SECTION 6C3-3 - SERVICE OPERATIONS -

GEN III V8 ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in this VX Service Information for correct workshop practices with regards to

safety and/or property damage.

NOTE: When fasteners are removed, always reinstall them at the same location from which they were removed. If a

fastener needs to be replaced, use the correct part number fastener for that application. If the correct part number

fastener is not available, a fastener of equal size and strength (or s tronger) m ay be us ed. Fasteners that ar e not to

be reused, or those requiring thread locking compound will be identified. The correct torque value must be used

when installing fasteners that require it. If the above conditions are not followed, parts or system damage could

result.

WHA T THIS SECTION CONTA I NS

This Section describes the correct service procedures to repair components of the Powertrain Management

Systems. Emphasis is placed on the proper procedures and repair of components related to the systems. The

service oper ation illust rations f or eac h proc edure in mos t c ases will res ide to the right of the tex t. In some c as es the

illustrations may be above or below the text.

3.1 SERVICE PRECAUTIONSTHE FOLLOWING REQUIREMENTS MUST BE OBSERVED

WHEN WORKING ON VEHICLES:

1. Before removing PCM/PIM or fuel system components, disconnect the battery earth lead.

2. Never start the engine without the battery being securely connected.

3. Never disconnect the battery from the on-board electrical system while the engine is running.

4. When charging the battery, disconnect it from the vehicle's electrical system.

5. Never subject the PCM/PIM to temperatures above 80°C i.e. paint oven. Always remove PCM first if this

temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected securely and that battery terminals are thoroughly clean.

7. The engine management system harness connectors are designed to fit one way only; there are indexing tabs

and slots on both halves of the c onnec tor. For cing the c onnec tor into place is not necessar y if it is being installed

with the correct orientation. F ailure to take car e to match the index ing tabs and slots to can cause damage to the

connector, the module, or other vehicle components or systems.

8. Never connect or disconnect cable harness plug at the PCM/PIM when the ignition is switched ON.

9. Before per f orming any electric welding ( Arc , MIG, etc.) on the vehic le, disc onnec t the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM or system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic Tables, since other test equipment may either give

incorrect results or damage good components.

12. A digital multimeter with an internal impedanc e rating of at least 10 m illion ohms per volt ( 10 megohm /volt) must

be used where required when testing circuits.

13. When a test light is s pecified, a low-power test light m u st be us ed. Do not use a high - wattage test light. While a

particular brand of test light is not suggested, a simple test on any test light will ensure it to be OK for PCM circuit

testing. Connect an accurate ammeter (such as the high-impedance digital multimeter) in series with the test

light being tested, and power the test light-ammeter circuit with the vehicle battery as shown below.

Techline

Techline

Figure 6C3-3-1 Test Light Check

If the am m eter indicates less than 3/10 am p c urrent

flow (0.3 A or 300 mA), the test light is OK to use.

If the am meter indic ates more than 3/10 amp curr ent

flow (0.3 A or 300 mA), the test light is NOT OK to

use.

+

BATTERY

-

DC AMPS

Test Light

3.2 PO WERTRAIN CONTROL MODULE (PCM)

PCM REPLACEMENT/ PROGRAMMING

Service of the PCM should norm ally consist of either

replacement of the PCM or EEPROM (flash

mem ory) program ming. If the diagnostic procedures

call for the PCM to be replaced, the PCM should be

first checked to ensure it is the correct part. If it is,

remove the faulty PCM and install the new PCM.

IMPORTANT:

The PCM used in this vehicle application is not

interchangeable with any other V8 GEN III program .

Only the PCM part number for this vehicle must be

used.

IMPORTANT:

The replacement PCM EEPROM will not be

programmed.

DTC P0601 and P0602 indicates the EEPROM is

not programmed or has malfunctioned. Refer to

Service Programming for programming

procedures.

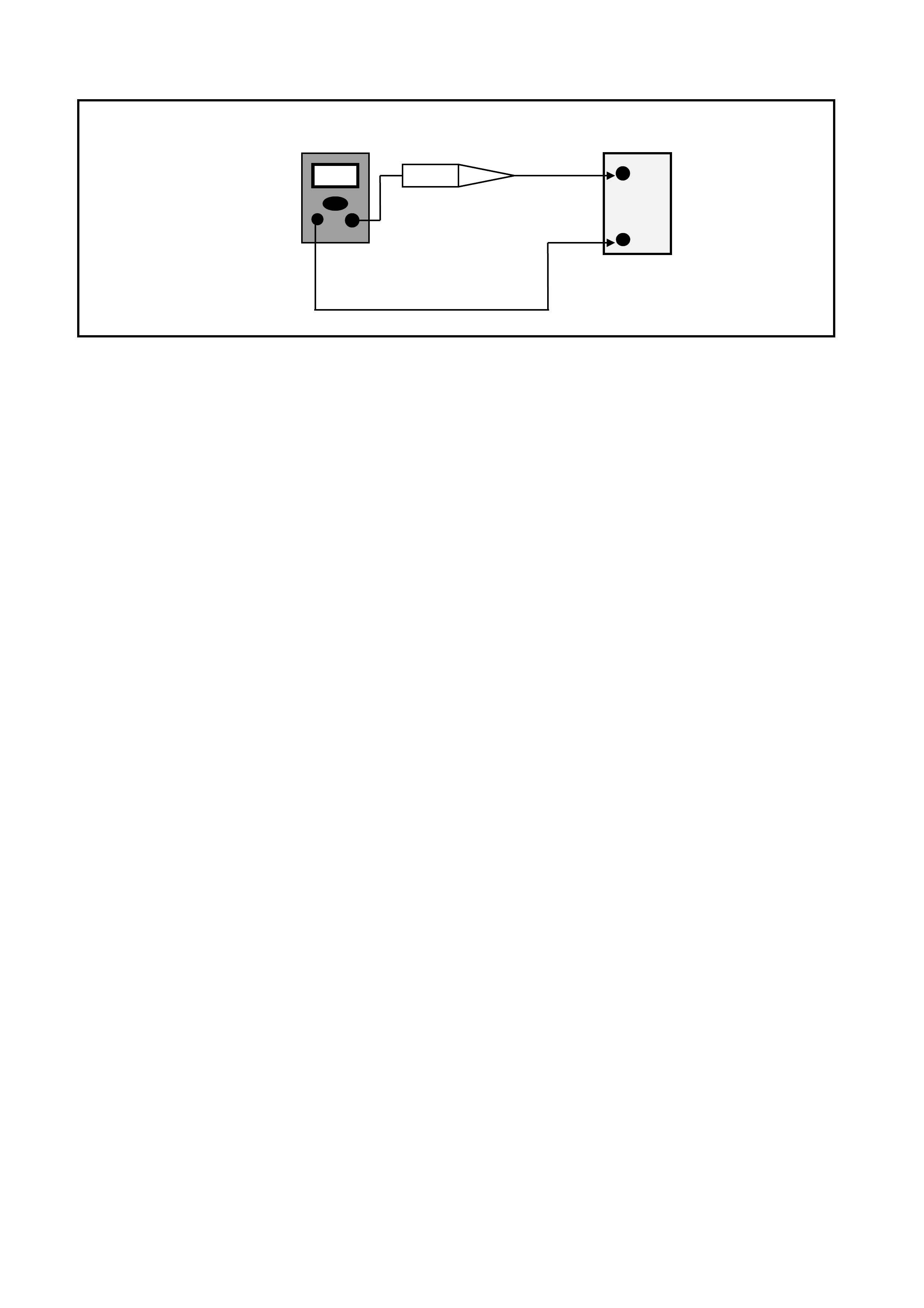

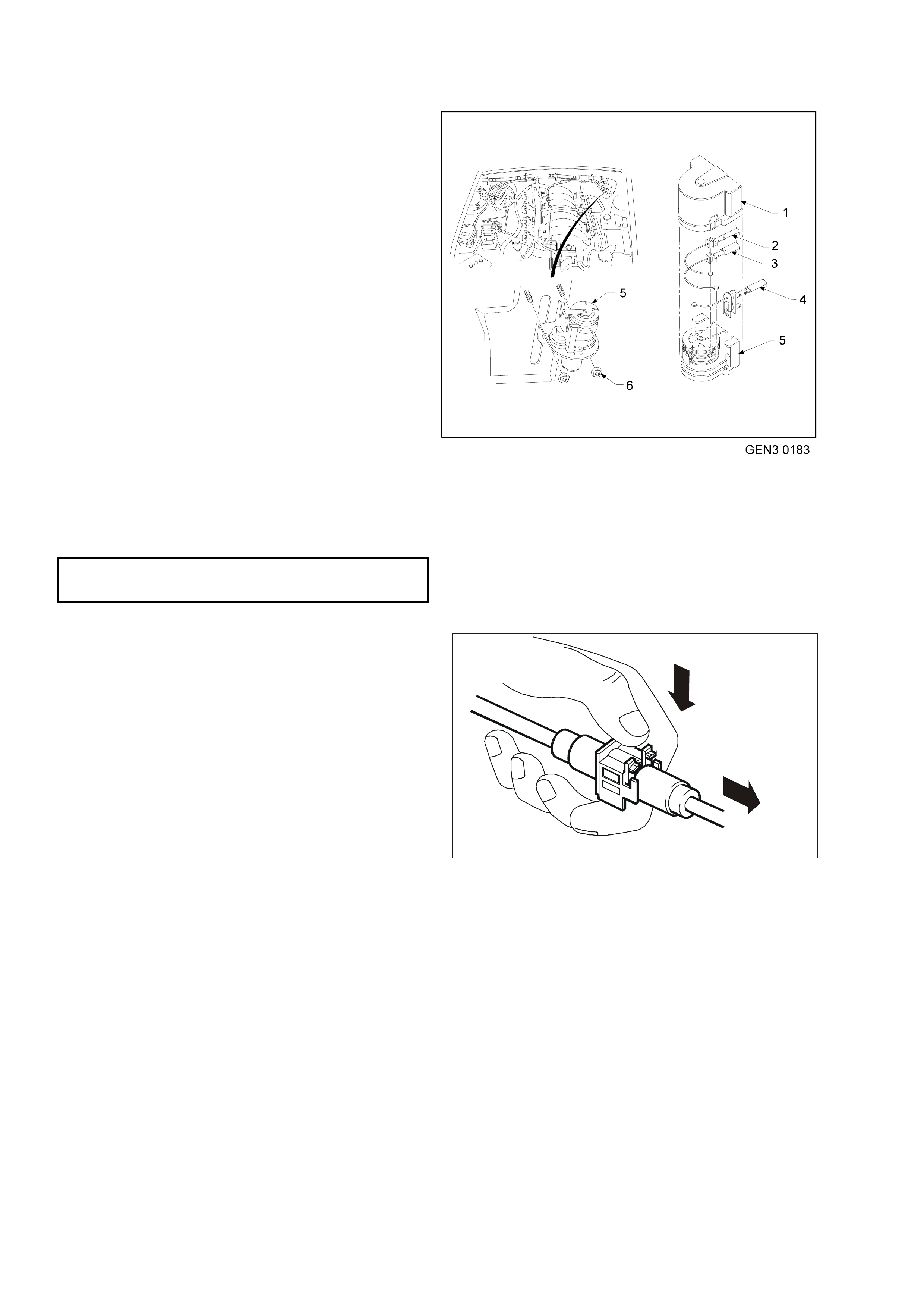

The PCM has two 80 pin connectors: J 1 Blue (1), J2

Red (2).

IMPORTANT:

The following must be performed anytime the PCM

is replaced:

1. Programming of the EEPROM

2. The Idle Learn Procedure

3. The Functional Check

1

2

Figure 6C3-3-2 Powertrain Control Module

The following must be performed anytime the PCM

is disconnected or loses power.

1. The Idle Learn Procedure

2. The Functional Check

All are described later in this section.

IMPORTANT:

To prevent internal PCM damage, the ignition must

be OFF when disconnecting or reconnecting power

to the PCM.

IMPORTANT:

Ensure that the cover is free of contaminants

(moisture) before servicing the PCM. The moisture

flows into the PCM c onnec tor body when the PCM is

disconnected and the hood is opened.

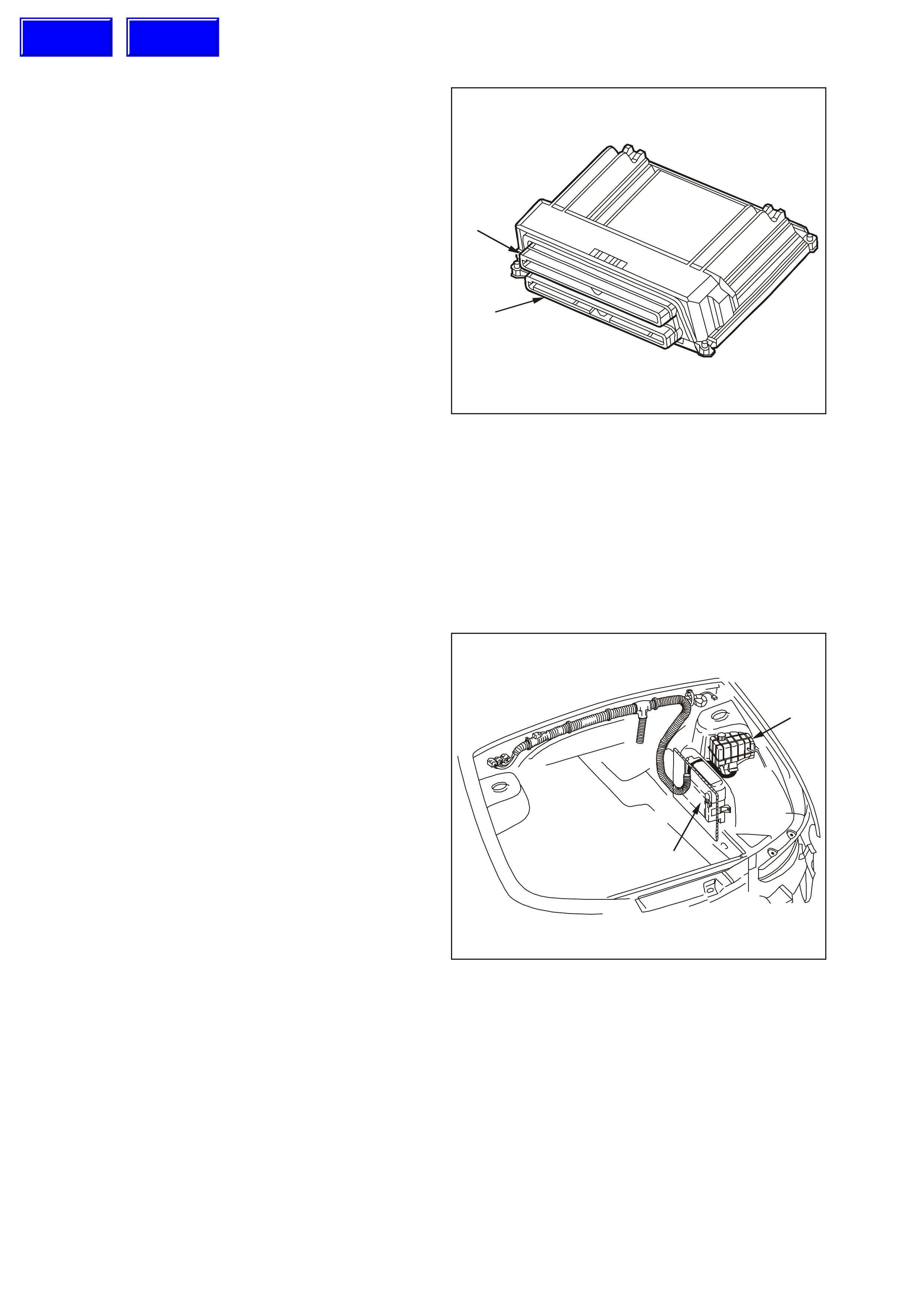

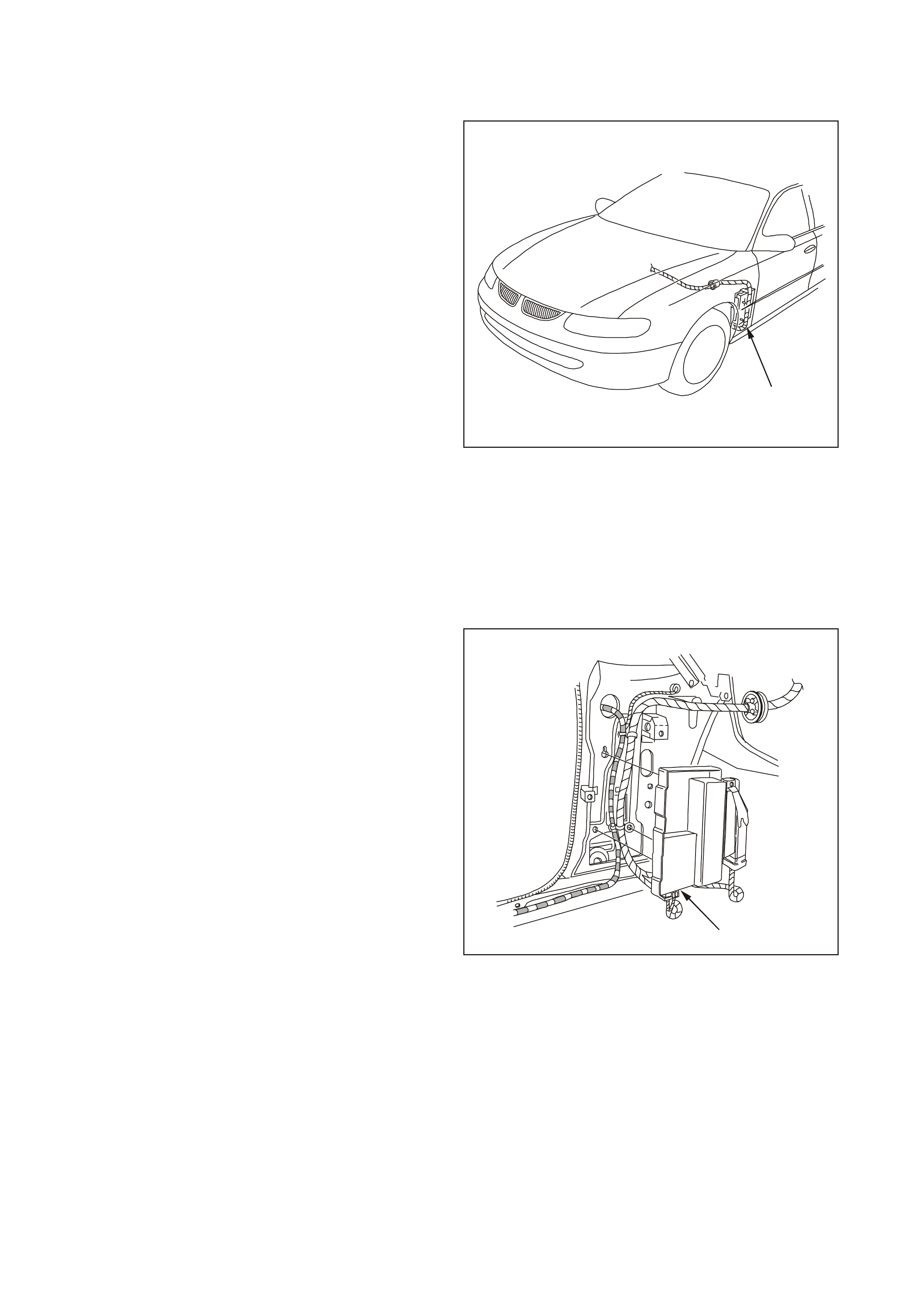

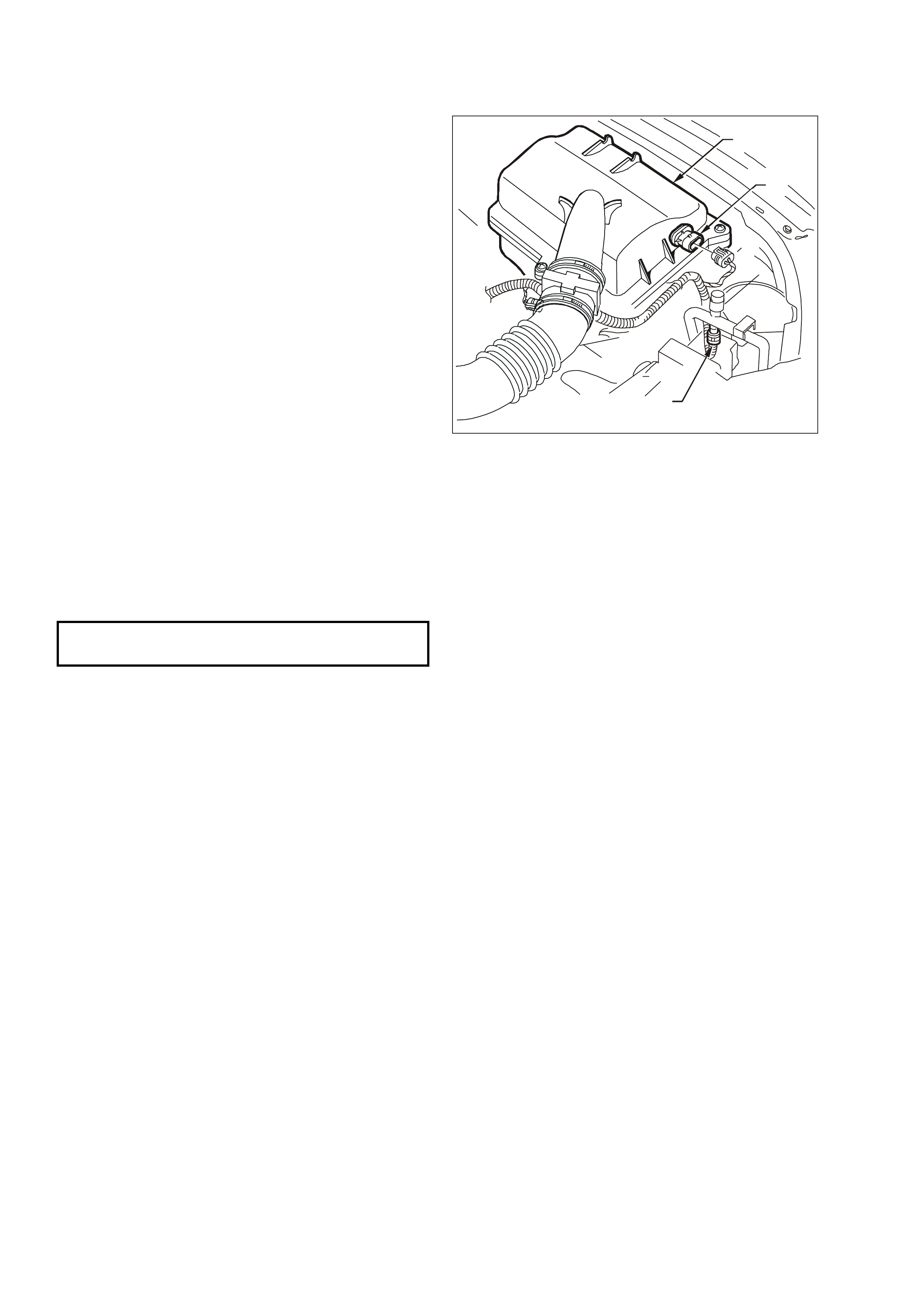

The location of the PCM (2) is by the left front

suspension tower, below the coolant surge tank (1).

REMOVE

IMPORTANT:

Remove any debris from the PCM connector

surf aces bef or e s ervic ing the PCM. Inspec t the PCM

module connector gaskets when diagnosing or

replacing the PCM. Ensure that the gaskets are

installed correctly as they prevent contaminant

intrusion into the PCM.

IMPORTANT:

Do not touch the connector pins or soldered

components on the circuit board in order to prevent

possible electrostatic discharge damage to the

PCM.

GE N 3 0005

1

2

Figure 6C3-3-3 Coolant Surge Tank and PCM Location

Techline

Techline

IMPORTANT:

To prevent internal damage to the PCM, the ignition

must be OFF when disconnecting or reconnecting

the PCM connector.

1. Ignition OFF.

2. Disengage the coolant surge tank from its

mounting points, refer

Section 6B3 ENGINE COOLING in VT Series II

Service Information.

IMPORTANT:

The coolant surge tank may be HOT. Allow the

coolant to cool before performing this procedure.

3. Lift the coolant surge tank up, turn it over and

disconnect the wiring harnes s c onnec tor from the

coolant level sensor. Set the surge tank to one

side.

4. Remove the air cleaner assembly, refer

3.23 Air Cleaner Assembly in this Section.

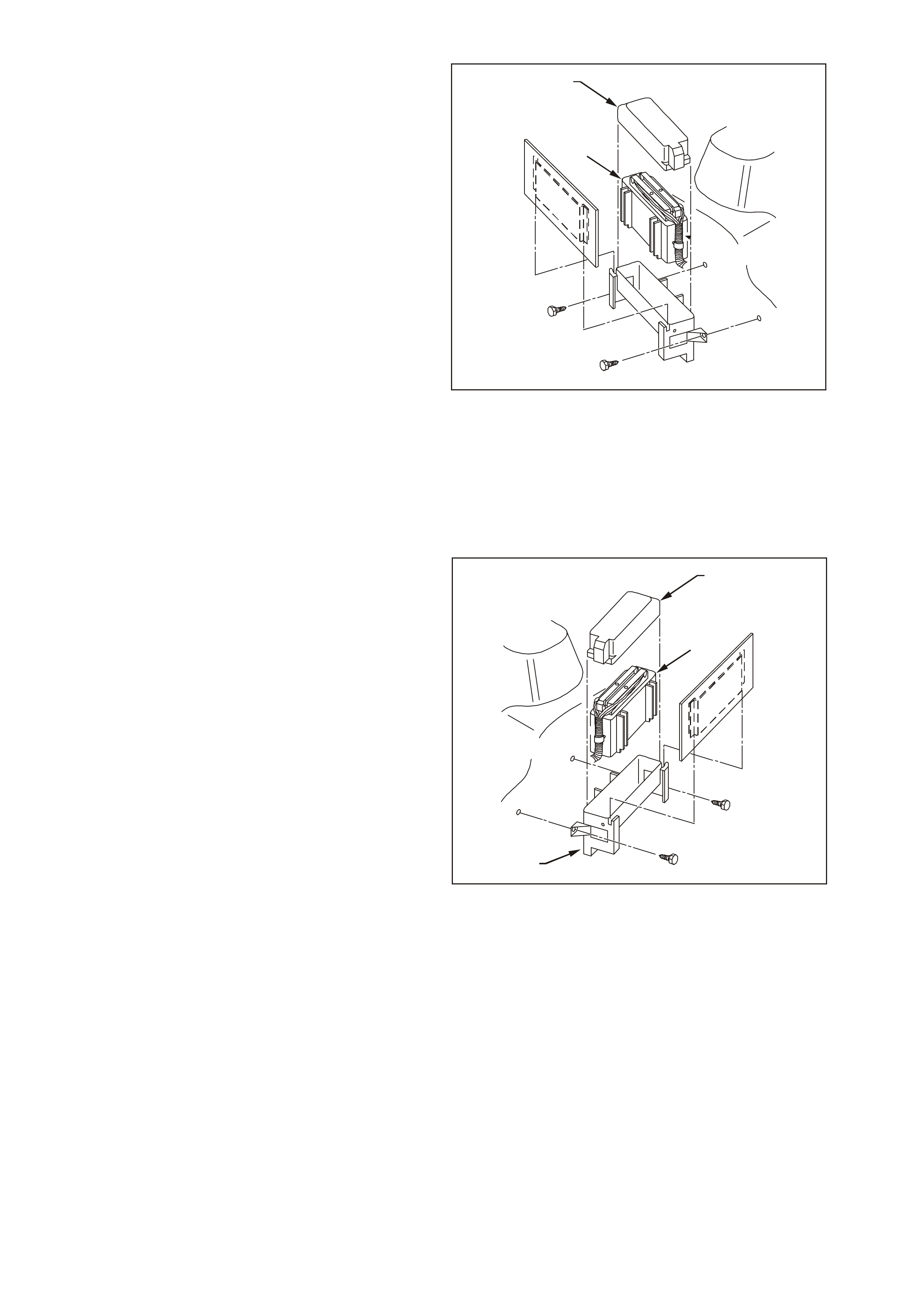

5. Remove PCM Harness Connector Cover (1).

6. Loosen the connector retaining screws at each

PCM connector and r emove the connector s from

the PCM.

7. Remove the PCM (2) from the mounting bracket

by levering back the bracket retainers at each

end, while lifting up the PCM.

GE N 3 0105

2

1

Figure 6C3-3-4 PCM Mounting Assembly

REINSTALL

IMPORTANT:

Do not touch the connector pins or soldered

components on the circuit board in order to prevent

possible electrostatic discharge damage to the PCM.

IMPORTANT:

To prevent internal damage to the PCM, the ignition

must be OFF when disconnecting or reconnecting

the PCM connector.

1. Install the PCM (1) to the mounting bracket (2).

2. Reconnect the PCM connectors.

3. Install PCM connector cover (3).

4. Install coolant surge tank.

5. Install air cleaner assembly.

IMPORTANT:

If a new PCM is being installed, program the PCM

memory using the following procedure.

GE N 3 0105

1

3

2

Figure 6C3-3-5 PCM Mounting Assembly

SERVICE PROGRAMMING

IMPORTANT:

Follow the programming instructions completely and do not key OFF during programming unless instructed. If the

key is turned OFF during programming, possible PCM damage may occur.

IMPORTANT:

Do not disconnect tech 2 during each programming step.

1. Setup - Ensure that the following conditions have been met:

- The battery is fully charged, but not charging during programming.

- The ignition is ON.

- Ensure that all PCM connections are OK.

2. Connect TECH 2 to the vehicle and select Service Programming System (SPS) / Request Info.

3. Connect TECH 2 to a TIS terminal and download latest software matching the vehicle. Refer to TIS

terminal/equipment users instructions.

4. Connect TECH 2 to the vehicle again and select Service Programming System (SPS) / Program ECU.

5. If the PCM fails to program, proceed as follows:

- Ensure that all PCM connections are OK.

- Attempt to re-program the PCM. If the PCM still cannot be programmed correctly, replace the PCM and

program it according to this procedure.

IMPORTANT:

Once new PCM has been progr amm ed, it mus t be Secur ity Linked. Refer to PCM/PIM/BCM Secur ity Link for linking

procedure. If updating calibrations to the vehicle’s existing PCM hardware, no linking procedure is necessary.

PCM/PIM/BCM SECURITY LINK

Once the PCM, PIM and/ or BCM have been replaced, the modules must be security linked to each other. If the

procedure is not performed, the vehicle will not crank or run.

This linking procedure is found under the BODY CONTROL MODULE of TECH 2 and is performed as follows:

• Connect TECH 2 to DLC and select:

- Diagnostic / (X) 20XX / VX Commodore / Body / Body Control Module / Security / BCM Link to PCM/PIM.

• The procedure ‘BCM Link to PCM/PIM’ will first ask to select the installed engine. If V8 GEN III is selected a

‘TIS program approve’ is required.

• Connect TECH 2 to TIS terminal and select ‘Program Approve’.

• After returning to the vehicle, select again the linking procedure. BCM and PIM are linked first, followed by the

PCM – PIM which is performed automatically.

For additional information regarding TECH 2 and TECH 2 test modes (including this linking procedure), refer to

TECH 2 DIAGNOSIS FOR BCM in Section 12J-1 L OW SERIES BCM or Sect ion 12J-2 HIG H SERIES BCM in VX

Service Information.

