Engine Management GEN IV V8 – Service Operations Page 6C4-3–1

Page 6C4-3–1

Section 6C4–3

Engine Management GEN IV V8 –

Service Operations

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................4

1.1 General Description............................................................................................................................................... 4

1.2 Service Precautions and Notes ............................................................................................................................ 5

2 General Service Operations ..................................................................................................................6

2.1 Service Operations Not Covered In This Section................................................................................................ 6

Fuel System Cleaning............................................................................................................................................ 6

Fuel System Leak and Pressure Test................................................................................................................... 6

Fuel Feed Hose to Fuel Rail .................................................................................................................................. 6

Fuel Line Quick Connect Fittings......................................................................................................................... 6

2.2 Engine Dress Covers............................................................................................................................................. 7

Remove................................................................................................................................................................... 7

Reinstall.................................................................................................................................................................. 7

2.3 Fuel Injector Coil and Balance Test ..................................................................................................................... 8

2.4 Fuel Injector Leak Down Test ............................................................................................................................... 9

3 Component Replacement ....................................................................................................................10

3.1 Components Not Covered In This Section ........................................................................................................ 10

Automatic Transmission Components .............................................................................................................. 10

A/C Pressure Switch............................................................................................................................................ 10

Brake Pedal Switches.......................................................................................................................................... 10

Clutch Pedal Switches......................................................................................................................................... 10

Cruise Control Switch Assembly........................................................................................................................ 10

Evaporative Emission Control Canister............................................................................................................. 10

Fuel Filter.............................................................................................................................................................. 10

Fuel Hose/Pipes ................................................................................................................................................... 10

Fuel Pump Motor Assembly and Fuel Pressure Regulator .............................................................................. 10

Fuel Sender Assembly ........................................................................................................................................ 11

Fuel Tank Pressure Sensor................................................................................................................................. 11

Fuses and Relays................................................................................................................................................. 11

Manual Transmission Components ................................................................................................................... 11

Neutral Start and Back-up Lamp Switch............................................................................................................ 11

Powertrain Interface Module (PIM) ..................................................................................................................... 11

Vehicle Speed Sensor ......................................................................................................................................... 11

3.2 Accelerator Pedal Position (APP) Sensor.......................................................................................................... 12

Remove................................................................................................................................................................. 12

Reinstall................................................................................................................................................................ 13

3.3 Accelerator Pedal Position (APP) Sensor Support Bracket ............................................................................. 14

Remove................................................................................................................................................................. 14

Reinstall................................................................................................................................................................ 14

Engine Management GEN IV V8 – Service Operations Page 6C4-3–2

Page 6C4-3–2

3.4 Air Cleaner Assembly.......................................................................................................................................... 15

Air Cleaner Upper Housing ................................................................................................................................. 15

Remove............................................................................................................................................................ 15

Reinstall ........................................................................................................................................................... 15

Air Cleaner Lower Housing................................................................................................................................. 16

Remove............................................................................................................................................................ 16

Reinstall ........................................................................................................................................................... 16

3.6 Camshaft Position (CMP) Sensor ....................................................................................................................... 17

Removal Procedure ............................................................................................................................................. 17

Installation Procedure ......................................................................................................................................... 18

3.7 Crankshaft Position (CKP) Sensor ..................................................................................................................... 19

Remove................................................................................................................................................................. 19

Reinstall................................................................................................................................................................ 19

3.7 Engine Control Module (ECM) ............................................................................................................................ 20

Remove................................................................................................................................................................. 20

Reinstall................................................................................................................................................................ 21

3.8 Engine Control Module (ECM) Bracket Assembly ............................................................................................ 22

Remove................................................................................................................................................................. 22

Reinstall................................................................................................................................................................ 22

3.9 Engine Coolant Temperature (ECT) Sensor ...................................................................................................... 23

Remove................................................................................................................................................................. 23

Test ....................................................................................................................................................................... 24

Resistance Check ............................................................................................................................................ 24

Reinstall................................................................................................................................................................ 25

3.10 Engine Oil Pressure (EOP) Sensor..................................................................................................................... 26

Remove................................................................................................................................................................. 26

Reinstall................................................................................................................................................................ 26

3.11 EVAP Canister Purge Solenoid Valve ................................................................................................................ 27

Remove................................................................................................................................................................. 27

Reinstall................................................................................................................................................................ 27

3.12 Fuel Rail Assembly .............................................................................................................................................. 28

Remove................................................................................................................................................................. 28

Disassemble..................................................................................................................................................... 29

Reassemble ..................................................................................................................................................... 30

Reinstall................................................................................................................................................................ 30

3.13 Heated O2 Sensors .............................................................................................................................................. 31

Service Precautions............................................................................................................................................. 31

Remove................................................................................................................................................................. 31

Reinstall................................................................................................................................................................ 32

Test ....................................................................................................................................................................... 32

Heater Resistance Check................................................................................................................................. 32

3.14 Ignition Coil / Module........................................................................................................................................... 33

Remove................................................................................................................................................................. 33

Test ....................................................................................................................................................................... 34

Reinstall................................................................................................................................................................ 34

3.15 Intake Air Temperature (IAT) Sensor.................................................................................................................. 35

Test ....................................................................................................................................................................... 35

Resistance Check ............................................................................................................................................ 35

3.16 Knock Sensors..................................................................................................................................................... 36

Remove................................................................................................................................................................. 36

Reinstall................................................................................................................................................................ 36

3.17 Manifold Absolute Pressure (MAP) Sensor ....................................................................................................... 37

Remove................................................................................................................................................................. 37

Reinstall................................................................................................................................................................ 37

3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct ............................................................................................. 38

Remove................................................................................................................................................................. 38

Reinstall................................................................................................................................................................ 39

Engine Management GEN IV V8 – Service Operations Page 6C4-3–3

Page 6C4-3–3

3.19 Spark Plugs .......................................................................................................................................................... 40

Service Precautions............................................................................................................................................. 40

Remove................................................................................................................................................................. 40

Clean, Inspect and Adjust ................................................................................................................................... 41

Spark Plug Inspection ......................................................................................................................................... 41

Poor Spark Plug Performance.......................................................................................................................... 41

Analysis of Spark Plug Condition ..................................................................................................................... 43

Reinstall................................................................................................................................................................ 45

3.20 Spark Plug Leads................................................................................................................................................. 46

Remove................................................................................................................................................................. 46

Inspect .................................................................................................................................................................. 46

Reinstall................................................................................................................................................................ 46

3.21 Throttle Body........................................................................................................................................................ 47

Handling Precautions .......................................................................................................................................... 47

Remove................................................................................................................................................................. 47

Inspect .................................................................................................................................................................. 48

Reinstall................................................................................................................................................................ 49

4 Specifications .......................................................................................................................................50

5 Torque Wrench Specifications............................................................................................................52

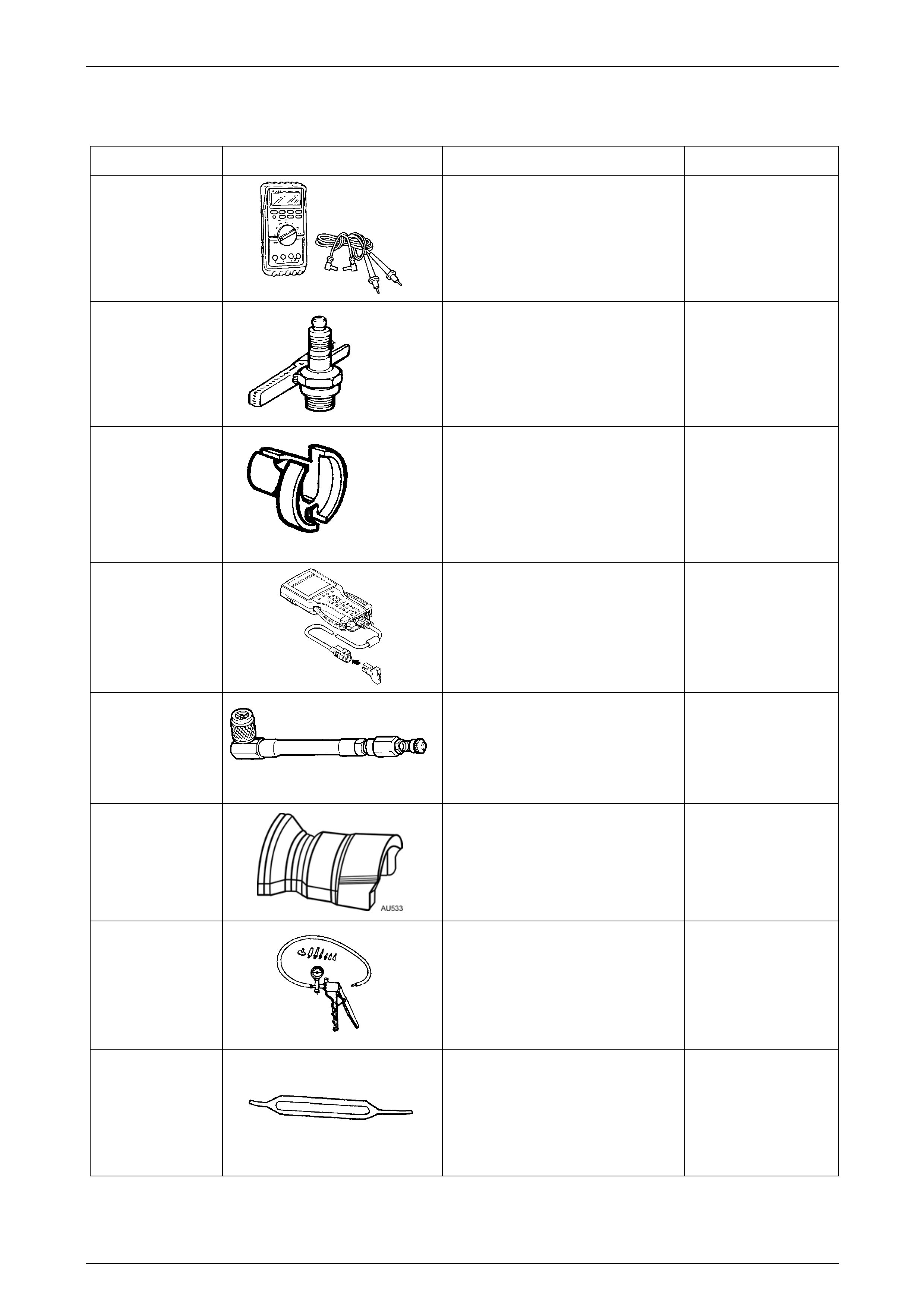

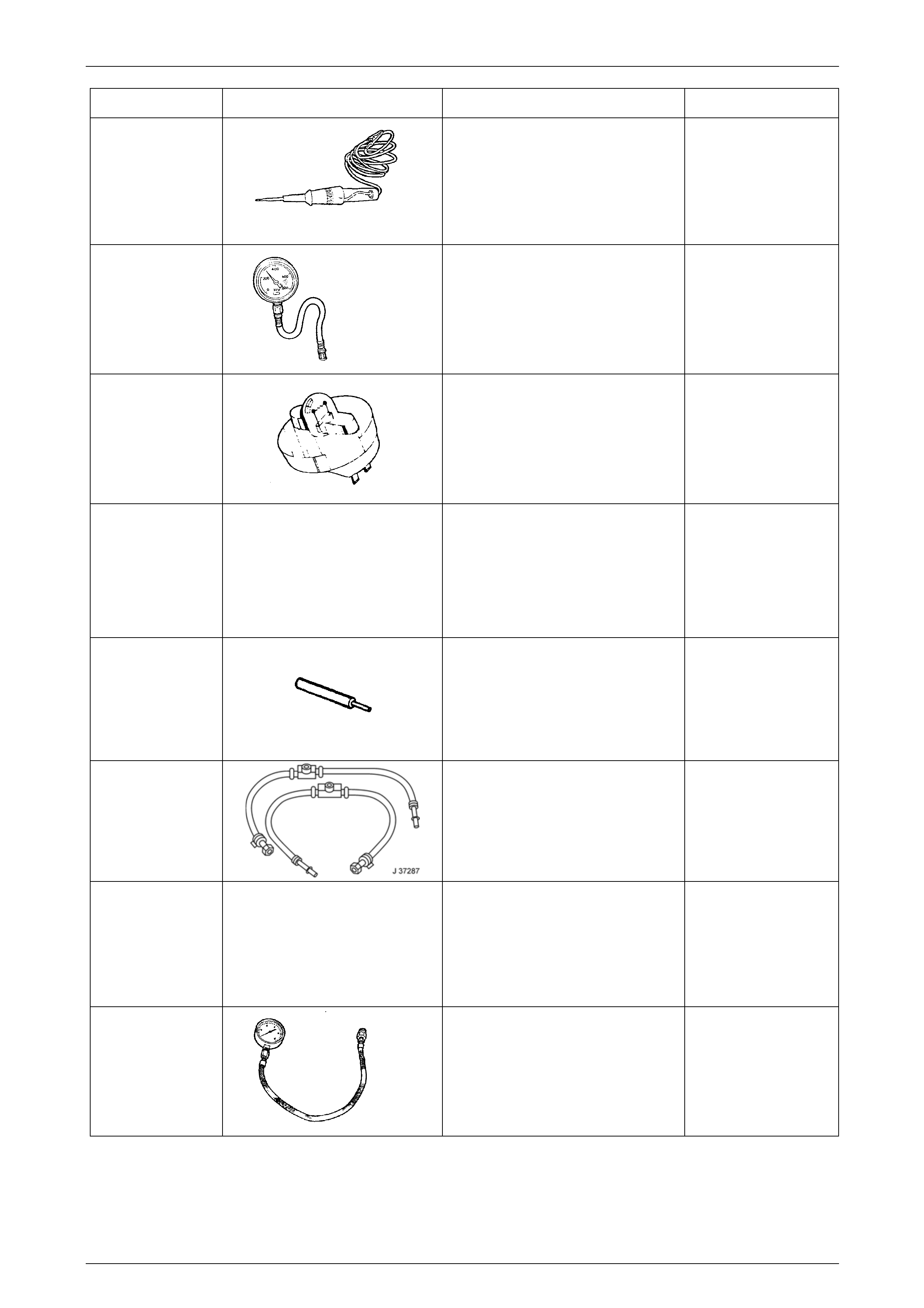

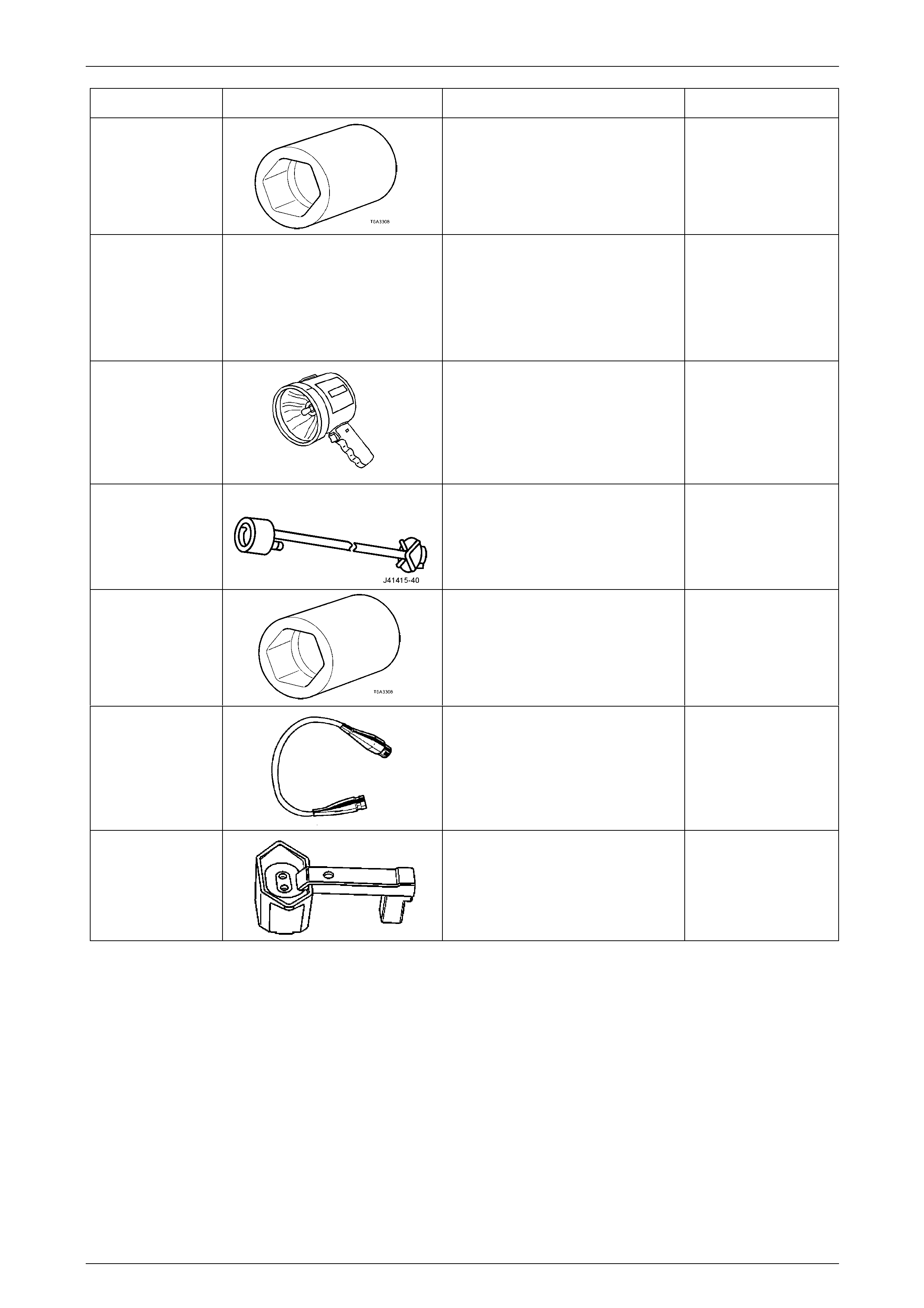

6 Special Tools ........................................................................................................................................53

Engine Management GEN IV V8 – Service Operations Page 6C4-3–4

Page 6C4-3–4

1 General Information

1.1 General Description

This Section describes the correct service procedures to repair components of the powertrain management system used

with the GEN IV V8 engine. Emphasis is placed on the proper procedures and repair of components related to this

specific system.

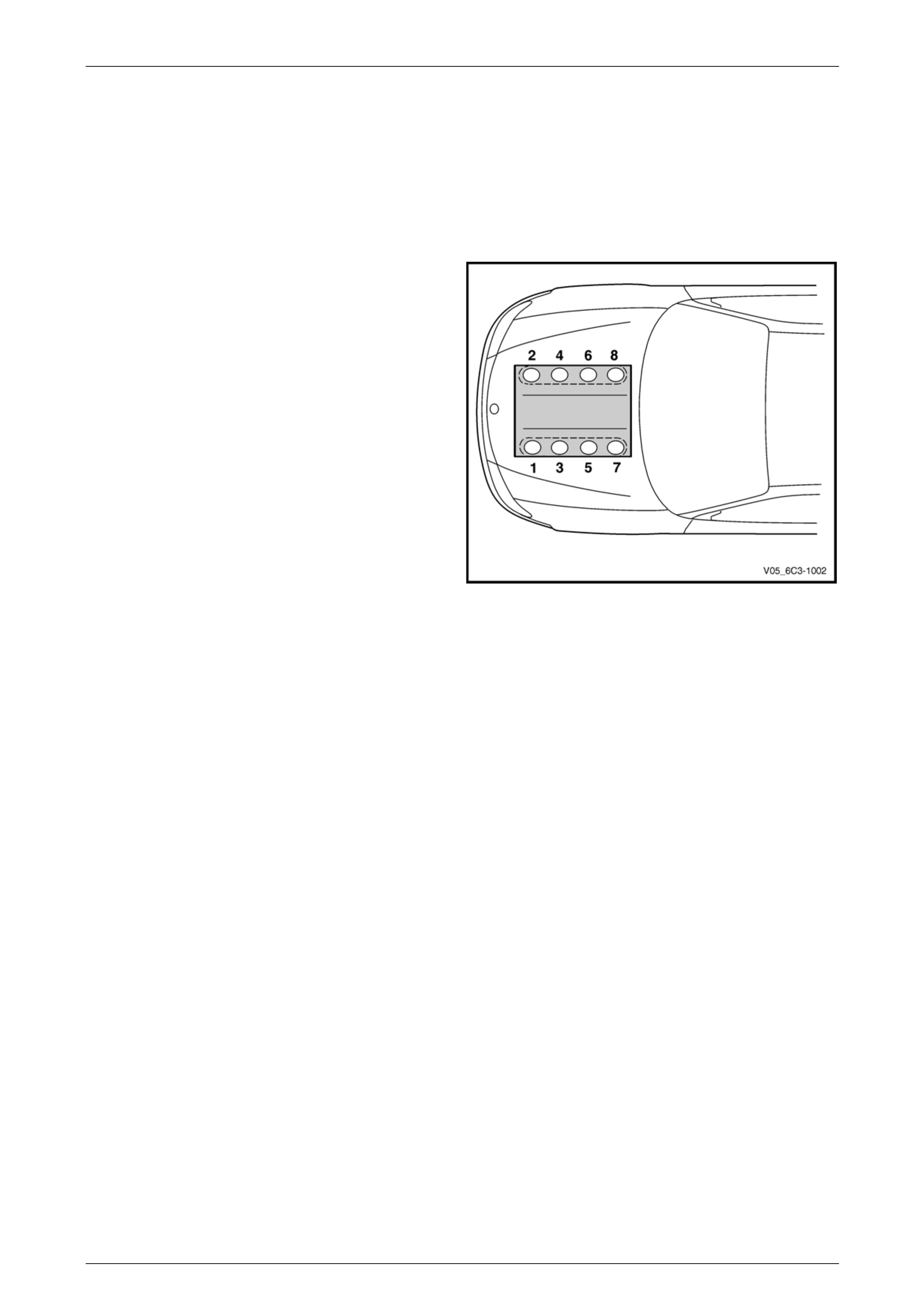

Engine cylinder identification follows the international

standard OBD II. This standard calls for the engine cylinder

bank number one to be identified by the location of cylinder

number one. Therefore the numbering for the GEN IV V8

engine is:

• 1, 3, 5, 7 – Left-hand side (Bank 1),

• 2, 4, 6, 8 – Right-hand side (Bank 2).

The engine firing order is 1, 8, 7, 2, 6, 5, 4, 3.

Figure 6C4-3 – 1

Engine Management GEN IV V8 – Service Operations Page 6C4-3–5

Page 6C4-3–5

1.2 Service Precautions and Notes

The following safety and precautionary

directions must be followed when servicing

the engine management system otherwise

personal injury and/or improper system

operation may occur:

• If working on a vehicle which has been subjected to an under bonnet thermal incident (fire), wear appropriate

protective clothing to prevent personal injury. Components that contain fluoro-elastomer may produce a corrosive

bi-product when subjected to extreme heat.

