SECTION 0B - LUBRICATION AND SERVICE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bags or seat belt pre-tensioners, driver’s and front passen ger’s air bag and lef t and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System before

performing any service operation on, or around any SRS components, the steering mechanism or wiring.

Failure to follow the SAFETY PRECAUTIONS could result in SRS deployment, resulting in possible

personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG fuel

system should be isolated by turning 'OFF' the manual service valve and then draining the LPG service

lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with the

Owner's Handbook for details or the appropriate Section of this Service Information CD for more specific

servicing information.

1. GENERAL INFORMATION

This Section provides details of the lubricants recom mended for VT Series II Models. Also included in this Section

are instructions on the time or distance intervals at which services should be carried out.

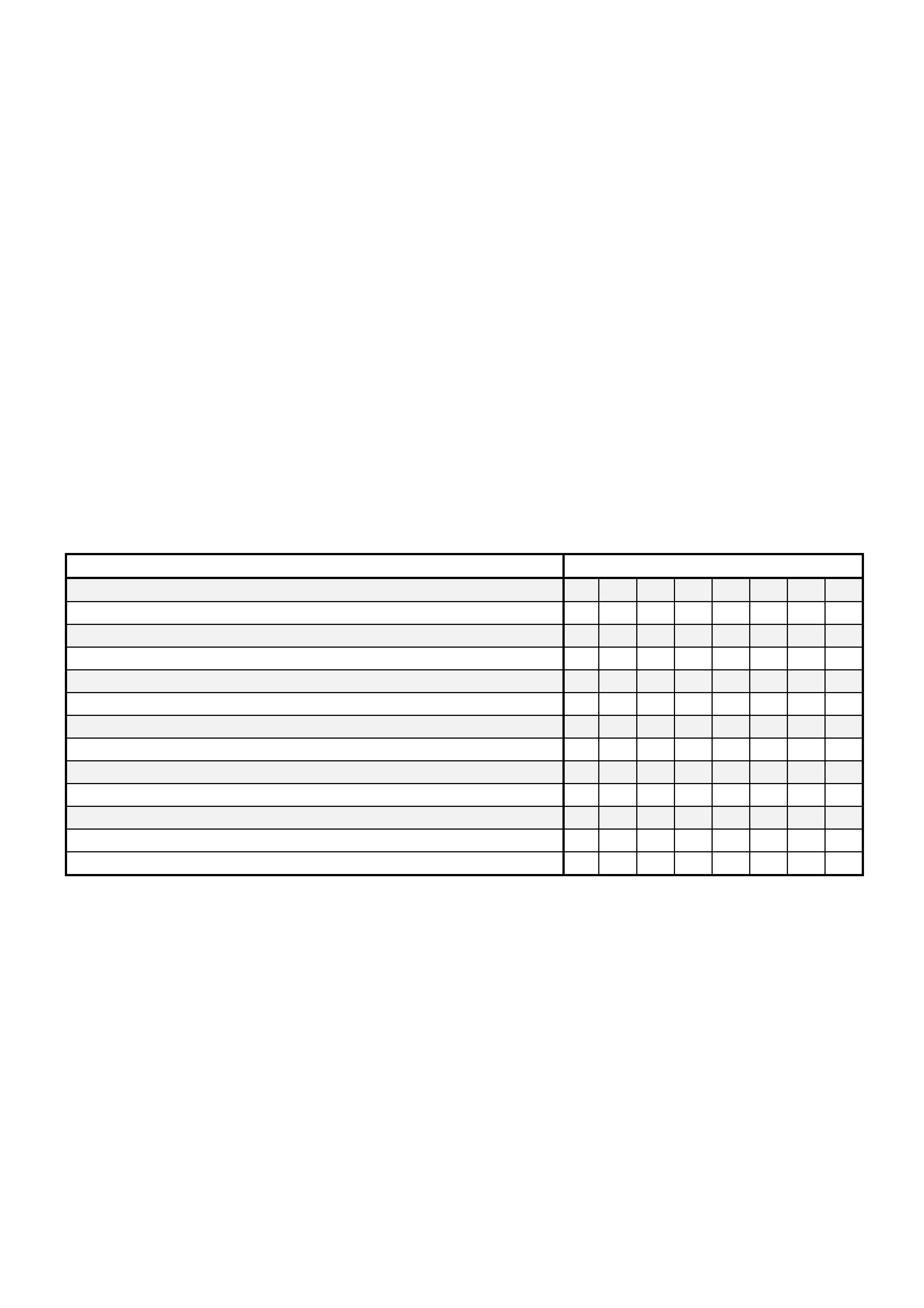

CAPACITIES CHART

LITRES

CAPACITIES (APPROXIMATE) 3.8 Litre V6 3.8 Litre V6

Supercharged 5.7 Litre GEN III

V8

Engine Oil Pan Refill (Less oil filter) 4.5 4.5 4.7

Add for Oil Filter 0.3 0.3 0.3

Supercharger - 0.12 -

Manual Transmission 2.0 NA 4.4

Automatic Transmission - Dry total 7.9 7.9 10.6

- Service refill 4.8 4.8 5

Cooling System 12 12 12

- Coolant Concentrate HN2043 at 50% HN2043 at 50% GM6277M at 50%

Brake Hydraulic System 0.616 0.616 0.616

Final Drive 1.7 1.7 1.7

Power Steering 0.70 0.70 0.80

Techline

Techline

Techline

Techline

Techline

2. ENGINE LUBRI CATION AND SERVICE

2.1 ENGINE OIL VISCOSITY AND CLASSIFICATION RECOMMENDATIONS

The grade of crankcase oil should be selected to give the best performance under the climatic and driving

conditions in the territory in which the vehicle is operated. When the crankcase is drained and refilled, the

crank case oil should be s elected, not on the basis of the existing tem perature at the tim e of the c hange, but on the

ambient temperature range anticipated for the period during which the oil will be used.

Excluding VT Series Models with LPG, use 10W/30 SJ GF2 engine oil for general use and high ambient

temperatures in both 3.8 litre V6 and 5.7 litre GEN III V8 engines. If this oil is unavailable, use SG, SH or SJ engine

oil with a viscosity of 20W/50 or 15W/40.

On vehicles fitted with 3.8 litre V6 engines and LPG, engine oil to Holden Specification HN2314 must be used. At

time of publication, products approved to this specification are: BP Vanellus Multigrade C3 15W/40 SH/CG4, Mobil

Delvac MX 15W/40 SH/CG4 and Mobil Super LPG oil 15W/40 SJ/CE4.

NOTE:

1. Non-detergent and low quality oils are specifically not recommended.

2. Only low phosphorous engine oils m ust be used. Jus t as lead can contam inate the ceram ic m onolith ins ide the

catalytic converter, so can phosphorous. Most leading brands of engine oil now limit phosphorus levels to “safe”

limits.

3. ‘Break-in’ oils, ‘tune-up’ compounds, ‘friction reducing’ compounds and other additives should not be used

unless recommended by Holden.

Their use will only increase operating costs and may contaminate the ceramic monolith inside the catalytic

converter, rendering it useless.

Techline

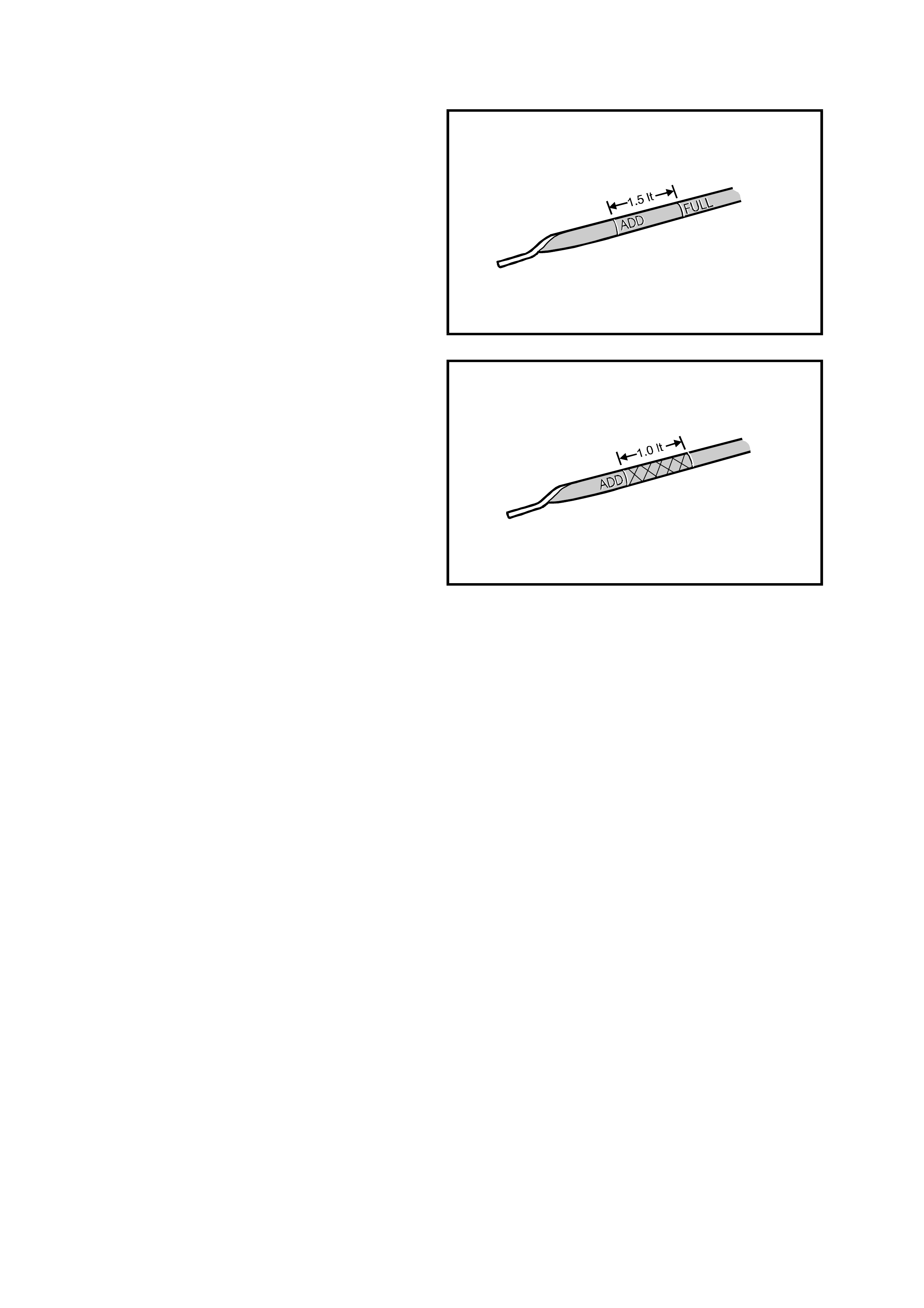

2.2 CHECKING ENGINE OIL LEVEL

CHECK

1. Ensure engine is at normal operating

temperature (idle for 10 minutes or equivalent).

2. Park vehicle on level surface (as this will affect

the accuracy indicated on dipstick:- this is a

critical requirement).

3. Do not check oil level for at least 10 minutes

after engine shut down to allow oil to drain back

into the oil pan.

4. Remove dipstick and wipe clean.

5. Reinstall dipstick, ensuring that it is fully

seated. Slowly rem ove to avoid smearing, then

hold horizontally or with the lower end slightly

down, to avoid oil running along dipstick.

NOTE: Reinstall V6 engine dipstick with the

FULL/ADD marks facing towards centre line of

engine. This aspect is very important due to the

angle that the dipstick enters the oil in the oil pan.

6. Observe the oil level where it passes over the

centre line of the dipstick.

If the engine oil level is below the ADD mark on

the dipstick, using the specified engine oil (refer

2.1 ENGINE OIL VISCOSITY AND

CLASSIFICATION in this Section), top up oil

level until the oil reaches the full mark;

FULL mark on V6 engines.

Line after the hatched section on GEN III V8

engines.

7. When topping up the engine oil, allow

approximately 10 minutes for the oil added to

fully drain into the oil pan.

T20B003

Figure 0B-1 V6 and V6 Supercharged engine oil dipstick

T20B002

Figure 0B-2 GEN III V8 engine oil dipstick

2.3 ENGINE OIL - CHANGE

NOTE: Quicker and more complete draining will

occur if the engine oil is at operating temperature.

However, care must be taken to avoid scalding

from the hot oil.

NOTE: While all oil pans are aluminium, they are

fitted with steel thread inserts to increase durability

of the thread and to avoid thread tearing when the

drain plug is removed from a hot engine.

1. Raise the engine hood and remove the oil fill

cap.

2. Raise the vehicle front and support with safety

stands. Refer to Section 0A GENERAL

INFORMATION in this Service Information CD.

