SECTION 12C - INSTRUMENTS, WIPERS/

WASHERS & HORN

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

1.1 VX AND VU SERIES II MODELS

The Instruments, Wipers/Washers and Horn fitted to VX and VU Series II Models carries over from VX Series I

Models, noting the following:

• A new wiper/washer control switch has been fitted to VX Series II Models.

• W ith the introduction of the theft deterrent system as standard equipment on all VX Series II Models, the theft

deterrent hor n pr eviously fitted to vehic les with a high s er ies BCM, has been f itted as standar d equipment on all

VX Series II Models.

For information relating to the Instruments, Wipers/Washers and Horn fitted to VX and VU Series II Models not

covered in this section, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS & HORN in the VX Series I

Service Information, in conjunction with Section 12C INSTRUMENTS, WIPERS/WASHERS & HORN in the

VT Series I and VT Series II Service Information.

Techline

Techline

Techline

1.2 WH SERIES II MODELS

The Instruments, W ipers/Washers and Horn fitted to WH Series II Models carries over from WH Series I Models,

noting the following:

• A new wiper/w asher control switch has been fitted to WH Series II Models.

• The instrument cluster colour and graphics have been revised.

For inf ormation relating to the Instr uments, Wipers/Washer s and Horn fitted to W H Series II Models not covered in

this section, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS & HORN in the WH Series II Service

Information, in conj unc tion with Section 12C INST RUMENTS, WIPERS/WASHERS & HORN in the VT Series I and

VT Series II Service Information.

2. SERVICE OPERATIONS

2.1 WI PER/WASHE R CONTROL SWITCH

REMOVE

CAUTION: If vehicle is equipped with SRS

(AIRBAG), disable the system. Refer to

Section 12M SUPPLEMENTAL RESTRAINT

SYSTEM in the VT Series I Service Information.

