SECTION 6A3 - ENGINE MECHANICAL -

GEN III V8 ENGINE

CAUTION:

This v ehicle will be equipped with a Supplemental Restraint System (SRS). An SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bags or seat belt pre-tensioners, driver’s and front passen ger’s air bag and lef t and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M , Supplemental Restraint System of the

VT Series I Service Information before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ET C FUNCTION CHECK, in Section 12L ABS & ABS/ET C, in either

VT Series I Service Information (V6 Engine) or 12L ABS & ABS/ETC of the VT Series II Service Information

(GEN III V8 Engine).

1. GENERAL DESCRIPTI ON

The 1999 Model Year 5.7 litre, GEN III, V8 engine ( produc tion option LS1) , is a 90°, V8, overhead valve des ign with

a bore of 99.00 mm and stroke of 92.00 mm. Displacement is 5,667 cm3 and compression ratio is 10.1:1.

Engine features include an aluminium cylinder block and heads, with cast iron sleeves cast into the cylinder block

during production. F our ‘torque to yield’ cylinder head bolts per cylinder have their thread boss es located deep into

the cylinder block to m inim ise distortion at the top of the bore. T he deep s kirt cylinder block also f eatures five m ain

bearings with each cap being secured by six bolts.

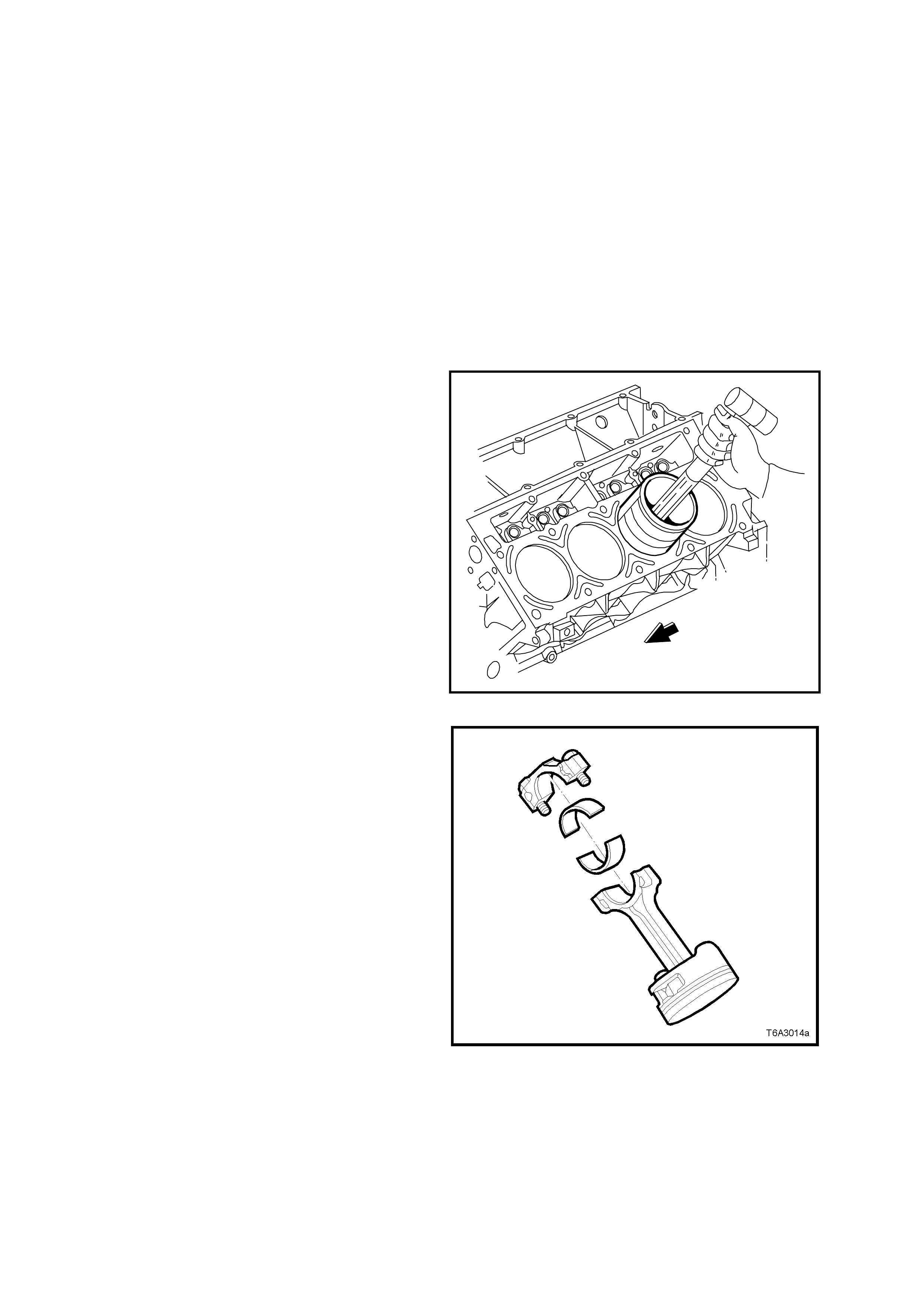

Powdered metal valves guides and seats are fitted to each cylinder head. The connecting rods are also

manufactured from forged powdered metal and the rodcap is separated during the manufacturing process, using

the ‘fractured’ method. This creates a stronger, visually seamless rod to cap union.

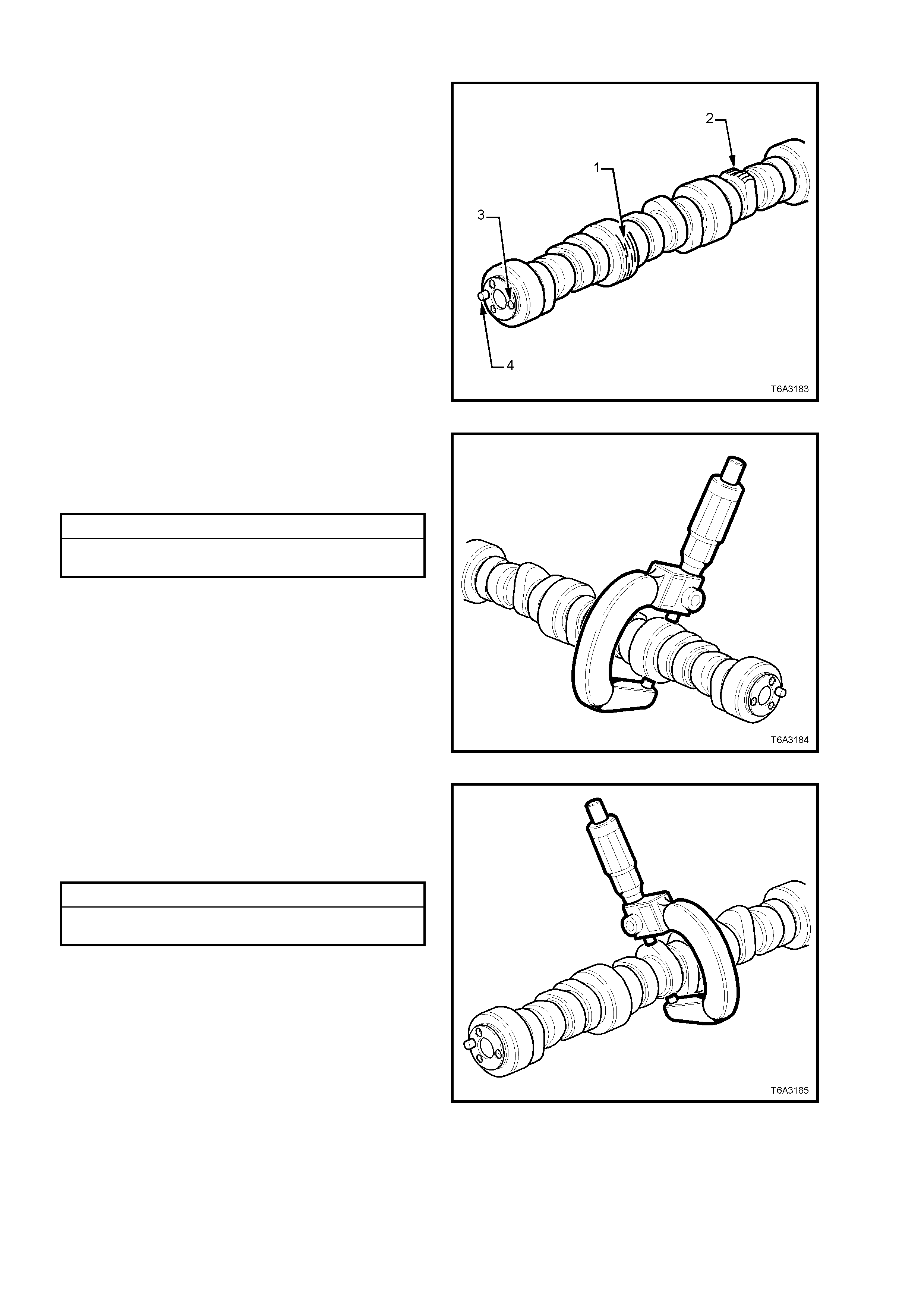

The five bearing camshaft is machined from 5150 steel billet and is drilled through the centre to reduce weight. A

reluctor ring for the cam position sensor is located between the fourth and fifth bearing journals.

The crank shaft is m anufactur ed from nodular cast iron and is dr illed through the centre of m ain bearing journals 2,

3, 4, and 5, also to reduce weight. A reluctor wheel is installed onto the rear of the crankshaft for the crankshaft

position sensor.

The firing order of 1-8-7-2-6-5-4-3, assists in achieving a smoother engine operation.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

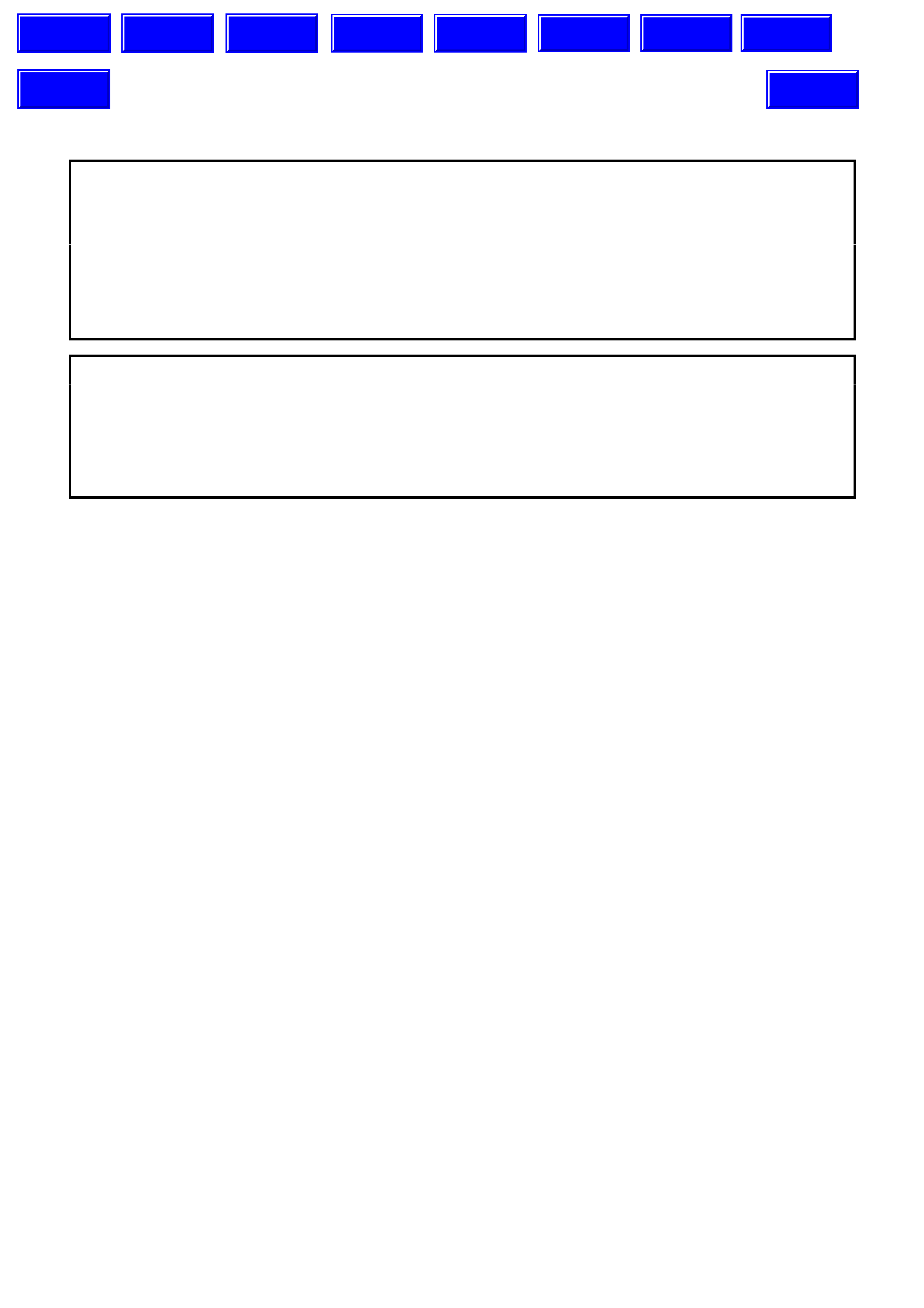

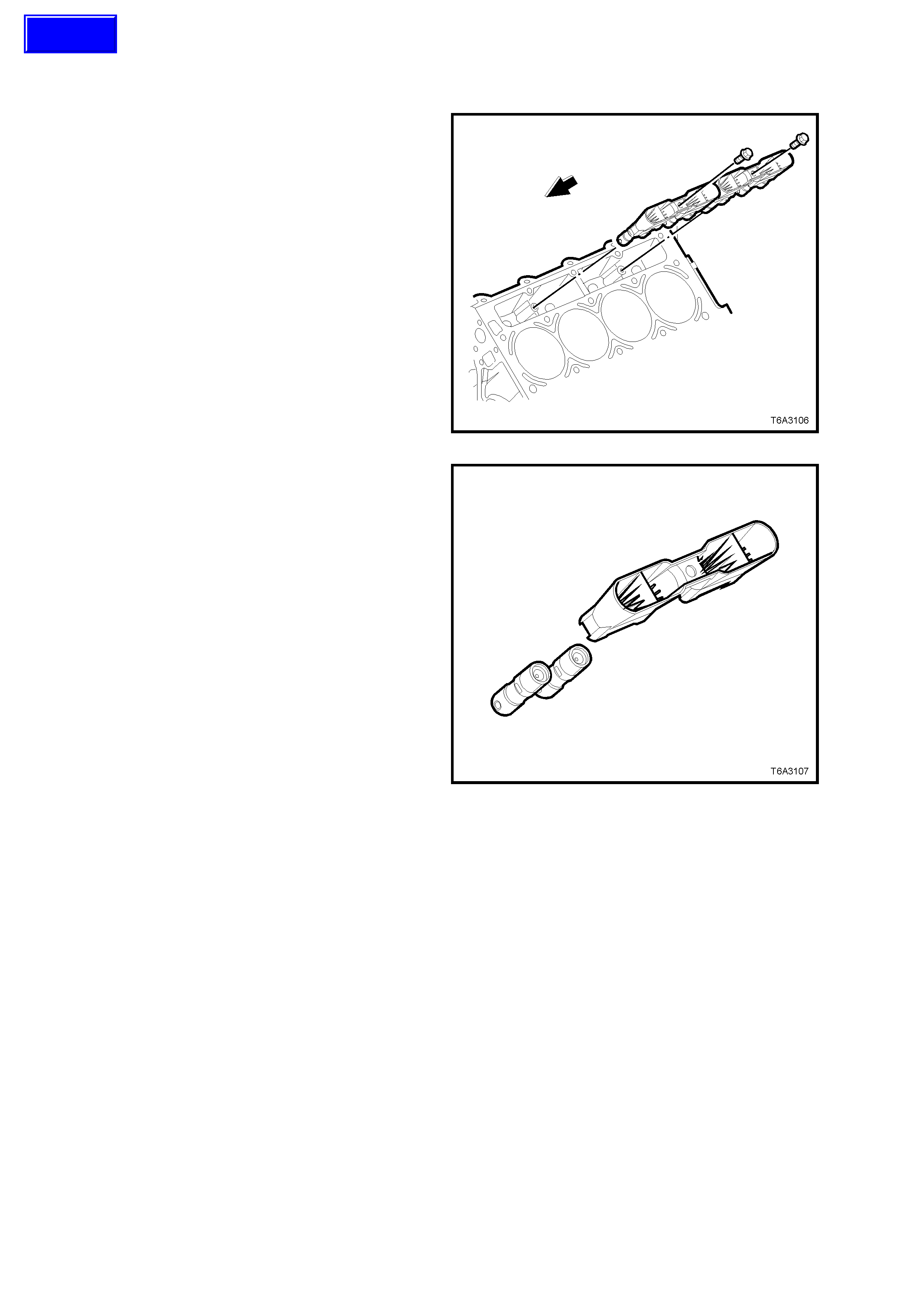

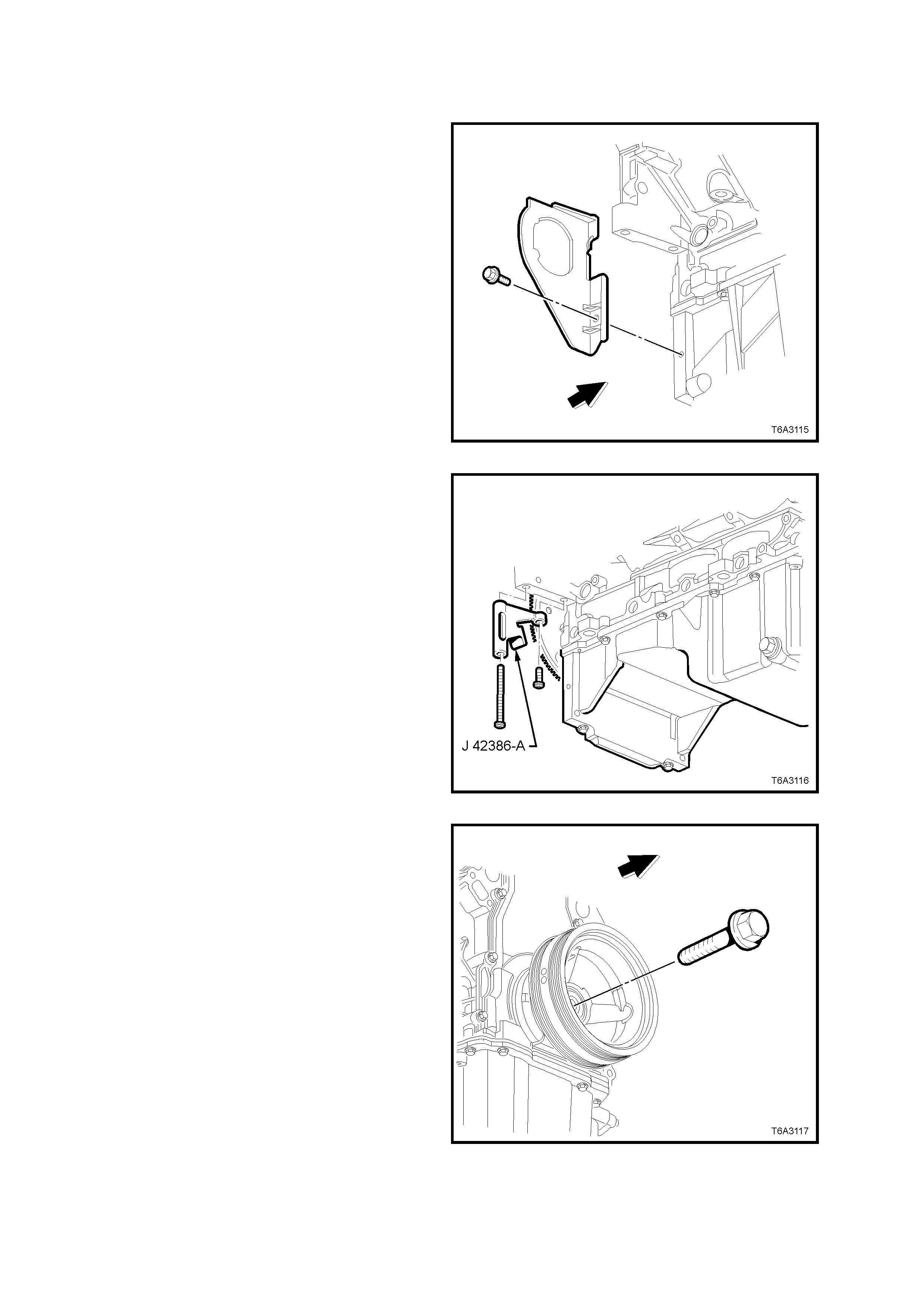

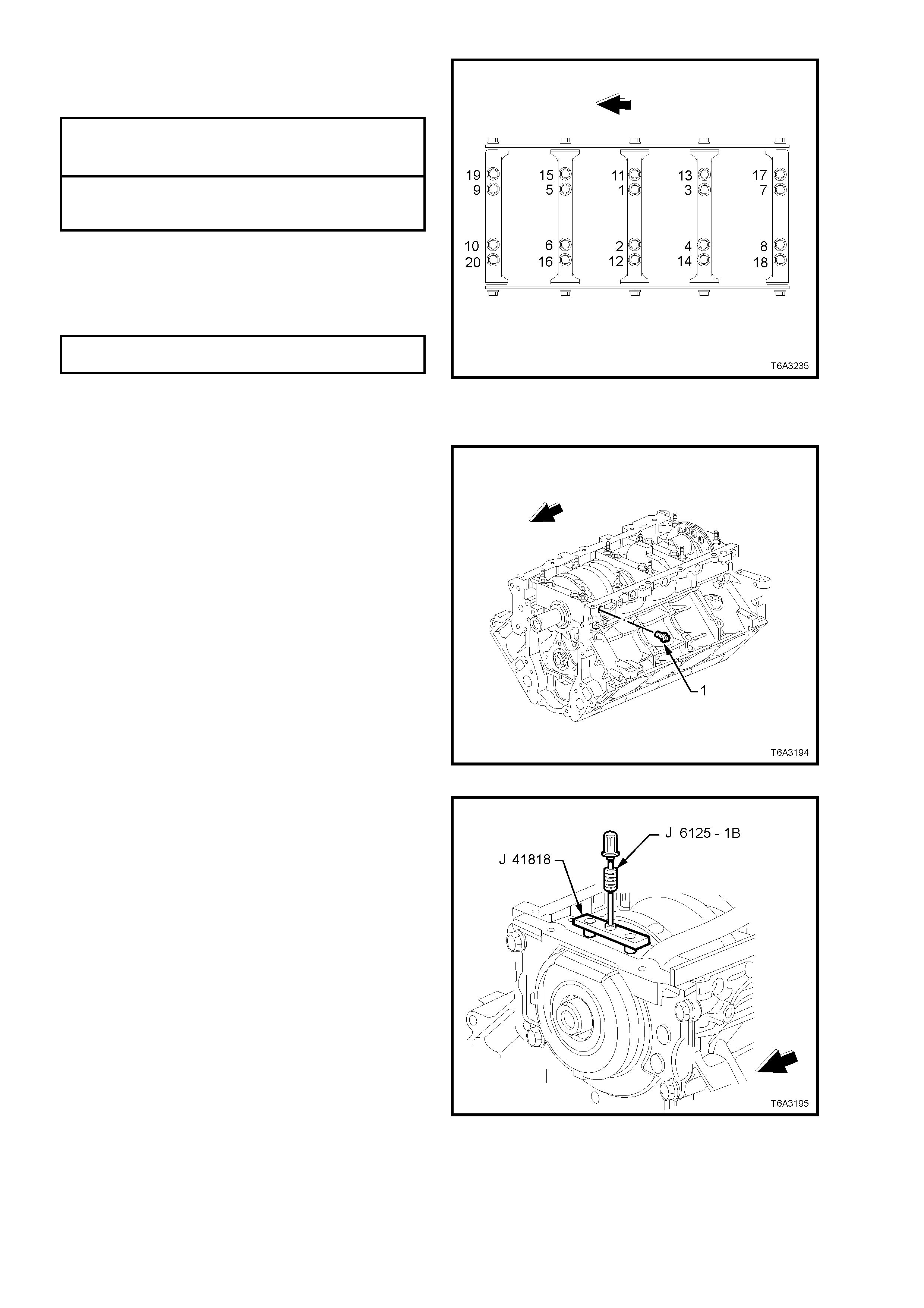

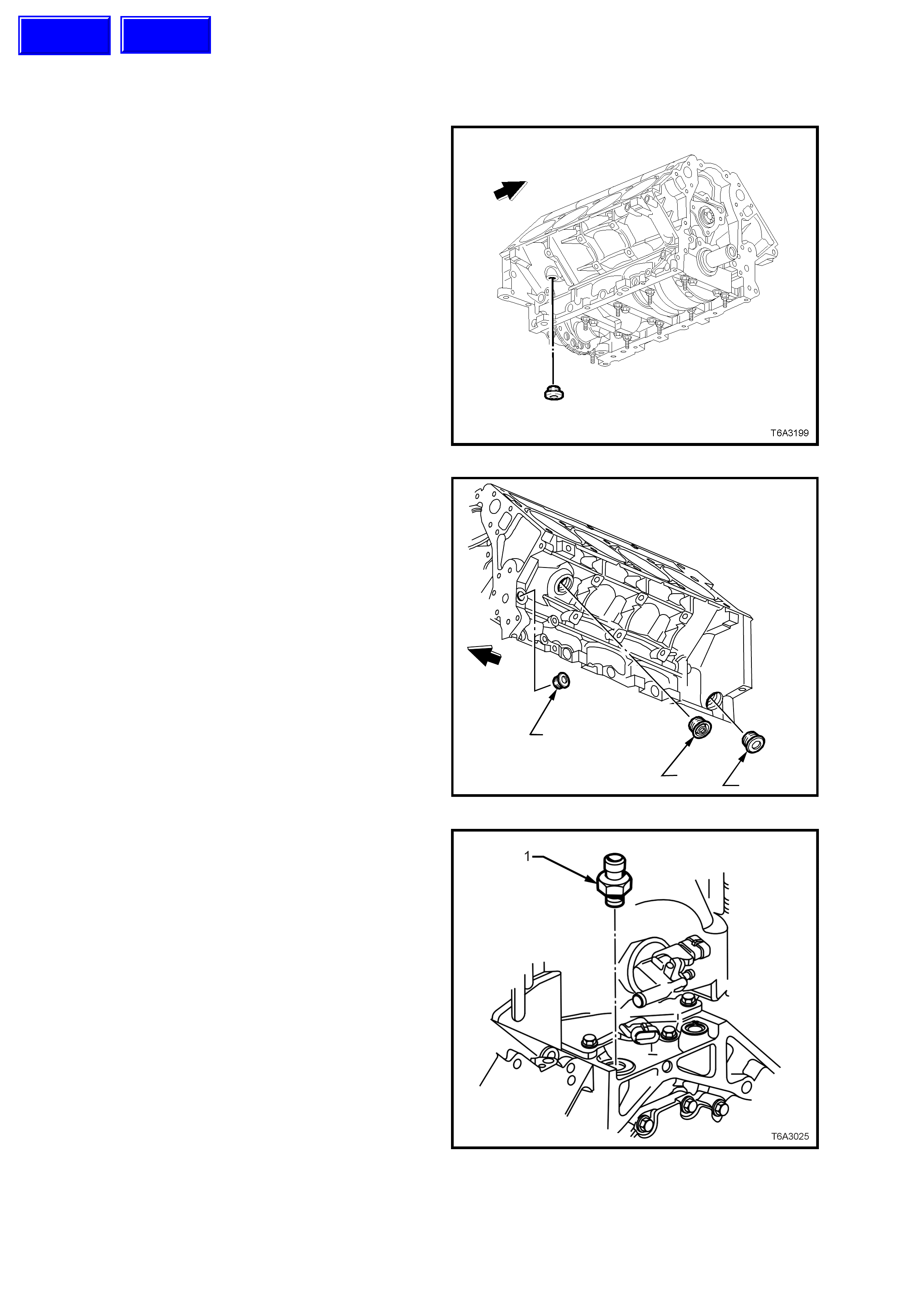

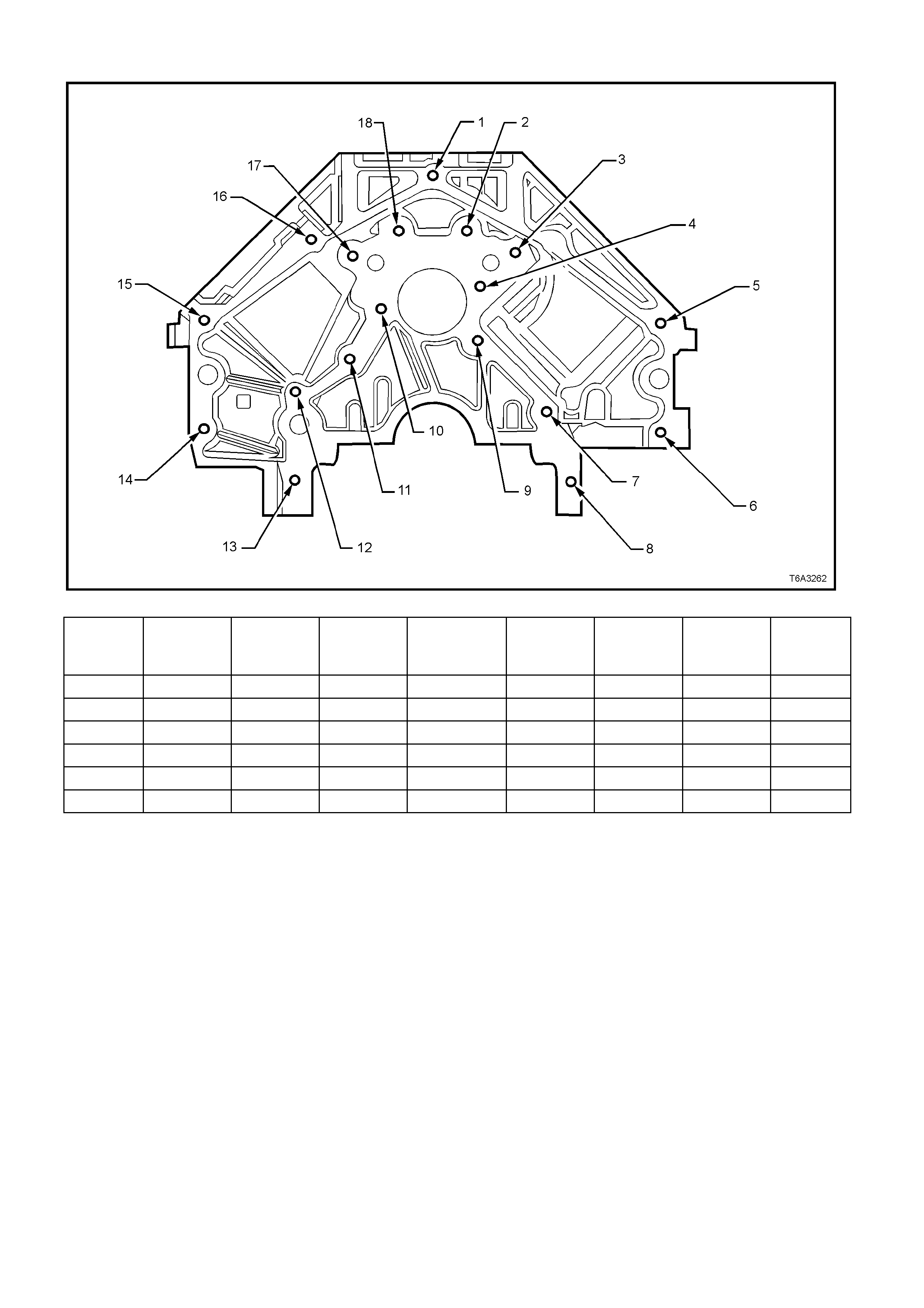

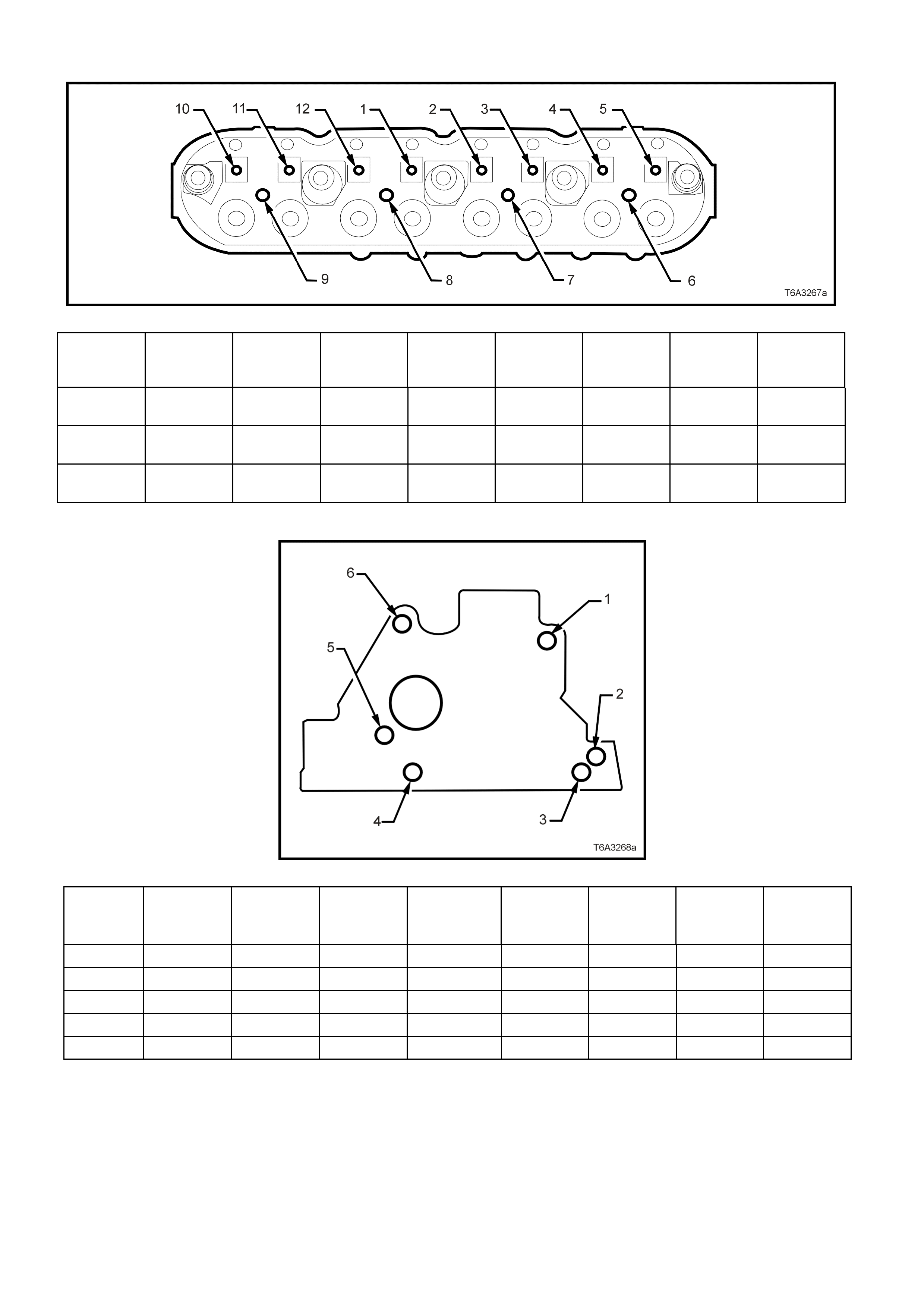

Figure 6A3-1

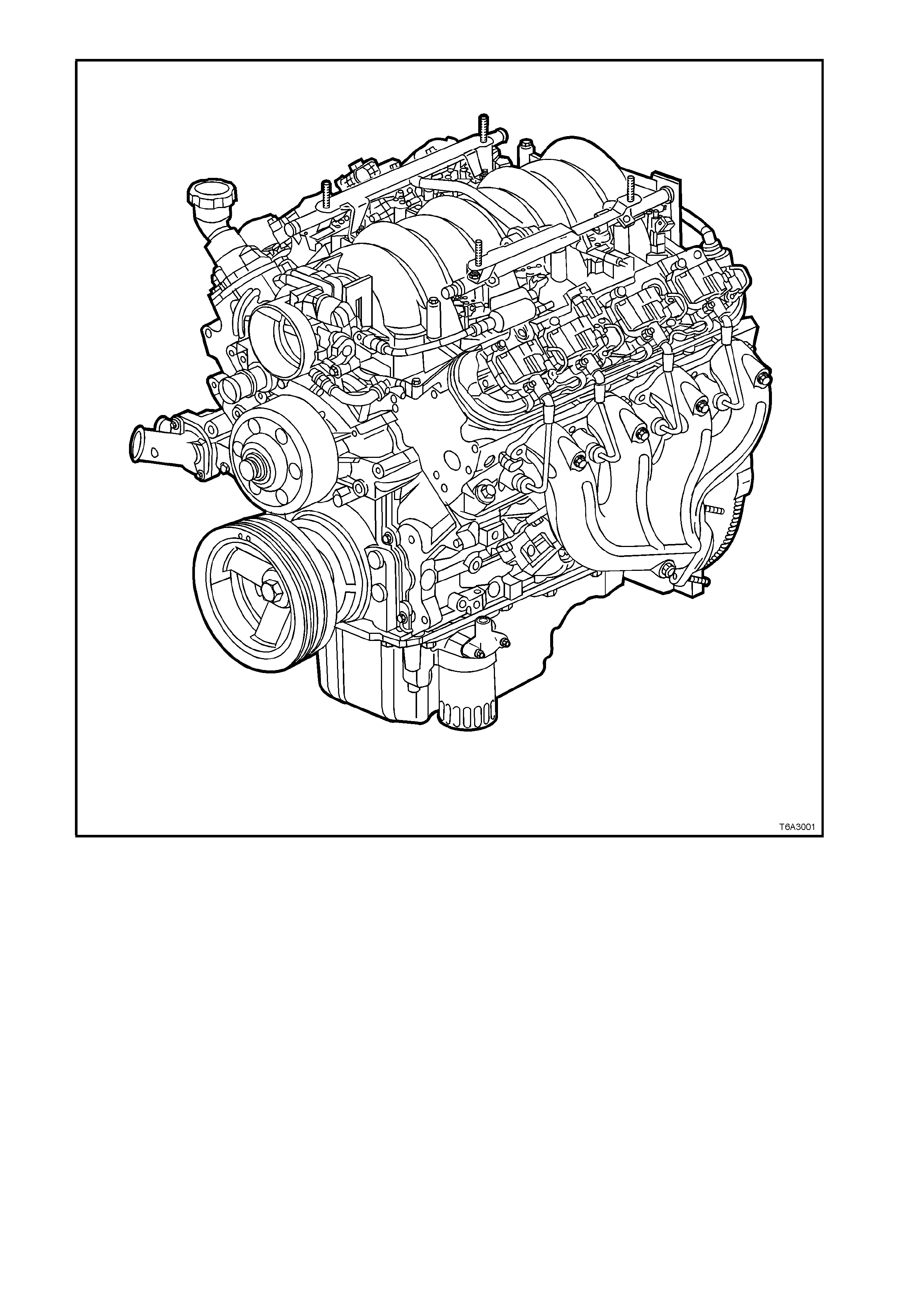

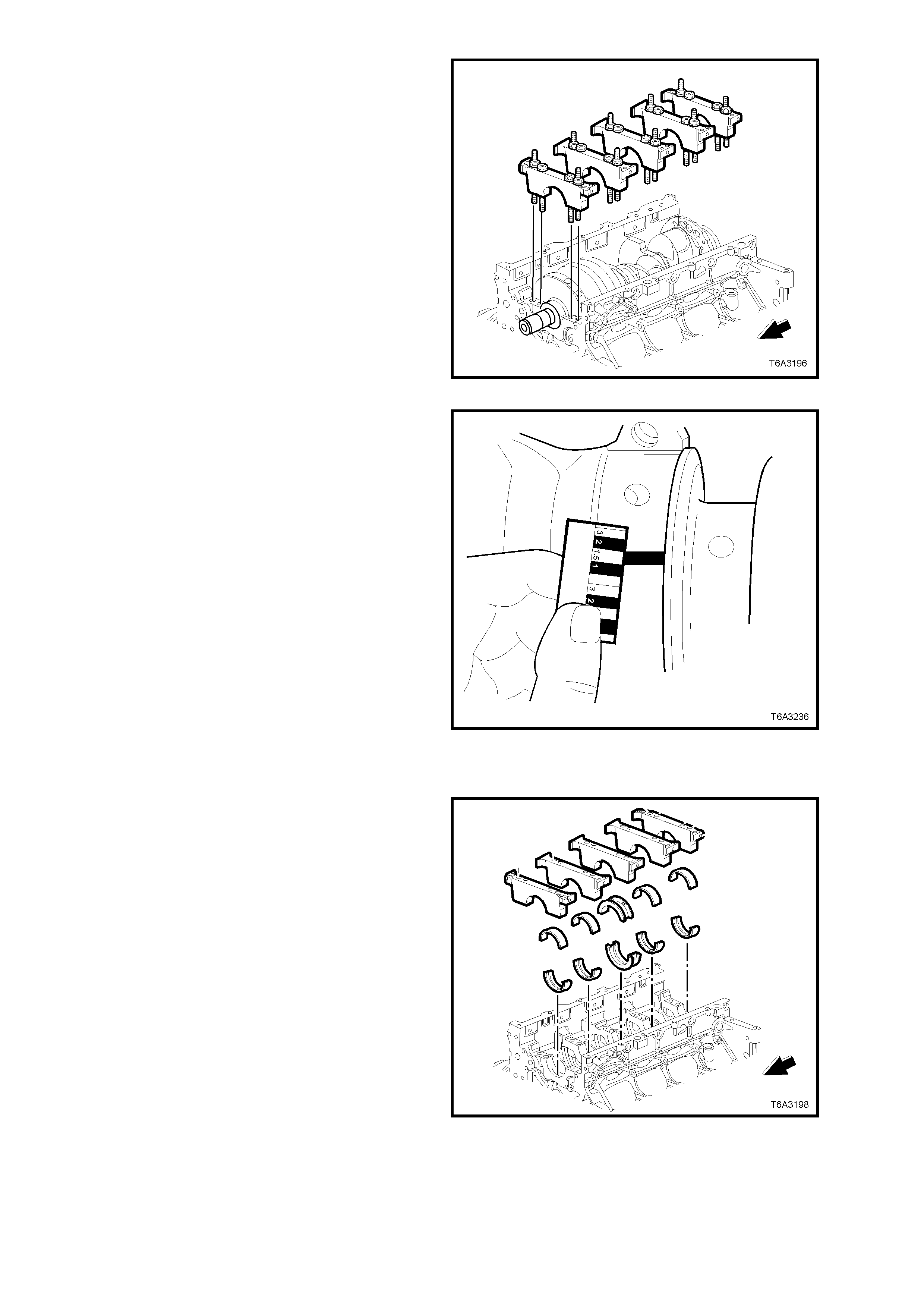

Figure 6A3-2 - Lower Front of Engine

Legend

1. Tube - Oil Level Indicator 18. Oil Seal - Crankshaft Front

2. O-ring Seal - Oil Lever Indicator Tube 19. Balancer - Crankshaft

3. Bolt - Valve Lifter Guide 20. Bolt - Crankshaft Balancer

4. Guide - Valve Lifter 21. Bolt - Engine Front Cover

5. Lifter - Valve 22. Camshaft

6. Engine Block 23. Retainer - Camshaft

7. Oil Seal - Crankshaft Rear 24. Sprocket - Camshaft

8. Bolt - Engine Rear Cover 25. Locating Pin - Camshaft Sprocket

9. Cover - Engine Rear 26. Bolt - Camshaft Sprocket

10.Gasket - Engine Rear Cover 27. Bolt - Camshaft Retainer

11.Plug - Engine Block Rear Oil Gallery 28. Bearings - Camshaft

12.Crankshaft Sprocket 29. Coolant Pump

13.Chain - Camshaft Timing 30. Bolt - Coolant Pump

14.Oil Pump Assembly 31. Gaskets - Coolant Pump

15.Bolt - Oil Pump Assembly 32. Indicator - Oil Level

16.Gasket - Engine Front Cover 33. Bolt - Oil Level Indicator Tube

17.Engine Front Cover

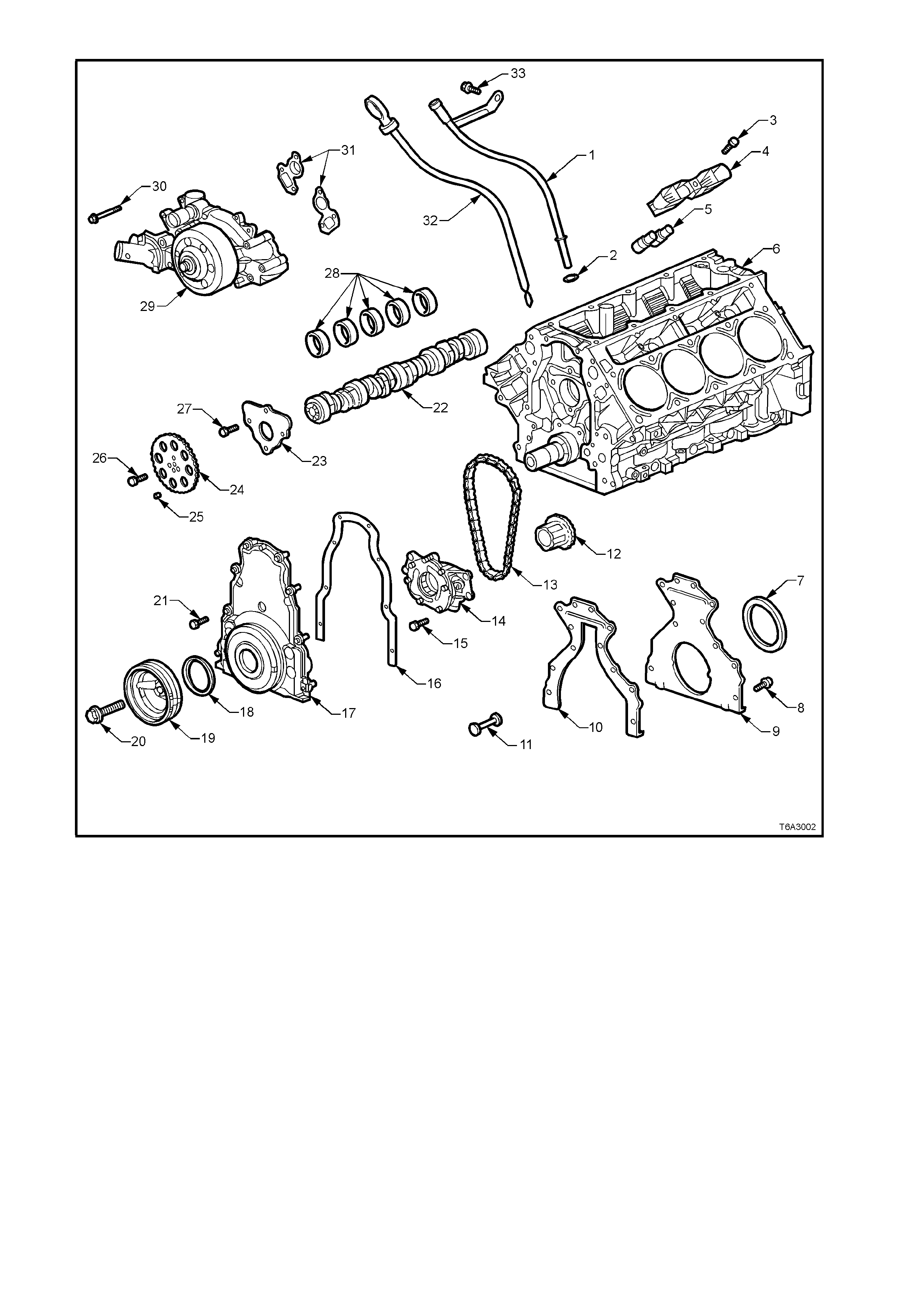

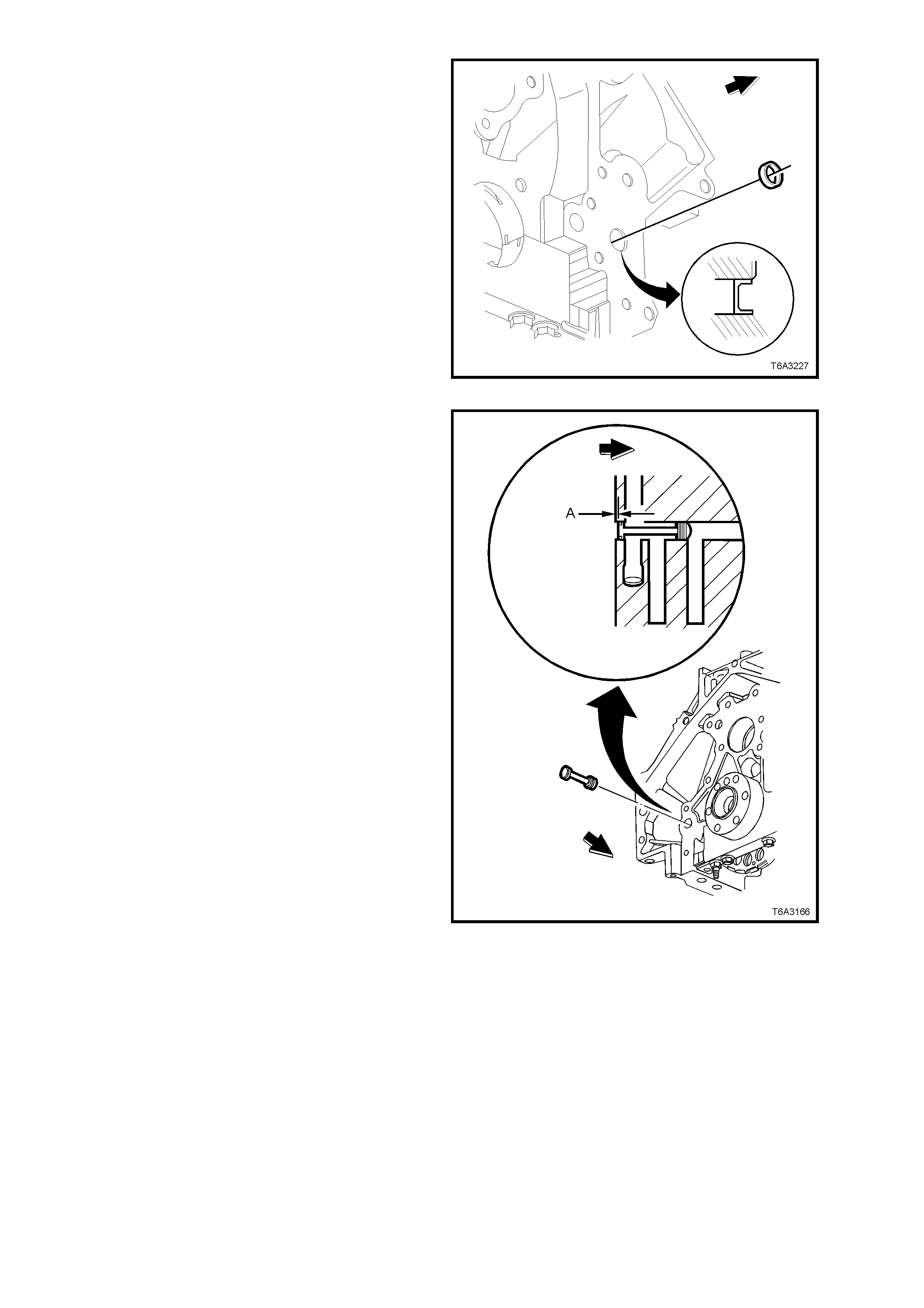

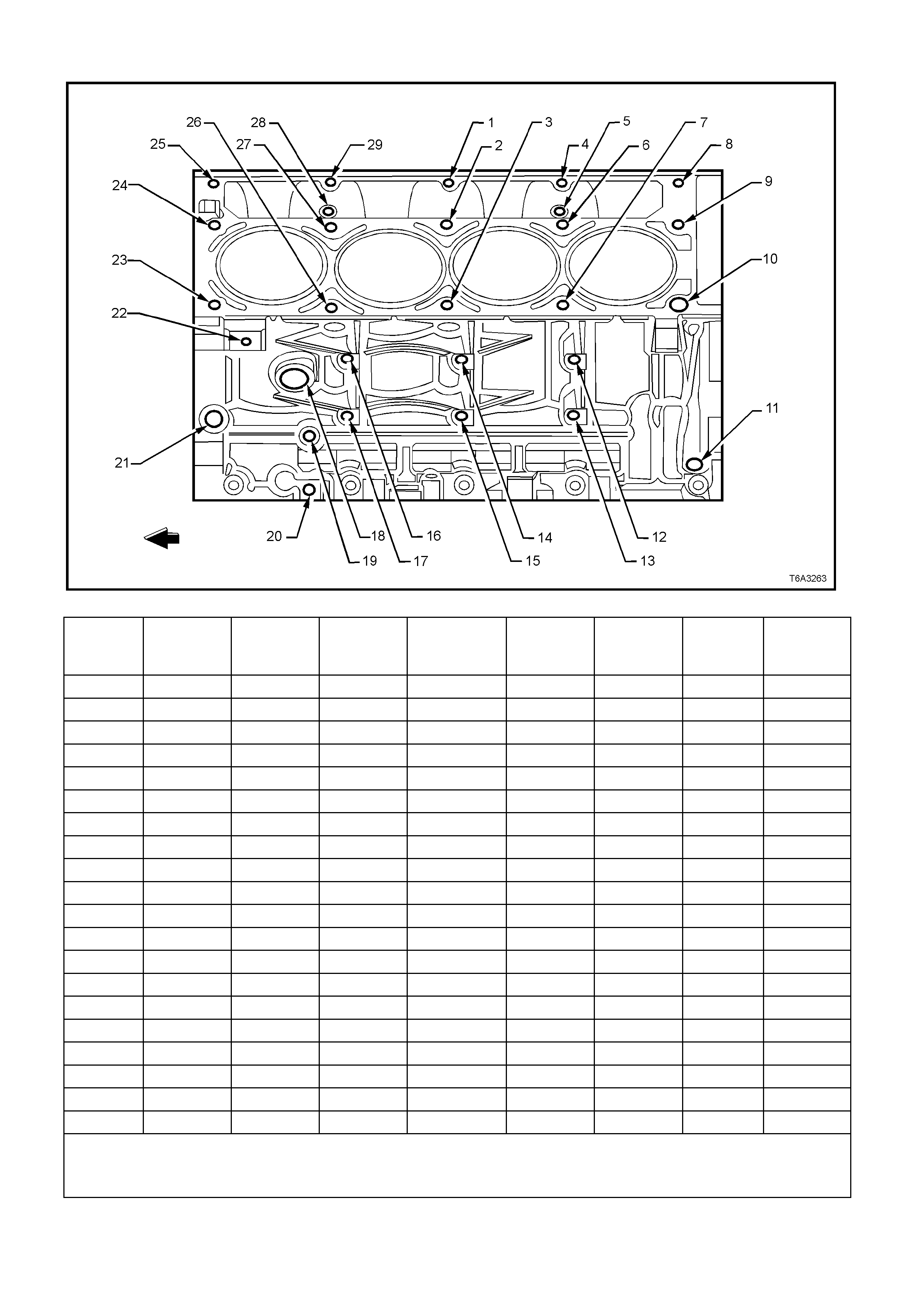

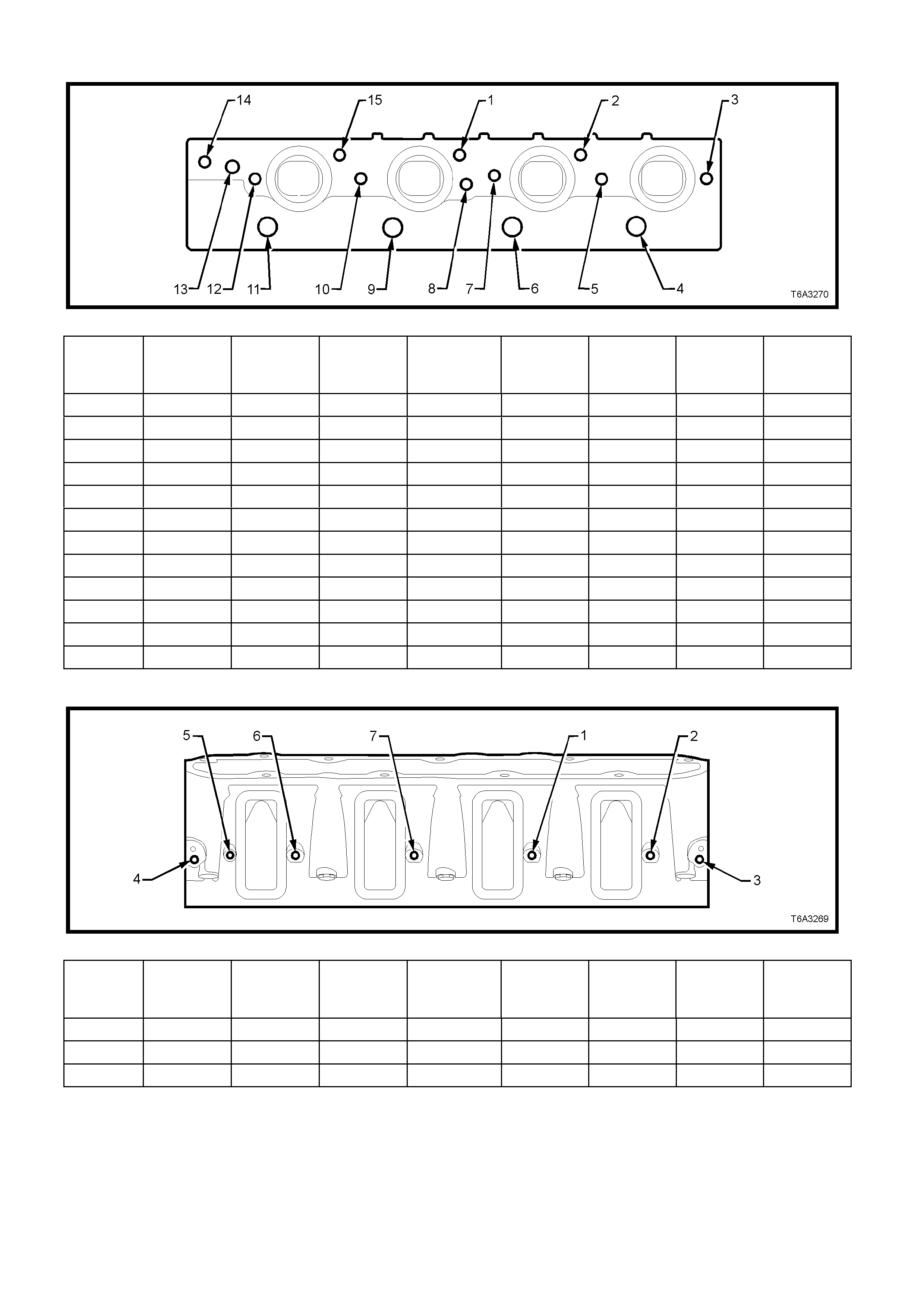

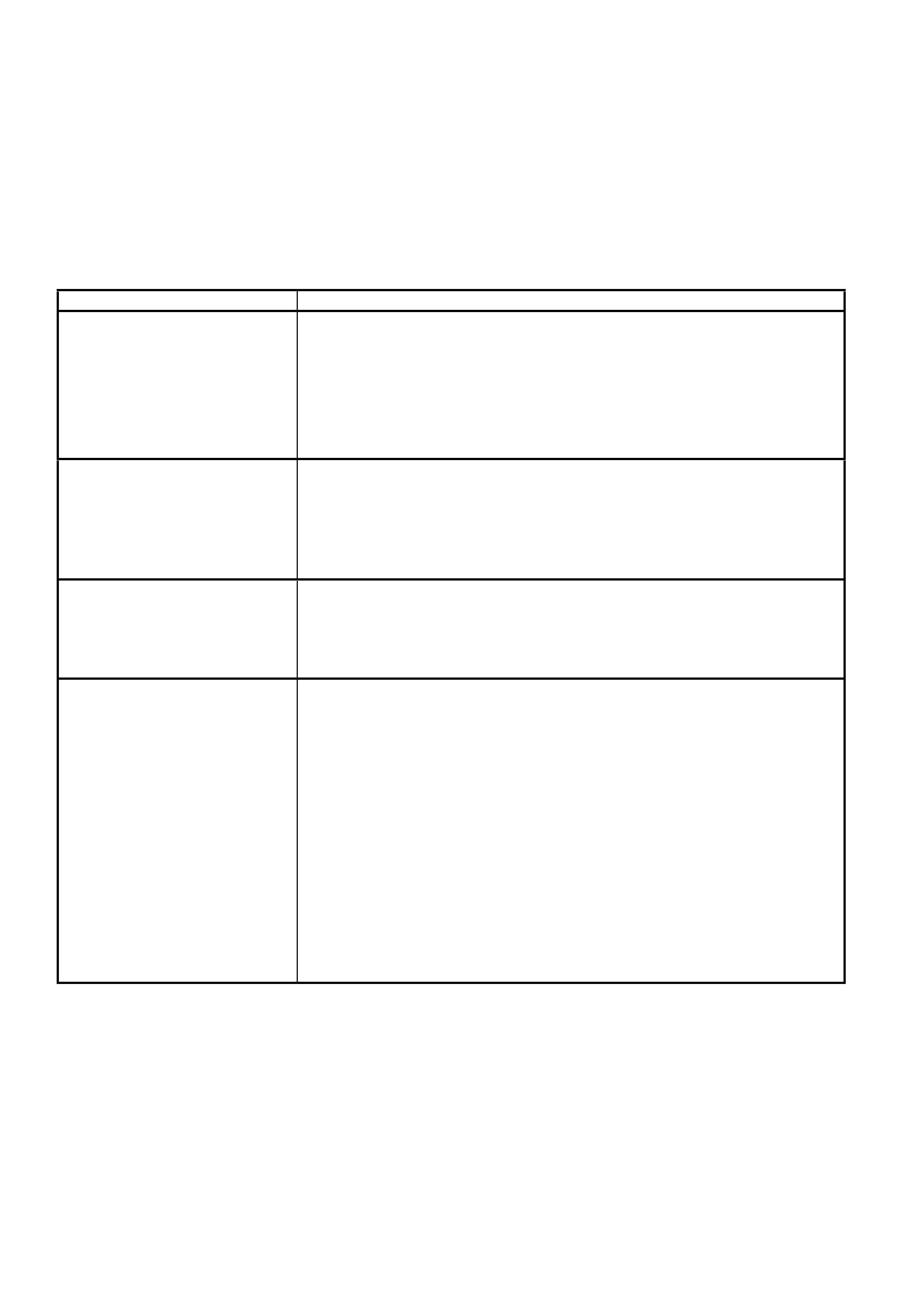

Figure 6A3-3 - Lower Engine Assembly

Legend

1. Bolt - Camshaft Position Sensor 17. Baffle - Oil Pan 33. Adaptor - Oil Filter

2. Cams haf t Position Sensor 18. Tube - Oil Transfer 34. Oil Filter

3. Sensor - Oil P ressure 19. Gasket - Oi l Transfer Tube 35. Plug - Drain

4. Engine Block 20. Gasket - Oi l P an 36. Bolt - Crank shaft B eari ng Cap Side

5. Pist on Rings 21. Bolt - E ngi ne Fl ywheel/F l explate 37. Caps - Cranks haft Main Bearing

6. Piston and Connecti ng Rod A ss’y 22. Bolt - Oi l P an Cl oseout Cover (RHS) 38. Stud - Main Beari ng Cap

7. Connecting Rod Bearings 23. Cover - Oil Pan Closeout (RHS) 39. Bolt - Main B eari ng Cap

8. Connecting Rod Cap 24. Cover - Oil Pan Closeout (LHS) 40. Bearings - Crankshaft Main

9. Bolt - Connecting Rod 25. Bolt - Oi l P an Cl oseout Cover (LHS) 41. Bearings - Crankshaft Main Thrust

10. Crankshaf t Oil Deflector 26. Plug - Oil P an Gal l ery 42. Plug - Rear Crankshaft

11. Engine Flywheel (Man. Trans.) 27. Bolt - Oil P an Transfer Tube 43. Bush - Manual Transmis sion Spigot

12. Engine Flexplate (Aut o. Trans.) 28. Oil Pan 44. O-Ring Seal - Oil Pump P i ck-up

13. Screen and Pi pe - Oi l P ump Pi ck-up 29. Gasket - Oi l Transfer Cover 45. Crankshaft

14. Screw - Oil Pump Pick-up to Pump 30. Cover - Oil Transf er 46. Key - Cranks haft Sproc ket

15. Nut - Oil Defl ector and Oil Pump P i ck-up 31. Nut - Oil Trans f er Cover 47. Plug - Engine Block Front Oi l Gal l ery

16. Bolt - Oil Pan Baff l e 32. Valve - Oil B ypas s 48. Plug - Cyli nder B l ock in Unused Hole

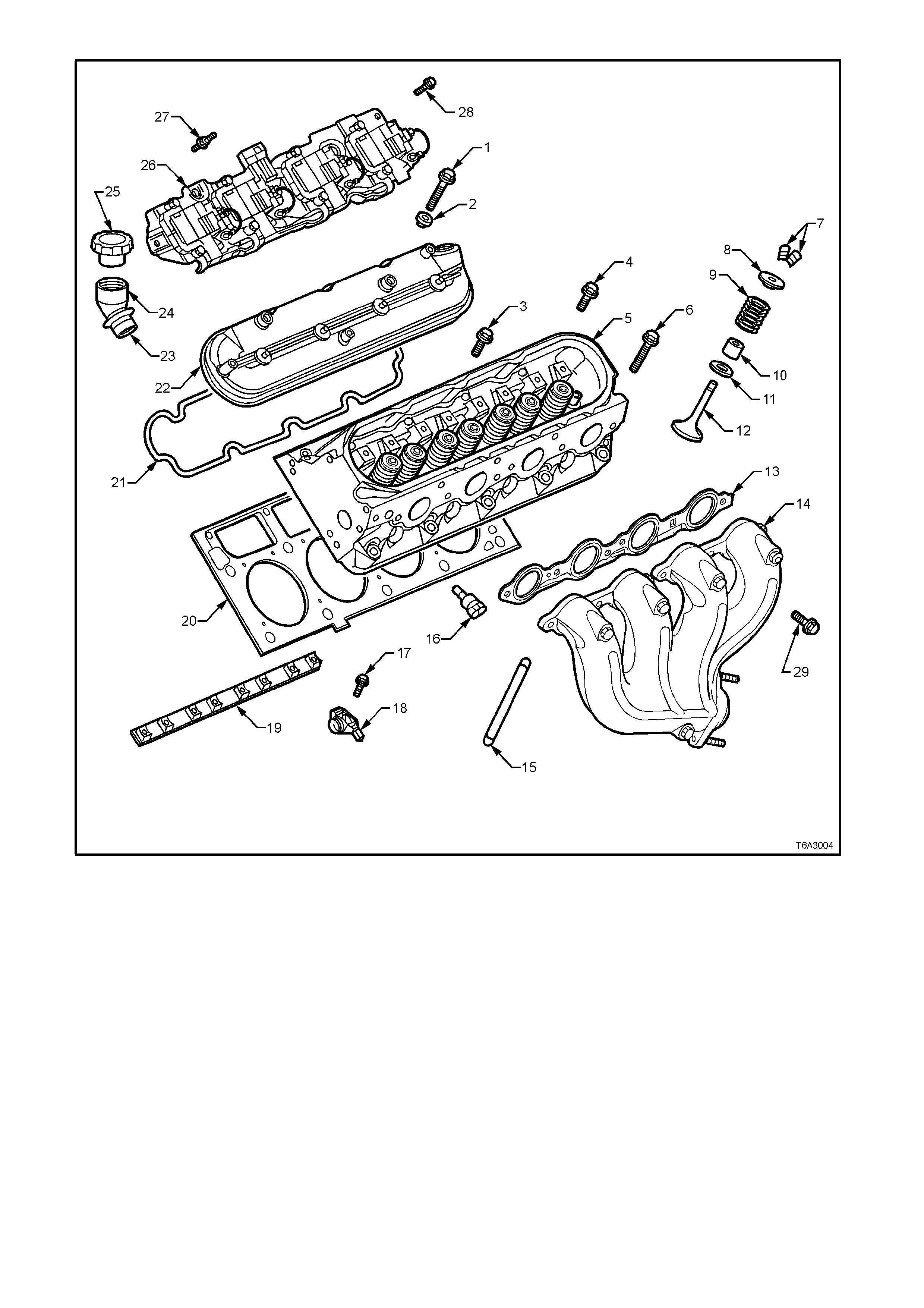

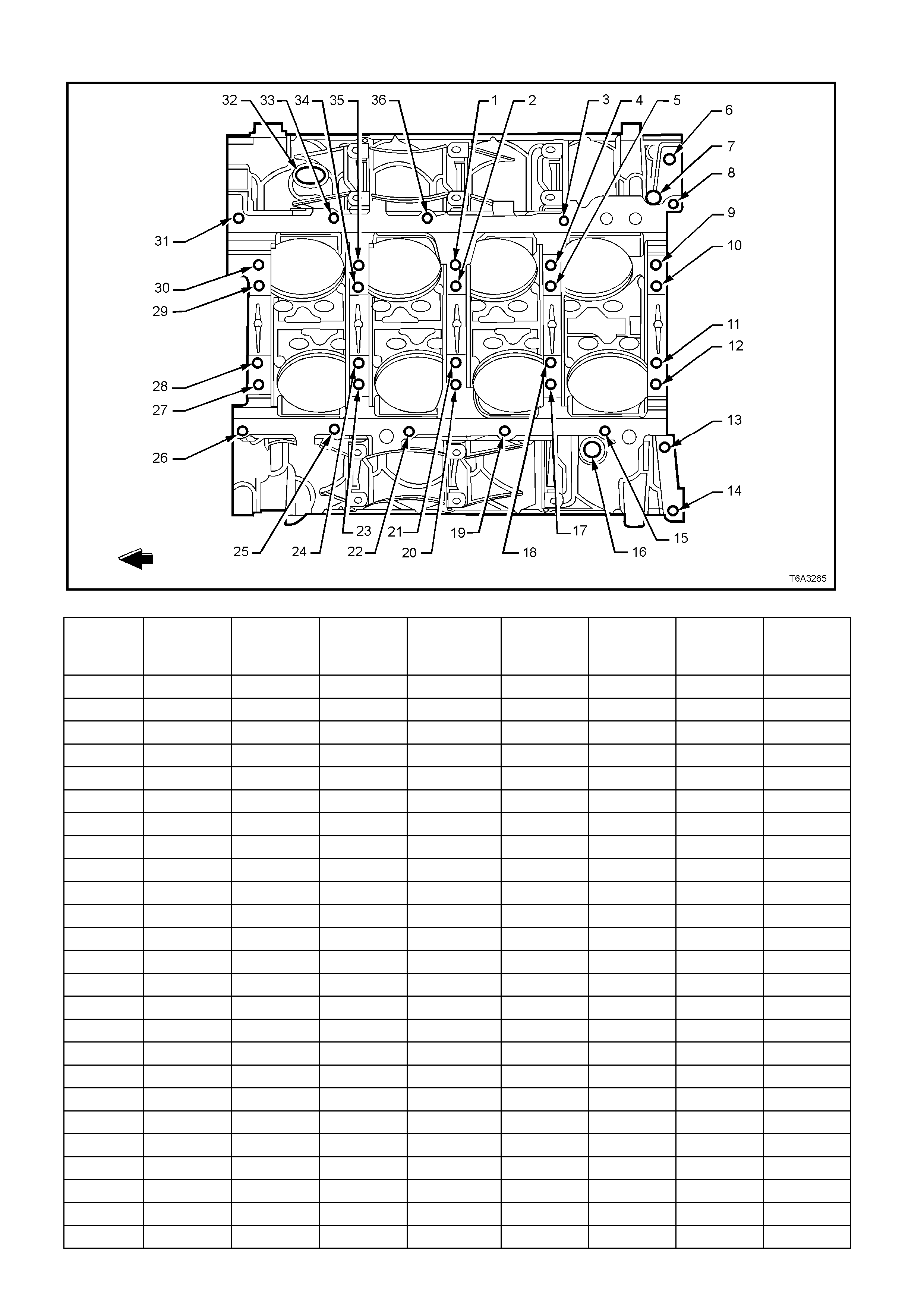

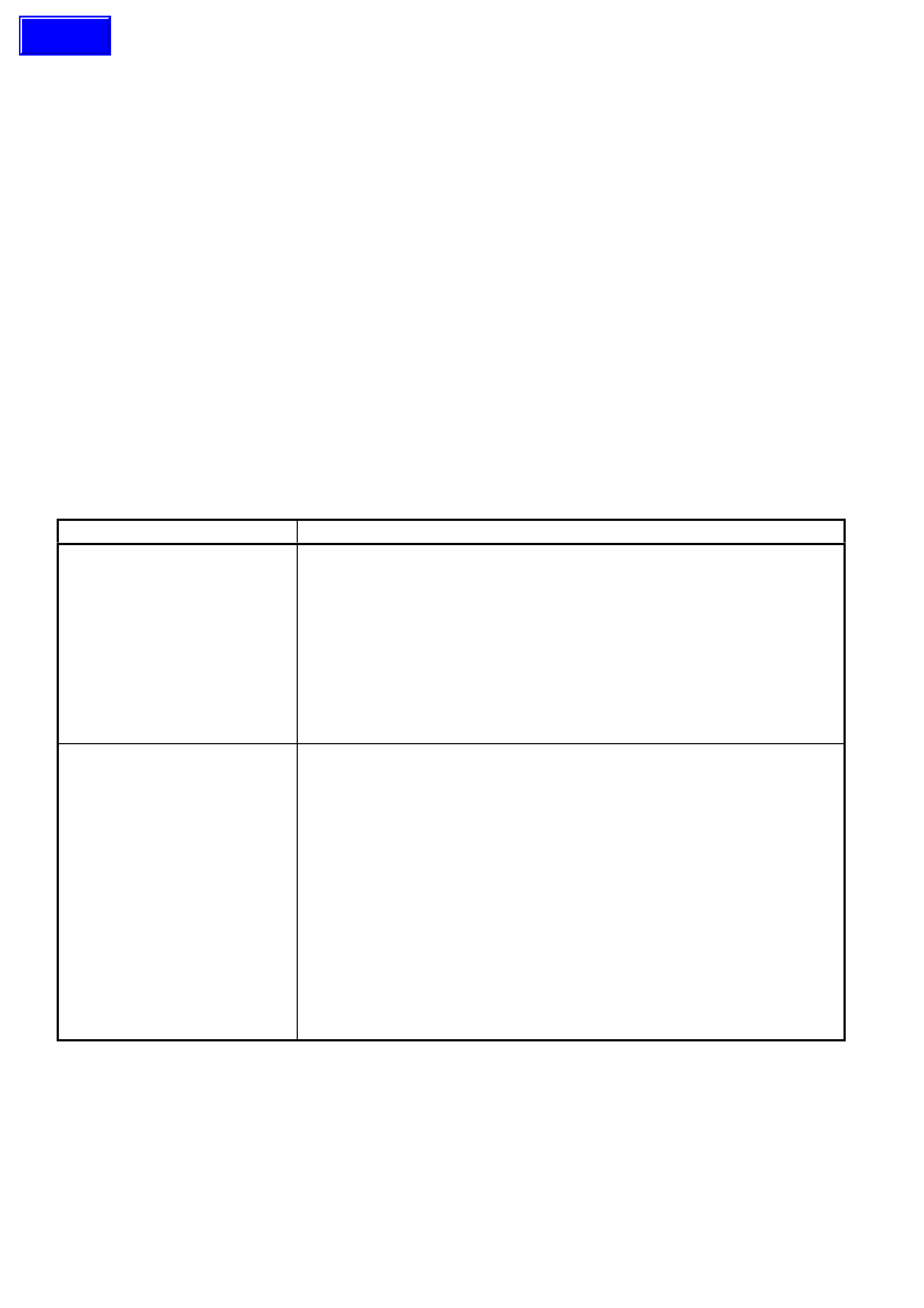

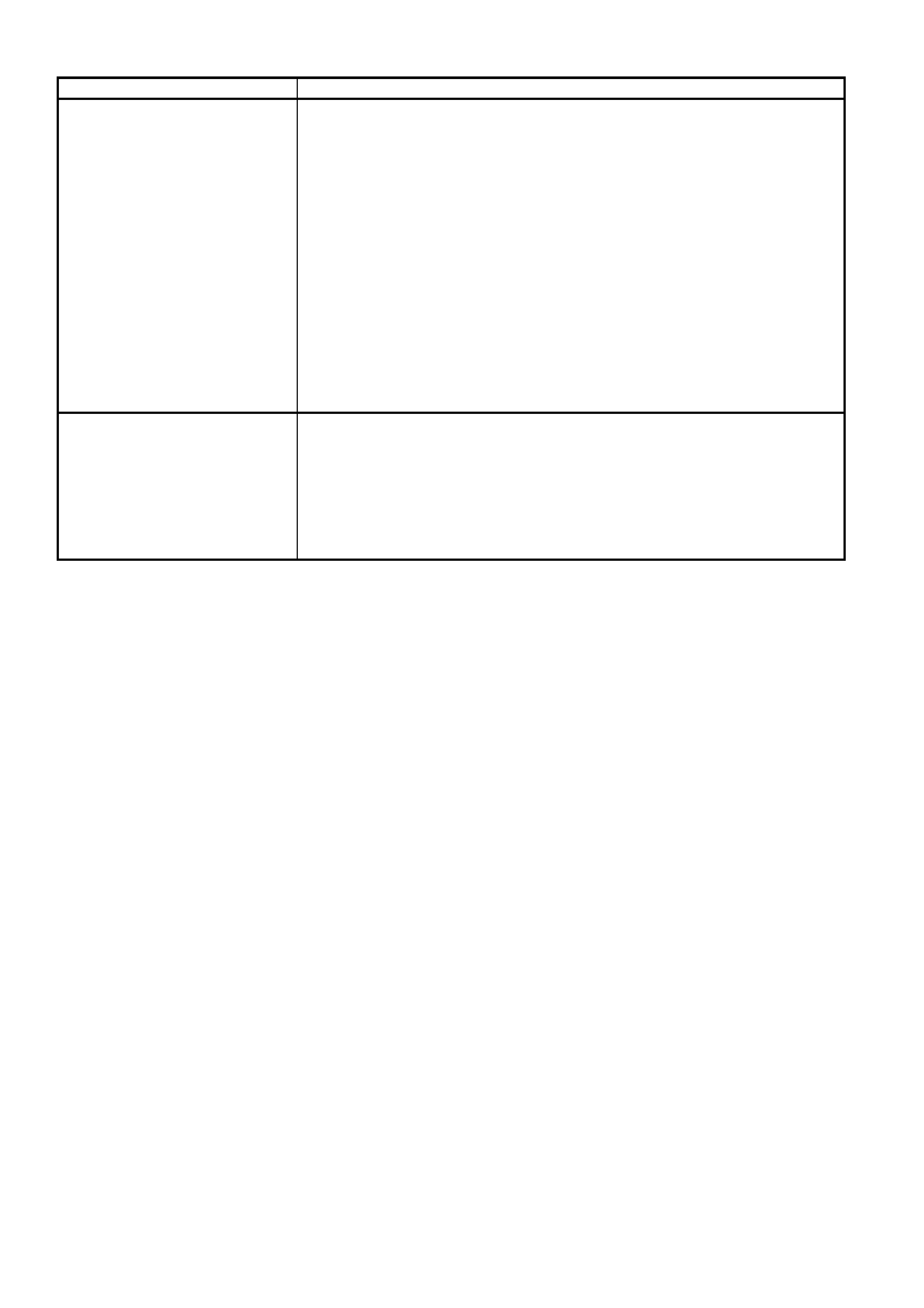

Figure 6A3-4 - Cylinder Head/Upper Engine

Legend

1. Bolt - Valve Rocker Arm Cover 16. Pushrod

2. Grommet - Valve Rocker Arm Cover 17. Sensor - Coolant Temperature

3. Bolt - Cylinder Head (Short) 18. Bolt - Valve Rocker Arm

4. Bolt - Cylinder Head (Medium) 19. Arm - Valve Rocker

5. Cylinder Head 20. Support - Valve Rocker Arm Pivot

6. Bolt - Cylinder Head (Long) 21. Gasket - Cylinder Head

7. Collets - Valve Stem Keys 22. Gasket - Valve Rocker Arm Cover

8. Cap - Valve Spring 23. Cover - Valve Rocker Arm

9. Spring - Valve 24. Tube - Oil Fill

10.Oil Seal - Valve Stem 25. Cap - Oil Fill Tube

11.Shim - Valve Spring 26. Assembly - Ignition Coil and Bracket

12.Valve 27. Stud - Ignition Coil Bracket Assembly

13.Gasket - Exhaust Manifold 28. Screw - Ignition Coil Bracket Assembly. Rear on each side

14.Manifold - Exhaust 29. Bolt - Exhaust Manifold

15.Bolt - Exhaust Manifold Heat Shield

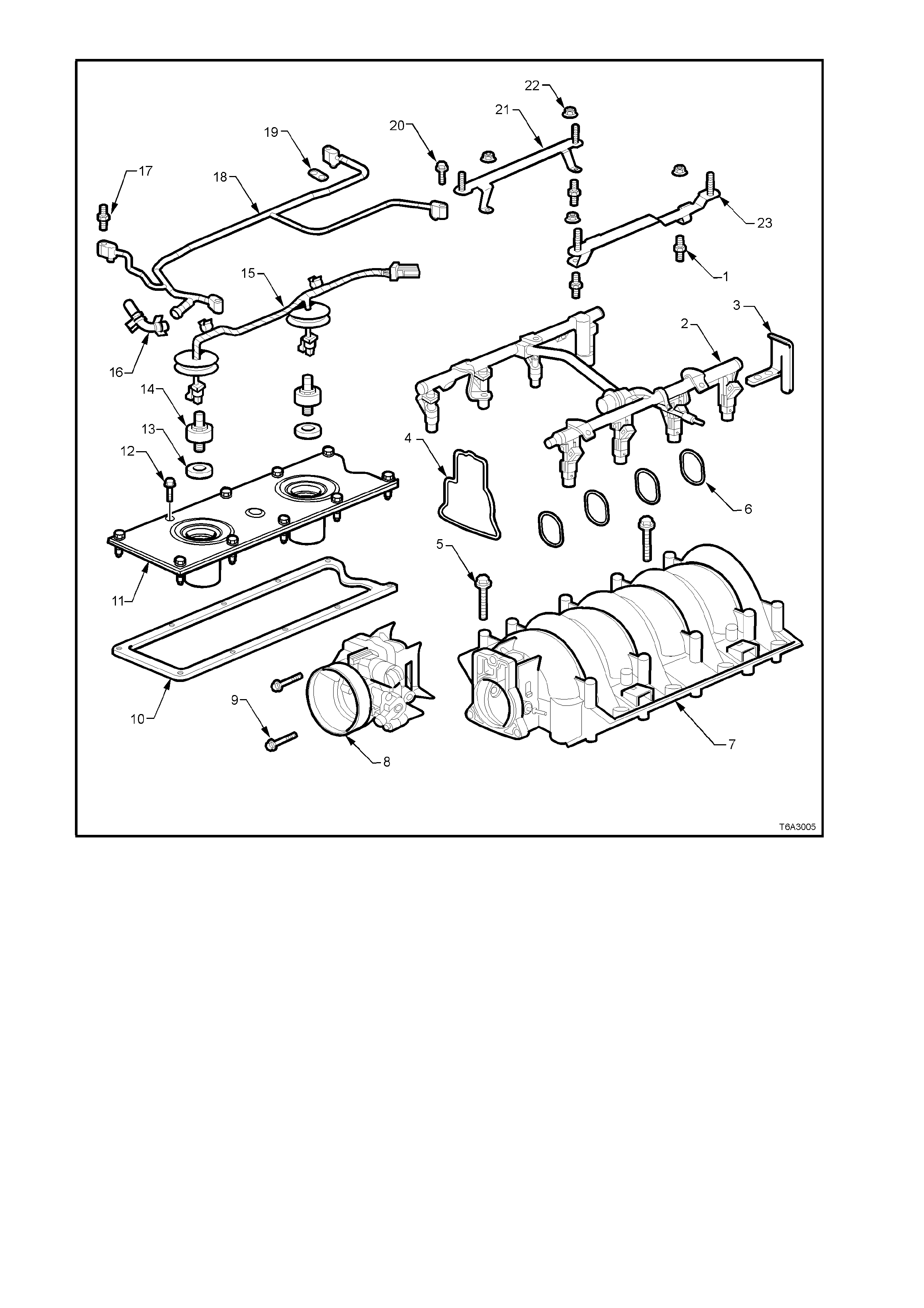

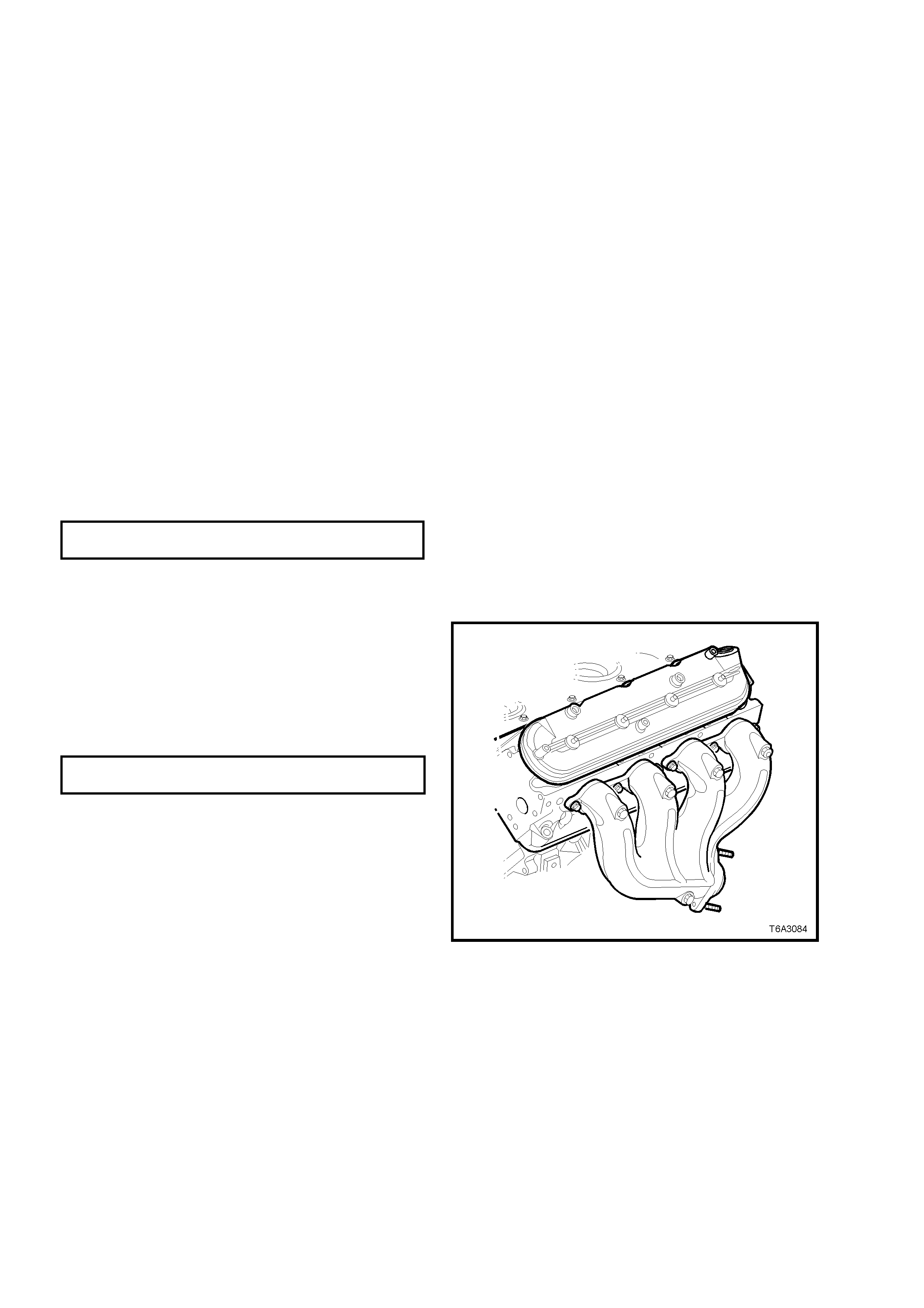

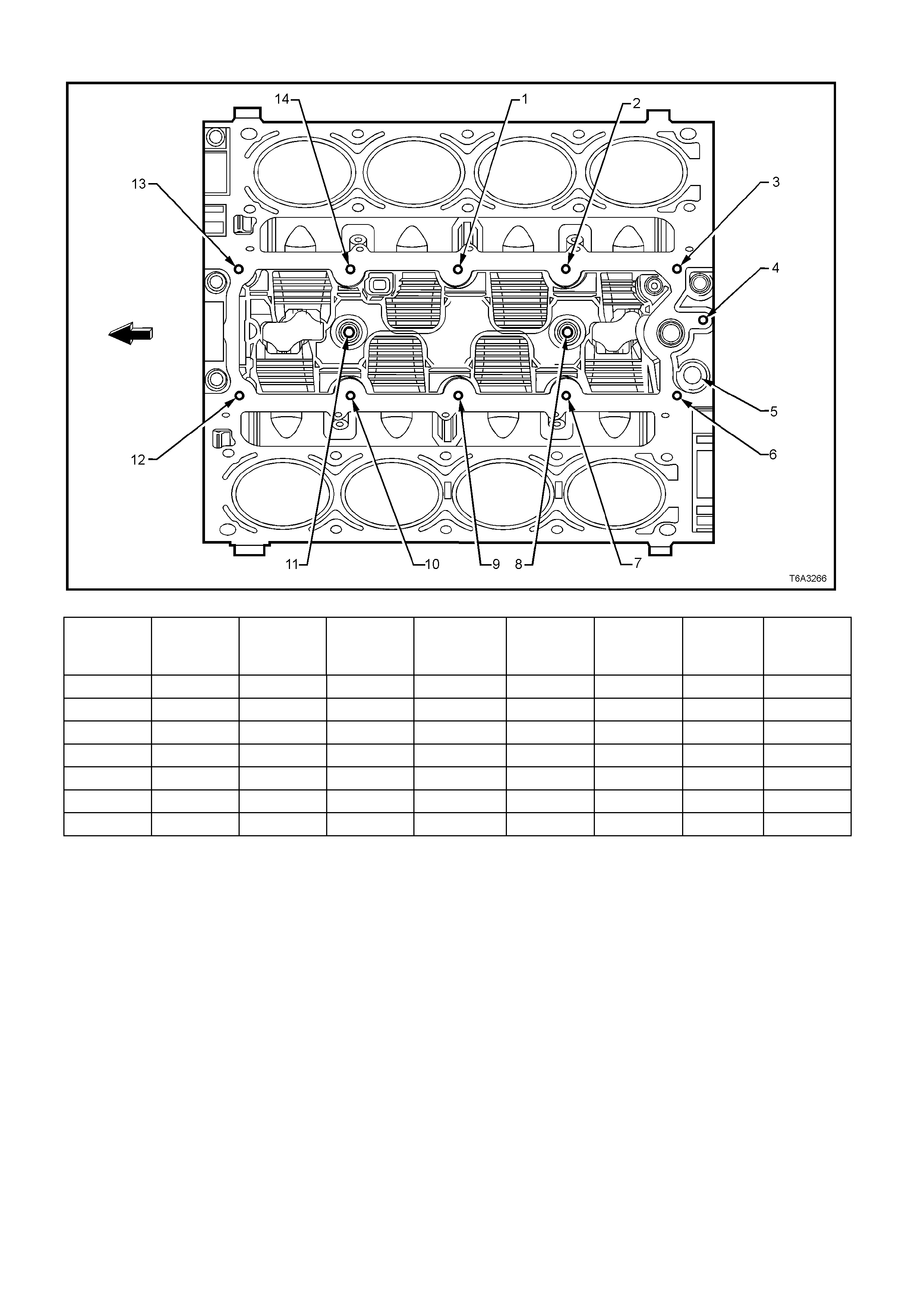

Figure 6A3-5 - Intake Manifold/Upper Engine

Legend

1. Stud - Fuel Rail 13. Oil Seal - Knock Sensor

2. Fuel Rail (with Injectors) 14. Knock Sensor

3. Bracket - Fuel Rail Stop 15. Knock Sensor Wire Harness

4. Gasket - Throttle Body 16. Hose - Vapour Vent Tube

5. Bolt - Intake Manifold 17. Stud - Vapour Vent Tube

6. Gaskets - Intake Manifold 18. Vapour Vent Tube

7. Intake Manifold 19. Gasket - Vapour Vent Tube

8. Throttle Body 20. Bolt - Vapour Vent Tube

9. Bolt - Throttle Body 21. Bracket - Engine Dress Cover, Right Hand Side

10.Gasket - Valley Cover 22. Nut - Engine Dress Cover Bracket

11.Valley Cover 23. Bracket - Engine Dress Cover, Left Hand Side

12.Bolt - Valley Cover

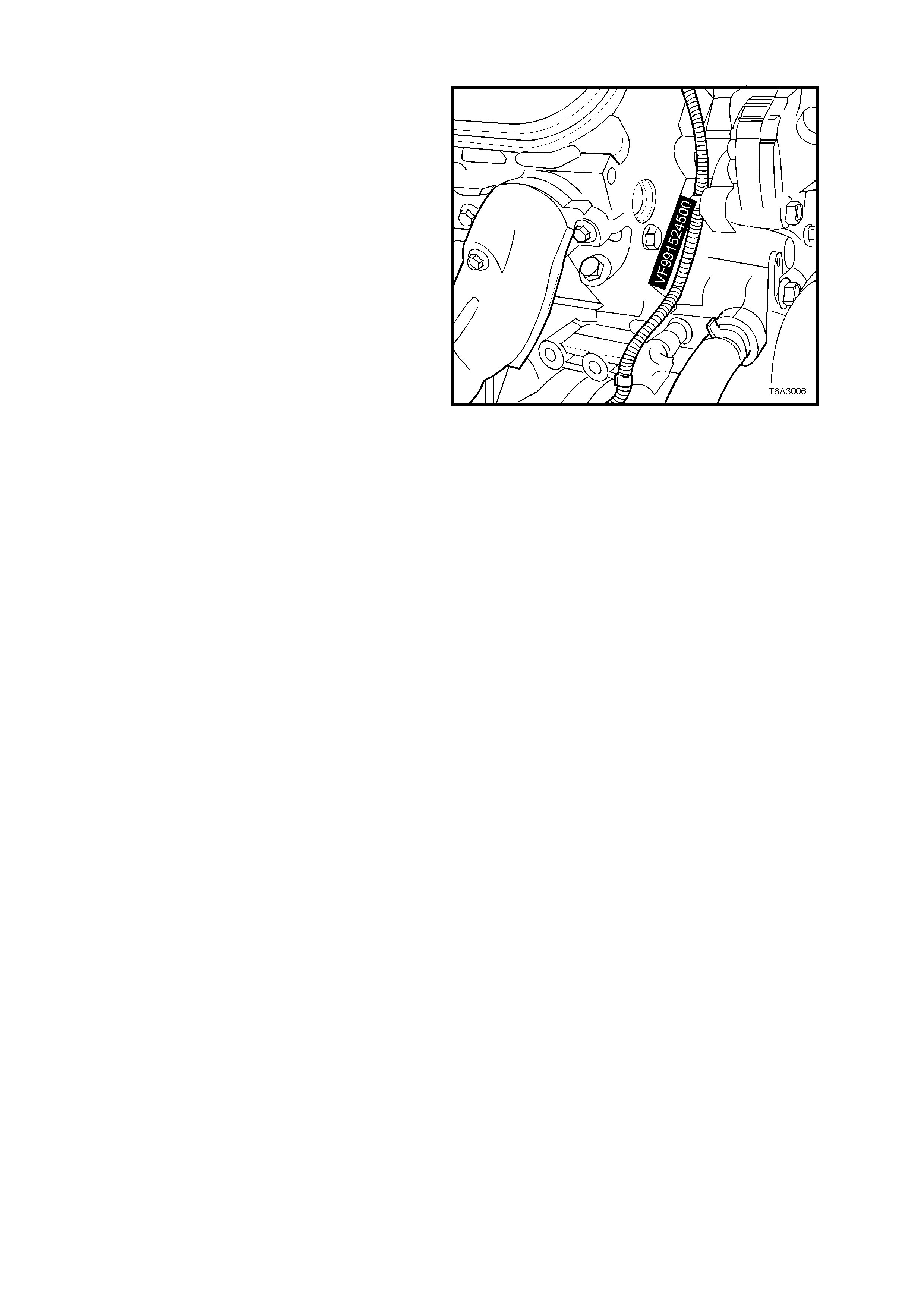

1.1 ENGINE SERIAL NUMBER

The engine number is stamped on the right hand

side front of the engine cylinder block, as shown.

