SECTION 6A2 ENGINE MECHANICAL - V8 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will

consist of either seat belt pre-tensio ners and a driver’s side air bag , or seat belt pre-

tensioners and a driver’s and front passenger’s side air bags. Refer to CAUTIONS,

Section 12M, before performing any service operation on or around SRS

components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deplo yment, resulting in possible p ersonal injury or unnecessary

SRS system repairs.

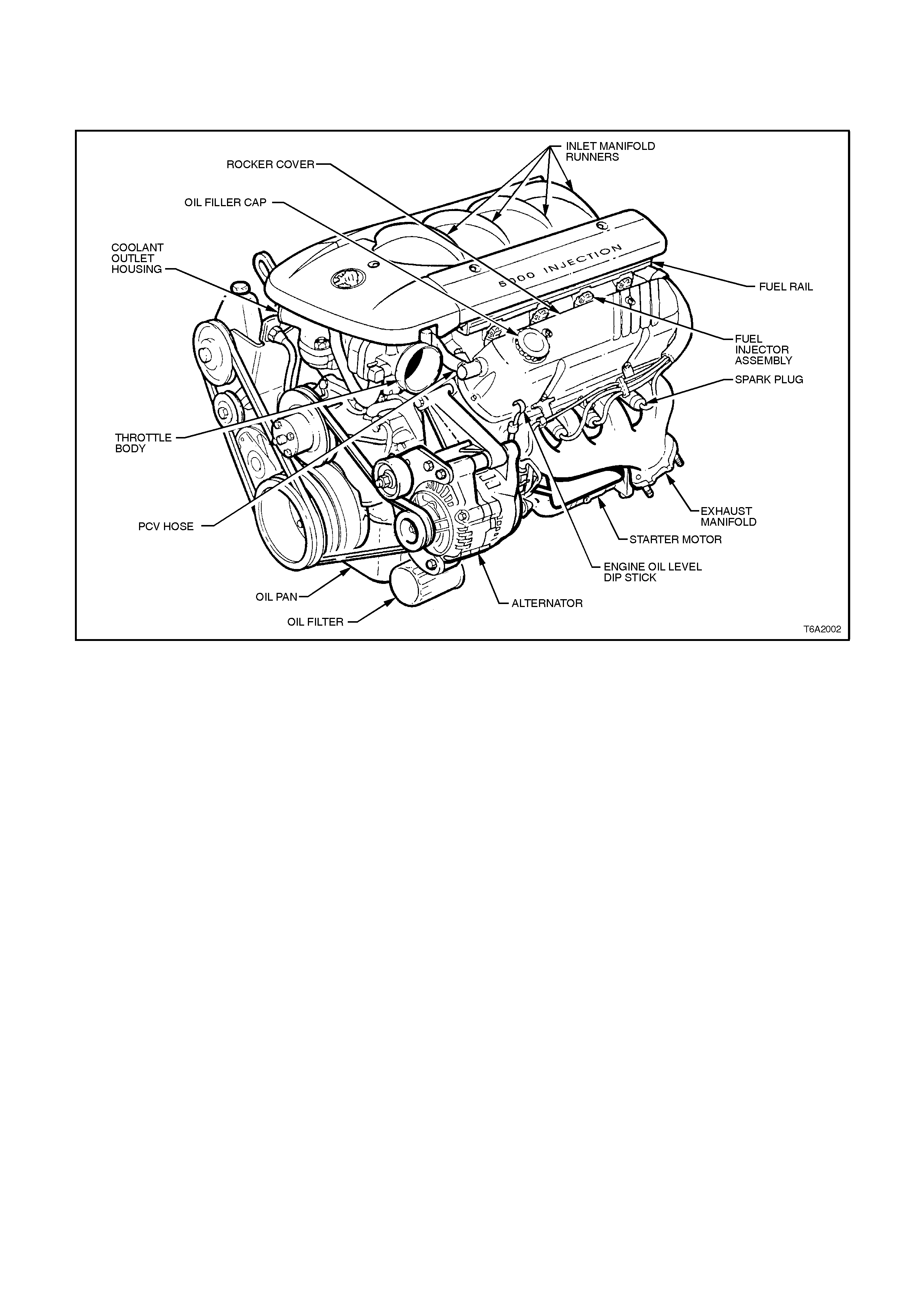

1. GENERAL DESCRIPTI ON

The 5.0 litre engine fitted to VT range of vehicles, known as production option LB9, is a port fuel injected eight

cylinder, overhead valve engine. The following text and illustrations describe the main design features of the engine.

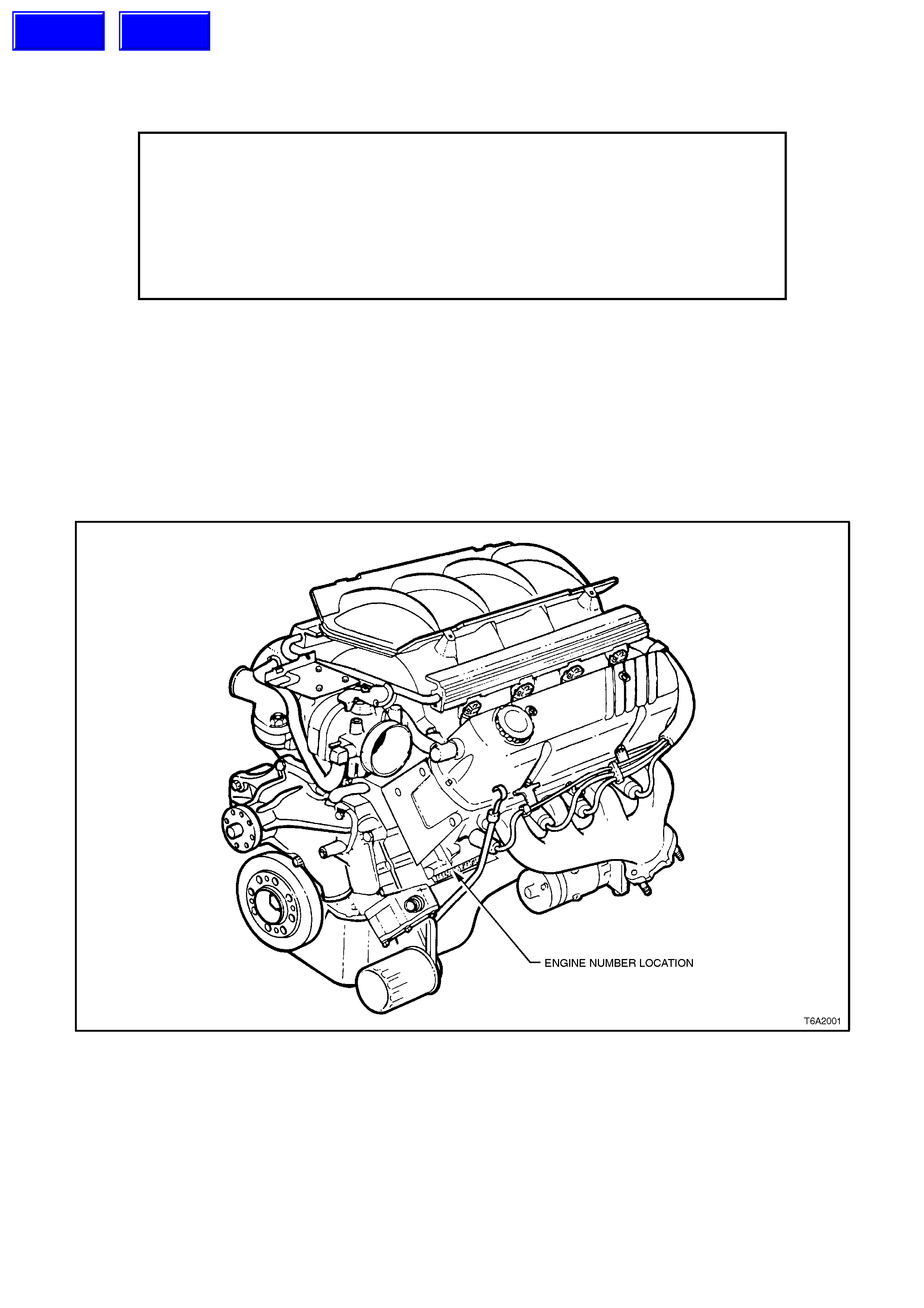

1.1 ENGINE IDENTIFICATION

Identification of the 5.0 litre engine fitted to VT vehicles, is provided by the black colouring and the engine number

stamping which is prefixed by the letters VM. The engine number is located on a cylinder block pad, forward of the

left hand side engine mount and directly above the oil pump, as shown in Fig. 6A2-1.

Figure 6A2-1

Techline

Techline

1.2 CYLINDER BLOCK

The cylinder block is made of cast iron and has two banks of cylinders arranged in a 90° 'V' configuration with four

cylinders in each bank. Five main bearings support the crankshaft. The cylinders are completely encircled by water

jackets.

Figure 6A2-2

1.3 CYLINDE R HEADS

The cast iron cylinder heads have integral valve guides and induction hardened exhaust valve seats. The inlet and

exhaust valve arrangement has been designed to complement the port fuel injection system.

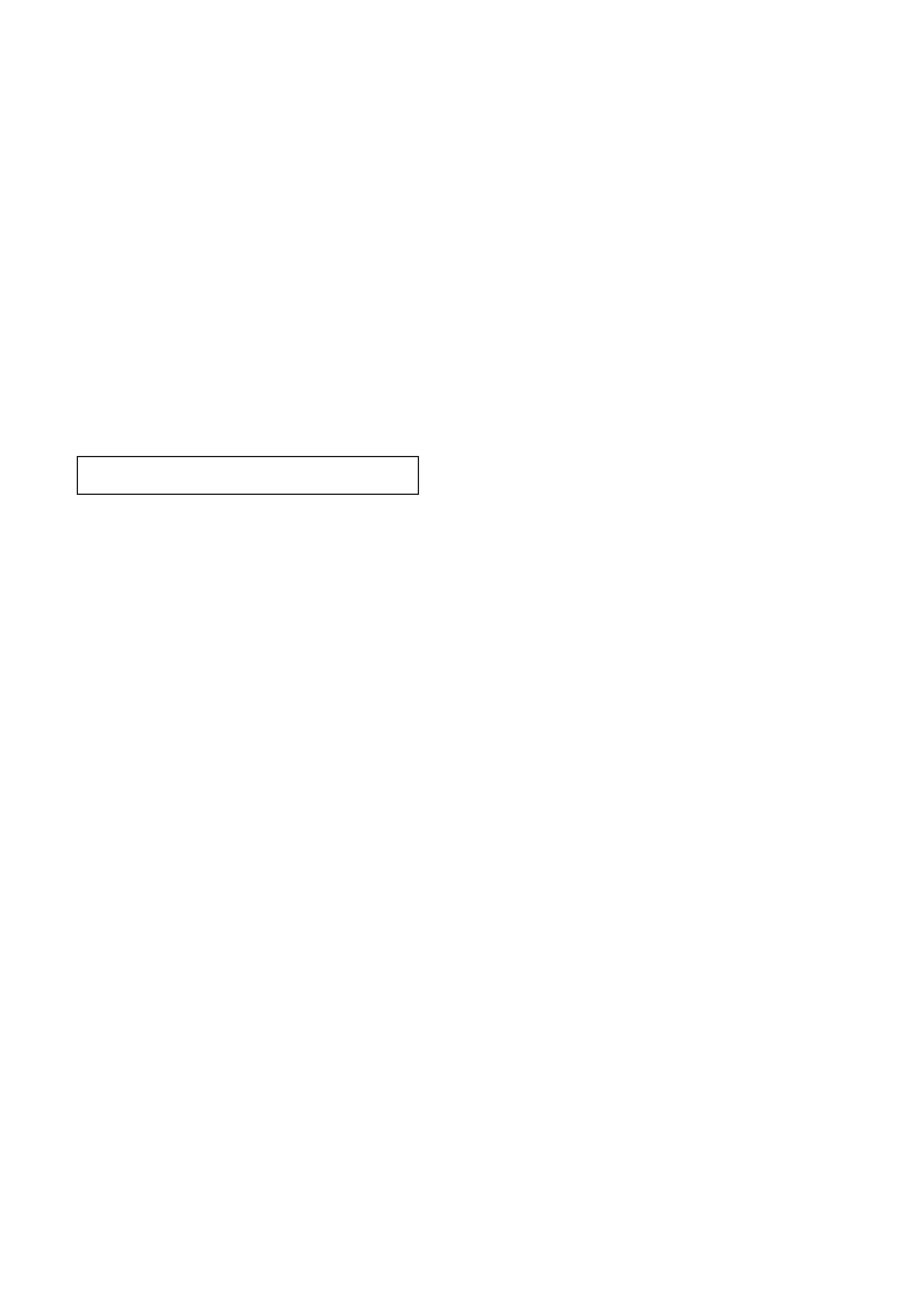

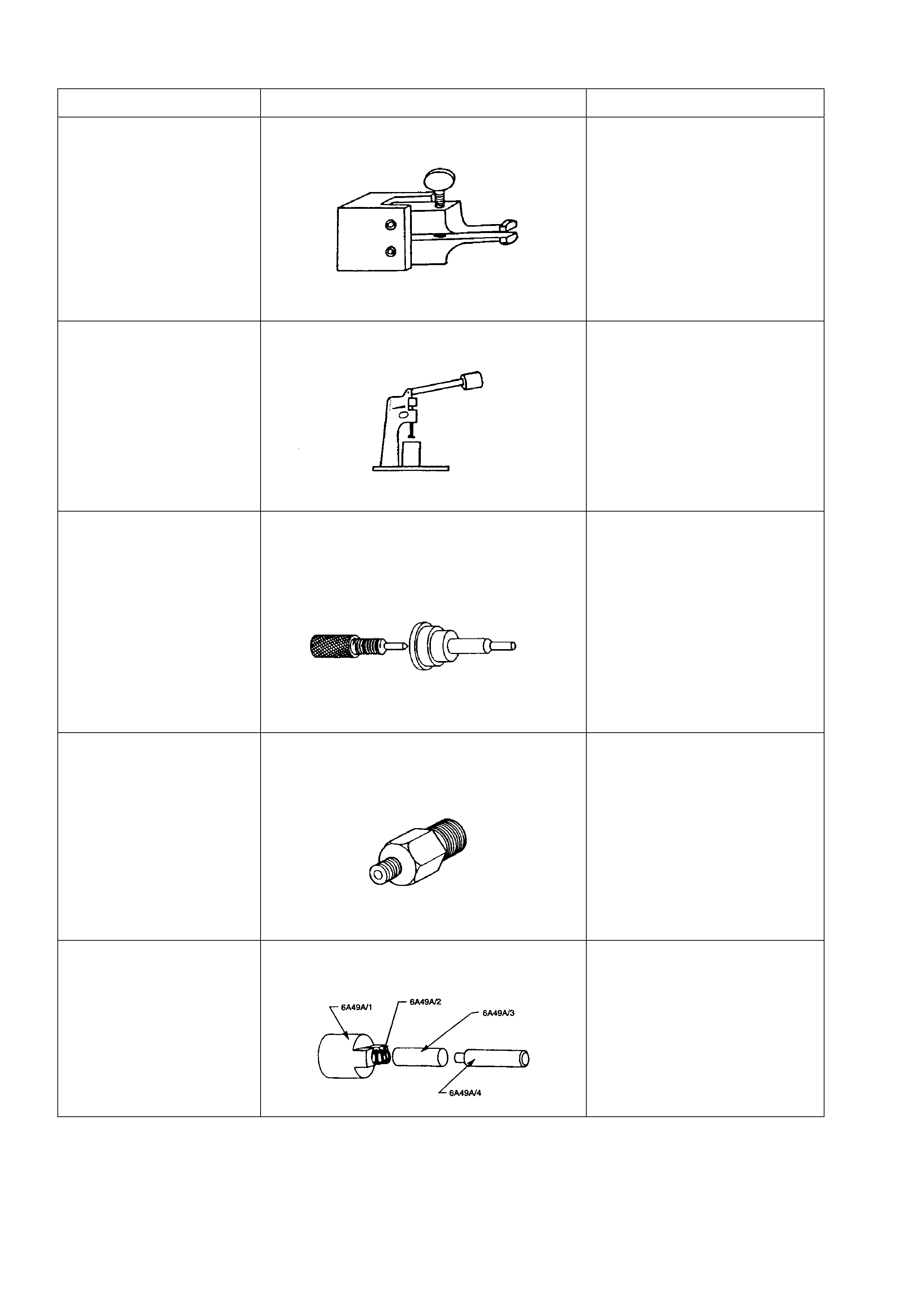

1.4 CRANKSHAFT

The crankshaft is cast nodular iron supported by five main bearings. The end thrust is taken on number five rear

main bearing. The precision type tri-metal bearings are of removable babbitt lined copper-lead, steel backed

construction.

1.5 PIS TONS AND CONNECTING RODS

The pistons are of strutless design and made of cast, high silicone content aluminium alloy. Each piston is fitted with

two compression rings and one oil control ring. The piston pins are offset 1.5 mm towards the thrust side to provide

a gradual change in thrust pressure against the cylinder wall, as the piston travels up and down the cylinder bore.

This also provides for quieter engine performance. The piston pins are a floating fit in the pistons and a press fit in

the connecting rods.

The connecting rods are made of forged steel. Full pressure lubrication is directed to the connecting rod bearings by

drilled oil passages from the adjacent main bearing journals.

A tapered strengthening rib over the big end bearing area is provided for additional bearing support.

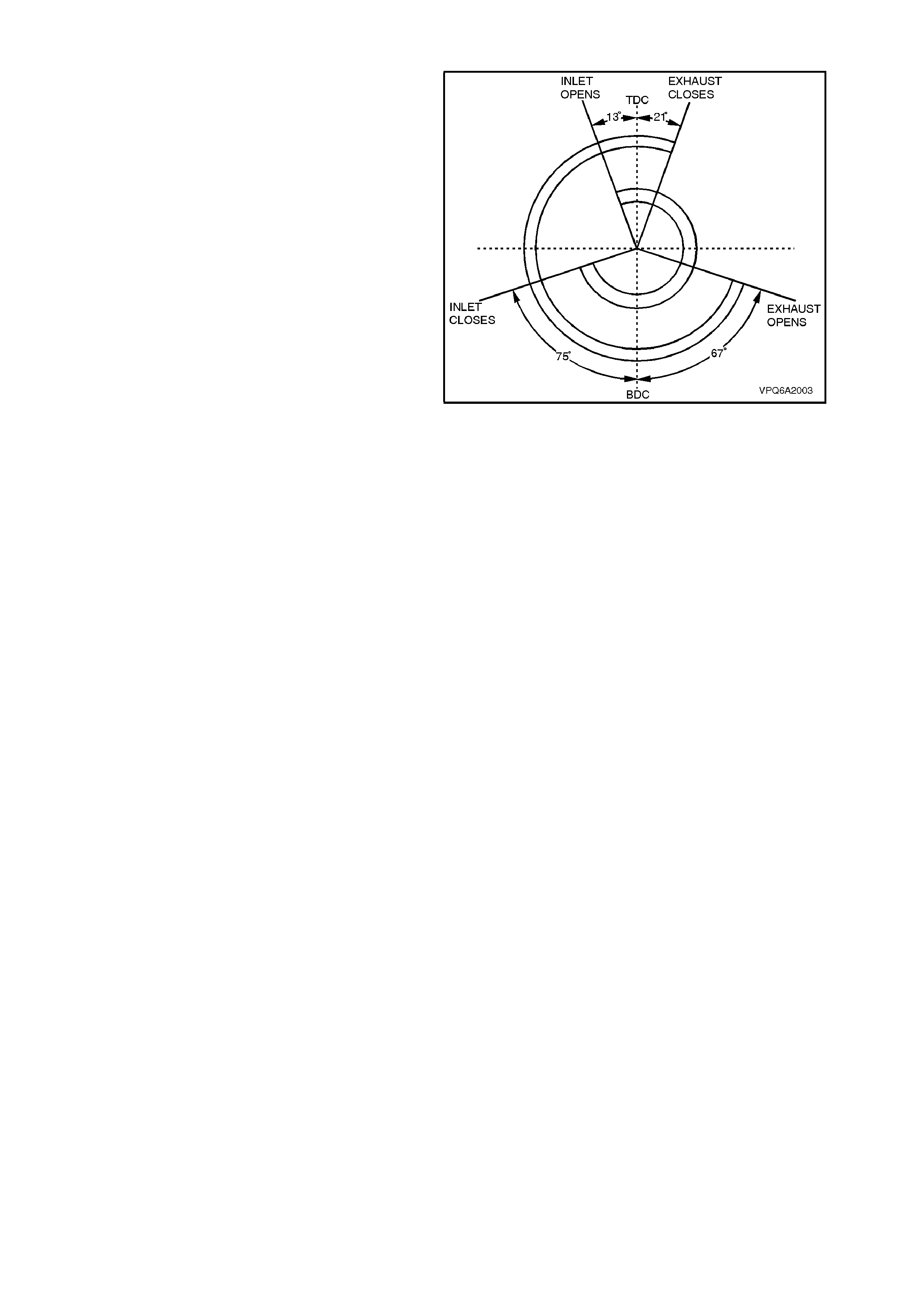

1.6 CAMSHAFT AND DRIVE

The steel camshaft is supported by five steel

backed lead Babbitt bearings and driven by the

crank shaf t through a tim ing chain at the fr ont of the

engine. Both the crankshaft and camshaft

sprockets have timing marks which, when aligned

with marks (bright links) on the timing chain,

provide the correct valve timing. Cast as integral

components of the camshaft, two helical gears are

provided at the front and rear of the camshaft to

provide drive for the oil pump and distributor,

respectively.

The cam s haft valve timing diagram is shown in Fig.

6A2-3.

Figure 6A2-3

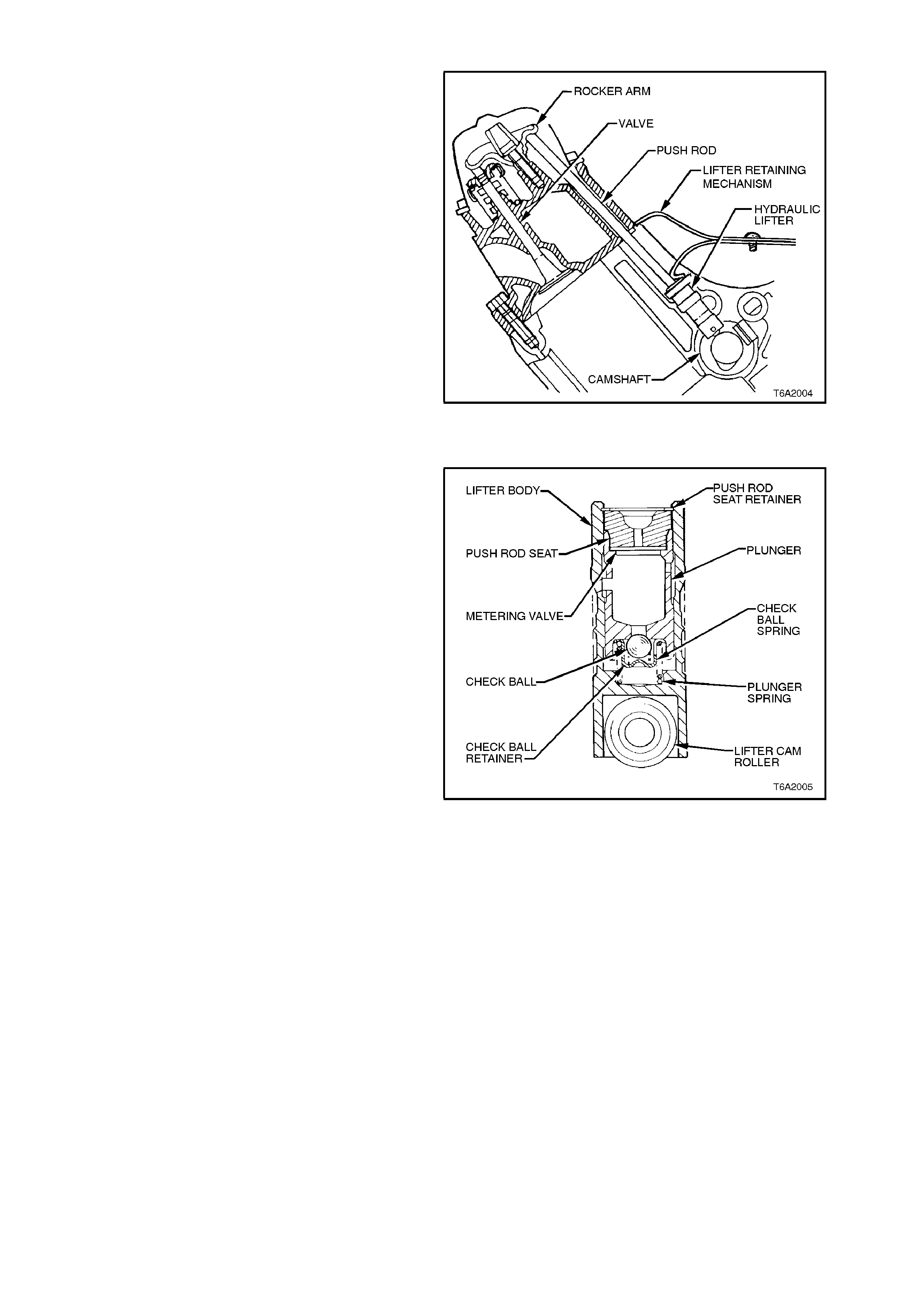

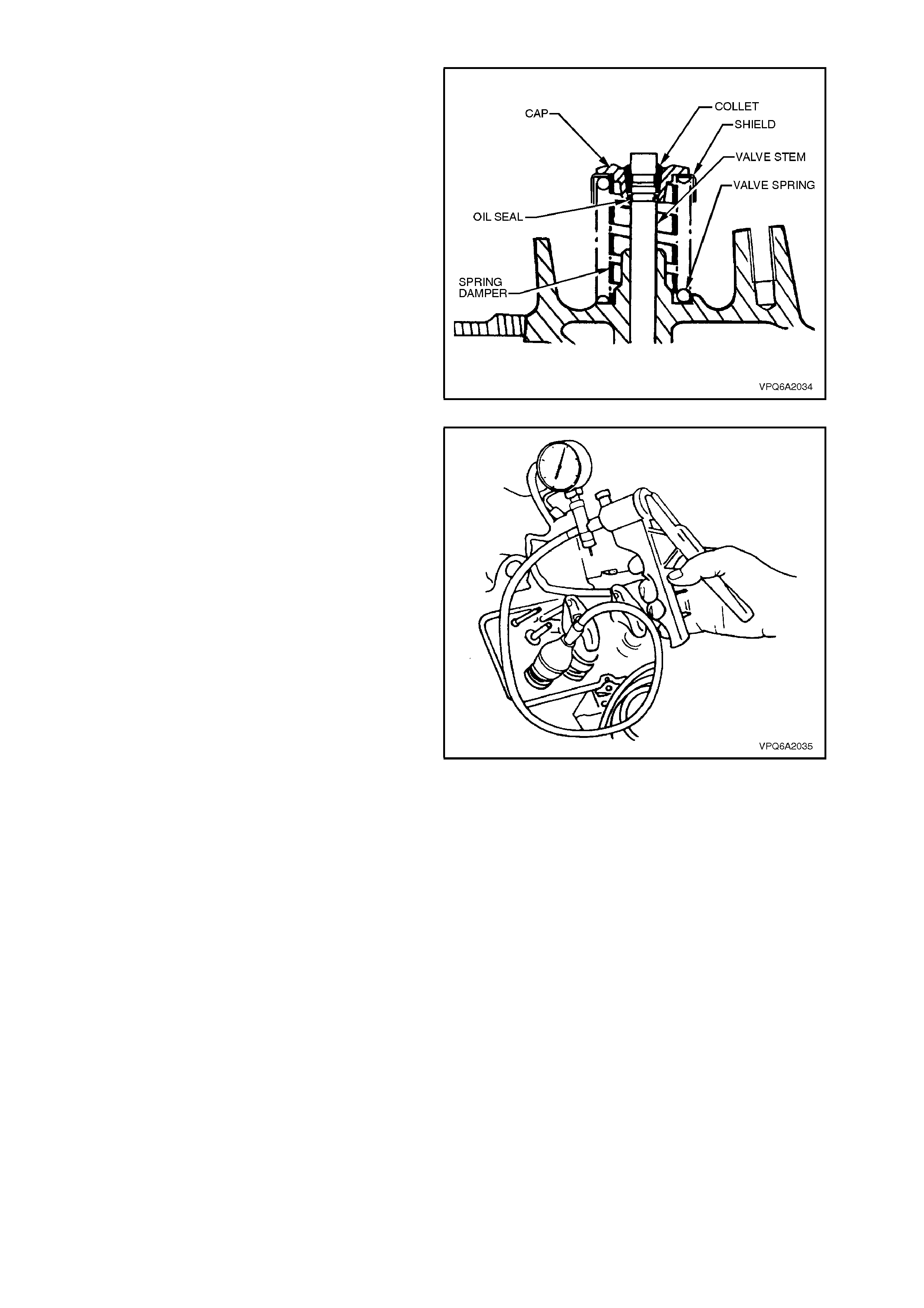

1.7 VALVE TRAIN

The valve train is push rod operated with non-

adjustable rocker arm pivots and hydraulic roller

valve lifters.

External shields are fitted to the inlet and exhaust

valve springs to reduce the amount of oil splashed

against the valve stem. Damper springs are fitted

inside both inlet and exhaust valve springs.

Figure 6A2-4

HYDRAULIC VALVE LIFTER OPERATION

Oil is supplied to each lifter through a hole in the

side of the lifter body that aligns with a groove and

hole in the lifter plunger. Oil is then metered past

the oil metering valve in the base of the lifter,

through the hollow push rods to the rocker arms.

W hen the lifter begins to ride up the cam lobe, the

check ball is held against its seat in the plunger by

the check ball spring, trapping the oil in the bas e of

the lifter body below the plunger. The plunger and

the lifter body then rise as a unit, pushing up the

push rod to actuate the rocker arm and open the

valve. The force of the valve spring which is

exerted on the plunger through the rocker arm and

push rod causes a slight amount of leakage

between the plunger and lifter body. This 'leak

down' allows a slow escape of trapped oil in the

base of the lifter body. As the lifter rides down the

other side of the cam lobe and reaches the base

circle or 'valve closed' position, the plunger spring

quickly moves the plunger back (up) to its original

position. This movement causes the check ball to

open against the check ball spring, oil from within

the plunger is then drawn into the base of the lifter,

restoring the lifter to zero lash.

Figure 6A2-5

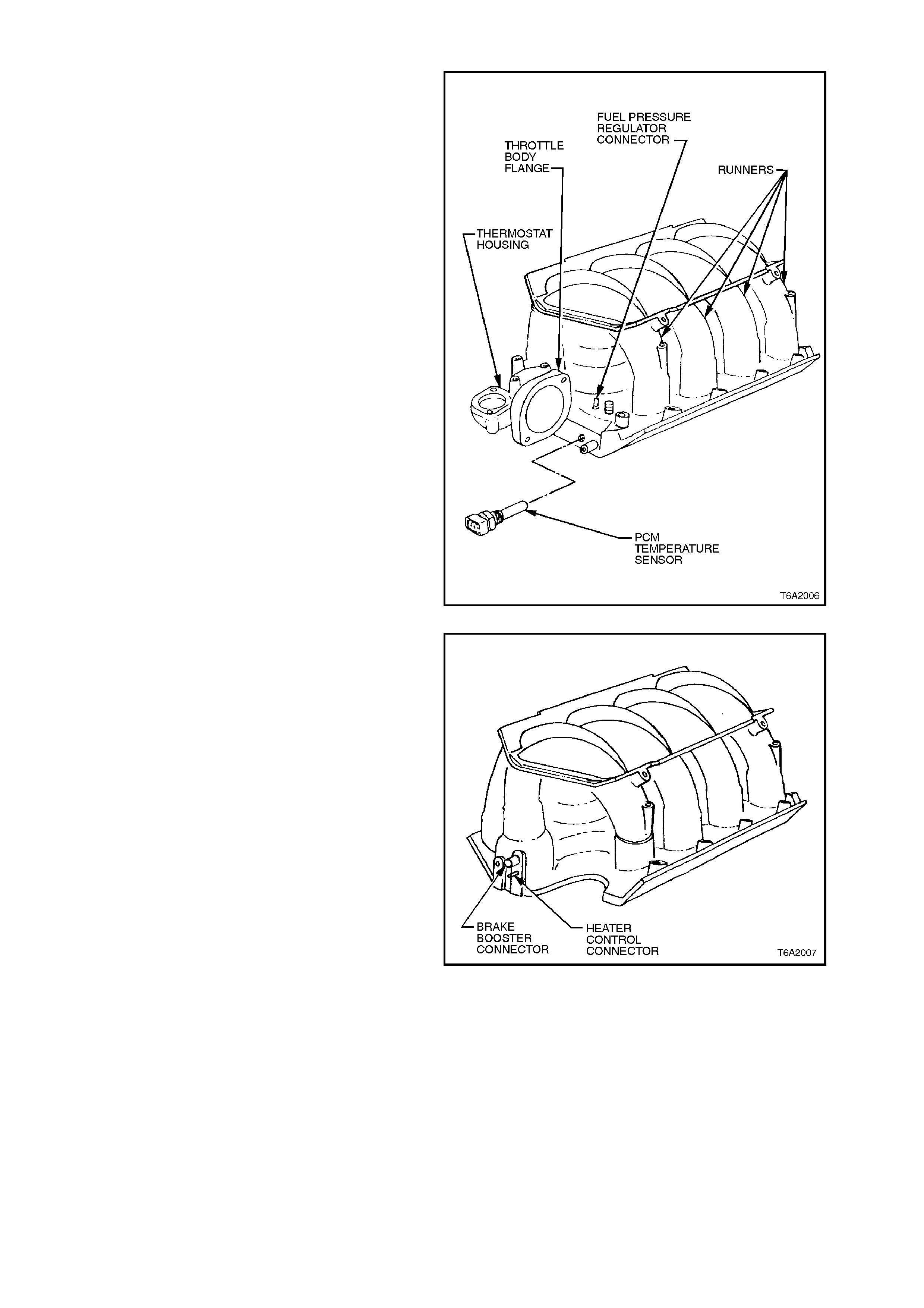

1.8 INLET AND EXHAUST MANIFOLDS

For a desc ription of the fuel inj ection com ponents,

refer to Section 6C2 POWERTRAIN

MANAGEMENT - V8 ENGINE.

The inlet manifold is a one piece alloy casting with

eight tuned length runners and a single plenum

cham ber. Vacuum c onnectors for the fuel pressure

regulator and MAF sensor are located on the inlet

manifold adjacent to throttle body.

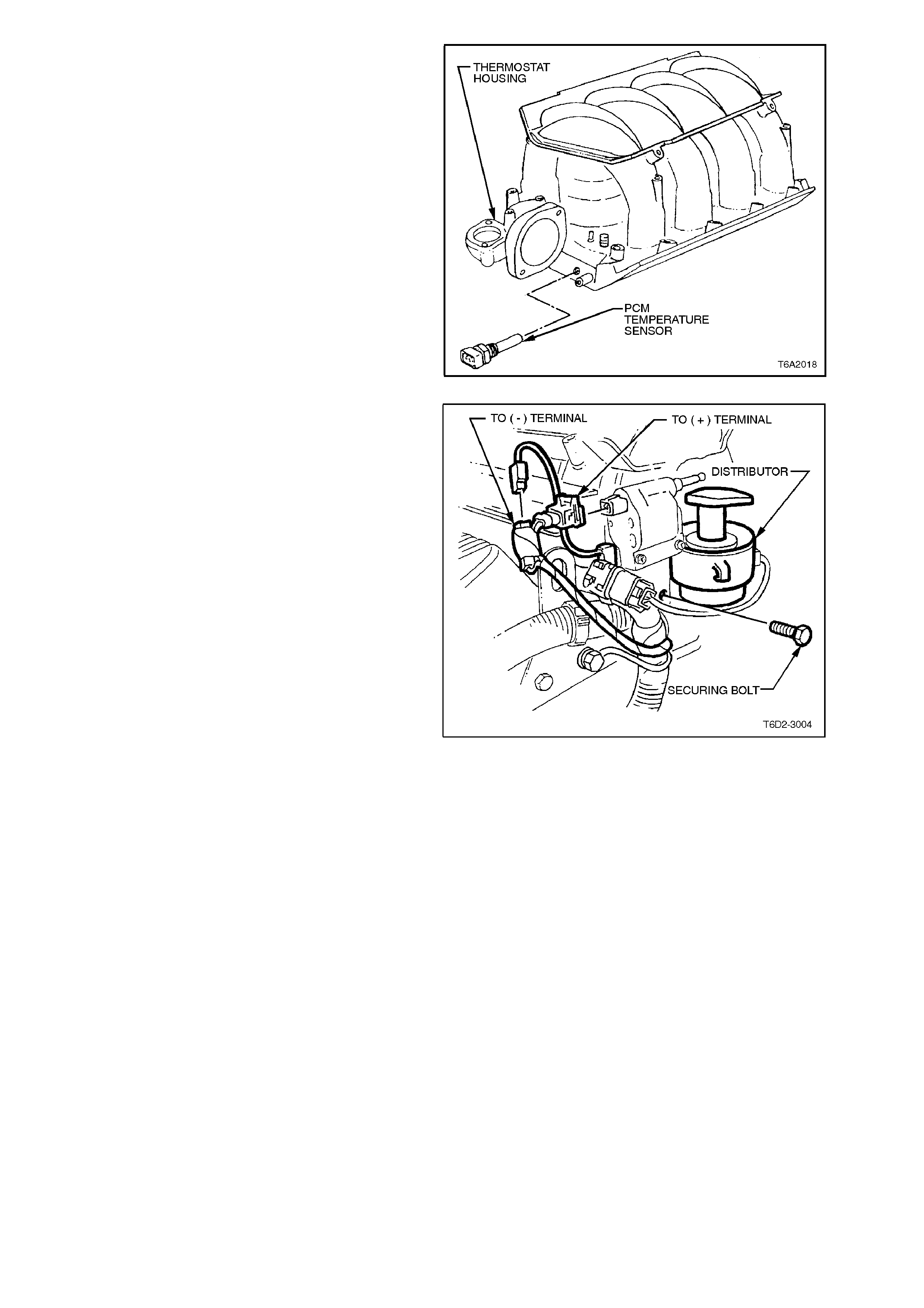

The PCM temperature sensor and the cooling

system thermostat are mounted at the front of the

inlet manifold.

Figure 6A2-6

The vacuum connections for the brak e booster and

heater controls at the rear of the manifold are

shown in Fig. 6A2-7.

Figure 6A2-7

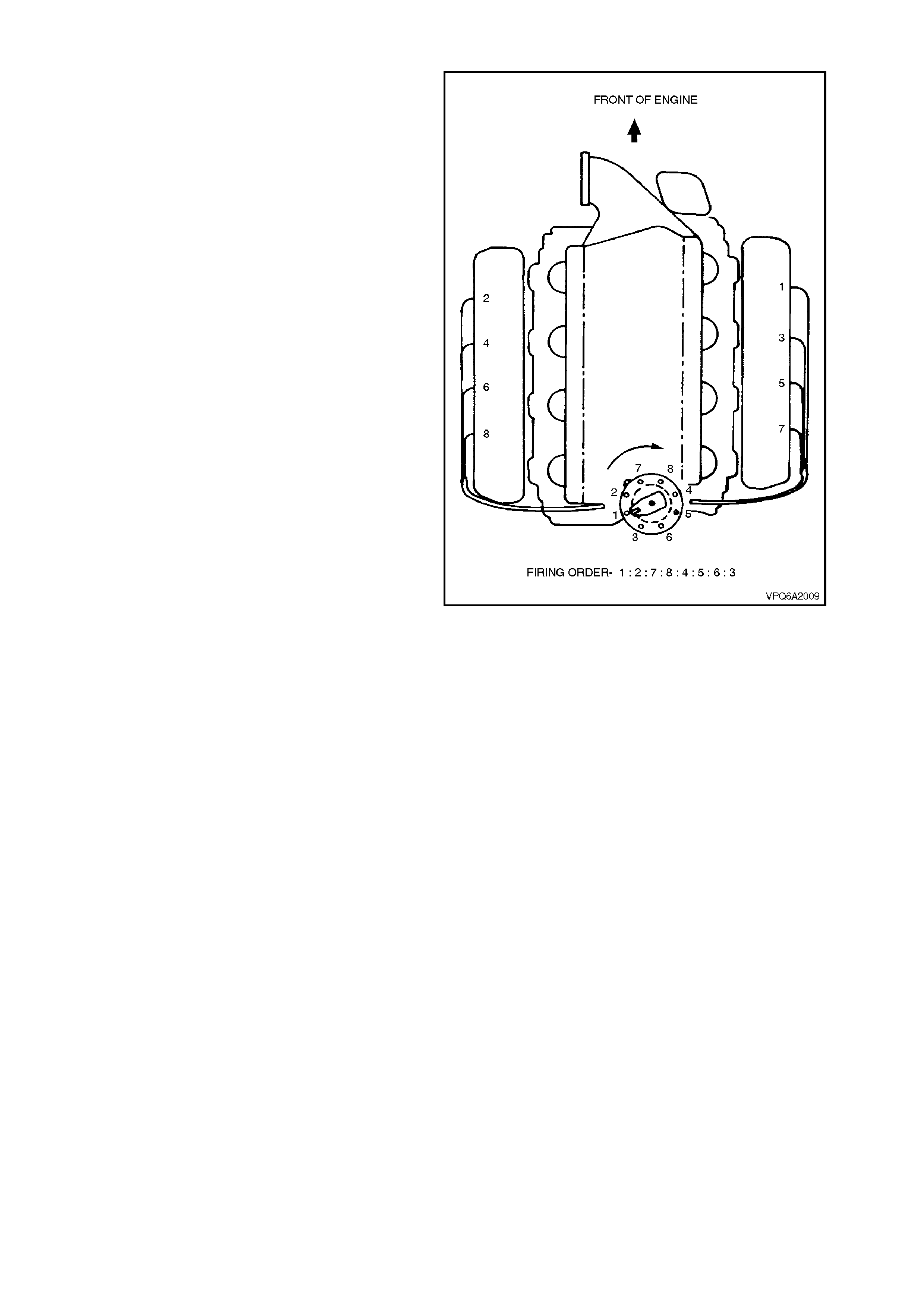

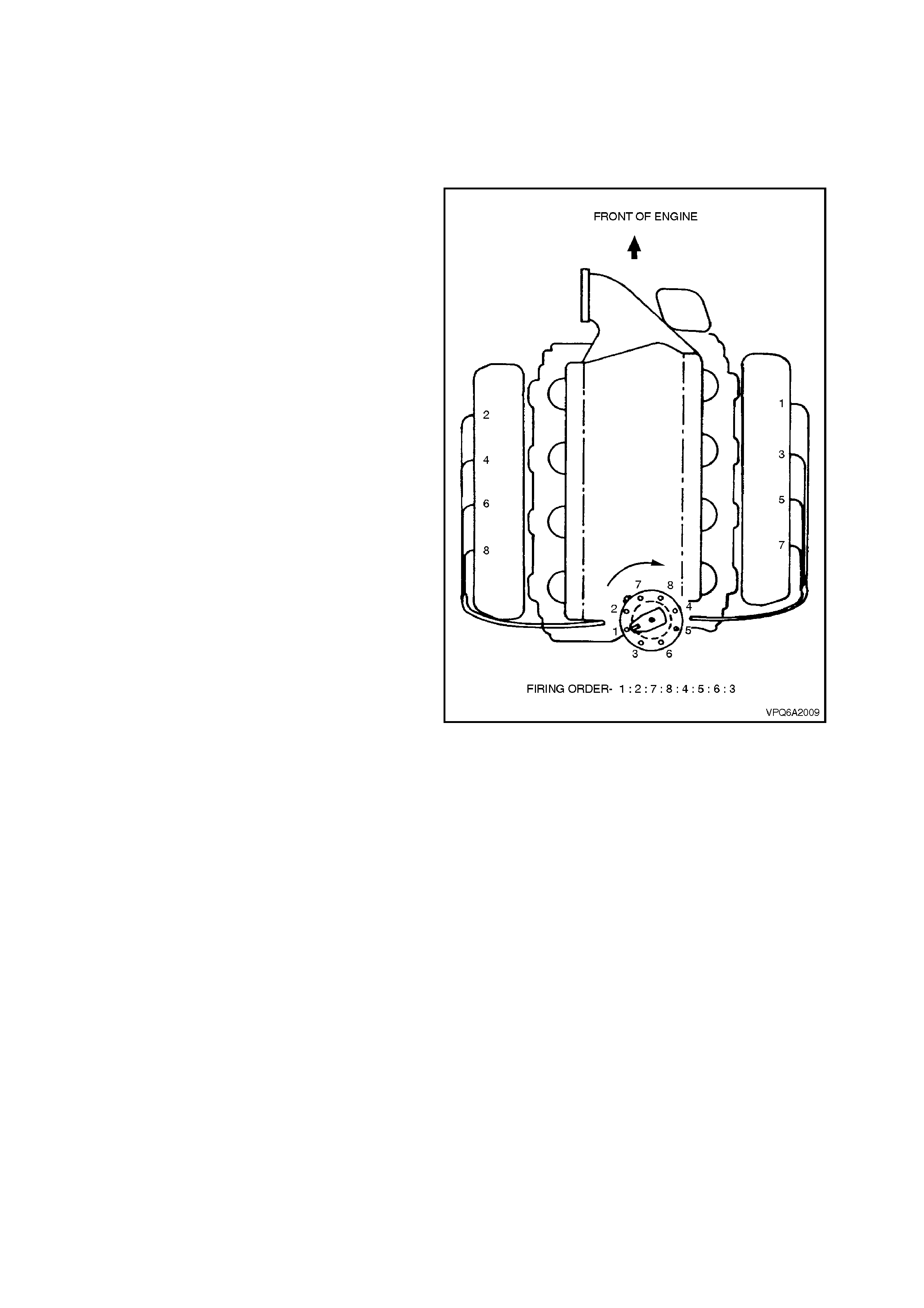

1.9 CYLINDER NUMBERING

The cylinder numbering sequence and firing order

are shown in Fig. 6A2-9.

