Lighting System Page 12B–1

Page 12B–1

Section 12B

Lighting System

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information, Sedan, Wagon, Utility and Crew Cab...............................................................8

1.1 Headlamp Assembly.............................................................................................................................................. 8

Level 1 Vehicles..................................................................................................................................................... 9

Level 2 and Level 3 Vehicles............................................................................................................................... 10

1.2 Front Fog Lamp Assembly .................................................................................................................................. 11

1.3 Tail Lamp Assembly............................................................................................................................................ 12

1.4 High-mount Stop Lamps..................................................................................................................................... 14

1.5 Interior Illumination ............................................................................................................................................. 15

Level 1................................................................................................................................................................... 15

Level 2 and Level 3.............................................................................................................................................. 16

1.6 Instrument and Switch Illumination ................................................................................................................... 17

Headlamp Switch................................................................................................................................................. 18

Police Lights-out Switch..................................................................................................................................... 18

Daylight Running Lamp (Option T82)................................................................................................................. 18

2 General Information, Coupe................................................................................................................19

2.1 Headlamp Assembly............................................................................................................................................ 19

2.2 Park and Front Fog Lamp Assembly.................................................................................................................. 20

2.3 Tail Lamp Assembly............................................................................................................................................ 21

2.4 High-mount Stop Lamps..................................................................................................................................... 22

2.5 Interior Illumination ............................................................................................................................................. 23

2.6 Instrument and Switch Illumination ................................................................................................................... 24

Headlamp Switch................................................................................................................................................. 24

3 General Information, Regular Cab and Crew Cab with 'Delete Tub' Option...................................25

3.1 Tail Lamp Assembly............................................................................................................................................ 25

3.2 Rear Licence Plate Lamp Assembly................................................................................................................... 26

3.3 Transport Bracket................................................................................................................................................ 27

4 General Information, AWD Wagon......................................................................................................28

4.1 Tail Lamp Assembly............................................................................................................................................ 29

4.2 Backup Lamp Assembly ..................................................................................................................................... 30

4.3 Liftgate Air Deflector Assembly and High-mount Stop Lamp Assembly........................................................ 31

Techline

Techline

Lighting System Page 12B–2

Page 12B–2

5 Service Operations — Exterior Illumination, Sedan, Wagon, Utility and Cre w Cab......................32

5.1 Headlamp and Front Fog Lamp Aiming............................................................................................................. 32

Headlamp Assembly Aim.................................................................................................................................... 32

Front Fog Lamp Assembly Aim.......................................................................................................................... 34

5.2 Headlamp and Park Lamp Assembly Bulbs...................................................................................................... 36

Level 1................................................................................................................................................................... 36

Replace — Low Beam Bulb ............................................................................................................................. 36

Replace — High Beam Bulb............................................................................................................................. 37

Replace — Park Lamp Bulb............................................................................................................................. 39

Level 2 and Level 3.............................................................................................................................................. 40

Replace — Low Beam Bulb ............................................................................................................................. 40

Replace — High Beam Bulb............................................................................................................................. 42

Replace — Park Lamp Bulb............................................................................................................................. 44

5.3 Front Turn Signal Lamp Bulb.............................................................................................................................. 45

Replace................................................................................................................................................................. 45

5.4 Front Fog Lamp Bulb Assemblies...................................................................................................................... 46

S and SS ............................................................................................................................................................... 46

Replace............................................................................................................................................................ 46

Level 2 and Level 3.............................................................................................................................................. 47

Replace............................................................................................................................................................ 47

5.5 Tail Lamp Assembly Bulbs ................................................................................................................................. 49

Sedan.................................................................................................................................................................... 49

Replace............................................................................................................................................................ 49

Wagon................................................................................................................................................................... 50

Replace............................................................................................................................................................ 50

Utility and Crew Cab............................................................................................................................................ 51

Replace............................................................................................................................................................ 51

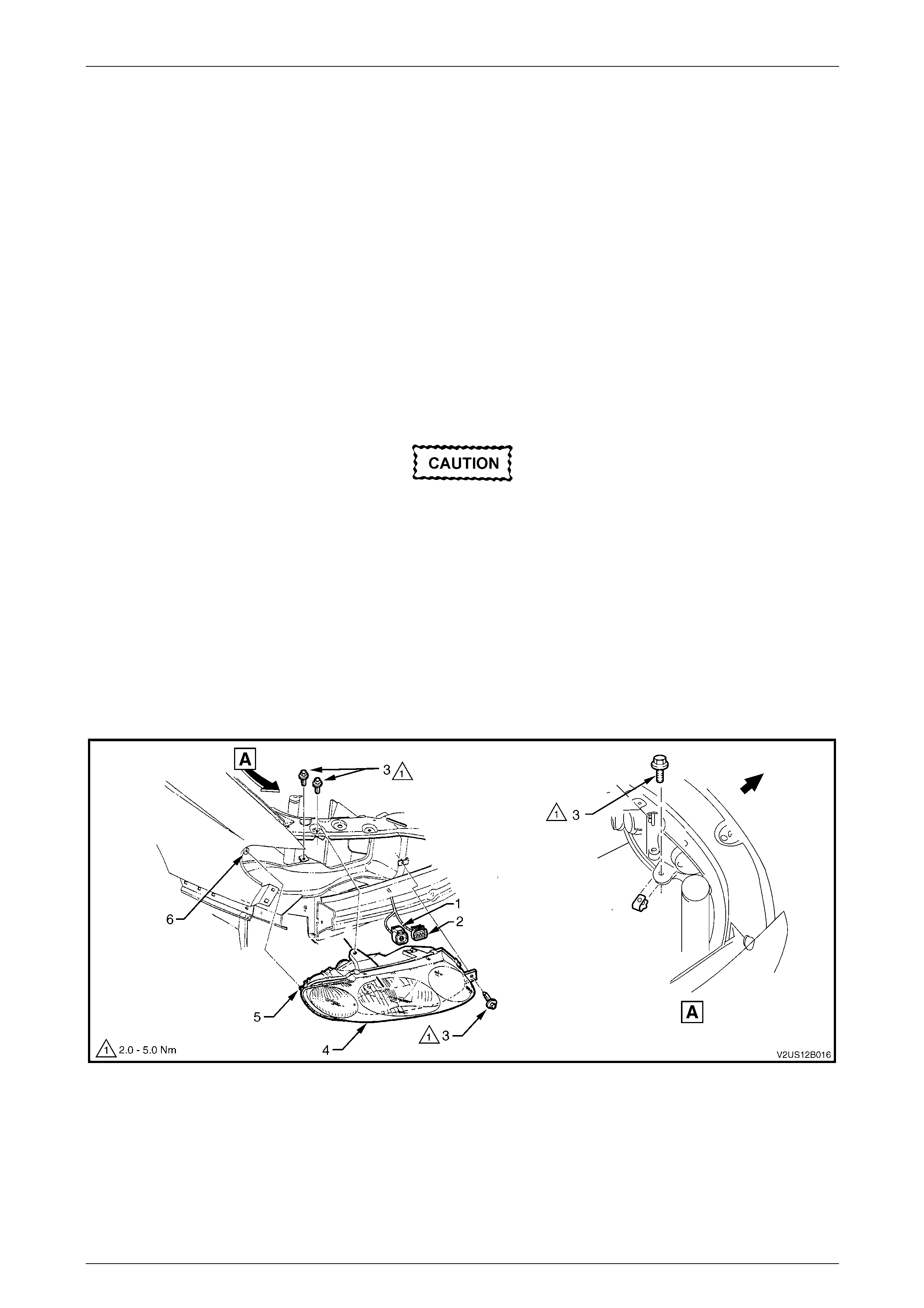

5.6 Headlamp Assembly............................................................................................................................................ 52

Remove................................................................................................................................................................. 52

Reinstall................................................................................................................................................................ 53

5.7 Front Fog Lamp Assembly .................................................................................................................................. 54

Remove................................................................................................................................................................. 54

Disassembly......................................................................................................................................................... 54

Reassembly.......................................................................................................................................................... 55

Reinstall................................................................................................................................................................ 55

5.8 Tail Lamp Assembly............................................................................................................................................ 56

Sedan.................................................................................................................................................................... 56

Remove............................................................................................................................................................ 56

Replace — Main Seal....................................................................................................................................... 57

Reinstall ........................................................................................................................................................... 57

Wagon................................................................................................................................................................... 58

Remove............................................................................................................................................................ 58

Reinstall ........................................................................................................................................................... 58

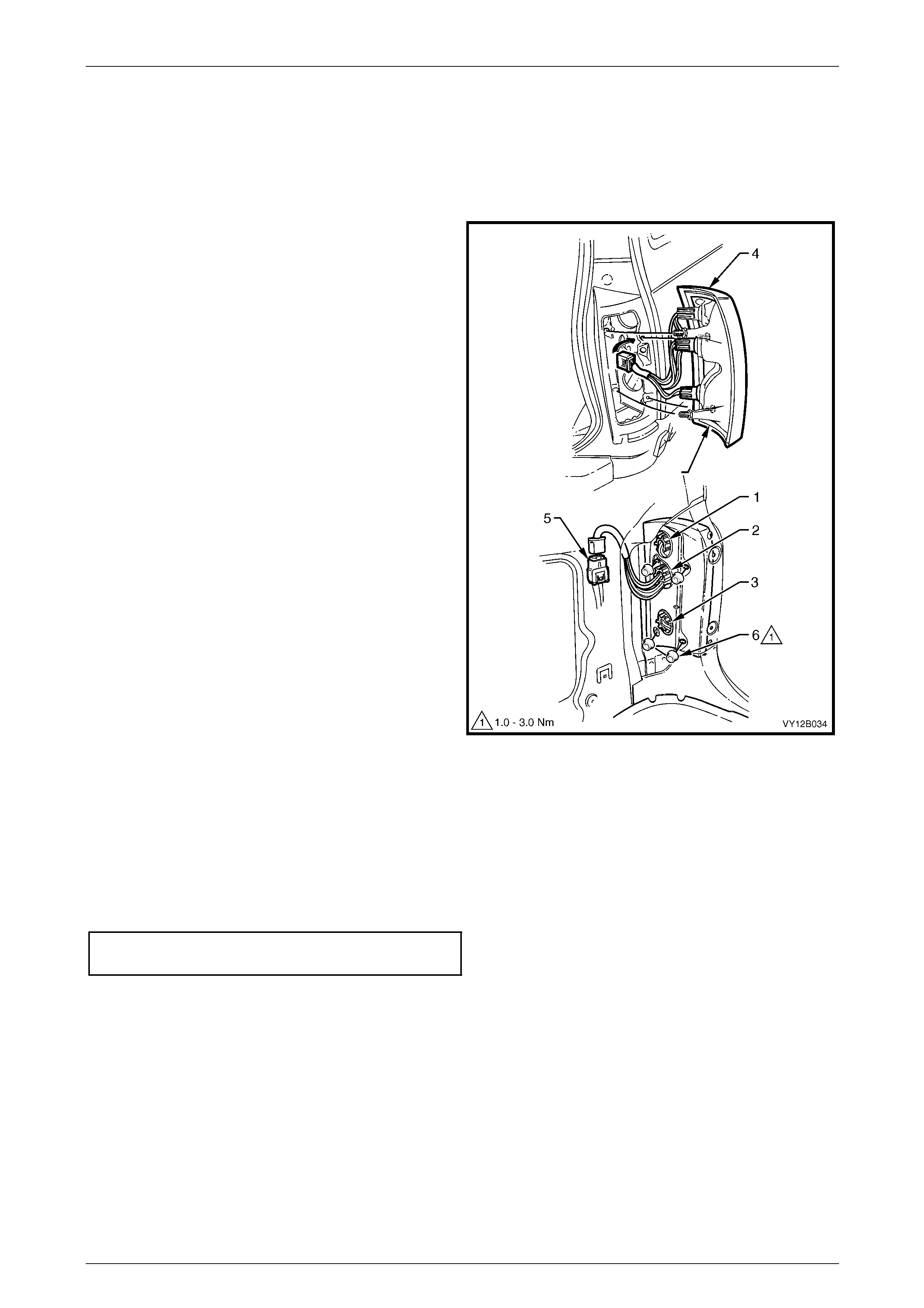

Utility and Crew Cab............................................................................................................................................ 59

Remove............................................................................................................................................................ 59

Reinstall ........................................................................................................................................................... 59

5.9 Side Repeater Lamp Assembly........................................................................................................................... 60

Except SS ............................................................................................................................................................. 60

Remove............................................................................................................................................................ 60

Reinstall ........................................................................................................................................................... 60

SS Only................................................................................................................................................................. 61

Remove............................................................................................................................................................ 61

Reinstall ........................................................................................................................................................... 61

Lighting System Page 12B–3

Page 12B–3

5.10 High-mount Stop Lamp Assembly ..................................................................................................................... 62

Sedan Without Rear-end Spoiler........................................................................................................................ 62

Bulb Replacement............................................................................................................................................ 62

Remove............................................................................................................................................................ 62

Reinstall ........................................................................................................................................................... 62

Sedan With Rear-end Spoiler.............................................................................................................................. 63

Wagon................................................................................................................................................................... 63

Bulb Replacement............................................................................................................................................ 63

Remove............................................................................................................................................................ 63

Reinstall ........................................................................................................................................................... 64

Utility (If Fitted)..................................................................................................................................................... 64

Remove............................................................................................................................................................ 64

Reinstall ........................................................................................................................................................... 65

5.11 Rear Licence Plate Lamp Assembly................................................................................................................... 66

Remove................................................................................................................................................................. 66

Reinstall................................................................................................................................................................ 67

Wiring Harnesses................................................................................................................................................. 67

Sedan............................................................................................................................................................... 67

Wagon.............................................................................................................................................................. 67

6 Service Operations — Exterior Illumination, Coupe.........................................................................68

6.1 Headlamp and Front Fog Lamp Aiming............................................................................................................. 68

Headlamp Assembly Aim.................................................................................................................................... 68

Front Fog Lamp Assembly Aim.......................................................................................................................... 70

6.2 Headlamp Assembly Bulbs................................................................................................................................. 71

Replace — Low Beam Bulb................................................................................................................................. 71

Replace — High Beam Bulb................................................................................................................................ 73

6.3 Front Turn Signal Lamp Bulb.............................................................................................................................. 75

Replace................................................................................................................................................................. 75

6.4 Park and Front Fog Lamp Bulb Assemblies...................................................................................................... 76

Replace — Fog Lamp Bulb.................................................................................................................................. 76

Replace — Park Lamp Bulb ................................................................................................................................ 76

6.5 Tail Lamp Assembly Bulbs ................................................................................................................................. 77

Replace................................................................................................................................................................. 77

6.6 Headlamp Assembly............................................................................................................................................ 79

Remove................................................................................................................................................................. 79

Reinstall................................................................................................................................................................ 80

6.7 Park and Front Fog Lamp Assembly.................................................................................................................. 81

Remove................................................................................................................................................................. 81

Reinstall................................................................................................................................................................ 81

6.8 Tail Lamp Assembly............................................................................................................................................ 82

Remove................................................................................................................................................................. 82

Replace — Main Seal........................................................................................................................................... 83

Reinstall................................................................................................................................................................ 83

6.9 Side Repeater Lamp Assembly........................................................................................................................... 84

Remove................................................................................................................................................................. 84

Reinstall................................................................................................................................................................ 84

6.10 High-mount Stop Lamp Assembly ..................................................................................................................... 85

Remove................................................................................................................................................................. 85

Disassembly......................................................................................................................................................... 85

Reassembly.......................................................................................................................................................... 86

Reinstall................................................................................................................................................................ 86

6.11 Rear Licence Plate Lamp Assembly................................................................................................................... 87

Remove................................................................................................................................................................. 87

Reinstall................................................................................................................................................................ 87

Wiring Harness..................................................................................................................................................... 87

Lighting System Page 12B–4

Page 12B–4

7 Service Operations — Exterior Illumination, Regular Cab and Crew Cab with 'Delete Tub'

Option....................................................................................................................................................88

7.1 Tail Lamp Assembly Bulbs ................................................................................................................................. 88

Replace................................................................................................................................................................. 88

7.2 Rear Licence Plate Lamp Bulb............................................................................................................................ 89

Replace................................................................................................................................................................. 89

7.3 Tail Lamp Assembly............................................................................................................................................ 90

Remove................................................................................................................................................................. 90

Reinstall................................................................................................................................................................ 90

7.4 Rear Licence Plate Lamp Assembly................................................................................................................... 91

Remove................................................................................................................................................................. 91

Reinstall................................................................................................................................................................ 91

7.5 Transport Bracket................................................................................................................................................ 92

Remove................................................................................................................................................................. 92

Reinstall................................................................................................................................................................ 92

8 Service Operations — Interior Illumination and Switching, Sedan, Wagon, Utility and Crew Cab93

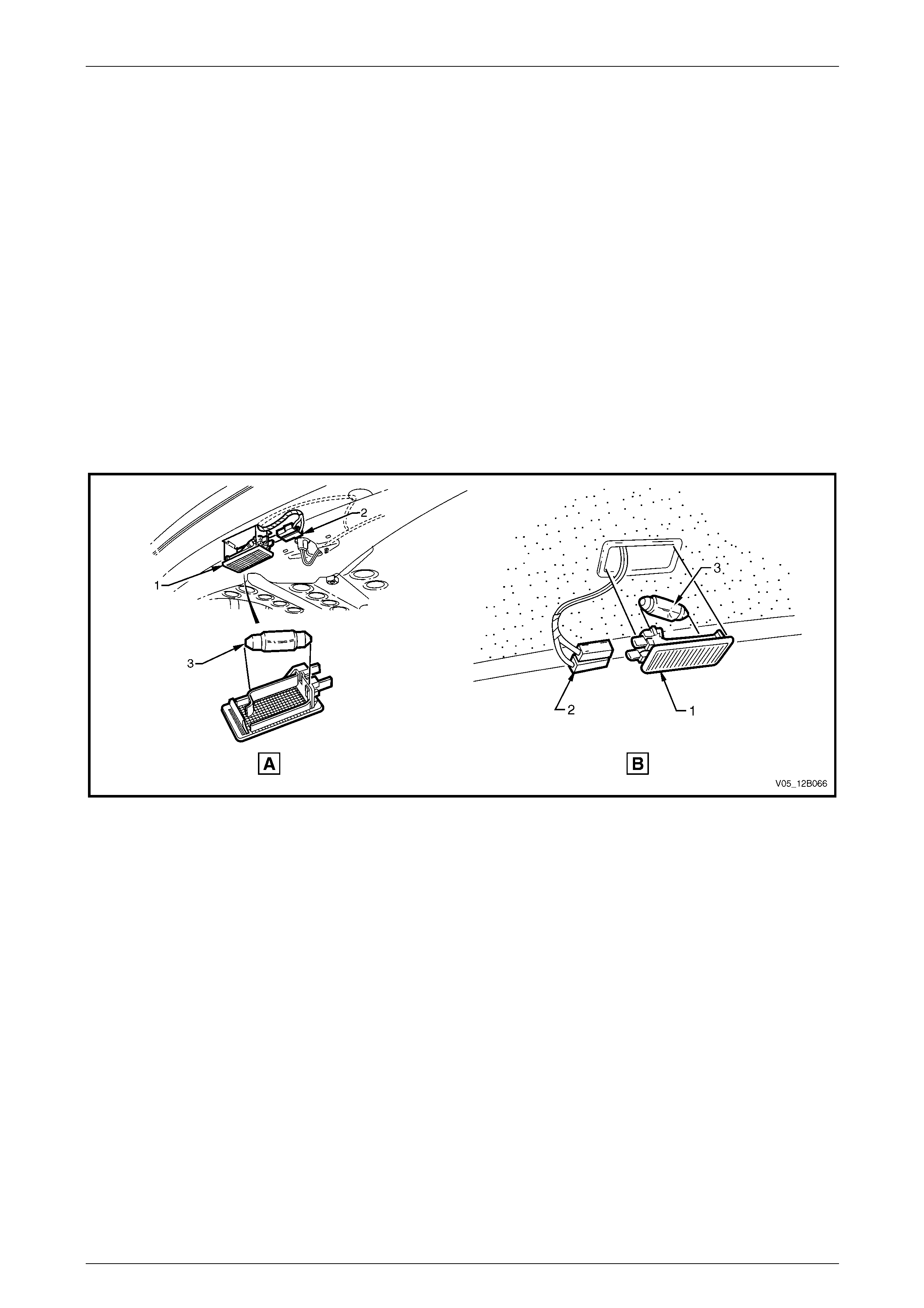

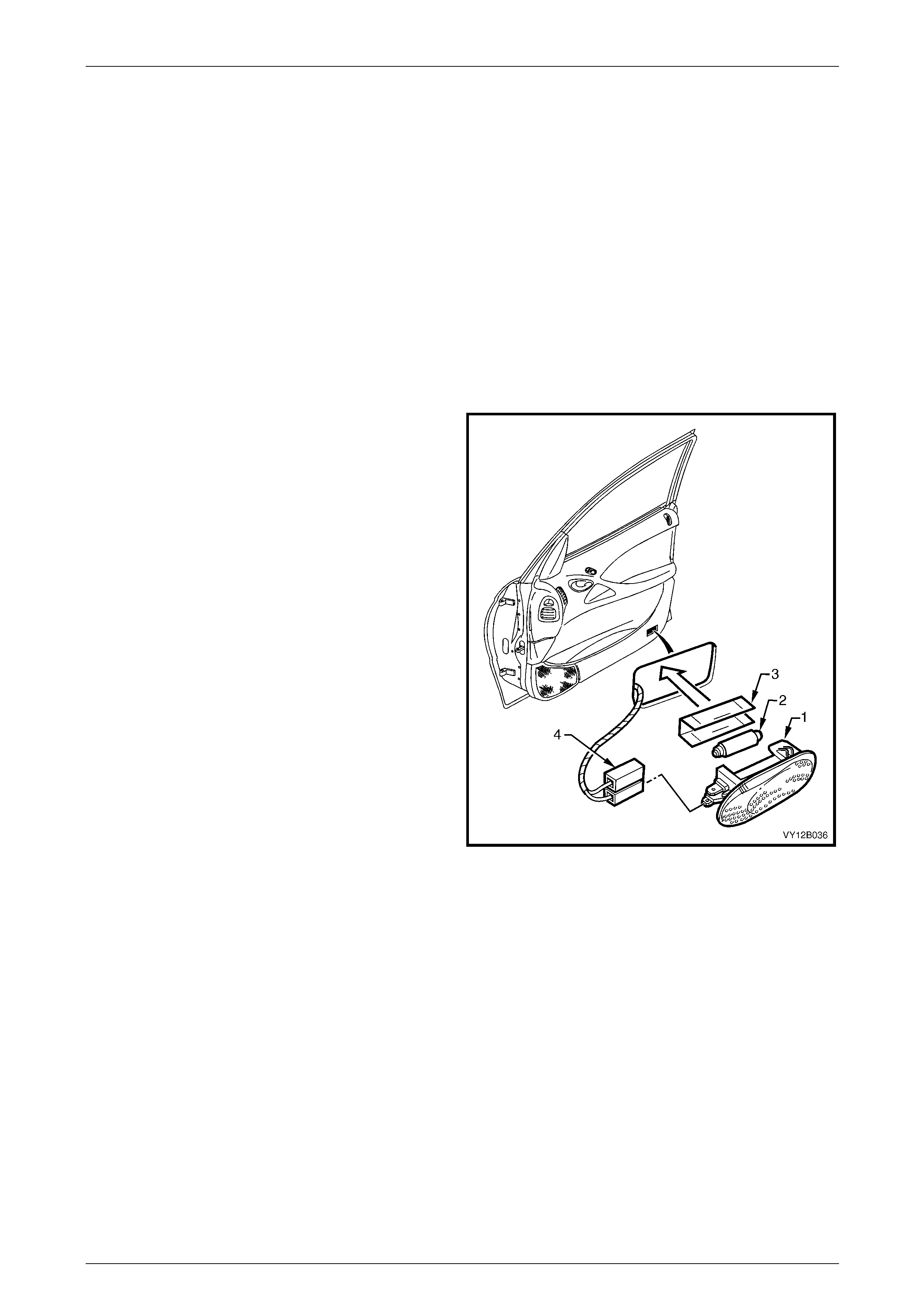

8.1 Side Door Courtesy Lamp Assembly................................................................................................................. 93

Remove................................................................................................................................................................. 93

Reinstall................................................................................................................................................................ 93

8.2 Instrument Panel Compartment Lamp Assembly............................................................................................. 94

Remove................................................................................................................................................................. 94

Reinstall................................................................................................................................................................ 94

8.3 Instrument Panel Compartment Lamp Switch Assembly................................................................................. 95

Remove................................................................................................................................................................. 95

Reinstall................................................................................................................................................................ 95

8.4 Rear Compartment Courtesy Lamp Assembly.................................................................................................. 96

Remove................................................................................................................................................................. 96

Reinstall................................................................................................................................................................ 96

8.5 Rear Compartment Courtesy Lamp Switch Assembly ..................................................................................... 97

Remove................................................................................................................................................................. 97

Reinstall................................................................................................................................................................ 97

8.6 Dome Lamp Assembly ........................................................................................................................................ 98

Bulb Replace........................................................................................................................................................ 98

Remove................................................................................................................................................................. 98

Reinstall................................................................................................................................................................ 98

8.7 Dome and Reading Lamp Assembly.................................................................................................................. 99

Bulb Replace........................................................................................................................................................ 99

Removal................................................................................................................................................................ 99

Reinstall................................................................................................................................................................ 99

8.8 Roof Console Assembly.................................................................................................................................... 100

Bulb Replace...................................................................................................................................................... 100

Remove............................................................................................................................................................... 101

Reinstall.............................................................................................................................................................. 101

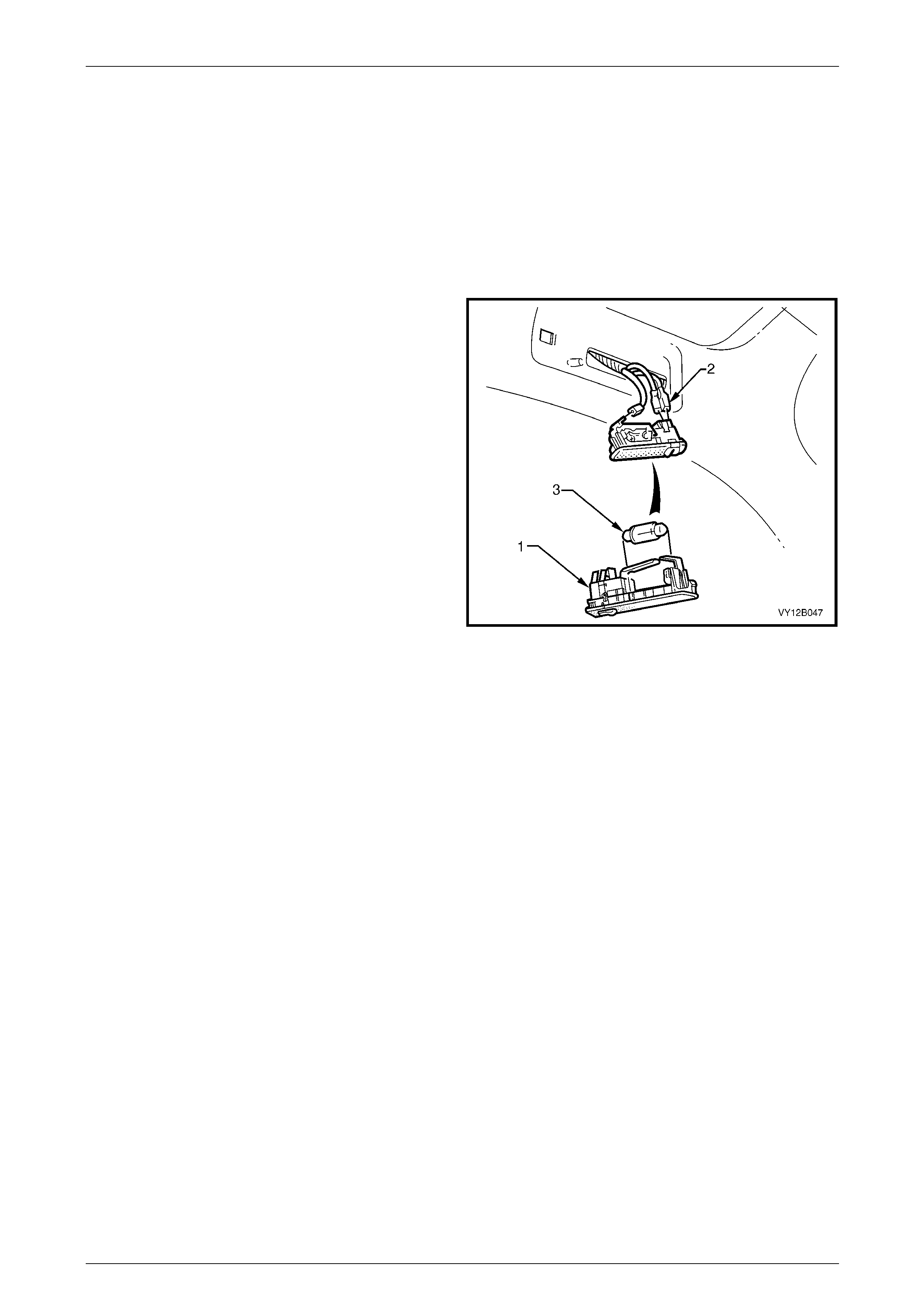

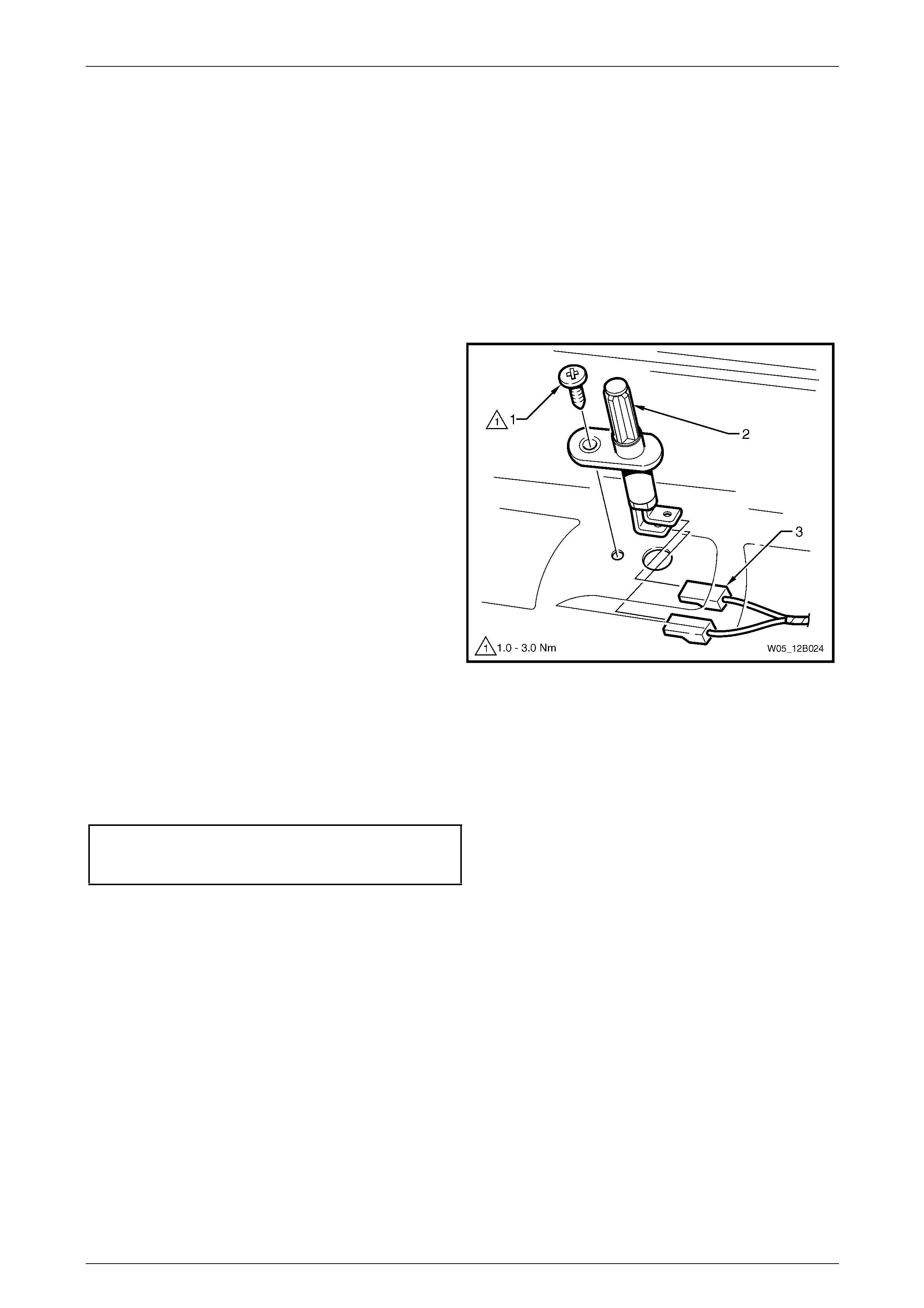

8.9 Door Ajar Switches............................................................................................................................................ 102

Remove............................................................................................................................................................... 102

Reinstall.............................................................................................................................................................. 102

8.10 Stepwell Lamps.................................................................................................................................................. 103

Replace............................................................................................................................................................... 103

8.11 Floor Console Compartment Lamp Assembly................................................................................................ 104

Remove............................................................................................................................................................... 104

Reinstall.............................................................................................................................................................. 104

Lighting System Page 12B–5

Page 12B–5

8.12 Floor Console Compartment Lamp Switch Assembly.................................................................................... 105

Remove............................................................................................................................................................... 105

Reinstall.............................................................................................................................................................. 105

8.13 Roof Rail Courtesy and Reading Lamp Assembly.......................................................................................... 106

Remove............................................................................................................................................................... 106

Reinstall.............................................................................................................................................................. 106

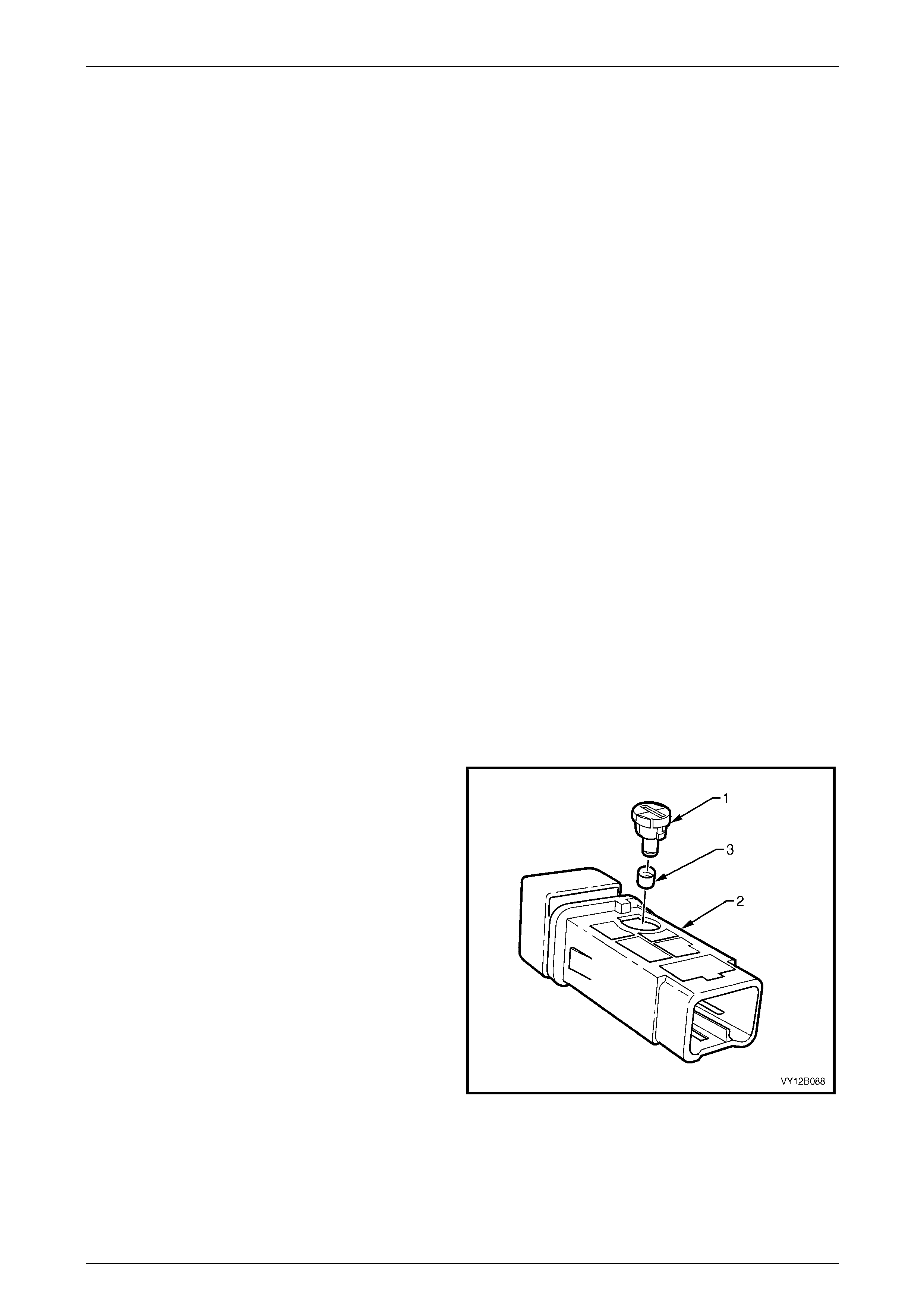

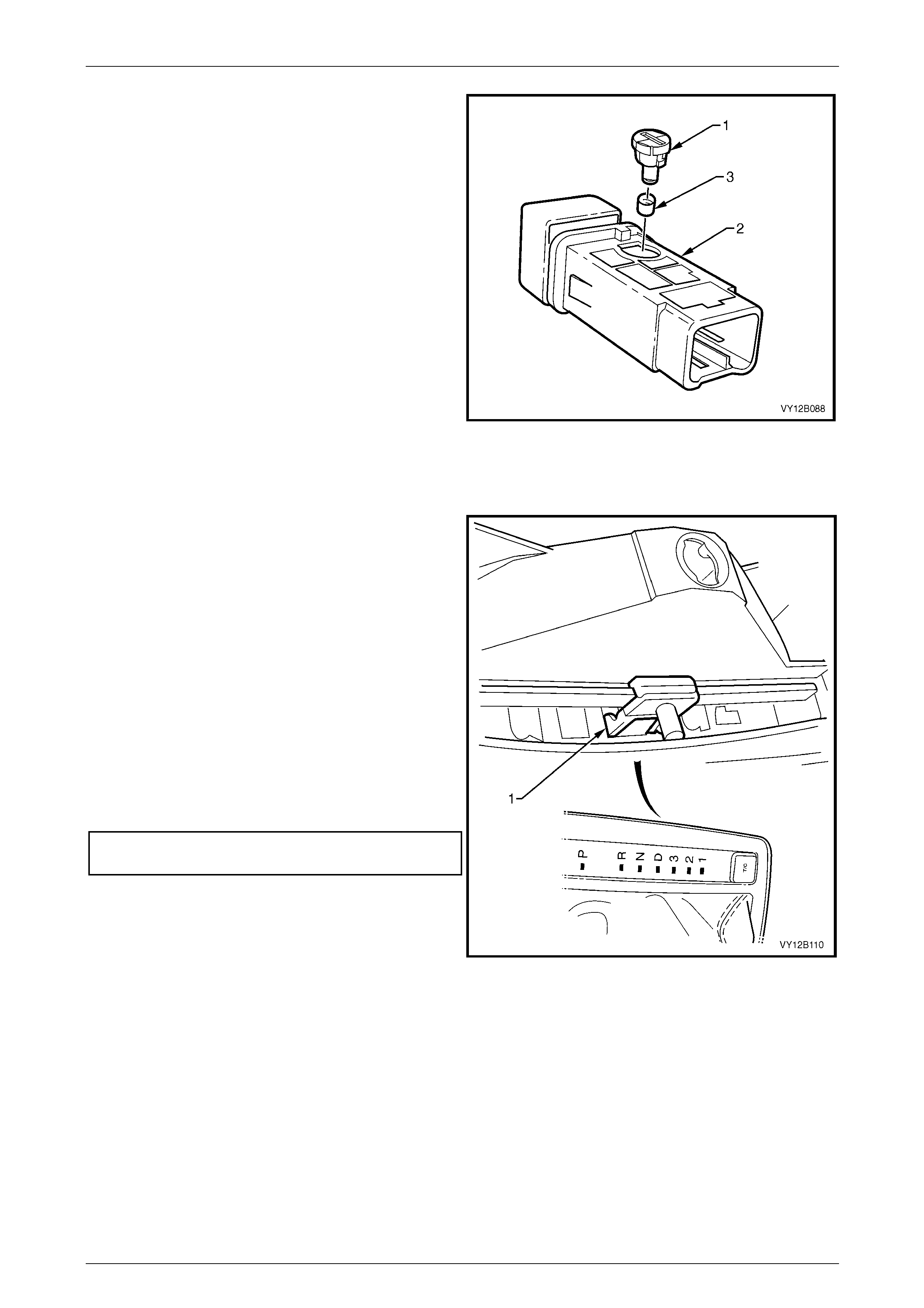

8.14 Automatic Transmission Control Position Lamp............................................................................................ 107

Replace............................................................................................................................................................... 107

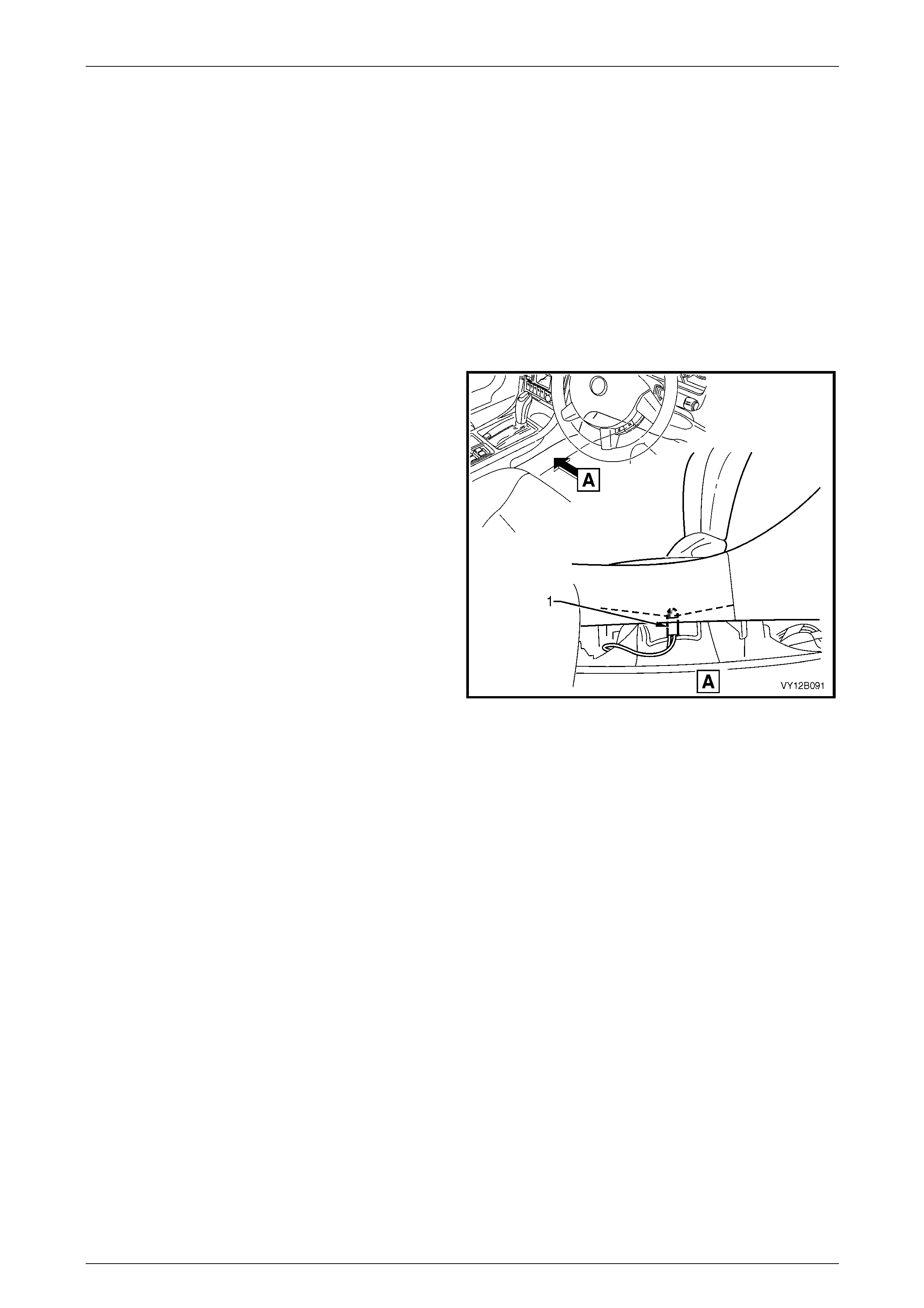

8.15 Ignition Lock Cylinder Bulb.............................................................................................................................. 108

Replace............................................................................................................................................................... 108

8.16 Stop Lamp Switch Assembly............................................................................................................................ 109

8.17 Switch Illumination............................................................................................................................................ 110

Auxiliary Switch Bulbs ...................................................................................................................................... 110

Replace.......................................................................................................................................................... 110

T/C or A/S and PWR Switch Bulbs ................................................................................................................... 111

Replace.......................................................................................................................................................... 111

Hazard Warning Switch Bulb............................................................................................................................ 115

Replace.......................................................................................................................................................... 115

8.18 Backup Lamp Switch Assembly....................................................................................................................... 116

8.19 Neutral Safety Backup Switch Assembly ........................................................................................................ 117

8.20 Turn Signal Switch Assembly (and Cruise Control if Fitted) ......................................................................... 118

Remove............................................................................................................................................................... 118

Reinstall.............................................................................................................................................................. 119

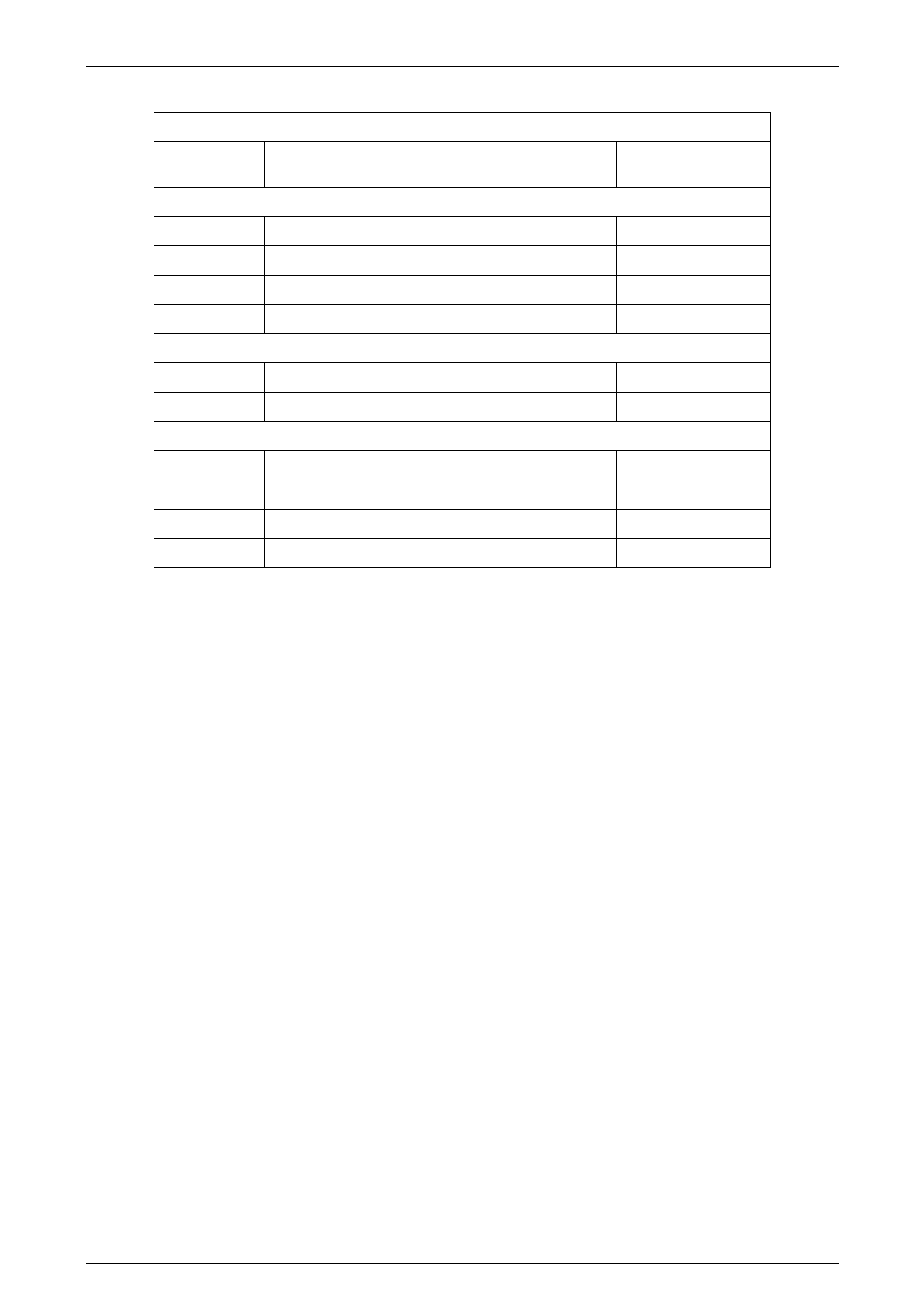

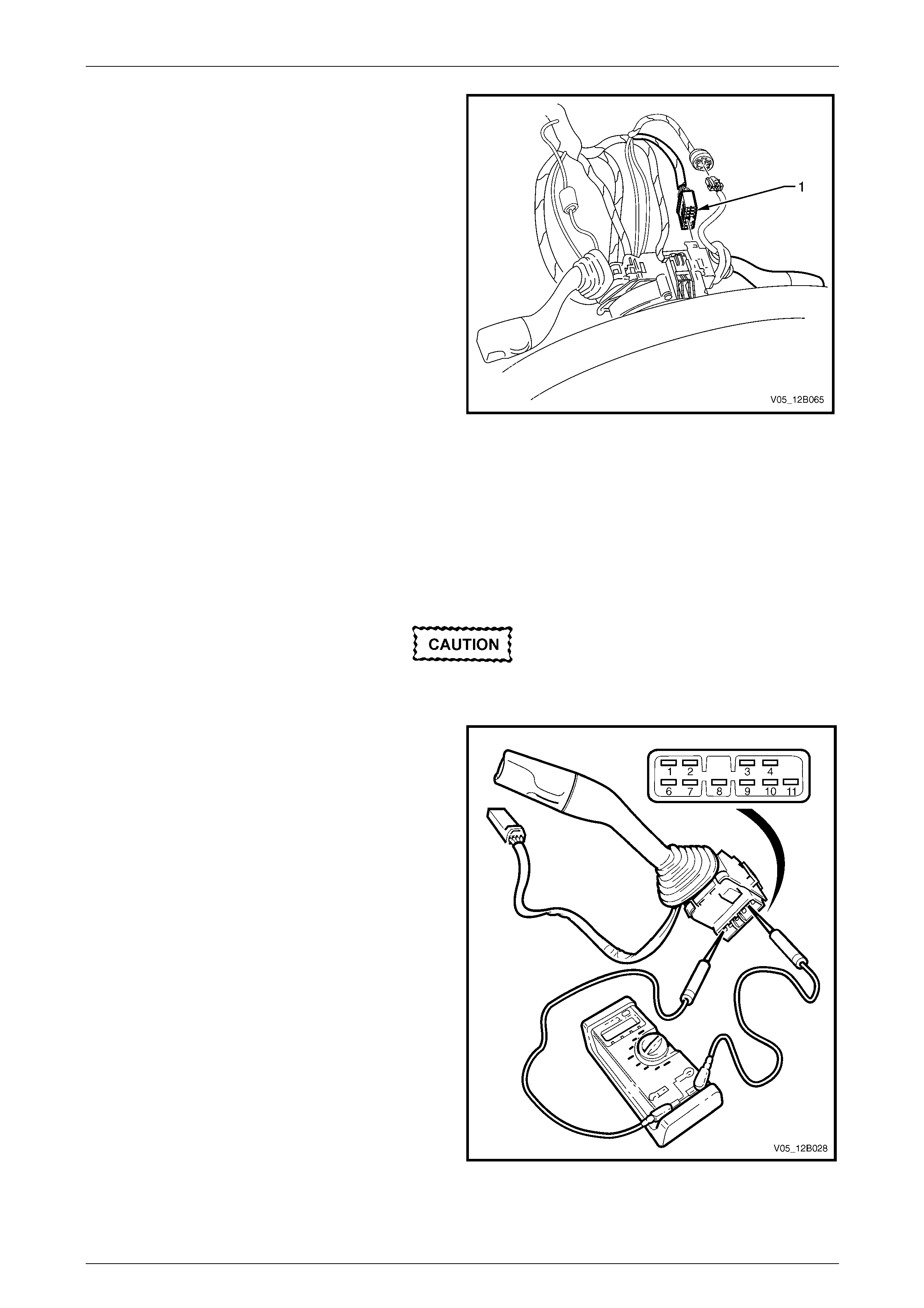

Testing................................................................................................................................................................ 119

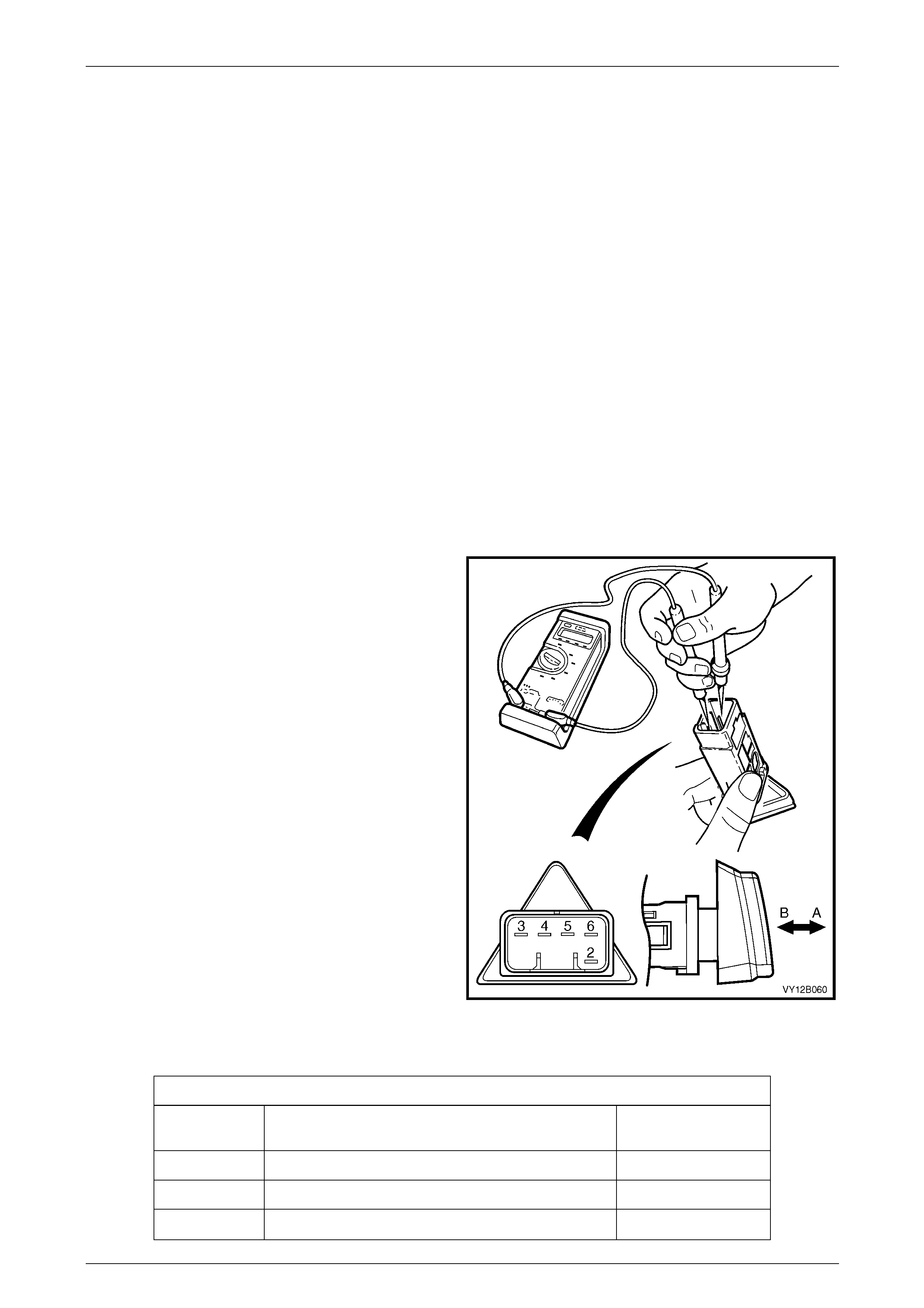

Turn Signal Switch Assembly......................................................................................................................... 120