1. Disconnect battery earth lead.

2. Remove ignition keys from ignition switch.

3. Lower fuse panel cover.

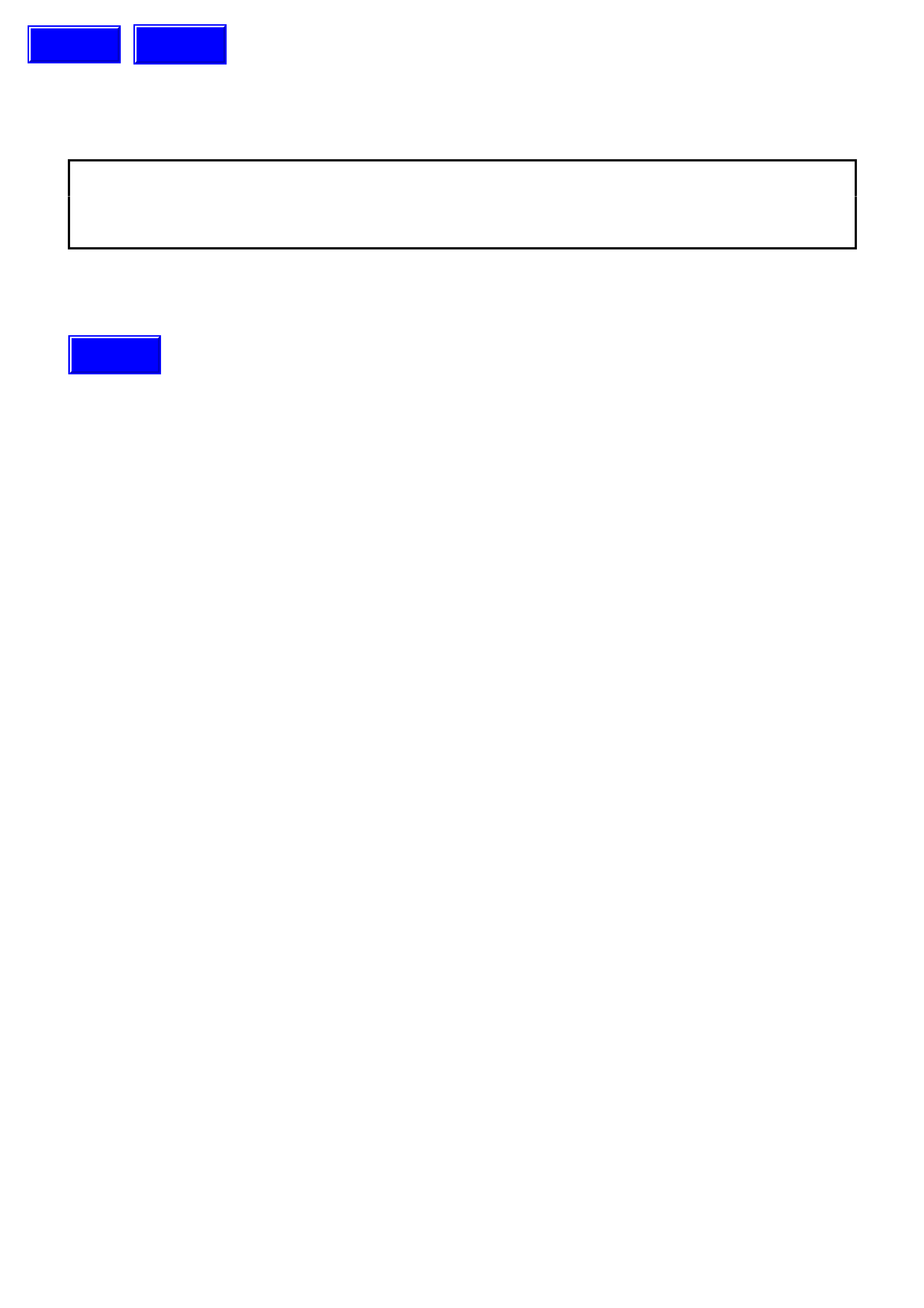

4. Release steering column height adjuster (1),

completely lower steering column and leave

lever in the release position.

5. Remove steering column lower cover (2) to

steering column attaching screw (3).

