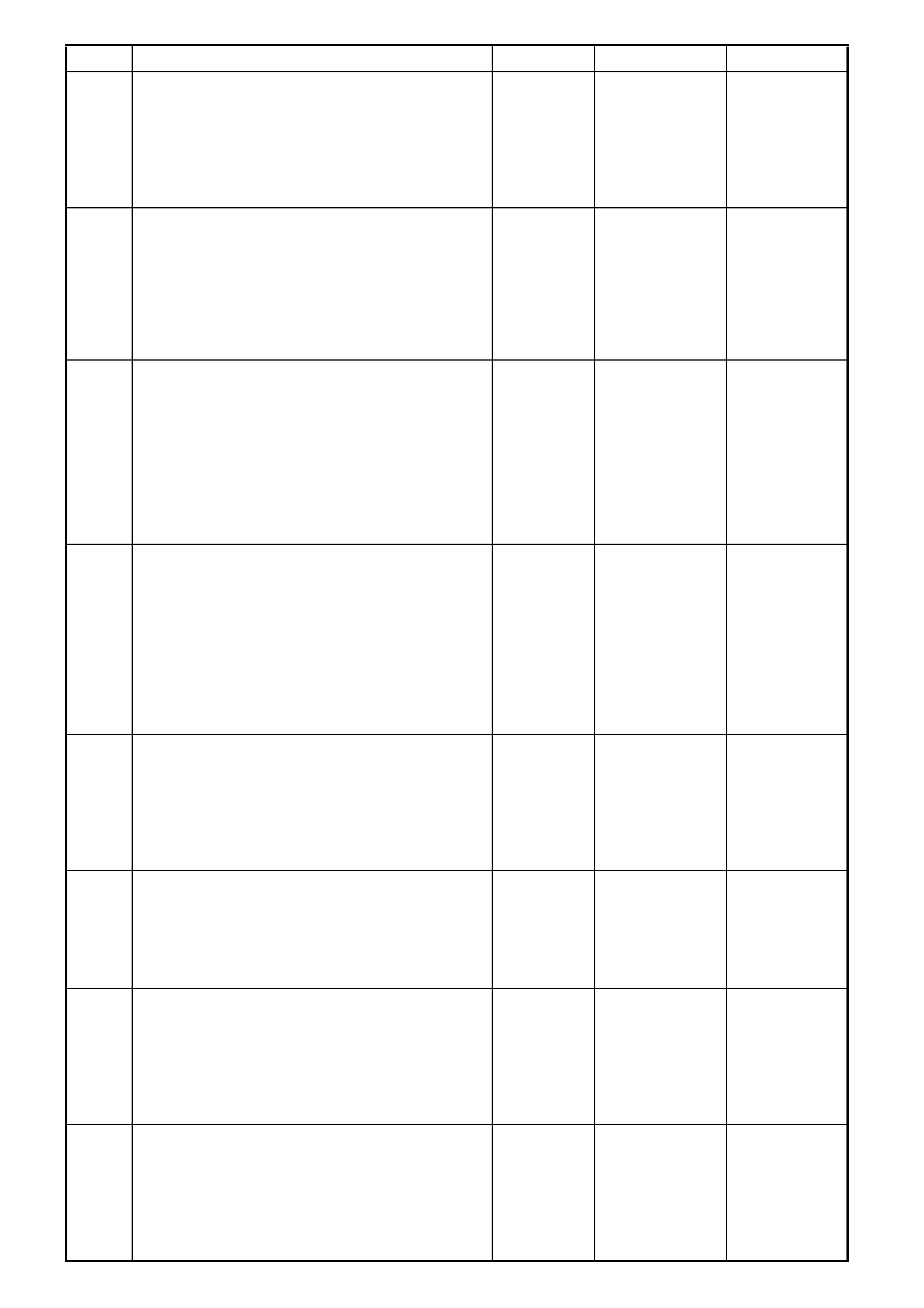

CIRCUIT OPERATION (Refer to Fig. 12J-2-36)