Figure 6A2-9

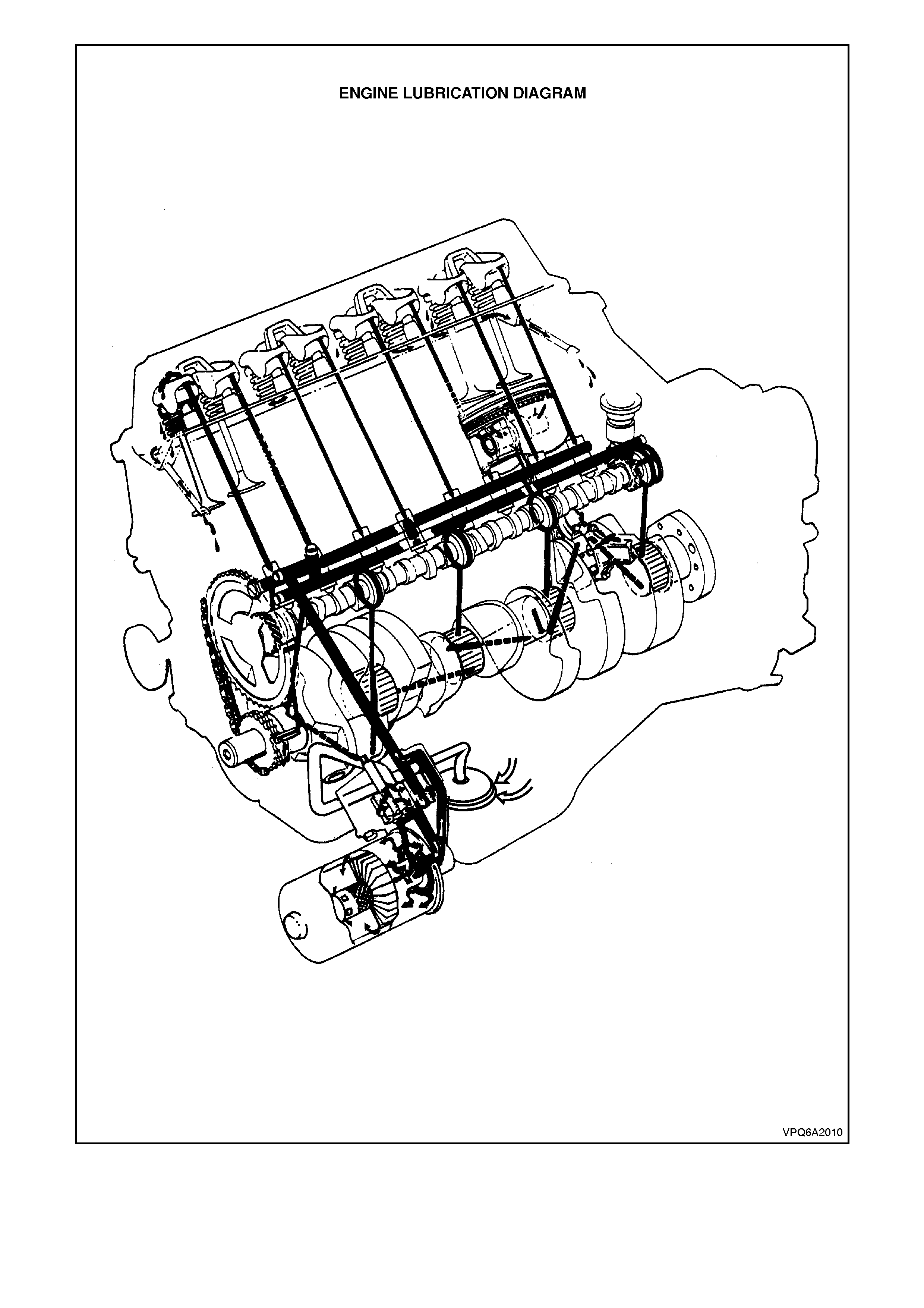

1.10 LUBRICATION

Pressurised lubrication (refer to Fig. 6A2-10) for engine internal components is provided by a positive displacement

gear type oil pump, which is driven by a short drive shaft, and a helical gear located on the front of the camshaft. Oil

from the reserve held in the oil pan is drawn through the screen and suction pipe to the low pressure (suction) side

of the oil pump via drillings in the cylinder block. Oil under pressure from the oil pump passes through a replaceable

full flow oil filter cartridge, where foreign debris and impurities are trapped within the filter elements.

Clean oil is supplied via drillings in the oil pump body and the cylinder block transfer passage, to the left hand (main)

oil gallery, which is interconnected to the right hand oil gallery by a groove and drilling in the No.4 camshaft support

webbing. The oil galleries are located above and adjacent to the camshaft.

The No.1 camshaft bearing oil supply is provided by the right hand gallery, and the No.1 crankshaft bearing oil

supply comes from the transfer passage. All the other camshaft and crankshaft bearings are supplied by the main

oil gallery, via a series of grooves and drillings in the cylinder block.

A metering nozzle pressed into a drilling that intersects the supply passage to No.1 crankshaft bearing, discharges

oil where the timing chain engages the crankshaft sprocket. Distributor drive lubrication is provided by an overflow

pressure relief aperture in the No.5 (rear) camshaft journal.

The rocker and overhead gear are lubricated through hollow push rods, using oil supplied from the hydraulic lifters.

The adjacent oil gallery supplies each bank of lifters. Excess oil drains from the overhead gear through apertures in

the cylinder block back into the oil pan.

Figure 6A2-10

OIL PUMP

The oil pump (refer to Fig. 6A2-11) consists of a drive shaft, two spur gears, a pressure relief valve and a bypass

valve enclosed in a two-piece aluminium body. The internal spur gears are driven by a helical gear mounted on the

pump drive shaft which in turn is driven by a mating gear on the front of the camshaft. The pump is mounted

externally on the left hand side of the cylinder block assembly and secured by four bolts. Two shorter bolts are used

to secure the pump body to the housing for assembly purposes.

Figure 6A2-11

The pr essure regulator valve regulates oil press ure

to 276 - 414 kPa at 2000 r pm. The bypass valve is

positioned between the high pressure (transfer

passage) and low pressure (suction) sides of the

oil pump. Should the full flow oil filter become

restr icted, full press ure oil distribution to the engine

is not affected. The oil filter bypass valve operates

at 62 - 76 kPa pressure differential.

Correct oil pressures for a new pump are as

follows:

ENGINE SPEED OIL PRESSURE

(Hot: approx. 71° C)

500 rpm

2000 rpm 48 kPa minimum

276 - 414 kPa

1.11 ENGINE MOUNTS

The engine and transmission assembly is supported at two front points and one rear point by steel backed rubber

mounts. The front mounts bolt to the front crossmember and are attached to the engine by means of brackets. The

rear mount, bolts directly to the rear of the transmission and to the rear crossmember.

2. MI NOR SERVICE OPERATIONS

SAFETY AND CAUTIONARY NOTE FOR VEHICLES FITTED WITH ABS

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4 DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & A BS/ETC.

2.1 INLET MANIFOLD

REMOVE

1. Disconnect battery earth cable from battery.

2. Drain cooling system, refer to

Section 6B2 ENGINE COOLING - V8

ENGINE.

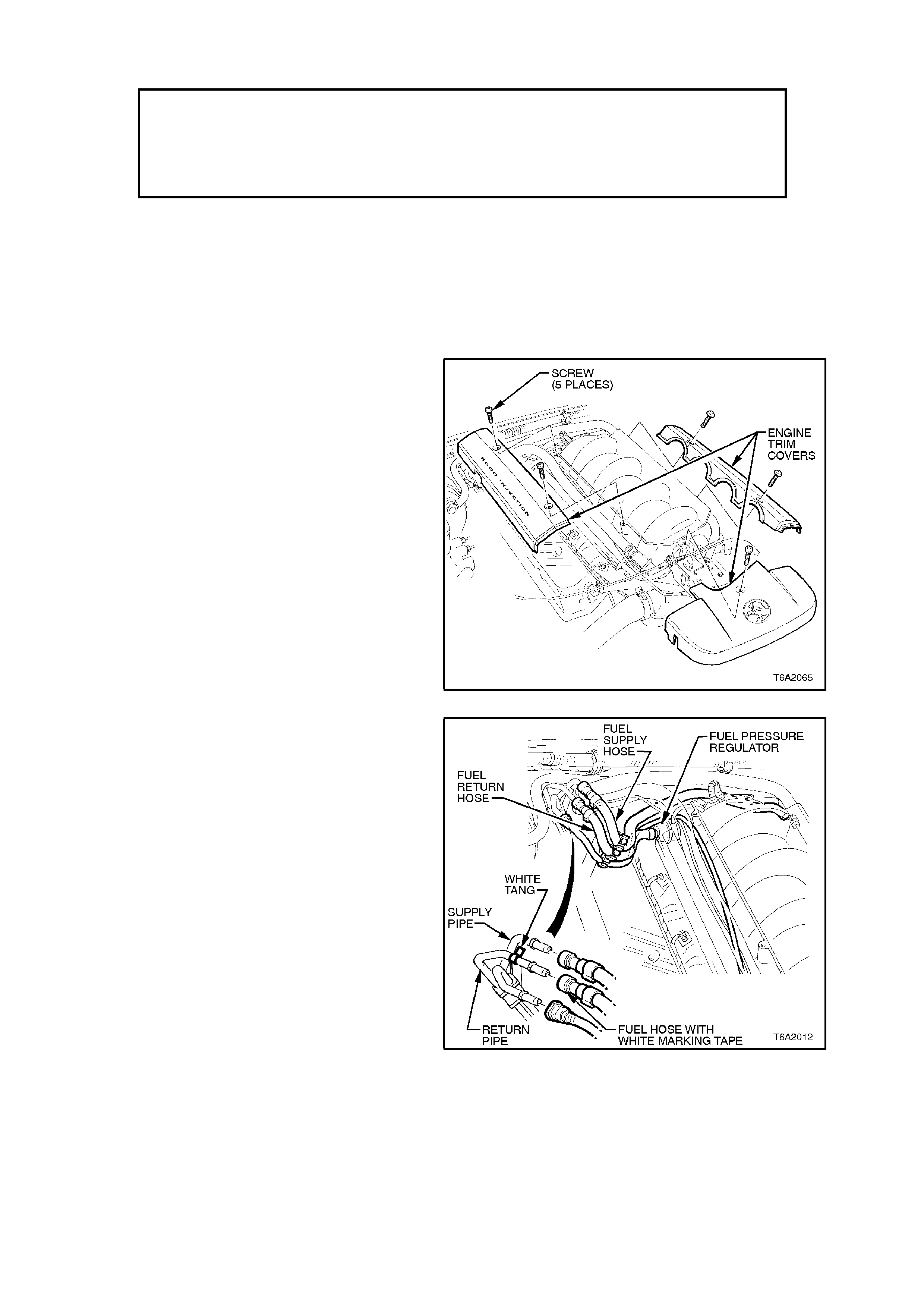

3. Remove engine trim covers.

4. Depressurise fuel rail, refer to

Section 6C2 POWERTRAIN M ANAGEM ENT

- V8 ENGINE.

Figure 6A2-12

5. Using quick connect release tool No. 7370

open tool and install over fuel line.

6. Close 7370 and pull into fuel line quick

connect to release it from fuel inlet line, pull

back on quick connect, disconnect fuel feed,

return and fuel evaporative canister hoses at

quick connects. Plug all openings to prevent

foreign matter entry.

NOTE:

Do not attempt to remove hoses from fuel rail

connections. Once removed from fuel rail

connection hoses require replacement.

Figure 6A2-13

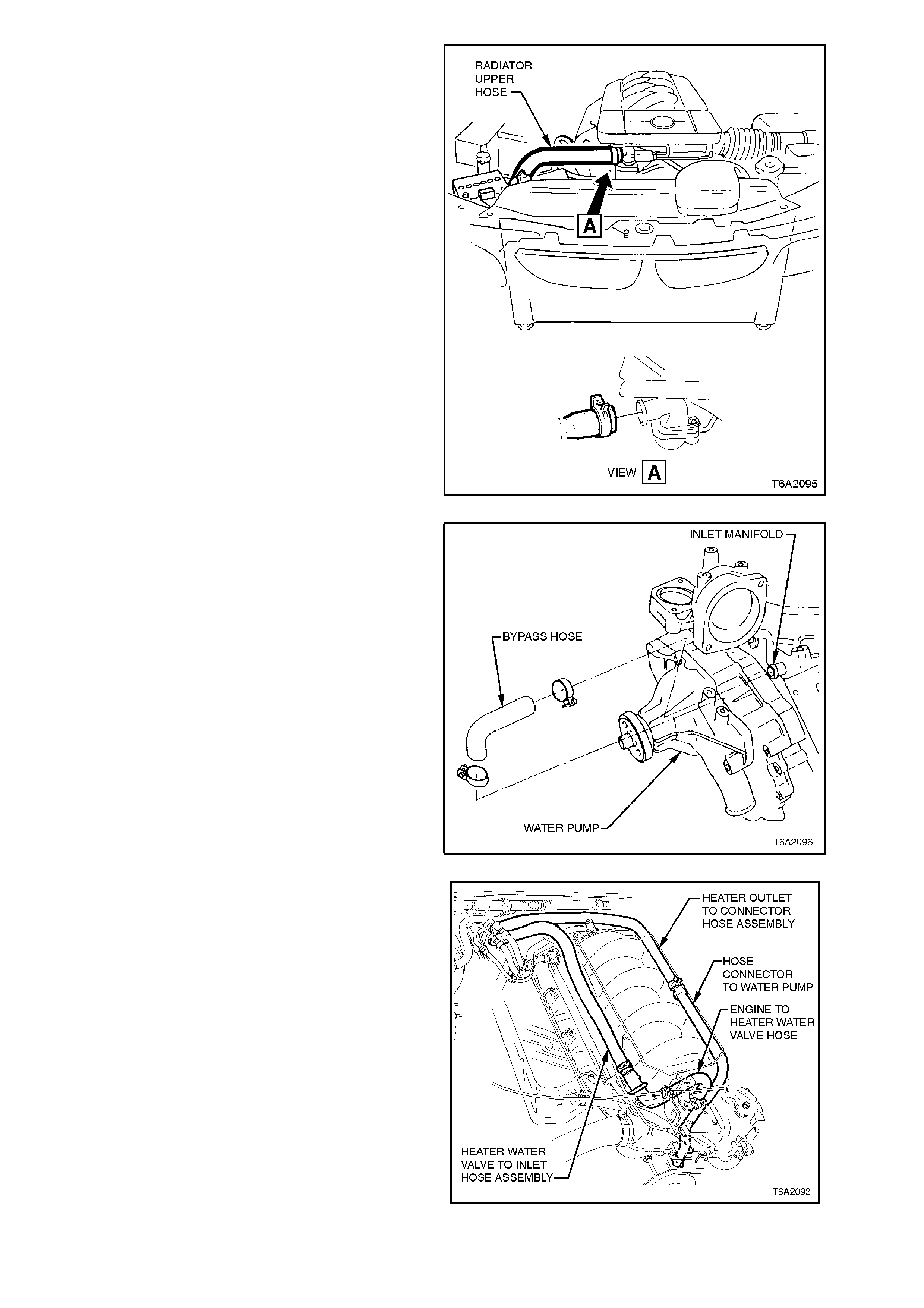

7. Disconnect upper radiator hose from

thermostat housing outlet cover.

Figure 6A2-14

8. Disconnect coolant bypass hose from inlet

manifold.

Figure 6A2-15

9. Disconnect heater hoses from inlet manifold

and water pump. Unbolt hose brackets from

fuel rail and secure heater hoses to one side.

Figure 6A2-16

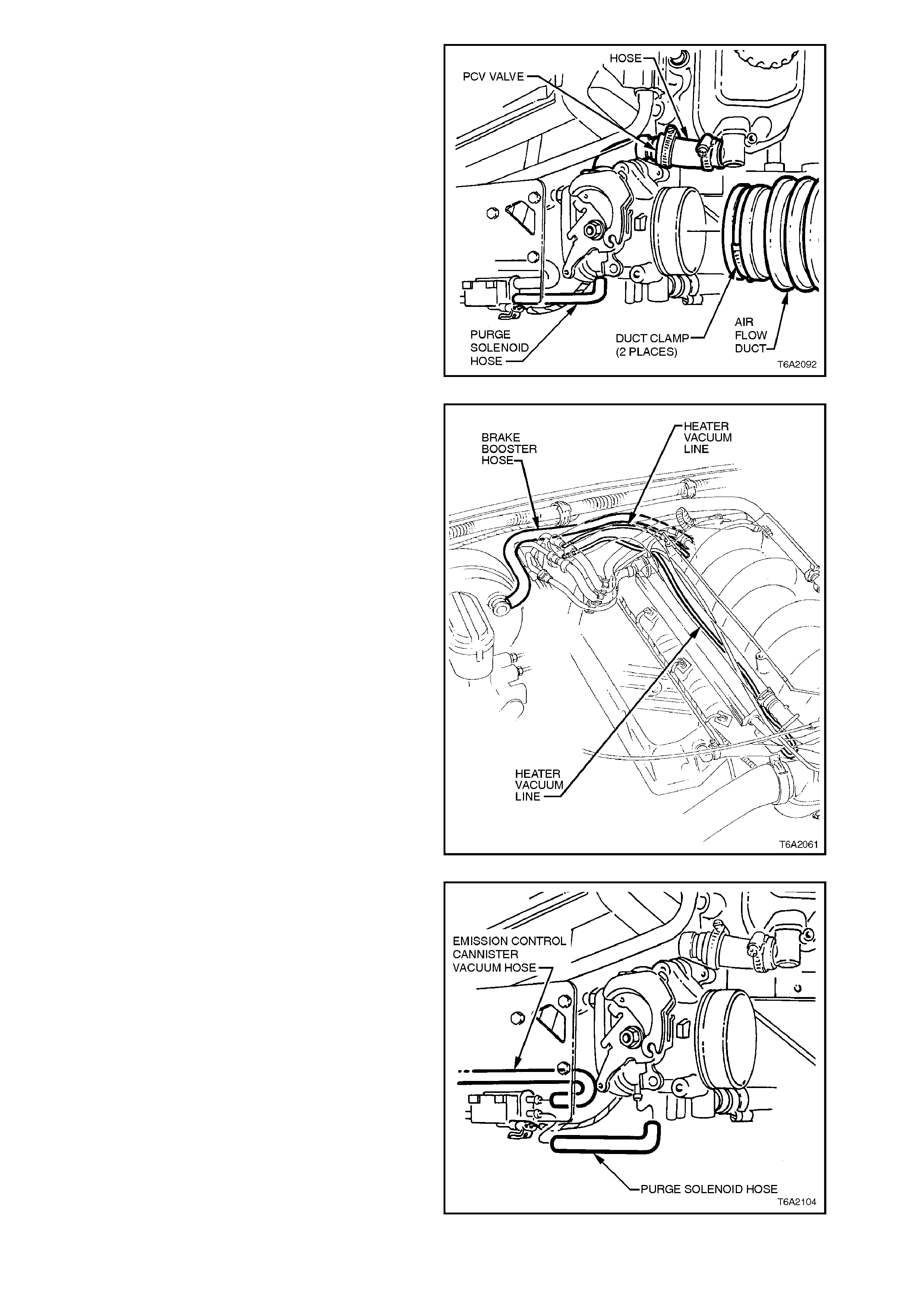

10. Disconnect inlet air duct from throttle body.

11. Disconnect PCV hoses from throttle body.

Figure 6A2-17

12. Disconnect the brake booster supply and

heater control hoses from the rear left hand

side of inlet manifold.

Figure 6A2-18

13. Disconnect emission control canister vacuum

hoses from purge solenoid and disconnect

purge hose from throttle body. Refer to

Section 6C2-3 SERVICE OPERATIONS - V8

ENGINE - CANISTER PURGE SOLENOID.

Figure 6A2-19

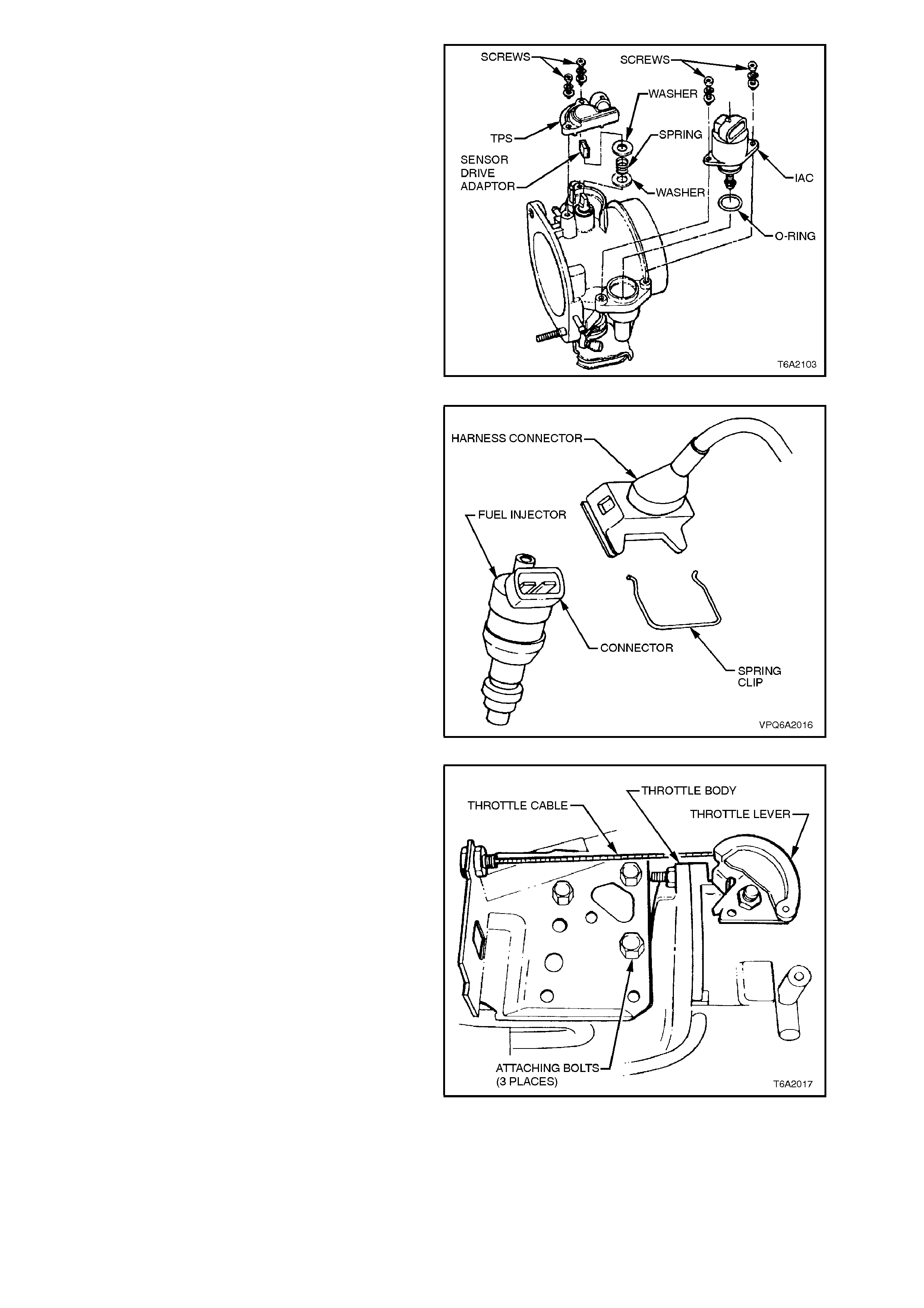

14. Disconnect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) electrical

connectors from throttle body. Refer to

Section 6C2-3 SERVICE OPERATIONS - V8

ENGINE - THROTTLE POSITION (TP)

SENSOR.

Figure 6A2-20

15. Disconnect fuel injector electrical connectors

and unclip connector harnesses from fuel rail.

Figure 6A2-21

16. Disconnect throttle cable and cruise control

cable (where fitted) from throttle body.

17. Remove throttle bracket attaching bolts and

secure bracket and cable assembly to one

side.

Figure 6A2-22

18. Disconnect PCM tem per ature sens or electr ical

connectors.

Figure 6A2-23

19. Remo ve bolt securing ignition coil as sembly to

inlet manifold.

Figure 6A2-24

Figure 6A2-25

20. Remo ve inlet manif old bolts, then rem o ve inlet

manifold.

21. Where it is required to remove the fuel rail,

fuel injectors and throttle body, refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE.

REINSTALL

1. If thermostat was removed, clean contact

surfaces and place thermostat and housing in

position. Fit a new O - ring and tighten

thermostat housing bolts to specified torque.

NOTE:

Purge solenoid locates on f ront therm ostat housing

bolt.

TORQUE SPECIFICATION 20 - 27 Nm

2. If the sensor was removed, apply pipe thread

sealant, such as Loctite 567 or equivalent

(Holden Specification HN 1584) to threads of

PCM temperature sensor. Reinstall, then

tighten to the specified torque.

PCM COOLANT

TEMPERATURE SENSOR

TORQUE SPECIFICATION 12 Nm

3. Clean gasket and seal surfaces on engine

block and manifold. Take care not to damage

any machined surfaces.

4. To avoid extrusion of the manifold front and

rear seals, the contact surfaces on the

cylinder block must be free of oil or any

sealing compound.

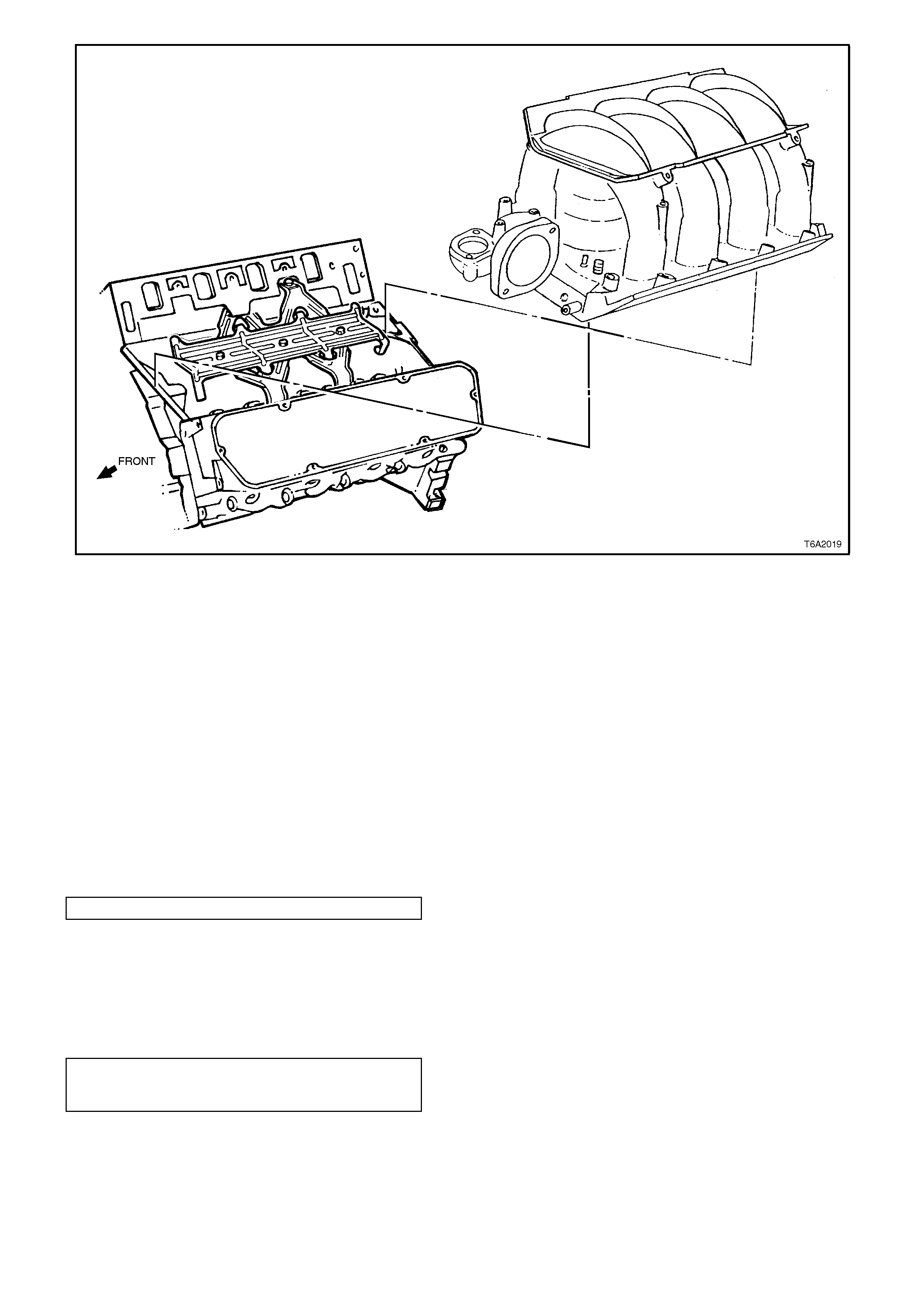

Figure 6A2-26

5. Install new manifold gaskets. Use plastic

retainers to locate gaskets. Note the 'R'

punched mark on the gasket must point to

rear of engine, on each side.

6. Apply RTV 732 sealant (Holden Specification

HN 1373) to the inlet manifold gasket slots, in

four places as indicated in Fig. 6A2-26.

7. Install new manifold front and rear seals on

engine block, ensuring that the ends of both

the front and rear seals are within the inlet

manifold gasket slots.

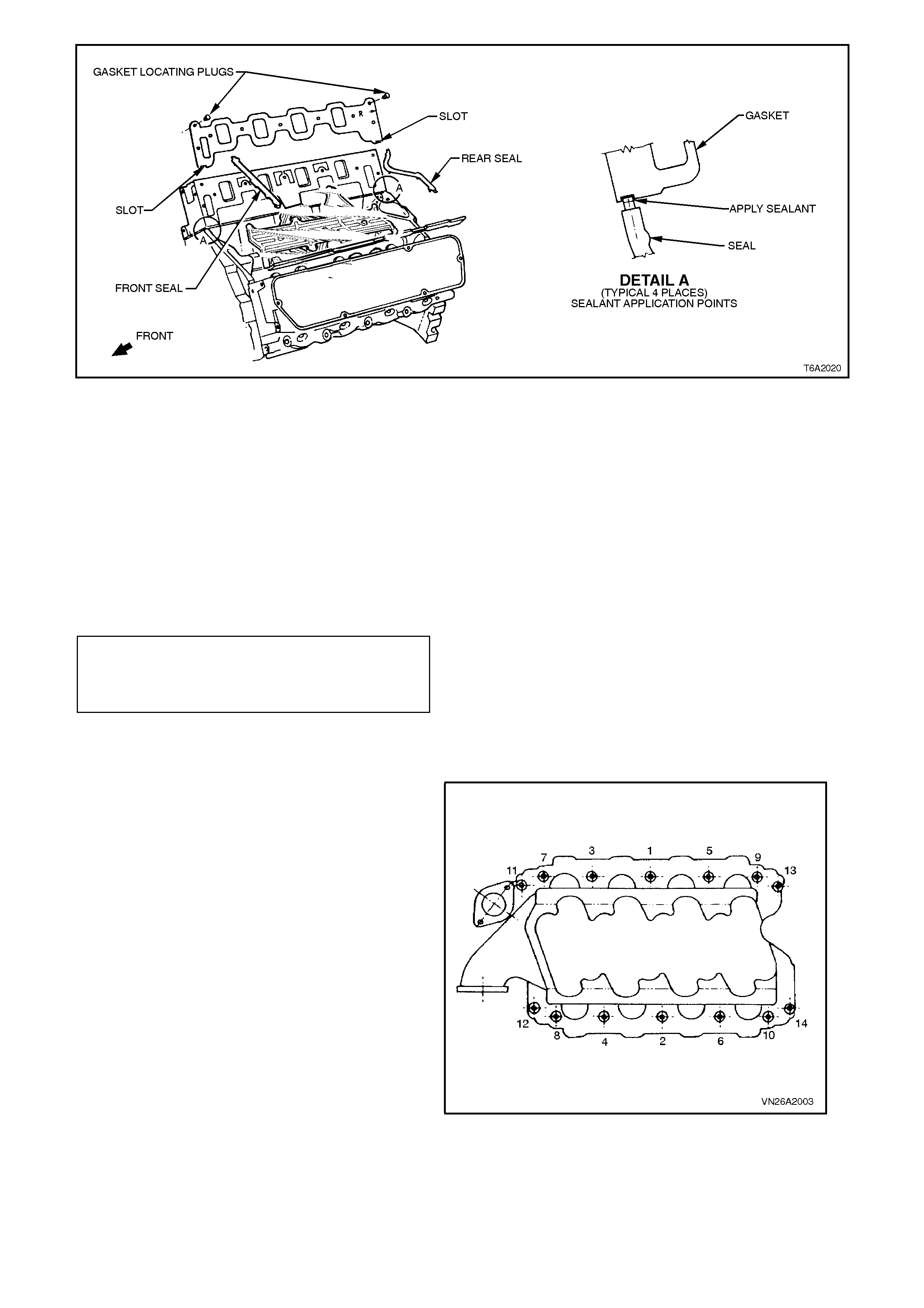

INLET MANIFOLD

SECURING BOLT

TORQUE SPECIFICATION:

STAGE 1

12 - 17 Nm

STAGE 2

34 - 41 Nm

NOTE:

The single lug on the front seal faces forward.

8. Reinstall manifold and tighten bolts to the

torque figures specified, in two stages and in

the sequence shown in Fig. 6A2-27.

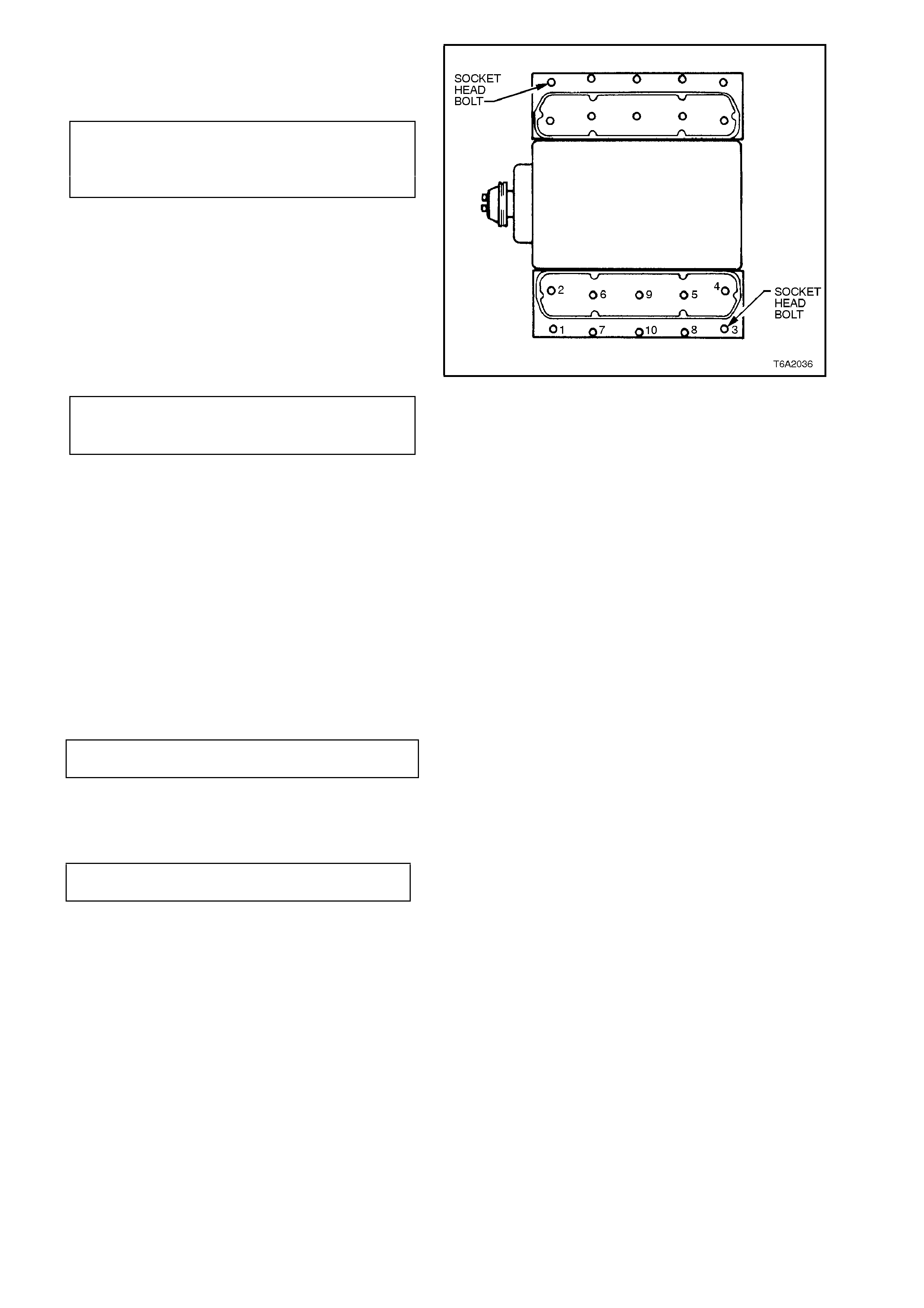

Figure 6A2-27

9. Reinstall remaining components in reverse

order to removal.

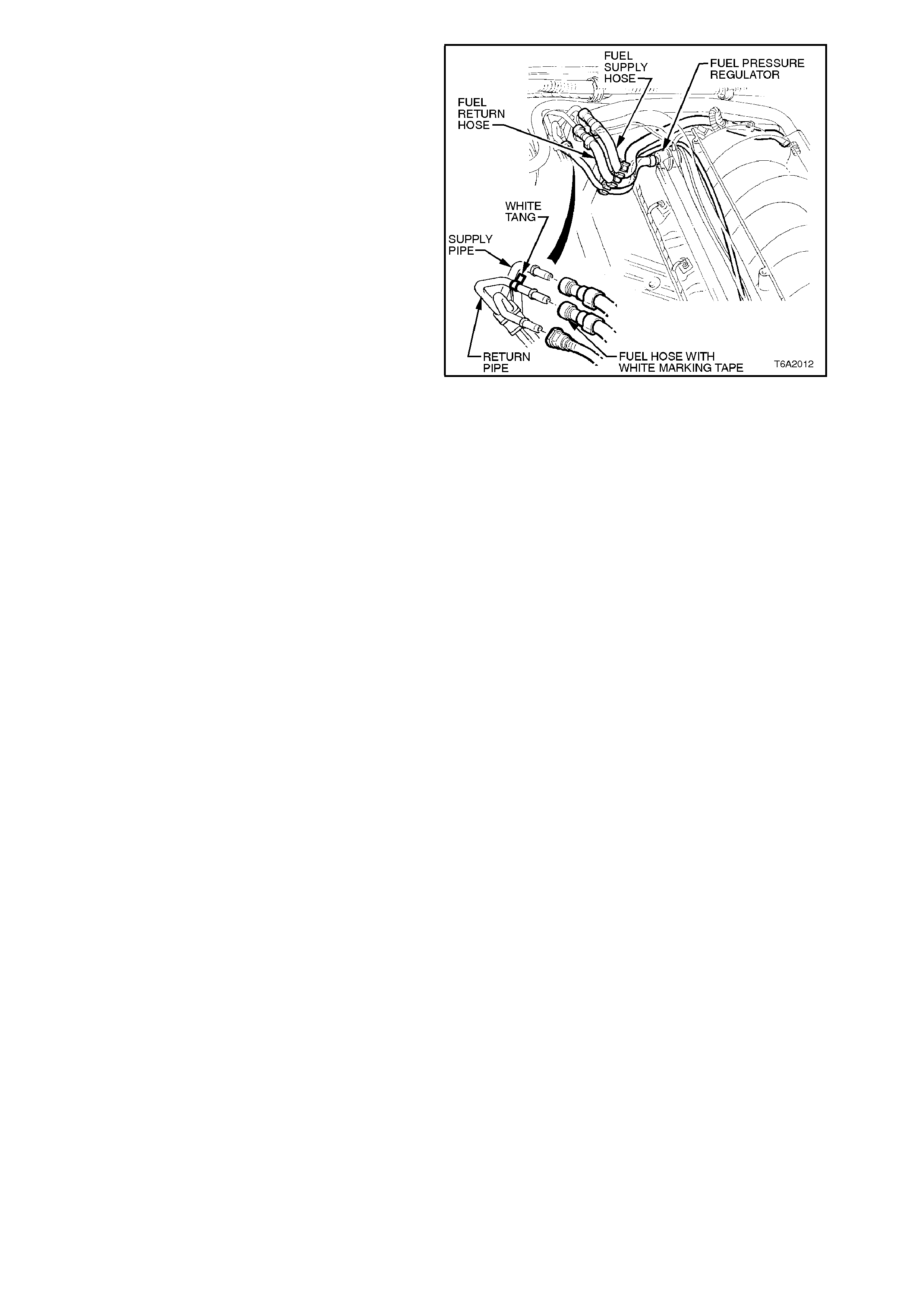

NOTE:

Reconnect the fuel supply, refer to Fig. 6A2-28.

10. Adjust the throttle cable

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE and cruise contr ol cables (where

fitted) Section 12E CRUISE CONTROL.

11. Refill cooling system with specified coolant, in

the correct proportion as detailed in

Section 6B2 ENGINE COOLING - V8

ENGINE.

12. Start engine and check for correct operation.

Figure 6A2-28

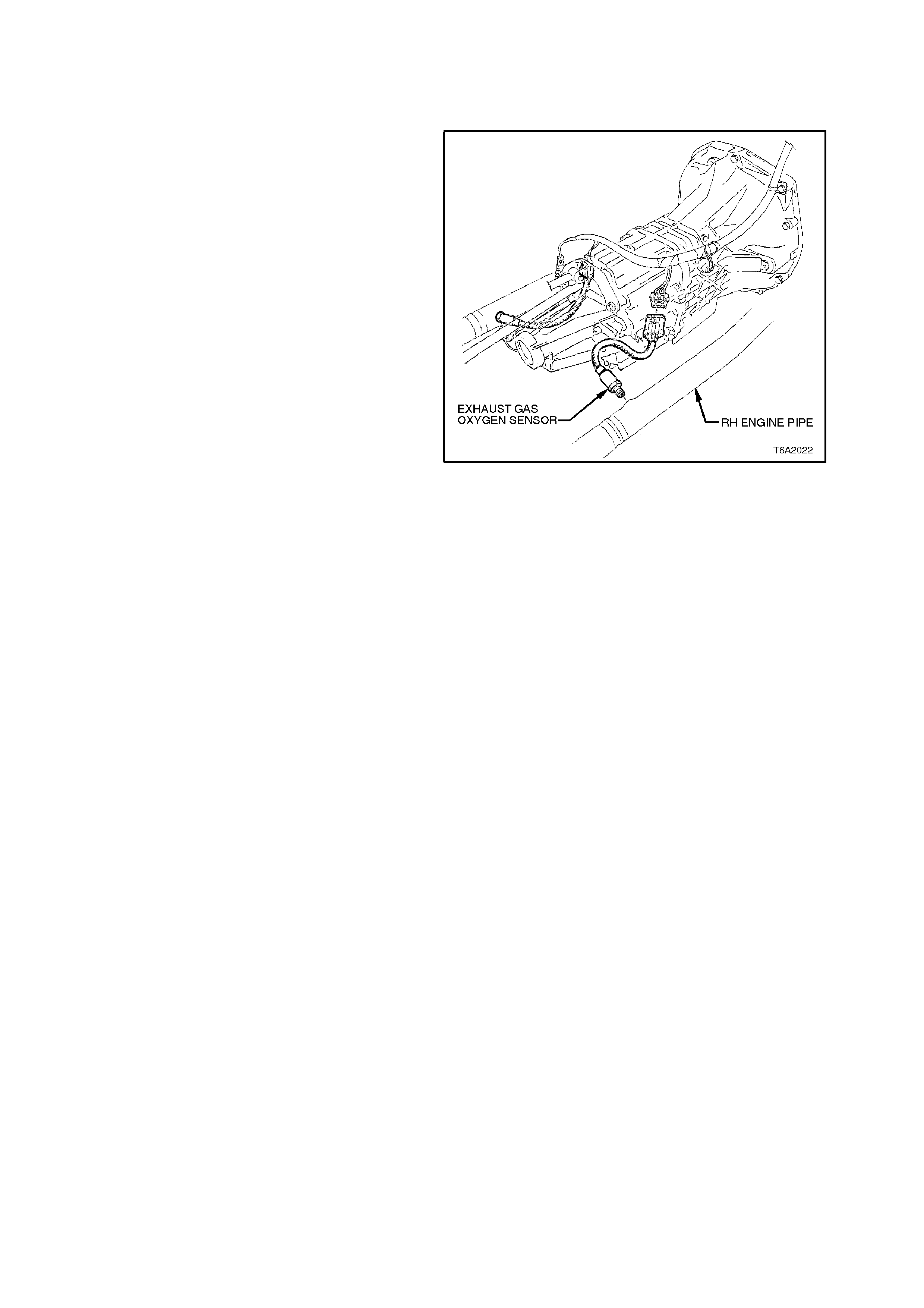

2.2 EXHAUST MANIFOLD

REMOVE

1. Disconnect battery earth cable from battery.

2. Disconnect oxygen sensor harness

connectors.