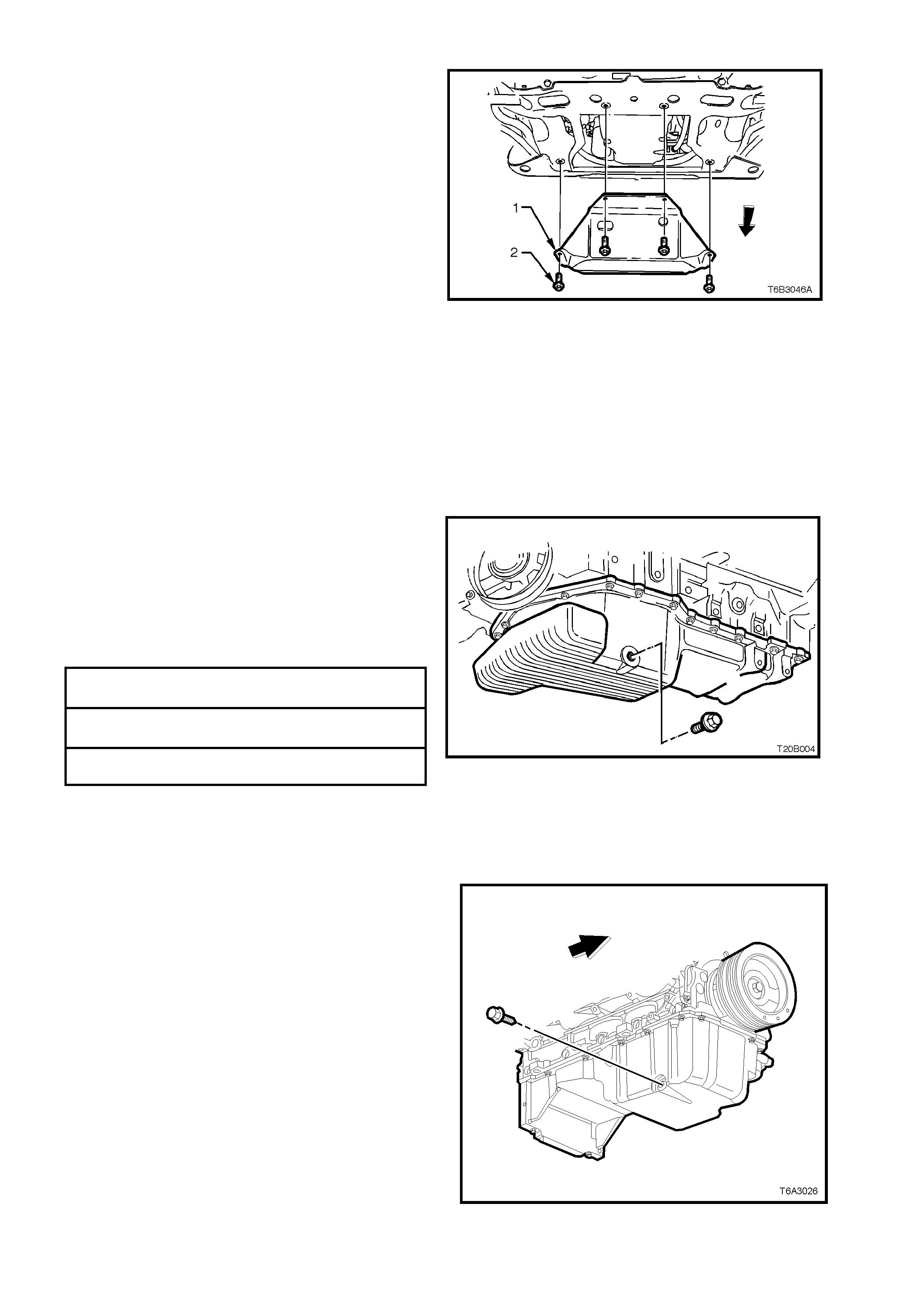

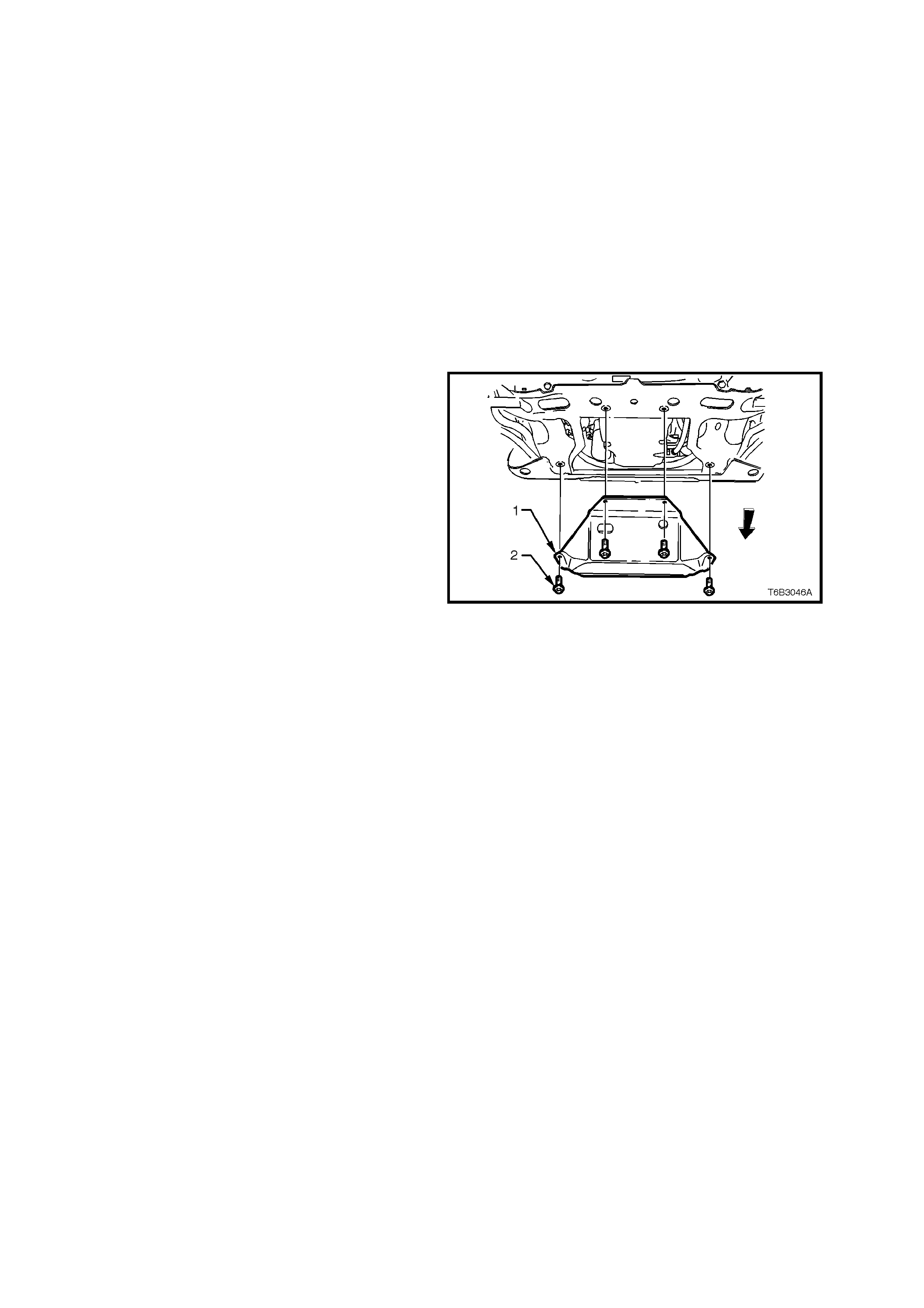

3. On vehicles with GEN III V8 engines, remove

the four oil pan under-tray securing bolts (2)

and remove under-tray (1).

4. Clean any foreign material from around the oil

pan drain plug.

5. Place an oil drain tray beneath the engine.

6. Using a suitable wrench r emove the drain plug,

taking car e to avoid scalding with the hot waste

oil.

Figure 0B-3 GEN III V8 oil pan under-tray

7. When the oil has drained sufficiently, reinstall

the drain plug, after ins pecting and c leaning the

threads. The drain plug O-ring seal may be re-

used if not cut or damaged. Tighten the drain

plug to the correct torque specification.

8. On vehicles with GEN III V8 engines, reinstall

the oil pan under-tray and tighten securing bolts

to the correct torque specification.

V6 ENGINE OIL PAN DRAIN PLUG

TORQUE SPECIFICATION 30 - 60 Nm

GEN III V8 ENGINE OIL PAN DRAIN

PLUG TORQUE SPECIFICATION 25 Nm

OIL PAN UNDER-TRAY SECURING

BOLT TORQUE SPECIFICATION 30 – 35 Nm

9. Lower the vehicle and fill the crankcase with the

specified engine oil, refer 2.1 ENGINE OIL

VISCOSITY AND CLASSIFICATION

RECOMMENDATIONS in this Section.

10. Start the engine and check for oil leaks.

Figure 0B-4 V6 Engine oil pan drain plug

Figure 0B-5 GEN III V8 engine oil pan drain plug

2.4 ENGINE OIL FILTER

The full-flow oil filter, filters all the engine oil

delivered by the oil pump. Accordingly, the oil filter

should be replaced at the tim e or distanc e intervals

specified in 9.2 MAINTENANCE SCHEDULE in

this Section (or the VT Owner’s Handbook) or

whenever the engine oil is contam inated by foreign

material and/or liquids.

Under prolonged dusty conditions, it is

recommended that the oil filter be replaced more

often.

NOTE: Whenever the oil filter is replaced, an

additional quantity of the recommended engine oil

must be added to fill the dry filter. Refer to the

CAPACITIES CHART in this Section.

REPLACE

1. Raise the vehicle front and support with safety

stands. Refer to Section 0A GENERAL

INFORMATION of this Service Information CD.

2. On vehicles with GEN III V8 engines, remove

the four oil pan under-tray securing bolts (2)

and remove under-tray (1).

Figure 0B-6 GEN III V8 oil pan under-tray

3. Place an oil drain tray beneath the engine and

remove the oil filter (1), using a commercially

available tool, taking care to avoid being

scalded with the hot waste oil.

4. After checking that the filter seal has not

adhered to the oil pan flange, inspect the oil

filter sealing surface for scratches or other

damage and c heck the oil filter adaptor threads

for damage.

NOTE: If necessary, refer to

Section 6A1-1 – ENGINE MECHANICAL – V6

ENGINE of this Service Information CD for

information on how to remove and install the oil

filter adaptor.

5. Smear some new engine oil onto the new filter

seal, then install filter assembly to engine.

6. V6 engine; screw filter into place until the seal

contacts the mating surface of the adaptor,

then tighten a further 2/3 of a turn.

GEN III V8 engine; Tighten oil filter to the

correct torque specification.

GEN III V8 ENGINE OIL FILTER

TORQUE SPECIFICATION 30 Nm

7. Clean any excess oil of filter and adaptor.

8. On vehicles with GEN III V8 engines, reinstall

the oil pan under-tray and tighten securing bolts

to the correct torque specification.

OIL PAN UNDER-TRAY SECURING

BOLT TORQUE SPECIFICATION 30 – 35 Nm

9. Lower the vehicle and check the oil level. Start

engine and check for leaks. Repair as

necessary.

NOTE: The oil level needs to be rechecked and oil

added as necessary, after running the engine, to

compensate for oil used to refill the oil filter. Refer

to 2.2 CHECKING ENGINE OIL LEVEL in this

Section for the recommended checking procedure

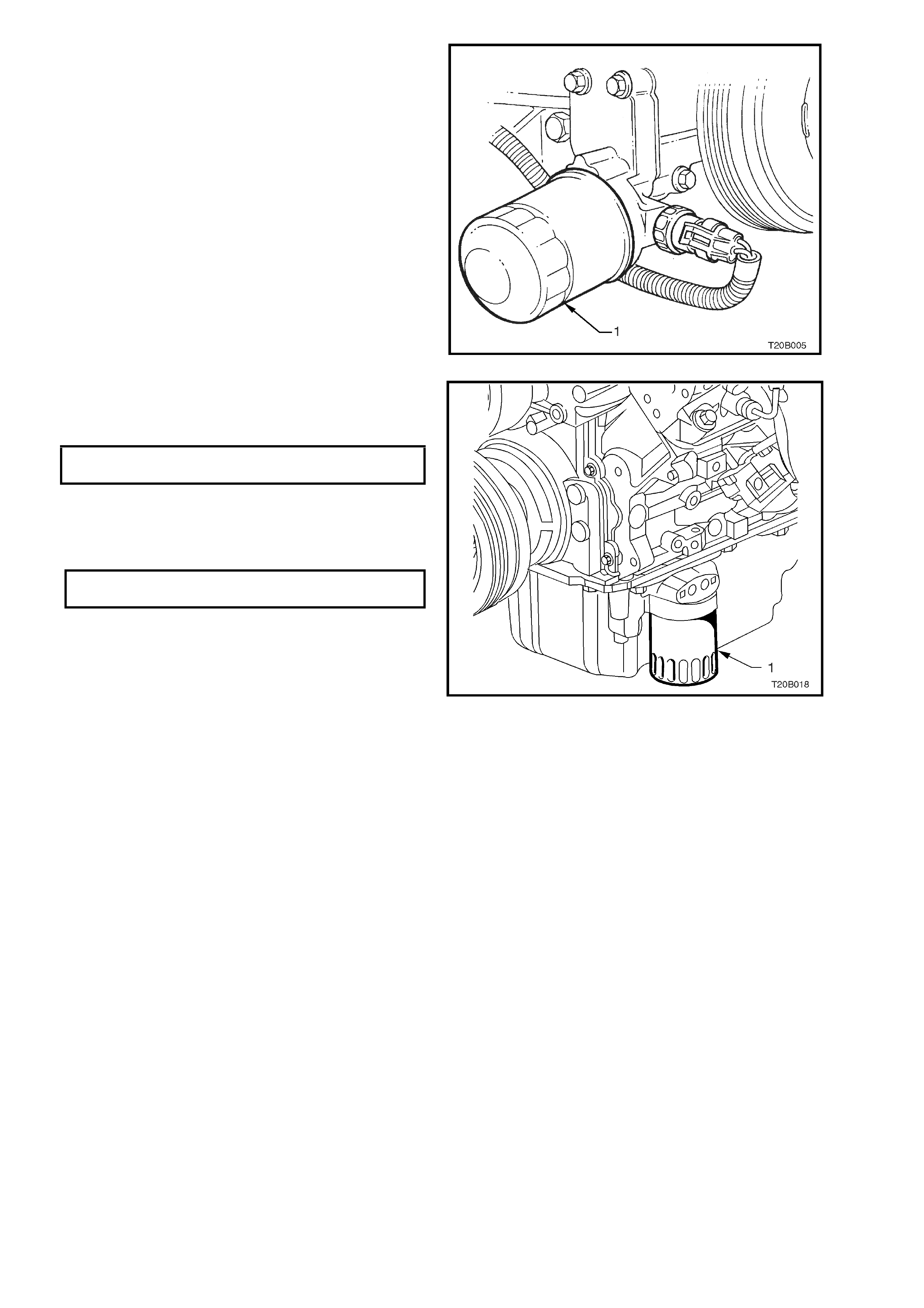

Figure 0B-7 V6 engine oil filter

Figure 0B-8 GEN III V8 engine oil filter

2.5 ENGINE VENTILATION SYSTEM

All VT Series Model engine ventilation systems,

use a P.C.V. valve and utilise engine vacuum to

draw blow-by gasses into the combustion

chambers where they are recycled through the

combustion process.

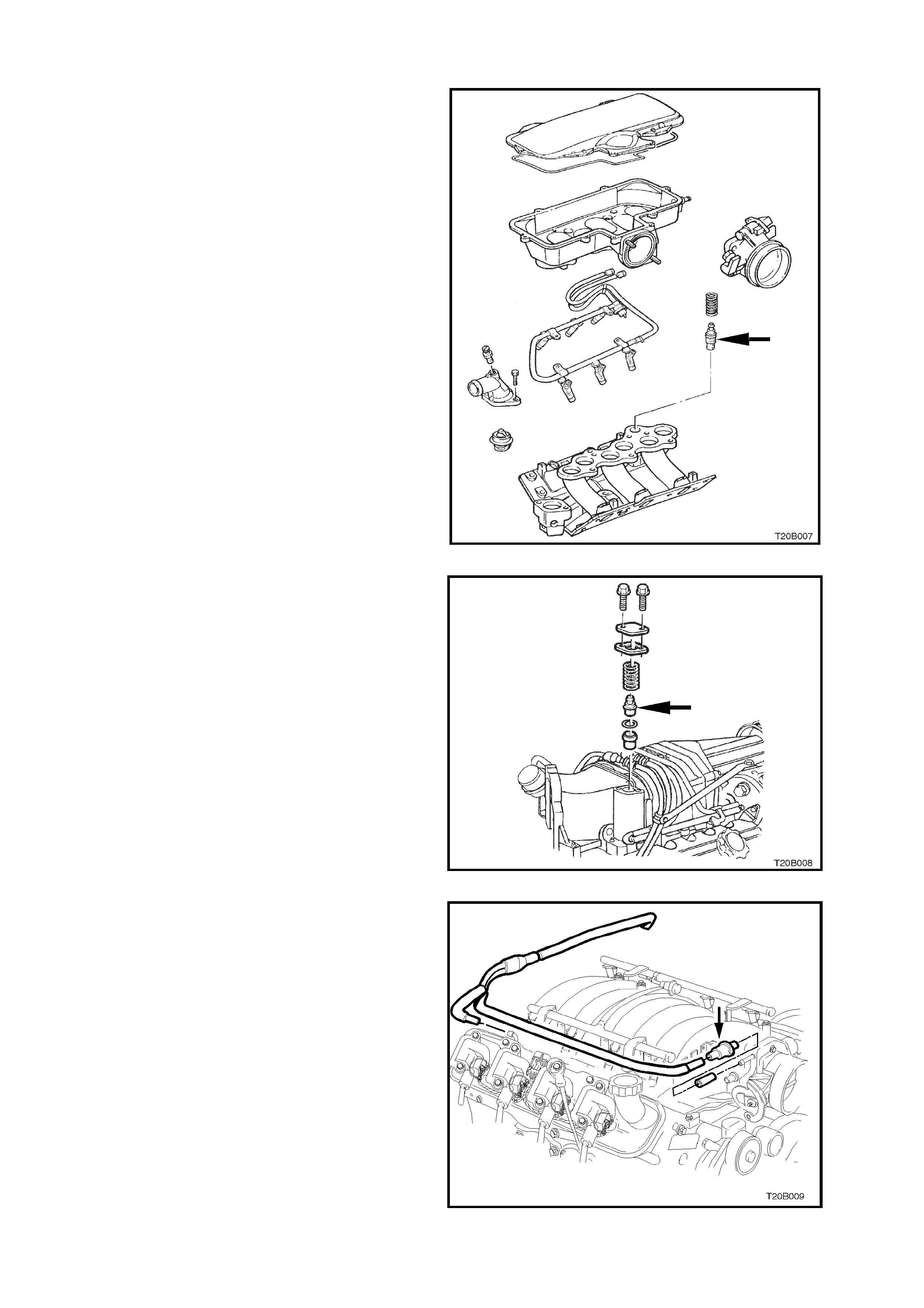

The location of the P.C.V. valve on a V6 engine is

in the inlet manifold, V6 super char ged engine in the

LH rear of the s upercharger as sem bly, and GEN III

engine it is externally mounted between the valve

cover and the throttle body.