Figure 12C-1

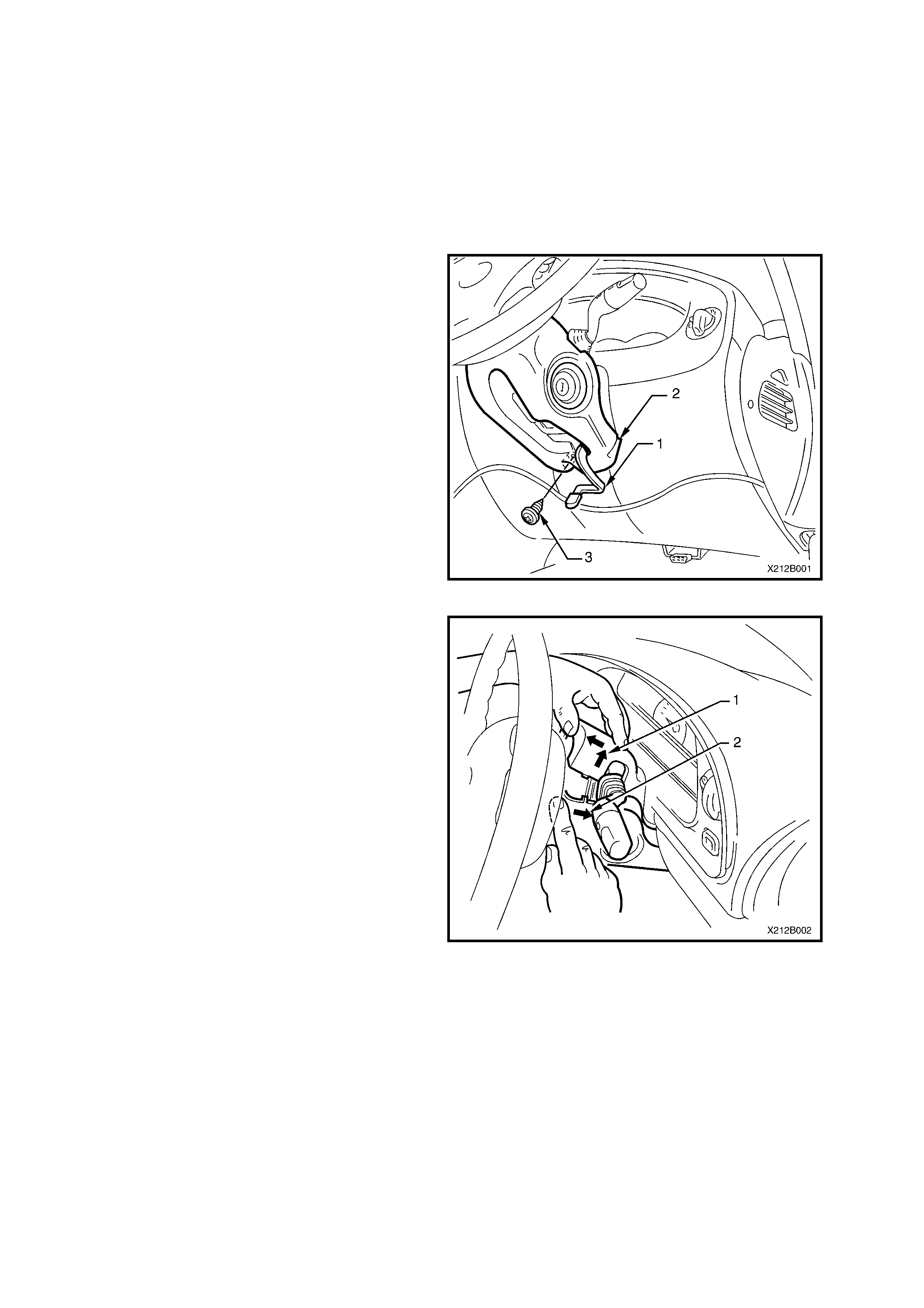

6. Place a clean shop rag over and around

steering column upper cover. This prevents any

possibility of damage to cover should there be

any c ontact with lower edge of ins trument facia

while removing the cover.

7. Insert finger between the steering wheel and

the lower cover as shown in Fig. 12C-2 and

apply a small amount of pressure (pushing

towards instrument cluster).

8. Pull steering column upper cover (1) up and

toward steering wheel at the same time pulling

lower cover (2) down and away from steering

wheel. This will release the steering column

lower cover end retainers from mating slots in

upper cover (refer item 4, Fig 12C-1).

9 Remove upper cover by lifting upwards and

rearwards.

10. While feeding the key reader outer surround

from lower cover, remove cover.