3. Remove the exhaust pipe to manifold flange

nuts, then lower the exhaust system assembly.

Figure 6A2-29

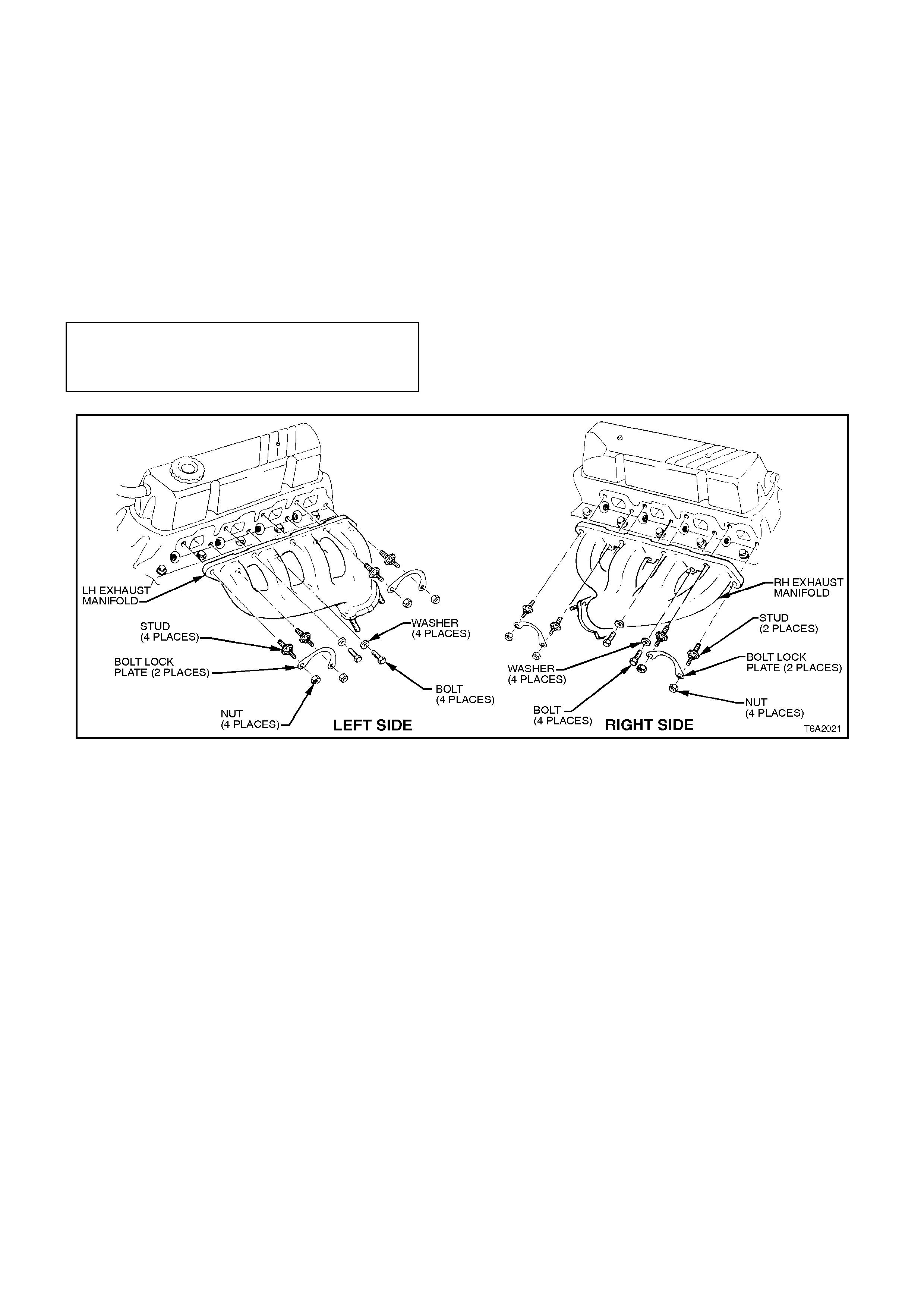

4. Remove spark plugs.

5. Unscrew retaining bolt lock nuts (four places

each side), then remove lock plates, refer to

Fig. 6A2-30.

6. Unscrew manifold retaining studs and bolts,

then remove exhaust manifold/s.

REINSTALL

1. Clean mating surfaces on manifold/s and

head/s. Take care not to damage machined

surfaces.

2. Installation is the reverse of removal

procedure, except for the following:

a. Apply anti-seize com pound s uc h as Kopr -

Kote or equivalent (Holden Specification

HN 1325) to the threads of exhaust pipe

to manifold attaching studs before

assembly.

b. Tighten manifold nuts evenly to specified

torque.

EXHAUST MANI F OLD STUDS A ND BOLTS

EXHAUST MANIF O LD LOCK PLAT E NUT S

OXYGEN SENSOR TO EXHAUST PIPE

EXHAUST PIPE TO MANIFOLD

20 - 28 Nm

15 - 20 Nm

38 - 46 Nm

15 - 35 Nm

Figure 6A2-30

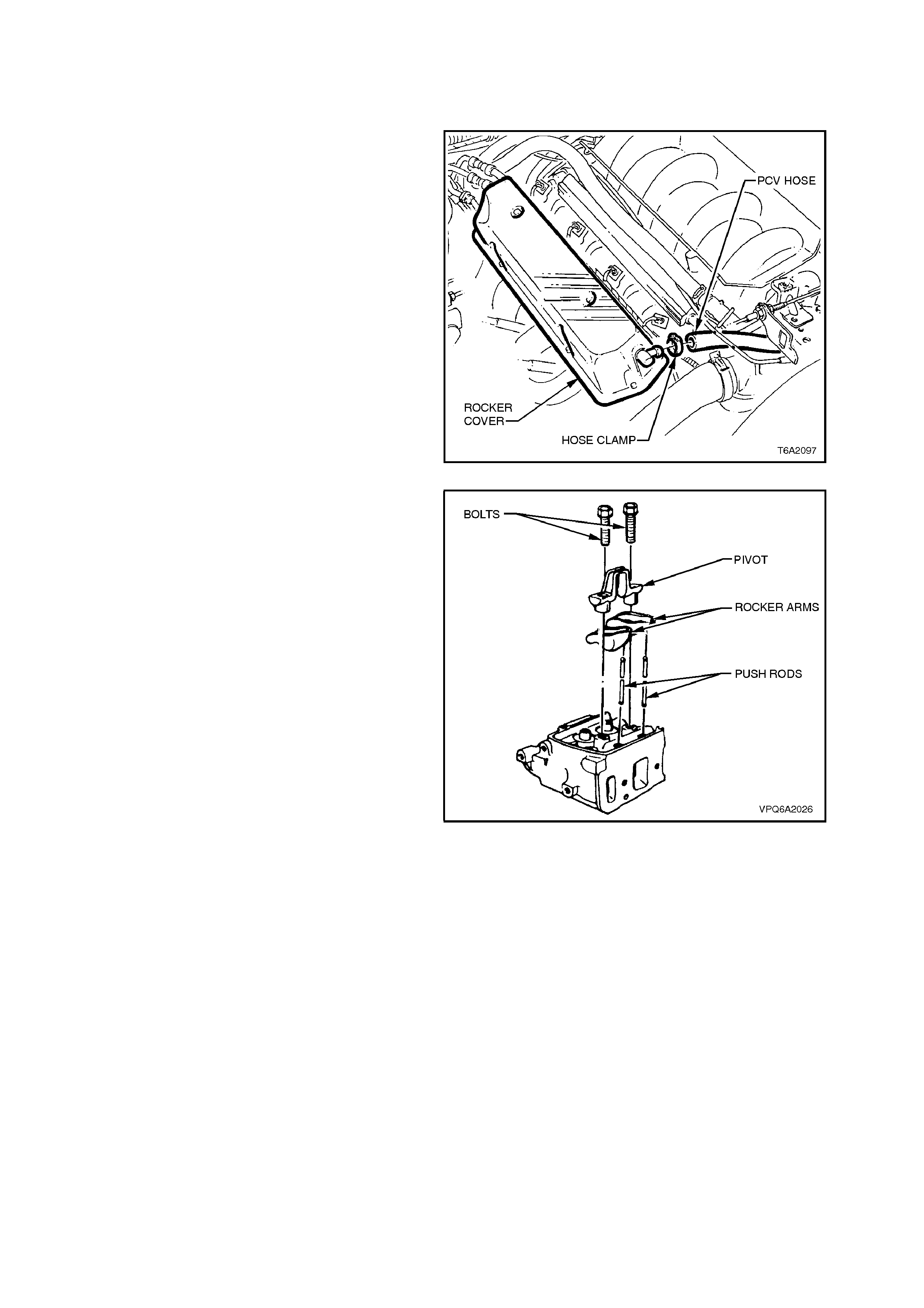

2.3 ROCKE R ARMS

REMOVE

1. Disconnect battery earth cable from battery.

2. Tag and disconnect spark plug leads from

spark plugs and support brackets.

3. Remove the engine trim covers, refer to

2.15 ENGINE TRIM COVERS in this Section.

4. Disconnect engine ventilation hose and

Positive Crankcase Ventilation (PCV) valve

hose from rocker covers.

5. Using a suitable Allen key, remove rocker

cover socket head retaining bolts, washers,

and seals f rom beneath the top bolts . Remove

spark plug lead brackets which are also

secured by the rocker cover bolts.

6. Remove rocker covers.

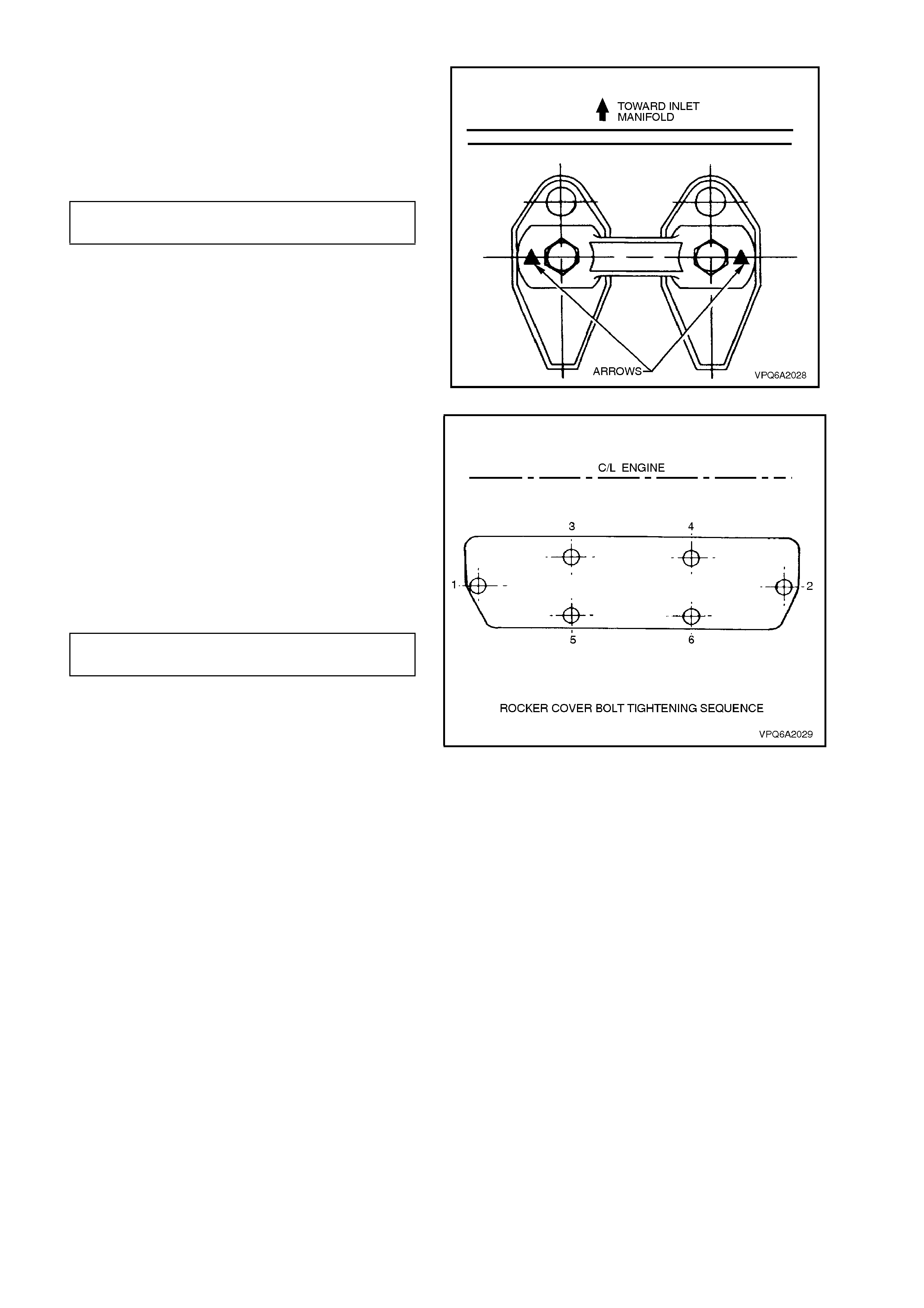

Figure 6A2-31

7. Remove rocker arm pivot bolts, pivots and

rocker arms.

NOTE:

Remove the rocker arms and pivots from each

cylinder as a set. It is important that the original

location of all pivots and arms is maintained for

reassembly. For this reason, parts should be

placed in a special rack.

Figure 6A2-32

REINSTALL

1. Coat rocker arm pivots and contact surfaces

with Molybdenum Disulphide grease (Holden

Specification HN 1271) before assembly.

2. Remove distributor cap.

3. Remove spark plugs for ease of crankshaft

rotation.

4. Rotate crankshaft by hand until distributor

rotor is in No.1 cylinder position, (refer to Fig.

6A2-33) i.e. both No.1 cylinder pushrods are

retracted (both valves closed).

Figure 6A2-33

5. Assemble No.1 cylinder rocker arms and

rocker arm pivots in their original locations with

the arrows on the rocker arm pivots pointing

towards the inlet manifold.

6. Install rocker arm pivot bolts and tighten to

specified torque.

ROCKER COVER BOLT 3 - 6

TORQUE SPECIFICATION Nm

7. Rotate crankshaft to next cylinder in the firing

order. Ensure that the push rods are fully

retracted (both valves closed), then install the

rocker arm set. Repeat this procedure for the

remaining cylinders.

Figure 6A2-34

8. Reinstall remaining components in reverse

order of removal procedure noting the

following:

a. Use new rocker cover gaskets.

b. Ensure spark plug leads are routed

correctly, refer Section 6D2-3 IGNIT ION

SYSTEM - V8 ENGINE.

c. Tighten rocker cover bolts to specified

torque and in the sequence s hown in Fig.

6A2-35.

ROCKER ARM PIVOT BOLTS 24 - 32

TORQUE SPECIFICATION Nm

Figure 6A2-35

2.4 VALVE TIMING CHECK

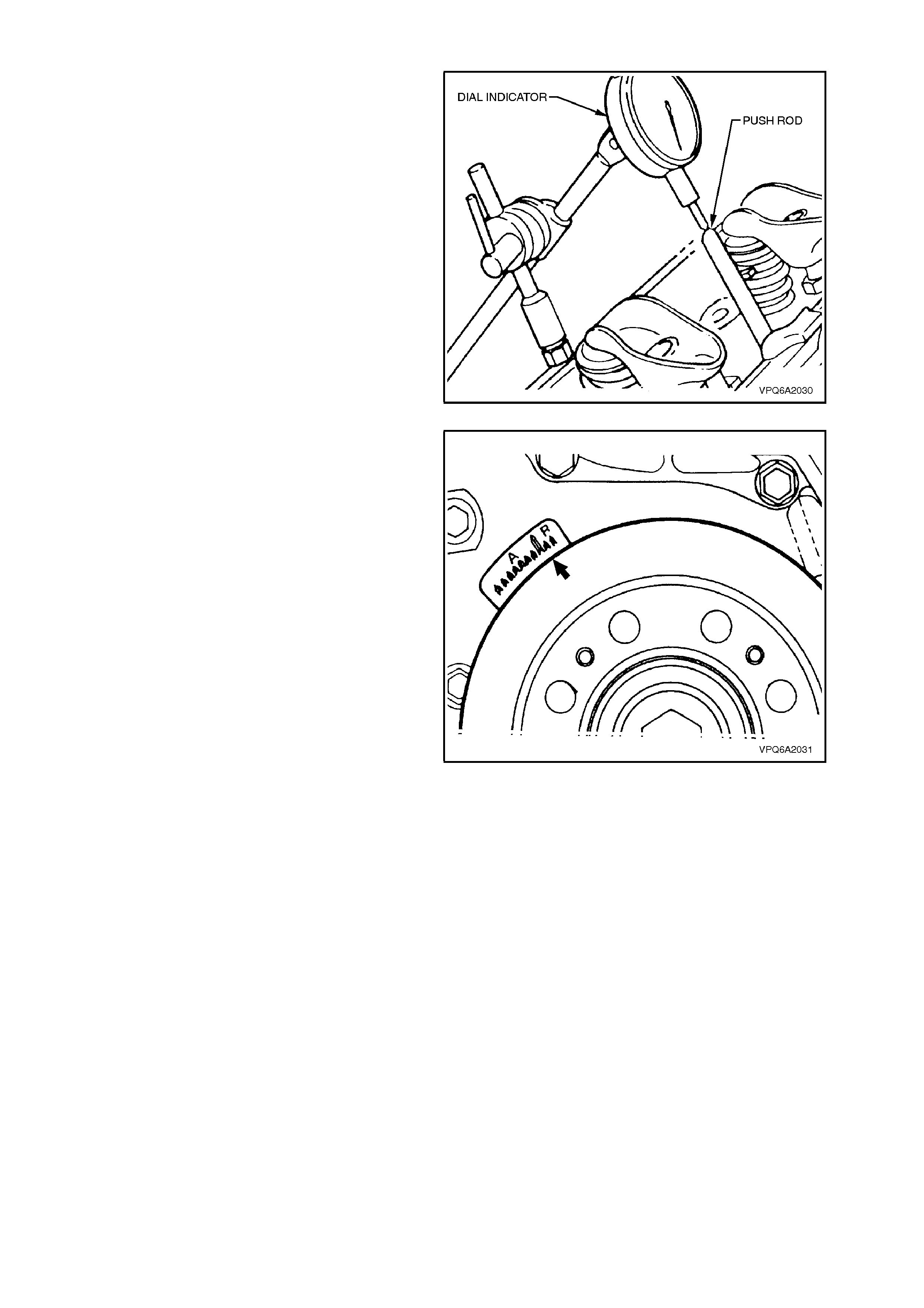

1. Remove No.1 cylinder rocker arm pivot

and rocker arms as described in

2.3 ROCKER ARMS in this Section.

2. Remove spark plugs for ease of crankshaft

rotation.

3. Mount a dial indicator with the plunger resting

on the top of the No.1 cylinder exhaust push

rod. The rocker arm pivot bolt holes (5/16

inches U.N.C. thread) can be used to mount

the dial indicator. Note that the exhaust push

rod is the f orem ost of the two push rods in this

instance.

4. Rotate the crankshaft by hand until the No.1

piston is at the top of its compression stroke

and both push rods are fully retracted (both

valves closed).

5. Set the dial indicator to zero.

Figure 6A2-36

6. Rotate the crankshaft in a clockwise direction

one revolution, until the timing mark on the

torsional damper is aligned at the T.D.C.

position (refer to Fig. 6A2-37).

7. Note the maximum lift that occurs while

rotating the crankshaft.

Maximum lift occurs approximately two thirds

turn after T.D.C. and should be 6.62 mm ±

0.13 mm.

8. With the timing mark aligned at T.D.C. the lift

should be 0.45 mm.

9. Repeat the procedure on the No.1 cylinder

inlet valve push rod. The maximum lift should

be 6.62 mm ± 0.13 mm, and lift at T.D.C.

should be 0.40 mm.

10. Remove the dial indicator.

11. Reinstall components as described in

2.3 ROCKER ARMS in this Section. Figure 6A2-37

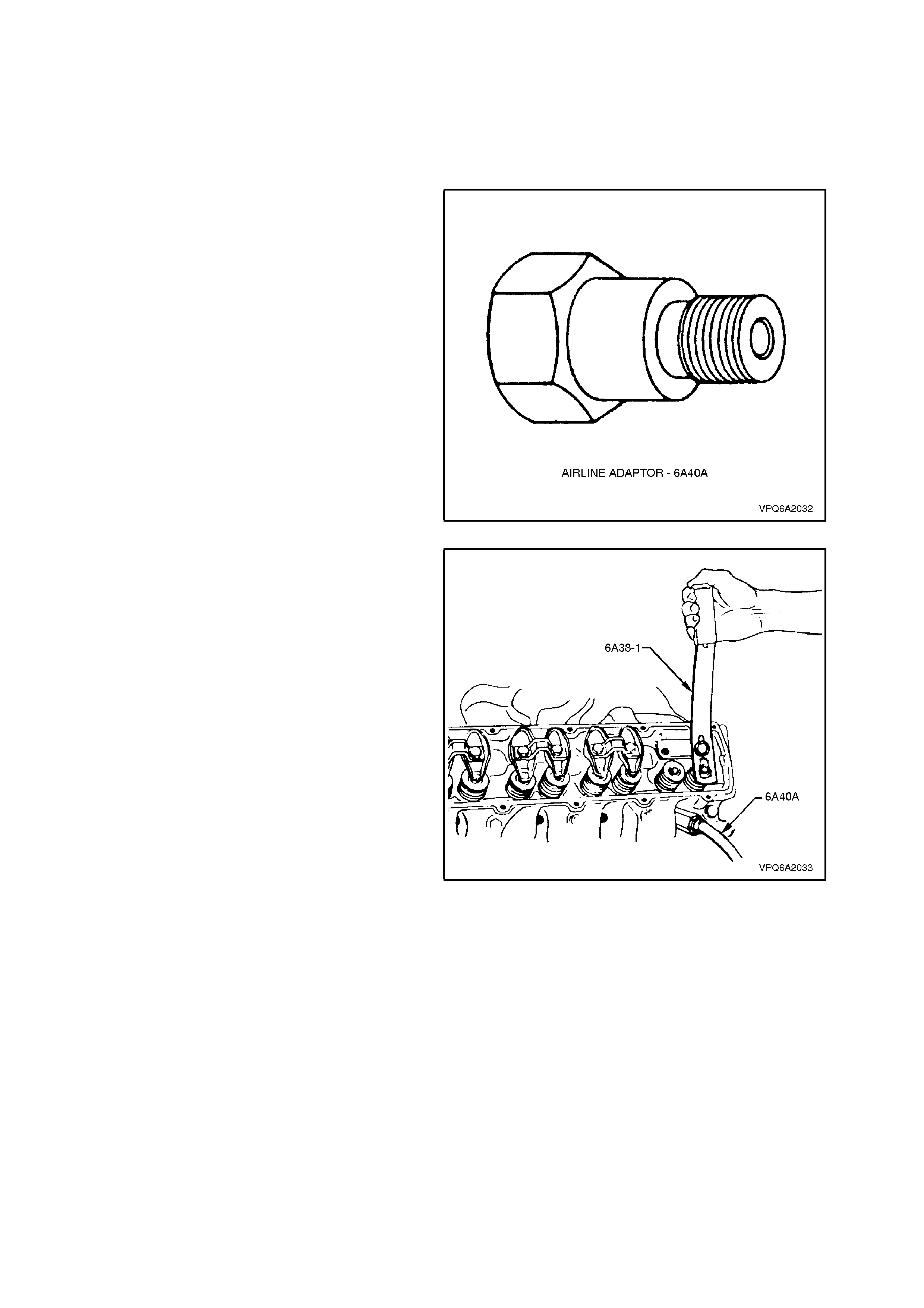

2.5 VALVE SPRING AND OIL SEAL

REMOVE

1. Remove relevant valve rocker arm pivot and

rocker arms as described in

2.3 ROCKER ARMS in this Section.

2. Remove both push rods.

3. Rem ove spark plug f rom relevant cylinder and

install air line adaptor, Tool No. 6A40A, into

the spark plug hole. Apply air pressure of

approximately 850 kPa to hold valves in

closed position.

Figure 6A2-38

4. Install valve spring compressor, Tool No.

6A38-1, using a 5/16 x 2-1/4 inch U.N.C. bolt

with a large, flat washer. The bolt is installed

into the rocker arm pivot bolt hole.

5. Use valve spring compressor to compress

valve spring. Remove valve stem collets.

NOTE:

It may be necessary to tap the valve end of the

spring compressor using a soft faced hammer, to

overcome binding of the valve stem collets.

6. Slowly release tool and remove cap, shield,

spring, damper and oil seal.

Figure 6A2-39

REINSTALL

1. Place damper, valve spring, shield and cap

over valve stem.

2. Use valve spring compressor, Tool No. 6A38-

1, to compress and hold valve spring in a

compressed condition.

3. Install new oil seal in lower groove of valve

stem. Ensure the seal is seated properly and

not twisted.

4. Reinstall valve collets, ensuring they locate

correctly in top groove of valve stem. Slowly

release valve spr ing com pre ssor check ing that

the collet s seat correctly.

NOTE:

Grease may be used to hold collets in place.

5. Remove valve spring compressor.

Figure 6A2-40

6. Rem ove air pressur e fr om air line adaptor and

remove air line adaptor from spark plug hole.

7. Using a suitable suction cup or a vacuum hand

pump and appr opriate fittings, apply a vacuum

to the valve cap. If the vac uum is lost, then the

seal is faulty. Replace the seal as necessary.

8. Reinstall push rods.

9. Reinstall roc ker arm com ponents as descr ibed

in 2.3 ROCKER ARMS in this Section.

Figure 6A2-41

2.6 CYLINDE R HEADS

REMOVE

1. Disconnect battery earth cable from battery.

2. Remove inlet manifold, refer to

2.1 INLET MANIFOLD in this Section.

3. Remove exhaust manifolds, refer to

2.2 EXHAUST MANIFOLD in this Section.

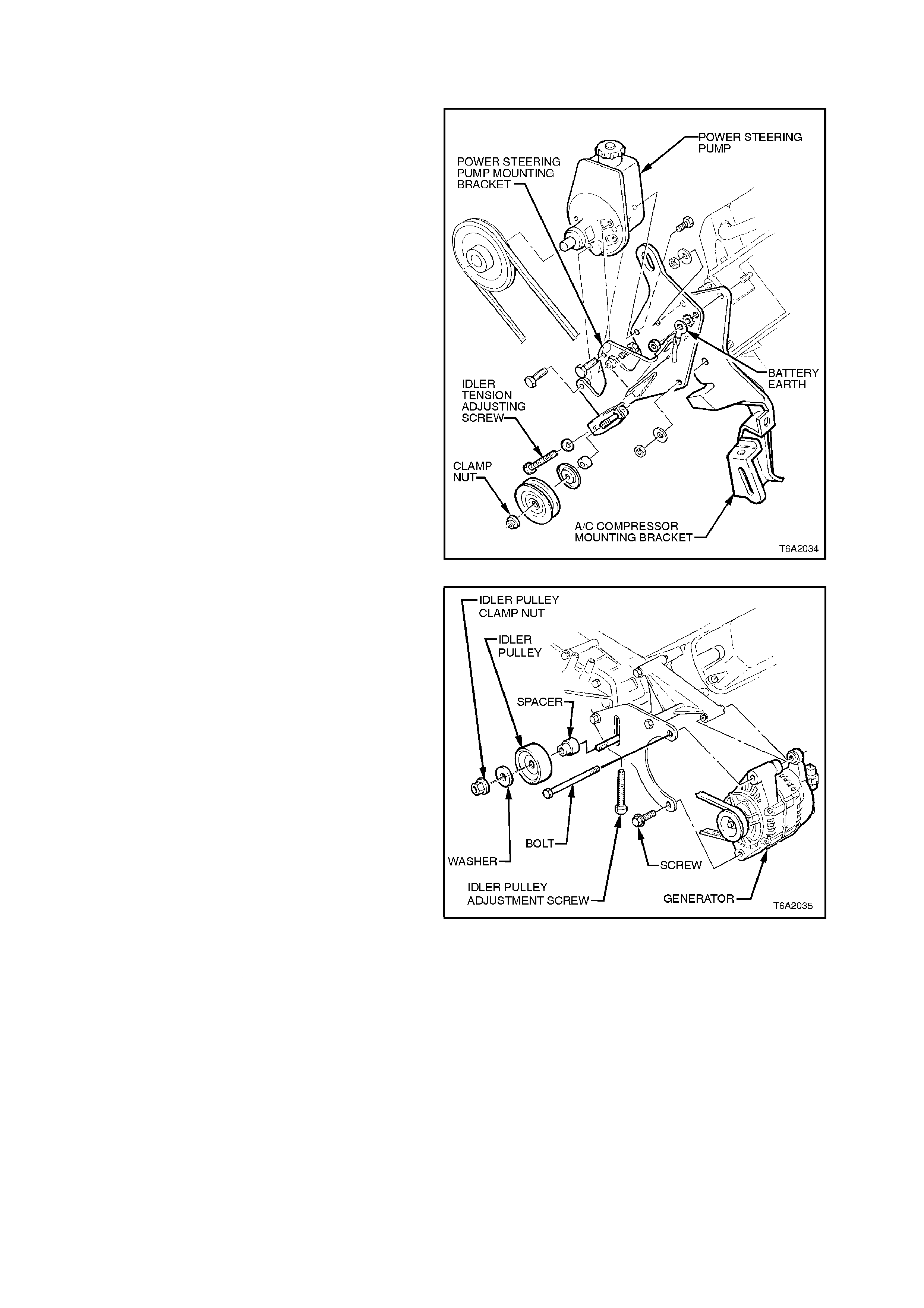

4. For R.H. Cylinder Head:

a. Release tension on power steering and

air conditioning drive belts and remove

belts.

b. Remove the three nuts securing the

power steering pump m ounting brack et to

the cylinder head, slide the bracket

forward off the mounting studs and m ove

to one side. Where fitted, remove the

lower bolt securing the air conditioning

compressor mounting bracket, this will

release the air conditioning compressor

mounting bracket. Slide the bracket

forward off mounting studs and move to

one side.

Figure 6A2-42

5. For L.H. Cylinder Head:

a. Remove the generator and mounting

brackets (refer to Section 6D2-1

CHARGING SYSTEM - V8 ENGINE).

Figure 6A2-43

6. Remove rocker arm pivots, rocker arms and

push rods, refer to 2.3 ROCKER ARMS in

this Section.

NOTE:

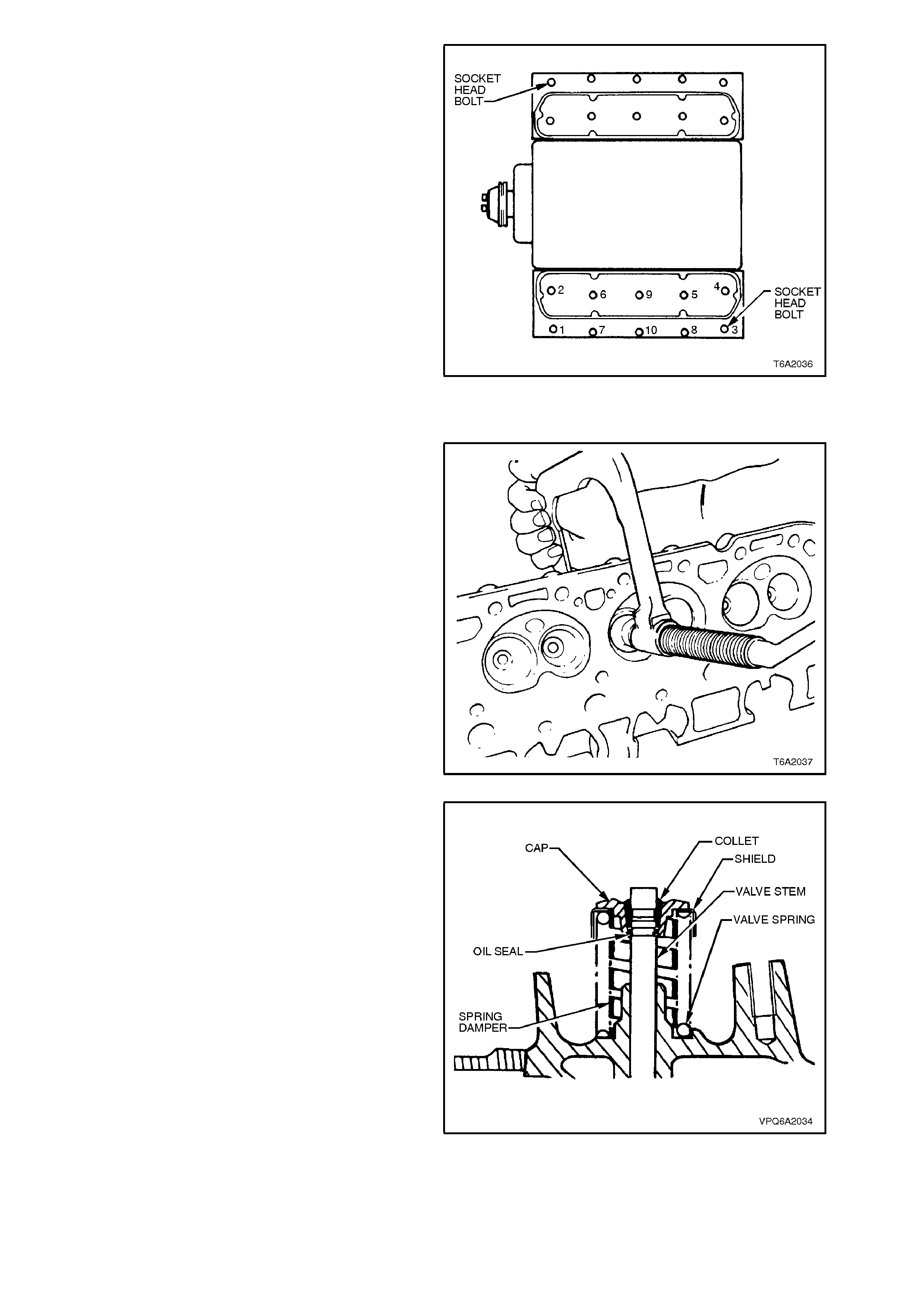

Each cylinder head is secured with nine internal

hexagon headed bolts and one socket head bolt.

7. With engine at ambient temperature (below

50o C), progressively loosen cylinder head

bolts in sequence shown in Fig. 6A2-44.

8. Remove cylinder head bolts, cylinder heads

and gaskets.

Figure 6A2-44

DISASSEMBLE

1. Using a conventional valve s pring c ompres s or ,

compress valve springs in turn and remove

valve collets.

NOTE:

It may be necessary to tap the cap of the spring

compressor using a soft faced hammer to

overcome binding of the valve stem collets.

Figure 6A2-45

2. Remove valve spring caps, shields, springs,

dampers and oil seals.

3. Remove valves from heads and place them in

a rack in sequence so they can be reinstalled

in their original positions.

CAUTION:

Do not force valves out of guides as

mushroomed ends or dirt in the guide and seal

grooves will damage guide. First remove any

burrs or dirt from end of valve stem.

Figure 6A2-46

CLEAN

1. Clean all carbon from combustion chambers,

valve ports, etc., using a soft rotary wire brush.

2. Thoroughly clean valve guides with solvent.

3. Clean valves with a buffing wheel.

4. Wash all parts in a cleaning agent and dry

thoroughly.

Figure 6A2-47

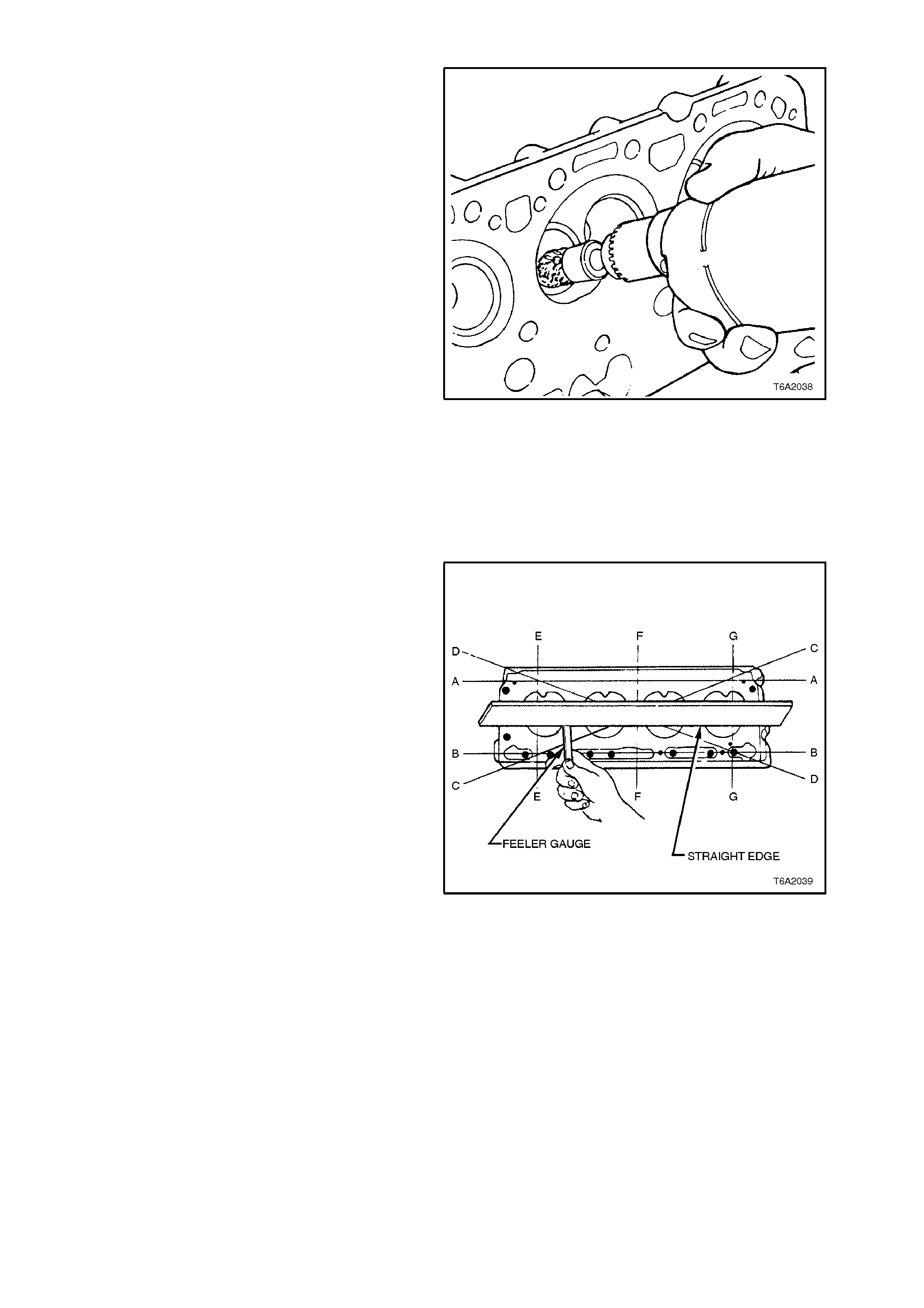

INSPECT

1. Inspect cylinder heads for cracks in valve

seats and combustion chambers, and for

external cracks to water jackets.

2. Inspect valves for burned or cracked faces or

damaged stems.

3. Check cylinder head surf ace for distor tion with

a straight edge and feeler gauge. Check

longitudinally, diagonally and transversely, as

shown by the alphabetical order in Fig. 6A2-

48.

4. If distortion exceeds allowable tolerance (refer

to 5. SPECIFICATIONS at the end of this

Section), machine head.

Figure 6A2-48

NOTE:

To determine if head has been machined

previously, measure distance from flat surface of

the combustion chamber side to top of machined

land on exhaust side of head (two lands at front,

two at rear of head). Refer to Fig. 6A2-49. The

minimum dimension for a standard head is 25.95

mm.

Figure 6A2-49

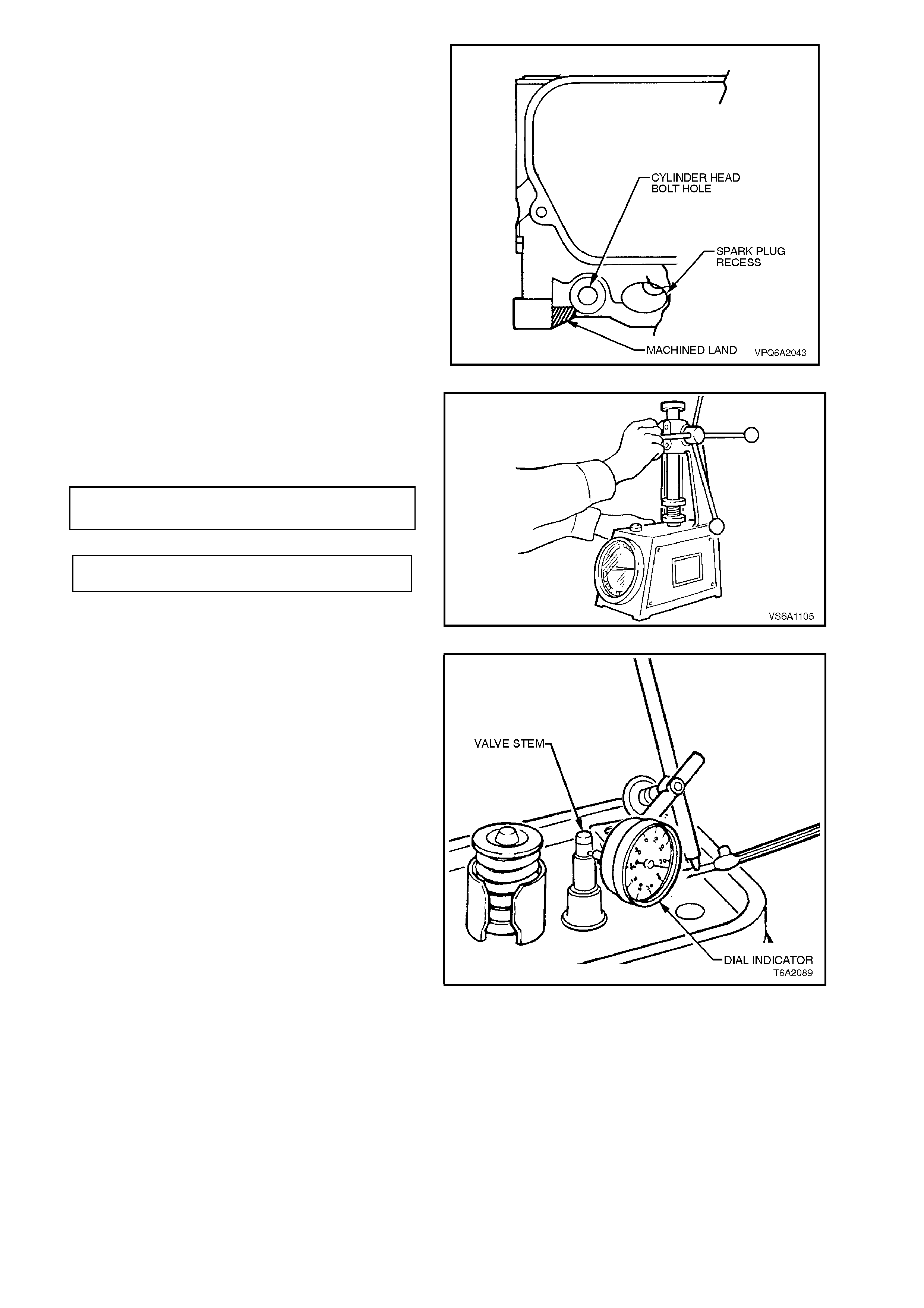

5. Check valve springs with a valve spring tes ter.

Compress springs (without dampers) to

specified height and read load. Replace

springs if outside specifications.

VALVE SPRING 51.56 mm

FREE LENGTH approx

VALVE SPRING 338 - 373 N

TENSION @ 45.2 mm

Figure 6A2-50

6. Measure valve stem clearance as detailed in

the following procedure:

a. Secure a dial indicator on the cylinder

head rocker c over gas ket rail, loc ating the

indicator so that movement of the valve

stem from side to side (across the head)

will cause a direct movement of the

indicator plunger. The indicator plunger

must contact the side of the valve stem

just above the valve guide.

b. With the valve head dropped

approximately 1.6 mm off the valve seat,

move the stem of the valve from side to

side, using a light force to obtain a

clearance reading.

c. Where clearance exceeds 0.094 mm for

inlet valves or 0.119 mm for exhaust

valves, recheck with a new standard size

valve.

d. If the clearance still exceeds

specification, ream the valve guides for

installation of oversize valves.