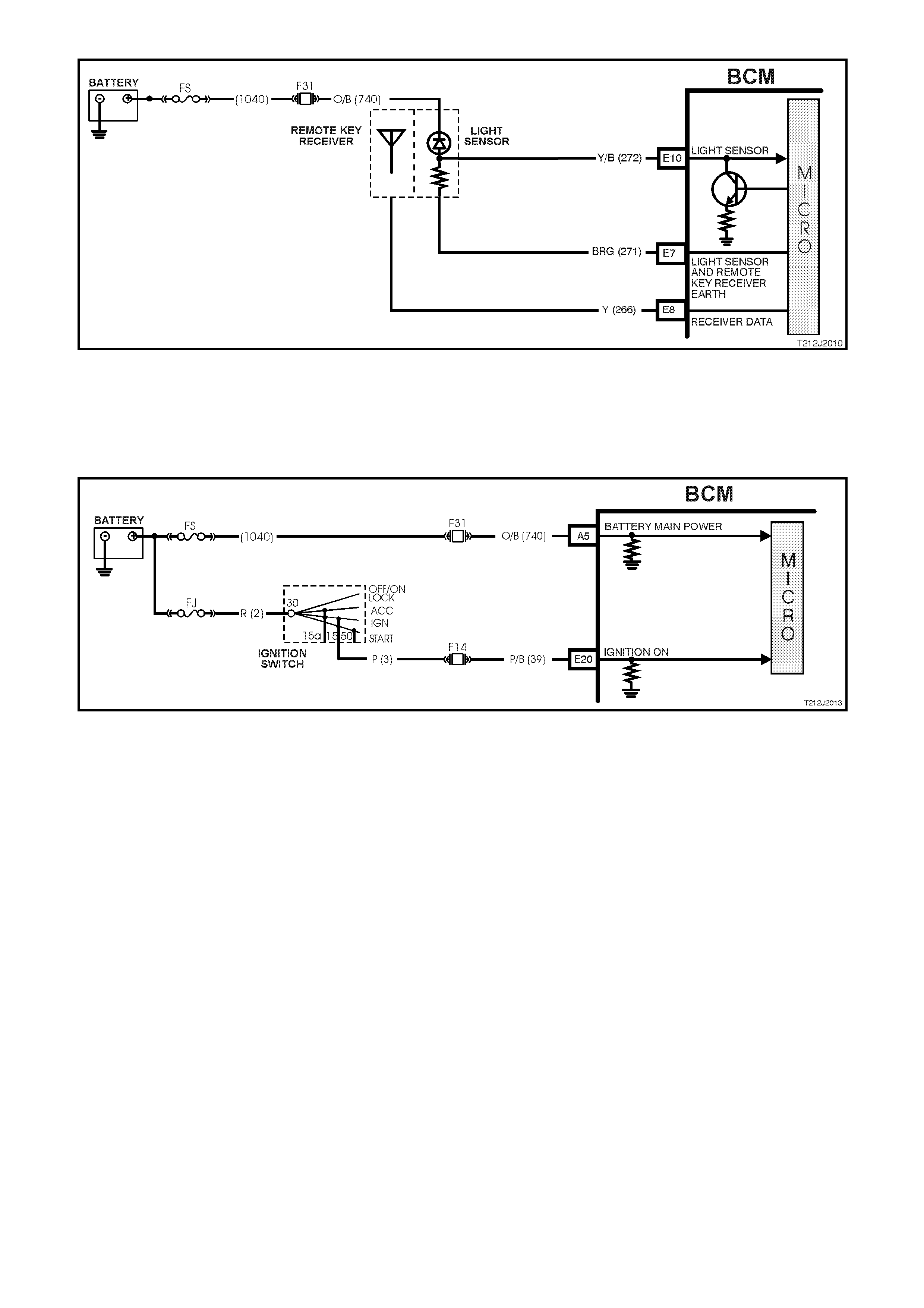

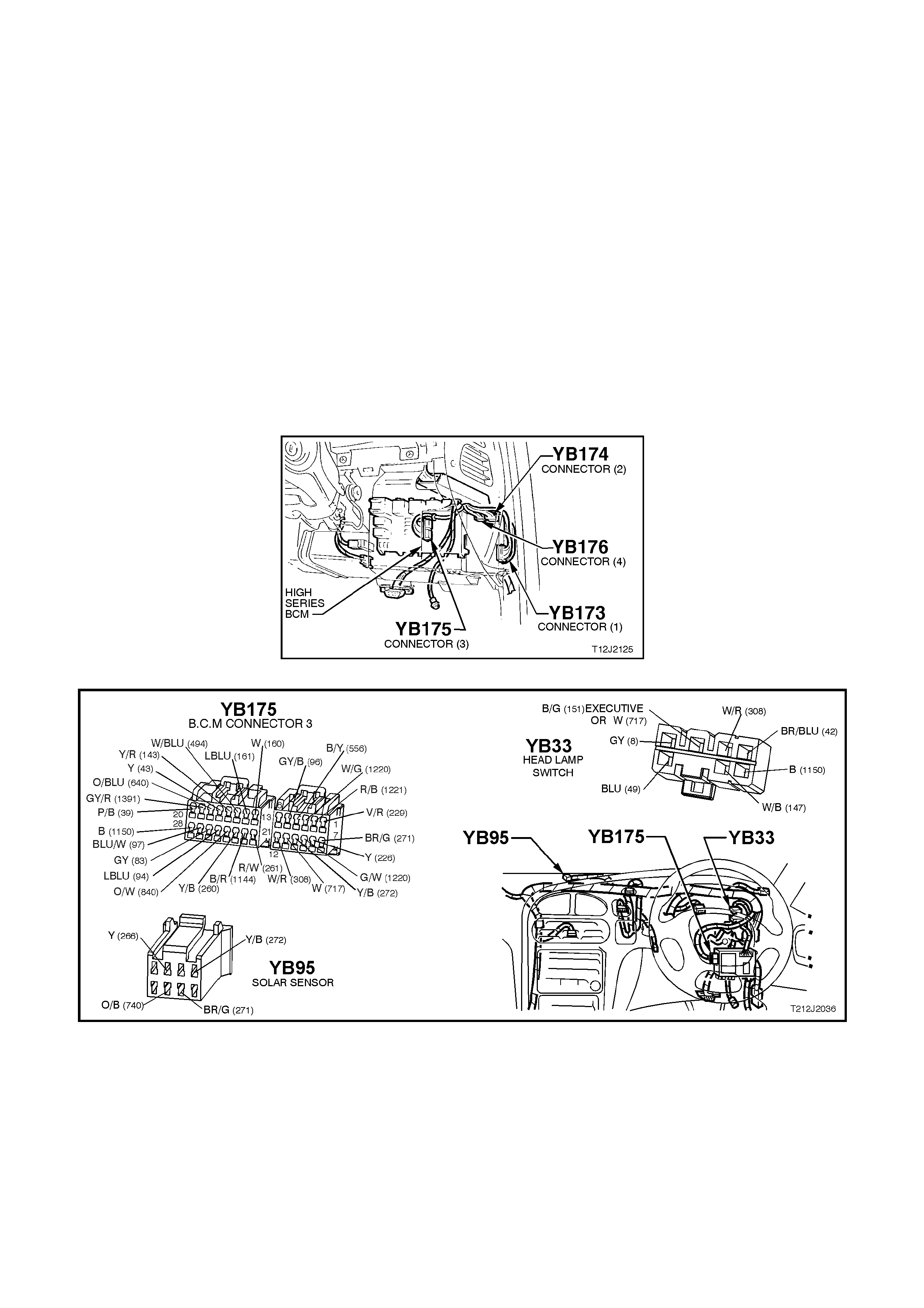

Light Sensor Control / Remote coded key Input (REFER TO FIG. 12J-2-34)

The light sensor produces a voltage proportional to the amount of ambient light. This voltage can vary between 0

and 5 volts depending on the am ount of light. The BCM determines the light value from the voltage on terminal E10,

circuit 272 (Yellow/Black wire). The BCM reads this input to determine the light level. TECH 2 should be used to

measure the performance of the light sensor.