For service instructions covering the testing, and

the removal and reinstallation procedures of the

P.C.V. valve, depending on the engine variant,

refer to Section 6E1 EMISSION CONTROL - V6

ENGINE (V6 and V6 supercharged engines) or

Section 6E3 EMISSION CONTROL – GEN III V8

ENGINE (GEN III V8 engine) of this Service

Information CD.

Figure 0B-9 V6 engine P.C.V. valve

Figure 0B-10 V6 supercharged engine P.C.V. valve

Figure 0B-11 GEN III V8 engine P.C.V. valve

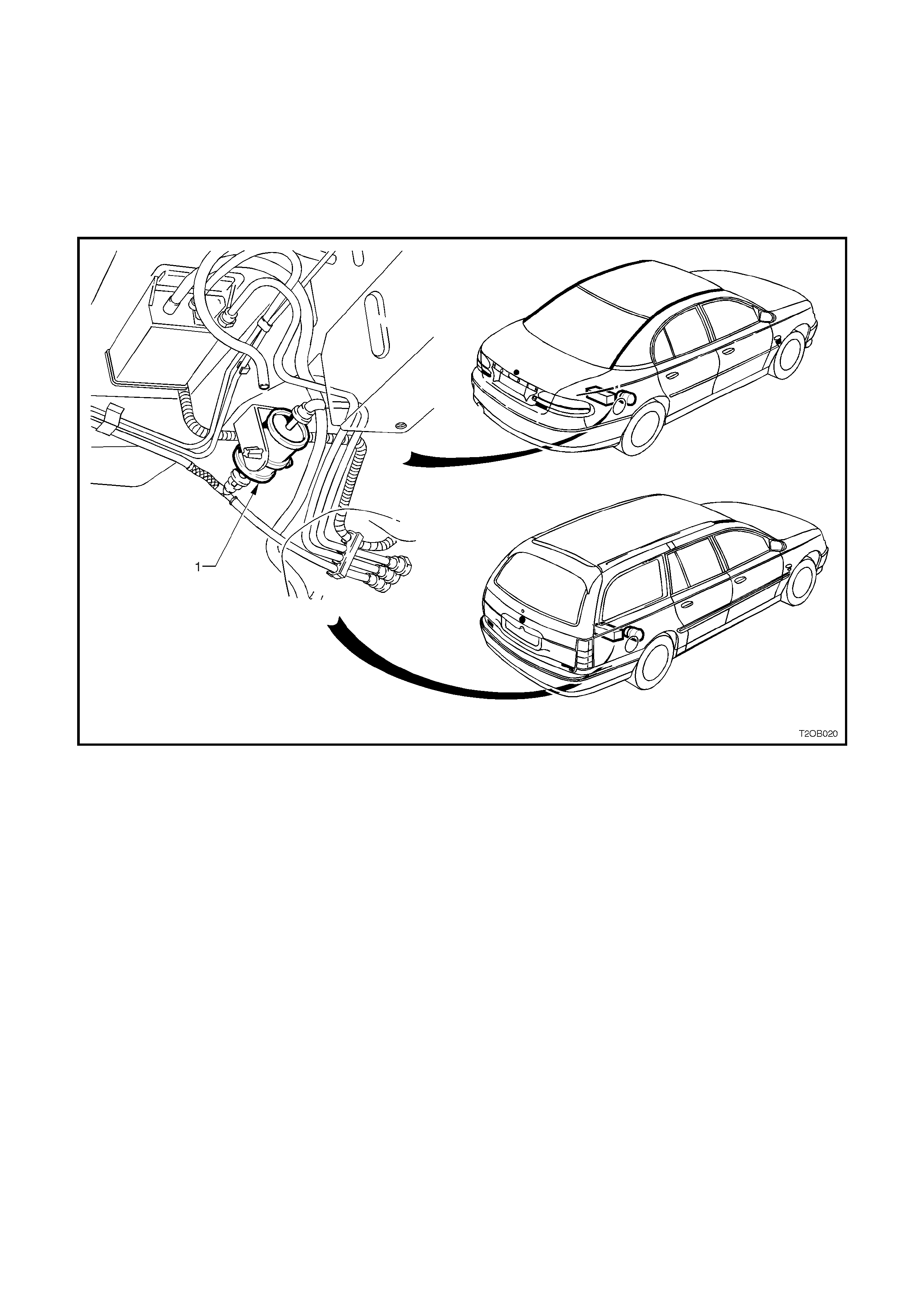

2.6 FUEL FILTER

The fuel filter is located on the pressure side of the high pressure fuel pum p and is attached to the f loor pan of the

vehicle, behind the final drive assembly.

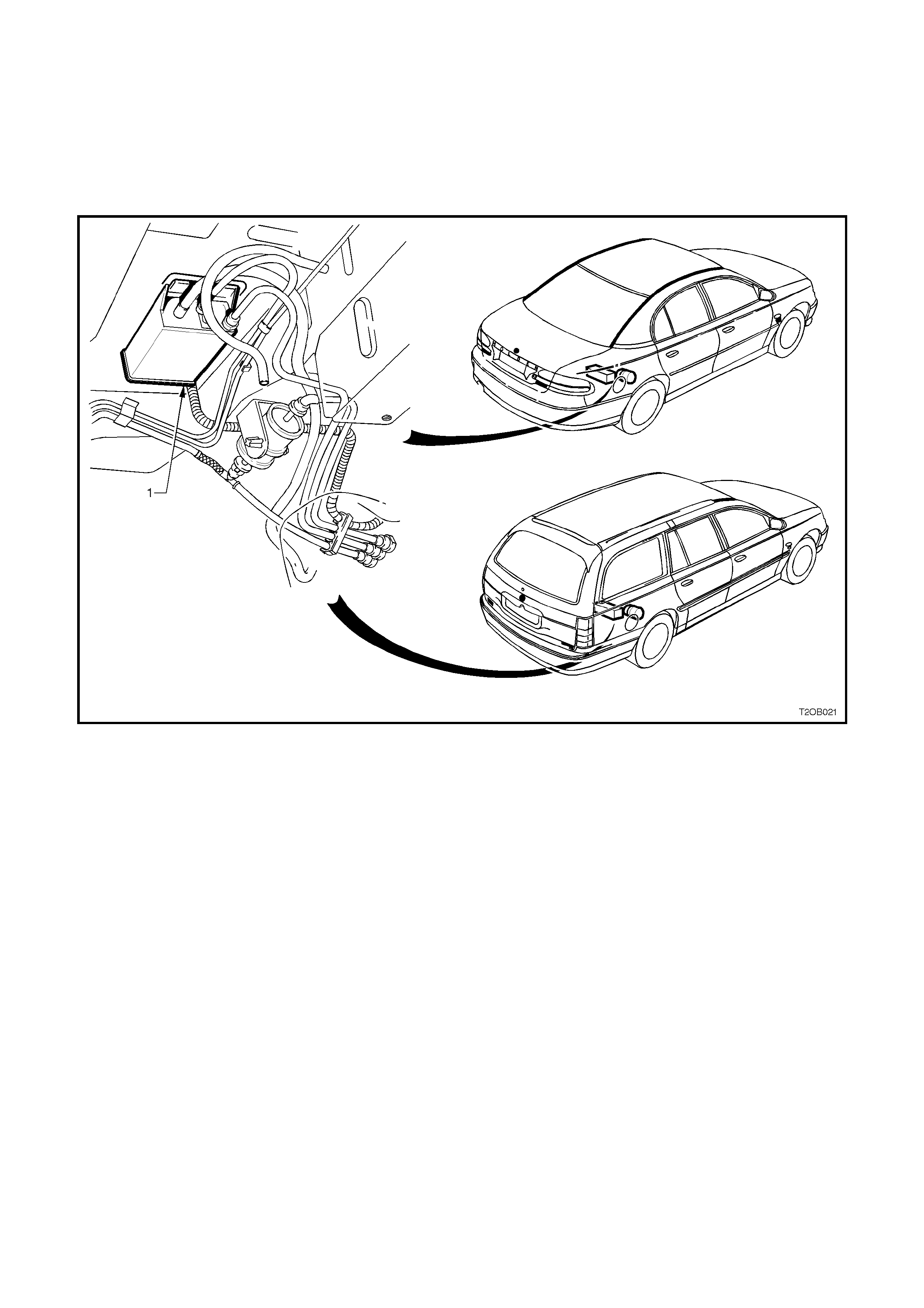

Refer to Fig. 0B-12 for filter location.

The fuel filter m us t be replaced at the tim e or dis tanc e intervals s pec if ied in 9.2 MAINTENANCE SCHEDULE in this

Section or in the VT Series Owner’s Handbook.

For ser vice ins tr uc tions c over ing the removal and ins tallation of the fuel f ilter, depending on the engine var iant, refer

to Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE or Section 6C3 POWERTRAIN MANAGEMENT -

GEN III V8 ENGINE of this Service Information CD.

Figure 0B-12

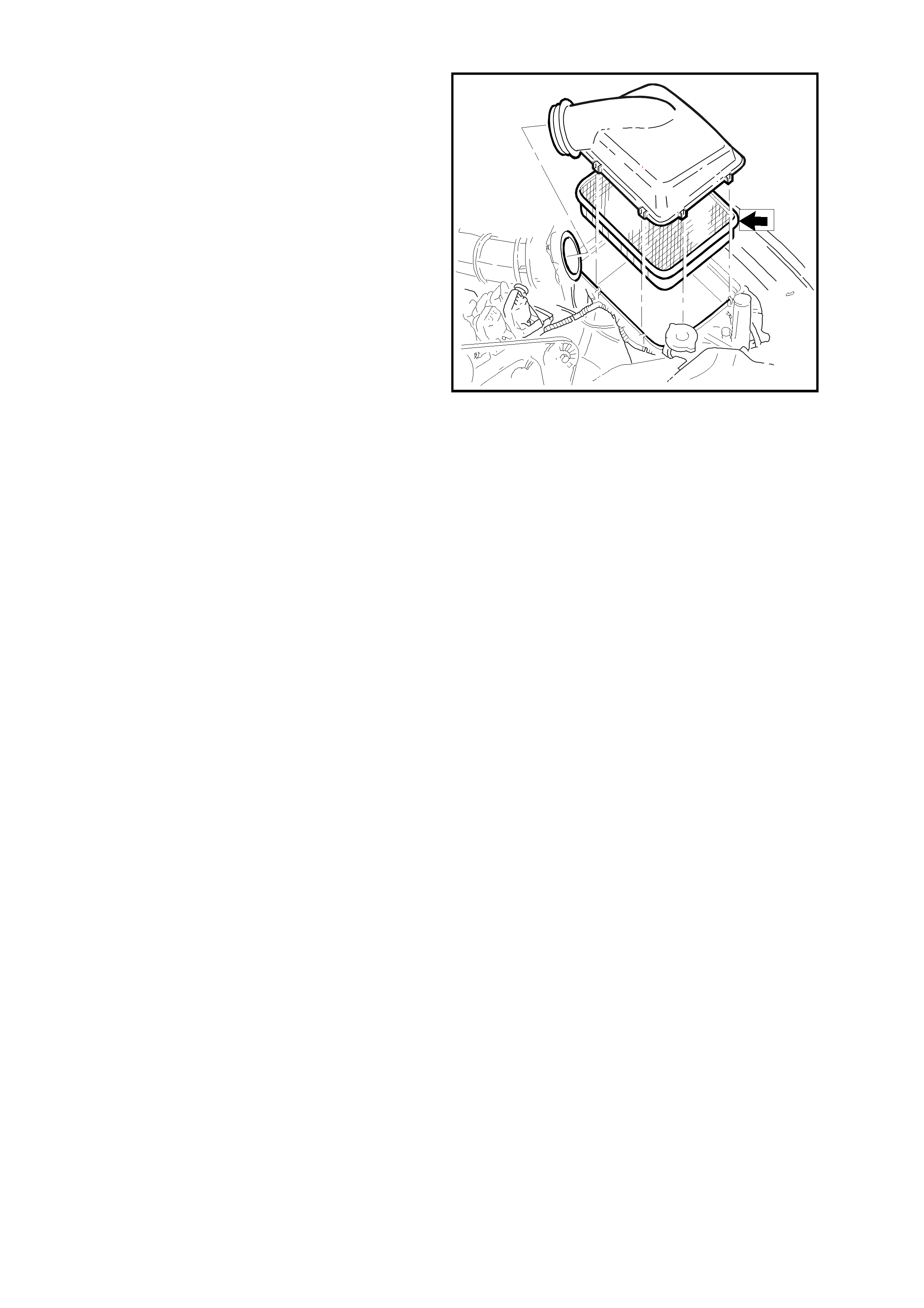

2.7 AIR CLEANER ELEMENT

The air c leaner elem ent m ay be partially cleaned of

dust by lightly tapping the element. It should not be

washed or oiled. The time or distance intervals at

which the element requires servicing depend on

vehicle operating conditions. Under dusty

conditions, the element should be checked for

restriction more often than for normal city

operation. Refer 9.2 MAINTENANCE SCHEDULE

in this Section for additional information on when

the filter should be serviced

Fig. 0B-13 shows the location of the element for a

typical air cleaner assembly.

For service instructions covering the removal and

installation of the air cleaner element, dependent

on the engine type, refer to Section 6C1

POWERTRAIN MANAGEMENT - V6 ENGINE or

Section 6C3 POWERTRAIN MANAGEMENT -

GEN III V8 ENGINE of this Service Information CD Figure 0B-13

2.8 EVAPORATIVE EMISSION CONTROL CANISTER

The Evaporative Emis sion Control ( EEC) canis ter is attac hed to the underbody on all VT Series Models, regardles s

of the engine configuration.

The canister should be serviced at the time or distance intervals specified in 9.2 MAINTENANCE SCHEDULE in

this Section or in the VT Series Owner’s Handbook.

For service instructions covering the testing, and the rem oval and reinstallation of the EEC canister, depending on

the engine variant, refer to Section 6E1 EMISSION CONTROL - V6 ENGINE or Section 6E3 EMISSION

CONTROL - GEN III V8 ENGINE of this Service Information CD.

Figure 0B-14

2.9 COOLING SYSTEM

V6 AND V6 SUPERCHARGED ENGINE

The cooling system is filled initially with a coolant

mixture comprising 50% water and 50% inhibited

ethylene Glycol to Holden Specification HN 2043.

CAUTION: Do not remove the radiator cap

when the engine and radiator are hot. Scalding

fluid and steam can be blown out under

pressure if the cap is removed.

The cooling system is designed to use formulated

coolant (a mixture of inhibited ethylene glycol and

water), rather than plain water. The coolant solution

must be used year round.