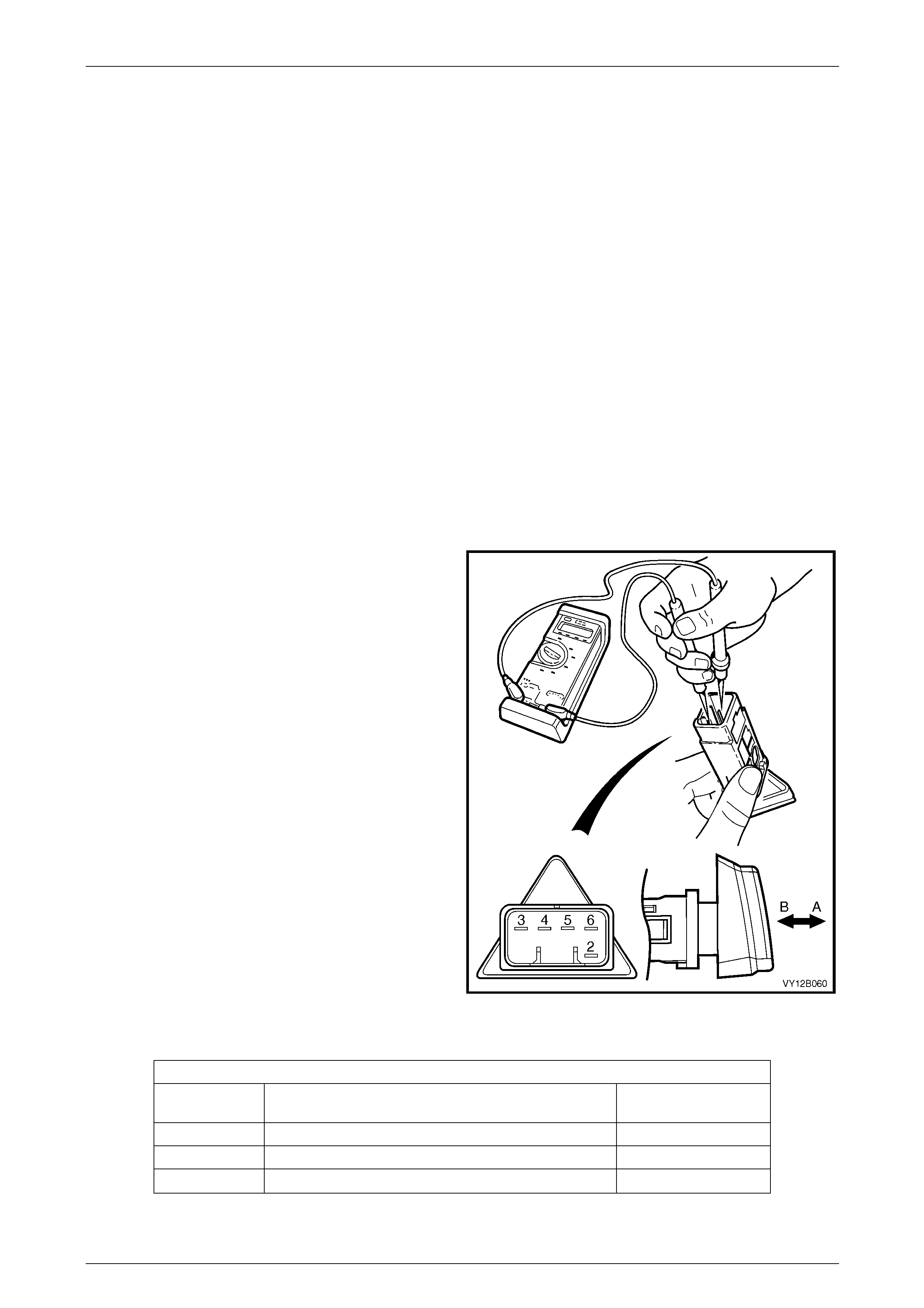

8.21 Headlamp Switch Assembly (and Front Fog Lamp if Fitted).......................................................................... 121

Remove............................................................................................................................................................... 121

Reinstall.............................................................................................................................................................. 121

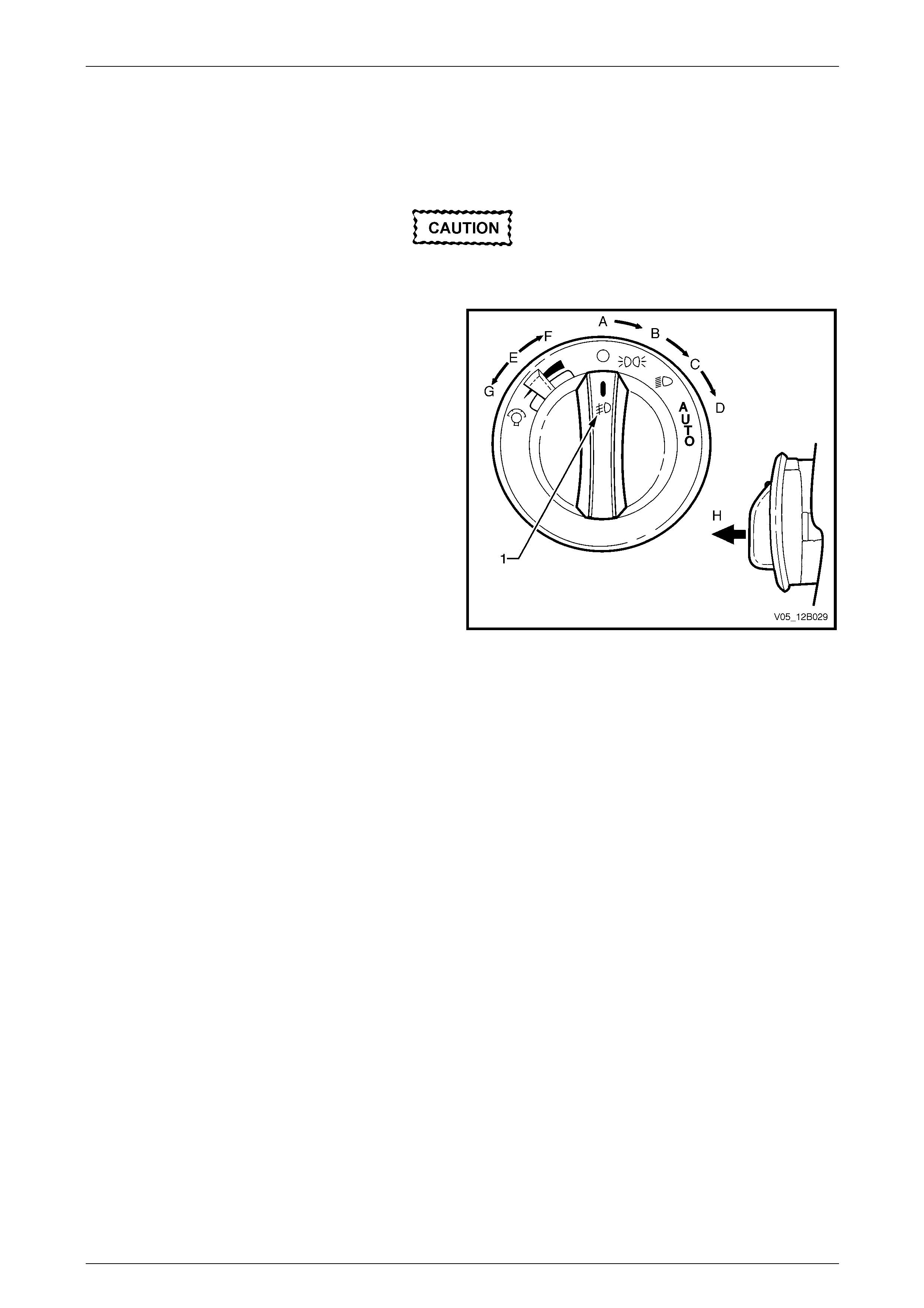

Testing................................................................................................................................................................ 122

Headlamp Switch Assembly (and Front Fog Lamp if Fitted) .......................................................................... 122

8.22 Daylight Running Lamp Assembly (Option T82)............................................................................................. 123

Remove............................................................................................................................................................... 123

Reinstall.............................................................................................................................................................. 123

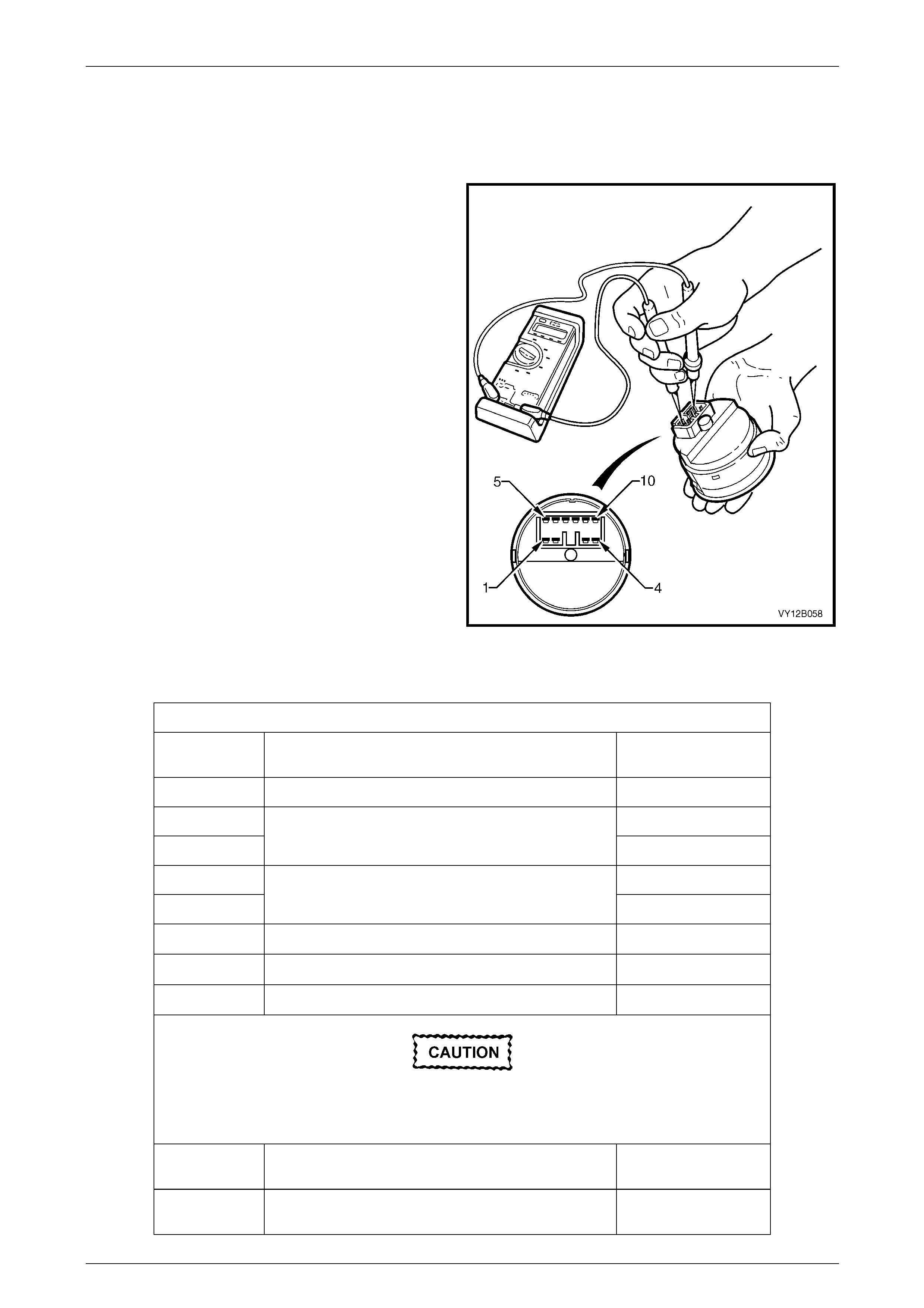

Testing................................................................................................................................................................ 124

8.23 Hazard Warning Switch Assembly ................................................................................................................... 125

Remove............................................................................................................................................................... 125

Reinstall.............................................................................................................................................................. 125

Testing................................................................................................................................................................ 125

Hazard Warning Switch Assembly................................................................................................................. 125

9 Service Operations — Interior Illumination and Switching, Coupe ..............................................126

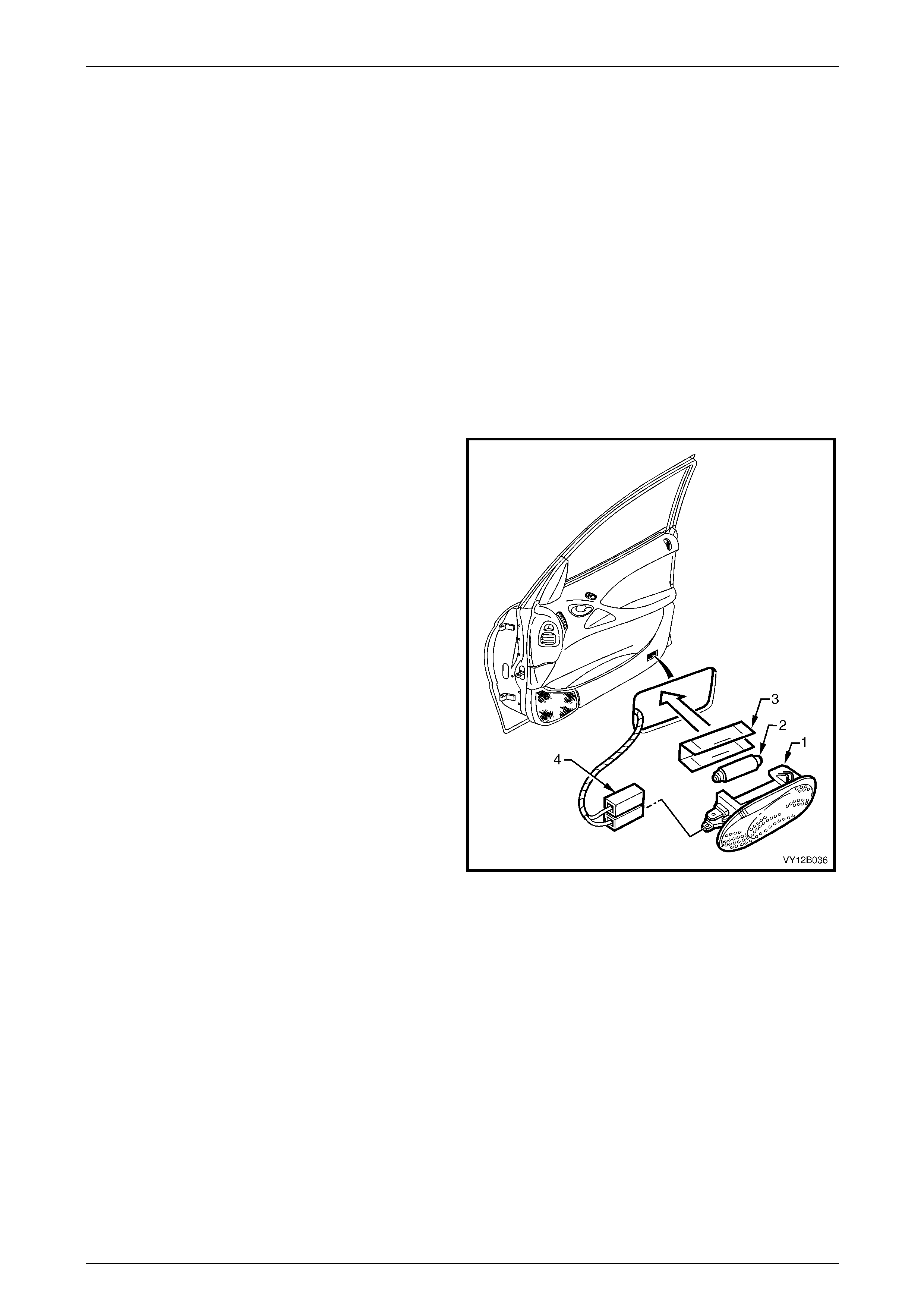

9.1 Side Door Courtesy Lamp Assembly............................................................................................................... 126

Remove............................................................................................................................................................... 126

Reinstall.............................................................................................................................................................. 126

9.2 Instrument Panel Compartment Lamp Assembly........................................................................................... 127

Remove............................................................................................................................................................... 127

Reinstall.............................................................................................................................................................. 127

9.3 Instrument Panel Compartment Lamp Switch Assembly............................................................................... 128

Remove............................................................................................................................................................... 128

Reinstall.............................................................................................................................................................. 128

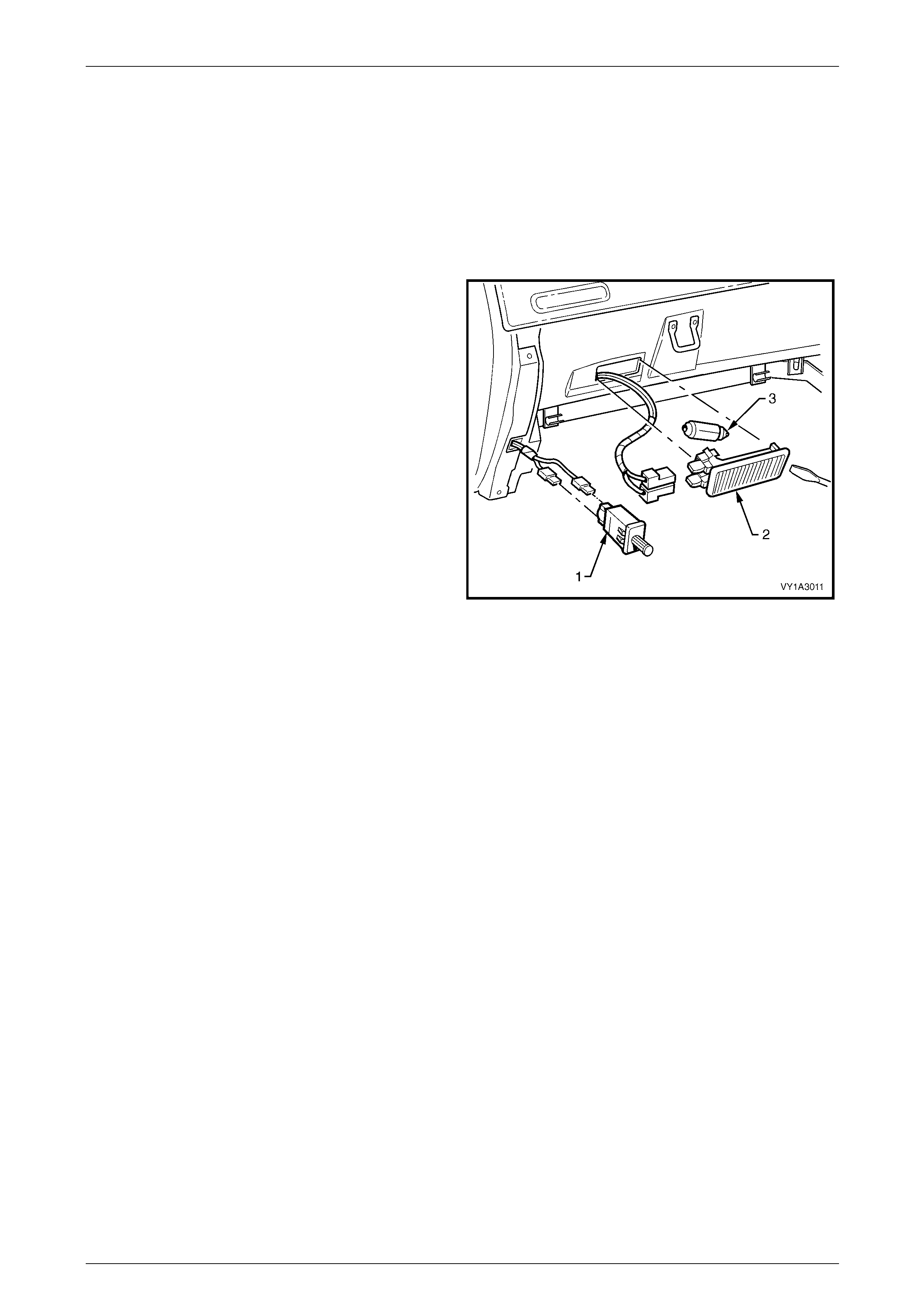

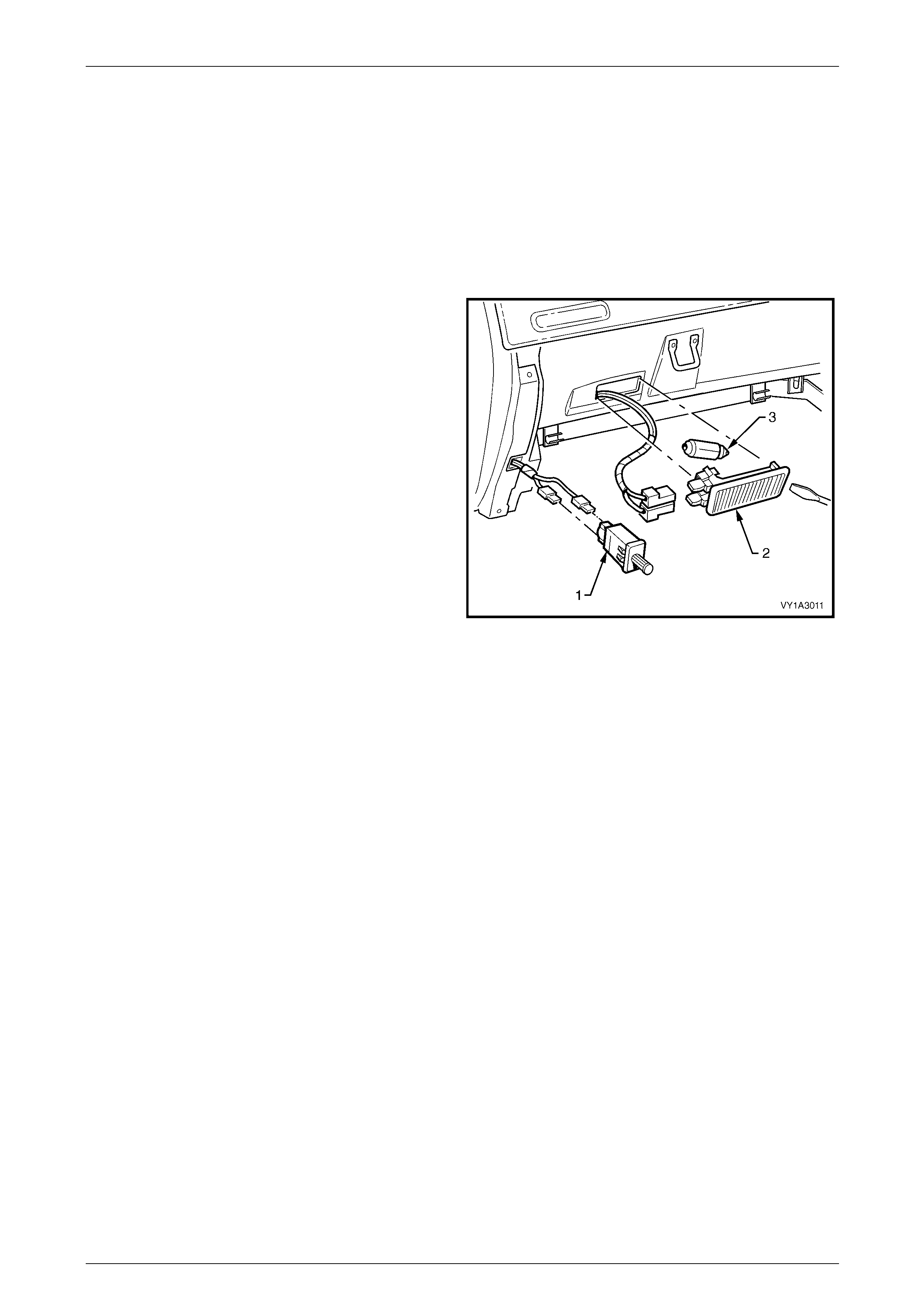

9.4 Rear Compartment Courtesy Lamp Assembly................................................................................................ 129

Remove............................................................................................................................................................... 129

Reinstall.............................................................................................................................................................. 129

Lighting System Page 12B–6

Page 12B–6

9.5 Rear Compartment Courtesy Lamp Switch Assembly ................................................................................... 130

Remove............................................................................................................................................................... 130

Reinstall.............................................................................................................................................................. 130

9.6 Dome and Reading Lamp Assembly................................................................................................................ 131

Bulb Replace...................................................................................................................................................... 131

Removal.............................................................................................................................................................. 131

Reinstall.............................................................................................................................................................. 131

9.7 Door Ajar Switches............................................................................................................................................ 132

Remove............................................................................................................................................................... 132

Reinstall.............................................................................................................................................................. 132

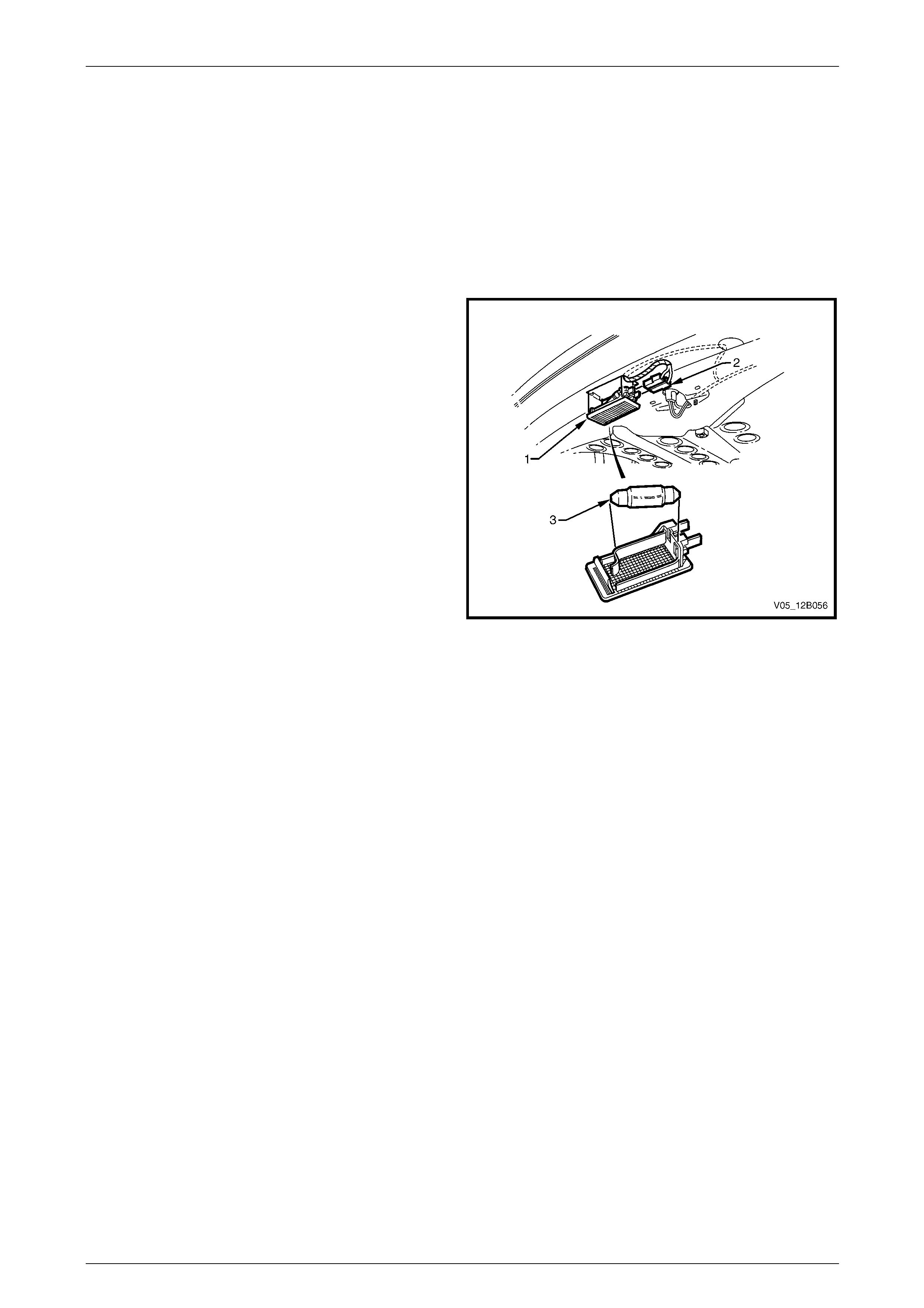

9.8 Stepwell Lamps.................................................................................................................................................. 133

Replace............................................................................................................................................................... 133

9.9 Floor Console Compartment Lamp Assembly................................................................................................ 134

Remove............................................................................................................................................................... 134

Reinstall.............................................................................................................................................................. 134

9.10 Floor Console Compartment Lamp Switch Assembly.................................................................................... 135

Remove............................................................................................................................................................... 135

Reinstall.............................................................................................................................................................. 135

9.11 Automatic Transmission Control Position Lamp............................................................................................ 136

Replace............................................................................................................................................................... 136

9.12 Ignition Lock Cylinder Bulb.............................................................................................................................. 137

Replace............................................................................................................................................................... 137

9.13 Stop Lamp Switch Assembly............................................................................................................................ 138

9.14 Switch Illumination............................................................................................................................................ 139

Auxiliary Switch Bulbs ...................................................................................................................................... 139

Replace.......................................................................................................................................................... 139

T/C Switch or A/S Switch Bulb.......................................................................................................................... 140

Replace.......................................................................................................................................................... 140

Hazard Warning Switch Bulb............................................................................................................................ 140

Replace.......................................................................................................................................................... 140

9.15 Backup Lamp Switch Assembly....................................................................................................................... 141

9.16 Neutral Safety Backup Switch Assembly ........................................................................................................ 142

9.17 Turn Signal and Cruise Control Switch Assembly.......................................................................................... 143

Remove............................................................................................................................................................... 143

Reinstall.............................................................................................................................................................. 144

Testing................................................................................................................................................................ 144

Turn Signal Switch Assembly......................................................................................................................... 145

9.18 Headlamp Switch Assembly ............................................................................................................................. 146

Remove............................................................................................................................................................... 146

Reinstall.............................................................................................................................................................. 146

Testing................................................................................................................................................................ 147

Headlamp Switch Assembly........................................................................................................................... 147

9.19 Hazard Warning Switch Assembly ................................................................................................................... 148

Remove............................................................................................................................................................... 148

Reinstall.............................................................................................................................................................. 148

Testing................................................................................................................................................................ 148

Hazard Warning Switch Assembly................................................................................................................. 148

Lighting System Page 12B–7

Page 12B–7

10 Service Operations, AWD Wagon.....................................................................................................149

10.1 Front Fog Lamps................................................................................................................................................ 149

Front Fog Lamp Assembly................................................................................................................................ 149

Remove.......................................................................................................................................................... 149

Replace.......................................................................................................................................................... 149

Disassembly................................................................................................................................................... 149

Reinstall ......................................................................................................................................................... 149

Front Fog Lamp Assembly Bulbs..................................................................................................................... 149

Replace.......................................................................................................................................................... 149

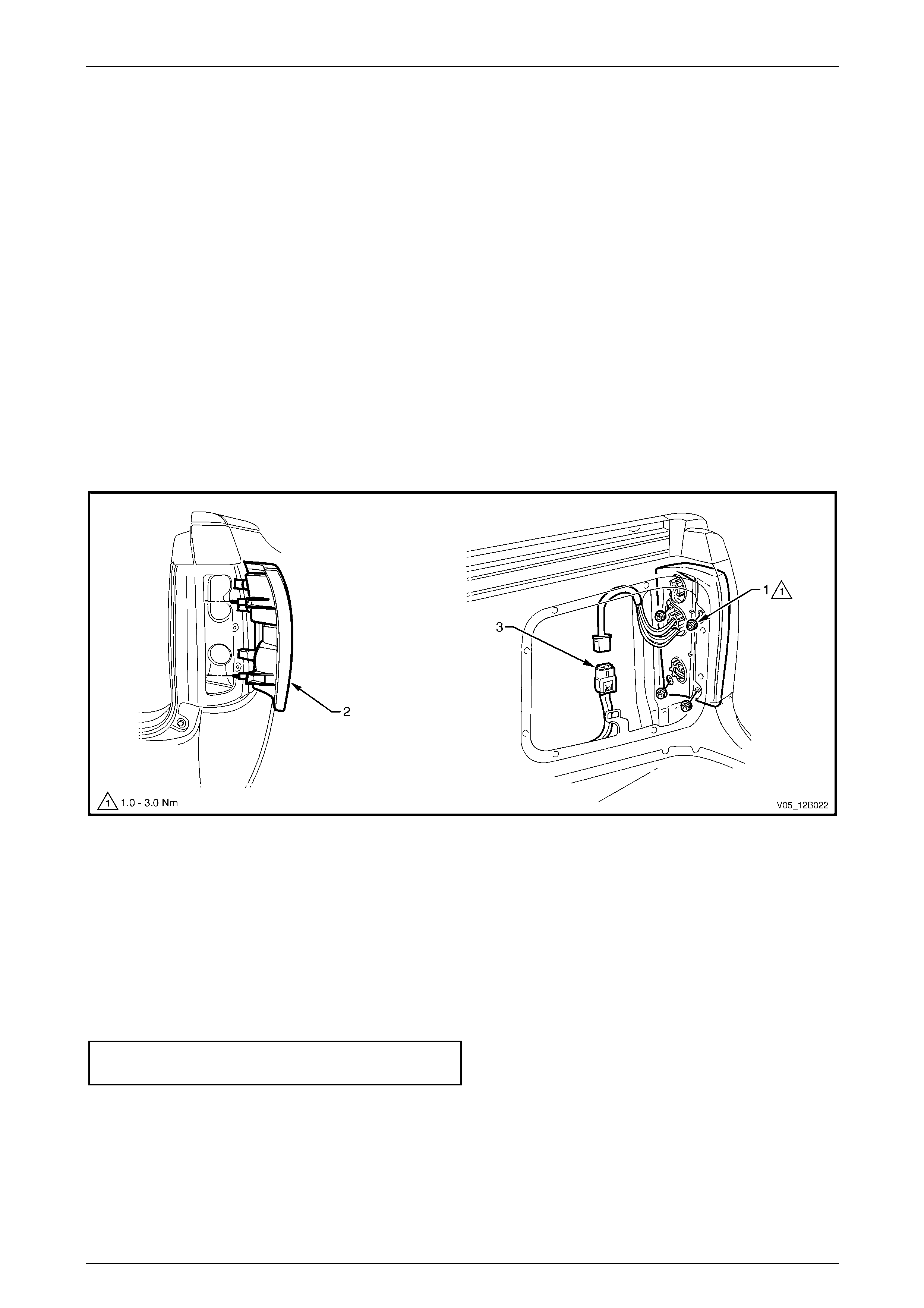

10.2 Tail Lamps.......................................................................................................................................................... 150

Tail Lamp Assembly.......................................................................................................................................... 150

Remove.......................................................................................................................................................... 150

Reinstall ......................................................................................................................................................... 150

Tail Lamp Assembly Bulbs ............................................................................................................................... 150

Replace.......................................................................................................................................................... 150

10.3 Backup Lamps ................................................................................................................................................... 151

Backup Lamp Assembly ................................................................................................................................... 151

Remove.......................................................................................................................................................... 151

Replace.......................................................................................................................................................... 151

Backup Lamp Assembly Bulbs......................................................................................................................... 151

Replace.......................................................................................................................................................... 151

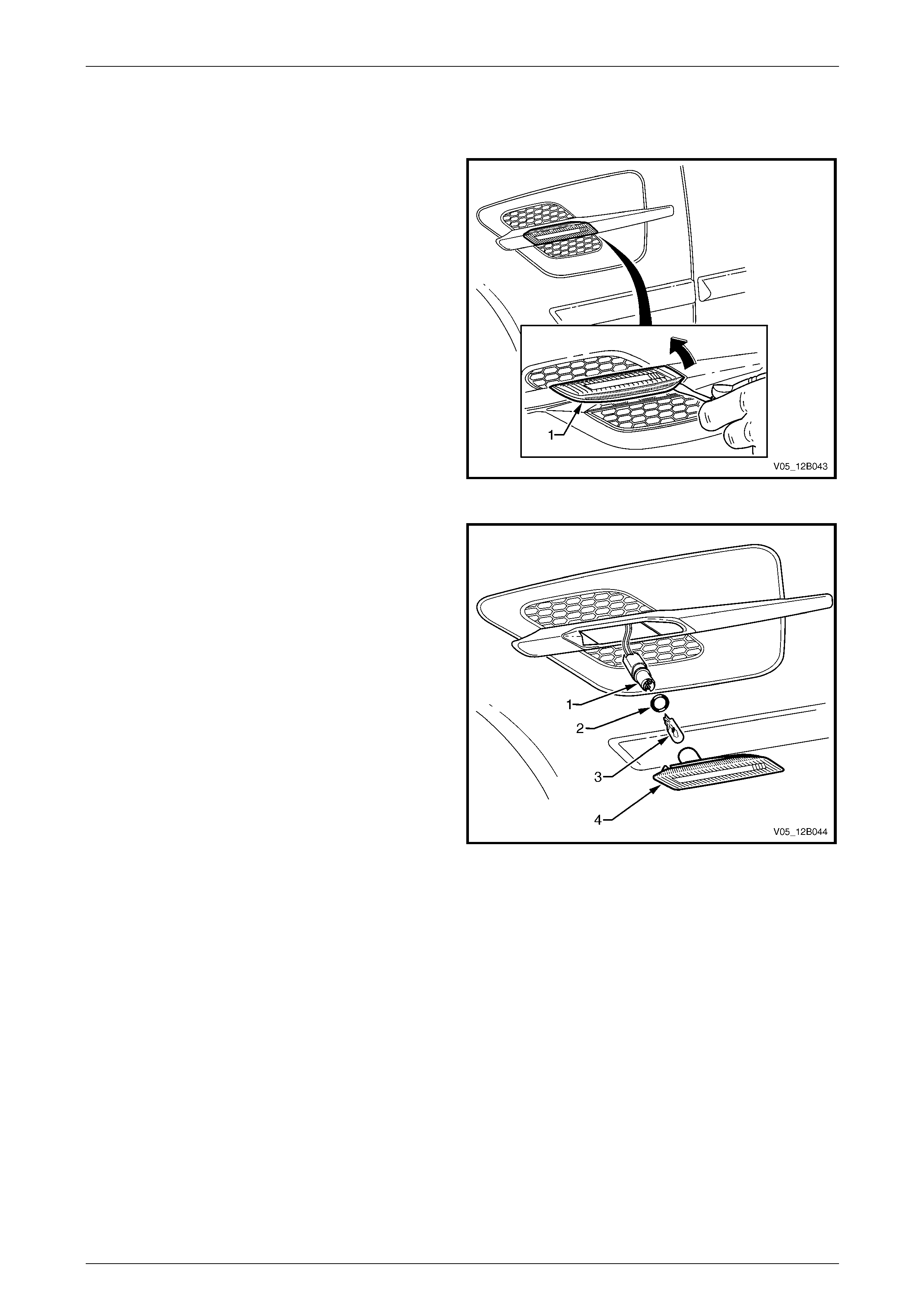

10.4 Liftgate Air Deflector Assembly and High-mount Stop Lamp Assembly...................................................... 152

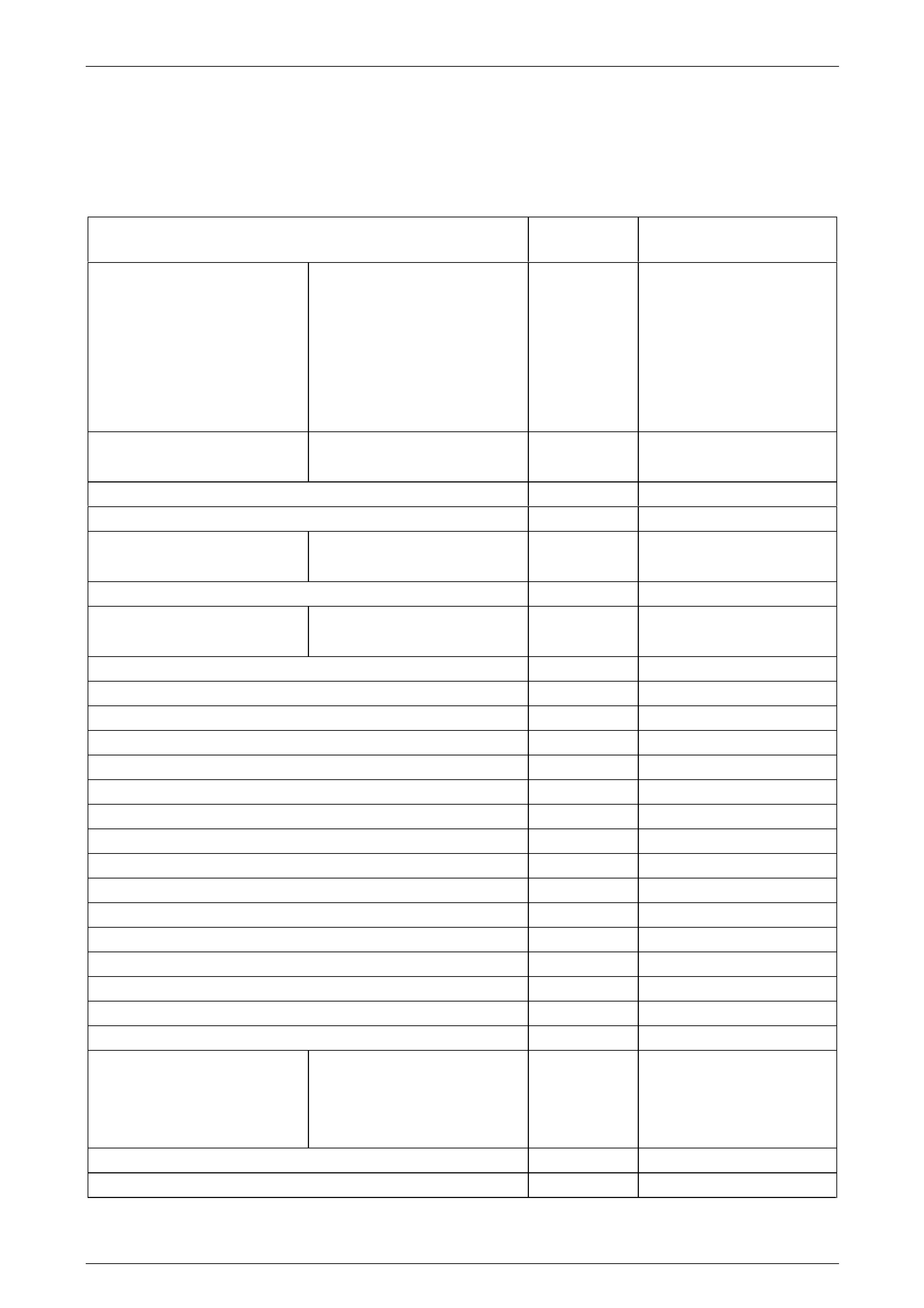

11 Specifications.....................................................................................................................................153

11.1 All Models (Except Regular Cab and Crew Cab with 'Delete Tub' Option) ................................................... 153

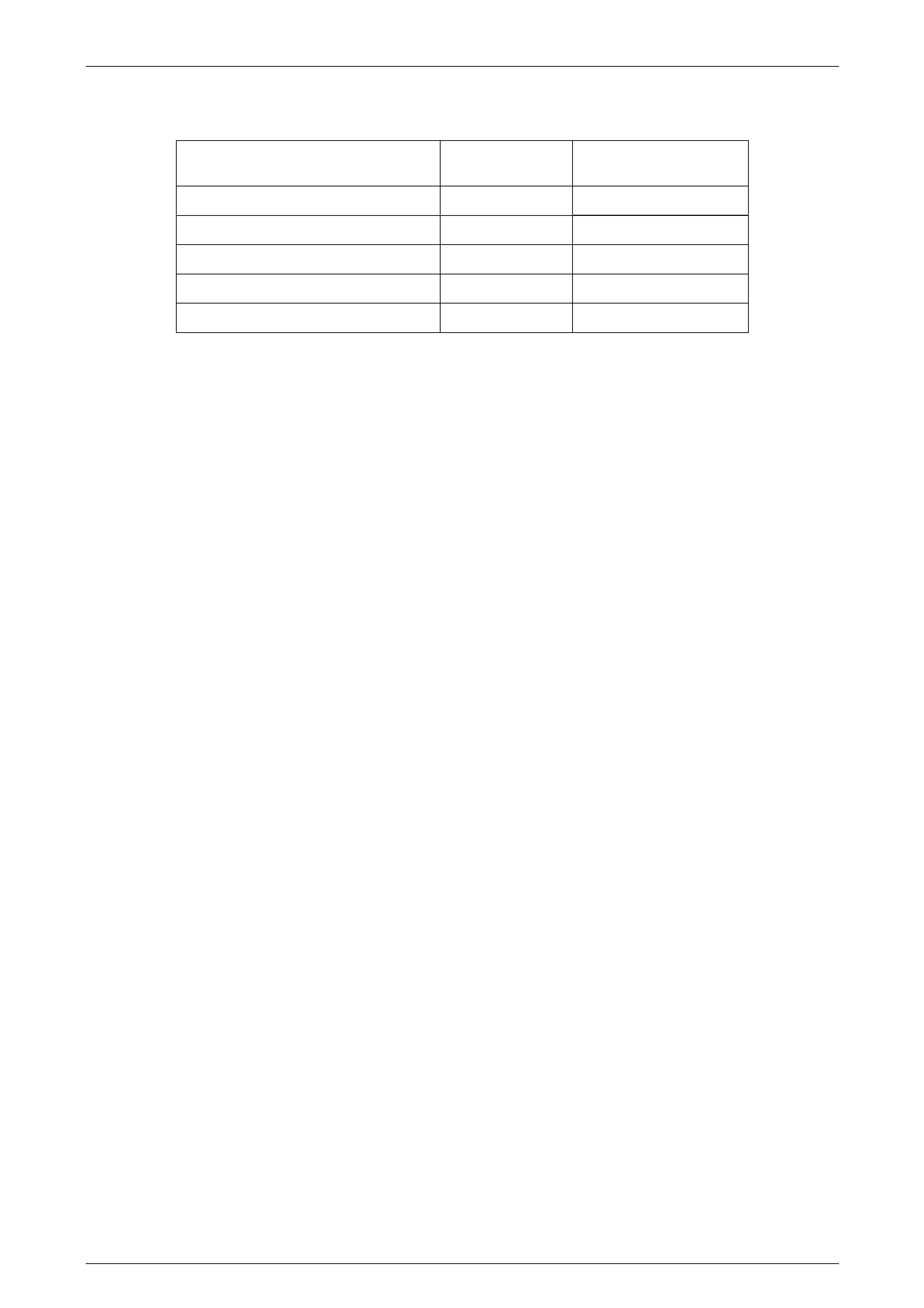

11.2 Regular Cab and Crew Cab with 'Dele te Tub' Option..................................................................................... 154

12 Torque Wrench Specifications..........................................................................................................155

12.1 Sedan, Wagon, Utility, Crew Cab and Coupe .................................................................................................. 155

12.2 Regular Cab and Crew Cab with 'Dele te Tub' Option..................................................................................... 156

12.3 AWD Wagon ....................................................................................................................................................... 157

Lighting System Page 12B–8

Page 12B–8

1 General Information, Sedan,

Wagon, Utility and Crew Cab

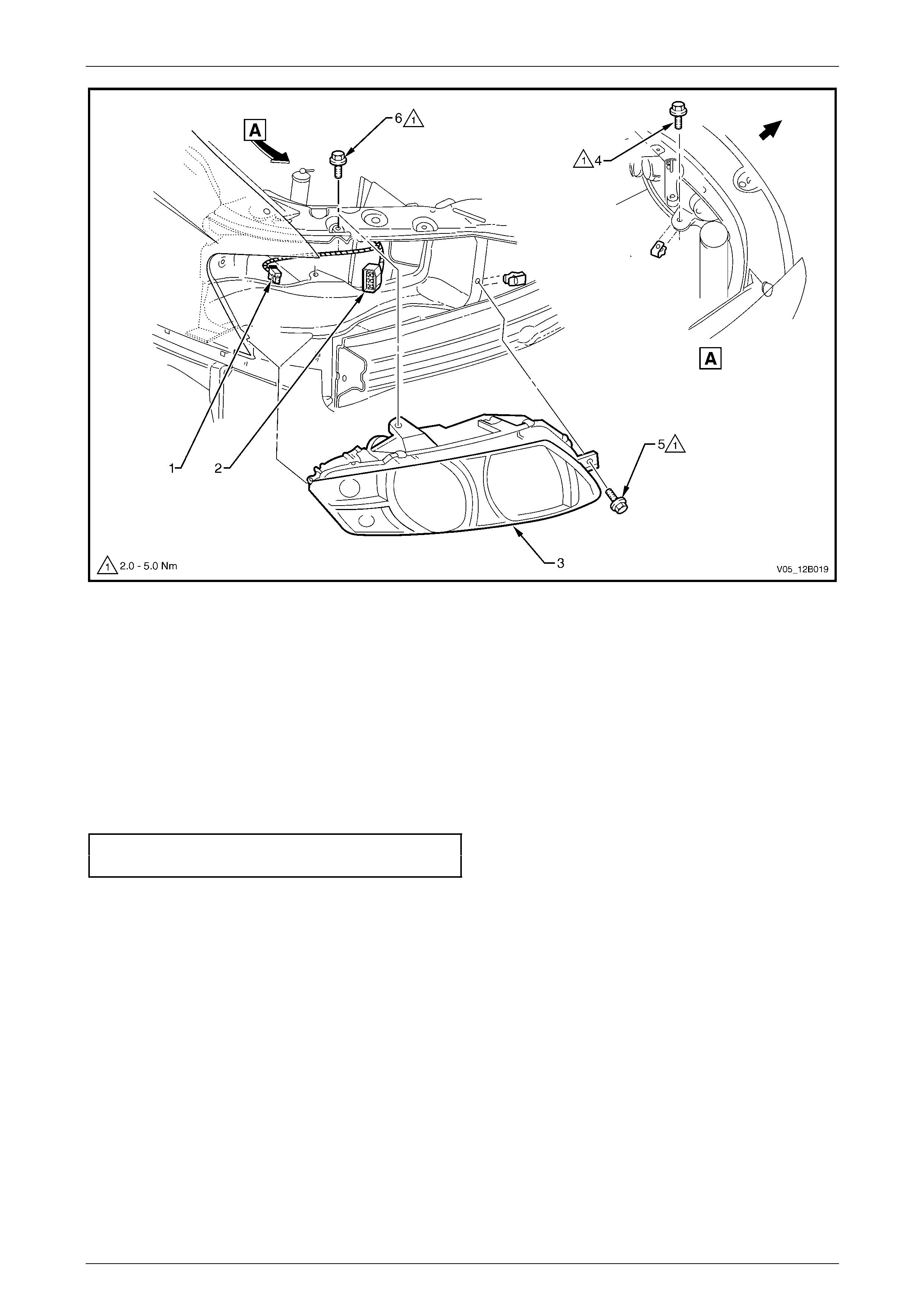

1.1 Headlamp Assembly

Headlamp assemblies inc orp orate the latest headlamp reflector technology. Two headlamp geometries are applicable:

• Level 1, or

• Level 2 and Level 3 vehicles.

Headlamp assemblies hav e the following features:

• All vehicles are equipp ed with low beam, high beam, park and turn signal lamps.

• Beam movement in the vertical and horizontal axes is controlled by the same type of adjustment device.

• Turn signal bulb holders a nd main wiring connectors are identical.

• Turn signal lamps are located on the o utsid e of the assembly; high beam is located in the inside of the assembly.

• The headlamp assemb lies have common mounting holes (that is, they all require three screws in the same

locations to secure the assemblies to the sheetmetal).

Lighting System Page 12B–9

Page 12B–9

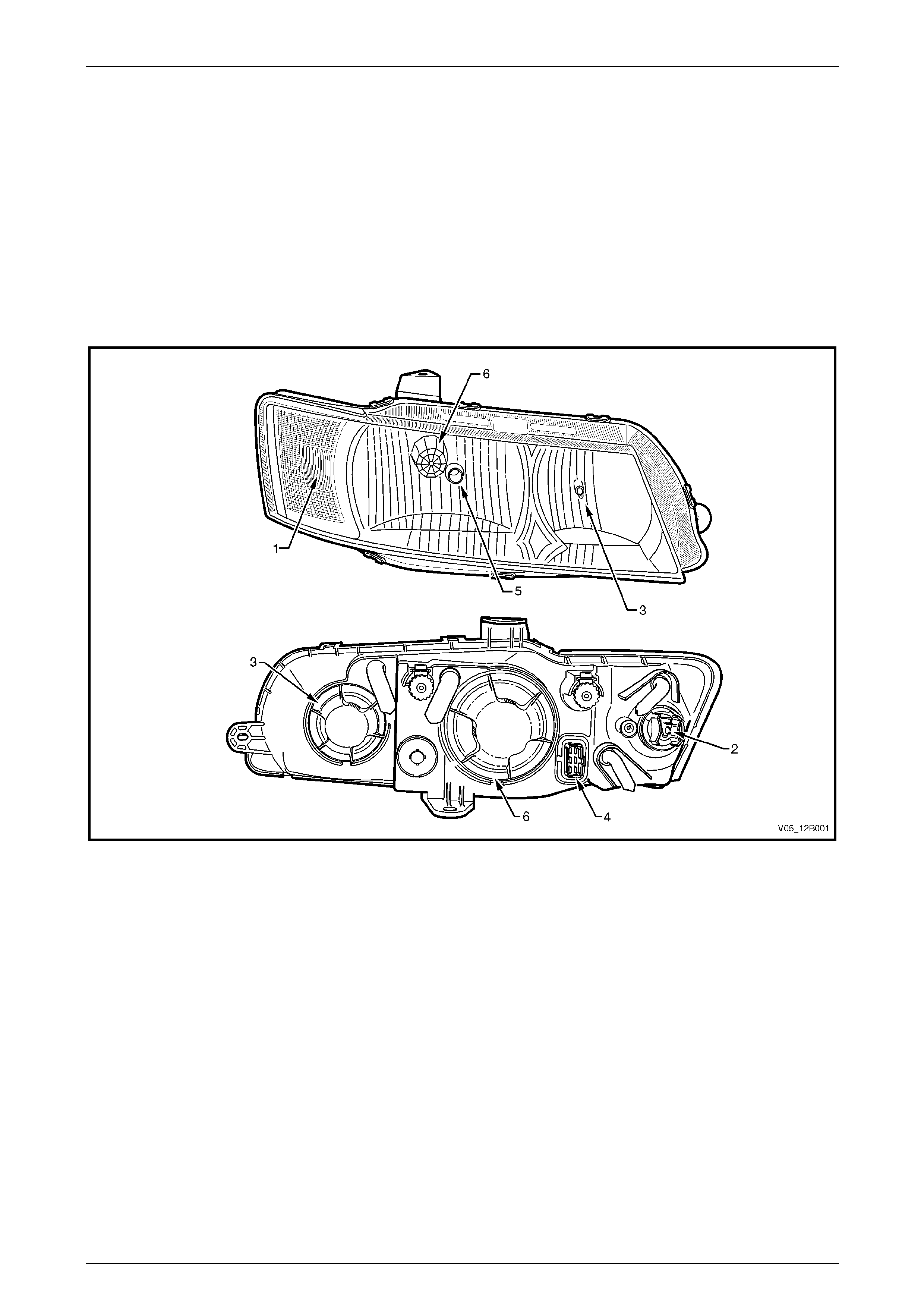

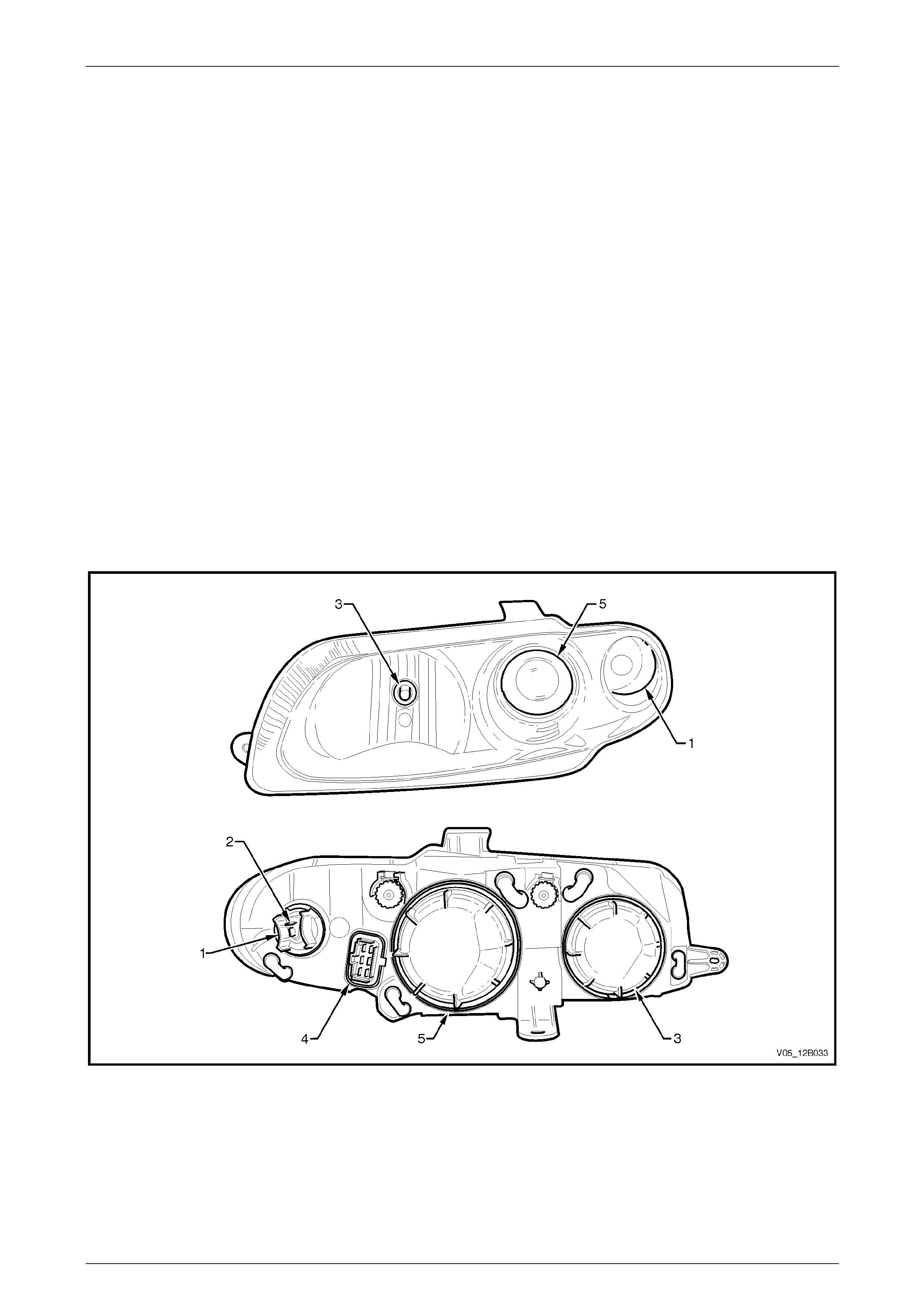

Level 1 Vehicles

Level 1 vehicle headlamp assemblies have the following featur es, depending on particular model specifications, refer to

Figure 12B – 1:

• The headlamps use compl ex reflector technology for low beam and high beam.

• Distinctive styling suits the Sedan vehicle bumper fascia.

• Headlamp bezels are either c hrome or b lack.