Figure 6A2-51

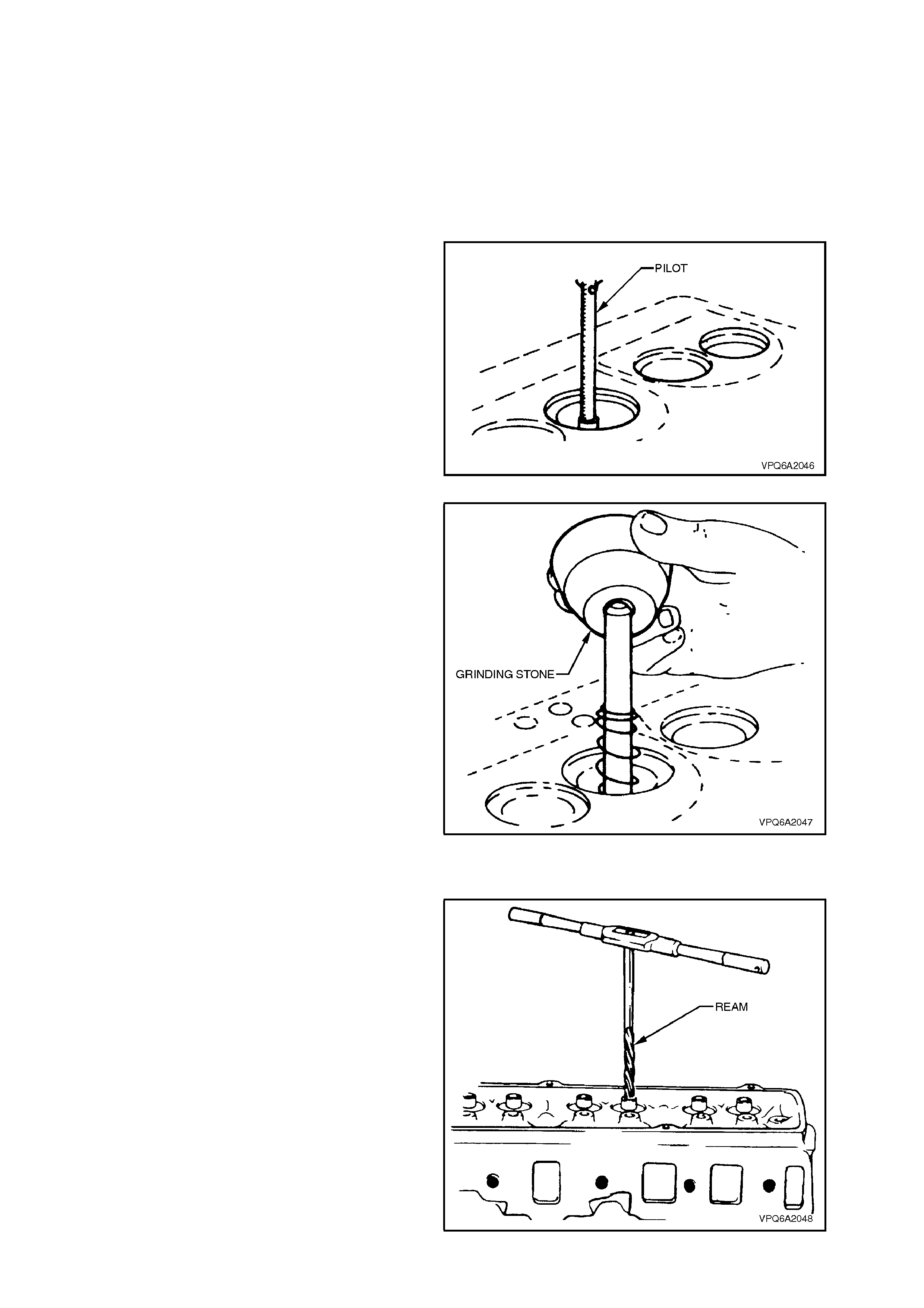

RECONDITION VALVE SEATS

NOTE:

5.0 litre VT Series engines feature induction

hardened exhaust valve seats. Use suitable

reconditioning equipment and carefully follow

equipment manufacturer's recommendations to

ensure satisfactory results.

1. Remove all carbon and dirt from valve guide

bores to ensure correct centring of pilot in

guide.

2. Secure expanding pilot in valve guide bores.

Figure 6A2-52

3. Use a 46º angle stone to cut exhaus t and inlet

valve seats.

4. Prior to cutting valve s eats, dress stone with a

diamond dressing tool in a suitable fixture.

5. Narrow down valve seats to specified width,

using a 30º or 60º grinding stone as

appropriate.

a. The inlet valve seat width should be

0.90 - 1.30 mm.

b. The exhaust valve seat width should be

0.97 - 1.35 mm.

Figure 6A2-53

REAM VALVE GUIDES

Inlet and exhaust valves are available with the

following oversize diameter valve stems: 0.04, 0.08,

0.20, 0.38 and 0.76 mm.

Use a suitable fixed blade reamer to enlarge the

bores of the valve guides when installing new

valves.

Check valve seating as outlined in the following

text.

Do not lap new valves into seats as the aluminised

valve surface will be removed.

Check valve stem height (as described in

MEASURE VALVE STEM HEIGHT) when valves

are installed.

Figure 6A2-54

RECONDITION VALVES

Valves that are warped or have excessive stem

wear should be replaced. Pitted valves can be

refaced with a valve refacing machine, ensuring

correct relationship between head and stem.

Several different types of equipment are available

for refacing valves. To obtain satisfactory results,

follow the instructions and recommendations of the

equipment manufacturer.

Set the valve refacing equipment to 45º to reface

both the inlet and exhaust valves.

After refacing a valve, check for correct seating as

follows:

1. Coat valve face with bearing blue.

2. Insert valve and rotate approximately 1/6th of

a revolution.

3. Remove valve and check for full surface

contact.

4. If part contact is indicated, insert valve again

and rotate through a full revolution. If blue on

seat indicates full contact, regrind face of

valve; if part contact is still indicated, cut valve

seat.

5. Measure valve stem height as outlined in the

following text.

Figure 6A2-55

MEASURE VALVE STEM HEIGHT

After reconditioning valves, valve seats or when

installing a new valve, measure the valve stem

height using the following procedure:

1. Hold valve firmly against its seat.

2. Measure distance from valve spring pad to

valve stem end.

3. If measurement exceeds 54.37mm, remove

valve from cylinder head and grind valve stem

end to achieve this dimension. Do not gr ind off

any more than is necessary.

4. After grinding the valve stem, assemble the

valve and spring assembly as outlined in the

following REASSEMBLE procedure.

Figure 6A2-56

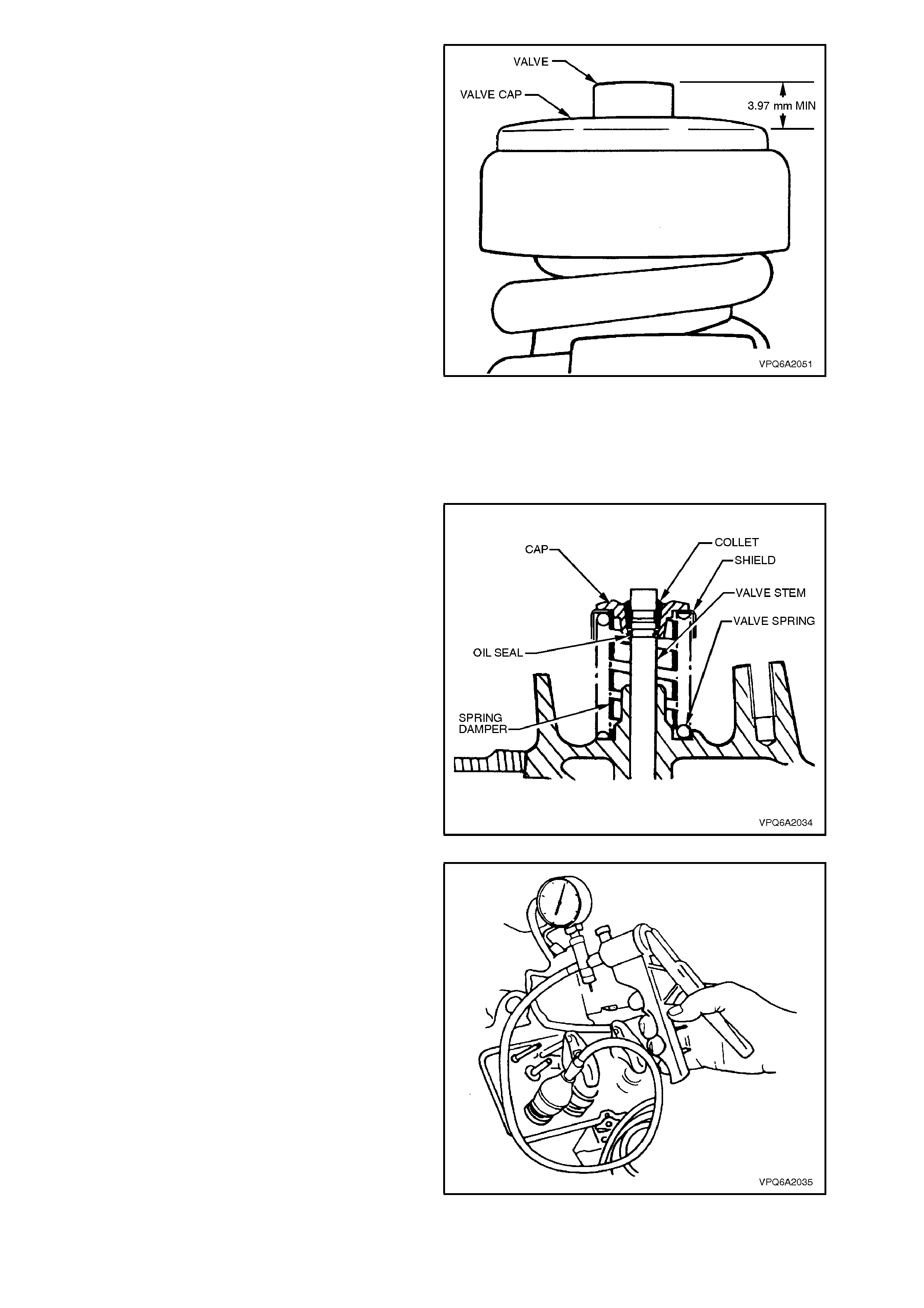

5. Measure distance between outer edge of valve

cap and top of valve stem.

6. If dimension is less than 3.97mm, replace the

valve.

Figure 6A2-57

REASSEMBLE

1. Thoroughly clean and dry all components.

2. Lubricate valve stem thoroughly with oil and

reinstall valve in corresponding guide.

3. Install new oil seal in lower groove of valve

stem. Ensure the seal is seated correctly and

not twisted.

4. Place damper, valve spring, shield and cap

over valve stem.

5. Compress the valve spring with a suitable

valve spring compressor.

6. Reinstall valve collets ensuring they locate

correctly in top groove of valve stem. Slowly

release valve compressor checking that collets

seat correctly.

NOTE:

Grease may be used to hold collets in place.

Figure 6A2-58

7. Using a suitable suction cup or a vacuum hand

pump and appr opriate fittings, apply a vacuum

to the valve cap. If the vac uum is lost, then the

seal is faulty . Replace the seal as necessary.

Figure 6A2-59

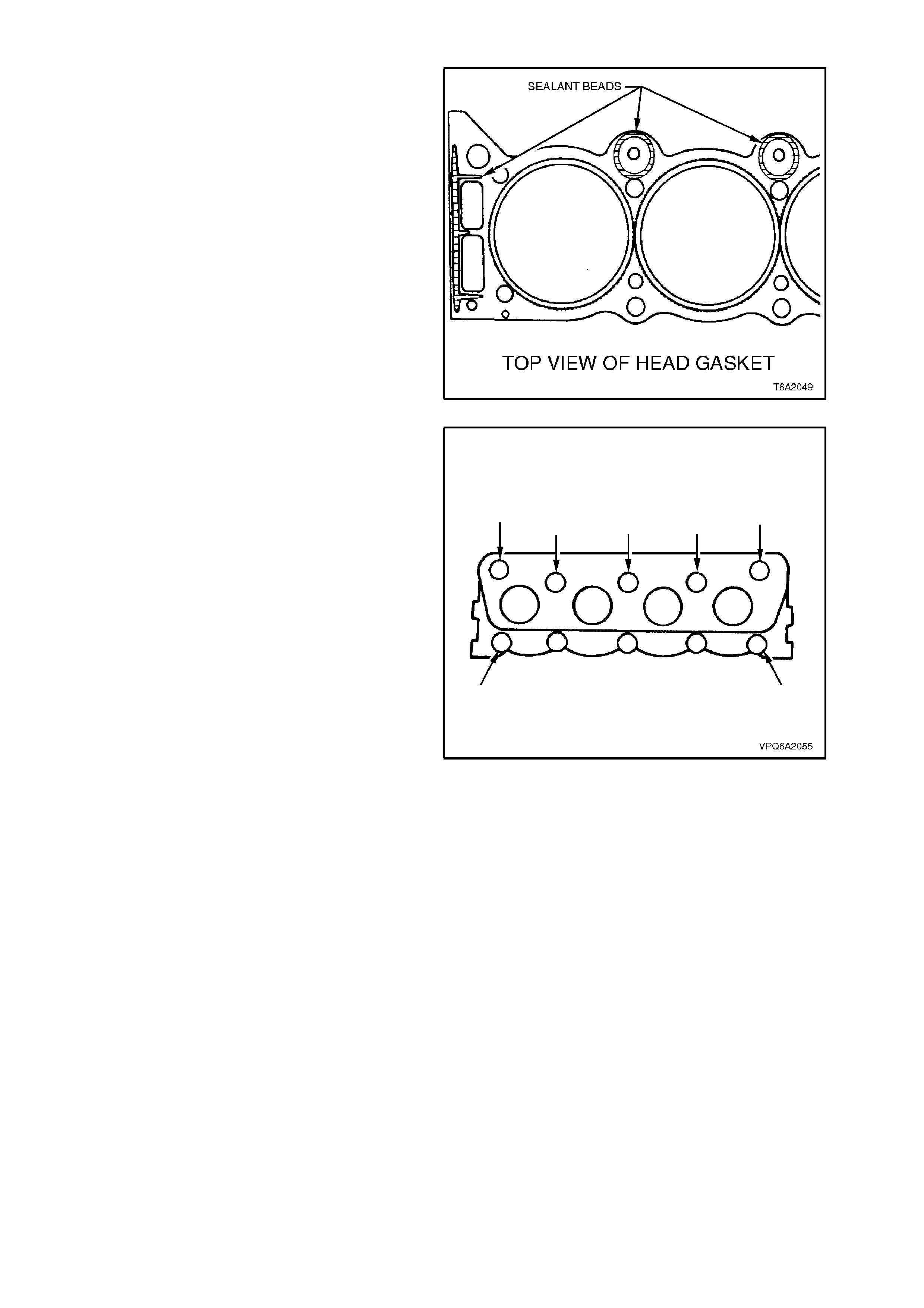

REINSTALL

1. Clean mating surfaces of cylinder block and

head taking care not to gouge or scratch

machined finish.

2. Place gasket in position over dowel pins with

the bead or side marked 'T OP' facing upward.

This can be confirmed by the fact that sealant

beads are applied to this surface of the

gasket, as shown in Fig. 6A2-60.

3. Carefully guide cylinder head into place over

dowel pins and gasket.

Figure 6A2-60

4. Apply a thin film of sealing compound Loctite

242 or equivalent (Holden Specification HN

1256) to the cylinder head bolt threads

entering the water jacket (refer to Fig. 6A2-

61), then install the bolts finger tight.

Figure 6A2-61

5. Tighten the cylinder head bolts to specified

torque in two stages, using the sequence

shown in Fig. 6A2-62.

STAGE 1

CYLINDER HEAD BOLT 50 - 55 Nm

TORQUE SPECIFICATION STAGE 2

77 - 83 Nm

6. Reinstall rocker arm pivots, rocker arms

and push rods as described in

2.3 ROCKER ARMS in this Section.

7. Remove engine lifting bracket if previously

fitted, reinstall power steering pump bracket

and air conditioning com pres sor brace br acket

(where fitted), tightening attaching nuts to the

specified torque.

POWER STEERING PUMP MOUNTING

BRACKET ATTACHING NUTS 15 - 20 Nm

TORQUE SPECIFICATION

8. Reinstall power steering pump and generator,

refer to Sections 9A STEERING and

Section 6D2-1 CHARGING SYSTEM - V8

ENGINE

9. Reinstall exhaust manifolds, refer to

2.2 EXHAUST MANIFOLD in this Section.

10. Reinstall inlet manifold, refer to

2.1 INLET MANIFOLD in this Section.

Figure 6A2-62

11. If a NEW cylinder head has been fitted, it will

be necessary to tighten the spark plugs to the

following torque specification, to 'coin' the

spark plug sealing seat in the cylinder head.

SPARK PLUG 'COINING'

TORQUE SPECIFICATION 20 - 28

Nm

Otherwise install spark plugs and tighten to

the specified torque.

SPARK PLUG

TORQUE SPECIFICATION 20

Nm

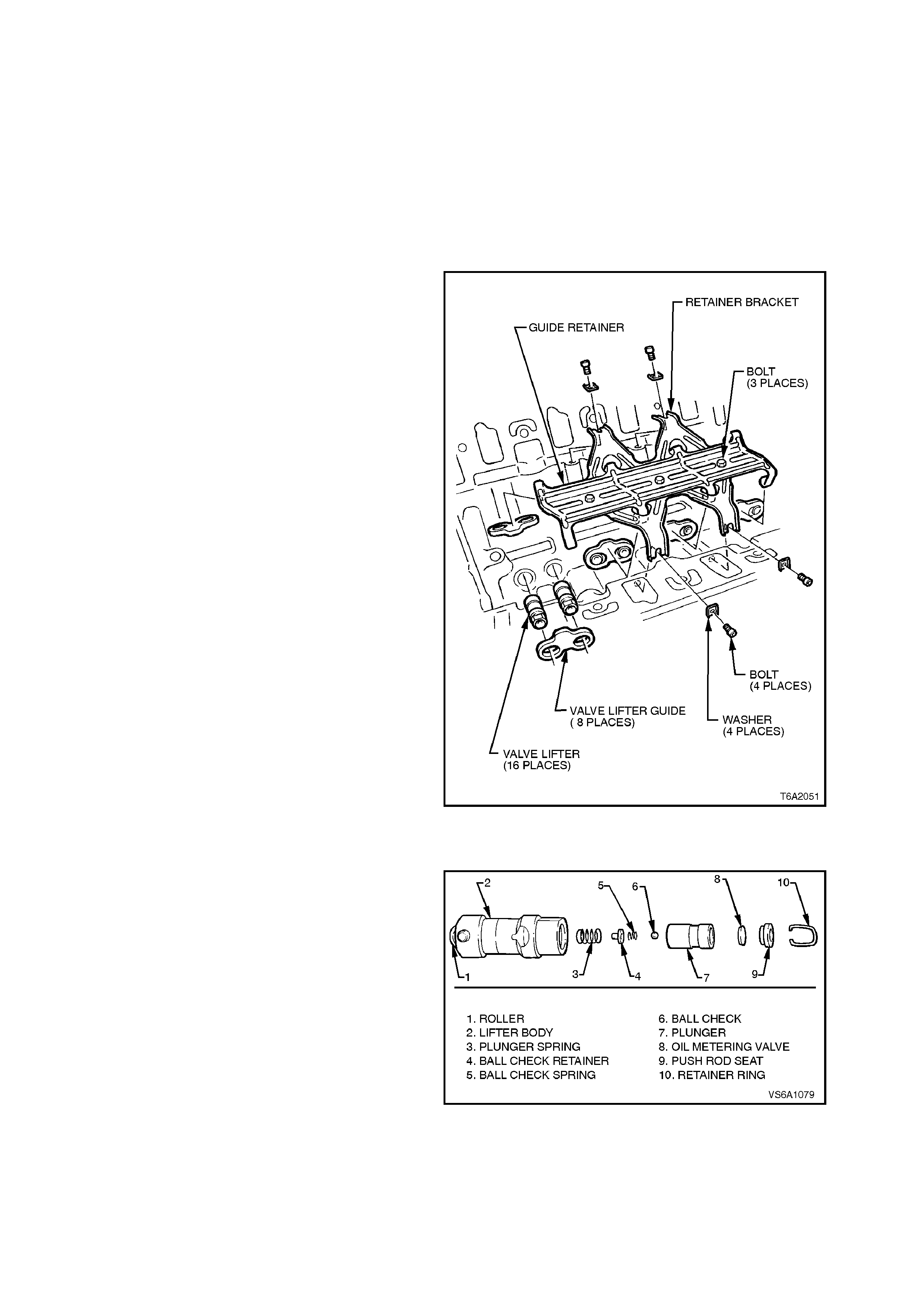

2.7 HYDRAULIC VALVE LIFTERS

REMOVE

1. Depressurise fuel lines, refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE - SERVICE OPERATIONS.

2. Disconnect battery earth lead.

3. Remove rocker arms and pushrods, refer to

2.3 ROCKER ARMS in this Section.

4. Remove inlet manifold, refer to

2.1 INLET MANIFOLD in this Section.

5. From valley in cylinder block, remove valve

lifter guide retainer bracket attaching bolts,

valve lifter guide retainer and valve lifter guide

assembly.

6. Remove lifters from cylinder block bores and

place in order on rack.

NOTE:

Ensure that all valve train components are kept in

order so they may be reinstalled, if required, in their

original locations.

REINSTALL

1. Reverse removal operations.

Figure 6A2-63

DISASSEMBLE

1. Using a small, fine bladed screwdriver,

remove push rod seat retainer ring.

2. Remove push rod seat, oil metering valve,

plunger assembly and plunger spring from

lifter body.

NOTE:

If the plunger is stuck in the lifter body, turn lifter

body upside down and tap on a block of wood.

If plunger c annot be moved, soak lifter assem bly in

a suitable cleaning fluid.

Figure 6A2-64

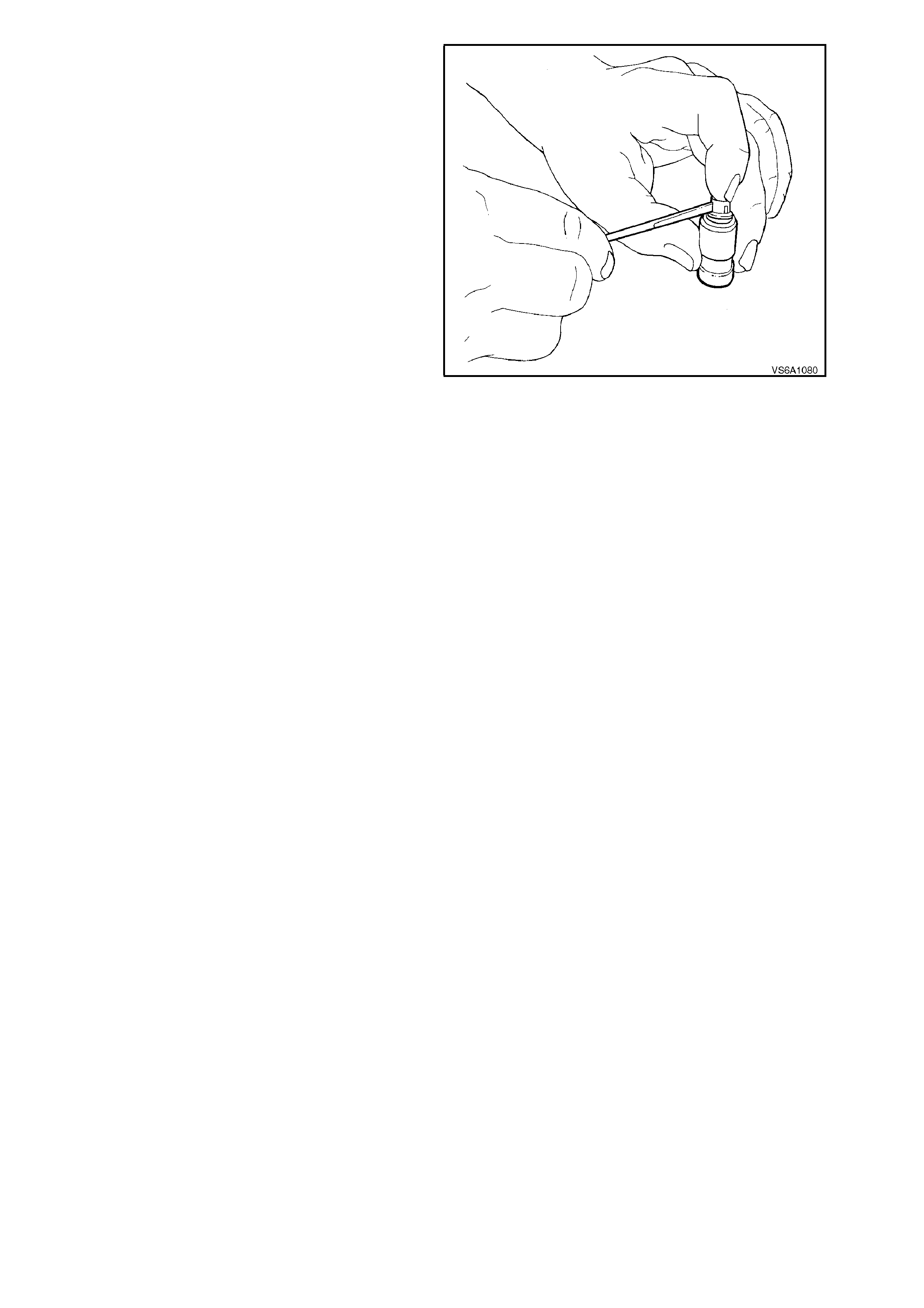

3. Remove check valve retainer, ball check

spring and ball from plunger assembly with a

small, fine bladed screwdriver.

Figure 6A2-65

CLEAN AND INSPECT

1. Thoroughly clean all parts in a suitable

cleaning fluid. Blow dry with clean dry

compressed air.

2. Inspect lifter body for;

a. Wear

b. Scuffing. Also inspect lifter bore in

cylinder block.

3. Inspect roller for;

a. Freedom of movement. Replace lifter if

roller binds or roughness can be felt.

b. Excessive looseness in the roller bearing

c. Flat spots. Replace lifter if roller is worn.

d. Pitting. Replace lifter if roller is pitted.

4. Inspect pushrod seat. If seat is worn, inspect

pushrod. Replace pushrod if worn.

5. If any lifter component is damaged or

excessively worn, replace entire lifter

assembly.

REASSEMBLE

NOTE 1:

Do not attempt to recondition lifter assemblies by

taking parts from other unserviceable lifters.

NOTE 2:

Cleanliness is very important when reassembling

lifters. Lint or dirt can cause the lifters to fail.

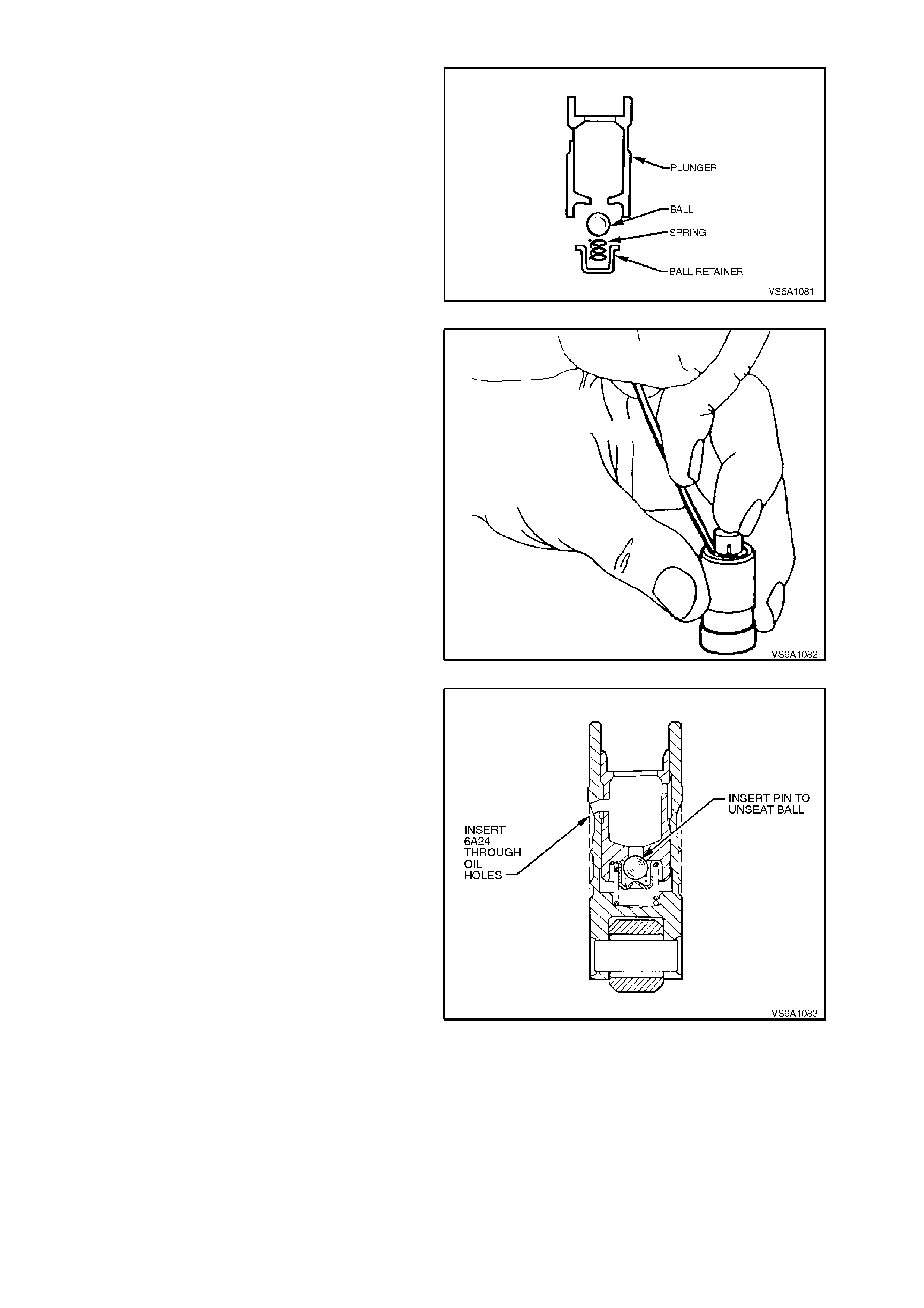

1. Place check ball on small hole in plunger.

Figure 6A2-66

2. Carefully place check ball spring and retainer

over ball and press retainer into position in

plunger with a small, fine bladed screwdriver.

3. Half fill valve lifter body with test fluid No.

E1151 (previously 361-1-93).

4. Reinstall plunger spring into lifter body.

5. Install plunger assembly in body, taking care to

align oil feed holes.

6. Fill lifter assembly with test fluid.

Figure 6A2-67

7. Use a 1 m m diameter pin to unseat check ball

in the plunger. Push plunger down to the full

extent of its travel.

8. Use Tool No. 6A24 to align oil feed holes in

body and plunger.

9. Fill lifter assembly with test fluid.

10. Reinstall oil metering valve, push rod seat (cup

side uppermost) and retaining ring.

NOTE:

The hydraulic lifter is now ready for checking as

outlined in the next operation.

Figure 6A2-68

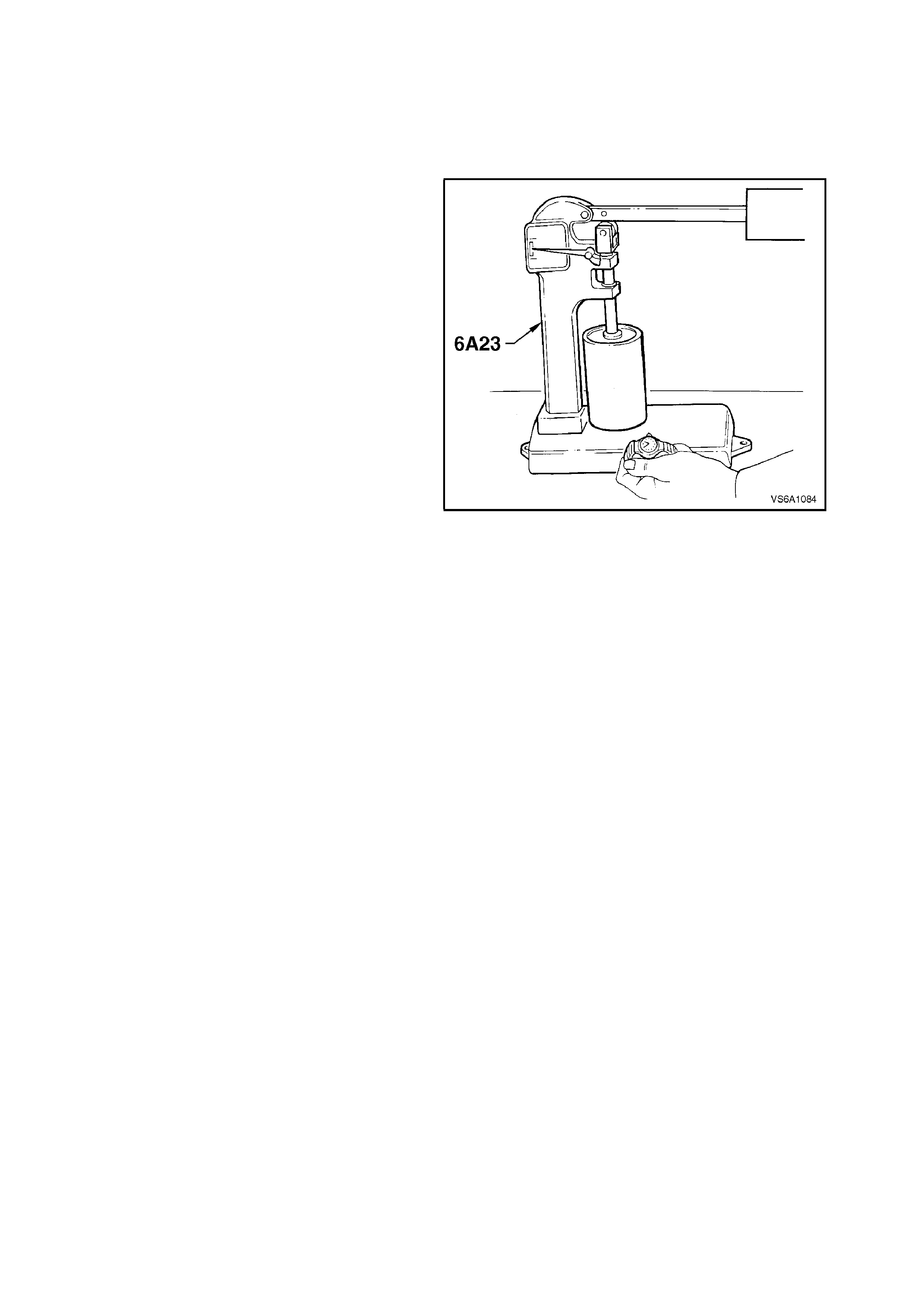

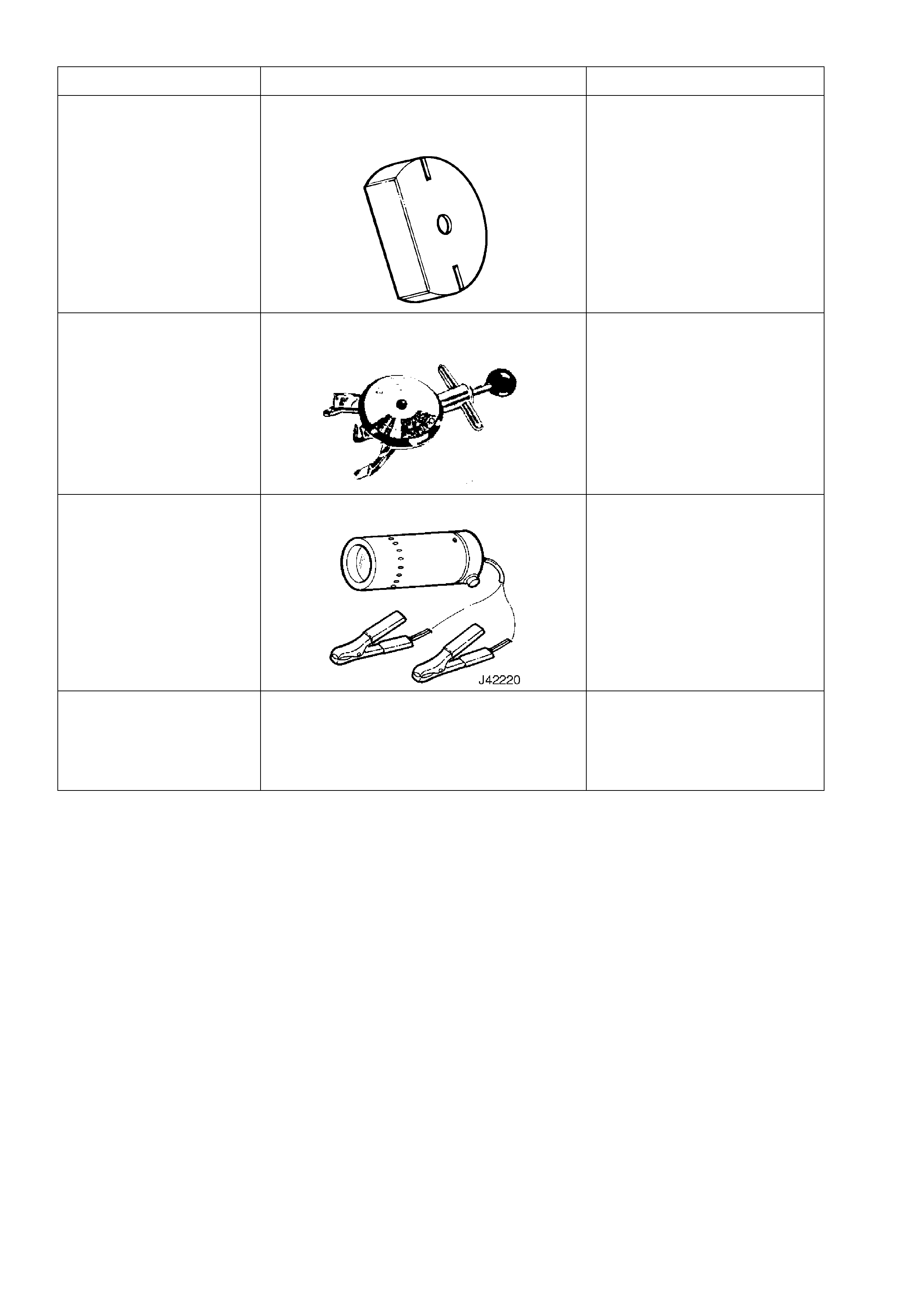

TESTING LIFTER LEAK DOWN RATE

After a hydraulic lifter has been cleaned, inspected

and assembled, it must be tested before it is

reinstalled in the engine. T he lifter test f ixture, Tool

No. 6A23, has been designed to test the leak down

rate of the lifter to determine whether it is within the

limits which assure satisfactory lifter operation.

1. Thoroughly clean cup of tes t fixture. Ins tall c up

on fixture and place lifter into cup.

NOTE:

On some versions of 6A23, it m ay be necessary to

make a small cup/support fixture to hold the base

of the lifter assembly inside the tester cup.

2. Add sufficient test fluid No. E1151 (previously

361-1-93) to completely cover lifter.

3. Place ball bearing supplied with test fixture in

push rod seat of lifter.

4. Lower test fixture ram to rest on ball bearing.

5. Operate lifter plunger through its maximum

travel to force all air out of lifter by using a

vigorous pumping action on test fixture weight

arm. Continue pumping action until

considerable resistance is built up in lifter and

lifter becomes solid.

6. Raise weight arm to allow lifter plunger to

come up to its retainer, then lower arm to rest

on ram.

7. Use a stop watch to check the time required

for the indicator to move from the 'START' to

0.125 in. position on the scale.

8. The leak down rate (time between start and

0.125 in. position) must be between 20 to 90

seconds to assure satisfactory lifter operation.

Figure 6A2-69

NOTE:

A doubtful lifter should be tested three or four

times. Any lifter which does not test within the

specified limits should be replaced.

9. After all lifters have been thoroughly tested,

place a cover over the test fixture to keep dirt

out of the cup.

10. Stand tested lifters upright so that fluid does

not drain from oil holes.

REINSTALL

1. Ensure that lifter bodies, rollers and lifter bores

are clean.

2. Lubricate lifter bodies and bores with Lubrizol

6612 or equivalent (Holden Specification HN

1961) and install lifters.

3. Install lifter guides, aligning flats on lifter body

with flats in guide.

4. Install valve lifter guide retainer and attaching

bolts. Tighten bolts to the correct torque

specification.

VALVE LIFTER GUIDE

RETAINER BOLT

TORQUE SPECIFICATION 26 - 34 Nm

5. Install rocker arms and pushrods, refer to

2.3 ROCKER ARMS in this Section.

6. Reinstall inlet manifold, refer to

2.1 INLET MANIFOLD in this Section.

7. Reconnect battery earth lead, start engine and

check for oil or fuel leaks and valve train

noise. Repair as necessary.

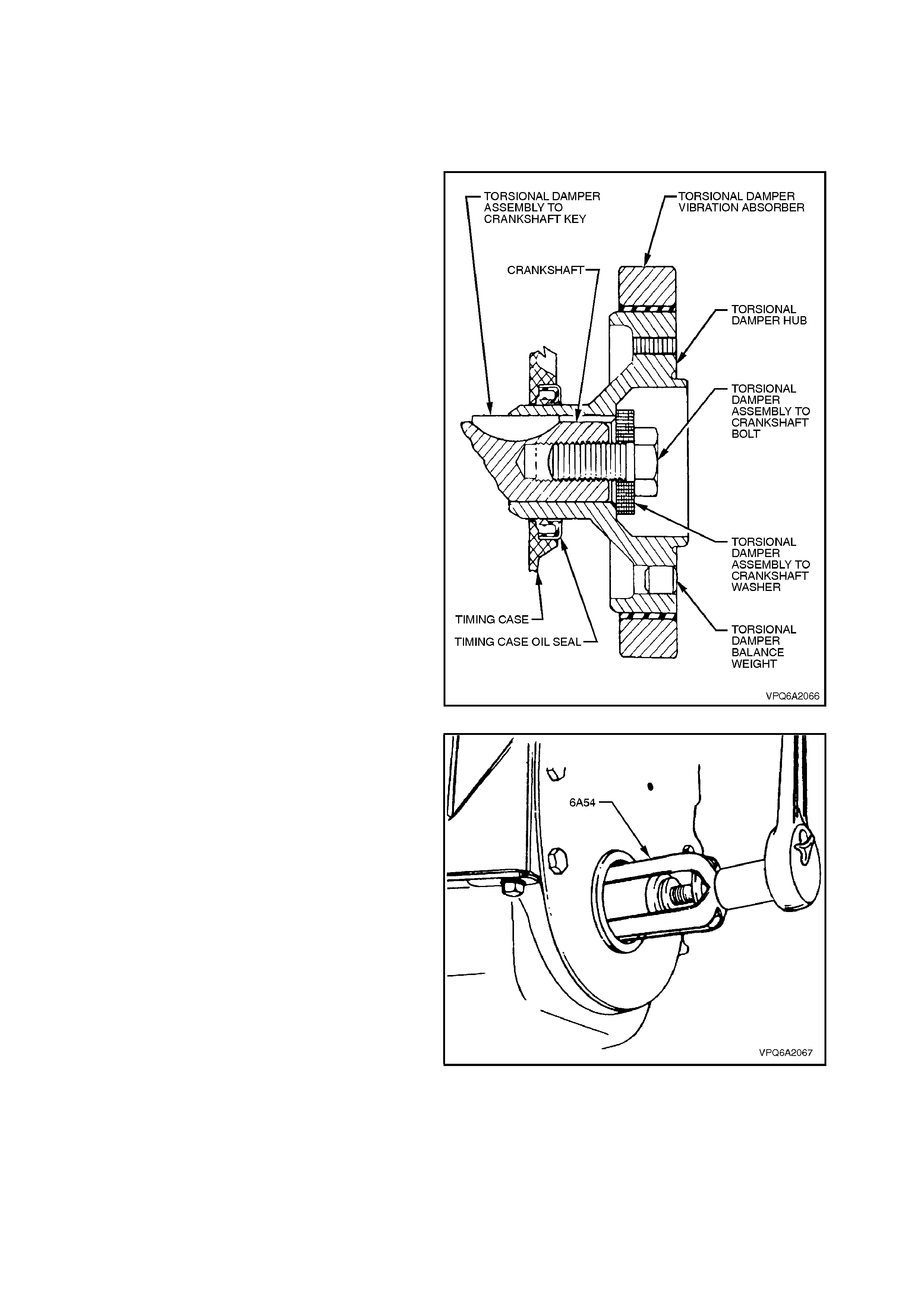

2.8 CRANKSHAFT FRONT SEAL

REPLACE

1. Disconnect battery earth lead.

2. Remove all drive belts fitted to crankshaft

drive belt pulley, refer to 2.13 DRIVE BELTS.

3. Remove torsional damper assembly to

crankshaft bolt and washer, then remove

torsional damper.