Inhibited ethylene glycol conforming to Holden

Specification HN 2043 is named ‘New Formula

Long Life All Seasons Coolant’, and is available in

the following quantities:

1 Litre, P/N 92140054*

5 Litre, P/N 92140057*

20 Litre, P/N 92140055*

* Always check with the latest Holden spare parts

information for the correct part number before

ordering parts.

NOTE: Do not mix different types of anti-freeze or

corros ion inhibitors as they may be inc ompatible. If

a different type has been used in the cooling

system, flush the system with clean water.

The water used for mixing with inhibited glycol

concentrate must be of low dissolved salt content,

preferably tank water or demineralised water.

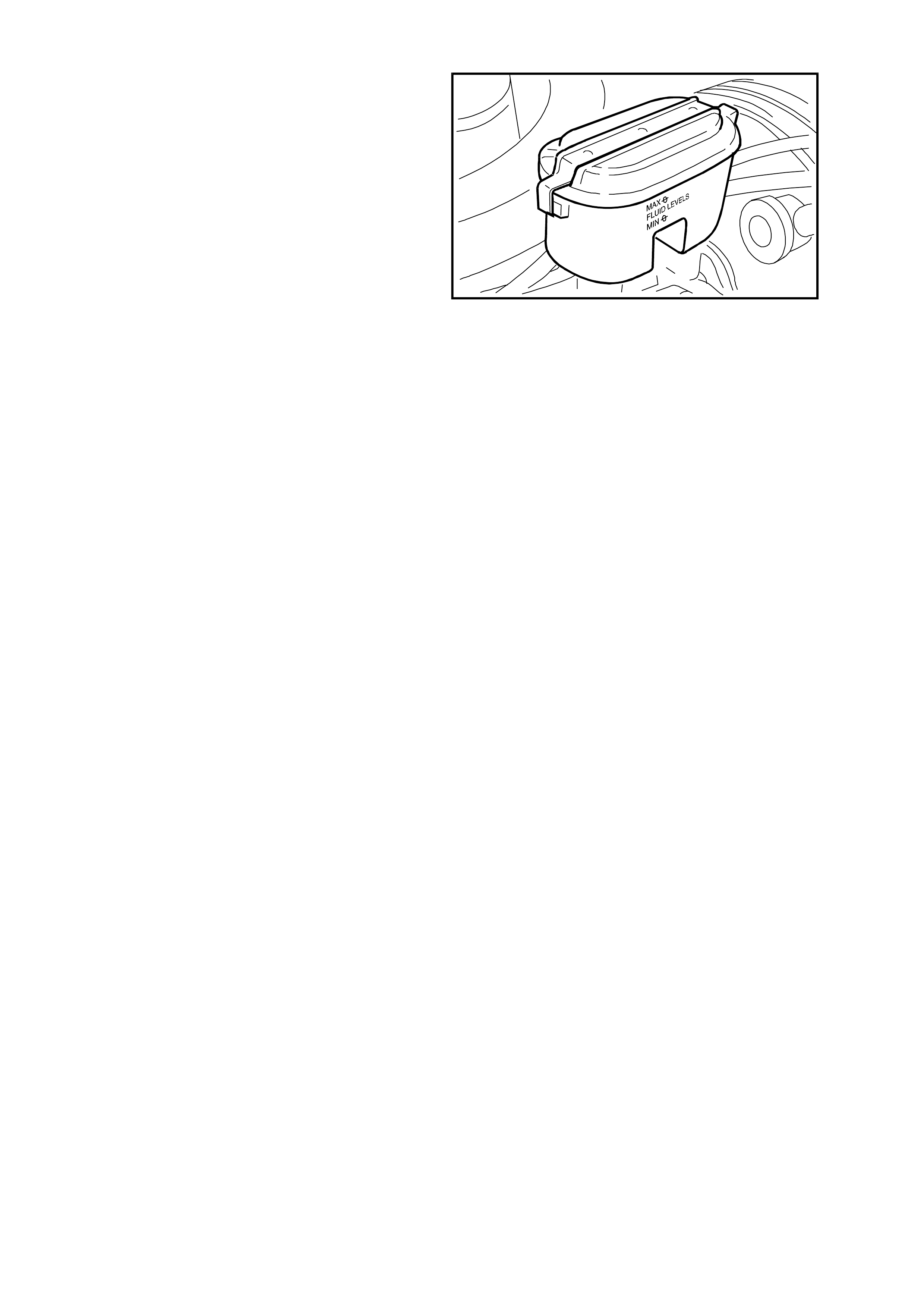

Check

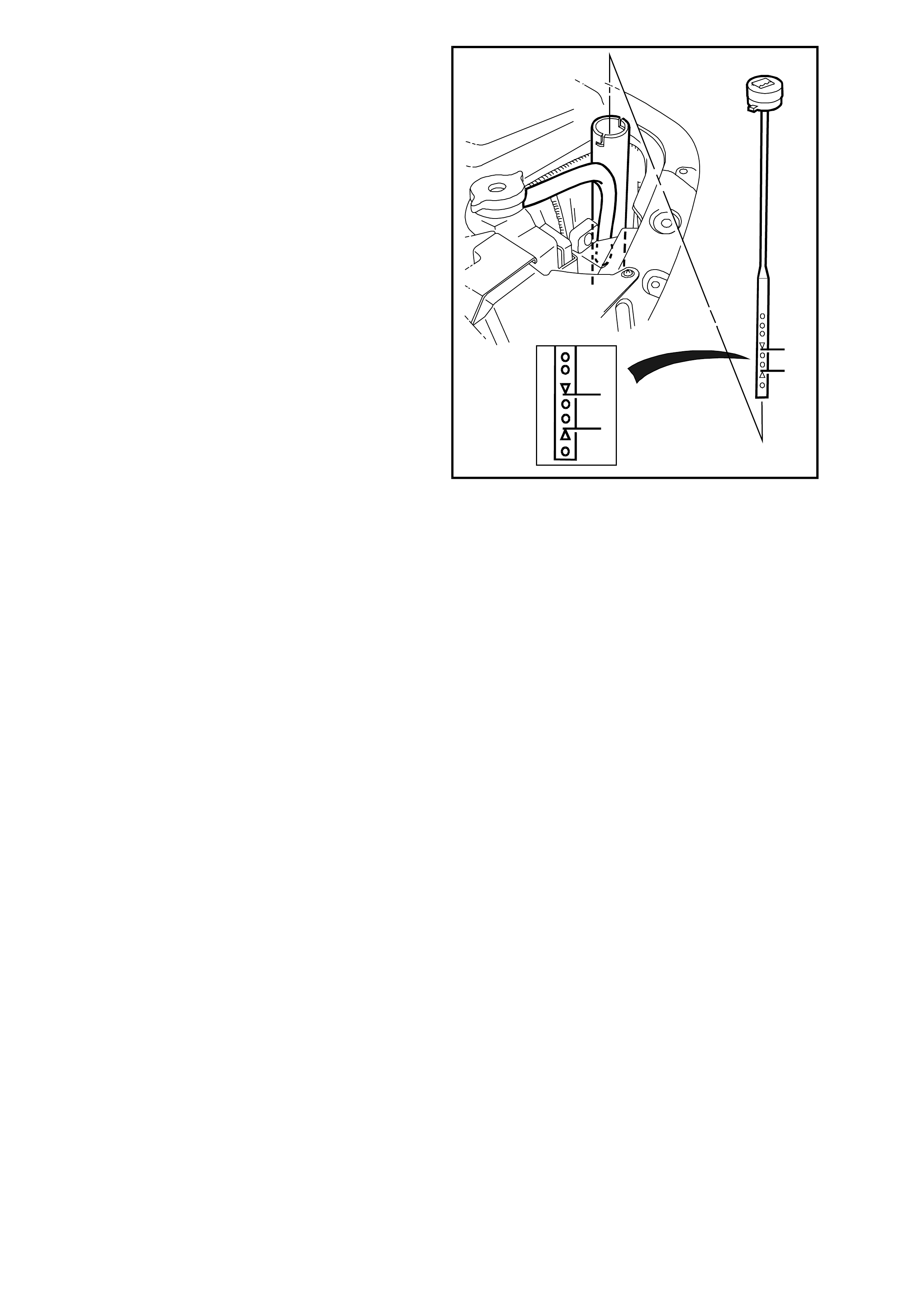

Turn the coolant dipstick cap one eighth of a turn

anti-clockwise and slowly pull out the dipstick.

There are two triangles on the dipstick repres enting

the Minimum ▲ and Maximum ▼ levels.

When the coolant is cold, the coolant level should

be at or above the Minim um ▲ triangle m ark on the

dipstick. After the engine has been driven and the

engine is at the normal operating temperature, the

level should be somewhere between the Minimum

▲ and Maximum ▼ triangles.

If the coolant level is correct, replace the dipstick

and turn the cap one eighth of a turn clockwise to

secure.

If the coolant level is low, add enough of a pre-

mixed coolant solution of water and a good quality

inhibited ethylene glycol (meeting Holden

specification HN 2043) to bring the level up to the

proper mark.

When the level is correct, replace the dipstick and

turn the cap one eighth of a turn clockwise to

secure.

It is of the utmost importance to maintain the

correct concentration level of glycol in the cooling

system.

To ensure the specified glycol concentration is

maintained in the engine coolant, the coolant

concentration must be checked at the time or

distance intervals outlined in 9.2 MAINTENANCE

SCHELDULE in this Section or in the VT Series

Owner’s Handbook.

Check coolant concentration as outlined in Section

6B1-1 ENGINE COOLING - V6 ENGINE or 6B1-2

ENGINE COOLING - V6 SUPERCHARGED of this

Service Information CD.

It is recommended that the coolant be drained, the

system flushed and refilled with clean water and

radiator coolant at the time or dis tance intervals set

out in 9.2 MAINTENANCE SCHEDULE in this

Section or the VT Series Owner’s Handbook.

T20B013

Figure 0B-15

Aluminium radiators should be protected at all

times by a coolant that is specifically recommended

for use with aluminium. Aluminium radiators may

be destroyed by the caustic solutions found in

some cleaners or the chemicals used in some

antifreeze’s and inhibitors.

For cooling system filling instructions, refer to

Section 6B1-1 ENGINE COOLING - V6 ENGINE

or 6B1-2 ENGINE COOLING - V6

SUPERCHARGED of this Service Information CD.

GEN III V8 ENGINE

CAUTION: Do not remove coolant surge tank

cap when the engine and radiator are hot.

Scalding fluid and steam can be blown out

under pressure if the cap is removed.

The cooling system is designed to use a specific

coolant (a mixture of DEX-COOL® coolant to GM

Specification 6277M coolant additive and water),

rather than plain water.

The use of this orange coloured coolant additive

also raises the boiling point and increases the

cooling system efficiency. For this reason, it is of

the utmost importance that the correct

concentration level of DEX-COOL® is maintained in

the cooling system.

Addition of plain water into the cooling system

when 'topping-up' may dilute the coolant m ixture to

a point where the specific properties of DEX-

COOL® become ineffective.

The coolant should comprise of a mixture 50%

DEX-COOL® (GM Specification 6277M) with 50%

clean, good quality water.

NOTE: Do not mix different types of antifreeze or

corros ion inhibitors as they m ay be incompatible. If

a different type has been used in the cooling

system, flush the system with clean water, refer to

Section 6B3 ENGINE COOLING - GEN III V8

ENGINE of this Service Information CD.

The water used f or m ixing with DEX- COOL coolant

must be of low dissolved salt content, preferably

tank water or demineralised water.

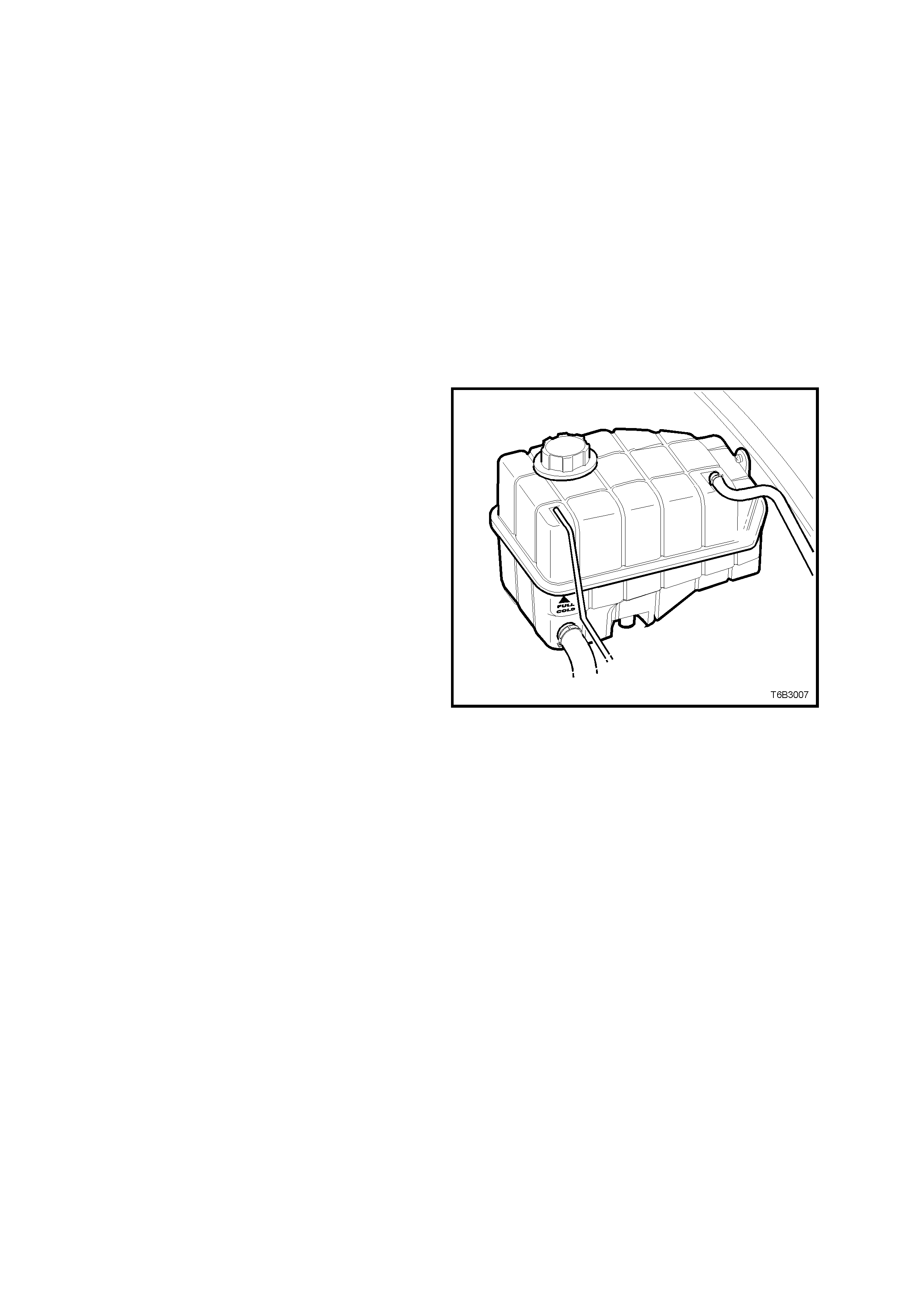

Check

The coolant level can be externally checked at the

coolant surge tank. With the engine cold, the

coolant level should be at the FULL CO LD m ar k on

the front of the coolant surge tank.

Pre-mixed coolant (50% DEX-COOL® to GM

Specification 6277M with 50% clean, good quality

water) may be added as necessary to bring the

level shown on the coolant surge tank but only

when the engine is cold.