• Disconnection of the battery affects certain vehicle electronic systems.

Refer to Section 00 Warnings, Cautions and Notes before disconnecting the battery.

• Prior to disconnecting or removal of any components associated with the fuel system, clean the area around any

connection points to avoid possible contamination of the fuel system.

• A depressurised fuel system contains fuel in the fuel system and fuel lines that can be spilled during service

operations. To reduce the chance of personal injury, cover the fittings with a shop towel to absorb any fuel spillage

prior to performing the service operation. Once the service operation has been completed, place the towel in an

approved container for disposal.

• To avoid accidental fuel discharge, it is advisable to disconnect the battery and remove the fuel pump relay if the

fuel line between the fuel pump and the fuel rail is to be disconnected/open for an indefinite period.

• Always tighten fasteners to the correct tightening torque, and where indicated in the service procedure, follow the

correct tightening sequence, precautions and recommendations to prevent premature failure of the fastener or

component, refer to Section 00 Warnings, Cautions and Notes for further information on fasteners.

• Do not use silicone based assembly lubricants as damage to the heated oxygen sensors may result.

• After completing the required service operations, road test the vehicle to ensure correct powertrain management

system operation.

• Before removing the ECM, disconnect the battery ground lead.

• Never start the engine without the battery being solidly connected.

• Never disconnect the battery while the engine is running or when charging the battery.

• Never touch the connector pins of any electronic component, such as an ECM, as Electrostatic Discharge (ESD)

damage may result. For further information, refer to Section 00 Warnings, Cautions and Notes .

• Never subject the ECM to temperatures below -40°C and above 125°C.

• Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

• The engine management system harness connectors are designed to fit only one way; there are indexing tabs and

slots on both halves of the connector. Forcing the connector into place is not necessary if it is being installed with

the correct orientation. Failure to take care to match the indexing tabs and slots correctly can cause damage to the

connector, the module, or other vehicle components or systems.

• Never connect or disconnect a cable harness plug at the ECM, or fuel system component when the ignition is

switched on.

• Before attempting any electric welding on the vehicle, disconnect the battery leads and the ECM connectors.

• When steam cleaning the engine, do not direct the steam cleaning nozzle at the ECM or other engine management

system components. If this happens, corrosion of the terminals can occur.

Use of incorrect electrical test equipment

when performing the engine management

service procedures could result in incorrect

results or damage to ECM system

components.

• Use only the test equipment specified in the diagnostic tables, since other test equipment may either

give incorrect results or damage serviceable components,

refer to Section 6C4-2 Engine Management – GEN IV V8 – Diagnostics.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–6

Page 6C4-3–6

2 General Service Operations

2.1 Service Operations Not Covered In This

Section

Fuel System Cleaning

For the fuel system cleaning procedure, refer to Section 8A1 Fuel System.

Fuel System Leak and Pressure Test

For the fuel system leak and pressure test procedure, refer to Section 8A1 Fuel System.

Fuel Feed Hose to Fuel Rail

For the fuel feed hose to fuel rail replacement service operations, refer to Section 8A1 Fuel System.

Fuel Line Quick Connect Fittings

For fuel line quick connect fittings, refer to Section 8A1 Fuel System.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–7

Page 6C4-3–7

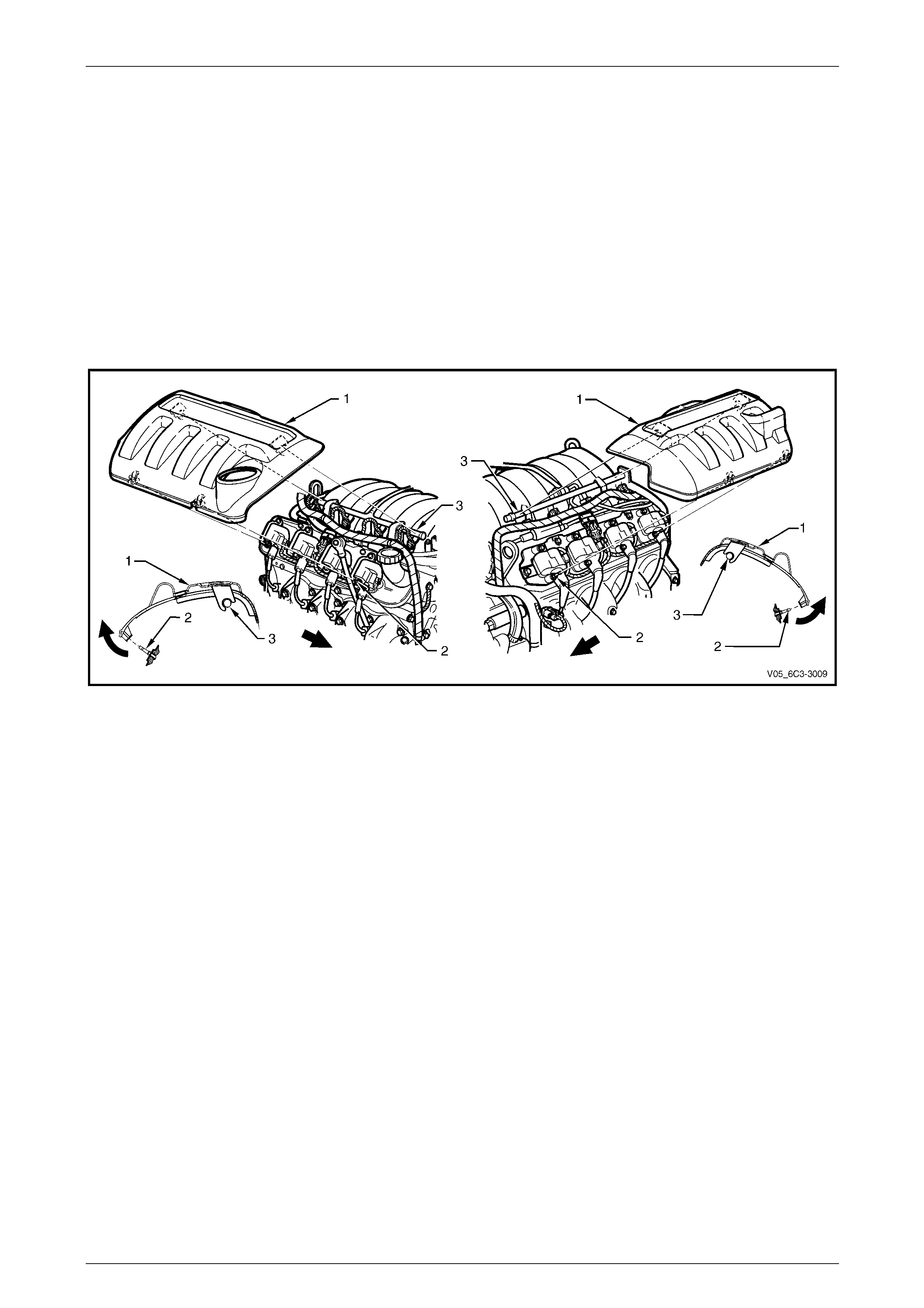

2.2 Engine Dress Covers

Remove

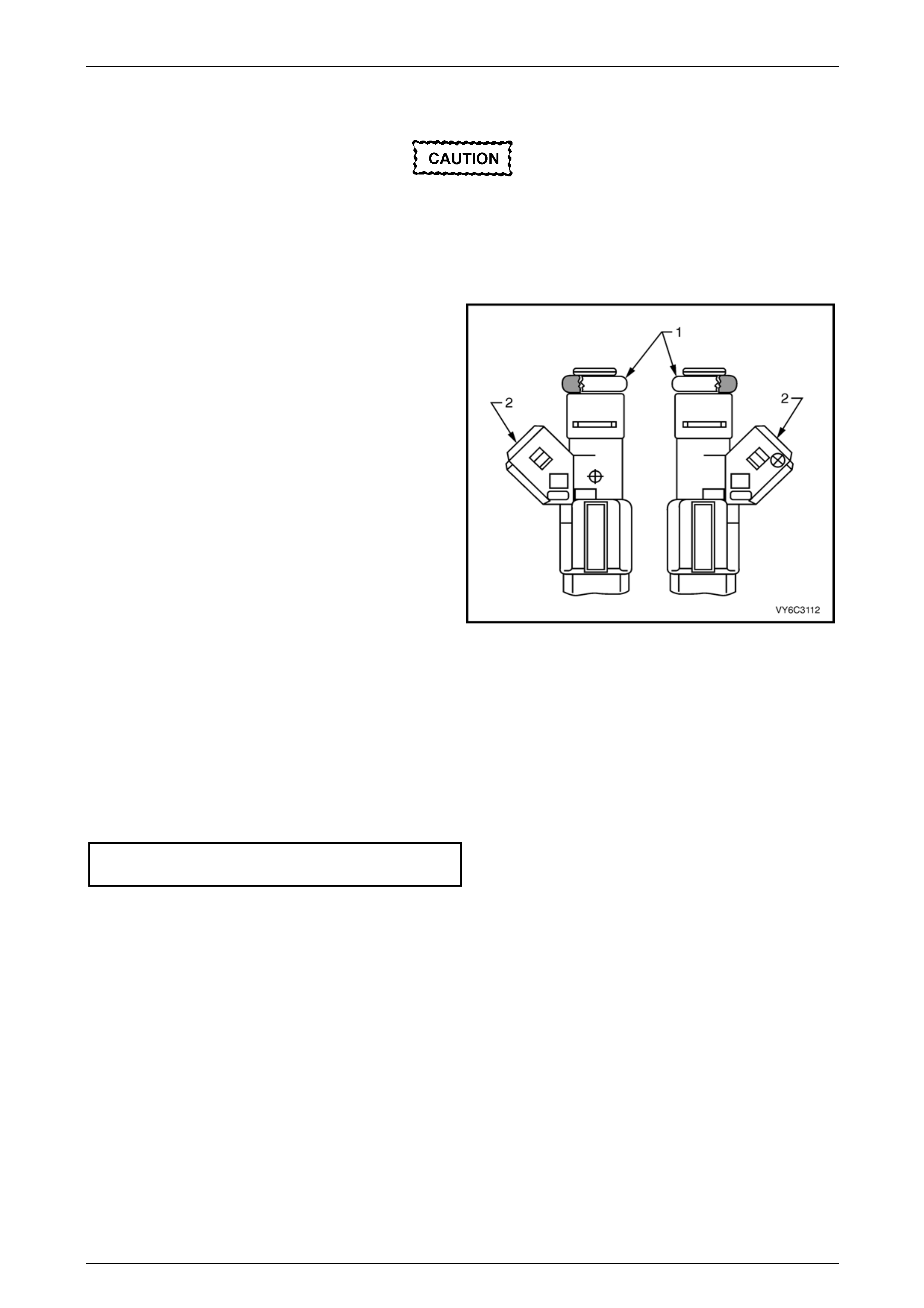

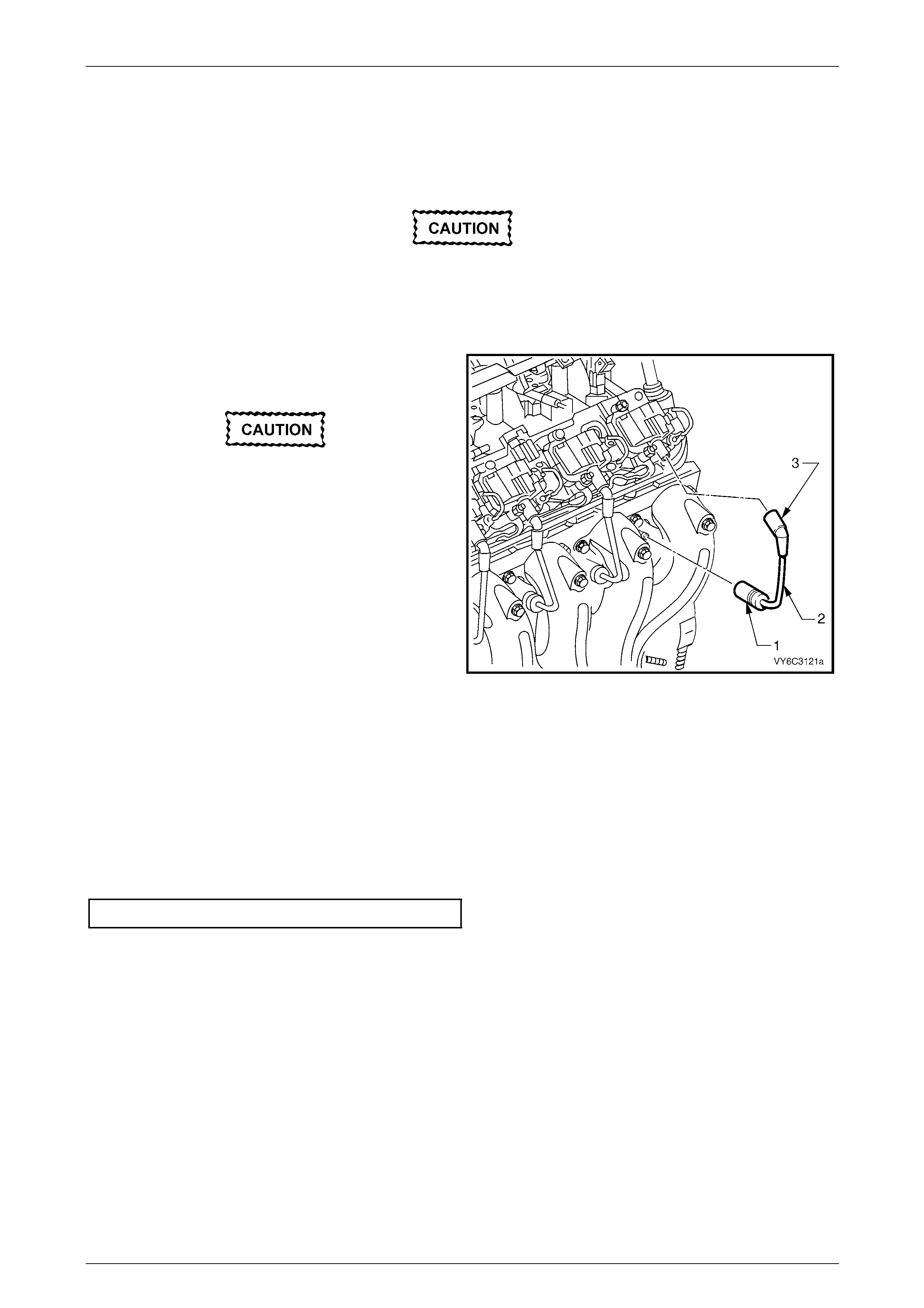

1 Remove either engine dress cover (1) by grasping the lower edge of the cover with the fingers of each hand and

pulling upward to dislodge from the retaining stakes (2), two places.

NOTE

The retaining stakes form part of the double

ended studs securing the ignition coils to the

mounting bracket.

2 Lift the cover upwards, then pull outward to dislodge the clips from the fuel rail (3).

Figure 6C4-3 – 2

3 Repeat Steps 1 and 2 for the other side.

Reinstall

Reinstallation of the engine dress covers is the same as the removal procedure, ensuring the engine dress covers are

securely clipped in place.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–8

Page 6C4-3–8

2.3 Fuel Injector Coil and Balance Test

Information not available at time of publication.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–9

Page 6C4-3–9

2.4 Fuel Injector Leak Down Test

1 Turn the ignition switch off.

NOTE

Do not disconnect the fuel feed hose from the

fuel rail.

Care must be taken when removing the fuel

rail and injector assembly to prevent damage

to the injector spray tips and injector harness

connector terminals.

Support the fuel rail and injector assembly

after removal.

2 Remove the fuel rail assembly, refer to 3.12 Fuel Rail Assembly.

3 Lift up and support the fuel rail and injector assembly.

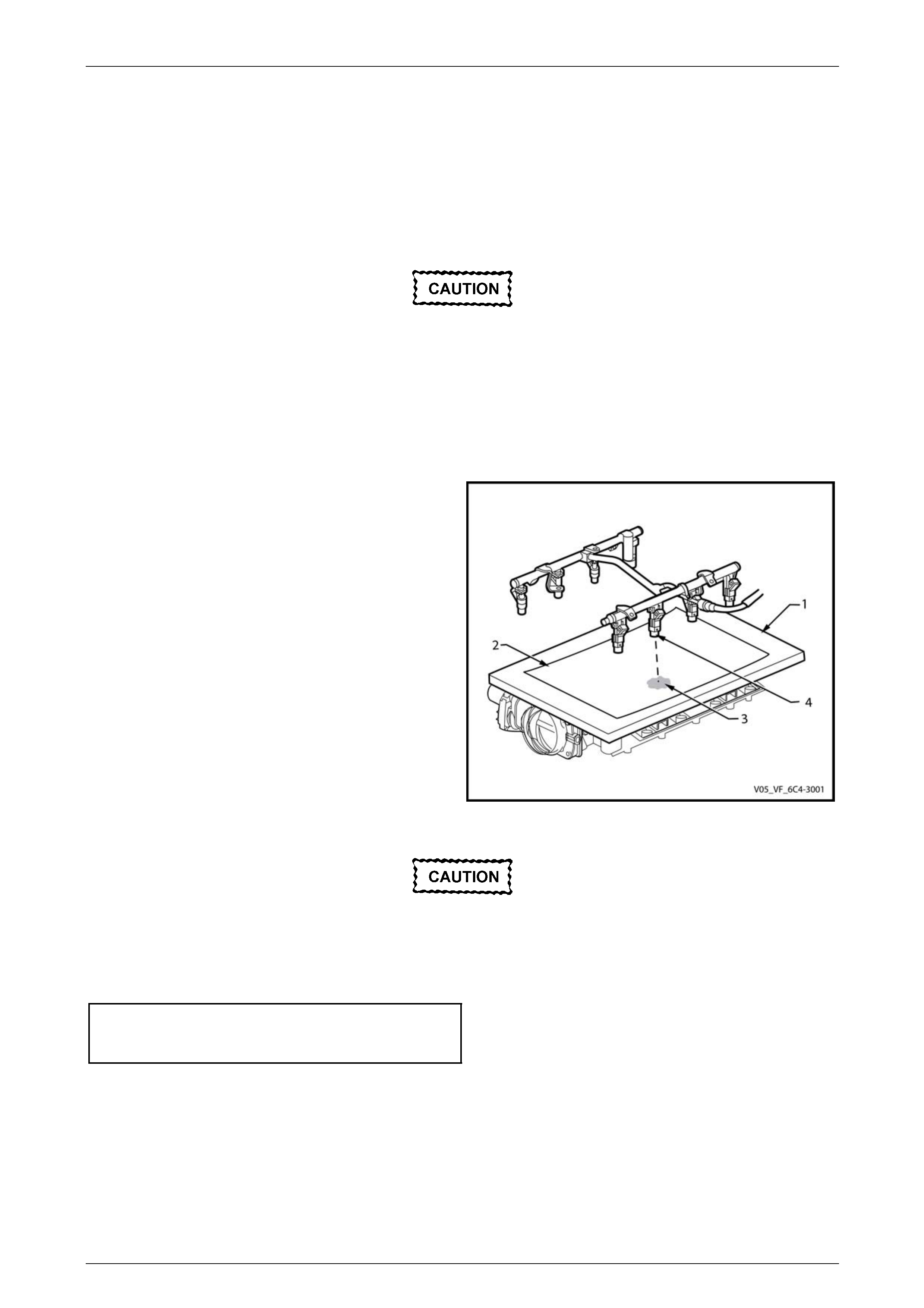

4 Place a board (1) with a sheet of clean paper (2),

preferably white, onto the intake manifold.

5 Using Tech 2, enable the fuel pump to pressurise the

fuel system, refer to Section 0C Tech 2 for this

procedure.

6 Whilst the fuel system is pressurised, check the

following:

• Signs of fuel stains on the paper (3).

• Signs of weeping at the fuel injector spray

tips (4).

7 If any of the above conditions are present,

replace the leaking fuel injector(s), refer to

3.12 Fuel Rail Assembly.

8 Carefully reinstall the fuel rail and injector assembly.

Figure 6C4-3 – 3

Ensure that the fuel injectors are correctly

seated in the lower intake manifold, and that

the fuel rail attaching brackets are correctly

located prior to tightening the attaching bolts.

9 Tighten the bolts attaching the fuel rail to the intake manifold to the correct torque specification.

Fuel rail to intake

manifold attaching bolt

torque specification ..................................8.0 – 12.0 Nm

10 Perform the following procedure to inspect for fuel leaks at the fuel rail:

a Turn the ignition switch on for two seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Inspect for fuel leaks at the fuel rail.

11 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–10

Page 6C4-3–10

3 Component Replacement

3.1 Components Not Covered In This

Section

There are cases where components used by the fuel injection system are covered in other sections of the service

documentation. To aid technicians in locating the necessary service procedures for these components, refer to the

following references/links.

Automatic Transmission Components

For automatic transmission sensors and other components,

refer to Section 7E4 Automatic Transmission – 4L65E – On-vehicle Servicing.

A/C Pressure Switch

For the A/C pressure switch service operation,

refer to Section 2B – HVAC Climate Control (Manual A/C) – Servicing and Diagnosis.

Brake Pedal Switches

For extended brake pedal travel switch and stop lamp switch service operations,

refer to Section 5A Service and Park Braking Systems.

Cruise Control Switch Assembly

For the cruise control switch assembly service operations, refer to Section 12E Cruise Control.

Evaporative Emission Control Canister

For the evaporative emission control canister, refer to Section 8A1 Fuel System.

Fuel Filter

For the fuel filter service operations, refer to Section 8A1 Fuel System.

Fuel Hose/Pipes

For the fuel hose/pipes layout, refer to Section 8A1 Fuel System.

Fuel Pump Motor Assembly and Fuel Pressure Regulator

For the fuel pump motor assembly and fuel pressure regulator assembly, refer to Section 8A1 Fuel System.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–11

Page 6C4-3–11

Fuel Sender Assembly

For the fuel sender assembly service operations, refer to Section 8A1 Fuel System.

Fuel Tank Pressure Sensor

For the fuel tank pressure sensor, refer to Section 8A1 Fuel System.

Fuses and Relays

For the fuse and relay locations, refer to Section 12O Fuses, Relays and Wiring Harnesses.

Neutral Start and Back-up Lamp Switch

For the neutral start and back-up lamp switch,

refer to Section 7E4 Automatic Transmission – 4L65E – On-vehicle Servicing.

Powertrain Interface Module (PIM)

For the PIM removal and installation procedure, refer to Section 6E4 Powertrain Interface Module – GEN IV V8 Engine.