Figure 6A2-70

4. Using Tool No. 6A54, remove oil seal.

Figure 6A2-71

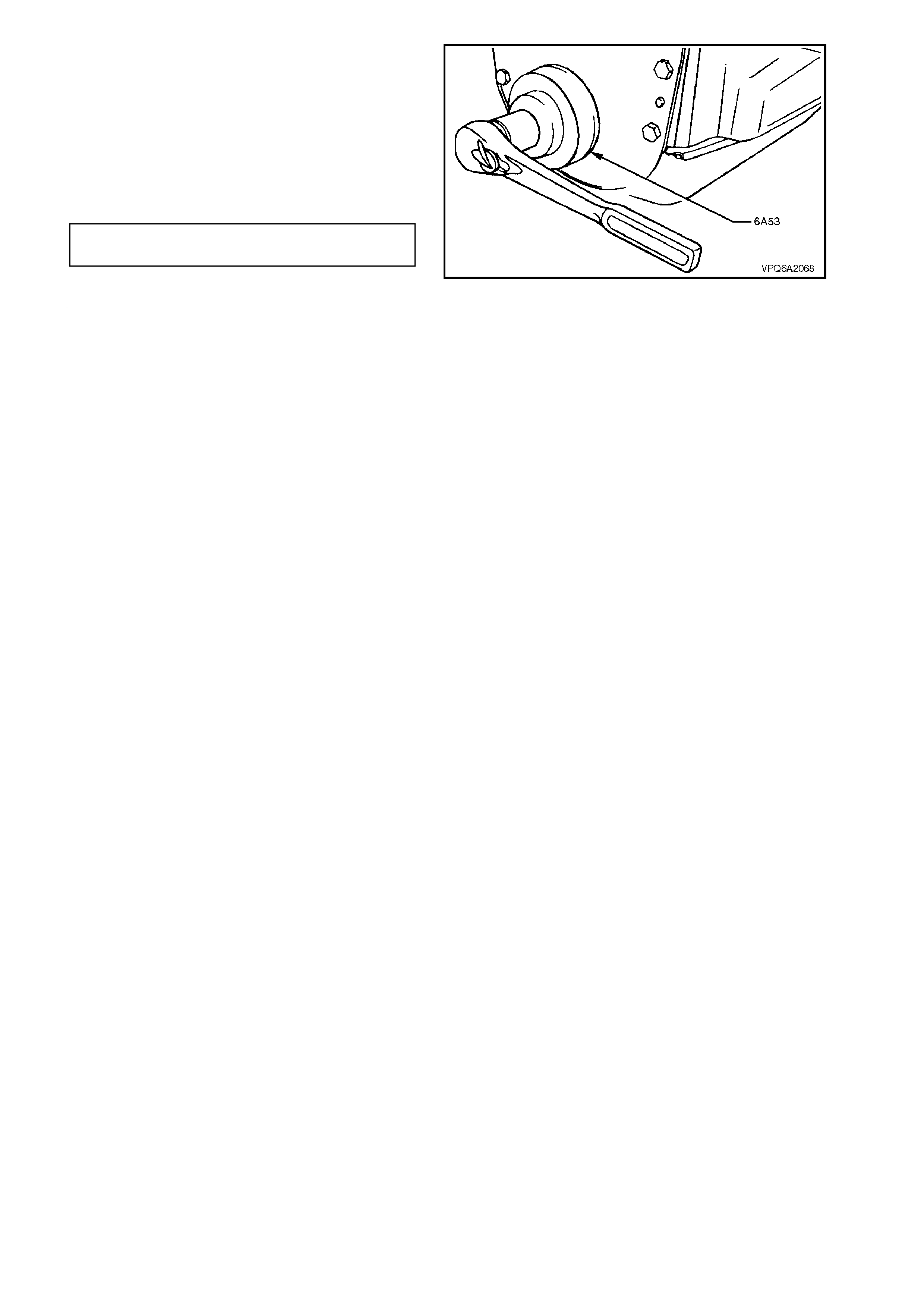

5. Install new oil seal with open end facing

inwards, using Special Tool No. 6A53.

6. Lubricate torsional damper hub bore with

hypoid lubricant and lubric ate seal s ur f ac e with

engine oil.

7. Position torsional damper on crankshaft and

install hub bolt and washer.

8. Tighten bolt to specification.

TORSIONAL DAMPER BOLT 190 Nm

TORQUE SPECIFICATION minimum

9. Reinstall pulley. Reinstall drive belts, then

adjust tensions of drive belts, refer to

2.13 DRIVE BELTS in this Section.

Figure 6A2-72

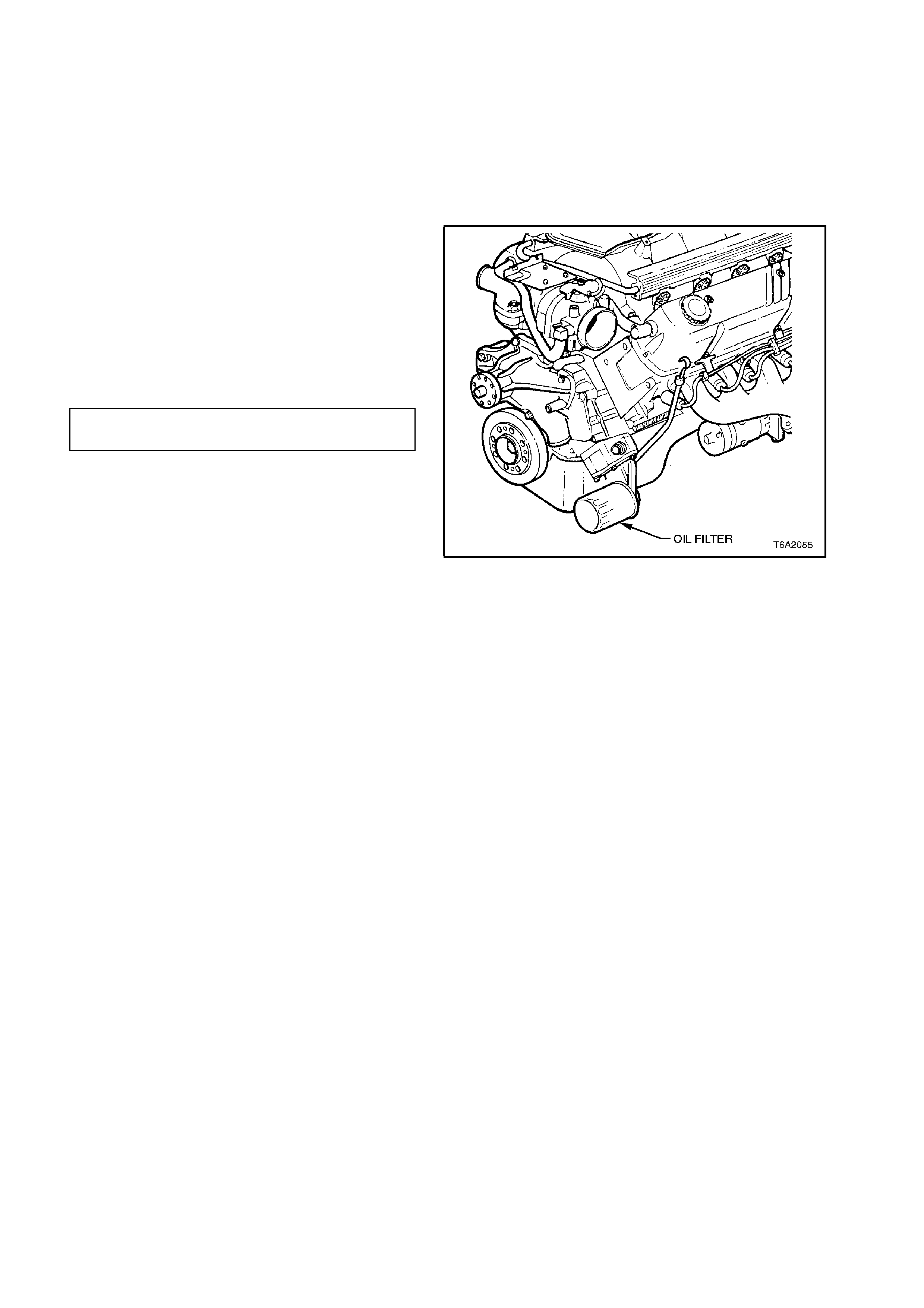

2.9 OIL FILTER

NOTE:

The oil filter should be replaced at the time

or distance intervals specified in

Section 0B LUBRICATION & SERVICE, or

whenever the engine oil is contam inated by foreign

material.

REMOVE

CAUTION:

To av oid the possibility of scalding, ensure that

the engine temperature is below 50°C, before

draining engine oil.

1. Place a suitable container below the oil pan,

and remove drain plug.

2. Allow the contents of the oil pan to drain, then

replace and tighten drain plug.

OIL PAN DRAIN PLUG 30 - 60

TORQUE SPECIFICATION Nm

3. Using a suitable oil filter loosen oil filter at the

oil filter adaptor in a counter-clockwise

direction, then remove and discard the oil

filter..

Figure 6A2-73

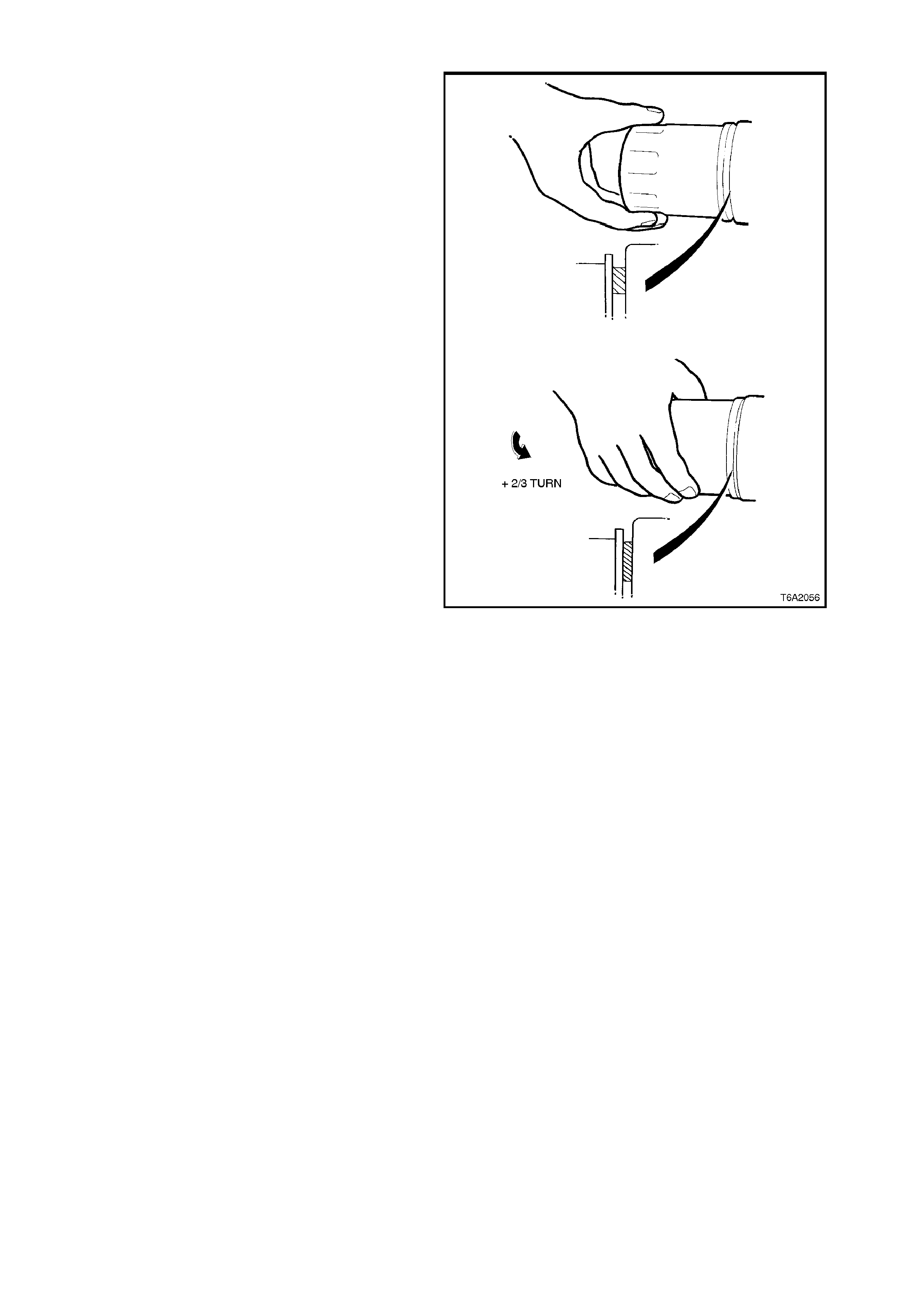

REINSTALL

1. Ensure new seal is correctly located in filter

recess, then apply a light film of clean engine

oil to the seal surface.

2. Install filter and rotate clockwise until seal

contacts mating face of pump body, then

tighten filter an additional two thirds (2/3) of a

turn.

Figure 6A2-74

NOTE:

Ensure that the drain plug is secured in position

before refilling the oil pan.

3. Refill the engine to correct level with clean

engine oil. Refer to Section 0B

LUBRICATION & SERVICE.

4. Fully depress the accelerator pedal, crank the

engine for a few seconds with starter motor,

then release the accelerator pedal and start

the engine. Check for oil leaks and rectify as

necessary.

2.10 OIL LEVEL CHECK

1. Engine must be at normal operating temperature (idle for 10 minutes or equivalent).

2. Park vehicle on level surface (as this will affect the accuracy indicated on dipstick, this is a critical

requirement).

3. Do not check oil level for at least 10 minutes after shut down to allow oil to drain back into the oil pan.

4. Remove dipstick and wipe clean.

5. Reinstall dipstic k with FULL/ADD m ar ks f ac ing towards c entr e line of engine. T h is as pec t is very im por tant due

to the angle that the dipstick enters the oil in the oil pan.

6. Ensure dipstick is fully seated and slowly rem ove to avoid sm ear ing. Hold horizontally or with lower end slightly

down to avoid oil running along dipstick.

7. Observe the oil level where it passes over the centre line of the dipstick.

8. When topping up the engine oil, allow approximately 10 minutes for the oil added to fully drain into the oil pan.

Alternatively, add 50 ml of oil for each millimetre below the “FULL” mark on the dipstick.

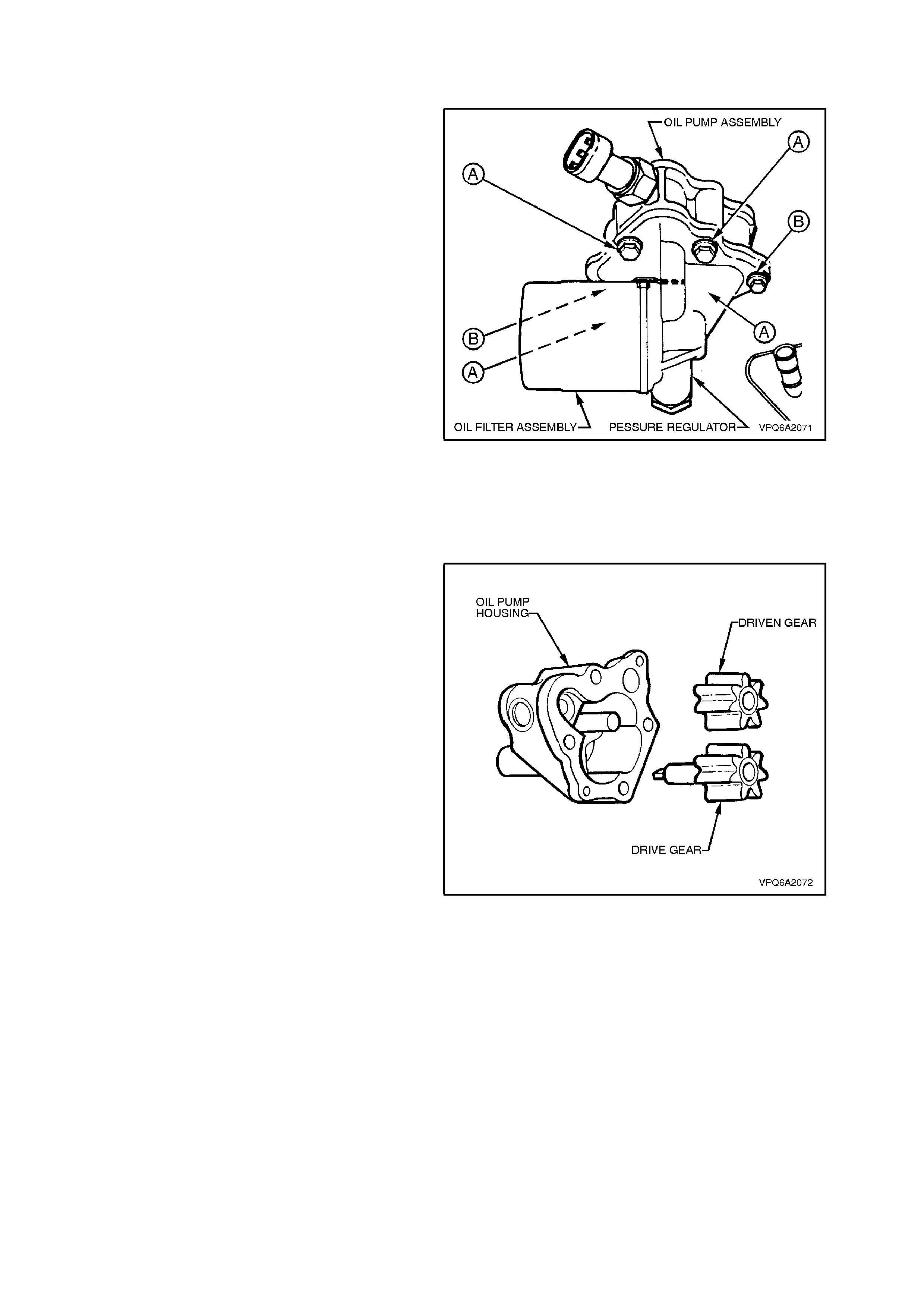

2.11 OIL PUMP

REMOVE

1. Remove oil filter, refer to 2.9 OIL FILTER in

this Section.

2. Remove electrical connector from oil pressure

switch.

3. Remove four bolts securing oil pump to

cylinder block. The bolts are labelled 'A' in Fig.

6A2-75.

4. Remove oil pump assembly.

Figure 6A2-75

DISASSEMBLE

1. Remove two bolts securing pump cover to

pump housing. The bolts are labelled 'B' in

Fig. 6A2-75. Remove body and gasket.

2. Match-mark the pump gears for subsequent

reinstallation.

3. Remove pump gears.

Figure 6A2-76

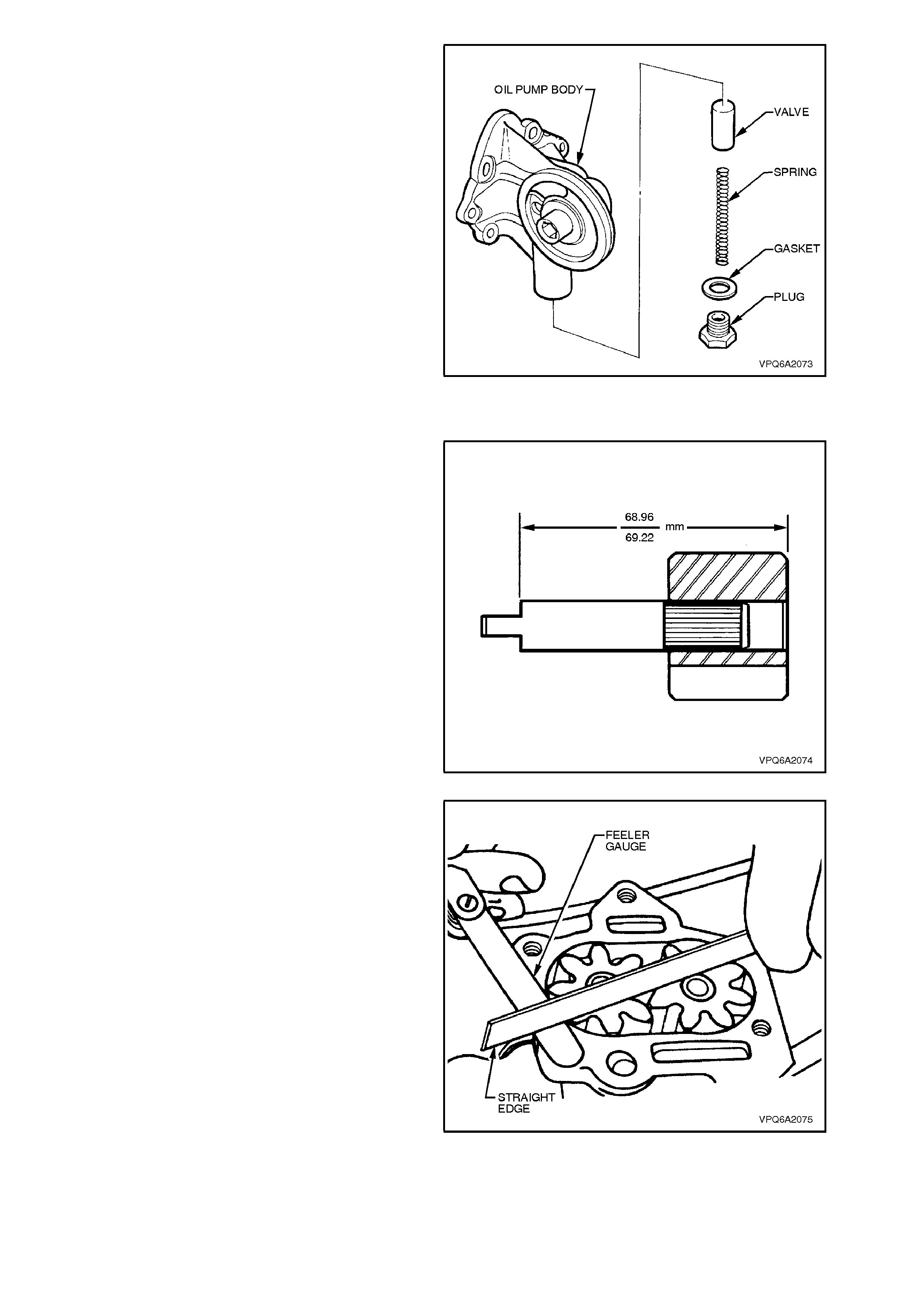

4. Unscrew and remove the plug retaining the

pressure regulator spring and valve.

Figure 6A2-77

INSPECT

1. Clean all components.

2. Inspect pump housing, driven gear shaft and

pump body for wear.

3. Check that drive shaft is tightly pressed into

drive gear.

4. Measure the distance from the shoulder on the

shaft to the outer face of the gear . The c orrect

dimension is 68.96 - 69.22 mm.

5. Inspect gears and drive shaft for wear.

Figure 6A2-78

6. Reinstall gears (as match-marked) and check

end of gear to pump housing face clearance

using a straight edge and feeler gauge. The

gears should protrude from the pump housing

0.051 - 0.153 mm.

7. Check that the gear backlash is within 0.229 -

0.381 mm.

8. Check fit of regulator valve in bore. It should

be a free sliding fit with a minimum of

clearance.

9. Check that the regulator valve spring is not

collapsed, worn or broken.

10. The free length of the spring should be

approximately 82.5 mm. The length of the

spring under a load of 4.76 kg should be 63.5

mm.

11. Visually inspect the bypass valve ass embly fo r

damage.

12. Replace any damaged or worn parts as

necessary.

Figure 6A2-79

REASSEMBLE

1. Reinstall pressure regulator spring and valve

and tighten plug to specified torque.

REGULATOR VALVE PLUG

TORQUE SPECIFICATION 34 - 41

Nm

2. Liberally coat the gears with clean engine oil

and reinstall in original positions relative to

one another as noted in disassembly.

3. After pre-filling a new oil filter, screw on to oil

pump body. Turn a further 2/3 turn after the

gasket contacts the oil pump body face.

4. While holding the oil pump assembly at

approximately 45°, near fill the chamber with

new oil of the recommended specification.

NOTE:

This operation is necessary to prime the oil pump

to reduce oil pressure build-up time on initial

engine start.

5. Install a new, genuine Holden's pump gasket,

to ensure correct clearance between gears

and pump.

6. Reinstall pump body and tighten two securing

bolts to specified torque, (bolts 'B' in

Fig. 6A2-75).

OIL PUMP BODY BOLTS

TORQUE SPECIFICATION 5 - 8

Nm

REINSTALL

Reinstallation is the reverse of the removal

procedure, note the following:

1. While maintaining the oil pump assembly at an

angle of 45º, fit a new gasket between pump

housing and cylinder block. Avoid wetting the

gasket with engine oil during fitment.

OIL PUMP BOLTS

TORQUE SPECIFICATION 23 - 30

Nm

2. Progressively tighten bolts to specified torque.

3. Rem ove the oil pressure switch and pr ime the

oil pump with clean engine oil, reinstall switch

and tighten to specified torque.

OIL PRESSURE SWITCH

TORQUE SPECIFICATION 12 - 14

Nm

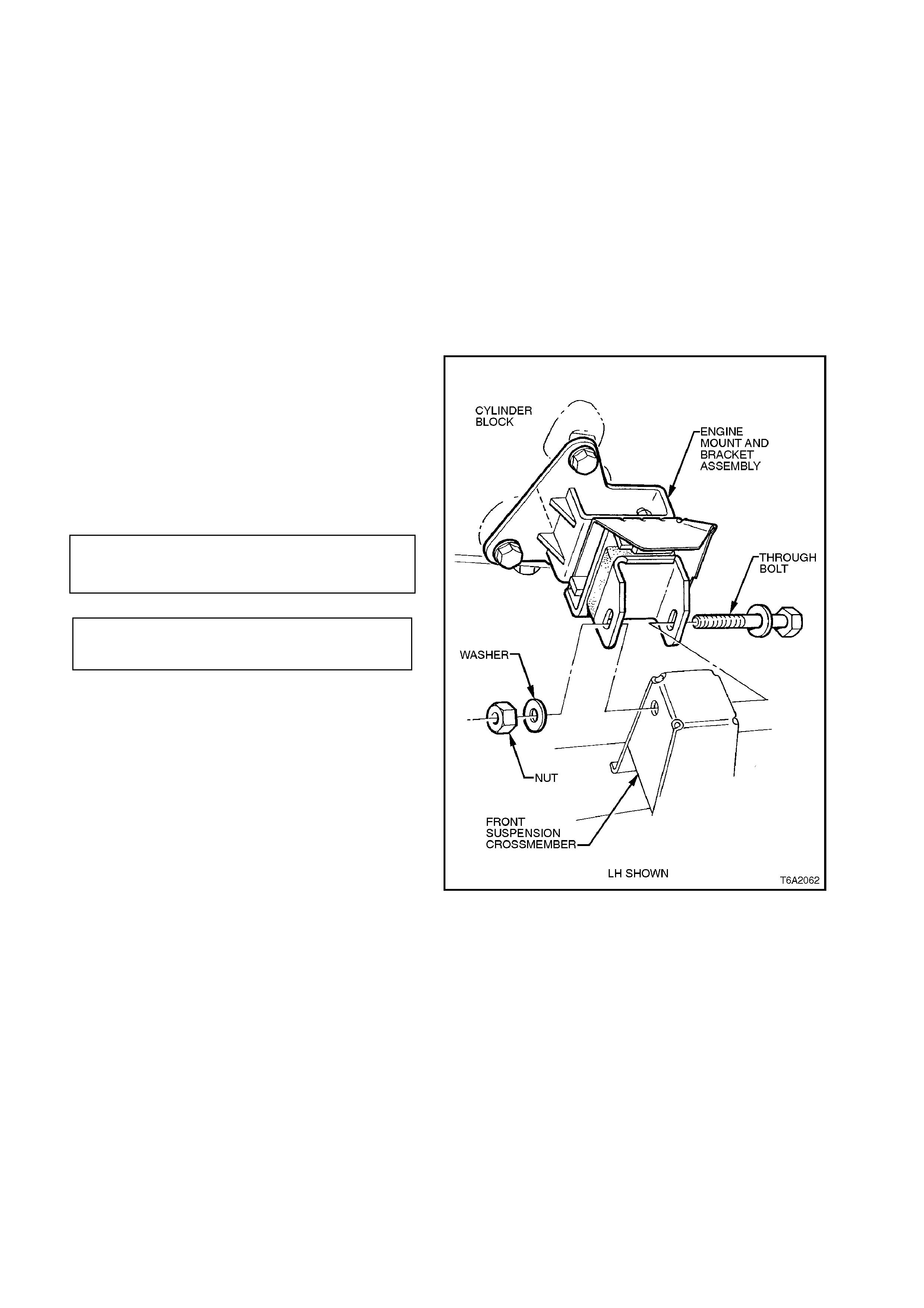

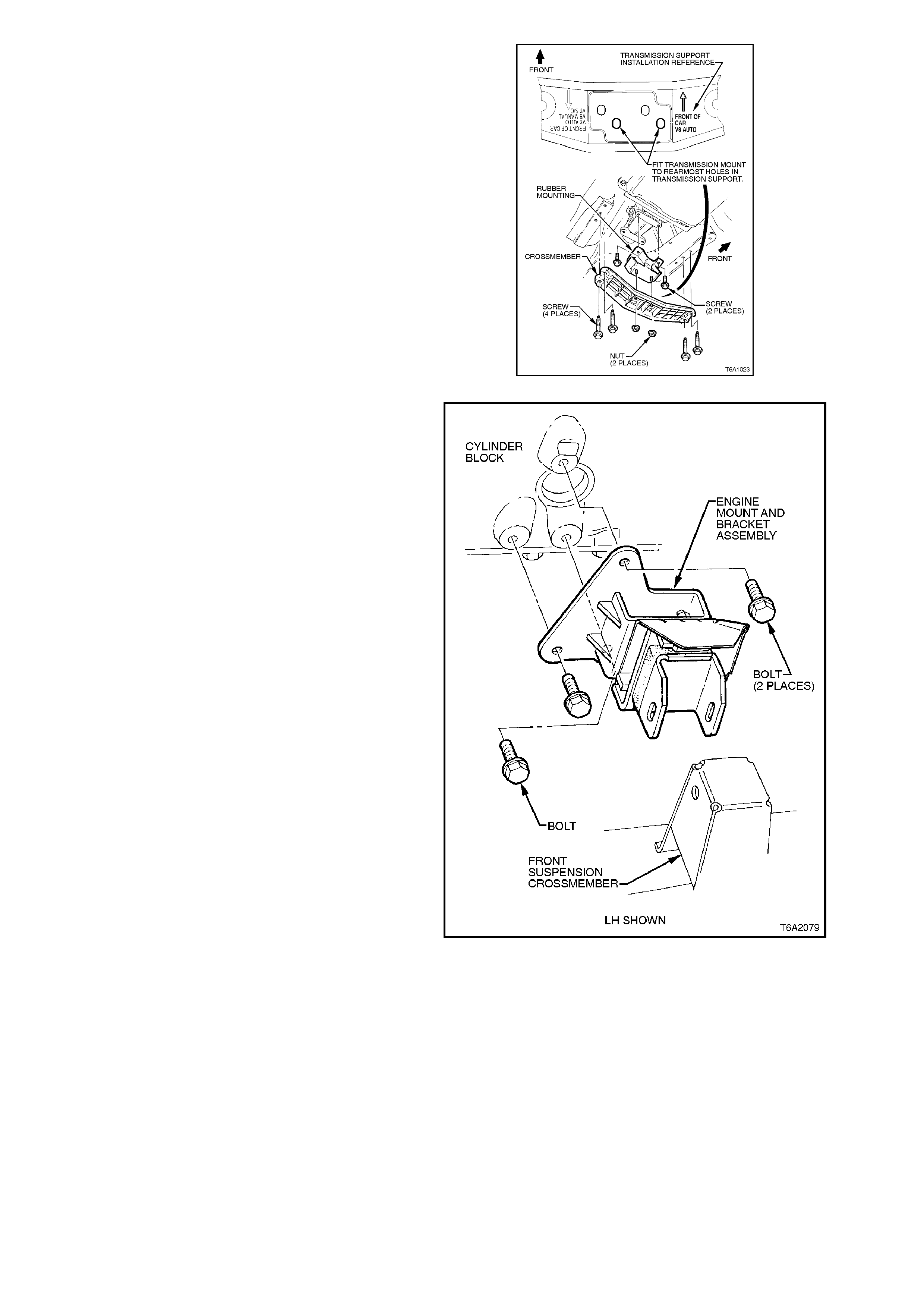

2.12 ENGINE MOUNTS

FRONT MOUNT

CHECK

Place a piece of wood between a suitable jack and

the oil pan, then raise the engine sufficiently to

check that rubber has not deteriorated, split or

separated from metal plates.

REPLACE

1. Raise front of vehicle and place on safety

stands. Refer to Section 0A GENERAL

INFORMATION.

2. Place a piece of wood between a suitable j ack

and the oil pan, then raise the engine

sufficiently to remove the weight from the

engine mounts.

3. Remove engine mount to crossmember

through bolt.

4. Using a shortened ring spanner remove nuts

securing engine mount to engine bracket.

5. Remove engine mount.

6. Install new mount in reverse order of the

removal procedure and tighten nuts and bolts

to specified torque.

ENGINE MOUNT TO ENGINE

BRACKET NUTS 20 - 28 Nm

TORQUE SPECIFICATION

REMAINING ENGINE MOUNT

NUTS & BOLTS 34 - 46 Nm

TORQUE SPECIFICATION

Figure 6A2-80

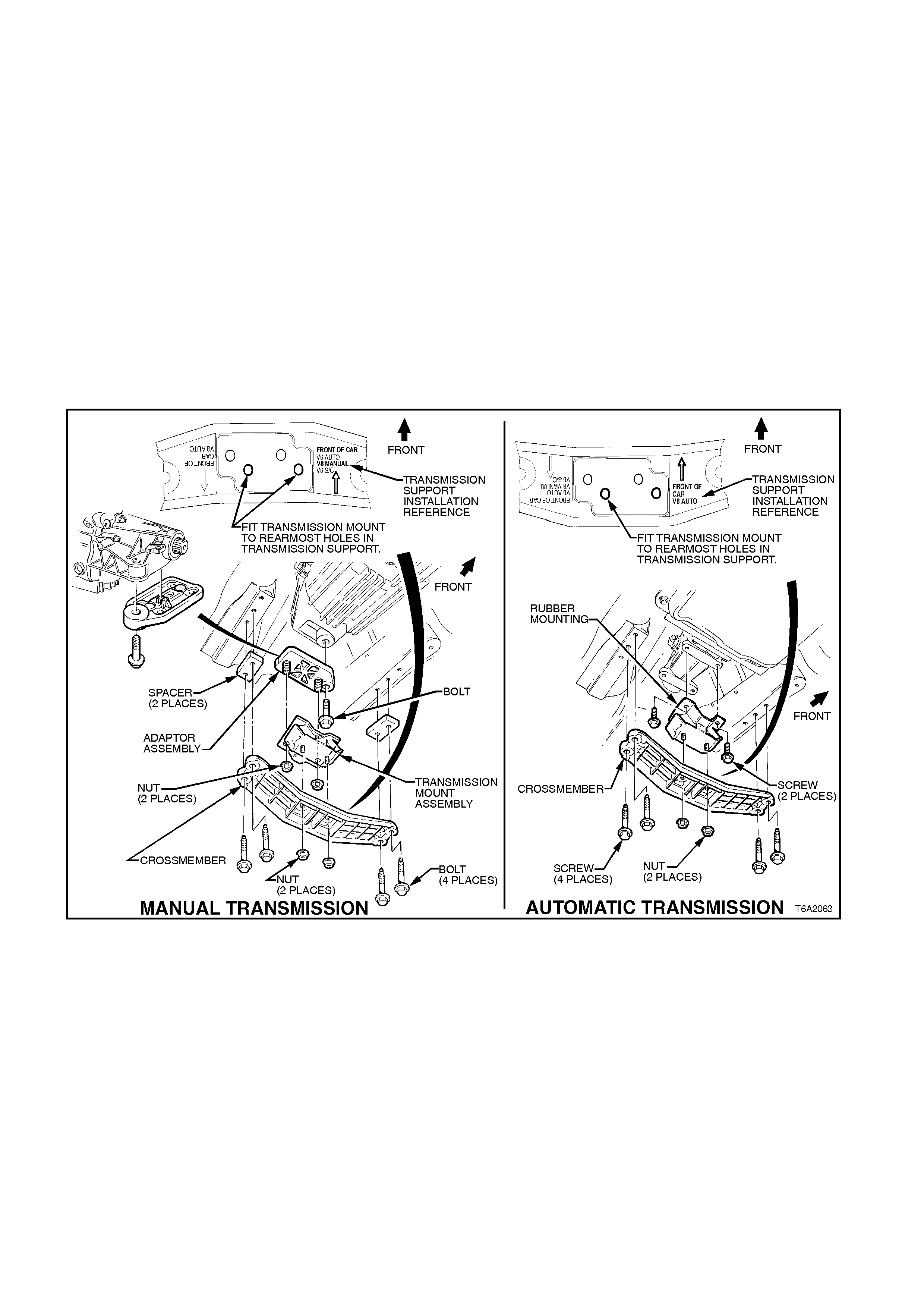

REAR MOUNT

REMOVE

1. Raise vehicle front and rear and place on

safety stands. For location of jacking points,

refer to Section 0A GENERAL

INFORMATION.

2. Support rear of transmission with a garage

jack.

NOTE:

Use a block of wood between transmission and

jack.

3. Remove nuts and washers attaching rear

mount to crossmember.

4. Remove crossmember to frame bolts and

washers, remove crossmember.

5. Remove rear mount to transmission rear

extension attaching bolts and remove rear

mount.

Figure 6A2-81

REINSTALL

1. Reinstall rear mount and attaching bolts to

transmission rear extension. Tighten bolts to

correct torque specification.

REAR MOUNT TO REAR

EXTENSION ATTACHING BOLT

TORQUE SPECIFICATION 35 - 65 Nm

2. Install crossmember to side frame bolts and

washers. Tighten bolts to correct torque

specification.

CROSSMEMBER TO SIDE

FRAME BOLT

TORQUE SPECIFICATION 35 - 65 Nm

3. Lower garage jack supporting transmission

and tighten crossmember to rear mount

attaching nuts to correct torque specification.

4. Remove safety stands and lower vehicle to

ground.

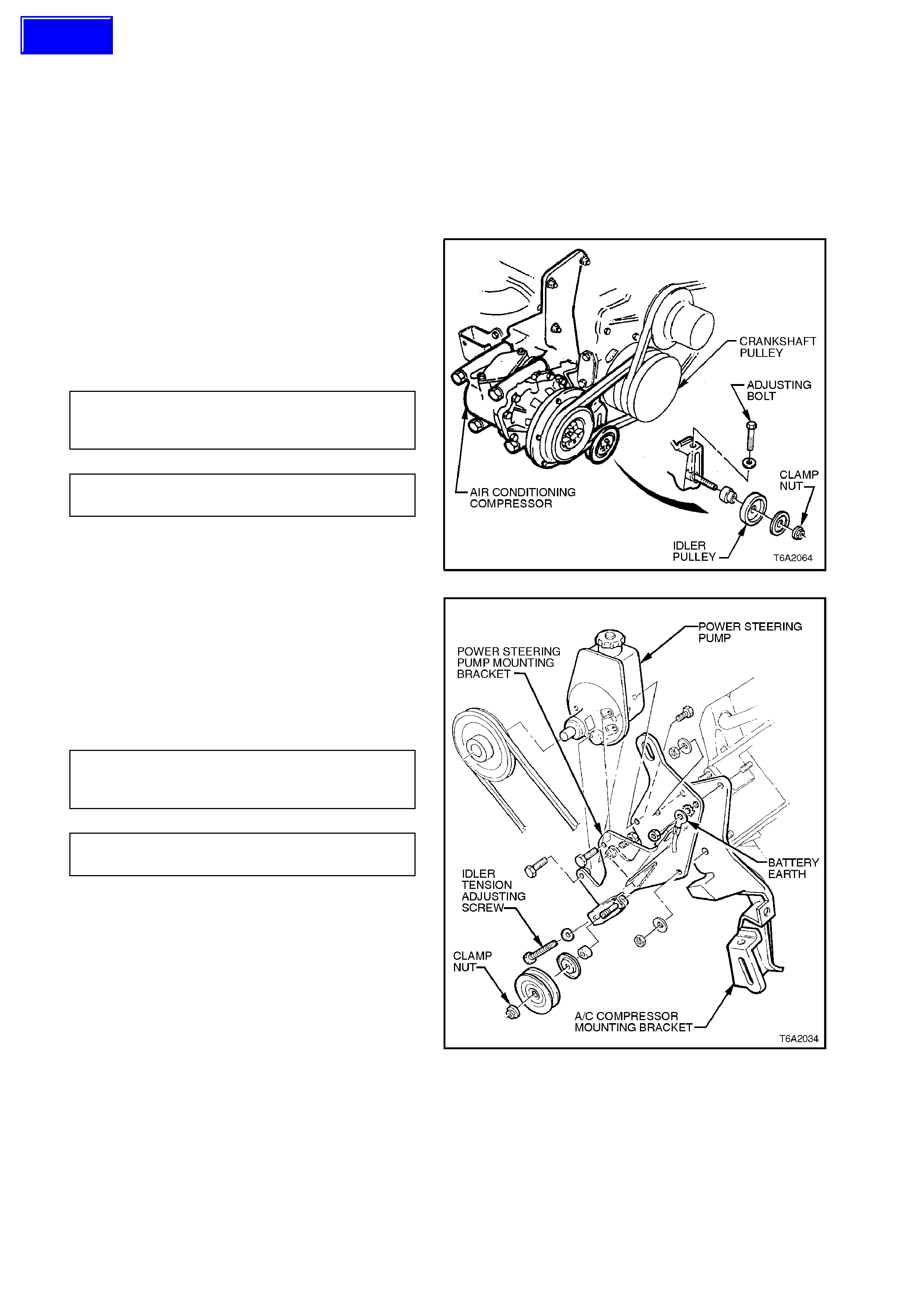

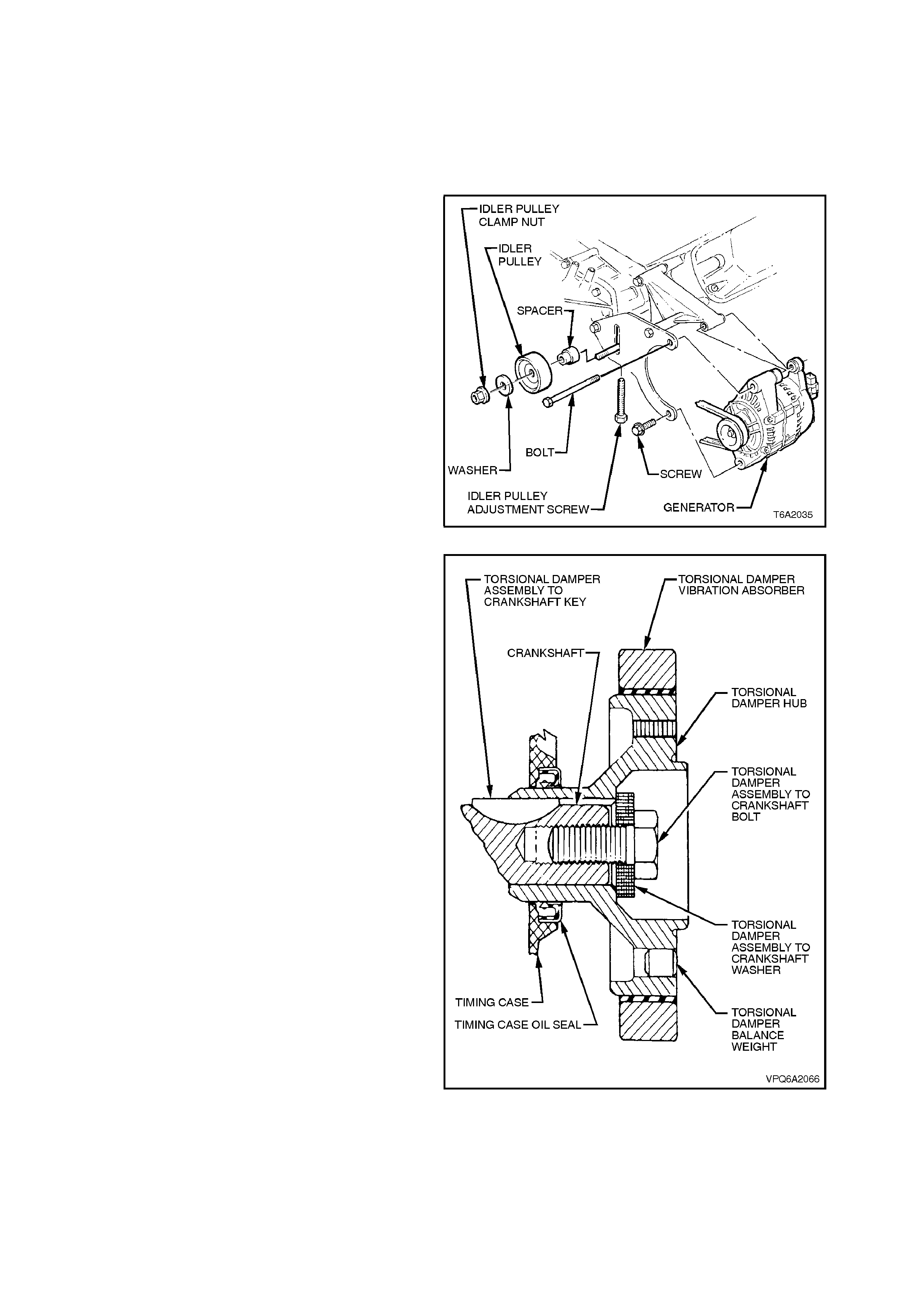

2.13 DRIVE BELTS

TENSION ADJUSTMENT

NOTE 1:

Belt tensions are specified as 'strand tension', and

measured with a suitable gauge, such as BT3373-

F.

NOTE 2:

A belt is to be considered used after 10 minutes

running.