IMPORTANT:

After the new PCM has been linked, you must then follow the Idle Learn Procedure in order for the PCM to learn

and reestablish the IAC valve position.

Techline

IDLE LEARN PROCEDURE

W henever the PCM or the battery is disconnected or the PCM loses power, the PCM’s learned position of the IAC

valve pintle is lost, resulting in an unstable idle.

Perform the following procedure in order to return the IAC valve pintle to the correct position:

Automatic Transmission

1. Turn OFF the ignition.

2. Restore the PCM battery feed.

3. Turn OFF the A/C controls.

4. Set the park brake and block the drive wheels.

5. Start the engine.

6. Shift the transmission selector to D (drive).

7. Allow the engine to idle for 10 minutes.

8. Turn ON the A/C controls.

9. Allow the engine to idle for 10 minutes.

10. Shift the transmission selector to P (park).

11. Allow the engine to idle for 10 minutes.

12. Turn OFF the A/C controls.

13. Allow the engine to idle for 10 minutes.

14. Turn OFF the engine for 30 seconds.

Manual Transmission

1. Turn OFF the ignition.

2. Restore the PCM battery feed.

3. Turn OFF the A/C controls.

4. Set the park brake and block the drive wheels.

5. Place the transmission in neutral.

6. Start the engine.

7. Turn ON the A/C controls.

8. Allow the engine to idle for 10 minutes.

9. Turn OFF the A/C controls.

10. Allow the engine to idle for 10 minutes.

11. Turn OFF the engine for 30 seconds.

FUNCTIONAL CHECK

1. Clear the Diagnostic Trouble Codes (DTCs).

2. Perform the Powertrain OBD System Check.

3. Start the engine and idle for one minute.

4. Use the Tech 2 scan tool to check for DTCs

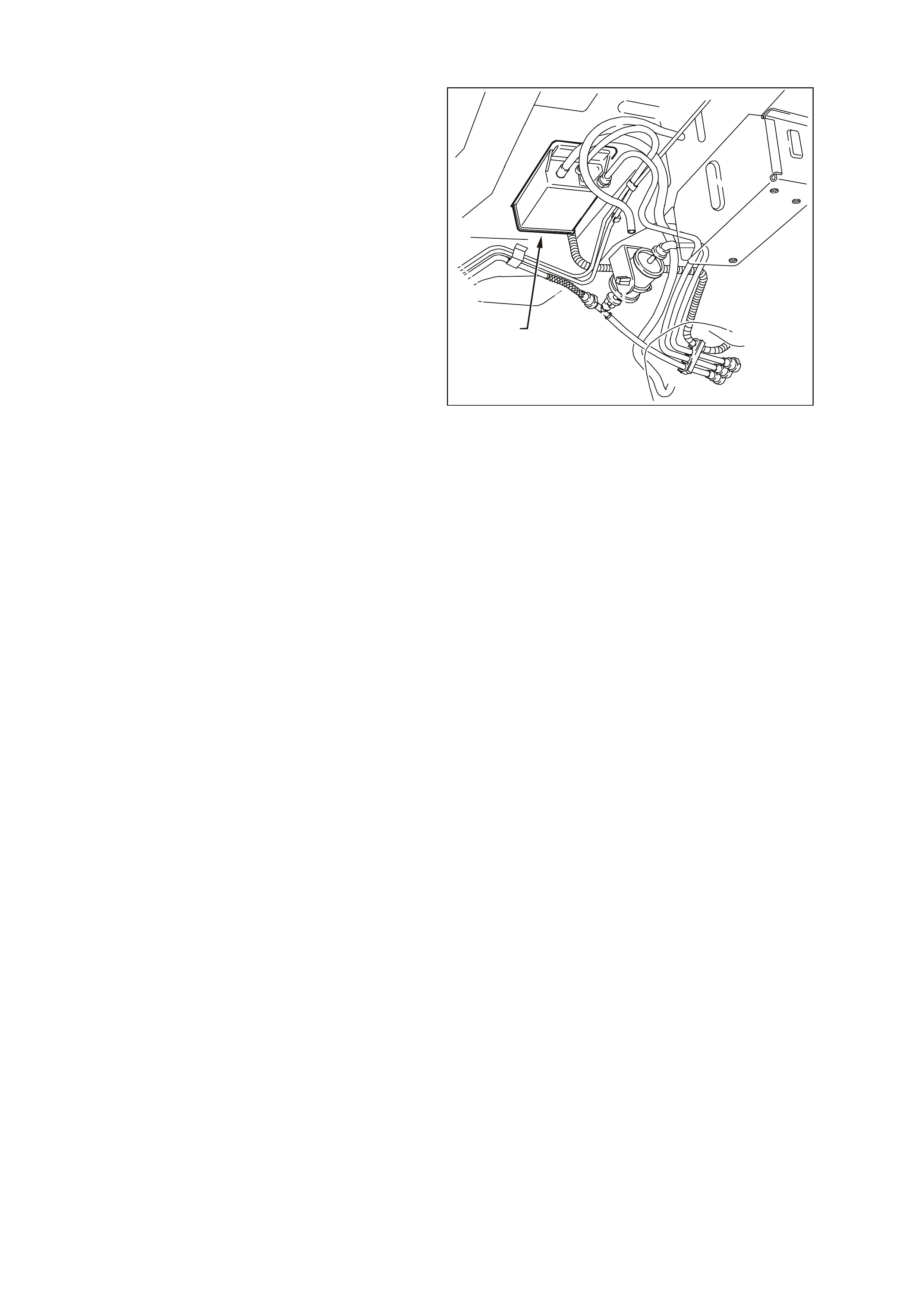

3.3 PO WERTRAIN INTERFACE MODULE (PIM)

PIM REPLACEMENT

If the diagnostic procedures call for the PIM to be

replaced, it should be checked first to ensure it is the

correc t part. If it is, rem ove the faulty unit and ins tall

the new PIM.

IMPORTANT:

To prevent internal PIM damage, the ignition must

be OFF when disconnecting or reconnecting power

to the PIM.

IMPORTANT:

Remove any debris from the PIM connector

surfaces before servicing the PIM. Inspect the PIM

module connector when diagnosing/replacing the

PIM.

IMPORTANT:

Do not touch the connector pins or soldered

components on the circuit board in order to prevent

possible electrostatic discharge (ESD) damage to

the PIM.

REMOVE

1. Ignition OFF.

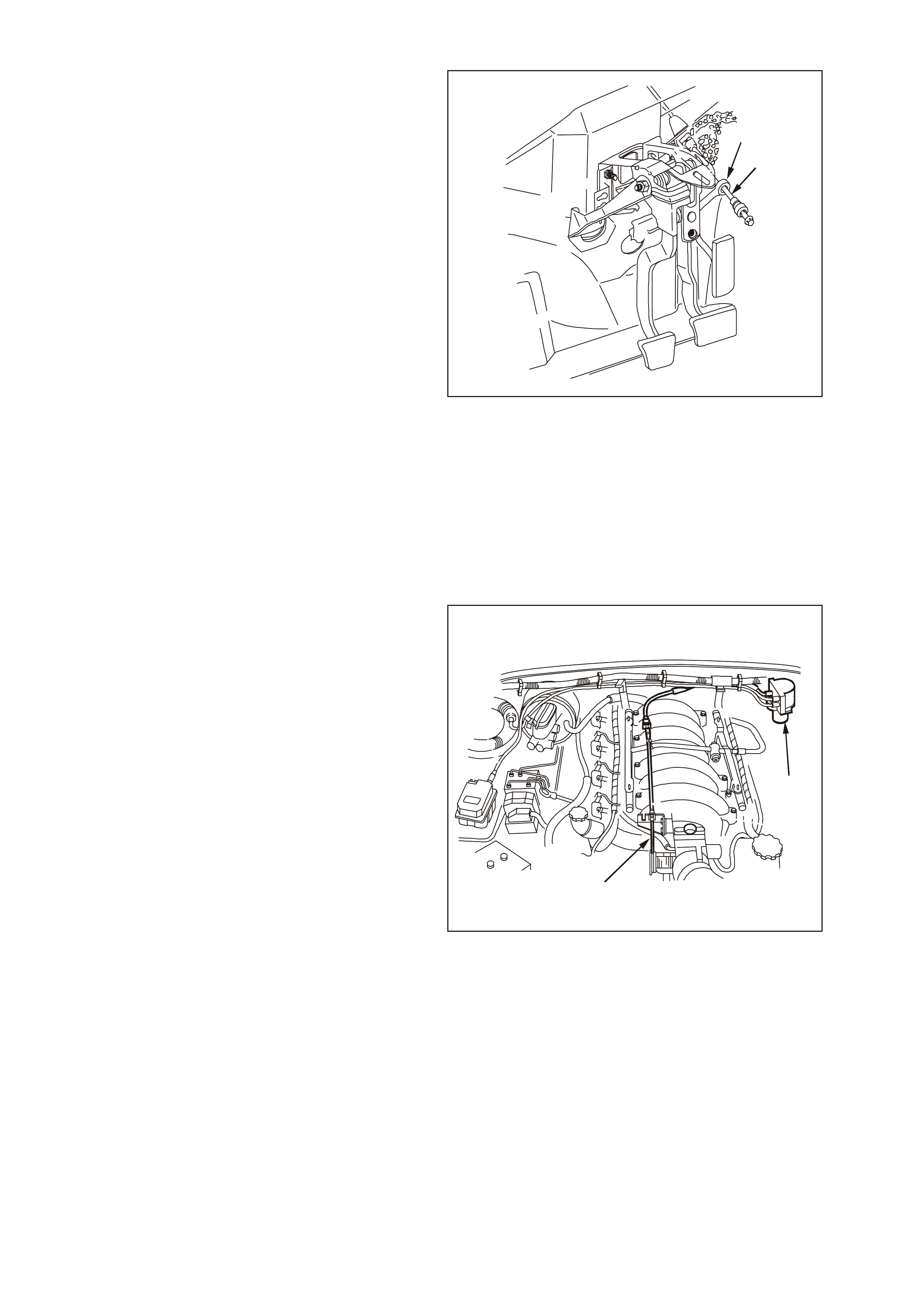

2. Remove left hand front shroud panel lower trim

assembly (kick panel trim).

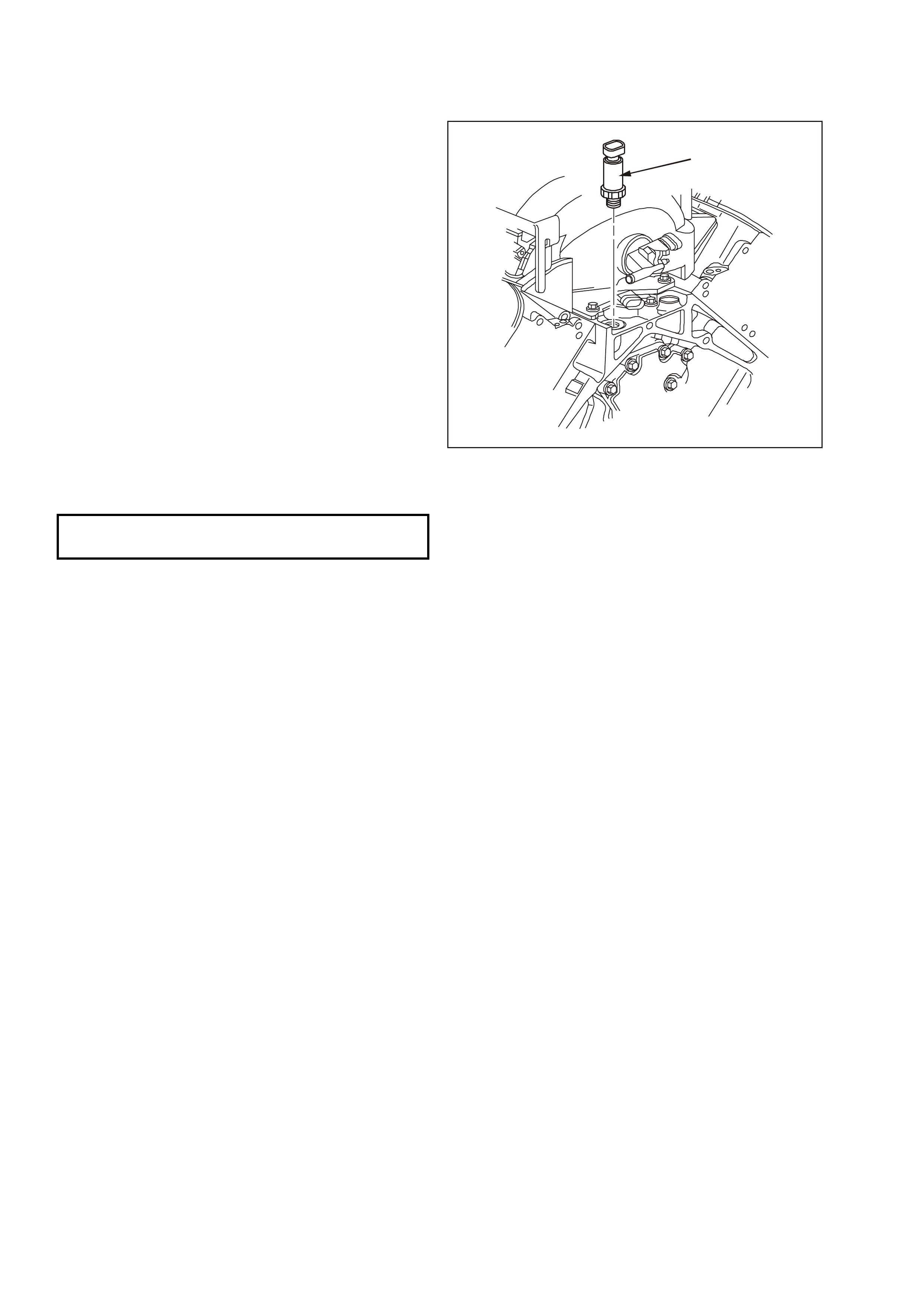

3. Remove PIM (1) from mounting bracket.

4. Remove wiring harness connector from PIM.

REINSTALL

1

Figure 6C3-3-6 Powertrain Interface Module (PIM)

Location

1. Install wiring harness connector to PIM.

2. Install PIM to the mounting bracket.

3. Install the left hand front shroud panel lower trim

assembly (kick panel trim).

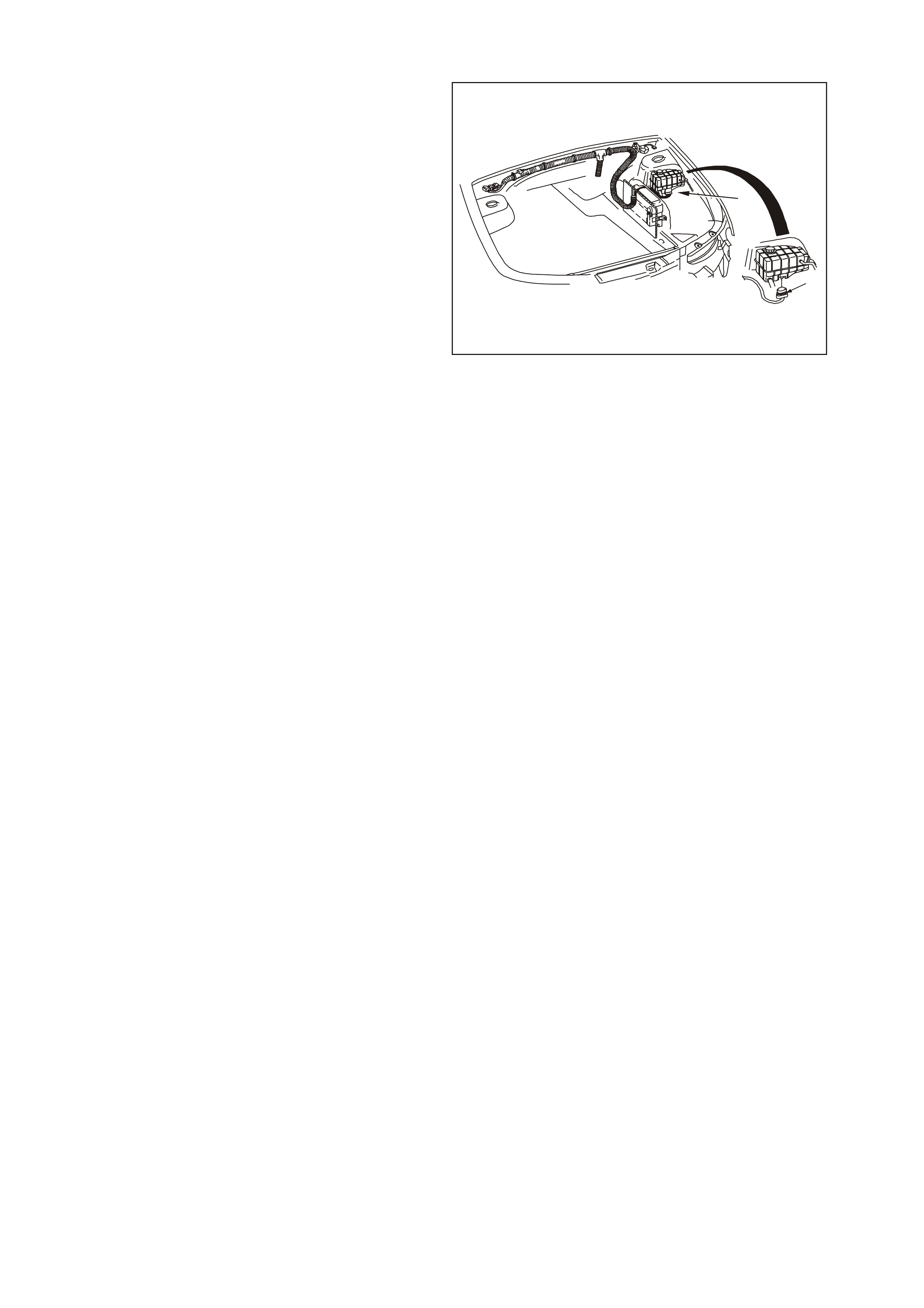

PCM/PIM/BCM SECURITY LINK

Once the PCM, PIM and/ or BCM have been

replaced, the modules must be security linked to

each other. If the procedure is not performed, the

vehicle will not crank or run.

This linking procedure is found under the BODY

CONTROL MODULE of TECH 2 and is performed

as follows:

• Connect TECH 2 to DLC and select:

- Diagnostic / (X) 20XX / VX Commodore / Body

/ Body Control Module / Secur ity / BCM Link to

PCM/PIM.

• The procedure ‘BCM Link to PCM/PIM’ will first

ask to select the installed engine. If V8 GEN III

is selected a ‘TIS program approve’ is required.

Connect TECH 2 to TIS terminal and select

‘Program Approve’.

1

Figure 6C3-3-7 Powertrain Interface Module (PIM)

After r eturning to the vehicle, s elect again the link ing

procedure. BCM and PIM are linked first, followed by

the PCM–PIM, which is performed automatically.

For additional information regarding TECH 2 and

TECH 2 test modes (including this linking

procedure), ref er to T ECH 2 DIAGNOSIS FO R BCM

in Sect ion 12J-1 Low Series BCM or Section 12J-

2 High Series BCM in VX Service Information.

FUNCTIONAL CHECK

1. Start the engine and idle for one minute.

2. Use the Tech 2 scan tool to check for any PIM

DTCs

3. If any PIM DTC s et, ref er to appr opriate PIM DTC

table.

3.4 ENGINE COOLANT TEMPERATURE (ECT) SENSOR

REMOVE

1. Raise the vehicle. Refer to

Section OA General Information in VT Series I

Series Information..

2. Drain the engine coolant. Refer to

Section 6B3 Engine Cooling in VX Service

Information.

3. Lower the vehicle.

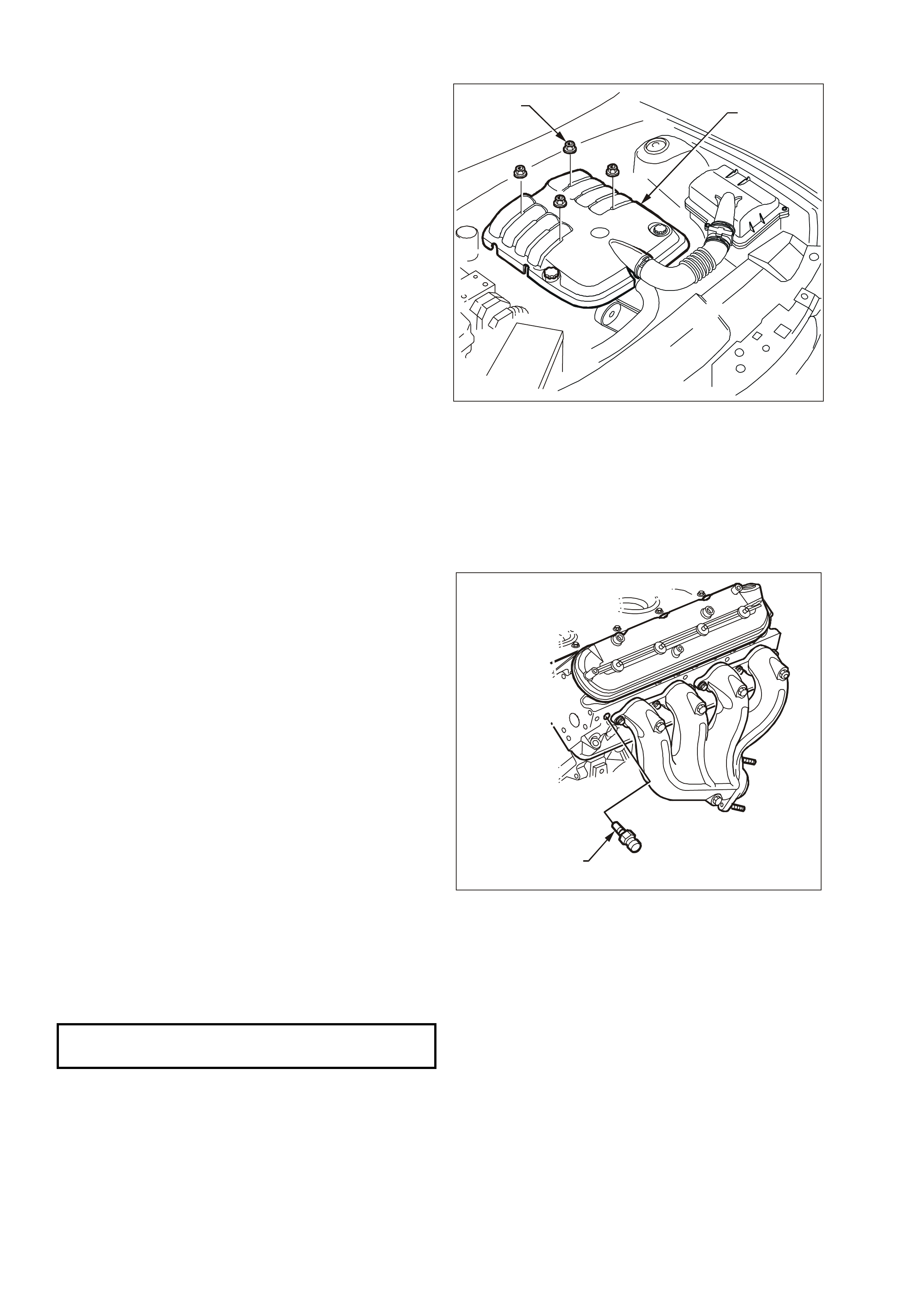

4. Remove the engine dress cover mounting nuts

(1) and the dress cover (2).

5. Disc onnect the electrical connec tor from the ECT

sensor (1).

6. Remove the No.1 spark plug lead from the spark

plug.

7. Remove the ECT sensor.

T6B3034

12

Figure 6C3-3-8 Engine Dress Cover

IMPORTANT:

Use care when handling the coolant sensor.

Damage to the coolant sensor will affect the

operation of the fuel control system.

REINSTALL

1. Coat the Engine Coolant Temperature (ECT)

sensor (1) thread with Loctite 242 sealer (Holden

Specification HN1256 Class 2, type 2) or

equivalent.

2. Install the ECT sensor into the left cylinder head.

3. Tighten the ECT sensor to the specified torque.

4. Install the No.1 spark plug lead onto the spark

plug.

5. Connect the ECT sensor electrical connector.

6. Refill the engine coolant. Refer to

Section 6B3 Engine Cooling in VX Service

Information.

7. Start the engine and check for leaks.

8. Recheck the engine coolant level. Refer to

Section 6B3 Engine Cooling in VX Service

Information.

9. Reinstall the engine dress cover.

T6B3047

1

Figure 6C3-3-9 Engine Coolant Temperature (ECT) Sensor

ECT Sensor Tightening

Torque 17 N.m

3.5 ENGINE COOLANT LEVEL SWITCH

IMPORTANT:

To avoid serious personal injury, never remove the

radiator or coolant surge tank when the engine is

hot, even if the cooling system should require filling.

Sudden release of cooling system pressure is very

dangerous.

The engine coolant level switch (1) is part of the

coolant surge tank assembly and is serviceable only

by replacing the coolant surge tank. Refer to

Section 6B3 Engine Cooling in VX Service

Information.

GE N 3 0153

1

1

Figure 6C3-3-10 Engine Coolant Level Switch

3.6 INTAKE AIR TEMPERATURE (IAT) SENSOR

REMOVE

IMPORTANT:

Care must be taken when handling IAT Sensor as

damage will affect the operation of the fuel control

system.

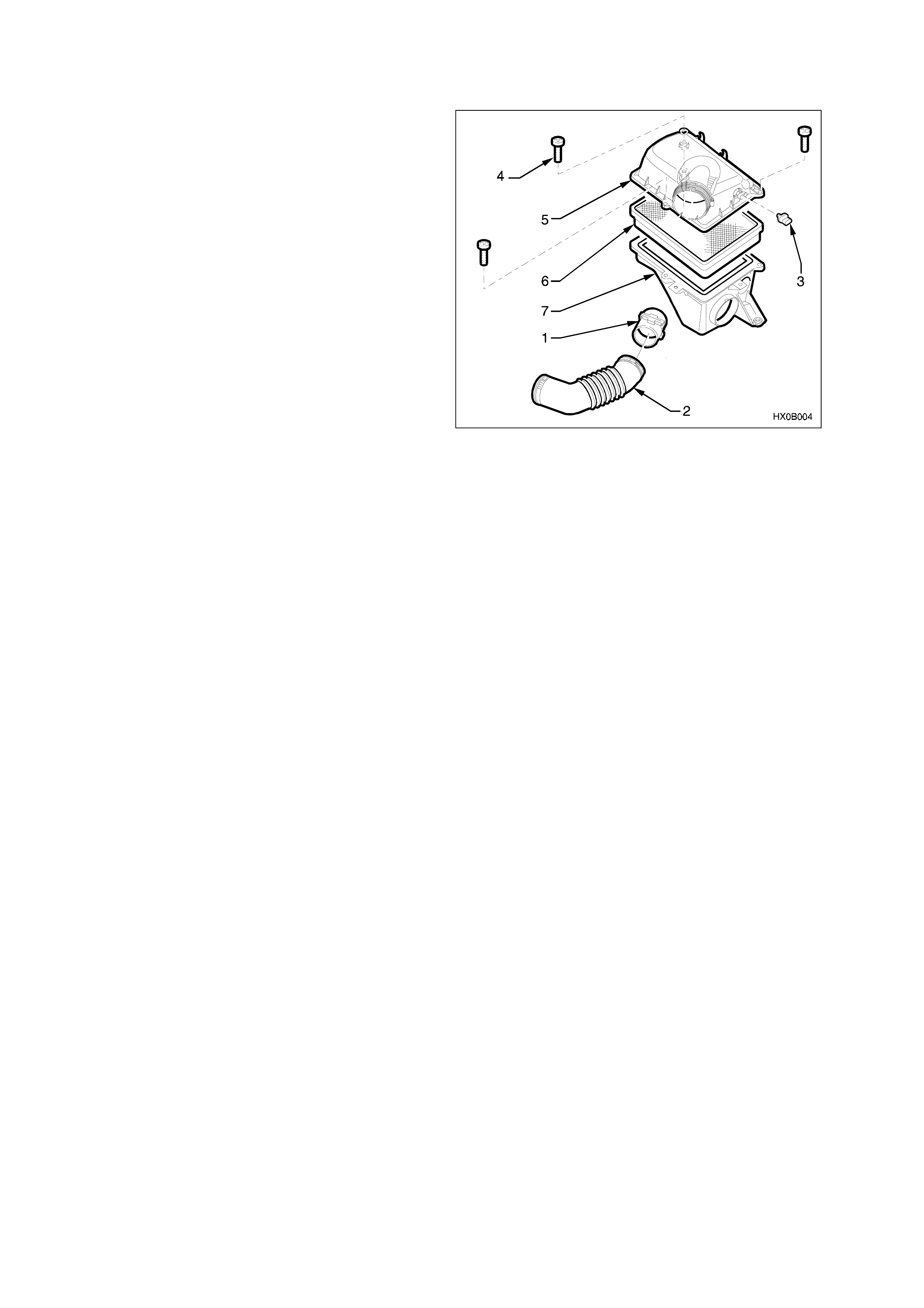

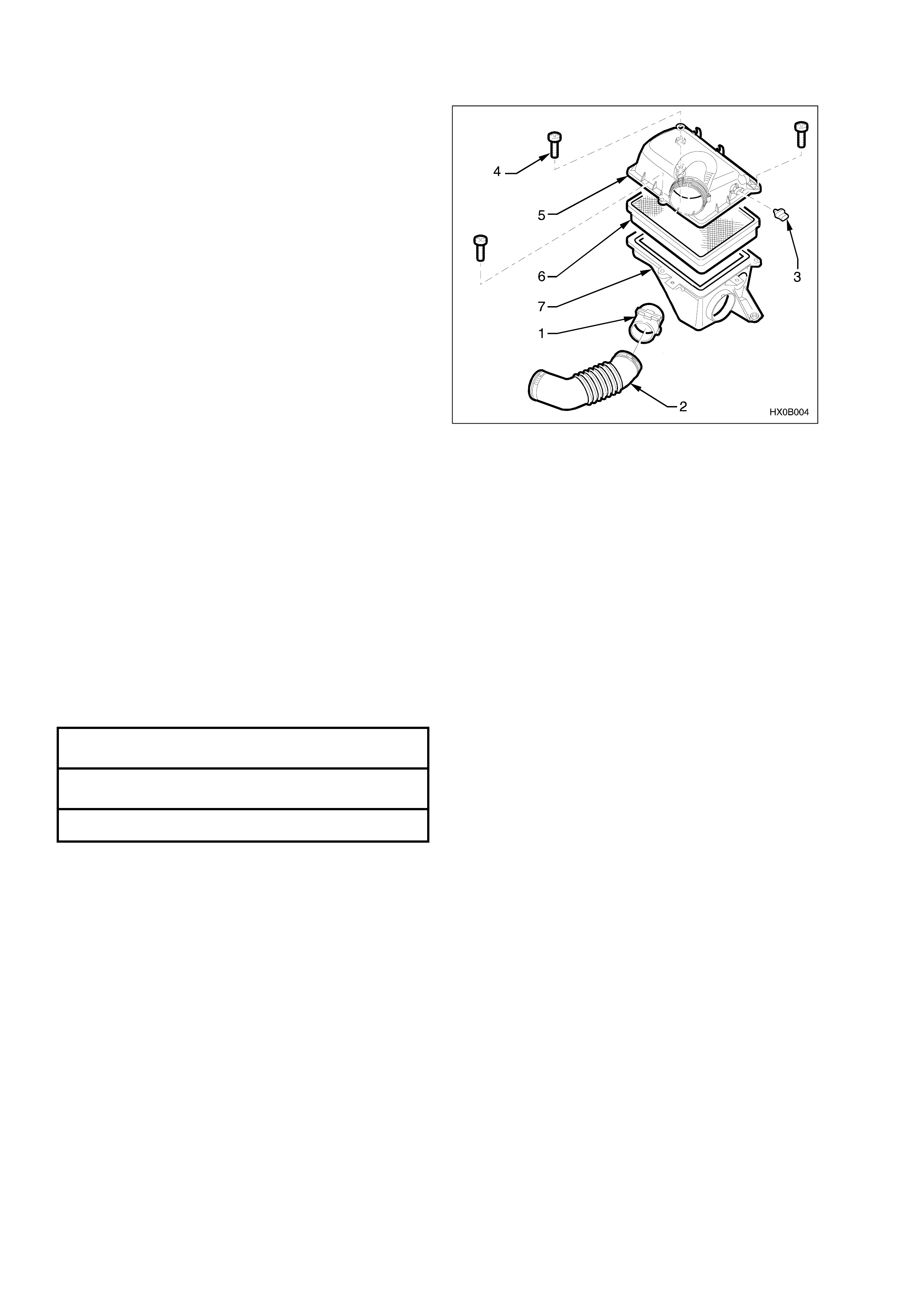

1. Lift up the tang on IAT sensor (3) wiring harness

connector and remove the connector from the

sensor.