Vehicle Speed Sensor

For the vehicle speed sensor service operations,

refer to Section 7E3 Automatic Transmission – 4L65E – On-vehicle Servicing for automatic transmission.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–12

Page 6C4-3–12

3.2 Accelerator Pedal Position (APP) Sensor

Remove

1 Turn the ignition switch off.

2 Remove the driver's side instrument panel lower trim plate assembly,

refer to Section 1A3 Instrument Panel and Console.

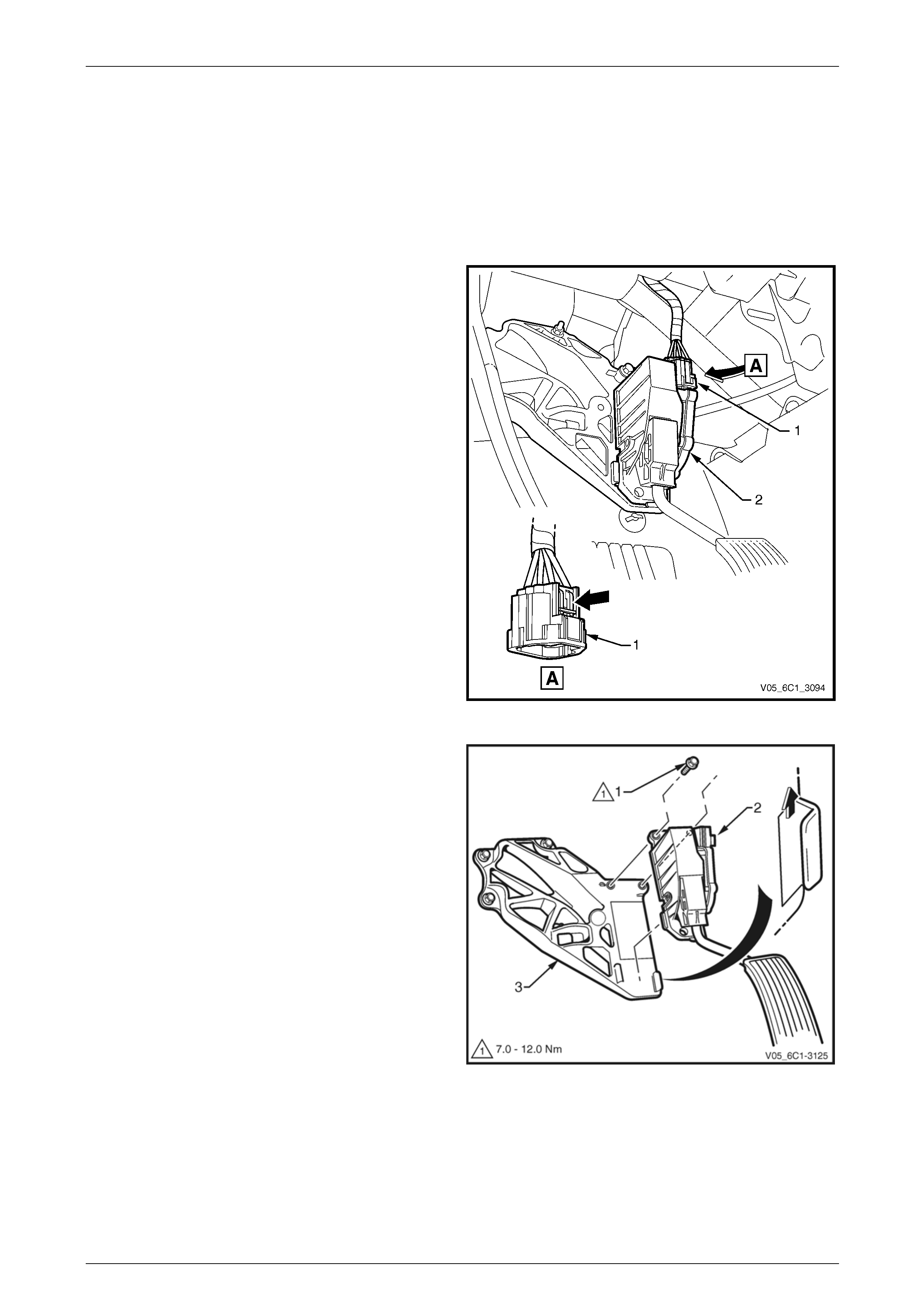

3 Disconnect the wiring harness connector (1) from the

Accelerator Pedal Position (APP) sensor (2) by

depressing the latch in the direction of the arrow.

NOTE

If difficulty is experienced in disconnecting the

harness connector from the APP sensor, remove

the sensor from the APP support bracket and

then disconnect the harness connector.

Figure 6C4-3 – 4

NOTE

If required, the APP sensor can be removed as

an assembly with the APP sensor support

bracket, refer to 3.3 Accelerator Pedal Position

(APP) Sensor Support Bracket.

4 Remove the bolt (1) in two places, attaching the APP

sensor (2) to the Accelerator Pedal Position (APP)

sensor support bracket (3).

5 Slide the APP sensor upwards in the direction of the

arrow, to disengage the sensor from the support

bracket.

Figure 6C4-3 – 5

Engine Management GEN IV V8 – Service Operations Page 6C4-3–13

Page 6C4-3–13

Reinstall

Reinstallation of the APP sensor is the reverse of the removal procedure, noting the following:

Make sure that the APP sensor engages

the APP support bracket, refer to

Figure 6C4-3 – 5.

1 Reinstall the bolt, two places, attaching the APP sensor to the support bracket and tighten to the correct torque

specification.

APP sensor attaching bolt

torque specification ...................................7.0 – 12.0 Nm

2 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–14

Page 6C4-3–14

3.3 Accelerator Pedal Position (APP) Sensor

Support Bracket

Remove

1 Turn the ignition switch off.

NOTE

The APP sensor support bracket may be

removed as an assembly with the APP sensor

attached.

2 If required, remove the Accelerator Pedal Position (APP) sensor,

refer to 3.2 Accelerator Pedal Position (APP) Sensor.

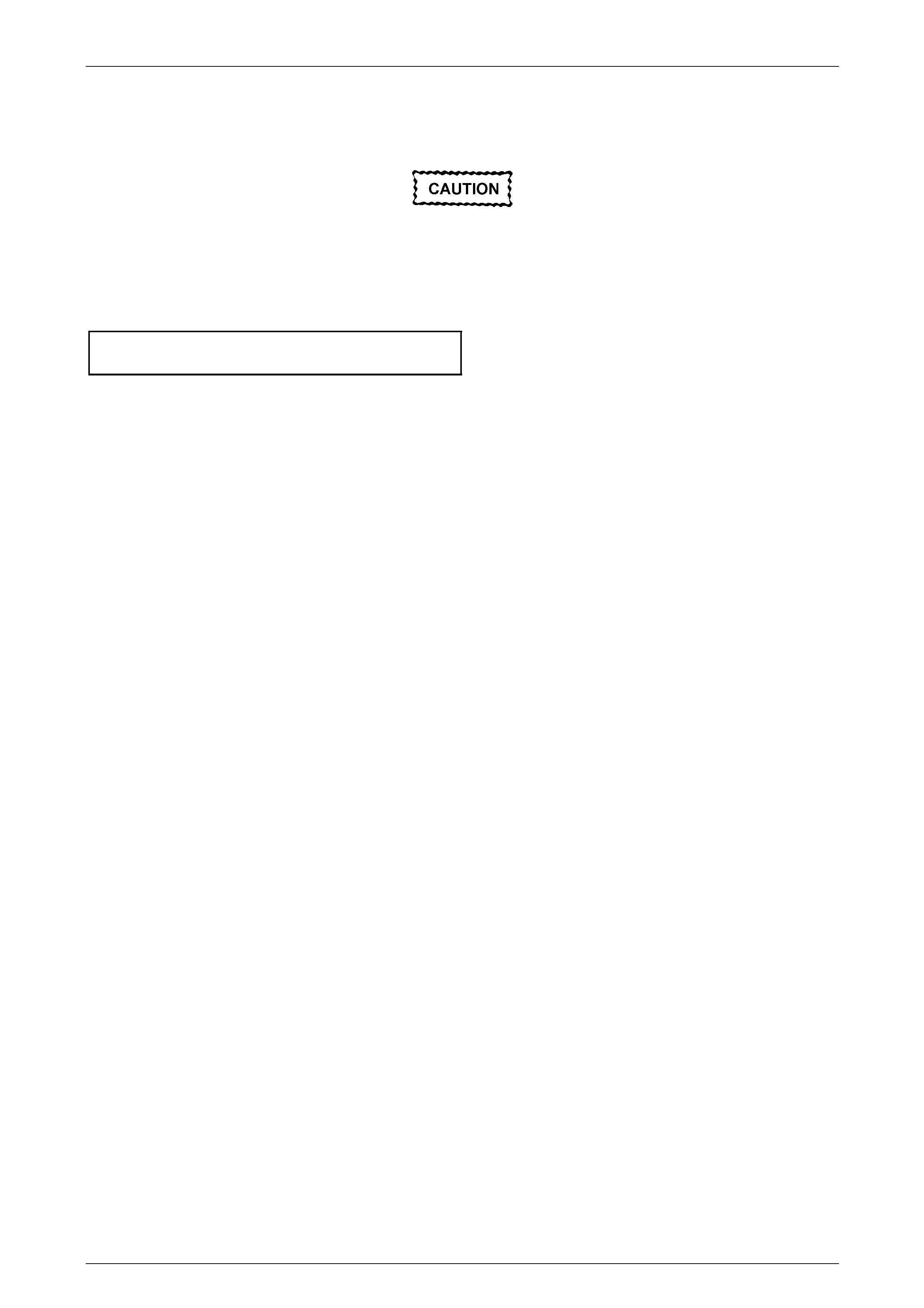

3 Remove the nut (1), in four places, attaching the APP

sensor support bracket (2) to the dash panel and

remove the support bracket.

Figure 6C4-3 – 6

Reinstall

Reinstallation of the APP sensor support bracket is the reverse of the removal procedure, noting the following:

1 Reinstall the nut, in four places, attaching the APP sensor support bracket to the dash panel and tighten to the

correct torque specification.

APP sensor support bracket

attaching nut torque specification............20.0 – 30.0 Nm

2 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–15

Page 6C4-3–15

3.4 Air Cleaner Assembly

Air Cleaner Upper Housing

Remove

1 Turn the ignition switch off.

2 Remove the upper radiator shroud, refer to Section 6B4 Engine Cooling – GEN IV V8 Engine.

3 Remove the air duct, refer to 3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct.

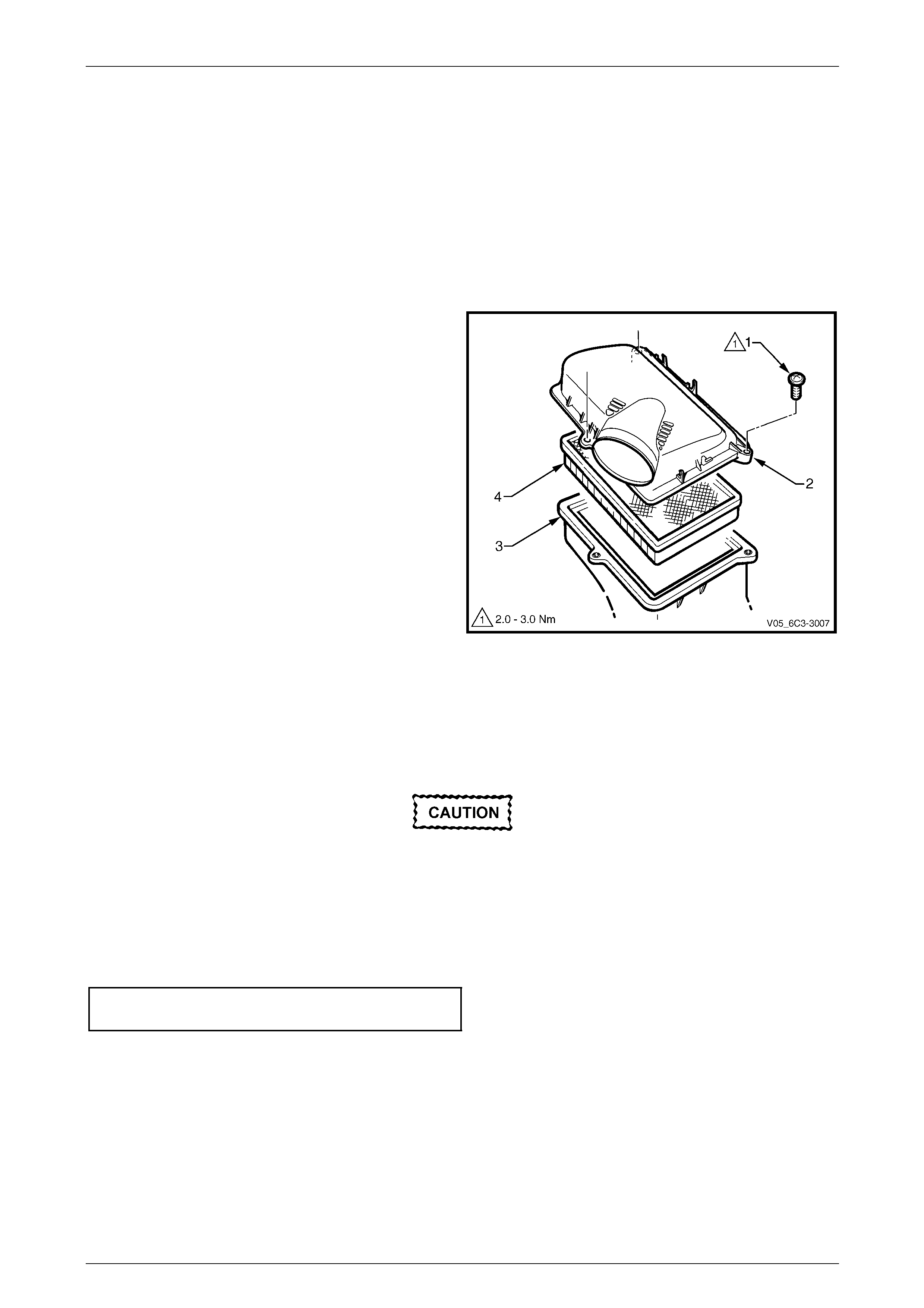

4 Remove the screw (1), three places, attaching the air

cleaner upper housing (2) to the air cleaner lower

housing (3).

5 Remove the upper housing and air cleaner

element (4).

Figure 6C4-3 – 7

Reinstall

Reinstallation of the air cleaner upper housing is the reverse of the removal procedure, noting the following:

1 Reinstall the air cleaner element.

Make sure that the air cleaner sealing rubber

is correctly located in the air cleaner lower

housing during installation. Failure to do this

may result in engine damage due to unfiltered

air entering the engine air intake system.

2 Reinstall the screw, in three places, attaching the air cleaner upper housing to the air cleaner lower housing and

tighten to the correct torque specification.

Air cleaner upper housing attaching

screw torque specification...........................2.5 – 3.0 Nm

3 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–16

Page 6C4-3–16

Air Cleaner Lower Housing

Remove

1 Turn the ignition switch off.

2 Remove the air cleaner upper housing as described previously.

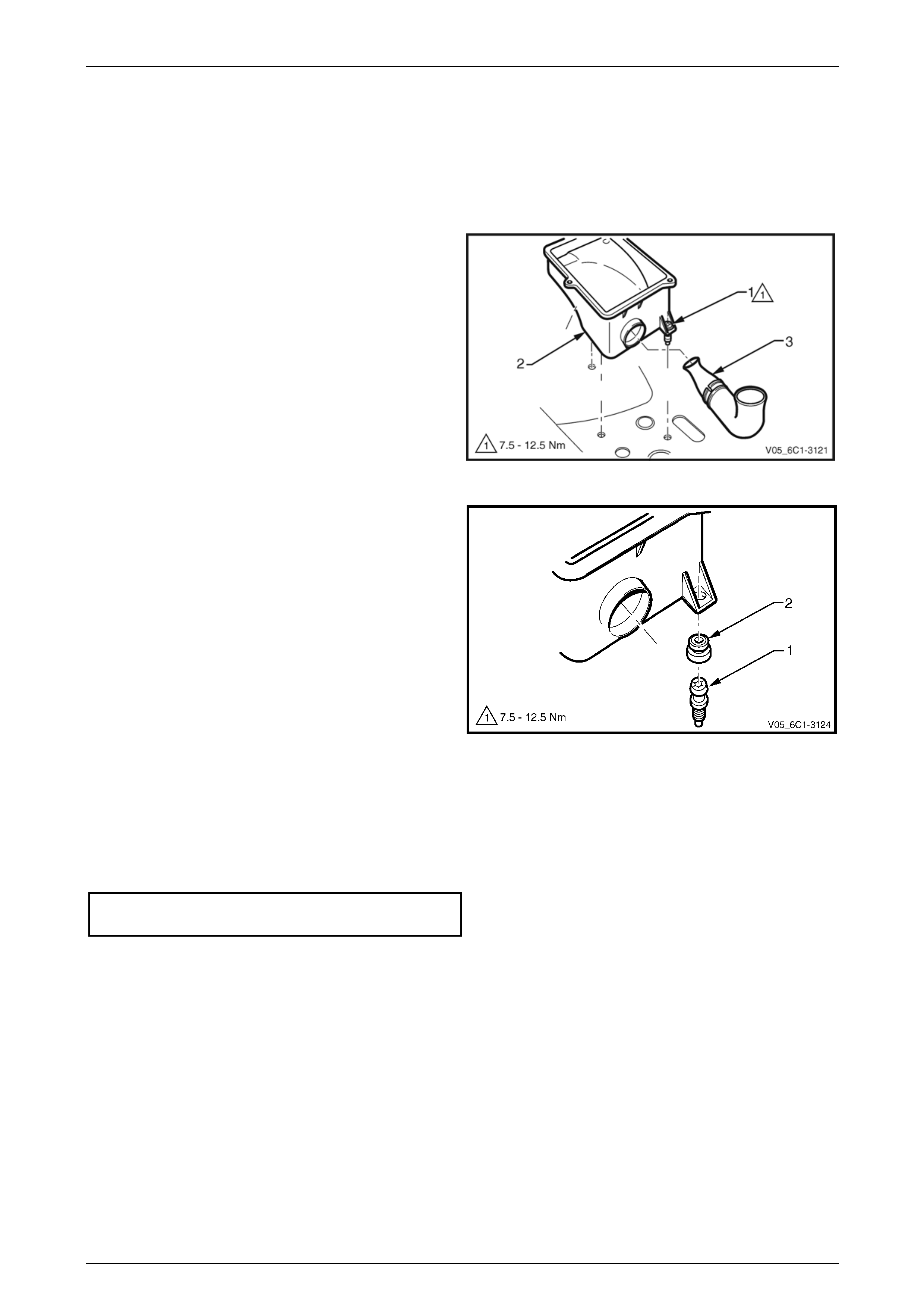

3 Fully loosen the stud (1), three places, attaching the

air cleaner lower housing (2) to the fender inner panel.

NOTE

The stud and air cleaner housing insulator are

removed with the air cleaner housing.

4 Disengage the air cleaner air inlet duct (3) from the

lower housing. Remove the lower housing.

Figure 6C4-3 – 8

5 If required, remove the stud (1) and air cleaner

housing insulator (2) from the air cleaner lower

housing.

Figure 6C4-3 – 9

Reinstall

Reinstallation of the air cleaner assembly is the reverse of the removal procedure, noting the following:

1 Reinstall the stud, three places, attaching the air cleaner lower housing to the fender inner panel and tighten to the

correct torque specification.

Air cleaner lower housing attaching

stud torque specification ...........................7.5 – 12.5 Nm

2 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–17

Page 6C4-3–17

3.6 Camshaft Position (CMP) Sensor

Removal Procedure

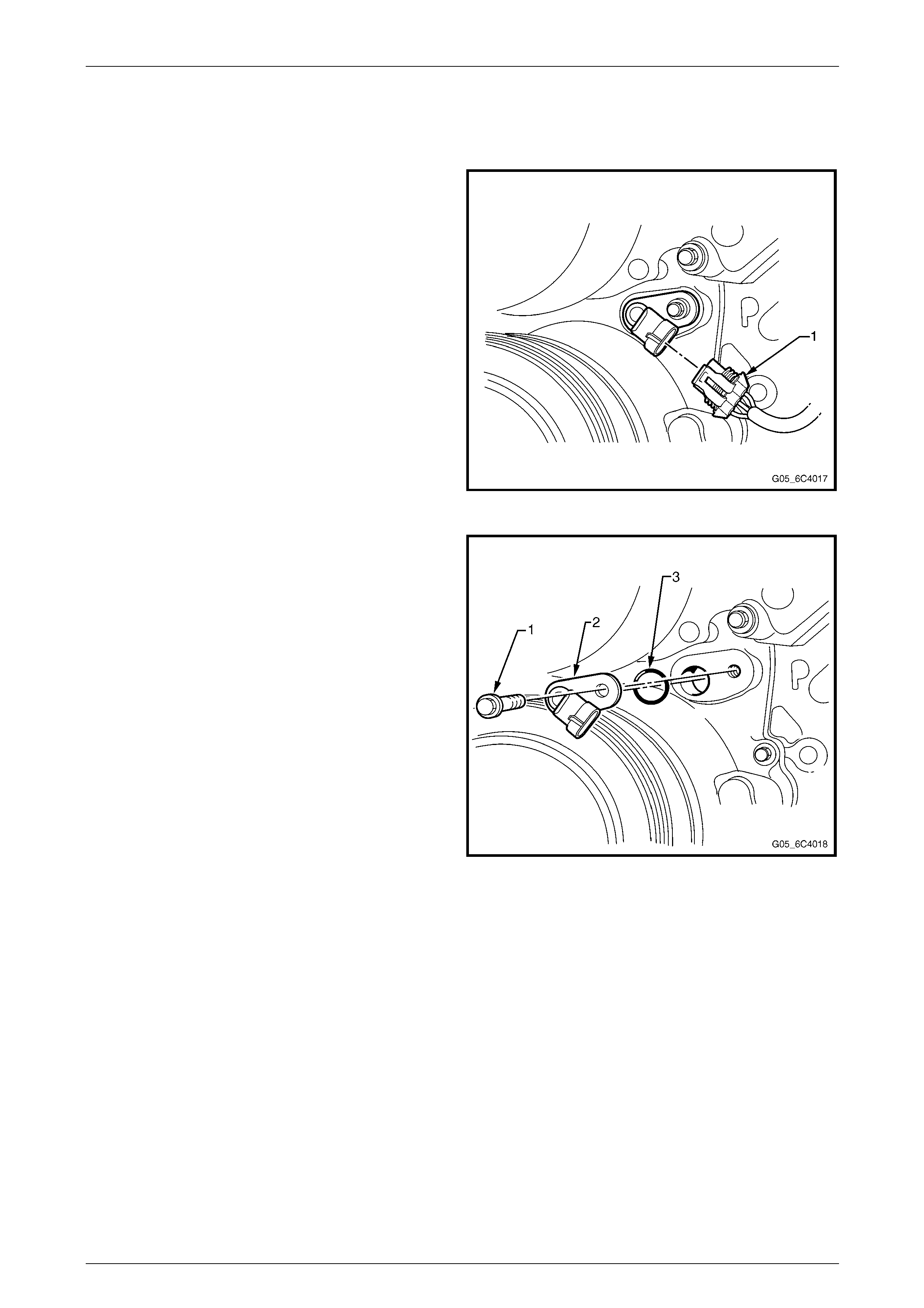

1 Remove the generator bracket assembly. Refer to

Generator Bracket Replacement in Engine Electrical.