The BCM monitors the input at terminal E8, circuit 266 (Yellow wire) to determine when the un-lock button on the

remote coded key has been pressed.

Figure 12J-2-34 Light sensor control and remote coded key input

Ignition Switch ON Input Signal (Refer to Fig. 12J-2-35)

The BCM uses this input signal to determ ine when the ignition switch is the ON or OF F position. W hen the ignition

switch is in the IGN or START position, battery voltage is applied to the BCM terminal E20 from the ignition switch

and fuse F14 via circuit 39 (Pink/Black wire).

Figure 12J-2-35 Ignition switch on input signalPower Supplies (Refer to Fig. 12J-2-36)

Battery voltage is applied to the low and high beam relays from fusible link FQ, circuit 2 (Red wire) and fuses F30

and F29. Battery voltage is applied to the parking lam ps relay from fus ible link F Q, cir cuit 2 (Red wire) and f use F4,

circuit 840 (Orange/White wire). The BCM controls the operation of the exterior lights by switching its internal

control circuits, which provide the earth circuits for the relays, on or off. If the ambient light level is low, or the

approach illumination has been activated, the BCM will energise the control circuits, turning the lights on. If the

ambient light level is high, the BCM will de-energise the control circuit, turning the lights off.

High Beam Relay Earth Circuit (Refer to Fig. 12J-2-36)

The earth circuit for the high beam headlamp relay is via circuit 10 (Blue/Yellow wire), through the headlamp and

turn signal control switch as sem bly, circuit 147 ( W hite/Blac k wire), headlam p switch contac ts to BCM term inal E12,

circuit 308 (W hite/Red wire) or terminal E11, circuit 717 (W hite wire) and then to earth through the internal control

circuit.

Low Beam Relay Earth Circuit (Refer to Fig. 12J-2-36)

The earth circuit for the low beam headlamp relay is via circuit 103 (W hite wire), through the headlamp and turn

signal control switch assembly, circuit 147 (White/Black wire), headlamp switch contacts to BCM terminal E12,

circuit 308 (W hite/Red wire) or terminal E11, circuit 717 (W hite wire) and then to earth through the internal control

circuit.

Parking lamps Relay Earth Circuit (Refer To Fig. 12J-2-36)

The earth circuit for the parking lamps relay is via circuit 49 (Blue wire), the closed parking lamp contacts in the

headlamp switch, through the BCM terminal E12, circuit 308 (White/Red wire) or terminal E11, circuit 717 (White

wire) and then to earth through the internal control circuit.