It is of the utmost importance to maintain the

correct concentration level of glycol in the cooling

system.

To ensure the specified glycol concentration is

maintained in the engine coolant, the coolant

concentration must be checked at the time or

distance intervals outlined in 9.2 MAINTENANCE

SCHEDULE in this Section or in the VT Series

Owner’s Handbook.

Check coolant concentration as outlined in Section

6B3 ENGINE COOLING - GEN III V8 ENGINE of

this Service Information CD.

It is recommended that the coolant be drained, the

system flushed and refilled with clean water and

radiator coolant at the time or dis tance intervals set

out in 9.2 MAINTENANCE SCHEDULE in this

Section or the VT Series Owner’s Handbook.

Figure 0B-16

Aluminium radiators should be protected at all

times by a coolant that is specifically recommended

for use with aluminium. Aluminium radiators may

be destroyed by the caustic solutions found in

some cleaners or the chemicals used in some

antifreeze’s and inhibitors.

For cooling system filling instructions, refer to

Section 6B3 ENGINE COOLING – GEN III V8

ENGINE of this Service Information CD.

3. MANUAL TRANSMI SSION LUBRICATION AND SERVICE

3.1 RECOMMENDED LUBRICANT

GETRAG 5 SPEED MANUAL TRANSMISSION (V6)

The recom m ended lubricant for the Getrag, Type 260 5 speed manual transm iss ion (Production Option M35) in VT

Series Models is Castrol VMX 80W oil (to Holden specification HN1855).

TREMEC 6 SPEED MANUAL TRANSMISSION (GEN III V8)

The recommended lubricant for the Tremec, Type T56, 6 speed manual transmission (production option MM6) is

fluid qualified to Dexron® III (to Holden specification HN2126).

3.2 CHECKING TRANSMISSION LUBRICANT LEVEL

The lubricant level is to be checked at the time or

distance intervals detailed in 9.2 MAINTENANCE

SCHEDULE in this Section or in the VT Series

Owners Handbook.

GETRAG 5 SPEED MANUAL TRANSMISSION (V6)

NOTE: Ensure the vehicle is on level ground and

that the transmission is cold.

1. Remove the filler plug (1) using a 17mm ring

spanner, from the right hand side of the

transmission case.

2. Check lubricant level: the level is correct when

the lubricant is at the bottom of the plug hole

threads.

If necessar y add the recom m ended lubricant to

bring to the correct level.

3. Clean the threads of the filler plug, reinstall and

tighten to the correct torque specification.

NOTE: Do not apply sealant or tape to the threads

of the filler (1) or drain (2) plugs.

GETRAG TRANSMISSION FILLER PLUG

TORQUE SPECIFICATION 40 - 60 Nm

T20B001

2

1

Figure 0B-17

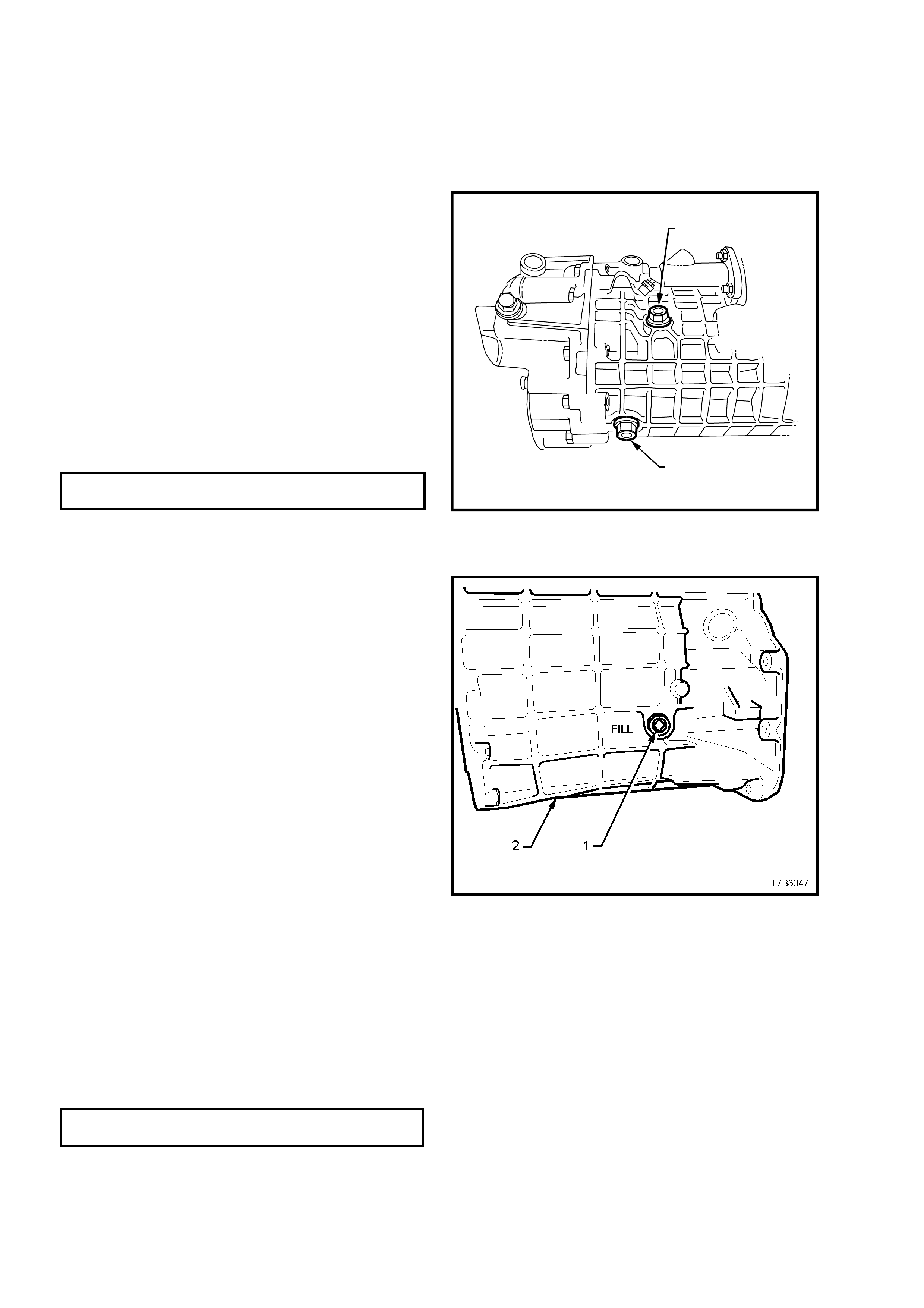

TREMEC 6 SPEED MANUAL TRANSMISSION (GEN III V8)

Important: This transmission is classified as

being a “Fill for Life” transmission and periodic

checking of the lubricant level is not required.

The only time that fluid level checking would be

appropriate, would be after c orr ec tion of a f luid leak

from the transmission or if the transmission had

been removed from the vehicle.

1. Raise the vehicle f ront and r ear and support on

safety stands, ensuring that the vehicle is level.

Refer to Section 0A GENERAL

INFORMATION of the VT Series I Service

Information, for the location of jacking points.

2. Place a drain tray beneath transmission and

remove transmission filler plug (1) from left

hand side of transmission case (2), using a 3/8”

drive socket bar.

NOTE: Depending on the severity of the loss, fluid

will probably flow from the filler plug hole, following

removal.

3. Allow excess fluid to drain until flow stops. If

required, top up fluid level until it does flow out.

Figure 0B-18

4. Clean the threads of the filler plug, apply thread

sealant such as Loctite 565 or equivalent (GM

P/N 12346004), then reinstall filler plug,

tightening to the correct torque specification.

Do not apply Teflon thread tape to the plug

threads.

TRANSMISSION FILLER PLUG

TORQUE SPECIFICATION 20 - 34 Nm

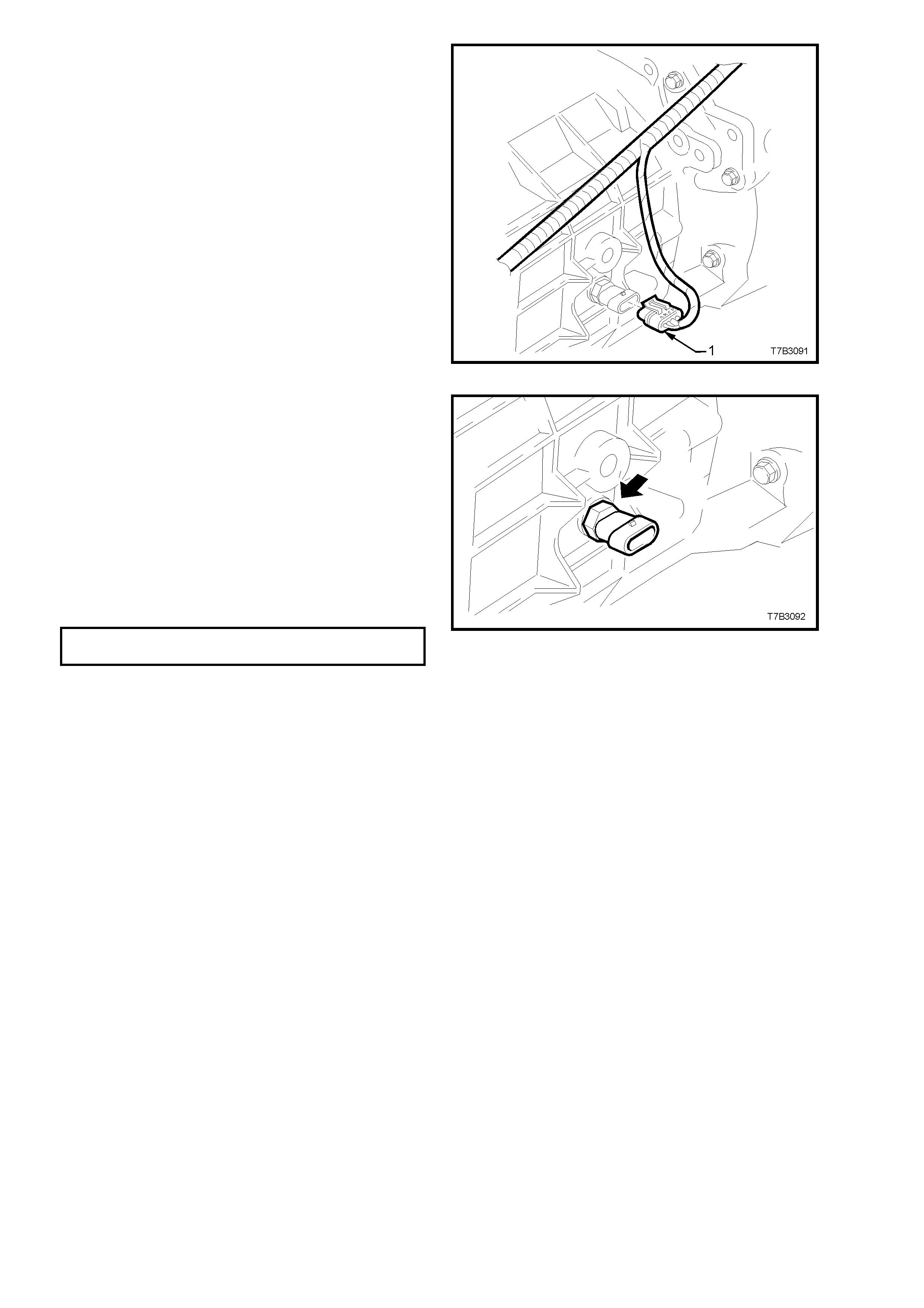

5. Remove the back-up lamp switch as follows:

a. Remove wiring harness connector (1) from

switch, located on the right hand side of the

transmission case .

Figure 0B-19

b. Loosen, then remove switch (arrow) from

the transmission case.

6. Using commercially available fluid dispensing

equipment, add a measured, 0.5 litres of the

recommended lubric ant to the trans miss ion, via

the back-up lamp switch threaded hole in the

transmission case .

7. Apply Loctite 565 or equivalent (GM P/N

12346004), to the cleaned threads of the bac k-

up lamp switch.

8. Install switch to transmission case and tighten

to the correct torque specification.

BACK-UP LAMP SWITCH

TORQUE SPECIFICATION 20 - 34 Nm

9. Install wiring harness connector to switch.

10. Remove safety stands and lower vehicle to

ground.

11. Check back-up lamp operation.

Figure 0B-20

3.3 DRAINING AND REFILLING TRANSMISSION

Should a lubricant change be required, then the

following procedure should be adopted.

NOTE: Periodic transmission lubricant changes are

not necessary. The lubricant should be changed

when overhauling the transmission.

GETRAG 5 SPEED MANUAL TRANSMISSION (V6)

1. To drain the transm ission, jack up vehicle front

and rear and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION of this Service Inf orm ation CD,

for the location of jacking points.

2. Place a drain tray beneath transmission and

remove the filler plug (1) and then the drain

plug (2) using a 17mm ring spanner.

3. W hen the transm ission has fully drained, clean

and refit drain plug and refill transmis sion to the

required level with Castrol VMX 80W oil (to

Holden specification HN1855) transmission

fluid, as outlined in 3.2 CHECKING

TRANSMISSION LUBRICANT LEVEL in this

Section.

4. Clean filler plug, reinstall and tighten both the

filler and drain plugs to the correct torque

specification.

NOTE: Do not apply sealant or tape to the threads

of the filler or drain plugs.

GETRAG TRANSMISSION FILLER PLUG

TORQUE SPECIFICATION 40 - 60 Nm

GETRAG TRANSMISSION DRAIN PLUG

TORQUE SPECIFICATION 40 - 60 Nm

T20B001

2

1

Figure 0B-21

TREMEC 6 SPEED MANUAL TRANSMISSION (GEN III V8)

1. To drain tr ans mission, j ac k up vehicle f ront and

rear and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION of this Service Inf orm ation CD,

for the location of jacking points.