2. Loosen the clamp on the air cleaner assembly

and move MAF sensor (1) to one side.

3. Disconnect air duct (2) from the air cleaner

assembly.

4. Remove three retainer bolts (4) securing the air

cleaner upper housing (5).

5. Remove air cleaner upper housing.

IMPORTANT:

The air filter should remain in the lower housing.

6. Using a pair of side cutters, cut across the IAT

sensor retainer to remove it. Once removed,

discard the retainer.

7. Pull the IAT sensor out from air cleaner upper

housing.

Figure 6C3-3-11 IAT Sensor Location

REINSTALL

1. Push new IAT sensor into air cleaner upper

housing, with the triangular tang on the m ounting

flange locating on the m ating r ib of the air c leaner

upper housing.

2. Position the upper air cleaner housing assembly,

with the IAT sensor on the work bench, pushing

up into the air cleaner upper housing.

3. Position new retainer onto IAT sensor (3) and

then using a 20 mm socket, push the retainer

fully onto the IAT sensor.

4. Assemble the air f ilter element into the air c leaner

upper housing and place the upper housing onto

the lower housing, ensuring that air filter element

remains in position.

5. Reinstall the three retainer bolts (4) securing the

air cleaner upper housing (5).

6. Reconnect wiring harness connector to IAT

sensor (3).

5. Carefully assemble the intake air duct and mass

air flow sensor onto air cleaner upper housing.

IMPORTANT:

Align the notch on air cleaner housing adapter with

notch in air duct adapter and notch in clamp.

8. Tighten the air duct clamp securely.

9. Check that the mass air flow sensor wiring

harness connector has remained firmly in place.

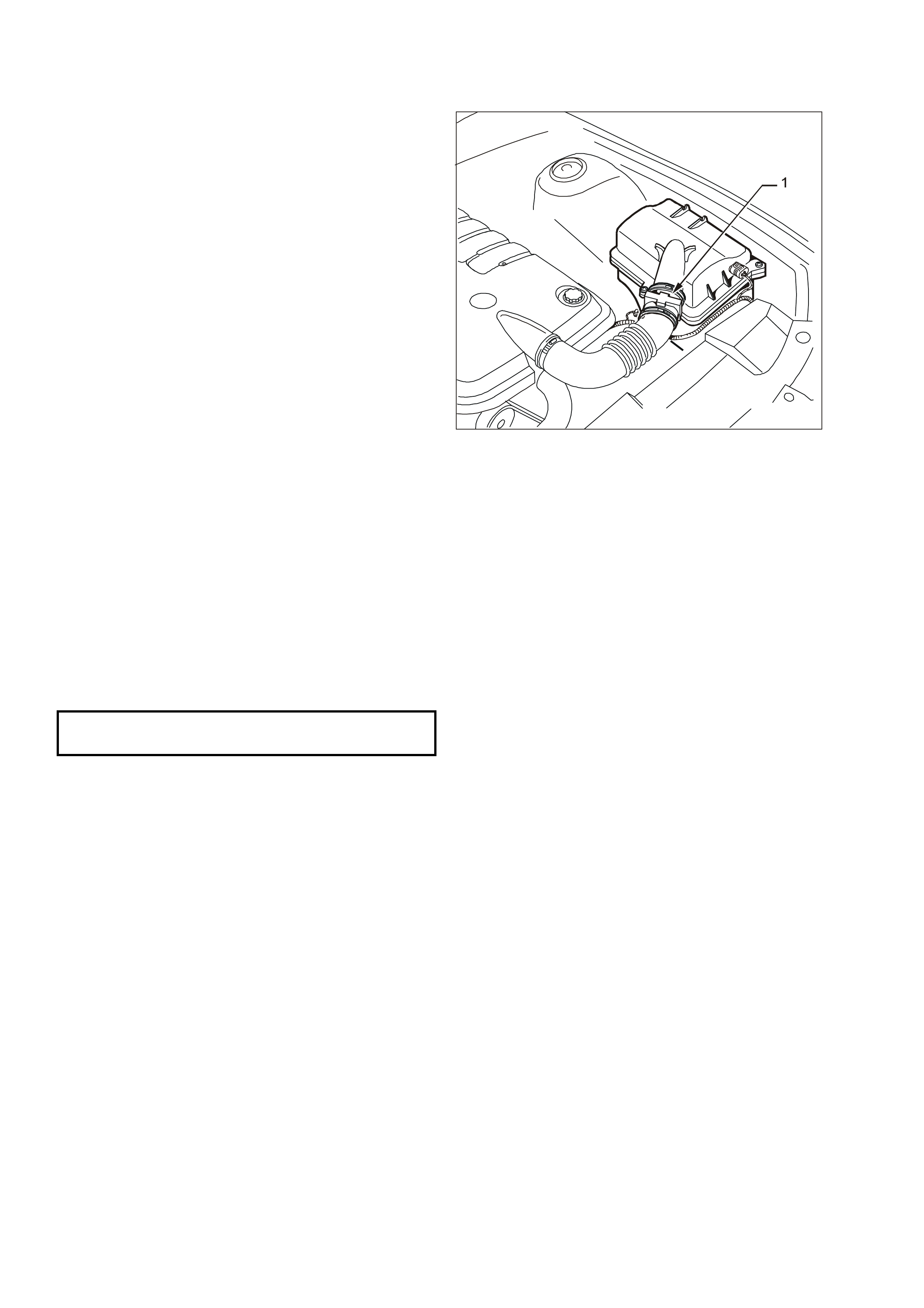

3.7 MASS AIR FLOW (MAF) SENSOR

REMOVE

IMPORTANT:

Care must be taken when handling the MAF sensor

as damage will affect the operation of PCM control.

1. Lift up the tang on the MAF sensor (1) wiring

harness connector and remove the connector

from sensor.

2. Loosen the clamp on air duct adapter, closest to

MAF sensor.

3. Loosen the clamp on the air duct at the MAF

sensor and pull back the air duct from the sensor.

IMPORTANT:

The air duct adapter (between air cleaner and MAF

sensor), retaining clamps, air duct and MAF sensor

have locating notches.

4. Remove MAF sensor from air duct adapter.

REINSTALL

IMPORTANT:

The embossed arrows on the MAF sensor indicate

the correct air flow direction. The arrows must point

towards the engine.

1. Install the MAF sensor into the air duct adapter

and air duct.

IMPORTANT:

Ensure all notches are aligned.

2. Install the retaining clamps, aligning notches,

tighten clamps to the specified torque.

3. Reconnect the MAF sensor wiring harness

connector

4. Start vehicle and check for air leaks.

T26C3002

Figure 6C3-3-12 MAF Sensor Location

Air Cleaner Duct Clamp

Tightening Torque 1.5 - 2.5 N.m

3.8 MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section.

2. Disconnect the MAP sensor electrical connector

(1).

3. Twist the MAP sensor (2) forward in order to

release it from the retainer.

4. Pull the MAP sensor upward.

REINSTALL

IMPORTANT: Lightly coat the MAP s ensor seal with

clean engine oil before installing the sensor.

1. Install the MAP sensor by pushing it down to

engage it into the retainer.

2. Connect the MAP sensor electrical connector.

3. Install engine dress cover.

2

1

Figure 6C3-3-13 MAP Sensor Location

3.9 HEATED OXYGEN SENSORS (HO2S)

IMPORTANT:

The heated oxygen sensors have a permanently

attached pigtail and connector. Do not remove the

pigtail from the sensor.

Handle the oxygen sensor carefully. Do not drop it

and keep it free of grease, dirt, or other

contaminants. Do not use cleaning solvents of any

type.

Do not repair the sensor or any of its parts.

Replace the oxygen sensor if any damage is

evident.

Correct oxygen sensor operation requires an

external air r efer ence. This external air ref erence is

obtained by way of the oxygen sensor signal and

heater wires. Any attempt to repair the wires, the

connectors, or the terminals results in the

obstruction of the air reference and degrades the

oxygen sensor performance.

NOTE 1:

The heated oxygen sensor may be difficult to

remove when the engine temperature is below

48°C (120°F). Excessive force may damage the

threads in the exhaust manifold or exhaust pipe.

NOTE 2:

It may be necessary to lower the exhaust system to

gain sufficient access to a HO2S and/or its

connector. Refer to Section 8B Exhaust System

in VX Service Information.

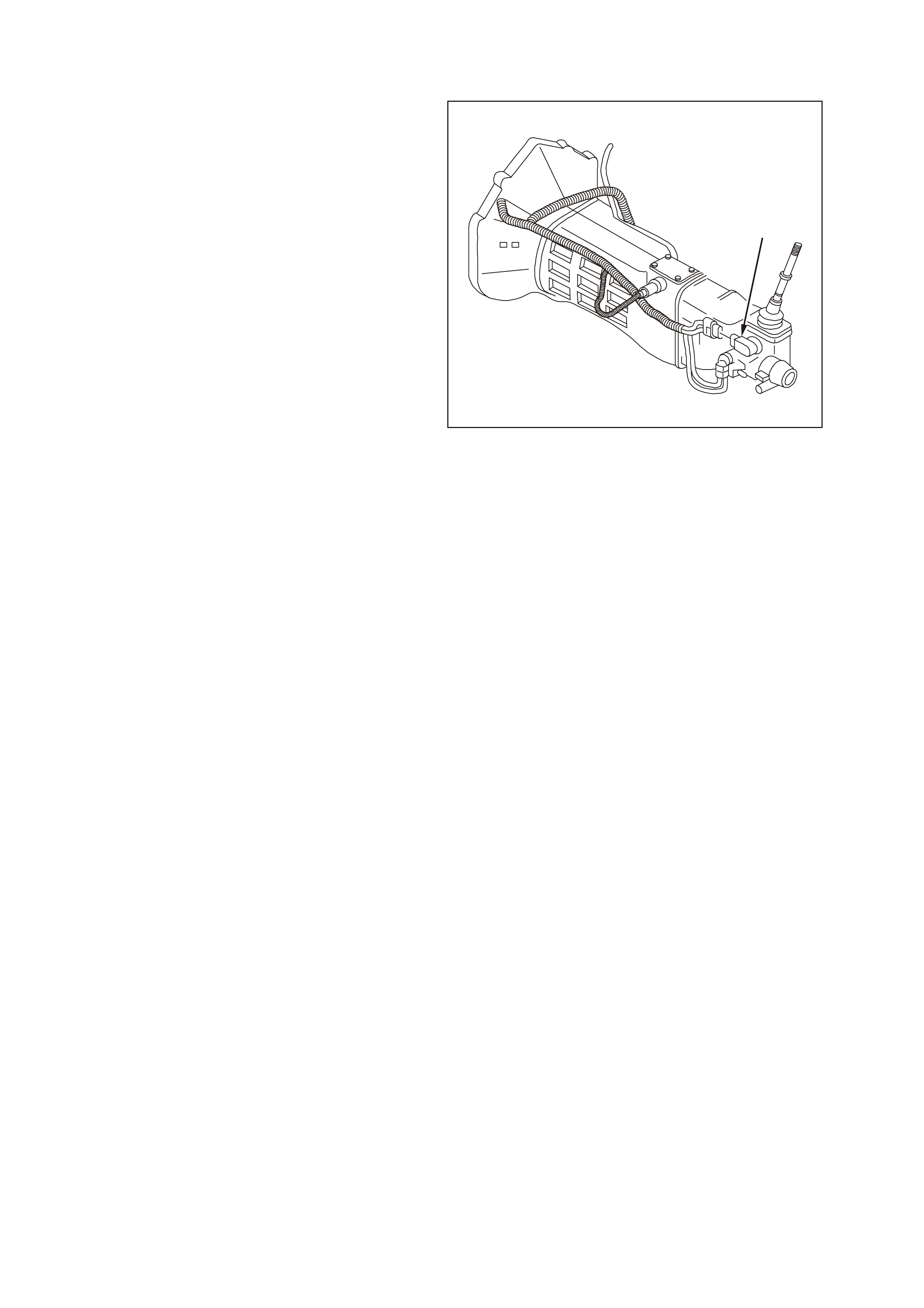

T26C3008

1

3

Figure 6C3-3-14 Left Hand HO2S Sensor 1

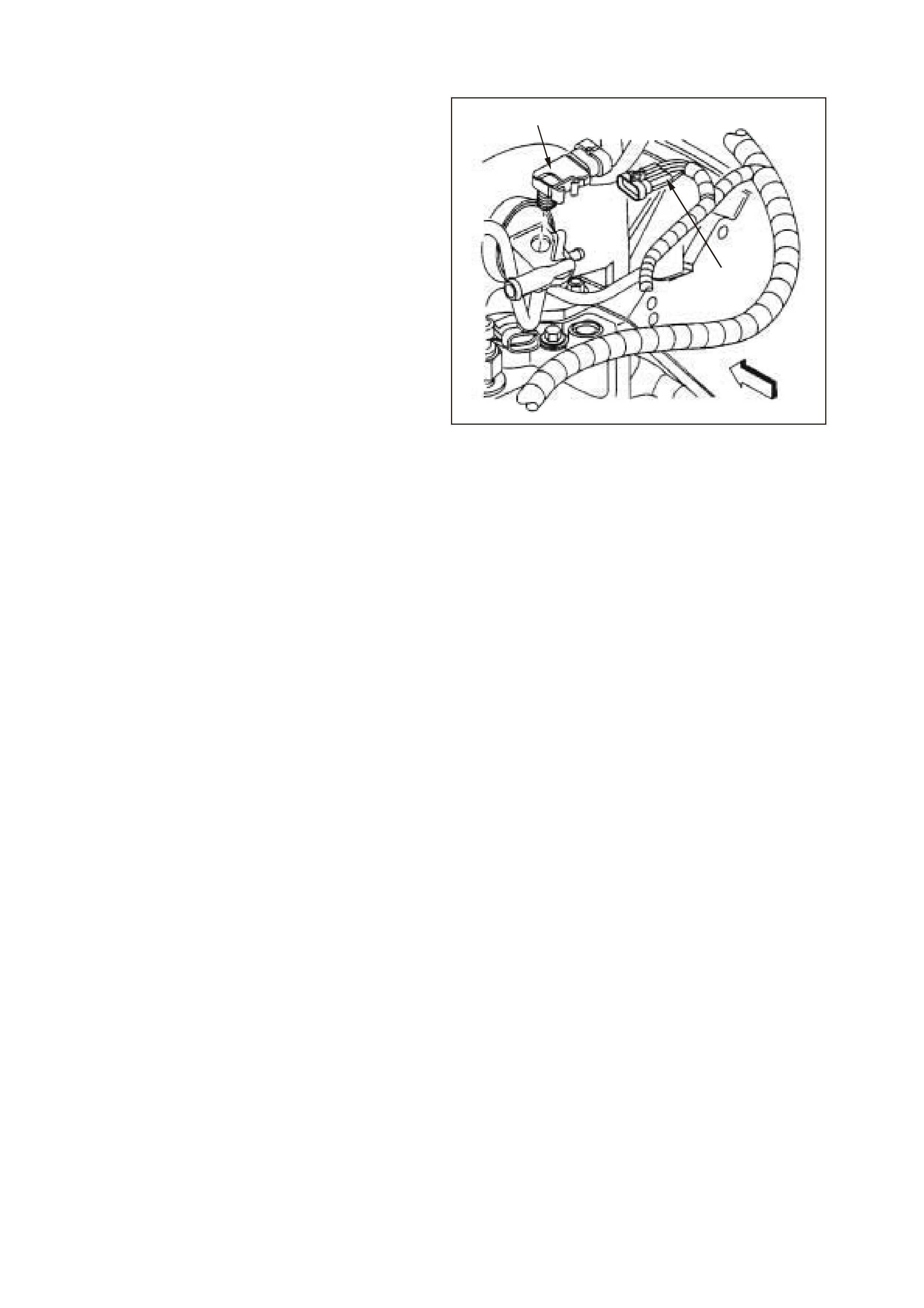

REMOVE

1. Raise the vehicle. Refer to Vehicle Lifting and

Jacking in Section 0A of VT Series I

Service Information.

2. Disconnect the left-hand (1) or right-hand (2)

HO2S electrical connector.

3. Car efully remove the HO2S f rom left-hand (3) or

right-hand (4) exhaust pipe

REINSTALL

IMPORTANT:

A special anti-seize compound is used on the

heated oxygen sensor threads. The compound

consists of graphite and glass beads suspended in

fluid. The graphite will burn away, but the glass

beads will remain, making the sensor easier to

remove. New or service sensors will have the

compound applied to the threads.

If a sensor is rem oved from an engine and is to be

reinstalled, the threads must have anti-seize

compound applied before reinstallation.

NOTE:

Specified anti-seize compound is available from

authorised Holden Parts Outlets as part number

5613695.

1. Coat the threads of the heated oxygen sensor

with anti-seize compound, if required.

2. Install the HO2S into the exhaust pipe and

tighten to the specified torque.

3. Connect the HO2S electrical connector.

4. Lower the vehicle.

4

2

Figure 6C3-3-15 Right Hand HO2S Sensor 1

Heated Oxygen Sensor

Tightening Torque 41 N.m

Techline

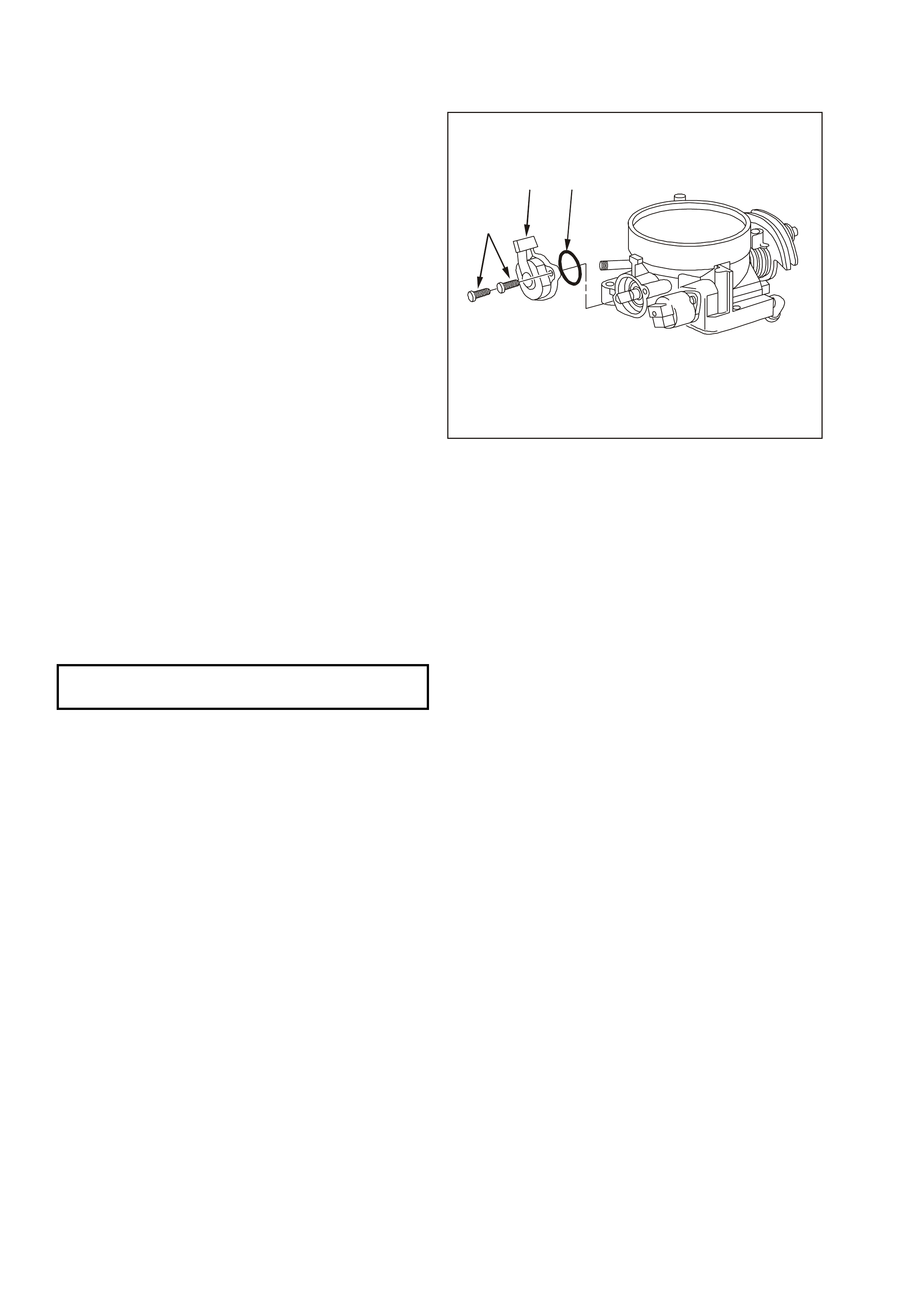

3.10 THROTTLE POSITION (TP) SENSOR

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section.

2. Depress the power steering reservoir retaining

clip and lift it up on the reservoir and set aside.

3. Unbolt and remove the power steering reservoir

mounting bracket.

4. Disconnect the electrical connector from the TP

sensor (1).

5. Remove the TP sensor attaching screws (2).

6. Remove the TP sensor and O-ring (3).

REINSTALL

1. Install the TP sensor O-ring seal on to the TP

sensor.

2. Install the TP sensor on the throttle body with

the throttle valve in the closed position.

IMPORTANT:

Ensure the TP sensor lever lines up with the TP

sensor drive lever on the throttle shaft.

3. Install the TP sensor attaching screws and

tighten to the specified torque.

4. Connect the TP sensor electrical connector.

5. Install the power steering reservoir mounting

bracket.

6. Install the power steering reservoir to mounting

bracket.

7. Install engine dress cover.

2

13

Figure 6C3-3-16 Throttle Position (TP) Sensor

TP Sensor Attaching

Screws Tightening Torque 2 N.m

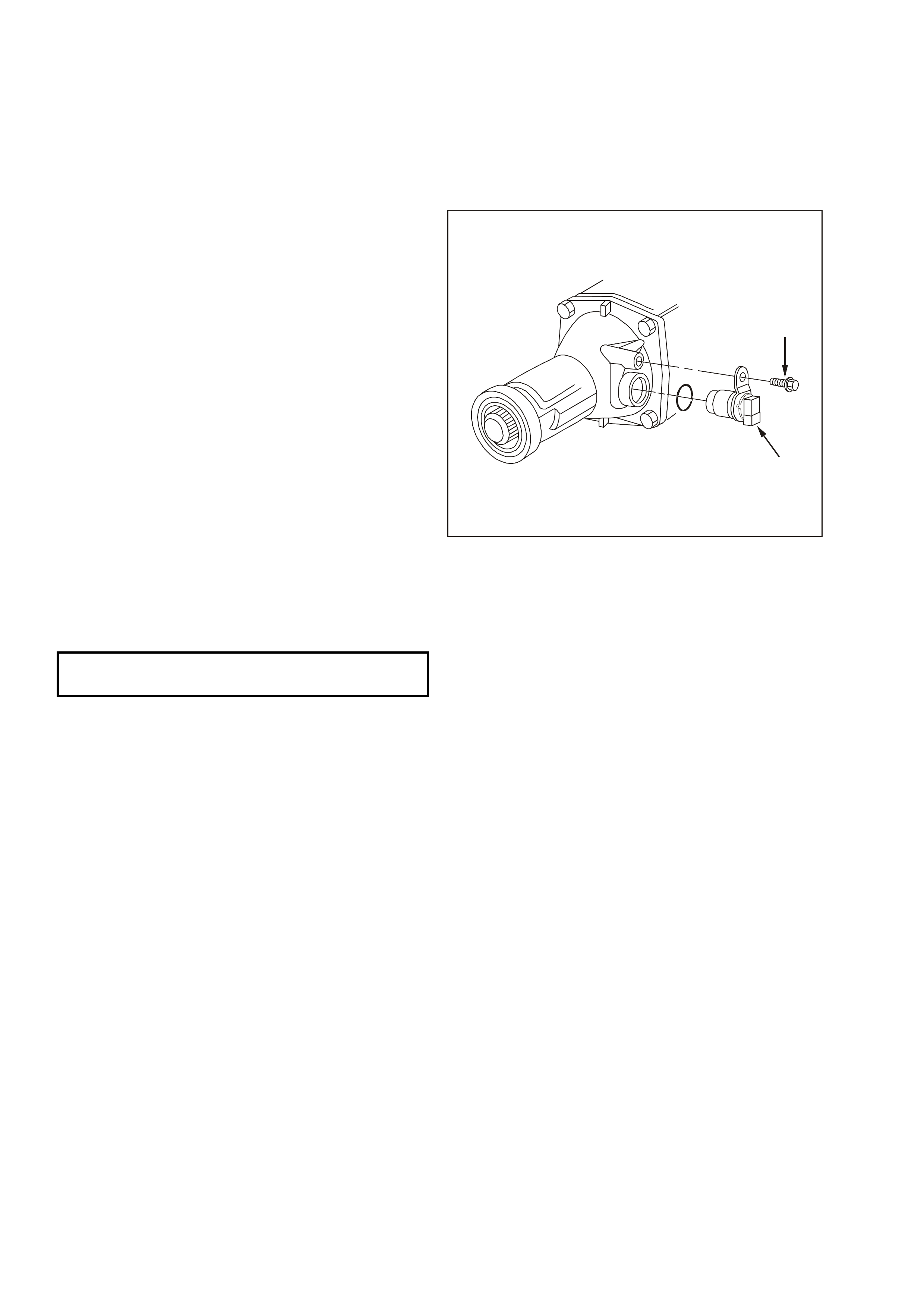

3.11 VEHICLE SPEED SENSOR

IMPORTANT:

This procedure refers to the vehicle speed sensor

fitted to vehicles with automatic transmission. For

manual trans m ission vehicle speed s ensor r em oval

and reinstallation, refer to Section 7B3 in VT

Series II Service Information.

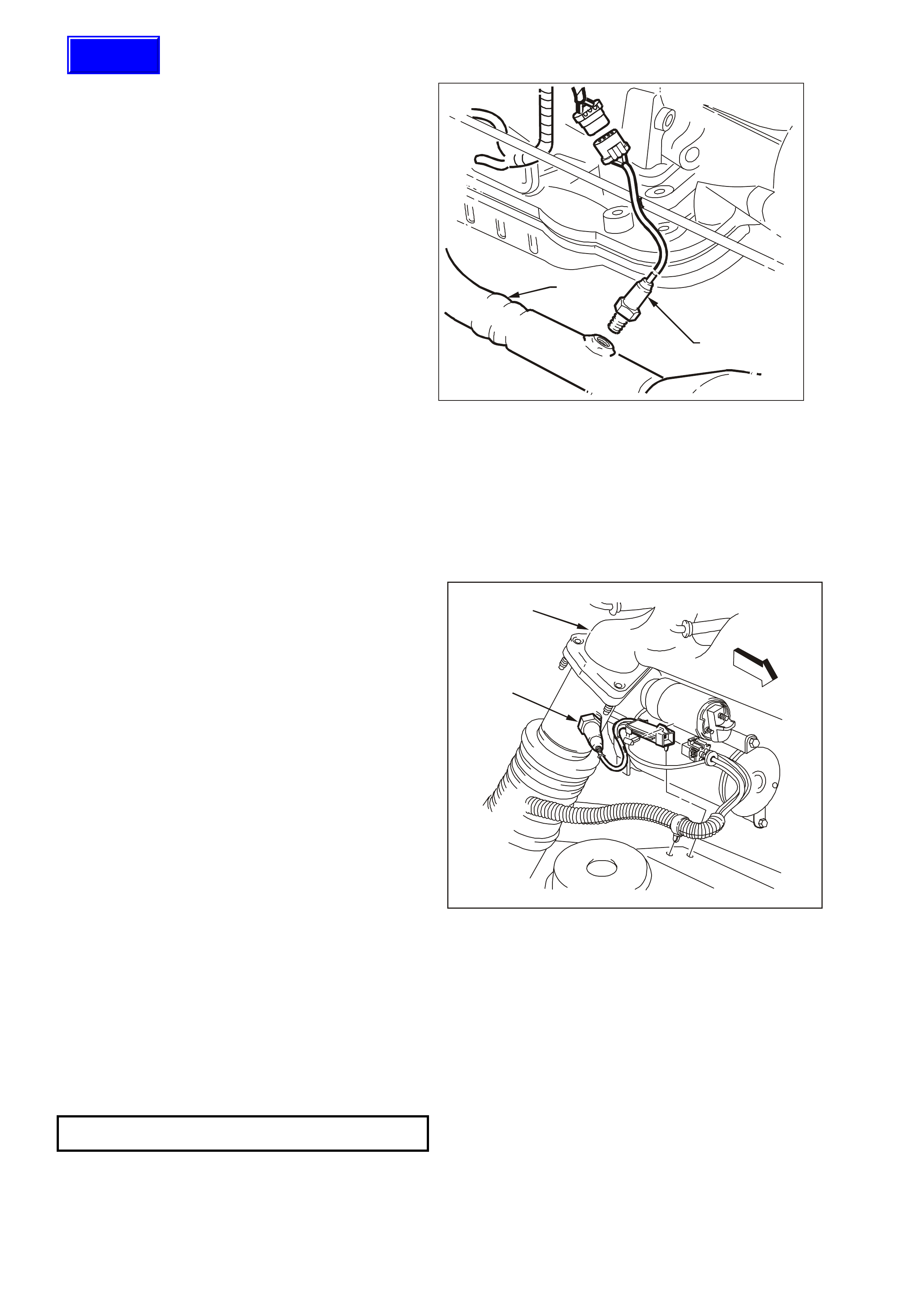

REMOVE

1. Raise the vehicle. Refer to

Section OA General Information in VT Series I

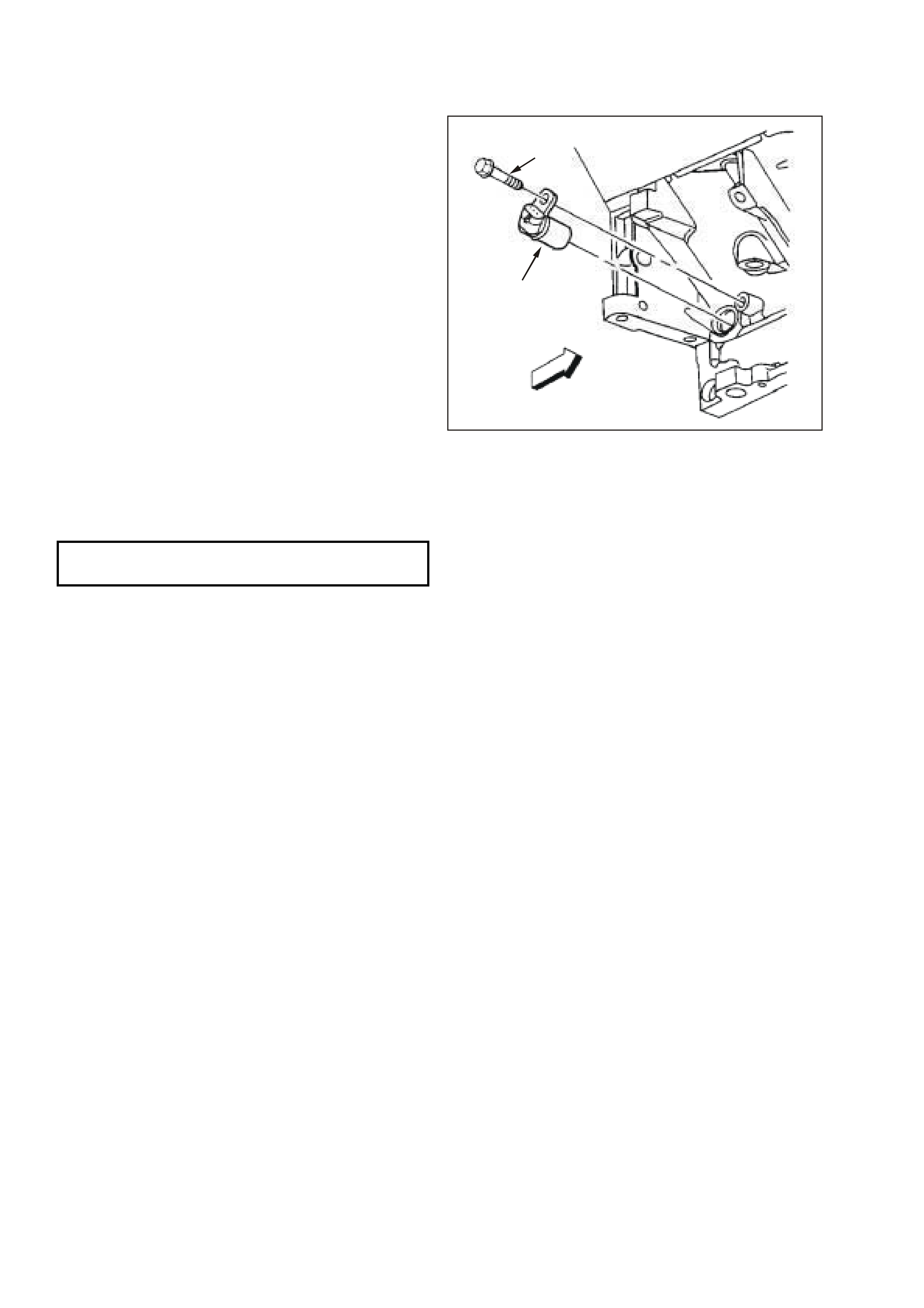

Service Information.