• Single-filament H1 and dual-filament H4 specification globes are fitted to the inn er and outer beam reflector

pockets respectively.

• The park lamp is located inboard of the low beam headlamp.

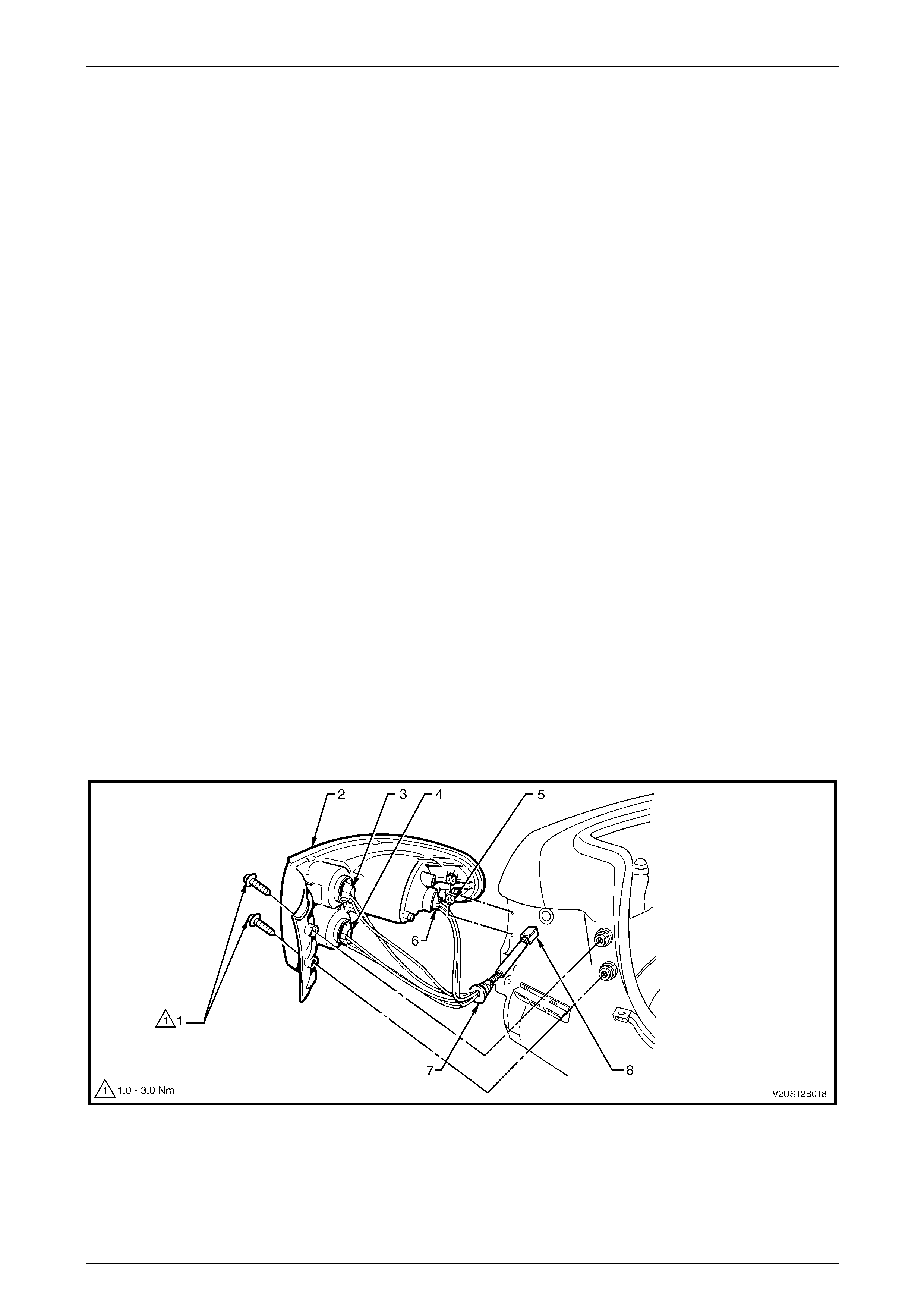

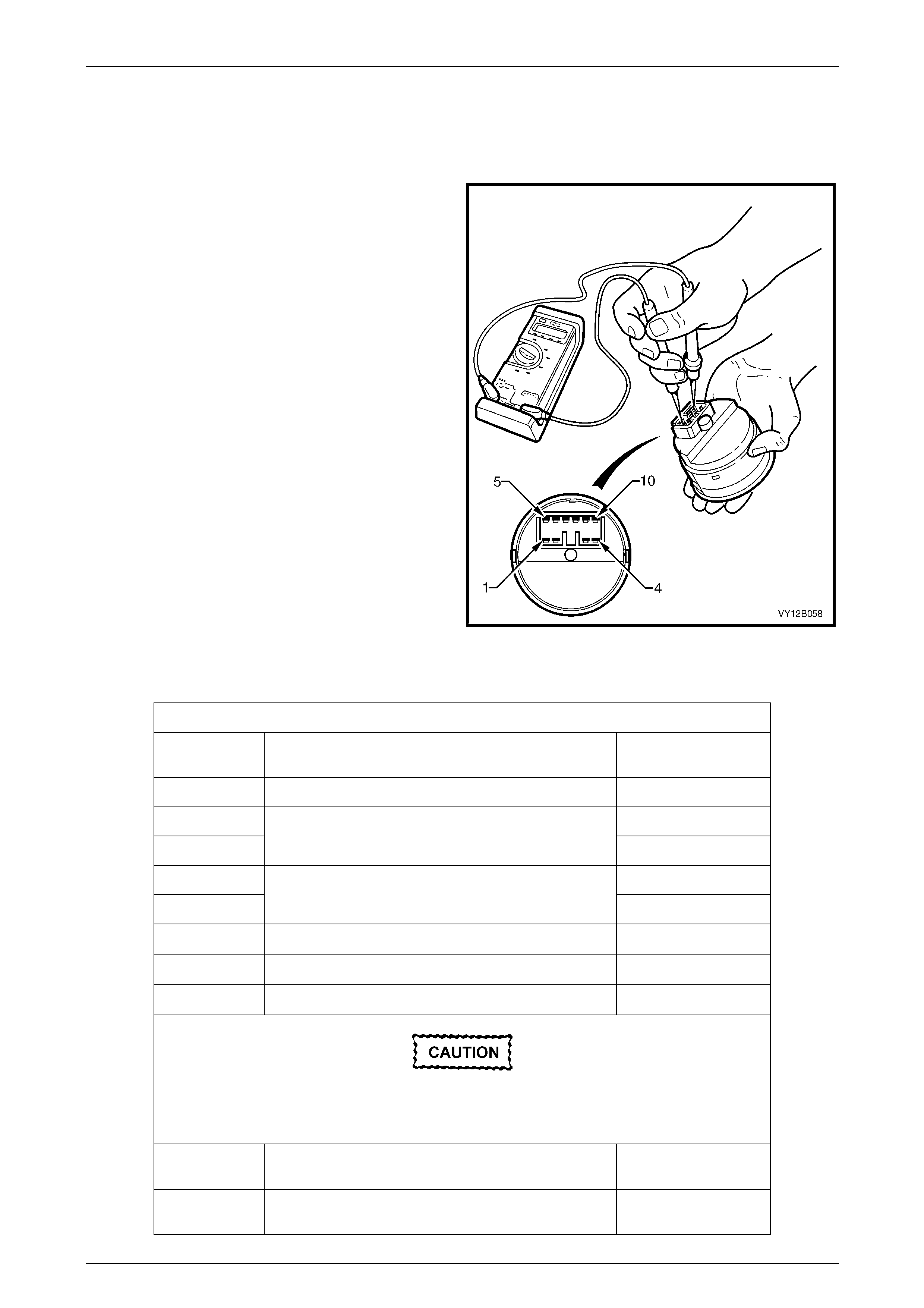

Figure 12B – 1

Legend

1 Turn Signal Lamp

2 Turn Signal Wiring Connector 3 Headlamp High Beam Bulb (H1)

4 Headlamp Main Wiring Connector 5 Park Lamp

6 Headlamp Low Beam Bulb (H4)

Lighting System Page 12B–10

Page 12B–10

Level 2 and Level 3 Vehicles

Level 2 and Level 3 vehicle head lamp assemblies have the following feat ures, refer to Figure 12B – 2:

• Distinctive styling suits the Level 2 and Level 3 vehicle bumper fascia.

• Headlamp bezels are either c hrome or b lack.

• Single-filament H9 and H11 specification globes are fitted to the high and low beam reflector pockets respectively.

• The low beam uses projector lamp technology to increase illumination and give distinctive styling, while high beam

uses complex reflector technology.

• The park lamp is located below the turn signal lamp in its own reflector housing.

Figure 12B – 2

Legend

1 Turn Signal Lamp

2 Turn Signal Wiring Connector 3 Headlamp High Beam Bulb (H9)

4 Headlamp Main Wiring Connector 5 Park Lamp

6 Headlamp Low Beam Bulb (H11)

Lighting System Page 12B–11

Page 12B–11

1.2 Front Fog Lamp Assembly

Fog lamp assemblies are located in the front fascia assembly and are adjustable in the vertical axis. The fog lamp

assemblies use H3 lamps.

Lighting System Page 12B–12

Page 12B–12

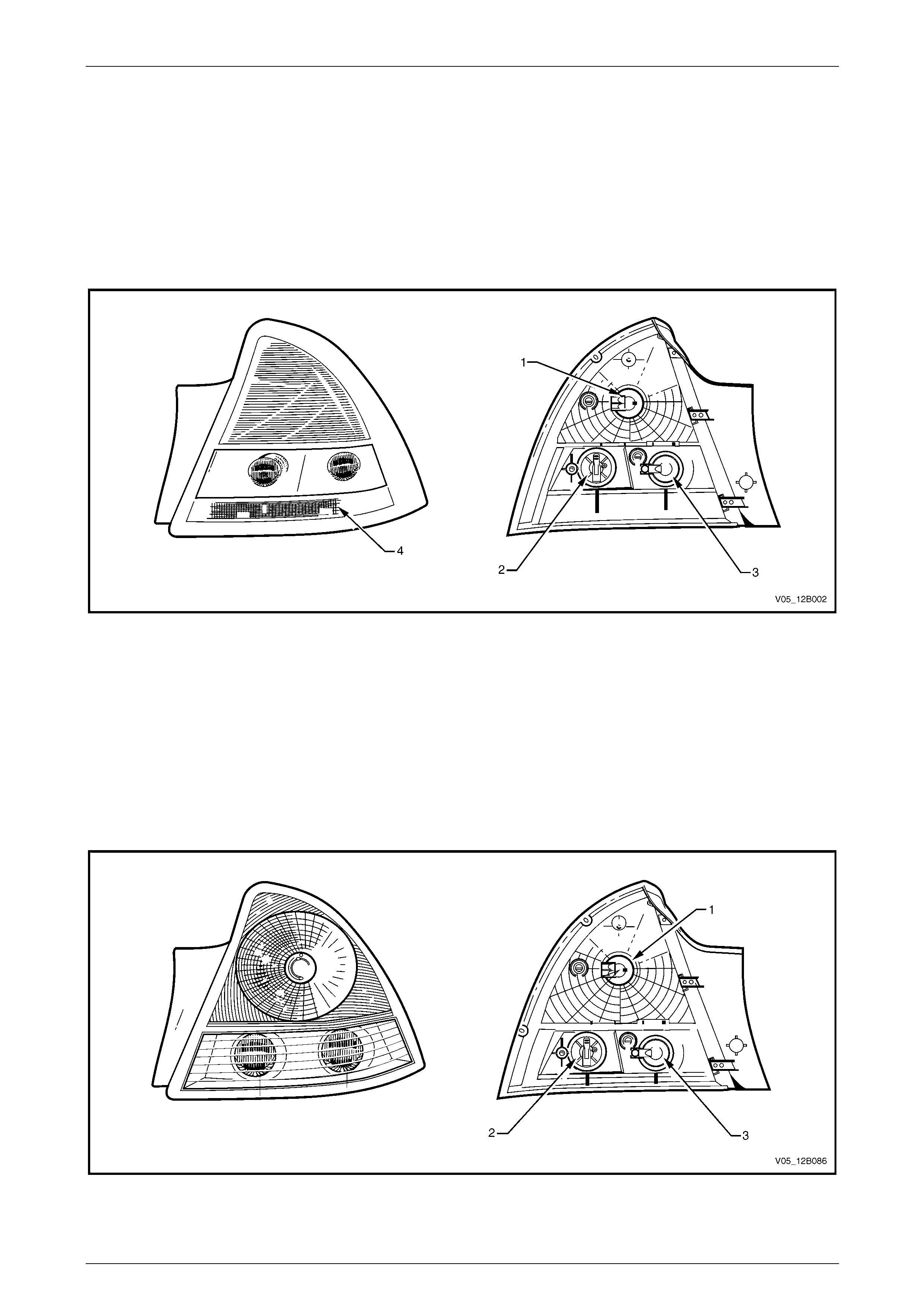

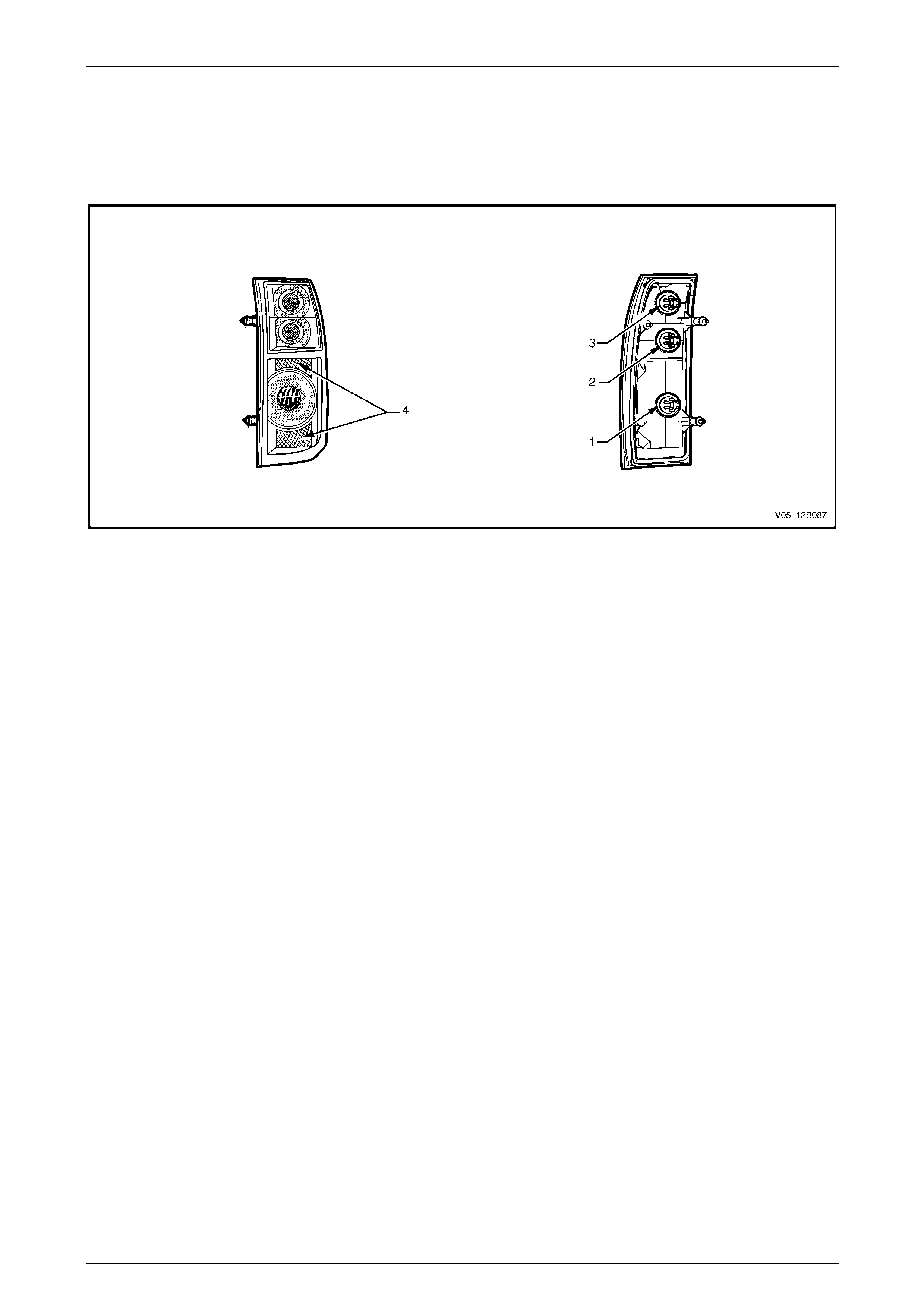

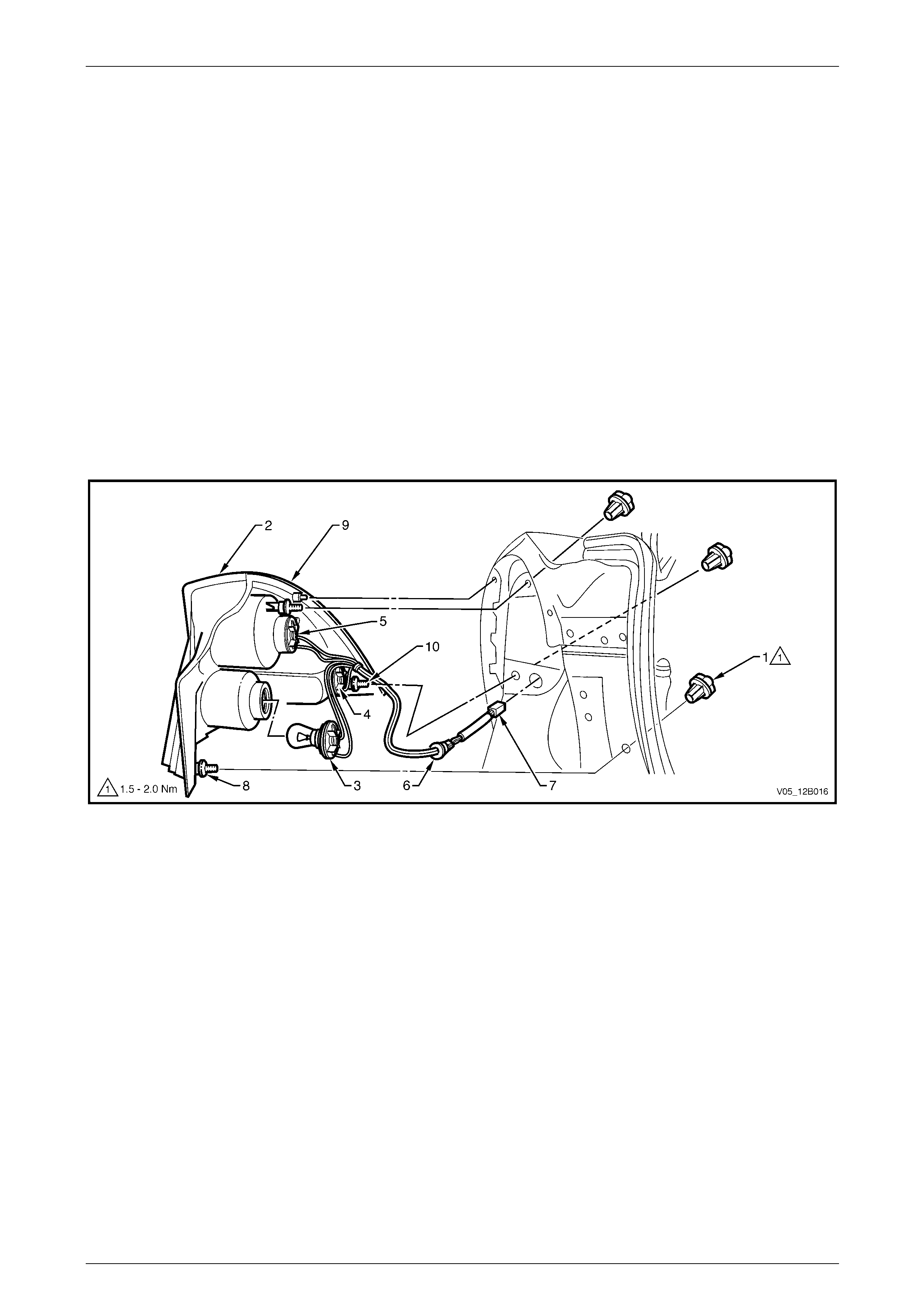

1.3 Tail Lamp Assembly

Tail lamps have three tail lamp geometries; each type is applicable to the following groups of vehicles:

• Refer to Figure 12B – 3 for Level 1 Sedan tail lamp front an d rear views.

• Refer to Figure 12B – 4 for Level 2 and Level 3 Sedan tail lamp front and rear views.

• Refer to Figure 12B – 5 for Utility and Wagon tail lamp front and rear views.

Depending on model specifications, Level 1 Sedan tail lamp assemblies have either chrome or black housings.

Figure 12B – 3

Legend

1 Stop/Tail Lamp

2 Turn Signal Lamp 3 Backup Lamp

4 Reflex Reflector

NOTE

Level 2 and Level 3 vehicles have reflex

reflectors on the rear bumper fascia, immediately

below the tail lamp assembly.

Lighting System Page 12B–13

Page 12B–13

Figure 12B – 4

Legend

1 Stop/Tail Lamp

2 Turn Signal Lamp 3 Backup Lamp

Figure 12B – 5

Legend

1 Stop/Tail Lamp

2 Turn Signal Lamp 3 Backup Lamp

4 Reflex Reflector

Lighting System Page 12B–14

Page 12B–14

1.4 High-mount Stop Lamps

All high-mount stop lamps fitted to the inside of the vehicl e use bulbs for illumination. High-mount stop lamps fitted to

Sedan rear spoilers use LEDs.

Lighting System Page 12B–15

Page 12B–15

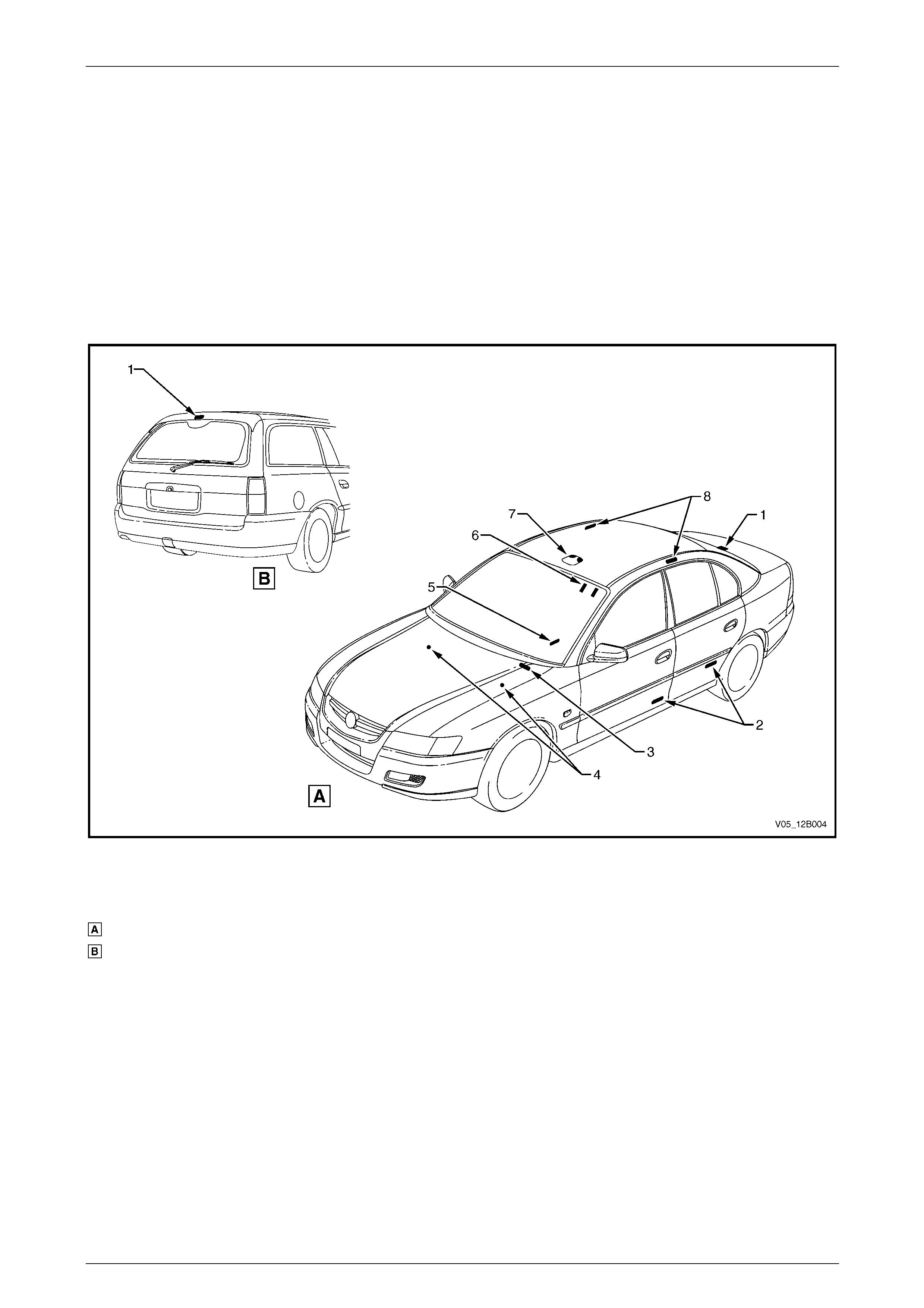

1.5 Interior Illumination

The type and number of interior illumination devices depends on the model level of the vehicle. All vehicles are fitted with

lamps adequate to illum inate the cabin area during low light conditions. In addition, all models are equipped with an

instrument panel compartment lamp and a r ear compartment lamp. Many lamps (and the dimming function for the interior

lamps) are controlled by the body control module (BCM), refer to Section 12J Bod y Control Module for further

information.

Refer to Figure 12B – 7 for interior lighting component locations.

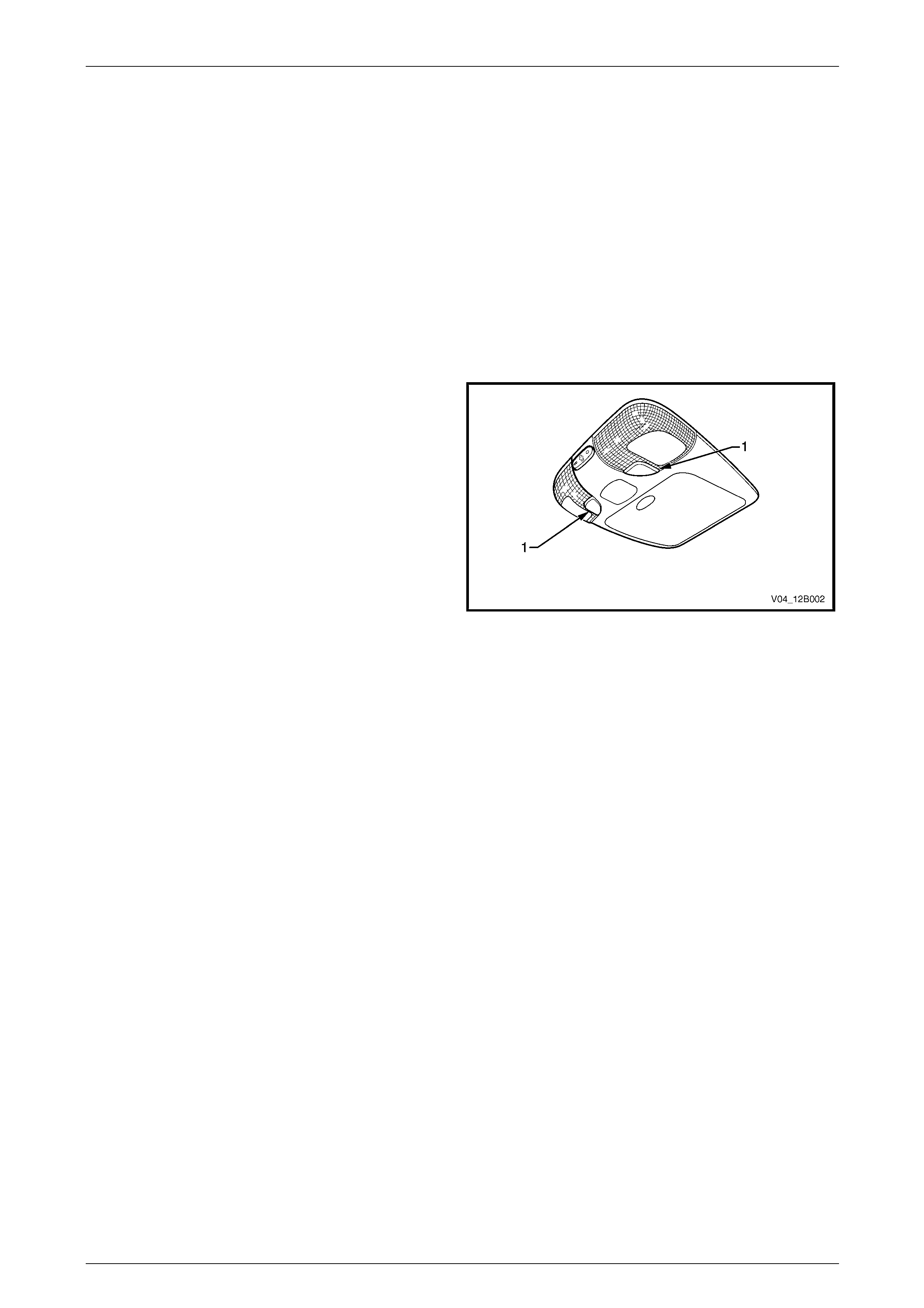

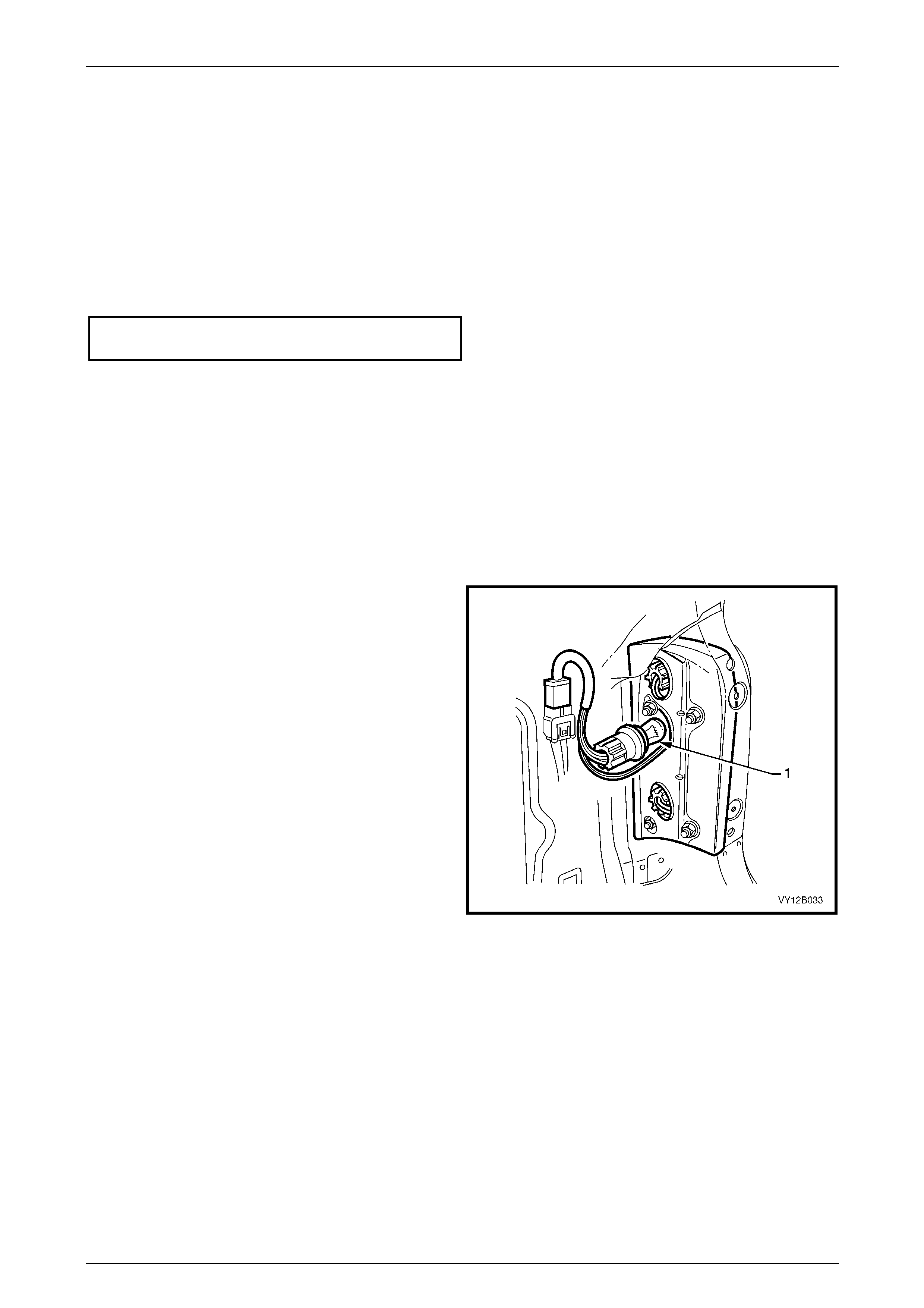

Level 1

Level 1 Sedans and Wagons have a roof console assembly, consisting of a dome lamp or a dome lamp with reading

lamps. A roof rail courtesy lamp and readin g lamp assembly is also fitted in vehicles with a roof console assembly.

Level 1 Utility and Level 1 Regular Cab vehicles have a dom e lamp assembly.

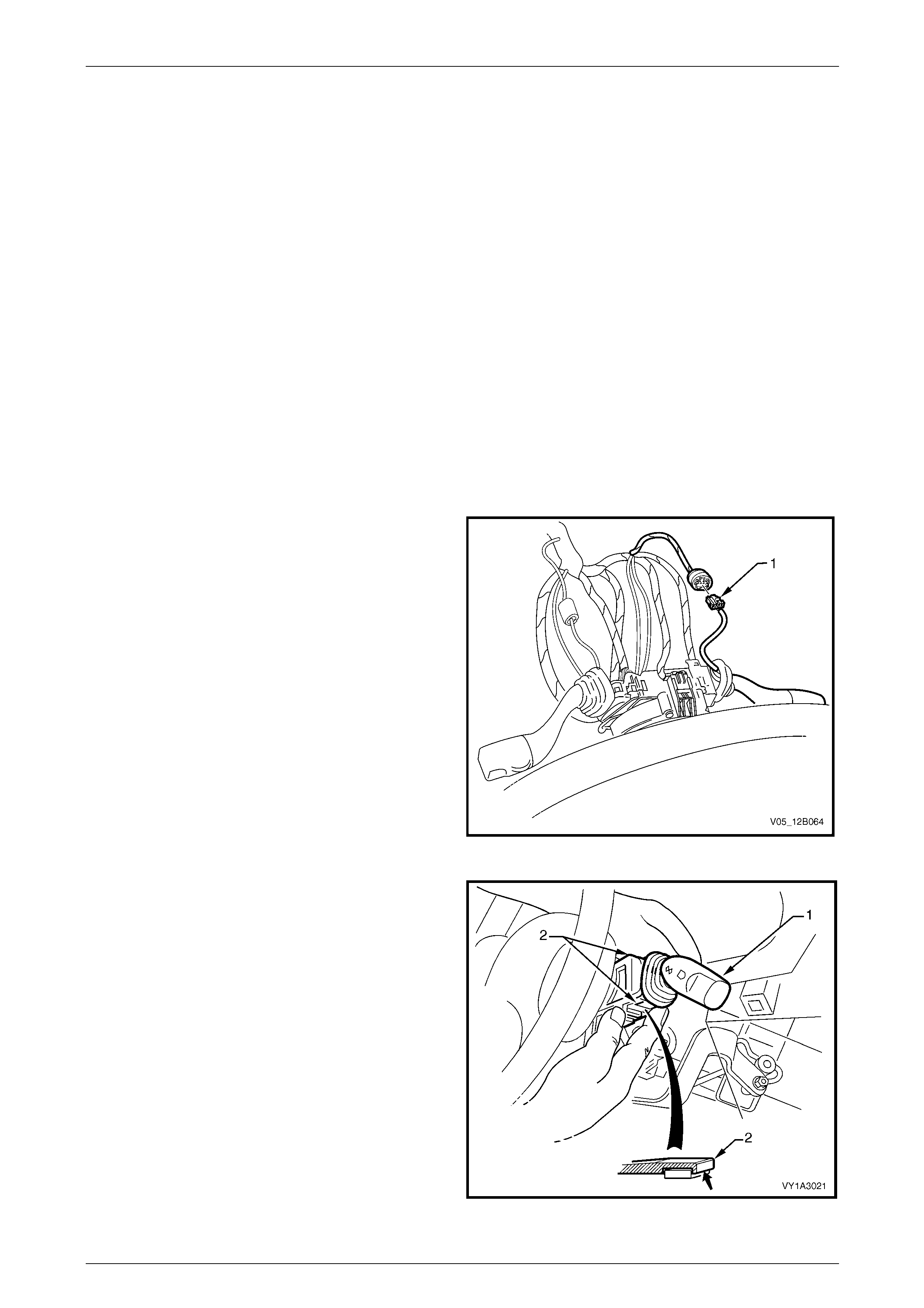

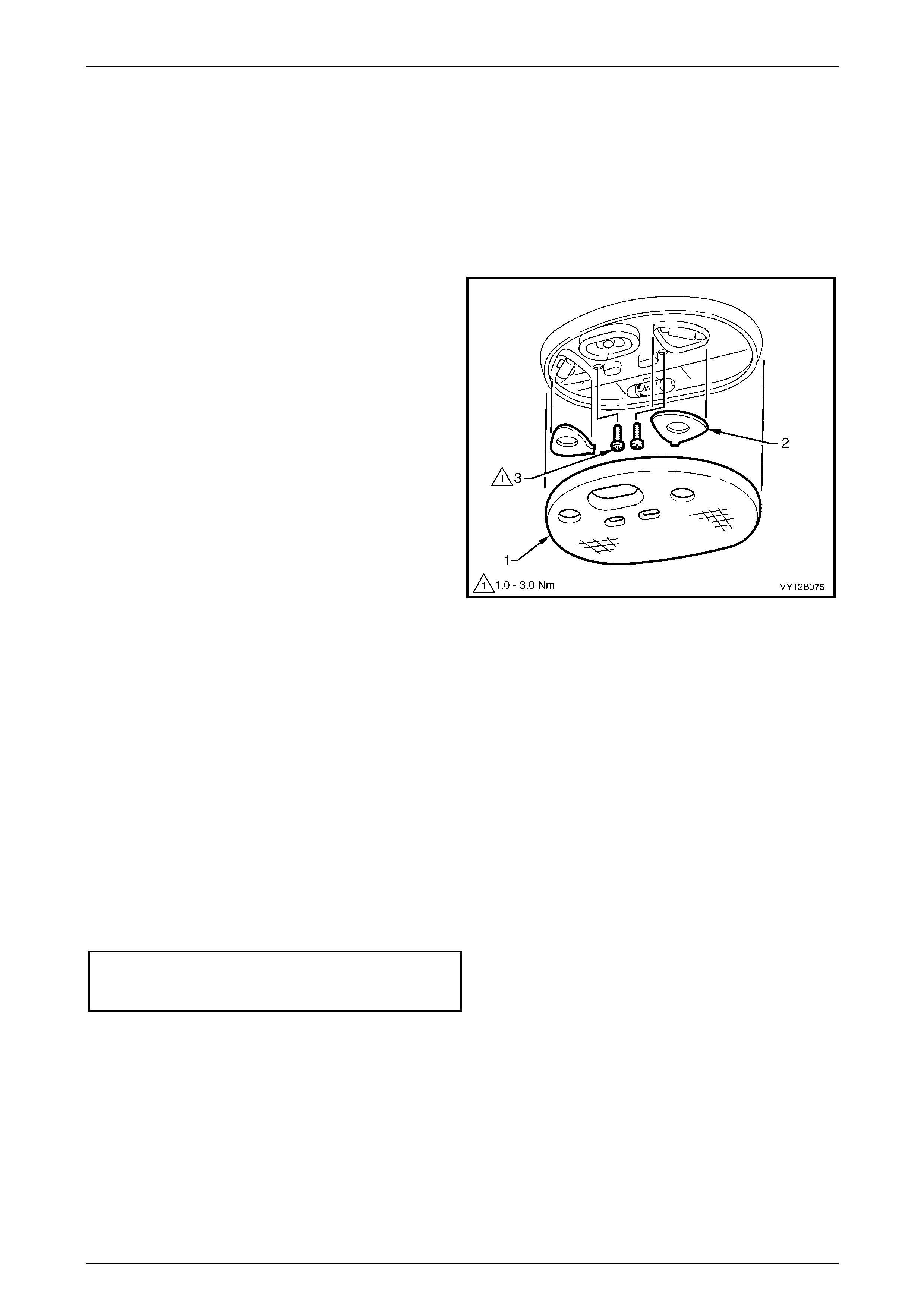

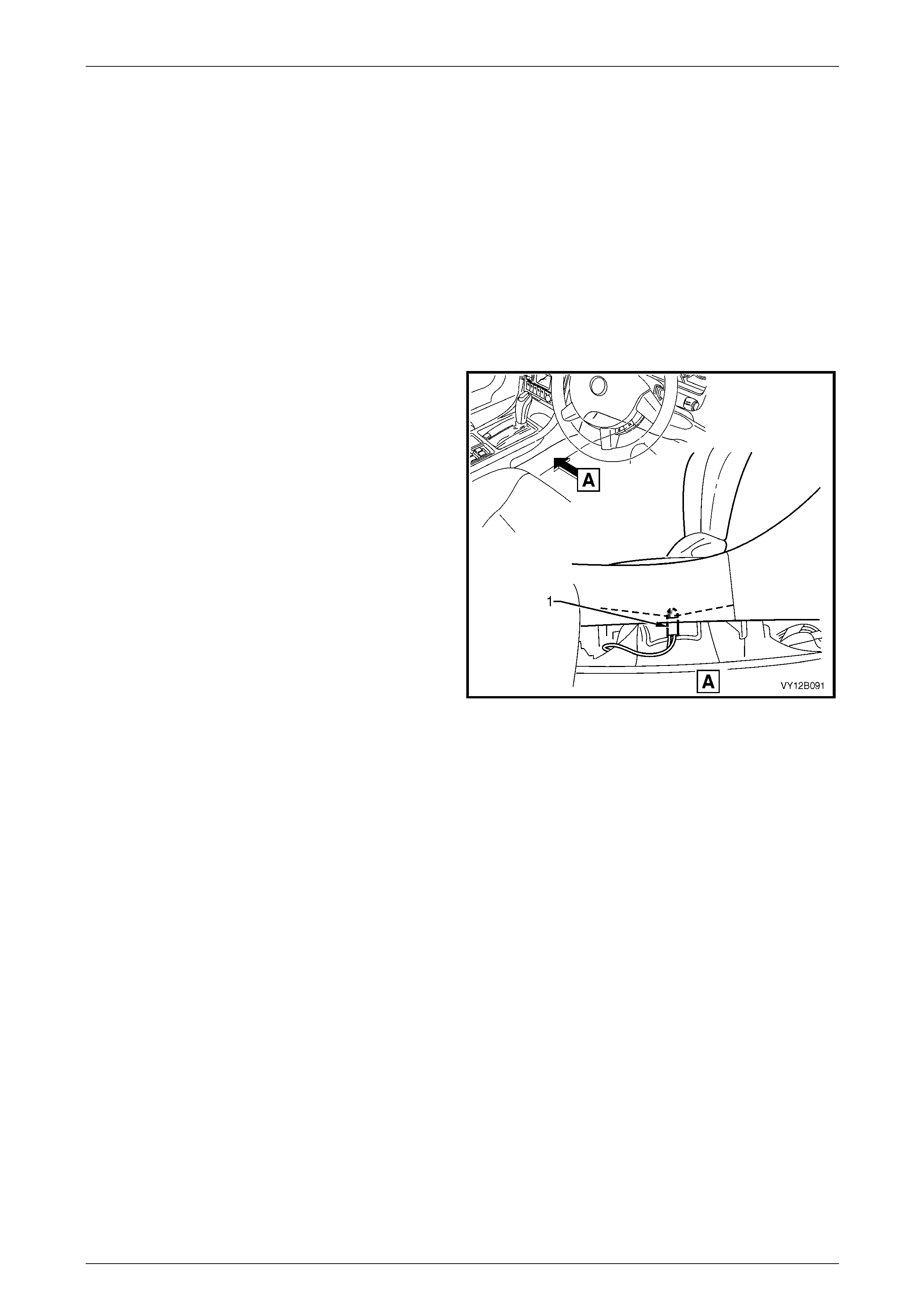

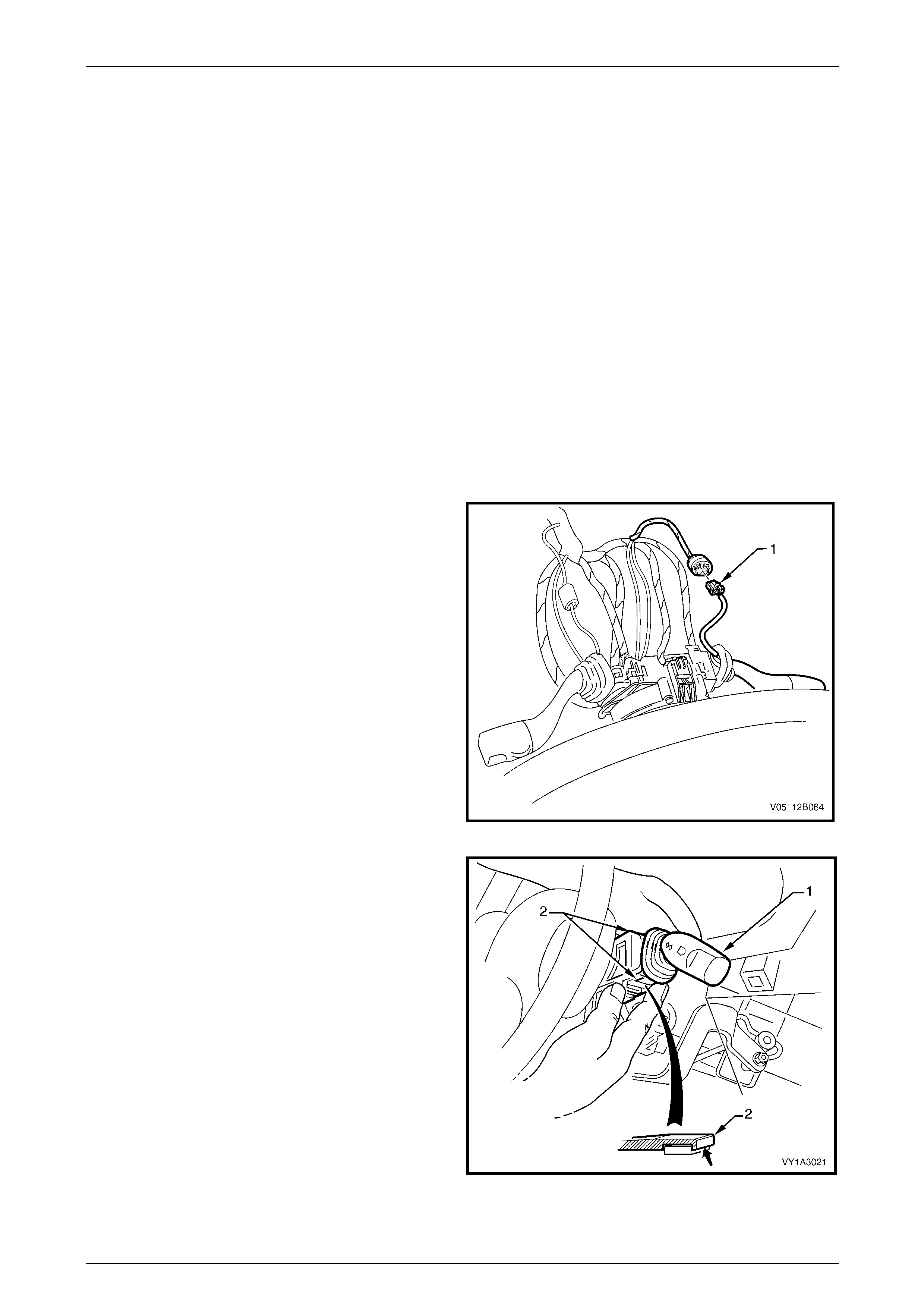

The roof console fitted to low Level vehic les is similar to

those fitted to high Level vehicles except for the two reading

lamps that do not have an individual switch.

A blank plate (1) is fitted in place of each reading lamp

switch. The operation of the reading lamps is automatic.

Figure 12B – 6

Lighting System Page 12B–16

Page 12B–16

Level 2 and Level 3

Level 2 and Level 3 vehicles have:

• roof console lamps,

• roof rail courtesy and reading lamp assembly,

• side door courtesy lamps,

• sunshade vanity mirror lamps (Level 3 onl y),

• stepwell lamps, and/or

• floor console compartment lamp (Level 3 only).

Figure 12B – 7

Legend

Sedan – Interior Illumination

Wagon – Interior Illumination

1 Rear Compartment Courtesy Lamp

2 Side Door Courtesy Lamps

3 Instrument Panel Compartment

Courtesy Lamp

4 Stepwell Lamps

5 Floor Console Compartment Lamp

6 Sunshade Vanity Mirror Lamps

7 Roof Console

8 Roof Rail Courtesy and Reading Lamps

Lighting System Page 12B–17

Page 12B–17

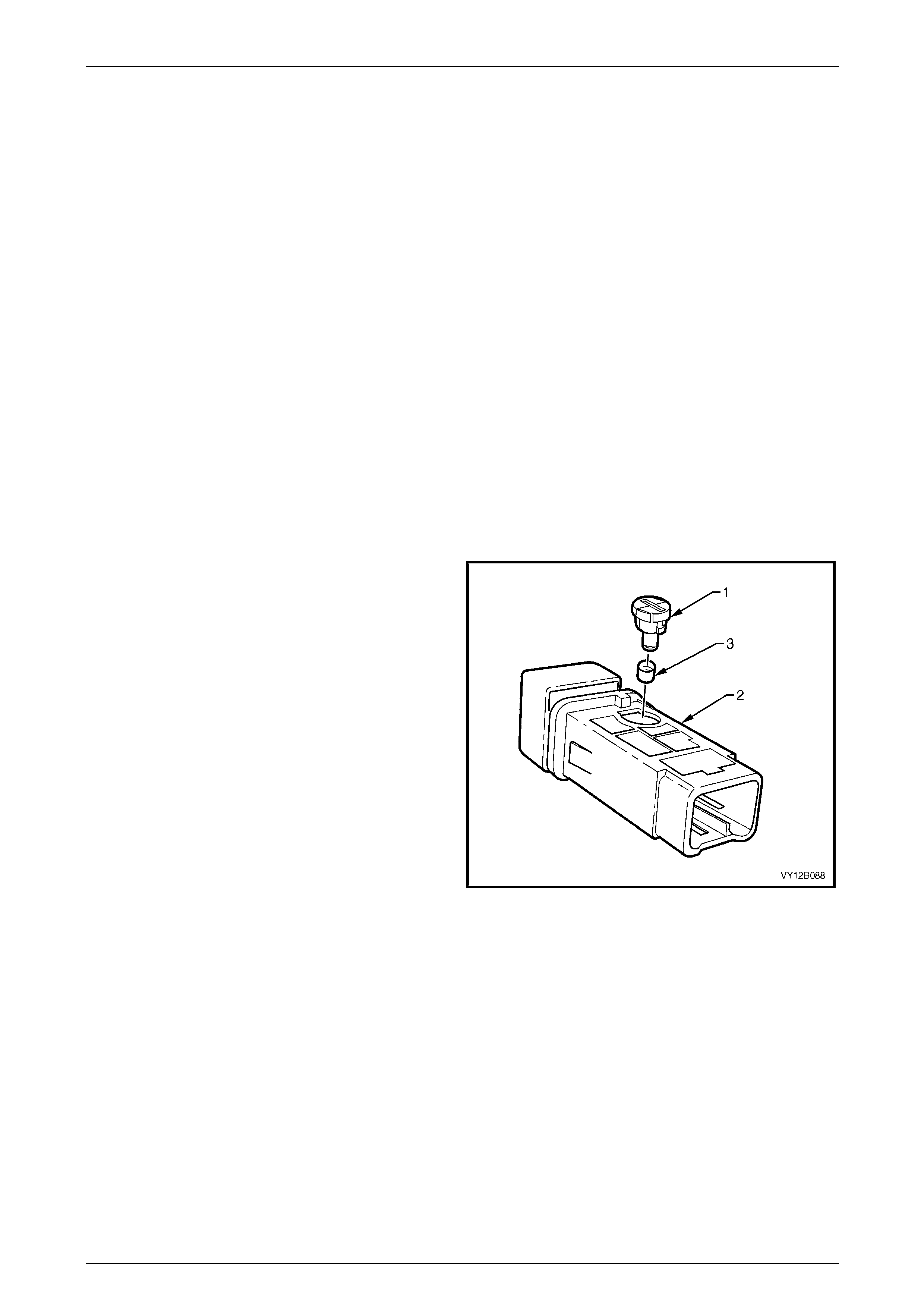

1.6 Instrument and Switch Illumination

All instrument and switch illum ination is provided by LEDs, except the following items that are illuminated with

conventional bulbs:

• hazard warning switch,

• A/S (active select) switch,

• T/C (traction control) switch,

• PWR (power) switch,

• electronic stability program (ESP) switch,

• headlamp switch,

• trip computer switch,

• side window switch assembly, and

• ignition lock cylinder.

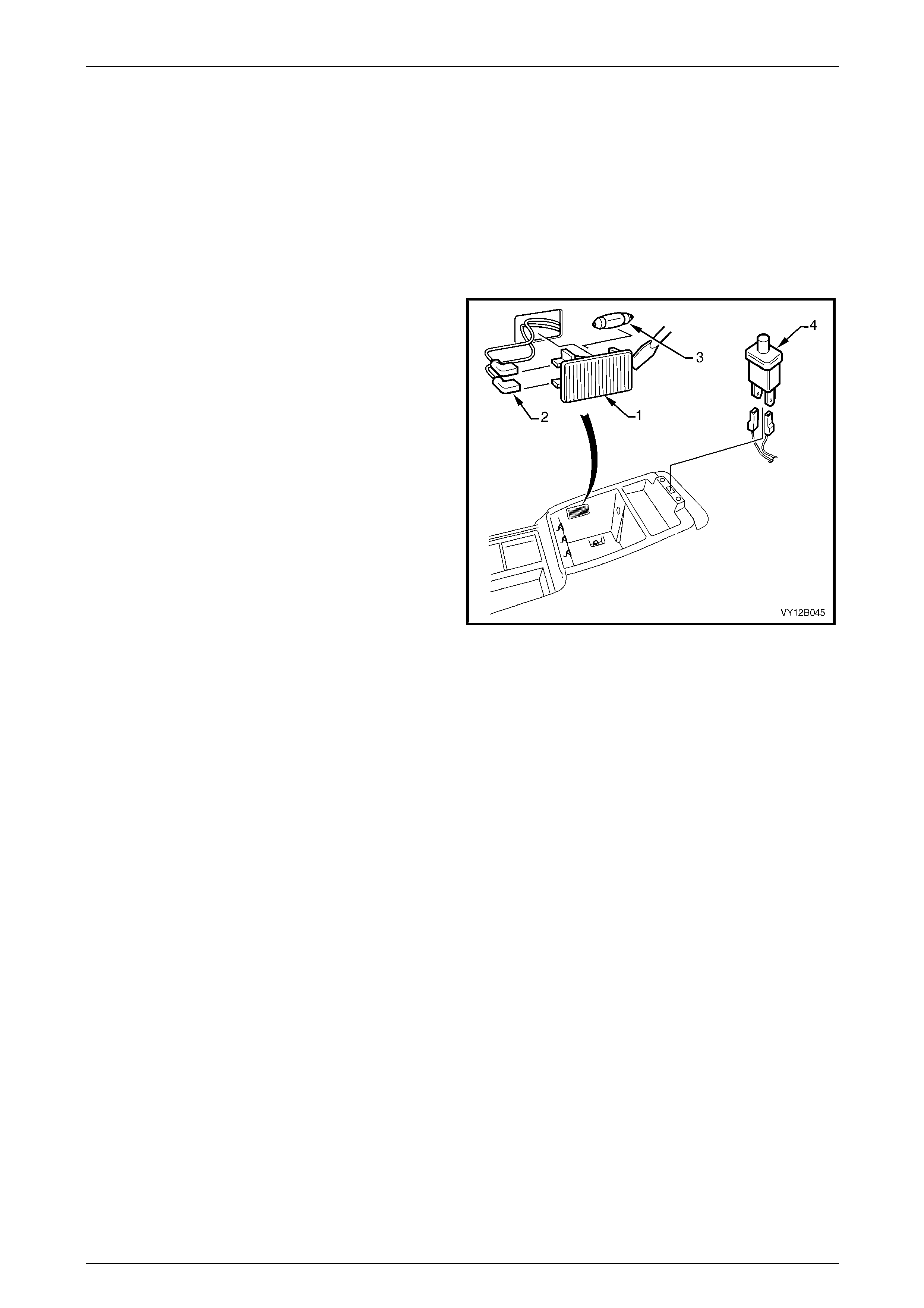

The T/C switch (or A/S switch) is located on the right side of the automatic transmission selector.

The headlamp, trip computer and side window switches are sealed units and the conventional bulbs can not be serviced

on these items.

LEDs are used instead of conventio nal bulbs due to their longevity in operation. If the illumination of any LED-equippe d

item no longer operates correctl y and the LE D is isolated as the fault, replace the assembly.