The number is prefixed by the letters ‘VF’.

A breakdown of the engine numbering system,

using and example of ‘VF991524500’, is;

• First two numbers (‘99’) indicates the engine

model year.

• Next three numbers (‘152’) is the Julian date

(day of the year), the engine was

manufactured.

• Next four numbers are the daily, sequential

build number.

Figure 6A3-6

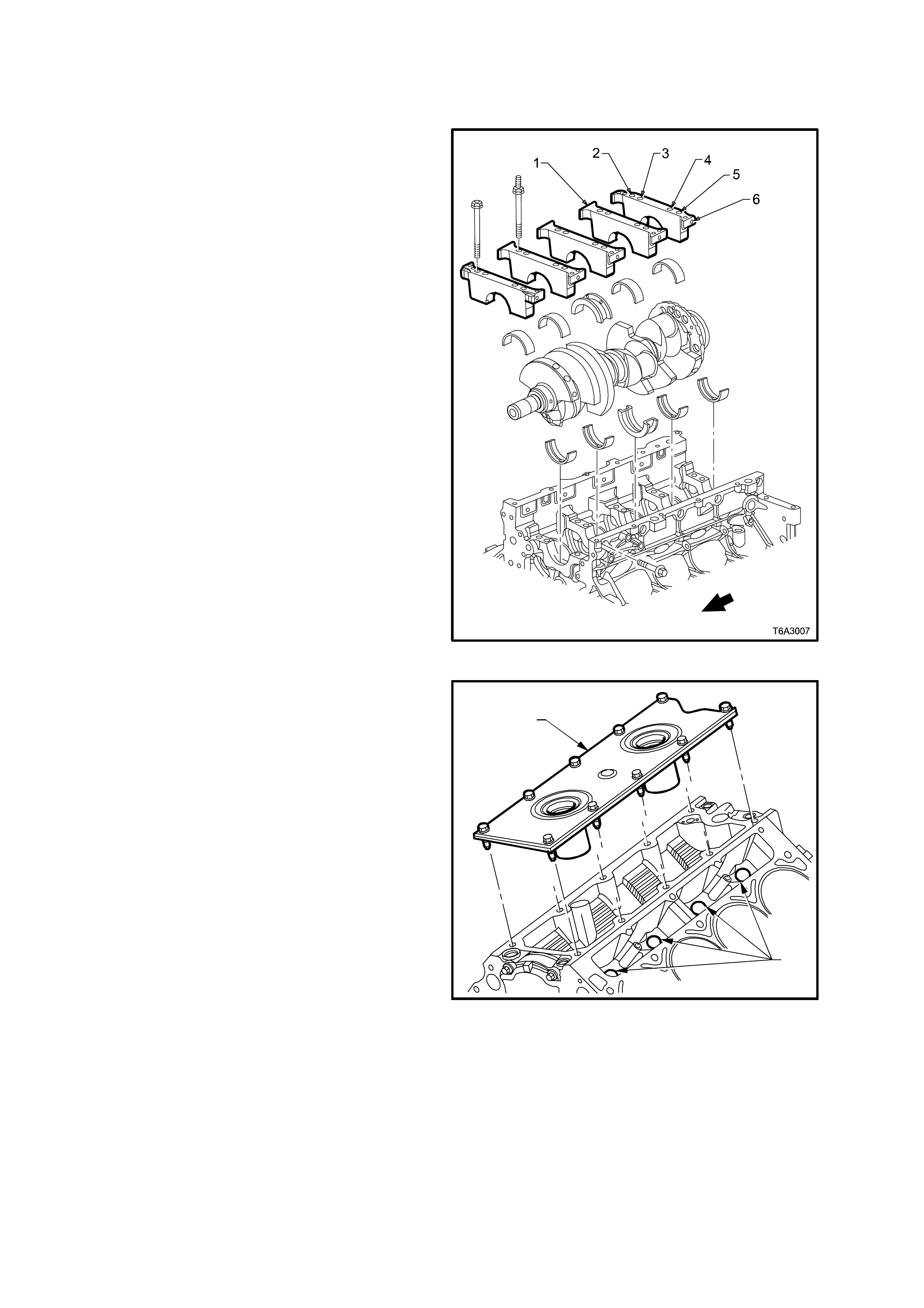

1.2 ENGINE CONSTRUCTION

CYLINDER BLOCK

The engine cylinder block is a cam-in-block, deep

skirt, 90° ‘V’ configuration with five crankshaft

bearing caps, manufactured from forged powdered

metal. The engine block is aluminium with cast in

place, cast iron cylinder bore liners. The f ive cr os s-

bolted crankshaft bearing caps each have four

vertical M10 (2, 3, 4, and 5) and two horizontal M8

(1 and 6) mounting bolts. Only cylinder honing is

permitted.

The c rankcas e s k ir t length, bear ing cap width, deck

width and upper rails have been optimised for

strength, using finite element analysis.

The camshaft is supported by five camshaft

bearings pressed into the block.

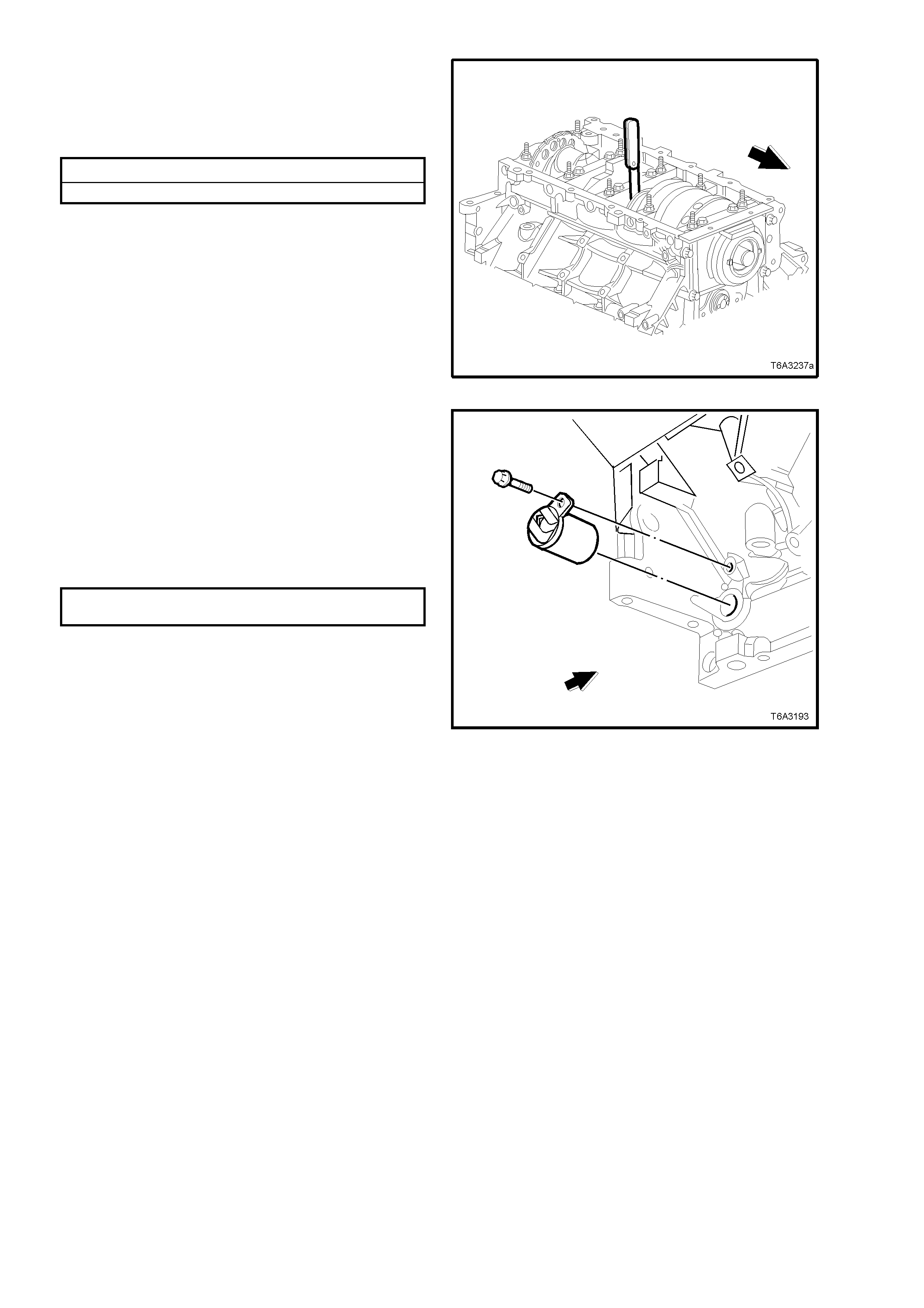

Figure 6A3-7

The cylinder block incorporates enclosed valve

lifter bores (2) under each cylinder head, that

results in a more stiff structure with quiet operation.

Utilising a struct ural die c as t aluminium valley cover

(1), ties both cylinder banks together, increasing

the block’s torsional and bending frequencies.

Having a closed valley area also prevents hot oil

from contacting the lower surface of the intake

manifold, allowing cooler air to enter the cylinders.

Overall, the cylinder block cons truction weighs 48%

less than an equivalent cast iron block and the

structural design features, coupled with the

inherently light cylinder heads, combine into an

engine with unique stiffness and light weight.

T6A3008

2

1

Figure 6A3-8

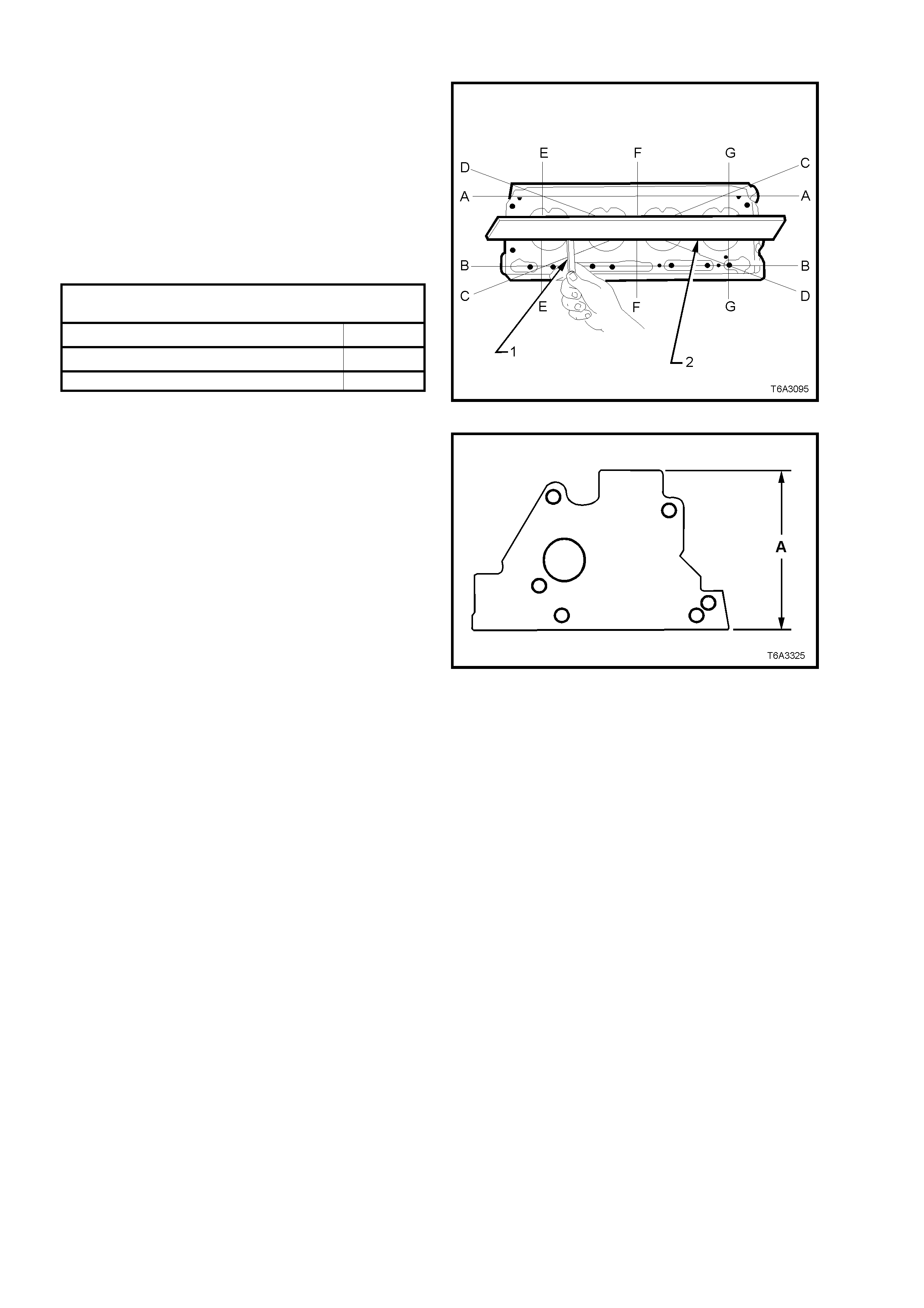

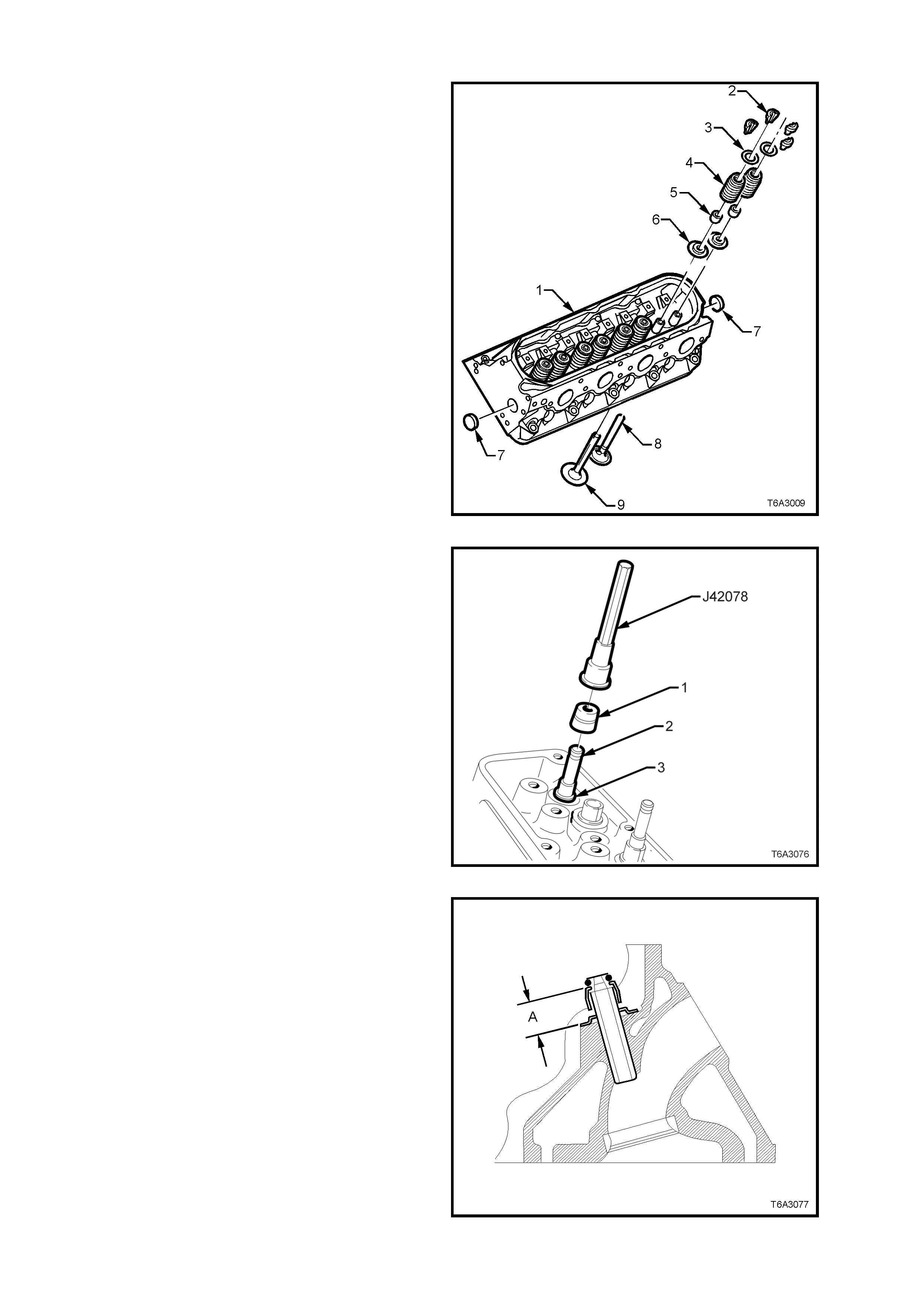

CYLINDER HEADS

The cylinder head assemblies are cast aluminium

and have pressed in place, powdered metal valve

guides and valve seats.

Intake and exhaust ports are identical for each

cylinder, ensuring a balanced air-flow distribution

for balanced combustion, resulting in a smoother

running engine.

The cylinder head is attached using a four bolt per

cylinder, deep threaded arrangement for minimal

bore distortion, allowing low friction pistons and

rings for reduced fuel consumption.

Cylinder head gaskets are made of a steel core

between layers of graphite and features stainless

steel PTFE coated flanges and lacing. Cylinder

head gaskets are unique for right and left hand

sides with preferential coolant flow.

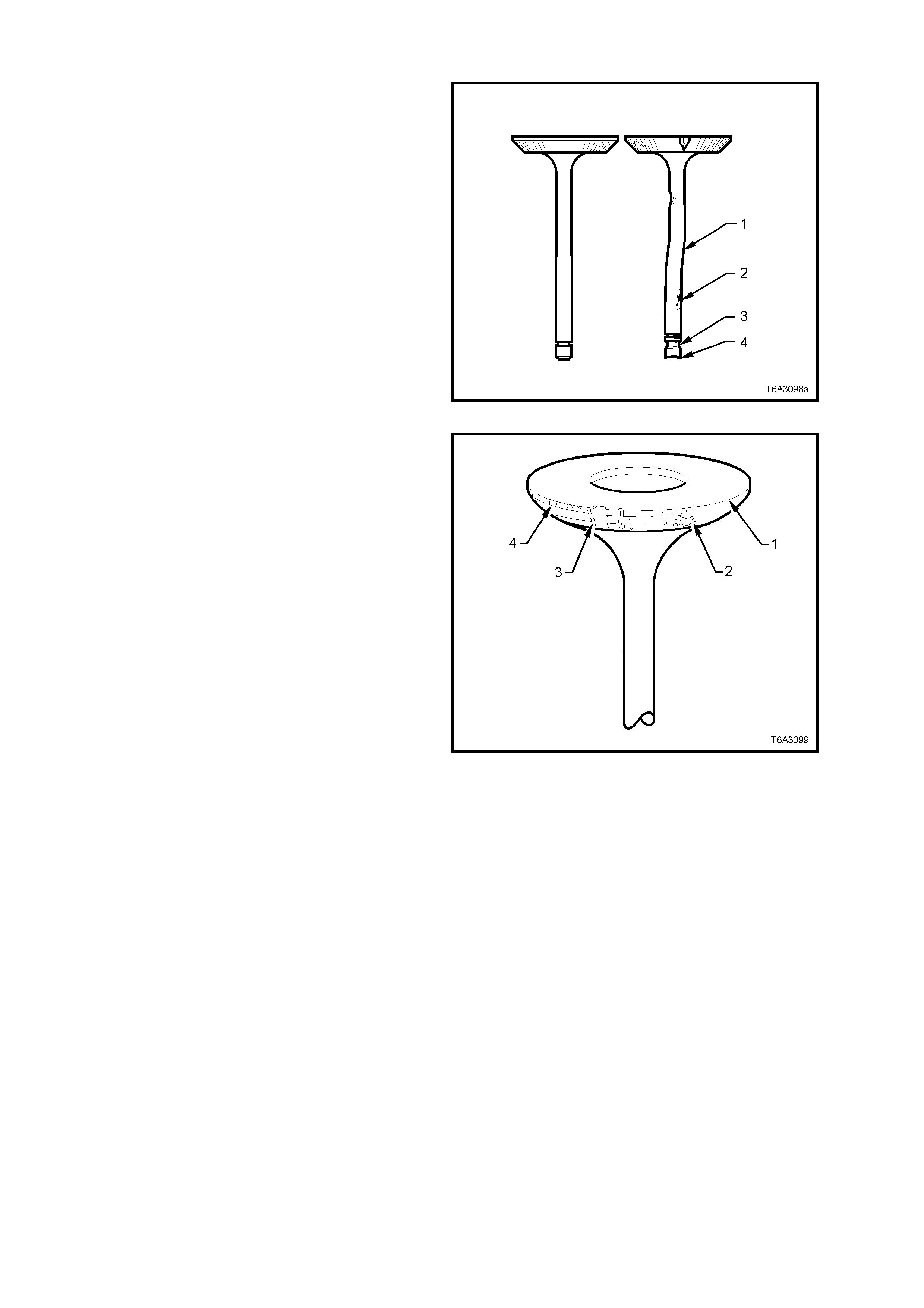

Legend

1. Cylinder Head

2. Valve Stem Collets

3. Valve Spring Cap

4. Valve Spring

5. Valve Stem Oil Seal

6. Valve Spring Shim

7. Cylinder Head Core Plugs

8. Exhaust Valve

9. Intake Valve Figure 6A3-9

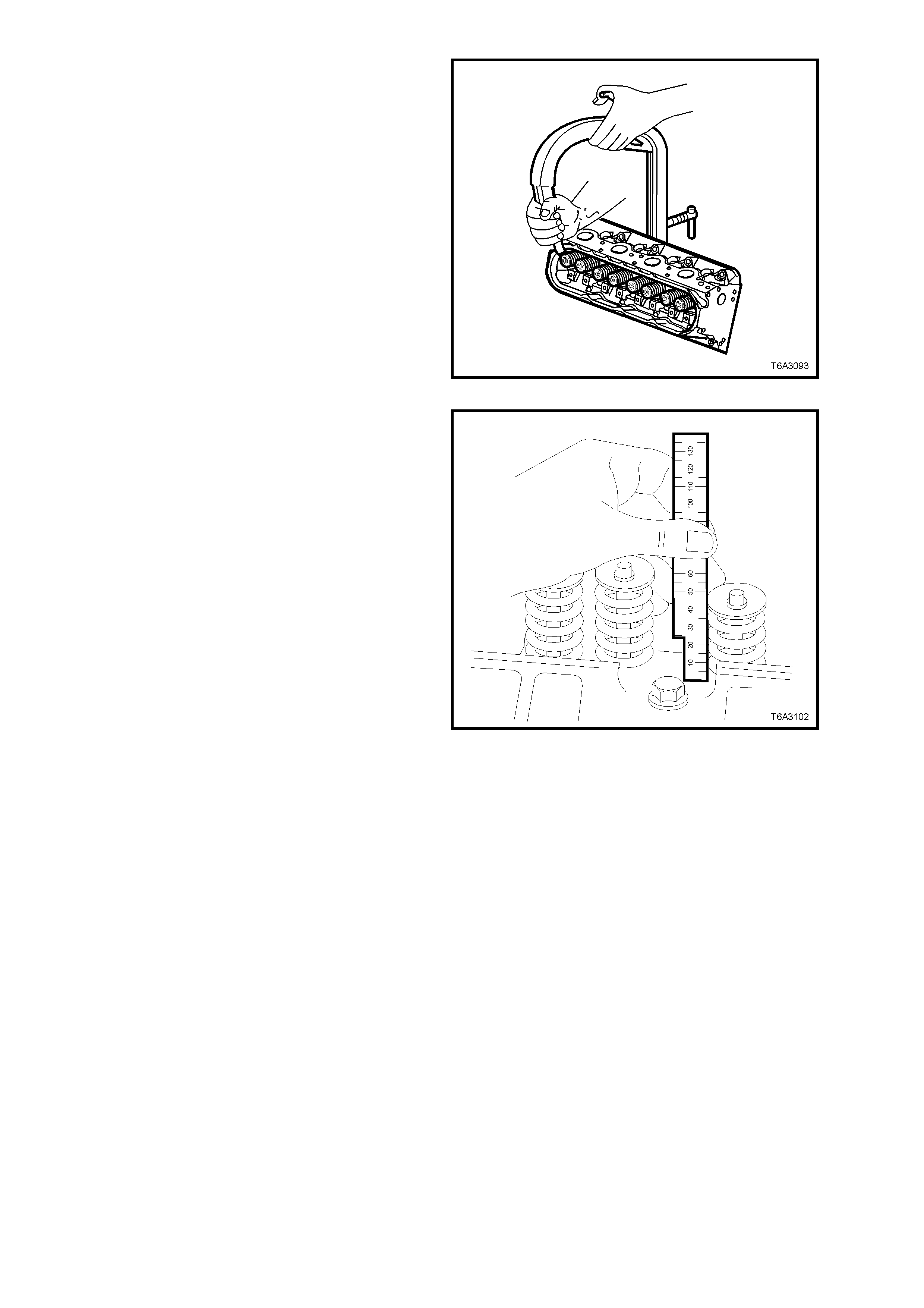

The intake ports are very tall, which enhances fuel

injector targeting. As air flows down to the valve

guide, it widens and shortens to the size of the

intake valve seat.

Figure 6A3-10

VALVE TRAIN

Motion is transmitted from the camshaft through

the hydraulic roller valve lifters and tubular

pushrods to the rocker arms. The valve lifter

guides position and retain the roller hydraulic valve

lifters. The valve rocker arms for each bank of

cylinders are mounted on pedestals (pivot

supports) . Eac h ro cker ar m is retained on the pivot

support and cylinder head by a bolt. Valve lash is

adjusted automatically each cycle by the hydraulic

valve lifters.

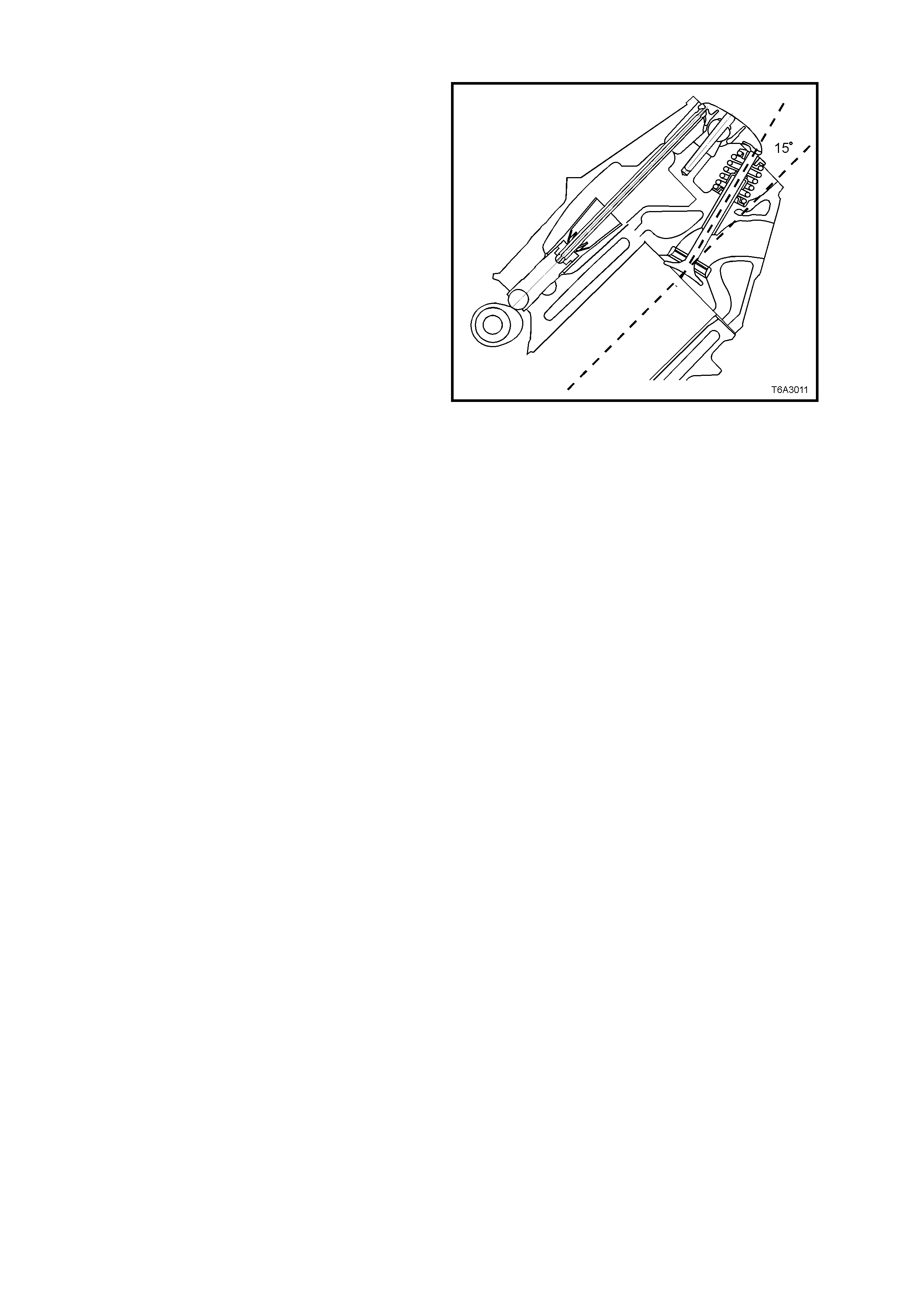

Both valves are angled at 15° to the cylinder bore

centreline, which creates a shallow combustion

chamber and a flat top piston, creating a

compression ratio of 10.1:1.

Both the exhaust and intake valve seat angles are

45° with an intake valve head diameter of 50.8 mm

and exhaust of 39.4 mm.

Valve springs ar e conical or ‘beehive’ in s hape and

made from chromium Silicone wire. The springs

are double shot peened to provide maximum

reliability. The reduced diameter end coils allows a

smaller diameter, lower mass, steel spring retainer

to be used, with single bead, valve stem k eys. T his

spring design also reduces spring mass and,

coupled with the increased stiffness in the valve

train, results in a reduction in the valve spring pre-

load, thereby reducing friction and valve train noise.

The roc k er arm s are m ade of investm ent cast steel

and have a ratio of 1.7:1, that allows a lower cam

lobe lift, resulting in lower valve train loading and

less noise.

The valve rocker arm covers are cast aluminium

and use a pre-moulded silicone gasket for sealing.

Mounted to each rocker cover are four individual

ignition coils. Incorporated into the covers are the

oil fill tube, the Positive Crankcase Ventilation

(PCV) system passages, and the engine fresh air

passages.

Figure 6A3-11

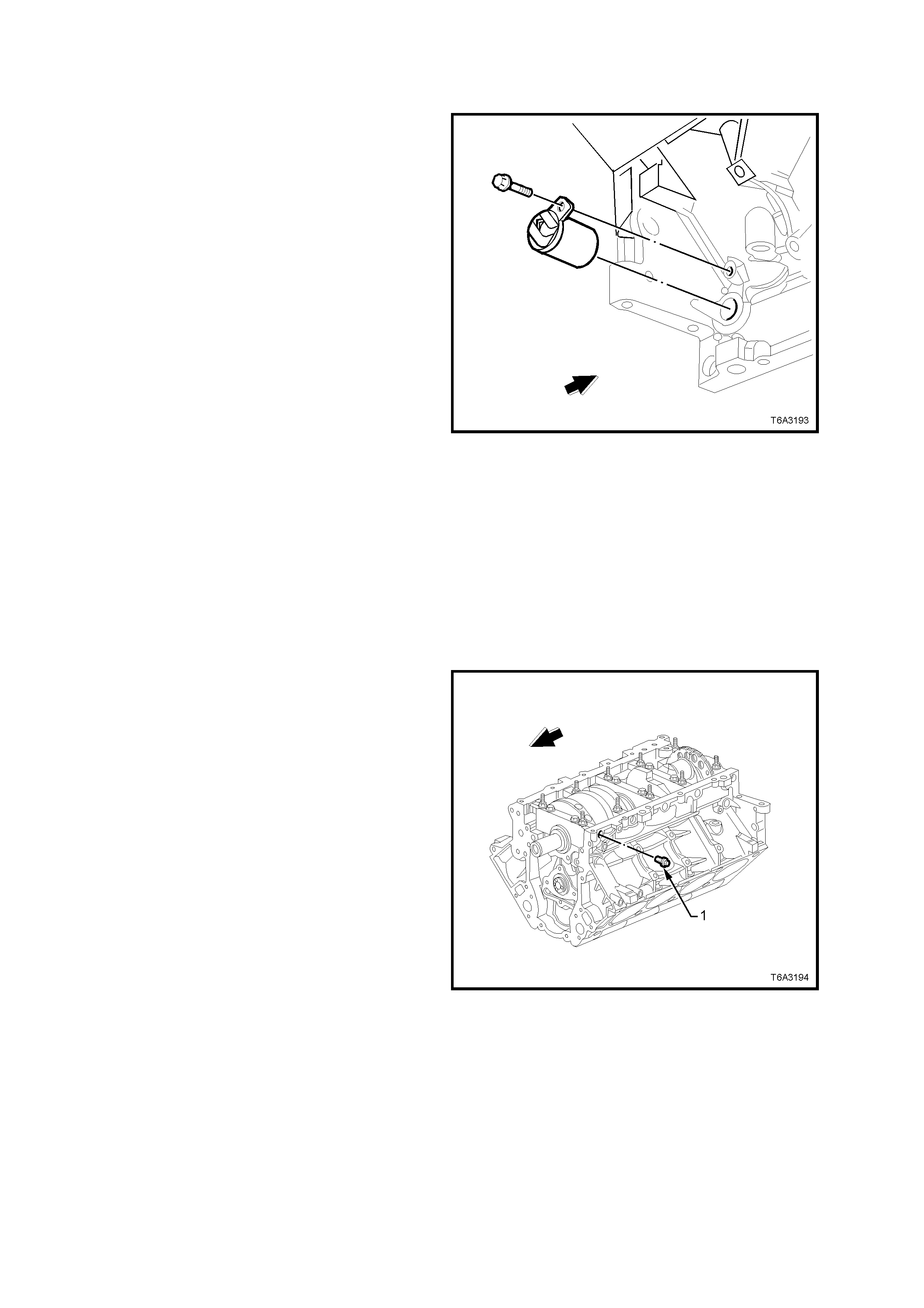

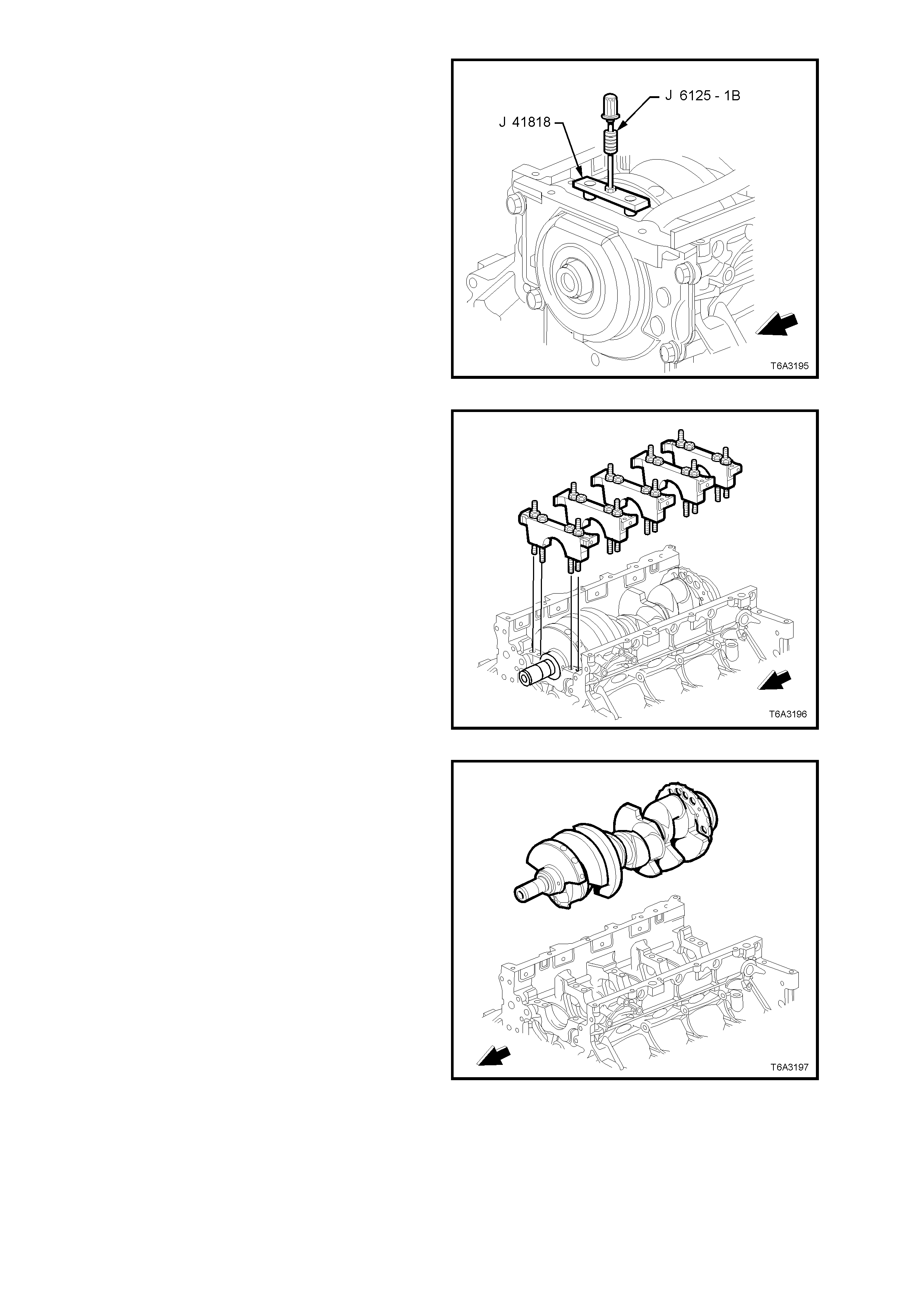

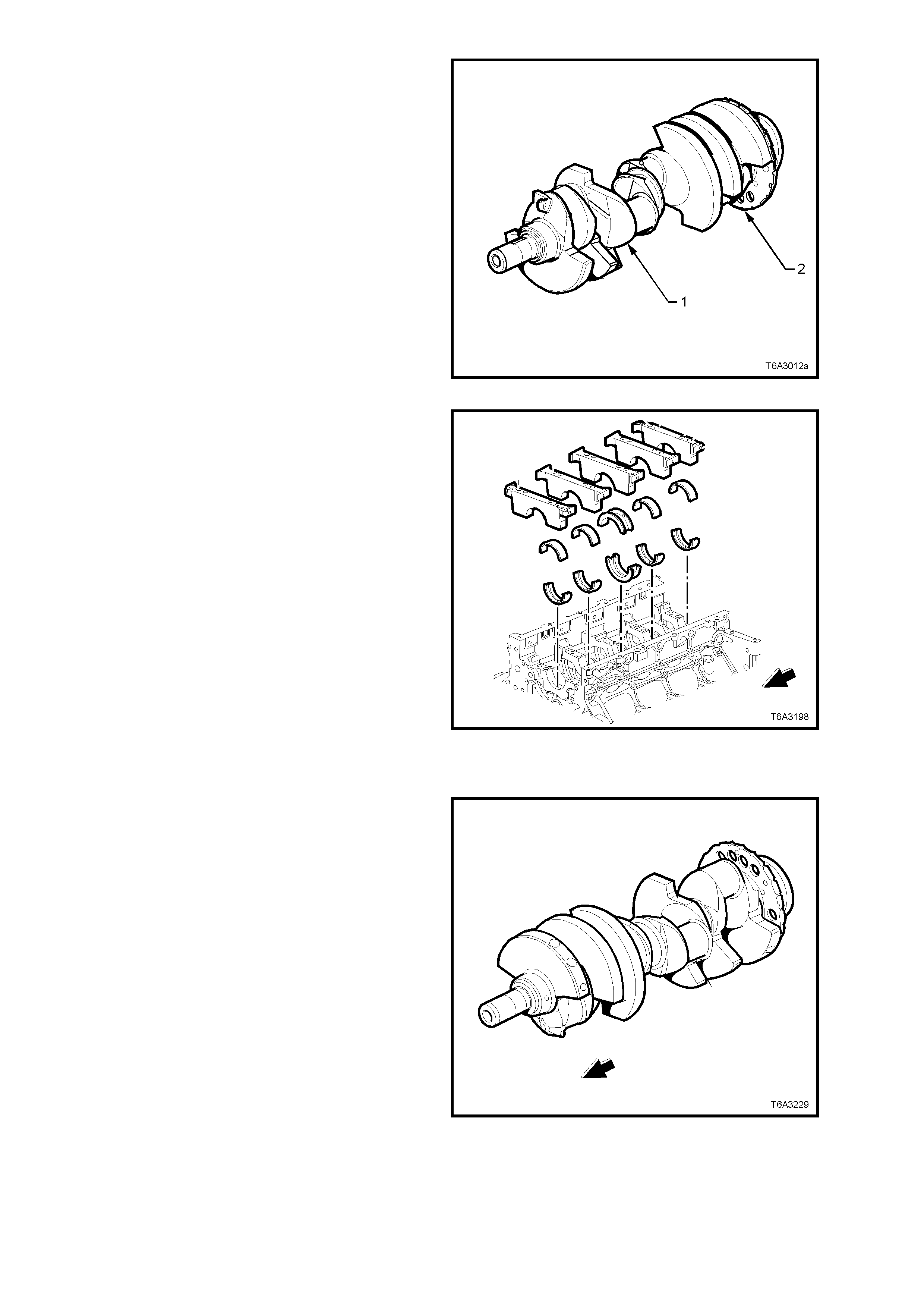

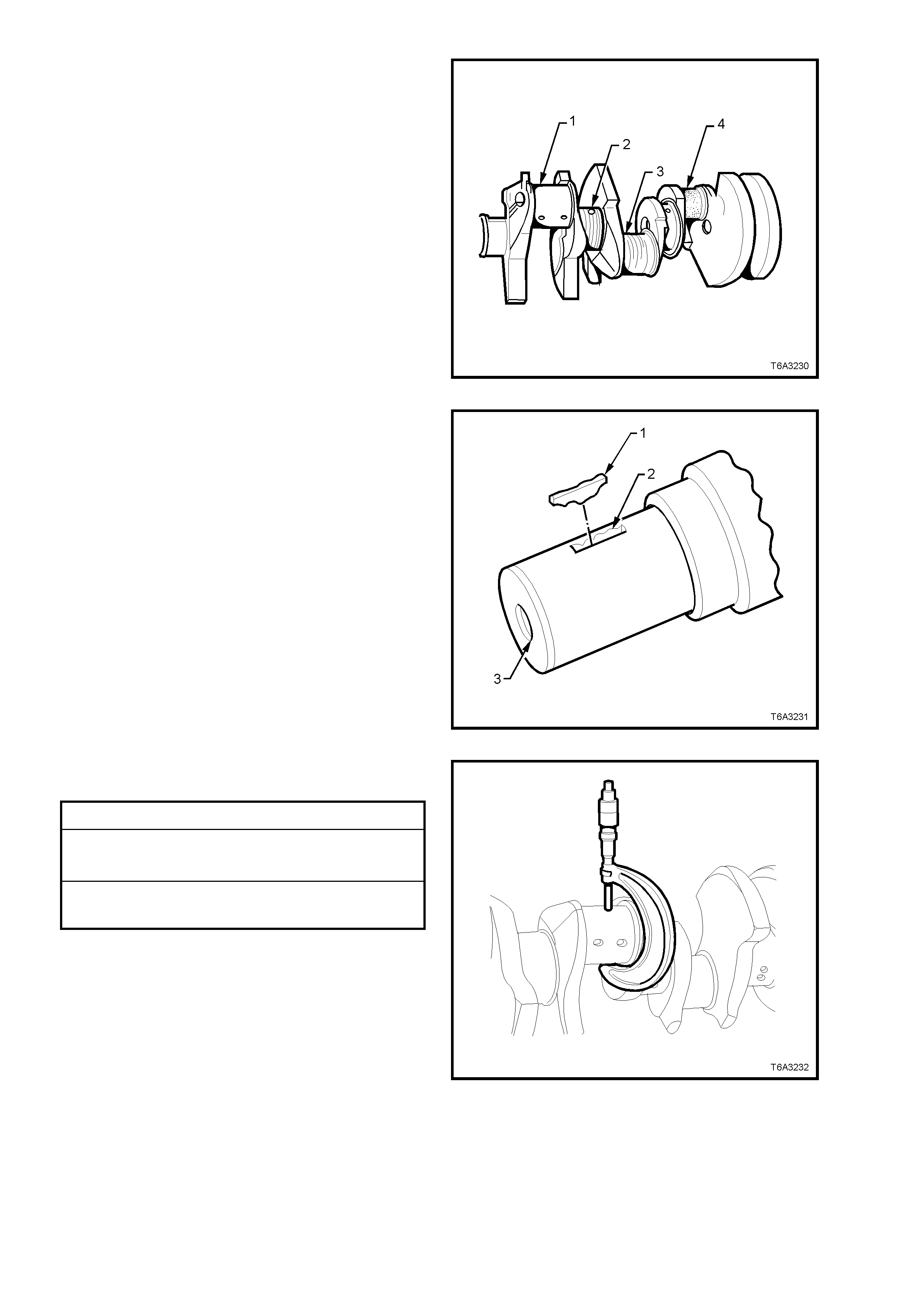

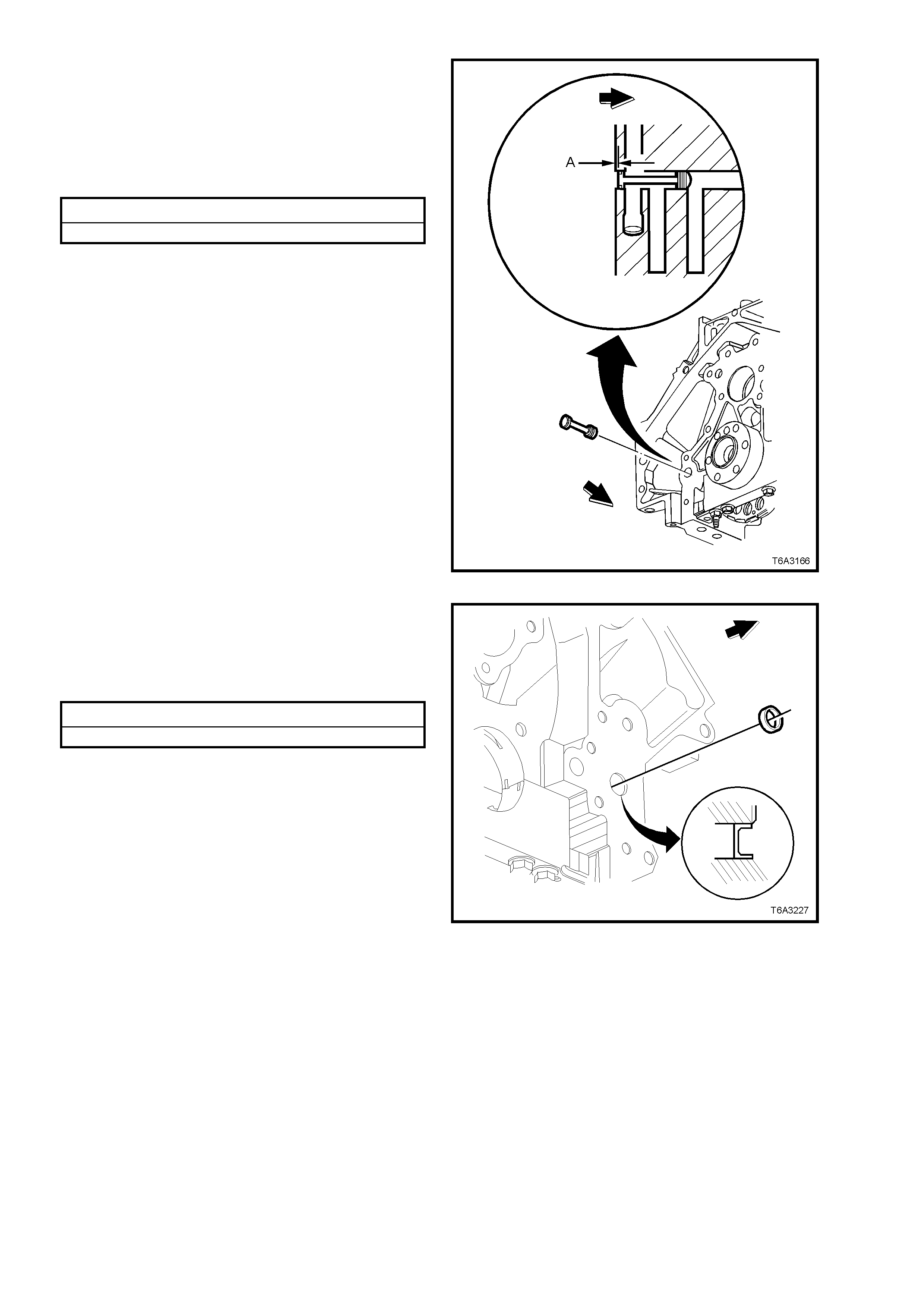

CRANKSHAFT

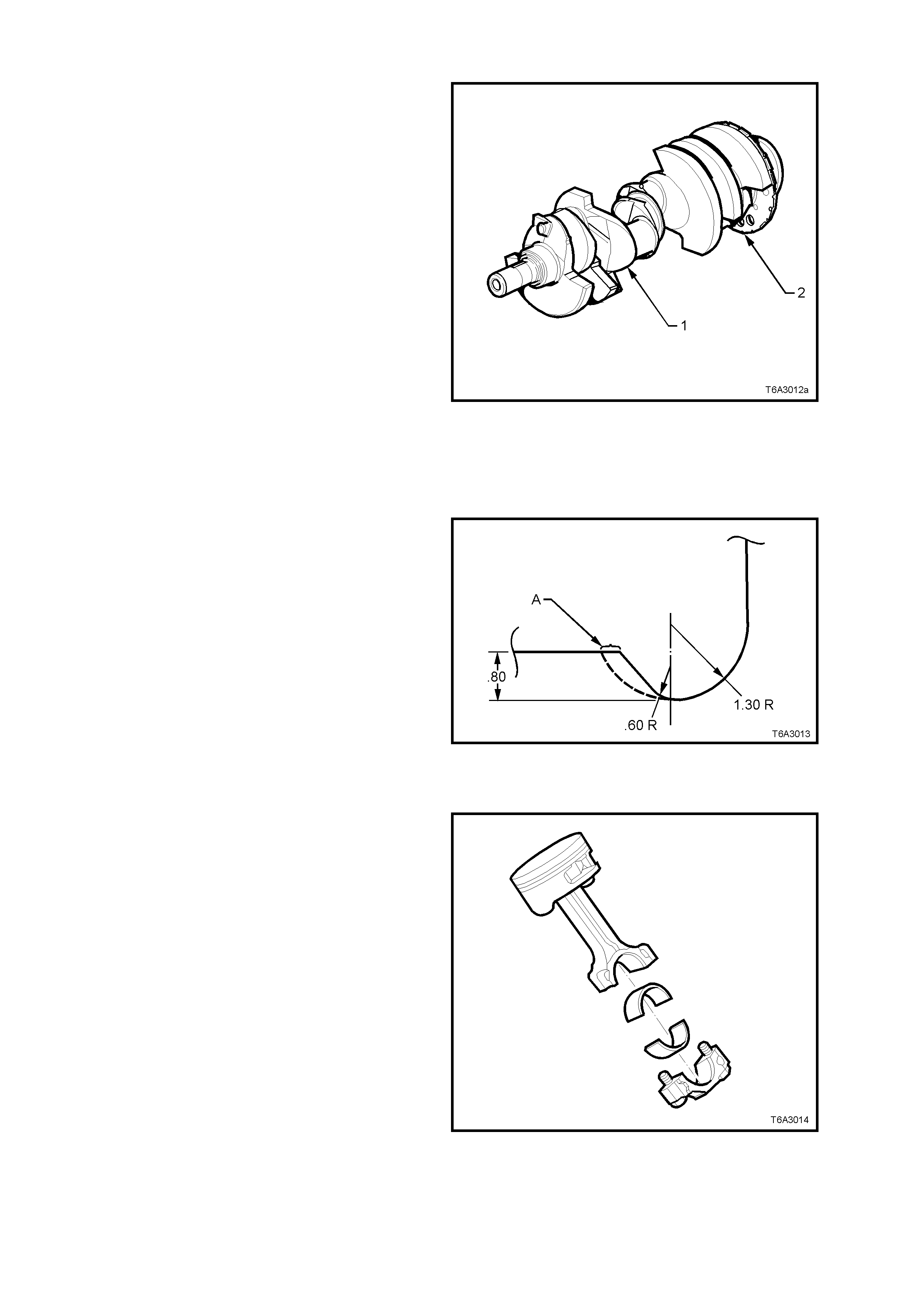

Manufactured from cast nodular iron, the

crankshaft (1) is supported by five crankshaft

bearings and are retained by 6 bolt crankshaft

bearing caps. The main bearing caps are machined

with the engine block for the proper alignment and

clearance.

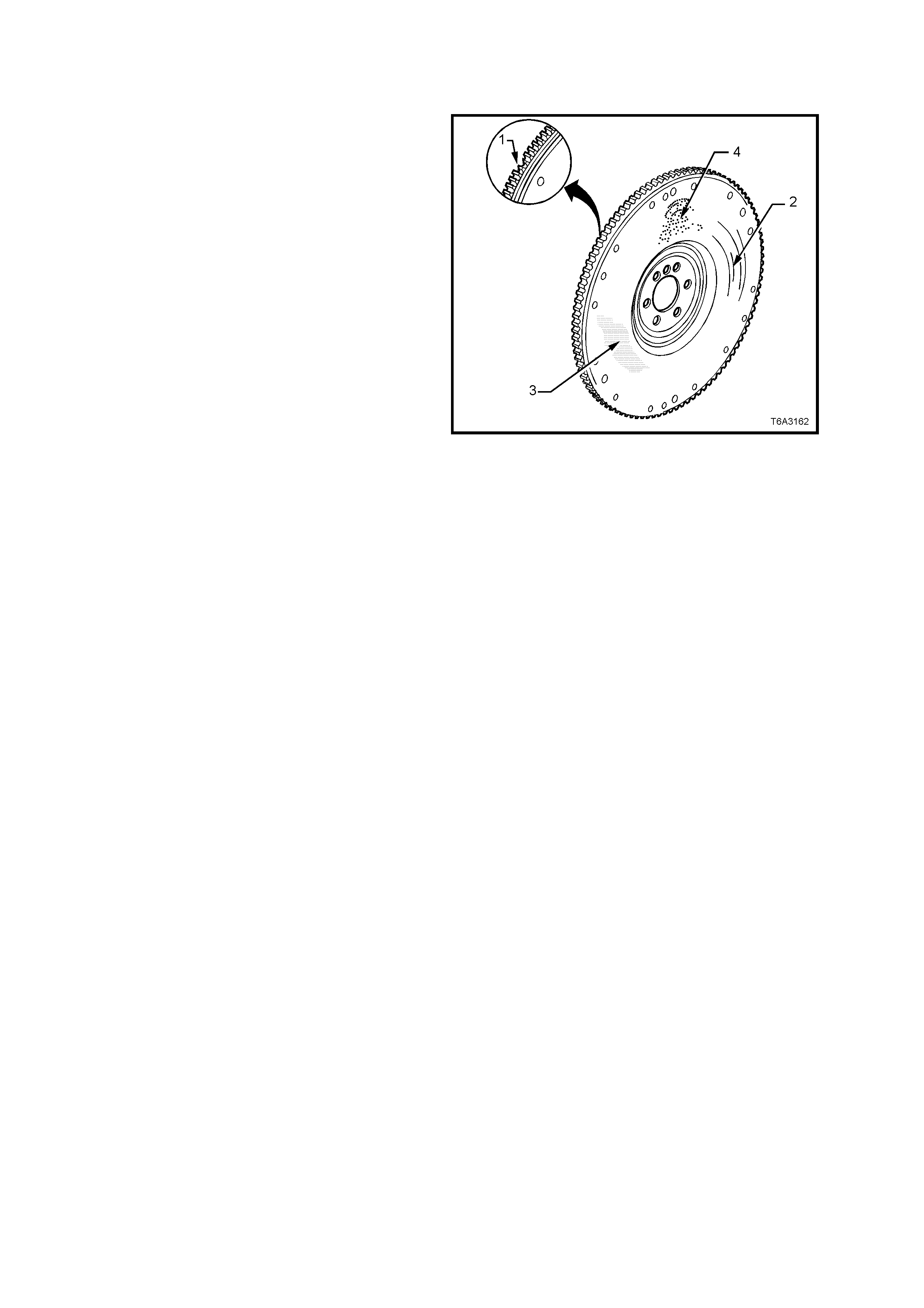

A 24X crankshaft position reluctor ring (2) is

mounted at the r ear of the num ber eight crank shaf t

counter weight. The reluctor ring is not serviced

separately.

Crankshaft thrust is taken by the centre (No. 3)

main bearing. This location is used to reduce the

expansion differences between the cast iron

crankshaft and the aluminium cylinder block.

By adopting a firing order of 1, 8, 7, 2, 6, 5, 4, 3,

crank throw stresses are reduced and main bearing

performance is improved.

The crankshaft has a drilled 25.4 m m hole through

the centre of main journals 2, 3, 4 and 5. Apart

from a reduction in crankshaft weight, this also

achieves engine breathing enhancement at low

speeds.

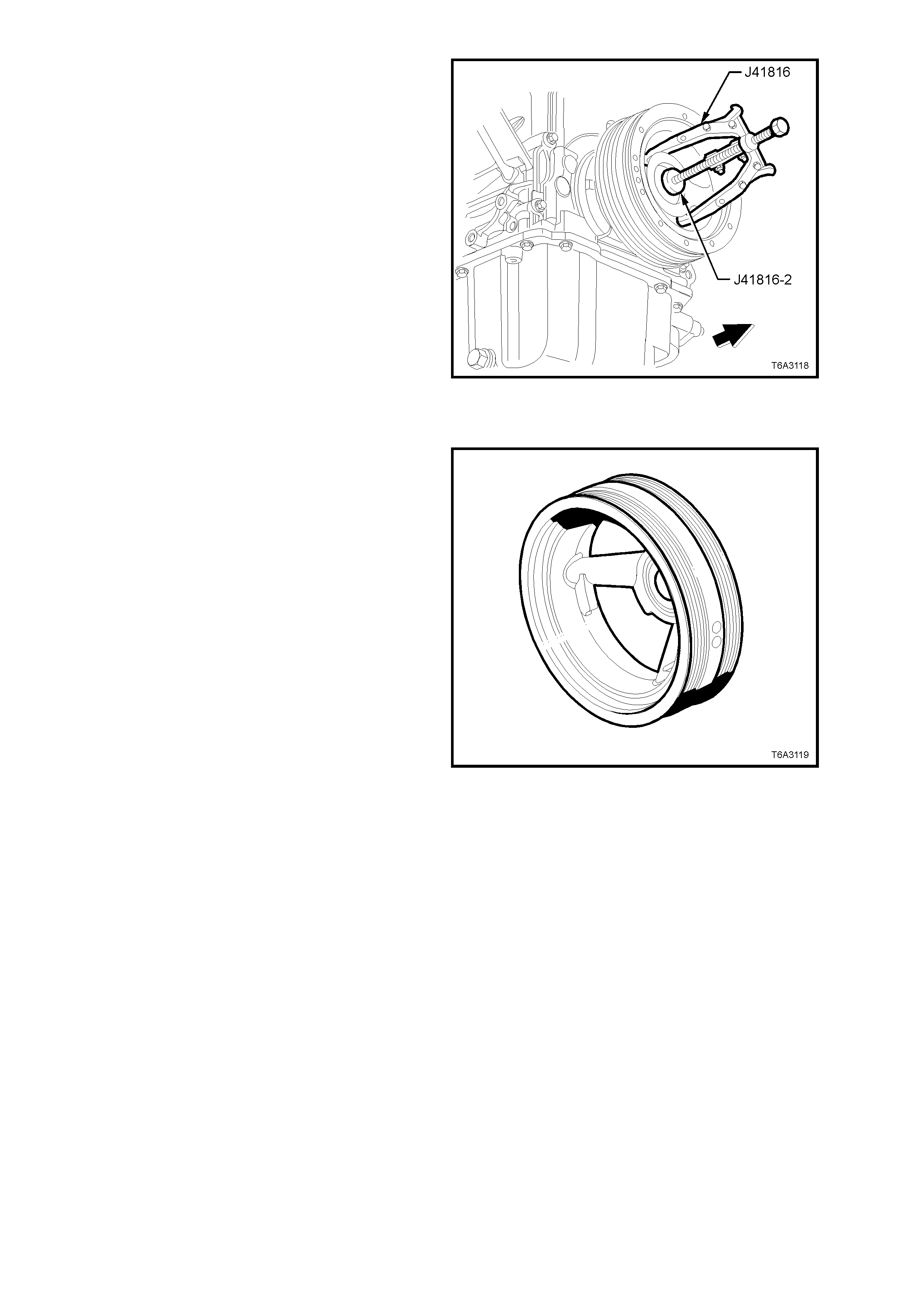

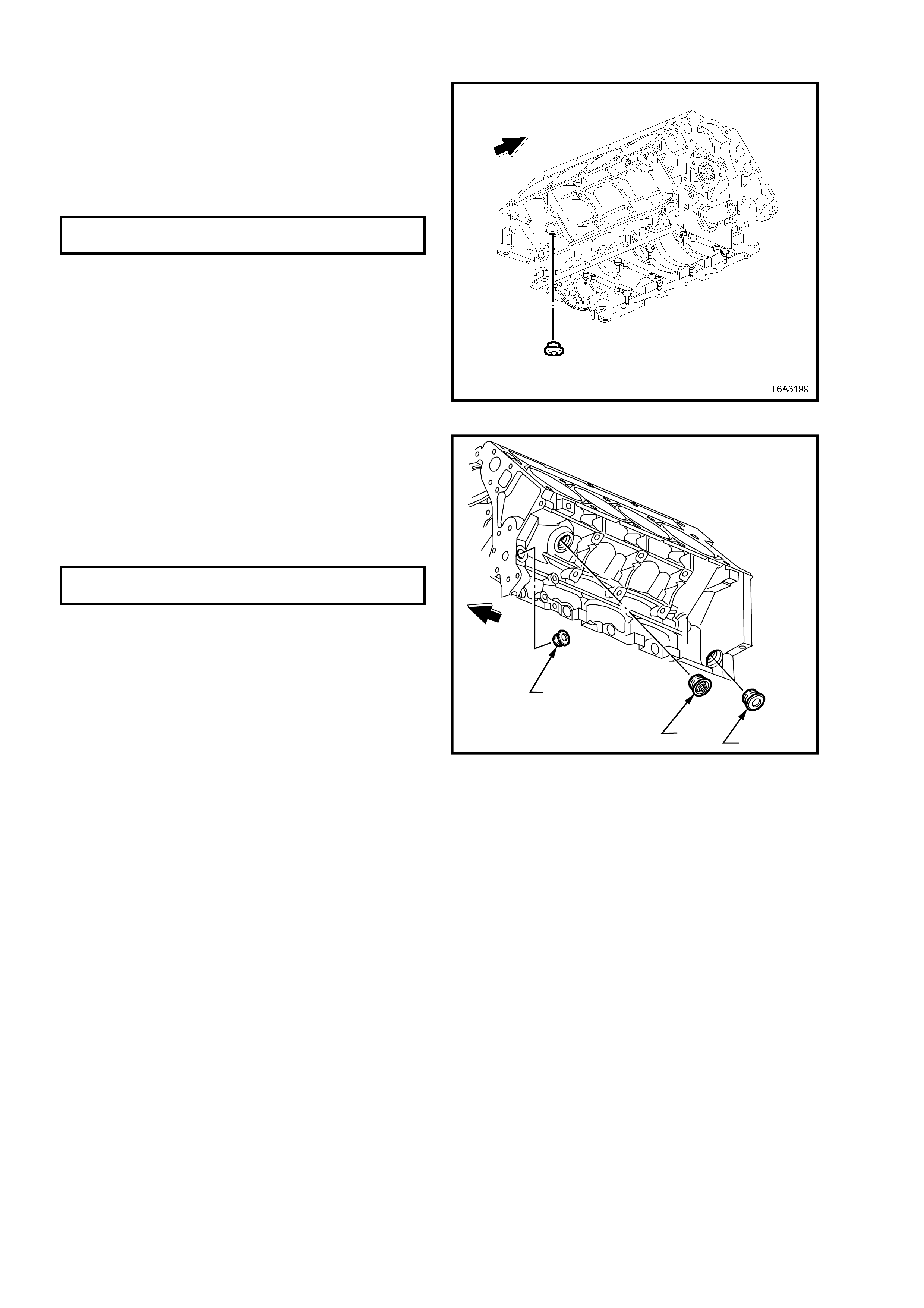

Figure 6A3-12

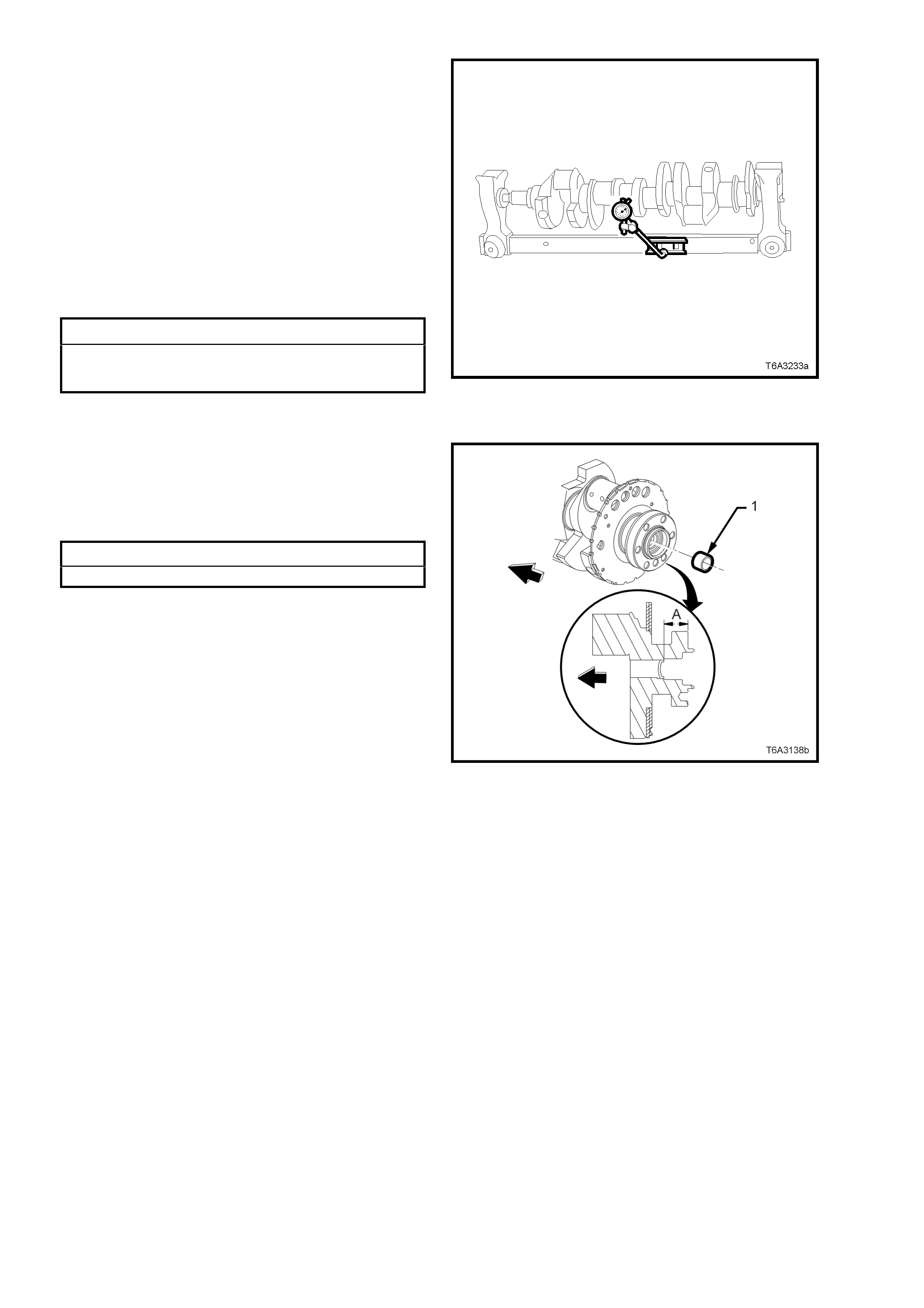

A variable radii undercut increases the effective

bearing widths by 0.4 m m eac h side (A), com pared

to a uniform undercut and rolled fillets are utilised

for improved fatigue strength.