2. Disconnect the electrical connector from the

vehicle speed sensor (1)

3. Remove the vehicle speed sens or attaching bolt

(2).

4. Remove the vehicle speed sensor and the O-

ring. Use a suitable container to catch any

transmission fluid that may spill.

REINSTALL

1. Install the vehicle speed sensor with new O-ring

seal.

2. Install the speed sensor bolt and tighten to the

specified torque.

3. Connect the electrical connector.

4. Lower the vehicle.

5. Check the transmission fluid and add as

required. Refer

Transmission Fluid Checking Procedure in

Section 7C4, VT Series II Service Information.

2

1

Figure 6C3-3-17 Vehicle Speed Sensor

Speed Sensor Attaching Bolt

Tightening Torque 11 N.m

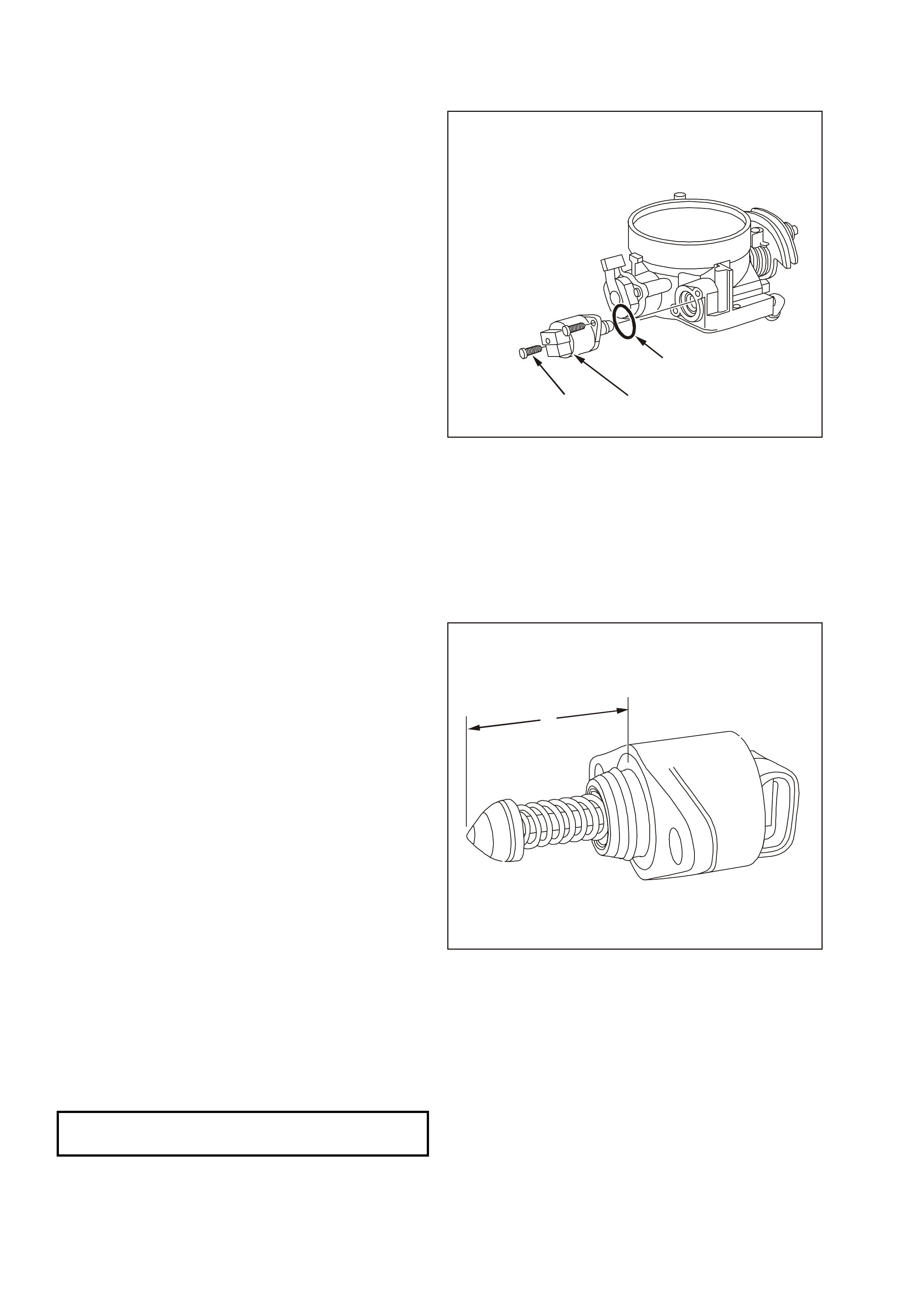

3.12 IDLE AIR CONTROL VALVE

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. Disconnect the elec trical c onnector f rom the IAC

valve (1).

3. Remove the IAC valve attaching screws (2).

4. Remove the IAC valve.

5. Remove the IAC valve O-ring seal (3).

IMPORTANT:

Do Not push or pull on the IAC valve pintle on

valves that have been in service. The force

required to move the pintle may damage the

threads on the worm drive.

6. Clean the IAC valve O-ring sealing surface, the

pintle valve seat and the air passage using GM

cleaner 1052626 or GM X-66 A. Use a shop

towel or parts brus h to rem ove heavy depos its. If

the air passage has heavy deposits, remove the

throttle body for complete cleaning.

NOTE:

Shiny spots on the pintle or seat are normal, and do

not indicate misalignment or a bent pintle shaft.

7. Inspect the IAC valve O-ring for cuts, cracks, or

distortion. Replace the O-ring if it is damaged.

1

2

3

Figure 6C3-3-18 Idle Air Control (IAC) Valve

REINSTALL

IMPORTANT:

If installing a new IAC valve, be sure to replace it

with an identical part. The pintle shape of the IAC

valve and the diameter of the IAC valve are

designed for the specific application.

1. Meas ure the distance between the tip of the IAC

valve pintle and the mounting surface (A). If the

distance is greater than 28 mm, use finger

pressure to slowly retract the pintle. The force

required to retract the pintle on a new valve will

not cause damage to the valve.

2. Lubr icate the IAC valve O-ring with clean engine

oil.

3. Install the IAC valve O-ring on the IAC valve.

4. Install the IAC valve.

5. Apply Loctite 242 or equivalent to the IAC valve

attaching screw threads.

6. Install the IAC valve attaching screws and

tighten to the specified torque.

7. Connect the IAC valve electrical connector.

8. Install engine dress cover.

9. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

A

Figure 6C3-3-19 IAC Valve Measured Distance

IAC Valve Attaching Screws

Tightening Torque 3 N.M

3.13 CAMSHAFT POSITION (CMP) SENSOR

REMOVE

1. Disconnect the negative battery cable to avoid

possible fuel discharge if an accidental attempt

is made to start the engine.

2. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

3. Relieve fuel system pressure. Refer to

Fuel Pressure Relief Procedure in this Section.

4. Remove the intake manifold. Refer to

Section 6A3 Engine Mechanical in VX Service

Information.

IMPORTANT:

Clean the area around the CMP before removal to

avoid debris from entering the engine.

5. Remove the electrical connector from the

Camshaft Position (CMP) sensor (2).

6. Remove the CMP sensor retaining bolt (1).

7. Remove the CMP sensor.

REINSTALL

1. Install the CMP sensor.

2. Install the CMP sensor retaining bolt and tighten

to the specified torque.

3. Connect the CMP sensor electrical connector.

4. Install the intake manifold. Refer to

Section 6A3 Engine Mechanical in VX Service

Information.

5. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds

- Turn the ignition switch OFF for 10 seconds.

- Turn the ignition switch ON.

- Check for fuel leaks.

6. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming.

7. Install engine dress cover.

1

2

Figure 6C3-3-20 Camshaft Position Sensor

CMP Sensor Attaching Bolt

Tightening Torque 25 N.m

3.14 THROTTLE CONTROL

Two Throttle Control cable systems are used with

the GEN III V8 Engine.

Vehicles that do not have Electronic Traction

Control (ETC), are fitted with a single throttle cable.

Vehicles that are fitted with ETC have two cables;

• an accelerator pedal cable which is routed

between the accelerator pedal and throttle

relaxer, and

• a throttle cable which is routed between the

throttle relaxer and throttle body .

Adjustment is only available on the throttle cables.

ACCELERATOR PEDAL CABLE - VEHICLES WITH ETC

ROUTING

1. Accelerator Pedal Cable

2. Throttle Relaxer

1

2

Figure 6C3-3-21 Accelerator Pedal Cable Routing, with ETC

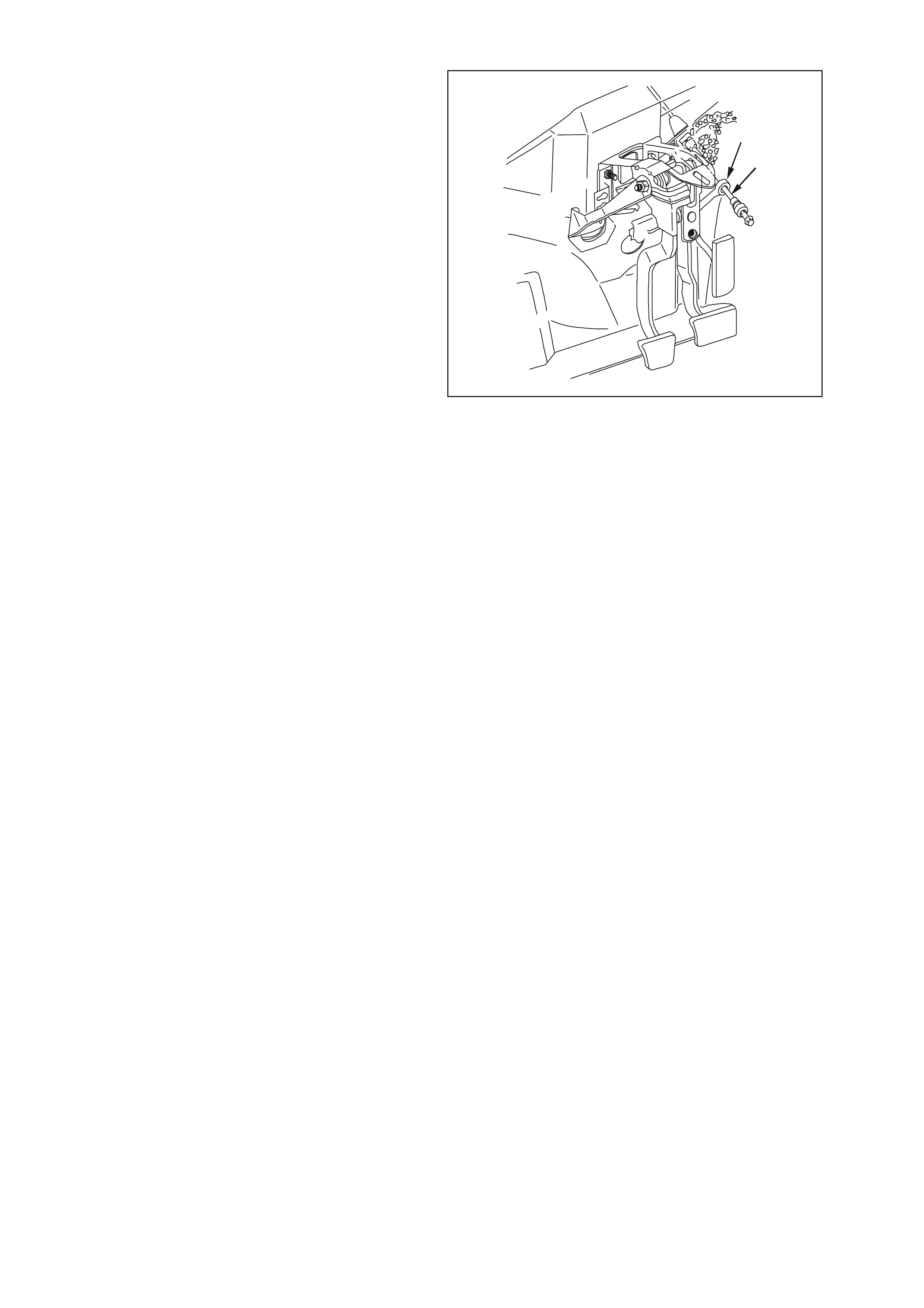

REMOVE

1. Remove the throttle relaxer cover (1).

2. Remove the cruise control cable (2) (if

equipped).

3. Remove the accelerator pedal cable (3).

4. Open the retainer clip at the brake booster, and

remove the cable from the clip.

1

2

3

Figure 6C3-3-22 Throttle Relaxer

5. Remove the right instrument panel lower trim.

6. Disconnect the accelerator pedal cable (1) from

the accelerator pedal lever (2).

7. Squeeze the accelerator pedal cable cover

tangs and push the cable through the dash

panel.

8. Remove the accelerator cable.

REINSTALL

1. Install the accelerator pedal cable through the

dash panel. Snap the retainer through the dash

panel.

2. Install the accelerator pedal cable through the

slot in the accelerator pedal lever. Seat the

retainer in the accelerator pedal lever.

3. Attach the accelerator pedal cable to the brake

booster cable retaining clip.

4. Attach the ac celerator pedal cable to the throttle

relaxer.

5. Attach the cruise control cable to the throttle

relaxer (if equipped).

6. Install the throttle relaxer cover.

7. Refit the instrument panel lower trim.

2

1

Figure 6C3-3-23 Accelerator Pedal to Cable

THROTTLE CABLE - VEHICLES WITH ETC

ROUTING

1. Throttle Cable (with ETC)

2. Throttle Relaxer

1

2

Figure 6C3-3-24 Throttle Cable Routing, with ETC

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. Remove the throttle relaxer cover (1).

3. Remove the throttle cable (2) from the throttle

relaxer.

4. Open the retainer clip at the intake manifold,

and remove the cable from the clip.

1

2

Figure 6C3-3-25 Throttle Relaxer

5. Lift the throttle cable (1) up at the throttle body

mounting bracket (2), and remove the cable

from the throttle body cam lever (3).

6. Remove throttle cable.

REINSTALL

1. Install the throttle cable to the throttle body cam

lever.

2. Attach the throttle cable to the throttle body

mounting bracket.

3. Attach the throttle cable to the retaining c lip over

the intake manifold.

4. Attach the throttle cable to the throttle relaxer.

5. Install the throttle relaxer cover.

6. Install the engine dress cover.

7. Adjust the throttle cable as described further in

this Section

1

2

3

Figure 6C3-3-26 Throttle Body Cable Mounting Bracket

THROTTLE CABLE - VEHICLES WITHOUT ETC

ROUTING

1. Accelerator Cable

2. Throttle Body Mounting Bracket

1

2

Figure 6C3-3-27 Throttle Cable Routing, without ETC

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. Lift the throttle cable (1) up at the throttle body

cable mounting bracket (2), and remove the

cable from the throttle body cam lever (3).

3. Remove the thr ottle cable f rom the r etaining clip

over the intake manifold.

4. Open the retainer clip at the brake booster, and

remove the throttle cable from the clip.

1

2

3

Figure 6C3-3-28 Throttle Body Cable Mounting Bracket

5. Remove the right instrument panel lower trim.

6. Disconnect the throttle cable (1) from the

accelerator pedal lever (2).

7. Squeeze the throttle cable cover tangs and push

the cable through the dash panel.

8. Remove the throttle cable.

REINSTALL

1. Install the throttle cable through the dash panel.

Snap the retainer through the dash panel.

2. Install the throttle cable through the slot in the

accelerator pedal lever. Seat the retainer in the

accelerator pedal lever.

3. Attach the throttle cable to the brake booster

cable retaining clip.

4. Attach the throttle cable to the retaining c lip over

the intake manifold.

5. Attach the throttle cable to throttle body

mounting bracket.

6. Install the throttle cable to the throttle body cam

lever.

7. Adjust the throttle cable as described in the

following Section.

8. Install the engine dress cover.

9. Install the right instrument panel lower trim.

2

1

Figure 6C3-3-29 Accelerator Pedal to Cable

THROTTLE RELAXER - VEHICLES WITH ETC

REMOVE

1. Remove the throttle relaxer cover (1).

2. Disconnect the throttle relaxer electrical

connector.

3. Remove the nuts attaching the adjuster

assembly to the mounting bracket (2).

4. Remove the accelerator pedal, throttle and

cruise control (if fitted) cables from the throttle

relaxer (3, 4, 5).

REINSTALL

1. Install the cables to the throttle relaxer

assembly.

2. Install the throttle relaxer assembly to the

mounting

3. bracket.

4. Tighten the assembly attaching nuts to the

specified torque.

5. Connect the electrical connector.

6. Adjust the throttle cables as described in the

following Section.

7. Install the throttle relaxer cover.

8. Install the engine dress cover.

Figure 6C3-3-30 Throttle Relaxer

Throttle Relaxer Attaching Nut

Tightening Torque 2 -3 N.m

THROTTLE CABLE ADJUSTMENT - ALL

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. With throttle cable fully installed, unlock the

adjustment locking lever.

3. Ensure throttle is in the closed position.

4. With adj uster unloc ked, pull bac k on accelerator

cable until the thr ottle cam begins to m ove from

the rest position.

5. Move the accelerator cable back towards the

throttle cam until the throttle cam is back at rest.

6. While holding the accelerator cable at the cam

rest position, lock the cable locking lever.

NOTE:

A small amount of slack in the inner cable is

desirable

7. Using a Tech 2 scan tool, check the throttle

angle. When the accelerator is fully depressed

the throttle angle should read 100 percent.

When the accelerator is released the throttle

angle should read 0 percent. If correct results

are not obtained, check the cables for kinks or

damage and repeat procedure.

8. Install engine dress cover.

T6A3055

Figure 6C3-3-31 Throttle Cable Lock Adjuster

3.15 FUEL CONTROL SYSTEM

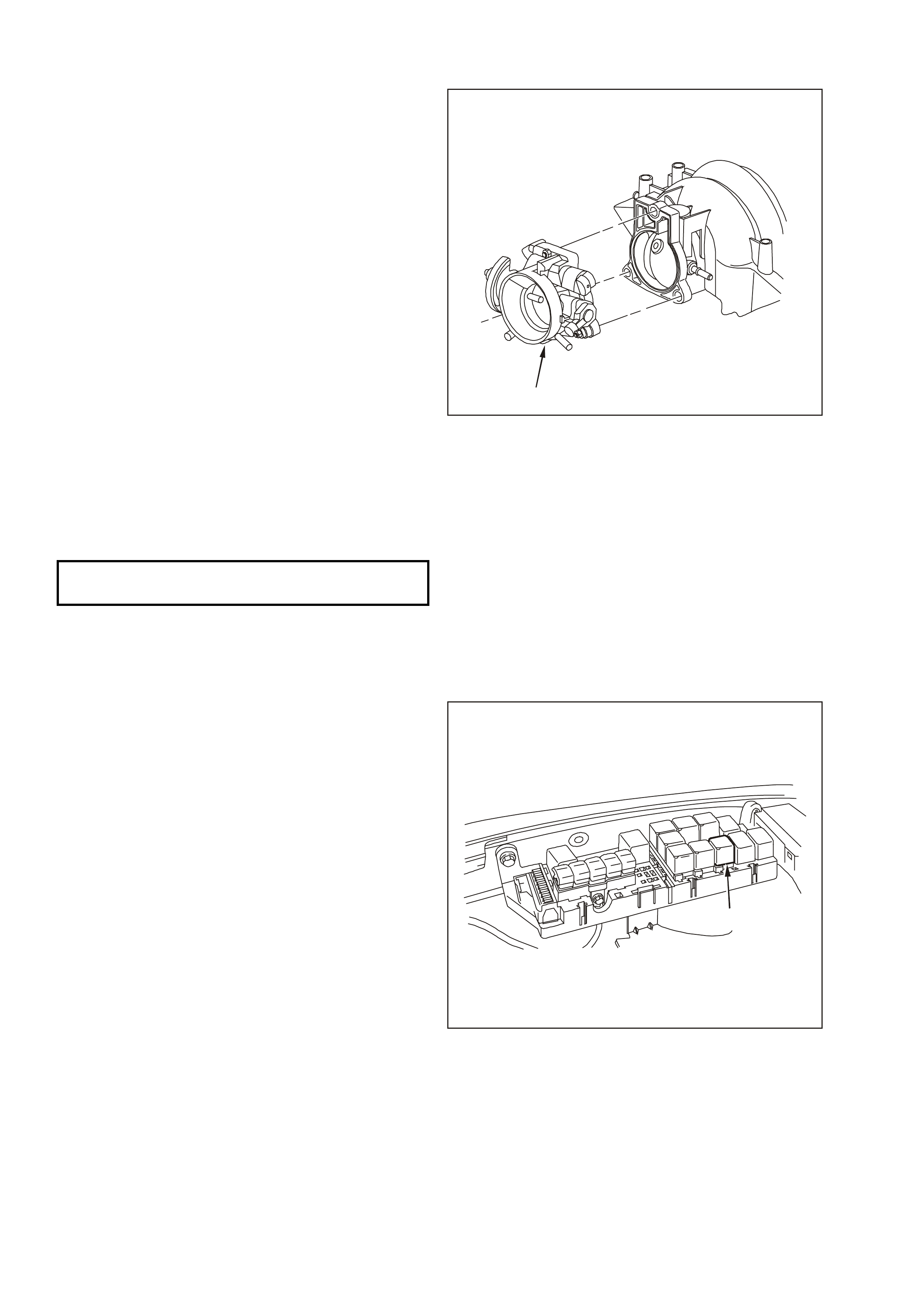

THROTTLE BODY

REMOVE

1. Disconnect the negative battery cable.

2. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

3. Partially drain the cooling system in order to

remove the hoses at the throttle body.

4. Remove the air intake duct from throttle body.

5. Disc onnect the IAC valve (1) and T P Sensor (2)

electrical connectors.

6. Disconnect the throttle cable and the cruise

control cable (if equipped) from the throttle

body.

7. Disconnect the crankcase ventilation hose from

the throttle body.

8. Disconnect the EECS pur ge hos e f or the thr ottle

body.

9. Remove the throttle body attaching bolts.

10. Remove the throttle body (3) and the gasket.

11. Discard the gasket.

12. Clean the gasket sealing surfaces.

NOTE:

To prevent damage to the sealing surfaces,

carefully use sharp tools when cleaning the old

gasket from the aluminum surfaces.

IMPORTANT:

Do Not soak the throttle body in cold immersion

type cleaner. The throttle valve has a factory

applied sealing com pound ( DAG m ater ial is applied

to the outside edge of the valve and the throttle

bore) to prevent air bypass at closed throttle.

Strong solvents or brushing will remove the

material. To clean the throttle body following

disassem bly, us e a spray type cleaner such as GM

X-66A or GM 1052626. Use a shop towel to

remove heavy deposits.

The TP sensor and the IAC valve are electrical

components and should NOT come in contact with

solvent or cleaner, as damage may result.

3

2

1

Figure 6C3-3-32 Throttle Body Location

REINSTALL

1. Install the throttle body (1) with a new gasket.

2. Install the throttle body attaching bolts and

tighten to the specified torque.

3. Connect the crankcase ventilation hose to the

throttle body.

4. Connect the EECS purge hose to the throttle

body.

5. Connect the cooling hoses to the throttle body.

6. Connect the thr ottle cable and the cruise control

cable (if equipped).

7. Connect the TP sensor and the IAC valve

electrical connectors.

8. Install the air intake duct.

9. Refill the cooling system.

10. Connect the negative battery cable.

11. With the engine OFF, check to see that the

accelerator pedal is free. Depress the

accelerator pedal to the floor and release.

12. Install engine dress cover.

13. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

1

Figure 6C3-3-33 Throttle Body to Intake Manifold

Throttle Body Attaching Bolt

Tightening Torque 12 N.m

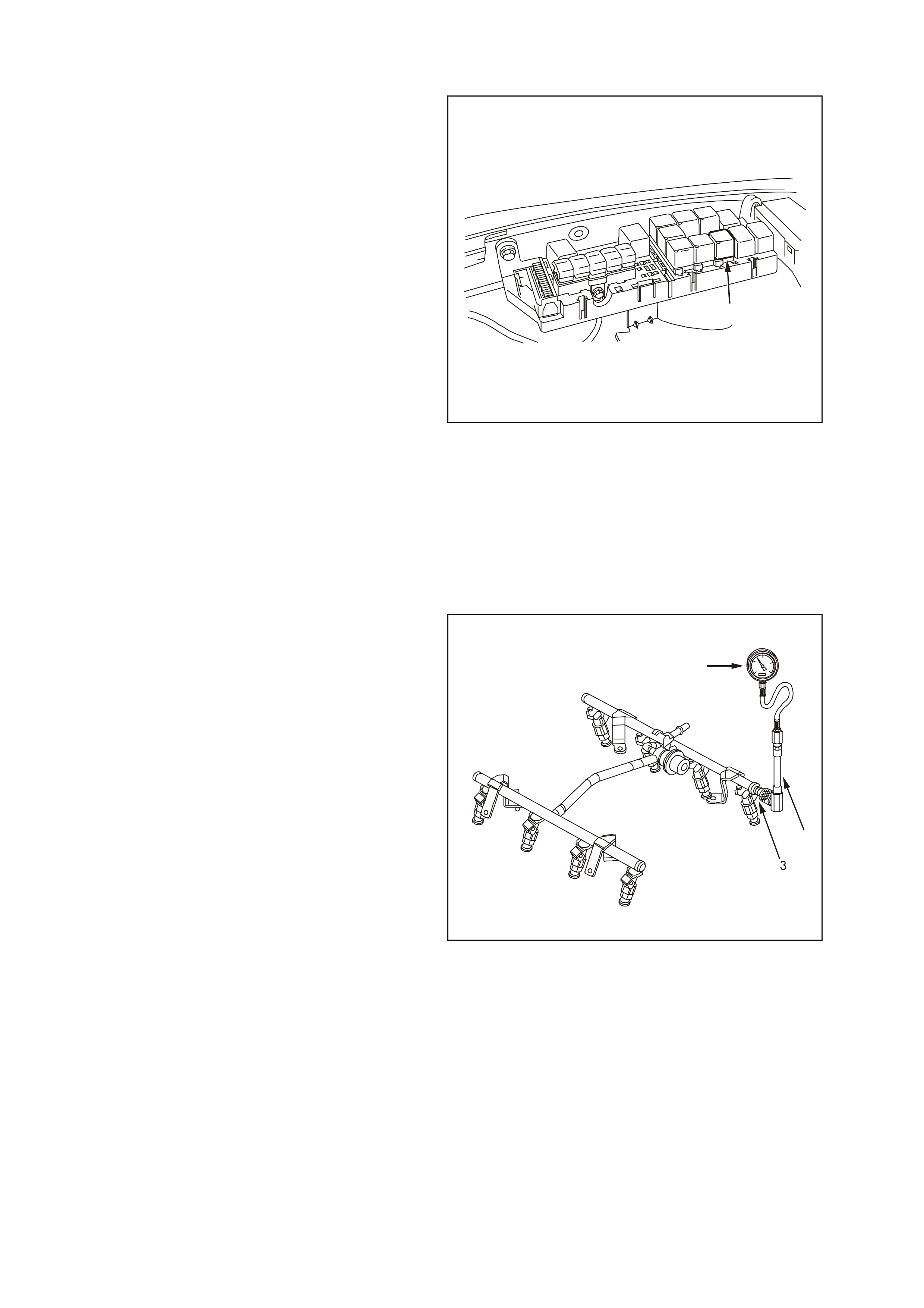

FUEL PUMP RELAY

REMOVE

NOTE:

The fuel pump relay is located in the engine

com par tment Fuse/Relay panel, forward of the r ight

side strut tower. Other than checking for loose

connectors, the only service possible is

replacement.

1. Turn OFF the ignition.

2. Remove the fuse/relay panel cover.

3. Remove the fuel pump relay (1) by pulling

upward.

REINSTALL

1. Install the fuel pump relay into the fuel pump

rela y socket.