Figure 12B – 8

Legend

1 Headlamp Switch

2 Trip Computer Switch

3 Hazard Warning Switch

4 A/S Switch (or T/C Switch or ESP Switch — 4-speed

Automatic Transmission)

5 PWR Switch

6 Auxiliary Switches

Lighting System Page 12B–18

Page 12B–18

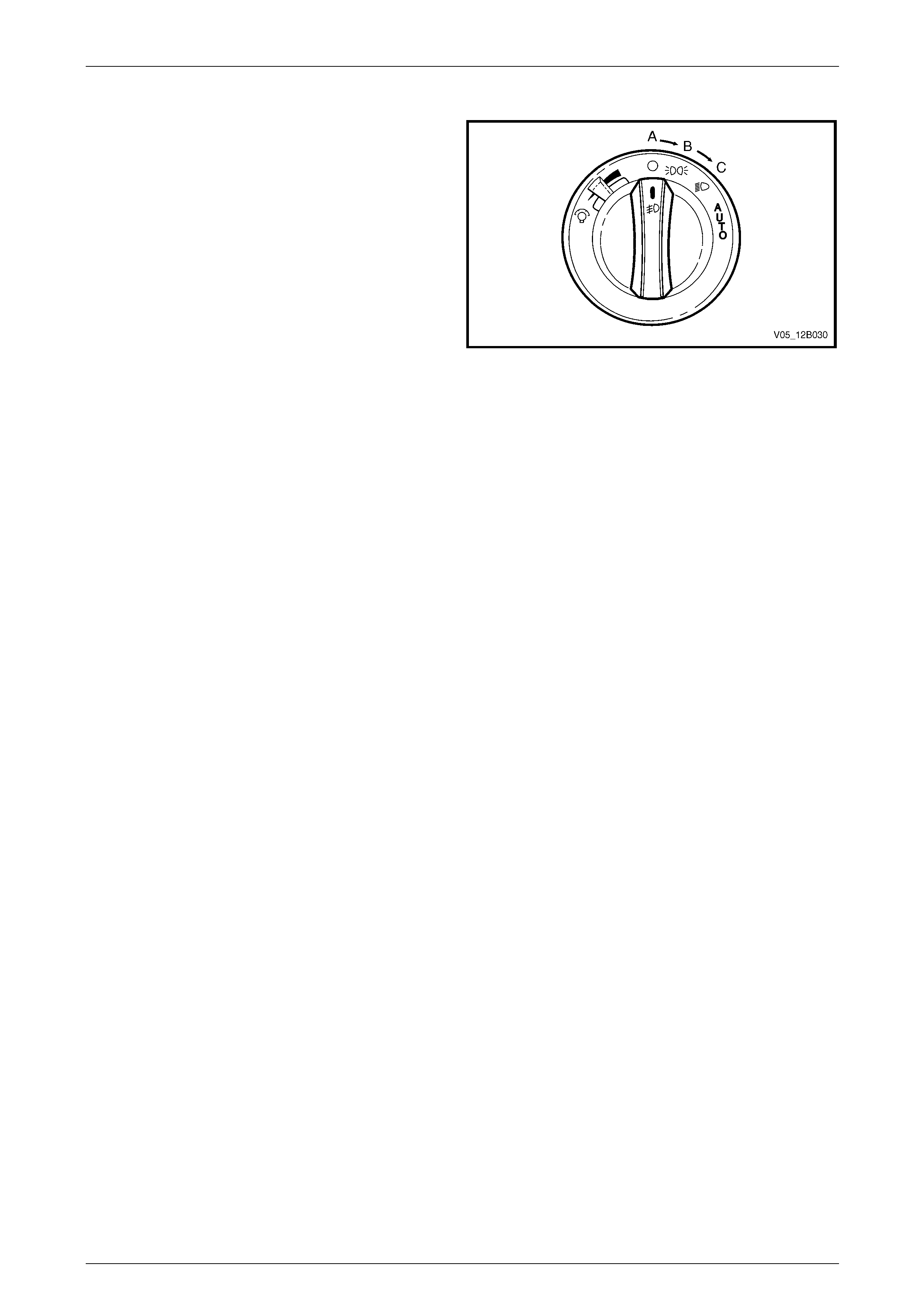

Headlamp Switch

An automatic headlamp control feature is fitted. When the headlamp switch is in the AUTO position, the BCM controls

the function of the low and high beam of the headlam ps, refer to F igure 12B – 116. For further information, refer to

Section 12J Body Control Module .

Police Lights-out Switch

The police lights-out switch is fitted to police vehicles when required. W he n activated, the police lights-out switch turns off

all interior lamps except reading lamps that can be operated individually.

NOTE

The police lights-out switch does not illuminate

when the park lamps are operating.

Daylight Running Lamp (Option T82)

On vehicles fitted with the daylight running lamp feature (option T82), the front headlamps operate while the ignition

switch is on.

Lighting System Page 12B–19

Page 12B–19

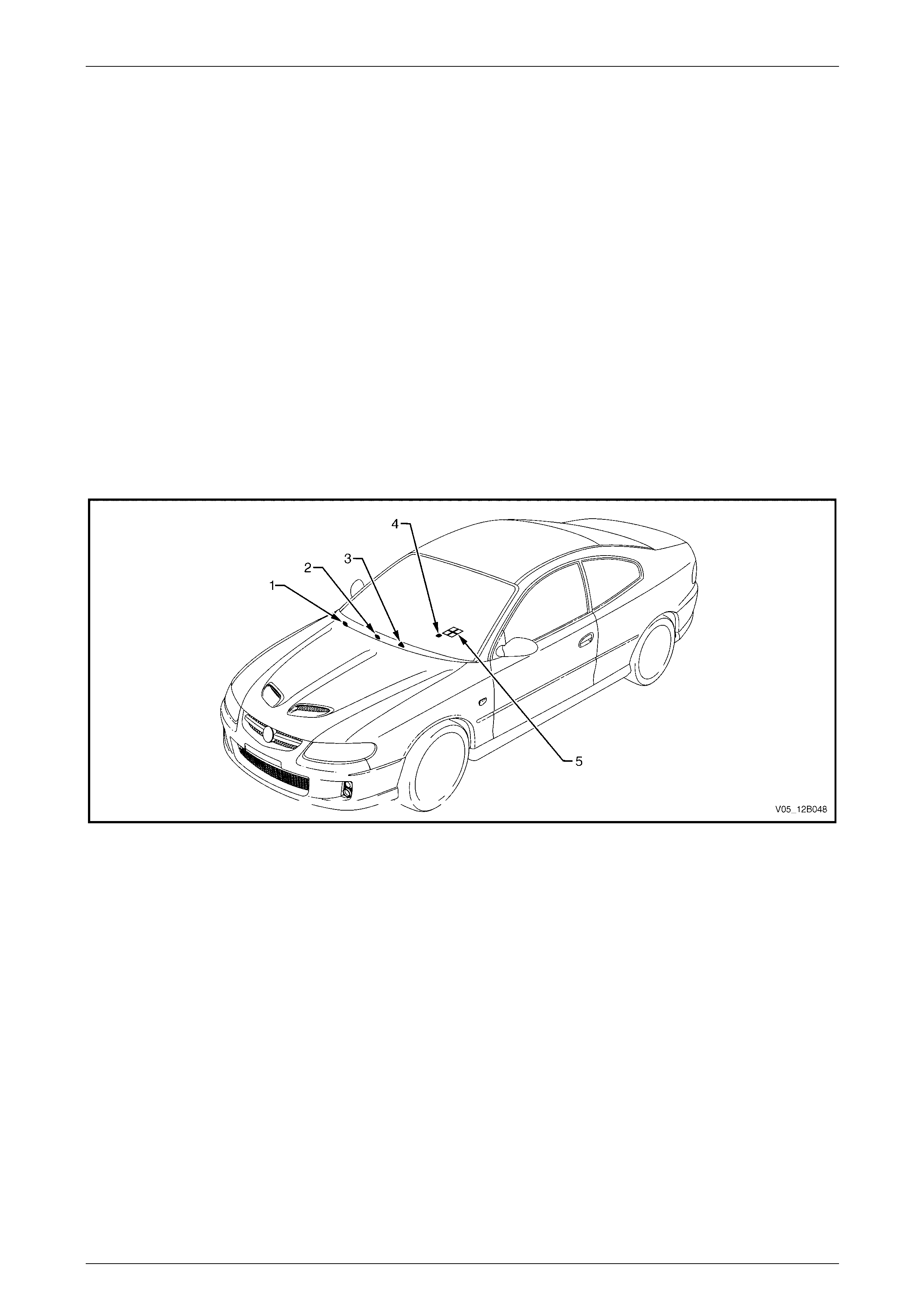

2 General Information, Coupe

2.1 Headlamp Assembly

Headlamp assemblies inc orp orate the latest headlamp reflector technology. The headlam p assemblies have the

following features:

• Headlamp assemblies are e quipped with low beam, high beam and turn s ignal lamps; park lamps are mounted on

the front fog lamp assembly.

• Beam movement in the vertical and horizontal axes is controlled by the same type of adjustment device.

• Turn signal bulb holders a nd main wiring connectors are identical.

• Turn signal lamps are located on the o utsid e extremities of the assembly.

• The high beam is located in the inboard side of the assembly.

• The headlamp assembly requires three screws to secure the assembly to the sheetmetal.

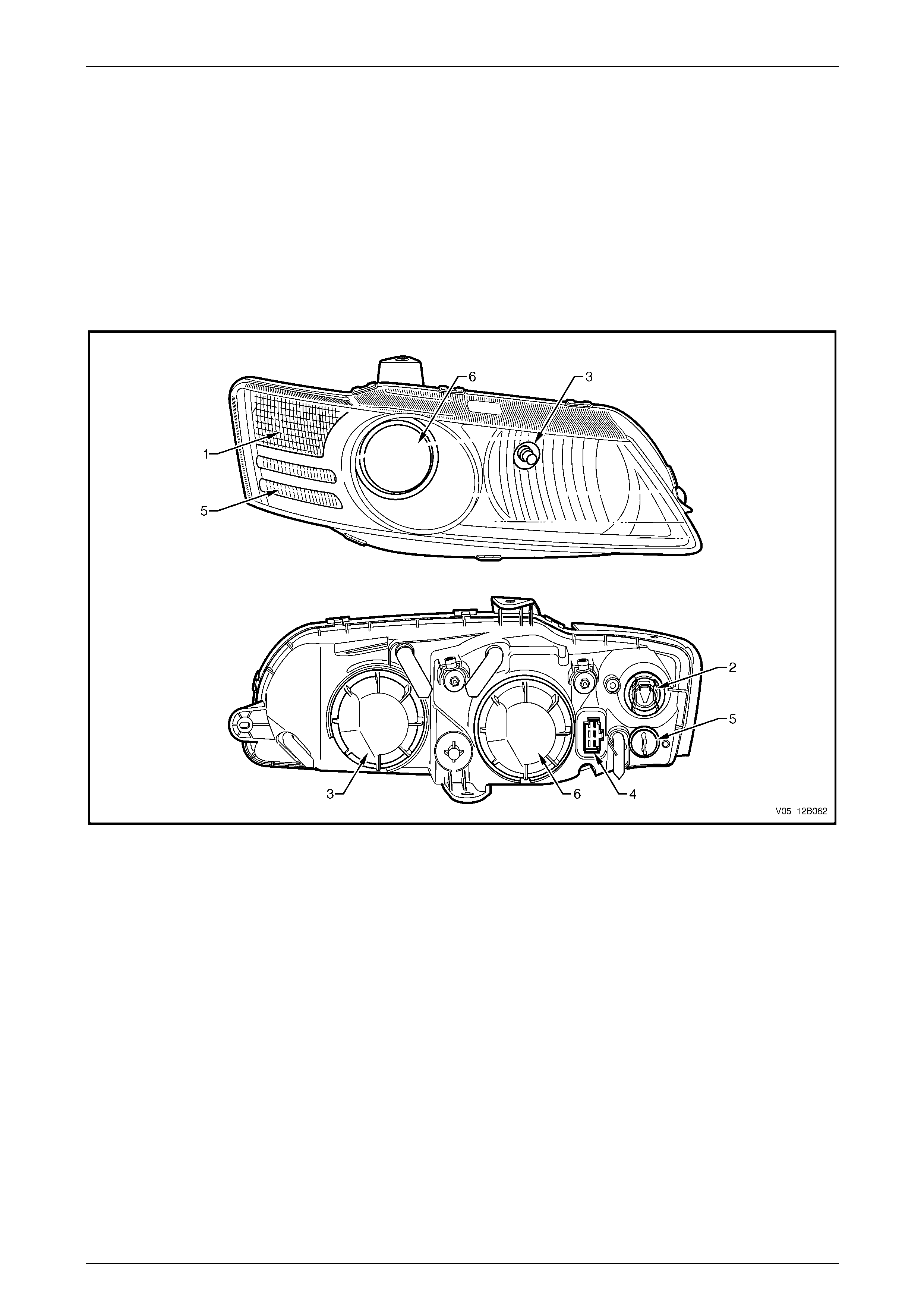

The Coupe headl amp assembly has the following features, refer to Figure 12B – 9:

• Distinctive styling suits the Coupe bumper fascia.

• Single-filament H9 and H11 specification globes are fitted to the high and low beam reflector pockets respectively.

• The low beam uses projector lamp technology to increase illumination and give distinctive styling, while high beam

uses complex reflector technology.

Figure 12B – 9

Legend

1 Turn Signal Lamp

2 Turn Signal Wiring Connector 3 Headlamp High Beam Bulb (H9)

4 Headlamp Main Wiring Connector 5 Headlamp Low Beam Bulb (H11)

Lighting System Page 12B–20

Page 12B–20

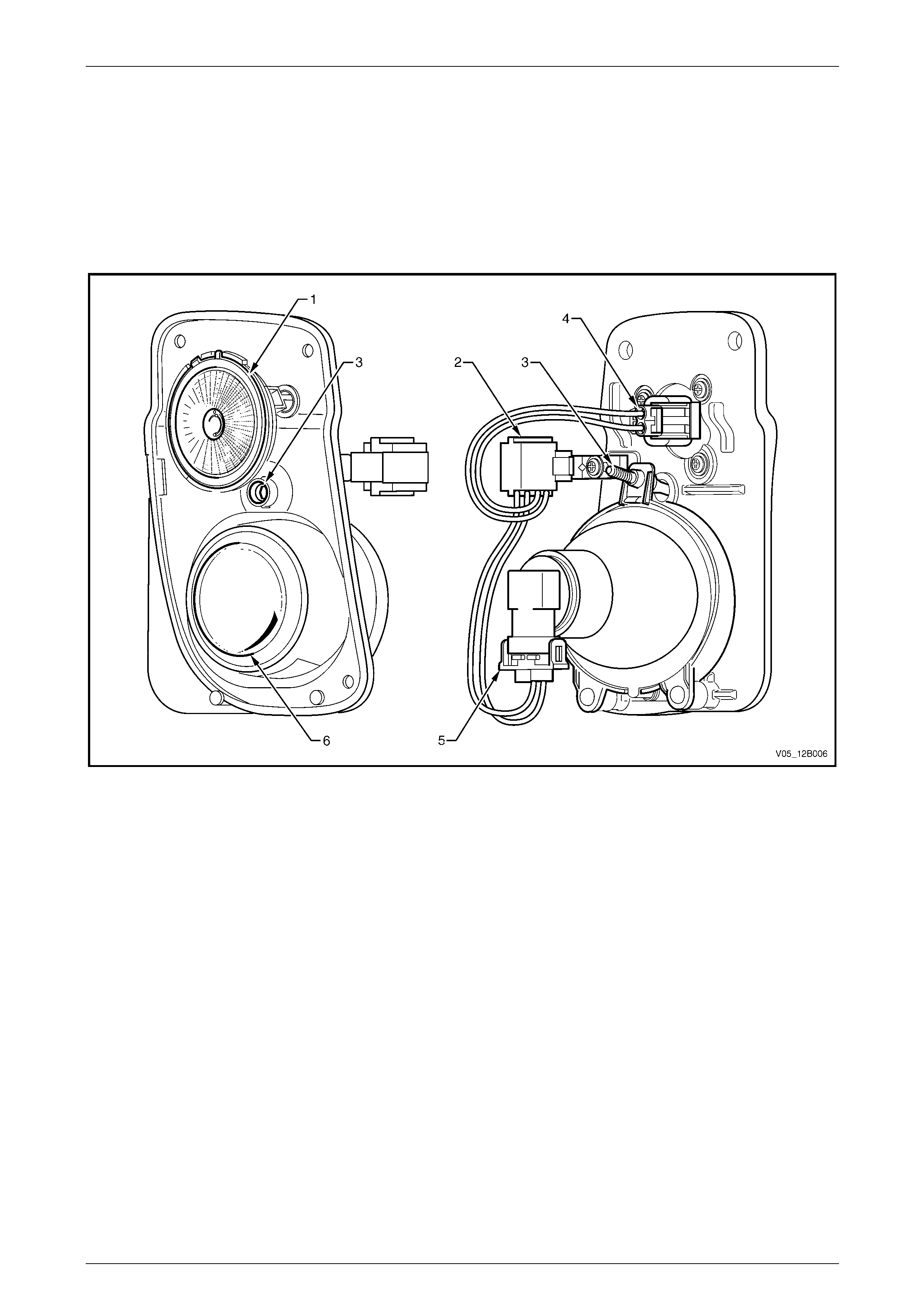

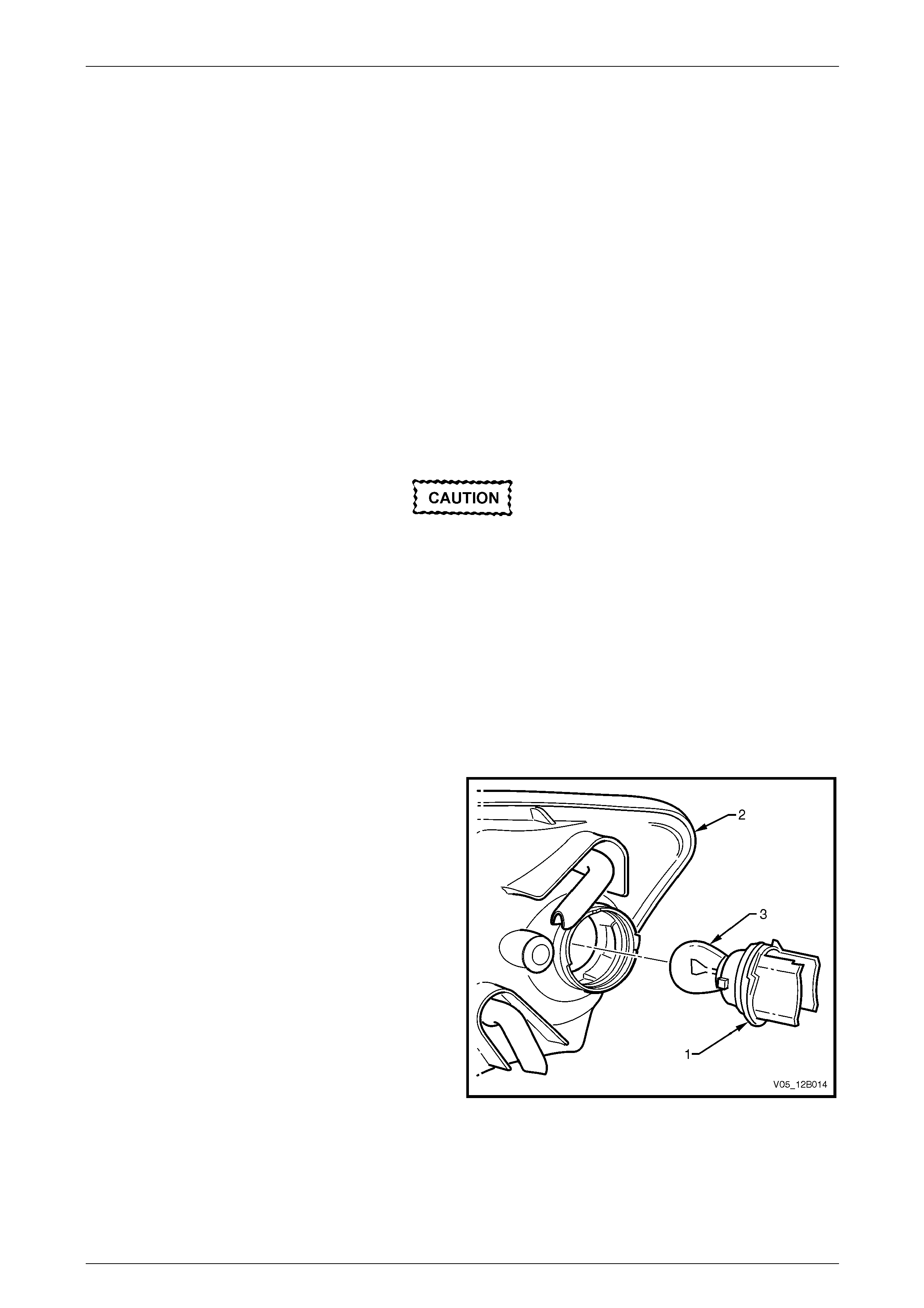

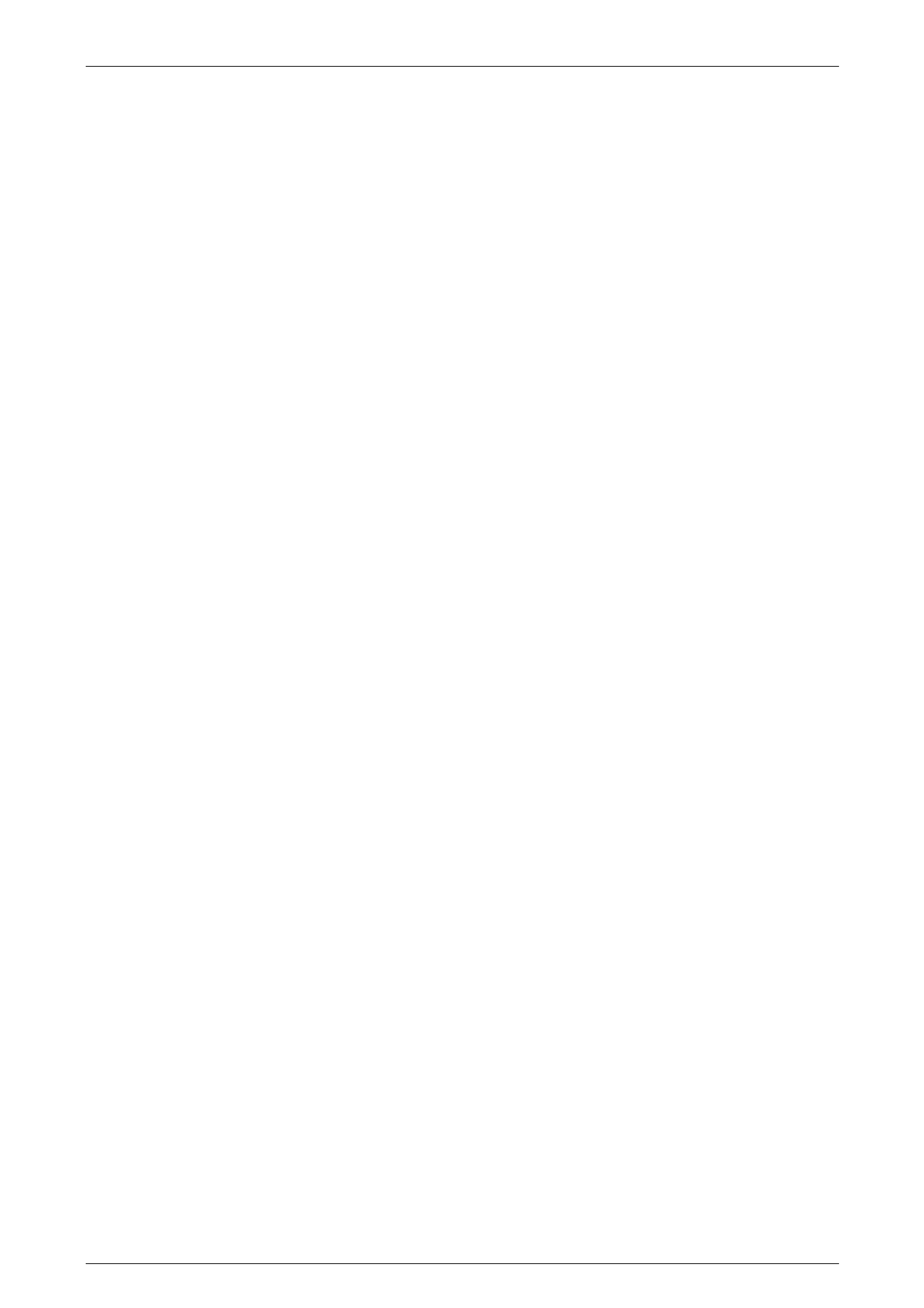

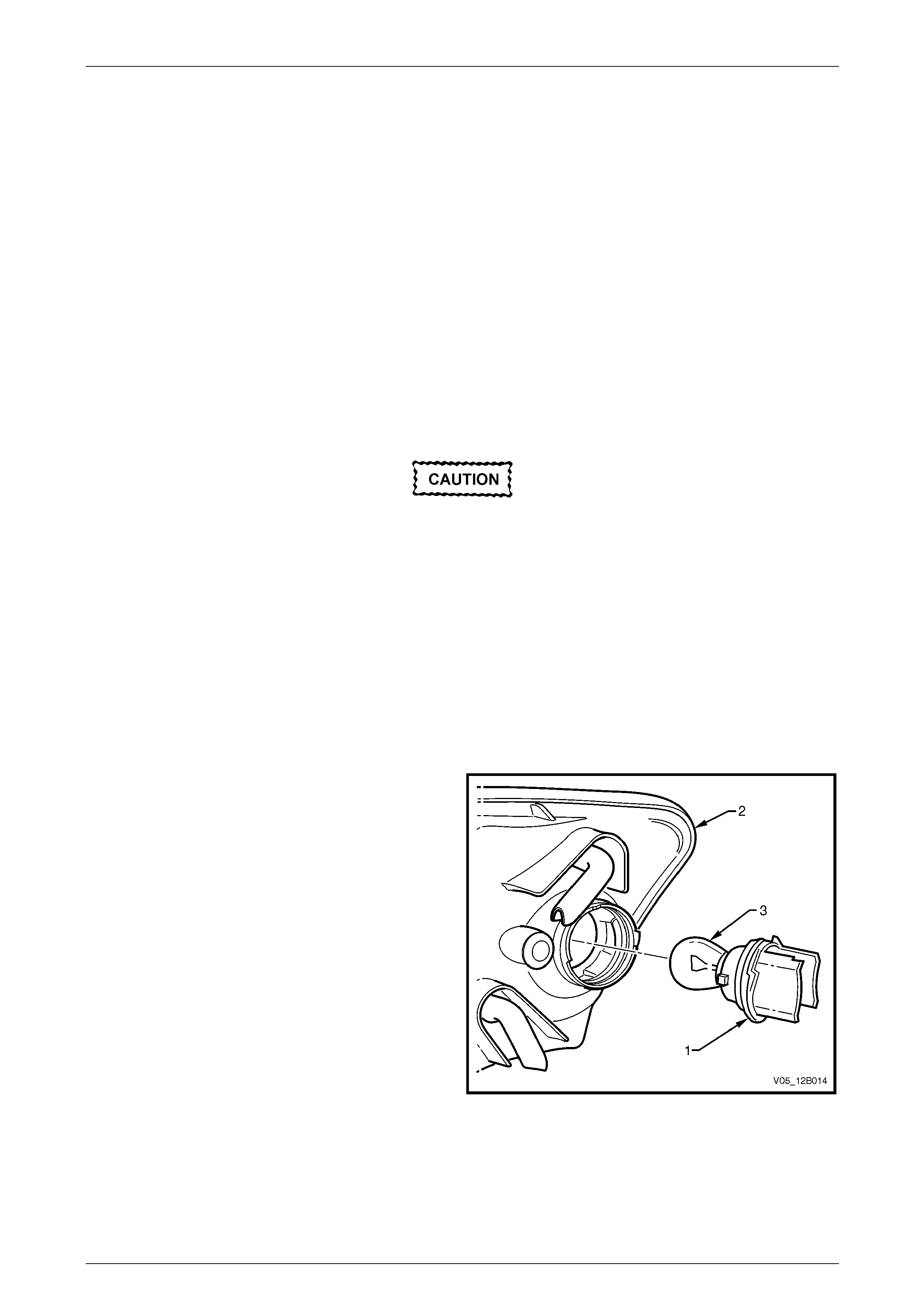

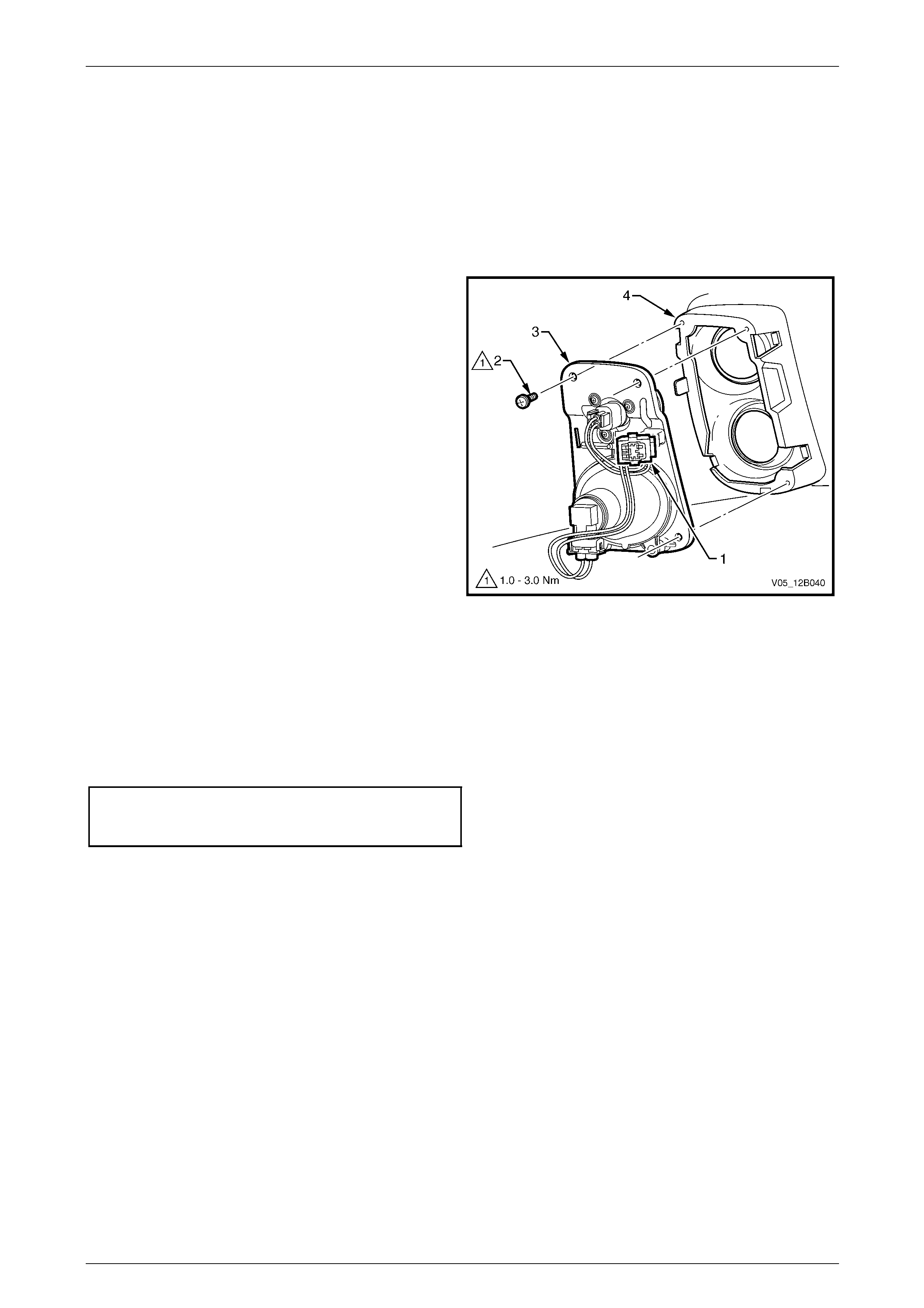

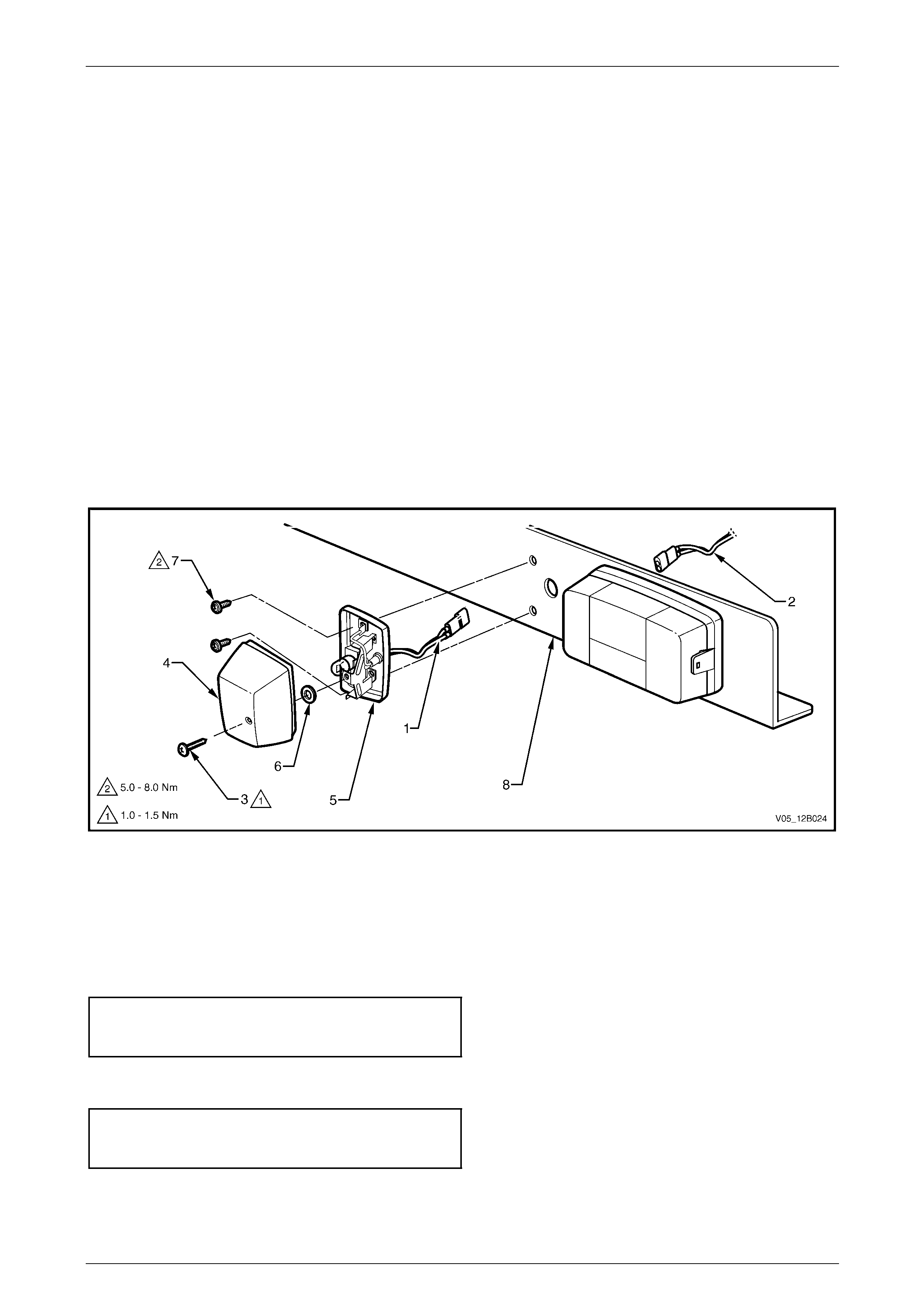

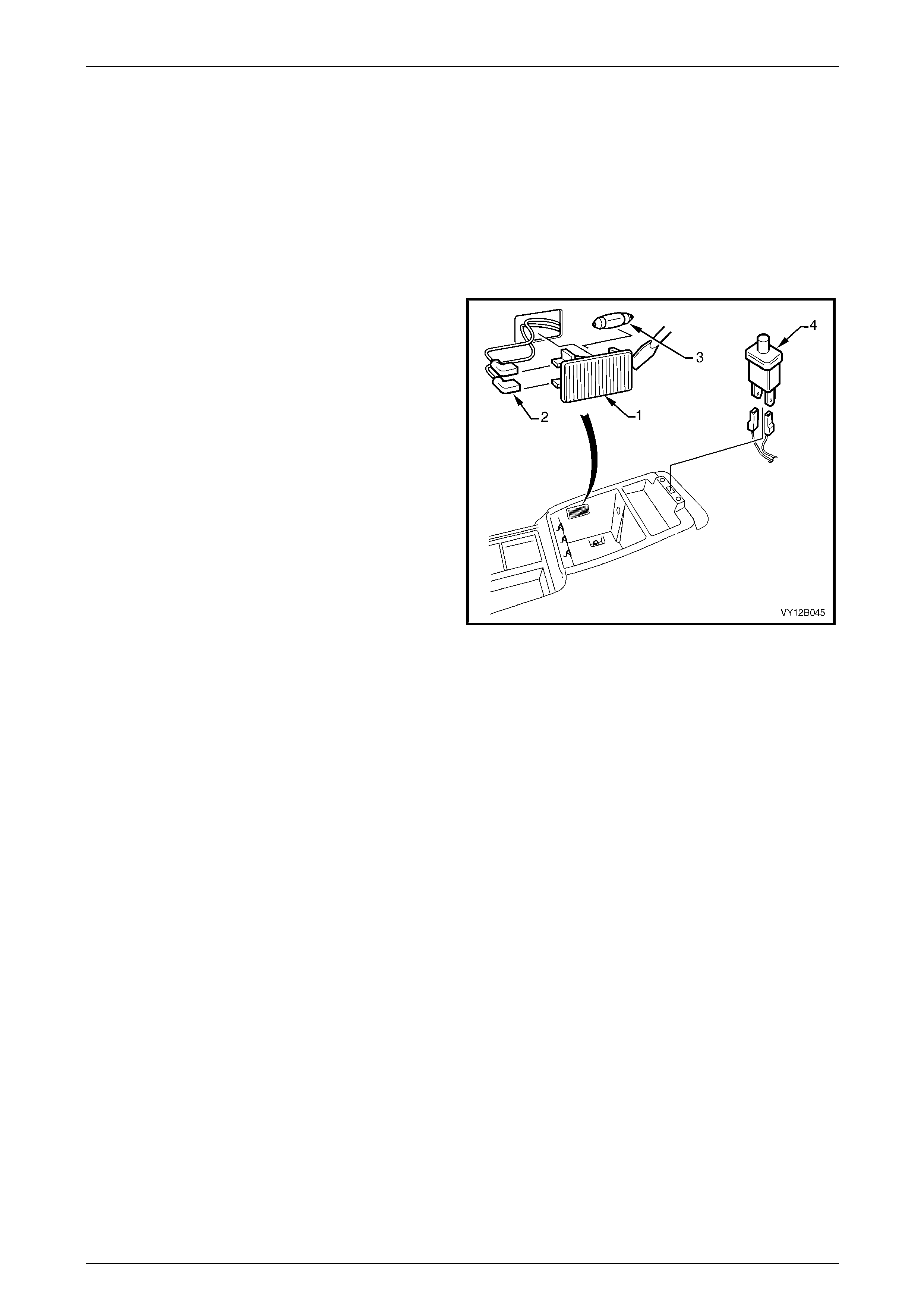

2.2 Park and Front Fog Lamp Assembly

The Coupe park and front fog lamp assembly consists of:

• a park lamp (at the top of the park and front fog lamp assembly), and

• a fog lamp (at the bottom of the park and front fog lamp assembly).

The front fog lamp can be adjusted vertically by using an Allen key from the front of the park and front fog lamp

assembly. A wiring connector on the park and front fog lamp assembly connects the park lamp and front fog lamp wires

to the front body wiring harnes s.

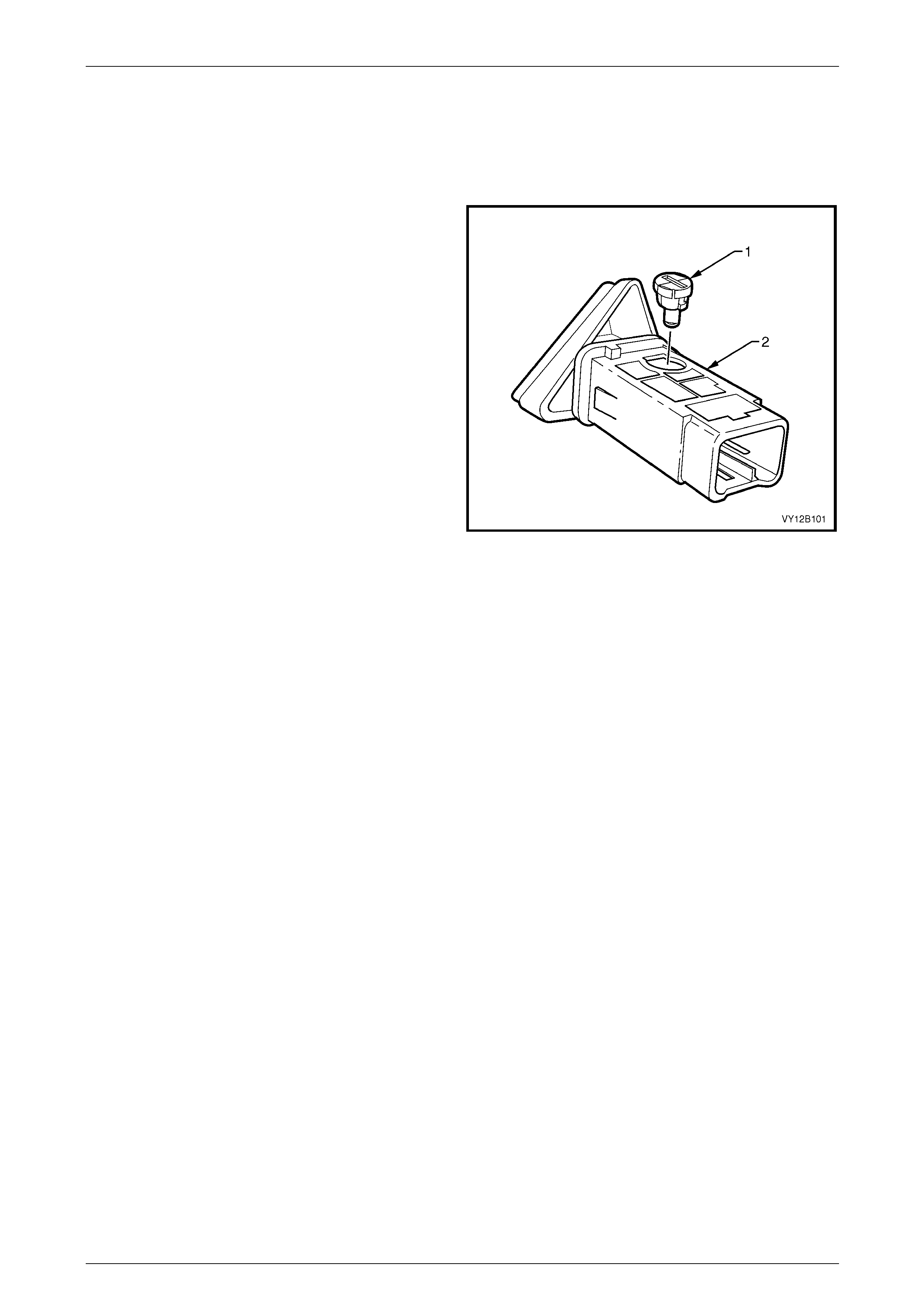

Figure 12B – 10

Legend

1 Park Lamp

2 Front Body Wiring Harness Connector

3 Fog Lamp Adjustment Mechanism

4 Park Lamp Connector

5 Fog Lamp Connector

6 Fog Lamp

Lighting System Page 12B–21

Page 12B–21

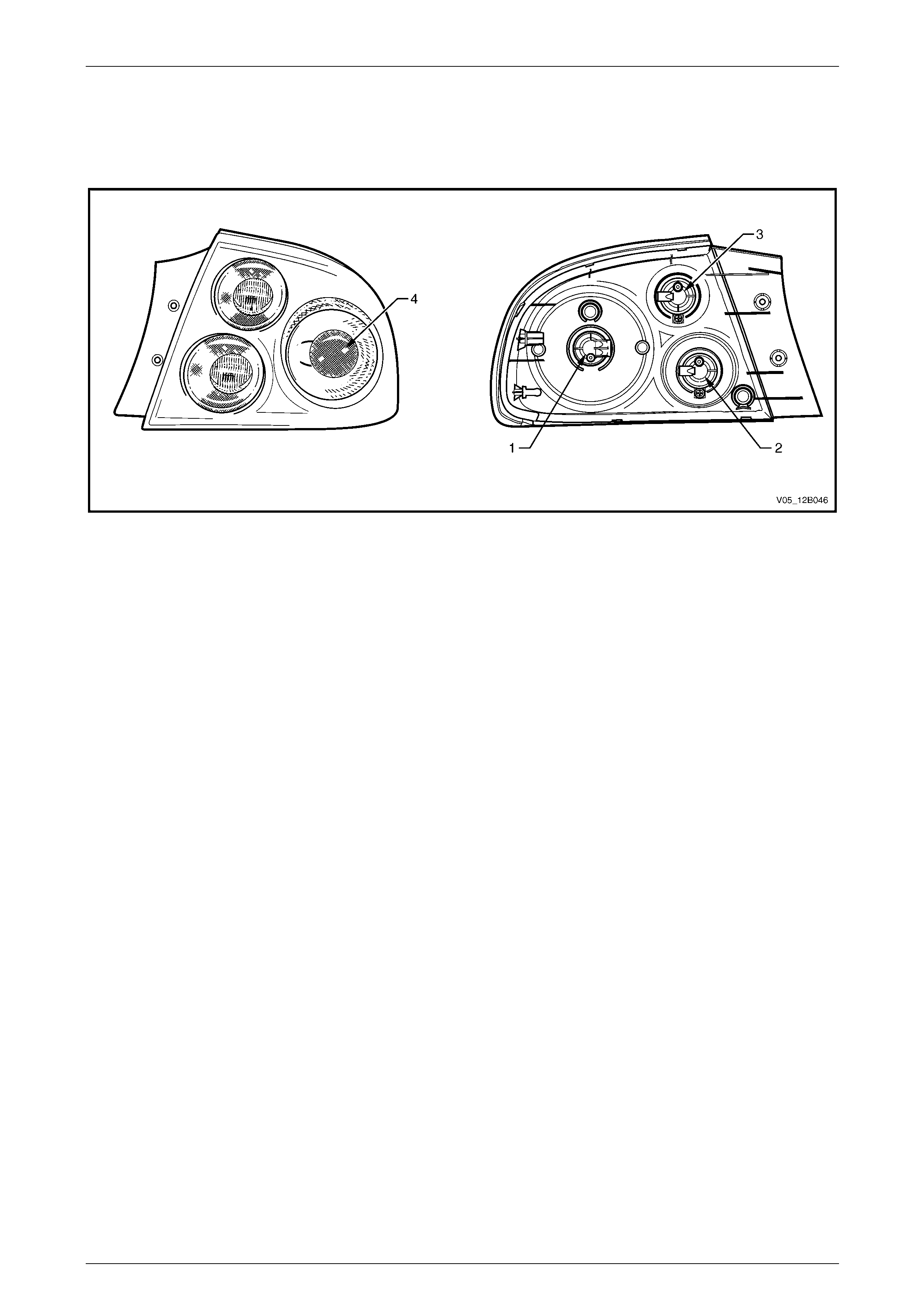

2.3 Tail Lamp Assembly

For views of the front and rear of the tail lamp assemblies, refer to Figure 12B – 11, where the following functions are

provided:

Figure 12B – 11

1 Stop/Tail Lamps

2 Turn Signal Lamps 3 Backup Lamps

4 Reflex Reflectors

Lighting System Page 12B–22

Page 12B–22

2.4 High-mount Stop Lamps

The high-mount stop lamp assembly is fitted to the inside of the vehicle and uses a strip of light emitting diodes (LEDs)

for illumination.

Lighting System Page 12B–23

Page 12B–23

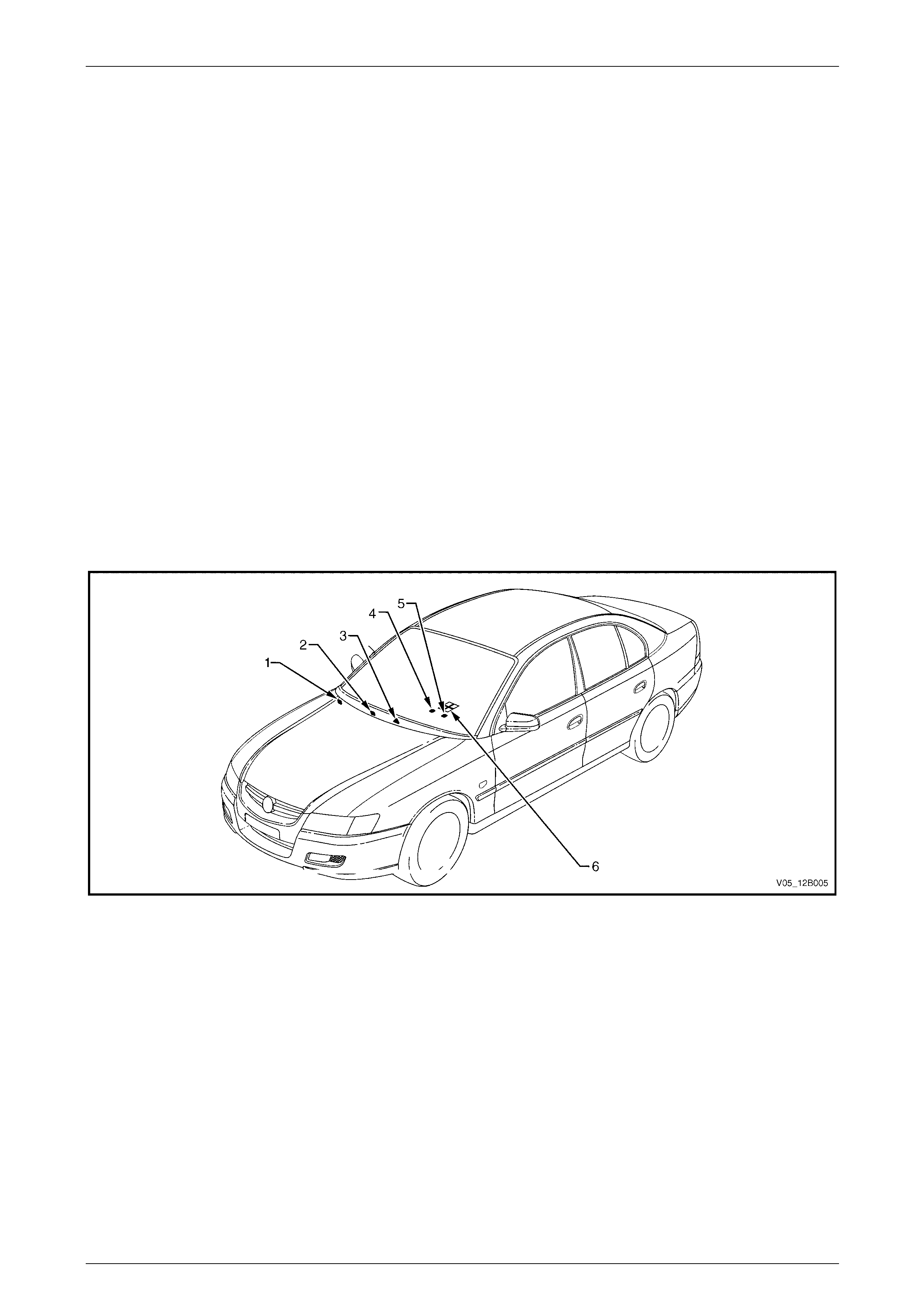

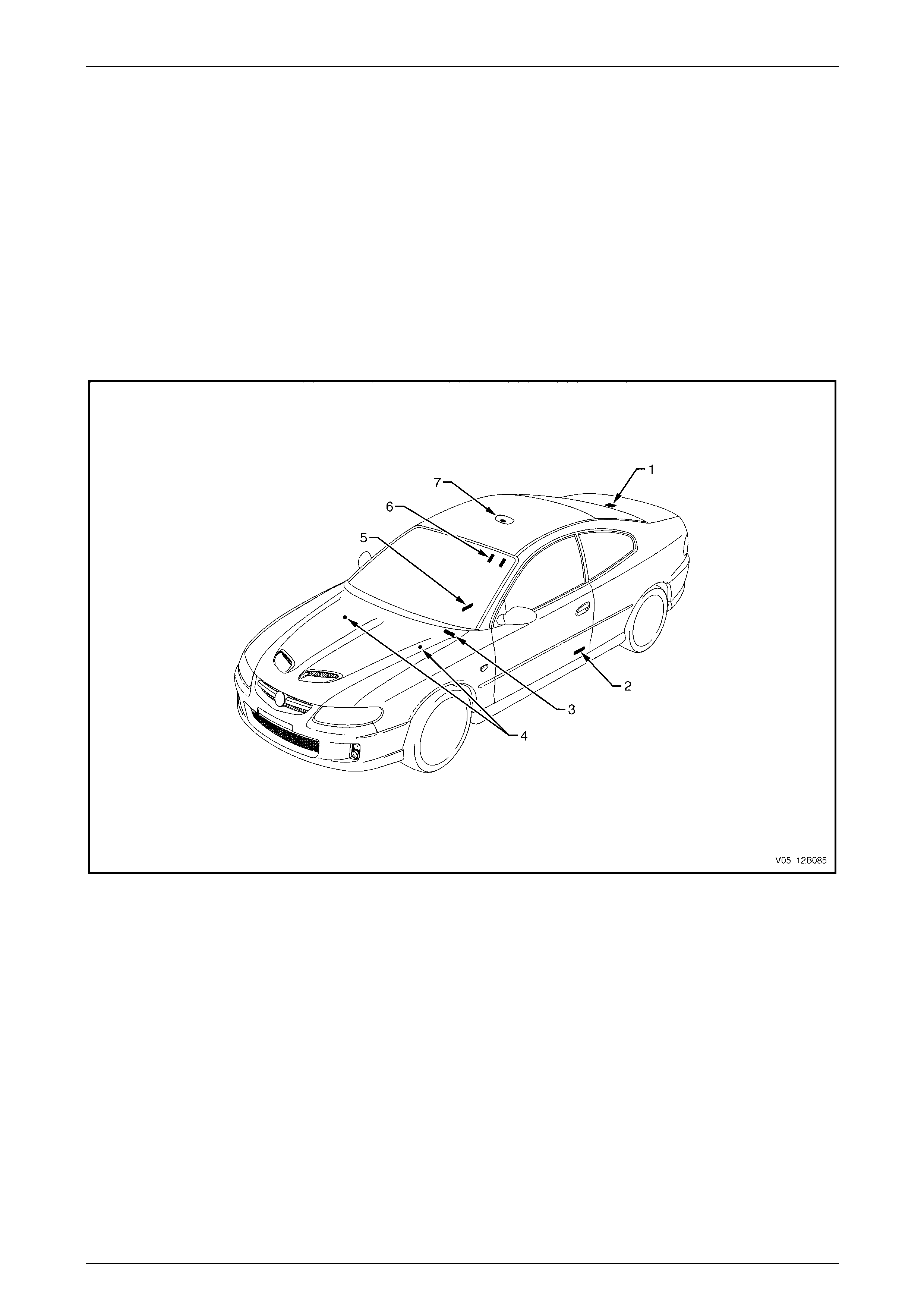

2.5 Interior Illumination

Vehicles are fitted with lamps adequate to illuminate the cabin area during l ow light conditions, including an instrument

panel compartment lamp and a rear compart ment lamp. Many lamps (and the dimming function for the interior lamps)

are controlled by the body control module (BCM), refer to Section 12J Body Control Module for further information.

Refer to Figure 12B – 12 for interior lighting compo nent locations. Vehicles have:

• dome and reading lamp assembly,

• side door courtesy lamps,

• stepwell lamps,

• sunshade vanity mirror lamps, and

• floor console compartment lamp.

Figure 12B – 12

Legend

1 Rear Compartment Courtesy Lamp

2 Side Door Courtesy Lamps

3 Instrument Panel Compartment Courtesy Lamp

4 Stepwell Lamps

5 Floor Console Compartment Lamp

6 Sunshade Vanity Mirror Lamps

7 Dome and Reading Lamp Assembly

Lighting System Page 12B–24

Page 12B–24

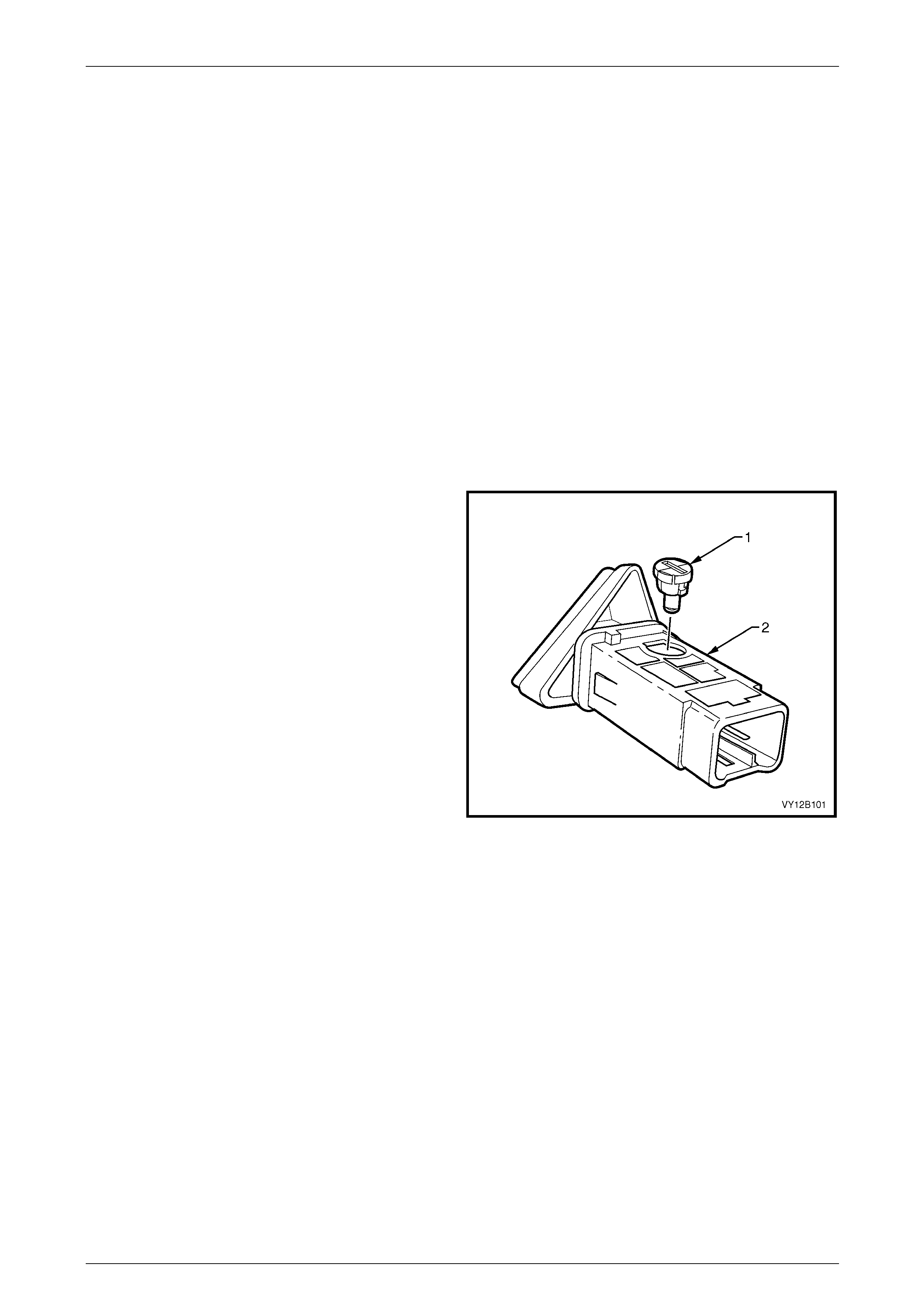

2.6 Instrument and Switch Illumination

All instrument and switch illum ination is provided by LEDs, except the following items that are illuminated with

conventional filament bulbs:

• hazard warning switch,

• T/C switch,

• headlamp switch,

• trip computer switch,

• side window switch assembly, and

• ignition lock cylinder.