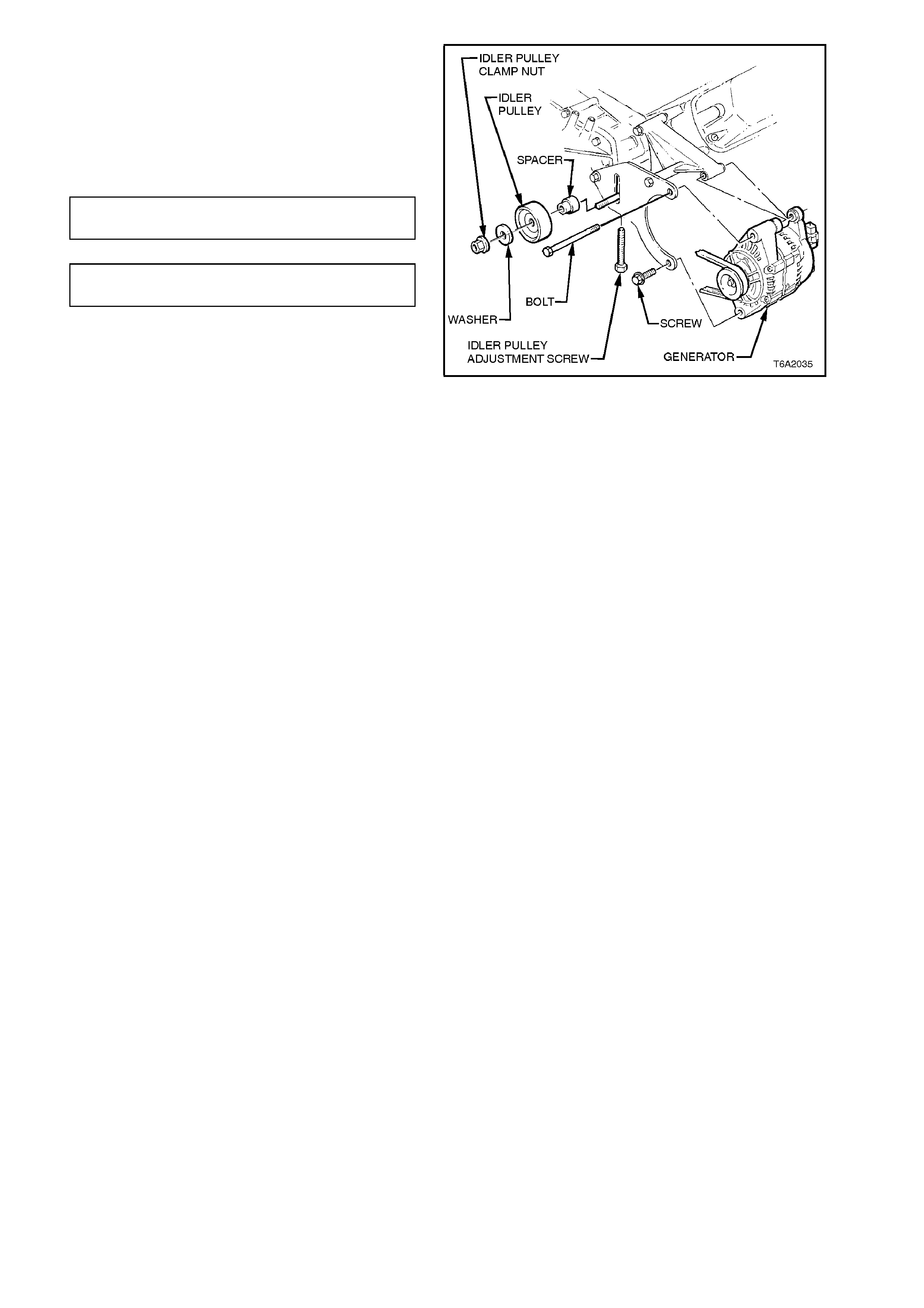

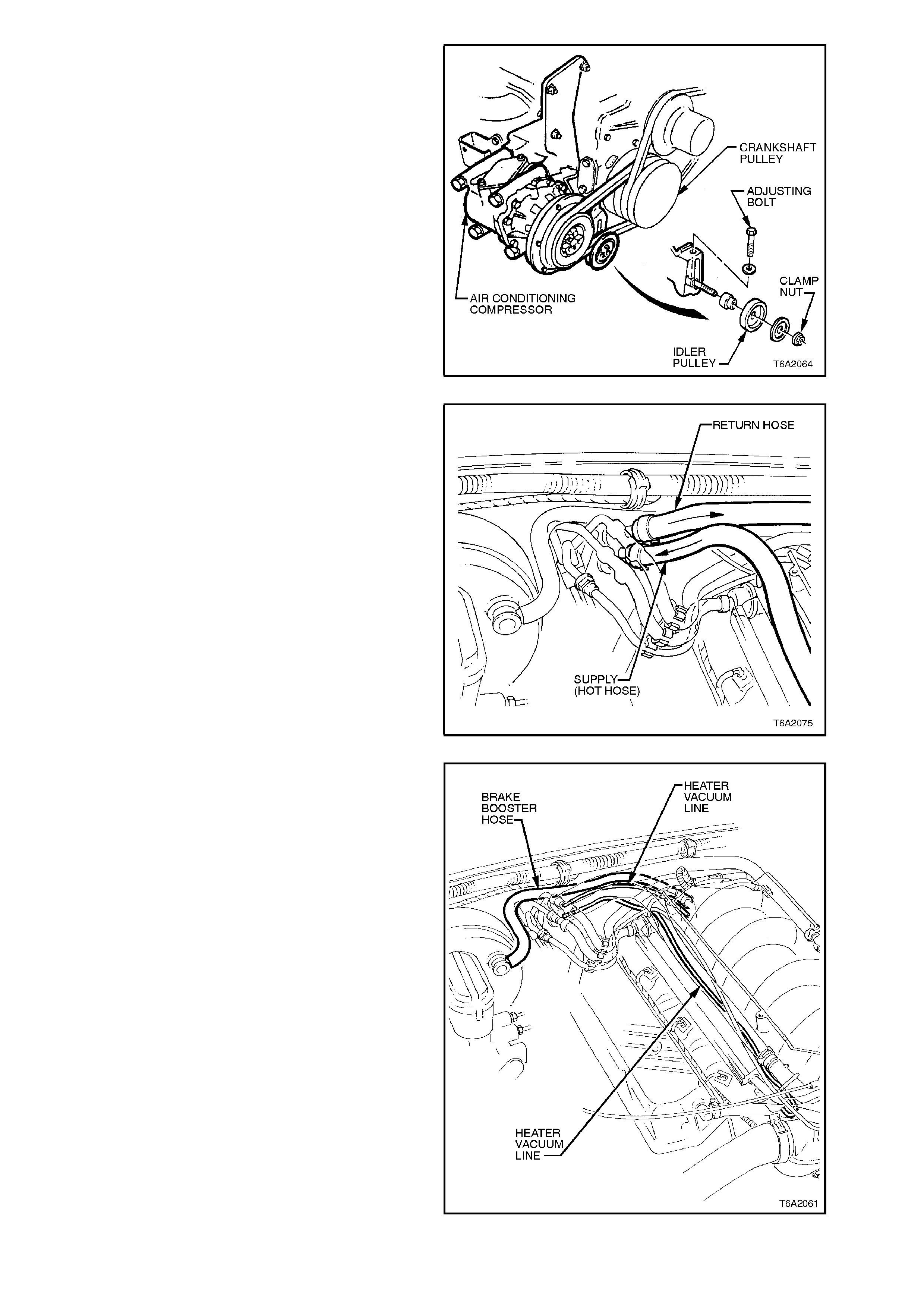

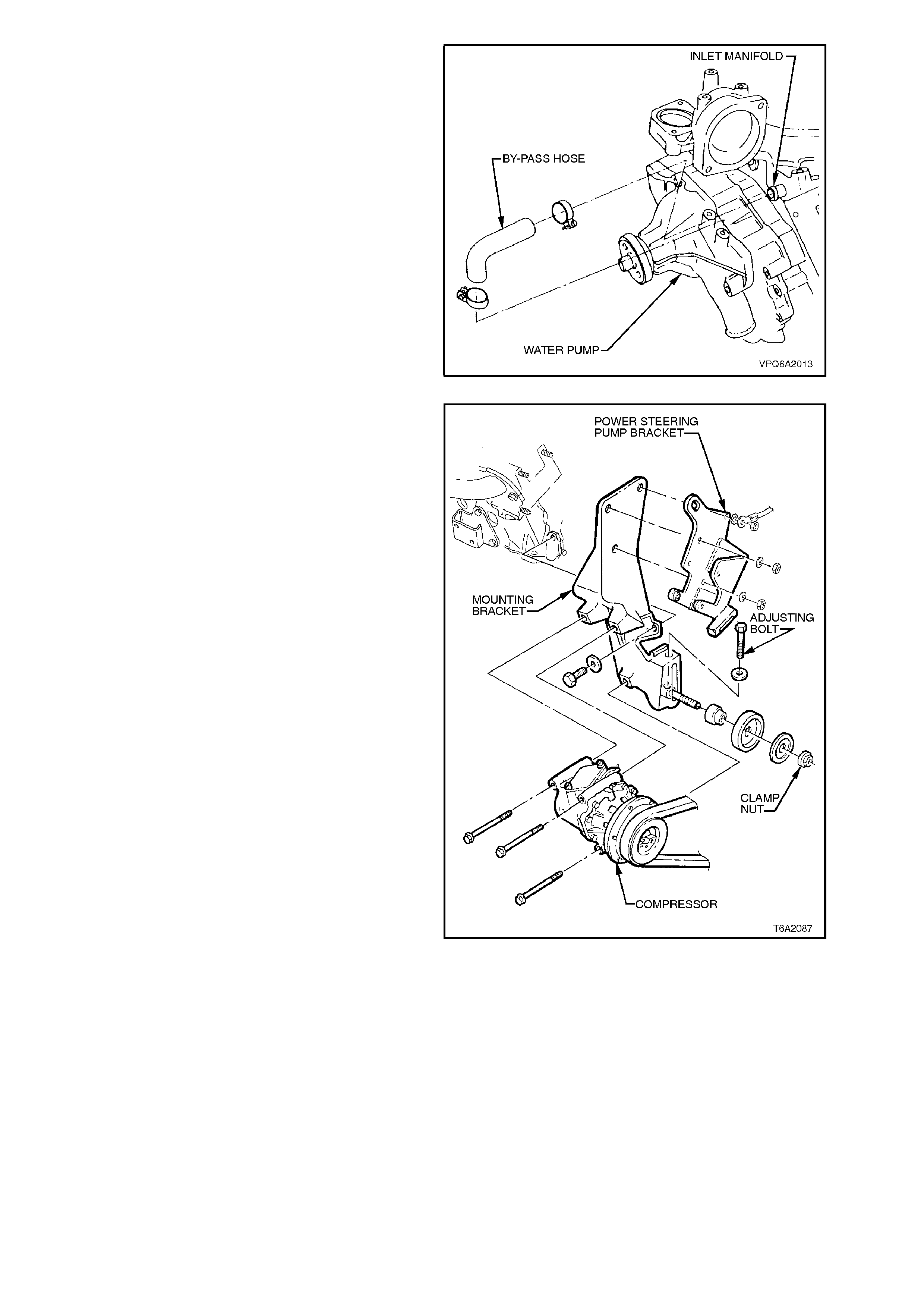

1. Loosen air conditioning compressor drive belt

idler pulley clamp nut.

2. Use the idler pulley adjusting bolt to achieve

specified belt tension, then tighten clamp nut

to specified torque. Belt tension can be

checked by using Tool No. BT3373-F, or

similar.

AIR CONDITIONER

COMPRESSOR BELT 64 kg New

TENSION SPECIFICATION 43 kg Used

IDLER PULLEY CLAMP NUT 35 - 65

TORQUE SPECIFICATION Nm

Figure 6A2-82

3. Loosen power steering pump drive belt idler

pulley clamp nut.

4. Use the idler pulley adjusting bolt to achieve

specified belt tension, then tighten clamp nut

to specified torque. Belt tension can be

checked by using Tool No. BT3373-F, or

similar.

POWE R STEERING

PUMP BELT 57 kg New

TENSION SPECIFICATION 34 kg Used

IDLER PULLEY CLAMP NUT 35 - 65

TORQUE SPECIFICATION Nm

Figure 6A2-83

Techline

5. Loosen generator drive belt idler pulley clamp

nut.

6. Use the idler pulley adjusting bolt to achieve

specified belt tension, then tighten clamp nut

to specified torque. Belt tension can be

checked by using Tool No. BT3373-F, or

similar.

GENERATOR BELT 64 kg Ne w

TENSION SPECIFICATION 43 kg Used

IDLER PULLEY CLAMP NUT 35 - 65

TORQUE SPECIFICATION Nm

Figure 6A2-84

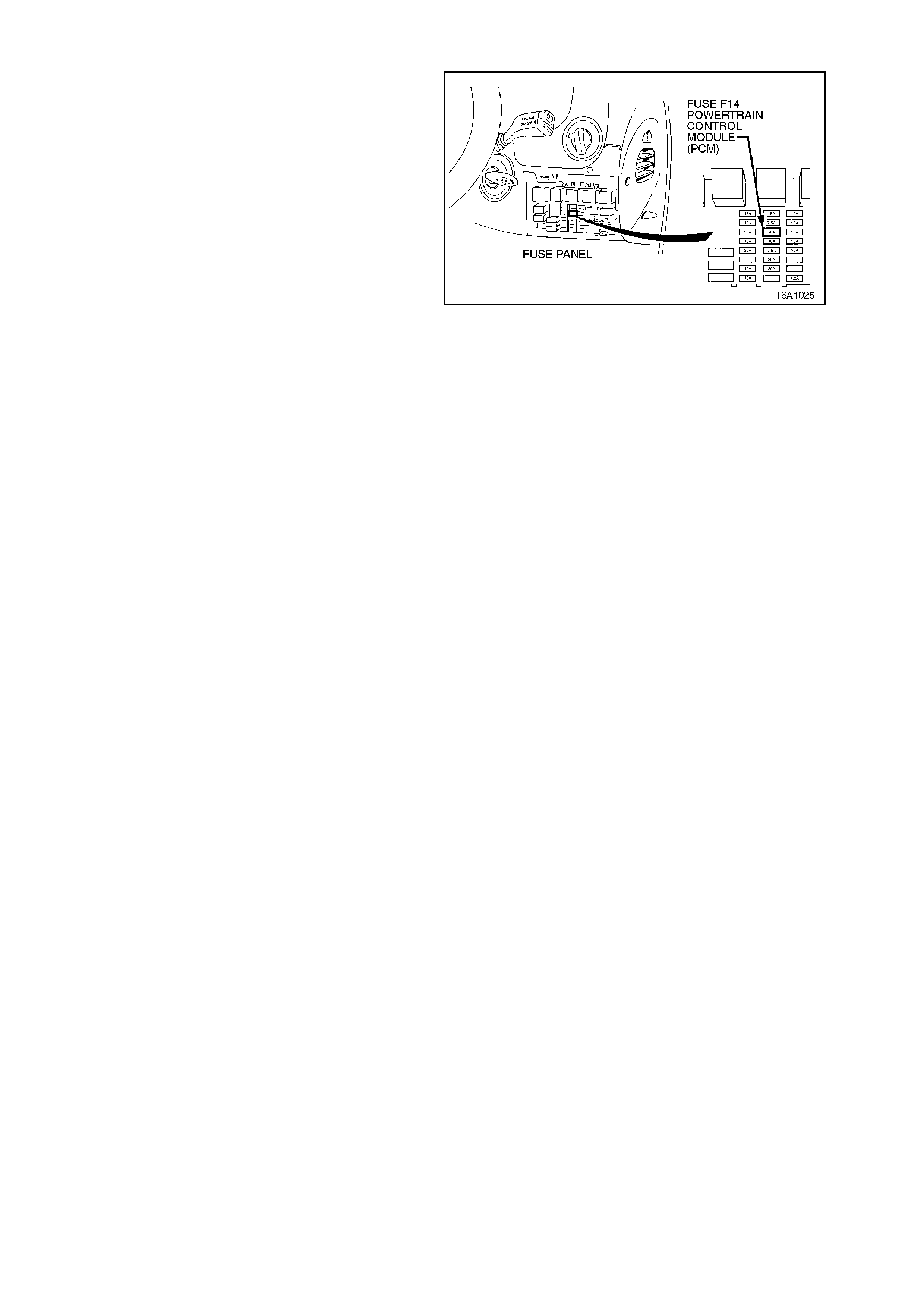

2.14 COMP RESSION CHECK

1. Before conducting this check, ensure that the

following conditions are met.

a. Engine is at operating temperature.

b. Battery is at or near to full charge.

c. All spark plugs are removed.

d. Fuse F14 is removed.

NOTE:

Removal of this fuse prevents both fuel injection

and ignition during crank ing operations. T his action

is necessary to prevent possible catalytic converter

damage.

e. Throttle fully opened.

f. Transmission is in the Neutral position

and the park brake is firmly applied.

2. Install a suitable compression tester.

3. Crank the engine and note the cylinder

pressure.

4. Repeat this process for the remaining

cylinders.

For satisfactory engine performance, the variation

between the highest and lowest cylinder

compression reading should be less than 138 kPa.

Figure 6A2-85

INTERPRETING COMPRESSION READINGS

Normal

Compression builds up quickly and evenly on

each cylinder.

Piston Rings; Faulty, Worn or Broken

Compression low on first stroke tending to

build up on subsequent strokes. Improves

considerably with the addition of oil into the

cylinder, via the spark plug hole.

Valves; Burnt or Incorrect Seating

Low on first stroke and does not tend to build

up on subsequent strokes. No significant

improvement occurs with the addition of oil to

the cylinder.

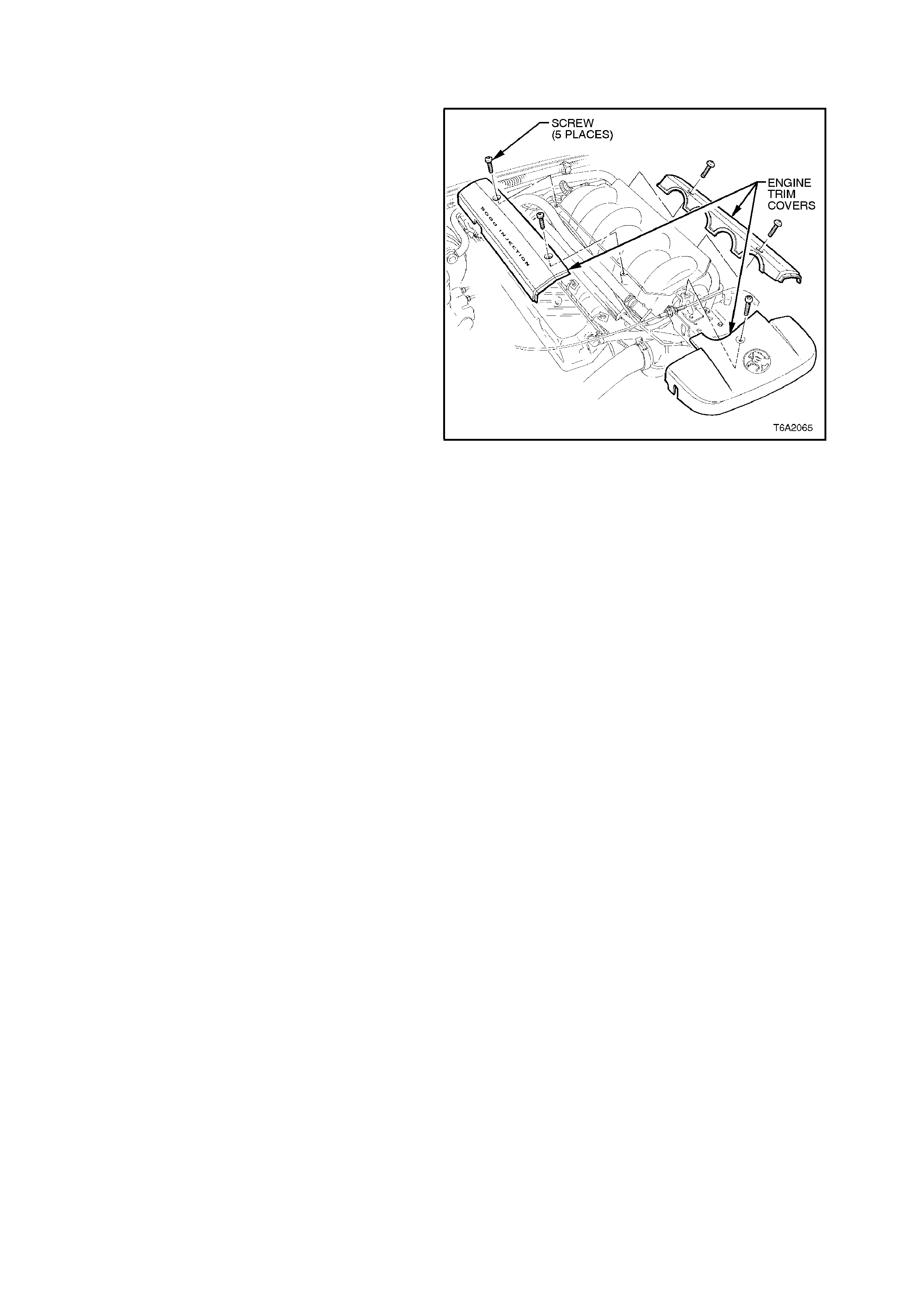

2.15 ENGINE TRIM COVERS

REMOVE

1. Remove the two screws securing the engine

trim covers to the inlet manifold, then remove

the trim covers.

2. Remove the screw securing the trim cover to

the throttle cable support bracket, then remove

the trim cover.

Figure 6A2-86

REINSTALL

Installation is the reverse of the removal procedure.

3. MAJOR SERVICE OPERATIONS

SAFETY AND CAUTIONARY NOTE FOR VEHICLES FITTED WITH ABS

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4 DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & A BS/ETC.

3.1 ENGINE ASSEMBLY

REMOVE

1. Disconnect battery earth cable from battery.

2. Remove radiator cap to release any cooling

system pressure.

WARNING:

TO AVOID SERIOUS PERSONAL INJURY,

NEVER REMOVE THE RADIATOR CAP WHEN

THE ENGINE IS HOT. SUDDEN RELEASE OF

COOLING SYSTEM PRESSURE IS VERY

DANGEROUS AND COULD CAUSE PERSONAL

INJURY.

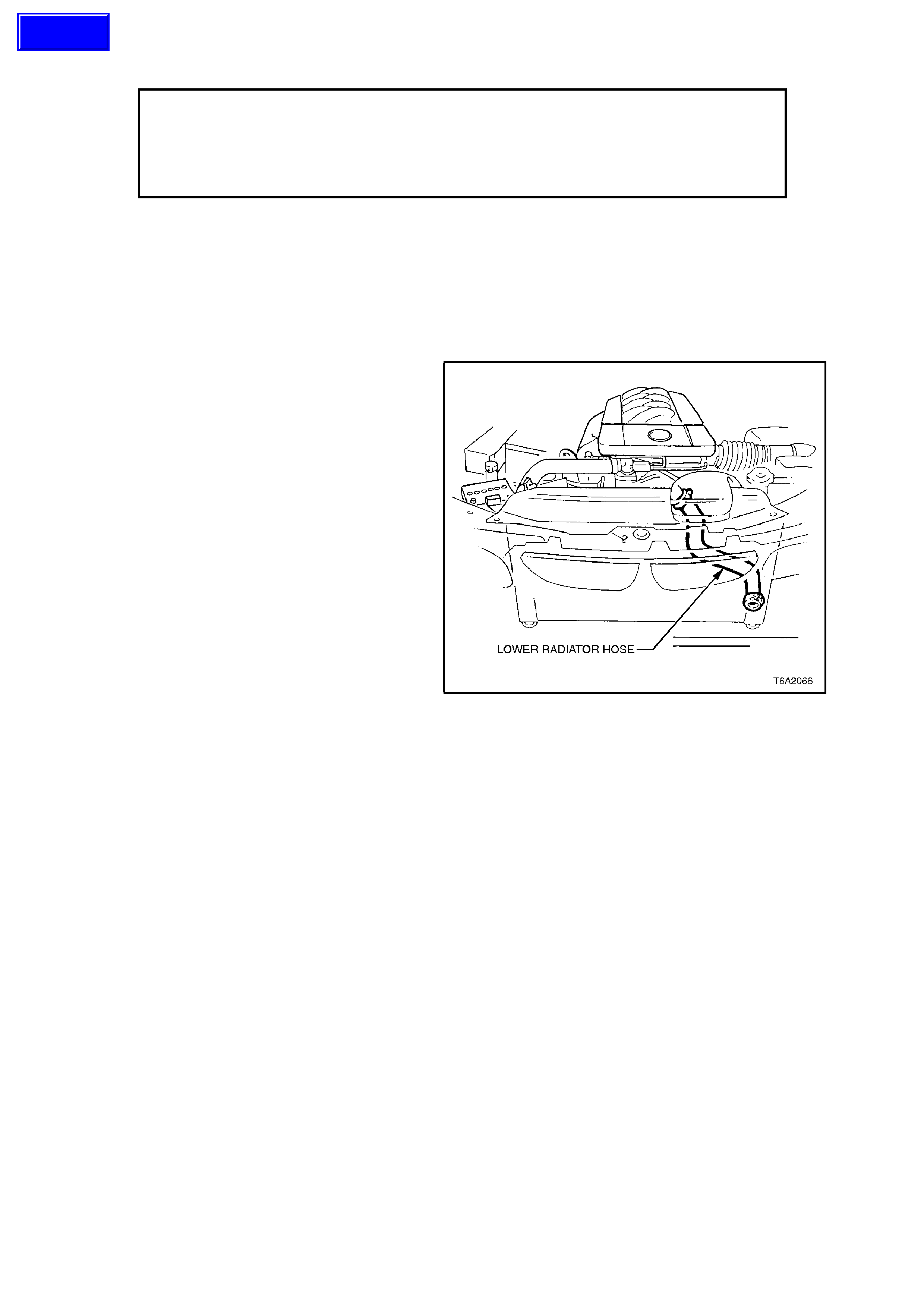

3. Place an oil drain tray beneath engine.

4. Loosen radiator lower hose clamp at radiator,

disconnect hose and allow coolant to drain.

Loosen hose clamps and disconnect radiator

hoses from engine.

Figure 6A2-87

5. Remove cooling fan and radiator assembly,

refer to Section 6B2 ENGINE COOLING -

V8 ENGINE.

6. Remove engine oil pan drain plug and allow

engine oil to drain.

Refit drain plug once oil has drained.

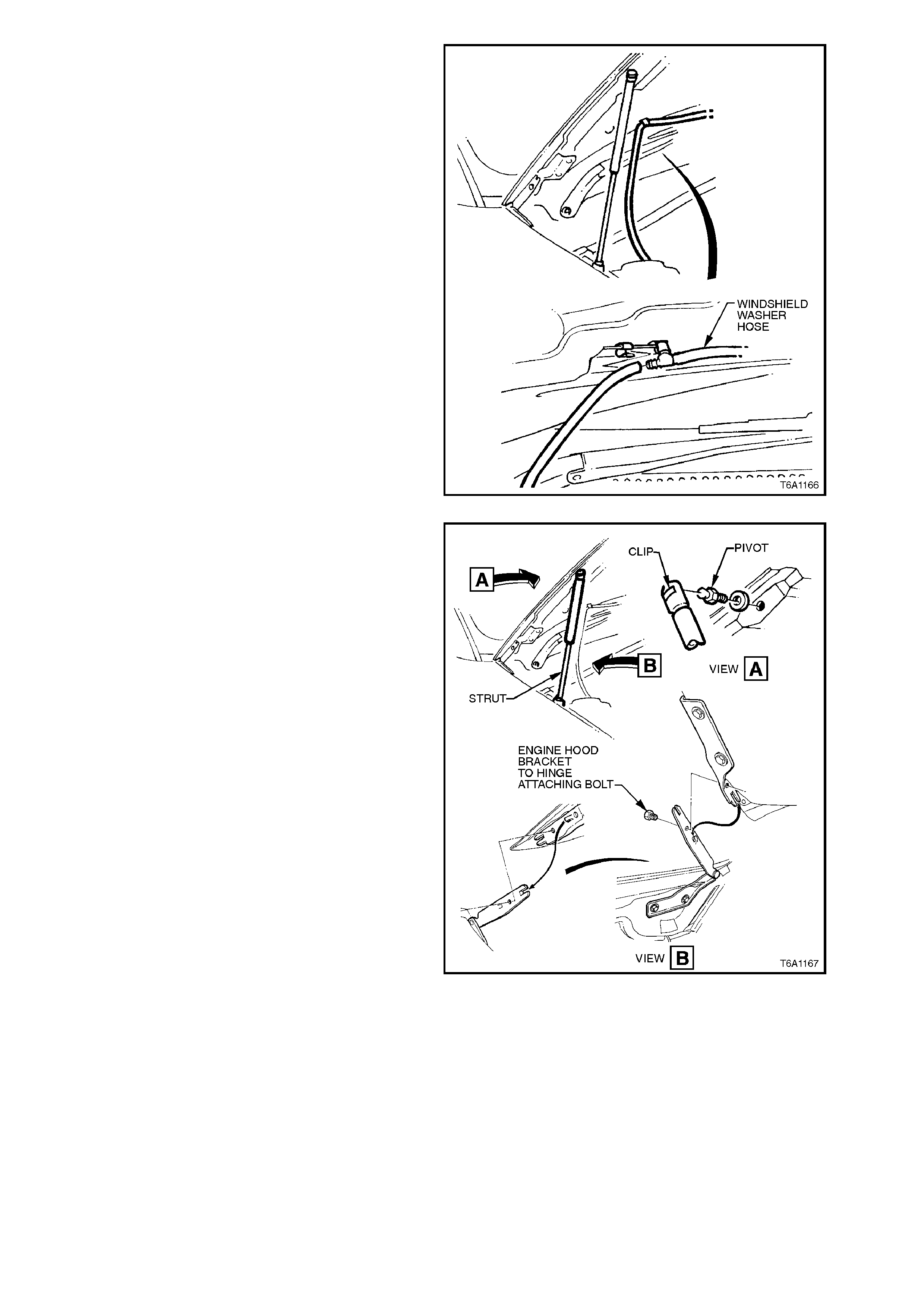

Techline

7. Disconnect windshield washer hose at the

inline connector located at the rear LH side of

hood.

Figure 6A2-88

8. With engine hood adequately supported,

remove clips securing upper end of struts to

hood pivots. Disengage struts from hood

pivots and lay strut down on fender inner

panel.

With the aid of an assistant hold hood

assembly, remove engine hood bracket to

hinge attaching bolt removing hood.

Figure 6A2-89

9. Remove engine trim covers, refer to

2.15 ENGINE TRIM COVERS in this Section.

10. Depressurise fuel lines, refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE.

11. Using quick connect release tool No. 7370

open tool and install over fuel line.

12. Close 7370 and pull into fuel line quick

connect to release it from fuel inlet line, pull

back on quick connect, disconnect fuel feed,

return and fuel evaporative canister hoses at

quick connects. Plug all openings to prevent

foreign matter entry.

NOTE:

Do not attempt to remove hoses from fuel rail

connections. Once removed from fuel rail

connection hoses require replacement.

Figure 6A2-90

13. Disconnect power steering high pressure pipe

connection from front of power steering pump.

Loosen low pressure hose clamp at rear of

pump reservoir connection and disconnect

hose from reservoir refer to

Section 9A STEERING.

NOTE 1:

Ensure all hose connections are plugged.

Alternatively rem ove the power steer ing pum p drive

belt and the nuts secur ing the power steer ing pump

brack et assem bly, tie the power steering pum p and

bracket assembly clear of the engine.

NOTE 2:

Using the alternative method will necessitate the

installation of an engine lifting bracket to the front of

the engine.

Figure 6A2-91

14. Disconnect main wiring harness to powertrain

and battery harness connectors at dash panel.

Figure 6A2-92

15. Remove wiring harness connector from ABS

modulator . Disconnec t power steering har ness

connector and remove clip from ABS

modulator bracket, and lay wiring harness

aside.

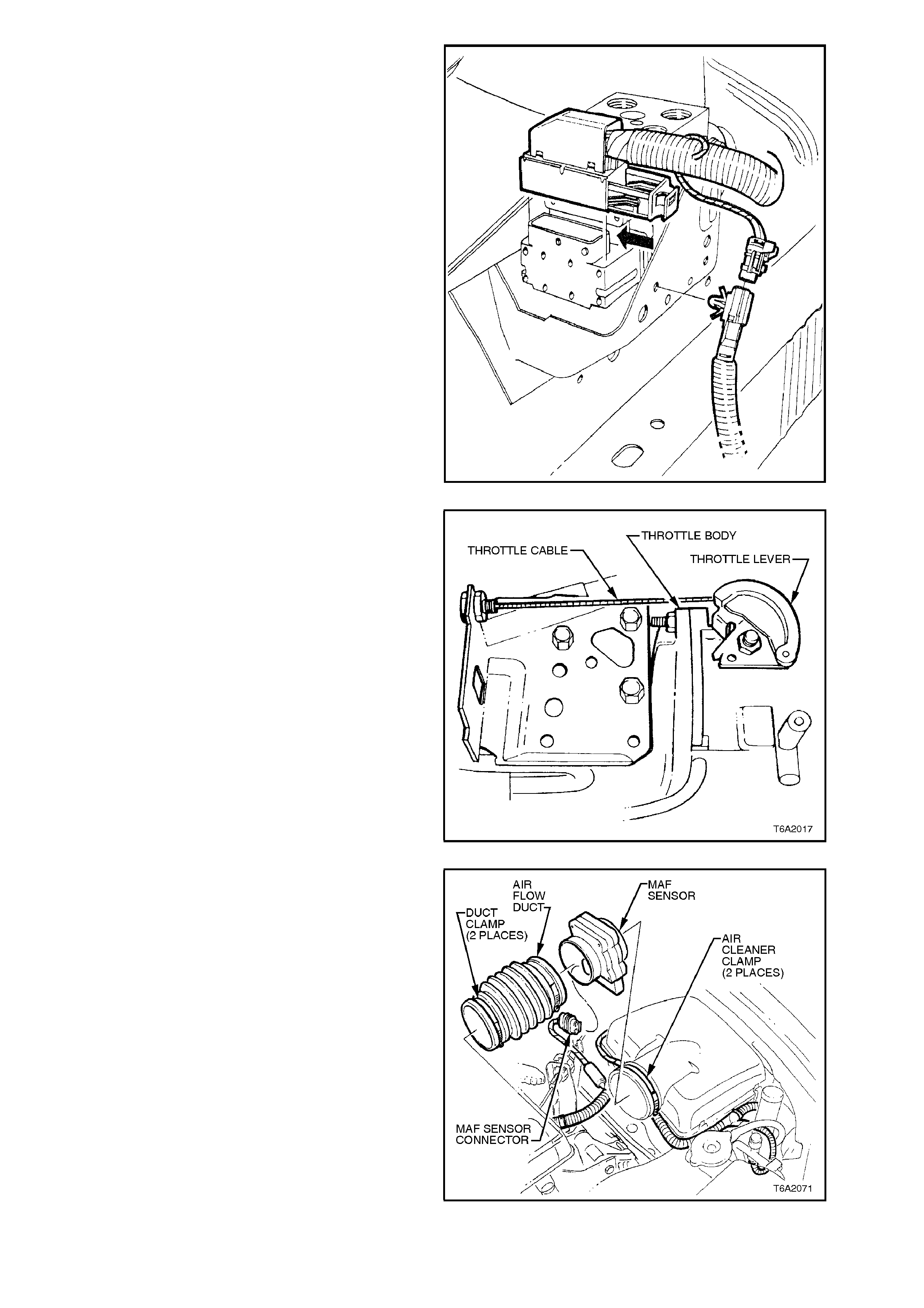

Figure 6A2-93

16. Remove throttle body and cruise control

cable, (where fitted) refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE.

Figure 6A2-94

17. Disconnect mass air flow sensor wiring,

loosen air flow duct rubber boot clamps at

throttle body and air cleaner, remove air flow

duct. Carefully place air flow duct and mas s air

flow sensor assembly to one side.

Figure 6A2-95

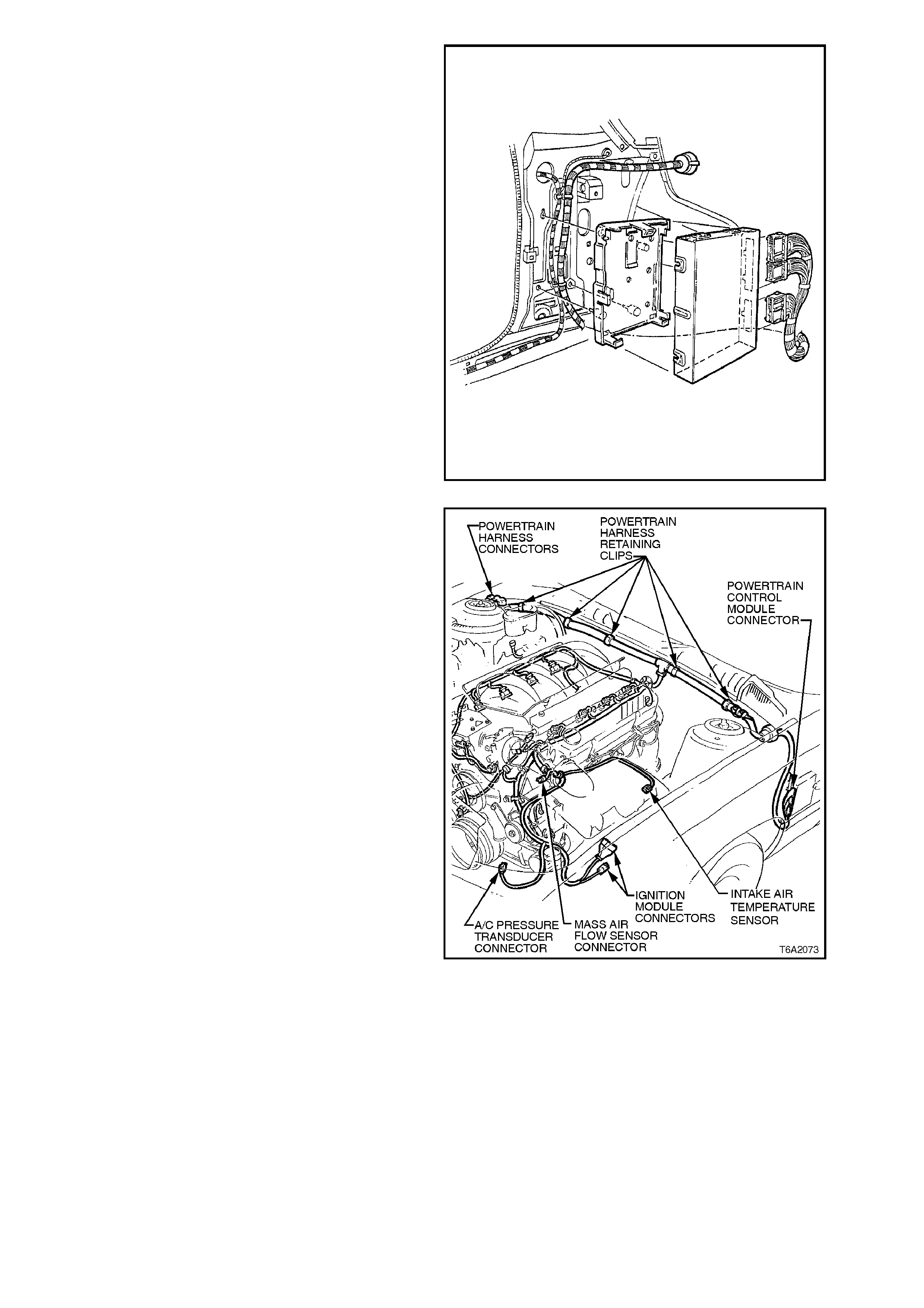

18. From inside vehicle, remove left hand cowl

panel trim, glove box assembly and taking

care to remove the screw beneath the rocker

panel cover, the lower left hand side trim

assembly, refer to Section 1A1 BODY.

19. Disconnect engine wiring harness

connectors from PCM. Refer to

Section 6C2 POWERTRAIN MANAGEMENT

- V8 ENGINE. Compress lugs on engine

harness plug at dash panel and push engine

harness and connectors out into engine

compartment.

Figure 6A2-96

20. From engine compartment release powertrain

harness to dash panel retaining clips,

disconnect intake air temperature sensor,

ignition module, idle air control motor

connectors at air cleaner and air conditioning

pressure transducer connector at air

conditioning condenser (where fitted), lay

wiring harness on top of engine.

Figure 6A2-97

21. Where fitted disconnect air conditioning

electrical connector from air conditioning

compressor, unbolt air conditioning

com press or from the brac k et assem bly, move

to one side without disconnecting hoses, refer

to Section 2B AIR CONDITIONING -

REMOVAL AND INSTALLATION.

NOTE:

When the alternative m ethod is used in step 13 the

air conditioning compressor and bracket assembly

(where fitted) can also be rem oved and tied c lear of

the engine.

Figure 6A2-98

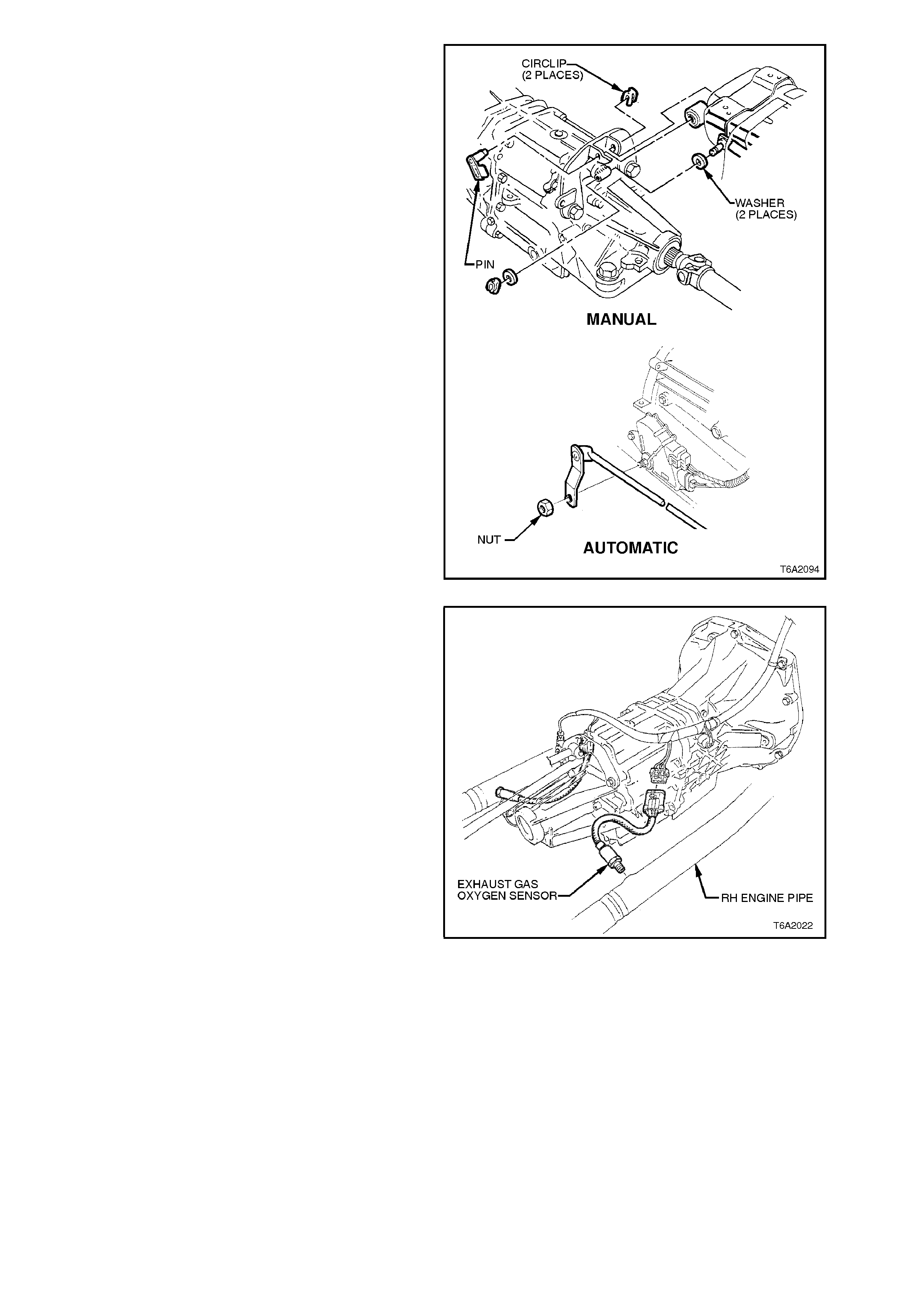

22. Tag and disconnect heater supply and return

hoses from dash panel.

Figure 6A2-99

23. Disconnect the brake booster vacuum hose

from brake booster.

24. Disconnect heater control vacuum line from

union at side of inlet manifold and at heater

water tap.