2. Ver ify relay operation by turning the key ON and

listening for relay operation (relay should

operate for 2 seconds when key is turned ON).

If relay did not operate, refer to

Fuel Pump Relay Circuit Diagnosis in this

Section.

3. Install the fuse/relay panel cover.

1

Figure 6C3-3-34 Fuel Pump Relay Location

FUEL PRESSURE RELIEF PROCEDURE

IMPORTANT:

Relieve the fuel system pressure before servicing

fuel system com ponents in order to r educe the risk

of fire and personal injury.

After r elieving the s ystem pr es s ure, a s mall amount

of fuel may be released when servicing the fuel

lines or connections. In order to reduce the chance

of personal injury, cover the fittings with a shop

towel before disconnecting. This will catch any fuel

that may leak out. Place the towel in an approved

container when the disconnection is complete.

1. Remove cover from engine compartment relay

housing.

2. Remove fuel pump relay (1).

3. With throttle closed, crank engine.

NOTE:

The engine may start and run until the fuel supply

remaining in the fuel delivery system is depleted.

4. When the engine stops, re-energise the starter

motor for 10 seconds to ensure that the line

pressure has been fully relieved. The fuel

system is now safe to service.

5. Reinstall the fuel pump relay.

1

Figure 6C3-3-35 Fuel Pump Relay Location

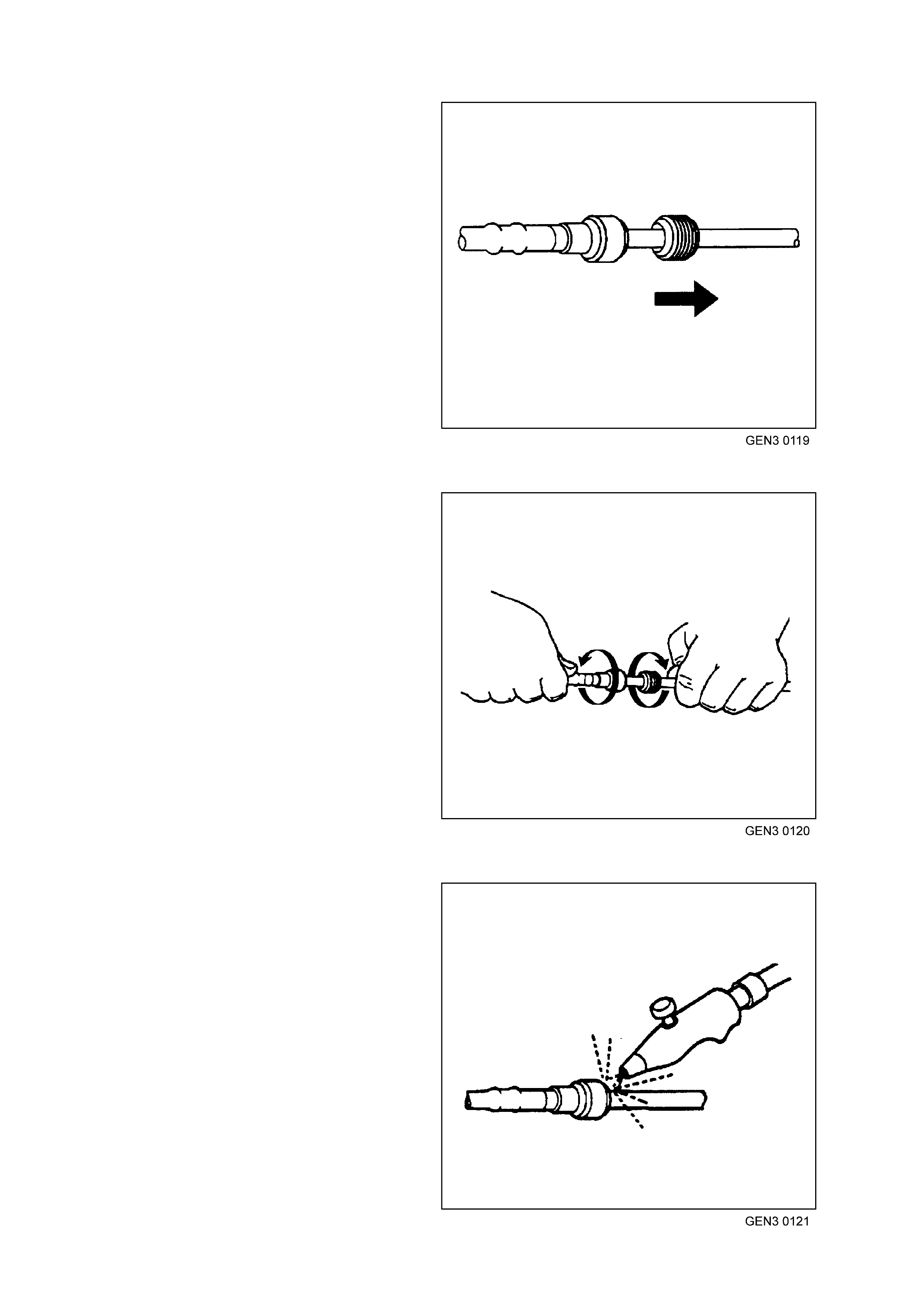

FUEL GAUGE INSTALLATION PROCEDURE

TOOL REQUIRED:

SD28018 OR AU338 Fuel Pressure Gauge, and

AU453 Fuel Gauge Schrader Fitting Adapter

1. Relieve fuel system pressure as previously

described.

2. Turn the ignition OFF.

3. Disconnect the negative battery cable in or der to

avoid possible fuel discharge if an accidental

attempt is made to start the engine.

4. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

5. Loosen the fuel filler cap in order to relieve the

fuel tank vapor pressure.

6. Connect the SD28018 or AU338 fuel pressure

gauge (1) to the AU453 fuel gauge schrader

fitting adapter (2), then connect to the fuel

pressure testing valve (3).

NOTE:

Wrap a shop towel around the fitting while

connecting the gauge to avoid and/or capture any

fuel spillage.

7. Install the bleed hose of the gauge into an

approved petrol container.

8. Open the valve on the gauge to bleed the

system pressure. Fuel connections are now

safe for servicing.

9. Drain any fuel remaining in the gauge into an

approved petrol container.

1

2

Figure 6C3-3-36 Fuel Pressure Gauge Connected to

Schrader Valve

QUICK CONNECT FITTINGS (METAL COLLAR)

REMOVE

TOOLS REQUIRED:

7370, and 7371 Quick Connect Release tools

IMPORTANT:

Relieve the fuel system pressure before servicing

any fuel system connection. Refer to the

Fuel Pressure Relief Procedure in this Section.

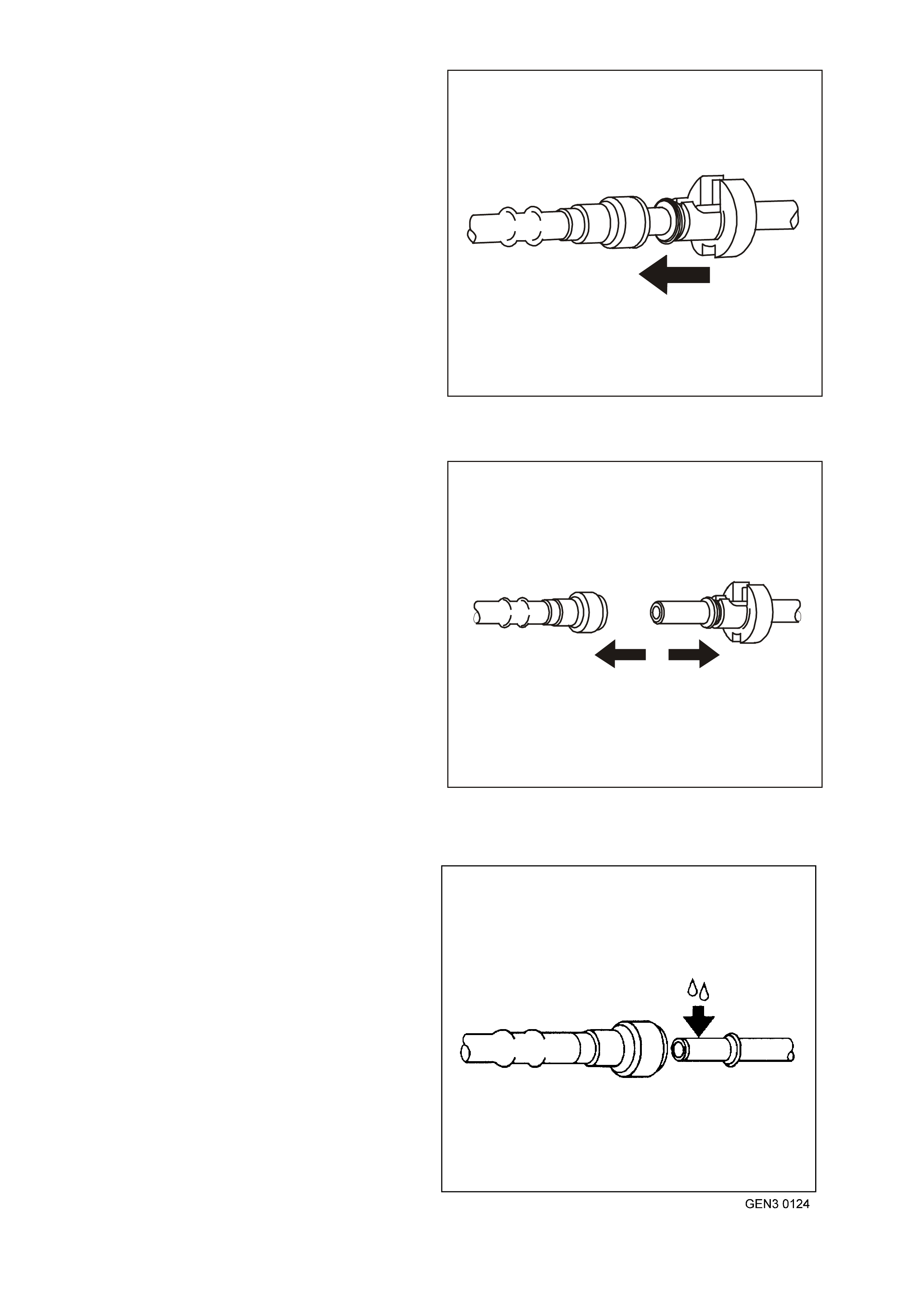

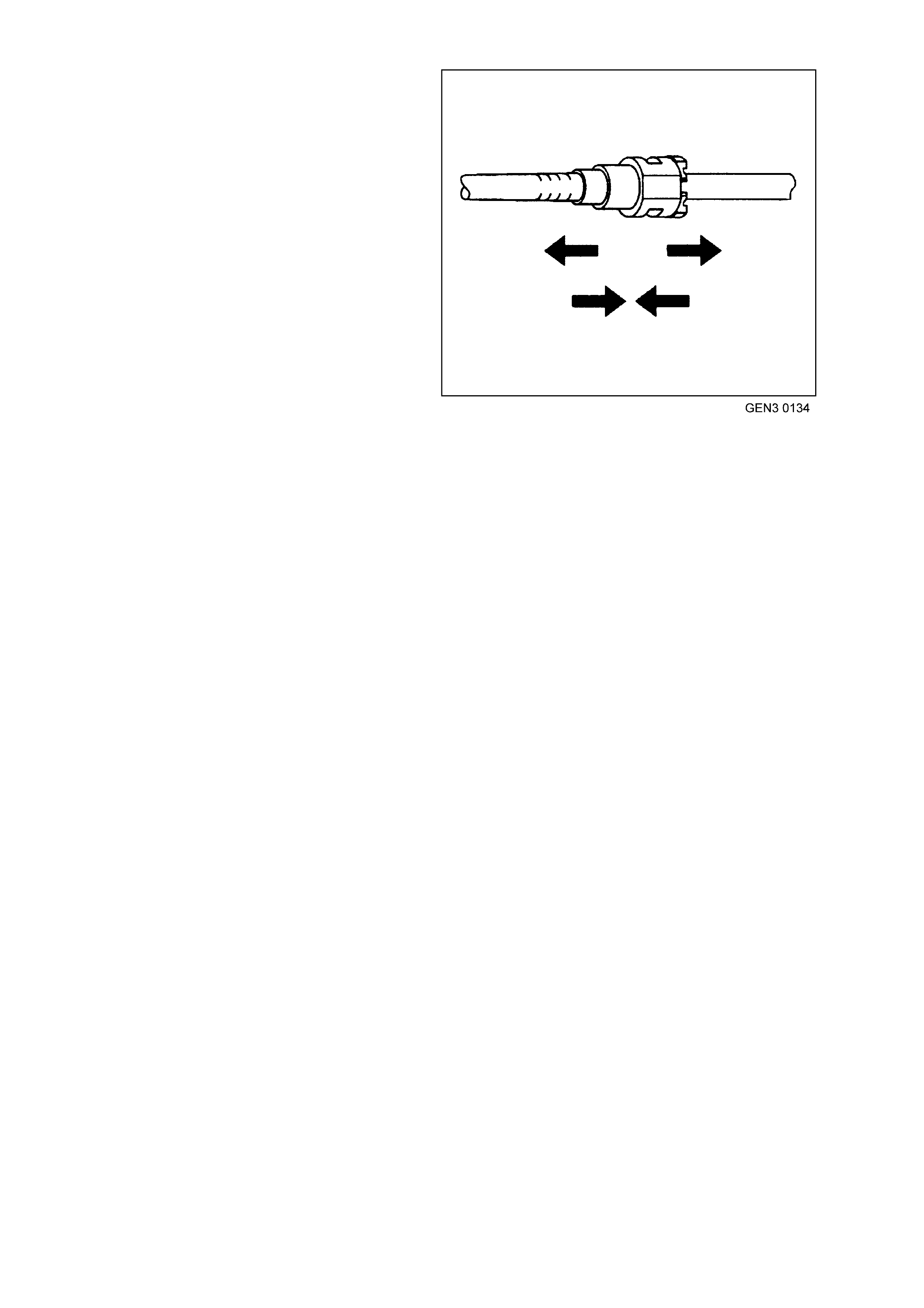

1. Slide the dust cover from the quick-connect

fitting.

Figure 6C3-3-37

2. Grasp both sides of the fitting. Twist the female

connector 1/4 turn in each direction to loosen

any dirt within the fitting.

Figure 6C3-3-38

3. Blow dirt out of the fitting using compressed air.

IMPORTANT:

Wear safety glasses when using compressed air,

as flying dirt particles may cause eye injury.

Figure 6C3-3-39

4. Choose the correct disconnection tool for the

size of the fitting. Insert the tool into the female

connector, then push inward to release the

locking tabs.

GE N 3 0122

Figure 6C3-3-40

5. Pull the connection apart.

NOTE:

If it is nec essar y to remove rus t or burr s f rom a fuel

pipe, use emery cloth in a radial motion with the

fuel pipe end in order to prevent damage to the O-

ring sealing surface.

6. Using a clean shop towel, wipe off the male pipe

end.

7. Ins pect both ends of the f itting for dir t and burrs.

Clean or replace the components as required.

GE N 3 0123

Figure 6C3-3-41

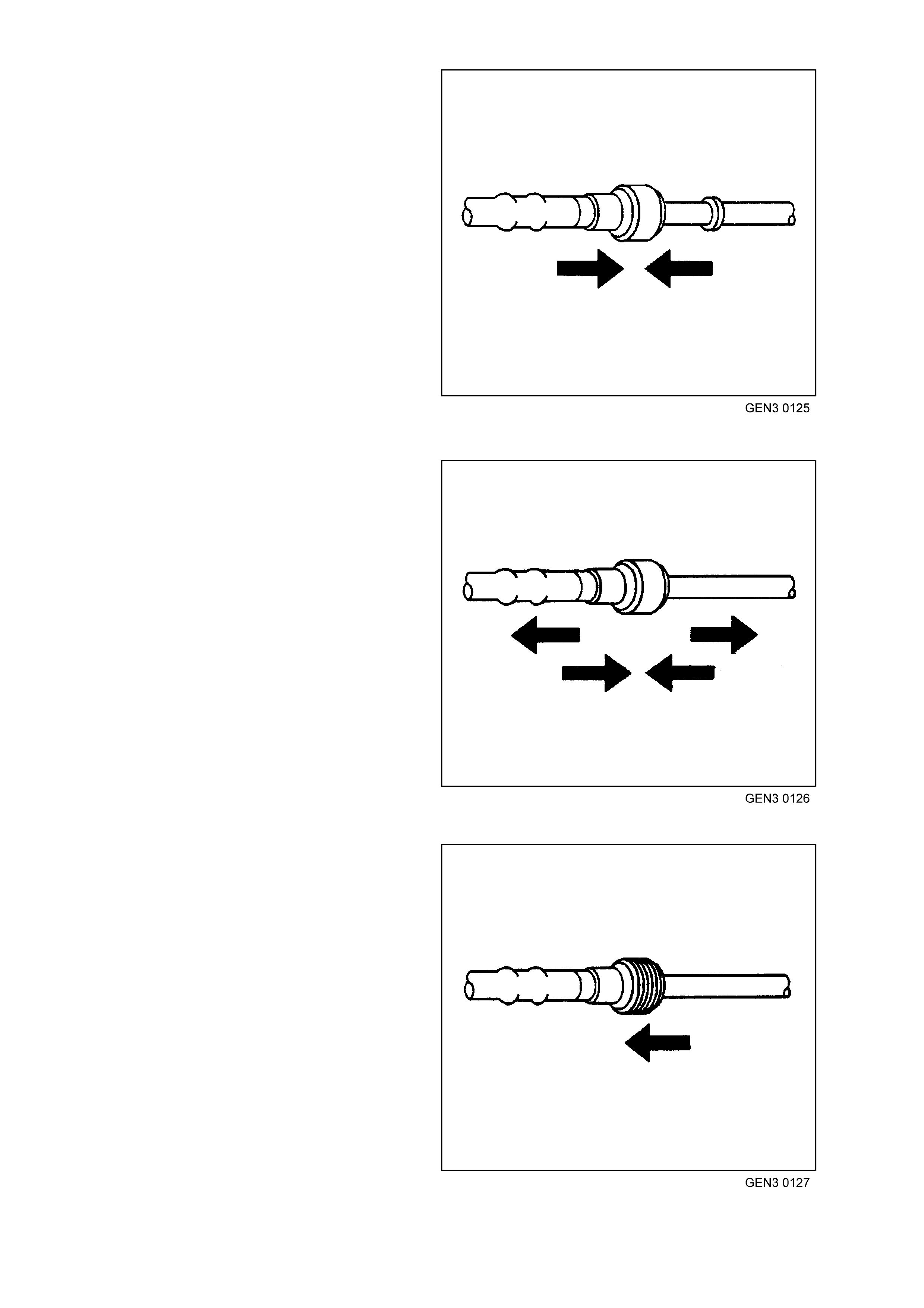

REINSTALL

IMPORTANT:

In order to reduce the risk of fire and personal

injury, before connecting fuel pipe fittings, always

apply a few drops of clean engine oil to the male

pipe ends.

This will ensure proper reconnection and prevent a

possible fuel leak.

During normal operation, the O-ring located in the

fem ale c onnector will swell and m ay prevent proper

reconnection if not lubricated.

1. Apply a few drops of clean engine oil to the

male pipe end.

Figure 6C3-3-42

2. Push both sides of the fitting together to cause

the retaining tabs to snap into place.

Figure 6C3-3-43

3. O nce installed, pull on both sides of the fitting to

ensure the connection is secure.

Figure 6C3-3-44

4. Reposition the dust cover over the quick-

connect fitting.

Figure 6C3-3-45

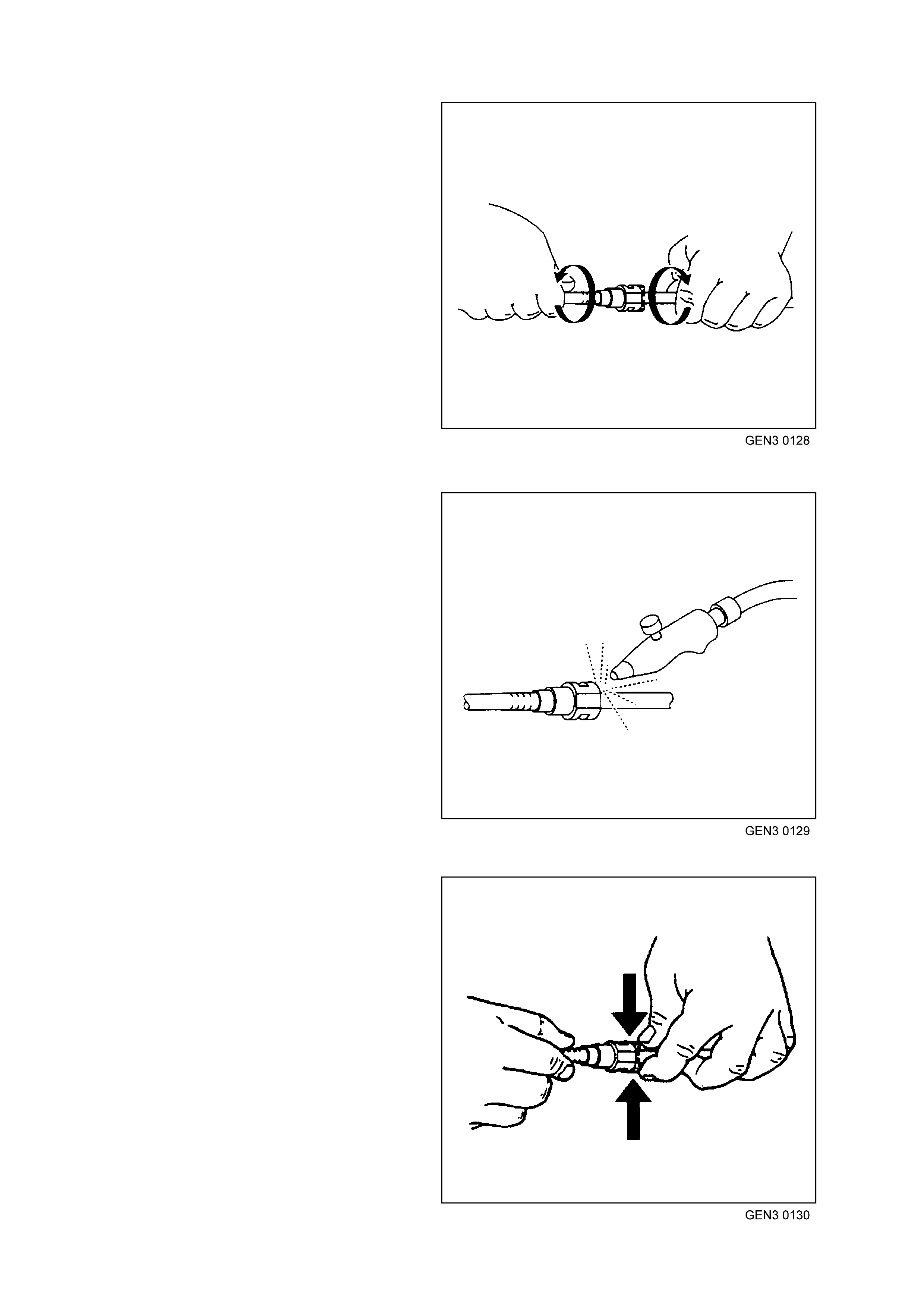

QUICK CONNECT FITTINGS (PLASTIC COLLAR)

REMOVE

IMPORTANT:

Relieve the fuel system pressure before servicing

any fuel system connection. Refer to the

Fuel Pressure Relief Procedure in this Section.

1. Grasp both sides of the quick-connect fitting.

Twist the female connector 1/4 turn in each

direction in order to loosen any dirt within the

quick-connect fitting.

Figure 6C3-3-46

2. Using compressed air, blow any dirt out of the

quick-connect fitting.

IMPORTANT:

W ear s afety glass es when using compres sed air in

order to prevent eye injury.

Figure 6C3-3-47

3. Squeeze the plastic retainer release tabs

Figure 6C3-3-48

4. Pull the connection apart.

Figure 6C3-3-49

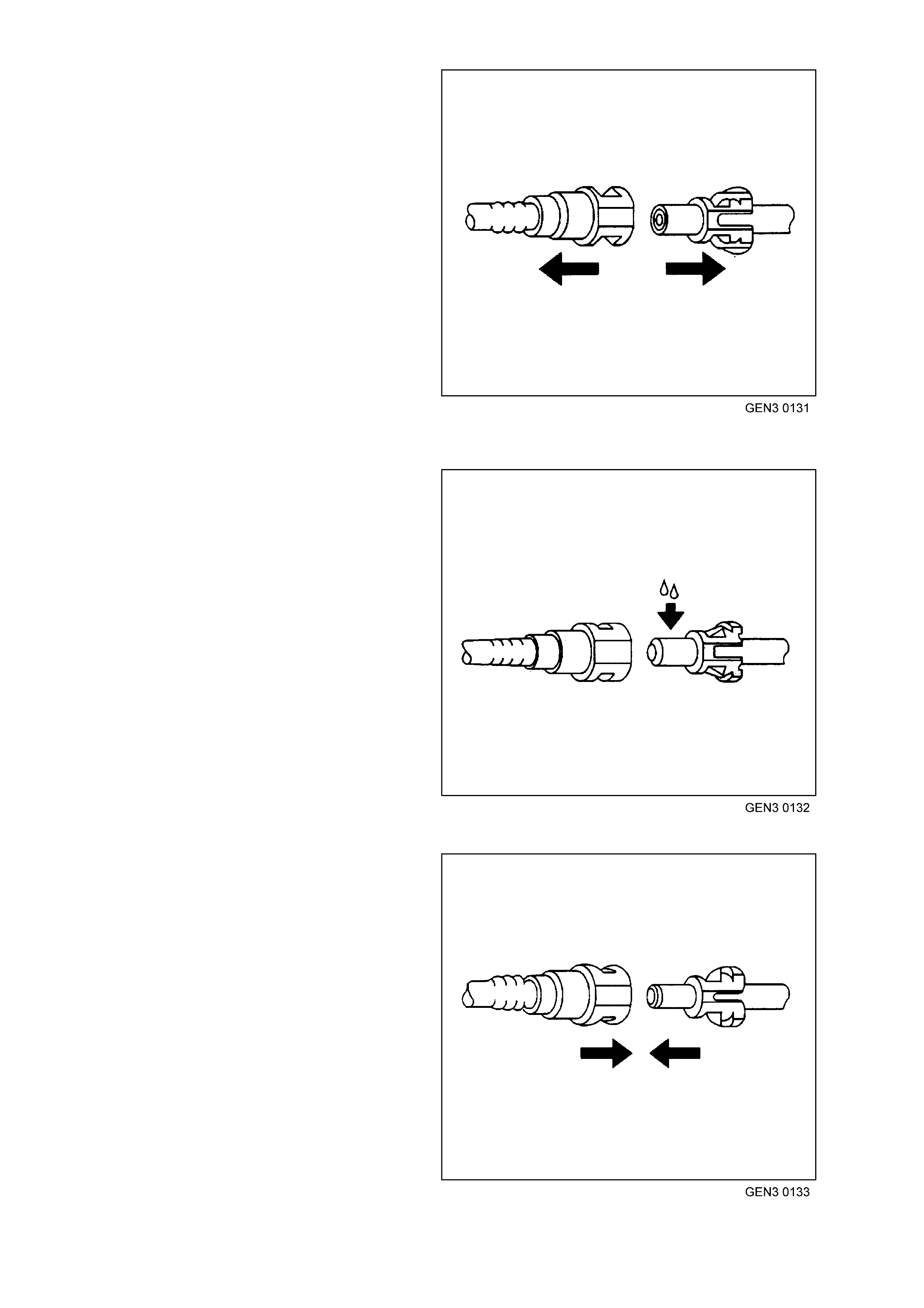

REINSTALL

IMPORTANT:

In order to reduce the risk of fire and personal

injury, before connecting fuel pipe fittings, always

apply a few drops of clean engine oil to the male

pipe ends.

This will ensure proper reconnection and prevent a

possible fuel leak.

During normal operation, the O-ring located in the

fem ale c onnector will swell and m ay prevent proper

reconnection if not lubricated.

1. Apply a few drops of clean engine oil to the

male fuel pipe end.

Figure 6C3-3-50

2. Push both sides of the quick-connect fitting

together in order to cause the retaining

tabs/fingers to snap into place.

Figure 6C3-3-51

3. Once installed, pull on both sides of the quick-

connect fitting in order to make sure the

connection is secure.

Figure 6C3-3-52

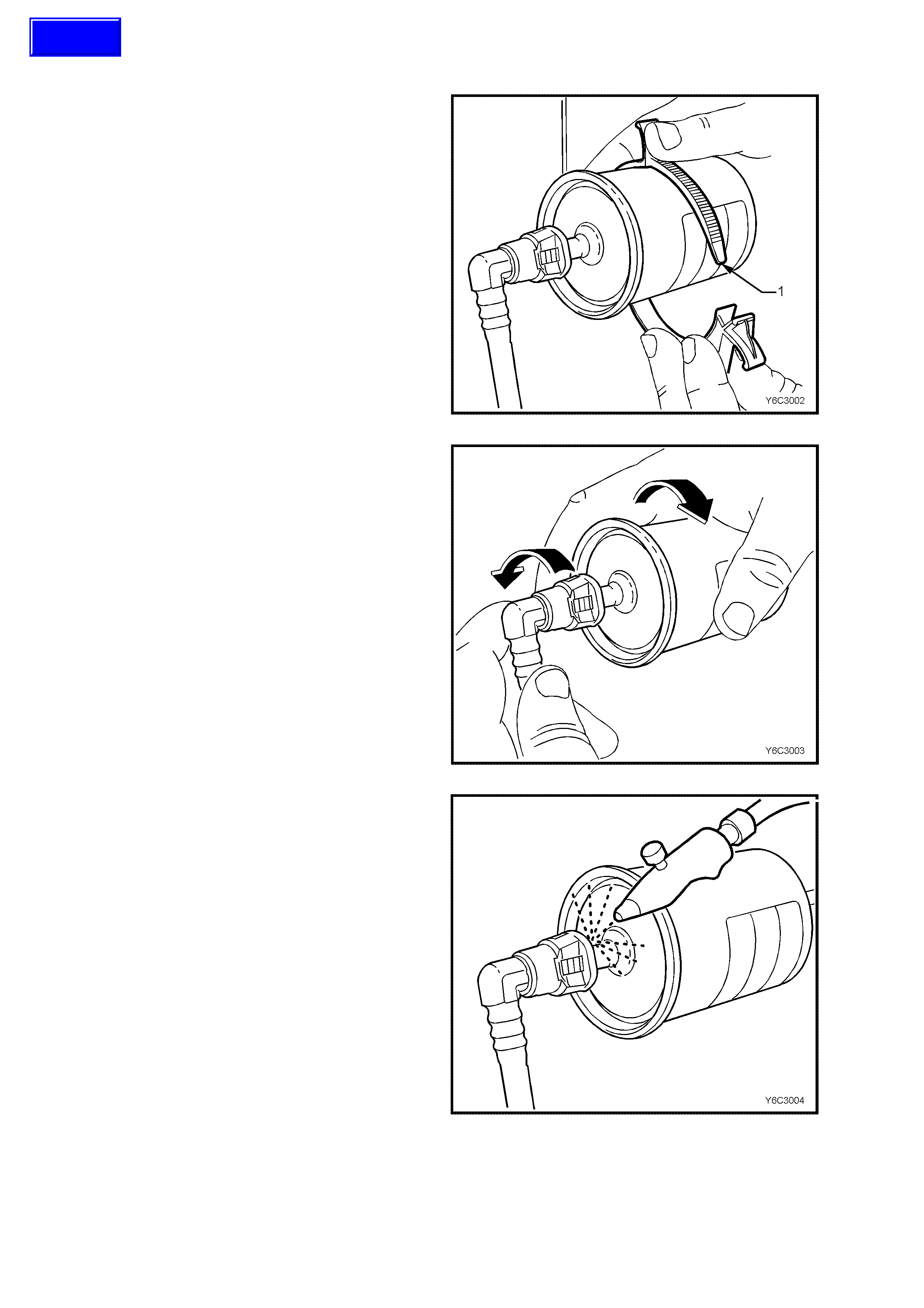

FUEL FILTER

REMOVE

IMPORTANT Relieve the fuel system pressure

before servicing any fuel system connection. Refer

to the Fuel Pressure Relief Procedure in

3.15, FUEL CONTROL SYSTEM in this Section.