Figure 6A3-13

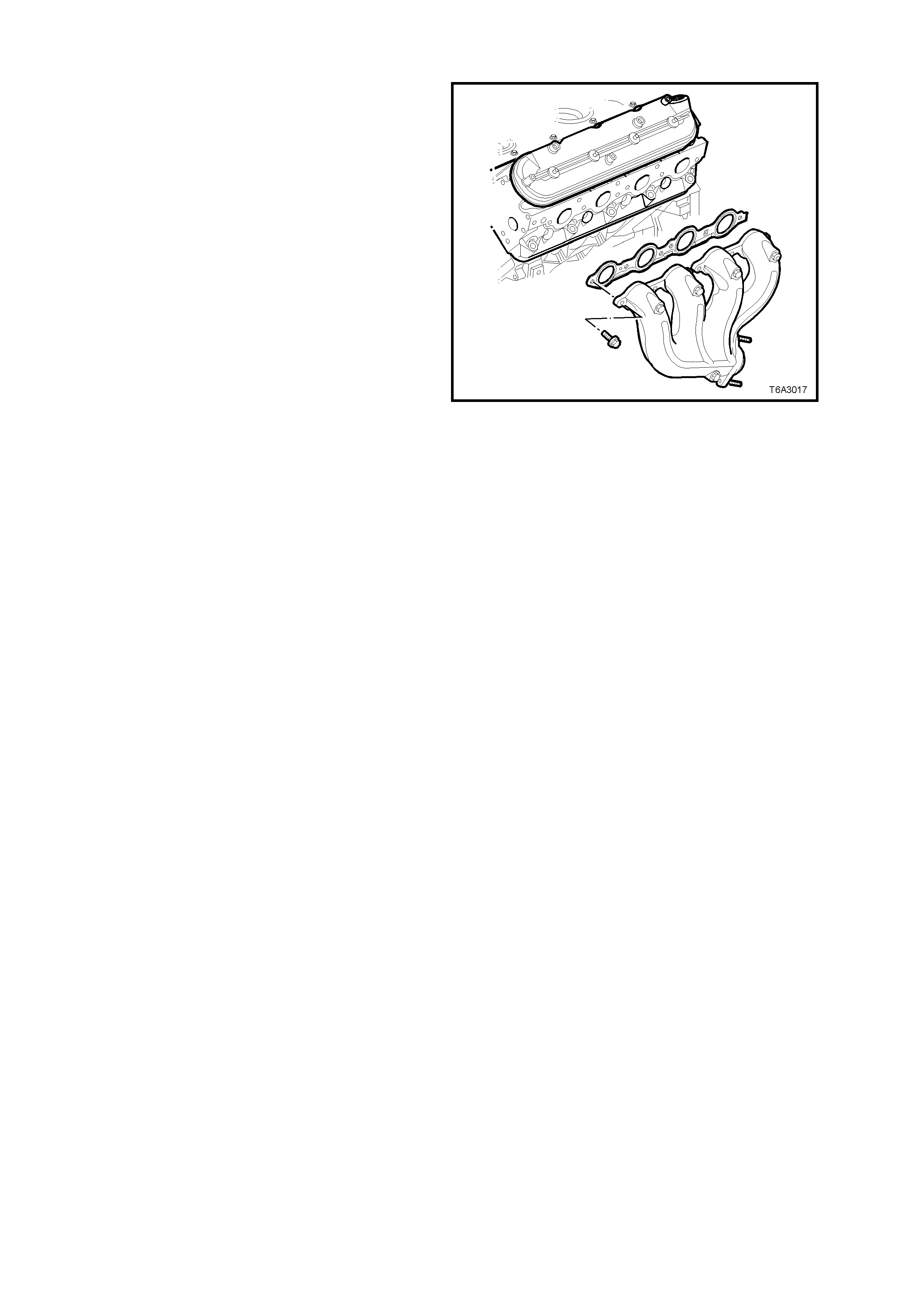

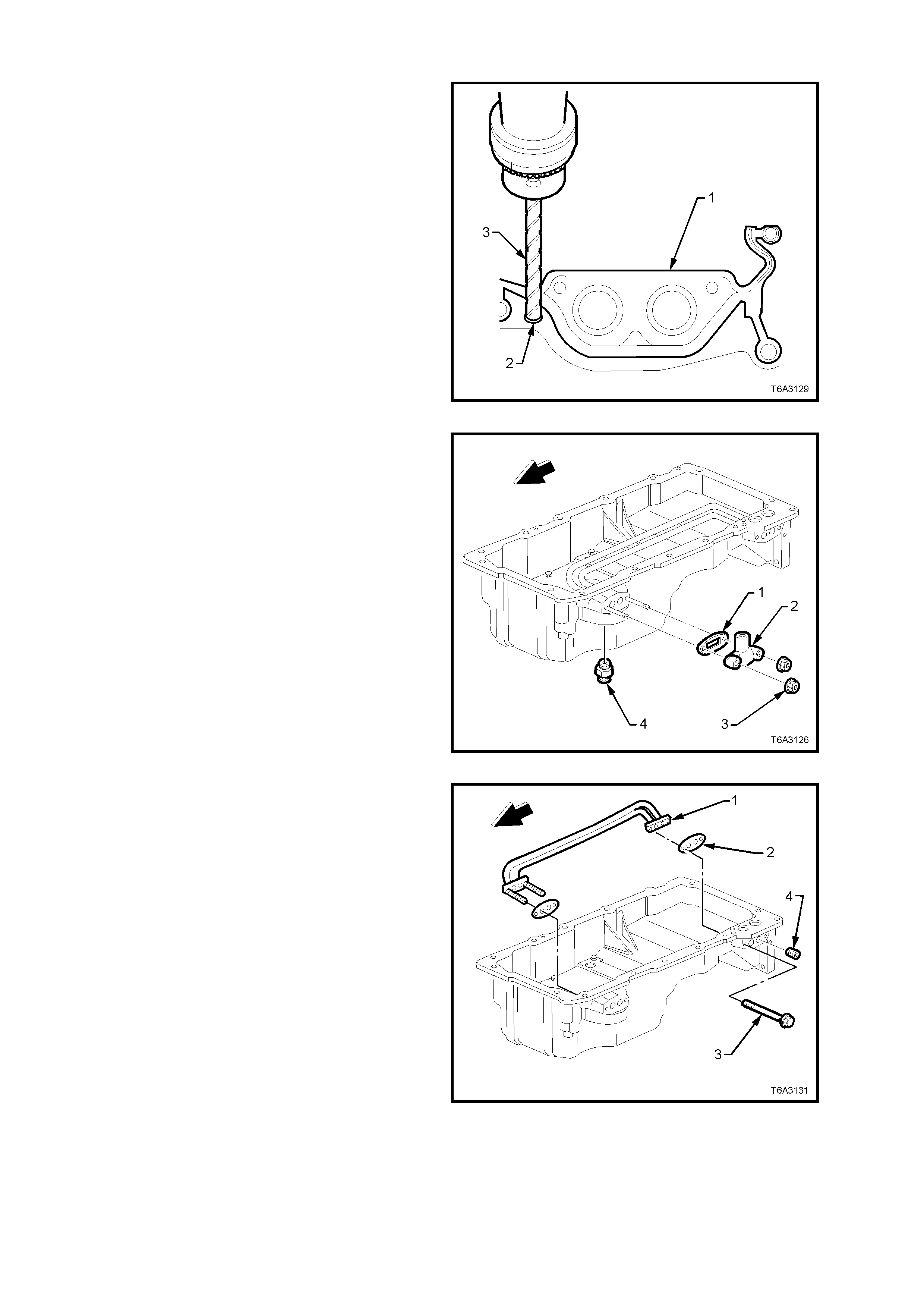

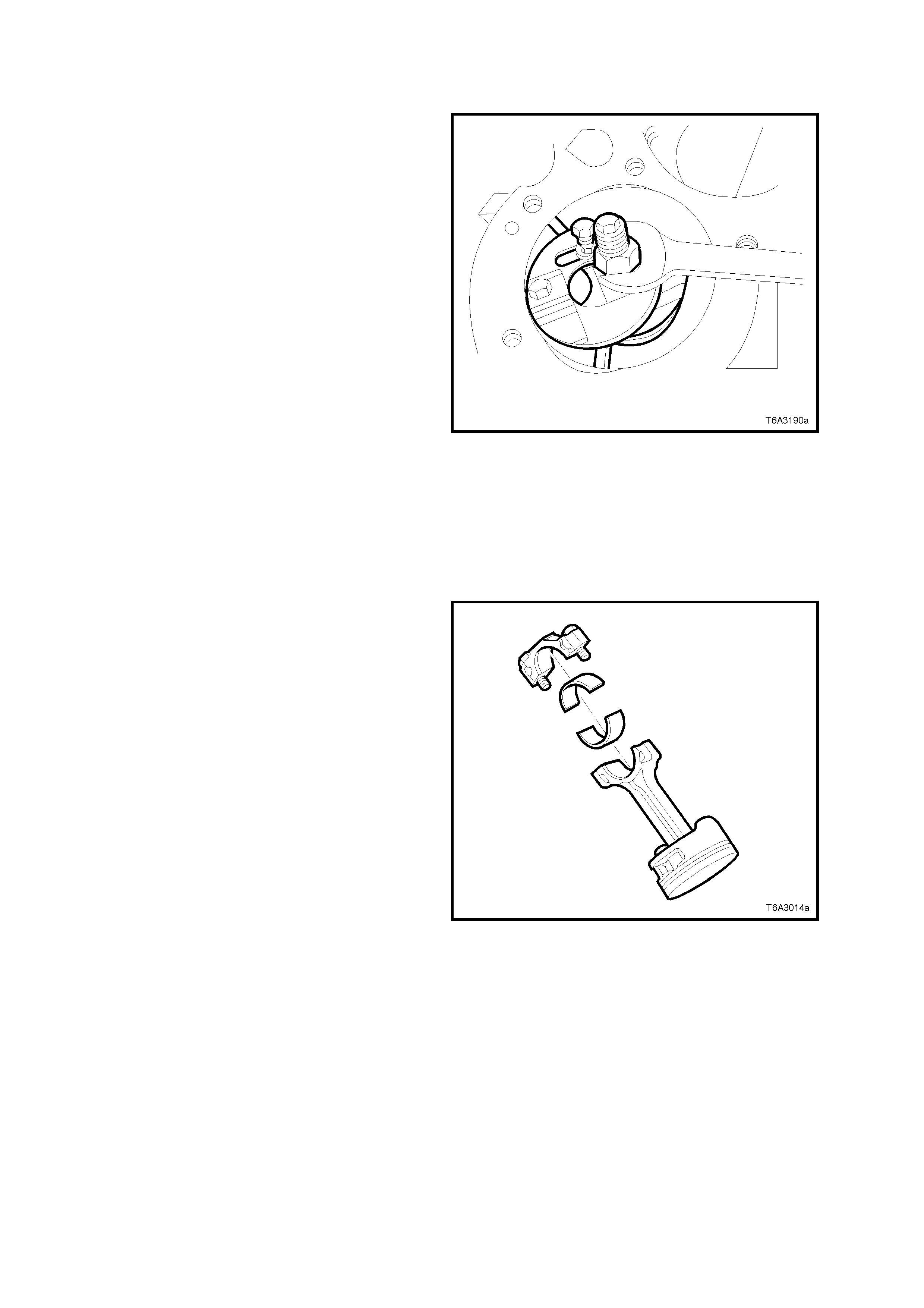

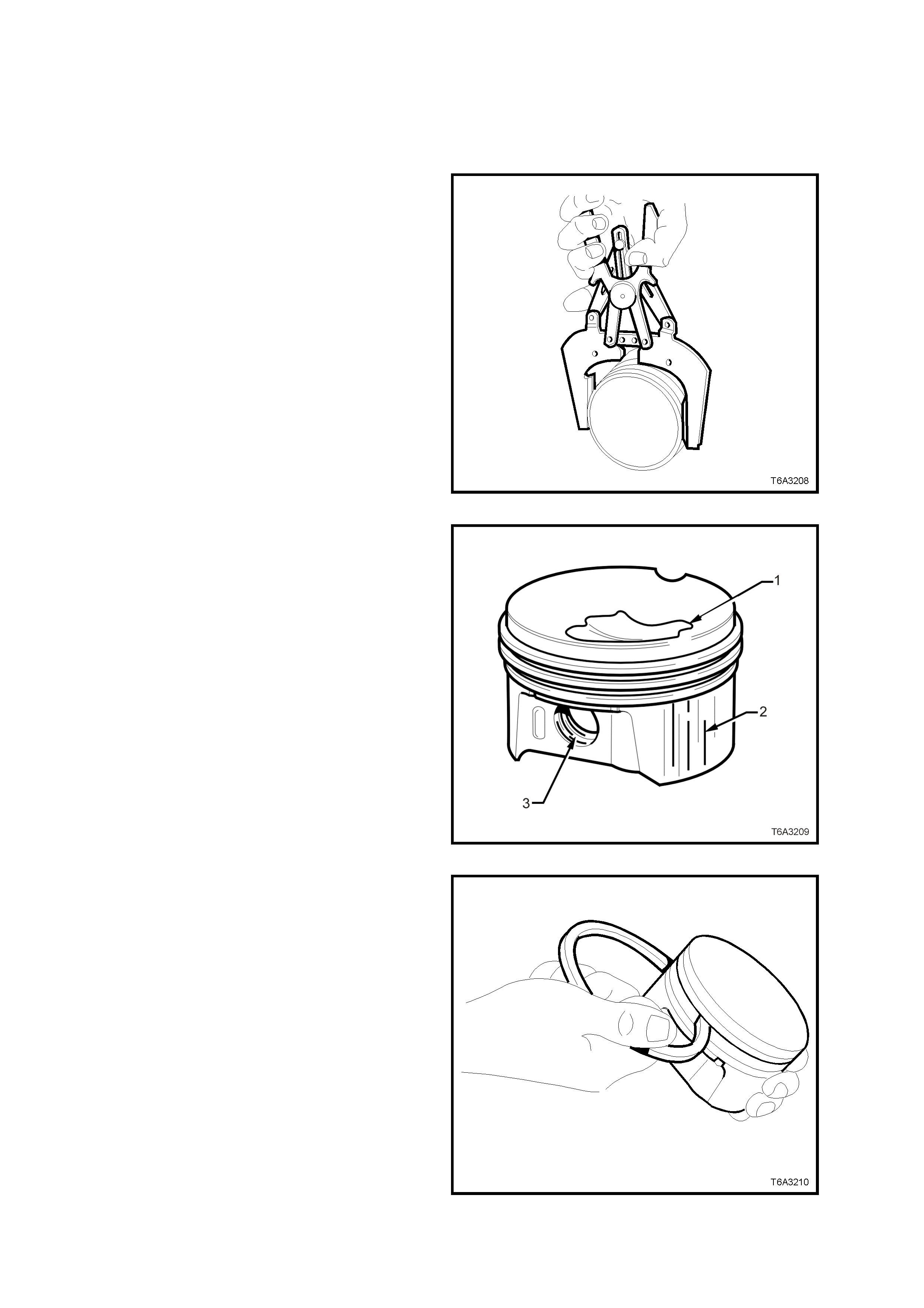

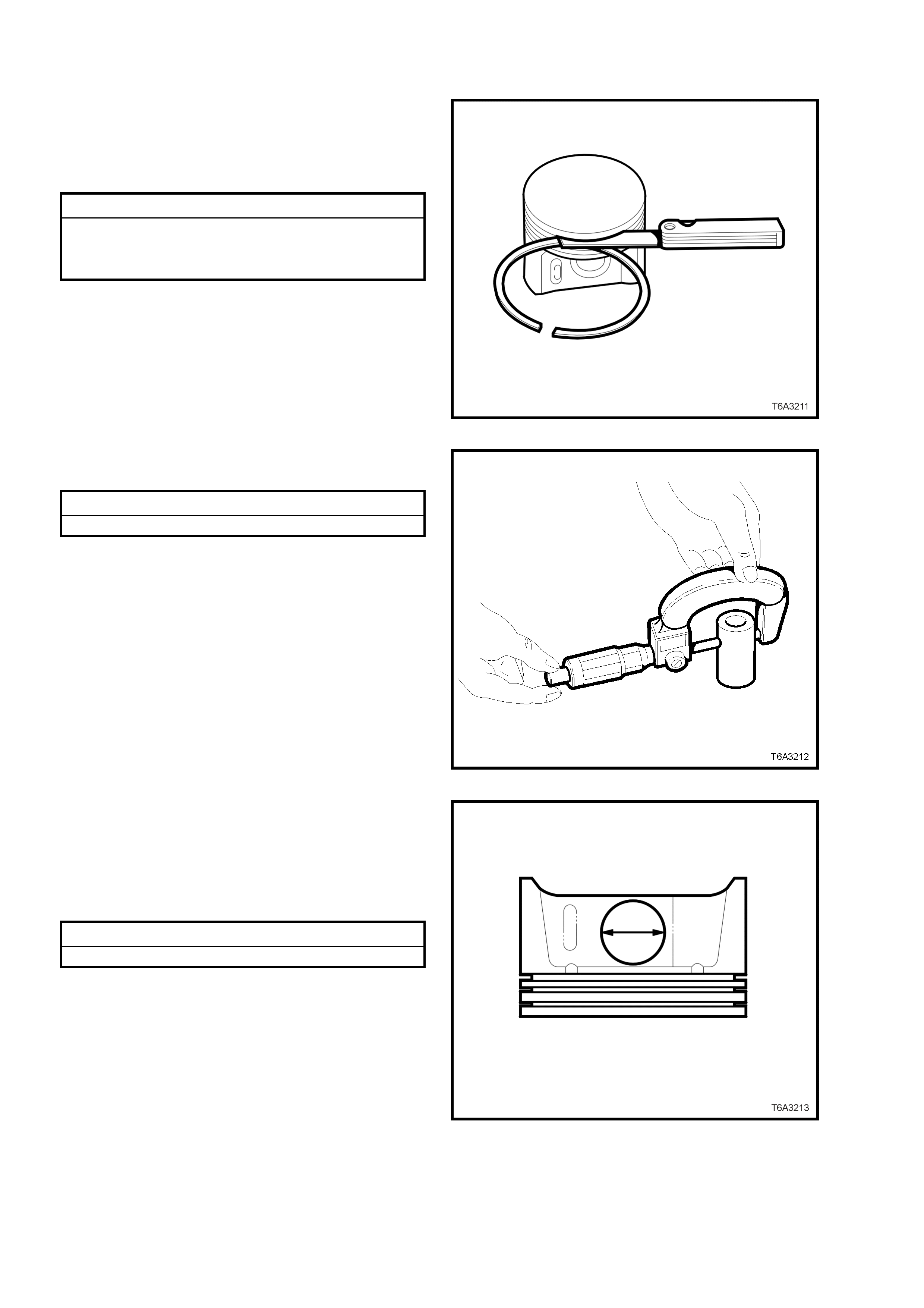

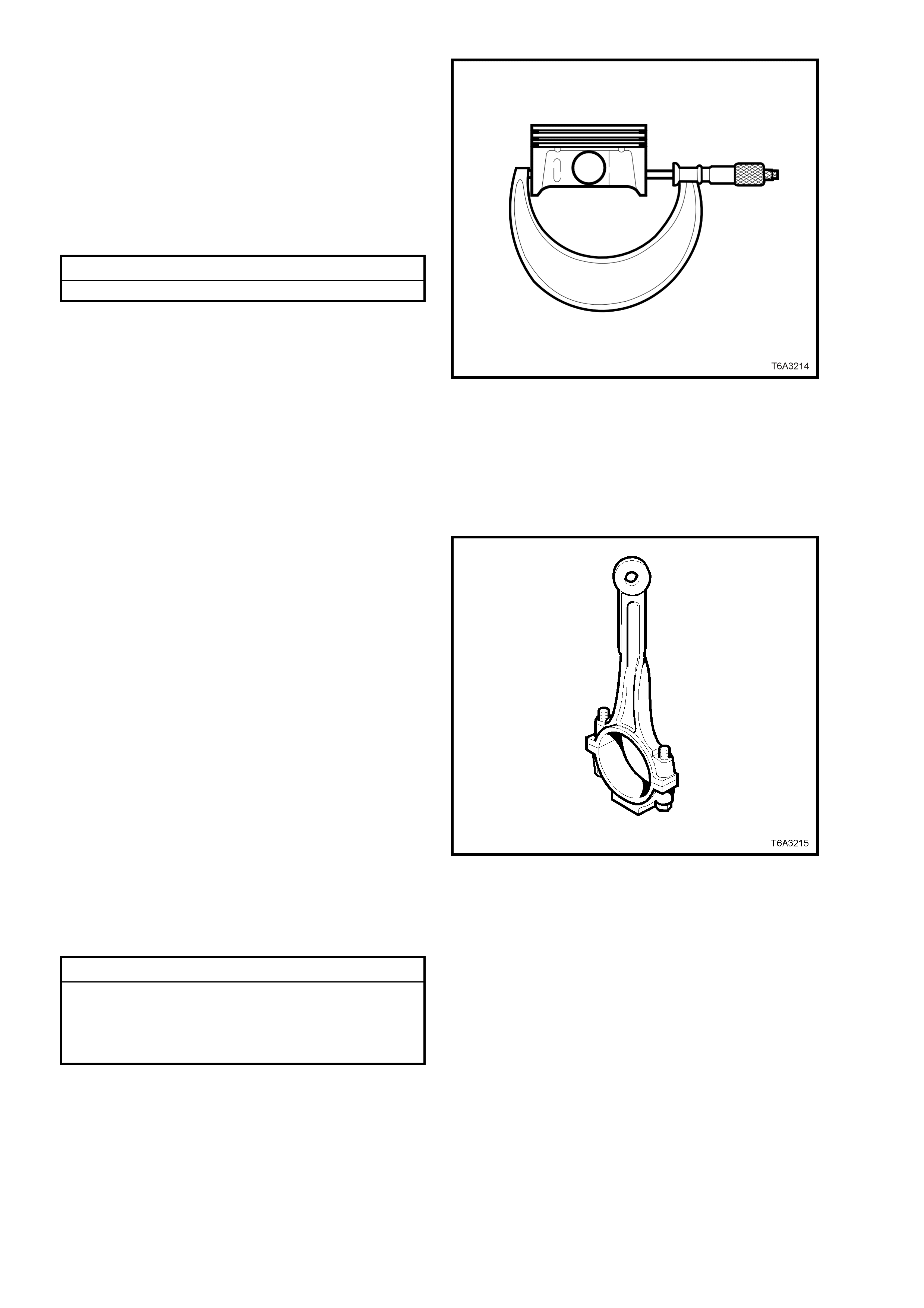

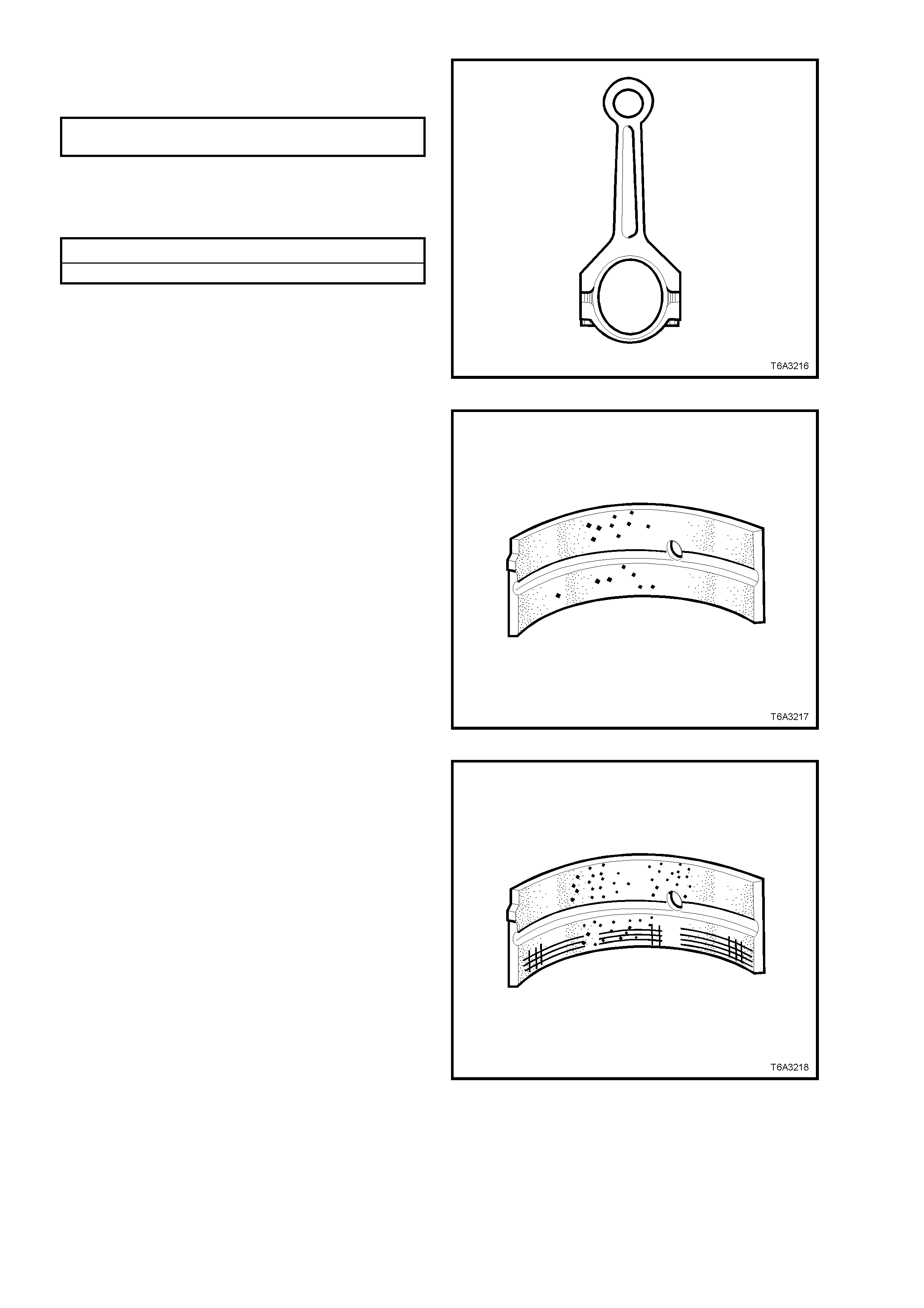

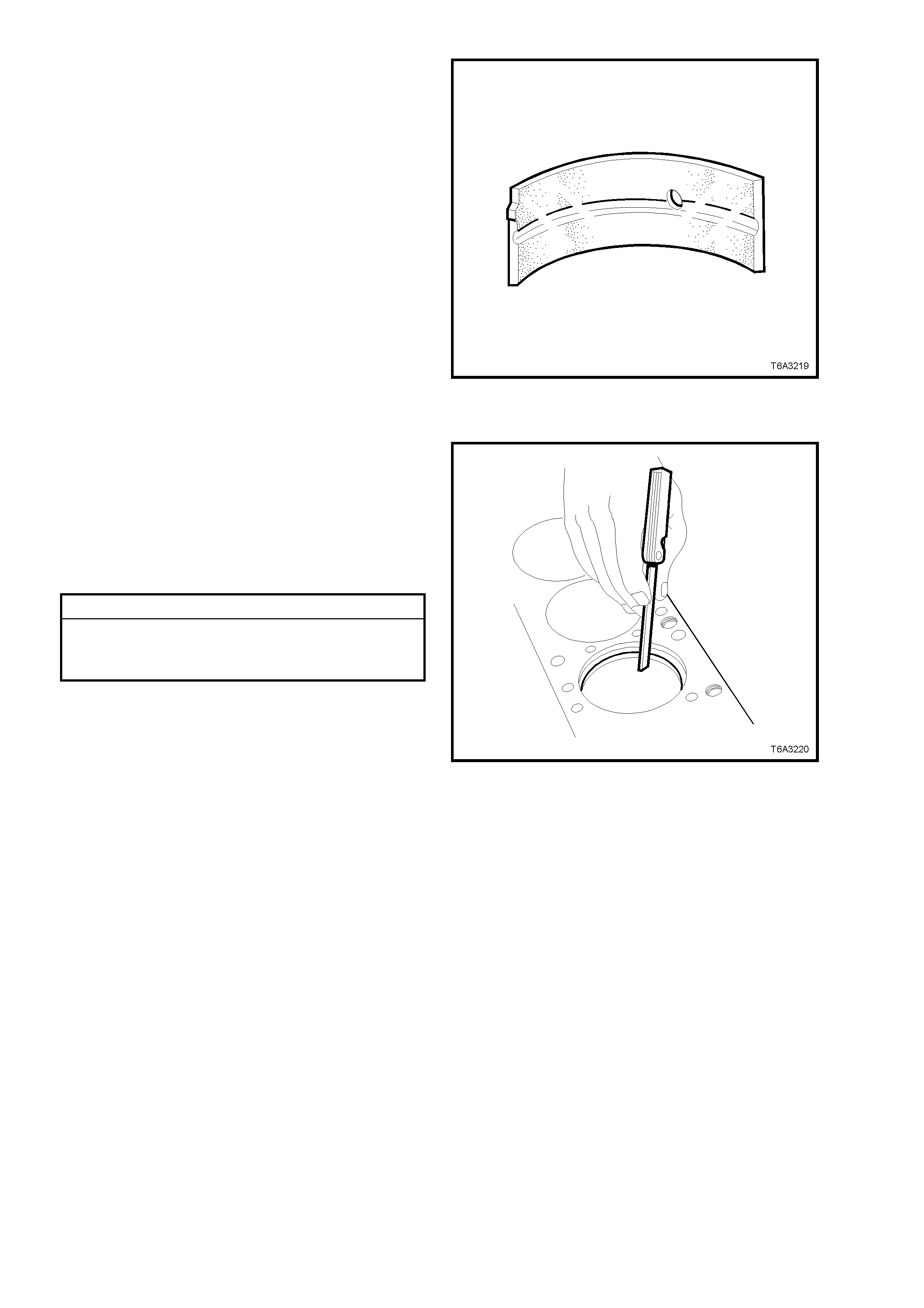

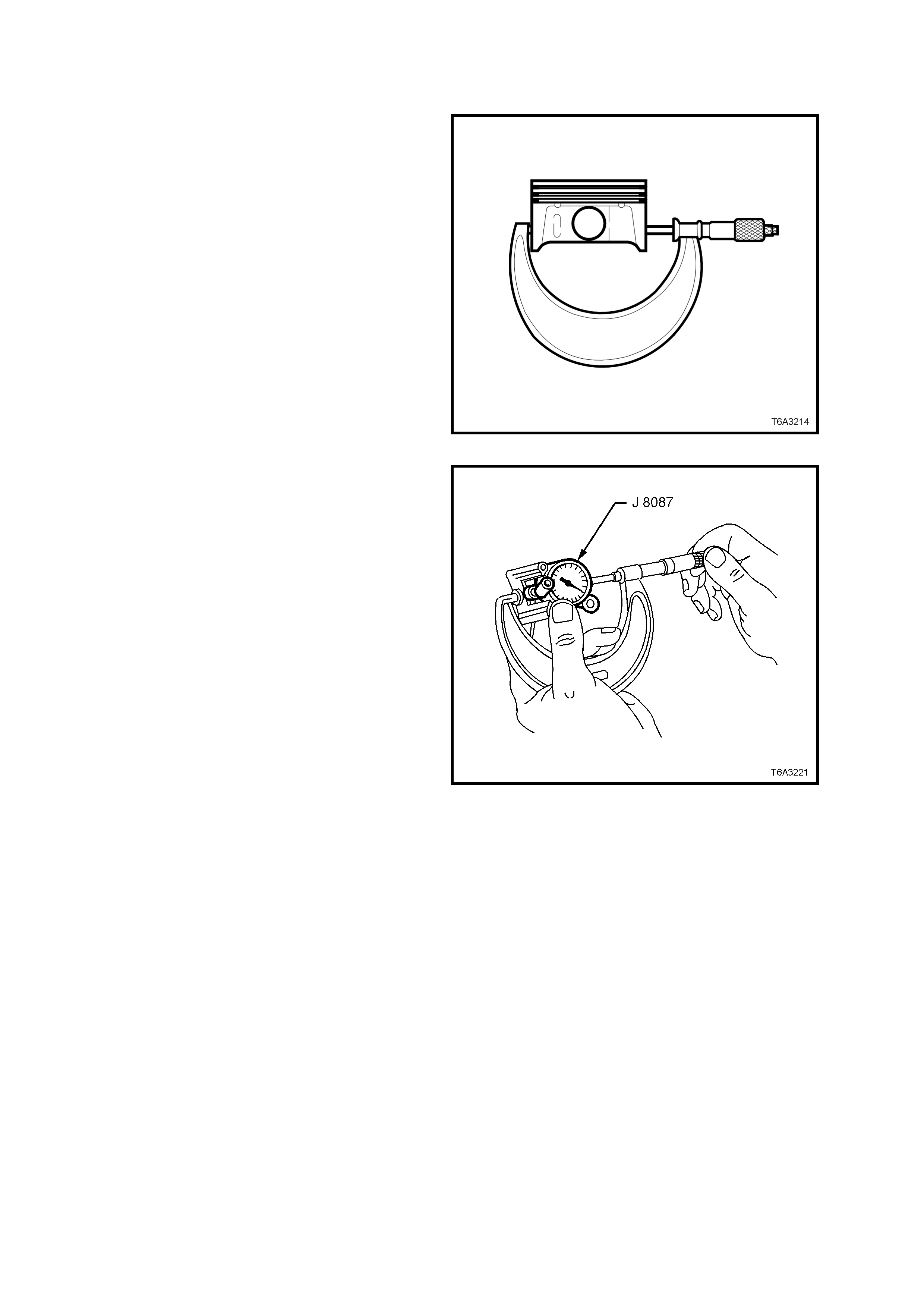

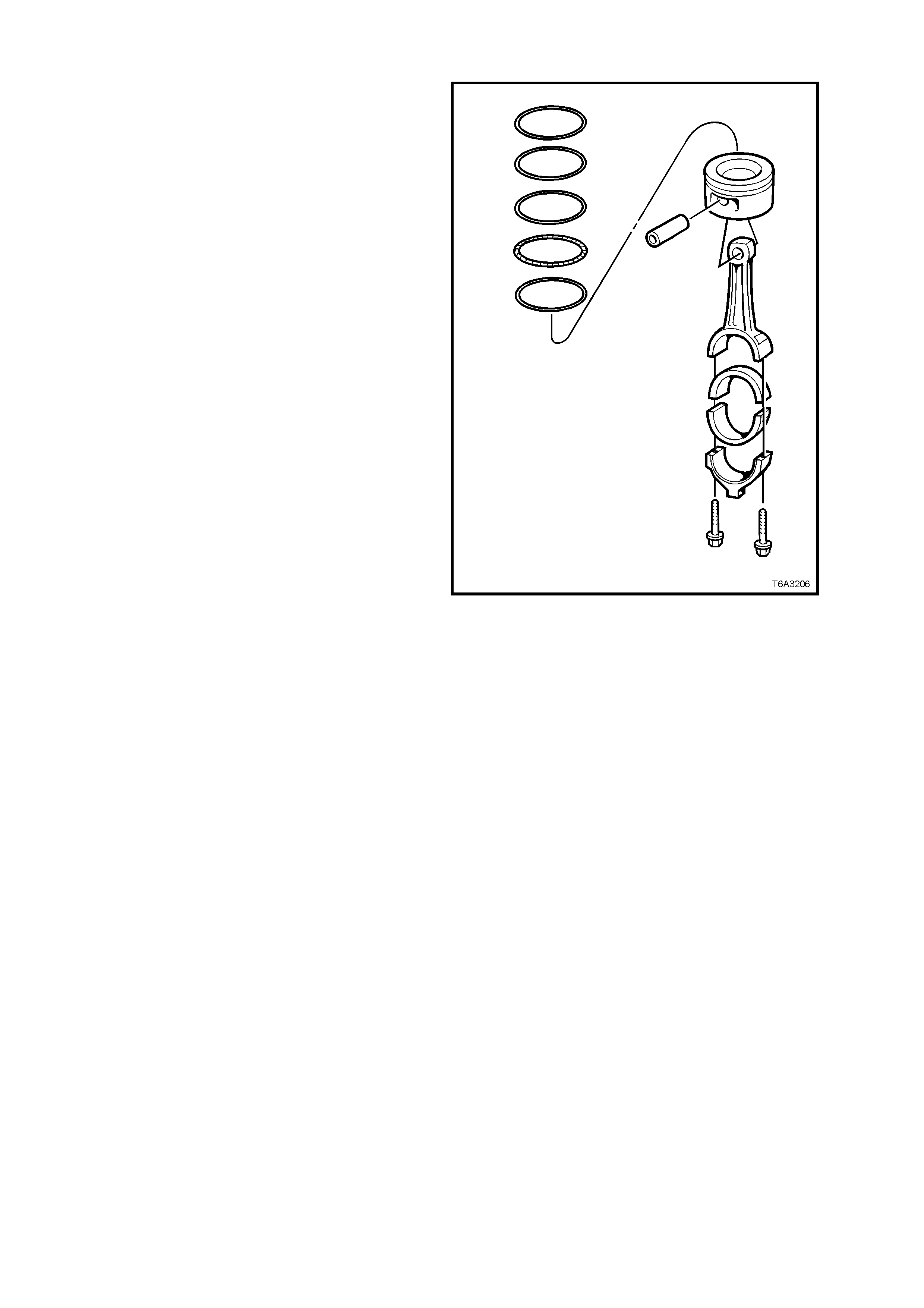

PISTONS AND CONNECTING RODS

The pistons are cast aluminium and have two

compression rings and one oil control ring

assembly fitted. Piston rings are of a thin, low

fric tion design, with the top ring located close to the

top of the piston crown to reduce hydrocarbon

emissions. The piston is a low friction, lightweight

design with a flat top and barrel shaped skirt.

Piston pins are c hr omium steel and ar e a f loating f it

in the piston and a press fit in the connecting rod.

The connecting rods are forged powdered metal.

The connecting rod cap is separated during the

manufactur ing proc ess , us ing the ‘f r act ure’ method.

This creates a stronger, visually seamless rod to

cap union. The reassembled rod is then machined

for the proper clearance.

A 0.25 mm oversize piston and piston ring set are

available for service, should cylinder honing be

required. Figure 6A3-14

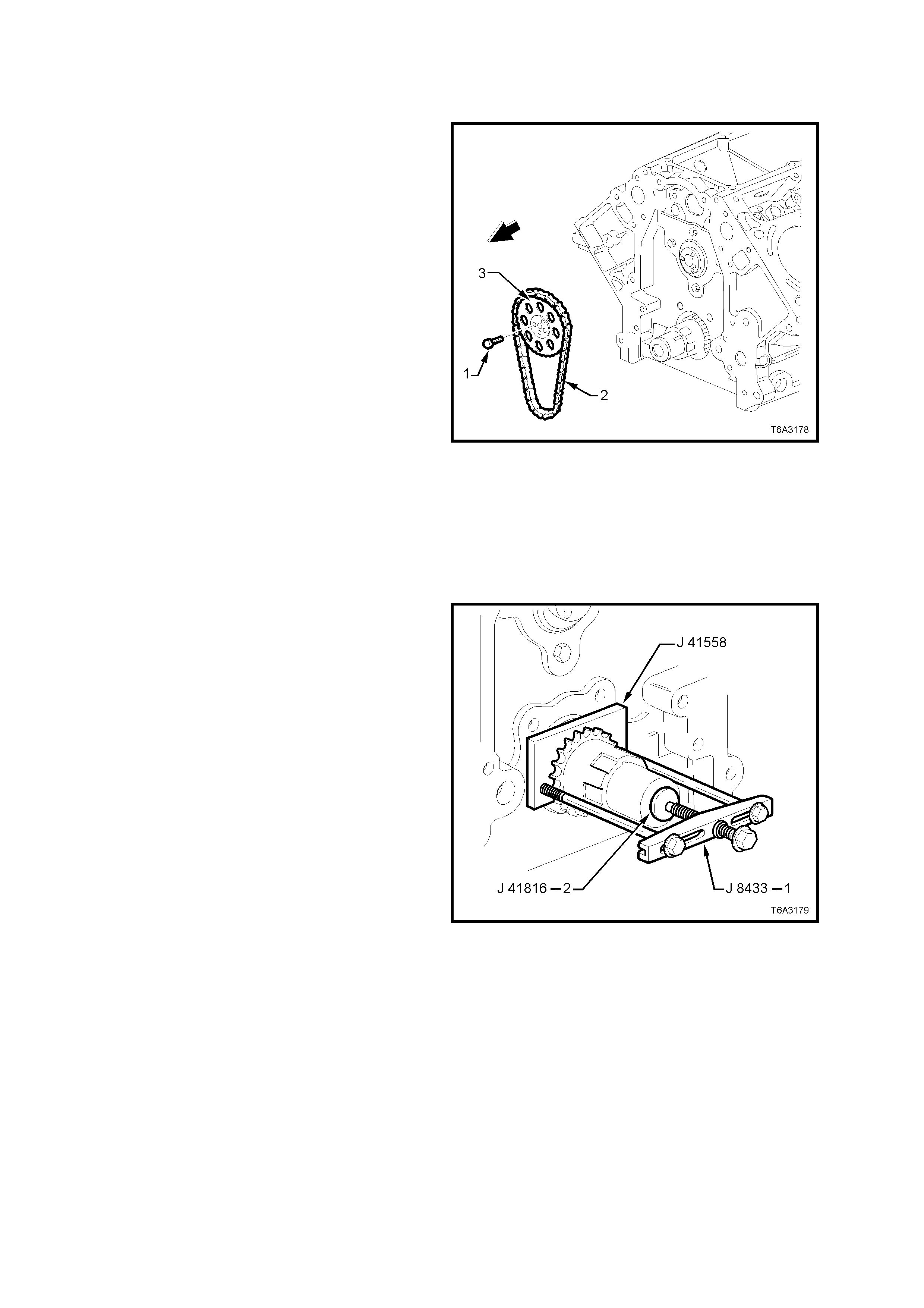

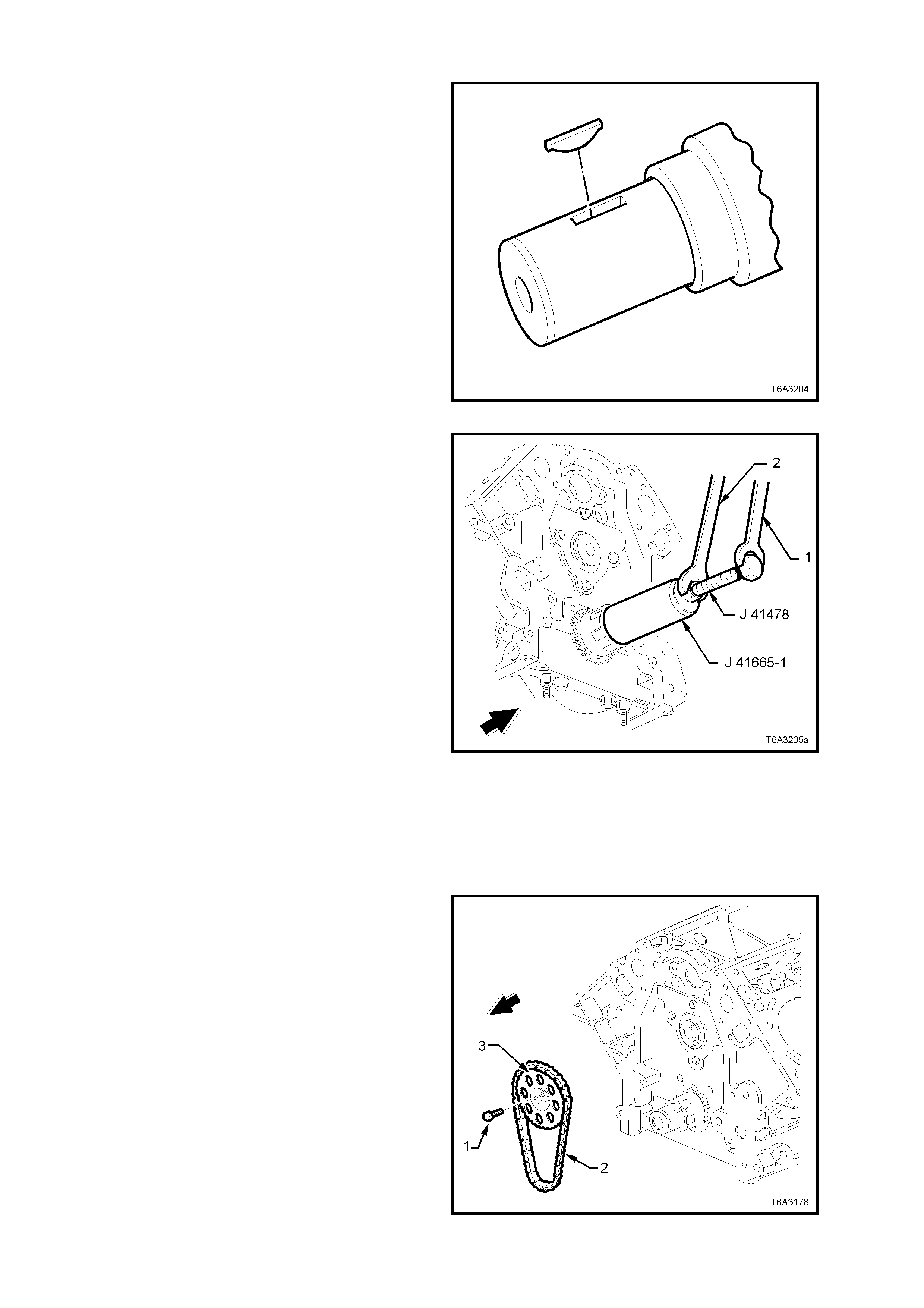

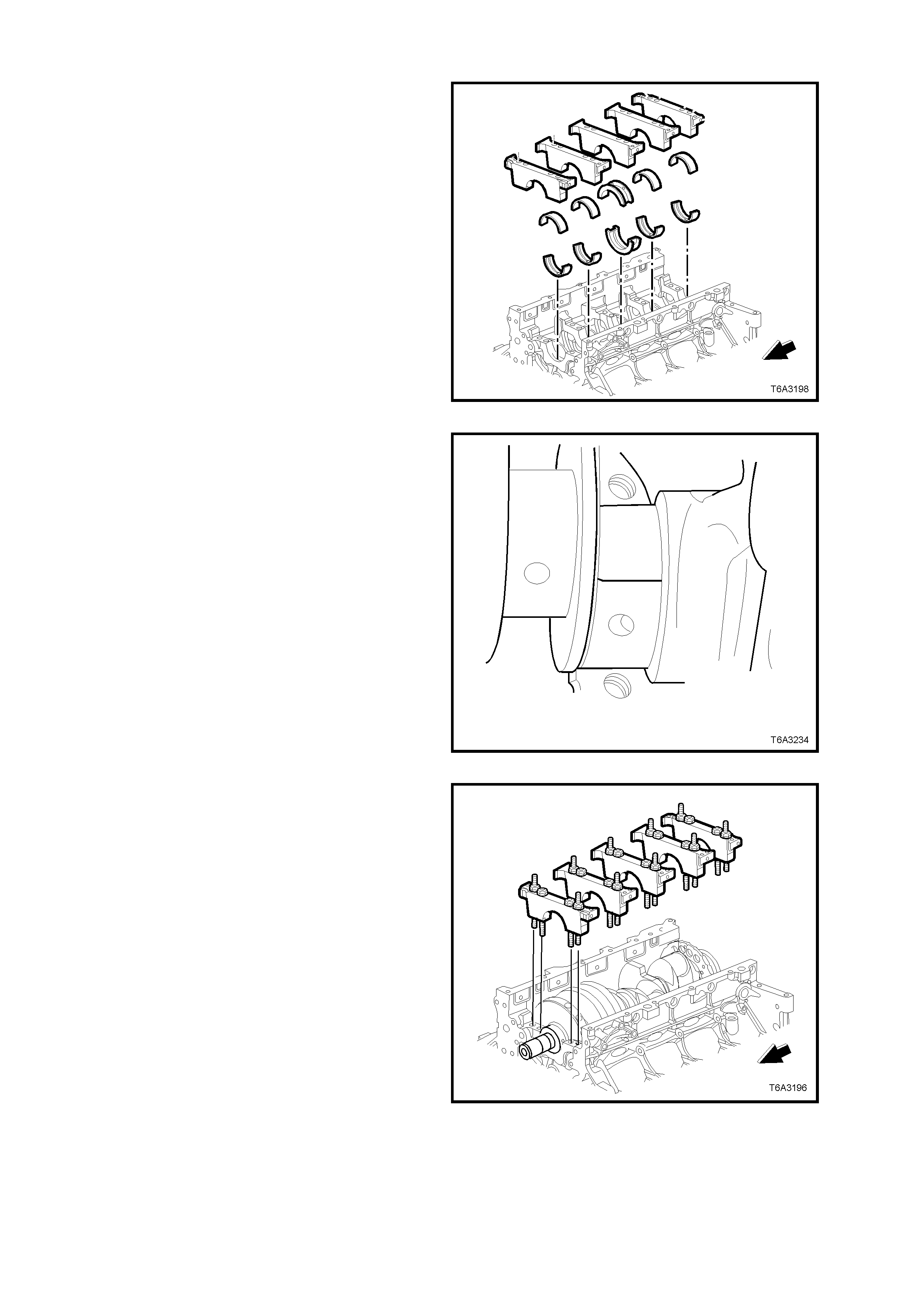

CAMSHAFT AND DRIVE

A billet steel, one piece camshaft is supported by

five bearings pressed into the engine block. The

cam s haf t has a machined c amshaft sens or r eluctor

ring incorporated between the fourth and fifth

bearing journals. To reduce vale train noise, both

the intake and exhaust cam lobes have slow

closing velocity ramps.

To reduc e weight, the cam shaft has a 17 m m gun-

drilled hole down its length.

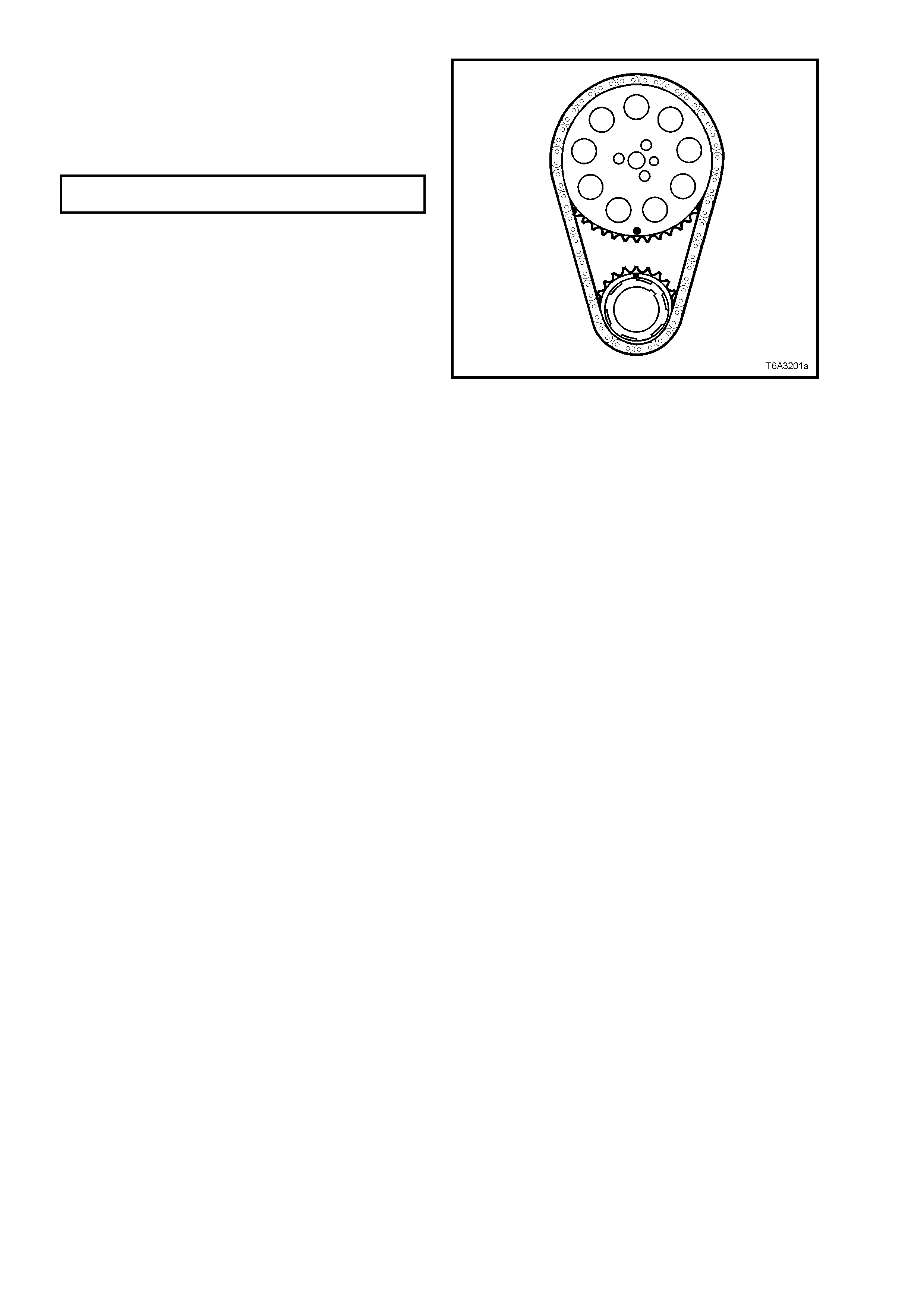

The c amshaf t (1) is driven by a traditional 9.52 m m

pitch roller chain (2) and powdered metal timing

sprockets mounted to the front of the camshaft (3)

and crankshaft (4). The crankshaft sprocket (4) is

splined and drives the oil pump driven gear. A

retaining plate (5) mounted to the front of the

engine block maintains the camshaft location. No

chain tensioner is required.

Figure 6A3-15

INTAKE MANIFOLD

The intake manifold (1) is a one piece composite

design that incorporates metal threaded inserts for

mounting the fuel rail (2), throttle cable bracket, and

throttle body.

The intak e manif old is sealed to the c ylinder heads

by eight separate non-reusable silicone sealing

gaskets which press into the grooves of the intake

housing.

The cable-actuated throttle body assembly bolts to

the front of the intake manifold (A). The throttle

body is sealed to the intake manifold by a one

piece, push-in-place silicone gasket.

The fuel rail assembly (2) with eight separate fuel

injectors (3) is retained to the intake manifold by

four bolts (4). The injectors are seated in their

individual manifold bores with O-ring seals to

provide sealing. The fuel pressure regulator (5) is

incorporated into the fuel rail design. A fuel rail

stop bracket is retained at the rear of the left fuel

rail by the intake manifold mounting bolts (not

shown).

The Manifold Absolute Pressure (MAP) sensor is

installed in the snap fit MAP sensor housing that is

mounted at the rear of the manifold and sealed by

an O-ring seal (not shown).

There are no coolant passages within the intake

manifold.

Figure 6A3-16

EXHAUST MANIFOLD

The exhaust manifolds are one piece, of high

temperature silicone molybdenum cast iron and

direct exhaust gases from the combustion

chambers to the exhaust system.

Each m anifold also has an externally mounted dual

wall heat shield attached, that is made of

aluminiumised steel.

Figure 6A3-17

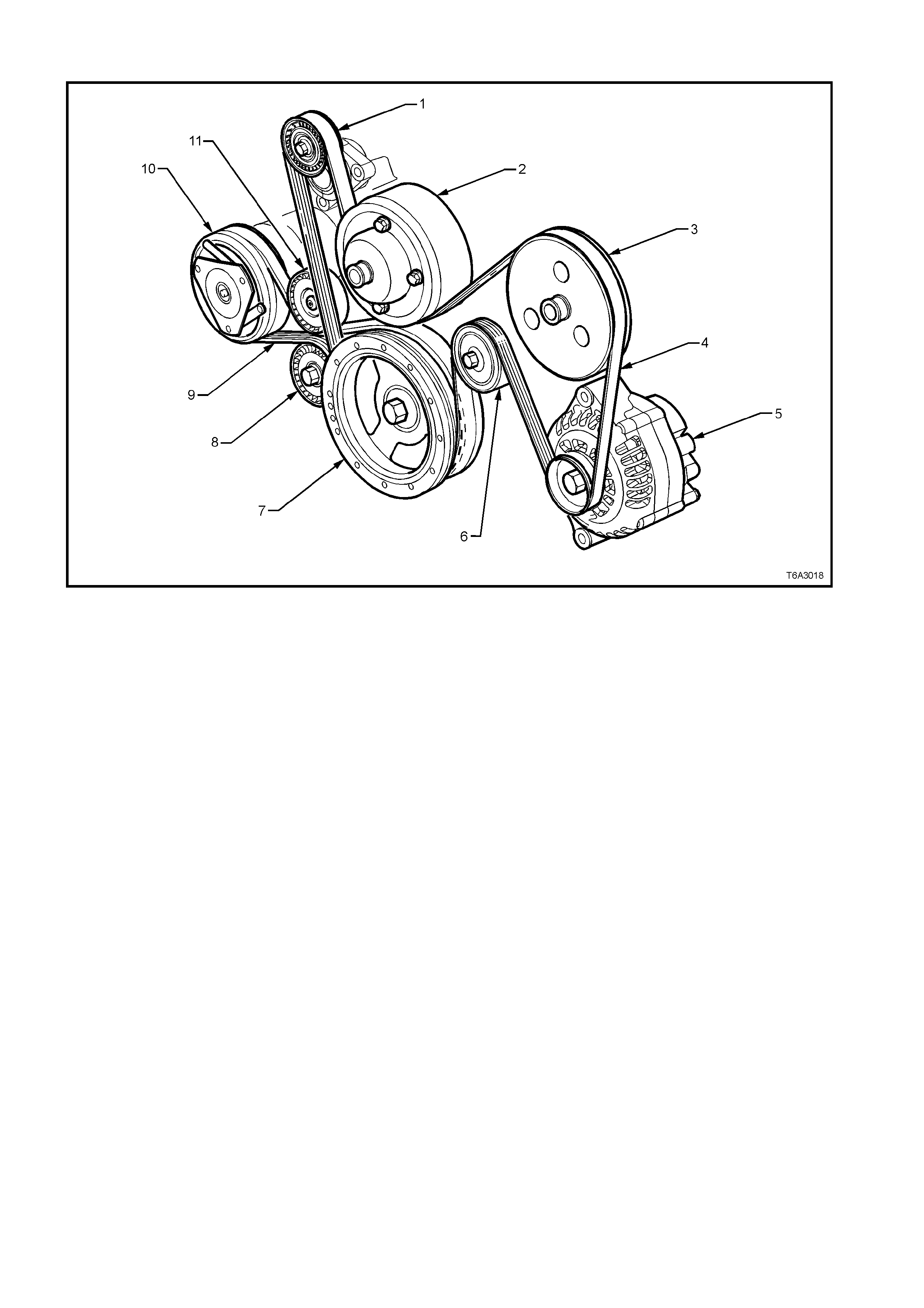

ACCESSORY DRIVE

The engine accessory drive consists of dual

serpentine belts, that decouple the generator and

air conditioning compressor for improved noise

isolation. Using dual belts also provides design

flexibility to optimise structural stiffness of support

brackets.

The system includes two automatic belt tensioners

with a low static tension for increased belt and

bearing life.

Figure 6A3-18

Legend

1. Accessory Drive Belt, Automatic Tensioner 7. Crankshaft Balancer Pulley

2. Water Pump Pulley 8. Air Conditioning Compressor Drive Belt Automatic Tensioner

3. Power Steering Pump Pulley 9. Air Conditioning Compressor Drive Belt

4. Engine Accessory Drive Belt 10. Air Conditioning Compressor

5. A.C. Generator 11. Air Conditioning Compressor Drive Belt, Idler Pulley

6. Accessory Drive Belt, Idler Pulley

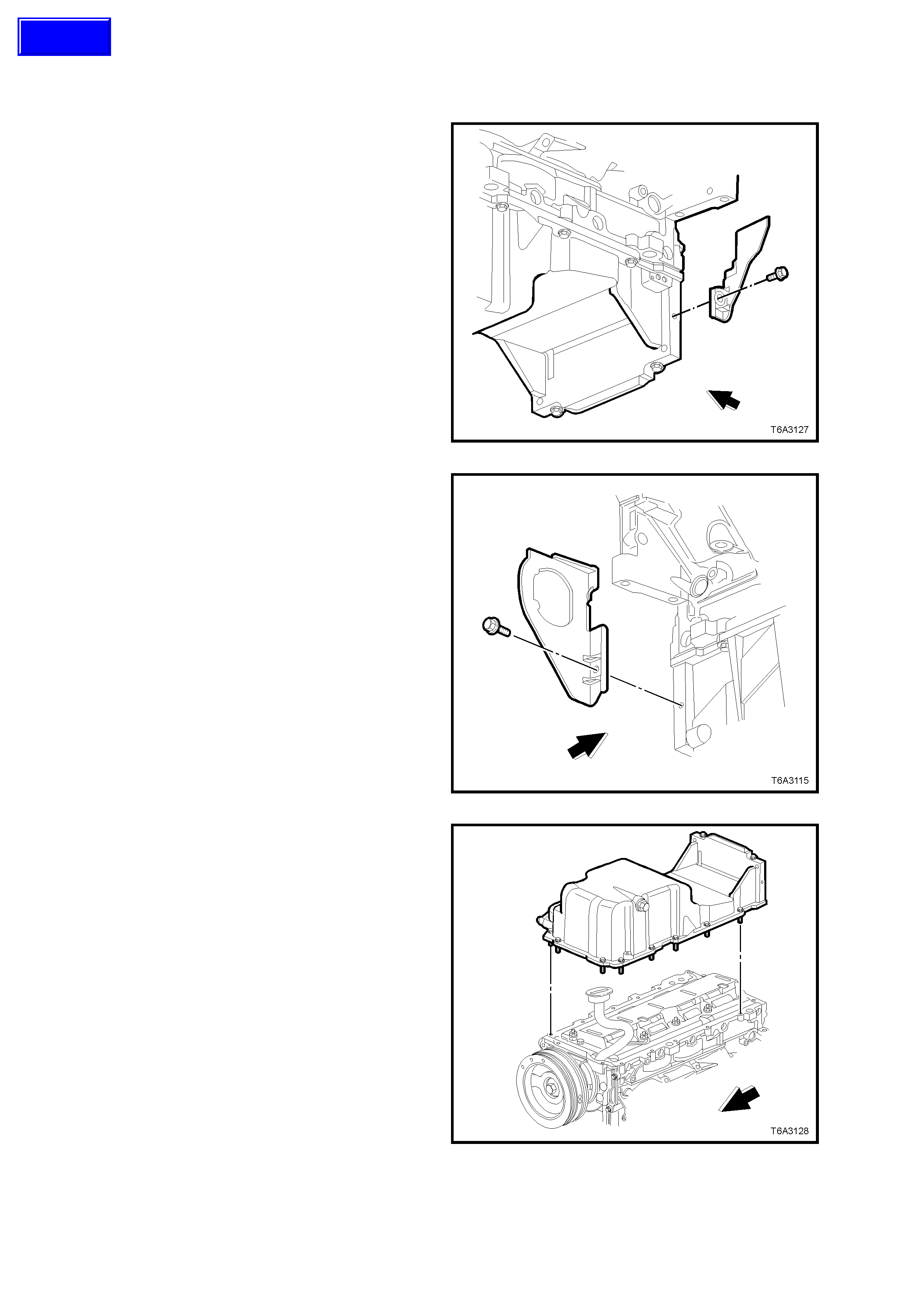

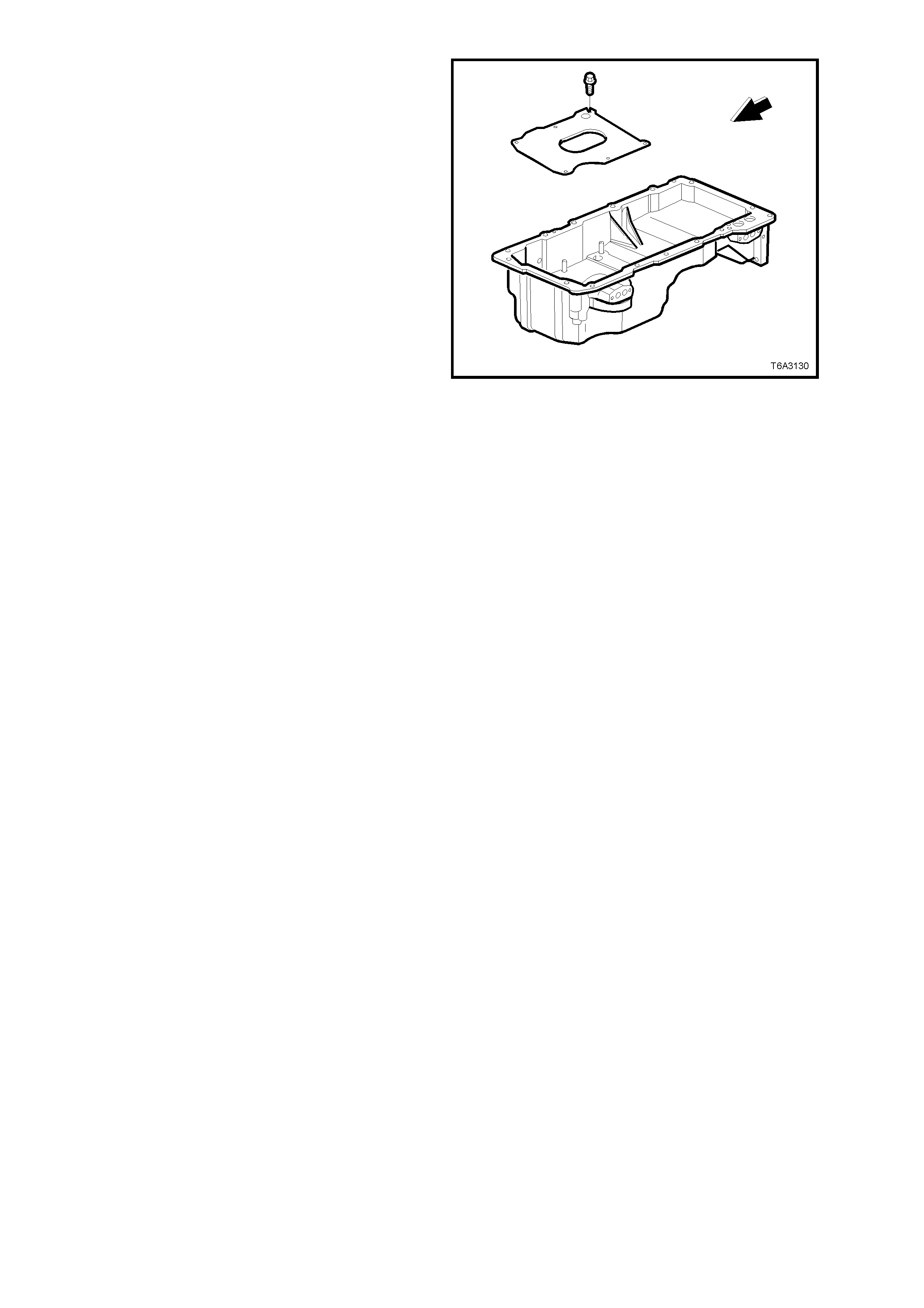

OIL PAN

The oil pan (1) is cast aluminium and forms a

structural part of the powertrain, by providing a

360° mounting for the transmission, whether it be

Manual or Automatic.

Cast-in dams incorporated into the oil pan design,

minim ise oil m igration during br aking and cor nering

manoeuvr es and oil is guided to the pick -up sc reen

(2), via strategically placed openings in the dam

walls.

Incorporated into the design are the oil filter

mounting boss (3), an opening for the drain plug

(4), and a stamped, oil pan baffle (6).

The oil pan baf f le ( 6), maintains an area ar ound the

pick-up screen to prevent oil starvation/aeration.

A crankshaft oil deflector (7) mounted to the main

bearing caps controls windage, sc rapes oil f r om the

crankshaft, facilitates drainback and reduces

aeration.

The oil pan gasket (8), is a controlled com pression

aluminium carrier gasket with silicone used as the

sealing agent.

Figure 6A3-19

1.3 ENGINE LUBRICATION SYSTEM

OIL PUMP

Engine lubrication is supplied by a “gerotor” type oil pump assembly. The pump is mounted on the front of the

engine block and driven directly by the crankshaft sprocket. The pump gears rotate and draw oil from the oil pan

sum p through a pick - up scr een and pipe. The oil is press urised as it pass es through the pum p and is sent through

the engine block oil galleries.

Contained within the oil pump assembly is a pressure relief valve that maintains oil pressure within a specified

range. Pressurised oil is directed through the lower gallery to the full flow oil filter where harmful contaminants are

removed. A bypass valve is incorporated into the oil filter that still allows oil to flow in the event that the filter

becomes blocked.

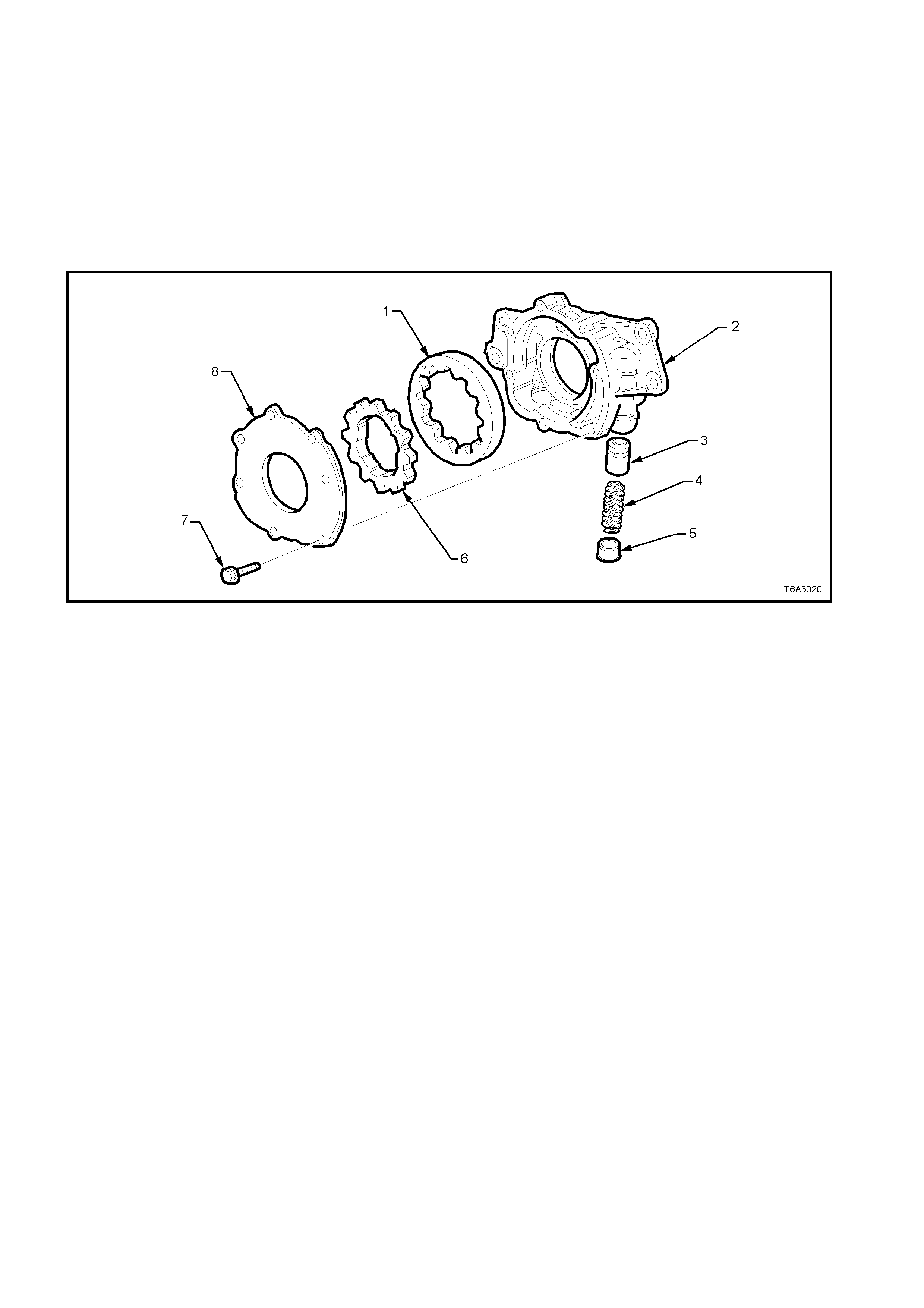

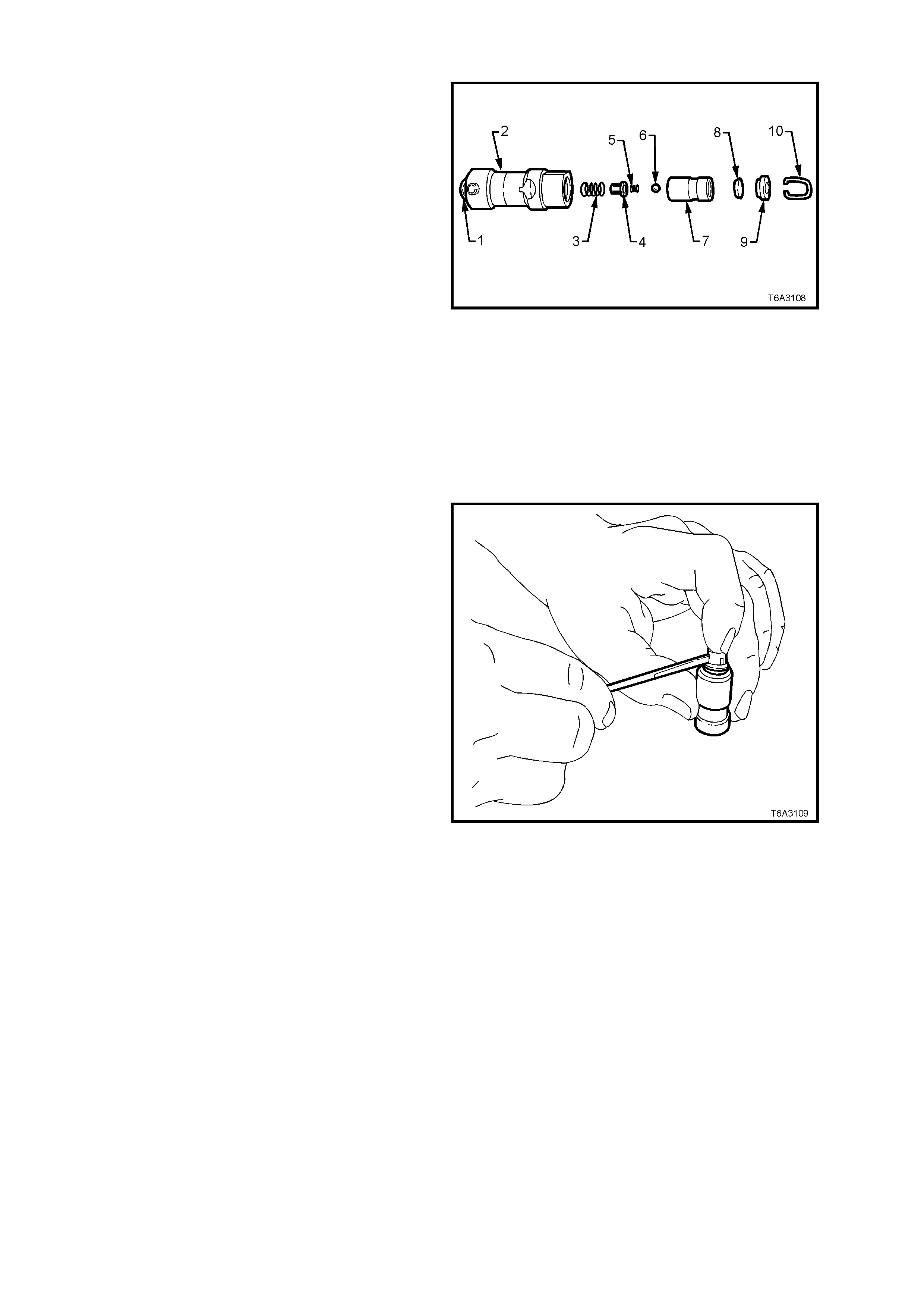

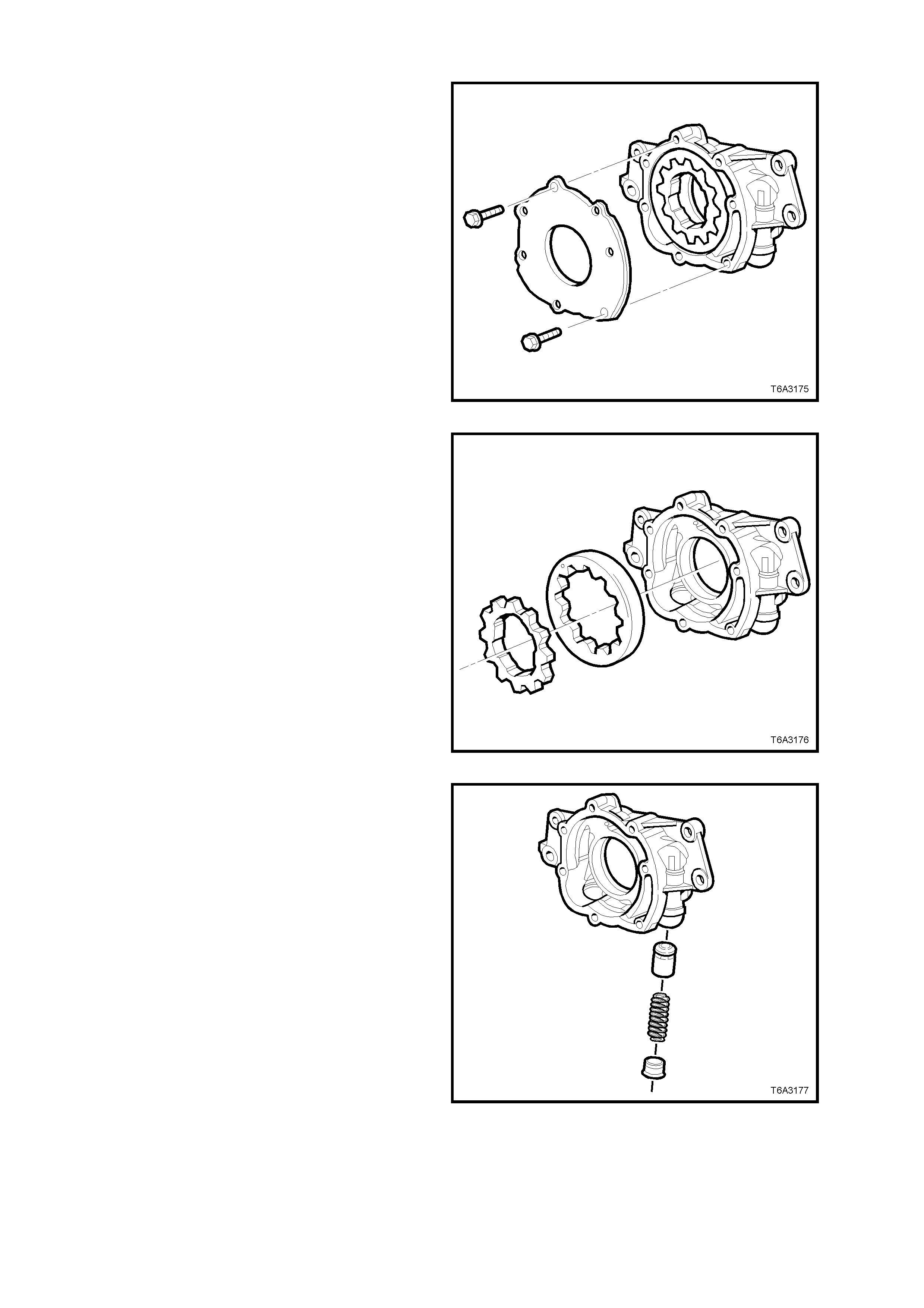

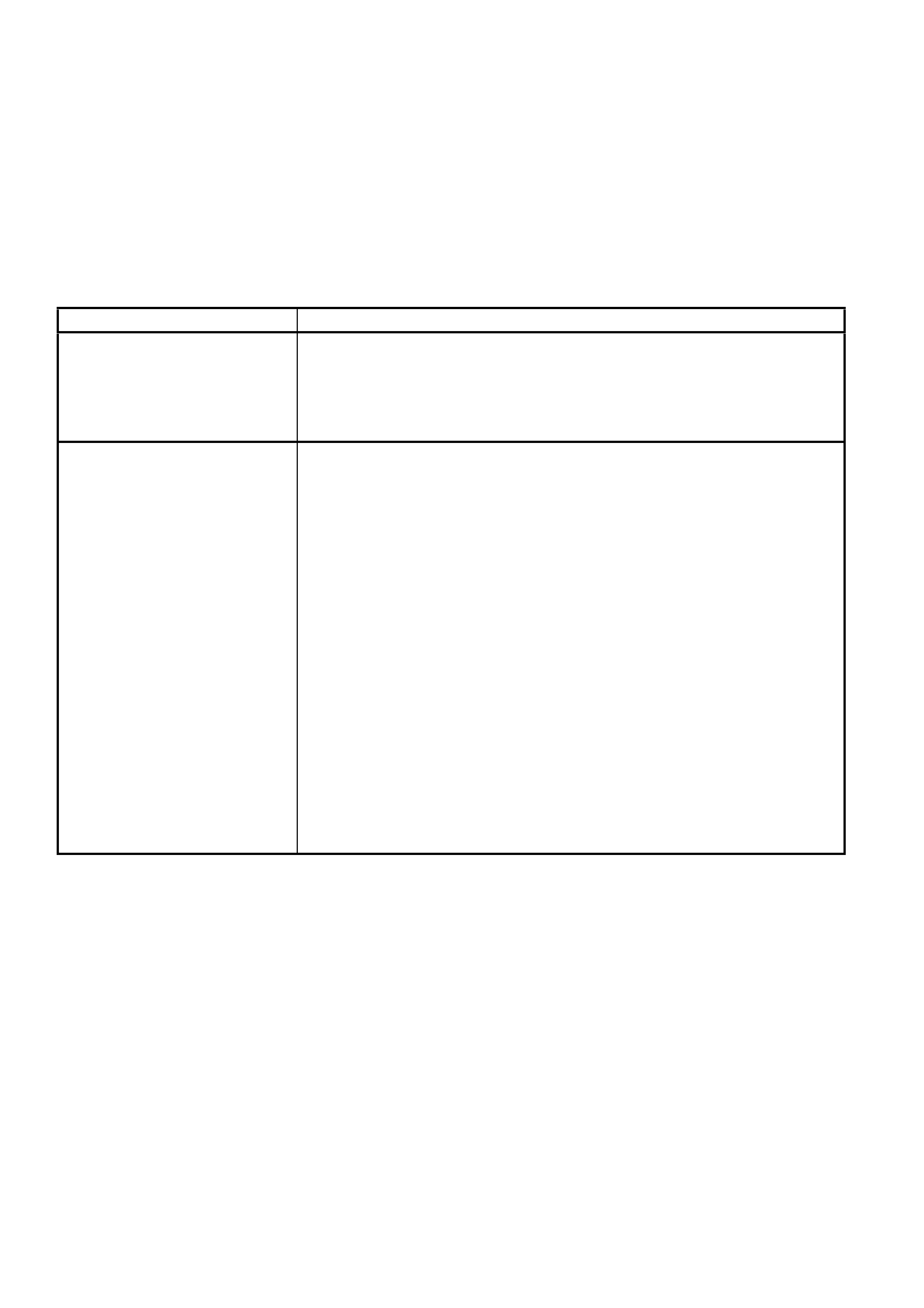

Figure 6A3-20 - Oil Pump Assembly

Legend

1. Driven Gear 4. Spring - Pressure Relief Valve 7. Bolt - Cover

2. Oil Pump Housing 5. Plug 8. Cover

3. Pressure Relief Valve 6. Drive Gear

At the rear of the block, oil is directed to the upper main oil galleries which are drilled just above the camshaft

assem bly. From there, oil is then direc ted to the crank s haft and c am shaf t bearings. O il that has enter ed the upper

ma in oil galleries also pres surises the valve lif ter ass emblies and is then pumped thr ough the pushrods to lubricate

the valve rocker arms and valve stems.

Oil returning to the pan is directed by the crankshaft oil deflector.