The T/C switch is located on the right side of the automatic transmission selector or in the floor console on vehicles with

manual transmission.

The headlamp, trip computer and side window switches are sealed units and the conventional bulbs can not be serviced

on these items.

LEDs are used instead of conventio nal bulbs due to their longevity in operation. If the illumination of any LED-equippe d

item no longer operates correctl y and the LE D is isolated as the fault, replace the assembly.

Figure 12B – 13

Legend

1 Headlamp Switch

2 Trip Computer Switch

3 Hazard Warning Switch

4 T/C Switch

5 Auxiliary Switches

Headlamp Switch

An automatic headlamp control feature is fitted. When the headlamp switch is in the AUTO position, the BCM controls

the function of the park lamp and low beam of the hea dlamps, refer to Figure 12B – 116. For further information, refer to

Section 12J Body Control Module .

Lighting System Page 12B–25

Page 12B–25

3 General Information, Regular

Cab and Crew Cab with 'Delete

Tub' Option

For information not contained in this Section, refer to 1 General Informatio n.

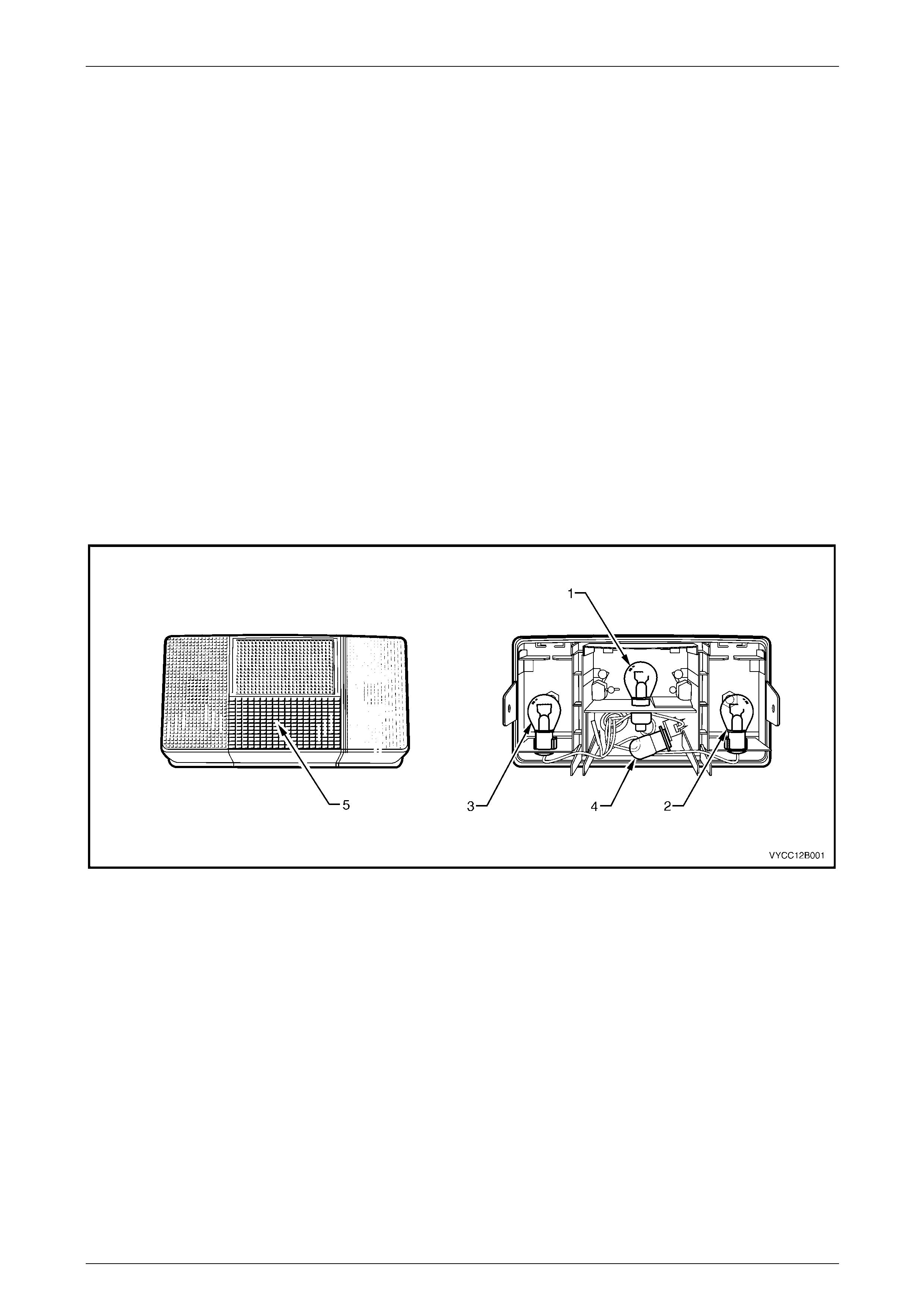

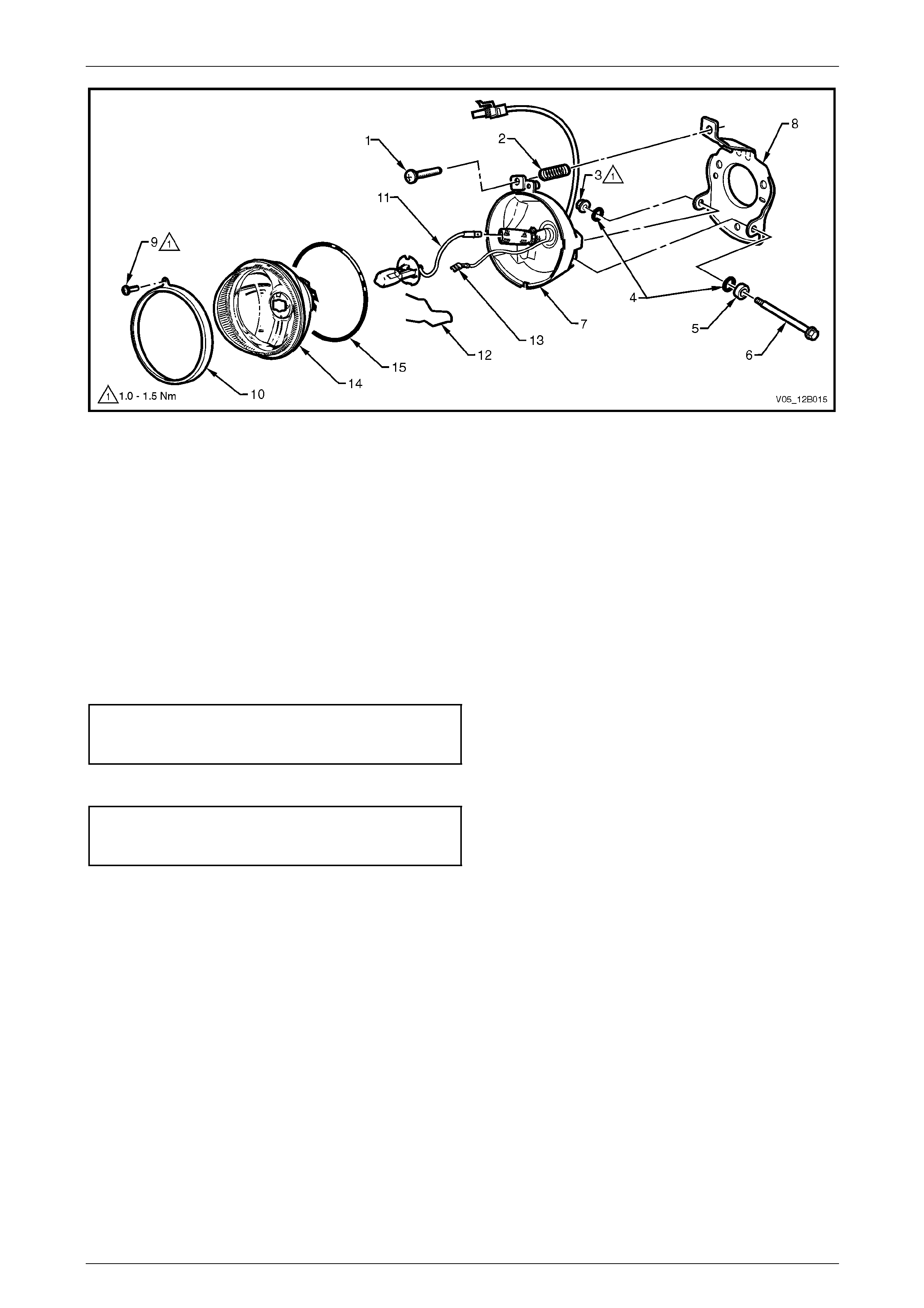

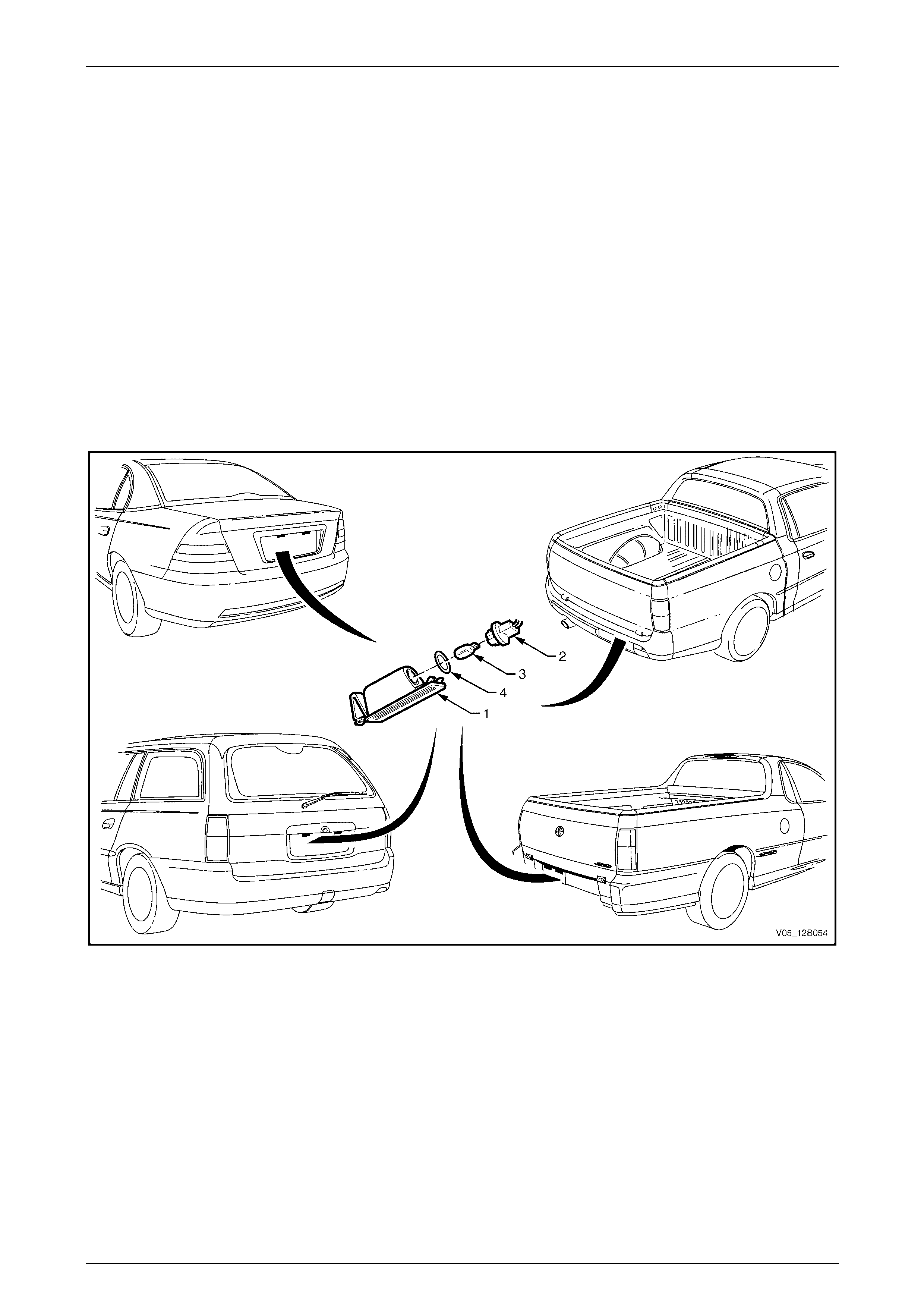

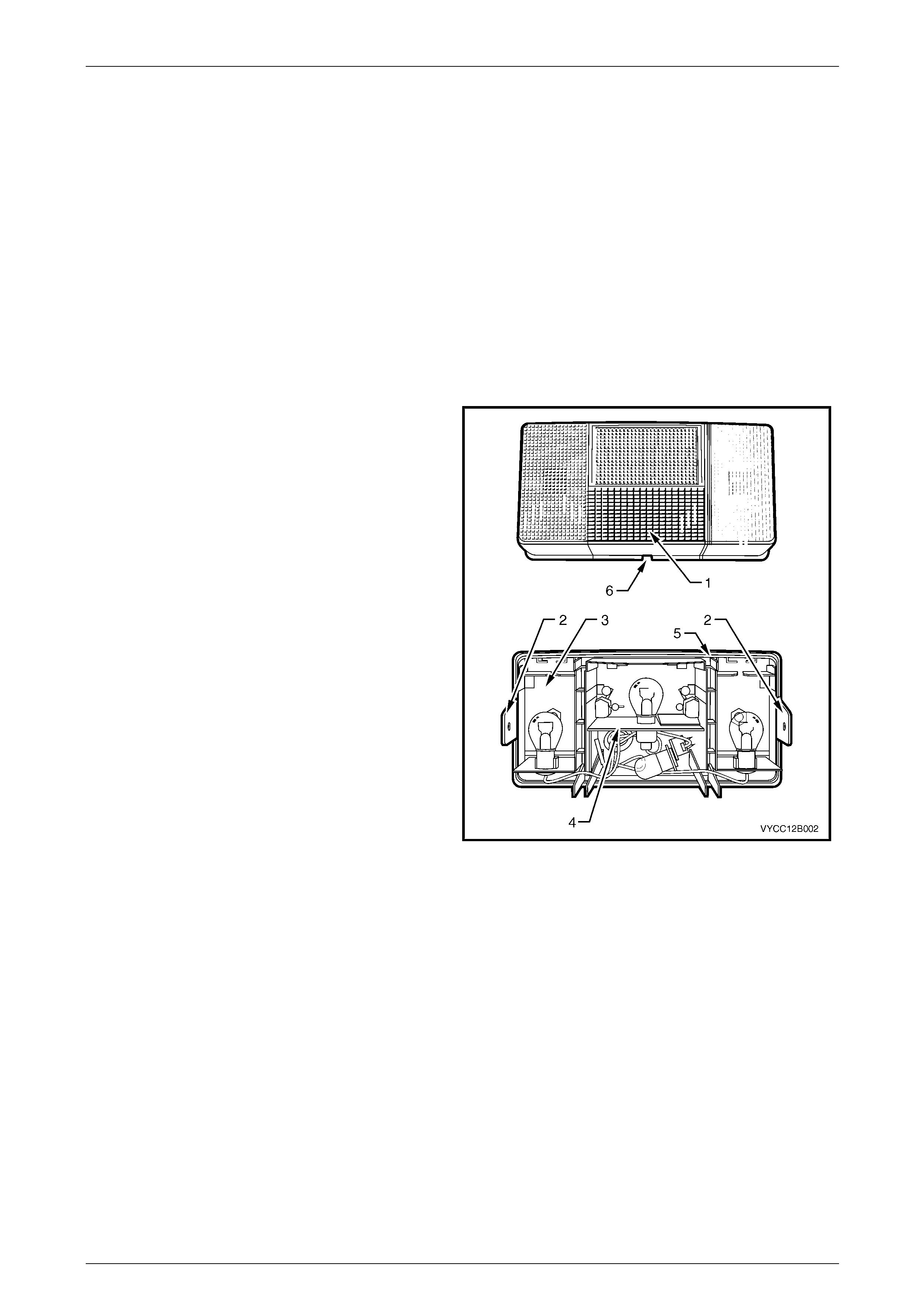

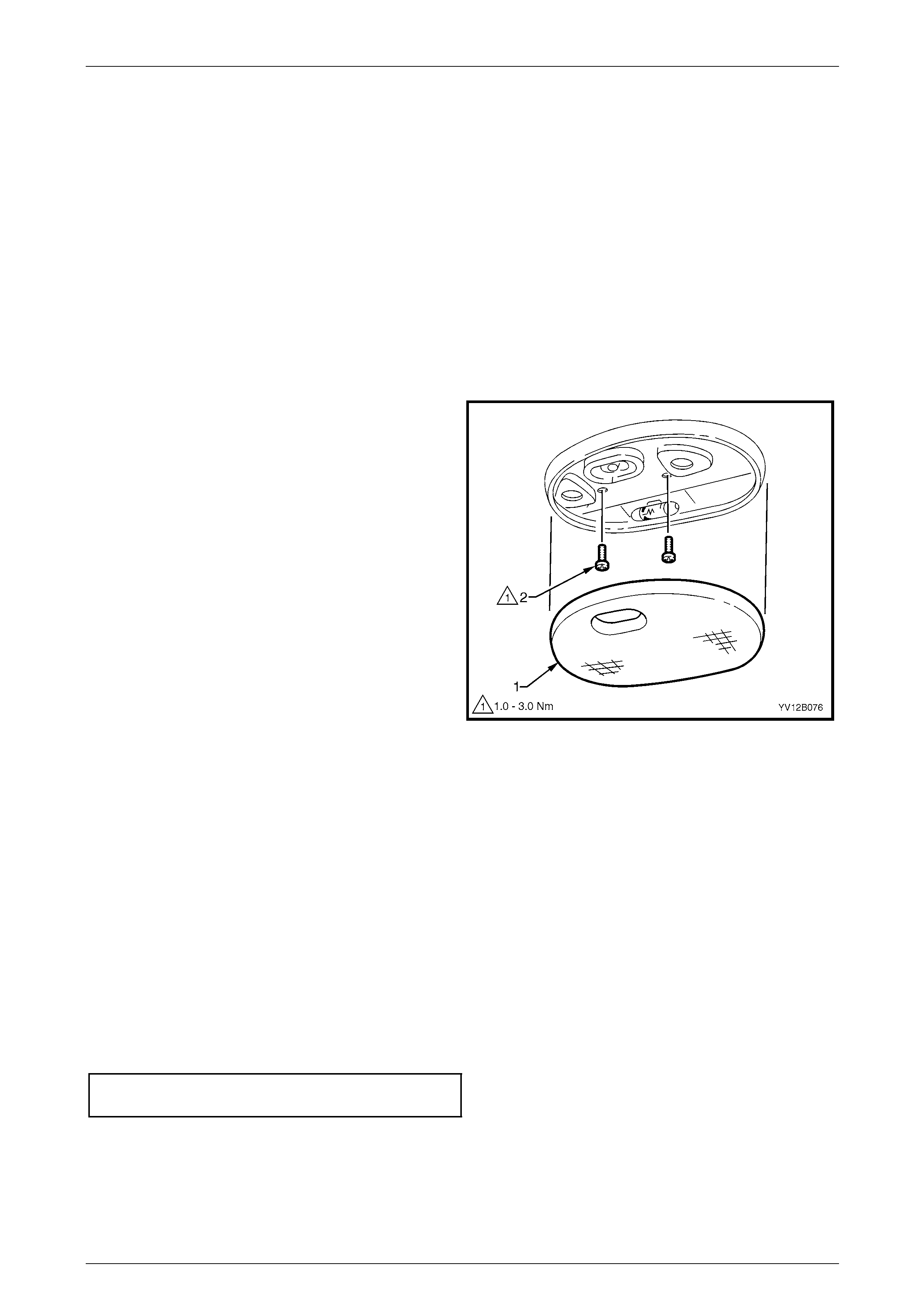

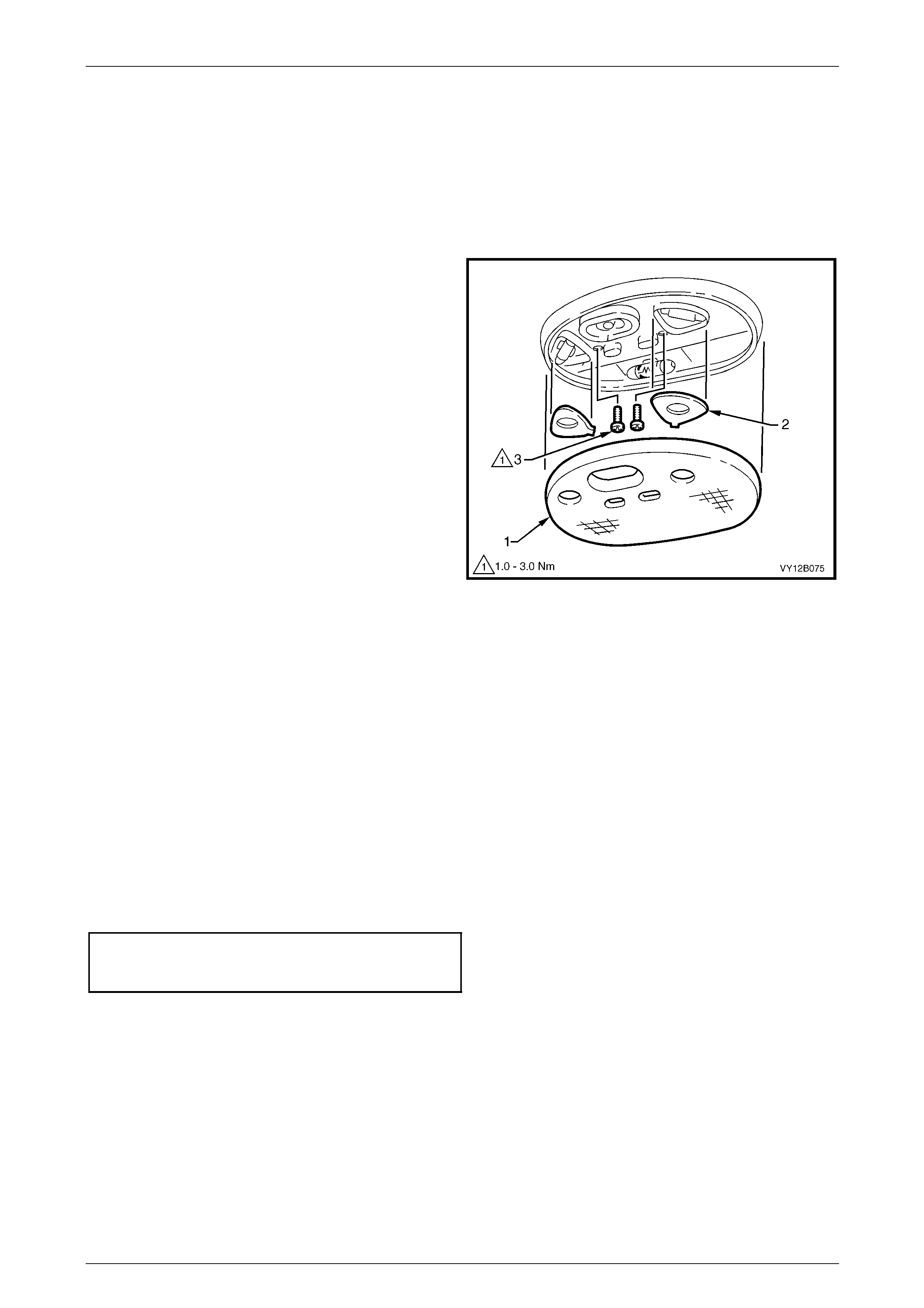

3.1 Tail Lamp Assembly

The tail lamp assemblies are self-contained units. Illumination is provided by bayonet-t yp e conventional bul bs. Electrical

connection is provided by weatherproof harness connectors. The tail lamp assemblies are mounted on the transport

bracket, fixed to the rear of the chassis.

For internal and external views of the tail lamp assemblies, refer to Figure 12B – 14.

The tail lamp assembly provid es the following functions:

• turn signal lamp,

• backup lamp,

• stop lamp,

• tail lamp, and

• reflex reflector.

Figure 12B – 14

Legend

1 Turn Signal Lamp

2 Backup Lamp

3 Stop Lamp

4 Park Lamp

5 Reflex Reflector

NOTE

Figure 12B – 14 shows a left tail lamp assembly.

With a right tail lamp assembly, the location of the

backup lamp and the stop la mp are opposite.

Lighting System Page 12B–26

Page 12B–26

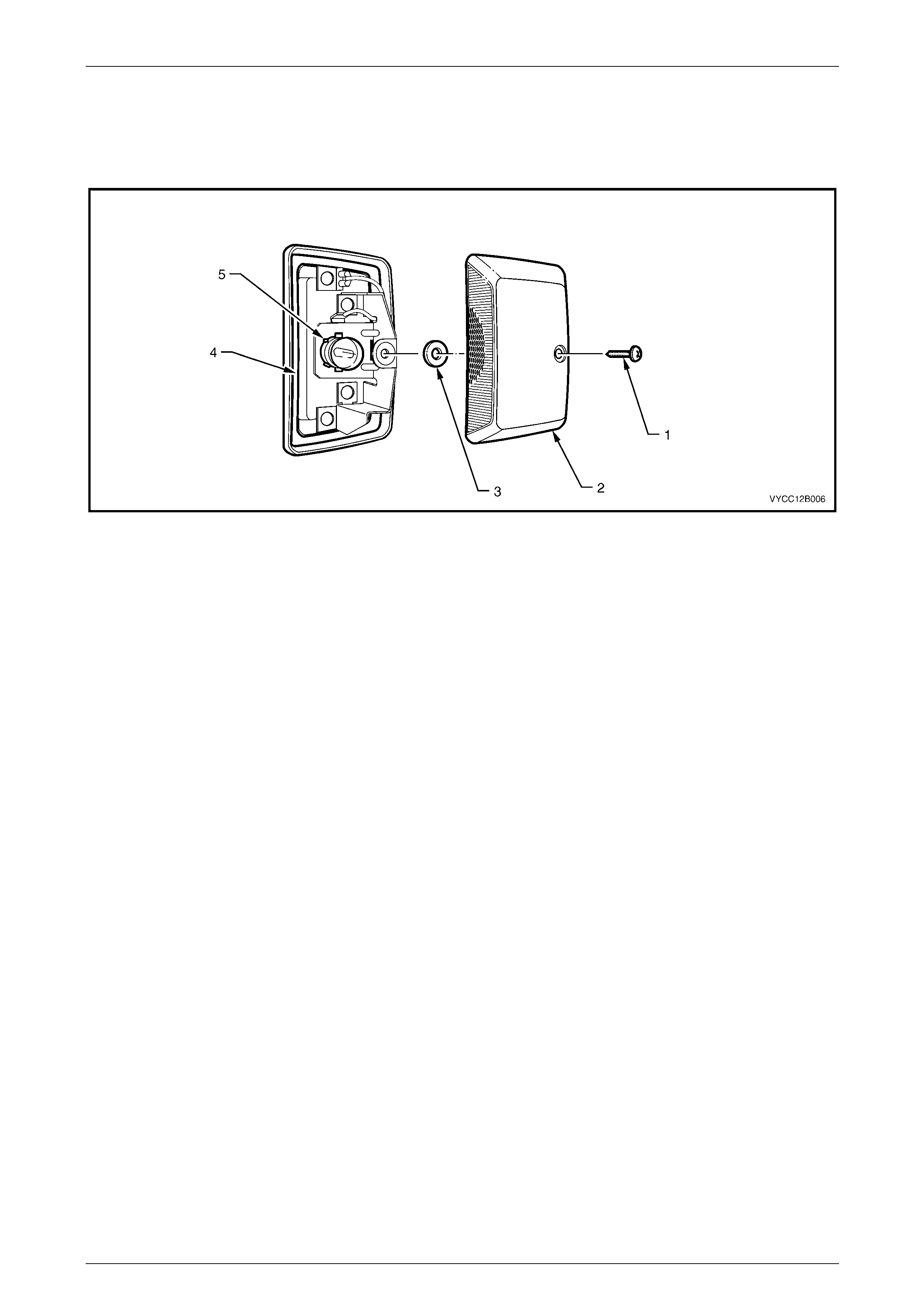

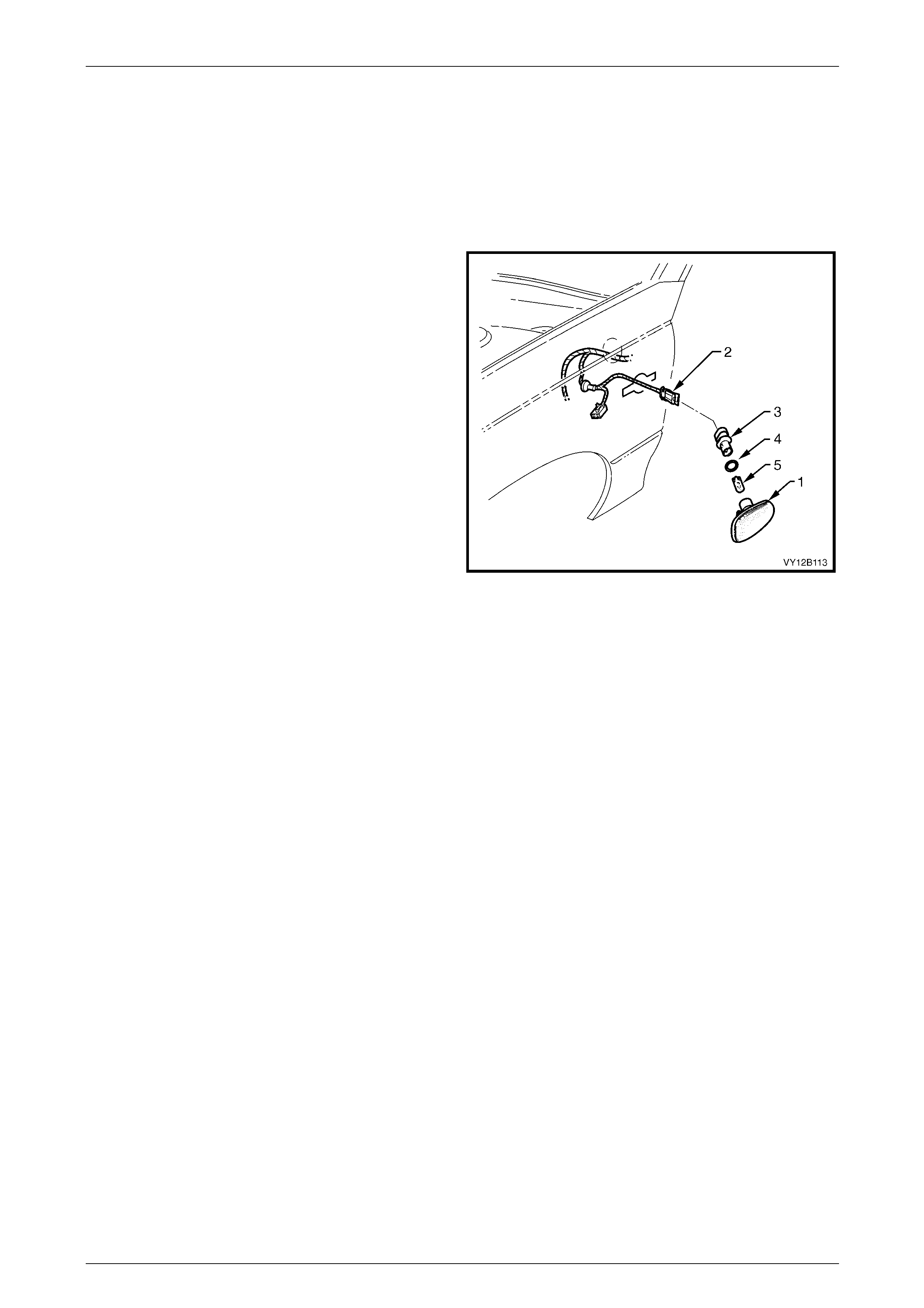

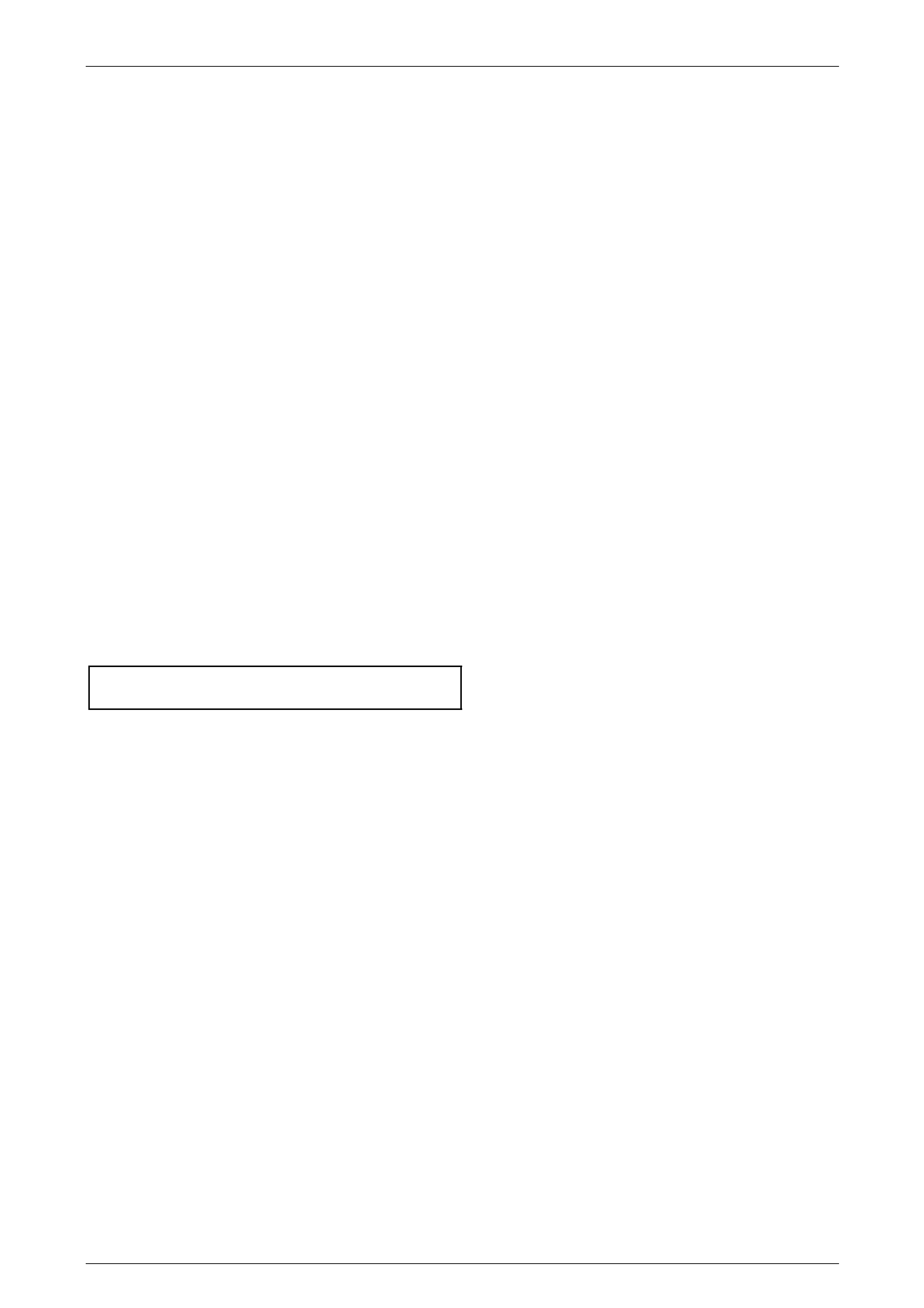

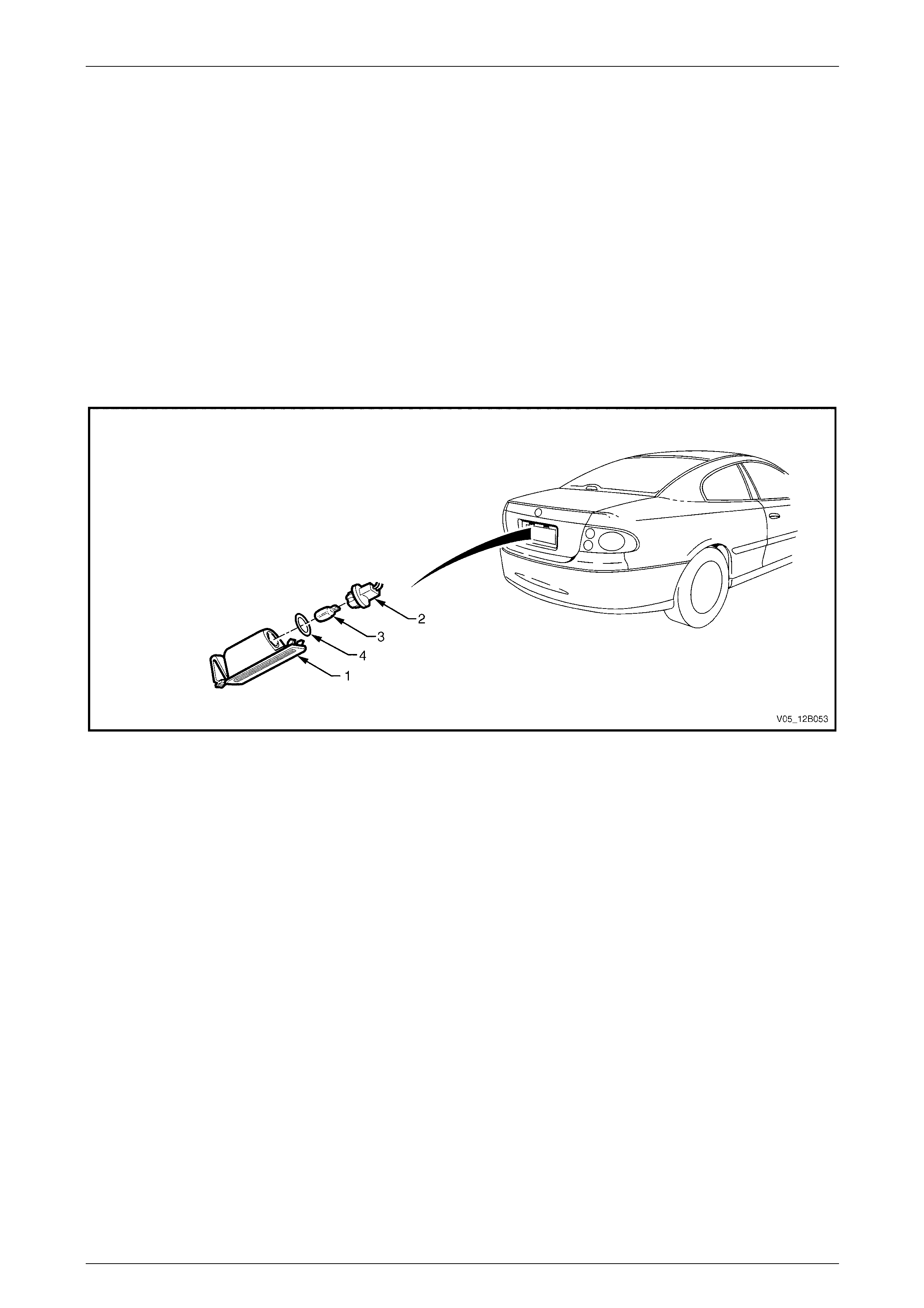

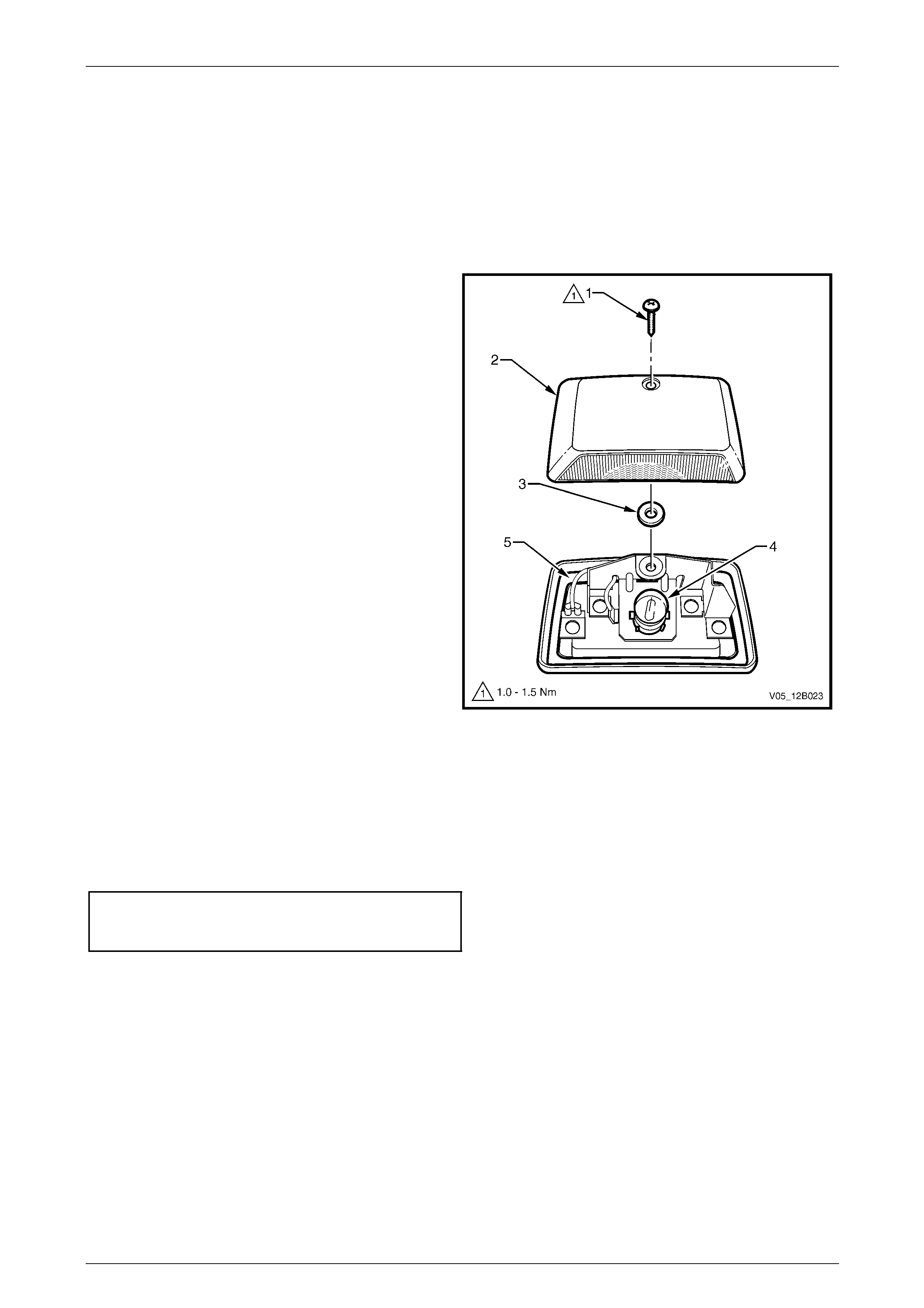

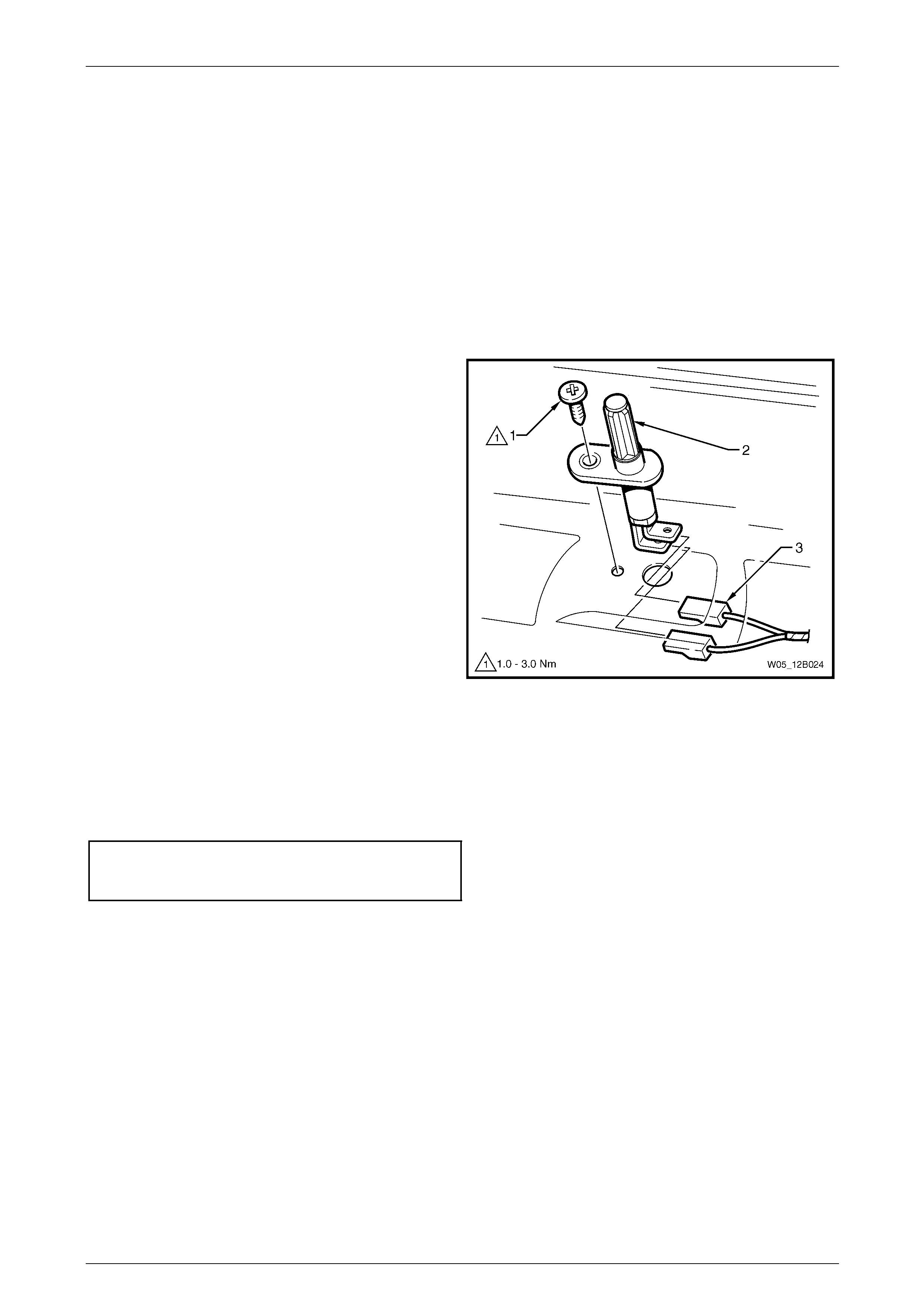

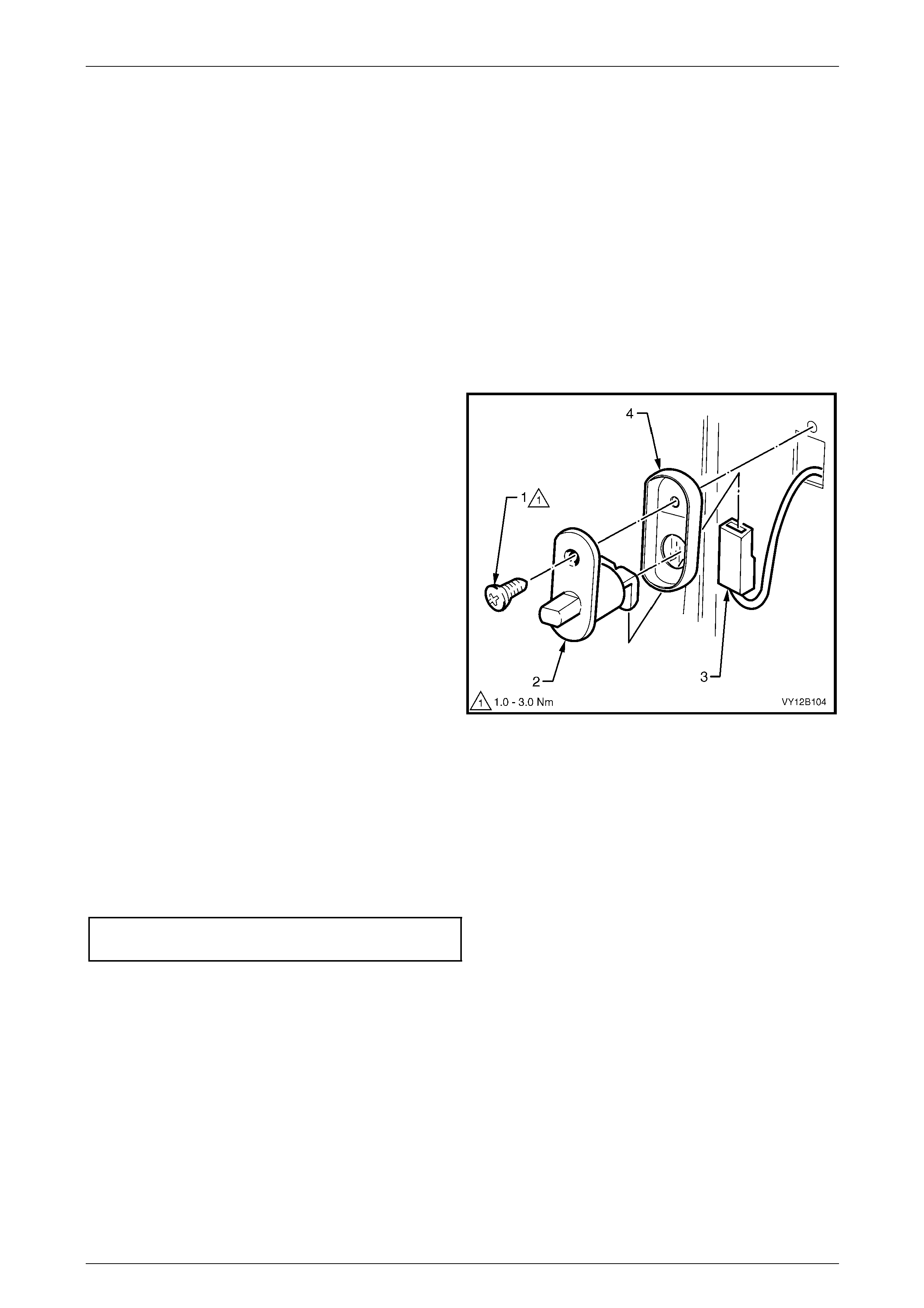

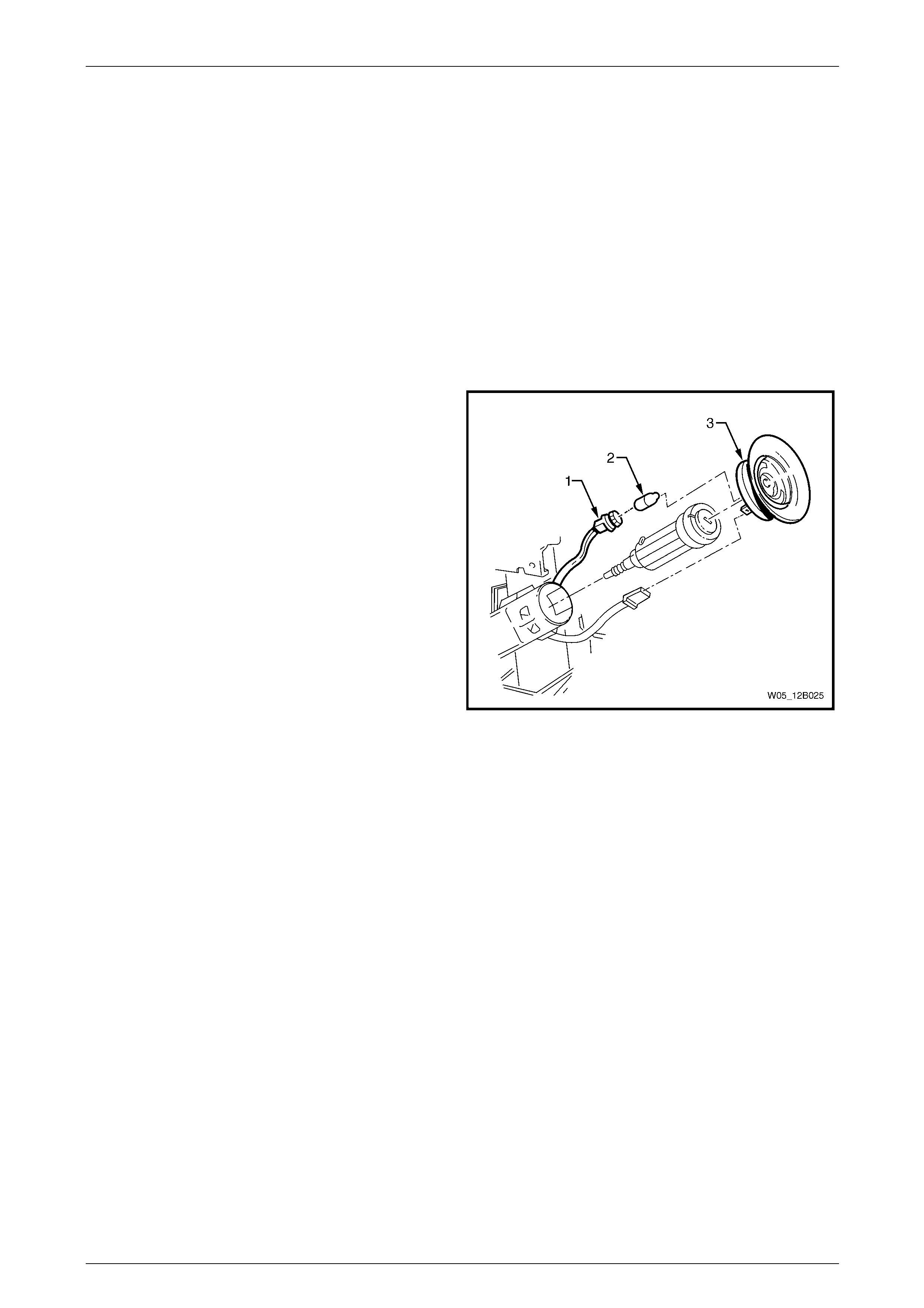

3.2 Rear Licence Plate Lamp Assembly

The rear licence plate lamp assembly is a sealed self-contained unit and has a weatherproof harness connector. The

rear licence plate lamp assembly is mounted on the transport bracket, fixed to the rear of the chassis.