Figure 12C-2

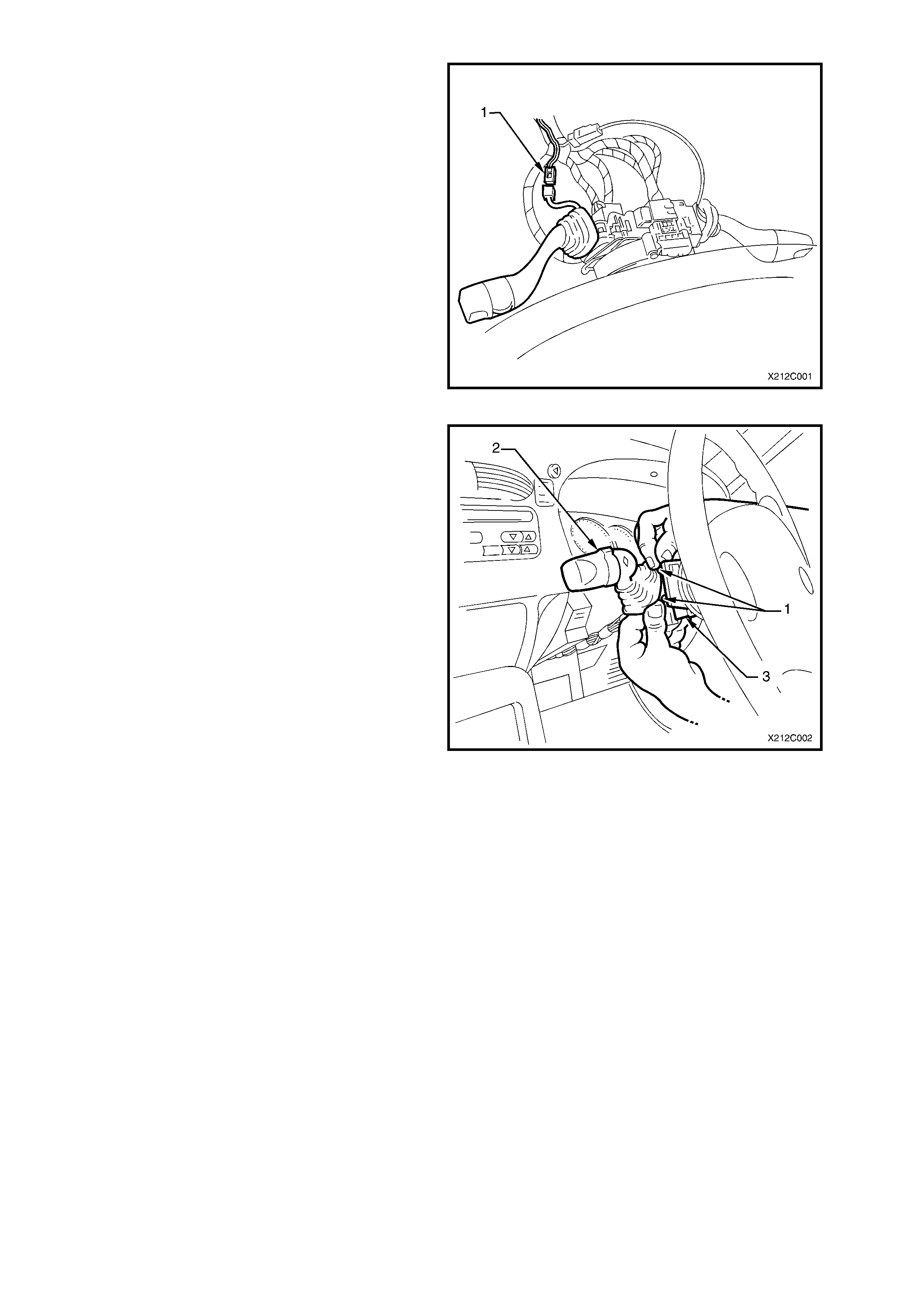

11. On vehicles with high series BCM, disconnect

the wiring harness connec tor to the wiper dwell

control switch harness connector (1) by

depressing harness retaining tang and pulling

connectors apart.

NOTE: The switch side of the harness connector

for the wiper dwell contr ol is wrapped in f oam as an

anti-rattle measure. Should the foam wrap be

damaged during the removal or test procedures, it

must be replaced with a suitable alternative.

Figure 12C-3

12. Depress r etaining tangs (1) on s witch ass embly

and withdraw wiper/washer switch (2) from

switch housing on steering column (3).

13. Lift up wiring harness connec tor retaining tangs

on either side of wiper/washer switch body and

pull connector from switch.