Figure 6A3-21 - Lubrication Flow Schematic

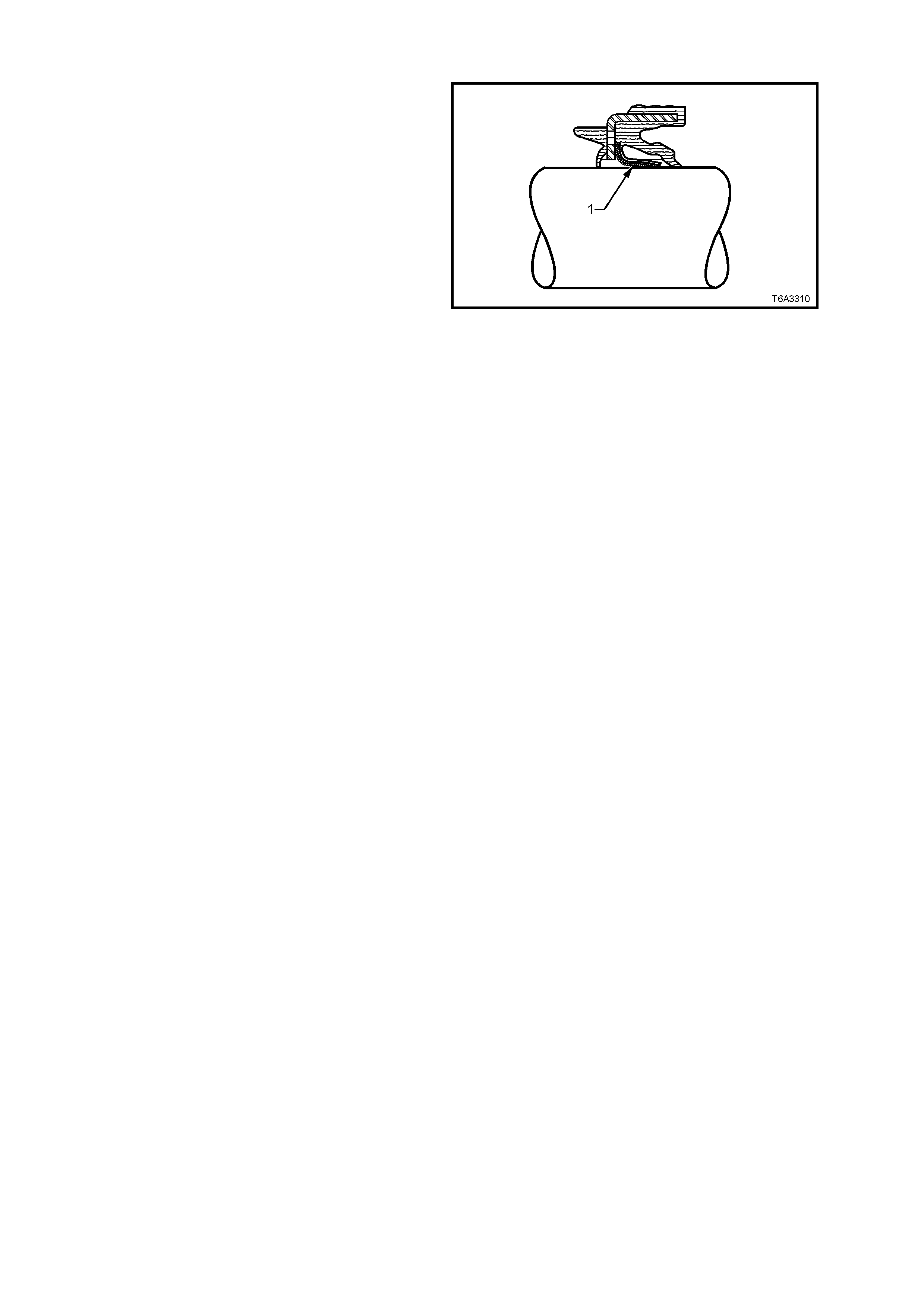

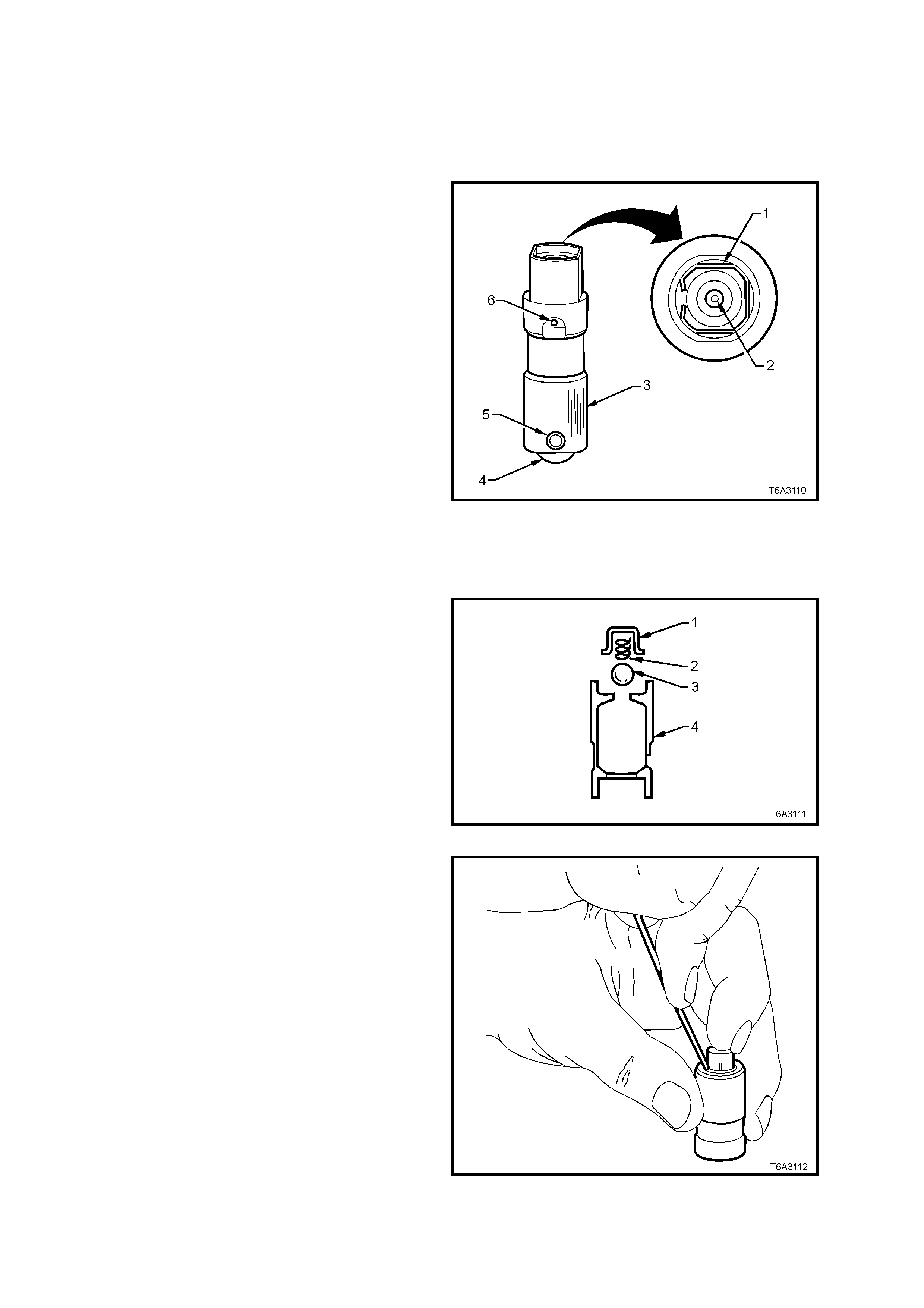

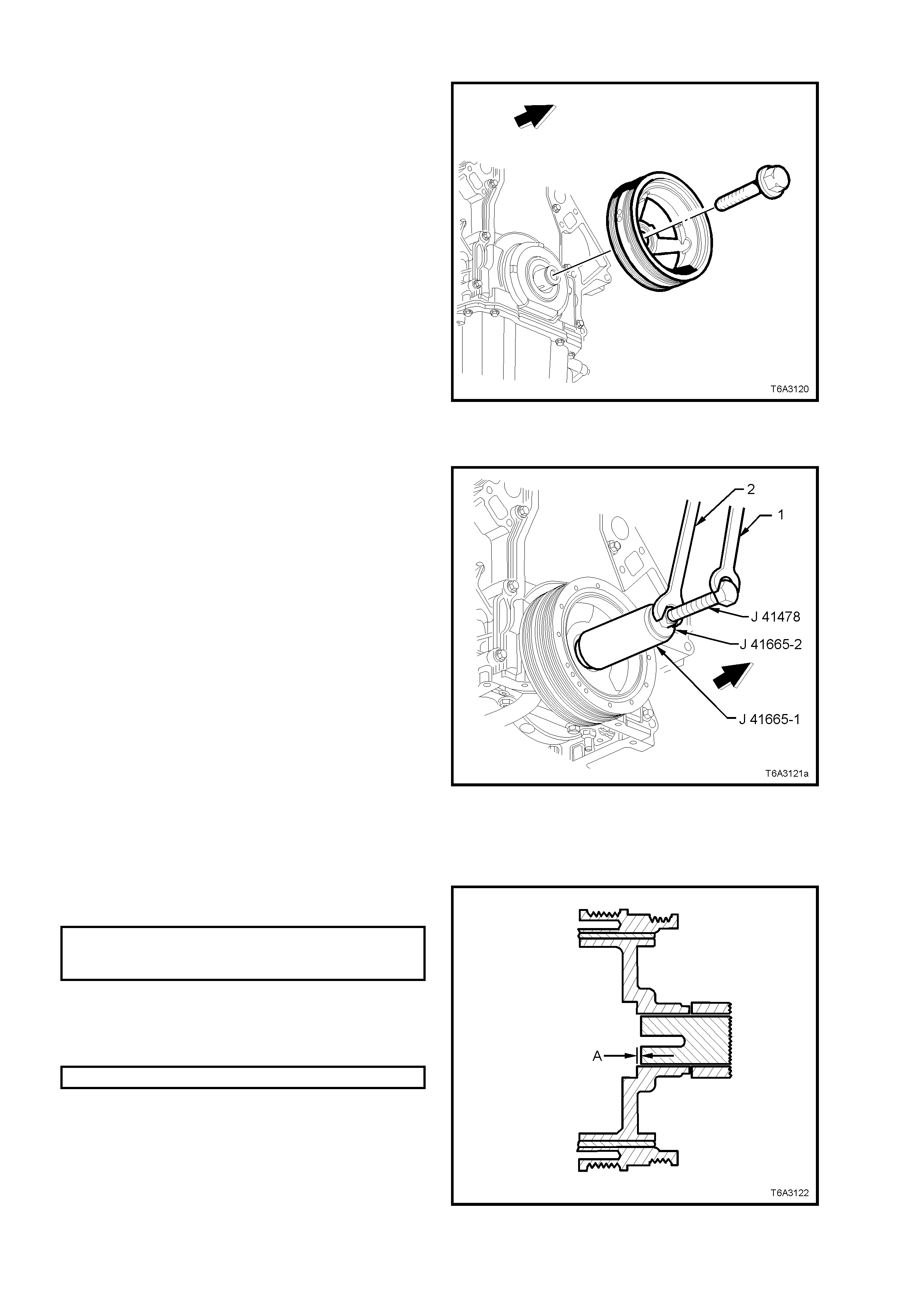

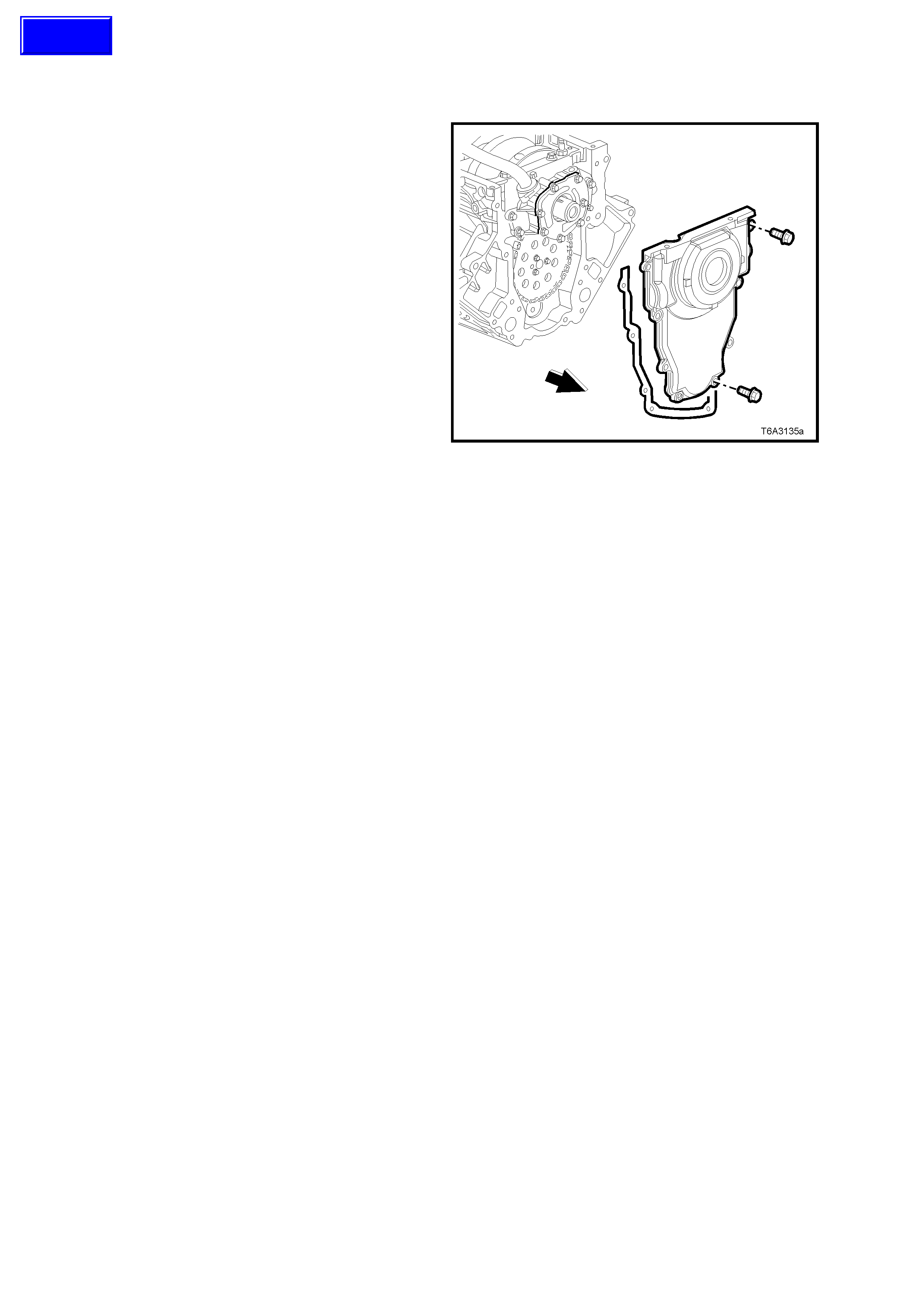

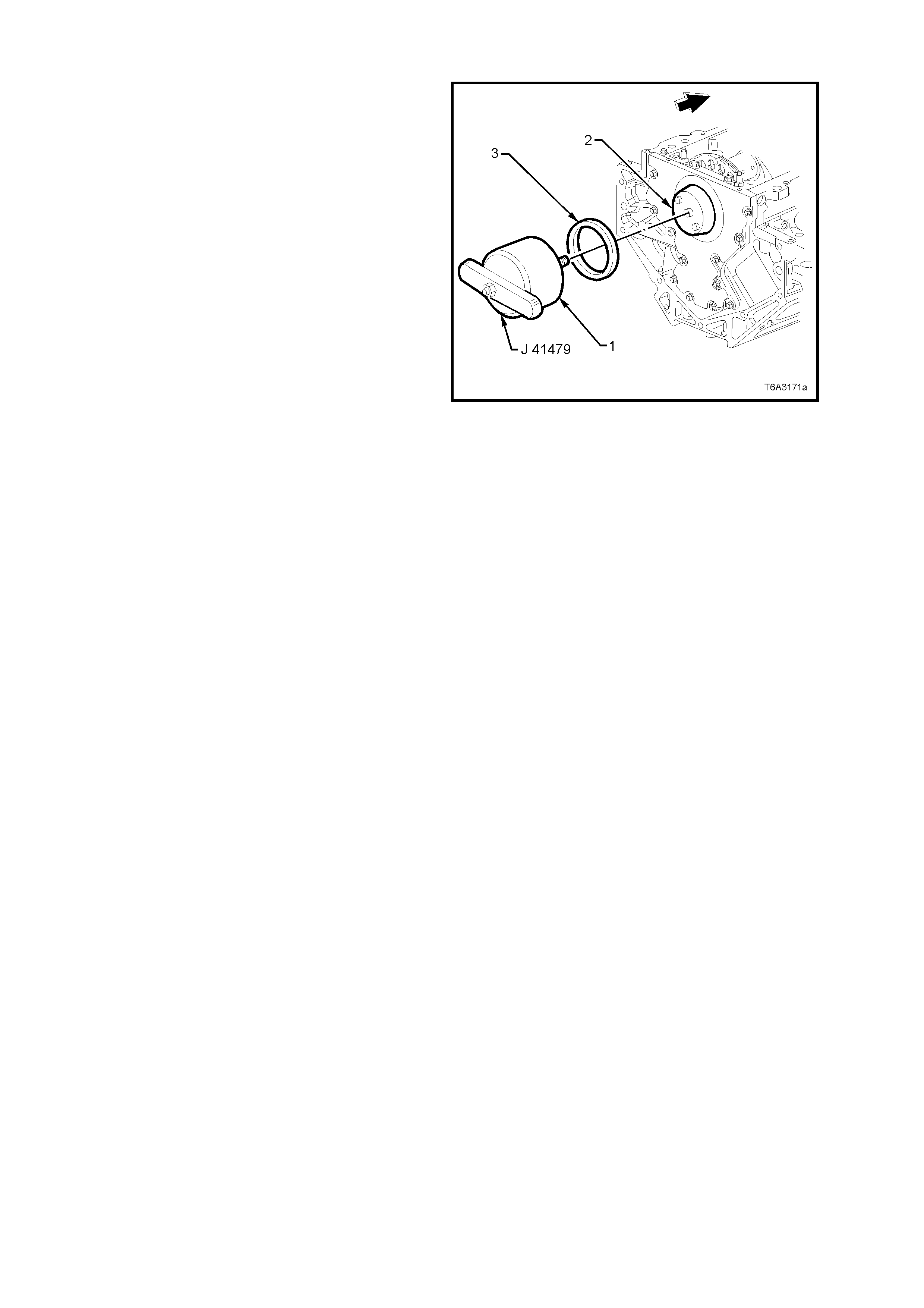

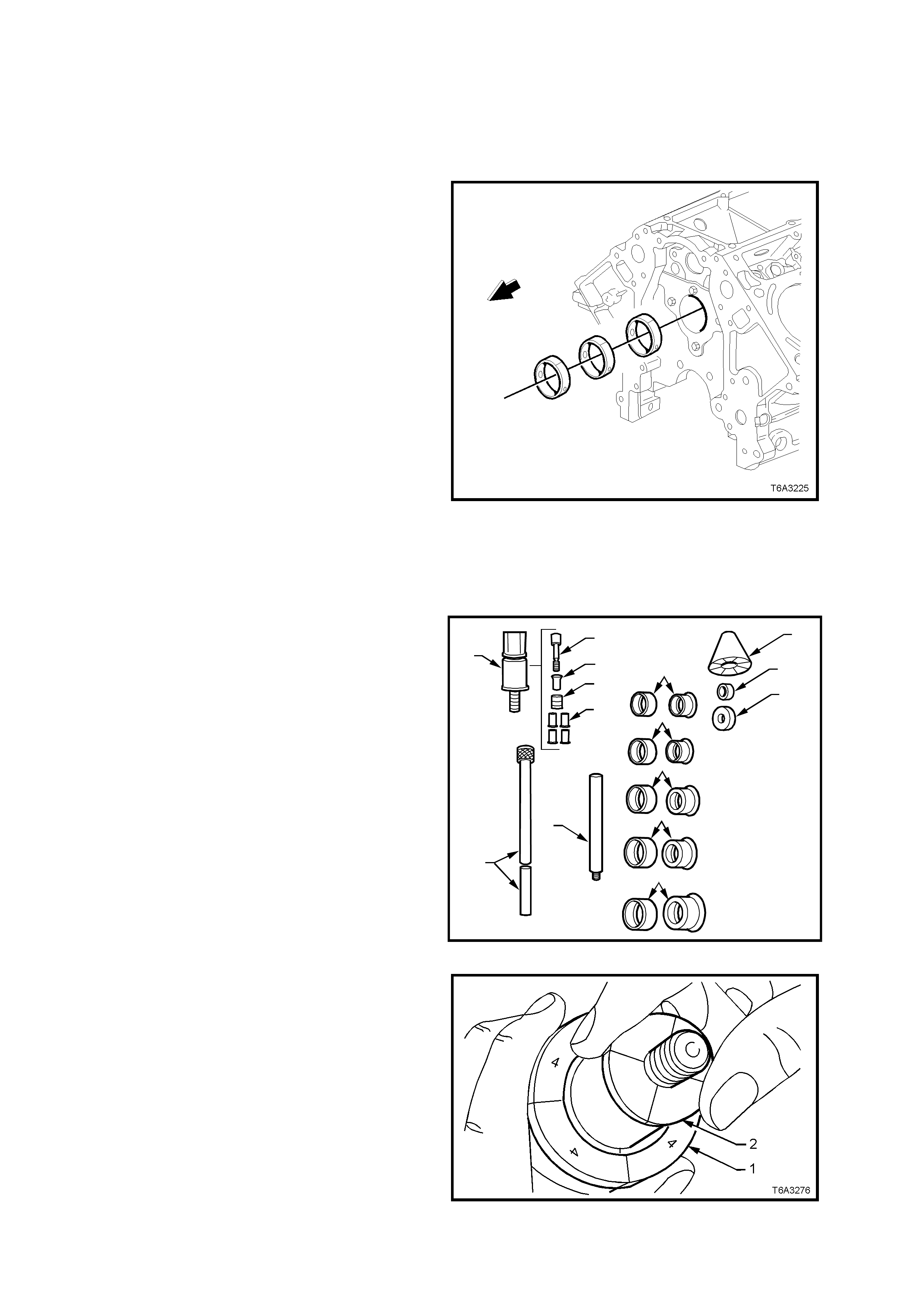

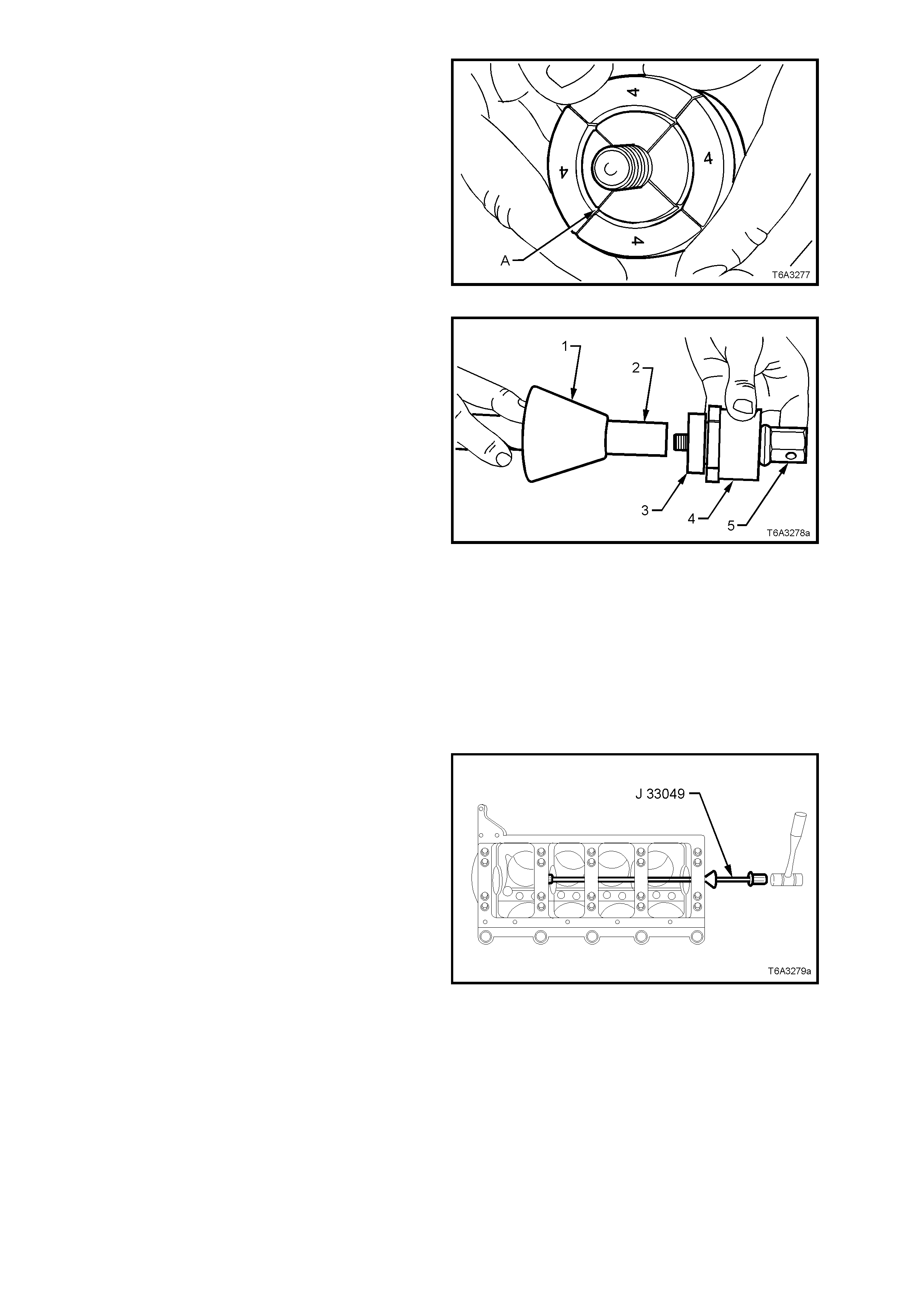

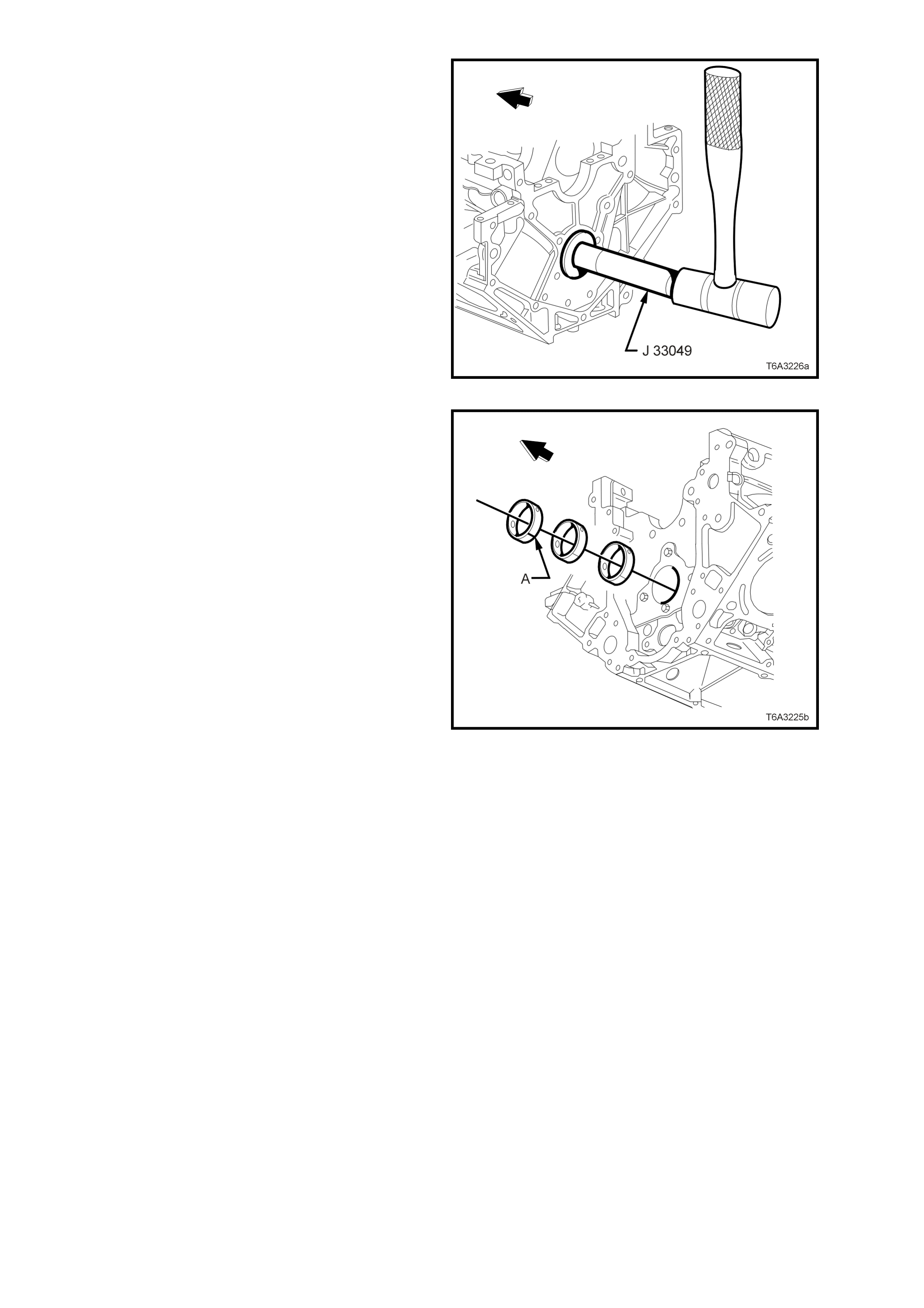

CRANKSHAFT OIL SEALS

The GEN III V8 engine uses a multiple lip

crankshaft rear main oil seal, designed for long life

operation.

The s eal includes a PTFE (Tef lon®) centre lip (1) to

m inimise a m ajor cause of r ear m ain oil seal leak s.

The anti-fric tion proper ties of the PT F E reduc es the

chances of “chok ing” or build-up of degraded oil on

the lip (causing the lip to lif t off the shaft), resulting

in a leak.

Like the rear main oil seal, the front crankshaft oil

seal also incorporates a PTFE lip.

Service implications for this seal material are that

no lubricant is to be added to the seal lip on

installation, as this will prevent correct ‘break-in’ of

the seal. T he PT F E is ac tually deposited on the dry

crankshaft seal surface during initial operation by

the heat generated from the rotating shaft.

The outside of the seal m ay be lubr icated sparingly

to ease installation.

Figure 6A3-22

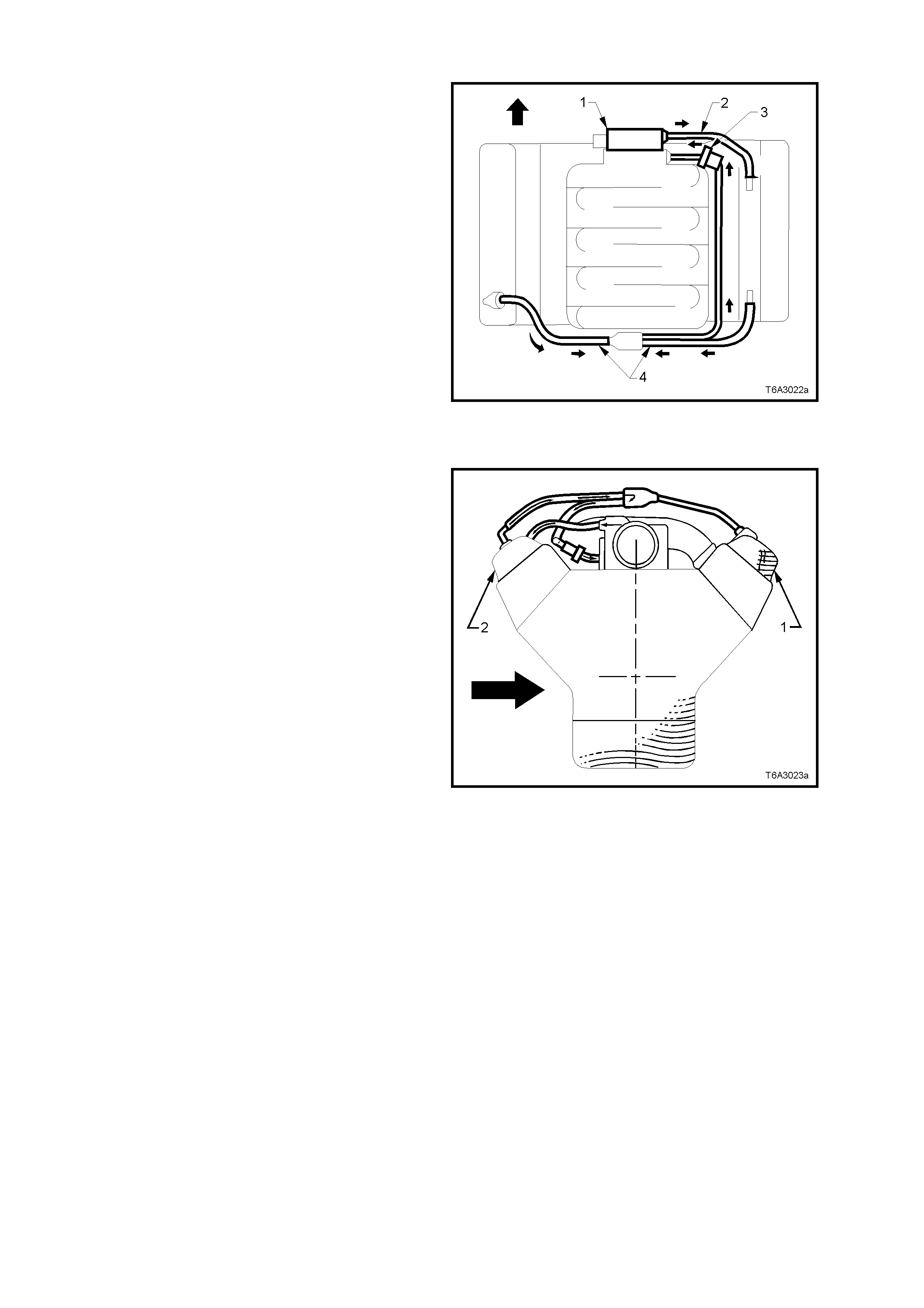

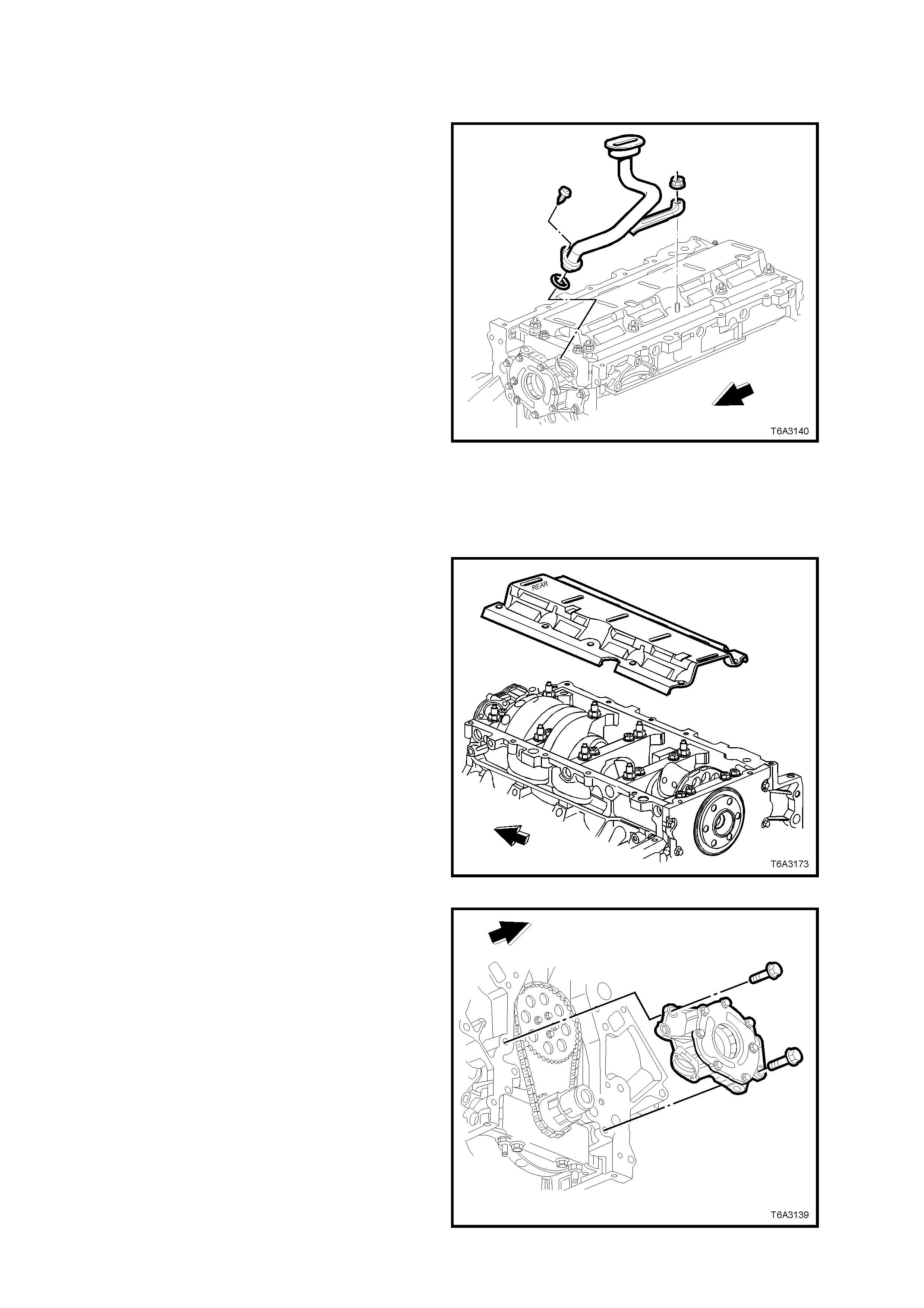

POSITIVE CRANKCASE VENTILATION SYSTEM

The engine ventilation system was developed to

minimise oil consumption and ensure that oil

ingestion could not occur during severe vehicle

handling manoeuvres.

Filtered fresh air is routed from upstream of the

throttle blade to the front of the right rocker cover

via a formed rubber hose (2). To reduce the

potential of oil pullover into the throttle bore area

due to back flow of the ventilation system, the fitting

in the right side rocker cover is located in a “quiet”

area located between, and shielded from, the

rocker arms. Crankcase blowby gases are routed

from the rear of both rocker covers, through

moulded nylon lines to a tee fitting, located on the

centreline of the engine at the rear of the intake

manifold (4). From there, a single hose carries

crankcase vapours through an externally mounted,

horizontal PCV valve (3) and enters the intake

manifold behind the throttle body (1).

The hoses are foam insulated and the PCV valve

(3) is conduction-heated from the cylinder block.

Figure 6A3-23

This “dual draw system” was developed to meet

high ‘g’ forces (bold arrow) incurred during severe

cornering m anoeuvres . During sust ained m aximum

lateral accelerations, the outboard rocker cover (1)

may fill with oil.

The “dual draw” system “passively switches”,

allowing the PCV valve to draw on the rock er cover

with the least resis tance. This res ults in the system

drawing on the air filled, or inboard, rocker cover

(2) and eliminates oil pullover that would result from

drawing on the oil filled outboard rocker cover.

Sectioned view shown is look ing rearward f rom the

engine front.

Figure 6A3-24

1.4 SERVICE NOTES

CLEANLINESS AND CARE

• Throughout this Section, it must be understood that proper cleaning and protection of machined surfaces and

friction areas is a part of the repair procedure. This is considered standard Workshop practice, even if not

specifically stated.

• When any internal engine parts are serviced, care and cleanliness is important.

• When components are removed f or s ervice, they should be mar ked, or ganised or r etained in a specif ic or der for

reassembly. Refer to; ’Separating Parts’ below.

• At the time of installation, components should be installed in the same location and with the same mating

surface as when removed.

• Any engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are

measured in hundredths of millimetres. These surfaces should be covered or protected to avoid component

damage.

• A liberal coating of clean engine oil should be applied to f ric tion areas dur ing assem bly, as proper lubr ication will

protect and lubricate friction surfaces during the initial engine start-up.

REPLACING ENGINE GASKETS

• Re-using gaskets and applying sealants.

− Do not reuse any gasket unless specified.

− Gaskets that can be reused will be identified in the service procedure.

− Do not apply sealant to any gasket or sealing surface unless called out in the service information.

• Separating components

− Use a rubber mallet to separate components.

− Bump the part sideways to loosen the components.

− Bumping should be done at bends or reinforced areas to prevent distortion of parts.

• Cleaning gasket surfaces

− Remove all gasket and sealing material from the part using a plastic or wood scraper (if required).

− Care must be used to avoid gouging or scraping the sealing surfaces.

− Do not use any other method or technique to remove sealant or gasket material from a part.

− Do not use abrasive pads, sand paper, or power tools to clean the gasket surfaces.

∗ These methods of cleaning can cause damage to the component sealing surfaces.

∗ Abrasive pads also produce a fine grit that the oil filter cannot remove from the oil.

∗ This grit is abrasive and has been known to cause internal engine damage.

• Assembling components

− When assembling components, use only the sealant specified or equivalent in the service procedure.

− Sealing surfaces should be clean and free of debris or oil.

− Specific components such as crankshaft oil seals or valve stem oil seals may require lubrication during

assembly.

− Components requiring lubrication will be identified in the service procedure.

− When applying sealant to a component, apply the amount specified in the service procedure.

− Do not allow the sealant to enter into any blind threaded holes, as it may prevent the bolt from clamping

properly or cause component damage when tightened.

− Only ever tighten bolts to specifications. Do not overtighten.

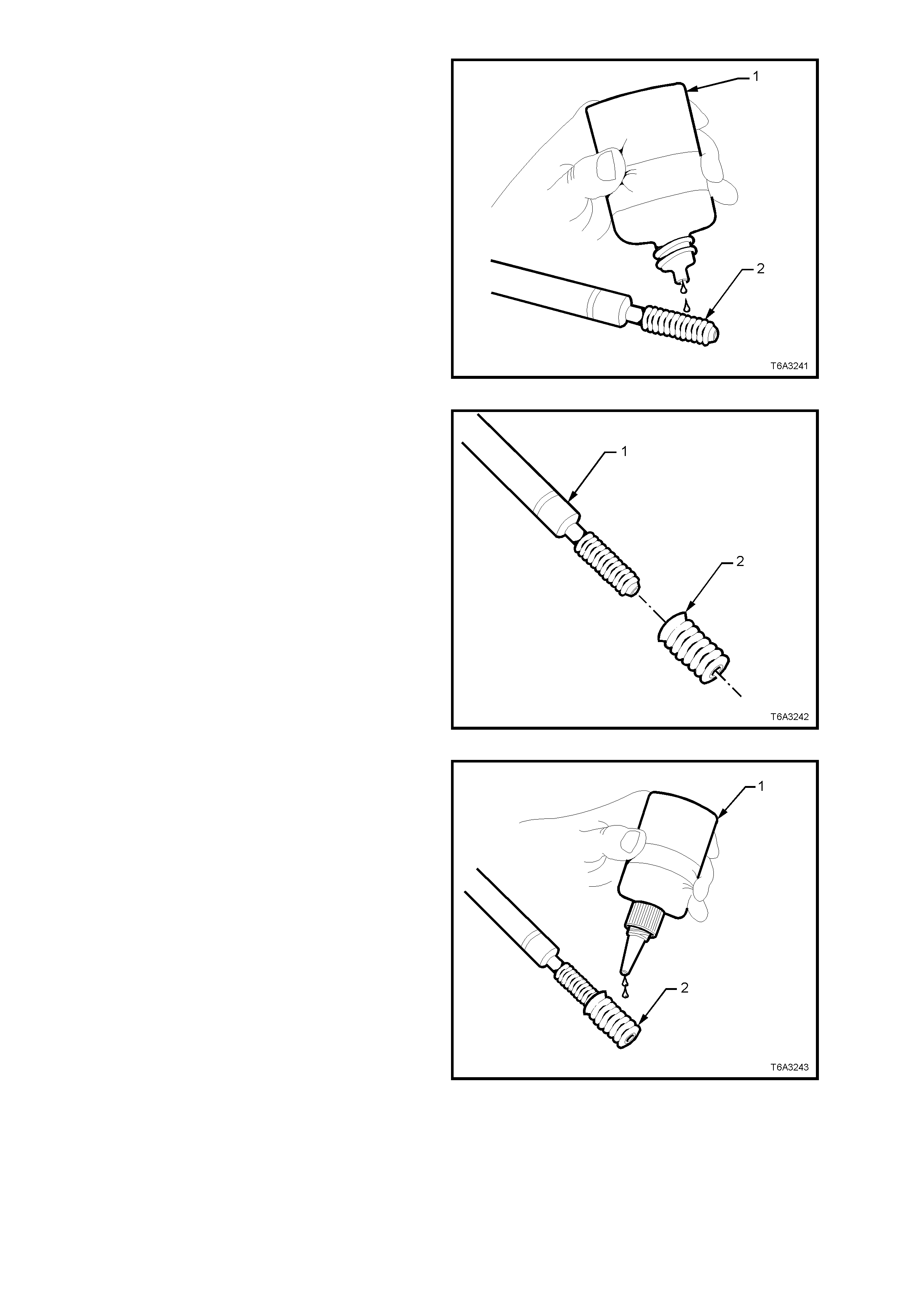

USE OF RTV AND ANAEROBIC SEALER

Important: A number of sealant types are commonly used in engines. Examples are; Room Temperature

Vulcanising (RTV) sealer, anaerobic gasket eliminator sealer, anaerobic thread sealant and pipe joint compound.

The correct sealant and amount must be used in the specified location to prevent oil leaks. DO NOT interchange

the different types of sealers. Use only the specific sealer or the equivalent as recommended in the service

procedure.

Pipe Joint Compound

• Pipe joint com pound is a pliable sealer that does not completely harden. T his type of s ealer is us ed where two

non-rigid parts (such as pressed steel and machined surfaces) are assembled together.

• Do not use pipe joint compound in areas where extreme temperatures are expected. These areas include:

exhaust manifold, head gasket, or other surfaces where gasket eliminator is specified.

• Follow all safety recommendations and directions that are on the container.

• To remove the sealant or the gasket material, refer to ’Replacing Engine Gaskets’ in this Section.

• Apply the pipe joint compound to a clean surface. Use a bead size or quantity as specified in the procedure.

Run the bead to the inside of any boltholes. Do not allow the sealer to enter any blind threaded holes, as it m ay

prevent the bolt from clamping properly or cause component damage when the bolt is tightened.

• Apply a continuous bead of pipe joint compound to one sealing surface. Sealing surfaces to be resealed must

be clean and dry.

• Tighten the bolts to specifications. Do not overtighten.

Exam ples of locations where a pipe s ealant type material suc h as Loctite 565 ( or other c om m ercial equivalent) is to

be used, are:

• Engine block coolant and oil gallery plugs.

• Oil pressure sensor threads.

• Engine block oil pan surface.

RTV Sealer

• Room T emperature Vulcanis ing (RT V) sealant hardens when exposed to air. T his type of s ealer is used where

two non-rigid parts (such as the intake manifold and the engine block) are assembled together.

• Do not use RTV sealant in areas where extrem e temperatures are experienced. These areas include: exhaust

manifold, head gasket, or other surfaces where a gasket eliminator is specified.

• Follow all safety recommendations and directions that are on the container.

• To remove the sealant or the gasket material, refer to Replacing Engine Gaskets.

• Apply RTV to a clean surface. Use a bead size as specified in the service procedure. Run the bead to the

inside of any bolt holes. Do not allow the sealer to enter any blind threaded holes, as it may prevent the bolt

from clamping properly or cause damage when the bolt is tightened.

• Assemble components while RTV is still wet (within 3 minutes). Do not wait for RTV to skin over.

• Tighten bolts to specifications. Do not overtighten.

Anaerobic Sealer

• Anaerobic gask et elim inator or thread sealant, hardens in the absence of air. T his type sealer is us ed where two

rigid parts (s uch as c astings ) are ass em bled together or where f asteners are subj ected to vibration or where the

holes are not blind. W hen two rigid parts are disassembled and no sealer or gasket is readily noticeable, the

parts were probably assembled using a gasket eliminator.

• Follow all safety recommendations and directions that are on the container.

• To remove the sealant or the gasket material, refer to Replacing Engine Gaskets in this Section.

• Apply a continuous bead of gasket eliminator to one f lange or on the bolt/s tud thr ead. All s urf ac es must be c lean

and dry.

• Spread the sealer evenly with your finger to get a uniform coating on the sealing surface.

• Do not allow the sealer to enter any blind threaded holes, as it may prevent the bolt from clamping properly or

cause damage when tightened.

Important: Anaerobic sealed joints that are partially torqued and allowed to cure more than five minutes may

result in incorrect shimming and sealing of the joint.

• Only ever tighten bolts to specification. Do not overtighten.

• After properly tightening the fasteners, remove the excess sealer from the outside of the joint.

Exam ples where thread locking sealants suc h as Loc tite 242 or Loctite 272 ( or other c ommerc ial equivalents ) ar e to

be used, are the fasteners for:

• Fuel rail. .................................... ‘242’

• Intake manifold.......................... ‘242’

• Cylinder head M8...................... ‘242’

• Exhaust manifold. ..................... ‘272’

SEPARATING PARTS

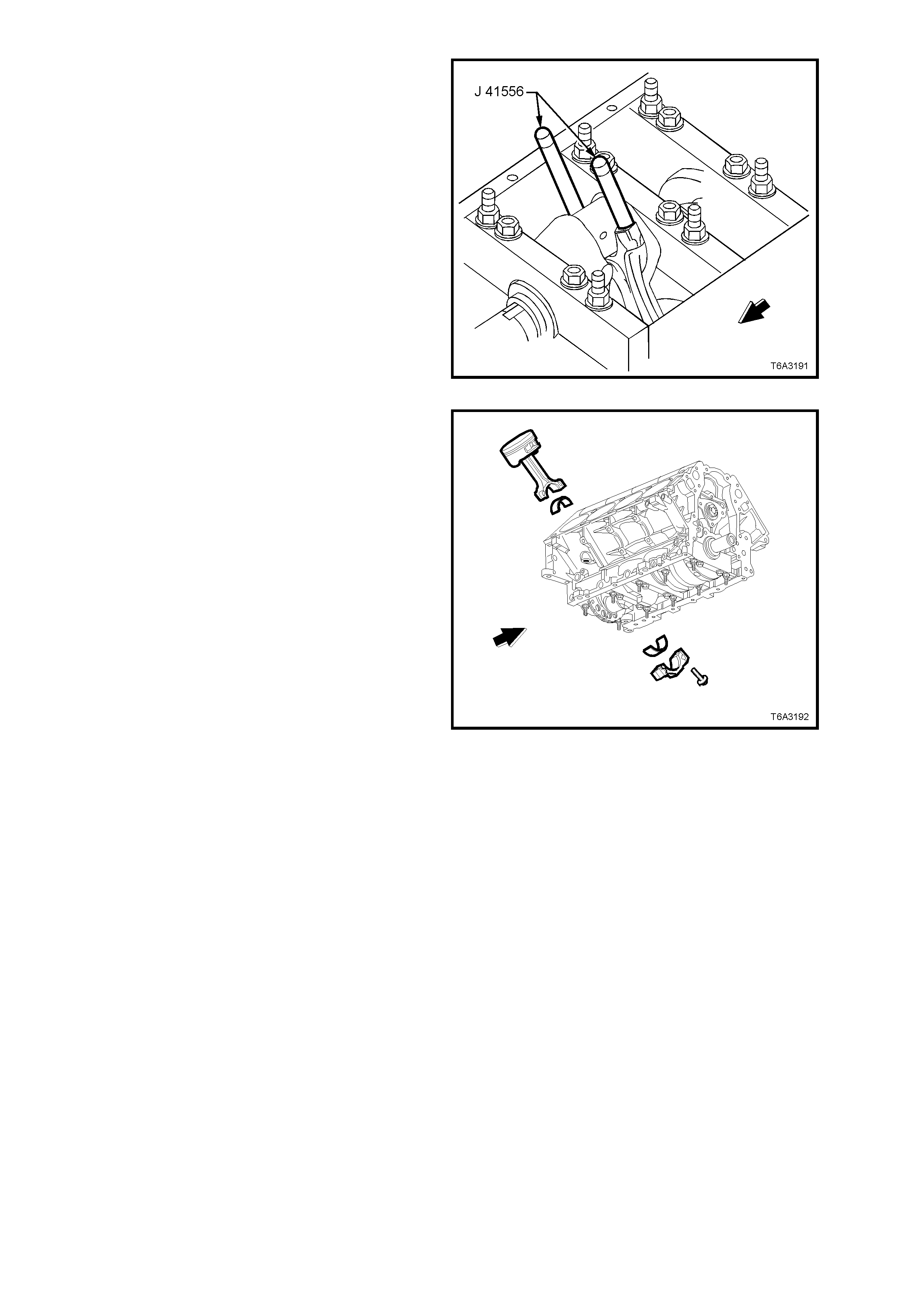

Important: Many internal engine components will develop specific wear patterns on their friction surfaces. So, when

disassembling the engine, internal components MUST be separated, marked, or organised in a way to ensure

reinstallation to their original location and position.

Separate, mark, or organise the following components:

− Piston and the piston pin.

− Piston to the specific cylinder bore.

− Piston rings to the specific piston.

− Connecting rod to the crankshaft journal.

− Connecting rod to the bearing cap.

− Crankshaft main and connecting rod bearings.

− Camshaft and valve lifters.

− Valve lifters, guides, pushrods, pivot supports and rocker arms.

− Valve to the valve guide.

− Valve spring and shim to the cylinder head location.

− Engine block main bearing cap location and direction.

− Oil pump drive and driven gears.