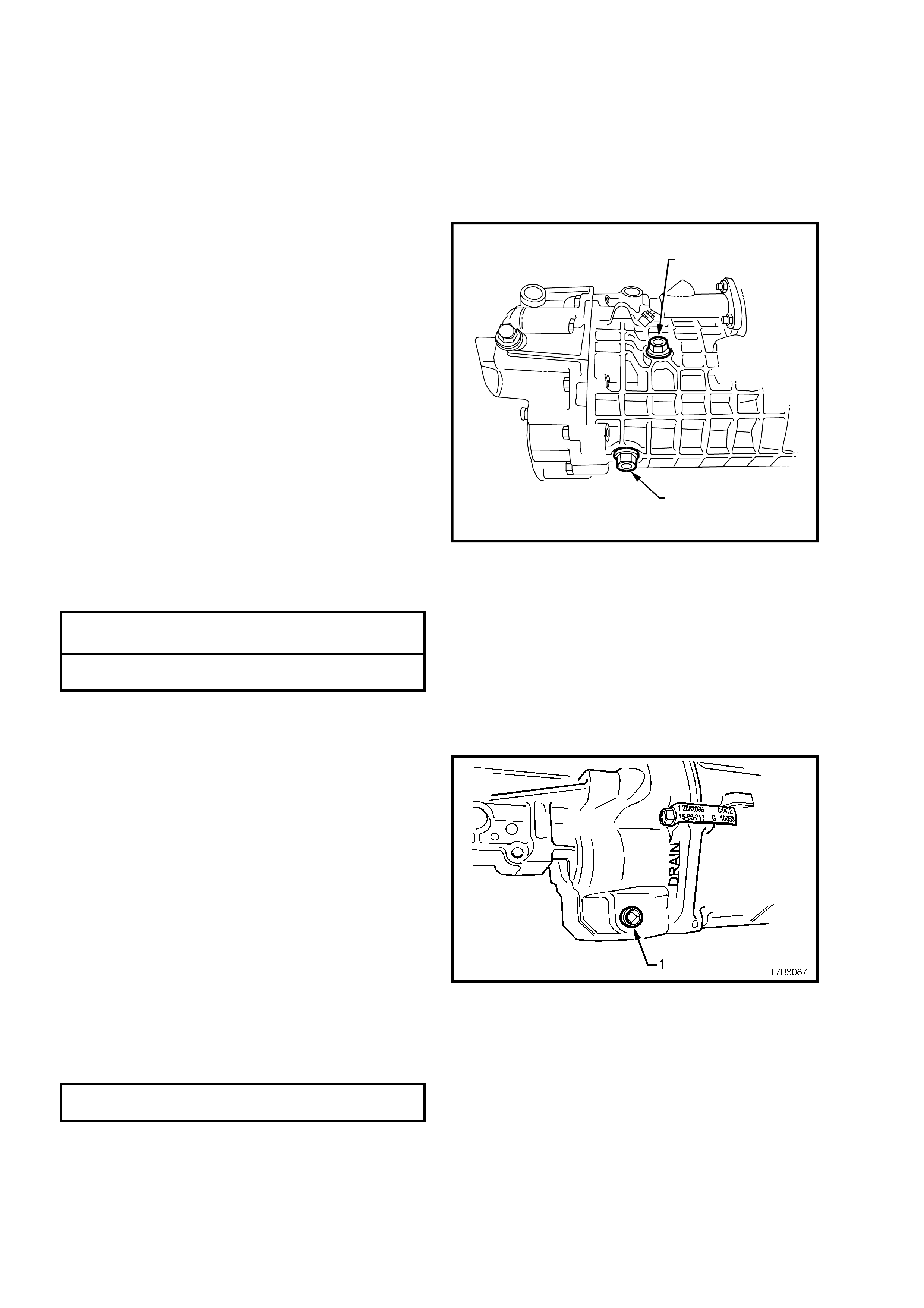

2. Place a drain tray beneath transmission and

remove filler plug (refer to ‘1’ in Figure 0B-18 )

and then the drain plug (1) from the

transmission extension housing using a 3/8”

drive socket bar.

3. After draining, clean the threads of the drain

plug, apply thread sealant such as Loctite 565

or equivalent (GM P/N 12346004), then

reinstall, tightening to the correct torque

specification.

NOTE: Do not apply Teflon thread tape to the plug

threads.

TRANSMISSION DRAIN PLUG

TORQUE SPECIFICATION 20 - 34 Nm

4. Refill transmission to the correct level with

Dexron III transmission fluid (to Holden

specification HN 2126) as outlined in

CHECKING TRANSMISSION LUBRICANT

LEVEL in this Section.

Figure 0B-22

4. AUTOM ATIC TRANSMISSION LUBRICATION AND SERVICE

4.1 RECOMME NDED FLUID

The automatic transmission for VT Series Models requires fluid qualified to Dexron® III (to Holden specification

HN2126).

4.2 CHECKING TRANSMISSION FLUID LEVEL

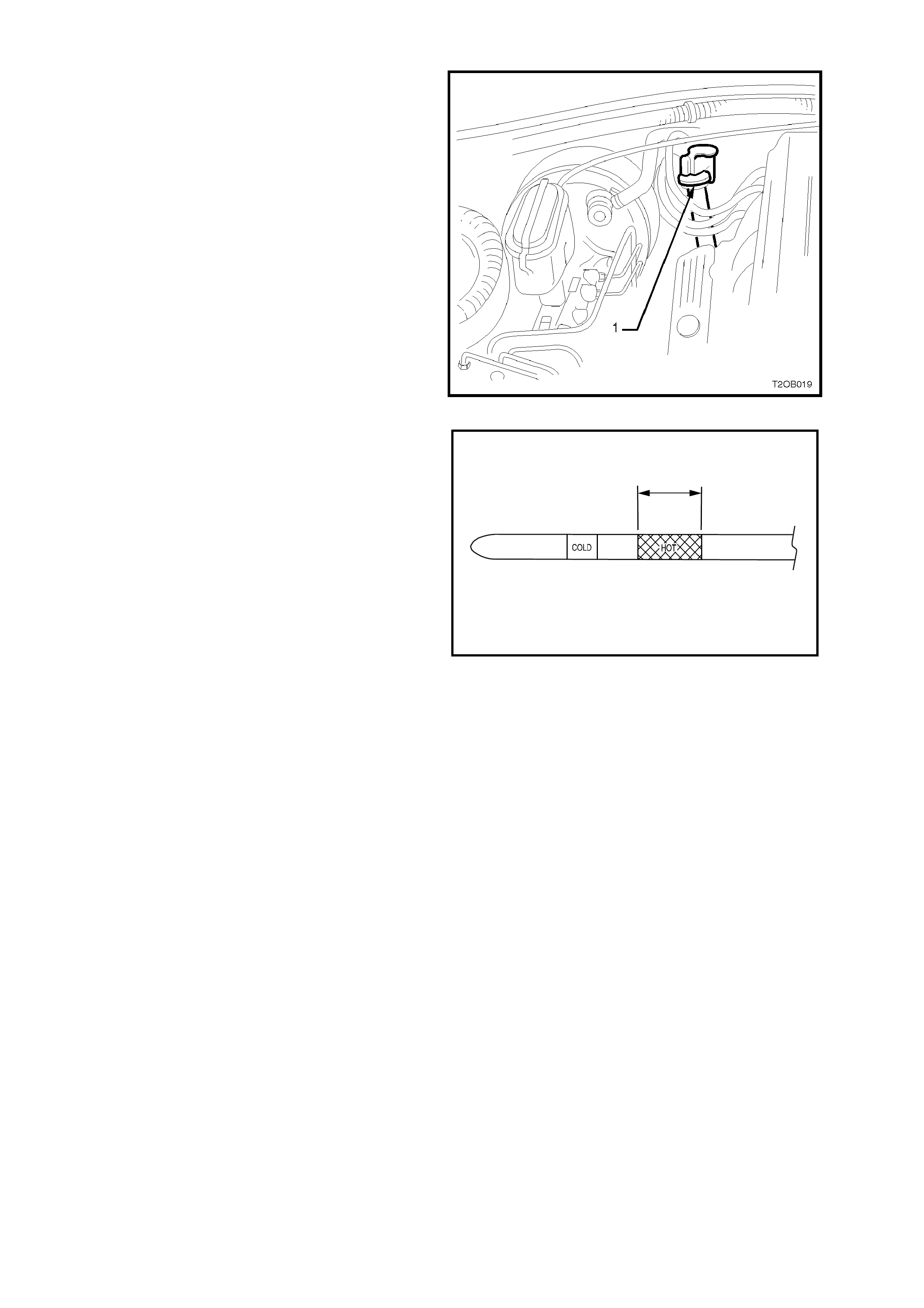

The transmission fluid level dipstick (1) is located

on the right hand side of the engine, refer to

Fig.0B-21.

1. Bring transmission to normal operating

temperature (82 - 94°C) (or drive vehicle for a

distance of 24km).

NOTE: As temperature affects transmission fluid

levels, this operation must be carried out with the

transmission at normal operating temperature. If

the vehicle is not at normal operating temperature,

and the proper checking procedures are not

followed, the result could be a false reading of the

fluid level on the dipstick.

2. Park vehicle on level ground.

3. Place selector lever in ‘P’ (PARK) position.

4. Apply park brake.

5. Let engine idle for 3 minutes with accessories

(i.e. air conditioning) turned off.

6. Lift the coloured dipstick locking lever, remove

dipstick and check fluid level.

The fluid level should be within the HOT

(hatched) area of the dipstick. If the level is

below this area, add only enough Dexron® III

fluid to bring the level into the HOT (hatched)

area of the dipstick.

NOTE 1: Inaccurate readings will result if the fluid

level is checked immediately after the vehicle has

been operating under an of the following conditions:

• In high ambient temperatures above 32°C.

• At sustained high speeds

• In heavy city traffic during hot weather.

• Towing

• In commercial use (i.e. taxi)

If the vehicle has been operating under any of the

above conditions, switch of the engine and allow

the vehicle to cool for approximately 30 minutes,

then restart the vehicle and continue from step 2.

NOTE 2: The cold m arkings on the dipstick should

only be used as an indicator when initially f illing the

transmission after the fluid has been completely

drained. The fluid should be rechecked when the

transmission is hot.

NOTE 3: Due to the shape of the filler tube, level

readings may be misleading. Look carefully for full

fluid ring on both sides of the dipstick. Recheck if

any doubt of fluid level occurs.

NOTE 4: Also check the fluid for contamination,

discolouration or if it smells burnt. This gives an

indication that frictional materials within the

transmission may need replacement. Refer to

Section 7C3 AUTOMATIC TRANSMISSION of

this Service Information CD for additional

information.

Figure 0B-23

0.5 lt.

T20B006

Figure 0B-24

4.3 FLUID CHANGE

The transmission fluid and strainer should be changed at the time or distance intervals specified in 9.2

MAINTENANCE SCHEDULE in this Section or in the VT Series Owner’s Handbook.

When changing the transmission fluid, refer to Section 7C4 AUTO TRANS. - GENERAL INFORMATION - 3.1

FLUID CHANGE AND FILTER REPLACEMENT of this Service Information CD.

5. BRAKE HYDRAULIC SYSTEM SERVICE

SAFETY AND CAUTIONARY NOTE FOR VEHICLES EQUIPPED WITH ABS/ETC:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4 DIAGNOSIS, ABS or ABS/ET C FUNCTION CHECK, in Section 12L ABS & ABS/ETC, in the VT

Series I Service Information (V6) or in the VT Series II Service Information (GEN III V8) of this Service

Information CD.

5.1 RECOMME NDED FLUID

The r ecom m ended f luid for the VT Ser ies brak e hydraulic system is heavy duty brak e f luid to Holden’s s pecif ication

HN1796.

5.2 BRAKE FLUID LEVEL CHECK

Check that the fluid level is between the MIN and

MAX level markings on the translucent reservoir

housing.

NOTE: If the fluid is between the markings, do not

rem ove r eser voir c ap, as brake f luid expos ed to the

atmosphere will quickly absorb moisture.

Should the addition of fluid be required, wipe clean

the sides of the reservoir cover, then unclip and

rem ove the reservoir cap. T op up f luid using heavy

duty brake fluid to Holden’s Specification HN1796.

T20B014

Figure 0B-25

5.3 BRAKE FLUID REPLACEMENT

The entire f luid content of the brak e hydraulic system m us t be changed at the tim e or dis tance intervals specif ied in

9.2 MAINTENANCE SCHEDULE in this Section or in the VT Series Owner’s Handbook.

Due to the complexities of the brake fluid replacement procedure, refer to Section 5A BRAKES of this Service

Information CD, noting the following:

When bleeding brakes on vehicles with ABS or ABS/ETC, refer to Section 12L ABS & ABS/ETC (V6 engine) or

Section 12L ABS & ABS/ETC (GEN III V8 engine) of this Service Information CD.

6. CLUTCH HYDRAULIC SYSTEM SERVICE

6.1 RECOMME NDED FLUID

The recom mended fluid for the VT Series clutch hydraulic system is heavy duty brak e fluid to Holden’s s pecif ication

HN1796.

6.2 CLUTCH FLUID LEVEL CHECK

Check that the fluid level is between the two

guidelines on the translucent reservoir housing.

NOTE: If the fluid is between the markings, do not

rem ove r eser voir c ap, as brake f luid expos ed to the

atmosphere will quickly absorb moisture.

Should the addition of fluid be required, wipe clean

the sides of the reservoir cap, then unscrew and

rem ove the reservoir cap. T op up f luid using heavy

duty brake fluid to Holden’s Specification HN1796.

Figure 0B-26

6.3 CLUTCH FLUID REP LACEMENT

The entire fluid content of the clutch hydr aulic system m us t be changed at the tim e or dis tance intervals specif ied in

9.2 MAINTENANCE SCHEDULE in this Section or in the VT Series Owner’s Handbook.

To replace the clutch hydraulic fluid, refer to Section 7A CLUTCH with V6 engines or Section 7A CLUTCH for

vehicles with GEN III V8 engine.

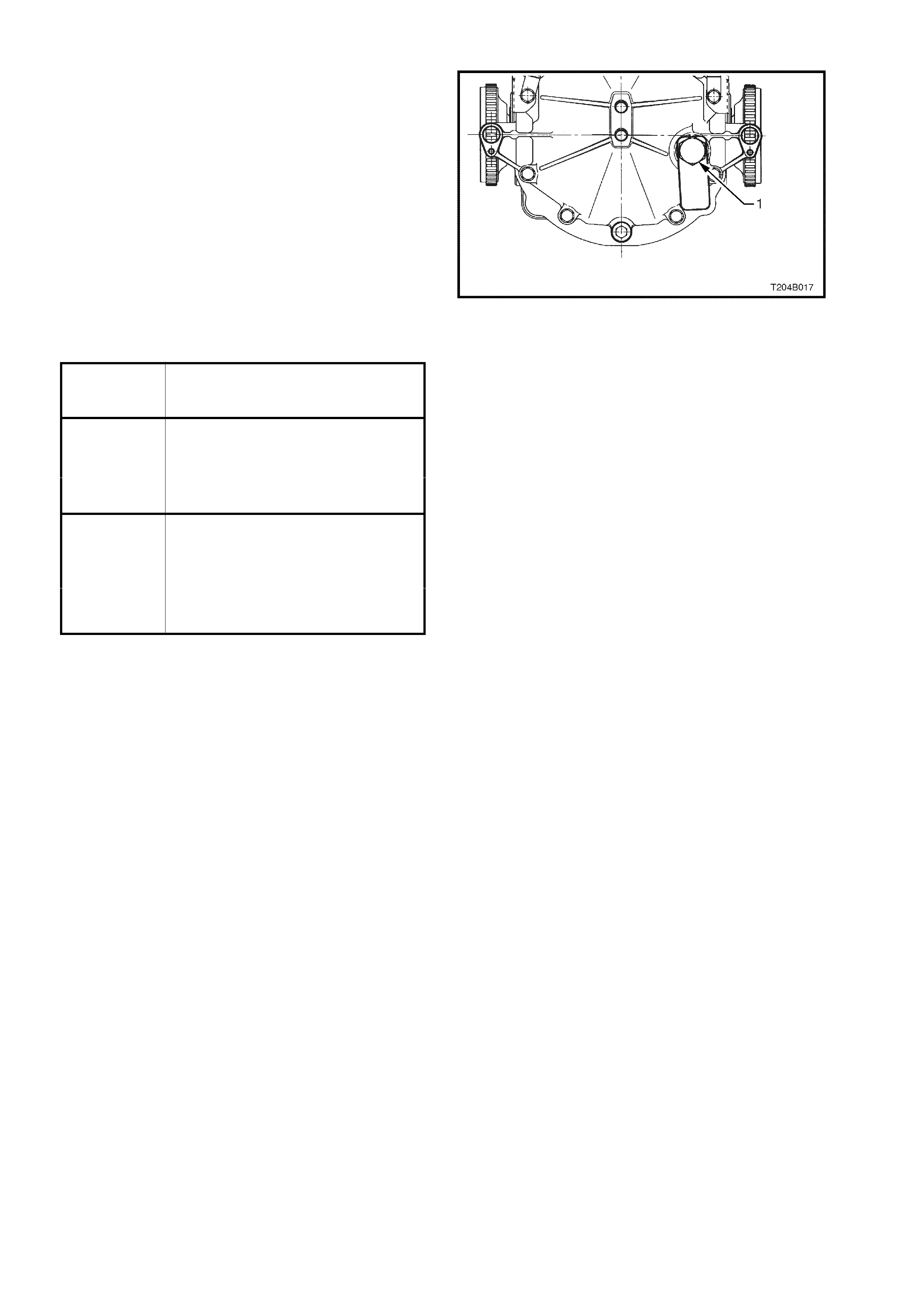

7.2 CHECKING FINAL DRIVE LUBRICANT LEVEL

The final drive lubricant level should be checked at

the time or distance intervals specified in 9.2

MAINTENANCE SCHELDULE in this Section or in

the VT Series Owner’s Handbook.