Figure 12B – 15

Legend

1 Screw

2 Rear Licence Lamp Housing

3 Grommet

4 Rear Licence Lamp Base

5 Lamp

Lighting System Page 12B–27

Page 12B–27

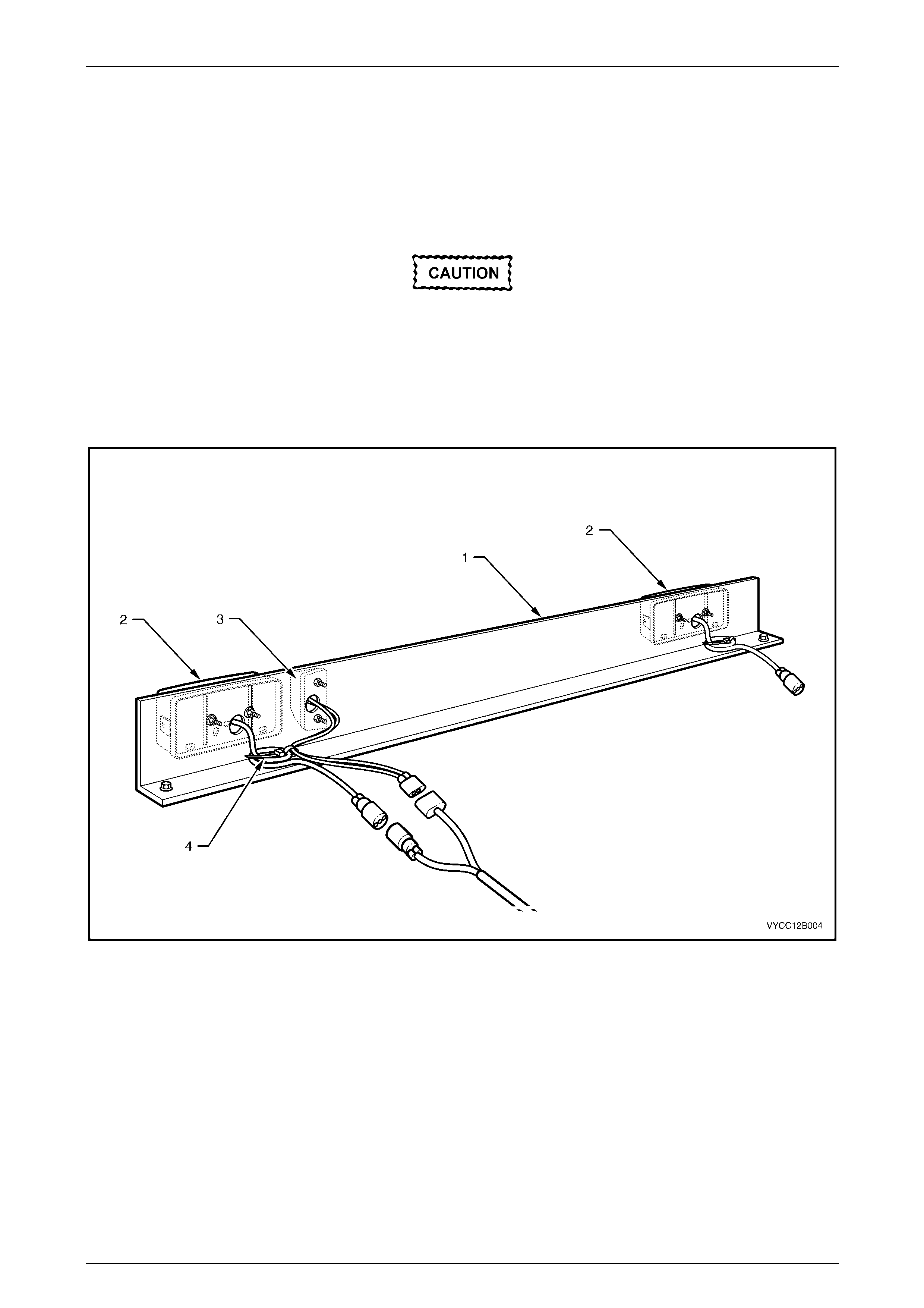

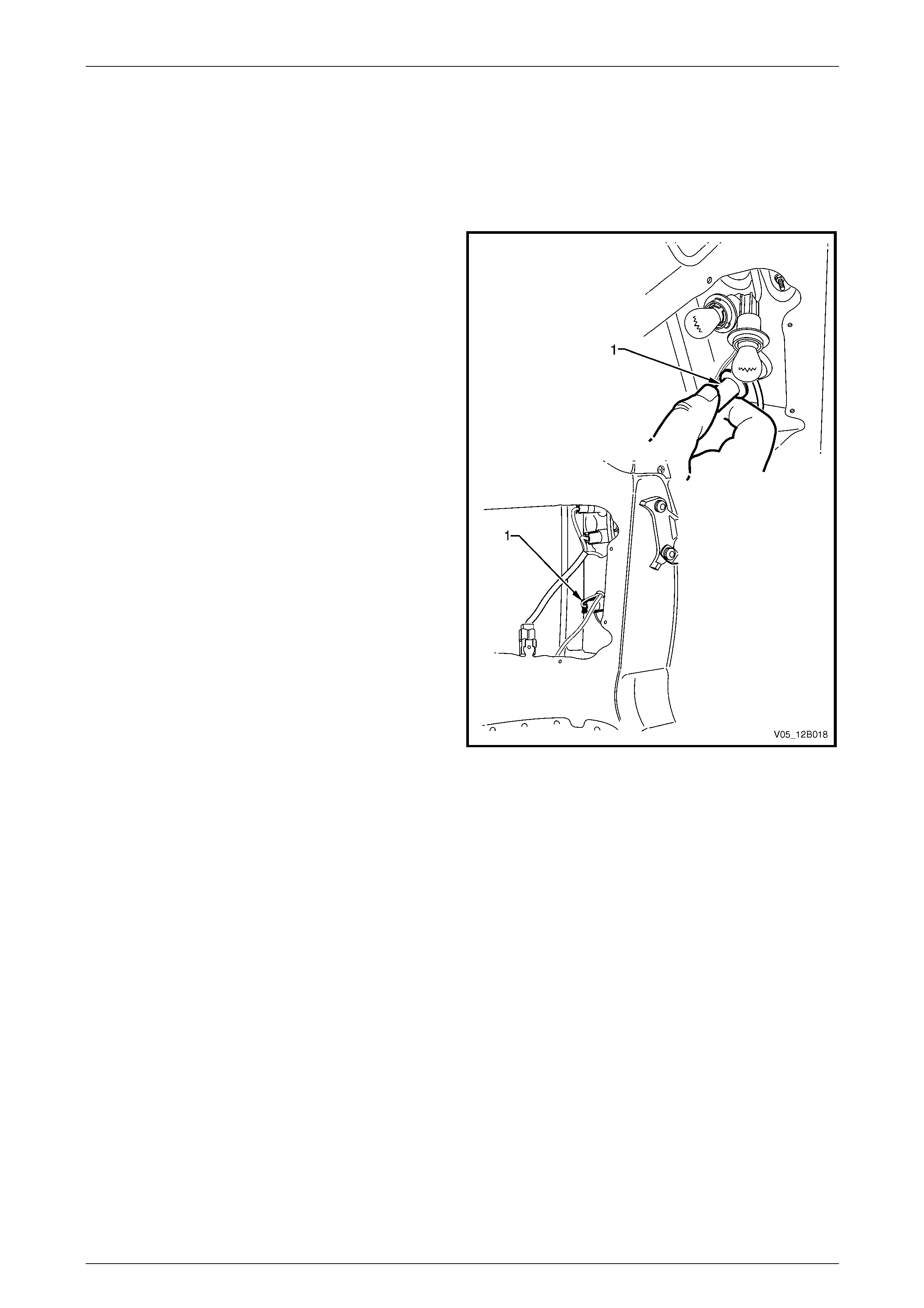

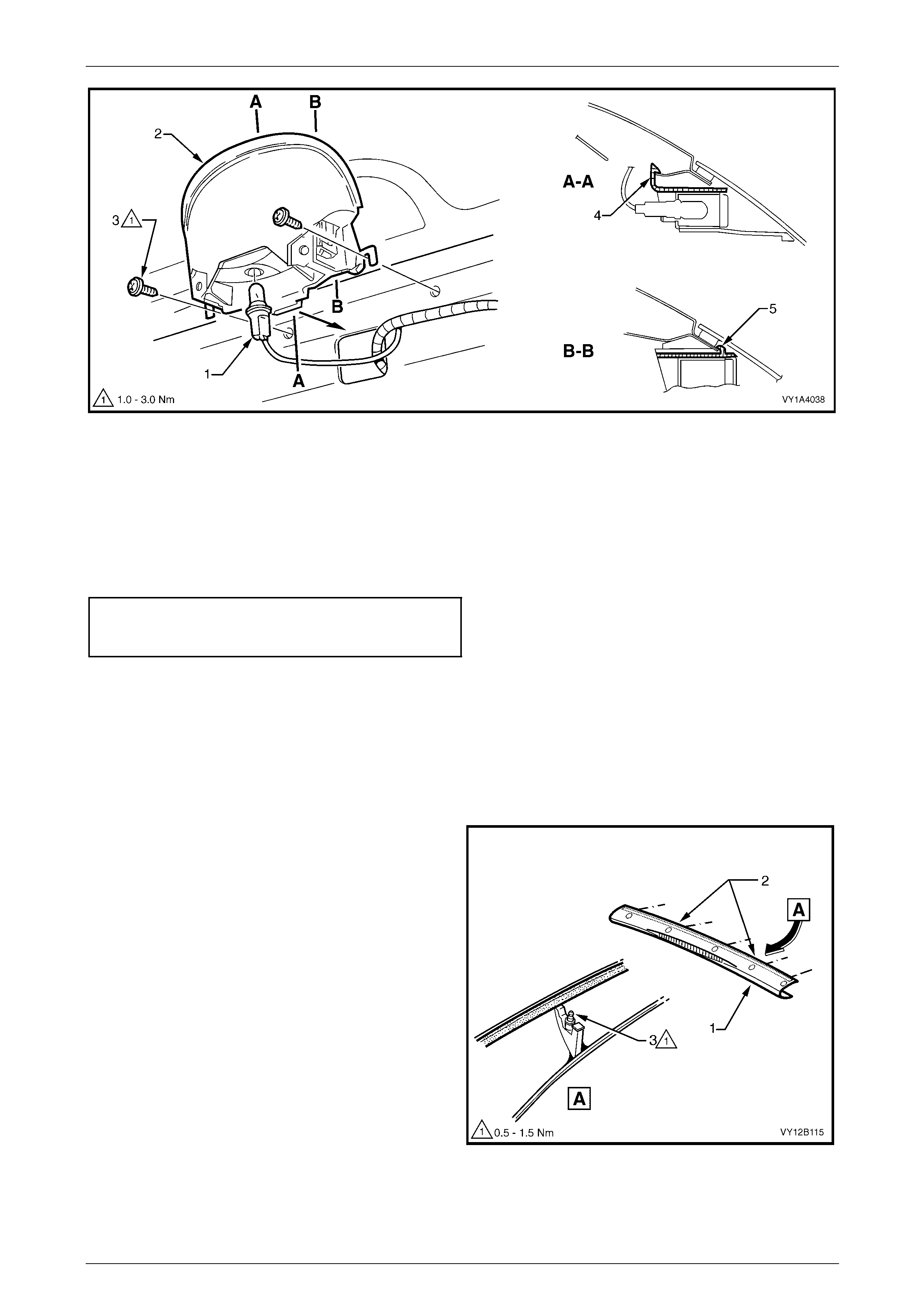

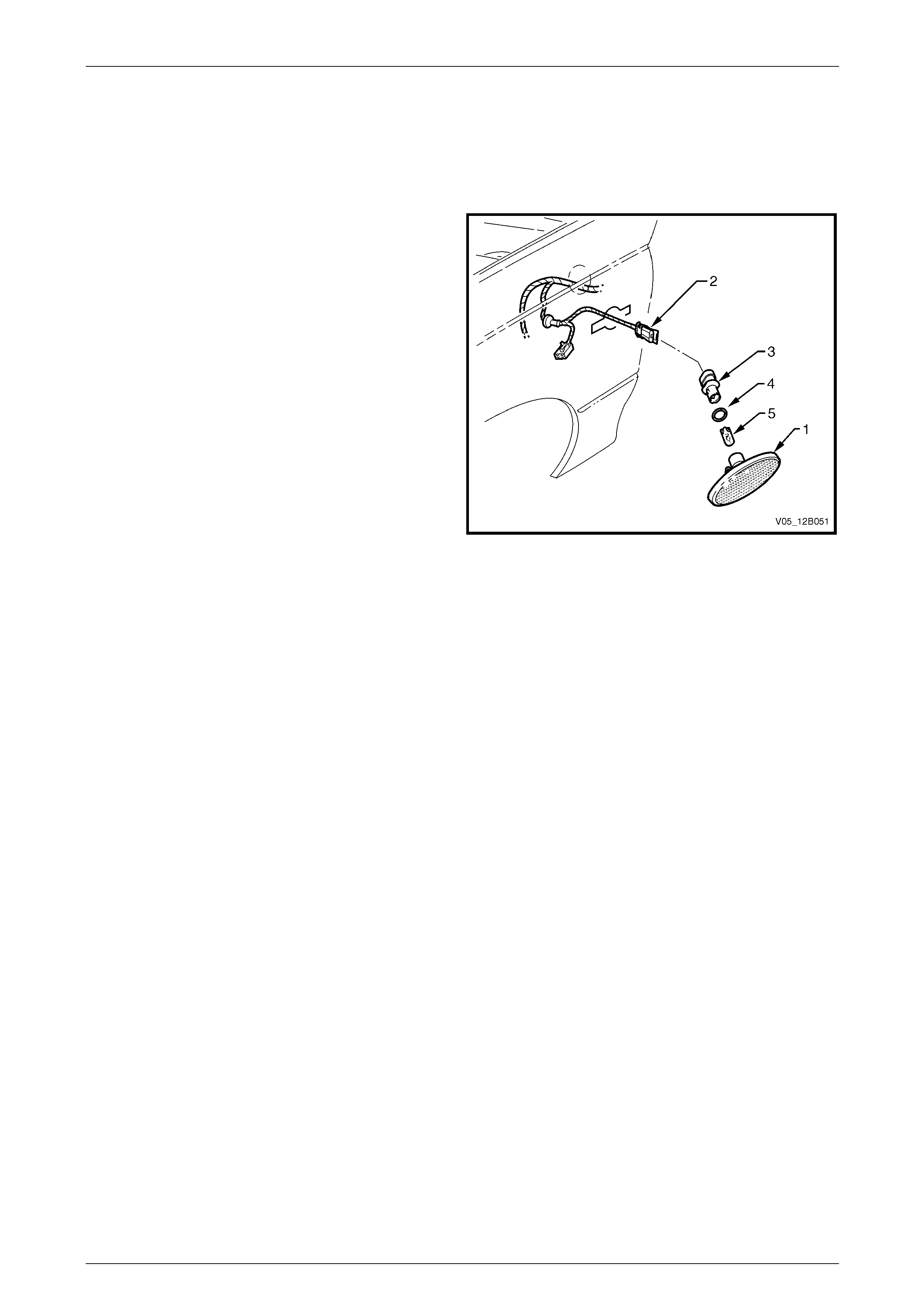

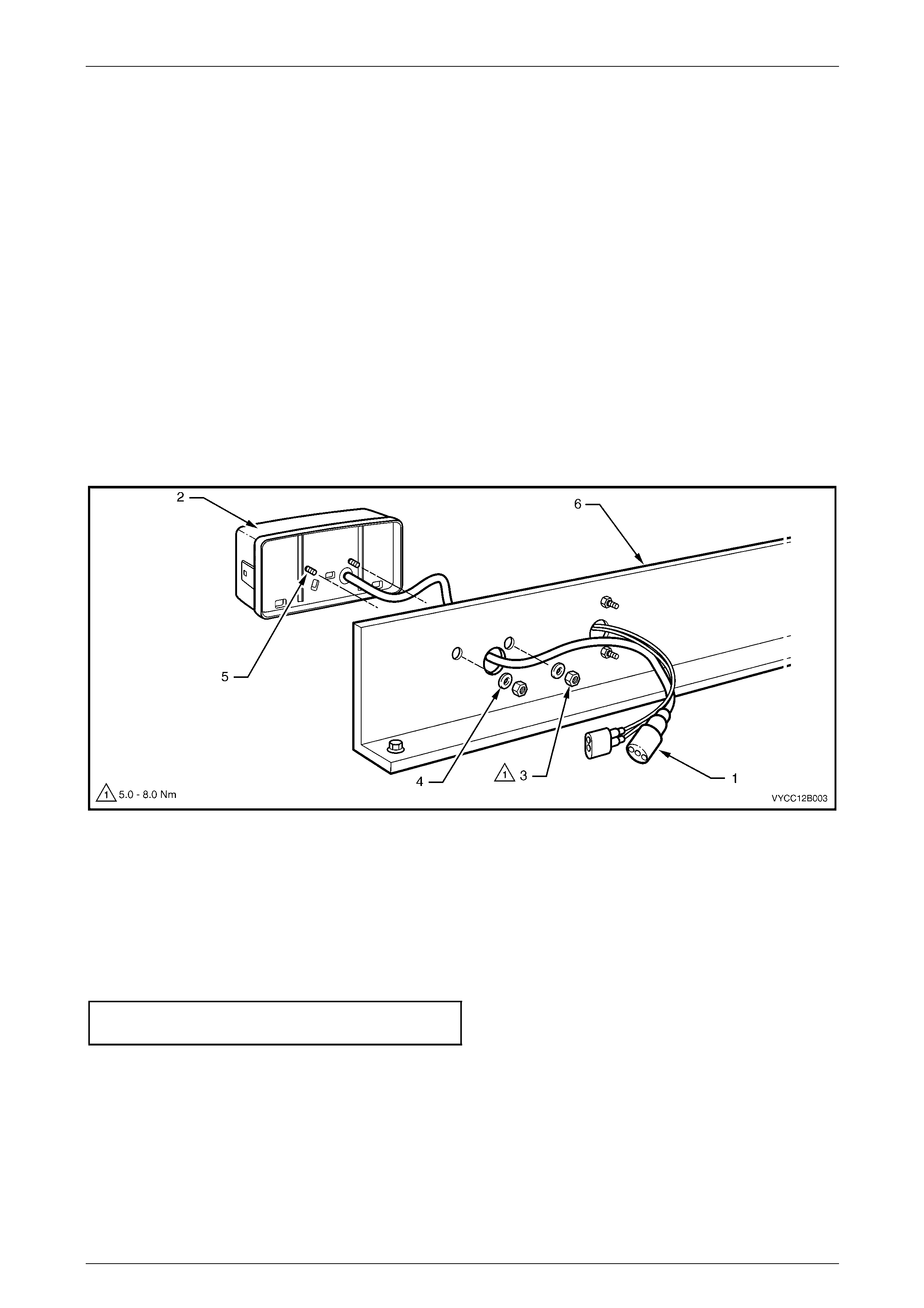

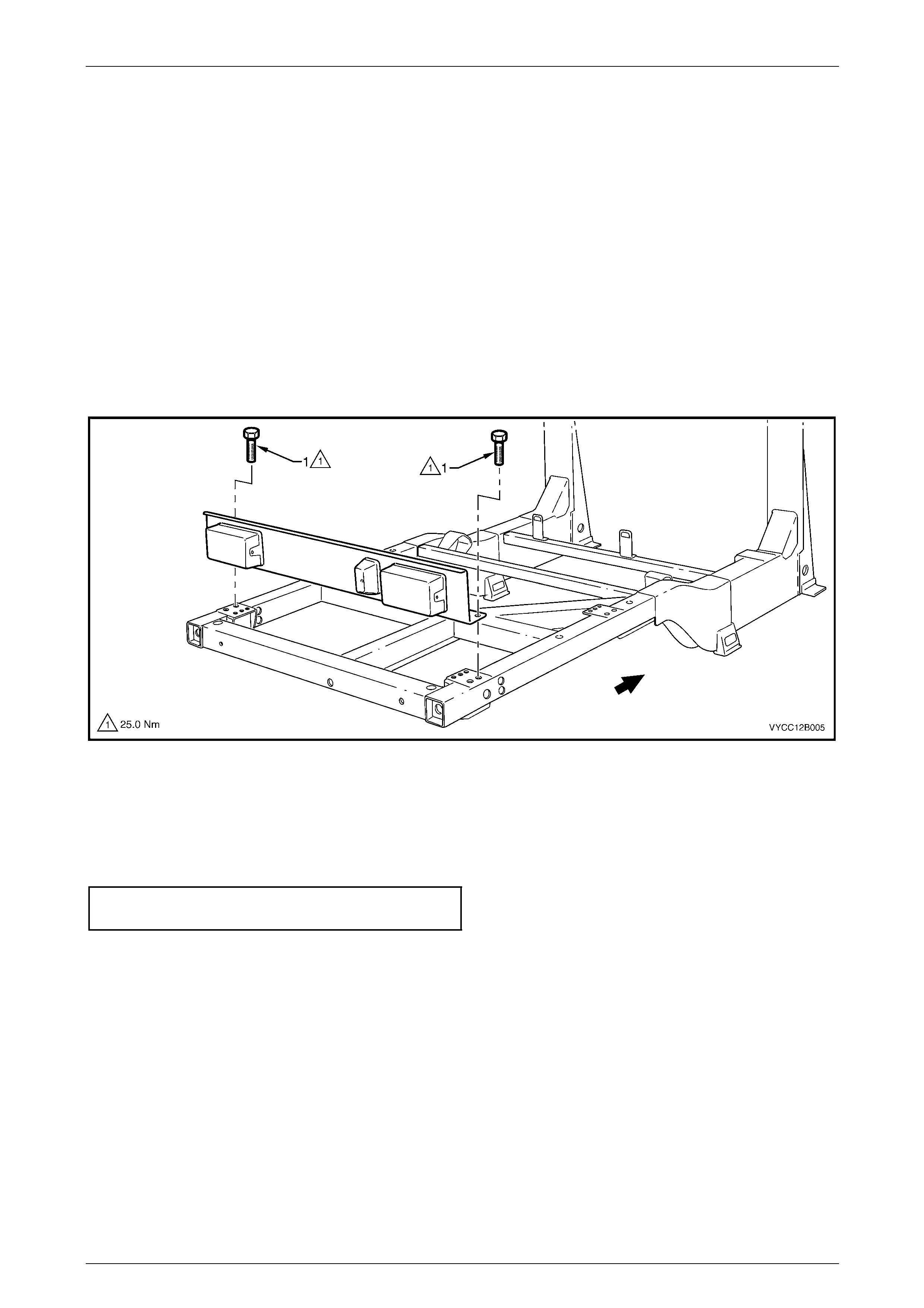

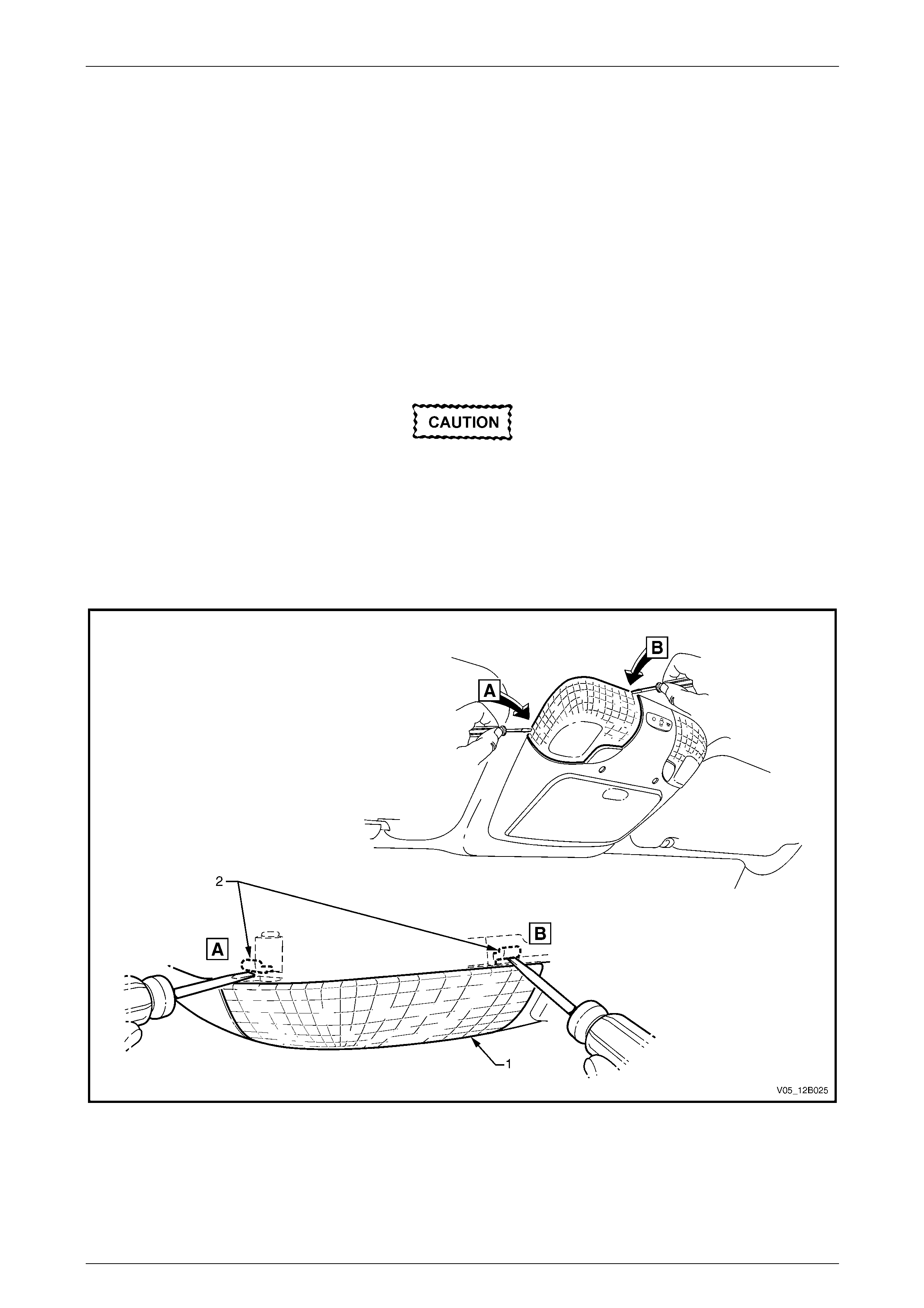

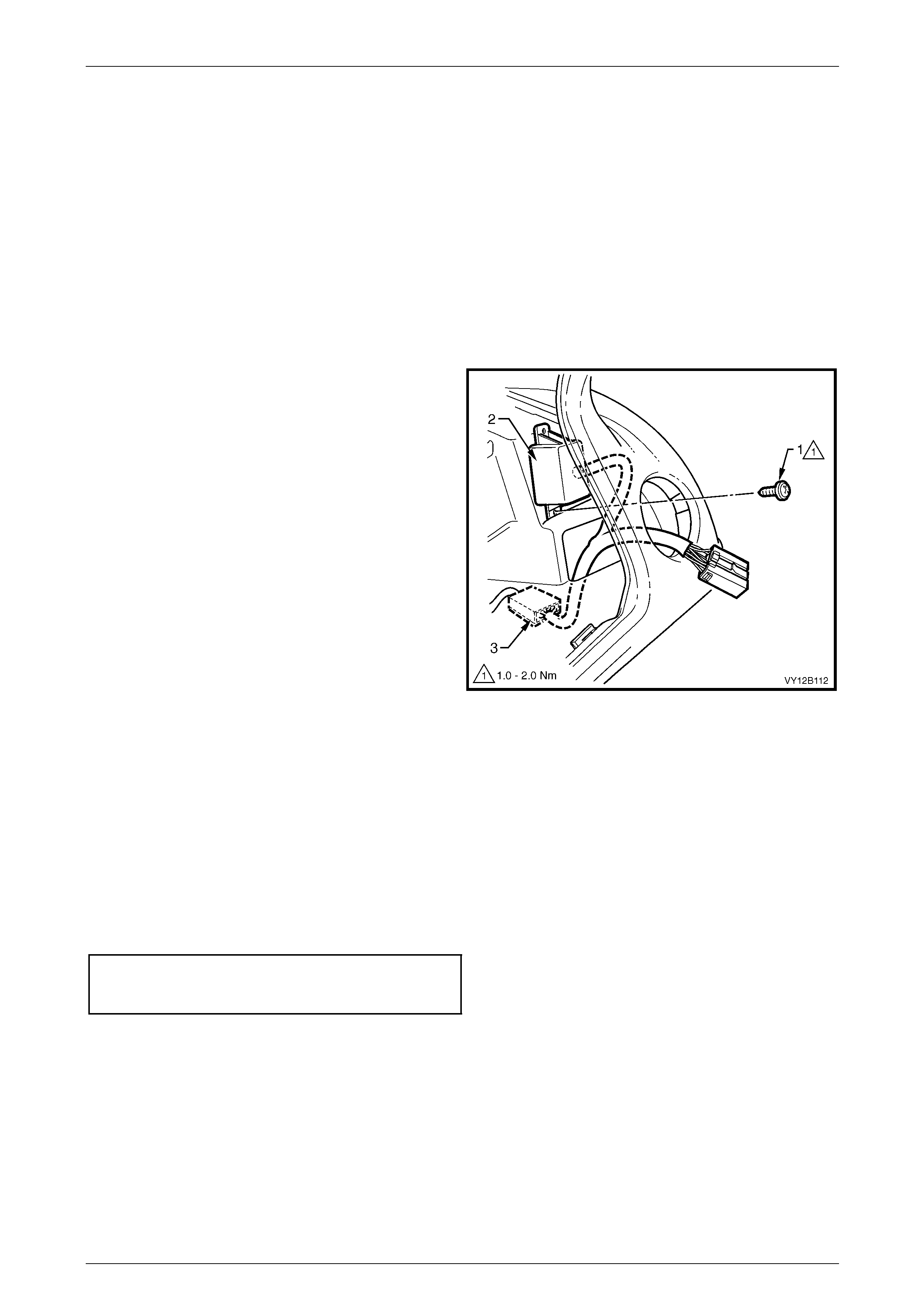

3.3 Transport Bracket

The transport bracket (1) is designed to hold tail lamp assemblies (2) and rear licence plate lamp assembly (3), refer to

Figure 12B – 16.

During tray installation, the tail lamp assembly and rear licence plate lamp assembly are removed from the transport

bracket and installed to the tray. The transport bracket is then discarded.

The attachment method of the lamp

assemblies to the tray should be similar to the

transport bracket. The position of lamp

assemblies fitted to the tray should be legally

compliant.

Custom-built and aftermarket trays are availa ble; refer to the appropriate supplier or body builder for the relevant service

information required for vehicle trays.

Figure 12B – 16

Legend

1 Transport Bracket

2 Tail Lamp Assembly 3 Rear Licence Lamp

4 Cable Tie

Lighting System Page 12B–28

Page 12B–28

4 General Information, AWD

Wagon

The following items on the AWD Wagon differ from other vehicles:

• tail lamps,

• backup lamps,

• liftgate air deflector assembly and high-mou nt stop lamp assembly, and

(A liftgate air deflector assembly and high-m ount stop lamp assembly is fitted as standard equipment on AWD

Wagon vehicles, refer to Section 1A4 Hood, Rear Compartment Lid, Liftgate and Endgate.)

• hill descent control switch.

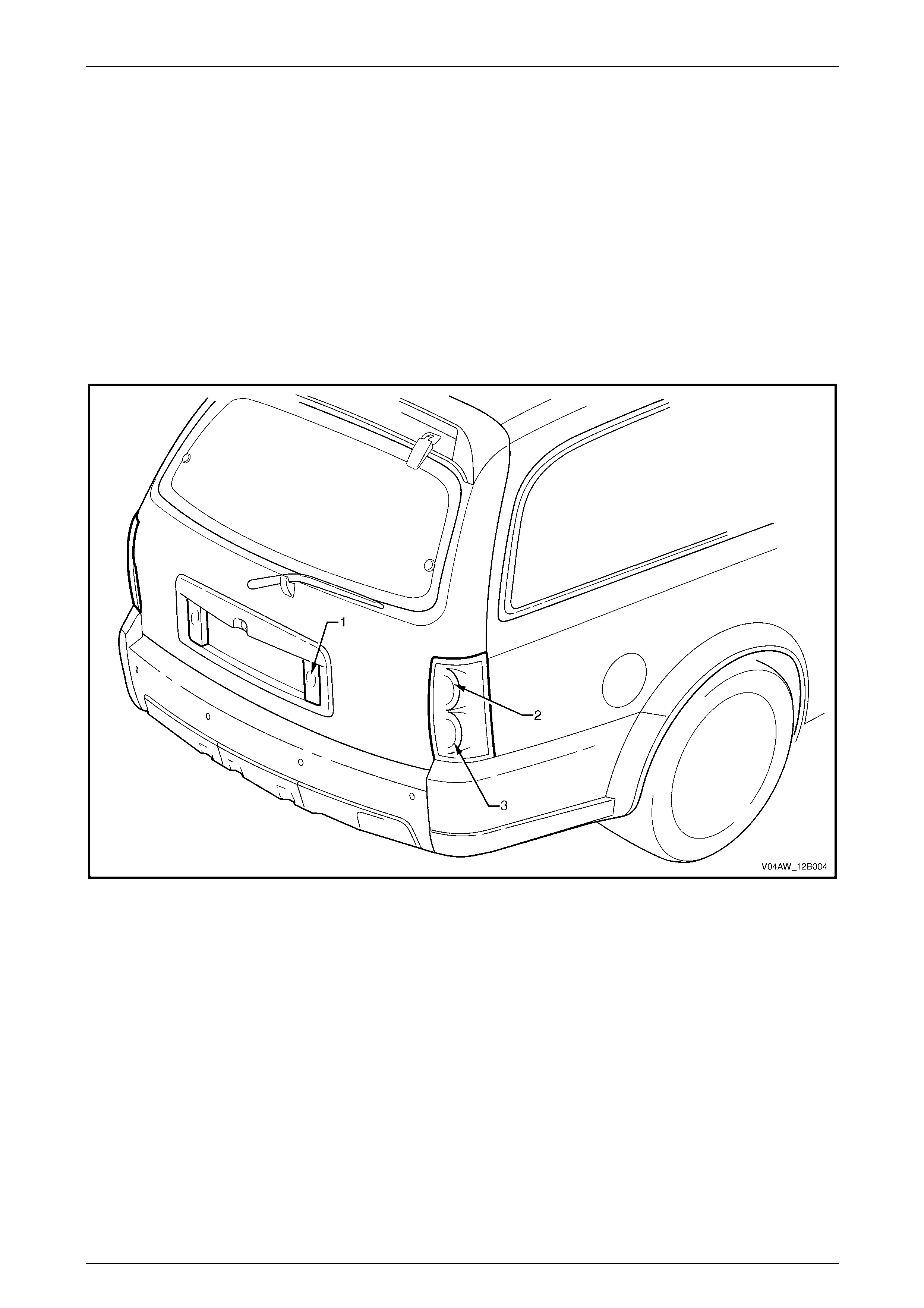

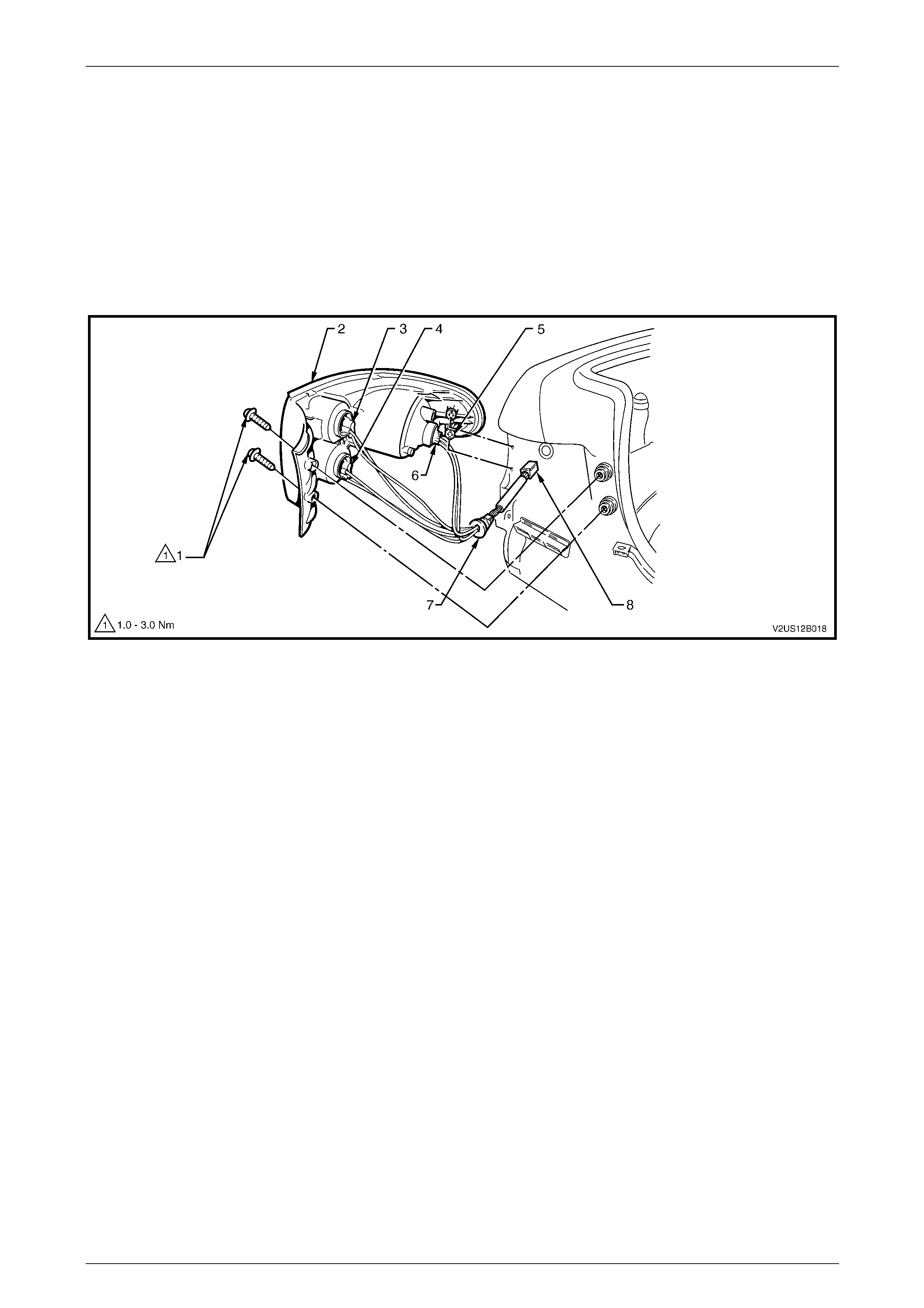

For a general vie w of the tail lamp assembli es and backup lamp assemblies, refer to Figure 12B – 17.

Figure 12B – 17

Legend

1 Backup Lamp

2 Stop/Tail Lamp 3 Turn Lamp

Lighting System Page 12B–29

Page 12B–29

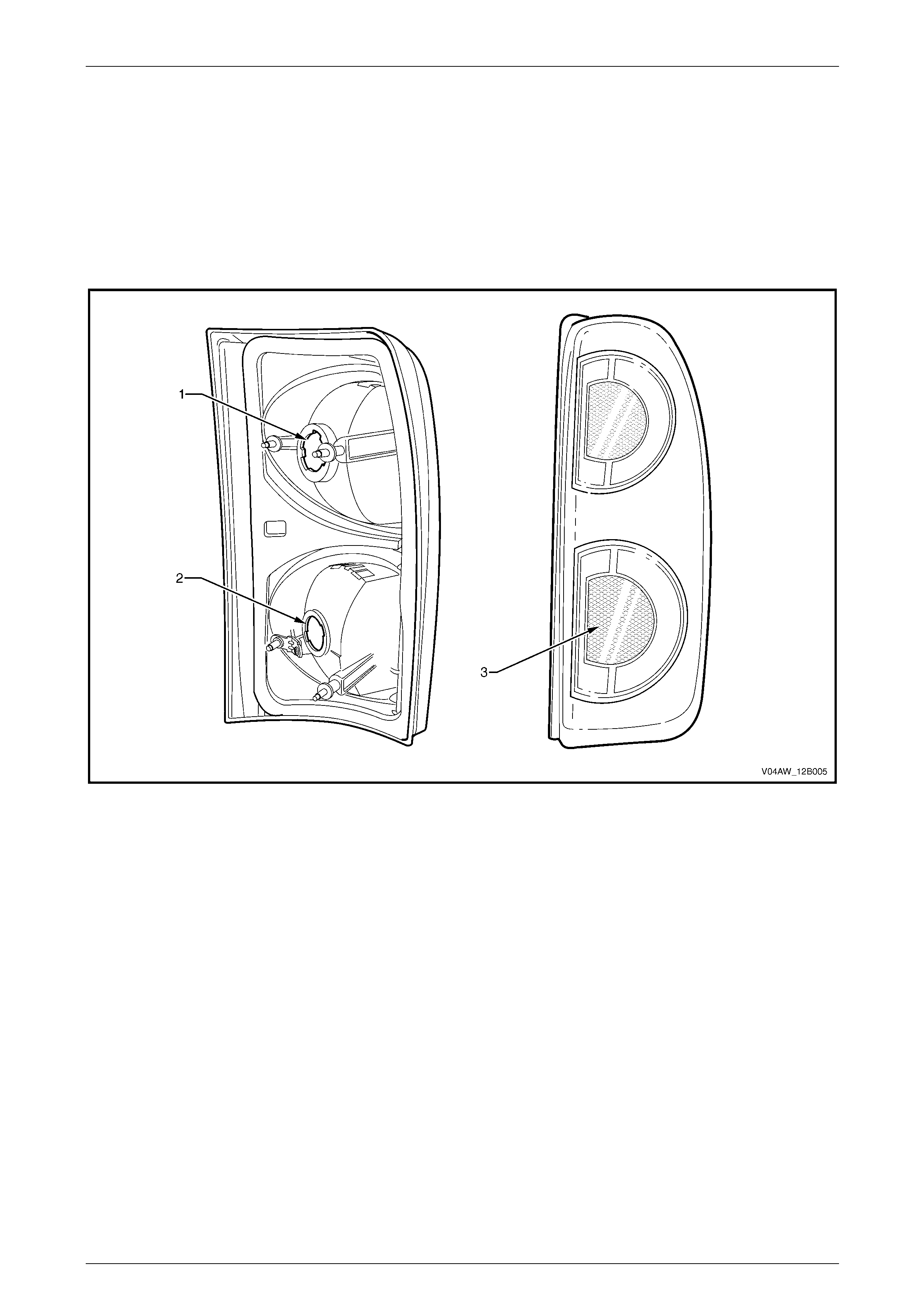

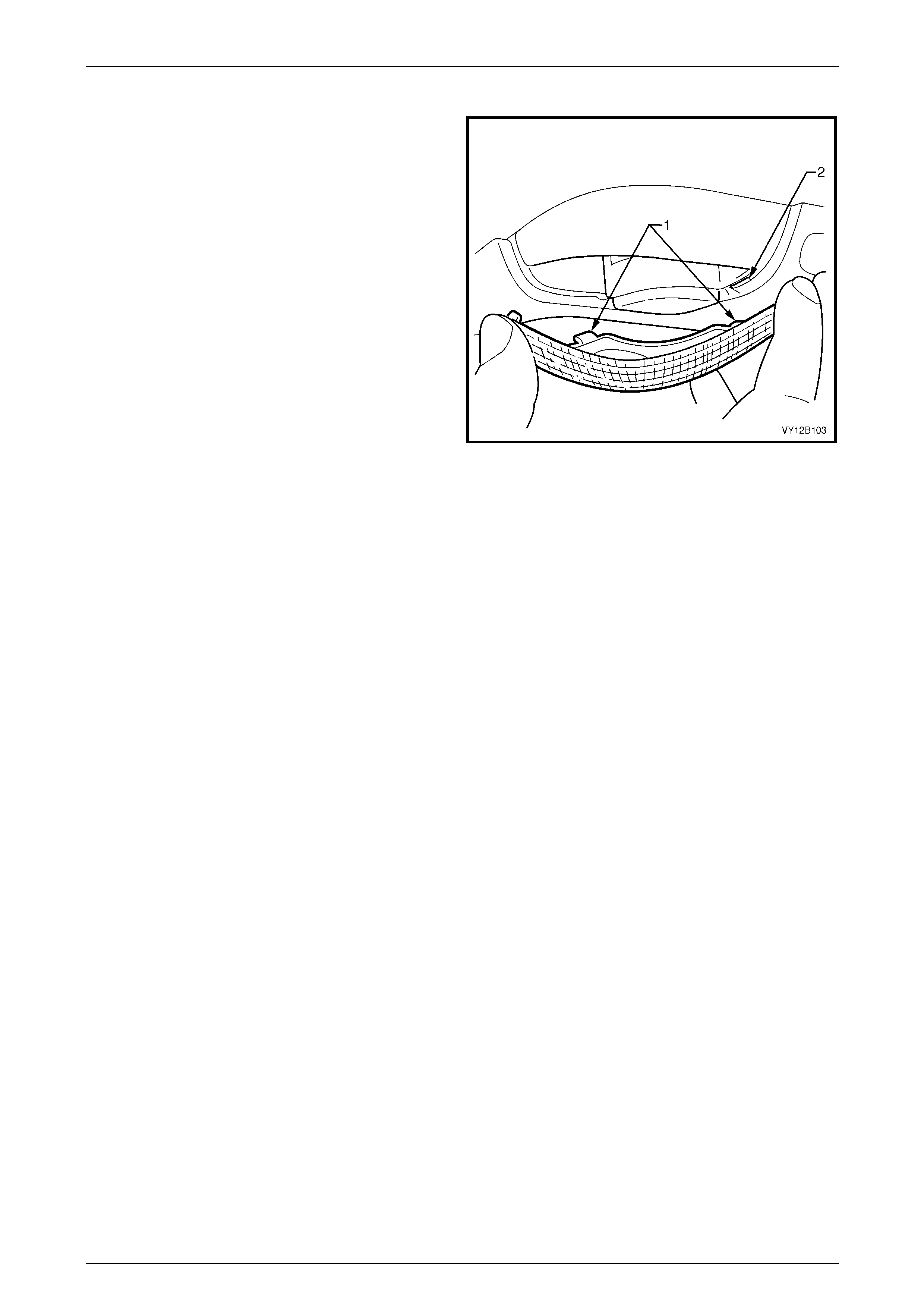

4.1 Tail Lamp Assembly

AWD Wagon tail lamp assemblies c onsist of:

• a turn signal lamp,

• a stop/tail lamp, and

• a reflex reflector.

For internal and external views of the AWD Wagon tail lamp assemb ly, refer to Figure 12B – 18.

Figure 12B – 18

Legend

1 Stop/Tail Lamp

2 Turn Lamp 3 Reflex Reflector

Lighting System Page 12B–30

Page 12B–30

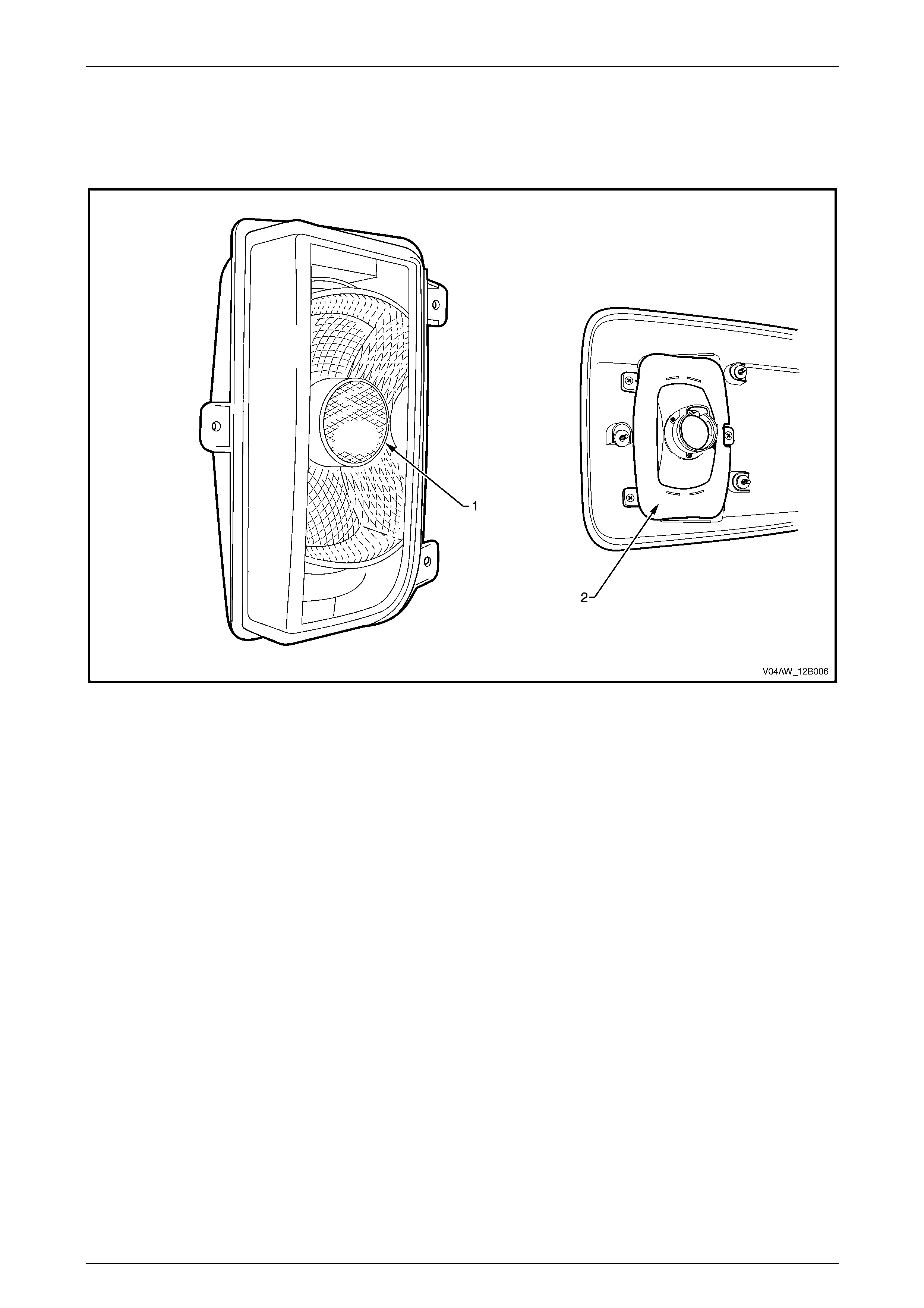

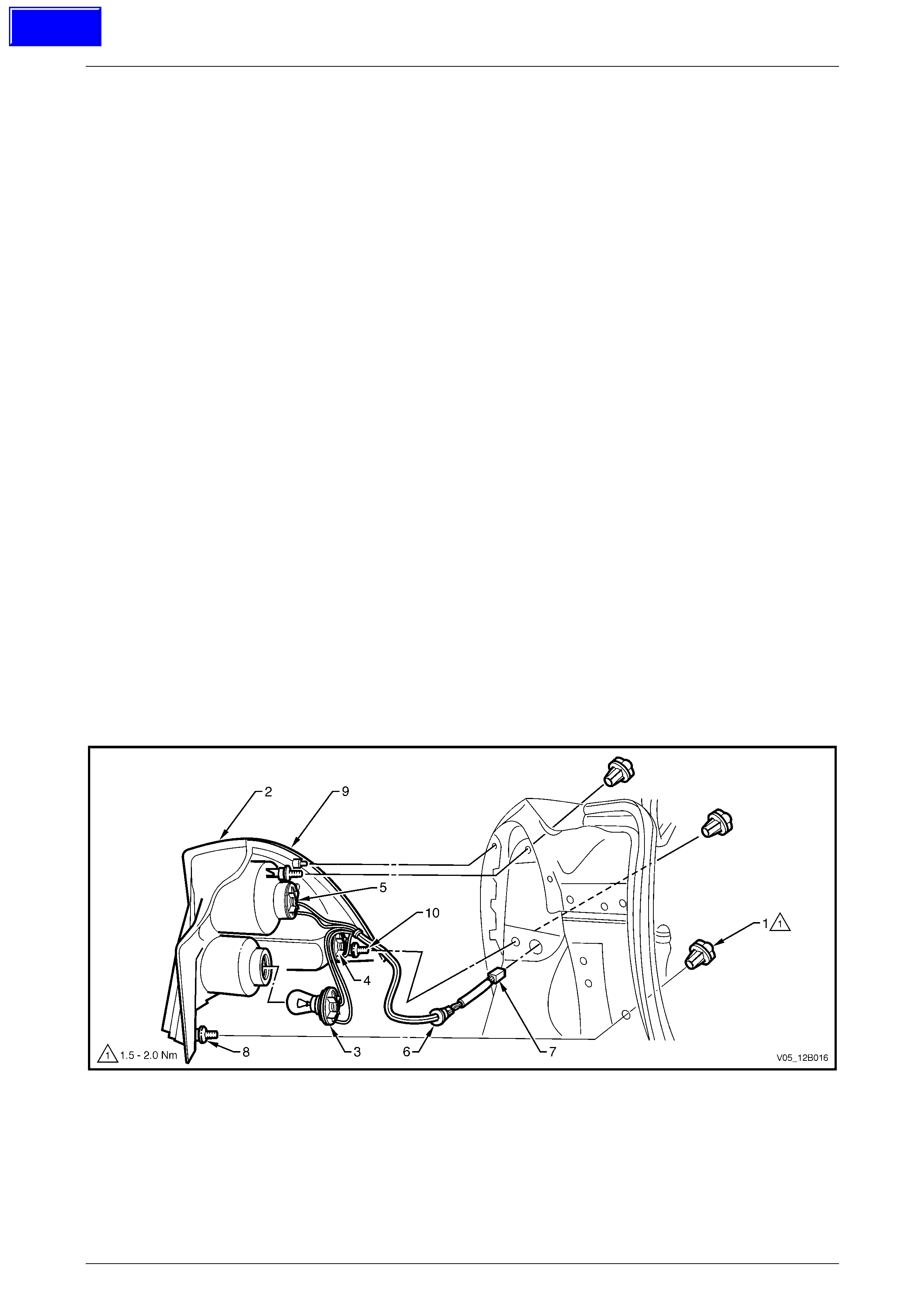

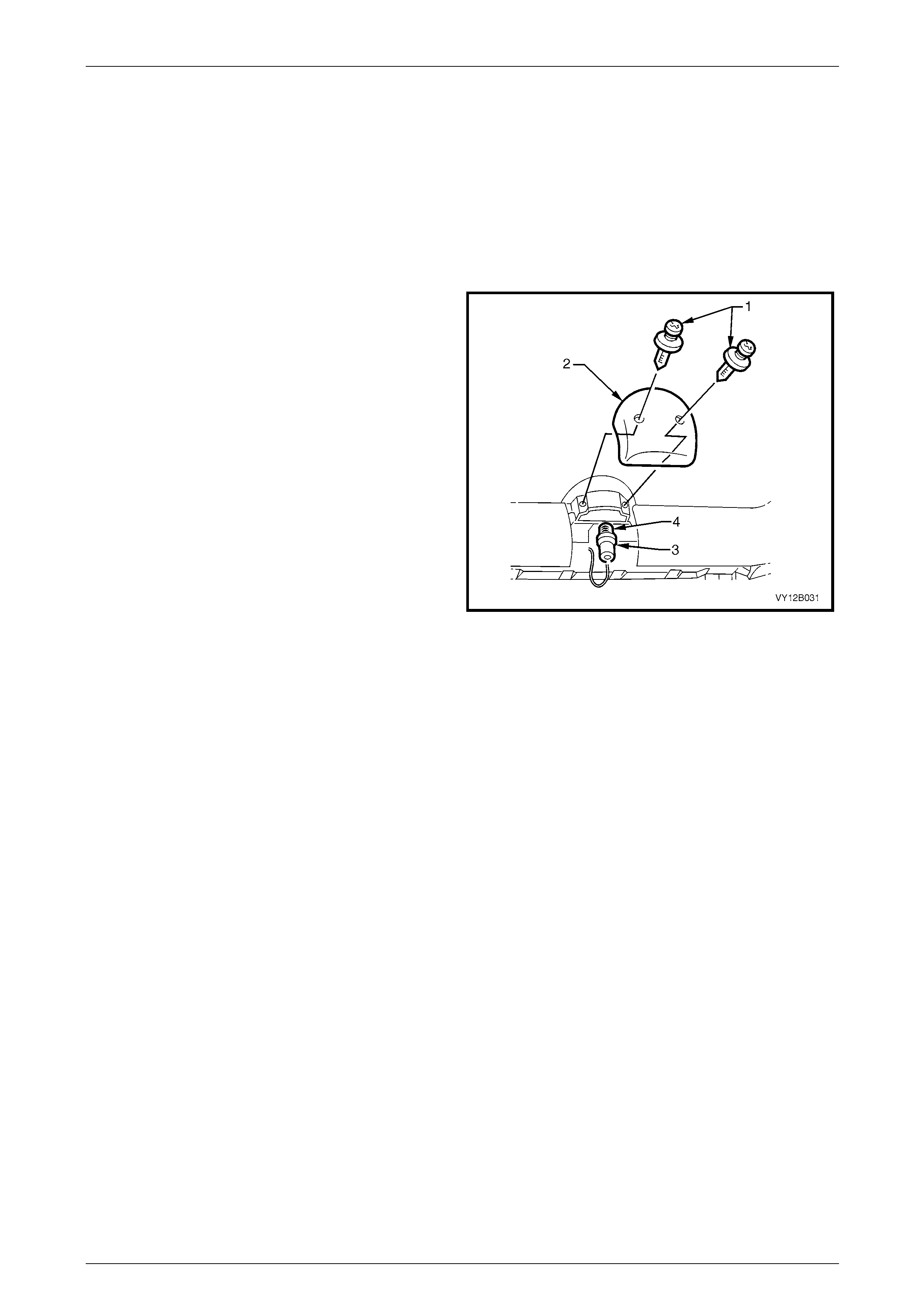

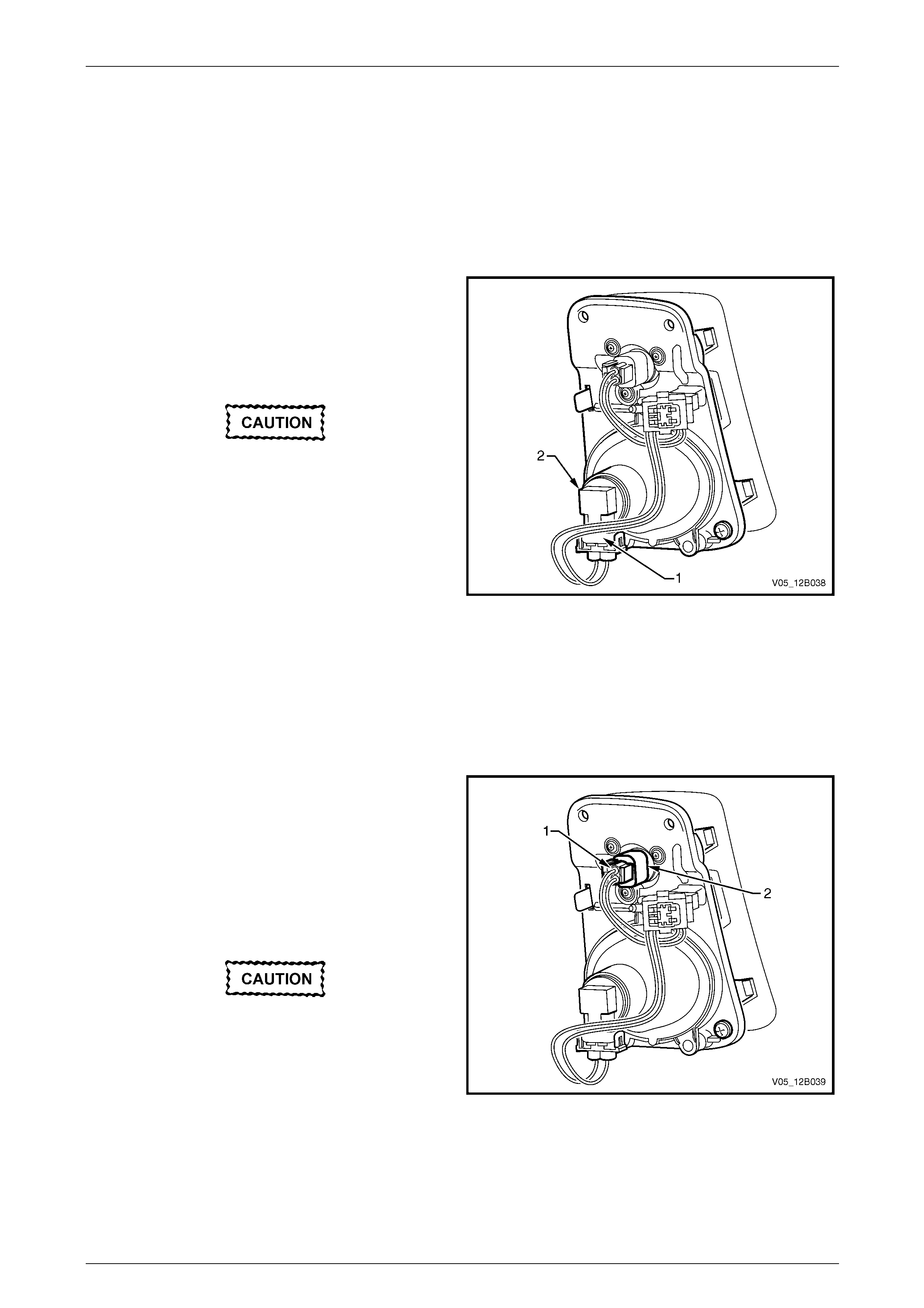

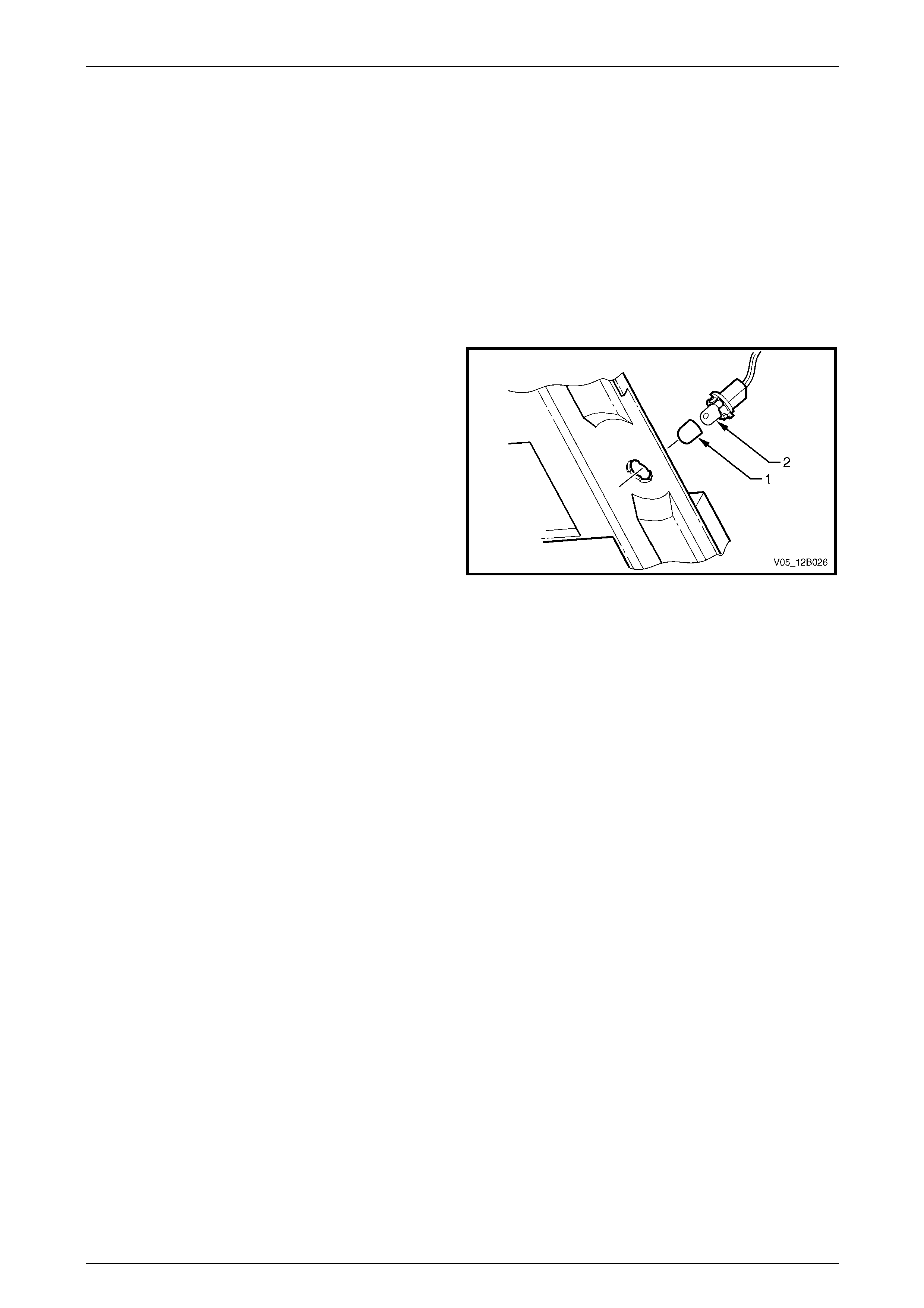

4.2 Backup Lamp Assembly

AWD Wagon backup lamp assembli es are attached to the liftgate appliqué assembly. For internal and external views of

the backup lamp assembly, refer to Figure 12B – 19.