2 Disconnect the camshaft position sensor electrical

connector (1).

Figure 6C4-3 – 10

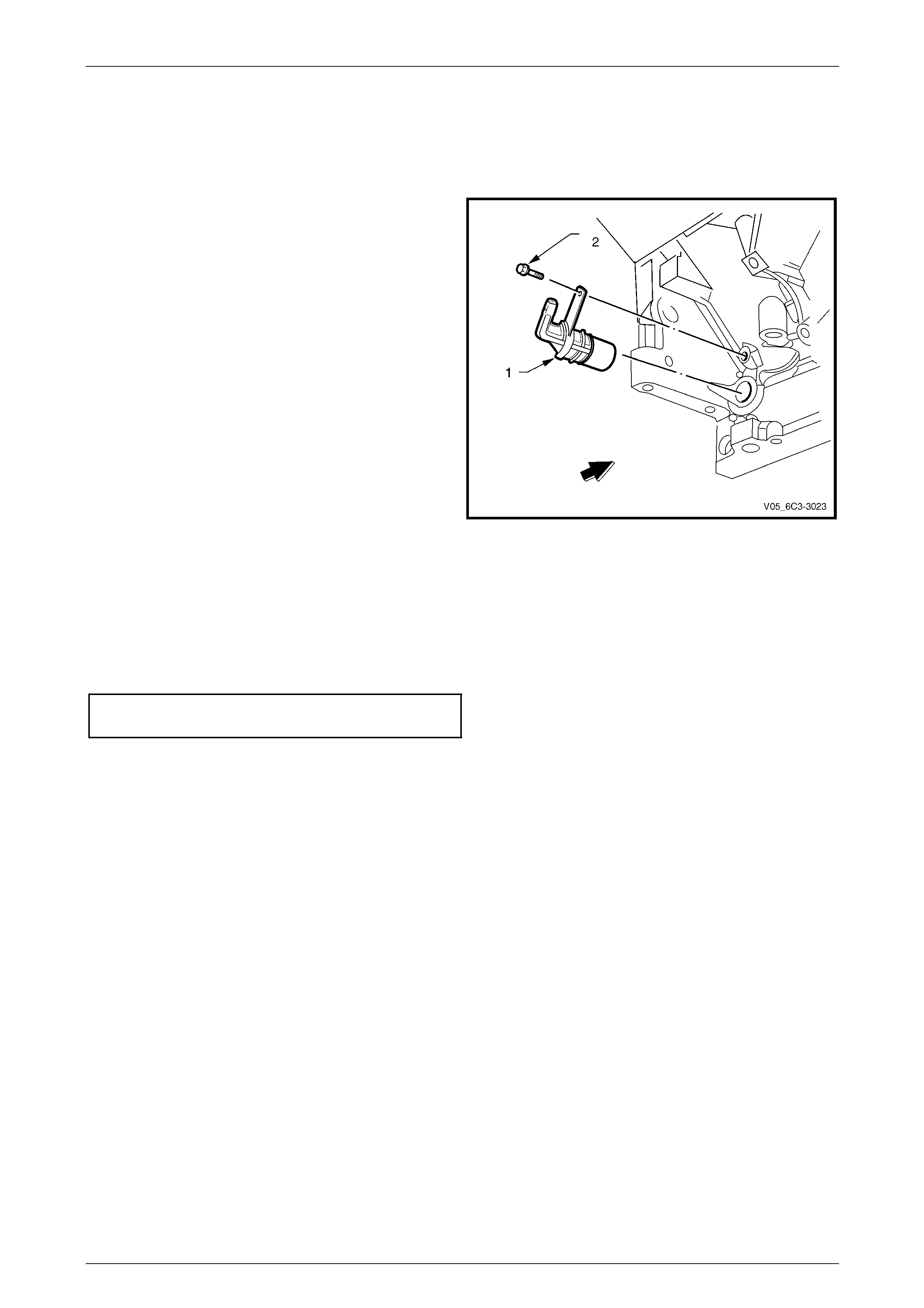

3 Remove the camshaft position sensor mounting bolt

(1).

4 Remove the camshaft position sensor assembly (2, 3)

from the engine front cover.

Figure 6C4-3 – 11

Engine Management GEN IV V8 – Service Operations Page 6C4-3–18

Page 6C4-3–18

Installation Procedure

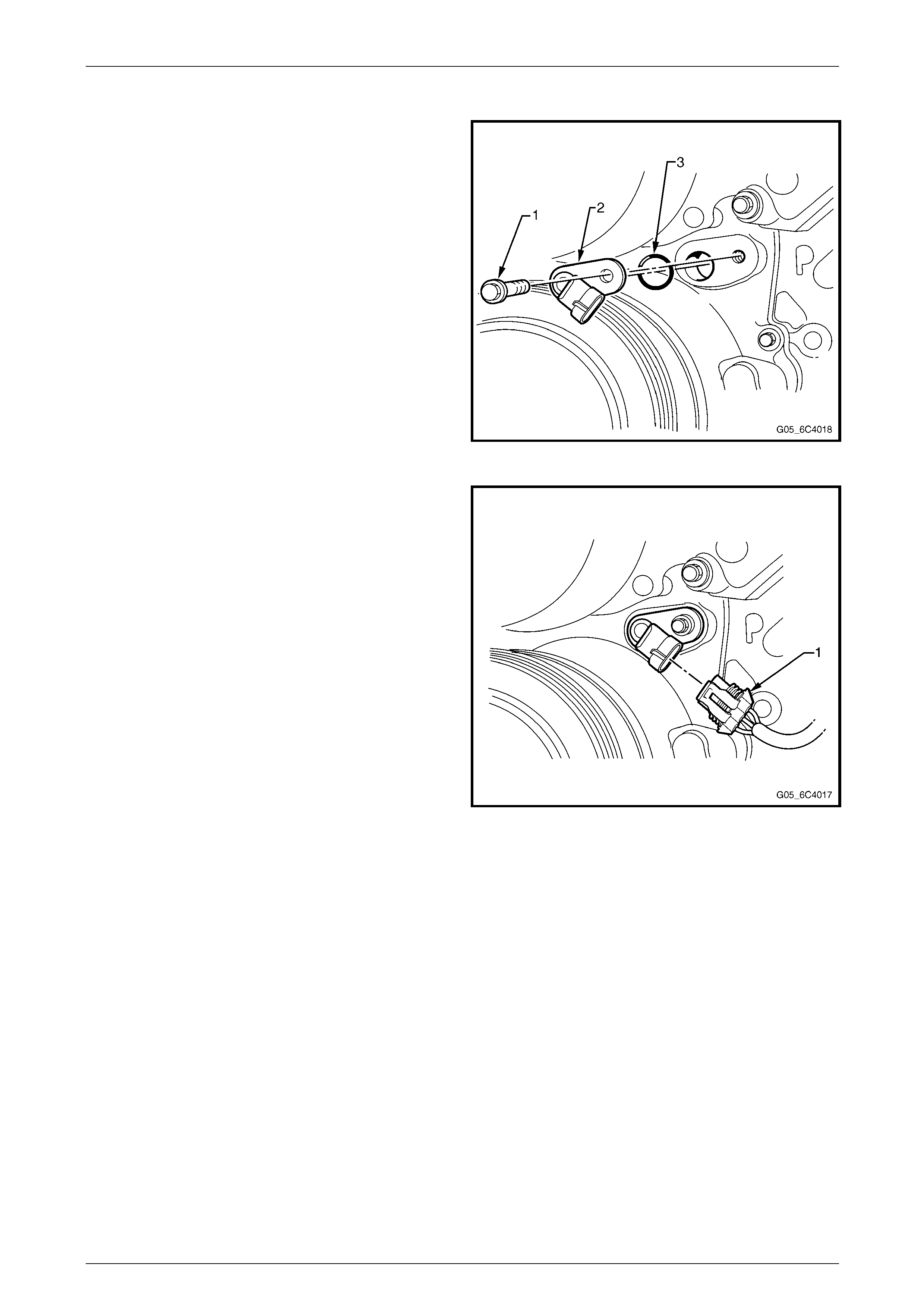

Important: Before installing the camshaft sensor assembly,

apply a small amount of clean motor oil to the O-ring (3).

1 If removed, install the O-ring onto the camshaft position

sensor.

2 Install the camshaft position sensor assembly into the

engine front cover.

Notice: Refer to Fastener Notice in Cautions and Notices.

3 Install the camshaft position sensor mounting bolts.

Tighten

Tighten the camshaft position mounting bolts to 25 N·m

(18 lb ft).

Figure 6C4-3 – 12

4 Reconnect the camshaft sensor electrical connector

(1).

5 Install the generator bracket assembly. Refer to

Generator Bracket Replacement in Engine Electrical.

Figure 6C4-3 – 13

Engine Management GEN IV V8 – Service Operations Page 6C4-3–19

Page 6C4-3–19

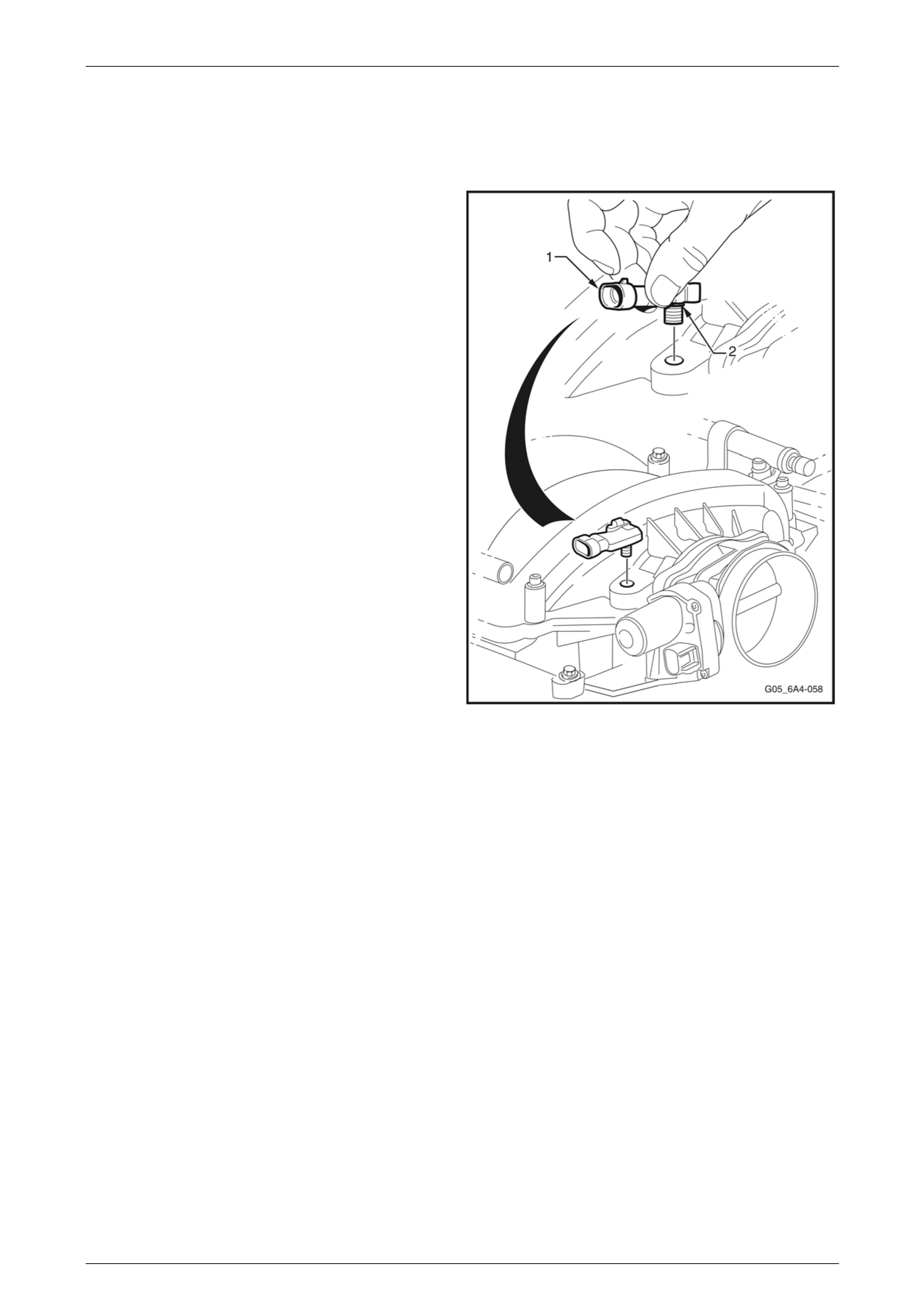

3.7 Crankshaft Position (CKP) Sensor

Remove

1 Remove the starter motor, refer to Section 6D3-2 Starting System – GEN III V8.

2 Disconnect the electrical connector from the

crankshaft position sensor (1).

3 Remove the crankshaft position retaining bolt (2).

4 Remove the sensor.

Figure 6C4-3 – 14

Reinstall

Reinstallation of the crankshaft position sensor is the reverse of the removal procedure, noting the following:

1 Lubricate the CKP sensor O-ring with clean engine oil prior to installation.

2 Reinstall the crankshaft position retaining bolt and tighten to the correct torque specification.

CKP Sensor Retaining Bolt

Torque Specification .............................................25 Nm

3 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–20

Page 6C4-3–20

3.7 Engine Control Module (ECM)

Service of the Engine Control Module (ECM) should normally consist of either replacement of the ECM, or ECM

programming. If the diagnostic procedures call for the ECM to be replaced, the ECM should be first checked to ensure it

is the correct part. If it is, replace the faulty ECM.

• Do not touch the ECM connector pins as

Electrostatic Discharge (ESD) damage may

result. For further information on ESD,

refer to Section 00 Warnings, Cautions and

Notes .

• When removing or reinstalling the ECM

harness connector/s, ensure that the

ignition switch is in the OFF position and

that the battery has been disconnected.

Failure to do so may result in damage to

the ECM and/or associated components.

• Disconnection of the battery affects

certain vehicle electronic systems.

Refer to Section 00 Warnings, Cautions

and Notes before disconnecting the

battery.

Remove

1 Turn the ignition switch off.

2 Disconnect the battery, refer to Section 00 Warnings, Cautions and Notes .

3 Remove the Connector Protection Assurance (CPA)

locks on each ECM electrical connector, then move

the connector lock levers to the unlock position.

4 Disconnect the wiring harness connectors.

Figure 6C4 – 15

Engine Management GEN IV V8 – Service Operations Page 6C4-3–21

Page 6C4-3–21

5 Remove the two screws (1) securing the ECM to the

mounting bracket

6 Remove the ECM.

Figure 6C4 – 16

Reinstall

Reinstallation is the reverse of the removal procedure, noting the following:

1 Reinstall the ECM screws, and tighten to the correct torque specification.

ECM retaining screw torque specification .........1 – 3 Nm

2 If the ECM has been replaced, perform the following procedures:

• ECM service programming, refer to Section 0C Tech 2.

• ECM/PIM/BCM security link, refer to Section 0C Tech 2.

• Main diagnostic functional check.

3 If the ECM has been removed, but not replaced, perform the main diagnostic table functional check.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–22

Page 6C4-3–22

3.8 Engine Control Module (ECM) Bracket

Assembly

Remove

1 Remove the ECM, refer to 3.7 Engine Control Module (ECM).

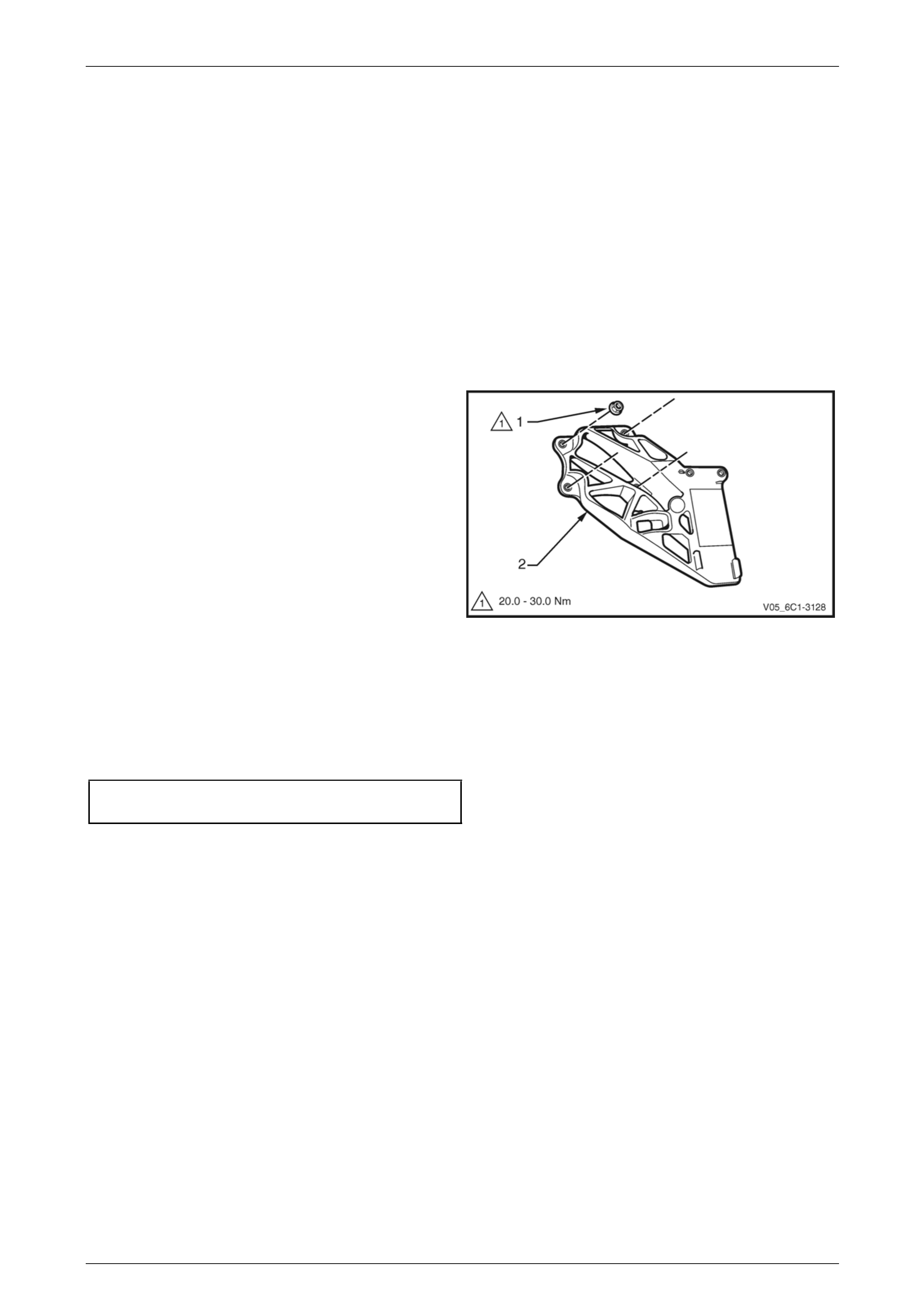

2 Remove nut (2) securing the ECM bracket (1) to the

body.

3 Remove the ECM mounting bracket by lifting up and

away from the body.

Figure 6C4 – 17

Reinstall

Reinstallation of the ECM mounting bracket is the reverse of the removal procedure, noting the following:

Tighten the nuts attaching the ECM mounting bracket to the body to the correct torque specification.

ECM mounting bracket attaching

nut torque specification .................................15 – 20 Nm

Engine Management GEN IV V8 – Service Operations Page 6C4-3–23

Page 6C4-3–23

3.9 Engine Coolant Temperature (ECT)

Sensor

Remove

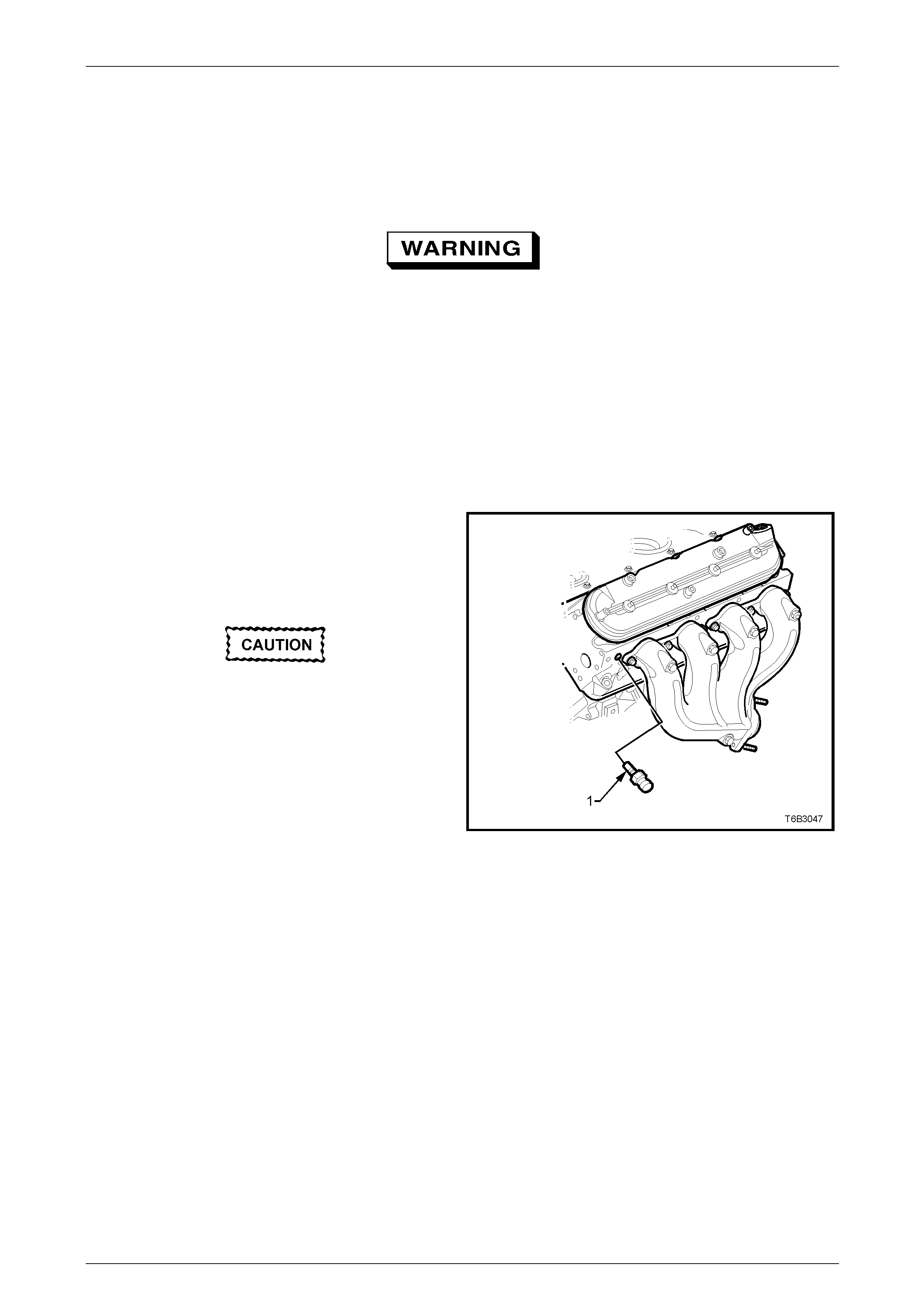

To avoid serious personal injury, never

remove the ECT sensor when the engine is

hot. Allow the engine to cool to ambient

temperature (less than 50° C) before

performing this procedure.