14. Remove switch.

Figure 12C-4

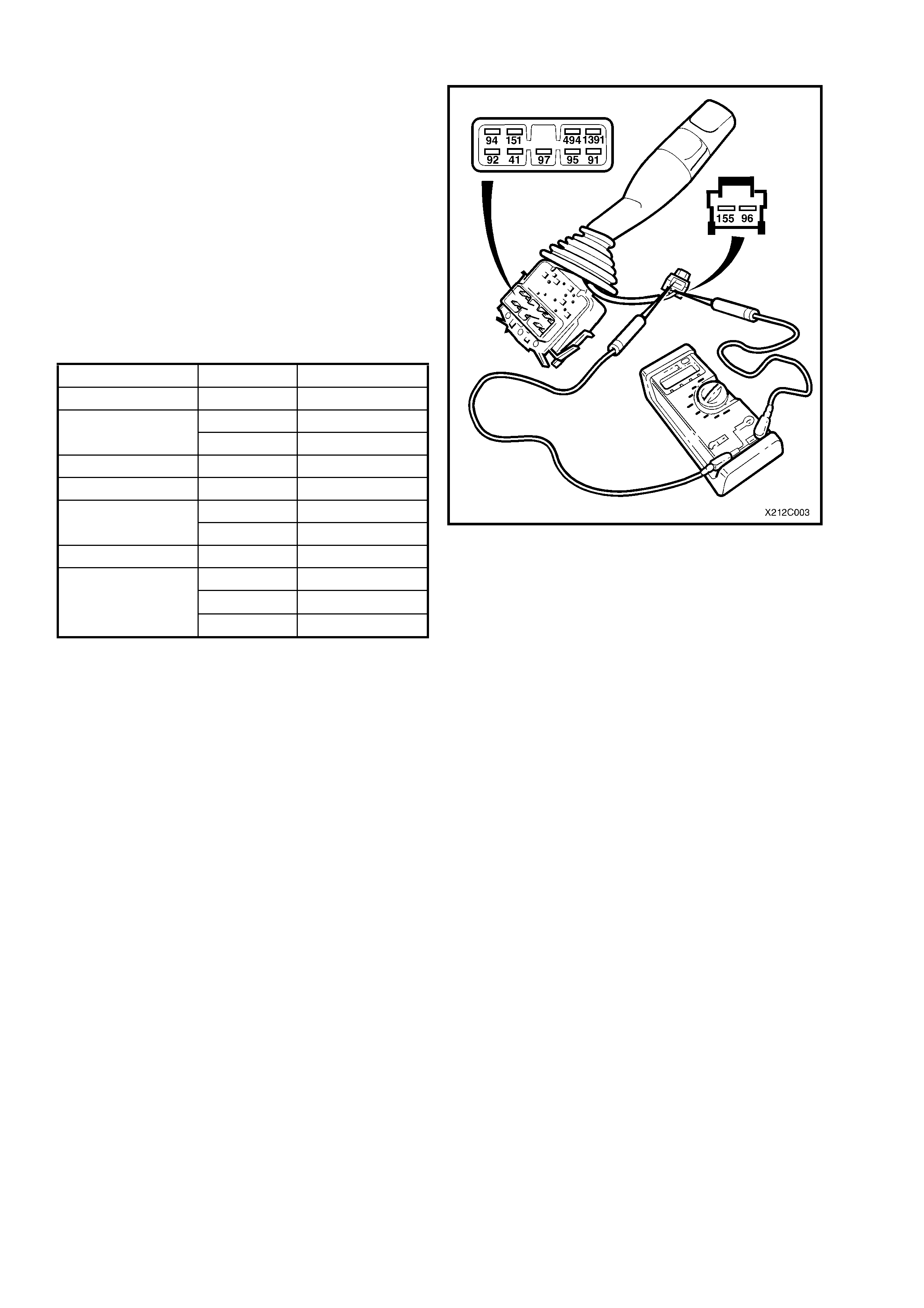

TESTING SWITCH

Using an ohmmeter connected to the various

switch terminals (refer to Fig. 12C-5), check the

operation of the wiper/washer switch as per the

following chart.

If continuity is not present at the specif ied term inals

for any given switch position, replace switch

assembly.

NOTE: With dwell control adjusted fully up,

multimeter should register approximately 4.2 to 6.5

kohms, and with control adjusted fully down,

approxim ately 476 to 889 ohms when connec ted to

terminals 155 and 96 on the wiper dwell harness

connector, refer to Fig. 12C-5.

Switch Position Terminals Indication if O.K.

Off 91 & 95 Continuity

91 & 95 Continuity

INT 97 & 41 Continuity

1 (Low Speed) 91 & 41 Continuity

2 (High Speed) 41 & 92 Continuity

94 & 41 Continuity Front Wash 151 & 494 Continuity

Rear Wipe 41 & 1391 Continuity

41 & 494 Continuity

41 & 1391 Continuity

Rear Wash

94 & 151 Continuity

Figure 12C-5

REINSTALL

Installation of the wiper/washer switch is the reverse

of the removal procedure, noting the following:

Check operation of all wiper/washer switch functions.

NOTE: The switch side of the harness connector f or

the wiper dwell control is wrapped in f oam as an anti-

rattle measure. Should the foam wrap be damaged

during the removal or test procedures, it must be

replaced with a suitable alternative.

IMPORTANT: If vehicle is equipped with SRS

AIRBAG, enable the system. Refer to

Section 12M SUPPLEMENTAL RESTRAINT

SYSTEM, in the VT Series I Service Information.