1. Relieve fuel pressure as described in

3.15, FUEL CONTROL SYSTEM - Fuel

Pressure Relief Procedure in this Section.

2. Disconnect batt er y earth lead.

3. Raise rear of vehicle and support on safety

stands, refer to Section OA, GENERAL

INFORMATION in the VT Service Information.

4. Place a drain tray beneath fuel filter.

5. Remove the fuel filter from the retaining

brack et (1) with the fuel lines still connected to

the fuel filter to allow easier access.

Figure 6C3-3-53 - Fuel Filter Retaining Bracket

QUICK CONNECT FITTINGS

(PLAST IC COLL AR)

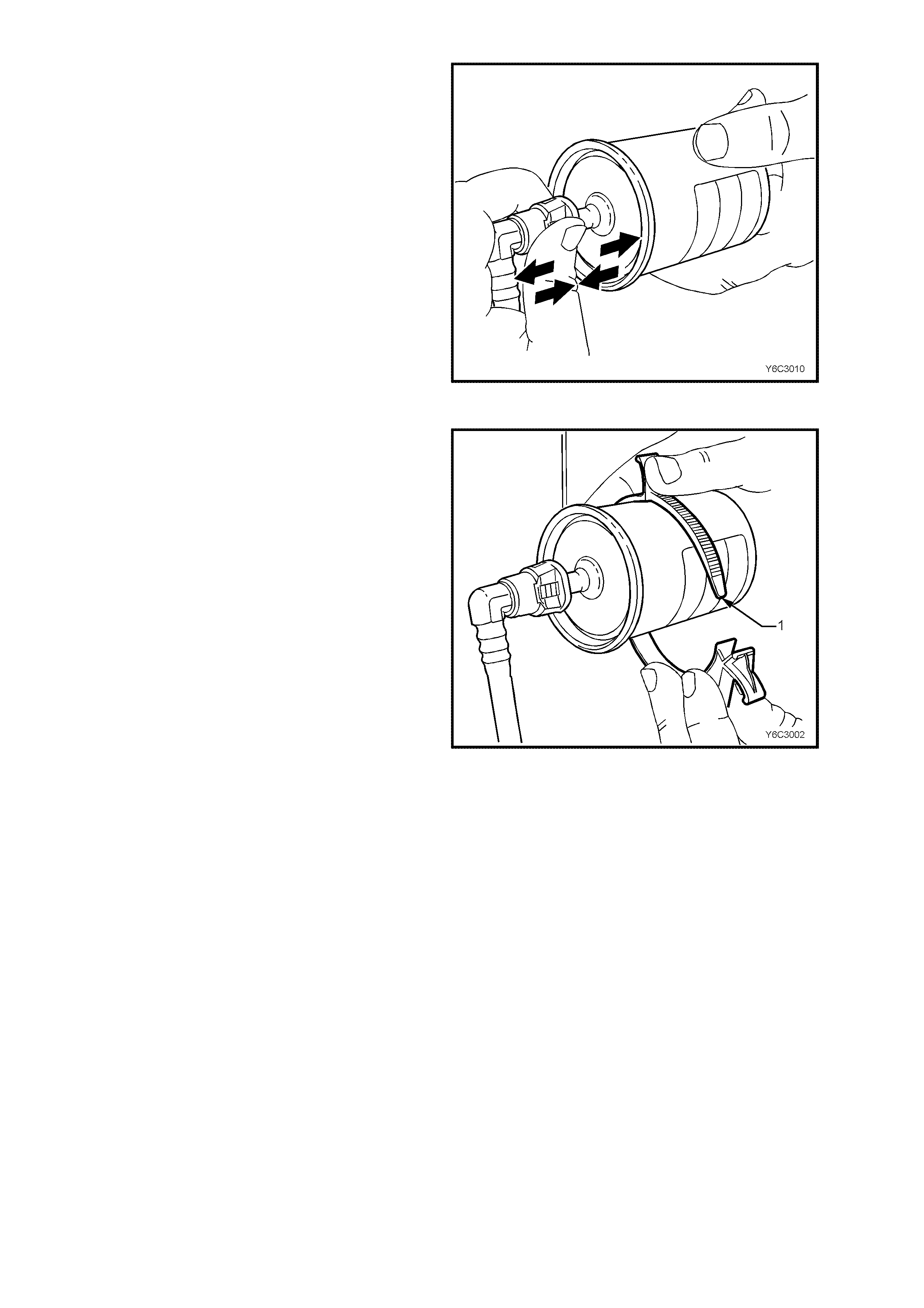

6. Grasp the quick-connect fittings both sides of

the fuel filter. Twist the female connectors 1/4

turn in each direction in order to loosen any dirt

within the quick-connect fitting.

Figure 6C3-3-54 - Fuel Filter & Quick-connect Fittings

7. Using compressed air, blow any dirt out of the

quick-connect fitting to aid the release of any

tension or binding on the release tabs .

IMPORTANT

W ear safety glas ses whe n using com pres sed air in

order to prevent eye injury.

Figure 6C3-3-55 - Cleaning Quick-connect Fittings

Techline

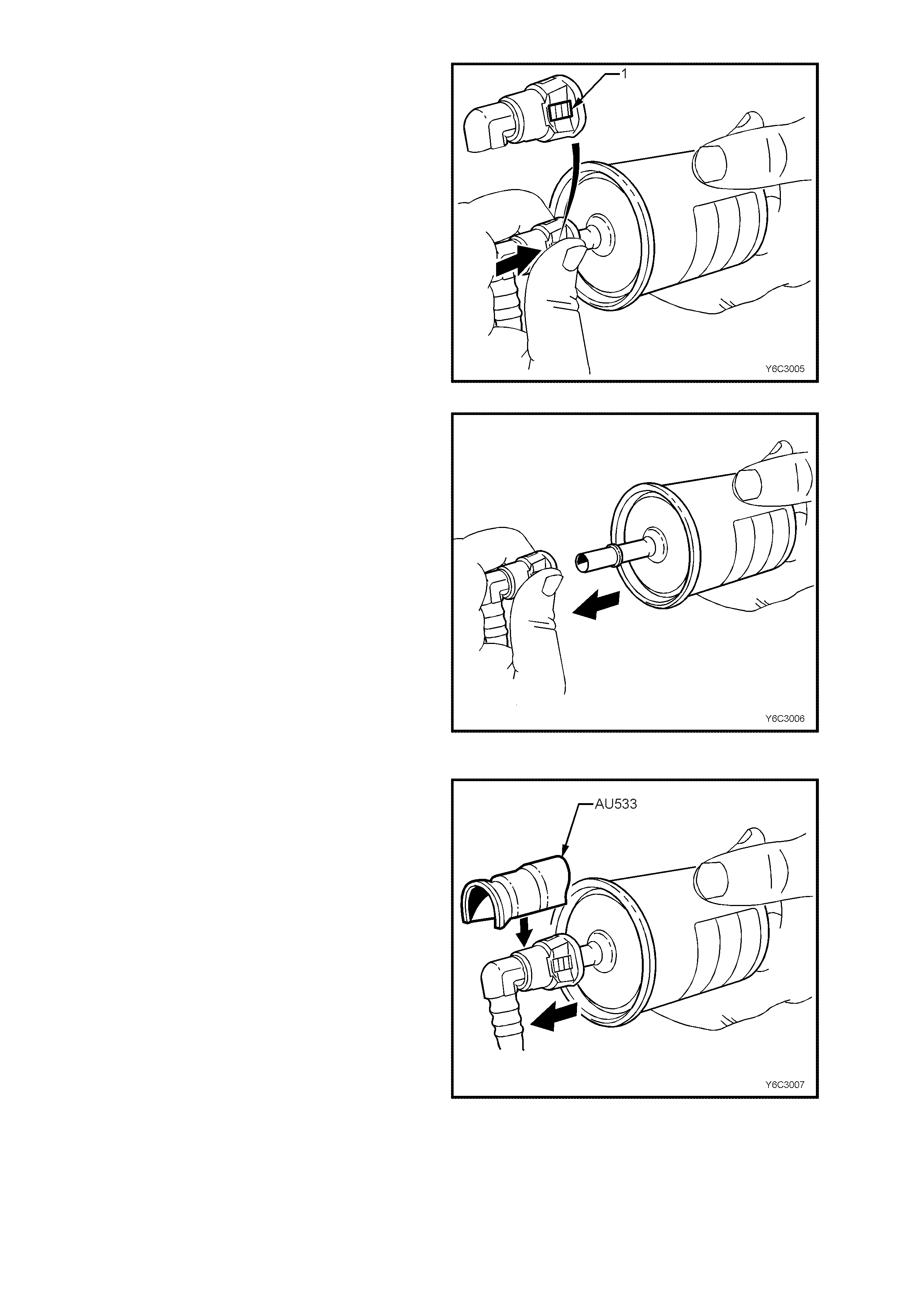

8. Hold t he fuel filt er firm ly in one hand t o support

the filter.

9. Using your other hand, grasp the one of the

quick-connect fittings and squeeze the plastic

retainer release tabs (1) on each side of the

fitting whil e pushing the f itting firmly toward the

fuel filter to release any tension on the release

tabs.

Figure 6C3-3-56 - Quick-connect Fitting Release Tabs

10. With the tension release tabs still held in the

squeezed position, move the complete quick-

connect fitting away from the fuel filter to

separate the connector fitting from the fuel

filter.

11. Apply the same method from step 8 to 10 for

the remaining quick-connect fitting.

Figure 6C3-3-57 - Disconnecting Quick-Connect Fittings

Without Special Tool

12. Alternat ely for s teps 8 to 10, use too l AU533 to

squeeze the release tabs, release the quick

connect fittings and remove both fuel pressure

hoses from the fuel filter.

13. Remove fuel filter from vehicle and disguard

safely remembering that some fuel will still

remain in the filter.

Figure 6C3-3-58 - Disconnecting Quick-Connect Fittings

With Special Tool

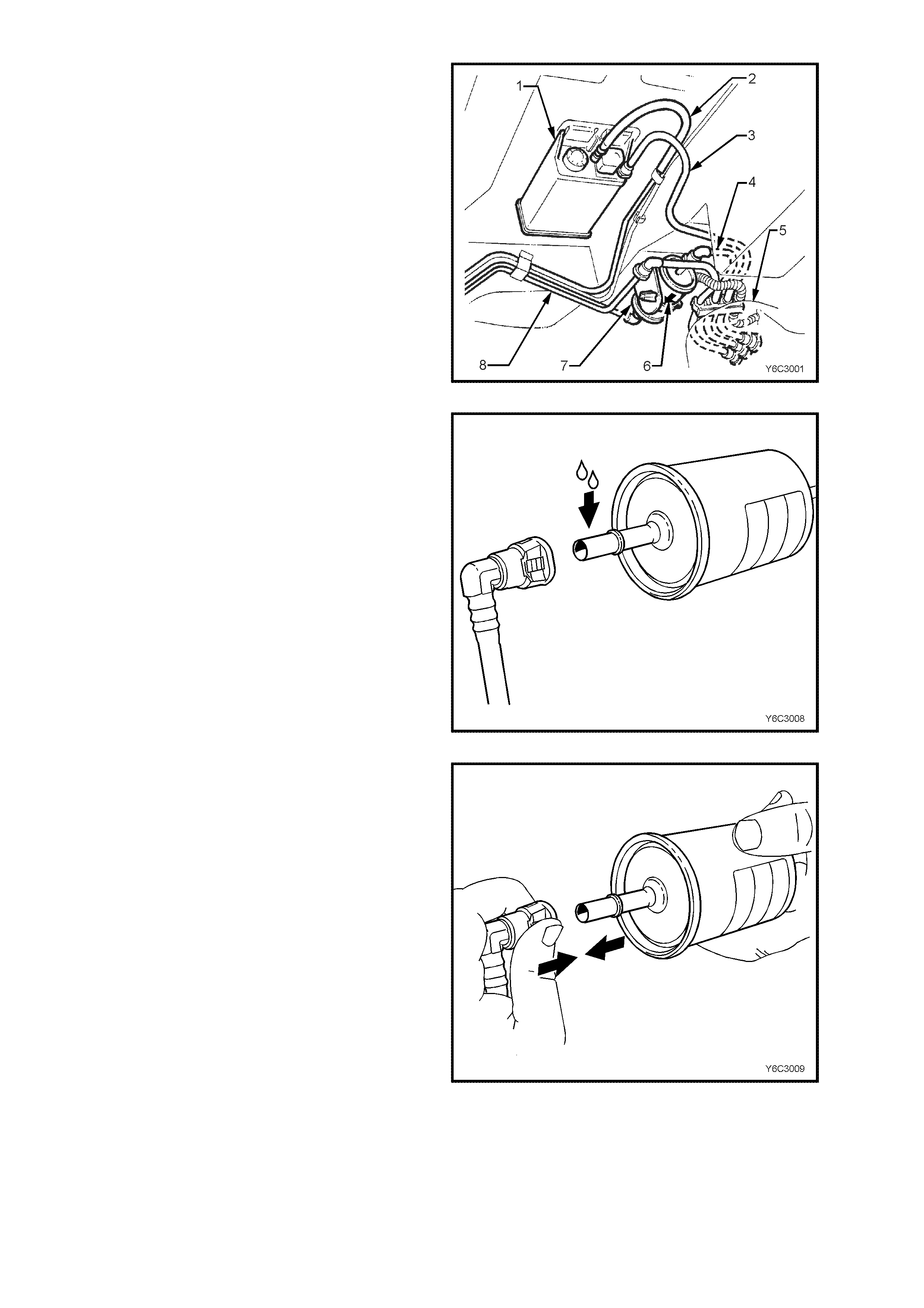

REINST ALL

IMPORTANT The fuel filter (7) must be installed

with the flow arrow (6) on its body pointing in the

same direction as the fuel flow to the front of the

vehicle.

Figure 6C3-3-59 - Fuel Filter Installation

IMPORTANT Before connecting fuel filter quick-

connect fittings, always apply a few drops of clean

engine oil to the male ends of the fuel filter.

This will e nsure proper r econnection and pr event a

possible fuel leak.

During normal operation, the O-ring located in the

fem ale connec tor will s wel l and may prevent pr oper

reconnection if not lubr icate d.

1. Apply a few drops of clean engine oil to each

male fuel filter end.

Figure 6C3-3-60 - Quick-Connect Fitting Seal lubrication

2. Push both the quick-connect fitting and the fuel

filter together in order to cause the retaining

tabs to snap into place. Apply this method to

both ends of the fuel filter and the respective

quick-connect fittings.

Figure 6C3-3-61 - Re-installation Of Quick-connect

Fitting To Fuel Filter

3. Onc e installed, pull and p ush on bo th the quic k-

connect fitting and the fuel filter in order to

make sure the connection is secure. Apply this

method to both ends of the fuel filter and the

respective quick-connect fittings.

Figure 6C3-3-62 - Quick-connect Fitting To Fuel

Filter Check

4. Install a new fuel filter to a new retaining bracket

(1).

5. Connect battery earth lead.

6. Check for fuel leaks, refer to

3.15, FUEL CONTROL SYSTEM – Leak

Testing in this Section of the VT Service

Information.

7. Remove safety stands and lower vehicle.

Figure 6C3-3-63 - Re-installation Of Fuel Filter To

Retainer Bracket

LEAK TESTING

Prior to st artin g the eng ine, f ollowing t he ins talla tion of an y fuel s ystem com ponent, c heck the fuel s ystem for leak s

using the following procedure:

1. Check to ensure that there is a sufficient level of fuel in the fuel tank.

2. Use sc an tool "Output T est" f or "Fuel Pum p." Enab ling the o utput test will activat e the fuel pump to pres surize

the fuel system.

3. Check fuel system for leaks.

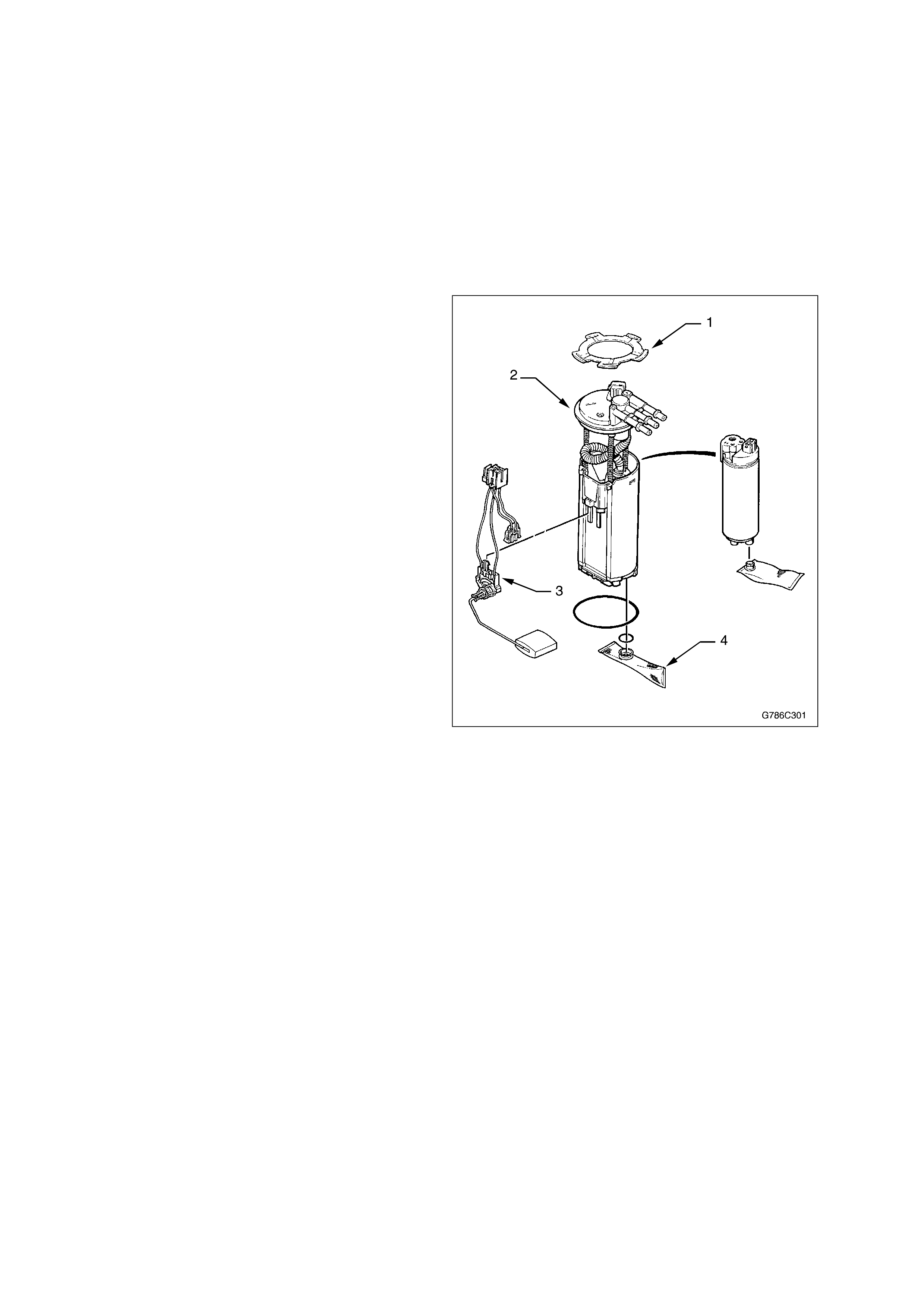

MODULAR FUEL SENDER ASSEMBLY

This Section describes the rem oval and installation

procedure for the modular fuel sender assembly,

and fuel level sensor. A full description of the

operation is provided in Section 8A, Fuel Tank in

VX Service Information.

NOTE:

The modular fuel sender assembly is not

serviceable except for the fuel level sensor. If any

other part is found to be faulty, the complete fuel

sender assembly must be replaced.

REMOVE

TOOL REQUIRED: J 39765 Fuel Sender Locknut

Wrench.

IMPORTANT:

In order to reduce the risk of fire or personal injury

that may result from fuel leakage, always replace

the fuel sender gasket when reinstalling the fuel

sender assembly.

NOTE:

Do Not handle the f uel sender assem bly by the f uel

pipes. The amount of leverage generated by

handling the fuel pipes could damage the joints.

1. Disconnect the negative battery cable.

2. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

Drain and remove the fuel tank. Refer to

Section 8A, Fuel Tank, in VX Service Information.

3. .

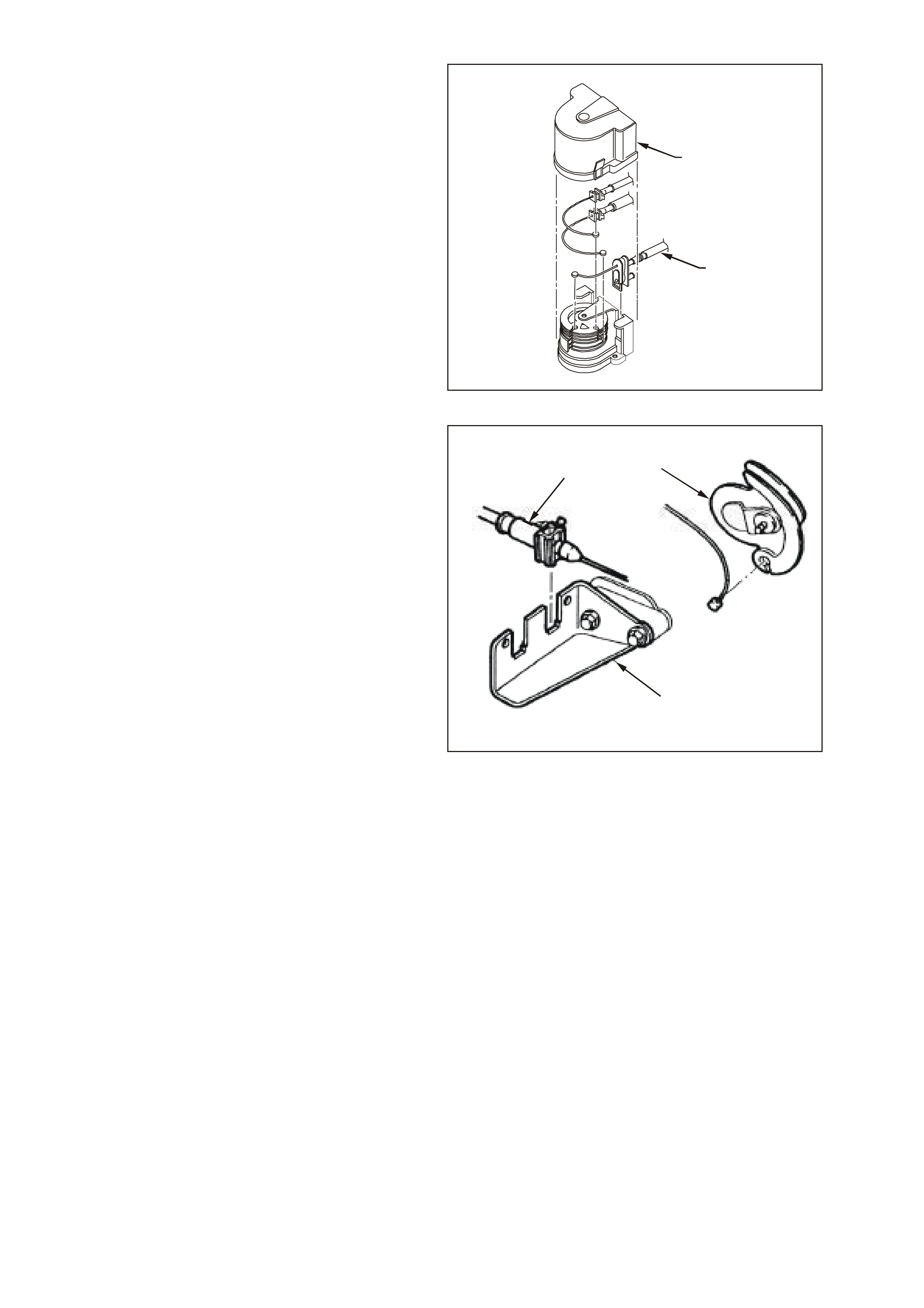

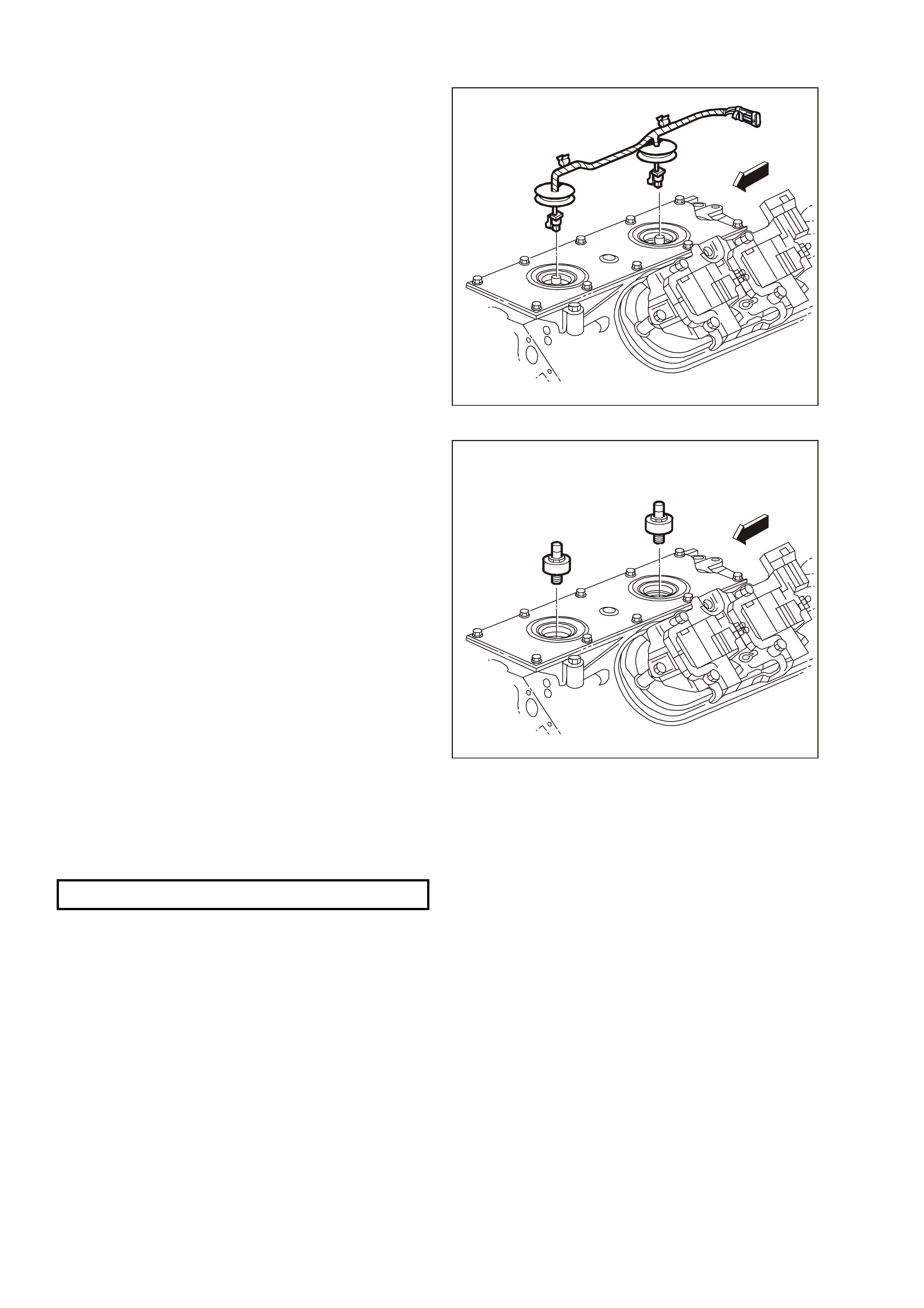

4. Rem ove the fuel sender assem bly r etaining ring

(1) using the J 39765 Fuel Sender Locknut

Wrench.

NOTE:

The modular fuel sender assembly will spring-up

when the locking ring is removed.

5. Pull the modular fuel sender assembly (2)

straight up while draining the fuel from the

reservoir.

IMPORTANT:

The r eservoir buck et on the sender as sem bly is f ull

of fuel. Tip the assembly slightly during removal in

order to avoid damage to the fuel level sensor (3)

float. Place any remaining fuel into an approved

container once the modular fuel sender

assembly is removed from the fuel tank.

6. Clean the gasket sealing surfaces.

7. If required, remove the fuel level sensor by

disconnecting the wiring connector and

squeezing the retainer tabs and sliding the

sensor from the sender assembly.

Figure 6C3-3-64 Modular Fuel Sender Assembly

REINSTALL

1. Fit the fuel level sensor to the modular fuel

sender assembly, ensuring the retaining tangs

are seated correctly.

2. Install the new gasket on the fuel sender

assembly.

IMPORTANT:

The f uel s tr ainer ( 4) must be in a horizontal position

when the sender assembly is installed. Ensure the

fuel strainer does not block the travel of the float

arm.

3. Care fully fold the strainer over itself to allow it to

fit through the opening in the fuel tank. Ensure

the strainer unfolds once it is placed in the tank.

4. Install the fuel sender assembly into the fuel

tank.

5. Fit and secure the sender assembly retaining

ring.

Install the fuel tank. Refer to

Section 8A, Fuel Tank, in VX Service Information.

6.

7. Refill the fuel tank.

8. Install the fuel filler cap.

9. Connect the negative battery cable.

10. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds

- Turn the ignition switch OFF for 10 seconds.

- Turn the ignition switch ON.

- Check for fuel leaks.

11. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

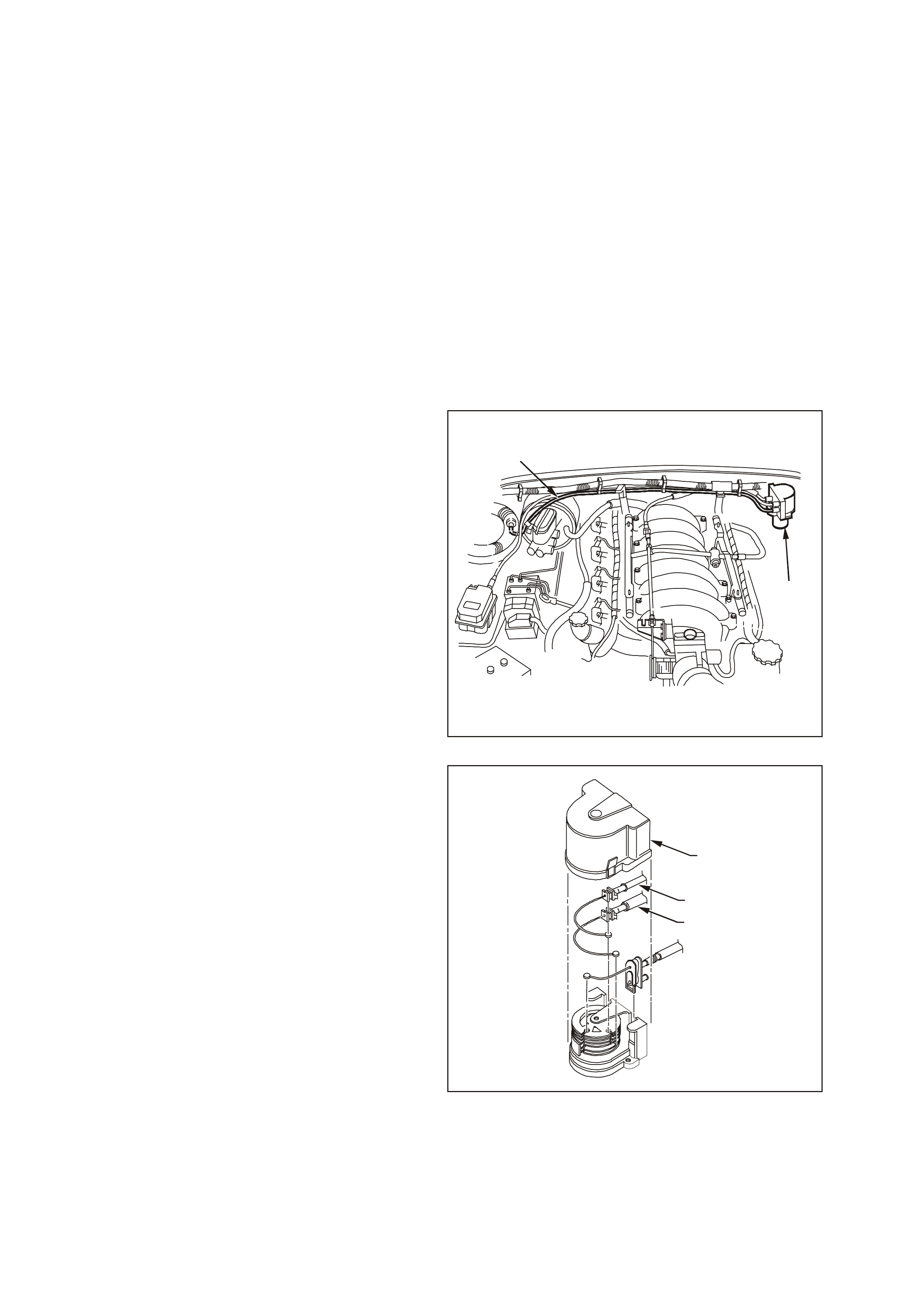

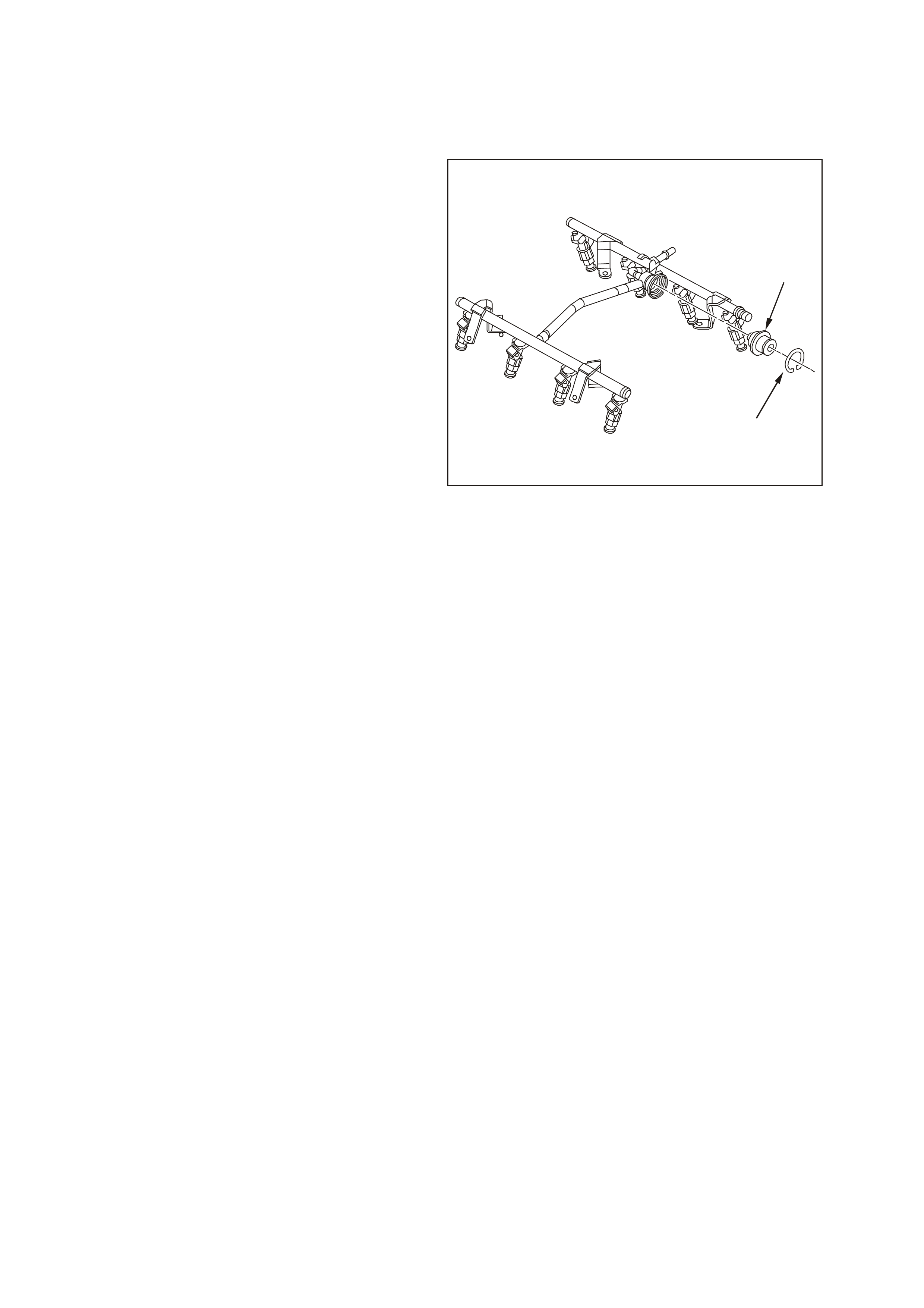

FUEL PULSE DAMPENER

REMOVE

1. Relieve the fuel system pressure. Refer to

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

4. Clean any dirt from the fuel pulse dampener

retaining ring.

5. Remove the fuel pulse dampener retaining ring

(1).

6. Discard the fuel pulse dampener retaining ring.

7. Remove the fuel pulse dampener (2) from the

fuel rail.

8. Remove and discard the fuel pulse dampener

O-ring.

REINSTALL

1. Install the new O-ring on the fuel pulse

dampener.

2. Lubricate the fuel pulse dampener O-ring with

clean engine oil.

3. Push the fuel pulse dampener into the fuel rail.

4. Install the new fuel pulse dampener retaining

ring.

5. Connect the negative battery cable.

6. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

7. Install engine dress cover.

8. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

2

1

Figure 6C3-3-65 Fuel Pulse Dampener

FUEL HOSE/ PIPES (ENGINE COMPARTMENT)

REMOVE

TOOLS REQUIRED:

J7370, and 7371 Quick Connect Release tools.

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Remove engine dress cover. Refer to

Engine Coolant Temperature in this Section

for removal procedure.

4. Clean all the engine compartment connecting

fuel pipe connec tions and the surrounding areas

before disconnecting to avoid possible

contamination of the fuel system.

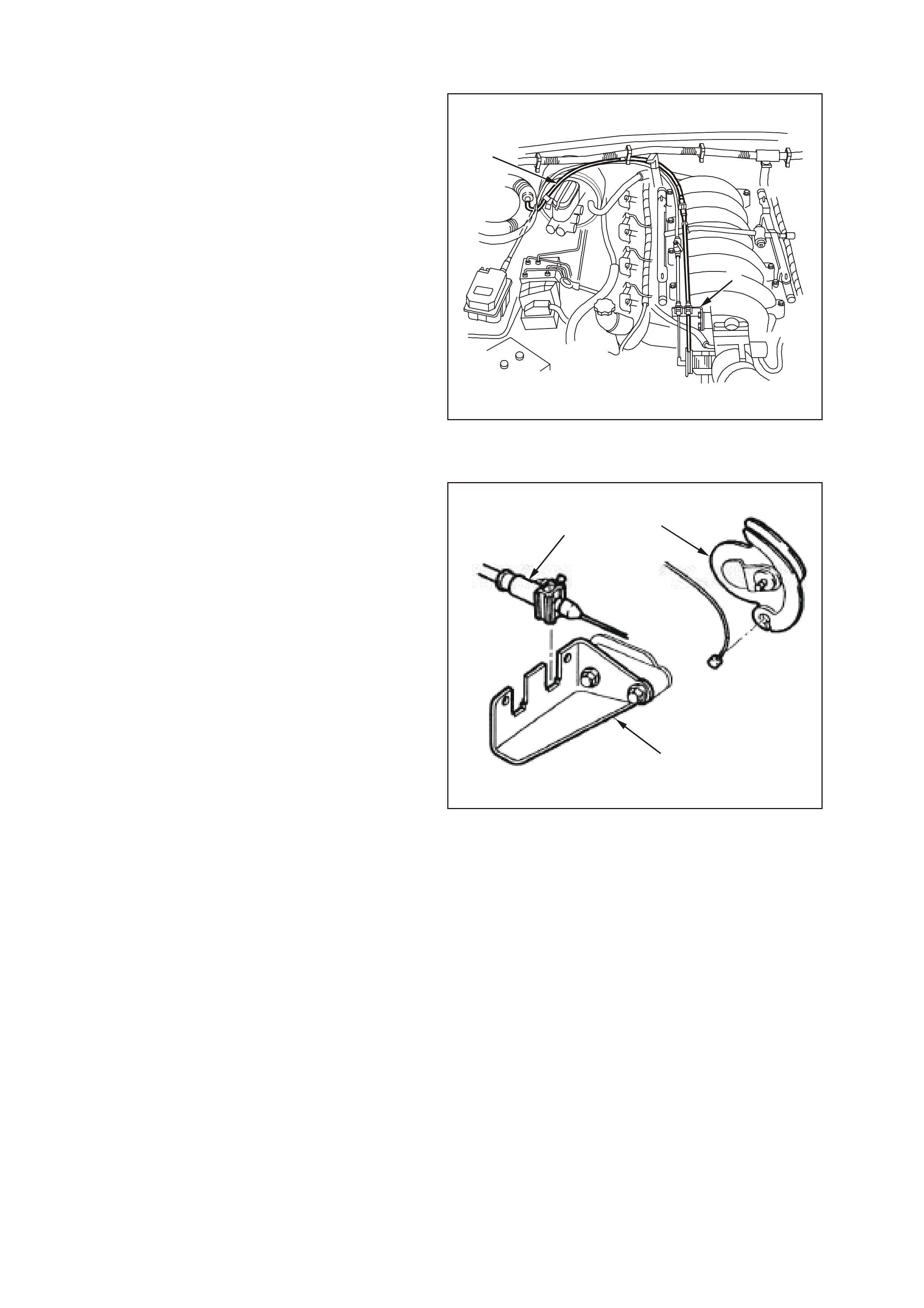

5. Disconnect the engine compartment fuel feed

pipe (1) at the fuel rail. Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

6. Disconnec t the engine compar tment EECS pipe

(2) at the EECS canister purge solenoid. Refer

to Quick Connect Fittings Service (Plastic

Collar) in this Section.

7. Disconnect the engine compartment fuel feed

pipe at the chassis fuel feed pipe (3). Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

8. Disconnec t the engine compar tment EECS pipe

at the chassis EECS pipe. Refer to

Quick Connect Fittings Service (Plastic

Collar) in this Section.

3

1

2

Figure 6C3-3-66 Engine Compartment Hose/Pipes

9. Cap the fuel pipes in order to prevent possible

fuel system contamination.

REINSTALL

1. Remove the caps from the fuel pipes.

2. Connect the engine compartm ent fuel feed pipe

to the chassis fuel feed pipe. Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

3. Connect the engine com partment EECS pipe to

the chassis EECS pipe. Refer to

Quick Connect Fittings Service (Plastic

Collar) in this Section.

4. Connect the engine compartm ent fuel feed pipe

to the fuel rail. Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

5. Connect the engine com partment EECS pipe to

the EECS canister purge solenoid. Refer to

Quick Connect Fittings Service (Plastic

Collar) in this Section.

6. Tighten the fuel filler cap.

7. Connect the negative battery cable.

8. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

- Install engine dress cover.

9. Perform the Idle Learn Procedure and

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

FUEL HOSE/PIPE ASSEMBLY (REAR PIPES)

REMOVE

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank. Refer to

Section 8A, Fuel Tank in VX Service

Information.

4. Raise the vehicle.

5. Clean all the fuel and EECS pipe and hose

connections and the surrounding areas before

disconnecting in order to avoid possible

contamination of the fuel system.

6. Remove the fuel tank (1). Refer to

Section 8A, Fuel Tank in VX Service

Information.

7. Remove the rear fuel feed (2), fuel return (3),

and the EECS vapour pipe (4) from the fuel

sender assembly (5). Refer to

Quick Connect Fittings Service (Plastic

Collar) in this Section.

8. Remove the rear fuel and EECS pipes (6).

9. Cap the fuel pipes to prevent possible fuel

system contamination.

1

32

4

5

6

Figure 6C3-3-67 Rear Hose/Pipes

REINSTALL

1. Remove the caps from the fuel pipes.

2. Connect the rear fuel feed, fuel return, and the

EECS vapour pipe to the fuel sender assembly.

Refer to

Quick Connect Fittings Service (Plastic

Collar) in this Section.

3. Install the fuel tank, refer to

Section 8A, Fuel Tank in VX Service

Information.

4. Lower the vehicle

5. Refill the fuel tank.

6. Connect the negative battery cable.

7. Tighten the fuel filler cap.

8. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this Section.

FUEL SYSTEM CLEANING

IMPORTANT: Only use oil free compressed air to

blow out the fuel pipes.

Inspect the fuel tank internally and clean the fuel

tank if you find a blocked fuel filter.

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank. Refer to

Section 8A Fuel Tank in VX Service

Information.

4. Remove the fuel tank. Refer to

Section 8A Fuel Tank in VX Service

Information.

5. Remove the modular fuel sender assembly.

Refer to Modular Fuel Sender Assembly in

this Section.

6. Inspect the fuel pump strainer. Replace fuel

modular sender assembly if strainer is

contaminated.

7. Inspect the fuel pump inlet for dirt and debris.

Replace modular fuel sender assembly if

strainer is contaminated.

8. Flush the fuel tank with hot water several times.

IMPORTANT:

When flushing the fuel tank, handle the fuel and

water mixture as a hazardous material. Handle the

fuel and water mixture in accordance with all

applicable local, state, and federal laws and

regulations.

9. Pour the water out of the fuel sender assembly

opening. Rock the tank to be sure that removal

of the water from the tank is complete.

NOTE:

Ensure all traces of water are removed from the

tank before proceeding.

10. Install the fuel sender assembly. Refer to

Modular Fuel Sender Assembly in this

Section.

11. Install the fuel tank. Refer to

Section 8A, Fuel Tank in VX Service

Information.

12. Refill the fuel tank.

13. Install the fuel filler cap.

14. Connect the negative battery cable.

15. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

16. Perform the Idle Learn Procedure and

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

FUEL PRESSURE CONNECTION (SCHRADER VALVE)

REMOVE

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

4. Loosen fuel filler cap.

5. Remove fuel pressure connection valve cap (1).

6. Clean the area around the fuel pressure

connection.

7. Remove the fuel pressure connection valve (2)

(schrader valve) using a standard valve core

removal and installation tool

REINSTALL

1. Install the fuel pressure connection valve (2)

(schrader valve) using a standard valve core

removal and installation tool.

2. Install the fuel pressure connection valve cap

(3).

3. Tighten the fuel filler cap.

4. Connect the negative battery cable.

5. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

6. Install engine dress cover.

7. Perform the Idle Learn Procedure and

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

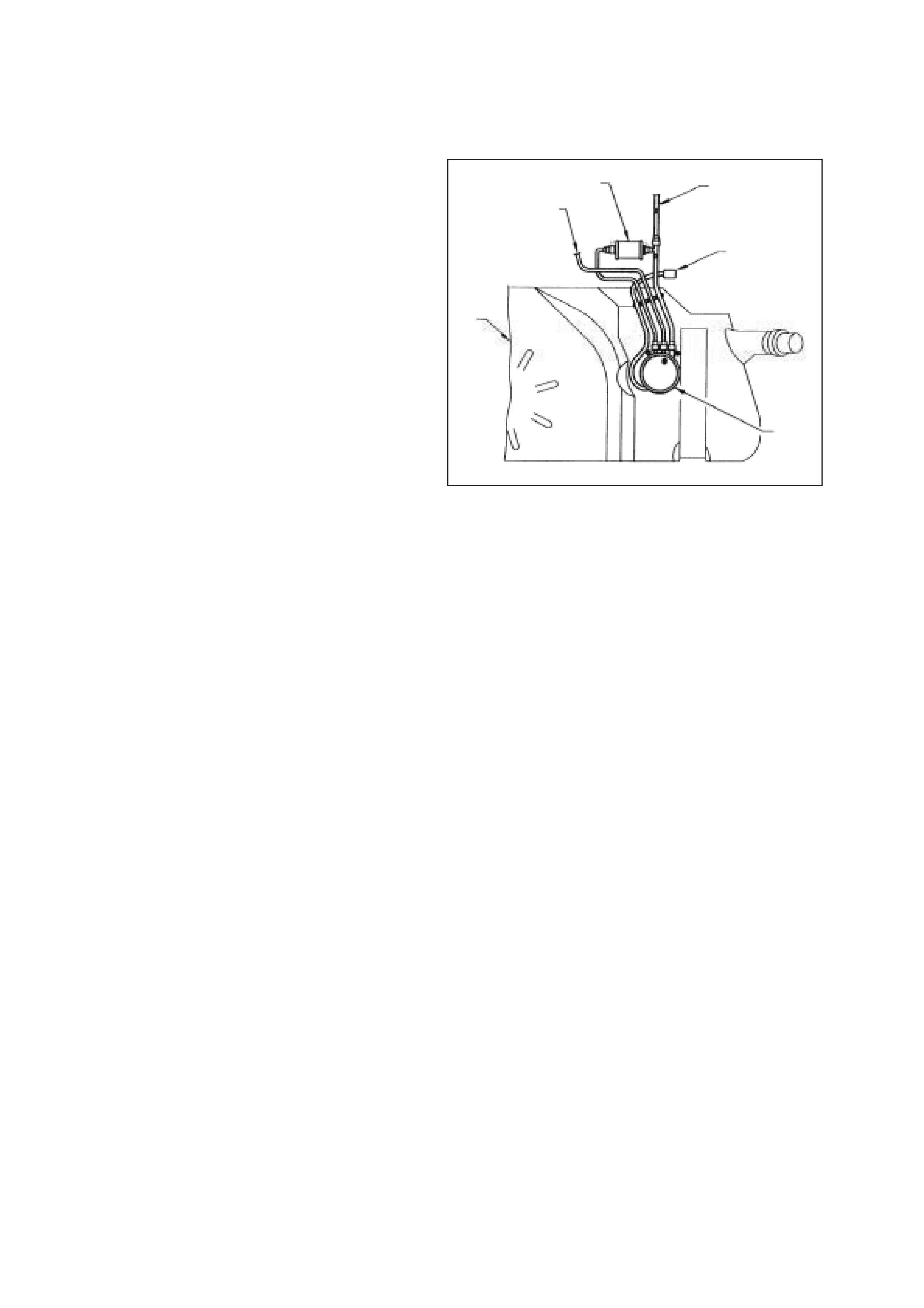

2

3

Figure 6C3-3-68 Fuel Pressure Connection Valve

(Schrader Valve)

FUEL RAIL ASSEMBLY

REMOVE

TOOLS REQUIRED:

J7370, and 7371 Quick Connect Release tools.

1. Remove engine dress cover. Refer to

Engine Coolant Temperature in this Section

for removal procedure.

2. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

3. Disconnect the negative battery cable.

4. Before removal, clean the fuel rail assembly with

a spray type engine cleaner, if necessary. Do

not soak fuel rails in liquid cleaning solvent.

NOTE:

Remove the fuel rail assembly carefully in order to

prevent damage to the injector electrical connector

terminals and the injector spray tips. Support the

fuel rail after the fuel rail is removed in order to

avoid damaging the fuel rail components.

Cap the fittings and plug the holes when servicing

the fuel system in order to prevent dirt and other

contaminants from entering open pipes and

passages.

5. Disconnect the fuel feed hose from the fuel rail.

Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

6. Disconnect the accelerator cable from the

throttle body and remove the retaining clip from

the fuel rail.

7. Move the throttle cable aside.

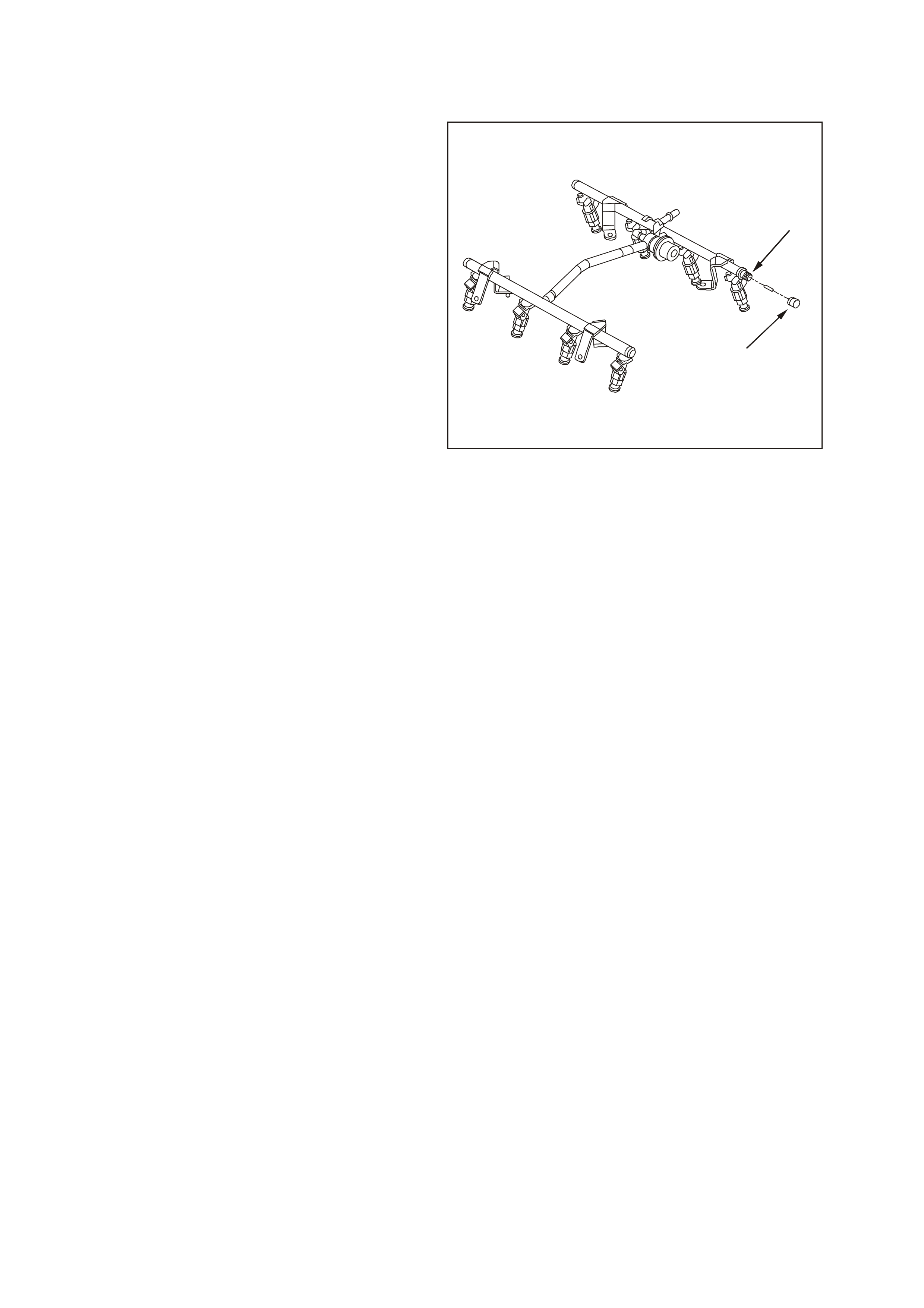

Figure 6C3-3-69 Fuel Rail Identification Number

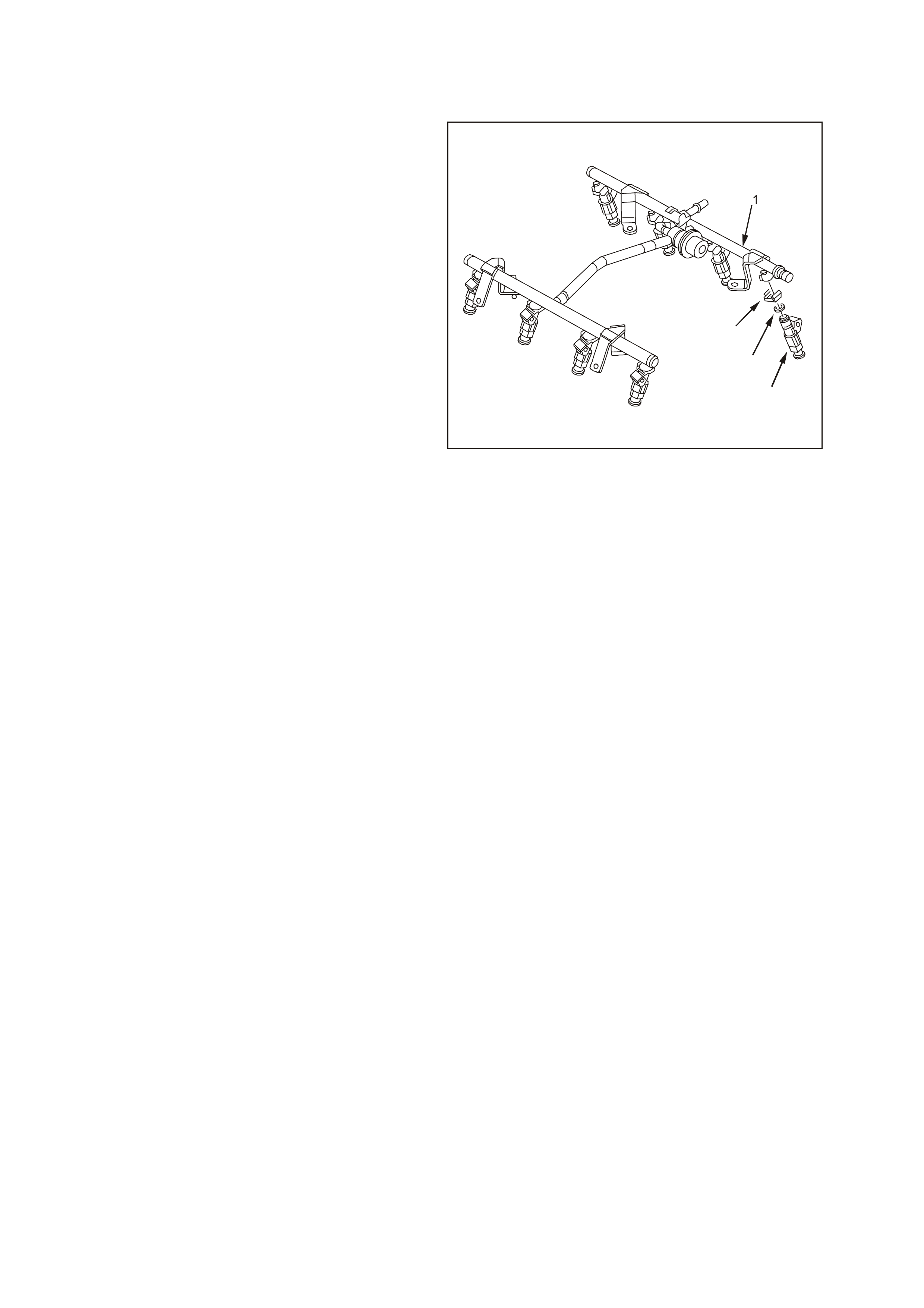

8. Disconnect the electrical connectors from the

fuel injectors (1). Identify the connectors to their

corresponding injectors to ensure correct

sequential injector firing order after reassembly.

9. Disconnect the electrical harness from the fuel

rail brackets.

10. Rem ove the fuel rail attac hing bolts and the fuel

rail assembly (2).

11. Remove and discard the injector lower O-ring

seal from the spray tip end of each injector.

1

2

Figure 6C3-3-70 Fuel Rail Assembly

REINSTALL

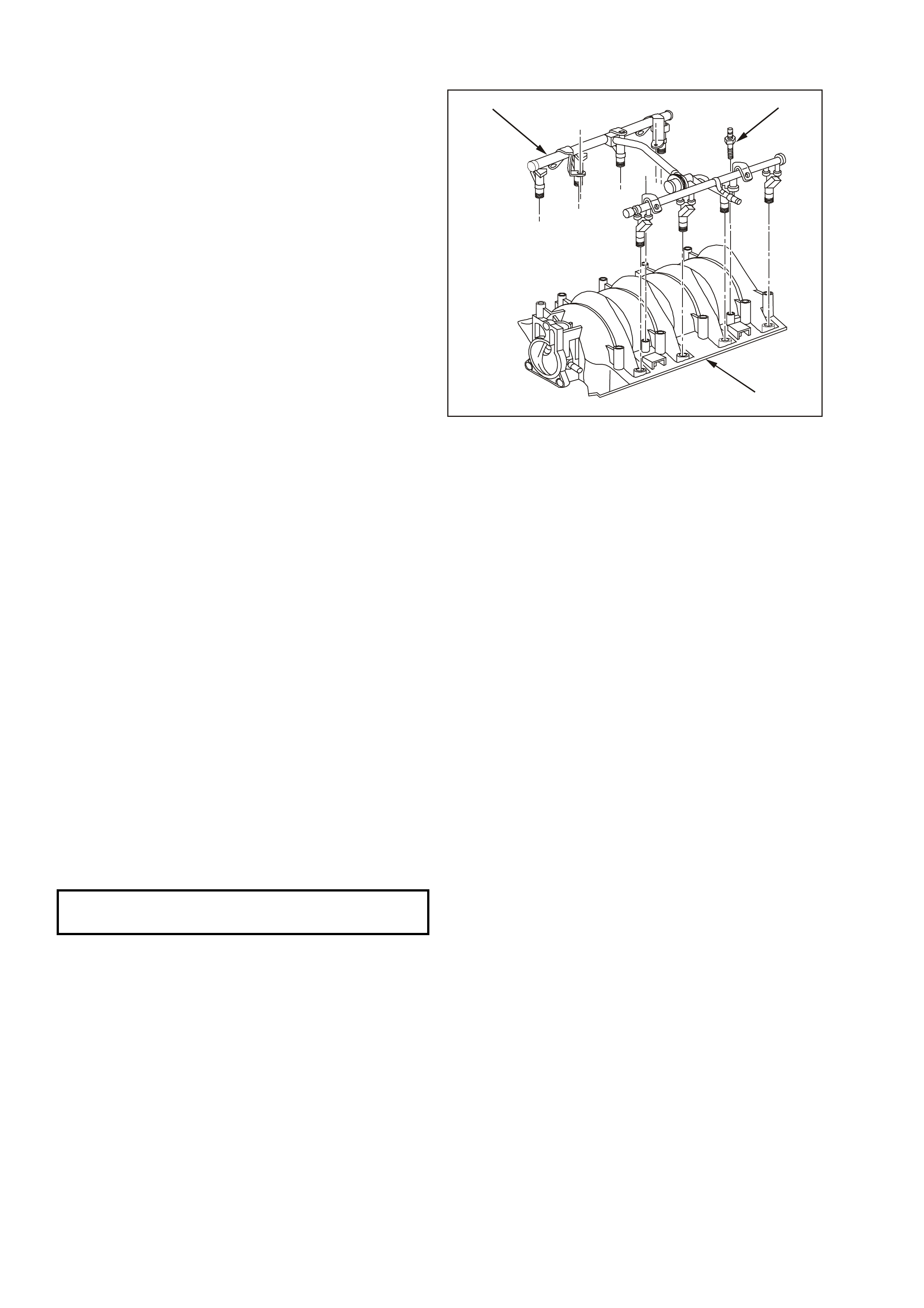

1. Lubricate the new lower injector O-ring seals

with clean engine oil.