1 Raise the vehicle and support on safety stands, refer to Section 0A General Information for the location of jacking

and support points.

2 Drain the engine coolant, refer to Section 6B4 Engine Cooling – GEN IV V8 Engine.

3 Lower the vehicle.

4 Remove the left-hand engine dress cover, refer to 2.2 Engine Dress Covers.

5 Disconnect the electrical connector from the ECT

sensor (1).

6 Remove the No. 1 spark plug lead from the spark plug.

7 Remove the ECT sensor.

Use care when handling the coolant sensor.

Damage to the coolant sensor will affect the

operation of the fuel control system.

Figure 6C4-3 – 18

Engine Management GEN IV V8 – Service Operations Page 6C4-3–24

Page 6C4-3–24

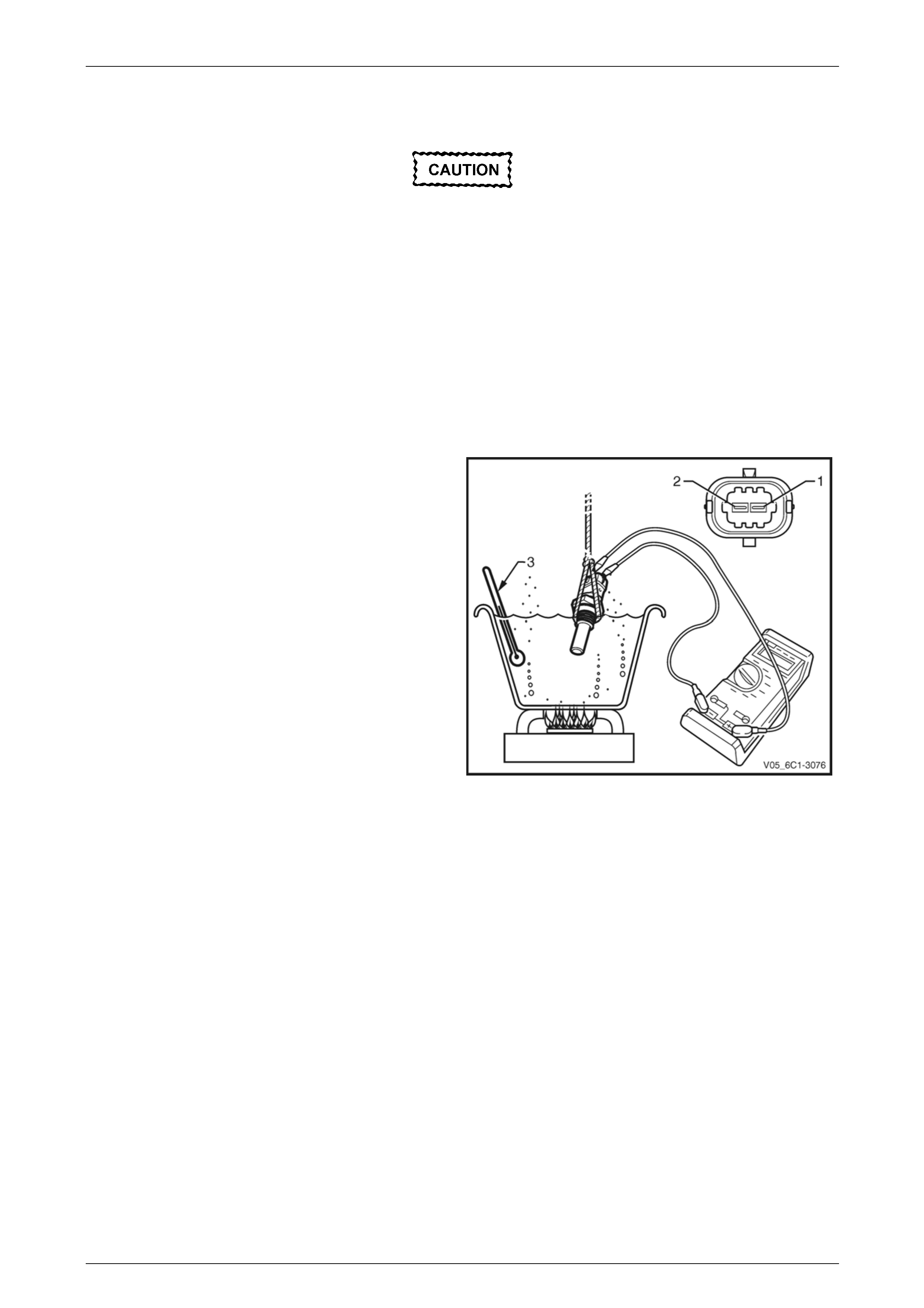

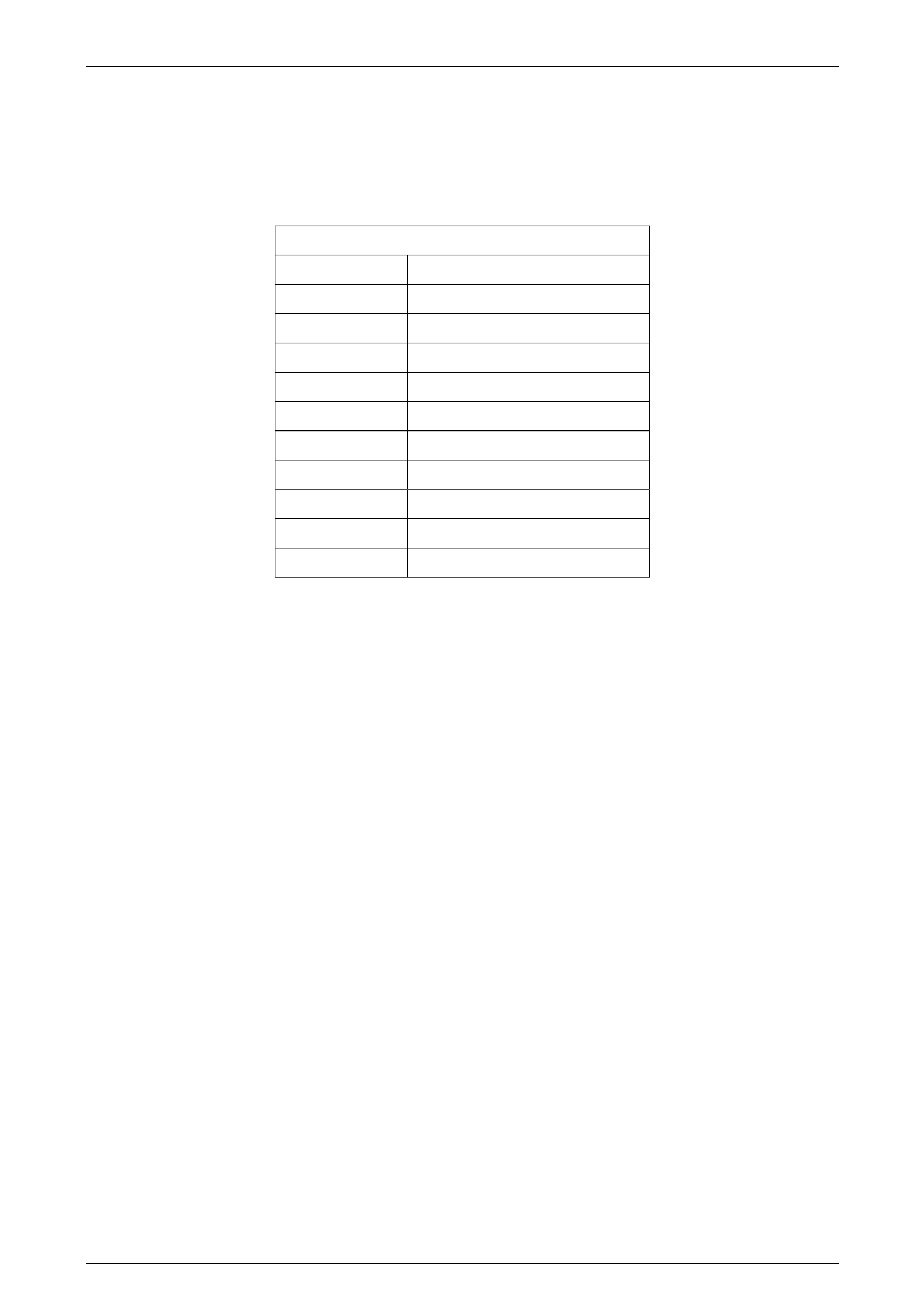

Test

To prevent component damage, use

connector test adaptor kit J 35616-A.

Resistance Check

1 Suspend the ECT sensor and a suitable thermometer in a container of 50/50 DEX-COOL® long life coolant or

equivalent and water.

NOTE

Neither the ECT sensor or thermometer should

rest on the bottom of the container due to an

uneven concentration of heat at this point when

the container is heated.

2 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the ECT sensor and measure

the resistance across terminals 1 and 2.

3 Whilst heating the container, observe the resistance

values as the temperature increases and compare the

temperature/resistance change to the specifications.

Figure 6C4-3 – 19

4 If the resistance is not within specifications, replace

the ECT sensor.

Engine Coolant Temperature Vs Resistance

Temperature °C Resistance – Ohms (Ω)

-10 16,180

0 9,420

20 3,520

25 2,796

40 1,459

60 667

80 332

100 177

120 100

140 60

Engine Management GEN IV V8 – Service Operations Page 6C4-3–25

Page 6C4-3–25

Reinstall

Reinstallation of the ECT sensor is the reverse of the removal procedure, noting the following:

1 Coat the Engine Coolant Temperature (ECT) sensor (1) thread with Loctite 242 or equivalent.

2 Tighten the ECT sensor to the correct torque specification.

ECT sensor torque specification ...........................17 Nm

3 Refill the cooling system, refer to Section 6B4 Engine Cooling – GEN IV V8.

4 Road test the vehicle and check for correct operation, taking particular note that there is no coolant leakage.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–26

Page 6C4-3–26

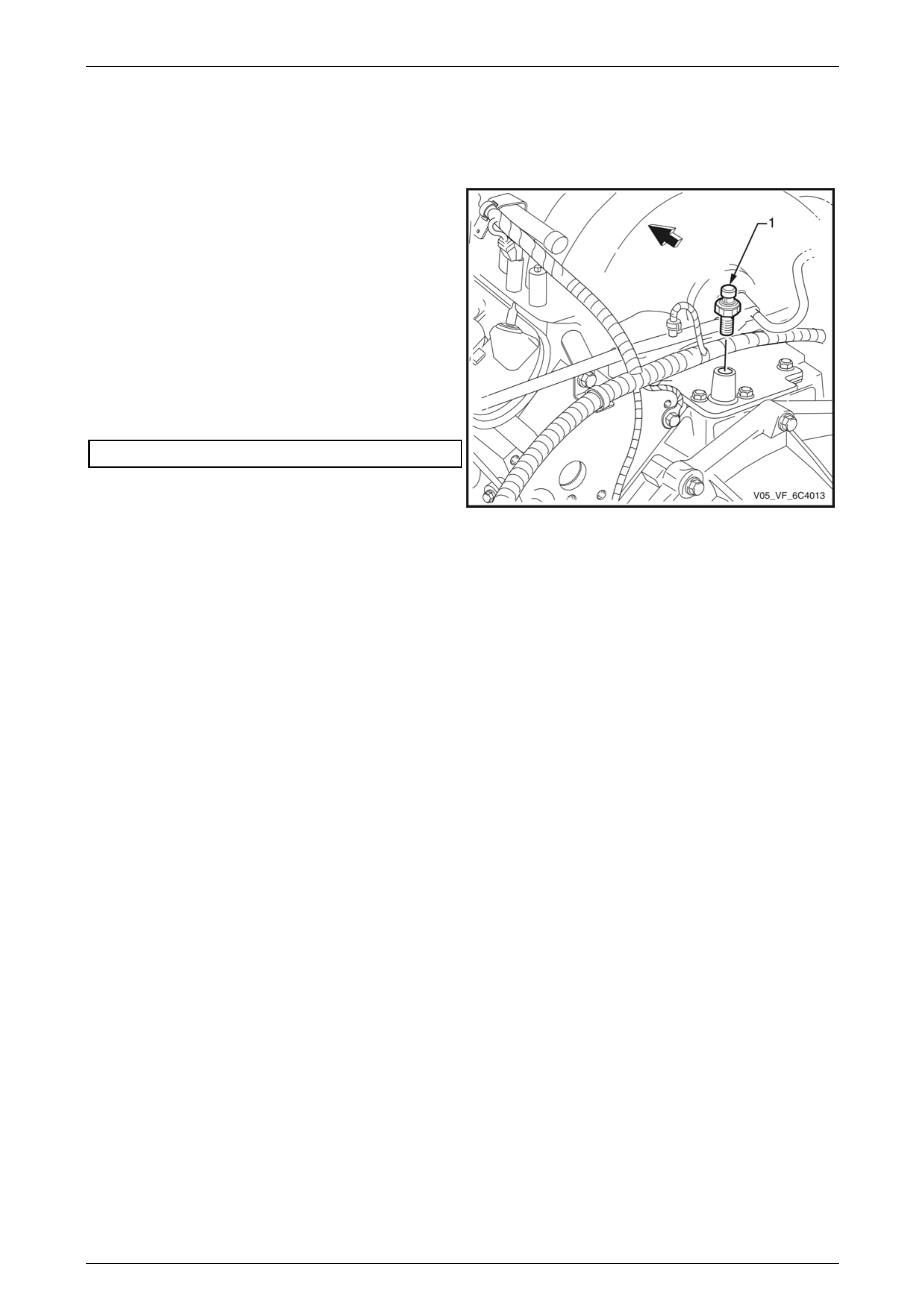

3.10 Engine Oil Pressure (EOP) Sensor

Remove

1 Clean around area of oil pressure sensor (1), so that

no foreign matter will enter the engine.

2 Disconnect the oil pressure sensor electrical

connector.

3 Using tool J 41712, remove the oil pressure sensor.

Reinstall

Reinstallation of the EOP sensor is the reverse of the

removal procedure, noting the following:

1 Reinstall the oil pressure sensor and tighten to the

specified torque.

EOP Sensor Torque Specification ........................20 Nm

2 Check engine oil level and top up if necessary.

3 Start engine and inspect for oil leaks. Figure 6C4-3 – 20

Engine Management GEN IV V8 – Service Operations Page 6C4-3–27

Page 6C4-3–27

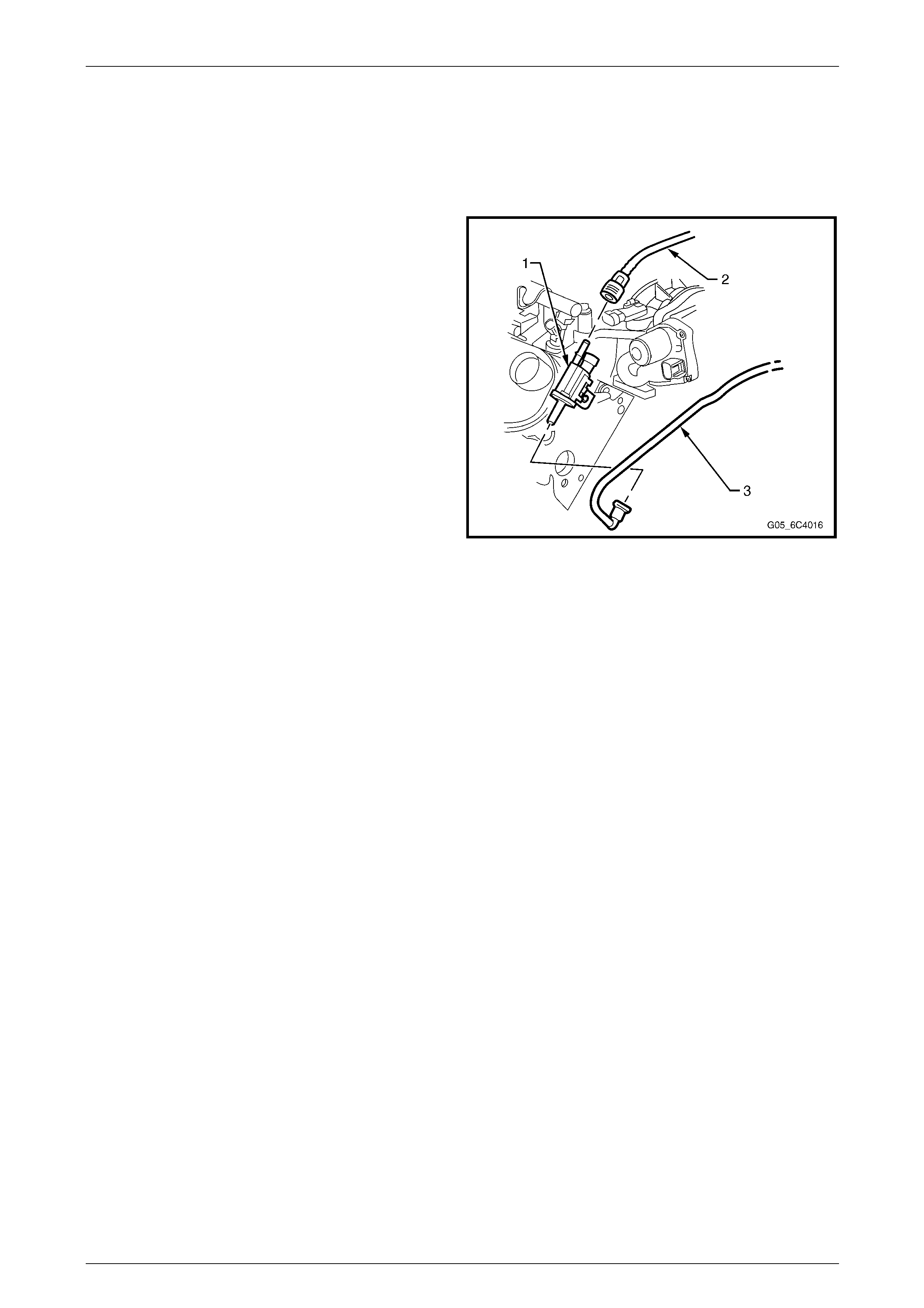

3.11 EVAP Canister Purge Solenoid Valve

Remove

1 Remove the left-hand engine dress cover, refer to 2.2 Engine Dress Covers.

2 Disconnect the electrical connector from the EVAP

purge solenoid.

3 Disconnect the front hose by squeezing the retaining

clip and pulling the hose from the solenoid.

4 Disconnect the hose from the purge solenoid using

tool AU533, refer to Section 8A1 Fuel System.

5 Lift and remove the EVAP purge solenoid from the

mounting bracket.

Figure 6C4-3 – 21

Reinstall

Reinstallation of the EVAP canister purge solenoid valve is the reverse of the removal procedure.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–28

Page 6C4-3–28

3.12 Fuel Rail Assembly

A depressurised fuel system contains fuel in

the fuel system and fuel lines that can be

spilled during service operations, refer to

Section 00 Warnings, Cautions and Notes for

further information on handling fuel.

Remove

1 Remove both engine dress covers, refer to 2.2 Engine Dress Covers.

2 Relieve the fuel system pressure, refer to Section 8A1 Fuel System.

3 Disconnect the negative battery cable.

4 If fitted, remove the front suspension strut brace, refer to Section 1A1 Body.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part, refer to Section 00 Warnings.

Cautions and Notes for correct workshop

practices when using compressed air.

5 If necessary, use compressed air to remove any foreign material from around the area where the fuel injectors

enter the intake manifold.

6 Disconnect the fuel feed hose from the fuel rail, refer to Section 8A1 Fuel System.

7 Detach the wiring harness clips (1), four places.

8 Disconnect the wiring harness connectors (2) eight

places, from the fuel injectors. Identify the connectors

with their corresponding injectors to ensure correct

sequential injector firing order after reassembly.

Figure 6C4-3 – 22

Engine Management GEN IV V8 – Service Operations Page 6C4-3–29

Page 6C4-3–29

9 Remove the four double ended studs (1) securing the

fuel rail (2) to the intake manifold.

10 Carefully lift the fuel rail and injectors assembly (2)

clear of the intake manifold.

Remove the fuel rail assembly carefully to

avoid damage to the injector electrical

connector terminals and the injector spray

tips. Support the fuel rail after the fuel rail is

removed to avoid damaging the fuel rail

components.

11 Cap the fittings and plug the holes when servicing the

fuel system, to prevent dirt and other contaminants

from entering open pipes and passages.