Figure 12B – 19

Legend

1 Backup Lamp Assembly 2 Foam Rubber Seal

Lighting System Page 12B–31

Page 12B–31

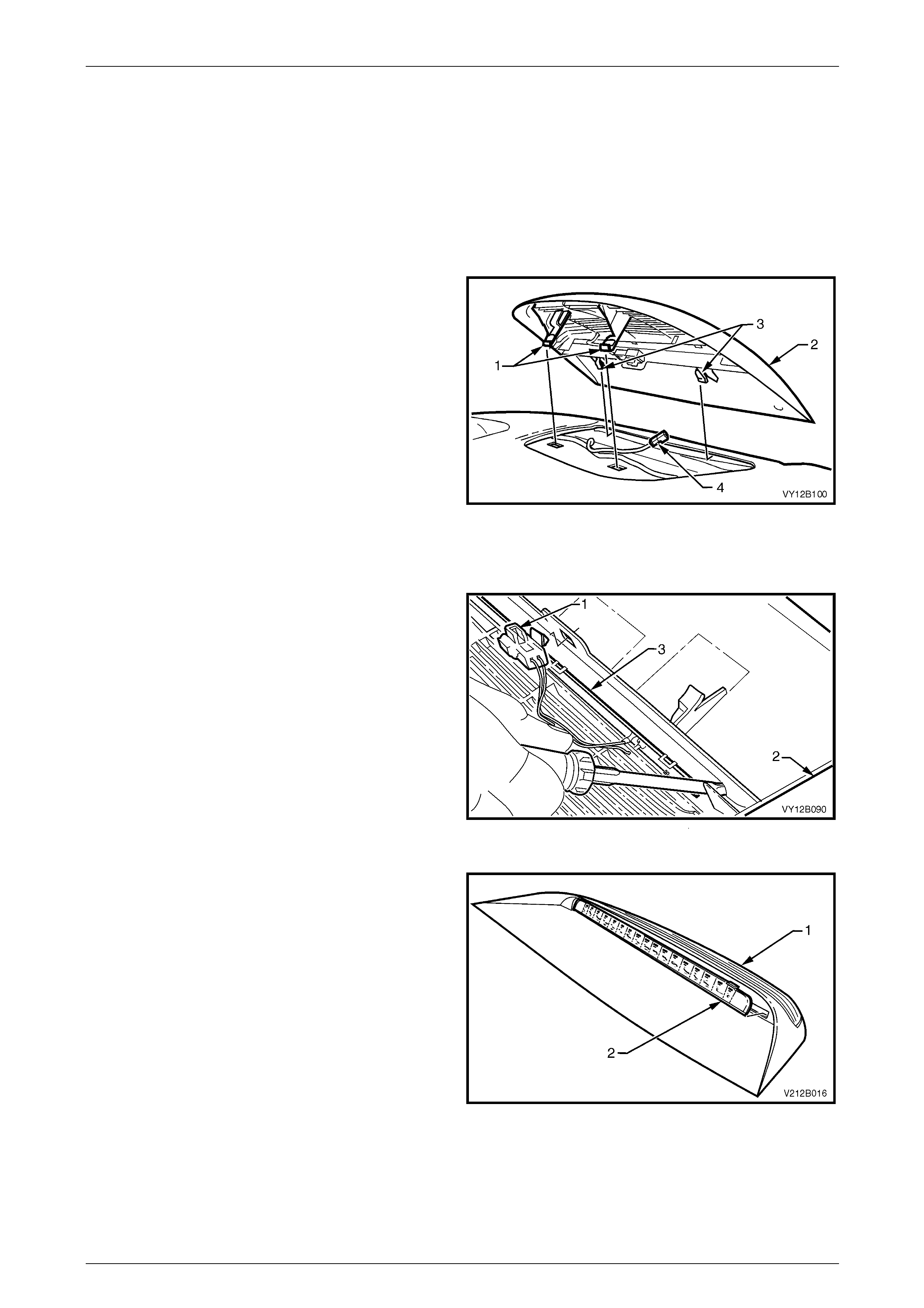

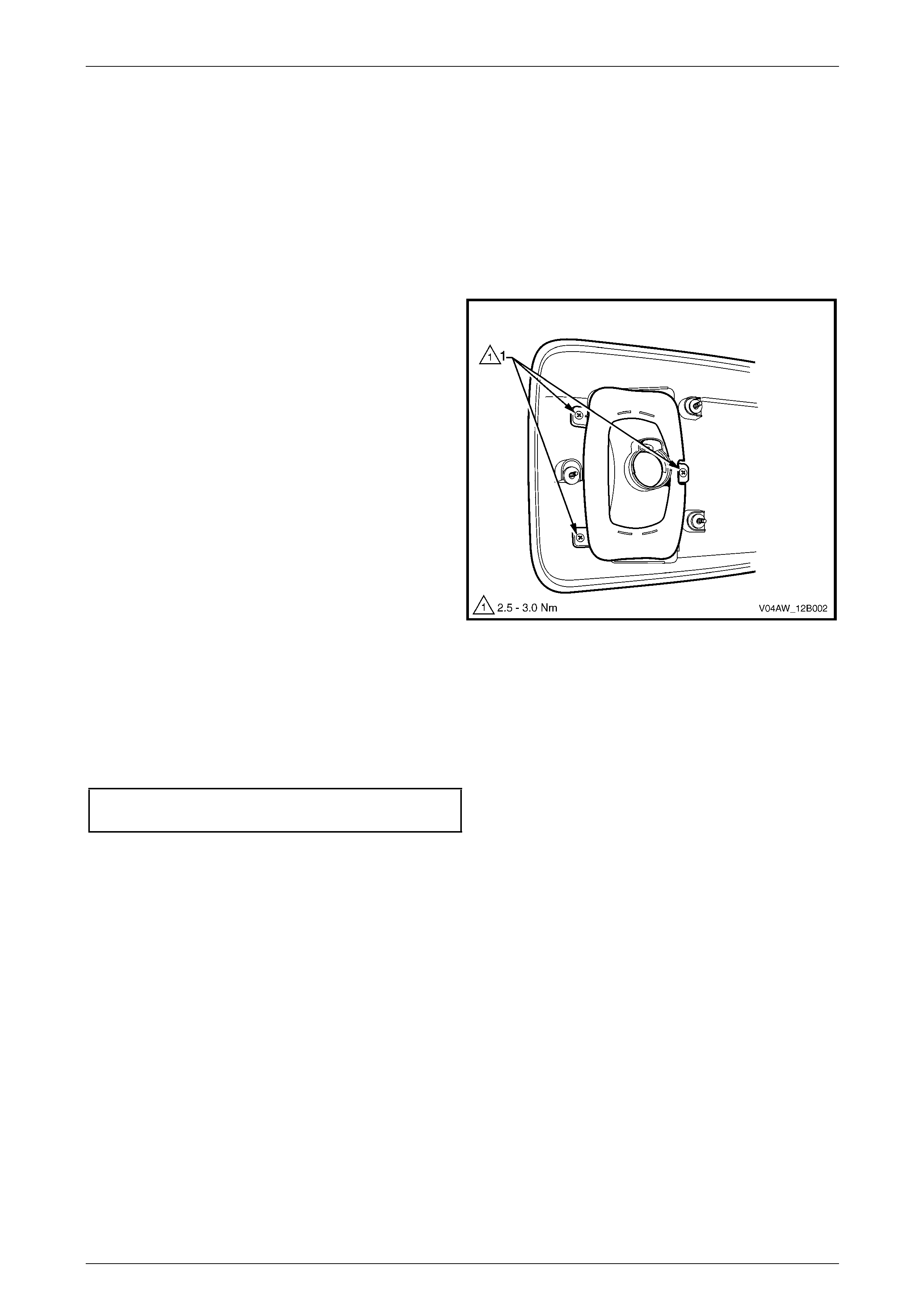

4.3 Liftgate Air Deflector Assembly and

High-mount Stop Lamp Assembly

The liftgate air deflector assembl y and high-mount stop lamp assembly is designed specifically for AWD Wagon vehicles

and is fitted as standard equipment on all AWD Wagon vehicles, refer to

Section 1A4 Hood, Rear Compartment Lid, Liftgate and Endgate.

Lighting System Page 12B–32

Page 12B–32

5 Service Operations — Exterior

Illumination, Sedan, Wagon,

Utility and Crew Cab

5.1 Headlamp and Front Fog Lamp Aiming

During headlamp assembly aiming, use a

cloth or similar material to cover the lens of

the headlamp assembly being adjusted. Do

not cover the beam o f the headlamp asse mbly

not being adjusted. Damage to the headlamp

assembly will result if the headlamp beam is

obstructed in this manner.

The headlamp assemblies (and front fog lamp assemblies, if fitted) must be correctly aimed to obtain the maximum road

illumination and safet y. Headl amps and front fog lamps must be checked for correct aim whenever a b ulb or lamp

assembly is replaced and after an y adjustments or repairs to the front-end sheetmetal.

Headlamp aiming devices are in general use. When usin g one of these devices, ensure that it is in good condition;

carefully follow the instructions of the manufacturer.

Regardless of the method used for checking headlam p and front fog lamp aim, the vehicle must be at kerb weight (that

is, with full fuel level, oil, water and spare t yre , but no passengers). Tyres must be unifor mly inflated to their specified

pressure.

NOTE

If the vehicle regularly carries an unusual load in

the rear compartment or if it is used to tow a

trailer, these loads should be on th e vehic le when

the headlamps and front fog lamps are checked.

Headlamp Assembly Aim

LT Section No. — 02–300

NOTE

Use this procedure only when suitable test

equipment is unavailable.

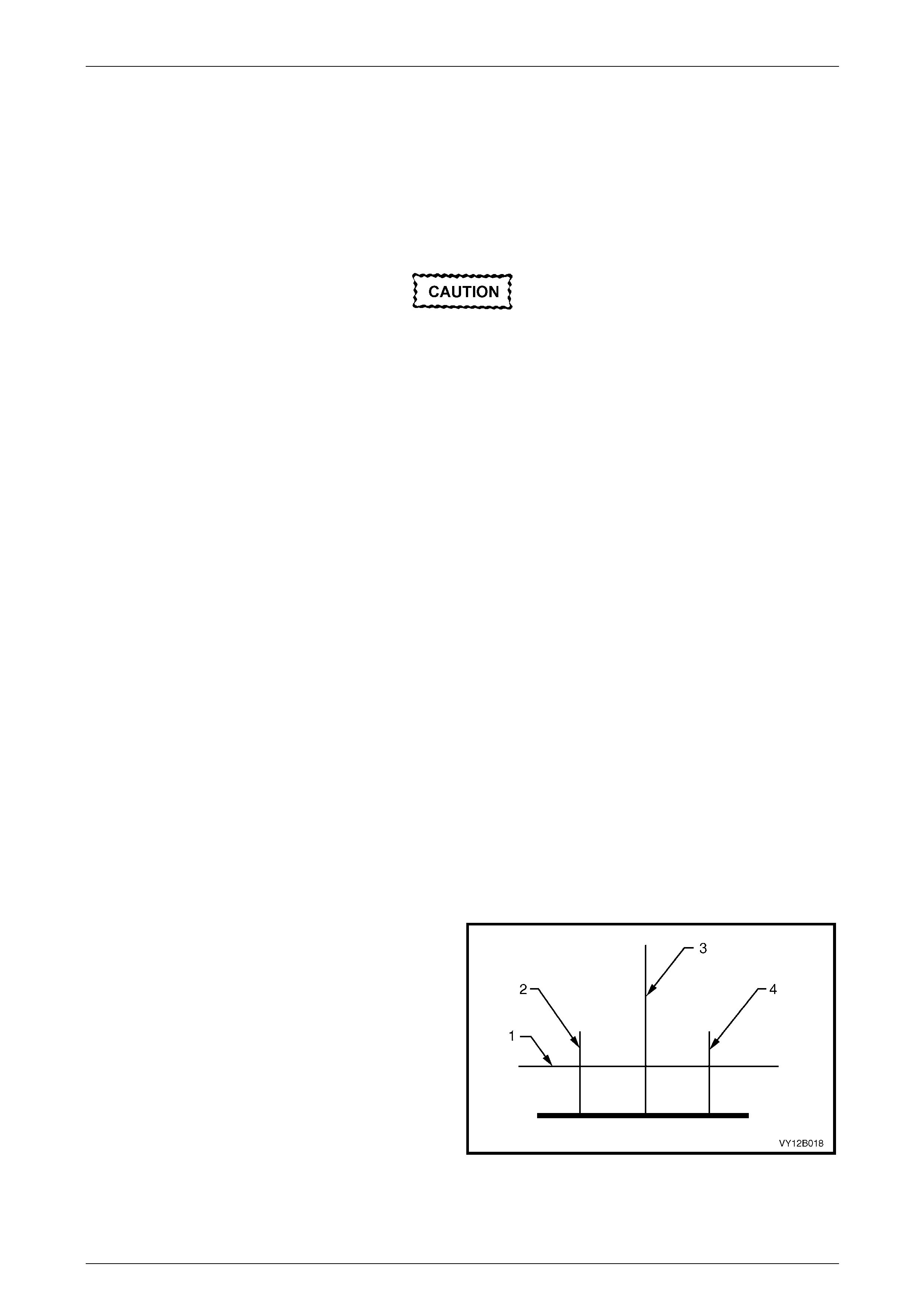

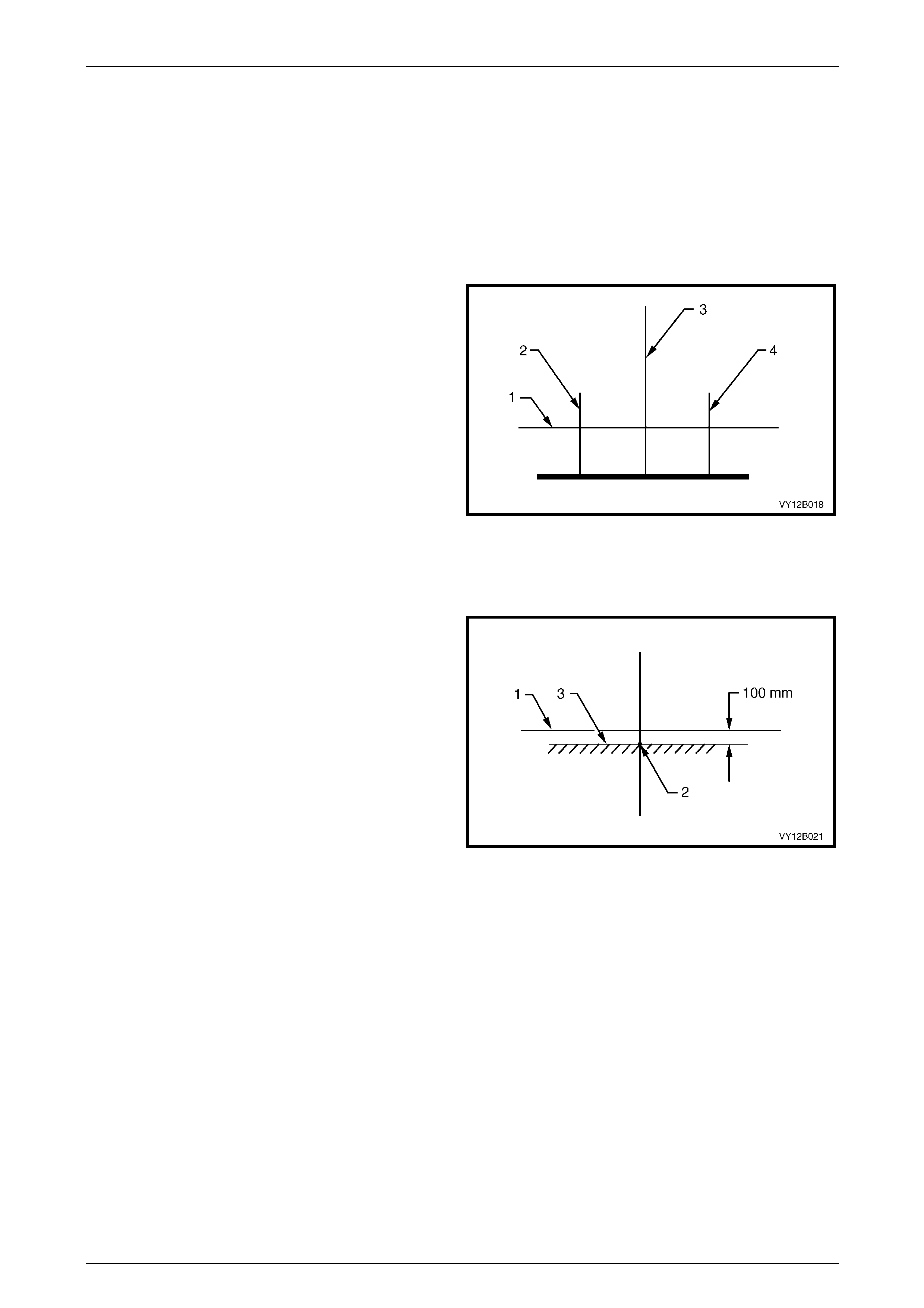

1 Set up a screen or use a vertical wall with a flat

horizontal floor. Park the vehi cle immediately in front

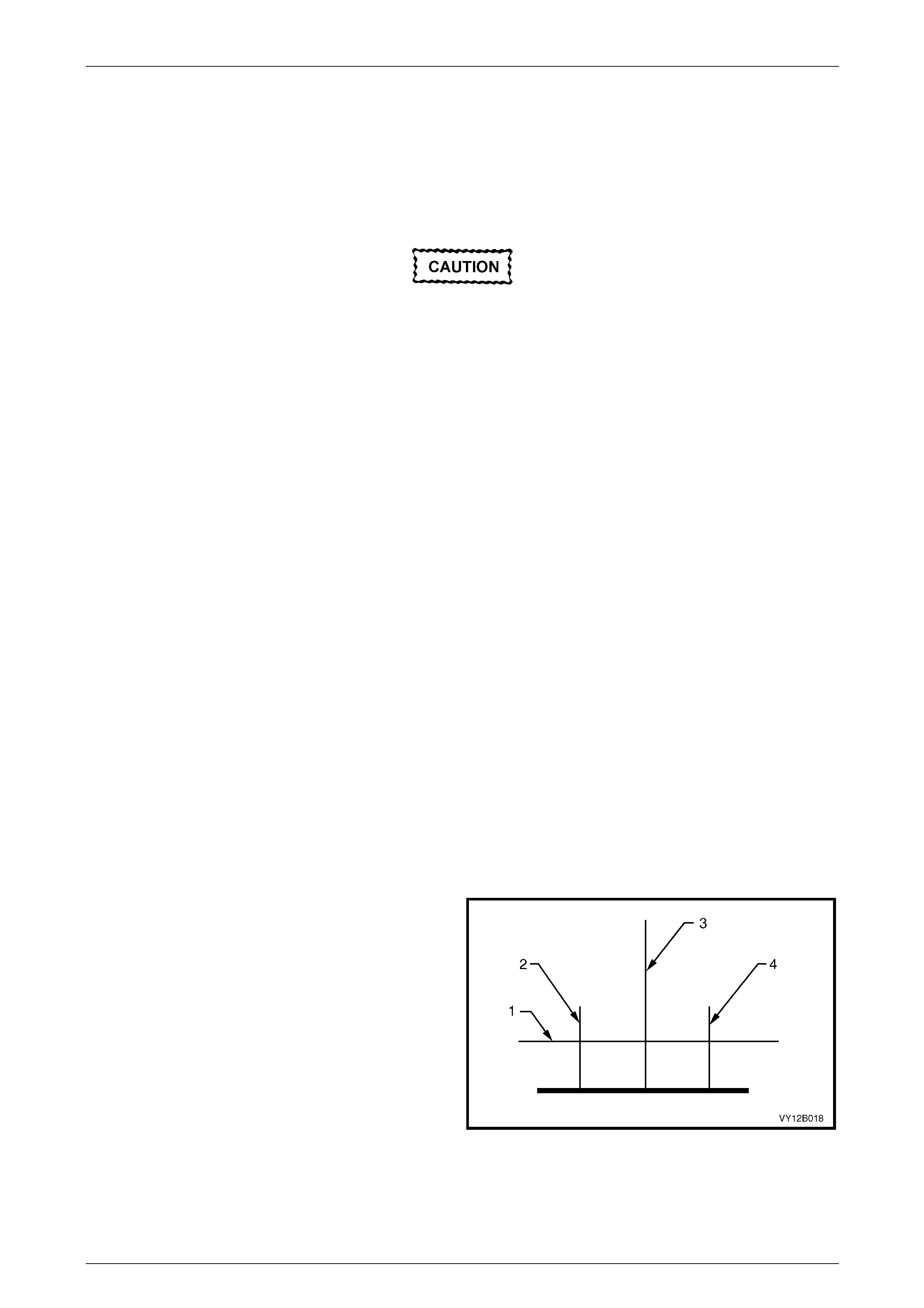

of the screen or wall and mark the follo wing li nes:

a a vertical centre-line (3), corresponding to the

centre of the vehicle;

b two vertical lines (2 and 4), corresponding to the

centre of the low beam bulb on each side of the

vehicle; and

c a horizontal line (1) corresponding to the centre

of the low beam bulb.

2 Turn on the headlights to check if the marks are

correctly positioned. Figure 12B – 20

3 Reverse the vehicle straight back so the front is five metres in front of the screen or wall, ensuring the centre of the

vehicle is aligned with the vehicle centre-line mark (3) on the screen.

Lighting System Page 12B–33

Page 12B–33

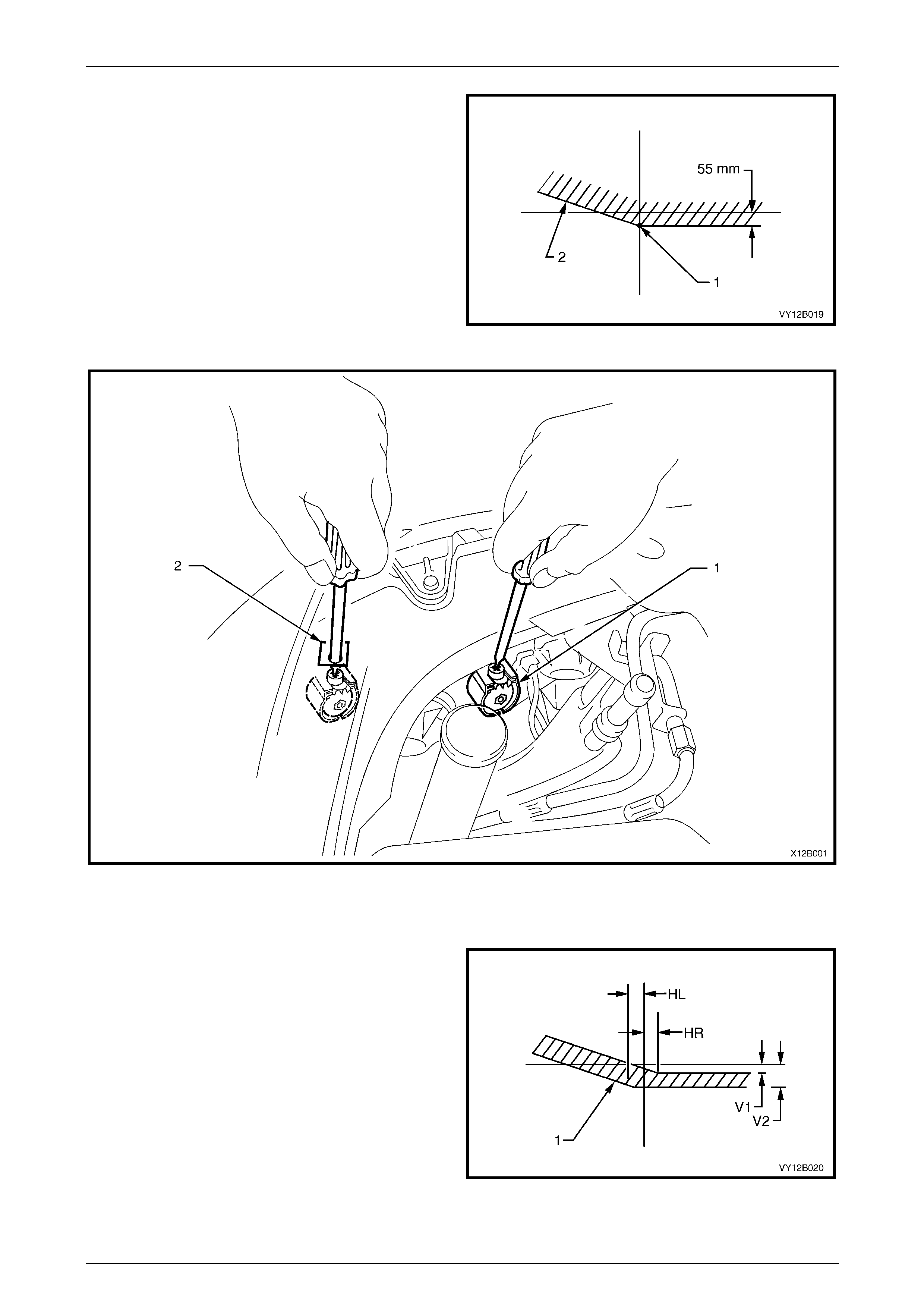

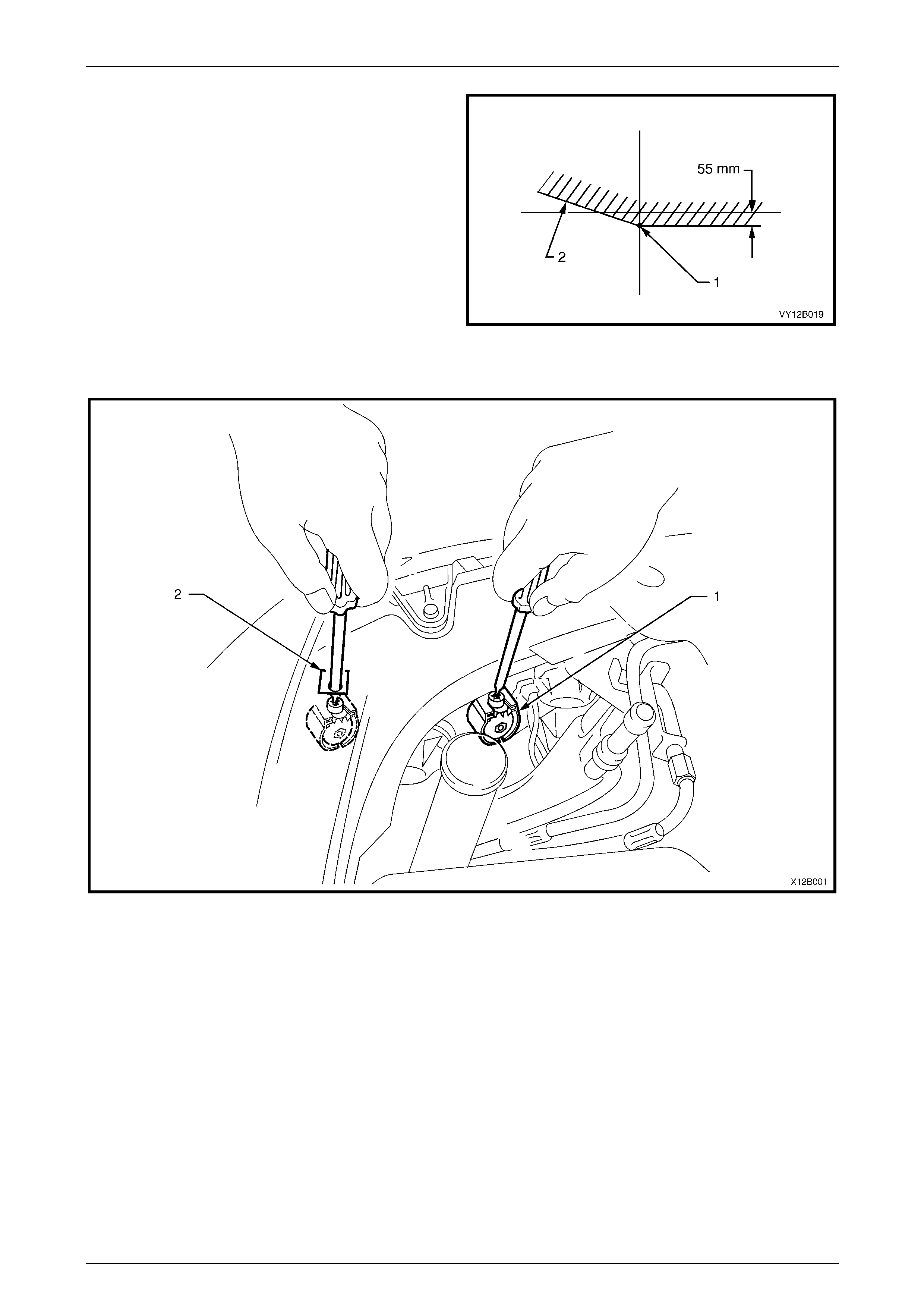

4 Aim each headlamp to a point (1) on its vertical centre-

line, 55 mm below the headlamp horizontal centre-line.

Item 2 is the cut-off line. To adjust the headlamp

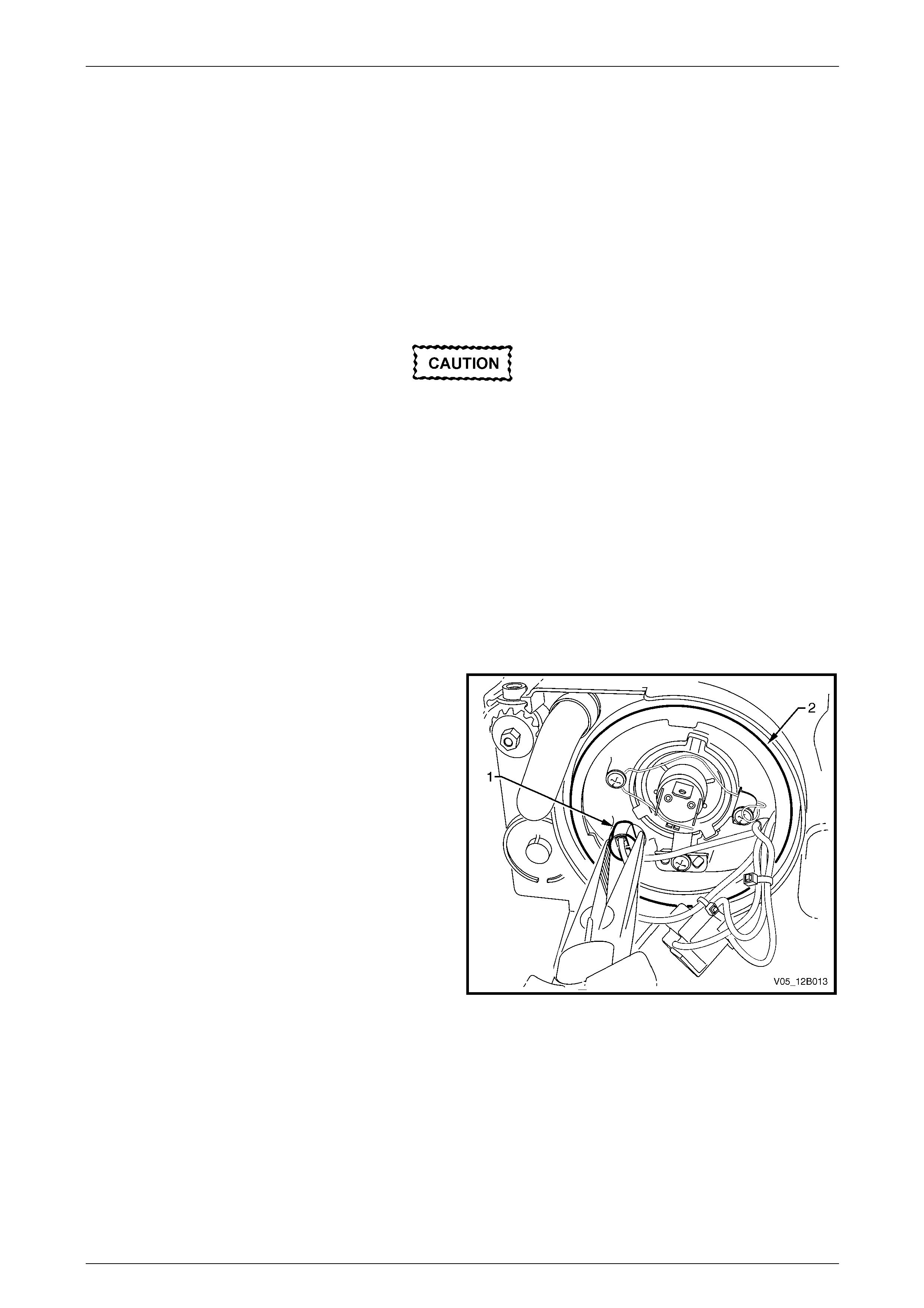

assembly, refer to Figure 12B – 22:

a Rotate the inboard adjuster (1) to move the

beam vertically.

b Rotate the outboard adjuster (2) to move the

beam horizontally.

Aiming directions for each adjuster are printed on the

headlamp assembly.

Figure 12B – 21

Figure 12B – 22

Legend

1 Inboard Adjuster 2 Outboard Adjuster

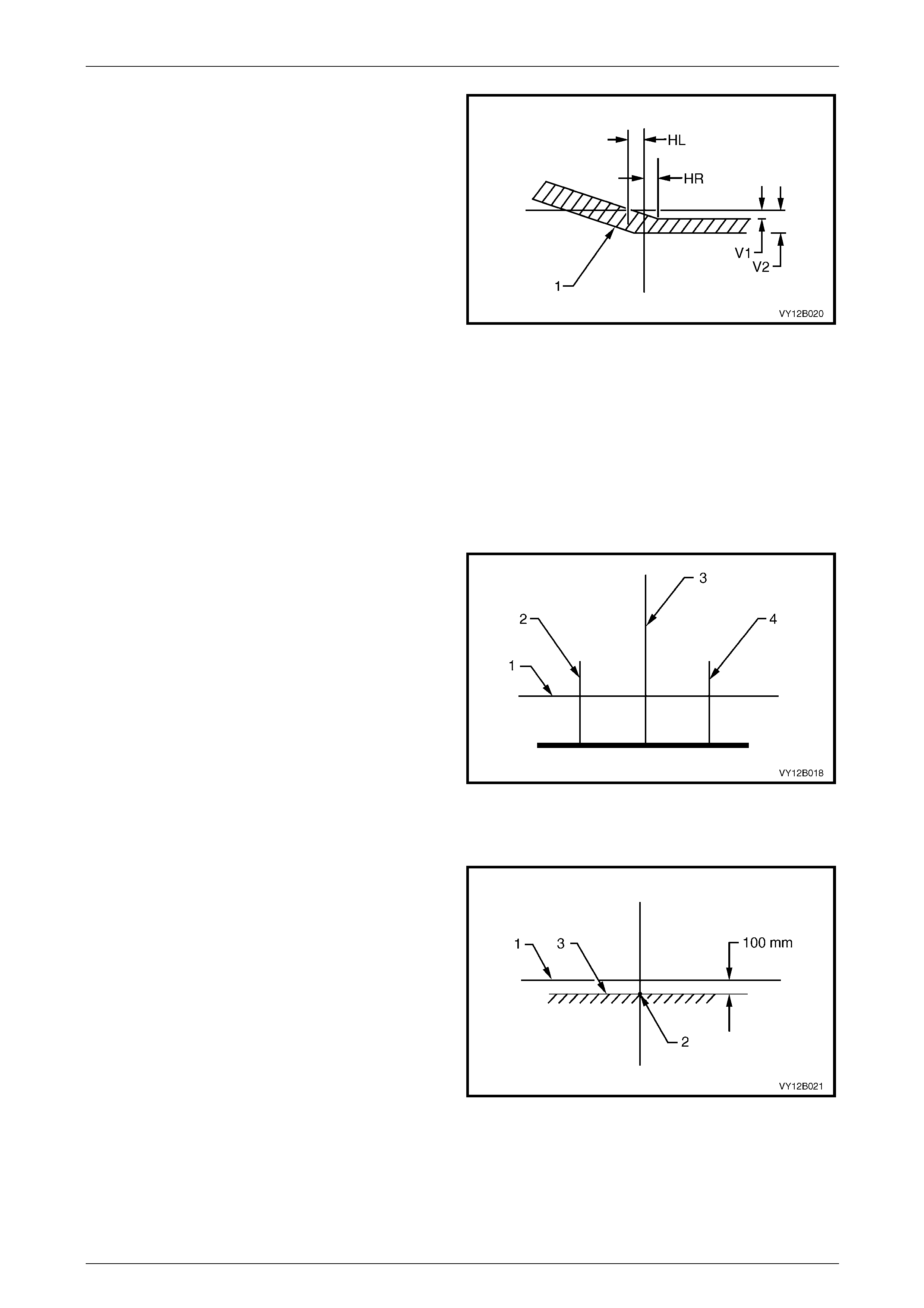

5 The allowable variations on headlamp aiming point

settings shown in Figure 12B – 23 are:

HL 50 mm

HR 0 mm

V1 50 mm

V2 60 mm

Maximum allowable vertical variation between any pair of

headlamps must not exceed 1 0 mm.

NOTE

The cut-off line must be within the shaded

zone (1). Figure 12B – 23

Lighting System Page 12B–34

Page 12B–34

Front Fog Lamp Assembly Aim

LT Section No. — 02–300

The aiming procedures for front fog lamps is the same for all vehicles.

NOTE

Use this procedure only when suitable test

equipment is unavailable.

1 Set up a screen or use a vertical wall, with a flat

horizontal floor. Park the vehi cle immediately in front

of the screen or wall and mark the follo wing li nes:

a a vertical centre-line (3) that corresponds to the

centre of the vehicle;

b two vertical lines (2 and 4), corresponding to the

centre of the front fog lamp bulb on each side of

the vehicle; and

c a horizontal line (1) that corresponds to the

centre of the front fog lamp bulb.

2 Turn on the front fog lamps to check whether the

marks are correctly positioned.

3 Reverse the vehicle straight back so the front is five

metres in front of the screen or wall, ensuring the

centre of the vehicle is aligned with the vehicle centre-

line mark (3) on the screen.

Figure 12B – 24

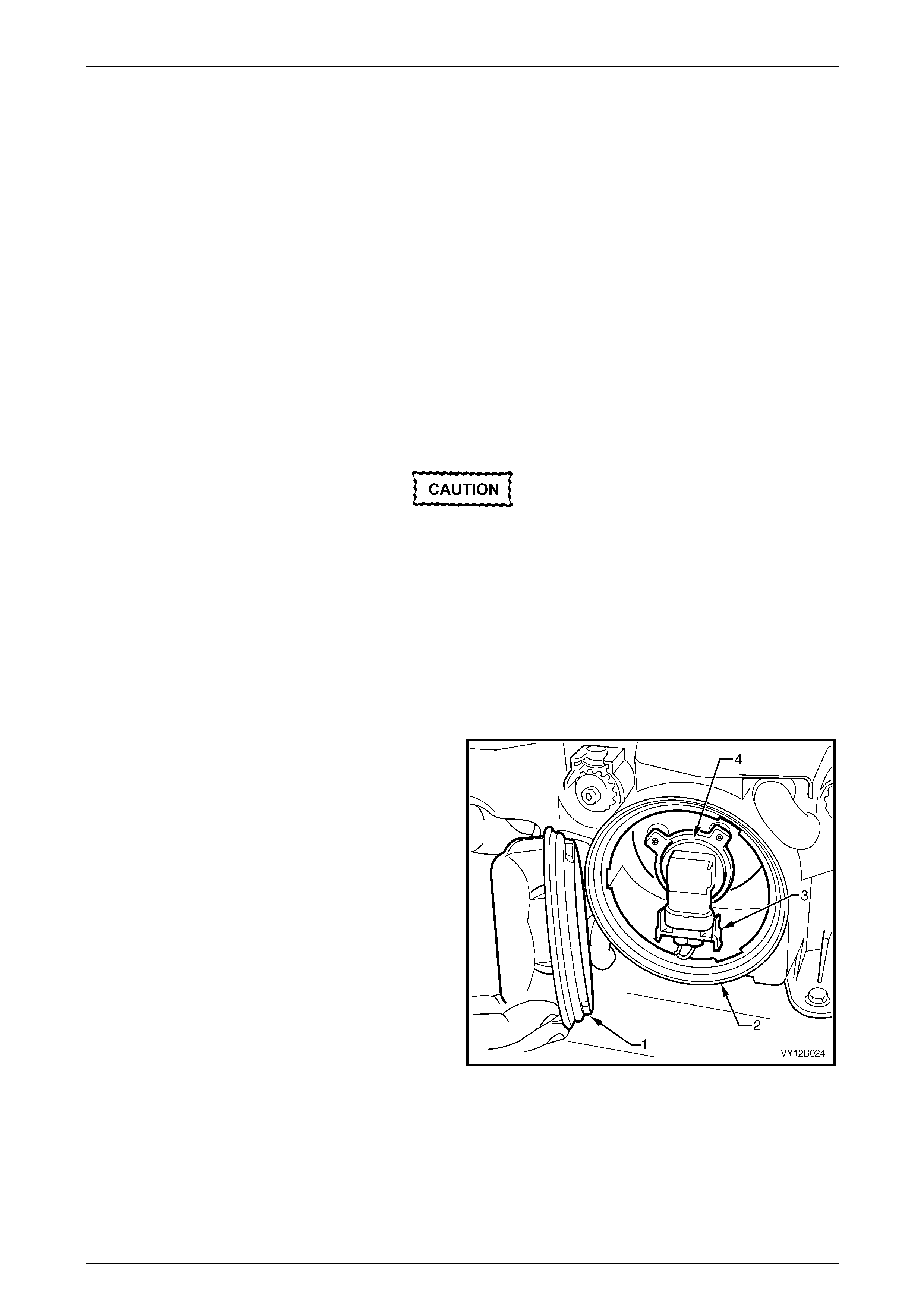

4 Turn on the front fog lamps. Aim each front fog lamp to

a point on its vertical centre-line (2), with the cut-off

line (3) 100 mm below the front fog lamp horizontal

centre-line (1).

NOTE

There is no provision for horizontal adjustment.

Front fog lamps are fixed to a vertical centre-line.

Figure 12B – 25

Lighting System Page 12B–35

Page 12B–35

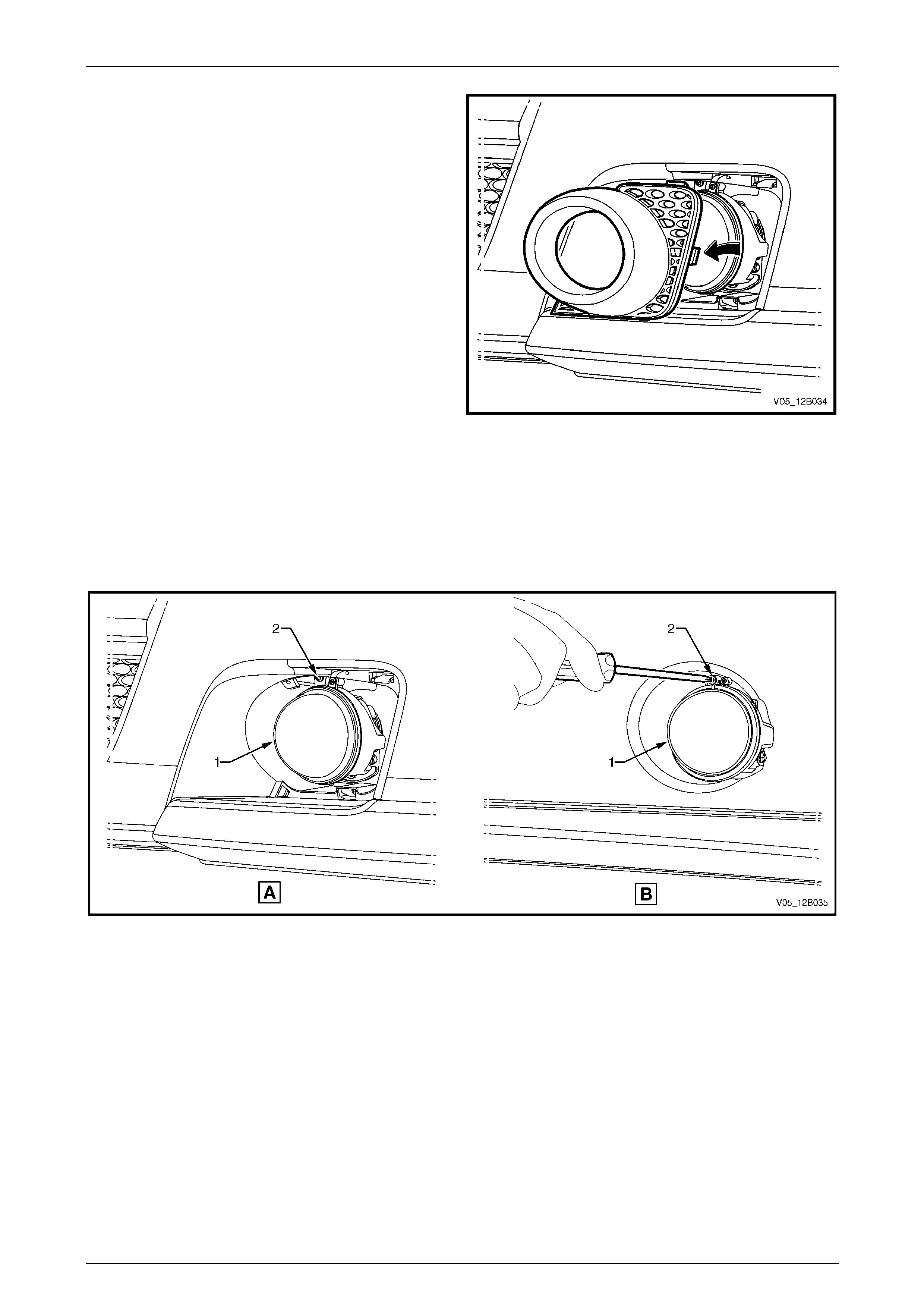

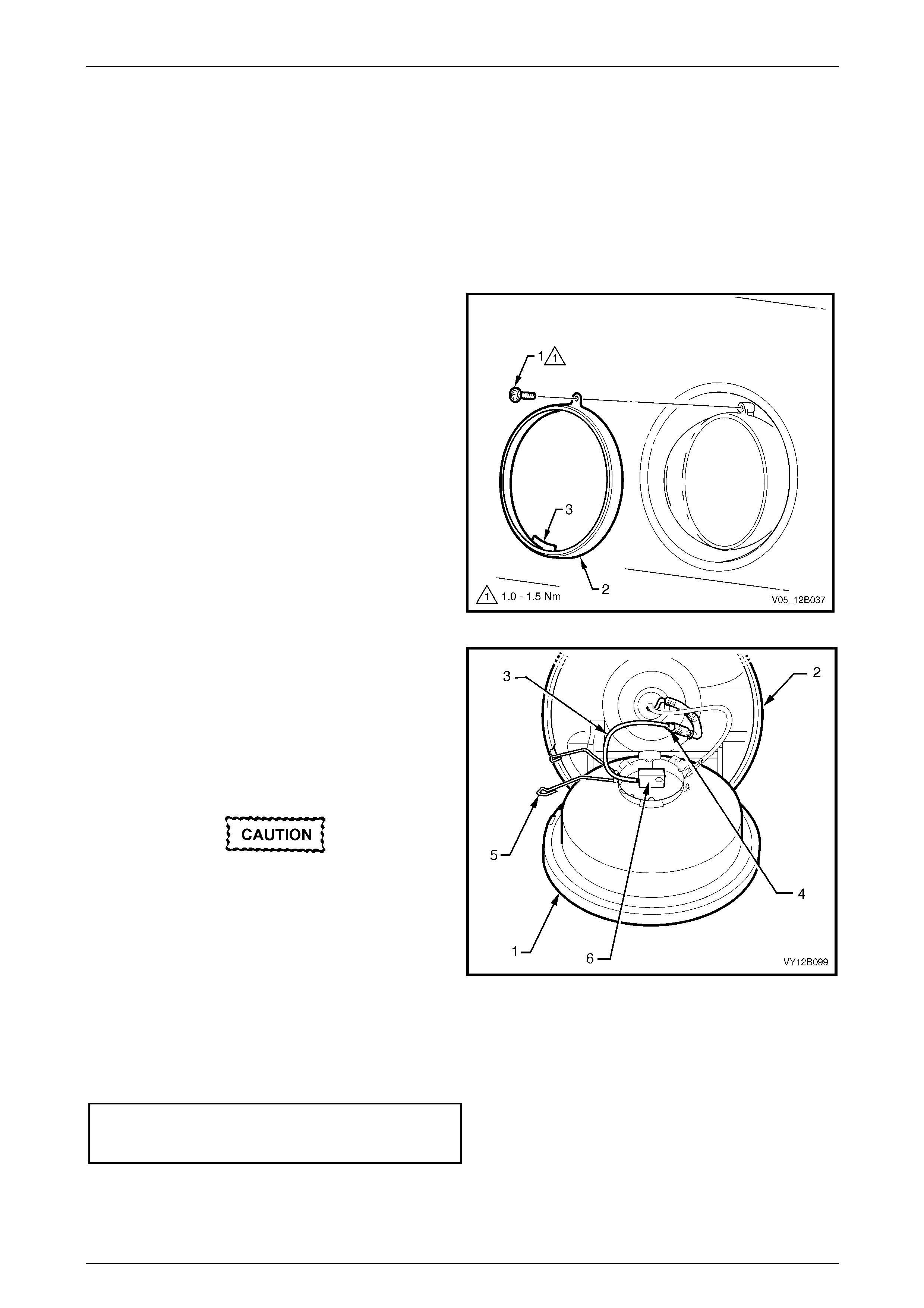

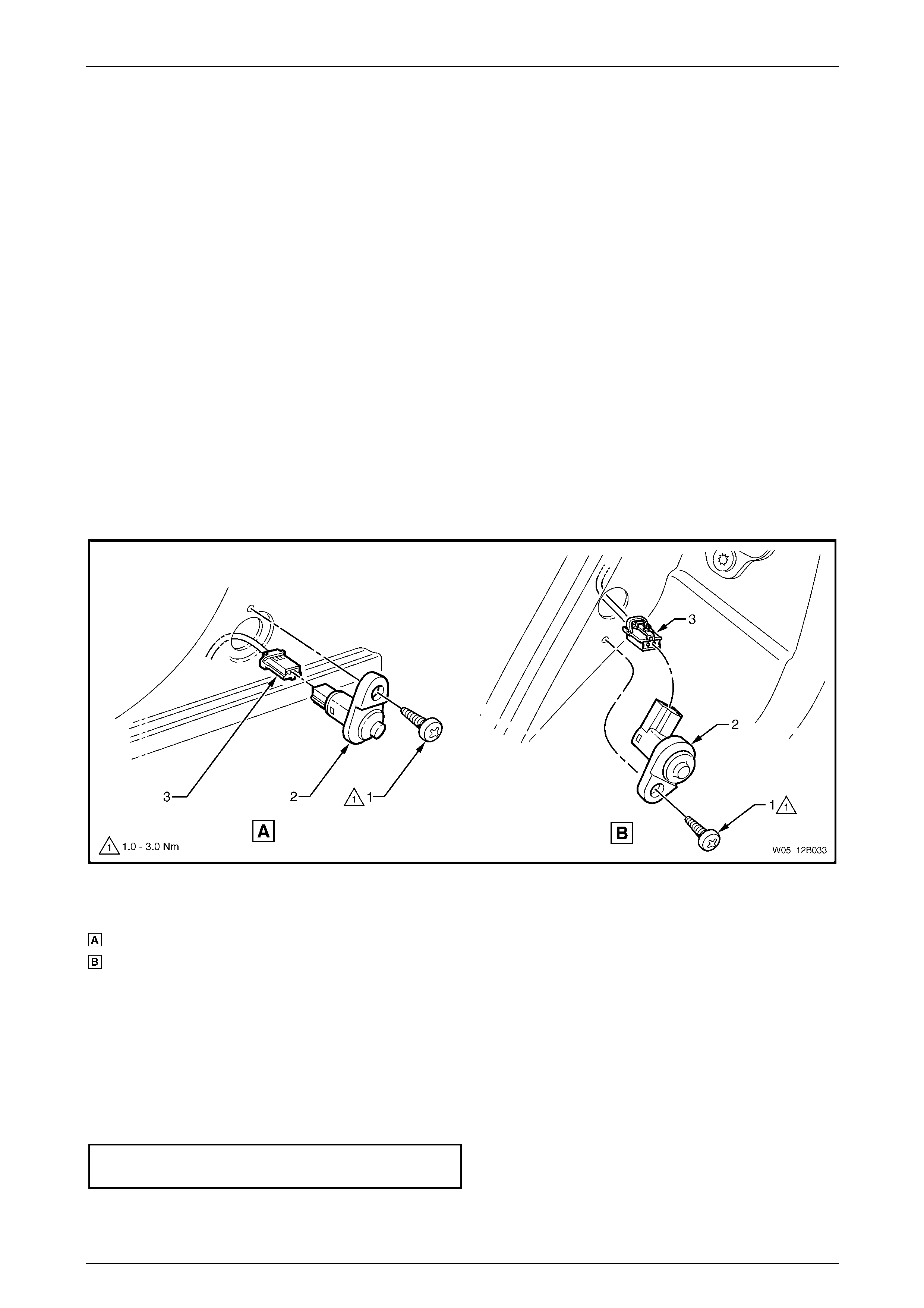

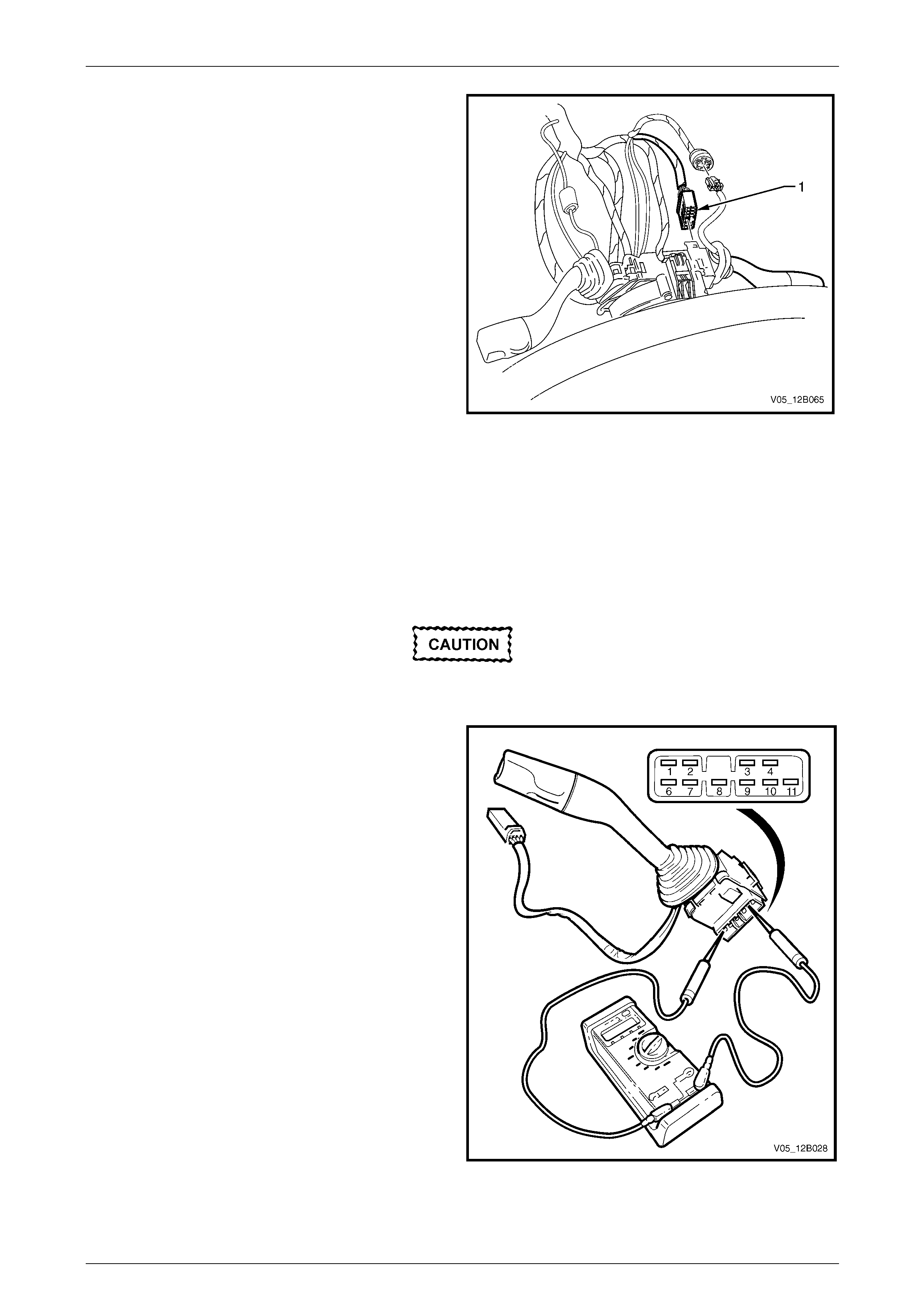

5 For Level 3 vehicles, the front fog lamp bezel

assembly must be removed to access the adjusting

screw. To remove the bezel assembly, refer to

Section 1D Bumper Bars.