To check final drive level:

1. Ensure the vehicle is level.

2. The final drive assembly is cold.

3. Clean the area around the filler plug (1).

4. Using a suitable socket and bar, remove the

filler plug.

5. The level is correct when the lubricant is at the

bottom of the filler plug hole.

6. Inspect filler plug for damage, if satisfactory,

refit into the final drive housing.

ENGINE &

FINAL DRIVE RECOM MENDE D L UBRICANT

TYPE

All V6 excludi ng Mineral Hypoid Gear Oil s uch as;

V6 Wagon AMPOL Gearlube SRD90, B P Lim slip 90,

with Manual CALTEX Gear Oil LSD, CA S T ROL LSX90,

Transm i ssion & MOBIL Lubrite LS 90, SHELL XD90LS,

V6 Supercharged VALVOLI NE HP Gear Oil LS 90 or equi val ent

Vehicl es lubricant to Holden's Specif i cation HN1561

All V8, V6 Wagon Synthetic Hypoid Gear Oil, such as ;

with Manual AMPOL Synthet ic Gear Oil 80W/140

Transm i s sion & CALTEX Synstar GL 80W-140

V6 Supercharged CASTROL S AF-XA

Vehicl es MOBIL Mobilube SHC Li mited Slip,

VALVOLI NE Synthetic Gear 75W-140, or

equivalent lubricant to Hol den's Spec ifi cat ion

HN2040

Figure 0B-27

7.3 PERIODIC SERVICING

Periodic draining of the final drive assembly is not

necessary.

Check for lubricant leaks at every service. If there

is evidence of leakage, repair leak and add

lubricant, if necessary, to the correct level.

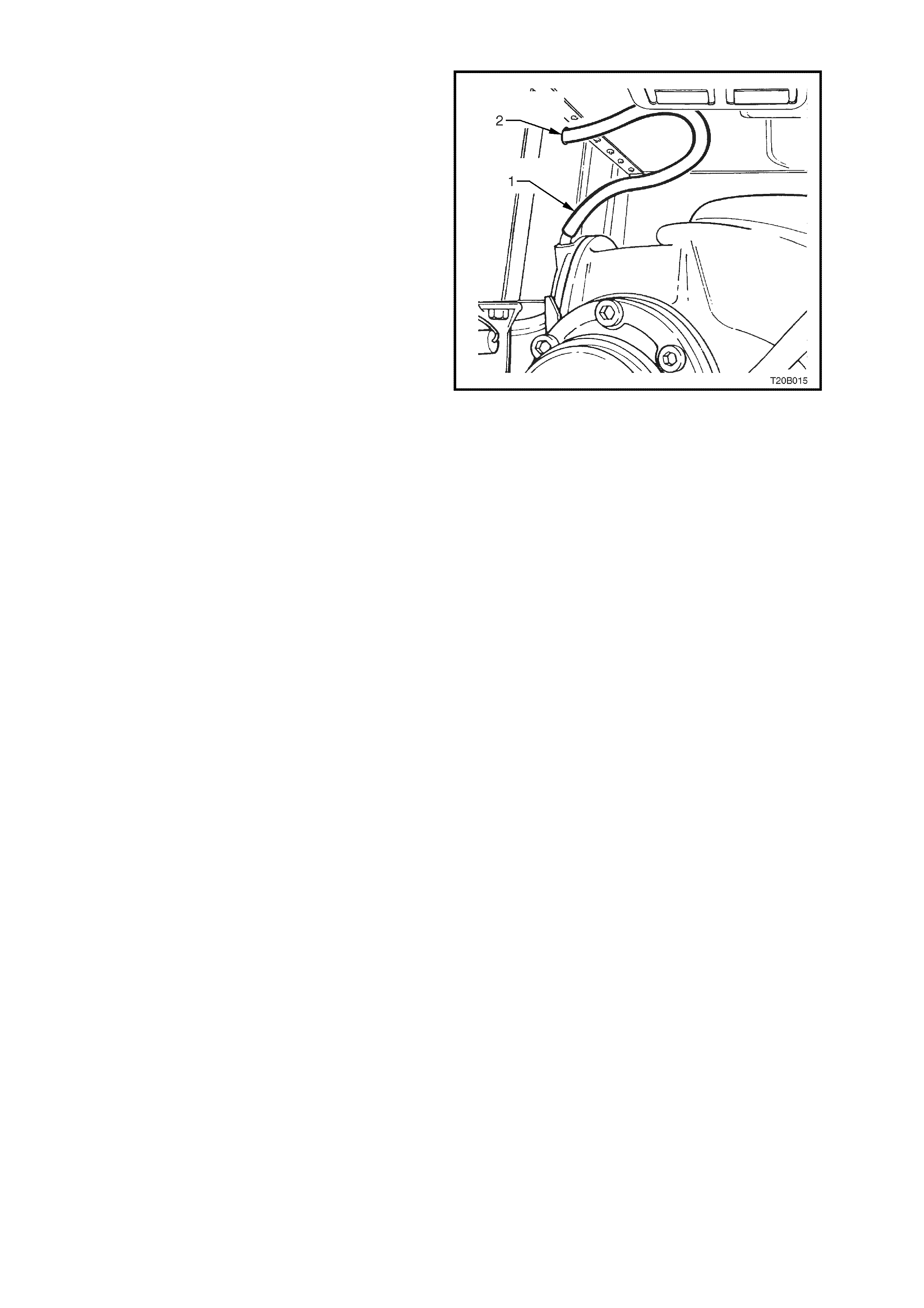

The final drive breather (1) should be checked

regularly to ensure that the hose is not kinked or

damaged.

The top end of the breather hose should be

inserted at least 25 mm into the vehicle underbody

crossmember hole (2).

Figure 0B-28

8. POWER STEERING

8.1 RECOMME NDED FLUID

The recommended fluid for the VT Series power steering system is automatic transmission fluid, qualified to Dexron

® III (to Holden specification HN2126).

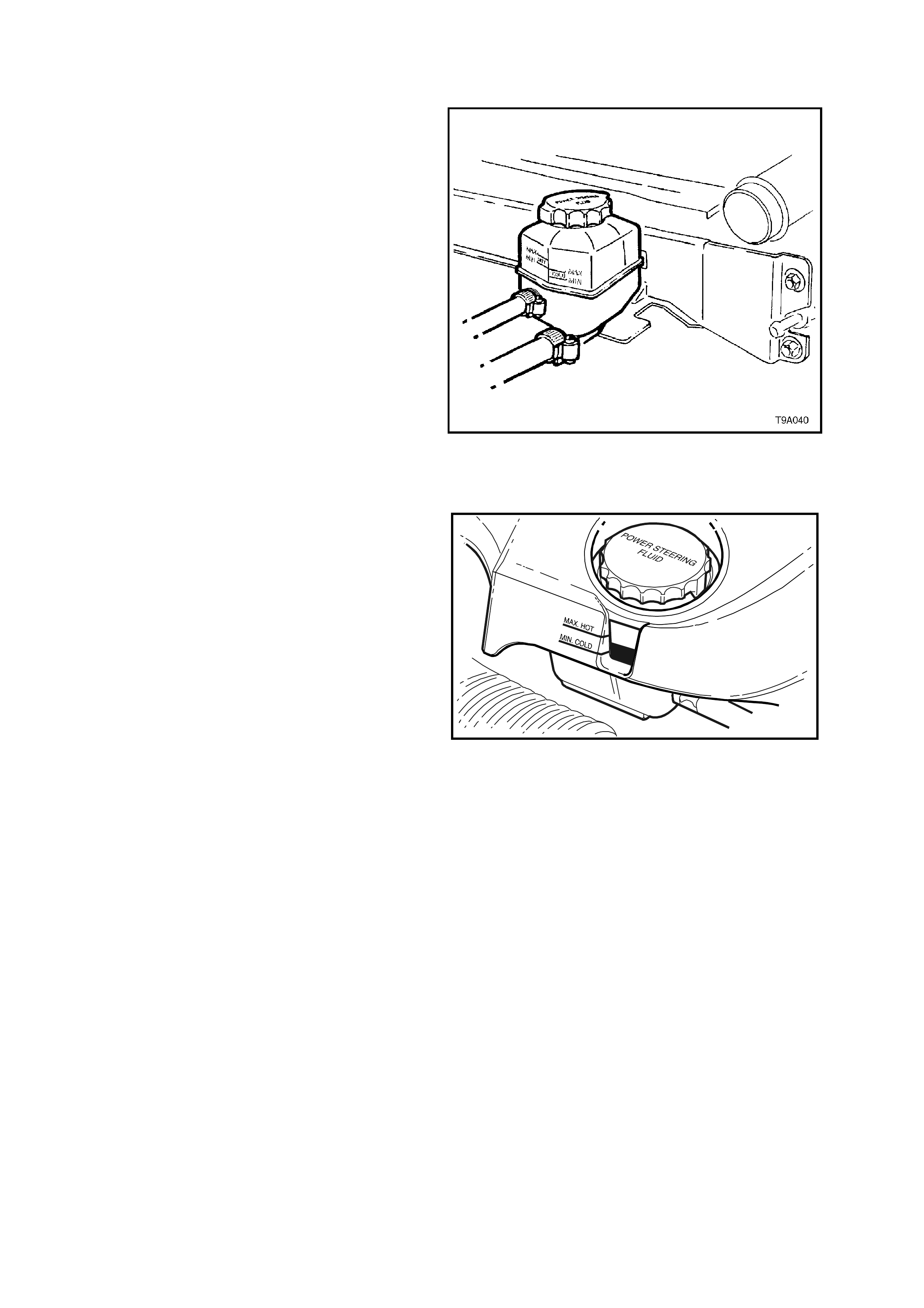

8.2 CHECKING POWER STEERING FLUID LEVEL

V6 AND V6 SUPERCHARGED ENGINE

The power steering fluid level is checked by

viewing the fluid through the transparent plastic

side of the reservoir (refer Fig.0B-29), which is

mounted to a bracket attached to the cooling fan

shroud.

If the fluid is cold, the level should be in the ‘COLD’

range. Sim ilar ly, if it is hot, the fluid s hould be in the

‘HOT’ range. If the fluid level is at the low side of

either range, f luid should be added to br ing the f luid

to the correct level.

Figure 0B-29

GEN III V8 ENGINE

With t he en gin e dress cover remov ed; the power

steering fluid level is checked in the same way as

the V6 and V6 supercharged engine power steering

fluid is checked, noting the following:

The power steering reservoir is mounted on the

front left hand side of the engine, above the power

steering pump.

With the en gine dress cover in stalled; chec k the

power steering fluid level by viewing the fluid

through the cut away in the engine dress cover at

the front of the engine.

The fluid level should be in the range of ‘Min cold’

and ‘max hot’ depending on the temper ature of the

fluid. If the fluid level is below the Min cold mark,

fluid should be added to bring the fluid to the

correct level.

T20B016

Figure 0B-30

8.3 PERIODIC SERVICING

Except under abnormal driving conditions (refer 9.1 ABNORMAL OPERATING CONDITIONS in this Section),

periodic draining of the power steering fluid is not necessary.

Check system f or f luid leaks at ever y service. If ther e is evidenc e of leakage, repair leak and add fluid, if neces sar y,

to the correct level.

9. SERVICING

9.1 ABNORMAL OPERATING CONDITIONS

If the car is driven under any of the abnormal conditions listed below it is recommended that some items be

serviced more frequently than in the maintenance plan.

The extra servic es are only required while the car is dr iven under the abnor mal c onditions. If any of these conditions

are encountered on a one off bas is, then any additional servicing should be for that time only. As a guide, if the car

is operated continually over a period of one month or 1000 km under the abnormal conditions, then additional

servicing may be required.

ABNORMAL CONDITIONS

A When driving less than 10,000 km in six months.

B Dust, dirt, loose road material.

C Muddy and wet areas.

D Cold weather (below 5°C) and when most trips are less than 5km.

E Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. Taxi, door to door delivery.

F Caravan or trailer towing.

G Extended heavy load high speed operation in temperatures above 35°C.

H When driving more than 250,000 km per 5 years.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change engine oil @ 6 months A

Change auto trans fluid and strainer @ 4 years A

Change automatic transmission fluid and strainer @ 20,000 km E F G

Inspect front suspension and steering for leaks, wear or damage @ 5,000 km BC

Replace engine oil filter @ 5,000 km or 3 months (whichever comes first) B

Change engine oil @ 5,000 km or 3 months (whichever comes first) BDFG

Relace air cleaner element @ 20,000 km B

Inspect and clean park brake linings @ 20,000 km BC

Change differential oil @ 20,000 km F G

Change brake fluid @ 1 year if 1,600 kg (or higher) tow bar fitted *F

Change power steering fluid @ 50,000 km F G

GEN III V8 only: change engine coolant H

Carbon canister: inspect @ 20,000 km and change @ 80,000 km BC

* Brak e fluid deterior ates with tim e and should norm ally be replaced every two years . However, heavy duty towing

requires fresher fluid due to the higher demand on the brak e system. Therefore, brake fluid should be replaced

each year if a 1,600 kg (or higher) tow bar is fitted, so that the brake sy stem can cope with the next year’s towing

requirements.

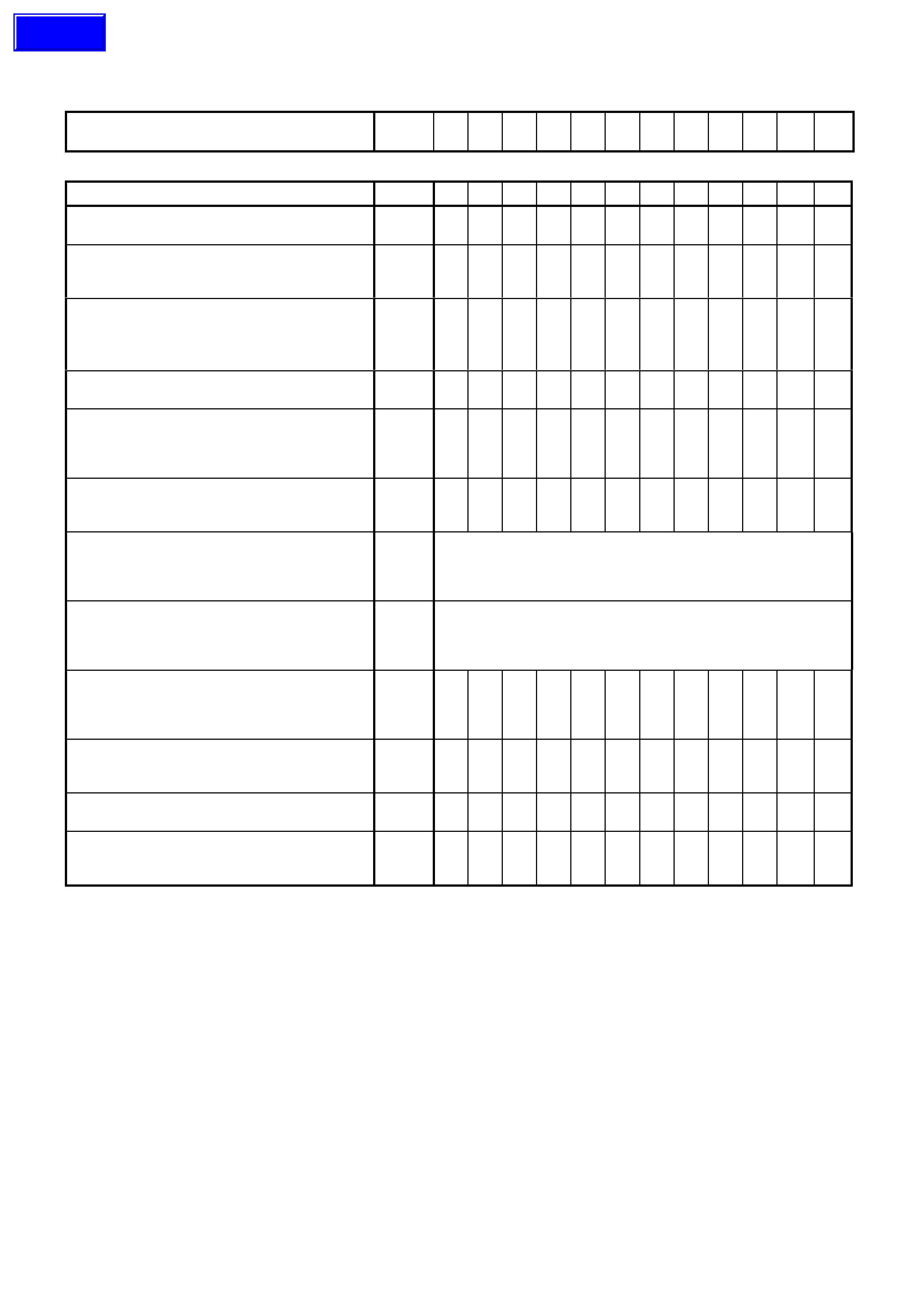

9.2 MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, together with a reference of where to find the necessary

service information in this Service Information CD for VT Series Models.