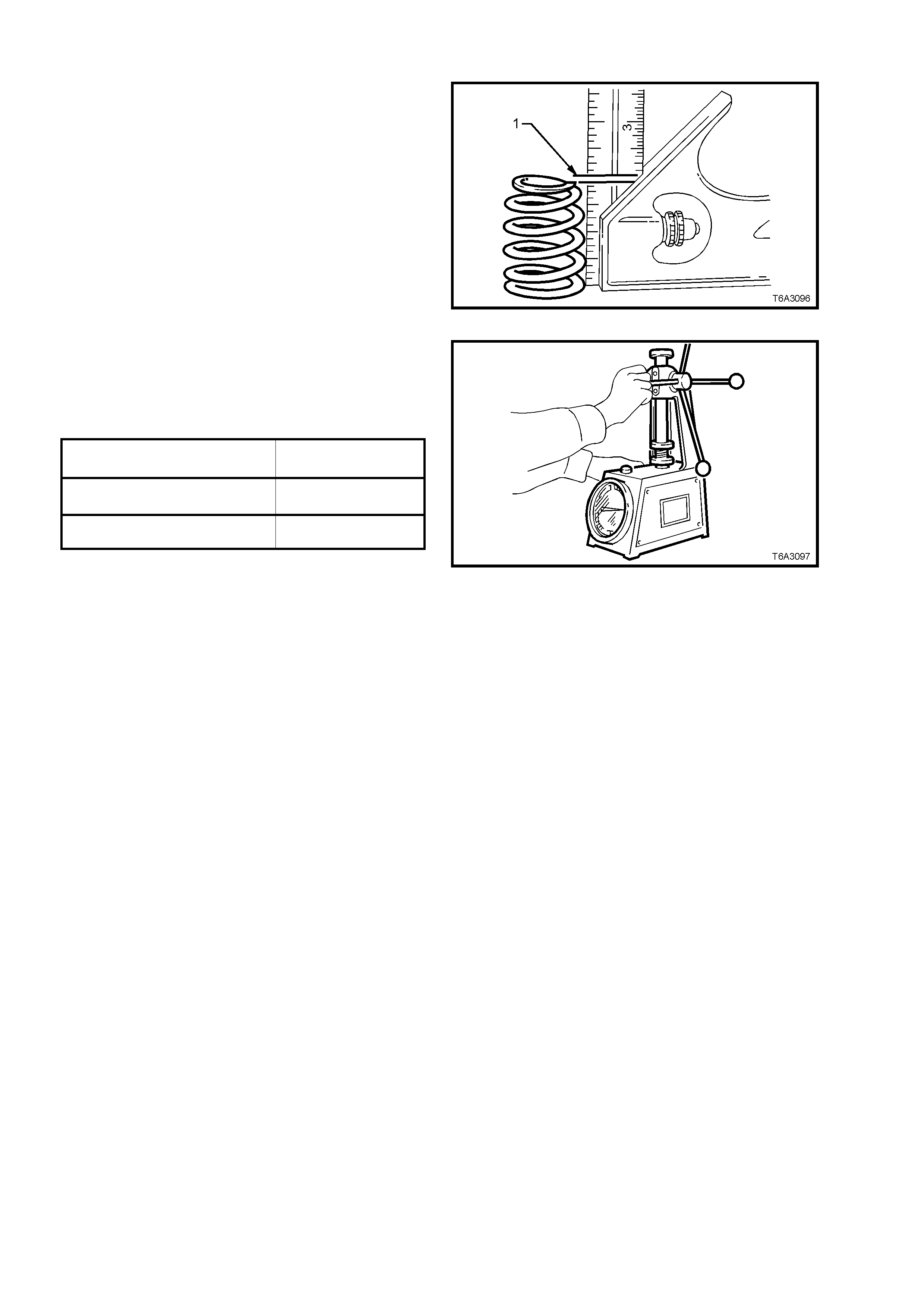

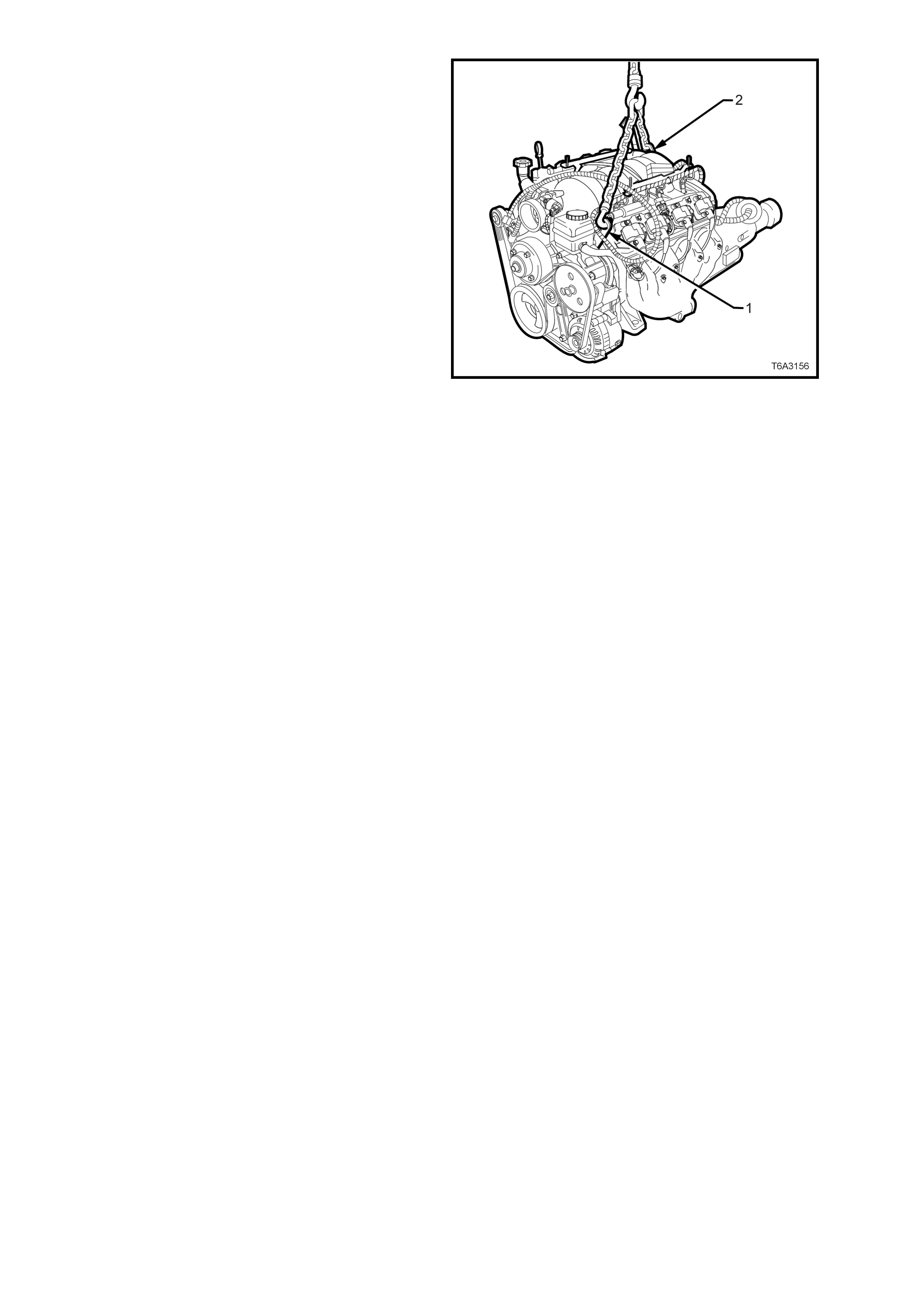

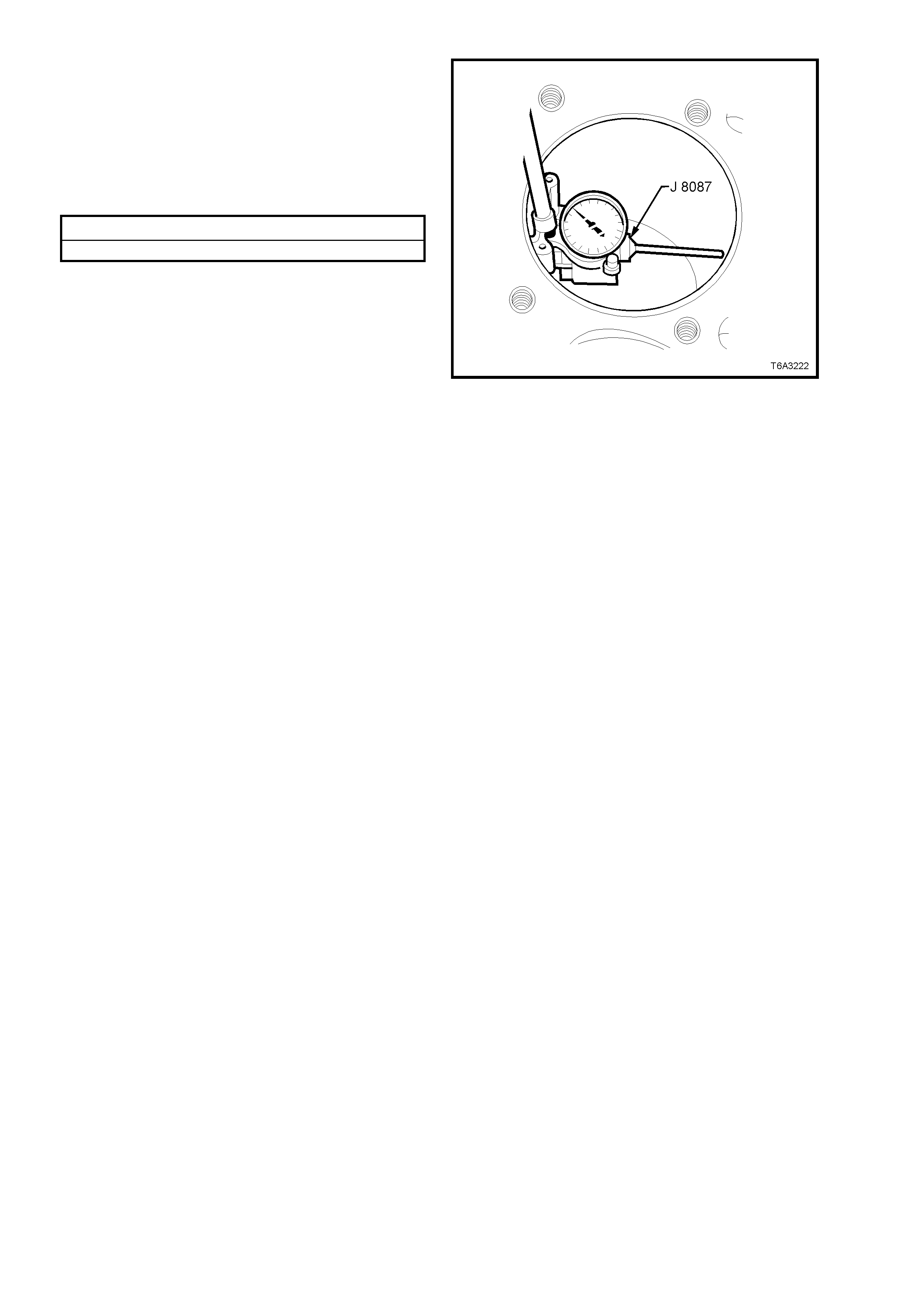

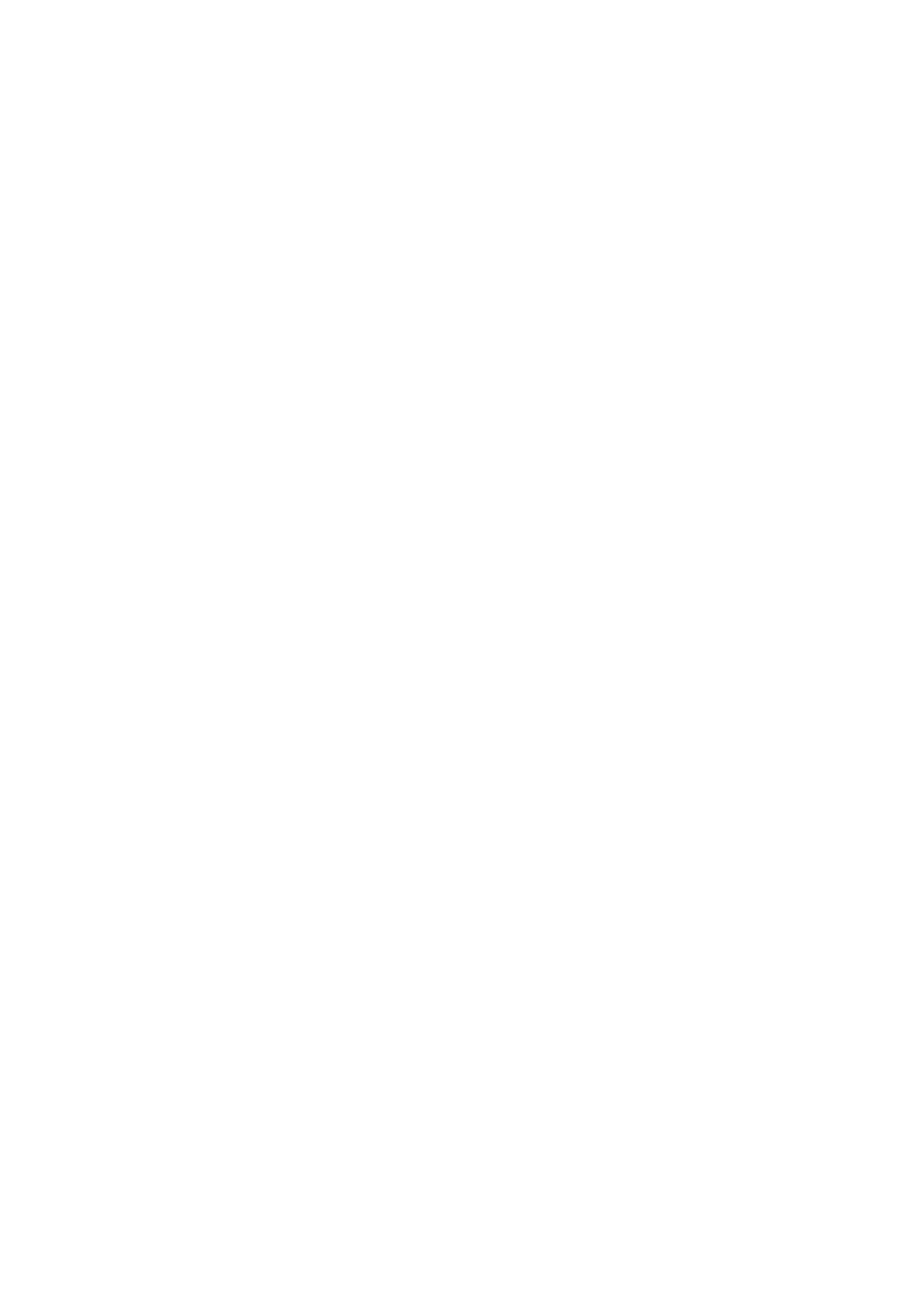

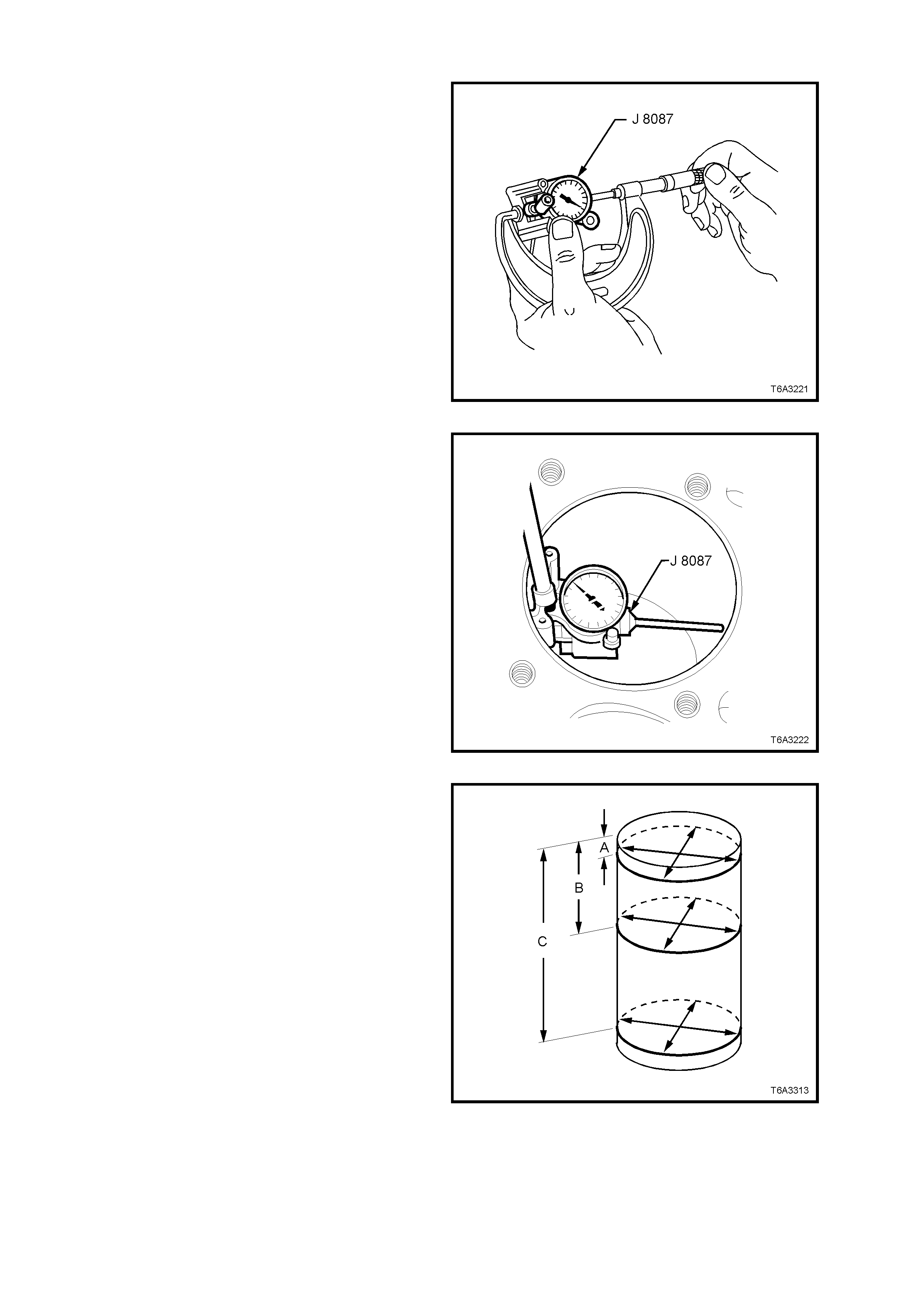

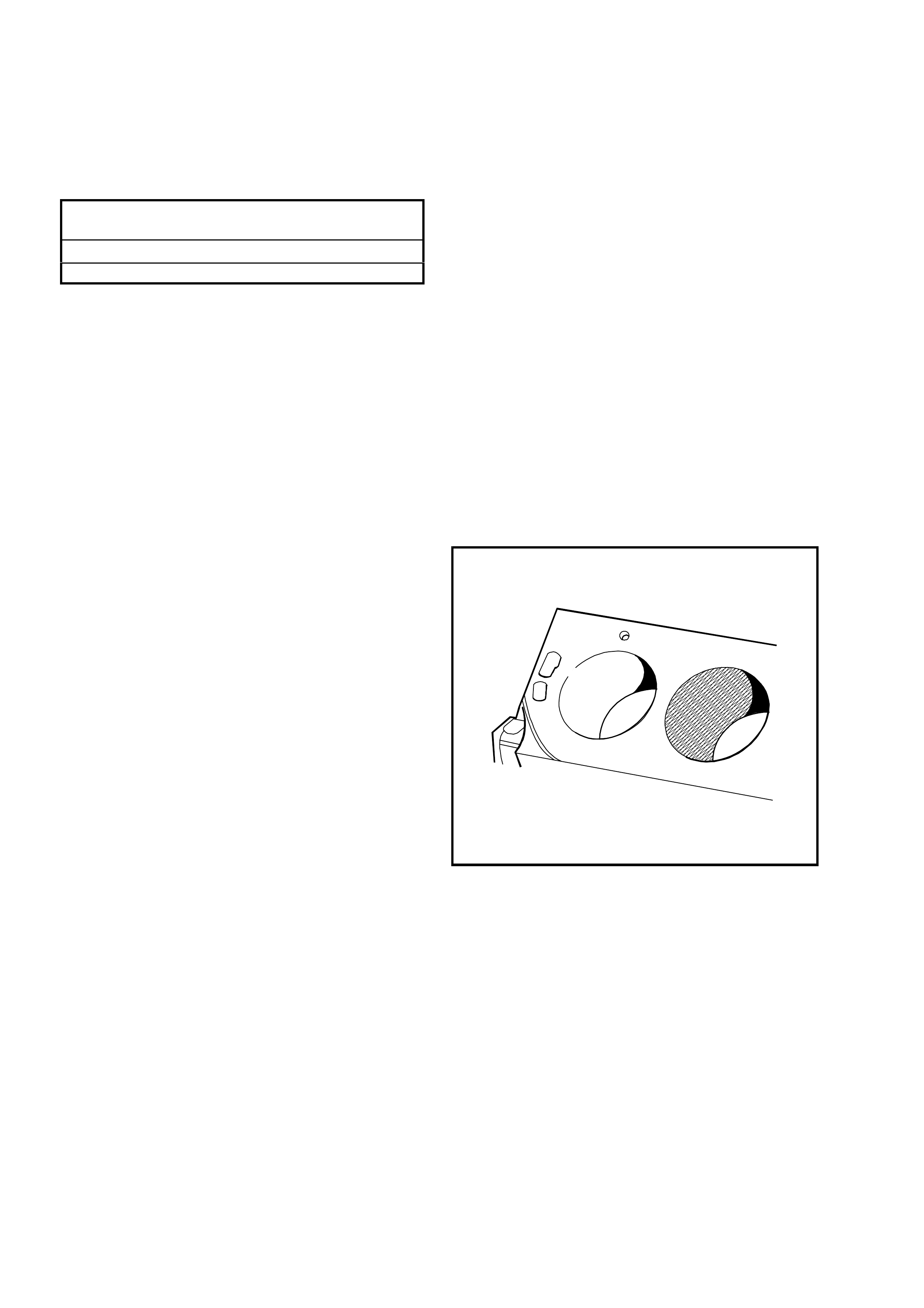

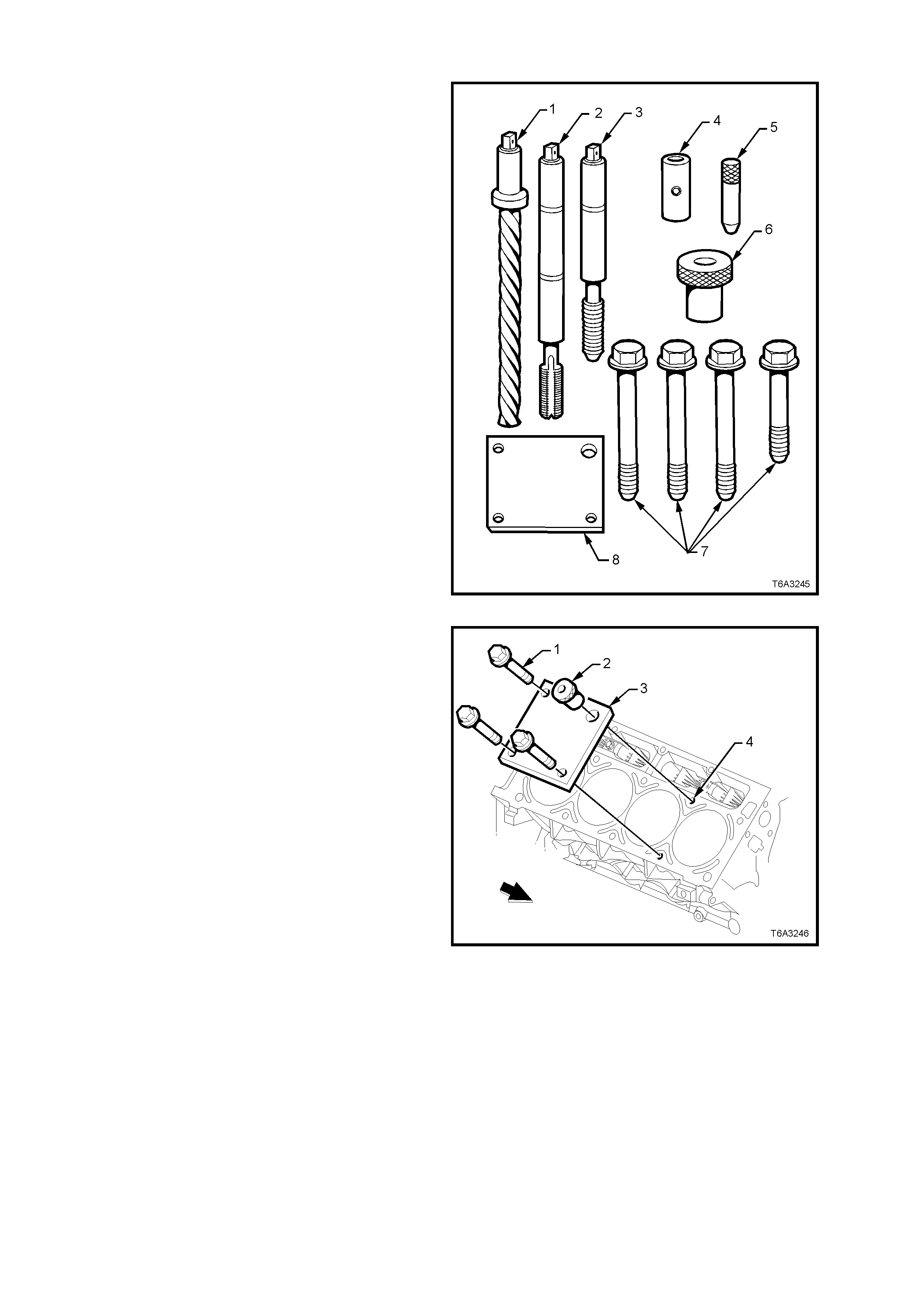

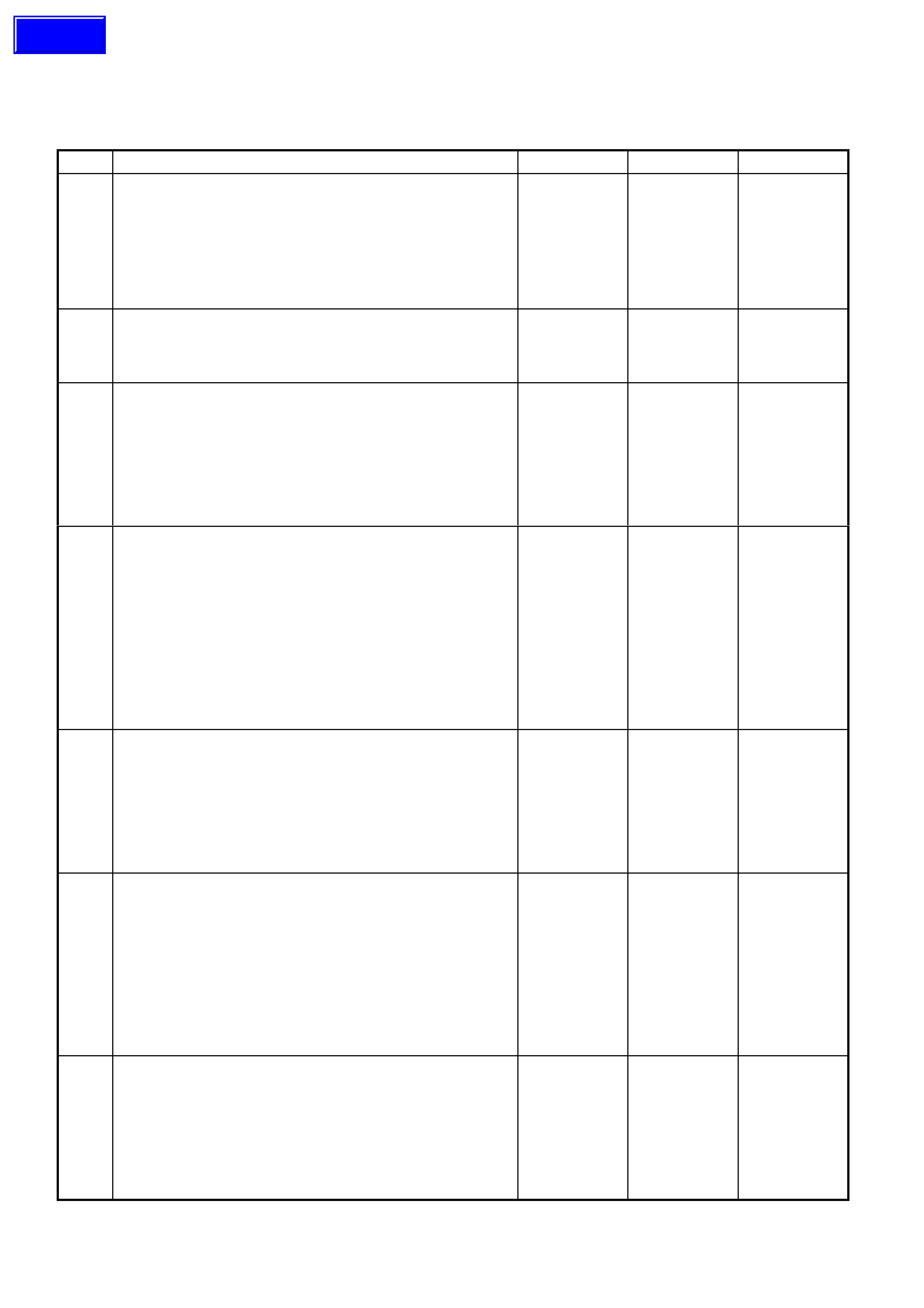

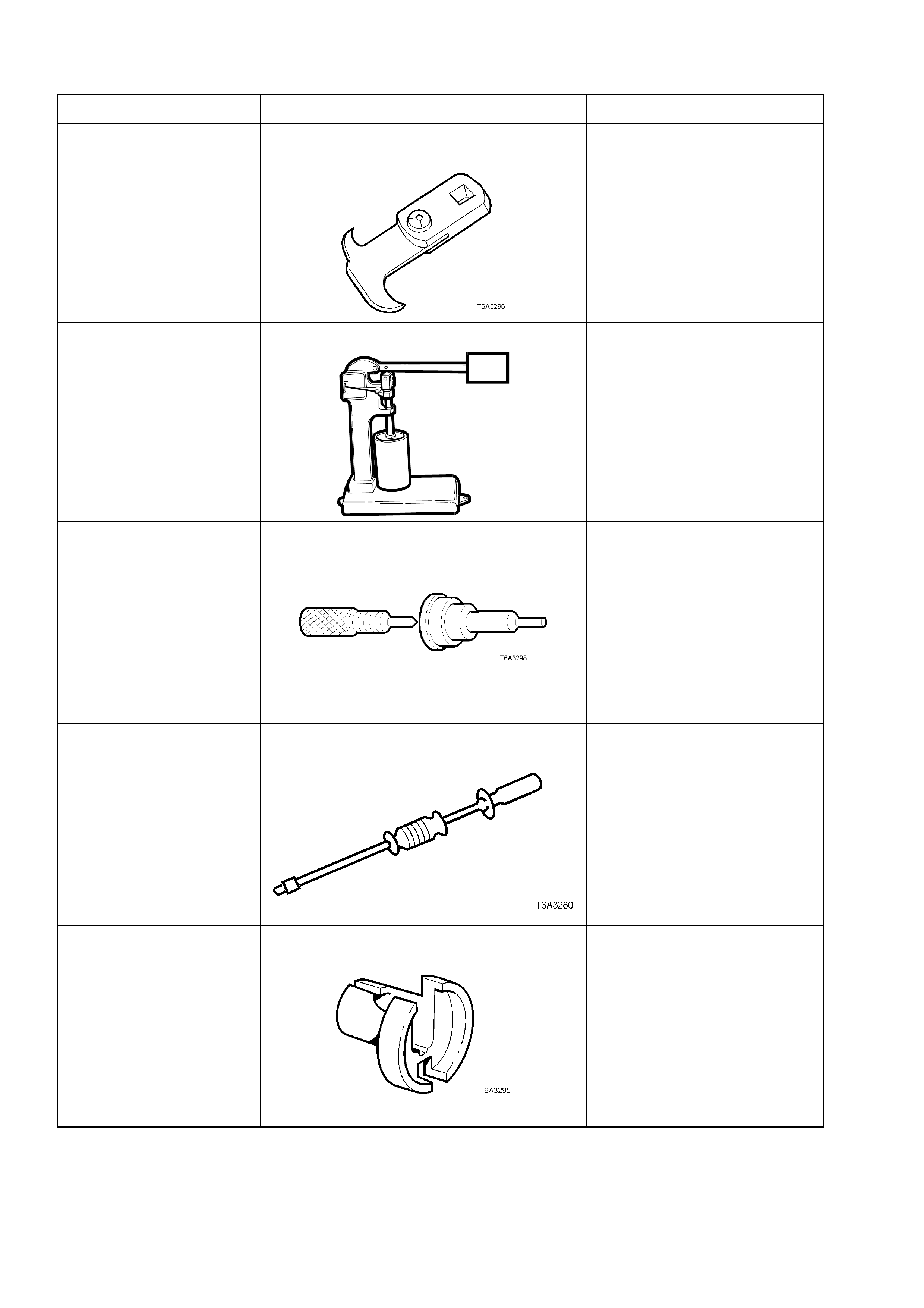

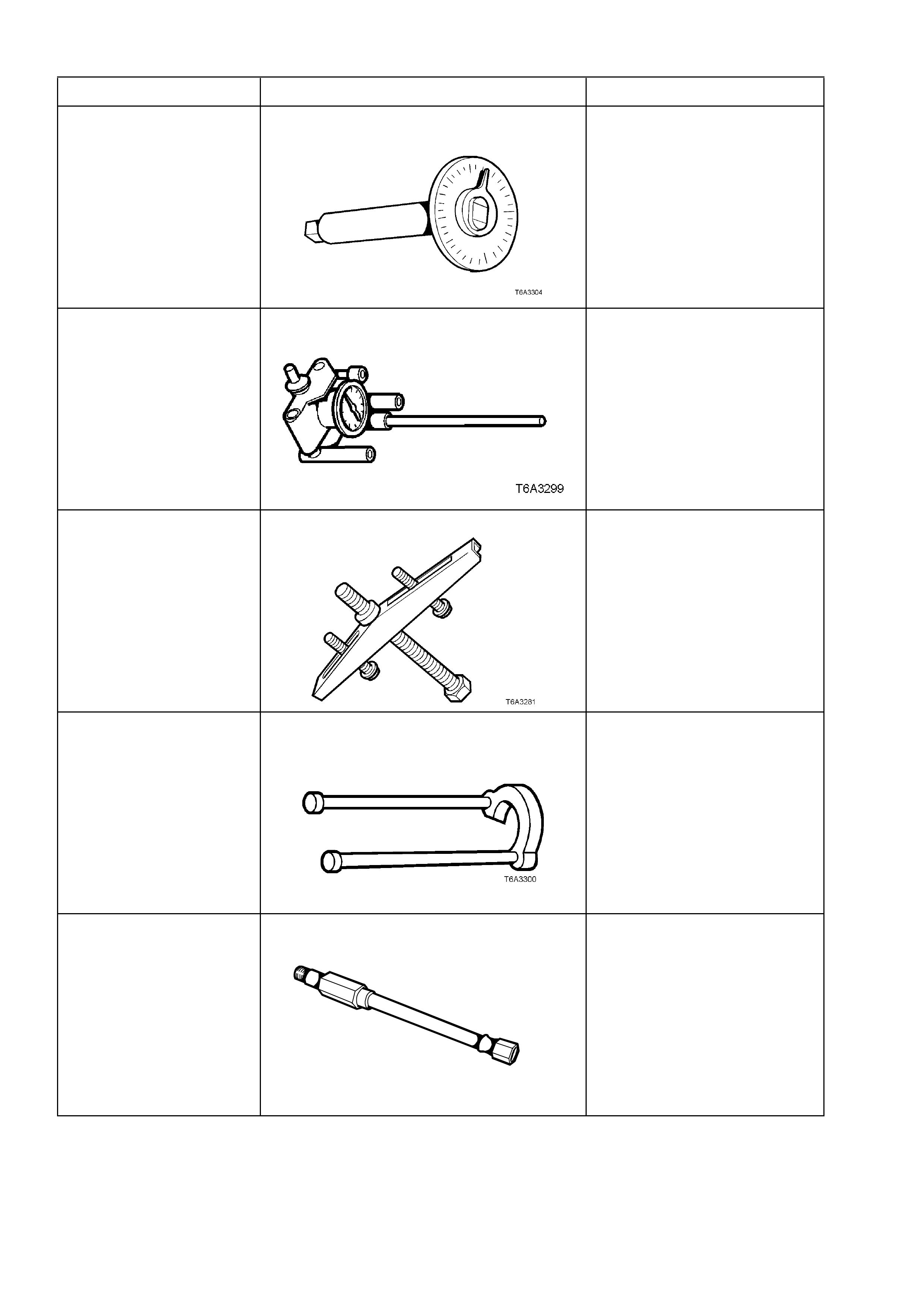

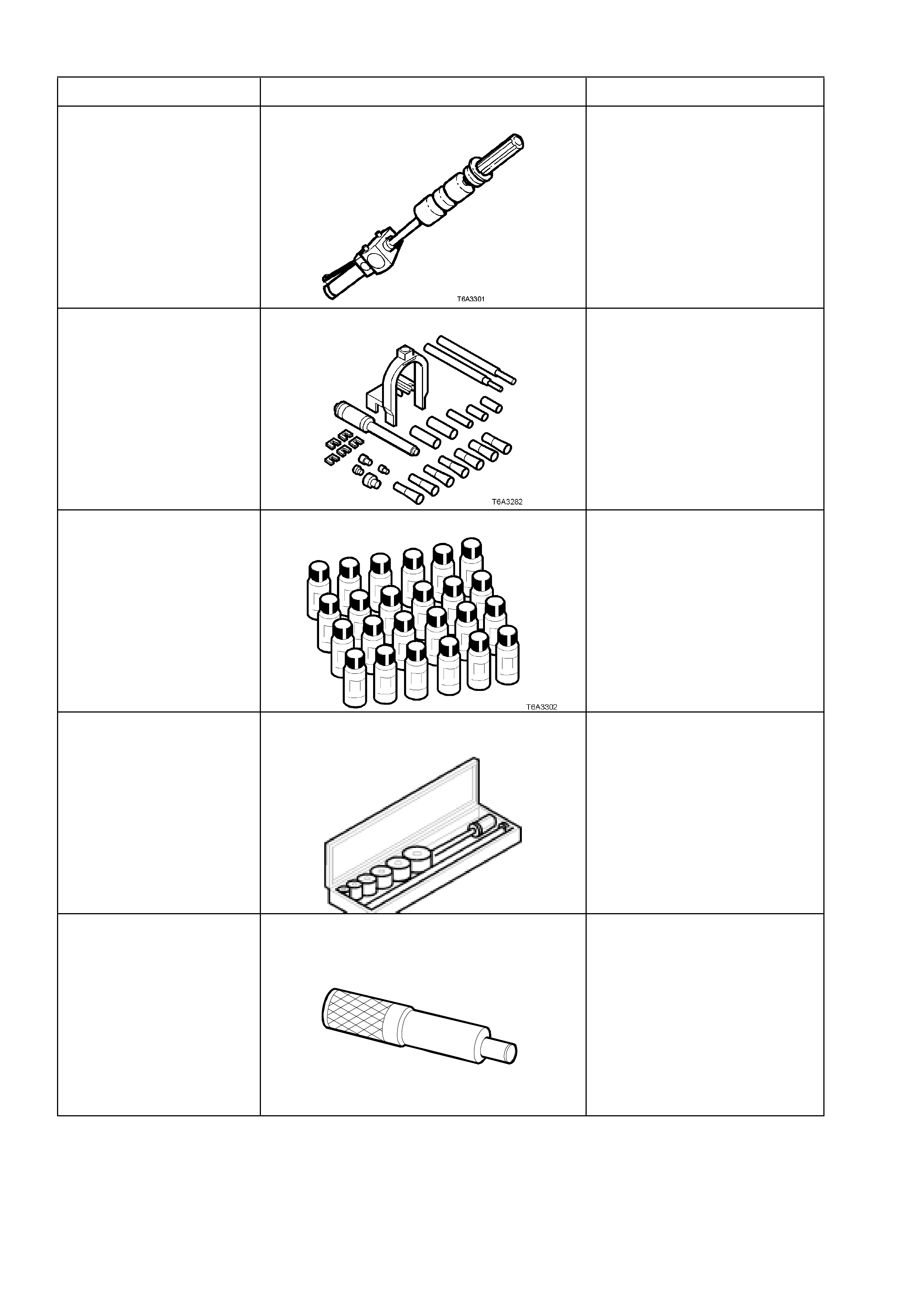

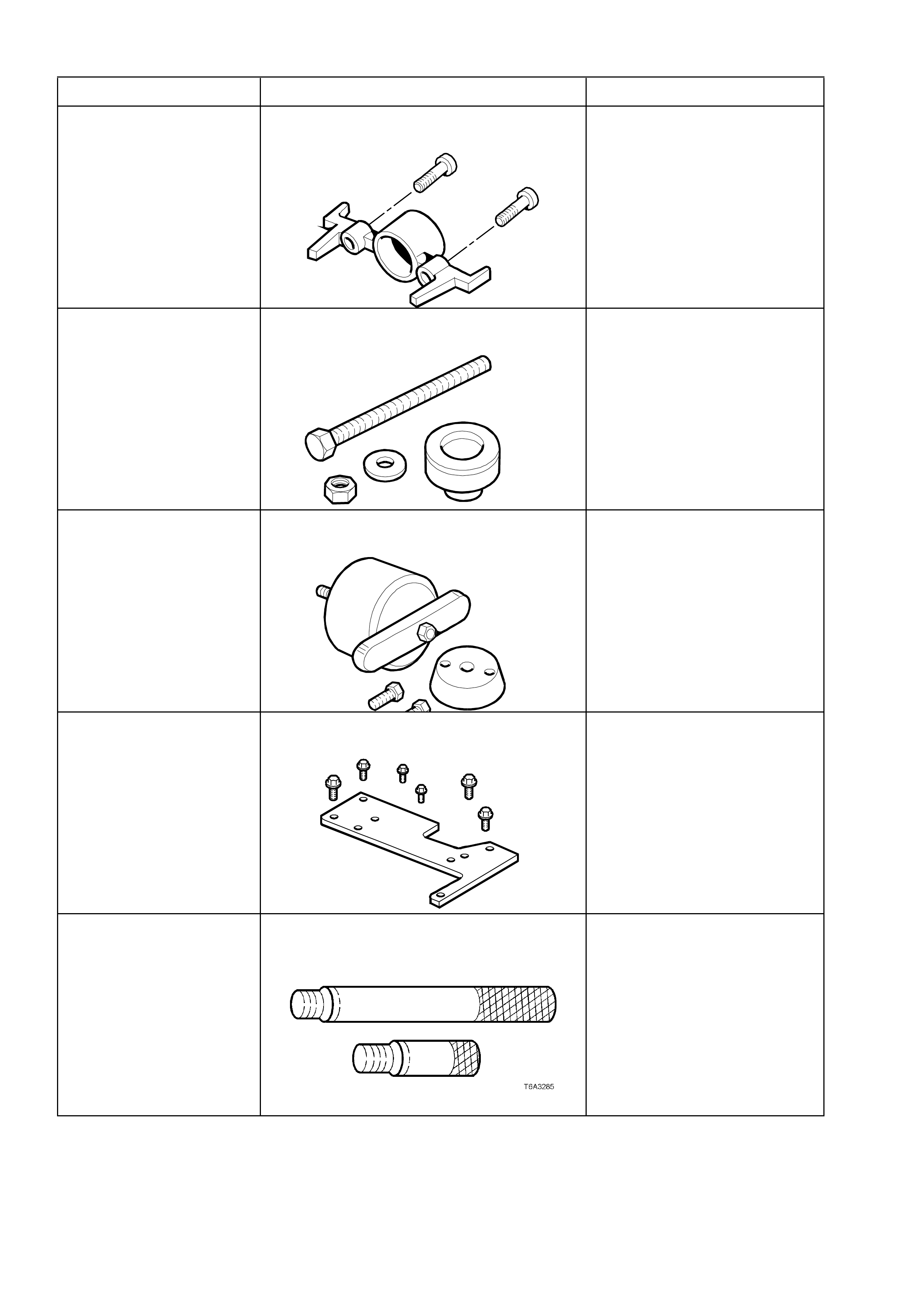

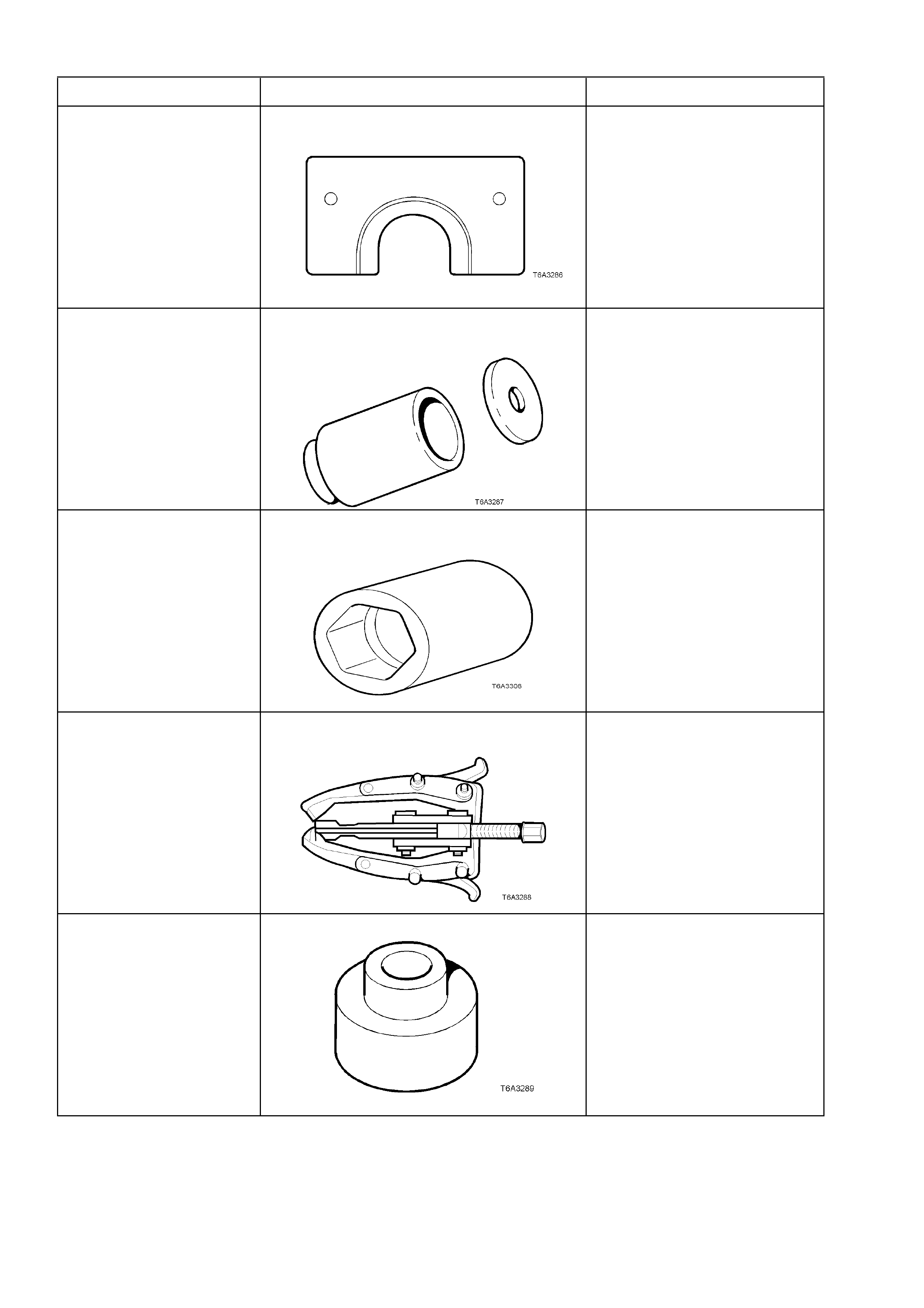

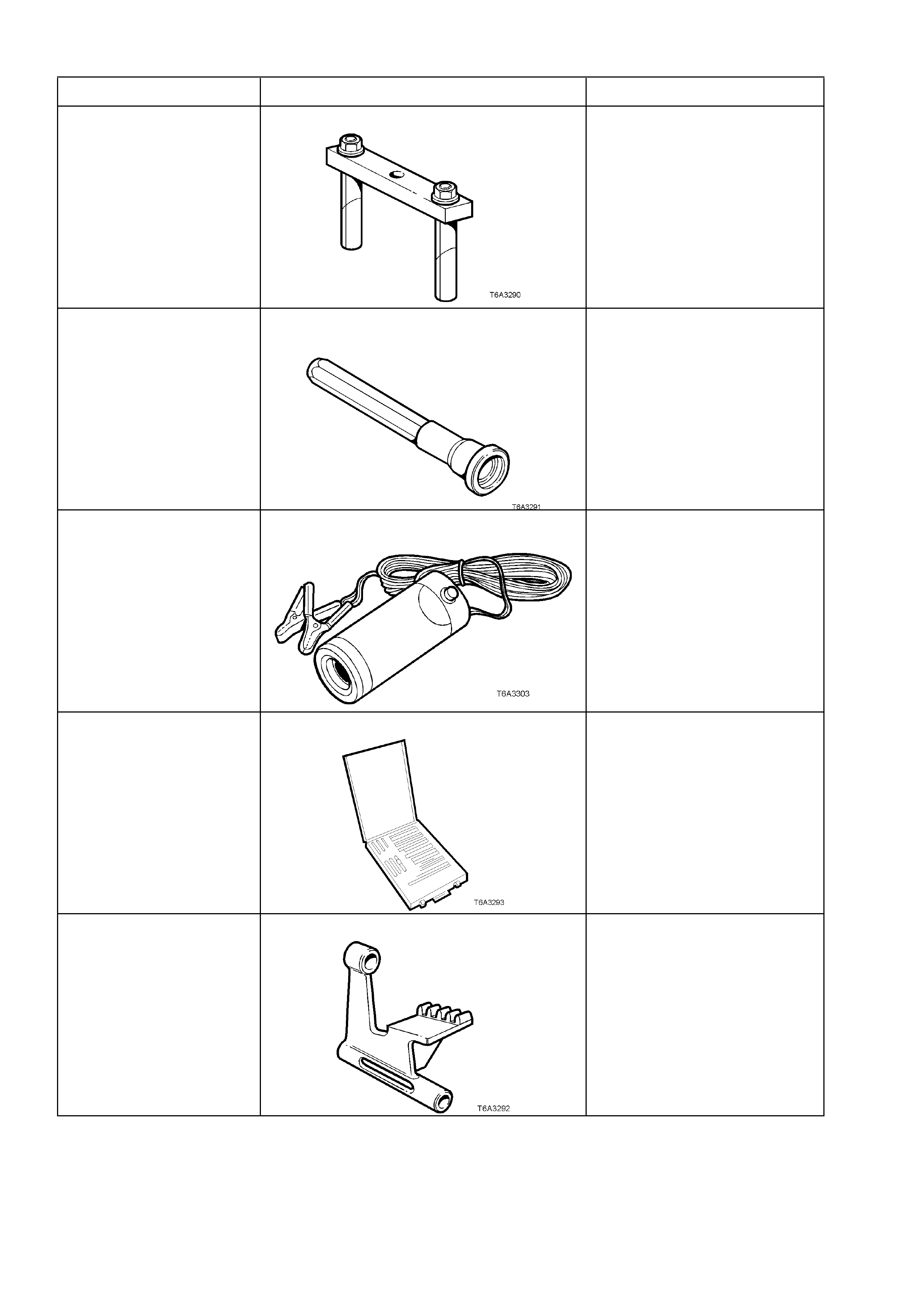

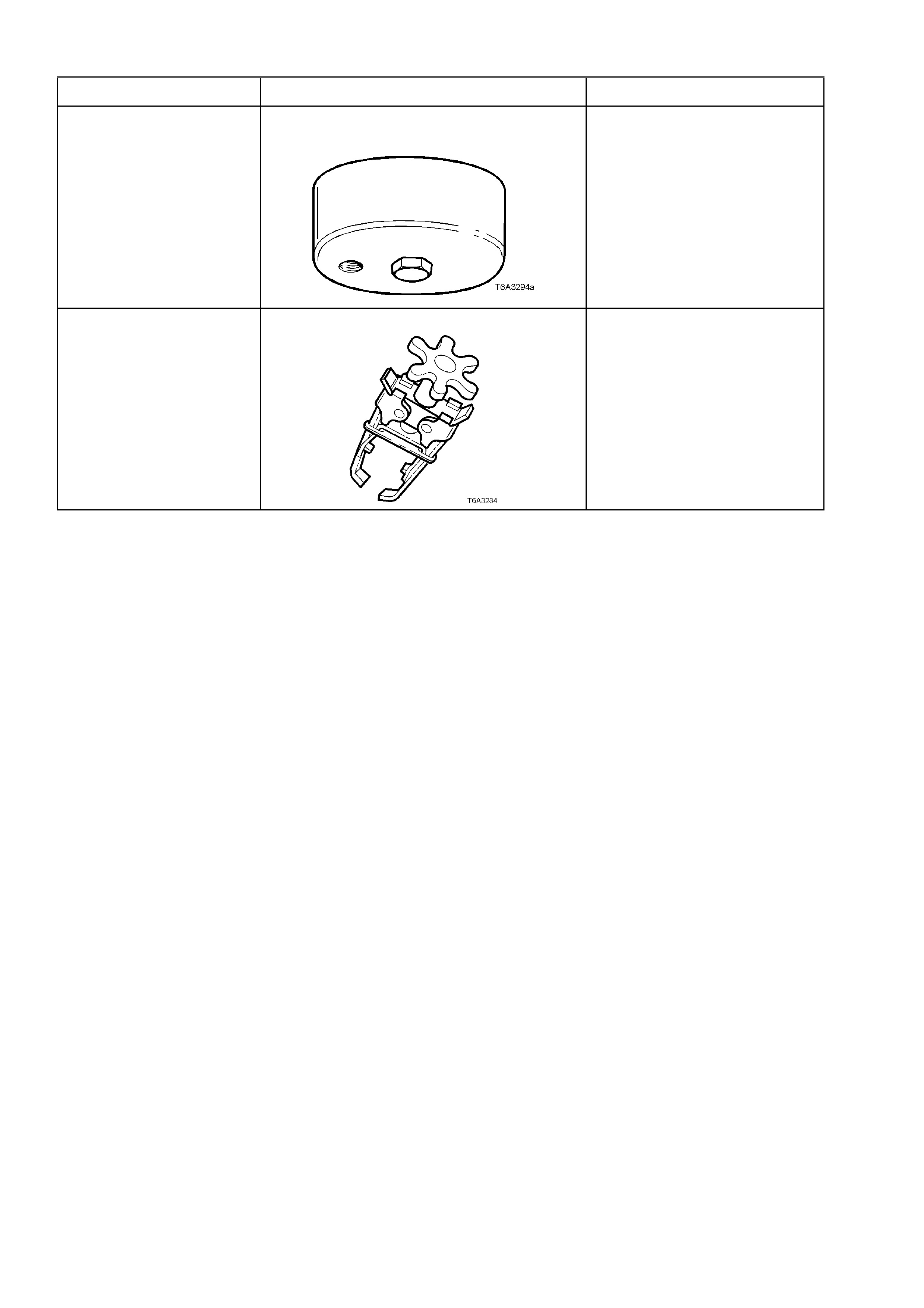

TOOLS AND EQUIPMENT

Special tools are listed and illustrated throughout this Section with a complete listing at the end of the Section.

These tools (or their equivalents) are specially designed to quickly and safely accomplish the operations for which

they are intended. The use of these special tools will also minimise possible damage to engine components. Some

precision m easuring tools are required for inspection of certain critical components. Torque wrenches and torque

angle tools are necessary for the proper tightening of various fasteners.

To properly service the engine assembly, the following items should be readily available:

− Approved eye protection and safety gloves.

− A clean, well-lit, work area.

− A suitable parts cleaning tank.

− A compressed air supply.

− Trays or storage containers to keep parts and fasteners organised.

− An adequate set of hand tools.

− Approved engine repair stand.

− An approved engine lifting device that will adequately support the weight of the components.

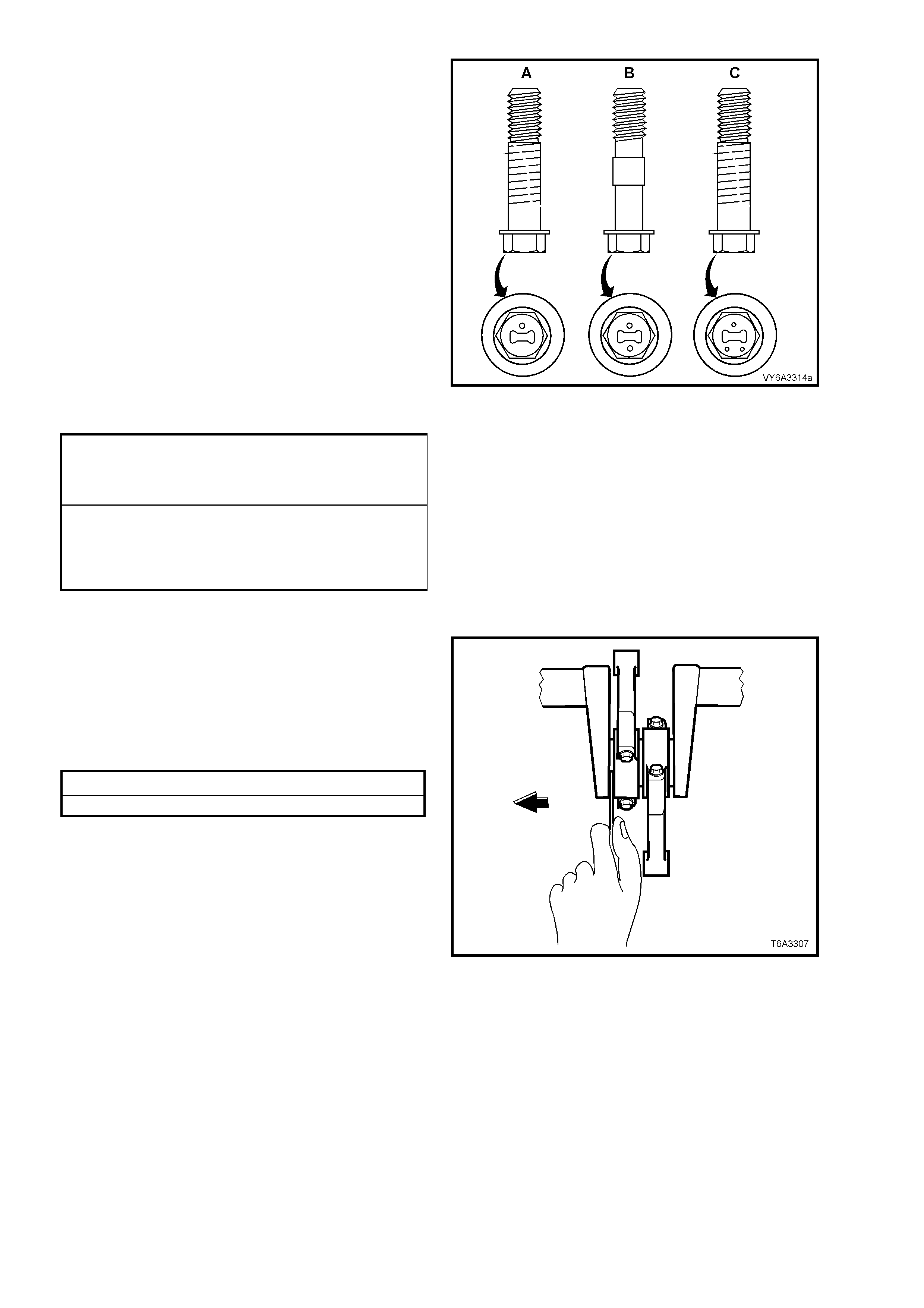

FASTENERS

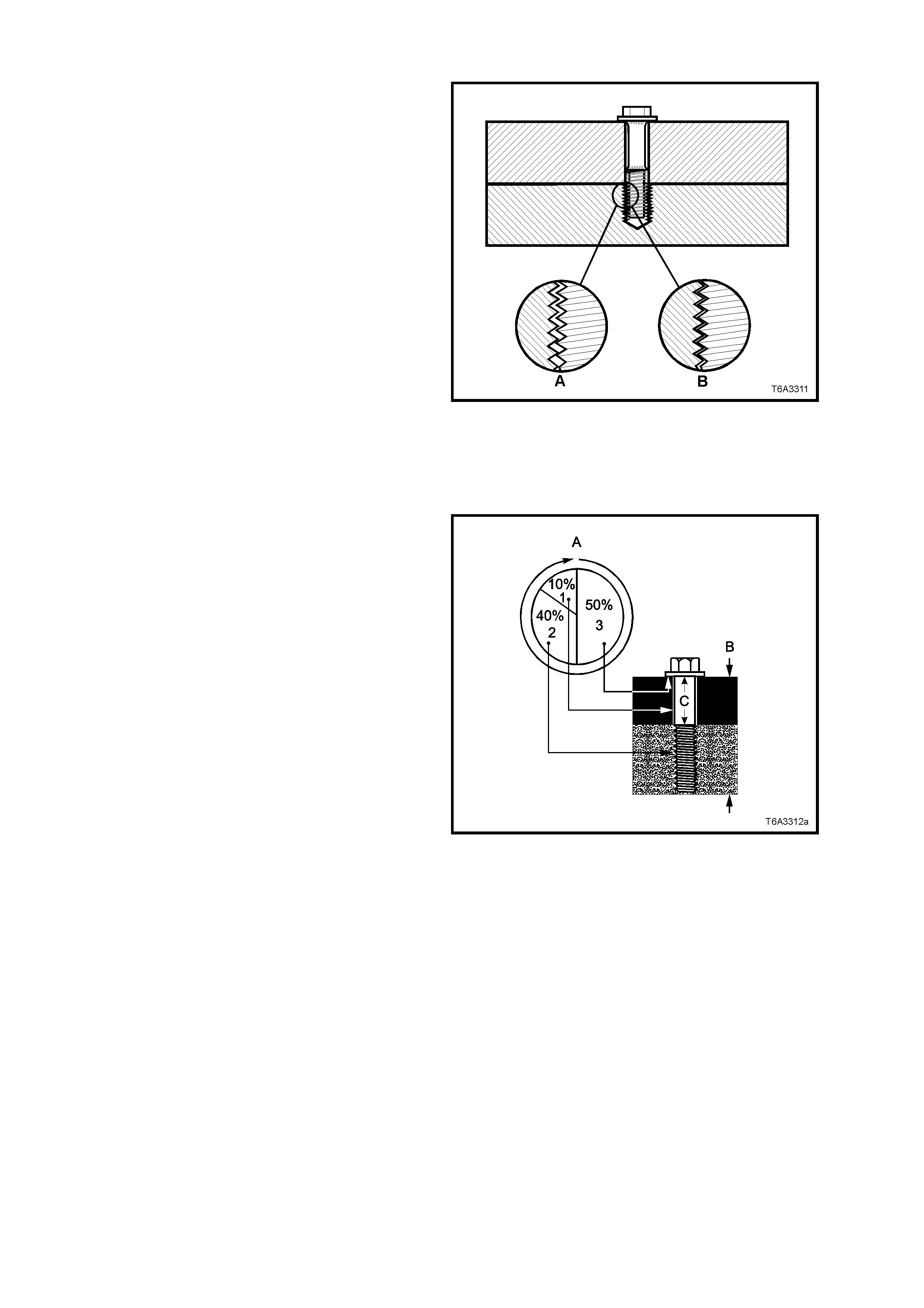

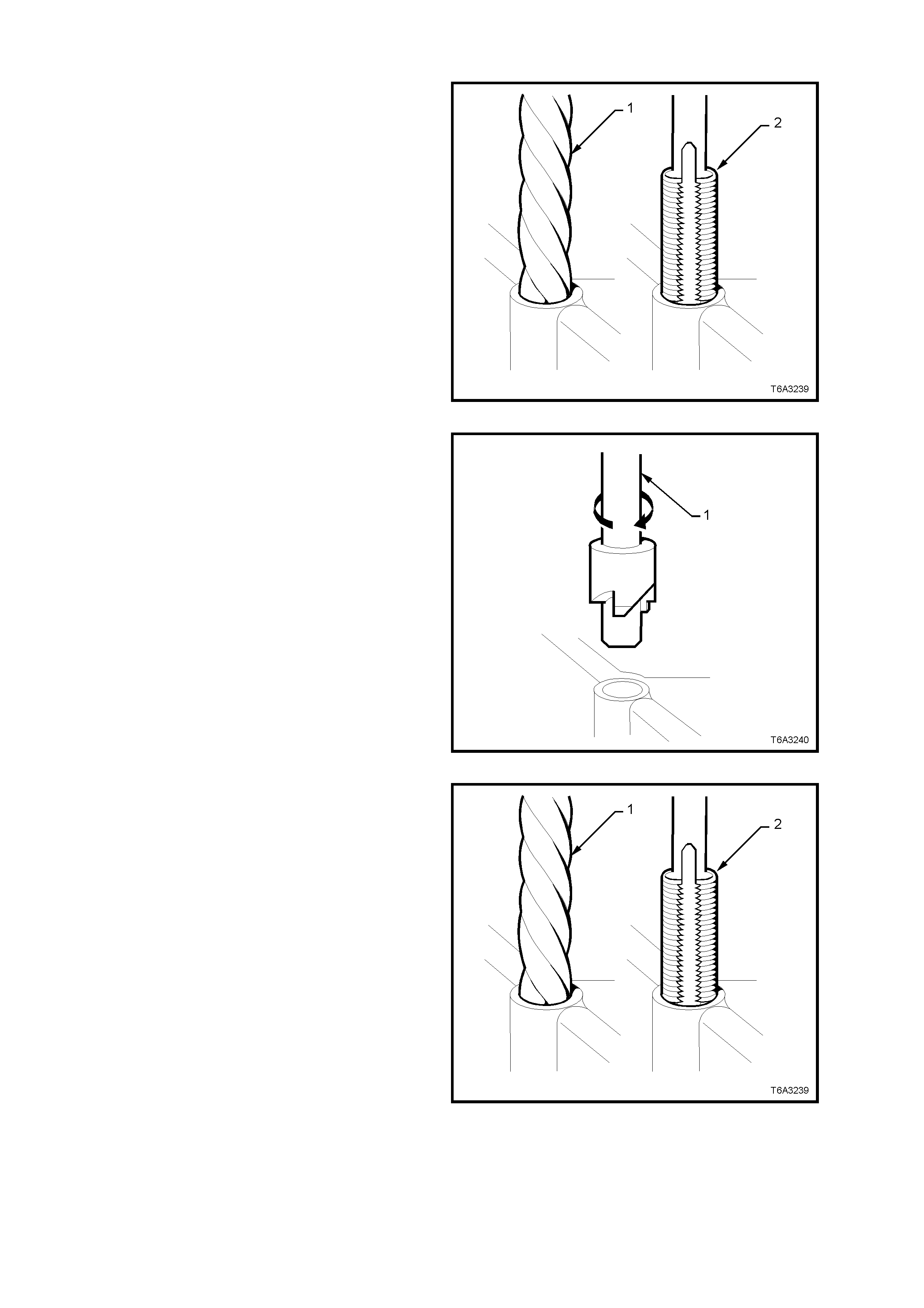

Fasteners are central to the reliable operation of

any engine and the GEN III V8 engine is no

exception.

Whenever any bolt or any other threaded

component is removed from the engine, it is

necess ary to first allow the engine to cool ( inset ‘B’)

before attempting fastener removal.

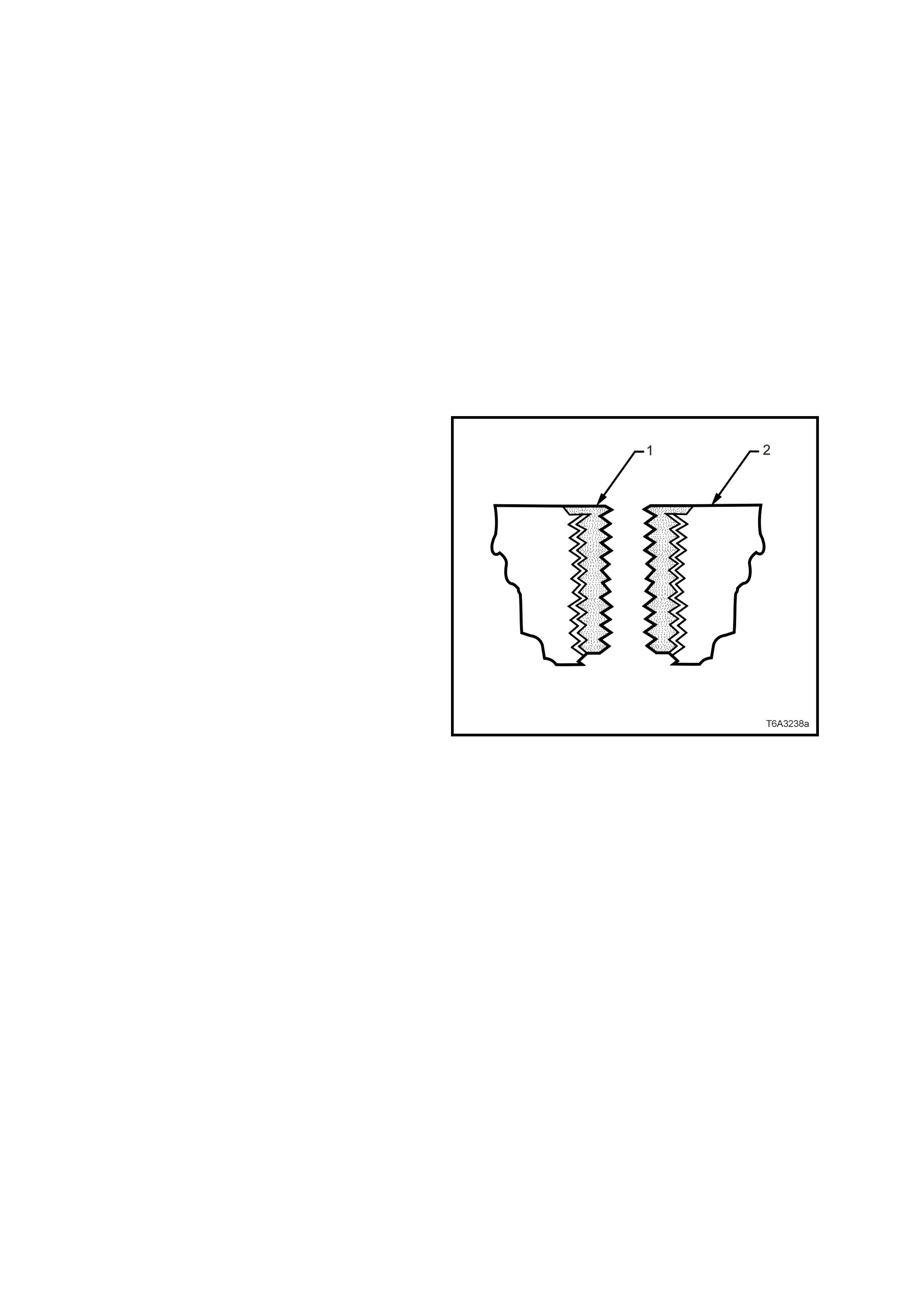

Because of the greater thermal expansion of

aluminium , bolt threads will change dimension to a

greater extent when hot with this m ater ial (ins et ‘A’)

when compared to cast iron.

If a bolt or other threaded component is removed

before the engine is allowed to cool to at least

50° C, threads could be pulled from the cylinder

block or cylinder head.

Also, DO NOT use impact tools to remove bolts

during engine disassembly. While this may be

common practice with cast iron engine

components, use of these tools is more likely to pull

the aluminium threads in the cylinder bloc k or head

of this engine.

Figure 6A3-25

Clamp Load

When torque is applied to a fastener, the fastener

stretches and the joint compresses. The force

developed in the fastener due to its s tre tch is c alled

tension (‘C’), while the force applied to the joint is

called “clamp load” (‘B’).

As shown, only a small portion of the applied torque

(‘A’) is transferred to the clamp load (inset ‘1’).

Friction under the bolt head (inset ‘3’) and in the

threads (inset ‘2’) absorbs much of the applied

torque (‘A’). Typically, only 10% (inset ‘1’) of the

torque is available to develop st retch (or tens ion) in

the fastener and clamp load in the joint.

Therefore, a slight variation in friction in the thread

or under the bolt head, results in a wide variation in

the clamp load applied to the joint.

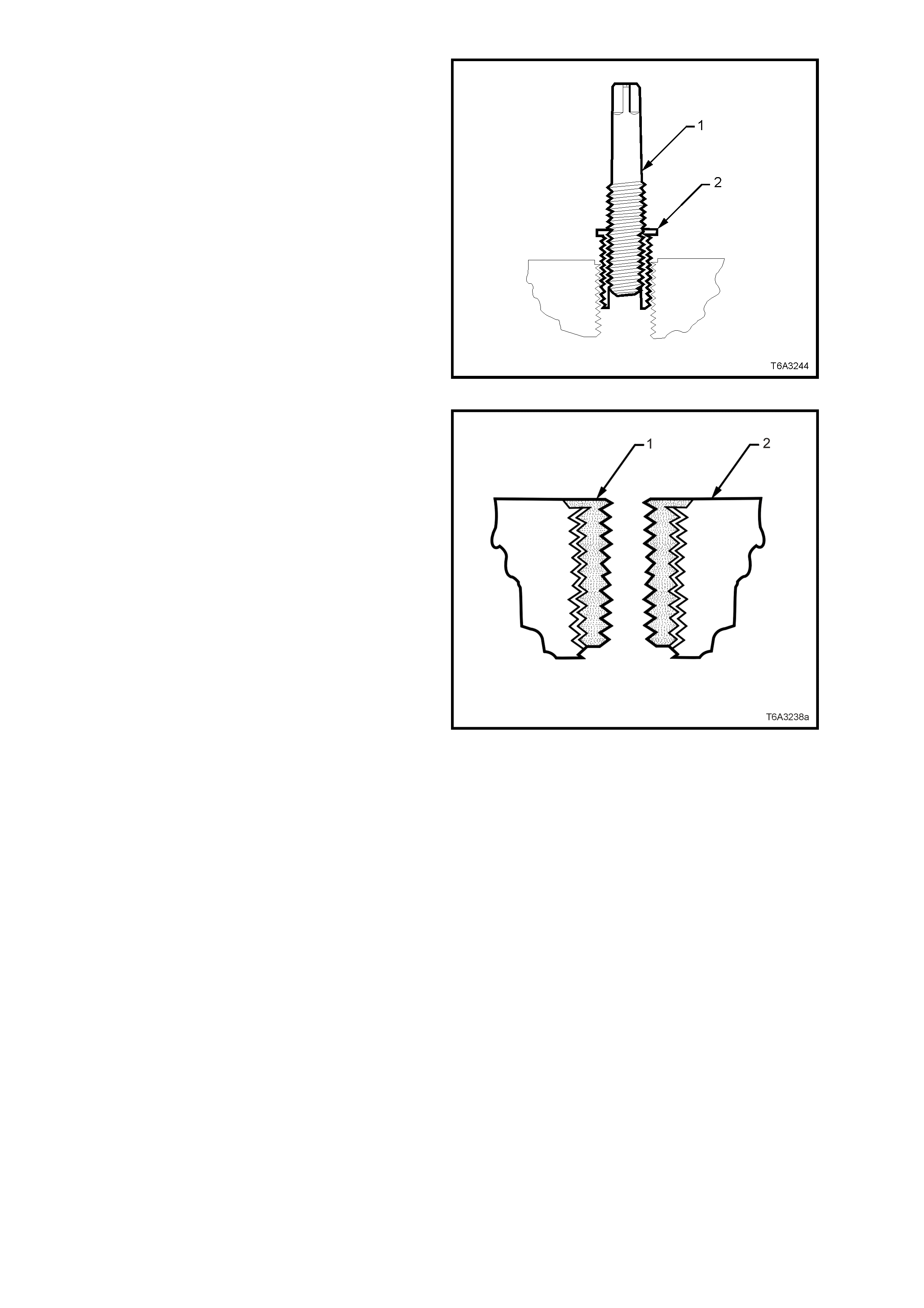

Torque Angle and Torque to Yield Fasteners

The torque angle method of applying torque to a

fastener has been developed to overcome the

effects of friction variation in fastener applications.

The application of the torque angle method does

not always mean that the fastener has to be

replaced after loosening. It is only when the

fastener has been angle tightened to the extent that

the “yield” point has been exceeded, that the

fastener must be replaced.

Examples in the GEN III V8 engine are the main

bearing caps that are angle tightened but the bolts

can be re-used, whereas the M11 cylinder head

bolts that are “T orque to Yield” fastener s, MUST be

replaced after loosening.

Figure 6A3-26

2. MI NOR SERVICE OPERATIONS

2.1 ENGINE OIL LEVEL CHECK

1. Engine must be at normal operating temperature (drive the vehicle for 15 minutes).

2. Park vehicle on level surface (as this will affect the accuracy indicated on dipstick:- this is a critical

requirement).

3. Do not check oil level for at least 10 minutes after engine shut down to allow oil to drain back into the oil pan.

4. Remove dipstick and wipe clean.

5. Reinstall dipstick, with the “ADD/FULL” marks facing towards the centre of the engine, ensuring that it is fully

seated. After leaving for several seconds, slowly remove to avoid sm earing, then hold horizontally to avoid oil

running along dipstick.

6. Observe the oil level where it passes over the centre line of the dipstick.

7. When topping up the engine oil, allow approxim ately 15 minutes f or the oil added to fully drain into the oil pan.

Alternatively, add 55 ml of oil for each millimetre below the “FULL” mark on the dipstick.

2.2 ENGINE OIL - CHANGE

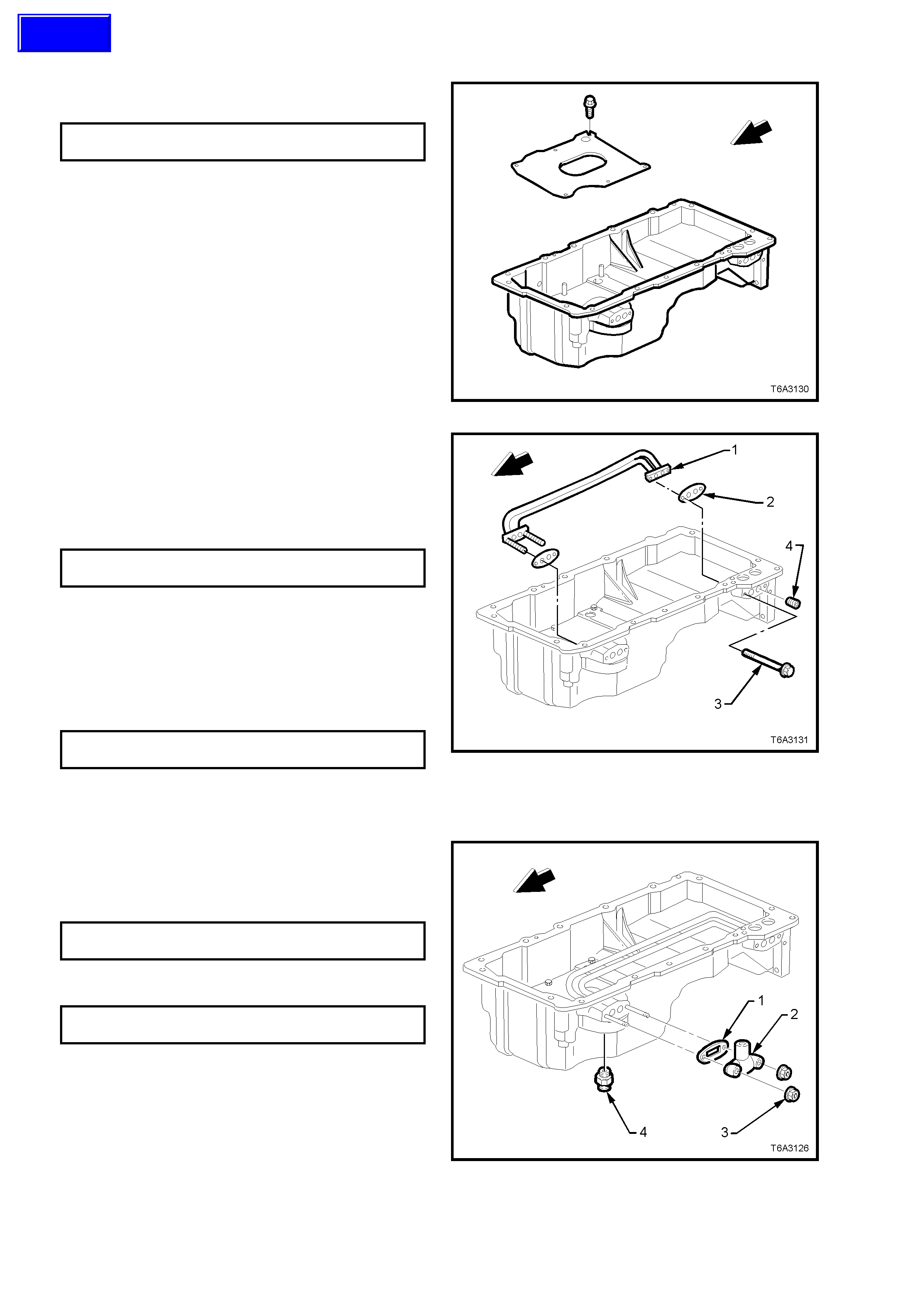

NOTE 1: Quicker and more complete draining will

occur if the engine oil is at operating temperature.

However, care must be taken to avoid scalding

from the hot oil.

NOTE 2: While the oil pan is aluminium, they are

fitted with steel thread inserts to increase durability

of the thread and to avoid thread tearing when the

drain plug is removed from the hot engine.

NOTE 3: It is als o r ec ommended that the oil f ilter is

changed at each engine oil change, refer

2.3 ENGINE OIL FILTER & ADAPTOR, in this

Section.

1. Raise the engine hood and remove the oil fill

cap.

2. Raise the vehicle front and rear to maintain a

level attitude and support with safety stands.

This is to ensure complete draining. Refer to

0A GENERAL INFORMATION in of the VT

Series I Service Information.

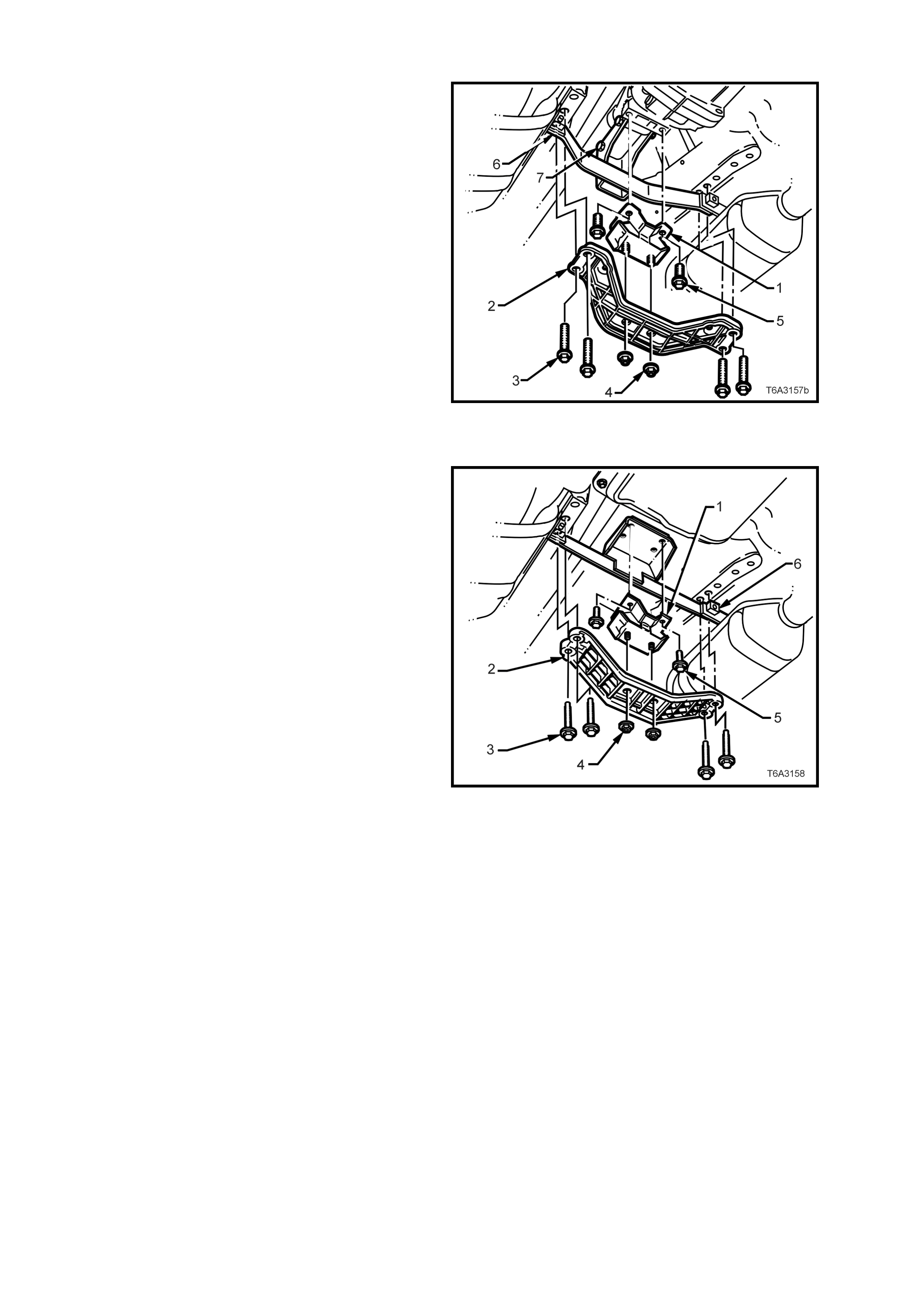

3. Remove the four bolts securing the oil pan

under-tray.

4. Clean any foreign m aterial from around the oil

pan drain plug.

5. Place an oil drain tray beneath the engine.

6. Using a 15 mm ring spanner, remove the

drain plug, taking care to avoid scalding with

the hot waste oil.

7. W hen the oil has drained sufficiently, reinstall

the drain plug, after inspecting and cleaning

the threads and inspecting the magnetic plug

end for f er rous material. T he dr ain plug O -r ing

seal may be re-used if not cut or damaged.

Tighten the drain plug to the correct torque

specification.

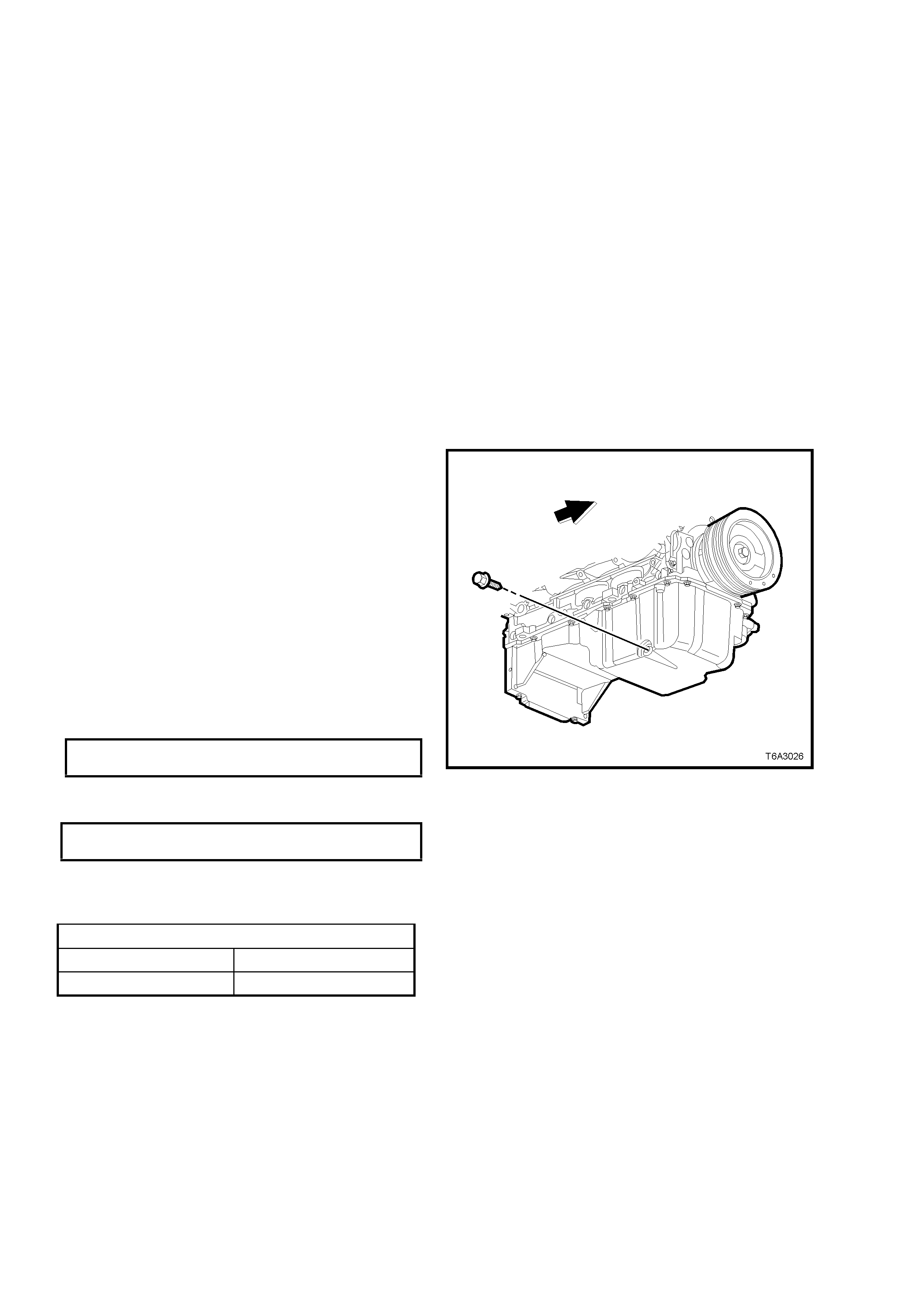

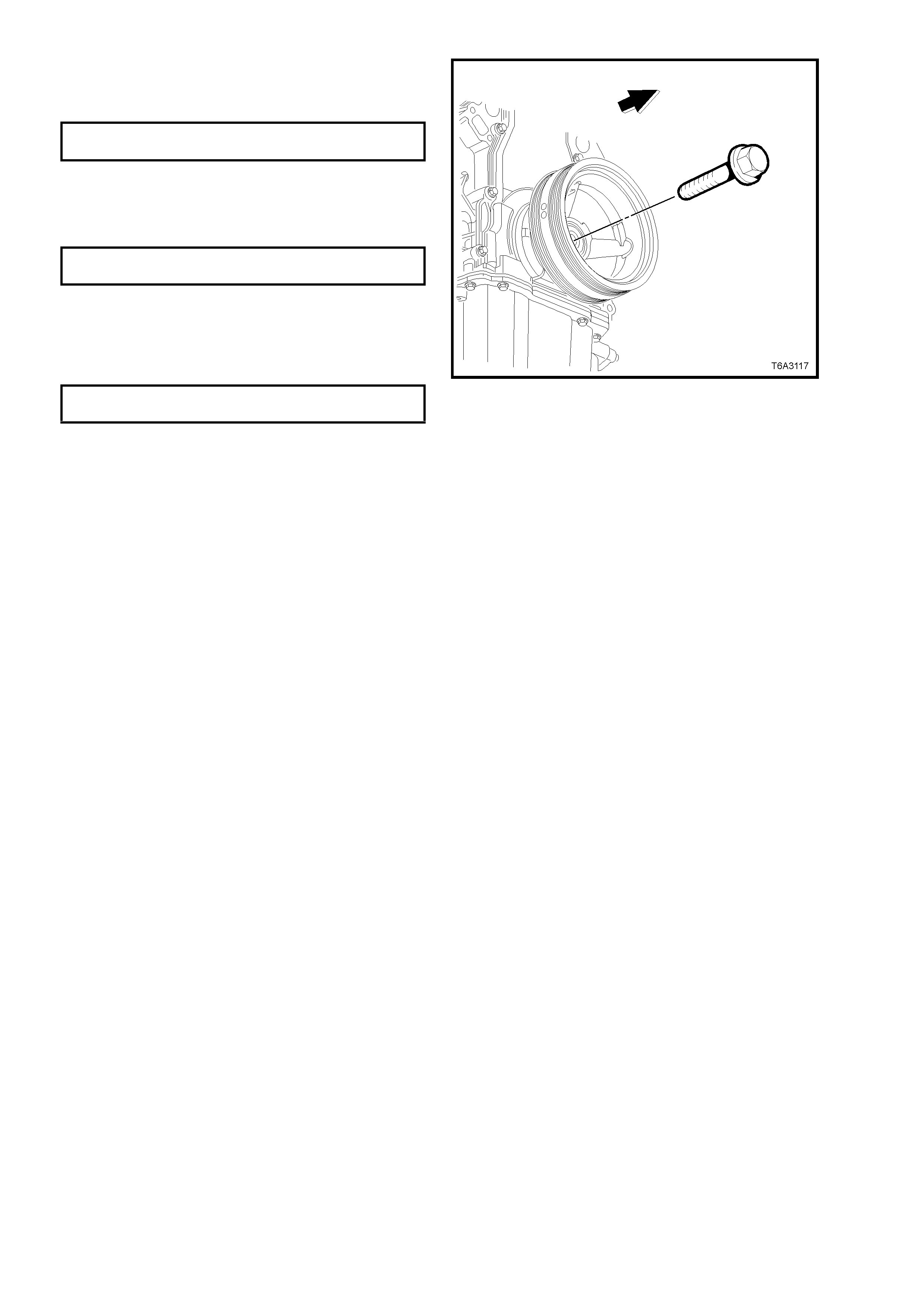

ENGINE OIL PAN DRAIN PLUG

TORQUE SPECIFICATION 25 Nm

8. Reinstall the oil pan under - tray and tighten the

four bolts to the correct torque specification.

OIL PAN UNDER-TRAY BOLT

TORQUE SPECIFICATION 30 - 35 Nm

9. Lower the vehicle and fill the crankcase with

the required amount of 10W - 30 SJ GF2

lubricant.

Figure 6A3-27

ENGINE OIL CAPACITY

Without Oil Filter Change 4.7 litres

With Oil Filter Change 5.0 litres

NOTE: Synthetic oils of this viscosity are also an

acceptable engine lubricant.

10. Start the engine and check for oil leaks.

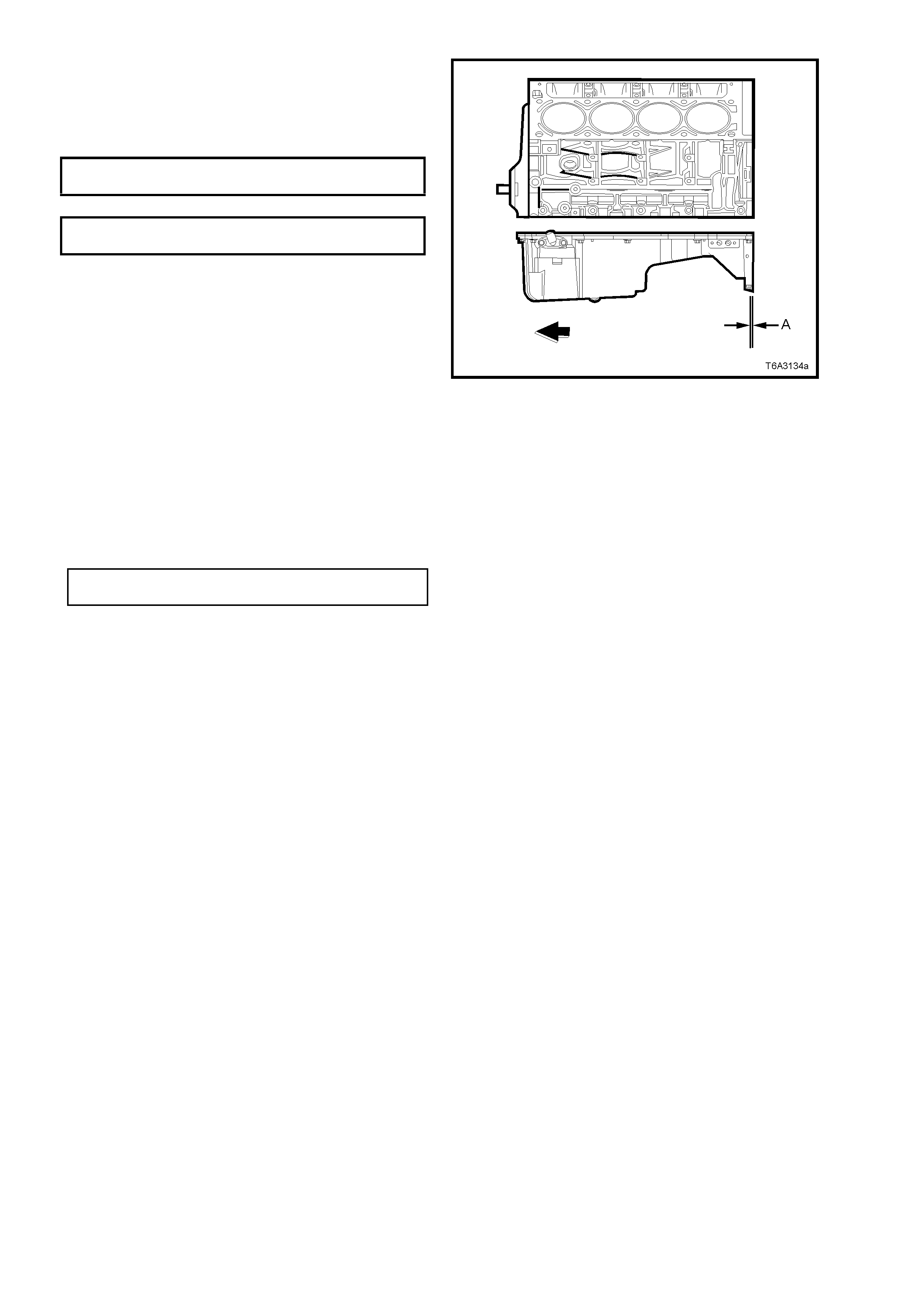

2.3 ENGINE OIL FILTER & ADAPTOR

NOTE: The oil filter should be replaced at the time

or distance intervals, specified in the Owner’s

Handbook or whenever the engine oil is changed.

REPLACE

1. Raise the engine hood and remove the oil fill

cap.

2. Raise the vehicle front and rear to maintain a

level attitude and support with safety stands.

This is to ensure complete draining. Refer to

0A GENERAL INFORMATION in of the VT

Series I Service Information.

3. Remove the four bolts securing the oil pan

under-tray.

4. Drain the engine oil as detailed in

2.2 ENGINE OIL - CHANGE, in this Section.

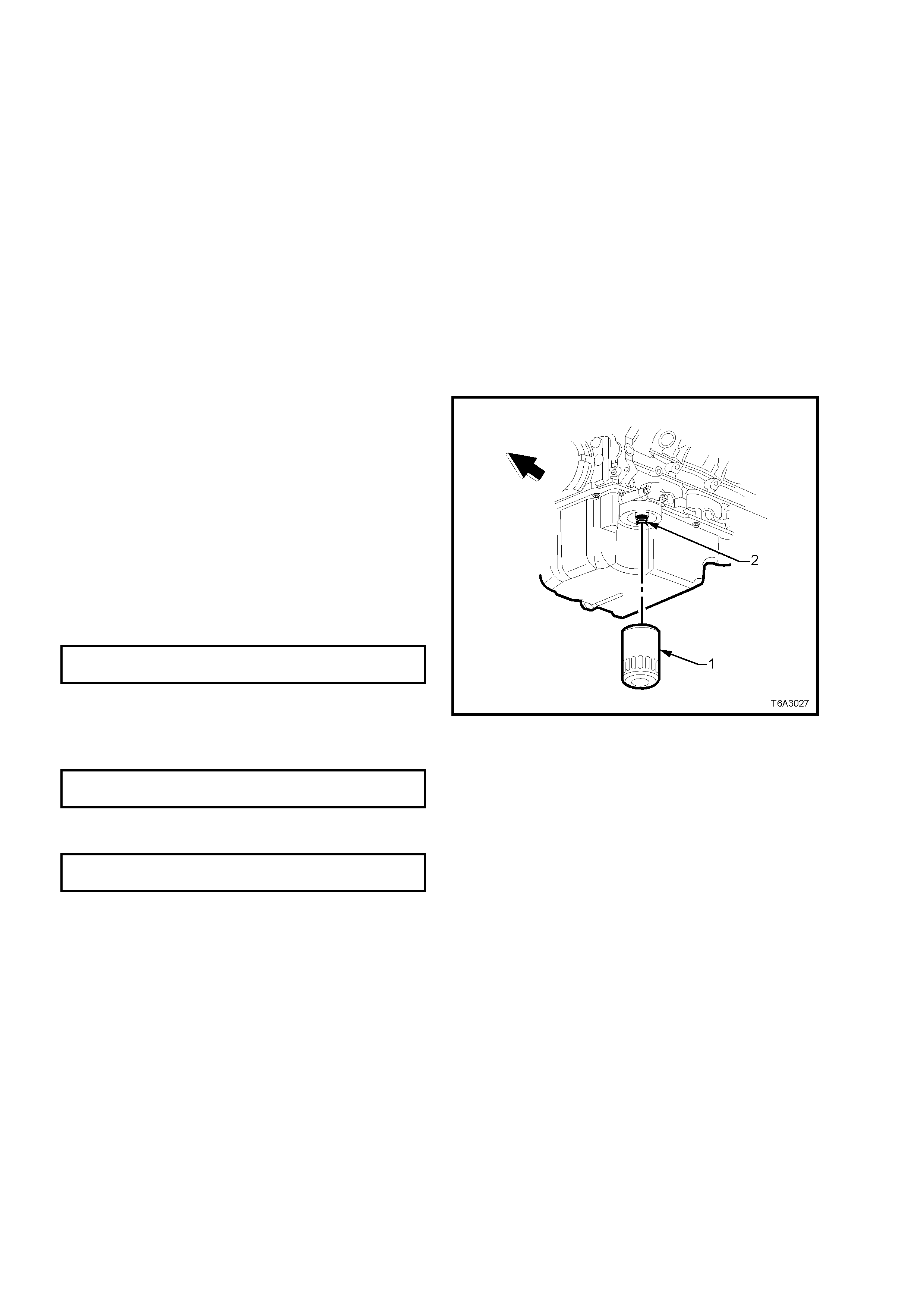

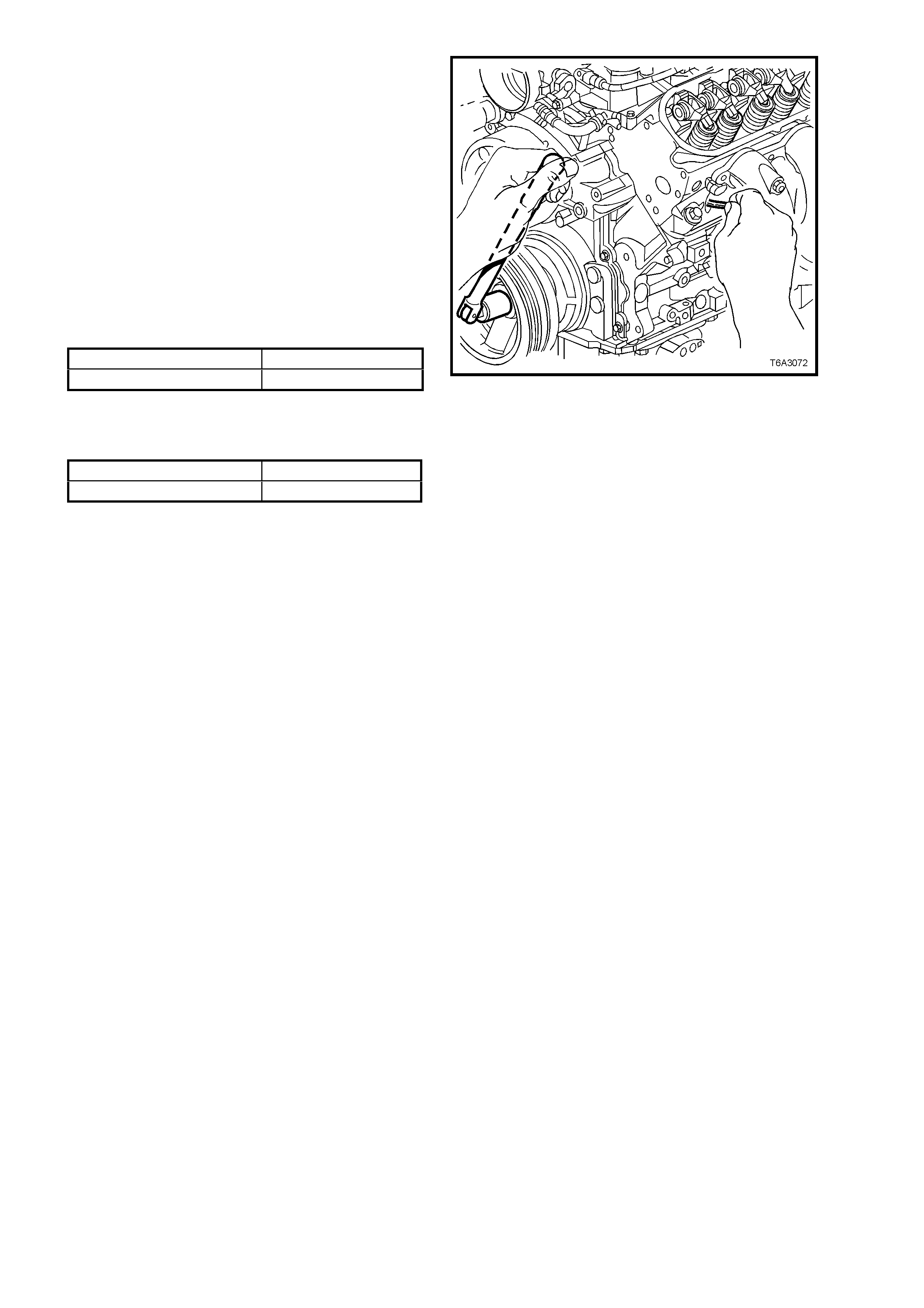

5. Remove the oil filter (1), using a commercially

available tool, taking care to avoid being

scalded with the hot waste oil.

6. Should it be required, remove the oil filter

adaptor (2) from the oil pan filter mounting

flange, using a suitable socket.

7. After checking that the filter seal has not

adhered to the oil pan flange, inspect the oil

filter sealing surface for scratches or other

damage and check the oil filter adaptor

threads for damage.

8. If removed, reinstall the oil filter adaptor and

tighten to the correct torque specification.

OIL FILTER ADAPTOR

TORQUE SPECIFICATION 55 Nm

9. Sm ear s om e new engine oil onto the new f ilter

seal, then install filter assembly to engine.

10. Tighten oil filter to the correct torque

specification.

ENGINE OIL FILTER

TORQUE SPECIFICATION 30 Nm

11. Reinstall the oil pan under- tray and tighten the

four bolts to the correct torque specification.

OIL PAN UNDER-TRAY BOLT

TORQUE SPECIFICATION 30 - 35 Nm

12. Lower the vehicle and fill the crankcase with

the required amount of recommended, new

lubricant. Refer to 2.2 ENGINE OIL -

CHANGE, in this Section for the

recommended procedure.

13. Start the engine and check for oil leaks.

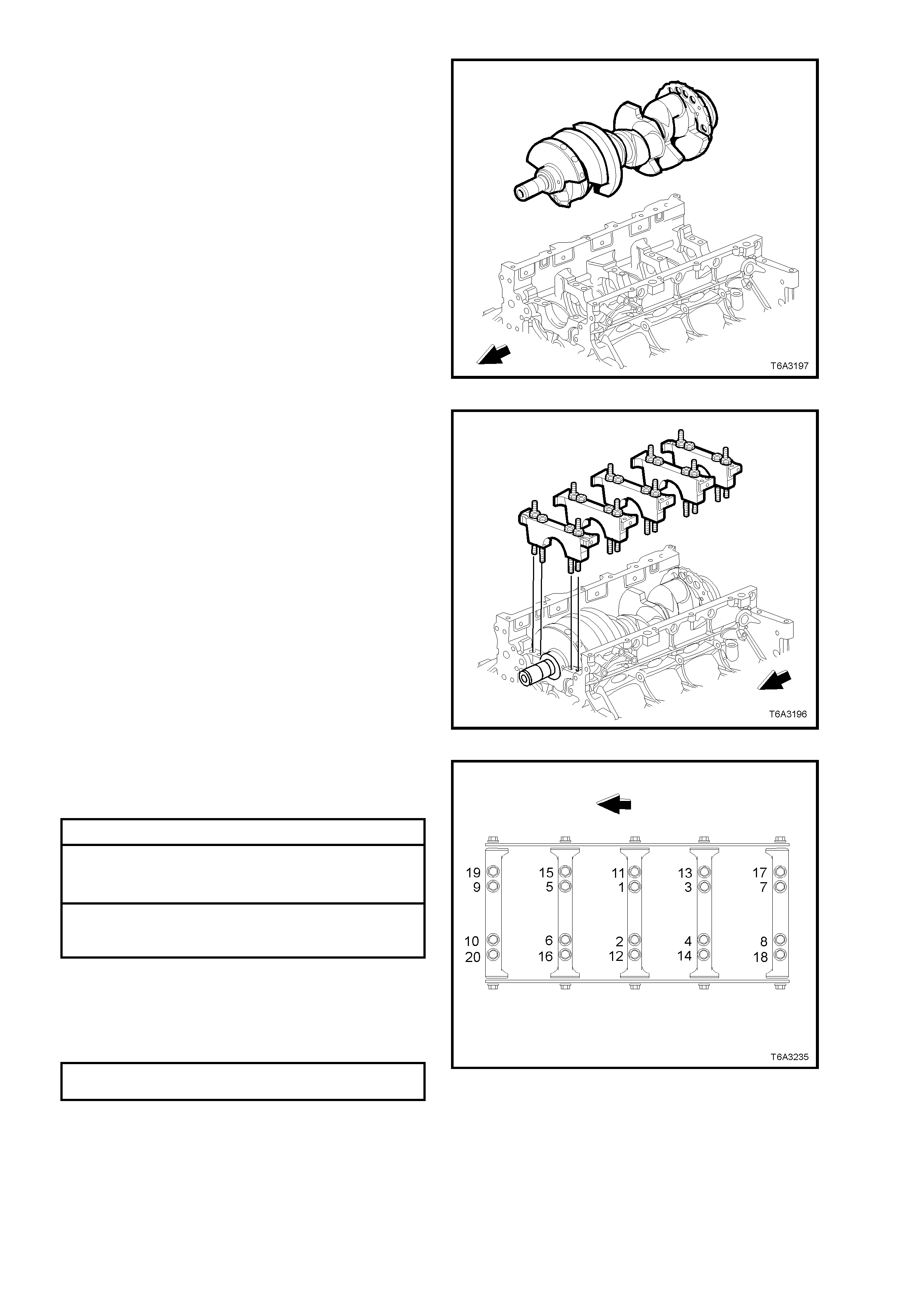

Figure 6A3-28

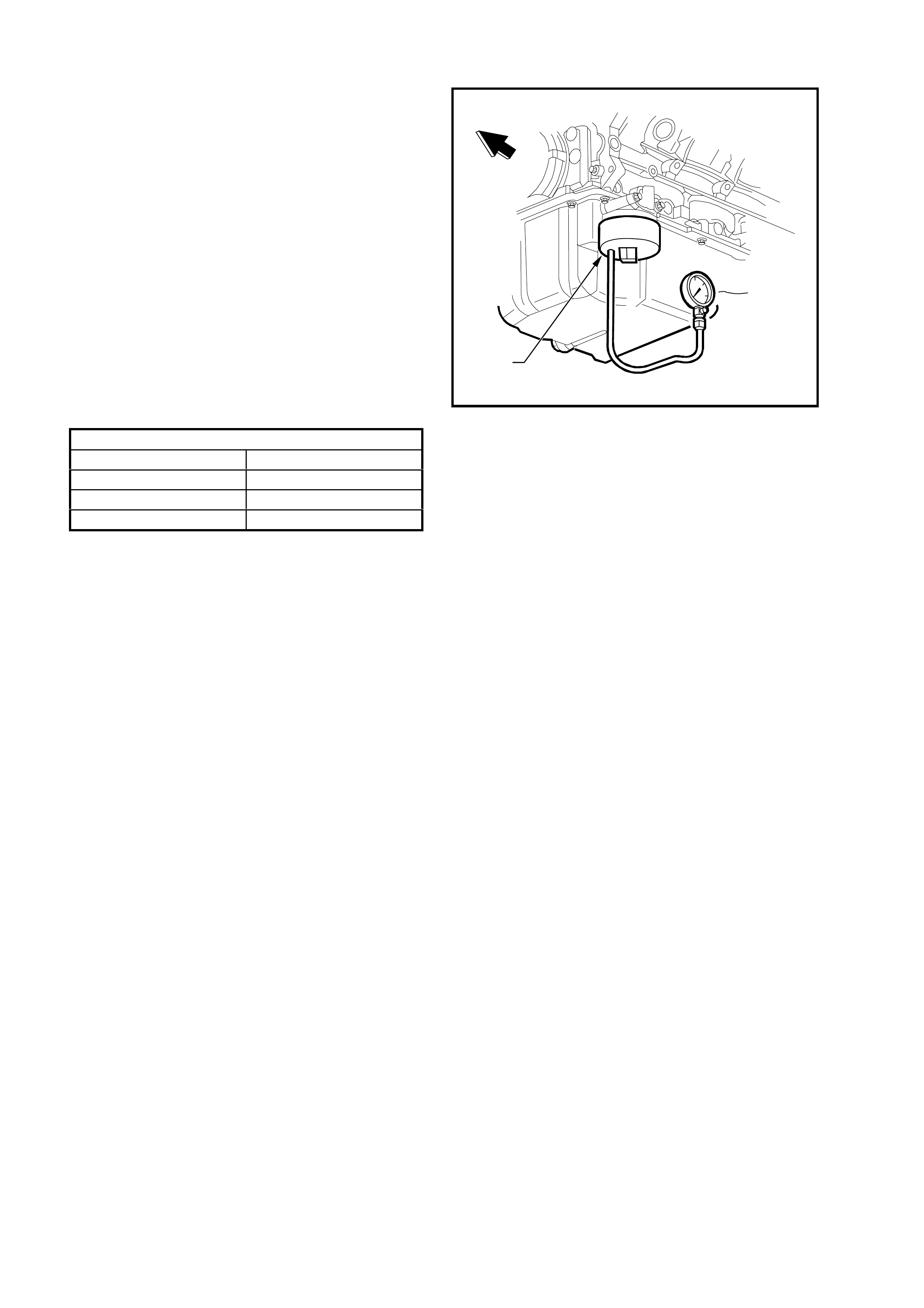

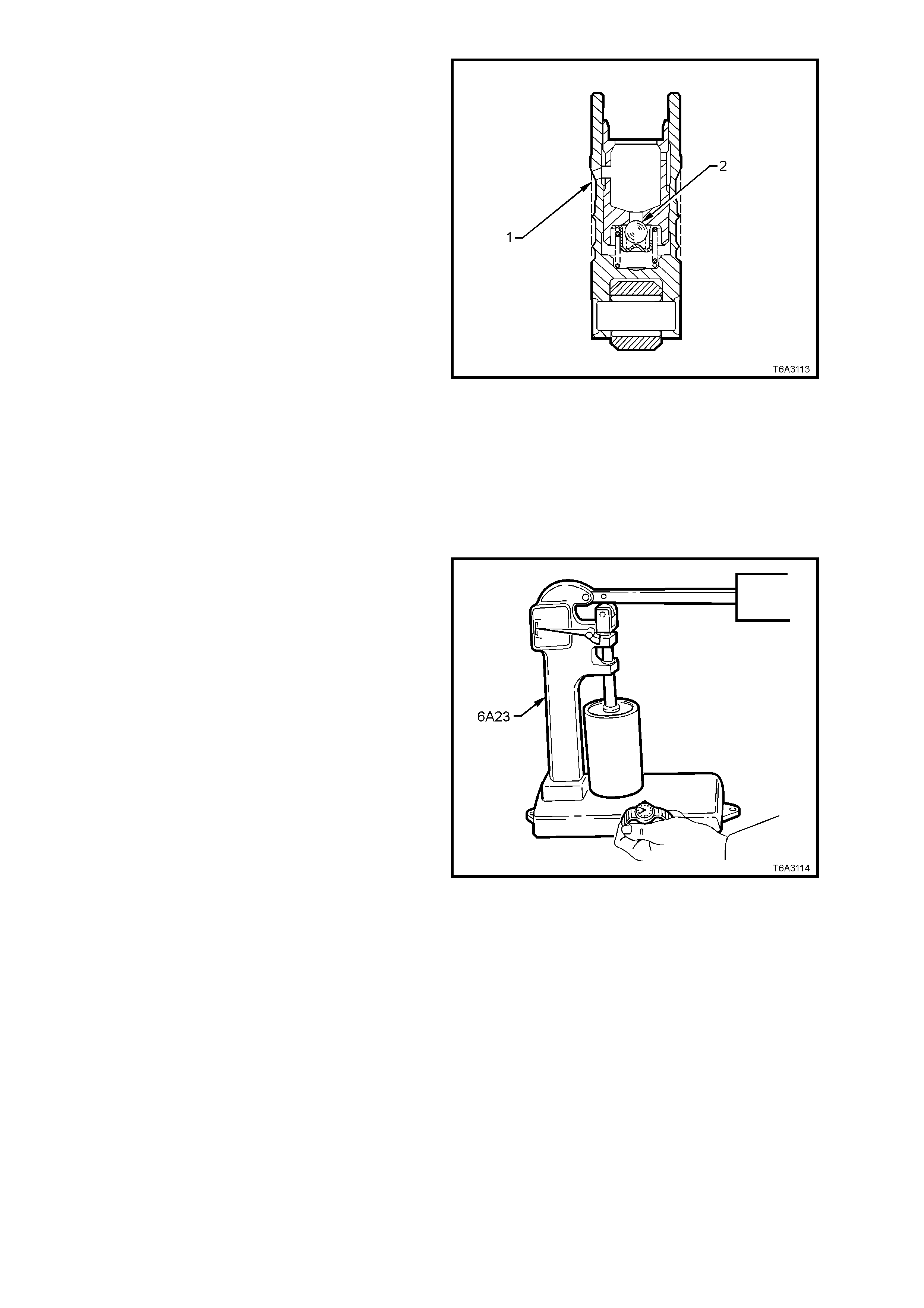

2.4 ENGINE OIL PRESSURE - CHECK

1. Ensure that engine is at operating

temperature. Driving a cold vehicle for 15

minutes, should be sufficient to normalise the

temperature.

2. Remove oil filter, as detailed in Operation 2.3.

3. Install adaptor J 42907 to the oil filter adaptor.

4. On a level surface, check engine oil level and

top up as required. See Operation 2.2 in this

Section.

5. Install commercially available, accurate oil

pressure gauge (capable of reading 800 kPa

or higher) and suitably rated pres sure hose, to

adaptor J 42907.

6. Start the engine and check the oil pressure

with the engine running with no load.

7. Check that the oil pressure is within the

following specifications.

NOTE: If the oil pressure check indicates that the

oil pressure is not to specification, then refer to

4.5 OIL PRESSURE DIAGNOSIS, in this Section.

T6A3082a

J 42907

Figure 6A3-29

8. After completing the pressure check, stop the

engine and remove the oil pressure gauge

and adaptor assembly.

9. Install the oil filter. Refer 2.3 ENGINE OIL

FILTER & ADAPTOR, in this Section.

10. Top up engine oil level as required.

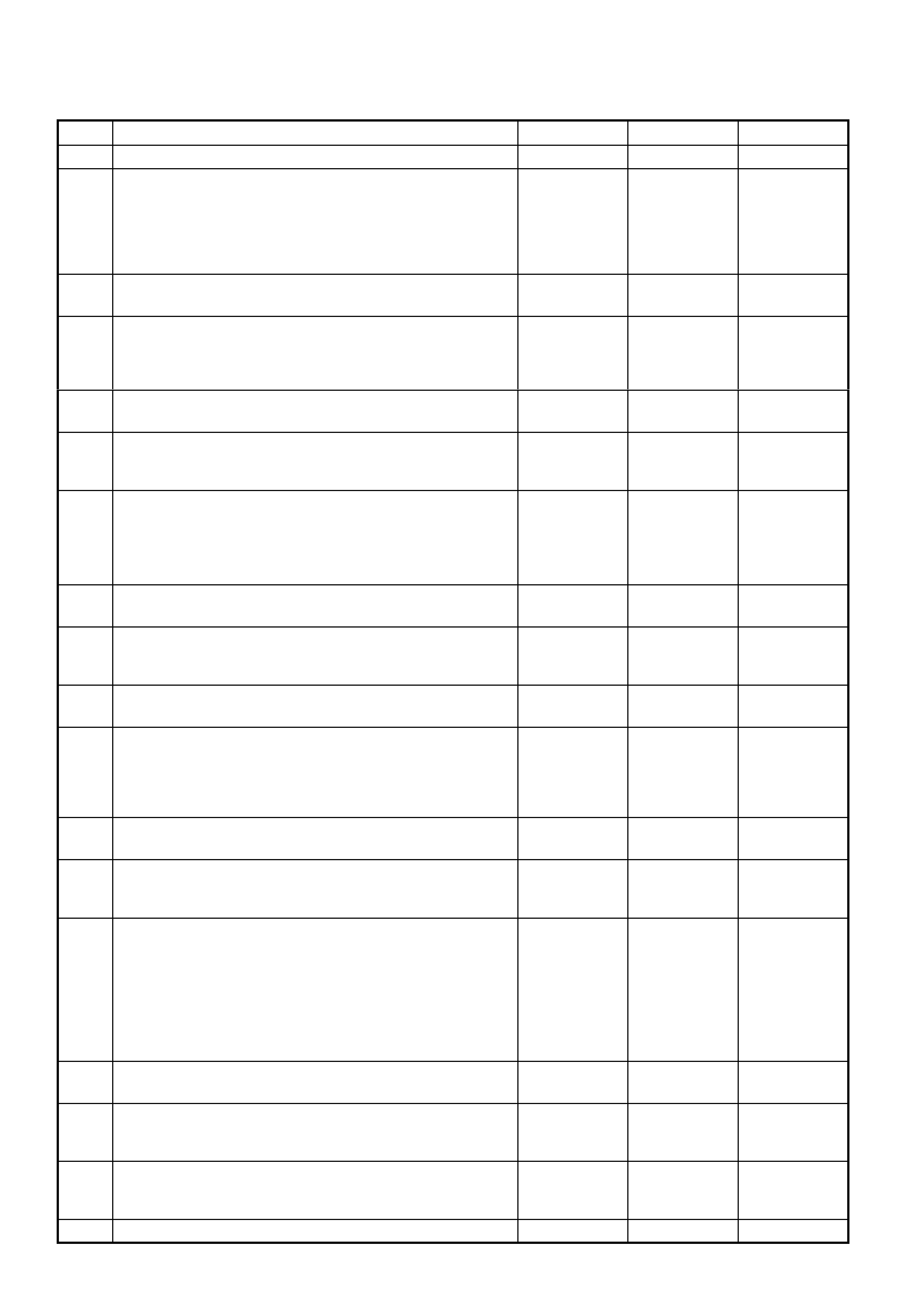

ENGINE OIL PRESSURE SPECIFICATION

ENGINE SPEED OIL PRESSURE READING

1,000 rpm 50 kPa (Minimum , Hot)

2,000 rpm 125 k P a (Mini mum, Hot)

4,000 rpm 165 k P a (Mini mum, Hot)

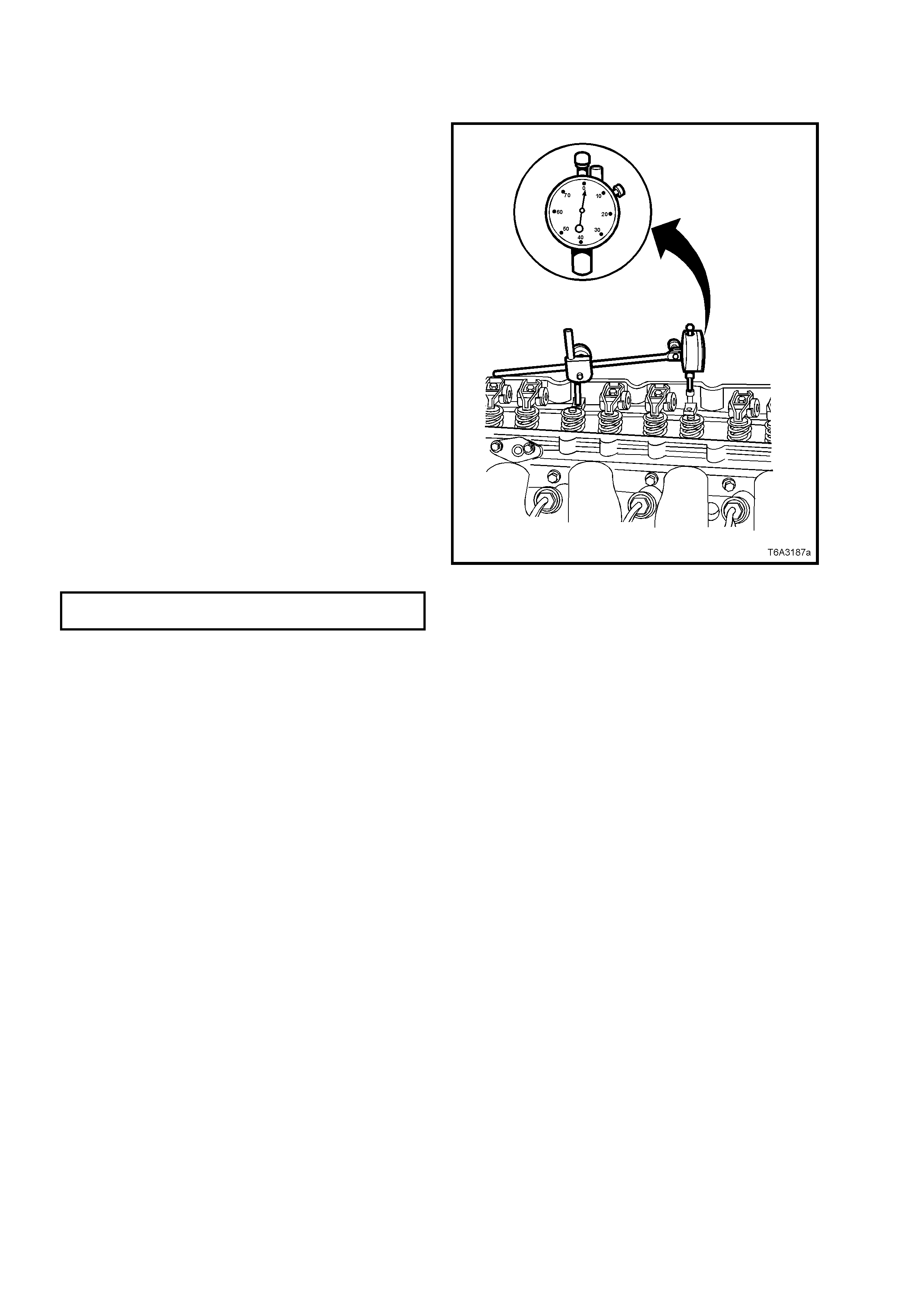

2.5 COMPRE SSION CHECK

1. Before conducting this check, ensure that the:

a. Engine is at operating temperature.

b. Battery is at or near a full state of charge.

c. Spark plugs are all removed.

d. Throttle plate is held wide open.