25. Raise vehicle and place on safety stands.

Figure 6A2-100

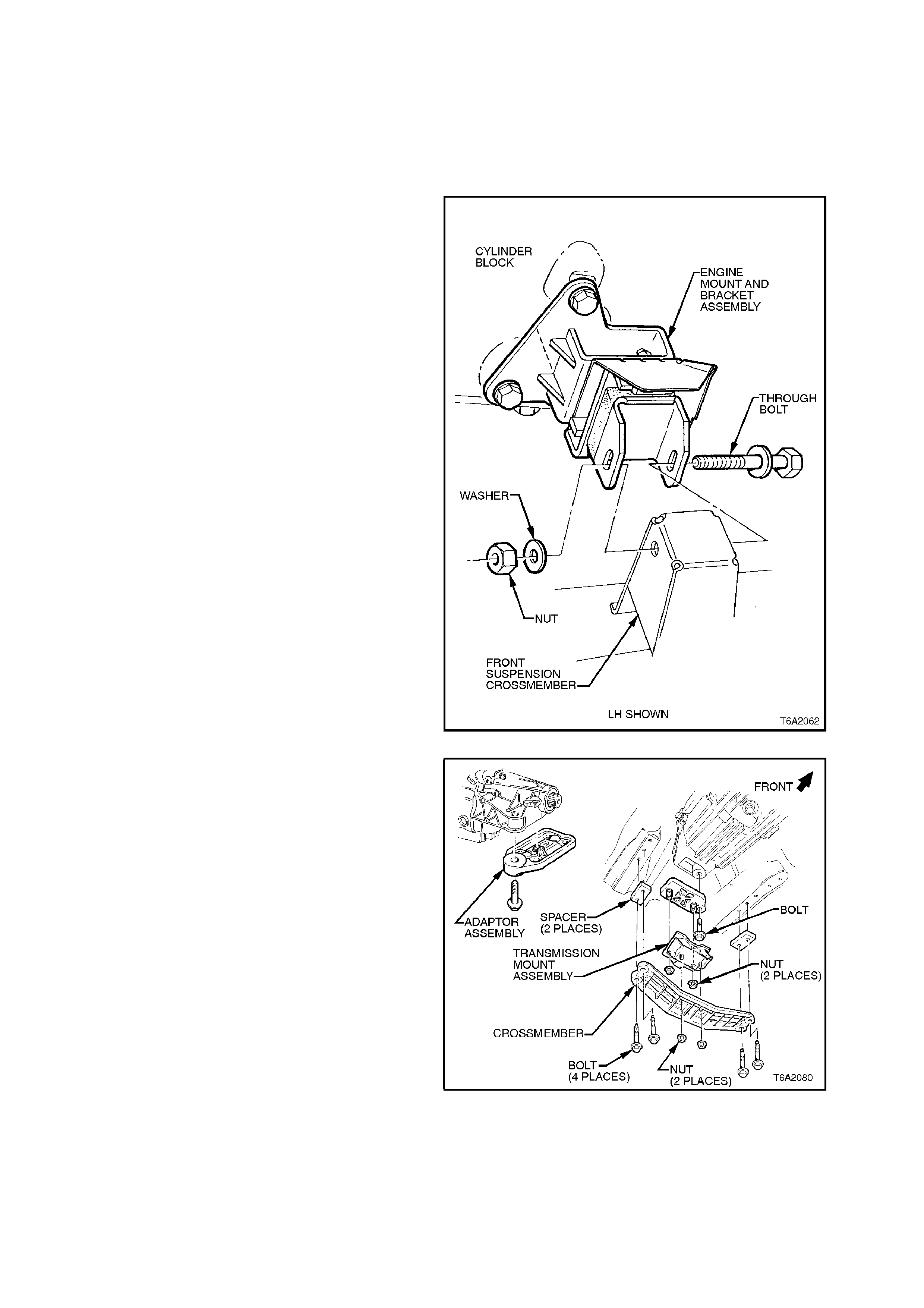

26. Disconnect control linkage from automatic or

manual transmission.

Figure 6A2-101

27. Disconnect the oxygen sensor wiring harness

connectors. Disconnect the exhaust pipes

from exhaust manifolds.

Figure 6A1-1-102

28. On vehicles with manual transmission,

disconnect the hydraulic line to the clutch

actuating cylinder, refer to

Section 7A CLUTCH.

29. Remove propeller shaft as described in

Section 4C PROPELLER SHAFT &

UNIVERSAL JOINTS.

30. Support engine with overhead lifting device

and raise slightly to take weight off engine

mounts.

NOTE:

Due to the routing of the spark plug leads to

cylinders 2, 4, 6 and 8, there is a c hance that these

leads may become damaged when lifting the

engine with an overhead lifting device. Therefore,

to prevent damage to these leads occurring during

this procedure, temporarily reposition spark plug

leads behind the rear engine lifting hook.

31. Remove engine front mount to crossmember

through bolts.

Figure 6A2-103

Vehicles fitted with manual transmission:

32. Remove engine rear power plant support to

frame bolts and washers. Remove support to

mount attaching nuts and remove support.

Figure 6A1-1-104

Vehicles fitted with automatic transmission:

33. Remove engine rear crossmember to frame

bolts and washers. Remove crossmember to

rear mounting attaching nuts and remove

crossmember.

Figure 6A1-1-105

34. Remove bolts securing left hand side engine

mount to crankcase and remove mount.

35. Raise front of engine until top of transmission

case almost contacts the floor pan.

36. Tilt the right hand side of engine upward, until

the right hand side engine mount clears

crossmember.

37. Move engine forward until engine mounts are

clear.

38. Raise engine with front tilted upwards and lift

engine and transmission out of vehicle.

CAUTION:

With air conditioned vehicles, do not allow

engine to swing forward and damage air

conditioning condenser or pipes.

Figure 6A2-106

DISASSEMBLE

1. Remove transmission (and clutch, if fitted)

referring to

Sections 7A CLUTCH, or

Section 7B1 M ANUAL TRANSMISSION - V6

ENGINE or

Section 7B2 M ANUAL TRANSMISSION - V8

ENGINE or

Section 7C4 AUTO TRANS. - ON-VEHICLE

SERVICING as appropriate.

2. Mount engine on a suitable engine stand.

3. Remove the following items as described in

the relevant Operation or Section.

-Generator and brackets, refer to

Section 6D2-1 CHARGING SYSTEM - V8

ENGINE.

-Starter motor, refer to Section 6D2-2

STARTING SYSTEM - V8 ENGINE.

-Water pump, refer to Section 6B2

ENGINE COOLING - V8 ENGINE.

-Oil pump assembly, refer to

2.11 OIL PUMP in this Section.

-Distributor, spark plugs and spark plug

leads, refer to Section 6D2-3 IGNITION

SYSTEM - V8 ENGINE.

-Inlet manifold, refer to

2.1 INLET MANIFOLD in this Section.

-Exhaust manifolds, refer to

2.2 EXHAUST MANIFOLD in this Section.

-Rocker arms, rocker arm pivots and push

rods, refer to 2.3 ROCKER ARMS in this

Section.

-Hydraulic valve lifters, refer to

2.7 HYDRAULIC VALVE LIFTERS in this

Section.

-Cylinder heads, refer to

2.6 CYLINDER HEADS in this Section.

-Oil pan, refer to 3.2 OIL PAN in this

Section.

-Oil pump suct ion pipe and screen, ref er to

3.7 OIL PUMP SUCTION PIPE AND

SCREEN in this Section.

- Crankcase front cover, refer to

- 3.3 CRANKCASE FRONT COVER in this

Section.

-Cams haft, refer to 3.6 CAMSHAFT in this

Section.

-Piston and connecting rod assemblies,

refer to 3.12 PISTON AND CONNECTING

ROD ASSEMBLY in this Section.

-Crankshaft, refer to 3.14 CRANKSHAFT

in this Section.

4. Discard all gaskets and seals.

5. For inspection procedures, refer to service

operations for each component as previously

listed.

REASSEMBLE

Reassembly is the reverse of the disassembly

procedure.

CAUTION:

Carefully follow the reinstallation procedure for

each component as outlined in the relevant

Operation. The relevant Operation or Section

for each component is referred to in the

disassembly procedure.

NOTE:

The rear m ain oil seal r eplacem ent is described in

3.9 REAR MAIN BEARING OIL SEAL in this

Section.

REINSTALL

Installation is the reverse of the r emoval proc edur e,

except for the following:

1. Apply anti-seize compound, such as Kopr-

Kote or equivalent (Holden Specification HN

1325), to the exhaust manifold stud threads

before reinstalling exhaust pipes.

2. Adjust drive belt tensions, refer to

2.13 DRIVE BELTS in this Section.

3. Tighten all fasteners to specified torque’s, as

listed.

OIL PAN DRAIN PLUG 30 - 60 Nm

REAR CROSSMEMBER BOLTS 35 - 65 Nm

ENGINE REAR MOUNT/CROSSMEMBER BOLT 20 - 45 Nm

EXHAUST PIPE TO MANIFOLD NUTS 15 - 35 Nm

CONTROL LINKAGE TO AUTO. TRANS 11 - 15 Nm

ENGINE FRONT MOUNT THROUGH BOLT 34 - 46 Nm

POWER STEERING PUMP BRACKET NUT 15 - 20 Nm

ENGINE HOOD HINGE BOLT 18 - 24 Nm

4. Use specified lubricant and coolant when

refilling lubrication and cooling systems.

5. Check transmission fluid level.

6. Install engine hood, checking alignment.

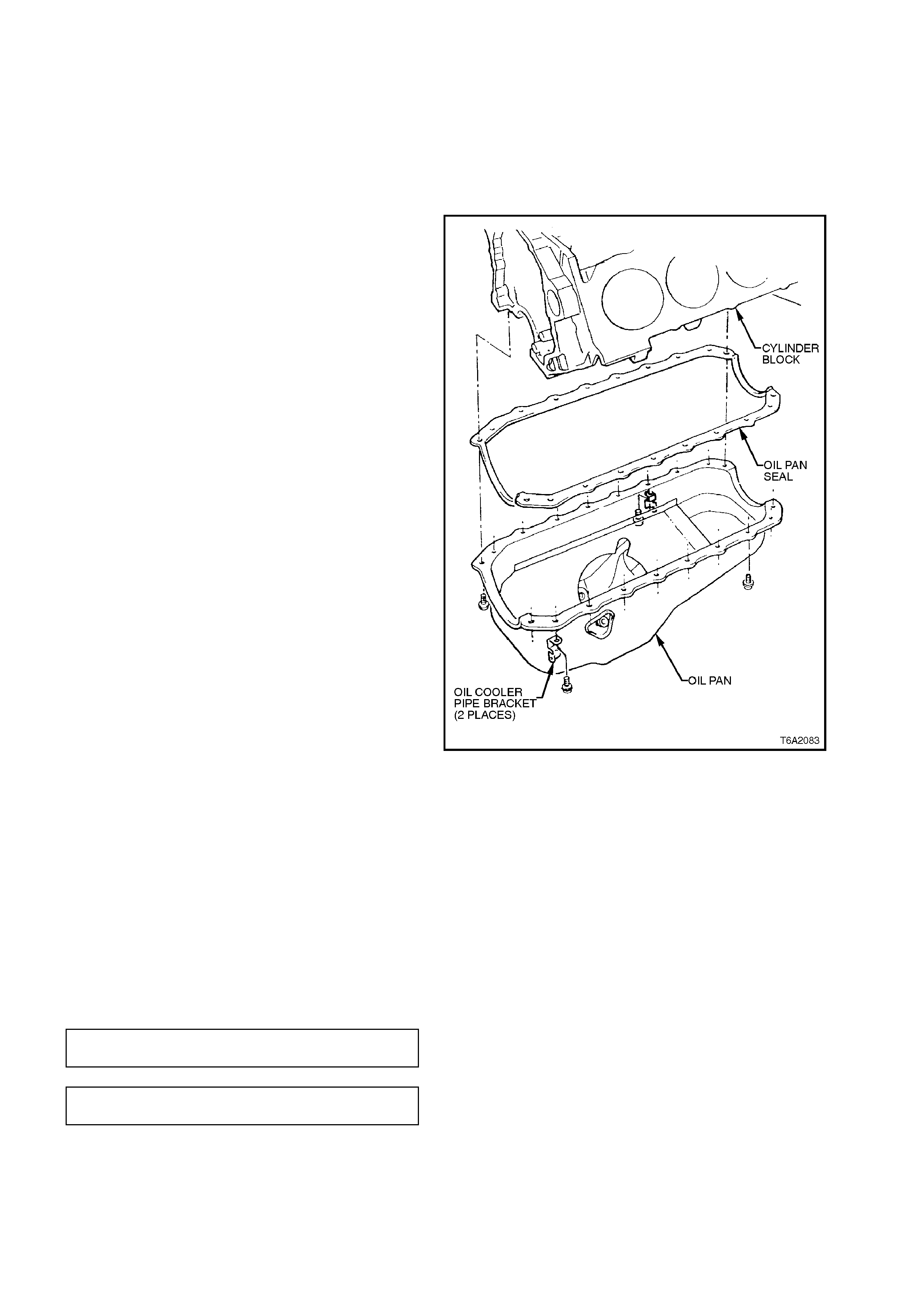

3.2 OIL PAN

REMOVE

1. Remove front crossmember, refer to

Section 3 FRONT SUSPENSION.

2. Drain contents of oil pan, then replace and

tighten drain plug.

3. Support engine on safety stands at engine

mounts.

4. Remove starter motor, refer to

Section 6D2-2 STARTING SYSTEM - V8

ENGINE. This is necessary to access oil pan

bolts if a special, thin socket spanner is not

available.

5. Rem ove oil pan attaching bolts and rem ove oil

pan.

Figure 6A2-107

REINSTALL

1. Remove old seal and thoroughly clean mating

surfaces of oil pan and cylinder block.

2. Apply a 1 - 2 m m bead of s ealant, s uch as 3M

EC776 or equivalent (Holden Specification

HN 2054), to the cylinder block to front cover

interface. Refer to Fig. 6A2-107 for specific

details.

3. Install seal taking care to align bolt holes

correctly.

4. Reinstall oil pan and tighten bolts to specified

torque.

OIL PAN DRAIN PLUG

TORQUE SPECIFICATION 30 - 60

Nm

OIL PAN BOLTS

TORQUE SPECIFICATION 8 - 10

Nm

5. Reinstall starter motor, refer to Section 6D2-

2 STARTING SYSTEM - V8 ENGINE.

6. Reinstall engine assembly, refer to

3.1 ENGINE ASSEMBLY in this Section.

7. Refill the engine to correct level with

specified engine oil. Refer to

Section 0B LUBRICATION & SERVICE.

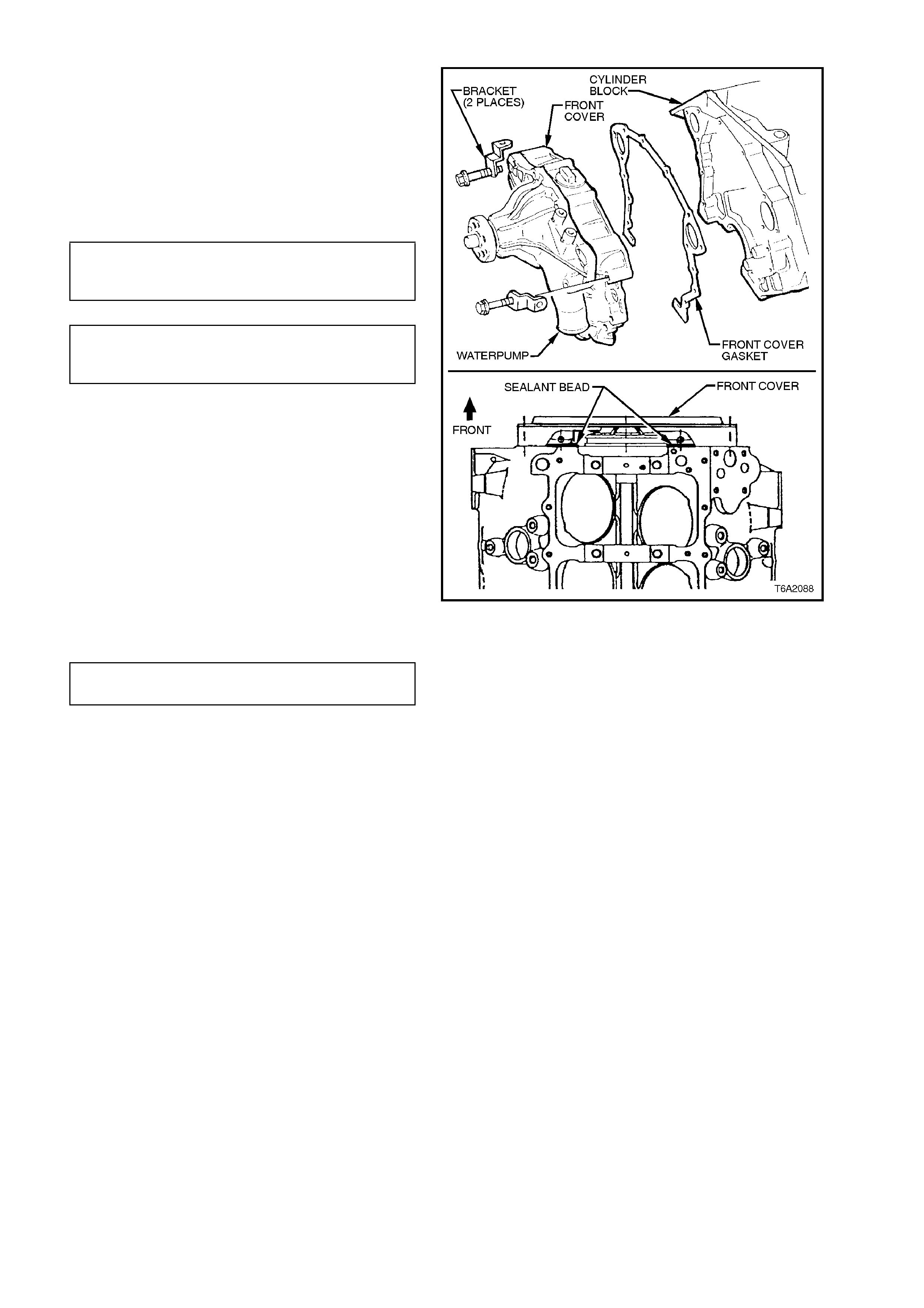

3.3 CRANKCASE FRONT COV ER

REMOVE

1. Drain cooling system, refer to Section 6B2

ENGINE COOLING - V8 ENGINE.

2. Remove engine cooling fan and pulley, refer to

Section 6B2 ENGINE COOLING - V8

ENGINE.

3. Remove all drive belts fitted to crankshaft

drive belt pulley, refer to Section

2.13 DRIVE BELTS in this Section.

4. Disconnect and remove generator, refer to

Section 6D2-1 CHARGING SYSTEM - V8

ENGINE.

5. Remove generator brackets.

Figure 6A2-108

6. Remove torsional damper assembly to

crankshaft bolt and washer, then remove

torsional damper assembly.

Figure 6A2-109

7. Disconnect heater hos e and bypass hose from

water pump.

Figure 6A2-110

8. Remove the three nuts and bolt securing air

conditioning compressor bracket and power

steering assembly and move to one side

without disconnecting hoses, refer to

Section 2B AIR CONDITIONING - REMOVAL

AND INSTALLATION.

9. Remove oil pan, refer to 3.2 OIL PAN in this

Section.

10. Remove crankcase front cover attaching bolts.

NOTE:

Engine harness brack ets are also s ecured by these

bolts.

11. Remove front cover and water pump

assembly.

Figure 6A2-111

REINSTALL

1. Thoroughly clean mating surfaces on cylinder

block and front cover.

2. Install front cover gasket on cylinder block.

Lubricate seal lip with engine oil.

3. Reinstall front cover and water pump

assembly, engine harness brackets and

generator brace. Tighten all bolts to specified

torque.

CRANKCASE FRONT

COVER BOLTS 23 - 30 Nm

TORQUE SPECIFICATION

GENERATOR BRACE BOLT

TO FR ONT COVER 17 - 24 Nm

TORQUE SPECIFICATION

4. Apply a 1 - 2 m m bead of sealant, such as 3M

E776 or equivalent (to Holden Specification

HN2054) to the front cover to engine block

interface as shown in Fig. 6A2-112.

5. Reinstall oil pan, refer to 3.2 OIL PAN in this

Section.

6. Lubricate torsional damper hub bore with

hypoid lubricant and lubric ate seal s ur f ac e with

engine oil.

7. Align keyway in damper with key on

crankshaft. reinstall torsional damper and

tighten bolt to specified torque.

TORSIONAL DAMPER BOLT 190 Nm

TORQUE SPECIFICATION minimum

8. Reinstall engine water pump pulley, refer to

Section 6B2 ENGINE COOLING - V8

ENGINE.

9. Reinstall and adjust all drive belts, refer to

2.13 DRIVE BELTS in this Section.

10. Reins tall generator m ounting br ack ets, ref er to

Section 6D2-1 CHARGING SYSTEM - V8

ENGINE.

11. Reinstall and reconnect generator, refer to

Section 6D2-1 CHARGING SYSTEM - V8

ENGINE.

12. Reconnect coolant and heater hoses to water

pump.

13. Refill engine cooling system with specified

coolant, refer to Section 6B2 ENGINE

COOLING - V8 ENGINE.

Figure 6A2-112

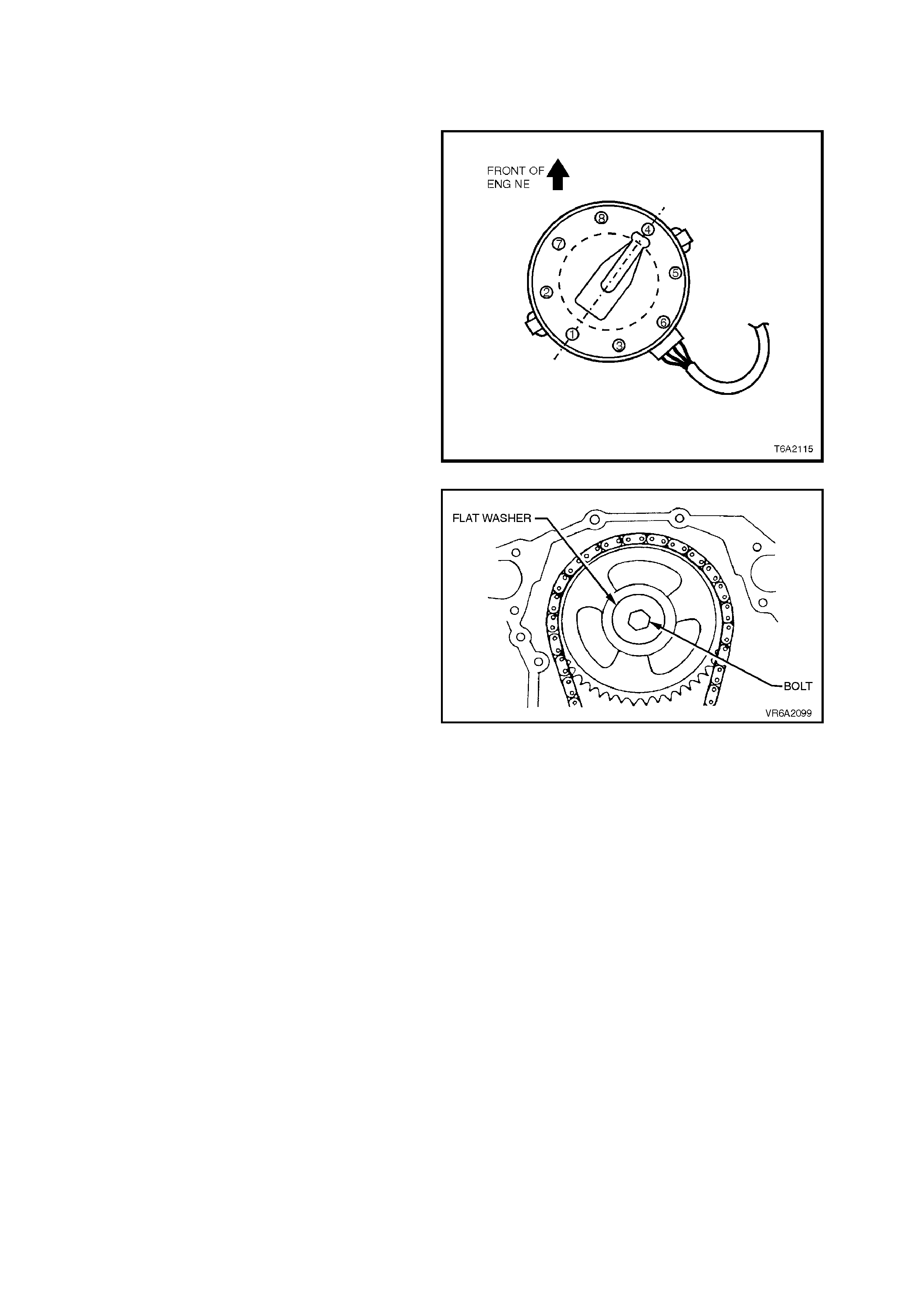

3.4 TIMING CHAIN AND SPROCKETS

REMOVE

1. Rotate the crankshaft by hand until the

distributor rotor is in the number 4 cylinder

position (i.e. number 4 piston is at the top of its

compression stroke with both valves closed,

valves for number 1 cylinder ‘rocking’).

2. Remove crankcase front cover, refer to

3.3 CRANKCASE FRONT COVER in this

Section.

NOTE:

Ensure crankshaft does not move during this

operation.

Figure 6A2-113

3. Remove bolt securing flat washer and

camshaft sprocket to camshaft.

4. Withdraw sprockets and timing chain. The

crankshaft sprocket is a push fit on the

crankshaft.

NOTE:

Do not rotate the crankshaft after removing the

timing chain and sprockets.

Figure 6A2-114

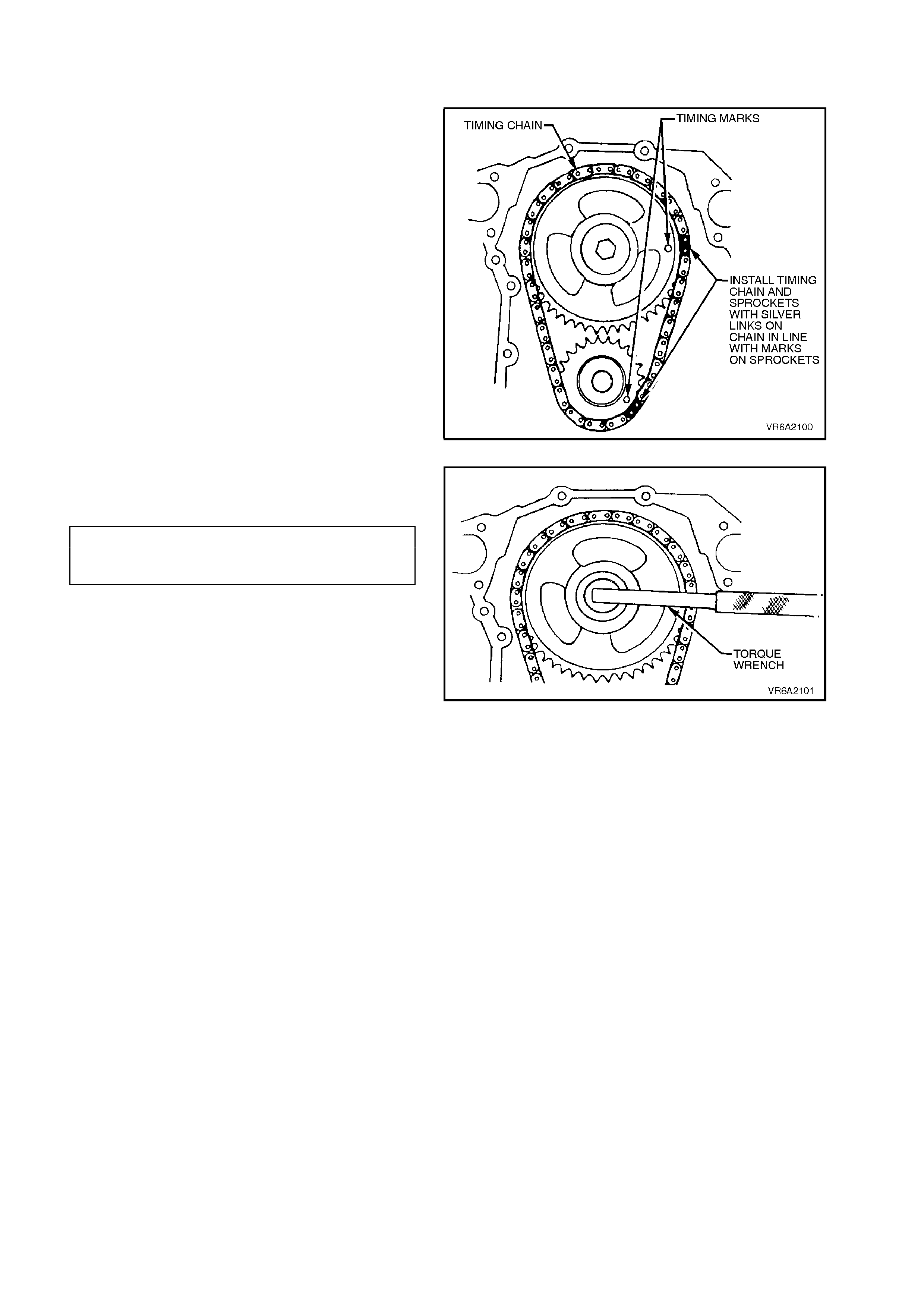

REINSTALL

1. Check that the number 4 cylinder is at T.D.C.

and both valves are closed.

2. Align dots on sprockets with silver links on

chain and reinstall sprockets and chain. Align

keyway in crankshaft sprocket with key on

crankshaft.

Figure 6A2-115

3. Reinstall flat washer and camshaft sprocket

retaining bolt. Tighten bolt to specified torque.

CAMSHAFT SPROCKET

RETAINING BOLT 61 - 74 Nm

TORQUE SPECIFICATION

4. Lubricate timing chain with engine oil.

5. Reinstall crankcase front cover, refer to

3.3 CRANKCASE FRONT COVER in this

Section.

Figure 6A2-116

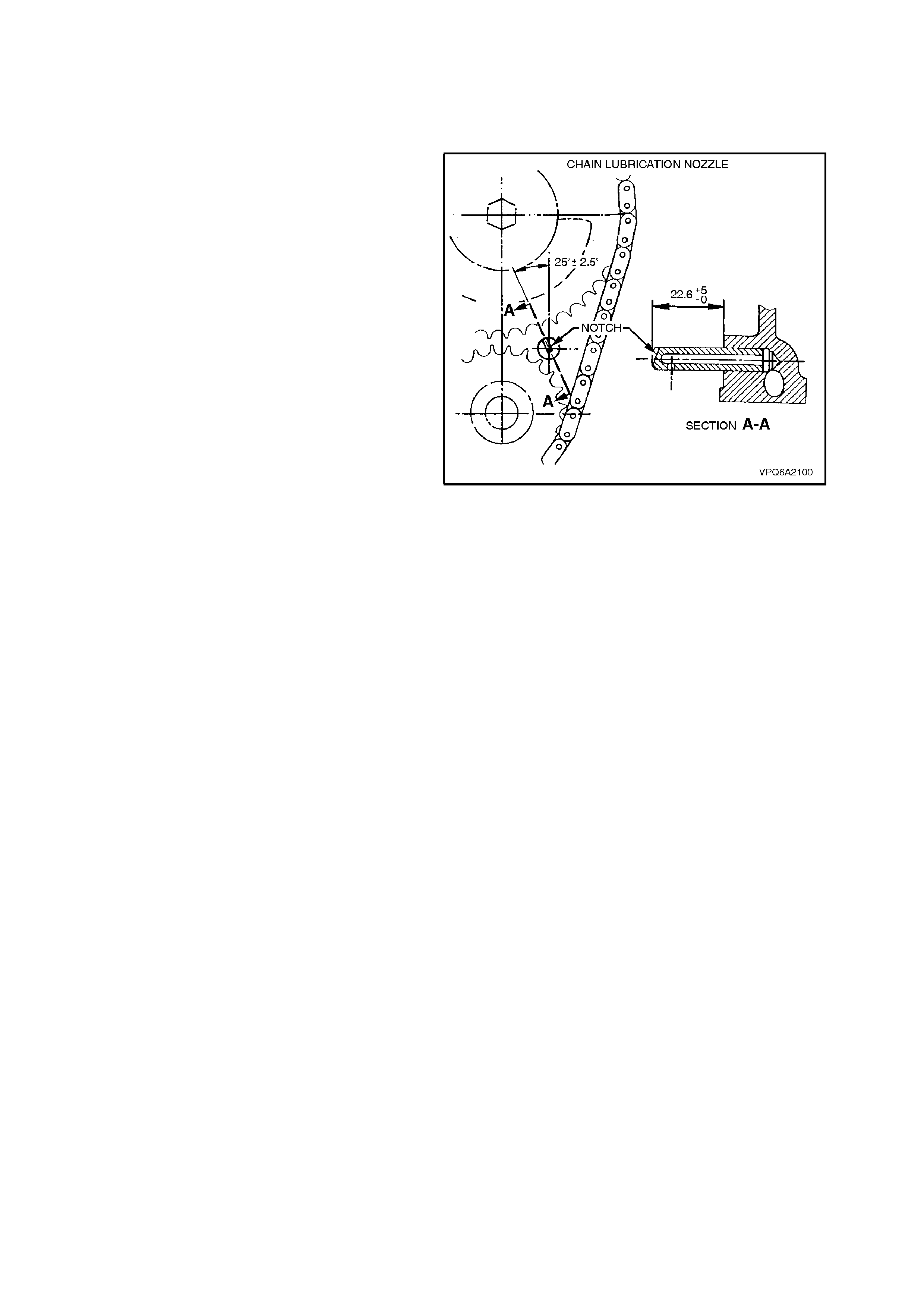

3.5 TIMING CHAIN LUBRICATION NOZZLE

REMOVE

1. Remove crankcase front cover, refer to

3.3 CRANKCASE FRONT COVER, in this

Section.

2. Using a pair of combination pliers or similar,

grasp the nozzle and pull with a twisting

motion.

REINSTALL

1. Align the oil hole of a new nozzle as shown in

Fig. 6A2-117, and drive into the cylinder block

using a suitable punch.

2. Ensure that the nozzle is only installed to the

depth shown in Fig. 6A2-117.

Figure 6A2-117

3.6 CAMSHAFT

REMOVE

1. With engine removed from vehicle and

mounted on an engine stand, remove timing

chain and sprockets, refer to

3.4 TIM ING CHAIN AND SPROCKETS in this

Section.

2. Remove hydraulic valve lifters, refer to

2.7 HYDRAULIC VALVE LIFTERS in this

Section.

3. Remove bolt securing camshaft locater and

remove locater.

4. Carefully withdraw camshaft from front of

engine.

Figure 6A2-118

INSPECT

NOTE 1:

The camshaft is supported on five steel-backed

Babbitt lined bearings which are pressed into the

cylinder block and then line reamed to size. Since

this operation requires special reaming equipment,

the original bearings should be retained unless they

are severely damaged.

NOTE 2:

Slightly scored camshaft bearings will be

satisf actory if the surf ace of the c ams haft journal is

polished and the bearings are cleaned to remove

burrs.

NOTE 3:

Bend a piece of 5 mm diameter rod at 90°, then

use the rod to probe the No.1 camshaft bearing oil

hole. Ensure that the oil hole and gallery are

correctly aligned, and that no obstruction is

present.

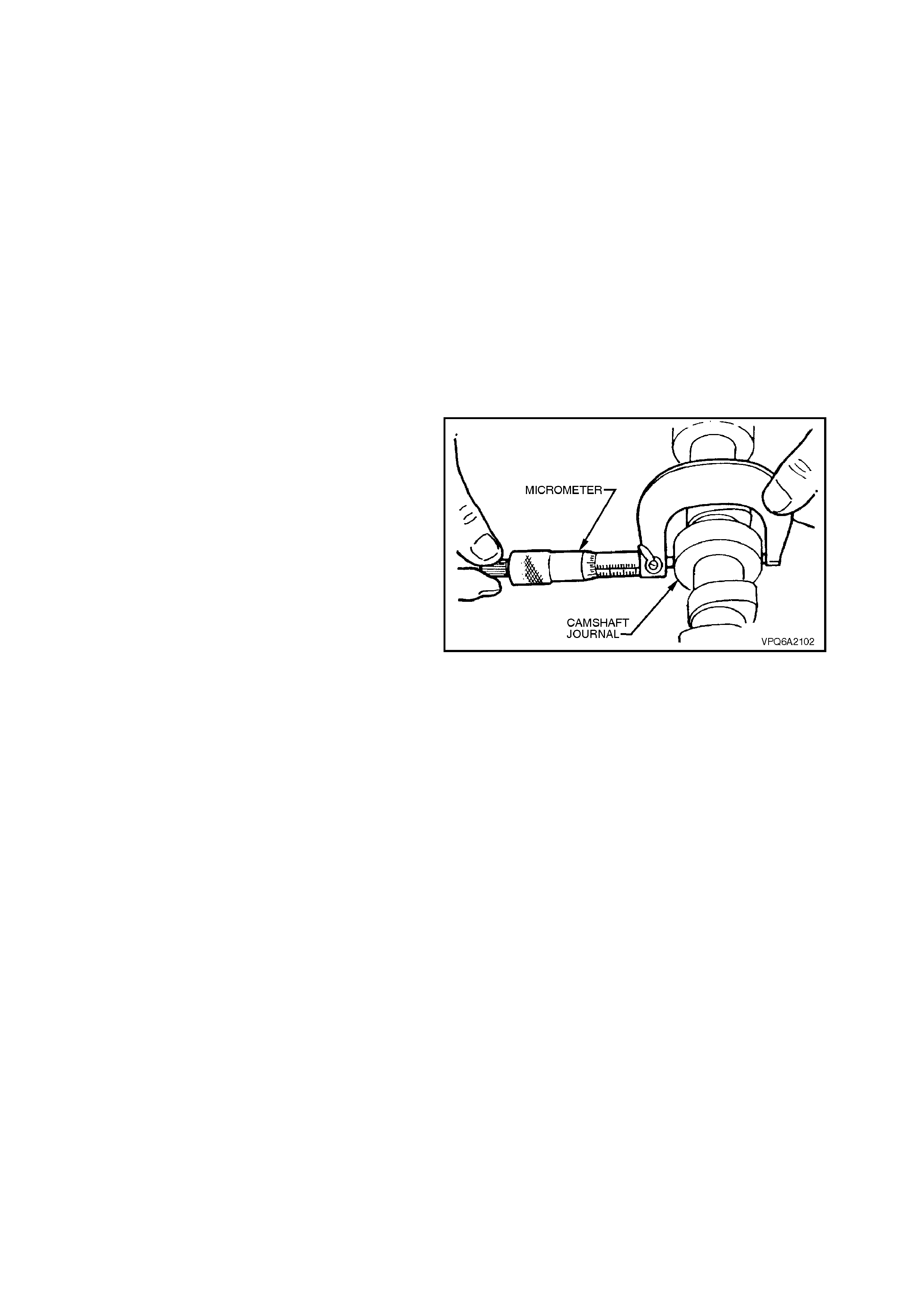

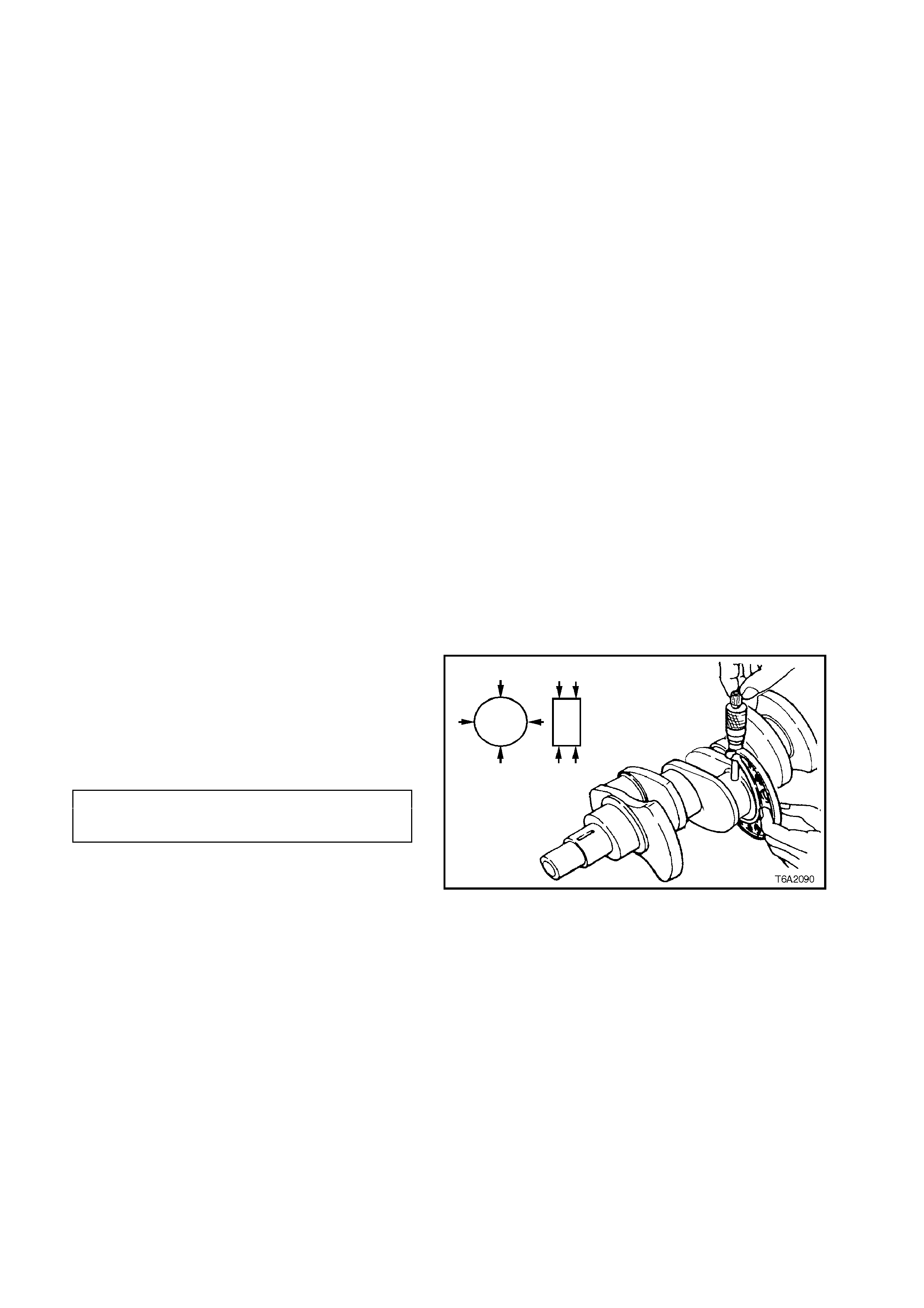

Check camshaft journals for misalignment using V

- block s and a dial indicator . Chec k for out-of-round

with a micrometer. If misalignment or out-of-round

exceeds 0.05 mm, replace camshaft.

Figure 6A2-119

REINSTALL

Installation of the camshaft is the reverse of

removal procedures, noting the following points:

1. Clean threads of camshaft thrust plate

attaching screws and mating threads in

cylinder block.

2. Lubricate cams haf t bearing j our nals with c lean

engine oil and all lobes with Lubrizol 6612 or

equivalent (Holden Specification HN 1961)

and install camshaft.

3. When installing camshaft, take care not to

disturb lubricant film on camshaft lobes.

4. Apply engine oil to camshaft contact surfaces.

5. Reinstall camshaft locater and tighten bolt to

specified torque.

CAMSHAFT LOCATER BOLT

TORQUE SPECIFICATION 68 - 81 Nm

6. Lubricate all lifters and lifter bores with

Lubrizol 6612 or equivalent (Holden

Specification HN 1961) before installing.

7. Reinstall hydraulic valve lifters, refer to

2.7 HYDRAULIC VALVE LIFTERS in this

Section.

8. Reinstall timing chain and sprockets, refer to

3.4 TIM ING CHAIN AND SPROCKETS in this

Section.

9. Start engine, check for oil or coolant leaks.

Check for valve train noise. Repair as

necessary.

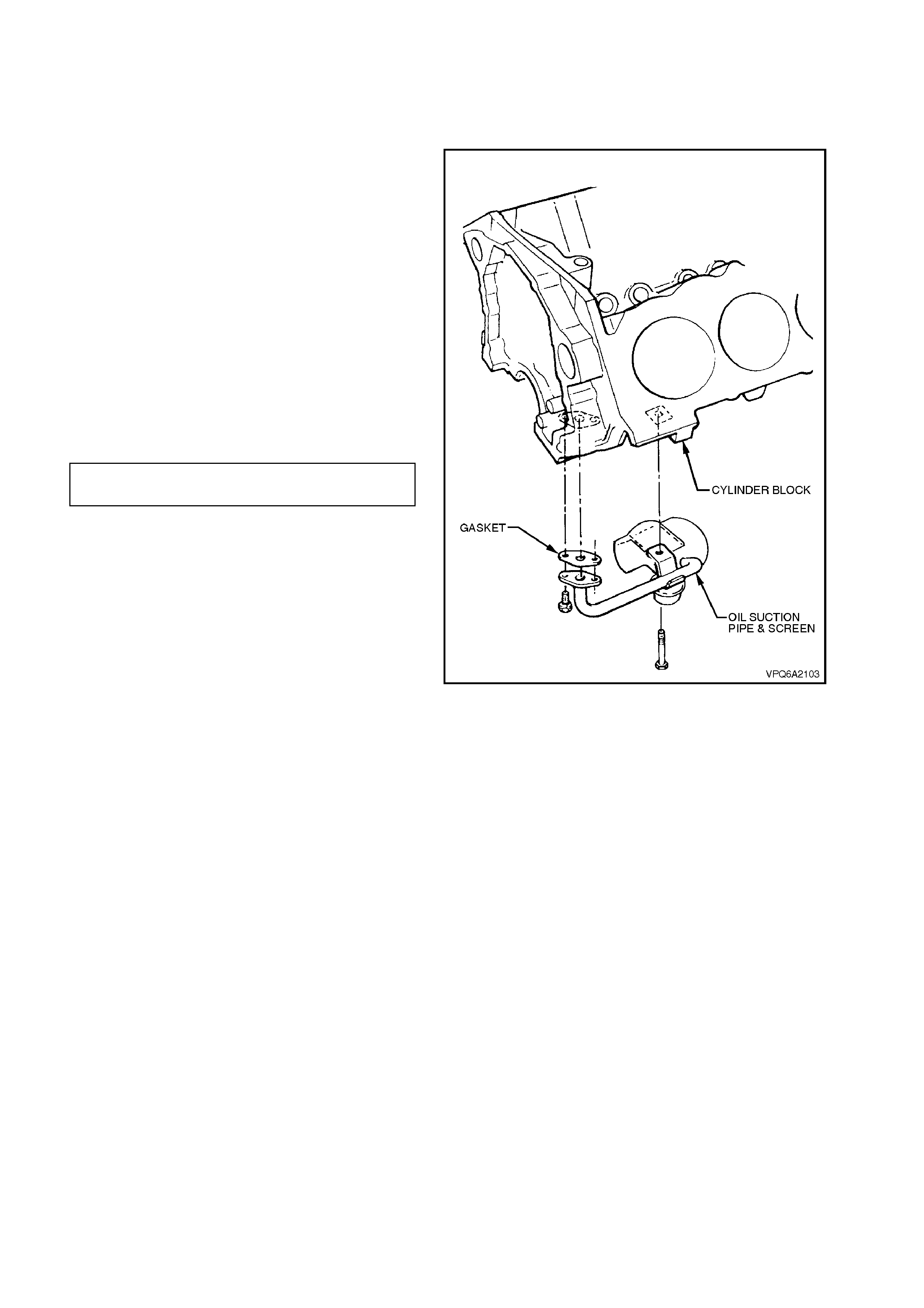

3.7 OIL PUMP SUCTION PIPE AND SCREEN

REMOVE

1. Remove oil pan, refer to 3.2 OIL PAN in this

Section.