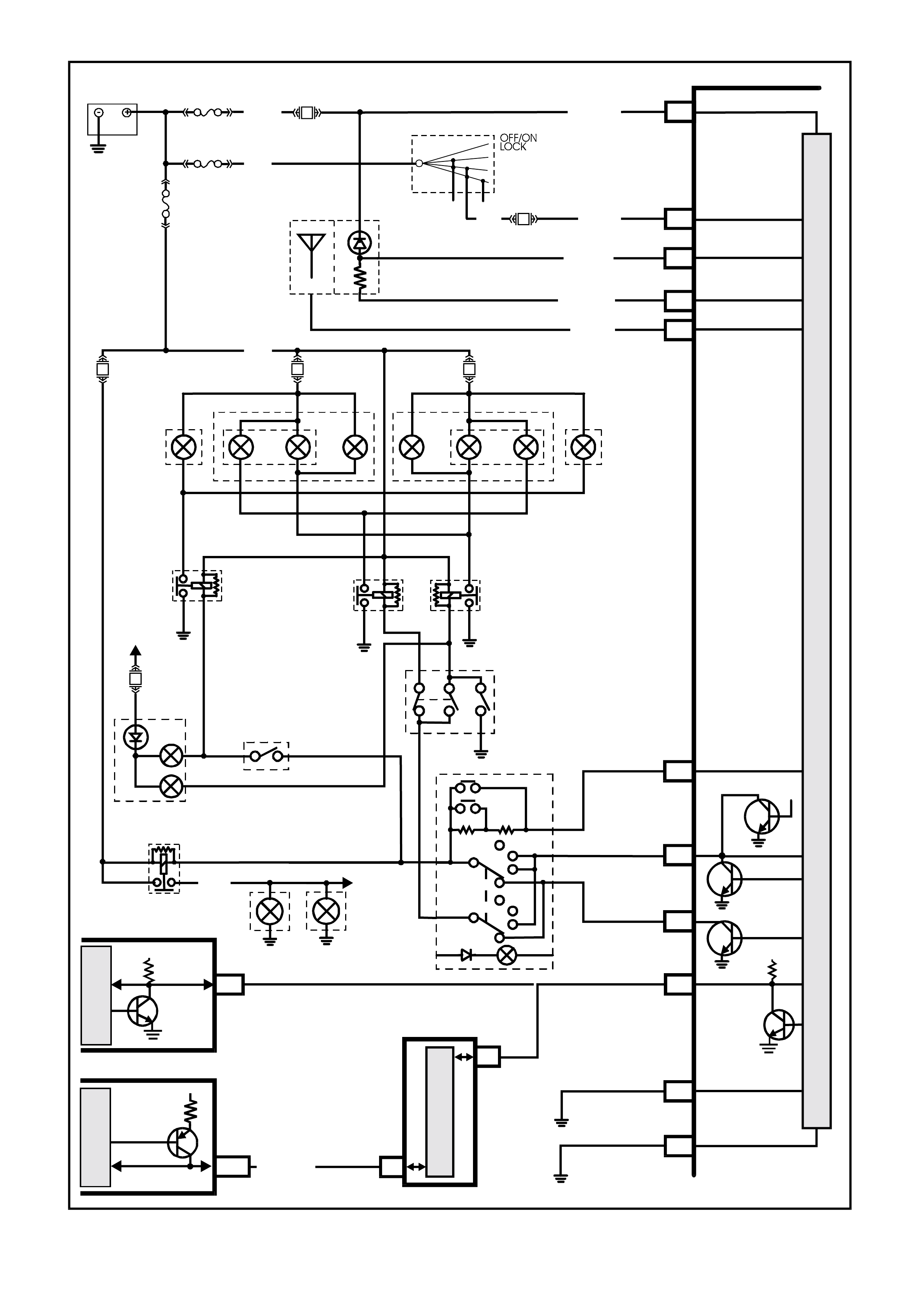

Figure 12J-2-36 Automatic lights ON and OFF / approach illumination circuit

BATTERY

FS

(1040)

BCM

B/G

(151)

B10 HIGH

CURRENT

EARTH

F31

E2

R/B

(1221) SERIAL

DATA

5V

T212J2029

B/Y

(155)

ELECTRONIC

EARTH

A1

FJ

R (2)

OFF

DARKER

BRIGHTER

PARK

ON

AUTO

OFF

PARK

ON

AUTO

F21

M

I

C

R

O

P

R

O

C

E

S

S

O

R

FLASH/DIP

SWITCH

FOG

LAMP

SWITCH

TO FJ

INSTRUMENT

DIMMING

& PARK L AMP

SWITCH

IGN

F OG LAMP &

HIGH BEAM IND.

BLU/Y

(10)

BLU

(49)

REAR

PARKING

LAMPS

TO REAR

LAMPS

PARKING LAMP

RELAY

BR (9)

LIGHT

SWITCH