2. Install the new O-ring s eals on the spr ay tip end

of each injector.

3. Install the fuel rail assembly (1) to the intake

manifold (2).

4. Apply Loctite 242 (Holden Specif ication HN1256

Class 2, Type 2) or equivalent to the threads of

the fuel rail bolts.

5. Install the f uel rail attaching bolts (3) and tighten

to the specified torque.

6. Connect the injector electrical connectors.

NOTE:

Ensure each connector is installed on the correct

injector to ensure correct sequential injector firing

order.

Rotate the injectors as required in order to avoid

stretching the wire harness.

7. Connect the electrical harness to the fuel rail

bracket.

8. Connect the throttle cable to the throttle body

and retaining clip.

9. Connect the fuel feed hose to the fuel rail fuel

pipe. Refer to

Quick Connect Fittings Service (Metal

Collar) in this Section.

10. Tighten the fuel filler cap.

11. Connect the negative battery cable.

12. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

Install engine dress cover.

13. Perform the Idle Learn Procedure and

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

13

2

Figure 6C3-3-71 Fuel Rail Removal

Fuel Rail Attaching Bolts

Tightening Torque 10 NM

FUEL INJECTOR

REMOVE

IMPORTANT:

Use care in removing the fuel injectors to prevent

damage to the electrical connector pins on the

injector and to prevent damage to the nozzle.

Service the fuel injector as a complete assembly

only. The fuel injector is an electrical component.

Do Not immerse the fuel injector in any type of

cleaner.

The engine oil m ay be contam inated with f uel if the

fuel injectors are leaking.

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect the negative battery cable.

3. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

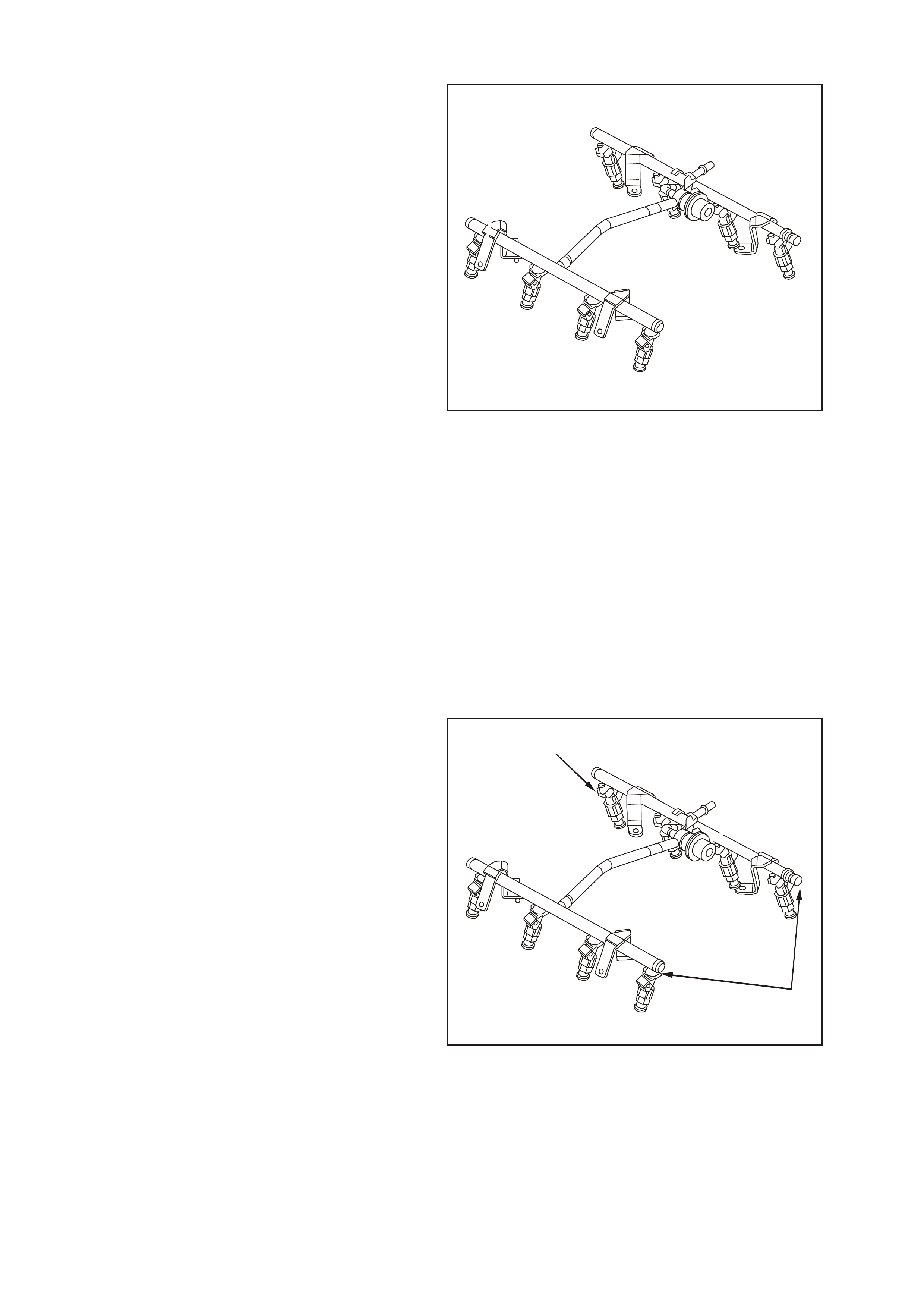

4. Remove the fuel rail assembly (1). Refer to

Fuel Rail Assembly Replacement in this

Section.

5. Spread the injector retainer clip (2) to release

the injector from the fuel rail.

6. Remove the fuel injector (3).

7. Discard the injector retainer clip.

8. Rem ove and discard the injector O-ring seal (4)

from both ends of the injector.

3

4

2

Figure 6C3-3-72 Fuel Rail and Injectors

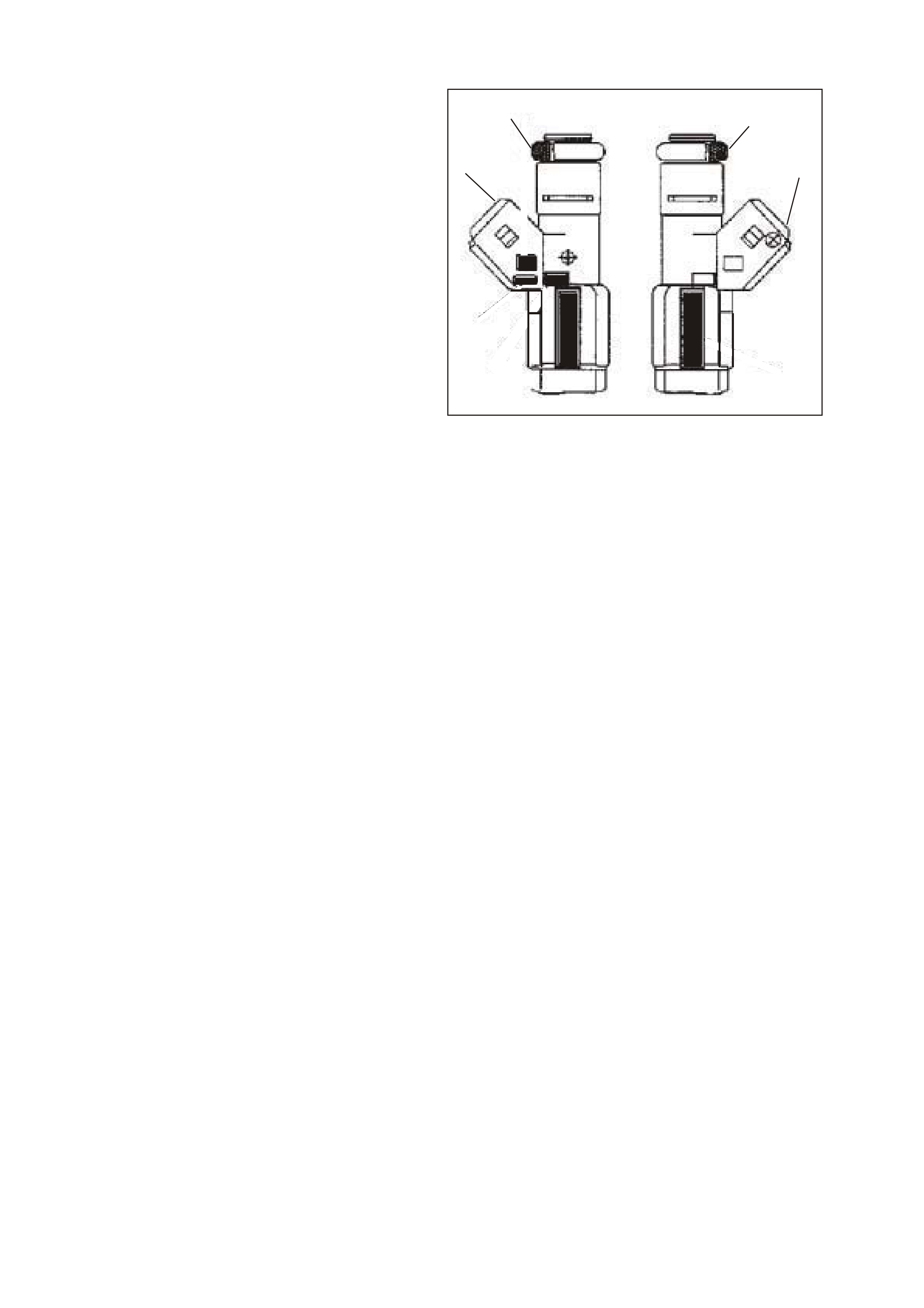

REINSTALL

IMPORTANT:

When ordering new fuel injectors, ensure to order

the correct injector for the application being

serviced The fuel inj ec tor as s embly is stamped with

a part number identification, a manufacturing date,

a week code, and a production plant number.

1. Lubricate the new injector O-ring seal (1) with

clean engine oil.

2. Install the new injector O-ring seal (1) on the

injector.

3. Install a new retainer clip on the injector.

4. Push the fuel injector into the fuel rail injector

socket with the electrical connector (2) facing

outward. The retainer clip locks on to a flange

on the fuel rail injector socket.

5. Install the fuel rail assembly. Refer to

Fuel Rail Assembly Replacement in this

Section.

6. Tighten the fuel filler cap.

7. Connect the negative battery cable.

8. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

9. Install engine dress cover.

10. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

1 1

2 2

Figure 6C3-3-73 Fuel Injector Identification

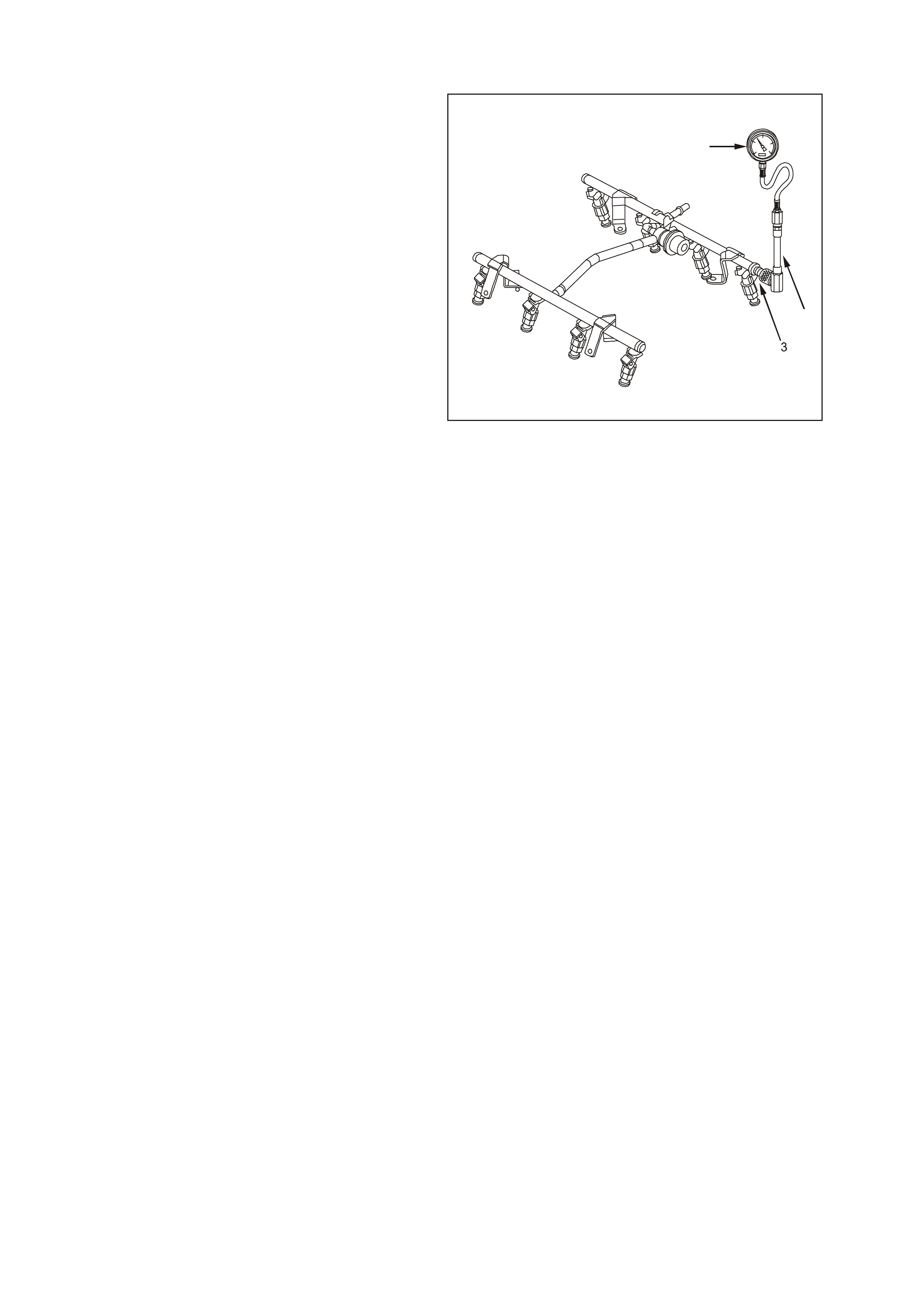

FUEL SYSTEM PRESSURE TEST

TOOLS REQUIRED:

SD28018 or AU338 Fuel Pressure Gauge, and

AU453 Fuel Gauge Schrader Fitting Adapter.

A f uel system pr essure test is part of s everal of the

Diagnostic Tables and Symptom checks. To

perform this test, follow this procedure.

IMPORTANT:

To reduce the risk of fire or personal injury, it is

necessary to relieve fuel system pressure before

performing this test. See Fuel Pressure Relief

Procedure in this Section.

IMPORTANT:

At no time must the fuel inlet hose or evaporative

hose be clamped or bent over as this will cause a

permanent kinking of the inner section of the hose

assembly and will result in restricted fuel flow.

1. Remove the engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. Loosen the fuel filler cap to relieve the fuel tank

vapour pressure.

3. Remove the fuel test valve cap.

4. Connect the SD28018 or AU338 fuel pressure

gauge (1) to the AU453 fuel gauge schrader

fitting adapter (2), then connect to the fuel

pressure testing valve (3). Wrap a shop towel

around the fitting while connecting the gauge in

order to avoid and/or capture any fuel spillage.

5. Install the bleed hose of the gauge into an

approved petrol container.

6. Using a Tech 2 scan tool, enable fuel pump to

pressurise the system.

7. With fuel pump energised, open the valve to

bleed the air out of the fuel gauge.

MEASURE

1. Using the Tech 2 scan tool once again, enable

the fuel pump to pressurise the system.

2. The fuel gauge reading should be 380-440 kPa

(55-62 psi) for the GEN III V8 Engine

application. If not, refer to

Section 6C3-2A Diagnostic Tables - Fuel

System Diagnosis in this Section.

3. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

4. Remove fuel pressure gauge and adapter.

5. Reinstall fuel test valve cap.

6. Inspect for leaks:

- Turn the ignition switch ON for 2 seconds.

- Turn the ignition switch OFF for 10

seconds.

- Turn the ignition switch ON.

- Check for leaks.

7. Install engine dress cover.

1

2

Figure 6C3-3-74 Fuel Rail with Fuel Gauge

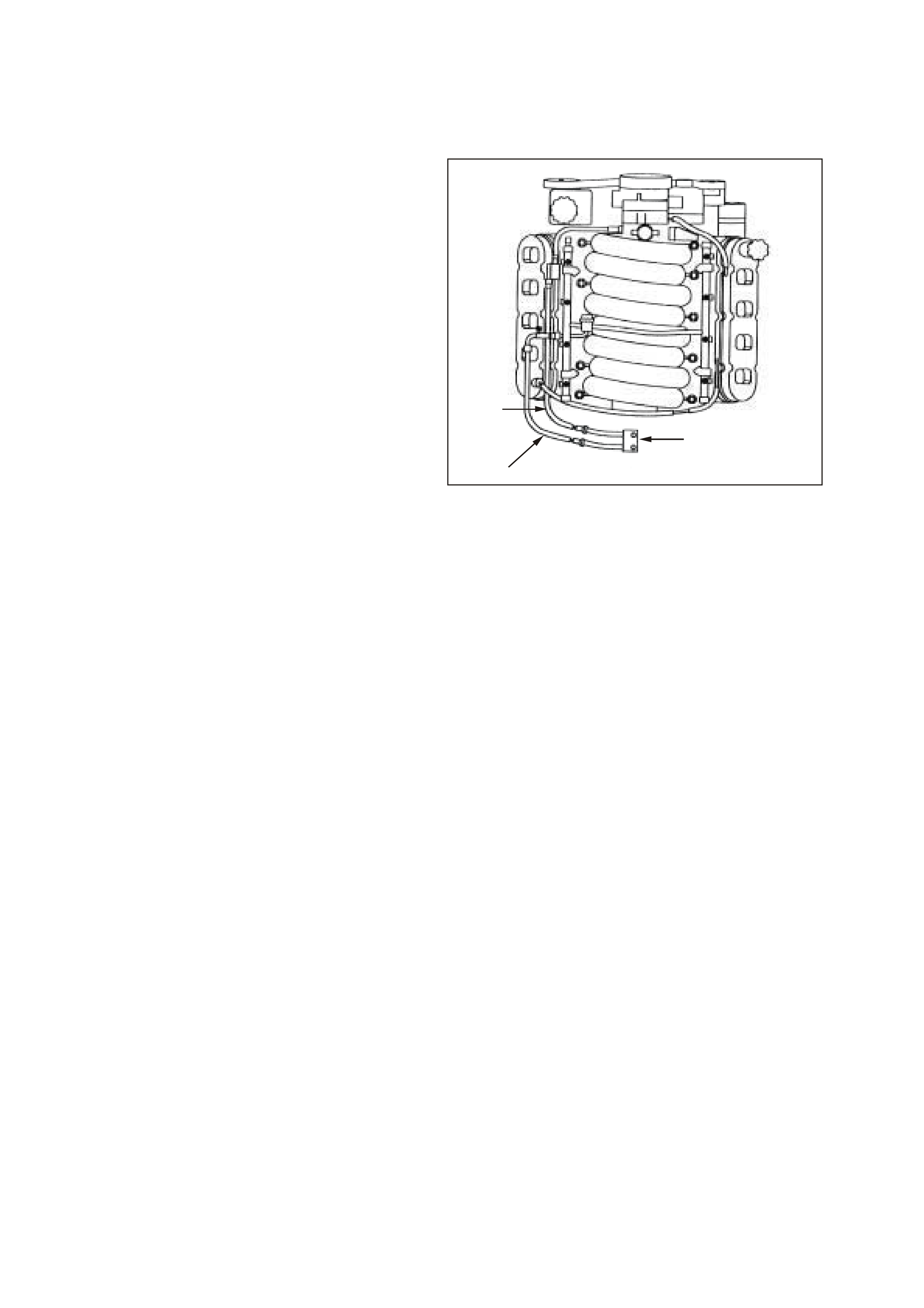

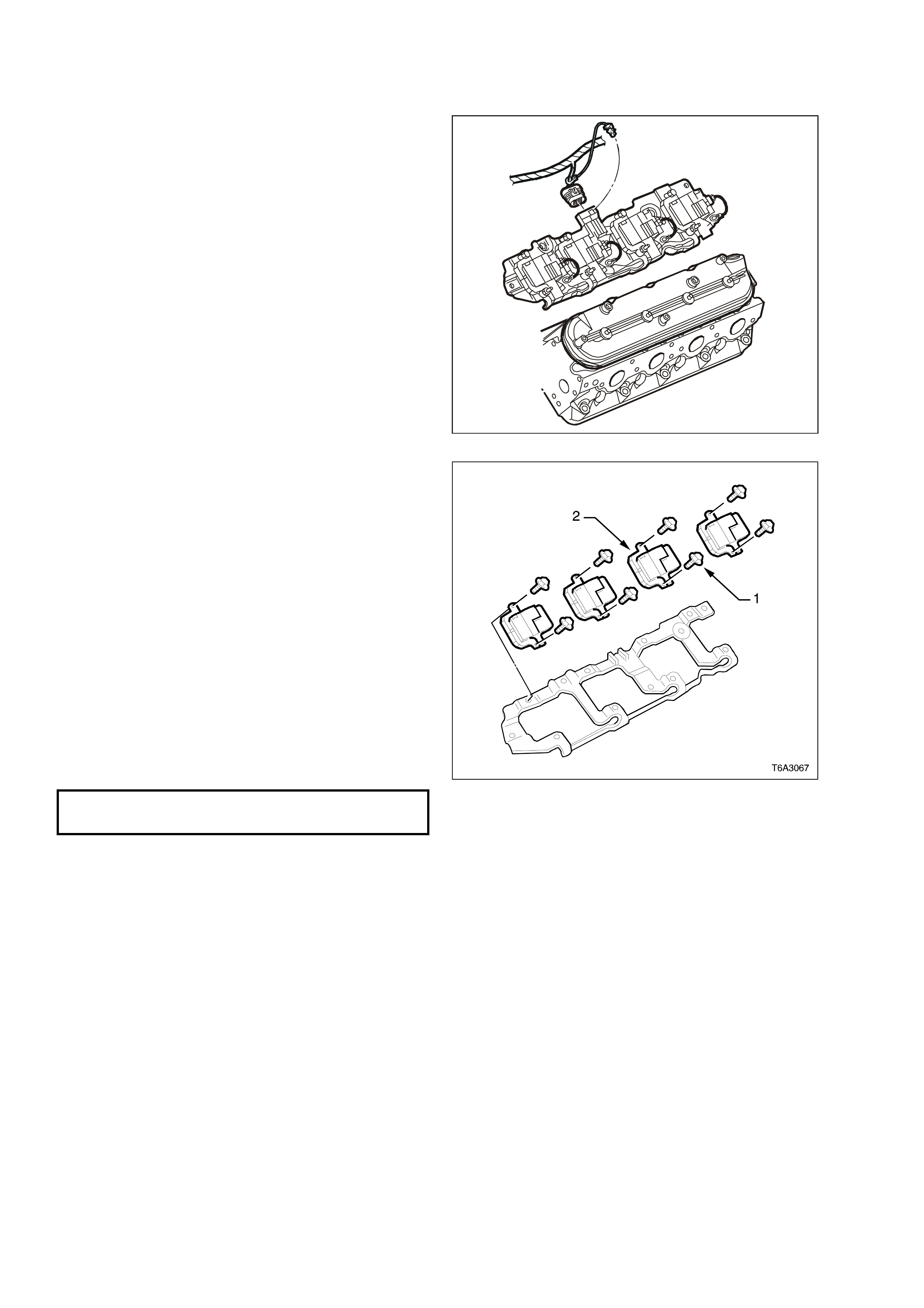

3.16 IGNITION COIL/MODULE

REMOVE

1. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

2. Disconnect the negative battery cable.

3. Disconnect the main electrical connector

feeding the ignition coils.

4. Disconnect the ignition coil harness connectors.

5. Disconnect the spark plug wire at the ignition

coil.

T6A3065

Figure 6C3-3-75 Ignition Coil/Module Location

6. Remove the ignition coil retaining bolts (1).

7. Remove the ignition coil/modules (2).

REINSTALL

1. Install the ignition coil.

2. Install the ignition coil retaining bolts.

3. Connect the spark plug wire to the ignition coil.

4. Connect the ignition coil harness connector.

5. Connect the main electrical connector feeding

the ignition coils.

6. Connect the negative battery cable.

7. Install engine dress cover.

8. Perform the Idle Learn Procedure and the

Functional Check. Refer to

PCM Replacement/Programming in this

Section.

Ignition Coil Retaining Bolt

Tightening Torque 12 N.m Figure 6C3-3-76 Ignition Coil/Modules

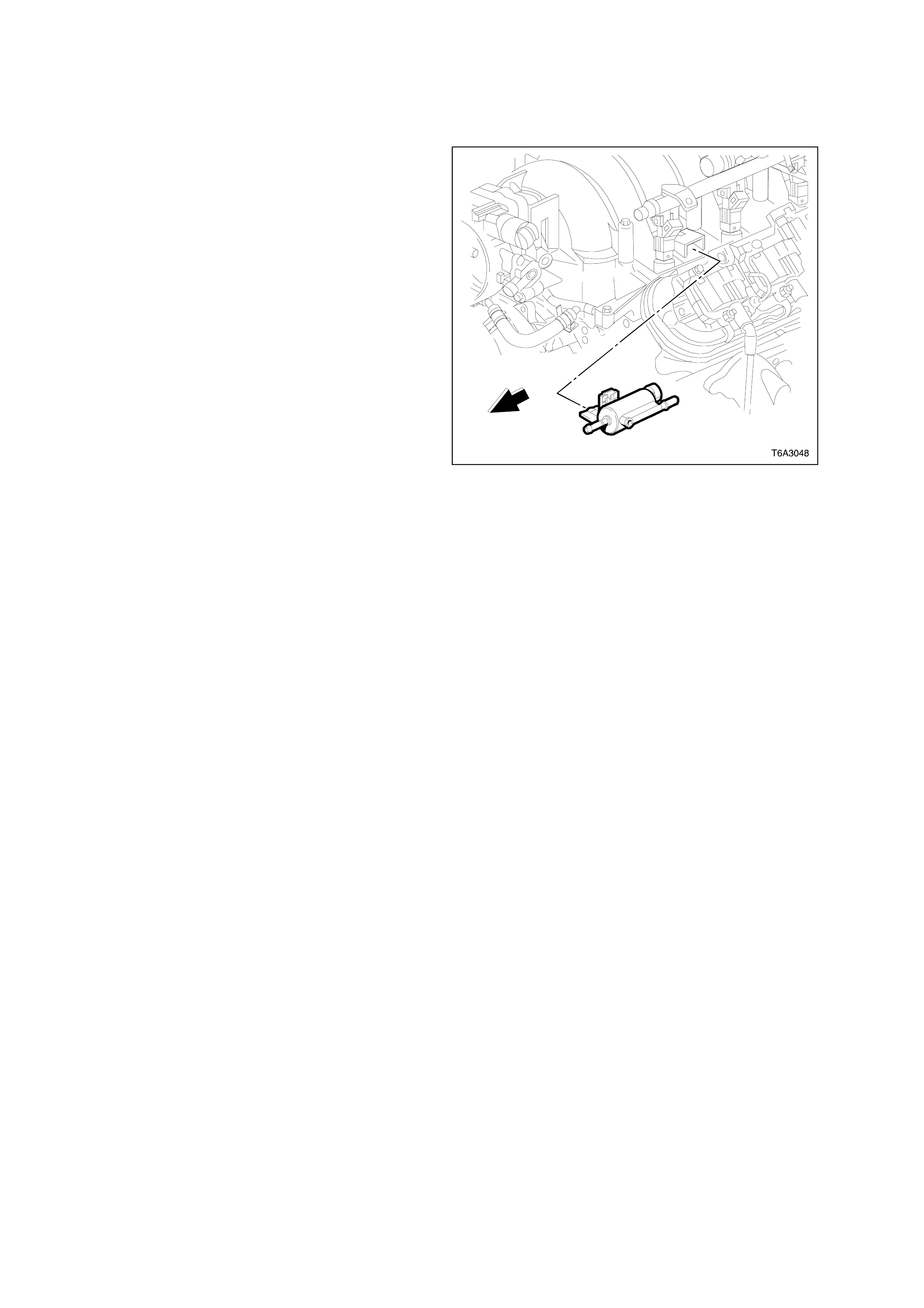

3.17 CRANKSHAFT POSITION (CKP) SENSOR

REMOVE

1. Remove the starter motor. Refer to

Section 6D3, Starting System in the VT

Series II Service Information.

2. Disconnect the electrical connector from the

crankshaft position sensor (1).

3. Remove the crankshaft position retaining bolt

(2).

4. Remove the sensor.

REINSTALL

1. Install the crankshaft position sensor.

2. Install the crankshaft position retaining bolt and

tighten to the specified torque.

3. Connect the sensor electrical connector.

4. Install the starter motor. Refer to

Section 6D3, Starting System in the VT

Series II Service Information.

5. Perform the Idle Learn Procedure and

the Functional Check. Refer to

PCM Replacement/Programming in this

Section.

1

2

Figure 6C3-3-77 Crankshaft Position Sensor Location

CKP Sensor

Tightening Torque 25 N.m

3.18 KNOCK SENSORS

REMOVE

1. Perform the fuel pressure relief procedure.

Refer to Fuel Pressure Relief Procedure in

this Section.

2. Disconnect the negative battery cable.

3. Remove engine dress cover. Refer to

Engine Coolant Temperature Sensor in this

Section for removal procedure.

4. Remove the intake manifold. Refer to