2. Remove two bolts securing s uction pipe f lange

to crankcase.

3. Remove bolt securing support bracket to

cylinder block remove oil suction pipe and

screen assembly.

REINSTALL

Installation is the reverse of the r em oval proc edure,

note the following:

1. Check that the suction pipe flange and

crankcase are clean, smooth and flat. Use a

new gasket between suction pipe flange and

cylinder block.

2. Tighten bolts to specified torque.

OIL PUMP SUCTION PIPE BOLT 8 - 11

TORQUE SPECIFICATION Nm

Figure 6A2-120

3.8 OIL PUMP DRIVE GEAR, SHAFT AND BUSH

REMOVE

1. Remove timing chain and sprockets, refer to

3.4 TIM ING CHAIN AND SPROCKETS in this

Section.

2. Remove oil pump, refer to 2.11 OIL PUMP in

this Section.

3. Remove roll pin securing the oil pump drive

gear to drive shaft.

4. Remove drive gear and withdraw drive shaft

downwards.

5. Use a suitable self tapping sc rew attached to a

slide ham mer to rem ove roll pin secur ing drive

shaft bush to crankcase.

6. Drive bush from crankcase boss with a

suitable drift and hammer.

Figure 6A2-121

INSPECT

Measure diameter of shaft in contact with bush. If

shaft diameter is less than 12.22 mm, replace

shaft. Inspect gear for wear.

REINSTALL

1. Install new bush, grooved face uppermost,

ensuring that the hole in bush aligns with oil

passage in crankcase behind bush.

Figure 6A2-122

2. Use a suitable bolt and washers to aid

installation. Install bus h until lower f ac e is f lus h

with lower face of boss.

Figure 6A2-123

3. Using a 4.7 mm drill bit, drill through the roll

pin hole to notch the new bush.

CAUTION:

Do not drill more than 19 mm deep. Take care

not to enlarg e diamet er of th e hol e in crankcase

boss.

4. Reinstall roll pin securing drive shaft bush to

crankcase.

5. Reinstall drive shaft, drive gear and roll pin

securing drive gear to shaft. Lubricate shaft

and gear with engine oil.

6. Reinstall timing chain and sprockets, refer to

3.4 TIM ING CHAIN AND SPROCKETS in this

Section.

7. Reinstall oil pump, refer to 2.11 OIL PUMP in

this Section.

Figure 6A2-124

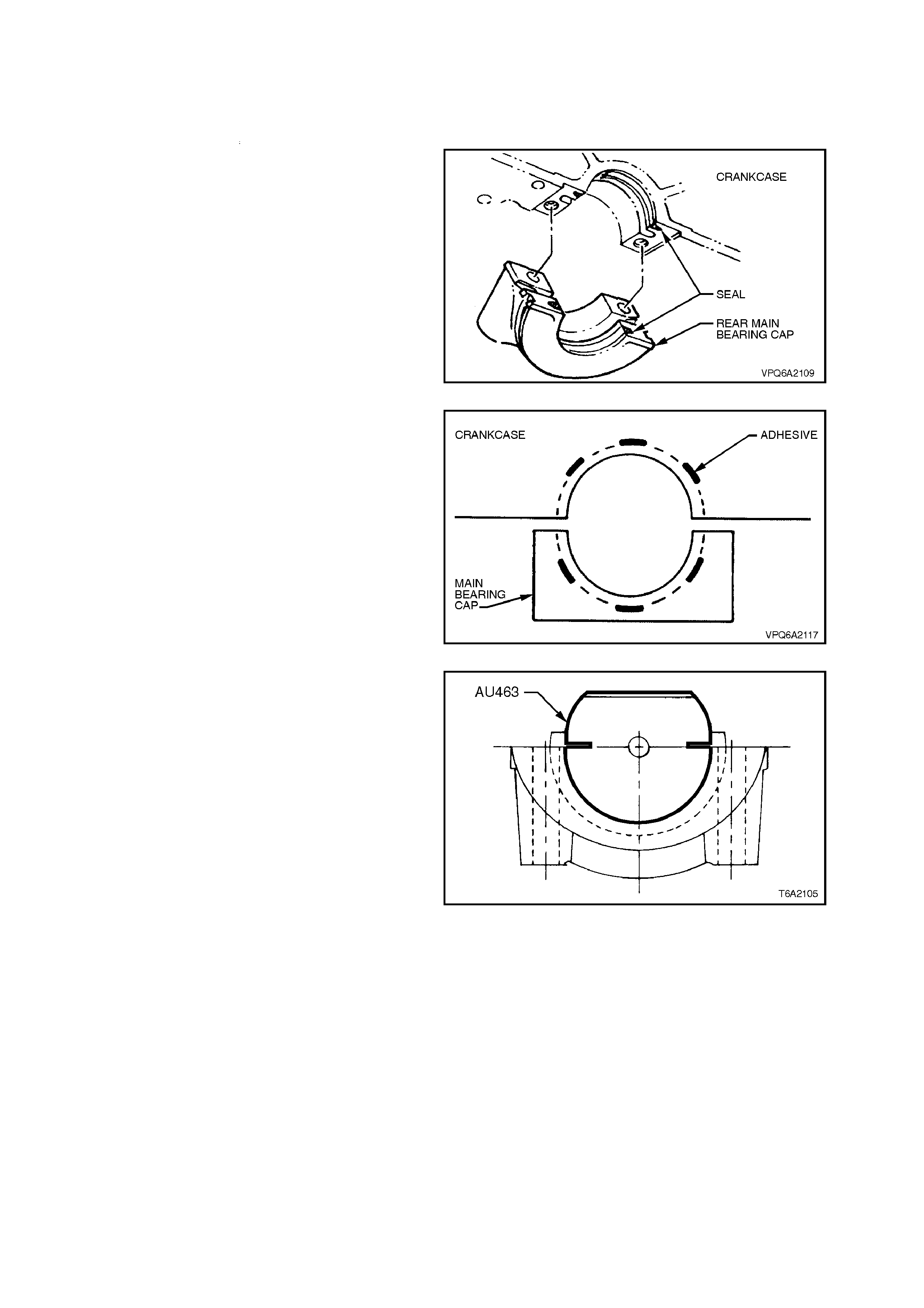

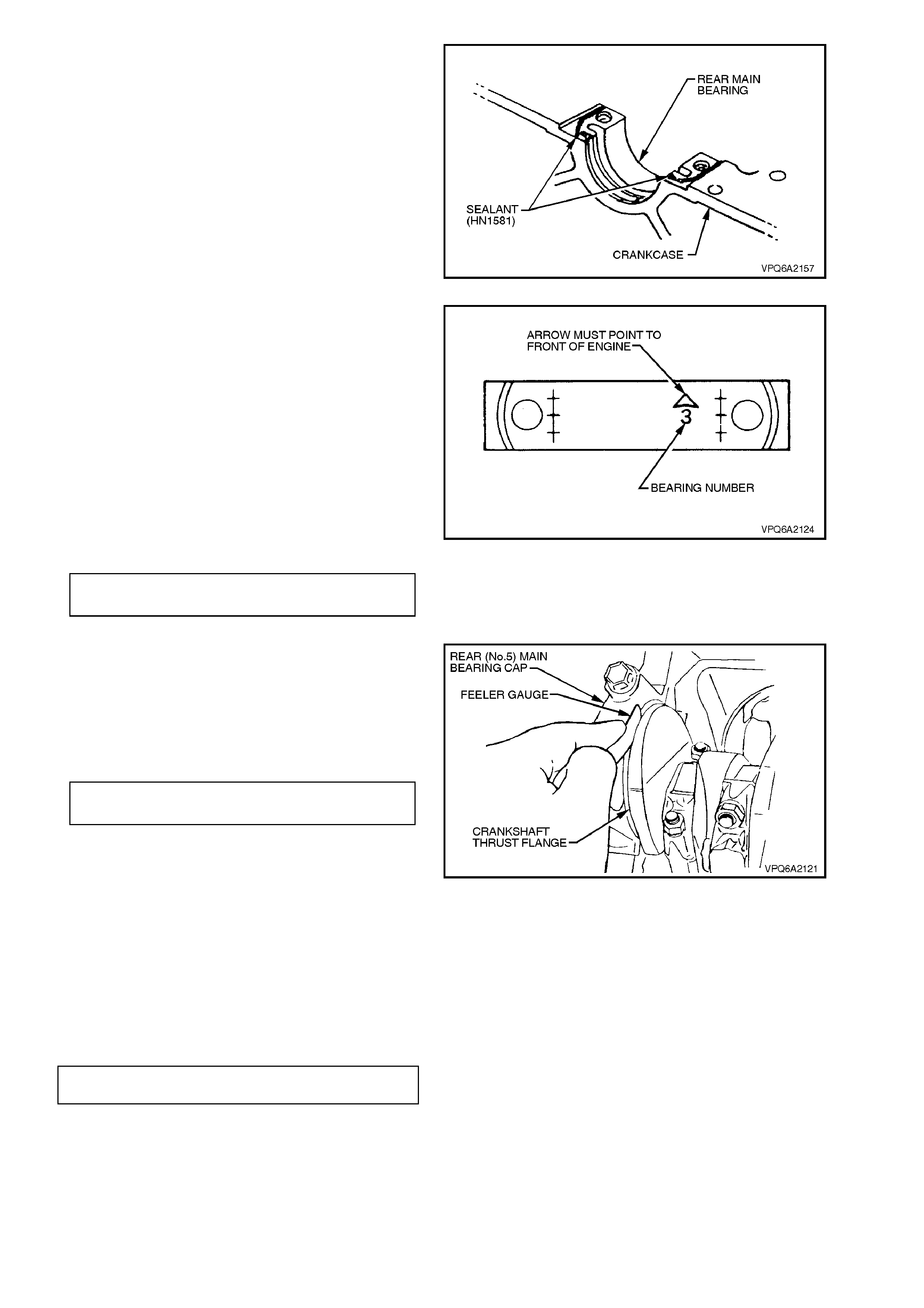

3.9 REAR MAIN BEARING OIL SEAL

REPLACE

1. Remove crankshaft, refer to

3.14 CRANKSHAFT in this Section.

2. Remove old rear main bearing oil seal from

crankcase and rear main bearing cap. Ensure

seal groove is clean and free of foreign matter.

Figure 6A2-125

3. Apply cyanoacrylate adhesive (Holden

specif ication HN 1539 Type 4 or equivalent) to

bearing cap and crankcase seal grooves as

shown in Fig. 6A2-126.

Figure 6A2-126

4. Fit seal into the seal groove of bearing cap,

with the sharper edge of the seal facing toward

the flywheel. Confirm that seal ends are

protruding equally at both sides.

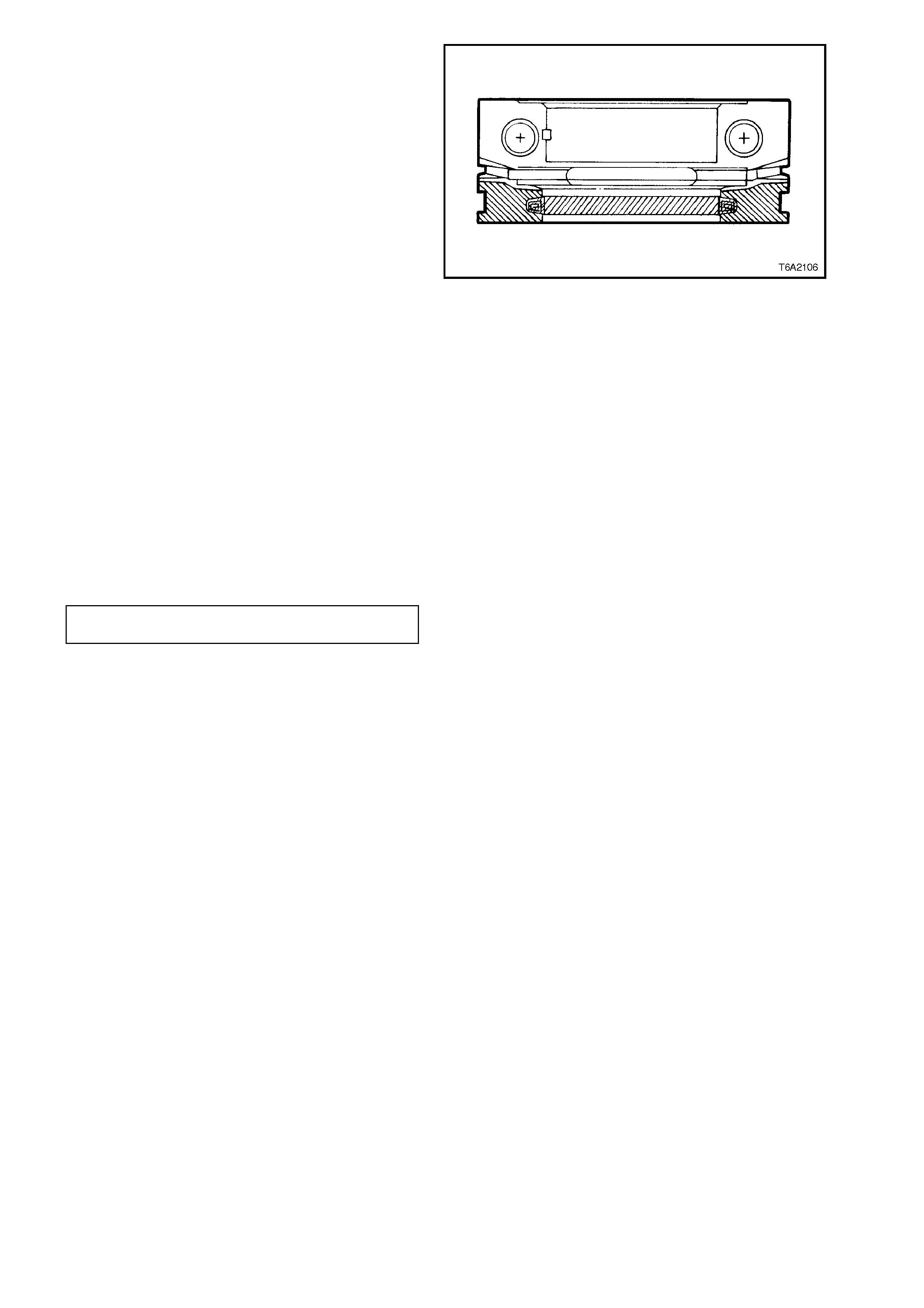

5. Using hand press and seal installation tool no.

AU463, push seal into the bearing cap seal

groove to full stop

6. Using sharp cutting tool, trim the protruding

ends of the seal flush with cap. The edges of

the trimm ed seal should be neat, without burrs

or debris.

7. Remove cap from press, and apply sealant

such as Loctite 515 Master Gasket or

equivalent (Holden Specification HN 1581)

around the area next to the s eal on the parting

plane on the cap only.

NOTE:

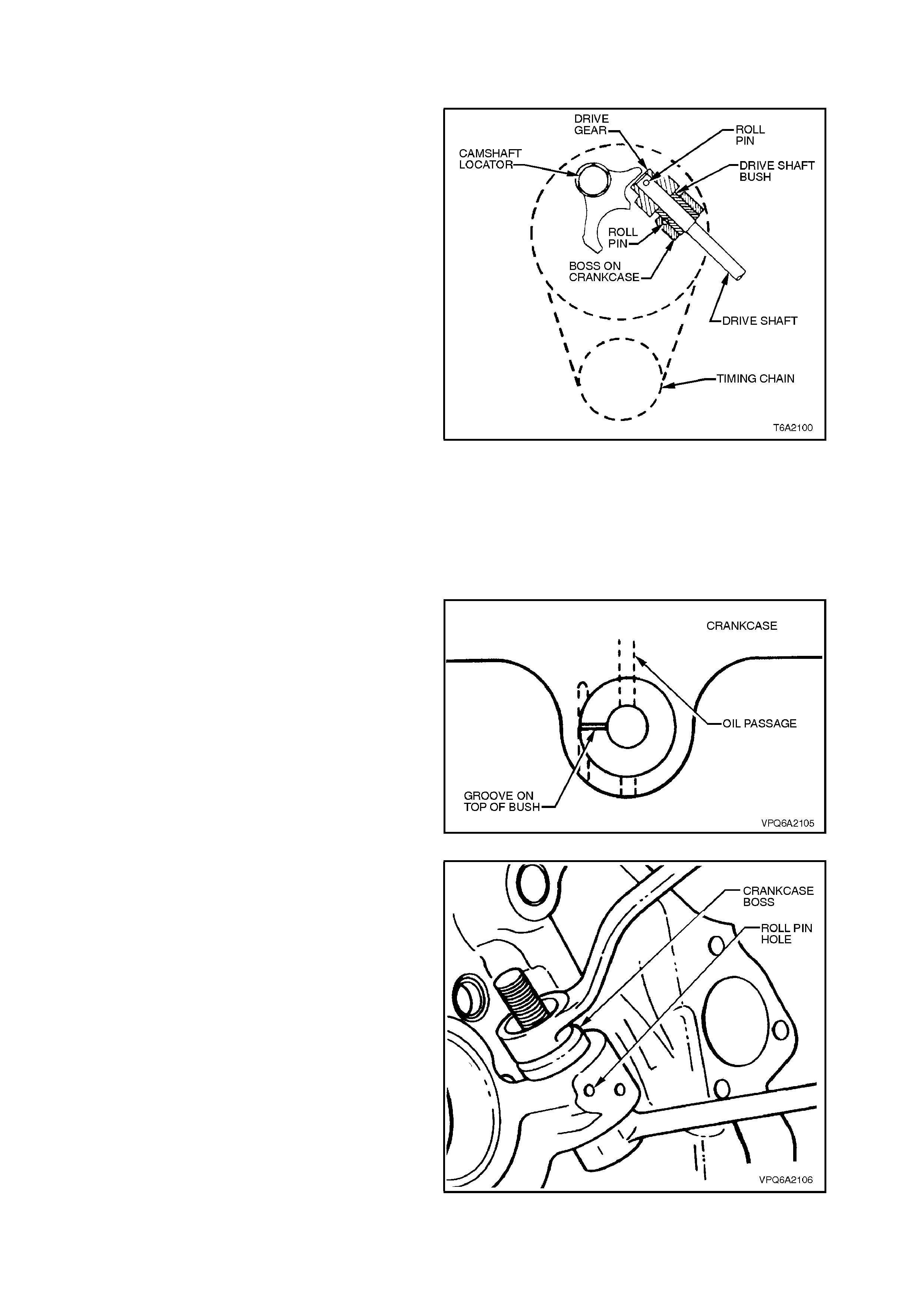

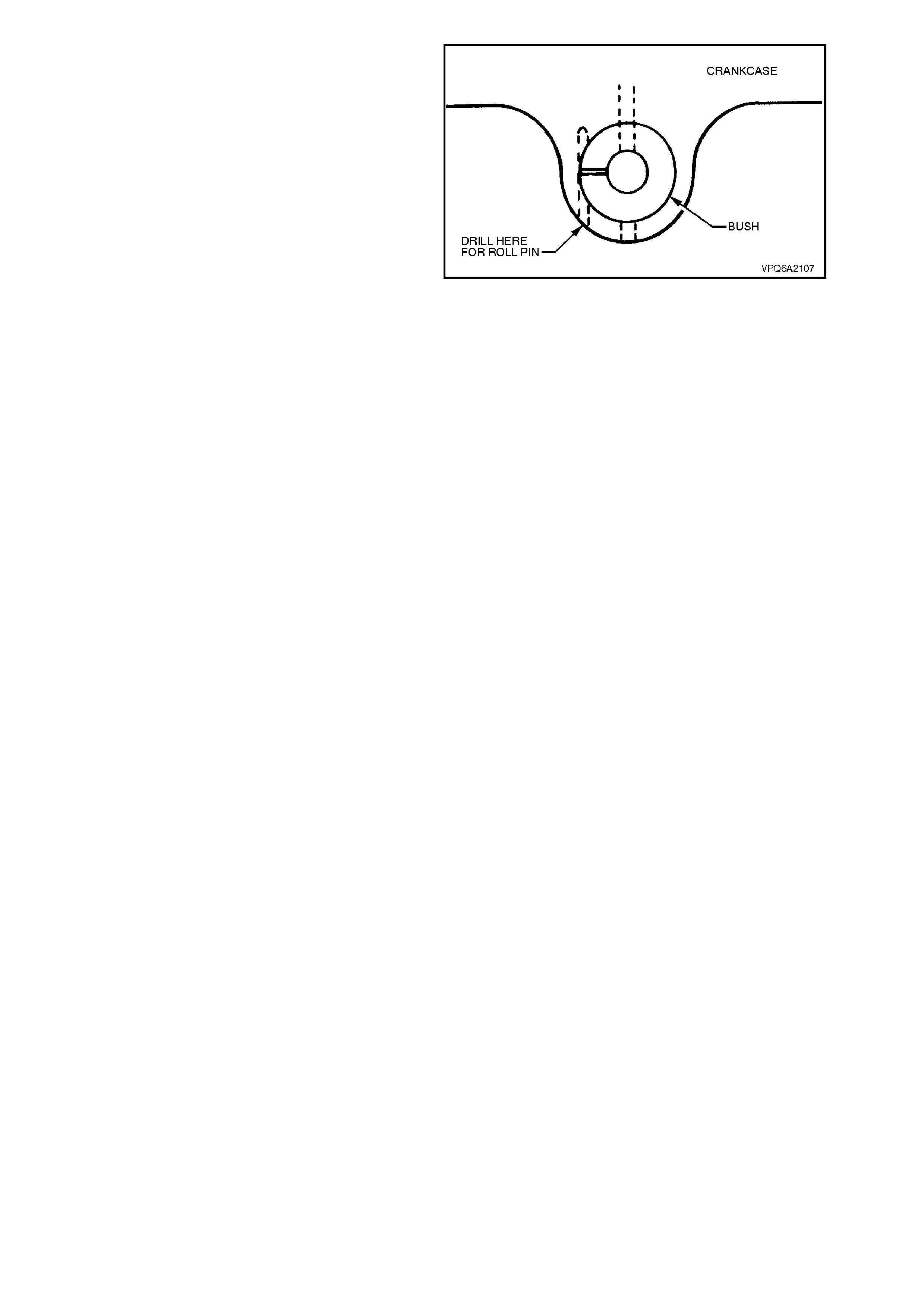

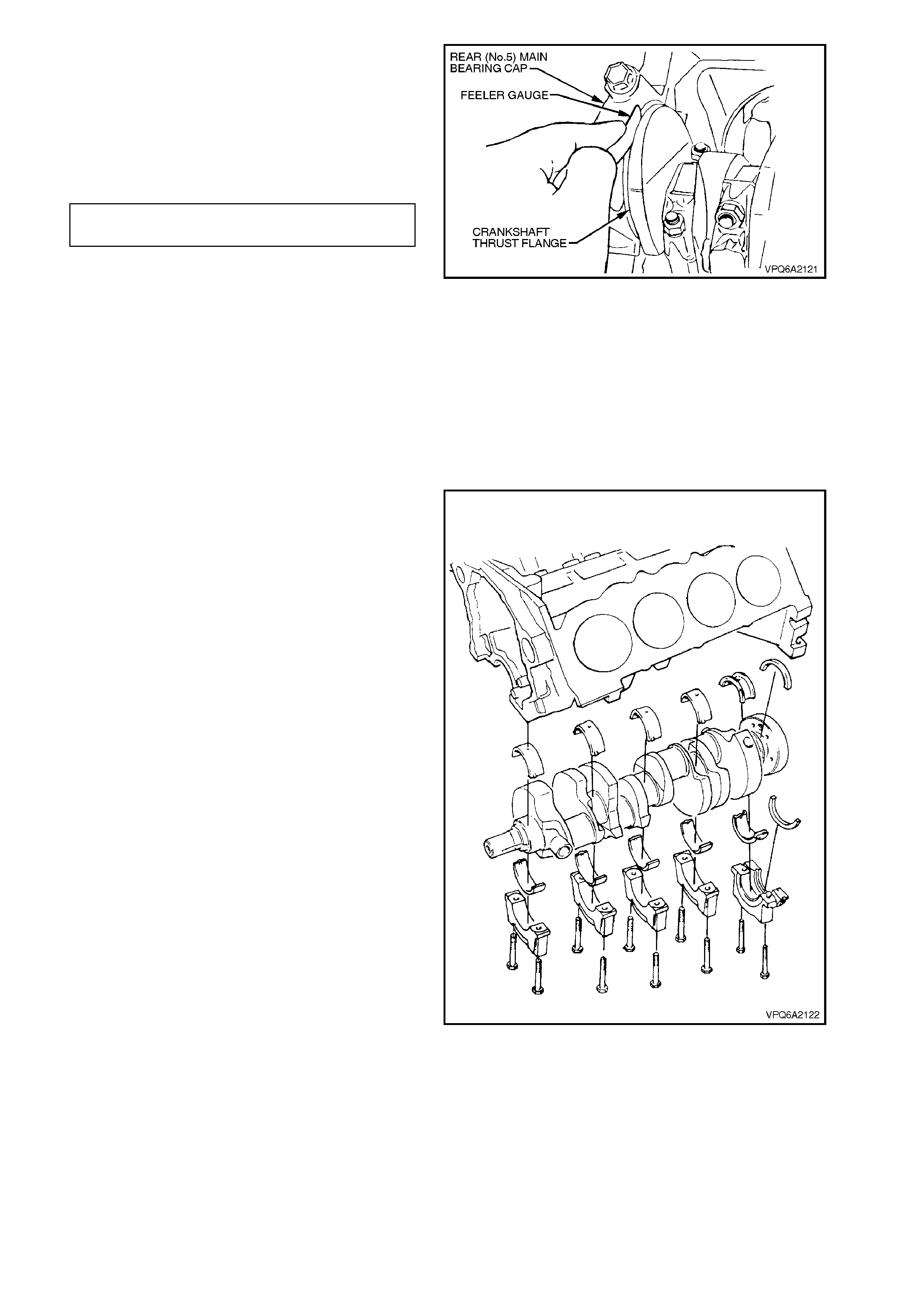

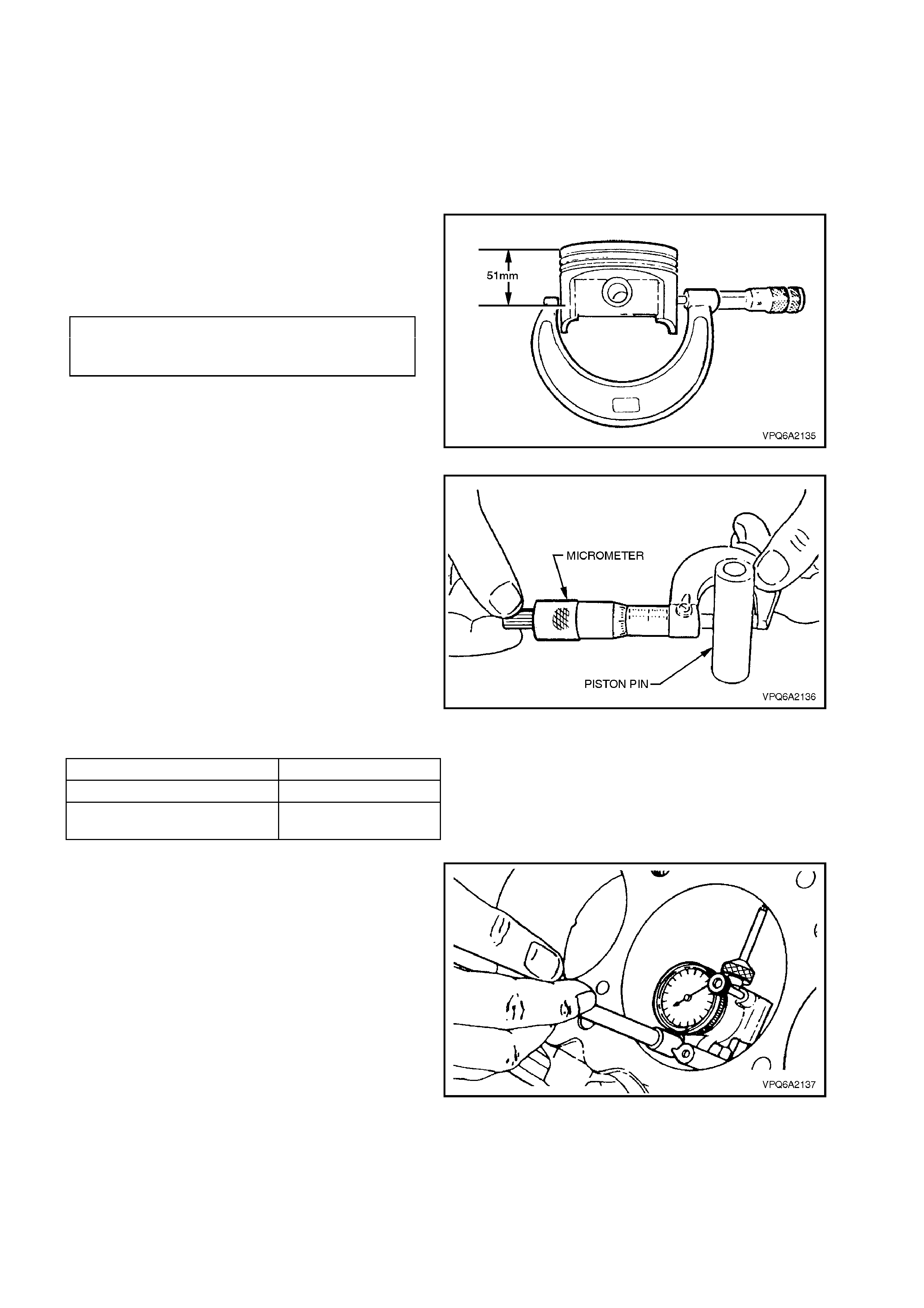

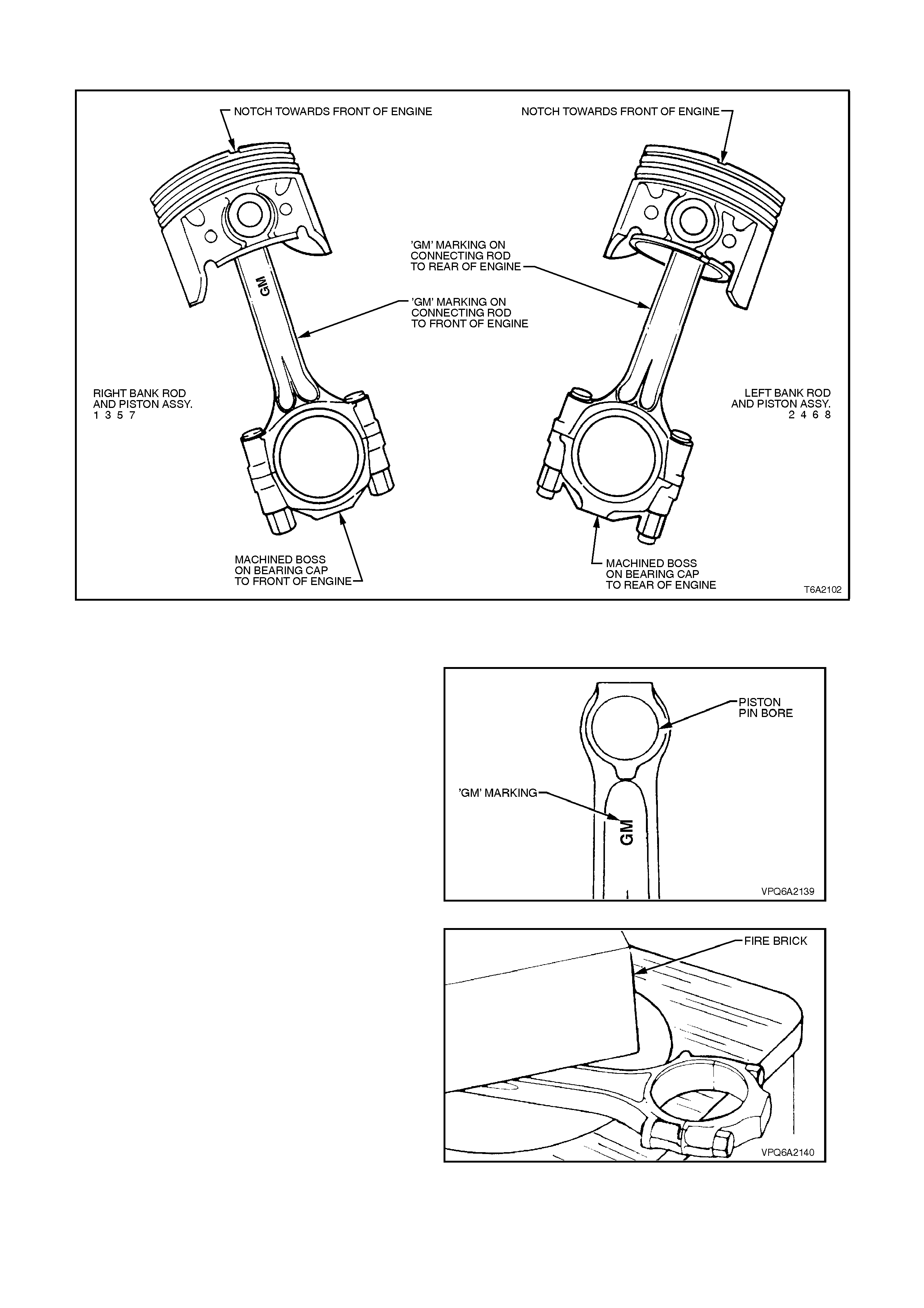

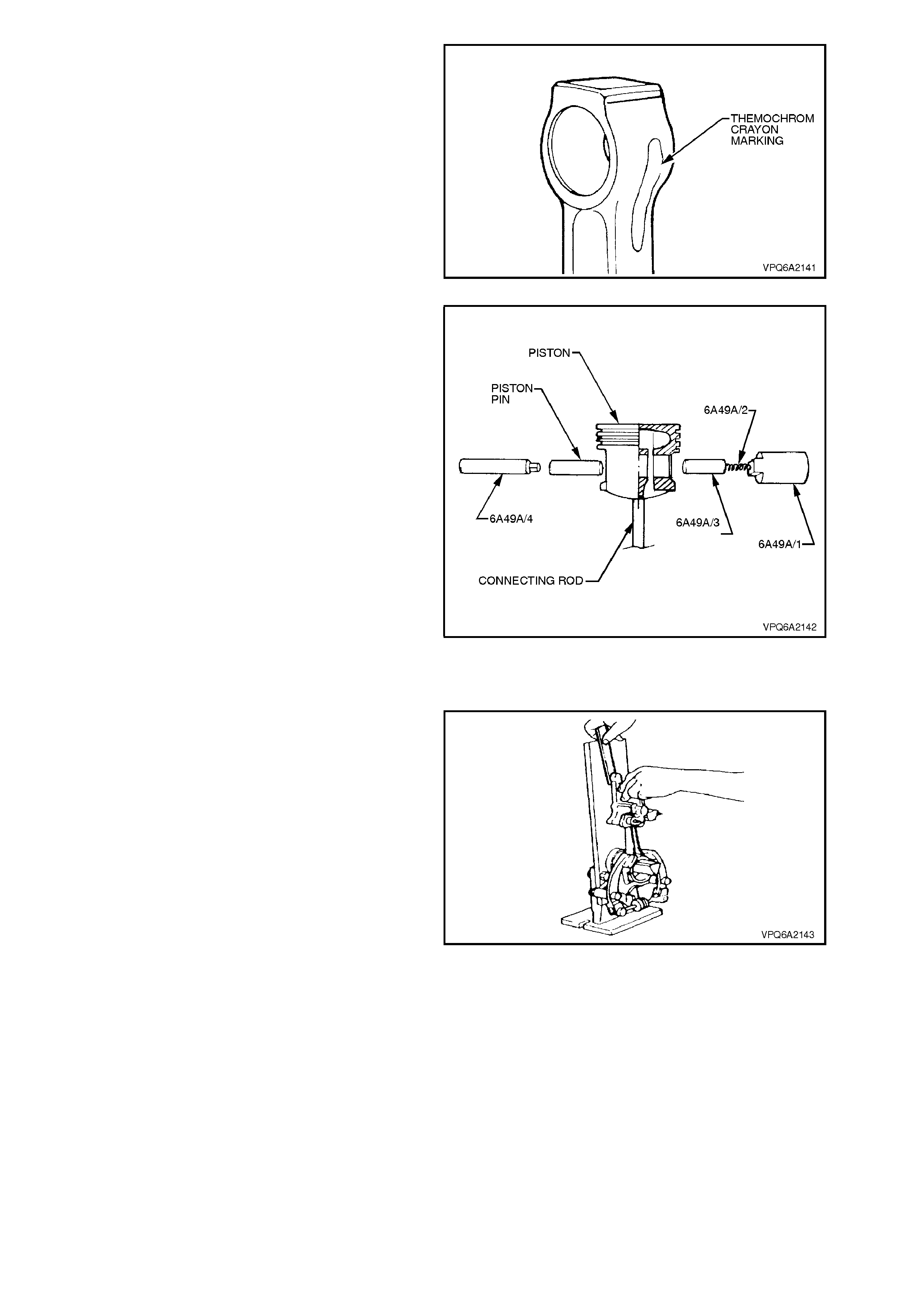

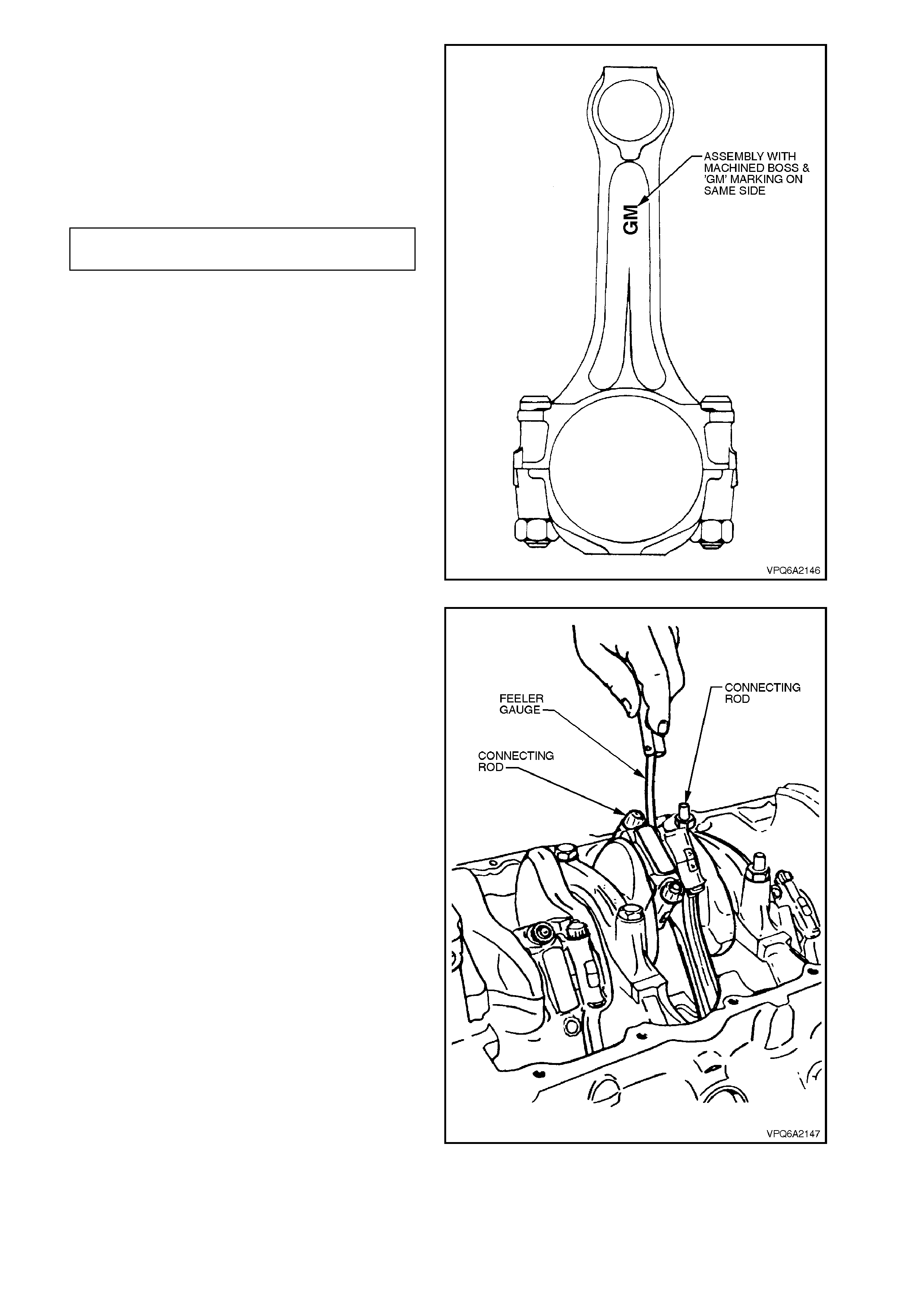

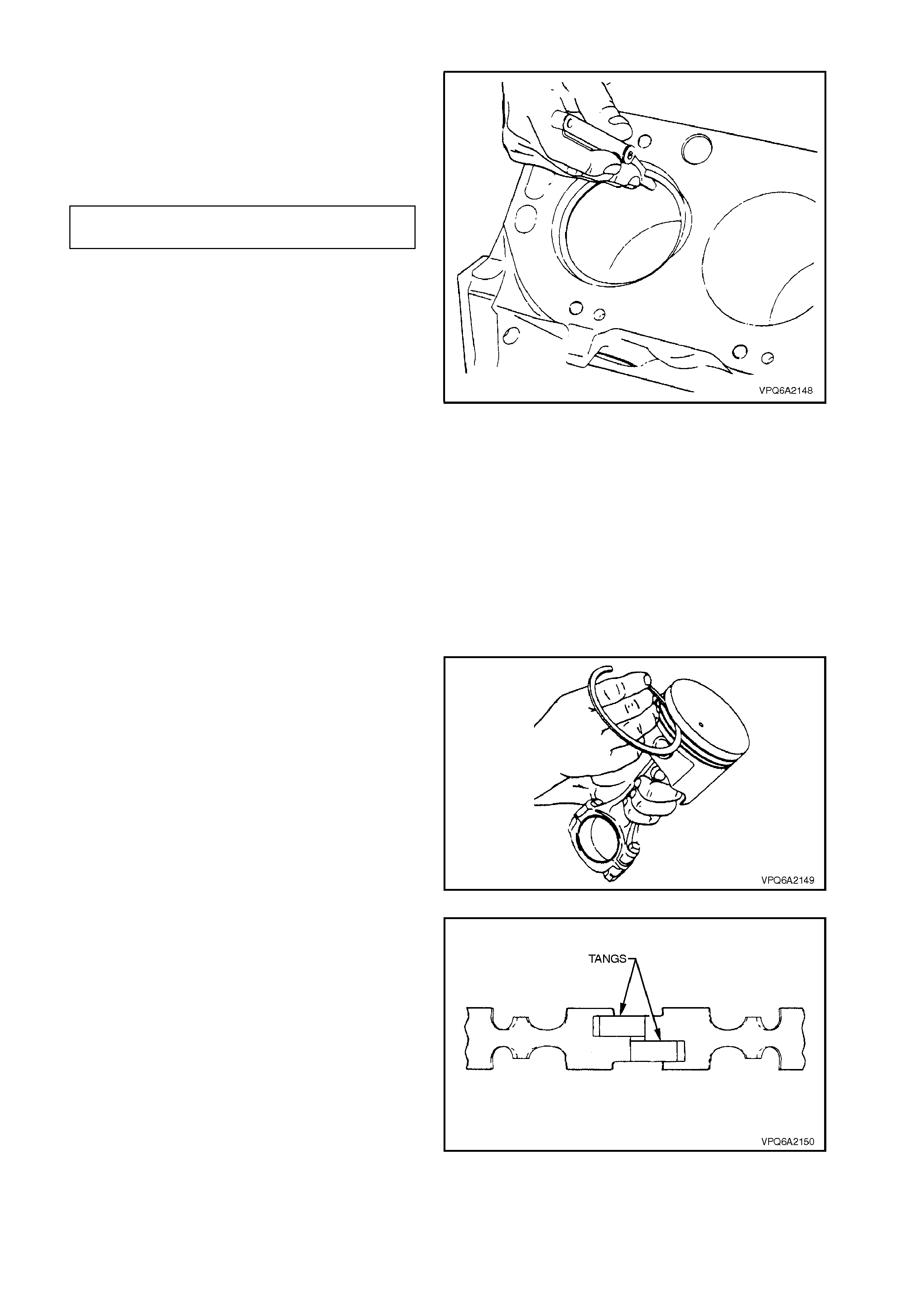

Do not apply sealant near crankshaft oil thrower.