Figure 12B – 26

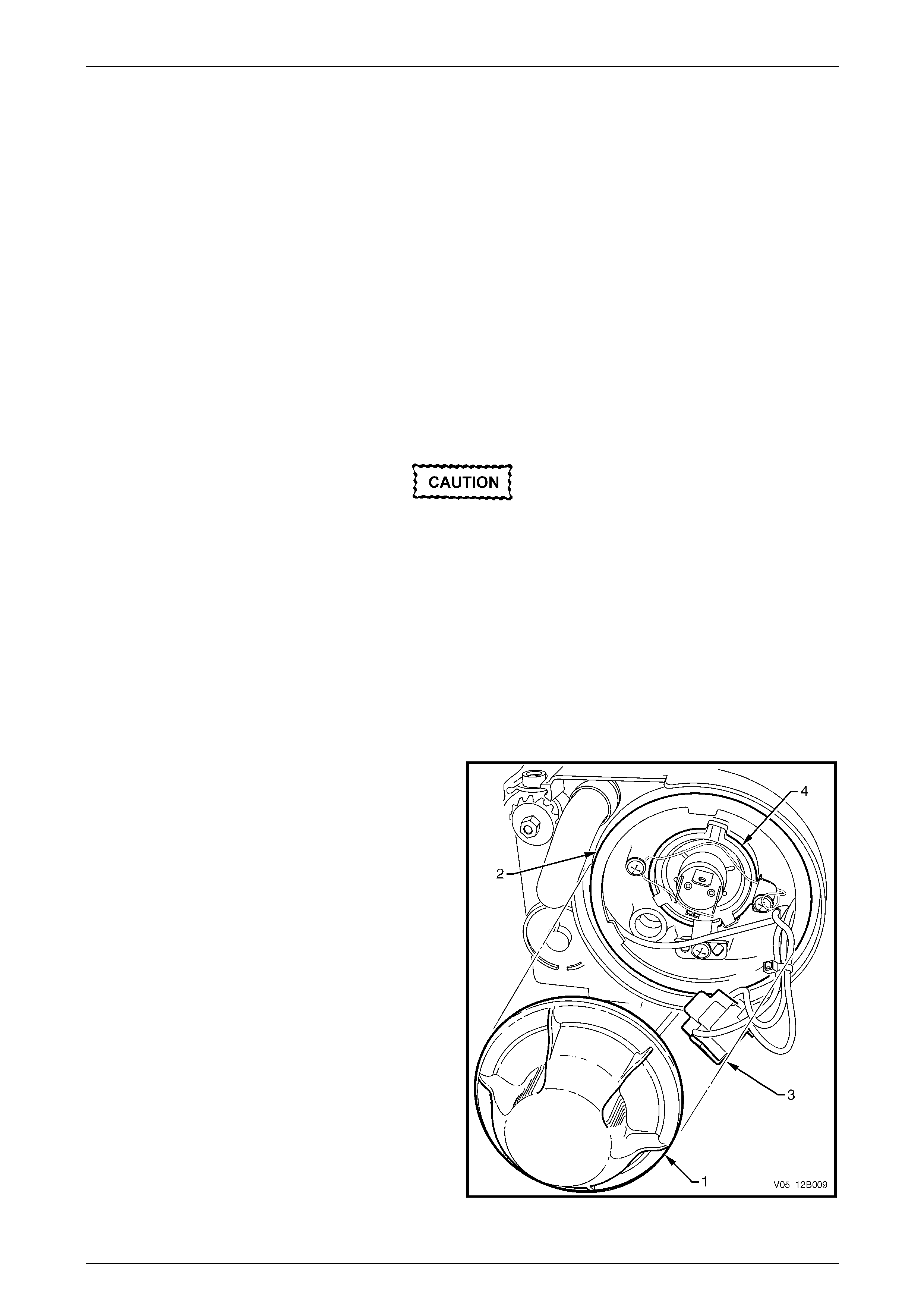

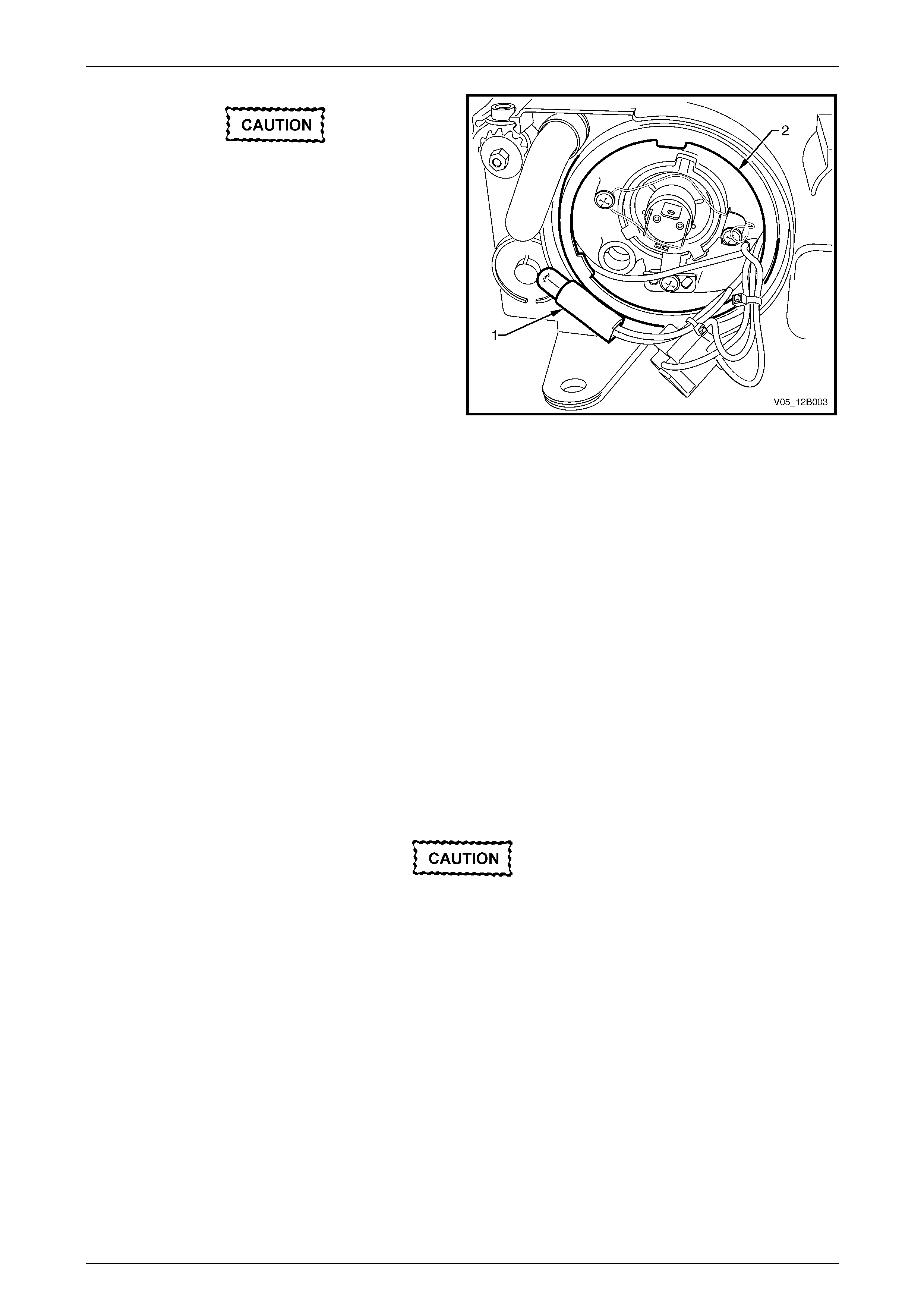

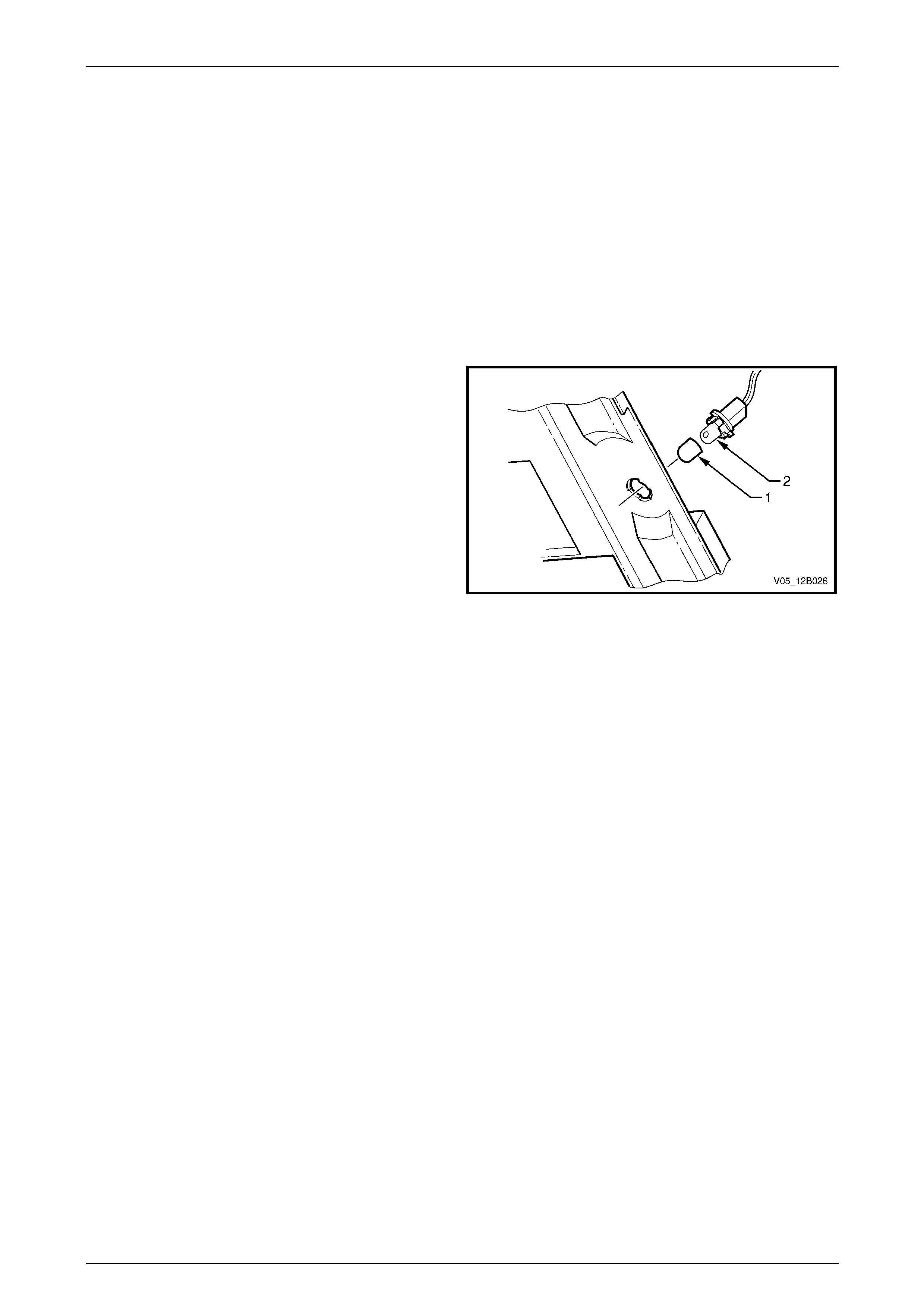

6 Adjust the beam of the front fog lamp (1) by rotating the adjusting screw (2) clockwise to raise the beam and

anticlockwise to lower the beam, refer to Figure 12B – 27 where:

• view A shows a Level 3 vehicle, and

• view B shows an SS front fog lamp assembly.

7 For Level 3 front fog lamp assemblies, install the bezel assembly.

Figure 12B – 27

Lighting System Page 12B–36

Page 12B–36

5.2 Headlamp and Park Lamp Assembly

Bulbs

LT Section No. — 02–300

Level 1

Replace — Low Beam Bulb

1 Remove fusible link F102 from the engine compartment fuse and relay panel assembly, refer to

Section 12O Fuses, Relays and Wiring Harnesses.

2 Open the hood and disconnect the wiring harness connector from the rear of the appropriate hea dlamp assembly.

3 If required, for vehicles with a GEN III V8 engine, remove the four retainers securing the upper ra diator shroud and

remove the shroud, refer to Section Section 6B3 Engine Cooling — GEN III V8.

4 For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access:

a If required, remove the battery hold-down bracket and move the battery to gain access,

refer to Section 12A Battery.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to

Section 00 Warnings, Cautions and Notes

before disconnecting the battery.

b If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment, refer to Section 12A Battery.

NOTE

For vehicles with a GEN III V8 engine, access the

left-hand bulb via the hole in the top of the air

intake duct.

5 For left-hand headlamp assemblies on vehicles with a V6 engine, remove the coolant filler bottle neck and place in

a safe location away from the immediate worksite.

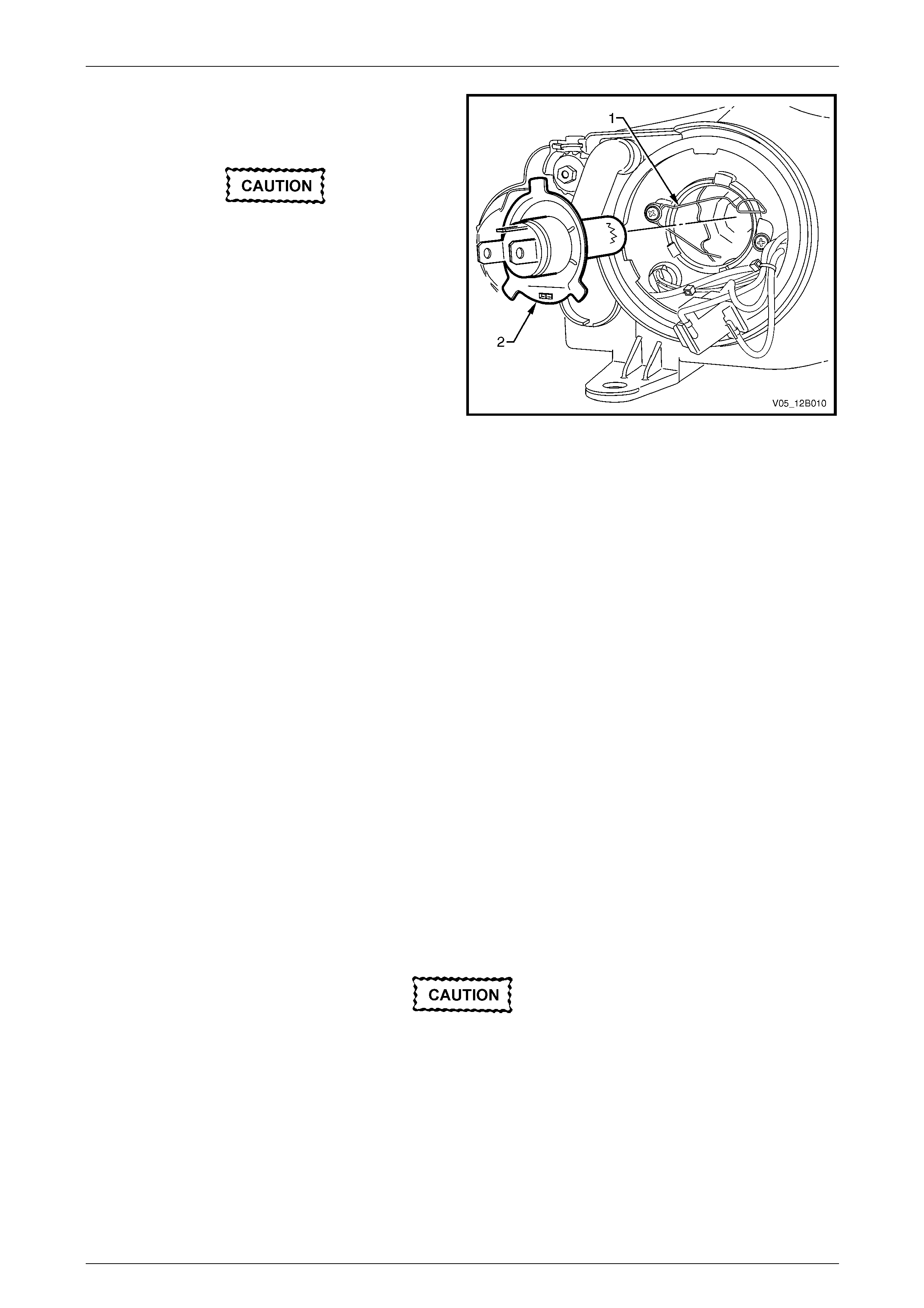

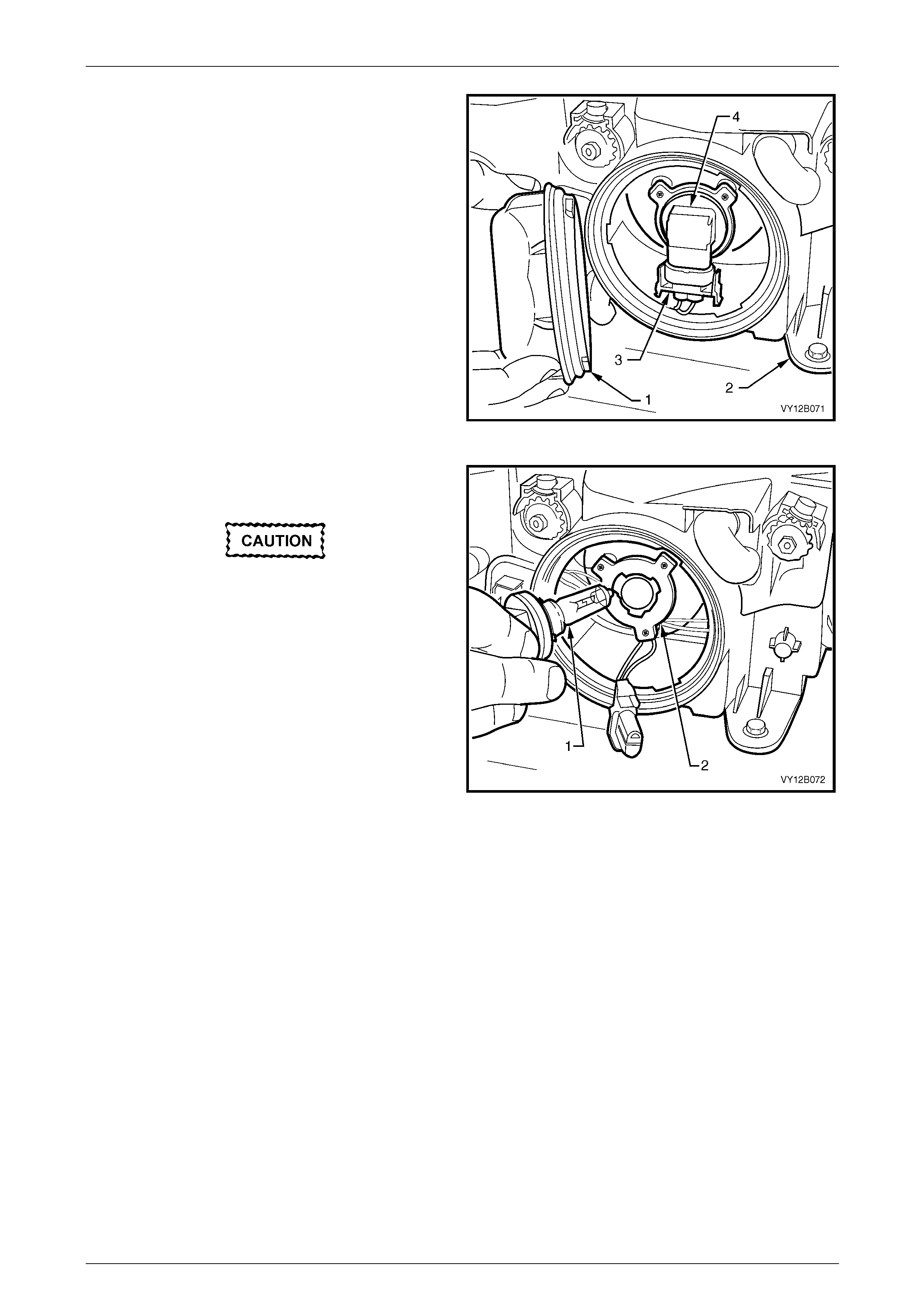

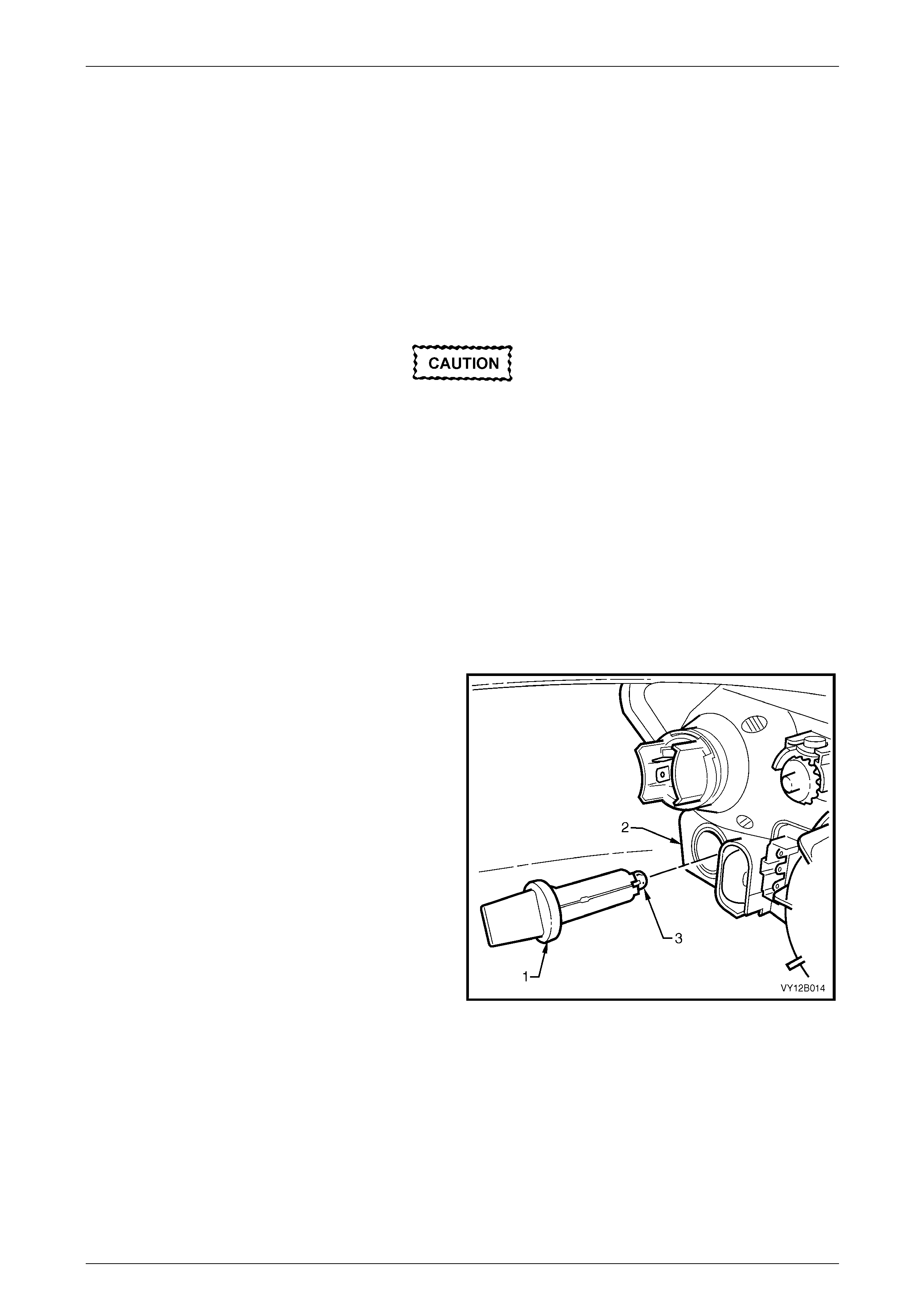

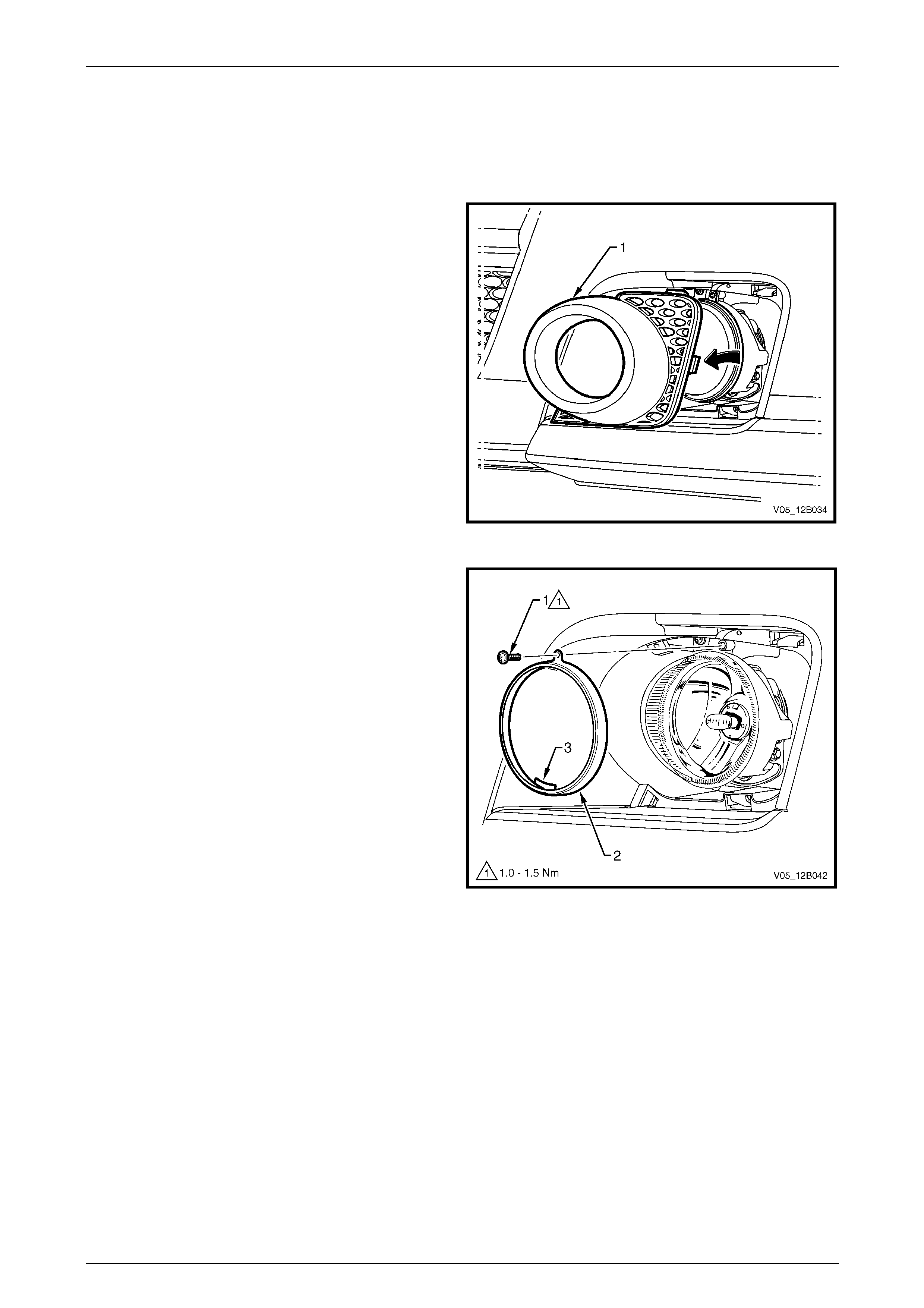

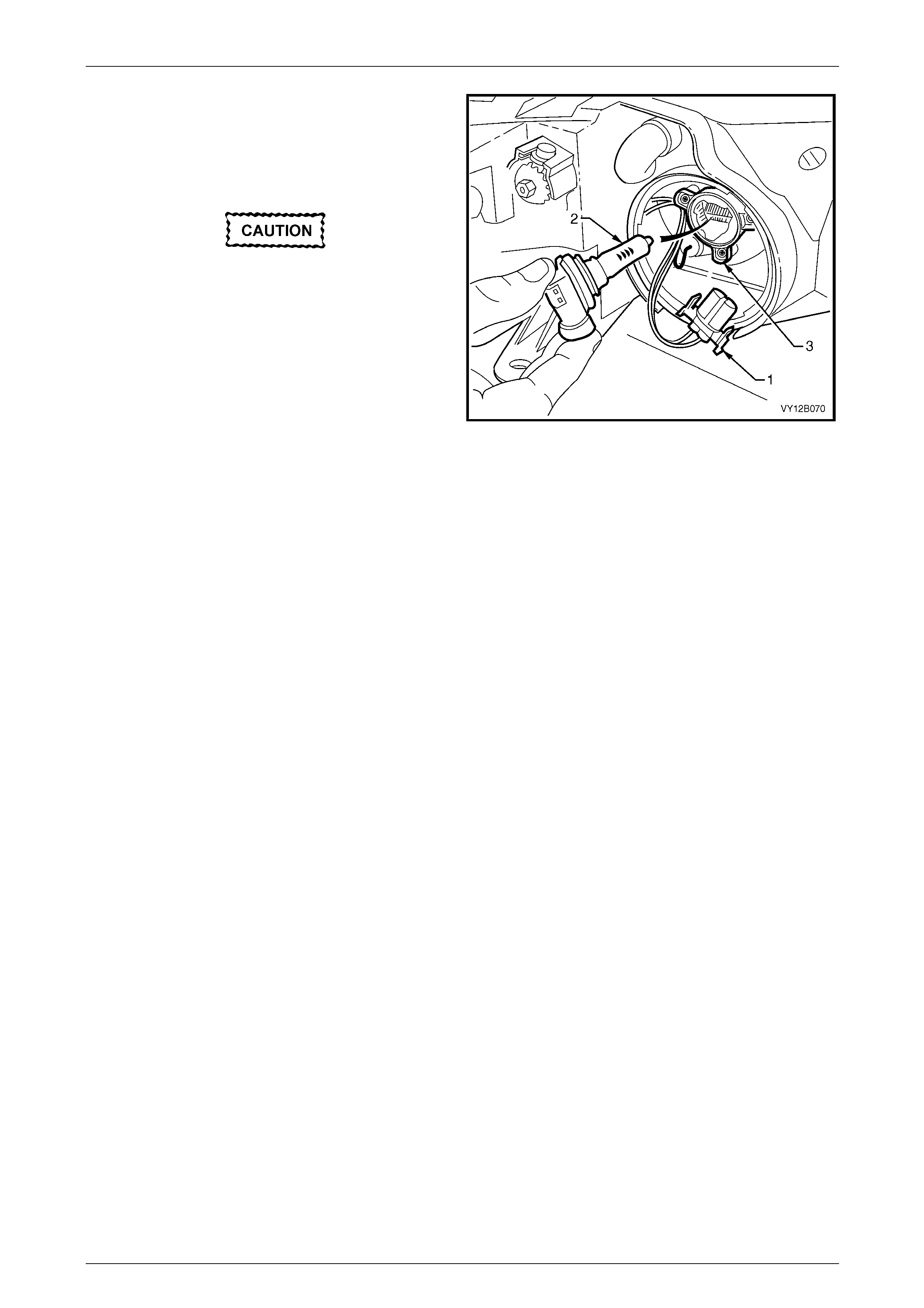

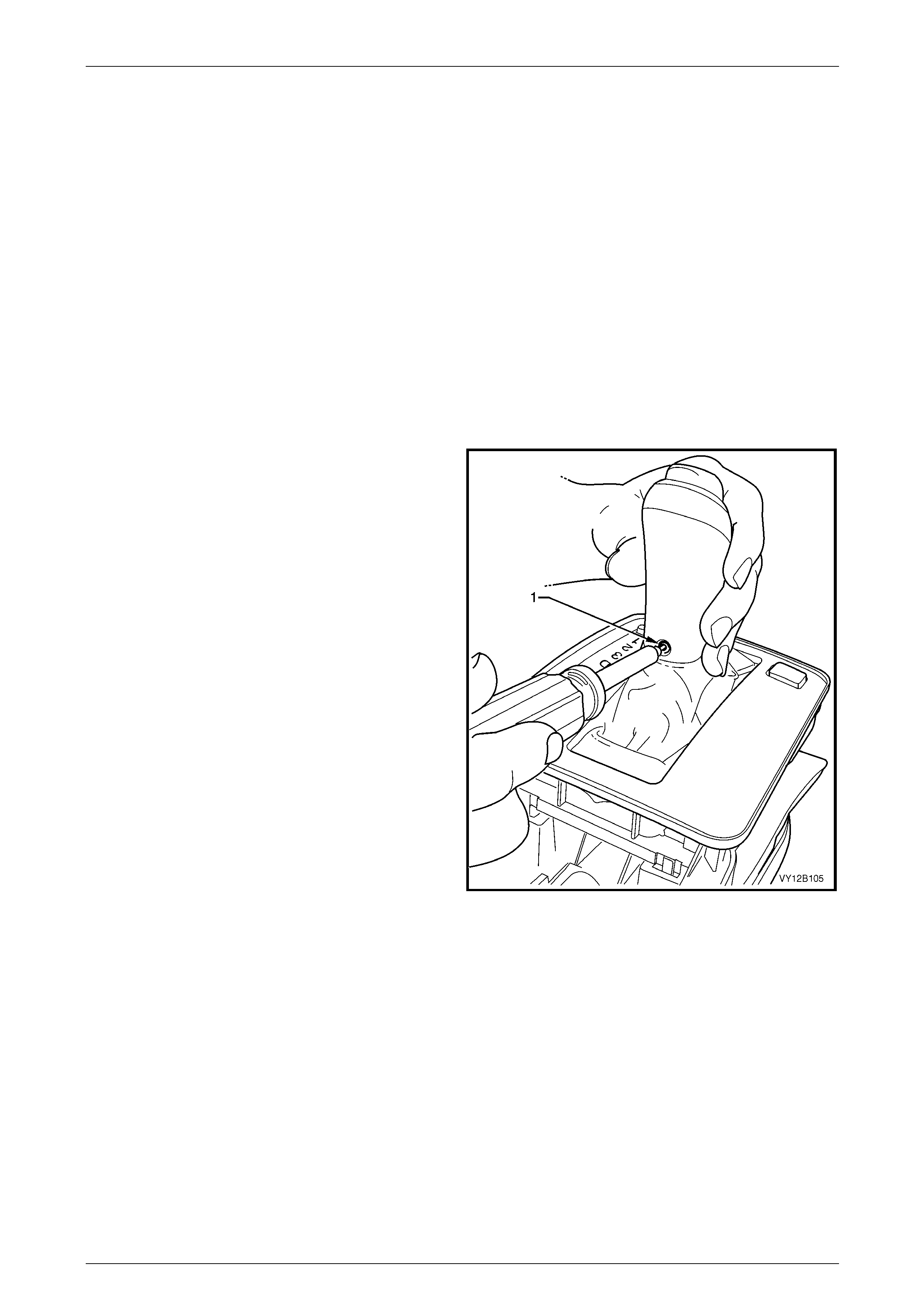

6 Remove the outboard dust cap (1) from the rear of the

headlamp assembly (2) by turning the dust cap

anticlockwise, then pulling it away from the headlamp

assembly. If the dust cap seal stays on the headlamp

assembly, remove the seal and install it onto the dust

cap.

7 Disconnect the wiring harness connector (3) from the

rear of the bulb (4).

Figure 12B – 28

Lighting System Page 12B–37

Page 12B–37

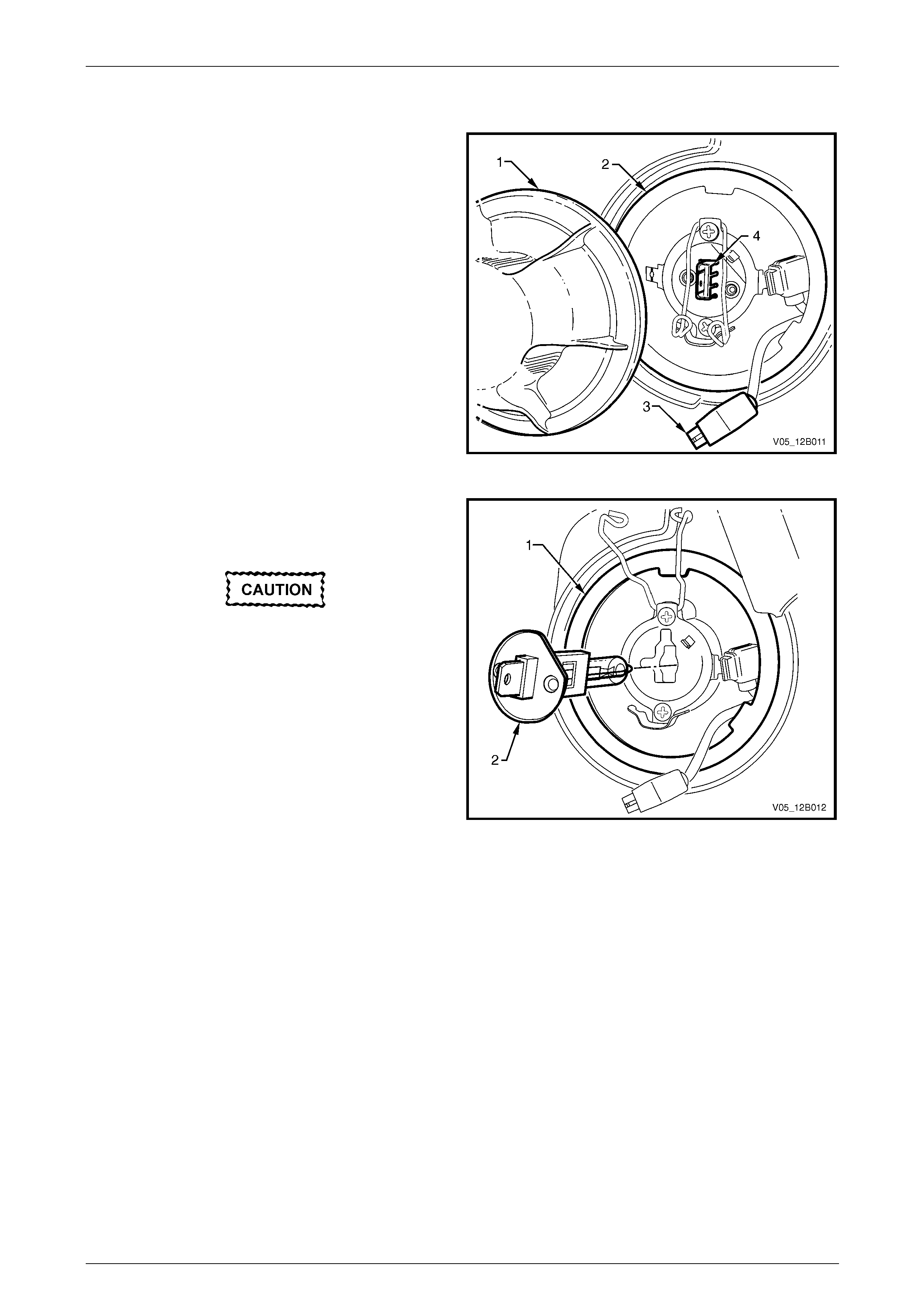

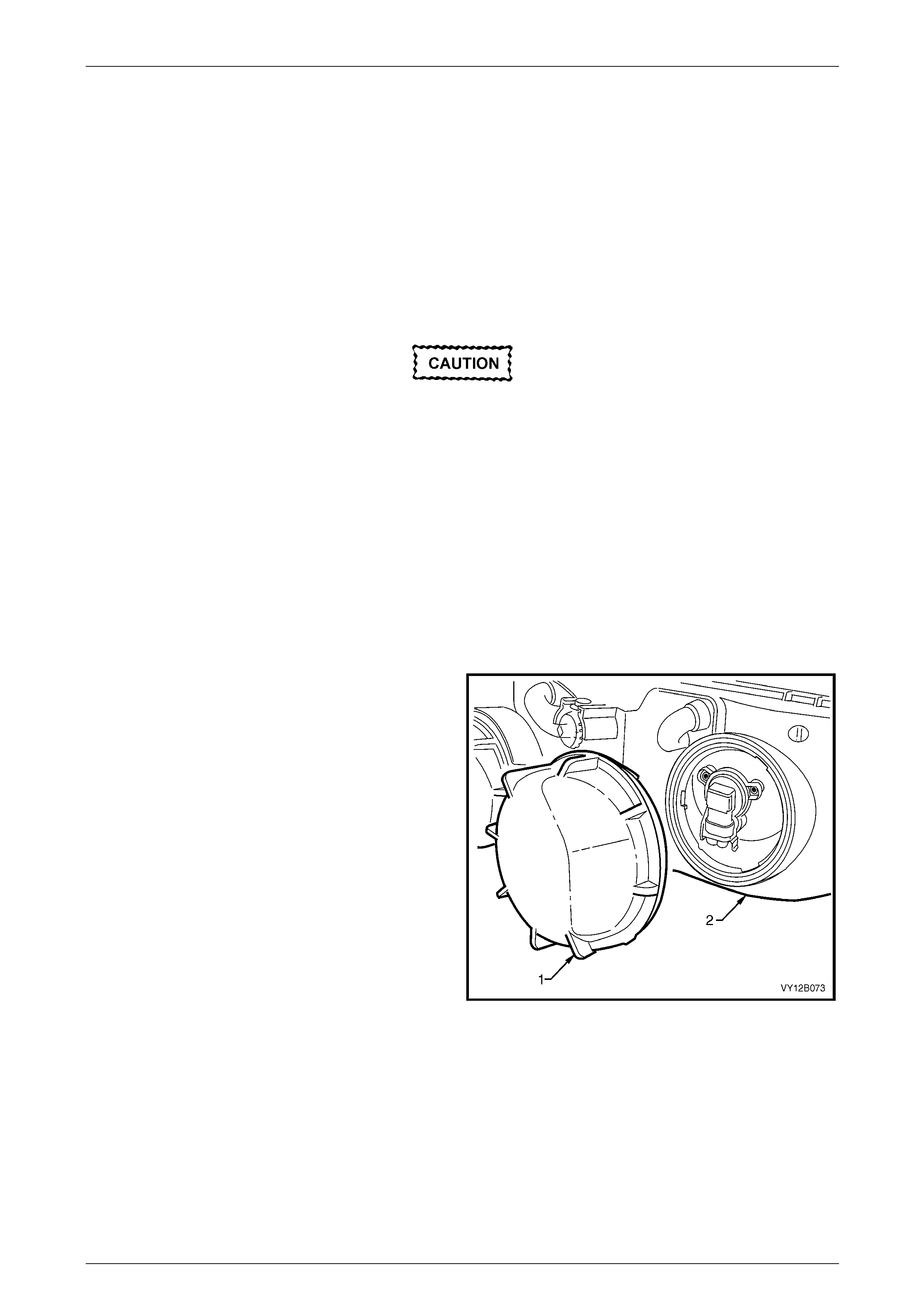

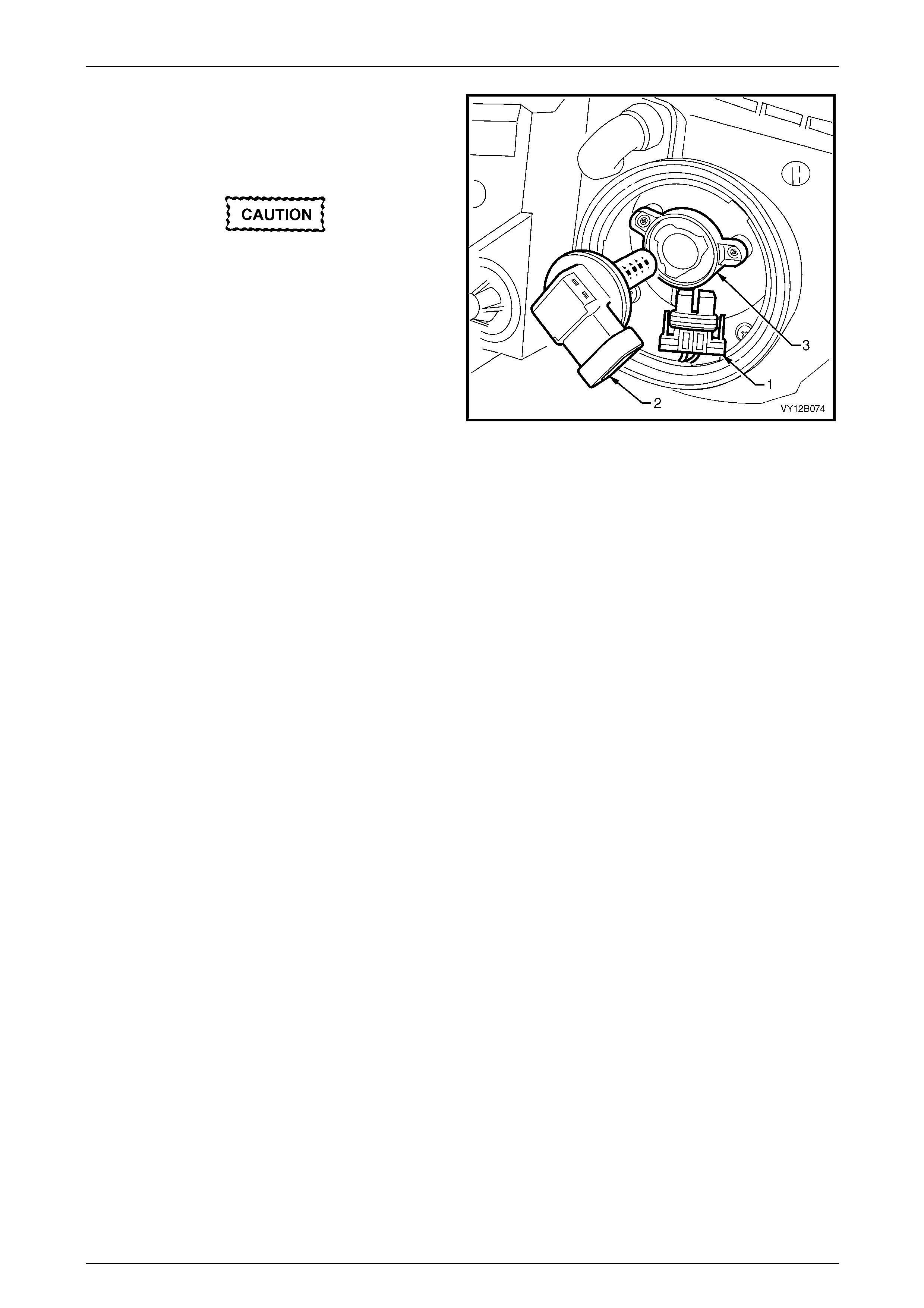

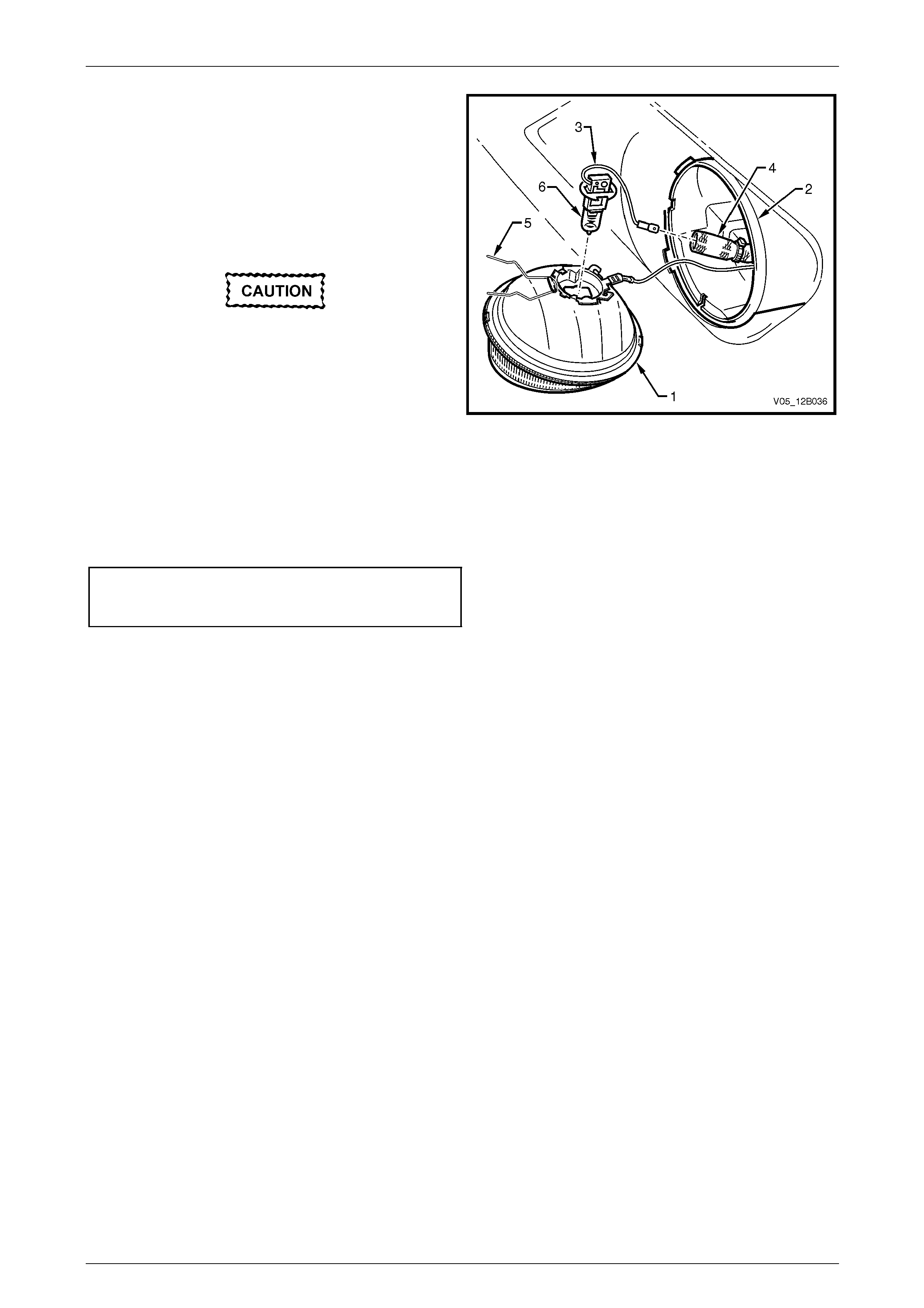

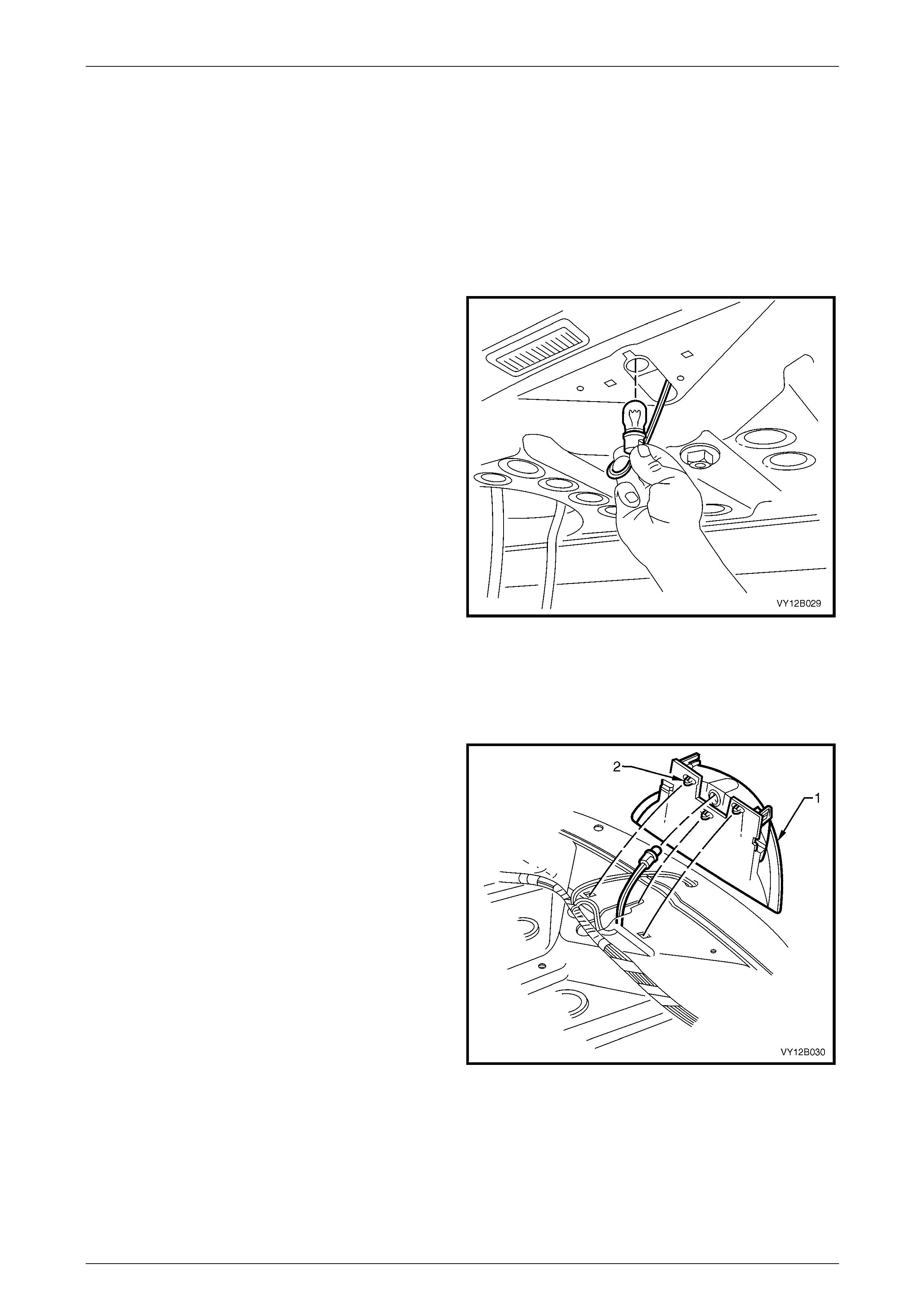

8 Press and unclip the bulb spri ng retainer (1) and pivot

clear of the bulb. Remove the bulb (2) from the

reflector.