Use odom eter reading or years, whichever occurs

first. x 1000

km 1.5102030405060708090100110

UNDER HOOD Extra

Change engine oil and engine oil filter (Refer this

Section). *XXXXXXXXXX X

Check f l ui d l evel s: brake, clut ch, power steering,

autom at i c transmission, washer (Ref er t hi s Section,

& 12C WIPERS/WASHERS & INSTRUMENTS).

X XXXXXXXXX X

Check c ool ant inhibit or % with tester and check level

(pressure test system if level is low). (Refer Section

6B1 ENGINE COOLING -V6 ENGINE or 6B3

ENGINE COOLI NG - GE N I II V8 ENGINE).

X XXXXXXXXX X

Check bat tery elect rol yte and fluid l evel , if appli cable

(Refer Section 12A BA TTE RY).

XXXXXXXXXXX X

Engine accessory dri ve bel ts, check l ength indicator

and belt condi tion (Refer Section 6A 1-1 E NGINE

MECHANICAL - V 6 ENGINE or 6A3-3 ENGINE

MECHANICAL - GEN III V8 ENGINE).

XXX X

Check f or signs of deterioration and/or leaks from

engine, fl ui d reservoirs, ai r ducts, all hoses and

clamps.

X XXXXXXXXX X

(V6 engine) Drain and refill cooling s ys t em with

recom mended inhibi tor, cl ean out side of radiator and

A/C condenser (Refer Section 6B 1 E NGINE

COOLING -V6 ENGINE).

Change every 2.5 years (regardless of km)

(GEN III V 8 engine) Drain and ref ill cooling system

with recom mended inhibi tor, cl ean out side of

radiator and A/ C condenser (Refer Secti on 6B3

ENGINE COOLI NG - GE N I II V8 ENGINE).

*Change every 5 years

Replace engine air cleaner element (Refer Secti on

6C1-3 POWE RTRA IN MANAGEMENT - V 6

ENGINE or 6C3-3 P OWERTRAIN MANAGEMENT –

GEN III V8 ENGINE).

*XX

(Supercharger) Chec k supercharger oi l level (Refer

Section 6A1-2 ENGINE MECHANICAL - V6

SUPERCHARGED).

XX

(V6 engine) Replac e spark plugs (Refer Section

6D1-3 IGNITION SYSTEM - V6 ENGINE)

XX

(GEN III V8 engine) Replac e spark plugs (Refer

Secti on 6D3-3 IGNITION S Y S T EM - GEN III V 8

ENGINE)

X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 9.1 ABNORMAL OPERATING CONDITIONS in this Section.

Techline

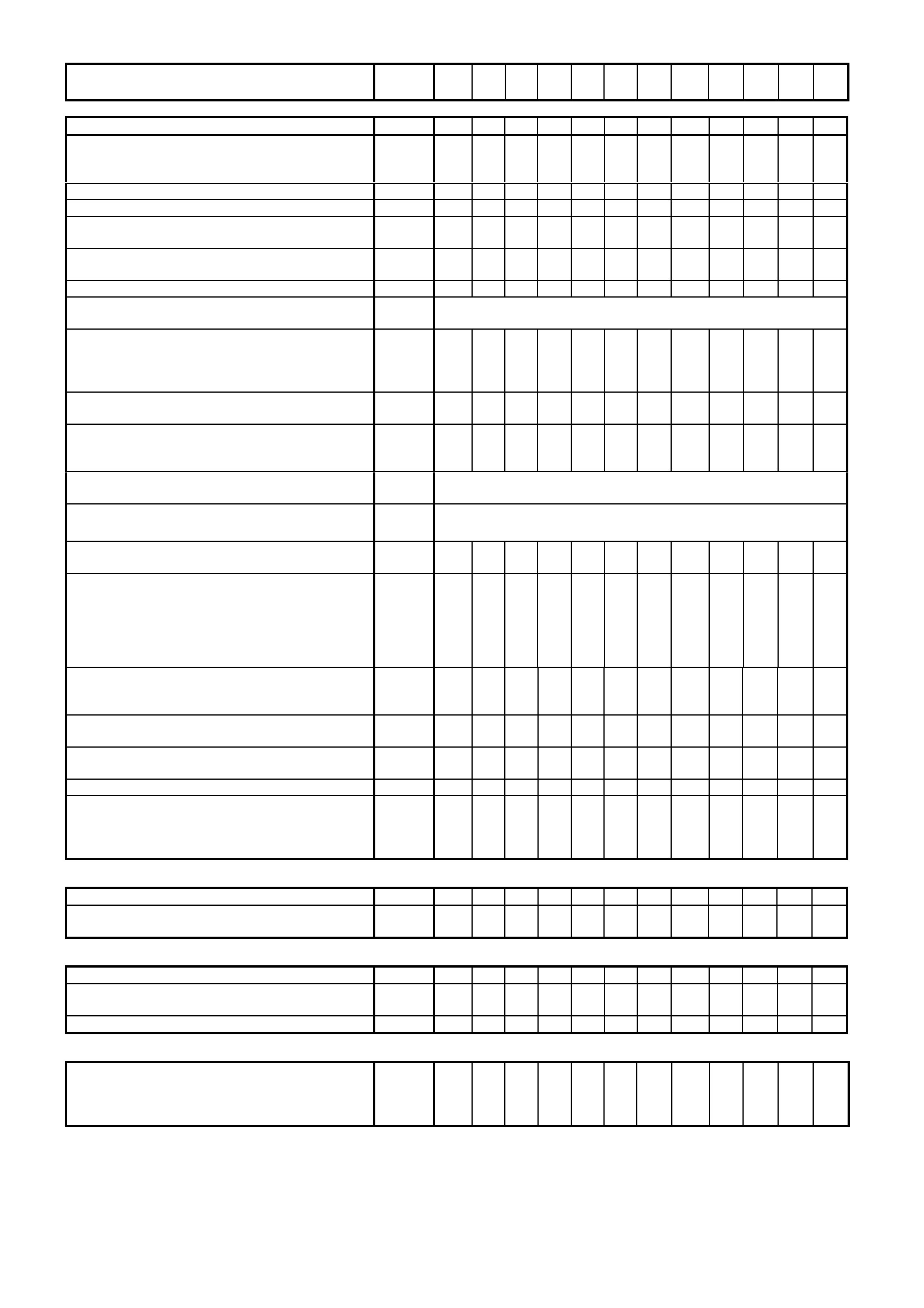

UNDER CAR

Use odom eter reading or years, whichever occurs

first. x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Extra

Replace fuel filter (Refer Section 6C1-3

POW ERTRAIN MANA GEMENT - V6 ENG or 6C3-3

POWE RT RAIN MANAGE MENT - GE N III V 8 ENG).

XX

Check f i nal dri ve oi l l evel (Refer this S ection). XX

Check f i nal dri ve and aut o trans for l eaks. X XXXXXX X XXXX

Change auto trans fluid and strainer (Refer Section

7C-4 AUTOMATIC TRANSMISSION). *X

Check manual transmission oil level (Refer this

Section). XX

Check manual transmi ssion f or l eaks. X XXXXX X XXXX

Change differential oil (Refer Section 4B FINAL

DRIVE & DRIVE SHAFTS). *Change not required under normal driving condi tions

Inspect front and rear disc pads for wear and disc

surface condition (Refer Section 5A STANDARD

BRAKES). Rotate wheels (Refer Section 10

WHEELS & TYRES).

XXXXX X XXXX

Check park brake linings and drum s for wear (Refer

Section 5A STANDARD BRAKES). *XX

Inspect tyres for irregular wear or damage. Check

for damaged wheels. Check air pressures. (Refer

Secti on 10 WHEELS & TYRES )

X XXXXXX X XXXX

Drain, refill and bleed brake system, check brake

perform ance when road testing (Ref er this S ection). *

Change every 2 years (regardless of km) under normal driving

conditions

Drain, refill and bleed clutch system (Refer Section

7A CLUTCH – V6 or 7A1 CLUTCH - GEN III V8.)

Change every 2 years (regardless of km)

Check all brake and fuel lines and hoses for

conditi on, attac hment and routing. X XXXXX X XXXX

Inspect front and rear suspension and steering

system for damaged, loose or missing parts, signs

of wear or lack of lubric ation. Inspec t power s teering

lines and hoses for condition, attachment and

routing, leaks, etc. Check condition of all rubber

boots and c overs.

*X XXXXX X XXXX

Inspect exhaust and adjacent underbody. Look for

damaged, missing or out-of-position parts, open

seam s, holes , or loose connec tions.

X XXXXX X XXXX

Inspect constant velocity joint for damage or torn

boot. XXXXX X XXXX

Clean and lubricate automatic transmission shift

linkage. XX X

Clean out air c ondi tioning drain t ubes. XX

Check carbon canister for leaks or restrictions

(Refer Section 6E1 EMISSION CONTROL - V6

ENG. or 6E3 EMISSION CONTROL - GEN III V8

ENG).

*XXX

CAR INTERIOR

Check park brake operation. XXXXXX X XXXX

Inspect seat belts, check webbing condition, buckle

operation and retrac tor mechanism. XXX X X

CAR EXTERIOR

Check operat i on of all exterior lights. X XXXXXX X XXXX

Lubricate hood catch, door hinges, rear door links

only and lock cylinders.XXX X X

Check t ransmi tter range of securit y s ystem. XXXXXX X XXXX

ROAD TEST

Check braking, steering, engine response and

transmission operation. Check operation of cruise

control. Check park pawl operation. Check A/C

perform ance. Check neutral s tart switch.

X XXXXXX X XXX X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 9.1 ABNORMAL OPERATING CONDITIONS in this Section.

10. LUBRICANT RECOMM E NDATIONS

APPLICATION LUBRICANTS

Body - Door Lock Striker Bolts

Door Lock Fork Bolts

Instrument Compartment Lid Lock Tongue

Engine Hood Catch

Engine Hood Lock

Engine Hood Hinge

Door Hinge and Rear Door Hold Opens Only

Rear Compartment Lid Hinge

Rear Compartment Lid Lock Mechanism

Door Window Regulators

Door Window Guides and Cams

Front Seat Adjuster

Recliner Assembly - Front Seat

Window Regulator Friction Surfaces

Front Door Lock Cylinder

Ignition and Steering Lock Cylinder

Rear Compartment Lid Lock Cylinder

Instrument Panel Compartment Lock Cylinder

Starter Motor Drive Mechanism

Starter Motor Bearings

Park Brake Shoe Assemblies

Brake Adjusting Screw and Nut

Park Brake Shoe Actuator Pivots

Brake and Clutch Hydraulic System

Propeller Shaft Centre Constant Velocity Joint

Final Drive:

All V6 excluding V6 W agon with manual

transmission & V6 supercharged engine

vehicles

All V8, V6 Wagon with manual

transmission & V6 supercharged engine

vehicles

Engine Oil:GEN III V8 and V6 excluding LPG

V6 LPG

Engine Supercharger

Clutch Throw-Out Bearing - Getrag 5 speed

manual transmission (V6)

Bearing Face of Clutch Throw-Out Bearing, input

shaft splines and spigot - Tremec 6 speed manual

transmission (GEN III V8)

Clutch and Brake Pedal Pivots and Bushes

Accelerator Pedal Pivots

Manual Transmission

Getrag 5 speed manual (V6)

GEN III V8

Solidoil

NLGI No. 1 Lithium Grease (with Zinc Oxide) meeting Holden

Specification HN1225

Lithium Based Grease Holden Specification Number HN1416

Powdered Graphite (applied through key aperture - do not oil)

Molybdenum Disulphide Grease to Holden Specification HN1271

Engine Oil at Overhaul

Special HT Grease to Holden Specification HN1227

Special HT Grease to Holden Specification HN1227

Mol

y

bdenum Disulphide Grease to Holden’s Specification HN1587

Heavy duty brake fluid to Holden Specification HN1796 (Part

No.92026651)

Molybdenum Disulphide Grease to Holden Specification HN1271

Mineral Hypoid Gear Oil SAE 90. A.P.I. GL5.

To Holden Specification HN1561.

Synthetic Hypoid Gear Oil A.P.I. GL5 SAE 80W-140

To Holden Specification HN2040.

10W-30 SJ GF2 Quality Engine Oil

15W-40 SH/CG4 or 15W-40 SJ/CG4 Quality Engine Oil to Holden

Specification HN2314

Supercharger Oil (Part No. 12345982)

Molybdenum disulphide grease to Holden Specification HN1271

Molybdenum disulphide grease to Holden Specification HN1271

Molybdenum Disulphide Grease to Holden Specification HN1271

Lithium Grease to Holden Specification HN1225

Castrol VMX 80W oil to Holden Specification HN1855

Dexron® III Automatic Transmission Fluid to Holden Specification

HN2126

APPLICATION LUBRICANTS

Automatic Transmission

Automatic Transmission Control Pivot Points

Steering Gear - Power (Mechanical)

(Hydraulic)

Windshield Wiper Pivot Points

Coolant Concentrate

V6 and V6 supercharged

GEN III V8 engine

Check Link Housing - Rear Door Only

Check Link Arm - Rear Door Only

Dexron® III Automatic Transmission Fluid to Holden Specification

HN 2126

Molybdenum Disulphide Grease to Holden Specification HN1416

EP Semi Fluid Lithium Base Type O Grease

Dexron® III Automatic Transmission Fluid to Holden Specification

HN2126

Molybdenum Disulphide Grease to Holden Specification HN1271

Inhibited Glycol Coolant to Holden Specification HN2043 only,

at 50% by Volume in water.

50% Dexcool to GM Specification GM 6277M and 50% water.

NLGI No. 2 Polyurea Grease (Mineral Oil Base) - 1.2g Applied to

Arm

NLGI No. 2 Lithium Complex Grease - 1.2g Applied to Housing