12 Remove and discard the injector lower O-ring seal

from the spray tip end of each injector. Figure 6C4-3 – 23

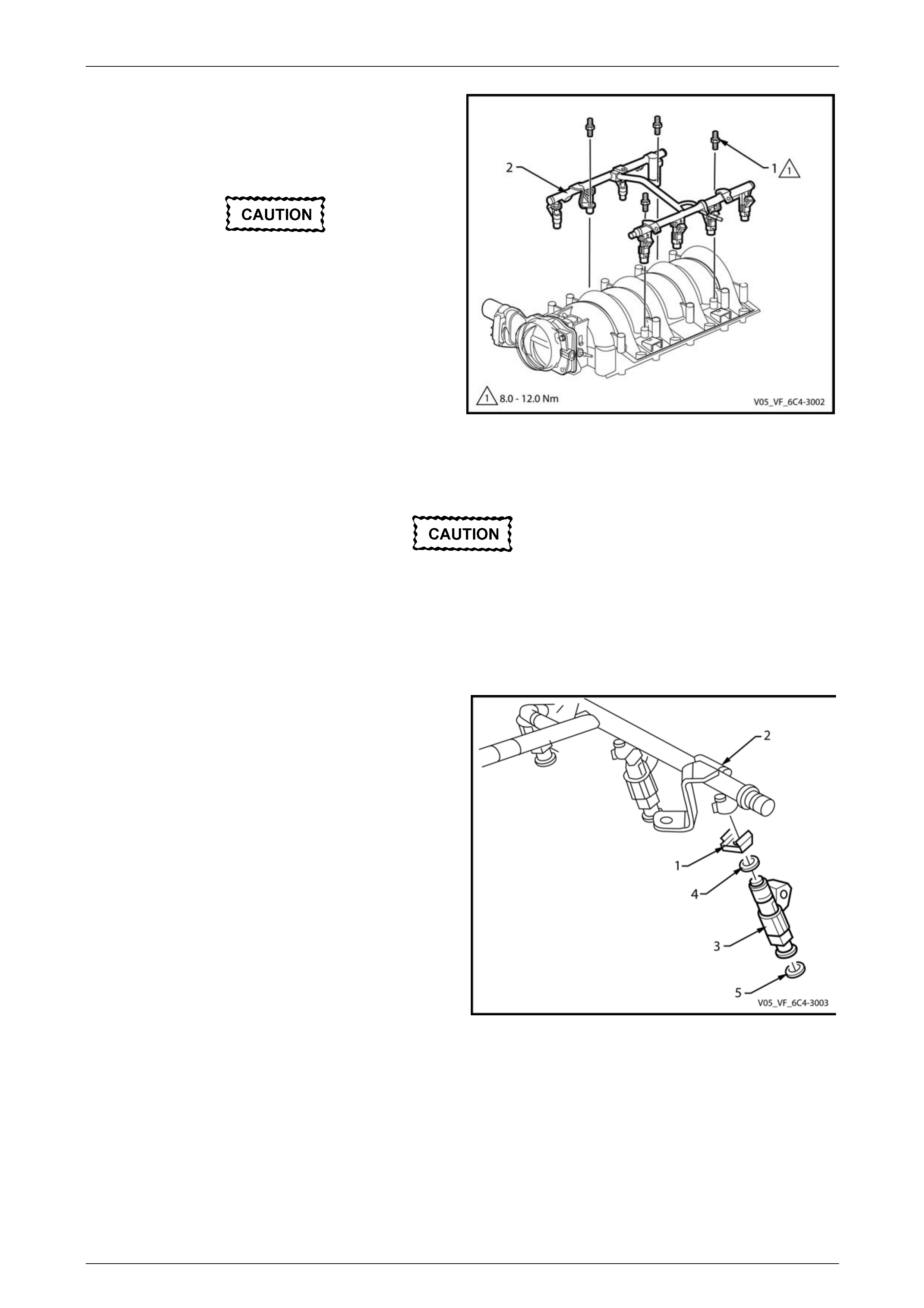

Disassemble

Use care in removing the fuel injectors to

prevent damage to the electrical connector

pins on the injector and to prevent damage to

the nozzle. Service the fuel injector as a

complete assembly only. The fuel injector is

an electrical component. Do not immerse the

fuel injector in any type of cleaner.

1 Pull the injector retainer clip (2) to release the injector

from the fuel rail.

2 Remove the fuel injector (3).

3 Discard the injector retainer clip (2).

4 Remove and discard the injector O-ring seals (4 and

5) from each end of the injector.

Figure 6C4-3 – 24

Engine Management GEN IV V8 – Service Operations Page 6C4-3–30

Page 6C4-3–30

Reassemble

When ordering new fuel injectors, ensure to

order the correct injector for the application

being serviced. The fuel injector assembly is

stamped with a part number identification, a

manufacturing date, a week code, and a

production plant number.

1 Lubricate a new injector O-ring seal (1) with clean

engine oil and install onto each injector.

2 Push the fuel injector into the fuel rail injector socket

with the electrical connector (2) facing outward. The

retainer clip locks on to a flange on the fuel rail injector

socket.

3 Reinstall a new retainer clip to retain each injector.

Figure 6C4-3 – 25

Reinstall

Reinstallation of the fuel rail assembly is the reverse of the removal procedure, noting the following:

1 Install a new O-ring on each fuel injector.

2 Lubricate the fuel injector O-ring seals with clean engine oil.

3 Apply Loctite 242 or equivalent to the cleaned threads of the fuel rail attaching studs, then tighten to the specified

torque.

Fuel Rail Attaching Stud

Torque Specification .............................................10 Nm

4 Connect the injector electrical connectors, ensuring that each connector is installed to the correct injector to ensure

the correct sequential injector firing order.

NOTE

Rotate the injectors as required to avoid

stretching the wire harness.

5 Perform the following procedure to inspect for leaks:

a Turn the ignition switch on for 2 seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Inspect for fuel leaks at the fuel injectors and fuel feed hose.

6 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–31

Page 6C4-3–31

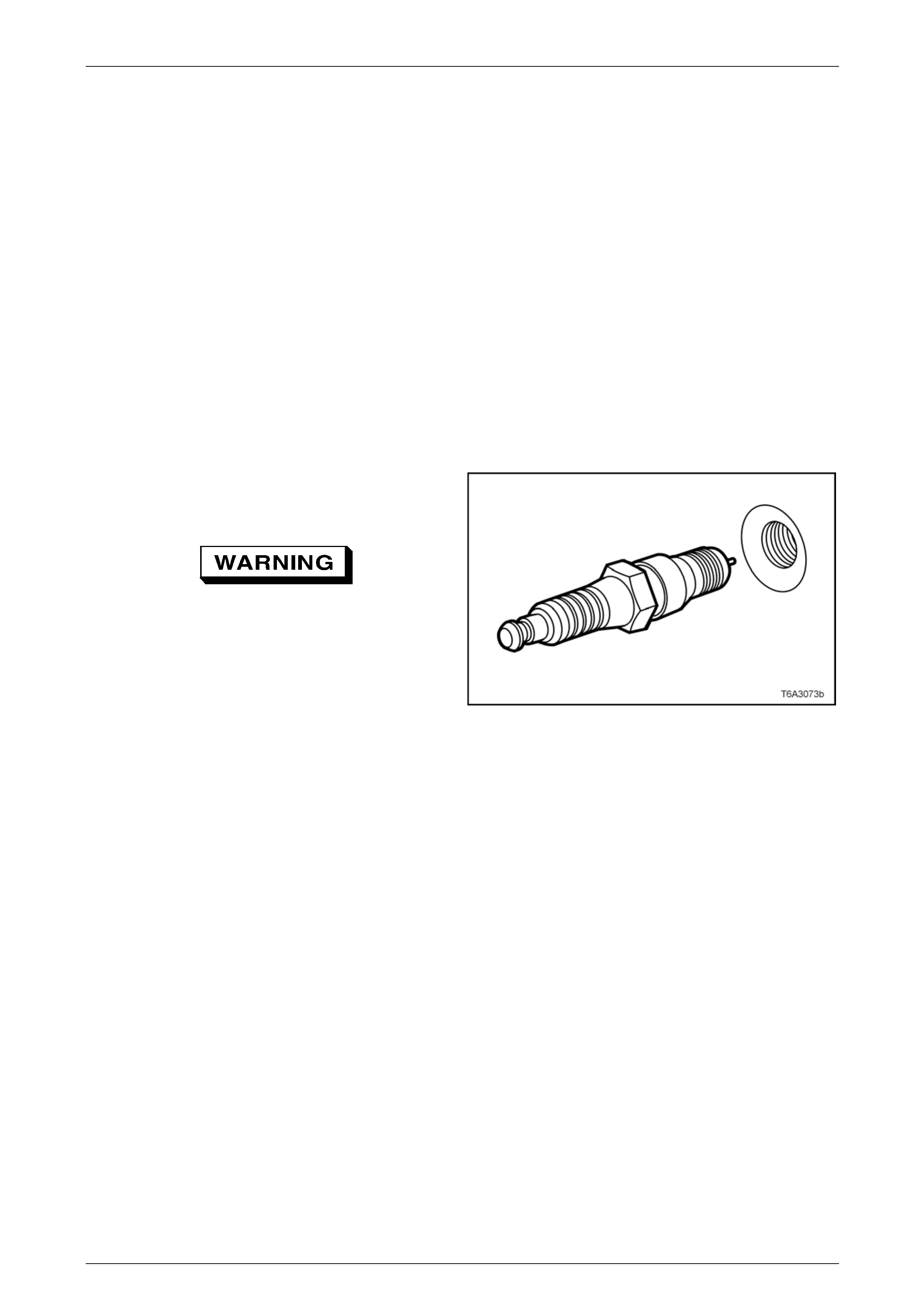

3.13 Heated O2 Sensors

To avoid the possibility of personal injury,

allow the exhaust pipe to cool to ambient

temperature (less than 50° C) before

attempting to remove the Heated O2 Sensor.

Service Precautions

• Handle the Heated O2 Sensor carefully. Do not drop it, and keep it free of grease, dirt and other contaminants. Do

not use cleaning solvents of any type on the sensor.

• Do not repair the sensor or any of its parts, including the wiring and connector. Replace the Heated O2 Sensor if

any damage is evident.

• The Heated O2 Sensor may be difficult to remove when the engine is cold. Excessive force may damage the

threads in the exhaust manifold or exhaust pipe.

• It may be necessary to lower the exhaust system to gain sufficient access to a Heated O2 Sensor and/or its

connector, refer to Section 8B Exhaust System.

• If the Heated O2 Sensor has been removed, but not replaced, then anti-seize compound must be applied to the

threads prior to installation. New Heated O2 Sensors will already have the anti-seize compound applied.

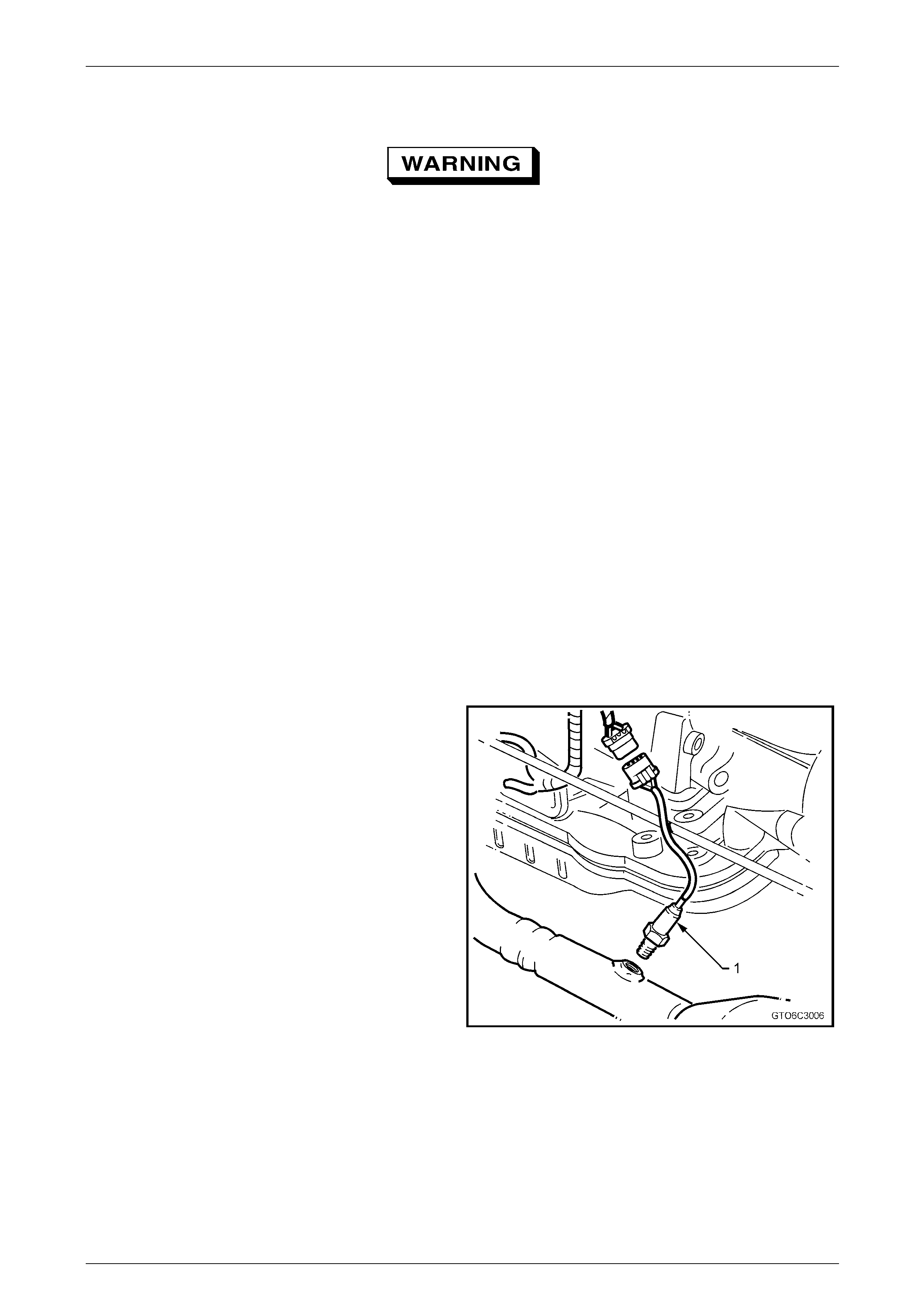

Remove

NOTE

While only one Heated O2 Sensor is shown, the

procedure for the other three Heated O2 Sensors

is similar.

1 Raise the front of vehicle and support on safety

stands, refer to Section 0A General Information for the

location of jacking and support points.

2 Disconnect the Heated O2 Sensor electrical connector

from the sensor to be removed.

3 Loosen and carefully remove the Heated O2 Sensor

from the exhaust pipe.

Figure 6C4-3 – 26

Engine Management GEN IV V8 – Service Operations Page 6C4-3–32

Page 6C4-3–32

Reinstall

Reinstallation is the reverse of the removal procedure, noting the following:

A special anti-seize compound is used on the

heated oxygen sensor threads. New Heated

O2 Sensors will already have the anti-seize

compound applied to the threads.

If a Heated O2 Sensor has been removed, but

not replaced, then anti-seize compound must

be applied to the threads prior to installation.

1 Coat the cleaned threads of the sensor with anti-seize compound, part number 12377953. Specified anti-seize

compound is available from authorised retailer parts outlets as part number 5613695.

2 Tighten the Heated O2 Sensor to the correct torque specification.

Heated O2 Sensor torque specification .............41.0 Nm

3 Road test the vehicle and check for correct operation, taking particular note that no exhaust leakage is evident.

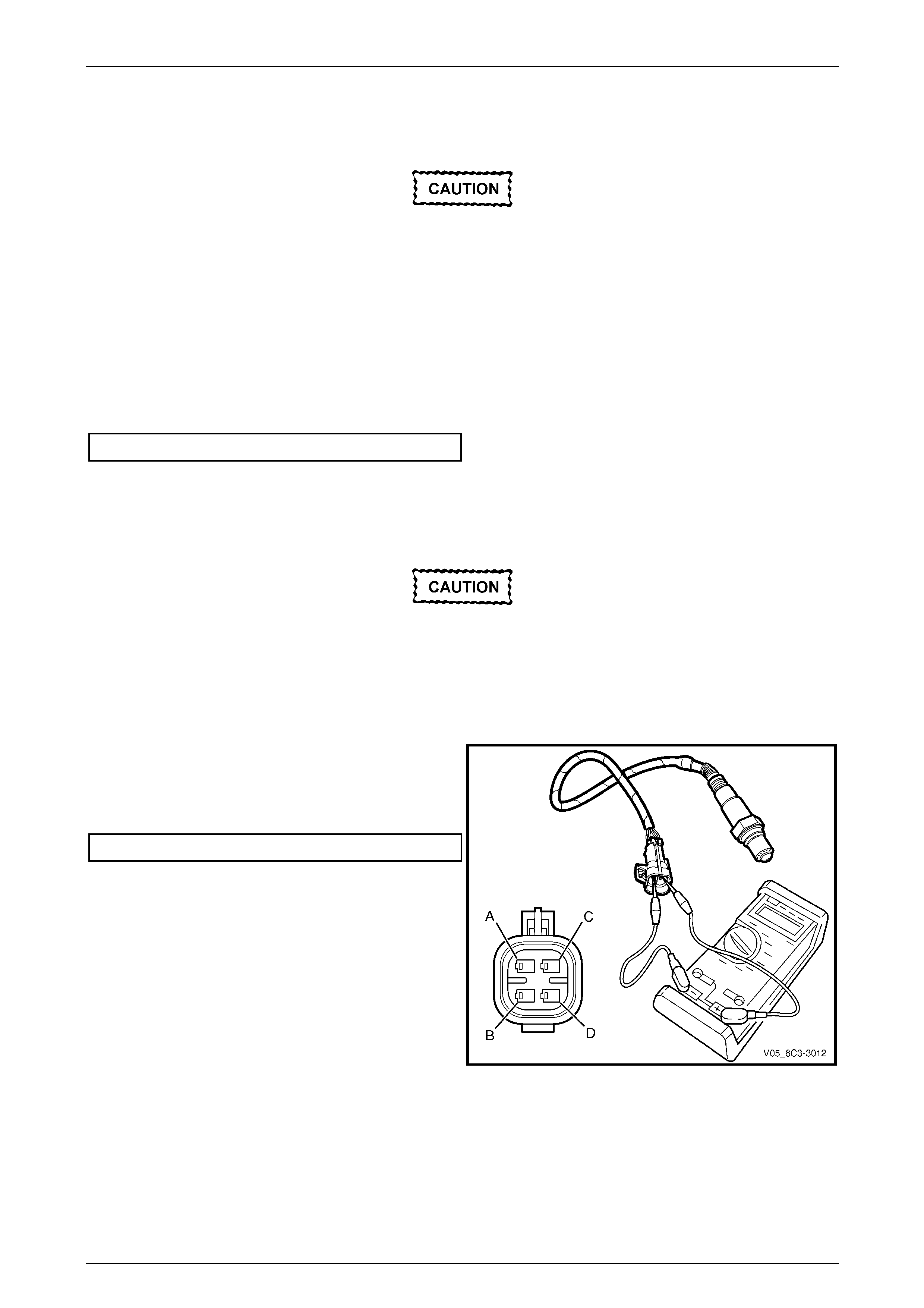

Test

• Under no circumstances should battery

voltage be applied to the Heated O2

Sensor heater.

• To prevent component damage use

connector test adaptor kit J 35616-A.

Heater Resistance Check

1 Using a digital ohmmeter and connector test adaptor

kit J 35616-A, measure the resistance across

terminals C and D.

2 Compare the reading against the specification.

Heated O2 Sensor heater resistance @ 20° C ...... 9.0 Ω

3 If the resistance is not within specification, replace the

Heated O2 Sensor.

Figure 6C4-3 – 27

Engine Management GEN IV V8 – Service Operations Page 6C4-3–33

Page 6C4-3–33

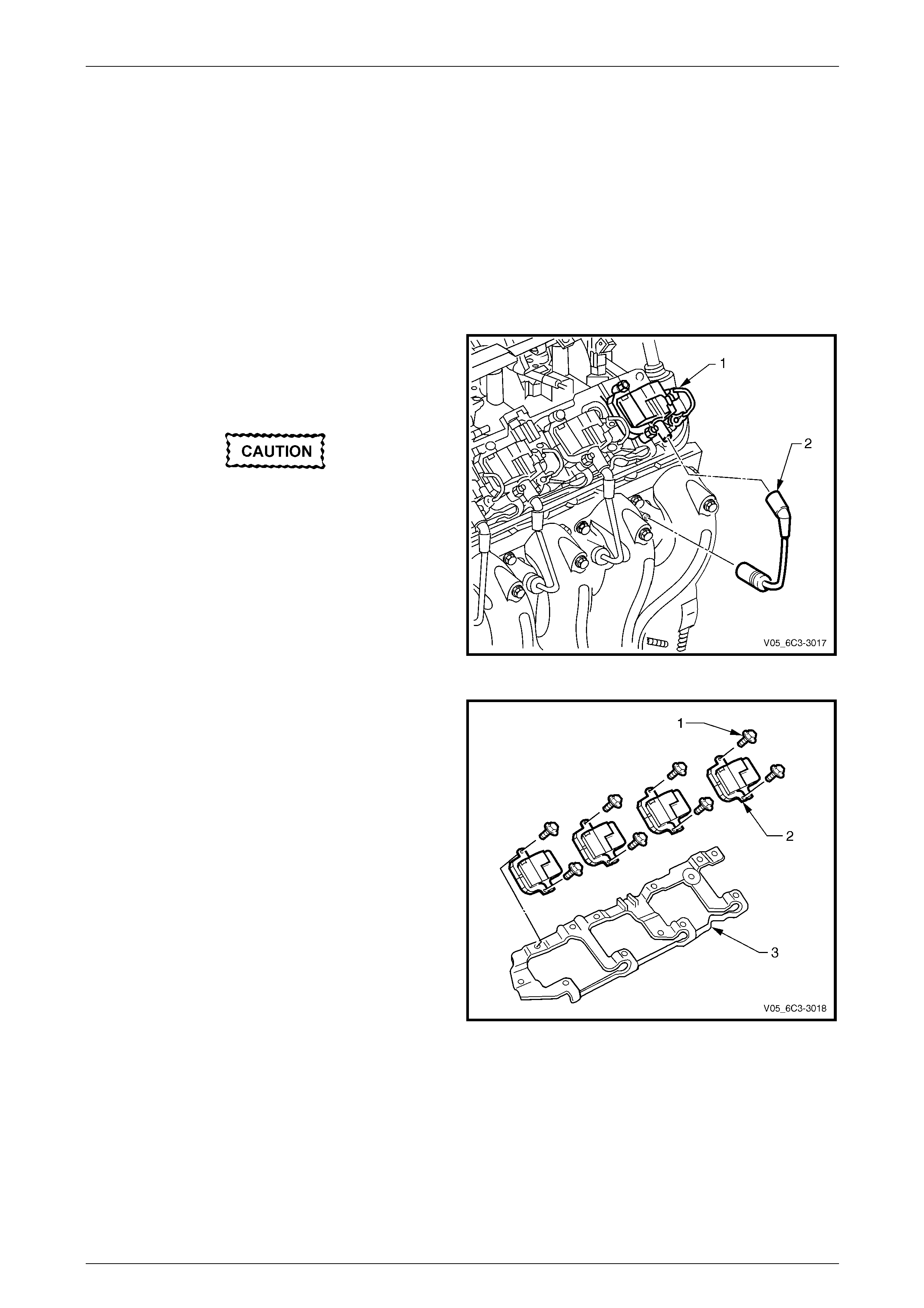

3.14 Ignition Coil / Module

NOTE

The ignition module is incorporated into the

ignition coil assembly, and is not serviced

separately.