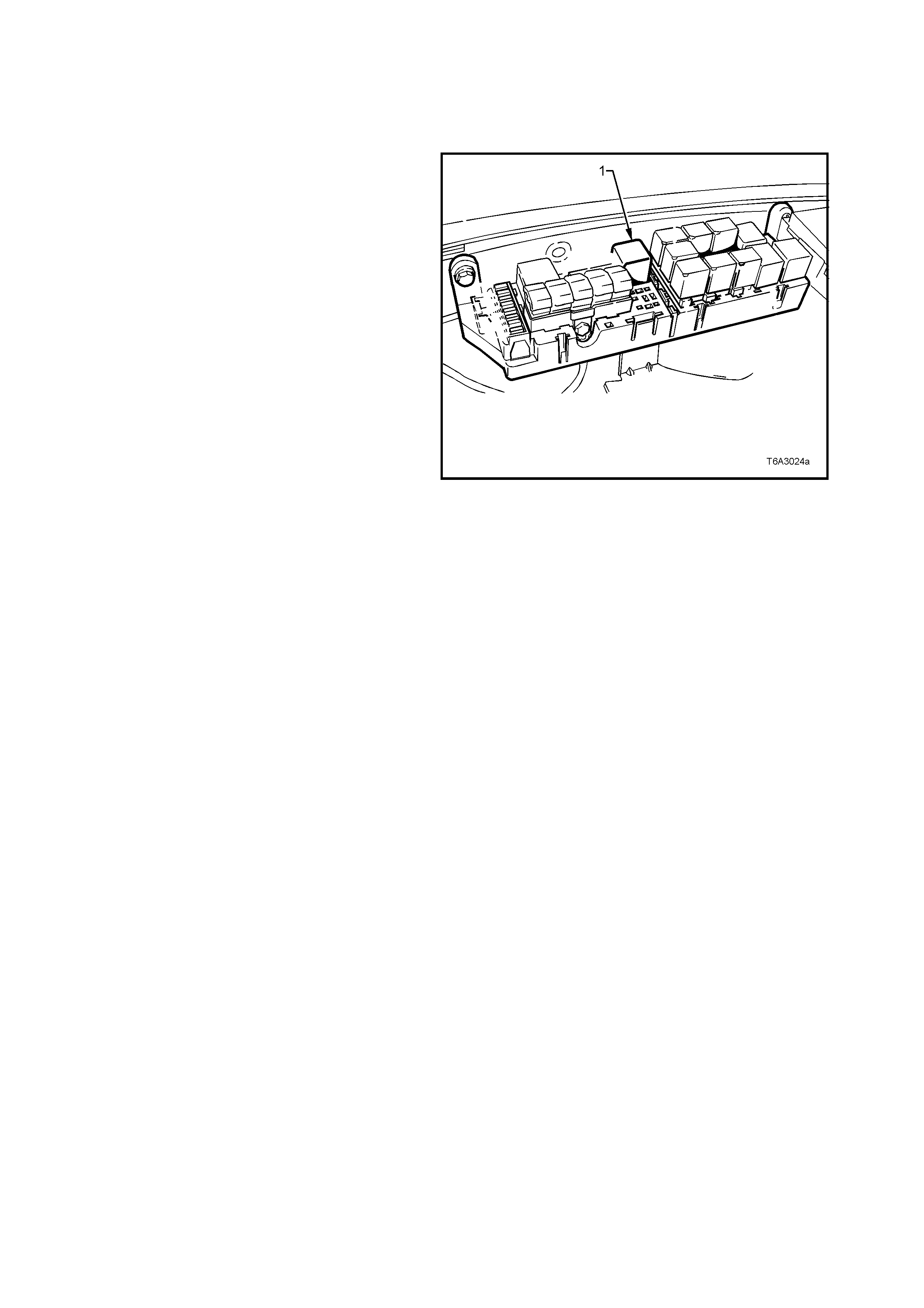

2. With the ignition switched OFF, disable the

ignition system and f uel injectors, by rem oving

the EFI relay (1), located in the engine

compartment.

3. Install a suitable, commercially available and

accurate, compression tester, that has been

reset to zero.

4. Crank the engine through approximately four

compression strokes (four ‘puffs’). Record the

reading.

5. Repeat this compression check for each

cylinder. Again, record each reading.

6. If a cylinder has low compres sion, inject about

15 ml (one tablespoon) of engine oil into the

combustion chamber through the spark plug

hole.

7. Recheck the compression and record the

reading.

Figure 6A3-30

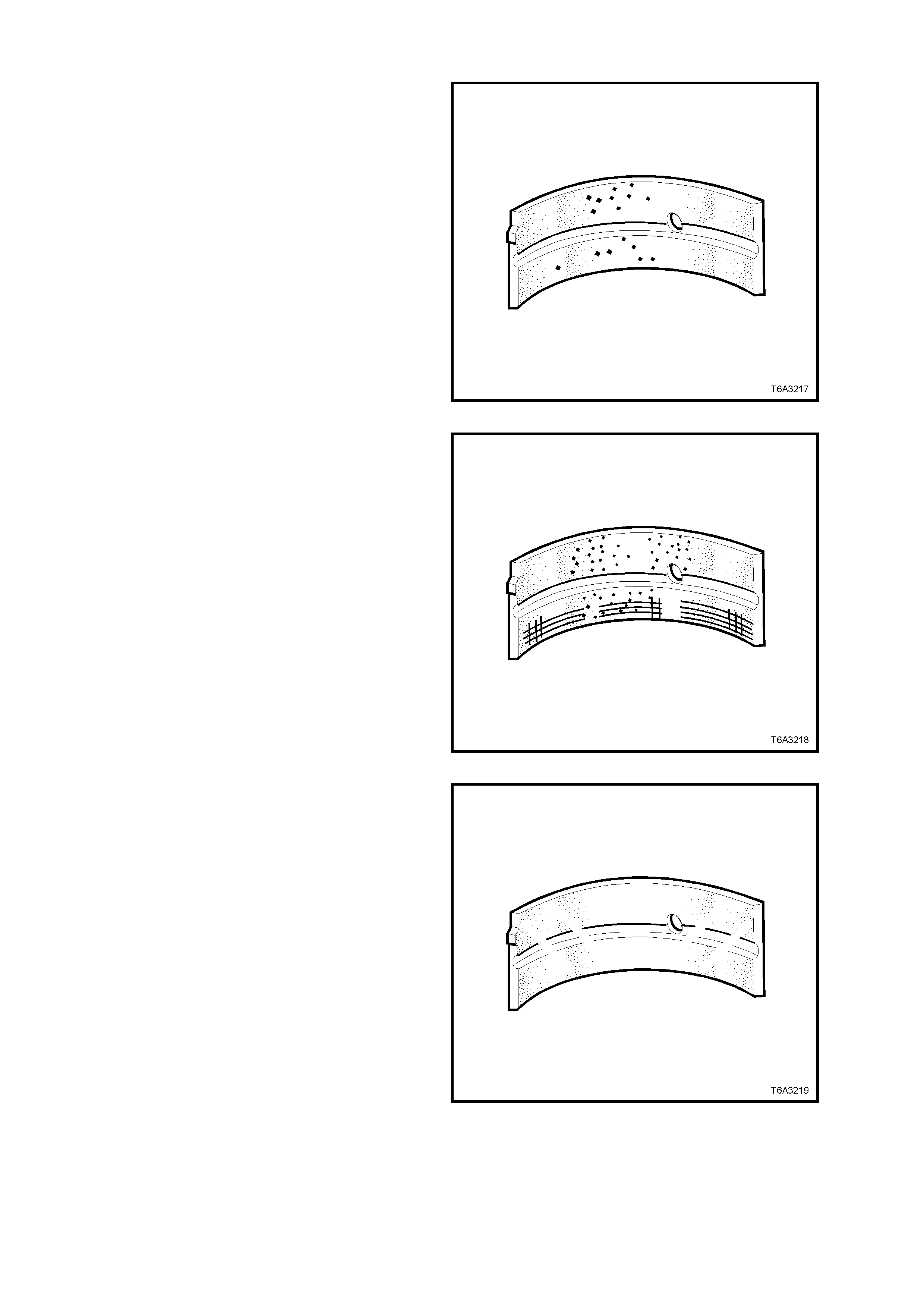

INTERPRETING COMPRESSION READINGS

The minimum compression in any one cylinder

should not be less than 70% of the highest

cylinder. No cylinder should read less than 690

kPa. For example, if the highest pressure in any

one cylinder is 1035 kPa, the lowest allowable

pressure for any other cylinder would be 725 kPa.

(1,035 x 70% = 725).

NORMAL - Compression builds up quickly and

evenly to the specified compression for each

cylinder.

PISTON RINGS LEAKING - Compression is low on

the first stroke. Compression then builds up with

the following strokes but does not reach normal.

Comp ression im proves cons iderably when you add

oil.

VALVES LEAKING - Compression is low on the

first strok e. Compression usually does not build up

on the following strokes. Compression does not

improve much when you add oil.

CYLINDER HEAD GASKET LEAKING - If two

adjacent cylinders have lower than normal

compression and injecting oil into the cylinders

does not increas e the com pres sion, the c ause m ay

be a head gasket leaking between the cylinders.

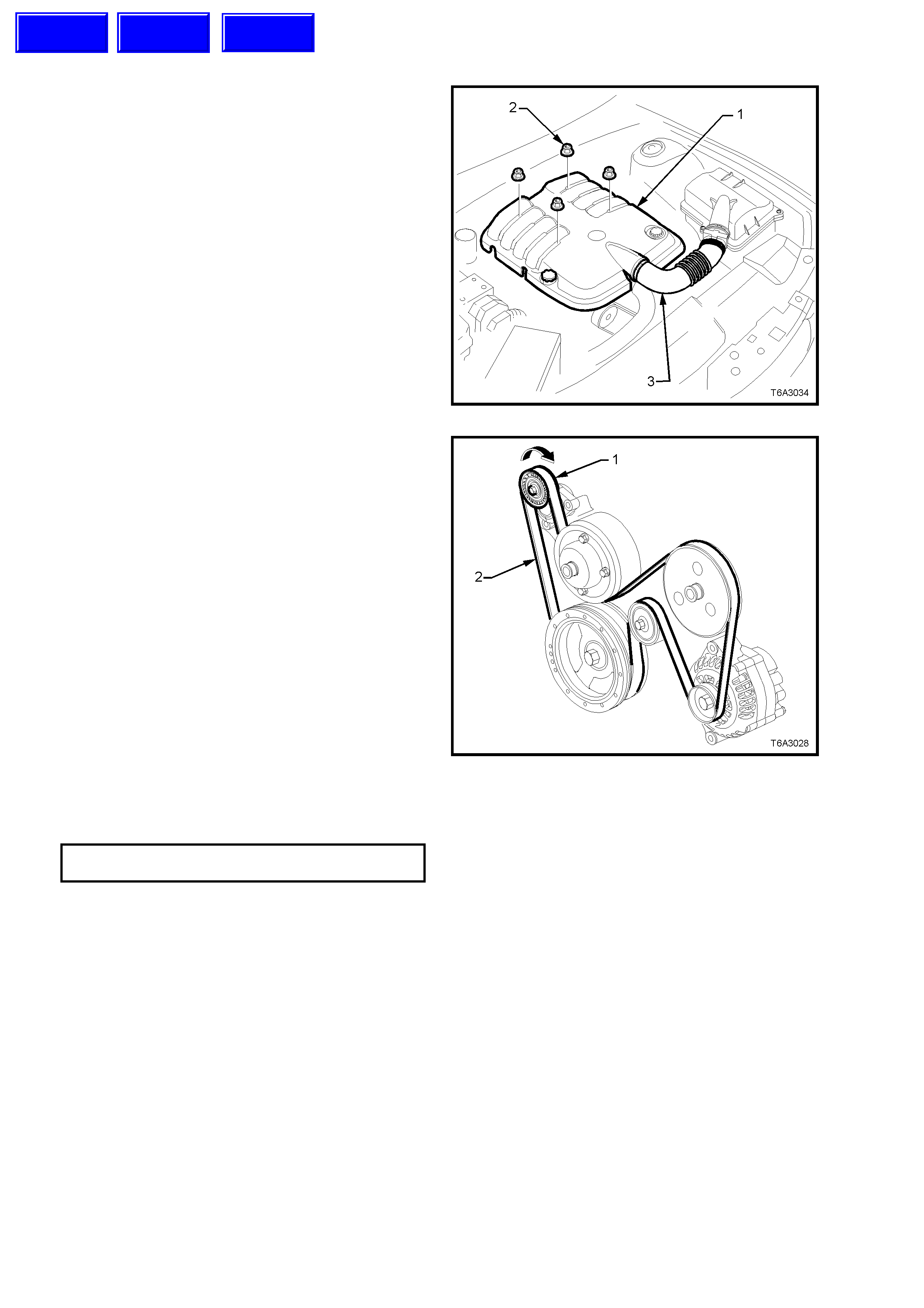

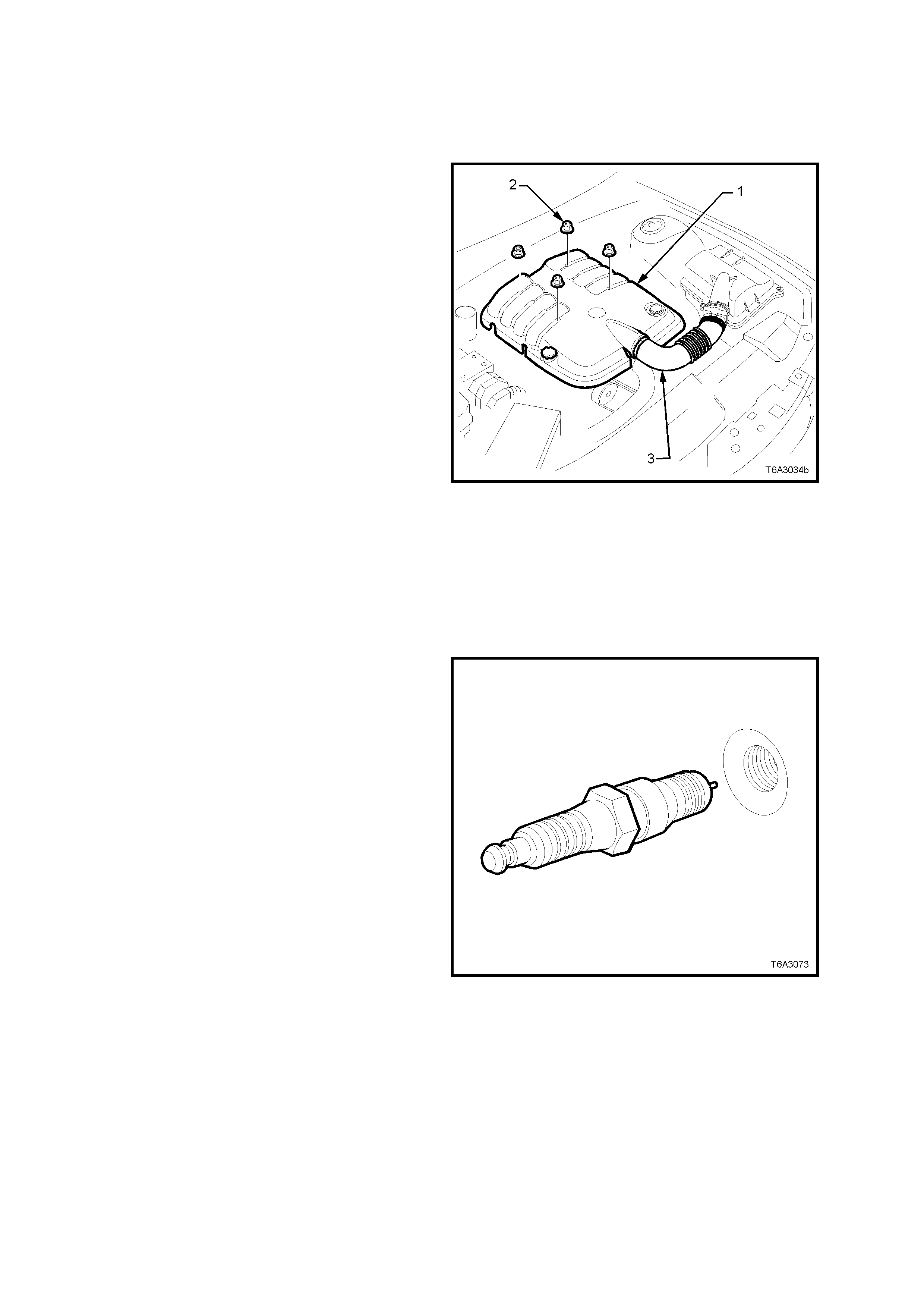

2.6 ENGINE DRIVE BELTS - REPLACE

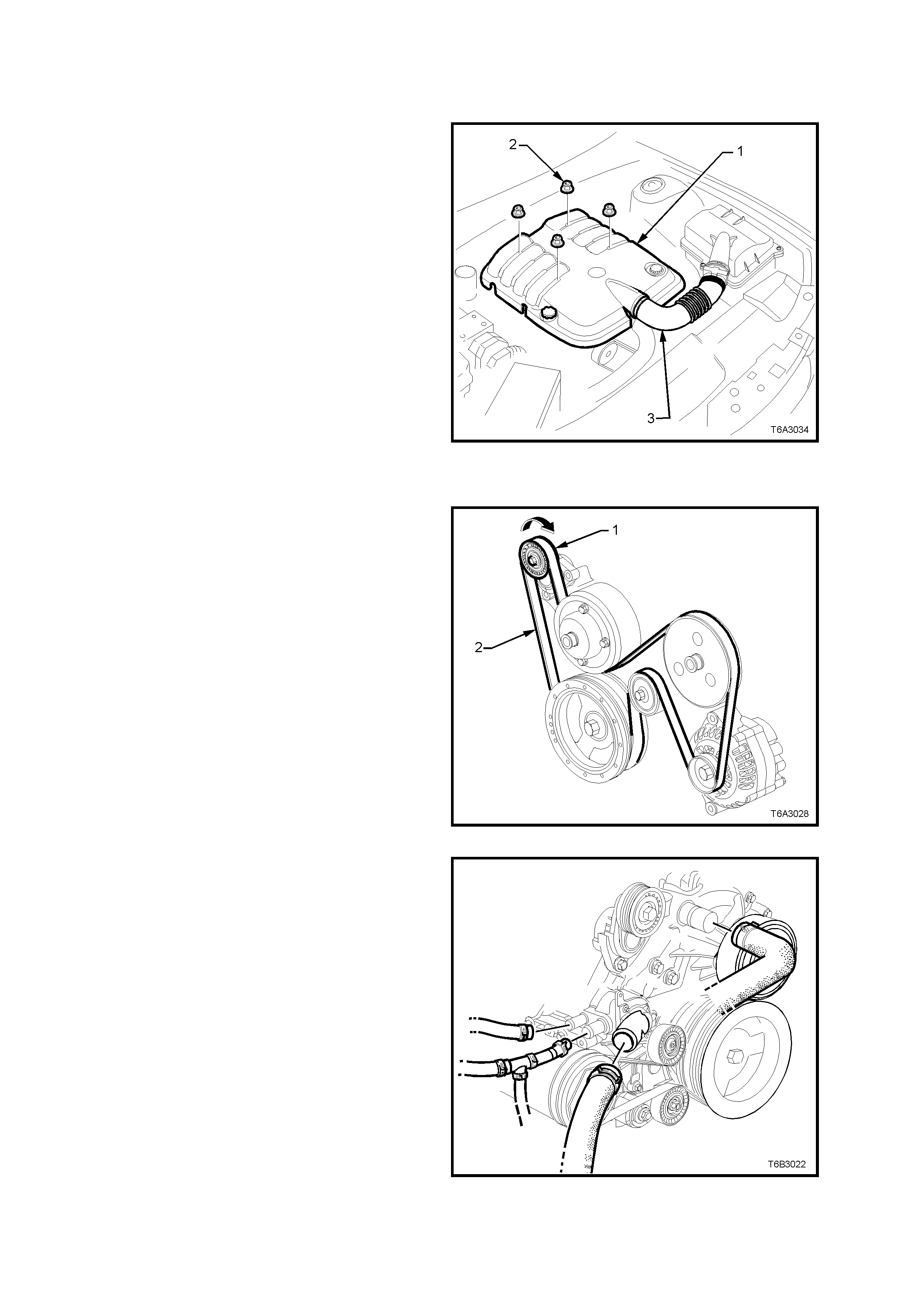

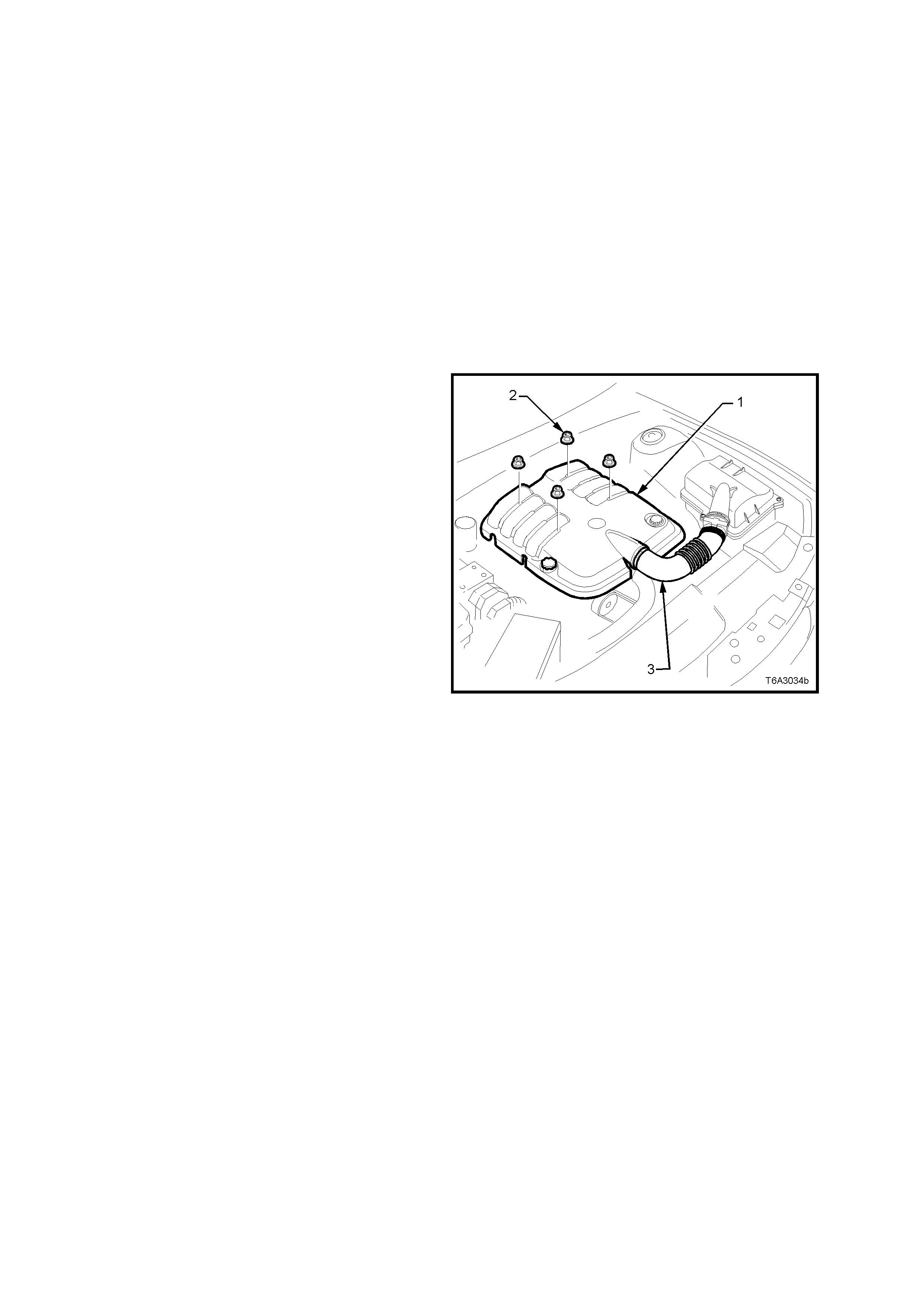

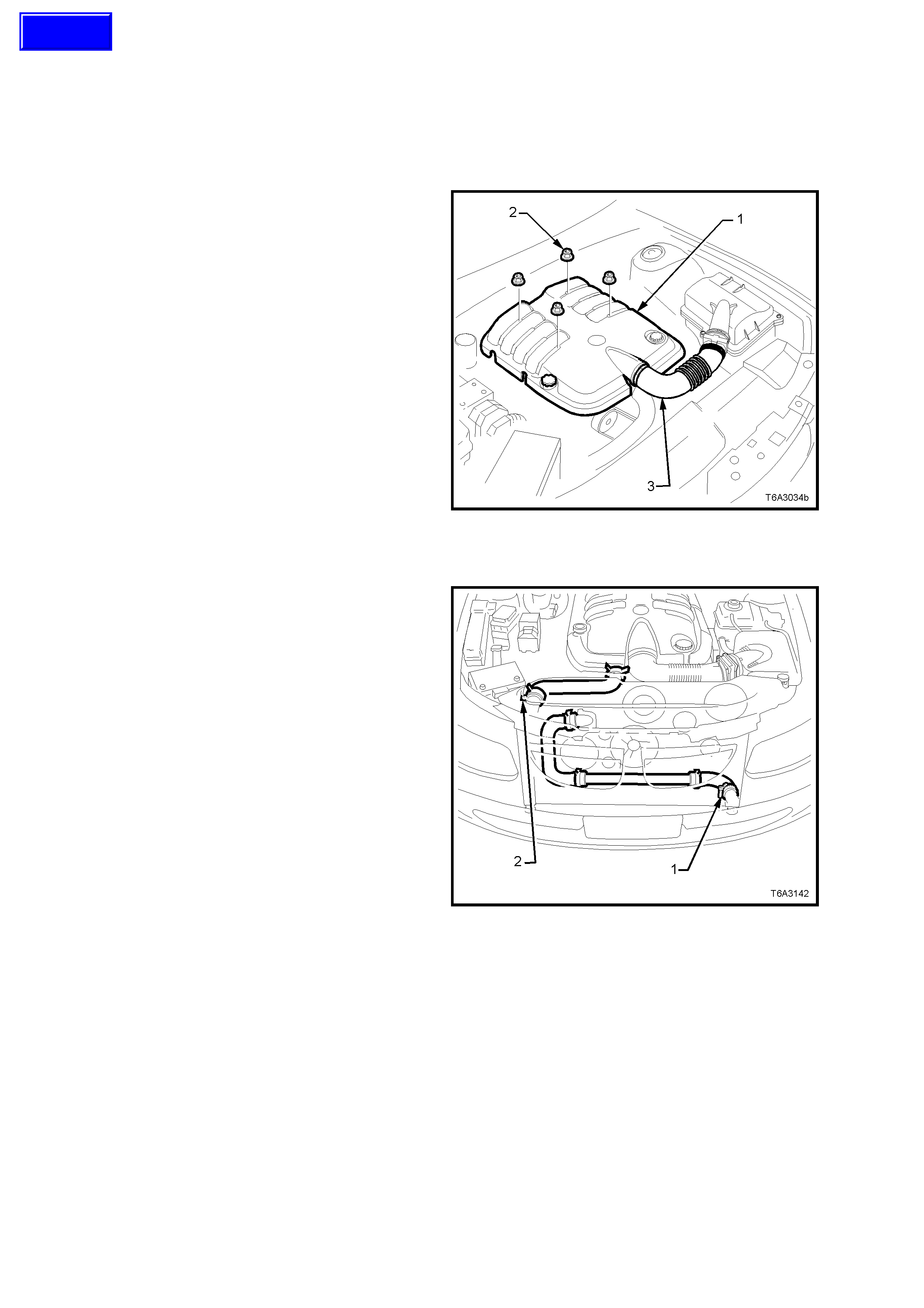

1. Remove the four engine dress cover

decorative nuts (2), then remove the dress

cover (1) from the engine.

2. Loosen both hose clamps securing the intake

hose (3) to the MAF sensor and the throttle

body. Remove the hose from the engine.

Figure 6A3-31

ENGINE A CCESSORY DRIVE BELT

3. Using a 15 mm ring spanner, rotate the

acces sor y automatic drive belt tens ioner ( 1) , in

the direction indicated, to reduce belt tension.

4. While holding the tensioner in the reduced

tension position, remove the accessory drive

belt (2), taking note of the belt routing.

NOTE: Use an assistant to maintain the tensioner

in the required position.

5. Clean the accessory drive belt running

surfaces and inspect the belt for damage.

6. While rotating the accessory drive belt

tensioner (1) in the direction indicated, install

the drive belt (2) over the pulleys, routing the

belt correctly, as shown.

7. Inspect the installation to ensure that the belt

is correctly aligned on all pulleys.

8. Reinstall the engine dres s cover , secur ing with

the four decorative nuts and tightening to the

correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 8.0 - 12 Nm

9. Start the engine to ensure correct operation.

Figure 6A3-32

Techline

Techline

Techline

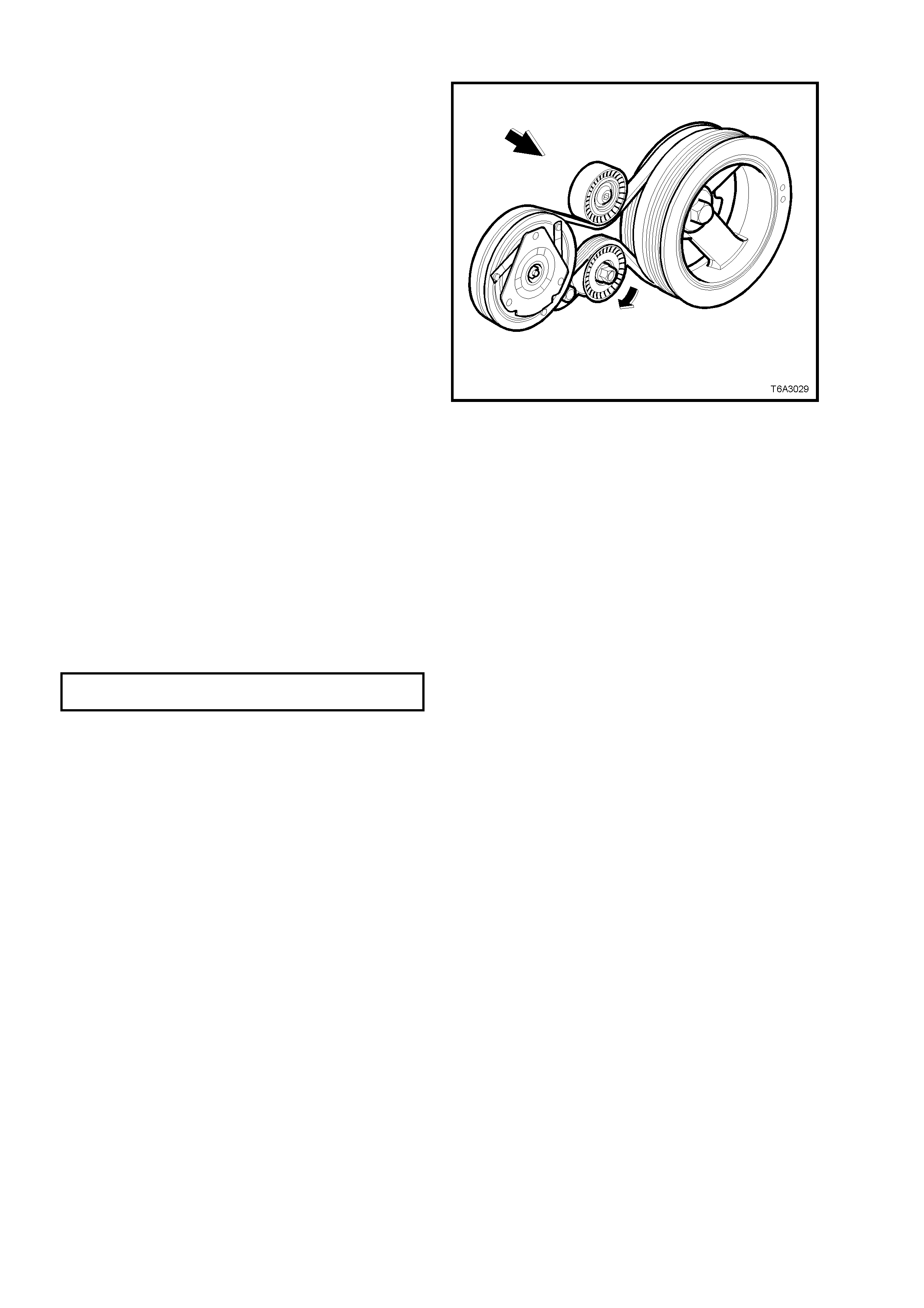

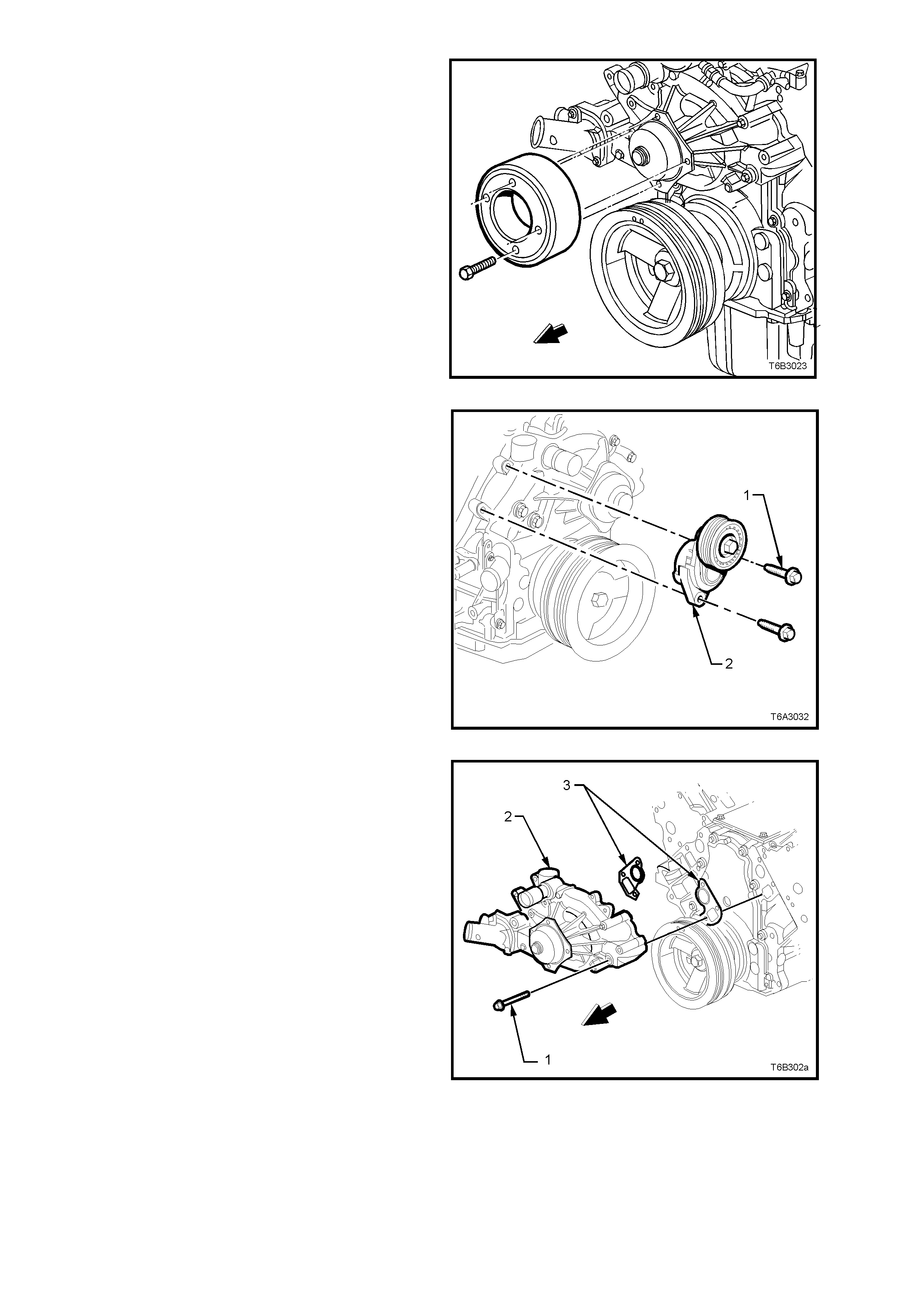

AIR CONDITIONING COMPRESSOR BELT

NOTE: The accessory drive belt must be

removed first to allow access to this belt. Refer

to the previous operation for details.

1. Raise the vehicle and support with safety

stands. Refer to Section 0A GENERAL

INFORMATION in of the VT Series I Service

Information.

2. Remove the four bolts securing the oil pan

under-tray.

3. From under the vehicle, rotate the A/C drive

belt tensioner in the direction shown, using a

15 mm set spanner, to relieve belt tension.

4. While using an assistant to maintain the

tensioner in the required position, remove the

drive belt from the pulleys.

NOTE: An alternative to using an assistant,

would be to secure the spanner using tie wire.

5. Clean the A/C drive belt running surfaces and

inspect the belt for damage.

6. While holding the A/C drive belt tensioner in

the direction indicated, install the drive belt

over the pulleys, routing the belt correctly, as

shown.

7. Inspect the installation to ensure that the belt

is correctly aligned on all pulleys.

Figure 6A3-33

8. Reinstall the ac c es sor y drive belt as des cr ibed

in the previous operation.

9. Start the engine to ensure correct operation.

10. Reinstall the oil pan under- tray and tighten the

bolts to the correct torque specification.

OIL PAN UNDER-TRAY BOLT

TORQUE SPECIFICATION 30 - 35 Nm

11. Lower the vehicle and test for correct

operation.

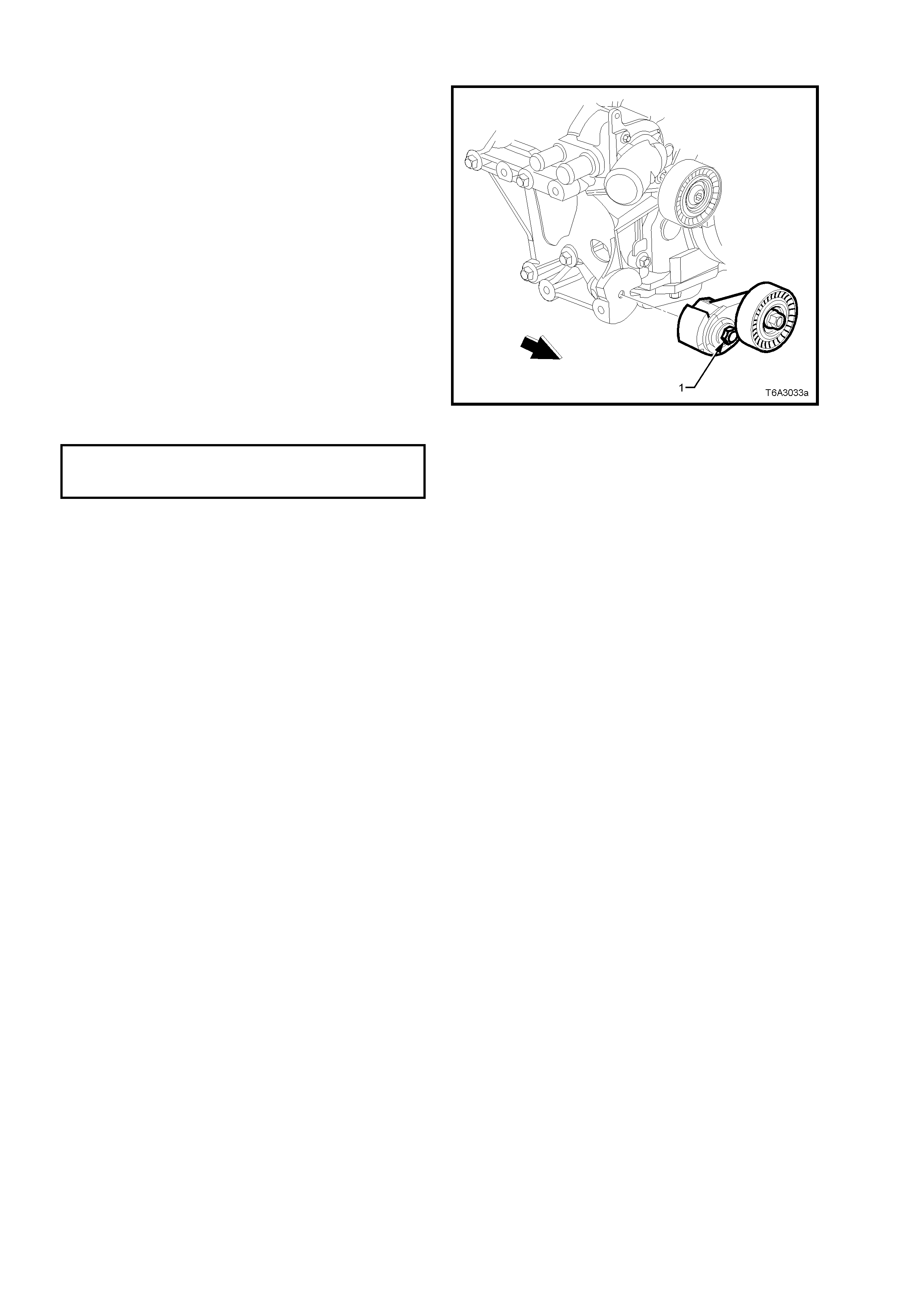

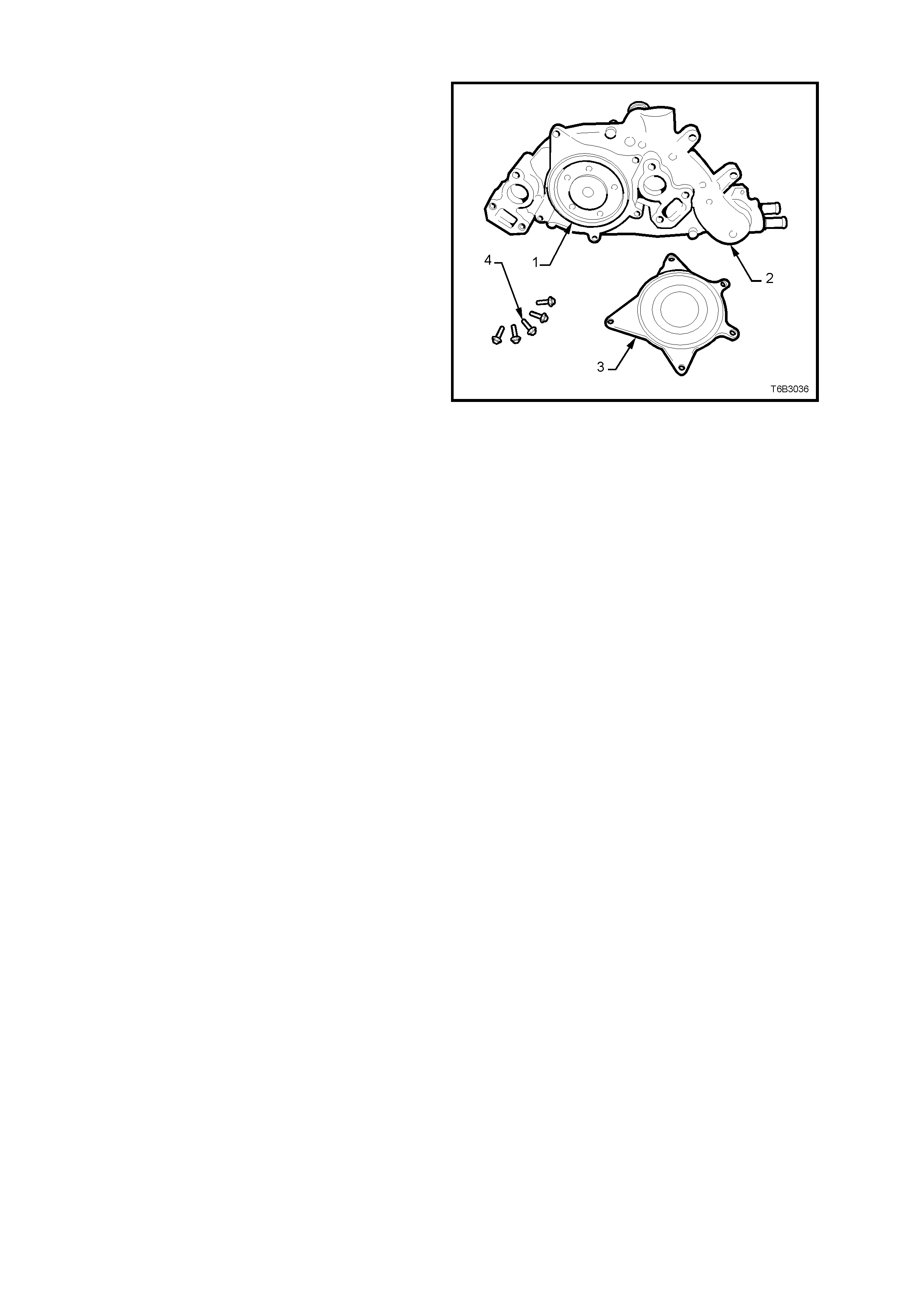

2.7 ACCESSORY BELT IDLER PULLEY

REPLACE

1. Remove the engine accessory drive belt.

Refer to Operation 2.6 in this Section for the

necessary procedure.

2. Remove the idler pulley retaining bolt, then

remove the pulley from its mounting boss, on

the generator mounting bracket.

3. Install the idler pulley to its mounting boss.

4. Install the idler pulley retaining bolt and tighten

to the correct torque specification.

ACCESSORY BELT IDLER PULLEY

BOLT TORQUE SPECIFICATION 40 - 60 Nm

5. Install the engine accessory drive belt. Refer

to Operation 2.6 in this Section for the

necessary procedure.

Figure 6A3-34

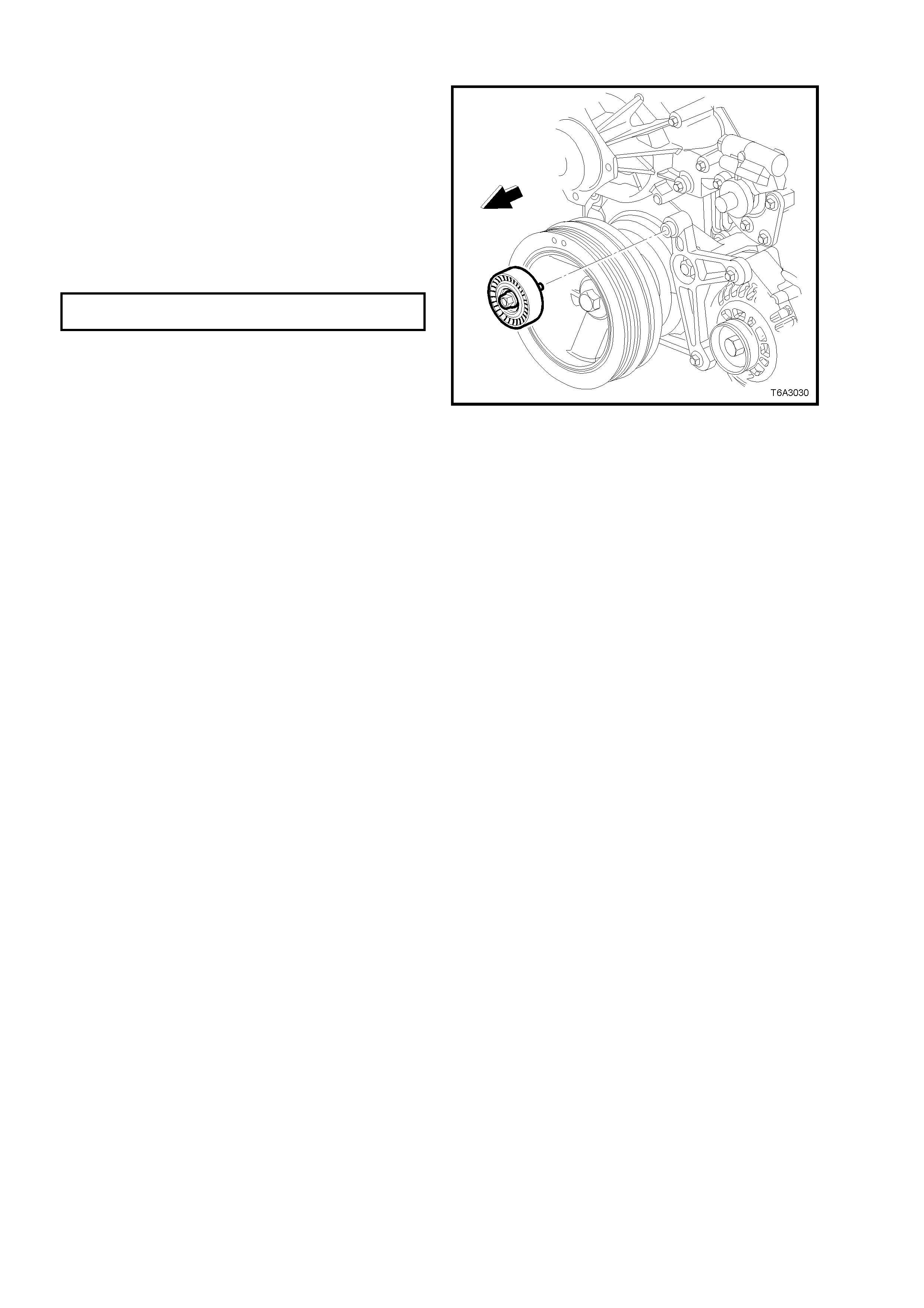

2.8 A/C BELT IDLER PULLEY

REPLACE

1. Raise the vehicle and support with safety

stands. Refer to 0A GENERAL

INFORMATION of the VT Series I Service

Information.

2. Remove the four bolts securing the oil pan

under-tray.

3. From under the vehicle, rotate the A/C drive

belt tensioner in the direction shown in Figure

6A3-33, using a 15 m m s et s panner, to relieve

belt tension.

4. While using an assistant to maintain the

tensioner in the required position, remove the

drive belt from the pulleys but leave hanging

on the crankshaft pulley.

NOTE: An alternative to using an assistant, would

be to secure the spanner using tie wire.

5. Using a commercially available Torx bit T50,

remove the bolt securing the A/C compressor

drive belt idler pulley to its mounting boss on

the coolant pump housing, then remove the

pulley assembly.

6. Install the idler pulley to its mounting boss.

7. Install the idler pulley retaining bolt and tighten

to the correct torque specification.

A/C COMPRESSOR BELT

IDLER PULLEY BOLT 40 - 60 Nm

TORQUE SPECIFICATION

8. Install the A/C compressor drive belt. Refer to

Operation 2.6 in this Section for the

necessary procedure.

9. Reinstall the oil pan under -tray and tighten the

bolts to the correct torque specification.

OIL PAN UNDER-TRAY BOLT

TORQUE SPECIFICATION 30 - 35 Nm

10. Lower the vehicle and test for correct

operation.

Figure 6A3-35

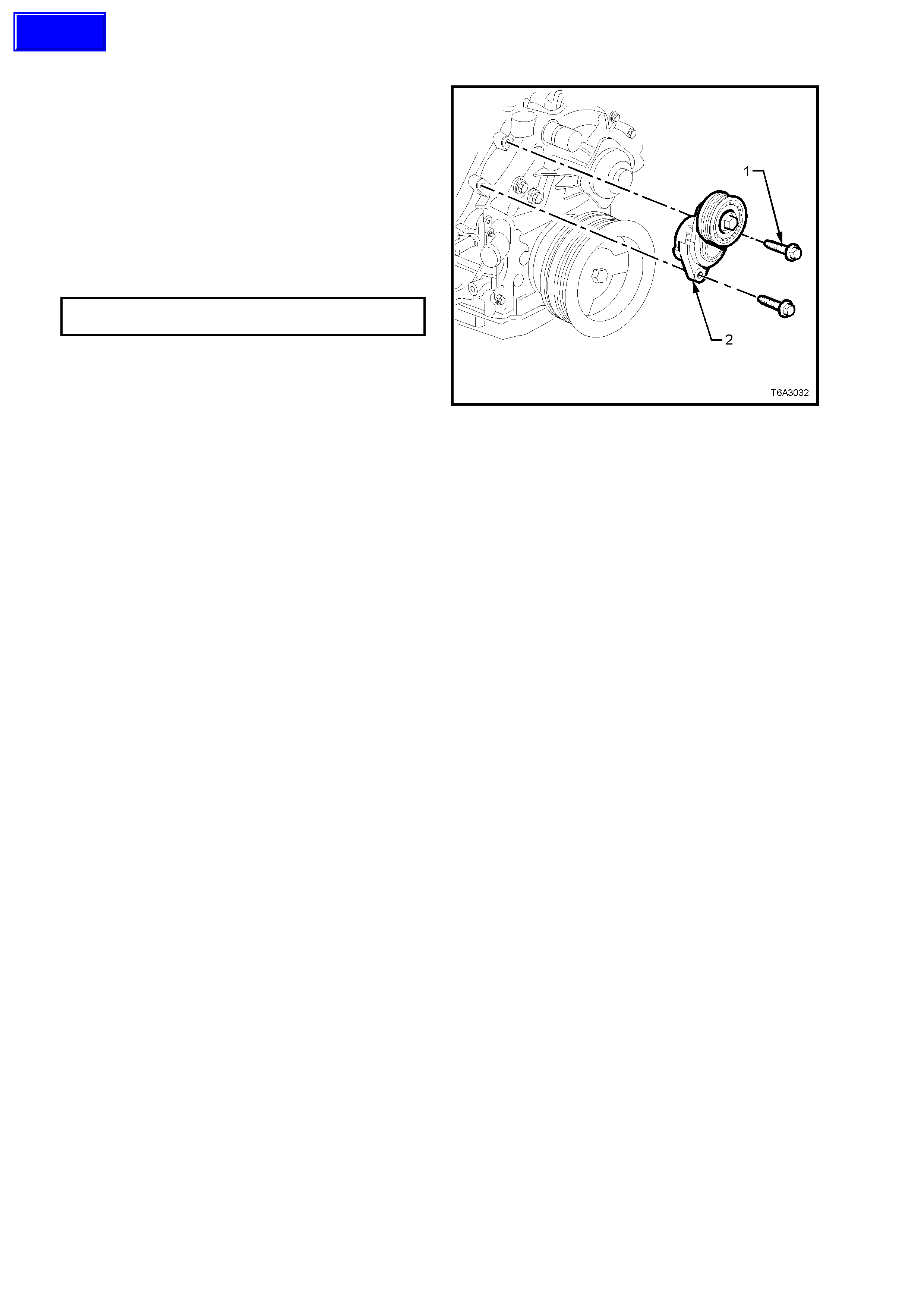

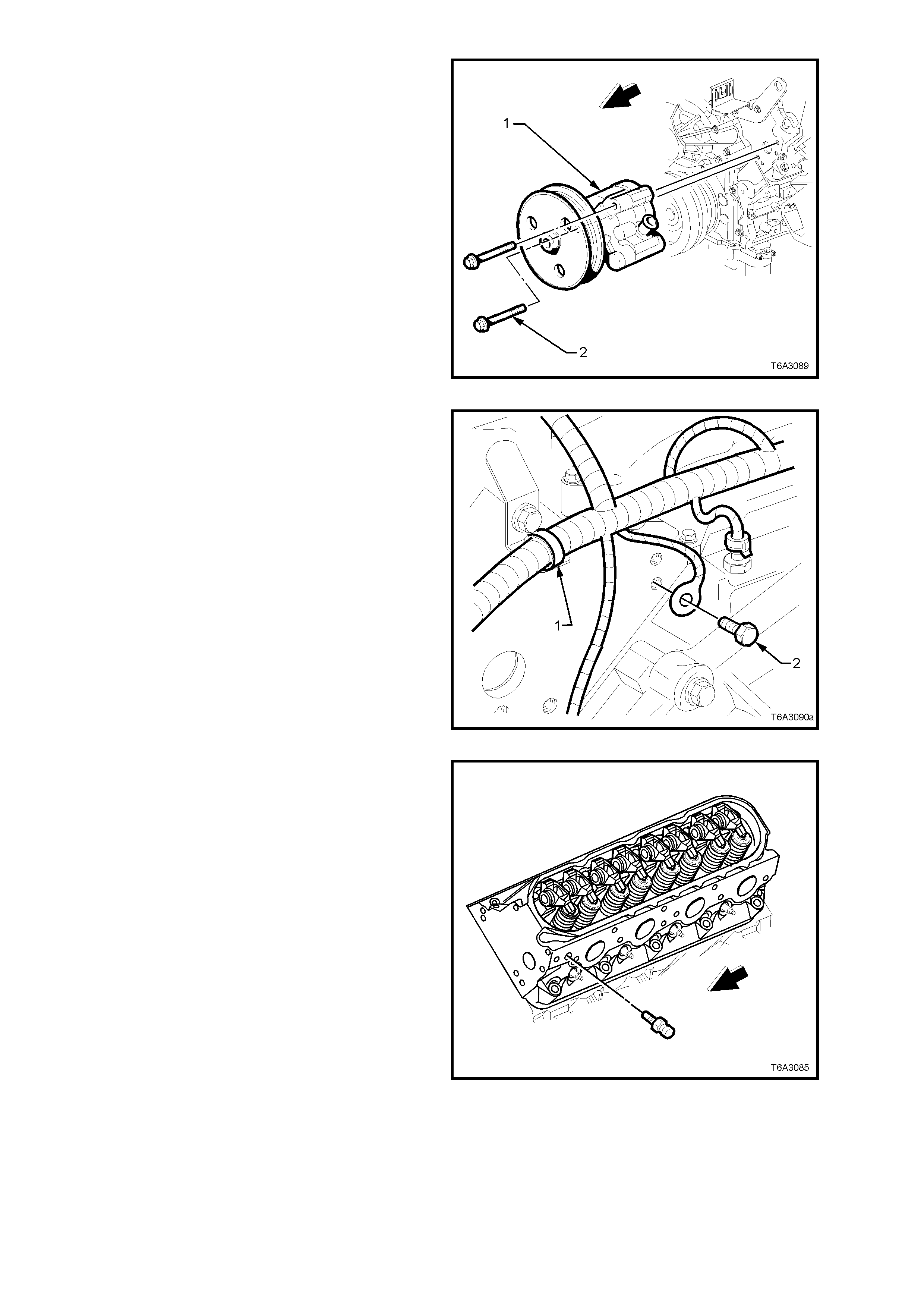

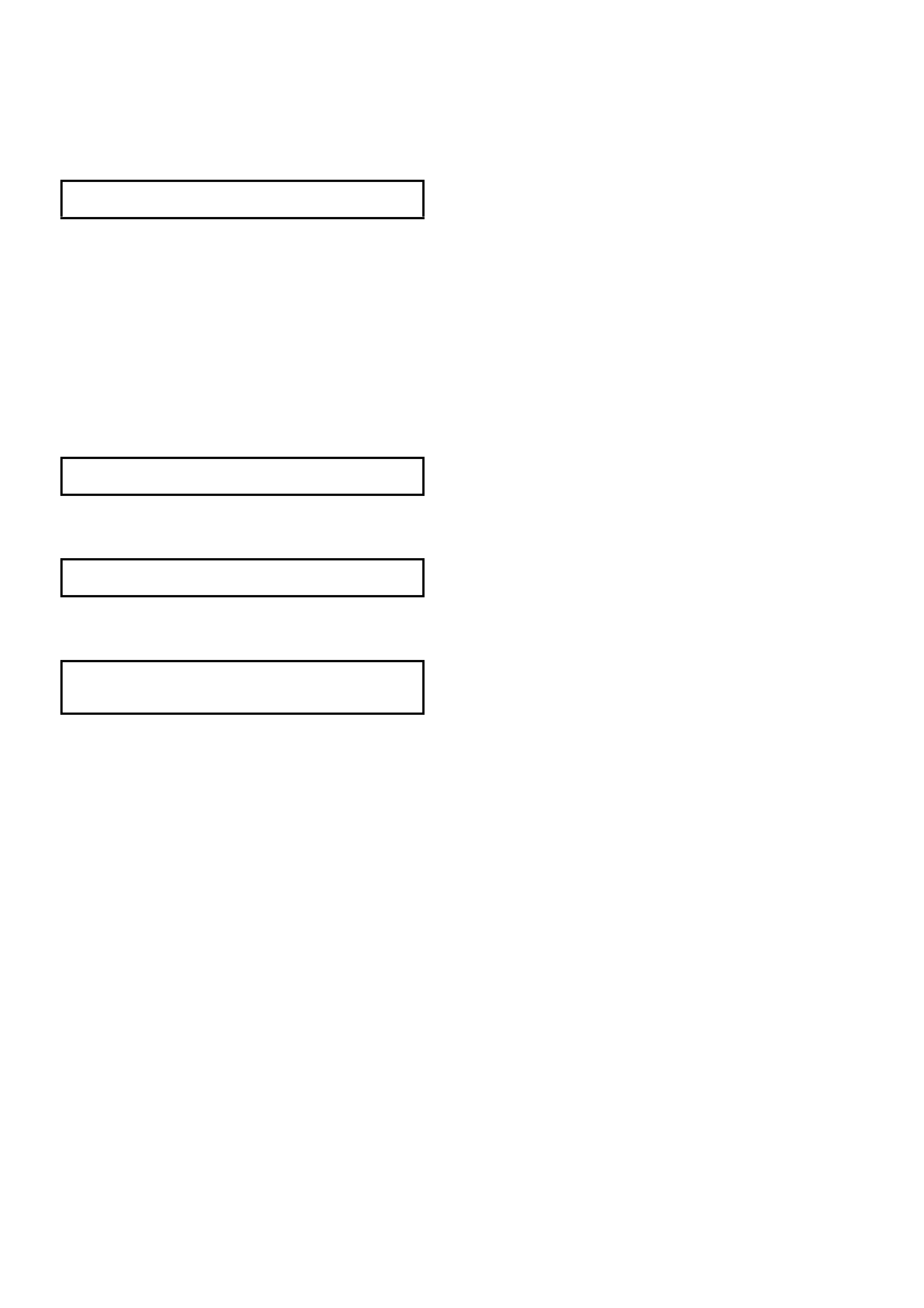

2.9 ACCESSORY BELT TENSIONER

REPLACE

1. Remove the engine accessory drive belt.

Refer to Operation 2.6 in this Section for the

necessary procedure.

2. Remove the tensioner pulley bracket retaining

bolts (1), then remove the assembly (2).

3. Install the tensioner assembly (2) and the two

mounting bolts.

4. Tighten both mounting bolts (1) to the correct

torque specification.

ACCESSORY BELT TENSIONER

BOLT TORQUE SPECIFICATION 40 - 60 Nm

5. Install the engine accessory drive belt. Refer

to Operation 2.6 in this Section for the

necessary procedure.

Figure 6A3-36

Techline

2.10 A/C BELT TENSIONER

REPLACE

1. From under the vehicle, rotate the A/C drive

belt tensioner in the direction shown in Figure

6A3-33, using a 15 m m s et s panner, to relieve

belt tension.

2. While using an assistant to maintain the

tensioner in the required position, remove the

drive belt from the pulleys but leave hanging

on the crankshaft pulley.

NOTE: An alternative to using an assistant,

would be to secure the spanner using tie wire.

3. Remove the bolt (1) securing the A/C

compressor drive belt tensioner, then remove

the assembly.

4. Install the tensioner assembly and the

mounting bolt.

5. Tighten the tensioner mounting bolt to the

correct torque specification.

A/C COMPRESSOR BELT

TENSIONER BOLT 21 - 29 Nm

TORQUE SPECIFICATION

6. Install the A/C compressor drive belt. Refer to

Operation 2.6 in this Section for the necessary

procedure.

Figure 6A3-37

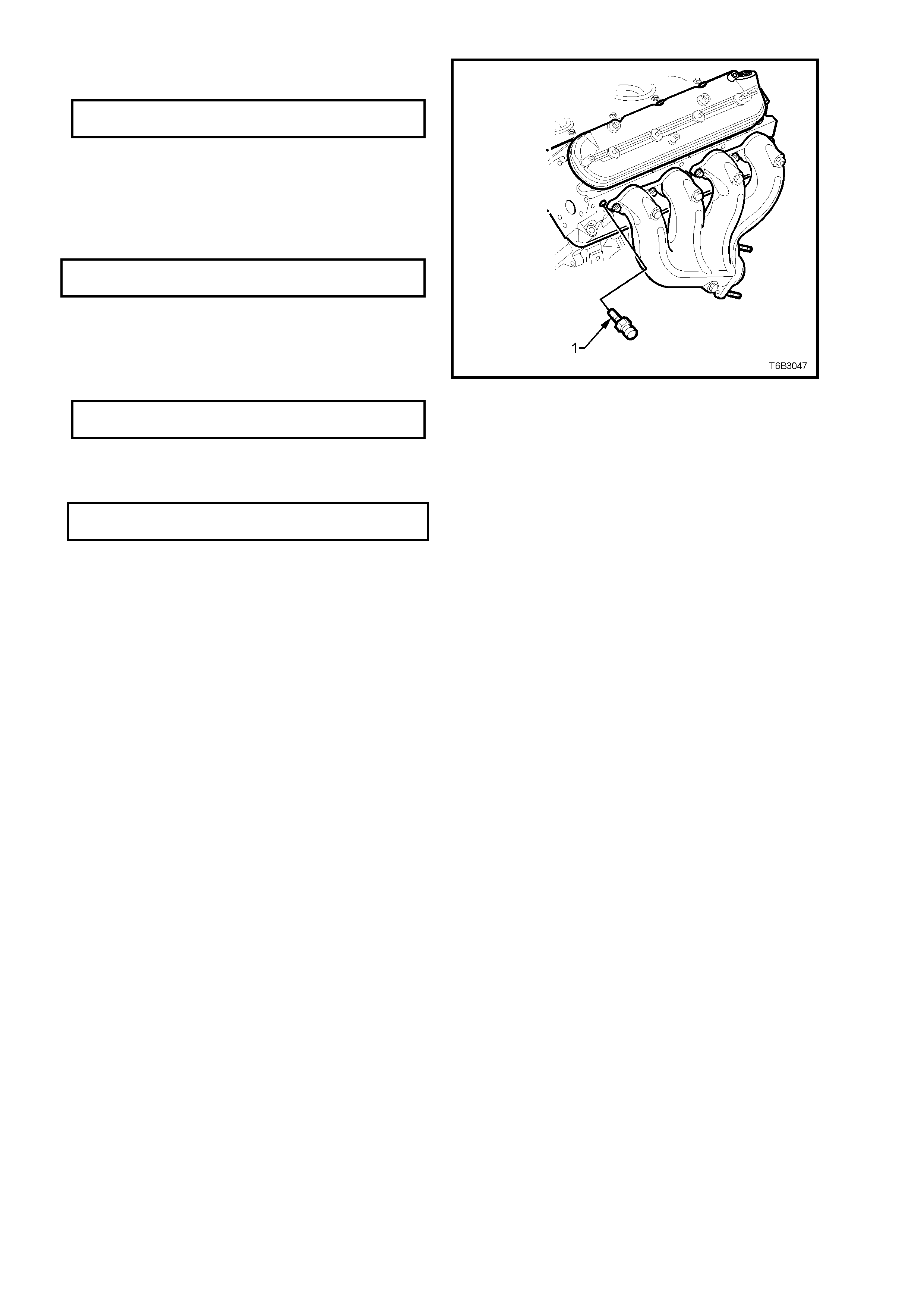

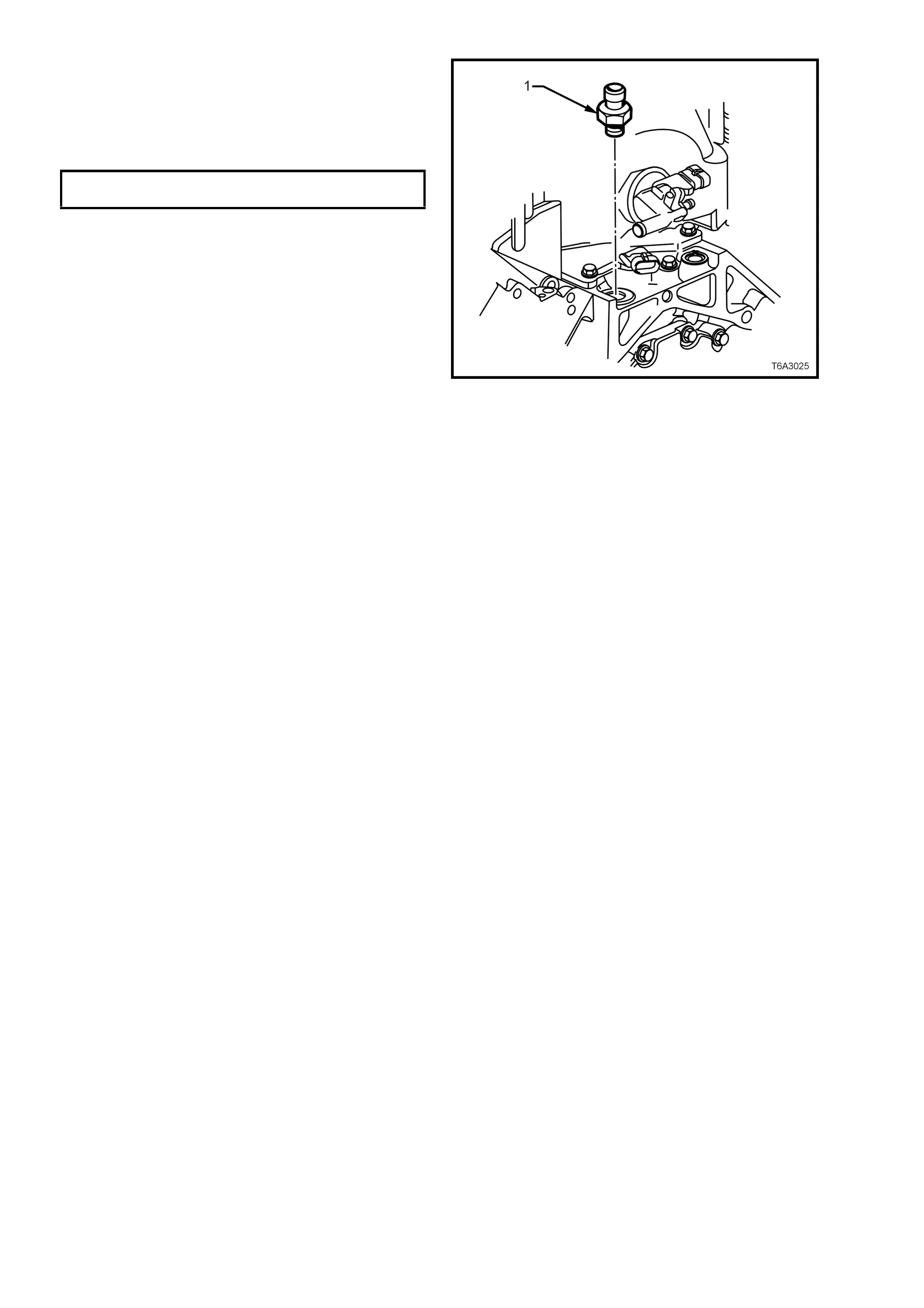

2.11 OIL PRESSURE SENSOR

REPLACE

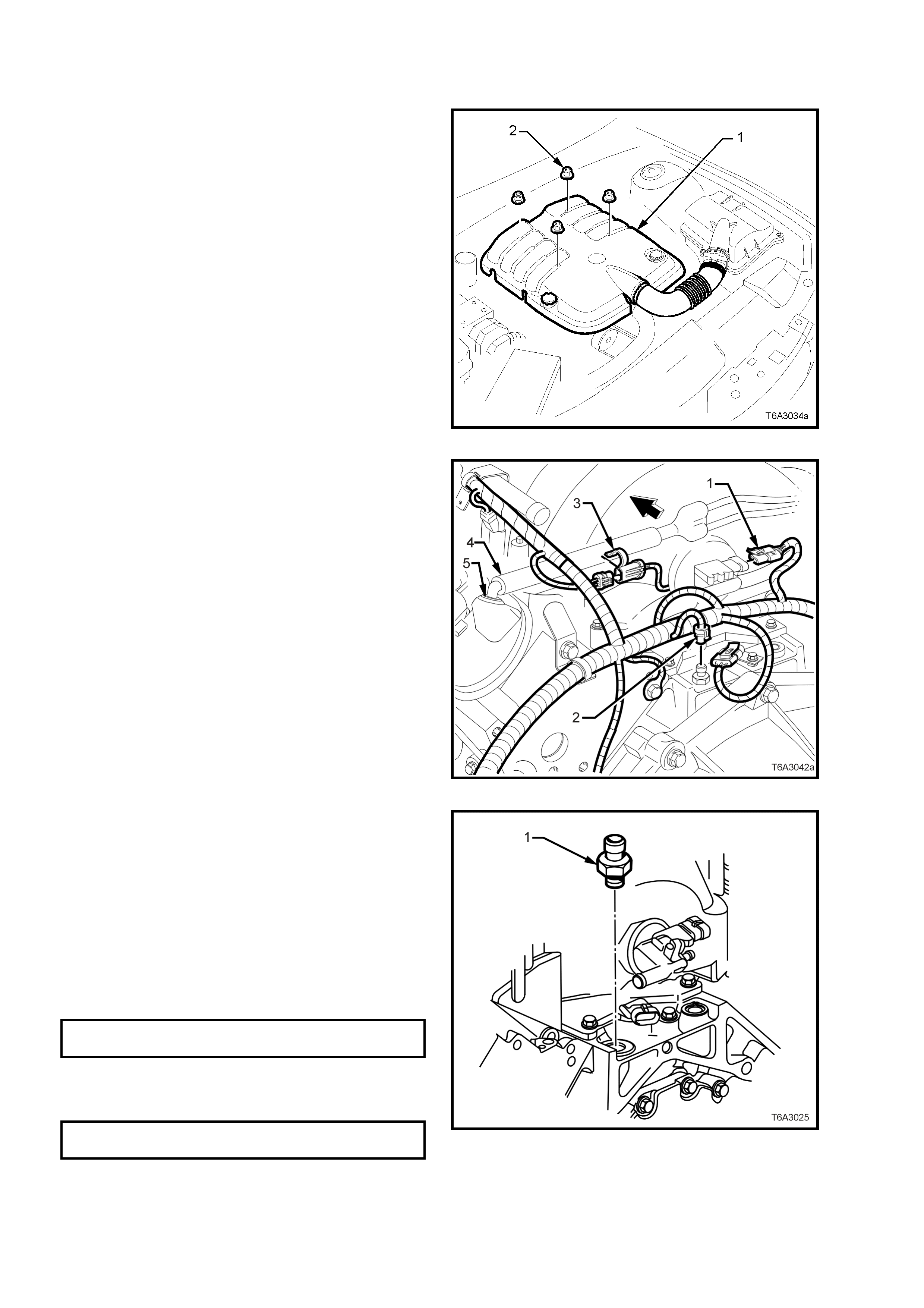

1. Remove the four engine dress cover

decorative nuts (2), then remove the dress

cover (1) from the engine.

Figure 6A3-38

2. Release the wiring harness connector locking

tang from the oil pressure sensor, then

remove the connector (2) from the sensor.

Figure 6A3-39

3. Using T ool No. J 41712 and suitable 3/8” drive

sock et equipm ent, remove oil pressur e sens or

(1) from the left hand rear of the engine

cylinder block.

4. Prior to reinstallation apply Loctite 565 sealant

(or equivalent) to the cleaned oil pressure

sensor threads.

5. Reinstall the oil pressure sensor (1) and

tighten with Tool No. J 41712 and suitable 3/8”

drive socket equipment, to the correct torque

specification.

OIL PRESSURE SENSOR

TORQUE SPECIFICATION 20 Nm

6. Reinstall the engine dres s cover , secur ing with

the four decorative nuts and tightening to the

correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 8.0 - 12 Nm

7. Start the engine to ensure correct operation.

Figure 6A3-40

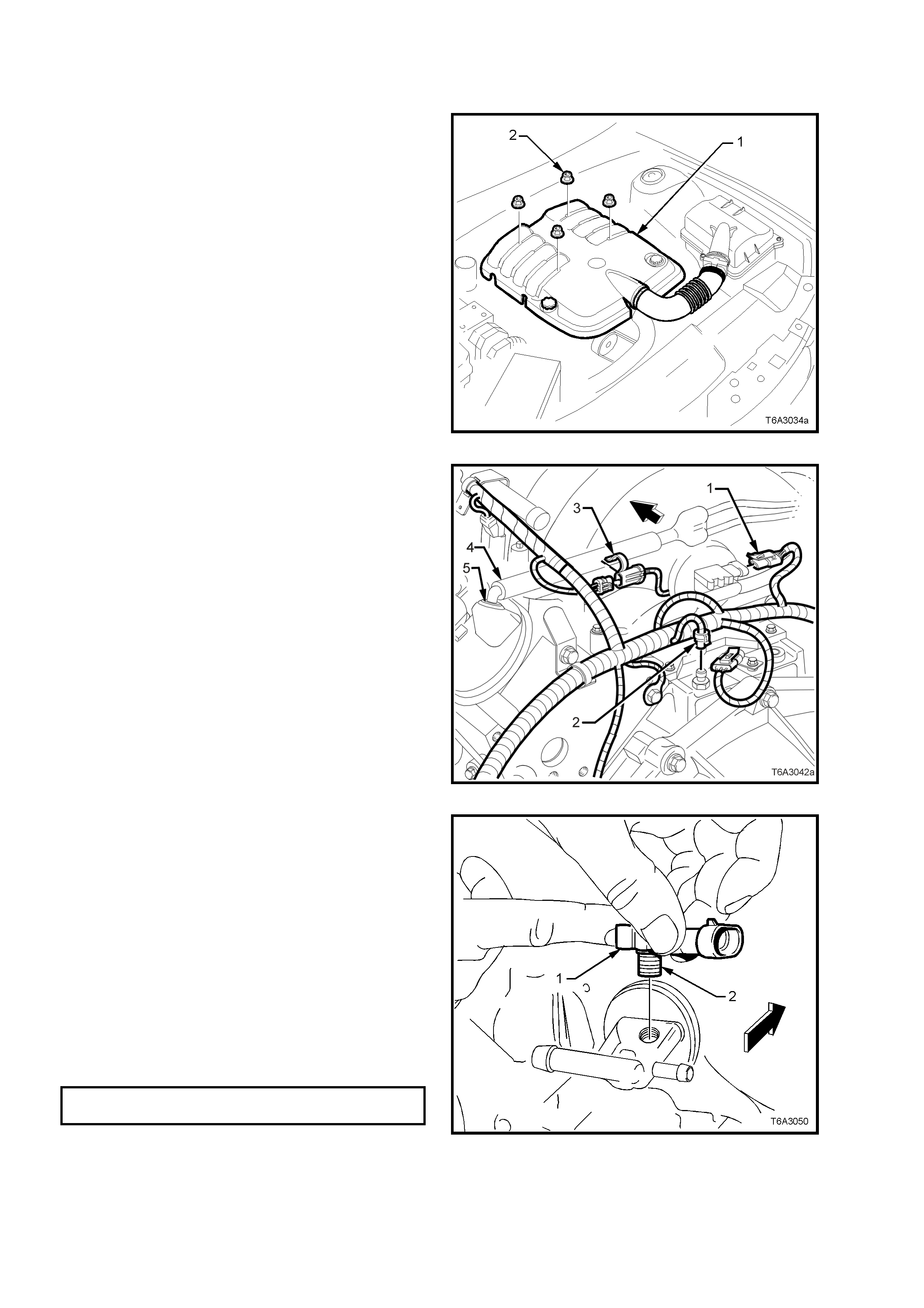

2.12 MANIFOLD ABSOLUTE PRESSURE SENSOR

REPLACE

1. Remove the four engine dress cover

decorative nuts (2), then remove the dress

cover (1) from the engine.

Figure 6A3-41

2. Release the wiring harness connector locking

tang (1) from the manifold absolute pressure

(MAP) sensor, then remove the connector

from the sensor.

Figure 6A3-42

3. Grasp the MAP sensor (1) at the rear of the

intake manifold and twist back and forth while

pulling upward, to remove.

4. Check the silicone r ubber seal (2) on the MAP

sensor to ensure it is not torn or damaged.

5. Reinstall the MAP sensor by pushing it down,

into the fitting at the rear of the intake

manifold.

6. Reinstall the wiring harness connector to the

MAP sensor, ensuring that the lock ing tab is in

place.

7. Reinstall the engine dres s cover , secur ing with

the four decorative nuts and tighten to the

correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 8.0 - 12 Nm

8. Start the engine to ensure correct operation. Figure 6A3-43

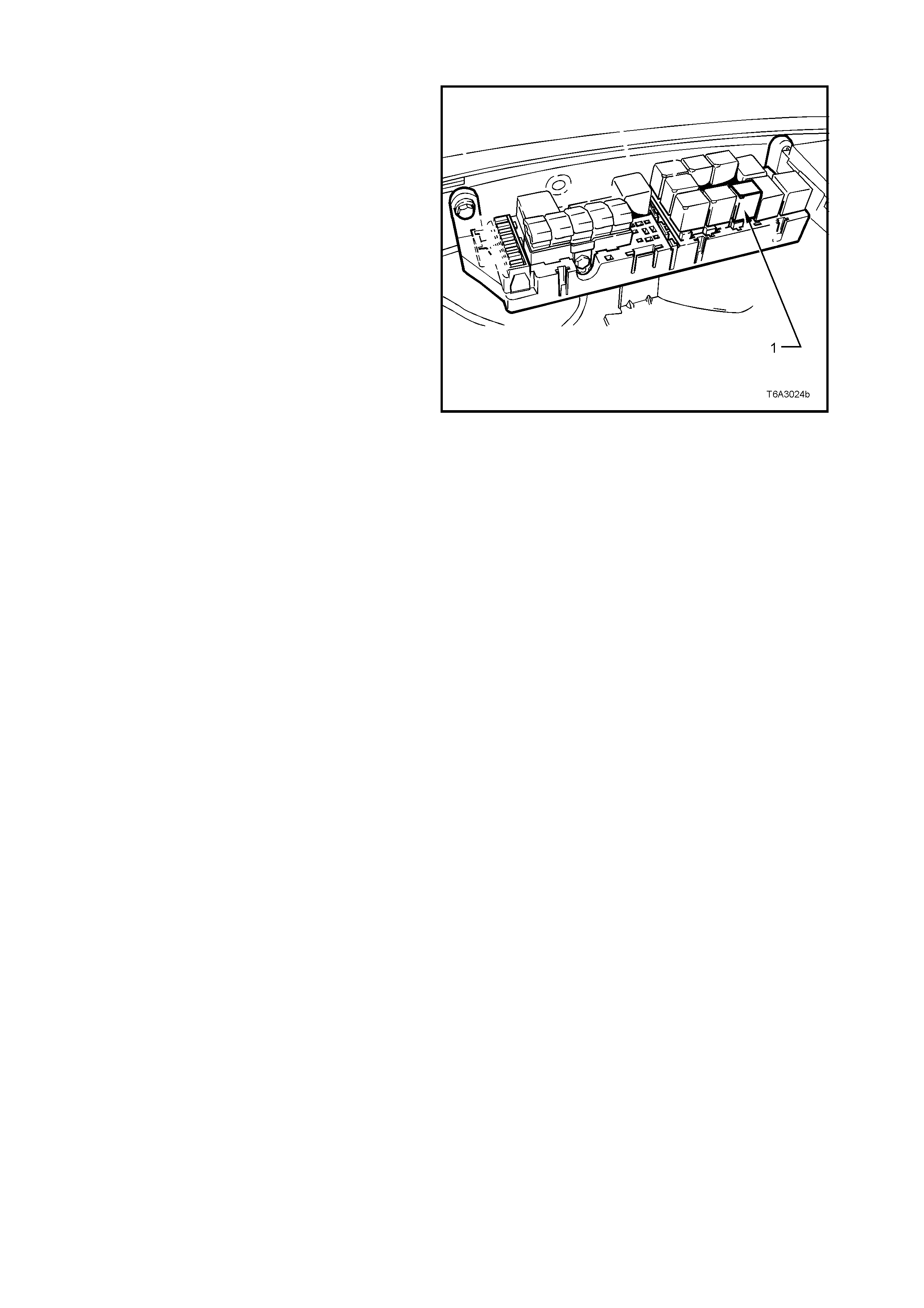

2.13 FUEL SYSTEM PRESSURE RELIEF

1. After removing the cover from the engine

compartment relay housing, remove the fuel

pump relay (1).

2. With the throttle closed, crank the engine.

NOTE: The engine may start and run until the fuel

supply remaining in the fuel delivery system is

burned.

3. When the engine stops, re-engage the starter

motor for 10 seconds to ensure that the line

pressure has been fully relieved.

4. Reinstall the fuel pump relay, taking care that

the wiring harness relay connector is not

dislodged and that the relay is fully installed.

CAUTION: Unless this procedure is followed

before servicing the fuel lines or fuel

connections, fuel spray into the engine

compartment could occur!

Figure 6A3-44

2.14 INTAKE MANIFOLD

NOTE: Unless individual components such as the

throttle body, fuel injection rail and/or injectors are

to be removed as individual components, then it is

recommended that the complete intake manifold

assembly is removed, as described in this service

operation.

REMOVE

1. Disconnect the battery earth cable from the

battery.

2. Drain the cooling system. Refer to

Section 6B3 ENGINE CO OLING - GEN III V8

ENGINE.

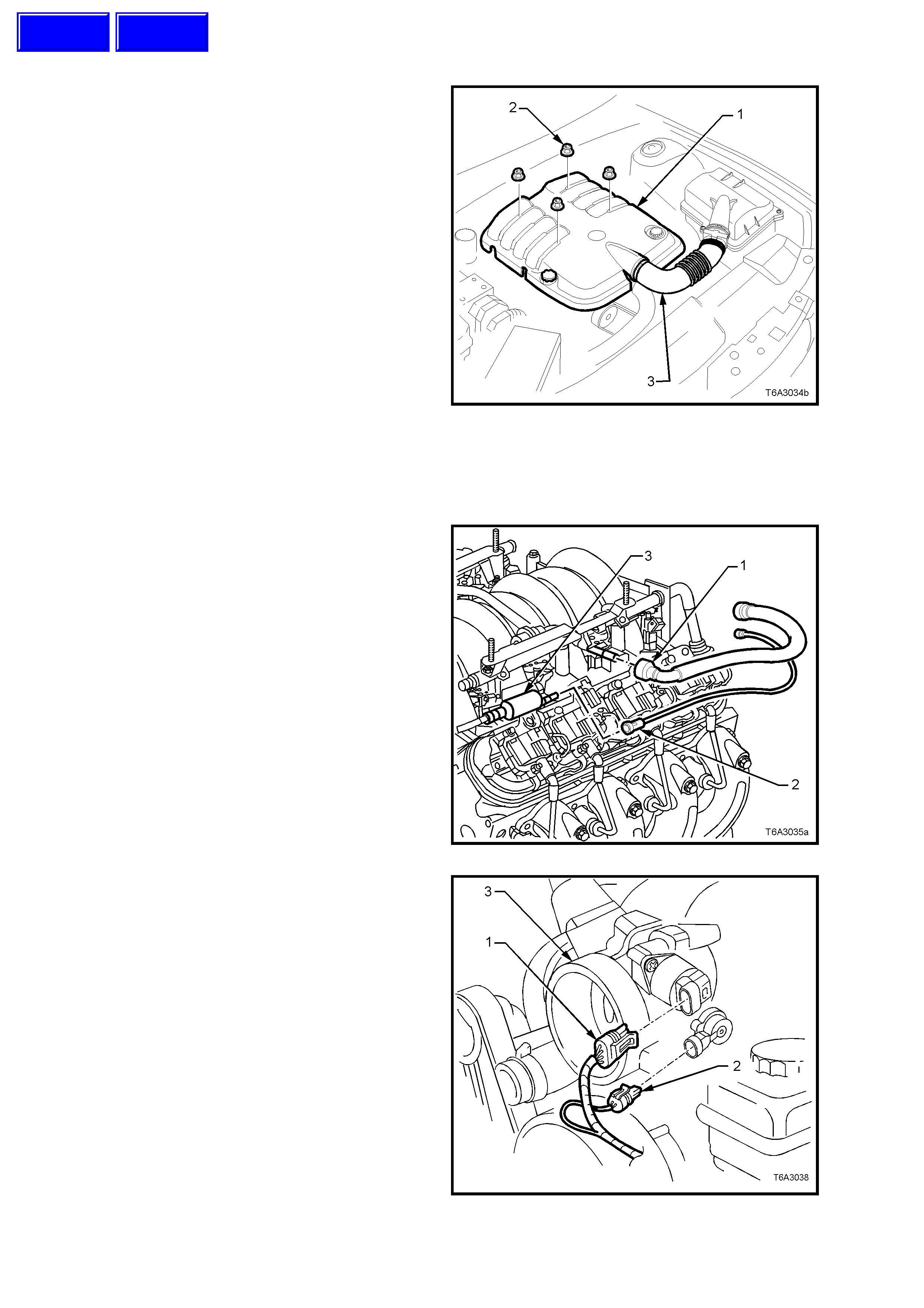

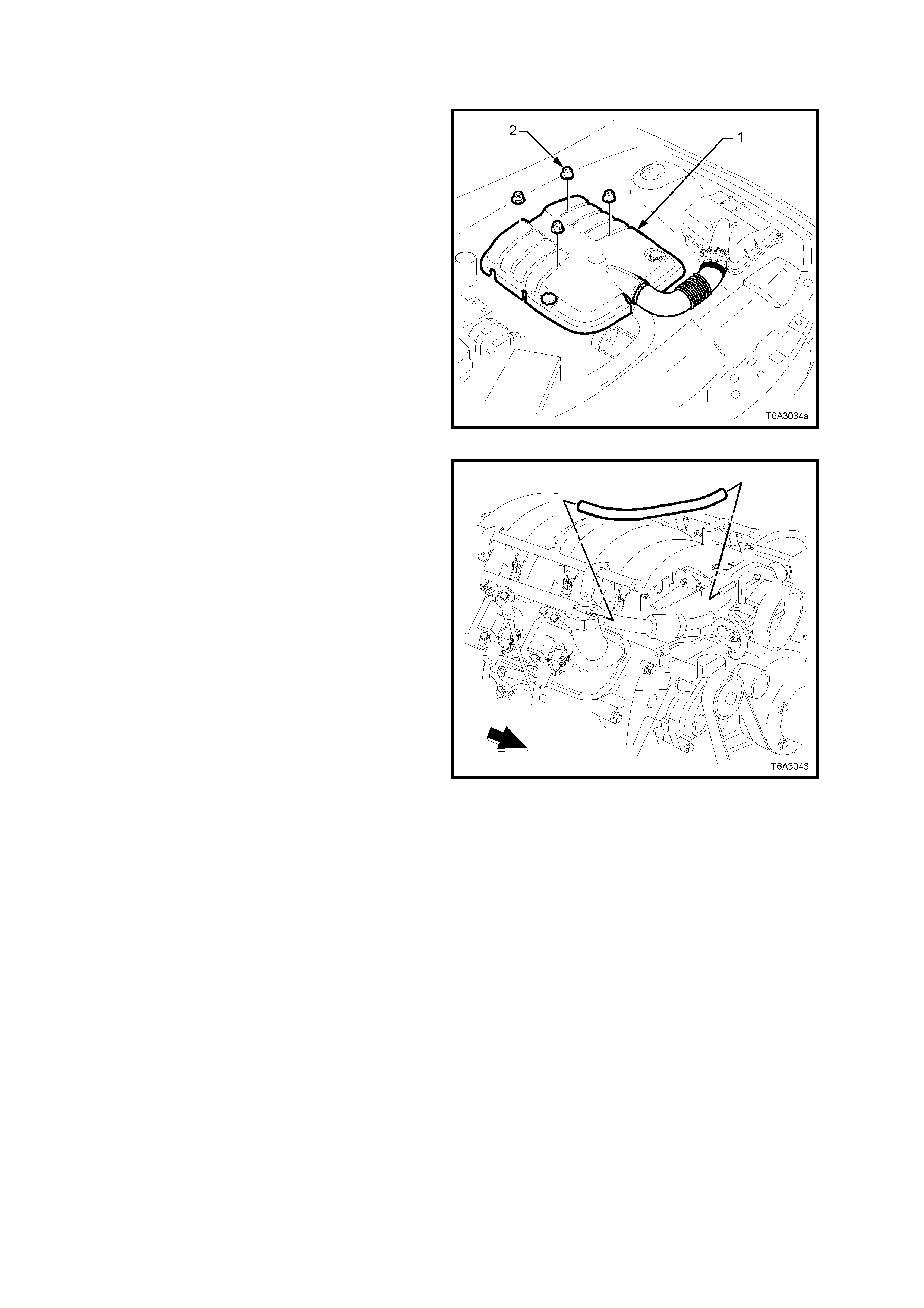

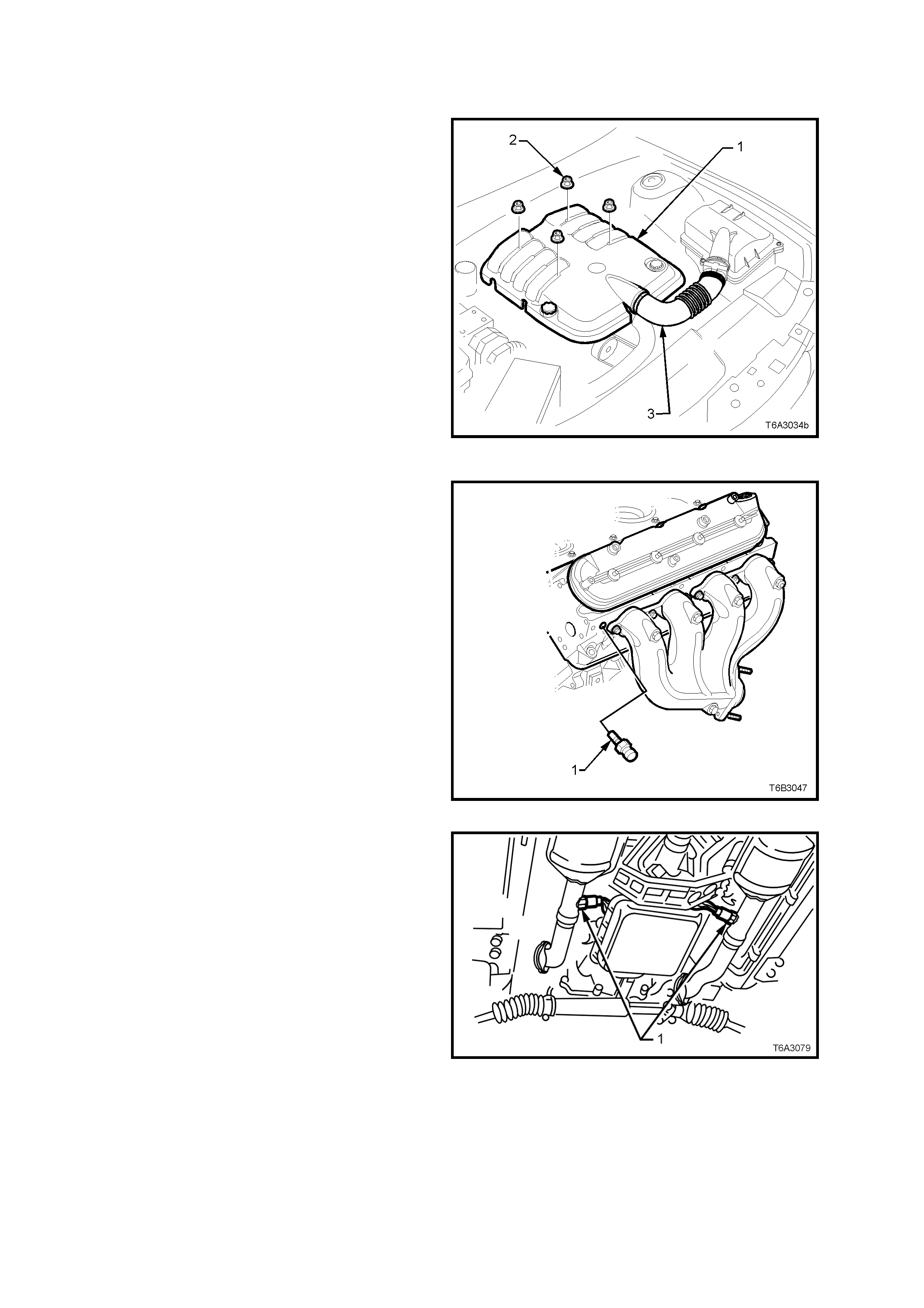

3. Rem ove the engine dress cover retaining nuts

(2), then remove the cover (1).

4. Loosen the two clam ps securing the air intake

duct (3) to the thr ottle body and Mas s Air Flow

(MAF) sensor.

5. Remove air intake duct (3) assembly from

throttle body and MAF sensor.

6. De-pressurise fuel rail. Refer to

Operation 2.13, in this Section.

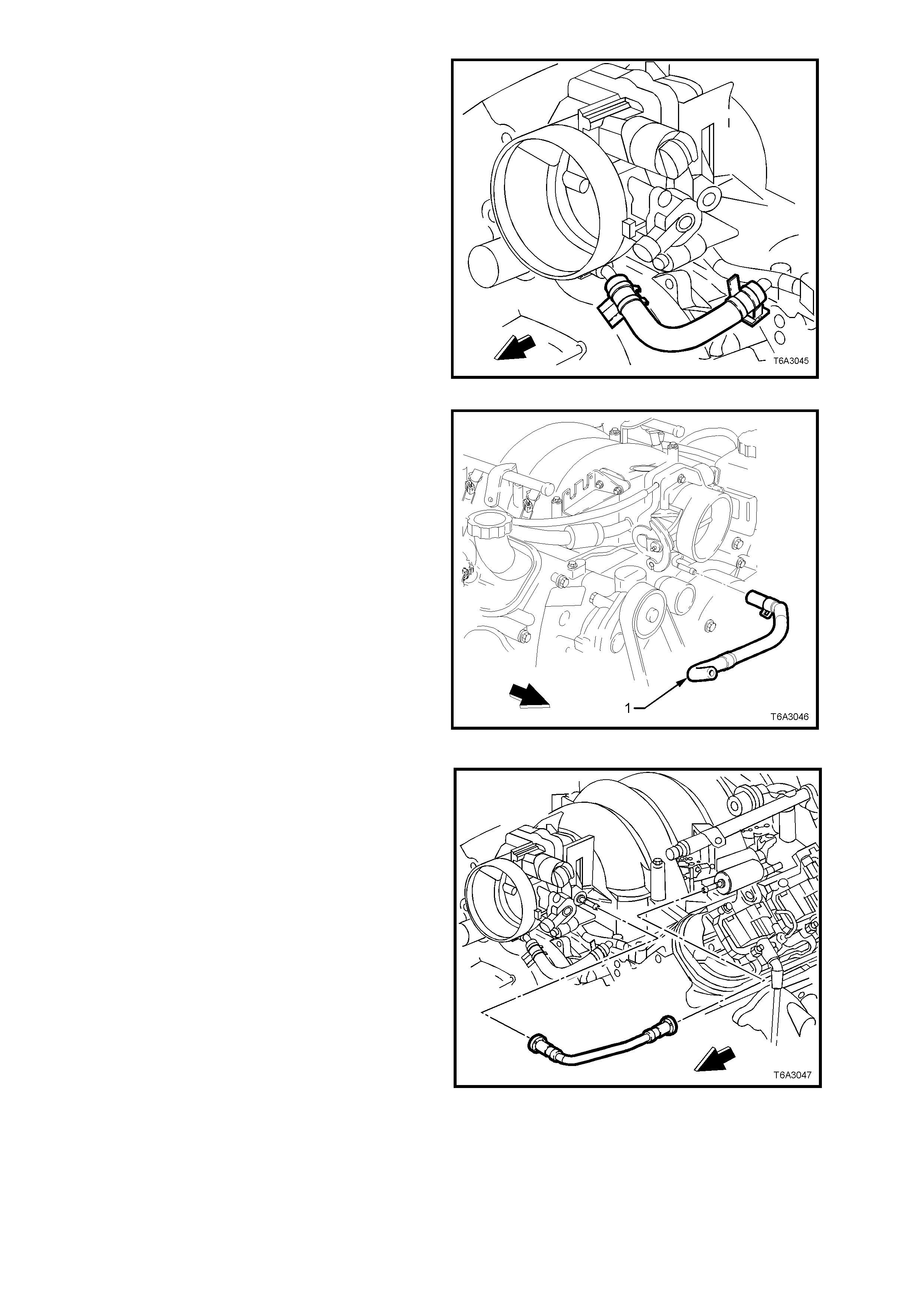

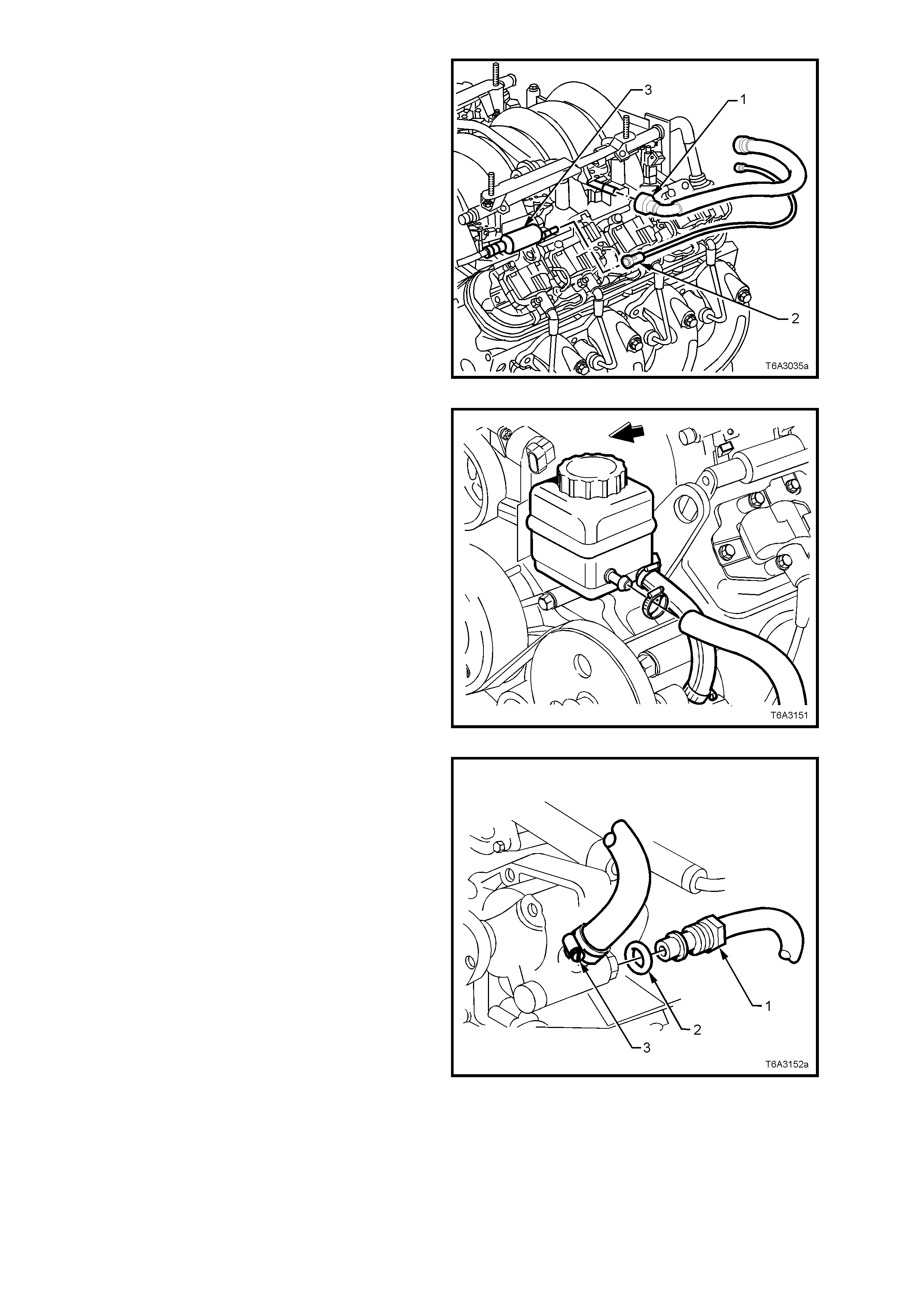

Figure 6A3-45

7. Using quick connect release Tool No. 7371,

install over fuel line.

8. While holding the fuel line quick connect (1),

push on Tool 7371 to release the quick

connect fitting (1) from the fuel rail. Pull back

on the quick connect and remove.

9. Disconnect the vapour line connector (2) from

the EVAP purge valve (3).

Important: Cap the fuel line fittings and plug the

holes after separating the fuel lines to prevent fuel

leaking and/or dirt and other contaminants from

entering the fuel system.

Figure 6A3-46

10. Disconnect wiring harness connector (1) from

the Intake Air Control (IAC) motor, at the

throttle body (3).

11. Disconnect the wiring harness connector (2)

from the Throttle Position (TP) sensor at the

throttle body (3).

Figure 6A3-47

Techline

Techline

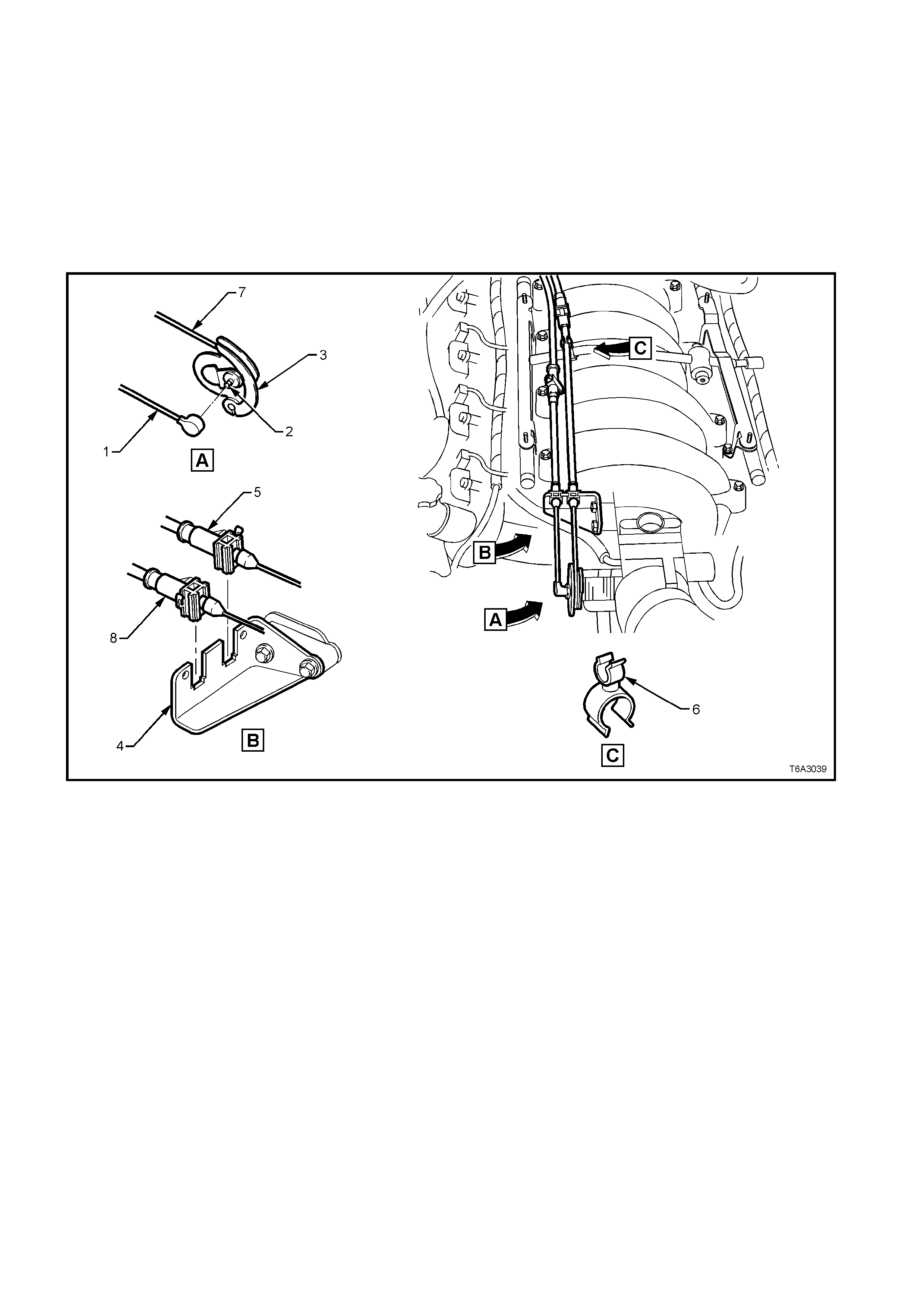

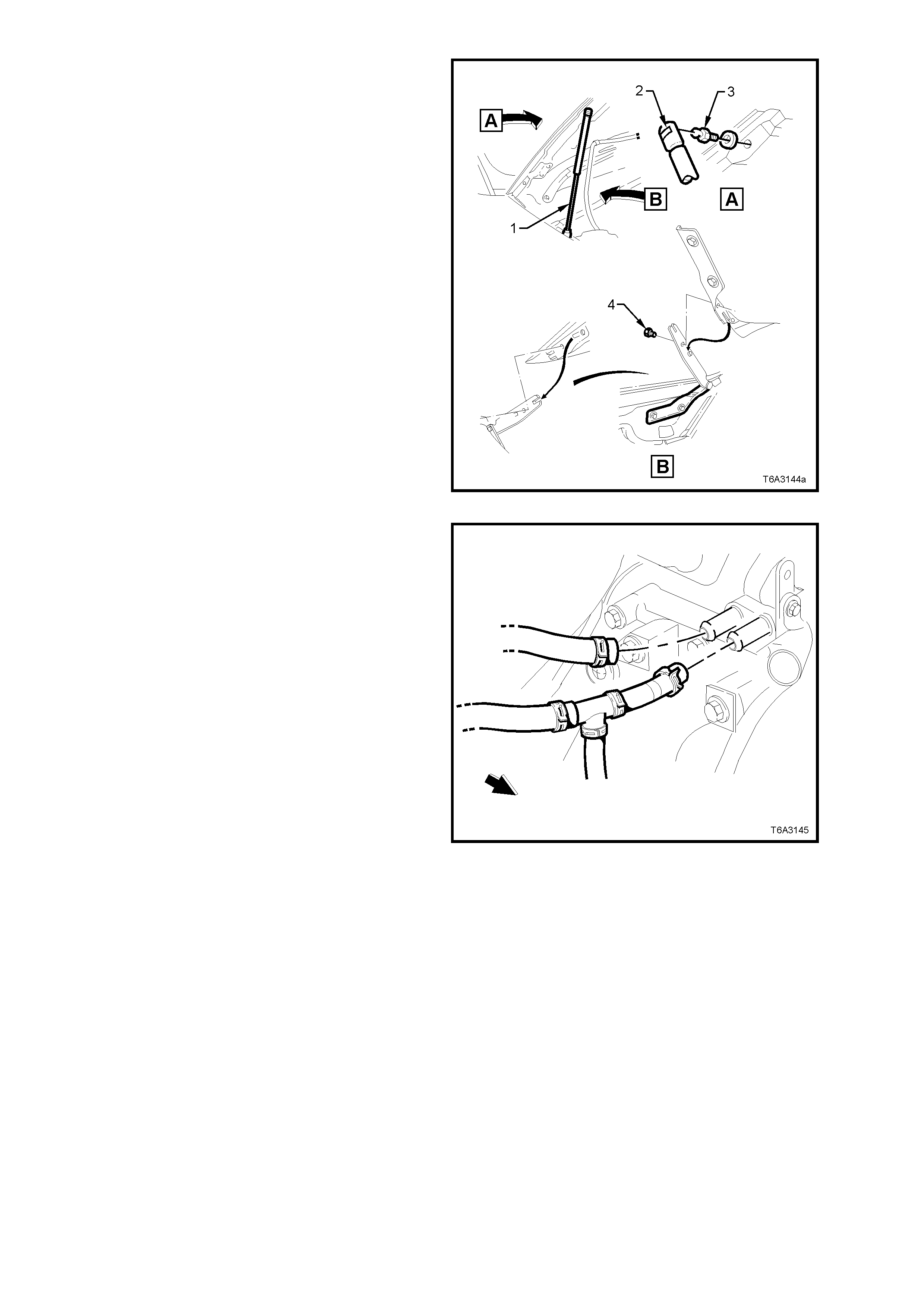

12. Disconnect the cruise control cable (1) (if

fitted) from the stud (2) on the throttle body

valve lever (3), then remove the outer cable

(8) from the retainer bracket (4). Refer Figure

6A3-48.

13. Lift the throttle cable (5) from the clip at the

fuel rail crossover pipe (6), then lift the cable

(5) from the retainer bracket (4).

14. Remove the inner throttle cable (7) from the

throttle body valve lever (3).

15. Set the cable/s to one side.

Figure 6A3-48

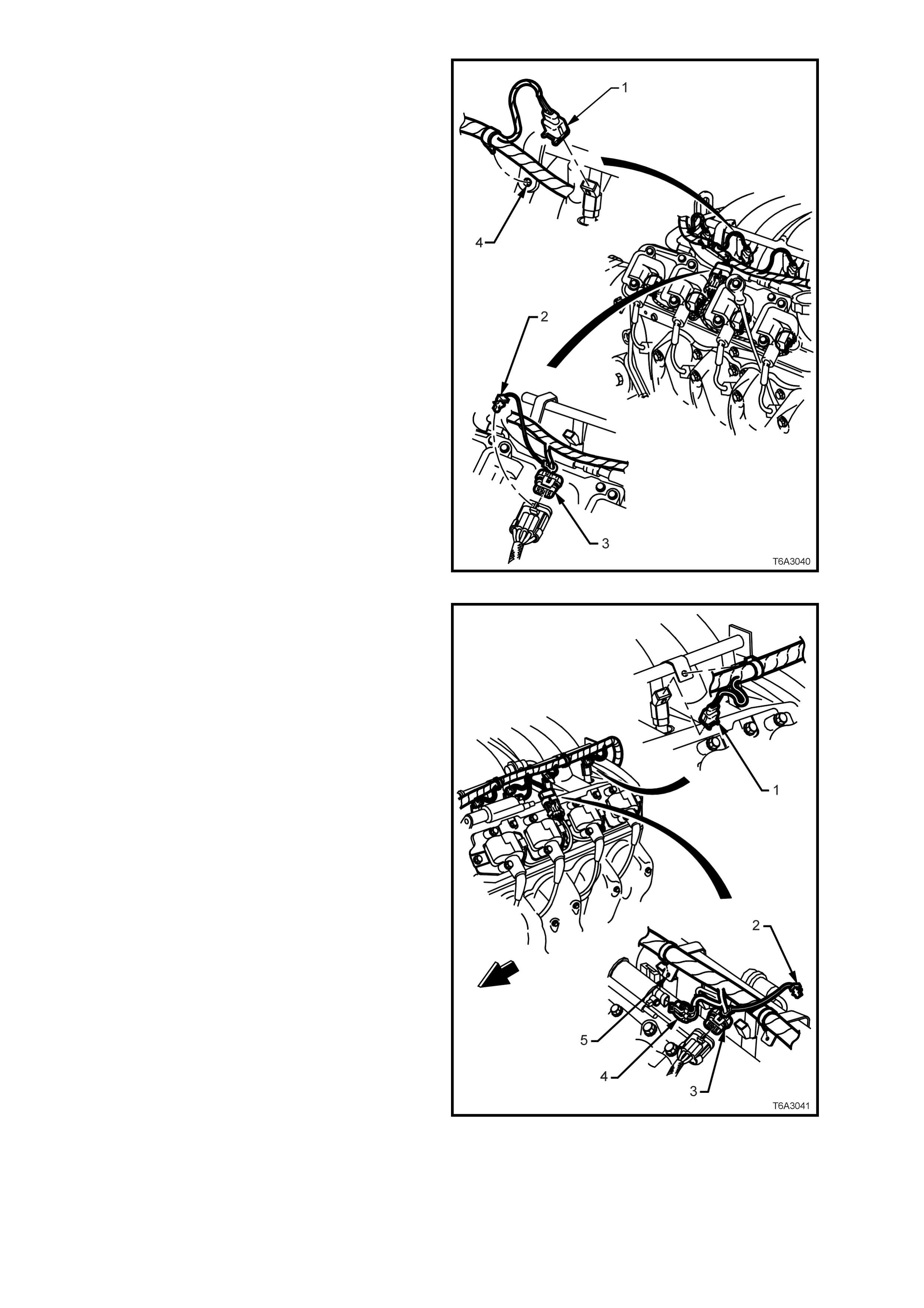

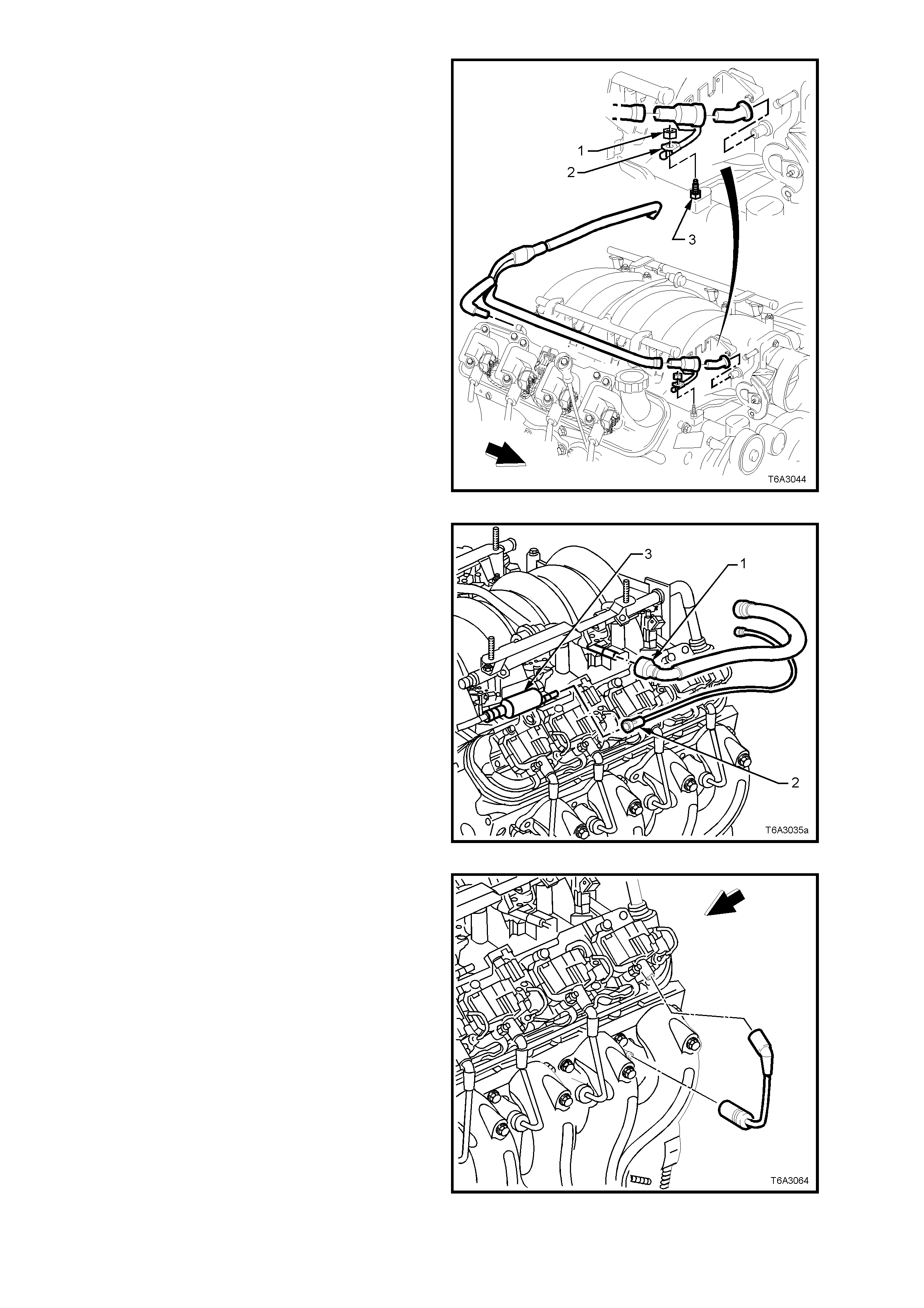

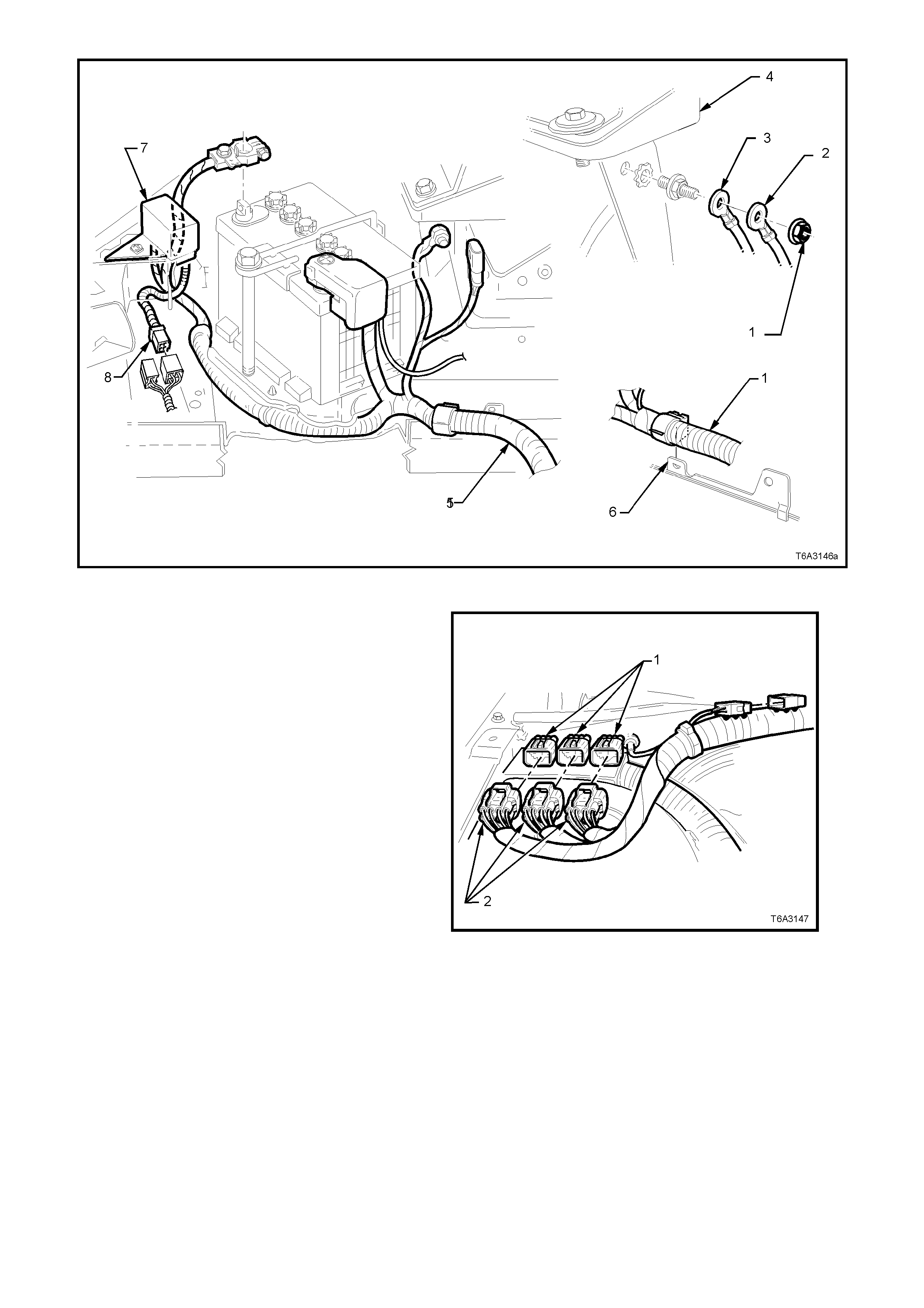

16. Disconnect the fuel injector wiring harness

connectors (1) from the right bank of fuel

injectors (4 places).

17. Rem ove the CPA lock (2) f rom the ignition coil

main connector (3) on the right hand side,

remove the connector (3), then the harness

securing clips from the fuel rail brackets (4)

and set the harness to one side.

Figure 6A3-49

18. Disconnect the fuel injector wiring harness

connectors (1) from the left bank of fuel

injectors (4 places).

19. Rem ove the CPA lock (2) f rom the ignition coil

main connector (3) on the left hand side, then

remove the wiring harness connector (3).

20. Remove the wiring harness connector from

the canister purge valve (4).

21. Remove the harness securing clips from the

fuel rail brackets (5) and set the harness to

one side.

Figure 6A3-50

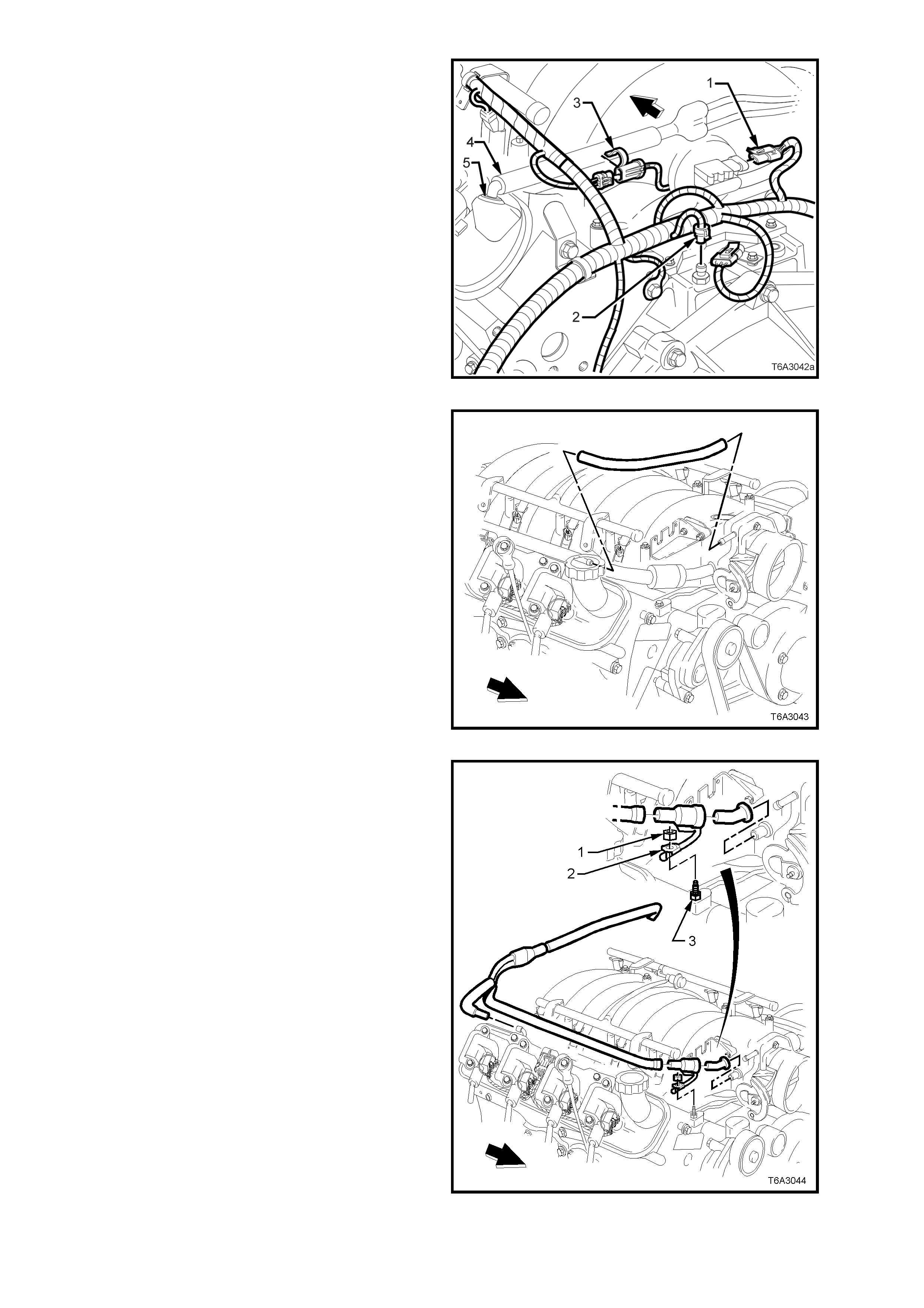

22. Disconnect the wiring harness connector (1)

from the MAP sensor, located at the rear of

the intake manifold.

23. Remove the knock sensor patch harness

connector r etaining clip (3) fr om the PCV hose

and disconnect the wiring harness connector.

24. Remove the PCV hose (4) from the PCV vent

valve grommet (5) (left bank).

Figure 6A3-51

25. Remove the fresh air hose from the front fitting

of the rocker cover and the throttle body.

Figure 6A3-52

26. Remove the nut (1) securing the PCV valve,

heat conducting strap (2) from the front right

hand vapour pipe screw (3).

27. Remove the PCV valve hose from the throttle

body and right hand rocker cover, rear fitting.

28. Remove the PCV valve and hose assembly

from the left hand rocker cover clip, then lift

hoses and valve assembly from the engine.

Figure 6A3-53

29. Remove the engine coolant, vapour vent hose

from the throttle body and the vapour vent

pipe.

Figure 6A3-54

30. Remove the engine coolant vapour vent outlet

hose (1) from the throttle body and left hand

radiator tank.

Figure 6A3-55

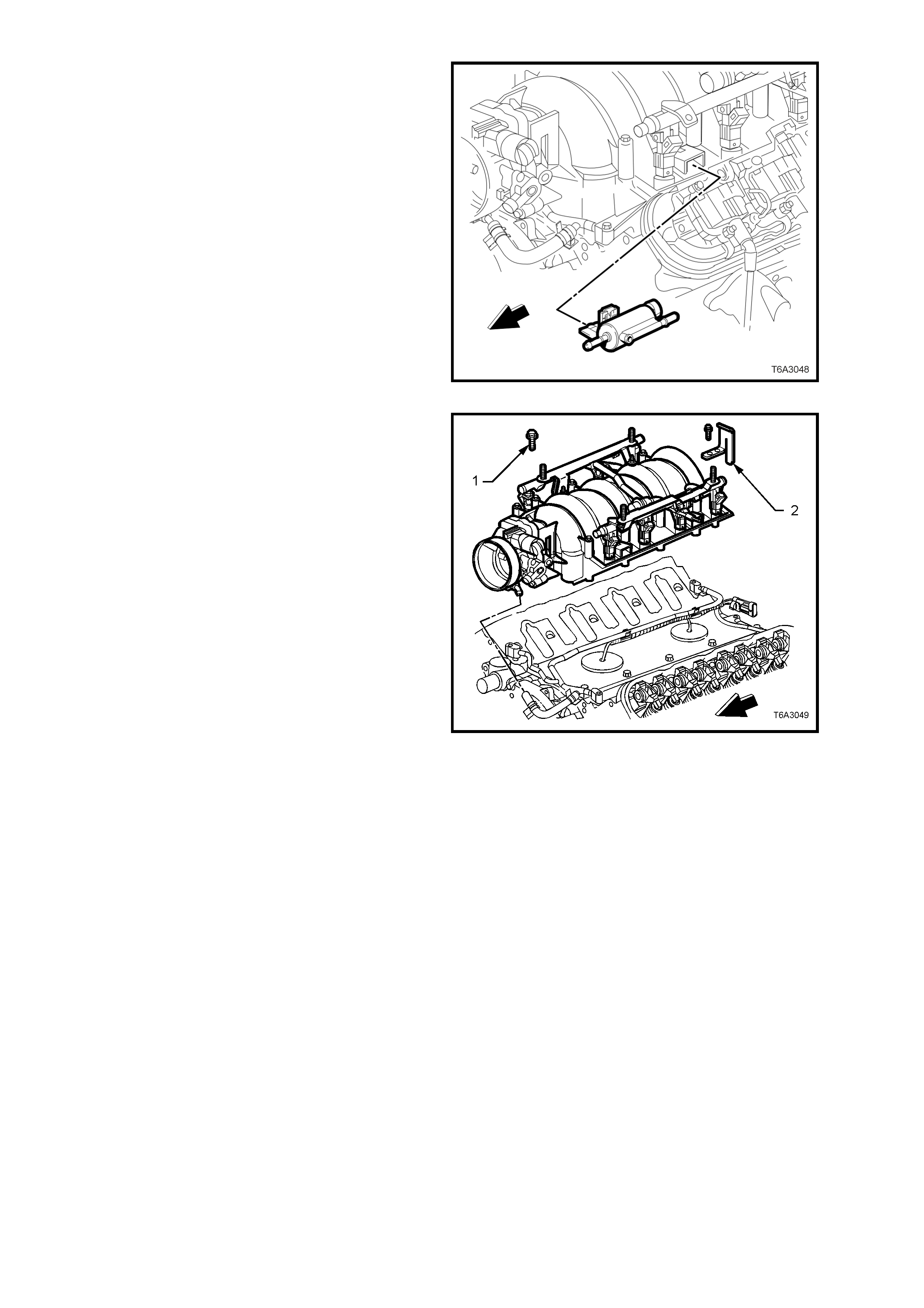

31. Remove the evaporative (EVAP) canister

purge valve tube fr om the purge valve and the

throttle body.

Figure 6A3-56

32. Remove the EVAP canister purge valve and

bracket from the intake manifold.

Figure 6A3-57

33. Progressively loosen the 10 intake manifold

retaining bolts (1), working diagonally from

outside to inside.

34. Remove the fuel rail stop bracket (2) with the

two, left rear bolts and set to one side.

35. Carefully bump the intake manifold to break

the gasket seal, then lift from the engine.

36. Remove the intake manifold to cylinder head

gaskets and discard.

Figure 6A3-58

DISASSEMBLE

If required, the following components can be

removed from the intake manifold:

1. Remove the Manifold Absolute Pressure

(MAP) sensor (1) from the fitting at the rear of

the intake manifold by twisting back and forth

while pulling on the sensor.

2. Check the silicone r ubber seal (2) on the MAP

sensor to ensure that it is not torn or

damaged.

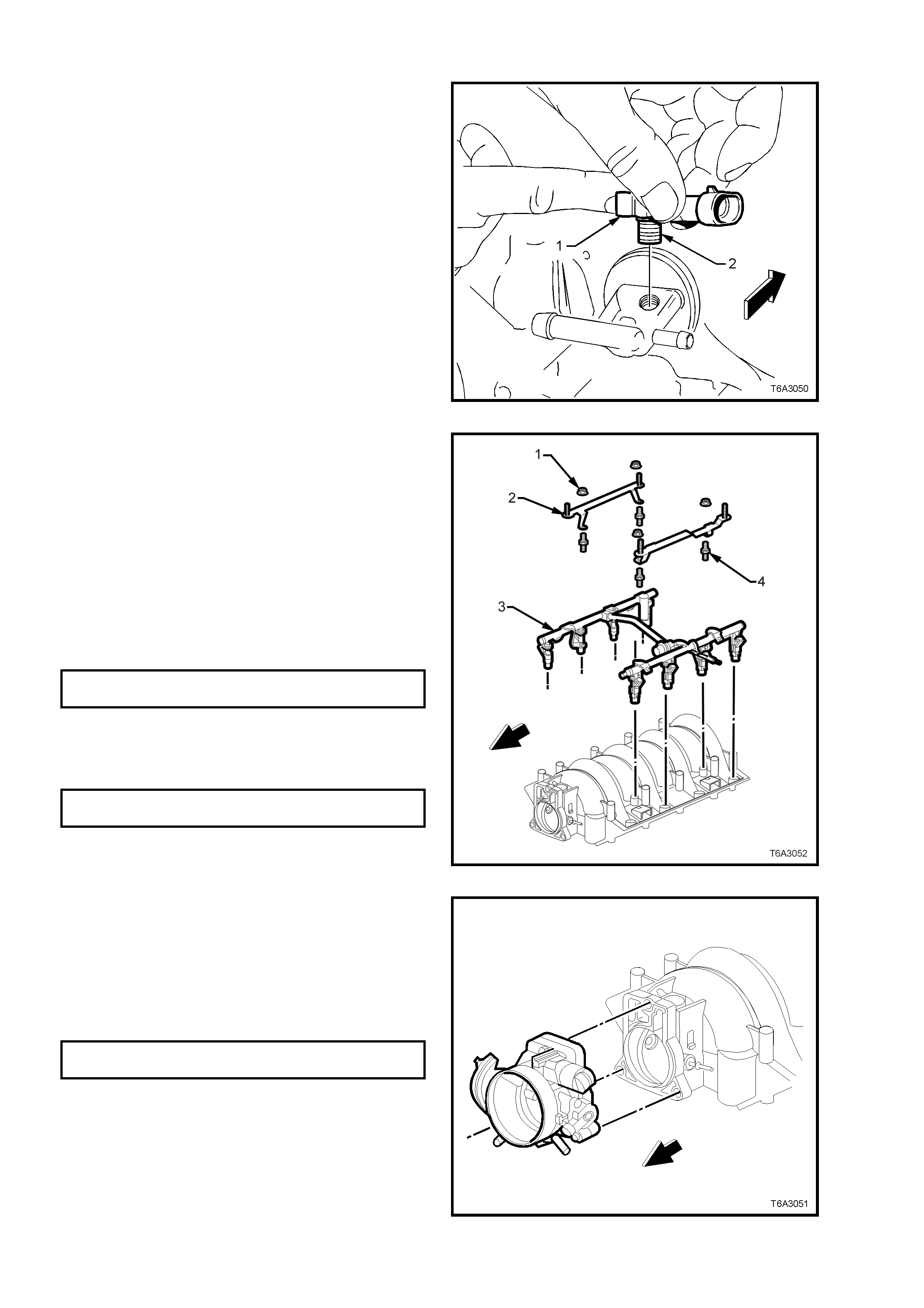

Figure 6A3-59

3. Remove the throttle body retaining bolts, then

the throttle body and gasket. Discard the

gasket.

Figure 6A3-60

4. Remove the four nuts (1) securing the engine

dress cover brackets (2) to the fuel rail (3),

then lift the two brackets from the fuel rail.

5. Remove the studs (4) securing the fuel rail

and injectors to the intake manifold, then

carefully remove the fuel rail and injectors as

an assembly.

Should further disassembly of the fuel injectors be

required, refer to Section 6C3 POWERTRAIN

MANAGEMENT - GEN III V8 ENGINE.

Figure 6A3-61

CLEAN AND INSPECT

1. Af ter cleaning the intake m anifold in a s uitable

solvent, dry off manifold using compressed

air.

CAUTION: Wear safety glasses to avoid eye

injury.

2. Ensure that the intake manifold gasket

grooves and vacuum passages in the rear of

the intake manifold are all clean and clear.

3. Inspec t throttle body and fuel r ail bolt ins ert s in

the composite intake manifold, for looseness

and/or damaged threads.

4. Inspect the intake manifold for cracks or

damage, including the areas between the

intake runners.

5. Inspect the fuel injector bores for excessive

scoring or damage.

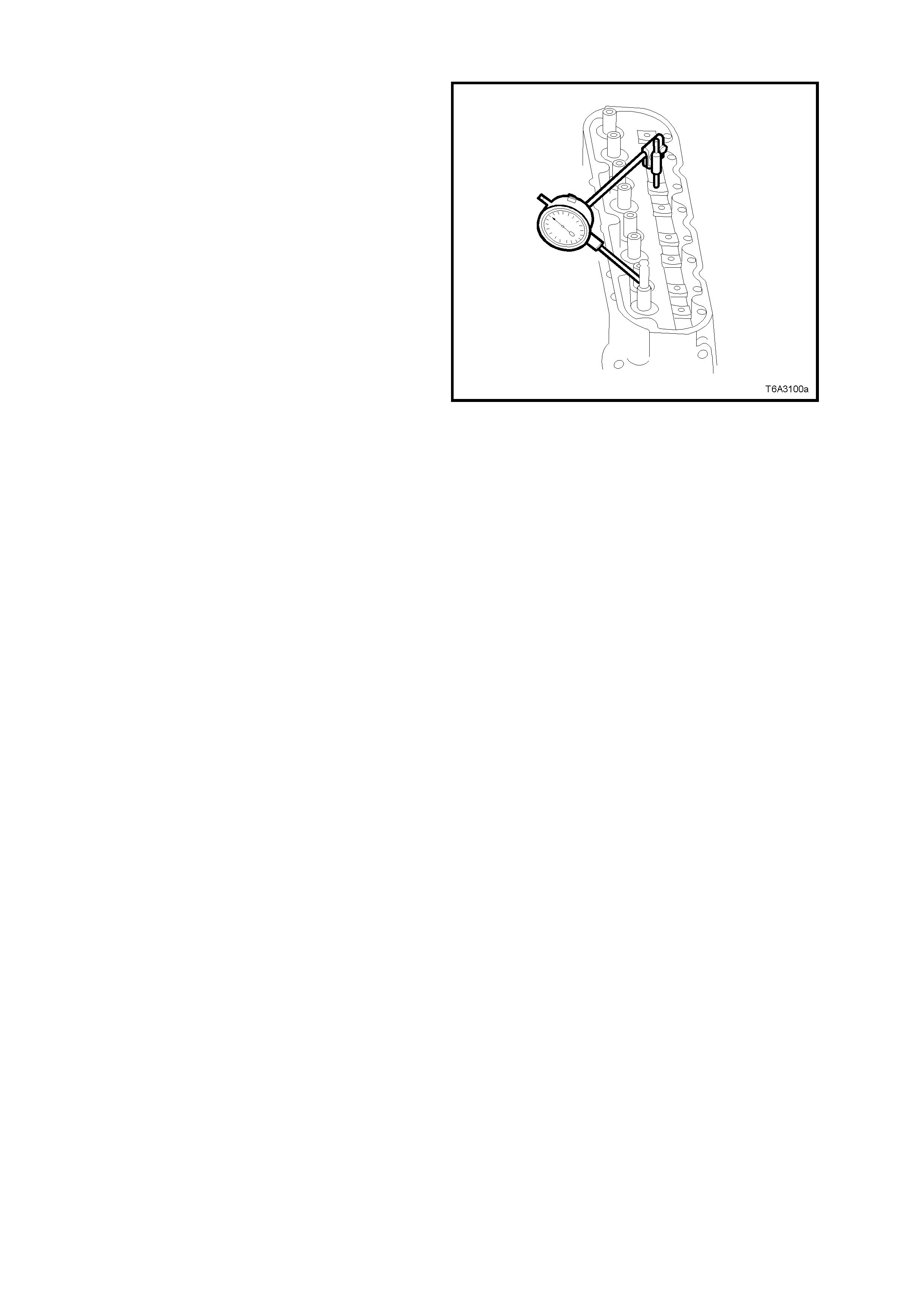

6. Inspect the intake manifold to cylinder head

faces for warpage, as follows:

a. Locate a straight edge across each of the

two surfaces and check for warpage,

using feeler gauges.

b. An intake manif old with warpage in excess

of 0.5 mm, must be replaced.

REASSEMBLE

Manifold Absolute Pressure (MAP) Sensor

If removed, install the MAP sensor as follows:

1. Check the MAP sensor seal (2) to ensure it is

seated correctly on the sensor.

2. Install the Manifold Absolute Pressure (MAP)

sensor (1) into the fitting at the rear of the

intake manifold by pushing the sensor into the

fitting.

Figure 6A3-62

Fuel Rail and Injectors

1. Lubric ate NEW injector O -r ing seals with clean

engine oil.

2. Install the NEW O-rings to the fuel injectors.

3. Install the fuel rail (with injectors) into the

intake manifold, pressing evenly on each side

until the injectors are all seated in their bores.

4. Apply a 5 mm band of thread sealant such as

Loctite 242 (or other c ommerc ial equivalent) to

the cleaned threads of the fuel rail attaching

studs (4) and install, tightening to the correct

torque specification.

FUEL RAIL ATTACHING BOLTS

TORQUE SPECIFICATION 8 - 12 Nm

5. Install the engine dress cover attaching

brack ets (2) to the fuel r ail attaching studs (4),

fit the retaining nuts (1) and tighten to the

correct torque specification.

ENGINE DRESS COVER BRACKET

NUT TORQUE SPECIFICATION 4 - 6 Nm

Figure 6A3-63

Throttle Body

1. Install a NEW throttle body gasket to the

intake manifold.

2. Install the throttle body and bolts to the intake

manifold.

3. Tighten the throttle body bolts to the correct

torque specification.

THROTTLE BODY BOLT

TORQUE SPECIFICATION 12 Nm

Figure 6A3-64

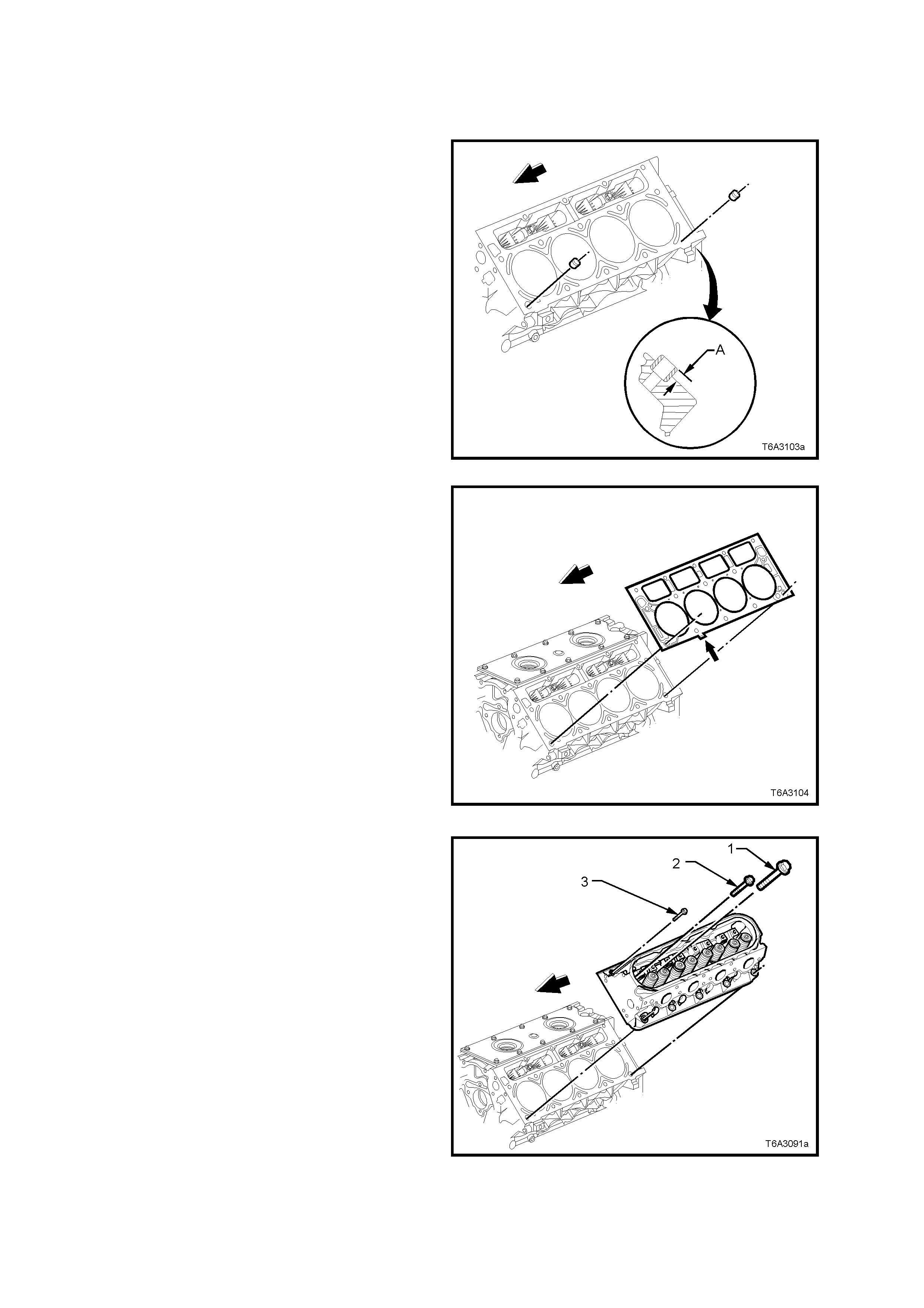

REINSTALL

1. Install NEW intake manifold to cylinder head

gaskets, then install the intake manifold.

2. Apply a 5 mm band of thread sealant such as

Loctite 242 (or equivalent to Holden

Specification HN 1256, Type 2, Class 2), to

the cleaned threads of the 10 intake manifold

attaching bolts (1).

Figure 6A3-65

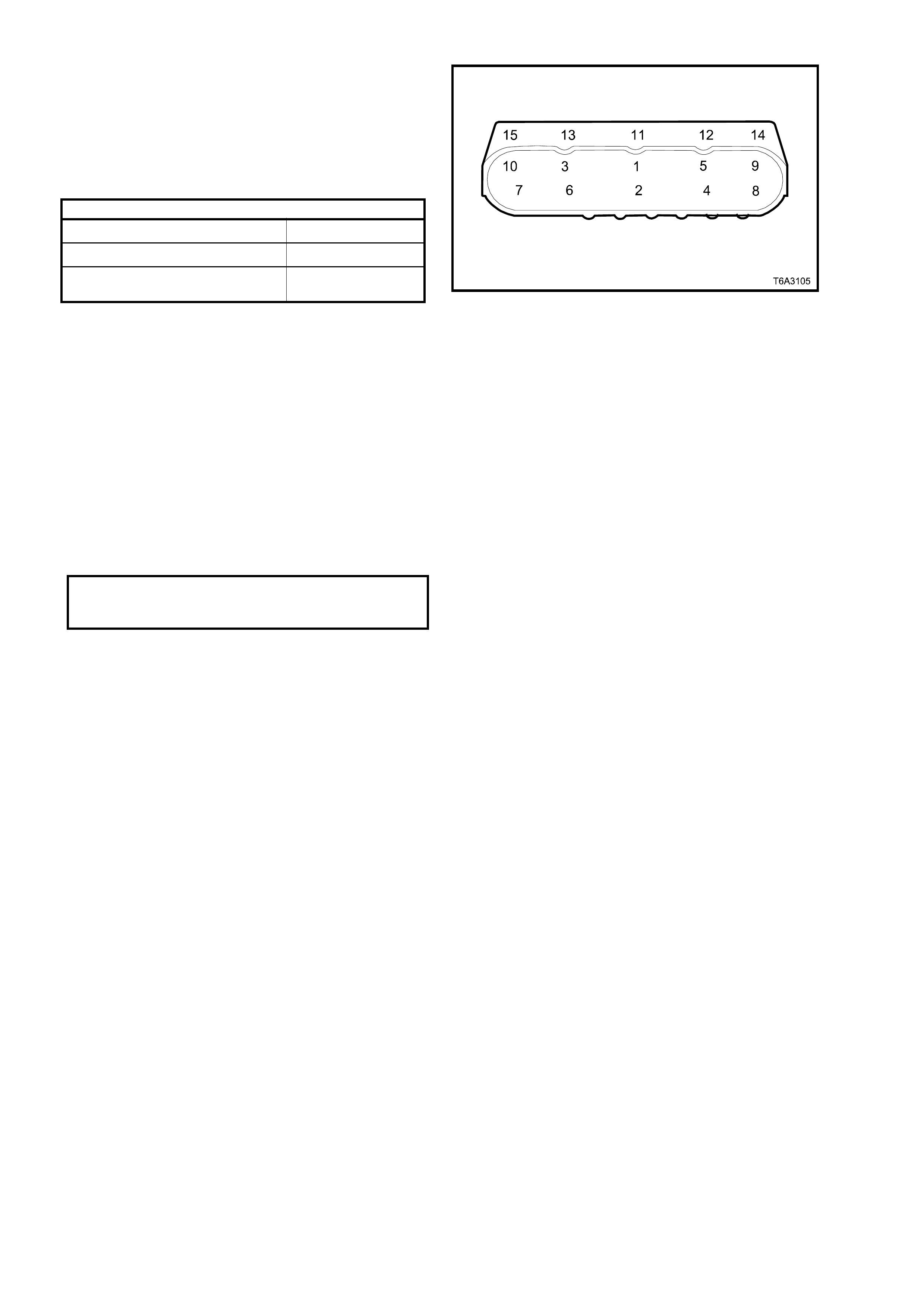

3. Install, the intake manifold bolts and fuel rail

stop bracket, tightening the bolts in two

stages, in the sequence shown, to the correct

torque specification.

INTAKE MANIFOLD BOLTS Stage 1 - 5 Nm

TORQUE SPECIFICATION Stage 2 - 8 Nm

CAUTION: Do not overlook installing the fuel

stop bracket. The stop bracket serves as a

protective shield for the fuel rail in the event of

a vehicle frontal collision. If the fuel stop

bracket is not installed and the vehicle is

involved in a collision, fuel could be sprayed,

possible causing a fire and personal injury from

burns.

Figure 6A3-66

The remainder of the installation process is the

reverse of the removal operations, except for the

following;

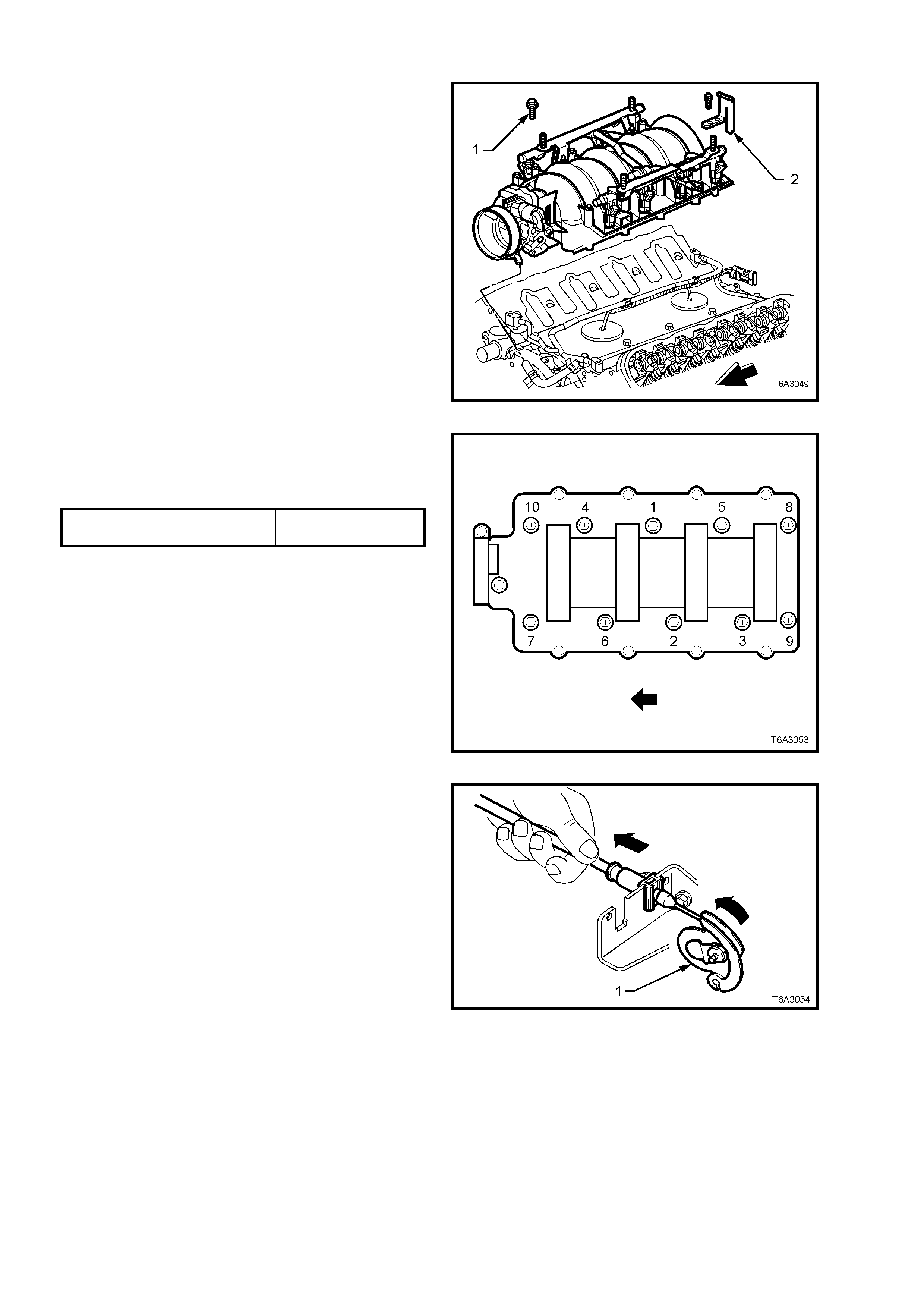

4. After installation, the throttle cable is to be

adjusted, as detailed:

a. Attach all cable fittings.

b. With the outer cable adjuster unlocked,

apply a tension to the adjuster, until the

throttle cam (1) begins to move.

Figure 6A3-67

c. Release the tension on the adjuster until

the throttle cam is back at rest (1), then

slightly compres s the adjuster (2) about 1

mm to lock.

Figure 6A3-68

5. If fitted, the cruise control cable must be

adjusted, as follows:

a. Connect the inner cable ( 1) to the s tud ( 2)

on the throttle cam (3), then slide the

outer cable into position in the throttle

cable bracket (4).

Figure 6A3-69

b. Unlock the adjustment locking lever (1).

c. Ensure that the throttle is fully closed,

then adjust the outer cruise control cable

(2), to achieve minimum slac k in the inner

cable.

d. Flip the adjustment lever (1) to lock the

outer cable (2) into position.

Figure 6A3-70

6. Install engine dress cover and the four

retaining nuts and tighten to the cor rect torque

specification.

ENGINE DRESS COVER

RETAINING NUT 8 - 12 Nm

TORQUE SPECIFICATION

7. Fill the cooling system. Refer to

Section 6B3 ENGINE CO OLING - G EN III V8

ENGINE.

8. Start engine check for leaks and normal

operation.

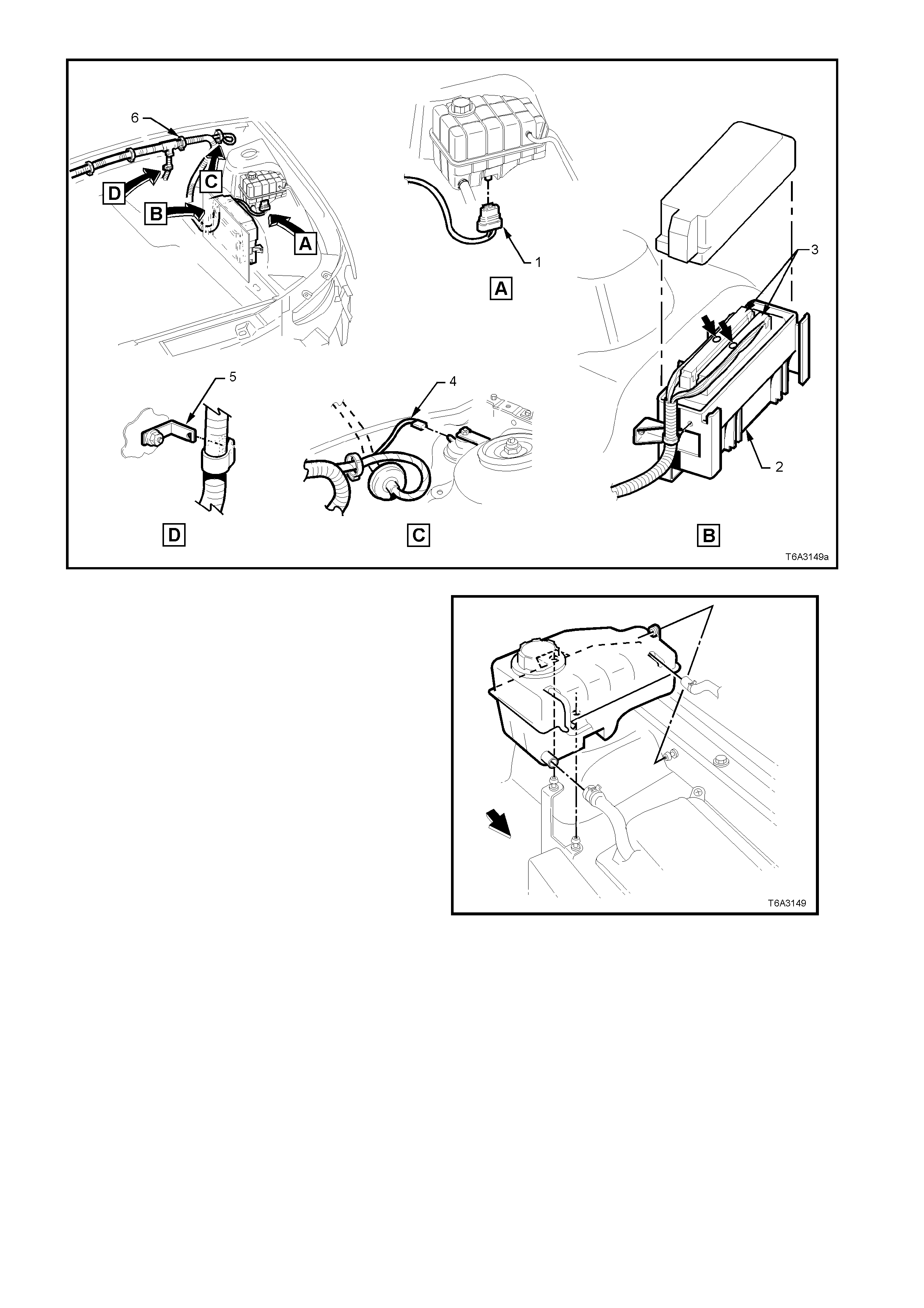

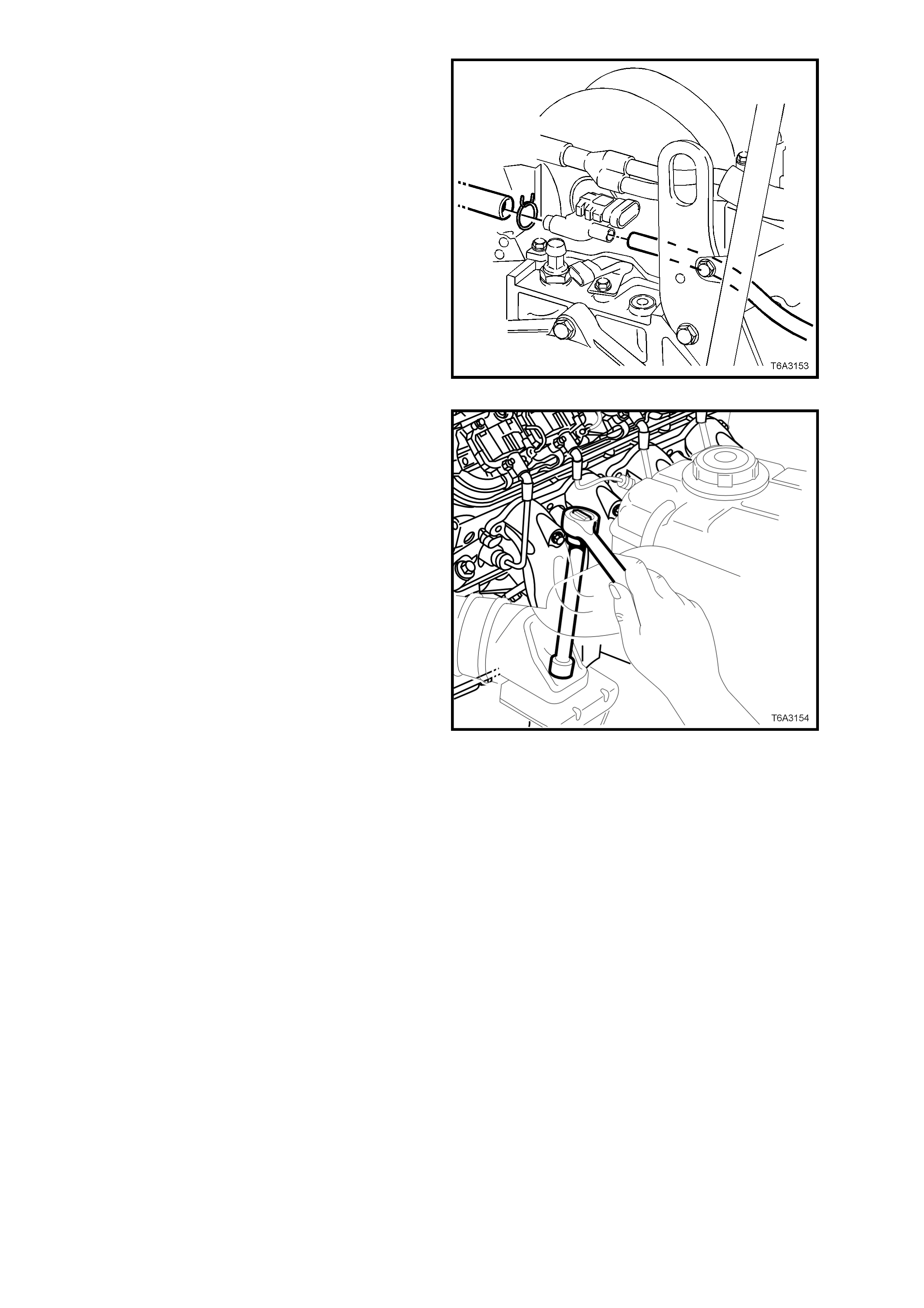

2.15 VAPOUR VENT PIPE

REMOVE

1. Disconnect the battery earth cable from the

battery.

2. Drain the cooling system. Refer to

Section 6B3 ENGINE CO OLING - GEN III V8

ENGINE.

3. Rem ove the engine dress cover retaining nuts

(2), then remove the cover (1).

4. De-pressurise fuel rail. Refer to

Operation 2.13, in this Section.

5. Loosen both hose clamps securing the intake

hose (3) to the MAF sensor and the throttle

body. Remove the hose from the engine.

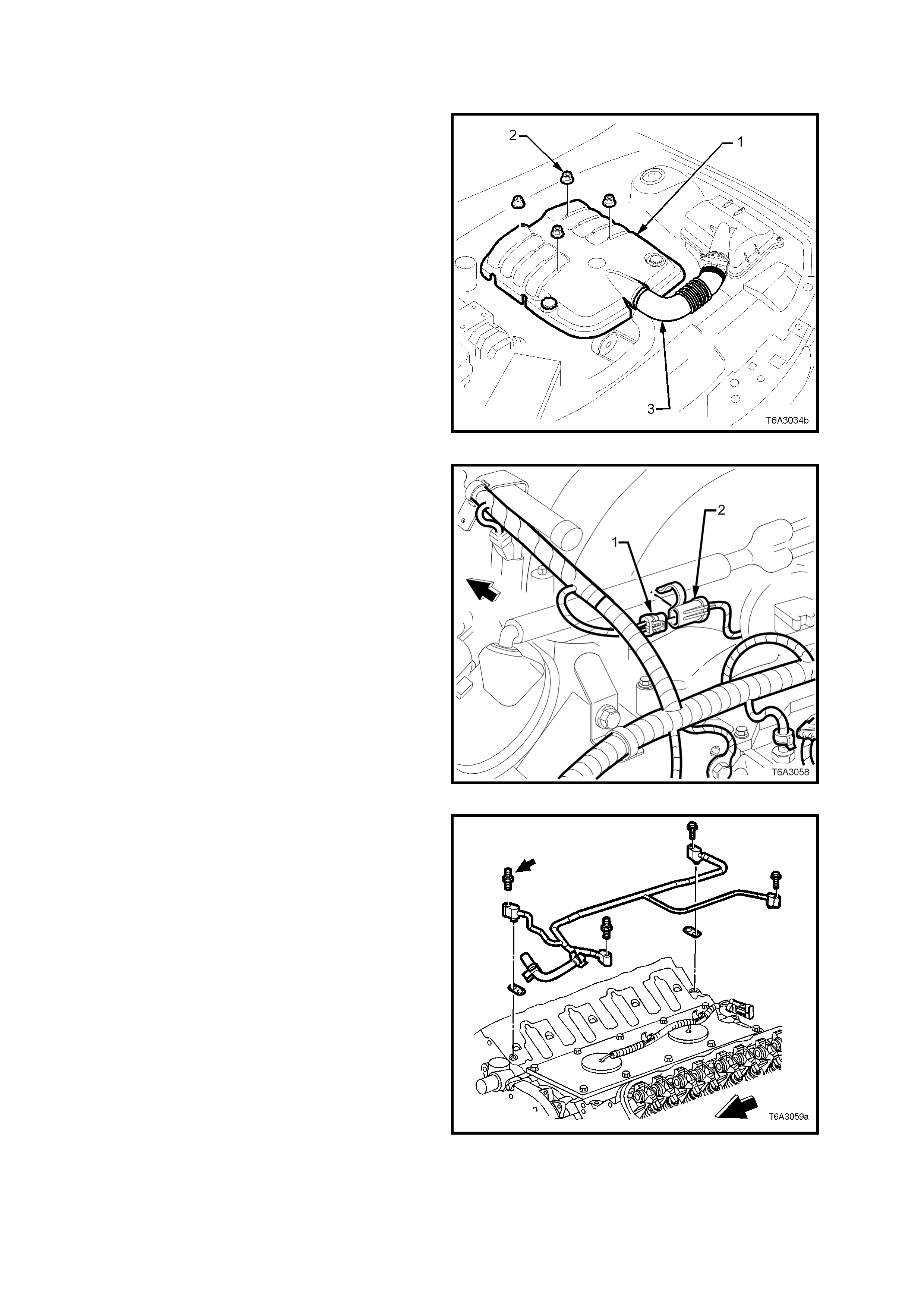

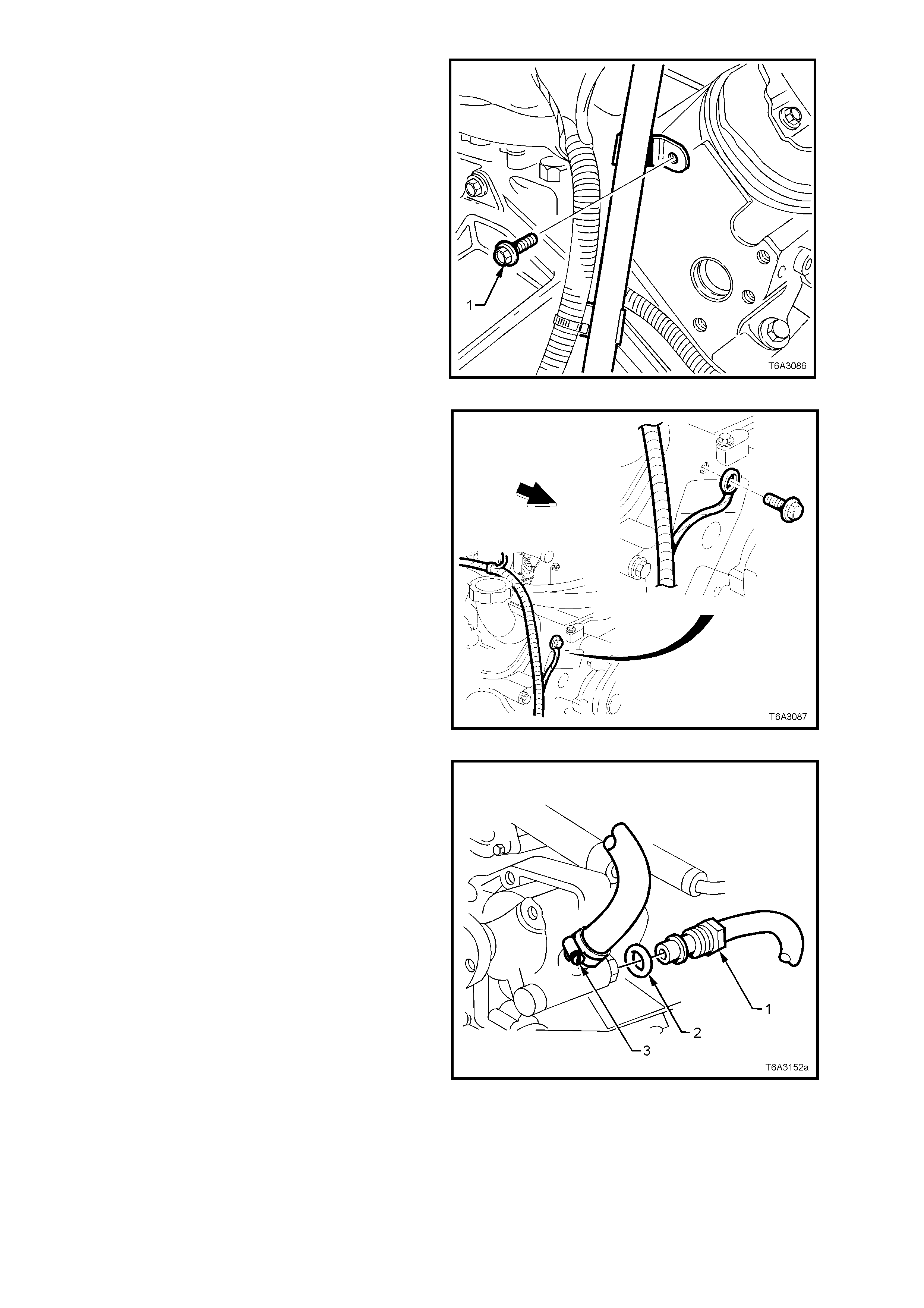

Figure 6A3-71

6. Remove intake manifold. Refer to

Operation 2.14 INTAKE MANIFOLD.

7. Rem ove the wiring harnes s connec tor (1) f rom

the knock sensor patch harness (2).

Figure 6A3-72

8. Unclip the knock sensor wiring harness clips

from the vapour vent pipe.

9. Remove the vapour vent pipe retaining

studs/bolts.