Remove

1 Turn the ignition switch off.

2 Remove the appropriate engine dress cover(s), refer to 2.2 Engine Dress Covers.

3 Remove the Connector Protection Assurance (CPA)

lock (1) securing the electrical connector to the ignition

coil, then disconnect the wiring harness connector(s)

from the coil(s) being removed.

Never pull on the ignition lead. Grasp the

ignition coil boot and twist to break the seal

before pulling directly from each ignition coil.

4 Disconnect the spark plug wire (2) at the ignition coil.

Figure 6C4-3 – 28

5 Remove each of the ignition coil retaining screws (1).

6 Remove the ignition coil(s) (2) from the mounting

bracket (3).

Figure 6C4-3 – 29

Engine Management GEN IV V8 – Service Operations Page 6C4-3–34

Page 6C4-3–34

Test

Never probe the ignition coil with a 12 Volt

tester as the ignition coil will be damaged.

Due to the internal components of the ignition coil assembly, it is not possible to perform any primary and/or secondary

resistance checks. For further information on the ignition coil operation, refer to

Section 6C4-1 Engine Management – GEN IV V8 – General Information.

Reinstall

Reinstallation of the ignition coil(s) is the reverse of the removal procedure, noting the following:

1 Reinstall the ignition coil retaining screws, and tighten to the correct torque specification.

Ignition coil retaining bolt

torque specification ...............................................12 Nm

2 Road test the vehicle and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–35

Page 6C4-3–35

3.15 Intake Air Temperature (IAT) Sensor

The Intake Air Temperature (IAT) sensor is part of the MAF sensor assembly,

refer to 3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct for the replacement procedure.

Test

To prevent component damage use connector

test adaptor kit J 35616-A.

Resistance Check

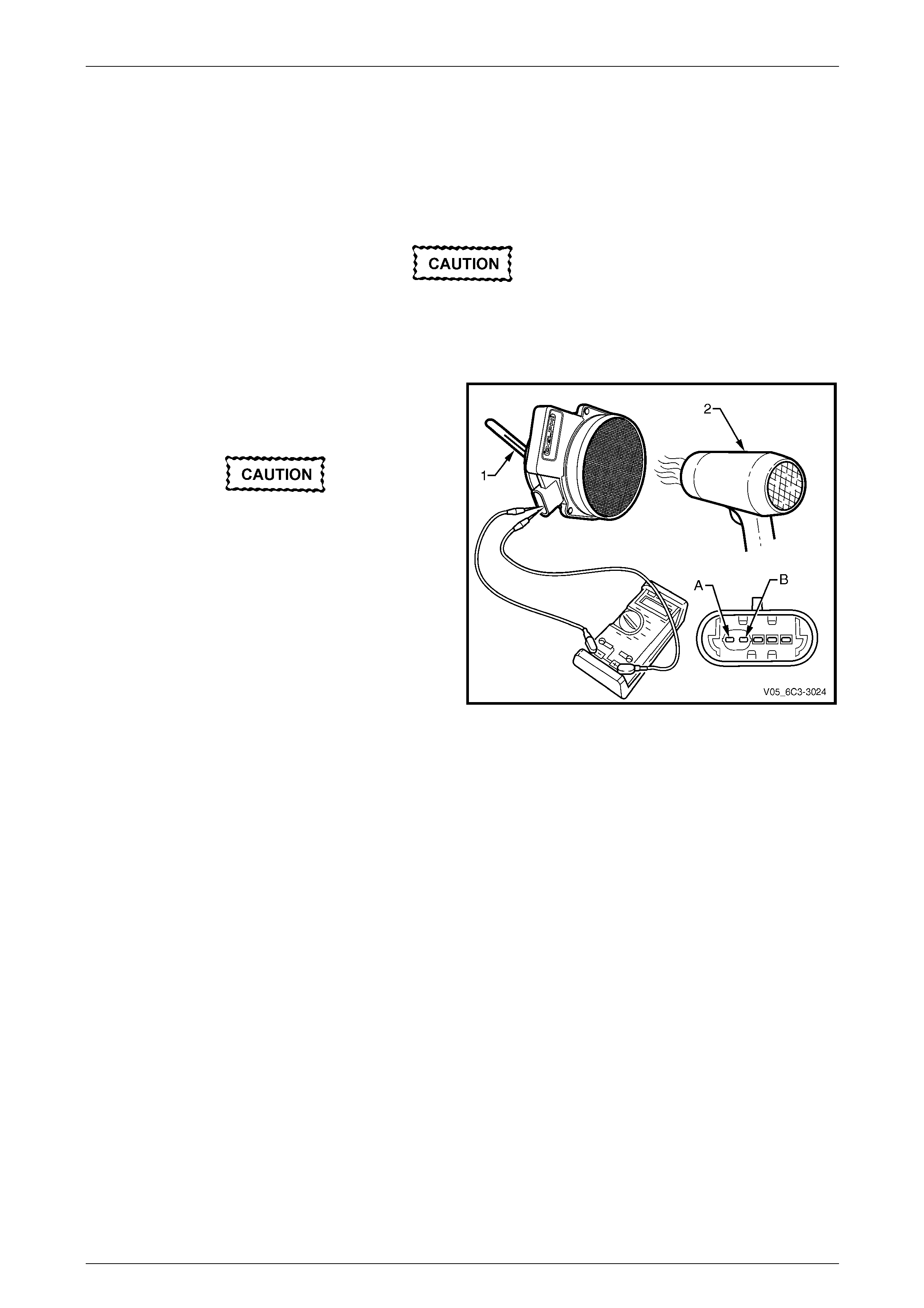

1 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the Mass Air Flow (MAF)

sensor across terminals (A) and (B).

Do not use a high temperature heat gun as

damage to the MAF sensor will result.

2 Whilst holding a thermometer (1), use a commercially

available hair dryer (2) to blow warm air through the

MAF sensor.

Figure 6C4-3 – 30

3 Observe the resistance values as the temperature

increases and compare the temperature/resistance

change to the specifications.

4 If the resistance is not within specifications, replace

the MAF sensor.

Intake Air Temperature Vs Resistance

Temperature °C Resistance – Ohms (Ω)

-10 16,180

0 9,420

20 3,520

25 2,796

40 1,459

60 667

80 332

100 177

120 100

140 60

Engine Management GEN IV V8 – Service Operations Page 6C4-3–36

Page 6C4-3–36

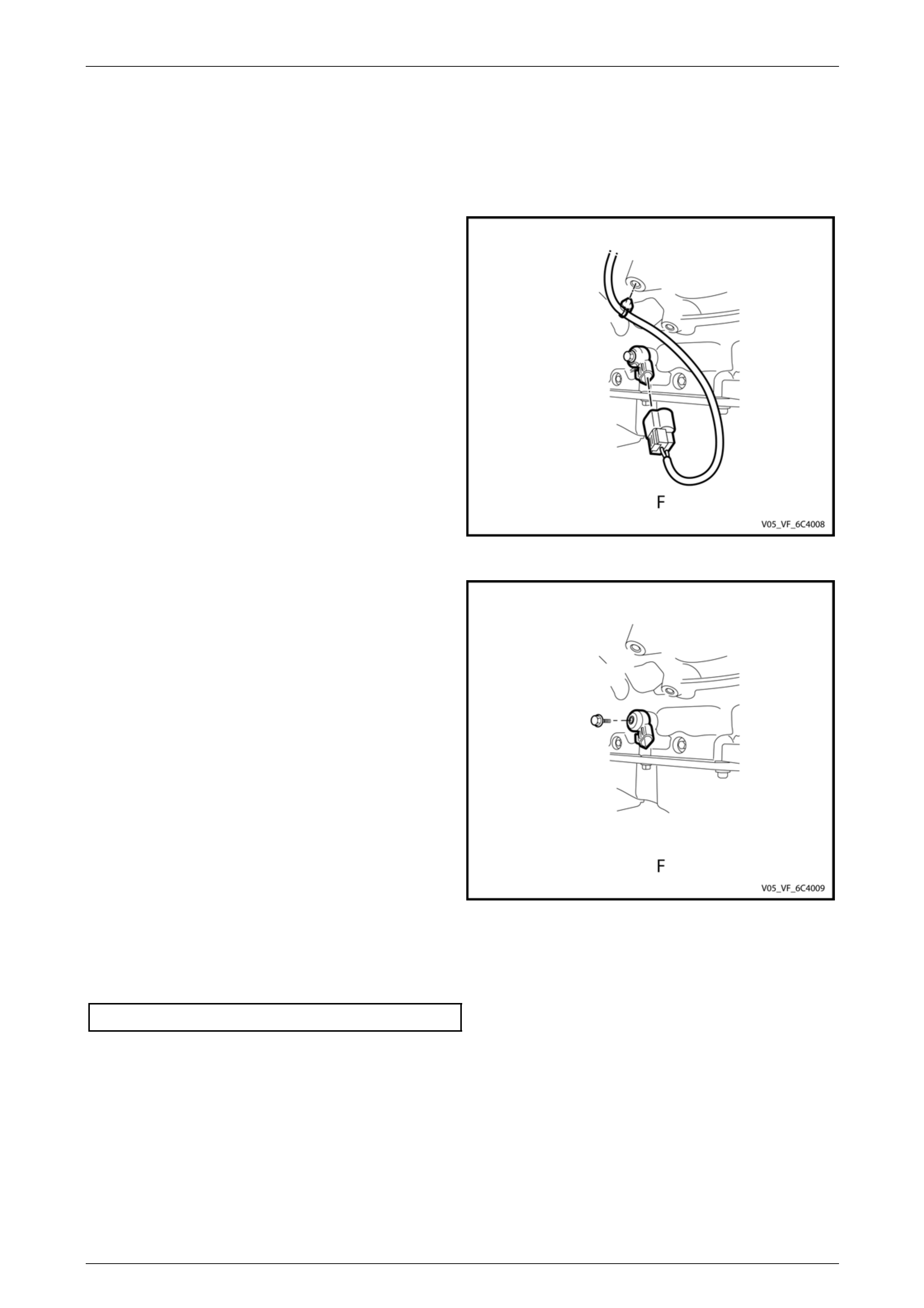

3.16 Knock Sensors

Remove

1 Remove under pan tray

2 Disconnect wiring connector at sensor

NOTE

Only left hand sensor shown

3 Undo retaining bolt

Figure 6C4-3 – 31

Reinstall

NOTE

Ensure the threads for the knock sensor

retaining bolt and block are in good condition

and are free of dirt or contamination. Do not

apply sealant or retaining washers to the

retaining bolt as this will change the operating

frequency of the knock sensor.

1 Fit knock sensor in placed and start bolt by hand

NOTE

Failure to observe the correct tightening

procedure will change the operating frequency of

the knock sensor.

2 Tighten to correct torque

3 Refit connector

Figure 6C4-3 – 32

Knock Sensor Torque Specification ........23Nm +/- 2 Nm

Engine Management GEN IV V8 – Service Operations Page 6C4-3–37

Page 6C4-3–37

3.17 Manifold Absolute Pressure (MAP)

Sensor

Remove

1 Disconnect the MAP sensor electrical connector (1).

2 Twist the MAP sensor (2) forward to release it from the

intake manifold adaptor.

3 Pull the MAP sensor upward.

Reinstall

Reinstallation of the MAP sensor is the reverse of the

removal procedure, noting the following:

1 Lightly coat the MAP sensor seal with clean engine oil.

2 Start the engine and check for vacuum leaks.

Figure 6C4-3 – 33

Engine Management GEN IV V8 – Service Operations Page 6C4-3–38

Page 6C4-3–38

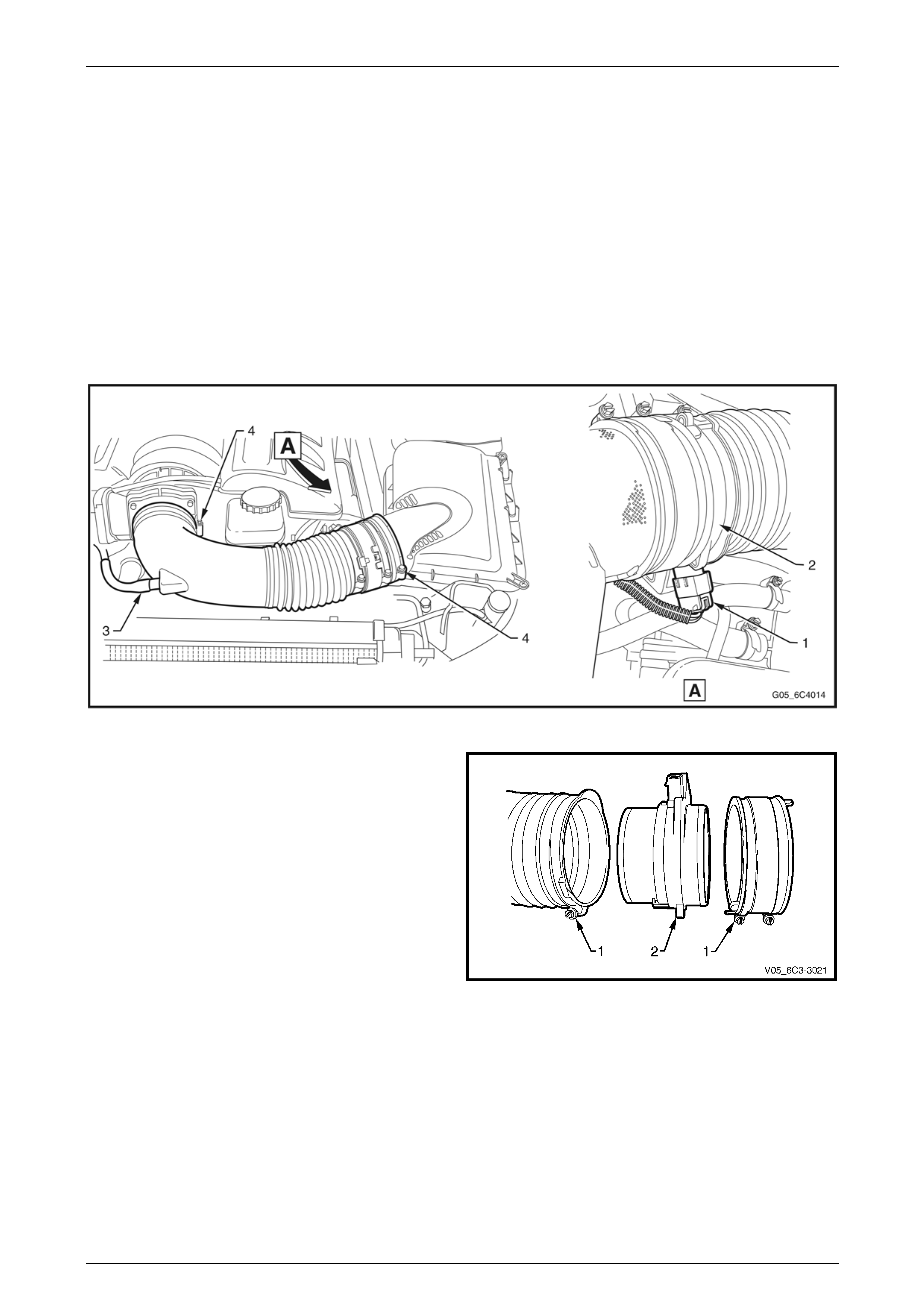

3.18 Mass Air Flow (MAF) Sensor and Intake

Air Duct

Remove

1 Remove the upper radiator shroud, refer to Section 6B4 Engine Cooling – GEN IV V8 Engine.

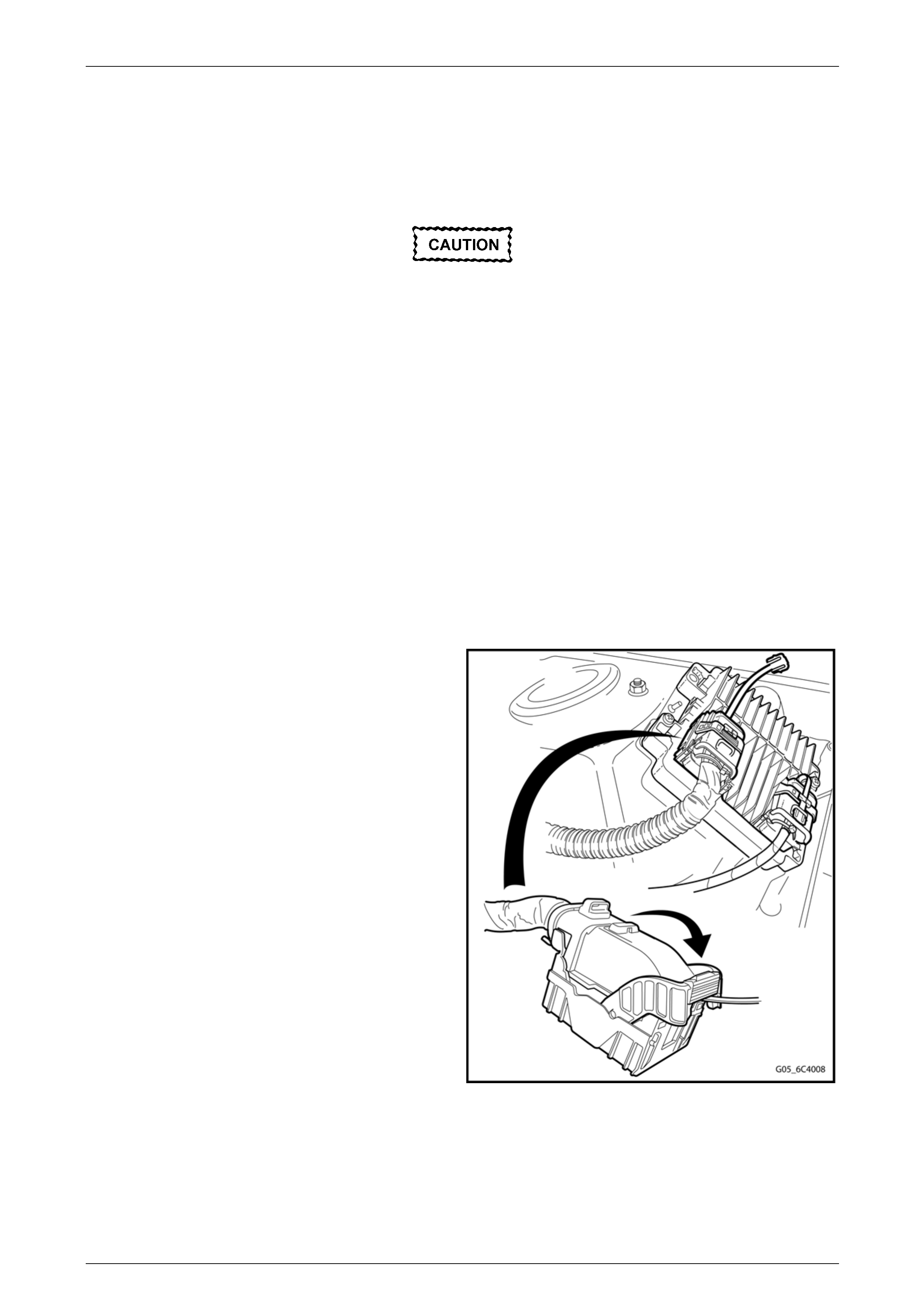

2 Remove the intake air duct:

a Lift up the security tang on the MAF sensor wiring harness connector (1) and remove the connector from

sensor (2).

b Disconnect the PCV hose (3) from the intake air duct.

c Loosen the clamps (4) at each end securing the intake air duct to the throttle body and the air cleaner upper

housing. Remove the duct.

Figure 6C4-3 – 34

3 Loosen the two clamps (1) securing the air intake duct

and the air duct adaptor to the MAF sensor (2).

Figure 6C4-3 – 35

Engine Management GEN IV V8 – Service Operations Page 6C4-3–39

Page 6C4-3–39

Reinstall

Reinstallation of the MAF sensor is the reverse of the removal procedure, noting the following:

NOTE

• The embossed arrows on the MAF sensor

indicate the correct air flow direction. The

arrows must point towards the engine.

• The air duct adaptor (between air cleaner and

MAF sensor), retaining clamps, air duct and

MAF sensor, all have locating notches.

Ensure all notches are aligned.

1 Reinstall the retaining clamps, aligning notches, tighten clamps to the specified torque.

Intake Air Duct Clamp

Torque Specification ...................................1.5 – 2.5 Nm

2 Start vehicle and check for air leaks.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–40

Page 6C4-3–40

3.19 Spark Plugs

Service Precautions

1 Allow the engine to cool (to at least 50° C) before attempting to remove spark plugs. Attempting to remove spark

plugs from a hot engine may cause the plug/cylinder head threads to bind, causing tearing of the alloy cylinder

head threads.

2 Clean the spark plug recess area before removing any spark plug. Failure to do so could result in engine damage

because of dirt or other foreign material entering the cylinder head or by the contamination of the cylinder head

threads. The contaminated threads may then prevent the correct seating of the new or replaced plug. If required,

use a ‘thread chaser’ to clean the threads of any contamination where this is suspected.

3 Only ever handle the spark lug lead boot when removing the ‘near plug’ coil lead from a spark plug. Do not pull on

the lead itself. Twist the boot first, to break the seal then pull to remove.

Remove

1 Remove both engine dress covers, refer to 2.2 Engine Dress Covers.

2 Remove the spark plug leads.

3 Using a suitable spark plug socket, loosen the spark

plug/s, then re-tighten to break away any carbon

deposits on the threads.

Wear eye protection to avoid injury.

4 Loosen the spark plug/s once again but, this time, only

one or two turns. Then use compressed air to remove

any foreign material that may otherwise enter the

combustion chamber.

Figure 6C4-3 – 36

NOTE

As each spark plug is removed, place in order.

This will enable any abnormal spark plug

condition to be identified with the correct cylinder.

5 Remove the spark plug.

6 Repeat steps 2 to 5 for each spark plug.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–41

Page 6C4-3–41

Clean, Inspect and Adjust

1 Replace any plug that has cracked insulation, broken insulation or loose electrodes.

2 Clean any oil from the plugs using a degreasing agent.

3 Dry the plugs using compressed air.

4 Clean the spark plugs using a purpose-built machine (sand blasting type).

5 Inspect the spark plugs for defects. Refer to Analysis of Spark Plug Condition in this Section for identification of the

condition of spark plugs.

6 Ensure that the threads are clean and in good order.

7 Use a round wire feeler gauge to check the spark plug

gap.

8 Adjust the gap to the correct specification by gently

bending the outer electrode.

Spark Plug Gap GEN IV V8 Engine .................... 1.5 mm

Figure 6C4-3 – 37

Spark Plug Inspection

Poor Spark Plug Performance

A spark plug can perform poorly due to wear, dirt, carbon fouling, excessive electrode wear, a broken insulator or

excessive gap.

Worn or Dirty Plugs

Worn or dirty plugs can give satisfactory operation while the vehicle is idling, but break down under load.