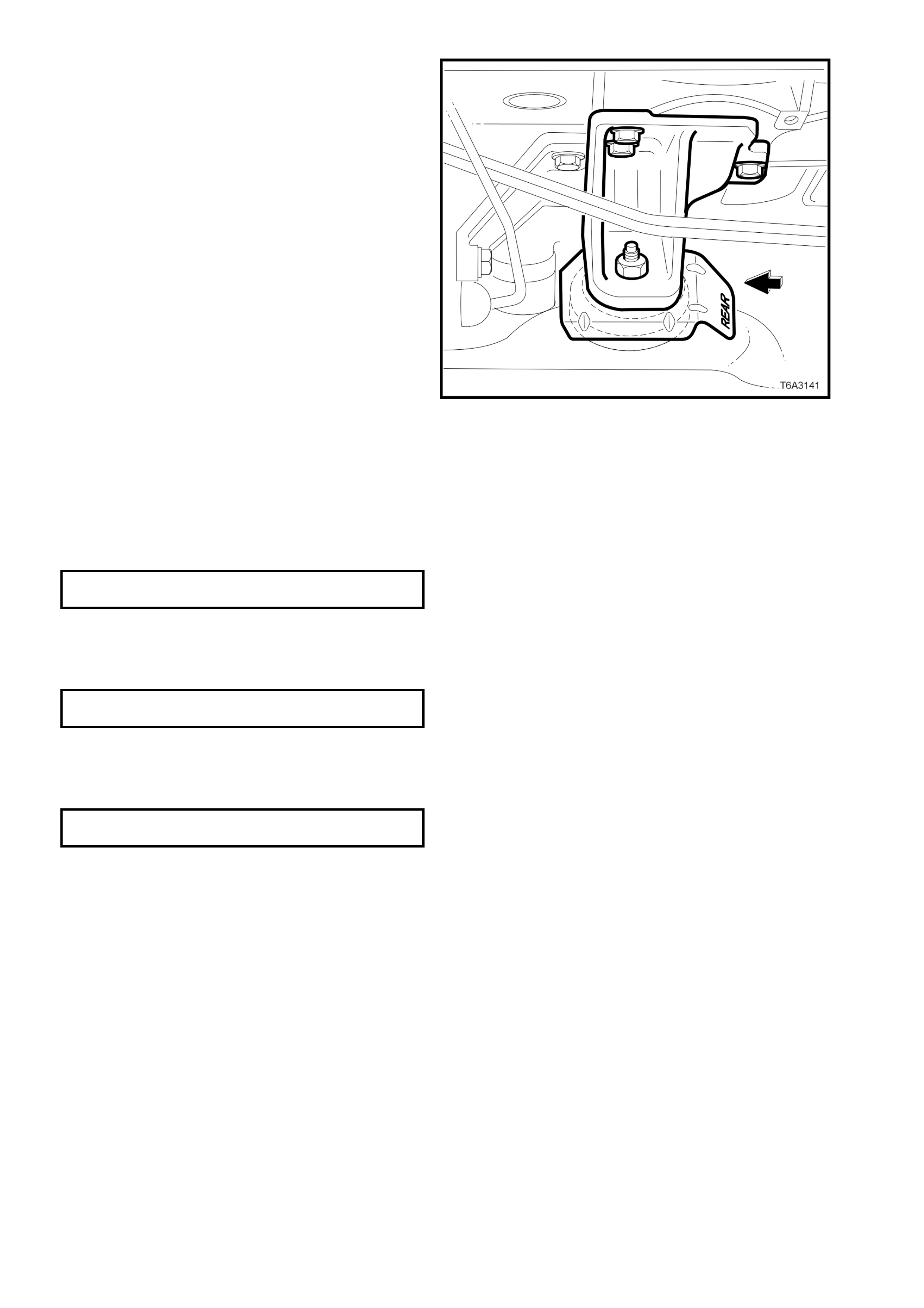

NOTE: Both front studs are double sided, with the

right hand one (arrow) being used to secure the

PCV valve braided strap, disconnected during the

intake manifold removal operation.

10. Remove the vapour vent pipe and gaskets

from the cylinder heads.

11. Remove the vapour vent pipe gaskets and

discard.

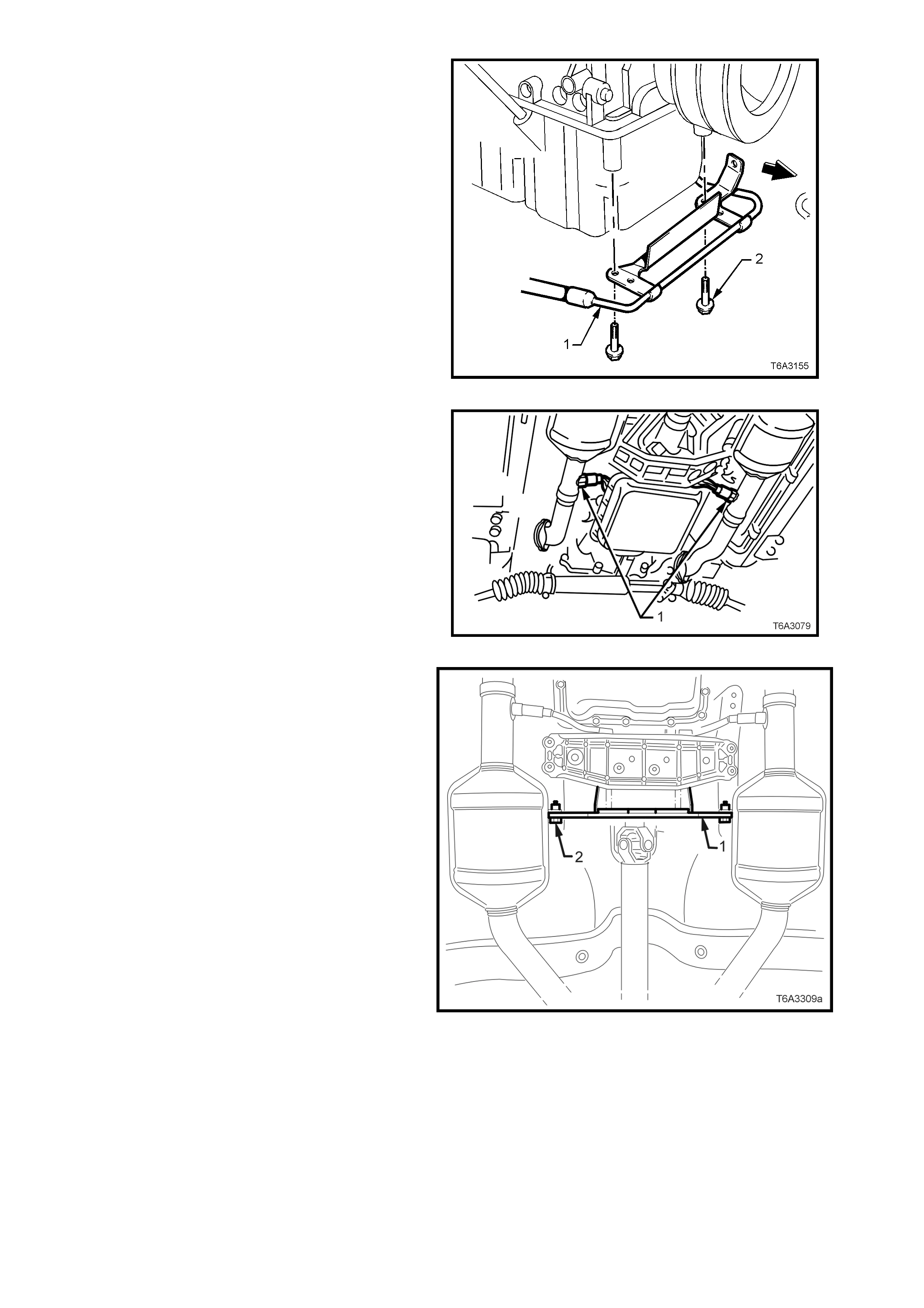

Figure 6A3-73

REINSTALL

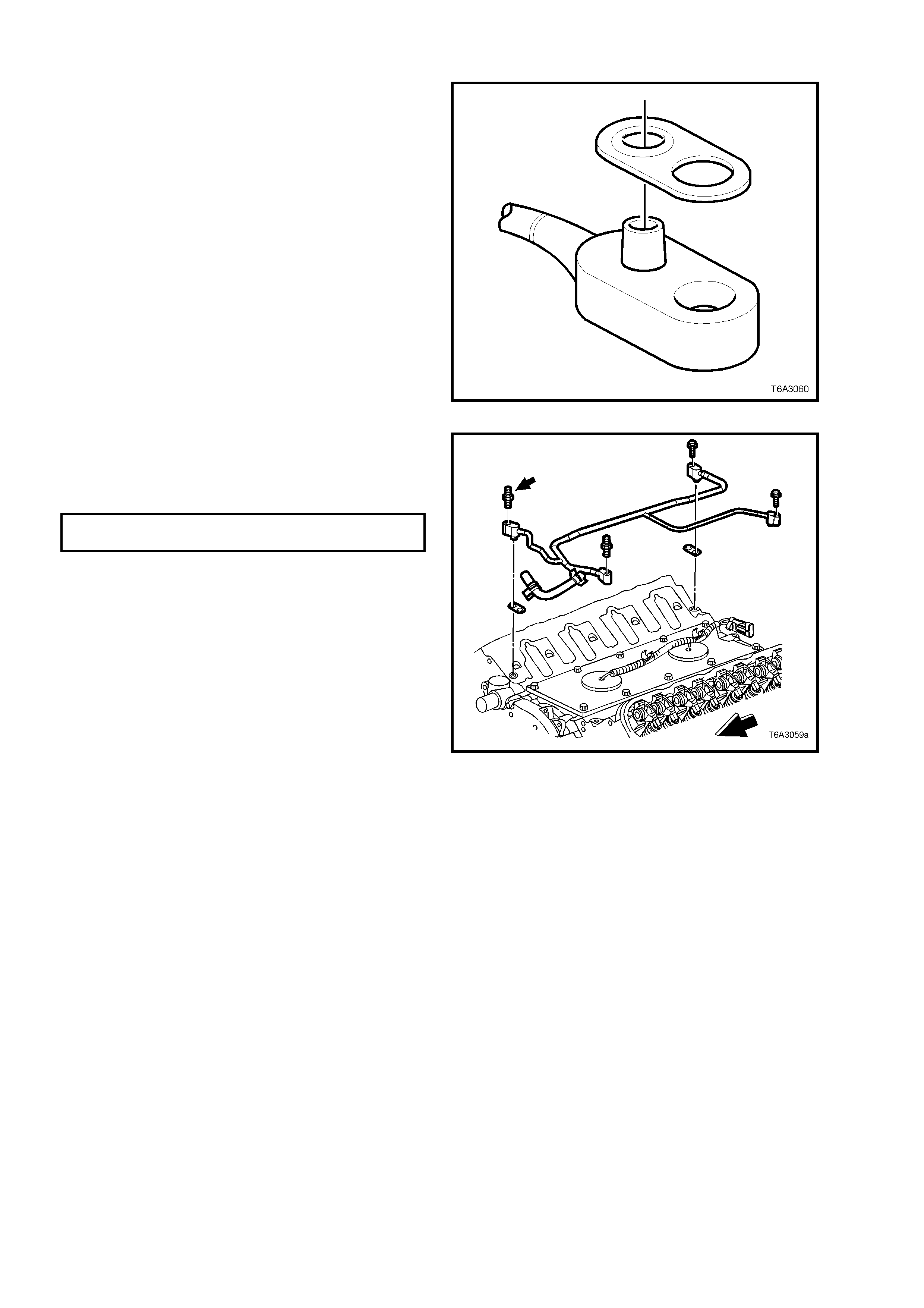

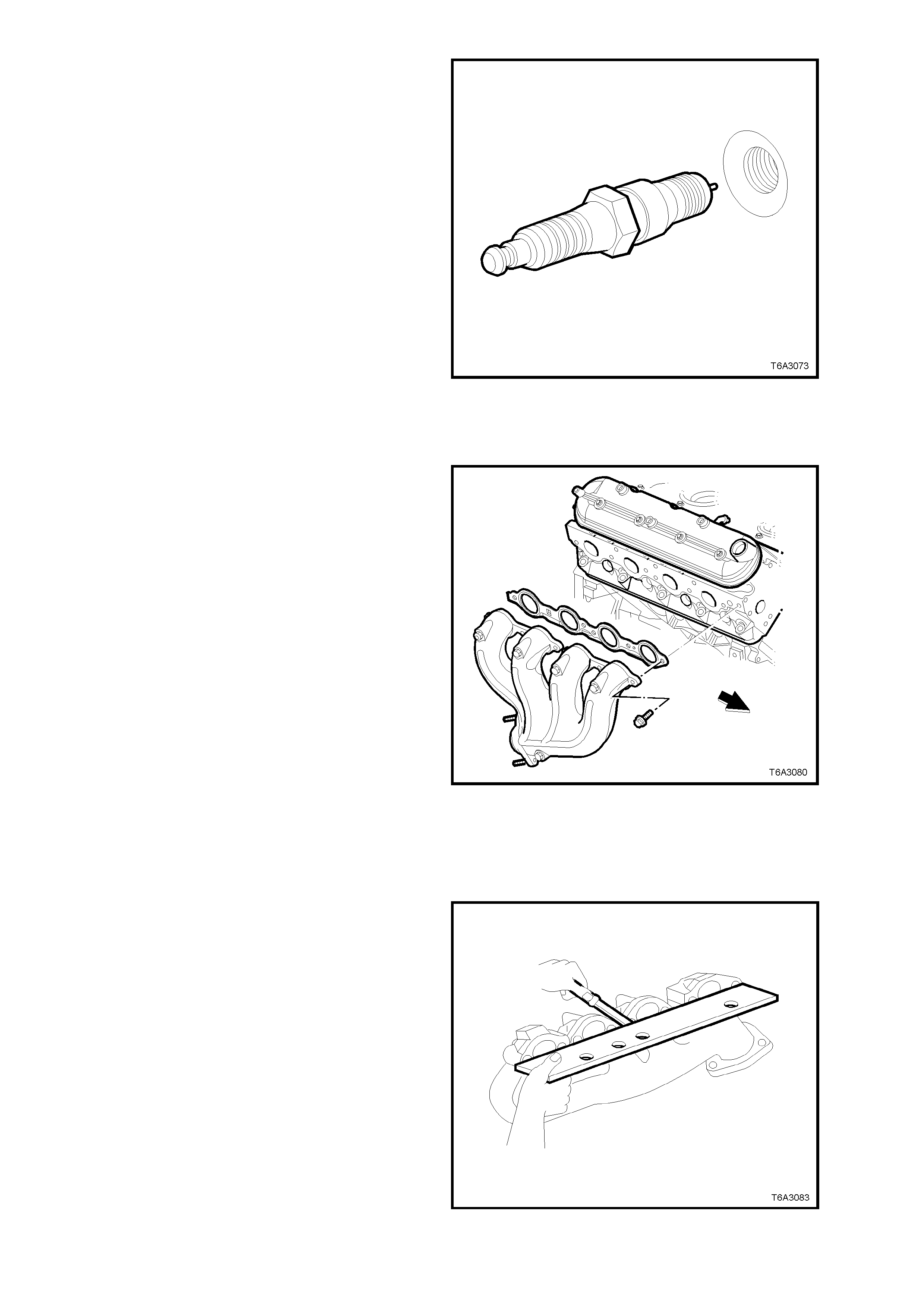

1. Correctly install NEW vapour pipe gaskets by

fitting the O-ring seal part, over the pipe fitting

nipple, as shown.

Figure 6A3-74

2. Install the vapour vent pipe and gaskets to the

cylinder heads.

3. Install the vapour vent pipe bolts/studs and

tighten to the correct torque specification.

VAPOUR VENT PIPE BOLT/STUD

TORQUE SPECIFICATION 12 Nm

4. Secure the knock sensor wiring harness clips

to the vapour vent pipe.

5. Install the intake manifold, as described in

2.14 INTAKE MANIFOLD - REINSTALL, in

this Section.

6. Install the vapour vent hose to the throttle body

and install the hose clamp securely.

Figure 6A3-75

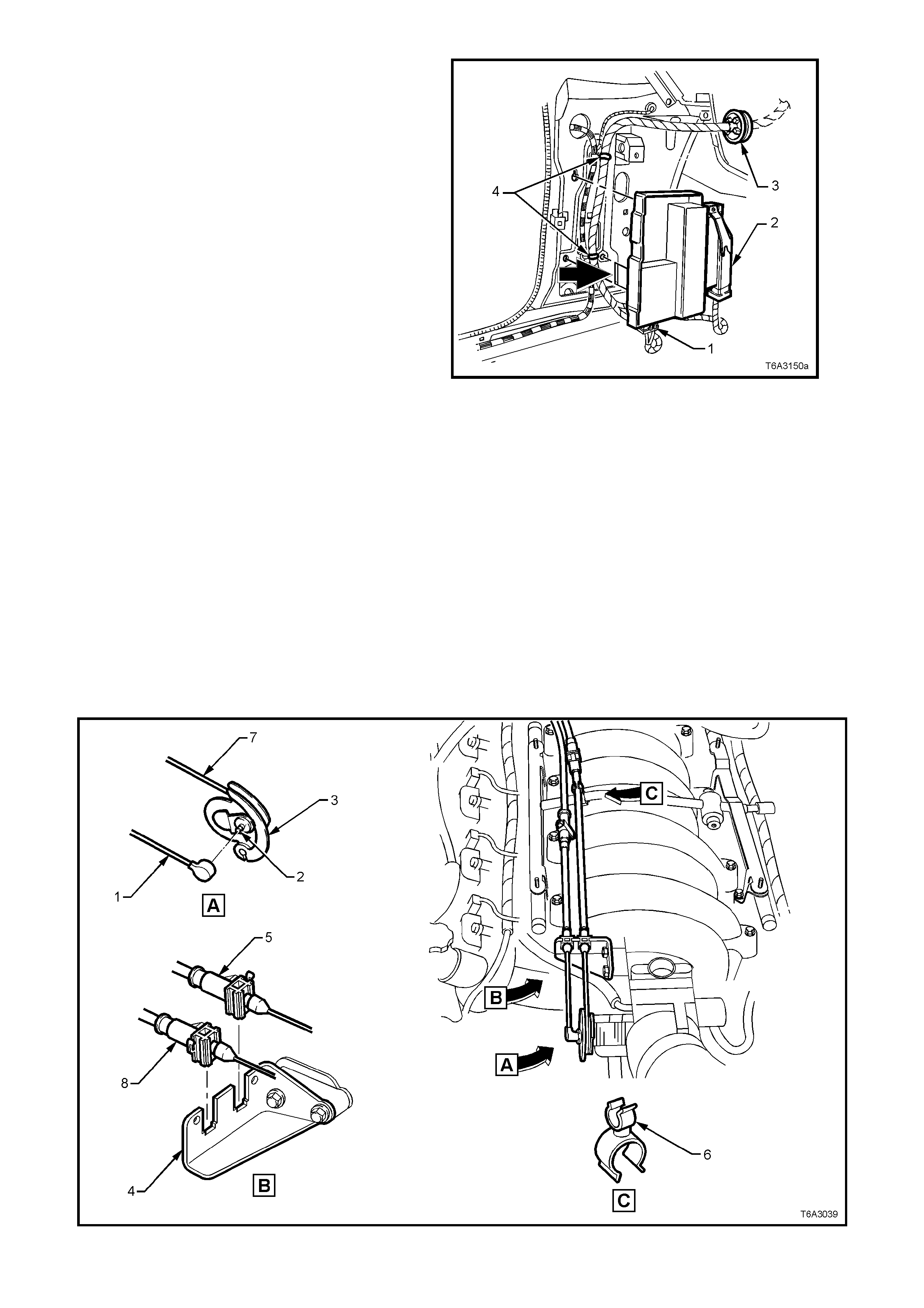

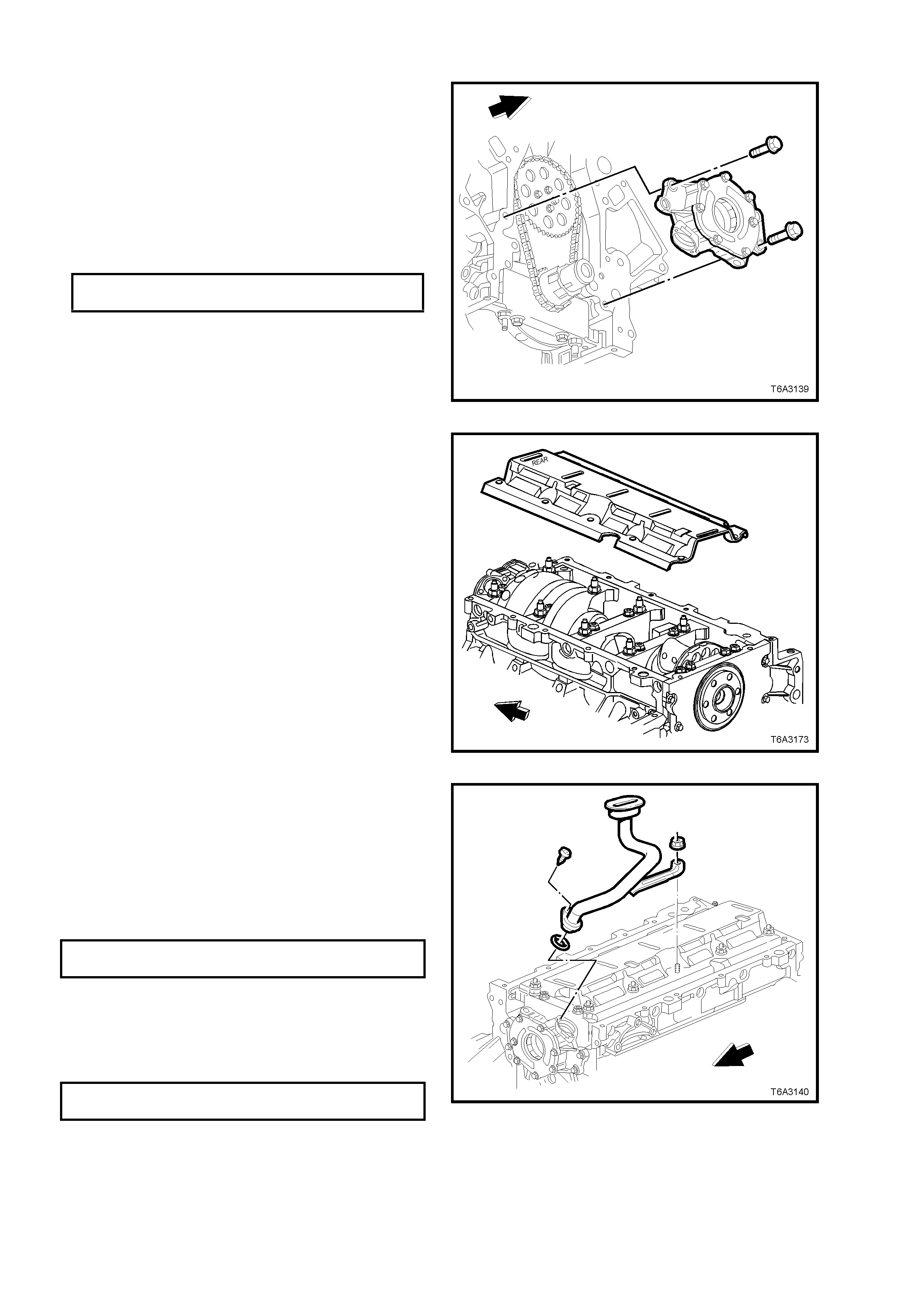

2.16 ENGINE VALLEY COVER

REMOVE

1. Disconnect the battery earth cable from the

battery.

2. Drain the cooling system. Refer to

Section 6B3 ENGINE CO OLING - GEN III V8

ENGINE.

3. Rem ove the engine dress cover retaining nuts

(2), then remove the cover (1).

4. De-pressurise fuel rail. Refer to

Operation 2.13, in this Section.

5. Loosen both hose clamps securing the intake

hose (3) to the MAF sensor and the throttle

body. Remove the hose from the engine.

6. Remove intake manifold. Refer to

Operation 2.14 INTAKE MANIFOLD.

7. Remove vapour vent pipe. Refer to

Operation 2.15 VAPOUR VENT PIPE.

Figure 6A3-76

8. To remove the knock sensor wiring harness,

carefully lift each sealing plug from the valley

cover, release each knock sensor harness

connector locking tab, then remove each

connector. Lift the knock sensor wiring

harness from the engine.

Figure 6A3-77

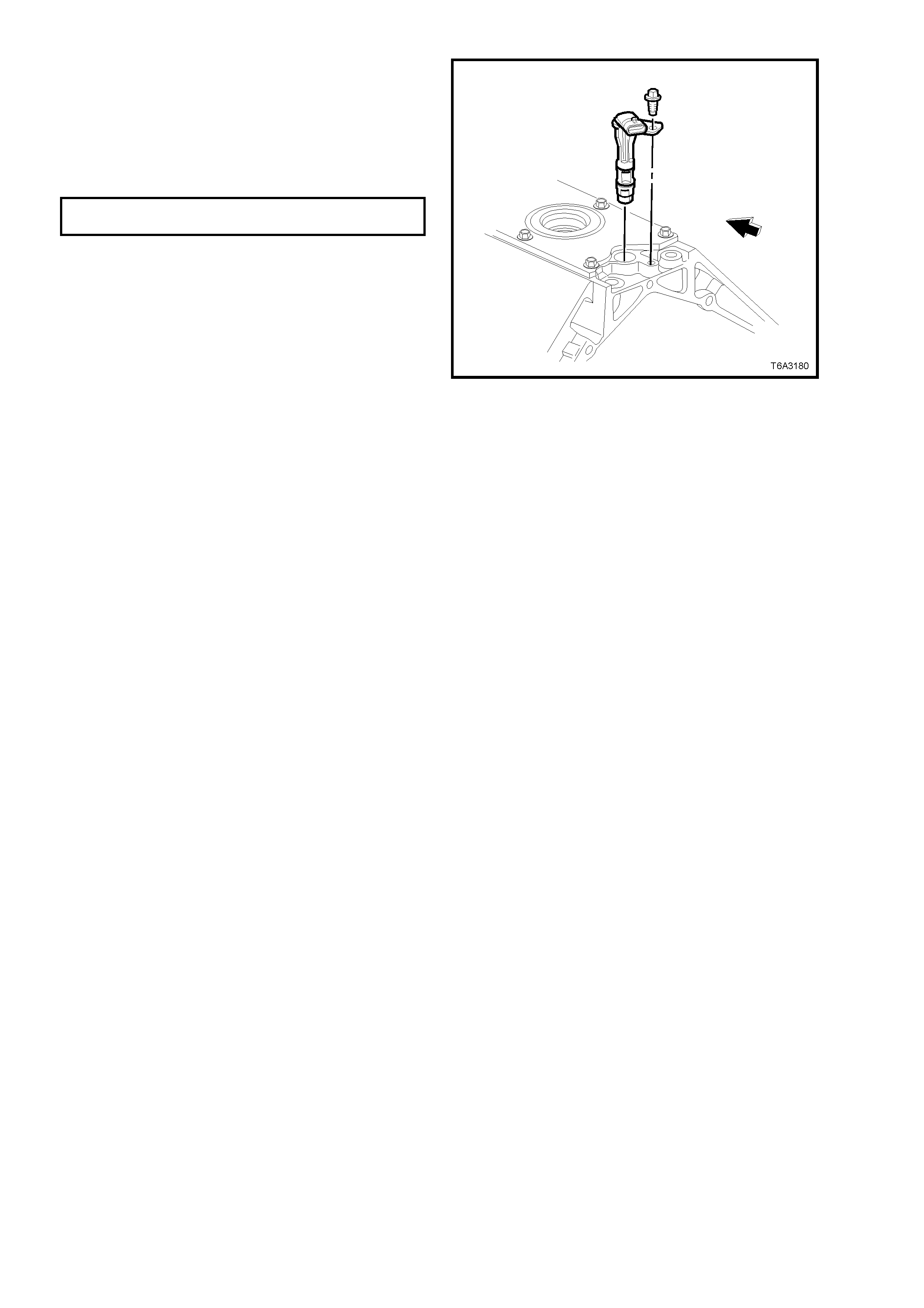

9. Remove both knock sensors, using a

commercially available, 22 mm deep socket.

NOTE: Unless a deep socket is used, damage to

the sensor connector will result.

Figure 6A3-78

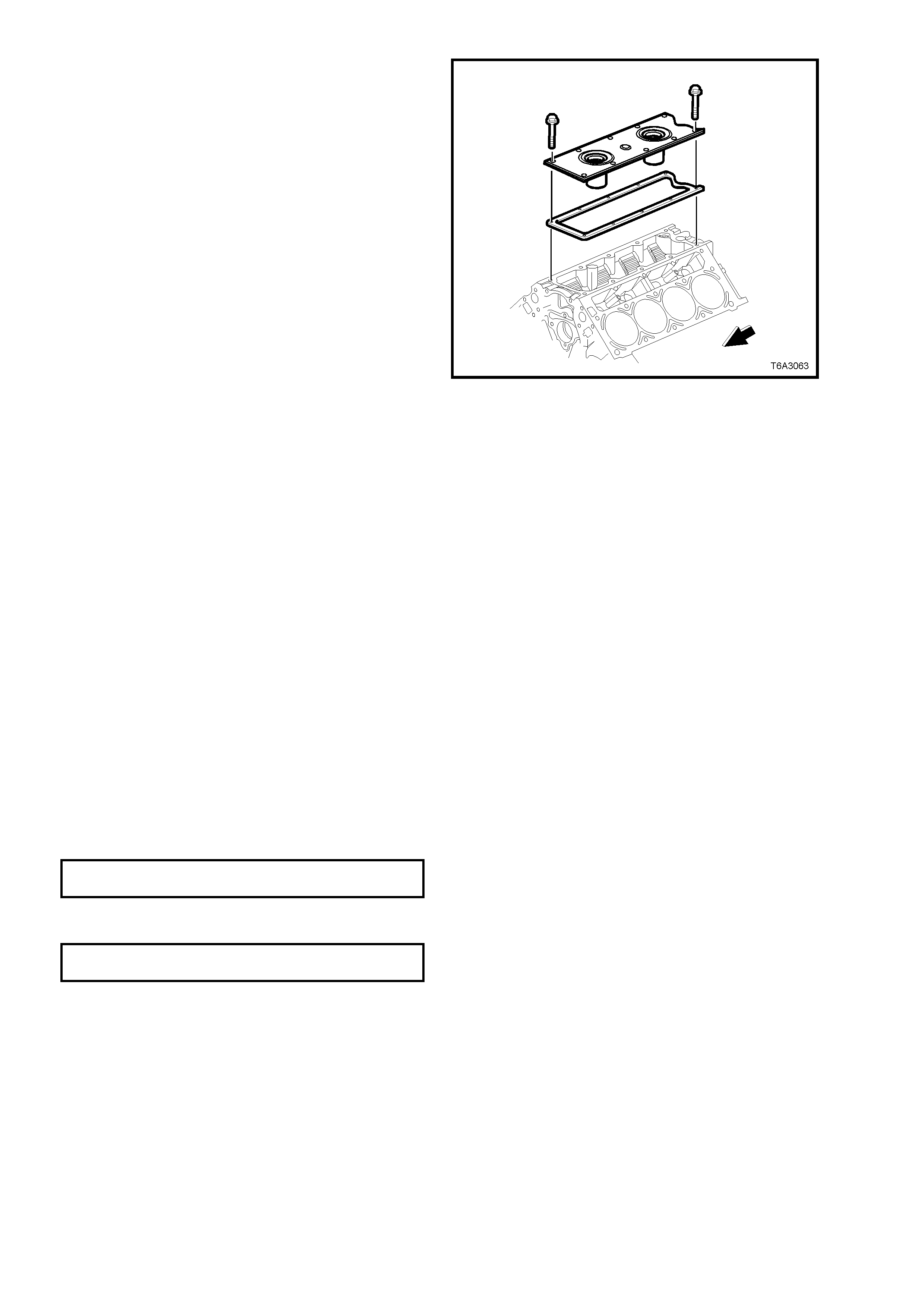

10. Remove the valley cover retaining bolts.

11. Remove the valley cover and gasket from the

cylinder block. Discard the gasket.

Figure 6A3-79

CLEAN AND INSPECT

1. Remove both knock sensor oil seals from the

valley cover.

2. Clean the valley cover in suitable solvent and

dry off with compressed air

CAUTION: Wear safety glasses to avoid eye

injury.

3. Inspect the valley cover sealing surfaces and

oil seal bores for ex cessive scr atches or other

damage.

REINSTALL

Reinstallation is the reverse of rem oval operations,

except for the following items.

1. Install NEW knock sensor oil seals into the

valley cover and lubricate with clean engine

oil.

2. Fit a NEW gasket to the valley cover and

install cover to the engine (refer to Figure 6A3-

79).

3. Install valley cover bolts and tighten to the

correct torque specification.

VALLEY COVER BOLT

TORQUE SPECIFICATION 25 Nm

4. Install the knock sensors and tighten to the

correct torque specification.

KNOCK SENSOR

TORQUE SPECIFICATION 20 Nm

2.17 VALVE ROCKER ARM COVER

REMOVE

1. Disconnect the battery earth cable from the

battery.

2. Rem ove the engine dress cover retaining nuts

(2), then remove the cover (1).

Figure 6A3-80

3. For the right hand rocker cover, remove the

fresh air hose from the front fitting of the

rocker cover and from the throttle body.

Figure 6A3-81

4. Remove the PCV hose connection from the

rear fitting at the end of the rocker cover,

being removed.

Figure 6A3-82

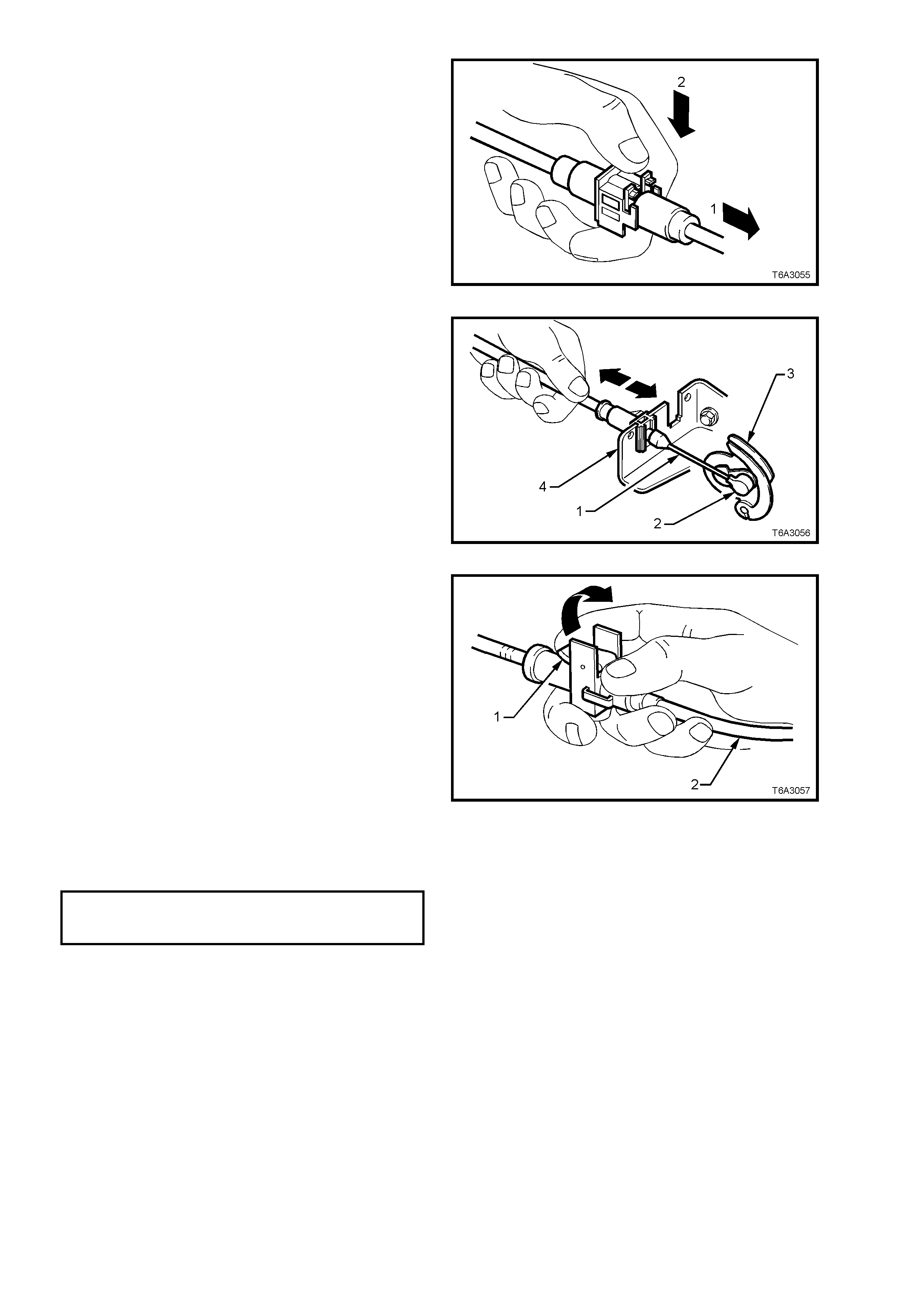

5. Using quick connect release Tool No. 7371,

install over fuel line.

6. While holding the fuel line quick connect (1),

push on Tool 7371 to release the quick

connect fitting (1) from the fuel rail. Pull back

on the quick connect and remove.

7. Disconnect the vapour line connector (2) from

the EVAP purge valve (3).

Important: Cap the fuel line fittings and plug the

holes after separating the fuel lines to prevent fuel

leaking and/or dirt and other contaminants from

entering the fuel system.

Figure 6A3-83

8. Remove the spark plug leads.

NOTE: Handle the boot only. DO NOT pull on the

lead. Twist the boot firs t to break the s eal, then pull

to remove.

Figure 6A3-84

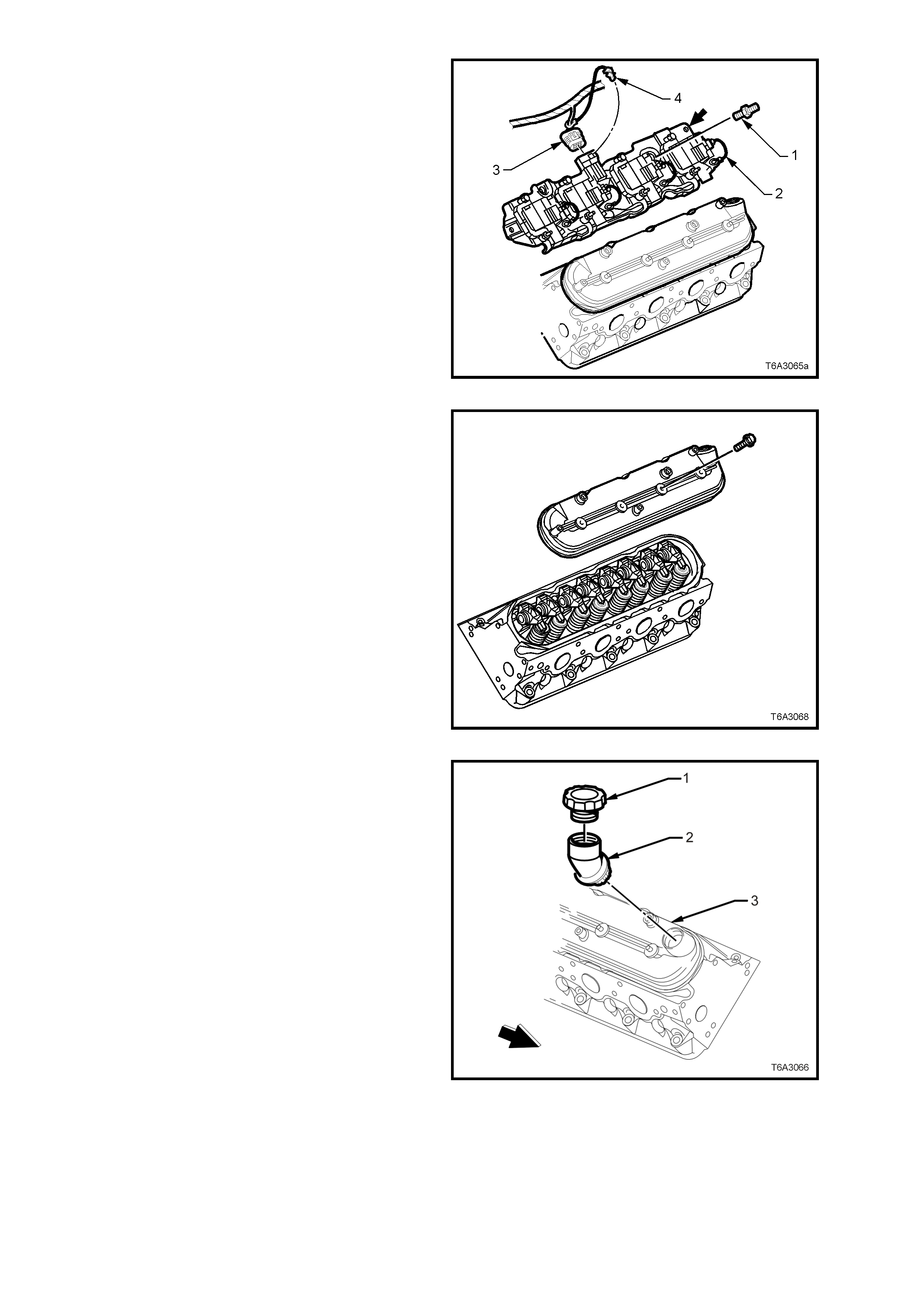

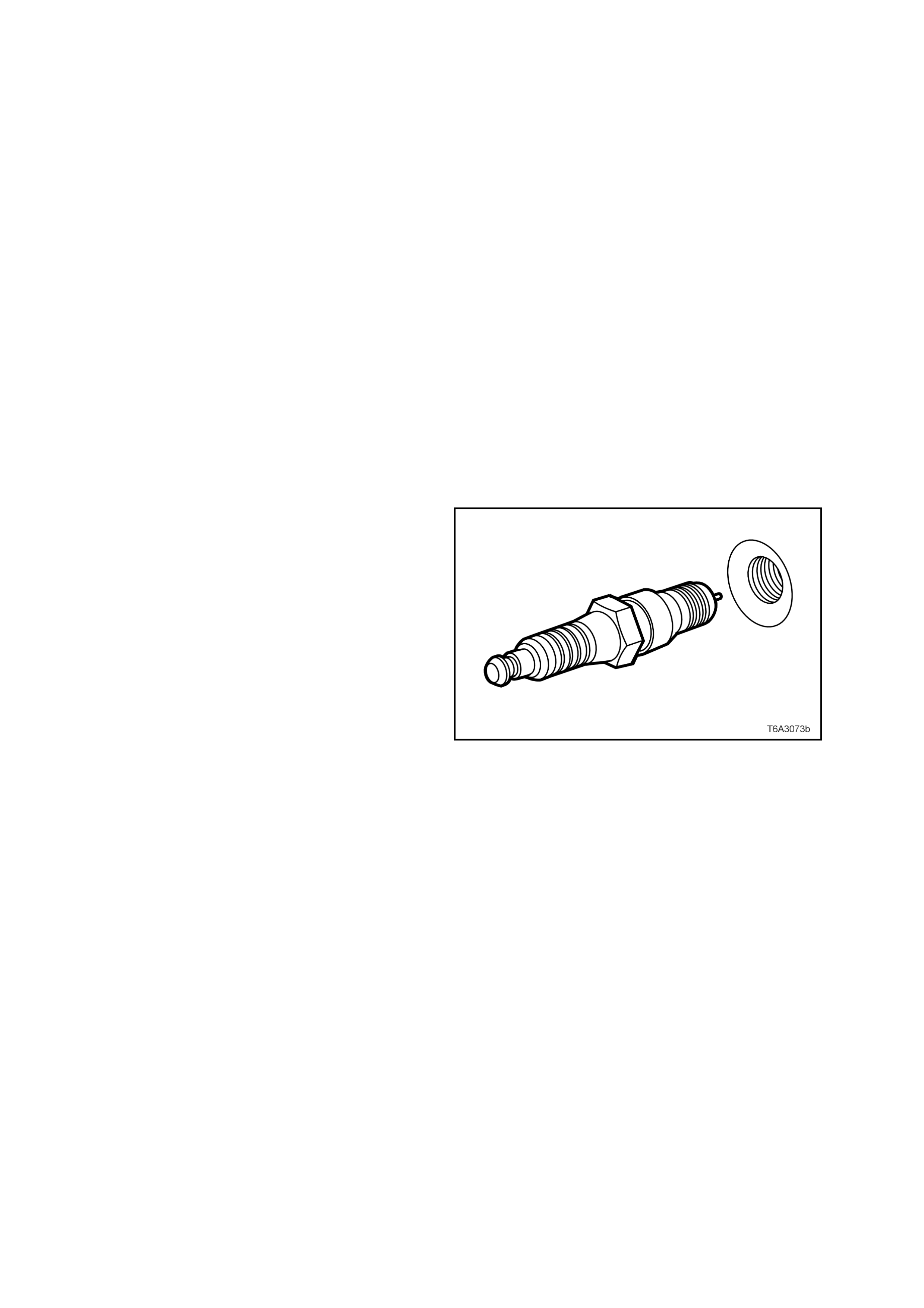

9. Rem ove the CPA lock ( 4) f rom the ignition coil

main connector on the rocker cover being

removed, then remove the wiring harness

connector (3).

10. Remove the 4 studs (1) and one screw

securing the ignition coil mounting bracket (2)

to the rocker c over being r emoved, then lif t the

ignition coils, wiring and bracket from the

engine.

NOTE: The rear attaching bolt on each coil

assem bly (arrow) is a conventional scr ew and not a

stepped stud. Fitment of this screw in the correct

position on reassembly is important to avoid

possible chaffing.

Figure 6A3-85

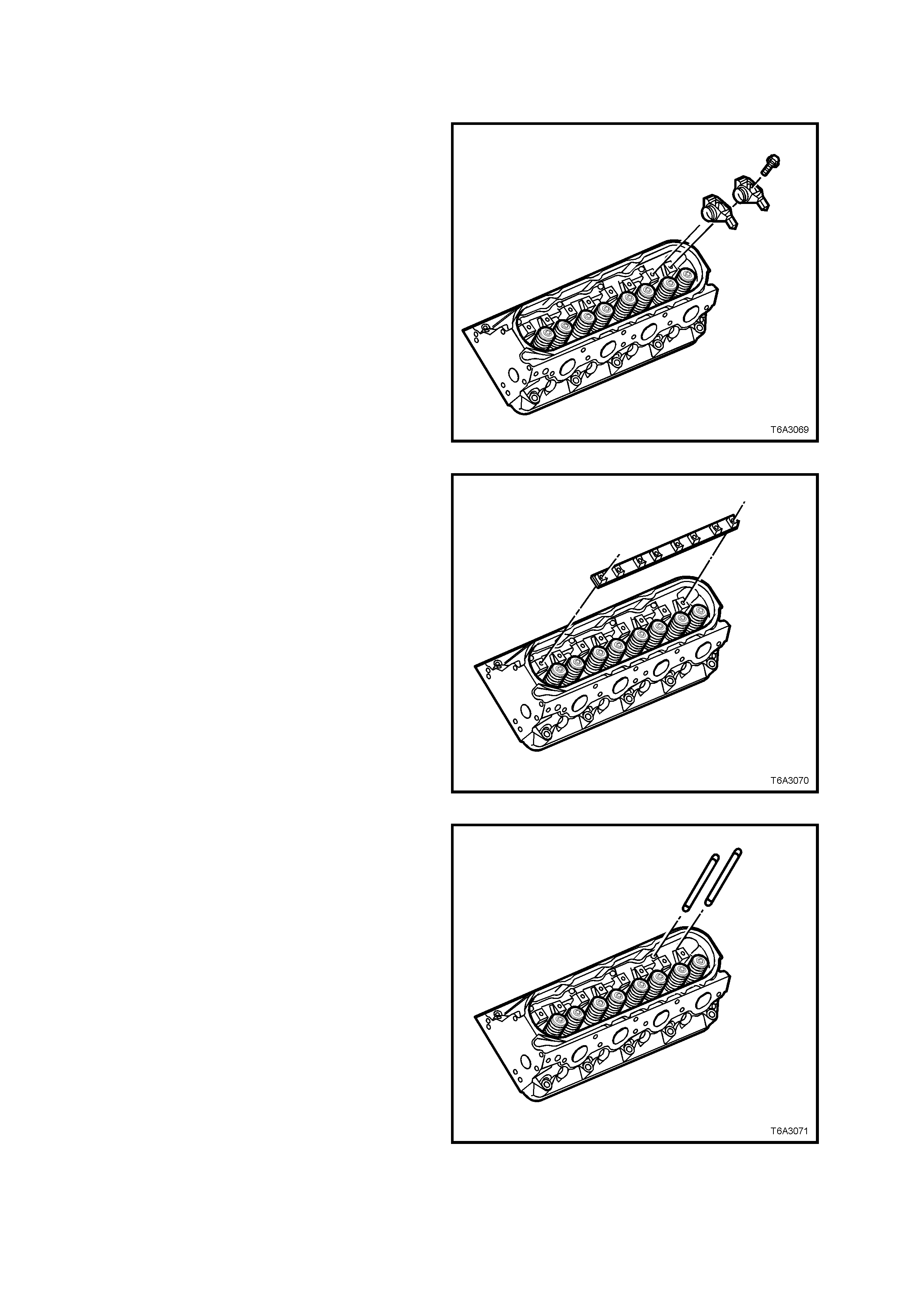

11. Remove the 4 valve rocker cover bolts, then

rem ove the cover and gasket f rom the cylinder

head.

NOTE: Do not rem ove the oil fill tube f rom the right

hand rocker cover unless replacement is required.

Figure 6A3-86

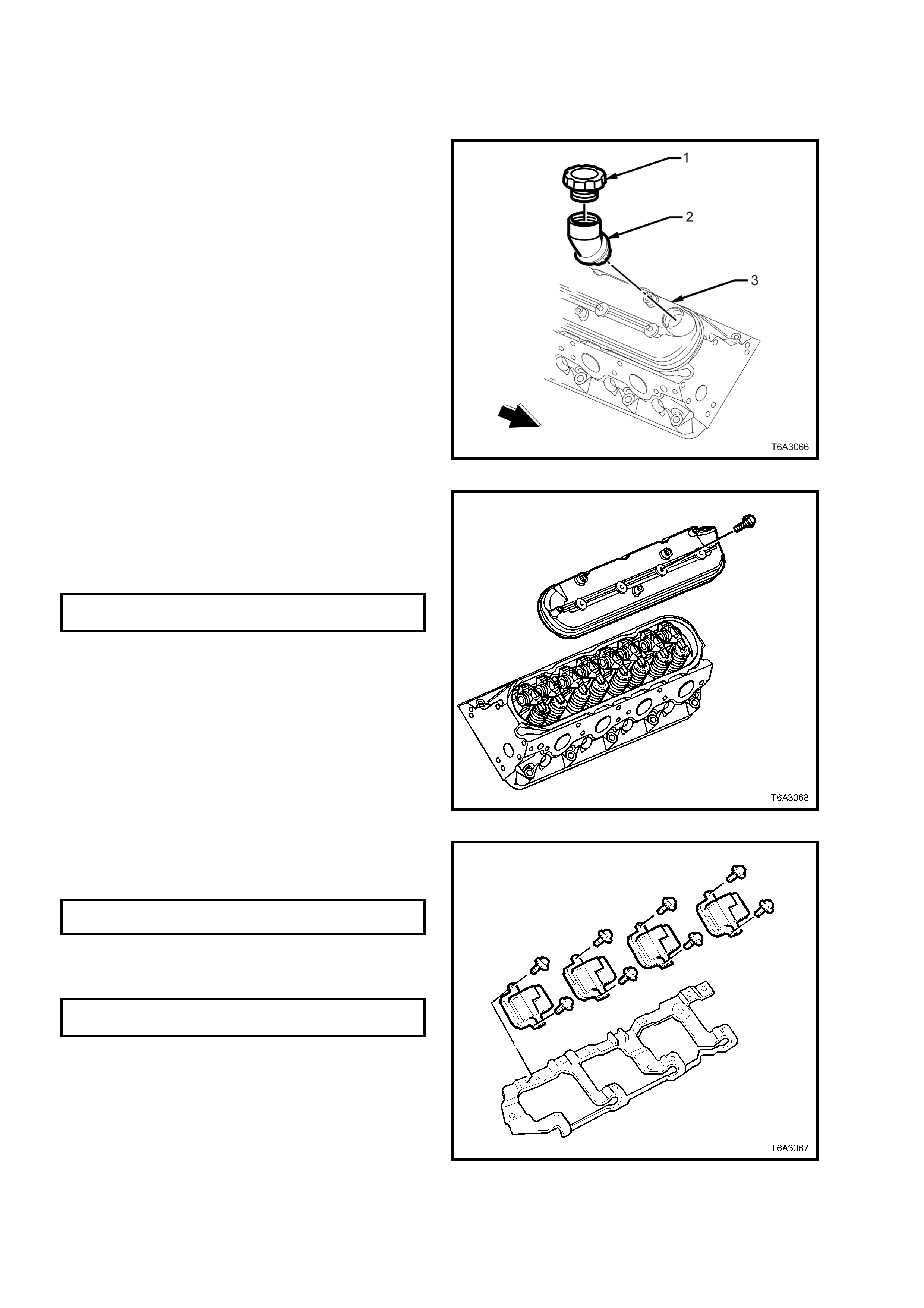

12. If required, remove the oil fill cap(1) and/or fill

tube (2) from the right hand rocker cover (3).

Discard the oil fill tube (2), as permanent

damage will occur on removal.

Figure 6A3-87

13. Remove the bolts securing the ignition coils to

the mounting bracket and remove the coils

and wiring harness.

Figure 6A3-88

CLEAN AND INSPECT

1. Clean the rocker cover in a suitable solvent

and dry off with compressed air.

CAUTION: Wear safety glasses to avoid eye

injury.

2. Inspect the ventilation system passages for

restriction.

3. Inspect the rocker cover gasket groove for

damage.

4. Inspec t the ignition coil m ounting boss thr eads

for damage.

REINSTALL

Reinstallation of the rocker cover is the reverse to

the removal procedure except for the following

items.

1. If the oil fill tube (2) was removed from the

right hand rocker cover (3), it must be

replaced with a NEW part ( when installed, it is

permanent).

2. Lubricate the O-ring seal of the NEW oil fill

tube (2) with clean engine oil.

3. Install the oil fill tube into the rocker cover (3),

rotating the tube clockwise until locked into the

correct position.

4. Install the oil fill cap (1), rotating clockwise until

locked into place.

Figure 6A3-89

5. Install a NEW gasket to the rocker cover.

6. Install the rocker cover bolts.

7. Install the rocker cover onto the cylinder head

and tighten the rocker cover studs to the

correct torque specification.

ROCKER COVER BOLT

TORQUE SPECIFICATION 12 Nm

Figure 6A3-90

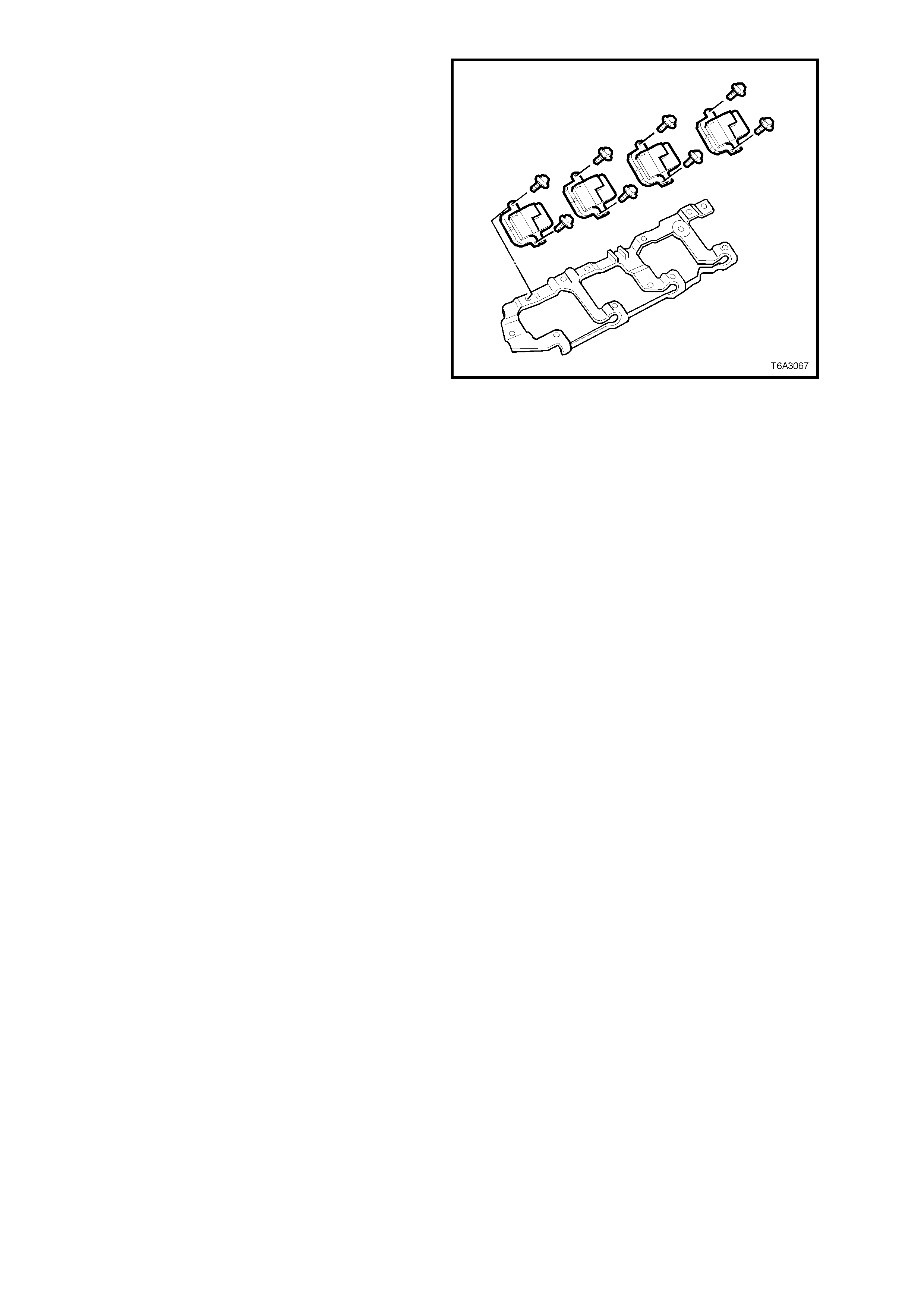

8. Install the ignition coils and coil wiring harness

to the mounting bracket and tighten the studs

and bolts to the correct torque specification.

IGNITION COILSTUD/ BOLT

TORQUE SP ECIFI CA T ION 12 Nm

9. Install the ignition coils and bracket assembly

to the rock er c over, and tighten the bolts to the

correct torque specification.

IGNITION COIL BRACKET BOLT

TORQUE SPECIFICATION 12 Nm

NOTE: The rear, left hand c oil brack et f astener is a

plain screw and not a stepped stud as are the

others. Fitment of this screw in the correct position

is important to avoid fuel/vapour line chaffing.

10. After installation of the ignition coil main

harness connector, install the CPA lock,

ensuring it is fitted securely. Figure 6A3-91

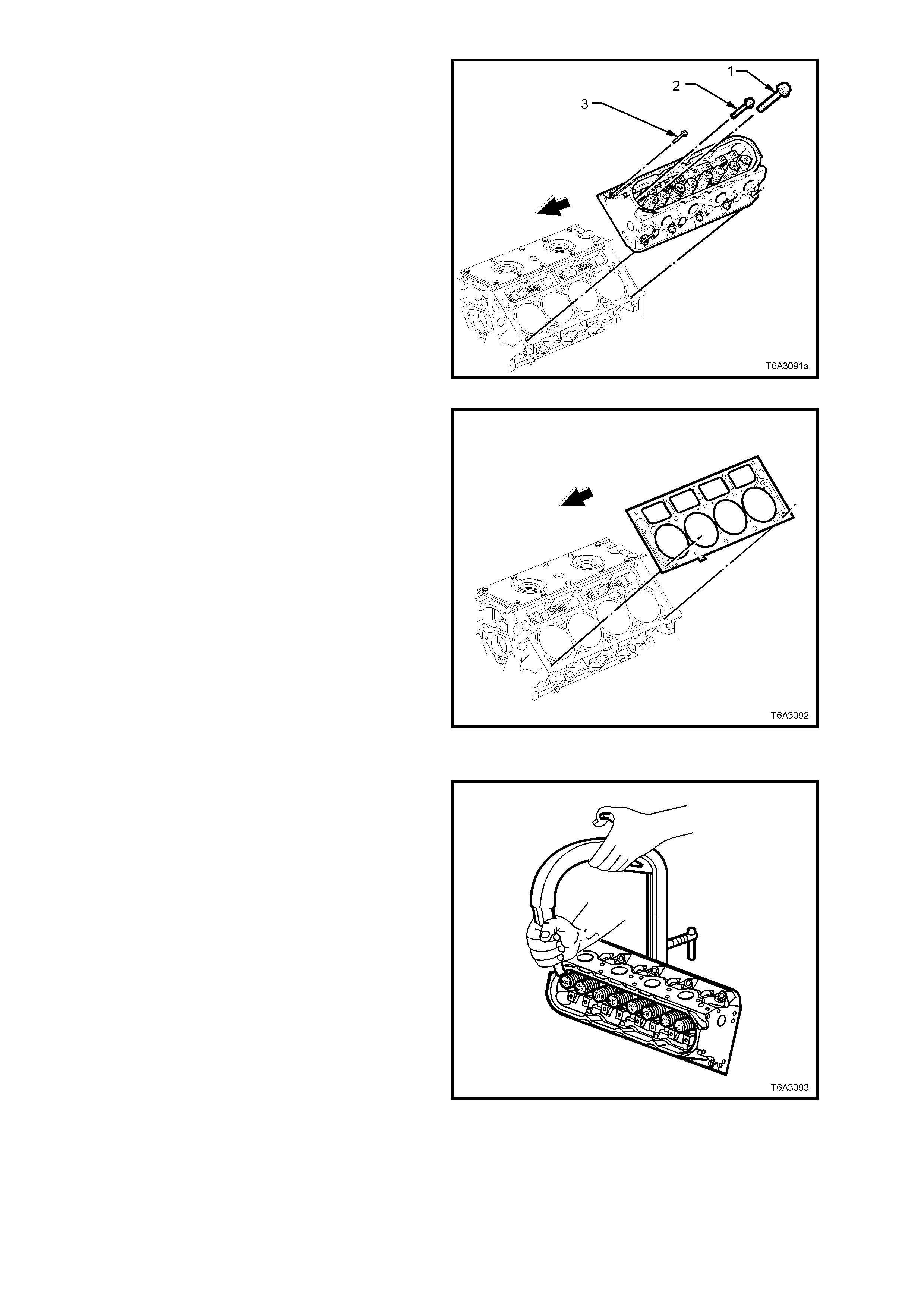

2.18 V ALVE ROCKER ARMS AND PUSH RODS

REMOVE

NOTE: While some views may show a cylinder

head that is not specif ic to the one required, unless

noted, it can be assumed that the operation is the

same for either cylinder head.

1. Rem ove the valve rock er arm cover/s. r efer to

2.17 VALVE ROCKER ARM COVER.

Important: Store all removed valve operating

mechanism com ponents in a suitable rack to avoid

being mixed. This will ensure that parts reinstalled

will be in the same relationship as on removal.

2. Remove all the rocker arm bolts on the

specific cylinder head.

3. Remove associated valve rockers arms.

Figure 6A3-92

4. Remove the valve rocker arm pivot support.

Figure 6A3-93

5. Remove the push rods.

Figure 6A3-94

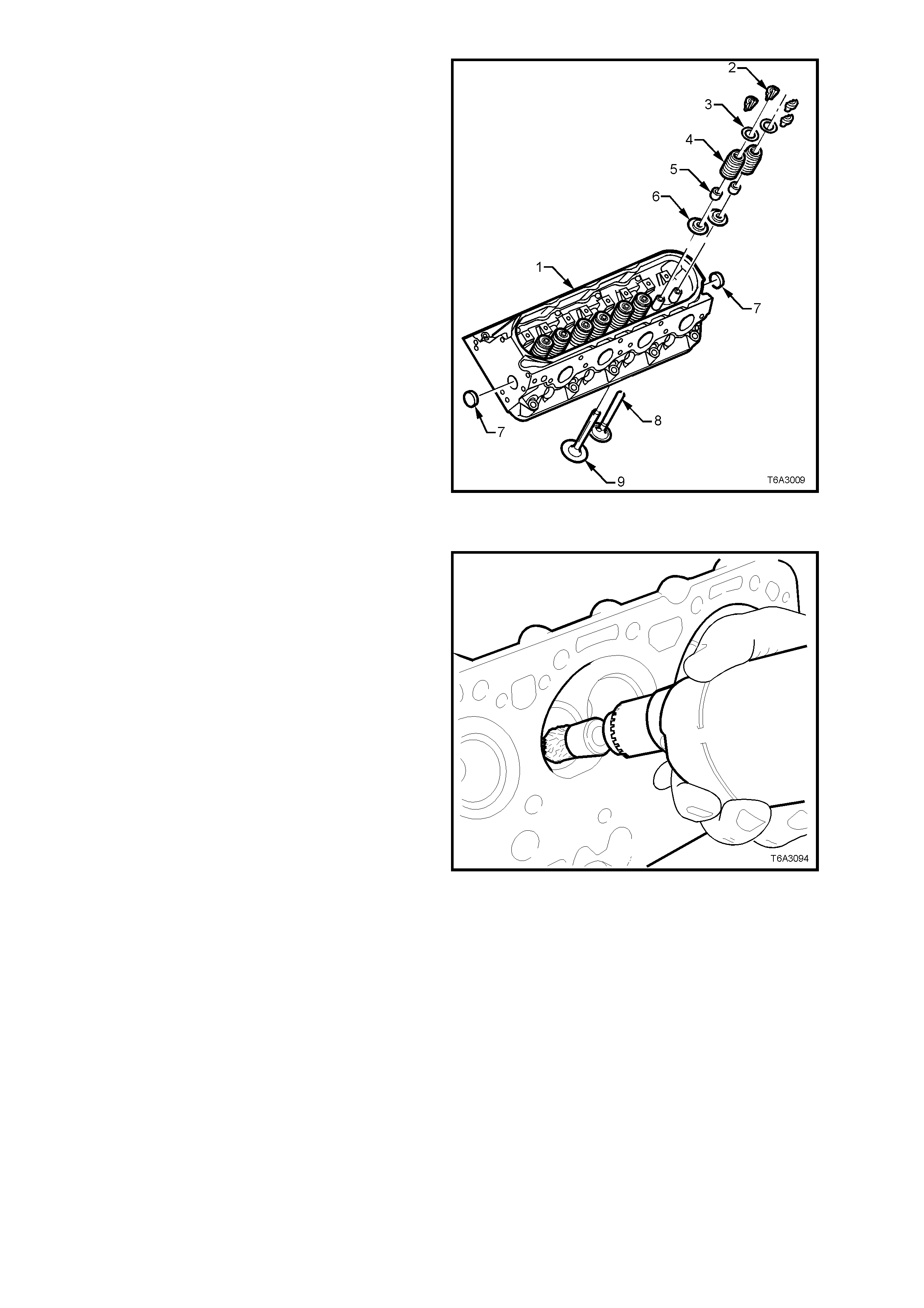

CLEAN AND INSPECT

1. Mark, sort or organise removed parts to retain in order removed.

2. Clean parts in a suitable solvent, then dry with compressed air.

CAUTION: Wear safety glasses to avoid eye injury.

3. Inspect parts, as follows:

a. Valve rocker arm bearings for binding or

roughness.

b. Valve rocker arm push rod sockets and

valve stem mating s ur f aces f or wear and/or

roughness.

c. Pushrods for worn or scored ends.

d. Also check for bent pushrods by rolling on

a flat surface.

e. Pushrod oil passages for restrictions.

f. Pivot supports for cracks, wear or other

damage.

REINSTALL

While the reinstallation process is the reverse of the

removal procedure, there are some specific

operations that must be complied with, and are

detailed here.

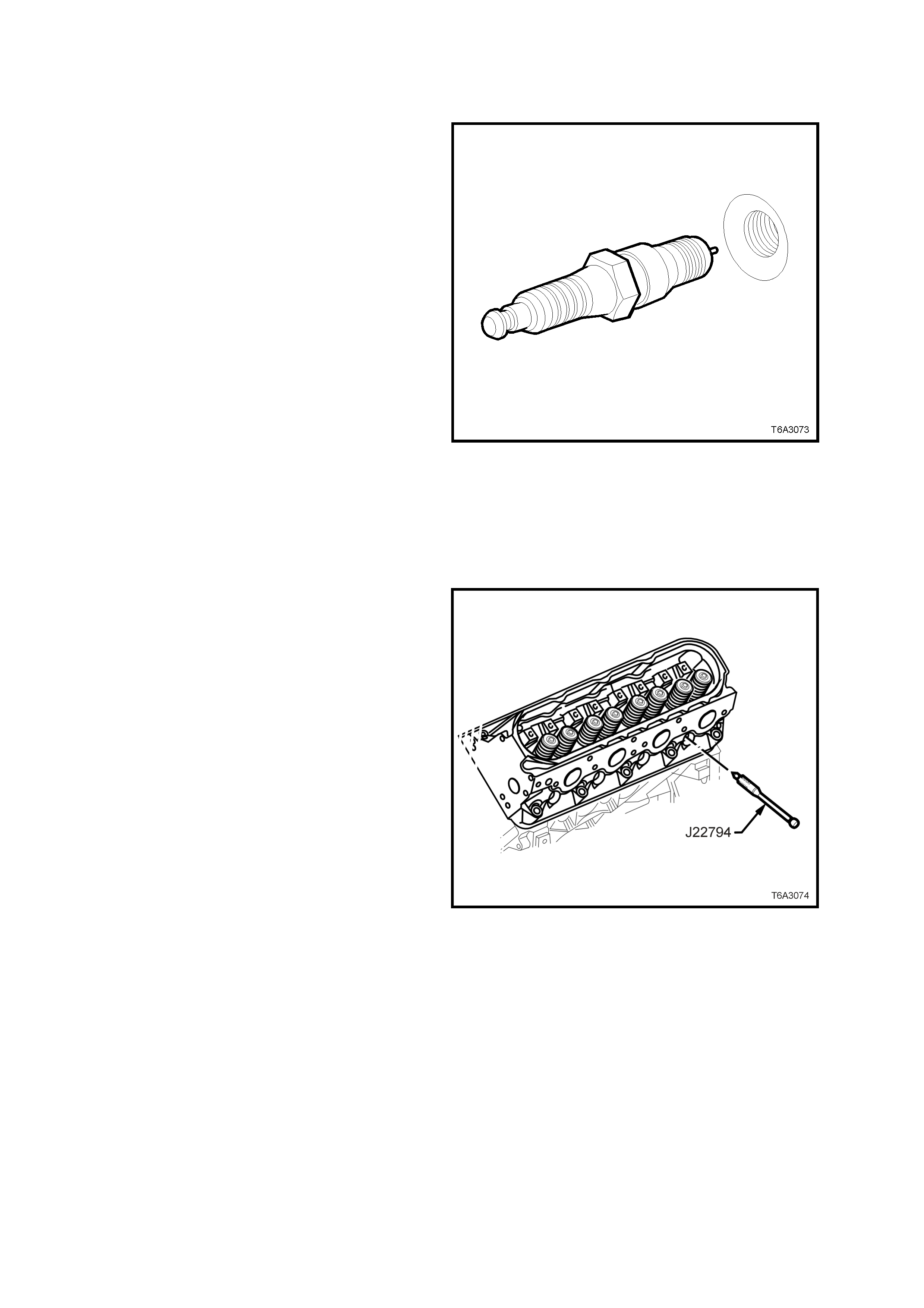

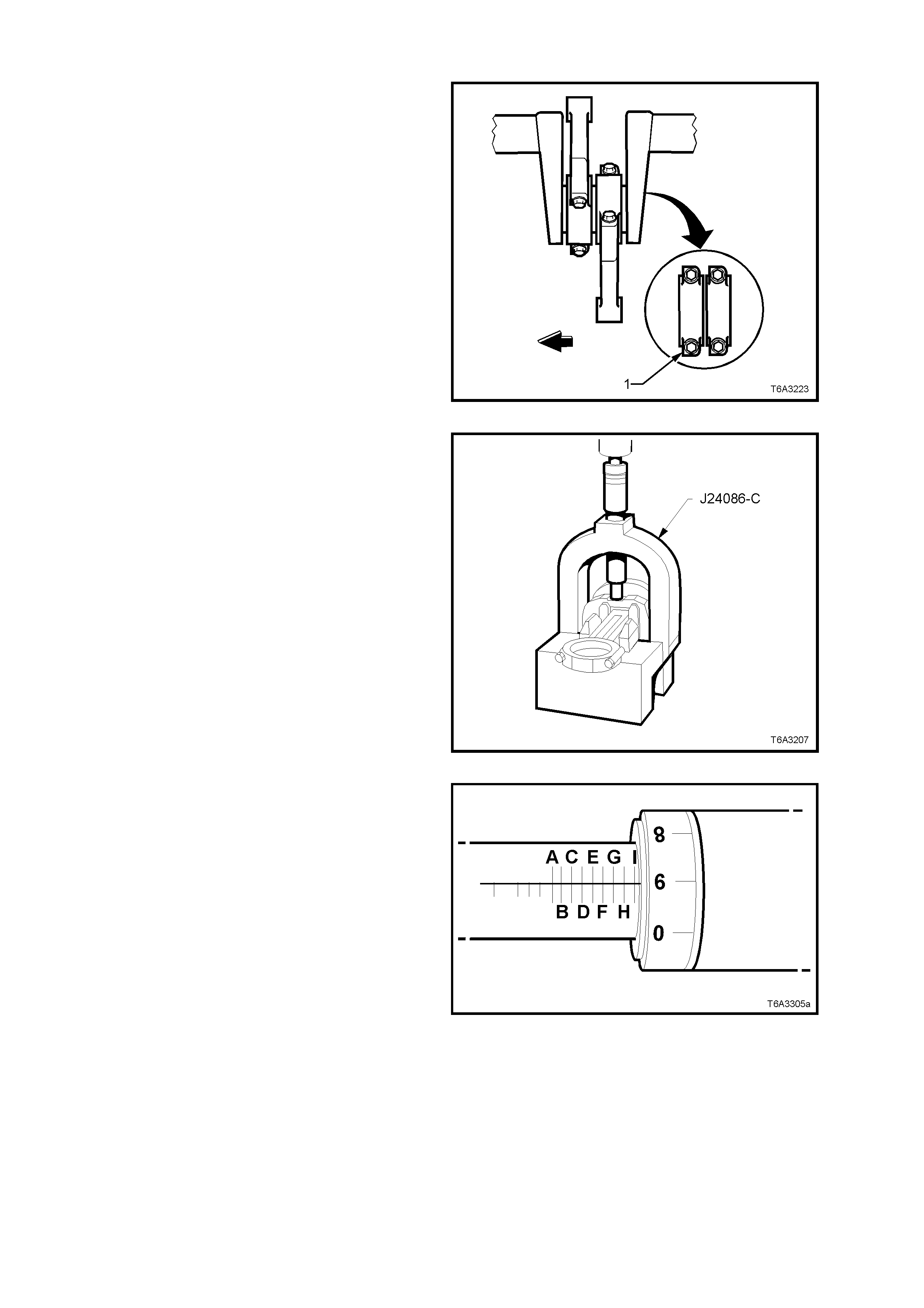

1. To reduc e the effor t required to tur n the engine

over by hand, remove the spark plugs, taking

note of the following;

a. The engine MUST be cold to at least

50° C. If not, then the spark plug and

cylinder head threads may bind, causing

the cylinder head threads to be torn.

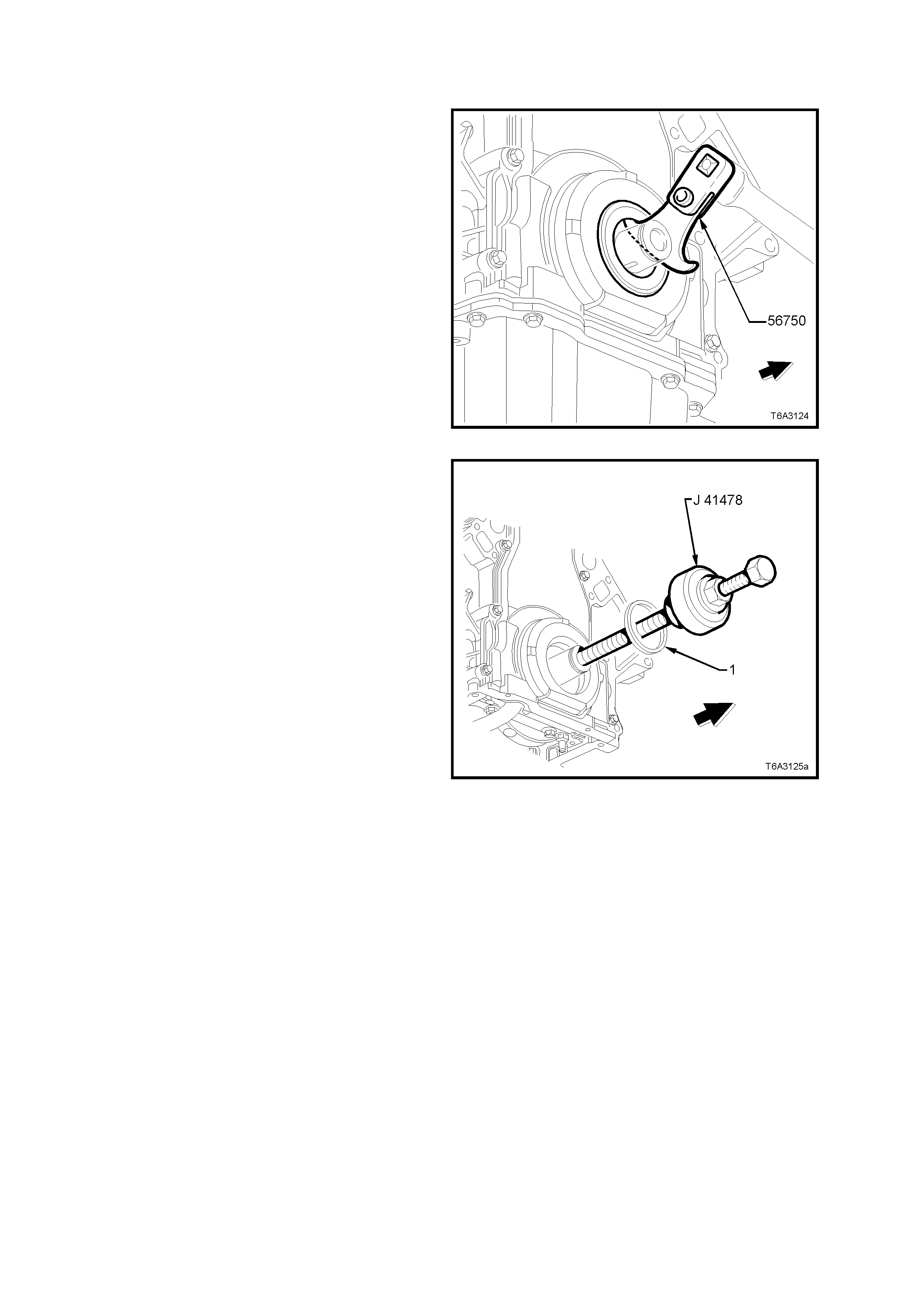

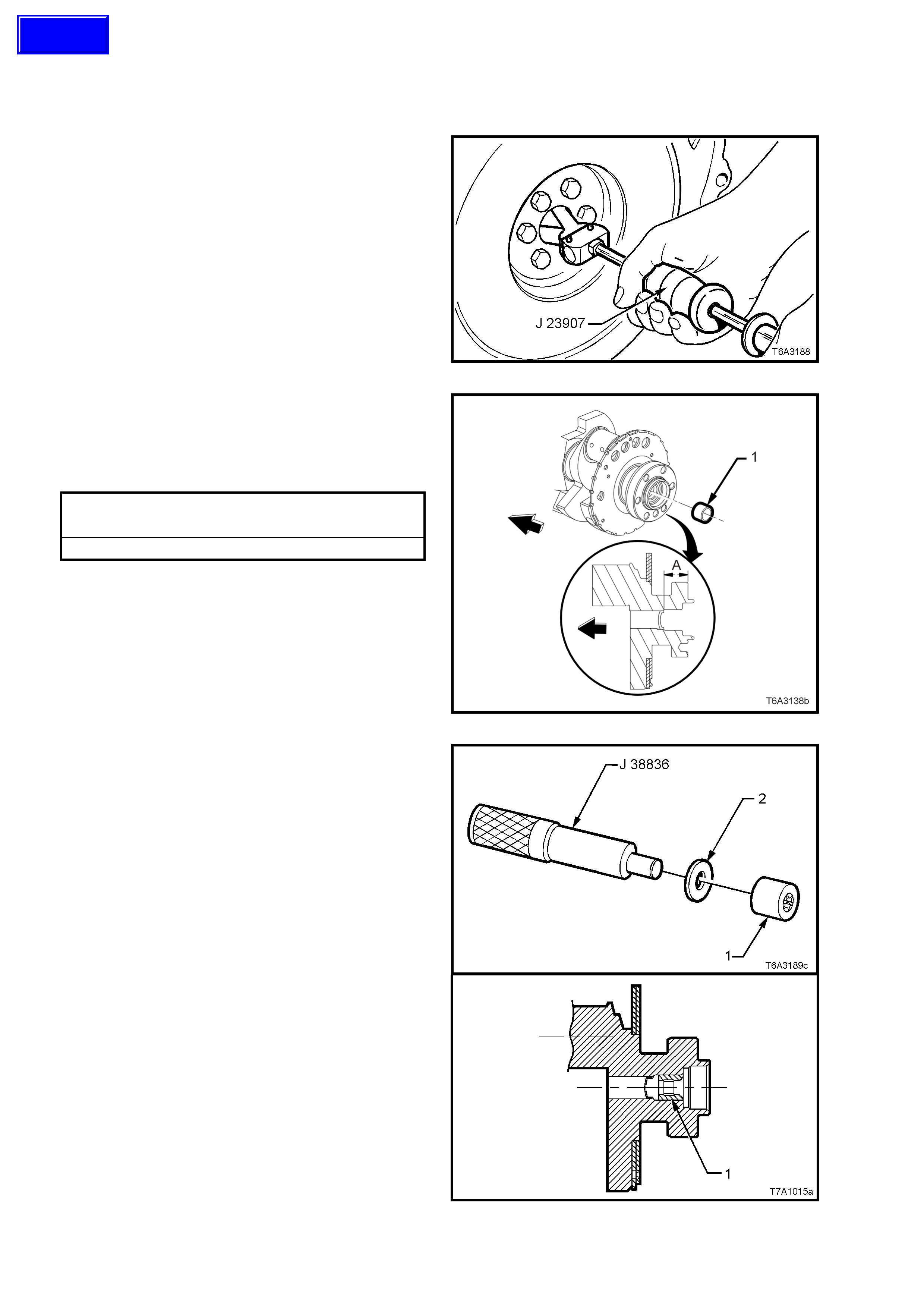

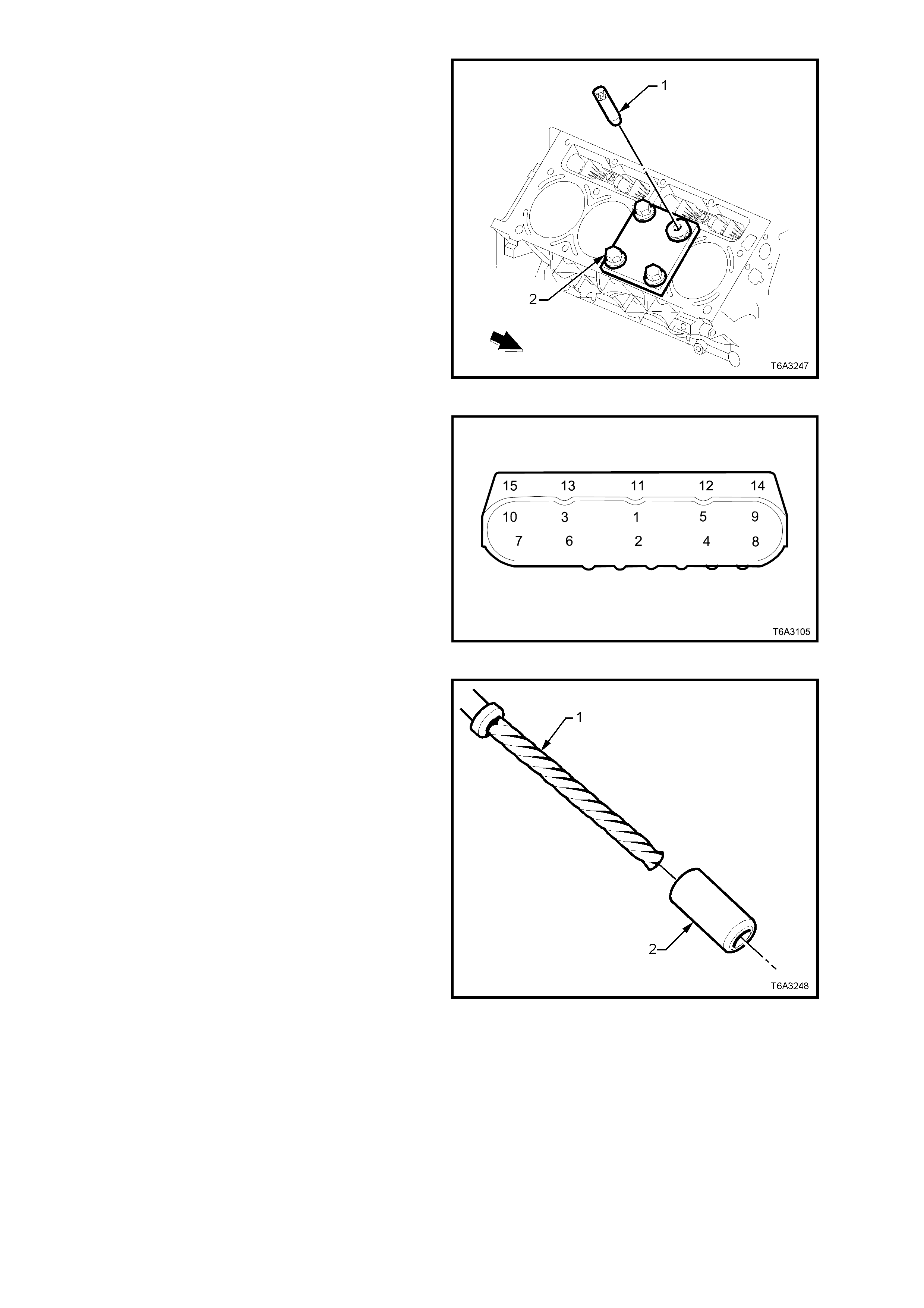

b. When removing spark plug leads, only