This can cause:

• Poor fuel economy

• Power loss

• Acceleration loss

• Difficult starting

• Generally poor engine performance

Carbon Fouling

Carbon fouling is indicated by black carbon deposits. The black deposits are usually the result of slow-speed driving and

short runs. In these circumstances, the optimum engine operating temperature is seldom reached.

Fouling can also be caused by:

• Worn piston rings

• Faulty ignition

• Rich fuel mixture

• Spark plugs that are rated too cold

Engine Management GEN IV V8 – Service Operations Page 6C4-3–42

Page 6C4-3–42

Excessive Electrode Wear

This often indicates:

• The engine is operating at high speeds

• The engine is operating at levels that are consistently greater than normal

• A plug that is rated too hot

• Excessively lean fuel mixture

• Plug/s overheating due to insufficient tightening (caused by combustion gases leaking past the threads)

Broken Insulator

Do not use a spark plug with a broken

insulator.

Broken insulators are usually the result of improper installation or carelessness.

Breaks in the upper insulator can result from a poor fitting spark plug socket or an impact. The cracked insulator may not

show up until oil or moisture penetrates the crack. The crack is often just below the crimped part of the shell and may not

be visible.

Breaks in the lower insulator often result from careless re-gapping and are usually visible.

This can also result from the plug operating too hot. For example, in periods of high speed operation or under heavy

loads.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–43

Page 6C4-3–43

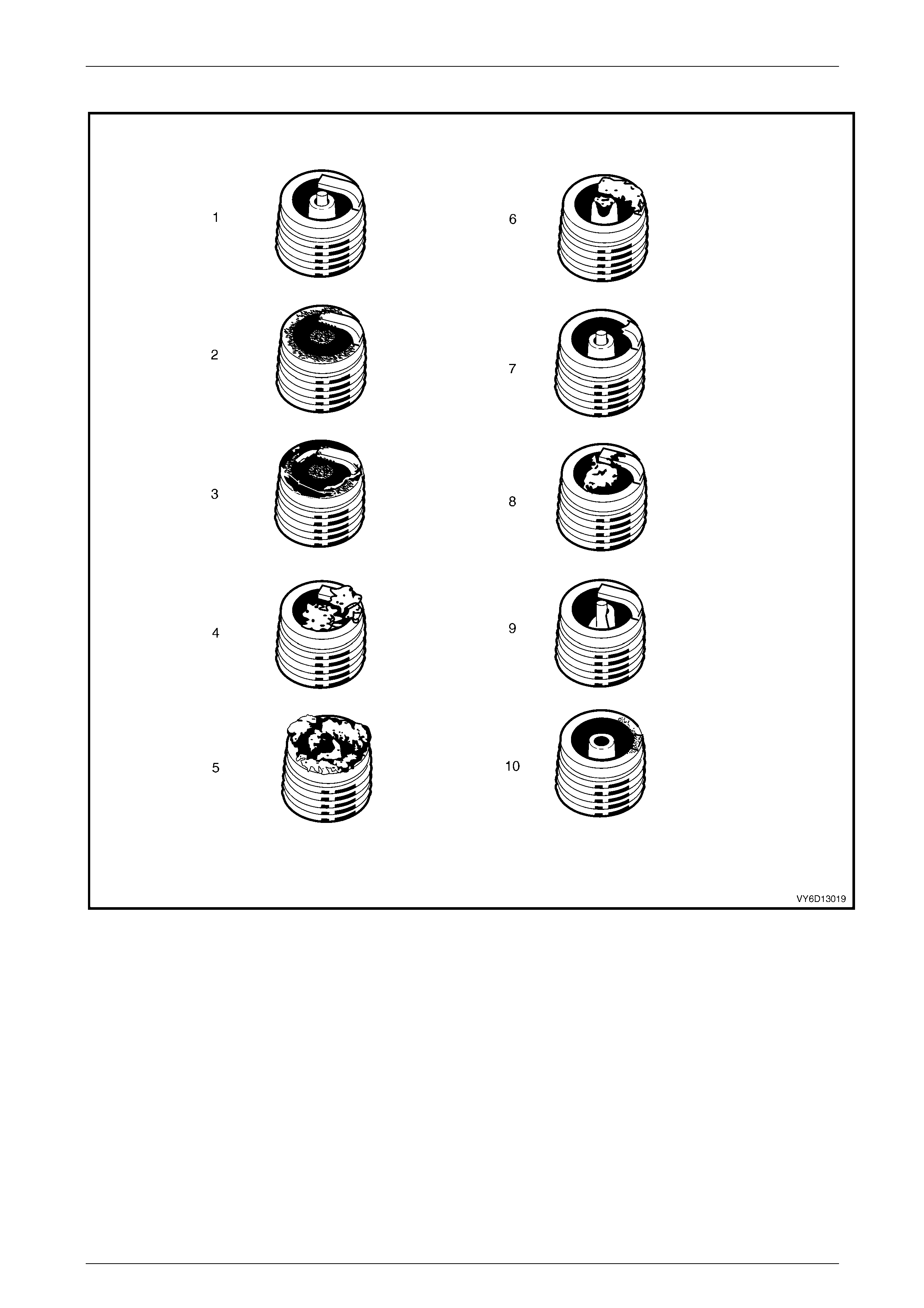

Analysis of Spark Plug Condition

Figure 6C4-3 – 38

Legend

1 Normal

2 Carbon Fouled

3 Oil Fouled

4 Deposit Fouling A

5 Deposit Fouling B

6 Deposit Fouling C

7 Detonation

8 Pre-ignition

9 Heated Shock Failure

10 Insufficient Installation Torque

Engine Management GEN IV V8 – Service Operations Page 6C4-3–44

Page 6C4-3–44

Normal Operation (1)

Brown or greyish-tan deposits and slight electrode wear indicate correct spark plug heat range and mixed periods of high

and low speed driving.

Carbon Fouled (2)

Dry, fluffy black carbon deposits possibly due to poor ignition output, weak coil, faulty spark plug leads, excessive idling

or slow speeds under light load. If spark plug temperatures remain too low for normal combustion, the deposits are not

burned off.

Oil Fouled (3)

Wet, oily deposits with minor electrode wear possibly due to oil leaking past worn piston rings.

Breaking in a new or recently overhauled engine before the rings are fully seated may also result in this condition.

Deposit Fouling A (4)

Red brown, yellow and white coloured coatings on the insulator tip which are by-products of combustion. They come

from the fuel and the lubricating oil which generally contain additives. Most powdery deposits have no adverse effect on

spark plug operation; however, they may cause intermittent missing under severe operating conditions.

Deposit Fouling B (5)

Deposits similar to those identified in Deposit fouling A (4). These are also by-products of combustion from the fuel and

lubricating oil. Excessive valve stem clearances and/or defective intake valve seals allow too much oil to enter the

combustion chamber. The deposits will accumulate on the portion of the spark plug that projects into the chamber and

will be heaviest on the side facing the intake valve. When you detect this condition in only one or two cylinders, check the

valve stem seals.

Deposit Fouling C (6)

Most powdery deposits identified in Deposit fouling A (4) have no adverse effect on the operation of the spark plug as

long as they remain powdery.

Under certain conditions of operation however, these deposits melt and form a shiny glaze coating on the insulator.

When hot, this acts as a good electrical conductor allowing the current to flow along the deposit instead of sparking

across the gap.

Detonation (7)

Commonly referred to as engine knock or ‘pinging’, detonation causes severe shocks inside the combustion chamber

causing damage to parts.

Pre-ignition (8)

Burnt or blistered insulator tip and badly eroded electrodes probably due to the excessive heat.

This is often caused by a cooling system blockage, sticking valves, improperly installed spark plugs or plugs that are the

wrong heat rating (too hot).

Sustained high speed with a heavy load can produce temperatures high enough to cause pre-ignition.

Heat Shock Failure (9)

A rapid increase in spark plug tip temperature under severe operating conditions can cause heat shock and result in

fractured insulators. This is a common cause of broken and cracked insulator tips.

Insufficient Installation Torque (10)

Poor contact between the spark plug and the cylinder head seat.

The lack of proper heat transfer that results from poor seat contact causes overheating of the spark plug. In many cases,

severe damage occurs, as shown.

Dirty threads in the cylinder head can cause the plug to seize before it is seated.

Ensure that the cylinder head and spark plug threads are free of deposits, burrs and scale before installation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–45

Page 6C4-3–45

Reinstall

Reinstallation of the spark plugs is the reverse of the removal procedure, noting the following:

1 Hand start each spark plug into the cylinder head thread.

Ensure that the spark plug has fully seated on

the cylinder head before the specified torque

is reached.

NOTE

When replacing spark plugs, use genuine spark

plugs or recommended spark plugs of the correct

heat range.

2 Tighten the plugs to the correct torque specification using a spark plug socket and accurate torque wrench.

Spark Plug Torque Specification

New Cylinder Head Only.......................................20 Nm

Existing Cylinder Head..........................................15 Nm

Engine Management GEN IV V8 – Service Operations Page 6C4-3–46

Page 6C4-3–46

3.20 Spark Plug Leads

Remove

Pulling or bending spark plug leads can

cause hidden damage. Follow the removal

steps carefully to avoid such damage.

1 Remove both engine decorative covers, refer to 2.2 Engine Dress Covers.

2 Firmly grasp the boot (1) at the spark plug end of the

lead (2).

Grasp the boot, not the lead.

3 Twist the boot in both directions, to relieve any suction

and to break the seal.

4 Pull the boot straight off the spark plug.

5 Repeat Steps 2 and 3 for the ignition coil end of the

lead (3).

6 Carefully set the lead to one side.

NOTE

As each spark plug lead is removed, place in

order. This will enable any abnormal condition to

be identified with the correct cylinder. Figure 6C4-3 – 39

7 Repeat Steps 2 to 6 for the remaining leads.

Inspect

1 Connect and Ohmmeter, capable of accurately reading to 20 kΩ, to each end of a lead.

2 Record the reading for each lead.

3 Compare the resistance readings taken against the specification.

Spark Plug Lead Resistance................. 700 Ω Maximum

4 Replace any lead that is significantly different from the stated specification.

Reinstall

Reinstallation of the spark plug leads is the reverse of the removal procedure, noting the following:

1 Only ever handle a spark plug lead by the boot at each end. Never the lead itself.

2 Push on the boot until the lead connection is fully engaged with the spark plug terminal. Ensure the actual lead

connection has connected with the spark plug.

3 Repeat this procedure for the coil end of each lead.

4 Start the engine and check for correct operation.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–47

Page 6C4-3–47

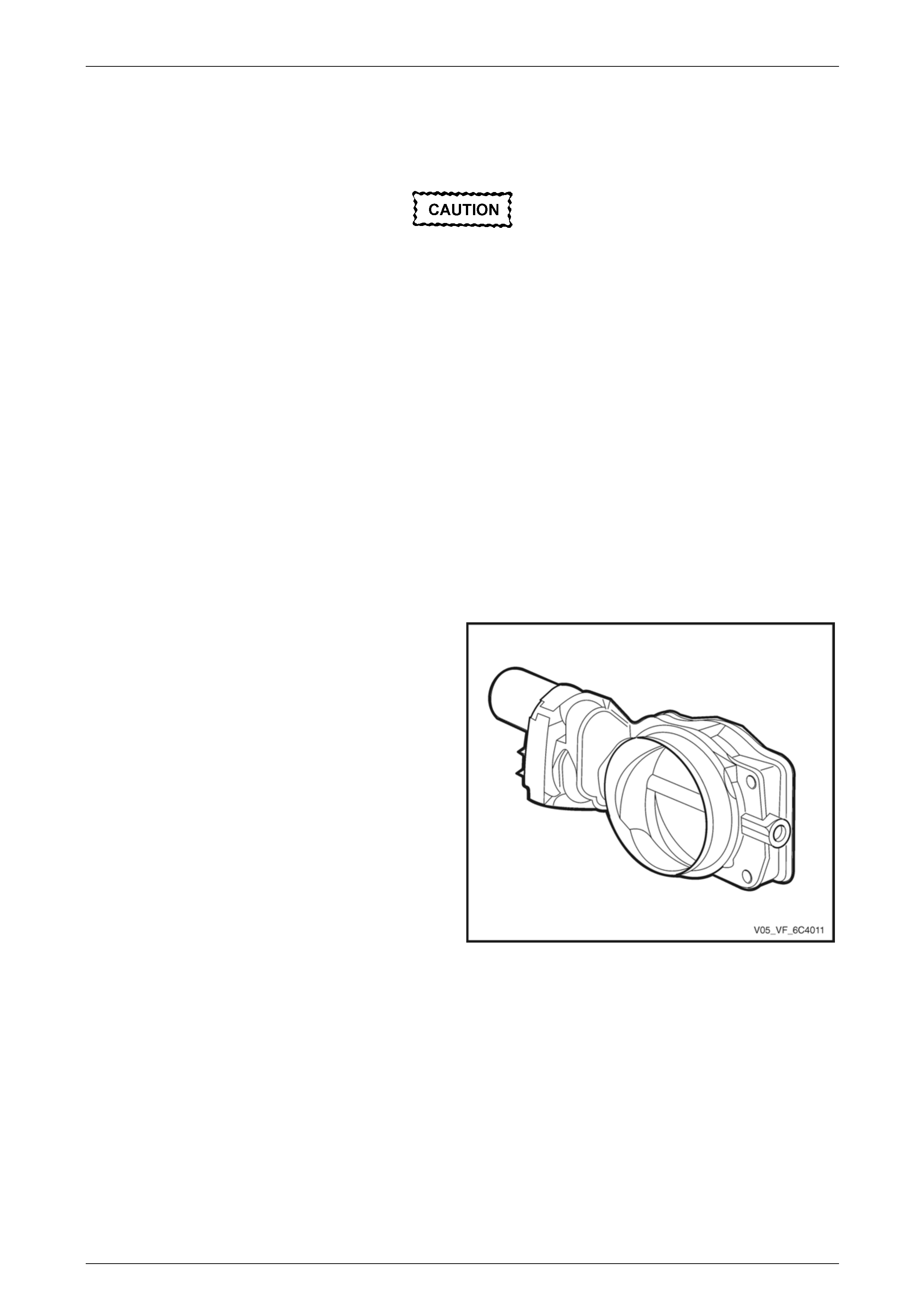

3.21 Throttle Body

Handling Precautions

Under no circumstances should the throttle

body be disassembled. If the throttle body is

disassembled, the vacuum seal between the

cover plate and the throttle body will be

broken. This will allow the ingress of foreign

particles and or moisture and render the

throttle body unserviceable.

The throttle body must not be subjected to

any form of shock such as dropping it. If the

throttle body is subjected to shock, damage

may result to the fragile motor magnets within

the throttle body.

Remove

1 Turn the ignition switch off.

2 Partially drain the cooling system before removing the cooling system hoses at the throttle body,

refer to Section 6B4 Engine Cooling – GEN IV V8.

3 Remove the intake air duct, refer to 3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct.

4 Disconnect the throttle body electrical connector (1).

5 Disconnect the cooling system hoses (2) from the

throttle body.

Figure 6C4-3 – 41

Engine Management GEN IV V8 – Service Operations Page 6C4-3–48

Page 6C4-3–48

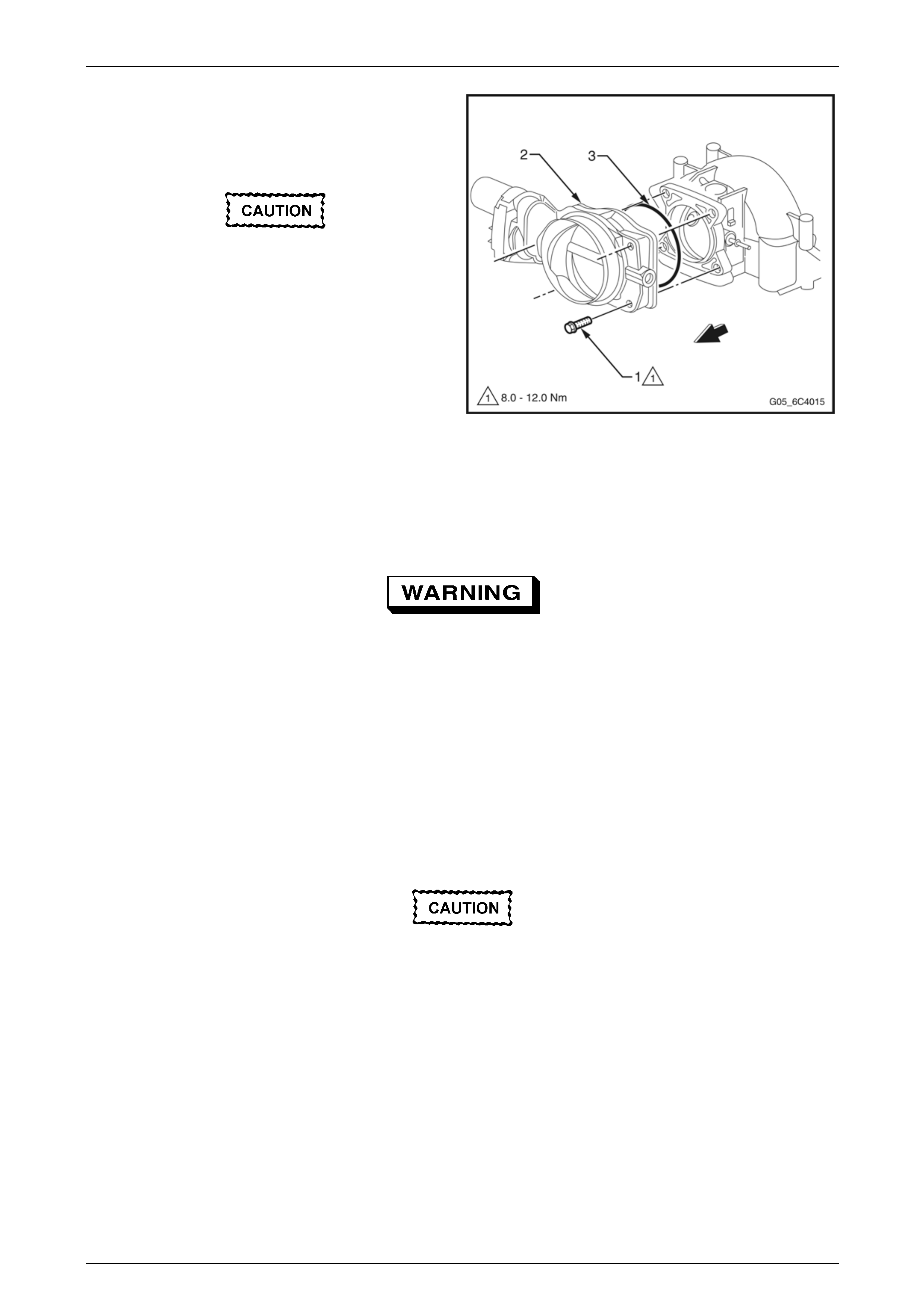

6 Remove the throttle body attaching bolts (1).

7 Remove the throttle body (2) and the seal (3).

8 Discard the removed seal.

• To prevent damage to the sealing

surfaces, it is preferred that only plastic

scrapers are used for cleaning deposits

from machined alloy surfaces.

• Do not soak the throttle body in cold

immersion type cleaner. To clean the

throttle body following disassembly, use

a spray type cleaner such as GM 1052626

or equivalent. Use a shop towel to remove

heavy deposits.

• The throttle body contains electrical

components that should not come in

contact with solvent or cleaner, as

damage may result.

9 Clean the both sealing surfaces.

Figure 6C4-3 – 42

Inspect

To avoid serious personal injury, never

attempt to rotate the throttle plate manually

whilst the throttle body harness connector is

connected to the throttle body.

The following throttle body inspection procedure may be carried out with the throttle body installed on the vehicle. Prior to

performing a throttle body on-vehicle inspection, perform the following:

1 Switch the ignition off.

2 Disconnect the throttle body harness connector.

3 Remove the air cleaner intake duct, refer to 3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct.

4 Fully open the throttle plate by hand in order to inspect the throttle body bore and the throttle plate for any deposits.

When cleaning / inspecting the throttle body:

• Do not subject the throttle body assembly

to an immersion cleaner or a strong

solvent. Damage to the throttle position

sensor and / or sealed throttle shaft

bearings will result.

• Never use a wire brush or scraper to clean

the throttle body. A wire brush or sharp

tool may damage the throttle body

components.

5 Use a clean shop towel and GM cleaner 1052626 or equivalent product to clean the throttle body bore and throttle

plate. If necessary, use a parts cleaning brush in order to remove heavy deposits.

6 To inspect the throttle body for a binding throttle plate, fully open and close the throttle plate by hand. The throttle

plate should open and close smoothly.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–49

Page 6C4-3–49

7 Inspect the throttle body for a bent or damaged throttle plate, and cracks, corrosion, or distortion in the throttle body

housing.

NOTE

The throttle body contains no serviceable parts

and should not be disassembled. If the throttle

body is damaged it must be replaced as an

assembly.

8 If the throttle body is affected by any of the above conditions, the throttle body must be replaced.

9 If an on-vehicle throttle body inspection was performed, reinstall the air cleaner intake duct,

refer to 3.18 Mass Air Flow (MAF) Sensor and Intake Air Duct.

10 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Reinstall

Reinstallation of the throttle body is the reverse of the removal procedure, noting the following:

1 Install a new throttle body seal.

2 Reinstall the throttle body attaching bolts and tighten to the correct torque specification.

Throttle body attaching bolt

torque specification ...............................................12 Nm

3 Refill the cooling system, refer to Section 6B4 Engine Cooling – GEN IV V8.

4 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Engine Management GEN IV V8 – Service Operations Page 6C4-3–50

Page 6C4-3–50

4 Specifications

Accelerator Pedal Position Sensor 1

Type.....................................................Three wire potentiometer

Accelerator pedal at rest ........................................ Below 1.25 V

Accelerator pedal fully depressed .......................5.0 V maximum

Resistance @ 20° C .............................................................TBA

Accelerator Pedal Position Sensor 2

Type.....................................................Three wire potentiometer

Accelerator pedal at rest ........................................ Below 1.25 V

Accelerator pedal fully depressed .......................5.0 V maximum

Resistance @ 20° C .............................................................TBA

Camshaft Position (CMP) Sensor

Type............................ Twin hall effect, interrupter ring triggered

Air gap ...................................................................0.1 – 1.8 mm

Air gap adjustment ................................................No adjustment

Crankshaft Position (CKP) Sensor

Type............................ Twin hall effect, interrupter ring triggered

Coil resistance @ 20° C......................................... 850 – 1040 Ω

Air gap ....................................................................0.1 – 1.5 mm

Air gap adjustment ............................................... No adjustment

Engine Coolant Temperature Sensor

Type........................ Negative temperature coefficient thermistor

Engine Coolant Temperature Vs Resistance